Compact cooling/heating air-conditioning and hot water supply three-purpose machine capable of building natural circulating flow for heat exchange

A natural circulation, heating and cooling air-conditioning technology, applied in the direction of reversible cycle compressors, heat exchangers, refrigerators, etc., to achieve high heat recovery efficiency, increase hot water production, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

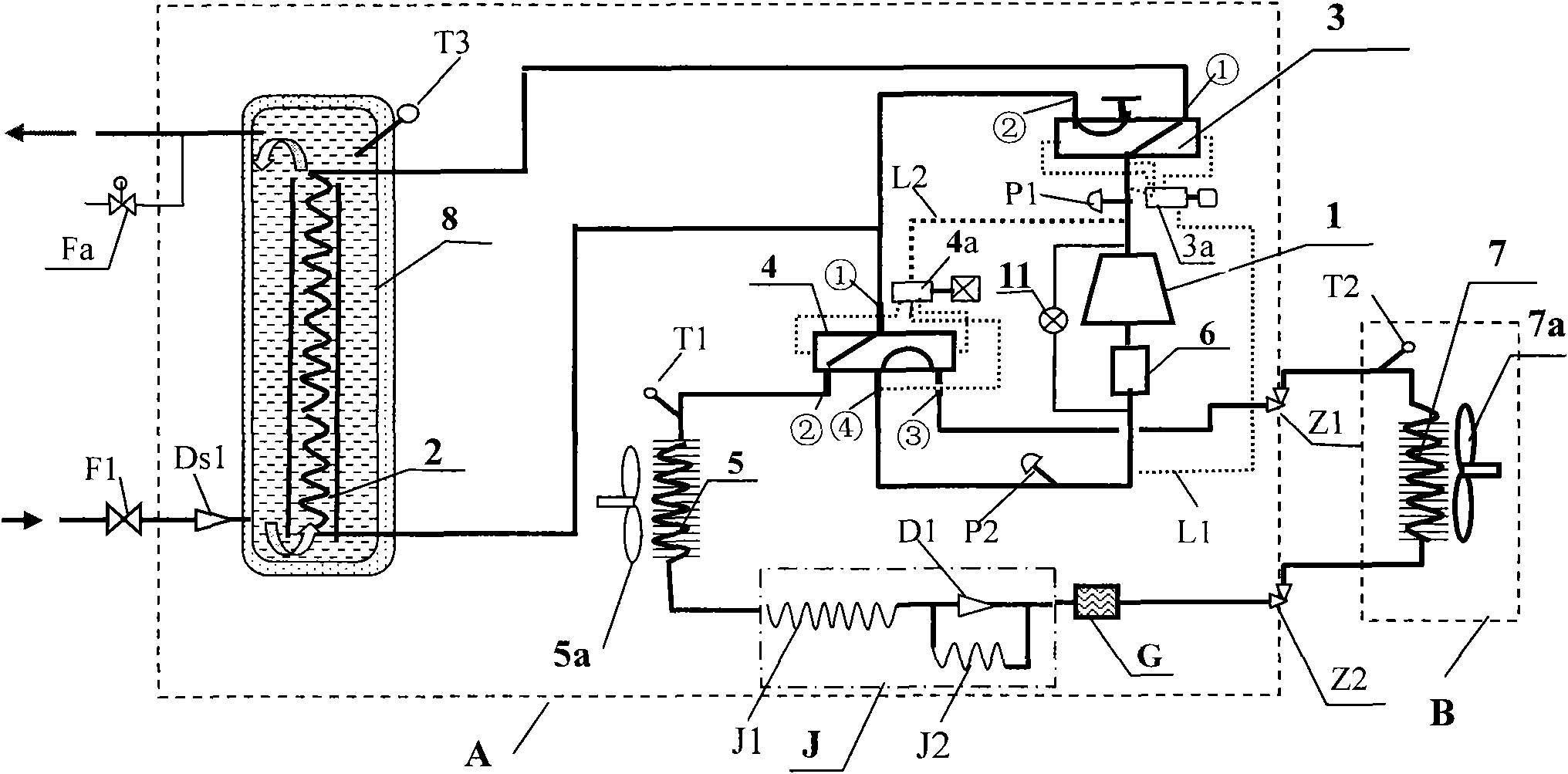

[0037] The structural relation and working principle of embodiment 1 are by figure 1 and Figure 6 common description.

[0038] Such as figure 1 as shown, figure 1 The two dotted-line boxes A and B respectively represent the outdoor unit and the indoor unit of the compact heating, air-conditioning and hot water three-purpose machine with self-built natural circulation flow heat exchange in the present invention; The hot water condensation heat exchanger 2 is placed upright in the water storage tank 8, and the water storage tank is also installed in the outdoor casing. A compressor 1, a three-way valve 3, a four-way valve 4, a throttle J, an outdoor air heat exchanger 5 and its fan 5a, a gas-liquid separator 6, etc. are also installed on the outdoor unit; The fan 7a is placed in the indoor unit; the water storage tank 8 is a pressurized water tank with an insulating layer for storing hot water; the single interface on one side of the main valve body of the four-way valve...

