Patents

Literature

3342results about "Hydrocarbon by hydrogenation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Hydroalkylation of aromatic hydrocarbons

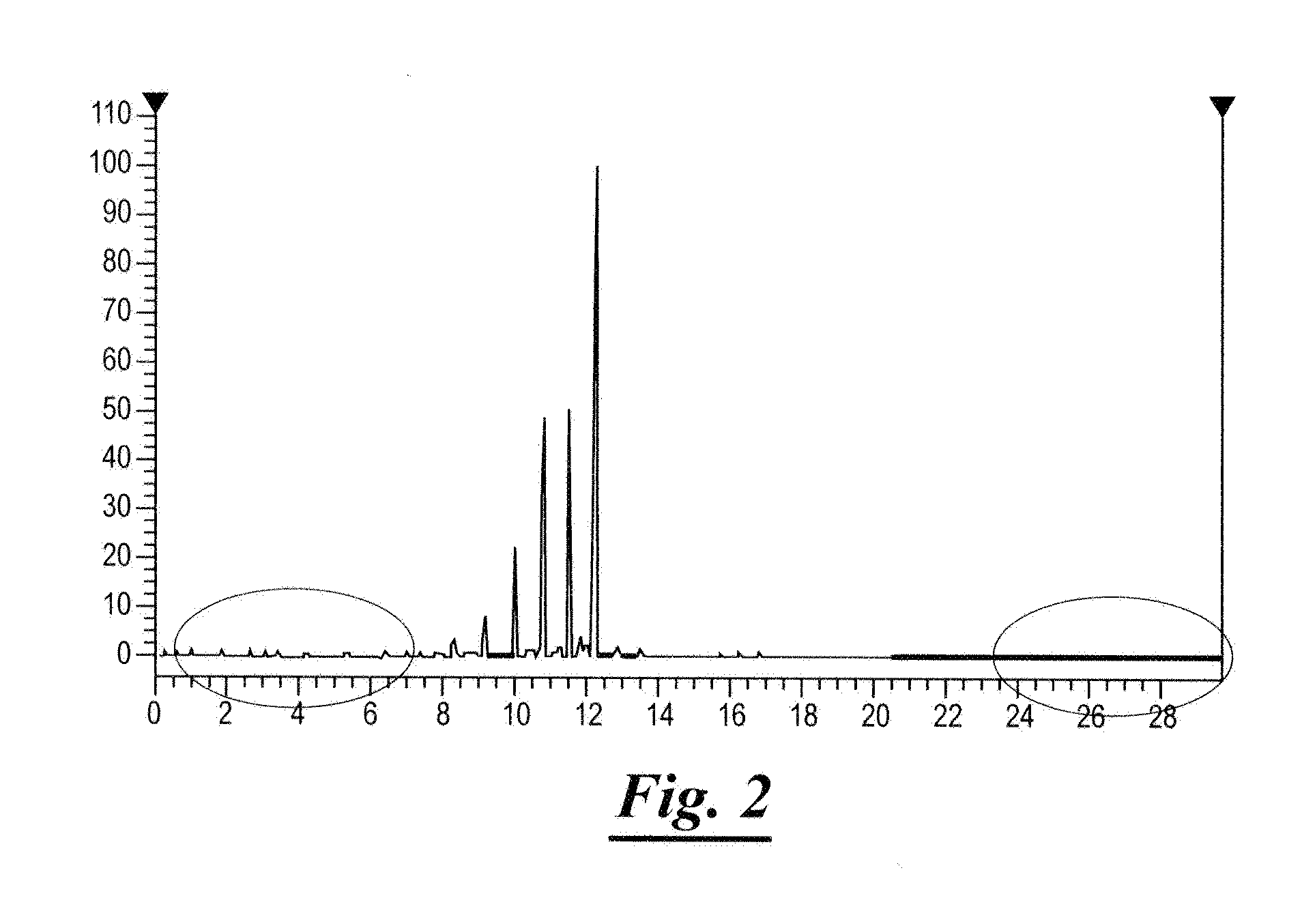

InactiveUS6037513AHigh activityHigh selectivityMolecular sieve catalystsOrganic compound preparationBenzeneX-ray

There is described a process and a catalyst for the hydroalkylation of an aromatic hydrocarbon, particularly benzene, wherein the catalyst comprises a first metal having hydrogenation activity and a crystalline inorganic oxide material having a X-ray diffraction pattern including the following d-spacing maxima 12.4+ / -0.25, 6.9+ / -0.15, 3.57+ / -0.07 and 3.42+ / -0.07.

Owner:MOBIL OIL CORP

Production of synthetic lubricant and lubricant base stock without dewaxing

InactiveUS6103099AThermal non-catalytic crackingRefining to change hydrocarbon structural skeletonAutomatic transmissionBoiling point

A lubricating base stock useful for forming lubricants such as a multigrade automotive oils, automatic transmission oils, greases and the like is prepared by hydroisomerizing a waxy hydrocarbon feed fraction having an initial boiling point in the 650-750 DEG F. range and an end point of at least 1050 DEG F., synthesized by a slurry Fischer-Tropsch hydrocarbon synthesis process. The hydroisomerization forms a hydroisomerate containing the desired base stock which is recovered, without dewaxing the hydroisomerate. The hydroisomerization is conducted at conditions effective to convert at least 67 wt. % of the 650-750 DEG F.+ waxy feed hydrocarbons to lower boiling hydrocarbons. When combined with a standard lubricant additive package, these base stocks have been formed into multigrade automotive crankcase oils, transmission oils and hydraulic oils meeting the specifications for these oils.

Owner:EXXON RES & ENG CO

Process for the manufacture of diesel range hydrocarbons

ActiveUS20070010682A1Fatty oils/acids recovery from wasteHydrocarbon by isomerisationIsomerizationReaction temperature

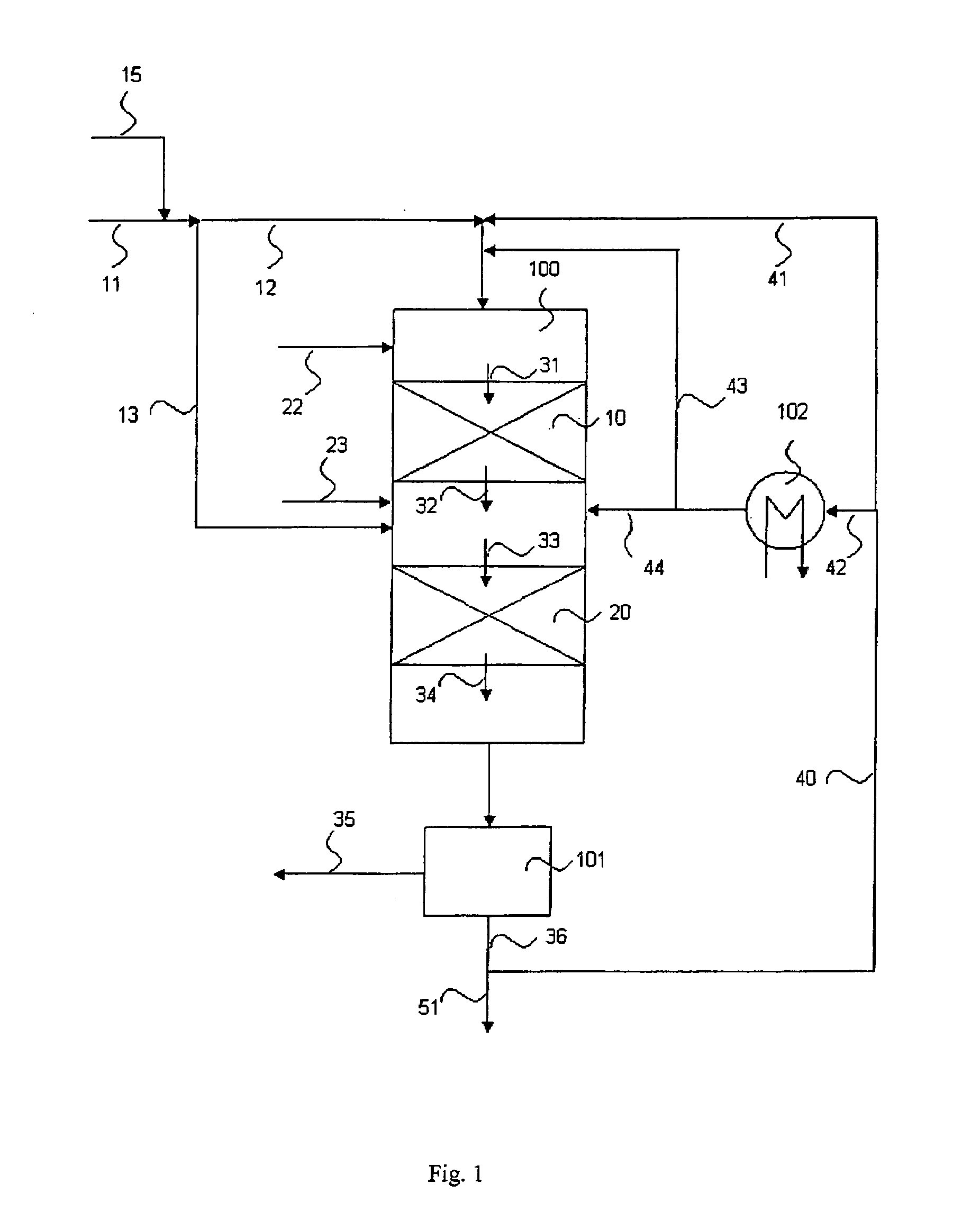

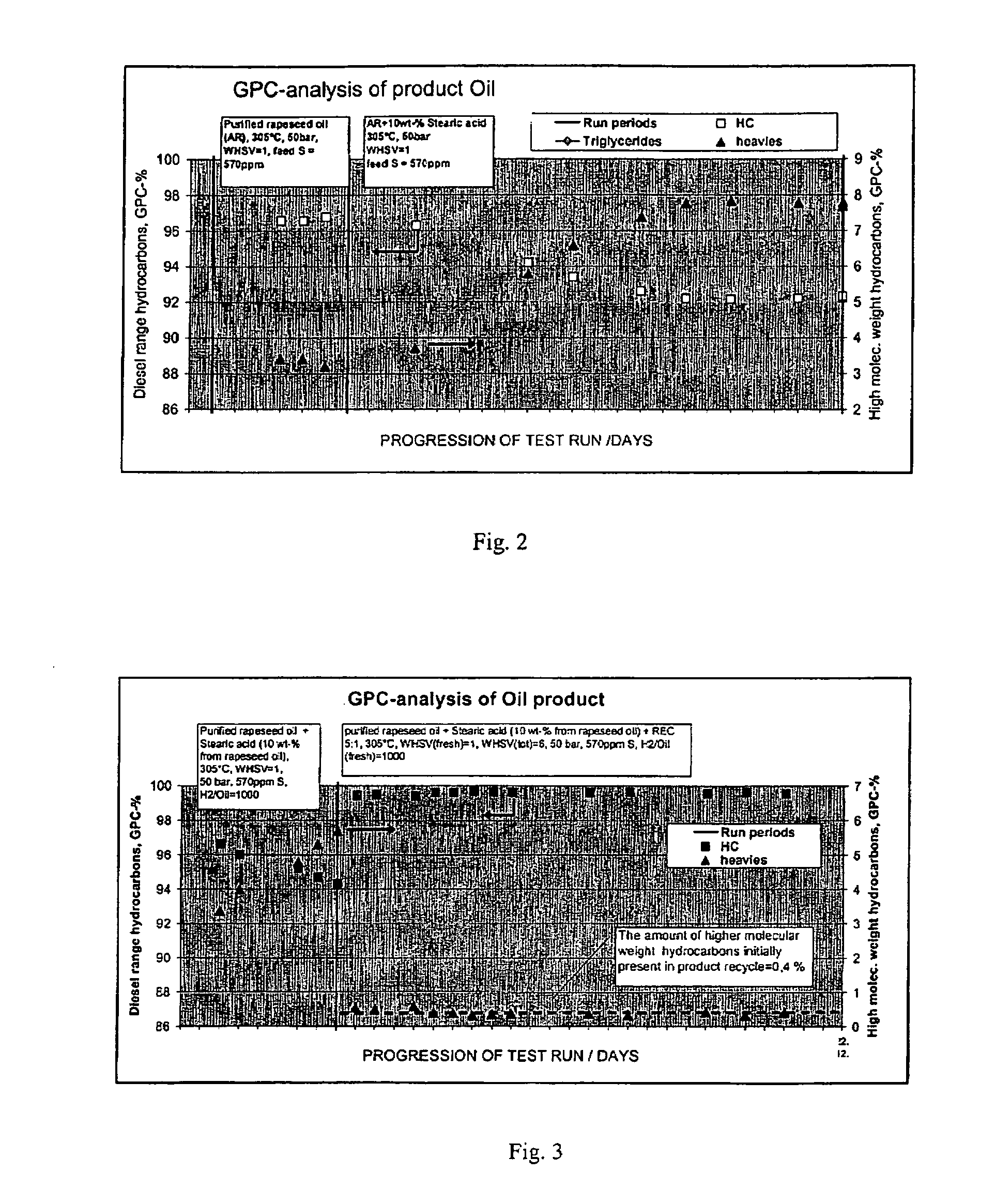

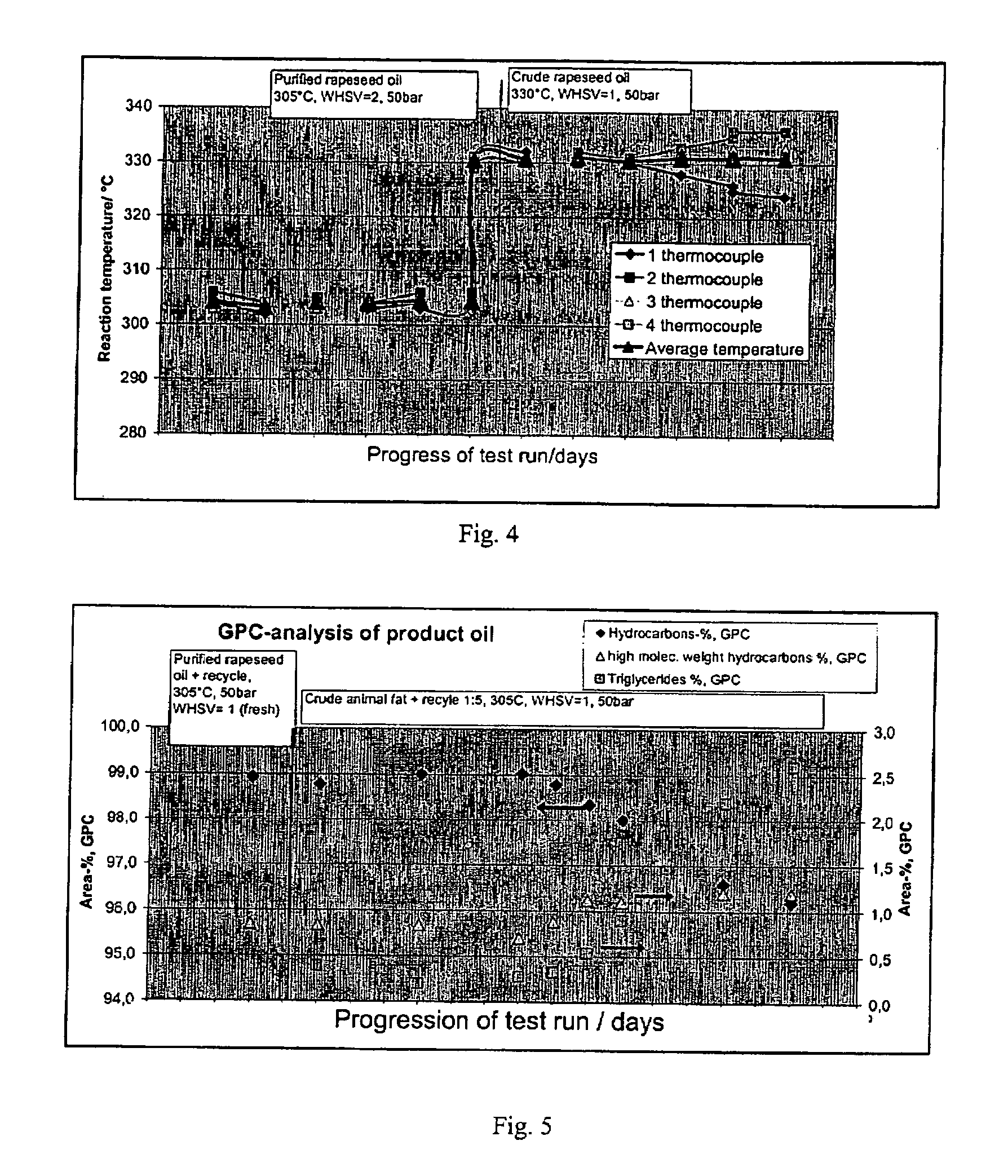

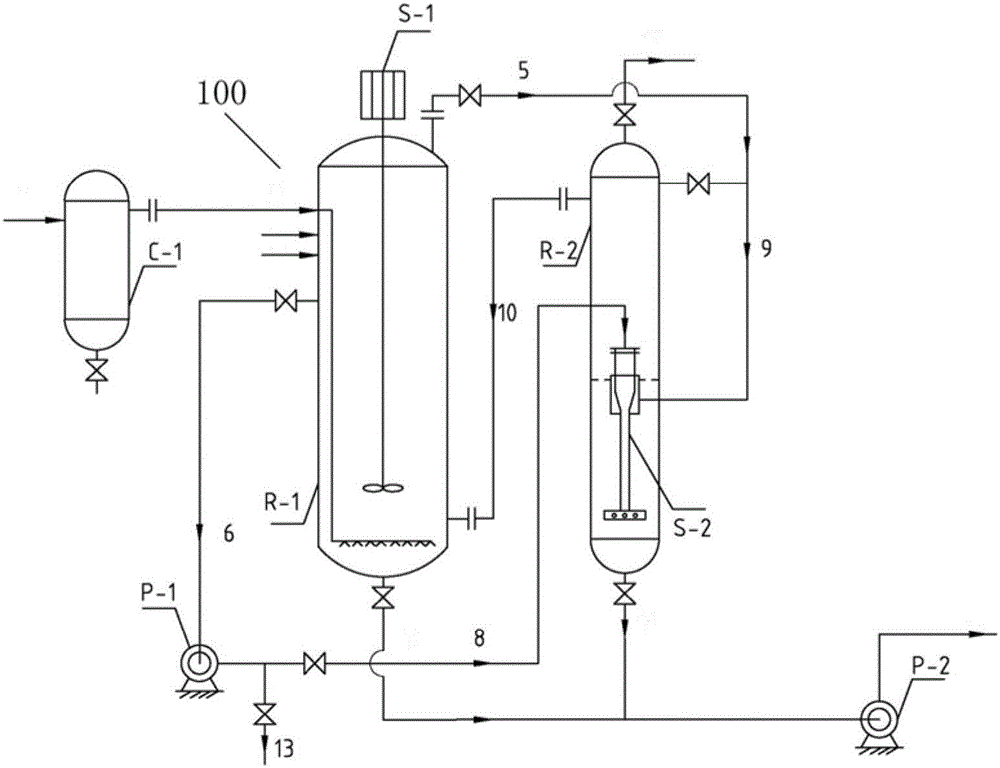

The invention relates to a process for the manufacture of diesel range hydrocarbons wherein a feed is hydrotreated in a hydrotreating step and isomerised in an isomerisation step, and a feed comprising fresh feed containing more than 5 wt % of free fatty acids and at least one diluting agent is hydrotreated at a reaction temperature of 200-400° C., in a hydrotreating reactor in the presence of catalyst, and the ratio of the diluting agent / fresh feed is 5-30:1.

