Patents

Literature

1354results about How to "Improve fullness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

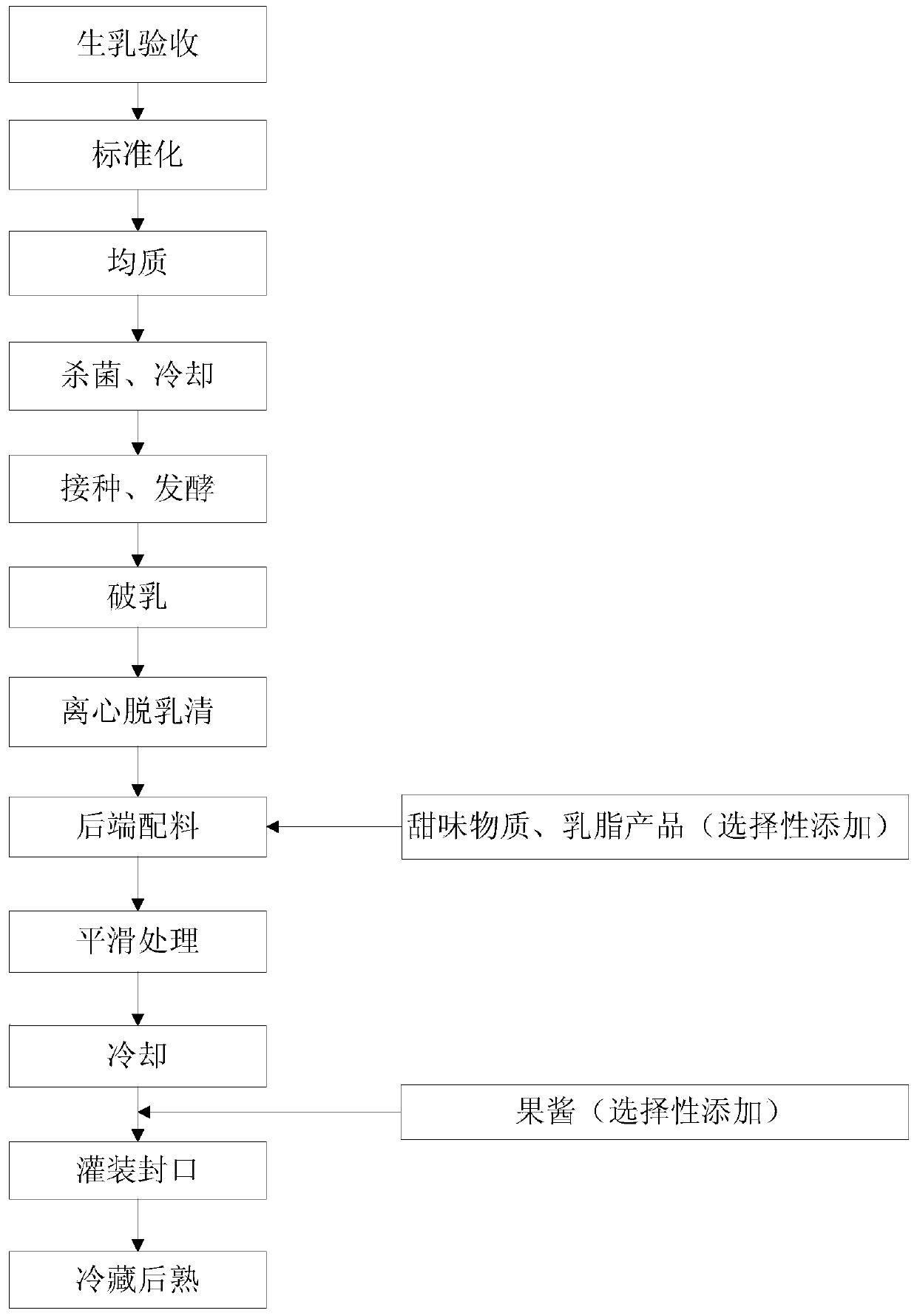

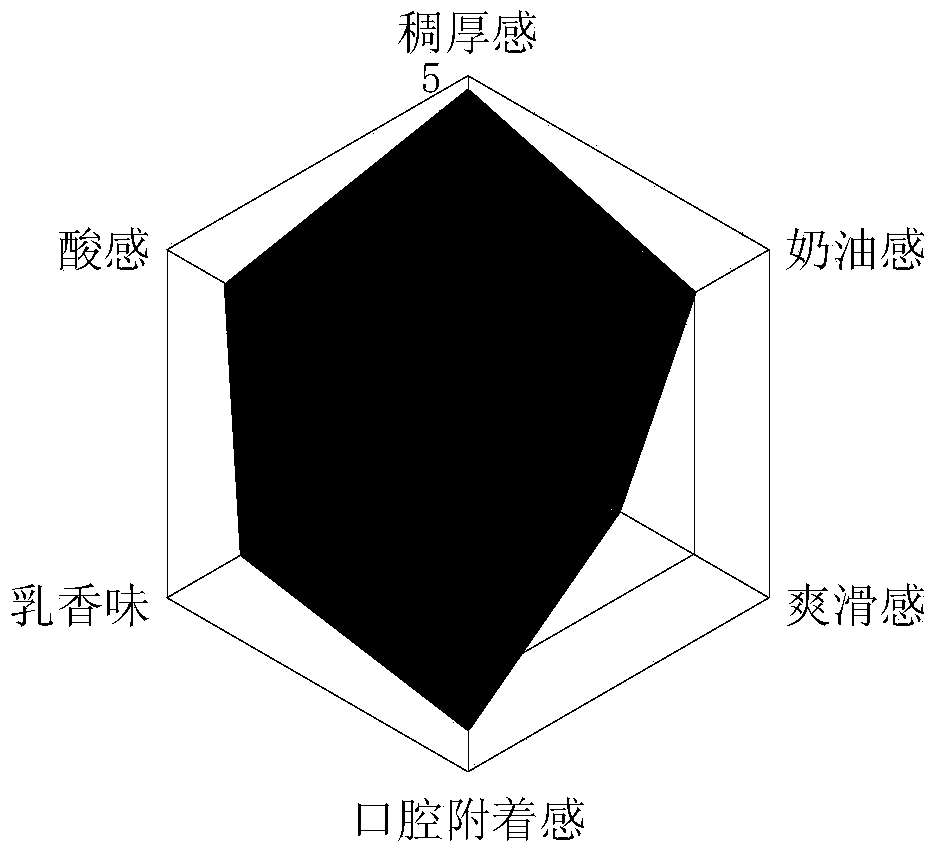

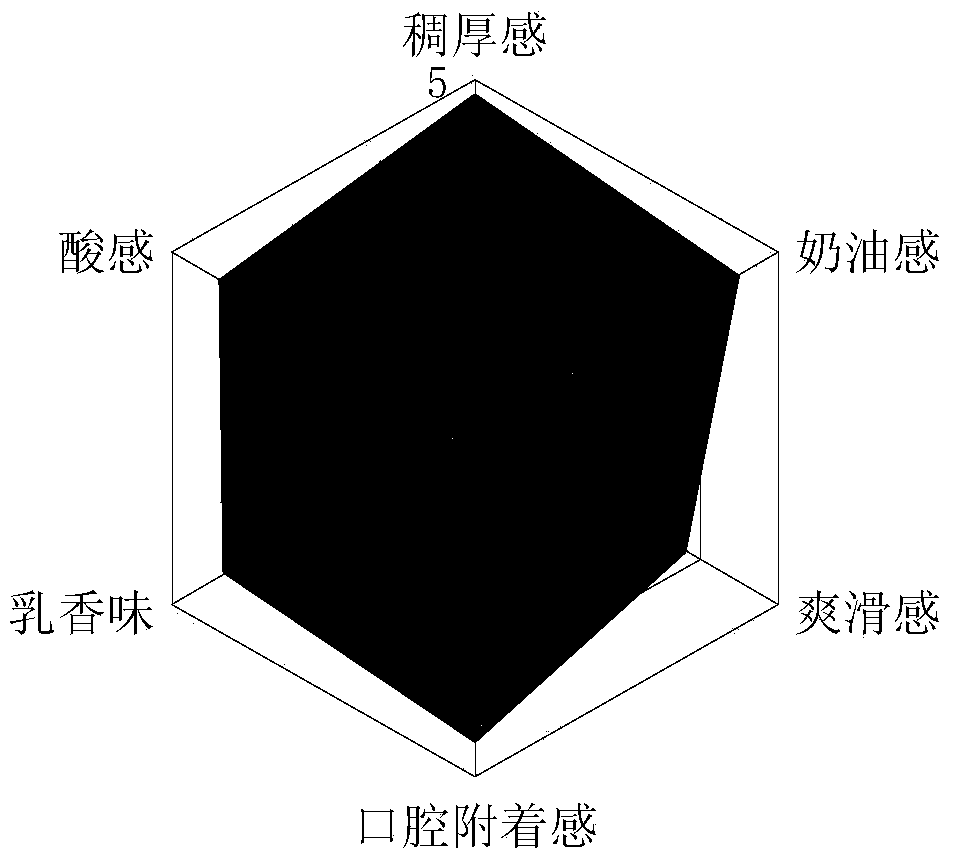

Fermented milk base material, whey-removed flavored fermented milk, raw material composite as well as preparation methods thereof

ActiveCN103431042AReduce production energy consumptionHigh nutritional valueMilk preparationEmulsionChemistry

The invention discloses a fermented milk base material, whey-removed flavored fermented milk, a raw material composite as well as preparation methods of the fermented milk base material, the whey-removed flavored fermented milk and the raw material composite. The preparation method of the fermented milk base material comprises the following steps: (1) homogenizing standard skimmed milk; (2) pasteurizing emulsion; (3) fermenting the emulsion to obtain a curd; and (4) stirring the curd and removing whey by a whey separator, wherein the whey separator is a centrifugal machine with parameters as follows: relative centrifugal force of 500-4000, centrifugation time of 5-30 minutes and centrifugation temperature of 38-45 DEG C. The raw material composite of the whey-removed flavored fermented milk contains the fermented milk base material and sweet substances. The preparation method of the whey-removed flavored fermented milk comprises the steps of mixing the fermented milk base material with the sterilized sweet substances, and performing smoothing. The whey-removed flavored fermented milk has improved nutritive value, improved taste texture, enhanced stability and enhanced water-retaining property, and can well meet the requirements of consumers suffering from lactose intolerance.

