Patents

Literature

57results about How to "Uniform furnace temperature" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

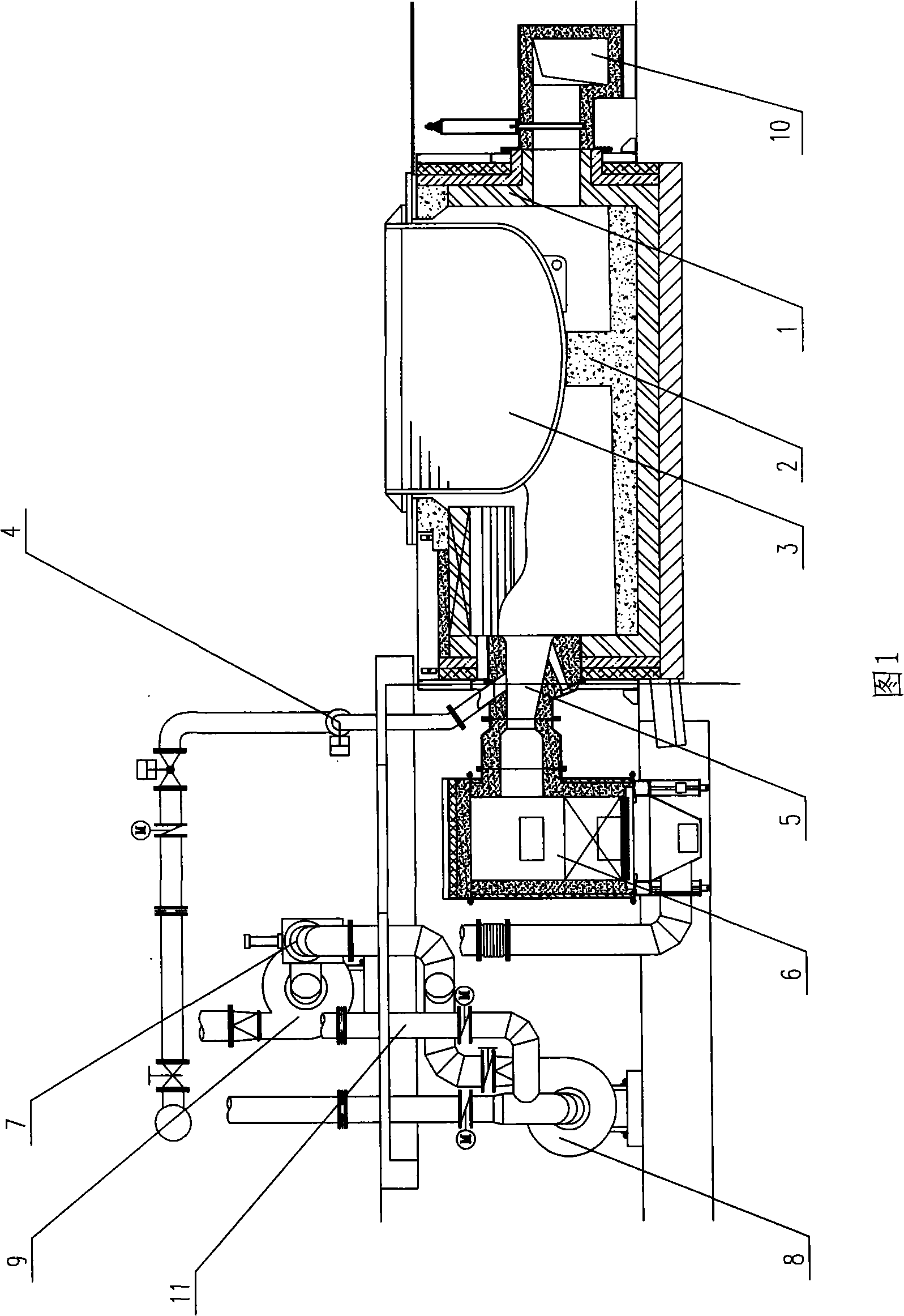

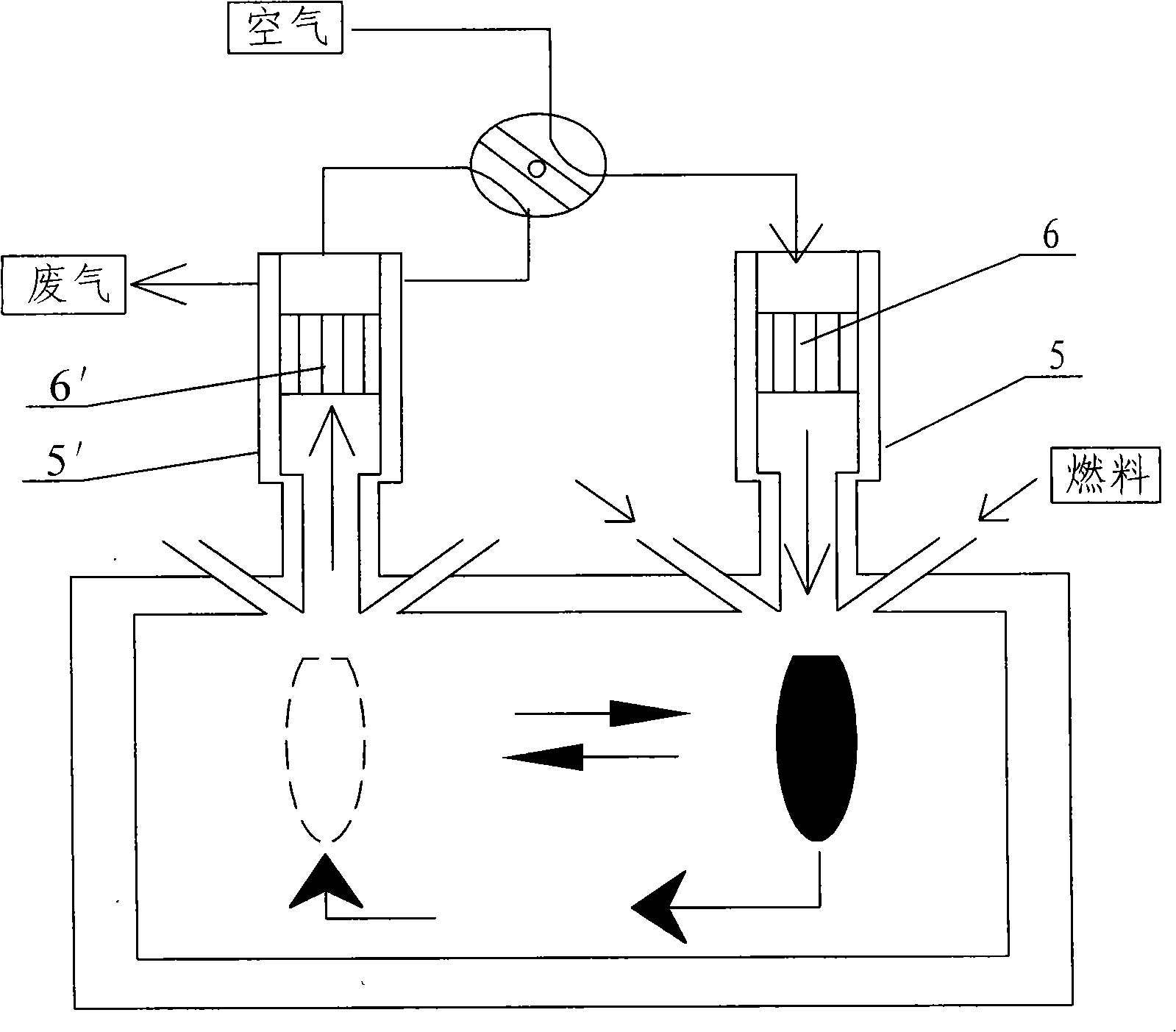

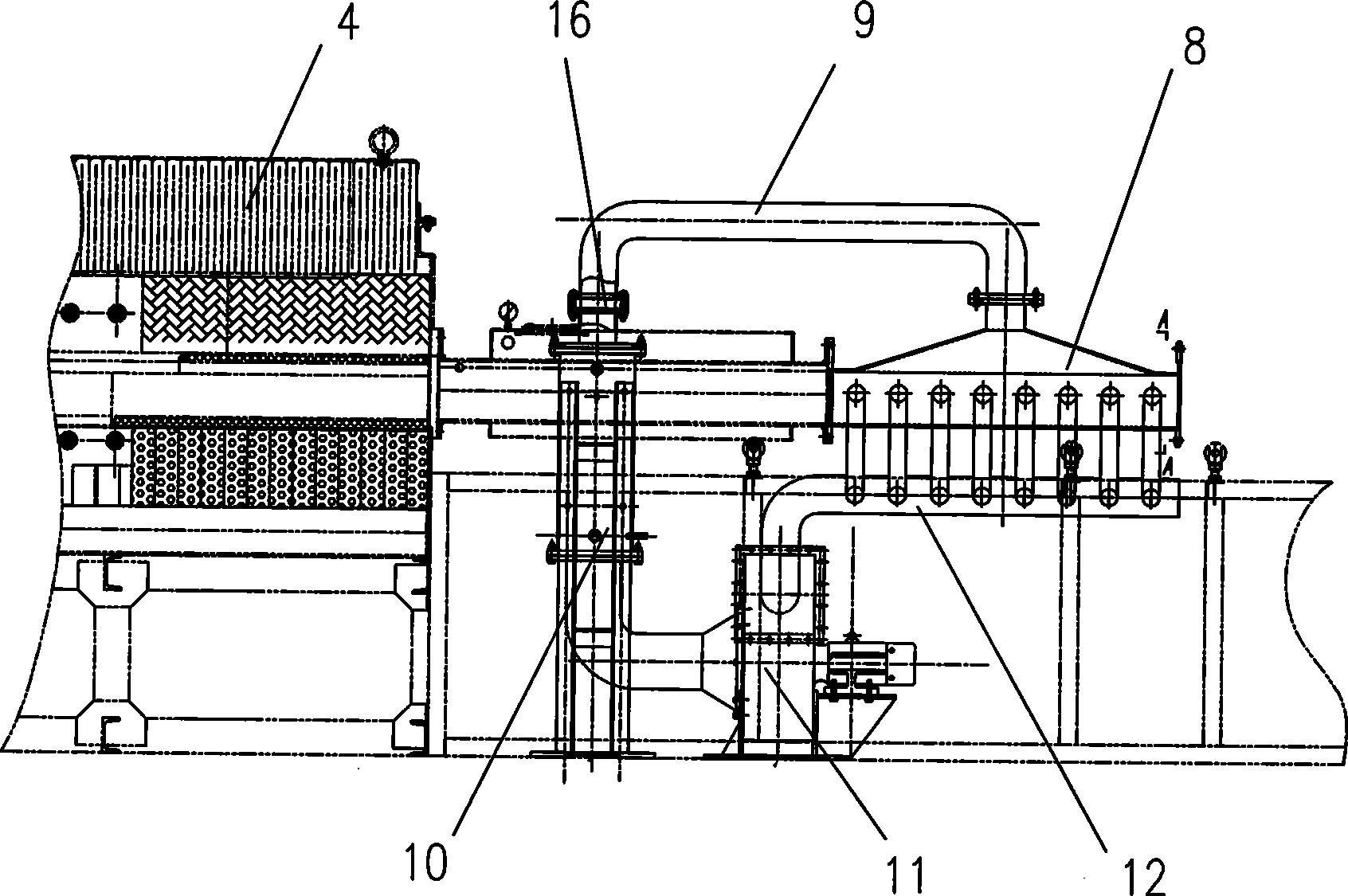

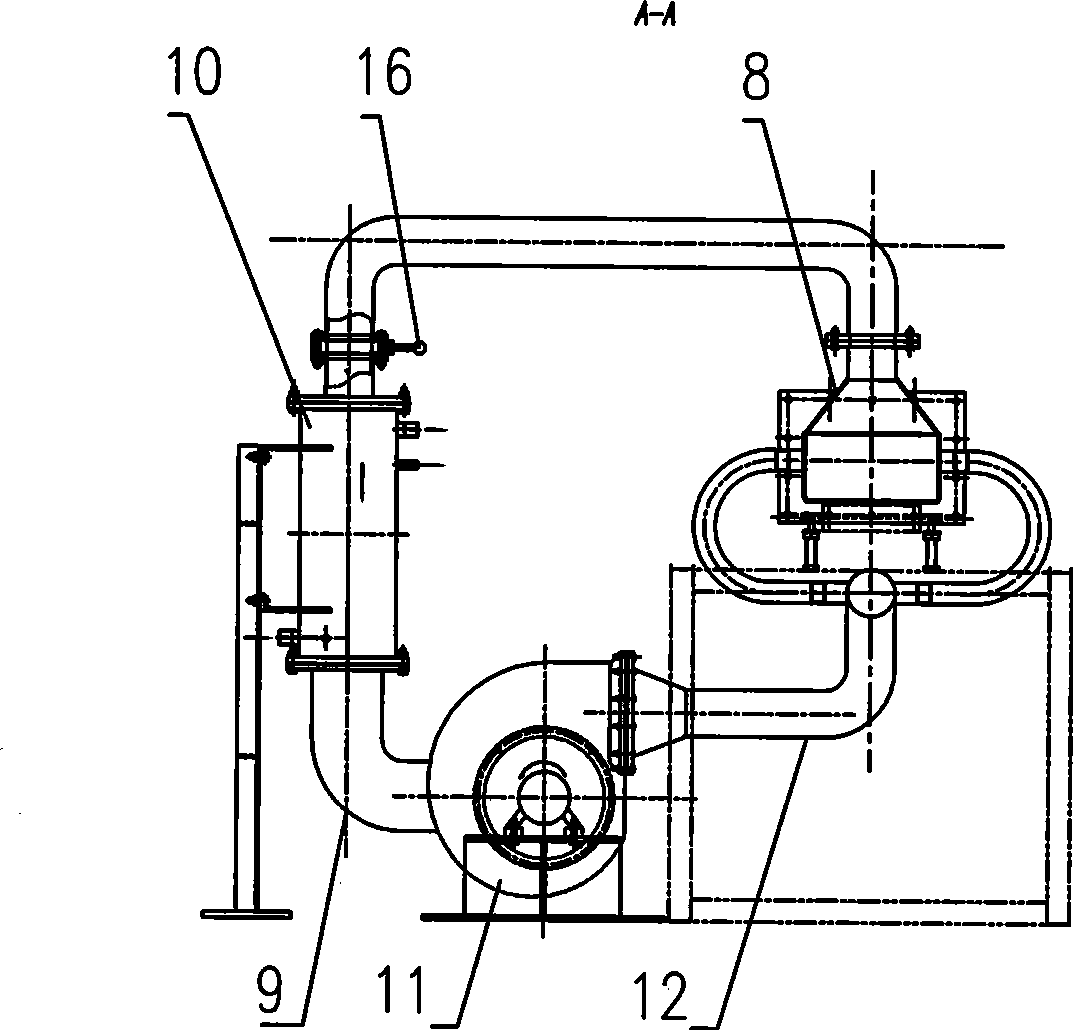

Heat accumulated type lead-melting furnace

InactiveCN101514871AEliminate high temperature zonesUniform furnace temperatureCrucible furnacesIndirect carbon-dioxide mitigationSmokeControl system

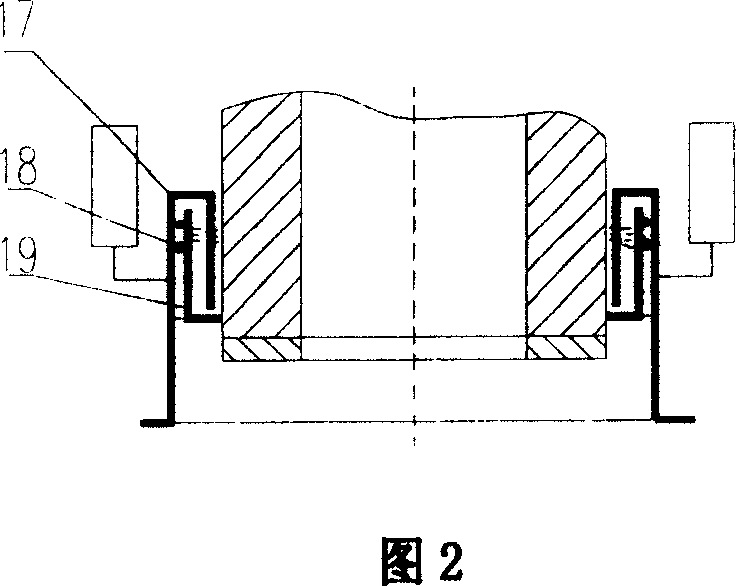

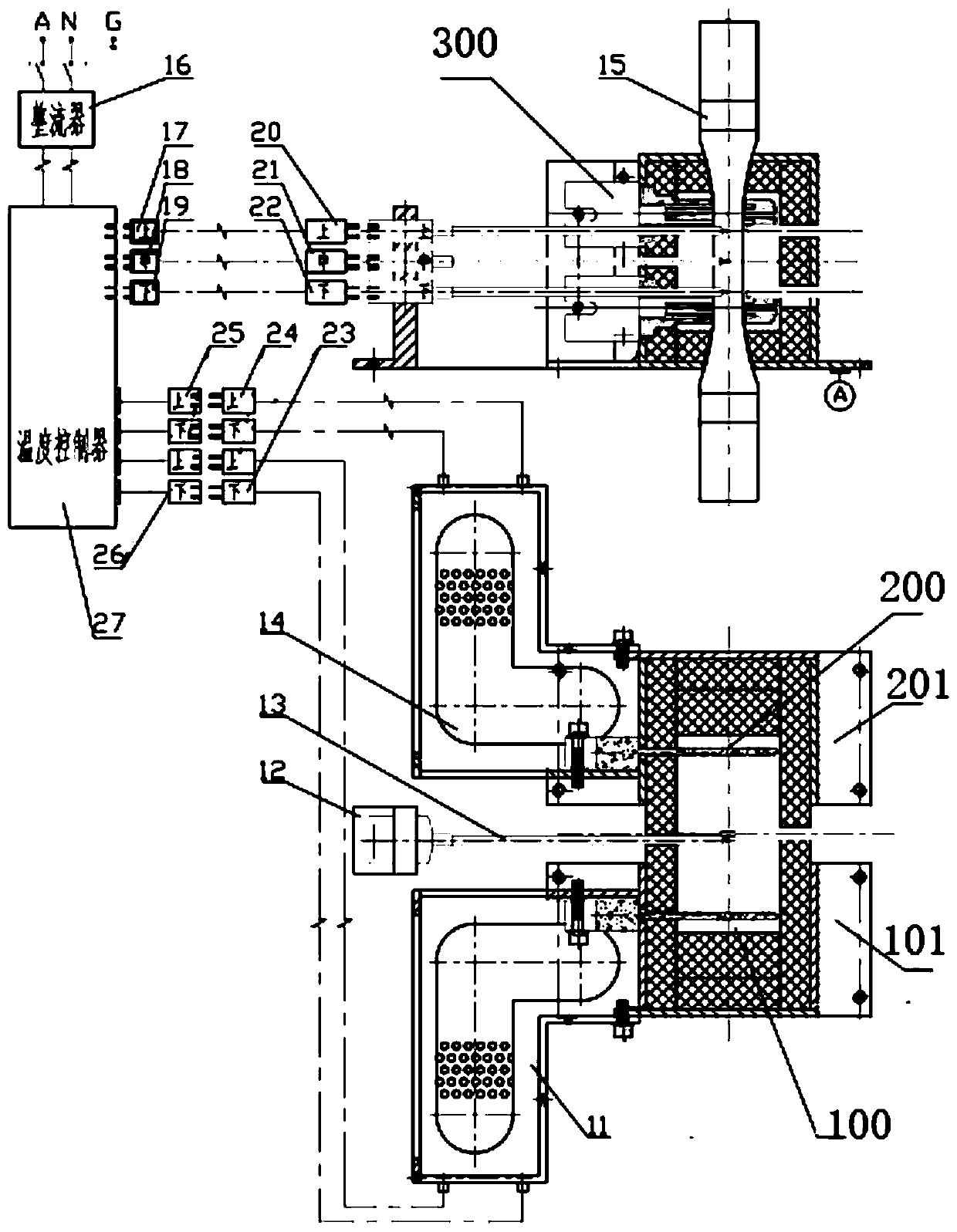

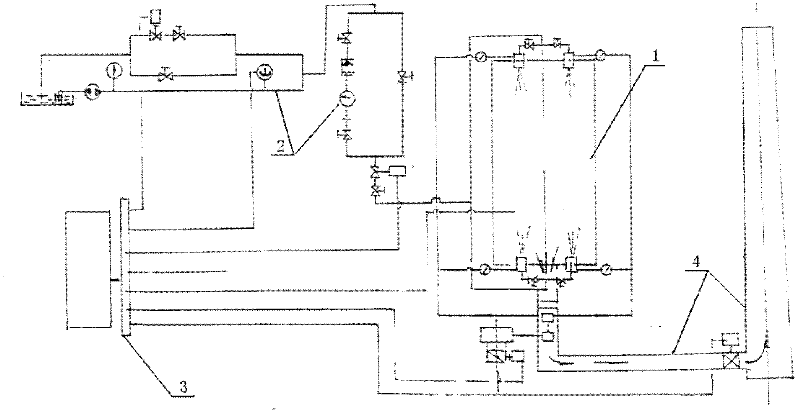

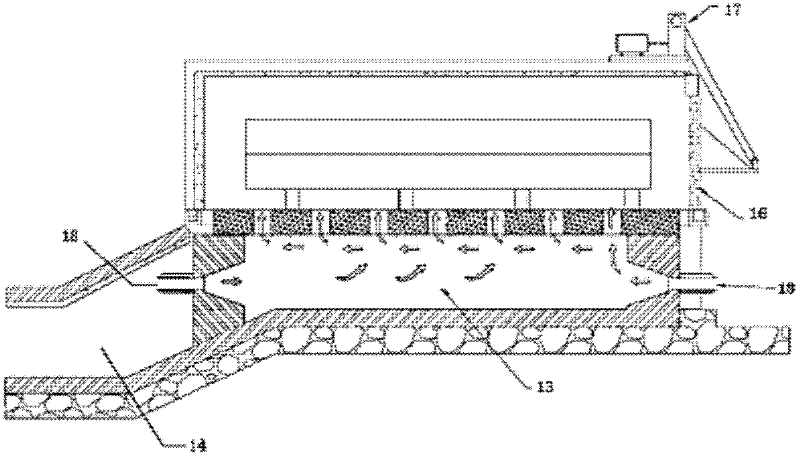

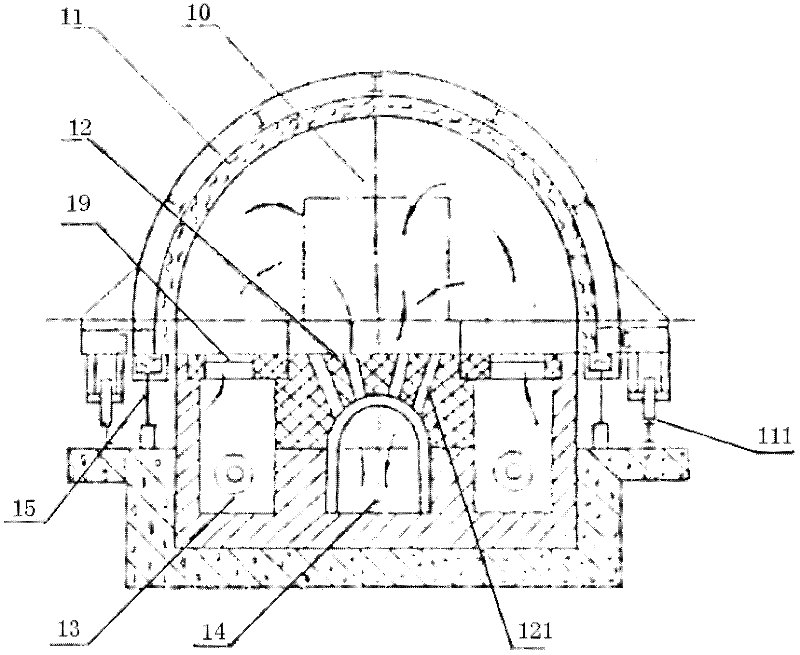

The invention discloses a heat accumulated type lead-melting furnace, which includes a furnace body, a heat accumulated type combustion system and a automatic combustion control system, wherein the heat accumulated type combustion system mainly includes heat accumulated type burners, a combustion gas pipeline, a smoke evacuation system and a air supplying system, the heat accumulated type burners are arranged at one side of the furnace body in pair, a main pipeline of the combustion gas pipeline extends to heat accumulated type burner tips of the two heat accumulated type burners through a combustion gas reversing valve and two branch pipelines, heat accumulated bodies of the heat accumulated type burners are respectively connected with a blower exhaust pipeline of the air supplying system and a draught fan smoking pipeline of the smoke evacuation system through the pipeline and a triple valve, and the triple valve is used for controlling air inlet or smoke evacuation. The invention can reduce fuel consumption, save energy, reasonably control combustion status in the furnace and increase operation security performance of the furnace.

