Patents

Literature

115results about How to "Reduce benzene content" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

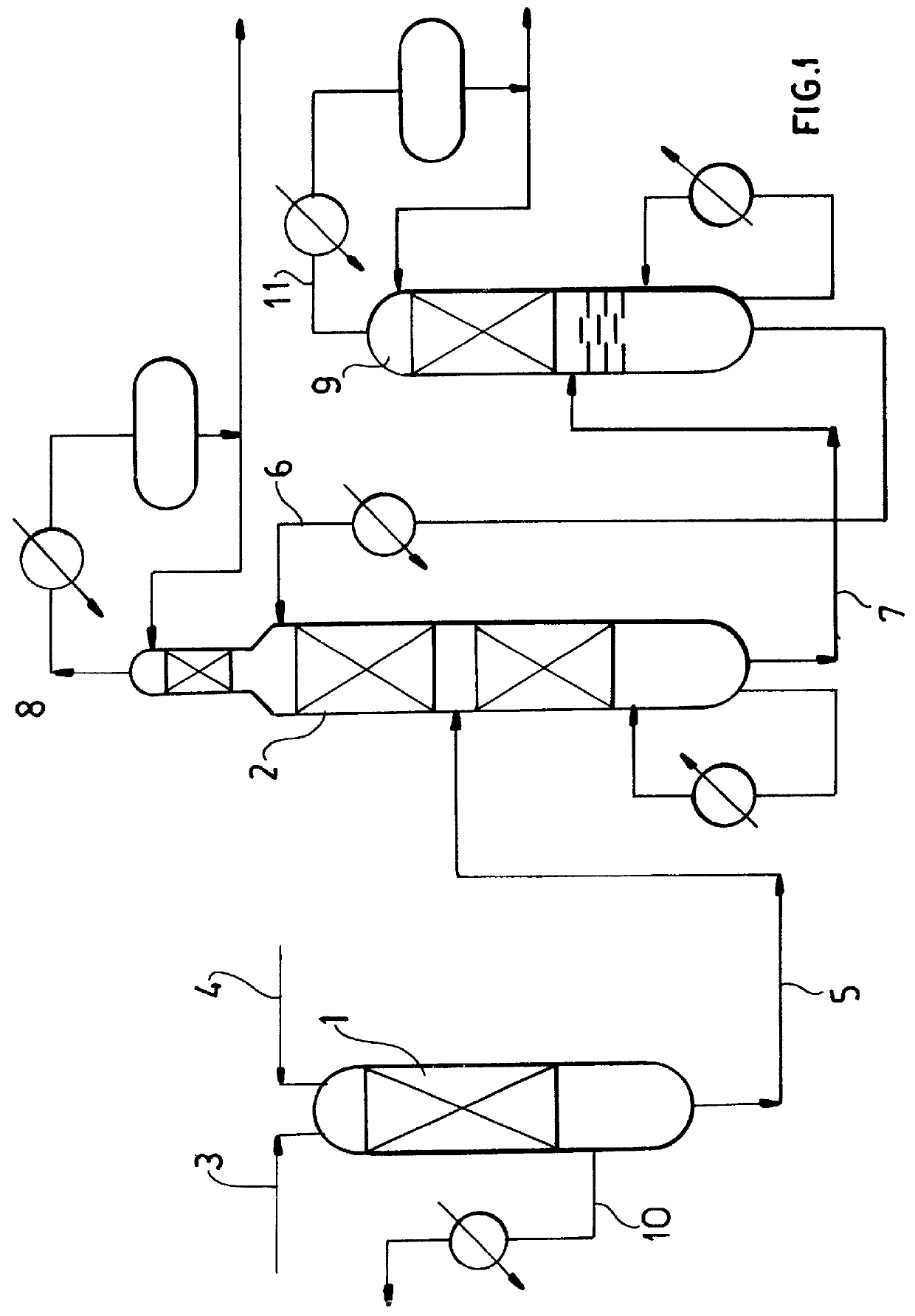

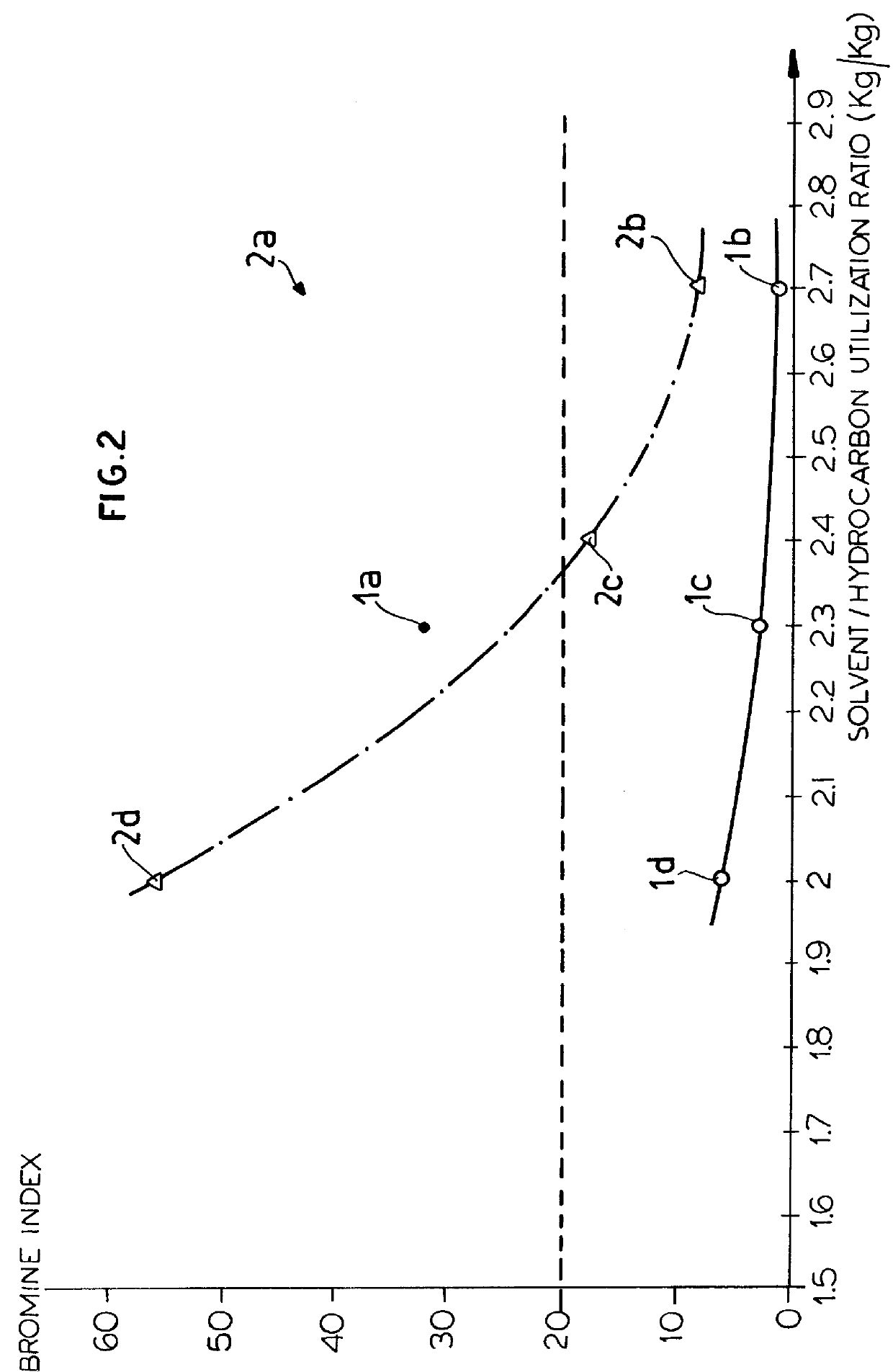

Process for generating pure benzene from reformed gasoline

InactiveUS6124514AReduce benzene contentAchieve separationThermal non-catalytic crackingCatalytic crackingBenzeneExtractive distillation

A process is disclosed for generating pure aromatic compounds from a reformed gasoline which contains aromatic compounds, olefins, diolefin, and triolefins, which comprises the steps of: (a) selectively hydrogenating the olefins, diolefins and triolefins in the reformed gasoline to obtain a mixture of hydrogenated, non-aromatic compounds and aromatic compounds; and (b) separating the aromatic compounds from the hydrogenated, non-aromatic compounds in the mixture formed during step (a) by either extractive distillation, liquid-liquid extraction or both to obtain the pure aromatic compounds.

Owner:BASF AG

Sorbent for reducing sulfur content of light hydrocarbon oil

ActiveCN101434854AHigh desulfurization activityEvenly distributedHydrocarbon oils refiningSorbentRare earth

The invention provides a sorbent used for reducing the content of sulfur in light hydrocarbon oil. According to weight percentage, the sorbent comprises 1-30 percent of phosphorus-modified rare earth faujasite, 5-40 percent of active metal oxide and 30-94% of carrier; wherein, the carrier comprises alumina and zinc oxide; the rare earth faujasite is modified by phosphorus and is pre-formed into porous heat-resistance solid grains together with carrier mixture; subsequently, the active metal oxide is led into the solid grains, thus preparing the sorbent; the light hydrocarbon oil raw material containing the sulfur and hydrogen donor enter a reactor filled with the sorbent; the materials are separated after reaction; the reaction products are sent to a subsequent separation system so that the product is separated; the sorbent to be regenerated after reaction is stripped, burned and regenerated; and the regenerated sorbent is reduced by the hydrogen donor and subsequently returns to the reactor so as to be circularly used. The sorbent realizes that the sulfur of light hydrocarbon oil is deeply removed, and simultaneously, the octane number of the outcome gasoline is higher, while thebenzene content is lower and the strength is higher.

Owner:CHINA PETROLEUM & CHEM CORP +1

Desulphurization sorbent

ActiveCN101433817AEvenly distributedHigh strengthOther chemical processesHydrocarbon oils refiningAdditive ingredientSorbent

The invention discloses a desulfurization adsorbent, which comprises 1 to 30 weight percent of rare earth-zeolite mixture, 5 to 40 weight percent of active metal oxide and 30 to 94 weight percent of carrier, wherein the carrier comprises alumina and zinc oxide; the rare earth-zeolite mixture and a carrier mixture are preformed into porous heat-resistant solid particles, and then active metal ingredients are introduced on the solid particles to obtain the adsorbent; and a light hydrocarbon oil raw material containing sulfur and a hydrogen donor enter a reactor filled with the adsorbent, materials remained after the reaction are separated, a reaction product is sent into a subsequent separation system for product separation, a spent adsorbent after the reaction is steam-stripped and then is subject to coke-burning regeneration, and the regenerated adsorbent is reduced by the hydrogen donor and is returned to the reactor for cyclic use. The adsorbent realizes the deep removal of sulfide in light hydrocarbon oil, and the produced gasoline has higher octane number, lower benzene content, and higher strength at the same time.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for reducing sulfide in light hydrocarbon oil

The invention provides a method used for reducing the content of sulfide in light hydrocarbon oil, which comprises the steps as follows: after being preheated, a hydrocarbon oil raw material containing sulfur, and hydrogen donor enter a reactor filled with a sorbent and a zeolite additive so as to react under the conditions as follows: temperature of 300-500 DEG C, pressure of 0.5-3.5MPa, weight hourly space velocity of raw material oil at 0.5-10h<-1> and weight ratio between total amounts of the sorbent and the hydrocarbon oil raw material at 1-20; the materials are separated after reaction; the reaction products are sent to a subsequent separation system so that the product is separated; the sorbent to be regenerated and the zeolite additive to be regenerated after reaction are stripped, burned and regenerated; and the regenerated sorbent and the zeolite additive are reduced by the hydrogen donor and subsequently returned to the reactor so as to be circularly used. The method adds the zeolite additive during the adsorption desulfurization process, realizes deep desulfurization, leads the removal rate of the sulfur to achieve more than 96wt percent when disposing the gasoline, reduces the olefin of the gasoline, improves the octane number of the outcome gasoline simultaneously, keeps high liquid recovery and has low benzene content in the outcome gasoline.

Owner:CHINA PETROLEUM & CHEM CORP +1

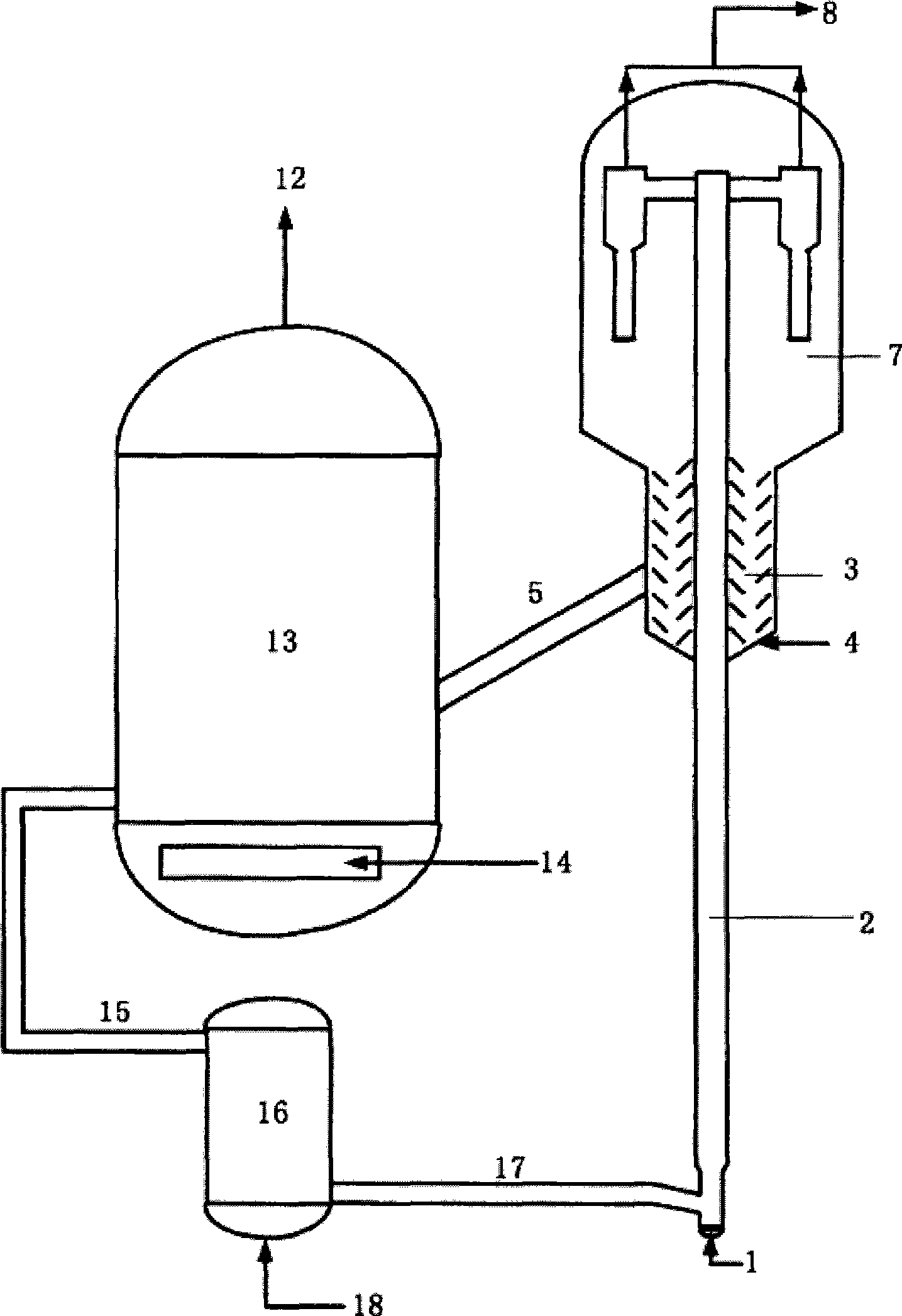

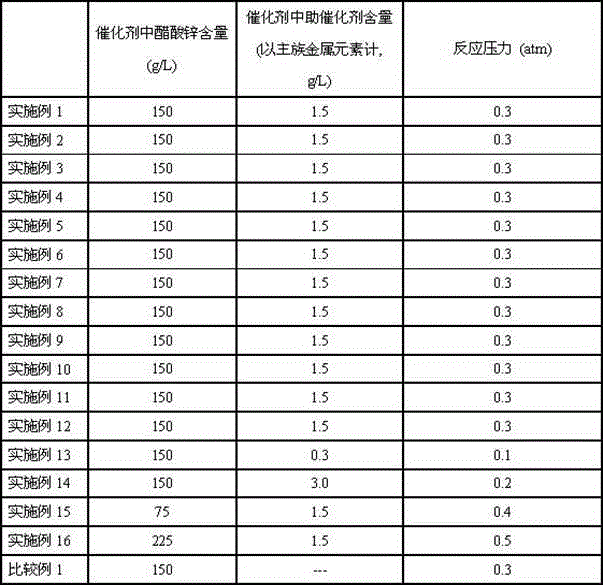

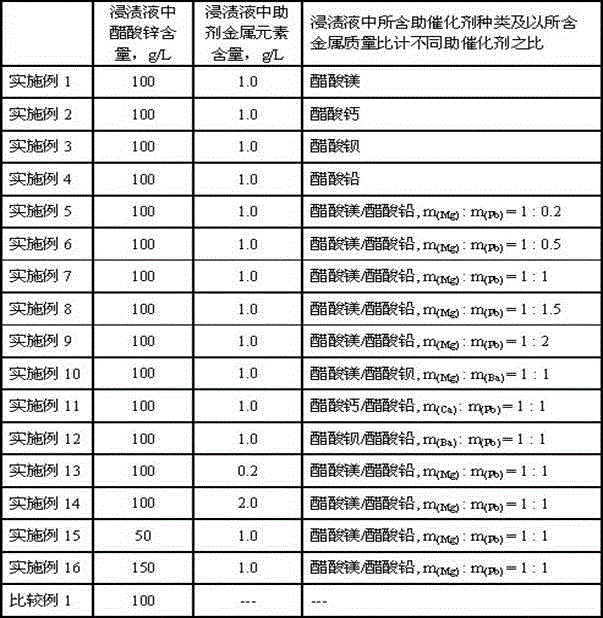

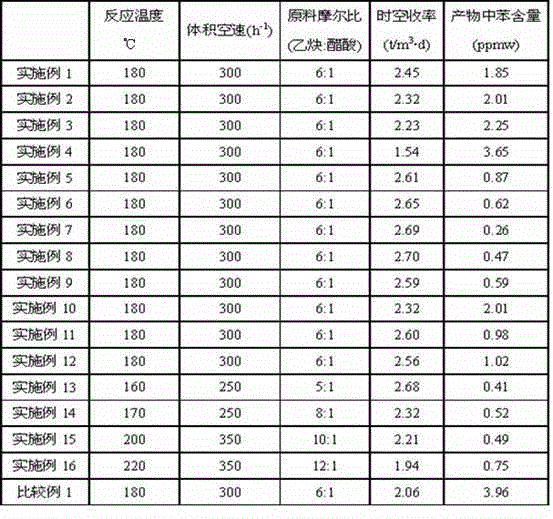

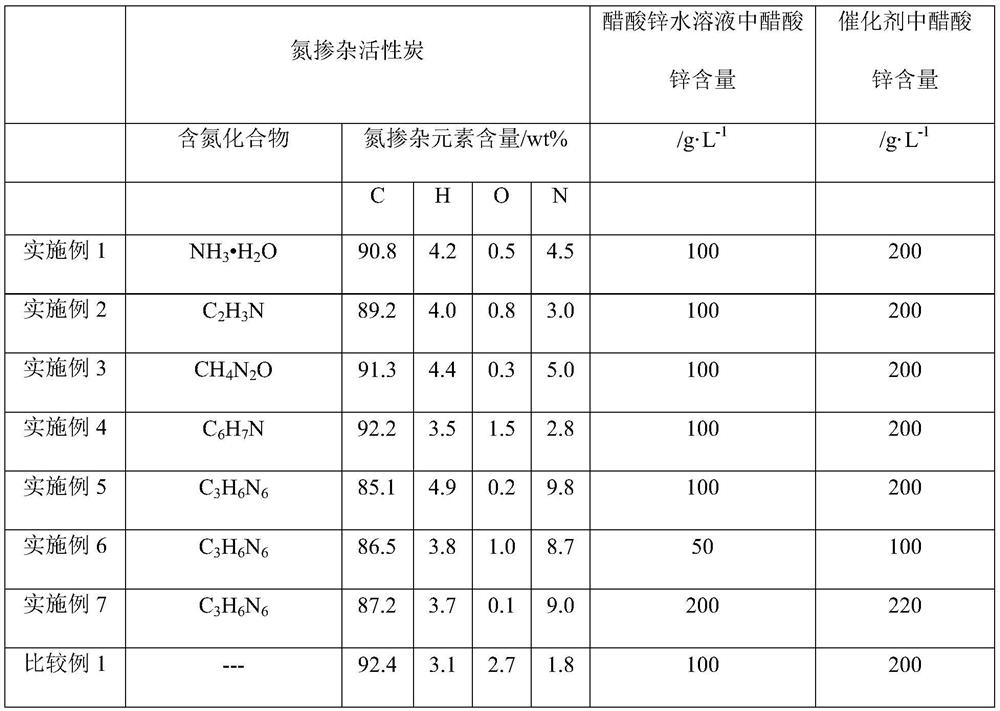

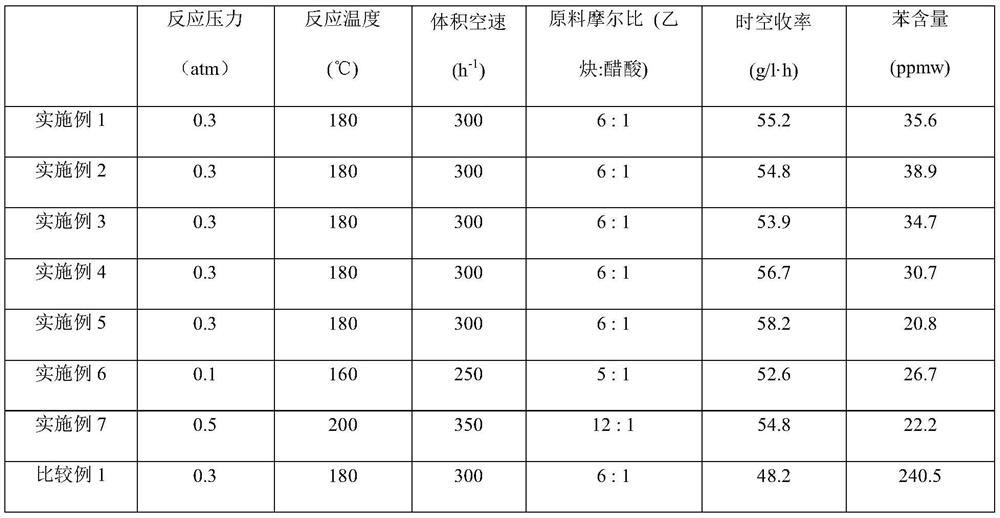

Catalyst for vinyl acetate synthesis by acetylene method and preparation method thereof

ActiveCN104549497AHigh selectivityReduce benzene contentOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsBenzeneActivated carbon

The invention relates to a catalyst for vinyl acetate synthesis by an acetylene method and a preparation method thereof as well as a synthesis method of vinyl acetate, and aims at mainly solving the problem in the prior art that the content of byproduct benzene in a vinyl acetate product is high. The problem is well solved by adopting the technical scheme that the catalyst comprises a carrier, an active component and a cocatalyst, wherein the carrier is active carbon, the active component is zinc acetate, and the content of zinc acetate in the catalyst is 80g / L-240g / L. The catalyst is characterized in that the cocatalyst of the catalyst is acetate of main group metal elements in the periodic table of elements, wherein the main group metal elements are selected from at least one of IIA group metal elements or IVA group metal elements. The catalyst can be used for industrial production of the synthesis of vinyl acetate by the acetylene method.