Owner:BRIGHT DAIRY & FOOD

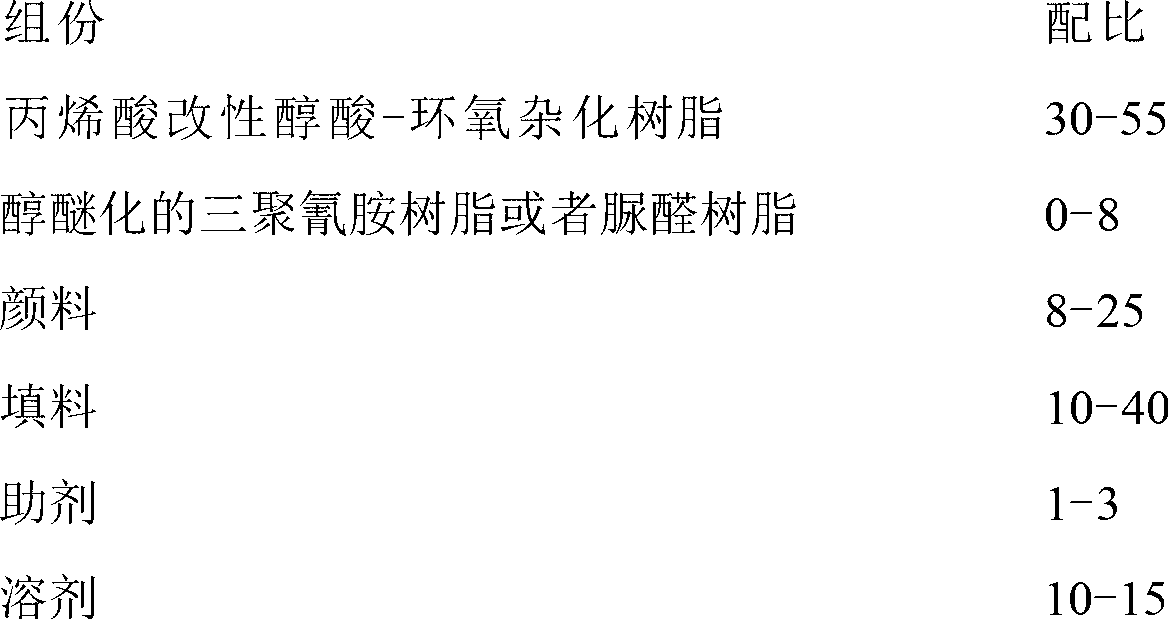

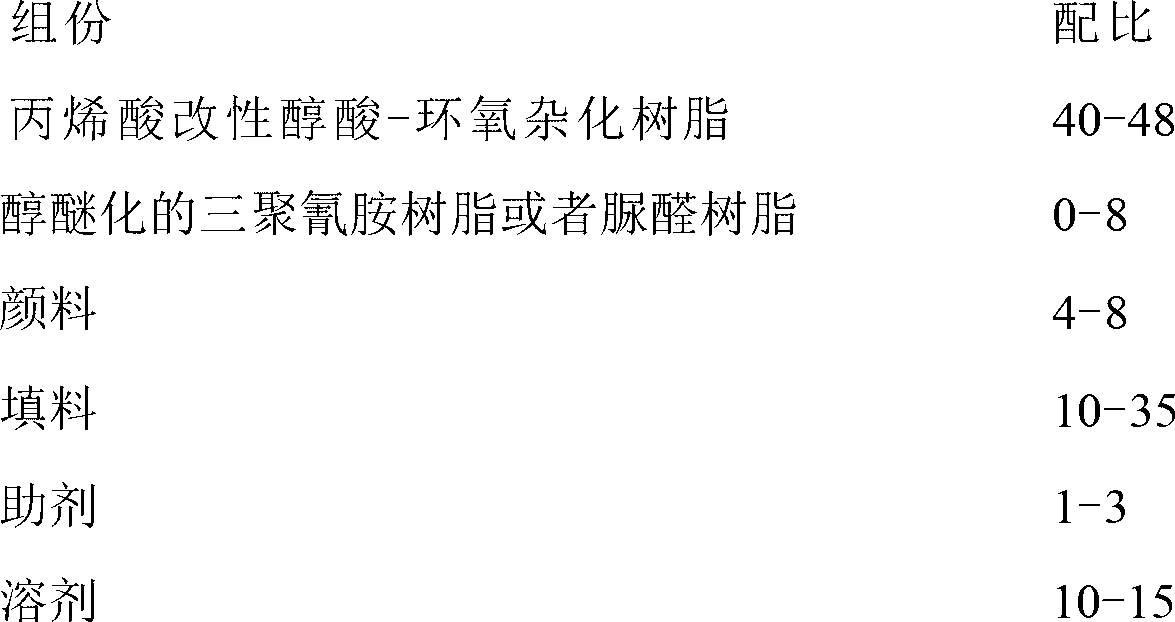

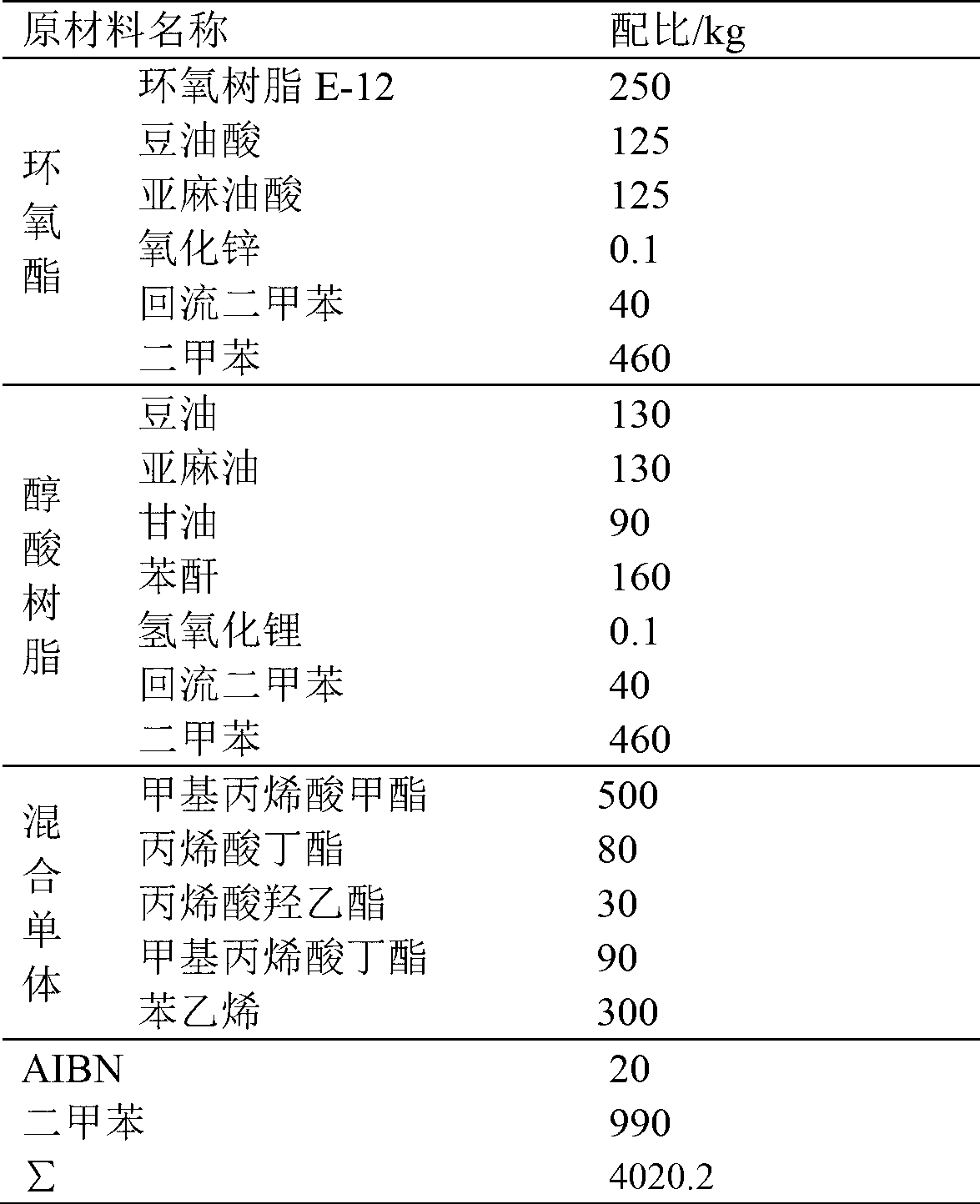

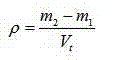

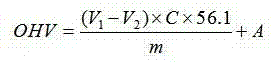

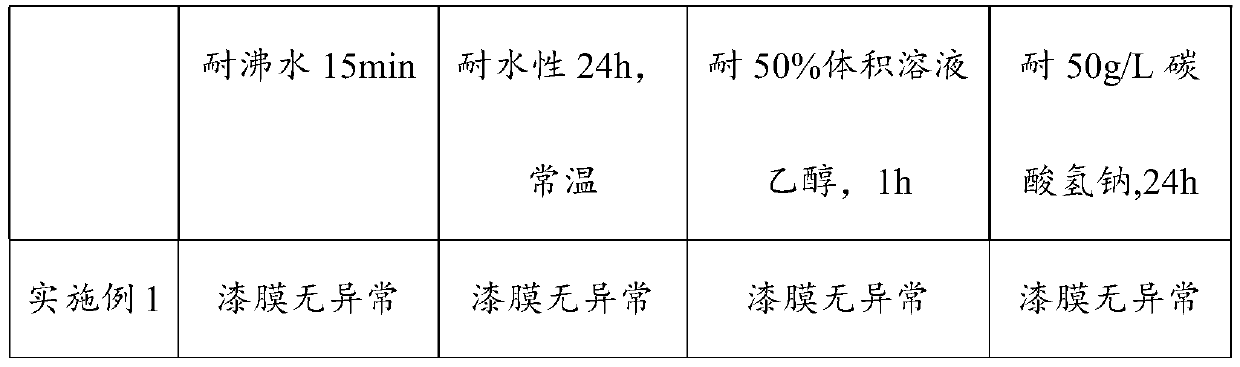

Acrylic-modified alcohol acid-epoxy ester hybrid resin and paint thereof

The invention relates to an acrylic-modified alcohol acid-epoxy ester hybrid resin which is prepared by the following steps: carrying out high-temperature esterification reaction on an epoxy resin and fatty acid under the action of an esterification catalyst to obtain epoxy ester; carrying out alcoholysis on vegetable oil and polyalcohol at high temperature, cooling, and adding polybasic acid for esterification, thereby obtaining an alkyd resin; and adding acrylic monomers into the epoxy ester-alkyd resin mixed solution, and carrying out graft polymerization under the action of an initiator to obtain the hybrid resin. The hybrid resin can be used as a main film forming material to prepare a high-temperature baking varnish together with a crosslinking agent. The high-temperature baking varnish can be used as various curtain-coating mirror back paints, including silver mirror back paints, aluminum mirror back paints, glass paints and the like, can satisfy the technological requirements for application of curtain coating production lines of which the width exceeds 3m, has a stable curtain coating, and can become completely dry after being baked at 150-130 DEG C for 3-5 minutes. The product has the advantages of low-temperature quick drying, high hardness, excellent adhesive force, dampness-heat resistance, chemical resistance, salt-fog resistance and the like.

Owner:常州市弘可利办公用品有限公司 +1

Quick-drying hydroxylated acrylic resin water dispersion and preparation method and use thereof

ActiveCN102161770AGood pigment wettingImprove performancePolyurea/polyurethane coatingsAcrylic resinPrepolymer

The invention relates to quick-drying hydroxylated acrylic resin water dispersion and a preparation method and use thereof, in particular to quick-drying aqueous automobile repair solid color paint prepared from the hydroxylated acrylic resin dispersion. The invention discloses a method for preparing the hydroxylated acrylic resin dispersion, which comprises: A, preparing a prepolymer of hydroxylated acrylic resin; and B, preparing aqueous prepolymer of the hydroxylated acrylic resin. And the invention also discloses a method for preparing quick-drying aqueous automobile repair solid color paint by using the dispersion. The coating of the quick-drying aqueous automobile repair solid color paint is accomplished at a low temperature or even at normal temperature, so the volatile organic compound (VOC) emission in a coating process of an automobile is reduced and energy conservation and emission reduction are realized. Thus, the quick-drying aqueous automobile repair solid color paint can be promoted and used easily.

Owner:广东绚缤材料科技有限公司

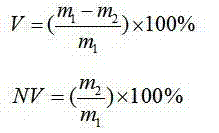

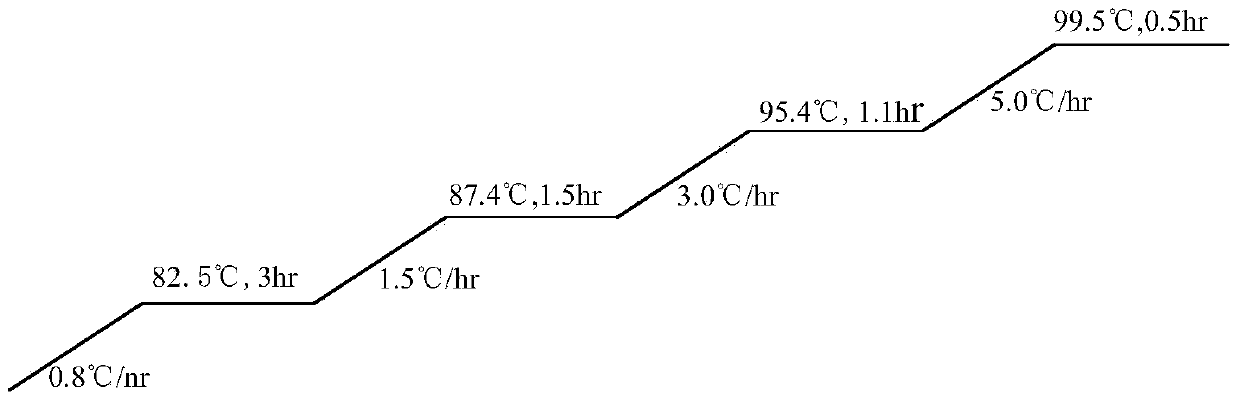

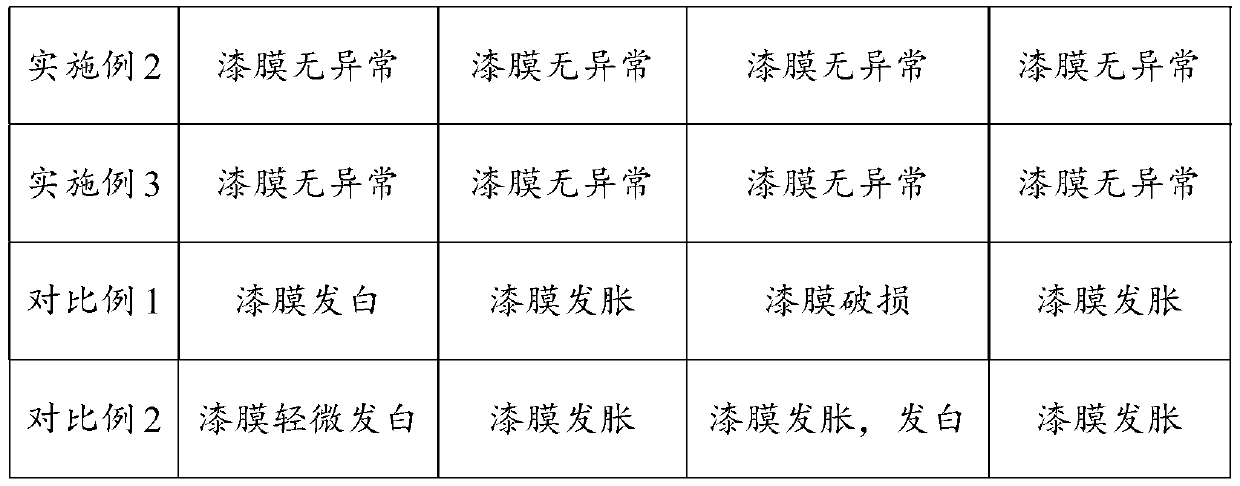

Method for preparing malts with high malt aroma and beer thereof

ActiveCN103773642AImprove foam stabilityRaise the level of freshnessMalt preparationBiotechnologyMaillard reaction

The invention relates to the field of malting and in particular relates to a method for preparing malts with high malt aroma and beer thereof. The method mainly comprises the following steps: selecting wheat, raw material pretreatment, steeping, sprouting, green malt drying, kilning and removing roots. According to the steeping and sprouting process, the sprouting uniformity is improved, lots of amino acids and reducing sugars are generated under the optimum water activity conditions, the degree of a Maillard reaction is controlled through the drying and gradient temperature rise kilning process, specific malt aroma components are generated, and due to sensory evaluation, the malt has pure and strong aroma, is clean and coordinative and does not have burnt taste and other odors. The method is used for improving the content of malt aroma substances in the malt, the defects that the malt prepared in the prior art is not obvious in aroma and partial specific malts have obvious burnt taste except certain malt aroma are overcome, the technical problem that the malt is aromatic but easily burnt is effectively solved, pure and strong malt aroma is presented, the malt can be used for preparing high-malt aroma wort or high-malt aroma beer, and the typical flavor characteristics of the malt aroma of the beer are reflected.

Owner:TSINGTAO BREWERY

Flat varnish for waterborne wood

The invention discloses a flat varnish for waterborne wood, comprising the following components in parts by weight: 30-70 percent of waterborne acrylic emulsion, 0-30 percent of waterborne aliphatic polyurethane and mixture emulsion, 3-10 percent of film forming aid, 0.01-2 percent of antifoaming agent, 0.01-2 percent of dispersing agent, 0.1-5 percent of extinction powder, 0-2 percent of wettingagent, 0.01-2 percent of rheological additive, 0.01-2 percent of wax additive, 0.01-2 percent of hand-feeling addictive, 0.01-2 percent of thickening agent, 0.01-2 percent of ammonia water, 0.01-2 percent of coupling agent and 5-30 percent of water. The flat varnish for waterborne wood has the advantage of ensuring that a varnish film has better fullness, hardness, high chemical resistance, super-strong hand feeling and strong adhesive force on an oil primer. In addition, the flat varnish for waterborne wood can solve the compatibility between the aquosity and the oilness, ensure the varnish film cannot fall off after being dried and can meet the requirement for consumers on high environmental protection, low odor and less pollution.