Owner:NESTE OIL OY

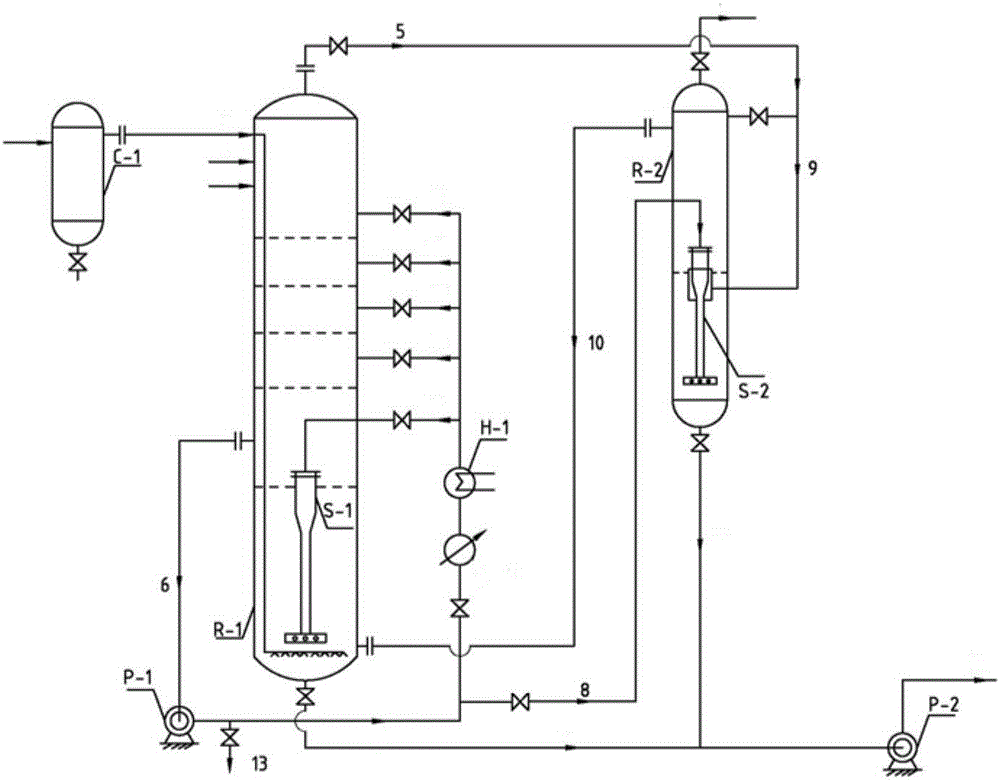

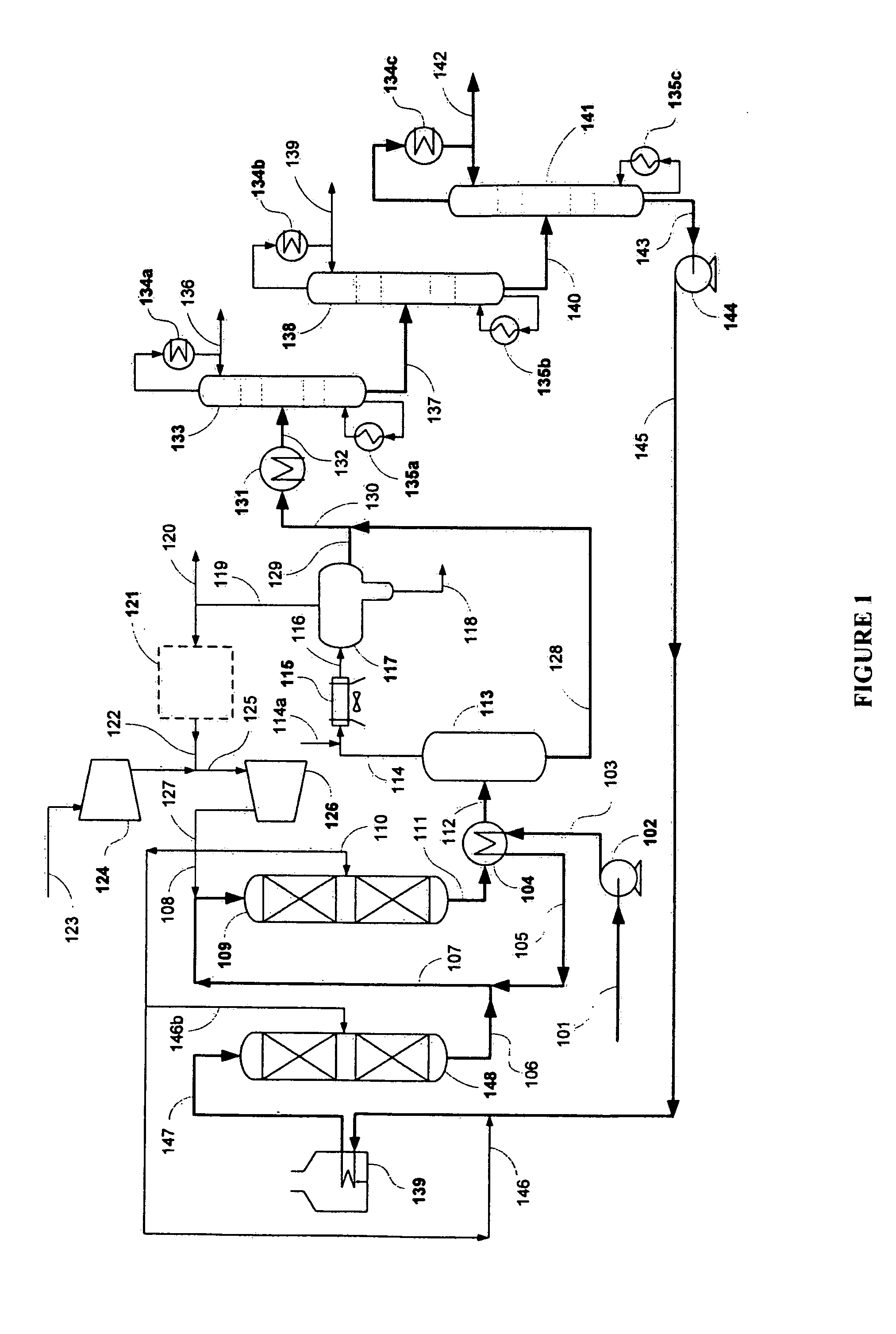

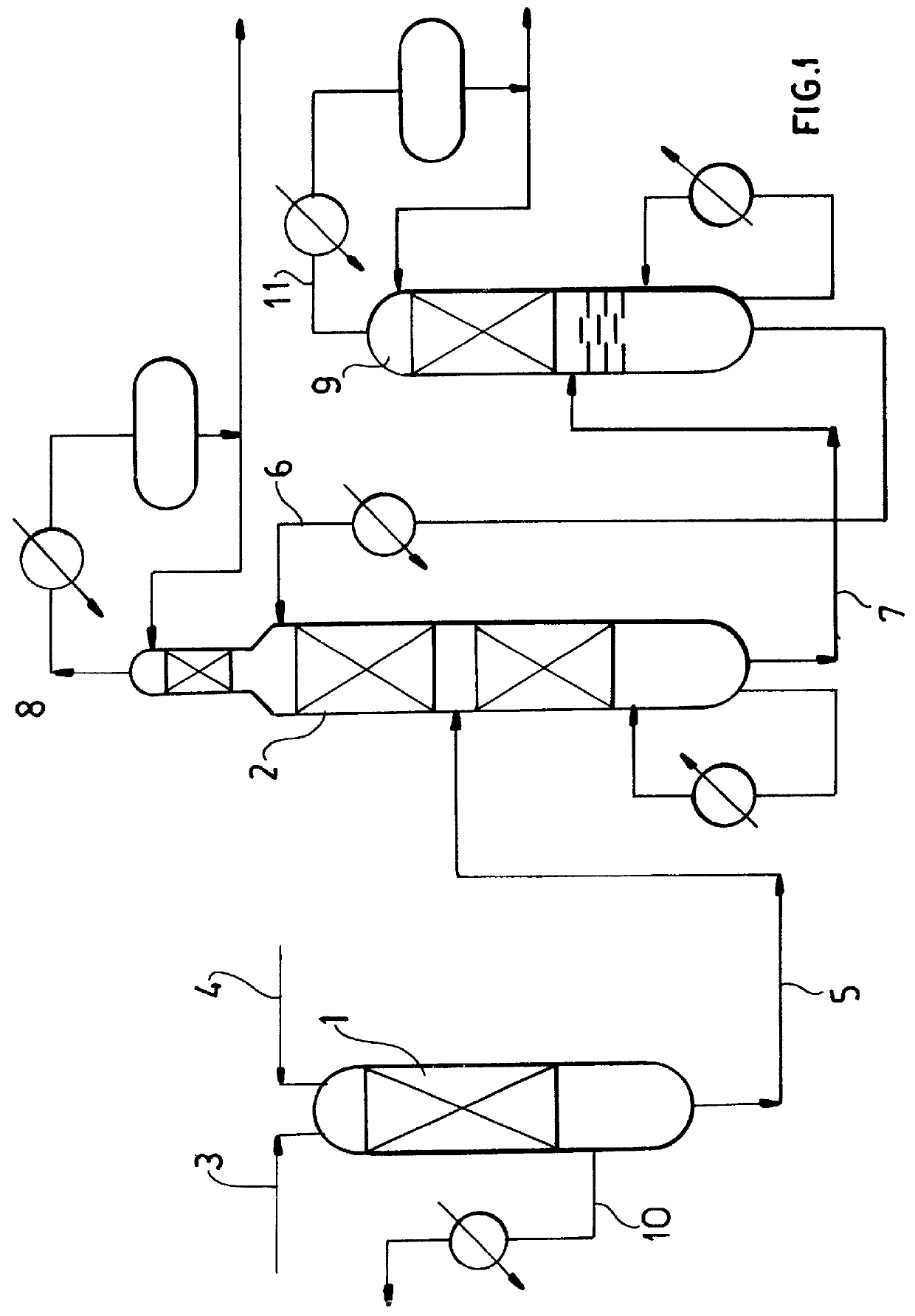

Device and technique for producing cyclohexane by benzene hydrogenation

ActiveCN106187660AImprove mass transfer efficiencyIncrease reaction rateHydrocarbon by hydrogenationBenzeneGas phase

The invention discloses a device and technique for producing cyclohexane by benzene hydrogenation. The device for producing cyclohexane by benzene hydrogenation comprises a reactor, a superfine bubble generator and a bubble breaker, wherein the reactor is provided with a first containing cavity; the wall of the first containing cavity is provided with a feed port, a circulation discharge port, a circulation return port and a gas phase outlet; the superfine bubble generator is provided with a second containing cavity; the wall of the second containing cavity is provided with a return port and a gas phase outlet; the return port of the superfine bubble generator communicates with the circulation return port of the reactor; the bubble breaker is arranged in the second containing cavity; the bubble breaker is provided with a gas phase inlet and a liquid phase inlet which communicates with the circulation discharge port of the reactor; and the gas phase inlet of the bubble breaker communicates with the gas phase outlet of the reactor. The device disclosed by the embodiment of the invention has the advantages of high mass transfer efficiency, high reaction rate, short reaction time, low material consumption and energy consumption, simple structure, low manufacturing cost and low maintenance cost.

Owner:NANJING UNIV

Process for upgrading naphtha

A method for upgrading a naphtha feed to a naphtha product containing less than about 10 wppm of nitrogen and less than about 15 wppm sulfur, the method comprising contacting said naphtha feed with hydrogen in the presence of a bulk multimetallic catalyst under effective reactor conditions to hydrodesulfurize and hydrodenitrogenize said naphtha feed to produce said naphtha product, wherein said bulk multimetallic catalyst comprises at least one Group VIII non-noble metal and at least two Group VIB metals.

Owner:EXXON RES & ENG CO

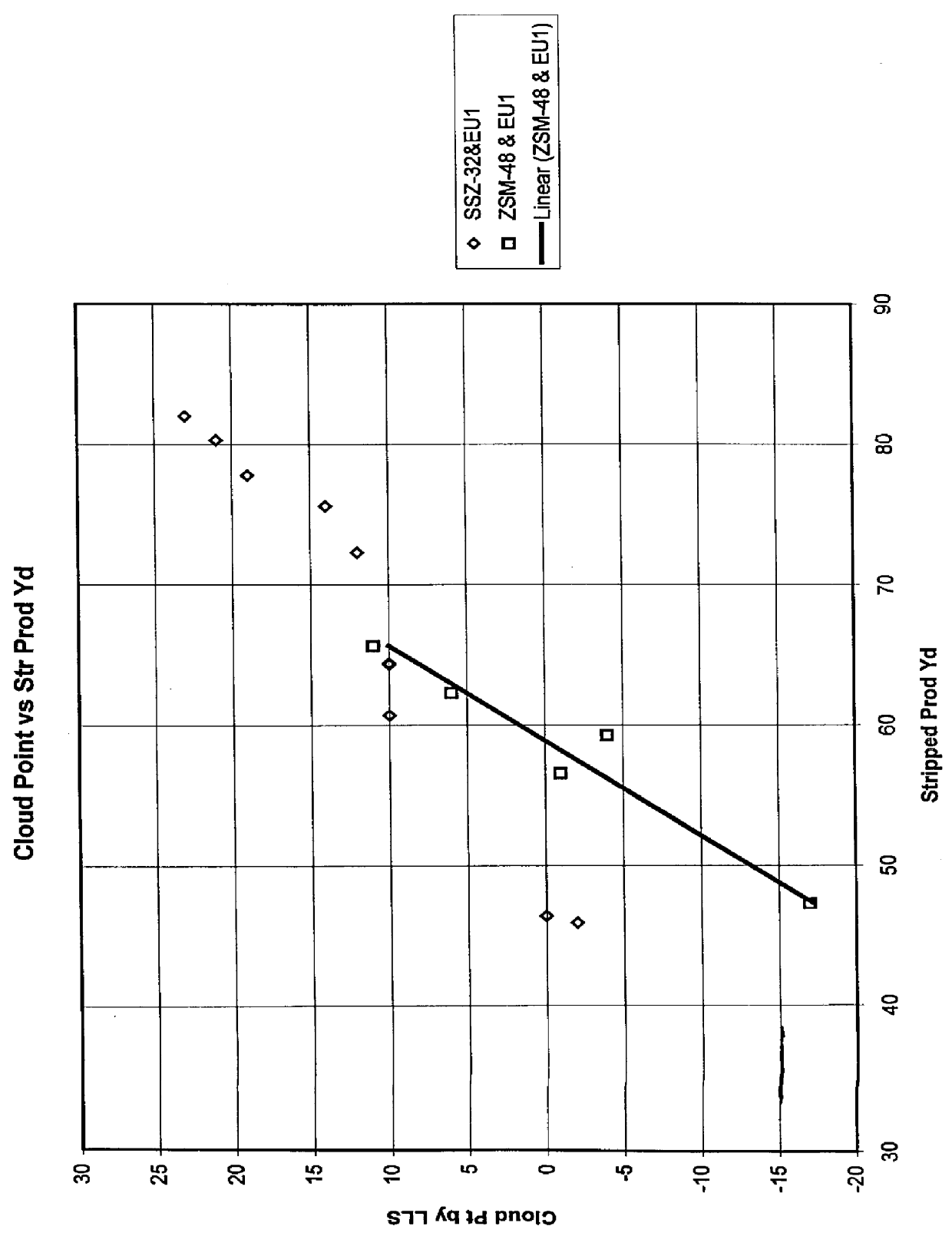

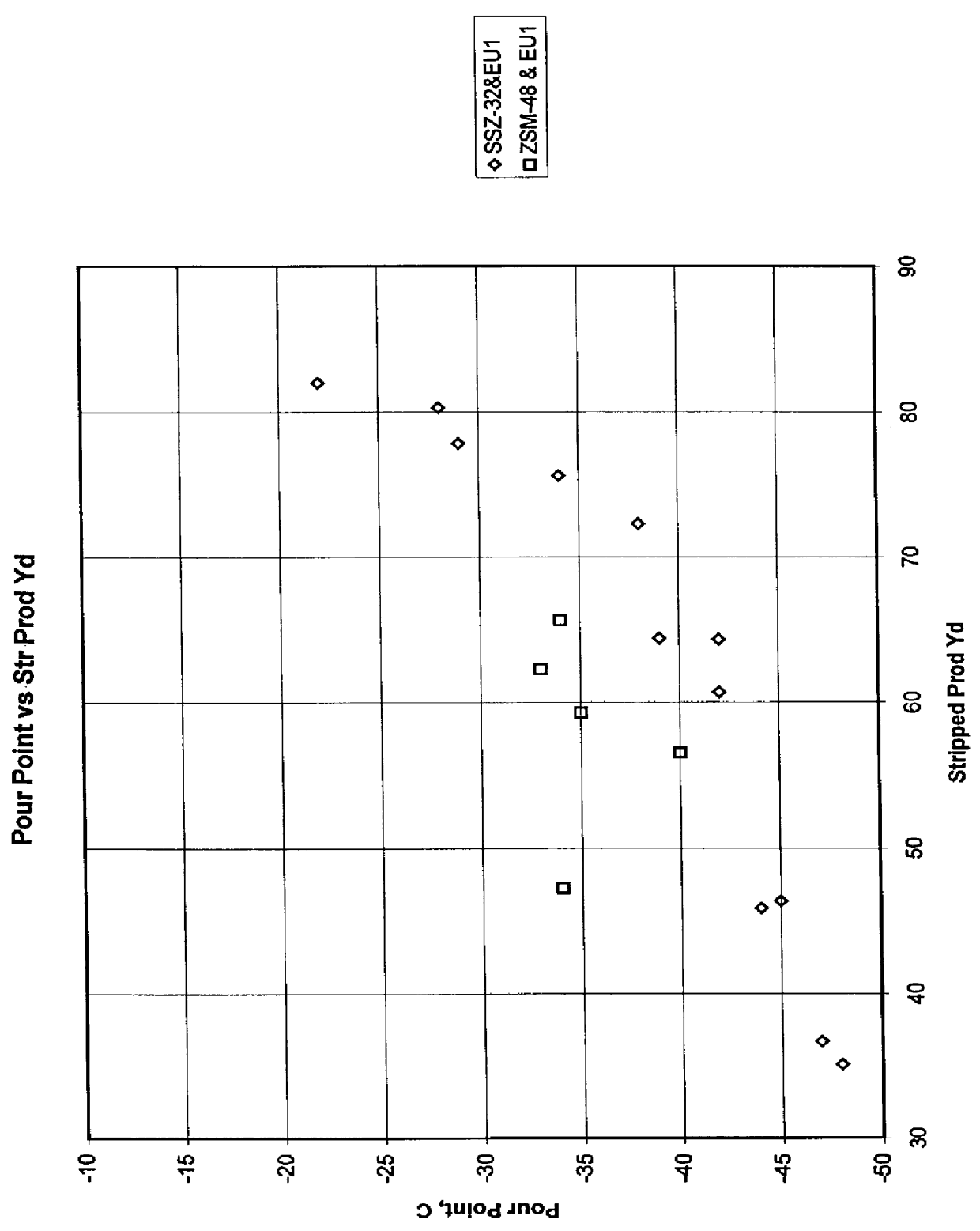

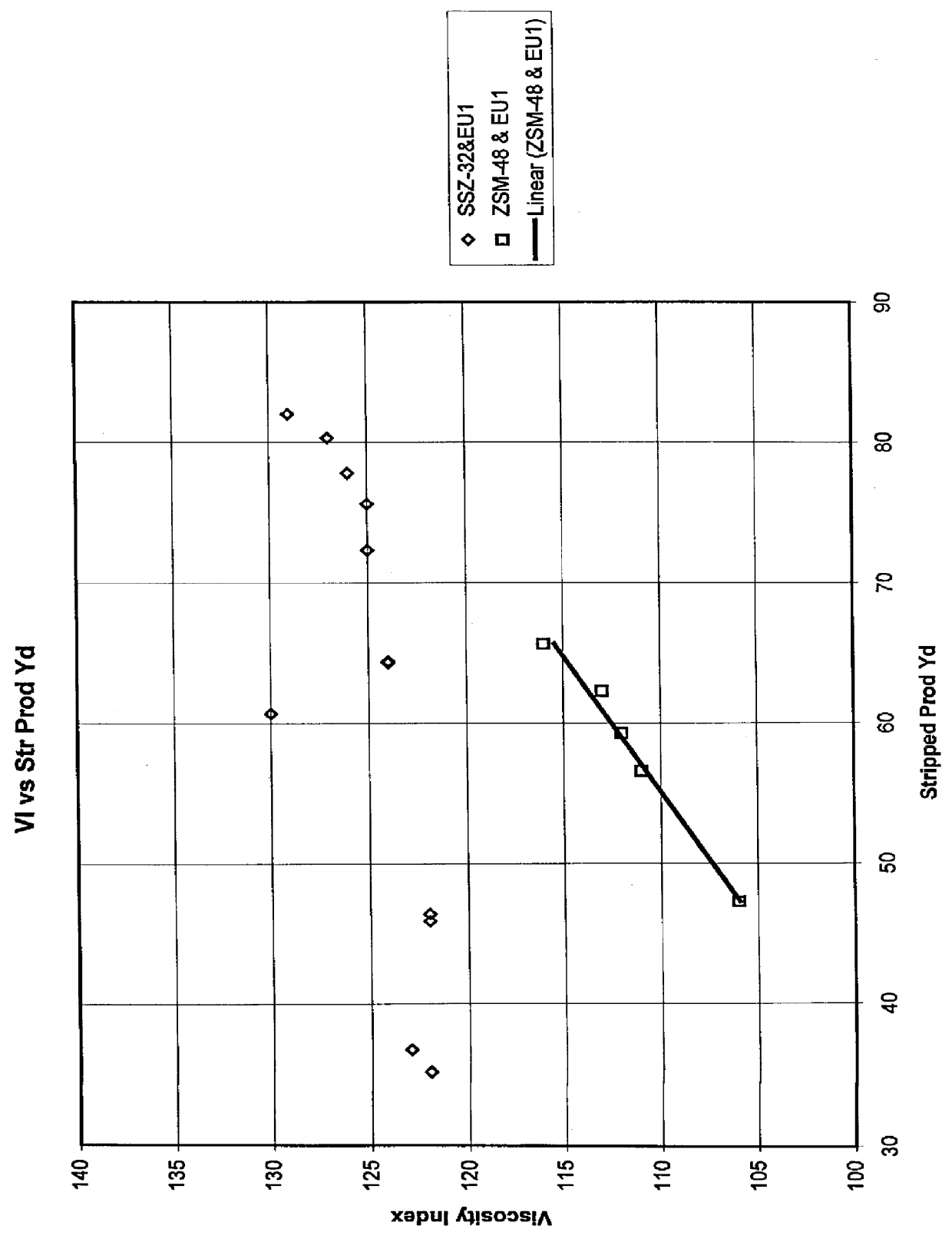

Process for reducing haze point in bright stock

InactiveUS6051129ASuperior lube oil yieldHigh yieldMolecular sieve catalystsRefining to change hydrocarbon structural skeletonHydrogenHaze

Owner:CHEVROU USA INC

Process for Co-Producing Jet Fuel and LPG from Renewable Sources

ActiveUS20080244962A1Improve cold flowHydrocarbon by hydrogenationLiquid hydrocarbon mixture productionEngineeringRenewable resource

The present invention generally relates to a method for producing an isoparaffinic product useful as jet fuel from a renewable feedstock. The method may also include co-producing a jet fuel and a liquefied petroleum gas (LPG) fraction from a renewable feedstock. The method includes hydrotreating the renewable feedstock to produce a hydrotreating unit heavy fraction that includes n-paraffins and hydroisomerizing the hydrotreating unit heavy fraction to produce a hydroizomerizing unit heavy fraction that includes isoparaffins. The method also includes recycling the hydroisomerizing unit heavy fraction through the hydroisomerization unit to produce an isoparaffinic product that may be fractionated into a jet fuel and an LPG fraction. The present invention also relates to a jet fuel produced from a renewable feedstock having improved cold flow properties.