Owner:ZHUZHOU FLASHLIGHT IND FURNACE

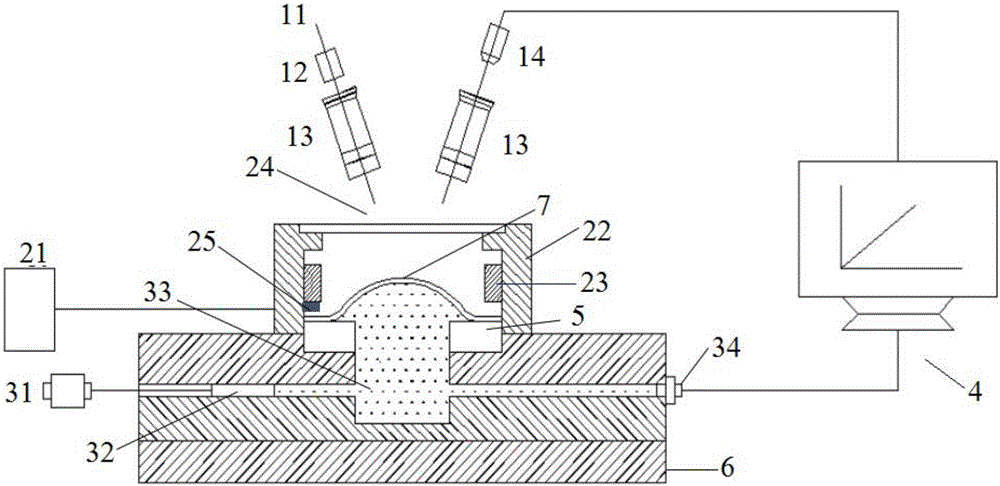

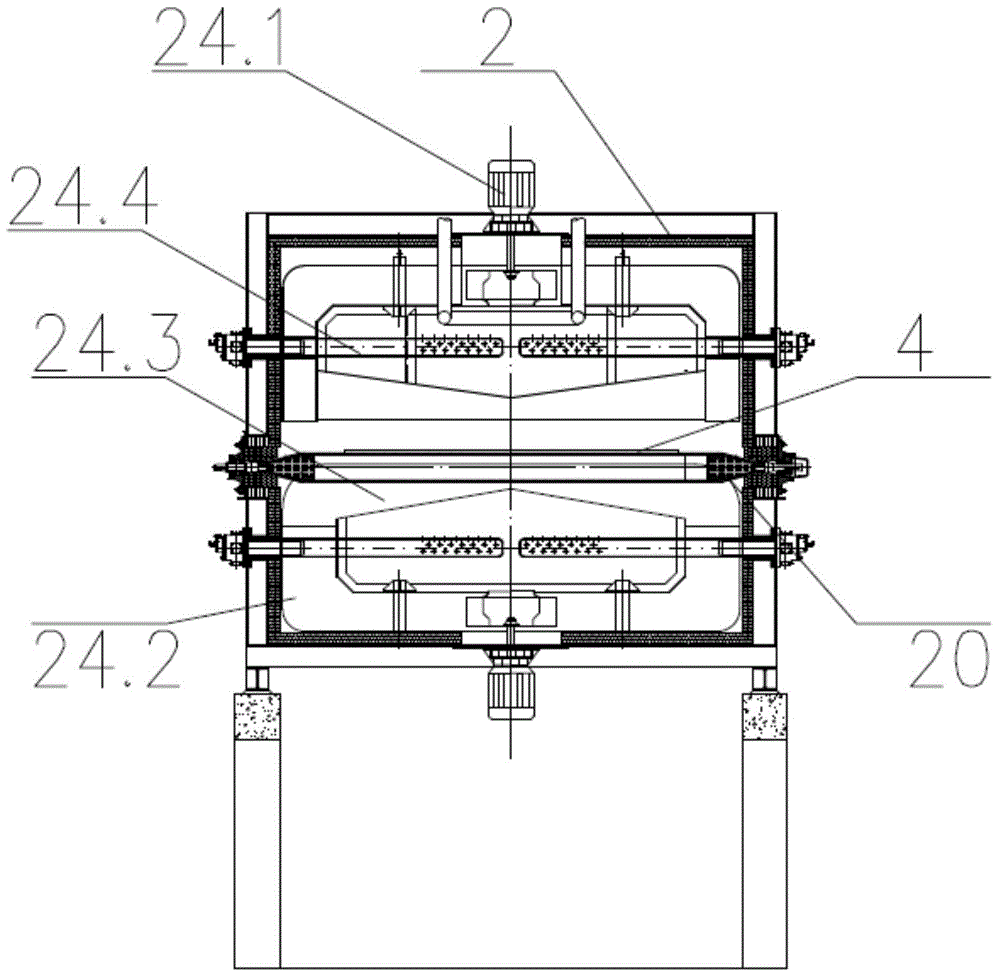

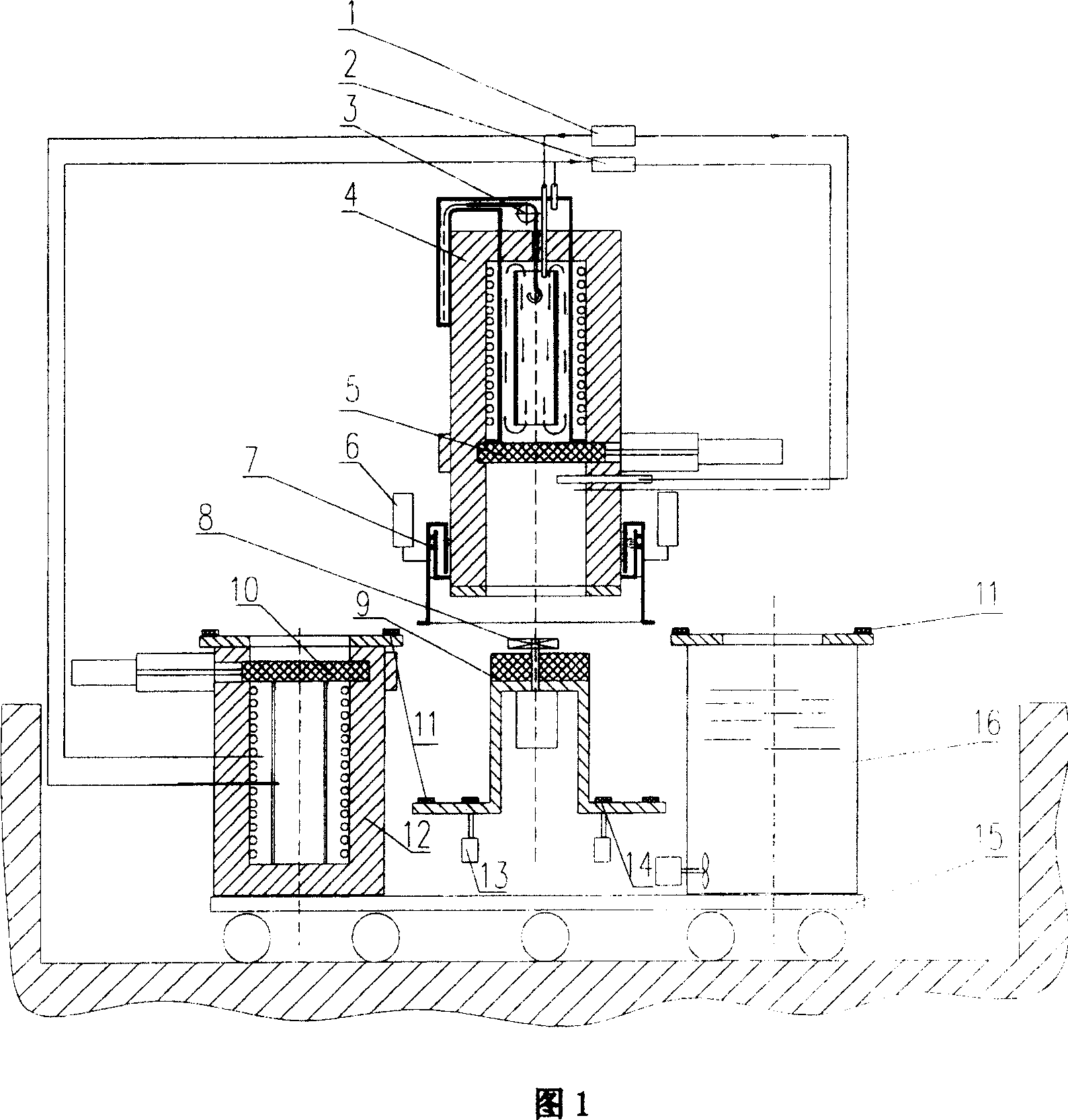

Device and method for measuring mechanical property of film under high temperature

InactiveCN106198206ALoading and unloadingUniform furnace temperatureMaterial strength using tensile/compressive forcesFull fieldOptical measurements

The invention discloses a device and a method for measuring mechanical property of a film under high temperature. The measuring device comprises an optical measurement component, a data processing and displaying component, a dynamic loading component, a heating component and a sample platform, wherein the optical measurement component, the heating component, the sample platform and the dynamic loading component are successively arranged; light sources and light spots sent during measurement are unchanged; due to the bulging effect, the film is deformed; a reflection angle of a light path transmitted to the film is changed due to the deformation of the film; the optical measurement component for receiving a reflected light path is remotely connected to the data processing and displaying component; the received light path is obtained by the optical measurement component; and the data processing and displaying component is used for visually displaying the measurement process and recording the change of the received light path. Through the measuring device, a heating device and a bulging device are combined together to measure the mechanical property of the film under high temperature; the measuring device is compact in structure, is applied to the films of various elasto-plastic systems, and is capable of achieving real-time and full-field measurement of the change of the mechanical property in the heating process.

Owner:XIANGTAN UNIV

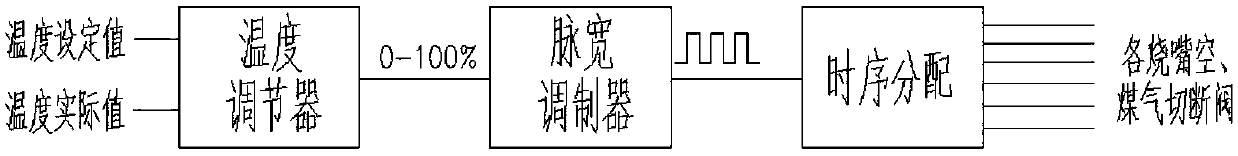

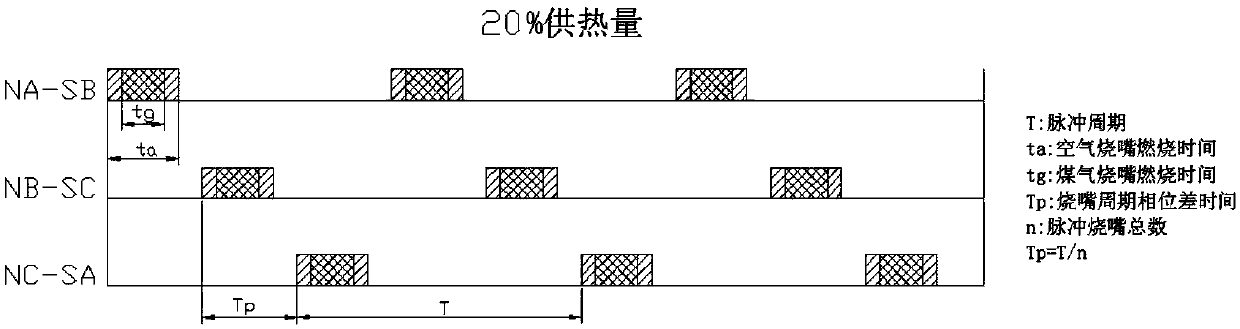

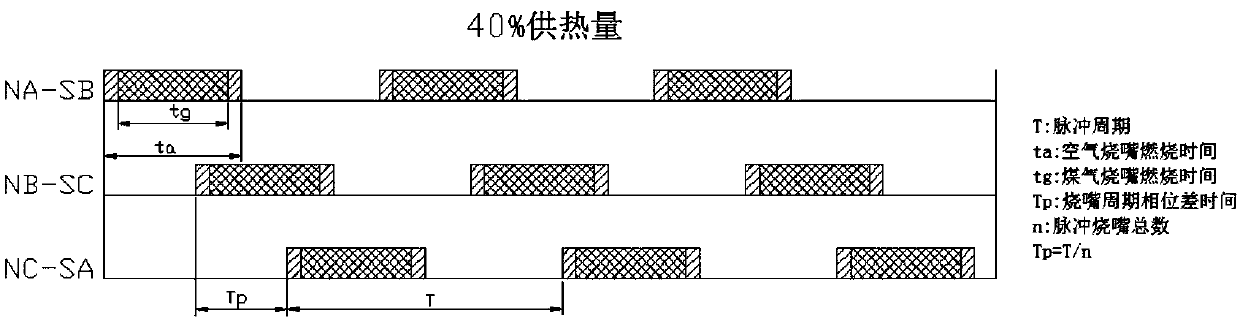

Heating furnace pulse control system and method

InactiveCN108317866AReduce distractionsFully disturbedWork heating devicesControl devices for furnacesPulse controlControl system

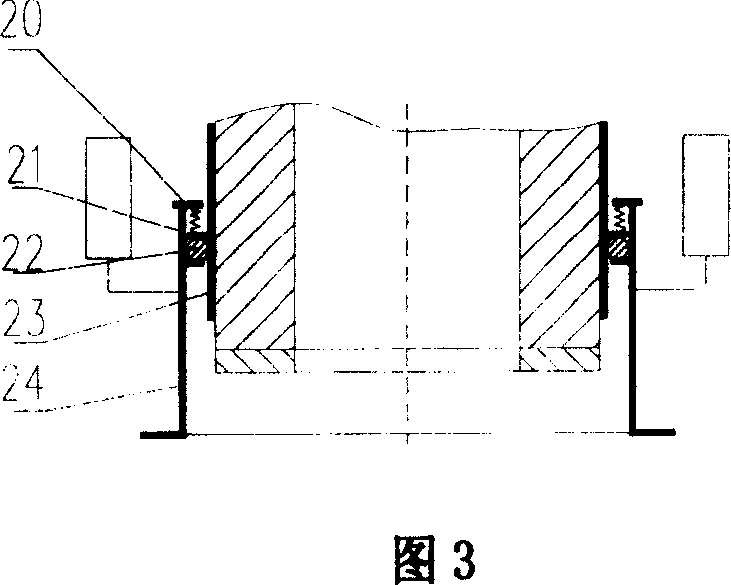

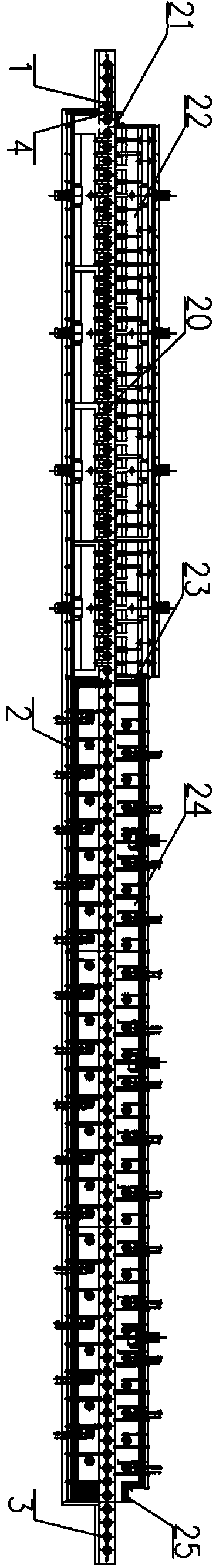

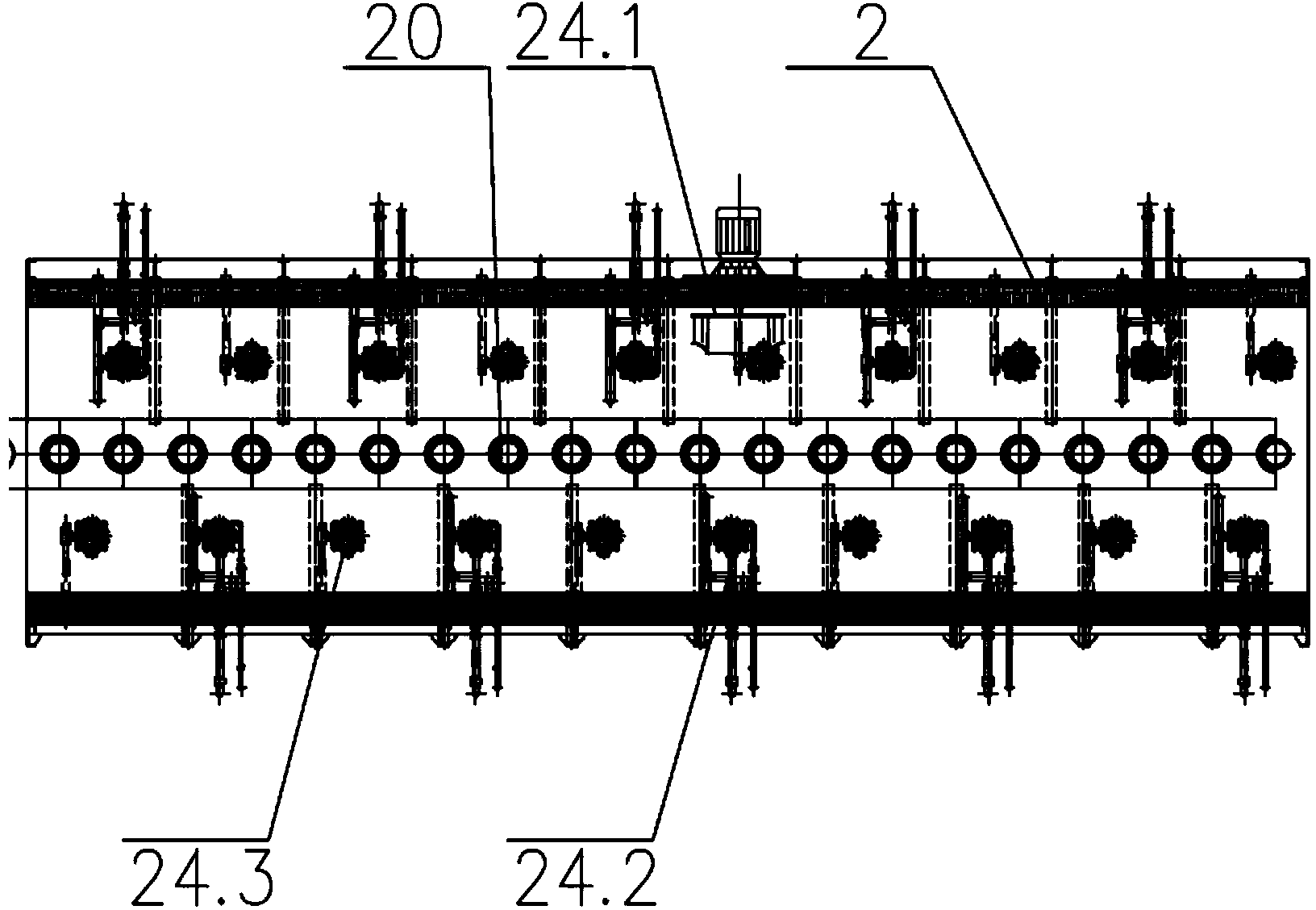

The invention provides a heating furnace pulse control system and method and belongs to the technical field of metallurgy. The upper section of the system conducts heat supply through flat flame burners, and the lower section of the system conducts heat supply through NOx burners. The three burners are arranged at the south end of the lower section, and the three burners are arranged at the northend of the lower section. The heating furnace pulse control system integrates the double-cross amplitude limit technology and the pulse control technology. Every two crossed burners of the six burnersof the lower section serve as a group, and the three groups of the burners work in sequence. According to the heating furnace pulse control system, the pulse combustion technology is adopted; as allthe burners work under high-load conditions, extrusive flames are long, and the thermal radiation capacity is high; thus, steel blanks can be heated uniformly, and the burners can be protected againstbackfire; moreover, through periodic switching of the pulse burners, the furnace atmosphere can be blended sufficiently, the gas thermal convection capability is enhanced at high radiation, and the heating uniformity of the plate blanks is further improved.

