Patents

Literature

374 results about "Model material" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Solid freeform fabrication using a plurality of modeling materials

InactiveUS20100191360A1Easy to burnImprove shrinkageAdditive manufacturing apparatusAdditive manufacturing with liquidsOperation modeMaterial supply

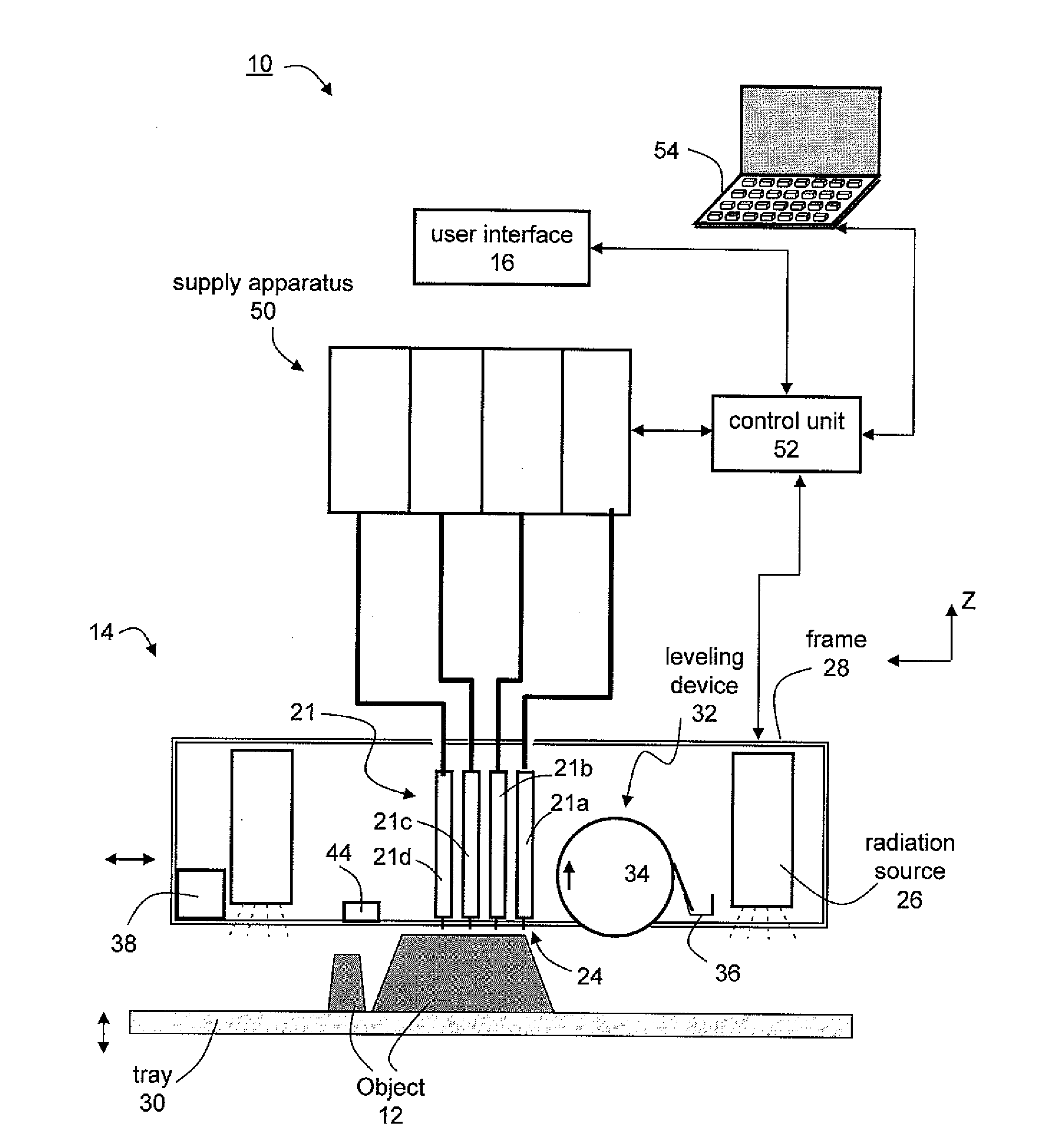

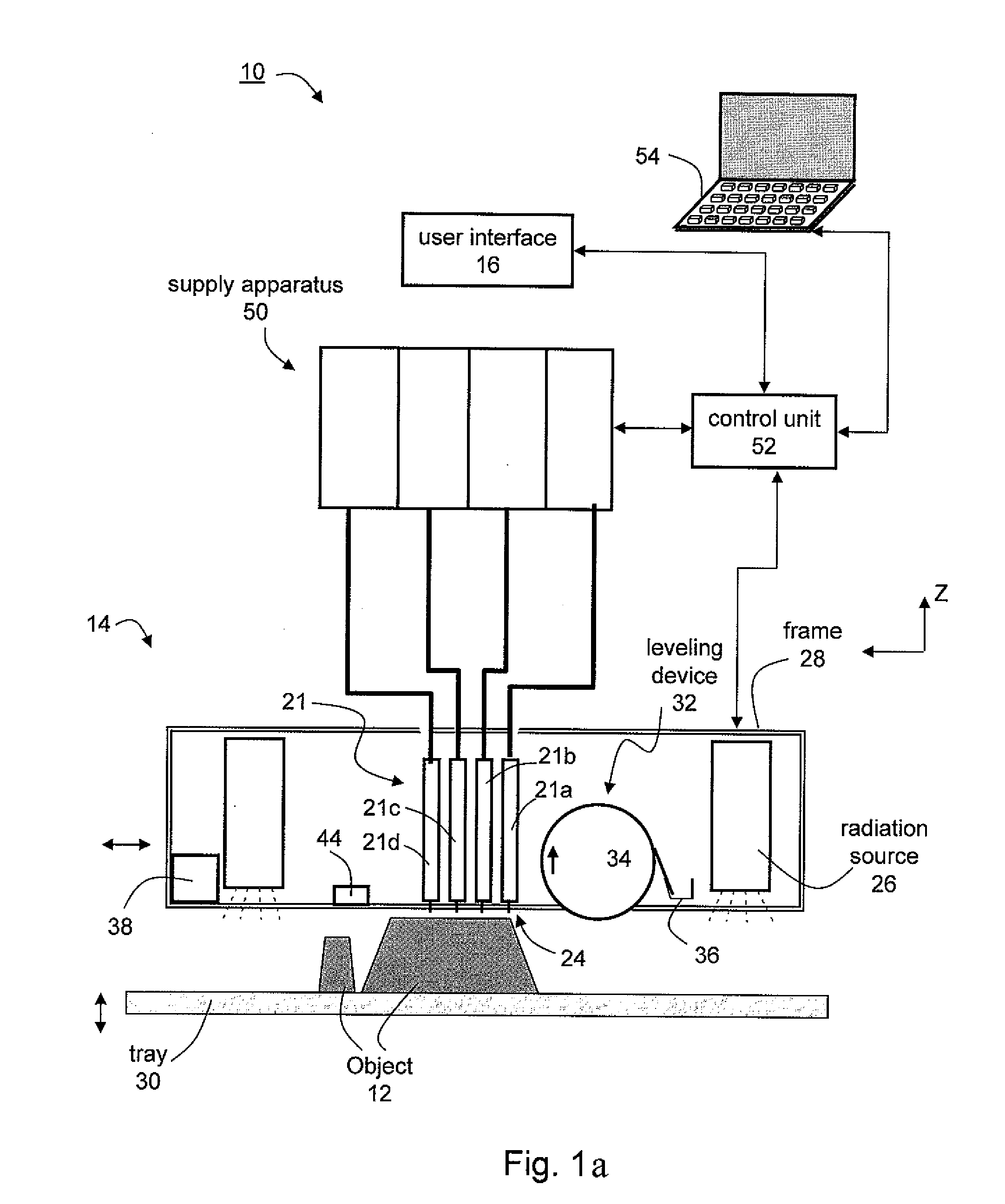

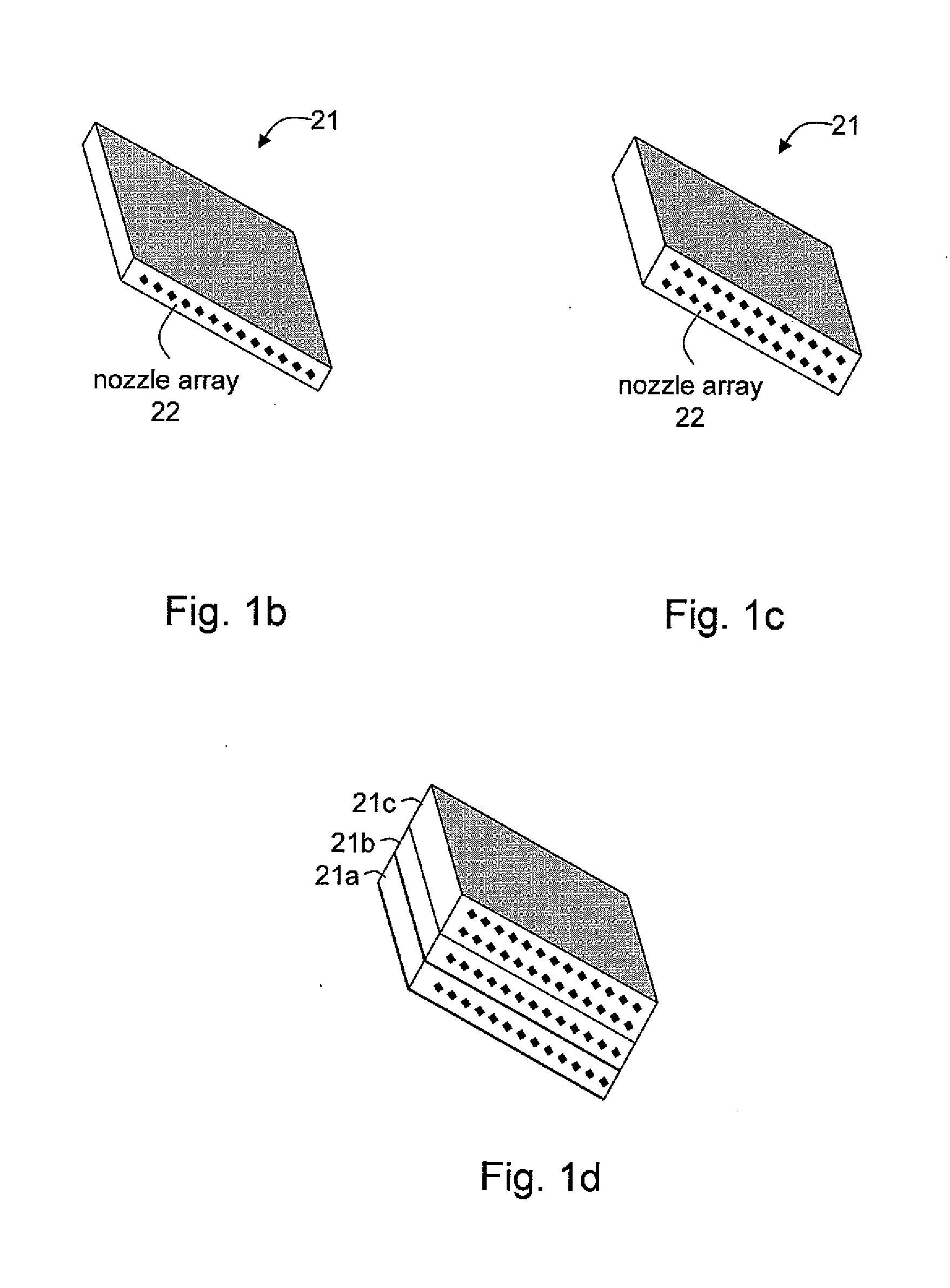

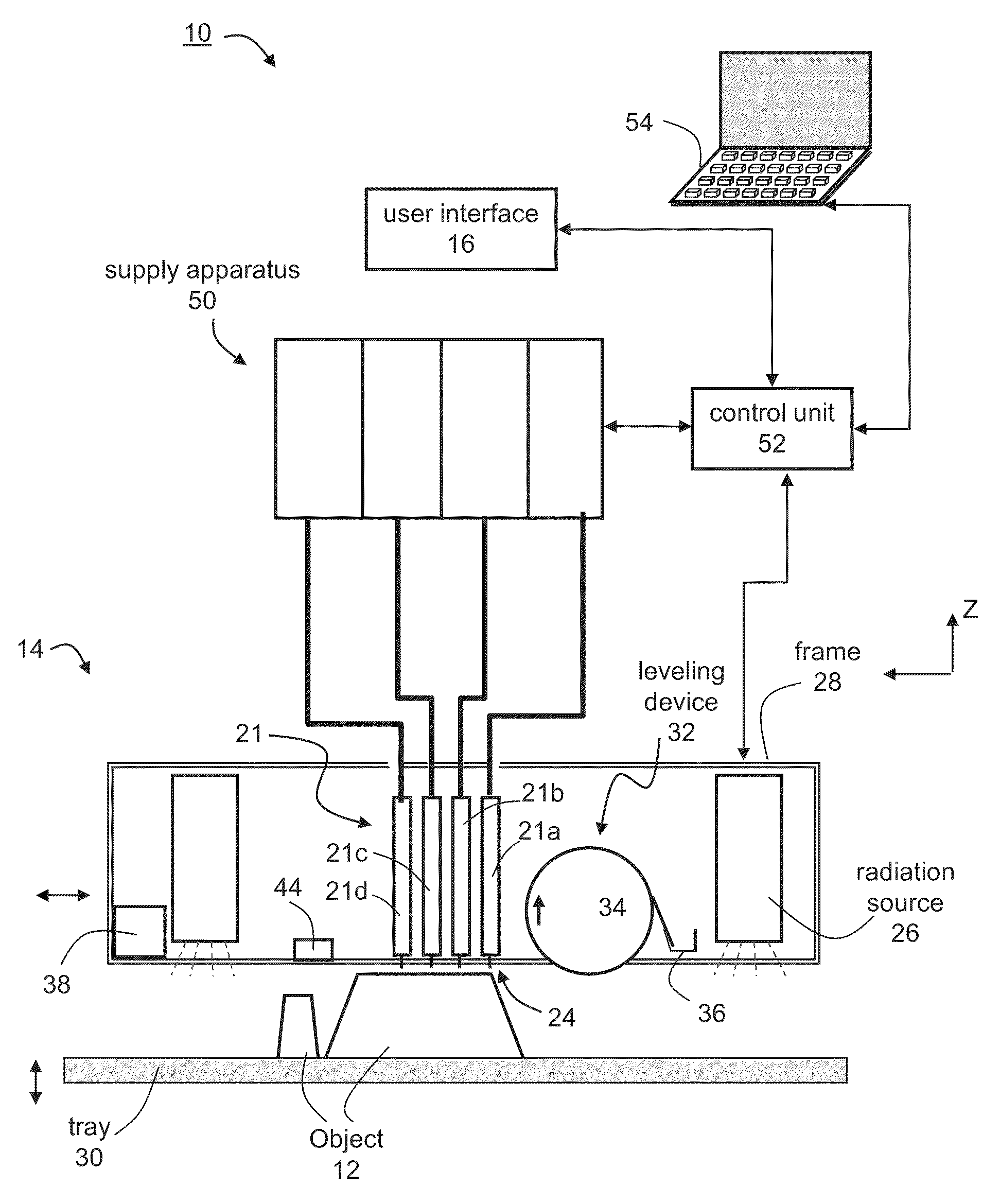

