Patents

Literature

8112results about How to "Simple composition" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

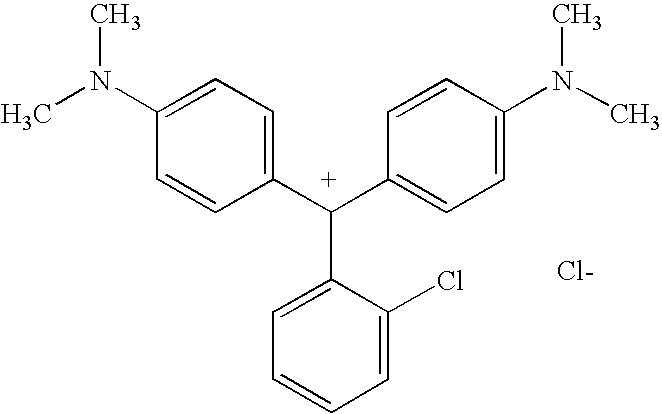

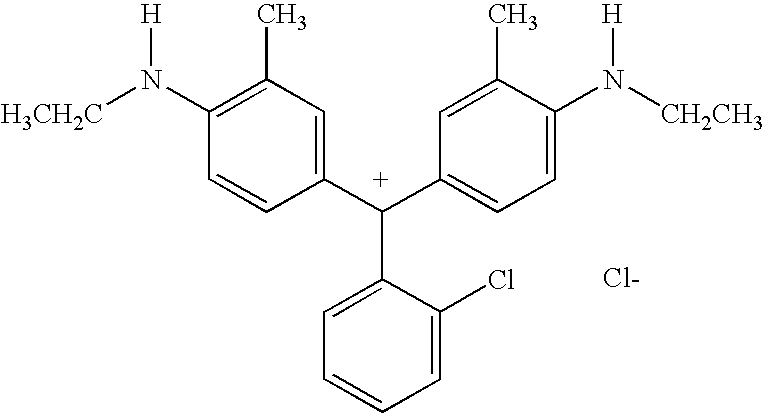

Laundry detergent compositions with efficient hueing dye

ActiveUS7208459B2Counter undesirable yellowingSimple compositionOrganic detergent compounding agentsNon-surface-active detergent compositionsActive agentLaundry

Laundry detergent compositions comprise (a) surfactant, and (b) a hueing dye, wherein the hueing dye exhibits a hueing efficiency of at least 10 and a wash removal value in the range of from about 30% to about 85%.

Owner:PROCTER & GAMBLE CO

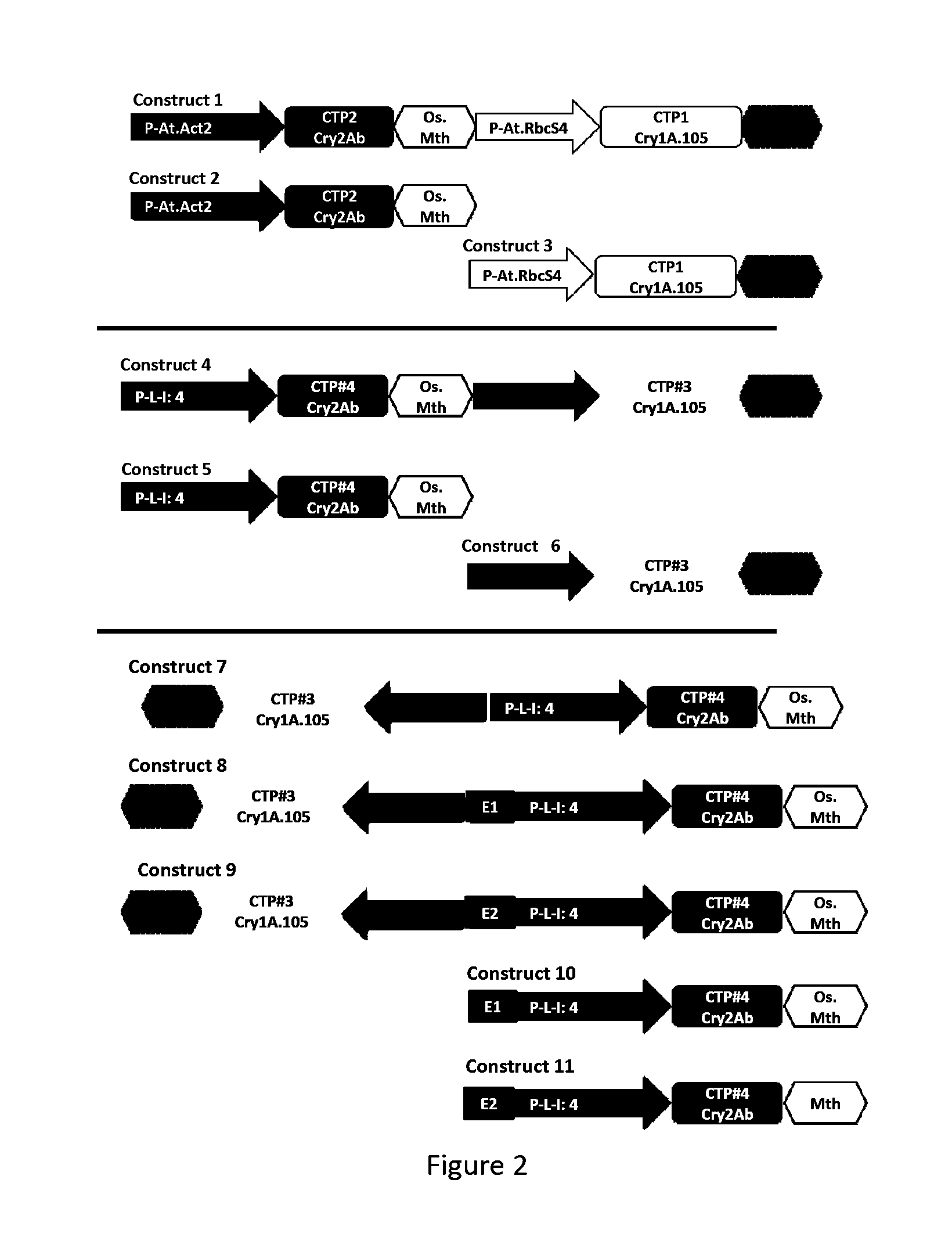

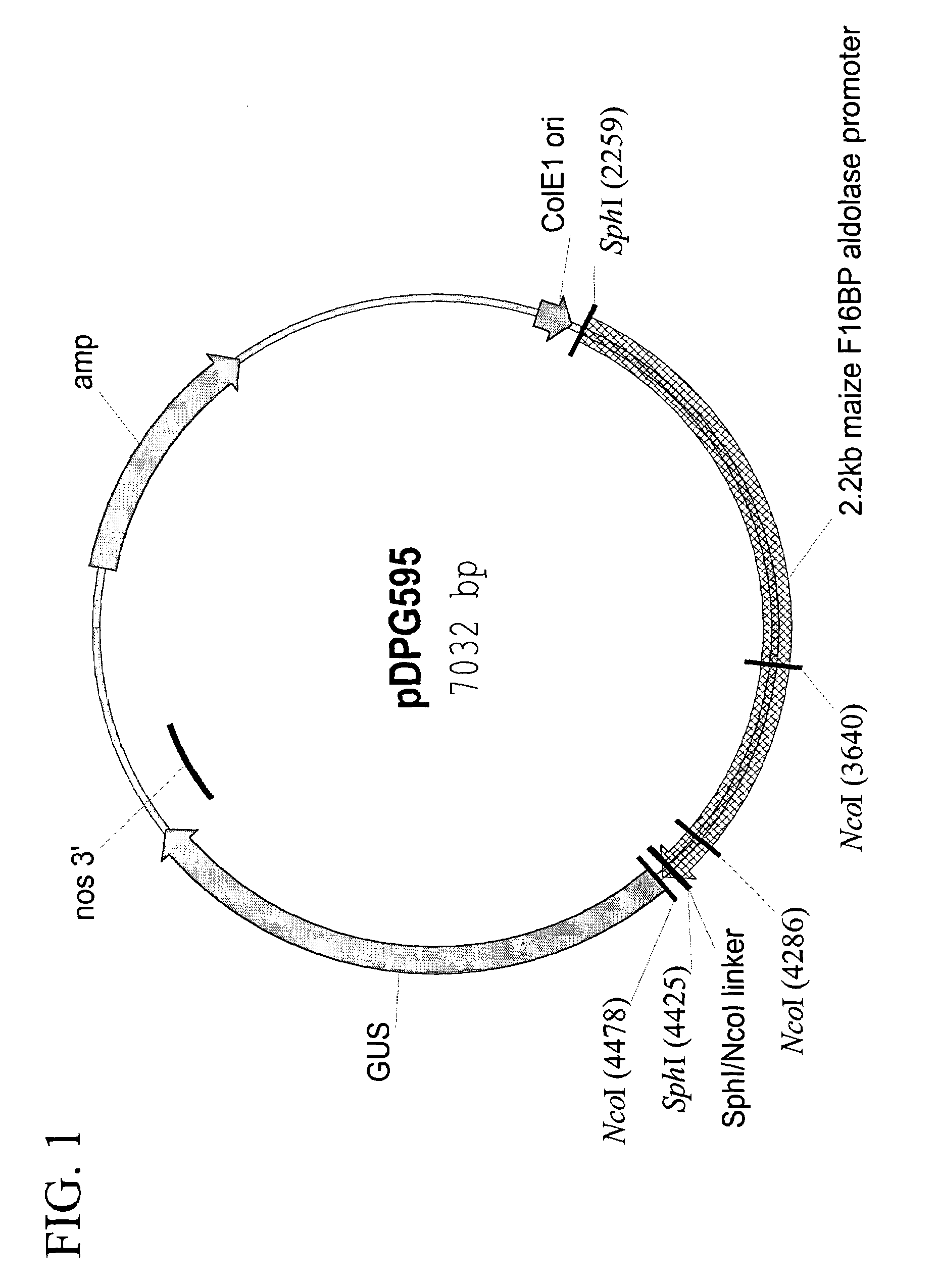

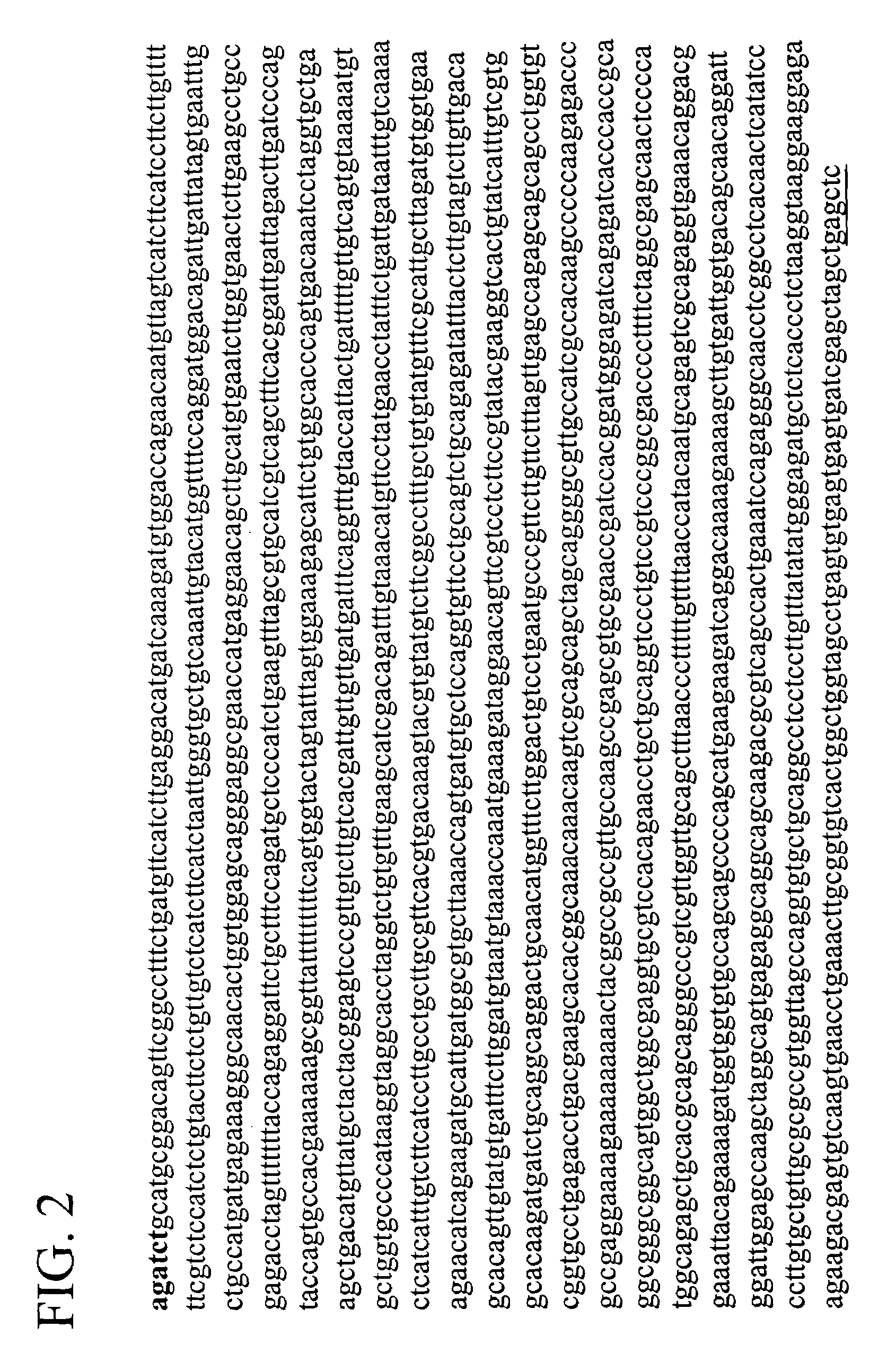

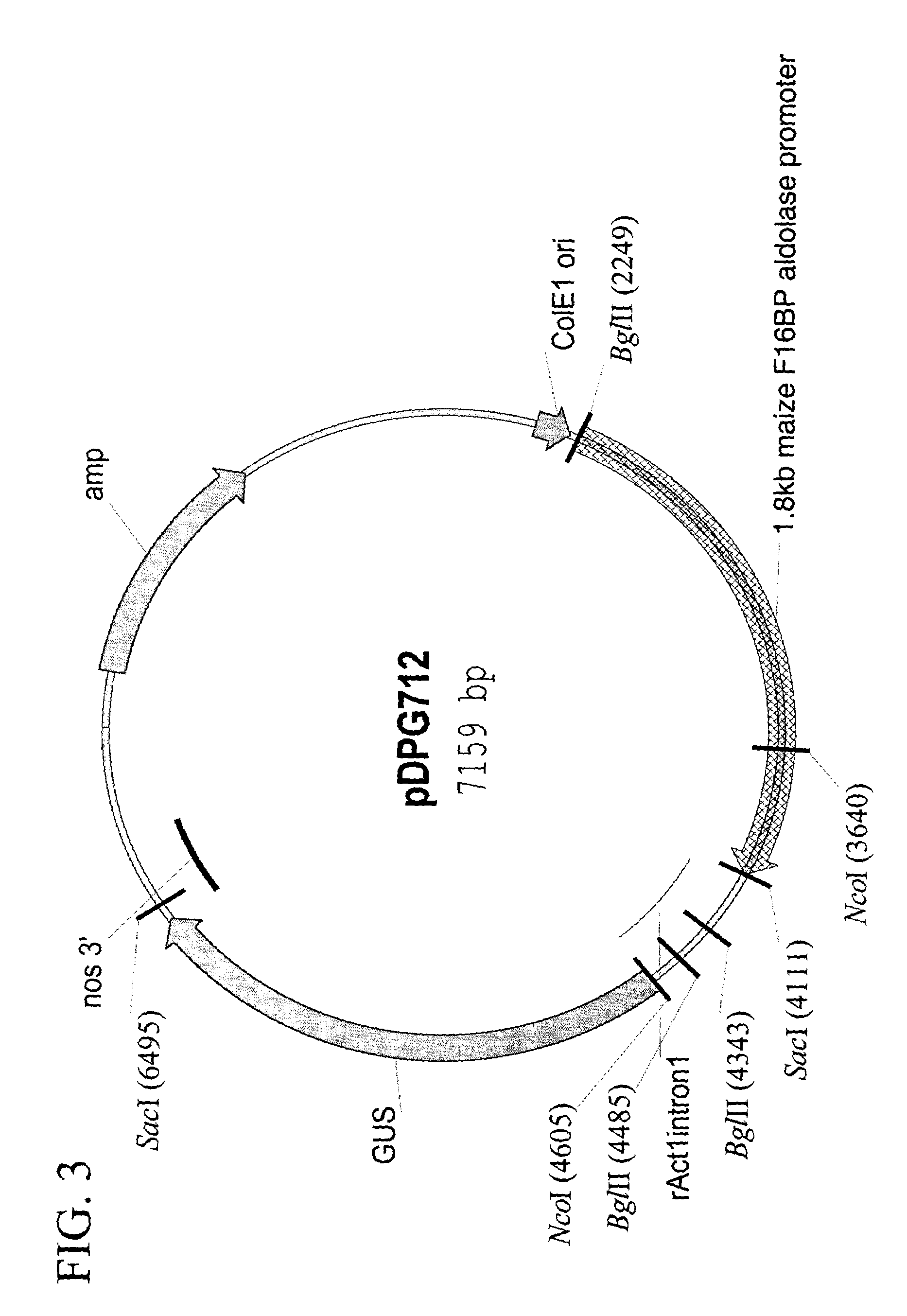

Maize chloroplast aldolase promoter compositions and methods for use thereof

ActiveUS7151204B2Simple compositionQuality improvementSugar derivativesOther foreign material introduction processesFructoseTransgene

The current invention provides the promoter of the Zea mays nuclear gene encoding chloroplast-localized fructose-1,6-bisphosphate (F16BP) aldolase. Compositions comprising this sequence are described, as are plants transformed with such compositions. Further provided are methods for the expression of transgenes in plants comprising the use of these sequences. The methods of the invention include the direct creation of transgenic plants with the chloroplastic F16BP aldolase promoter by genetic transformation, as well as by plant breeding methods. The sequences of the invention represent a valuable new tool for the creation of transgenic plants, preferably having one or more added beneficial characteristics.

Owner:MONSANTO TECH LLC

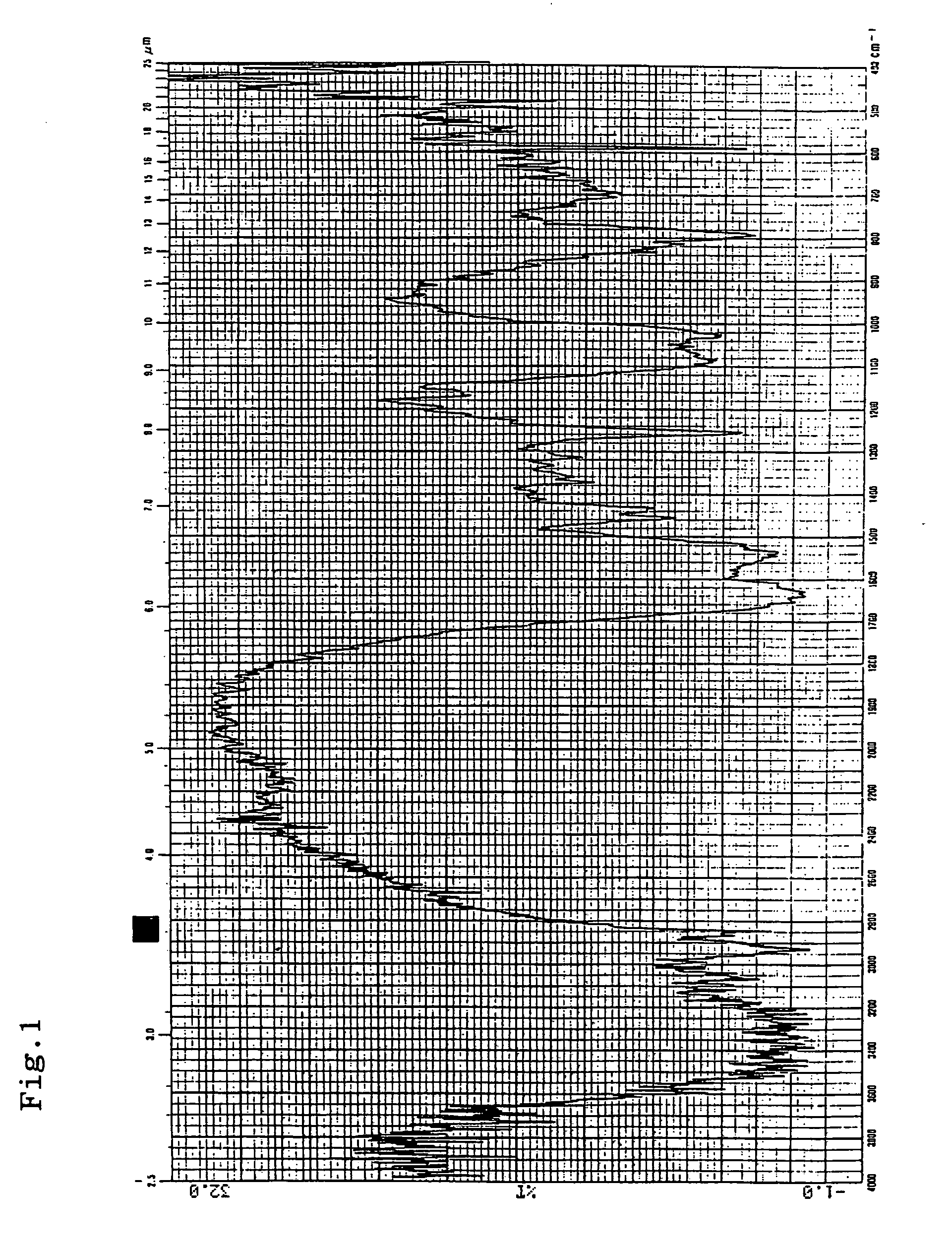

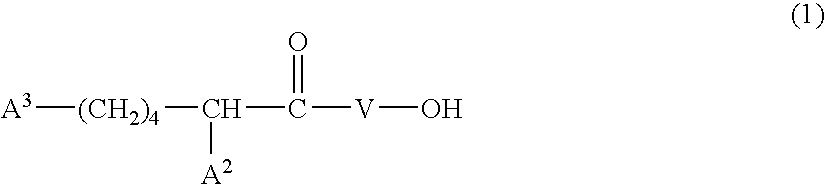

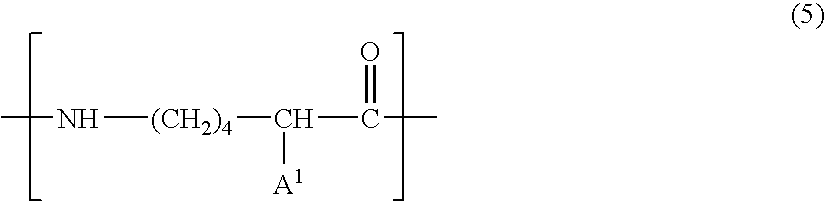

Cosmetic composition and production thereof

InactiveUS20060018867A1Efficient use ofReduce the amount requiredCosmetic preparationsHair cosmeticsEpsilon-PolylysineEmulsion

It has been desired to develop a highly preservative and antibacterial cosmetic composition that can easily be applied to both emulsion and non-emulsion type cosmetics. It has also been desired to develop a method of improving a preservative and / or antibacterial effect(s) of a cosmetic composition comprising polyorganosiloxane-containing epsilon-polylysine and thereby reducing the amount of antibacterial preservative agent to be used. There is provided a cosmetic composition comprising one or a combination of two or more of polyorganosiloxane-containing epsilon-polylysine compounds obtained by reacting epsilon-polylysine with polyorganosiloxane or a physiologically acceptable salt thereof, and polyhydric alcohol.

Owner:CHISSO CORP

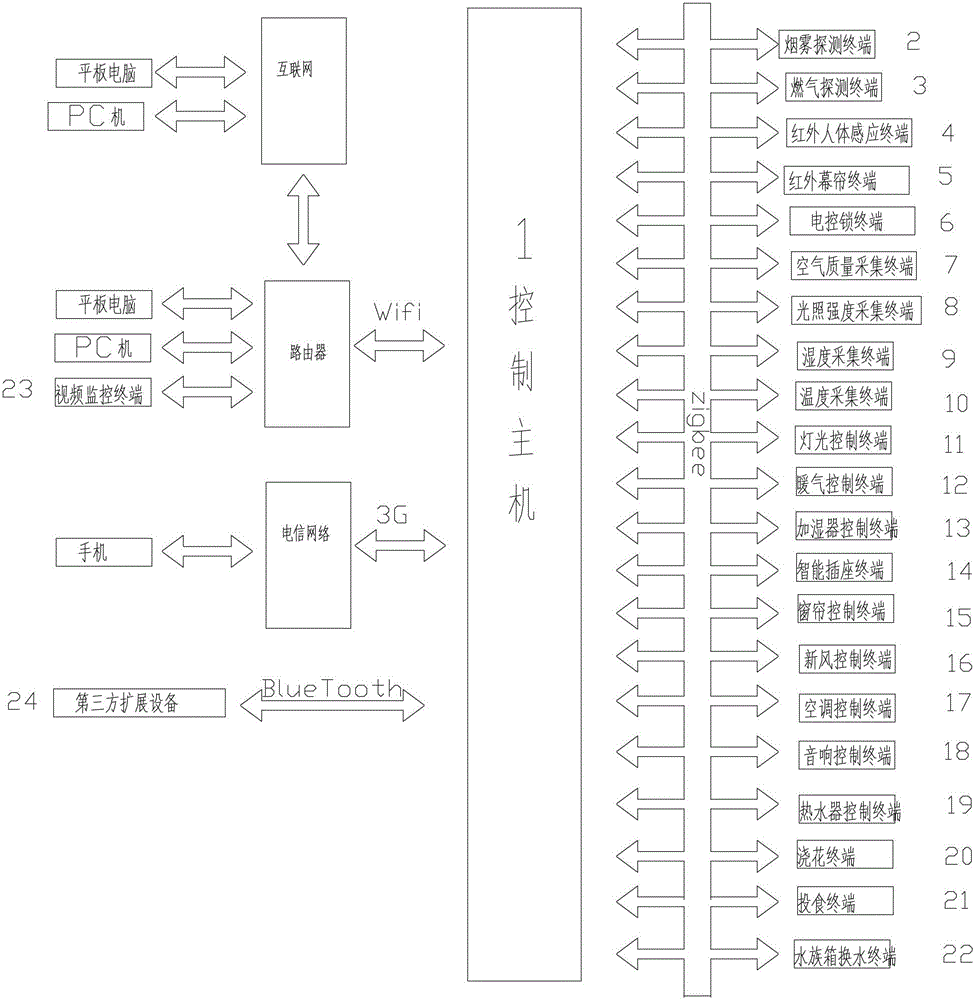

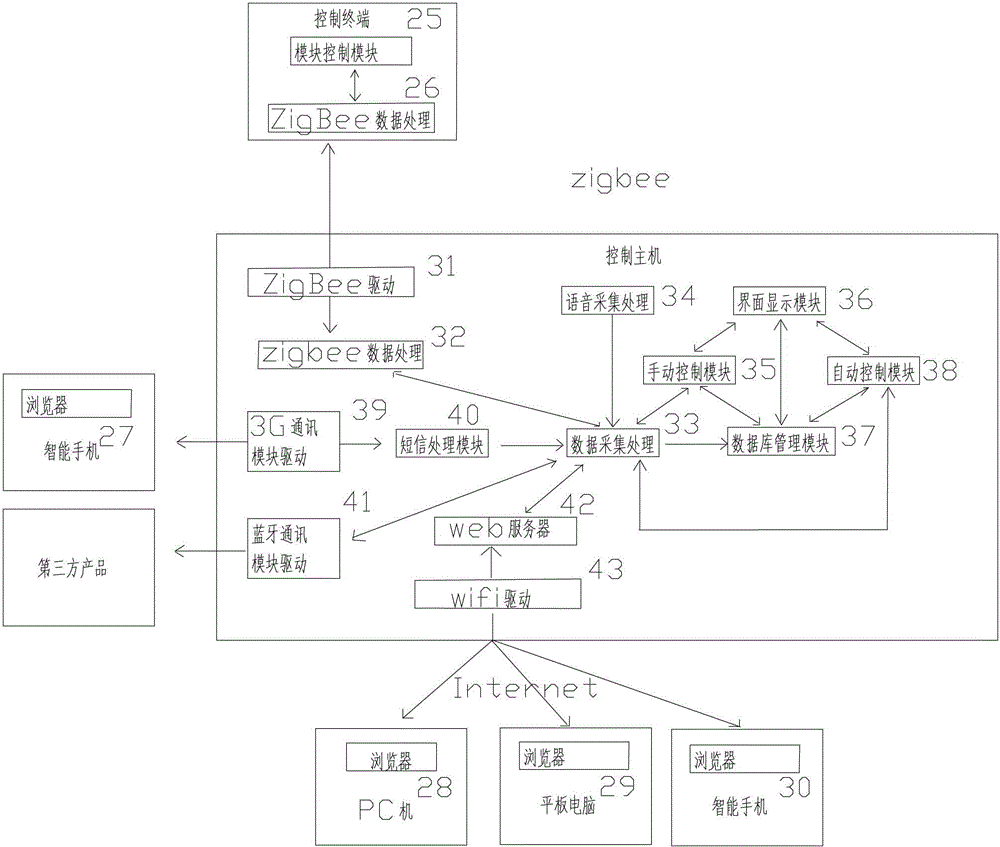

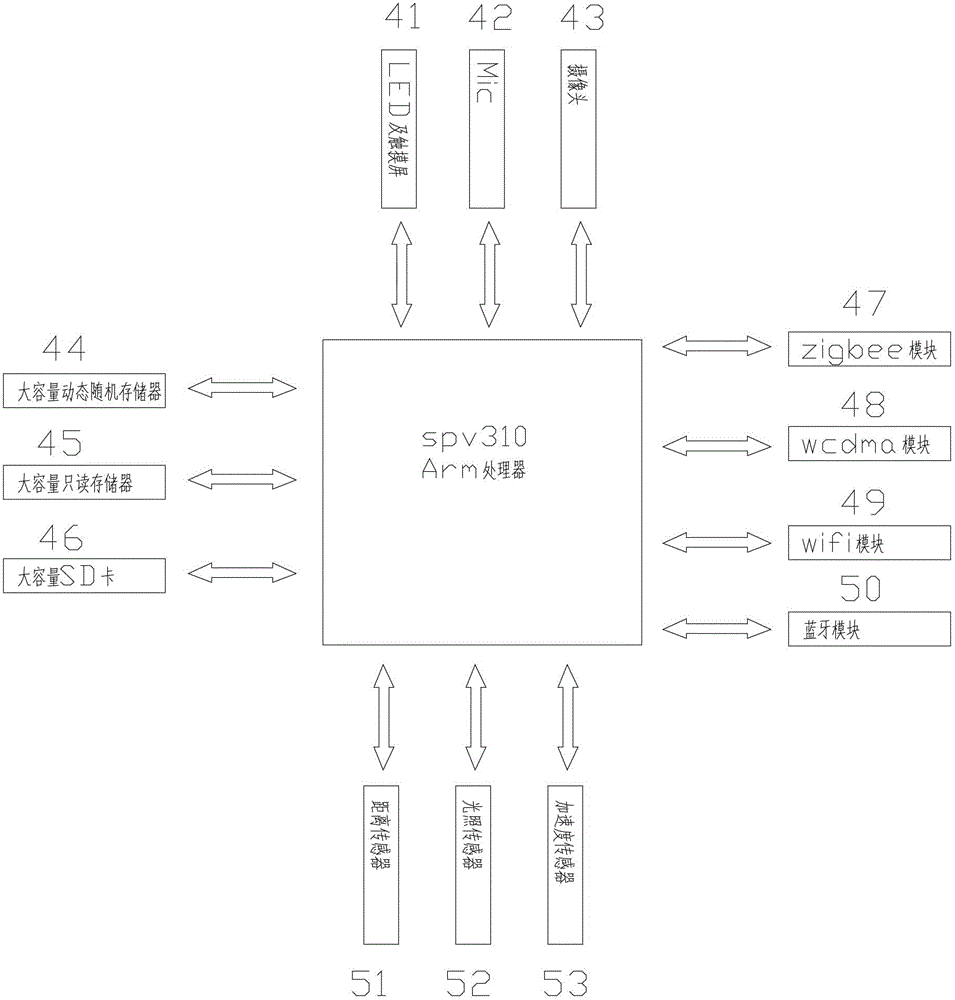

Internet-of-things and android system based intelligent home system and control method

InactiveCN102882752ARealize automatic arming and disarmingReduce complexityData switching by path configurationAutomatic controlWeb service

The invention discloses an internet-of-things and android system based intelligent home system which comprises a control host and a plurality of terminal devices. The control host is provided with a high-performance arm processor, a touch screen and an android operation system, supports zigbee, blueTooth, wifi (wireless fidelity), 3G (the third generation) communication, is provided with a built-in web server and a built-in database, has functions of display, operation, control data storage, server, energy management, and particularly has functions of automatic control, hand-operated control, voice control and remote control. The terminal devices include a sensor terminal, a security terminal and a control terminal, are provided with independent processors and network addresses, have functions of data acquisition, data transmission, instruction receiving, transmitting and processing and IO (input / output) control, and support one or multiple wireless communication manners of zigbee, blueTooth, wifi and 3G.

