Patents

Literature

59 results about "Nanoindenter" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A nanoindenter is the main component for indentation hardness tests used in nanoindentation. Since the mid-1970s nanoindentation has become the primary method for measuring and testing very small volumes of mechanical properties. Nanoindentation, also called depth sensing indentation or instrumented indentation, gained popularity with the development of machines that could record small load and displacement with high accuracy and precision. The load displacement data can be used to determine modulus of elasticity, hardness, yield strength, fracture toughness, scratch hardness and wear properties.

Hot stamp molded article, and method for producing hot stamp molded article

ActiveCN104040011AExcellent hole expandabilityHot-dipping/immersion processesFurnace typesHot stampingUnit mass

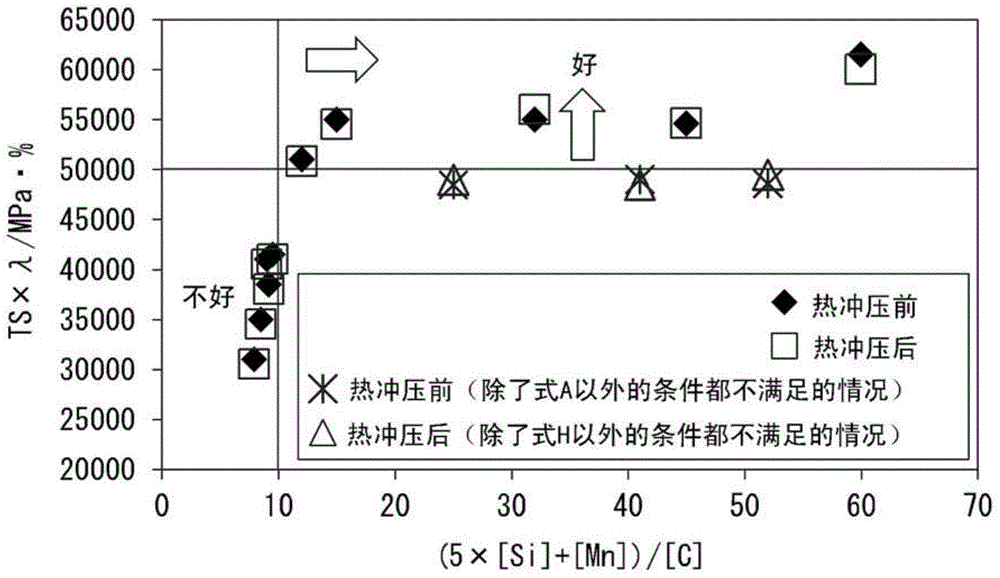

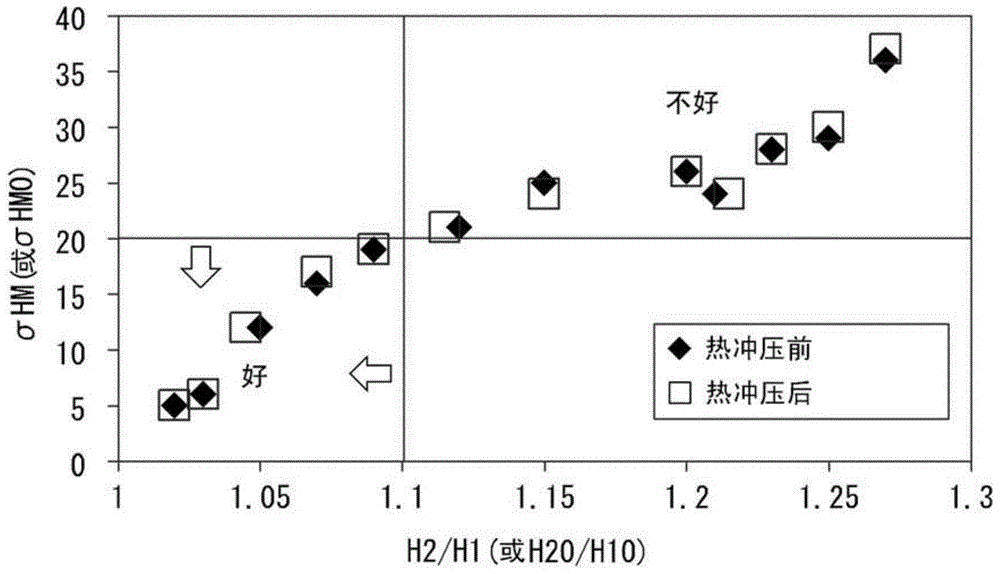

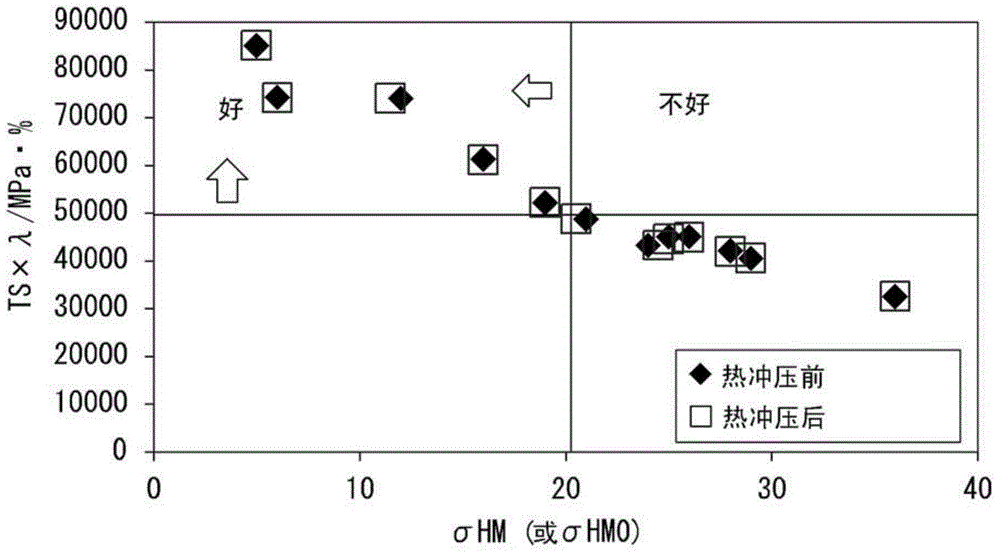

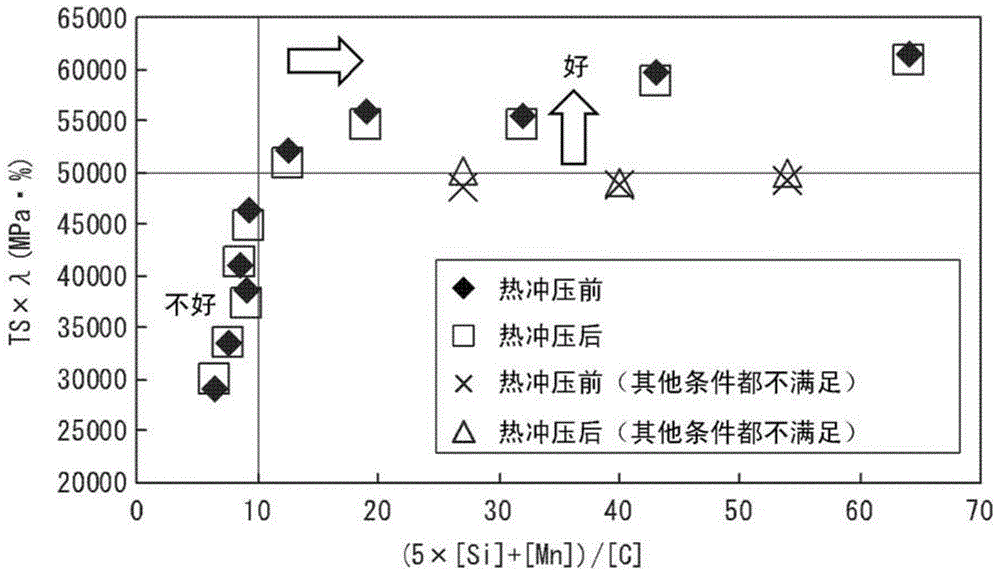

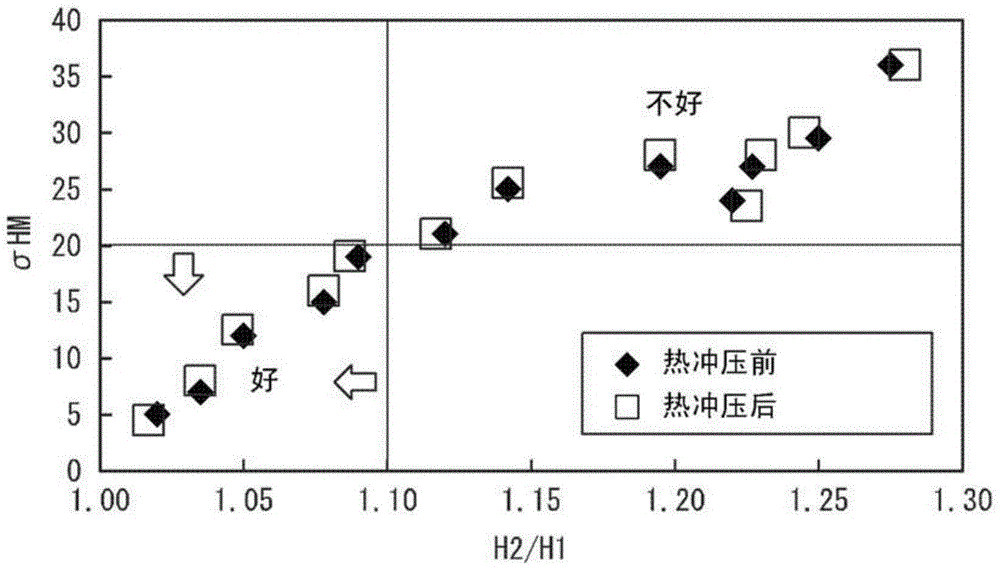

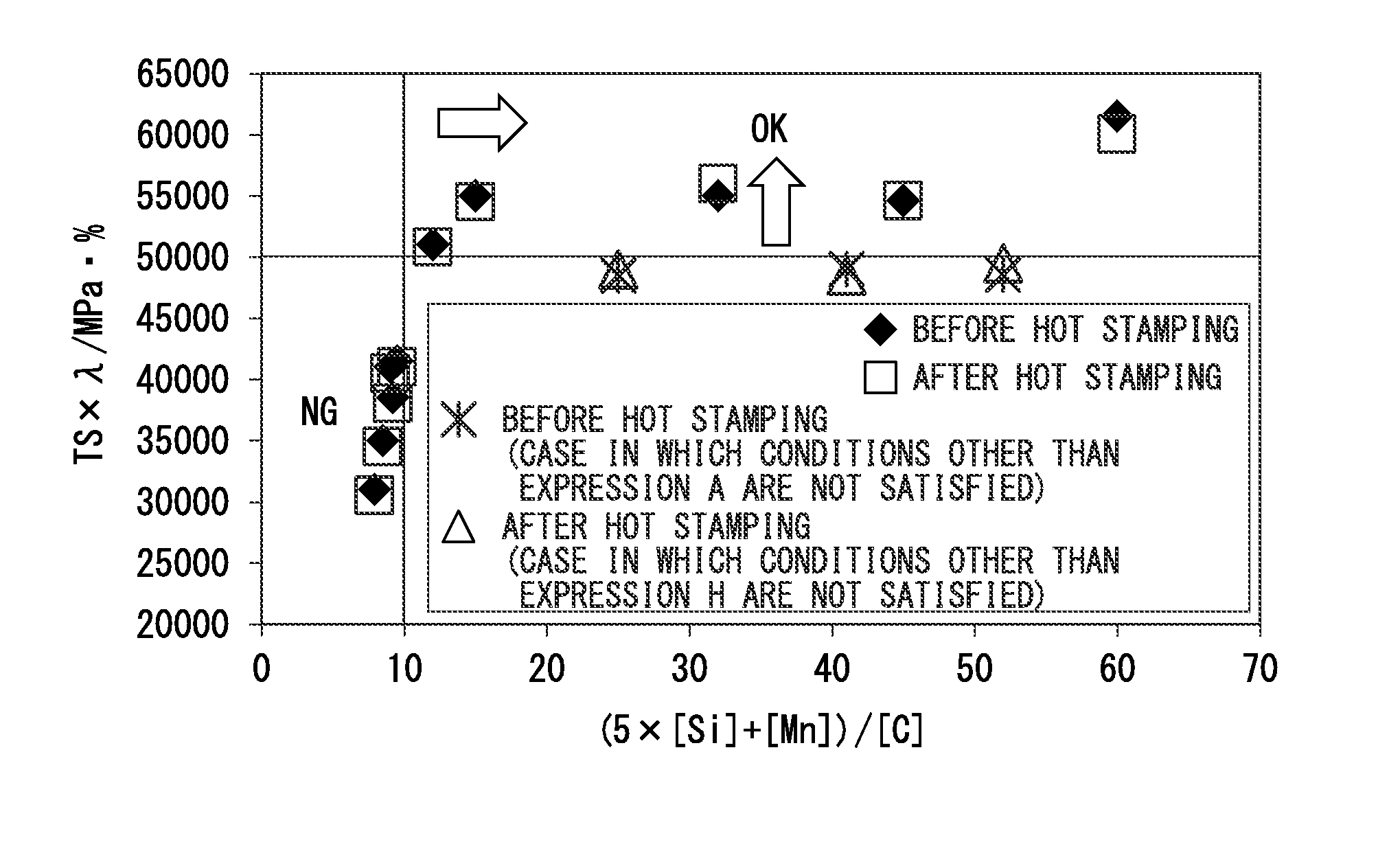

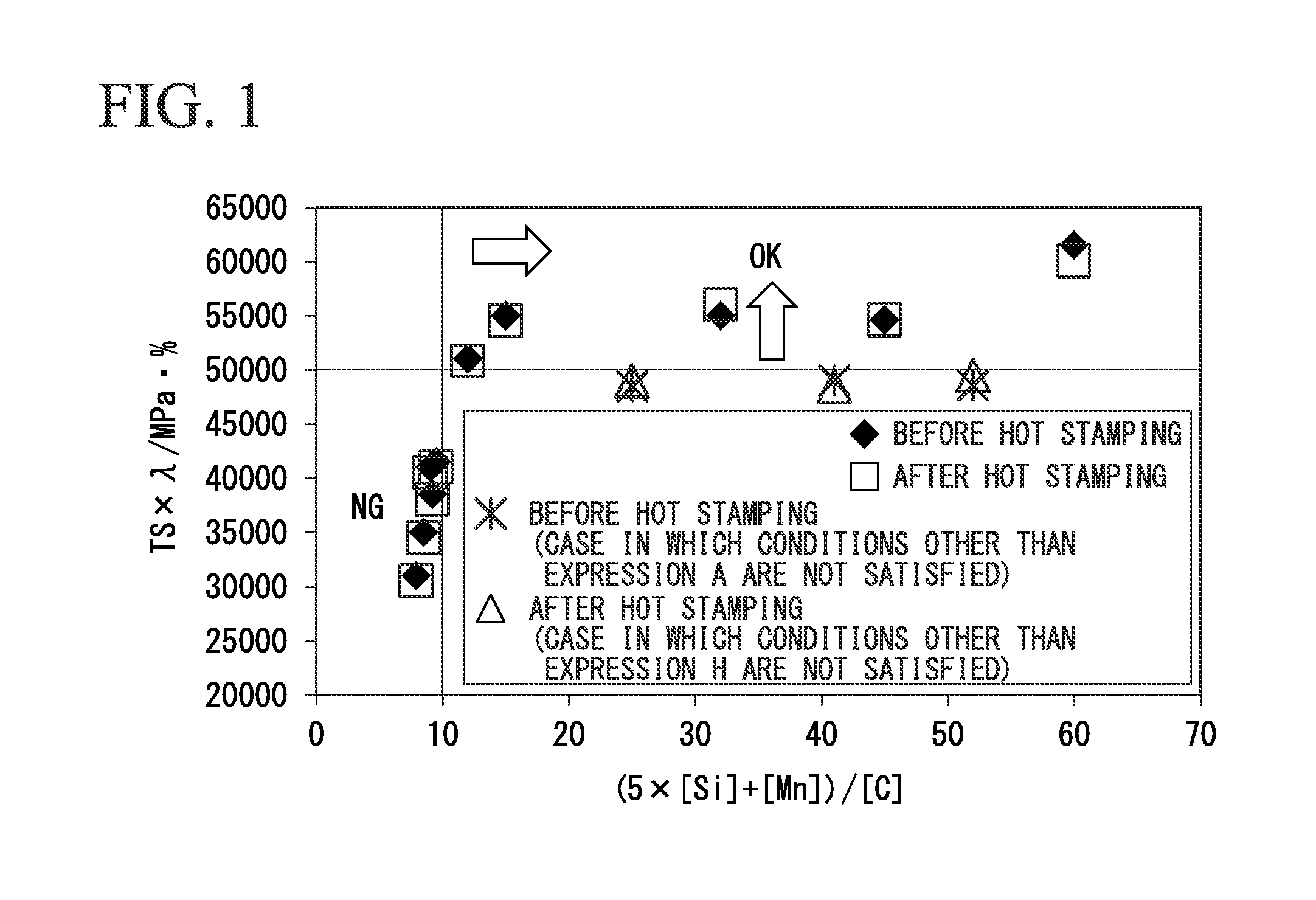

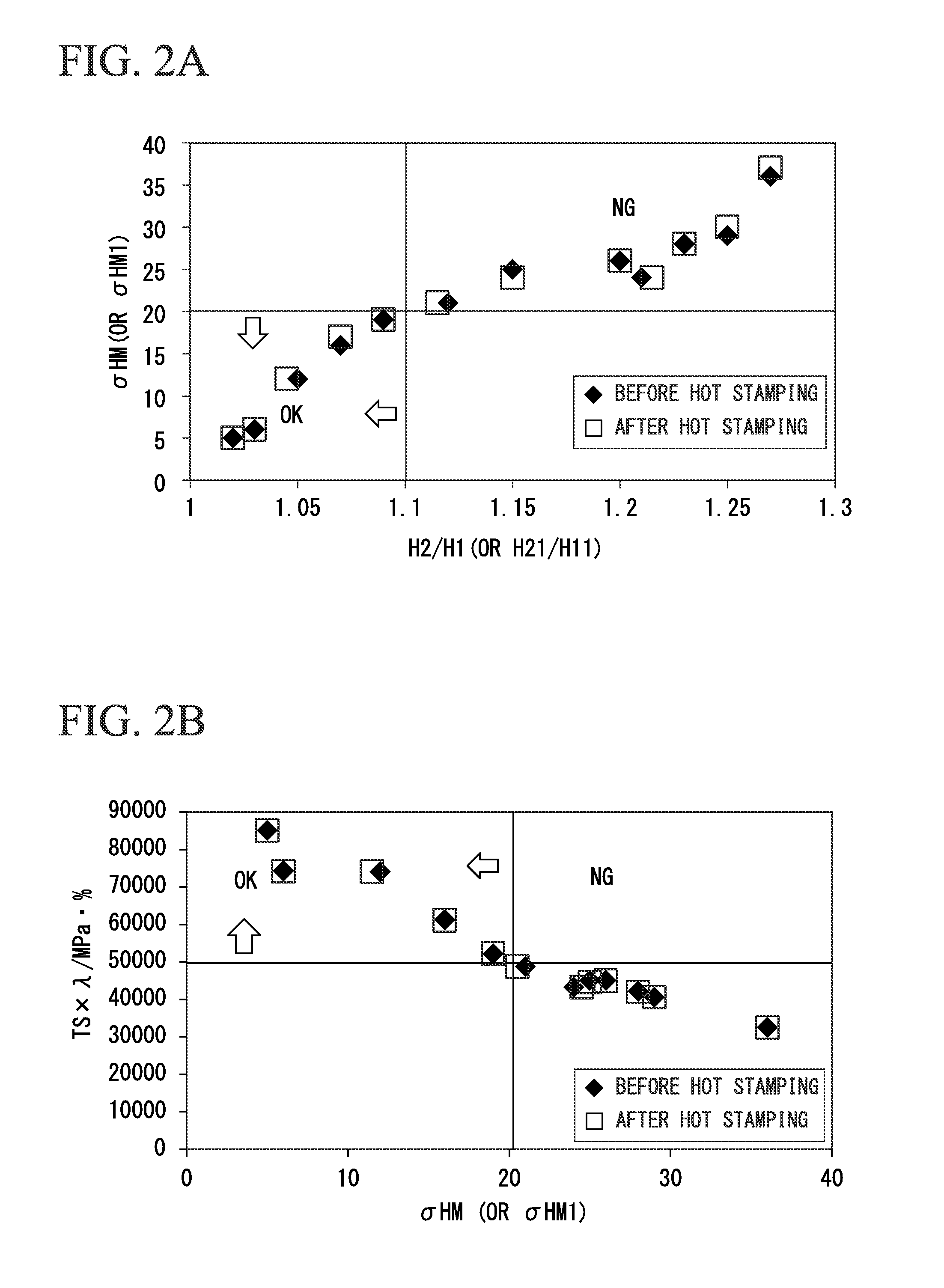

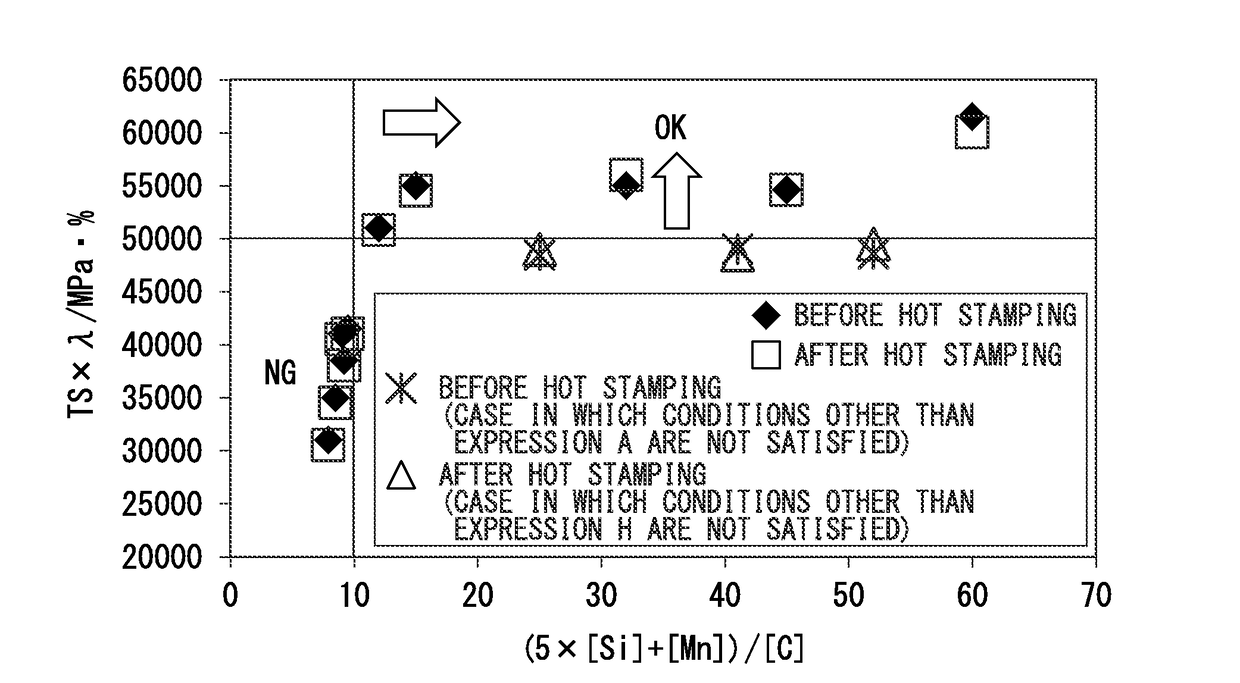

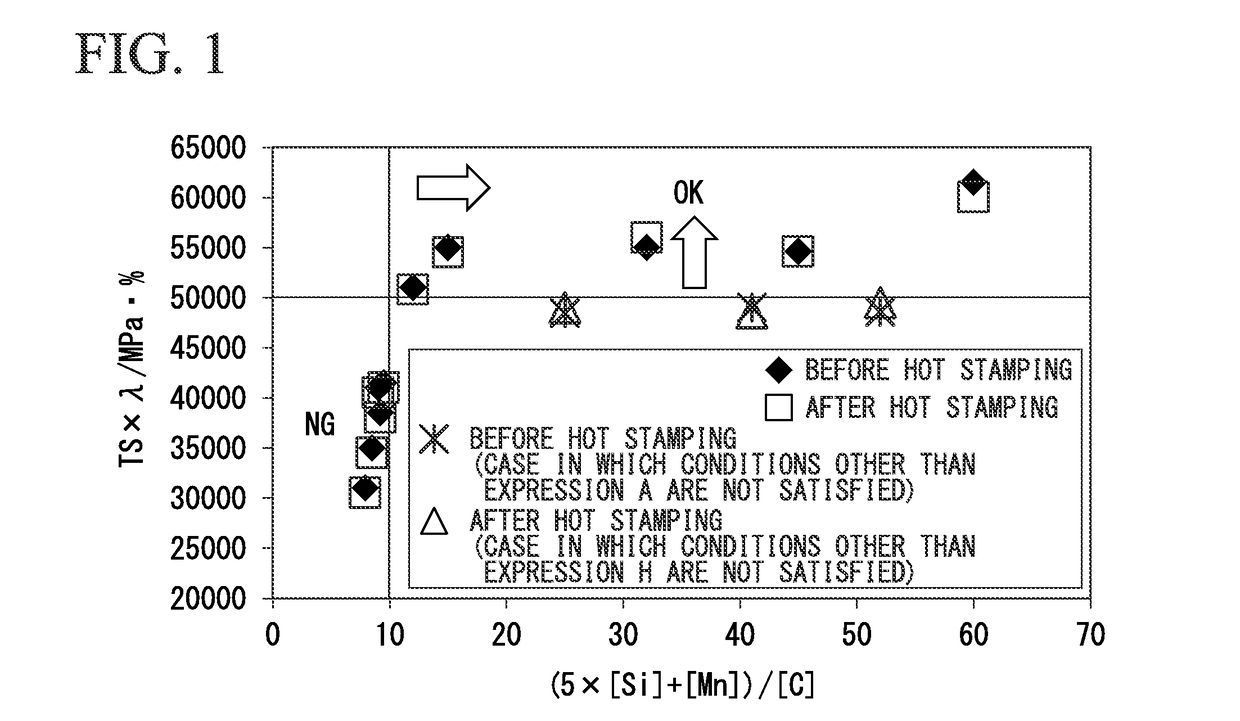

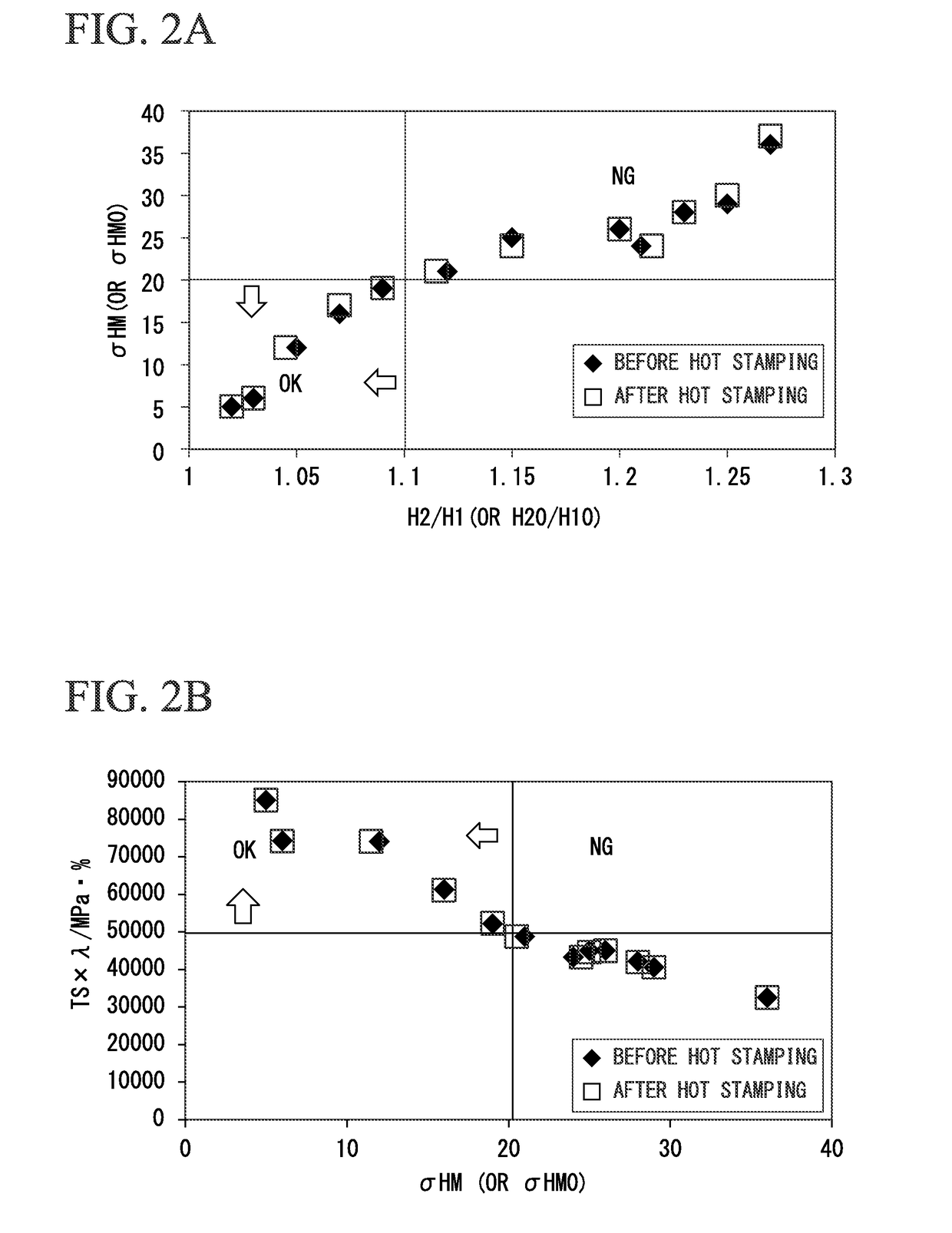

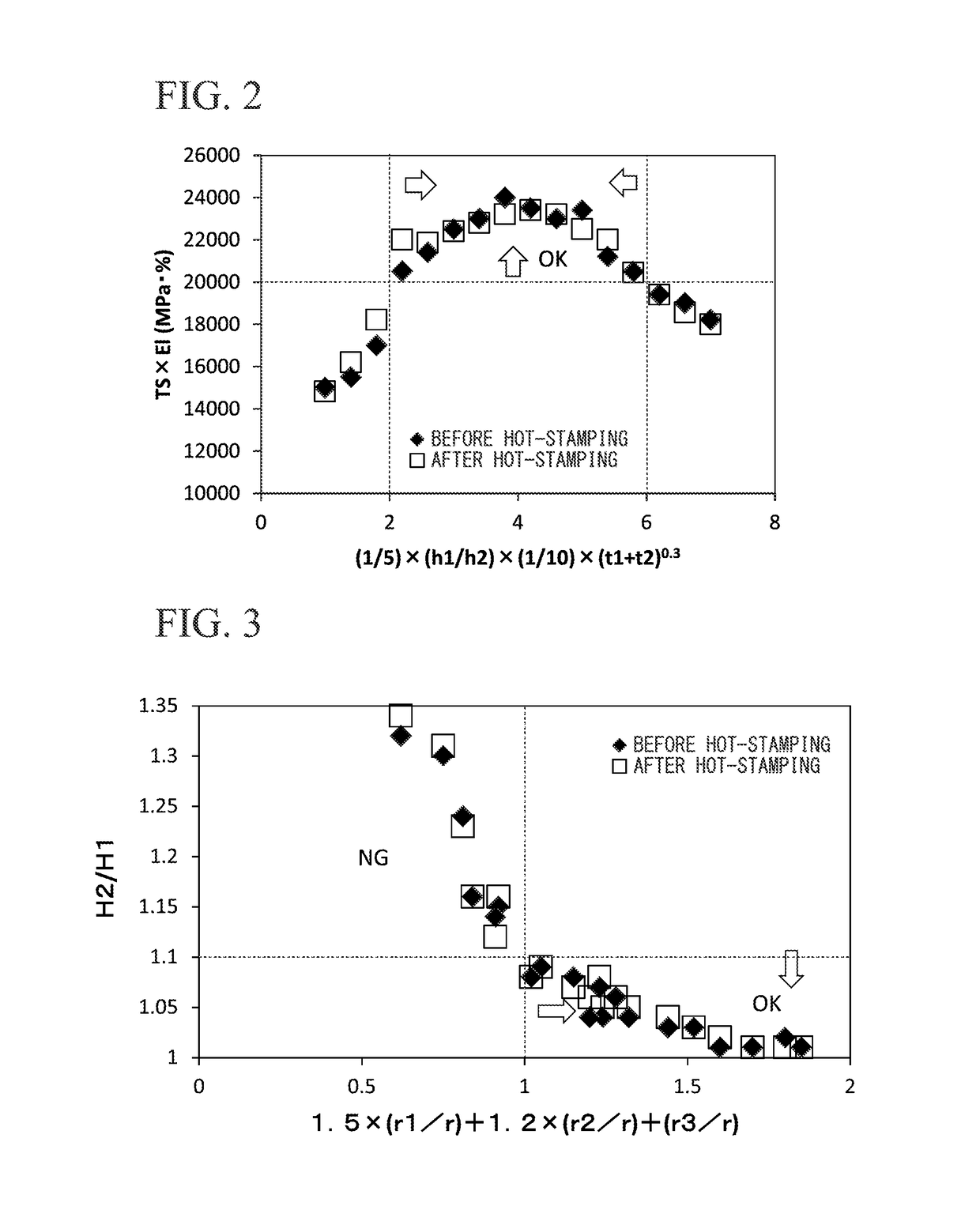

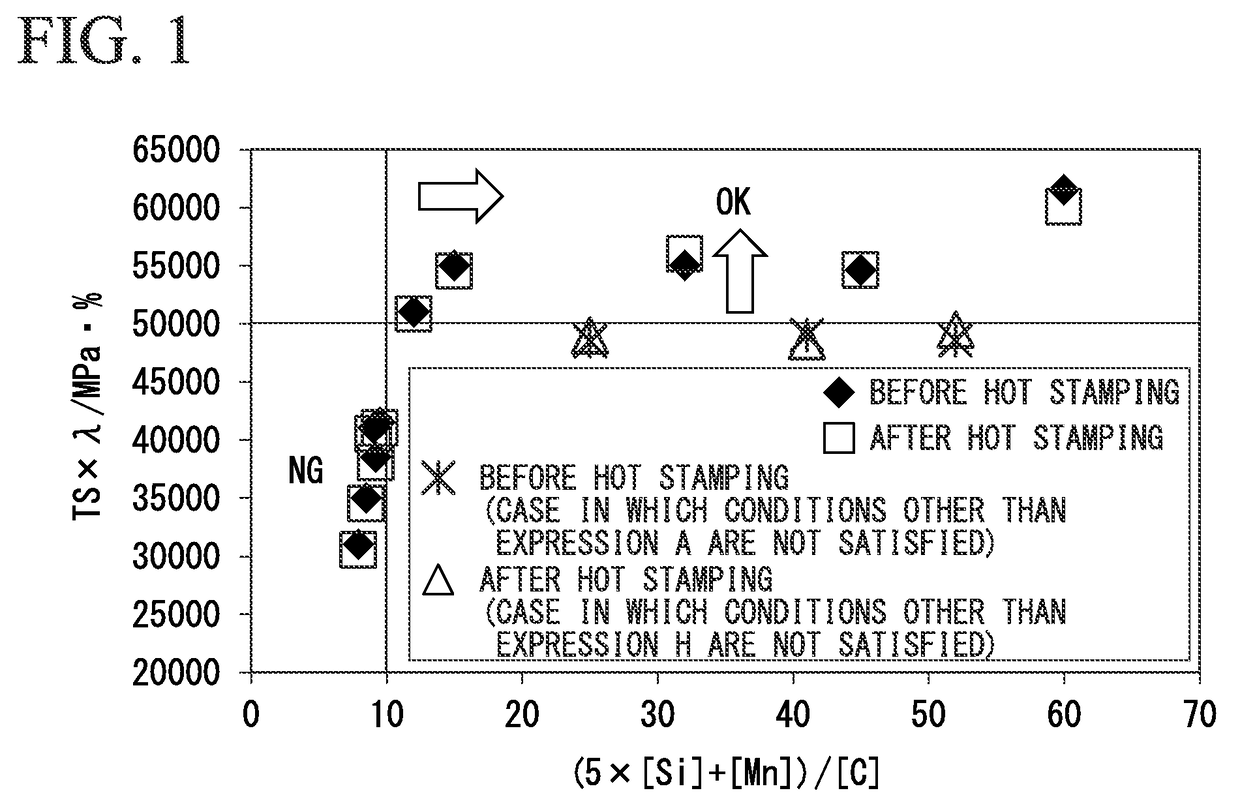

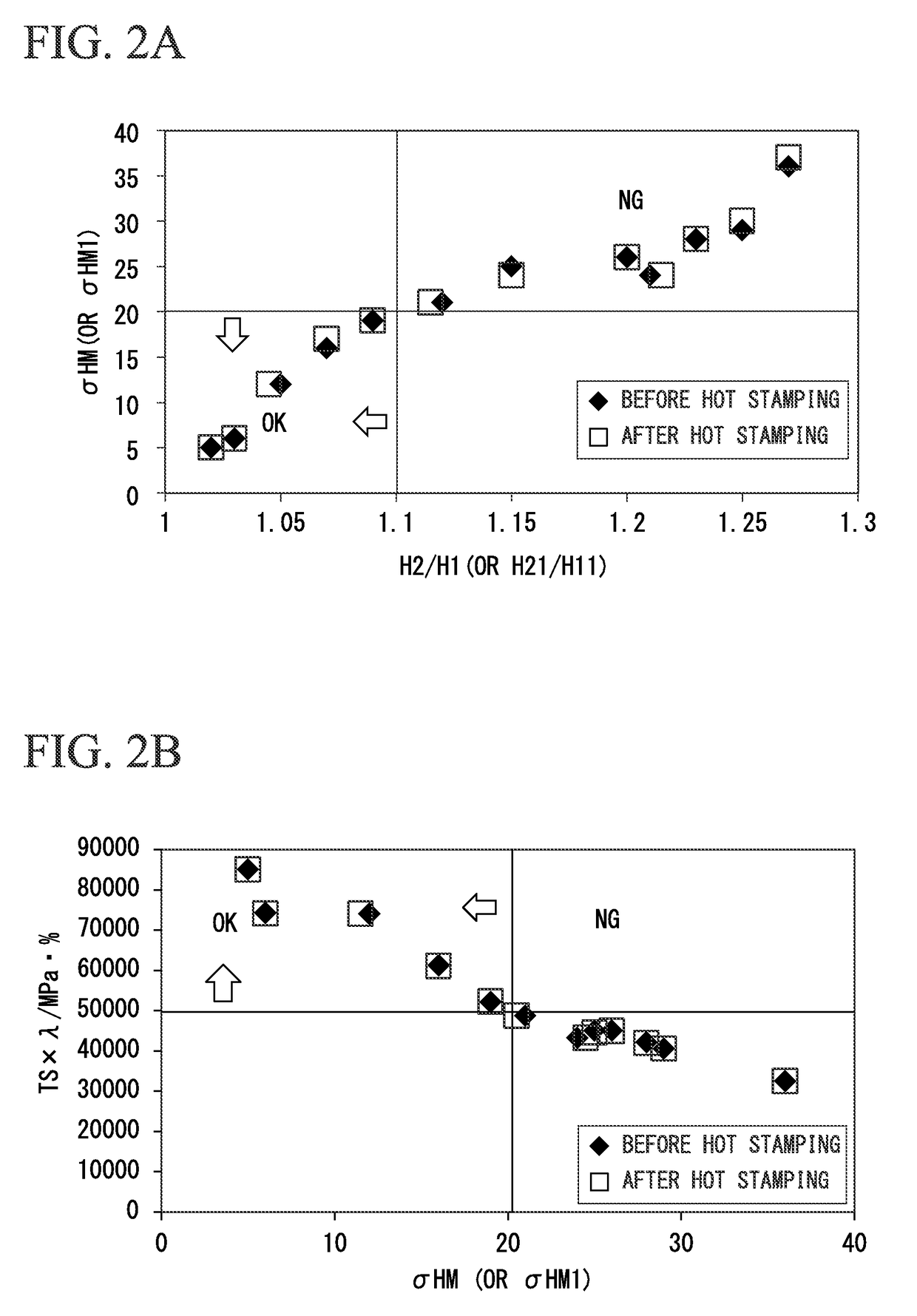

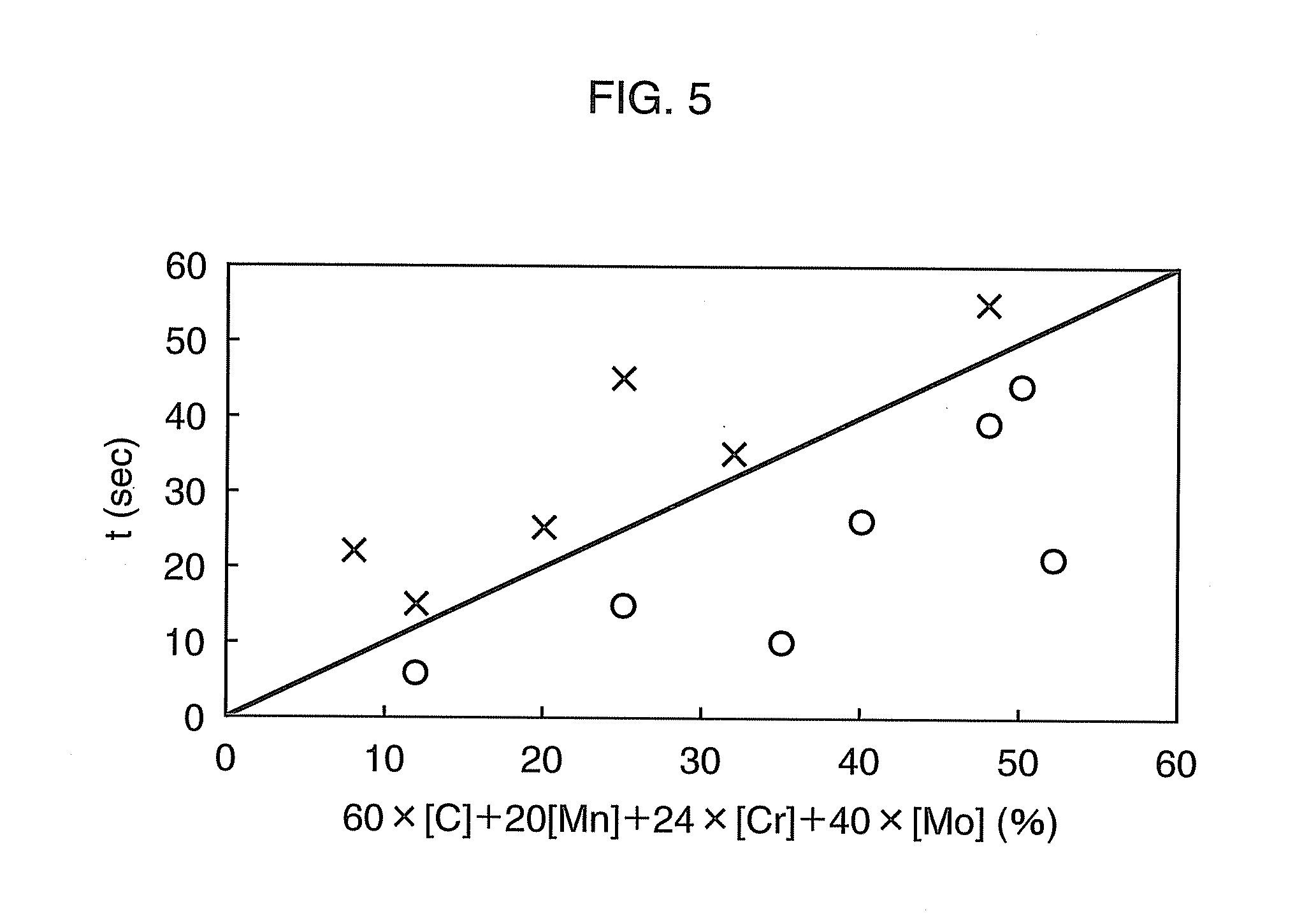

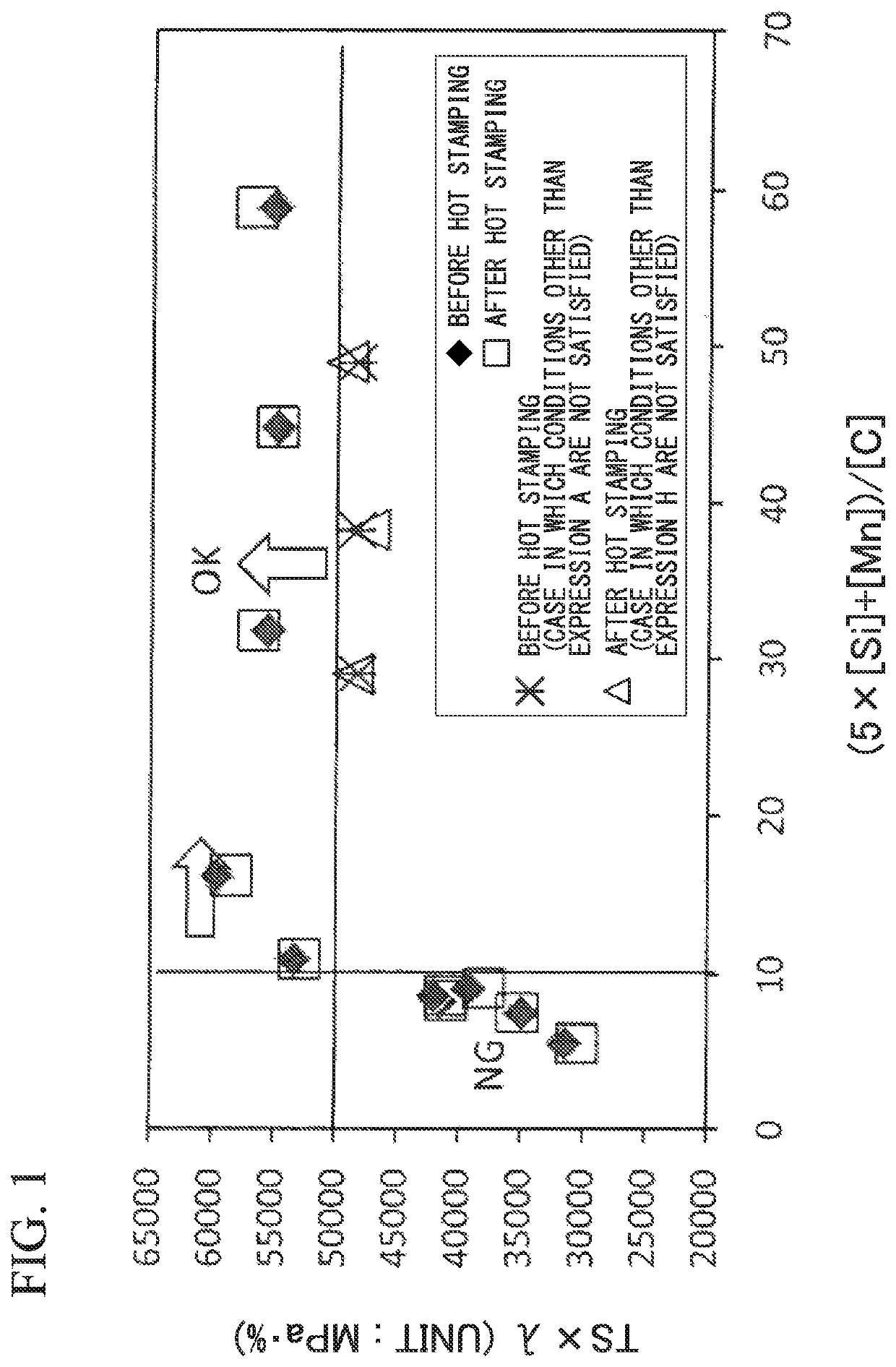

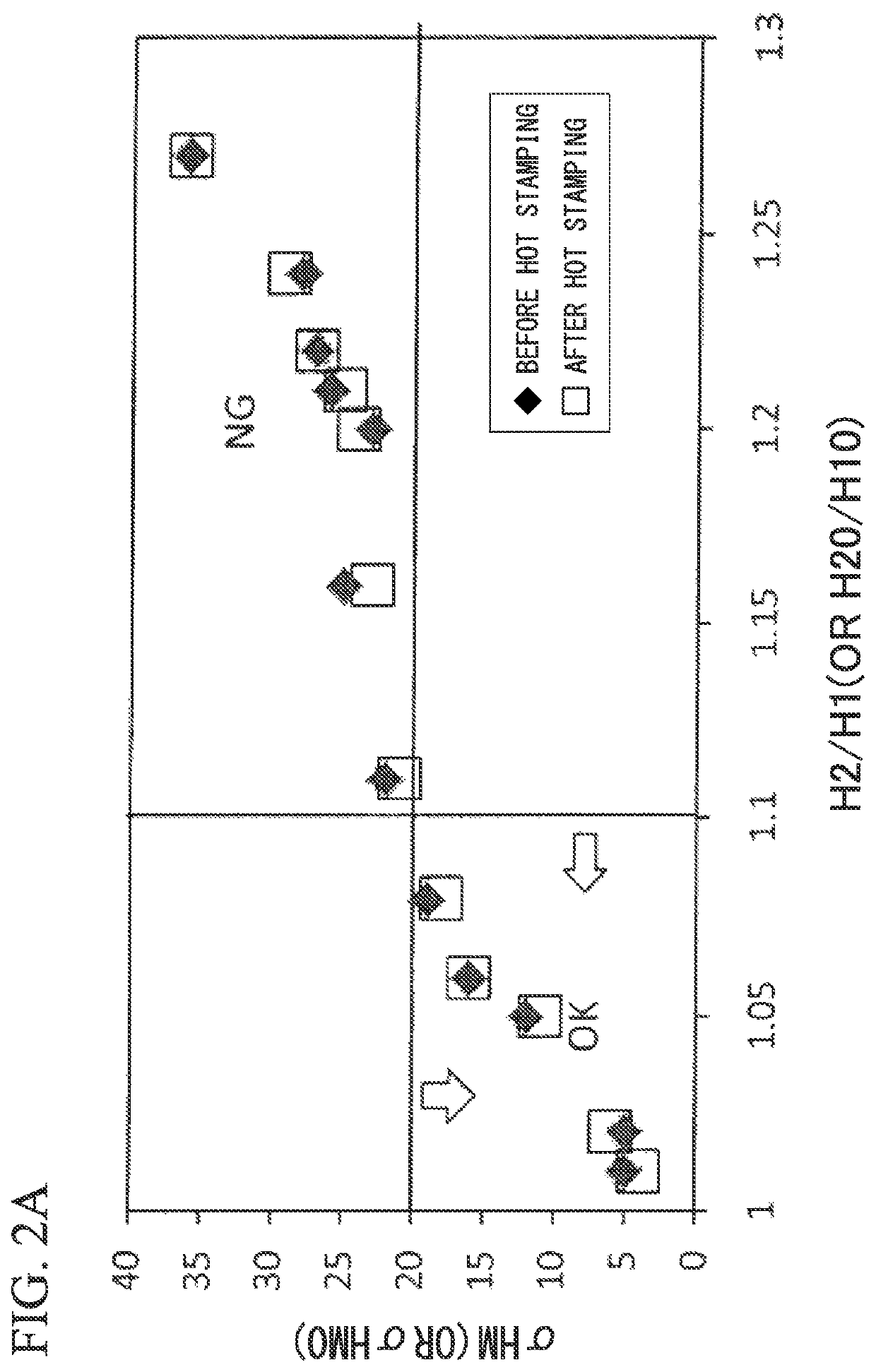

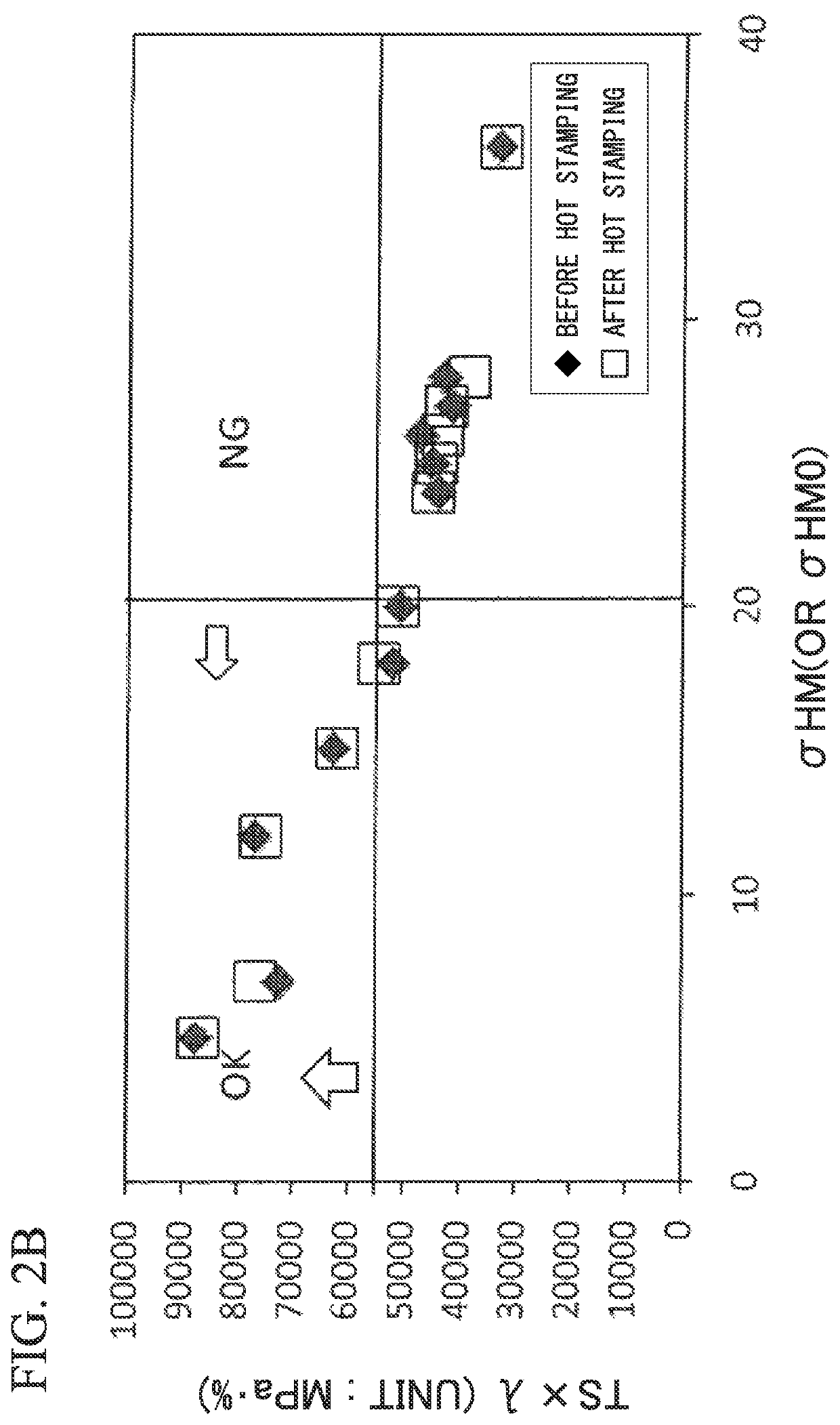