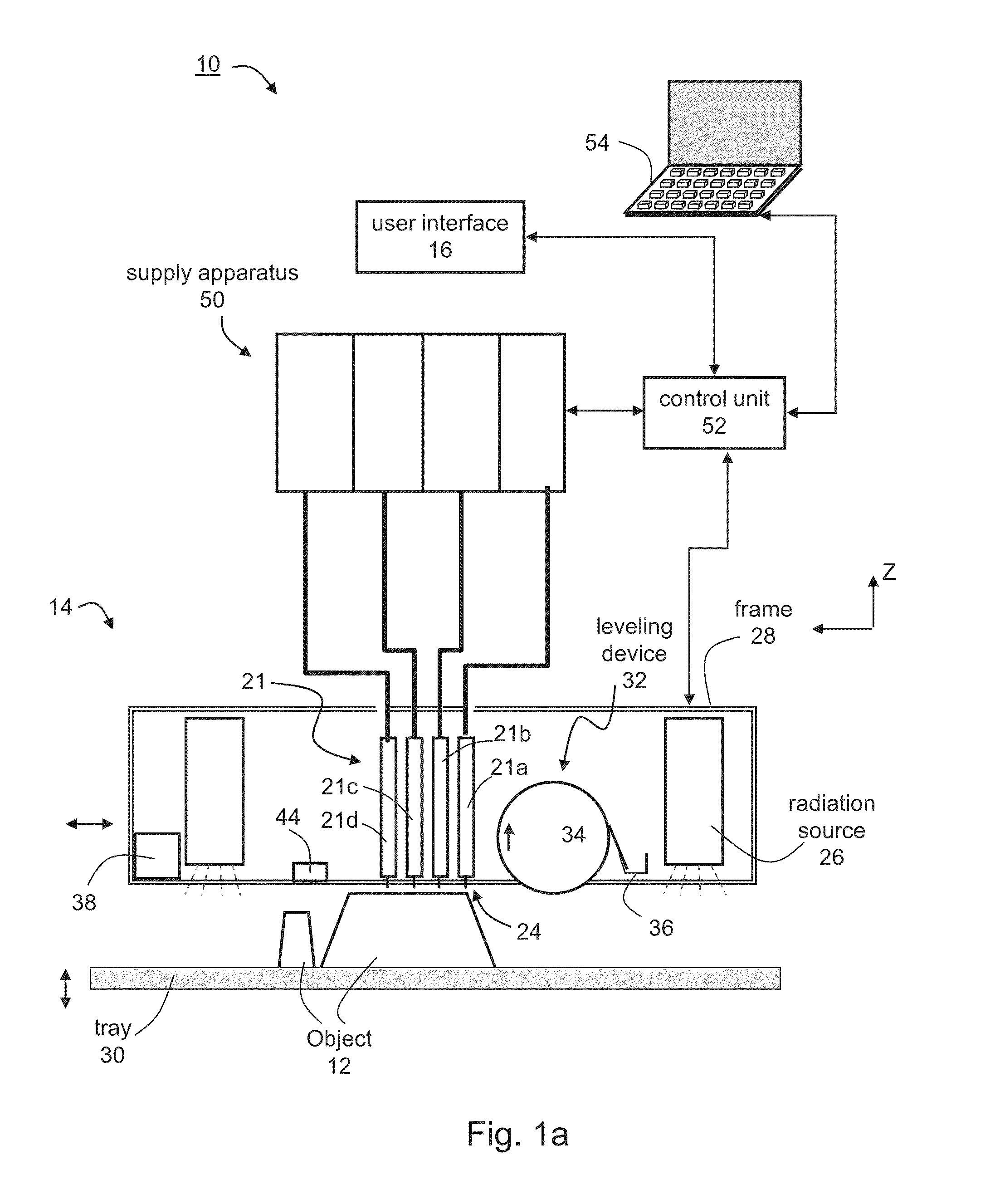

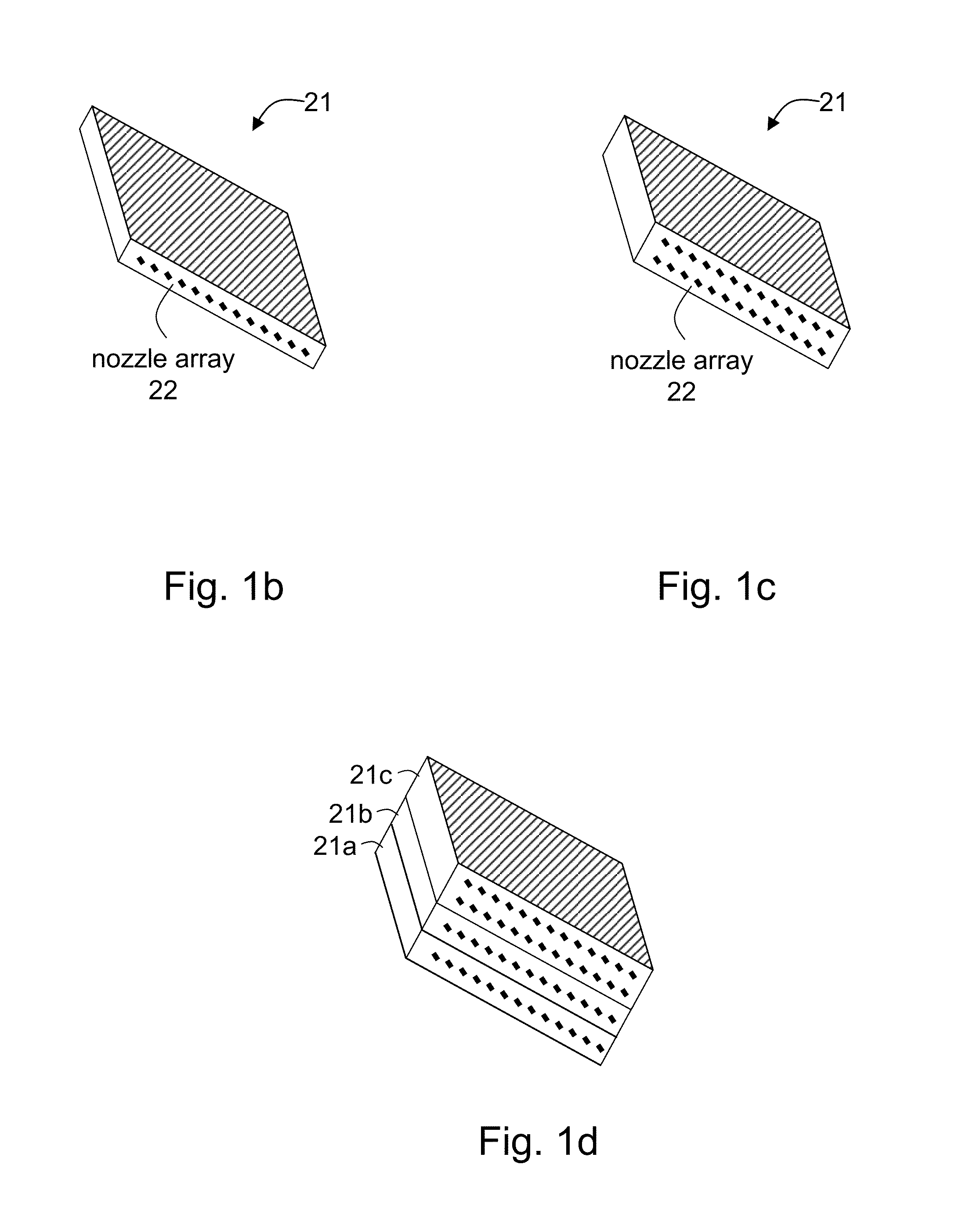

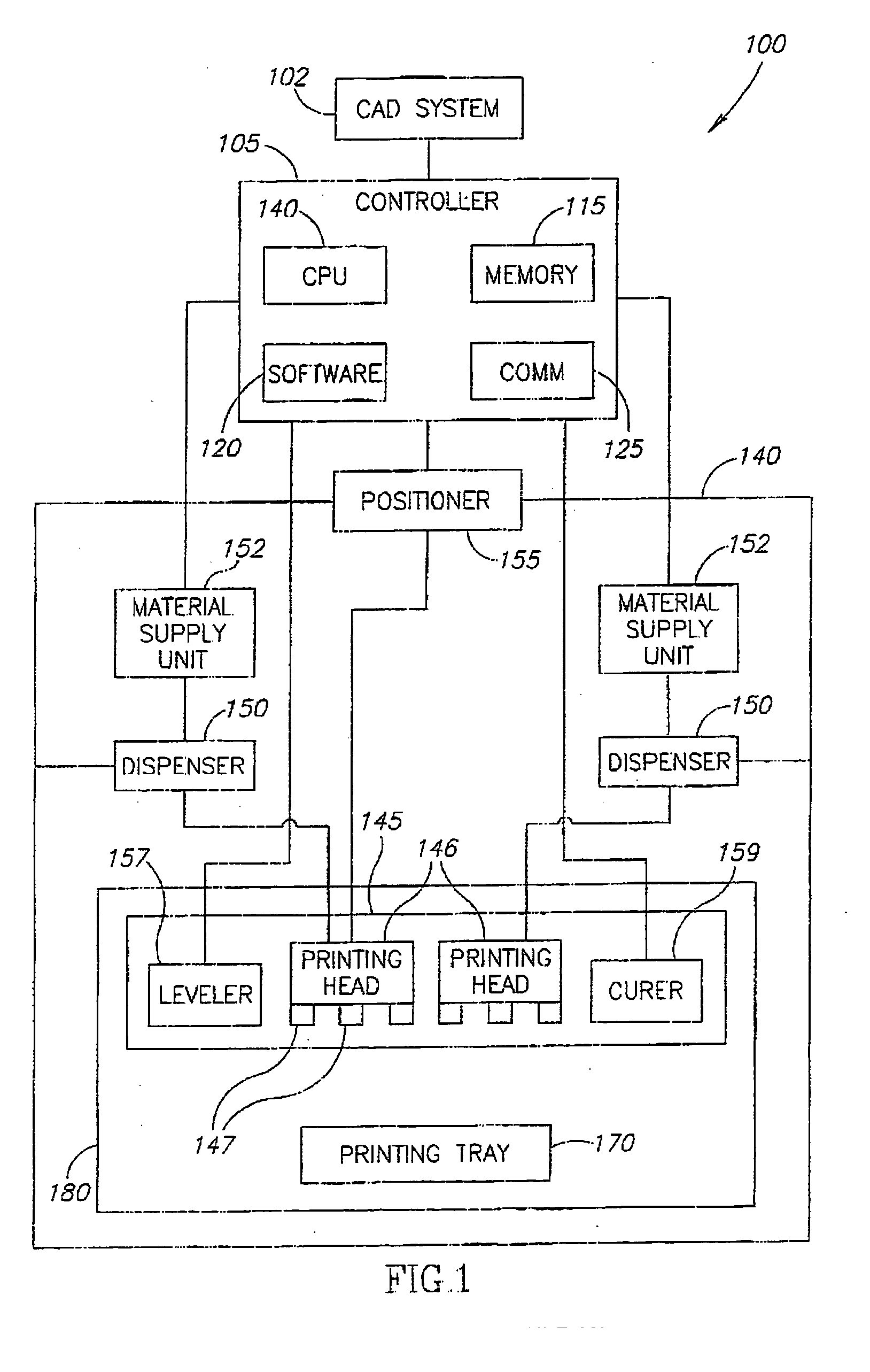

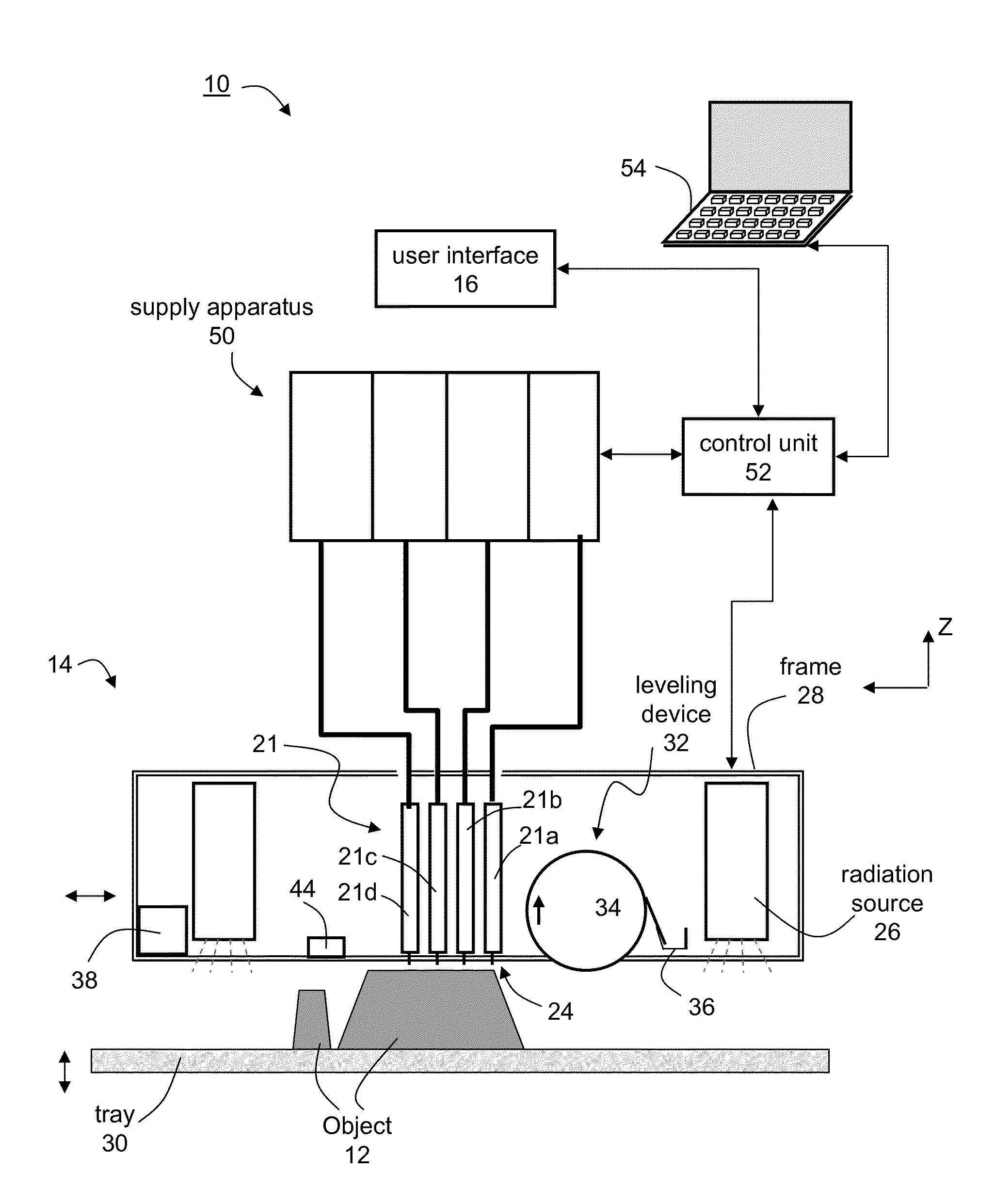

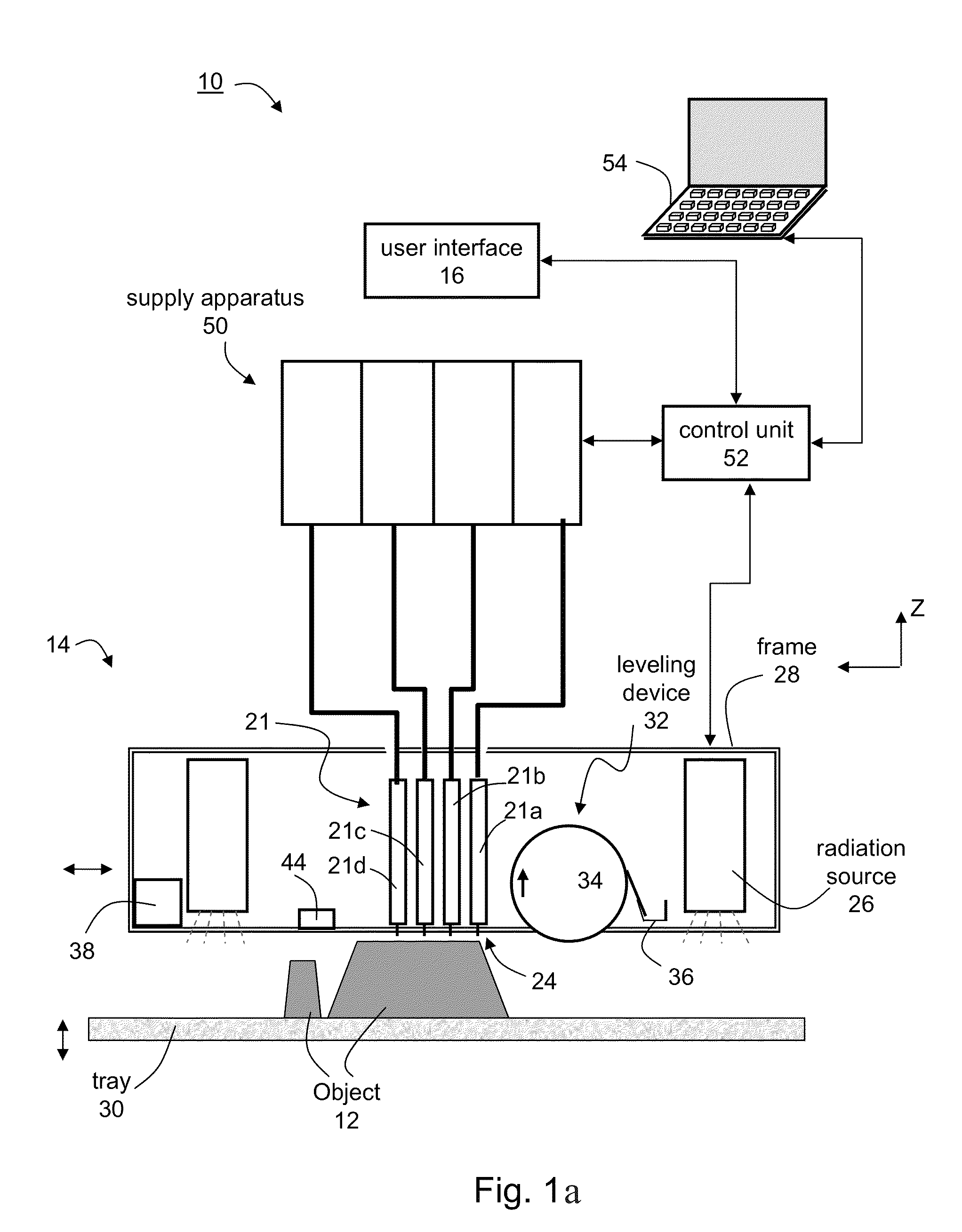

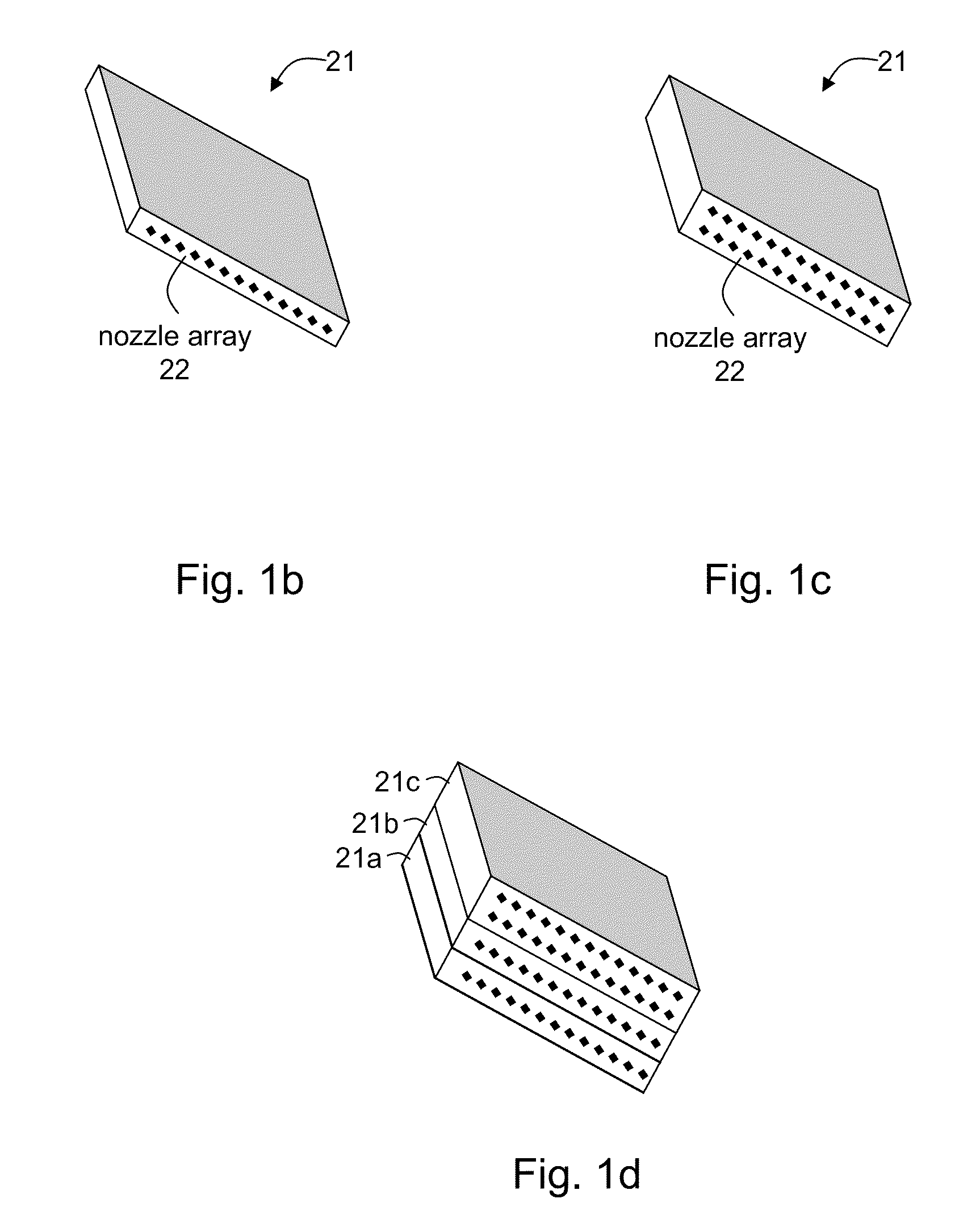

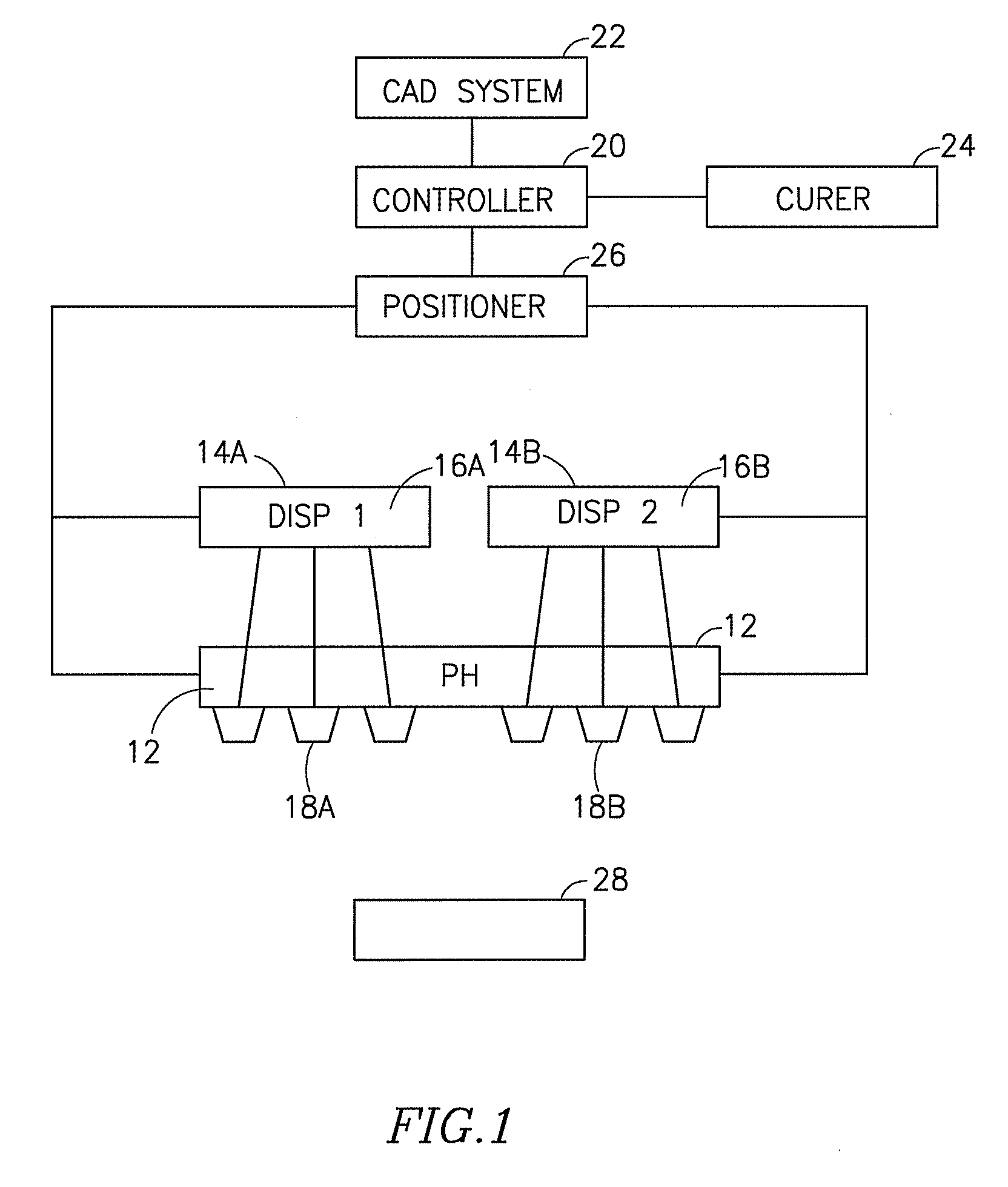

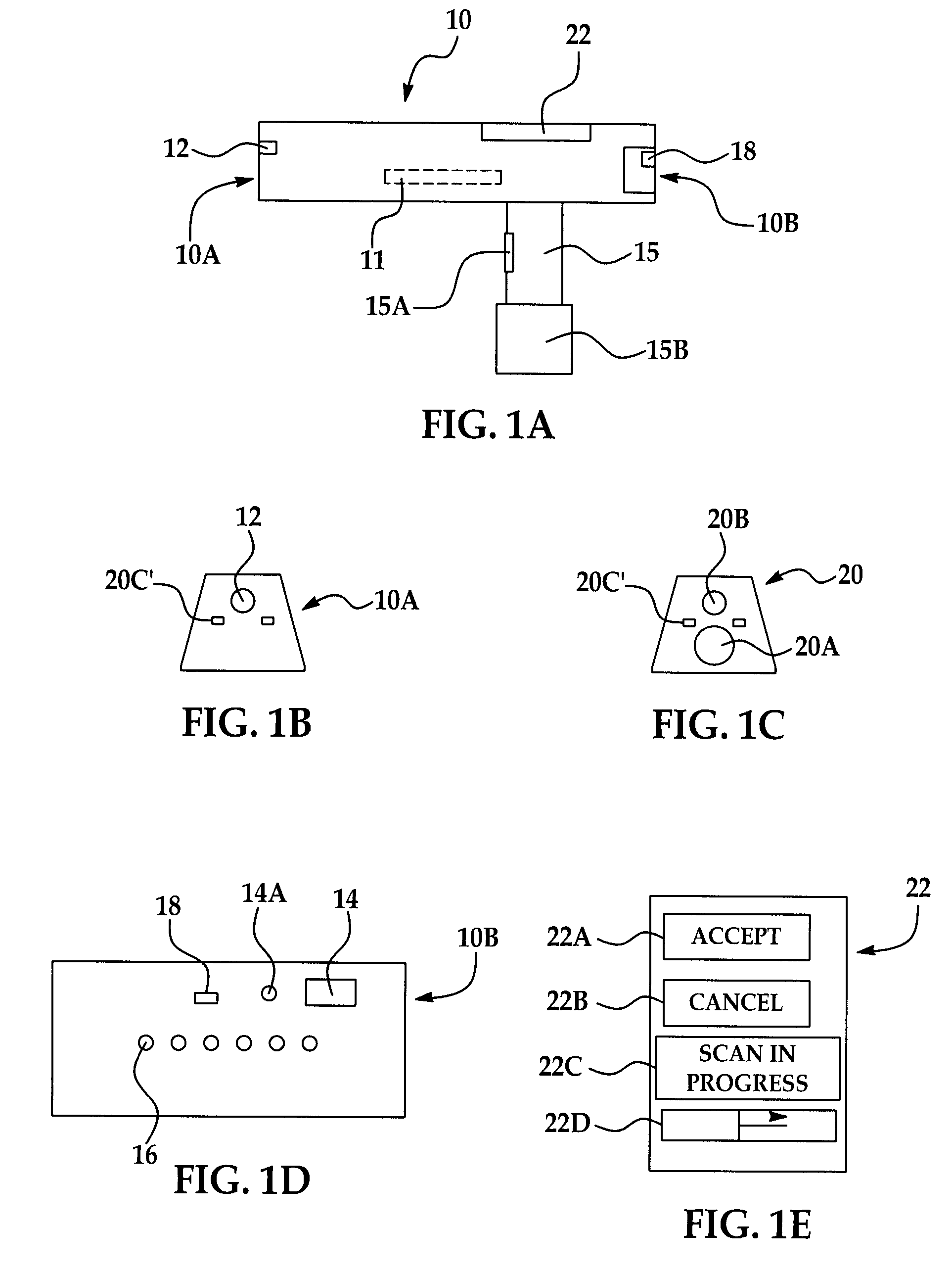

A system and methods for solid freeform fabrication of an object is disclosed. The system comprises a solid freeform fabrication apparatus having a plurality of dispensing heads, a building material supply apparatus configured to supply a plurality of building materials to the fabrication apparatus, and a control unit configured for controlling the fabrication apparatus and the supply apparatus based on an operation mode selected from a plurality of predetermined operation modes.

Owner:OBJET GEOMETRIES

Solid freeform fabrication using a plurality of modeling materials

ActiveUS9031680B2Easy to burnImprove shrinkageAdditive manufacturing apparatusAdditive manufacturing with liquidsOperation modeSolid freeform fabrication

A system and methods for solid freeform fabrication of an object is disclosed. The system comprises a solid freeform fabrication apparatus having a plurality of dispensing heads, a building material supply apparatus configured to supply a plurality of building materials to the fabrication apparatus, and a control unit configured for controlling the fabrication apparatus and the supply apparatus based on an operation mode selected from a plurality of predetermined operation modes.