Embodiment 2

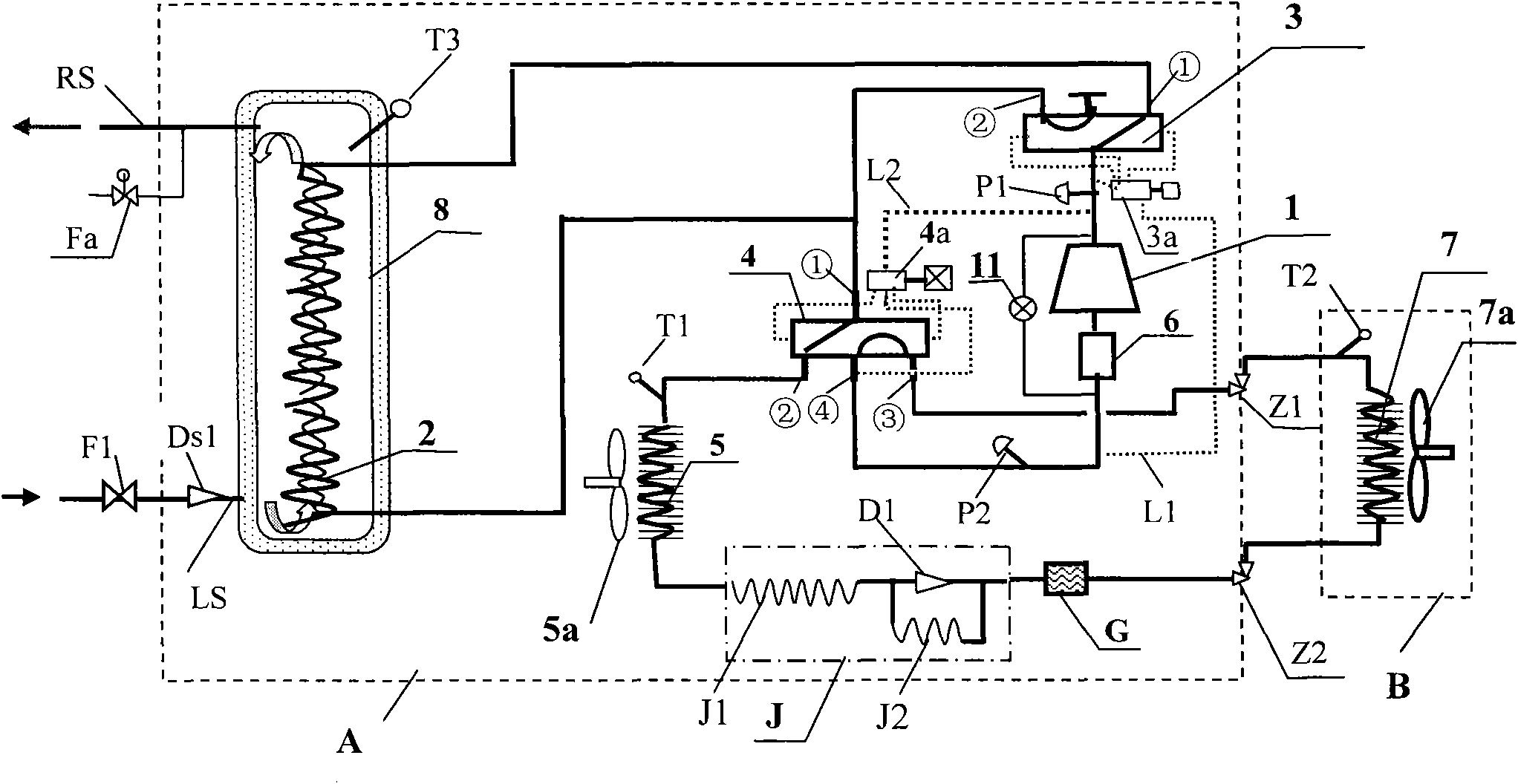

[0050] The structural relation and working principle of embodiment 2 are by figure 2 and Figure 7 common description.

[0051] The compact heating, air-conditioning and hot water three-purpose machine of the self-built natural circulation flow heat exchange of embodiment 2 is exactly the same as the three-purpose machine of embodiment 1 in the refrigerant circuit system, only in that the hot water condensing heat exchanger automatically There are different ways to create natural circulation flow; for example figure 2 and Figure 7 As shown, the hot water condensing heat exchanger is a multi-layer spiral tube reel type hot water condensing heat exchanger, which is directly placed in the water storage tank by placing the 3-layer spiral tube reel in the natural circulation flow heat exchange in the tank. Type water heat exchange circuit system; the diameter of the inner reel of the 3-layer spiral tube reel is 80mm, the diameter of the middle reel is 110mm, and the diameter ...