Owner:WUHAN IRON & STEEL ENG TECH GROUP

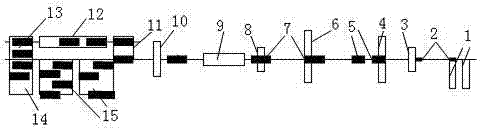

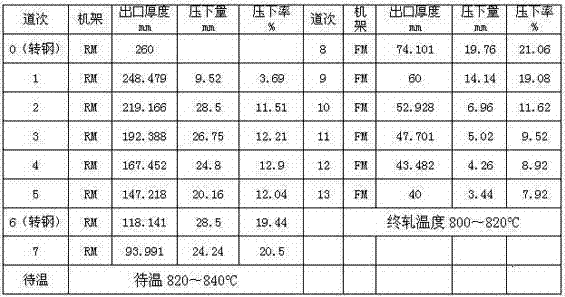

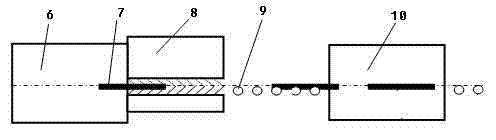

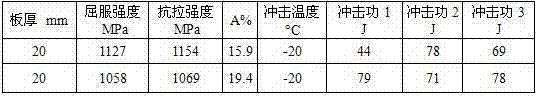

Production process of high-toughness and ultra-high strength steel and production system thereof

The invention relates to a production process of high-toughness and ultra-high strength steel and a production system thereof. The production system comprises a descaling box, a roughing mill, a temperature waiting roller table, a finishing mill, an ultra-fast cooling system, a thermal straightening machine, steel splitting racks and an open flame tempering furnace. The production process comprises the following steps of: fully heating a plate blank, discharging the plate blank from a furnace, descaling the plate blank, sequentially performing rough rolling, temperature waiting, finish rolling, on-line ultra-fast quenching and fast thermal straightening, separating the plate blank from a main production line through the steel splitting racks, fast sending a steel plate into the open flame tempering furnace for heat insulation, performing carbon distribution at PT (carbon distribution temperature), discharging the steel plate from the furnace, and then performing air cooling. The sequential arrangement of equipment of the production line is as follows: the heating furnace, the plate blank, the descaling box, the roughing mill, an intermediate blank, the finishing mill, a pre-straightening machine, an ultra-fast cooling unit, the thermal straightening machine, the first steel splitting rack, the open flame tempering furnace, the second steel splitting rack, a thick plate cooling bed and an intermediate plate cooling bed.