Owner:REG SYNTHETIC FUELS LLC

Catalyst and process of paraffin hydrocarbon conversion

InactiveUS20040077914A1Improve solubilityEasy to useHydrocarbon by isomerisationHydrocarbon by hydrogenationAlkanePtru catalyst

A catalyst composition and process for the conversion of linear and / or branched paraffin hydrocarbons based on the use of an ionic liquid catalyst in combination with a Brønsted Acid, which provides a catalytic composition with an increased activity compared with said ionic liquid. Under suitable reaction conditions this conversion is leading to paraffin hydrocarbon fraction with higher octane number.

Owner:HALDOR TOPSOE AS

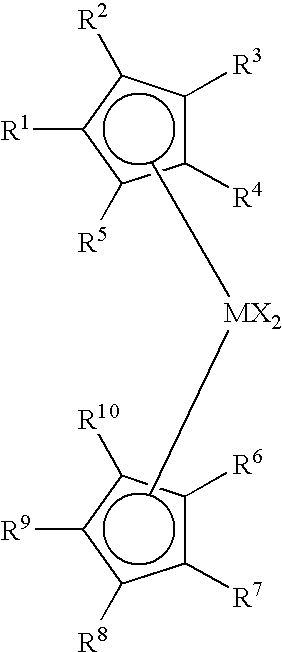

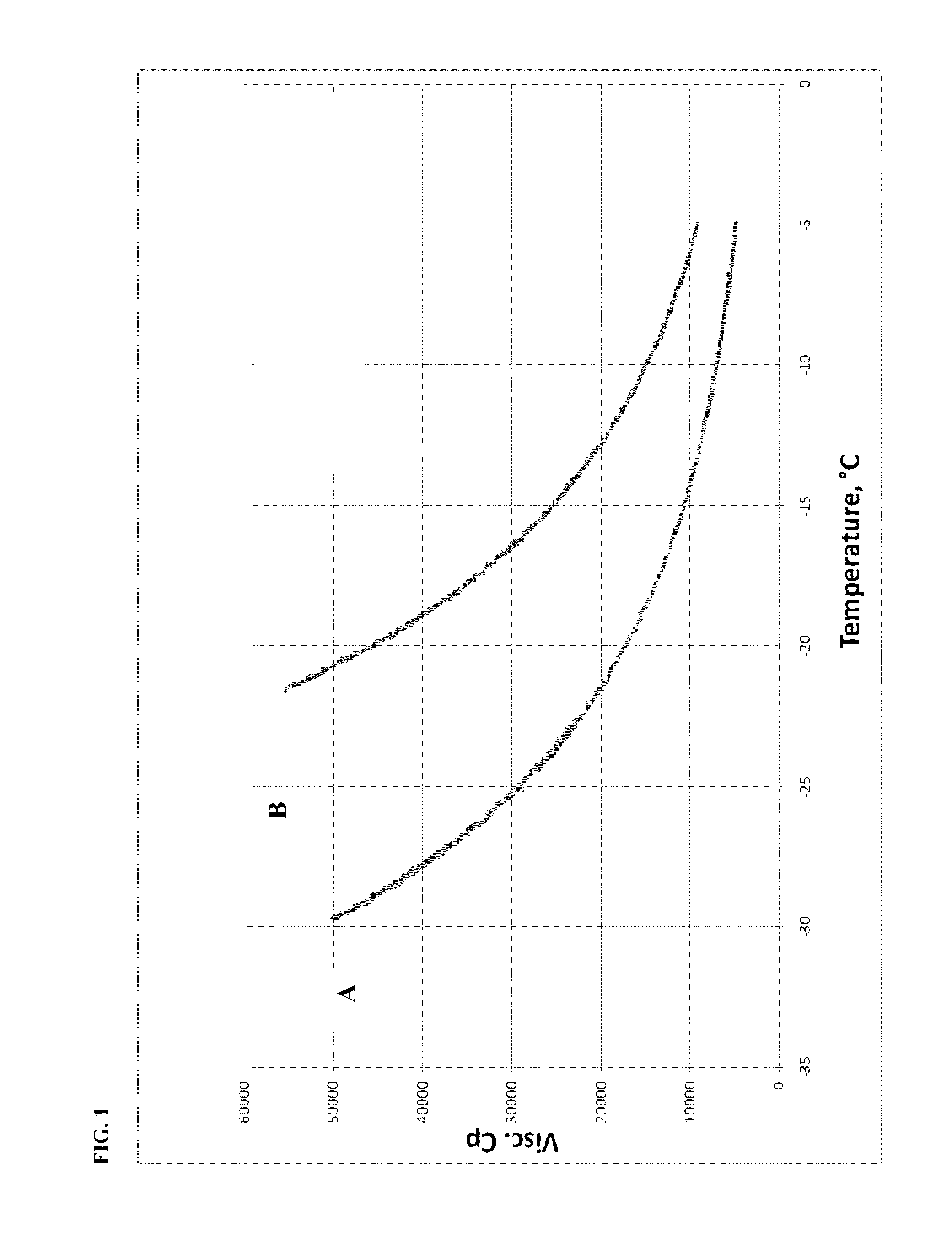

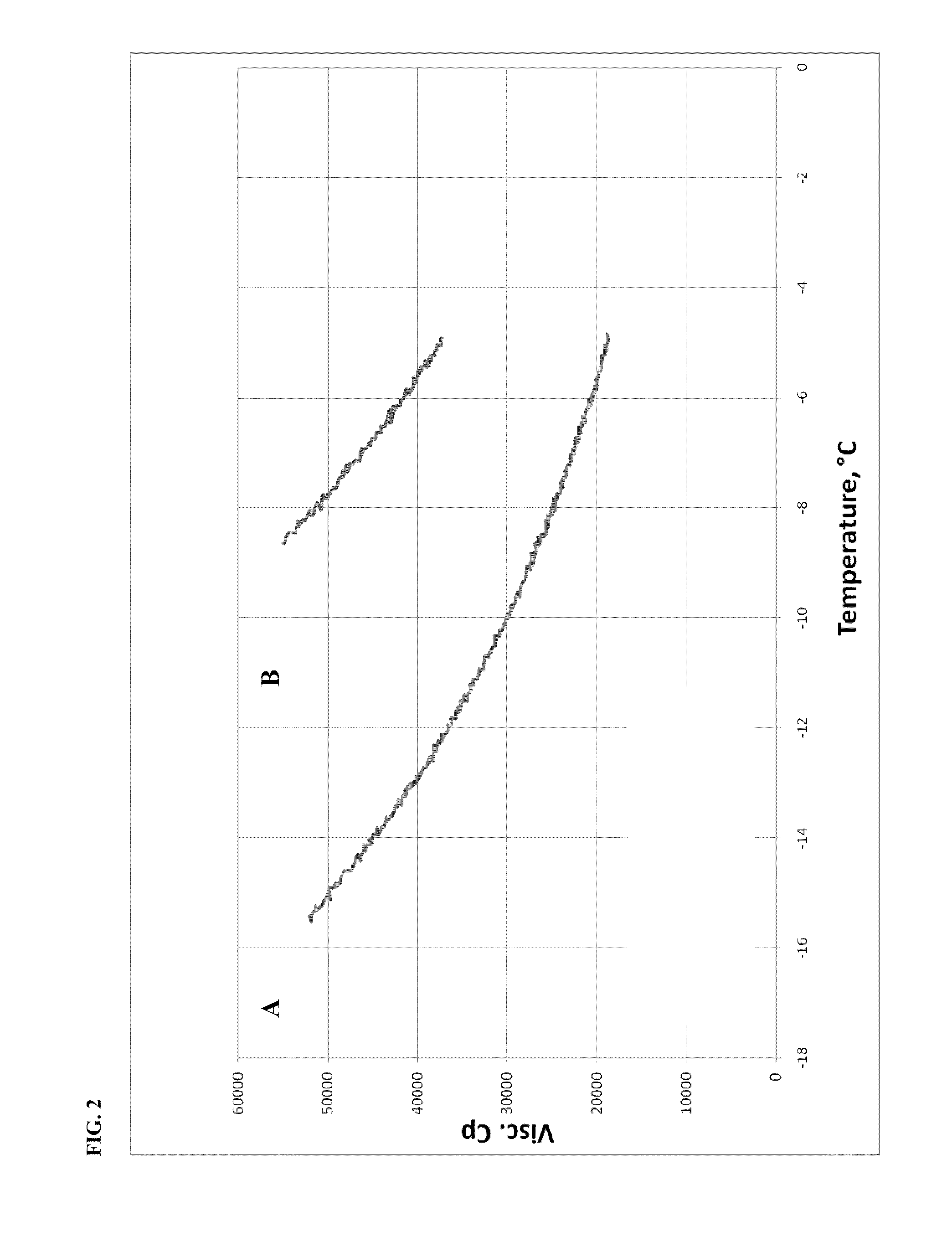

Process to produce low viscosity poly-alpha-olefins

ActiveUS20070043248A1Hydrocarbon by hydrogenationHydrocarbons from unsaturated hydrocarbon additionPolyolefinAlpha-olefin

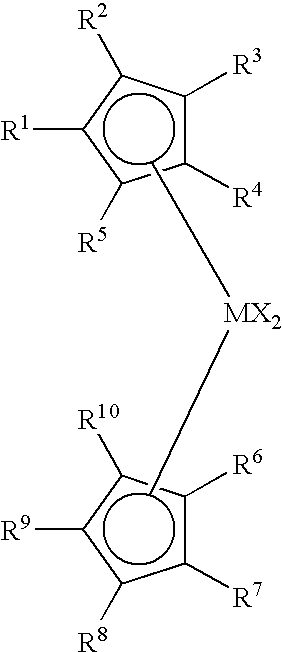

This invention relates to a process to produce a polyalpha-olefin comprising: 1) contacting one or more alpha-olefin monomers having 3 to 24 carbon atoms with an unbridged substituted bis cyclopentadienyl transition metal compound having: 1) at least one non-isoolefin substitution on both cyclopentadientyl rings, or 2) at least two substitutions on at least one cyclopentadienyl ring, a non-coordinating anion activator, and optionally an alkyl-aluminum compound, where the molar ratio of transition metal compound to activator is 10:1 to 0.1:1, and if the alkyl aluminum compound is present then the molar ratio of alkyl aluminum compound to transition metal compound is 1:4 to 4000:1, under polymerization conditions wherein: i) hydrogen is present at a partial pressure of 0.1 to 50 psi, based upon the total pressure of the reactor or the concentration of the hydrogen is from 1 to 10,000 ppm or less by weight; ii) wherein the alpha-olefin monomer(s) having 3 to 24 carbon atoms are present at 10 volume % or more based upon the total volume of the catalyst / activator / alkylaluminum compound solutions, monomers, and any diluents or solvents present in the reaction; iii) the residence time of the reaction is at least 5 minutes; iv) the productivity of the process is at least 43,000 grams of total product per gram of transition metal compound; v) the process is continuous or semi-continuous, and vi) the temperature in the reaction zone does not rise by more than 10° C. during the reaction; and vii) ethylene is not present at more than 30 volume % of the monomers entering the reaction zone; and 2) obtaining a polyalpha-olefin (PAO), optionally hydrogenating the PAO, wherein the PAO comprises at least 50 mole % of a C3 to C24 alpha-olefin monomer, and wherein the PAO has a kinematic viscosity at 100° C. of 20 cSt or less.

Owner:EXXONMOBIL CHEM PAT INC

Isoparaffinic base stocks by dewaxing fischer-tropsch wax hydroisomerate over Pt/H-mordenite

A high VI and low pour point lubricant base stock is made by hydroisomerizing a high purity, waxy, paraffinic Fischer-Tropsch synthesized hydrocarbon fraction having an initial boiling point in the range of 650-750° F., followed by catalytically dewaxing the hydroisomerate using a dewaxing catalyst comprising a catalytic platinum component and an H-mordenite component. The hydrocarbon fraction is preferably synthesized by a slurry Fischer-Tropsch using a catalyst containing a catalytic cobalt component. This combination of the process, high purity, waxy paraffinic feed and the Pt / H-mordenite dewaxing catalyst, produce a relatively high yield of premium lubricant base stock.

Owner:EXXON RES & ENG CO

Process of paraffin hydrocarbon isomerisation catalysed by an ionic liquid in the presence of a cyclic hydrocarbon additive

InactiveUS6797853B2High selectivityHigh degree of branchingHydrocarbon by isomerisationCatalytic crackingAlkaneIonic liquid

Owner:HALDOR TOPSOE AS

Method for the manufacture of hydrocarbons

ActiveUS20060161032A1Reduce hydrogen consumptionMaterial nanotechnologyRefining to change hydrocarbon structural skeletonHydrogenDistillation

Feedstock originating from renewable sources is converted to hydrocarbons in diesel fuel distillation range by contacting with a supported catalyst comprising VIII group metal / metals, whereby the consumption of hydrogen is decreased.

Owner:NESTE OIL OY

Oligomerization of alpha olefins using metallocene-ssa catalyst systems and use of the resultant polyalphaolefins to prepare lubricant blends

ActiveUS20100317904A1Improve productivityHydrocarbon by hydrogenationAdditivesOligomerViscosity index

This disclosure provides for alpha olefin oligomers and polyalphaolefins (or PAOs) and methods of making the alpha olefin oligomers and PAOs. This disclosure encompasses metallocene-based alpha olefin oligomerization catalyst systems, including those that include at least one metallocene and an activator comprising a solid oxide chemically-treated with an electron withdrawing anion. The alpha olefin oligomers and PAOs prepared with these catalyst systems can have a high viscosity index combined with a low pour point, making them particularly useful in lubricant compositions and as viscosity modifiers.

Owner:CHEVRON PHILLIPS CHEMICAL CO LP

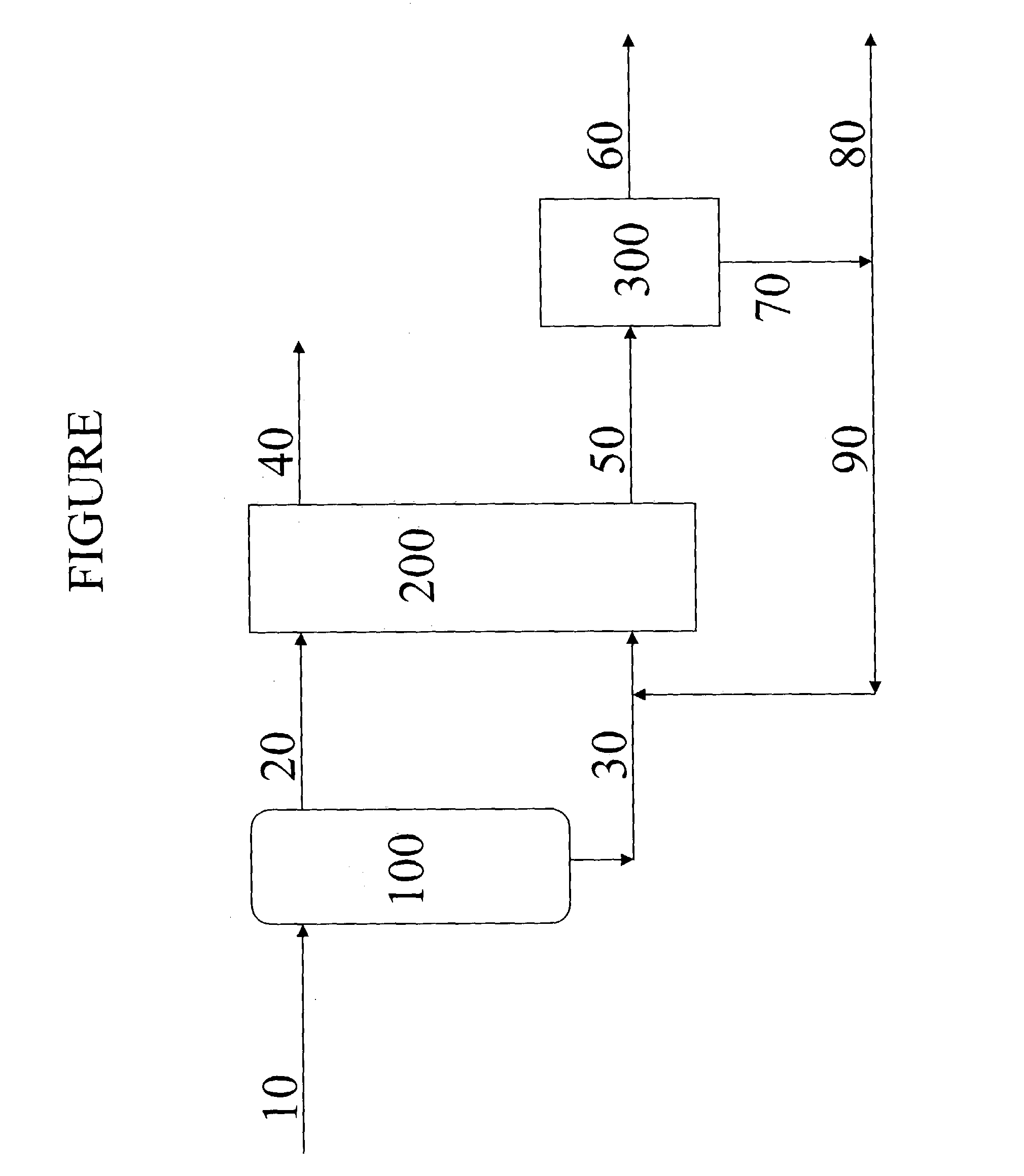

Method for the manufacture of hydrocarbons

ActiveUS7491858B2Reduce hydrogen consumptionMaterial nanotechnologyRefining to change hydrocarbon structural skeletonHydrogenDistillation

Feedstock originating from renewable sources is converted to hydrocarbons in diesel fuel distillation range by contacting with a supported catalyst comprising VIII group metal / metals, whereby the consumption of hydrogen is decreased.

Owner:NESTE OIL OY

Process for upgrading naphtha

A method for upgrading a naphtha feed to a naphtha product containing less than about 10 wppm of nitrogen and less than about 15 wppm sulfur, the method comprising contacting said naphtha feed with hydrogen in the presence of a bulk multimetallic catalyst under effective reactor conditions to hydrodesulfurize and hydrodenitrogenize said naphtha feed to produce said naphtha product, wherein said bulk multimetallic catalyst comprises at least one Group VIII non-noble metal and at least two Group VIB metals.

Owner:EXXON RES & ENG CO

Method for producing hydrocarbons and oxygen-containing compounds from biomass

InactiveUS20050112739A1Improve direct utilizationImprove utilizationOrganic compound preparationHydrocarbon by hydrogenationChemical industryChemical reaction

The present invention generally relates to biochemical and chemical industry, and more particularly to a method which can be used in fermenting carbohydrate substrates of plant origin for producing C1-C5 alcohols, and for synthesis of higher alcohols, other oxygen-containing compounds and hydrocarbons as well as for the production of motor fuel components from biomass. Since C6 and higher alcohols, ethers, acetals, and higher hydrocarbons are not obtainable by a direct biochemical route, it is proposed to synthesize these using known chemical reactions, wherein by-products of fermentation are as raw materials for said synthesis.