When the carbon content, silicon content and manganese content of this hot stamp molded article are expressed as [C], [Si] and [Mn], respectively, in terms of unit mass%, a relationship of (5 × [Si] + [Mn]) / [C] > 11 holds; and the metal structure after hot stamping contains ferrite at 40% to 90% and martensite at 10% to 60% by area ratio, and the sum of the area ratio of ferrite and the area ratio of martensite is at least 60%. Furthermore, the hardness of the martensite, as measured by a nanoindenter, satisfies H2 / H1 < 1.10 and sigmaHM < 20, and TS × lambda, which is the product of the tensile strength (TS) and hole expansion rate (lambda), is at least 50000 MPa.%.

Owner:NIPPON STEEL CORP

Hot stamp molded article and method for producing same

ActiveCN104040008AExcellent hole expandabilityHot-dipping/immersion processesFurnace typesManganeseHardness

A hot stamp molded article is characterized in that when the carbon content (mass%), silicon content (mass%) and manganese content (mass%) are expressed as [C], [Si] and [Mn], respectively, a relationship of (5*[Si] + [Mn]) / [C] > 10 holds, and if the metal structure contains martensite at 80% or more by area ratio, and further contains one or more of perlite at 10% or less by area ratio, retained austenite at 5% or less by volume ratio, ferrite at 20% or less by area ratio, and bainite at less than 20% by area ratio, TS lambda, which is the product of the tensile strength (TS) and hole expansion rate (lambda), is at least 50000 MPa.%, and the hardness of the martensite, as measured by a nanoindenter, satisfies H2 / H1 < 1.10 and sigmaHM < 20.