Owner:HUNAN VALIN XIANGTAN IRON & STEEL CO LTD

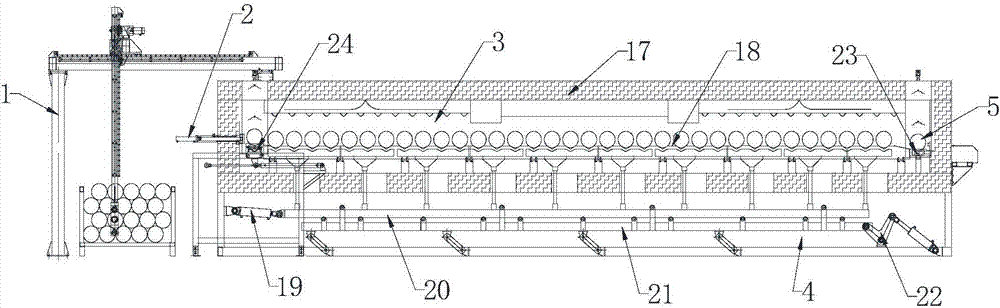

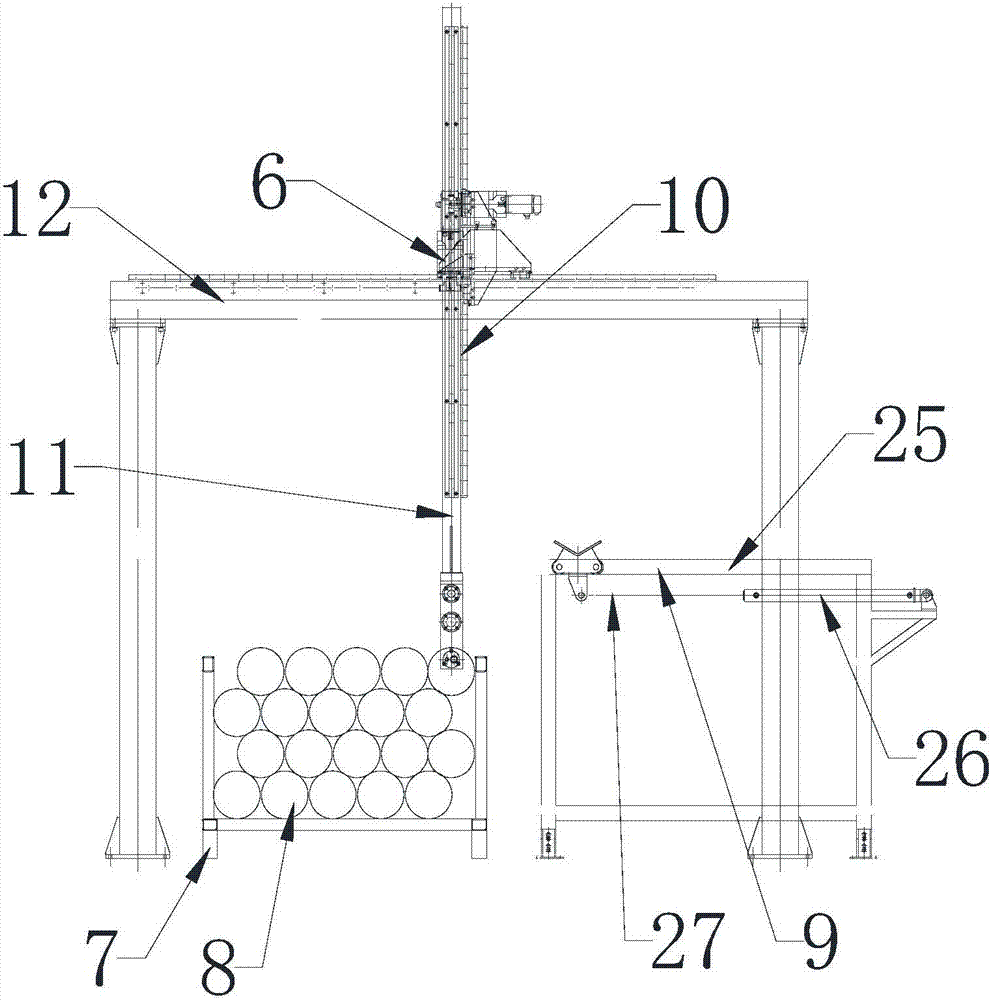

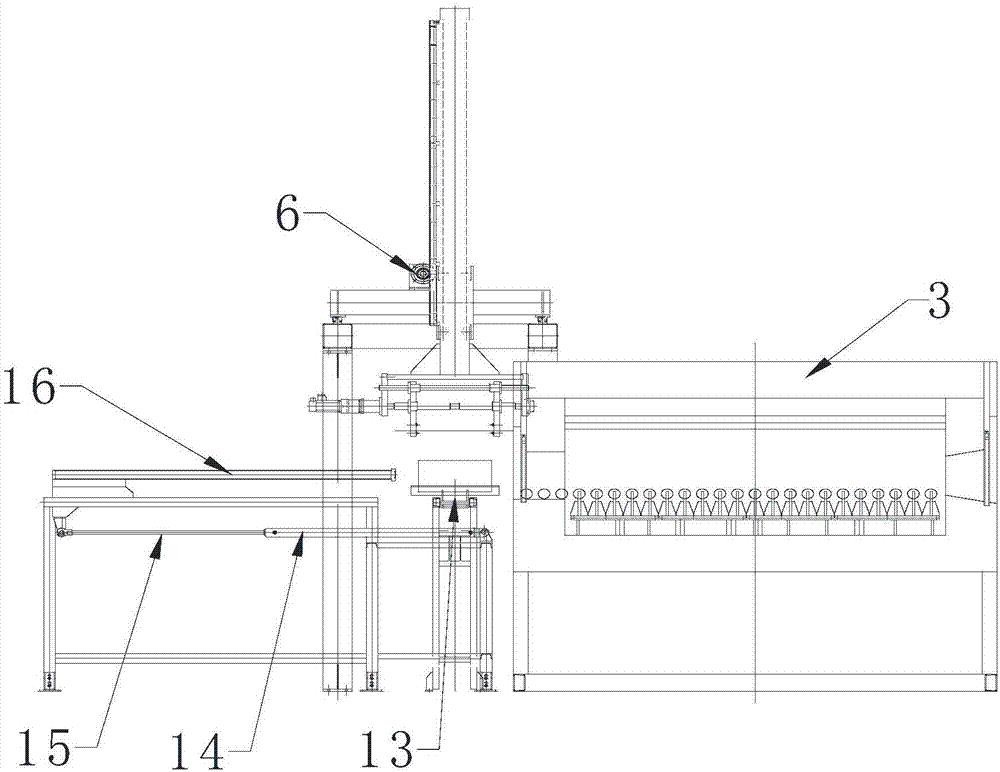

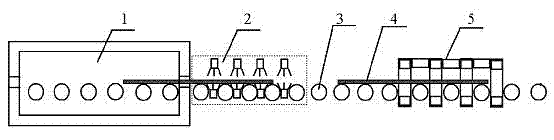

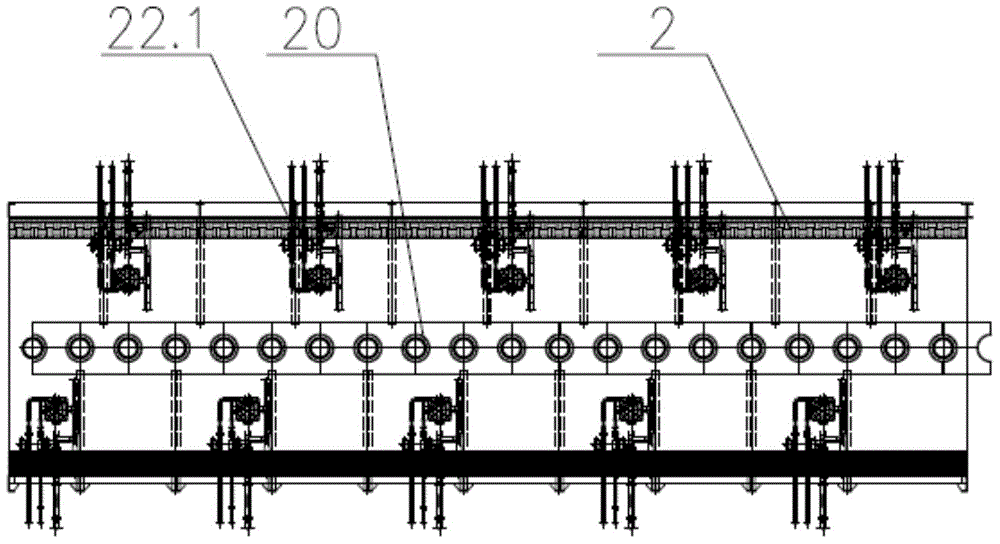

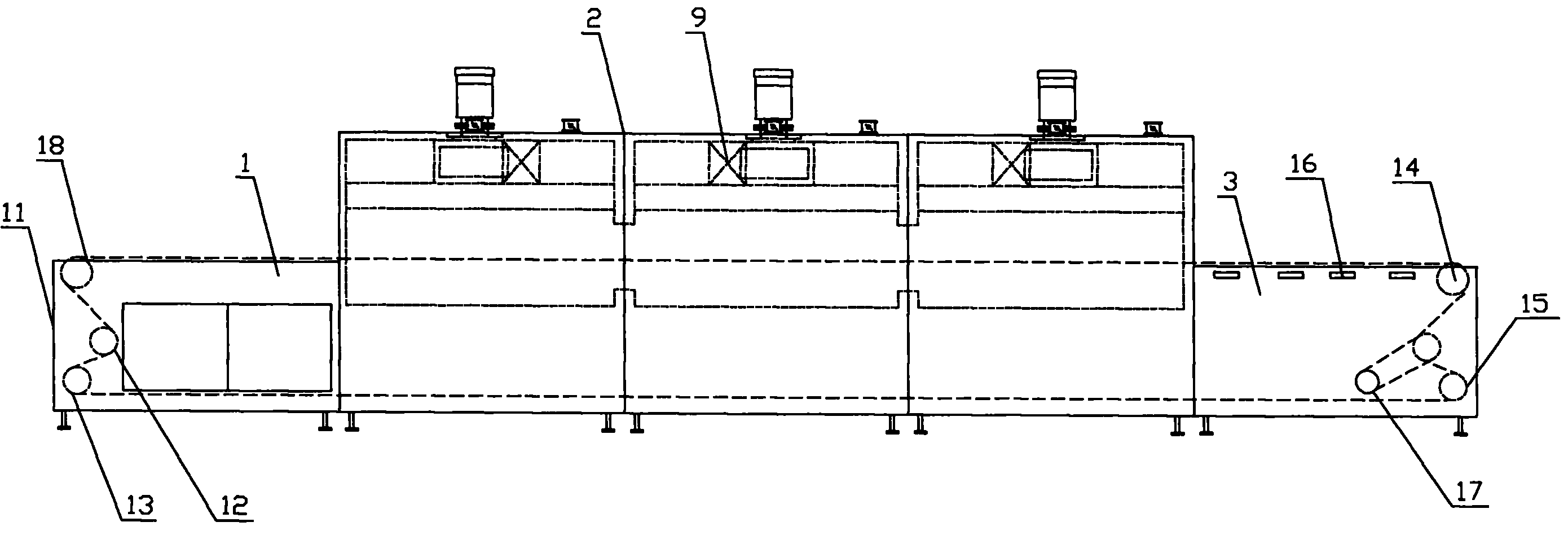

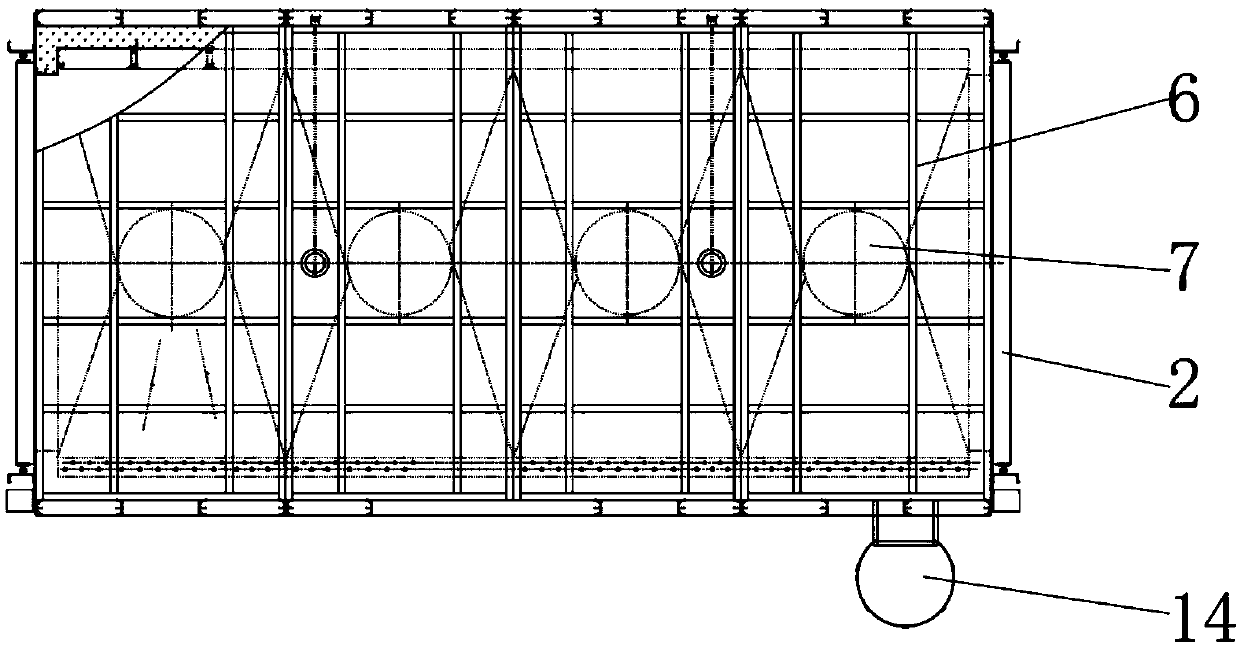

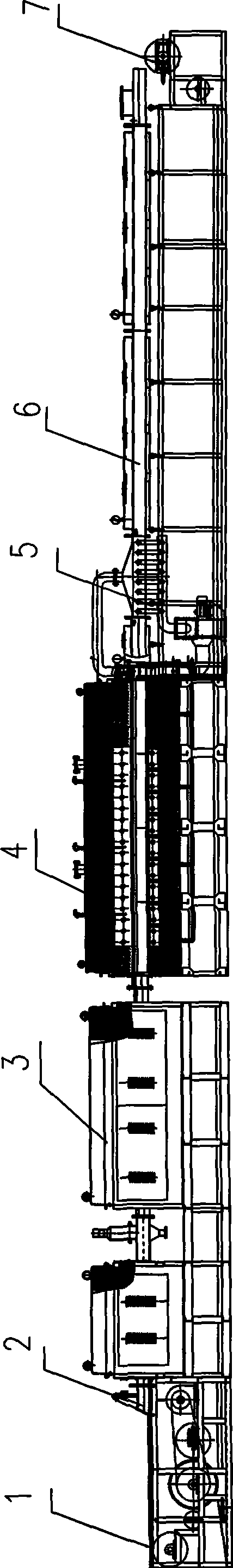

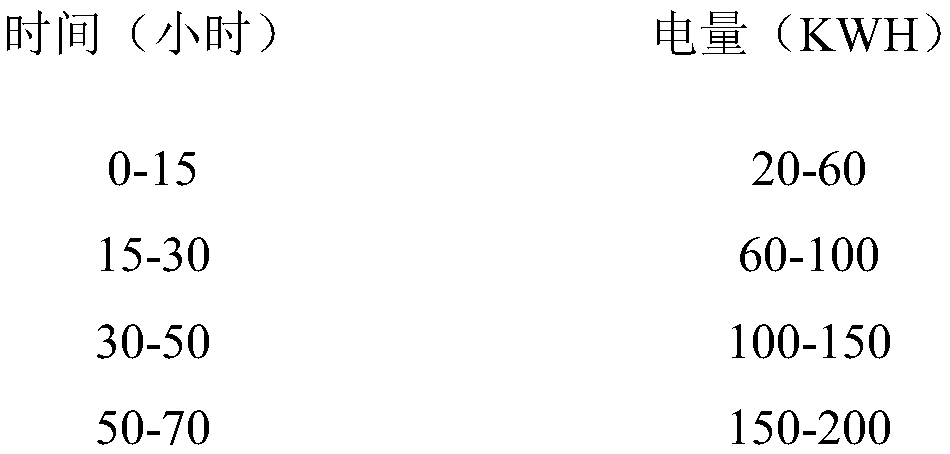

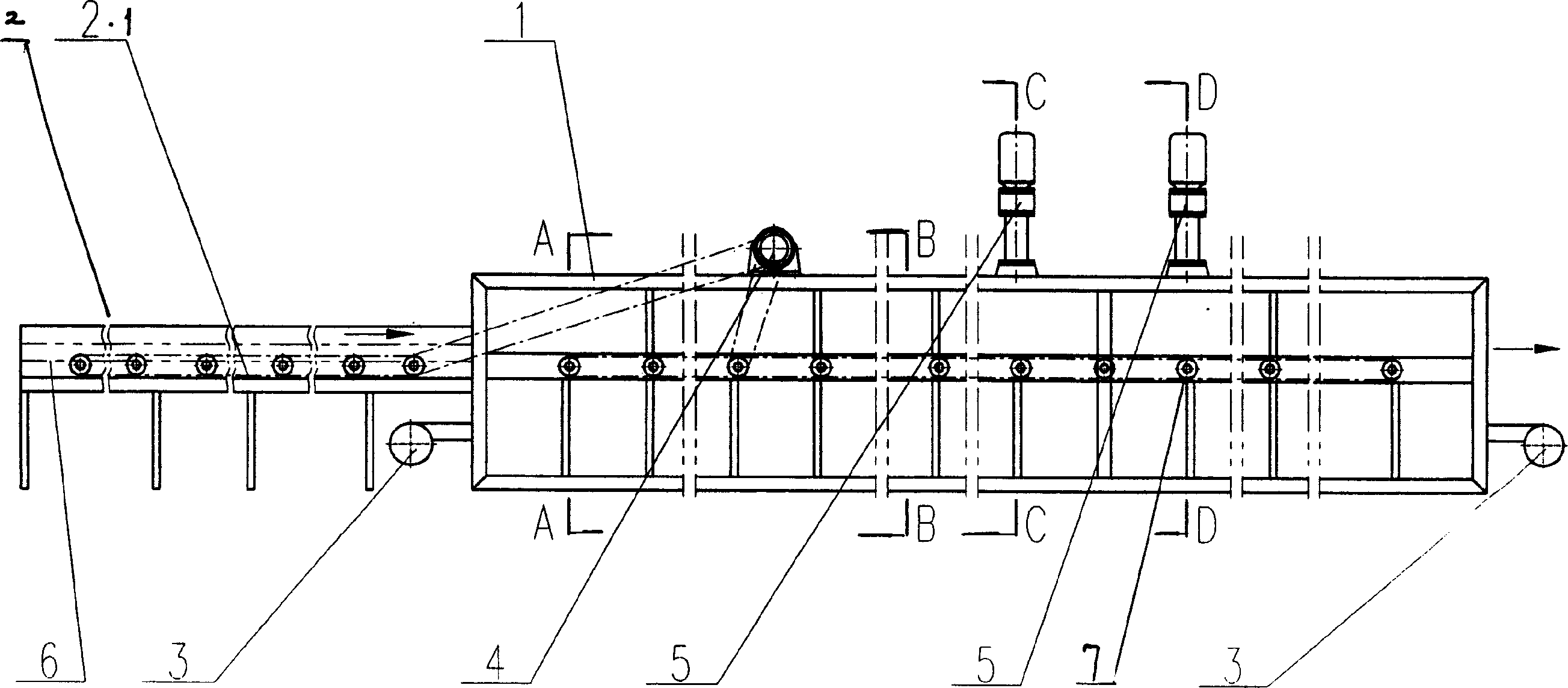

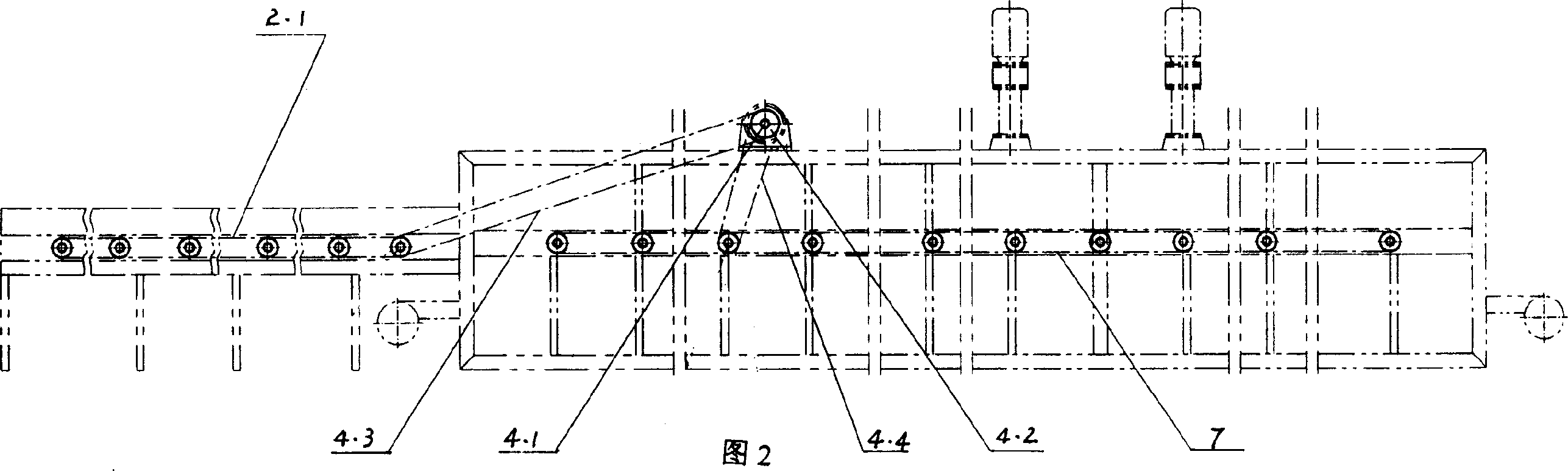

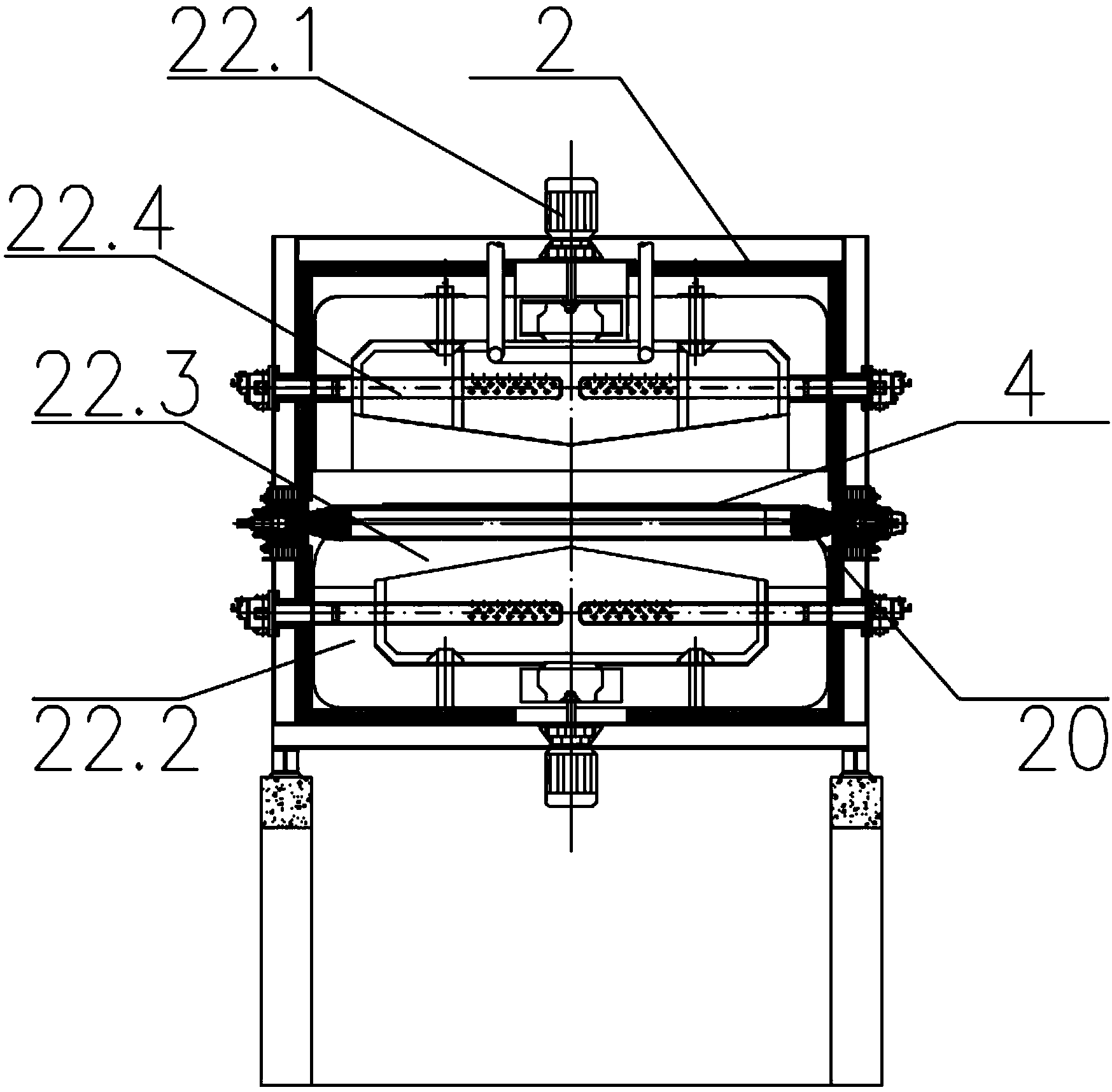

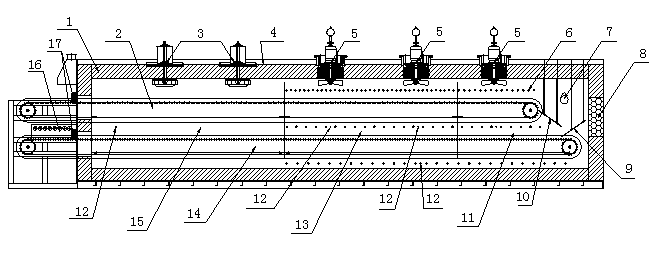

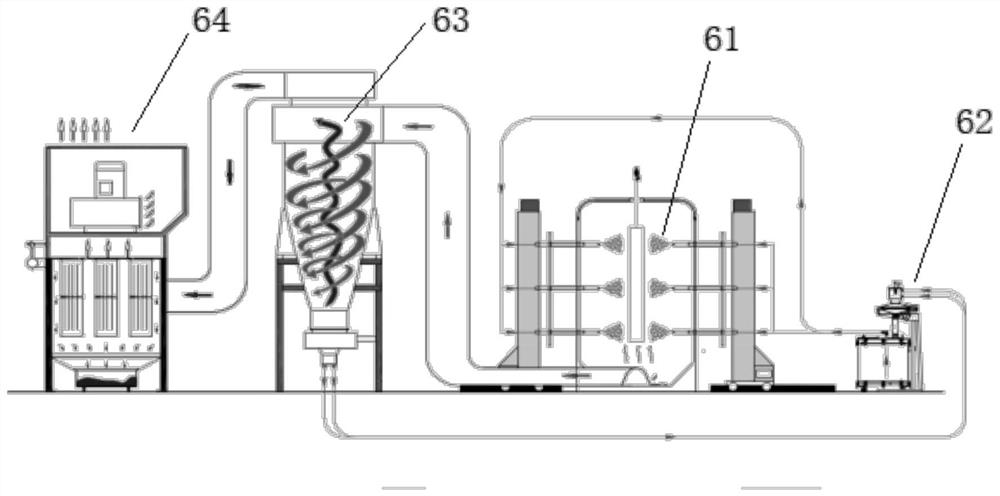

Full-automatic heating production line for short aluminum bars and method thereof

ActiveCN106955903AEvenly heatedStable and trouble-free rod movementFurnace temperatureProduction line

The invention provides a full-automatic heating production line for short aluminum bars and a method thereof. The full-automatic heating production line sequentially comprises an automatic feeding mechanism, a heating mechanism, a bar jacking mechanism arranged between the automatic feeding mechanism and the heating mechanism, a bar moving mechanism and an ejecting mechanism arranged in the heating mechanism; and the automatic feeding mechanism comprises a material frame, the short aluminum bars are arranged in the material frame, a manipulator is arranged above the material frame, a bar feeding mechanism is arranged on the side, close to the heating mechanism, of the material frame. According to the full-automatic heating production line for the short aluminum bars, a heating furnace in the heating mechanism adopts the mode that the multiple short aluminum bars are heated, double-segment circulating heating is conducted, and owing to uniform furnace temperatures, the short aluminum bars do not need to be subjected to homogenization treatment after being subjected to heating treatment through the full-automatic heating production line for the short aluminum bars; the bar moving mechanism adopts horizontal moving type bar moving, the short aluminum bars on the whole rise, fall and move by a fixed distance, and bar moving is smooth and steady, and malfunction is avoided; feeding adopts the servo manipulator, so that automatic feeding is achieved, and the length and quantity can be automatically calculated; and bar discharging adopts idler wheel bar discharging.

Owner:佛山市精业机械制造有限公司

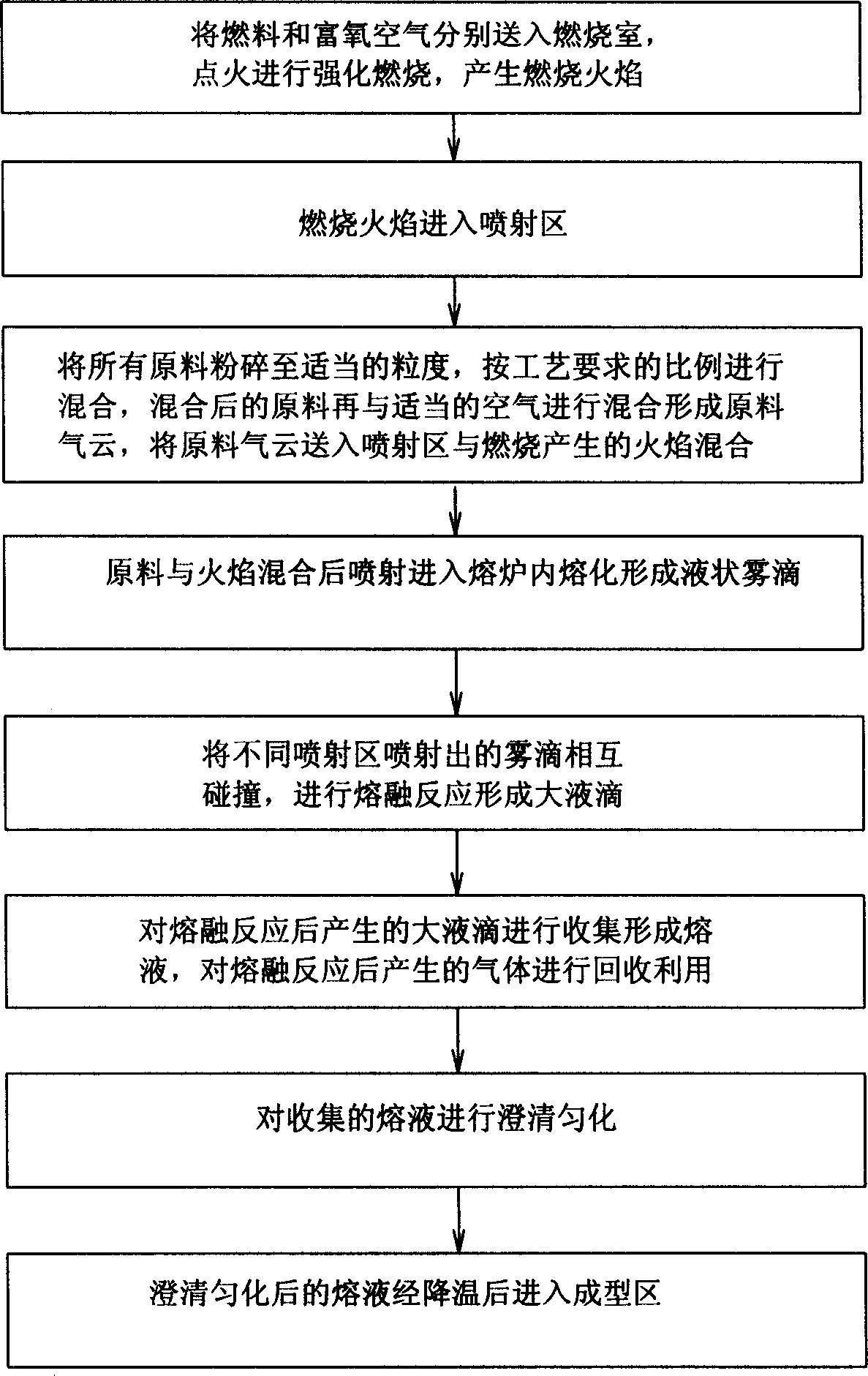

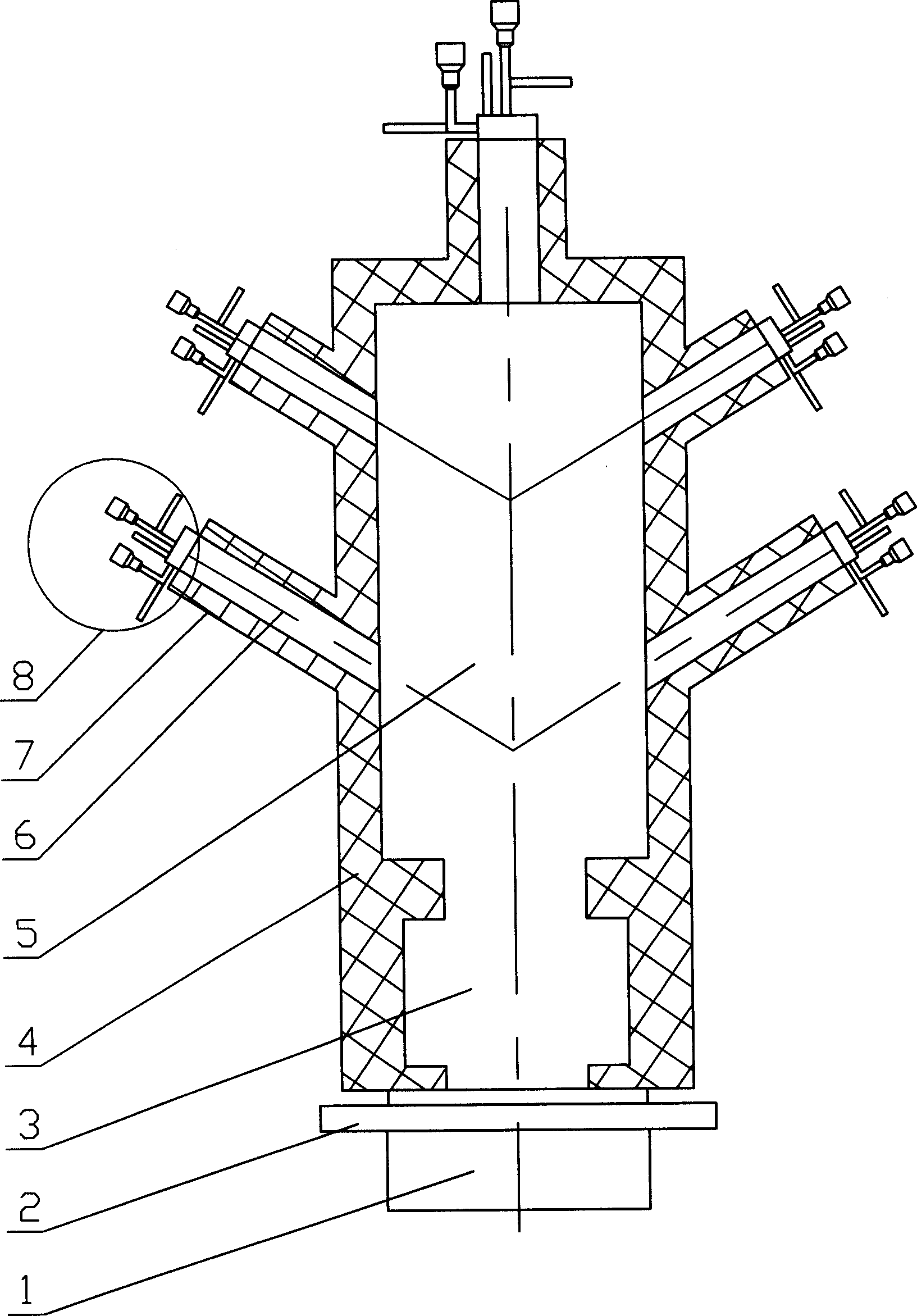

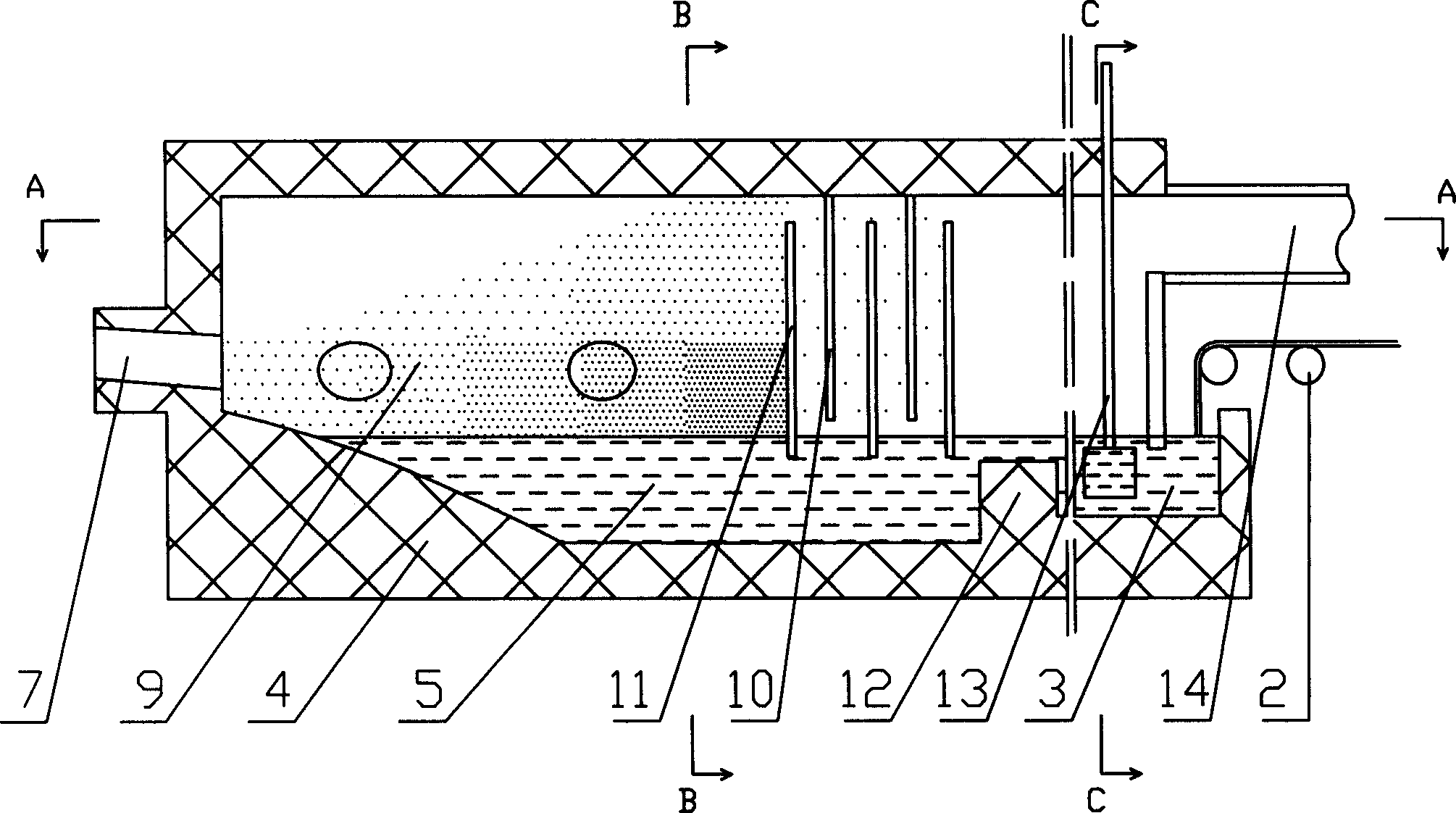

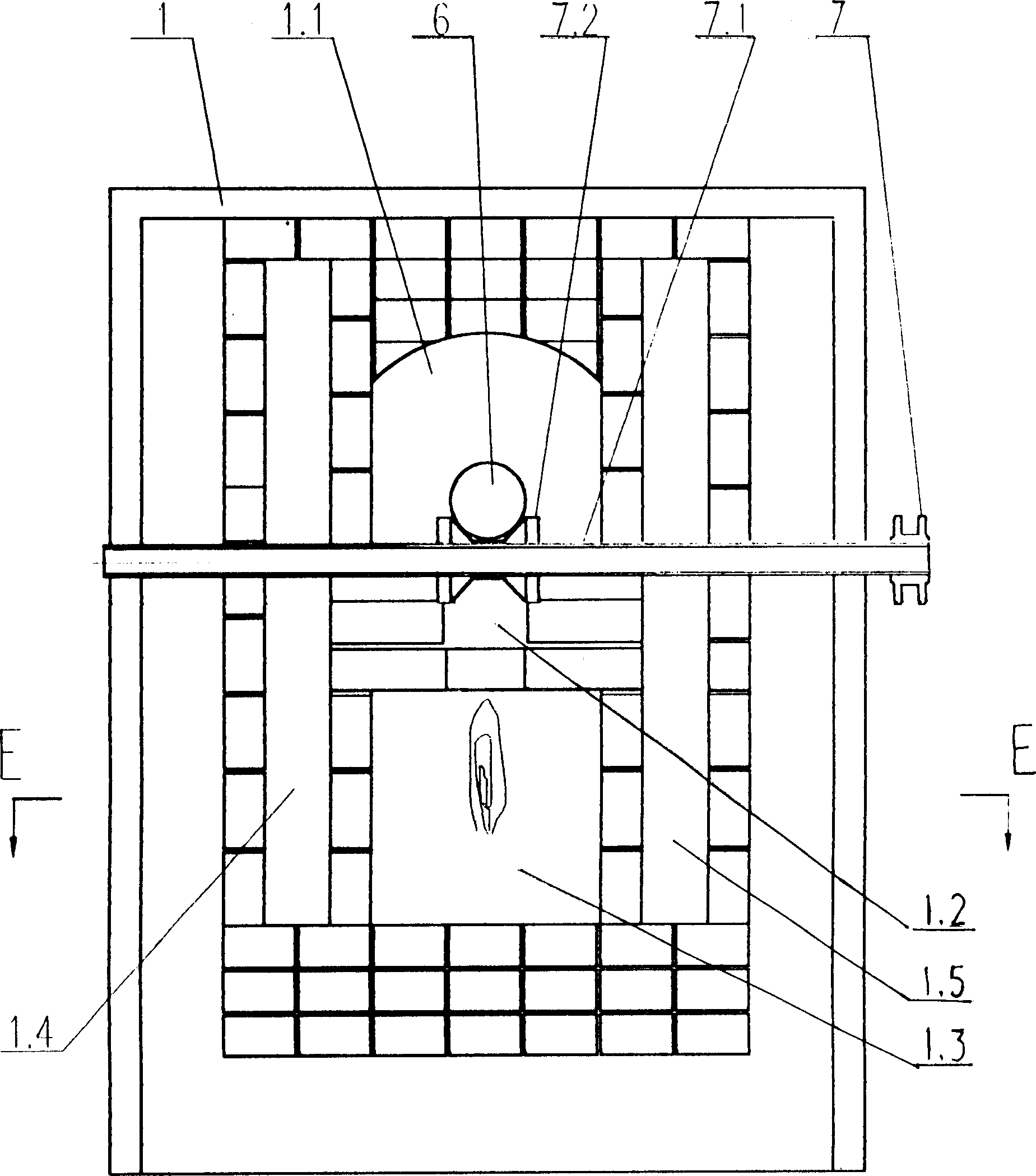

Full premixed combustion smelting method and smelting furnace for producing glass using the method

InactiveCN1594149AAvoid wastingSolve pollutionCharging furnaceGlass furnace apparatusCombustionHeat energy

The invention relates to a full premixed combustion smelting method and smelting furnace for producing glass using the method, wherein the method consists of disintegrating the raw materials, mixing and loading into flame for full contact with the flame, thus realizing completely premixed combustion and smelting, the droplets formed in smelting fall into the smelting pool through colliding each other and forming shaped liquid. The disclosed method can increase utilization factor of heat energy substantially.