Owner:STRATASYS LTD

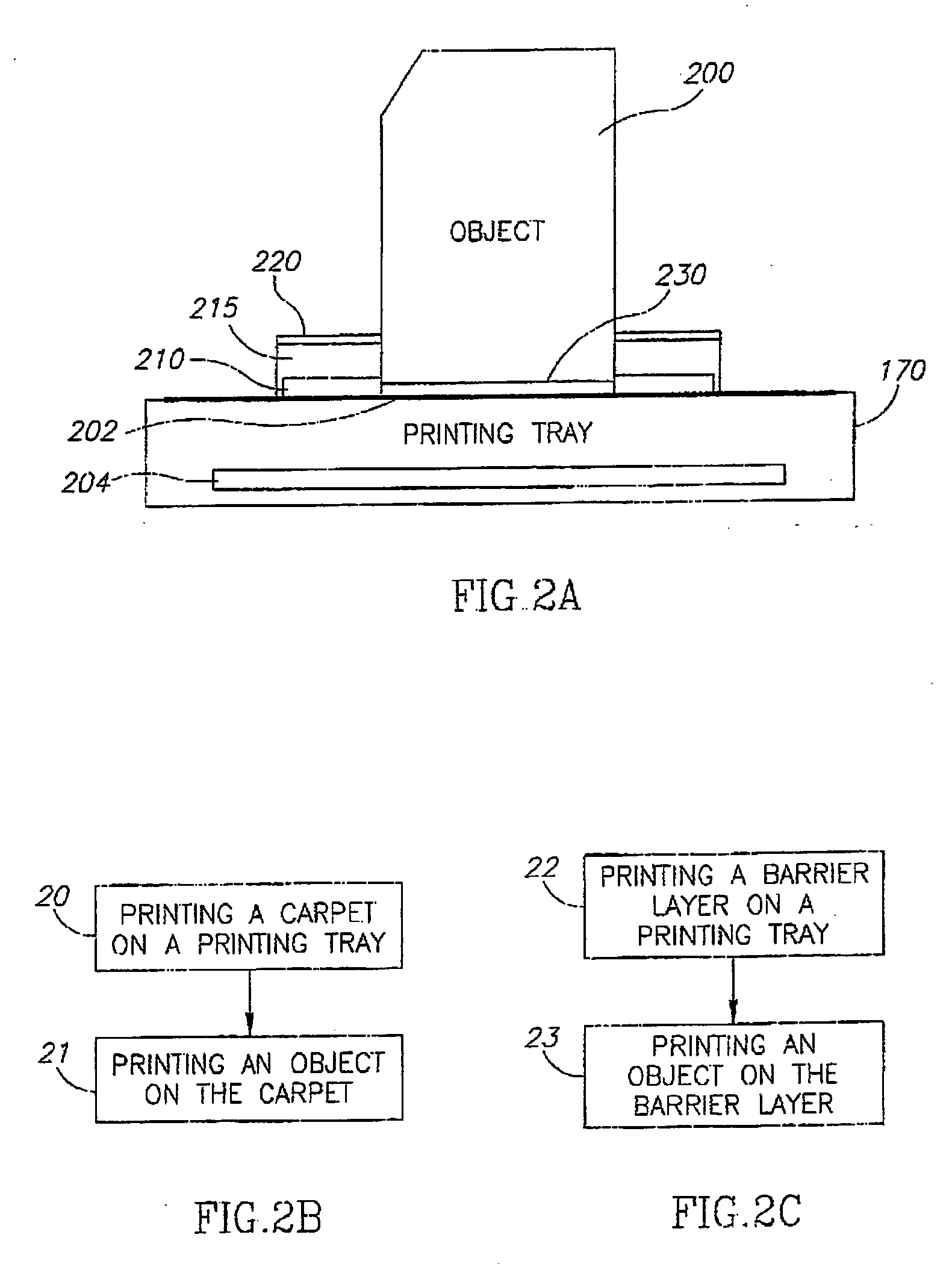

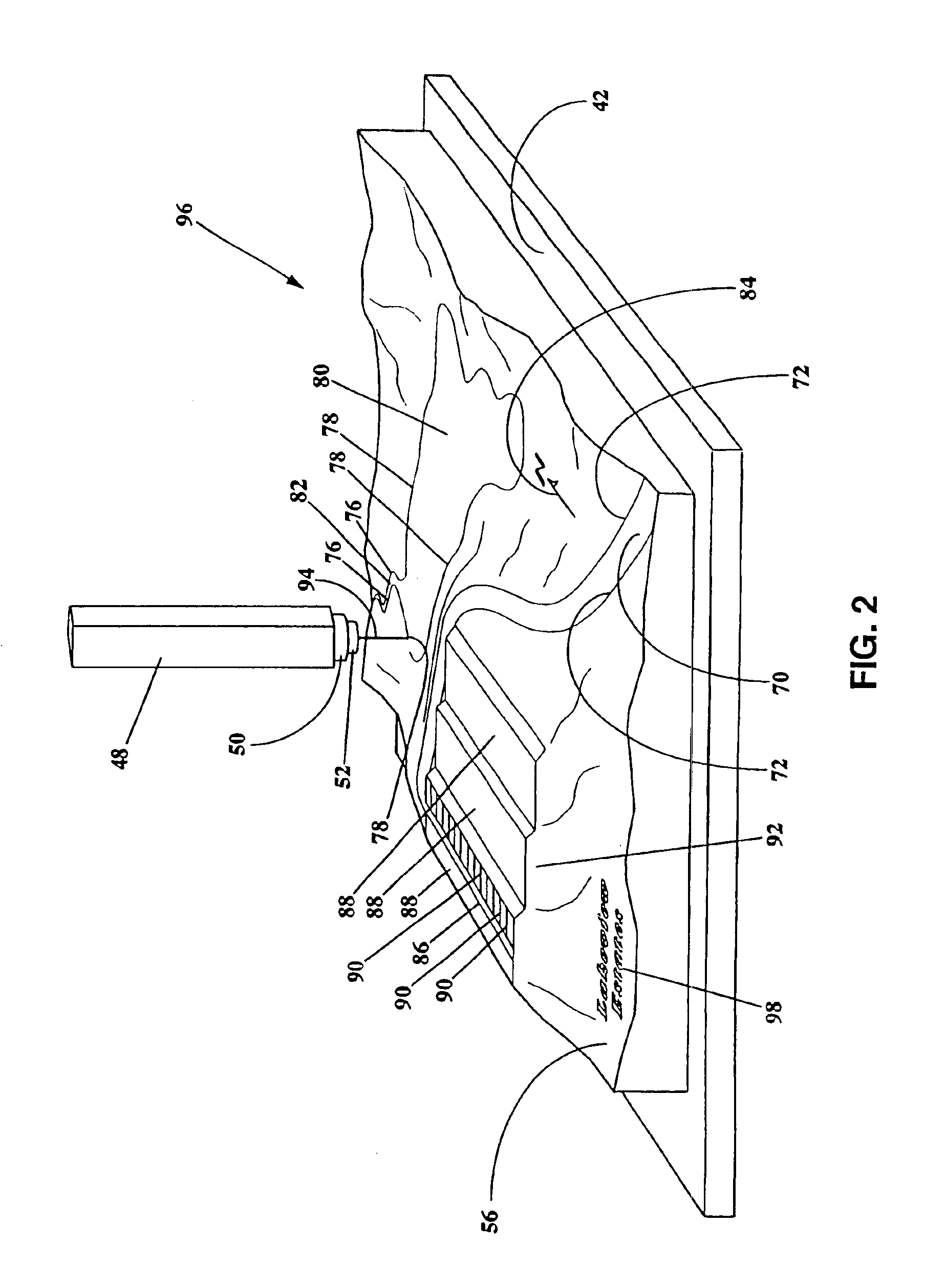

Process of and apparratus for three-dimensional printing

InactiveUS20060054039A1Low adhesion characteristicAvoid mechanical deformationManufacturing platforms/substratesPattern printingTemperature controlEngineering

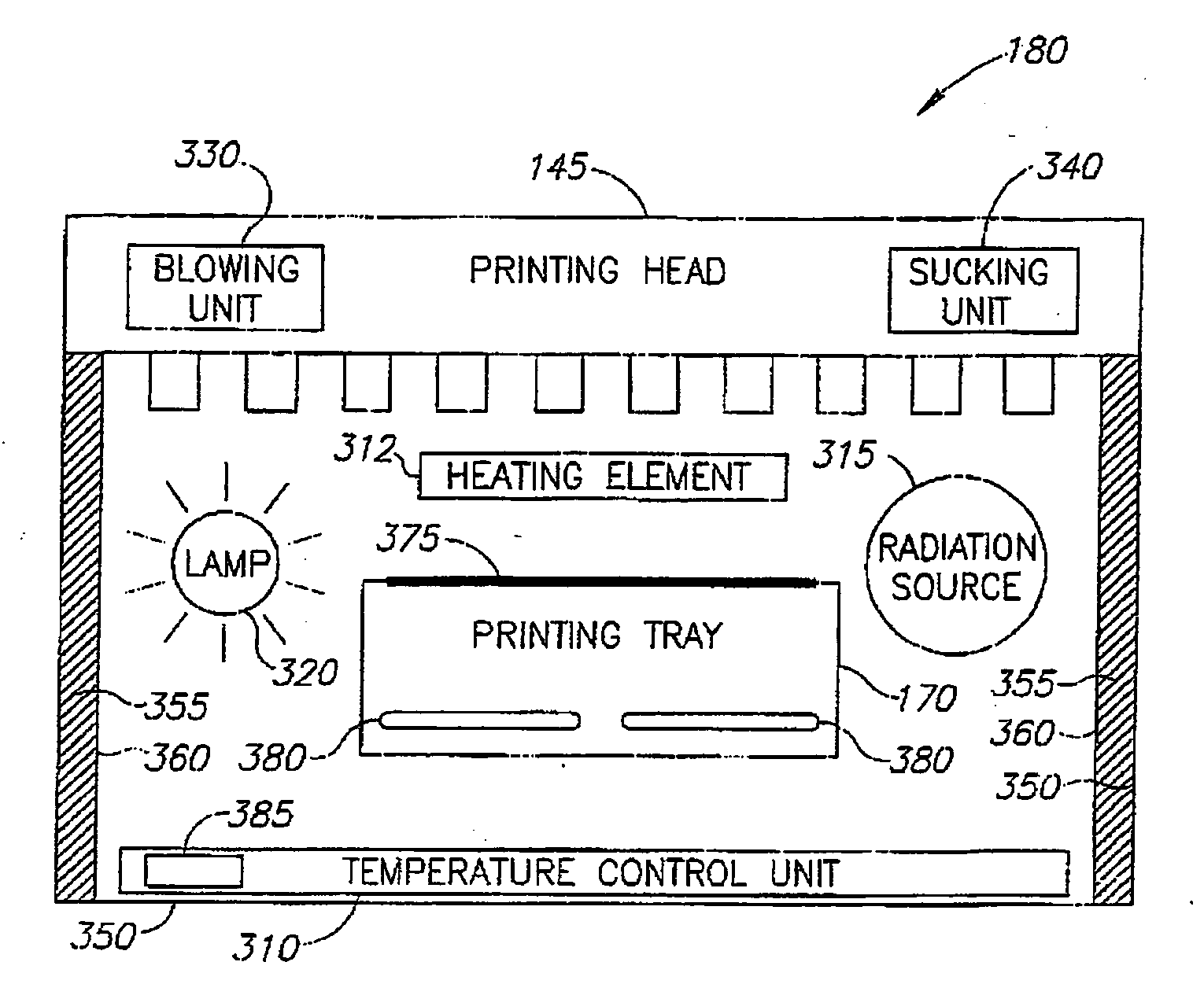

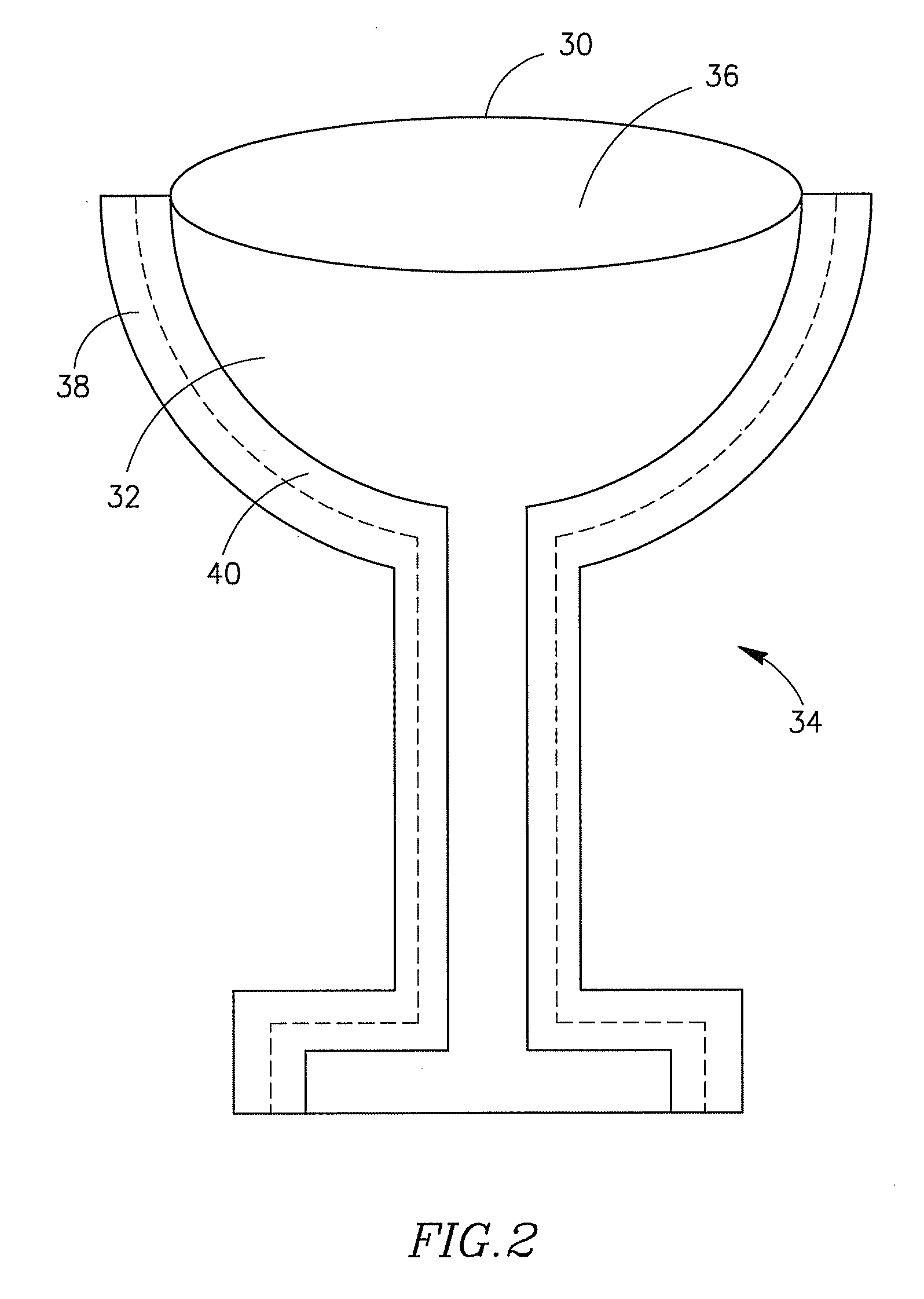

A process of, and apparatus for, three-dimensional printing of an object (200) from modeling material (220) including a printing tray (170) having a surface coating (202), a carpet (210), a support material (215), a support pedestal (210), a barrier layer (230) and a temperature control unit (204).