Owner:TIANJIN GUANGHONG TECH

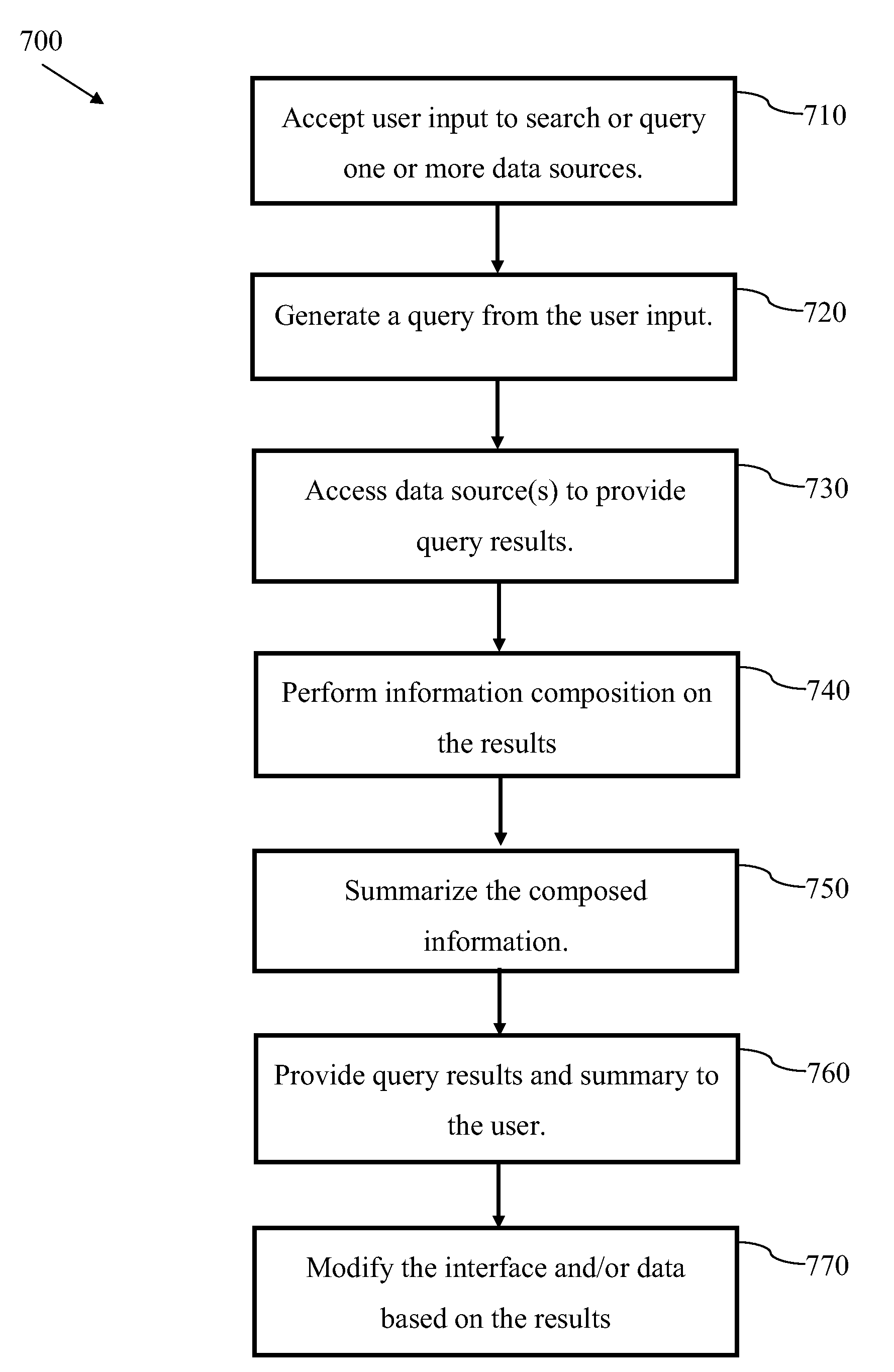

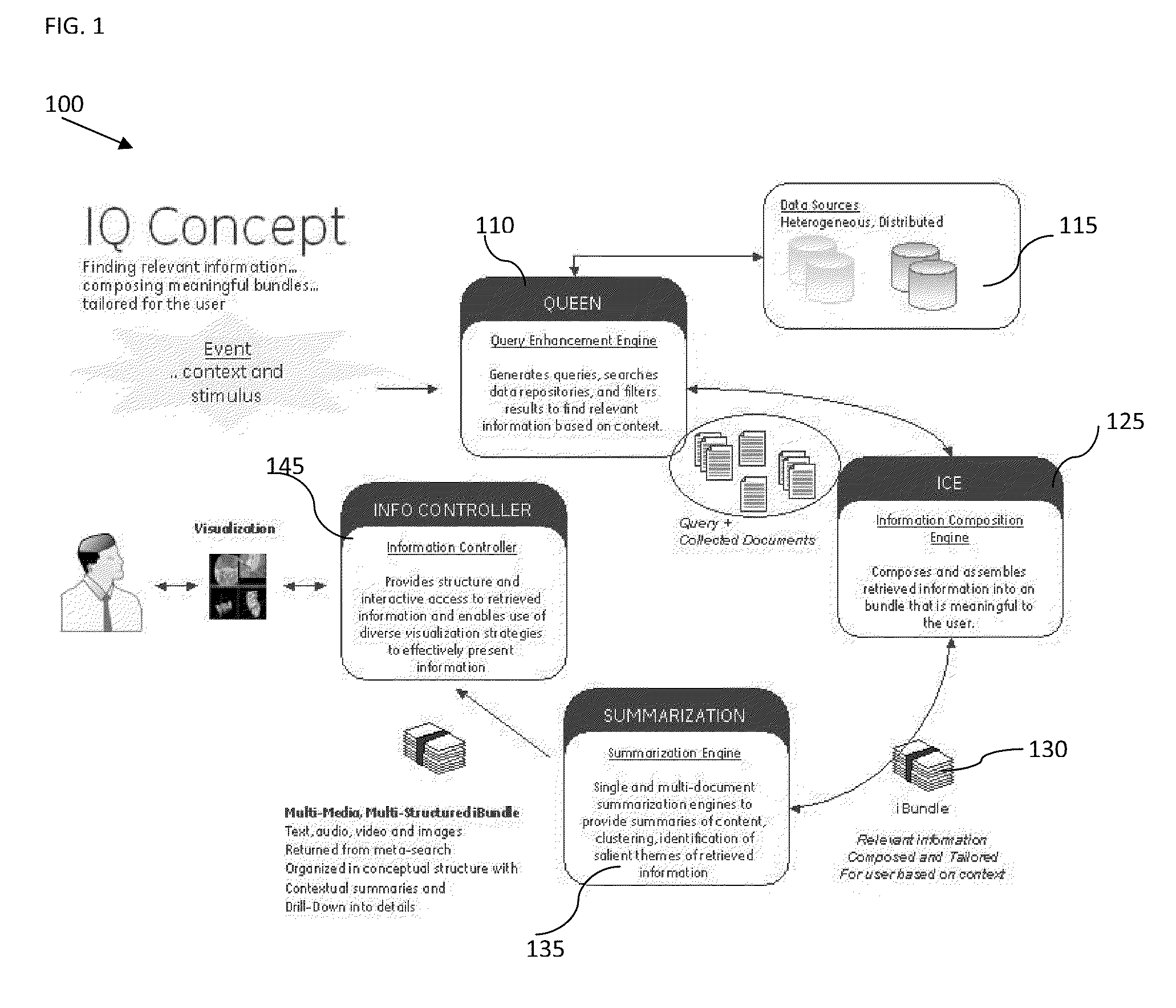

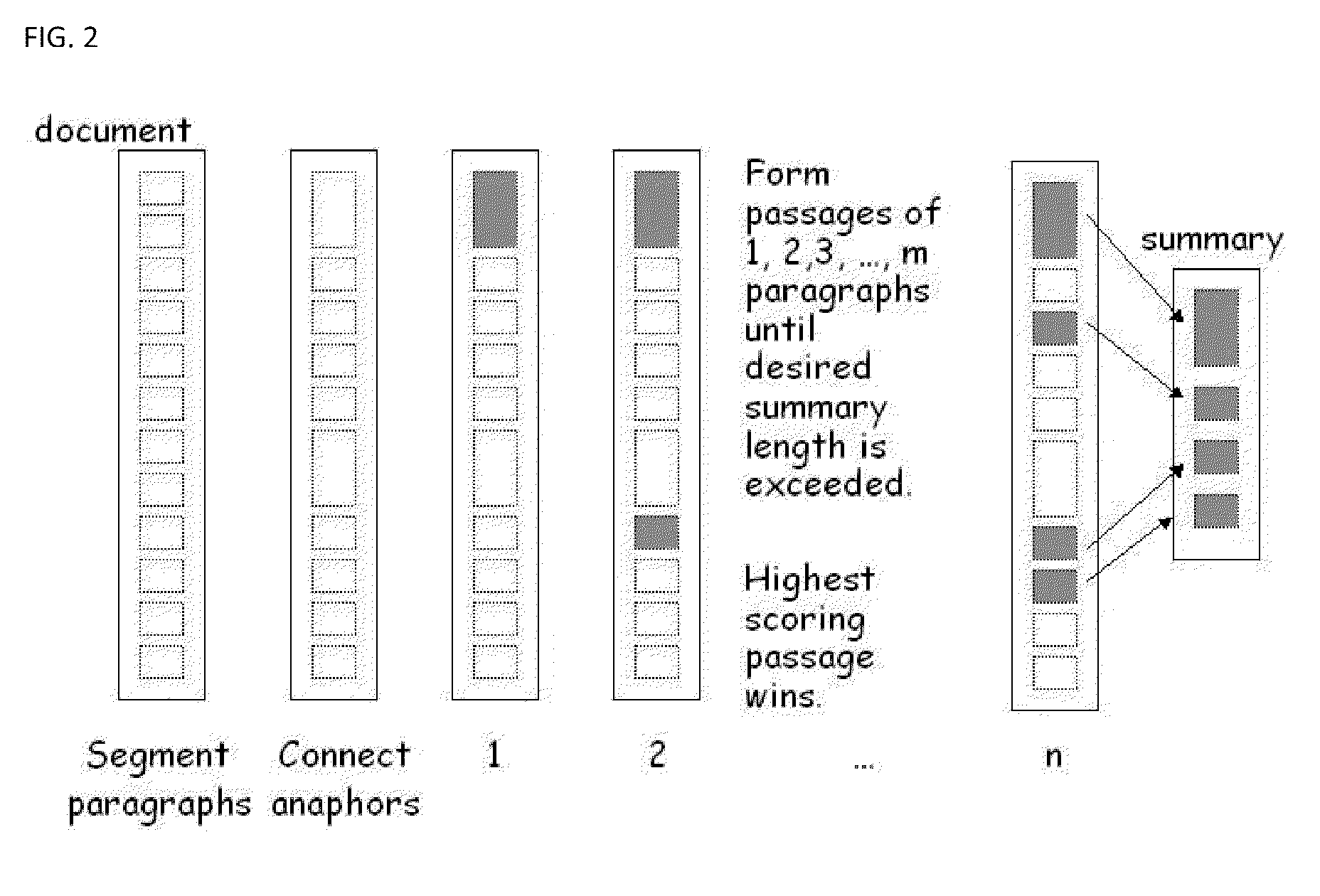

Automated healthcare information composition and query enhancement

InactiveUS20100131498A1Speed up querySimple compositionDigital data information retrievalDigital data processing detailsDocument summarizationUser input

Certain embodiments of the present invention provide systems and methods for information composition and query enhancement. Certain embodiments provide an information composition and query enhancement system. The system includes a query generation and enhancement engine generating and conducting a query of one or more data sources based on user input and a data context to produce query results. The system also includes an information composition engine assembling the query results to provide a bundle of documents meaningful to the particular user. The system further includes a document summarization engine clustering and summarizing the bundle of documents to provide a content summary in addition to the bundle of documents for output in a presentation to a user.

Owner:GENERAL ELECTRIC CO

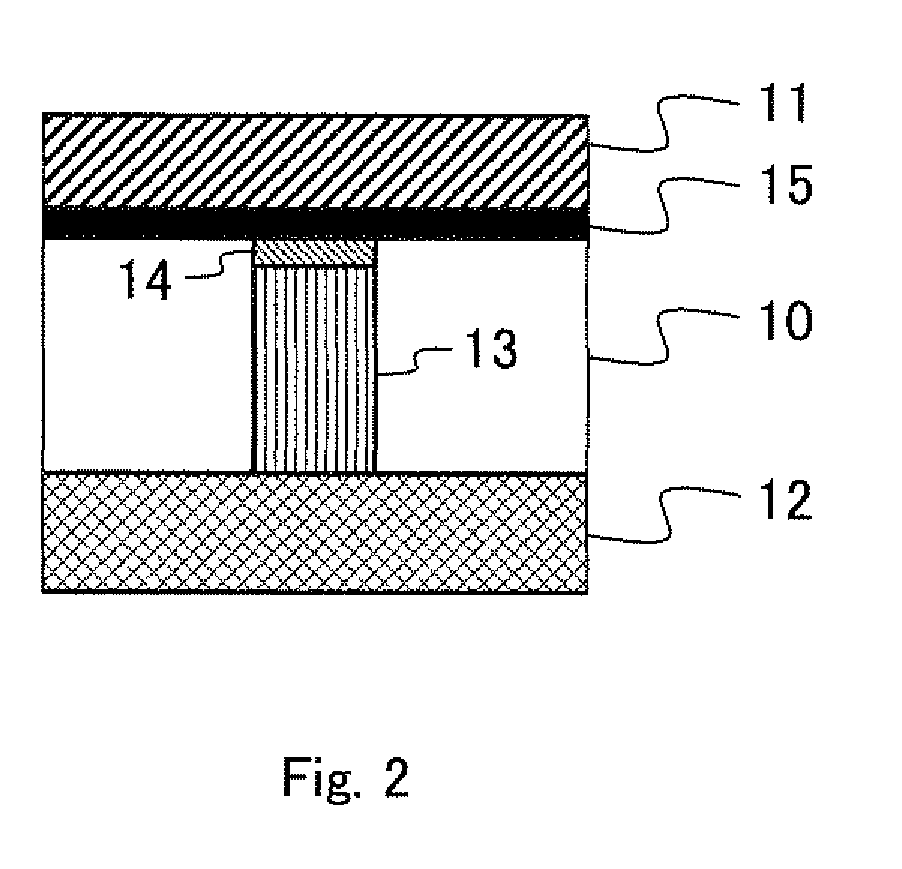

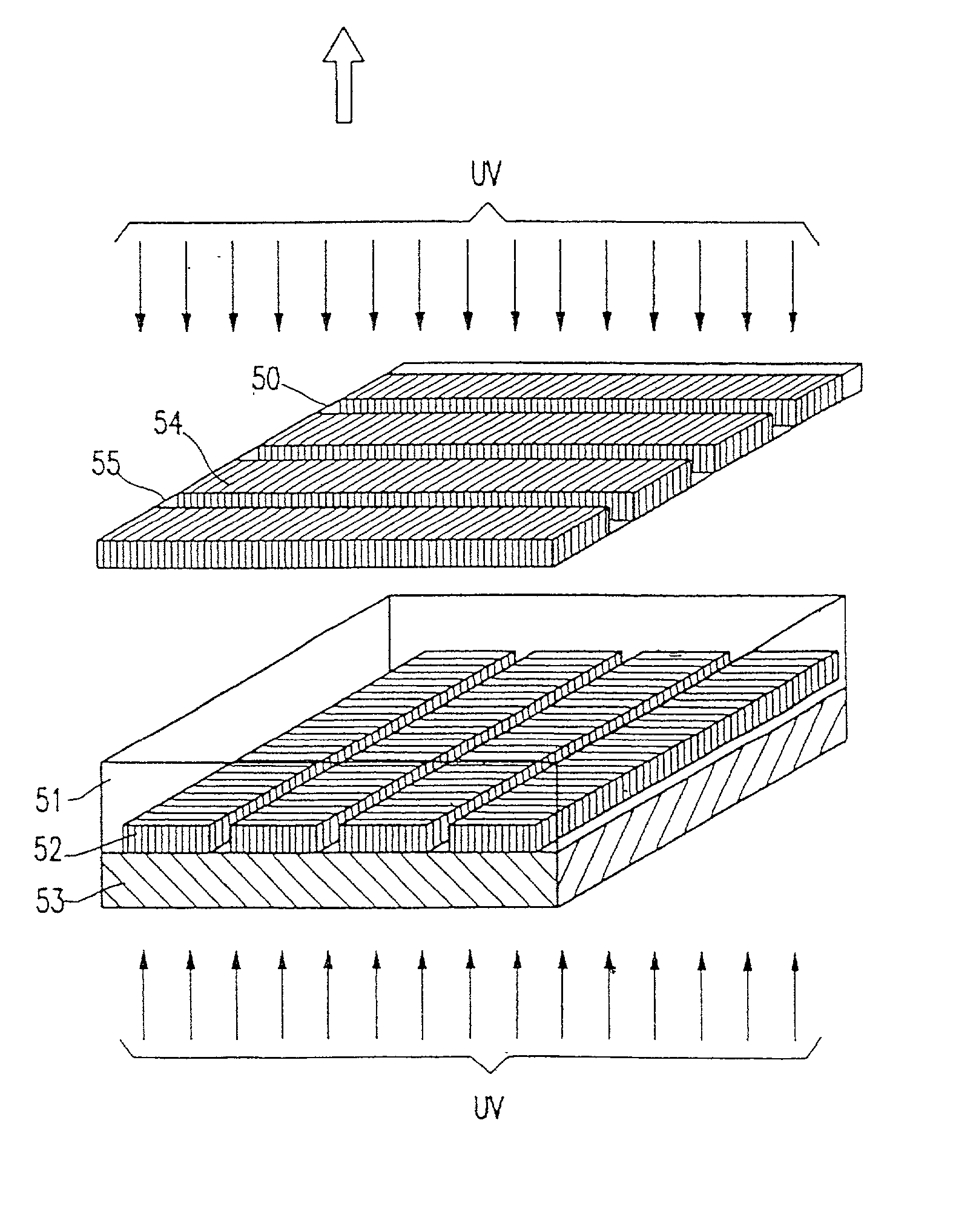

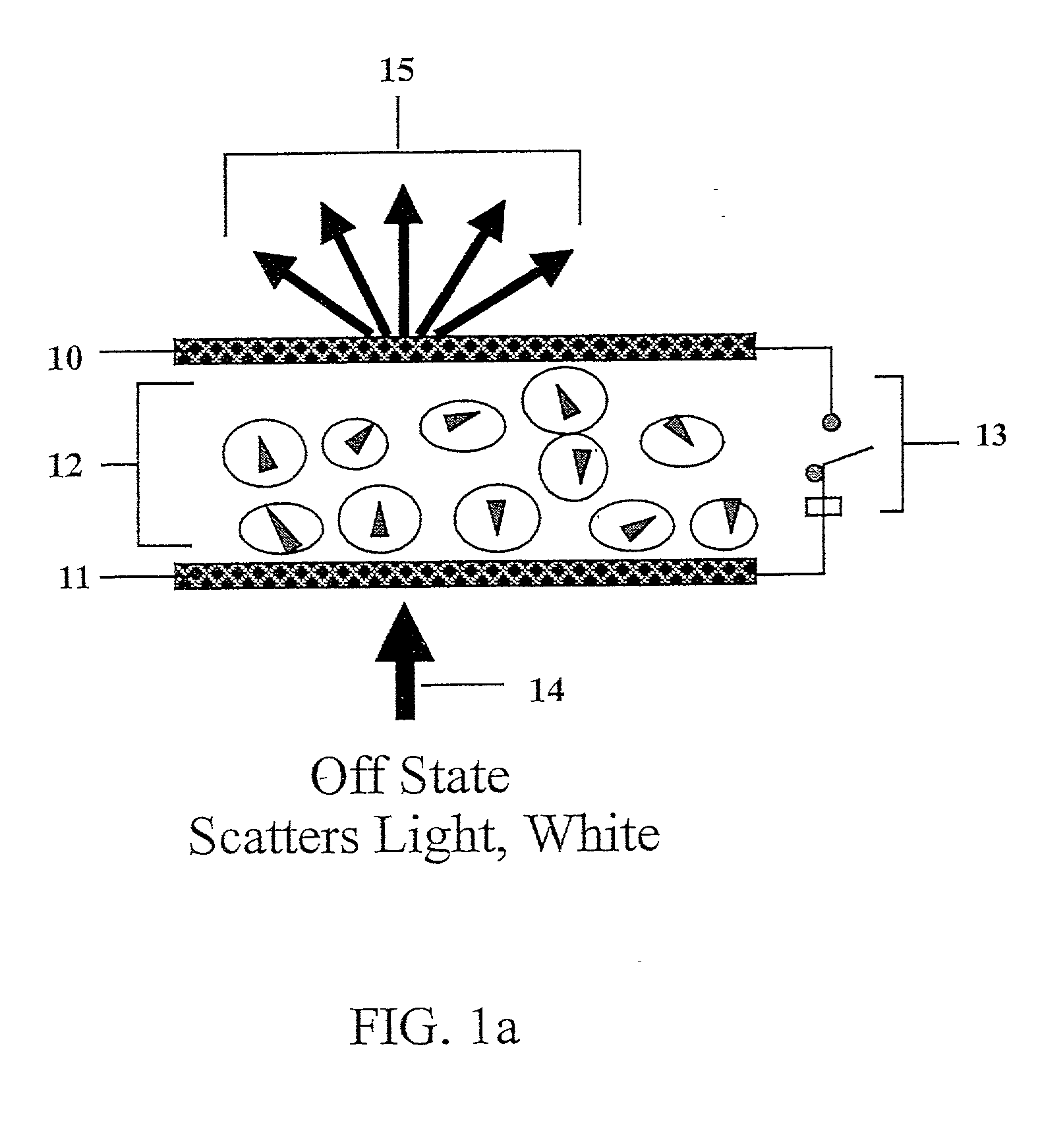

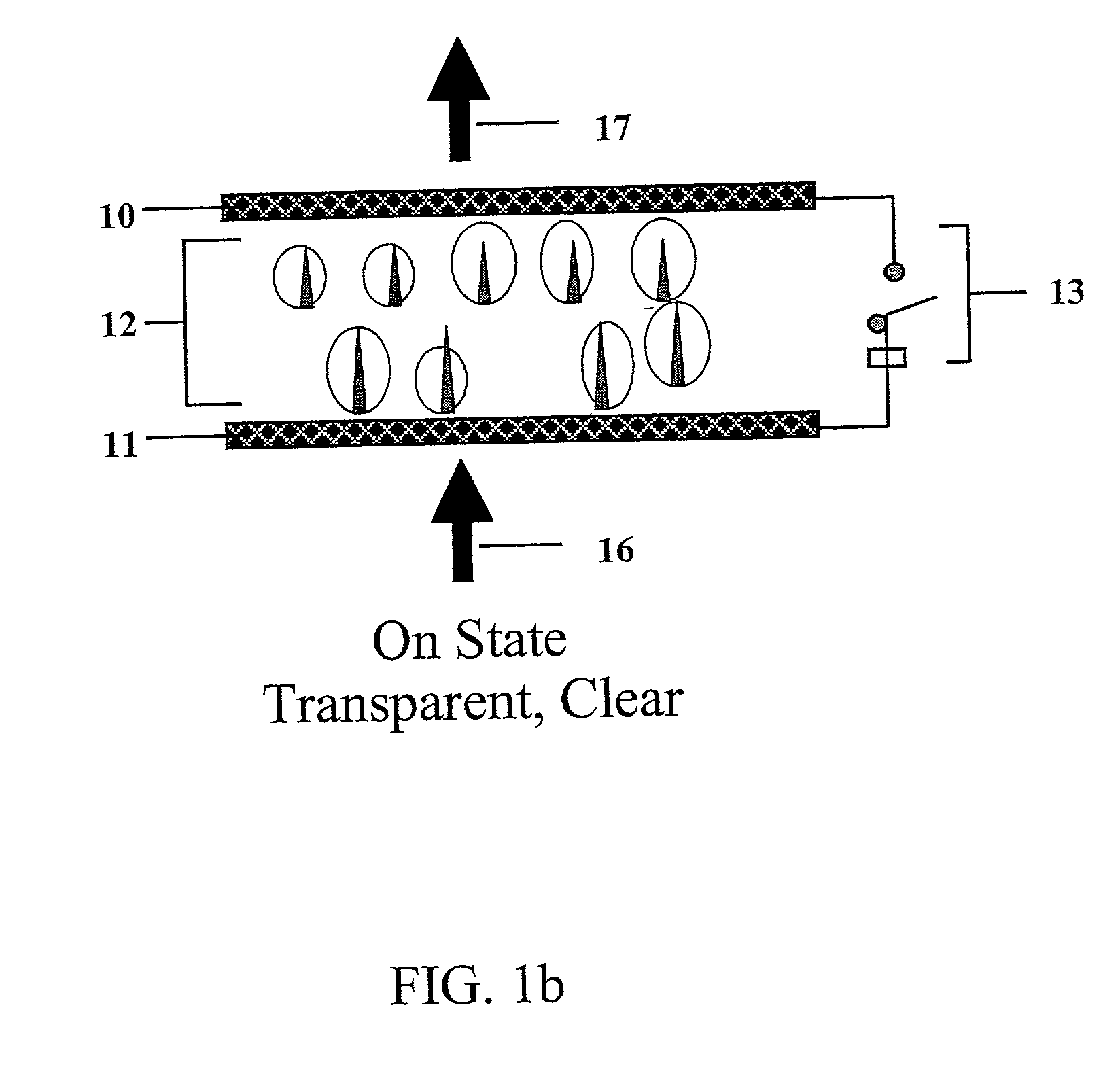

Transmissive or reflective liquid crystal display and novel process for its manufacture

InactiveUS20020126249A1Improve contrast ratioImprove color saturationLiquid crystal compositionsNon-linear opticsCrystallographyLiquid-crystal display

This invention relates to liquid crystal (LC) displays comprising cells of well-defined shape, size and aspect ratio which cells are filled with a liquid crystal composition preferably containing dichroic dye(s), and novel processes for their manufacture.