Owner:CHINA PETROLEUM & CHEM CORP +1

Desulphurization sorbent composition

ActiveCN101433819AHigh desulfurization activityEvenly distributedOther chemical processesHydrocarbon oils refiningSorbentRare earth

The invention discloses a desulfurization adsorbent composition, which comprises 1 to 30 weight percent of phosphorus-modified rare earth-zeolite mixture, 5 to 40 weight percent of active metal oxide and 30 to 94 weight percent of carrier, wherein the carrier comprises alumina and zinc oxide; a rare earth-zeolite mixture is modified by phosphorus and then is preformed with a carrier mixture into porous heat-resistant solid particles, and then active metal components are introduced on the solid particles to obtain an adsorbent; and a light hydrocarbon oil raw material containing sulfur and a hydrogen donor enter a reactor filled with the adsorbent, materials remained after the reaction are separated, a reaction product is sent into a subsequent separation system for product separation, a spent adsorbent after the reaction is steam-stripped and then is subject to coke-burning regeneration, and the regenerated adsorbent is reduced by the hydrogen donor and is returned to the reactor for cyclic use. The adsorbent realizes the deep removal of sulfide in light hydrocarbon oil, and the produced gasoline has higher octane number, lower benzene content, and higher strength at the same time.

Owner:CHINA PETROLEUM & CHEM CORP +1

Environment-friendly healthy matt floor paint

The invention relates to an environment-friendly healthy matt floor paint which is prepared by raw materials that are well-chosen in the world. The matt floor paint is formed by scientifically mixing A components including plant oil short-oil alkyd resin, solvent, dispersing agent, anti-settling agent, matting powder, glass powder, antifoaming agent, leveling agent and wetting agent, and B component comprising polyisocyanate curing agent. The environment-friendly healthy matt floor paint belongs to healthy type without pure benzene, and has the characteristics of high solid, low viscosity, good leveling property, strong adhesive attraction, high hardness, good hand feeling, impact resistance, wear-resisting property, waterproof property, various household cleaning agent resistance, etc. The environment-friendly healthy matt floor paint has high cost performance, is suitable for surface decoration of wood of indoor luxury wooden floor, stairs and the like, can be used for brush coatingand spraying construction, and has wide market prospect.

Owner:SKSHU PAINT

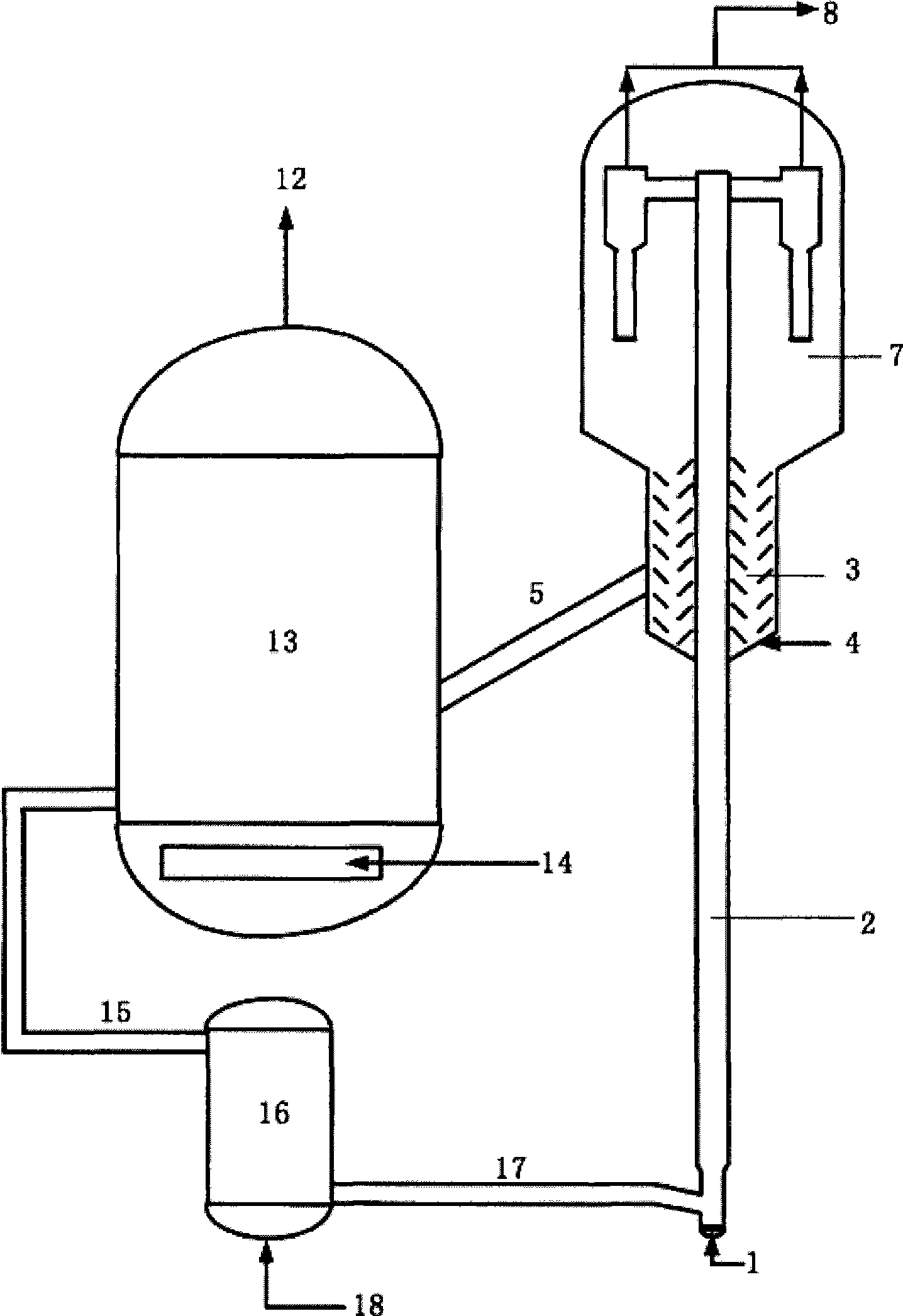

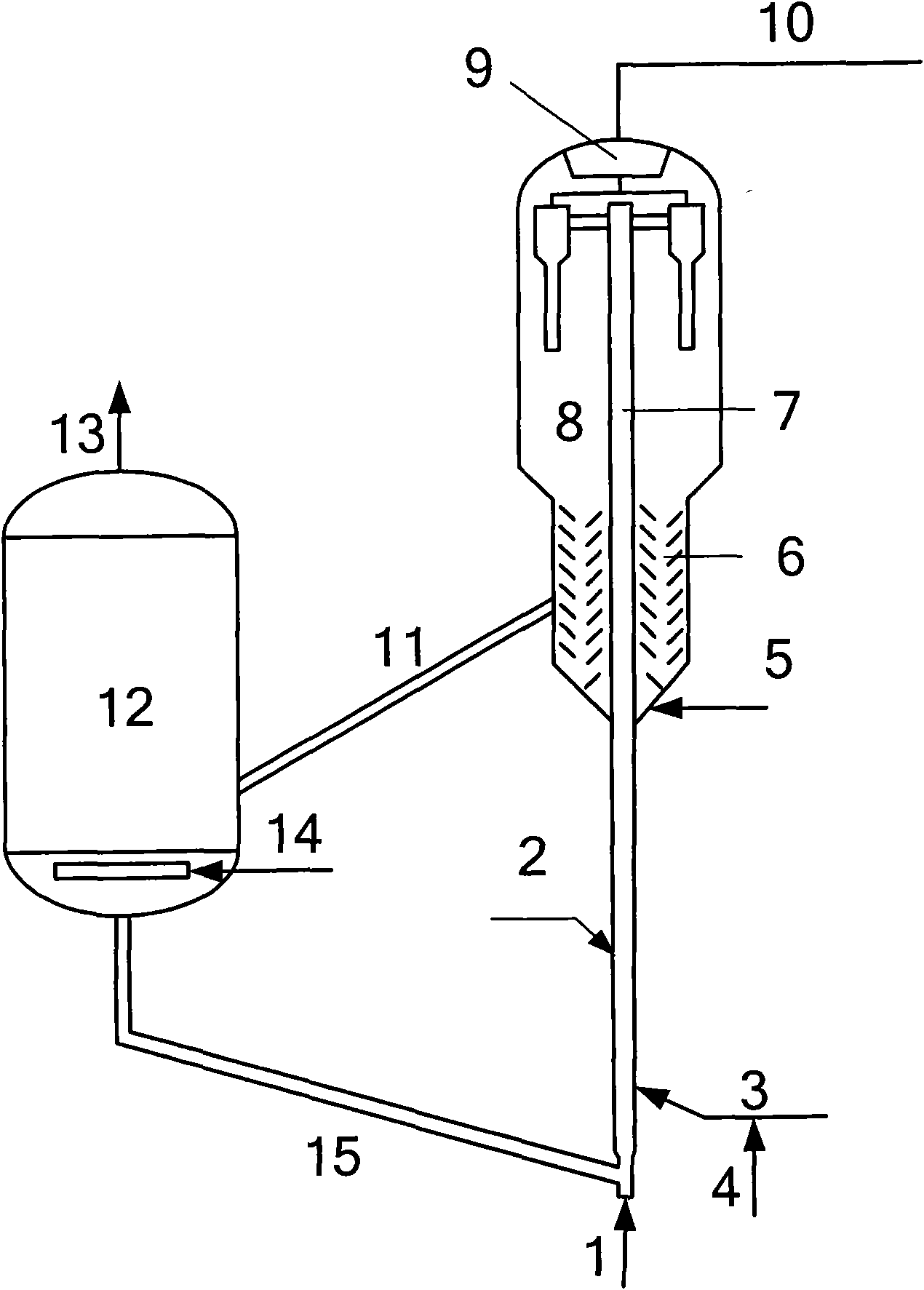

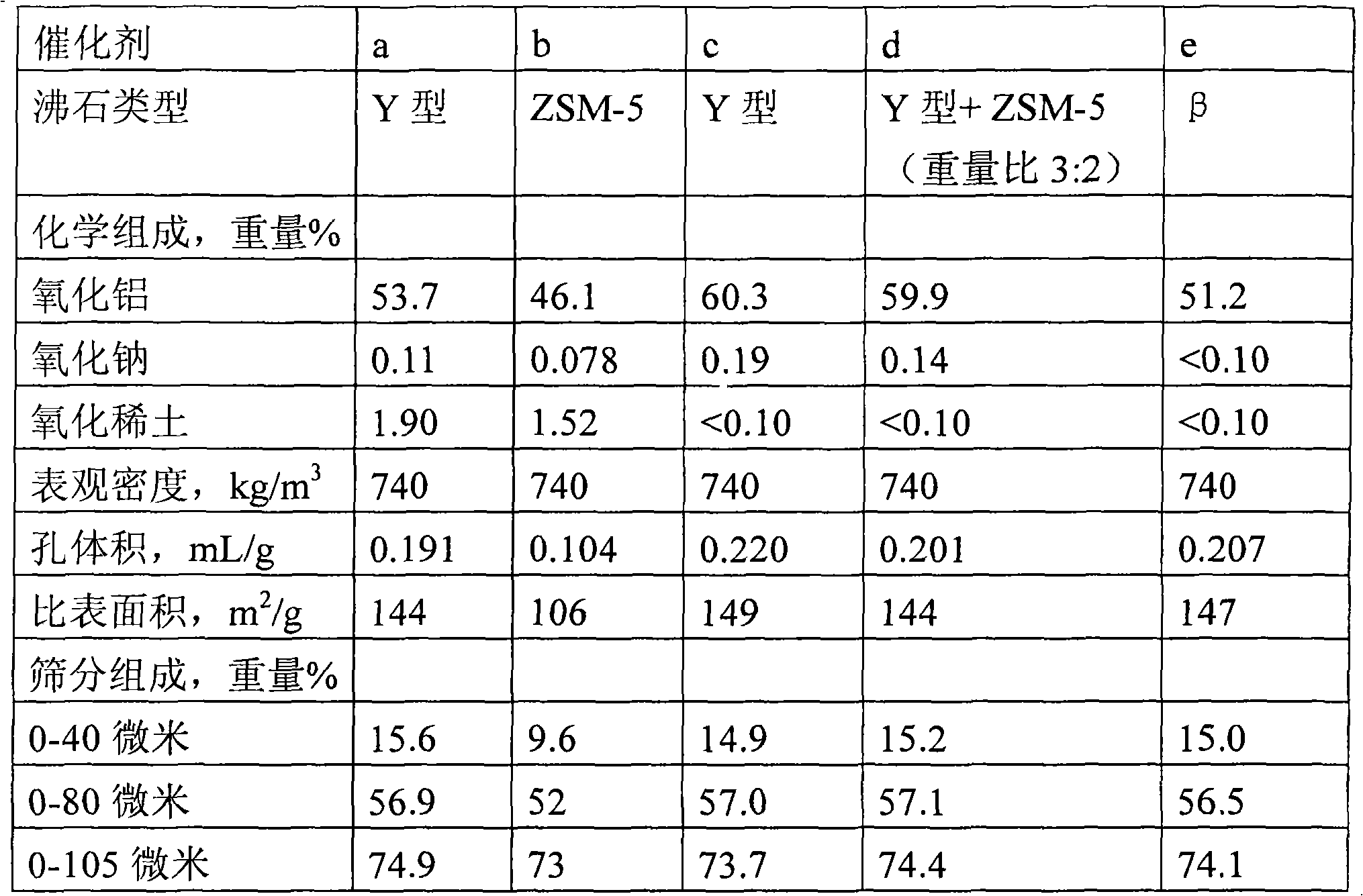

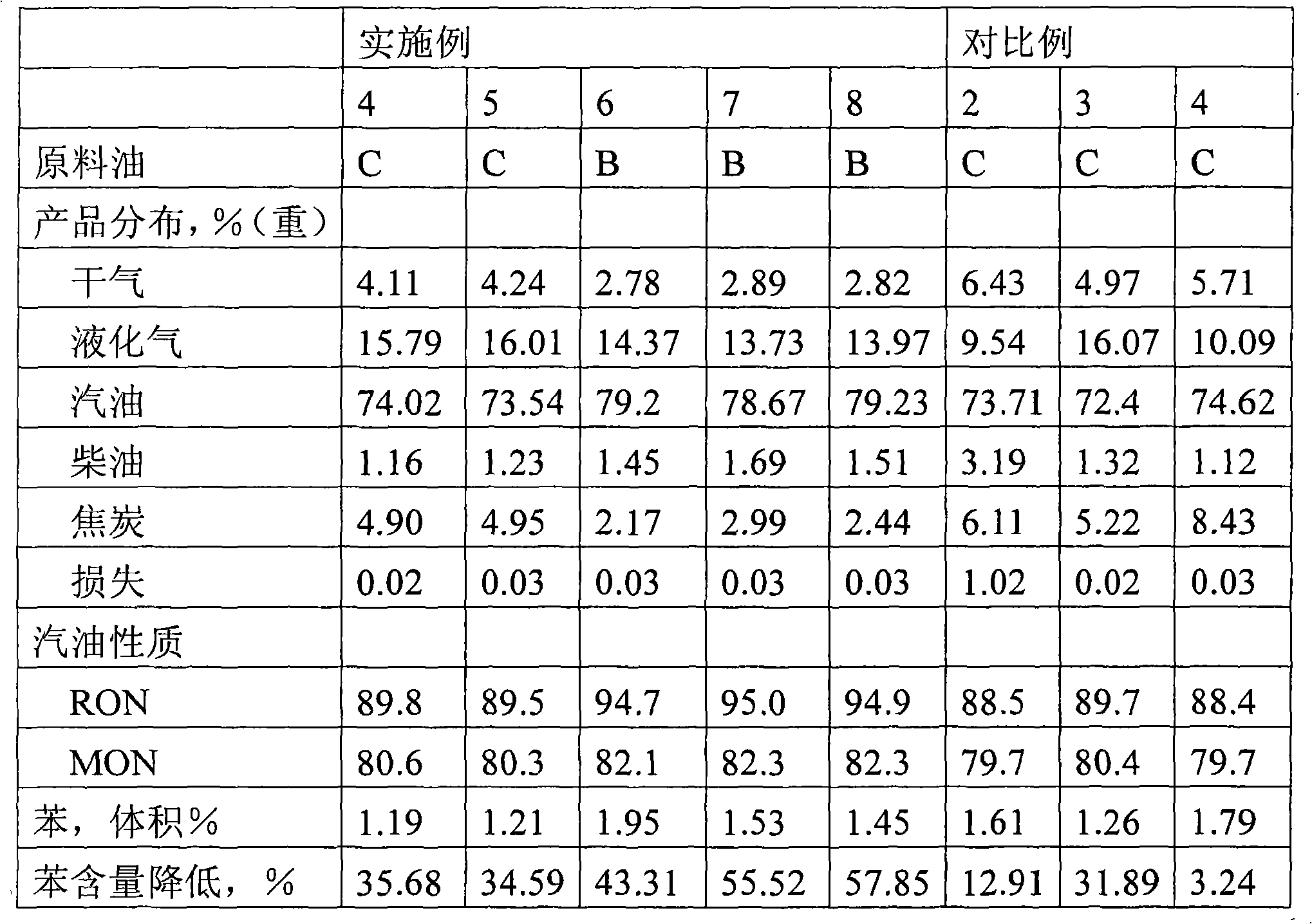

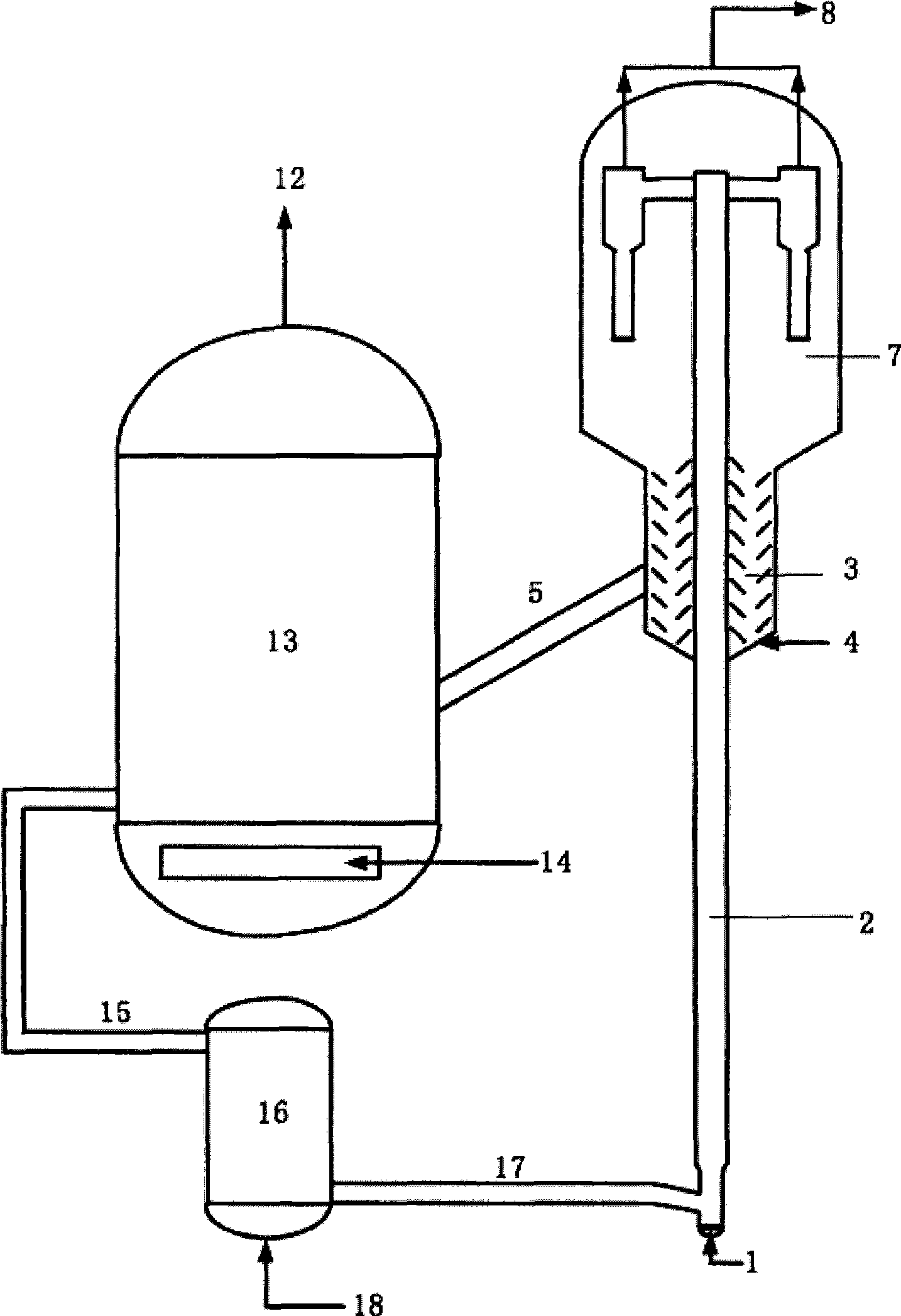

Catalytic conversion method for reducing benzene content in gasoline

ActiveCN102051199AReduce benzene contentQuality improvementCatalytic crackingLiquid hydrocarbon mixture productionBenzeneAlcohol

A catalytic conversion method for reducing benzene content in gasoline comprises steps as follows: in a fluidized bed and / or riser reactor, allowing benzene-containing gasoline to be contacted with catalytic cracking catalyst to separate out the gasoline with reduced benzene content, wherein the catalytic cracking catalyst contains zeolite and heat resistant inorganic oxide, and the zeolite is mesoporous and / or macroporous zeolite. When the benzene-containing gasoline is treated with the method provided by the invention, the benzene content in the gasoline can be reduced by more than 60% (v / v); since benzene reacts with alcohol to be converted to gasoline fraction, the gasoline yield is increased; and since benzene reacts with alcohol to be converted to aromatic hydrocarbon, the gasoline octane number is improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