Owner:OBJET GEOMETRIES

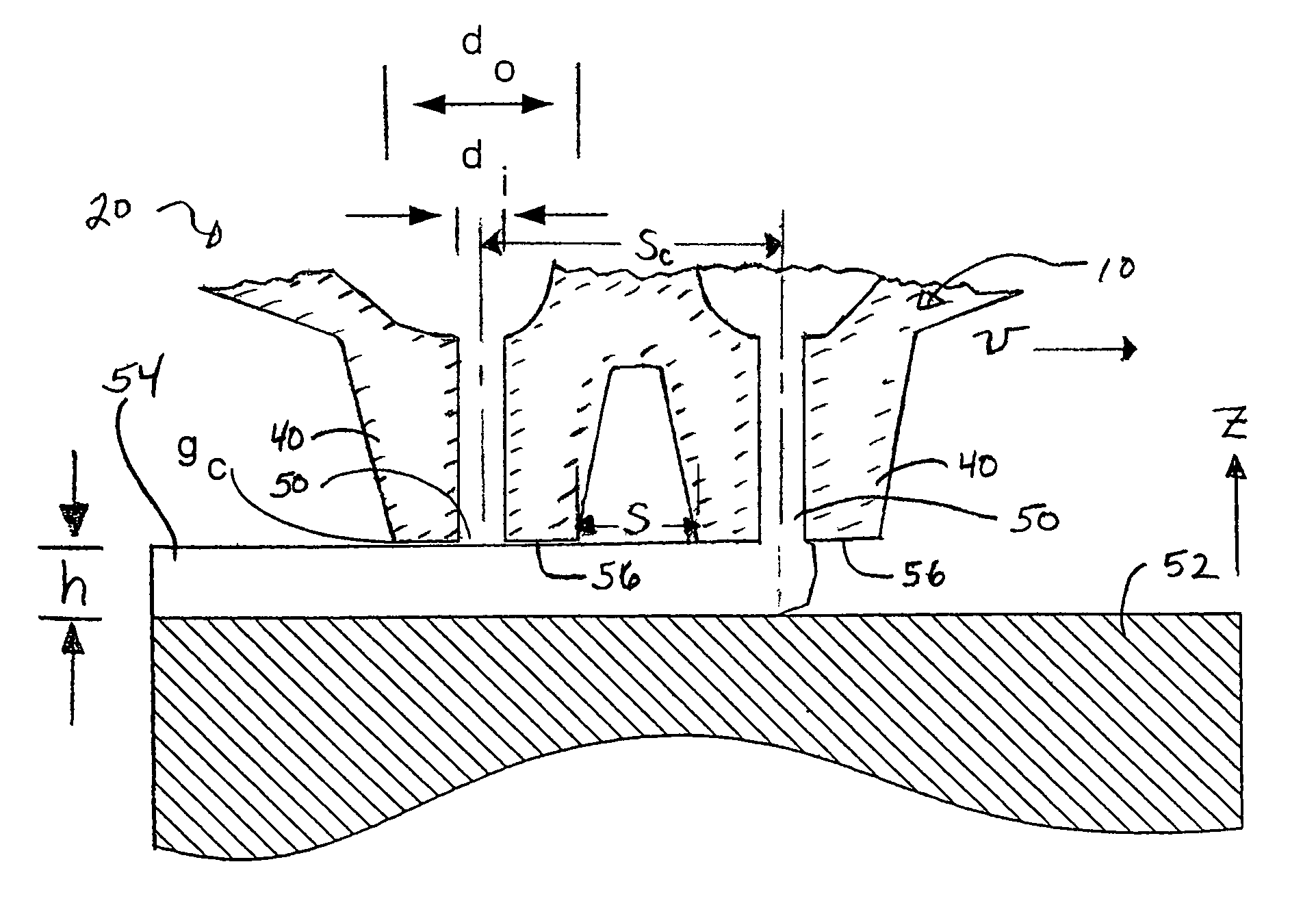

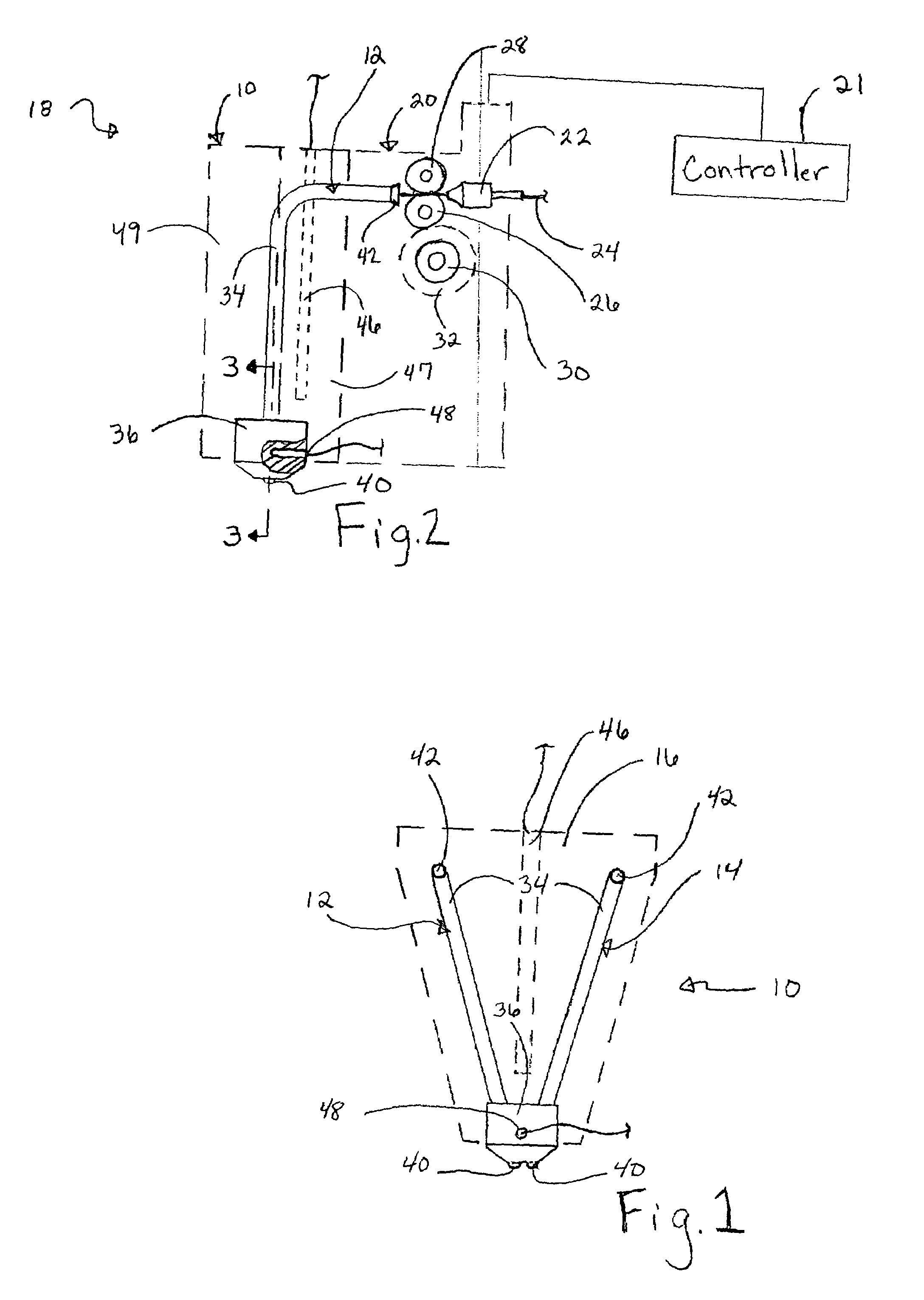

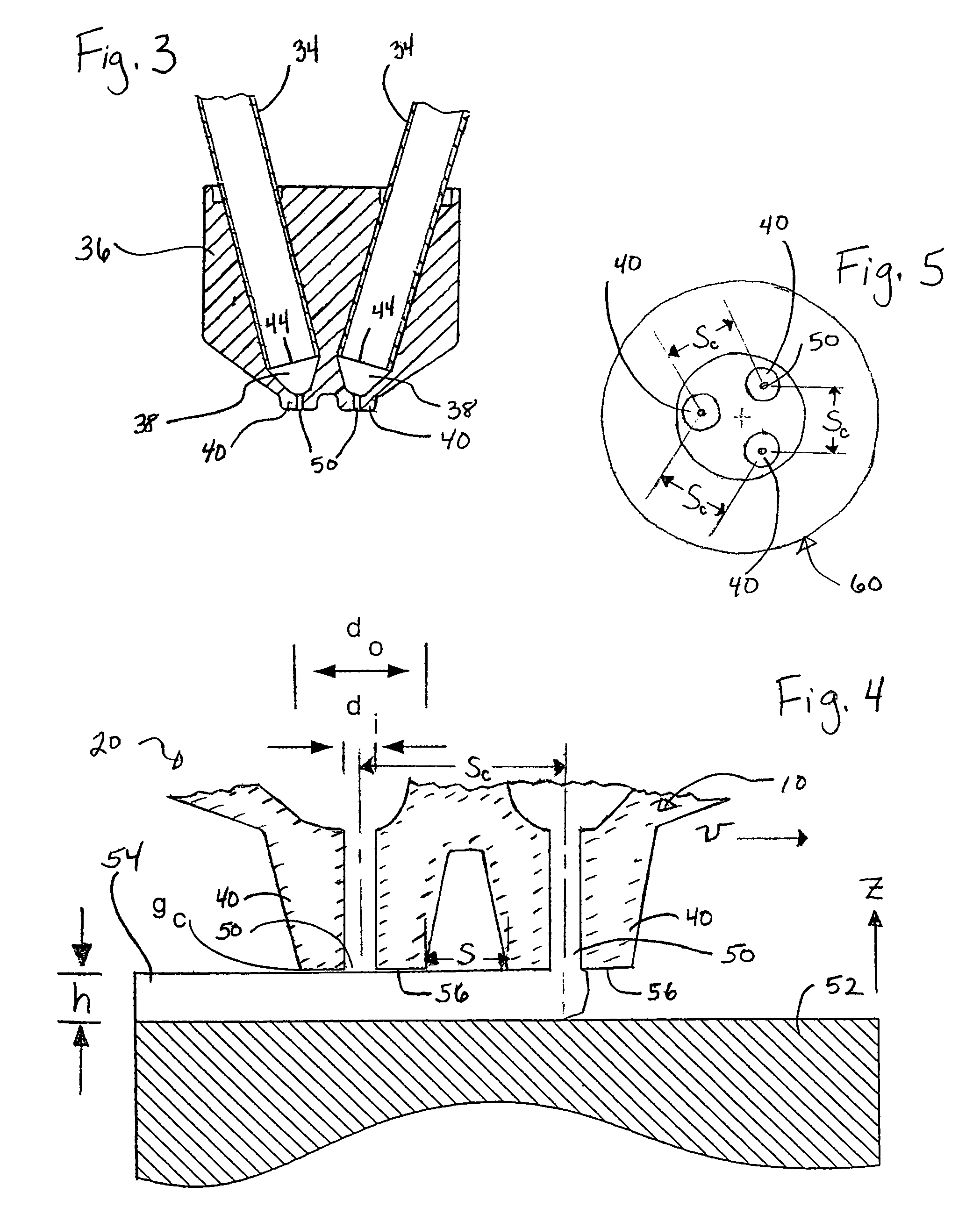

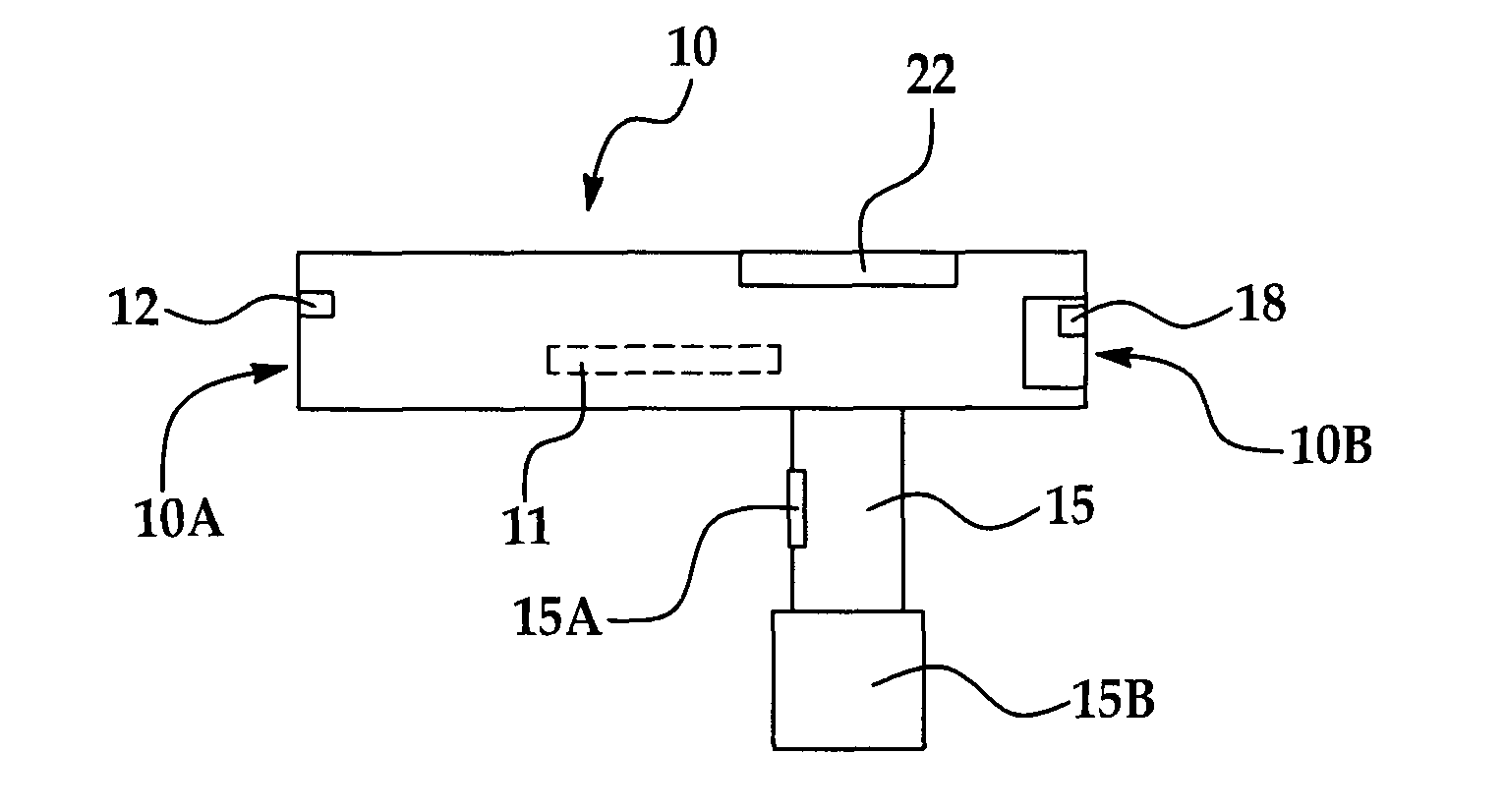

Extrusion method for three dimensional modeling

InactiveUS6998087B1Efficient productionLimited spaceAdditive manufacturing apparatusCeramic shaping apparatusDimensional modelingEngineering

A multi-tip extrusion method and apparatus for building a three-dimensional object deposits modeling materials from distinct supply sources, each in a layerwise predetermined pattern, from dispensers having co-planar dispensing tips. The tip spacing is controlled so that