Owner:HUIZHOU CHANGRUNFA PAINT

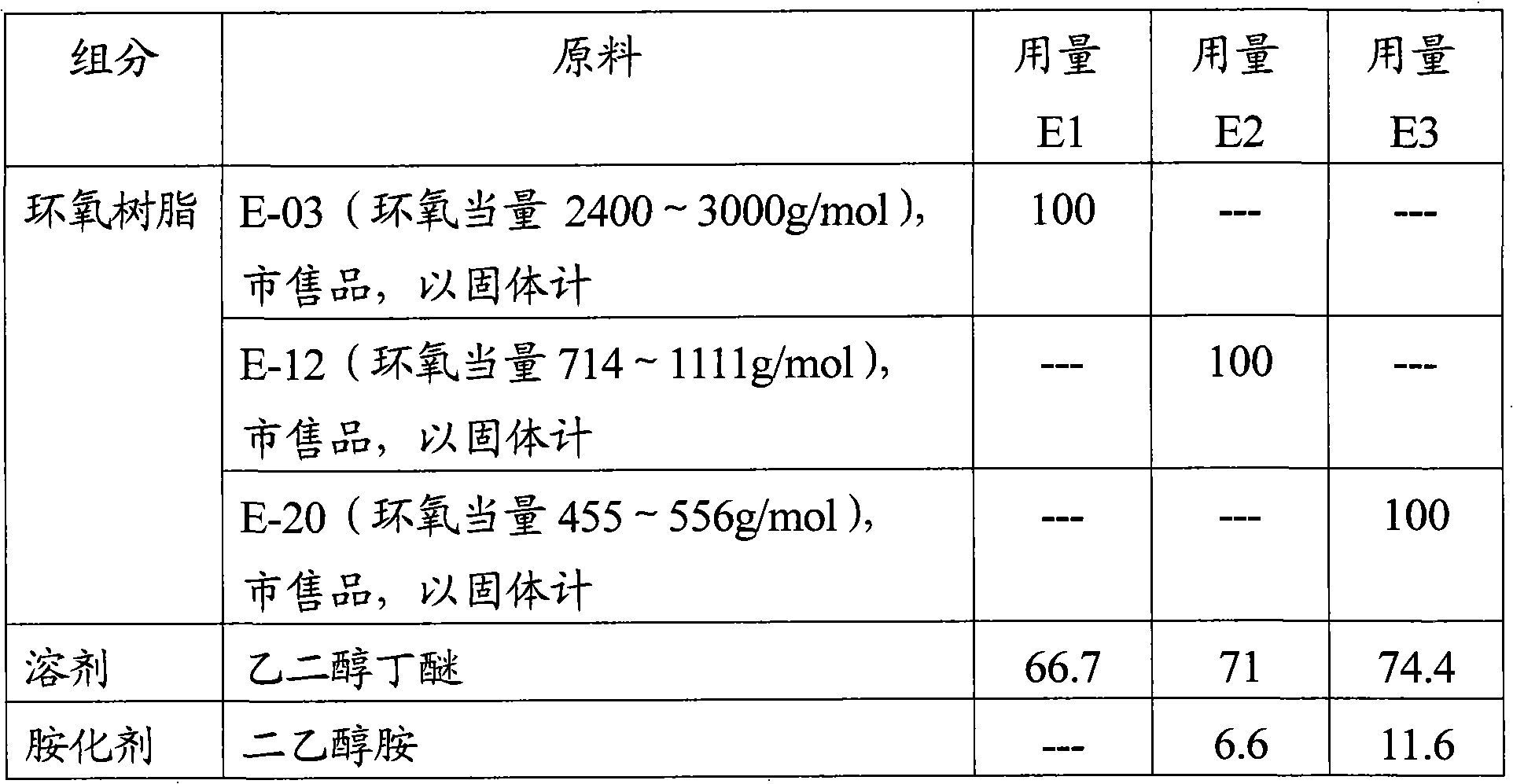

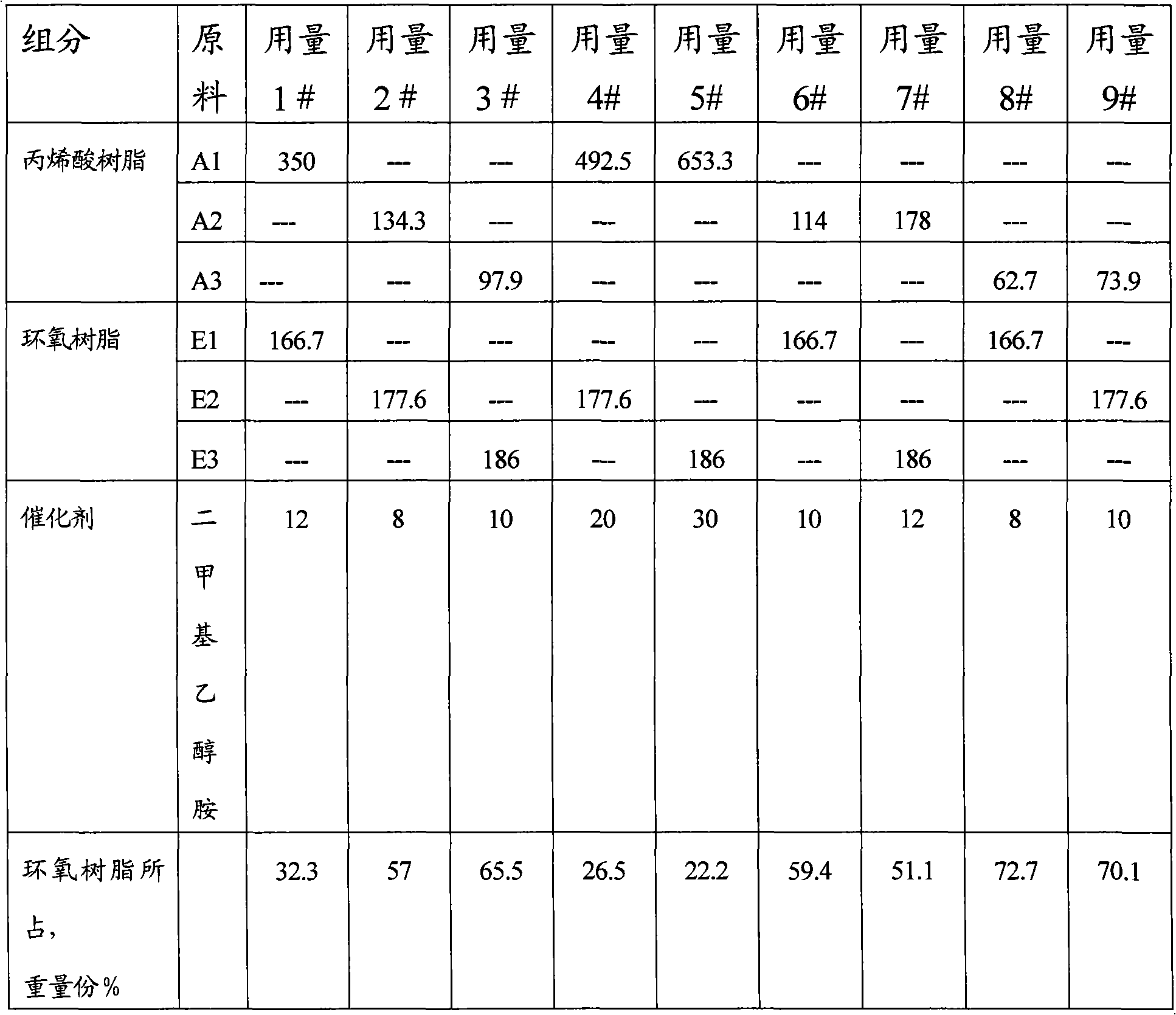

Water soluble acrylic acid epoxy resin and preparation method thereof

The invention relates to water soluble acrylic acid epoxy resin and a preparation method thereof. The epoxy resin is emulsion formed by neutralizing and self-emulsifying a product of a catalytic esterification reaction of acrylic acid resin and epoxy resin, and the variation of tu-4 cup viscosity of the emulsion stored for 6 months is less than 5 percent; epoxy equivalent of the epoxy resin is between 180 and 5,000g / mol, and the epoxy resin accounts for 10 to 80 percent of gross weight of the epoxy resin and the acrylic acid resin; the acrylic acid resin is polymerized from hydroxyl-containing acrylic acid, carboxyl-containing acrylic acid, other acrylic acids and styrene monomers which are initiated by peroxide, and has the acid value of between 50 and 500mgKOH / g and the number average molecular weight of between 5,000 and 60,000g / mol; and the epoxy resin with the epoxy equivalent less than 1,300g / mol does not need bisphenol A chain extension, has simple operation, and is convenient for regulating the proportion of the epoxy resin. The method can be used for preparing the water soluble acrylic acid epoxy resin with wider proportion of the epoxy resin and stable storage.

Owner:CNOOC CHANGZHOU PAINT & COATINGS IND RES INST +1

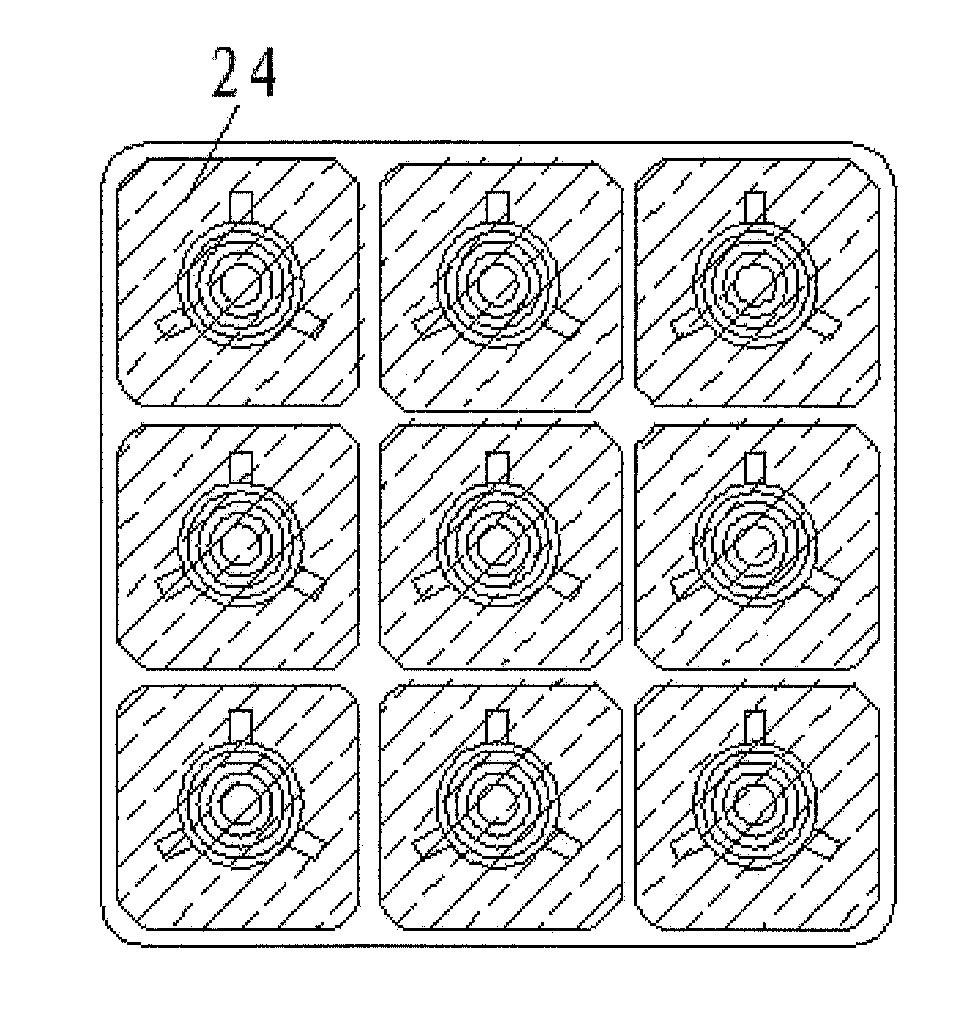

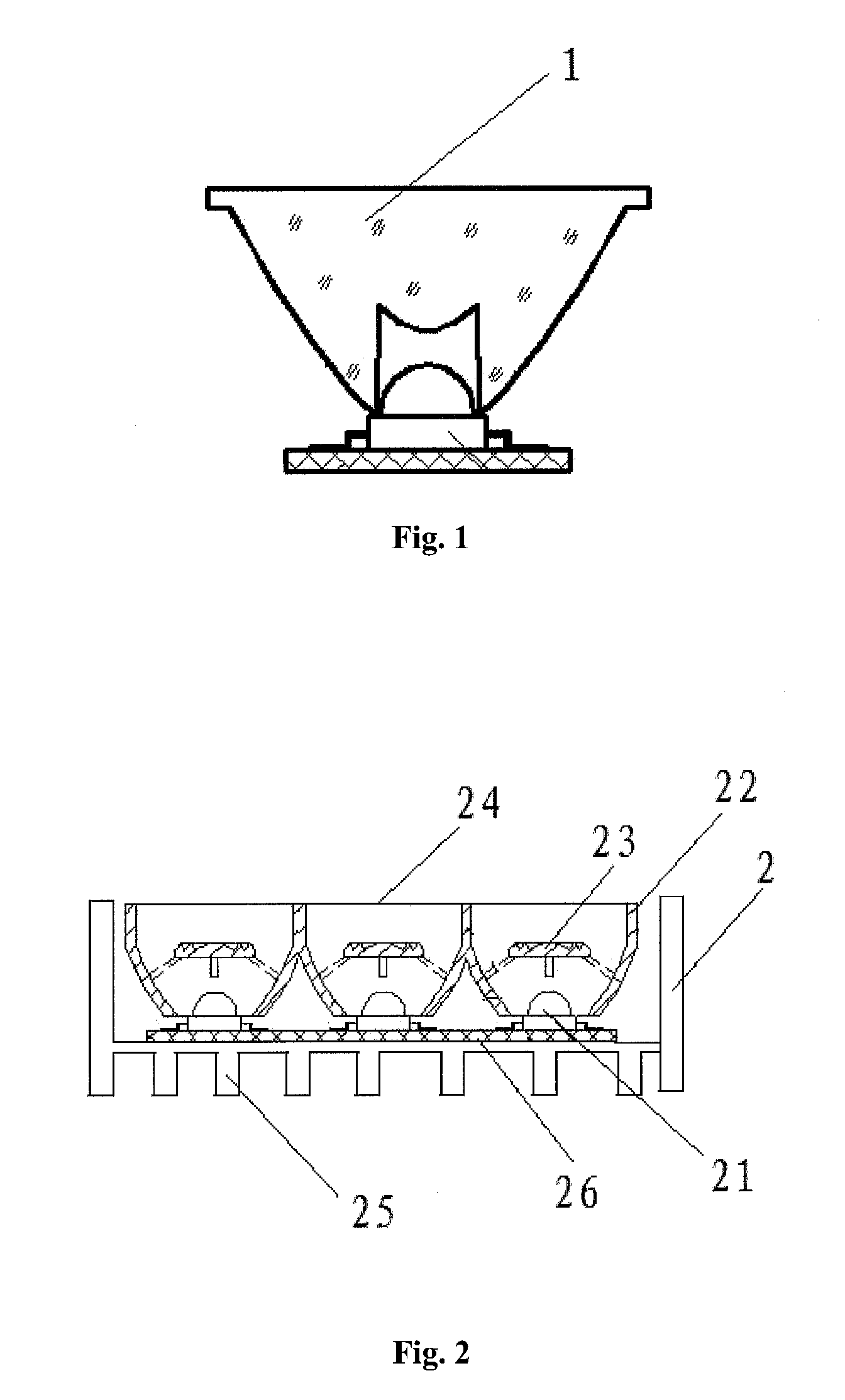

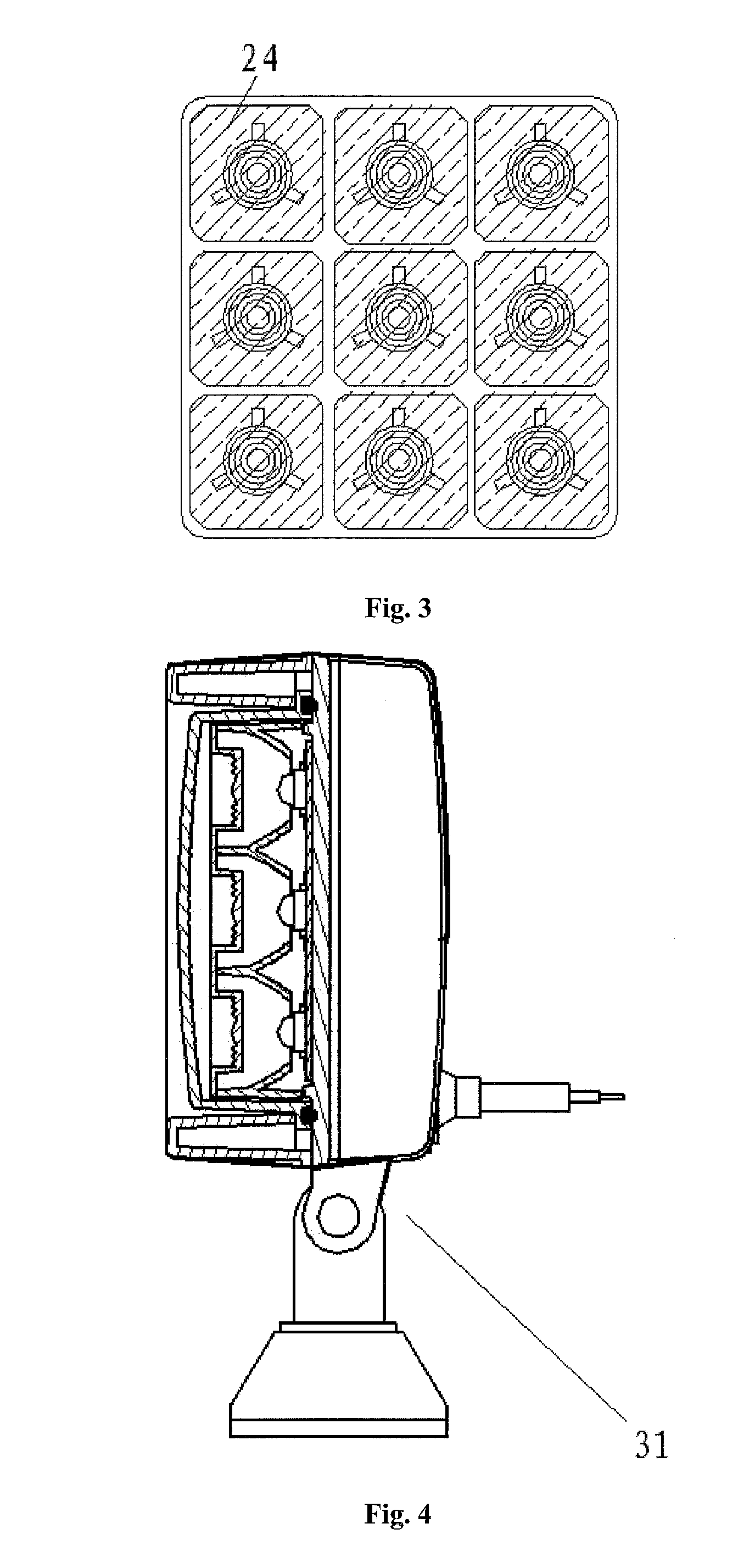

Highly-efficient and high-power LED light source, an LED lamp which uses the light source and the application of the lamp

InactiveUS20110228534A1Improve luminous efficiencyImprove fullnessPlanar light sourcesLighting support devicesEngineeringLED lamp

The present invention relates to a highly-efficient and high-power LED light source and LED lamp which uses the light source and the application of the lamp, particularly relates to a high-power LED light source and to a high-power LED lamp which uses such light source, and also to the application of such lamp. A highly-efficient and high-power LED light source comprising an LED, a condenser which condenses the light of the LED, wherein the said condenser is a concave mirror, and wherein the emitting part of the said LED is located at the focus of the concave mirror; and a converging lens which is located in front of the said LED, wherein the focus of the said converging lens is located at the emitting part of the said LED. The present invention solved the problem of low luminous efficiency of existing high-power LED light sources, and the problem of inadequate fullness and softness of the light emitted by existing high-power LED light sources.

