Patents

Literature

166 results about "Cycloparaffins" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Alicyclic hydrocarbons in which three or more of the carbon atoms in each molecule are united in a ring structure and each of the ring carbon atoms is joined to two hydrogen atoms or alkyl groups. The simplest members are cyclopropane (C3H6), cyclobutane (C4H8), cyclohexane (C6H12), and derivatives of these such as methylcyclohexane (C6H11CH3). (From Sax, et al., Hawley's Condensed Chemical Dictionary, 11th ed)

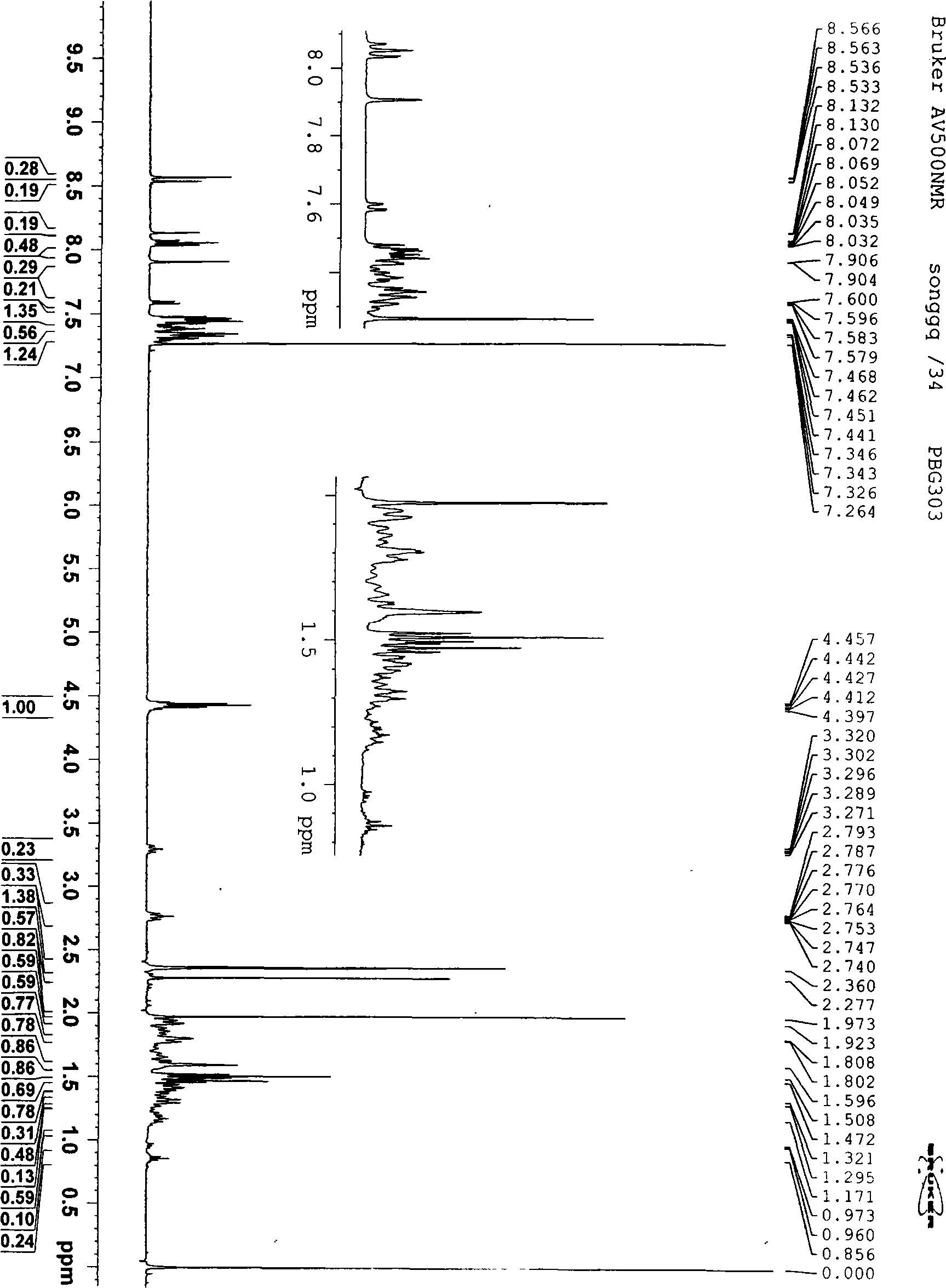

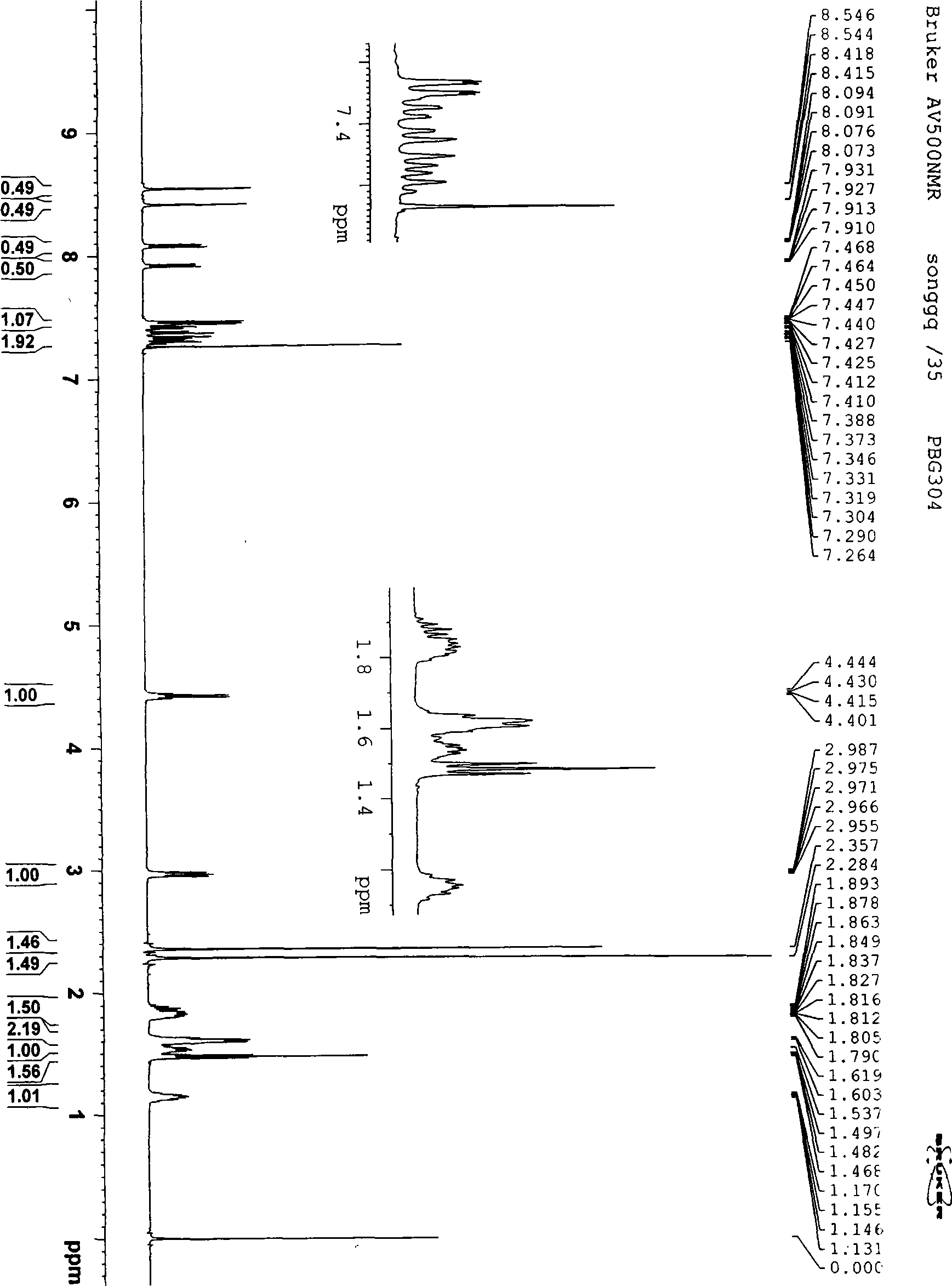

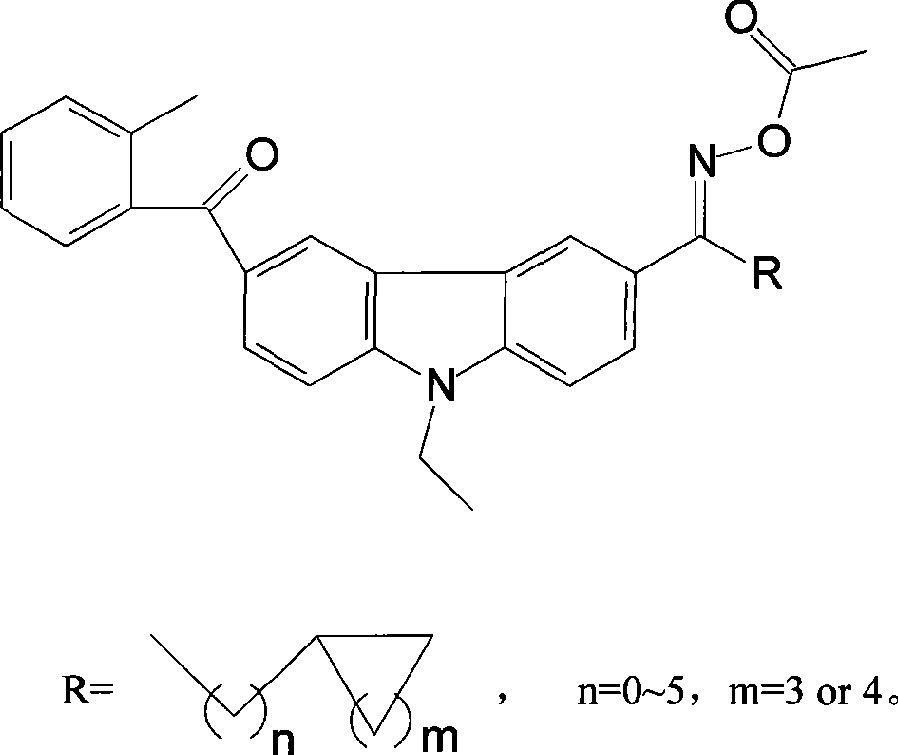

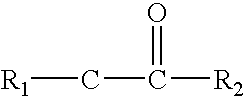

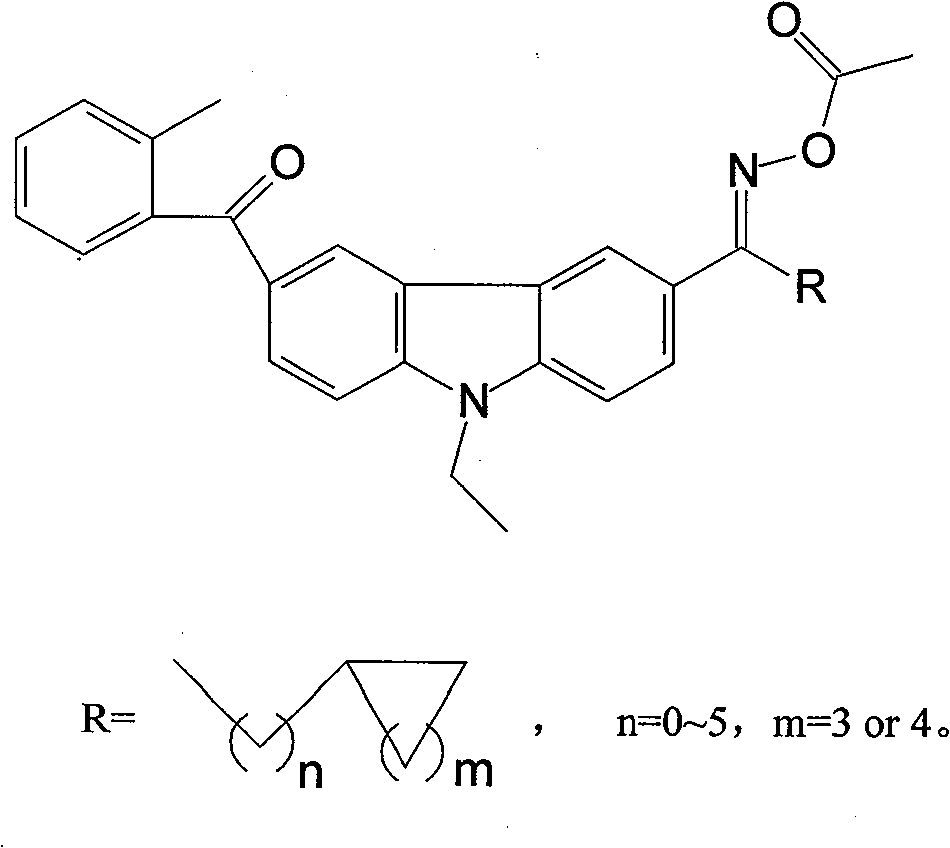

Carbazole oxime ester lightlike initiating agent

The invention relates to the photoinitiator technical field, in particular to an oxime ester photoinitiator and a preparation method thereof. A carbazole oxime ester photoinitiator has a structural general formula as the right formula, R=formula (1), n=0-5, m=3 or 4, R radical is aliphatic ketone with cyclane, the cyclane is cycloaliphatic ring from cyclopropane to cyclooctane, branched-chain aliphatic hydrocarbon connects the cyclane and the ketone, and the chain usually has 0-6 carbon atoms. The carbazole oxime ester photoinitiator with the structure is a brand-new compound with good photoinitiator performance, and solves the problem of poor sensitivity, thermal stability and solubility of the existing carbazole oxime ester photoinitiators.

Owner:CHANGZHOU TRONLY NEW ELECTRONICS MATERIALS

Composition of lubricating base oil with high monocycloparaffins and low multicycloparaffins

ActiveUS7083713B2Improve Oxidation StabilityHigh viscosity indexRefining to change hydrocarbon structural skeletonHydrocarbon purification/separationCycloparaffinsBase oil