Owner:NIPPON STEEL CORP

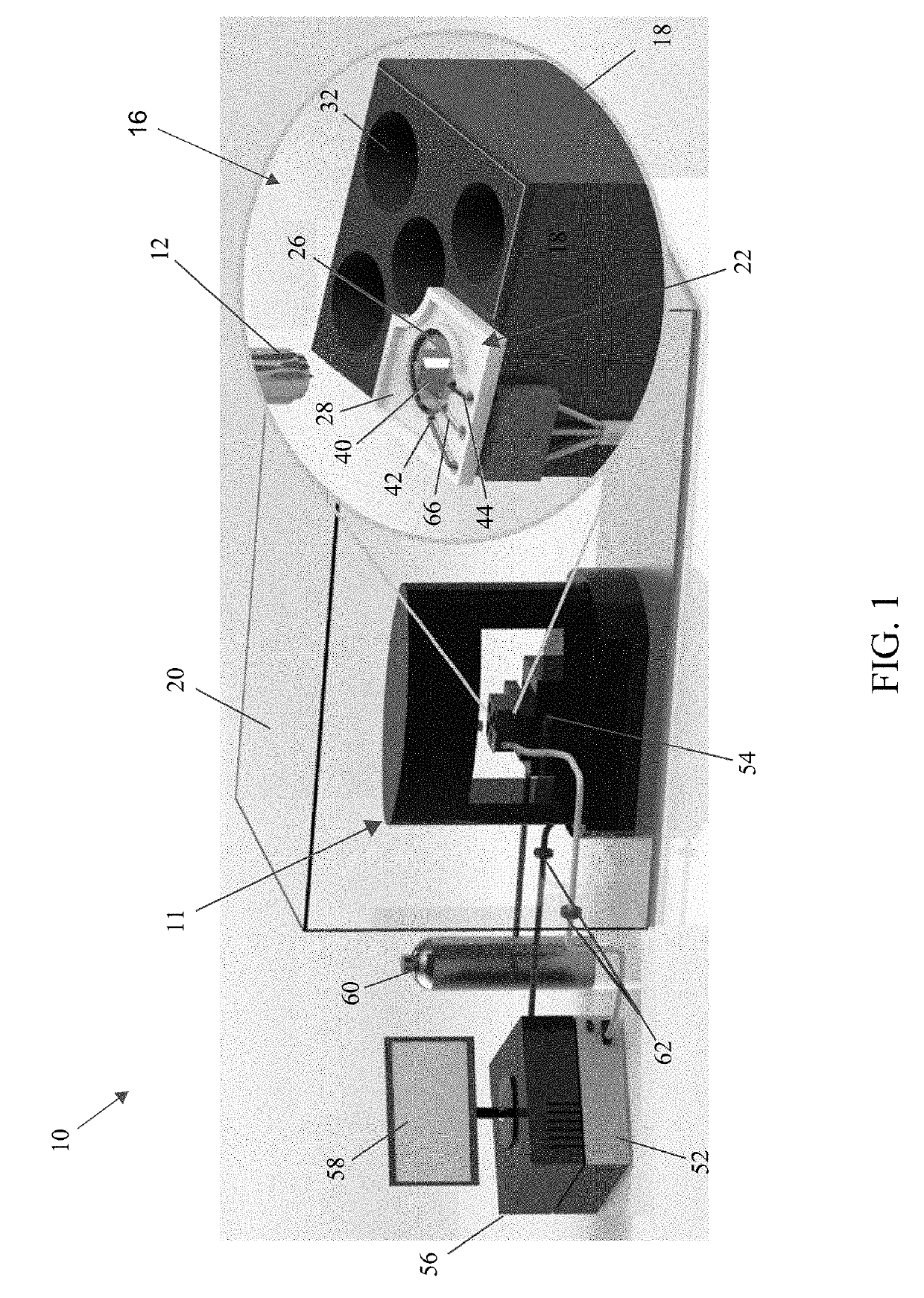

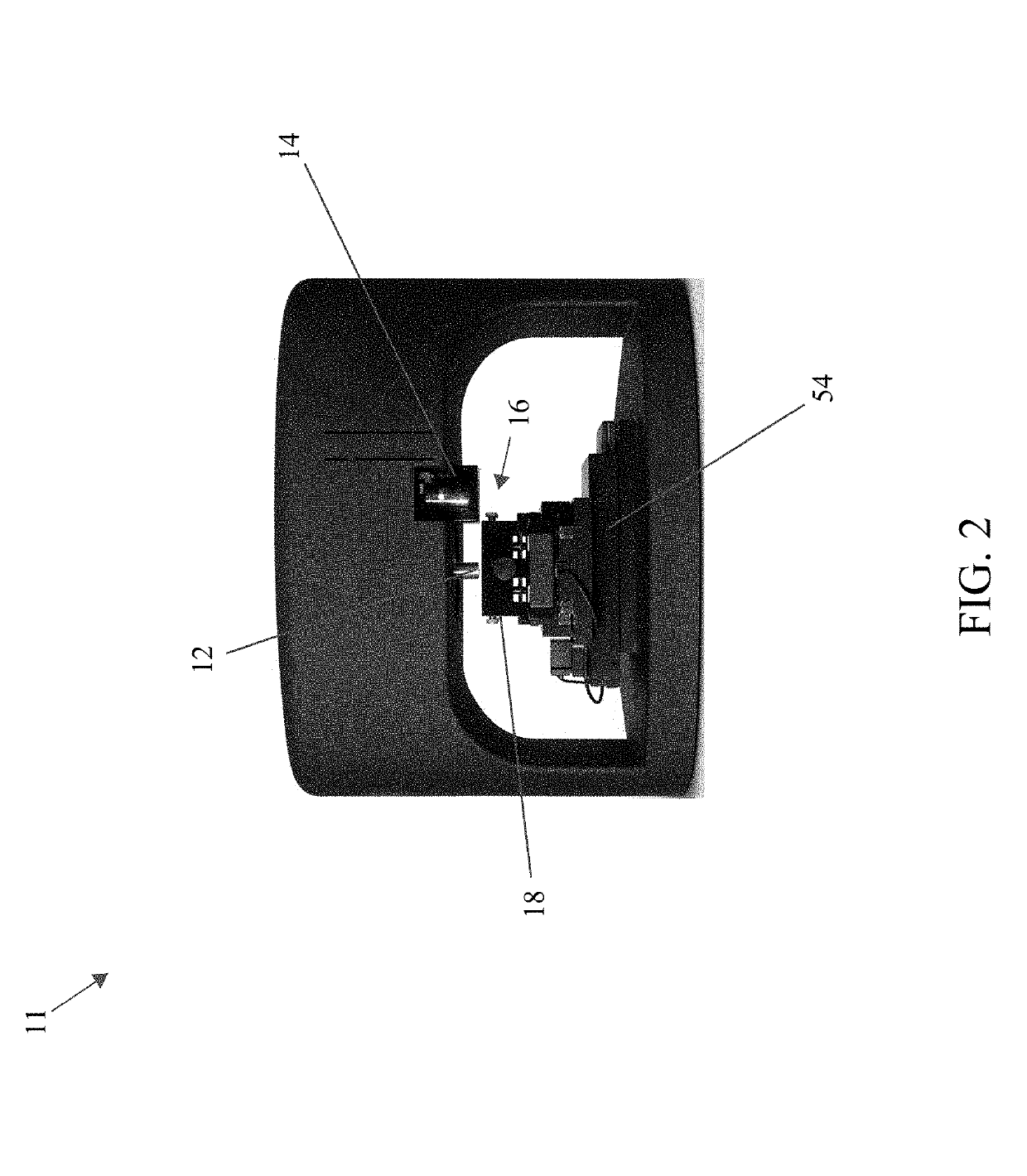

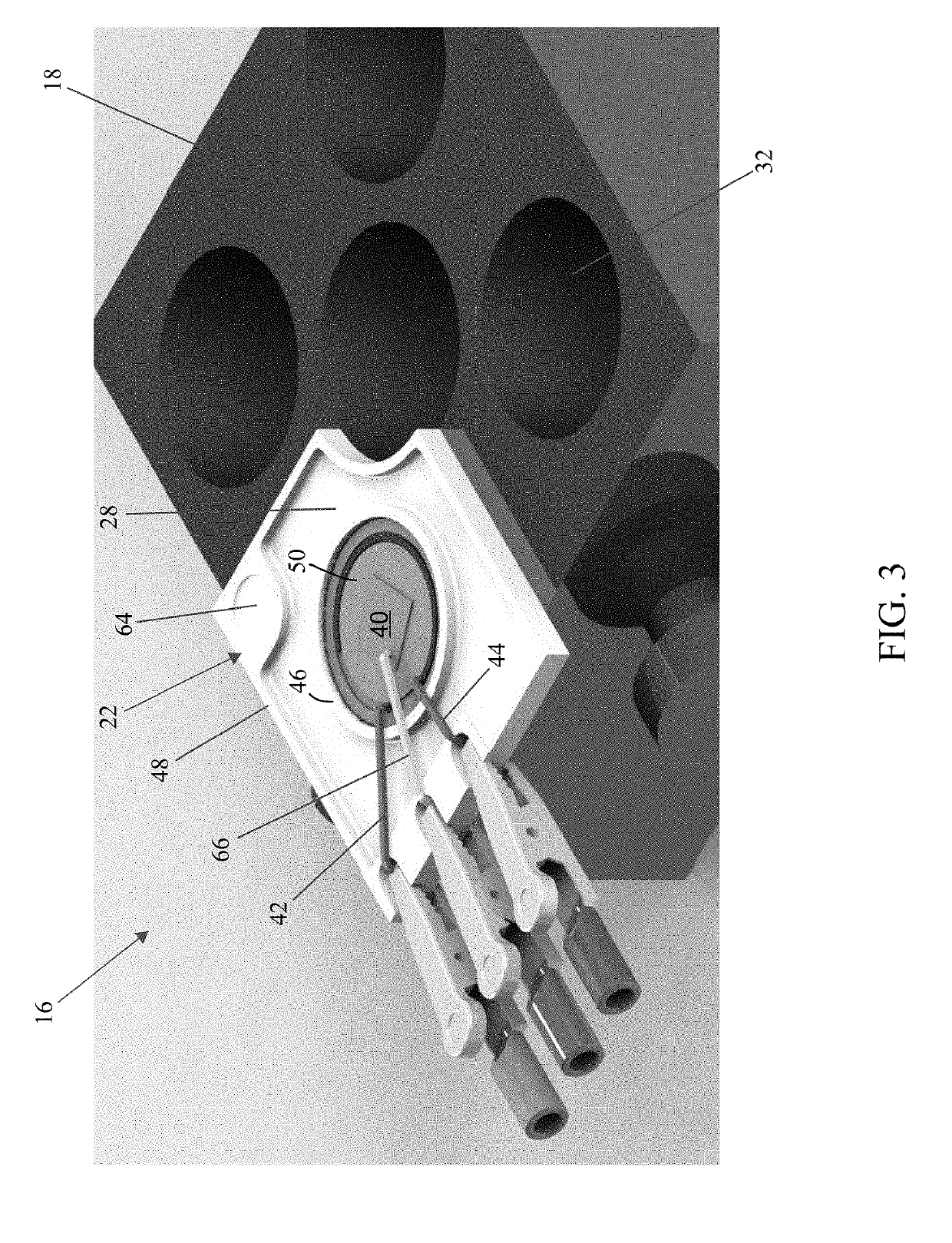

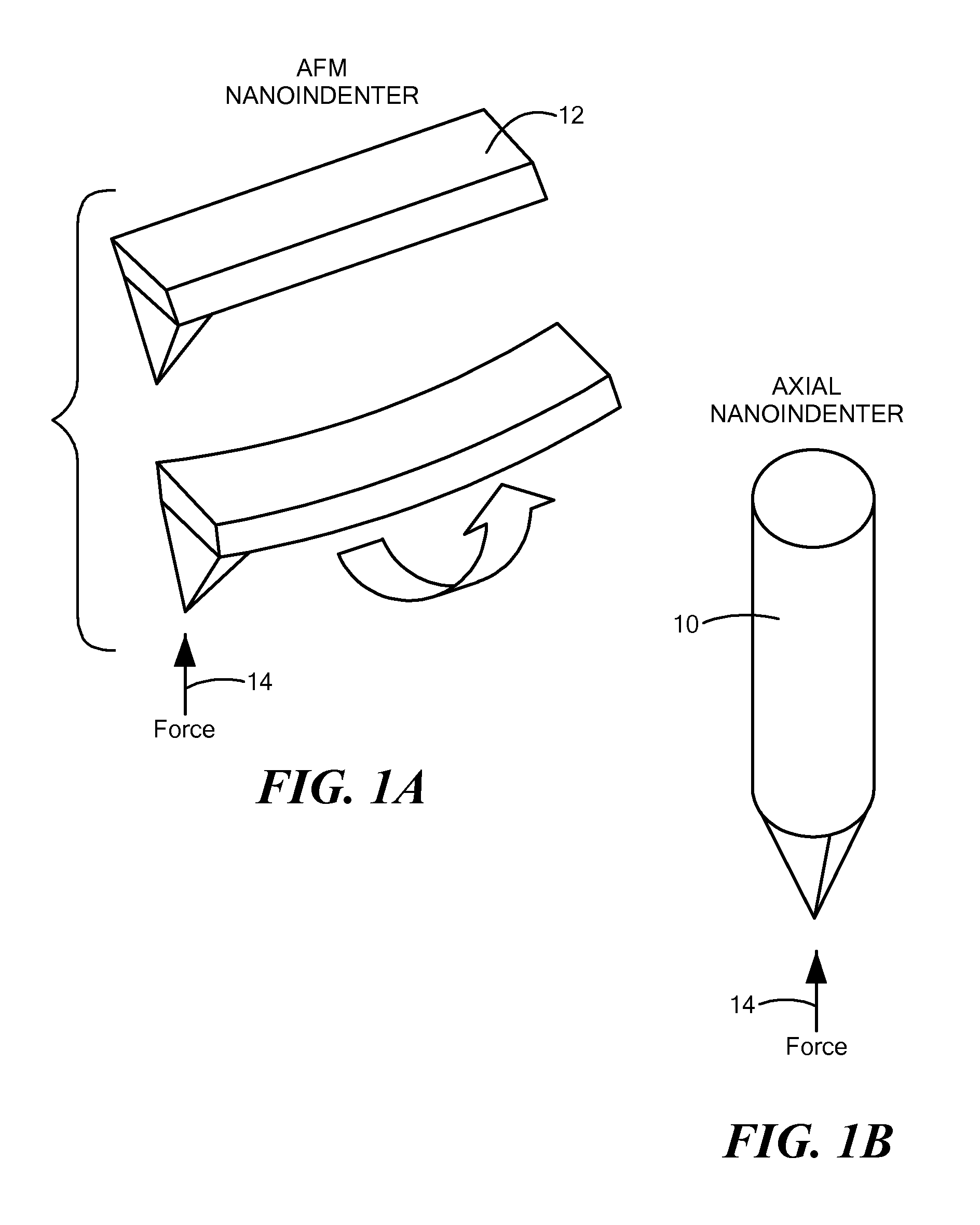

Mems Nanoindenter

ActiveUS20080276727A1Material nanotechnologyFluid pressure measurement using elastically-deformable gaugesAtomic force microscopyEngineering

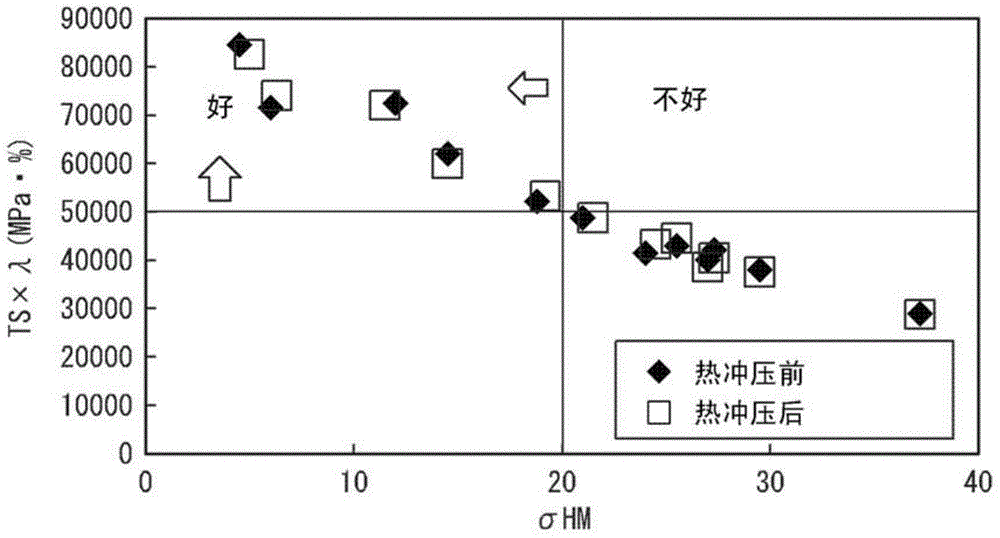

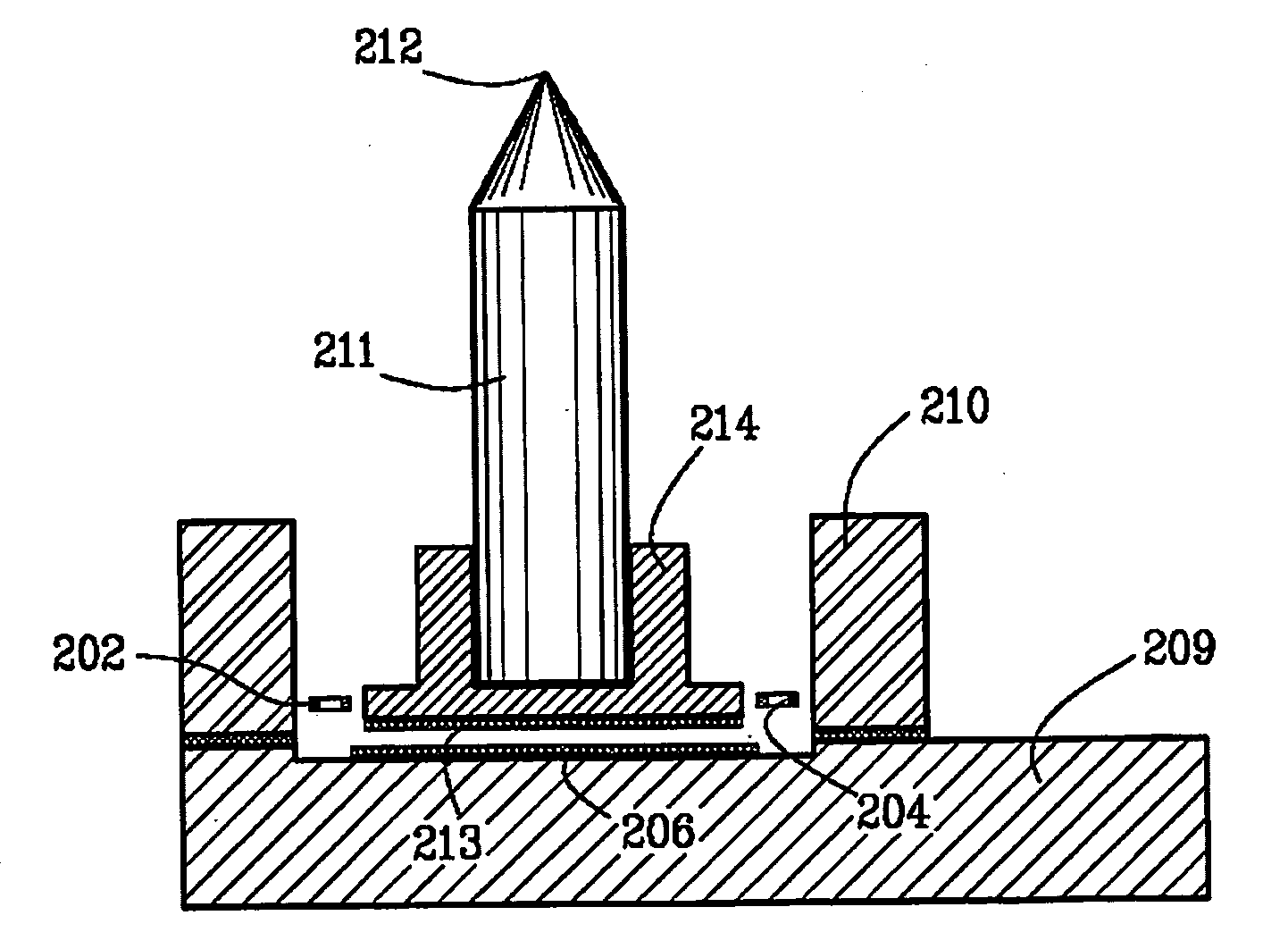

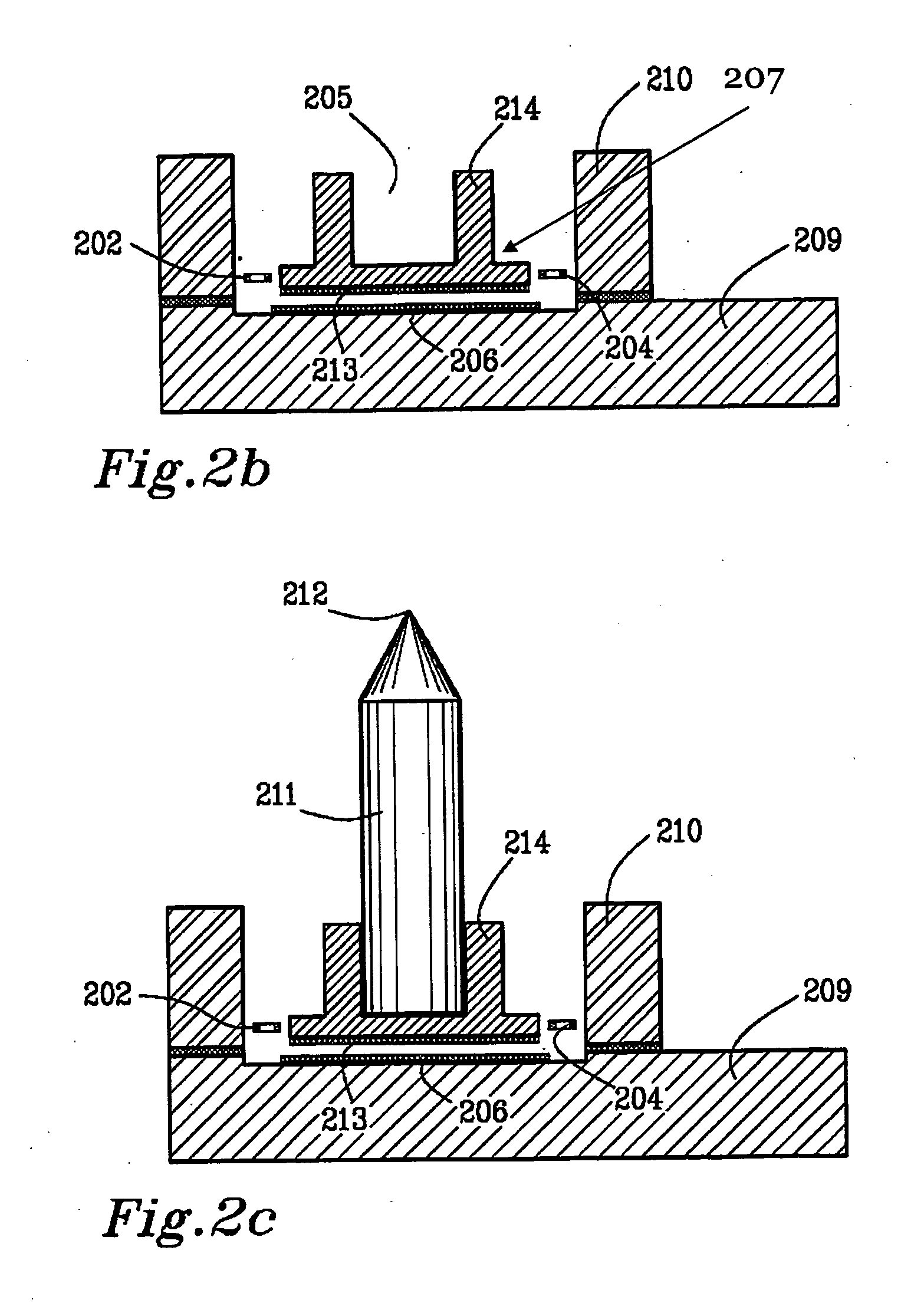

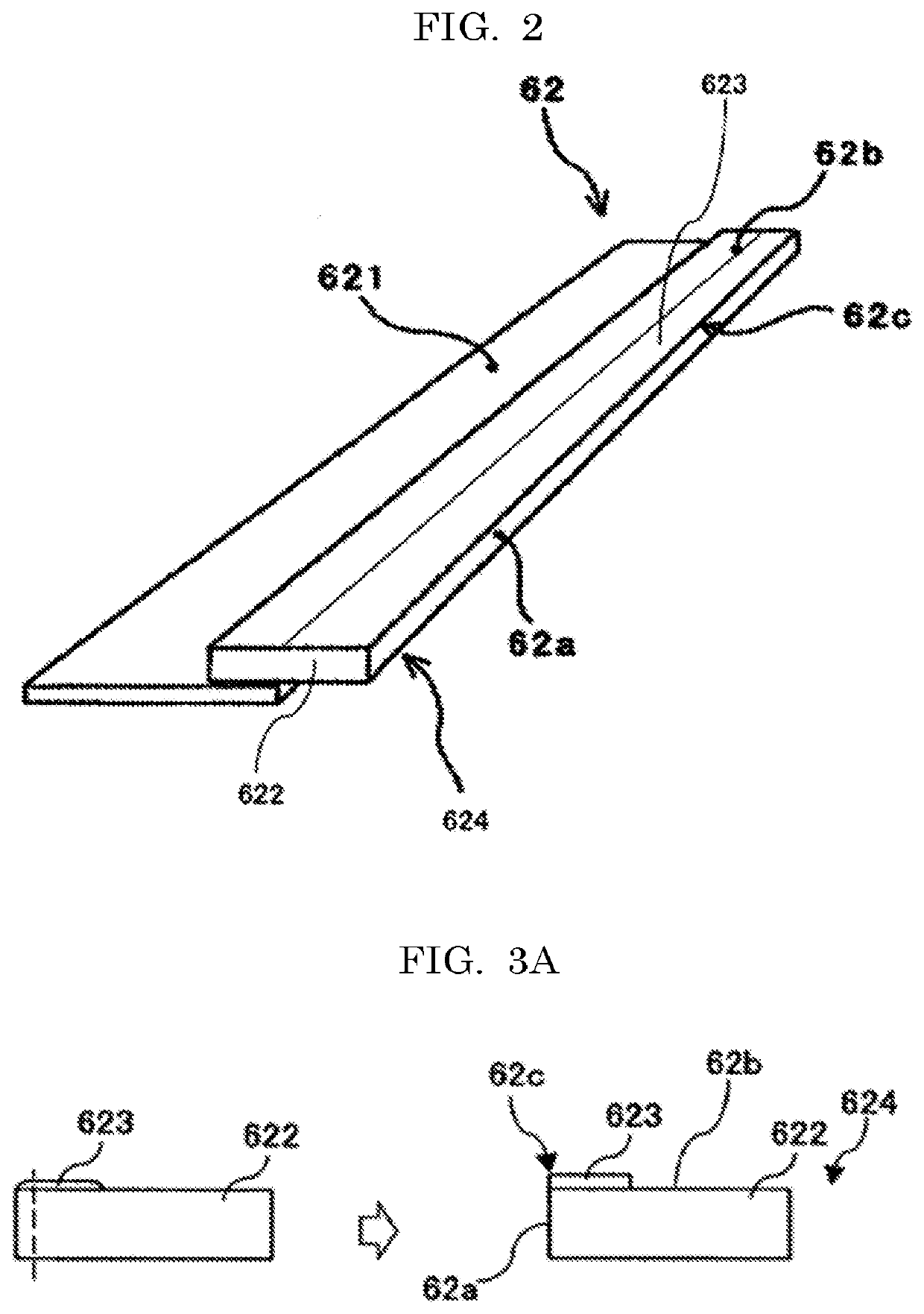

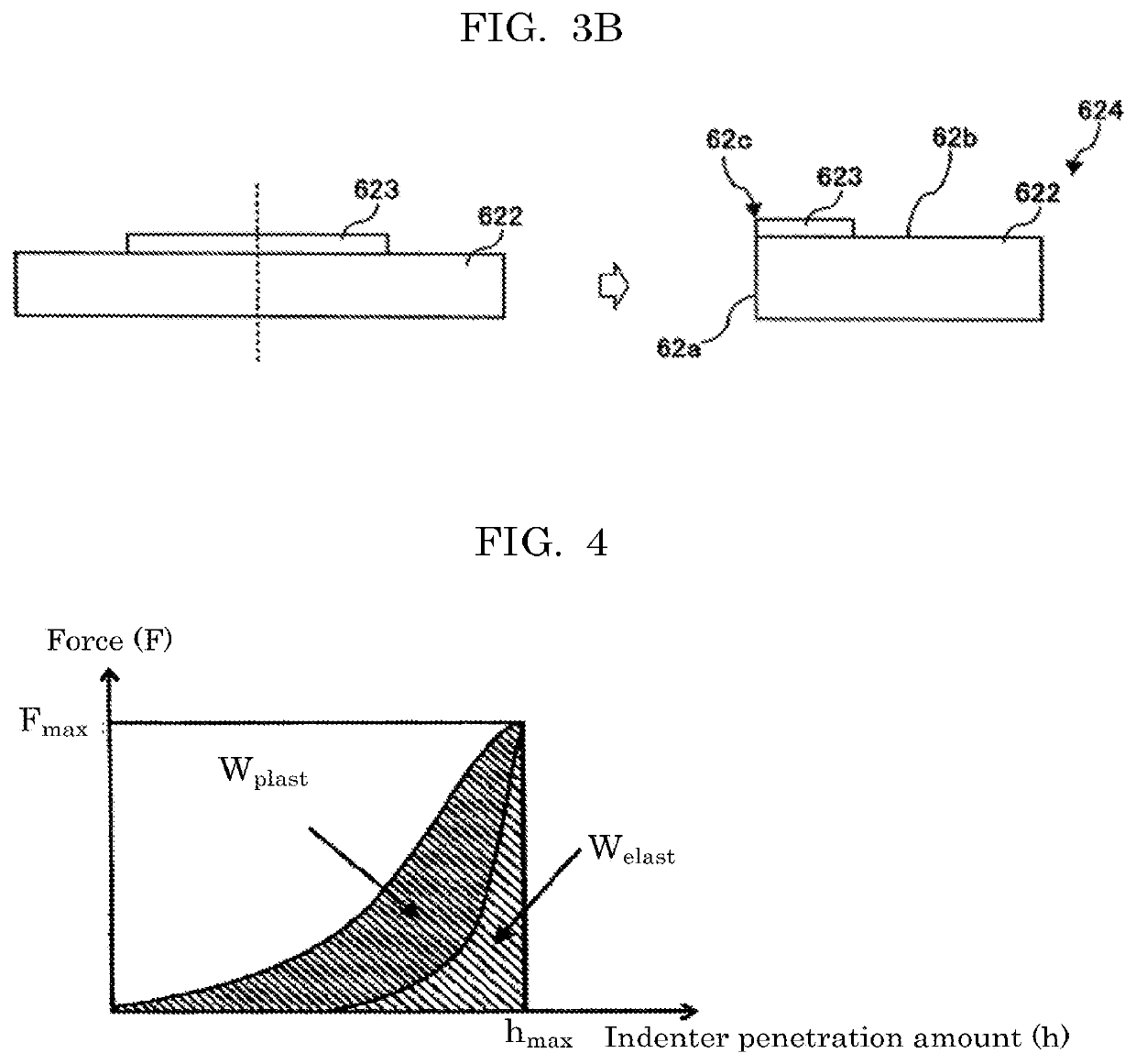

In recent years there has been a growing market for more universal analysis instruments. Analysis tools such as AFM1, TEM2 and nanoindentation work in similar environments. It is therefore possible, within limits, to use the same equipment to do all of these analyses. Conducting nanoindentation experiments in a TEM has also the advantage of increased accuracy compared to the tests done today. 1 Atomic Force Microscopy 2 Transmission Electron MicroscopeThis project is focused on design and fabrication of a capacitive force sensor for AFM and / or nanoindentation measurements in a TEM. Nanofactory Instruments, the initiator of this, project, has developed a specimen holder for TEM that can be used for nanoindentation experiments. The measurement system used today has its limitations of being to large to be mounted in a TEM and thus an improved model was desired.The idea to combine an AFM and nanoindenter sensor in the same design is however at this stage inhibited by a relatively large diamond tip that was specified for the nanoindentation experiments. The work was therefore concentrated on the design and fabrication of a nanoindenter sensor. The design is done with an integrated fixture for a diamond tip with specified dimensions. The sensor design has been manufactured using double-sided lithography, DRIE3 etch and anodic bonding. The resulting wafer was sawed into components and the components were evaluated. 3 Dry Reactive Ion EtchEvaluation of the sensor shows that it was possible to manufacture a micromachined nanoindenter sensor with an integrated fixture for a standard diamond tip. CV4-measurements conducted with HP 4284A indicates a force dependent capacitance change when a force within the specification range is applied. Future work will involve a more detailed characterization using a read-out chip from SmartTec. 4 Capacitance-Voltage measurements

Owner:FEI CO

Cold-rolled steel sheet and method for manufacturing same, and hot-stamp formed body

ActiveUS20150225830A1Improve ductilityGood formabilityHot-dipping/immersion processesVacuum evaporation coatingHot stampingChemical composition

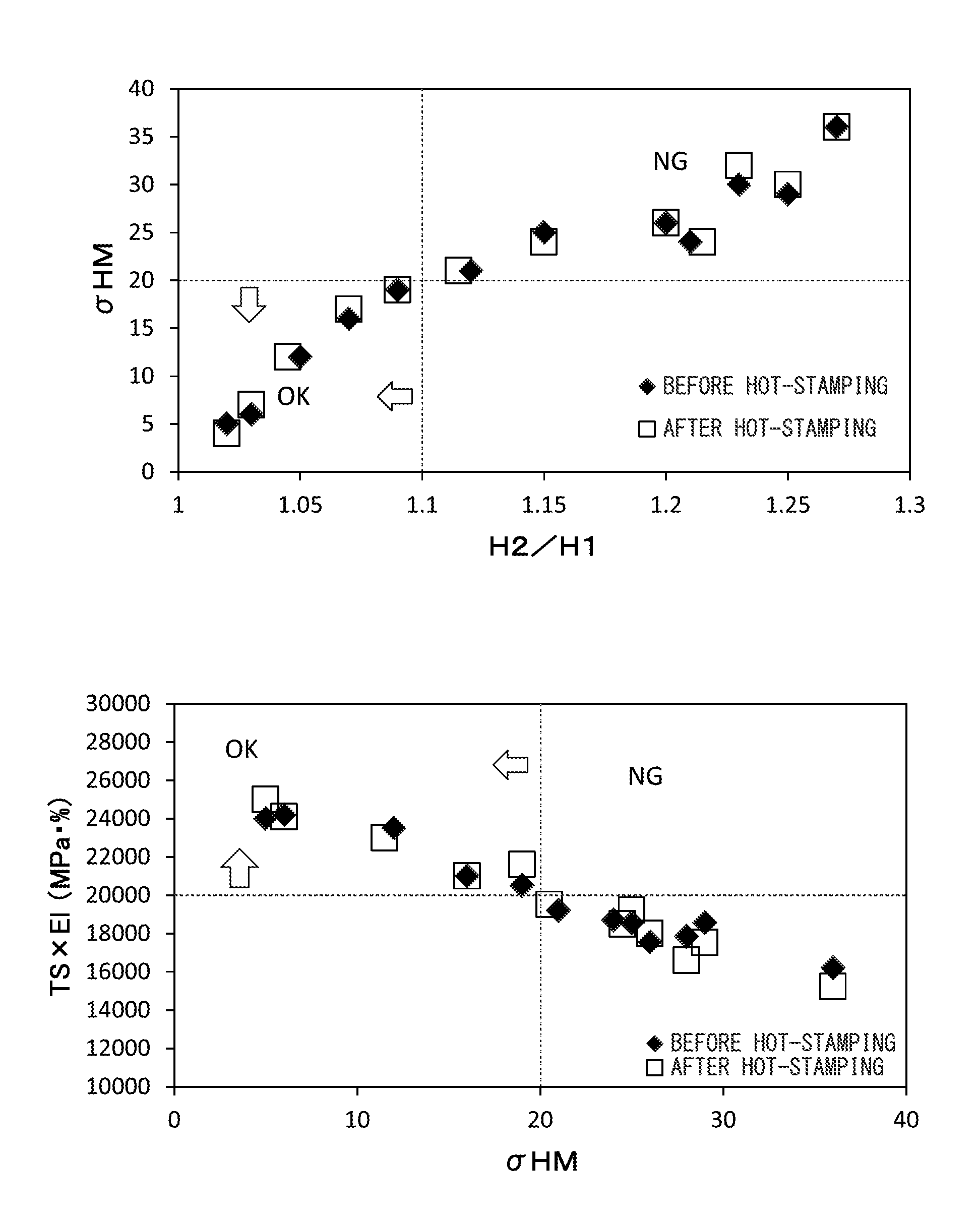

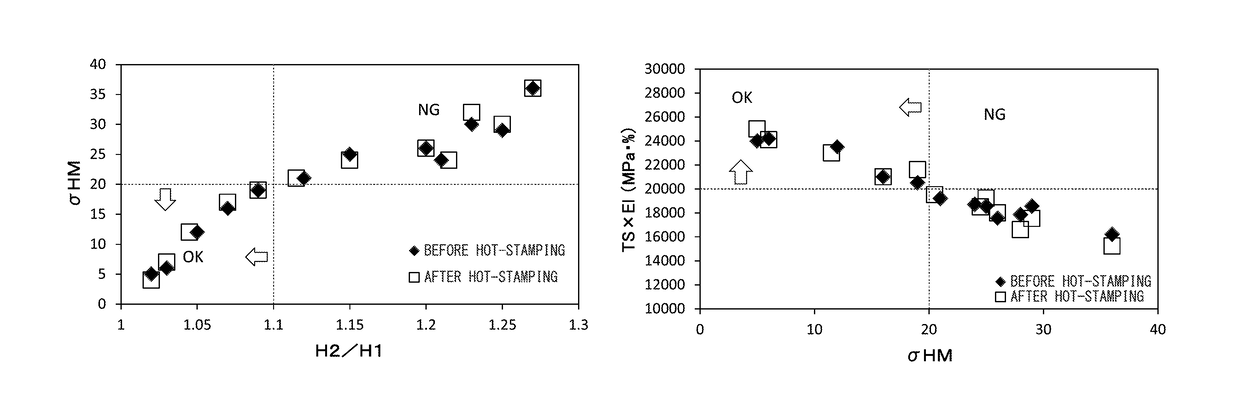

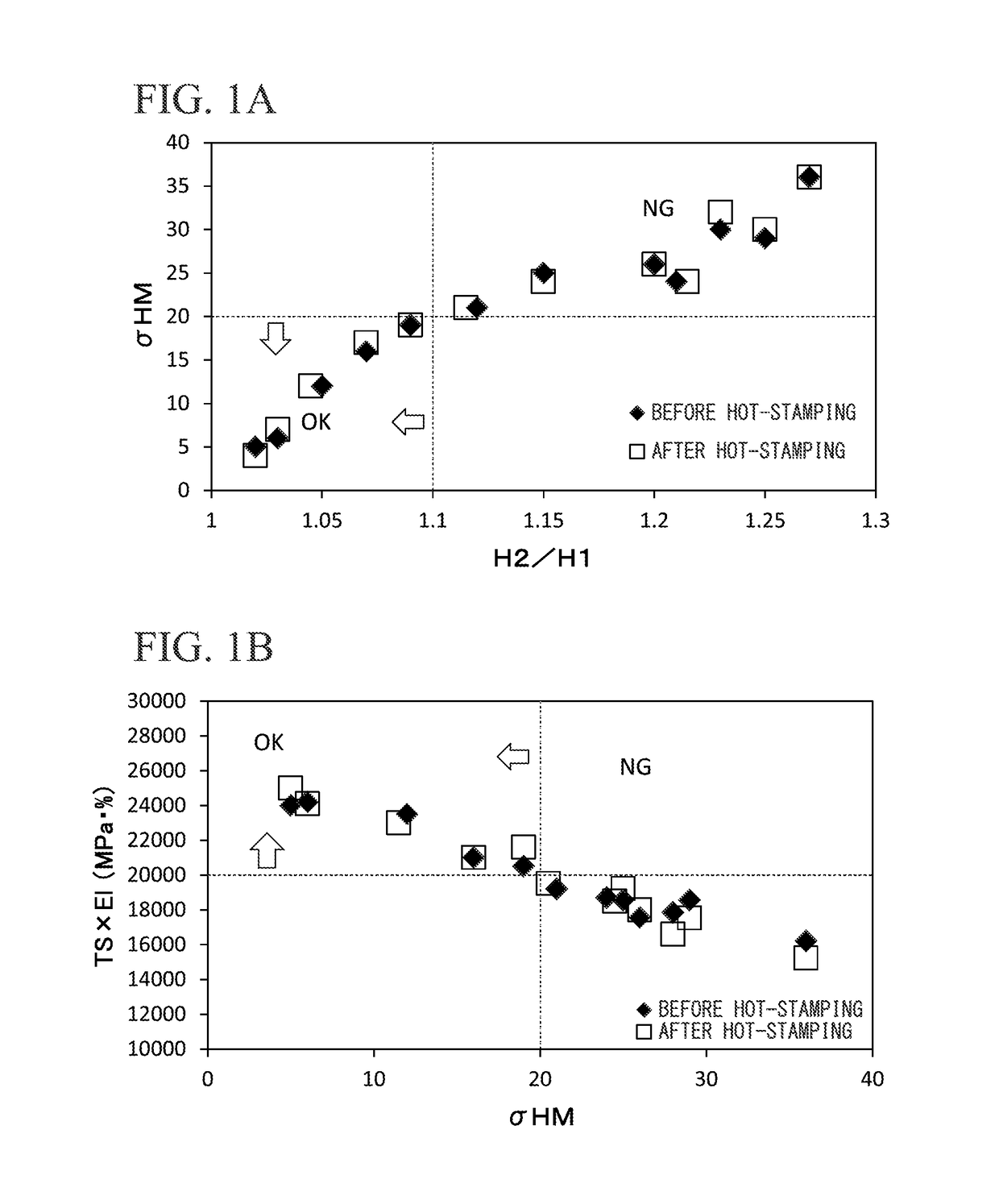

A cold-rolled steel sheet has a predetermined chemical composition, in which a structure before and after a hot-stamping includes ferrite: 30 area % to 90 area %, martensite: 0 area % or more and less than 20 area %, pearlite: 0 area % to 10 area %, retained austenite: 5 volume % to 20 volume %, and rest structure: bainite, a hardness of the retained austenite measured with a nano indenter before and after the hot-stamping satisfies relations of H2 / H1<1.1 and σHM<20, and a relation of TS×El>20000 MPa.% is satisfied.