Owner:SWEDISH BIOFUELS AB

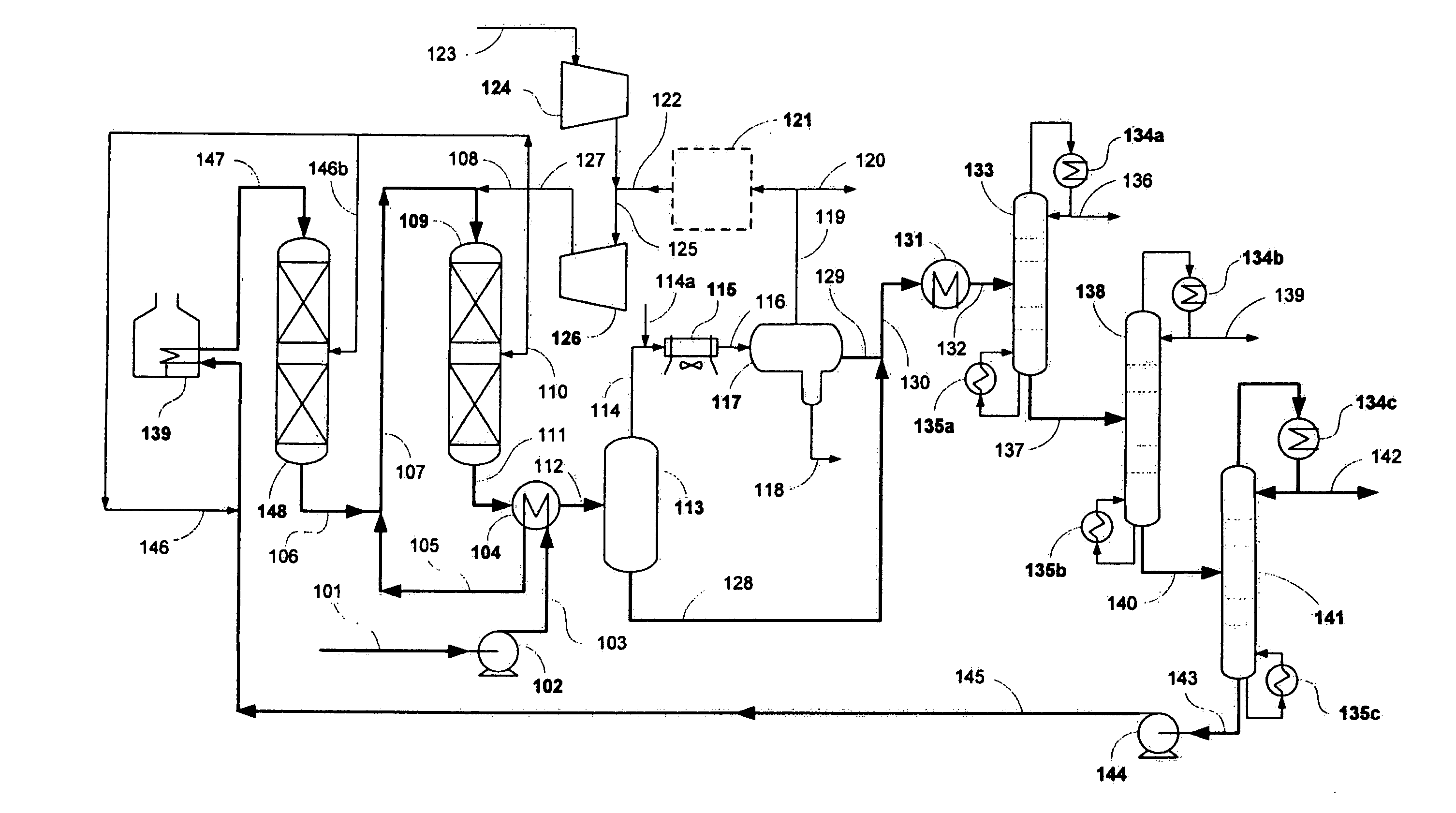

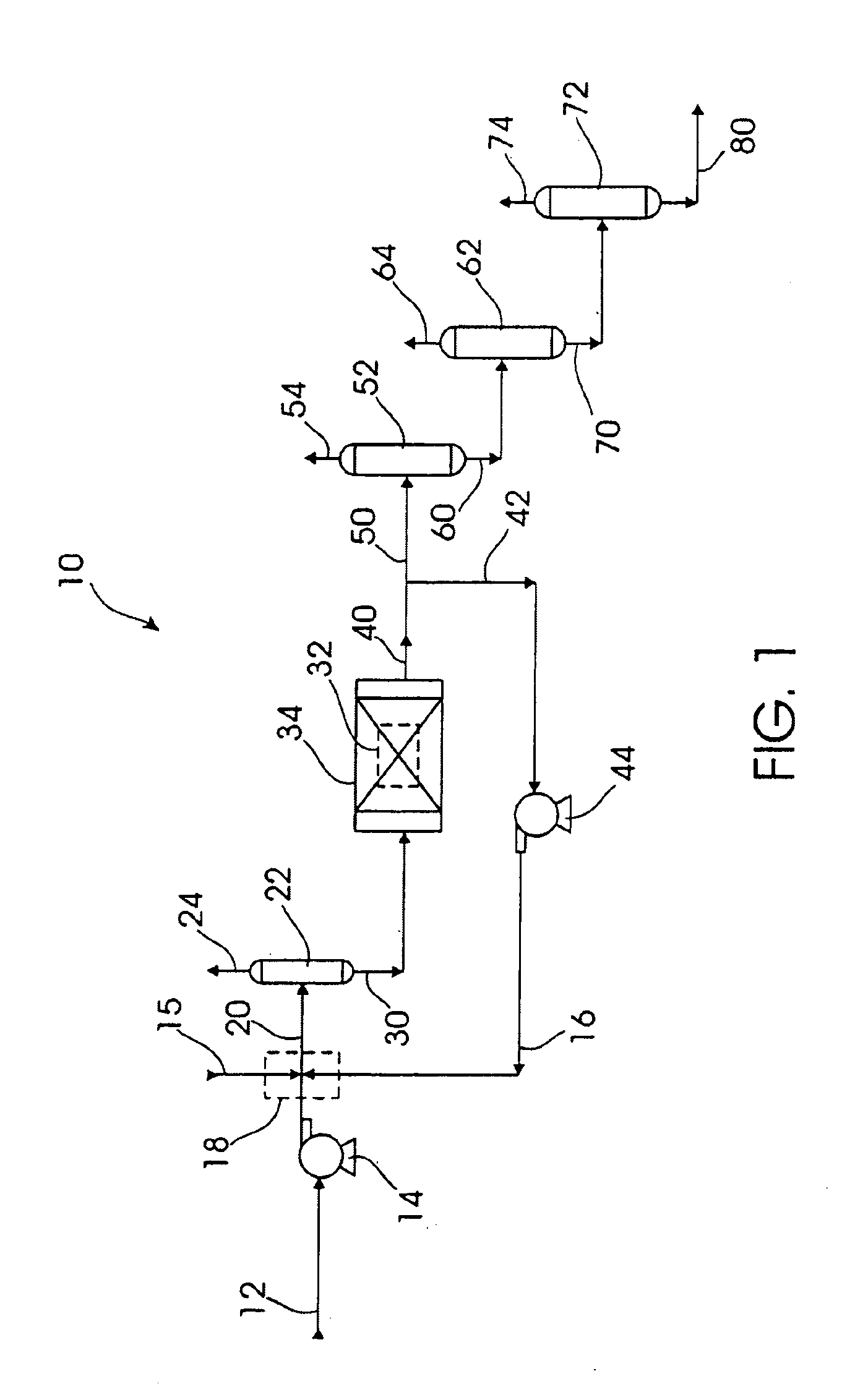

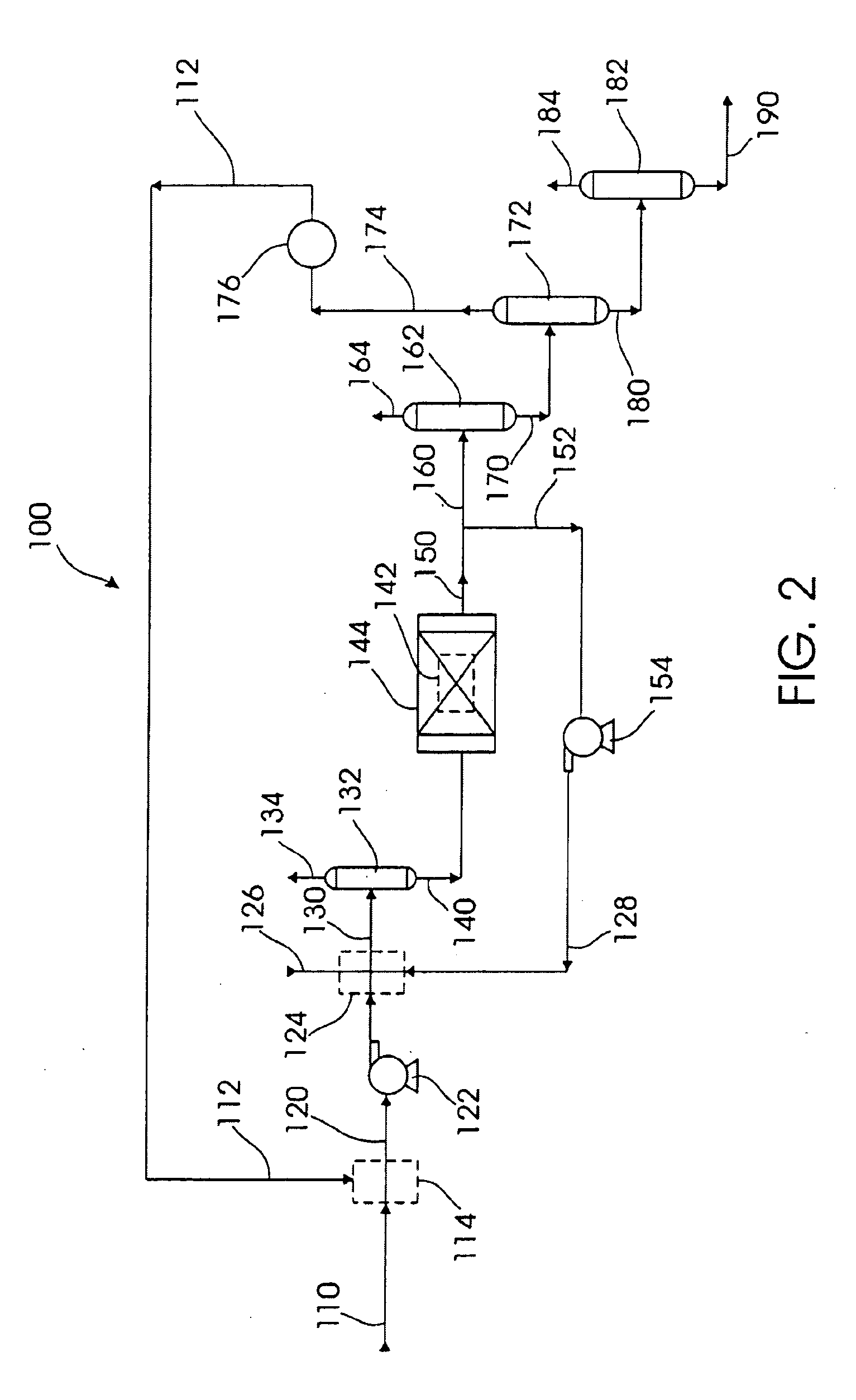

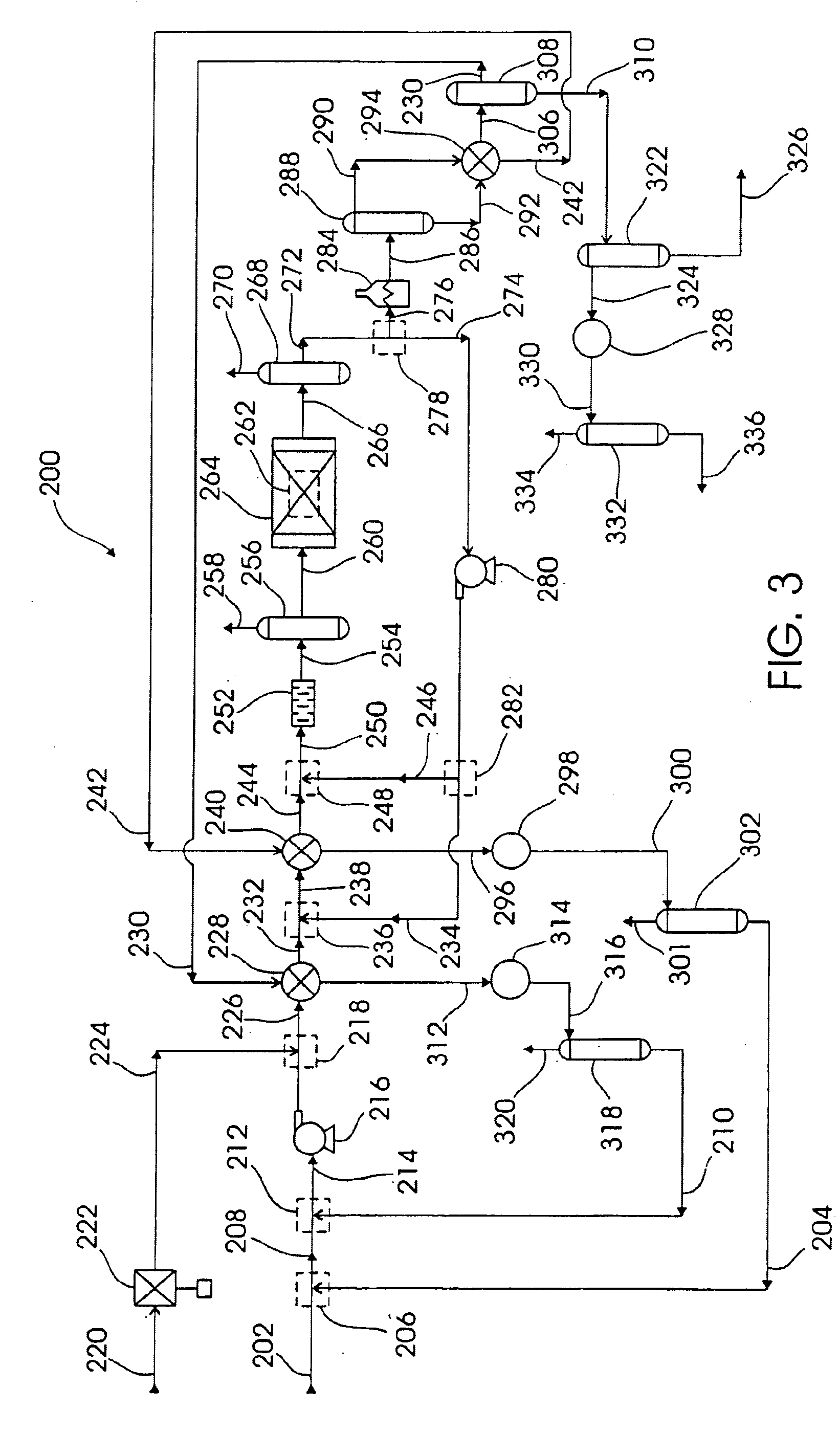

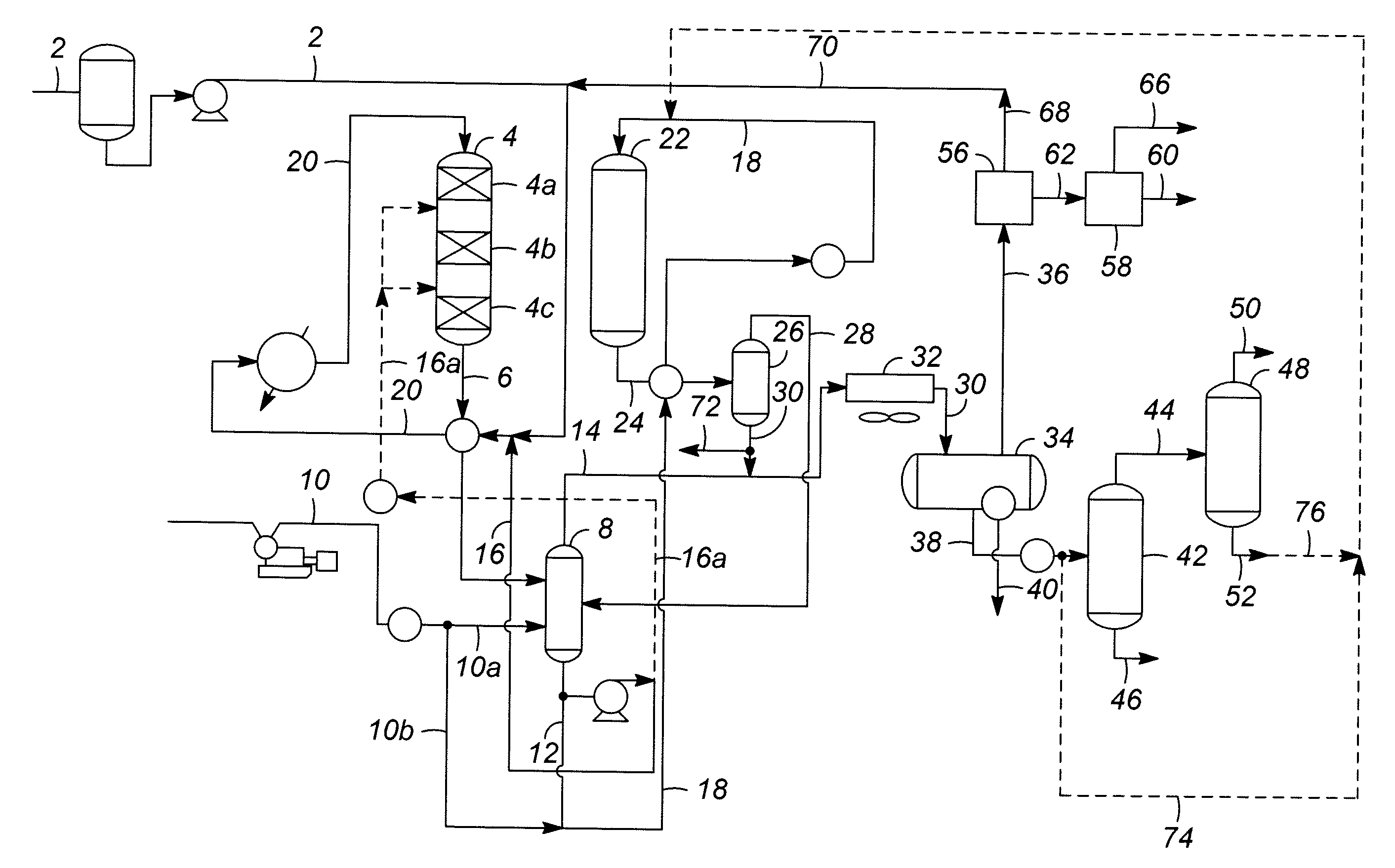

Two phase hydroprocessing

InactiveUS6881326B2Eliminate needHydrogen solubility is “Physical/chemical process catalystsOrganic compound preparationSolubilityHydrogen

A process where the need to circulate hydrogen through the catalyst is eliminated. This is accomplished by mixing and / or flashing the hydrogen and the oil to be treated in the presence of a solvent or diluent in which the hydrogen solubility is “high” relative to the oil feed. The type and amount of diluent added, as well as the reactor conditions, can be set so that all of the hydrogen required in the hydroprocessing reactions is available in solution. The oil / diluent / hydrogen solution can then be fed to a plug flow reactor packed with catalyst where the oil and hydrogen react. No additional hydrogen is required, therefore, hydrogen recirculation is avoided and trickle bed operation of the reactor is avoided. Therefore, the large trickle bed reactors can be replaced by much smaller tubular reactor.

Owner:EI DU PONT DE NEMOURS & CO

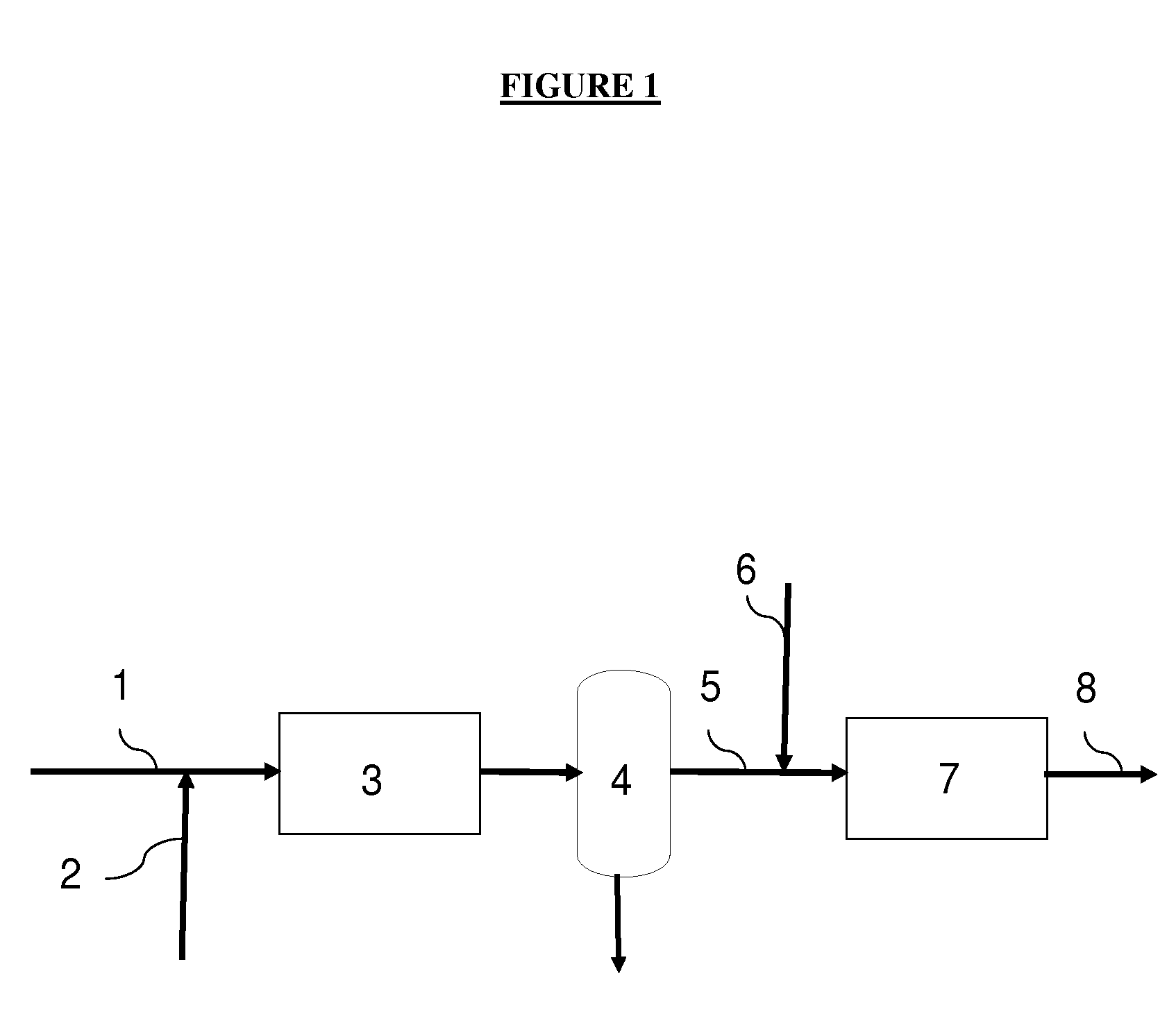

Method of converting feedstocks coming from renewable sources into high-quality gas-oil fuel bases

ActiveUS20080161615A1The implementation process is simpleHydrocarbon by hydrogenationSolid fuelsVegetable oilEngineering

Owner:INST FR DU PETROLE

Premium synthetic lubricant base stock (Law734) having at least 95% noncyclic isoparaffins

A premium synthetic lubricating oil base stock having a high VI and low pour point is made by hydroisomerizing a Fischer-Tropsch synthesized waxy, paraffinic feed wax and then dewaxing the hydroisomerate to form a 650-750° F.+ dewaxate. The waxy feed has an initial boiling point in the range of about 650-750° F., from which it continuously boils up to at least 1050° F. and has a T90-T10 temperature difference of at least 350° F. The feed is preferably hydroisomerized without any pretreatment, other than optional fractionation. The 650-750° F.+ dewaxate is fractionated into two or more base stocks of different viscosity.