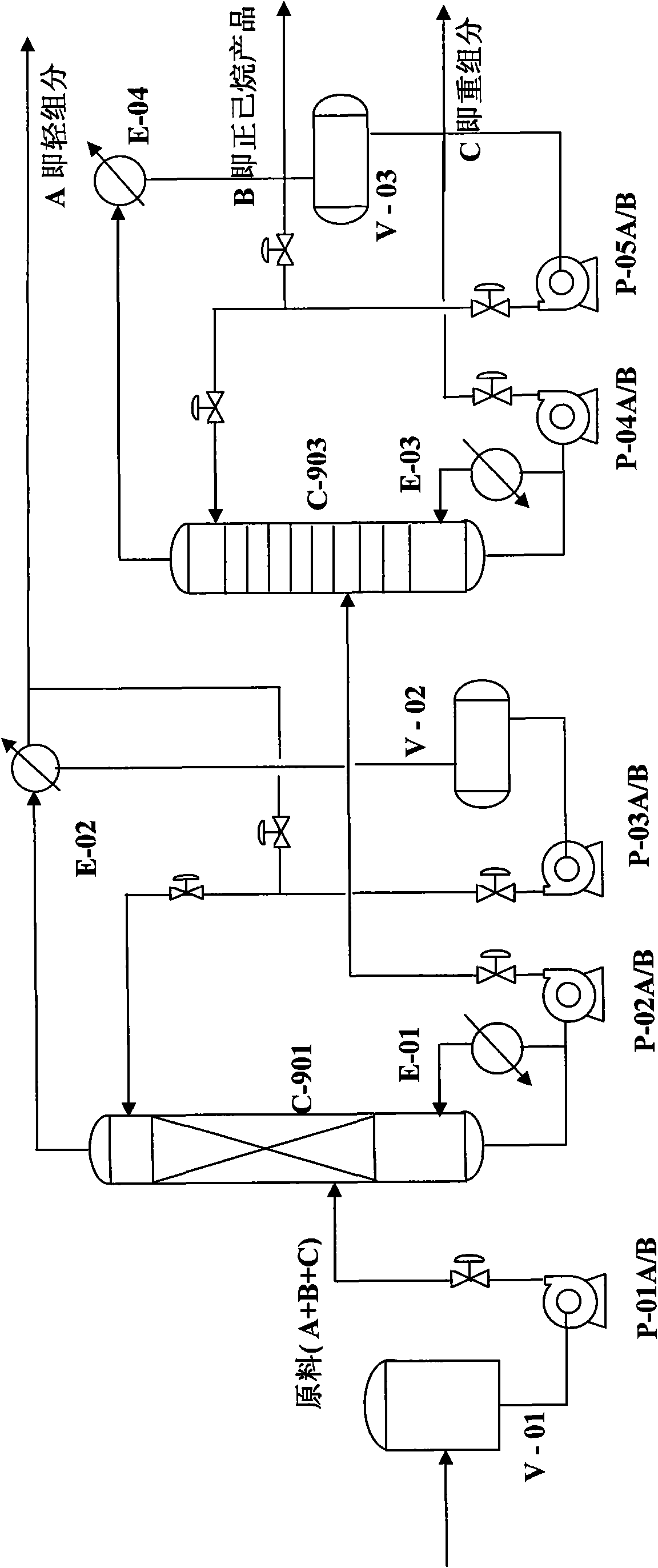

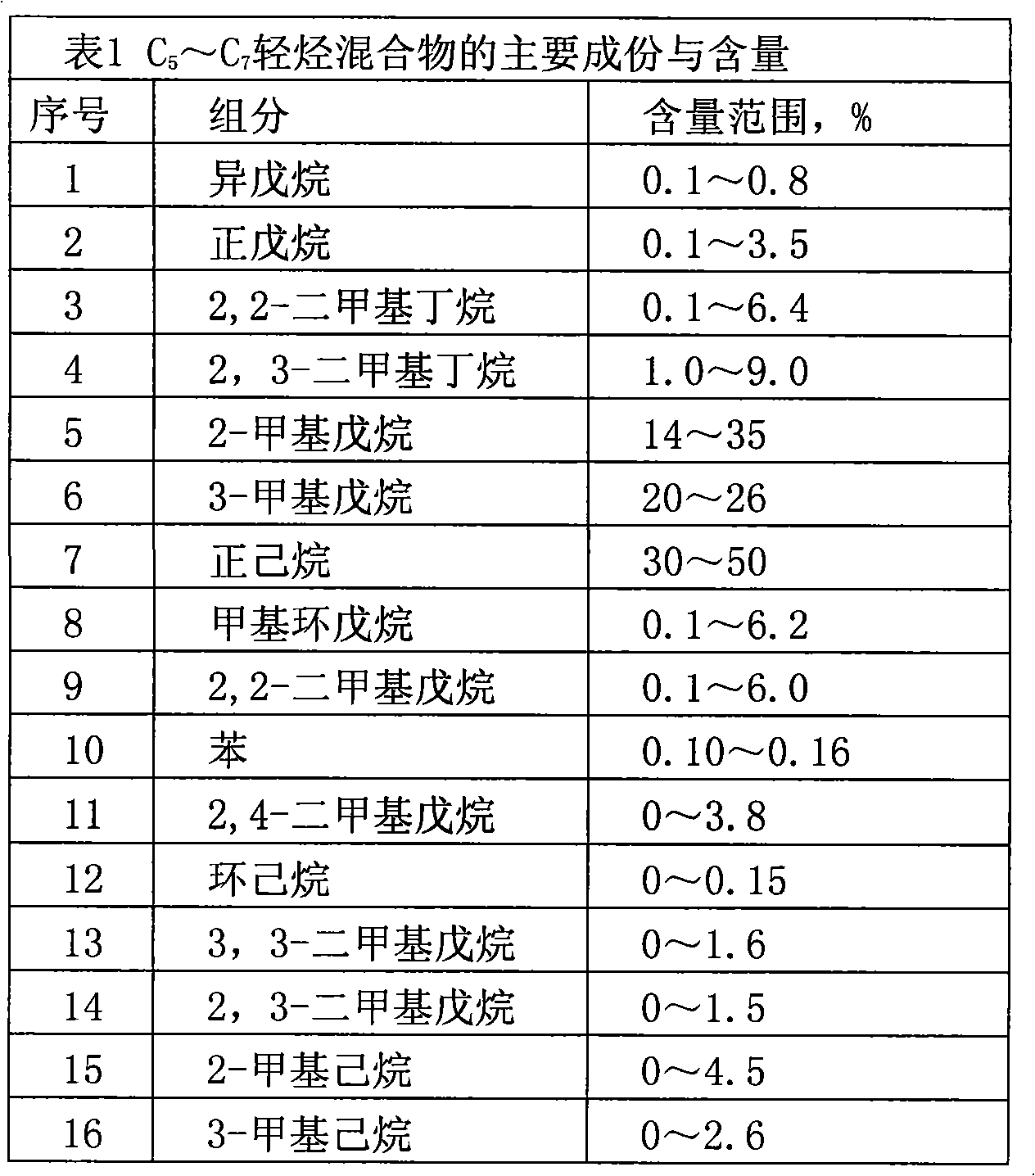

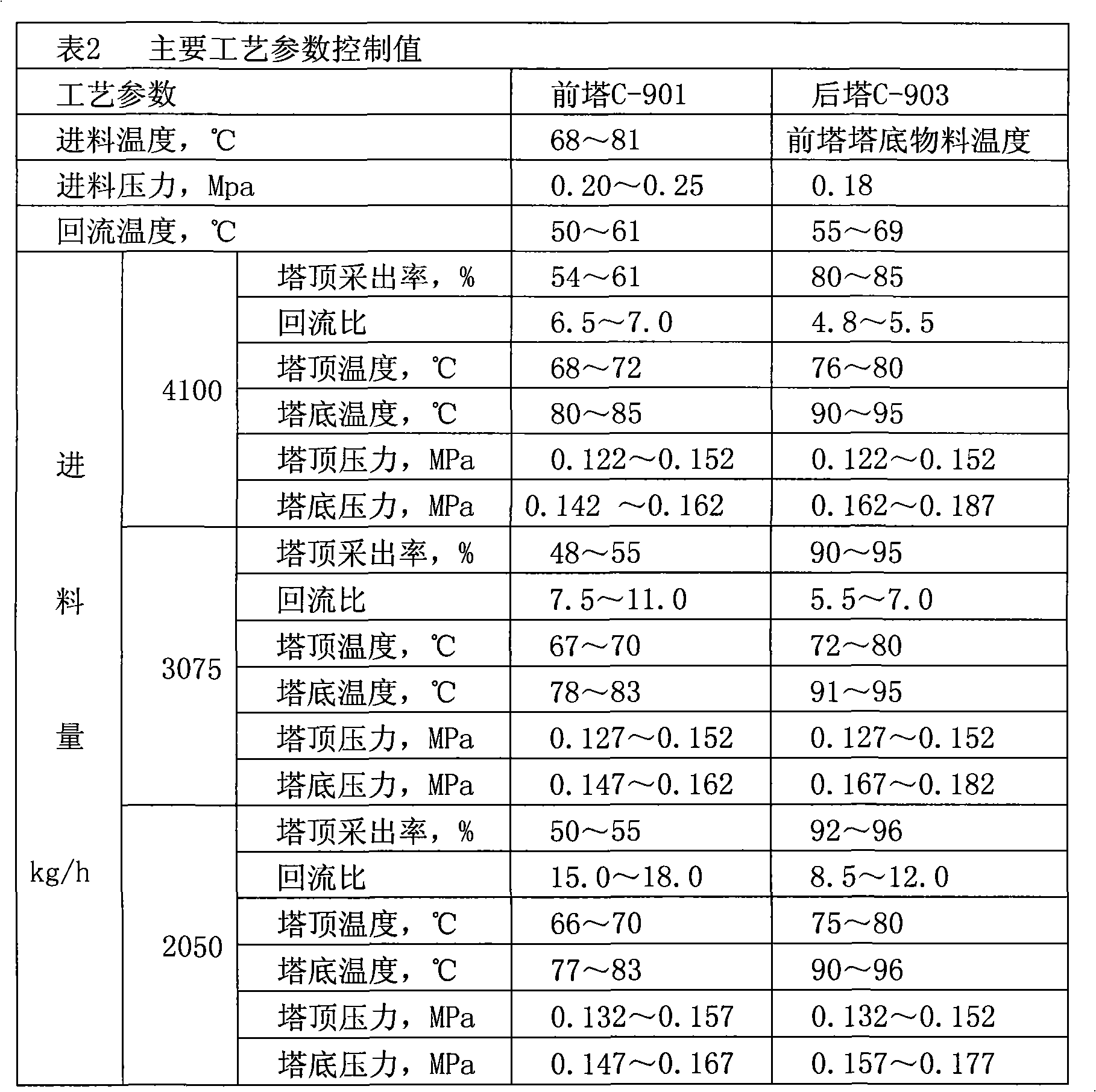

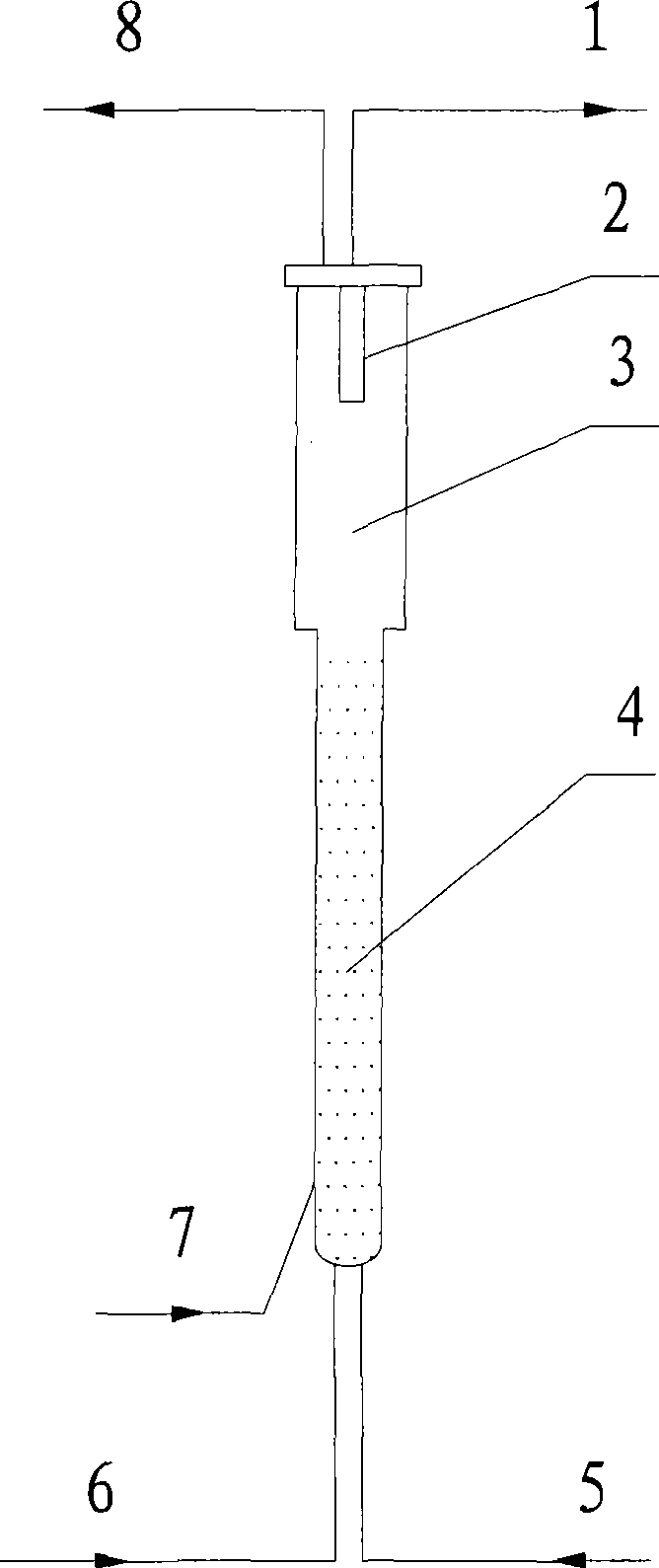

Method for separating narrow cut fraction industrial grade n-hexane from C5 to C7 light hydrocarbon mixture, as well as packed towel and float valve tower thereof

ActiveCN101830768ASolve the widthHigh yieldHydrocarbon distillationDistillation purification/separationBenzeneDistillation

The invention relates to a method for separating narrow cut fraction industrial grade n-hexane from a C5 to C7 light hydrocarbon mixture, as well as a packed tower and a float valve tower thereof. The method uses the C5 to C7 light hydrocarbon mixture as a raw material and adopts the simple rectification process of a two-tower separation sequence including the regular packed tower and the float valve tower, wherein the former tower is mainly used for stripping n-hexane, and the latter tower is mainly used for stripping benzene. The invention solves the three technical difficulties of narrowing the range of product fractions, reducing benzene content and increasing n-hexane yield during the production of industrial n-hexane, the content of product n-hexane is from 70 to 98 percent, the benzene content is not more than 0.1 percent, the distillation range is from 0.5 to 3 DEG C, and the yield is from 85 to 98 percent. The light components separated by the method are mixed with heavy components to obtain the product of solvent oil No.6, so that the resources of the original C5 to C7 light hydrocarbon mixture are thoroughly utilized, and thus, the economic benefits are increased.

Owner:KANGJIA INDAL RESPONSIBLE +1

Catalyst for acetylene-method vinyl acetate and synthesis method of vinyl acetate

ActiveCN104437626AHigh selectivityReduce benzene contentOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsBenzeneActivated carbon

The invention relates to a catalyst for acetylene-method vinyl acetate synthesis and a preparation method thereof. The catalyst is mainly used for solving the problem in the prior art that the content of a byproduct benzene in the vinyl acetate product is high. According to the catalyst for acetylene-method vinyl acetate synthesis, through adopting the technical scheme that the catalyst comprises an active ingredient which is zinc acetate, a cocatalyst which is potassium acetate and a carrier which is fullerene modified activated carbon, the problem is better solved; and the catalyst can be applied to the industrial production of acetylene-method vinyl acetate.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for modifying gasoline

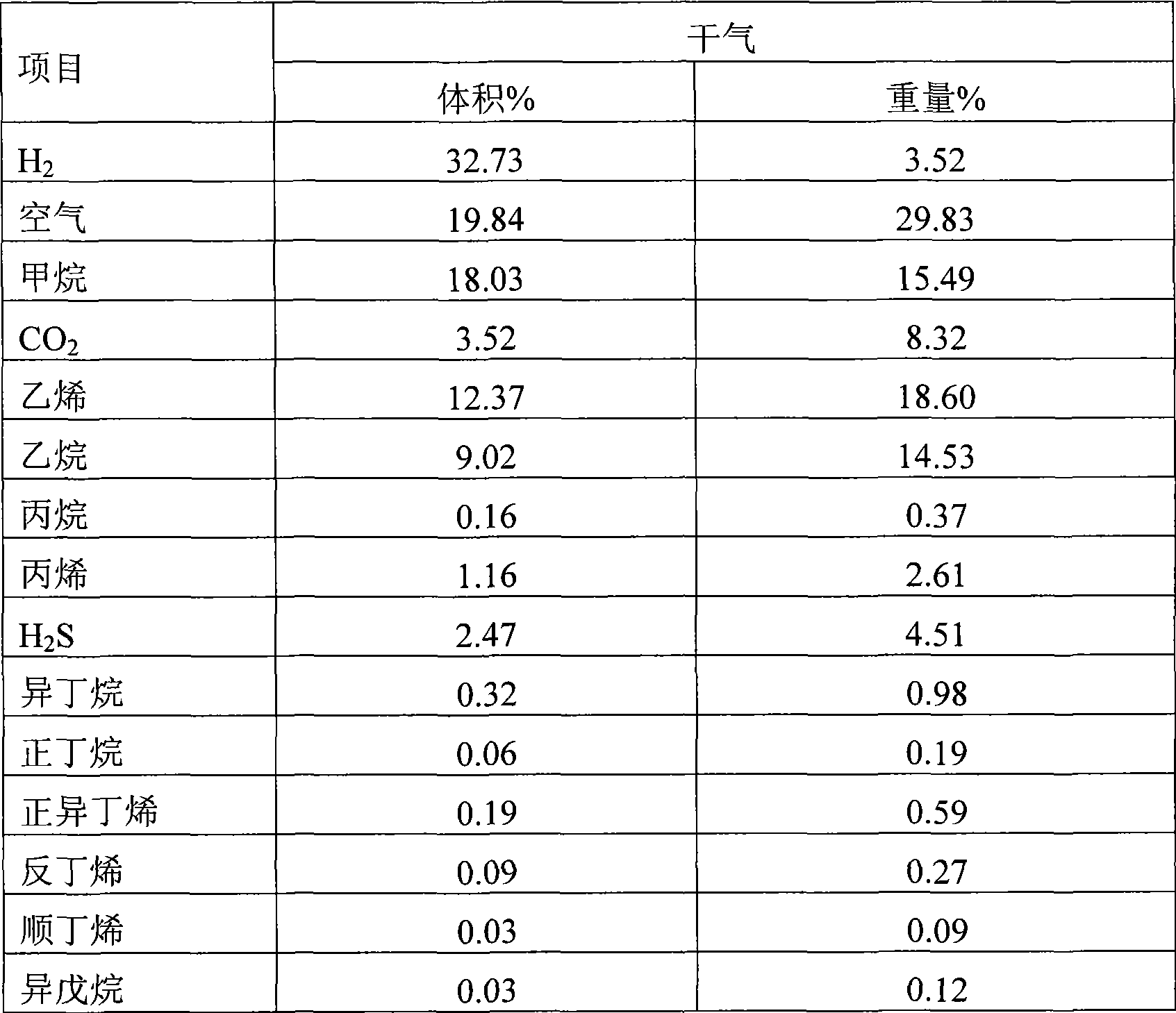

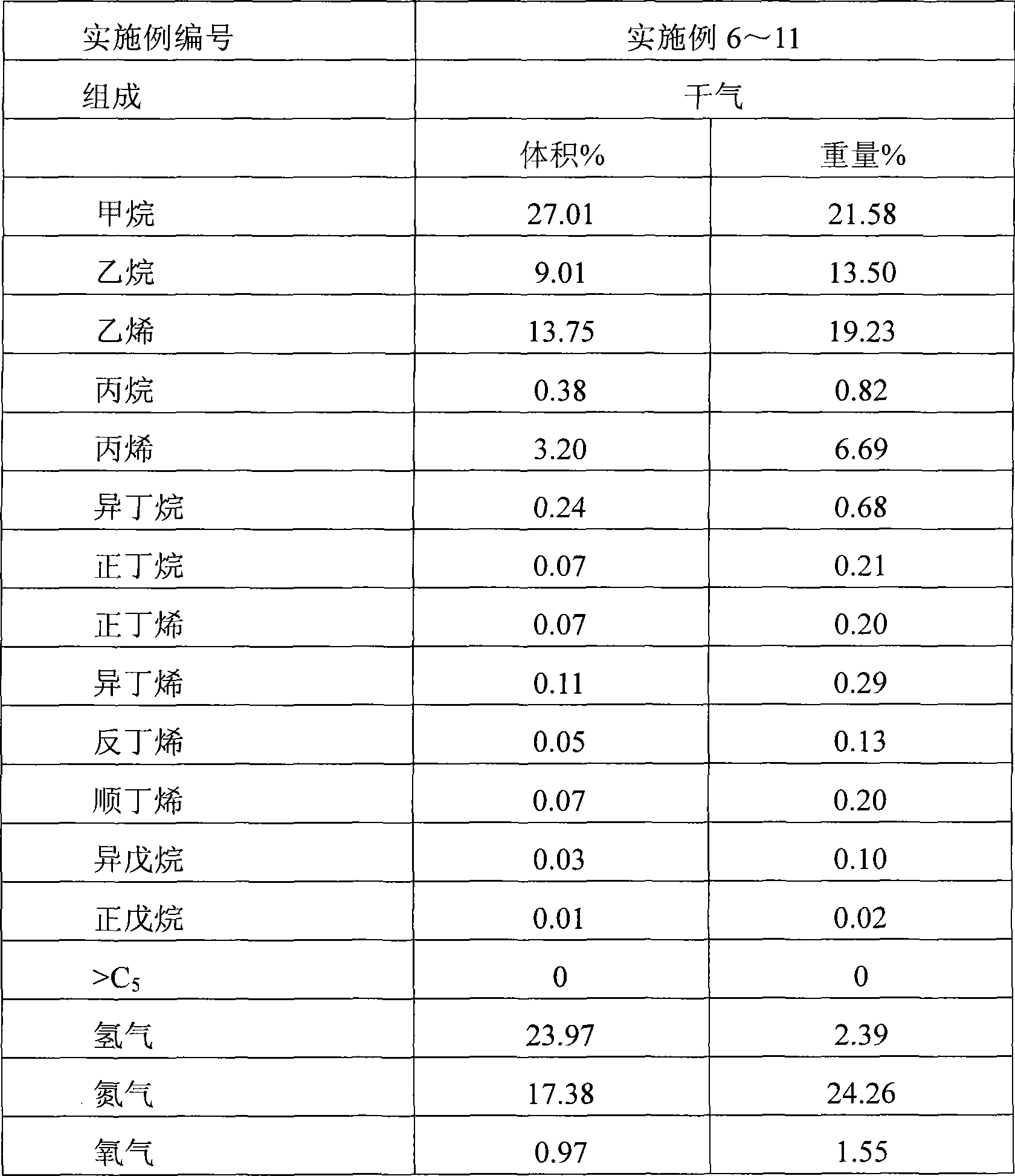

The invention discloses a method for modifying gasoline to solve the defect that gasoline with the benzene content of 1% to 2% by volume is difficultly treated in the prior art. The method is as follows: poor gasoline and dry gas enter a fluidized bed reactor respectively or after being mixed, and are in contact reaction with a catalyst to obtain clean gasoline; the reaction temperature is 200 to 400 DEG C, the reaction pressure is 0.2 to 2 MPa, the poor gasoline weight hourly space velocity is 0.5 to 4.0 h-1, the ethylene weight hourly space velocity in dry gas is 0.03 to 0.5 h-1, and the used catalyst is an catalyst with the active constituent of ZSM-5 or Y type molecular sieve. The application of the method in the invention can efficiently reduce the benzene content in gasoline and simultaneously efficiently uses refinery dry to be converted into valuable product.