Owner:NIPPON STEEL CORP

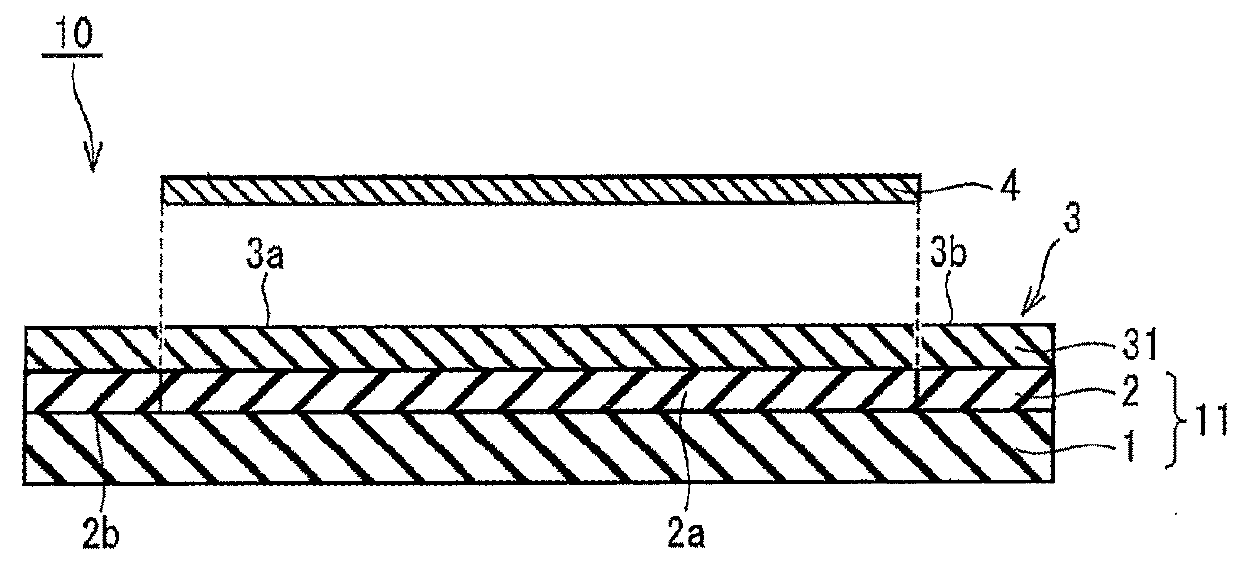

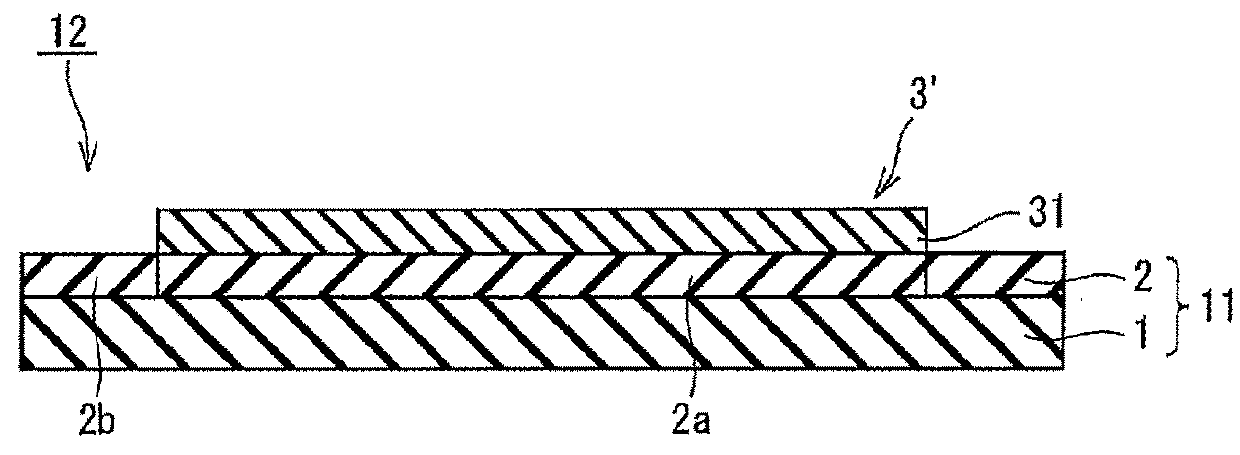

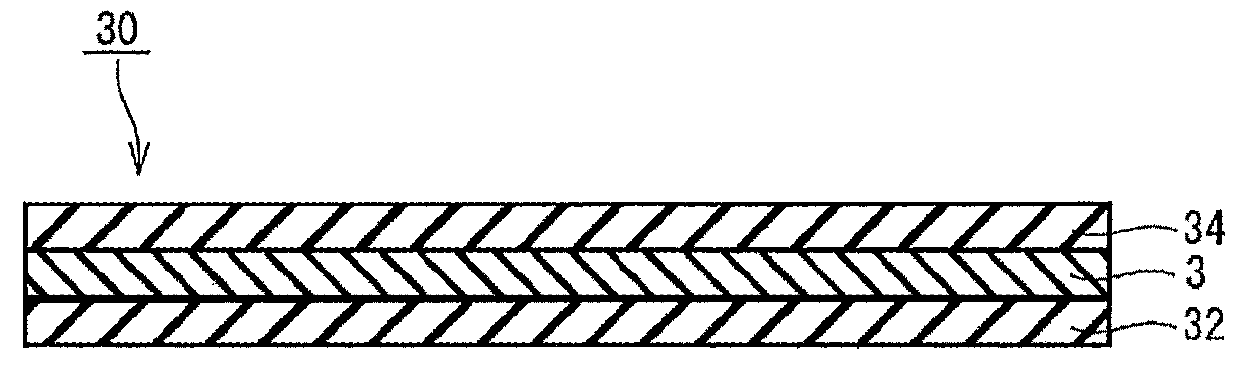

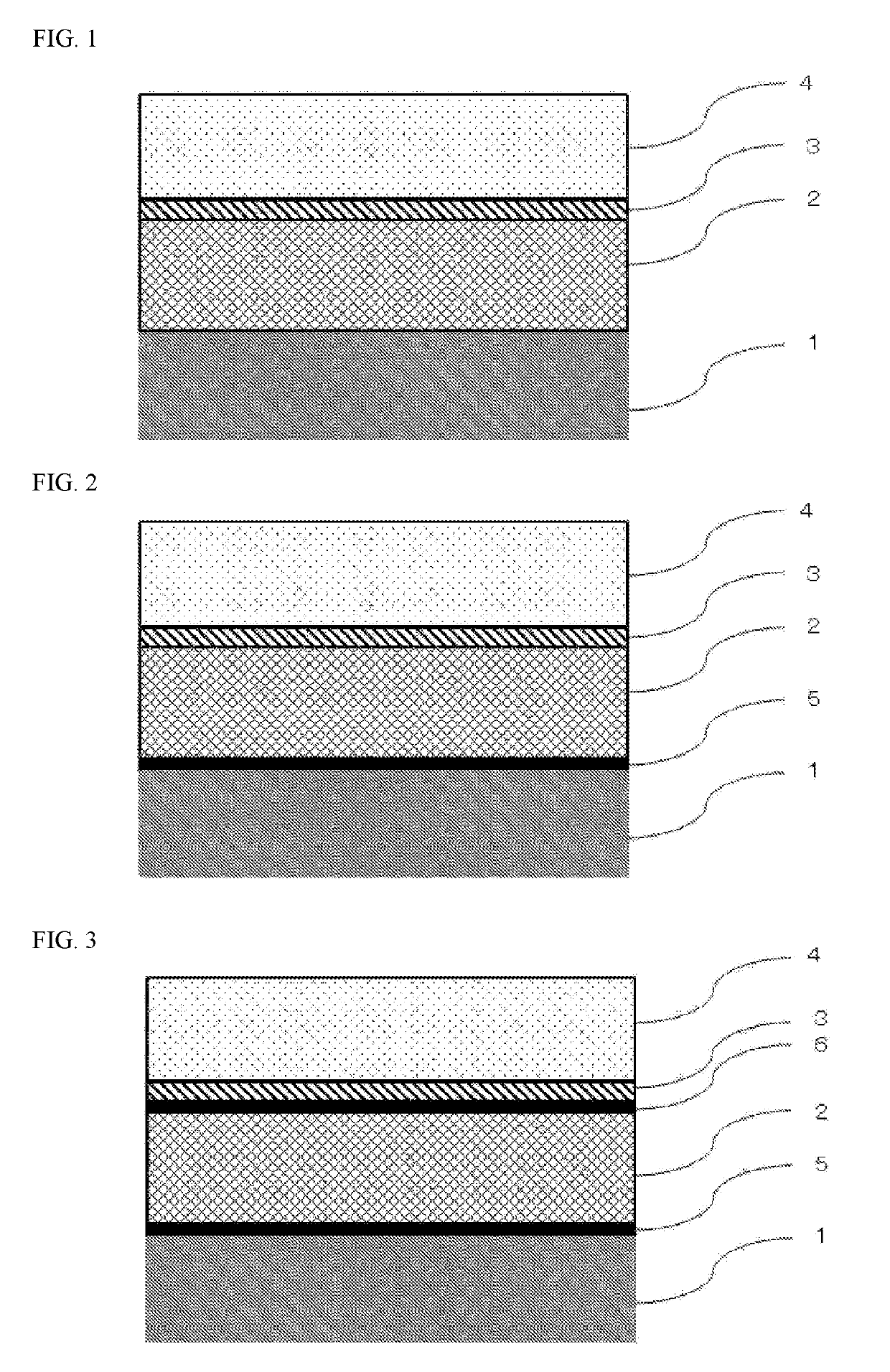

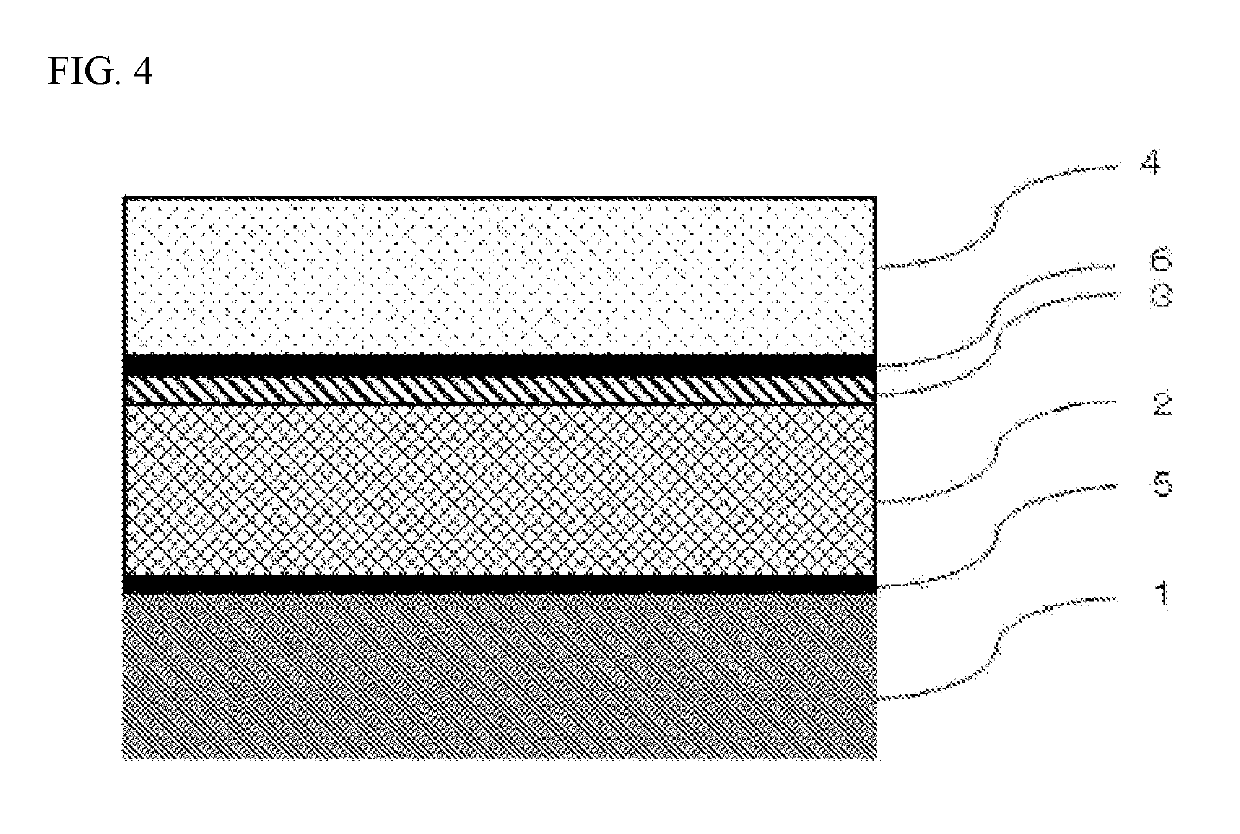

Power-cell packaging material

ActiveUS20150380692A1Improve insulation qualityFinal product manufactureSynthetic resin layered productsHardnessSealant

A power-cell packaging material including a layered body obtained by layering at least a substrate layer, a metal layer, an insulating layer, and a sealant layer, in this order. The insulating layer has a hardness in the range of 10-300 MPa, when measured by using a nanoindenter and pressing the indenter 5 μm into the insulating layer from a cross-section of the layered body in the layering direction thereof.

Owner:DAI NIPPON PRINTING CO LTD

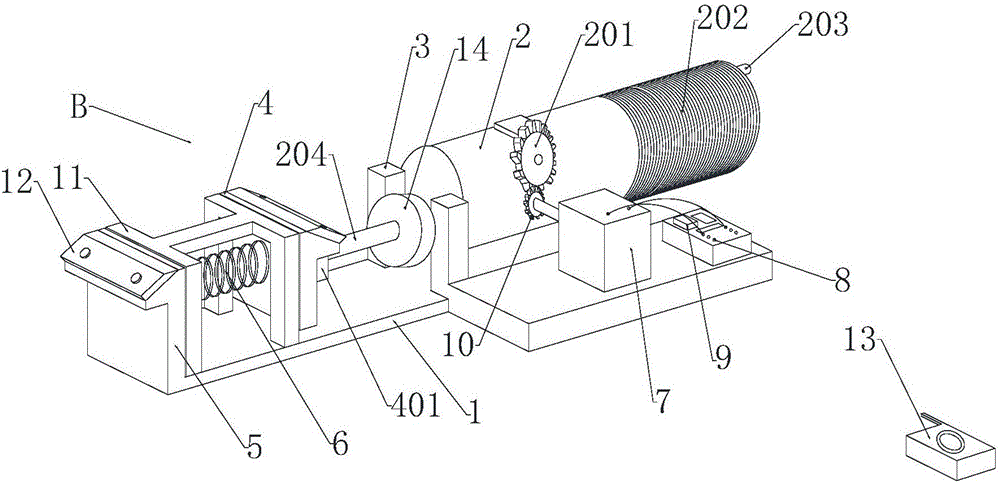

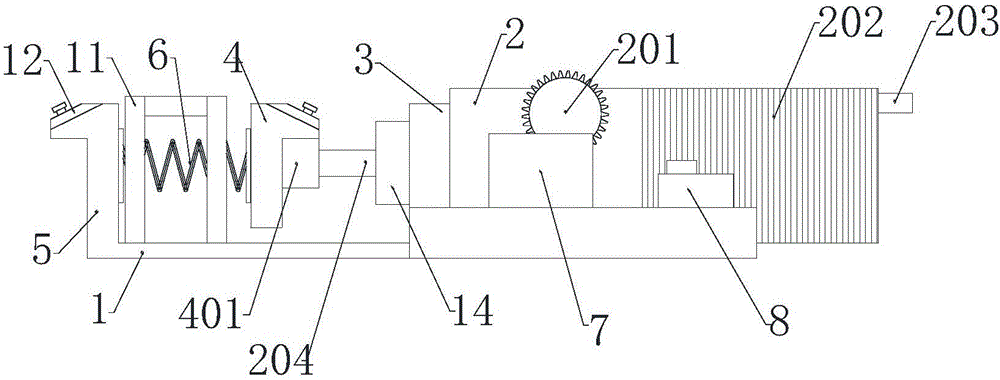

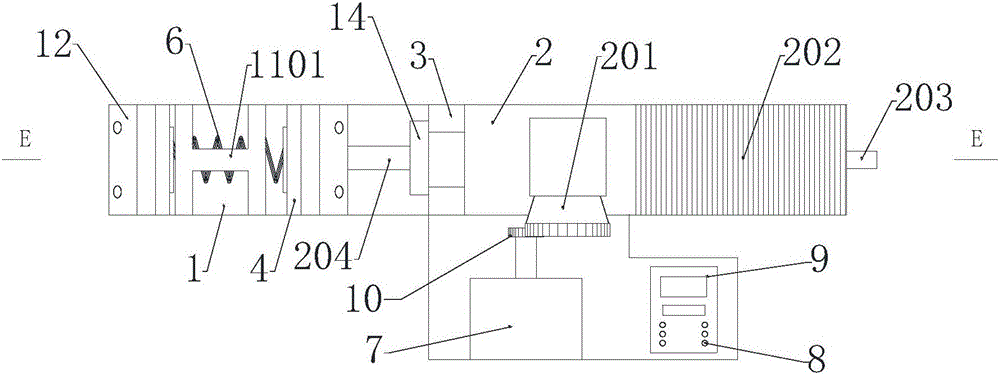

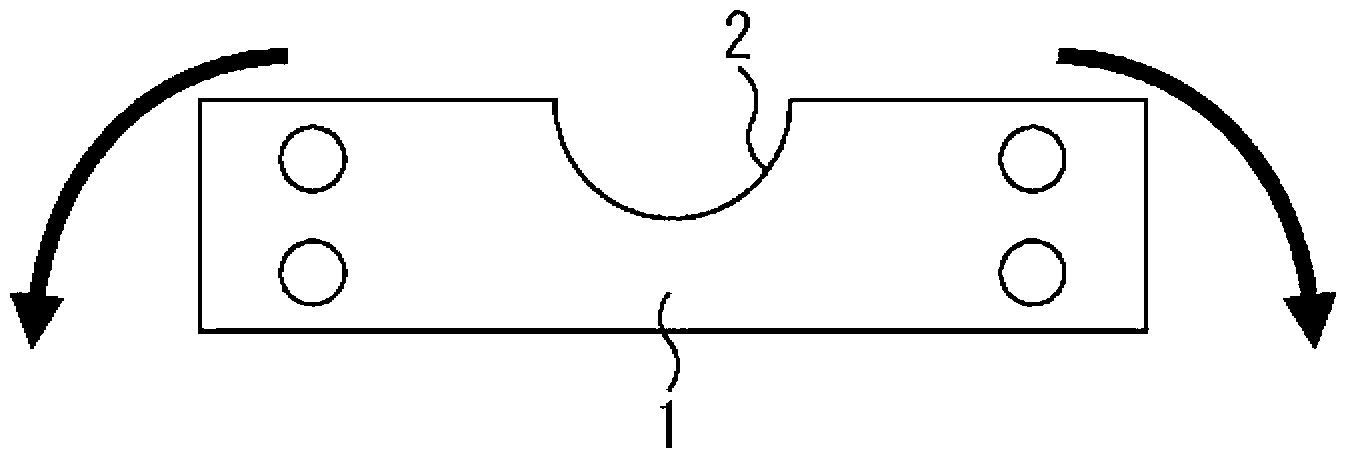

Amorphous alloy ribbon stretching device combined with nanoindenter and use method of amorphous alloy ribbon stretching device

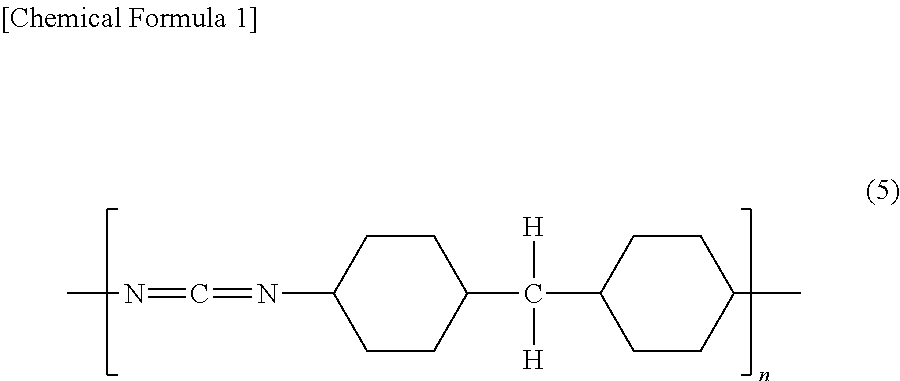

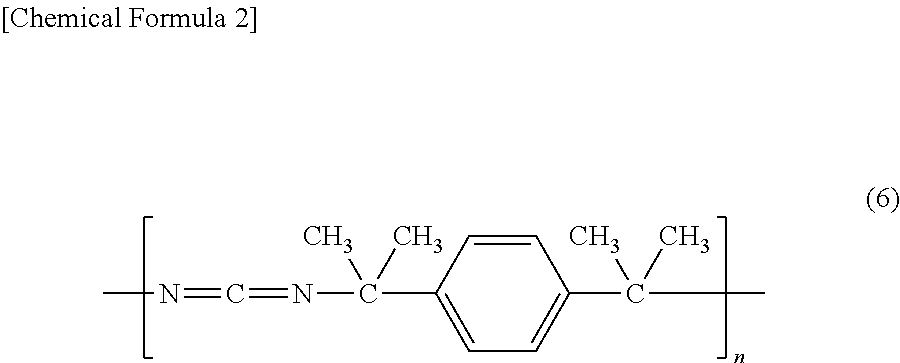

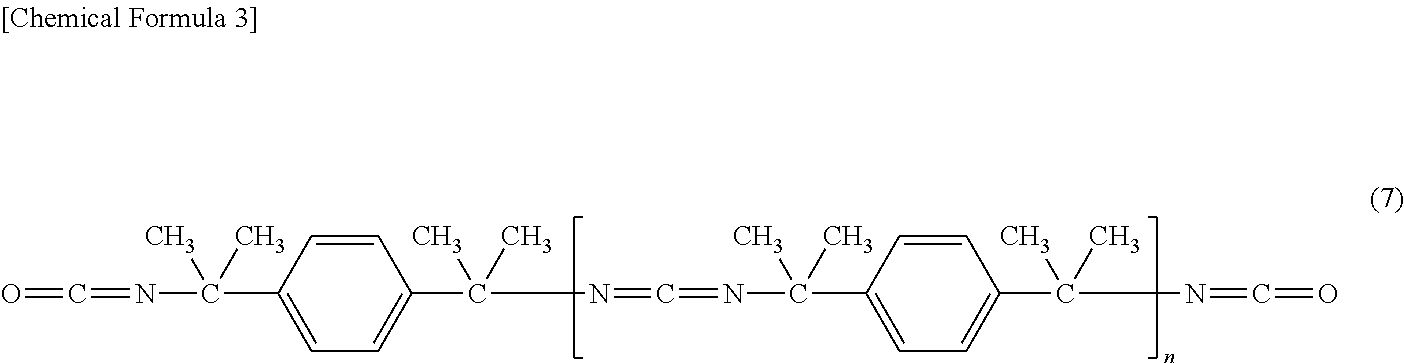

ActiveCN106483021AAchieve continuous stretch deformationPrecise control of strainMaterial strength using tensile/compressive forcesTensile strainMicro nano

An amorphous alloy ribbon stretching device combined with a nanoindenter comprises a base, a high-precision turbo-type coarse and fine tuning differential head, fixed columns, a movable baffle, a fixed baffle, a motor, a motor power supply, a gear, a sample holder, clamps and a remote control, wherein the high-precision turbo-type coarse and fine tuning differential head is located between the fixed columns, one end of the high-precision turbo-type coarse and fine tuning differential head is connected with the movable baffle, the fixed baffle is located at one end of the base and is integrally connected with the base, a spring is sandwiched between the movable baffle and the fixed baffle, the sample holder is arranged on the base and located between the movable baffle and the fixed baffle, the clamps are attached to the sample holder, the motor and the motor power supply are fixed on the base, and a drive shaft of a micro motor is connected with the high-precision turbo-type coarse and fine tuning differential head through the gear. The device is used for testing micro-nano rheological mechanical behaviors, and has controllable deformation and strain and high accuracy. The device is particularly suitable for testing micro-nano mechanical behaviors of a film material in different tensile strain states in a tensile strain process.

Owner:XIANGTAN UNIV

Cold rolled steel sheet and method for producing cold rolled steel sheet

ActiveUS20140342185A1Excellent hole expandabilityHot-dipping/immersion processesSurface reaction electrolytic coatingHot stampingHardness

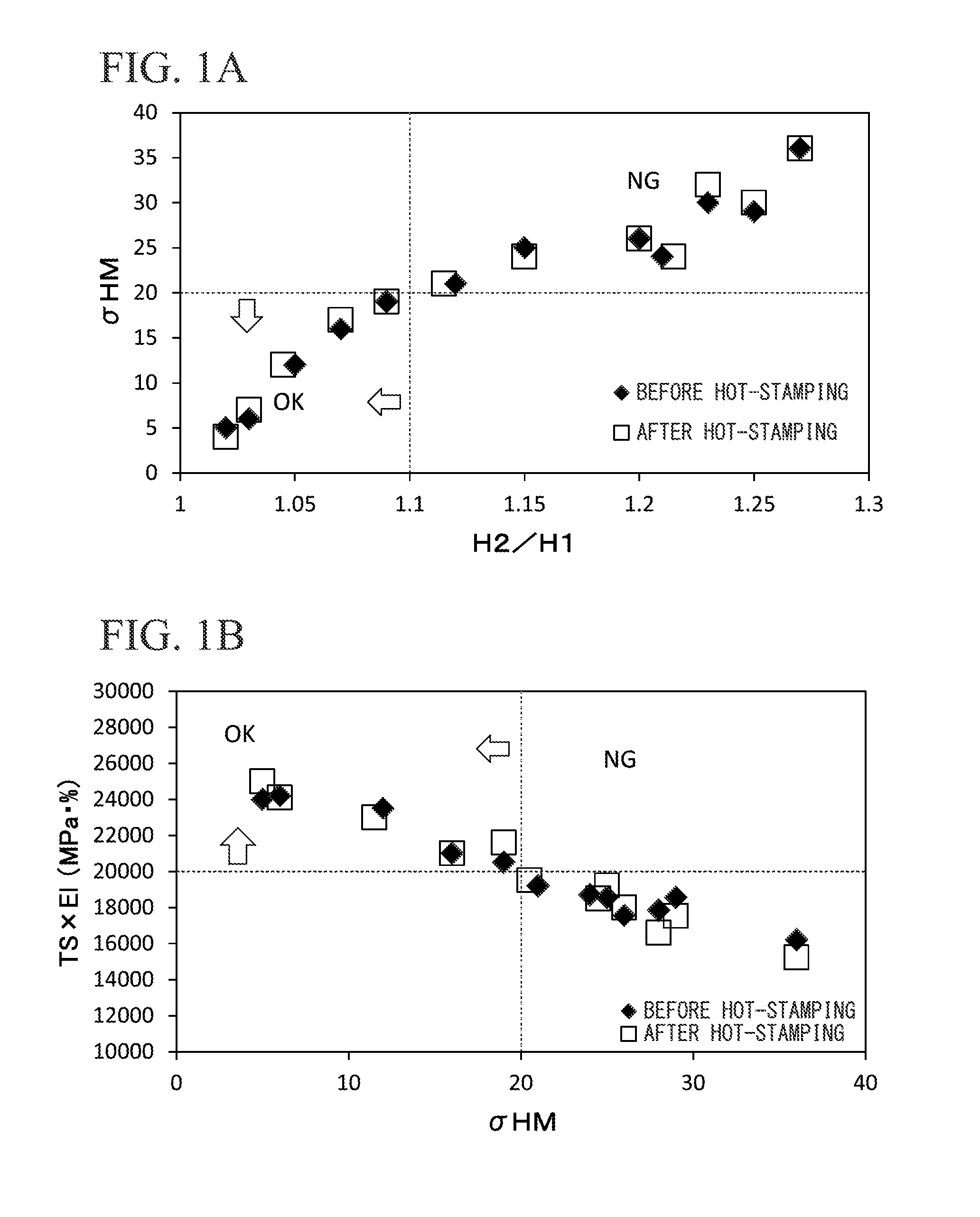

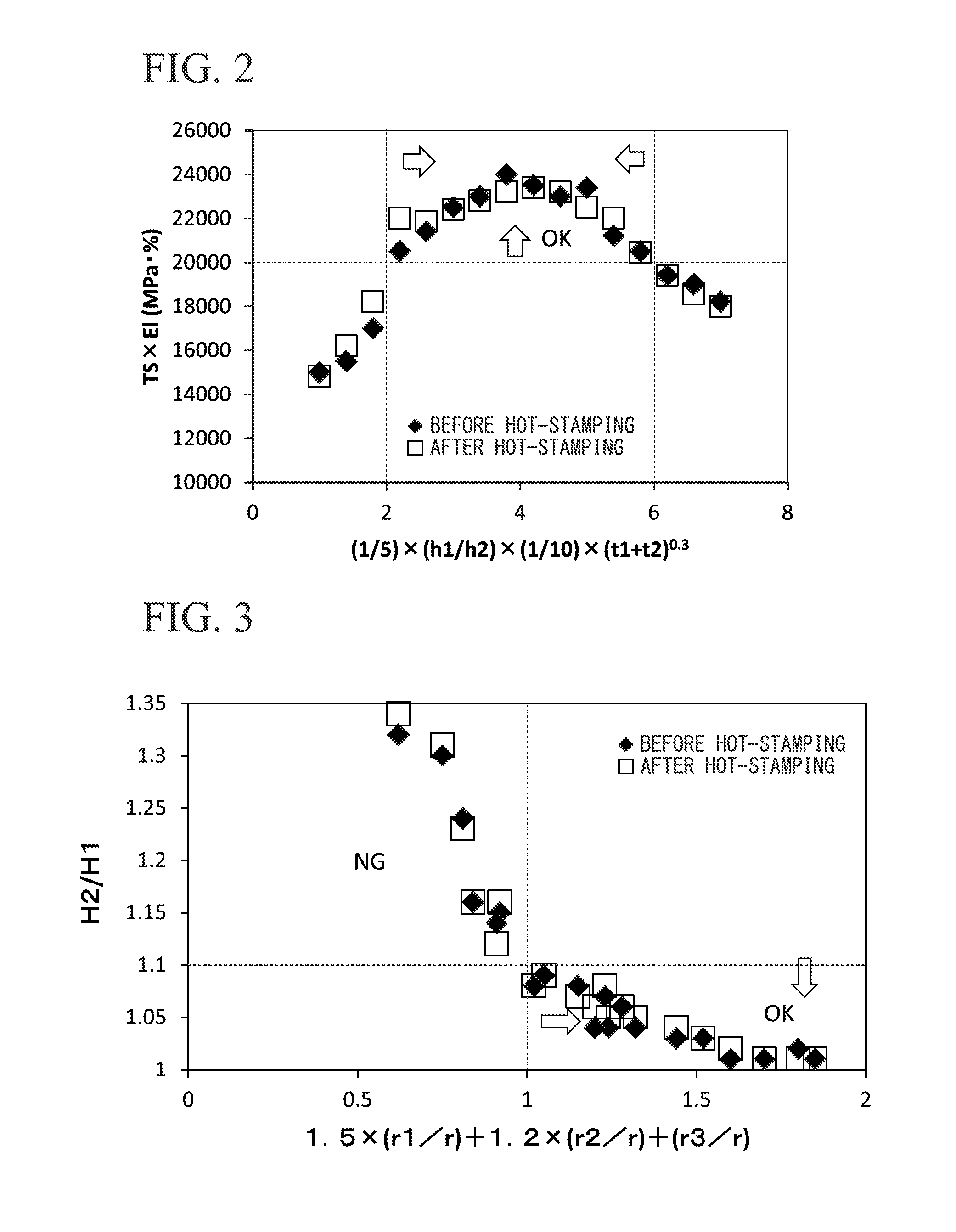

A cold rolled steel sheet according to the present invention satisfies an expression of (5×[Si]+[Mn]) / [C]>11 when [C] represents an amount of C by mass %, [Si] represents an amount of Si by mass %, and [Mn] represents an amount of Mn by mass %, a metallographic structure before hot stamping includes 40% to 90% of a ferrite and 10% to 60% of a martensite in an area fraction, a total of an area fraction of the ferrite and an area fraction of the martensite is 60% or more, a hardness of the martensite measured with a nanoindenter satisfies an H2 / H1<1.10 and σHM<20 before the hot stamping, and TS×λ which is a product of a tensile strength TS and a hole expansion ratio λ is 50000 MPa·% or more.

Owner:NIPPON STEEL CORP

Hot stamped steel and method for producing hot stamped steel

ActiveUS9945013B2Excellent hole expandabilityHot-dipping/immersion processesFurnace typesHot stampingHardness

A hot stamped steel according to the present invention satisfies an expression of (5×[Si]+[Mn]) / [C]>11 when [C] represents an amount of C by mass %, [Si] represents an amount of Si by mass %, and [Mn] represents an amount of Mn by mass %, a metallographic structure after hot stamping includes 40% to 90% of a ferrite and 10% to 60% of a martensite in an area fraction, a total of an area fraction of the ferrite and an area fraction of the martensite is 60% or more, a hardness of the martensite measured with a nanoindenter satisfies an H2 / H1<1.10 and σHM<20, and TS×λ, which is a product of a tensile strength TS and a hole expansion ratio λ is 50000 MPa·% or more.

