Amorphous alloy ribbon stretching device combined with nanoindenter and use method of amorphous alloy ribbon stretching device

A nano-indenter and amorphous alloy technology, which is applied in the direction of measuring devices, using stable tension/pressure to test the strength of materials, instruments, etc., can solve temperature drift, limited space size, and very high requirements for sample surface flatness, etc. problem, to achieve the effect of stable temperature, small device height, and small overall size of the device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

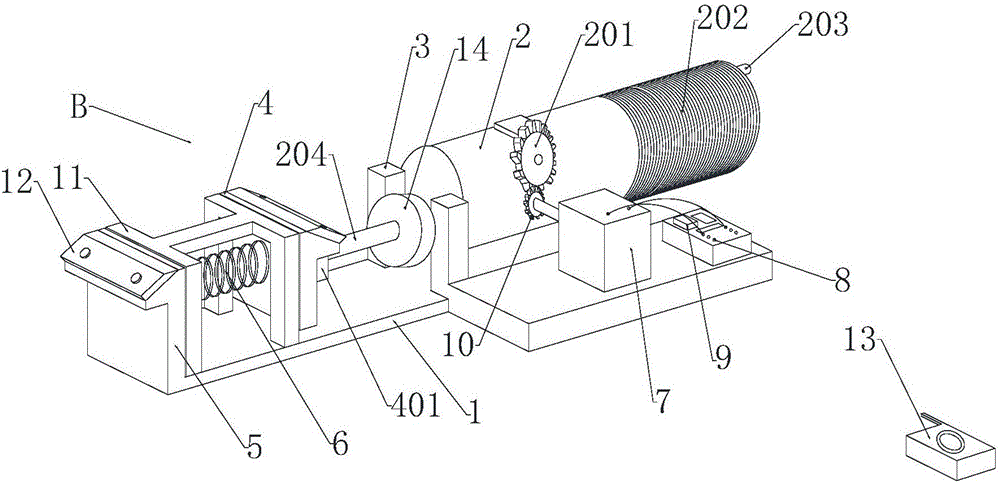

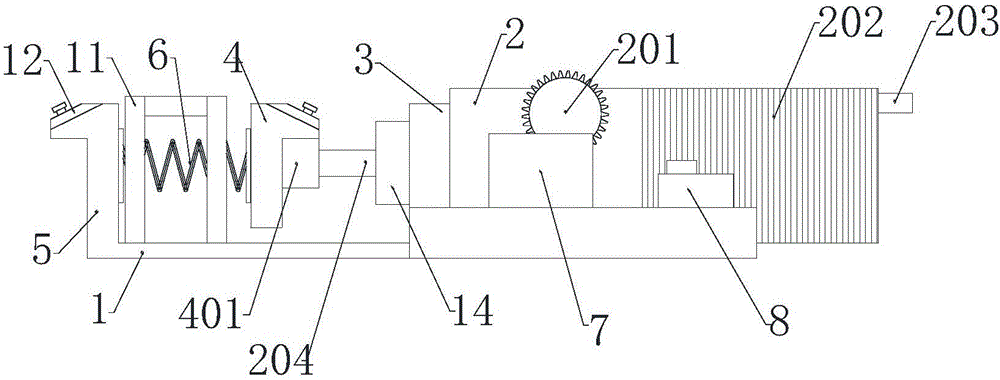

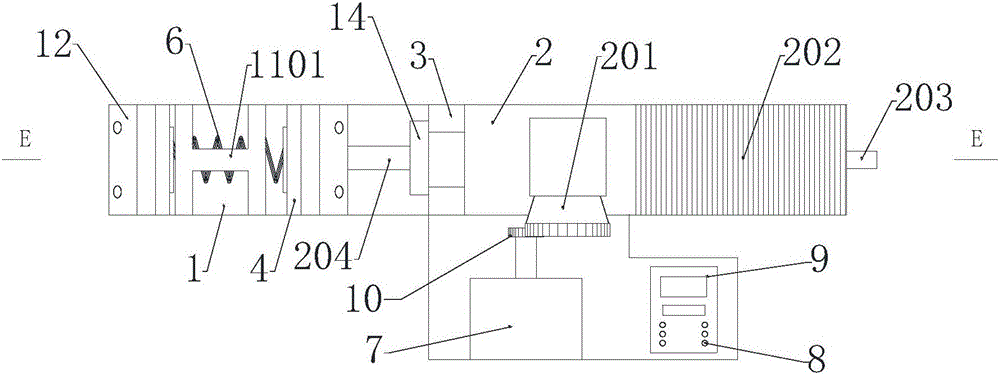

[0095] Such as figure 1 , an amorphous alloy thin strip stretching device B used in conjunction with a nano-indentation instrument A, the device B includes a base 1, a high-precision turbine type coarse and fine-tuning differential head 2, a fixed column 3, a movable baffle 4, a fixed baffle Plate 5, motor 7, motor power supply 8, sample holder 11, two clamps 12. Wherein: one end of the base 1 is provided with a fixed baffle 5 . The other end of the base 1 is provided with a fixed column 3 . The high-precision turbine type coarse and fine adjustment micrometer head 2 is arranged on the fixed column 3 and connected with the telescopic rod connector 401 on the movable baffle 4 . The movable baffle 4 is located between the fixed baffle 5 and the fixed column 3 . The sample holder 11 is placed on the base and is located between the movable baffle 4 and the fixed baffle 5 . A clamp 12 is respectively provided on the top of the movable baffle 4 and the fixed baffle 5 . The moto...

Embodiment 2

[0098] Embodiment 1 is repeated, except that the device B also includes a control system 16 . The control system 16 includes a receiving device 9 and a remote control device 13 . The control system 16 connects and controls the motor power source 8 and the motor 7 .

Embodiment 3

[0100] Embodiment 2 is repeated, except that the motor 7 is connected with the high-precision turbine type coarse and fine adjustment differential head 2 through gears. The fine adjustment button 201 and the coarse adjustment button 202 control the movement of the telescopic rod 204 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com