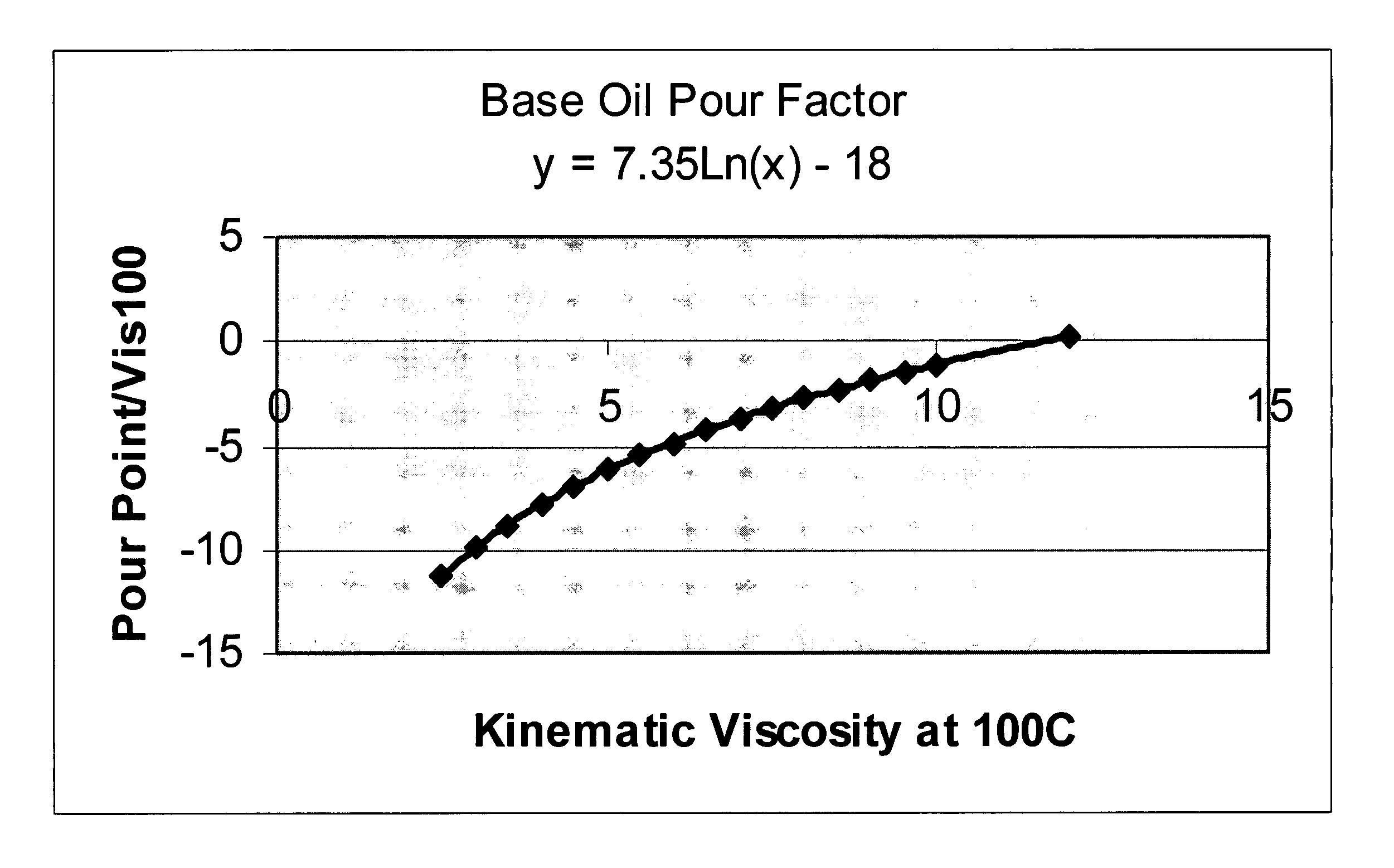

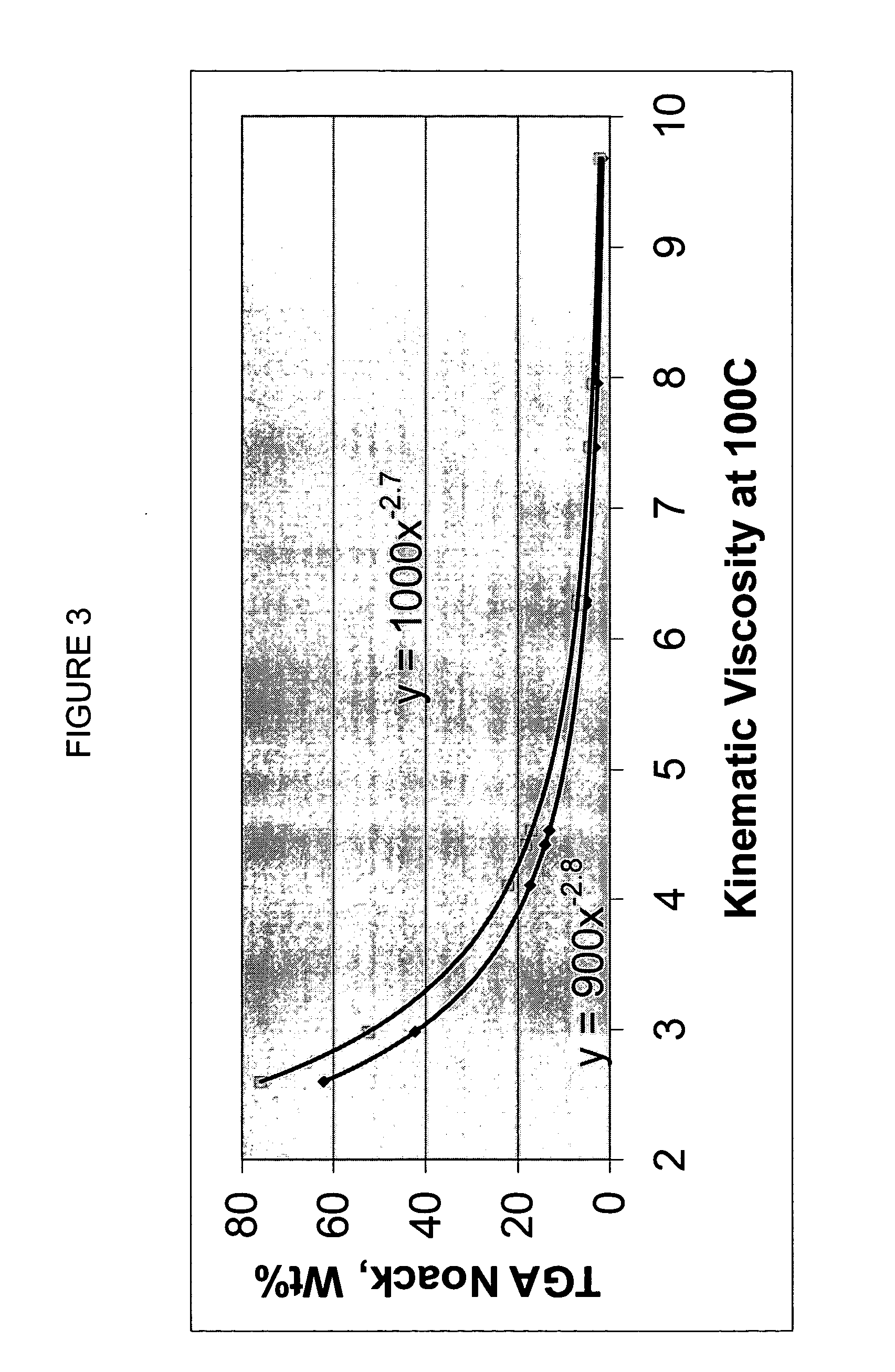

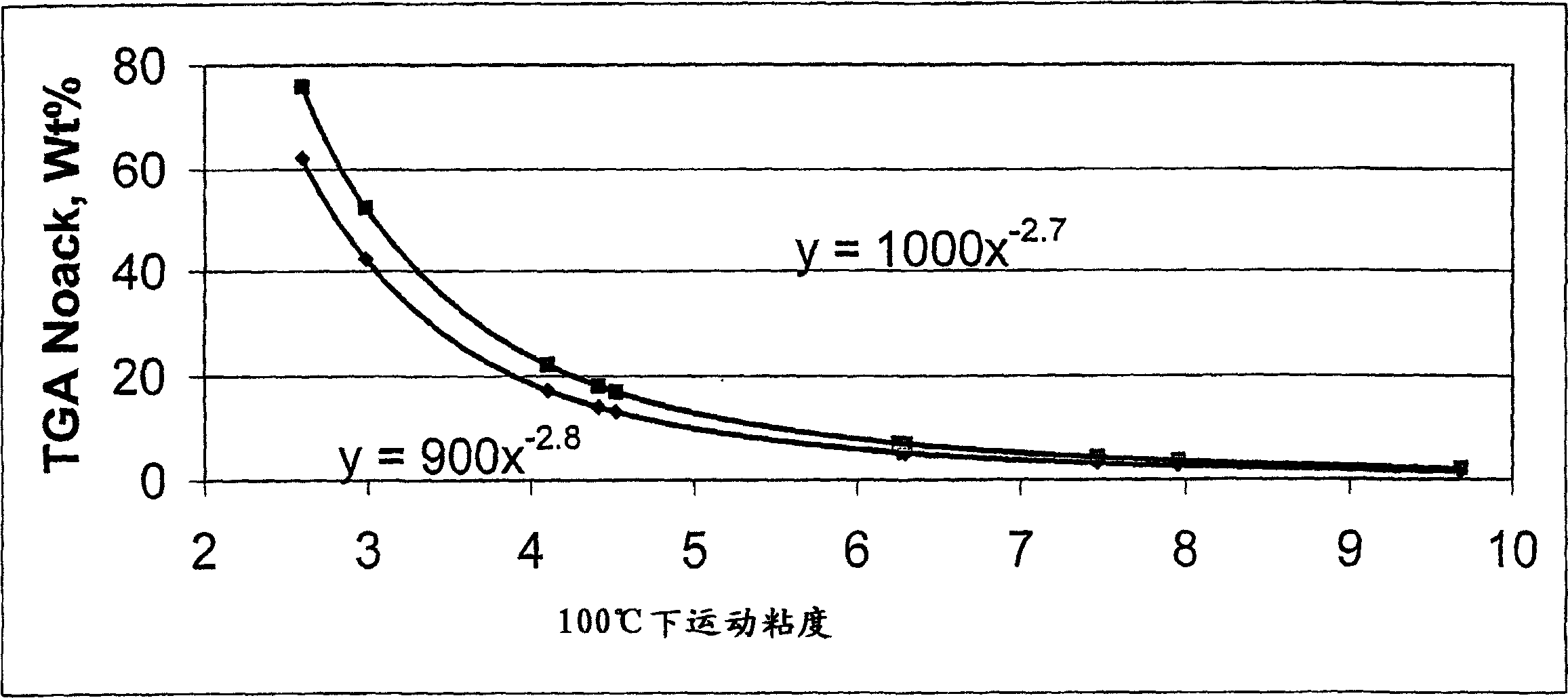

A composition of lubricating base oil having a weight percent of all molecules with at least one aromatic function less than 0.30, a weight percent of all molecules with at least one cycloparaffin function greater than 10, and a ratio of weight percent of molecules with monocycloparaffins to weight percent of molecules with multicycloparaffins greater than 15.

Owner:CHEVROU USA INC

Process for making lubricating base oils with high ratio of monocycloparaffins to multicycloparaffins

InactiveUS20060289337A1Liquid hydrocarbon mixture productionTreatment with hydrotreatment processesMolecular sieveWax

A process for manufacturing a lubricating base oil, comprising dewaxing a substantially paraffinic wax feed by hydroisomerization dewaxing using a shape selective intermediate pore size molecular sieve under hydroisomerization conditions including a hydrogen to feed ratio from about 712.4 to about 3562 liter H2 / liter oil, whereby a lubricating base oil is produced having a)a total weight percent of molecules with cycloparaffinic functionality greater than 10, and b) a ratio of weight percent molecules with monocycloparaffinic functionality to weight percent molecules with multicycloparaffinic functionality greater than 30. Also a method for producing a base oil having a high ratio of weight percent molecules with monocycloparaffinic functionality to weight percent molecules with multicycloparaffinic functionality by hydroisomerization dewaxing a selected Fischer-Tropsch wax under hydroisomerization conditions including a hydrogen to feed ratio from about 712.4 to about 3562 liter H2 / liter oil. Also a lubricating base oil manufacturing plant.

Owner:CHEVROU USA INC

Composition of lubricating base oil with high monocycloparaffins and low multicycloparaffins

ActiveUS20050133408A1Improve Oxidation StabilityHigh viscosity indexHydrocarbon purification/separationLiquid hydrocarbon mixture productionCycloparaffinsBase oil

A composition of lubricating base oil having a weight percent of all molecules with at least one aromatic function less than 0.30, a weight percent of all molecules with at least one cycloparaffin function greater than 10, and a ratio of weight percent of molecules with monocycloparaffins to weight percent of molecules with multicycloparaffins greater than 15.

Owner:CHEVROU USA INC

Multigrade engine oil prepared from Fischer-Tropsch distillate base oil

InactiveUS20060027486A1Refining to change hydrocarbon structural skeletonLiquid carbonaceous fuelsCycloparaffinsPackage design

A multigrade engine oil meeting the specifications for SAE J300 revised June 2001 requirements and a process for preparing it, said engine oil comprising (a) between about 15 to about 94.5 wt % of a hydroisomerized distillate Fischer-Tropsch base oil characterized by (i) a kinematic viscosity between about 2.5 and about 8 cSt at 100° C., (ii) at least about 3 wt % of the molecules having cycloparaffin functionality, and (iii) a ratio of weight percent molecules with monocycloparaffin functionality to weight percent of molecules with multicycloparaffin functionality greater than about 15; (b) between about 0.5 to about 20 wt % of a pour point depressing base oil blending component prepared from an hydroisomerized bottoms material having an average degree of branching in the molecules between about 5 and 9 alkyl-branches per 100 carbon atoms and wherein not more than 10 wt % boils below about 900° F.; and (c) between about 5 to about 30 wt % of an additive package designed to meet the specifications for ILSAC GF-3.

Owner:CHEVROU USA INC

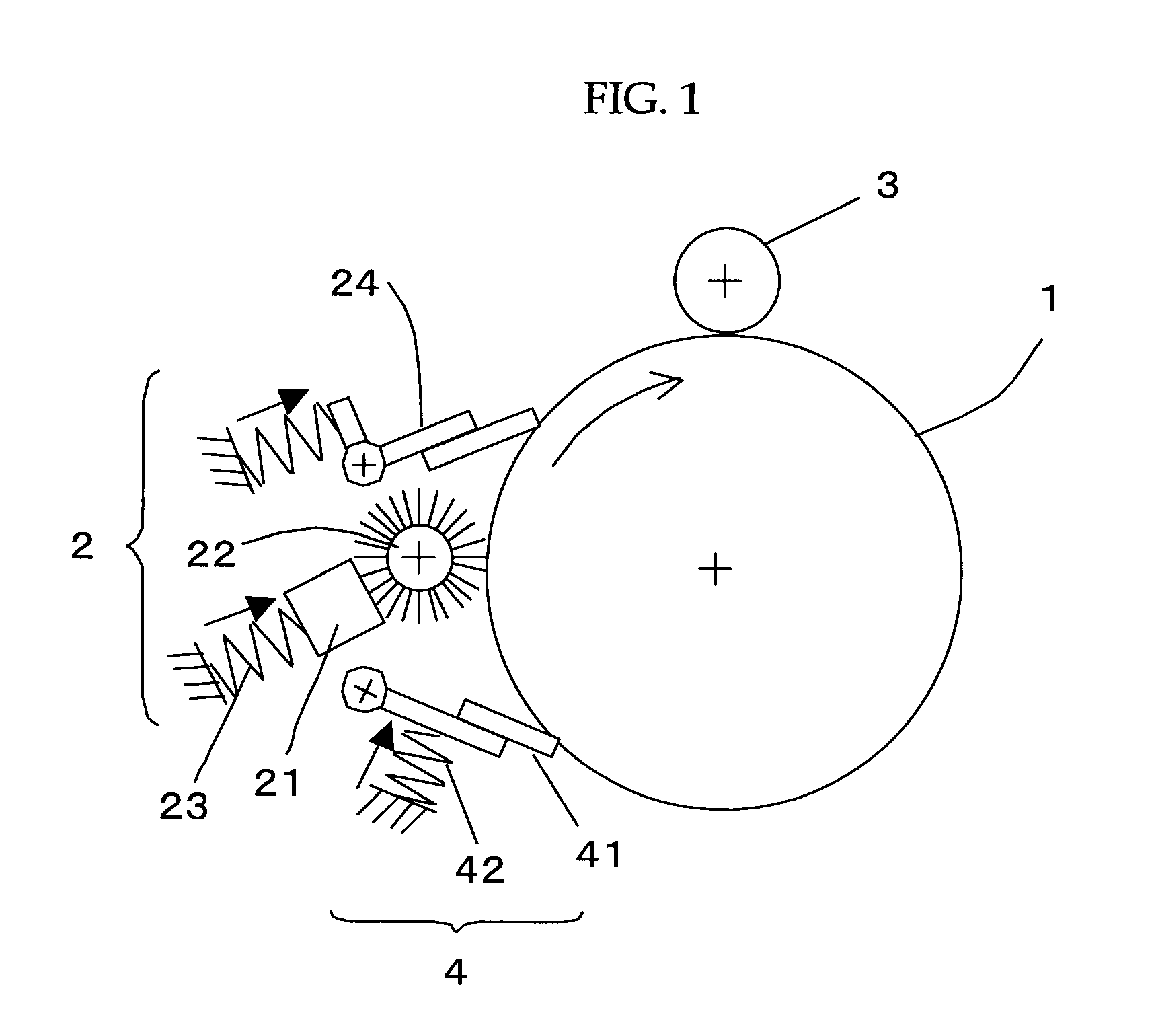

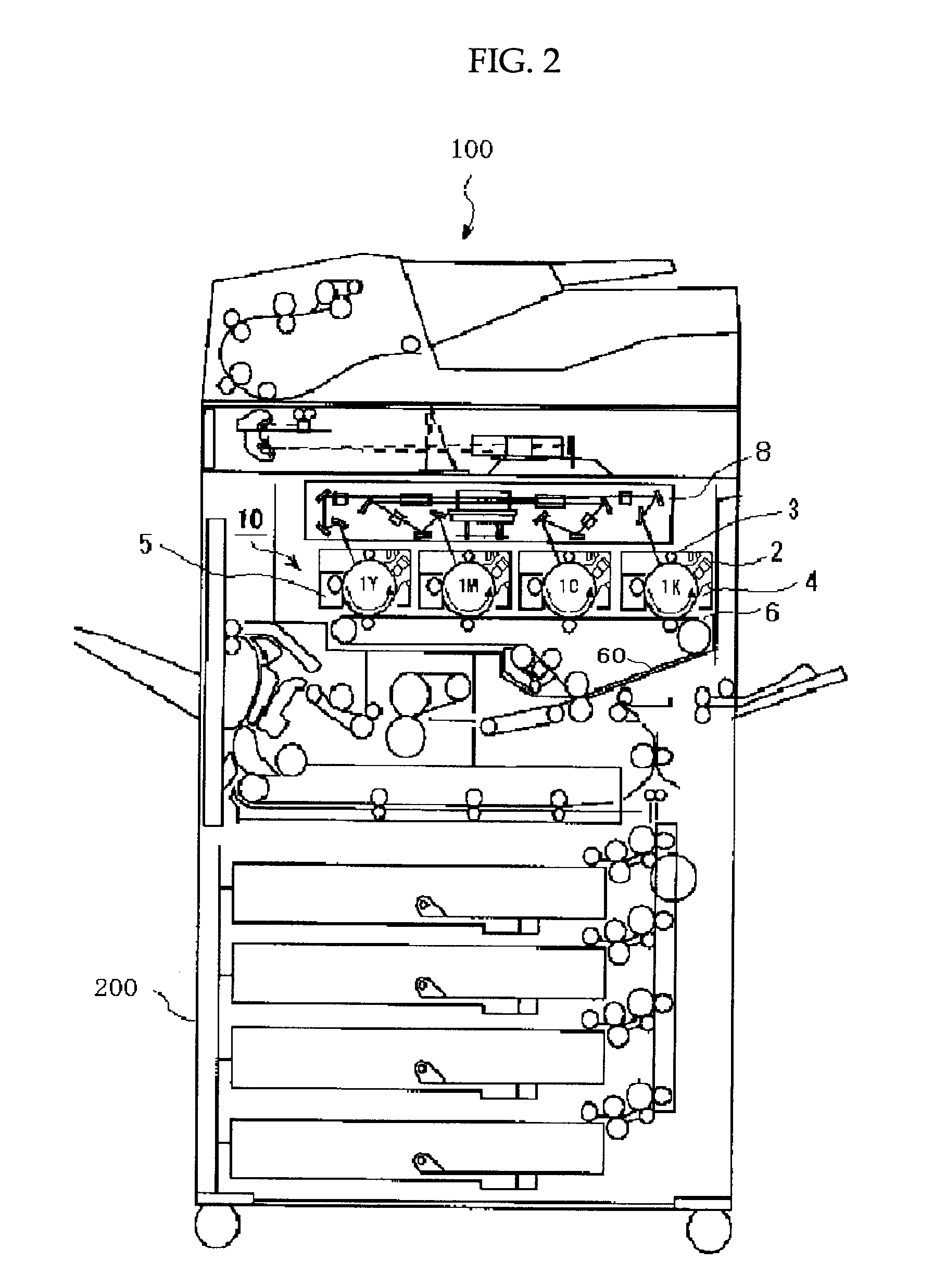

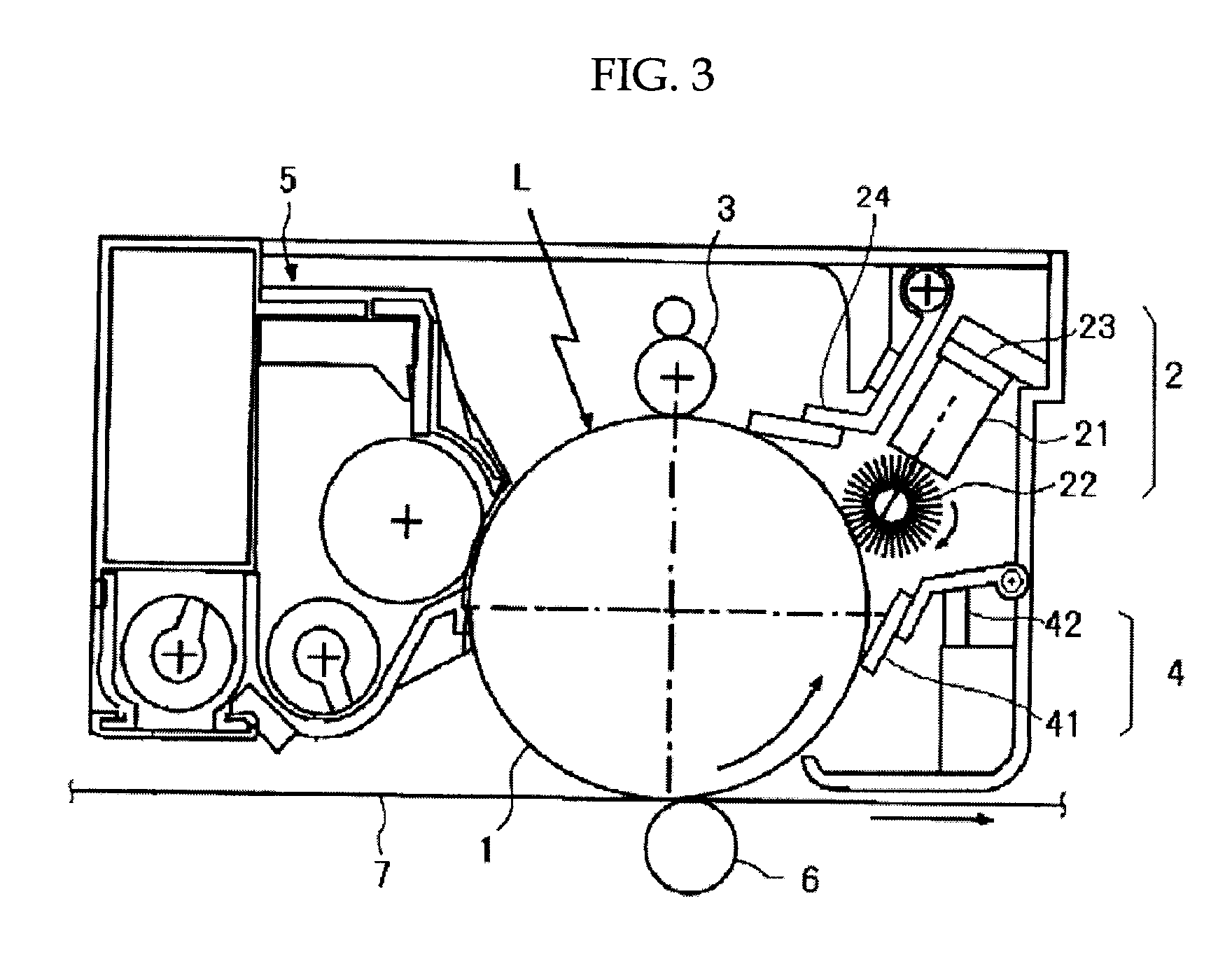

Protecting agent for image bearing member and production method therefor, protection layer forming apparatus, image forming method, image forming apparatus, and process cartridge

ActiveUS20070224528A1Low effect on qualityQuality improvementInksElectrographic process apparatusWaxCycloparaffins

To provide an image bearing member protecting agent that includes at least a hydrophobic organic compound and an amphiphile organic compound. Preferred embodiments are that the hydrophobic organic compound is a hydrocarbon wax, and the hydrocarbon wax is at least a wax selected from normal paraffins, isoparaffins, and cycloparaffins; and that the amphiphile organic compound is an polyalcohol esterified compound including a nonionic surface active surfactant, and the nonionic surface active surfactant is an alkyl carboxylic acid represented by a structural formula, CnH2n+1COOH.

Owner:RICOH KK

Lubricating oil with high oxidation stability

InactiveUS20070142250A1Improve Oxidation StabilityReduce volatilityAdditivesBase-materialsCycloparaffinsAntioxidant

A lubricating oil (made from Group III base oil having a sequential number of carbon atoms) having a VI between 155 and 300, a RPVOT greater than 680 minutes, and a kinematic viscosity at 40° C. from 19.8 cSt to 748 cSt. A lubricating oil having a high VI and high RPVOT comprising: a) a Group III base oil with a sequential number of carbon atoms, and defined cycloparaffin composition or low traction coefficient, b) an antioxidant additive concentrate and c) no VI improver. A process comprising: a) hydroisomerization dewaxing of a waxy feed, b) fractionating the produced base oil, c) selecting a fraction having a VI greater than 150, and a high level of molecules with cycloparaffinic functionality or a low traction coefficient, and d) blending the fraction with an antioxidant additive concentrate. Also, a method of improving the oxidation stability of a lubricating oil.