Owner:谢西平

Heat treatment system used for producing ultrahigh strength steel

InactiveCN102363829AFully return redEasy to shapeFurnace typesHeat treatment process controlSheet steelHearth

The invention discloses a heat treatment system used for producing ultrahigh strength steel. The technological layout of the system is that: (1) a quenching machine is arranged behind a roller-hearth quenching furnace; a long transporting roll table with a length of 30 to 35m is arranged behind the quenching machine; and an open-fire low-temperature roller-hearth tempering furnace is arranged behind the transporting roll table; (2) a steel plate is heated in the roller-hearth quenching furnace, and the temperature is maintained; (3) the quenching machine is configured as in a quenching mode; and the technological speed of the quenching machine is controlled at 5 to 6m / min according to the thickness of the steel plate, wherein the thickness of the steel plate is 8 to 60mm. (4) the steel plate is heated; the temperature is maintained; the steel is fetched and quenched; the quenched steel plate is places on the transporting roll table for self-tempering, wherein the self-tempering temperature is Ms to Mf (the specific temperature is determined according to the steel type); (5) when self-tempering is finished, the steel plate is delivered to the tempering furnace in time with high speed for carrying out carbon distribution, wherein the temperature is maintained; the steel plate is delivered forward according to a preset technological speed; (6) when a carbon distribution time is satisfied, the steel plate is fetched from the furnace in time to be air-cooled; (7) when the steel plate is processed through a Q+P process, the steel plate can be transported to another tempering furnace for tempering when necessary.

Owner:HUNAN VALIN XIANGTAN IRON & STEEL CO LTD

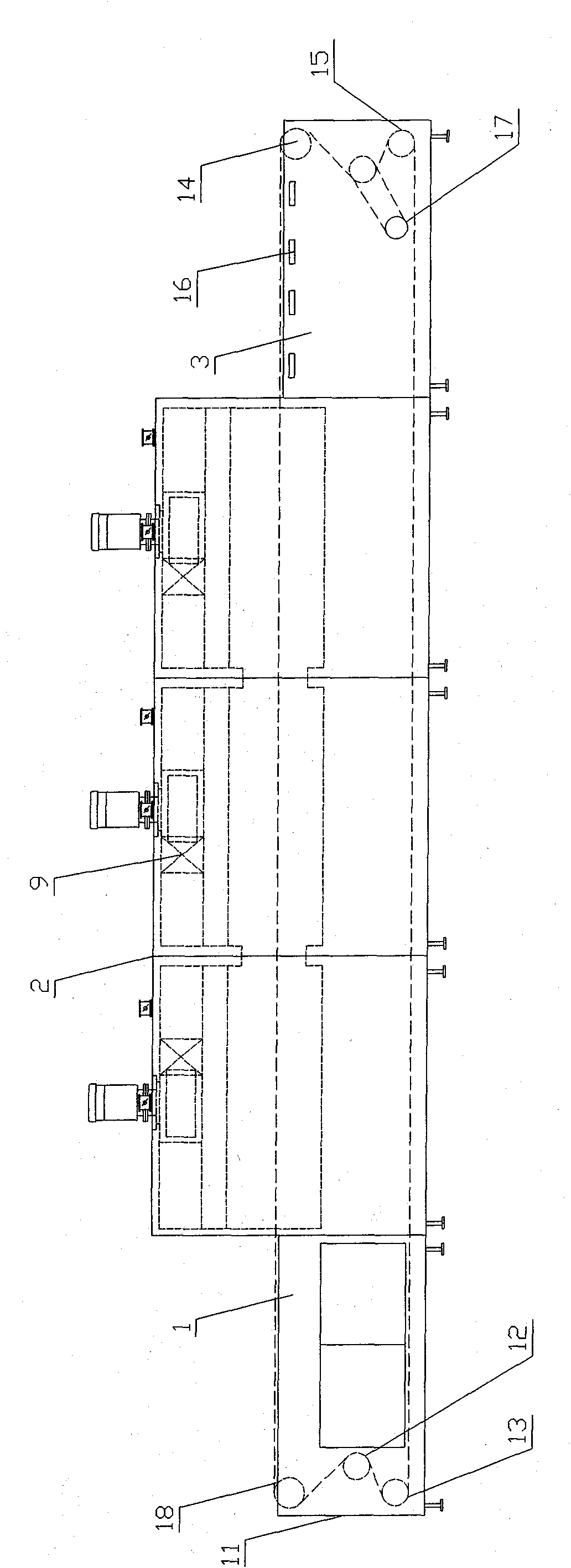

Continuous tempering furnace of roller hearth plates and annealing method thereof

ActiveCN104313295AUniform furnace temperatureBlast furnace temperature control accuracyFurnace typesHeat treatment furnacesFurnace temperatureHearth

The invention discloses a continuous tempering furnace of roller hearth plates. The continuous tempering furnace comprises a furnace body, a feeding device and a discharging device which are installed at the two ends of the furnace body, wherein the furnace body comprises a flame heating segment and strong convection heat preservation segment connected with the flame heating segment, the hearth of the strong convection heat preservation segment is communicated with the hearth of the flame heating segment, the furnace body is provided with a conveying roller way used for conveying plates, the conveying roller way penetrates through the hearths of the strong convection heat preservation segment and the flame heating segment, a flame heating device with adjustable firepower is arranged in the flame heating segment, and a strong convection spray heating device used for circulating heating and spraying hot air is arranged on the strong convection heat preservation segment; the feeding device comprises a feeding roller way connected with the feeding end of the conveying roller way; and the discharging device comprises a discharging roller way connected with the discharging end of the conveying roller way. The continuous tempering furnace of roller hearth plates achieves the function of one multipurpose furnace, and the furnace temperature control precision is high.

Owner:WISDRI WUHAN WIS IND FURNACE

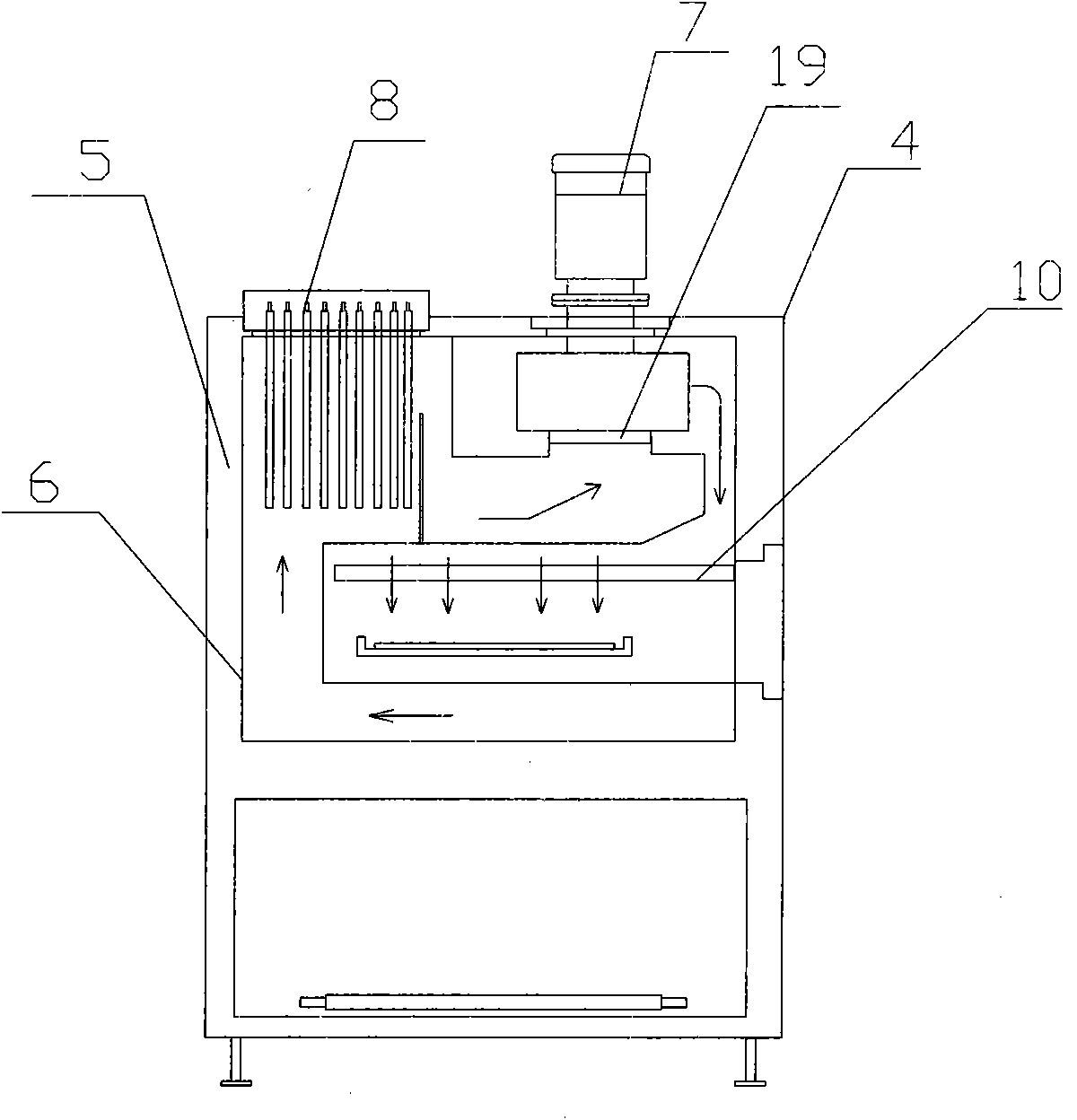

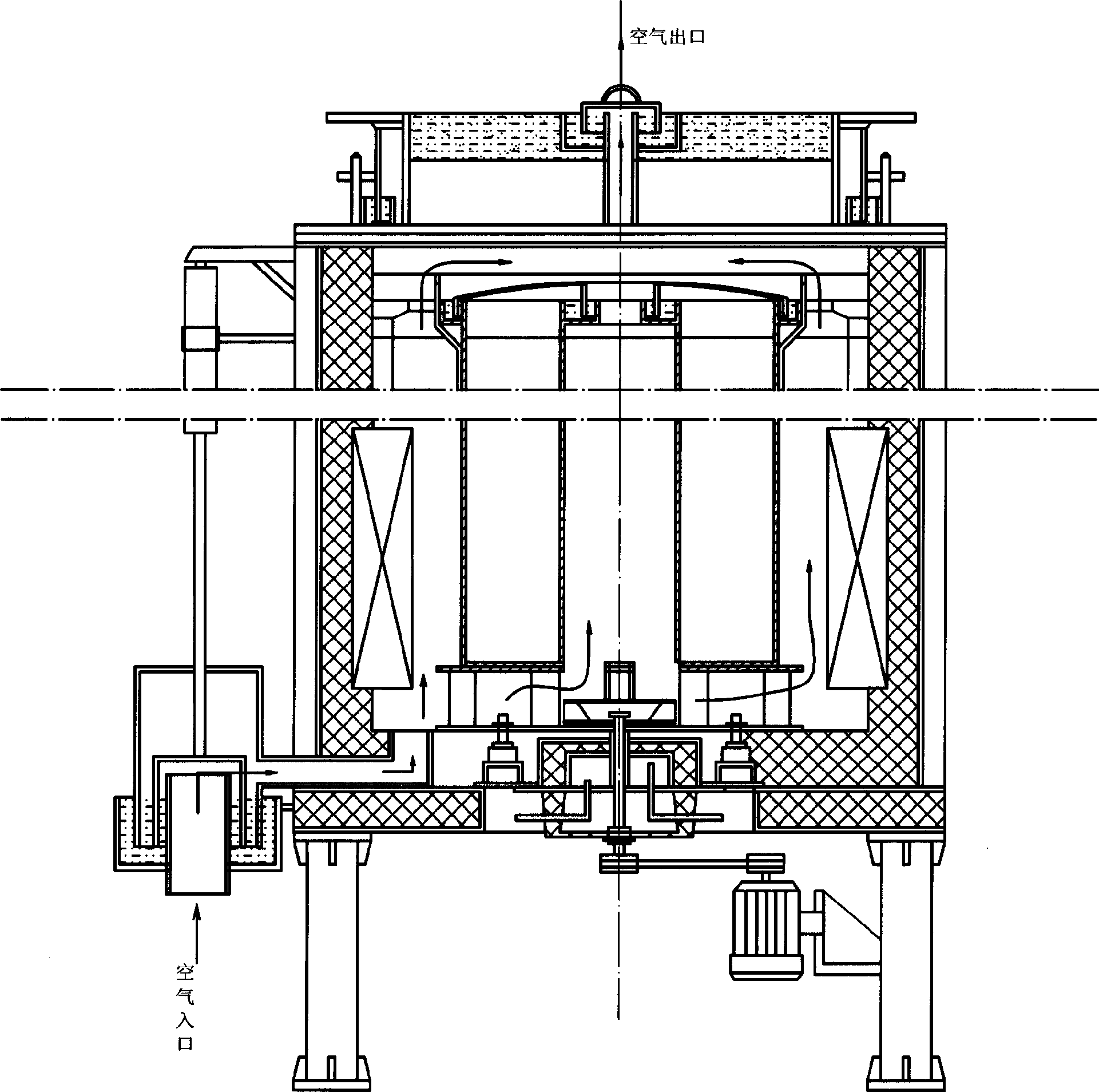

Novel heated-air circulation tempering furnace

InactiveCN101892360AUnique structureChange lengthFurnace typesHeat treatment furnacesCold airFurnace temperature

The invention relates to a novel heated-air circulation tempering furnace, and belongs to a medium-and-low temperature soft thermal treatment device for metal. The novel heated-air circulation tempering furnace comprises a feeding table, a furnace body and a discharging table, wherein the furnace body comprises an outer furnace shell, a furnace body heat preservation layer, an inner liner, and a blower and heating elements which are arranged on the furnace body; the blower is provided with an air suction inlet and an air outlet; a hot flow guide system is arranged below the air outlet; carrier rollers are arranged below the hot flow guide system; a first roller, a second roller and a third roller are arranged inside the feeding table; a fourth roller, a fifth roller, an out-furnace cold air blowing system and a speed reducer are arranged in the discharging table; and the furnace body is of a modular structure. The heated-air circulation tempering furnace has a unique structure of a heated-air circulation channel and is convenient for circulating heated air more uniformly so as to ensure the higher uniformity of the furnace temperature; the modular structure is adopted and each area is a module; and according to process characteristics of processed products, the modules can be added or reduced randomly so as to change the length of the furnace body to adapt to different thermal treatment processes.

Owner:苏州工业园区姑苏科技有限公司

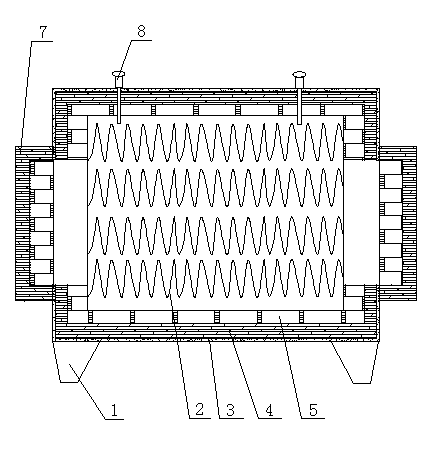

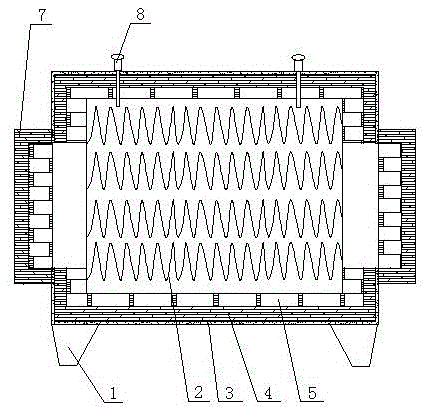

Box-type resistance furnace

ActiveCN103822469AGuaranteed furnace temperatureUniform furnace temperatureFurnace componentsFiberFurnace temperature

The invention provides a box-type resistance furnace comprising a furnace stand, a furnace body and a heating element. The furnace body is fixed on the furnace stand and provided with a hearth inside. The furnace body comprises a furnace shell, an insulation layer and a fireproof layer sequentially from outside to inside. The fireproof layer is made out of refractory bricks smaller than 1100kg / m<3> in density. The insulation layer is made of aluminum silicate refractory fiber. The space between the furnace shell and the insulation layer is filled with vermiculite powder. The heating element is made of corrugated resistance tapes evenly disposed on the refractory layer of the furnace body. Two sides of the furnace body are provided with furnace doors which both are side-opening doors. Each furnace door comprises an inner layer of refractory cellucotton and an outer layer of a steel plate. The box-type resistance furnace is high in loading capacity and high in production efficiency, especially suitable for thermal treatment of small and medium sized machine parts, uniform in furnace temperature and good in insulation effect, can save energy by more than 20%, and is pollution free and good in environmental protection benefit.

Owner:江苏新江南炉业科技有限公司

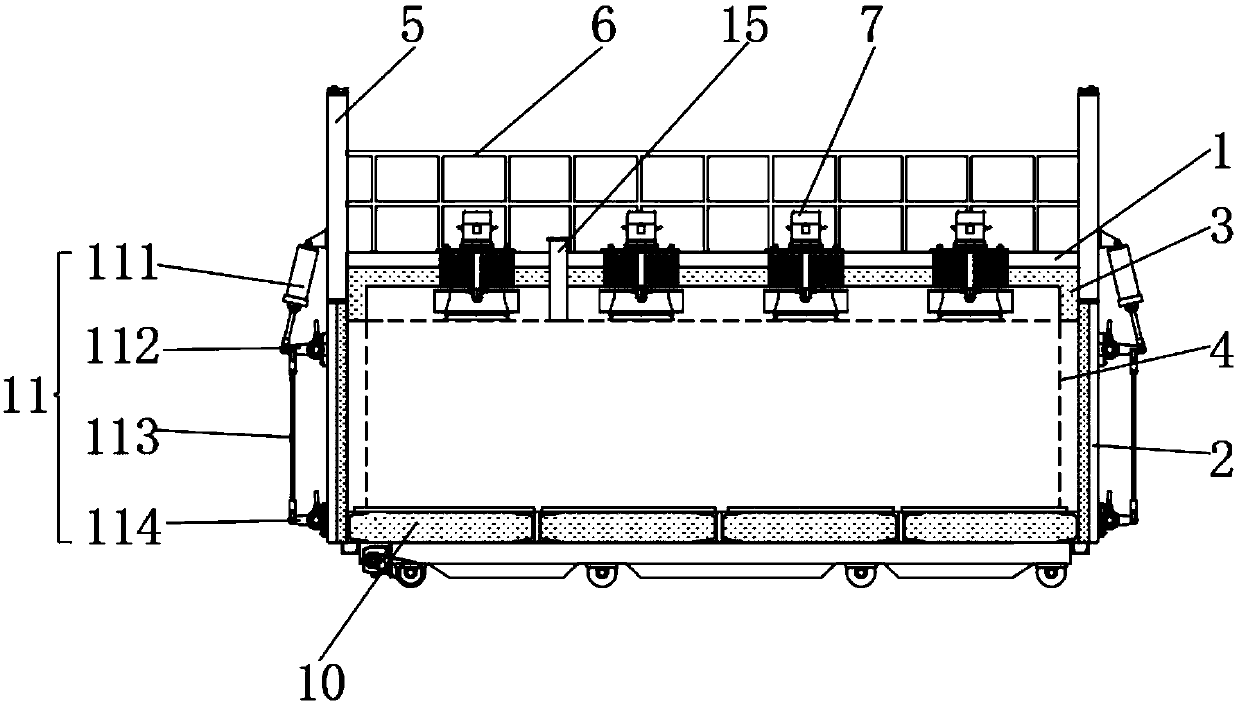

Trolley type aluminum alloy aging furnace

InactiveCN109536693AEasy to storeAvoid churnFurnace typesHeat treatment furnacesAluminium alloyHeating element

The invention discloses a trolley type aluminum alloy aging furnace, and belongs to the technical field of aging furnaces. The trolley type aluminum alloy aging furnace comprises a box body and an airadjusting door device; furnace doors with the same structure are hinged to the positions through holes, four groups of vertical centrifugal hot air circulating fans are uniformly arranged on the topof the box body from left to right, and a fan shaft is arranged at the bottom end of each of the four groups of centrifugal hot air circulating fans; and a ventilating duct is arranged between a heatpreservation layer and an inner container, a trolley main body is arranged at the bottom of the part which is located between the two groups of furnace doors, furnace door mechanisms with the same structure are arranged on the outer sides of the two groups of vertical plates respectively, and a sealing mechanism is arranged at the bottom of the outer wall at the rear side of the box body. According to the trolley type aluminum alloy aging furnace, four groups of vertical centrifugal hot air circulating fans are adopted, the heat emitted by a heating element is forced to flow circularly, so that the temperature in the furnace is promoted to be uniform; and meanwhile, the heat preservation layer and the heat preservation material layer can well preserve heat, so that the heat can be prevented from being rapidly lost, and the heating quality and efficiency of a workpiece in the furnace can be greatly improved.