Owner:E INK CALIFORNIA

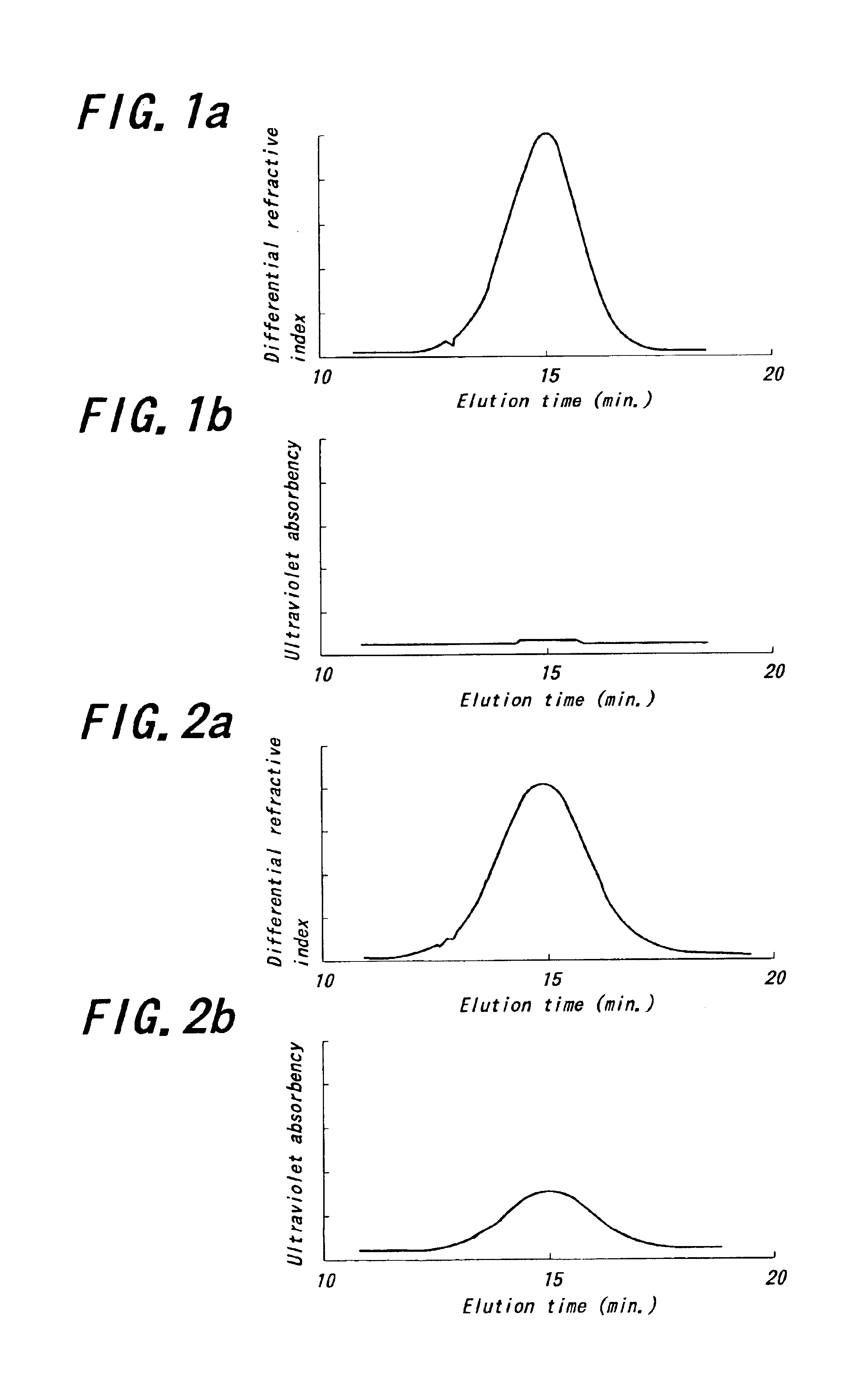

Modified conjugated diene polymer and method of producing the same and rubber composition

A novel modified conjugated diene polymer is obtained by polymerizing a conjugated diene compound with a specified catalyst consisting of components (a)-(c) and then reacting with at least one specified compound selected from the group consisting of components (d)-(l), and has a content of cis-1,4-bond of not less than 85% and a ratio of weight average molecular weight to number average molecular weight of not more than 4. And also, a rubber composition comprises the modified conjugated diene polymer a rubber ingredient.

Owner:JSR CORPORATIOON +1

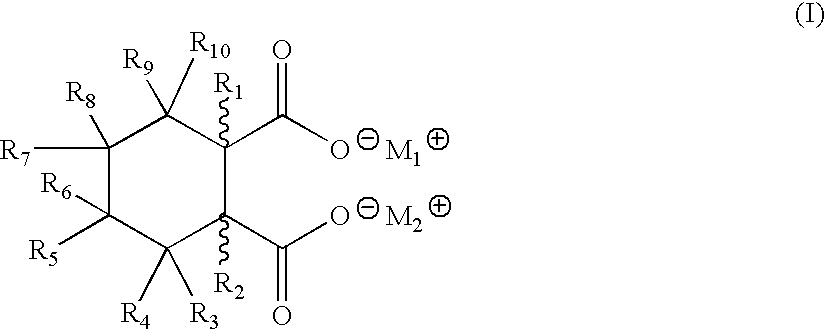

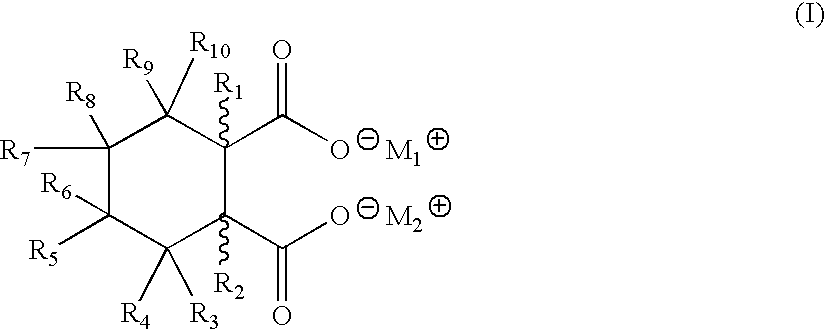

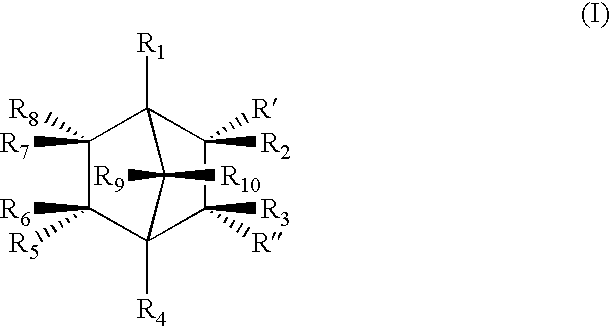

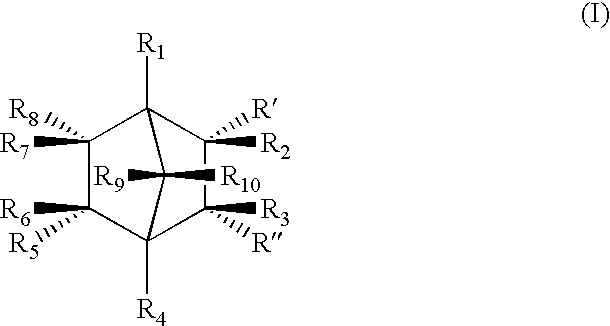

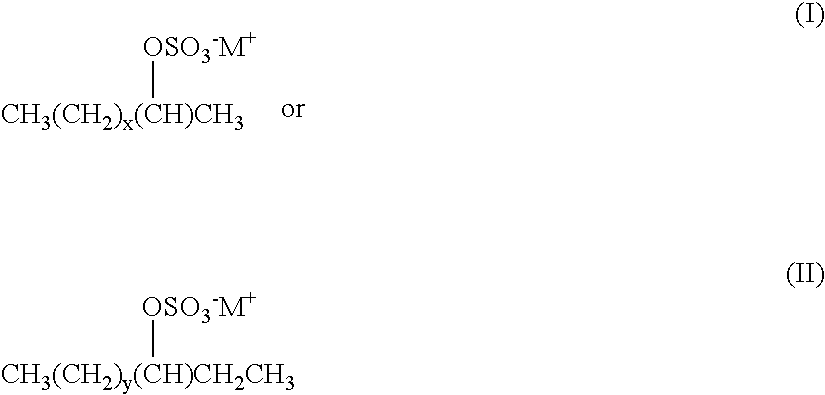

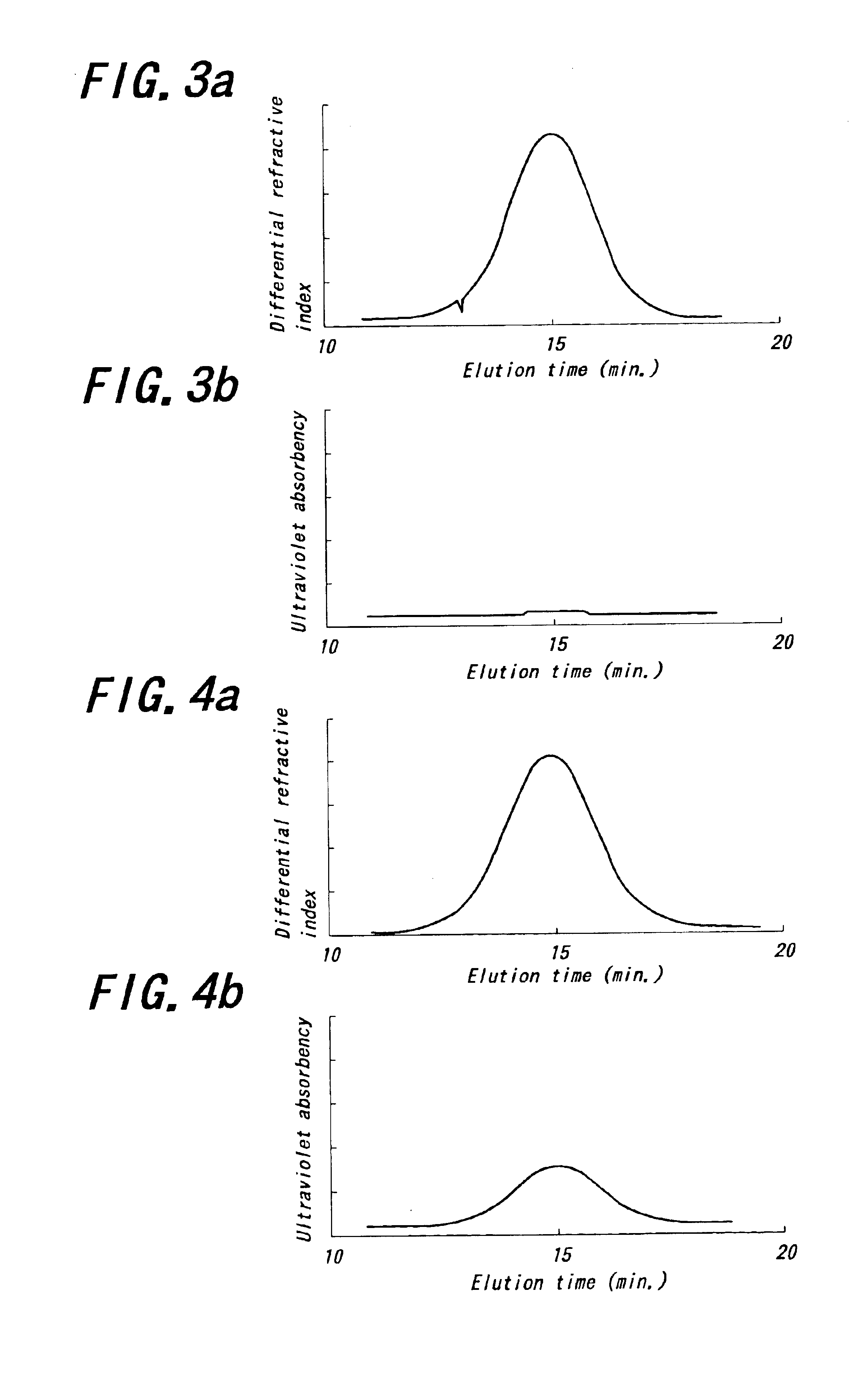

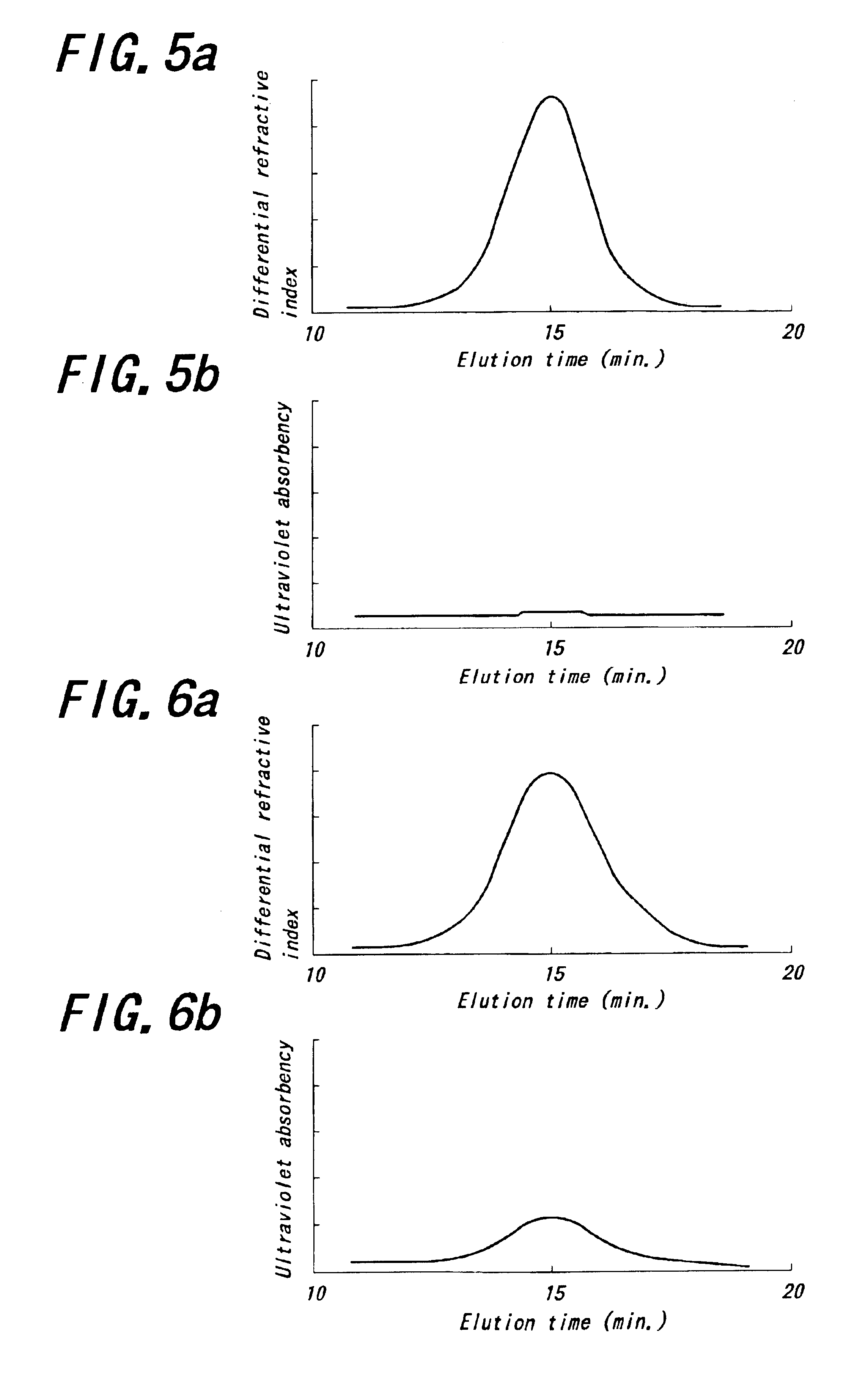

Bicyclo[2.2.1]heptane dicarboxylate salts as polyolefin nucleators

InactiveUS6465551B1Exceptional nucleation efficacyExcellent calcium stearate compatibilityOrganic chemistryOrganic compound preparationChemistryPolyolefin

Compounds and compositions comprising specific metal salts of bicyclo[2.2.1 ]heptane dicarboxylate salts in order to provide highly desirable properties within polyolefin articles are provided. The inventive salts and derivatives thereof are useful as nucleating and / or clarifying agents for such polyolefin, provide excellent crystallization temperatures, stiffness, and calcium stearate compatibility within target polyolefin. Also, such compounds exhibit very low hygroscopicity and therefore excellent shelf stability as powdered or granular formulations. Polyolefin additive compositions and methods of producing polyolefin with such compounds are also contemplated within this invention.

Owner:MILLIKEN & CO

Topically Bioavailable Acne and Rosacea Treatment Compositions

InactiveUS20040156873A1Reduce stimulationSynergistic superior anti-acneBiocideCosmetic preparationsAdditive ingredientIrritation

The present invention relates to acne and rosacea compositions by a six-prong synergistic combination treatment strategy that includes (1) control of excess sebum production, (2) control of undesirable bacteria or mites, (3) control of inflammation, (4) enhanced desquamation of follicular infundibulum cells, (5) reduction of irritation from anti-acne or rosacea compositions themselves, and (6) enhancement of the topical bioavailability of anti-acne and rosacea compositions. This is achieved by a synergistic combination of commonly utilized topical anti-acne and rosacea ingredients with a topical bioavailability enhancement composition, which results in enhanced anti-acne and rosacea action from such ingredients. Moreover, additional inclusion of an anti-inflammatory composition, and also a vascular micro-circulation enhancement composition, further results in synergistic superior anti-acne and rosacea benefits from such compositions. The present invention discloses additional surprising synergistic combinations for the control of acne and rosacea that are suitable for a variety of delivery systems and packaging forms.

Owner:GUPTA SHYAM K

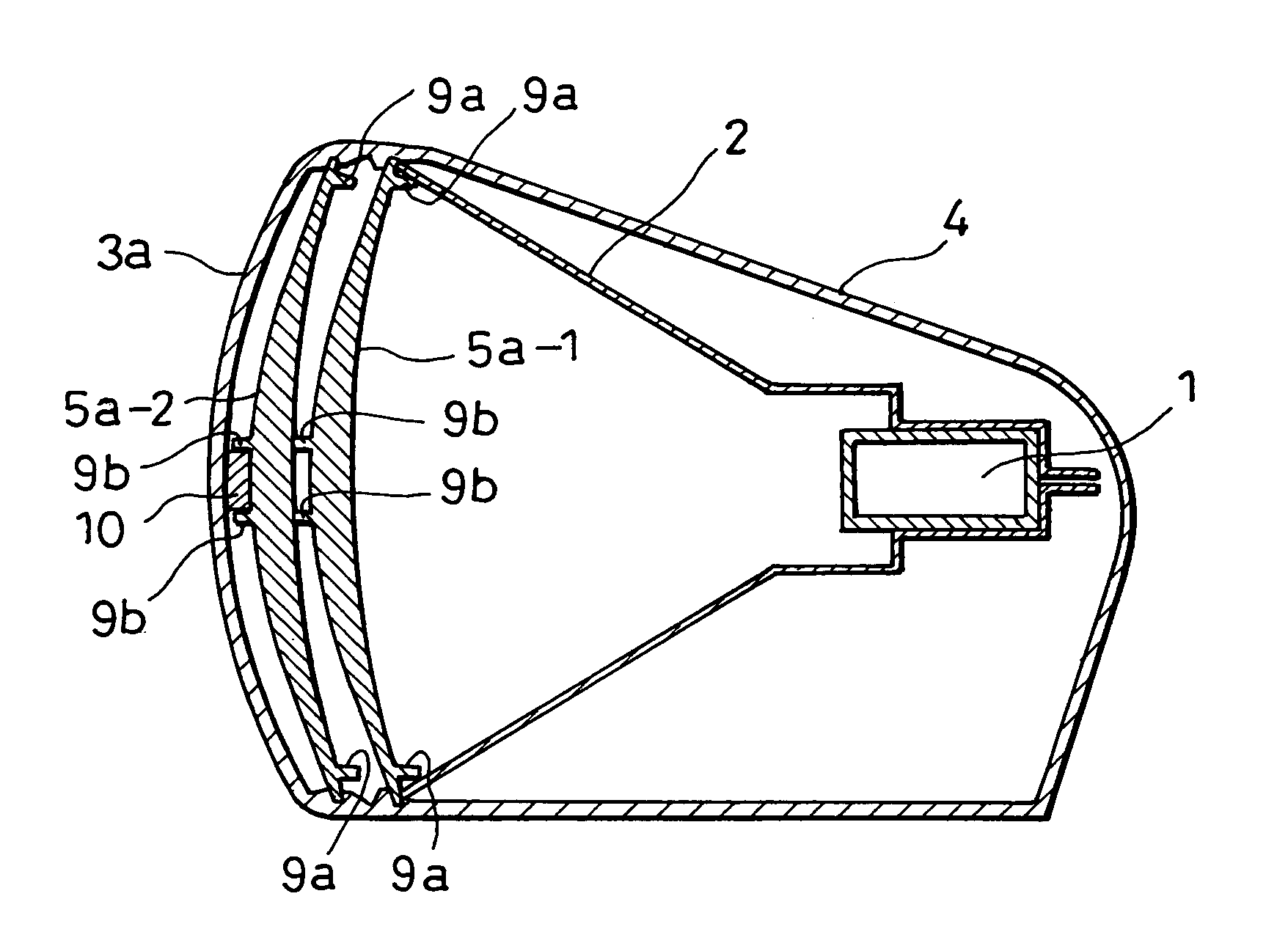

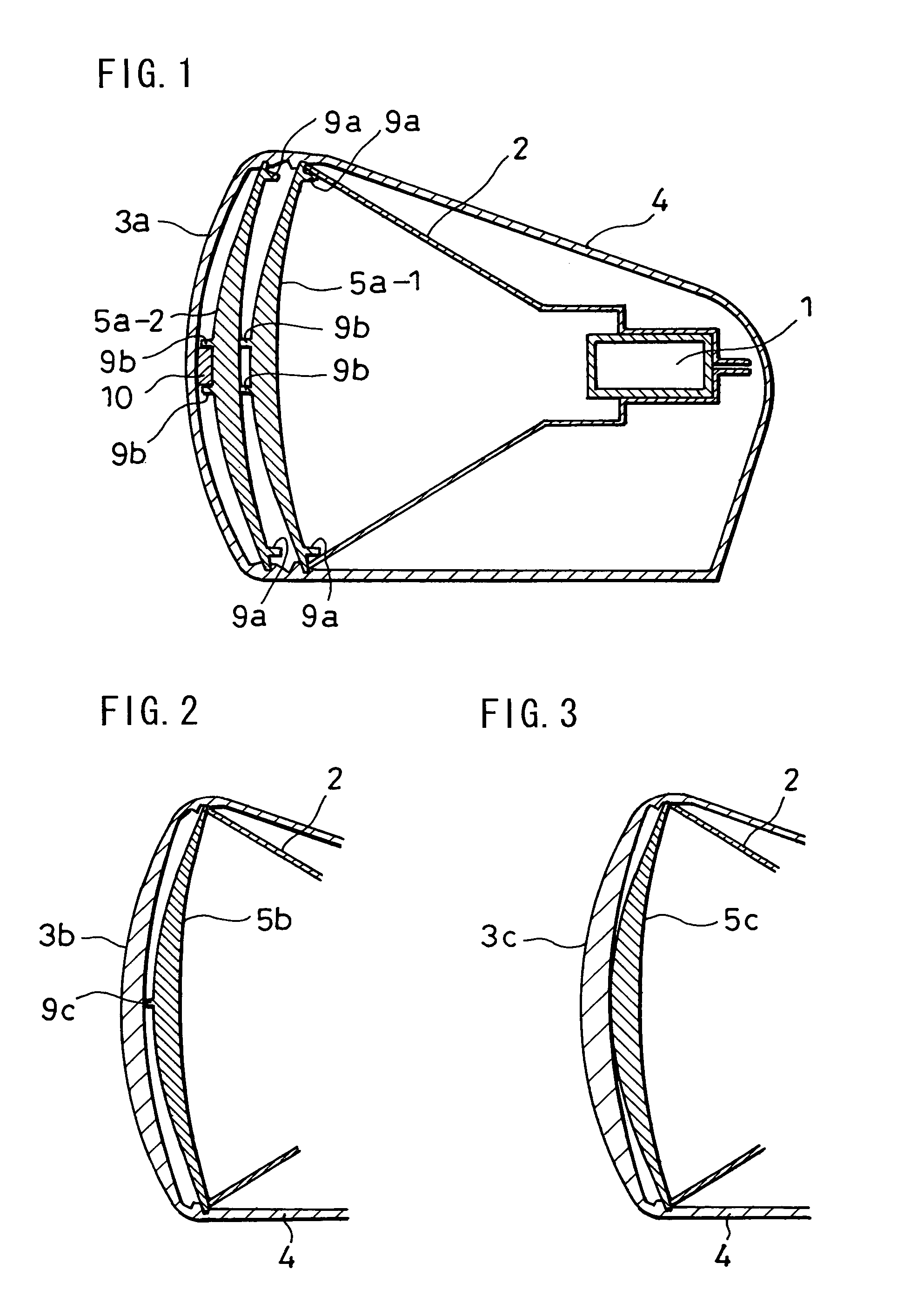

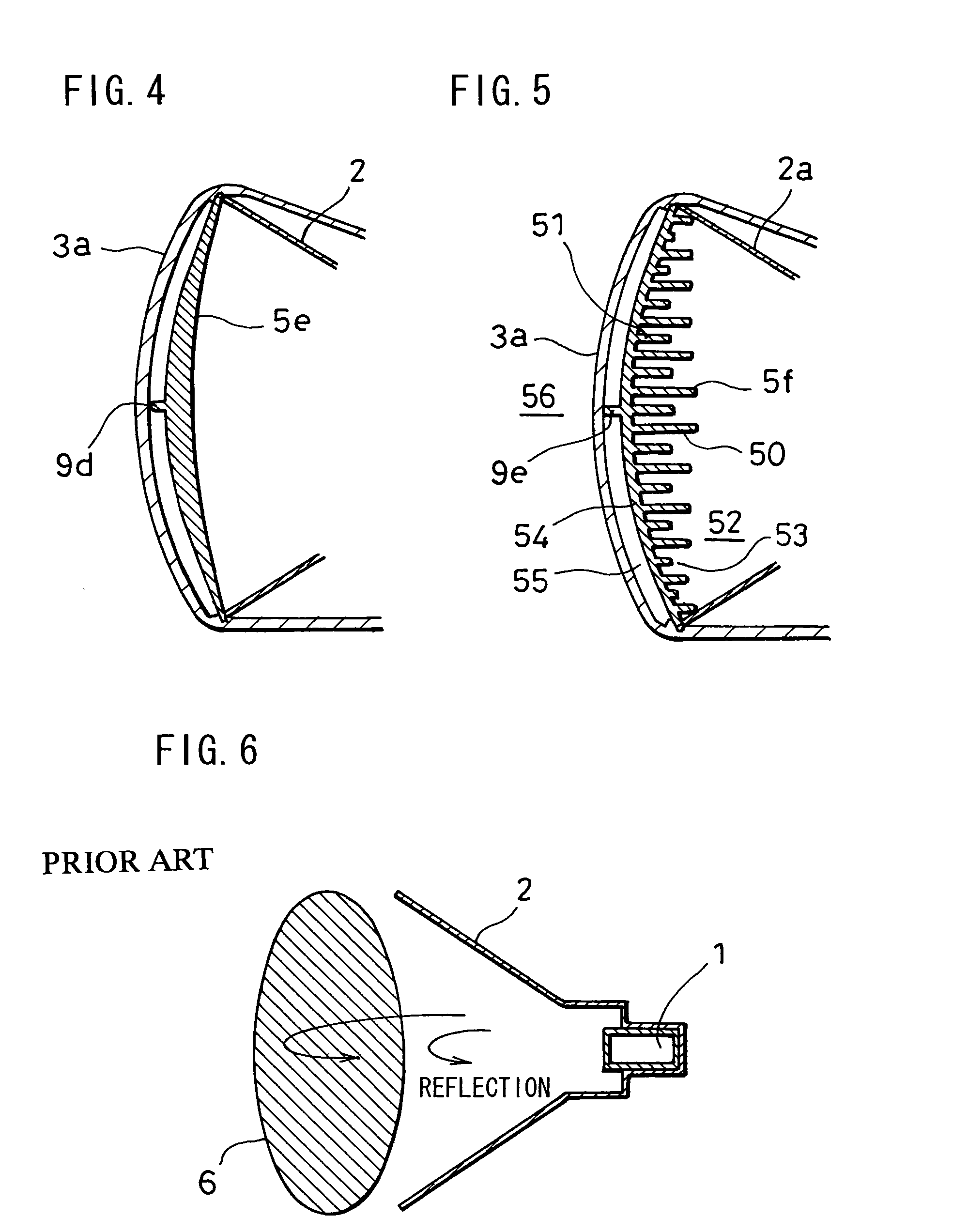

Fan-beam antenna

InactiveUS7075496B2Simple compositionSmall reflectionWaveguide hornsRadiating element housingsDielectric plateLight beam

An object of the invention is to provide a fan-beam antenna which comprises a flare which is long in a horizontal direction thereof and whose cross section is horn-shaped, and a water-proof box housing components of said antenna, in which a vertical beam width is made narrow without spreading a vertical size to increase gain. Accordingly, this invention is characterized in that a radome radiation surface is constituted of a plurality of dielectric plates equivalently, and at least one of the dielectric plates is made a dielectric lens having a characteristic similar to a convex lens.