Owner:CHEVROU USA INC

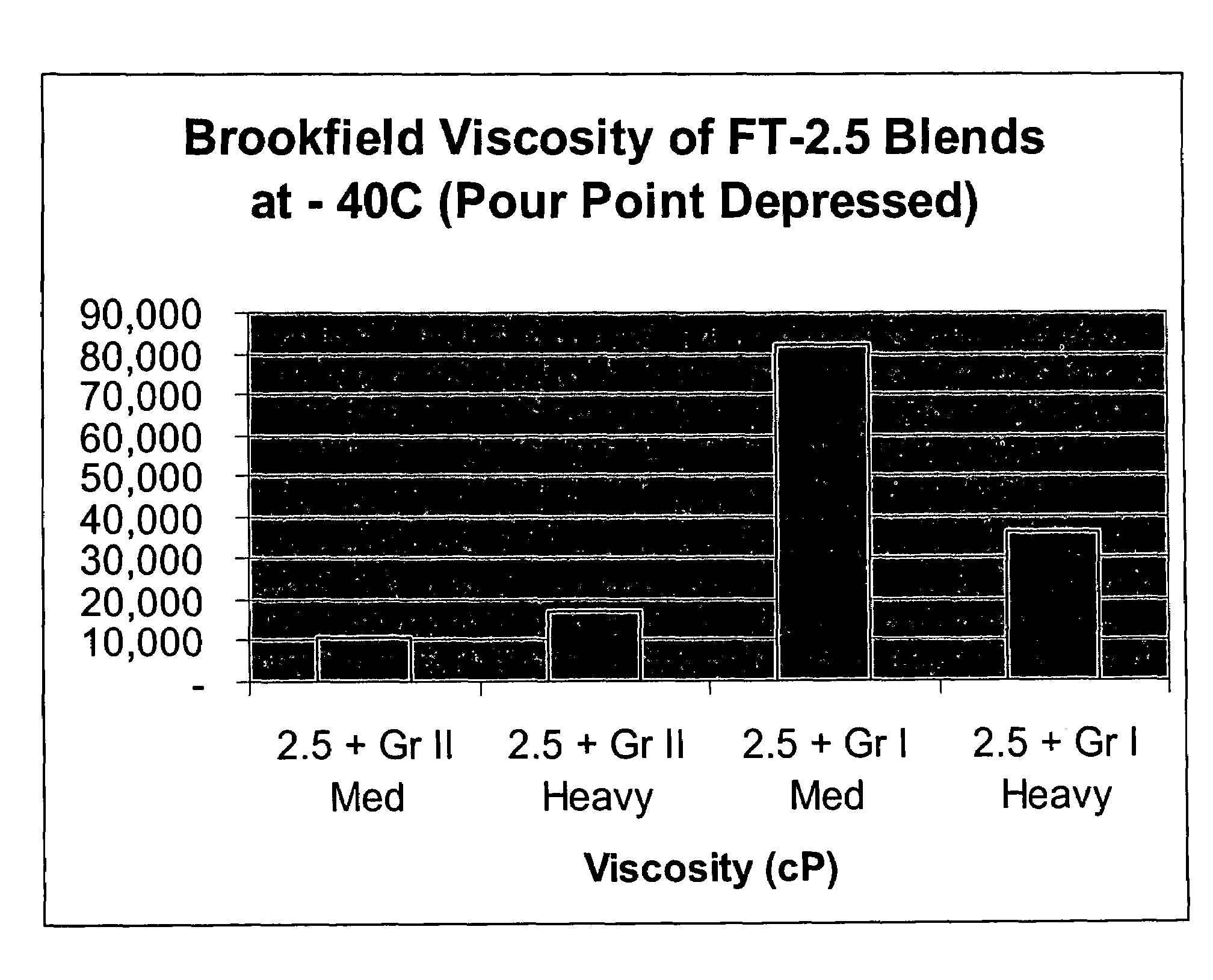

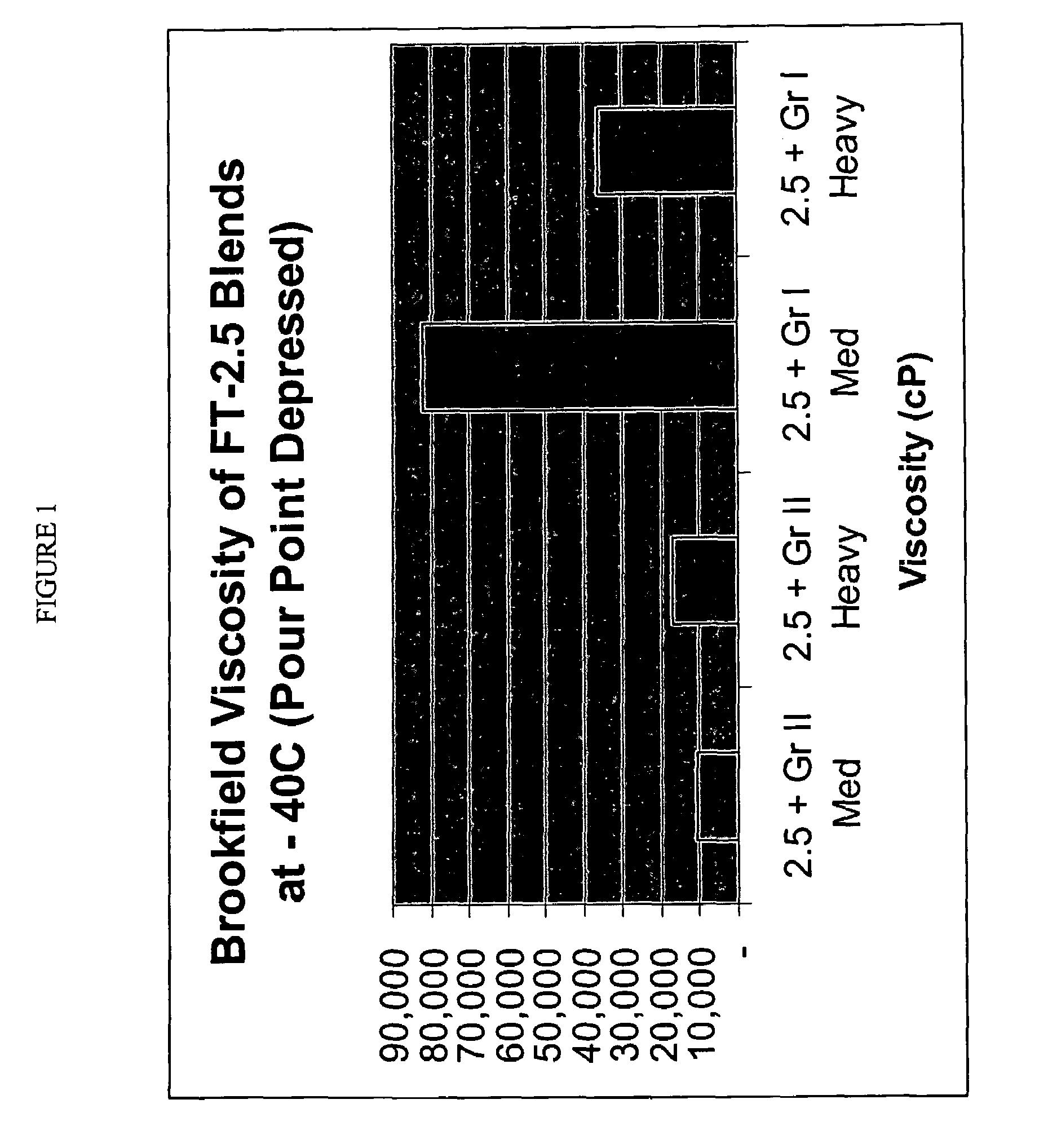

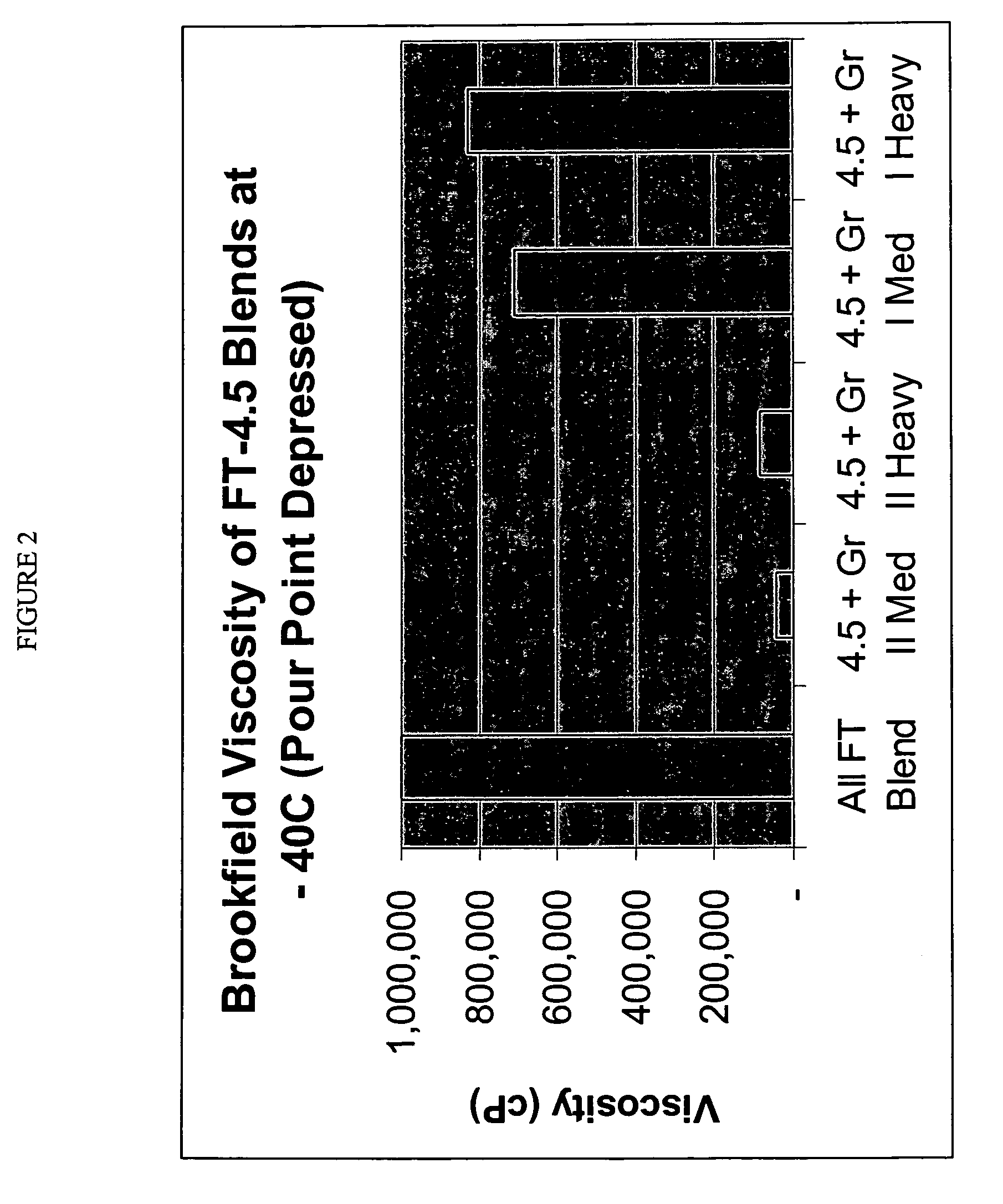

Gear lubricant with low Brookfield ratio

Gear lubricant with a low Brookfield Ratio, comprising: a base oil having sequential carbon atoms, low aromatics, greater than 20 wt % molecules with cycloparaffins and a high ratio of monocycloparaffins to multicycloparaffins; less than 22 wt % of a second base oil having less than 40 wt % molecules with cycloparaffins and a lower ratio of monocycloparaffins to multicycloparaffins; a pour point depressant, an EP additive; and less than 10 wt % VI improver. Gear lubricant with a low Brookfield Ratio, comprising a first base oil having low aromatics and high VI; less than 22 wt % of a second base oil with a lower VI; a pour point depressant; and an EP additive. Gear lubricant having a low Brookfield Ratio comprising: an FT derived base oil; a pour point depressing base oil blending component; and an EP additive. Processes for making gear lubricants with low Brookfield Ratios. Method for reducing Brookfield Ratio.

Owner:CHEVROU USA INC

Compressor Lubricant Compositions and Preparation Thereof

InactiveUS20090181871A1Reduce energy consumptionReduce volatilityLiquid carbonaceous fuelsAdditivesAlkaneFoaming agent

A compressor lubricant composition providing energy savings and exhibiting excellent oxidation stability is provided. The composition comprises (i) 80 to 99.999 weight percent of an isomerized base oil; and (ii) 0.001-20 weight percent of at least an additive selected from an additive package, oxidation inhibitors, pour point depressants, metal deactivators, metal passivators, anti-foaming agents, friction modifiers, anti-wear agents, and mixtures thereof; wherein the isomerized base oil has consecutive numbers of carbon atoms, less than 0.05 wt. % aromatics, a ratio of molecules with monocycloparaffinic functionality to molecules with multicyloparaffinic functionality greater than 2. In one embodiment, compressors employing the lubricant composition with isomerized base oil consumes at least 1% less power than compressors employing the lubricant compositions of the prior art.

Owner:CHEVROU USA INC

Kerosene base fuel

InactiveUS20110005190A1Improve low temperature performanceSuitable for useNon-fuel substance addition to fuelCombustion enginesAlkaneHigh density

The subject invention relates to a kerosene base fuel having an initial boiling point in the range 130 to 160° C. and a final boiling point in the range 250 to 300° C. as determined according to ASTM method D86, and comprising less than 15% by weight of aromatic compounds, and at least of 80% by weight of aliphatic hydrocarbons, of which at least 20% by volume are n-paraffins and at least 25% by volume are cycloparaffins, as determined by according to ASTM method D2425. It further relates to the use of this base fuel in fuel compositions, as well for he use of the kerosene base fuel in a fuel composition comprising a petroleum based kerosene base fuel having a higher density and a lower energy content than that of the kerosene base fuel, to increase the energy density above that of the petroleum derived kerosene fuel.

Owner:SHELL OIL CO

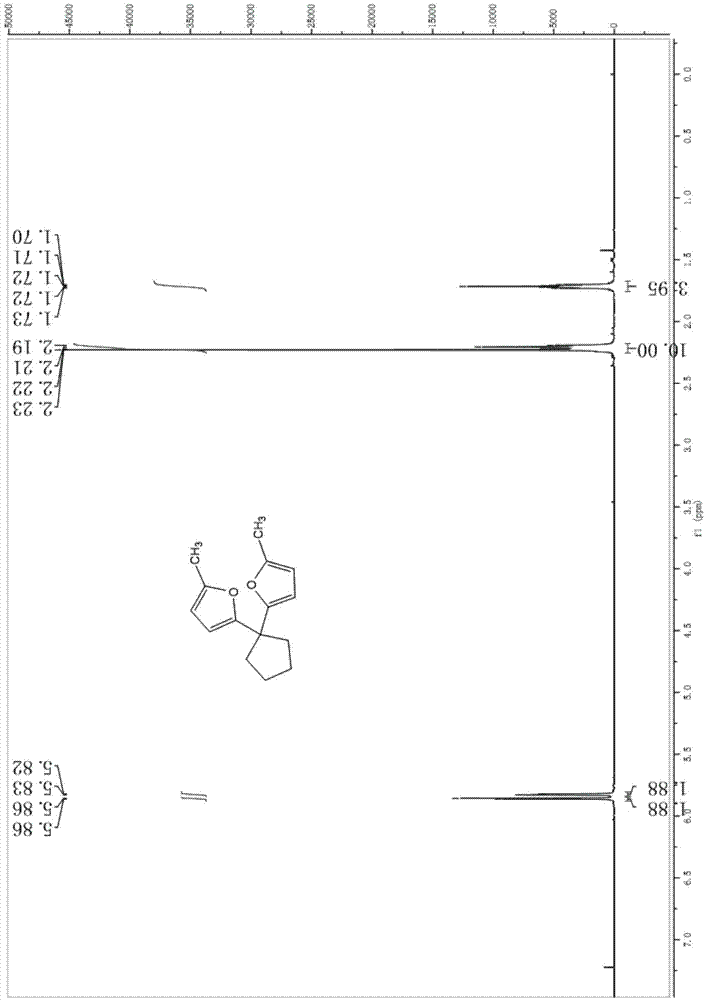

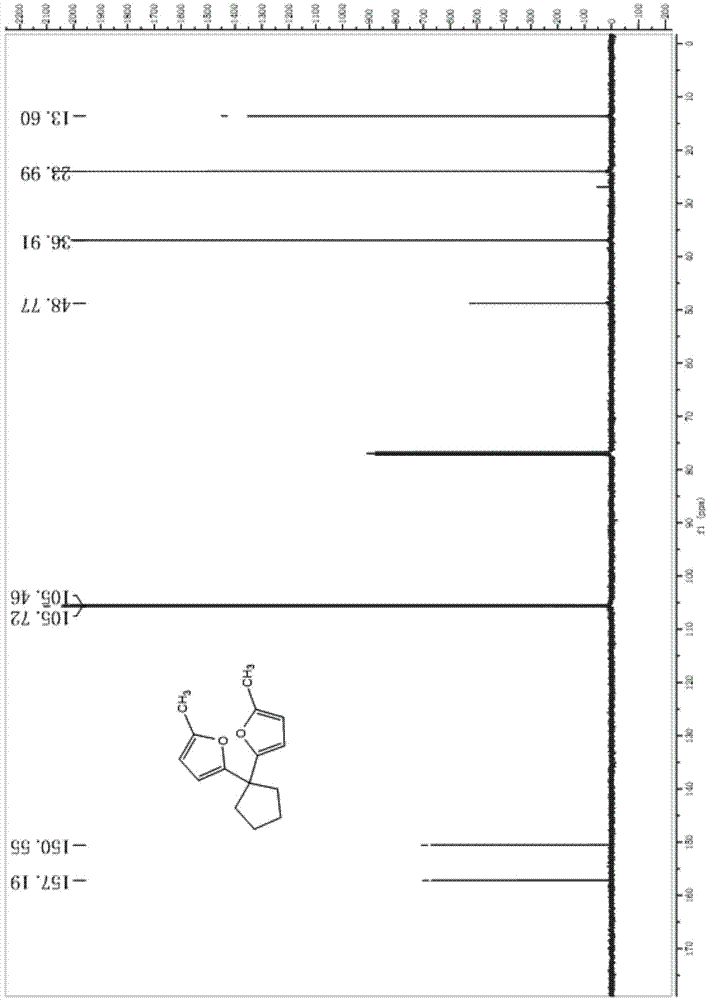

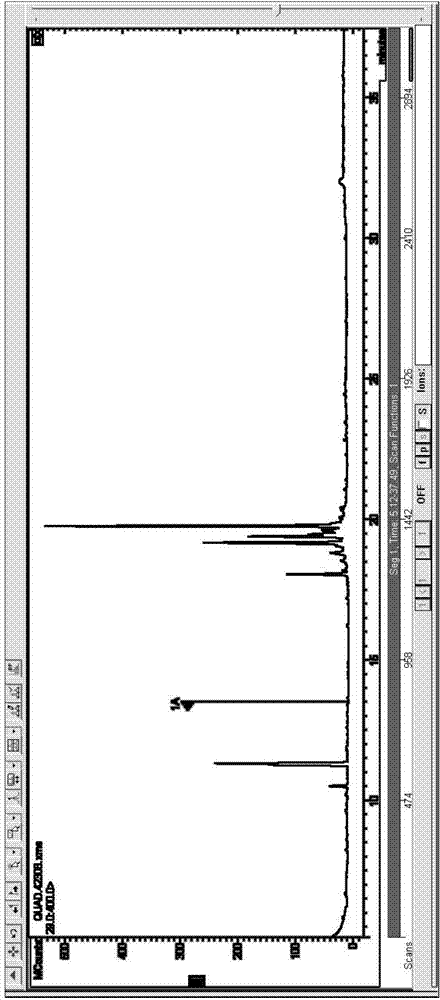

Method for preparing cycloparaffin as aviation kerosene or diesel oil by biomass route

ActiveCN104711021AGood choiceSimple operation processTreatment with hydrotreatment processesHydrocarbon oils treatment productsAlkaneCellulose