Owner:CHINA PETROCHEMICAL CORP +1

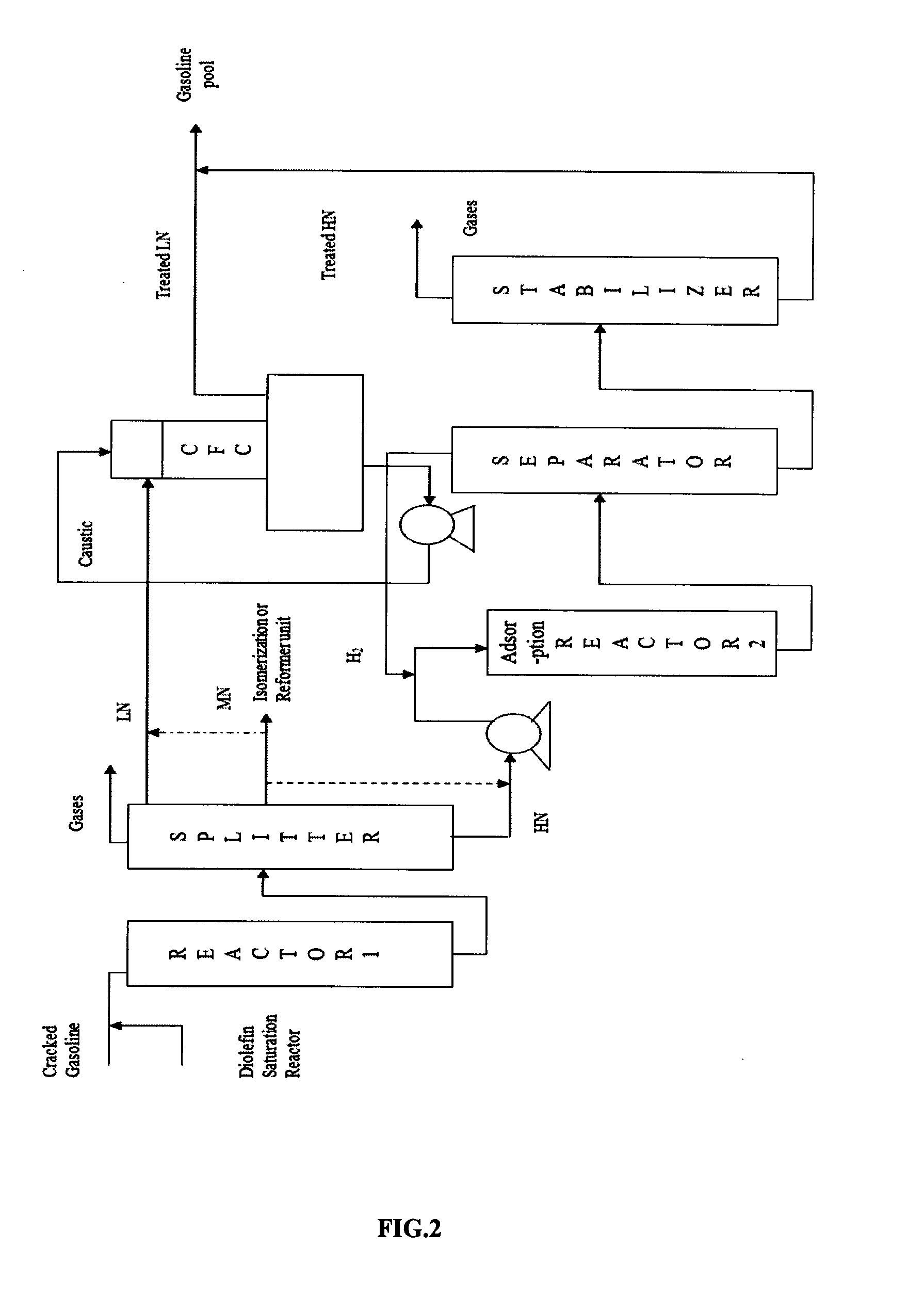

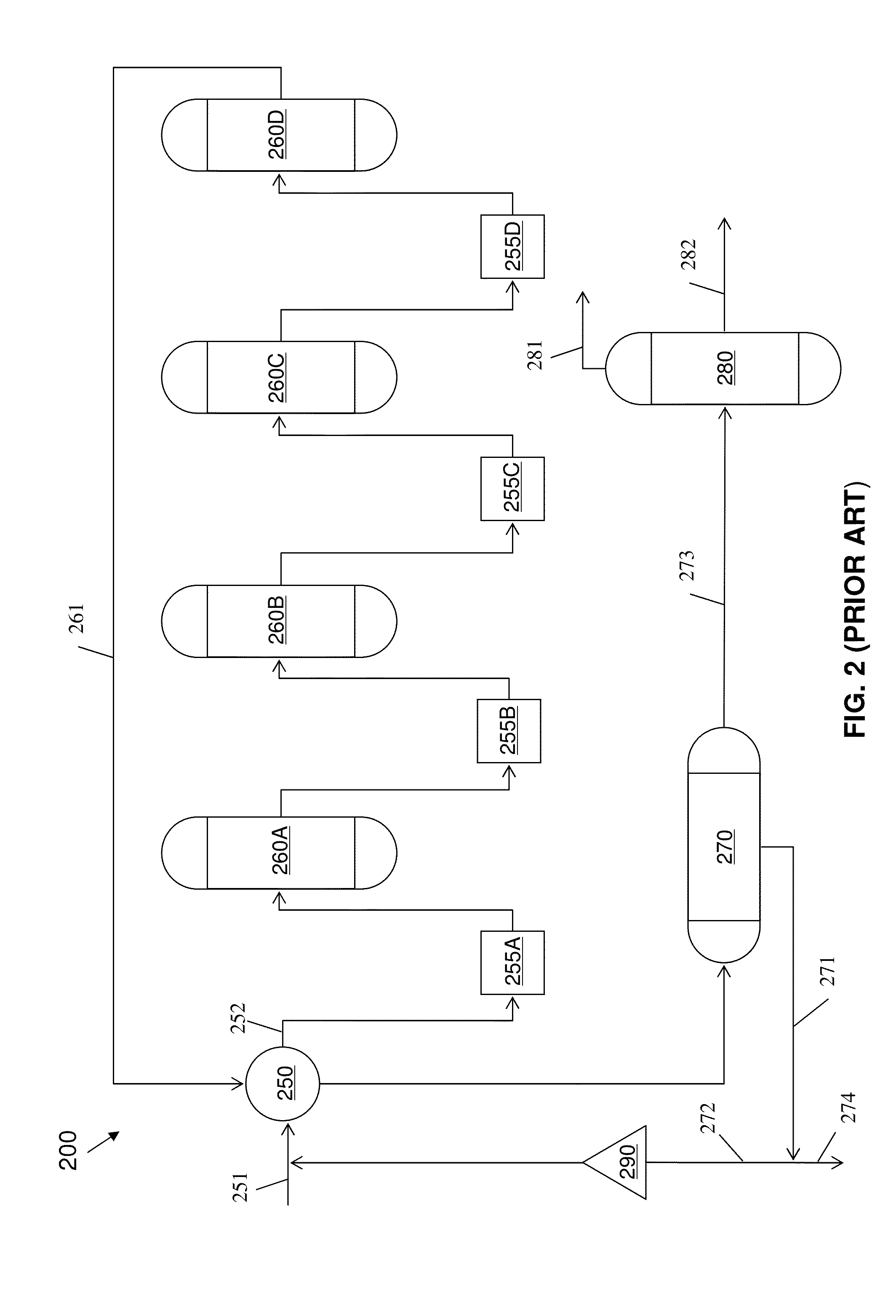

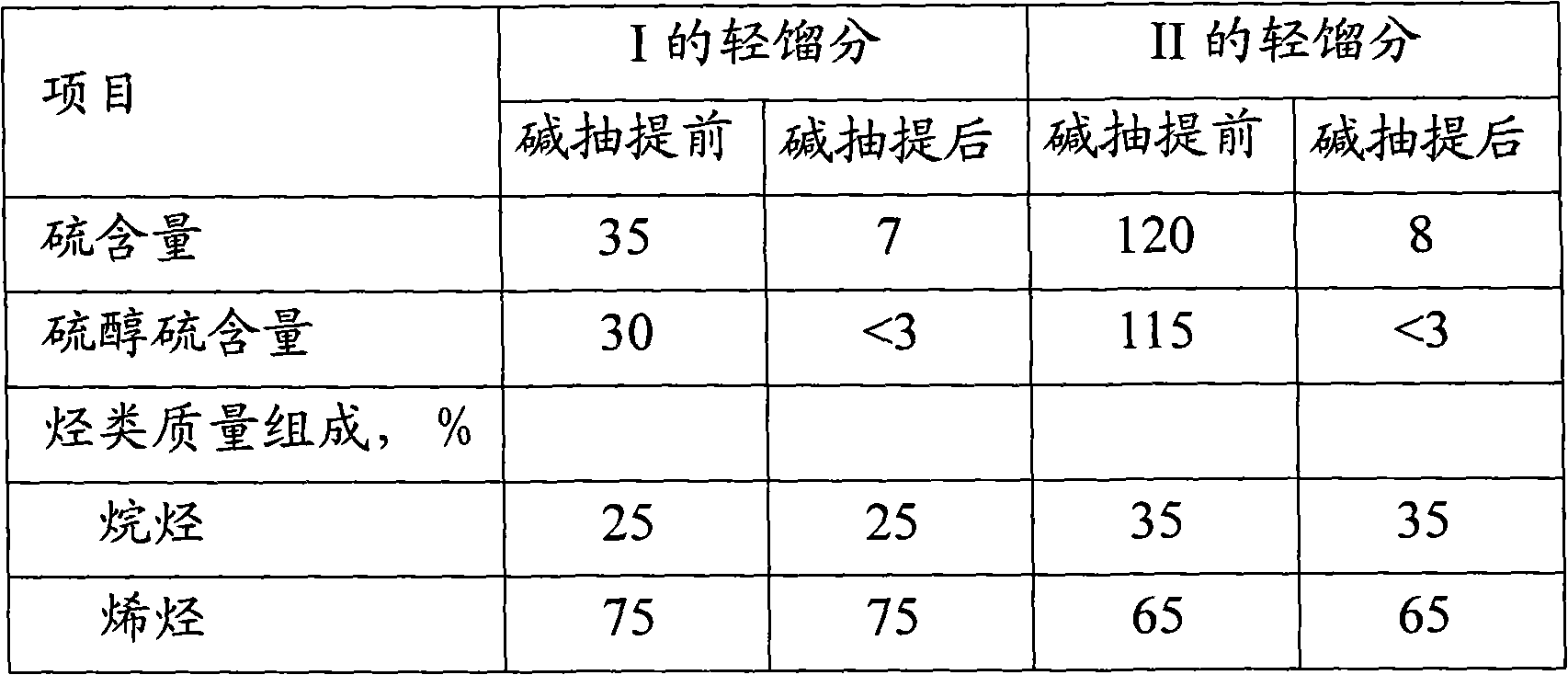

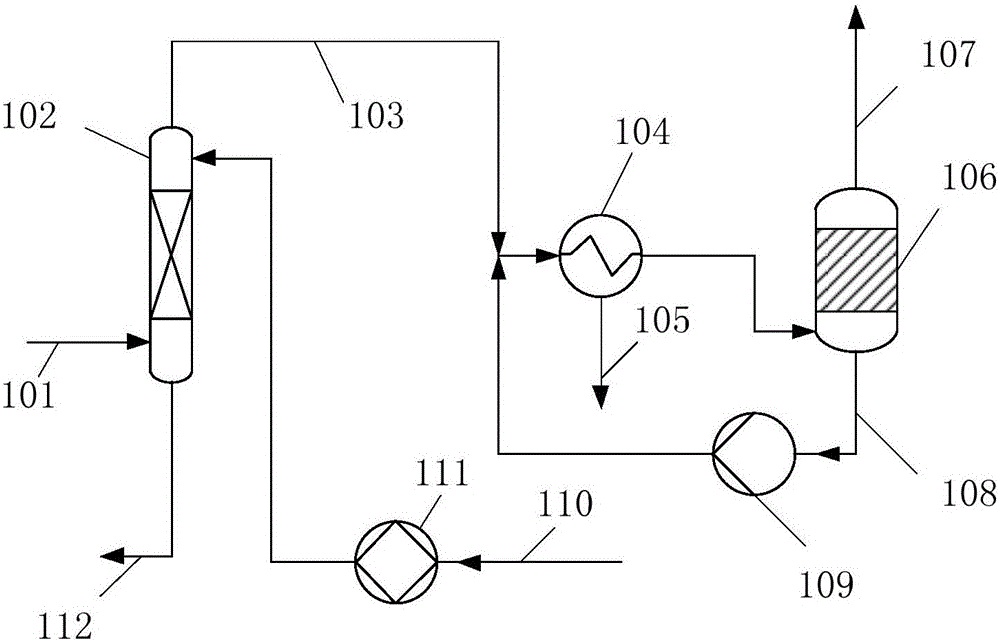

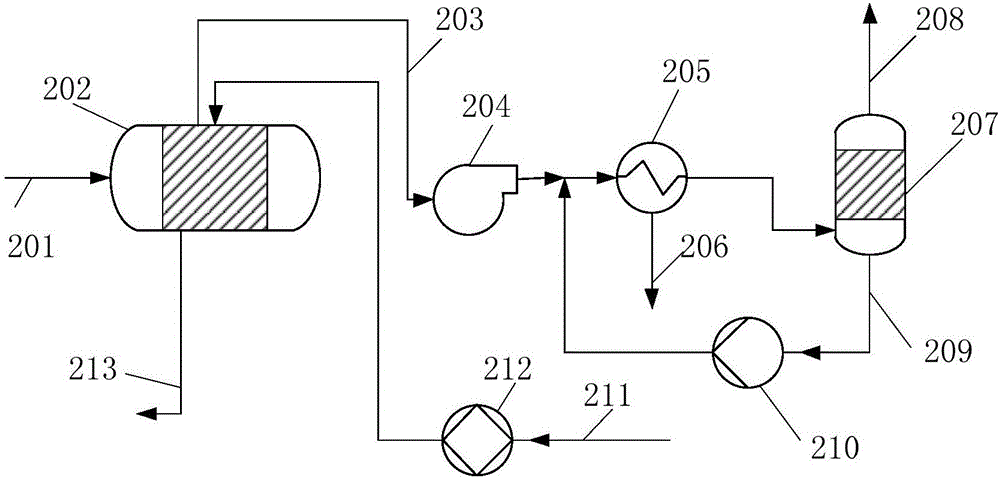

Process for deep desulfurization of cracked gasoline with minimum octane loss

ActiveUS20130240405A1Reduce benzene contentAvoid deactivationRefining with oxygen compoundsTreatment with hydrotreatment processesVisbreakerIsomerization

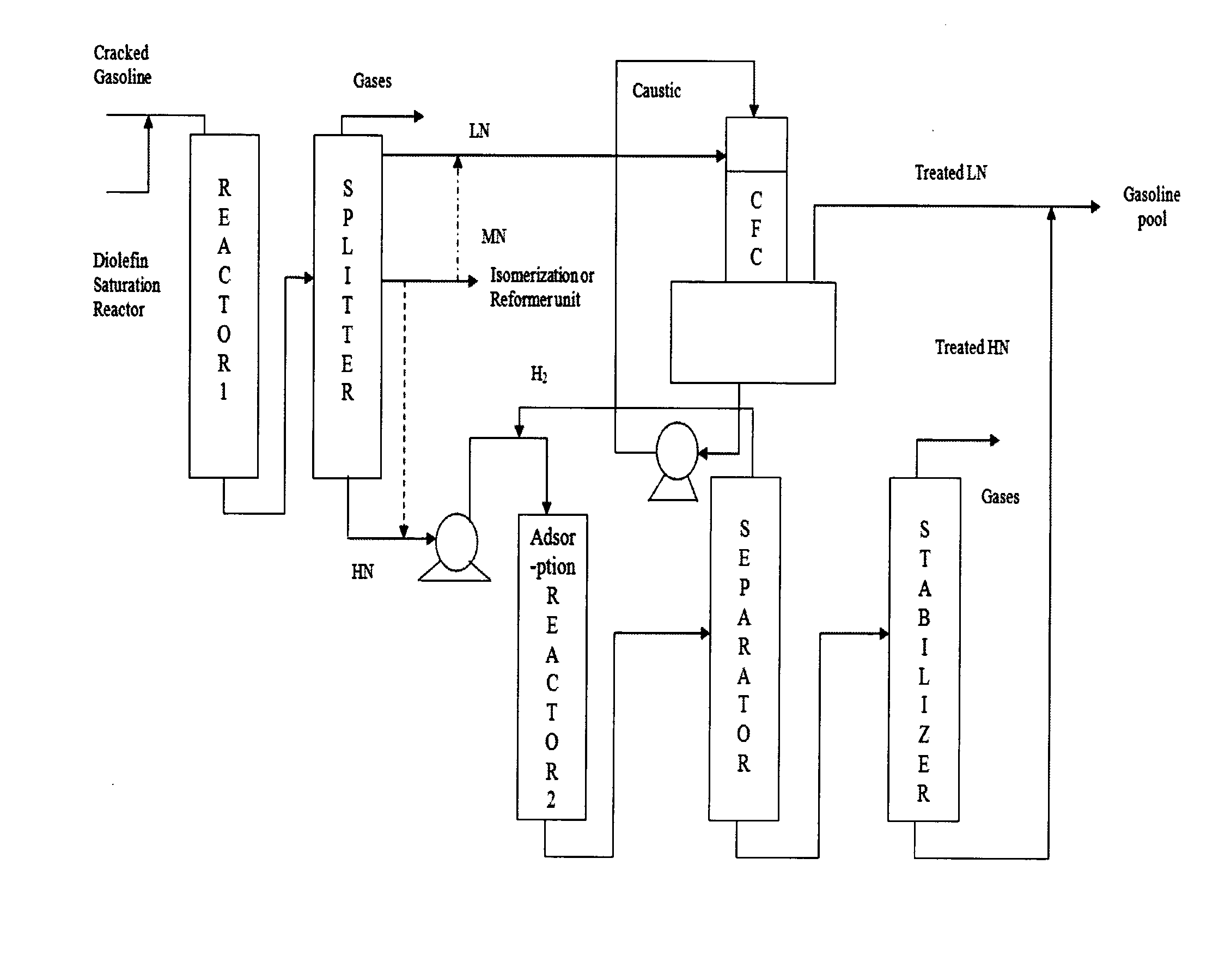

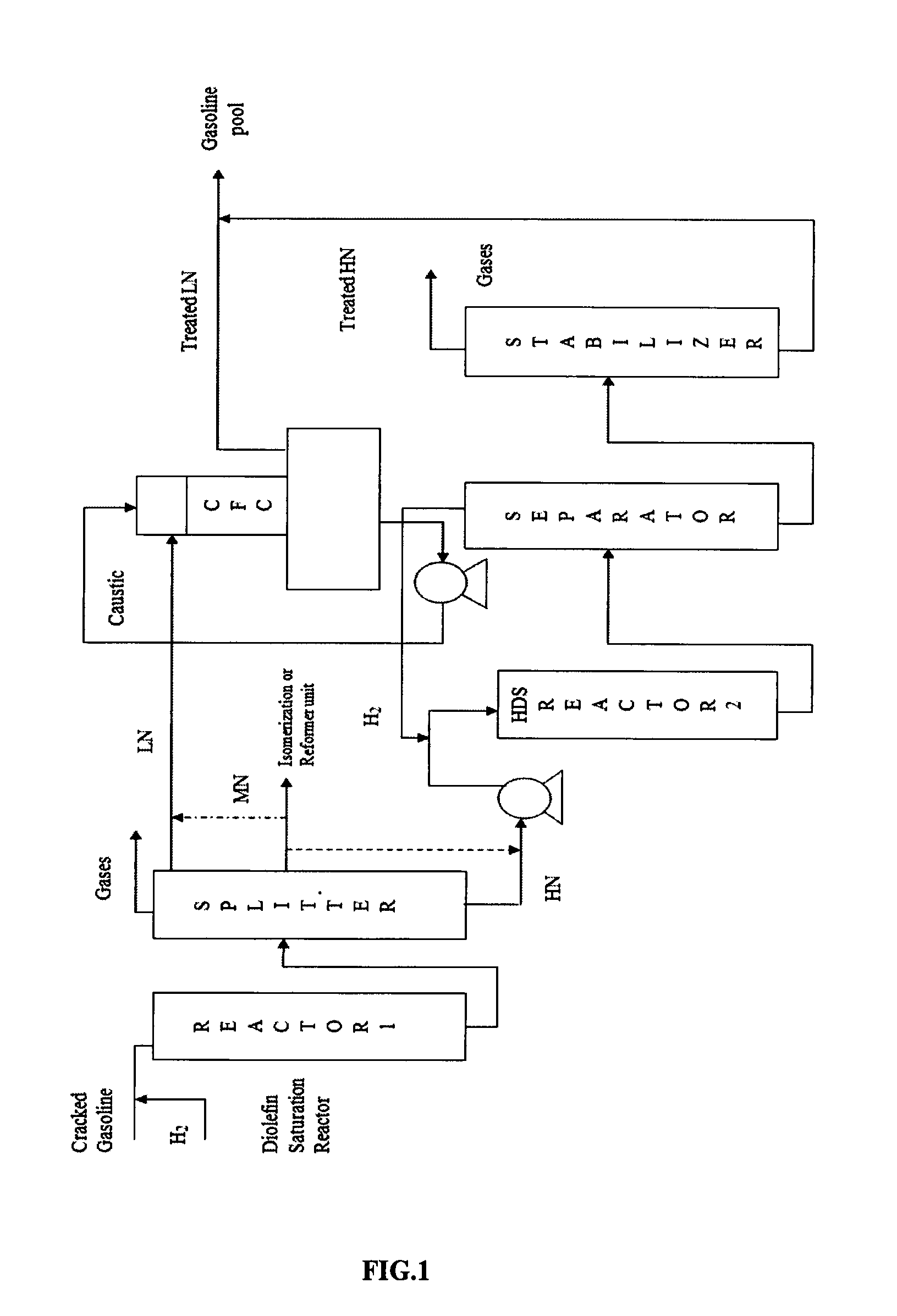

The present invention provides a process for deep desulphurization of cracked gasoline with minimum octane loss of about 1-2 units. In this process full range cracked gasoline from FCC, Coker, Visbreaker etc is sent to Diolefin Saturation Reactor for selective saturation of diolefins. After saturation of diolefins, the stream is sent to Splitter for splitting into three cuts i.e Light Cut (IBP-70° C.), Intermediate Cut (70-90° C.) and Heavy Cut (90-210° C.). The Light Cut which contains majority of the high octane olefins and mercaptan sulfur is desulfurized with caustic treatment using Continuous Film Contactor (CFC). The sulfur in the Intermediate Cut is also predominantly mercaptans and the cut can be desulfurised by caustic treatment using CFC along with Light cut or separately desulfurised before being sent for isomerization. The Heavy Cut containing mainly thiophinic sulfur compounds is treated either by using conventional HDS process or reactive adsorption process.