Owner:NIPPON STEEL CORP

Cold-rolled steel sheet and method for manufacturing same, and hot-stamp formed body

ActiveUS10072324B2Improve ductilityGood formabilityHot-dipping/immersion processesFurnace typesHot stampingChemical composition

A cold-rolled steel sheet has a predetermined chemical composition, in which a structure before and after a hot-stamping includes ferrite: 30 area % to 90 area %, martensite: 0 area % or more and less than 20 area %, pearlite: 0 area % to 10 area %, retained austenite: 5 volume % to 20 volume %, and rest structure: bainite, a hardness of the retained austenite measured with a nano indenter before and after the hot-stamping satisfies relations of H2 / H1<1.1 and σHM<20, and a relation of TS×El≥20000 MPa·% is satisfied.

Owner:NIPPON STEEL CORP

Cold rolled steel sheet and method for producing cold rolled steel sheet

ActiveUS9920407B2Excellent hole expandabilityHot-dipping/immersion processesThin material handlingHot stampingMartensite

A cold rolled steel sheet according to the present invention satisfies an expression of (5×[Si]+[Mn]) / [C]>11 when [C] represents an amount of C by mass %, [Si] represents an amount of Si by mass %, and [Mn] represents an amount of Mn by mass %, a metallographic structure before hot stamping includes 40% to 90% of a ferrite and 10% to 60% of a martensite in an area fraction, a total of an area fraction of the ferrite and an area fraction of the martensite is 60% or more, a hardness of the martensite measured with a nanoindenter satisfies an H2 / H1<1.10 and σHM<20 before the hot stamping, and TS×λ which is a product of a tensile strength TS and a hole expansion ratio λ is 50000 MPa·% or more.

Owner:NIPPON STEEL CORP

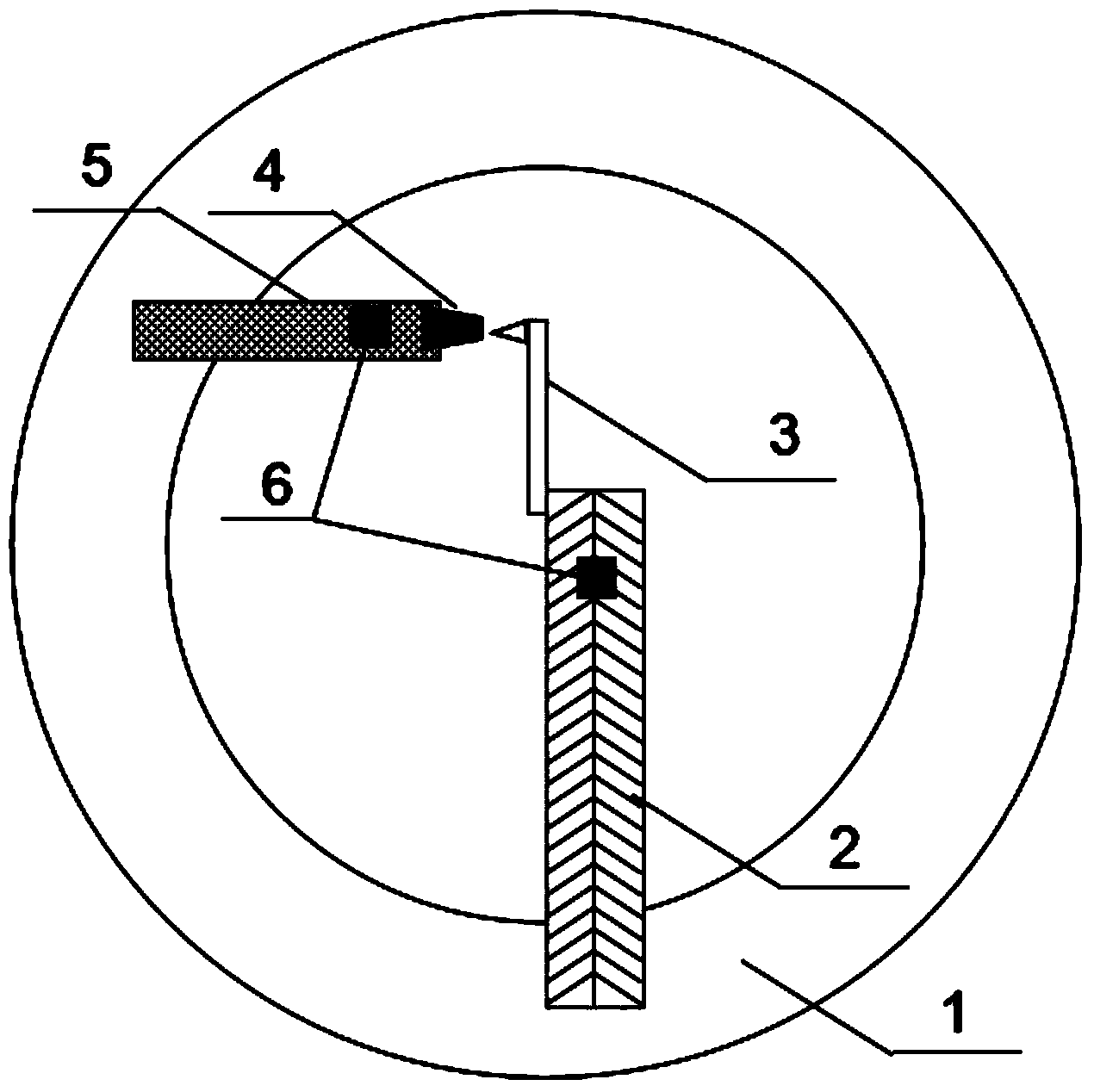

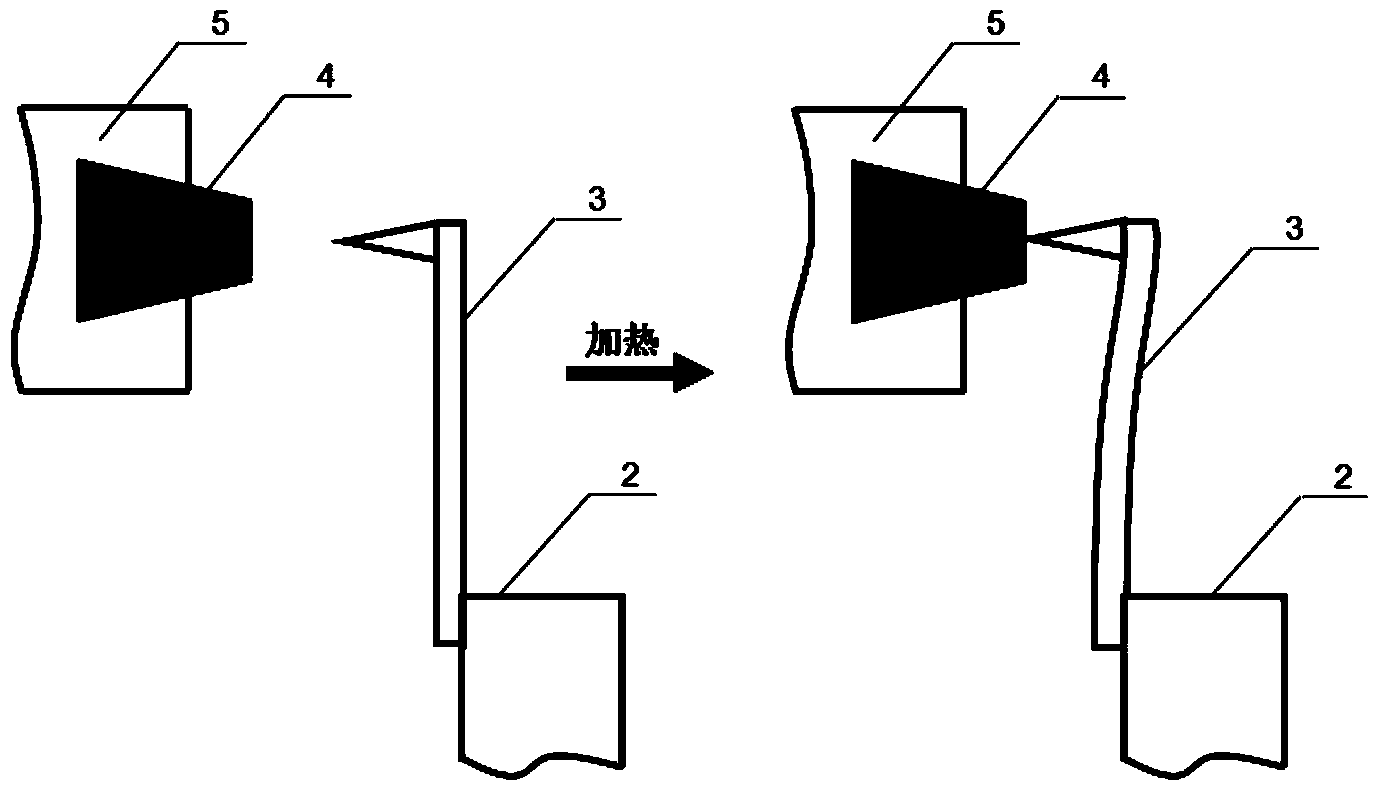

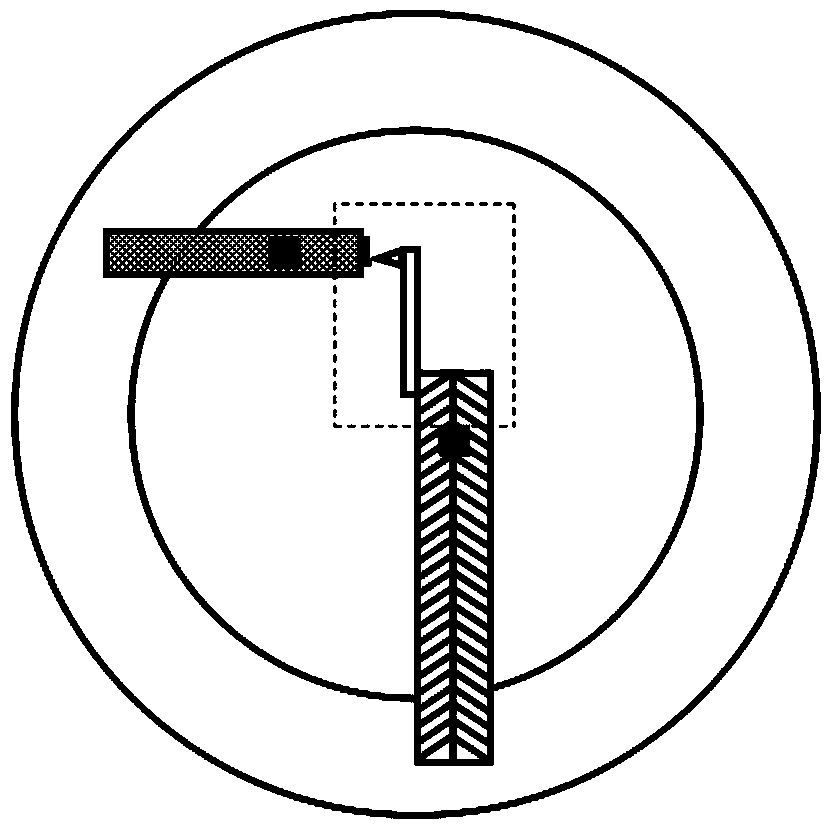

In-situ double-axis tilting nanoindenter for transmission electron microscope

InactiveCN103645199AFunction increaseImprove performanceMaterial analysis by transmitting radiationCantilevered beamMicrometer

The invention provides an in-situ double-axis tilting nanoindenter for a transmission electron microscope and belongs to the nanomaterial in-situ test field. one end of a thermal bimetal sheet is fixed on a metal ring, and the other end is a free end. A cantilever beam needle point is fixed at the free end and one side with a low thermal expansion coefficient. The needle point of the cantilever beam needle point is arranged to be back to the thermal bimetal sheet. A sample is fixed at one end of a sample support. The other end of the sample support is fixed on the metal ring and the sample is arranged to directly face the cantilever beam needle point. The gap between the sample and the needle point is 2-50 micrometers. The thermal bimetal sheet and the cantilever beam needle point, and the sample and the sample support are fixed together through conductive materials respectively. The thermal bimetal sheet and the sample support are fixed on the metal ring respectively in an insulation state. Electrodes are welded on the thermal bimetal sheet and the sample support respectively, and the electrodes are connected with an external test circuit. The nanoindenter keeps two freedom degrees of X axis and Y axis at the same time, and performs real-time in-situ atomic scale observation of structures of nanomaterials during compression.

Owner:BEIJING UNIV OF TECH

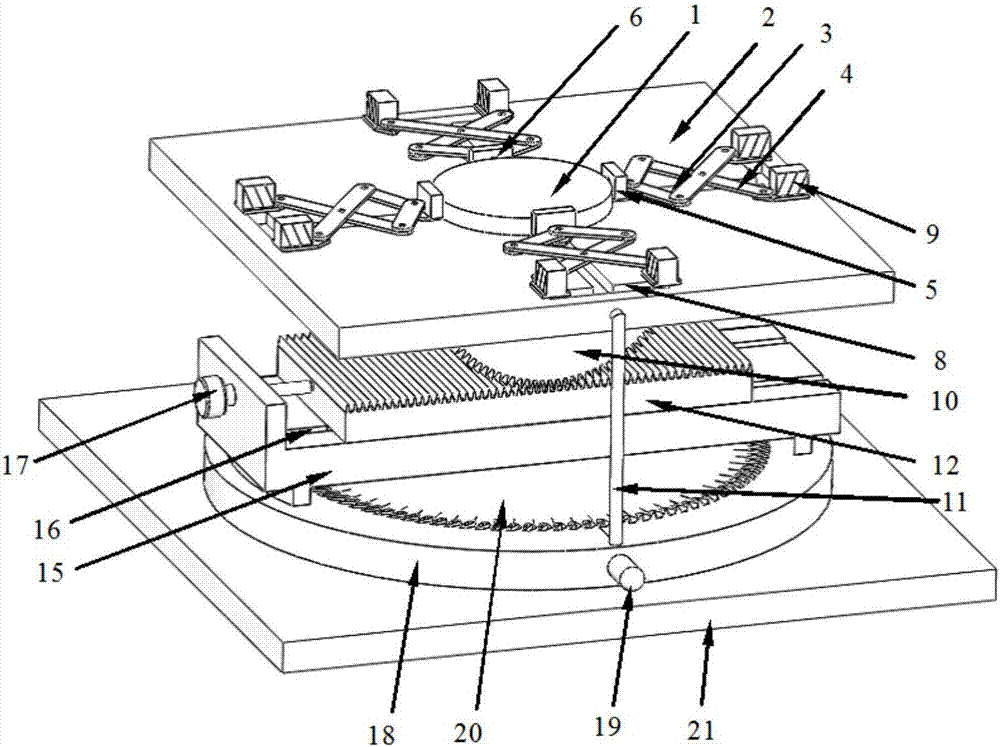

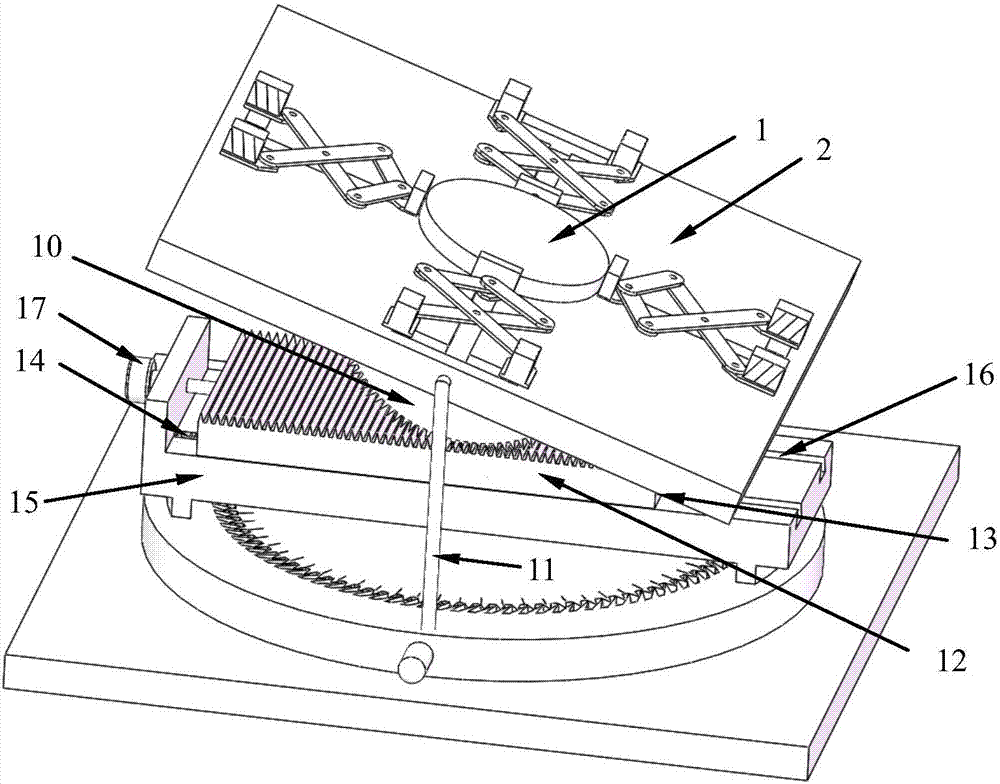

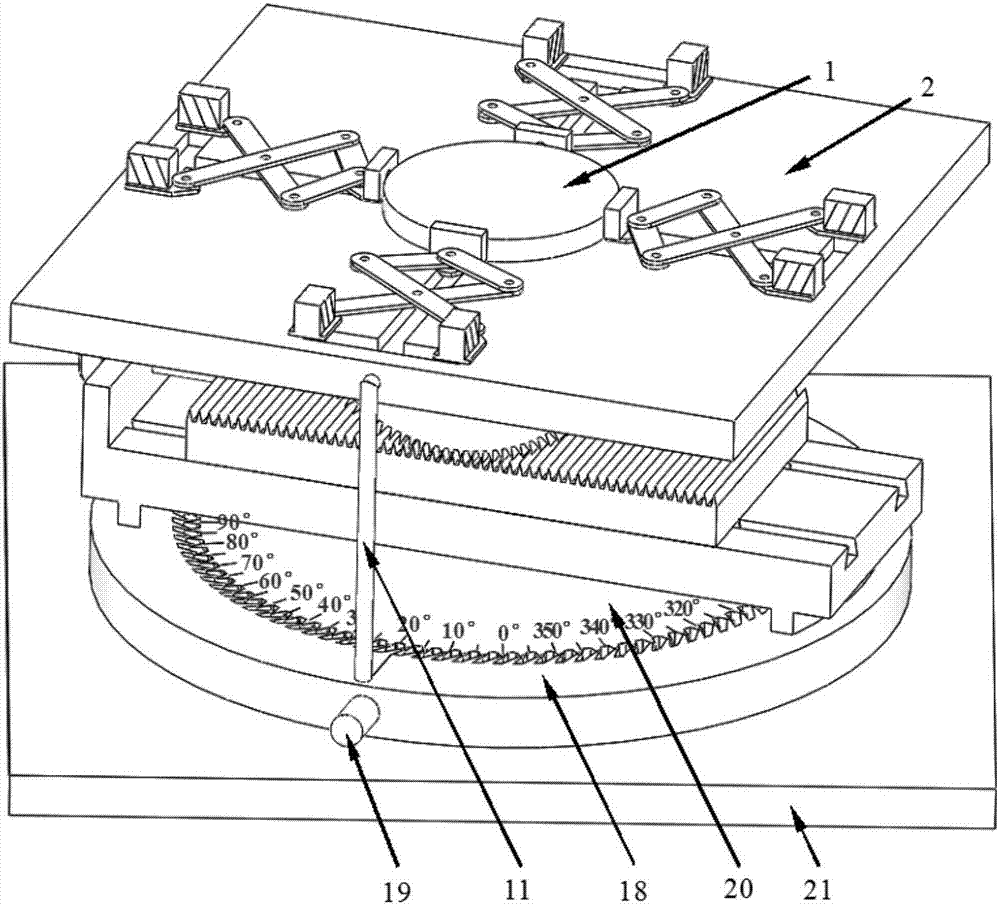

Clamp special for nanoindenter

The invention relates to a clamp special for a nanoindenter. The clamp comprises the following components: four telescoping racks and workpiece clamping blocks are arranged on the upper surface of a workpiece supporting plate, the bottom parts of the telescoping racks are provided with telescoping slide blocks, and the workpiece supporting blocks and the telescoping slide blocks are embedded in atelescoping slide way; the tail ends of the telescoping racks are provided with electromagnets, an inclined gear is arranged below the workpiece supporting plate, and rotation supporting racks are arranged at the side of the workpiece supporting plate; the inclined gear and an inclined tooth bar are connected in engagement, the bottom of the inclined tooth bar is connected to a movable slide way by a movable slide bar, the slide bar is internally provided with a spring, and the end of a micrometer is connected to an inclined tooth bar in contact connection; the rotation supporting rack bottompart and a tooth bar rack are fixed at a rotating disk at the lower part; the inner side of the rotating disk is provided with gear teeth with inclination angles, the outside of a fixed disk is provided with uniformly distributed gear teeth, and the rotating disk is connected to the fixed disk in engagement connection through gear teeth. The clamp has simple operation, can realize multi-freedom motion of the workpiece, and ensures good contact between a pressure head and a workpiece to be measured in the working process of the nanoindenter with accurate and reliable experiment results.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

High-strength steel plate having excellent formability, and production method for same

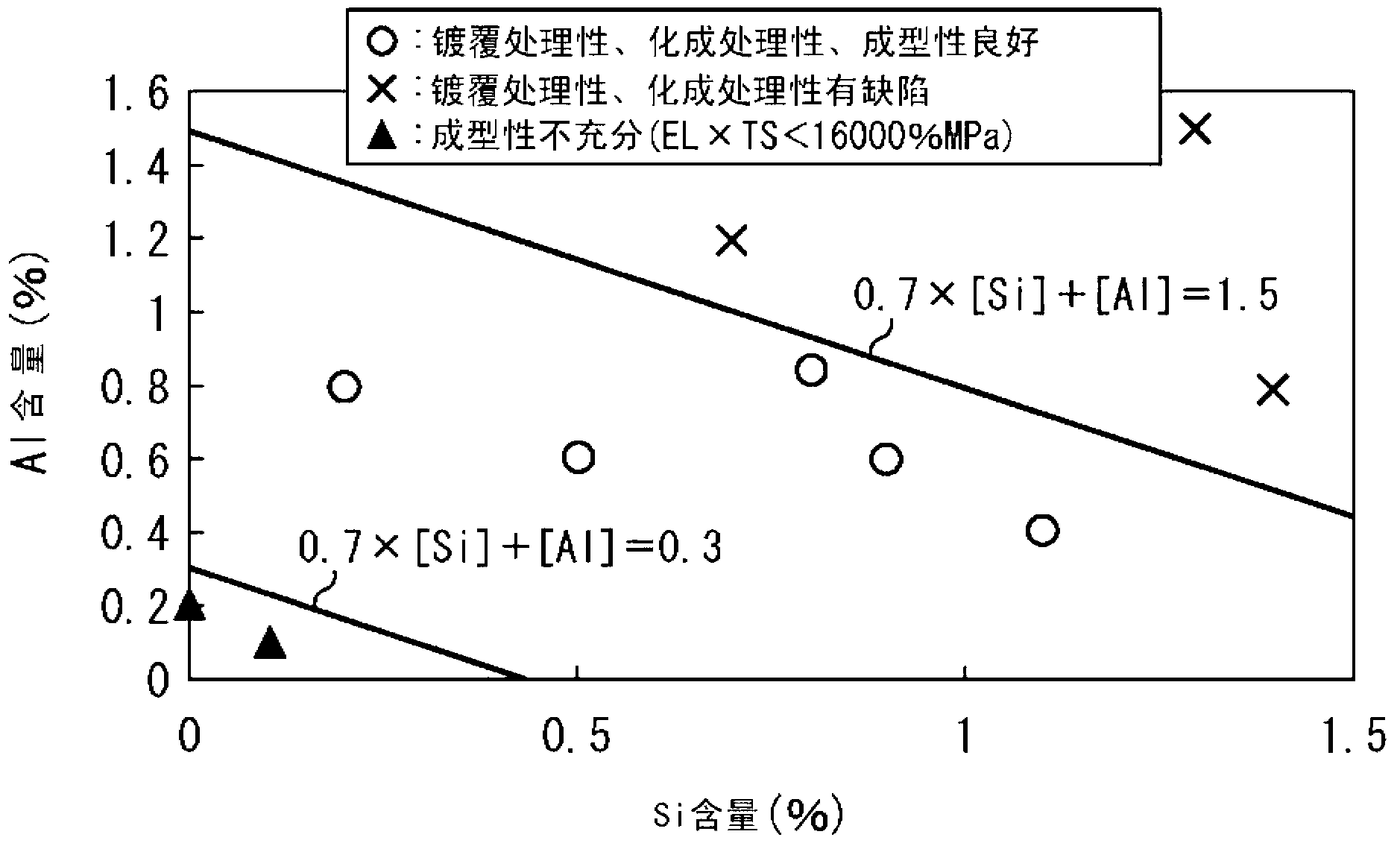

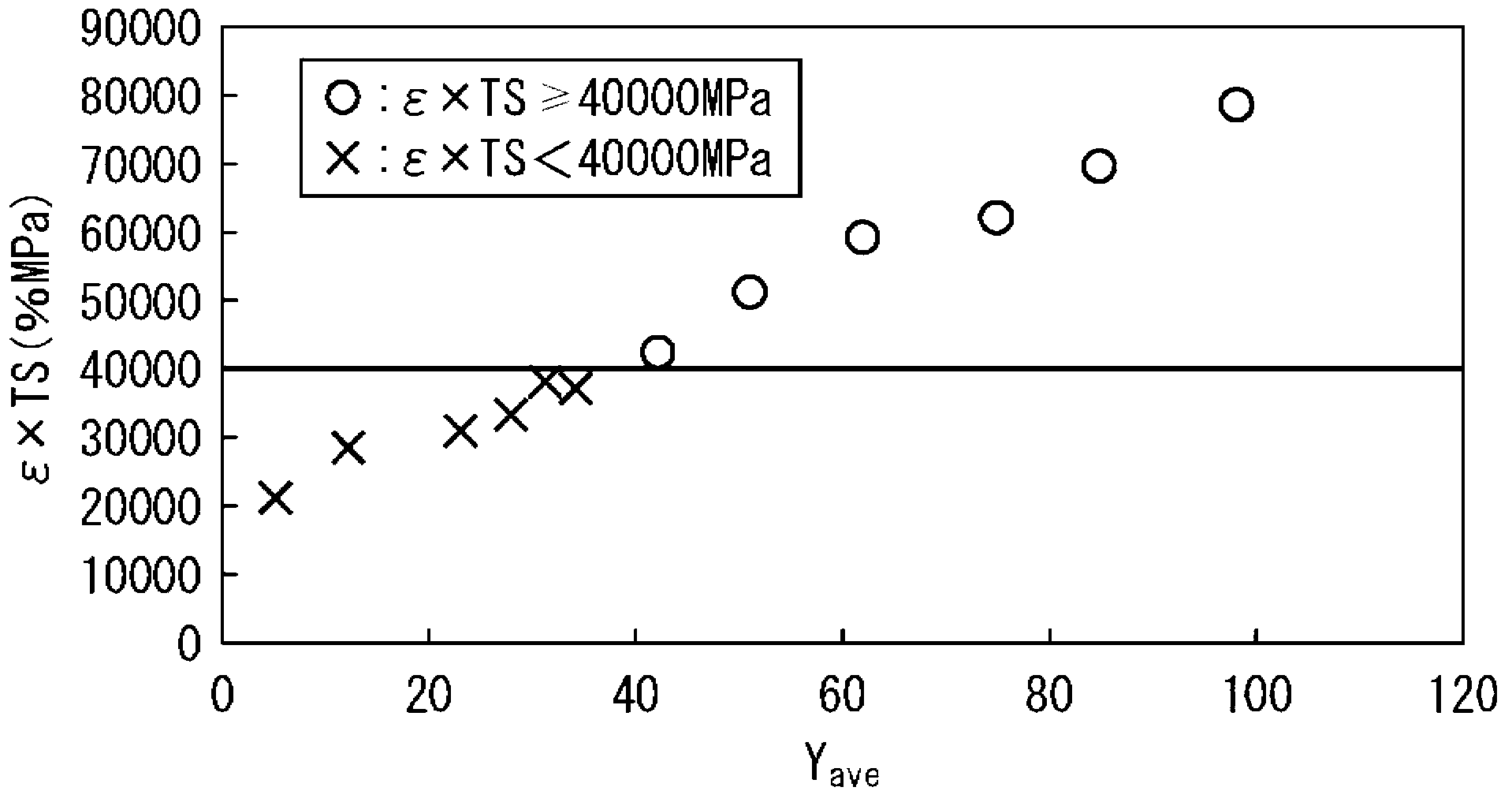

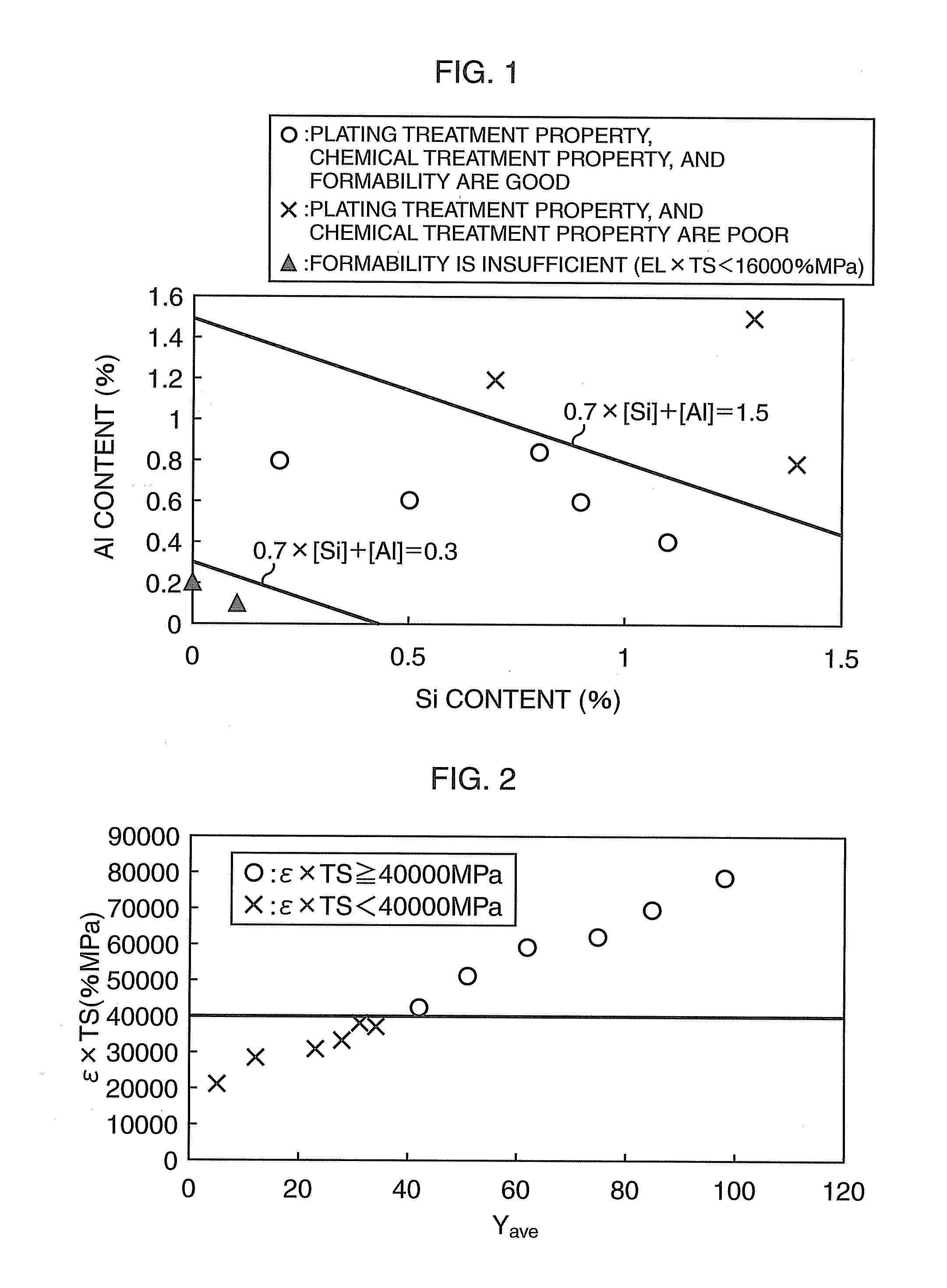

Disclosed is a high-strength steel plate wherein the Al content (%) and the Si content (%) conform to the relationship delimited by formula (A), and the average value Yave as defined by formula (B), which relates to the hardness as measured at 100 or more locations by means of a nanoindenter is 40 or higher. Formula (A): 0.3 = <0.7 * [Si] + [Al] =< 1.5 Formula (B): Yave = Sigma(180 * (Xi - 3)-2 / n) (Therein, [Al] represents the Al content (%), [Si] represents the Si content (%), n represents the total number of hardness measurement locations, and Xi represents the hardness (GPa) at the i-th measurement location (with i being an integer not greater than n))