The invention relates to a novel cycloparaffin fuel synthesis route which utilizes a platform chemical compound raw material prepared from lignocellulose and is completely independent of fossil energy. The liquid fuel produced by the method can be used as an aviation kerosene or diesel oil substitute or as an additive for improving fuel cetane number and cold resistance so that through the liquid fuel, a degree of dependence on liquid fuel import is reduced. The method comprises that 1, on a novel solid acid catalyst, cyclopentanone and a furan platform chemical compound (such as fura, methyl furan and hydroxyl methyl furan) prepared from lignocellulose are used as raw materials and undergo an acid catalytic alkylation reaction to produce an oxygen-containing organic compound with carbon chain length of 8-21, and 2, the alkylation product is subjected to hydrogenation deoxidation by a metal-solid acid double function catalyst so that the cycloparaffin which has carbon chain length of 8-21, has high energy density and stability and is suitable as biomass aviation kerosene or high-grade diesel oil is obtained.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

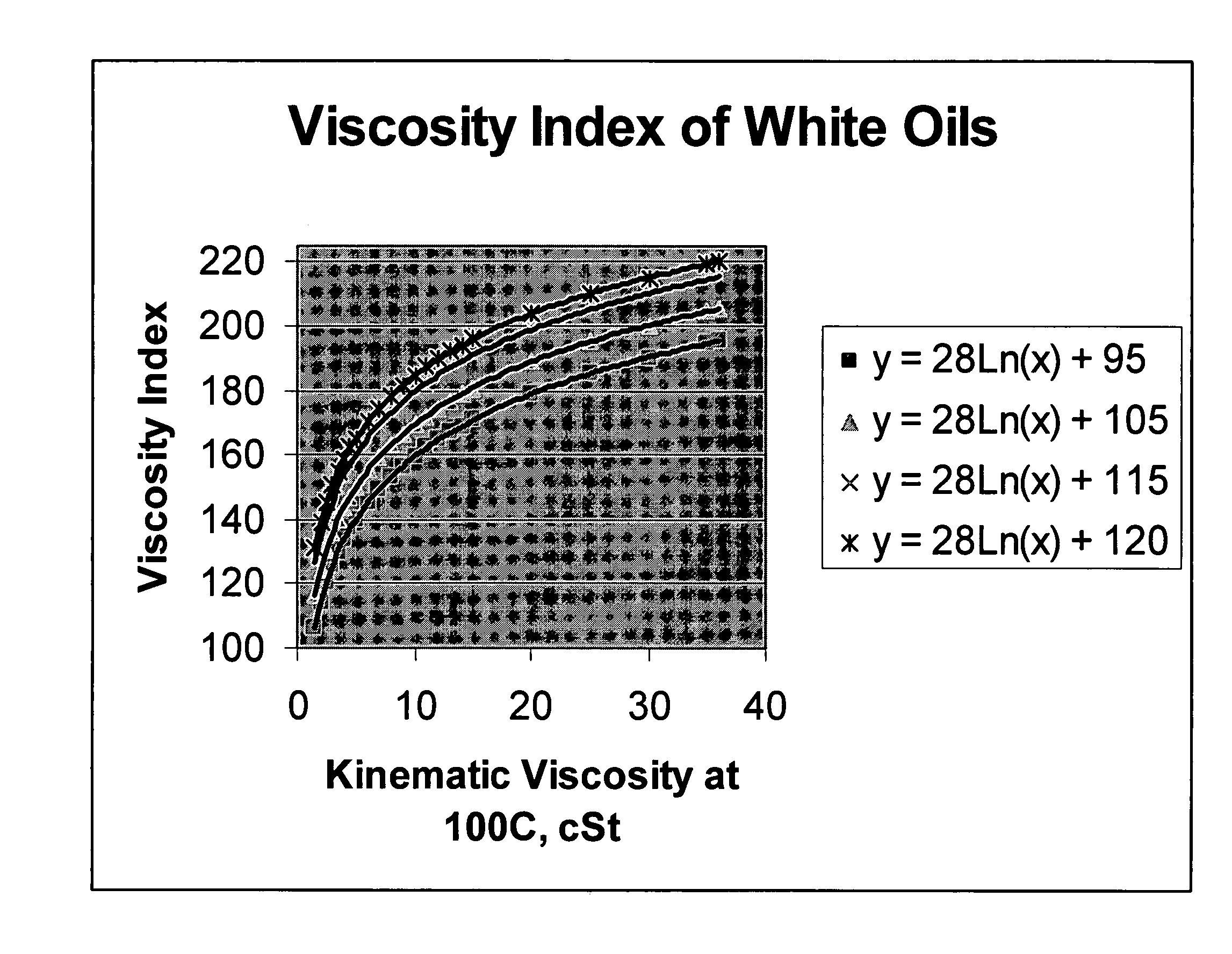

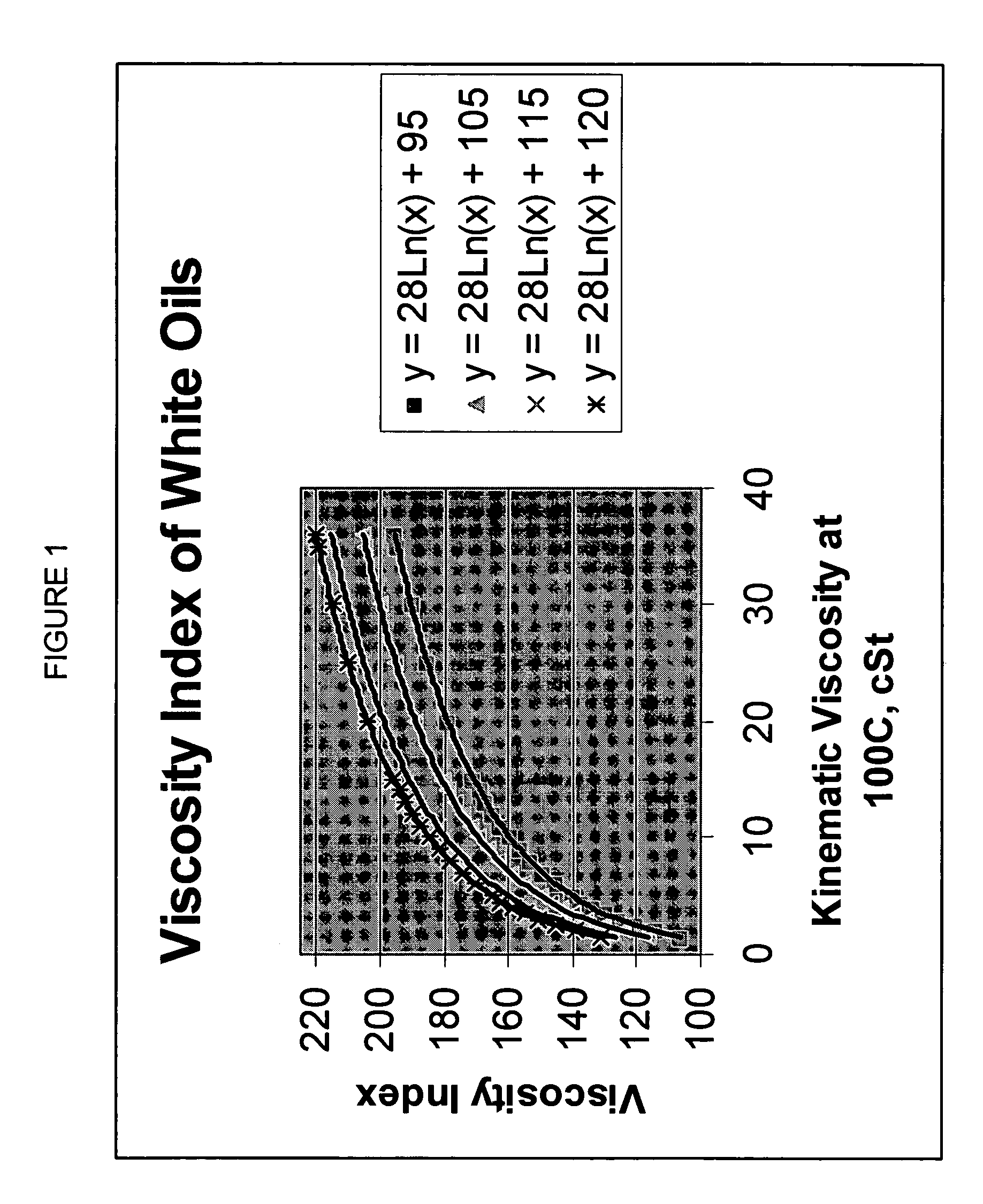

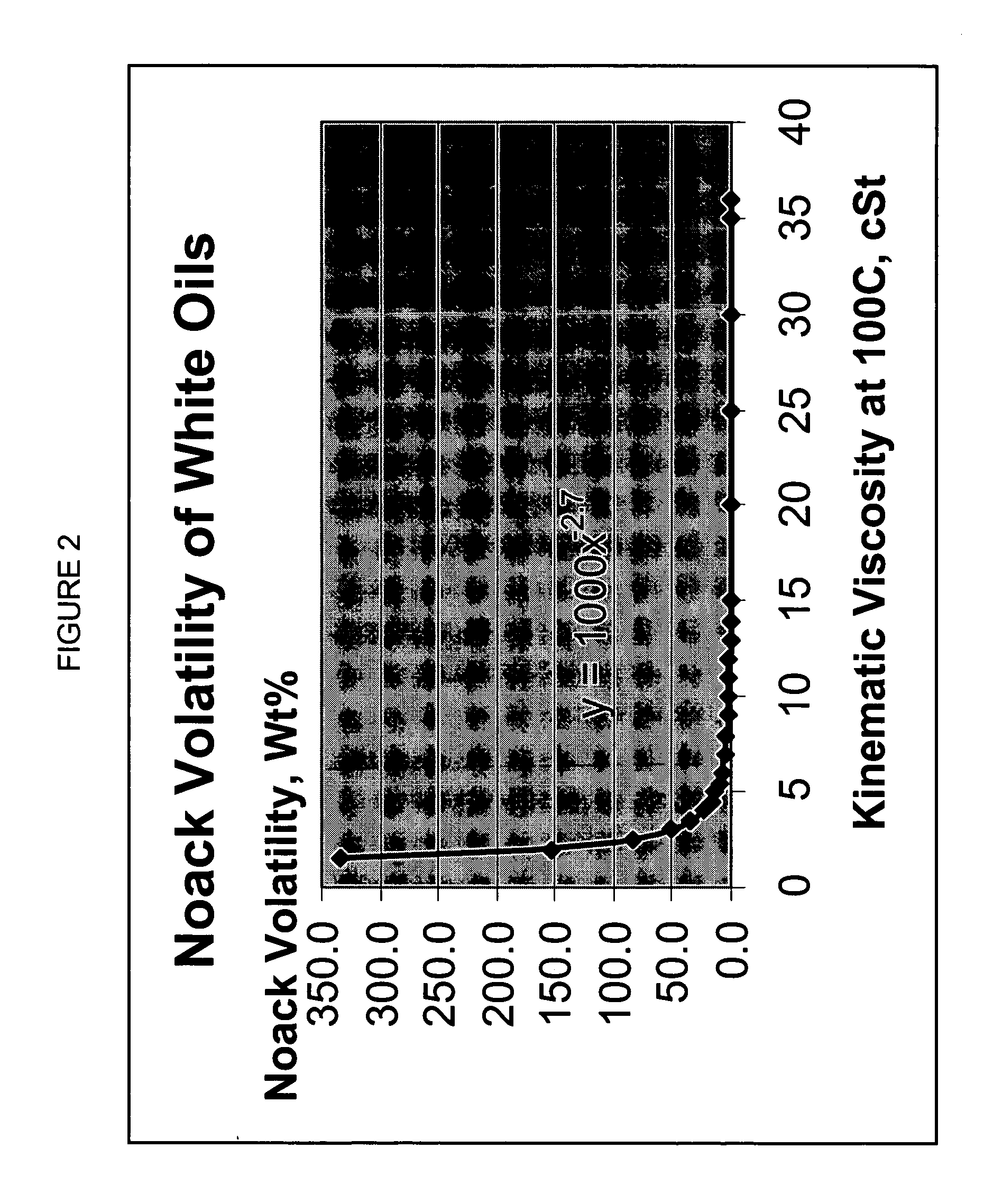

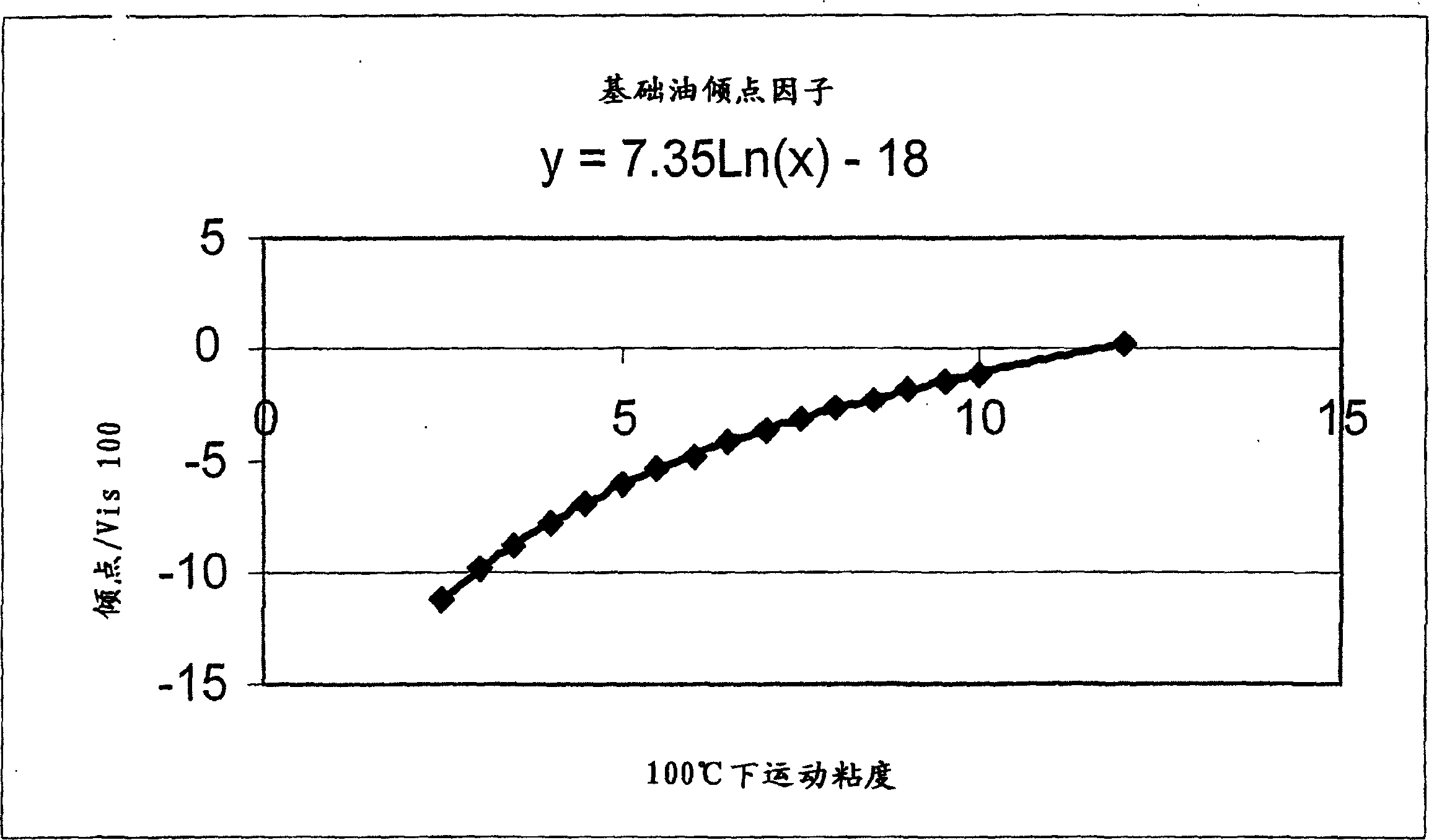

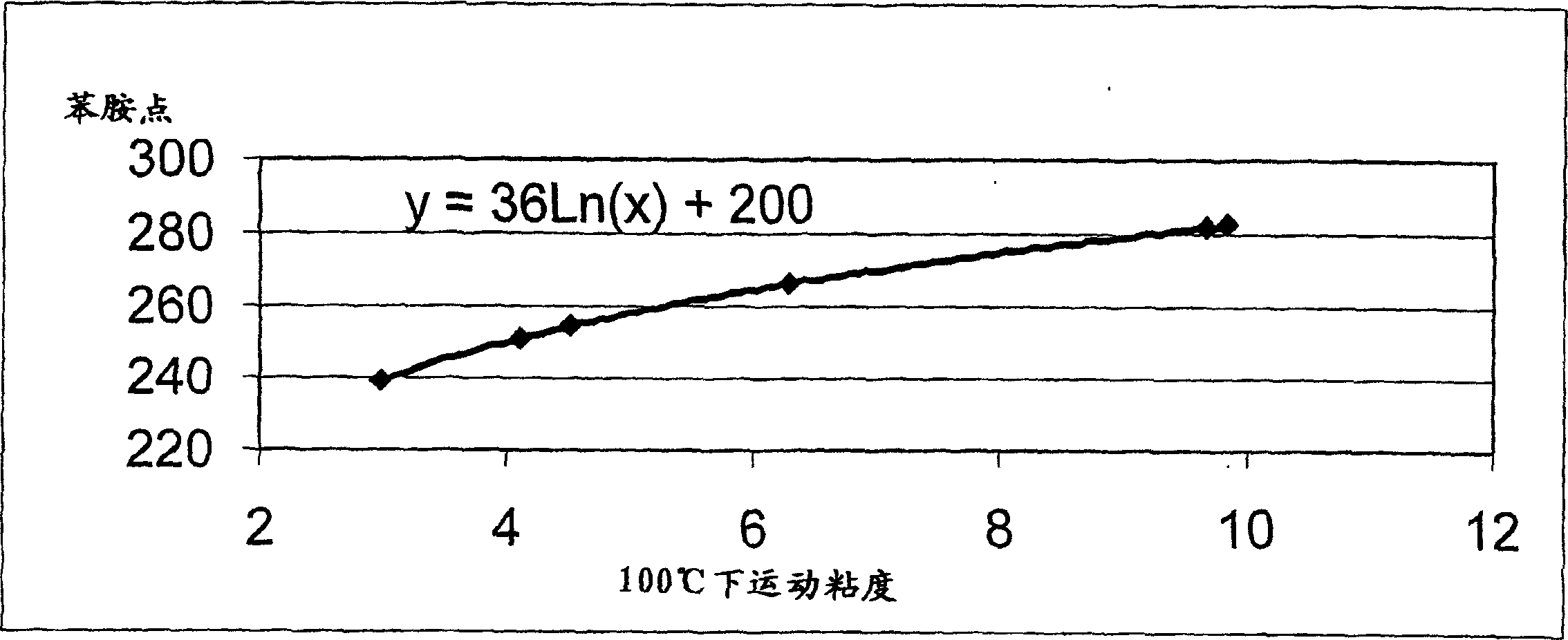

White oil from waxy feed using highly selective and active wax hydroisomerization catalyst