Owner:EXXON RES & ENG CO

Isomerization/dehazing process for base oils from Fischer-Tropsch wax

InactiveUS7198710B2Hydrocarbon by hydrogenationTreatment with hydrotreatment processesWaxMolecular sieve

A method for producing lubricant base oils is provided comprising the steps of: (a) separating a feedstock into a light lubricant base oil fraction and a heavy fraction; (b) hydroisomerizing the fractions over a medium pore size molecular sieve catalyst under hydroisomerization conditions to produce an isomerized light lubricant base oil fraction having a pour point less than or equal to a target pour point of the lubricant base oils and an isomerized heavy fraction having a pour point of equal to or greater than the target pour point of the lubricant base oils and a cloud point greater than the target cloud point of the lubricant base oils; and (c) dehazing the isomerized heavy fraction to provide a heavy lubricant base oil having a pour point less than or equal to the target pour point of the lubricant base oils and a cloud point less than or equal to the target cloud point of the lubricant base oils.

Owner:CHEVROU USA INC

Catalyst and process for the selective hydrogenation of unsaturated compounds in hydrocarbon streams

InactiveUS6350717B1Maintain good propertiesHigh selectivityOrganic chemistry methodsHydrocarbon by hydrogenationHydrocarbonChemistry

A catalyst comprising at least one metal of the 10th group of the Periodic Table of the Elements and at least one metal of the 11th group of the Periodic Table of the Elements on an aluminum oxide support, wherein the metal or metals of the 10th group is or are essentially concentrated in an outer layer close to the surface of the catalyst particle, the metal or metals of the 11th group is or are distributed essentially uniformly over the volume of the catalyst particle and the weight ratio of the metal or metals of the 11th group to the metal or metals of the 10th group is not more than 1.95.

Owner:BASF AG

Process for generating pure benzene from reformed gasoline

InactiveUS6124514AReduce benzene contentAchieve separationThermal non-catalytic crackingCatalytic crackingBenzeneExtractive distillation

A process is disclosed for generating pure aromatic compounds from a reformed gasoline which contains aromatic compounds, olefins, diolefin, and triolefins, which comprises the steps of: (a) selectively hydrogenating the olefins, diolefins and triolefins in the reformed gasoline to obtain a mixture of hydrogenated, non-aromatic compounds and aromatic compounds; and (b) separating the aromatic compounds from the hydrogenated, non-aromatic compounds in the mixture formed during step (a) by either extractive distillation, liquid-liquid extraction or both to obtain the pure aromatic compounds.

Owner:BASF AG

Catalytically inactive heat generator and improved dehydrogenation process

An improved dehydrogenation catalyst bed system for olefin production utilizing classical processing techniques is disclosed. The catalyst bed system comprises a dehydrogenation catalyst comprising an active component selected from an oxide of a metal of Group 4 or Group 5 or Group 6 and combinations thereof and a support selected from aluminum oxide, aluminas, alumina monohydrate, alumina trihydrate, alumina-silica, transition aluminas, alpha-alumina, silica, silicate, aluminates, calcined hydrotalcites, zeolites and combinations thereof mixed with a first inert material selected from any material that is catalytically inactive when subjected to reaction conditions that can effect dehydrogenation of olefins and that has a high density and high heat capacity and that is not capable of producing heat during any stage of the dehydrogenation process, and the dehydrogenation catalyst plus the first inert material then being physically mixed with a secondary component comprising a heat-generating inert material and a carrier capable of supporting the heat-generating inert material, wherein the secondary component is catalytically inert with respect to dehydrogenation reactions or to cracking or to coking and generates heat after being exposed to reducing and / or to oxidizing reaction conditions.