a road of material extruded by a leading one of the tips will cool and shrink from the plane of the tips before a trailing one of the tips passes over the road. In this manner, smearing of the road by a trailing one of the tips is avoided.

Owner:STRATSYS INC

Solid freeform fabrication using a plurality of modeling materials

ActiveUS20130073068A1Easy to burnImprove shrinkageAdditive manufacturing apparatusAdditive manufacturing with liquidsOperation modeSolid freeform fabrication

Owner:STRATASYS LTD

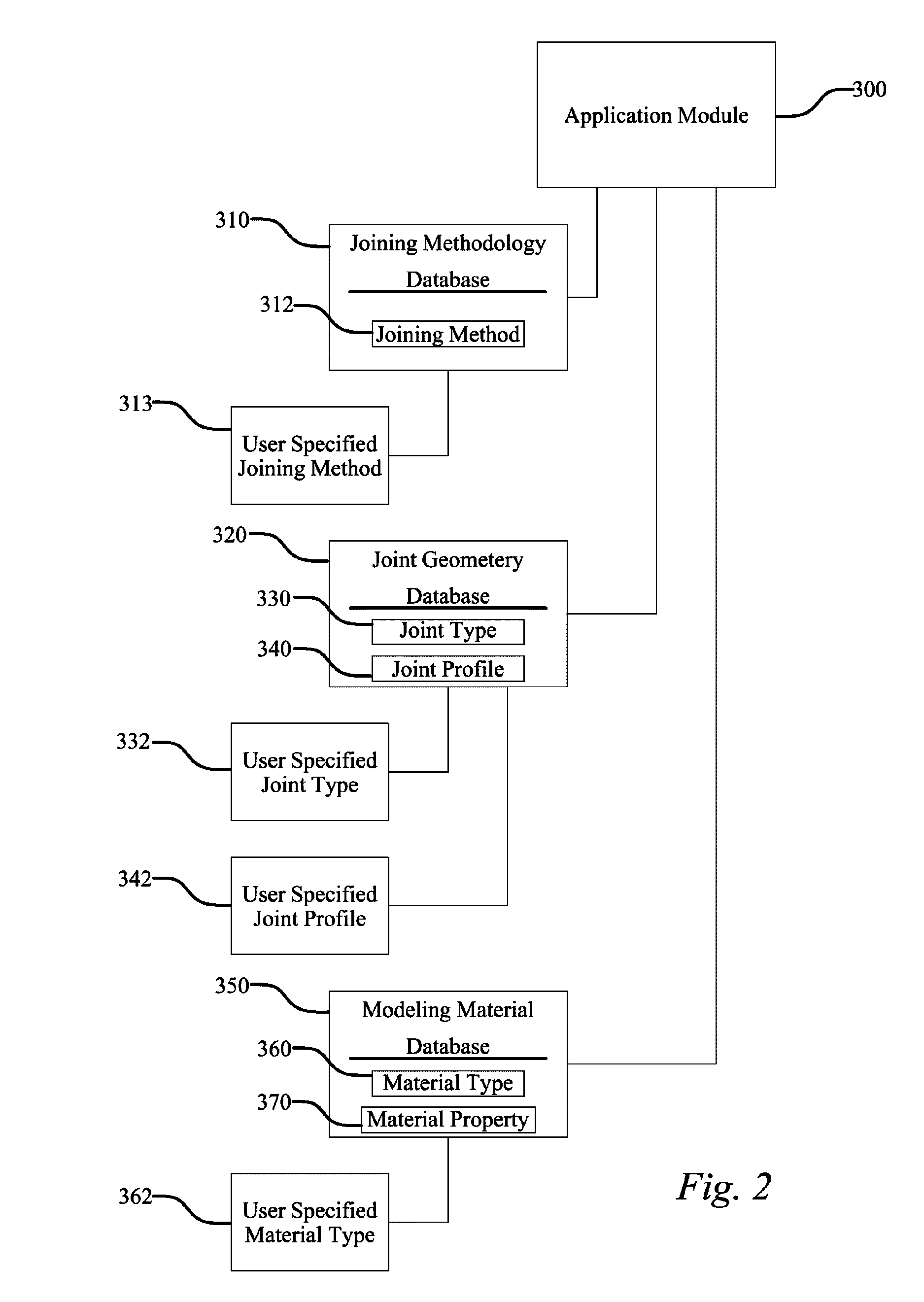

Remote High-Performance Computing Material Joining and Material Forming Modeling System and Method