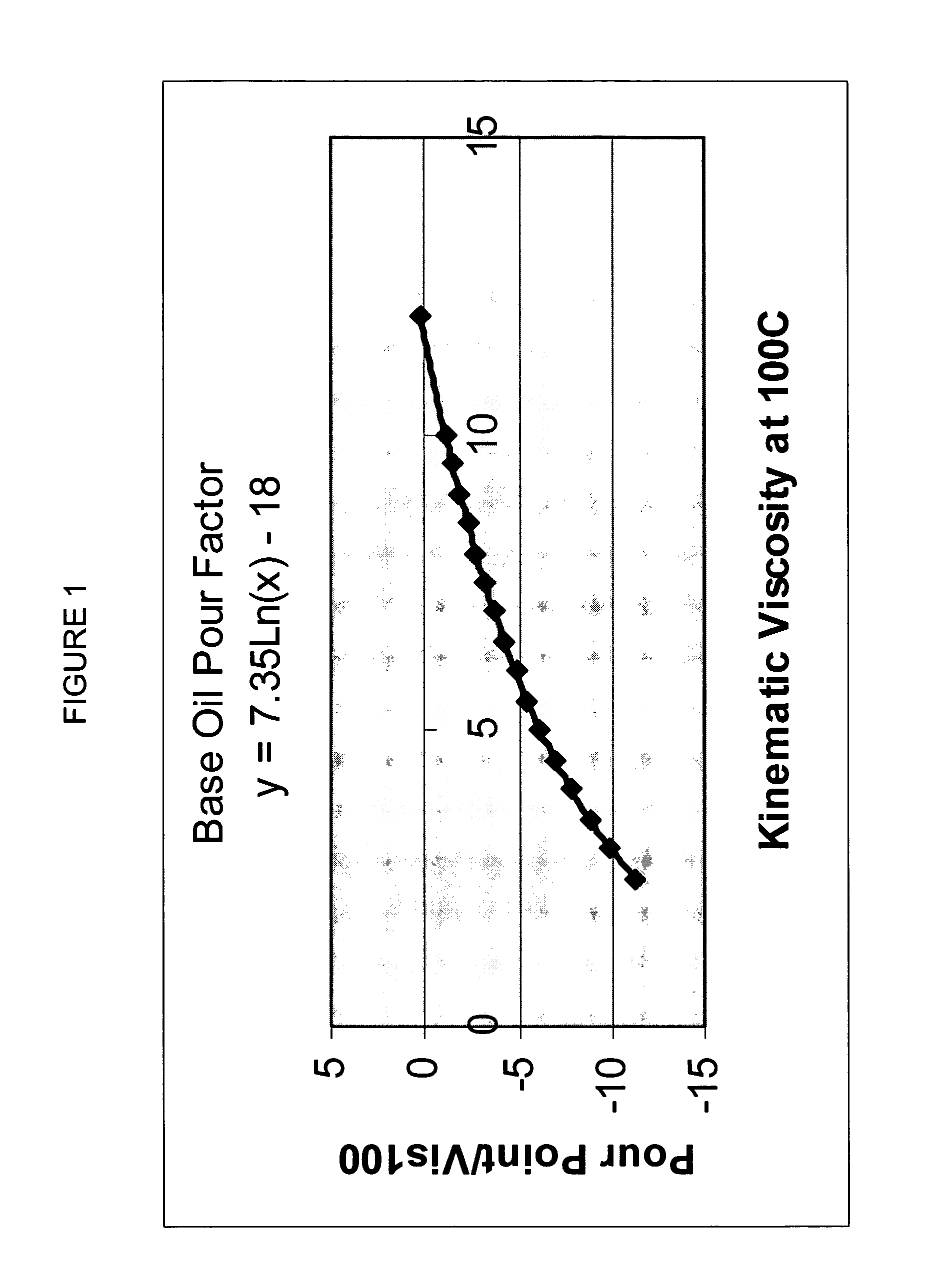

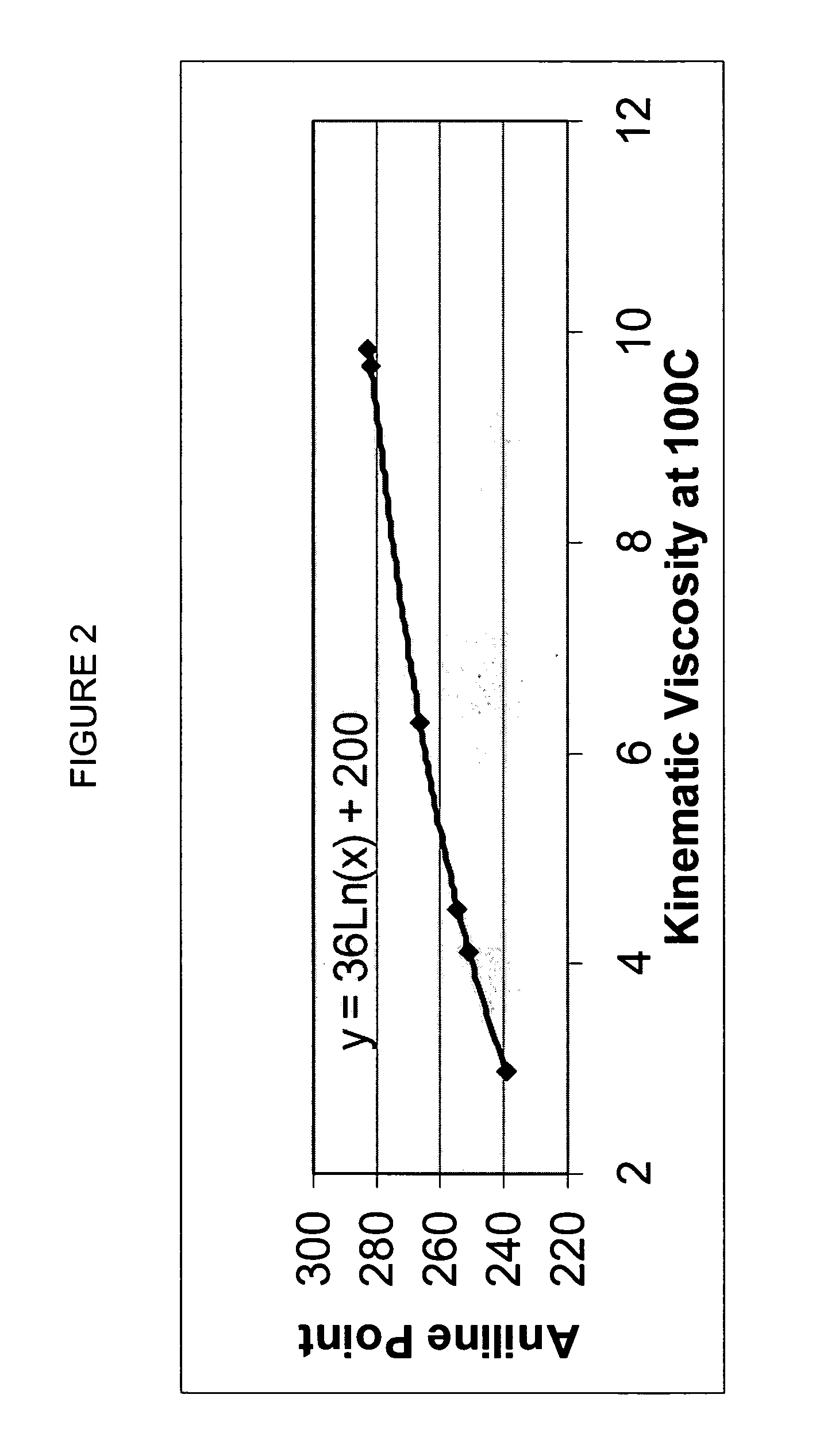

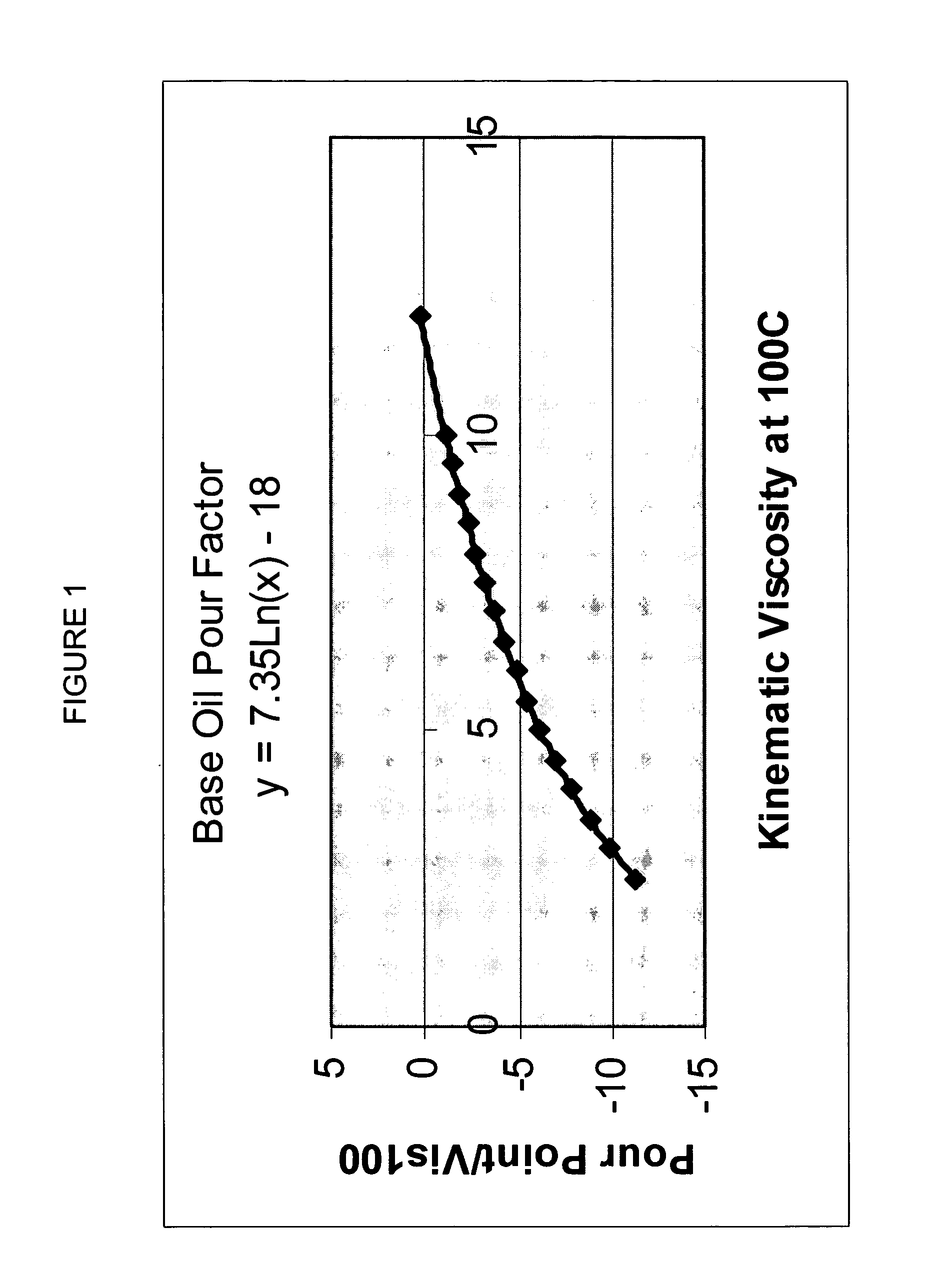

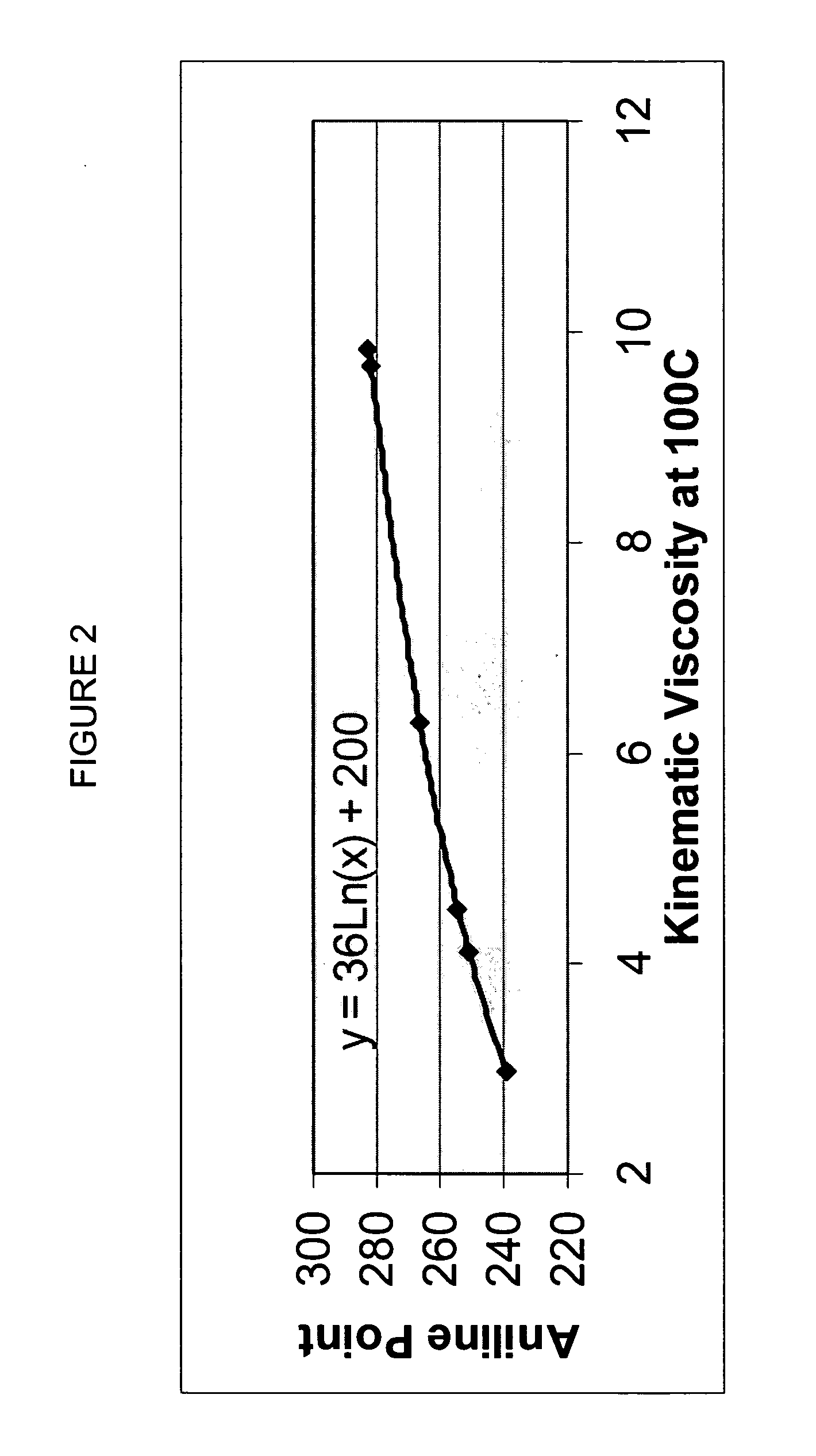

A composition of white oil having a kinematic viscosity at 100° C. between about 1.5 cSt and 36 cSt, a viscosity index greater than an amount calculated by the equation: Viscosity Index=28×Ln(the Kinematic Viscosity at 100° C.)+105, less than 18 weight percent of molecules with cycloparaffin functionality, a pour point less than zero degrees C., and a Saybolt color of +20 or greater. Also, a composition of white oil having a kinematic viscosity at 100° C. between about 1.5 cSt and 36 cSt, a viscosity index greater than an amount calculated by the equation: Viscosity Index=28×Ln(the Kinematic Viscosity at 100° C.)+95, between 5 and less than 18 weight percent of molecules with cycloparaffin functionality, less than 1.2 weight percent molecules with multicycloparaffin functionality, a pour point less than zero degrees C., and a Saybolt color of +20 or greater.

Owner:CHEVROU USA INC

Lubricating base oil with high monocycloparaffins and low multicycloparaffins

InactiveCN1906277AImprove solubilityGood Elastomer CompatibilityRefining to change hydrocarbon structural skeletonLiquid hydrocarbon mixture productionPolymer scienceCycloparaffins

A composition of lubricating base oil having a weight percent of all molecules with at least one aromatic function less than 0.30, a weight percent of all molecules with at least one cycloparaffin function greater than 10, and a ratio of weight percent of molecules with monocycloparaffins to weight percent of molecules with multicycloparaffins greater than 15.

Owner:CHEVROU USA INC

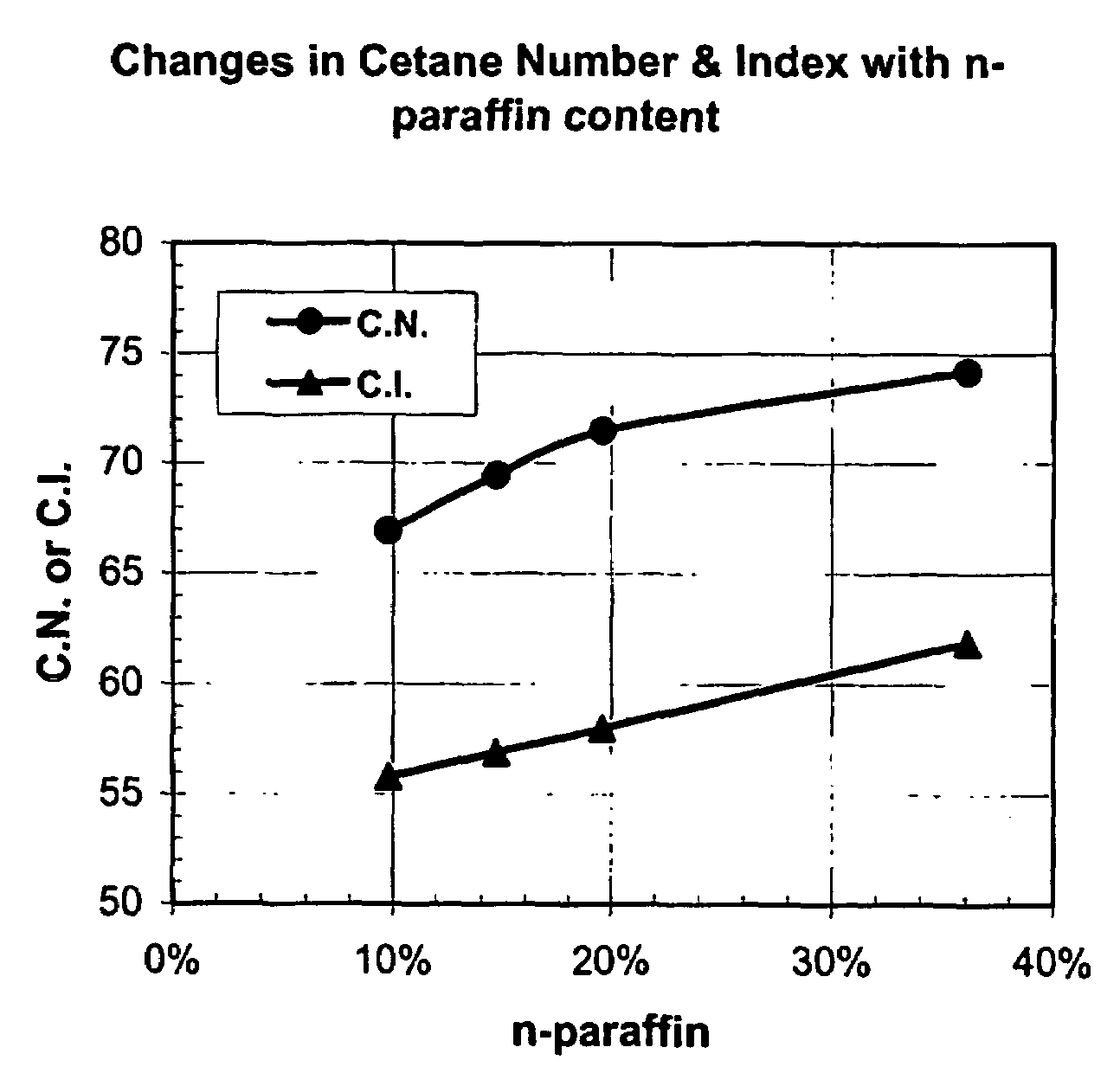

Self-lubricating diesel fuel and method of making and using same

A diesel fuel comprising a mixture of normal paraffins and branched paraffins. The normal paraffins present in the diesel fuel is less than about 99% by weight; and the aromatic content in the diesel fuel is less than about 10% by weight. The diesel fuel has a cetane number of at least 40 and a sulfur content of less than about 100 ppm. Optionally, the diesel fuel may further include cycloparaffins, i.e., naphthenes. To increase the lubricity of the diesel fuel, a lubricity additive, such as fatty acid methyl ester, can be added to the diesel fuel.

Owner:SHELL USA INC

Lubricant blends with low brookfield viscosities

ActiveUS7273834B2Improve low temperature performanceLow viscosityOrganic compound preparationOxygen compounds preparation by reductionSulfurBase oil

Lubricant blends and finished gear oils comprising a Fischer-Tropsch derived lubricant base oil fraction, a petroleum derived base oil, and a pour point depressant are provided. The Fischer-Tropsch derived lubricant base oil fraction comprises less than 0.30 weight percent aromatics, greater than 5 weight percent molecules with cycloparaffinic functionality, and a ratio of weight percent of molecules with monocycloparaffinic functionality to weight percent of molecules with multicycloparaffnic functionality greater than 15. The petroleum derived base oils comprises greater than 90 weight percent saturates and less than 300 ppm sulfur and is preferably selected from the group consisting of a Group II base oil, a Group III base oil, and mixtures thereof. These lubricant blends have surprising low Brookfield viscosities at −40° C.