Owner:上海开腾信号设备股份有限公司

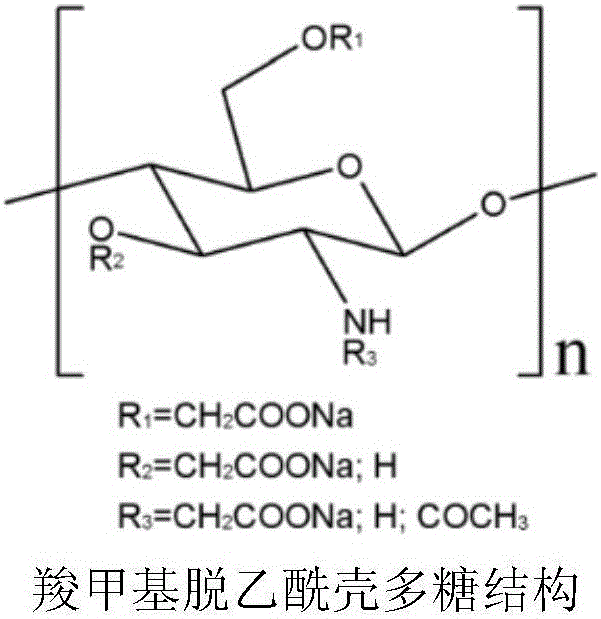

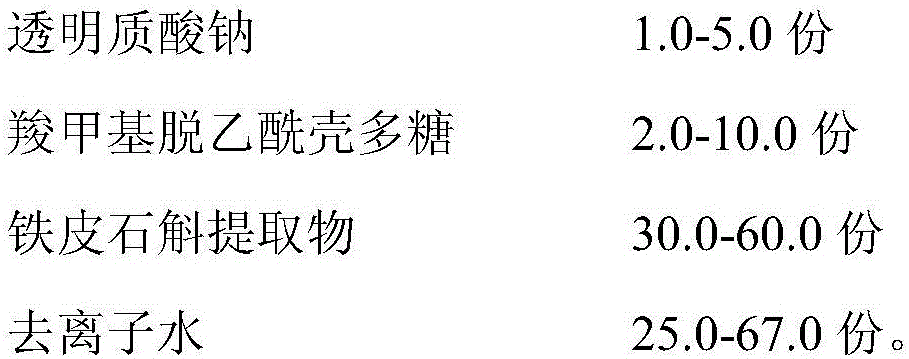

Moisturizing composition, and preparation method and application thereof

ActiveCN106727164AImprove moisturizing functionRaise the barrierCosmetic preparationsToilet preparationsLoss rateSkin barrier function

The invention relates to a moisturizing composition, and a preparation method and application thereof, which belong to the field of cosmetics. The moisturizing composition is prepared from the following components in parts by weight: 1.0 to 5.0 parts of sodium hyaluronate, 2.0 to 10.0 parts of carboxymethyl deacetyl chitosan, 30.0 to 60.0 parts of dendrobium officinale extract, and 25.0 to 67.0 parts of deionized water. The moisturizing composition can well form a netted natural biomimetic membrane with skin, the sodium hyaluronate performs the water supplementation and moisturizing in the biomimetic membrane, the carboxymethyl deacetyl chitosan forms a biomimetic sterile membrane, so that natural moisturizing factors such as the sodium hyaluronate can be effectively locked, the water loss rate is decreased; and the dendrobium officinale polysaccharide is combined with the natural biomimetic sterile membrane, so that the moisturizing lasting property after long-term use can be further improved, the restoration effect is improved, and the dryness and allergy problems of the skin can be fundamentally solved. The moisturizing composition has multidimensional efficacy such as moisturizing function, restoration function and skin barrier increasing function.

Owner:广西诗琳茉莉生物科技集团有限公司

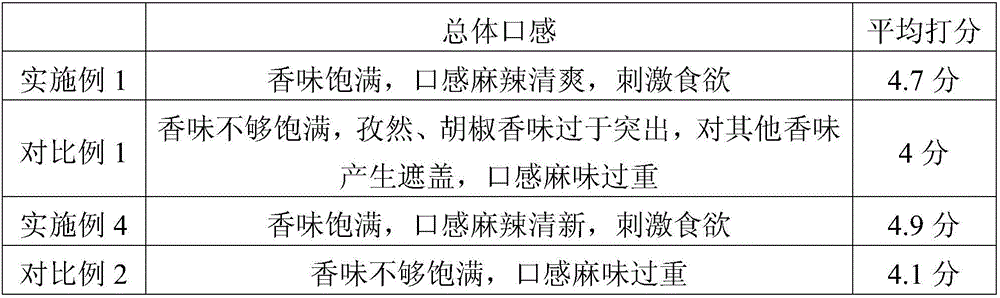

Spicy chilli oil and preparation method thereof

InactiveCN106212732ASpicy and full-bodiedLong-lasting fragranceEdible oils/fatsStar AnisesPericarpium citri reticulatae

The invention relates to the technical field of food processing, in particular to spicy chilli oil and a preparation method thereof. The spicy chilli oil is prepared from the following raw materials in parts by weight: 70 to 90 parts of vegetable oil, 5 to 10 parts of chilli, 5 to 10 parts of Sichuan pepper, 1 to 2 parts of shallot, 1 to 2 parts of ginger, 0.1 to 0.5 part of myrcia, 0.3 to 0.8 part of fructus amomi, 0.5 to 1 part of star anise, 0.1 to 0.5 part of cinnamon, 0.3 to 0.8 part of amomum tsao-ko, 0.3 to 0.8 part of cumin, 0.1 to 0.5 part of fennel, 0.1 to 0.5 part of kaempferiae, 0.1 to 0.5 part of pepper, 0.1 to 0.5 part of radix angelica sinensis, 0.1 to 0.5 part of pericarpium citri reticulatae, 0.1 to 0.5 part of clove and 0.05 to 0.15 part of radix angelicae. Under the synergistic effect of the raw materials for preparing the chilli oil, the chilli oil has full and durable fragrance, and spicy and fresh mouthfeel. Under combination of the limited oil temperature and the raw material adding sequence in the preparation method provided by the invention, the fragrance and the moutfeel of the chilli oil are further improved.

Owner:郑州雪麦龙食品香料有限公司

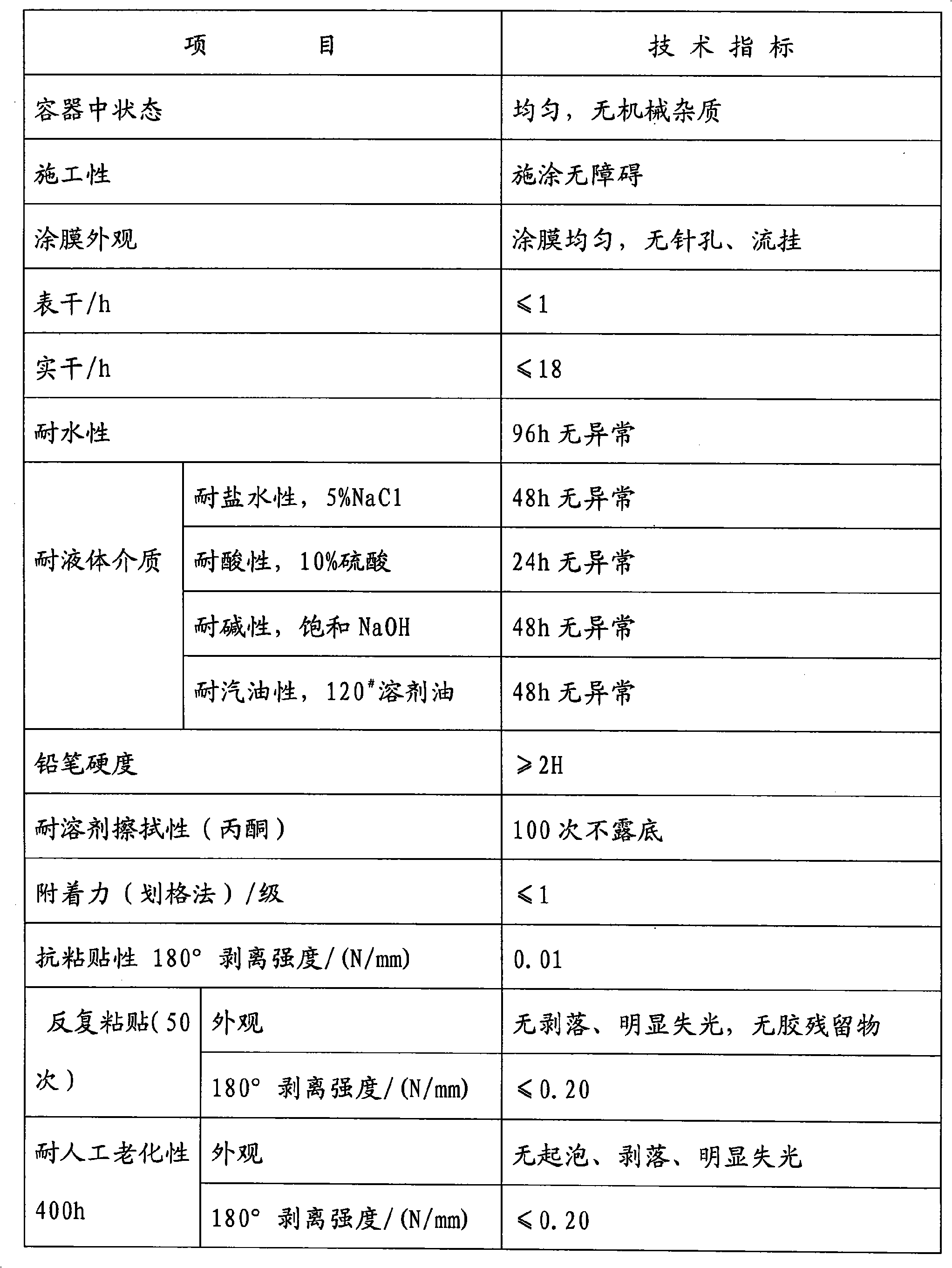

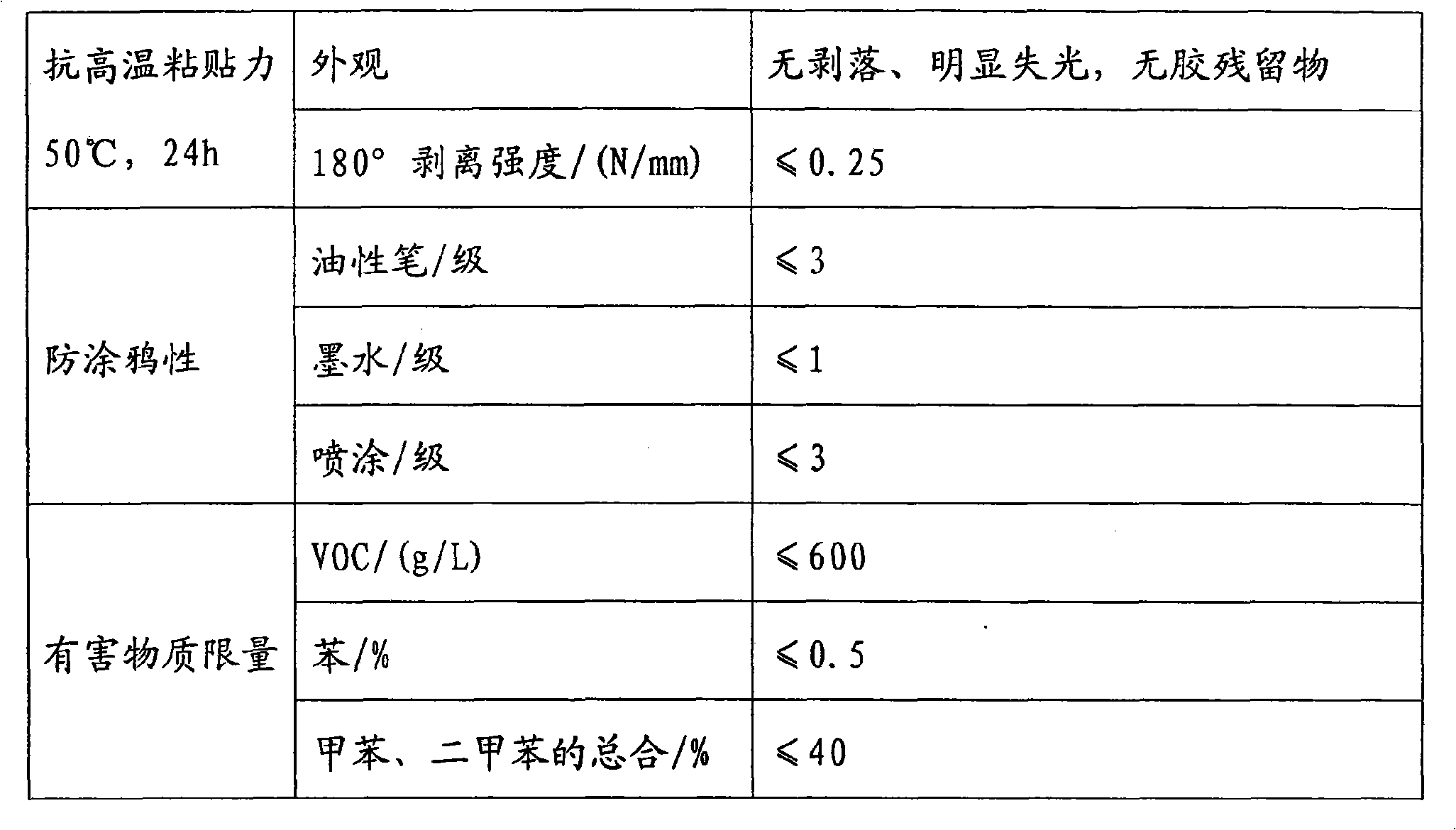

Oil-based anti-graffiti adhesion resistant paint and preparation method thereof

ActiveCN101585995AHigh hardnessImprove self-cleaningPolyurea/polyurethane coatingsAcrylic resinPolydimethyl siloxane

The invention discloses oil-based anti-graffiti adhesion resistant paint and a preparation method thereof, and belongs to paint and a preparation method thereof. Components A of the paint comprise hydroxy acrylic resin, fluorocarbon resin, modified polydimethyl siloxane resin, polyacrylate modified organic silicon resin, smooth flow agent, flatting agent, antifoaming agent, drier, dibutyl tin laurate, butyl acetate and dimethyl benzene; components B comprise hexamethylene diisocyanate, butyl acetate and ethylene glycol monoethyl ether acetate; and the mixture ratio of the components A to the components B is 3:1. The invention also discloses the preparation method thereof. The paint has the advantages of good anti-graffiti adhesion resistant function, super-strong scrubbing resistance, easy cleaning, and quick and convenient construction, has limited harmful substances, and achieves national requirement.