Owner:INDIAN OIL CORPORATION

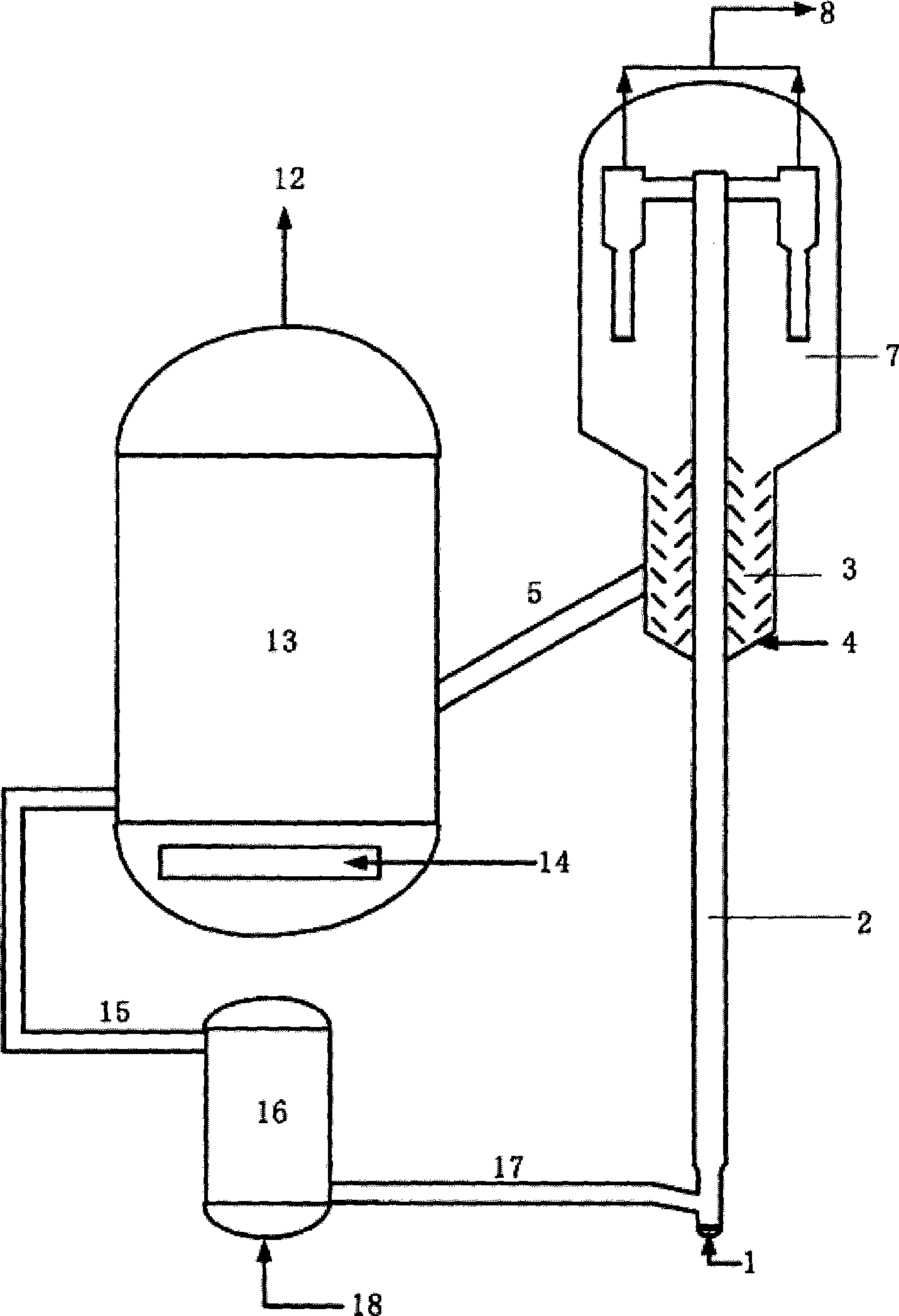

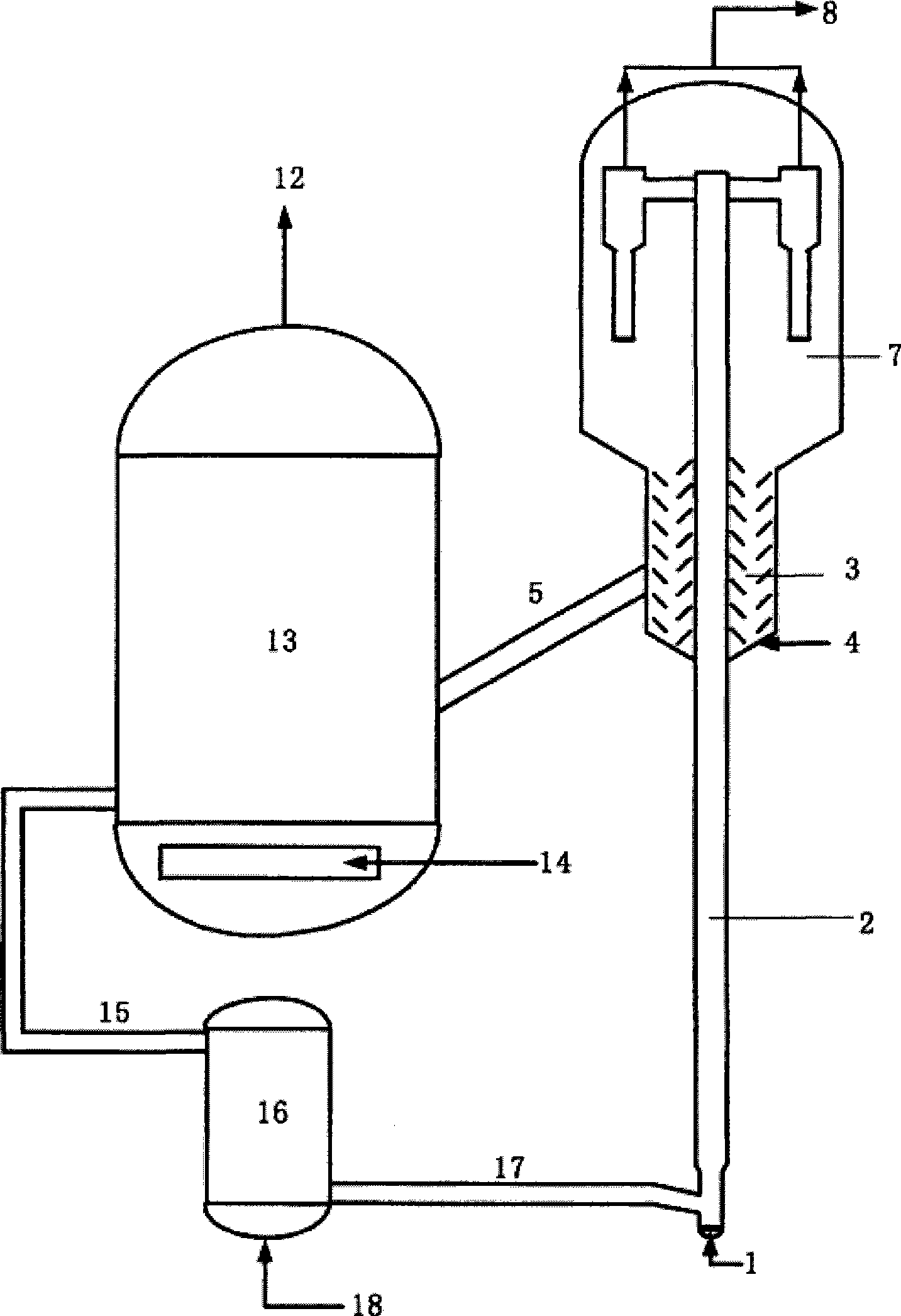

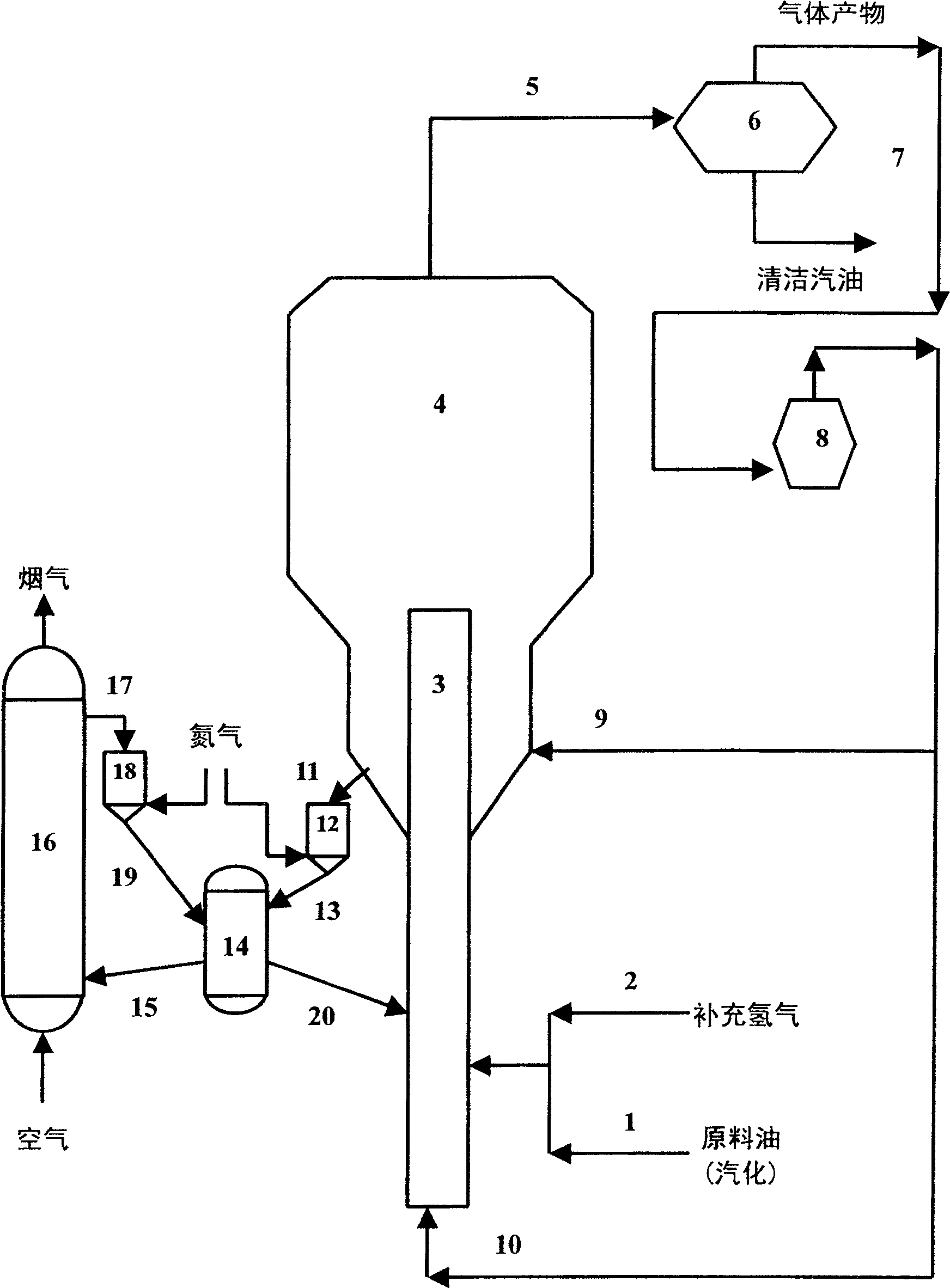

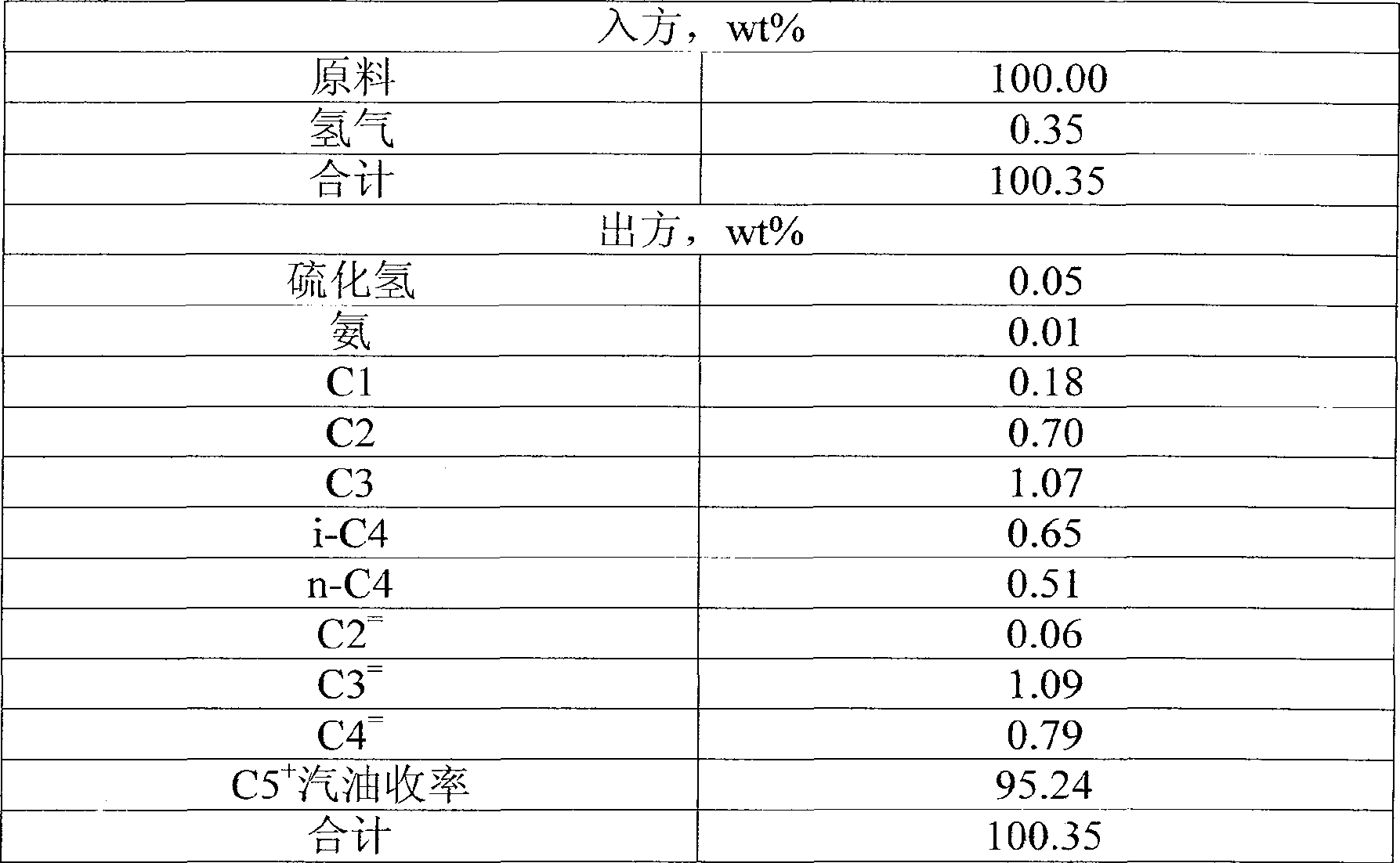

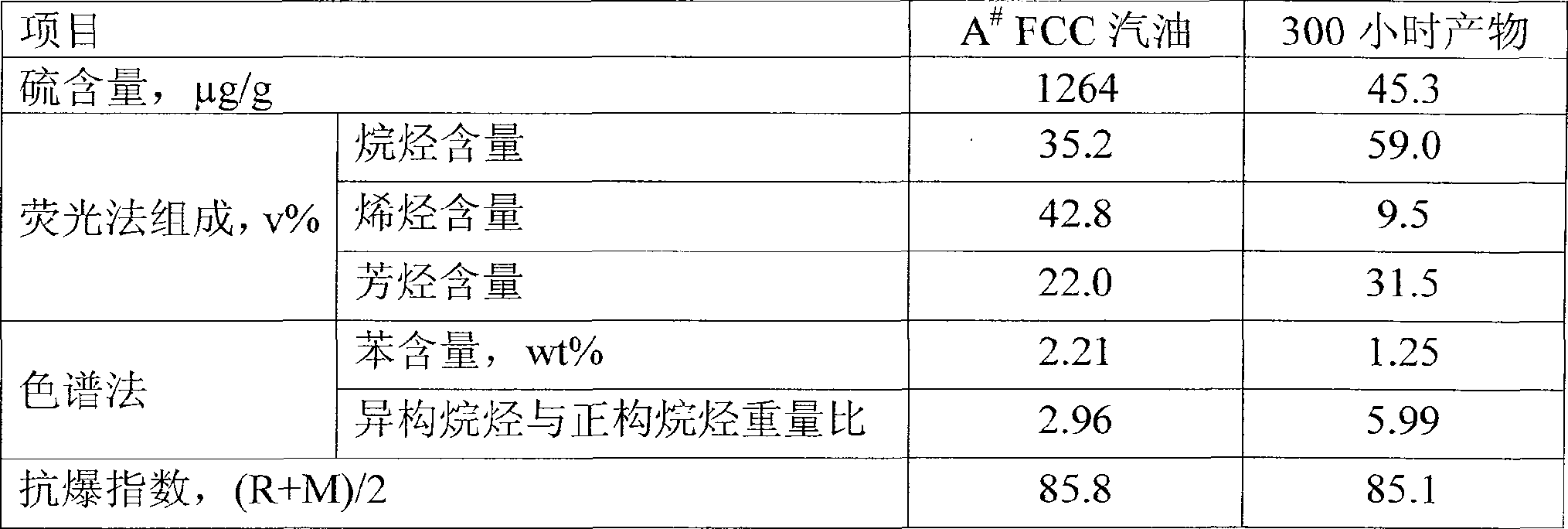

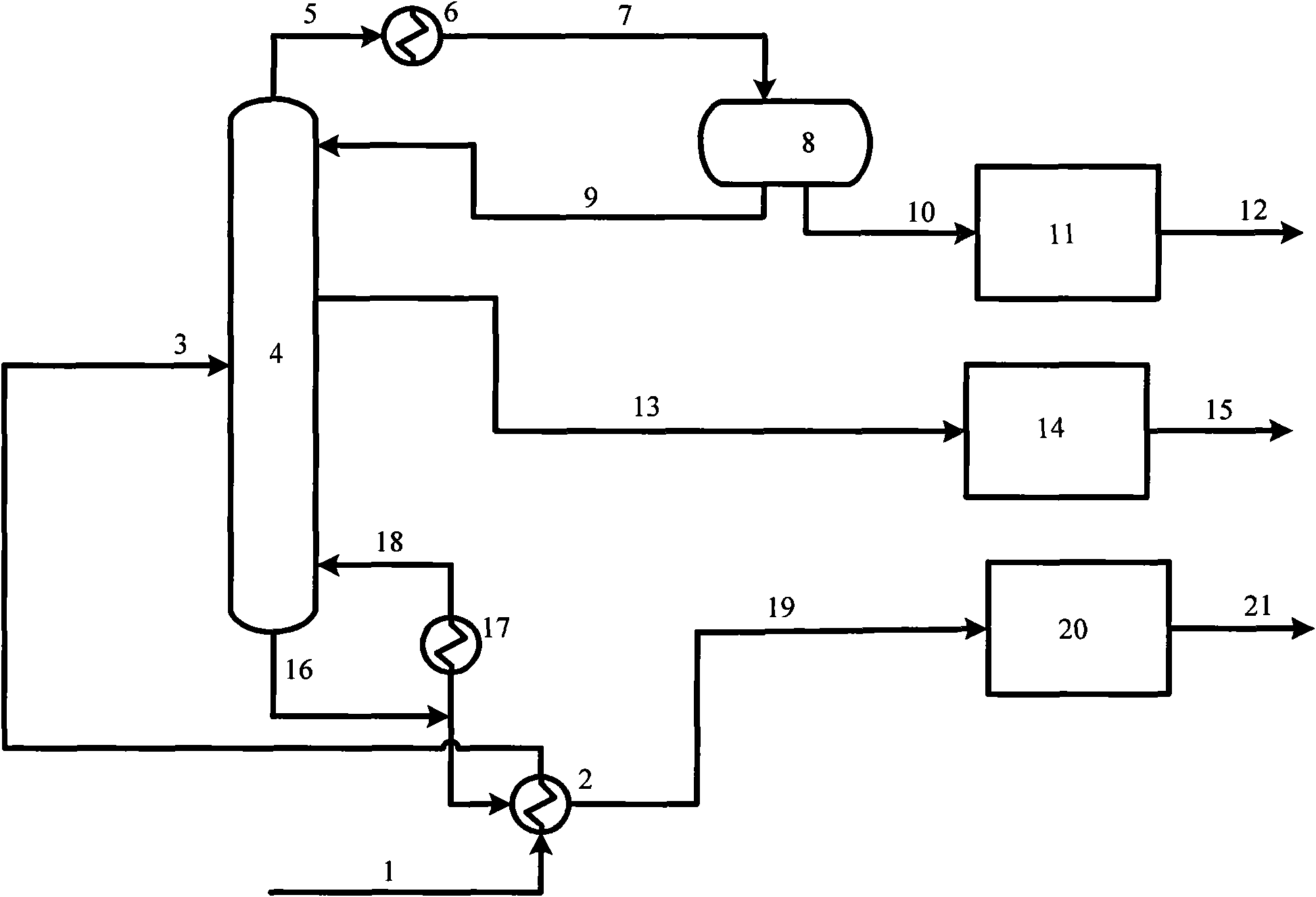

Production process of producing cleaning gasoline

ActiveCN100526430CReduce sulfur contentReduce olefin contentHydrocarbon oils refiningPtru catalystFluidized bed

The invention discloses a method for producing clean gasoline from inferior gasoline fractions. The method is to use a fluidized bed continuous regeneration method to process inferior gasoline fractions. The process includes inferior gasoline raw materials and hydrogen contacting the hot desulfurization-reducing olefin catalyst in the riser, and lifting them to a fluidized bed reactor for reaction; then , the desulfurized olefin products and hydrogen sulfide-containing gas are separated from the raw catalyst for gas-solid separation, and the raw catalyst is transported to the regenerator after being stripped; in the regenerator, the raw catalyst is regenerated by burning charcoal in the presence of air; the obtained The regenerated catalyst is returned to the fluidized bed reactor for recycling. Compared with the prior art, the method of the present invention can greatly reduce the sulfur content, olefin content and benzene content of low-quality gasoline, and at the same time, the antiknock index ((R+M) / 2) of the produced clean gasoline does not lose substantially .