Owner:NIPPON STEEL CORP

Porous material constitutive relation solving method based on nanoindentation theory

ActiveCN111855458ASimple methodGood precisionInvestigating material hardnessComplex mathematical operationsEngineeringElectronic packaging

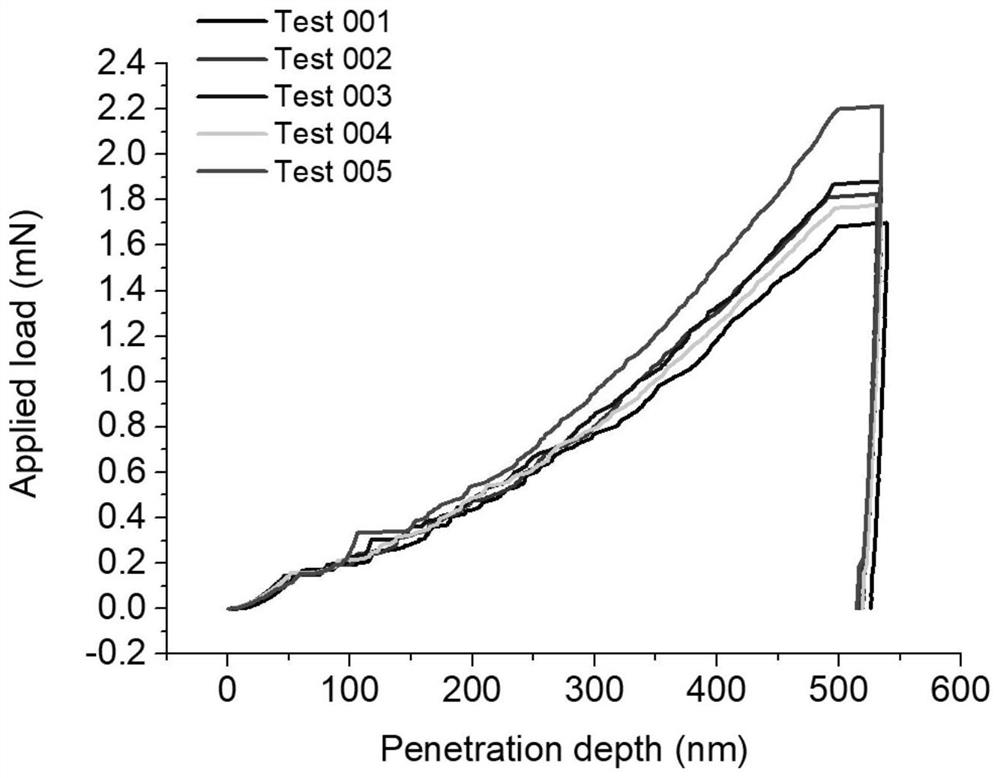

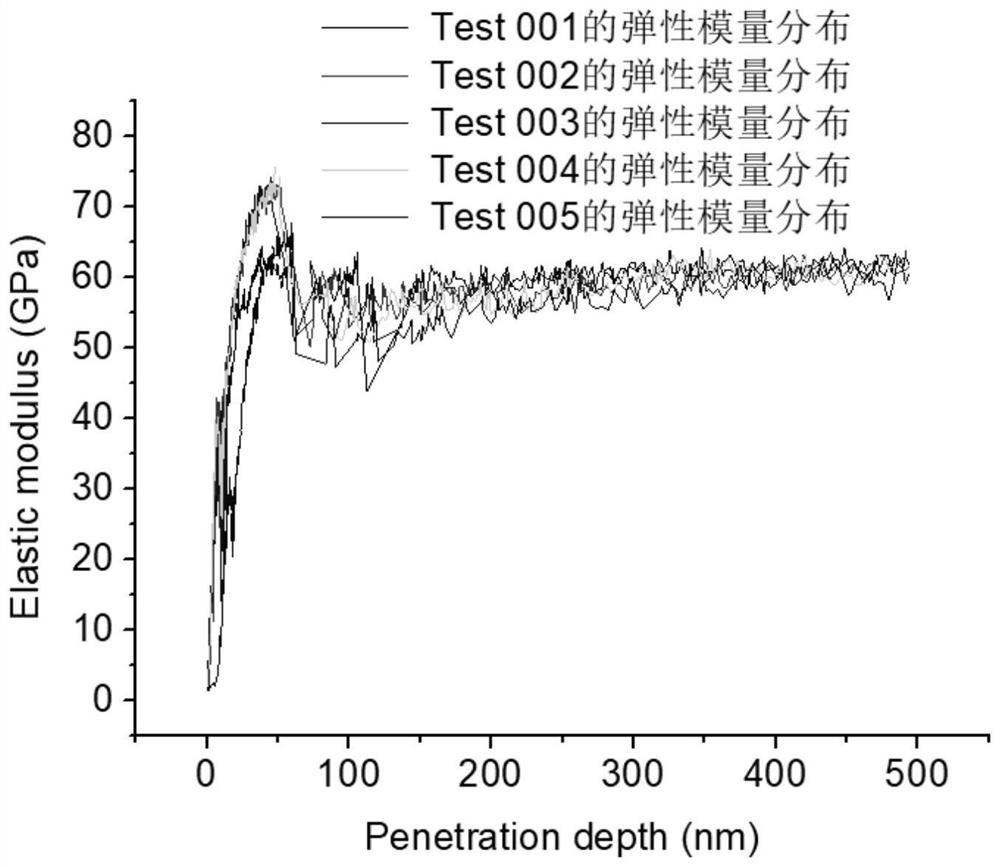

The invention relates to the technical field of electronic packaging nanometer mechanical property testing, particularly to a porous material constitutive relation solving method based on a nanoindentation theory. According to the specific technical scheme, the method comprises the steps: carrying out indentation on a porous material matrix multiple times by using a nanoindenter to obtain a plurality of displacement-load curves, removing the curve with large error, carrying out average curve fitting on the rest curves to obtain an average curve, and taking the average elastic modulus of the average curve as an experimental elastic modulus E; then determining a characteristic stress sigma r, and determining a hardening index n according to a dimensionless function; determining characteristic strain epsilon r and yield stress sigma y; and finally obtaining a constitutive curve according to the hardening index n, the yield stress sigma y and the elastic modulus E. According to the method,the problems that in the prior art, material attributes and stress-strain curves are not in one-to-one correspondence, the number of iterations is large in the simulation process, and the consumed time is long are solved.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

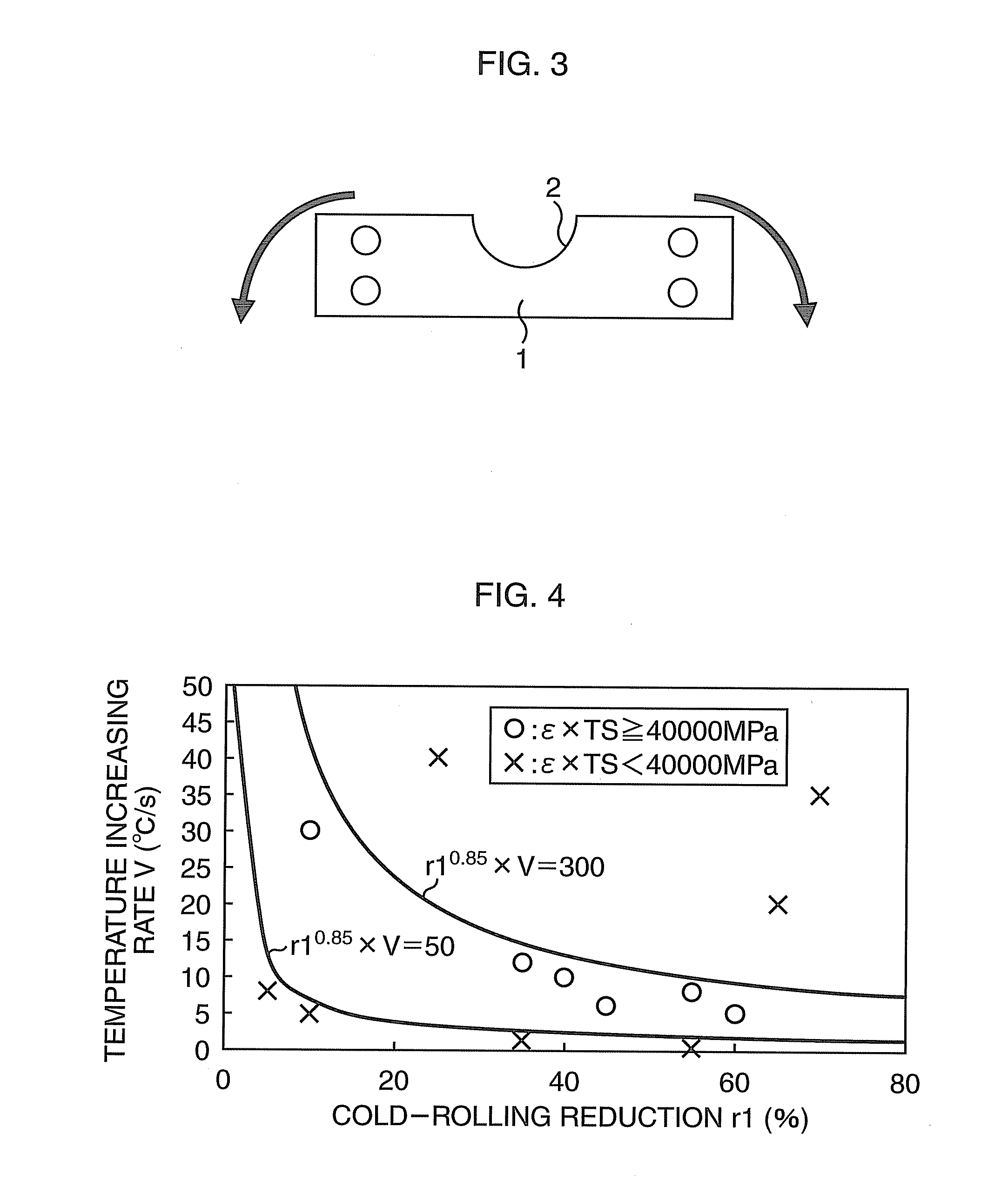

High tensile steel sheet superior in formability and method of manufacturing the same

InactiveUS20120328901A1Appropriate hardness distributionHot-dipping/immersion processesWork treatment devicesSheet steelHigh intensity

With regard to an Al content (%) and a Si content (%), a relation of a formula (A) is established, and an average value Yave defined by a formula (B) regarding hardnesses measured at 100 points or more with a nanoindenter is equal to or more than 40.0.3≦0.7×[Si]+[Al]≦1.5 (A)Yave=Σ(180×(Xi−3)−2 / n) (B)([Al] indicates the Al content (%), [Si] indicates the Si content (%), n indicates a total number of the measuring points of the hardnesses, and Xi indicates the hardness (GPa) at the i-th measuring point (i is a natural number equal to or less than n).

Owner:NIPPON STEEL CORP

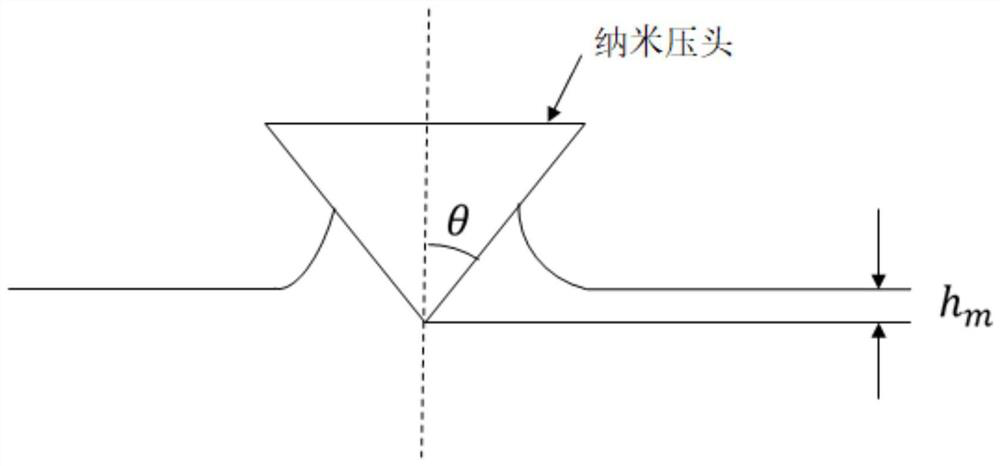

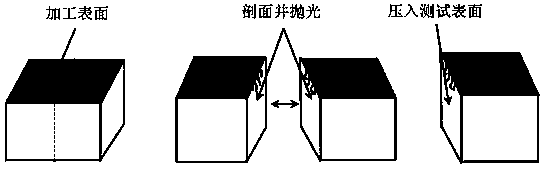

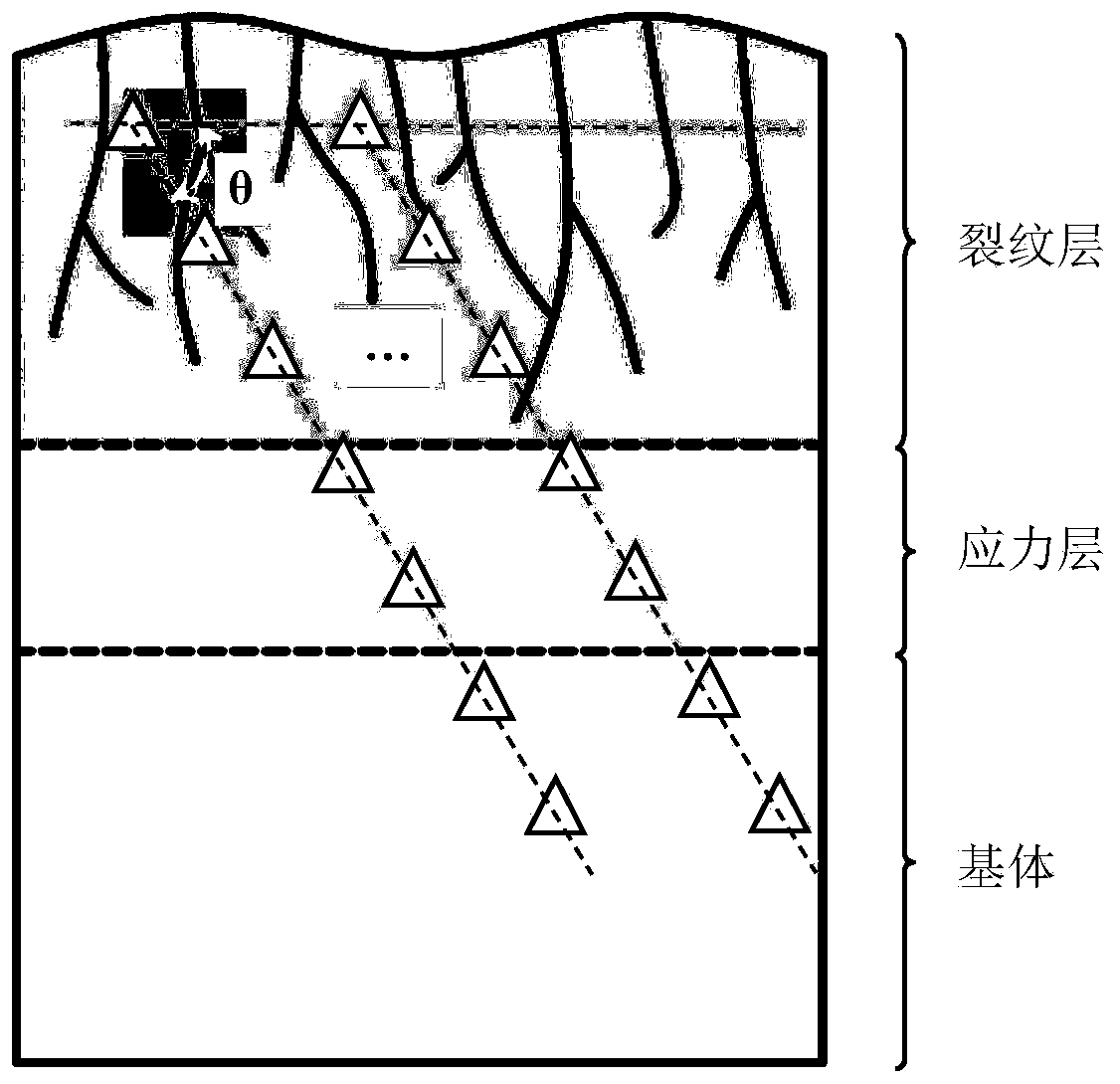

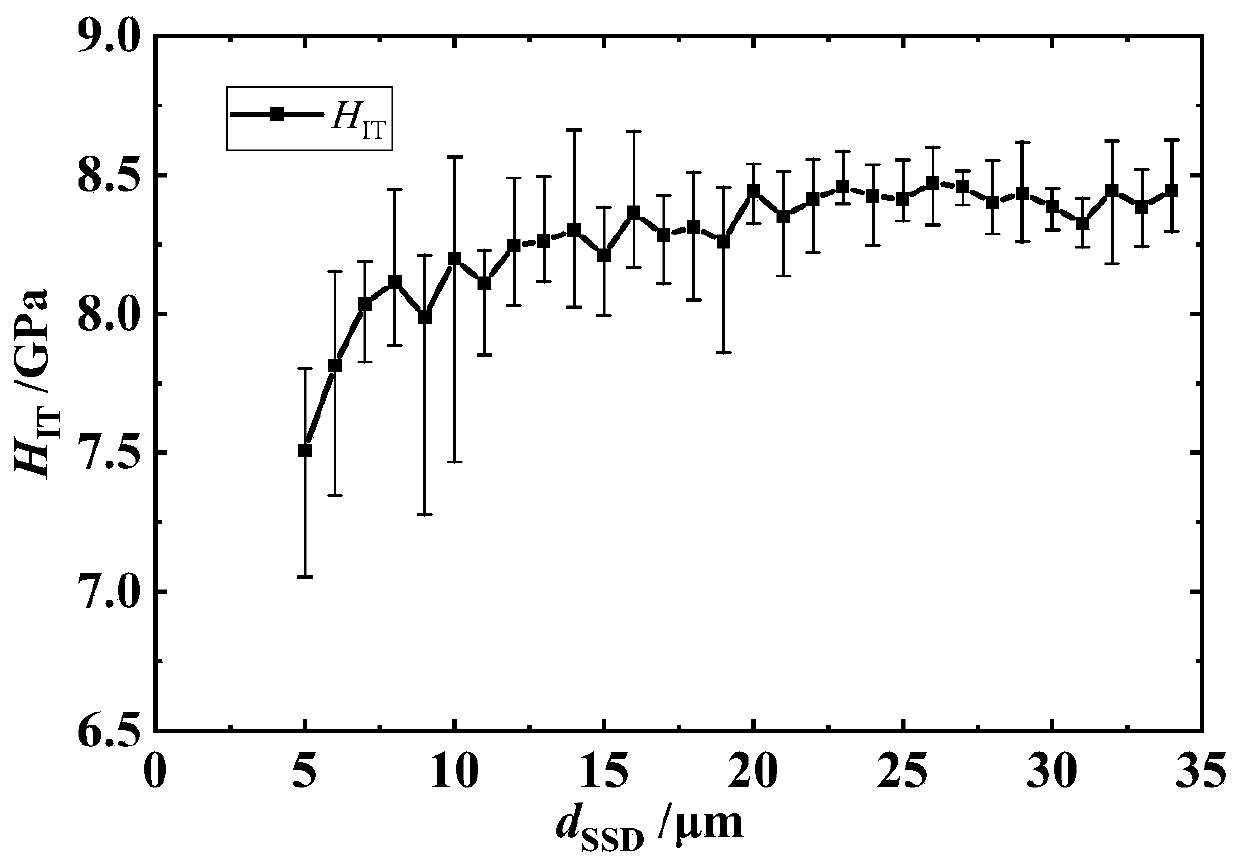

Mechanical characterization method for subsurface damage of optical glass

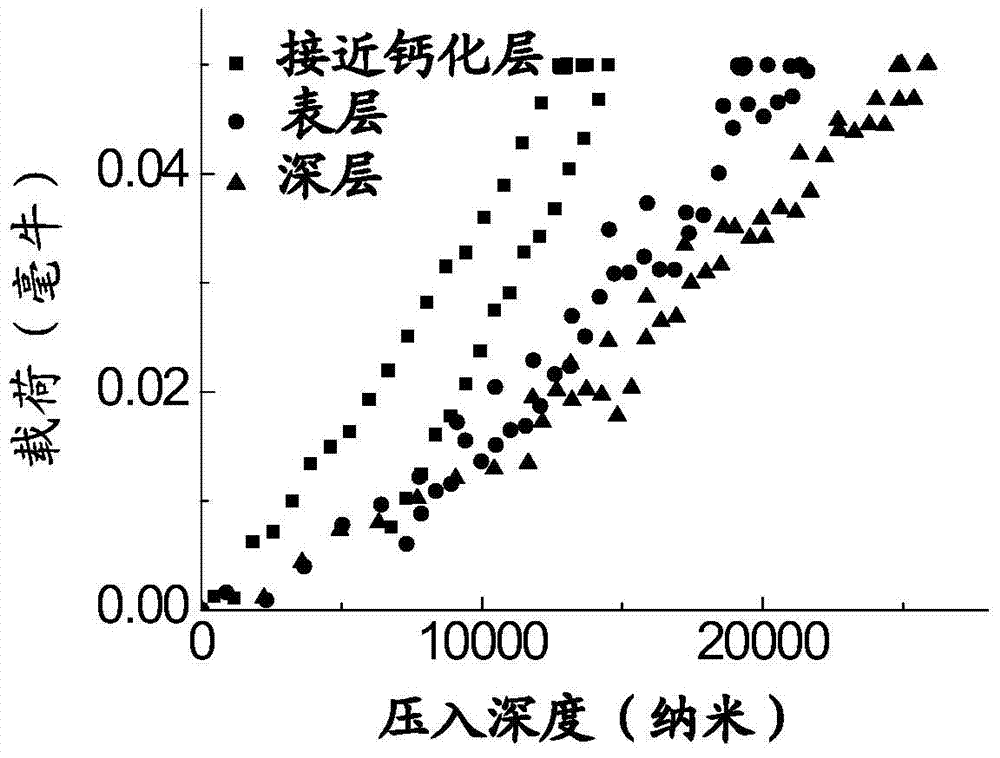

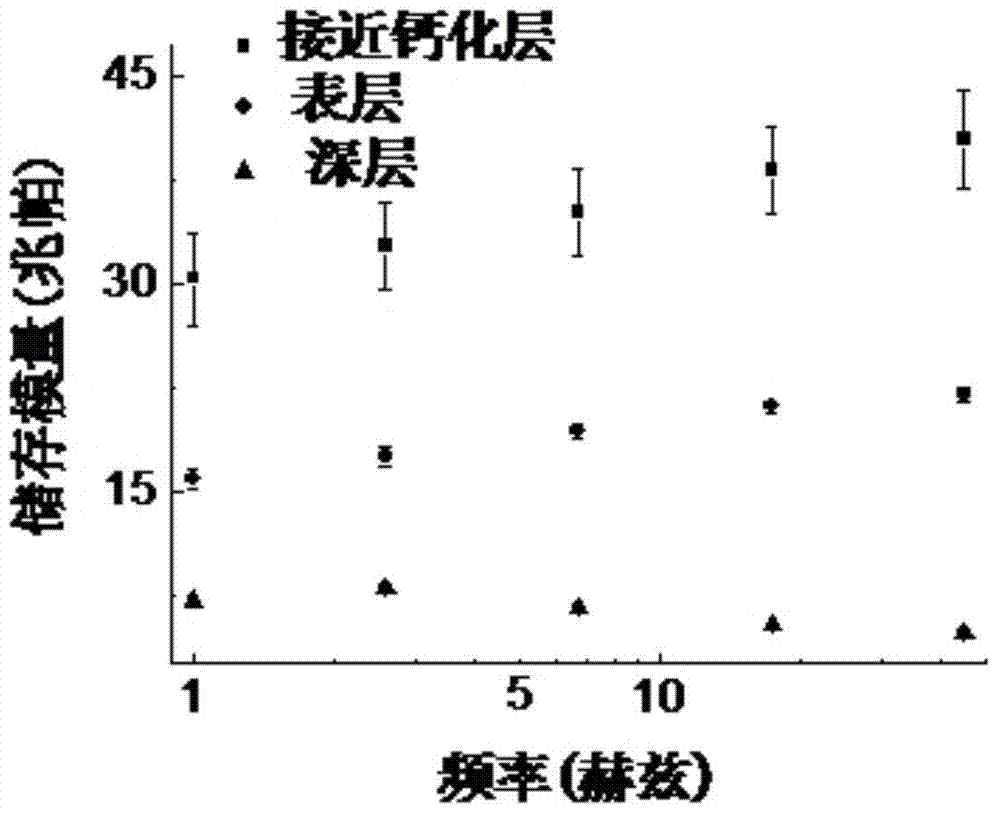

InactiveCN111024534AImprove measurement efficiencyImprove engineering applicabilityInvestigating material hardnessHardnessDepth direction

The invention discloses a mechanical characterization method for subsurface damage of optical glass, which comprises the following steps: cutting an optical glass sample to obtain a section vertical to the surface, and polishing the section; performing etching treatment on the polished sample, performing ultrasonic cleaning, and drying the sample; carrying out a nano-indentation test on the driedsample section, measuring the indentation hardness and indentation elastic modulus of the section along the depth direction, and recording the depth information of each test point, wherein the included angle between the indentation direction and the surface is theta; and finally, determining the subsurface damage depth of the sample by analyzing a gradient change curve of mechanical indexes (hardness and elasticity modulus) measured in the section along the depth direction. According to the mechanical characterization method for sub-surface damage of optical glass provided by the invention, gradient change of mechanical parameters in a damaged layer is tested by using a nanoindenter, and geometric indexes and mechanical indexes of the subsurface damage can be obtained by one-time testing.

Owner:ZHEJIANG NORMAL UNIVERSITY

Thermal Bonding Sheet and Thermal Bonding Sheet with Dicing Tape

ActiveUS20180269175A1Non-macromolecular adhesive additivesSemiconductor/solid-state device detailsDicing tapeHardness

A thermal bonding sheet includes a layer, in which hardness of the layer after being heated at a heating rate of 1.5° C. / sec from 80° C. to 300° C. under pressure of 10 MPa, and then held at 300° C. for 2.5 minutes is in a range of 1.5 GPa to 10 GPa in measurement using a nanoindenter.

Owner:NITTO DENKO CORP

Apparatus to measure mechanical properties of electrodes during electrochemical reactions and method of using the same

ActiveUS20190204194A1NanotechnologyInvestigating material hardnessElectrochemical responseEngineering

Methods and apparatuses for measuring mechanical properties of electrodes during electrochemical reactions. Such an apparatus includes a fixture having a fluid reservoir that is open to a surrounding atmosphere, first and second electrodes located within the fluid reservoir, and a contact for coupling with a sample material located in the fluid reservoir to define a third electrode. The apparatus further includes a nanoindenter configured for applying a load to a surface of the sample material to form an indentation therein and measuring the load and the size of the indentation over time, a housing enclosing the fixture and the nanoindenter within an inert atmosphere, and a potentiostat configured to charge and discharge an electrochemical cell that is defined by the first, second, and third electrodes and an electrolyte solution in the fluid reservoir while the nanoindenter is applying the load.

Owner:PURDUE RES FOUND INC

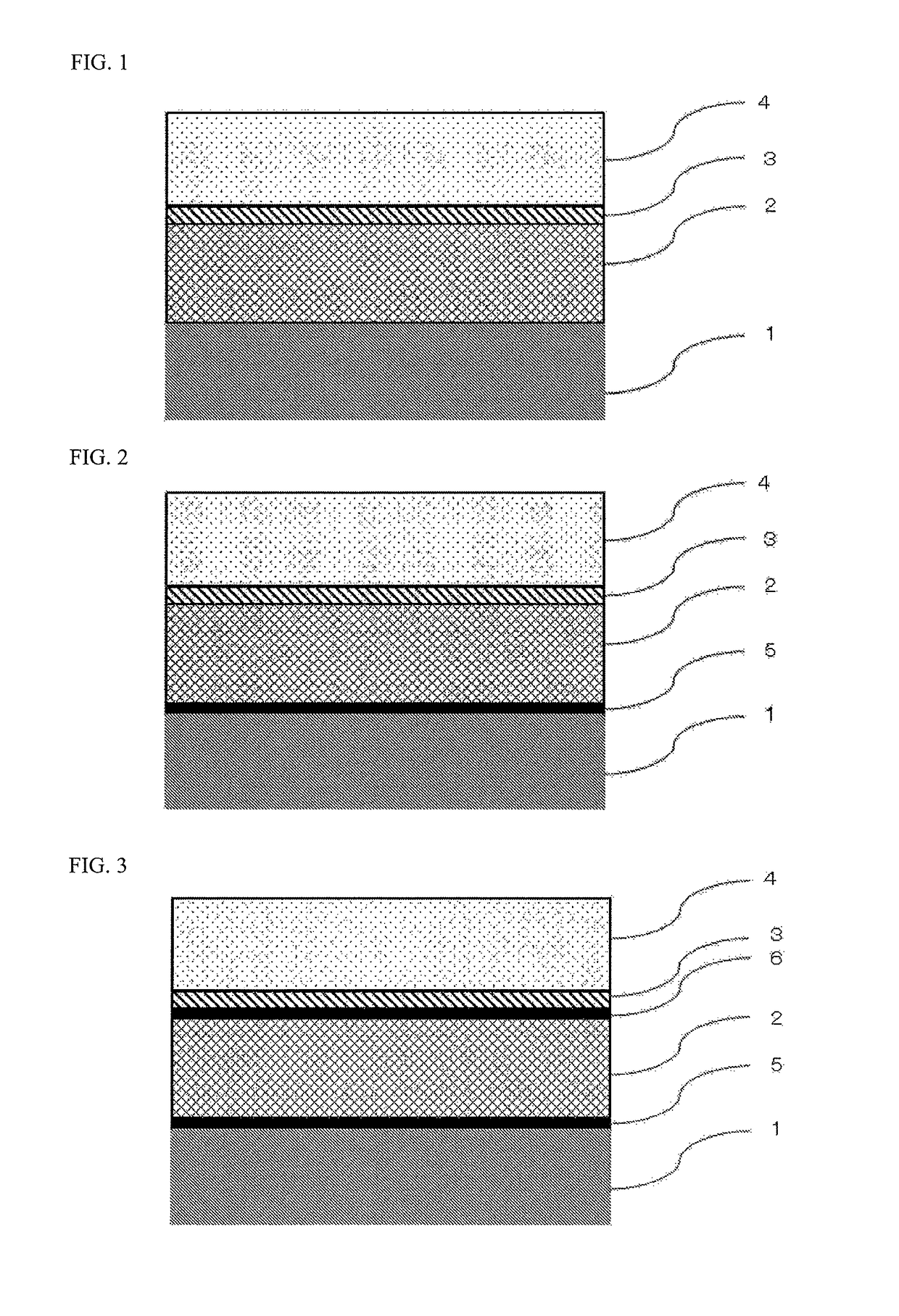

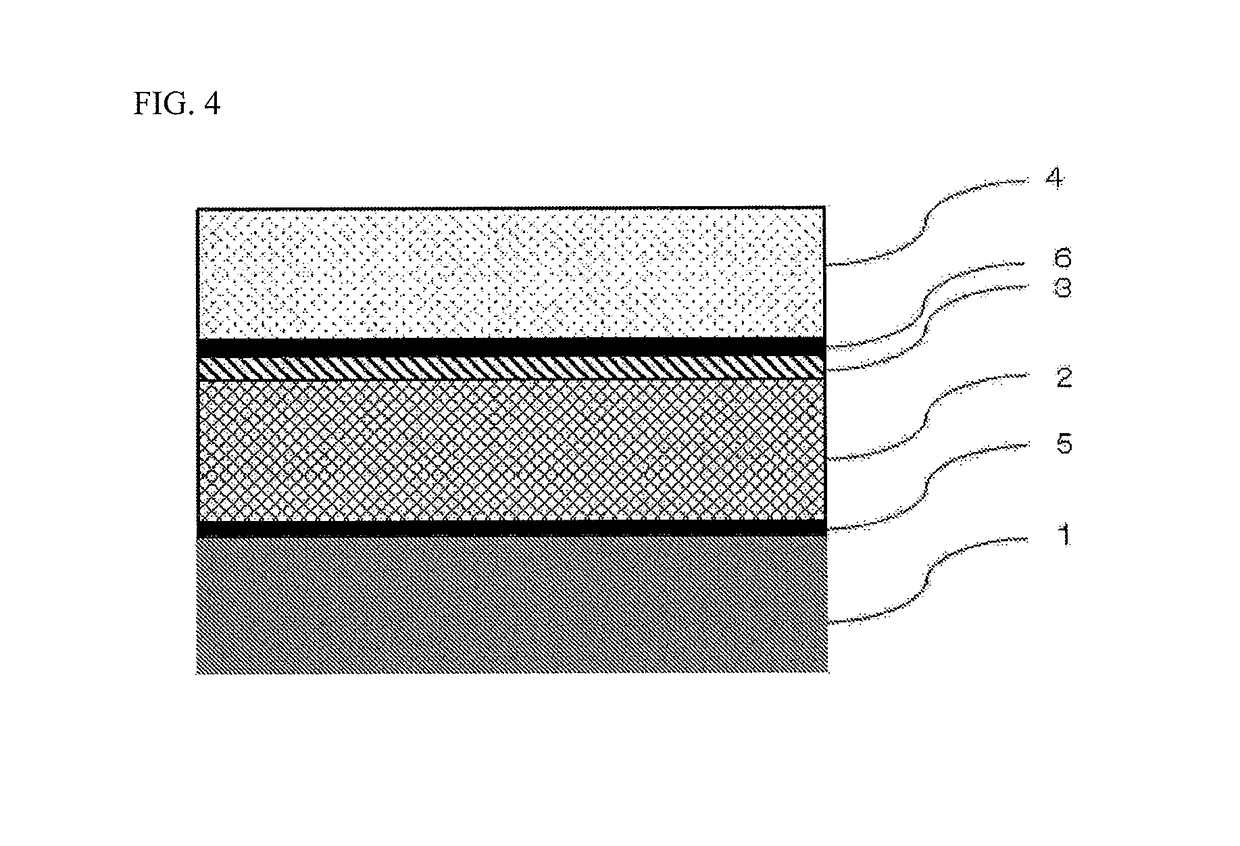

Power-cell packaging material

ActiveUS20190157633A1Improve insulation qualityFinal product manufactureSynthetic resin layered productsPower batteryPolymer science

A battery packaging material includes a laminate that includes at least a base material layer, a metal layer, an insulating layer, and a sealant layer laminated in this order. The insulating layer is formed of a resin composition containing a modified polyolefin resin modified with an unsaturated carboxylic acid or acid anhydride thereof and has a hardness, when measured by using a nanoindenter and pressing an indenter 5 μm into the insulating layer from a cross-section of the laminate in the laminating direction thereof, that ranges from 10 MPa to 300 MPa. In the sealant layer, an elastic modulus, when measured by using a nanoindenter and pressing an indenter 5 μm into the sealant layer from a cross-section of the laminate in the laminating direction thereof, ranges from 100 MPa to 1000 MPa.