Owner:CHEVROU USA INC

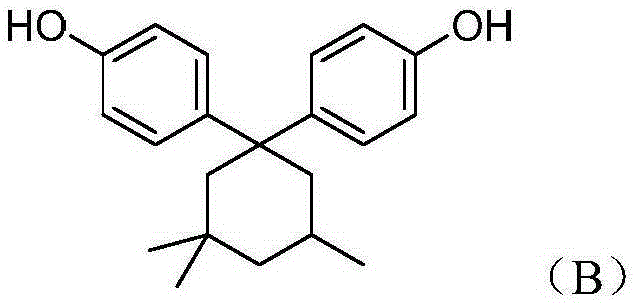

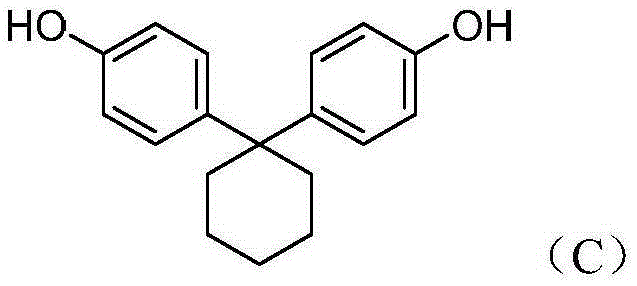

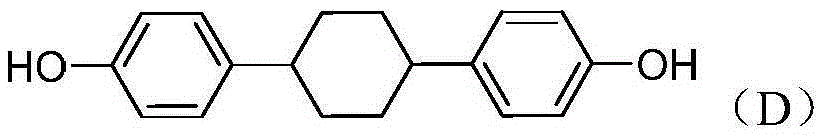

High-transparent polysulfone resin and preparation method thereof

The invention belongs to the technical field of high polymer materials, and discloses high-transparent polysulfone resin and a preparation method thereof. The preparation method particularly comprises the steps of a salt-forming reaction, a polymerization reaction and post-treatment. A cycloparaffin bisphenol compound is added in the polymerization reaction, the regularity of a polymer chain is destroyed, the degree of crystallinity is decreased, the hydroxy end-capping high-transparent polysulfone resin is prepared, original excellent properties of polysulfone are reserved, the high-transparent advantage is achieved, and better application prospect and great market value are achieved. By controlling the solid content of a system and adopting specific solvent and high-pressure polymerization, the time of the polymerization reaction is greatly shortened, the energy consumption is reduced, a water separation agent does not need to be added, and the post-treatment processes are reduced.

Owner:GUANGDONG YOUJU ADVANCED MATERIAL RES CO LTD

Ashless lubricating oil with high oxidation stability

InactiveUS20070142240A1Improve Oxidation StabilityReduce volatilityLiquid carbonaceous fuelsAdditivesAntioxidantCycloparaffins

An ashless hydraulic fluid or paper machine oil having a VI between 155 and 300, a RPVOT greater than 680 minutes, and a kinematic viscosity at 40° C. from 19.8 cSt to 748 cSt. An ashless hydraulic fluid or paper machine oil having a high VI and high RPVOT comprising: a) a Group III base oil with a sequential number of carbon atoms, and defined cycloparaffin composition or low traction coefficient, b) an ashless antioxidant additive concentrate, and c) low amount of VI improver. A process for making an ashless hydraulic fluid or paper machine oil comprising a) hydroisomerization dewaxing, b) fractionating, c) selecting a fraction having a very high VI, and a high level of molecules with cycloparaffinic functionality or a low traction coefficient, and d) blending the fraction with an ashless antioxidant. Also, a method of improving the oxidation stability of an ashless hydraulic fluid or paper machine oil.

Owner:CHEVROU USA INC

Polyol ester lubricants, especially those compatible with mineral oils, for refrigerating compressors operating at high temperatures

InactiveUS20010038088A1Good hygroscopicityPromote undesirable corrosionHeat-exchange elementsRefrigeration componentsSolubilityRefrigeration compressor

A high quality lubricant for compressors operated during at least part of their compression cycle at temperatures above normal human comfort temperatures, such as most automotive air conditioners, especially those using chlorine free hydro-fluorocarbon refrigerant working fluids, is provided by mixed esters of hindered polyols, most desirably pentaerythritol, with a mixture of carboxylic acids including at least some iso-pentanoic acid along with one or more of iso-nonanoic acid, isooctanoic acid, and dibasic acids such as adipic. When the mixture includes about 7% adipic and amounts of branched C8-9 and C5 monobasic acids in a ratio of at least 0.75:1.00, the esters formed have excellent solubility for paraffinic and naphthenic mineral oils and are therefore especially well suited for lubricating vehicle air conditioners formerly containing chlorine containing heat transfer fluids and mineral oil lubricants.

Owner:COGNIS CORP

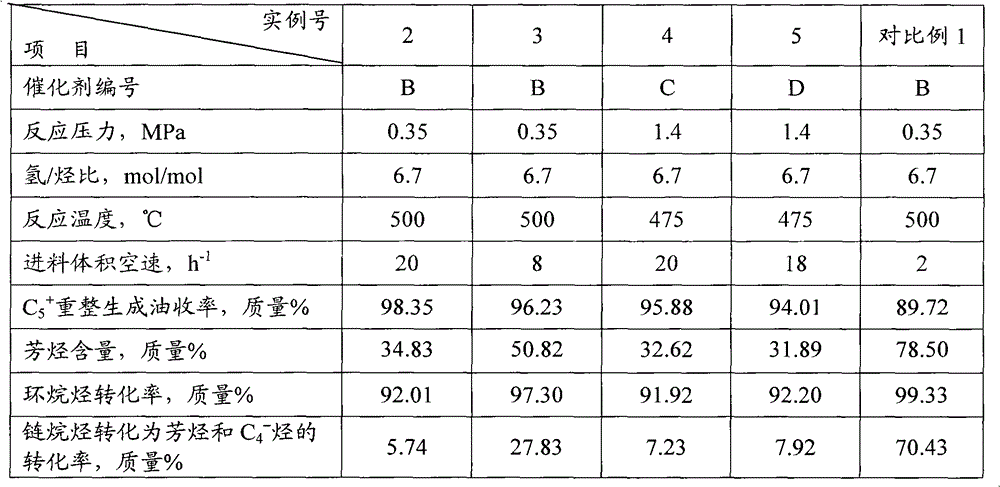

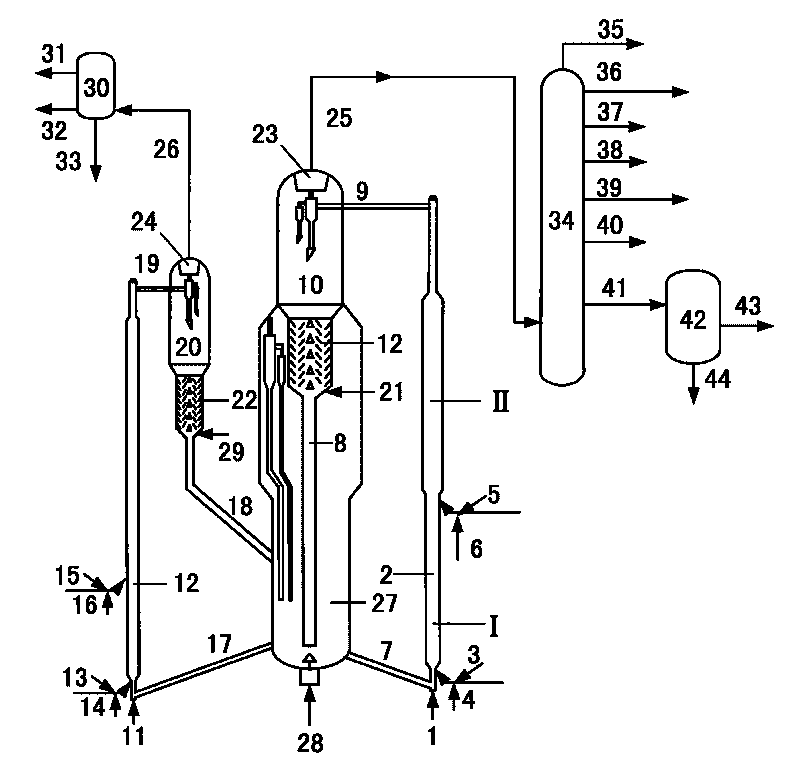

Catalytic reforming method for naphtha

ActiveCN102796553ALess reservedCatalytic naphtha reformingTreatment with hydrotreatment processesCatalytic reformingNaphtha

The invention discloses a catalytic reforming method for naphtha, which comprises a step that: naphtha is in contact with a reforming catalyst under the conditions that the pressure is 0.15-3.0MPa, the temperature is 300-540 DEG C and the hourly space velocity is 2.1-50 / h so as to carry out shallow catalytic reforming reaction, so that the cycloparaffin conversion rate of the naphtha is greater than 85 mass%, and the ratio of converting paraffin into arene and C4-hydrocarbon is less than 30 mass%. According to the method, naphtha can largely produce paraffin while producing arene, so that the naphtha becomes a raw material which both can be used for producing arene and high-quality raw materials for ethylene cracking.

Owner:CHINA PETROLEUM & CHEM CORP +1

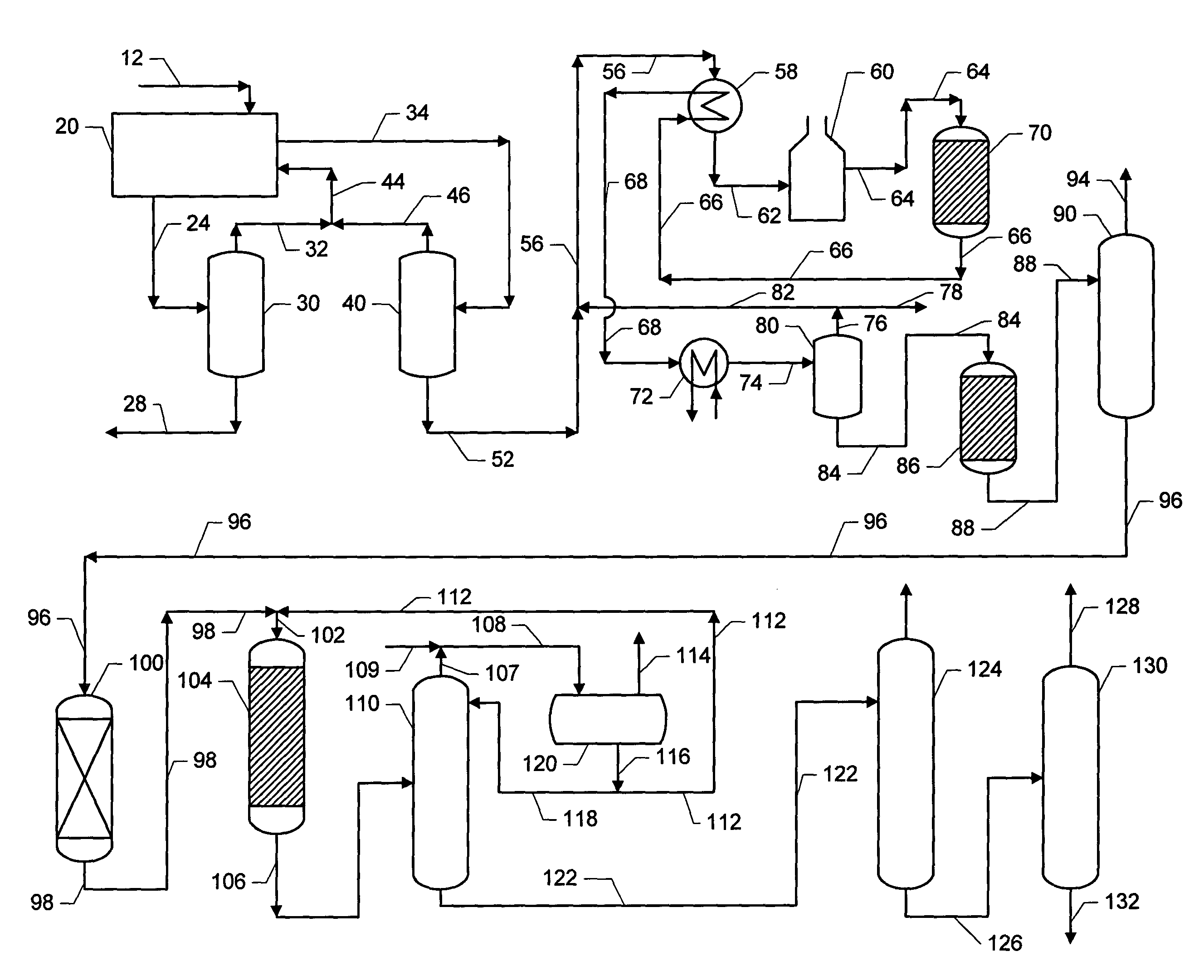

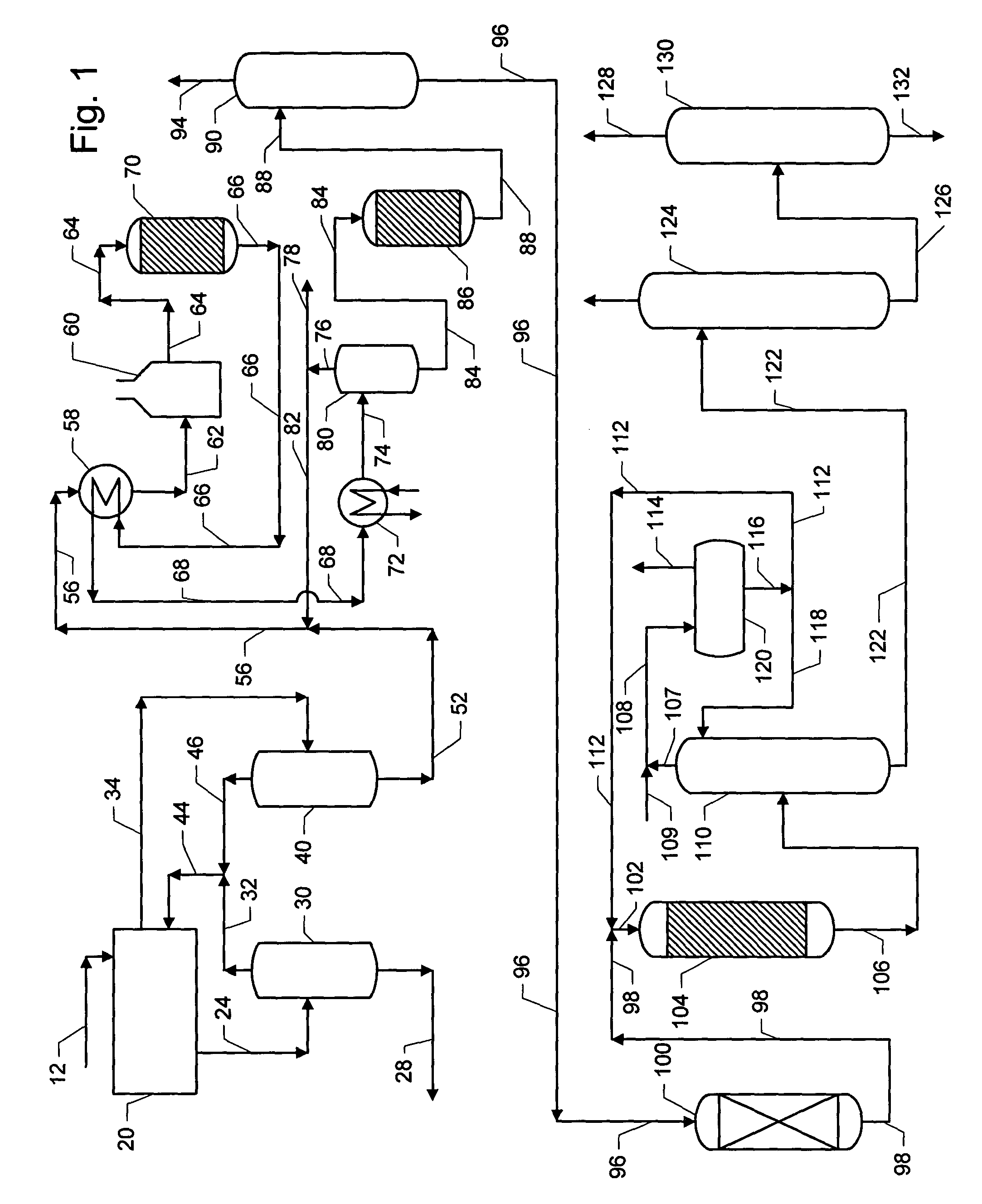

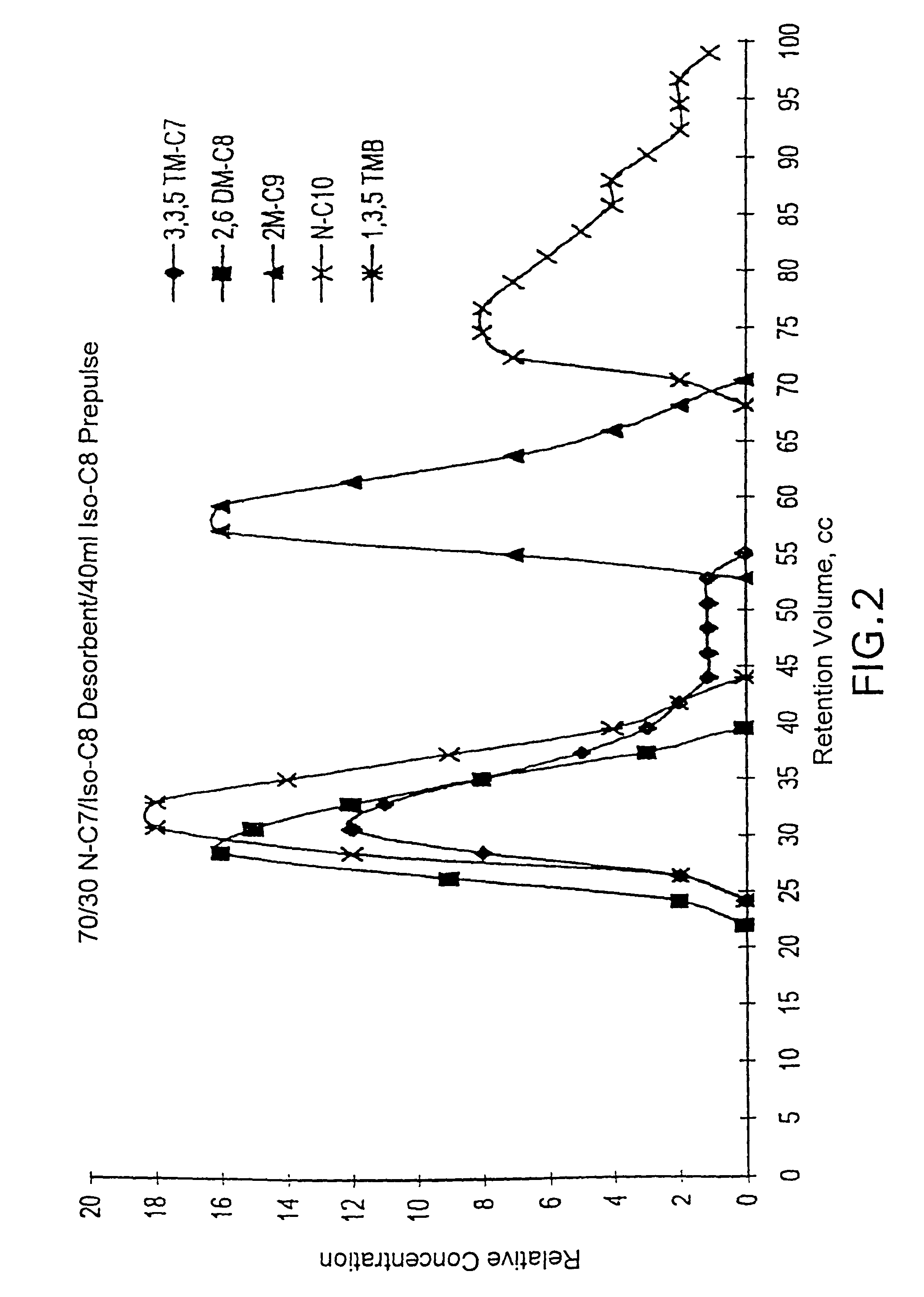

Phenyl-alkane compositions produced using an adsorptive separation section

The present invention is a process for producing phenyl-alkanes by paraffin adsorptive separation followed by paraffin dehydrogenation and then by alkylation of a phenyl compound by a lightly branched olefin. The adsorptive separation step employs a silicalite adsorbent and, as the desorbent, a C5-C8 linear paraffin, a C5-C8 cycloparaffin, a branched paraffin such as isooctane, or mixtures thereof. The effluent of the alkylation zone comprises paraffins that are recycled to the adsorptive separation step or to the dehydrogenation step. This invention is also a process that that sulfonates phenyl-alkanes having lightly branched aliphatic alkyl groups that to produce modified alkylbenzene sulfonates. In addition, this invention is the compositions produced by these processes, which can be used as detergents having improved cleaning effectiveness in hard and / or cold water while also having biodegradability comparable to that of linear alkylbenzene sulfonates, as lubricants, and as lubricant additives. This invention is moreover the use of compositions produced by these processes as lubricants and lubricant additives.