Owner:XUZHOU LINT TOP CABLE TECH CO LTD

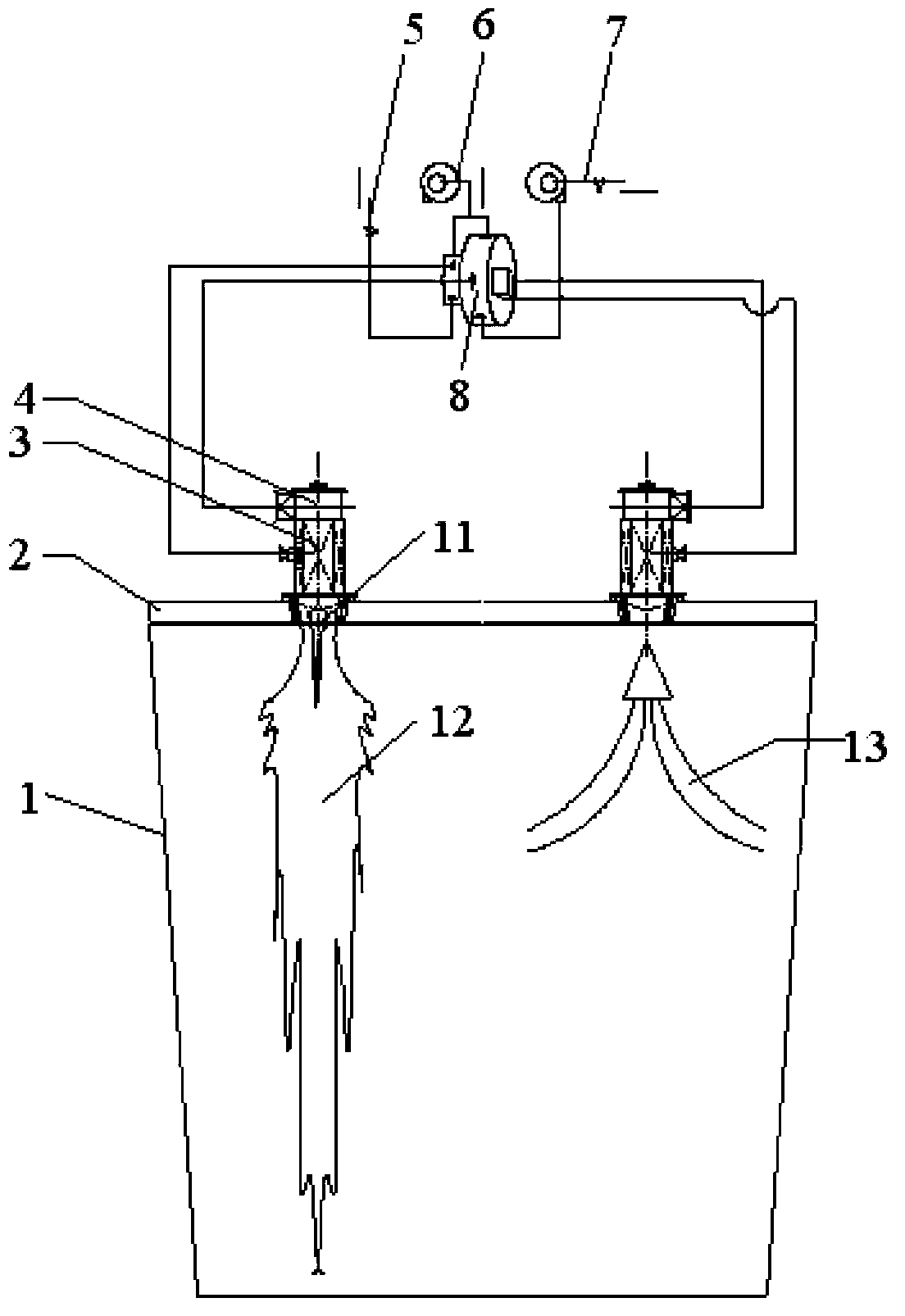

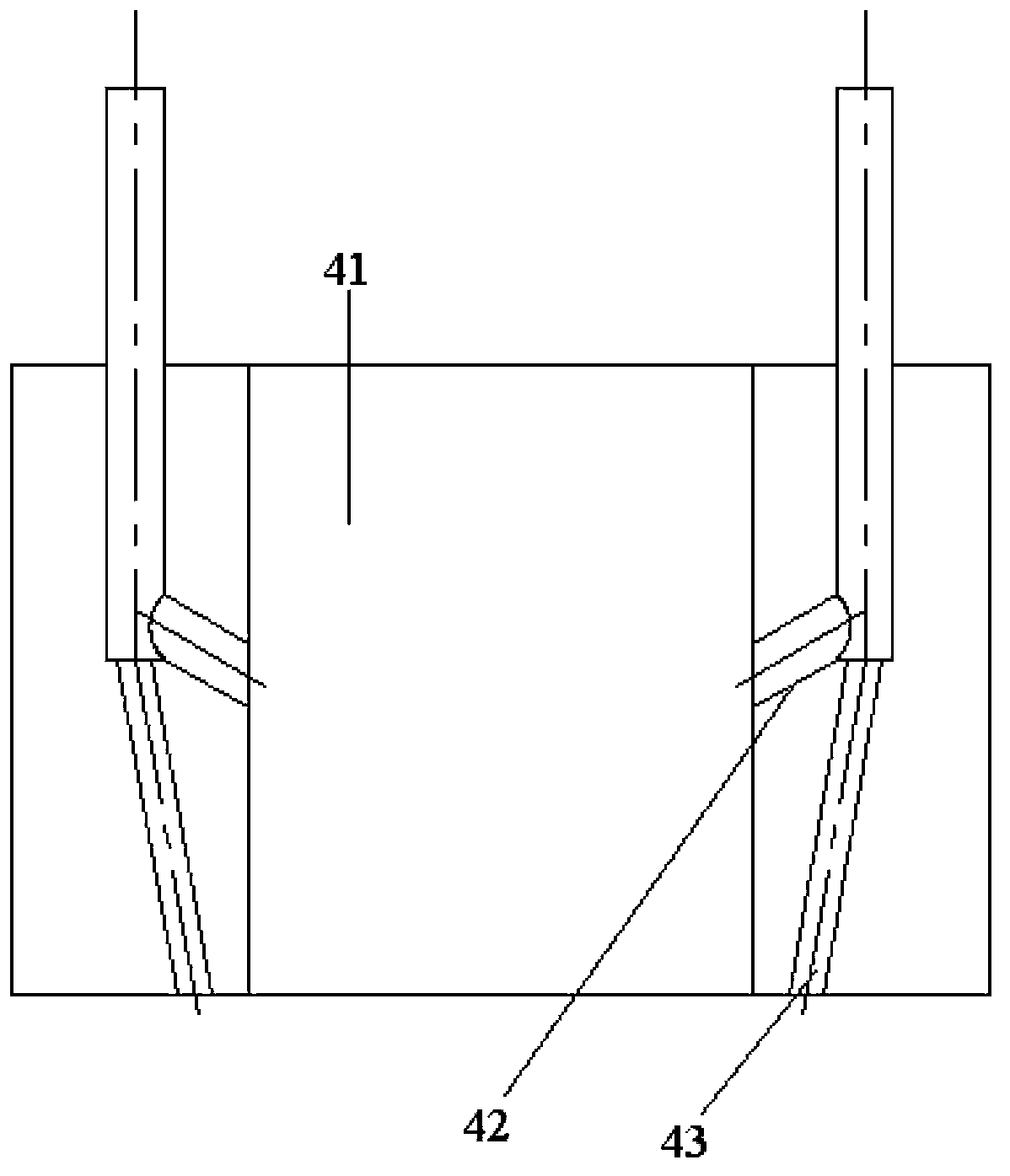

Heat accumulating type steel ladle baking system capable of remarkably reducing NOX (nitrogen oxide) and baking method

The invention provides a heat accumulating type steel ladle baking system capable of remarkably reducing NOX and a baking method. The heat accumulating type steel ladle baking system capable of remarkably reducing NOX comprises a steel ladle, at least two combustors, a fuel gas subsystem, a combustion air system, a smoke exhaust subsystem, an air-fuel gas reversing valve and a control subsystem, wherein a heat retainer, at least one concentrated combustion nozzle and at least one light combustion nozzle are arranged in each combustor; and during baking, the fuel gas sprayed out of the concentrated combustion nozzles combusts concentratedly, and simultaneously, the fuel gas sprayed out of the light combustion nozzles combusts lightly. Compared with the prior art, the heat accumulating type combustion is combined with the concentrated combustion and the light combustion, so that the temperature in a furnace is very uniform, NOX pollutants are prevented from being generated, the maximum reduction amount can be higher than 70%, and the problem of high pollution due to the combustion is completely solved by virtue of the combustion manner.

Owner:SHANGHAI BAOSTEEL ENERGY TECH

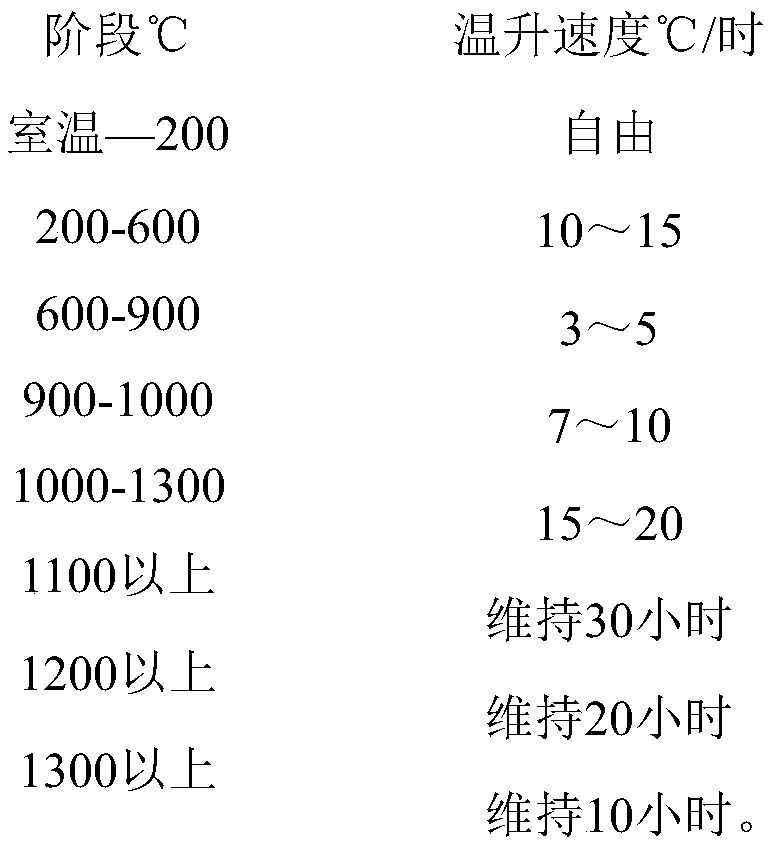

Preparation method of quartz ceramic hollow roll bar for toughened glass heating furnace

A preparation method of a quartz ceramic hollow roll bar for toughened glass heating furnace relates to the technical field of quartz ceramic. A fused quartz raw material with the chemical purity that SiO2 is more than or equal to 99 percent is adopted; based on the mass percentage of granules and gradation, the fused quartz comprises 40 to 50 percent of quartz with granularity of 1 to 0.5 mm, 20 to 30 percent of quartz with granularity of 0.3 to 0.1 mm and 20 to 30 percent of quartz with granularity of less than 0.01 mm; and the quartz ceramic hollow roll bar is obtained by the steps of grinding materials, preparing colloid slurry, forming, drying and sintering. According to the preparation method, a gel casting process is adopted, so the aims of short forming time, accurate and consistent overall dimensions, smooth surface and uniform internal structure are fulfilled, the weight of the prepared quartz ceramic hollow roll bar is reduced by 20 to 30 percent compared with that of a quartz ceramic roll bar, the energy is saved and uniform furnace temperature is guaranteed.

Owner:洛阳索莱特材料科技有限公司

Fast cooling method for lithium iron phosphate steel belt type reducing furnace

InactiveCN101475154AIncrease productionQuality improvementPhosphorus compoundsLithium iron phosphateSteel belt

The invention discloses a quick cooling method for a lithium iron phosphate steel band type reducing furnace, which comprises the following steps: adding lithium iron phosphate onto a steel band of the steel band type reducing furnace through a feeding section, then sintering the lithium iron phosphate through a pre-burning section and a sintering section, quickly cooling the sintered lithium iron phosphate, and discharging the quickly-cooled lithium iron phosphate through a discharging section to finish the whole sintering process, wherein the cooling rate is between 8.8 and 15.8 DEG C per minute. The quick cooling method for the lithium iron phosphate steel band type reducing furnace has large yield, and is convenient for process adjustment and quality control.

Owner:ADVANCED FOR MATERIALS & EQUIP

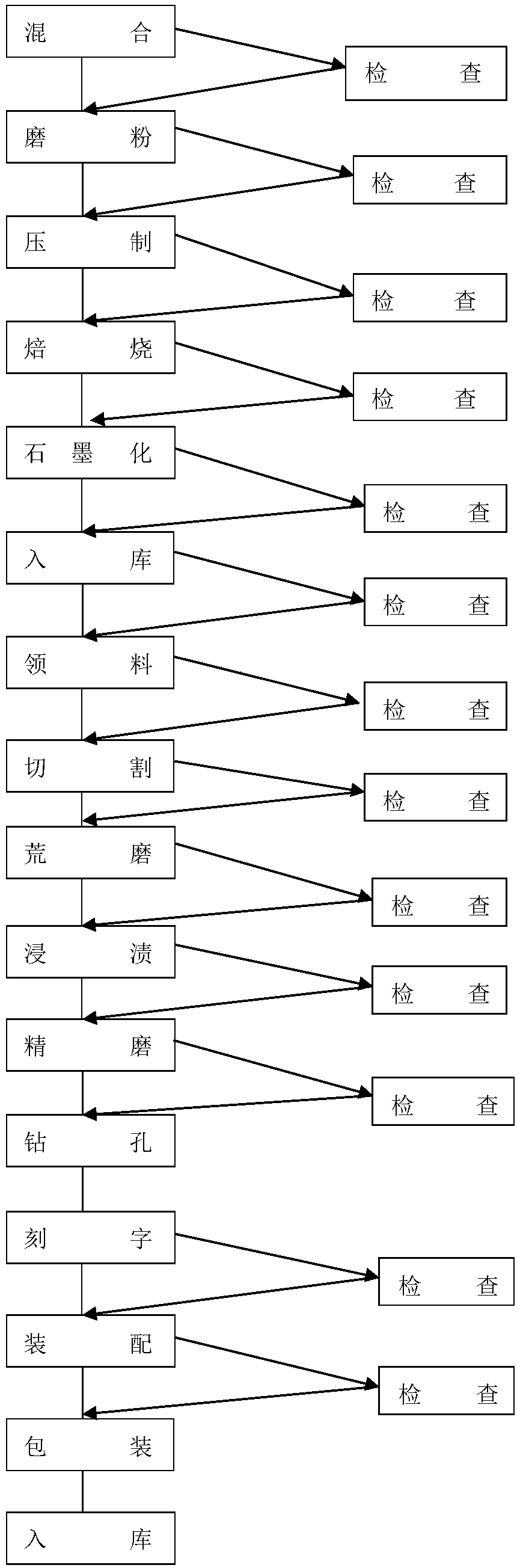

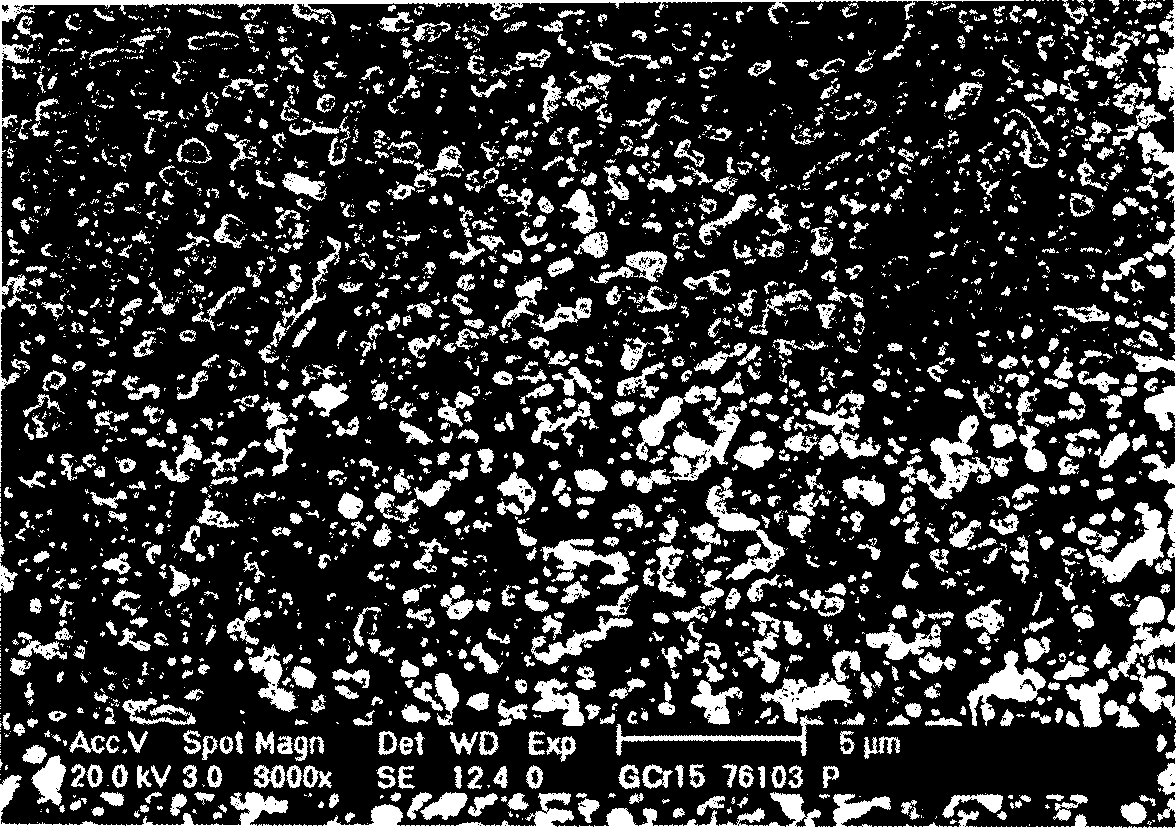

A brush for railway electric machine and its preparation method are provided

ActiveCN109004482AGuaranteed stabilitySolve the problem of brushing off braidsRotary current collectorBrushes manufacturePorosityWeight gaining

The invention discloses a railway electric motor brush and a preparation method thereof, belonging to the technical field of brush processing. The brush is prepared by two stages of production. One stage of production is prepared by heating and mixing carbon black, modified pitch and coal tar, roasting, and grinding to obtain a stage product after roasting is completed. Two-stage production is bymixing the first-stage product, carbon black, modified pitch and sulfur by heating, rolling, grinding, pressing, roasting, graphitizing, impregnating, finishing grinding, drilling and assembling to produce brushes. The invention also provides a preparation method of the electric brush. The performance uniformity of the electric brush is improved from 60% to 98%; The pull-out tension of the brush product can be increased by 2 to 3 times, up to 750kgf, the weight gain rate of the product is obviously increased, the weight gain rate is as high as 12%, the porosity is significantly reduced, and the porosity is up to 1%. The brush can meet the needs of the market. The brush is suitable for railway electric machines.

Owner:美尔森哈碳电碳(哈尔滨)有限公司

Double-layer sealing non-standard cover furnace

InactiveCN102534180ATightness is not requiredImprove uniformityBell type furnacesHeat treatment furnacesSilicon rubberMechanical property

The invention belongs to the technical field of heat treatment processing equipment, and relates to an improved non-standard heat treatment cover furnace with a double-layer sealing structure. The cover furnace mainly comprises a furnace base, a furnace base cross supporting frame and a furnace cover, and is characterized in that: a double-layer sealing ring is arranged between the furnace base and the furnace cover; and an inner layer of the double-layer sealing ring is an asbestos packing, and an outer layer of the double-layer sealing ring is a silicon rubber ring. The cover furnace can meet the requirement on the mechanical property of a novel steel strip after the novel steel strip is annealed, is particularly suitable for annealing a steel strip made from a BSYE-N material, fills in the blank of the steel strip product in China, and eliminates the technical bottleneck which restricts the development of the technology. Compared with the traditional cover furnace, the cover furnace has the advantage that: production cost is greatly reduced.