Owner:CHINA PETROLEUM & CHEM CORP +1

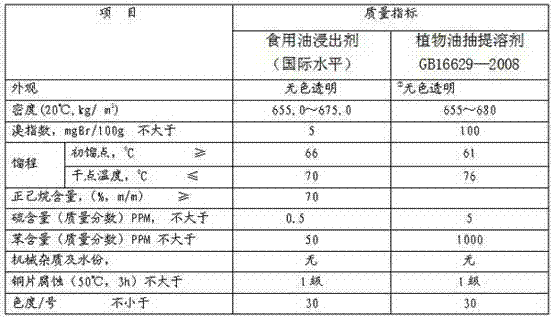

Preparation method of environment-friendly vegetable oil low-temperature extraction solvent

InactiveCN102199488AMaintain protein activityReduce benzene contentFatty-oils/fats productionBenzeneHydrogen

The invention relates to a preparation method of an environment-friendly vegetable oil low-temperature extraction solvent. In the preparation method, with No.6 solvent oil as a main raw material, high-purity hydrogen and the like as auxiliary raw materials and methyl pentane as a main extraction ingredient, residues are reduced to a maximum extent in the process of extracting vegetable oil and desolventizing dregs under the condition of low temperature; the protein activity in the dregs is kept; the benzene content in an extracting agent and the residual solvent content in the oil and the dregs can be reduced; and the distilling range is short, and therefore the purposes of convenient desolventizing process, easy control and low trace residues can be achieved. In the whole desolventizing process, energy saving and environment-friendliness are realized, and the pollution of normal hexane to atmosphere is greatly reduced.

Owner:彭长根 +2

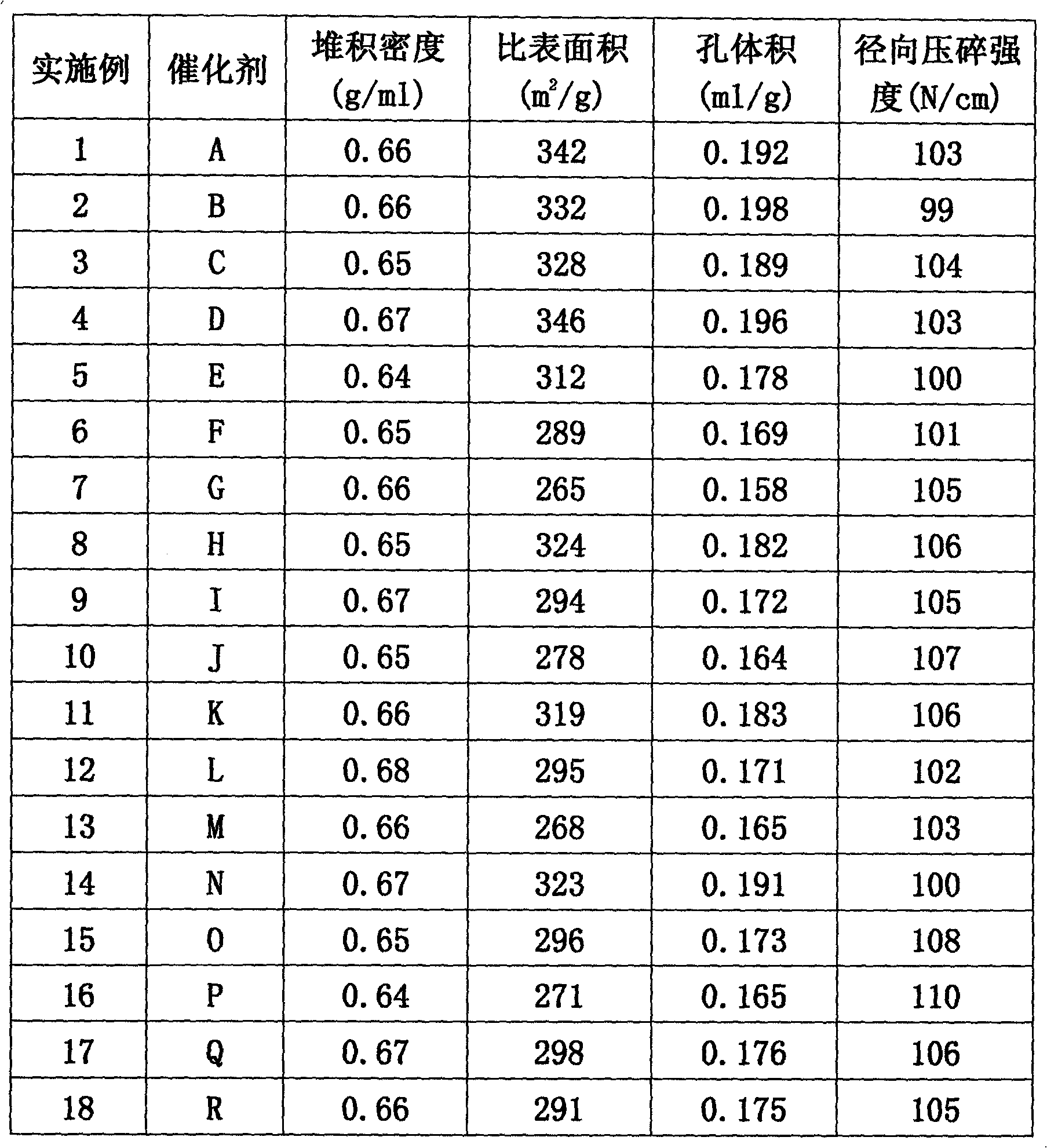

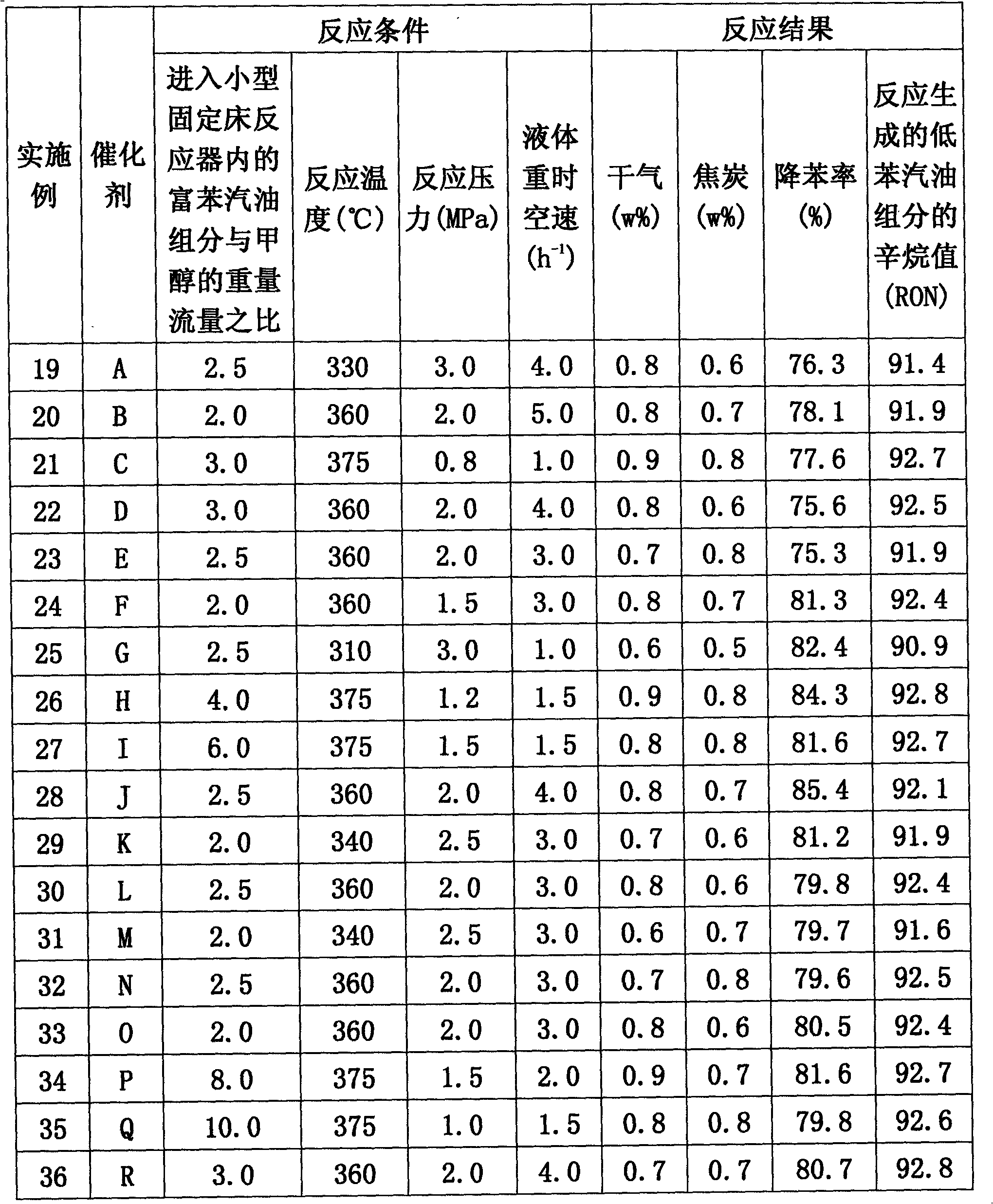

Catalytic conversion method for lowering benzene content of benzene-rich gasoline component

ActiveCN103725312AImprove stabilityNot easy to inactivateMolecular sieve catalystsHydrocarbon oils refiningRare-earth elementAdhesive

The invention discloses a catalytic conversion method for lowering the benzene content of a benzene-rich gasoline component, and aims to solve various problems caused by excessively high reaction temperature, excessively low reaction pressure and excessively low mass ratio of the benzene-rich gasoline component and methanol in a conventional method for lowering the benzene content of the benzene-rich gasoline component by performing alkylation reaction on the benzene-rich gasoline component and methanol. According to the method, the weight flow ratio of the benzene-rich gasoline component and methanol is 2.0 to 10.0, the reaction temperature is 300 to 375 DEG C, the reaction pressure is 0.8 to 3.0 MPa, the weight hourly space velocity of liquid is 1.0 to 5.0 h<-1>, a catalyst consists of 55 to 91 weight percent of HZSM-5 type molecular sieve, 0 to 25 weight percent of HY type molecular sieve, 0 to 25 weight percent of Hbeta type molecular sieve, 0 to 15 weight percent of oxide of a modifying element and 9 to 45 weight percent of adhesive, and the modifying element is phosphorus, iron, magnesium, silver, a rare earth element or zinc.

Owner:CHINA PETROCHEMICAL CORP +1

Sorbent for reducing sulfide in light hydrocarbon oil

The invention provides a sorbent used for reducing the content of sulfide in light hydrocarbon oil. According to weight percentage, the sorbent comprises 1-30% of phosphorus-modified rare earth shape-selective zeolite, 5-40% of active metal oxide and 30-94% of carrier; wherein, the carrier comprises alumina and zinc oxide; the rare earth shape-selective zeolite is modified by phosphorus and is pre-formed into porous heat-resistance solid grains together with carrier mixture; subsequently, the active metal oxide is led into the solid grains, thus preparing the sorbent; the light hydrocarbon oil raw material containing the sulfur and hydrogen donor enter a reactor filled with the sorbent; the materials are separated after reaction; the reaction products are sent to a subsequent separation system so that the product is separated; the sorbent to be regenerated after reaction is stripped, burned and regenerated; and the regenerated sorbent is reduced by the hydrogen donor and subsequently returns to the reactor so as to be circularly used. The sorbent realizes that the sulfide of light hydrocarbon oil is deeply removed, and meanwhile, the octane number of the outcome gasoline is higher, while the benzene content is lower and the strength is higher.