Owner:UOP LLC

Production of distillate blending components

InactiveUS20110105811A1Organic-compounds/hydrides/coordination-complexes catalystsHydrocarbon purification/separationAlkyl transferCycloparaffins

A process to produce an alkylate distillate blending component in one embodiment comprising: providing at least one olefinic C5+ product which was produced by conversion of synthesis gas in a Fischer Tropsch process; and alkylating the olefinic C5+ product in the presence of an acidic ionic liquid alkylation catalyst with hydrocarbons selected from the group consisting of isoparaffins, cycloparaffins, and their mixtures to form an alkylate distillate blending component is described.

Owner:CHEVROU USA INC

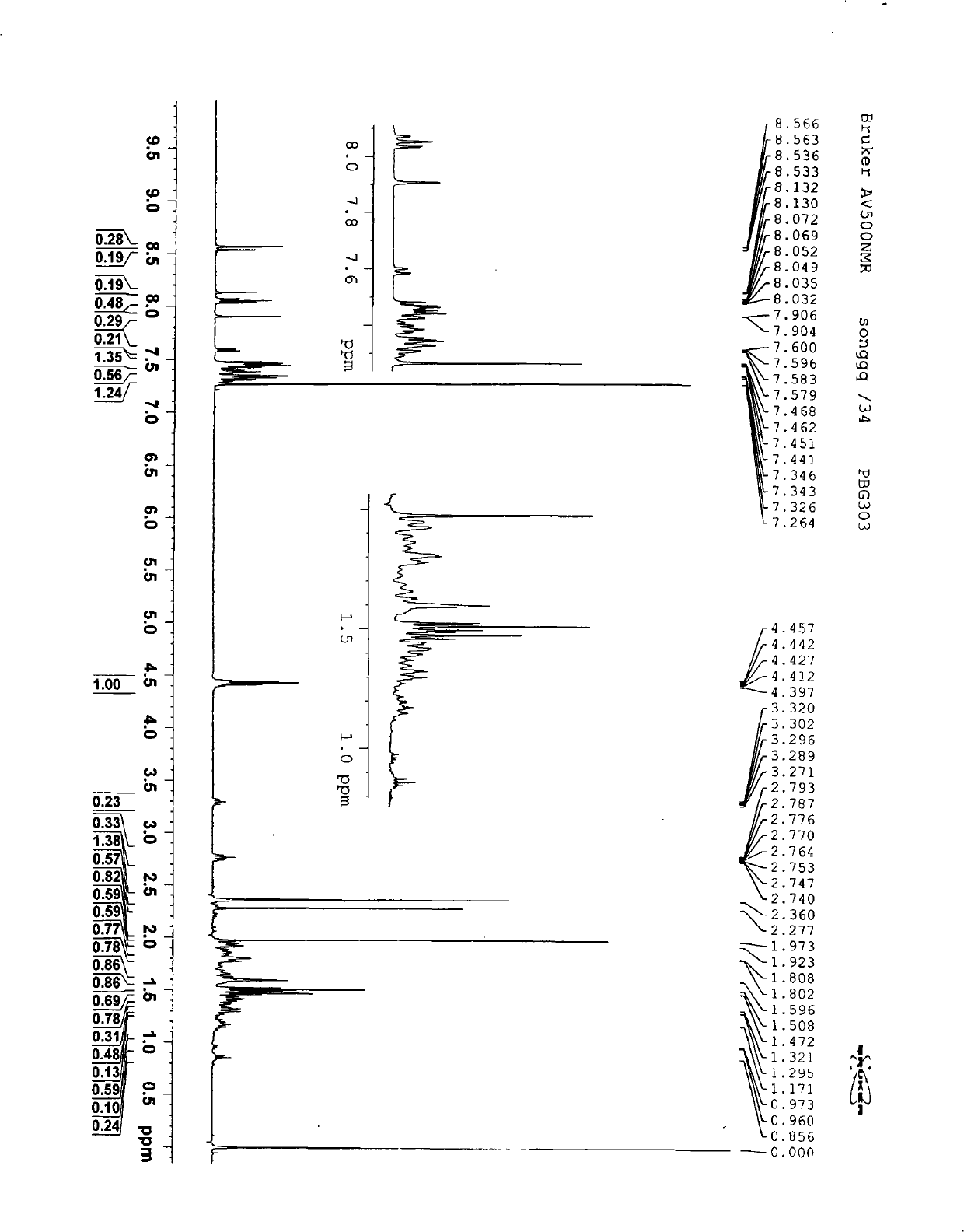

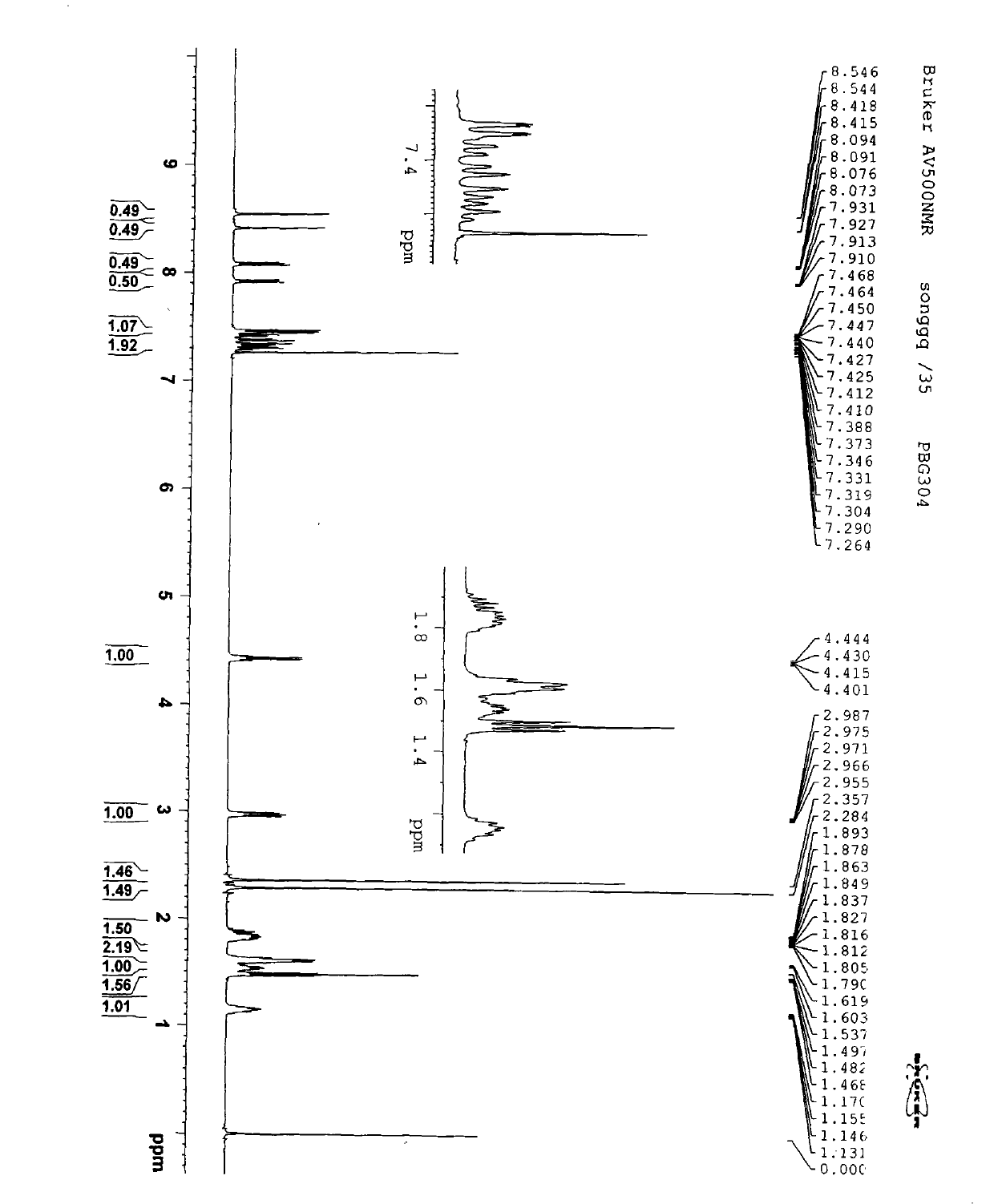

Carbazole oxime ester lightlike initiating agent

The invention relates to the photoinitiator technical field, in particular to an oxime ester photoinitiator and a preparation method thereof. A carbazole oxime ester photoinitiator has a structural general formula as the right formula, R=formula (1), n=0-5, m=3 or 4, R radical is aliphatic ketone with cyclane, the cyclane is cycloaliphatic ring from cyclopropane to cyclooctane, branched-chain aliphatic hydrocarbon connects the cyclane and the ketone, and the chain usually has 0-6 carbon atoms. The carbazole oxime ester photoinitiator with the structure is a brand-new compound with good photoinitiator performance, and solves the problem of poor sensitivity, thermal stability and solubility of the existing carbazole oxime ester photoinitiators.

Owner:CHANGZHOU TRONLY NEW ELECTRONICS MATERIALS

Plasticizer and method for making same

The present invention relates to the method for preparing the elasticizer which includes purifying the petroleum distillate and separating the extractive by the selective solvent, the extractive is treated by dimethylsulfoxide with weight ratio 1 :( 2.0-4.0) at the temperature ranging from 30 to 120 degree, and the gained raffinate is used as elasticizer. The extractive is the remaining extractive or the mixture of the remaining and the distilled extractive. The extractive is diluted by the alkane-cycloparaffin solvent with weight ratio 1: (0.1-0.5). The elasticizer includes the following components: the aromatic hydrocarbons with the weight percentage from 60 to 90, wherein the polycyclic aromatic hydrocarbon provided with three or more rings is 1.5 to 2.9 percentages by weight; the rest is alkane-cycloparaffin and resin.

Owner:ORGKHIM BIOCHEM HLDG MANAGEMENT

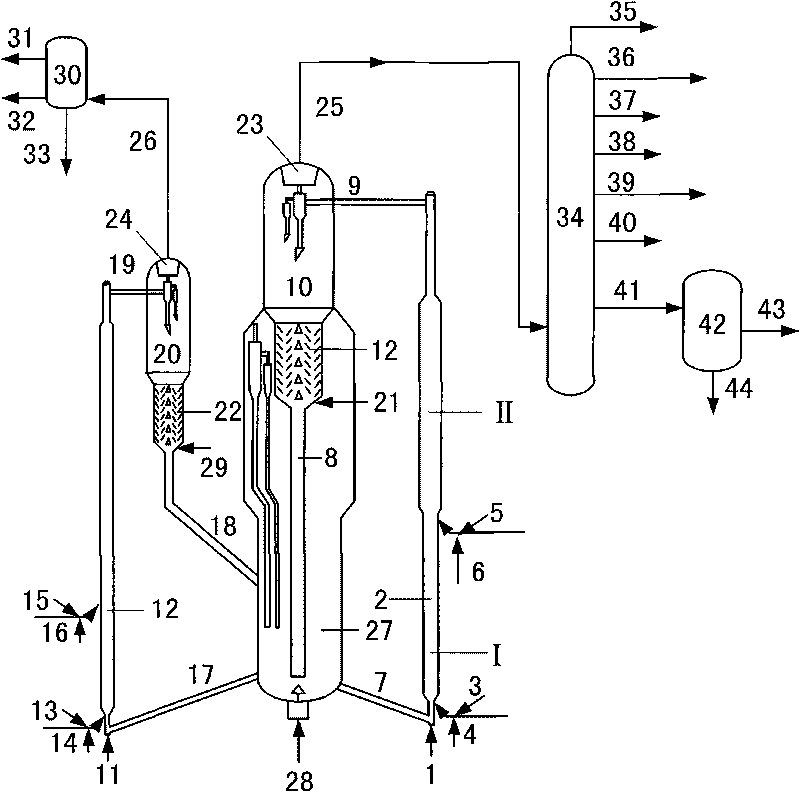

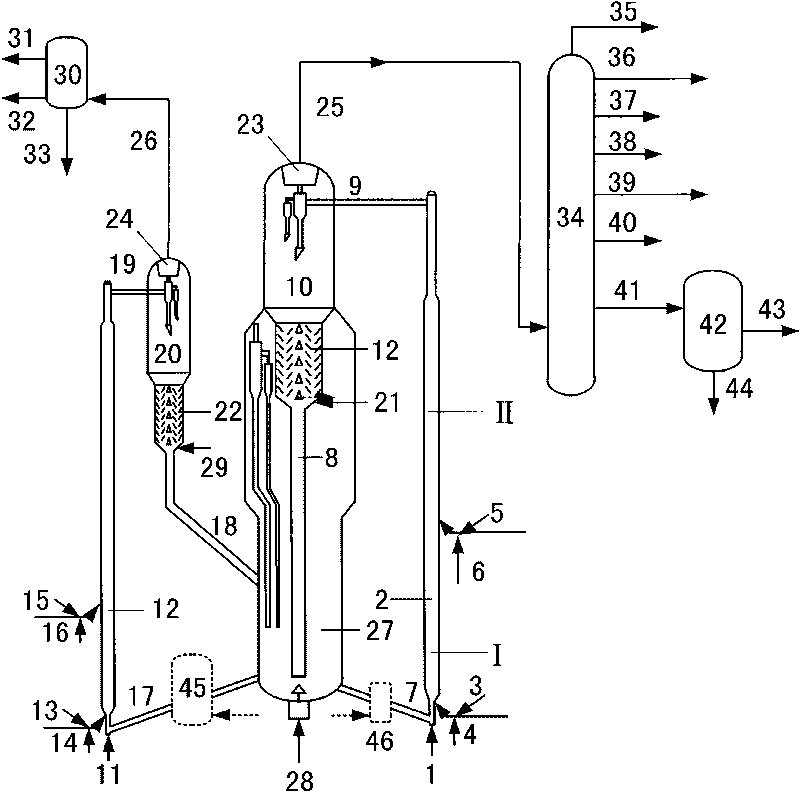

Catalytic conversion method for preparing light fuel oil and propylene

ActiveCN101724431AImprove propertiesExtended operating cycleCatalytic crackingChemical recyclingAlkaneCycloparaffins

The invention relates to a catalytic conversion method for preparing light fuel oil and propylene, comprising: leading inferior crude oil to enter a catalytic conversion reactor to be contacted with catalyst and have reaction; separating the reaction product, and obtaining the product containing the propylene, crude gasoline and catalytic wax oil, wherein leading the crude gasoline to enter another catalytic conversion reactor to be contacted with catalytic conversion catalyst to have reaction; treating the catalytic wax oil by hydrotreating or / and solvent extraction; and taking the catalyticwax oil obtained by hydrotreating or / and raffinate oil of the catalytic wax oil as raw material of the catalytic conversion reactor or other catalytic conversion reactors. In the method, after the catalytic wax oil which is obtained by carrying out mild catalytic conversion on the inferior crude oil is treated by hydrotreating or / and solvent extraction, the obtaining catalytic wax oil obtained byhydrotreating or / and raffinate oil contains alkane or cycloparaffin, and is very suitable for catalytic conversion, thus realizing high efficiency utilization of oil resources.

Owner:CHINA PETROLEUM & CHEM CORP +1

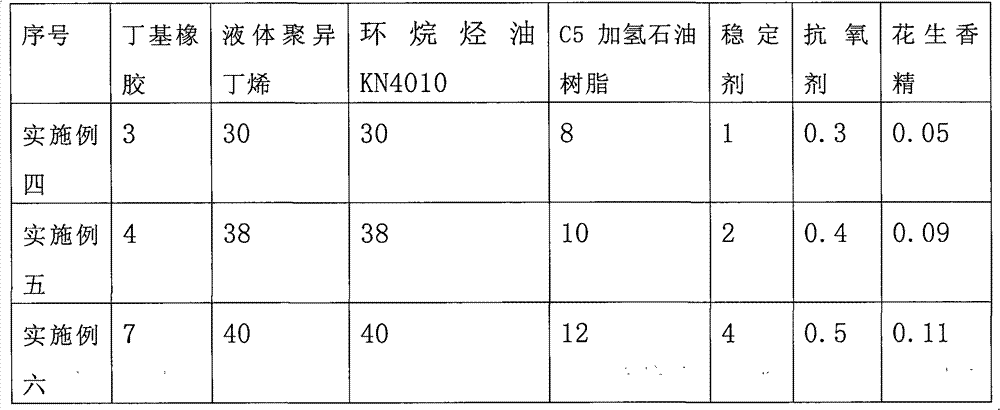

Rat glue having attraction effects, preparation method of the rat glue and rat glue plate coated with the rat glue

InactiveCN102850966AIncrease profitQuality improvementMineral oil hydrocarbon copolymer adhesivesNon-macromolecular adhesive additivesAntioxidantCycloparaffins

The invention discloses rat glue having attraction effects, a preparation method of the rat glue and a rat glue plate coated with the rat glue. The rat glue having attraction effects is prepared from 3 to 8 parts by weight of butyl rubber, 30 to 50 parts by weight of liquid polyisobutene, 30 to 50 parts by weight of cycloparaffin oil, 8 to 15 parts by weight of C5 petroleum resin, 1 to 6 parts by weight of polyethylene, 0.3 to 0.6 parts by weight of an antioxidant and 0.05 to 1.5 parts by weight of peanut essence. The rat glue having attraction effects has stable quality, can be used for a long time, does not need an additional attractant because of the attraction effects so that rat sticking failure is avoided because of falling-off or rolling-off of the attractant, has high trapping efficiency, and does not produce damage on the environment, people and livestock.