Owner:CLARIANT INT LTD

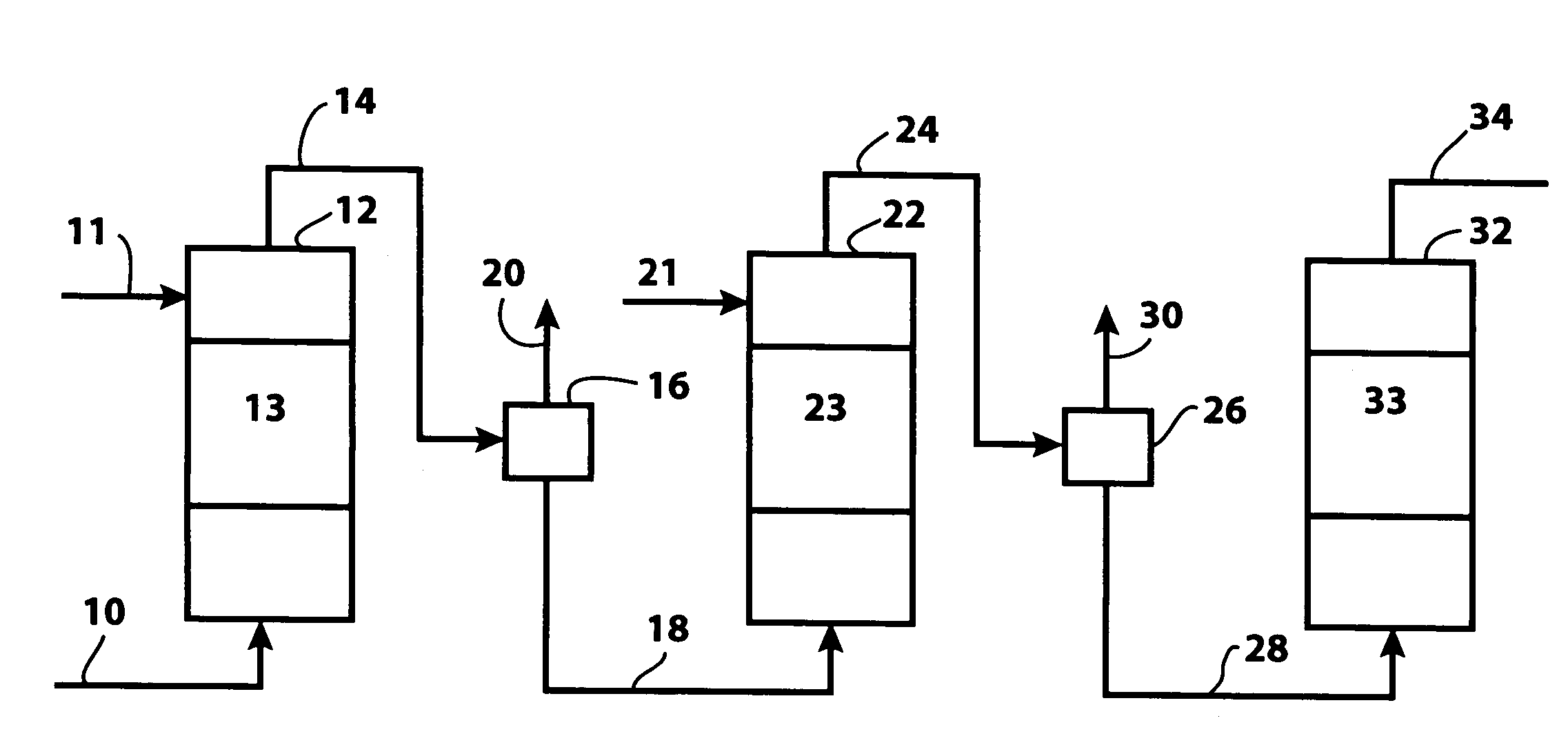

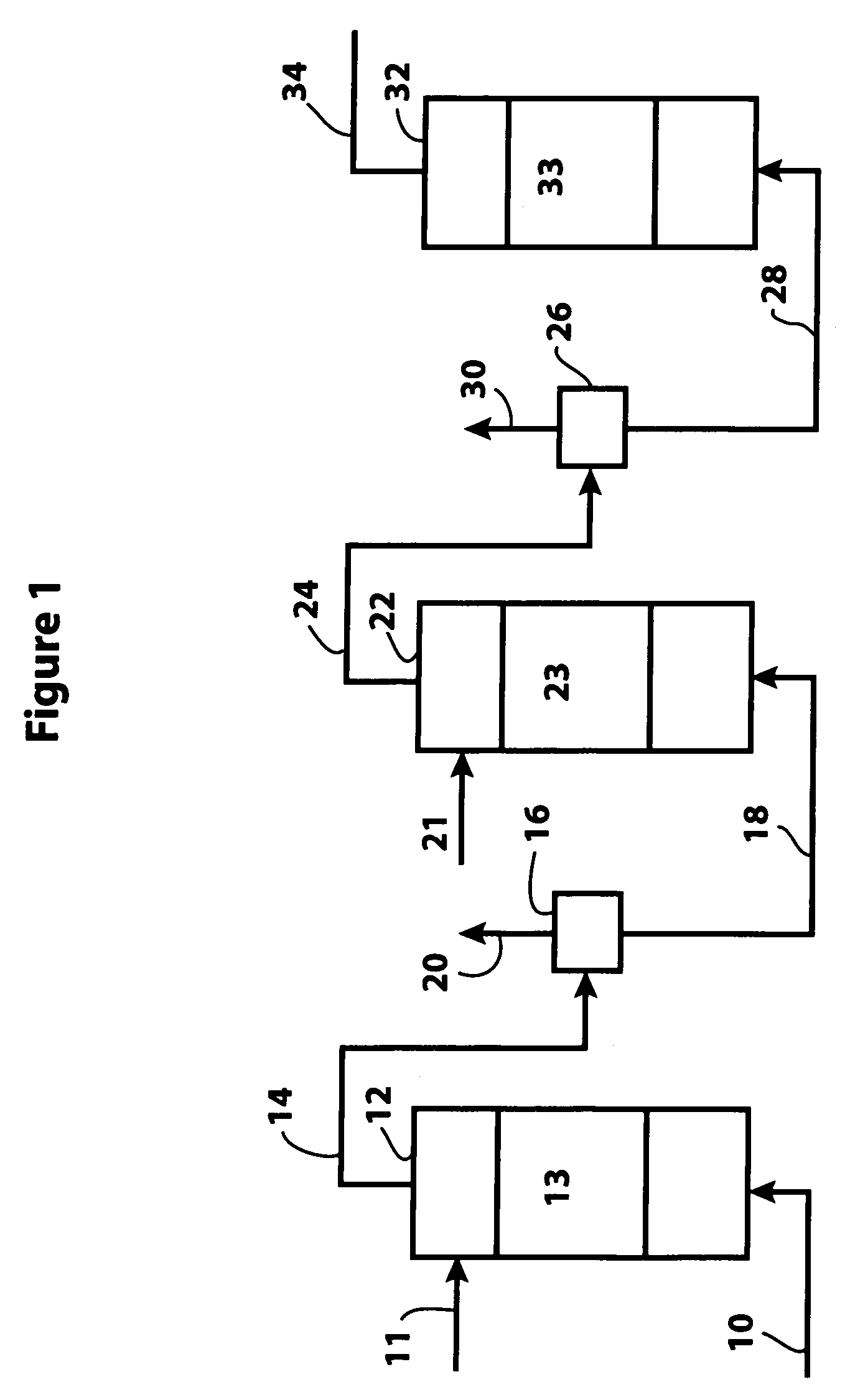

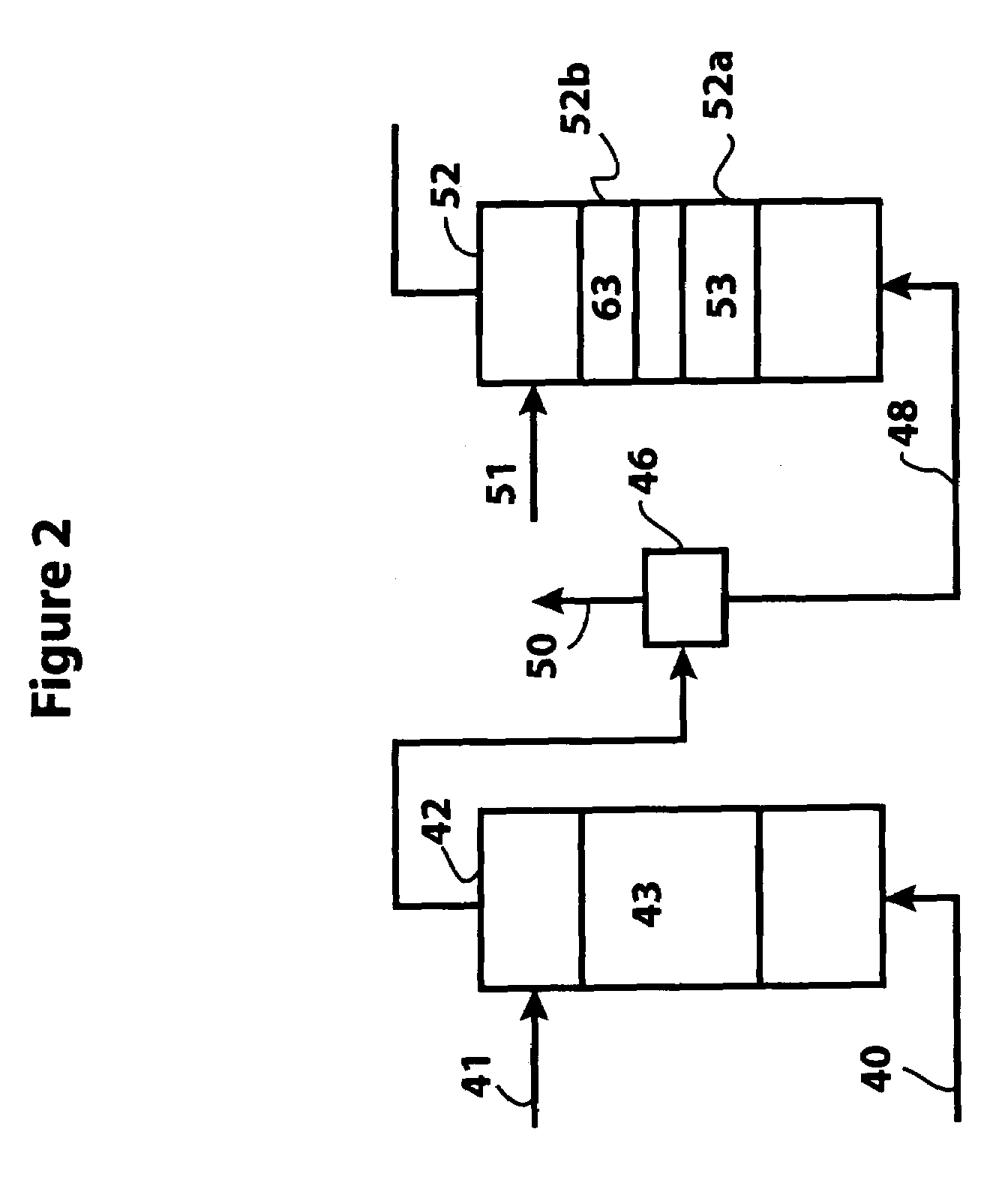

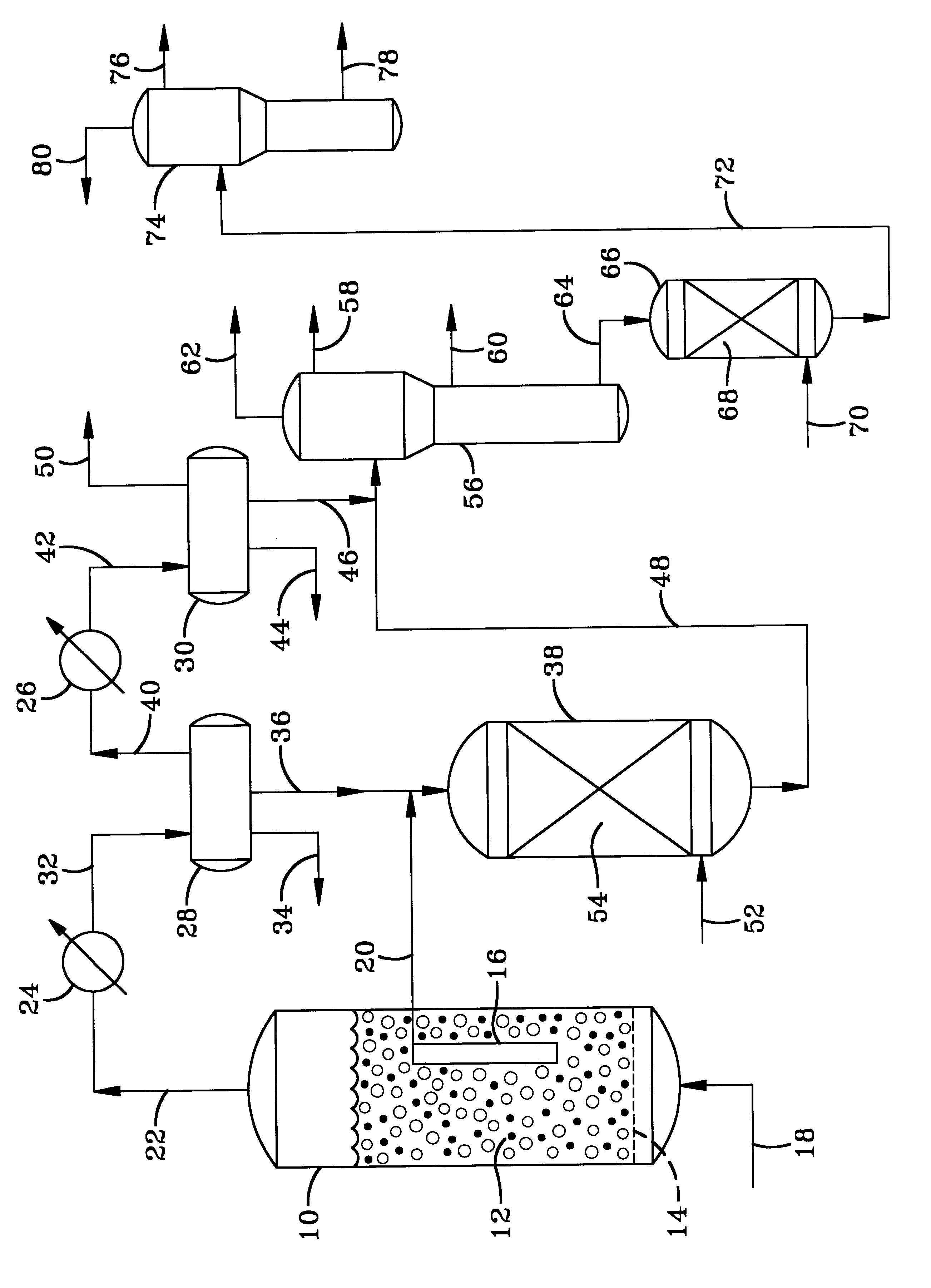

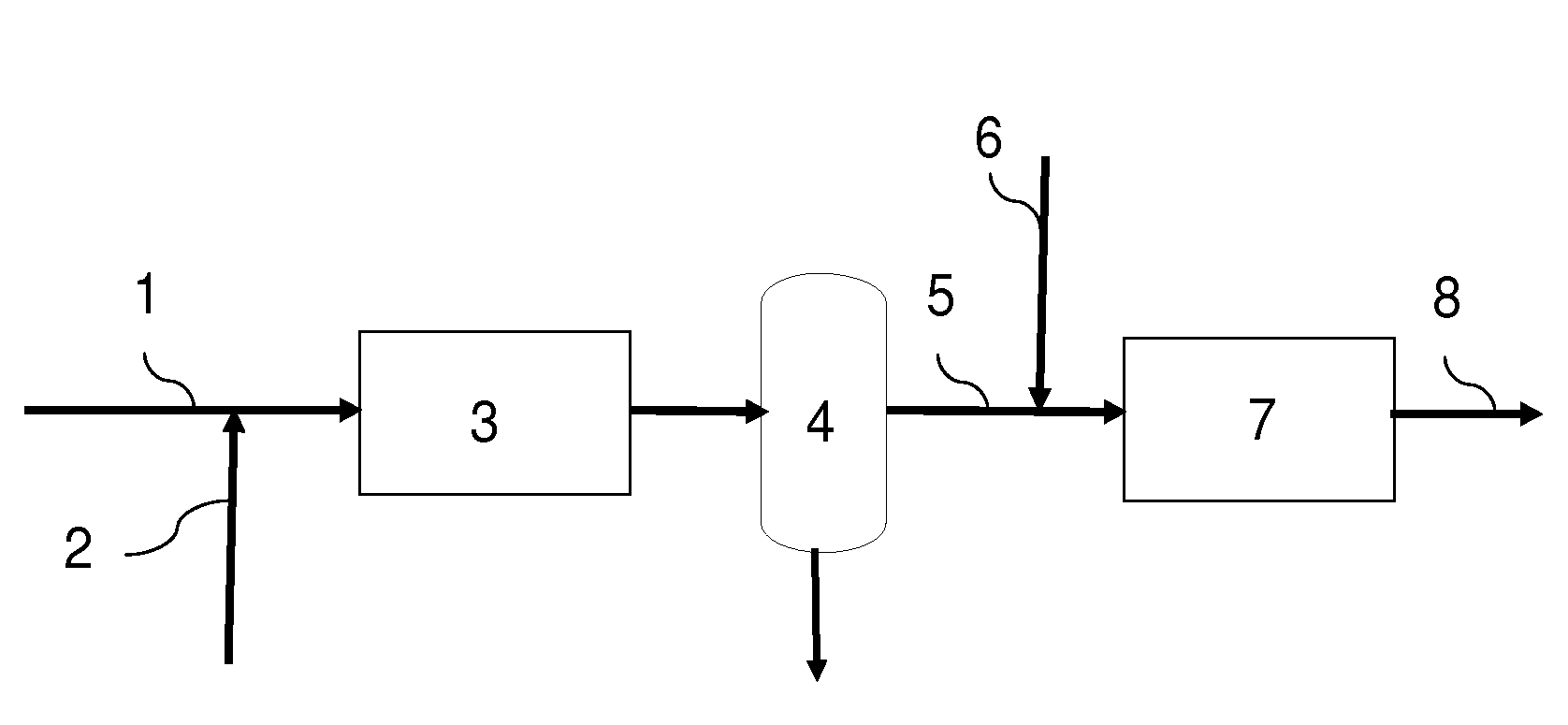

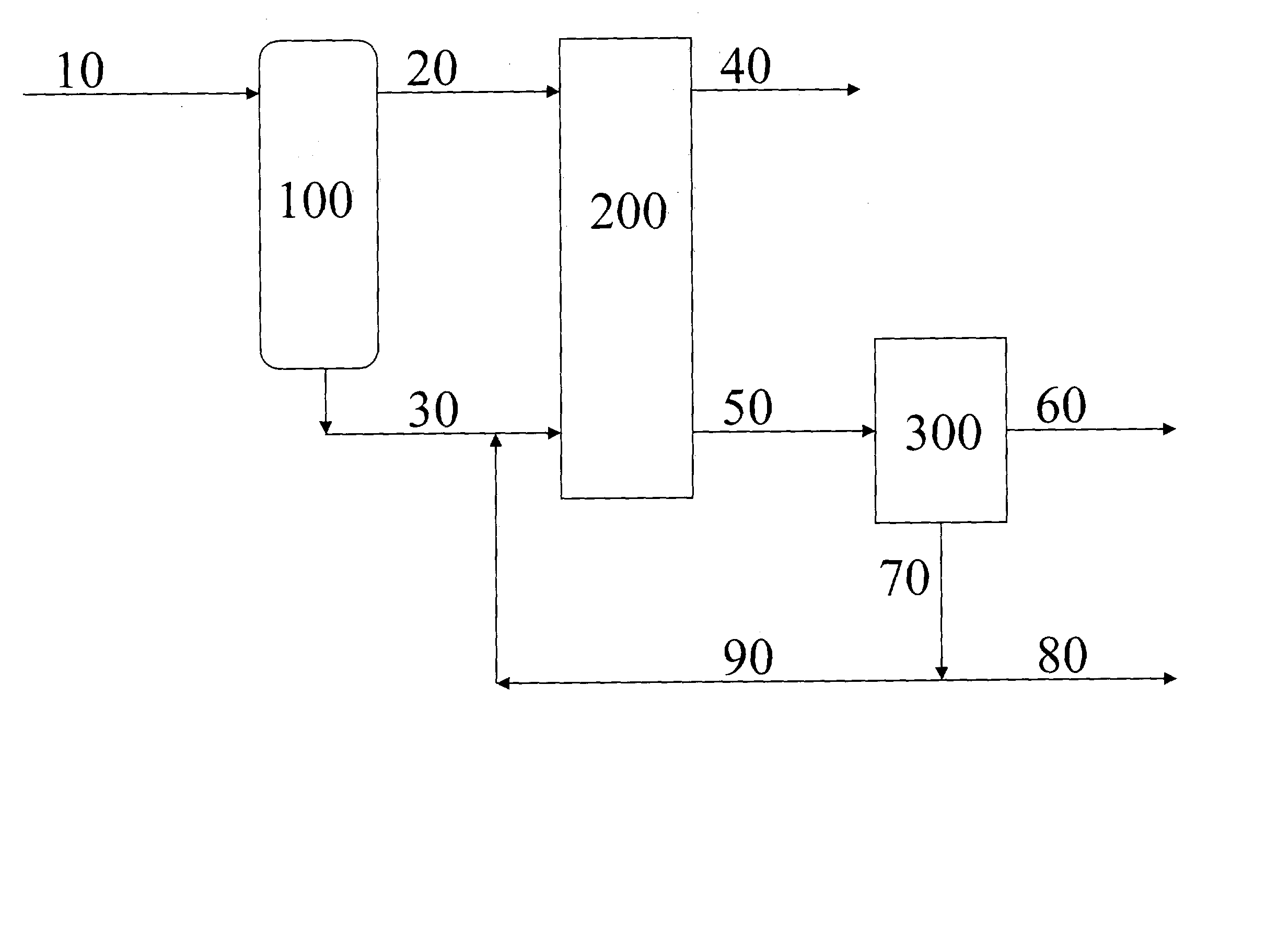

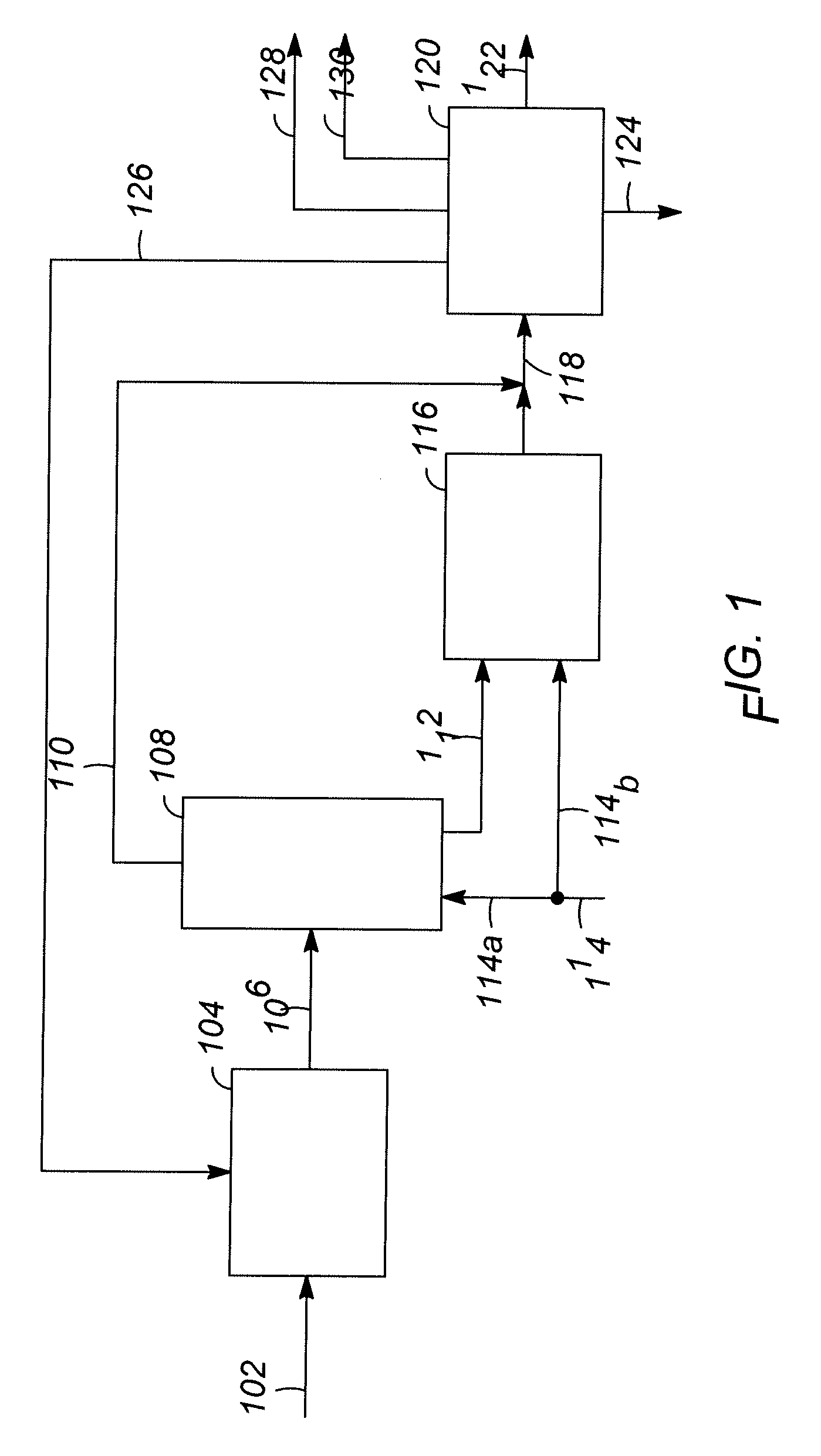

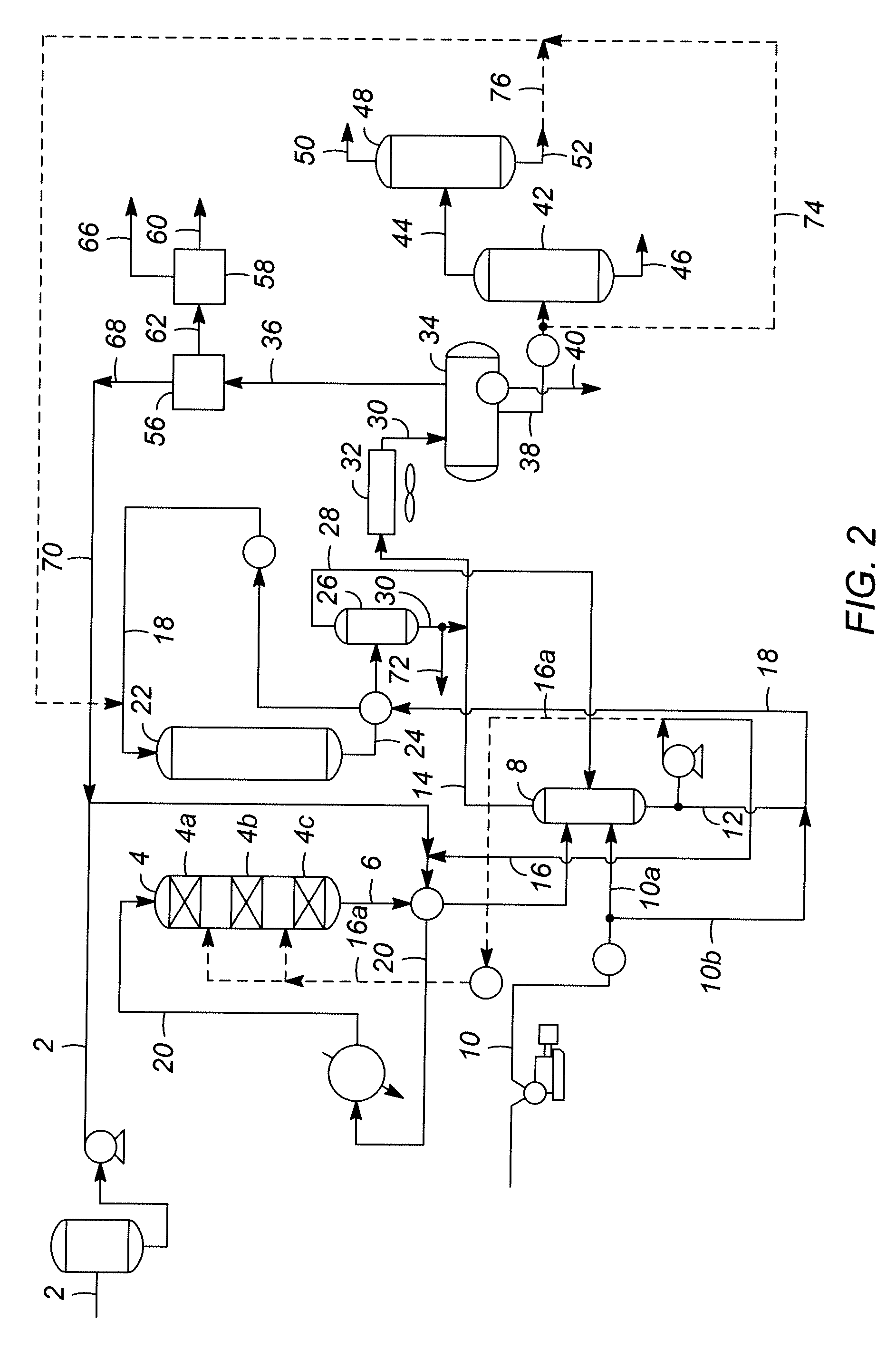

Production of Diesel Fuel from Biorenewable Feedstocks

ActiveUS20090077866A1Refining to change hydrocarbon structural skeletonHydrocarbon by hydrogenationSolubilityHydrogen

A process has been developed for producing diesel boiling range fuel from renewable feedstocks such as plant oils and animal oils, fats, and greases. The process involves treating a renewable feedstock by hydrogenating and deoxygenating i.e. decarboxylating, decarbonylating, and / or hydrodeoxygenating to provide a hydrocarbon fraction useful as a diesel boiling range fuel or diesel boiling range fuel blending component. If desired, the hydrocarbon fraction can be isomerized to improve cold flow properties. A portion of the hydrogenated and deoxygenated feedstock is selectively separated and then recycled to the treatment zone to increase the hydrogen solubility of the reaction mixture.