Owner:CHINA PETROLEUM & CHEM CORP +1

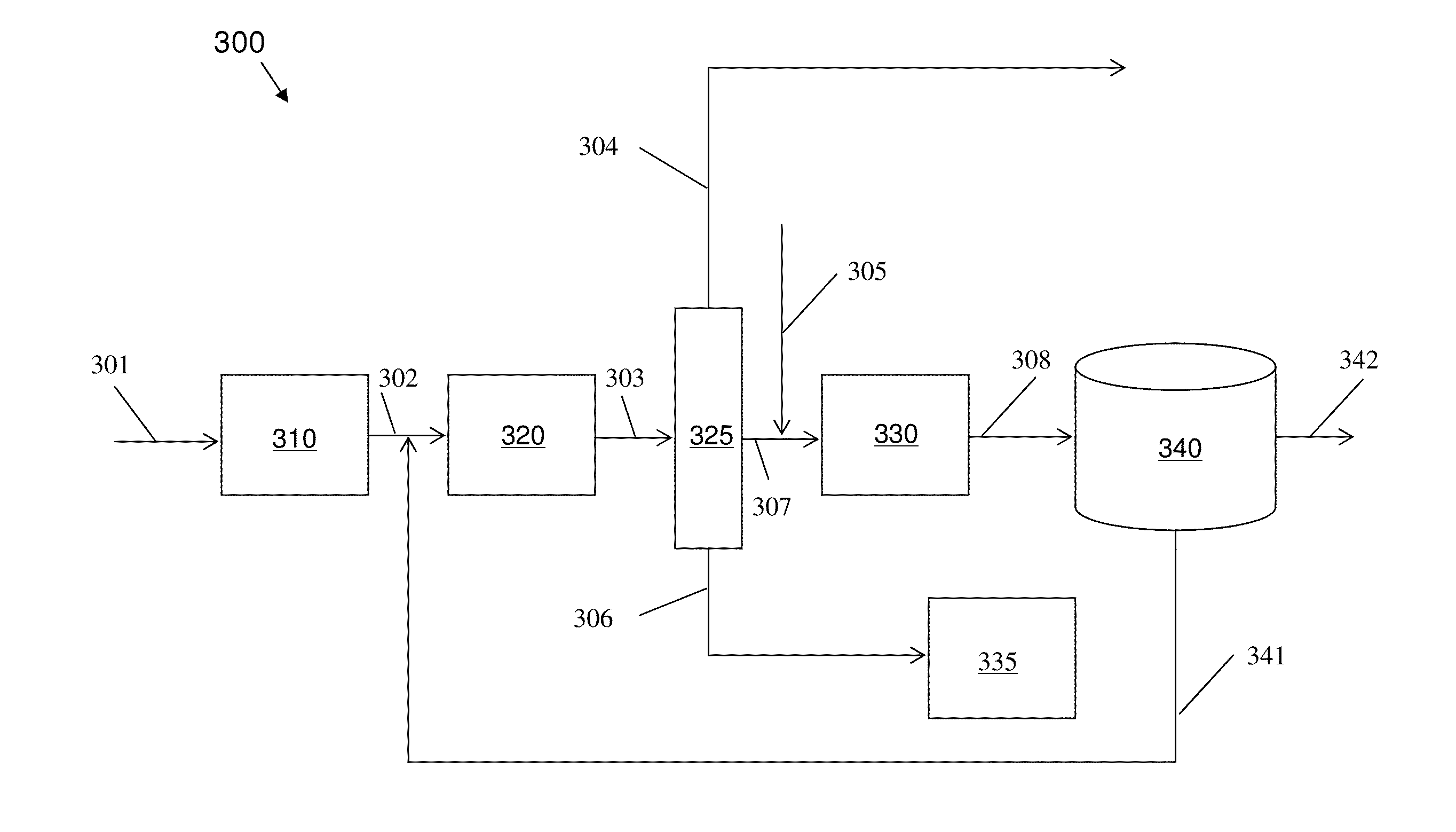

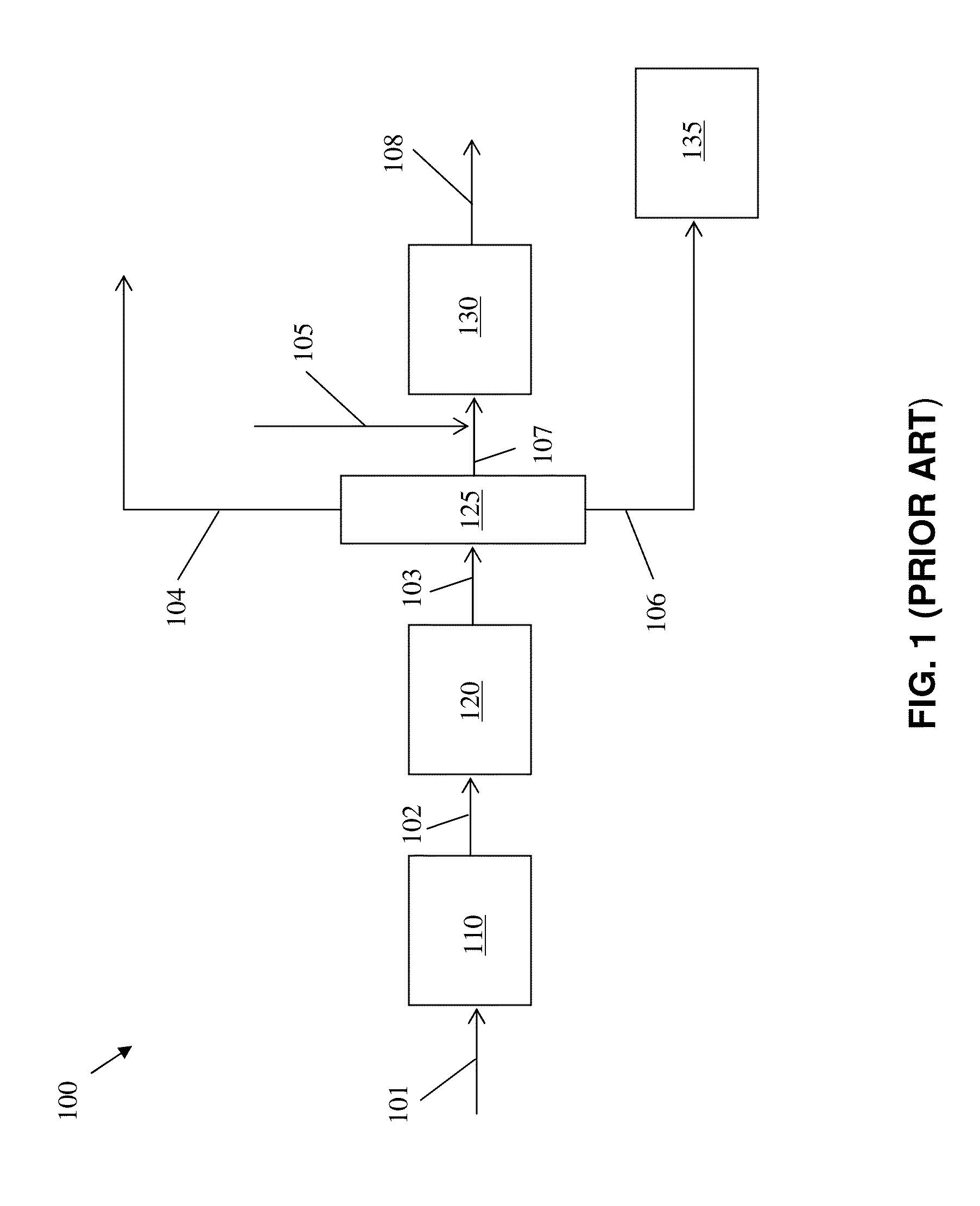

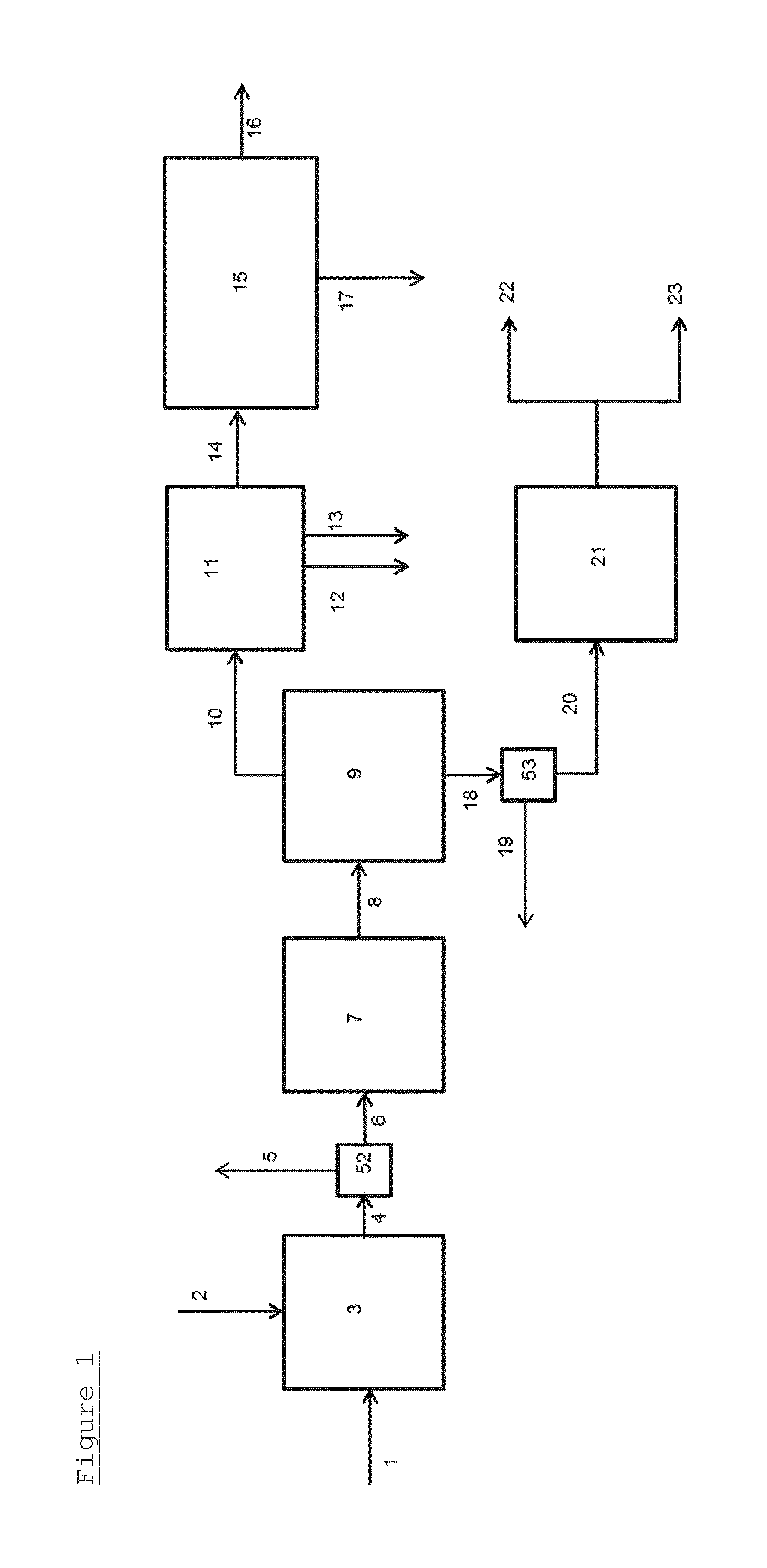

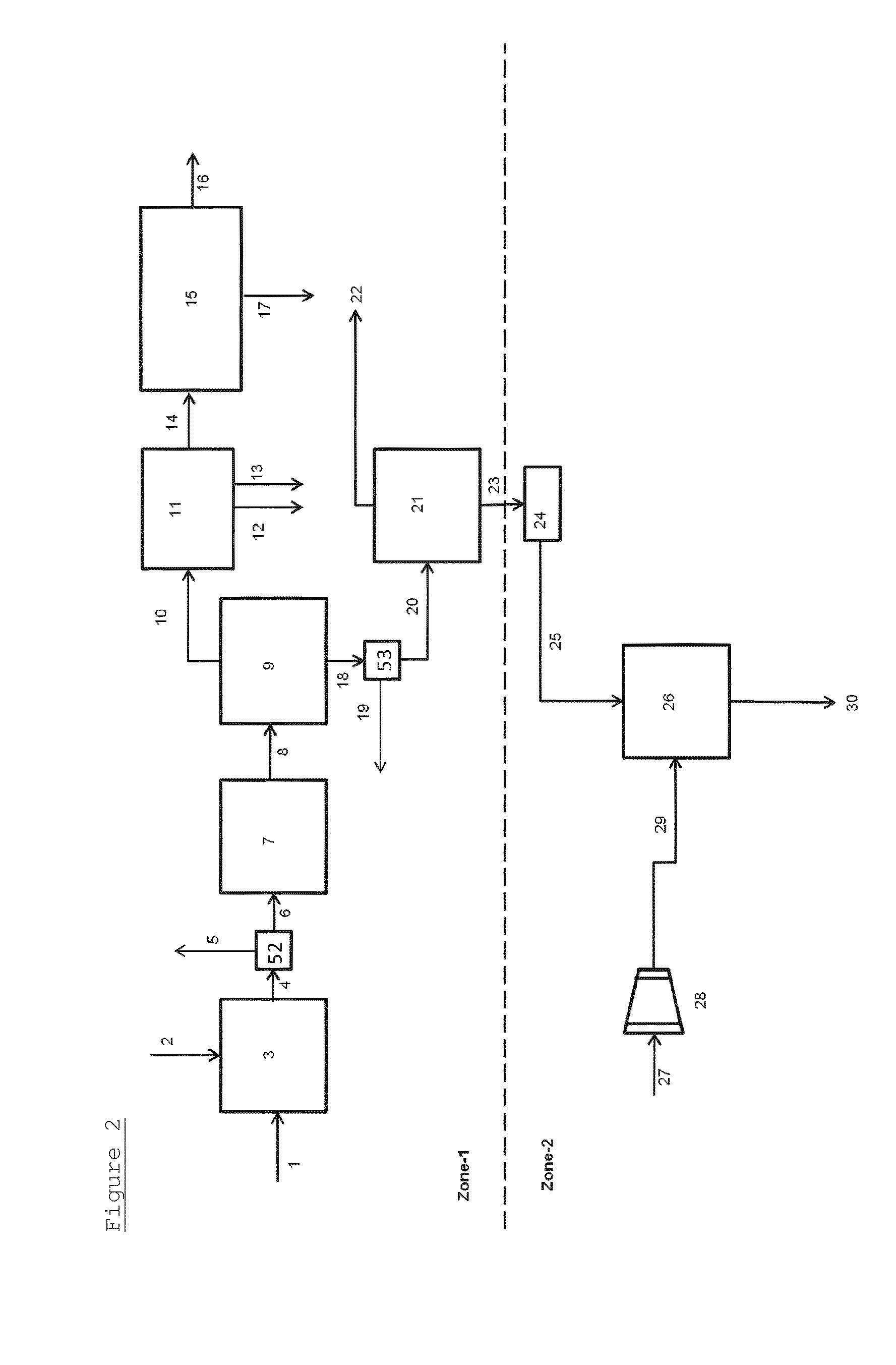

Catalytic reforming process and system for producing reduced benzene gasoline

ActiveUS20130193034A1Increase available hydrogen content and relative hydrogen purityReduce benzene contentHydrogenOrganic compound preparationChemistryBenzene

A catalytic reforming process for producing gasoline of reduced benzene content includes the steps of reforming a reformer feedstock that includes a naphtha stream to produce a gasoline reformate product stream; splitting the gasoline reformate product stream into one or more relatively benzene-rich fractions and one or more relatively benzene-lean fractions; and hydrogenating the one or more relatively benzene-rich fractions to produce a cyclohexane-rich effluent, at least a portion of which cyclohexane-rich effluent is recycled to constitute a portion of the reformer feedstock.

Owner:SAUDI ARABIAN OIL CO

Method for converting aromatic hydrocarbons

InactiveUS6972347B1Increase contentReduce benzene contentHydrocarbon by isomerisationMolecular sieve catalystBenzeneAromatic hydrocarbon

A method for converting aromatic hydrocarbons by contacting an aromatic hydrocarbon starting material including benzene and having a non-aromatic compound content of 1% by weight or less, with a catalystto generate useful C7 and C8 aromatic hydrocarbons while reducing the catalyst deactivation.

Owner:TORAY IND INC

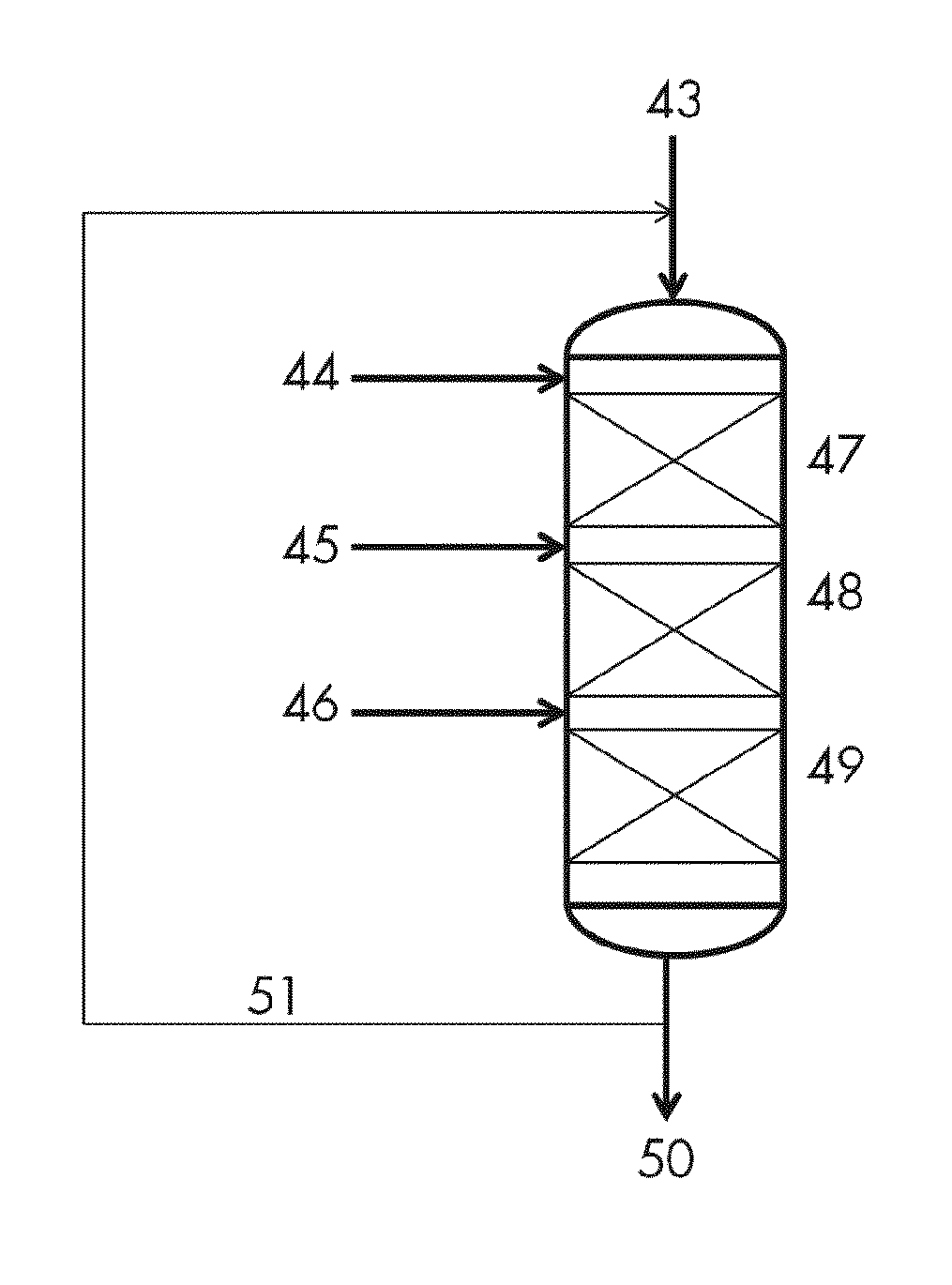

Gasoline processing method

ActiveCN102757817AExpand sourceMeet the requirements of the feedTreatment with hydrotreatment processesBenzeneLiquid product

A gasoline processing method includes: subjecting raw materials of full distillates to a fractionating tower to be fractioned into three fractions, and removing mercaptan sulfur in a light fraction by means of alkali extraction to obtain a liquid product I which is a gasoline blending component; processing an intermediate fraction through a first hydrogenation unit to obtain a liquid product II which is a qualified aromatics extraction raw material; and processing a heavy fraction through a second hydrogenation unit to obtain a liquid product III which is a gasoline blending component. By the gasoline processing method, a qualified aromatic hydrocarbon product and a qualified gasoline product can be obtained simultaneously, sources of the aromatic hydrocarbon product are widened, and compared with raw materials, the obtained gasoline product has the advantages that the induction period is greatly prolonged, sulfur content is greatly reduced, and aromatic hydrocarbon content, especially benzene content is reduced.

Owner:CHINA PETROLEUM & CHEM CORP +1

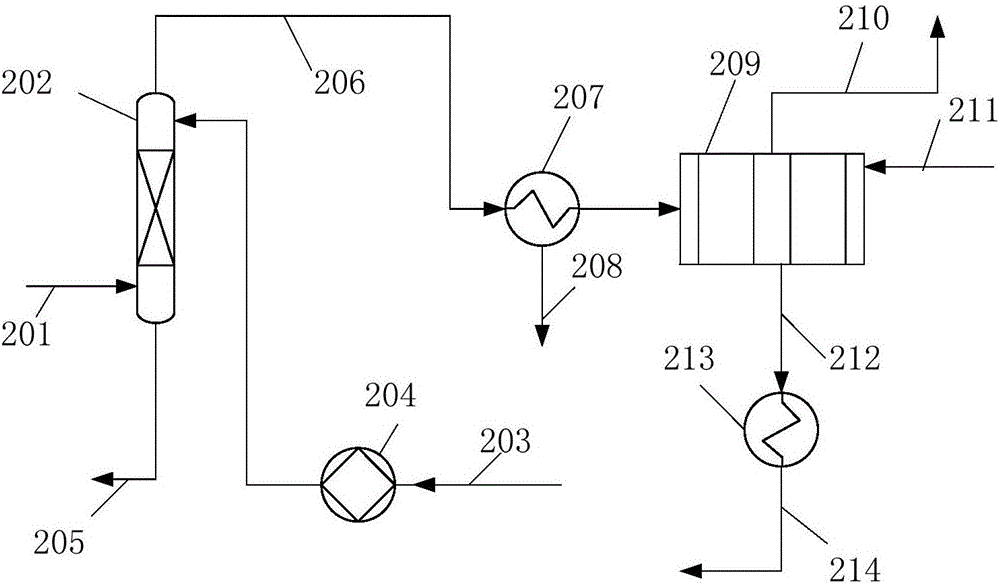

Treatment method for gas containing high-concentration benzene

ActiveCN106621711AEmission complianceTo achieve the purpose of purificationGas treatmentDispersed particle separationExhaust gasBenzene

The invention relates to a treatment method for gas containing high-concentration benzene. The treatment method comprises the following steps: (a) carrying out absorption treatment on the gas containing the high-concentration benzene in absorption equipment by using an absorbent to form absorption liquid and absorbed gas, and recycling the absorption liquid; (b) carrying out condensation treatment on the absorbed gas by a condenser at the condensation temperature of 0 to 70DEG C to form condensed liquid and condensed gas, and recycling the condensed liquid; (c) carrying out adsorbing purification on the condensed gas by an adsorbent in an adsorber to form purified gas, and exhausting the purified gas; carrying out vacuumizing desorption on the adsorbent to form desorbed gas, and returning the desorbed gas to an inlet of the condenser or an inlet of the absorption equipment. The invention aims to achieve the aim that the concentration of the benzene in the benzene-containing gas is reduced to be 4mg / Nm<3> or lower; meanwhile, the absorption liquid and the condensed liquid can be easily treated or can be directly used for other processes. The treatment method disclosed by the invention is applied to treatment of tail gases generated by a benzene material dumper and a benzene storage tank, other high-concentration benzene-containing gases, and the like.

Owner:BEIJING CREDITCONGRUITY ENERGY TECH CO LTD

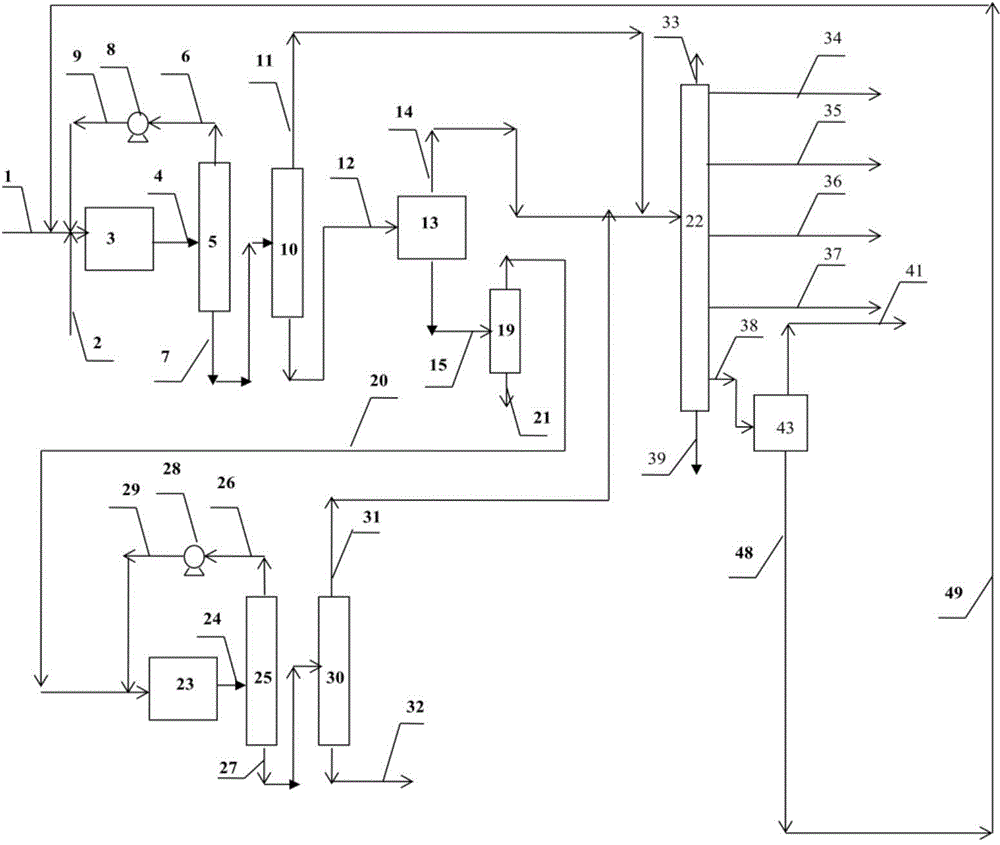

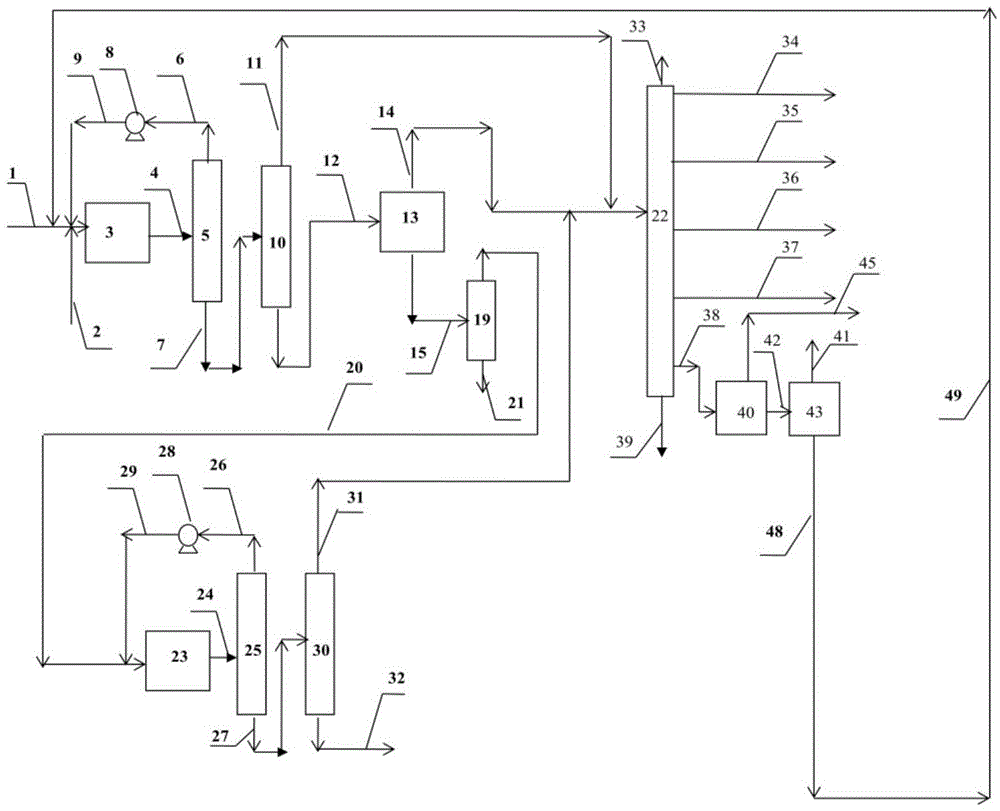

Conversion of biomass or residual waste material to biofuels

PendingUS20170009143A1Reduced aromatics contentReduce benzene contentLiquid hydrocarbon mixture productionTreatment with hydrotreatment processesDeoxygenationChemistry

The present invention provides a process for producing liquid hydrocarbon products from solid biomass and / or residual waste feedstocks, said process comprising the steps of: a) hydropyrolysing the solid feedstock in a hydropyrolysis reactor vessel in the presence of molecular hydrogen and one or more deoxygenation catalyst, producing a product stream comprising partially deoxygenated hydropyrolysis product, H2O, H2, CO2, CO, C1-C3 gases, char and catalyst fines; b) removing said char and catalyst fines from said product stream; c) hydroconverting said partially deoxygenated hydropyrolysis product in a hydroconversion reactor vessel in the presence of one or more hydroconversion catalyst and of the H2O, CO2, CO, H2, and C1-C3 gas generated in step a), producing a vapour phase product comprising substantially fully deoxygenated hydrocarbon product, H2O, CO, CO2, and C1-C3 gases; d) condensing the vapour phase product of step d) to provide a liquid phase product comprising substantially fully deoxygenated C4+ hydrocarbon liquid and aqueous material and separating said liquid phase product from a gas phase product comprising H2, CO, CO2, and C1-C3 gases; e) removing the aqueous material from the substantially fully deoxygenated C4+ hydrocarbon liquid; and f) hydroprocessing at least a portion of the substantially fully deoxygenated C4+ hydrocarbon liquid in a hydroprocessing reactor vessel in the presence of hydrogen and one or more hydroprocessing catalysts, each hydroprocessing catalyst comprising at least one reduced metal on a solid support, in order to provide an upgraded liquid hydrocarbon stream.