Owner:DAI NIPPON PRINTING CO LTD

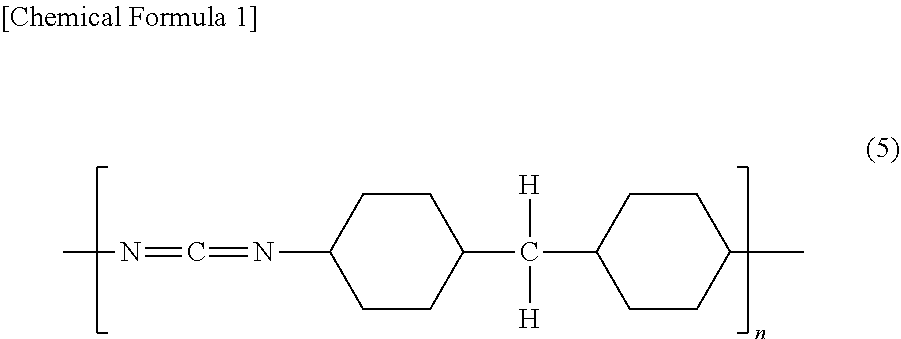

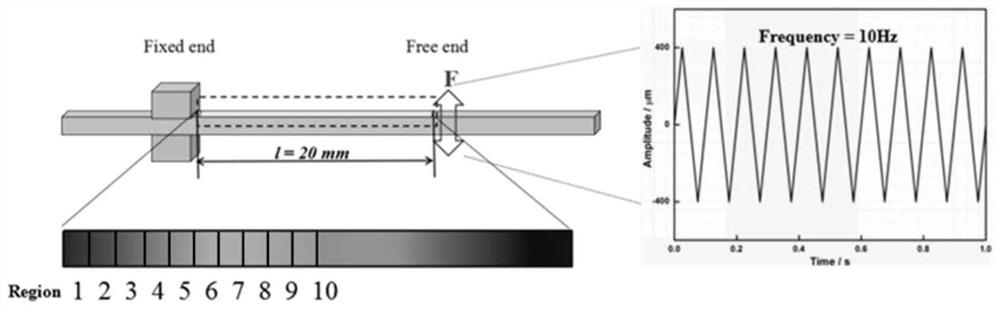

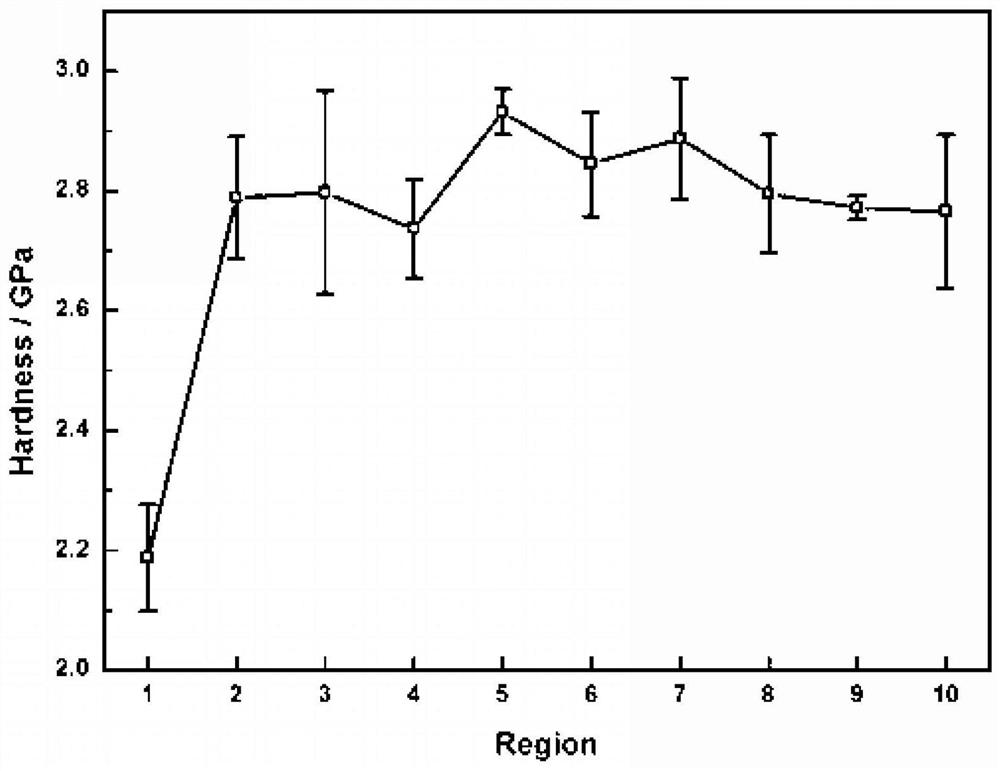

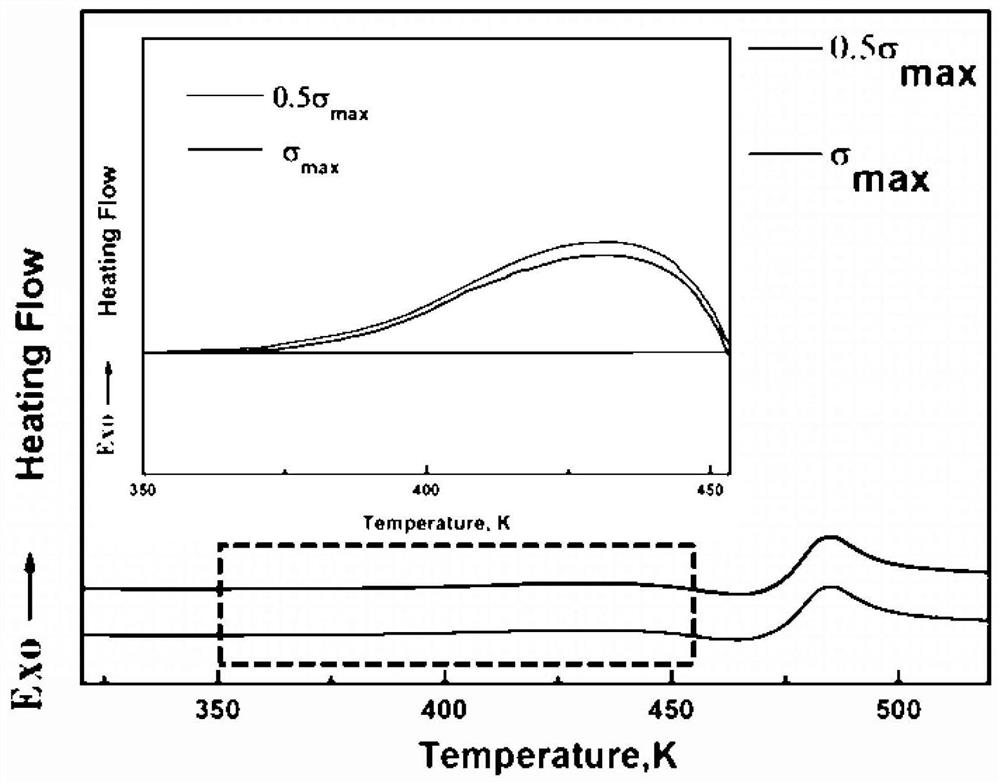

Method for driving amorphous alloy to achieve rejuvenation by applying cyclic loading mode

The invention discloses a method for driving amorphous alloy to achieve rejuvenation by applying a cyclic loading mode, and belongs to the field of amorphous alloy materials. The method comprises thefollowing steps that (1) a clean La-based amorphous alloy sample is selected; (2) single cantilever beam cyclic loading treatment is carried out on the sample, wherein the sample is placed on a Q800 DMA single cantilever beam clamp, 5N of torsion is applied to the fixed end of the clamp, the free end is ensured to enable the clamp to be tightly attached, a shell is closed, nitrogen protective gasis introduced, the vibration frequency is set to be 10 Hz, the temperature is set to be 30 DEG C, and the time is set to be 2 hours; and (3) surface hardness analysis is carried out on the amorphous alloy block sample subjected to cyclic loading through a nanoindenter, and after cyclic loading after a certain stress is achieved, the surface hardness is reduced by 20%. The loading mode also has a good rejuvenation effect on amorphous alloy with high brittleness, and a new idea and scheme are provided for further improving the plastic deformation capacity of the amorphous alloy.

Owner:XI AN JIAOTONG UNIV

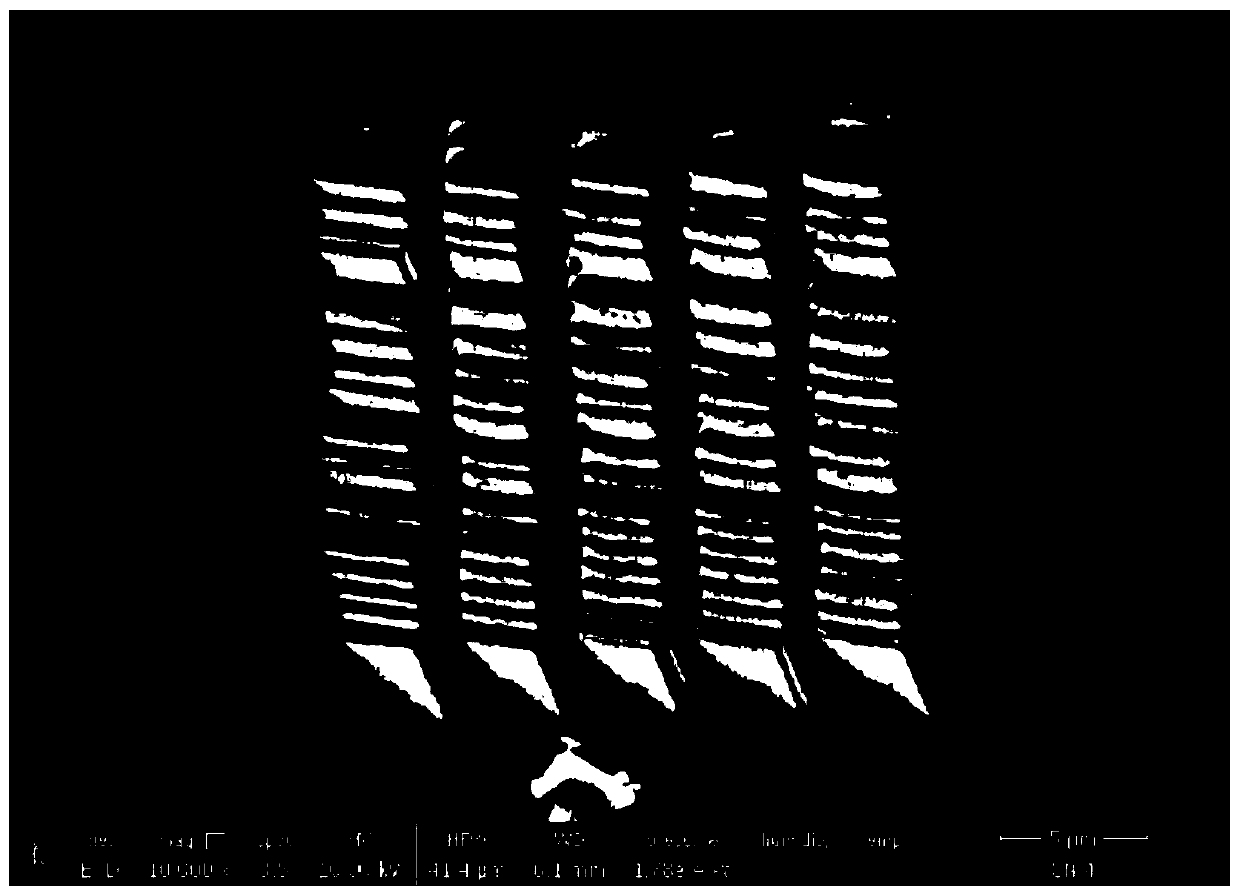

Composite SERS substrate and preparation method and application thereof

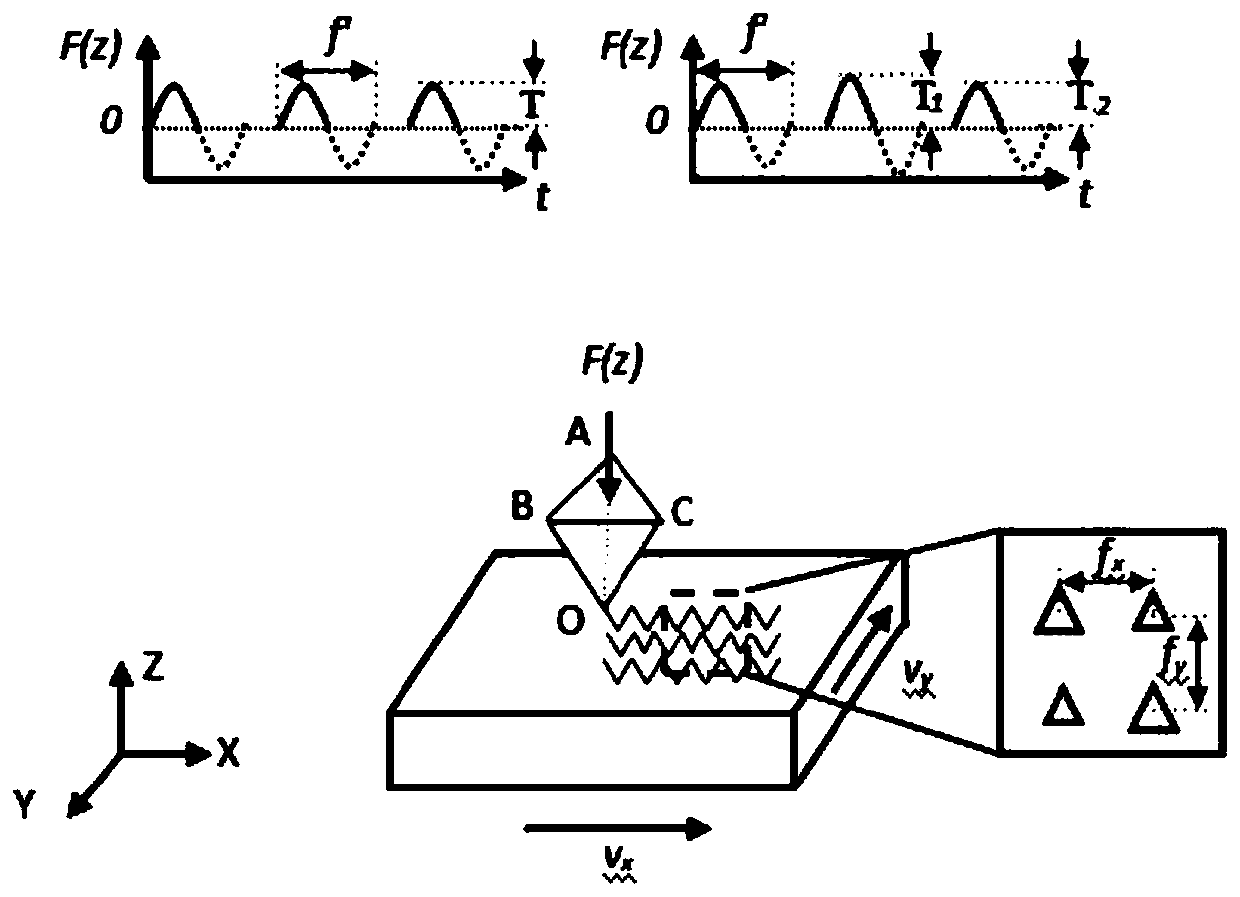

ActiveCN110697650AGood structural consistencyImprove detection accuracyDecorative surface effectsRaman scatteringNano structuringElectrical field strength

The invention provides a composite SERS substrate and a preparation method and application thereof, and belongs to the technical field of micro-nano structure processing. The preparation method of thecomposite SERS substrate provided by the invention comprises the following steps: preparing a micro-nano structure on the surface layer of a two-dimensional material by adopting a nanoindenter to obtain the composite SERS substrate; the two-dimensional material comprises a metal bottom layer and a graphene surface layer which are laminated. The micro-nano structure prepared by the nanoindenter isgood in structural consistency, and the equipment is convenient and simple to operate. The composite SERS substrate prepared by the preparation method provided by the invention can be used for detecting chemical pesticide molecules; the micro-nano structure has an enhanced effect on the electric field intensity, and meanwhile, the graphene has an enhanced effect on chemical adsorption, so that the composite SERS substrate has high detection accuracy, high sensitivity and low detection limit on chemical pesticide molecules, and the preparation method is simple to operate and suitable for large-scale production.

Owner:CHANGCHUN UNIV OF SCI & TECH

Articular cartilage microstructure nanoindentation inlaying and water-retaining sample stage and experiment method

InactiveCN103575591AShow microstructureReliable mechanical propertiesPreparing sample for investigationMaterial strength using tensile/compressive forcesMedicineSacroiliac joint

The invention relates to an articular cartilage microstructure nanoindentation inlaying and water-retaining sample stage and an experiment method. The sample stage is composed of a stage body, a containing groove, sleeve, an articular cartilage and a resin. The articular cartilage microstructure nanoindentation inlaying and water-retaining sample stage can solve the problems that the surface of a cartilage sample is difficult to treat and the surface of the cartilage is dehydrolyzed when an inlaying method is adopted, so that the whole tested sample does not have any micro disturbance in the surface treatment and test processes. The sample stage treats the surface of the cartilage in a grinding and polishing manner, and can effectively show the microstructure of the surface of the cartilage; and the sample can not cause disturbance in the grinding and polishing process and the test process. All the existing nanoindenters in China basically depend on import, and water-retaining assemblies thereof are high in cost. The experiment method lowers the experiment cost, and the credibility is higher than that of an assembly configured on the nanoindenter.

Owner:BEIJING UNIV OF TECH

Power-cell packaging material

ActiveUS10236479B2Improve insulation qualityFinal product manufactureSynthetic resin layered productsElectrical batteryHardness

A power-cell packaging material including a layered body obtained by layering at least a substrate layer, a metal layer, an insulating layer, and a sealant layer, in this order. The insulating layer has a hardness in the range of 10-300 MPa, when measured by using a nanoindenter and pressing the indenter 5 μm into the insulating layer from a cross-section of the layered body in the layering direction thereof.

Owner:DAI NIPPON PRINTING CO LTD

Sliding member

Owner:DAIDO METAL CO LTD

Image forming apparatus and image forming method

An image forming apparatus including developing unit to develop electrostatic latent image with toner to form visible image, and cleaning unit including elastic member including surface layer and configured to remove the toner, wherein Martens hardness A and Martens hardness B of the surface layer measured by applying load of 1 μN and load of 1,000 μN, respectively, to position of the surface layer in thickness direction thereof using nanoindenter are both 2.5 N / mm2 or greater but 32.5 N / mm2 or less, and Martens hardness A and Martens hardness B satisfy inequality,Martens hardness A>Martens hardness Bwherein coefficient of dynamic friction of the surface layer against polycarbonate is 0.5 or less, and the toner includes polyester resin insoluble to THF and Tg of THF-insoluble component of the toner determined from DSC curve of first heating of DSC is −60° C. or higher but 20° C. or lower.

Owner:RICOH KK

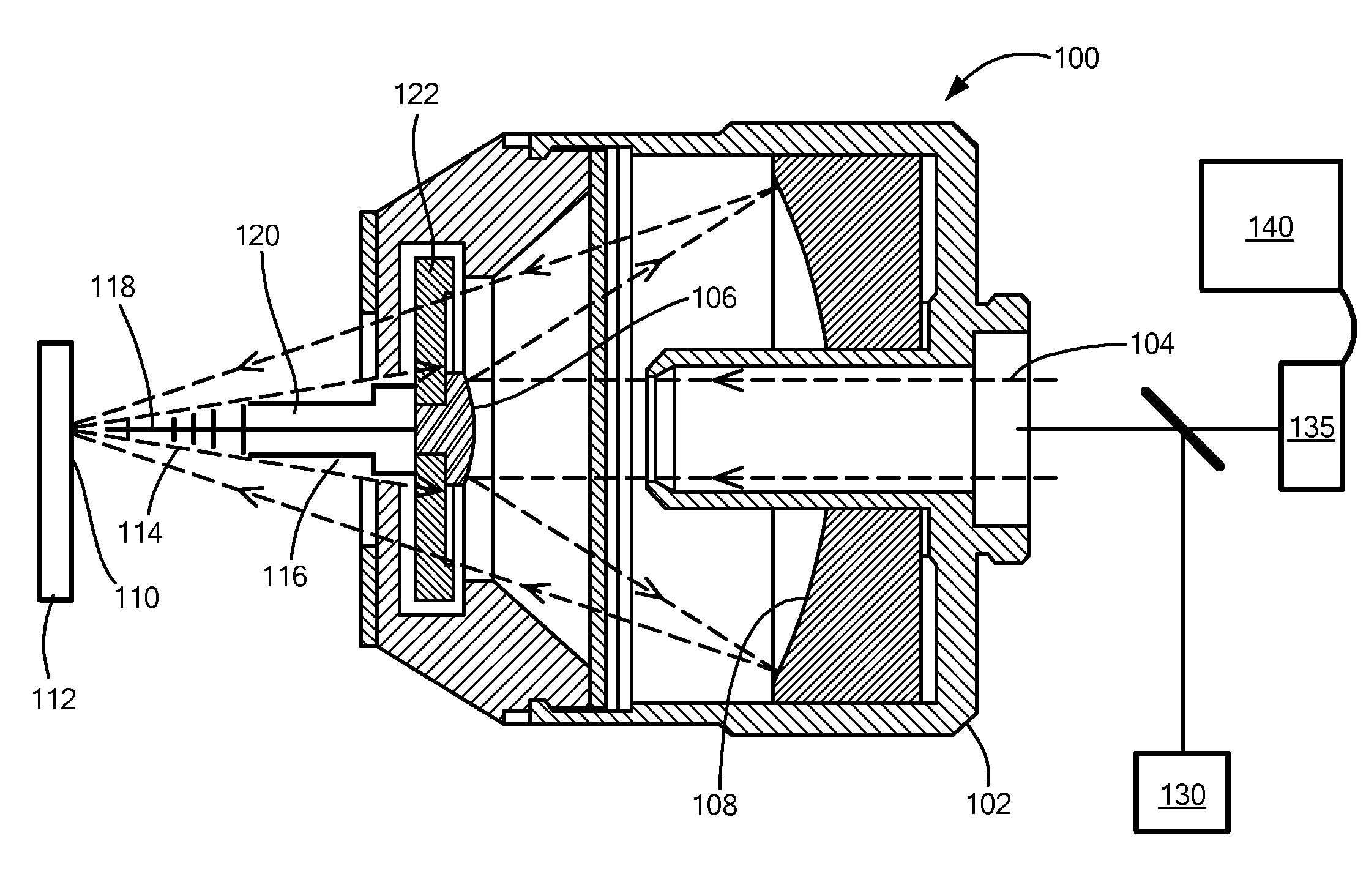

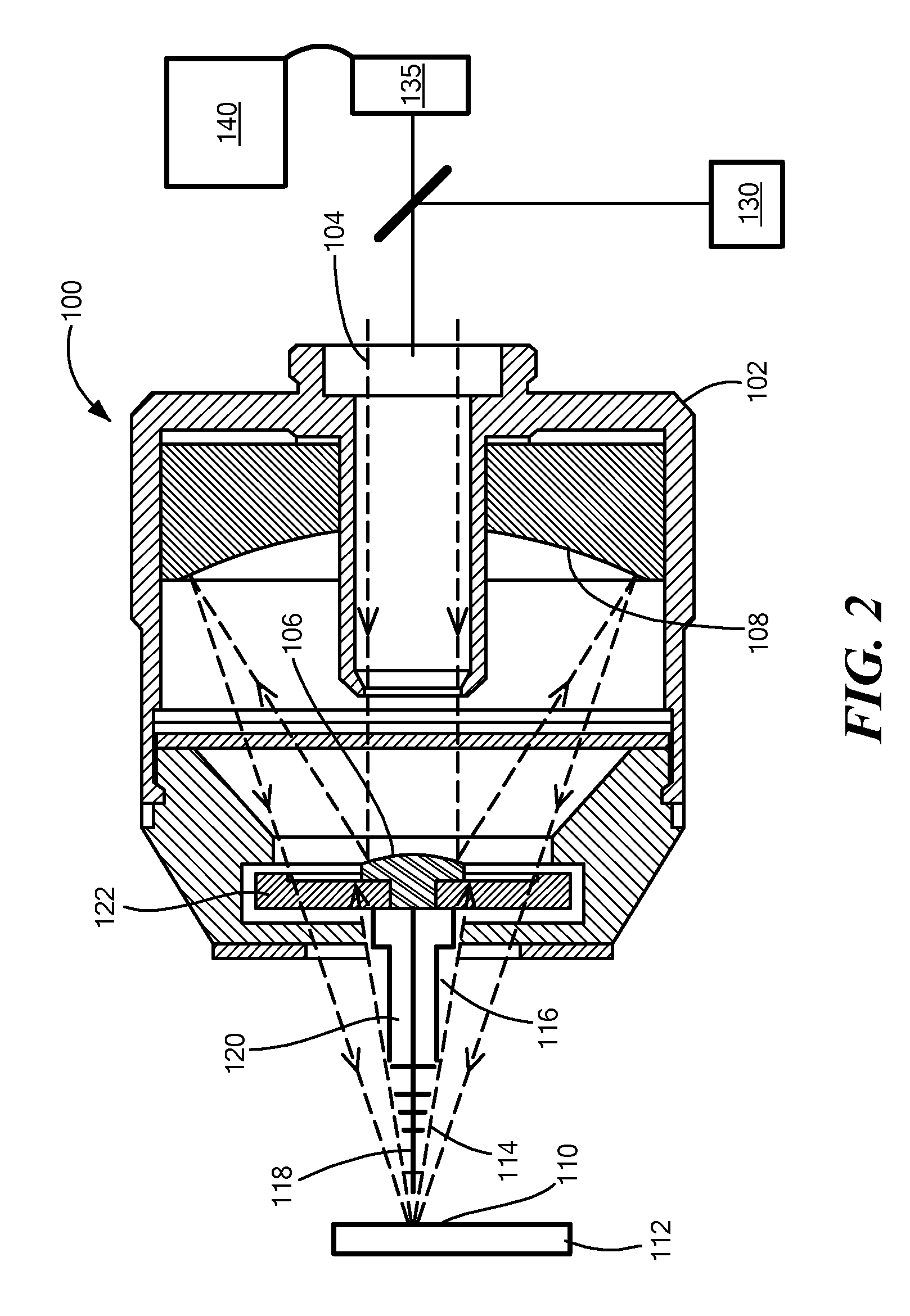

Nanoindenter Multimodal Microscope Objective for Mechanobiology

ActiveUS20150168239A1Force measurement by measuring optical property variationMicroscopesMechanobiologyOptical axis

Methods and apparatus for characterizing a sample in situ as to both its mechanical and optical characteristics. The apparatus comprises a reflective microscope with a concave primary mirror and a convex secondary mirror sharing a common optical axis, and an actuator vignetted by the convex secondary mirror for applying a force to a nanoprobe in a direction having a component along the common optical axis. The apparatus may addition include a source for generating an illuminating beam, a detector, and a processor for forming an image based on a signal provided by the detector.

Owner:THE BOARD OF TRUSTEES OF THE UNIV OF ILLINOIS

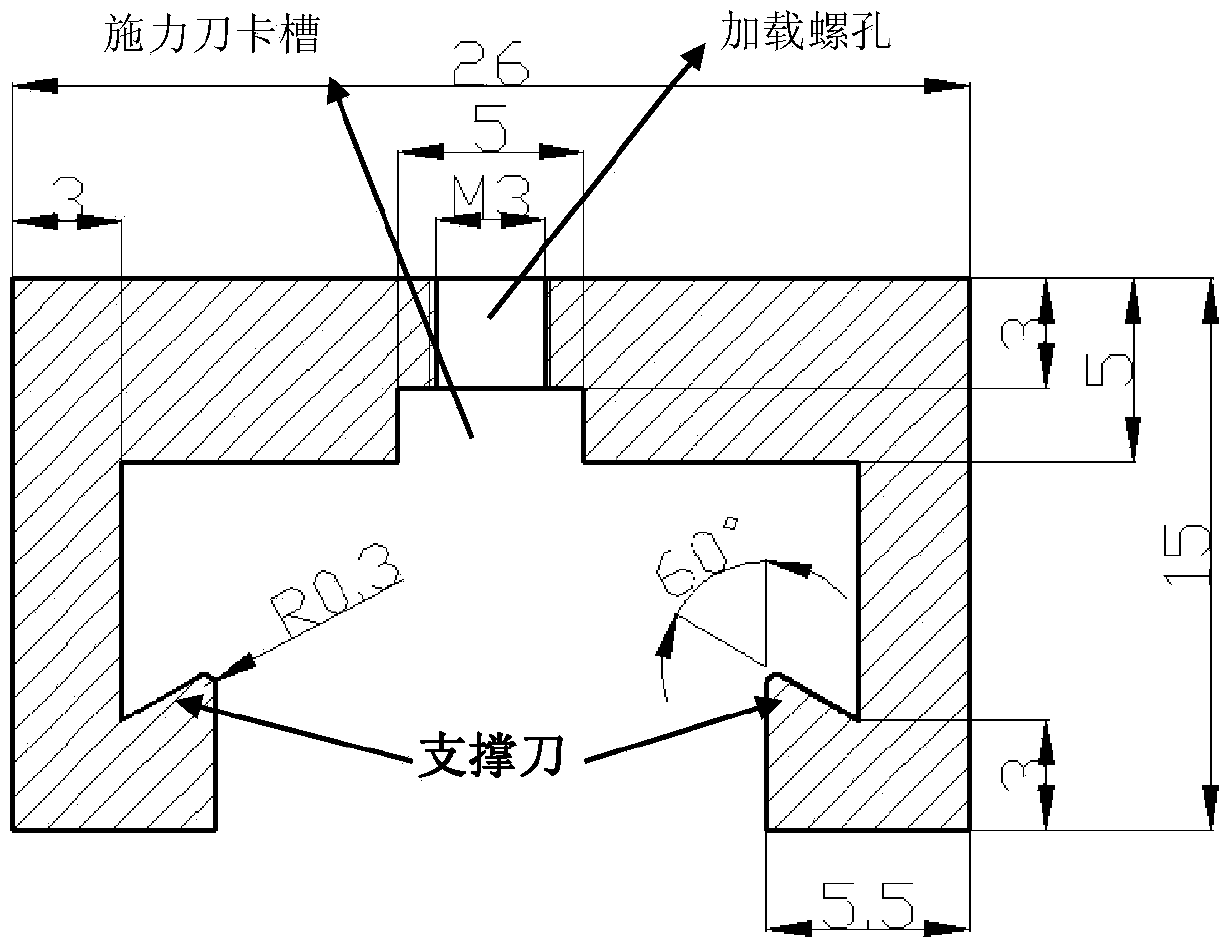

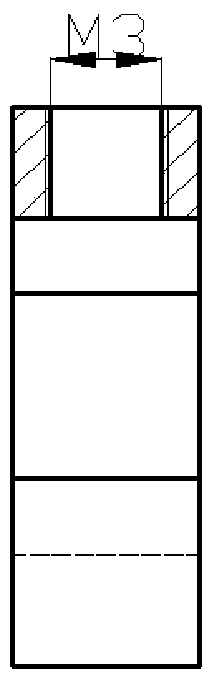

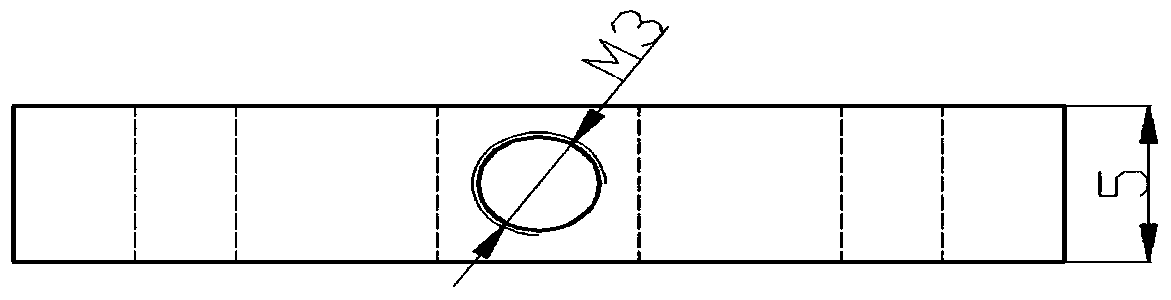

Loading method and device for measuring micromechanical property of material under action of stress

InactiveCN103698214ALoad method is simpleEasy loadingMaterial strength using tensile/compressive forcesPositive pressureEngineering

The invention provides a loading method and device for measuring micromechanical property of a material under the action of stress. The loading device comprises a main loading device body, a force application cutter and a bolt, wherein the main loading device body is provided with a loading screw hole, a force application cutter clamp groove is formed below the loading screw hole, and two side frames consist of support cutters to serve as a support platform; the force application cutter adopts a sharp wedge shape, and a cutter head in the sharp wedge shape is a round angle; and a thread on the bolt is matched with the loading screw hole of the main loading device body, and a straight groove is formed in the top of a nut, so that the nut is screwed into the loading screw hole and applies positive pressure on the force application cutter. According to the loading device and method, a NanoIndenter (MTS, USA) can be applied conveniently, easily and directly without transformation or processing, so that the loading method is further simplified, and a theoretical calculating value and a true value of the material stress coincide better.