Owner:LANZHOU XUNMEI PAINT IND TECH

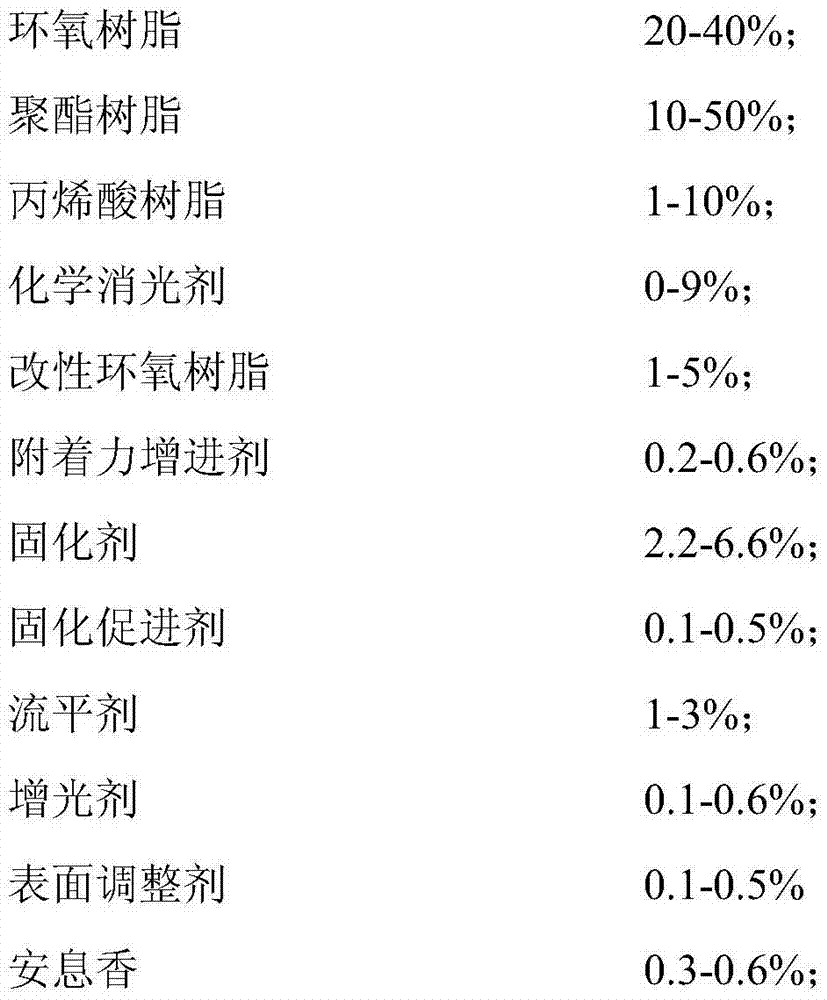

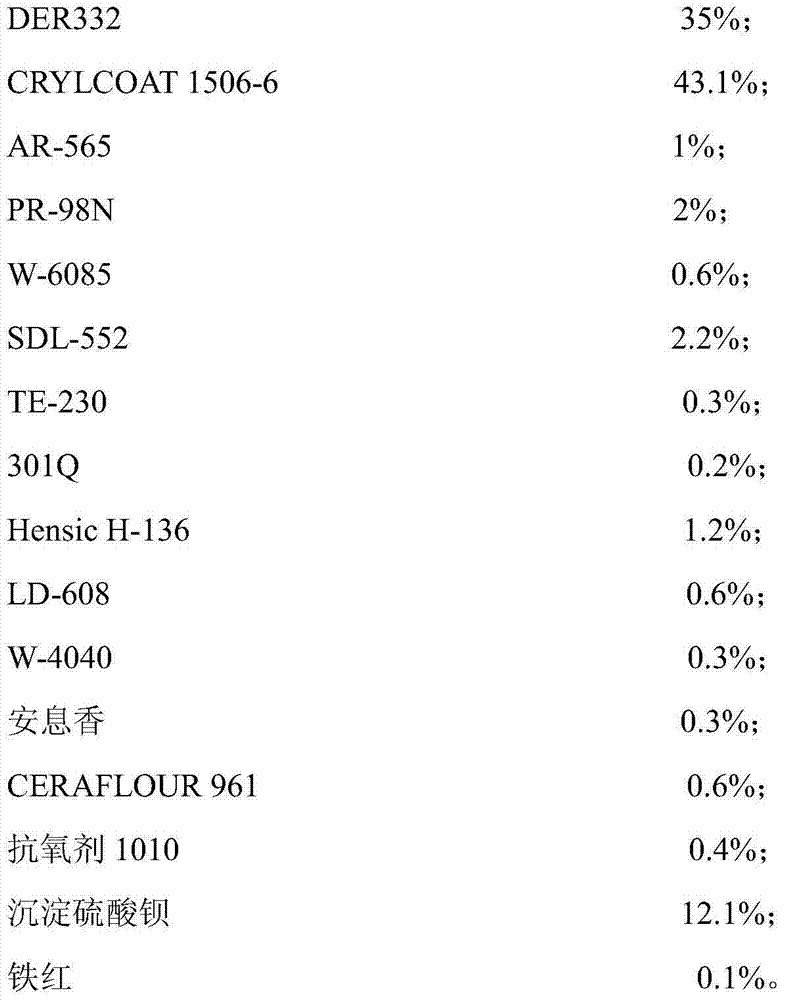

Super-levelling low-temperature curing powder coating for MDF

PendingCN104497797AAdjust glossImprove the level ofPowdery paintsEpoxy resin coatingsEpoxyAcrylic resin

The invention belongs to the field of functional powder coatings, and particularly relates to a super-levelling low-temperature curing powder coating for an MDF. The powder coating is prepared from the following raw materials in percentage by weight: 20%-40% of epoxy resin, 10%-50% of polyester resin, 1%-10% of acrylic resin, 0-9% of a chemical flatting agent, 1%-5% of modified epoxy resin, 0.2%-0.6% of an adhesion promoter, 2.2%-6.6% of a curing agent, 0.1%-0.5% of a curing accelerator, 1%-3% of a flatting agent, 0.1%-0.6% of a gloss enhancer, 0.1%-0.5% of a surface conditioning agent, 0.3%-0.6% of benzoin, 0.2%-0.8% of a degassing agent, 0.3%-0.7% of an antioxidant, and 10%-20% of filler and pigment. According to the super-levelling low-temperature curing powder coating, the glossiness is adjusted by adjusting the amount of acrylic resin and the chemical flatting agent; highlight, matt and flat coats can be prepared; and the super-levelling low-temperature curing powder coating has the advantages of excellent levelling property, good adhesive force and low curing temperature.

Owner:山东朗法博粉末涂装科技有限公司

Anti-sagging spraying prime coat

InactiveCN102732133AEasy to fillGood flexibilityPolyurea/polyurethane coatingsEpoxy resin coatingsPolyesterPolymer science

The present invention discloses an anti-sagging spraying primer coat, which comprises, by weight, 10-25% of a two functionality aliphatic polyurethane acrylate, 20-30% of a modified epoxy acrylate, 10-20% of a polyester acrylate, 10-15% of a monomer, 25-30% of a filler, 3-5% of a photoinitiator, 0.5-2% of an anti-sagging additive, 0.2-0.5% of an anti-foaming agent, and 0.1-0.3% of a leveling agent. With application of the UV paint as the spraying primer coat, the problem of sagging during a coating process can be avoided, the whole coating efficiency can be improved, the environment-friendly characteristic is provided, and the organic solvent emission can be reduced.

Owner:HUIZHOU CHANGRUNFA PAINT

Dual-purpose modification process for native breed sheepskin leather

InactiveCN102839236AHas softnessIncrease shrinkage temperatureTanning treatmentPre-tanning chemical treatmentExtensibilityWork in process

The invention discloses a dual-purpose modification process for native breed sheepskin leather. The process sequentially comprises the following steps of processing native breed sheepskin semi-finished products: (1) classifying skin; (2) returning water; (3) soaking; (4) softening; (5) pickling; (6) performing chromium aluminum tanning; (7) performing tanning post-processing; (8) performing chrome retanning; (9) performing chrome retanning before dyeing; and (10) dyeing. According to the dual purpose modification process, commercially available native breed semi-finished skin (namely white skin) is processed, and the native breed semi-finished skin is tanned by increasing aldehyde aluminum tanning particularly, so that the extensibility of the native breed sheepskin can be effectively improved, the problem of dyeing defects is solved, and the uniformity in the post dyeing is ensured. The dual purpose modification process is matched with other steps and appropriate additives, and each additive is added according to reasonable additive amount, so that the final products have good handfeeling, high tearing resistance and high fullness, and the quality of the native breed sheepskin leather is greatly improved.

Owner:桐乡市雄鹰皮草股份有限公司

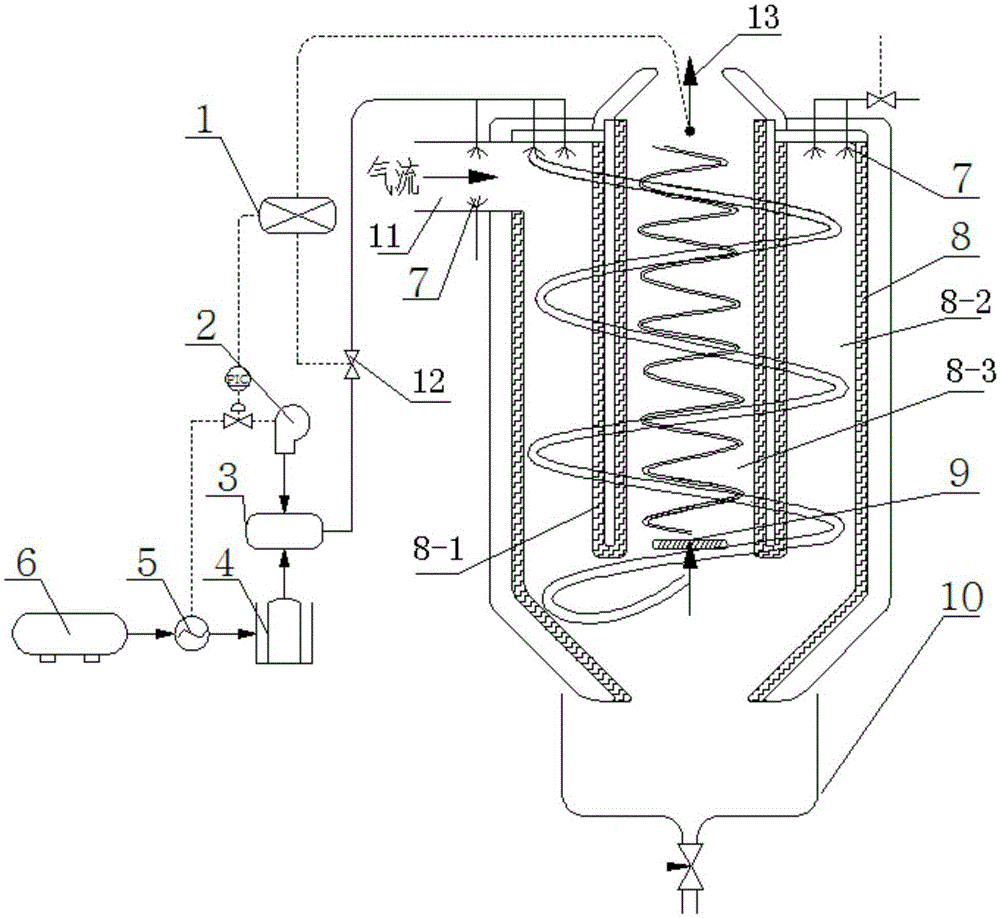

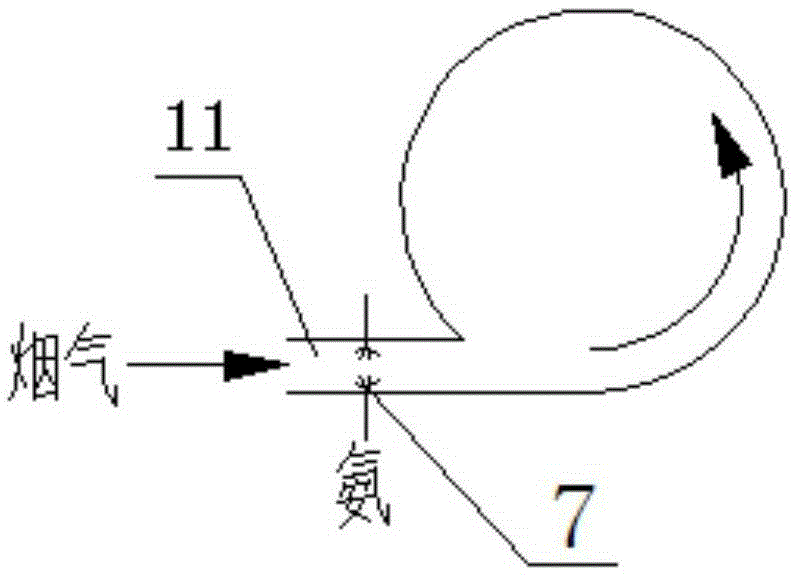

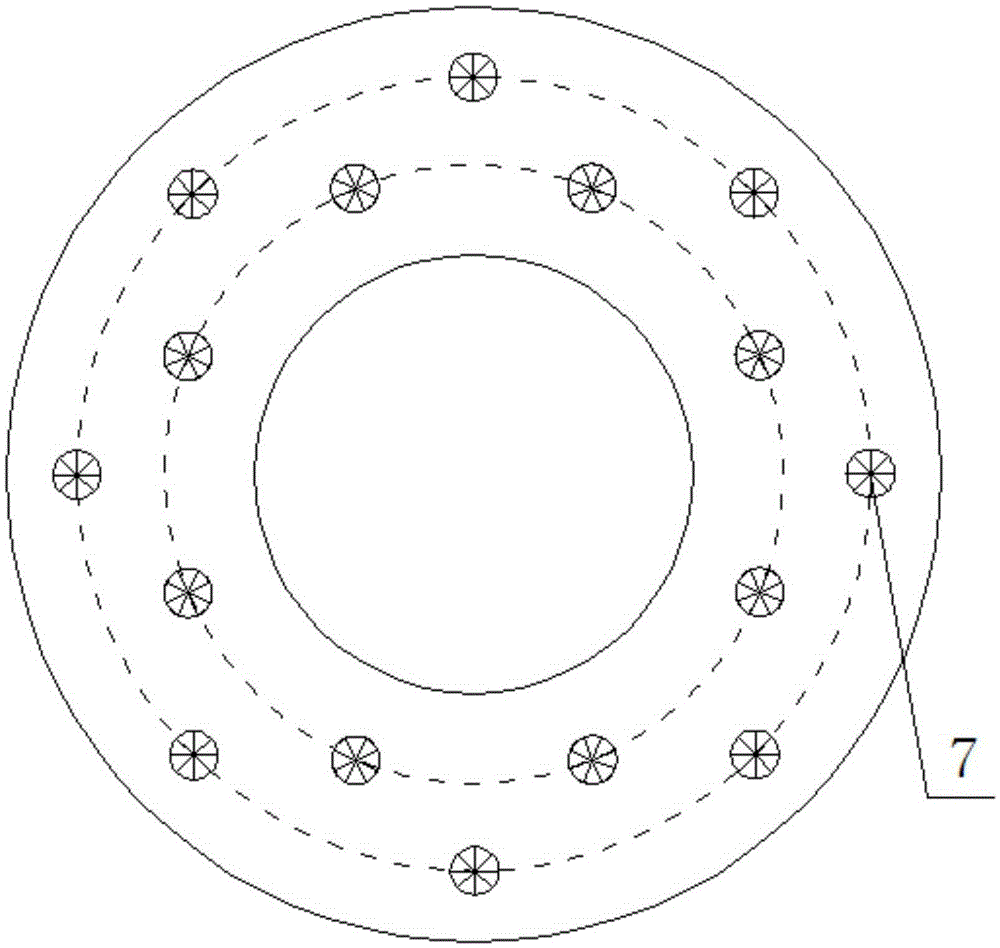

Double-rotation SCR denitration method and apparatus thereof

ActiveCN105289301AImprove denitrification efficiencyIncrease contact timeDispersed particle separationCycloneFlue gas

The invention discloses a double-rotation SCR denitration method and an apparatus thereof. According to the invention, a first eddy flow catalytic reaction chamber and a second eddy flow catalytic reaction chamber are arranged along a denitrating tower body; a flue gas introduction pipeline is arranged on a sidewall of the denitrating tower body; several eddy flow atomizing nozzles are respectively arranged on inner periphery of the flue gas introduction pipeline and the inner periphery at top of the first eddy flow catalytic reaction chamber; when flue gas is introduced into the flue gas introduction pipeline, the flue gas and ammonia gas injected by the eddy flow atomizing nozzle are mixed, and a mixture enables spiral sinking along circumference of the first eddy flow catalytic reaction chamber from up to down in a tangent circle mode, under effect of a cyclone, and then the mixture enable spiral rise along circumference of the second eddy flow catalytic reaction chamber from down to up in the tangent circle mode. Under prerequisite that high efficiency denitration is ensured, catalyst amount is less, operation of technical means is simple and easy, compared with the prior art, a denitrating tower structure is simple, cost of the apparatus is low, denitration efficiency is high, energy consumption is low, escapement ratio of ammonia is reduced, denitration cost is greatly reduced, and economic benefit is obviously increased.