Owner:SHELL OIL CO

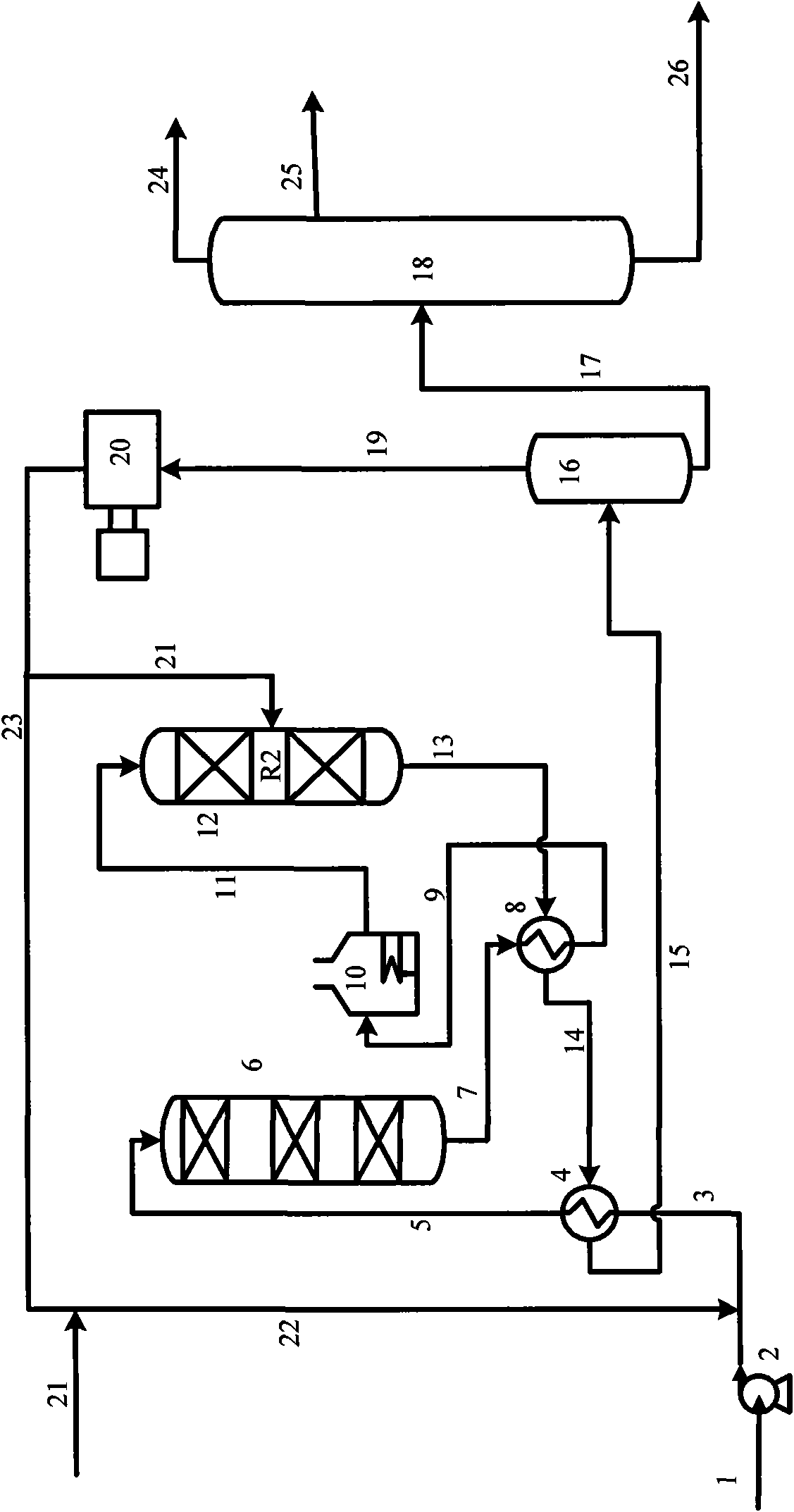

Method for producing olefin and low-benzene-content gasoline component from naphtha

ActiveCN104927919AHigh yieldReduce benzene contentTreatment with hydrotreatment processesHydrocarbon by hydrocarbon crackingCatalytic reformingAlkane

A method for producing olefin and a low-benzene-content gasoline component from naphtha comprises the steps: naphtha is subjected to extractive distillation, an extract oil containing aromatic hydrocarbon and C6 naphthene and a raffinate oil containing alkane and C6 naphthene are obtained, wherein the mass ratio of the C6 naphthene in the raffinate oil and the C6 naphthene in naphtha is 70-96%; and the obtained raffinate oil is sent into a steam cracking device and is subjected to a cracking reaction, a cracking reaction product is separated, cracked gasoline obtained from the separation is hydrofined, hydrofined cracked gasoline is obtained, the obtained extract oil is subjected to a catalytic reforming reaction, a reforming reaction product is separated, gas, a C3-C4 fraction and a low-benzene-content reformed generated oil are obtained, the C3-C4 fraction in the reformed products is sent into the steam cracking device, and the obtained hydrofined cracked gasoline returns to be mixed with naphtha and then is subjected to extractive distillation. The method improves the utilization rate of naphtha, and can produce the low-benzene-content gasoline component while producing more ethylene, propylene and butadiene.

Owner:CHINA PETROLEUM & CHEM CORP +1

Modification method for heavy components of methanol-based gasoline

ActiveCN104342198ADurene reductionMeet the requirements of durene contentRefining with non-metalsMolecular sieve catalystsBenzeneMolecular sieve

The invention discloses a modification method for heavy components of methanol-based gasoline, aiming to overcome the problems that the content of heavy components, especially durene in the methanol-based gasoline is higher. The method comprises the following steps: performing transalkylation reaction to methanol-based gasoline heavy components with benzene at the presence of a catalyst, wherein the mole ratio of benzene to the methanol-based gasoline heavy components is (3-6) to 1, the transalkylation reaction is carried out under the conditions that the temperature is at 380DEG C-450DEG C, the idle speed is 1.0h<-1>-4.0<-1>, and the pressure is at 0.5Mpa-5.0Mpa, and the catalyst for transalkylation reaction is a molecular sieve catalyst modified by rare earth and citric acid. Through using the method, polymethyl benzene, especially durene in the heavy components can be converted into aromatic hydrocarbon taking C8 and C9 as mains, and the yield of the methanol-based gasoline can be greatly improved.

Owner:LUOYANG PETROCHEMICAL ENG CORP SINOPEC +1

Preparation method of edible oil leaching agent

InactiveCN102212392AImprove product qualityHigh effective component n-hexane contentTreatment with hydrotreatment processesFatty-oils/fats productionOil and greaseDistillation

The invention relates to a preparation method of an edible oil leaching agent, in particular to a preparation method of the leaching agent used in edible oil industries; and the preparation method comprises the following steps of: taking aromatic raffinate oil refined by petroleum as a raw material, and by using a fibrous membrane contactor, carrying out washing and desulfuration, dehydration, hydrogenation deolefination, hydrogenation dearomatization, distillation and the like so as to obtain the leaching agent with high quality. The preparation method has the advantages of increasing the product quality and recovery rate of a solvent, decreasing residual oil in oil residuals, reducing the solvent loss and energy consumption, being beneficial to increasing the quality of oil and oil residuals, having no influence on environments and being safe to human bodies.

Owner:广州赫尔普化工有限公司

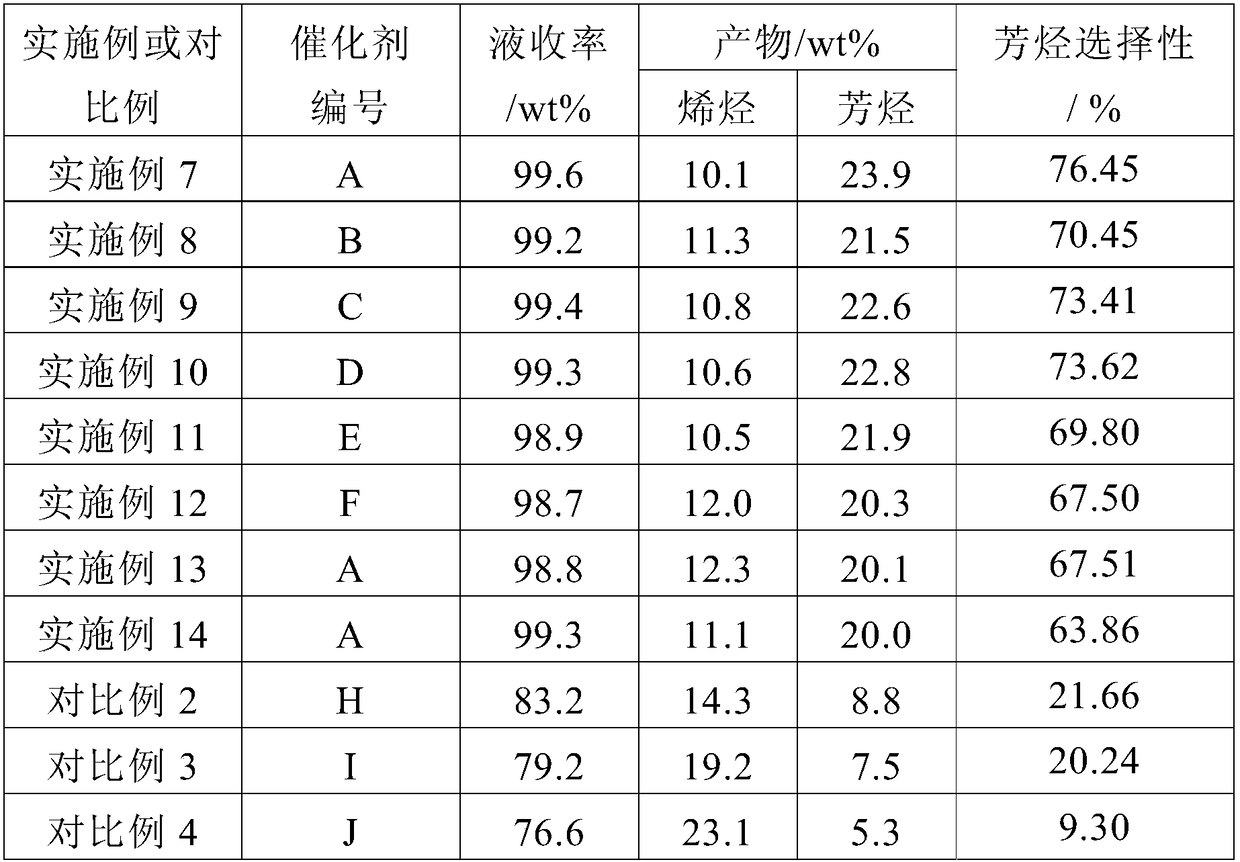

Aromatization catalyst and preparation method, regeneration method and aromatization method thereof

ActiveCN108479846AHigh aromatization activityImprove conversion rateMolecular sieve catalystsHydrocarbon oils refiningMolecular sieveIon exchange

The invention provides an aromatization catalyst and a preparation method, regeneration method and aromatization method thereof. The preparation method comprises mixing a zeolite molecular sieve and abinder to obtain a catalyst precursor, orderly performing ion exchange modification and first modification treatment on the catalyst precursor, and after hydrothermal treatment, carrying out active metal loading and second modification treatment to obtain the aromatization catalyst. A modification element used in the first modification is at least one selected from metals in the group IA, group VA and lanthanide line in the periodic table, the active metal is at least one element selected from elements in the group VIIB, group VIII, group IB and group IIB, and the modifying element used for the second modification is at least one element selected from elements in the group VA and lanthanide line in the periodic table. The aromatization catalyst has good carbon deposition resistance and high aromatization activity, can complete the aromatization reaction under mild conditions, and has high aromatic selectivity and a liquid yield of 98.5% or more.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

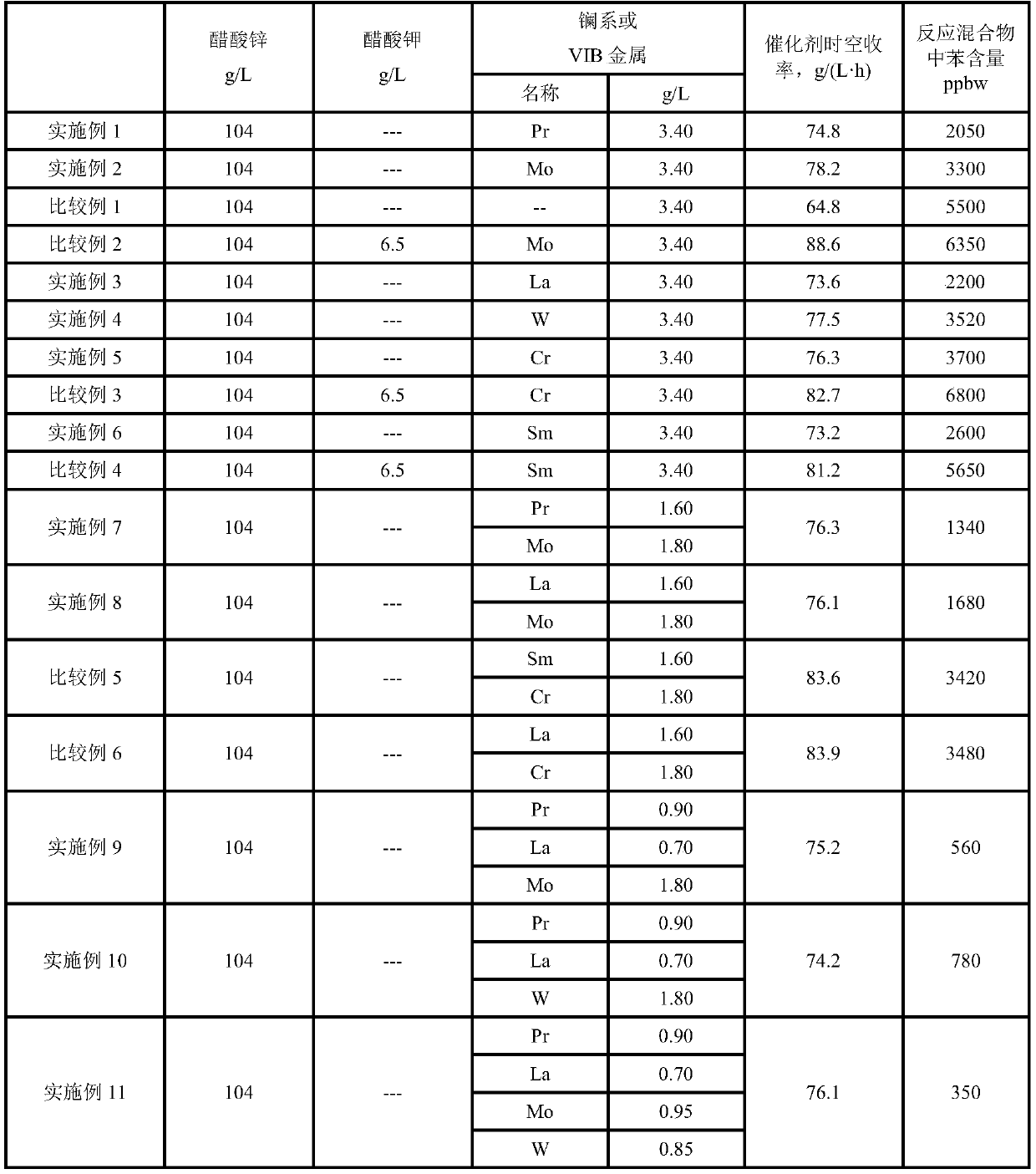

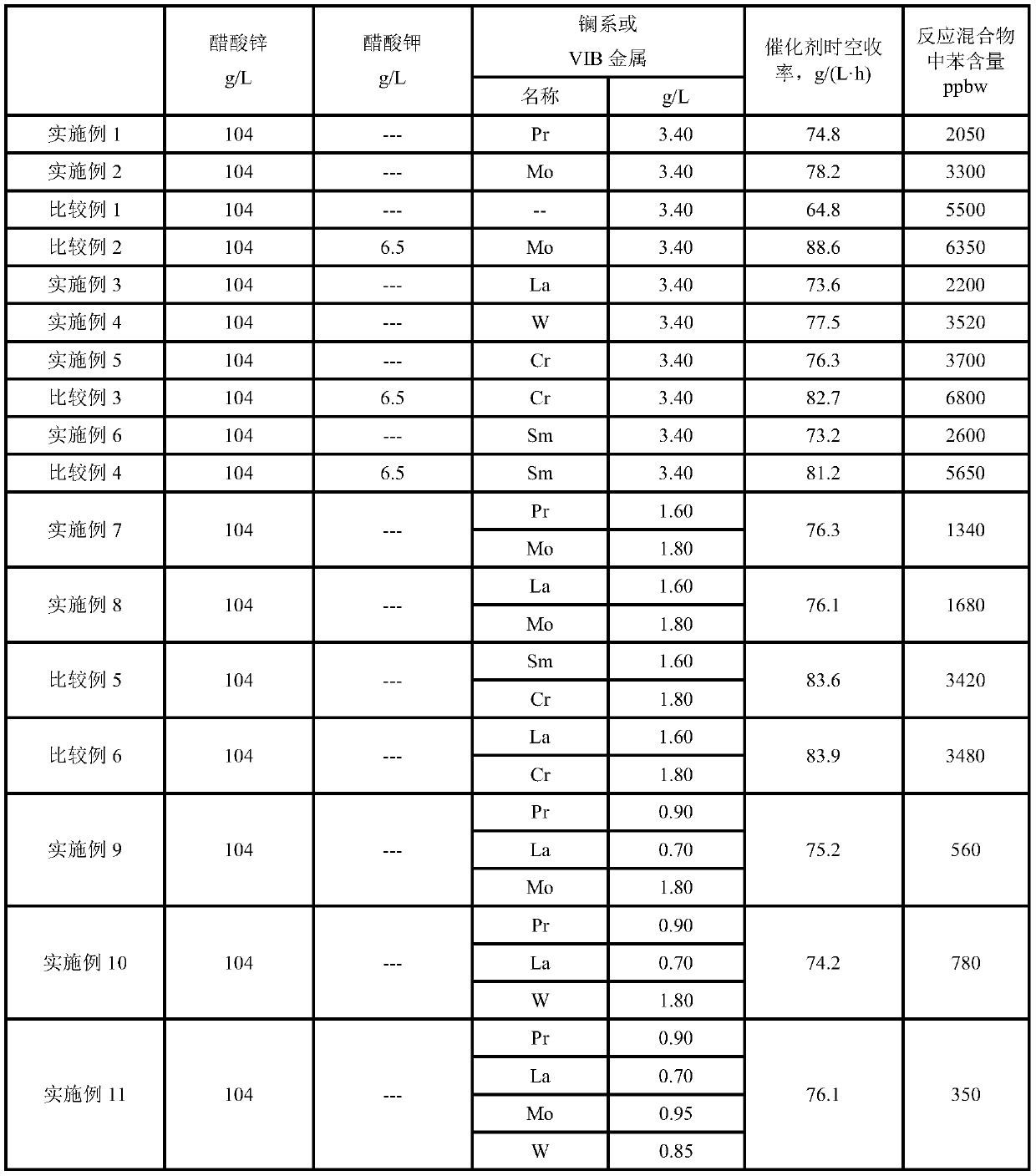

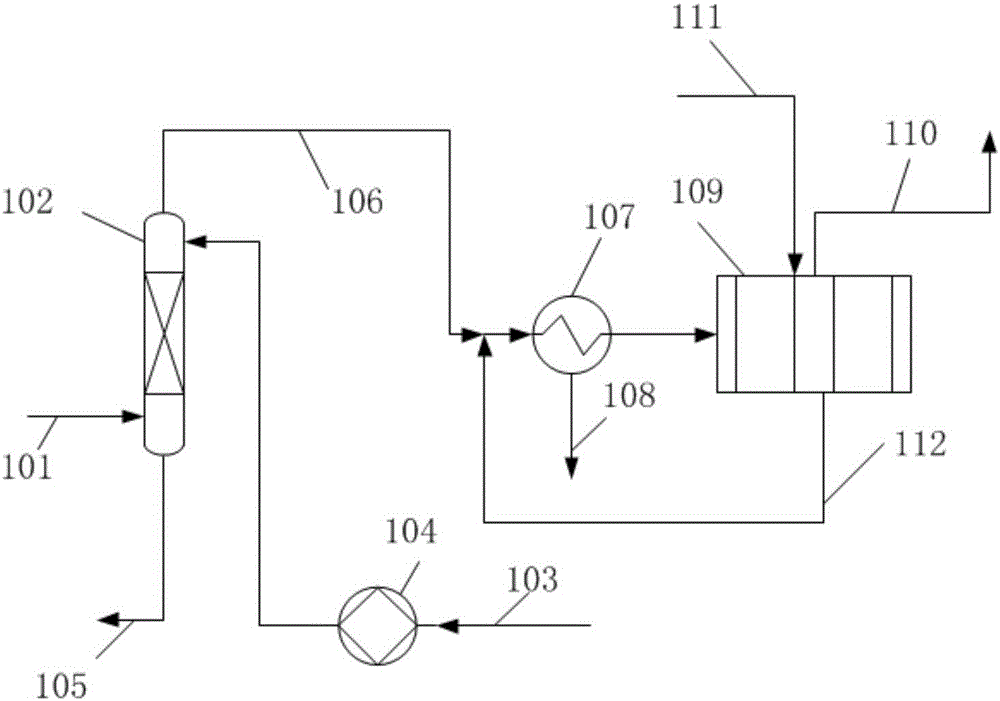

Catalysts for the production of vinyl acetate

ActiveCN107774321BReduce benzene contentOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsBenzeneActive component

Owner:CHINA PETROLEUM & CHEM CORP +1

Low-odor ultraviolet-curing woodenware paint formula

InactiveCN105585940AImprove adhesionImprove heat resistancePolyurea/polyurethane coatingsEpoxy resin coatingsBenzeneEpoxy

The invention discloses a low-odor ultraviolet-curing woodenware paint formula. The paint comprises the following components by weight percentage: 35-50% of epoxy resin, 25-35% of aliphatic polyurethane resin, 8-12% of a monomer EO-HDDA, 8-12% of a monomer EO-TMPTA, 4-7% of a monomer HEMA, 3-6% of a photoinitiator, and 0.2-1% of an auxiliary agent. The auxiliary agent comprises a leveling agent and an antifoaming agent. The prepared paint has the advantages of good adhesive force, high heat resistance, low benzene content, low odor before and after curing is carried out, and little influence on human body.

Owner:彭绍宾

Catalyst for acetylene method vinyl acetate synthesis

PendingCN112439455AHigh activityReduce benzene contentOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsActivated carbonPtru catalyst

The invention relates to a catalyst for acetylene method vinyl acetate synthesis and a preparation method thereof, and mainly aims to solve the problem of high benzene content in a vinyl acetate product in the prior art. According to the technical schemes of the invention, the catalyst for acetylene method vinyl acetate synthesis comprises an active component and a carrier; the active component iszinc acetate; the carrier is nitrogen-doped activated carbon; the content of the N element in the carrier is 2.8-10wt%; and therefore, the problem is better solved, and the method can be used for industrial production of acetylene-method vinyl acetate.

Owner:CHINA PETROLEUM & CHEM CORP +1

Catalyst for Synthesis of Vinyl Acetate by Acetylene Process

ActiveCN107774320BReduce benzene contentOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsBenzeneActivated carbon

The invention relates to a catalyst for synthetizing vinyl acetate by an acetylene method and a preparation method thereof, and mainly solves the problem that in the prior art, the content of by-products of benzene is high. The catalyst for synthetizing vinyl acetate by the acetylene method has the technical scheme that the catalyst uses active carbon as a carrier; active ingredients include zincacetate and cocatalysts; the cocatalysts include at least one metal element selected from lanthanide series metal elements and at least one metal element in VIB elements. The problem is better solved;the catalyst can be used for industrial production of acetylene method vinyl acetate synthesis.

Owner:CHINA PETROLEUM & CHEM CORP +1

Absorption and adsorption treatment method of high-concentration benzene gas

ActiveCN106669215AEmission complianceTo achieve the purpose of purificationGas treatmentDispersed particle separationActivated carbonFiber

The invention relates to an absorption and adsorption treatment method of high-concentration benzene gas. The method comprises the steps of (a) carrying out absorption treatment on the high-concentration benzene gas by using efficient absorption equipment, forming absorption liquid and absorbed gas and recycling the absorption liquid; (b) carrying out condensation treatment on the absorbed gas through a condenser, wherein the condensation temperature is -40 DEG C to 5 DEG C, and forming condensate and a condensed gas after condensation treatment and recycling the condensate; and (c) adsorbing and purifying the condensed gas through activated carbon fiber adsorber, forming a purified gas for discharging, carrying out desorption treatment to form desorbed gas and forming recyclable desorbed gas condensate after condensation. The absorption and adsorption treatment method aims at solving the technical problem of how to reduce the concentration of benzene in the benzene gas to 4mg / Nm<3> or below, and meanwhile, the absorption liquid and the condensate can be separated or can be directly used for other processes. The method provided by the invention is applied to treatment of a benzene material lift truck, tail gas generated by a benzene storage tank and other high-concentration benzene gases.

Owner:BEIJING CREDITCONGRUITY ENERGY TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com