Owner:LIYANG HONGDA MACHINERY EQUIP

Aluminium alloy single-bar rapid heating stove

InactiveCN1743777AImprove thermal efficiencyUniform furnace temperatureFurnace typesCombustion chamberCombustor

This invention refers to aluminium alloy single bar quick heating furnace, which contains furnace body, burner, circulation fan and driving roller way, which features said furnace body has heating chamber in upper part and burning chamber in lower part, central part set with path, the driving roller path in heating chamber, said burning chamber separated by partition wall to from two burning chambers, left and right longitudinal air channel connected with two burning chambers, two burners set at outer ends of front and rear burning chambers, two circulation fans set at the top position corresponded to heating chamber. Said invention has high heating efficiency and low failure rate.

Owner:李国建

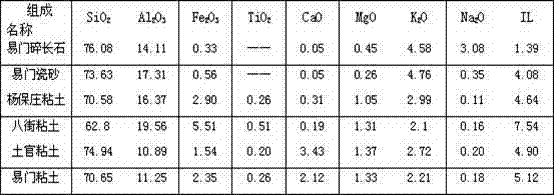

Ceramic railing with high weatherability, and preparation method thereof

ActiveCN102515701AReduce the maximum thermal expansion coefficientAvoid crackingFencingBridge structural detailsWeather resistanceGlaze

The invention provides a ceramic railing with high weatherability, and a preparation method thereof. Because of self-factors, when a ceramic railing is used, glaze-surface falling and cracks on parts of the structures can easily occur; under weather conditions with large temperature differences, glaze-surface bursting might occur, and normal application is severely influenced; during a firing procedures, because of uneven air flow, slow heat transfer and low heat exchange efficiency in a kiln, regular and controllable temperature gradient can hardly be formed longitudinally in a firing zone in the kiln, such that the firing period is prolonged. With the method provided by the invention, the technical problem is solved. According to the invention, a raw material formula is modified, and a local clay resource in Yunnan Province is adopted as a raw material. The formulas for a ceramic railing blank and a glaze are further optimized, and a firing process procedure is also modified, such that the weatherability of a finished product is improved. Indexes of performances such as water absorption rate, freezing resistance, quick-chilling resistance, quick-heating resistance and appearancequality of the ceramic railing product satisfy a construction colored glaze product standard JC / T765-2006.

Owner:YIMEN DIANYUAN CERAMIC

Work piece sealing transfer device of vertical heating treatment production line

InactiveCN1303227CFlexible heat treatmentHeat treatment suitableFurnace typesHeat treatment furnacesProduction lineTransfer system

A sealed workpiece transferring system for a vertical heat treating line is composed of the protecting atmosphere system and vacuum system, which are respectively coupled with the upper and lower parts of heating furnace and the preheating furnace, an insulating vacuum sealing valve, movable sealing hood linked with its lift mechanism, the preheating furnace, furnace cover and quenching bath, which are arranged on a small train, and relative sealing rings.

Owner:SHANGHAI JIAO TONG UNIV

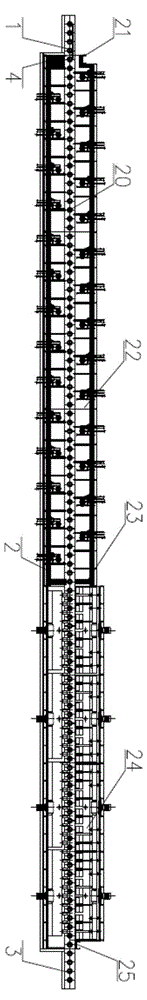

Roller-hearth type plate continuous tempering furnace and tempering method thereof

ActiveCN104388662AUniform furnace temperatureBlast furnace temperature control accuracyFurnace typesHeat treatment furnacesFurnace temperatureEngineering

The invention discloses a roller-hearth type plate continuous tempering furnace, comprising a furnace body, a loading device and an unloading device, wherein the loading device and the unloading device are arranged at two ends of the furnace body; the furnace body comprises a strong convection heating section and an open fire heating / holding section which is connected with the strong convection heating section; a hearth of the strong convection heating section is communicated with a hearth of the open fire heating / holding section; the furnace body is provided with a conveying roller which is used for conveying a plate; the conveying roller runs through the hearths of strong convection heating section and the open fire heating / holding section; the strong convection heating section is provided with a strong convection blowing and heating device which is used for circularly heating and blowing hot air; an open fire nozzle, a furnace gas disturbance fan and a hot air jet pipe are arranged in the open fire heating / holding section; the loading device comprises a loading roller which is connected with a feeding end of the conveying roller; and the unloading device comprises a discharge roller which is connected with a discharge end of the conveying roller. The roller-hearth type plate continuous tempering furnace disclosed by the invention is capable of achieving the multi-purpose function, and simultaneously is high in furnace temperature control accuracy.

Owner:WISDRI WUHAN WIS IND FURNACE

Method for melting copper through line frequency furnace

ActiveCN105274354AImprove airtightnessImprove energy savingProcess efficiency improvementIngotShaft furnace

The invention discloses a method for melting copper through a line frequency furnace. The method comprises the following steps that 1, a waste copper piece and waste are subjected to primary treatment; 2, screening is carried out; 3, classification is carried out; 4, accessories are fed into furnaces, wherein the accessory I, the accessory II and the accessory III are fed into the shaft furnace, the open-hearth furnace and the line frequency cored copper melting copper to be refined, and a product I, a product II and a product III are obtained; 5, the product I and the product II are transported to a copper continuous casting and rolling unit for casting treatment, a steel rod is obtained, and the product III is placed in a pig casting machine to be machined and treated, and a copper ingot is obtained; and 6, the steel rod in the step 5 is drawn, and a qualified copper piece is obtained. The method for melting copper through the line frequency furnace achieves energy saving and is environmentally friendly, and manufactured steel is good in quality.

Owner:NINGXIA RUIYIN NONFERROUS METAL TECH CO LTD

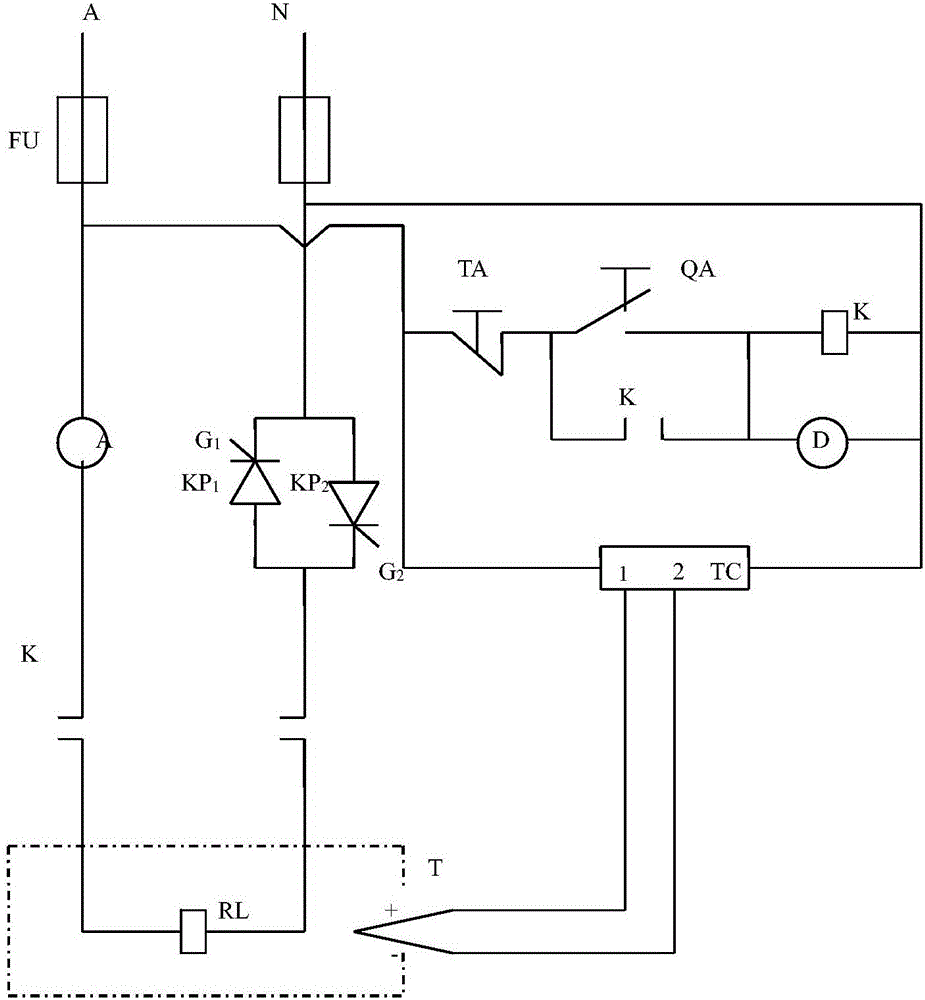

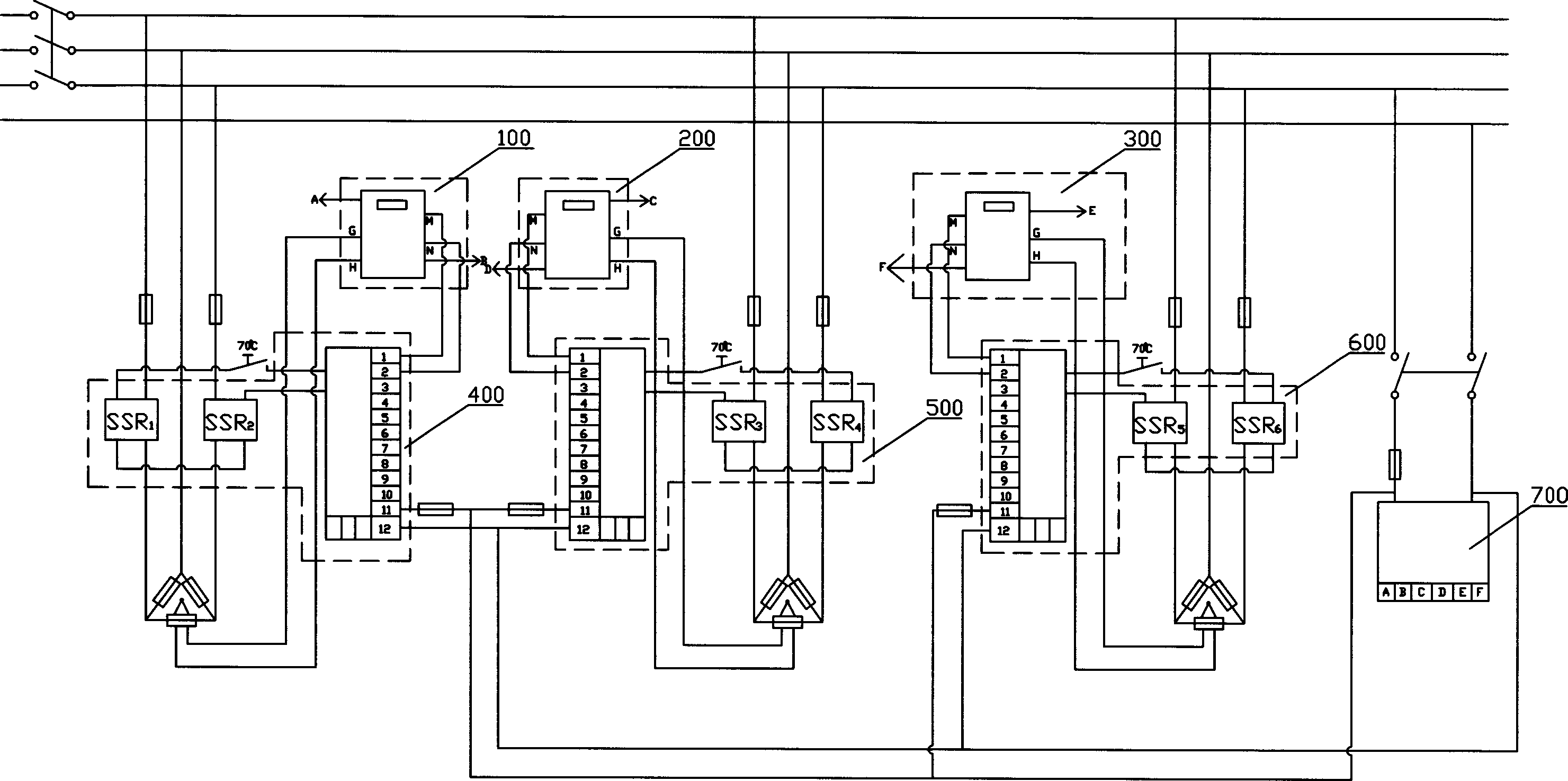

PLC controlled intelligence well-type electric furnace

InactiveCN1834267AHigh degree of automationHeating temperature rises quicklyHeat treatment process controlTemperature controlElectrical resistance and conductance

This invention discloses a PLC-controlled intelligentized well-type electric furnace, which is composed of a furnace body, a furnace cover and a resistance heater. Besides, the electric furnace is also composed of a system for PLC-controlling of the load main circuit. The system performs zoning temperature control on the main circuit, and is composed of three programmable PID controllers, three integrated threephase electric power controllers and one temperature-controlling meter connecter. In each temperature control zone, a thermal couple is equipped to connect the programmable PID controller. The input side of the thermal couple is connected with the temperature-controlling meter connector, and the output side is connected with the integrated threephase electric power controller, and is connected with the main circuit in a serial-parallel mode through a temperature-controlling switch and a solid-state relay. The threephase electric power controller can collect the input signals from the programmable PID controller, and perform closed-loop control on the heating system. The well-type furnace has such advantages as rapid heating, uniform temperature distribution, low error and rapid cooling.

Owner:LINFA BEARING STEEL WIRE DALIAN

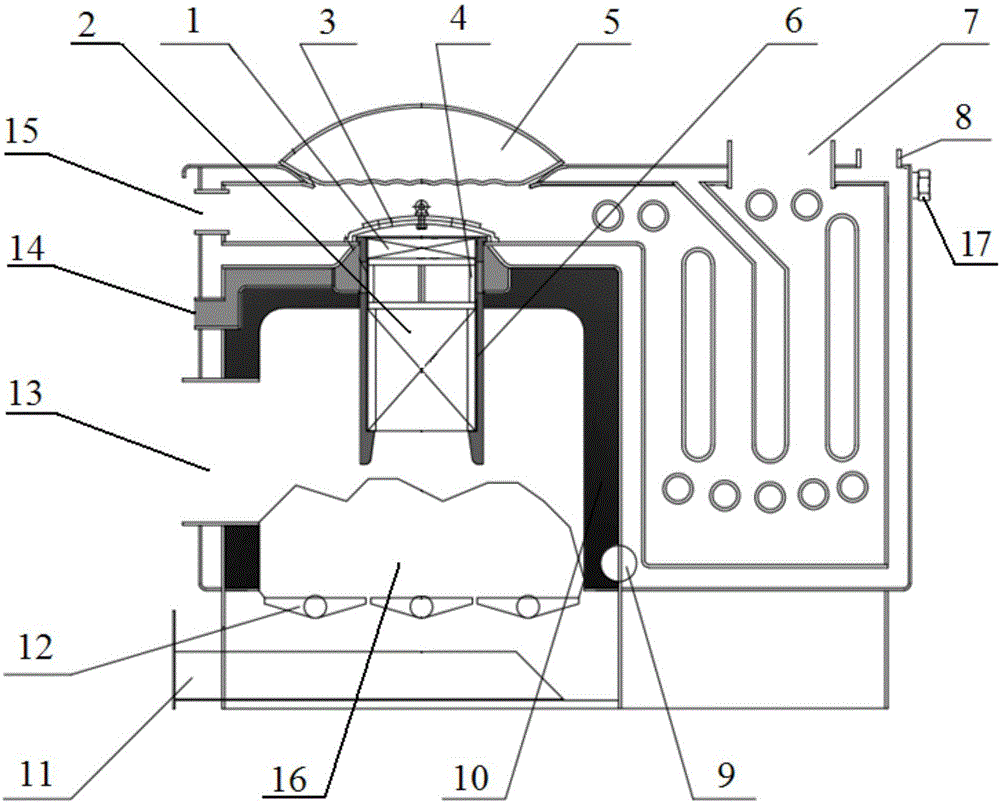

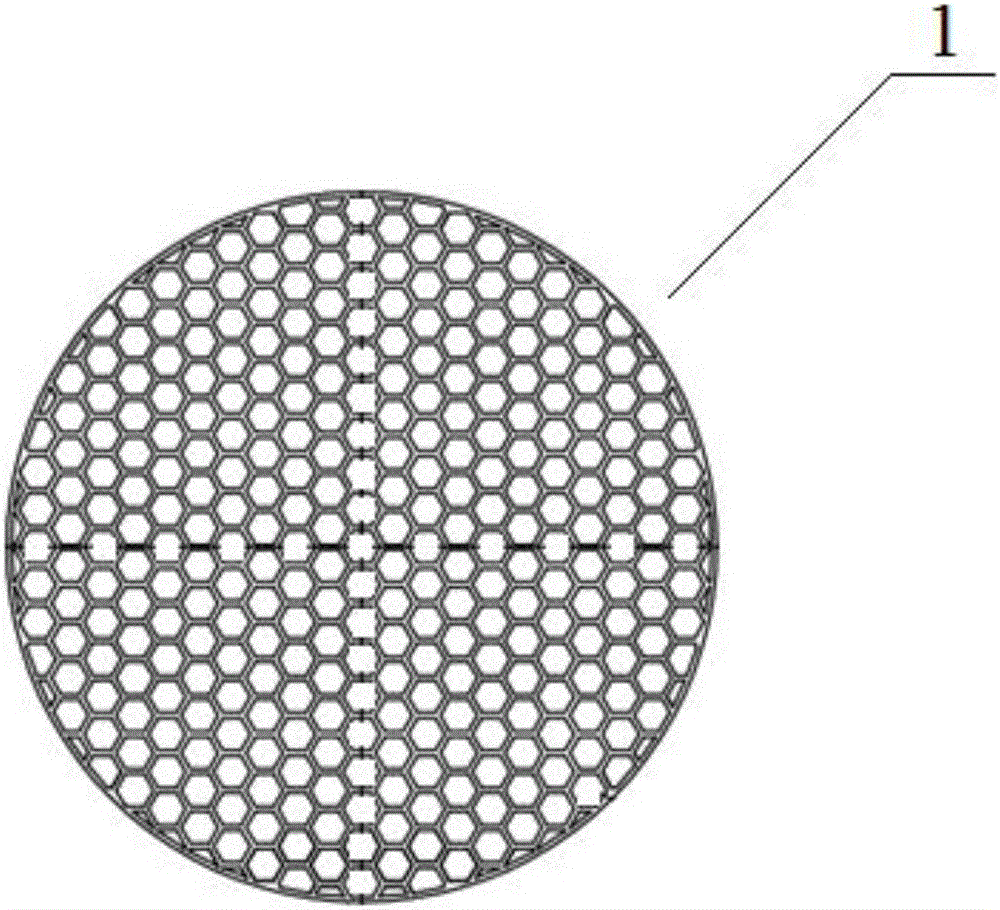

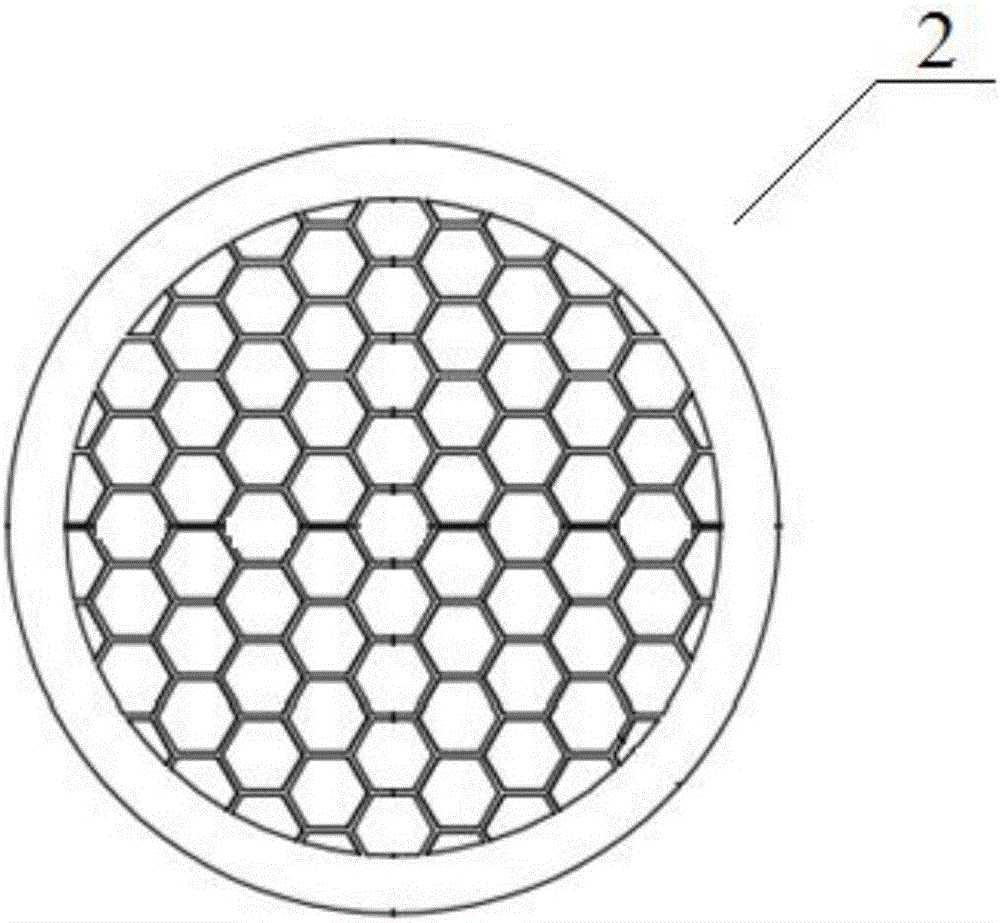

Heating stove based on honeycomb ceramic heat accumulators

ActiveCN105823090ALow ash contentBurn fullyLighting and heating apparatusStove/ranges for heating waterCombustion chamberMaterials science

The invention belongs to the technical field of heating stoves and relates to a heating stove based on honeycomb ceramic heat accumulators. The heating stove based on the honeycomb ceramic heat accumulators comprises a stove body. A stove chamber is formed in the stove body. A flame outlet is formed in the upper end of the stove chamber. A protective sleeve is arranged in the flame outlet in an embedded mode. The first honeycomb ceramic heat accumulator and the second honeycomb ceramic heat accumulator are arranged in the protective sleeve in an embedded mode. The first honeycomb ceramic heat accumulator is located above the second honeycomb ceramic heat accumulator. The first honeycomb ceramic heat accumulator and the second honeycomb ceramic heat accumulator are separated through a supporting body, and a secondary combustion chamber is formed. The first honeycomb ceramic heat accumulator and the second honeycomb ceramic heat accumulator are each provided with a plurality of through holes formed in the vertical direction. The cross section area of each through hole of the first honeycomb ceramic heat accumulator is smaller than that of each through hole of the second honeycomb ceramic heat accumulator. Fire bars used for supporting fuel are arranged at the bottom of the stove chamber. The lower end of the protective sleeve is suspended above the fuel. A fuel feeding and first air distribution port, a second air distribution port and a third air distribution port are formed in the stove body. By the adoption of the heating stove based on the honeycomb ceramic heat accumulators, the fuel utilization rate is increased, the pollutant discharge amount is decreased, energy is saved, and environmental friendliness is achieved.