Owner:TAIYO MUSEN

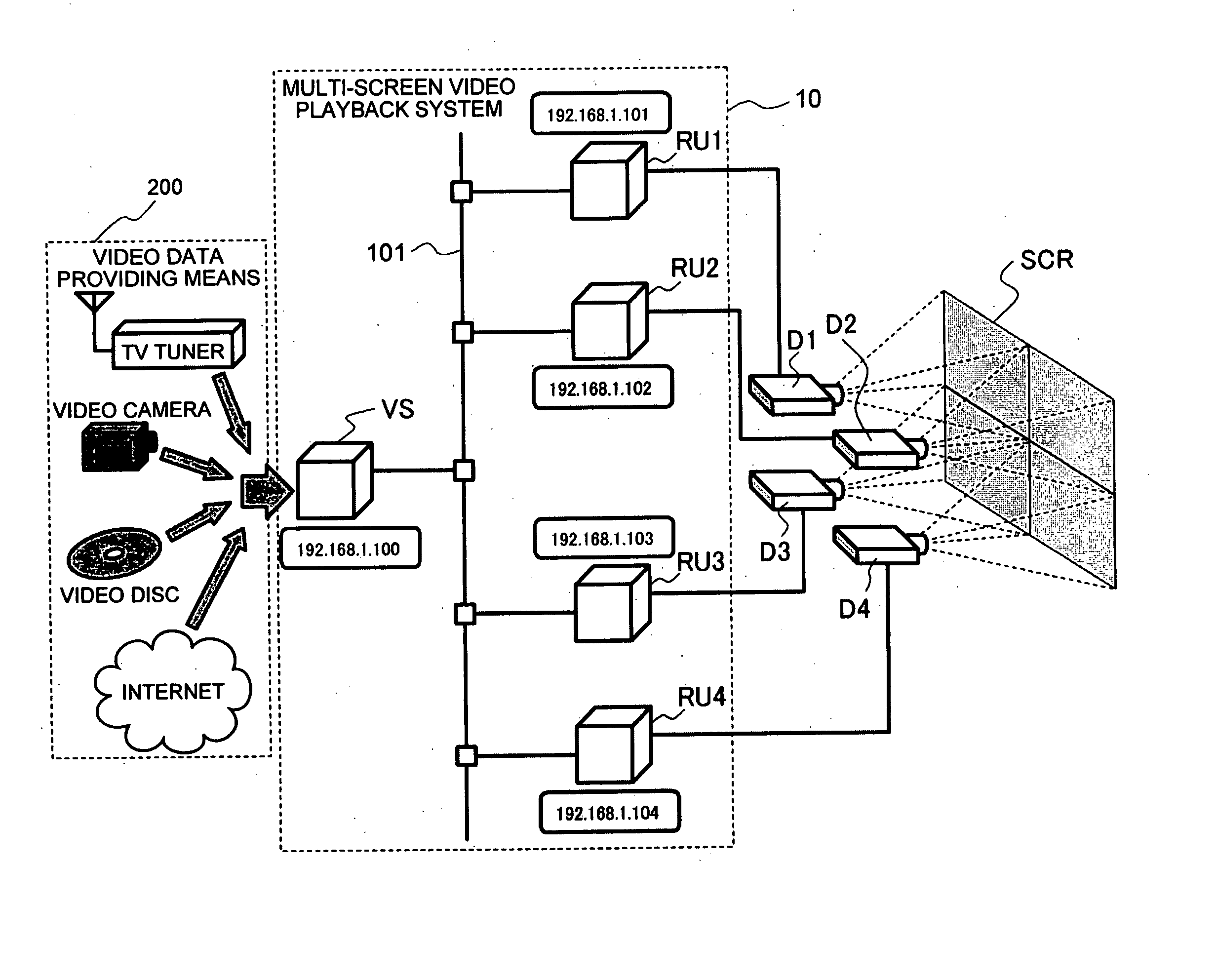

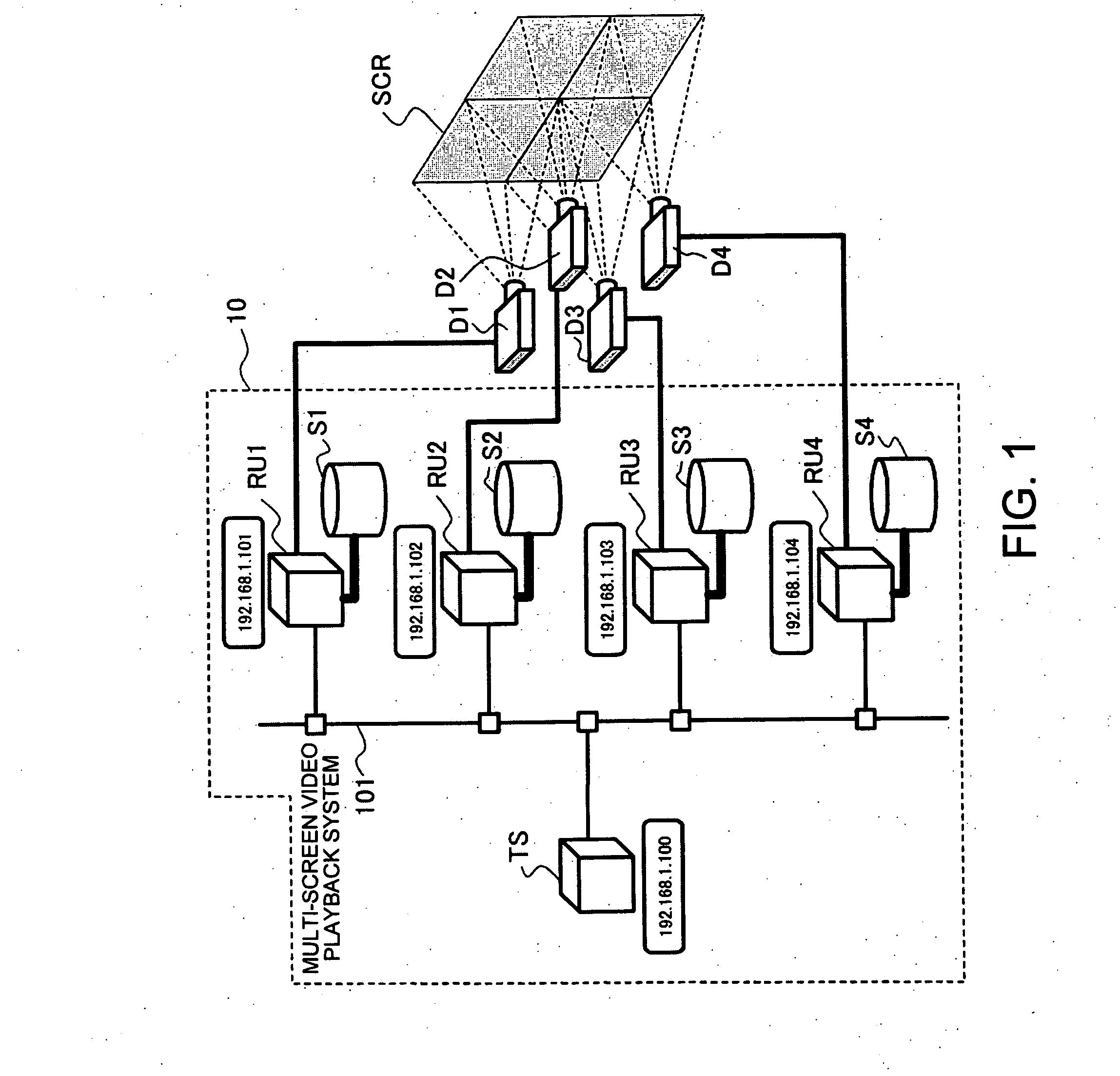

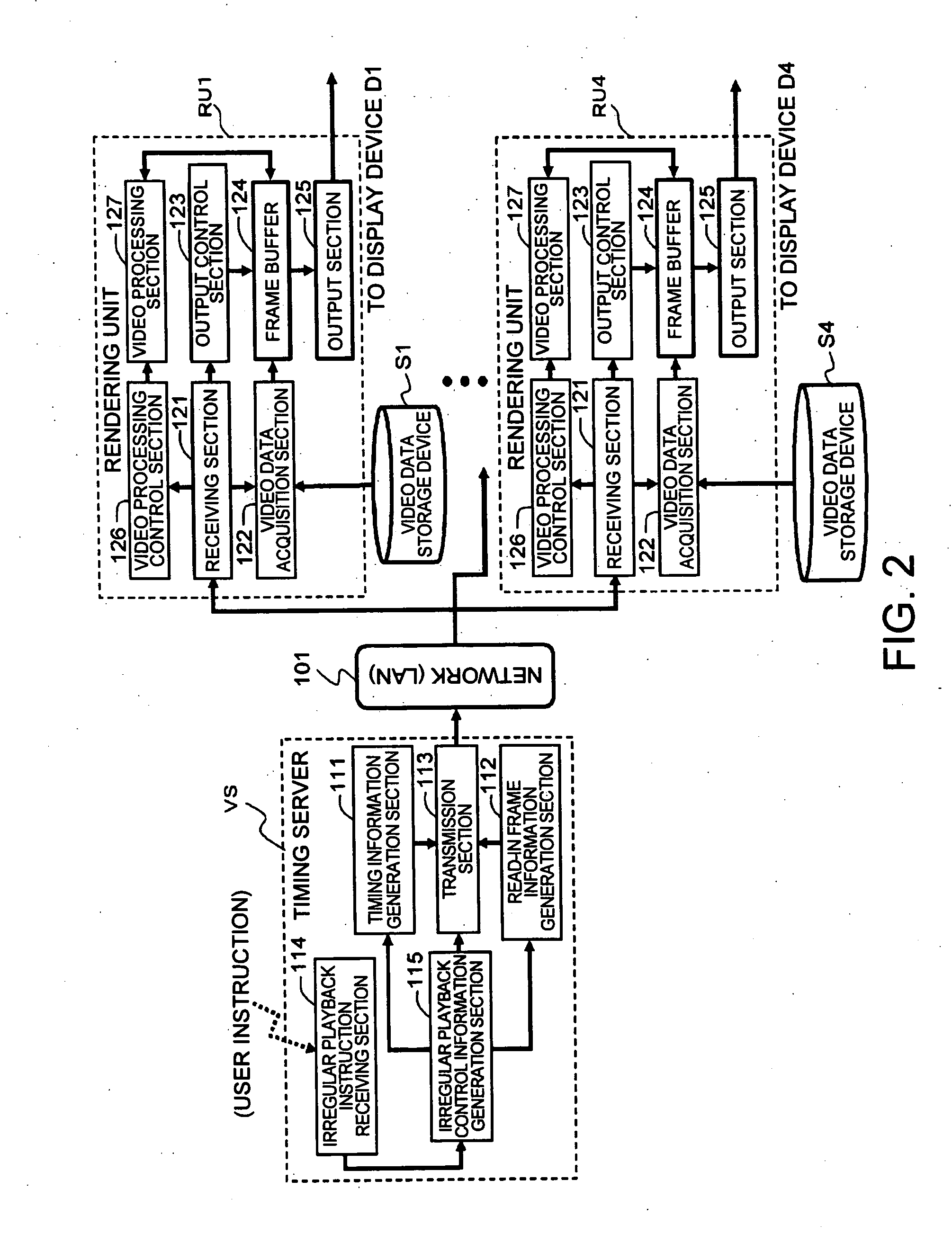

Multi-screen video playback system

ActiveUS20050168630A1Simple compositionEasy to performTelevision system detailsCathode-ray tube indicatorsTime informationComputer graphics (images)

Exemplary embodiments of the invention provide a multi-screen video playback system which enables synchronized video playback, and at the same time enables irregular playback such as color processing, contents change. According to exemplary embodiments, a multi-screen video playback system includes a plurality of rendering units RU1 through RU4 which are connected to LAN as a network and output video data to a plurality of display devices D1 through D4; a function which is connected to LAN and distributes timing information to the rendering units RU1 through RU4 by simultaneous transmission; a timing server TS which generates the irregular playback control information to enable irregular playback, such as color correction and contents change to the video data, in a plurality of rendering units RU1 through RU4 which output video data to each corresponding display device of the plurality of display devices D1 through D4; and video data storage devices S1 through S4 to store video data to be reproduced.

Owner:SEIKO EPSON CORP

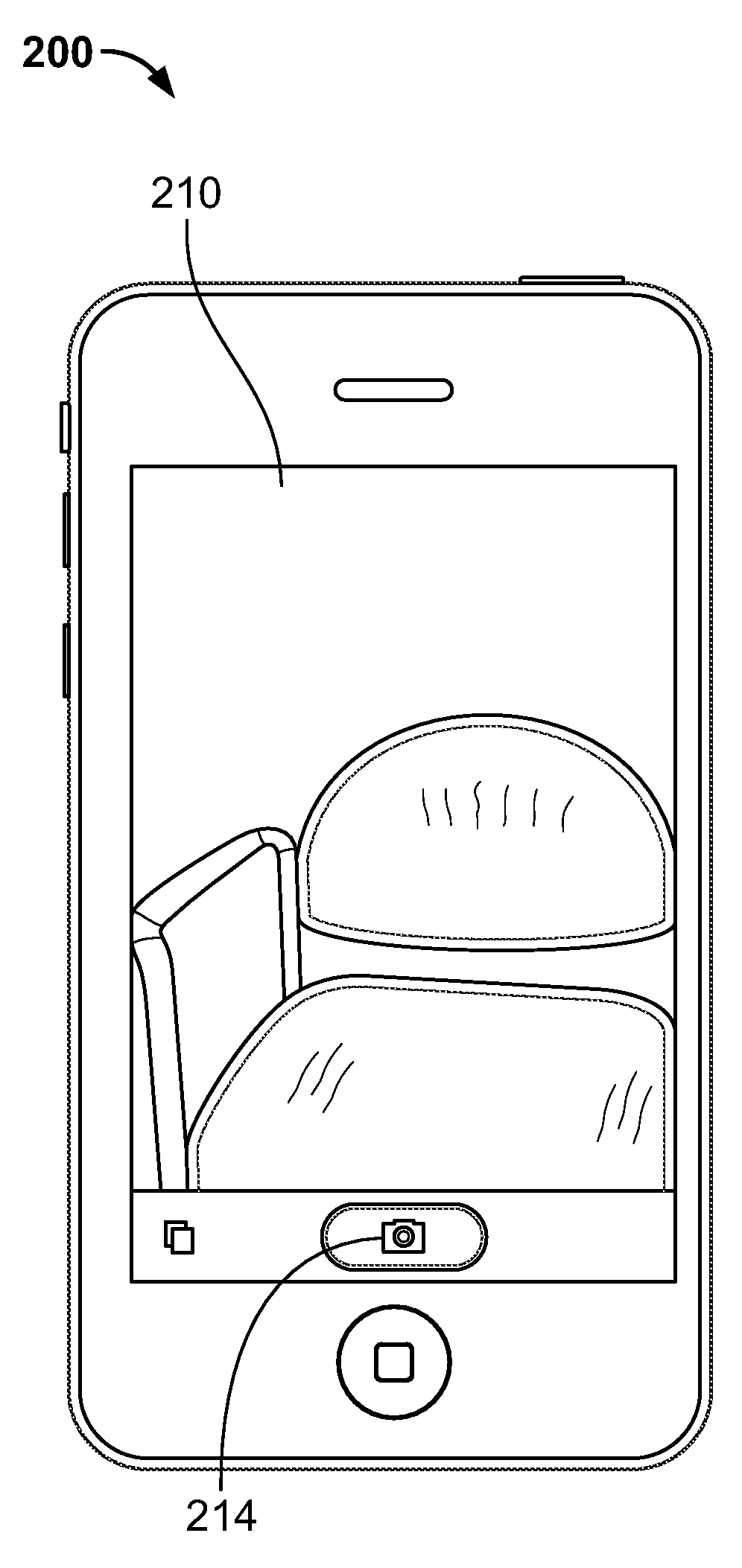

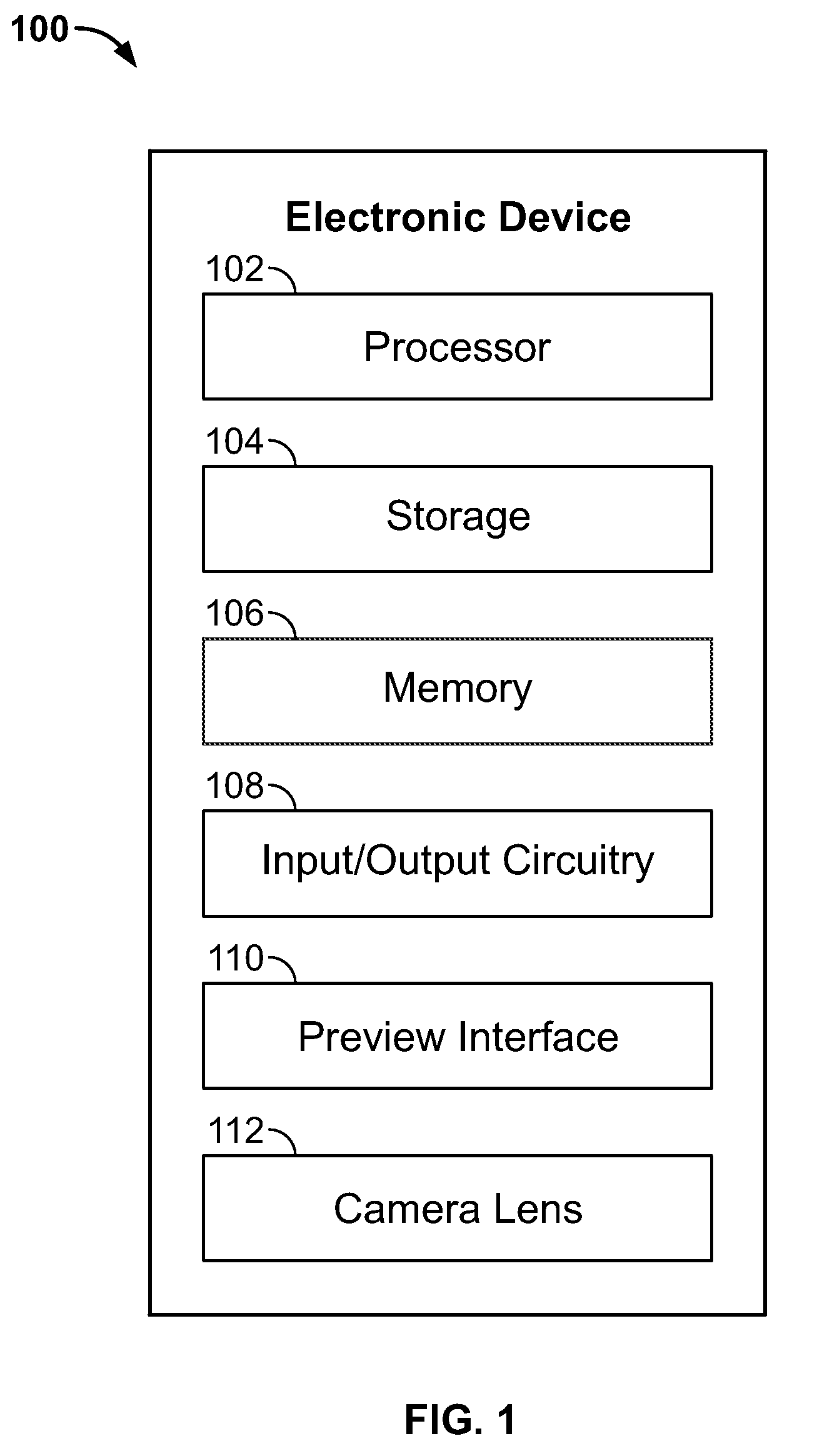

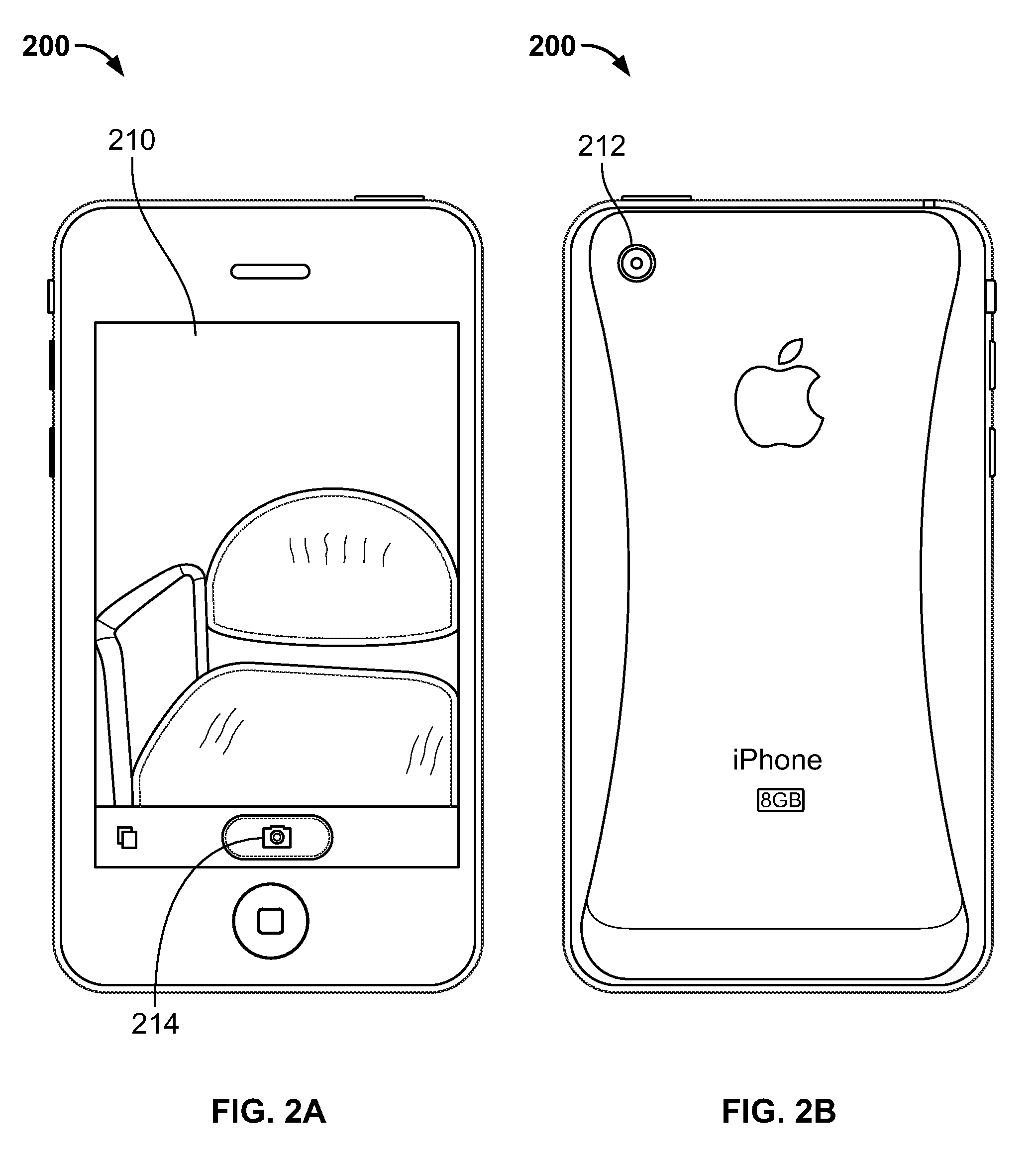

Systems and methods for centering a photograph without viewing a preview of the photograph

InactiveUS20100225773A1Enhance photographTaking imageTelevision system detailsCharacter and pattern recognitionCamera lensMotion sensing

Systems and methods are providing for capturing images of objects or faces without previewing the image to be captured. In particular, systems and methods are provided for using a detection algorithm to determine when a camera lens of an electronic device is properly oriented to capture an item (e.g., a face in a self-portrait). The detection algorithm can be configured to identify specific faces or objects, and can direct the electronic device to automatically store a captured image in response to detecting objects or faces of interest. In some embodiments, a motion-sensing component can be used to help align the lens.

Owner:APPLE INC

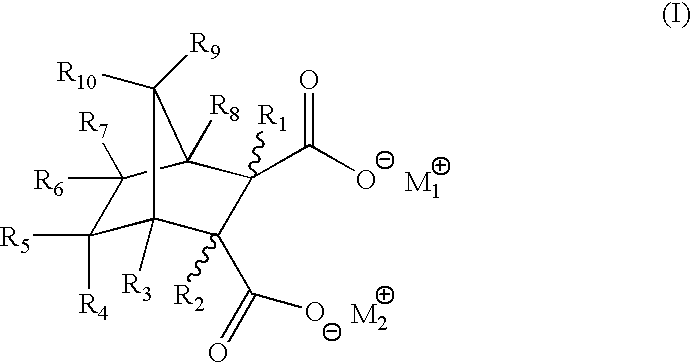

Metal salts of hexahydrophthalic acid as nucleating additives for crystalline thermoplastics

InactiveUS6599971B2Excellent calcium stearate compatibilityExcellent high peak crystallization temperatureOrganic compound preparationFibre treatmentThermoplasticScavenger

Compounds and compositions comprising specific metal salts of hexahydrophthalic acid (HHPA) in order to provide highly desirable properties within thermoplastic articles are provided. The inventive HHPA derivatives are useful as nucleating and / or clarifying agents for such thermoplastics, are practical and easy to handle. Such compounds provide excellent crystallization temperatures, stiffness, and acid scavenger compatibility within target polyolefins. Also, such compounds exhibit very low hygroscopicity and therefore excellent shelf stability as powdered or granular formulations. Thermoplastic additive compositions and methods of producing polymers with such compounds are also contemplated within this invention.

Owner:MILLIKEN & CO

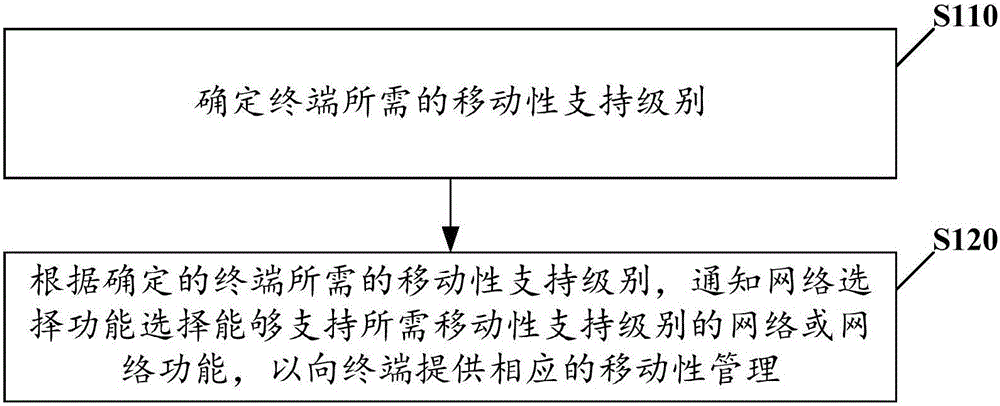

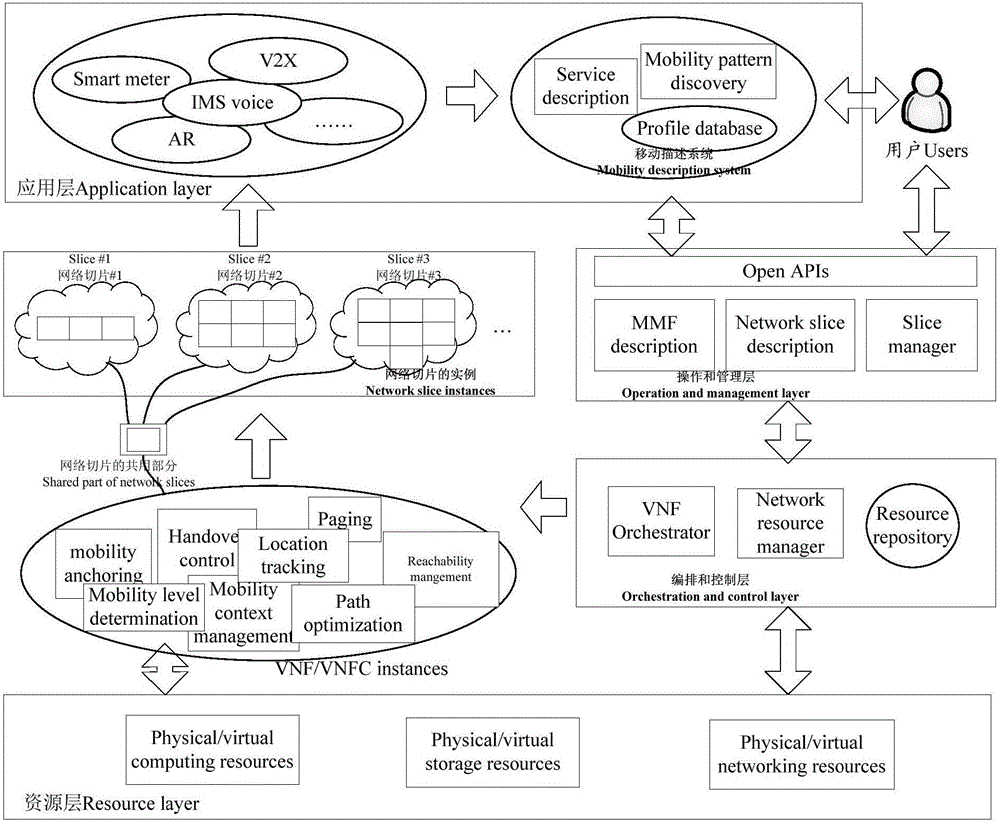

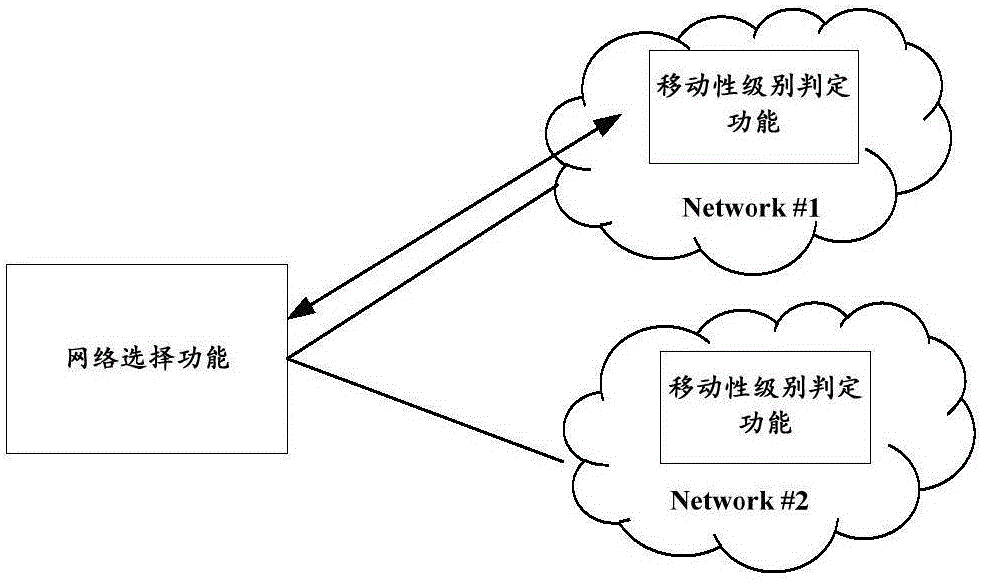

Method and device for selecting mobility management mechanism for terminal as required

ActiveCN105813195ASimple compositionAvoid complicatedData switching networksWireless communicationComplex networkEngineering

The embodiment of the invention provides a method and device for selecting a mobility management mechanism for a terminal as required.The method includes the steps that the mobility support level required by the terminal is determined; the network selection function is informed to select a network or a network function capable of supporting the required mobility support level according to the determined mobility supporting level required by the terminal, so that corresponding mobility management is provided for the terminal.Different networks offer services to terminals of different mobility supporting requirements, complex network function configuration is avoided, and complexity of mobility management is effectively lowered.