Owner:SOUTH CHINA UNIV OF TECH

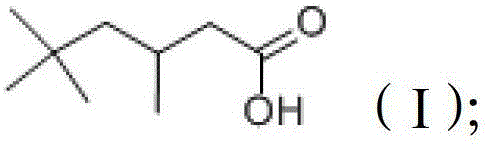

Modified alkyd resin, preparation method thereof and two-component glossy white finish

The invention provides modified alkyd resin and a preparation method of the modified alkyd resin. The modified alkyd resin is prepared by carrying out a reaction on an alkyd mixture, wherein the alkyd mixture comprises 15-25 parts by weight of 3, 5, 5-trimethyl hexanoic acid; 3-9 parts by weight of 1, 2-propanediol, 25-35 parts by weight of phthalic anhydride; 0.35-0.75 part by weight of maleic anhydride, 18-24 parts by weight of trimethylol propane, 2-5 parts by weight of pentaerythritol, 2-4 parts by weight of water aqua, 0.05-0.2 part by weight of subtractive antioxidant and 14-16 parts by weight of letdown solvent. Because the 3, 5, 5-trimethyl hexanoic acid replaces cocinic acid and lauric acid to modify alkyd resin, a finish film has excellent fullness, gloss and yellowing resistance and is easy to use. The invention further provides a two-component glossy white finish.

Owner:CARPOLY CHEM GRP

Brewing method of fruit-flavored dry red wine

ActiveCN105219574AOutstanding FeaturesHighlight significant progressMicroorganism based processesWine preparationHarvest timeSteeping

The invention discloses a brewing method of fruit-flavored dry red wine. The brewing method comprises such processing steps as determining a harvest time and harvesting, removing stems, sorting, crushing, extracting juice, cold-steeping, undergoing alcoholic fermentation with peels, separating peels and dregs, undergoing alcoholic fermentation with clear juice, storing, stabilizing, blending, freezing, sterilizing, filling and the like, so that produced dry red wine is intense, elegant and exquisite in fruit flavor, smooth and soft in taste, and is balanced and coordinated in wine body.

Owner:YANTAI CHANGYU PIONEER WINE CO LTD

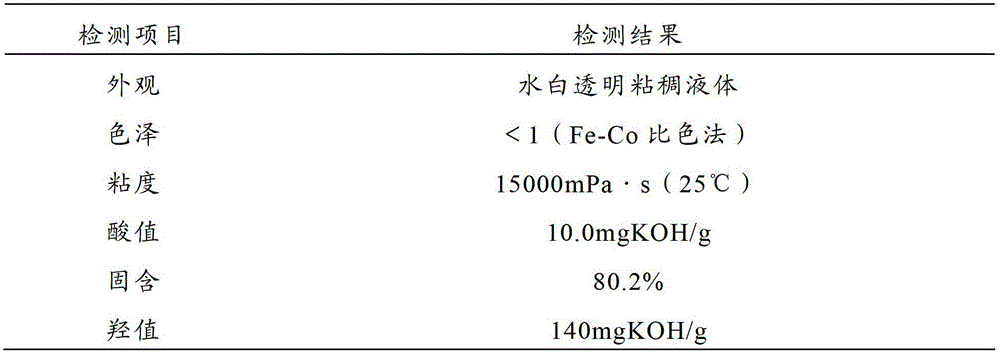

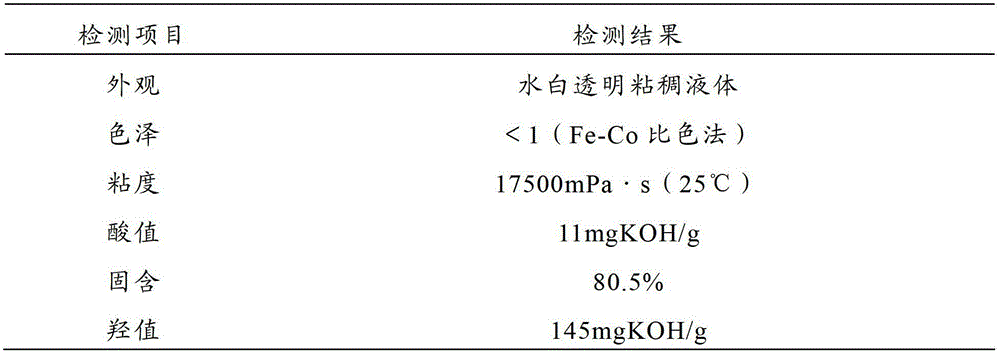

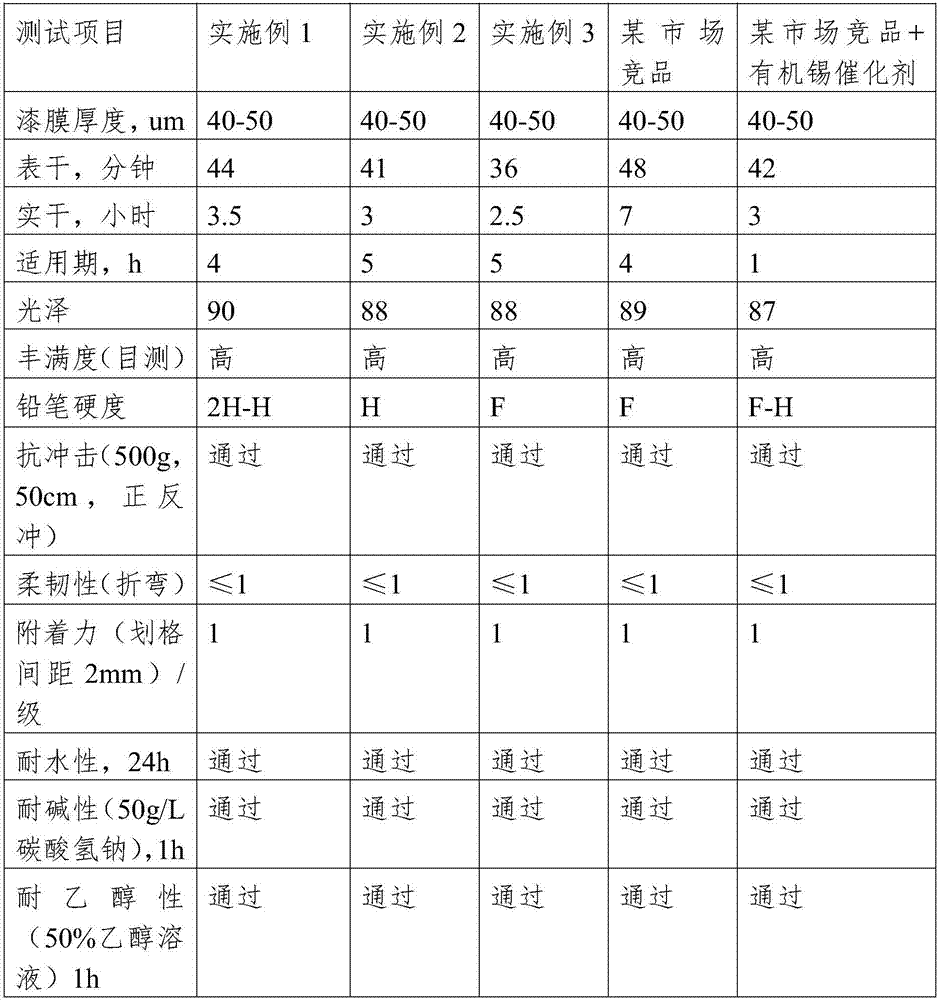

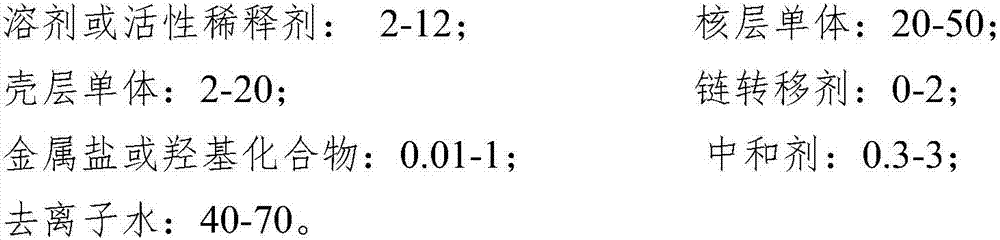

Quick-drying hydroxyacrylic resin aqueous dispersion with long working life and preparation method thereof

ActiveCN107163177AHigh glossImprove fullnessPolyurea/polyurethane coatingsWorking lifeMetal catalyst

The invention relates to a quick-drying hydroxyacrylic resin aqueous dispersion with long working life and a preparation method thereof. Metal ions are chelated in the aqueous dispersion and are used as a catalyst, and in an aqueous phase system, a catalyst component is wrapped by a hydrophobic core layer of the dispersion, but is not contacted with an isocyanate component, so that the activation period is not shortened; in the later stage of construction, moisture is basically evaporated completely, a hydrophobic part inside the dispersion is contacted and fused with the isocyanate component, and the metal catalyst starts to catalyze a reaction of the hydroxyl group and the isocyanate to promote curing of a coating film, so that the aqueous dispersion has the characteristics of long working life and quick drying. When the aqueous dispersion is applied to a waterborne double-component polyurethane coating, the coating film has excellent gloss and fullness, high hardness, good flexibility, excellent water resistance and solvent resistance; the aqueous dispersion can be widely applied to coating of wood furniture and large transporting tools, industrial coating and automobile repairing.

Owner:广东拓普合成科技股份有限公司

Water-based woodenware matte varnish

InactiveCN101186773AGood chemical resistanceImprove grinding effectLiquid surface applicatorsCoatingsWater basedCross-link

The invention discloses matte transparent finish paint for the surface of wooden ware which is used for family decorates and furniture production. The formula and mixture ratio are that self-cross linking acrylic resin is 75-85, polysiloxane antifoaming agent is 0.3-0.6, organic silicon flatting and slipping agent is 0.3-0.6, polyether modified wetting agent is 0.3-0.5, macromolecular dispersant is 0.3-0.5, silica matting agent is 1.5-3, Dipropylene Glycol Methyl Ether is 5-8, propyleneglycol monobutyl ether is 5-8, polyurethane associated rheological additives are 1-3, and water is 4-6. The invention is characterized by 1, good chemical resistance, 2, excellent blocking resistance, 3, good sanding ability, 4, high hardness, 5, good waterproof property, 6, excellent fullness and hand feeling.