Embodiment 3

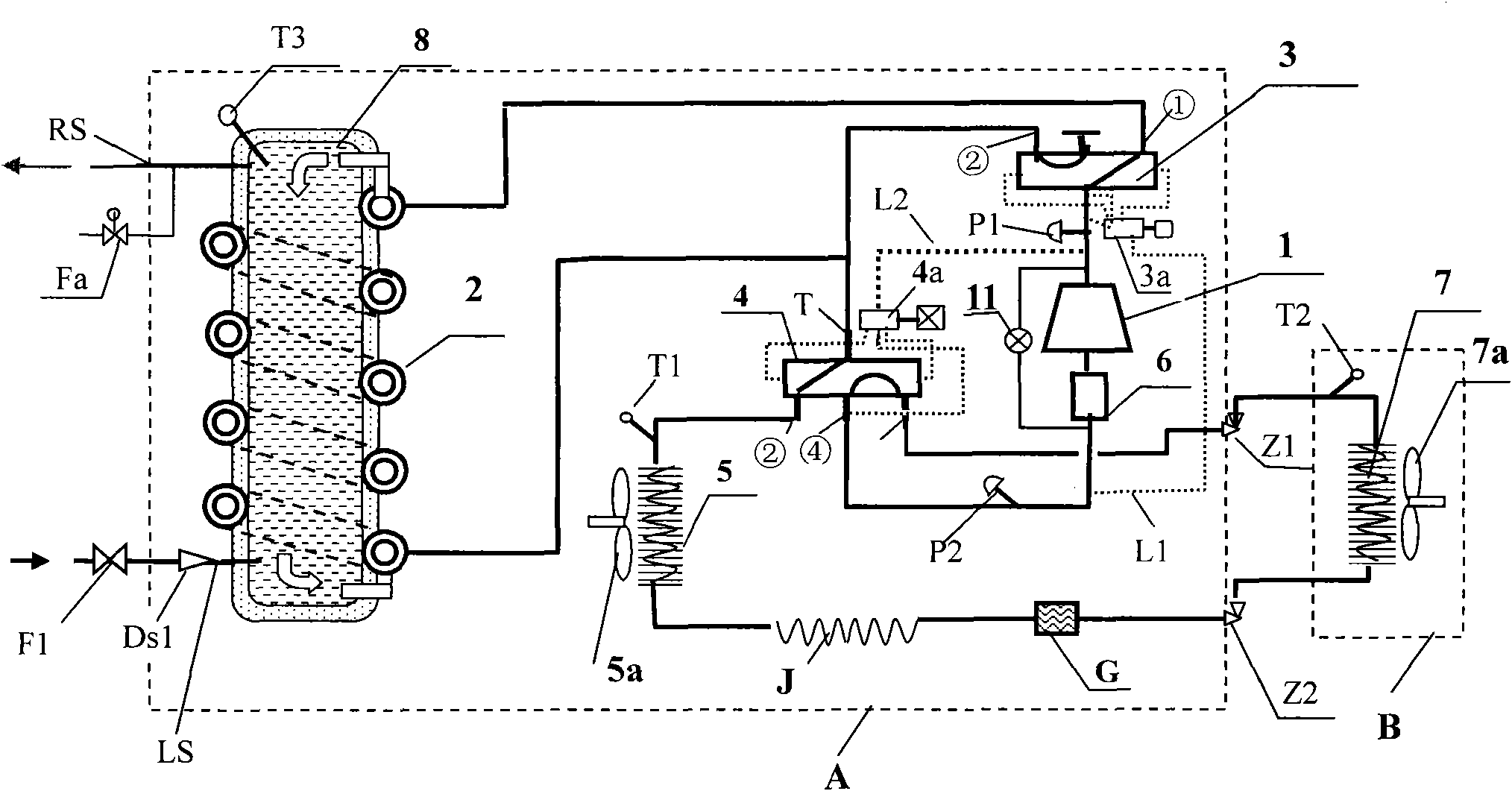

[0052] The structural relation and working principle of embodiment 3 are by image 3 To further illustrate, the self-built natural circulation flow heat exchange compact three-purpose machine for cooling, heating, air conditioning, and hot water in Example 3 is completely the same as that of Example 1 and Example 2, and the refrigerant circuit system is completely the same; the main difference is that Example 3 The water heat exchange circuit system is a water heat exchange circuit system of the header type natural circulation flow heat exchange type formed by connecting the water storage tank with the external hot water condensation heat exchanger 2; Heat exchanger 2 is a spiral-drum hot water condensing heat exchanger rolled with coaxial sleeves. The spiral drum is tightly sleeved on the outer wall of the water storage tank. The height of the spiral drum is close to the height of the water storage tank; the coaxial sleeve The upper and lower ports of the inner tube of the pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com