Owner:DATANG MOBILE COMM EQUIP CO LTD

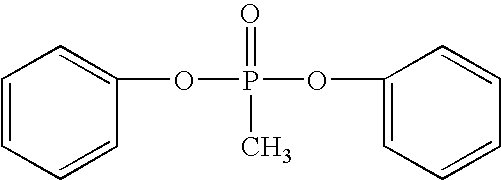

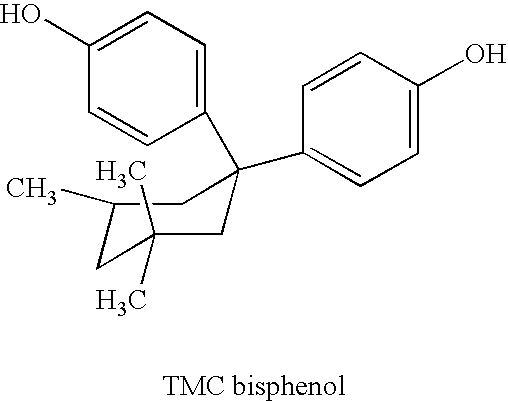

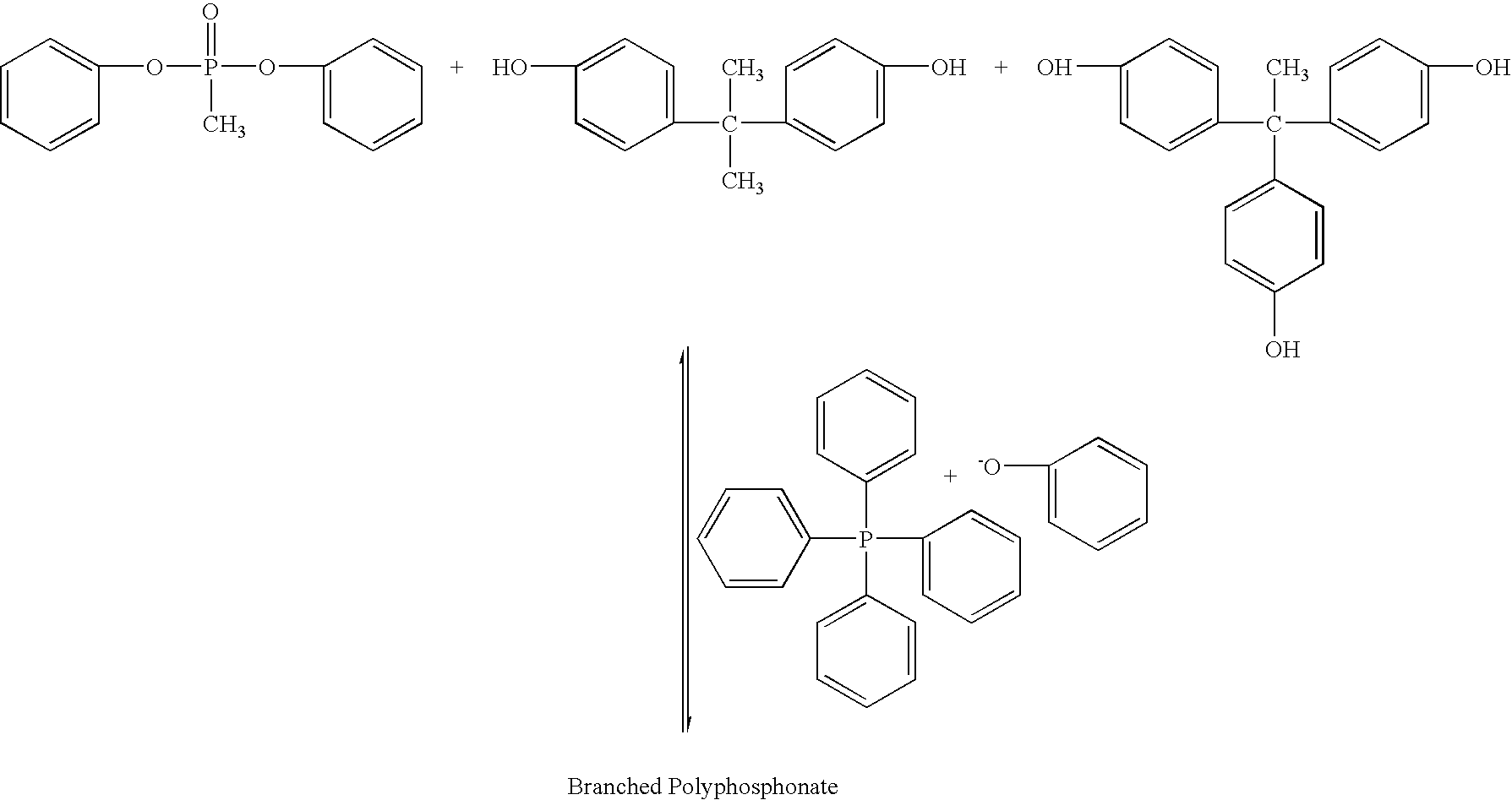

Branched polyphosphonates that exhibit an advantageous combination of properties, and methods related thereto

Disclosed are branched polyphosphonates produced via a superior transesterification process, and methods related thereto. These branched polyphosphonates exhibit a unique and advantageous combination of properties, such as outstanding fire resistance, improved heat stability, improved toughness, and superior processing characteristics. Also disclosed are polymer compositions that comprise these branched polyphosphonates and at least one other polymer, wherein the resulting polymer compositions exhibit flame retardant properties. Further disclosed are articles of manufacture produced from these polymers, such as fibers, films, coated substrates, moldings, foams, fiber-reinforced articles, or any combination thereof; these articles may be coated with a moisture barrier to enhance their moisture resistance properties.

Owner:FRX POLYMERS LLC

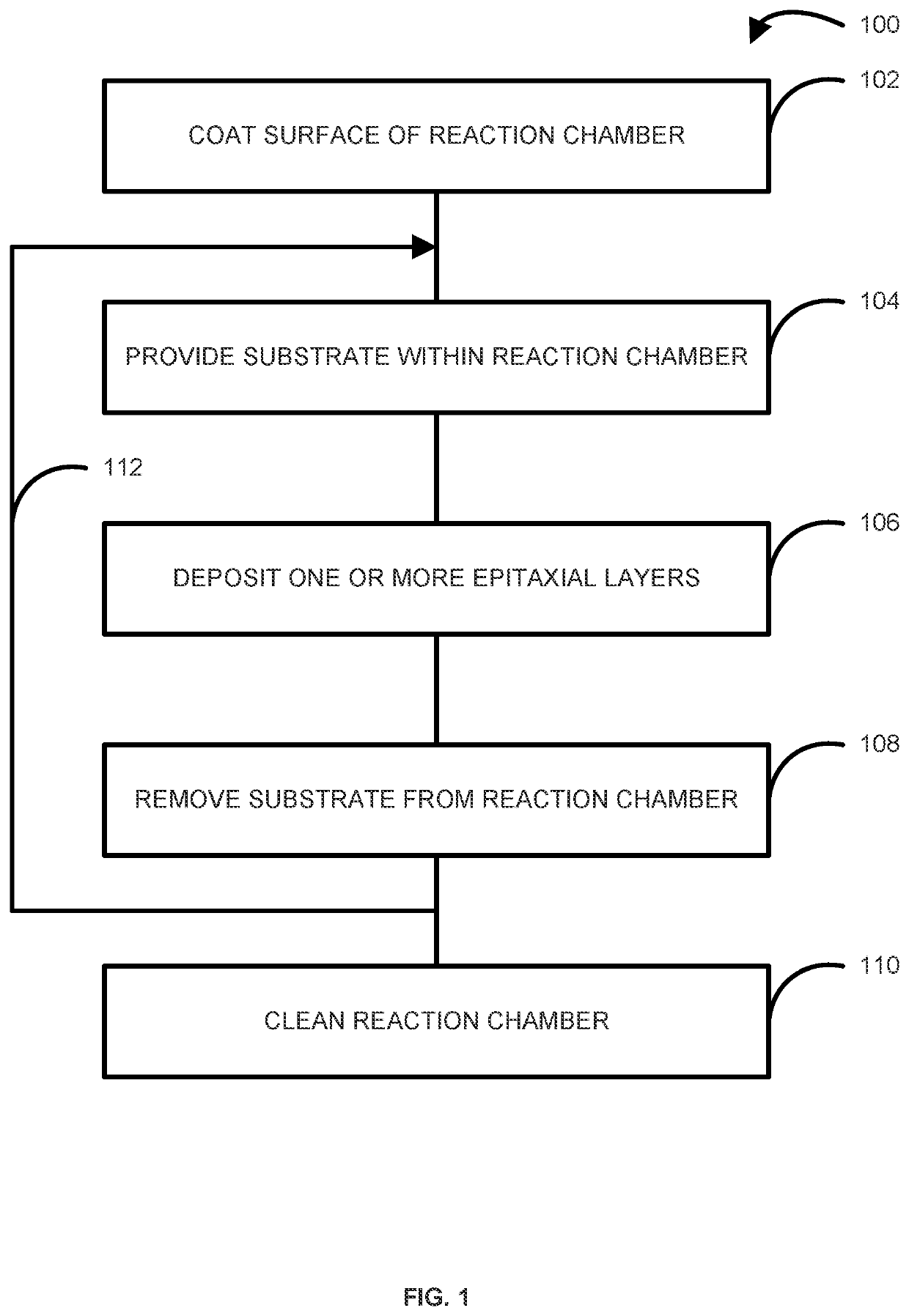

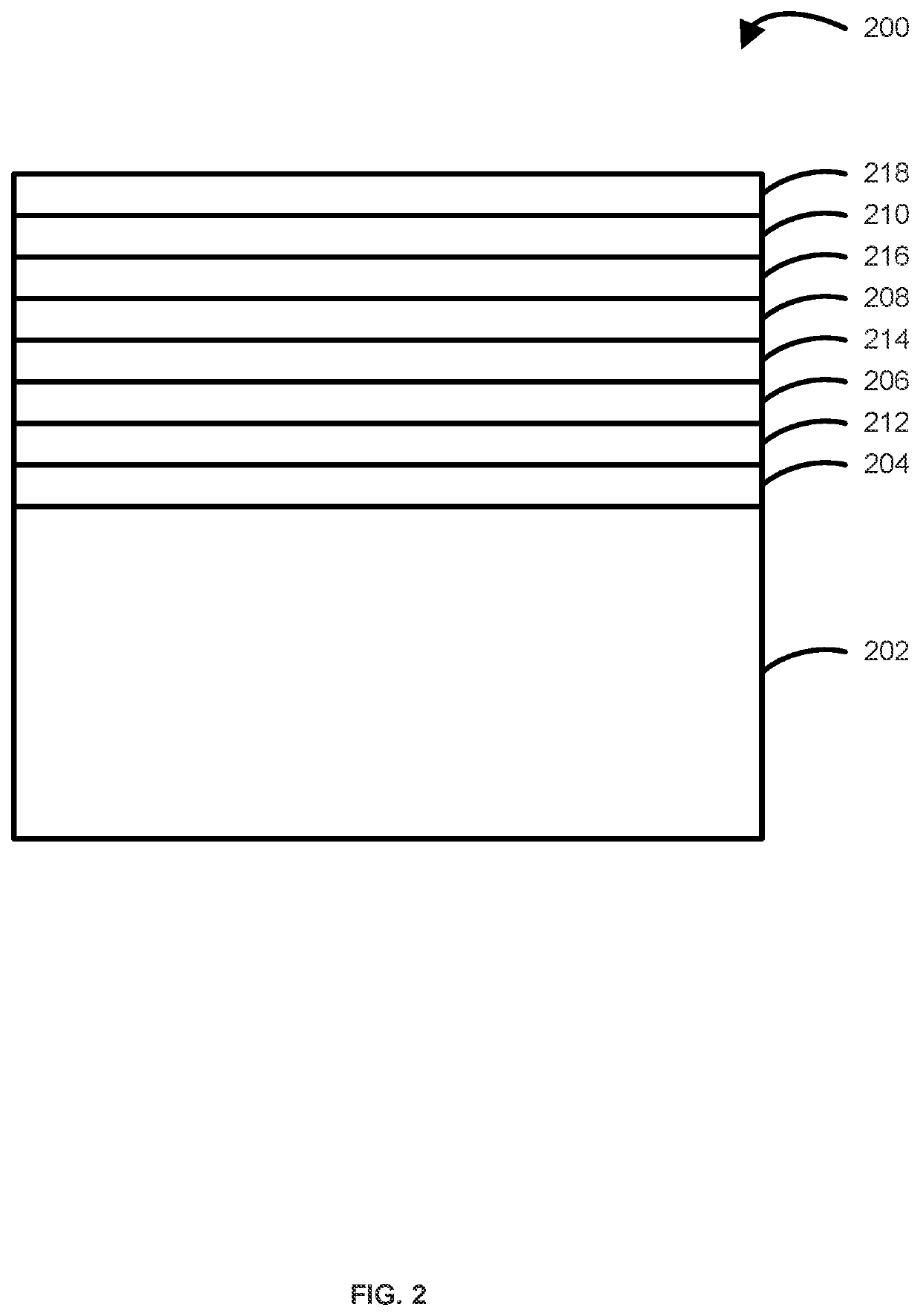

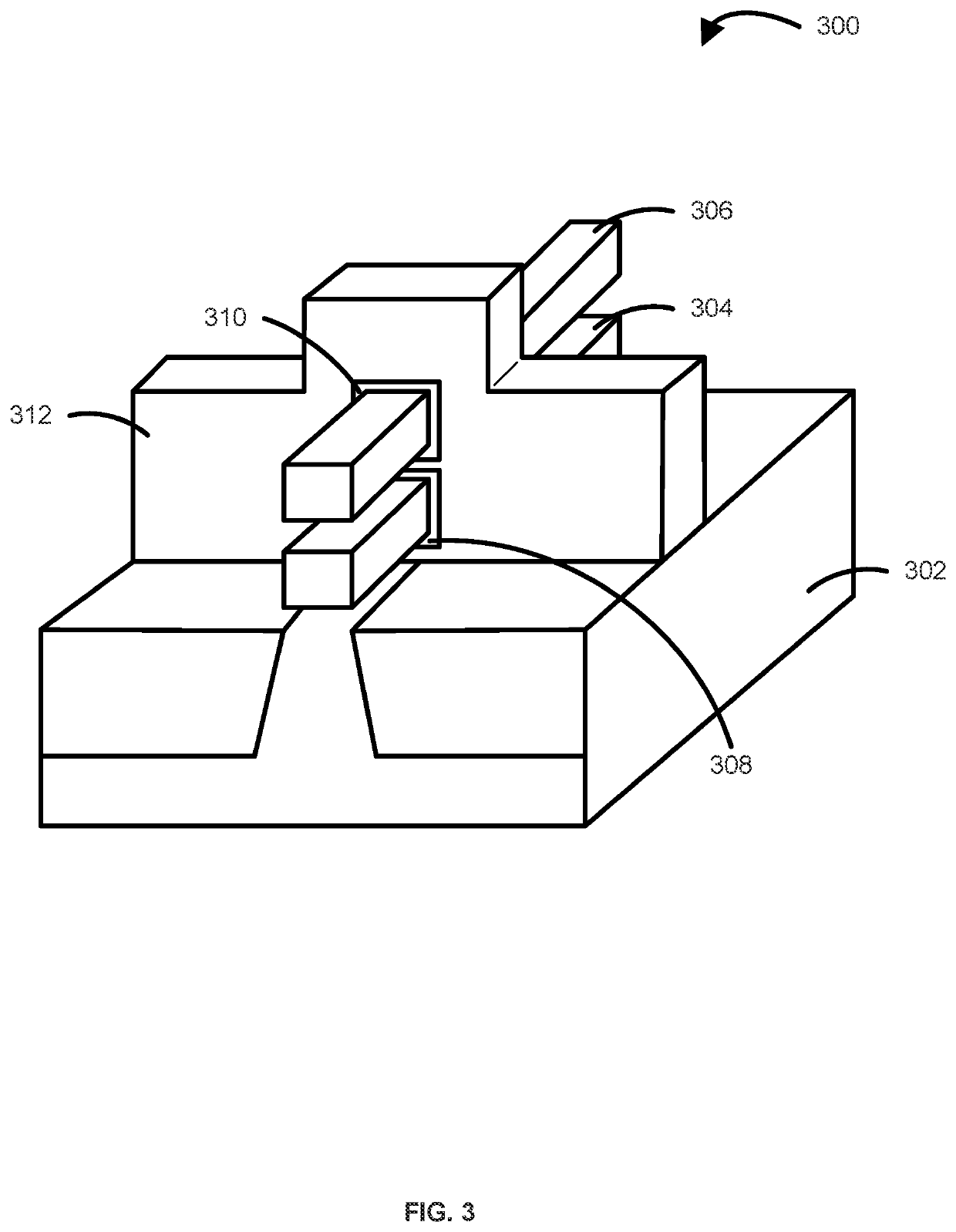

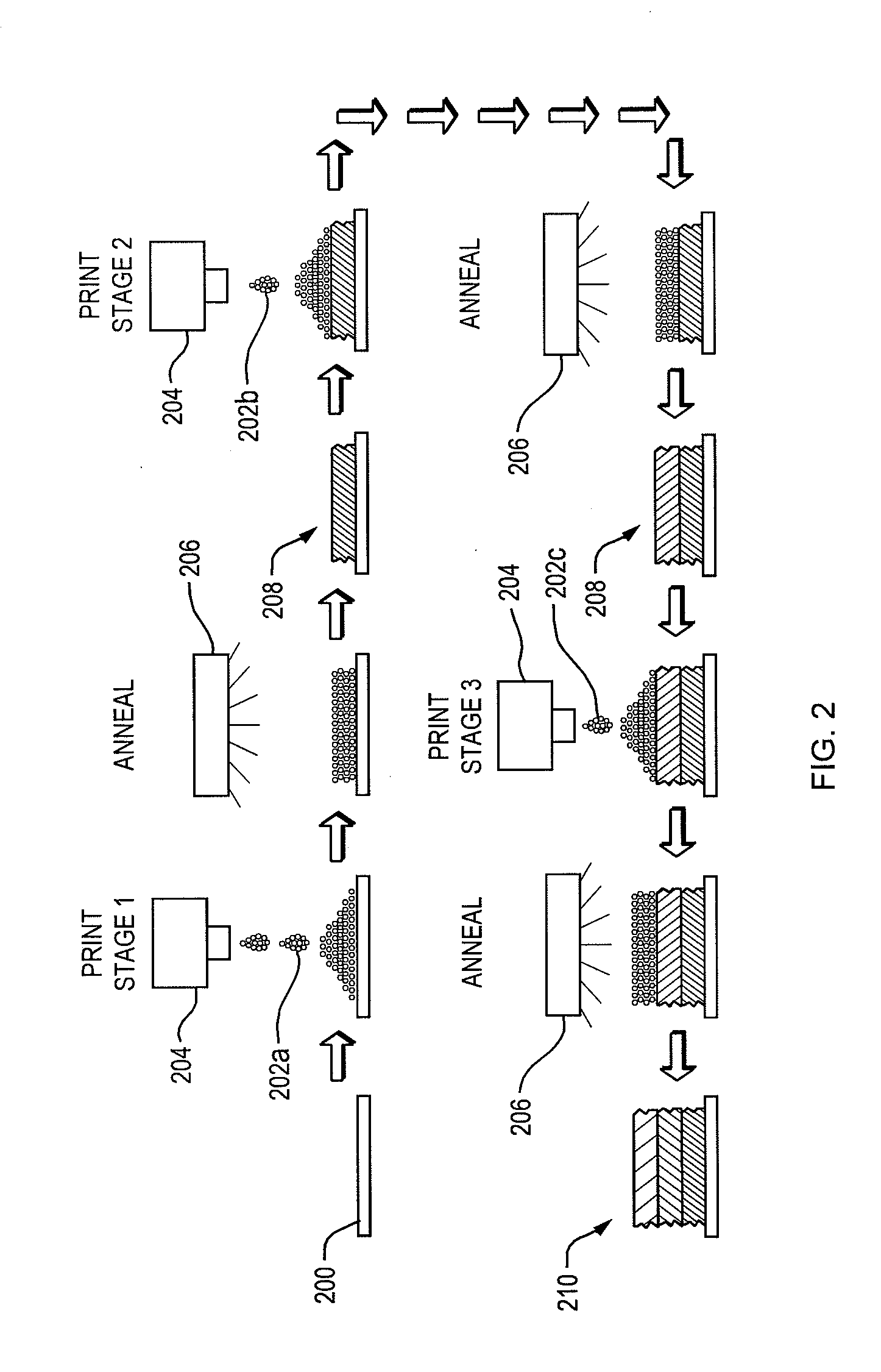

Method of depositing epitaxial material, structure formed using the method, and system for performing the method

PendingUS20210292902A1Improve throughputThe material is lowPolycrystalline material growthSemiconductor/solid-state device manufacturingEpitaxial materialEngineering

A method of depositing one or more epitaxial material layers, a device structure formed using the method and a system for performing the method are disclosed. Exemplary methods include coating a surface of a reaction chamber with a precoat material, processing a number of substrates, and then cleaning the reaction chamber.

