Device and method for measuring mechanical property of film under high temperature

A measuring device, high temperature mechanics technology, applied in measuring device, using stable tension/pressure test material strength, scientific instruments and other directions, can solve the problem that the loading speed of the pressure device cannot be stably controlled, the preparation of the film sample to be measured is complex, The heating temperature range is limited, etc., to achieve the effect of convenient loading and unloading, low thermal conductivity, and uniform furnace temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] The present invention will be described in further detail and completely below in conjunction with Examples and Comparative Examples.

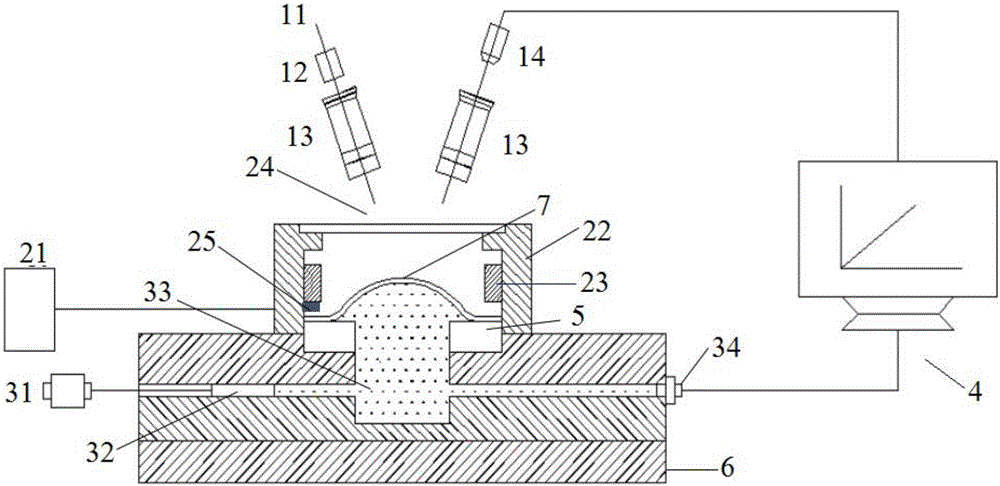

[0052] Such as figure 1 The schematic diagram of an embodiment of the device for measuring the high-temperature mechanical properties of thin films of the present invention is shown. The device includes an optical measurement component 1 , a heating component 2 , a power loading component 3 and a data processing and display component 4 . Wherein the optical measurement component 1, the heating component 2, the sample stage 5 and the power loading component 3 are arranged in sequence, in other words, the optical measurement component 1, the heating component 2, the sample stage 3 and the power loading component 3 are arranged in sequence from top to bottom, and the When the sending optical path remains unchanged, the bulging effect causes the film to deform. The optical measurement component 1 is remotely connected to the data processin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com