Owner:GUANGDONG SANVO CHEM IND TECH

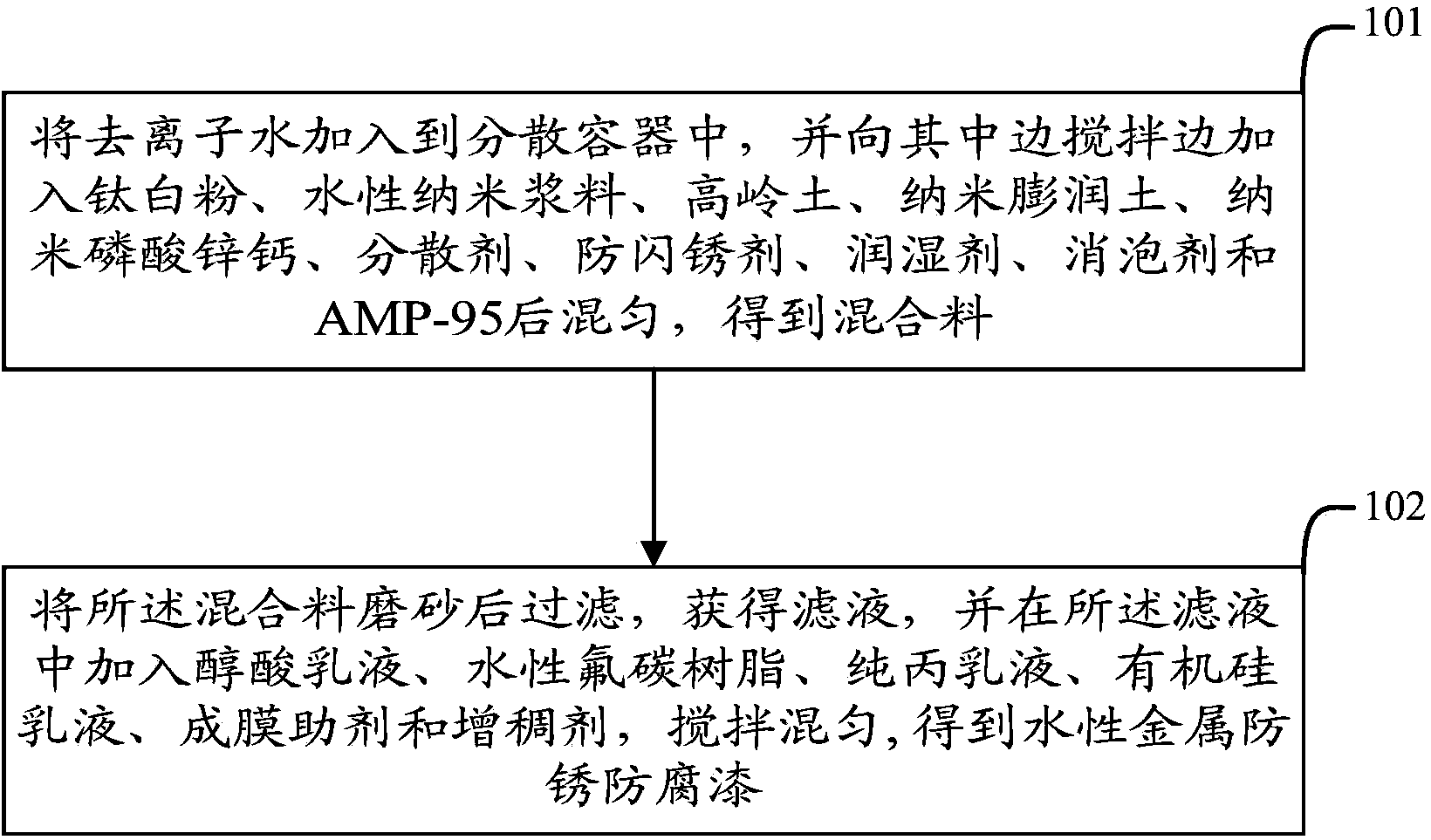

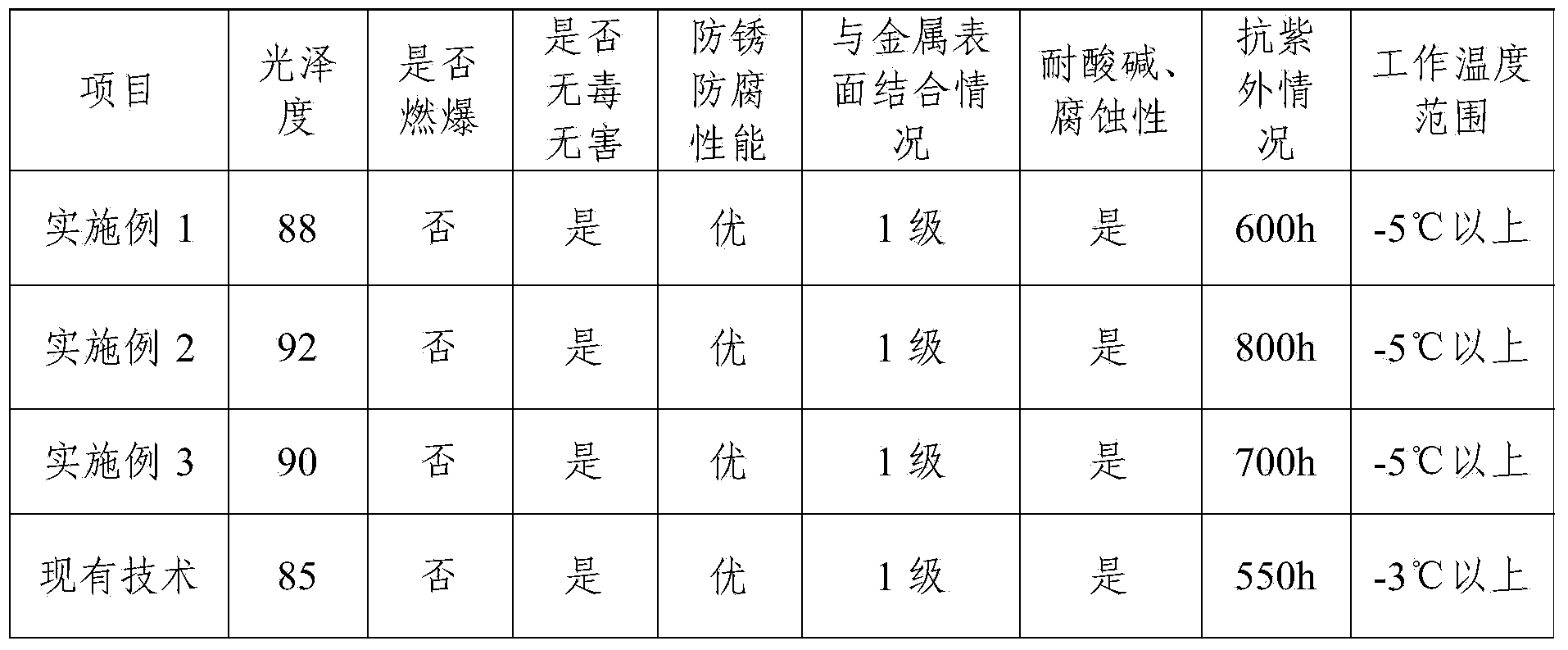

Water-based antirust and antiseptic paint for metal and preparation method thereof

InactiveCN104098972AEasy to modifyImprove adhesionAnti-corrosive paintsPolyester coatingsEnvironmental resistanceWater based

The invention relates to the field of coating for building materials, and in particular relates to a water-based antirust and antiseptic paint for metal and a preparation method thereof. The water-based antirust and antiseptic paint for metal comprises the following components in parts by weight: 200-250 parts of deionized water, 180-220 parts of titanium dioxide, 60-100 parts of water-based nanometer sizing agent, 20-40 parts of kaolin, 20-40 parts of nanometer bentonite, 8-15 parts of nanometer zinc calcium phosphate, 40-60 parts of alcoholic acid emulsion, 80-130 parts of water-based fluorocarbon resin, 150-200 parts of pure acrylic emulsion, 20-60 parts of organosilicone emulsion, 10-30 parts of propylene glycol, 1-3 parts of nanometer silicon dioxide, 4-8 parts of dispersing agent and 10-40 parts of coalescing agent. The water-based antirust and antiseptic paint for metal provided by the invention has high brightness, glossiness and plumpness, is non-toxic and harmless in material, non-combustible, unexplosive, safe and environment-friendly, and has excellent antirust and antiseptic performance with the matching of the components.

Owner:江苏硕成新材料科技有限公司

Large fried melon seed and processing method thereof

The invention relates to a large fried melon seed and a processing method thereof. The processing method comprises the following steps: firstly sorting the following raw materials in parts by weight: 97-103 parts of large melon seed, 2.0-2.5 parts of edible salt, 0.3-0.4 part of sodium cyclamate, 0.9-1.0 part of fennel, 1.3-1.4 parts of liquorice, 0.7-0.8 part of plant oil and 0.10-0.13 part of liquorice extract; and then soaking, demoulding, cooking, baking, frying, cooling, selecting, packaging, and warehousing. The tea seed prepared by processing method provided by the invention has the advantages that the liquorice fragrance is strong, the aftertaste of five spices is long, the taste is smooth and soft, the seed can be broken into two sections once being cracked between the teeth, the seed kernel is full, the appearance is bright, and the seed is full of nutriments, thus the seed is a natural nutritious leisure food.

Owner:ANHUI TRUELOVE FOODS

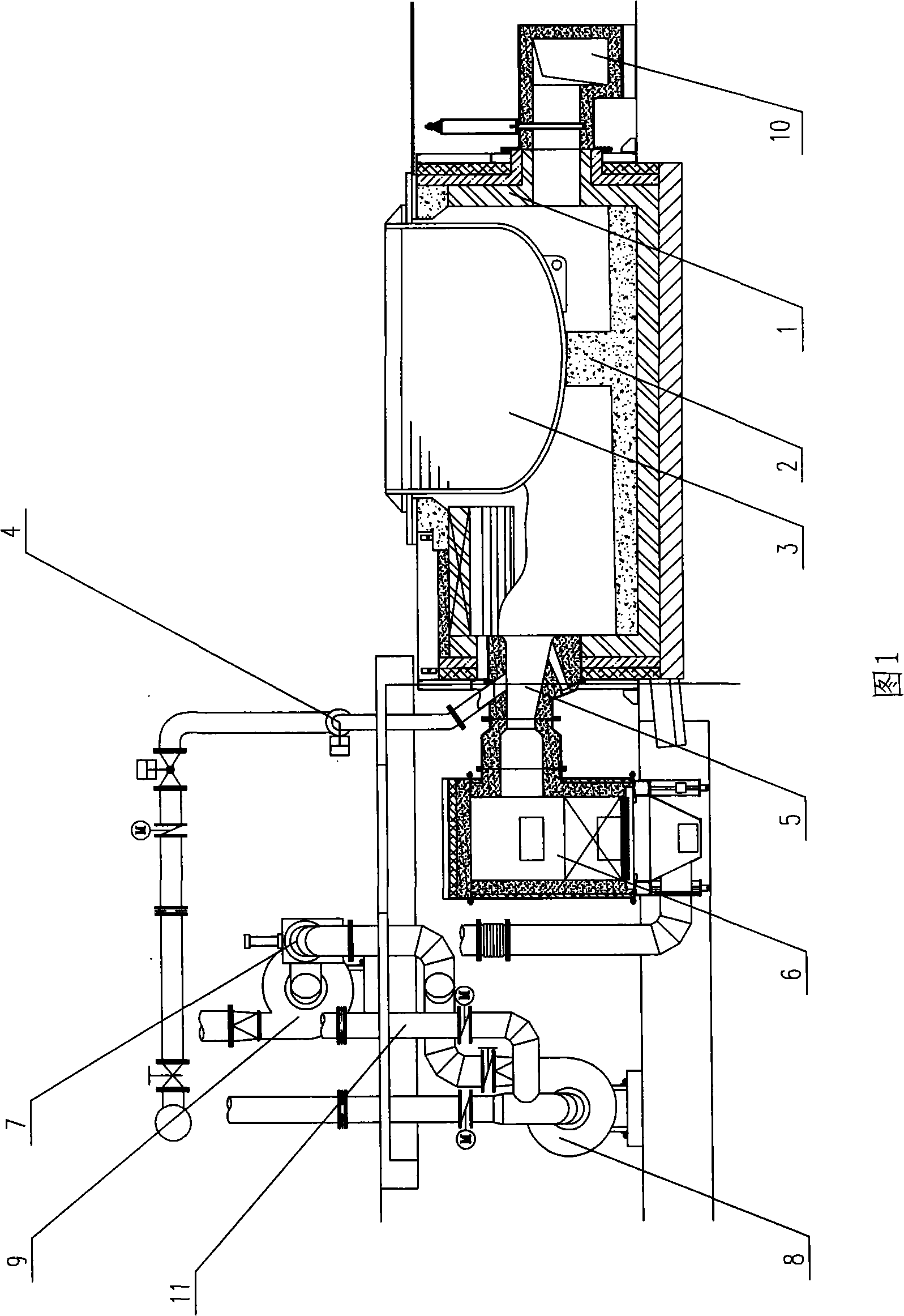

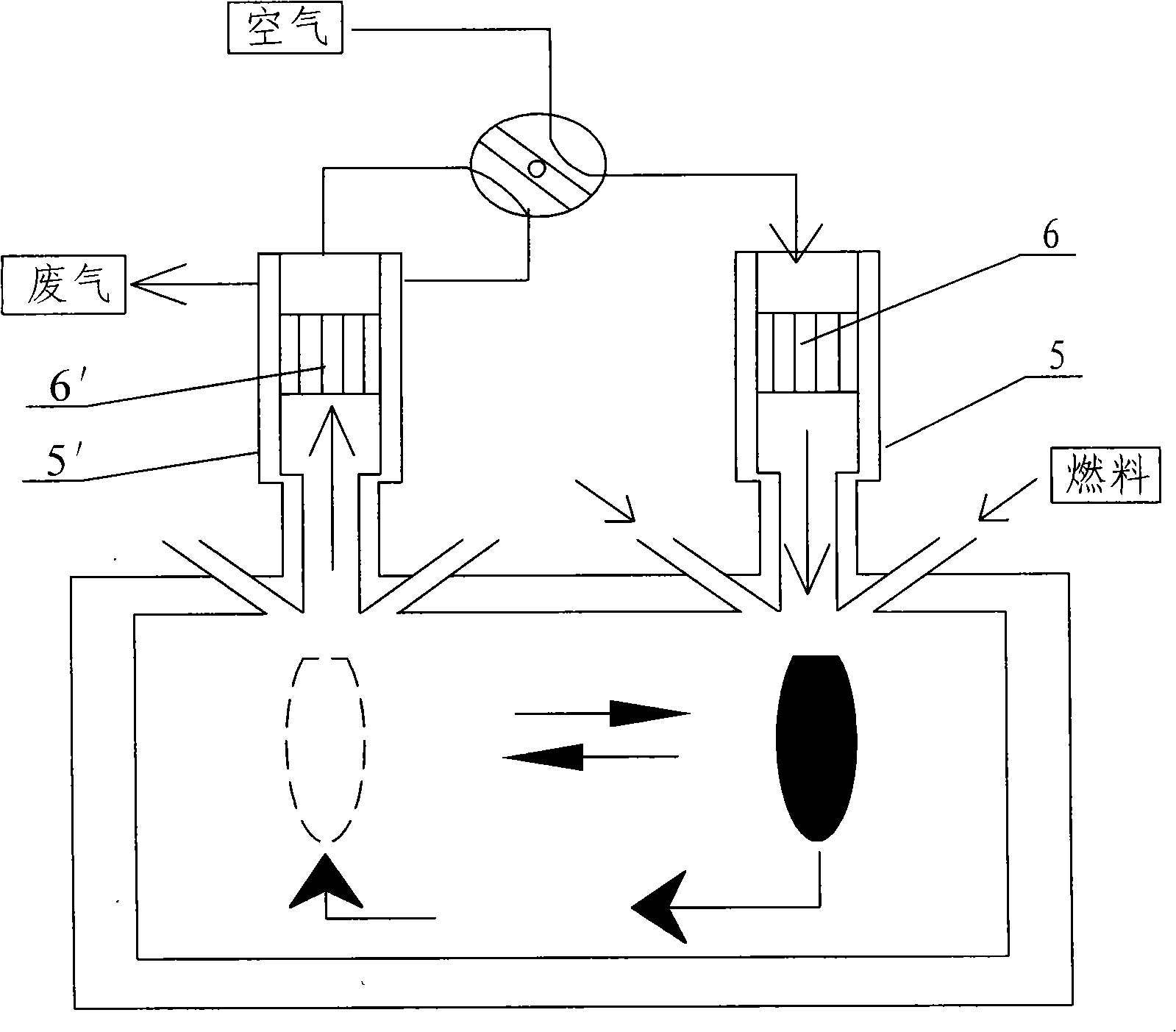

Heat accumulated type lead-melting furnace

InactiveCN101514871AEliminate high temperature zonesUniform furnace temperatureCrucible furnacesIndirect carbon-dioxide mitigationSmokeControl system

The invention discloses a heat accumulated type lead-melting furnace, which includes a furnace body, a heat accumulated type combustion system and a automatic combustion control system, wherein the heat accumulated type combustion system mainly includes heat accumulated type burners, a combustion gas pipeline, a smoke evacuation system and a air supplying system, the heat accumulated type burners are arranged at one side of the furnace body in pair, a main pipeline of the combustion gas pipeline extends to heat accumulated type burner tips of the two heat accumulated type burners through a combustion gas reversing valve and two branch pipelines, heat accumulated bodies of the heat accumulated type burners are respectively connected with a blower exhaust pipeline of the air supplying system and a draught fan smoking pipeline of the smoke evacuation system through the pipeline and a triple valve, and the triple valve is used for controlling air inlet or smoke evacuation. The invention can reduce fuel consumption, save energy, reasonably control combustion status in the furnace and increase operation security performance of the furnace.

Owner:ZHUZHOU FLASHLIGHT IND FURNACE

High-performance aqueous alkyd resin paint

InactiveCN102604517AGood storage stabilitySave raw materialsPolyester coatingsCooking & bakingCombustion

The invention relates to a high-performance aqueous alkyd resin paint prepared through the steps that: (a) plant oil aliphatic acid is subject to a reaction with polybasic acid and polyol, such that oleiferous alkyd resin is obtained; (b) oleiferous alkyd resin is subject to a reaction with trimellitic anhydride, such that oleiferous alkyd resin with excessive carboxyl is obtained; (c) the oleiferous alkyd resin with excessive carboxyl is neutralized by using a neutralizing agent, such that aqueous alkyd resin is obtained; and (d) the aqueous alkyd resin is mixed with aqueous amino resin and water, and the pH value is regulated, such that the aqueous alkyd resin paint is obtained. The aqueous alkyd resin paint provided by the invention has good storage stability, and a paint film prepared with the paint has good mechanical properties. With the novel preparation method provided by the invention, reaction time is shortened, and production energy consumption is reduced. Water is used as a diluent of the product. The product causes no toxicity, no combustion, and no pollution to the environment. The paint can be used as common industrial baking paint, vehicle top paint, bicycle baking paint, and the like.

Owner:ETERNAL CHEM (CHINA) CO LTD

Ultraviolet-curable waterborne polyurethane emulsion as well as preparation method and application thereof

The invention belongs to the technical field of new polymer materials, and particularly relates to an ultraviolet-curable waterborne polyurethane emulsion as well as a preparation method and application thereof. According to the invention, polypropylene carbonate dihydric alcohol, diisocyanate and a reactive monomer are used as main raw materials; a UV-curable double bond group then is introducedso that the acrylate resin and the polyurethane resin are connected through chemical bonds, therefore, organic unification of respective excellent properties of the two resins is effectively achieved,and a film cured by the ultraviolet-curable waterborne polyurethane emulsion is high in hardness and has good solvent resistance, corrosion resistance, scratch resistance and mechanical strength. Moreover, the raw materials of the ultraviolet-curable waterborne polyurethane emulsion do not need an organic solvent, acetone is not required to be used as a solvent to reduce the viscosity of the system during preparation, the reactive monomer can reduce the viscosity of the system, the use of the organic solvent is avoided, the problem of VOC emission is further solved, and the pollution to the environment and the harm to health are reduced.