Owner:ASM IP HLDG BV

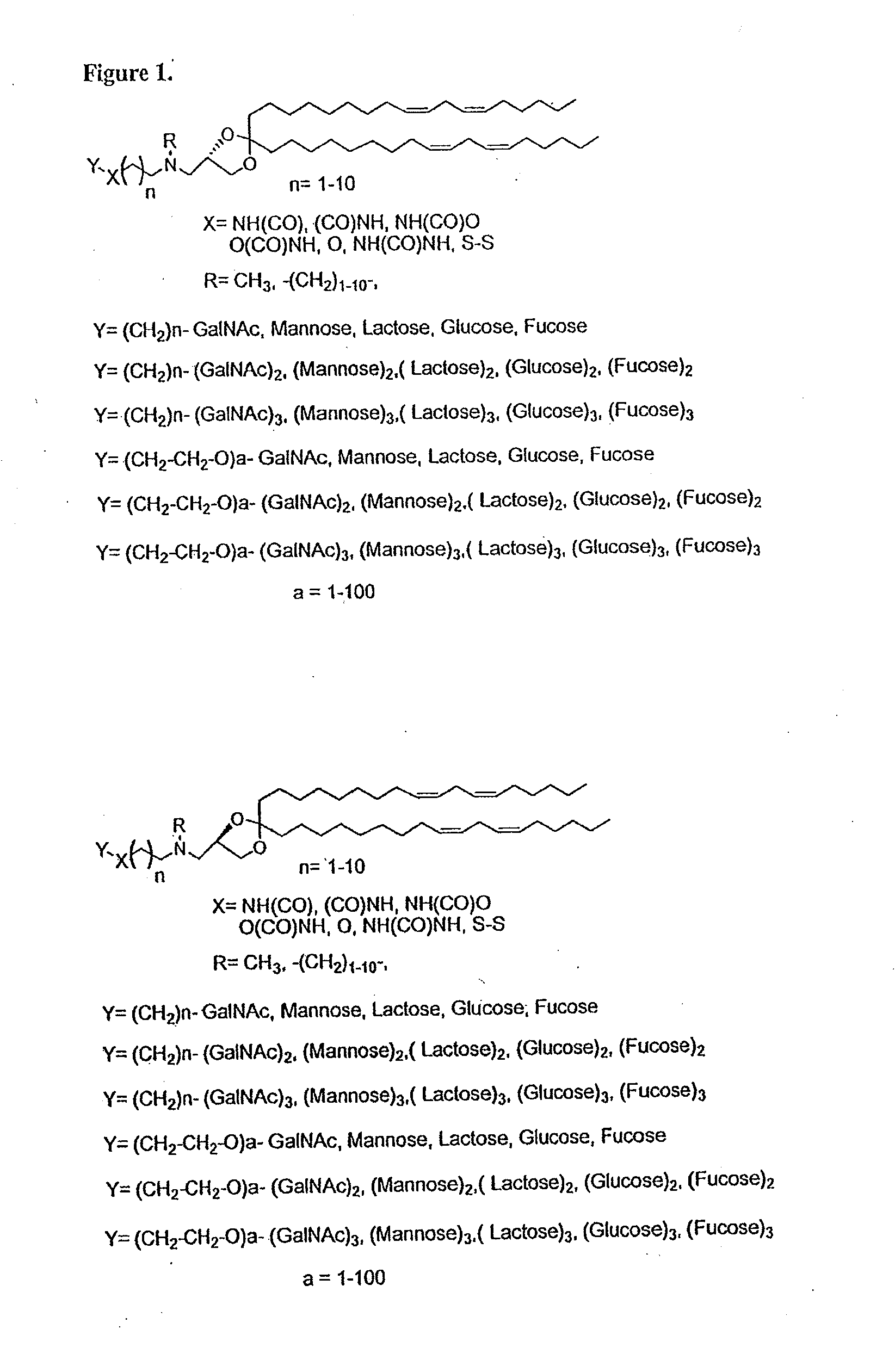

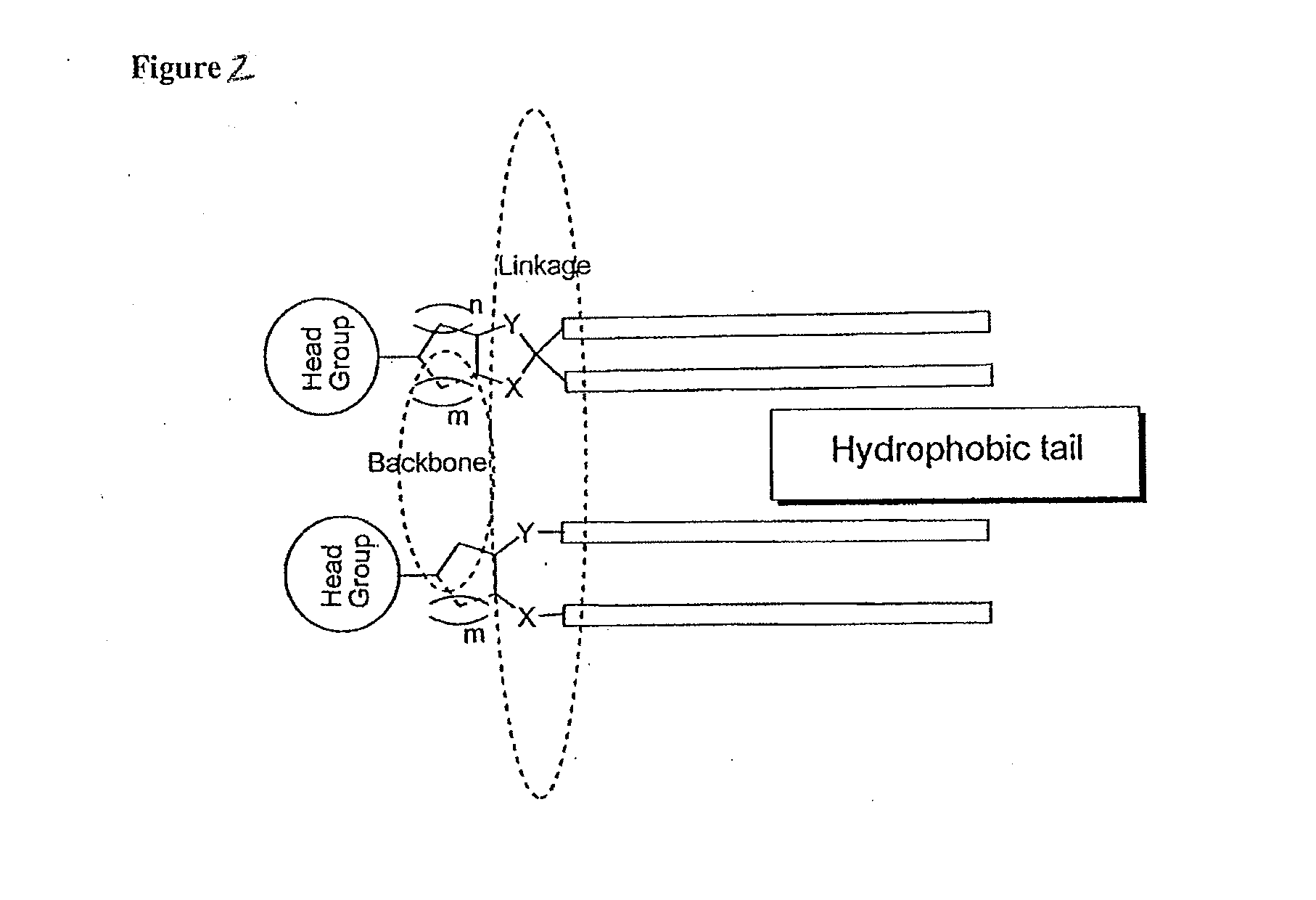

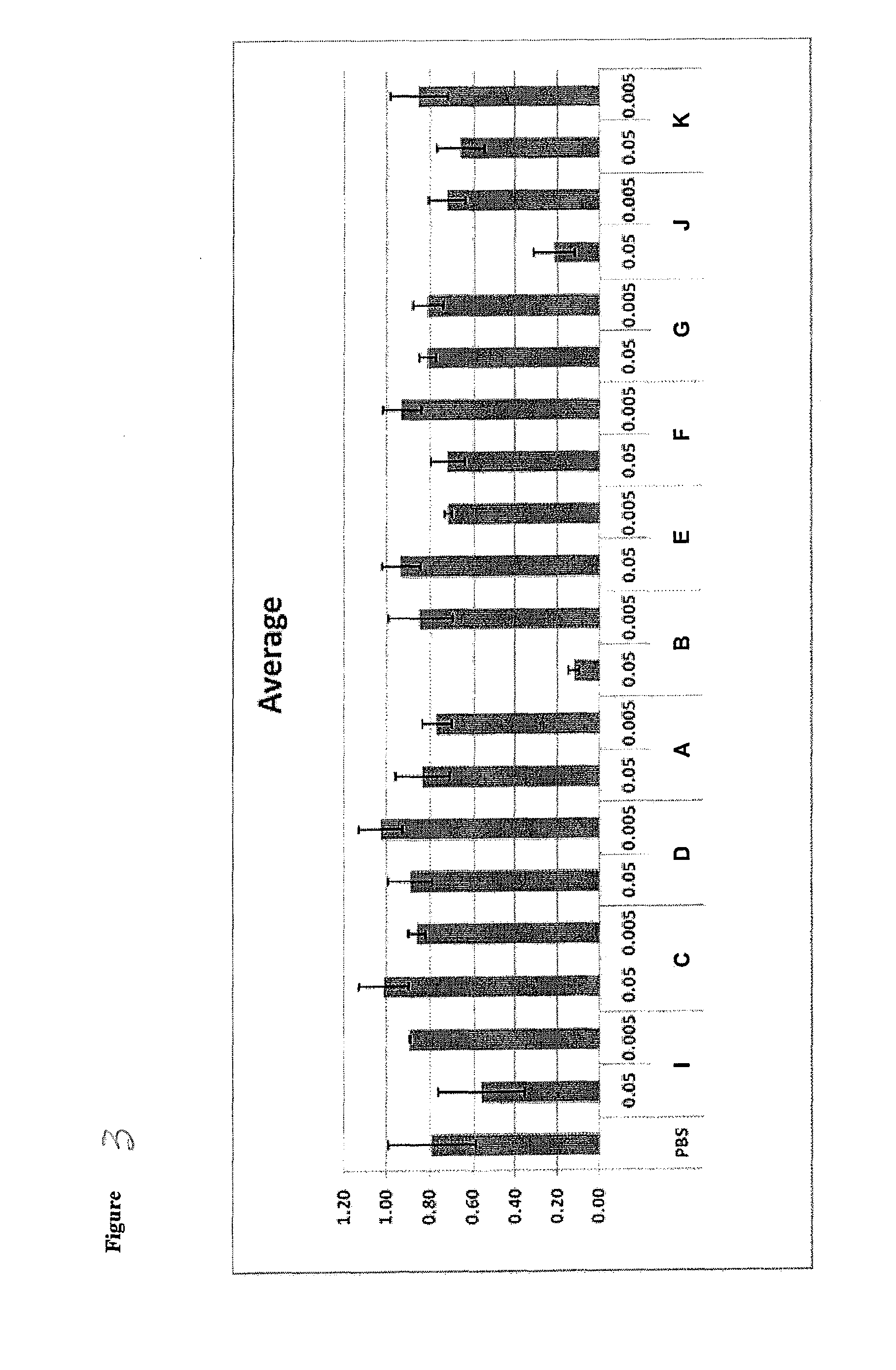

Novel lipids and compositions for the delivery of therapeutics

ActiveUS20110311583A1Adequate therapeutic indexSimple compositionAntibacterial agentsOrganic active ingredientsLipid formationAryl

(A1) Translate this text The present invention provides lipids that are advantageously used in lipid particles for the in vivo delivery of therapeutic agents to cells. In particular, the invention provides lipids having the following structure (I) wherein R1 and R2 are each independently for each occurrence optionally substituted C10-C30 alkyl, optionally substituted C10-C30 alkenyl, optionally substituted C10-C30 alkynyl, optionally substituted C10-C30 acyl, or -linker-ligand; R3 is H, optionally substituted C1-C10 alkyl, optionally substituted C2-C10 alkenyl, optionally substituted C2-C10 alkynyl, alkylhetrocycle, alkylphosphate, alkylphosphorothioate, alkylphosphorodithioate, alkylphosphonates, alkylamines, hydroxyalkyls, ?-aminoalkyls, ?-(substituted)aminoalkyls, ?-phosphoalkyls, ?-thiophosphoalkyls, optionally substituted polyethylene glycol (PEG, mw 100-40K), optionally substituted mPEG (mw 120-40K), heteroaryl, heterocycle, or linker-ligand; E is O, S, N(Q), C(O), N(Q)C(O), C(0)N(Q), (Q)N(CO)O, O(CO)N(Q), S(O), NS(O)2N(Q), S(O)2, N(Q)S(O)2, SS, O═N, aryl, heteroaryl, cyclic or heterocycle; and, Q is H, alkyl, ?-aminoalkyl, ?-(substituted)aminoalky, ?-phosphoalkyl or ?-thiophosphoalkyl.

Owner:ARBUTUS BIOPHARMA CORPORAT ION

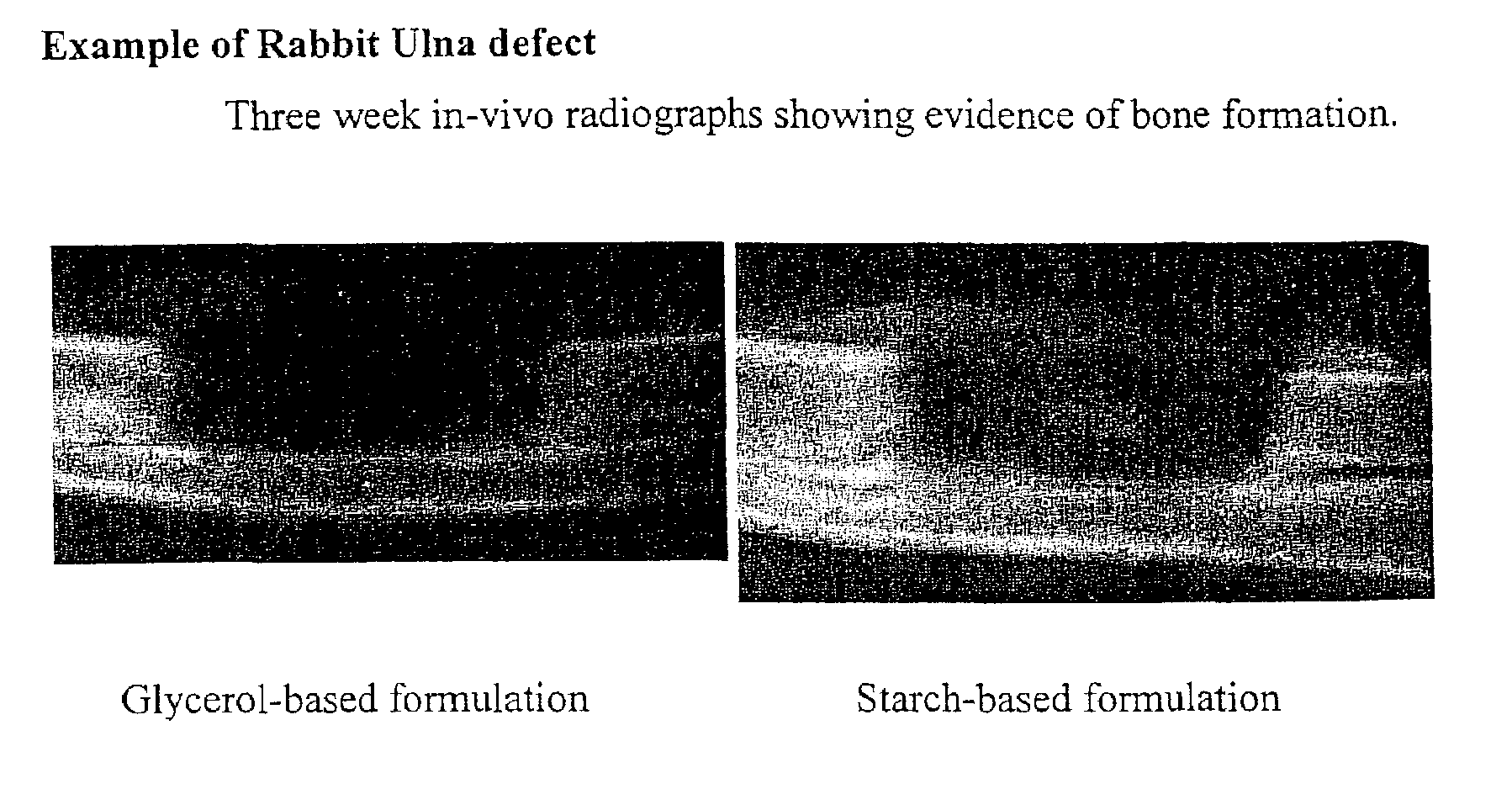

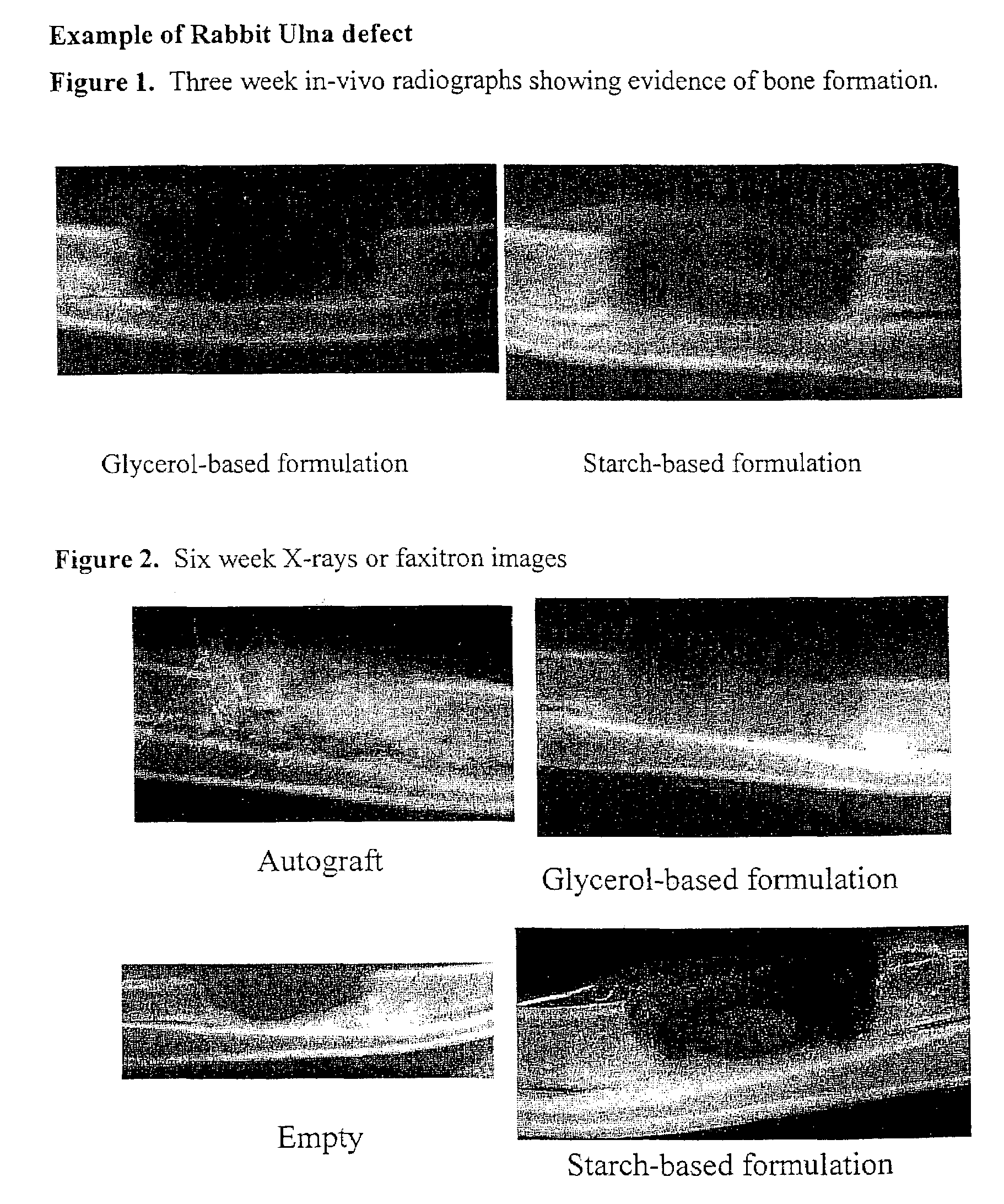

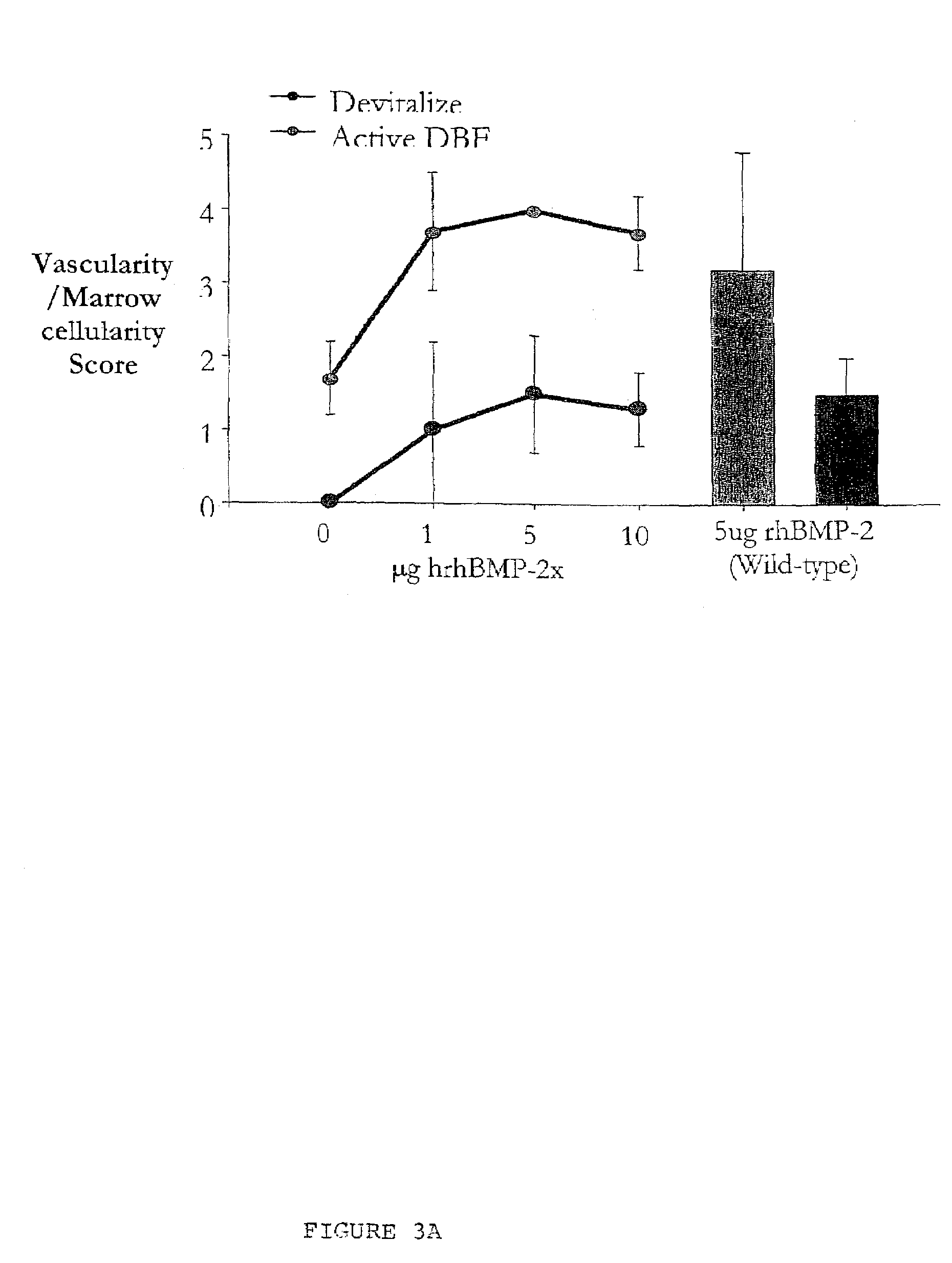

Bone graft

ActiveUS7163691B2Fast reduction in osteoinductiveGood curative effectOrganic active ingredientsImpression capsOSTEOINDUCTIVE FACTORIn vivo

An improved demineralized bone matrix (DBM) or other matrix composition is provided that has been mixed with a stabilizing agent that acts as (1) a diffusion barrier, (2) a enzyme inhibitor, (3) a competitive substrate, or (4) a masking moiety. A diffusion barrier acts as a barrier so as to protect the osteoinductive factors found in DBM from being degraded by proteolytic and glycolytic enzymes at the implantation site. Stabilizing agents may be any biodegradable material such as starches, modified starches, cellulose, dextran, polymers, proteins, and collagen. As the stabilizing agents degrades or dissolves in vivo, the osteoinductive factors such as TGF-β, BMP, and IGF are activated or exposed, and the activated factors work to recruit cells from the preivascular space to the site of injury and to cause differentiation into bone-forming cells. The invention also provides methods of preparing, testing, and using the inventive improved osteodinductive matrix compositions.

Owner:WARSAW ORTHOPEDIC INC

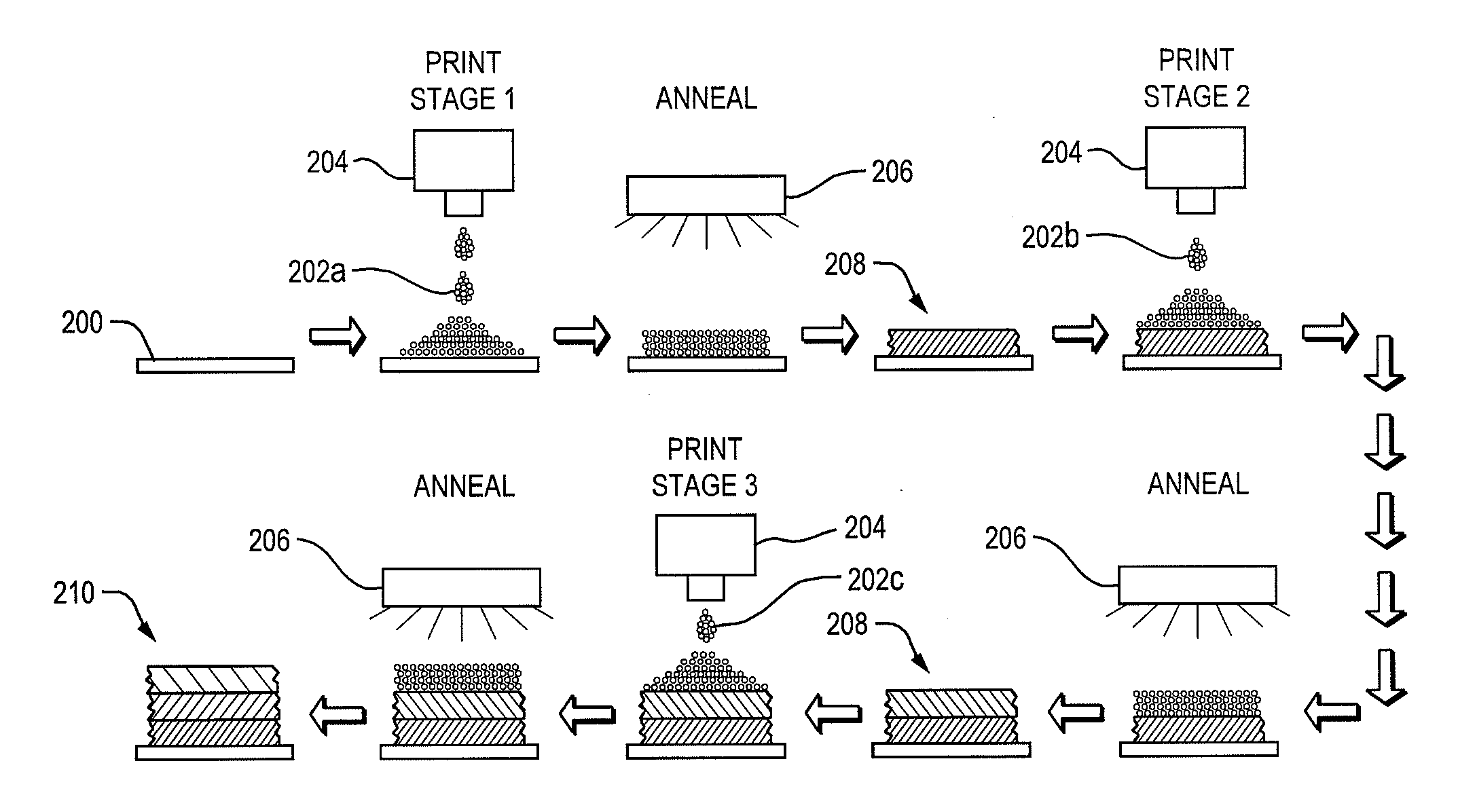

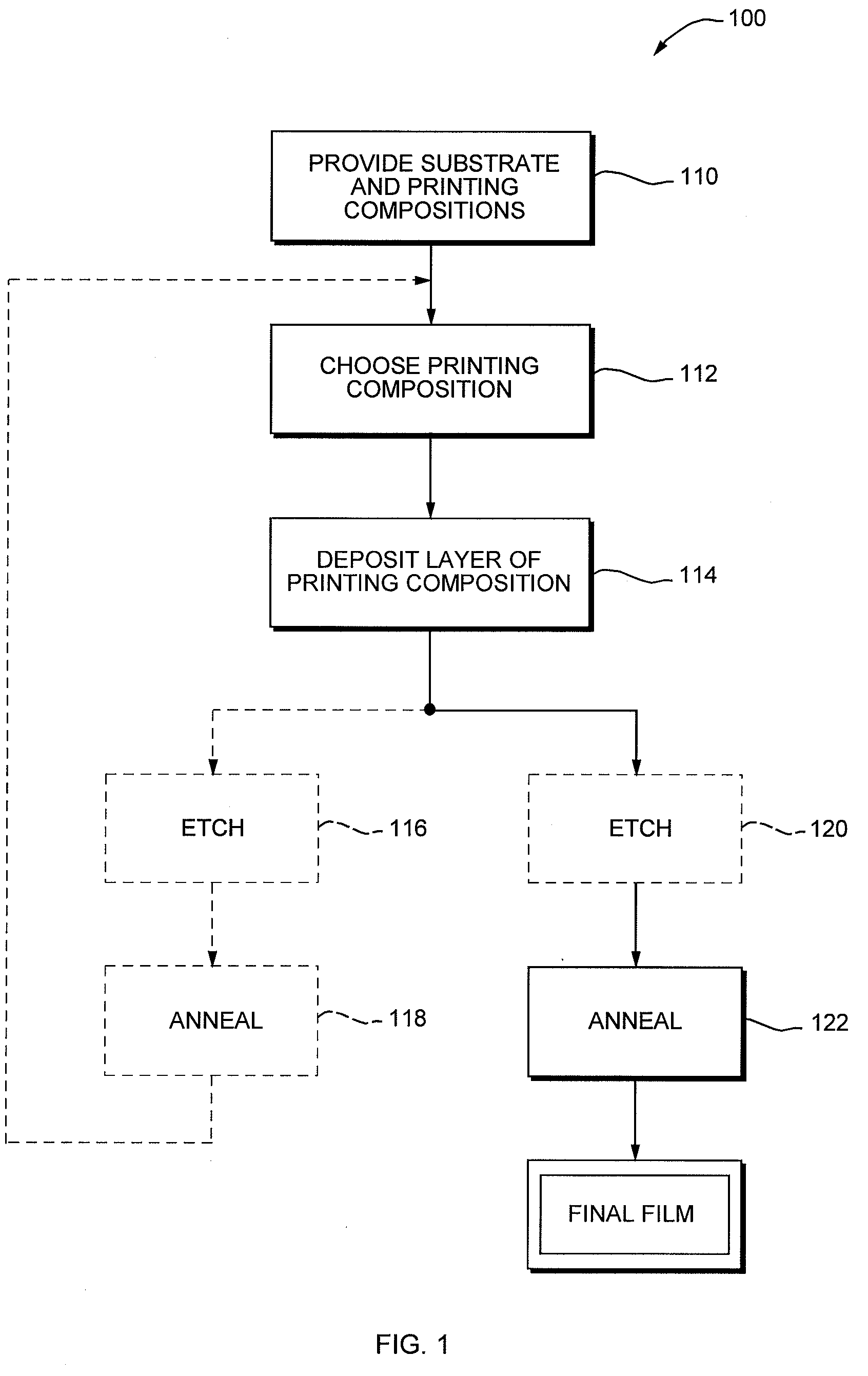

Fabrication of Electrically Active Films Based on Multiple Layers

InactiveUS20080257201A1Easy to manufactureCheap and more conveniently practicedFinal product manufactureSemiconductor/solid-state device manufacturingNanometreElectrical and Electronics engineering

Owner:NANOCO TECH LTD

Highly nucleated thermoplastic articles

InactiveUS6534574B1Exceptional nucleation efficacyExcellent calcium stearate compatibilityOrganic active ingredientsOrganic chemistryPolyolefinCrystallization temperature

Compounds and compositions comprising specific metal salts of bicyclo[2.2.1 ]heptane dicarboxylate salts in order to provide highly desirable properties within polyolefin articles are provided. The inventive salts and derivatives thereof are useful as nucleating and / or clarifying agents for such polyolefin, provide excellent crystallization temperatures, stiffness, and calcium stearate compatibility within target polyolefin. Also, such compounds exhibit very low hygroscopicity and therefore excellent shelf stability as powdered or granular formulations. Polyolefin additive compositions and methods of producing polyolefin with such compounds are also contemplated within this invention.

