Lubricating base oil with high monocycloparaffins and low multicycloparaffins

一种润滑基础油、单环烷烃的技术,应用在润滑基础油领域,能够解决粘度指数和氧化稳定性降低等问题,达到低挥发度、优异氧化稳定性、粘度指数高的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1、 Embodiment 2 and comparative example 3

[0140] Three lubricating base oils with kinematic viscosities below 3.0 cSt at 100°C were prepared by dewaxing the Fischer-Tropsch wax by hydroisomerization and fractionating the isomerized oil into different fractions. The properties of these samples are shown in Table II.

[0141] performance

Embodiment 1

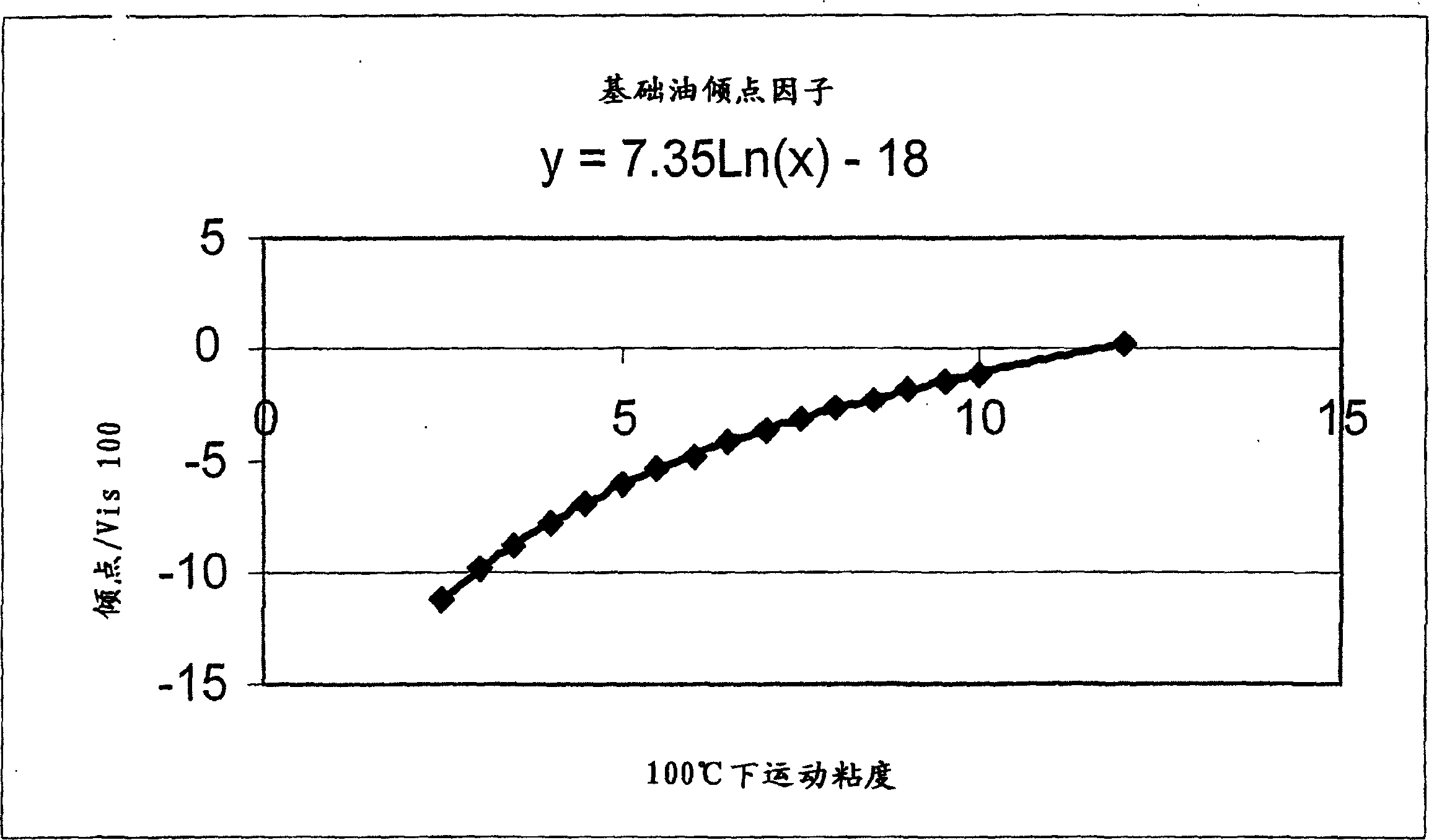

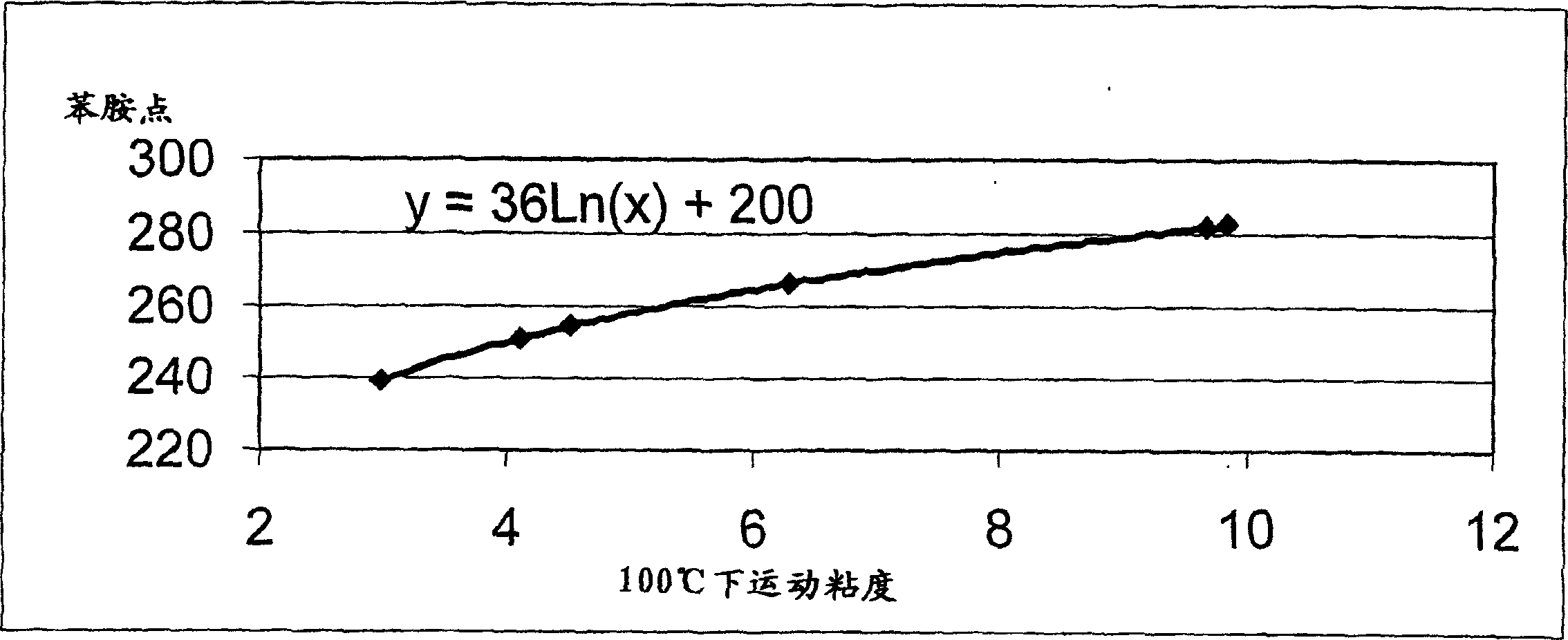

[0142] In Example 1 and Example 2, all the molecular weight percentages containing at least one aromatic functional group are low, all the molecular weight percentages containing at least one cycloalkane functional group are high, and the molecular weight percentage containing monocycloalkane is the same as the molecular weight percentage containing polycycloalkane The percentage ratio is high. Note that the weight percentage of all molecules containing at least one cycloalkane functional group in Example 1 is not greater than 10, but the weight percentage of all molecules containing at least one cycloalkane functional group is greater than 100°C kinematic viscosity times 3. In Example 1, the ratio of the pour point to the kinematic viscosity at 100°C is high, which meets the performance of the preferred lubricating base oil of the present invention. Furthermore, the aniline points of Examples 1 and 2 are below the line given by the formula: 36×Ln (kinematic viscosity at 100° ...

Embodiment 4、 Embodiment 5、 Embodiment 6 and Embodiment 7

[0144] Four lubricating base oils with kinematic viscosities at 100°C between 4.0 and 5.0 cSt were prepared by hydroisomerization dewaxing Fischer-Tropsch wax and fractionating the isomerized oil into different fractions. The properties of these examples are shown in Table III.

[0145] performance

[0146] Examples 4, 5, 6 and 7 all have the properties required for the lubricating base oil of the present invention. Examples 4 and 7 have exceptionally high oxidation stability, greater than 40 hours. Examples 4 and 7 also had low aniline points, which would provide desirable additive solubility and elastomer compatibility.

PUM

| Property | Measurement | Unit |

|---|---|---|

| kinematic viscosity | aaaaa | aaaaa |

| kinematic viscosity | aaaaa | aaaaa |

| conversion efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com