Owner:北京绿叶世纪日化用品有限公司

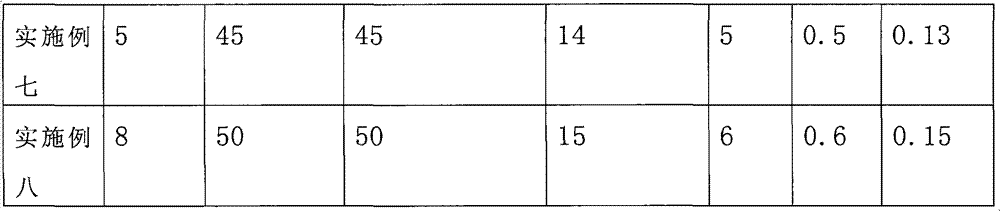

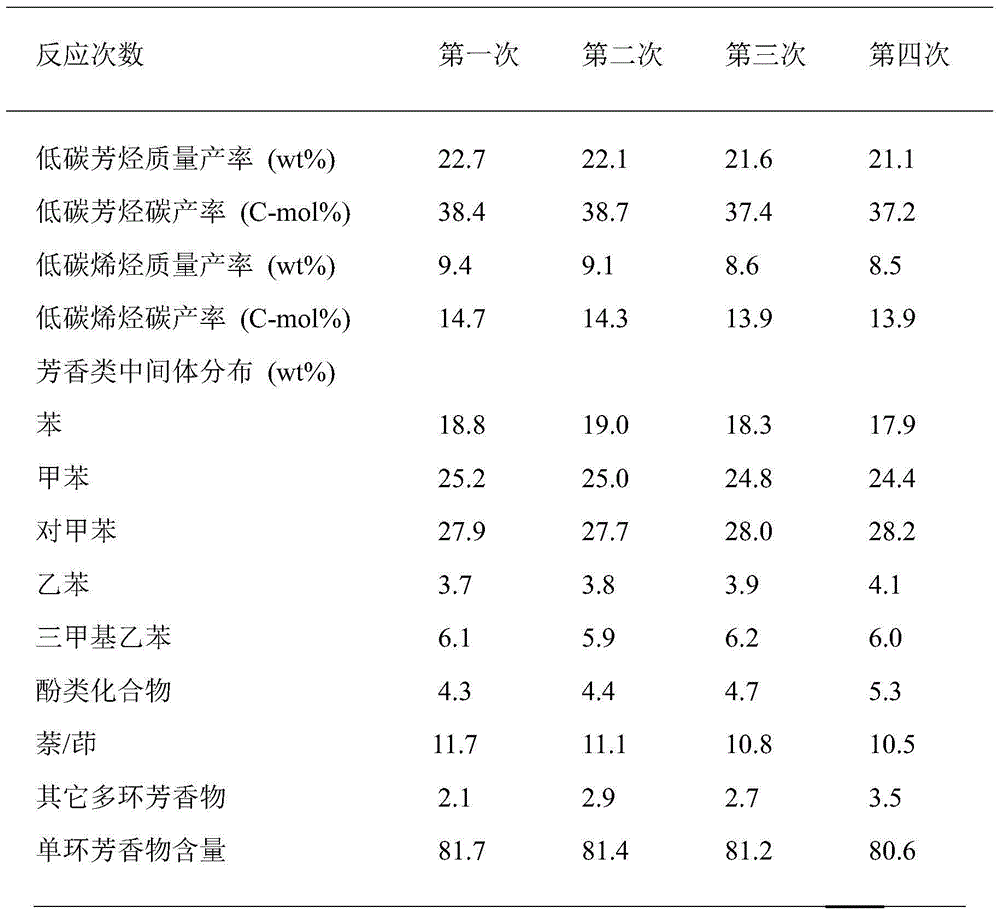

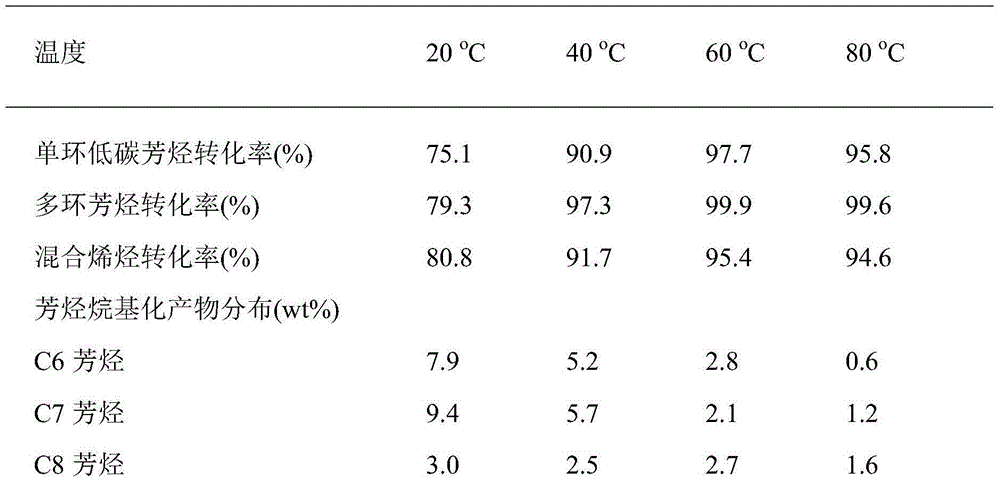

Method for synthesizing aviation kerosene cycloparaffin and aroma components by utilization of wood chips

ActiveCN105623702AAbundant resourcesAchieve recyclingLiquid hydrocarbon mixture productionTreatment with hydrotreatment processesCycloparaffinsKerosene

The invention provides a method for synthesizing aviation kerosene cycloparaffin and aroma components by the utilization of wood chips. The method comprises the following steps: Step 1, wood chips undergo catalytic cracking to obtain low-carbon aromatics: a catalyst is nickel / magnesium-containing modified NiO / MgO / Al-MCM-41, and low-carbon aromatics based on C6-C8 is formed after catalytic reaction of wood chips; Step 2, low-carbon aromatics is directionally converted to aromatics within the range of kerosene: an alkylating agent is low carbon olefins obtained after synchronous catalytic cracking of wood chips, a catalyst is a highly acidic xPF6-[bmim]-yAlCl3 (x,y=0.5-2) ionic liquid, and aromatics based on C9-C14 is formed after electrophilic substitution reaction of low-carbon aromatics; and Step 3, C9-C14 aromatics is directionally converted to cycloparaffin: a catalyst is palladium modified Pd / Al-MCM-22, and cycloparaffin based on C9-C14 is formed. Basic technical requirements of common aircraft fuel can be met. The method can be used for synthesizing aroma and cycloparaffin components in biological aviation kerosene.

Owner:UNIV OF SCI & TECH OF CHINA

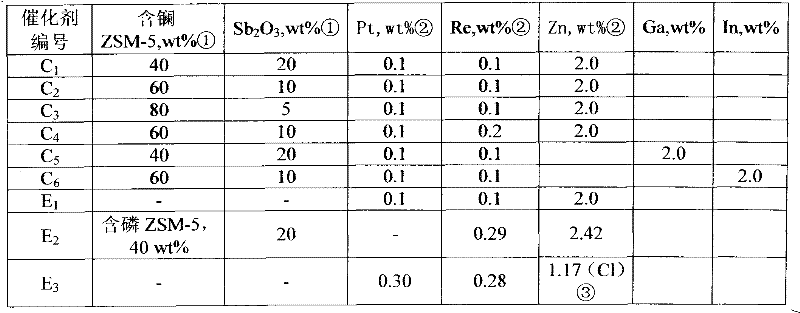

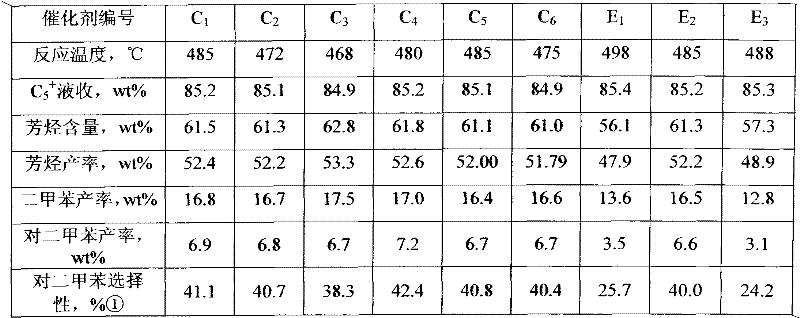

Aromatization catalyst and application thereof in highly selective preparation of p-xylene

ActiveCN102441412AHigh selectivityEasy to desorbHydrocarbon by isomerisationMolecular sieve catalystsRheniumIndium

The invention discloses an aromatization catalyst and application thereof in the highly selective preparation of p-xylene. The aromatization catalyst consists of a carrier and active metal components, the carrier contains at least one type of mesoporous molecular sieve, antimony oxide and inorganic refractory oxide, the mesoporous molecular sieve contains lanthanum oxide, the active metal components are platinum, rhenium and a third component, and the third component is at least one of gallium, zinc, indium and tin. The aromatization catalyst is used in the reforming process of the highly selective preparation of p-xylene with paraffin, cycloparaffin, alkene, or naphtha andor the like as raw oil material, and has the advantages of high stability, high p-xylene selectivity and the like.

Owner:CHINA PETROLEUM & CHEM CORP +1

Montmorillonite-TiCl4 catalyst and process for preparing polyolefin/montmorillonite composition

InactiveCN1330101ADoes not involve processing technologyDoes not involve post-processingPhysical/chemical process catalystsPolyolefinCycloparaffins

A montmorillonite-TiCl4 catalyst for preparing the nm-class composition of the olefine polymer or copolymer (polyethylene or polypropylene) contains laminated silicate clay montmorollonite, magnesiumcompound, alcohol compound for dissolving said magnesium compound, TiCl4 and electron providing reagent. Said nm-class composition is prepared by use of saturated paraffin or cycloparaffin as solvent. Its advantages are high teasion strength (32-50 MPa) and low cost.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

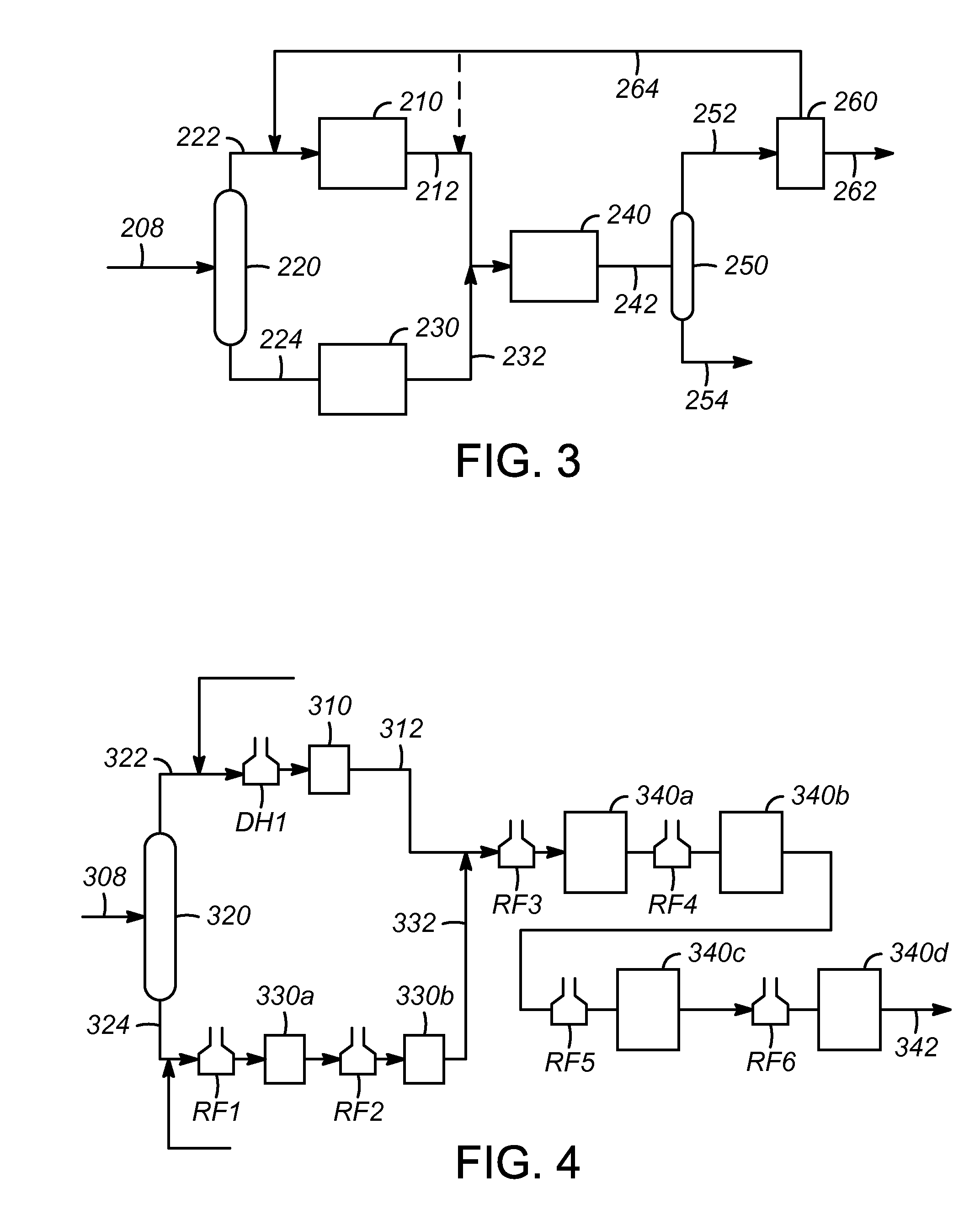

Initial hydrotreating of naphthenes with subsequent high temperature reforming

InactiveUS20130158320A1Reduce energy loadHigh aromatic contentHydrocarbon by dehydrogenationHydrocarbonsCycloparaffinsHydrocarbon

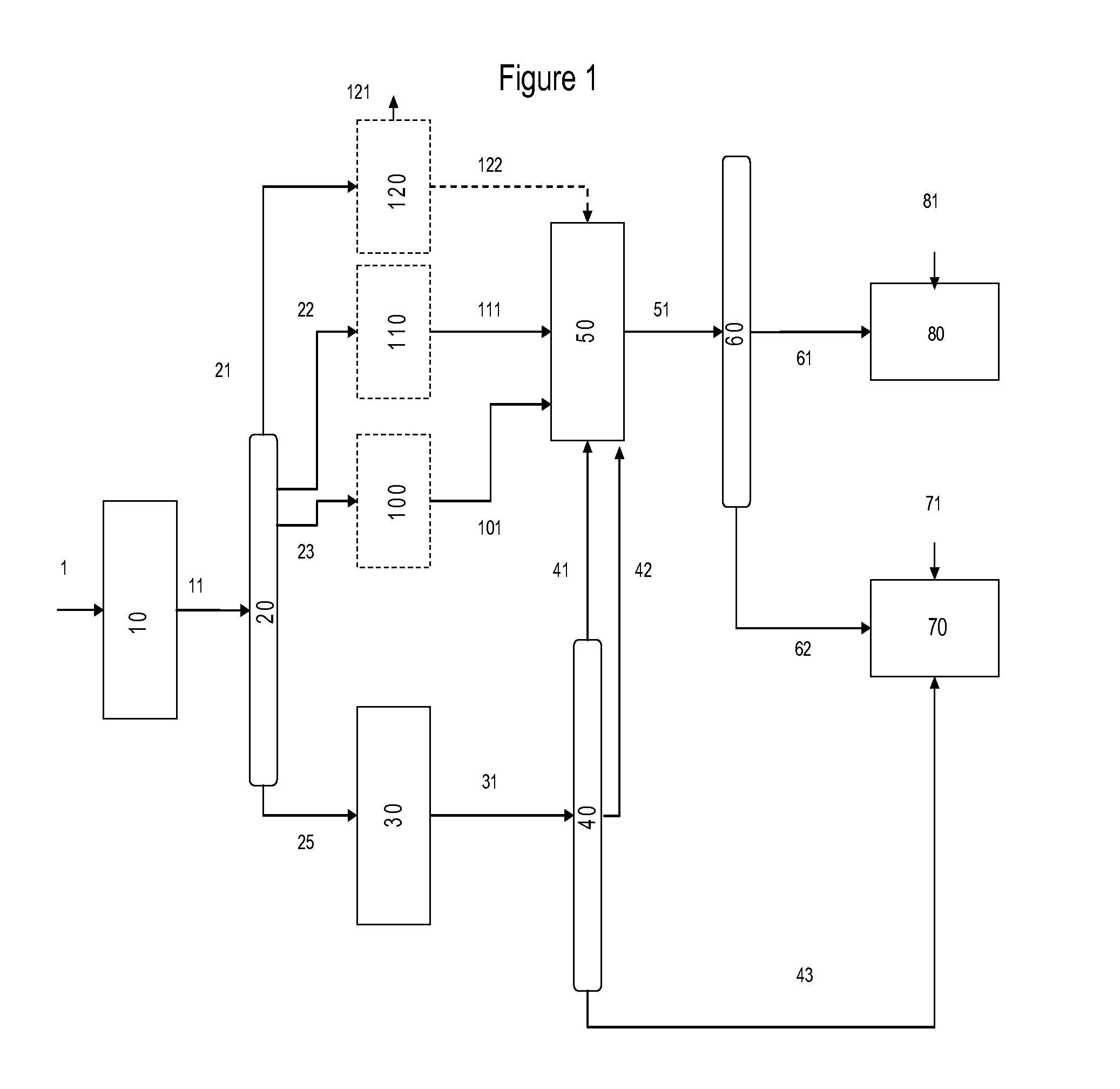

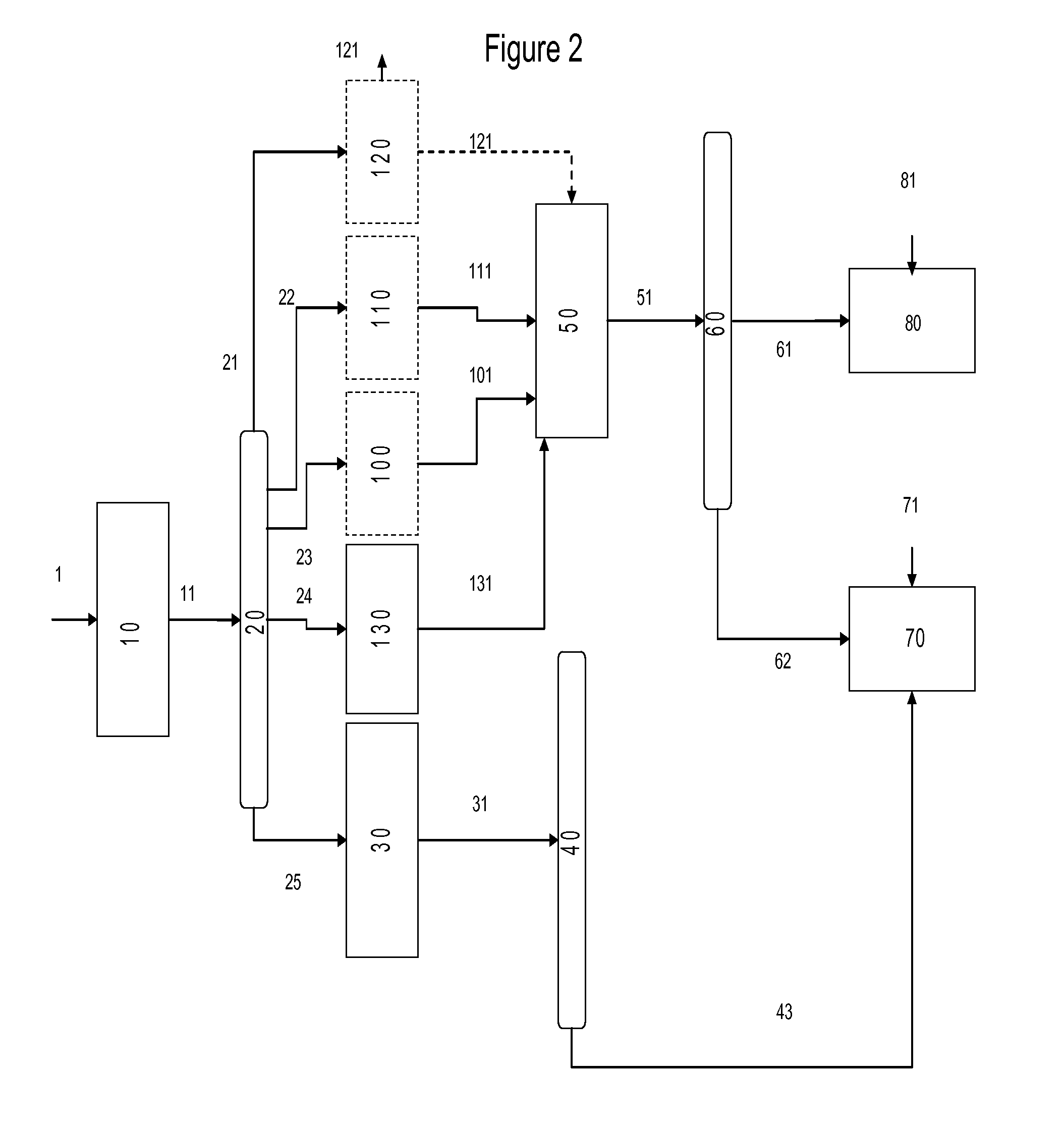

A process for the production of aromatics through the reforming of a hydrocarbon stream is presented. The process utilizes the differences in properties of components within the hydrocarbon stream to increase the energy efficiency. The differences in the reactions of different hydrocarbon components in the conversion to aromatics allows for different treatments of the different components to reduce the energy used in reforming process.

Owner:UOP LLC

Multigrade engine oil prepared from Fischer-Tropsch distillate base oil

InactiveUS7520976B2Refining to change hydrocarbon structural skeletonLiquid carbonaceous fuelsCycloparaffinsPackage design

A multigrade engine oil meeting the specifications for SAE J300 revised June 2001 requirements and a process for preparing it, said engine oil comprising (a) between about 15 to about 94.5 wt % of a hydroisomerized distillate Fischer-Tropsch base oil characterized by (i) a kinematic viscosity between about 2.5 and about 8 cSt at 100° C., (ii) at least about 3 wt % of the molecules having cycloparaffin functionality, and (iii) a ratio of weight percent molecules with monocycloparaffin functionality to weight percent of molecules with multicycloparaffin functionality greater than about 15; (b) between about 0.5 to about 20 wt % of a pour point depressing base oil blending component prepared from an hydroisomerized bottoms material having an average degree of branching in the molecules between about 5 and 9 alkyl-branches per 100 carbon atoms and wherein not more than 10 wt % boils below about 900° F.; and (c) between about 5 to about 30 wt % of an additive package designed to meet the specifications for ILSAC GF-3.

Owner:CHEVROU USA INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com