Owner:MILLIKEN & CO

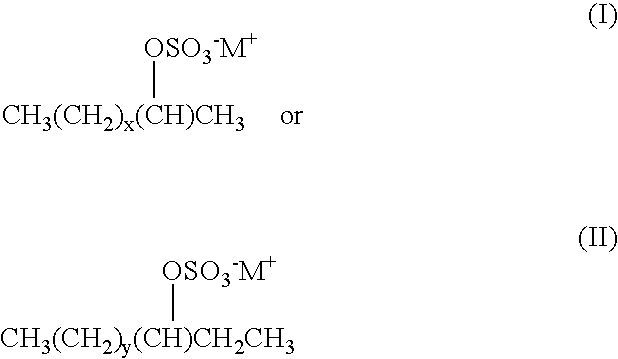

Laundry detergent compositions with efficient hueing dye

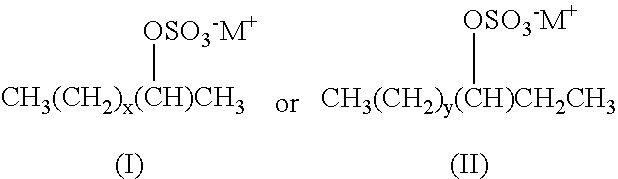

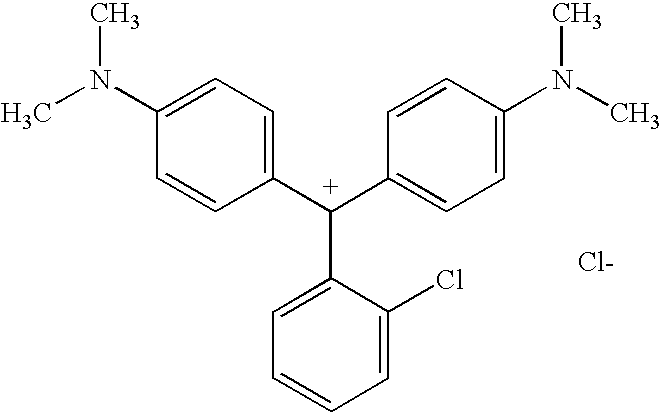

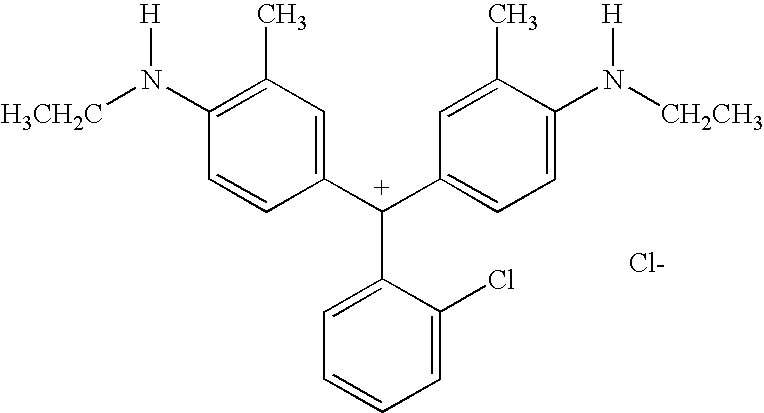

InactiveUS20050288206A1Counter undesirable yellowingSimple compositionDiaryl/thriaryl methane dyesDetergent dyesOrganic chemistrySURFACTANT BLEND

Laundry detergent compositions comprise (a) surfactant, and (b) a hueing dye, wherein the hueing dye exhibits a hueing efficiency of at least 10 and a wash removal value in the range of from about 30% to about 80%.

Owner:THE PROCTER & GAMBLE COMPANY

Stabilized antibody-containing formulations

ActiveUS20090291076A1Good cakingIncrease of the viscosity of the high-concentration antibody-containing solutionAntibody ingredientsImmunoglobulinsArginineThreonine

The present invention relates to antibody-containing lyophilized formulations free from reducing sugars, non-reducing sugars, sugar alcohols or polysaccharides as excipients and including one or more amino acid selected from the group consisting of arginine, histidine, lysine, serine, proline, glycine, alanine and threonine or a salt thereof.

Owner:CHUGAI PHARMA CO LTD

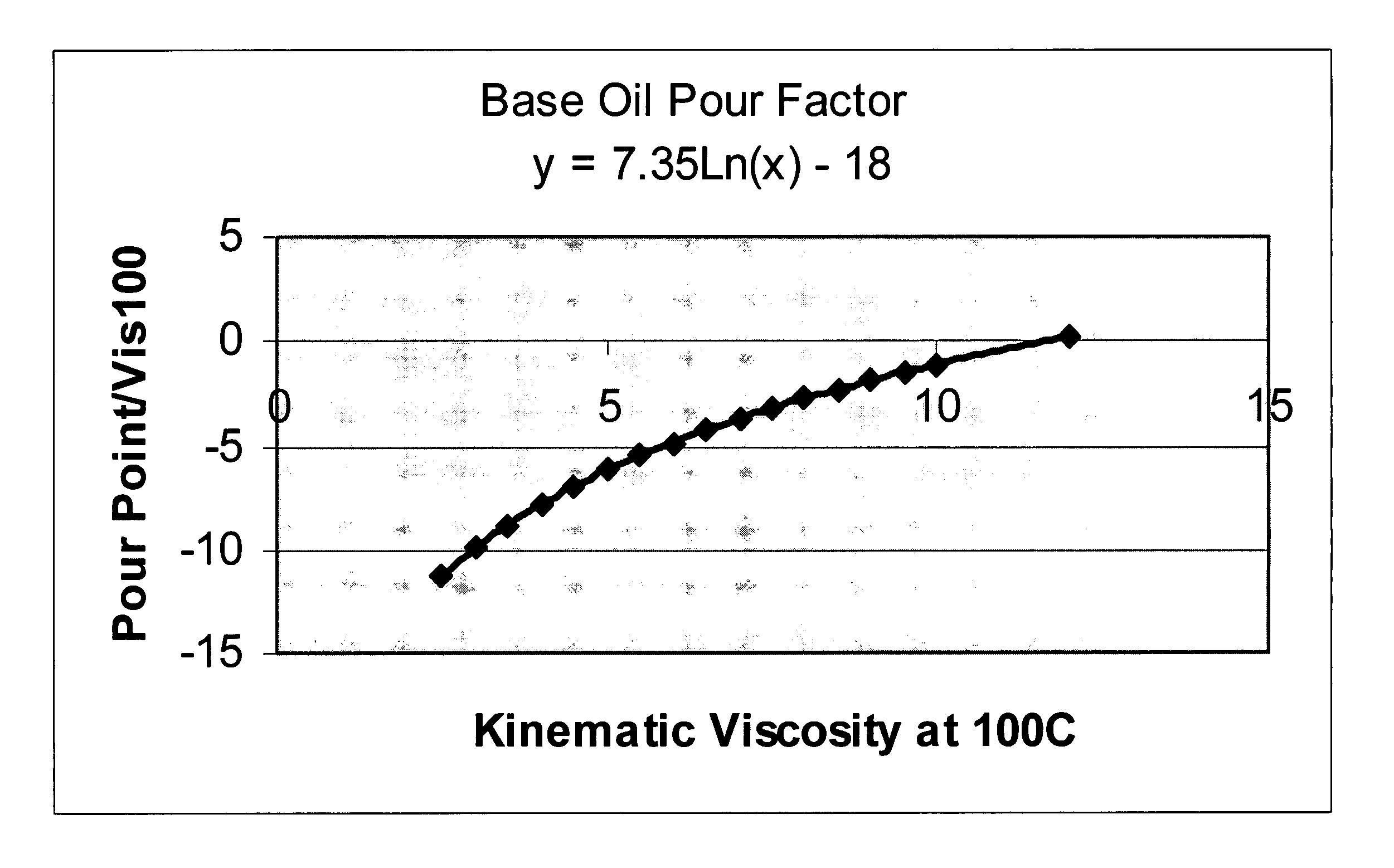

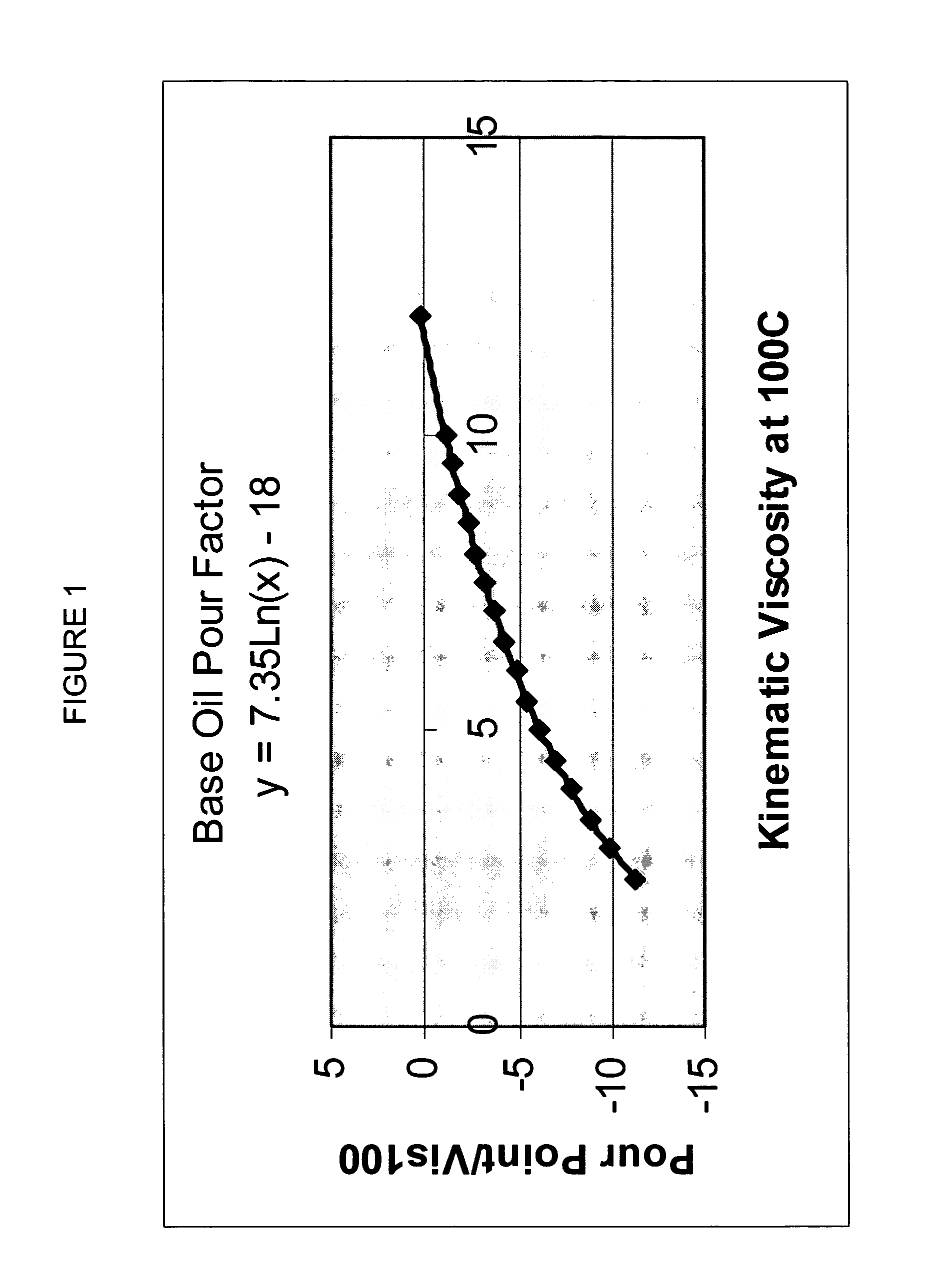

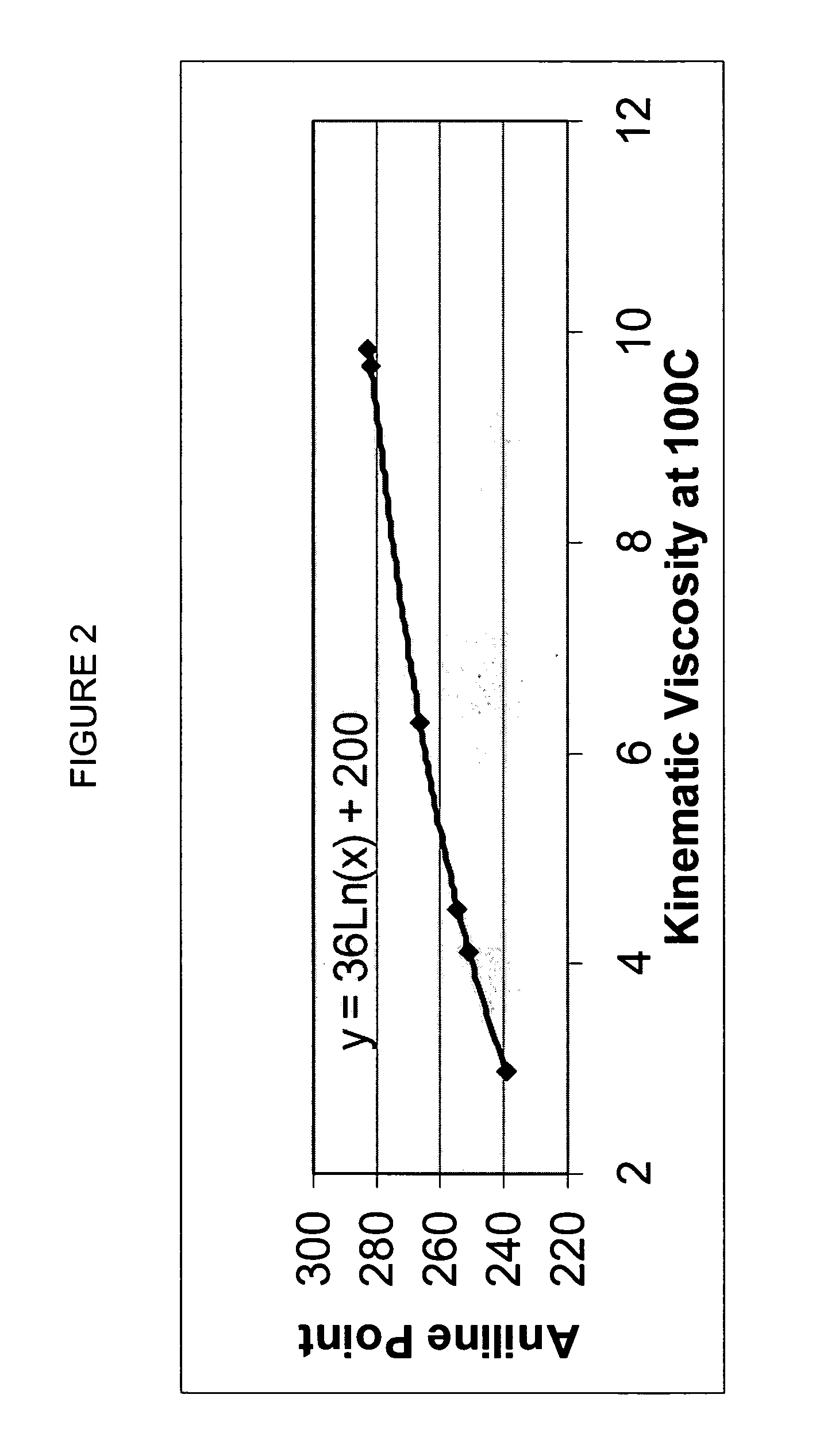

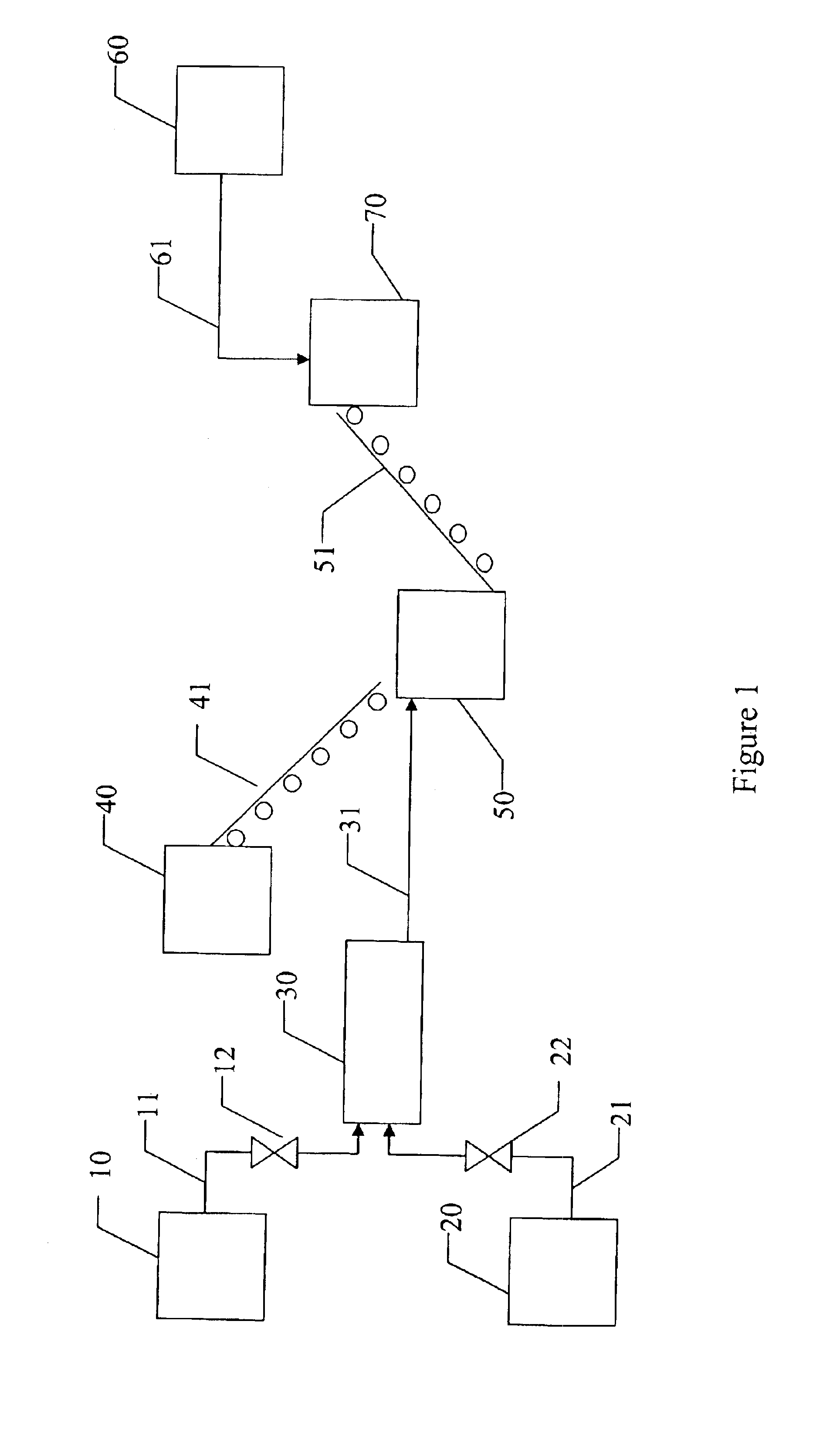

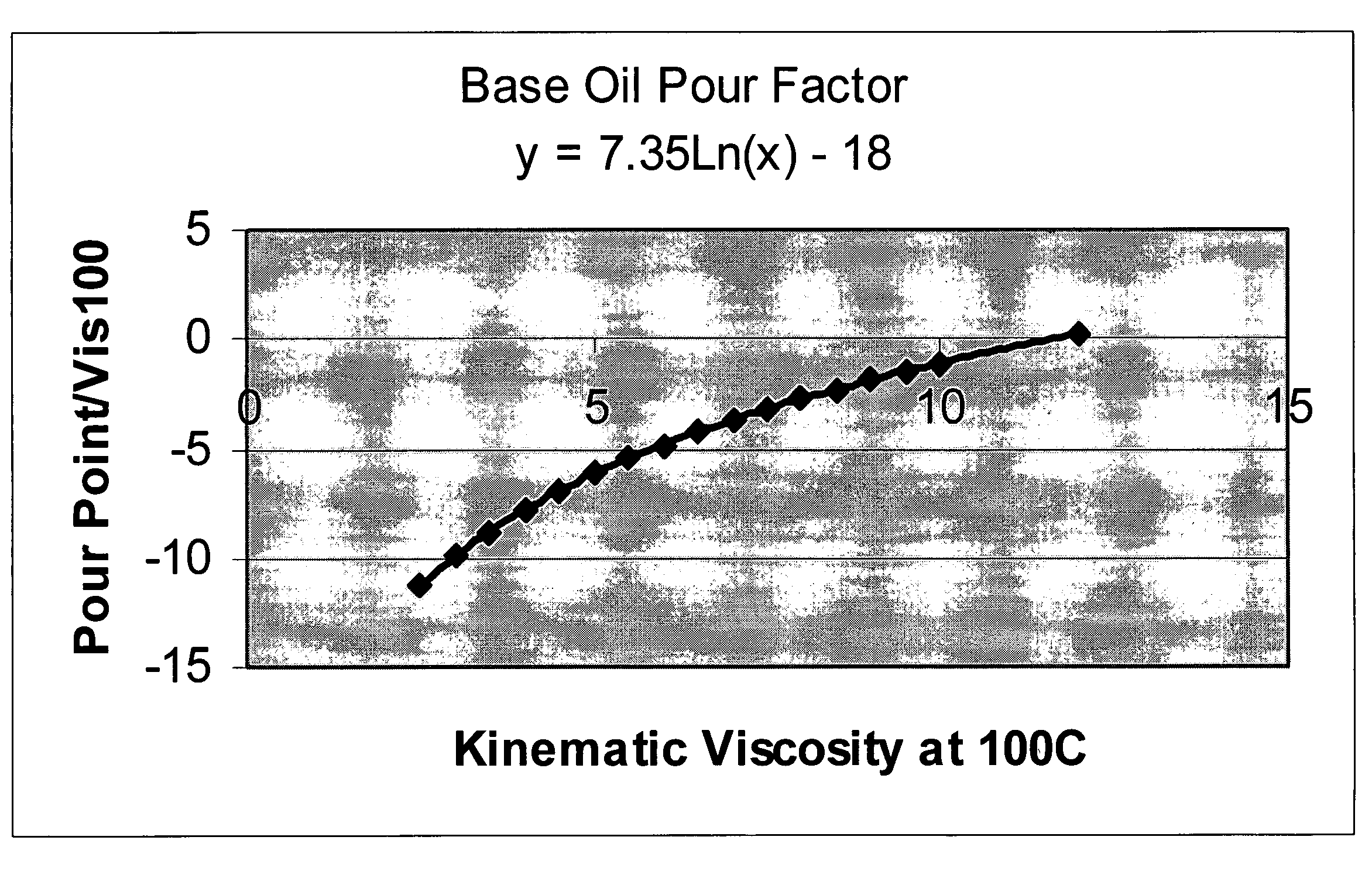

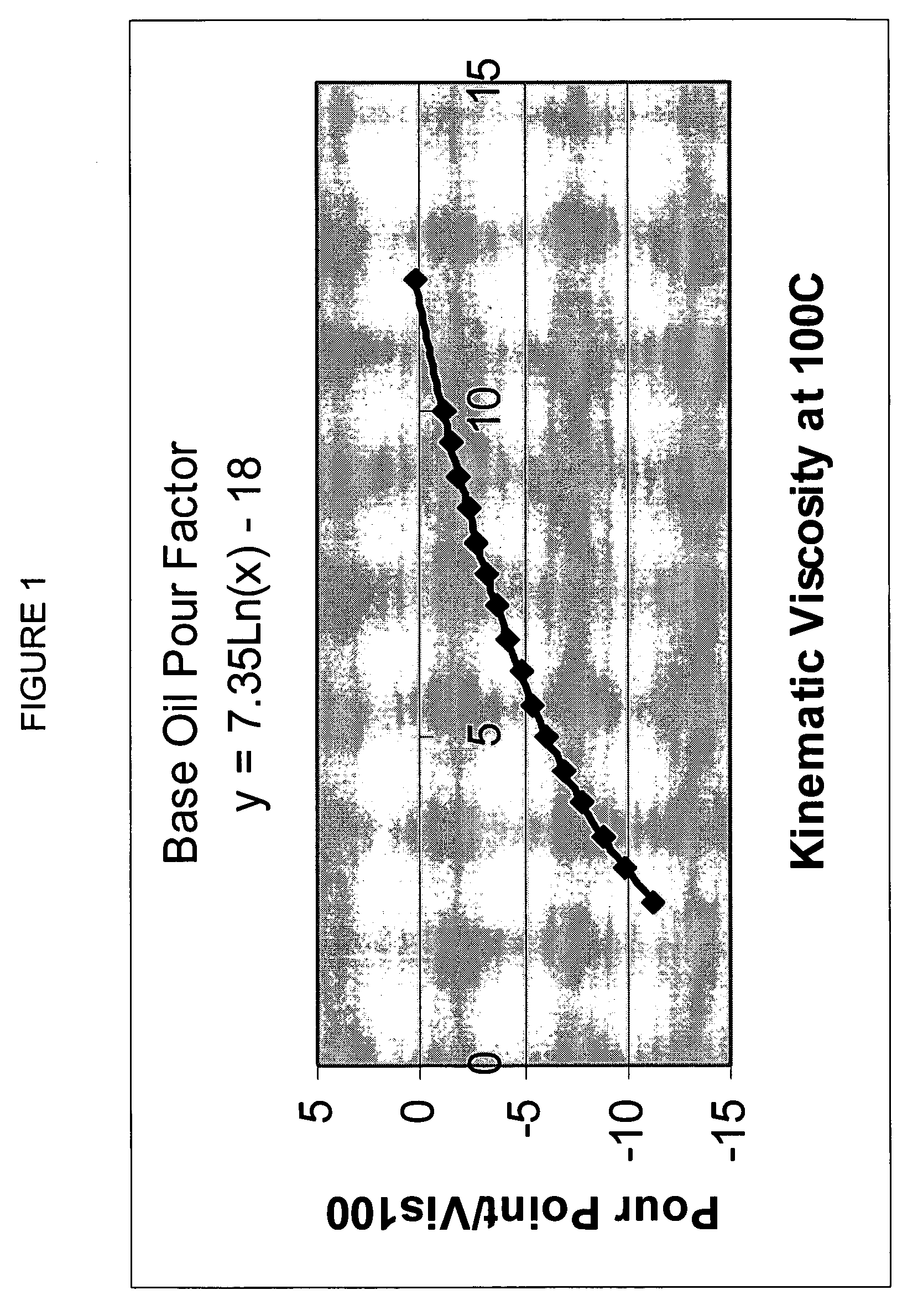

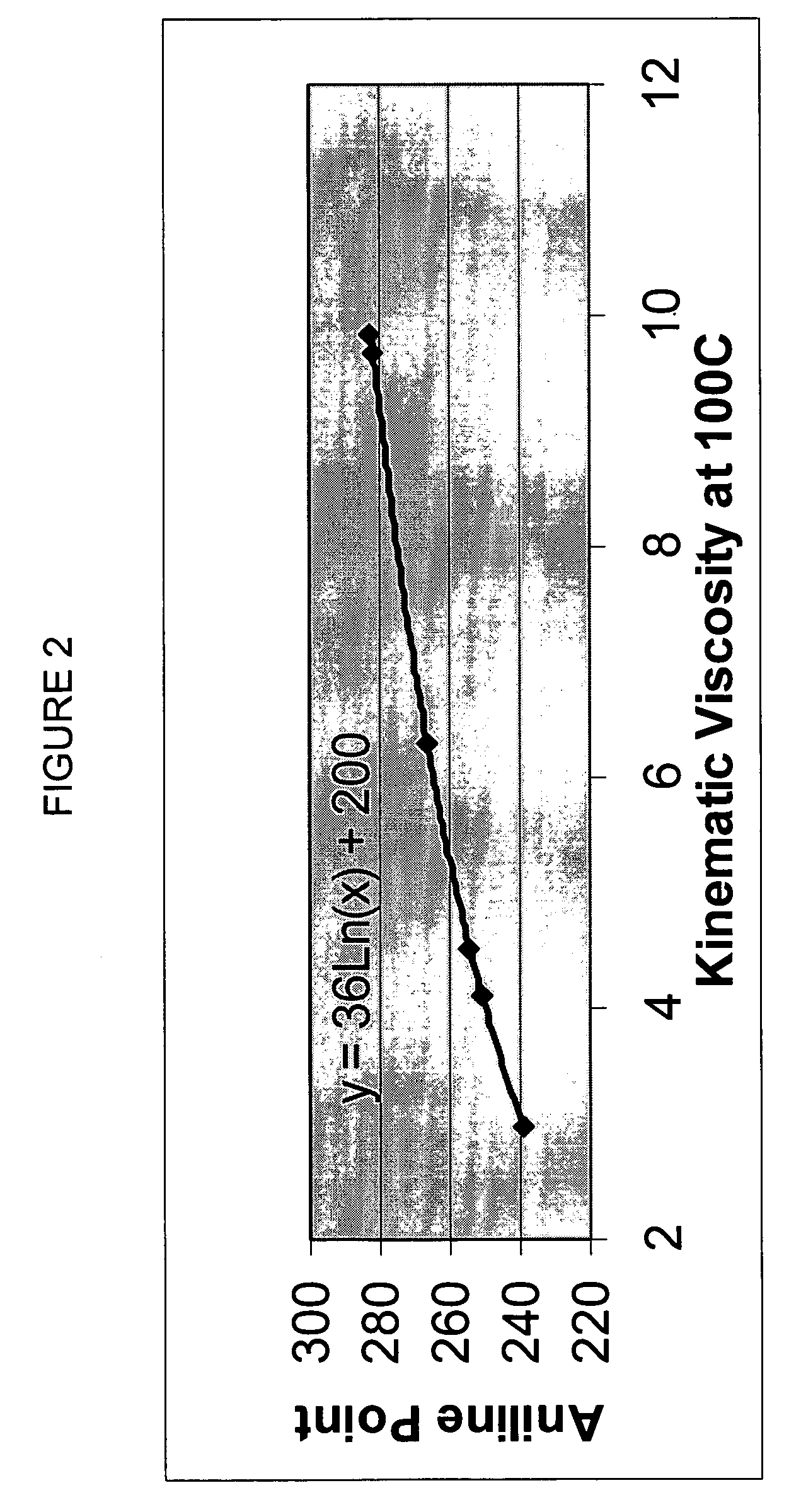

Composition of lubricating base oil with high monocycloparaffins and low multicycloparaffins

ActiveUS7083713B2Improve Oxidation StabilityHigh viscosity indexRefining to change hydrocarbon structural skeletonHydrocarbon purification/separationCycloparaffinsBase oil

A composition of lubricating base oil having a weight percent of all molecules with at least one aromatic function less than 0.30, a weight percent of all molecules with at least one cycloparaffin function greater than 10, and a ratio of weight percent of molecules with monocycloparaffins to weight percent of molecules with multicycloparaffins greater than 15.