Owner:UNIV OF SCI & TECH BEIJING

Hot-stamped steel, cold-rolled steel sheet and method for producing hot-stamped steel

ActiveUS10544475B2Excellent hole expandabilityChemical conversion treatment propertyHot-dipping/immersion processesFurnace typesChemical compositionHardness

A hot-stamped steel according to the present invention has a predetermined chemical composition, satisfies (5×[Si]+[Mn]) / [C]>10 when [C] is the amount of C by mass %, [Si] is the amount of Si by mass %, and [Mn] is the amount of Mn by mass %, includes 40% to 95% ferrite and 5% to 60% martensite in area fraction, and optionally further includes 10% or less pearlite in area fraction, 5% or less retained austenite in volume fraction, and less than 40% bainite in area fraction. The total of the area fraction of ferrite and the area fraction of martensite is 60% or more, the hardness of martensite measured with a nanoindenter satisfies H2 / H1<1.10 and σHM<20, and TS×λ which is product of tensile strength TS and hole expansion ratio λ is 50000 MPa·% or more.

Owner:NIPPON STEEL CORP

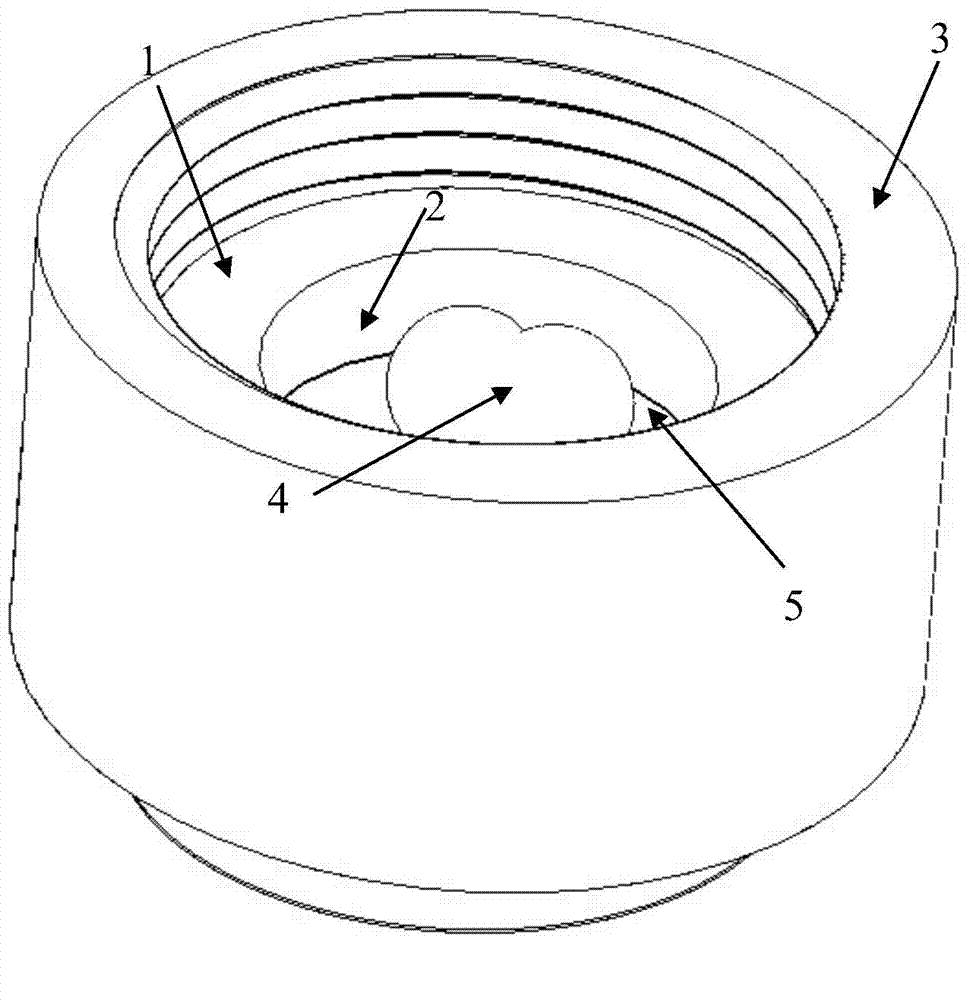

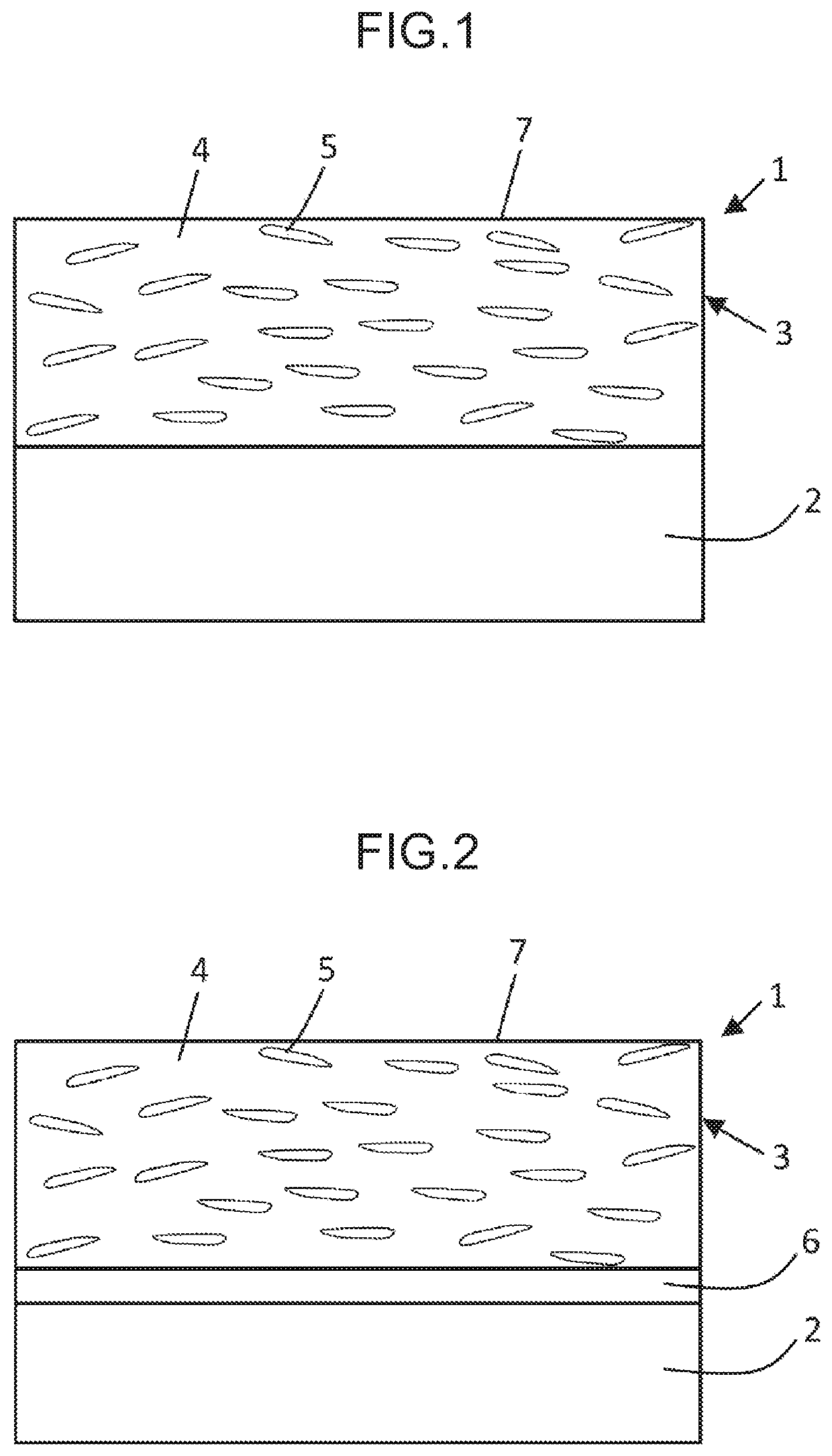

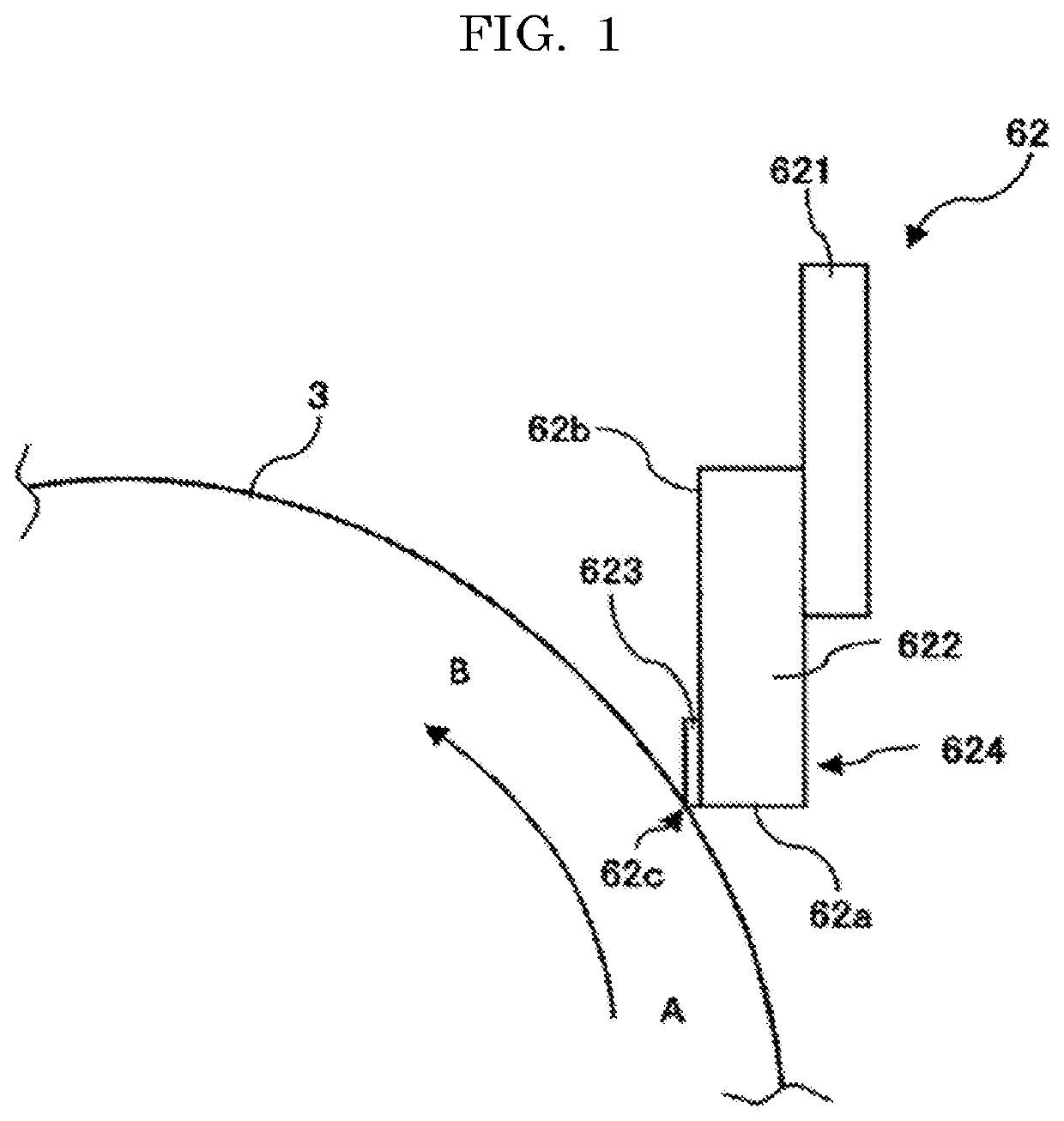

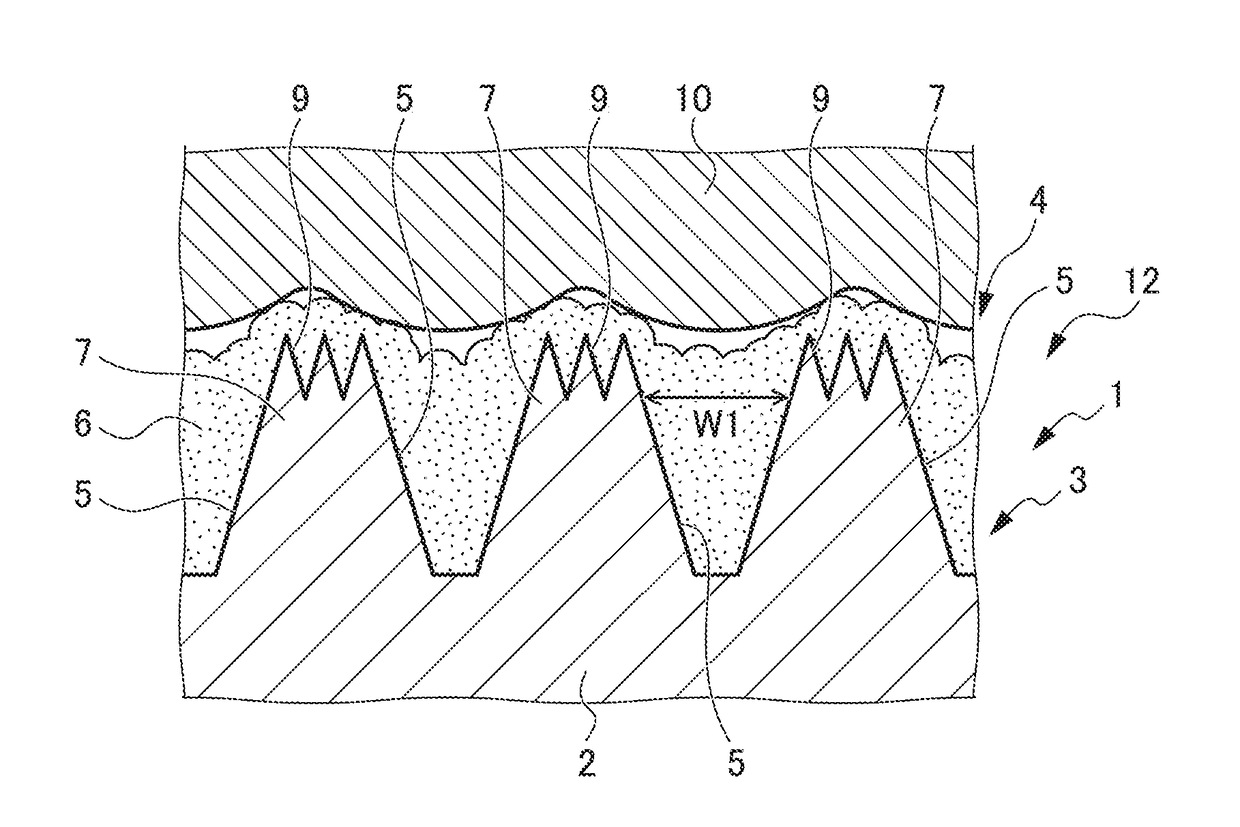

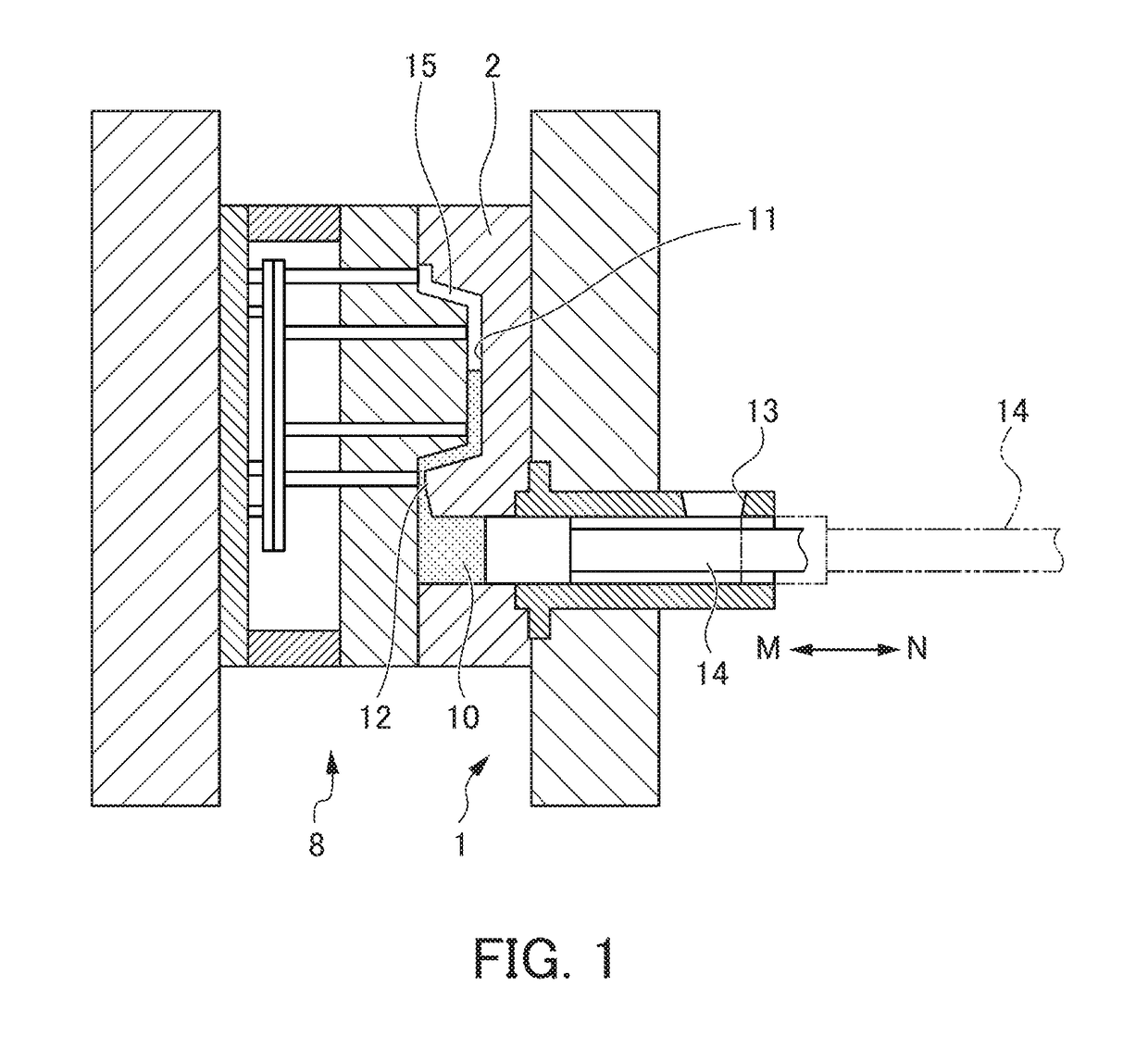

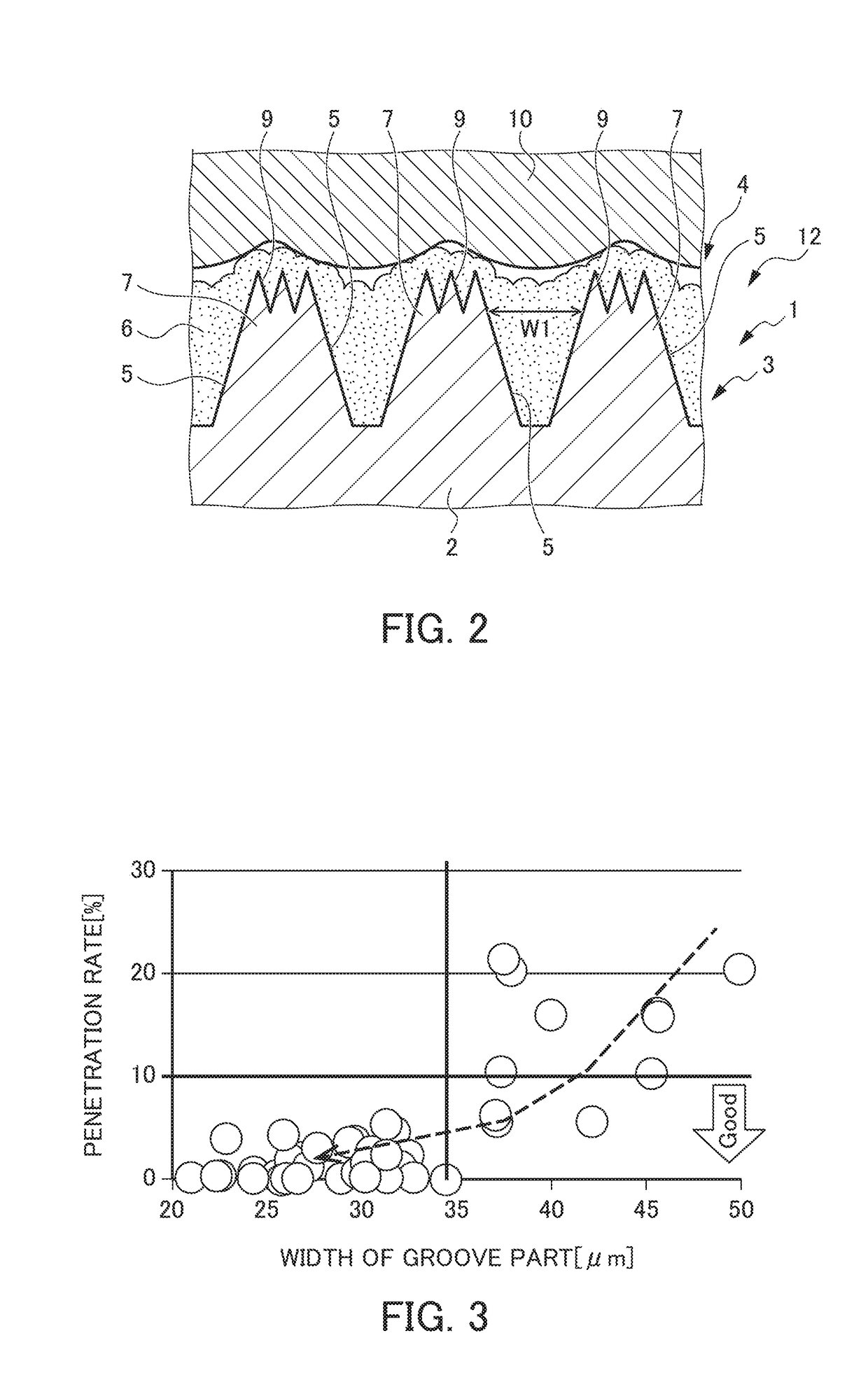

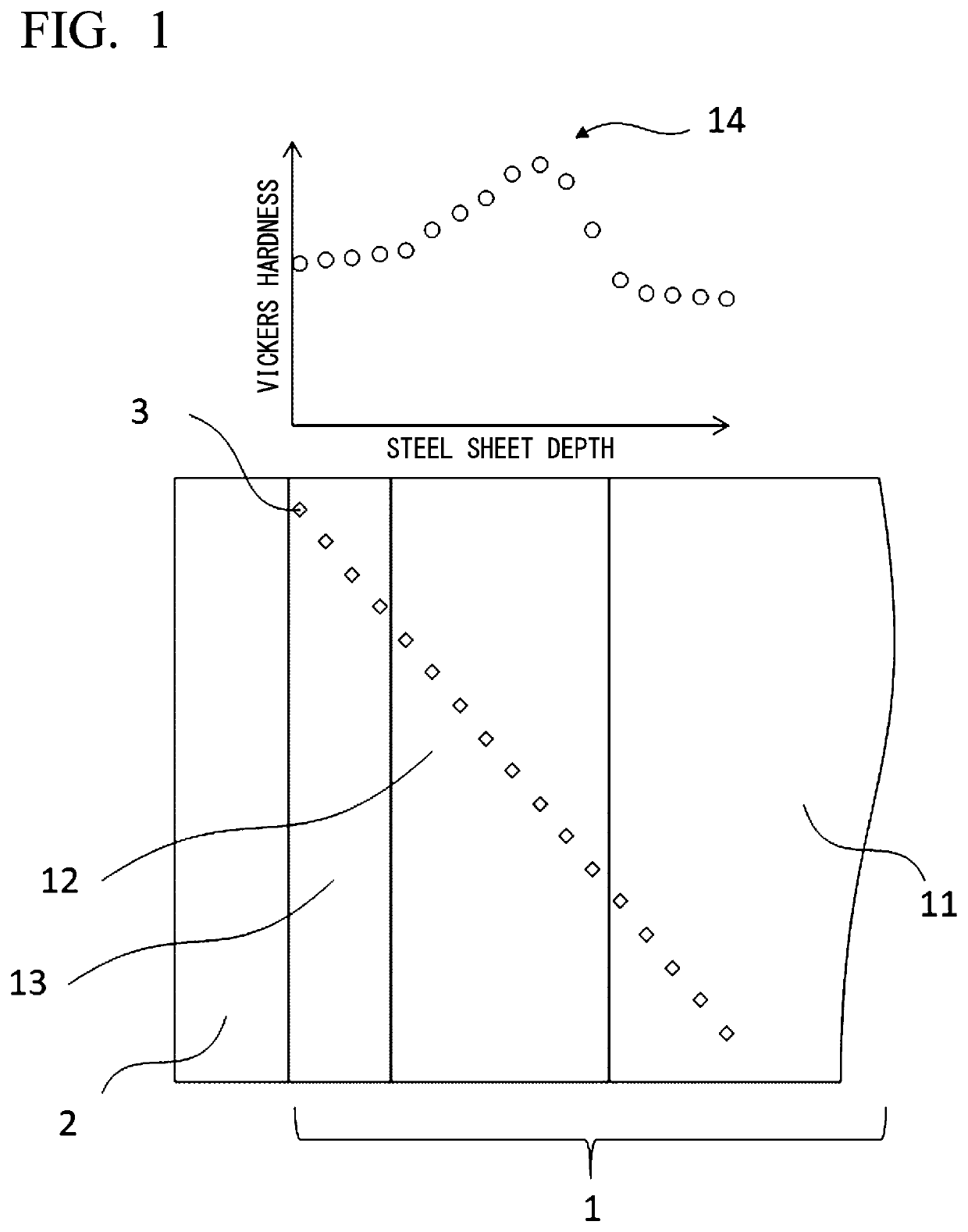

Casting mold, and production method thereof

ActiveUS20180207714A1Maintain liquiditySuppressing exfoliationFoundry mouldsFoundry coresCarbon filmCasting mold

A casting mold and a production method thereof with which exfoliation of coating is controlled and liquidity of molten metal can be maintained are provided. This casting mold 1 includes a surface processing part 3 in which a plurality of groove parts 5 of a grid groove 4 formed in a surface of a molten metal contact part of a mold material 2 is coated with a carbon film 6. In this surface processing part 3, a width W1 of the groove parts 5 is 35 μm or narrower, skewness Ssk of three-dimensional surface roughness is in a range of −0.8 to −0.2, and indentation hardness of the carbon film 6 tested by a nanoindenter is 1000 N / mm2 or higher. With this arrangement, it is possible to optimize the surface processing part 3 in such a manner that a penetration rate of the molten metal (aluminum 10) is controlled to be low and the coating (carbon film 6) is unlikely to exfoliate from the groove parts 5.

Owner:HONDA MOTOR CO LTD

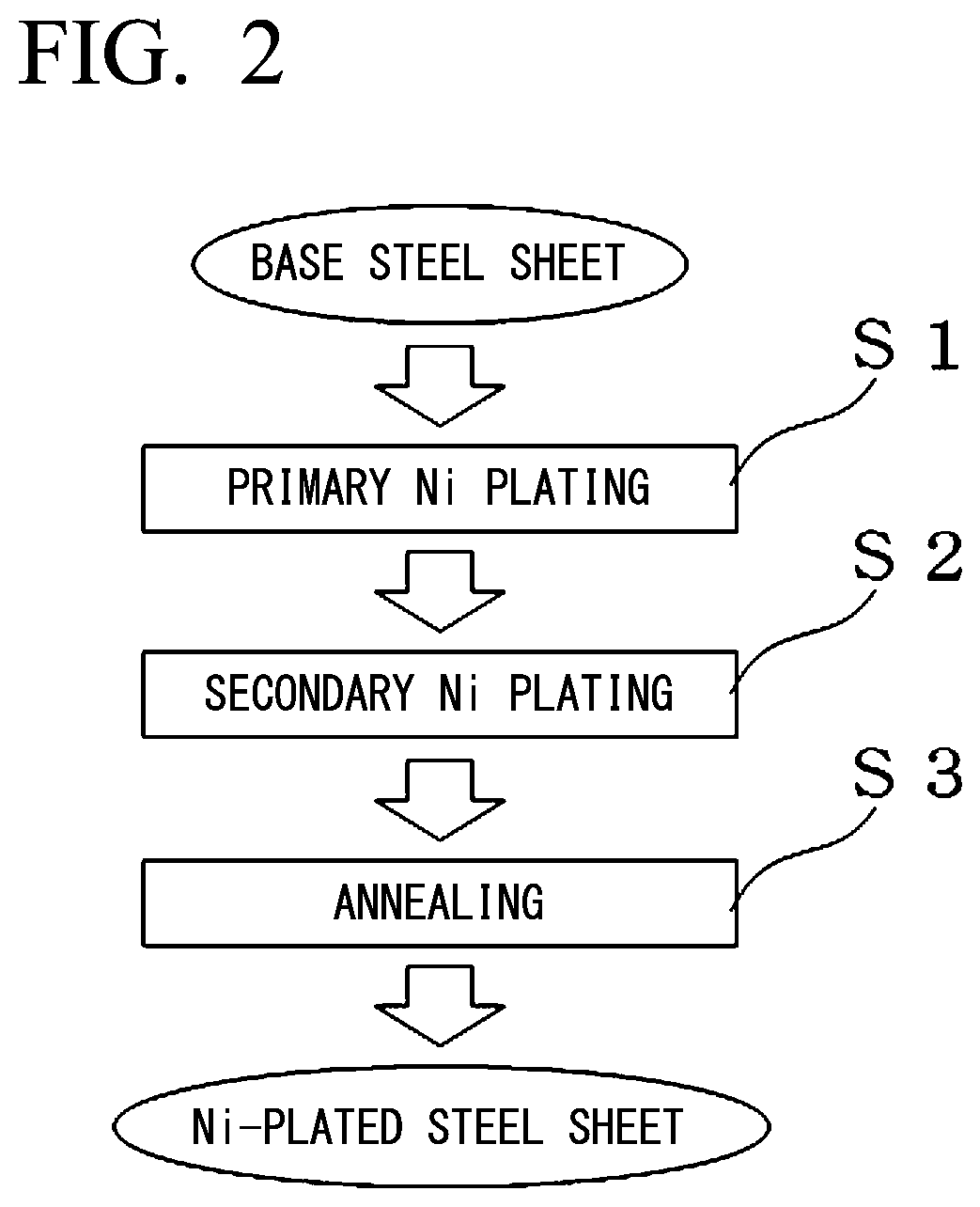

Ni-COATED STEEL SHEET HAVING EXCELLENT CORROSION RESISTANCE AFTER WORKING AND METHOD FOR MANUFACTURING Ni-COATED STEEL SHEET

PendingUS20220010450A1Improve corrosion resistanceSolid state diffusion coatingFurnace typesAlloyHardness

A Ni-coated steel sheet according to an aspect of the present invention includes: a base steel sheet; a diffusion alloy layer disposed on the base steel sheet; and a Ni-coated layer disposed on the diffusion alloy layer, in which a depth-hardness curve obtained by continuously performing Vickers hardness measurement on a cross section perpendicular to a rolled surface of the base steel sheet from a surface layer of the Ni-coated layer to the base steel sheet using a nanoindenter includes, in the diffusion alloy layer, a peak indicating a Vickers hardness of 1.50 times or more a Vickers hardness of the surface layer of the Ni-coated layer.

Owner:NIPPON STEEL CORP

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com