Owner:GUANGDONG UNIV OF TECH

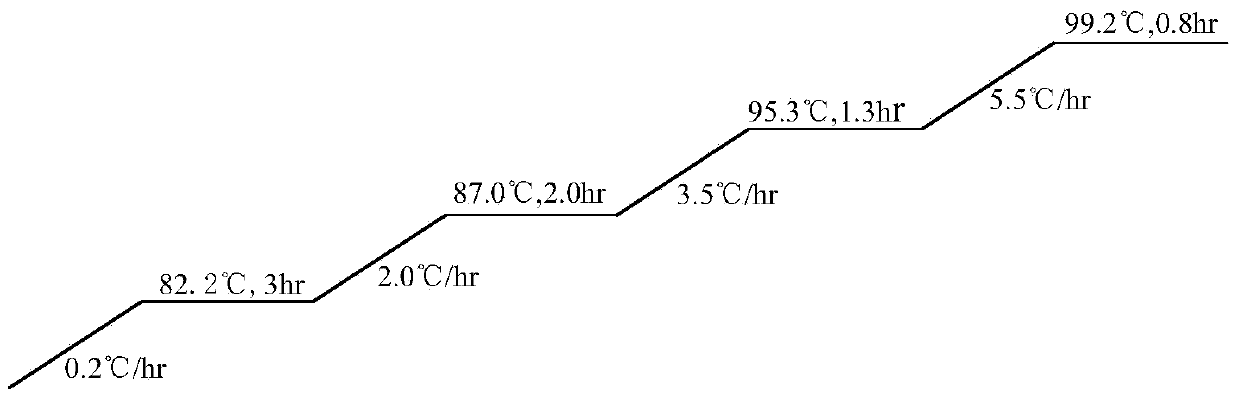

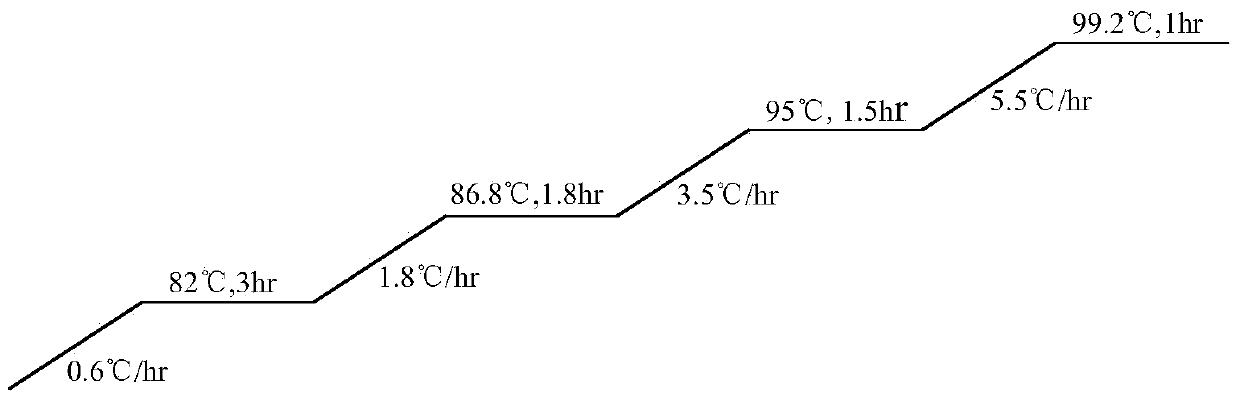

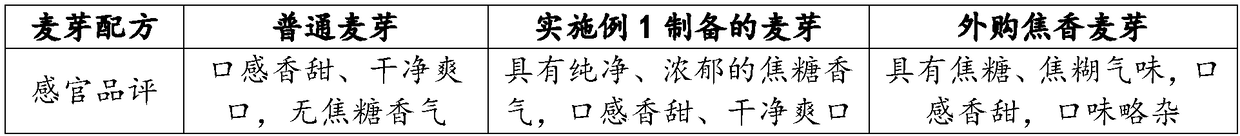

Preparation method of burnt malt with high caramel aroma and beer

ActiveCN108102825AFully stimulate vitalityIncrease concentrationMalt preparationMaillard reactionHordeum vulgare

Belonging to the malt manufacturing field, the invention provides a preparation method of burnt malt with high caramel aroma and beer. The malt preparation method includes the steps of: barley selection, raw material pretreatment, wheat dipping, germination, green malt saccharification, baking and root removal. Specifically, during barley selection, barley with moderate protein content is adoptedas the raw material; the wheat dipping process provides barley grains sufficient internal moisture content to fully stimulate the vitality of the endogenous enzyme system of malt, thus providing sufficient conditions for subsequent acquisition of a Maillard reaction substrate; the saccharification process is carried out in four stages, so that green malt can effectively degrade cellulose, proteinand starch under an appropriate water condition, and the concentration of the Maillard reaction substrate is increased; and then baking is carried out at an appropriate generation temperature of DMHFso as to enrich DMHF product substantially. The obtained malt has significant caramel aroma, the aroma is pure and strong, sensory evaluation indicates that the malt is free of scorched flavor, burntflavor and other foreign and miscellaneous smell, and can be used for production of beer with high caramel aroma.

Owner:TSINGTAO BREWERY

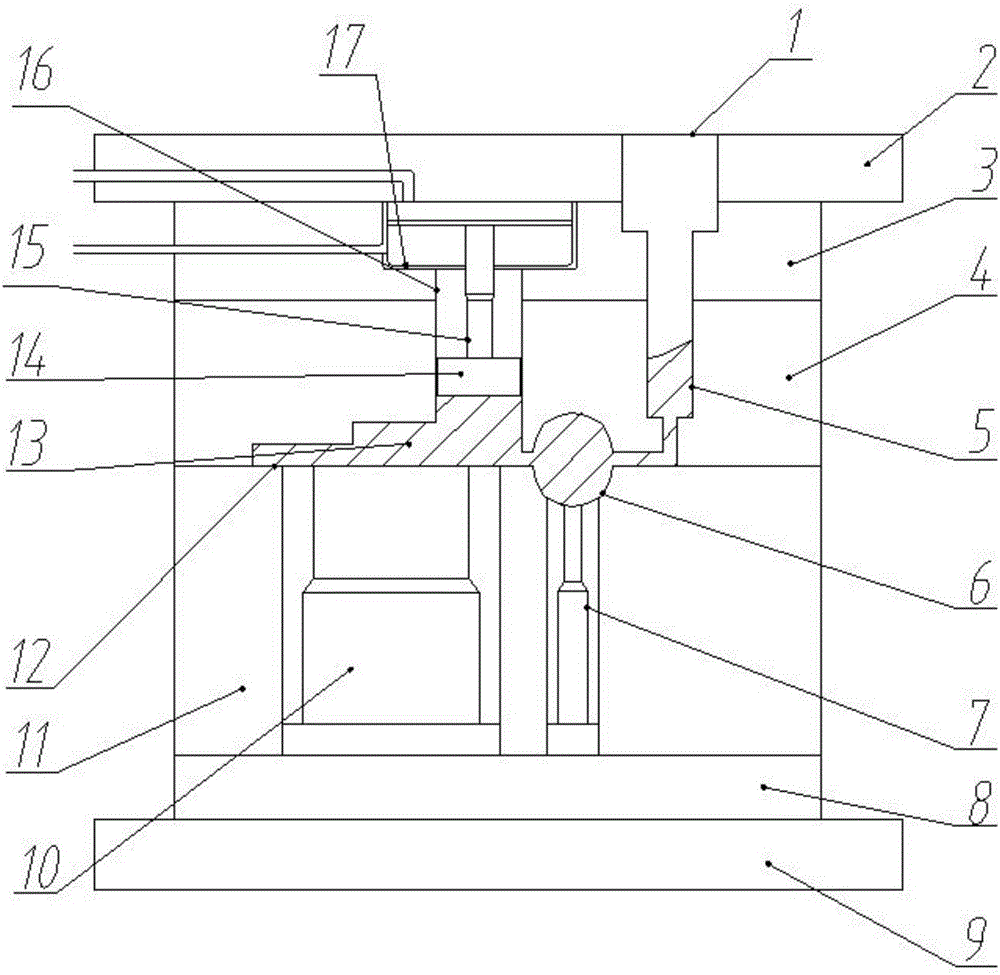

Die casting technology for shrinkage-prevention die casting

InactiveCN105817599AIncrease fullnessSolve shrinkage cavity, shrinkage porosityPush outShrinkage porosity

The invention discloses a die-casting process for anti-shrinkage cavity die-casting parts. The die-casting method comprises the following steps: starting the die-casting machine → installing the mold → debugging the mold → cleaning the preheated mold → spraying paint → closing the movable mold and the fixed mold → pouring →holding pressure→feeding and compaction→pressurization→separation of movable mold and fixed mold→push out the die casting→cut off the riser and gate on the die casting→saturate the die casting→surface the die casting. The die-casting process of this kind of anti-shrinkage cavity die-casting effectively solves the problems of product shrinkage and porosity, and finally obtains dense and intact parts, reducing the defective rate.

Owner:安徽纯启动力科技有限公司

Unsaturated polyester modified polyurethane coating varnish

The invention provides unsaturated polyester modified polyurethane top coat paint which consists of a main agent of the top-coat paint, a firming agent, an evocating agent and a diluent. In the main agent of the top-coat paint, an unsaturated polyester resin with a weight of 35.0 to 40.0 percent of the gross weight of the main agent of the top-coat paint and acrylic resin with a weight of 40.0 to 45.0 percent of the gross weight of the main agent of the top-coat paint are included. The unsaturated polyester modified polyurethane top-coat paint can effectively solve the problems of construction complexity and compatibility; besides, the product has the advantages of good abundance, easy polishing, high rigidity and being very suitable for the coating production of a musical instrument. The surface of the coated product has the characteristics of high rigidity, good abundance, and high adhesive attraction, being hard to generate air bubbles and pinholes as well as uneasy cracking. Besides, compared with the construction mode of mixing polyurethane paint and unsaturated polyester paint used in the current market, the unsaturated polyester modified polyurethane top-coat paint has simpler construction performances and appearance effect of a coated film.

Owner:上海展辰涂料有限公司 +2

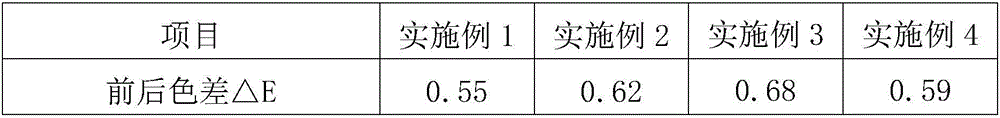

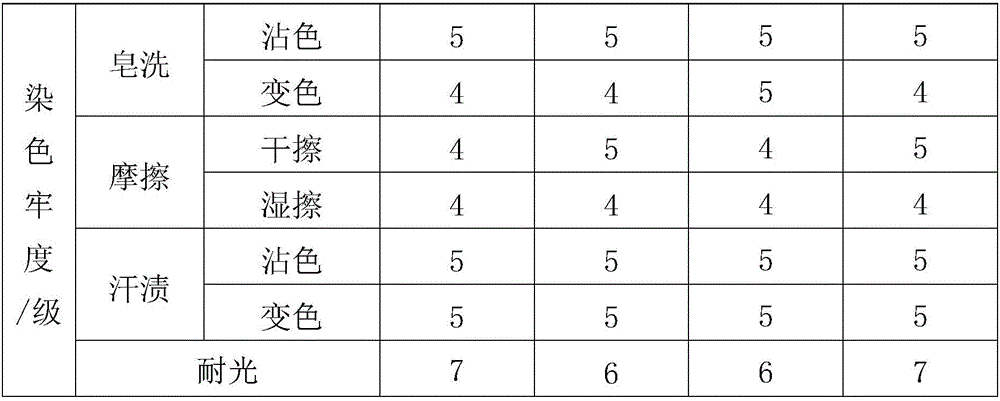

Dyeing and finishing process for polyester blended fiber fabric

ActiveCN106223003ASoft touchImprove water absorptionHeating/cooling textile fabricsHeat resistant fibresDisperse dyeAfter treatment

The invention discloses a dyeing and finishing process for a polyester blended fiber fabric. The process comprises the following steps of 1, pretreatment, wherein the polyester blended fiber fabric is sequentially subjected to scouring, bleaching and enzyme washing; 2, mercerizing and sizing, wherein the fabric is subjected to padding of alkali liquor under the room temperature for pre-sizing; 3, dyeing, wherein the fabric is soaked into dye liquor formed by disperse dyes, dyeing is performed under the temperature of 30-40 DEG C, temperature is increased to 90-110 DEG C at the heating rate being 0.8-1 DEG C / min, washing is performed through warm water, infrared ray pre-heating is performed, and then hot-blast air drying is performed; padding is performed again under the room temperature to reduce the suspended solid dye liquor formed by dyes, a reduction solution is subjected to padding, steam reduction and oxidation are performed, washing is performed through warm water, soaping is performed, and then washing and drying are performed; 4, after-treatment, wherein soft and flame-proof treatment is performed in sequence. According to the dyeing and finishing process for the polyester blended fiber fabric, the touch feeling, elasticity and other properties of the fabric are improved remarkably, dyeing is uniform, the color fastness is high, and the color is full.

Owner:ANHUI YAYUAN PRINTING & DYEING CO LTD

Ultraviolet (UV)-natural matte finishing paint

InactiveCN103305120AHigh surface flatnessLow softnessPolyurea/polyurethane coatingsEpoxy resin coatingsPolyesterAcrylic resin

The invention discloses ultraviolet (UV)-natural matte finishing paint. The finishing paint comprises the following components in percentage by weight: 40 to 80 percent of 100 percent UV matte resin, 10 to 20 percent of cellulose acetate butyrate, 0.1 to 0.5 percent of antifoaming agent, 1.0 to 2 percent of dispersant, 5 to 10 percent of stuffing, 3 to 8 percent of initiator, 0.1 to 1 percent of flatting agent, 1 to 1.5 percent of anti-settling agent and the balance of monomers; the 100 percent UV-resin is one or a mixture of polyurethane acrylic resin, modified epoxy acrylate and polyester acrylic resin; and the 100 percent UV matte resin is one or a mixture of the polyurethane acrylic resin, the modified epoxy acrylate and the polyester acrylic resin. The UV-natural matte finishing paint has high liquidity, fine surface and high fullness; and a formed paint film structure is high in scratch resistance, particularly on open or semi-open or imitation antique floors, thereby protecting the surfaces of wood furniture and wood floors for a long time.

Owner:JIANGSU HIMONIA TECH

A kind of high-solid single-coat high-gloss black plastic paint and preparation method thereof

The invention relates to a high-solid volume, single-coating and high-lustre black plastic paint and a preparation method thereof. The plastic paint comprises the following components: 30-40wt% of saturated polyester resin, 35-45wt% of hydroxy acrylic resin, 2-4wt% of high-purity carbon black pigment, 1-3wt% of carbon black dispersing agent, 0.5-1wt% of flatting agent, 0.3-0.6wt% of scratch-resisting agent, 0.2-0.5wt% of defoaming agent, 0.02-0.04wt% of drier and 15-25wt% of organic solvent. Compared with the prior art, the black plastic paint has the advantages of low cost, high efficiency, good effect and the like.

Owner:DONGLAI COATING TECH SHANGHAI

Special organic fertilizer for walnuts and preparation method for special organic fertilizer

InactiveCN102633572AImprove disease resistancePromote absorptionFertilizer mixturesDiseaseDrug biological activity

The invention provides a special organic fertilizer for walnuts, which is prepared from, by weight, 45-55 parts of weathered coal, 5-10 parts of wheat bran, 5-10 parts of pepper powder residues, 20-30 parts of straws, 1-2 parts of urea, 50-60 parts of water, 10-12 parts of trichoderma culture solution, 1-2 parts of phosphorus sources, 0.01-0.02 part of iron sources, 0.01-0.02 part of zinc sources, 0.01-0.02 part of copper sources, 0.01-0.02 part of manganese sources and 0.05-0.1 part of boron sources. The invention further provides a preparation method for the organic fertilizer. The organic fertilizer has the advantages that raw material sources are wide, a production method is simple, biological activity of products is high, sufficient comprehensive nutrition is provided for walnut trees and the like, and enables the walnut trees to grow robustly and be higher in stress resistance and disease resistance, fruit setting rate of the walnut trees can be increased, empty shell rate of the walnuts is decreased, and the special organic fertilizer for the walnuts has the advantage of no chemical residue.

Owner:XINJIANG TIANZAOYUAN QIUCI BIOTECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com