Owner:CHEVROU USA INC

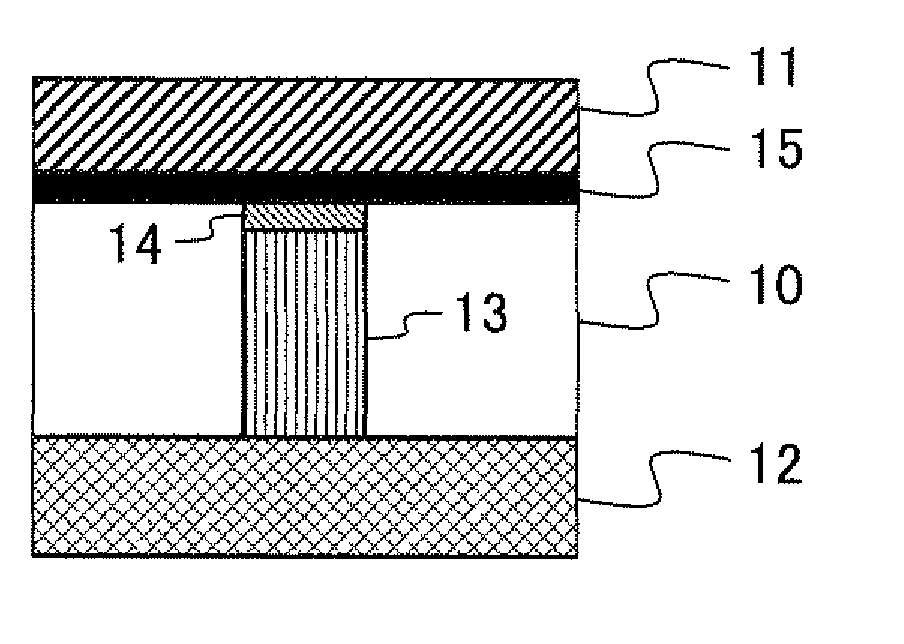

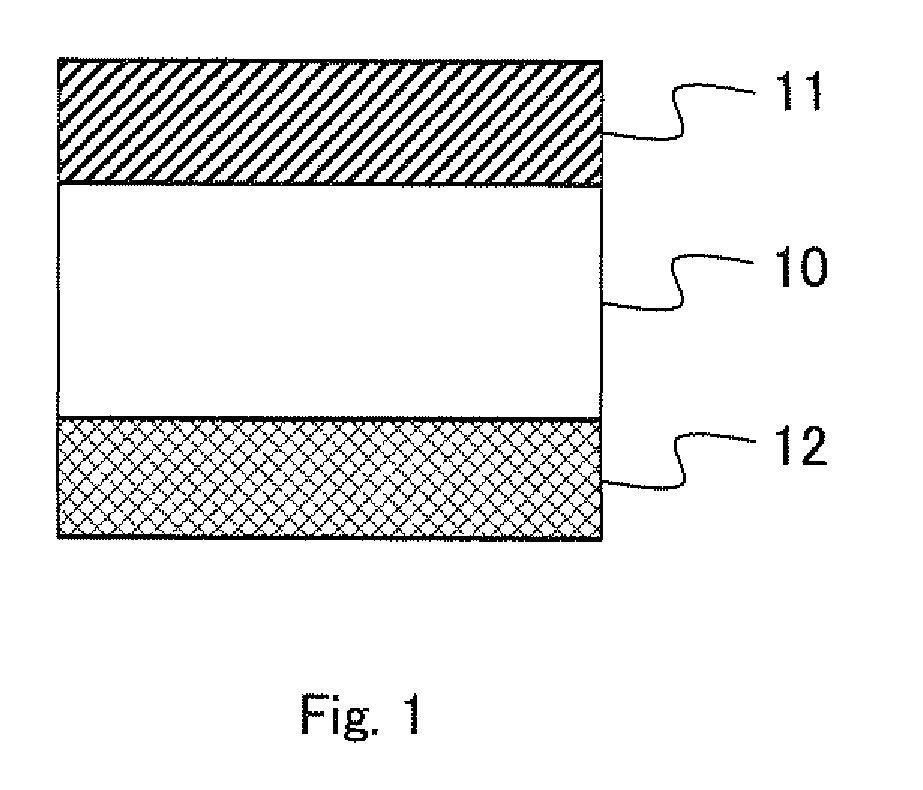

Variable resistive element, manufacturing method for same, and non-volatile semiconductor memory device

ActiveUS8054674B2Improve processingSimple compositionSolid-state devicesDigital storageInterfacial oxidePower flow

Provided is a variable resistive element which performs high speed and low power consumption operation. The variable resistive element comprises a metal oxide layer between first and second electrodes wherein electrical resistance between the first and second electrodes reversibly changes in accordance with application of electrical stress across the first and second electrodes. The metal oxide layer has a filament, which is a current path where the density of a current flowing between the first and second electrodes locally increases. A portion including at least the vicinity of an interface between the certain electrode, which is one or both of the first and second electrodes, and the filament, on an interface between the certain electrode and the metal oxide layer is provided with an interface oxide which is an oxide of at least one element included in the certain electrode and different from the oxide of the metal oxide layer.

Owner:SHARP KK +1

Enhanced efficacy antiperspirant compositions containing strontium or calcium

InactiveUS6923952B2Improve efficacySimple compositionCosmetic preparationsToilet preparationsStrontiumWater soluble

Owner:THE GILLETTE CO

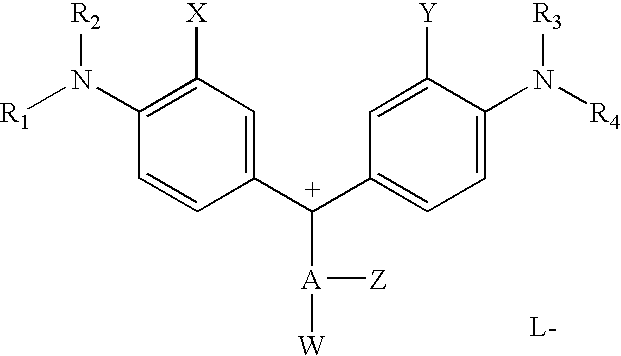

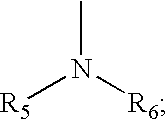

Laundry detergent compositions with hueing dye

ActiveUS7205269B2Counter undesirable yellowingSimple compositionDetergent dyesLiquid soapsAnthraquinonesOxazine dye

Laundry detergent compositions comprise (a) surfactant, and (b) a hueing dye selected from triarylmethane blue and violet basic dyes, methine blue and violet basic dyes, anthraquinone blue and violet basic dyes, azo dyes basic blue 16, basic blue 65, basic blue 66 basic blue 67, basic blue 71, basic blue 159, basic violet 19, basic violet 35, basic violet 38, basic violet 48, oxazine dyes, basic blue 3, basic blue 75, basic blue 95, basic blue 122, basic blue 124, basic blue 141, Nile blue A and xanthene dye basic violet 10, and mixtures thereof.

Owner:PROCTER & GAMBLE CO

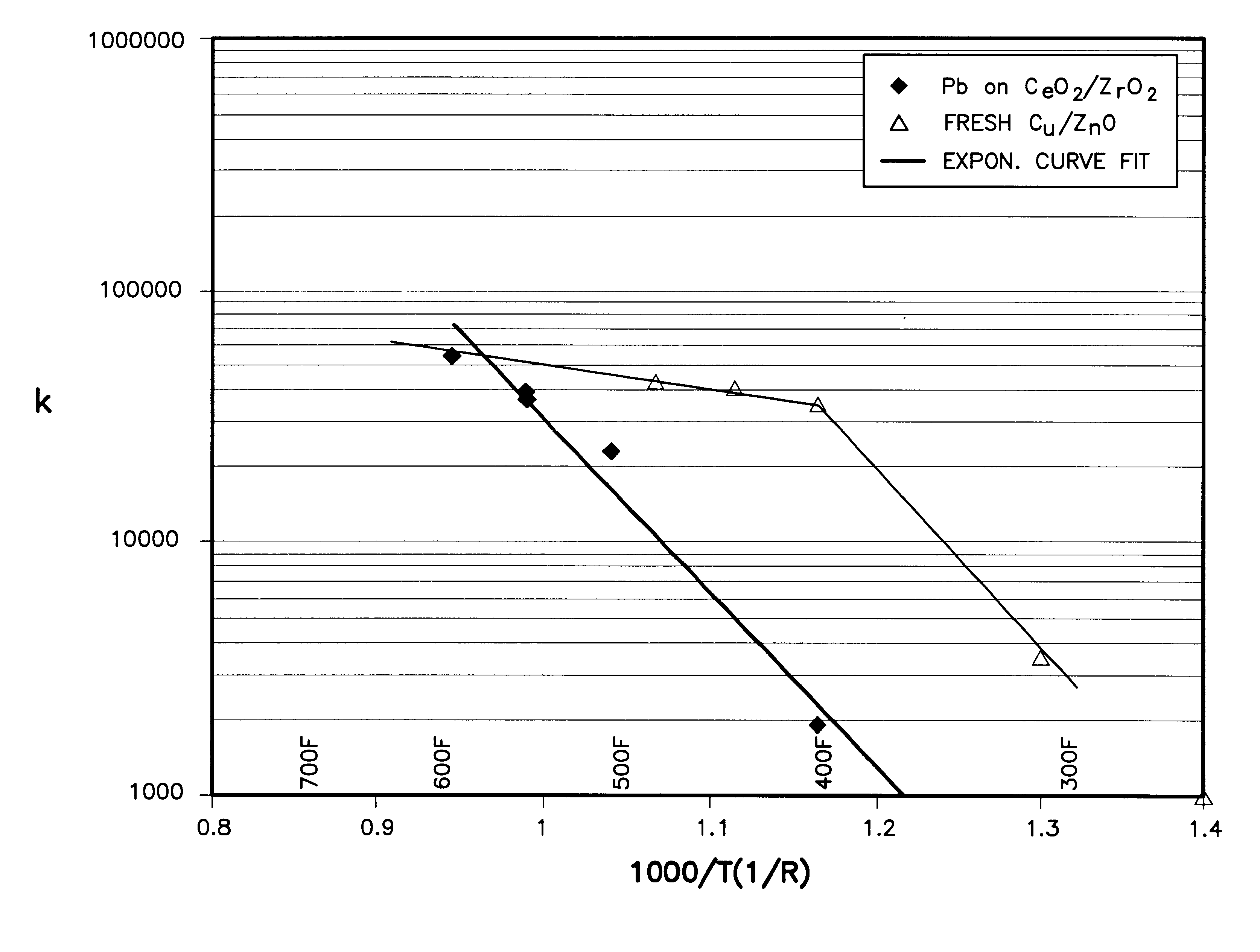

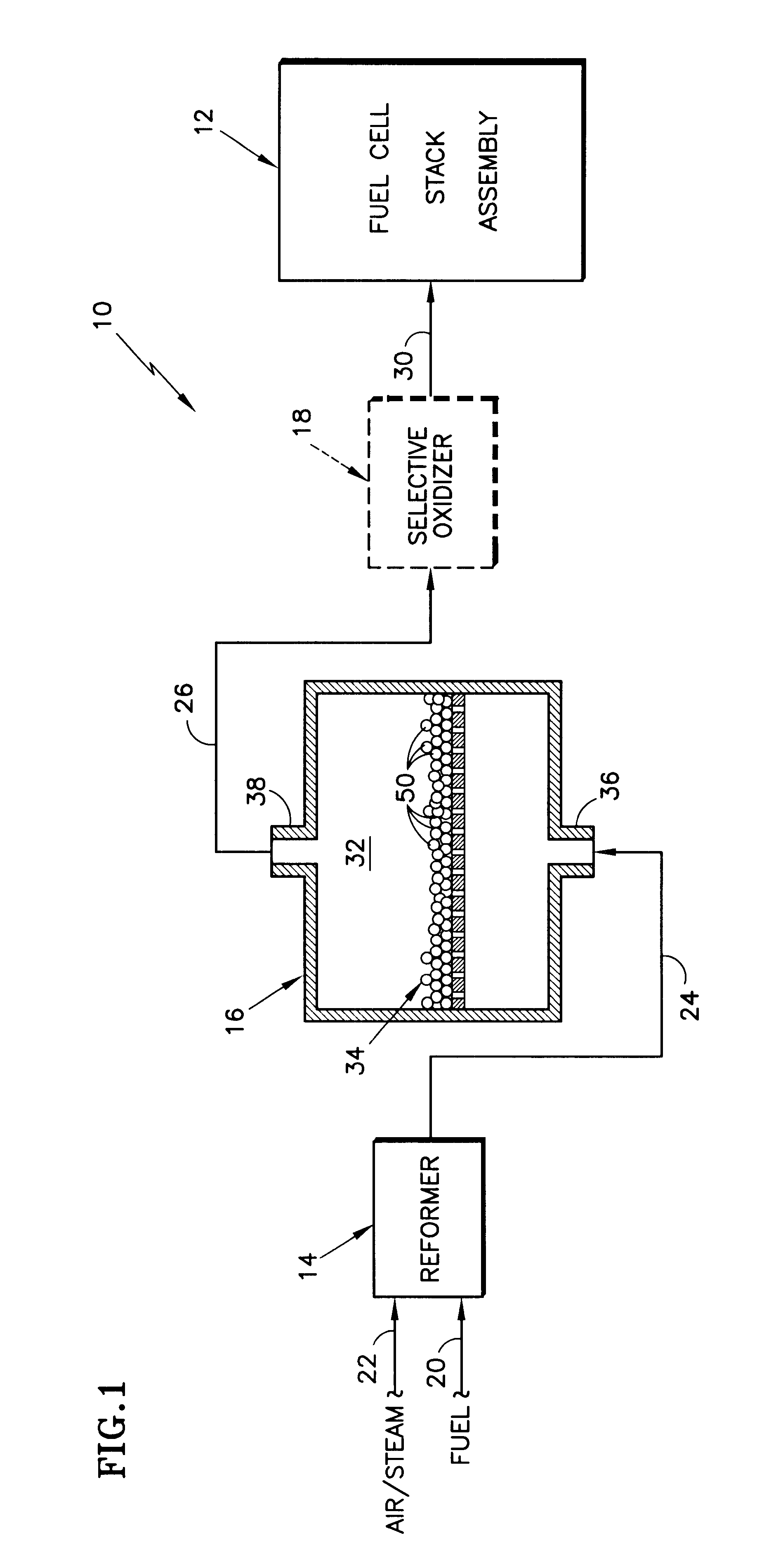

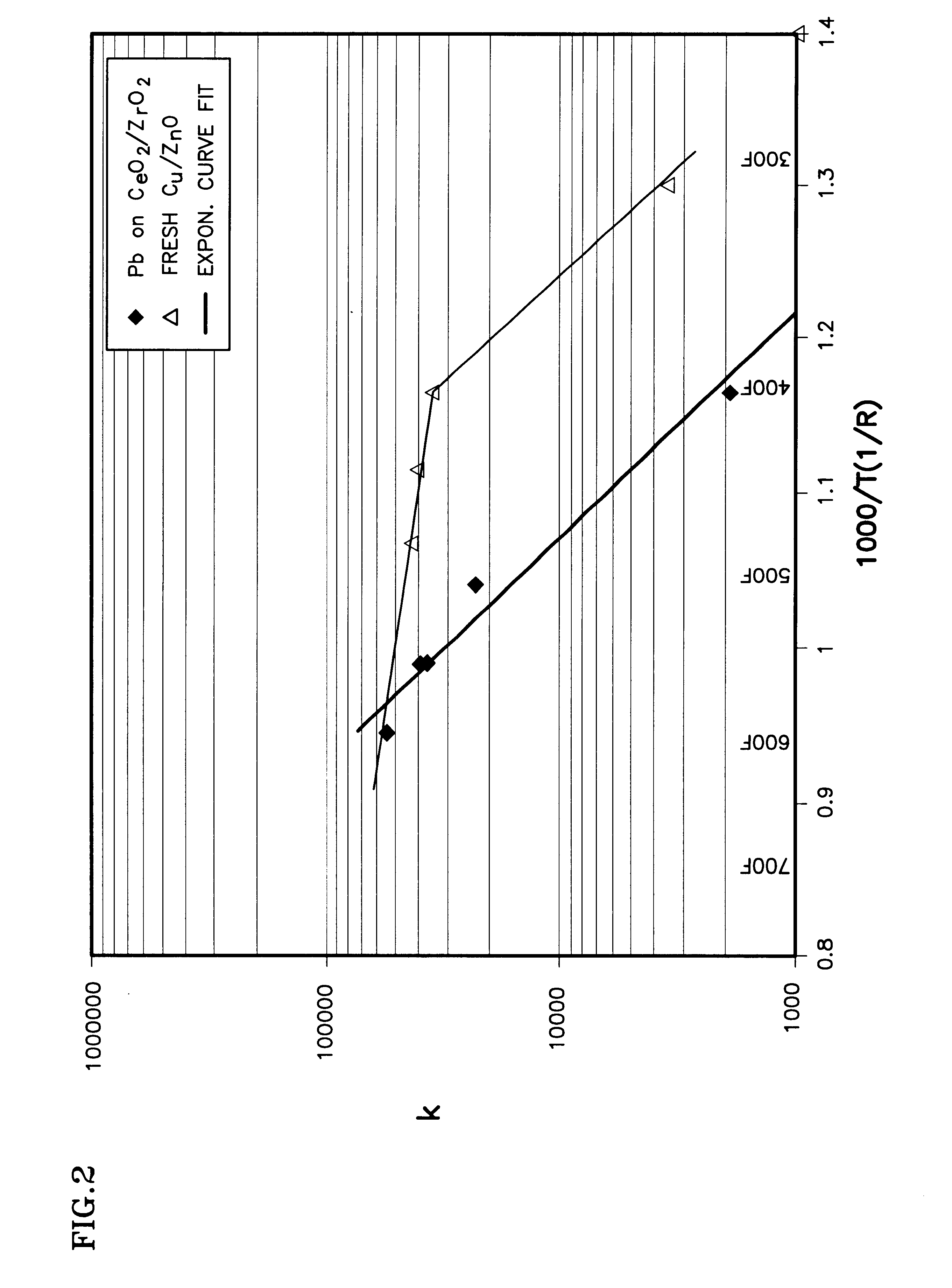

Shift converter having an improved catalyst composition, and method for its use

InactiveUS6455182B1Reduce amountImproved catalyst compositionHydrogenCatalyst carriersFuel cellsCerium

A shift converter (16) in a fuel processing subsystem (14, 16, 18) for a fuel cell (12) uses an improved catalyst composition (50) to reduce the amount of carbon monoxide in a process gas for the fuel cell (12). The catalyst composition (50) is a noble metal catalyst having a promoted support of mixed metal oxide, including at least both ceria and zirconia. Cerium is present in the range of 30 to 50 mole %, and zirconium is present in the range of 70 to 50 mole %. Additional metal oxides may also be present. Use of the catalyst composition (50) obviates the requirement for prior reducing of catalysts, and minimizes the need to protect the catalyst from oxygen during operation and / or shutdown.

Owner:HYAXIOM INC

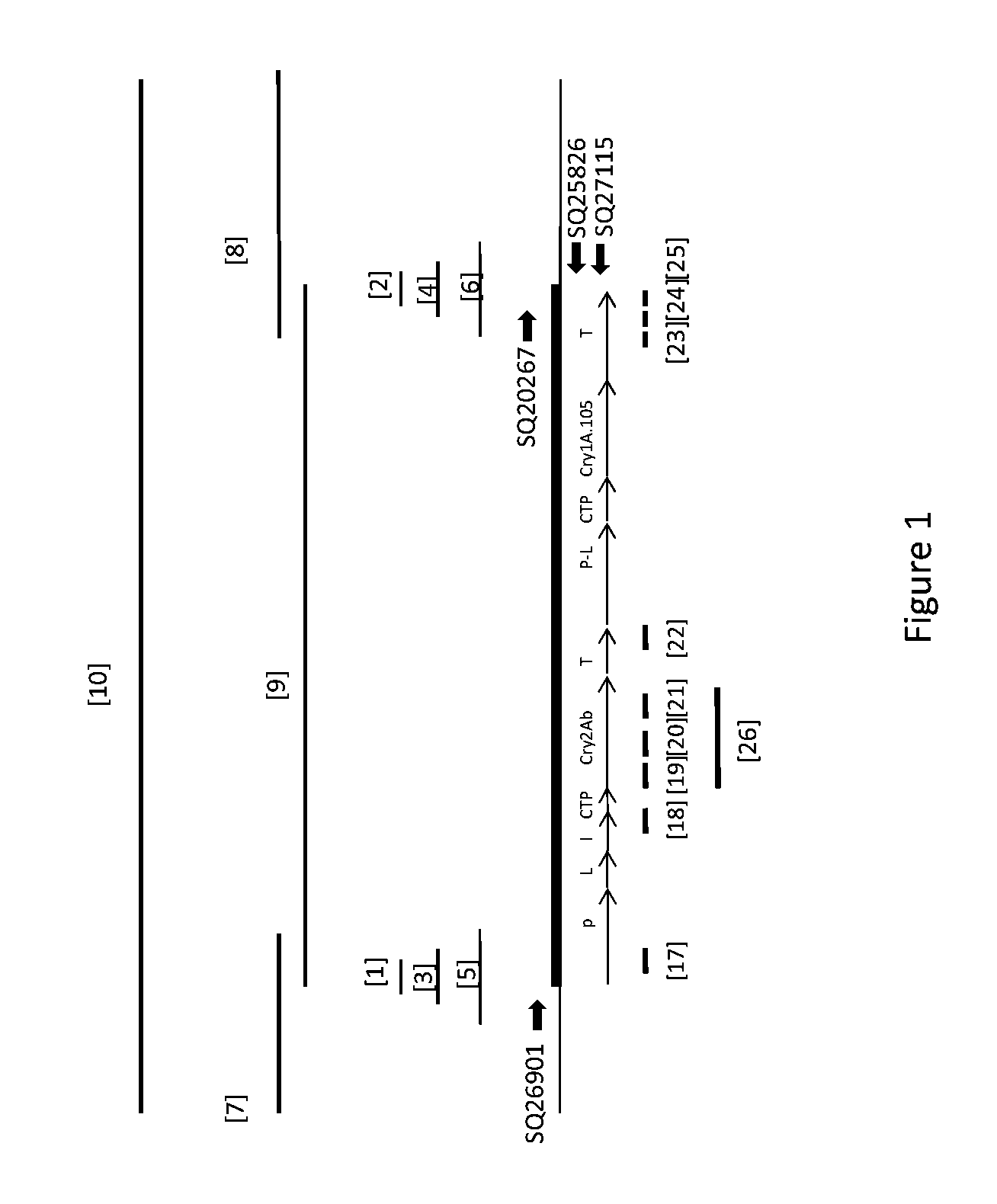

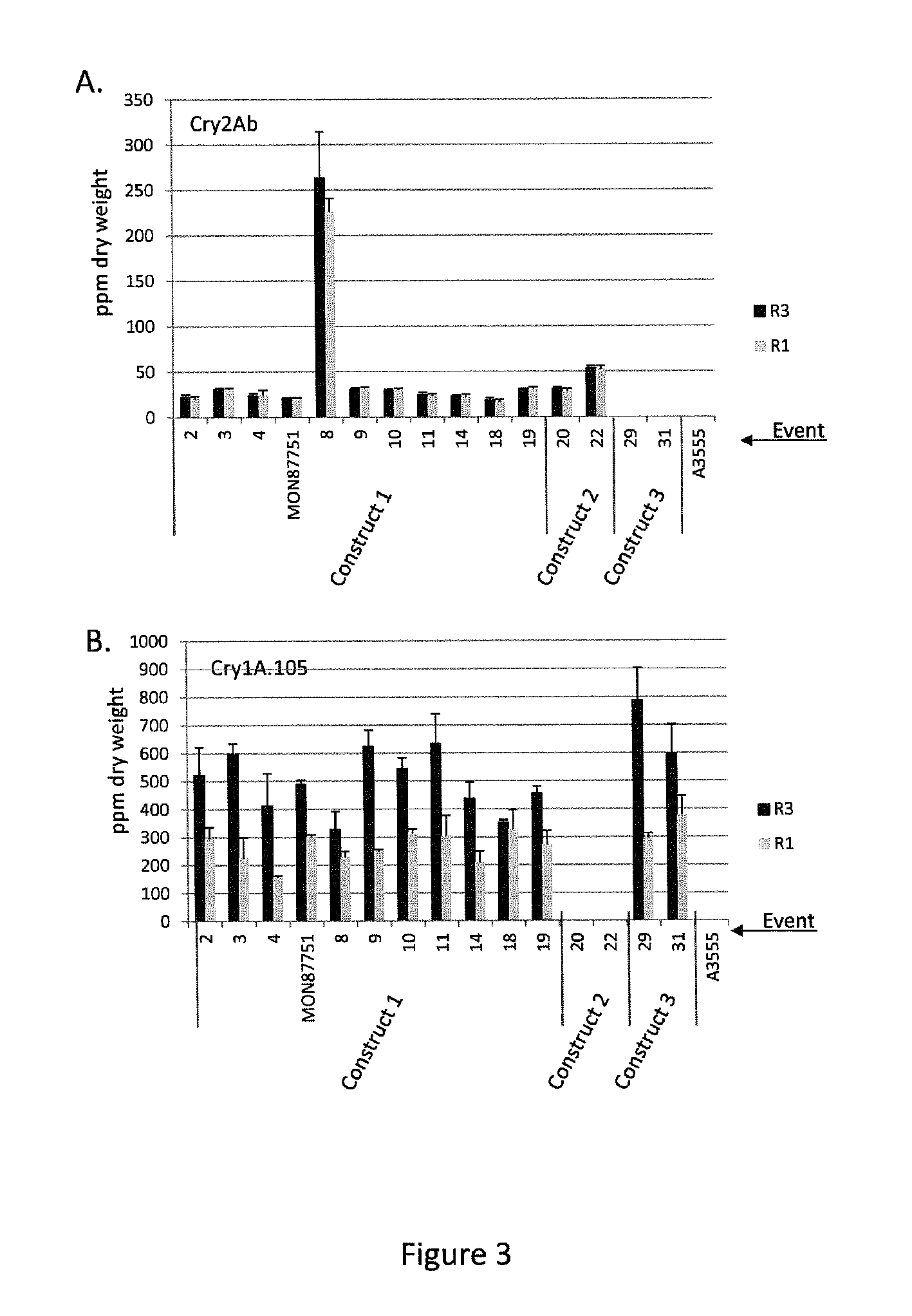

Soybean transgenic event mon87751 and methods for detection and use thereof

ActiveUS20140373191A1Maintain good propertiesImprove performanceCheese manufactureVector-based foreign material introductionGlycinePlant cell

The invention provides a transgenic Glycine max event MON87751, plants, plant cells, seeds, plant parts, progeny plants, and commodity products comprising event MON87751. The invention also provides polynucleotides specific for event MON87751, plants, plant cells, seeds, plant parts, and commodity products comprising polynucleotides for event MON87751. The invention also provides methods related to event MON87751.

Owner:MONSANTO TECH LLC

Methods and compositions for consolidating proppant in subterranean fractures

InactiveUS6962200B2Improved componentsSimple compositionFluid removalDrilling compositionFracturing fluidImproved method

Improved methods and compositions for coating proppant particles with a hardenable resin composition, suspending the coated proppant particles in a fracturing fluid, and consolidating the proppant particles after being placed in fractures into permeable masses are provided. These methods and compositions are especially suitable for low temperature well, specifically those around the 60° F. to 250° F. ranges. Preferably, a liquid hardenable resin component is mixed with a liquid hardening agent component on-the-fly to form a hardenable resin composition. The hardenable resin composition is coated onto proppant particles on-the-fly that are conveyed from a source thereof to form resin-coated proppant particles in real-time. The resin-coated proppant particles are suspended in the fracturing fluid to be utilized down hole.

Owner:HALLIBURTON ENERGY SERVICES INC

Process for manufacturing lubricating base oil with high monocycloparaffins and low multicycloparaffins

InactiveUS7282134B2Reduce weightHigh weight ratioTreatment with hydrotreatment processesAdditivesAlkaneWax

A process for manufacturing a lubricating base oil by: a) performing Fischer-Tropsch synthesis on syngas to provide a product stream; b) isolating from said product stream a substantially paraffinic wax feed having less than about 30 ppm total nitrogen and sulfur, and less than about 1 wt % oxygen; c) dewaxing said feed by hydroisomerization dewaxing using a shape selective intermediate pore size molecular sieve comprising a noble metal hydrogenation component, wherein the hydroisomerization temperature is between about 600° F. (315° C.) and about 750° F. (399° C.), to produce an is dimerized oil; and d) hydrofinishing said isomerized oil to produce a lubricating base oil having specific desired properties.

Owner:CHEVROU USA INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com

![Bicyclo[2.2.1]heptane dicarboxylate salts as polyolefin nucleators Bicyclo[2.2.1]heptane dicarboxylate salts as polyolefin nucleators](https://images-eureka.patsnap.com/patent_img/7d258cb1-9493-44a8-9f4d-3c287732759f/US06465551-20021015-C00001.png)

![Bicyclo[2.2.1]heptane dicarboxylate salts as polyolefin nucleators Bicyclo[2.2.1]heptane dicarboxylate salts as polyolefin nucleators](https://images-eureka.patsnap.com/patent_img/7d258cb1-9493-44a8-9f4d-3c287732759f/US06465551-20021015-C00002.png)

![Bicyclo[2.2.1]heptane dicarboxylate salts as polyolefin nucleators Bicyclo[2.2.1]heptane dicarboxylate salts as polyolefin nucleators](https://images-eureka.patsnap.com/patent_img/7d258cb1-9493-44a8-9f4d-3c287732759f/US06465551-20021015-C00003.png)