Owner:UOP LLC

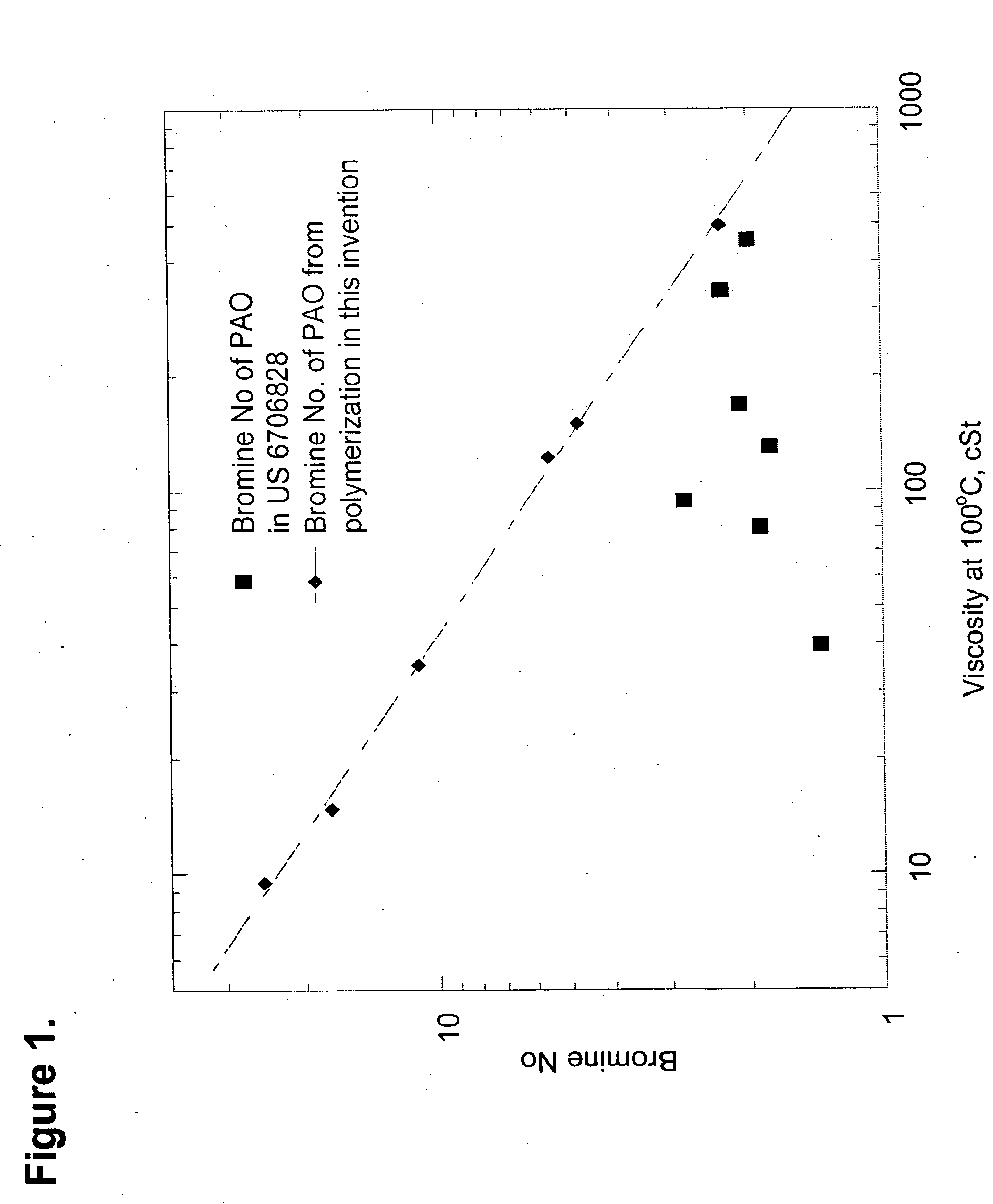

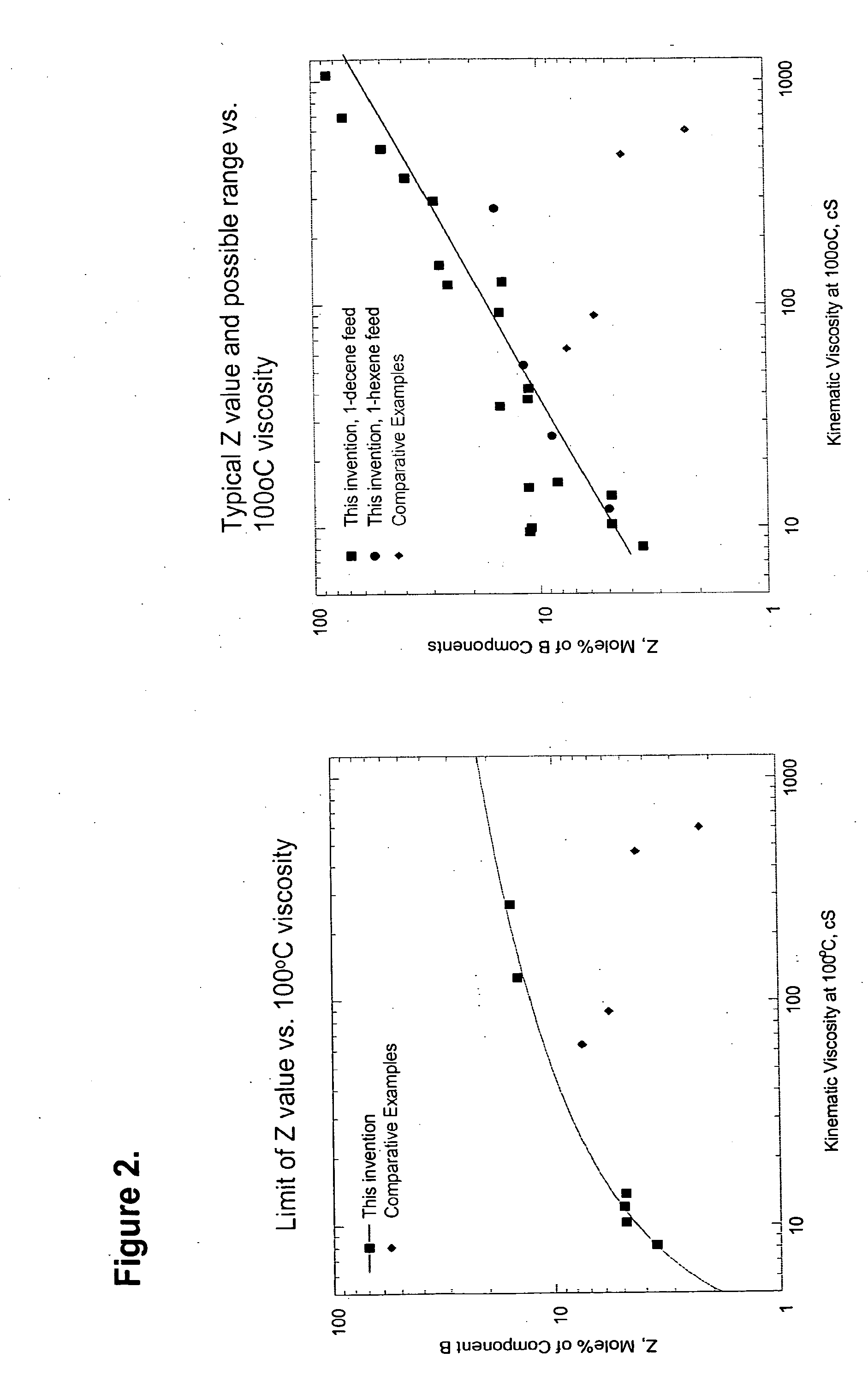

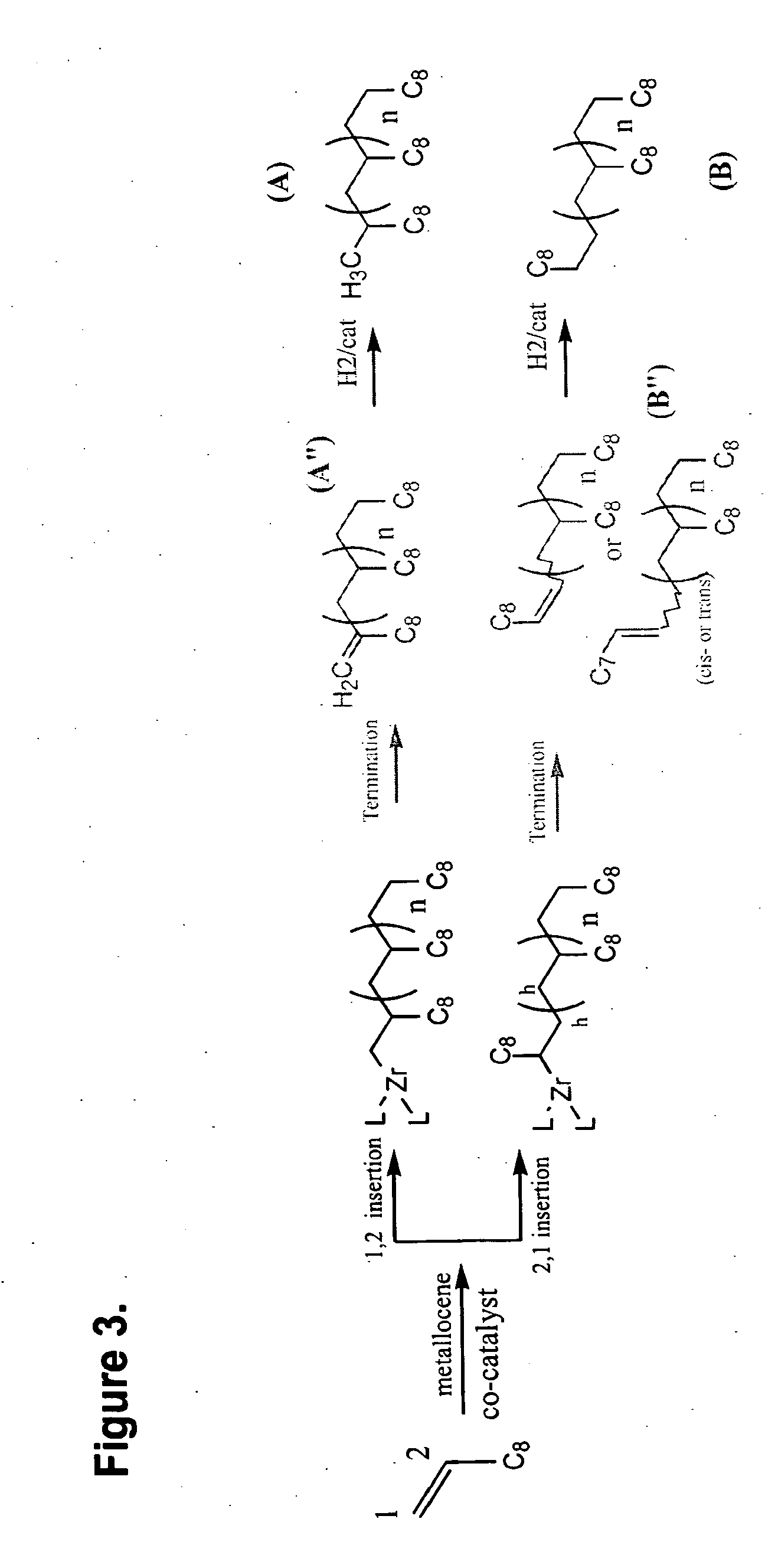

Polyalpha-Olefin Compositions and Processes to Produce the Same

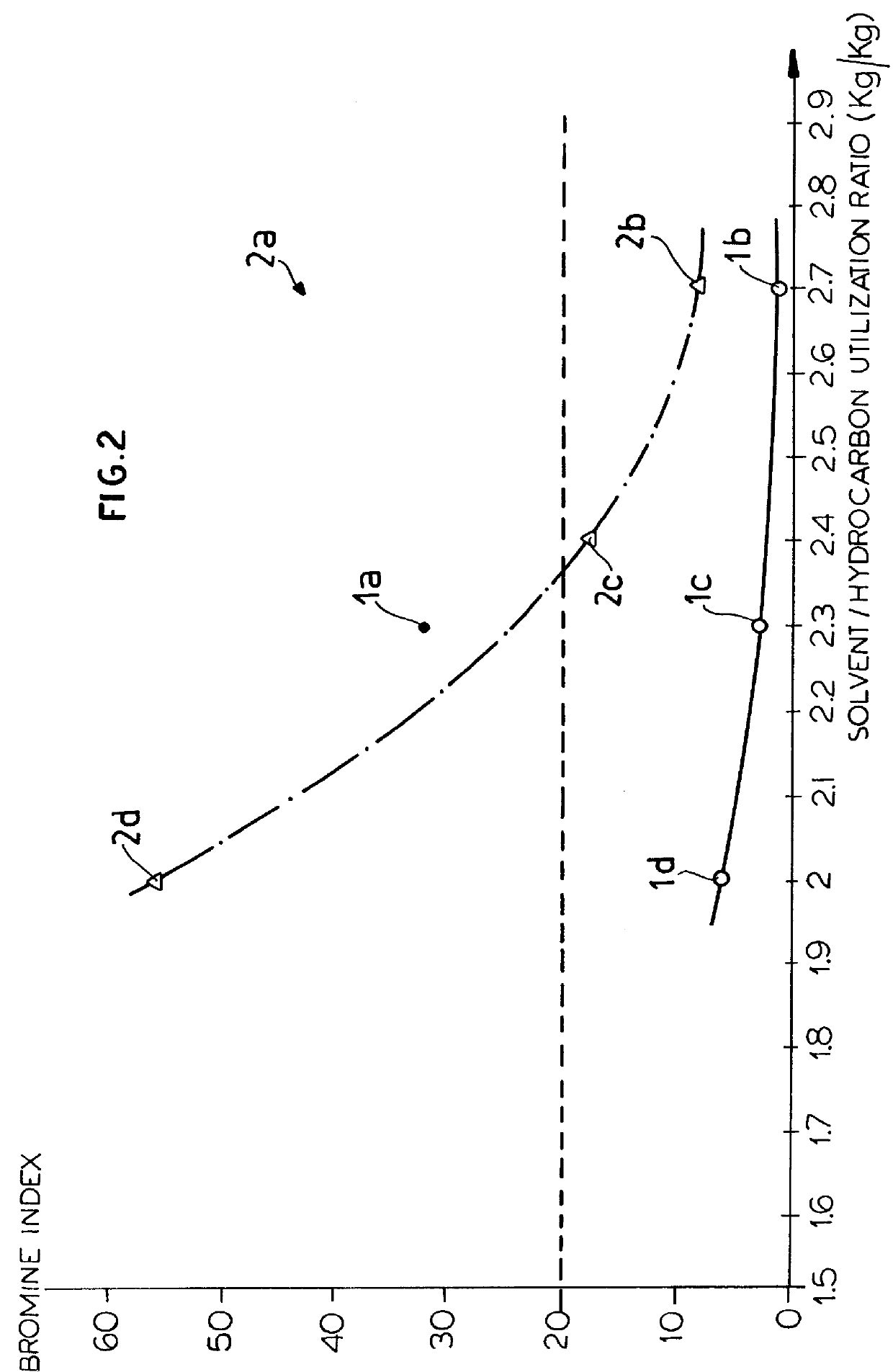

ActiveUS20090005279A1Hydrocarbon by hydrogenationHydrocarbons from unsaturated hydrocarbon additionBromine numberPolymer science

This invention relates to a polyalpha-olefin (and hydrogenated analogs thereof) comprising more than 50 mole % of one or more C5 to C24 alpha-olefin monomers where the polyalpha-olefin has: a) 40 mole % or more of mm triads, b) a Bromine number of Y or greater, where Y is equal to 89.92*(V)′°5863, where V is the Kinematic Viscosity of the polyalpha-olefin measured at 100° C. in cSt, and c) 1,2 disubstituted olefins present at 7 mole % or more, preferably having Z mole % or more of units represented by the formula: where j, k and m are each, independently, 3, 4, 5, 6, 7, 8, 9, 10, 11, 12, 13, 14, 15, 16, 17, 18, 19, 20, 21, or 22, n is an integer from 1 to 350, and where Z=8.420*Log(V)−4.048, where V is the kinematic viscosity of the polyalpha-olefin measured at 1000 C in cSt This invention also relates to process to produce such polyalpha-olefins.

Owner:EXXONMOBIL CHEM PAT INC

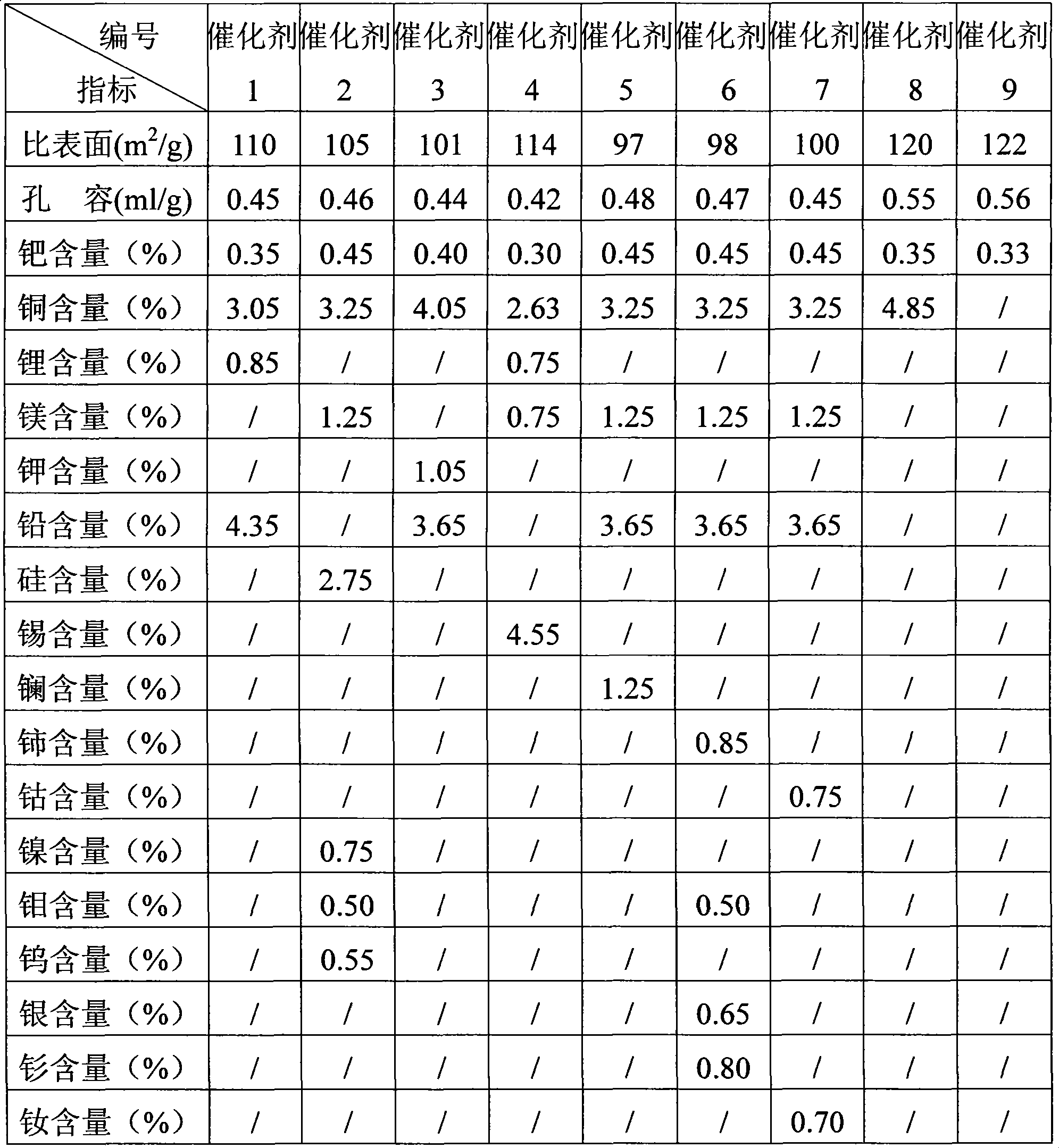

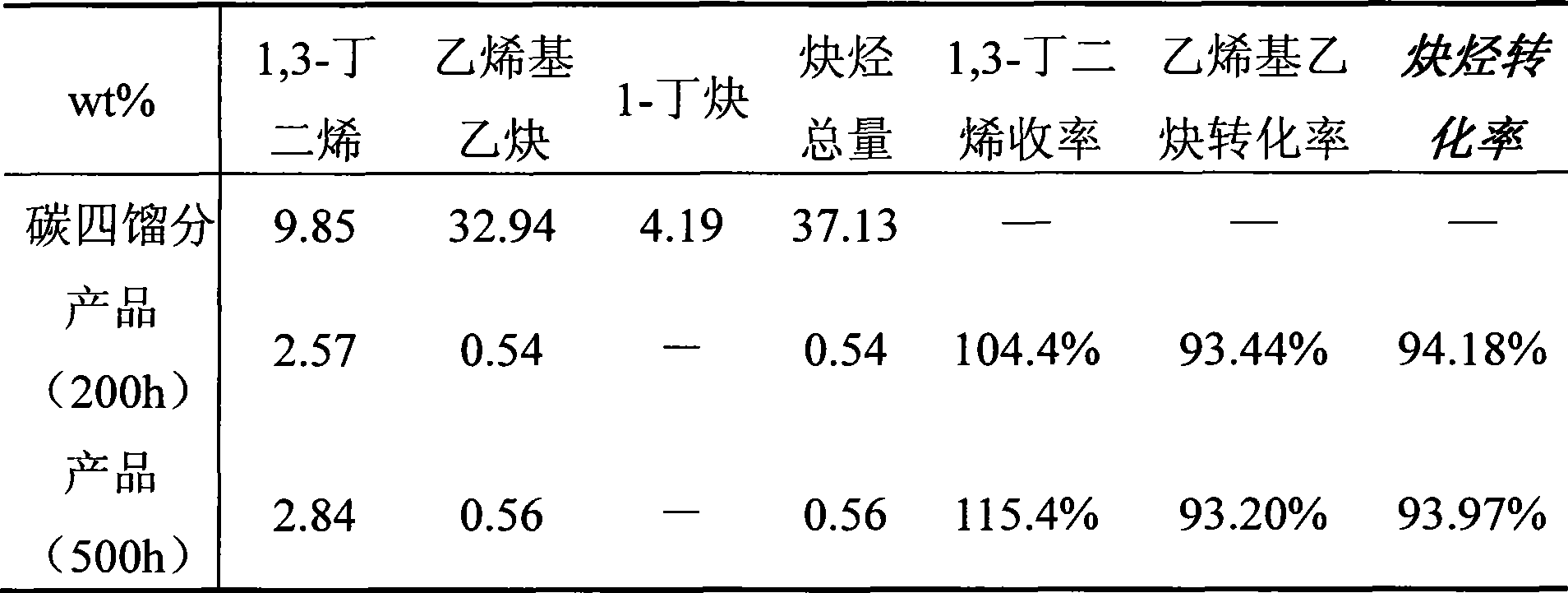

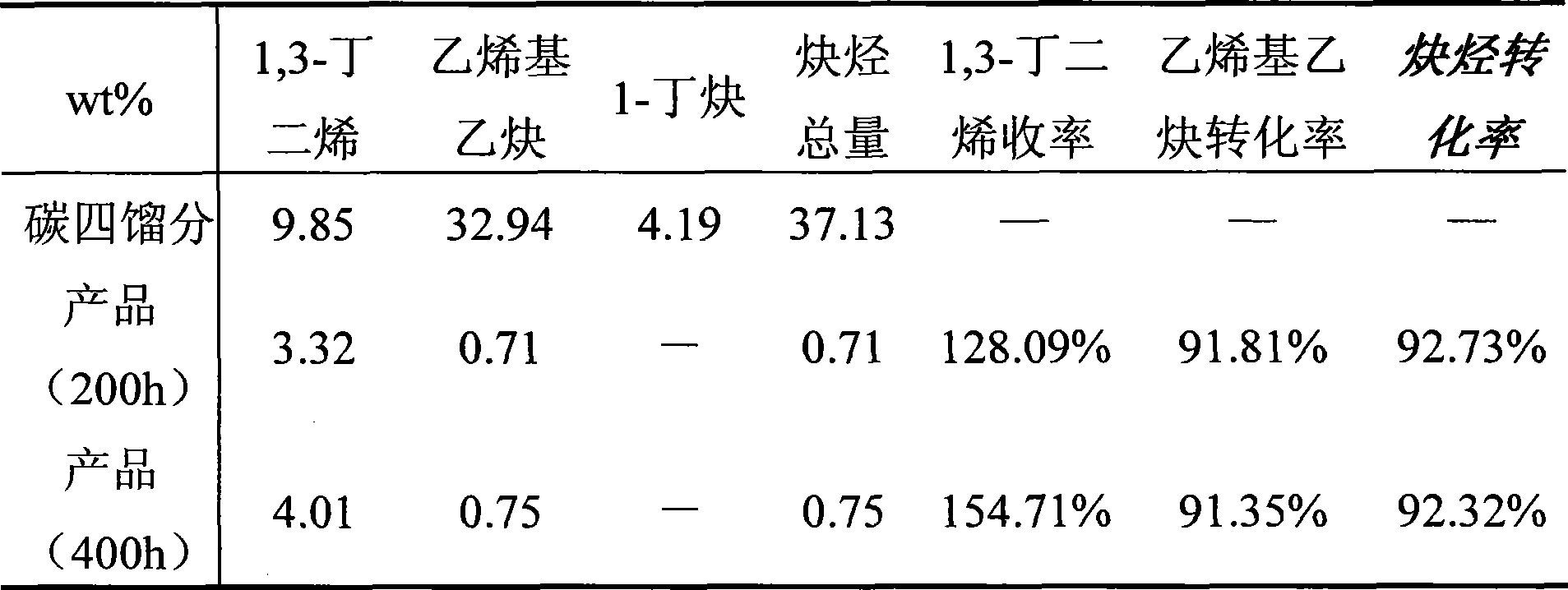

Acetylene hydrocarbon selective hydrogenation method

ActiveCN101434508AGood hydrogenation effectImprove hydrogenation activityHydrocarbon by hydrogenationHydrocarbon purification/separationButadiene DioxideUnsaturated hydrocarbon

The invention relates to a selective hydrogenation method of high unsaturated hydrocarbons in C4 fractions, which is characterized in that salvage stores which are rich in acetylene hydrocarbon and prepared by extracting butadiene are used as the material, and a fixed bed reactor is adopted to obtain 1, 3-budiene by selective hydrogenation under the existence of a catalyst. The adopted process conditions are as follows: the reaction temperature is between 30 DEG C and 90 DEG C, the reaction pressure is between 1.0 MPa and 4.0 MPa and the liquid space velocity is 7 to 20h<-1>. The catalyst is preferably a palladium system catalyst with alumina as a carrier, the specific surface is 50 to 150m<2> / g and the specific pore volume is 0.25 to 1.0ml / g. The method has remarkable good effects on reducing waste of resources and improving economic benefits by effectively utilizing the salvage stores rich in acetylene hydrocarbon and prepared by extracting butadiene.