Owner:SHIJIAZHUANG JINTONG MACHINERY CO LTD

Energy-saving mesh belt type air isothermal furnace

The invention relates to an energy-saving mesh belt type air isothermal furnace comprising a heat insulation shell, wherein the heat insulation shell is internally divided into an isothermal region, a heating region and a heat exchange region; a feeding conveyor mesh belt is arranged above the inside of the heat insulation shell, and a discharging conveyor mesh belt is arranged below the inside of the heat insulation shell; one side of the heat insulation shell is provided with a feeding hole and a discharging hole; the isothermal region and the heating region are internally provided with heaters; the feeding conveyor mesh belt arranged in the isothermal region is shorter than the discharging conveyor mesh belt; the heat insulation shell arranged at the tops of the isothermal region and the heating region is provided with a high-temperature circulating fan; the heat insulation shell arranged at the top of the heat exchange region is provided with a heat exchange fan. The energy-saving mesh belt type air isothermal furnace can be used for fully-automatically carrying out high-temperature tempering treatment and is provided with the heat exchange fan at a heat exchange section, so that heat exchange can be sufficiently carried out between a hot material and a cold material; the high-temperature circulating fan is arranged in the heating region and the isothermal region, so that the furnace temperature is more uniform; heating pipes are distributed at the upper, middle and lower parts of the heating region and a heat insulation region in the furnace, and are uniform in heating, capable of ensuring good uniformity of furnace temperature and long in service life.

Owner:苏州工业园区胜龙电炉制造有限公司

Thermal treatment method of MgYNdZr alloy

InactiveCN104109826AGuaranteed heat treatment performanceUniform furnace temperatureRoom temperatureTherapeutic effect

The invention relates to a thermal treatment method of an MgYNdZr alloy. A uniform furnace temperature in a furnace is ensured by utilizing a fan through regulating thermal treatment parameters, heating and uniformly cooling are carried out twice, thereby ensuring that elements such as strengthening phases zirconium, yttrium are sufficiently dissolved in a matrix, so that effects of the strengthening phases are brought into play to the greatest extent. The thermal treatment method disclosed by the invention guarantees thermal treatment effects of the MgYNdZr alloy, so that after the material thermal treatment, room-temperature mechanical performances meet the following requirements: sigma b is not less than 250MPa, sigma 0.2 is not less than 185MPa, and sigma 4 is not less than 4%, and an qualification rate is over 80%; and moreover, performances of the MgYNdZr alloy are stable, and application requirements of casting pieces under a great-load condition are satisfied.

Owner:HARBIN DONGAN ENGINE GRP

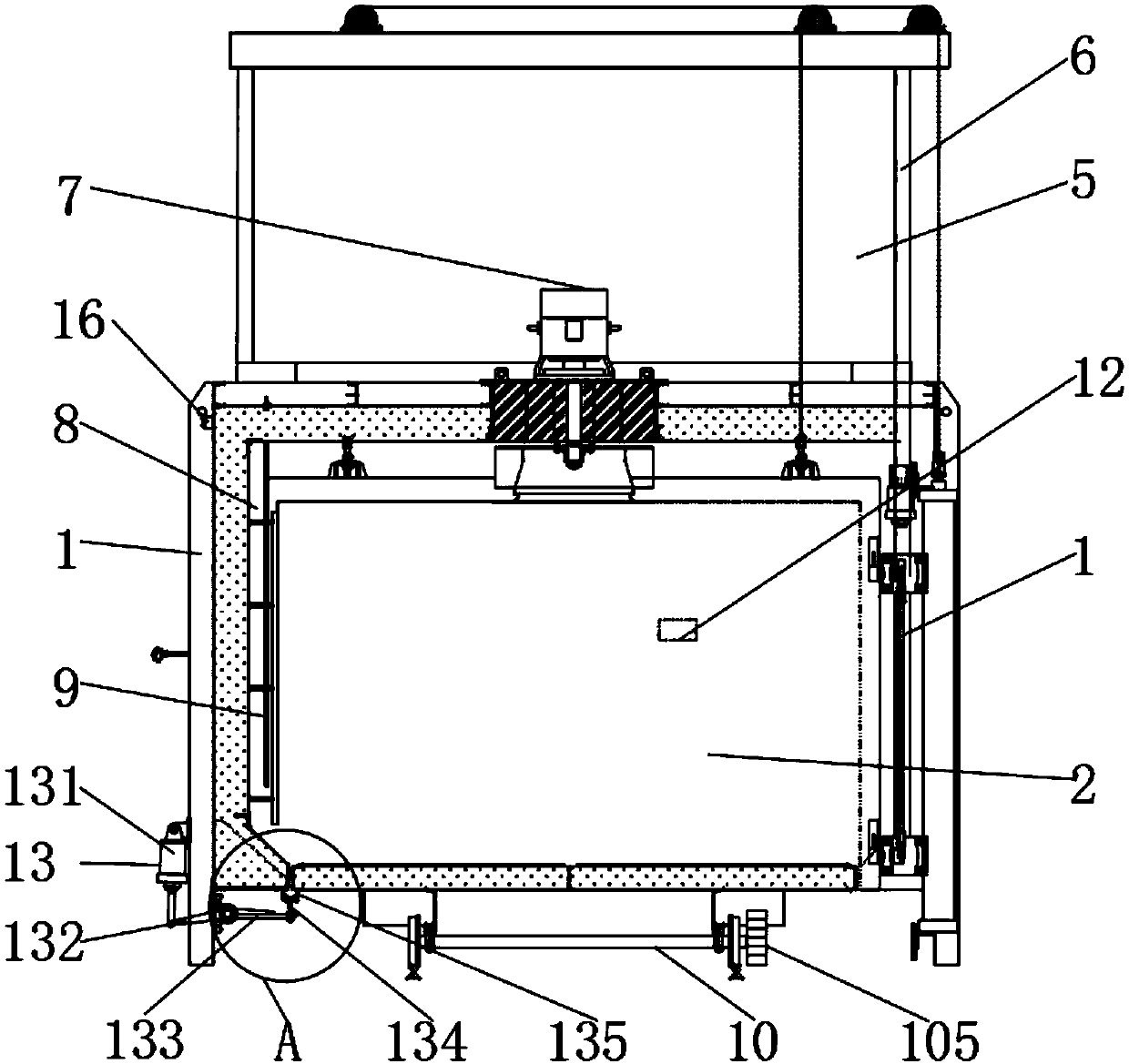

High temperature heating furnace device for testing of high temperature mechanical properties of material

PendingCN110345763ARealize thermal fatigue experimentRealize temperature controlMaterial strength using tensile/compressive forcesMaterial strength using steady bending forcesTemperature controlCombustion chamber

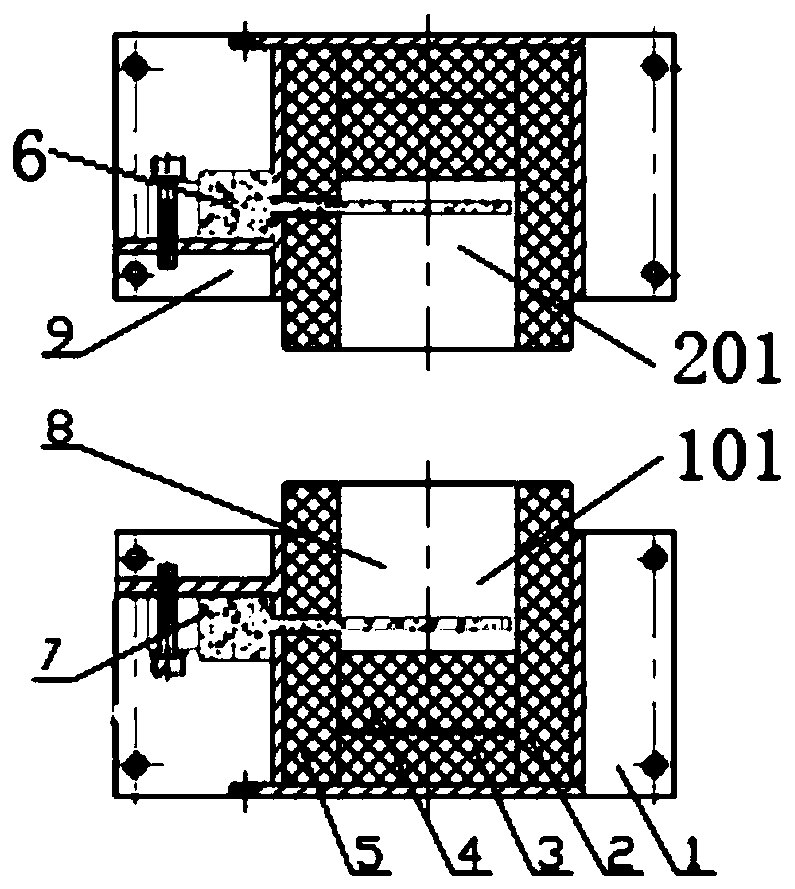

The invention discloses a high temperature heating furnace device for testing of high temperature mechanical properties of a material. A high temperature furnace comprises a lower furnace body and anupper furnace body, and further comprises a pair of ceramic linings. The ceramic linings are symmetrical in the up-and-down direction. One ceramic lining is pressed into the lower furnace body, and alower furnace heating component is fixedly installed in the lower furnace body, so that a lower furnace is formed. The other ceramic lining is pressed into the upper furnace body, and an upper furnaceheating component is fixedly installed in the upper furnace body, so that an upper furnace is formed. A lower furnace junction box and the lower furnace are connected, so that a lower furnace assembly is formed. An upper furnace junction box and the upper furnace are connected, so that an upper furnace assembly is formed. The upper furnace assembly and the lower furnace assembly are combined in an opening-to-opening mode. Thermocouples are installed on a thermocouple support and installed on the center line of a combustion chamber. The upper furnace heating component is connected with a temperature controller through the upper furnace junction box, and the lower furnace heating component is connected with the temperature controller through the lower furnace junction box. By the adoption of the high temperature heating furnace device, the temperature can be increased to 1200 DEG C according to the heating rate, and the high temperature heating furnace device is suitable for the constitutive relation, creep deformation and fatigue experiment research under the external load conditions of pull, press, bending and the like.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

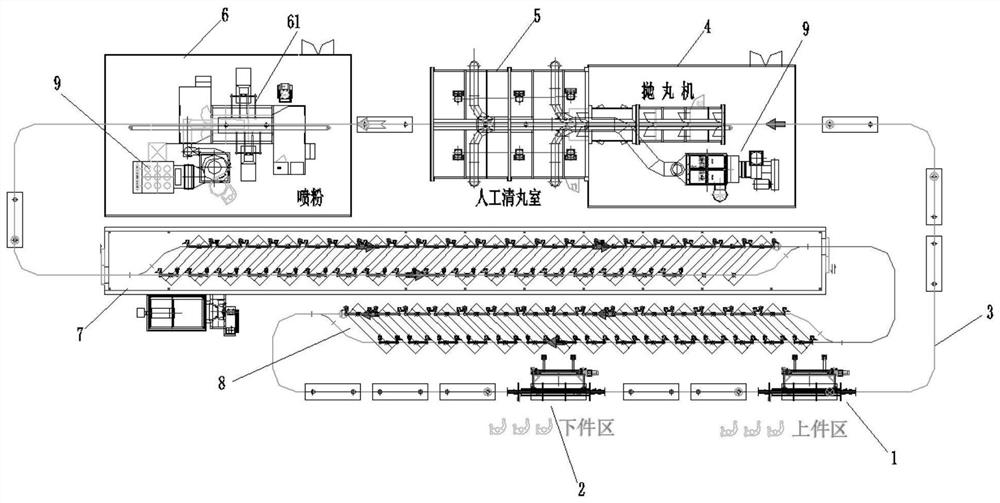

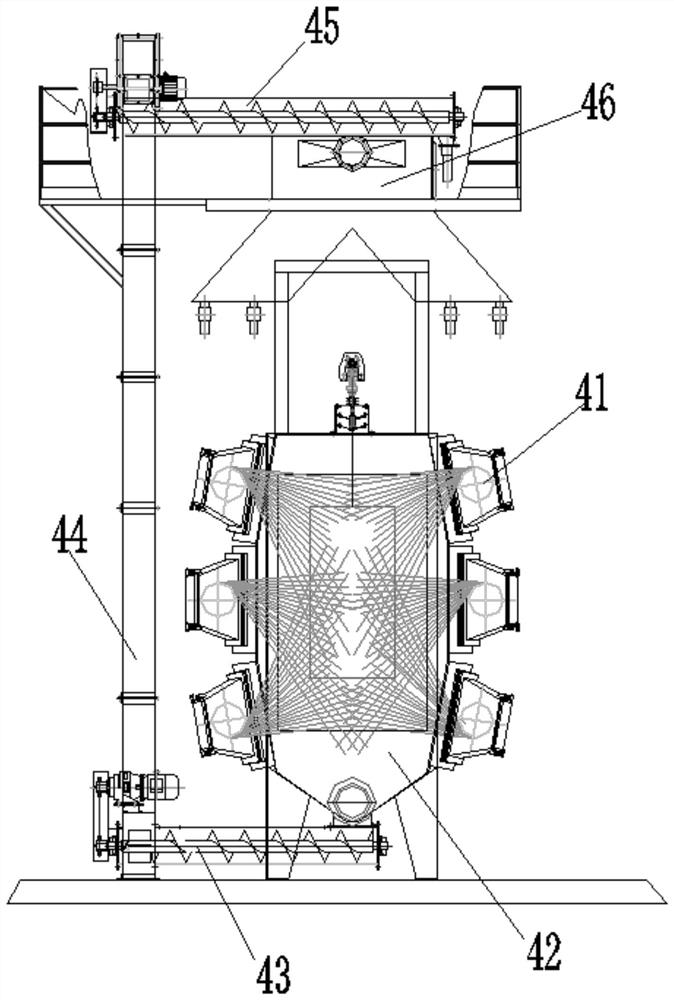

Construction hoist standard knot coating production line and coating process

PendingCN112934546AReduce labor costsEliminate surface stressImpeller wheelsRotor bladesProduction lineSemi automatic

The invention discloses a construction hoist standard knot coating production line. The construction hoist standard knot coating production line comprises a workpiece feeding area, a workpiece discharging area, a conveying track, a shot blasting machine, a shot cleaning chamber, a spraying room, a curing room and a cooling station, a conveying track sequentially penetrates through the workpiece feeding area, the shot blasting machine, the shot cleaning chamber, the spraying room, the curing room, the cooling station and the workpiece discharging area to form a continuous operation production line, a plurality of shot blasting devices with opposite openings are arranged on the inner wall of the shot blasting chamber in the shot blasting machine, the shot blasting chamber communicates with the shot cleaning chamber, a plurality of shot cleaning guns are arranged in the shot cleaning chamber, a recovery device inclining from the shot cleaning chamber to the shot blasting machine is arranged at the bottom of the shot cleaning chamber, so that cleaned and fallen balls fall back into the shot blasting machine, the top of the shot blasting chamber and the top of the shot cleaning chamber both communicate with a filter cartridge dust remover, a plurality of movable spray guns are arranged on two sides of the conveying track in the spraying room, and a heating system is arranged in the curing room and used for heating passing standard knots. According to a semi-automatic production line mode, less labor is needed, and the problem of high labor cost is solved.

Owner:GUANGXI CONSTR ENG GROUP CONSTR MACHINERY MFG

Box resistance furnace

ActiveCN103822469BGuaranteed furnace temperatureUniform furnace temperatureFurnace componentsFiberFurnace temperature

The invention provides a box-type resistance furnace comprising a furnace stand, a furnace body and a heating element. The furnace body is fixed on the furnace stand and provided with a hearth inside. The furnace body comprises a furnace shell, an insulation layer and a fireproof layer sequentially from outside to inside. The fireproof layer is made out of refractory bricks smaller than 1100kg / m<3> in density. The insulation layer is made of aluminum silicate refractory fiber. The space between the furnace shell and the insulation layer is filled with vermiculite powder. The heating element is made of corrugated resistance tapes evenly disposed on the refractory layer of the furnace body. Two sides of the furnace body are provided with furnace doors which both are side-opening doors. Each furnace door comprises an inner layer of refractory cellucotton and an outer layer of a steel plate. The box-type resistance furnace is high in loading capacity and high in production efficiency, especially suitable for thermal treatment of small and medium sized machine parts, uniform in furnace temperature and good in insulation effect, can save energy by more than 20%, and is pollution free and good in environmental protection benefit.

Owner:江苏新江南炉业科技有限公司

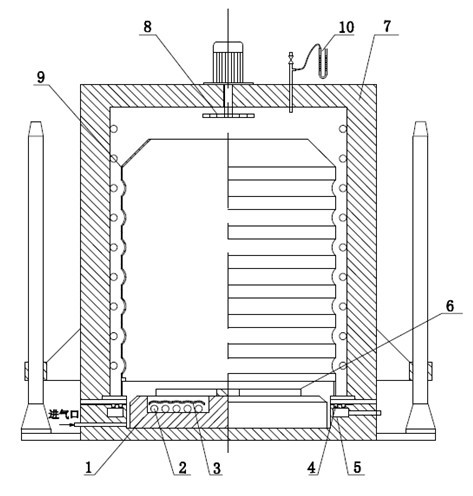

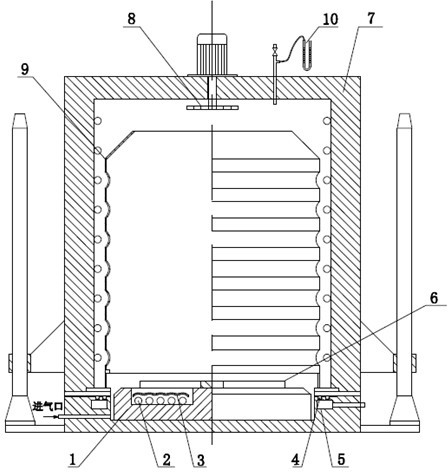

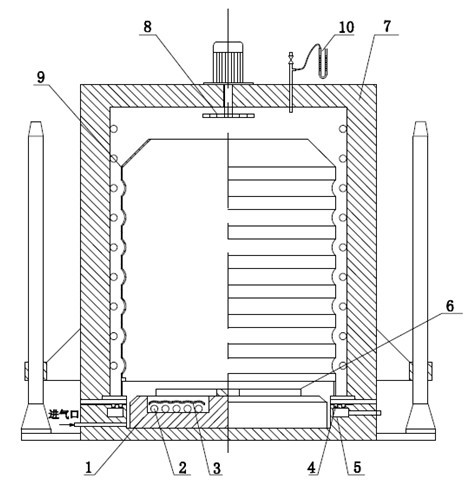

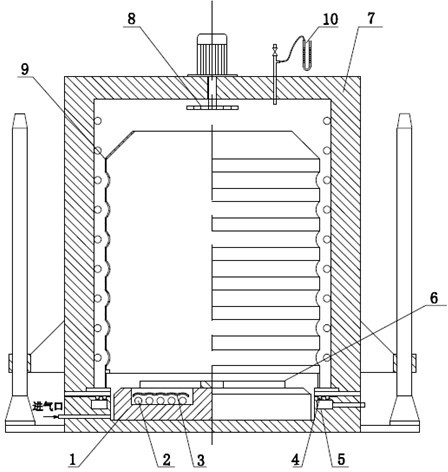

Nonstandard bell-type furnace

The invention belongs to the technical field of heat treatment processing equipment and relates to a nonstandard bell-type furnace. The nonstandard bell-type furnace comprises a furnace base, a furnace bottom cross supporting frame and a furnace bell. The nonstandard bell-type furnace is characterized in that base heating elements are distributed on the furnace base, and a corrugated cover plate is covered on the heating elements; the side surface of the furnace base is provided with an air inlet; a double-layer sealing ring and a water cooled jacket are arranged between the furnace base and the furnace bell; the top of the furnace bell is provided with a convection fan and a U-type pressure gauge; and a corrugated inner cover air guide barrel is arranged in the furnace bell. The nonstandard bell-type furnace can meet the requirement of novel steel belts on mechanical performance after annealing, is particularly suitable for the annealing of steel belts of BSYE-N materials, fills the blank of the steel belt products in China and eliminates the technical bottleneck restricting the development of the technology. Compared with that of a traditional bell type furnace, the production cost of the nonstandard bell-type furnace is greatly reduced.

Owner:LIYANG HONGDA MACHINERY EQUIP

Heat treatment furnace with movable furnace cover

InactiveCN102312078AReduce cooling areaImprove atomization effectBell type furnacesFlueCombustion chamber

The invention relates to a heat treatment furnace with a movable furnace cover and belongs to the technical field of heat treatment. The heat treatment furnace with a movable furnace cover is connected with a combustion system, a measurement and control system and a smoke evacuation system, and comprises a furnace stage, inside which two combustion chambers and a flue are vertically arranged, wherein the flue is positioned between the two combustion chambers and two ends of the combustions are equipped with burners. The upper surface of the furnace stage is provided with a movable furnace cover, two ends of which are equipped with fire doors. A heating chamber is disposed in the inner space of the furnace cover. And the heating chamber respectively communicates with the combustion chambers and the flue through open pores on the furnace stage. In comparison with car-type furnaces, the heat treatment furnace provided by the invention has advantages of light furnace cover, low mobile power of the furnace cover, good furnace seal performance, uniform furnace temperature, few burners, full combustion and the like. The thermal efficiency of the furnace reaches up to more than 36% through measuring and calculating.

Owner:王家琪

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com