Owner:PETROCHINA CO LTD

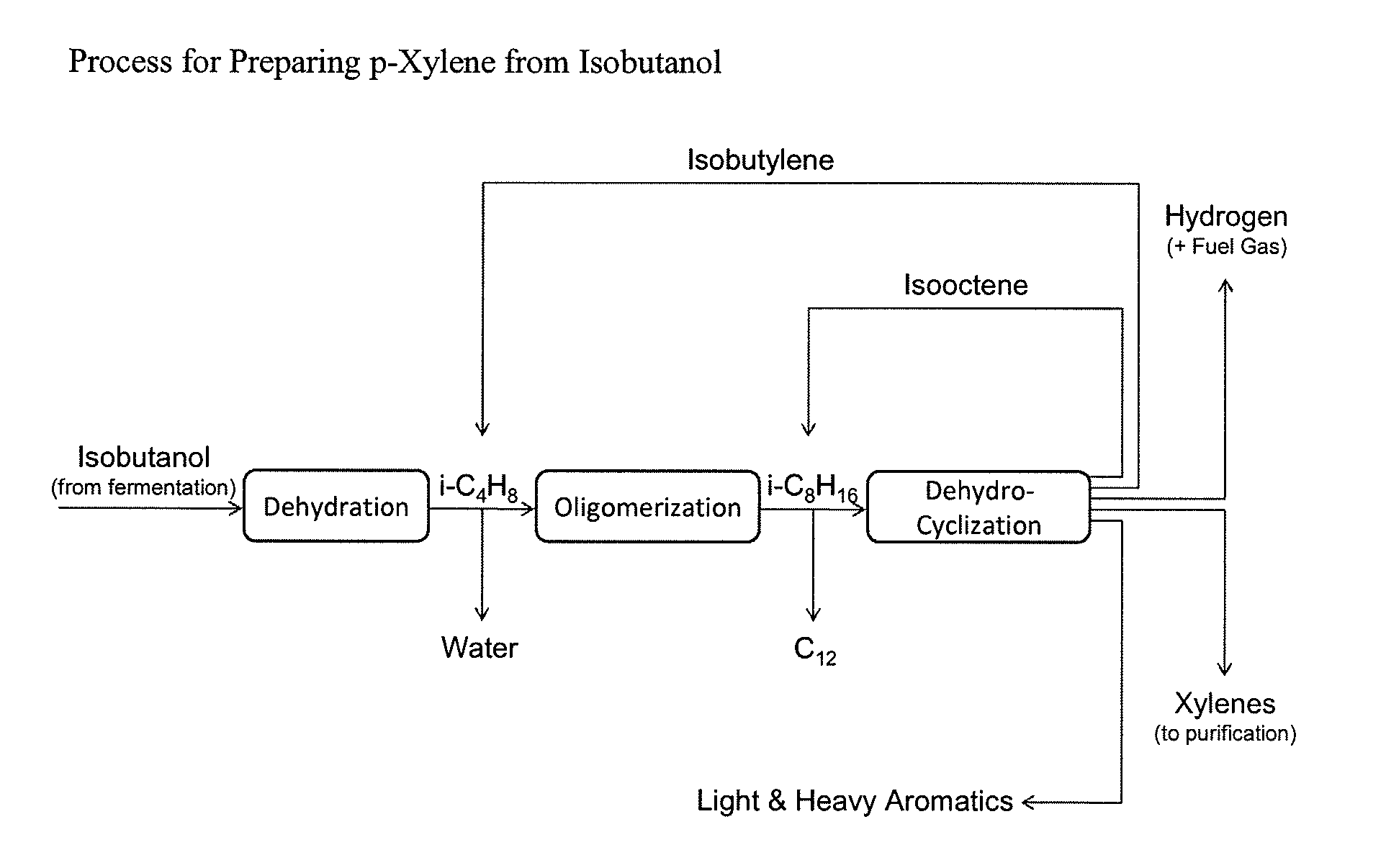

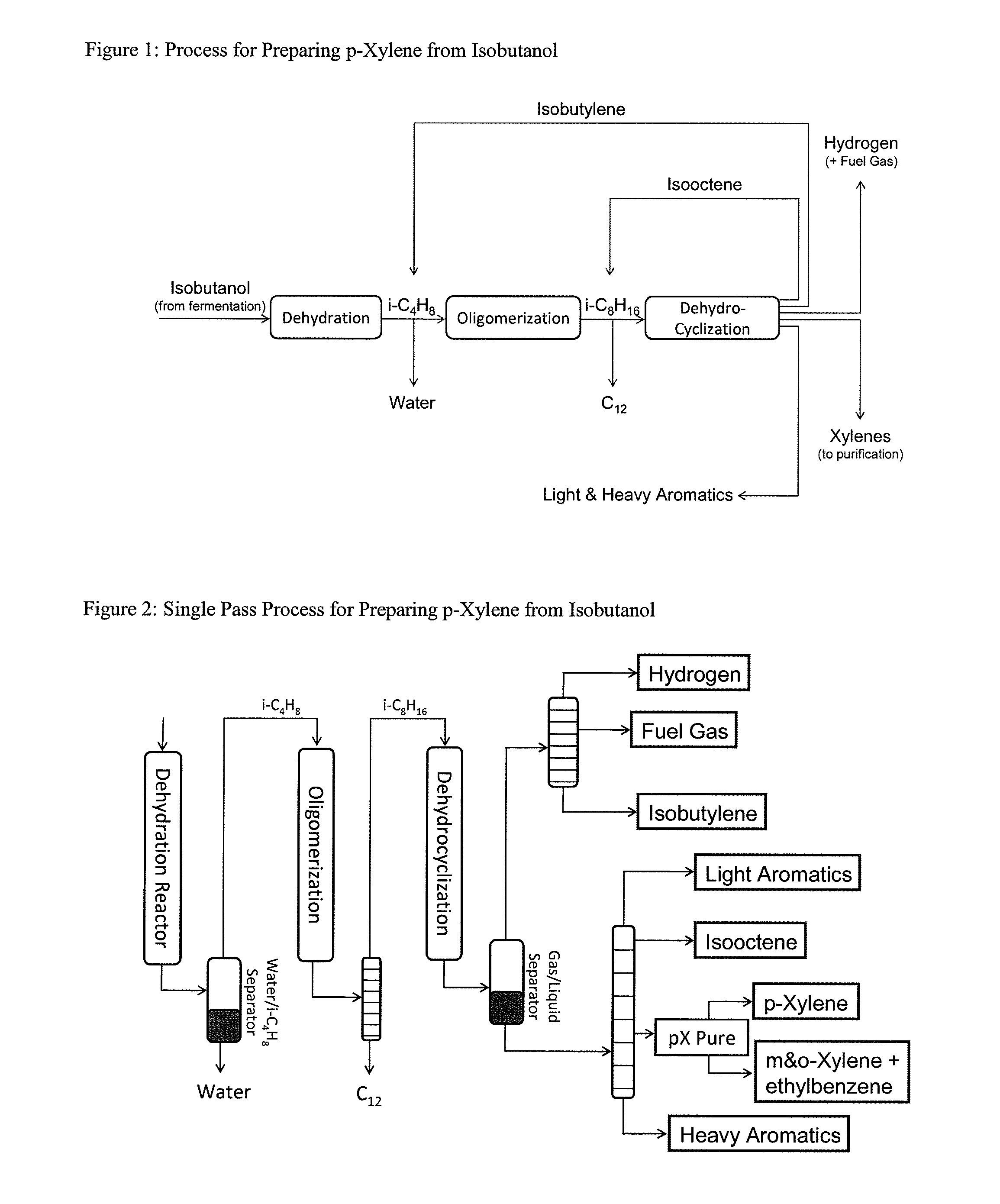

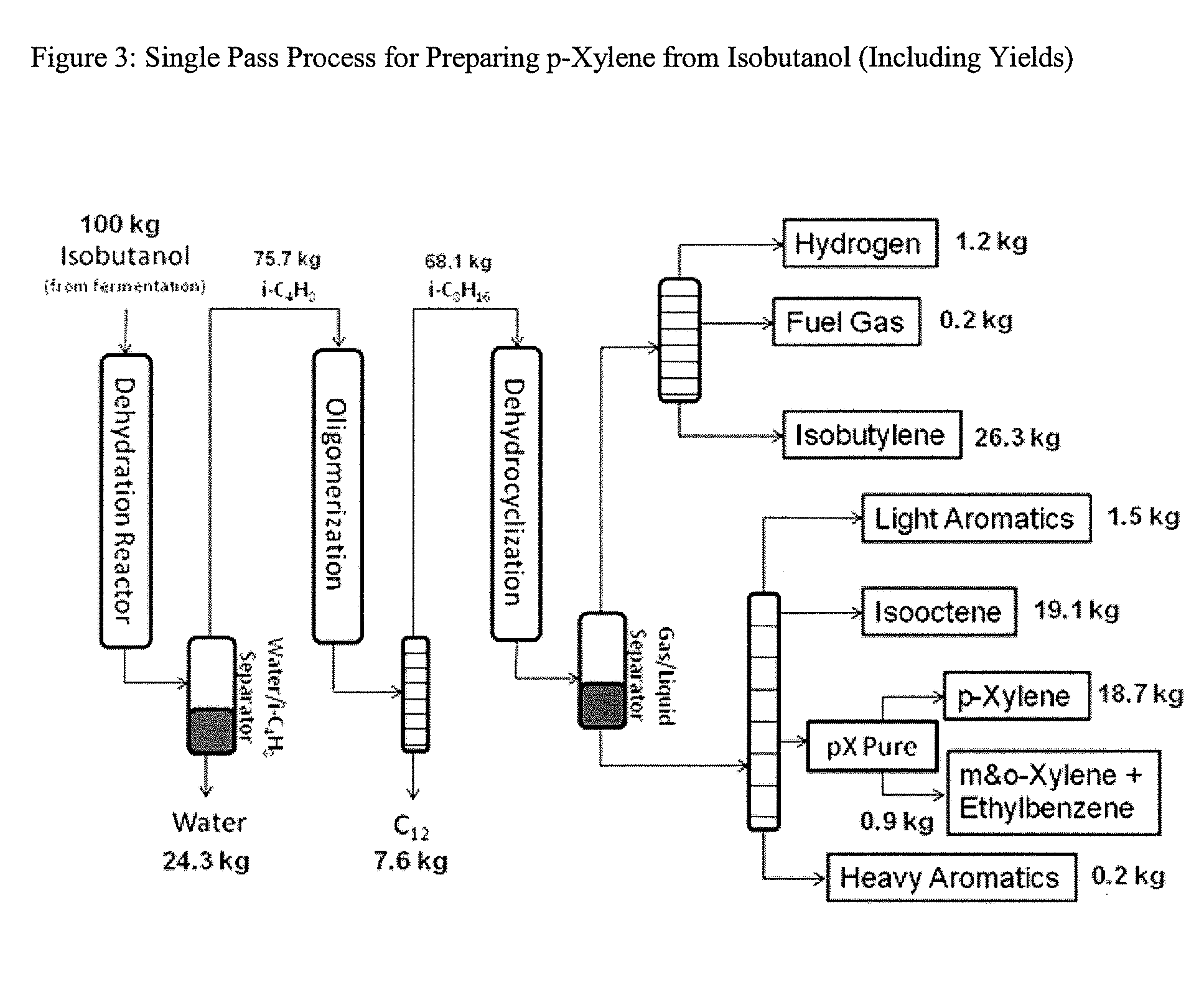

Integrated Process to Selectively Convert Renewable Isobutanol to P-Xylene

The present invention is directed to a method for preparing renewable and relatively high purity p-xylene from biomass. For example, biomass treated to provide a fermentation feedstock is fermented with a microorganism capable of producing a C4 alcohol such as isobutanol, then sequentially dehydrating the isobutanol in the presence of a dehydration catalyst to provide a C4 alkene such as isobutylene, dimerizing the C4 alkene to a form one or more C8 alkenes such as 2,4,4-trimethylpentenes or 2,5-dimethylhexene, then dehydrocyclizing the C8 alkenes in the presence of a dehydrocyclization catalyst to selectively form renewable p-xylene in high overall yield. The p-xylene can then be oxidized to form terephthalic acid or terephthalate esters.

Owner:GEVO INC

Solid-acid isomerization catalyst and process

ActiveUS7041866B1Improve performanceImprove stabilityHydrocarbon by isomerisationCatalytic crackingAlkaneSulfation

A catalyst and process is disclosed to selectively upgrade a paraffinic feedstock to obtain an isoparaffin-rich product for blending into gasoline. The catalyst comprises a support of a sulfated oxide or hydroxide of a Group IVB (IUPAC 4) metal, a first component comprising at least one Group III A (IUPAC 13) component, and at least one platinum-group metal component which is preferably platinum.

Owner:UOP LLC

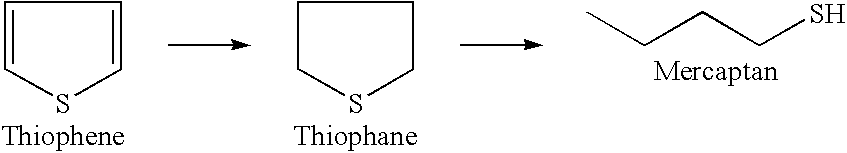

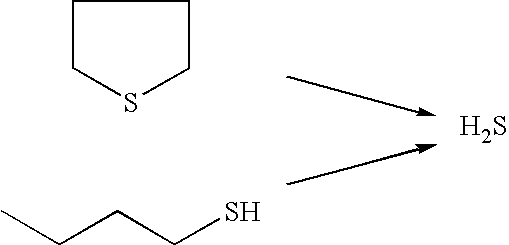

Process for the production of gasolines with low sulfur contents

InactiveUS6692635B2Increase chanceMinimizing the octane lossHydrocarbon by hydrogenationHydrocarbon purification/separationDecompositionGasoline

Process for the production of gasoline with a low sulfur content that comprises at least the following two stages:a) a hydrogenation stage of the unsaturated sulfur containing compounds,b) a decomposition stage of saturated sulfur containing compounds,and optionally a preliminary stage for pretreatment of the feedstock such as selective hydrogenation of dienes.

Owner:INST FR DU PETROLE

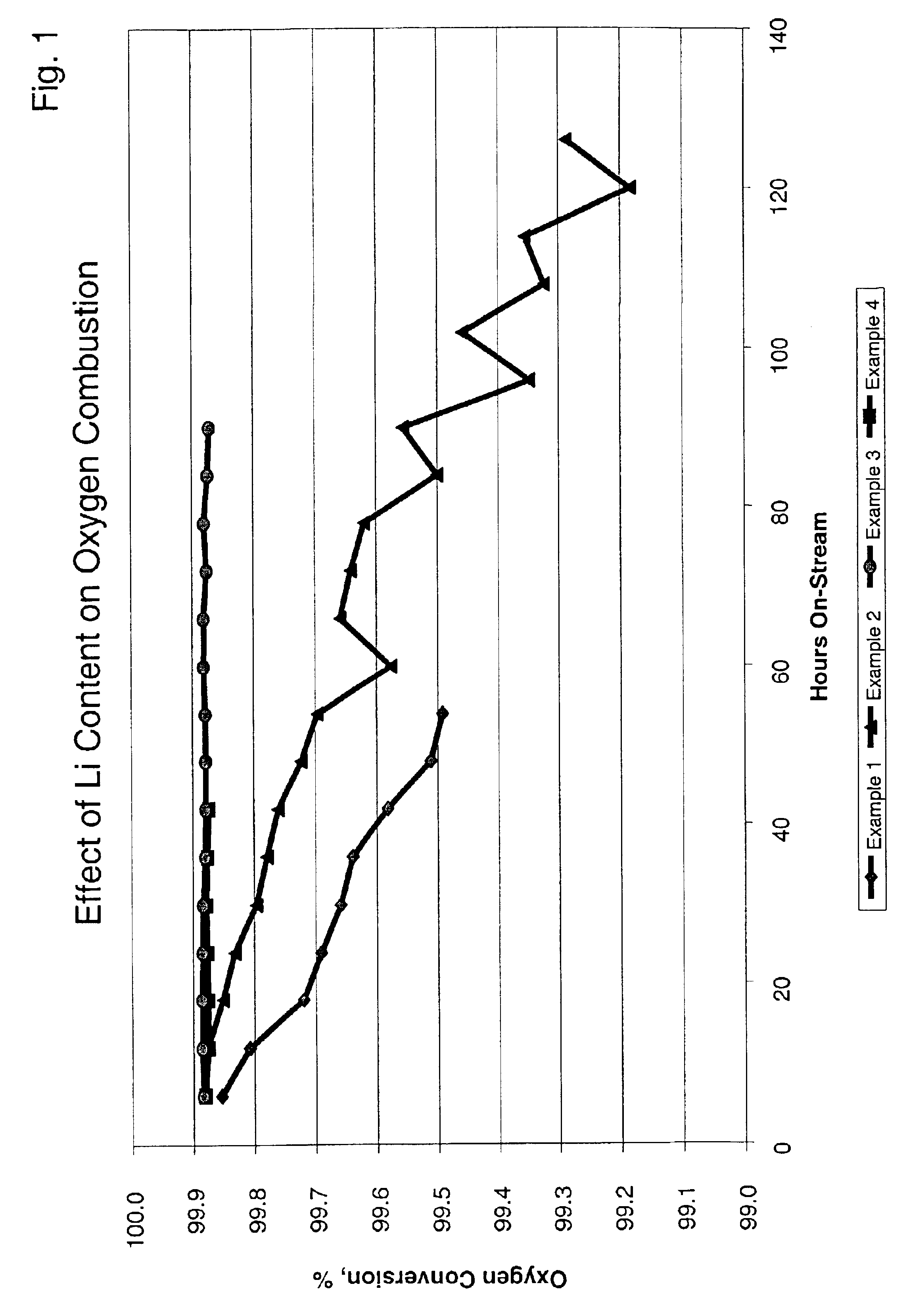

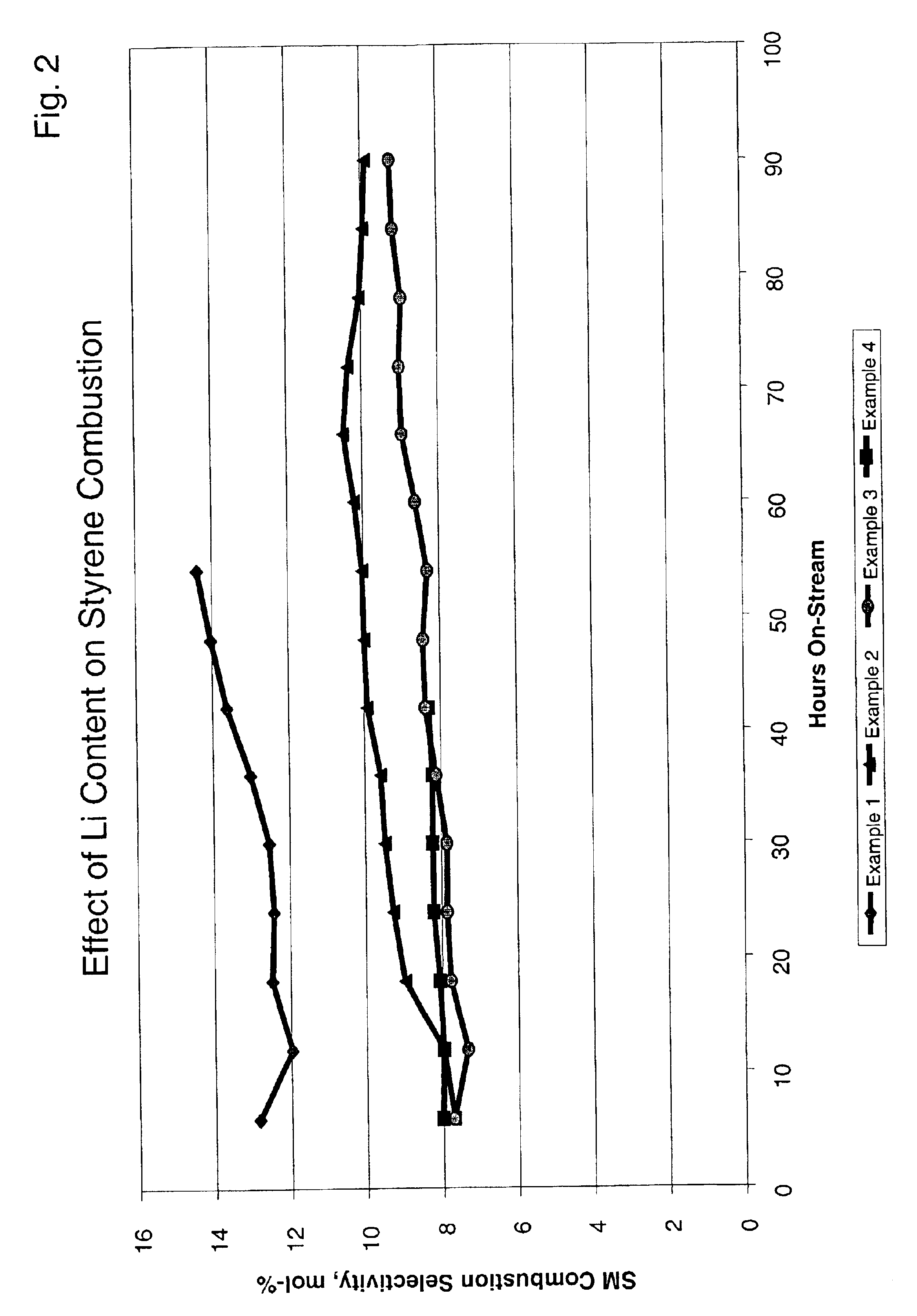

Lithium aluminate layered catalyst and a selective oxidation process using the catalyst

InactiveUS6858769B2Thermal non-catalytic crackingHydrocarbon by isomerisationHydrogenDehydrogenation

A catalyst for the selective oxidation of hydrogen has been developed. It comprises an inert core such as cordierite and an outer layer comprising a lithium aluminate support. The support has dispersed thereon a platinum group metal and a promoter metal, e.g. platinum and tin respectively. This catalyst is particularly effective in the selective oxidation of hydrogen in a dehydrogenation process.

Owner:UOP LLC

Popular searches

Catalysts Hydrocarbon from oxygen organic compounds Hydrocarbons Hydrocarbon by hydrocarbon and non-hydrocarbon condensation Hydrocarbon by addition and hydrogenation Base-materials Petroleum wax recovery Petroleum chemical modification Hydrocarbon oils treatment products Oxygen compounds preparation by reduction

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com