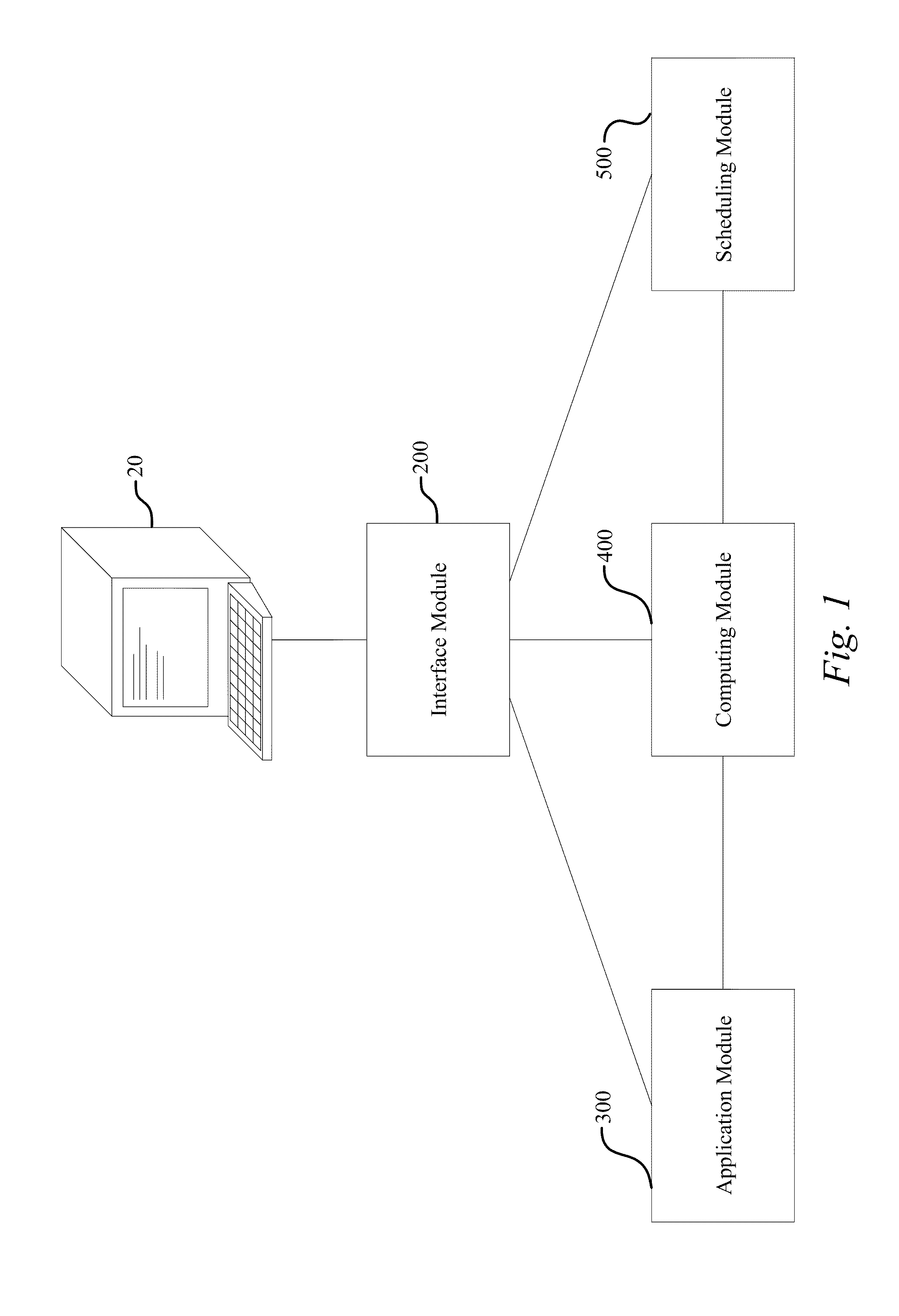

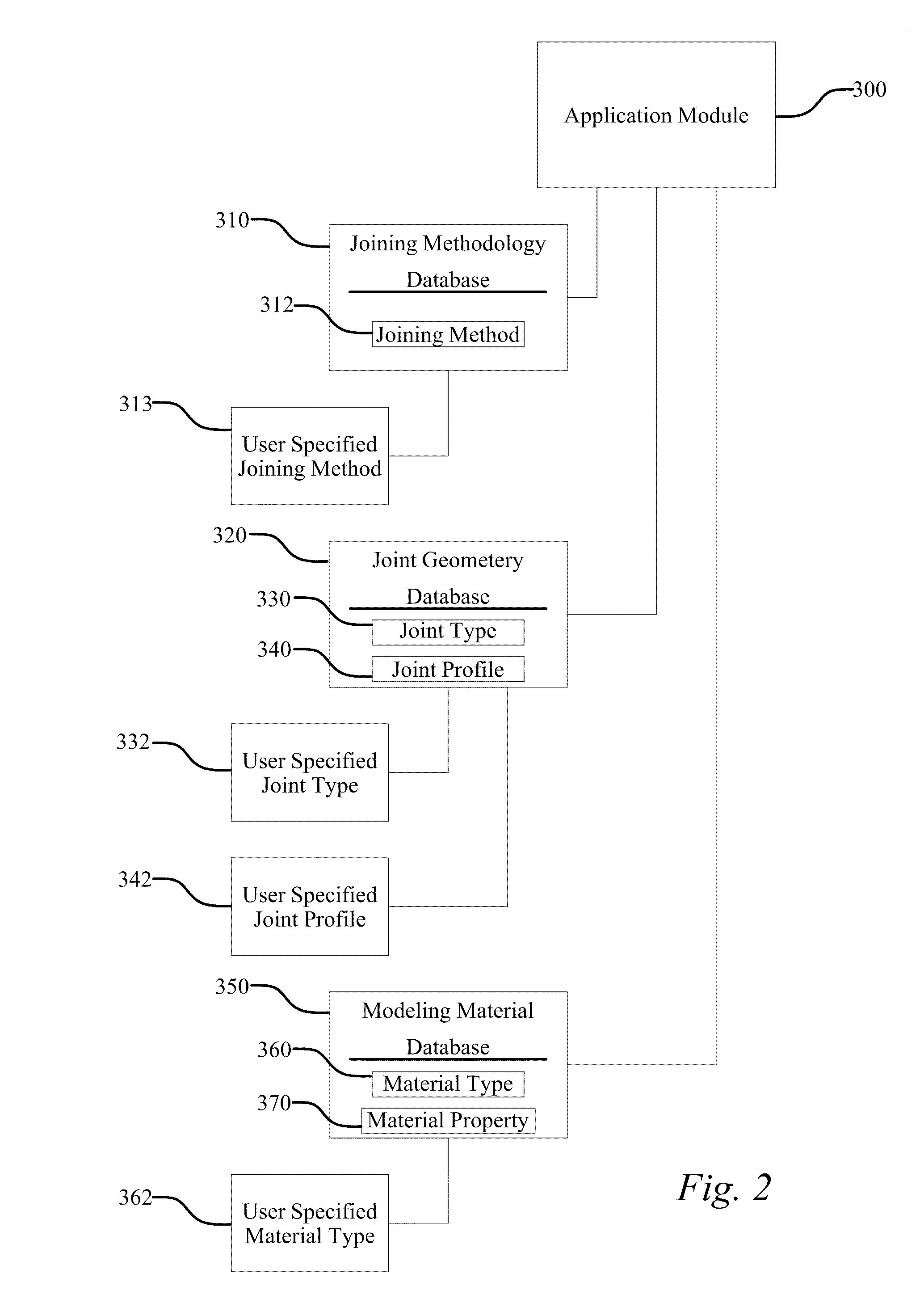

InactiveUS20100121472A1Arc welding apparatusAnalogue computers for control systemsPerformance computingModelSim

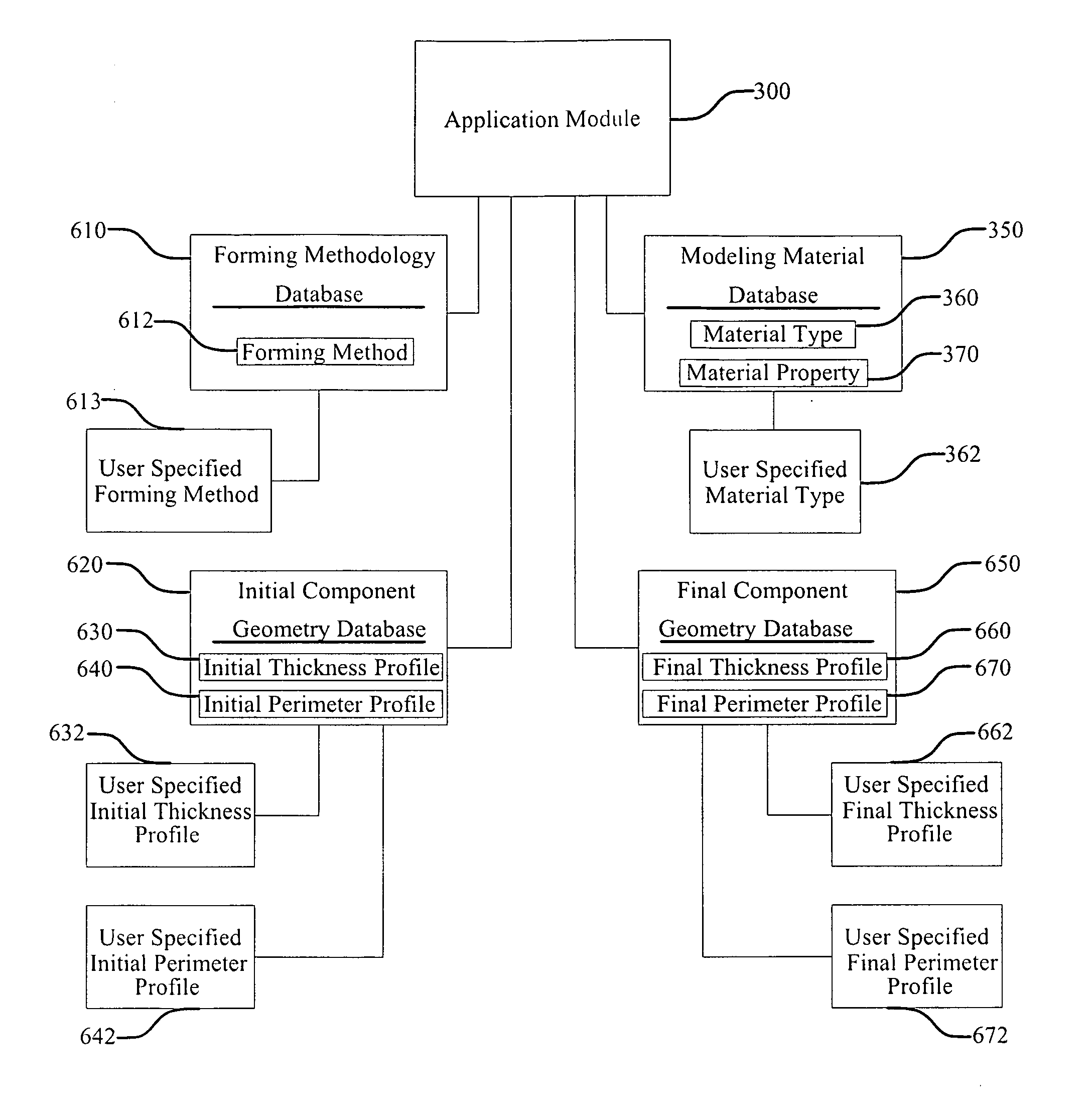

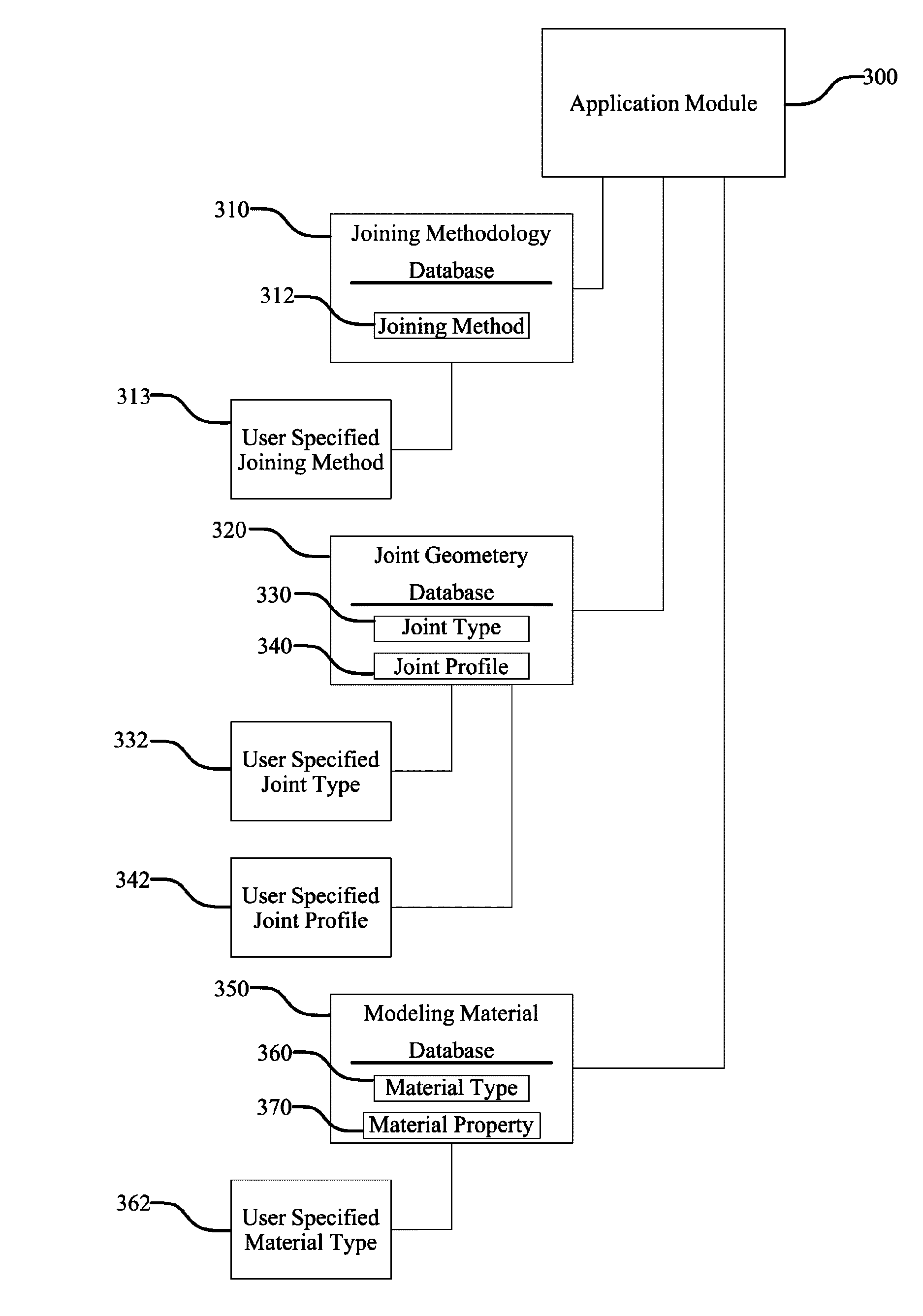

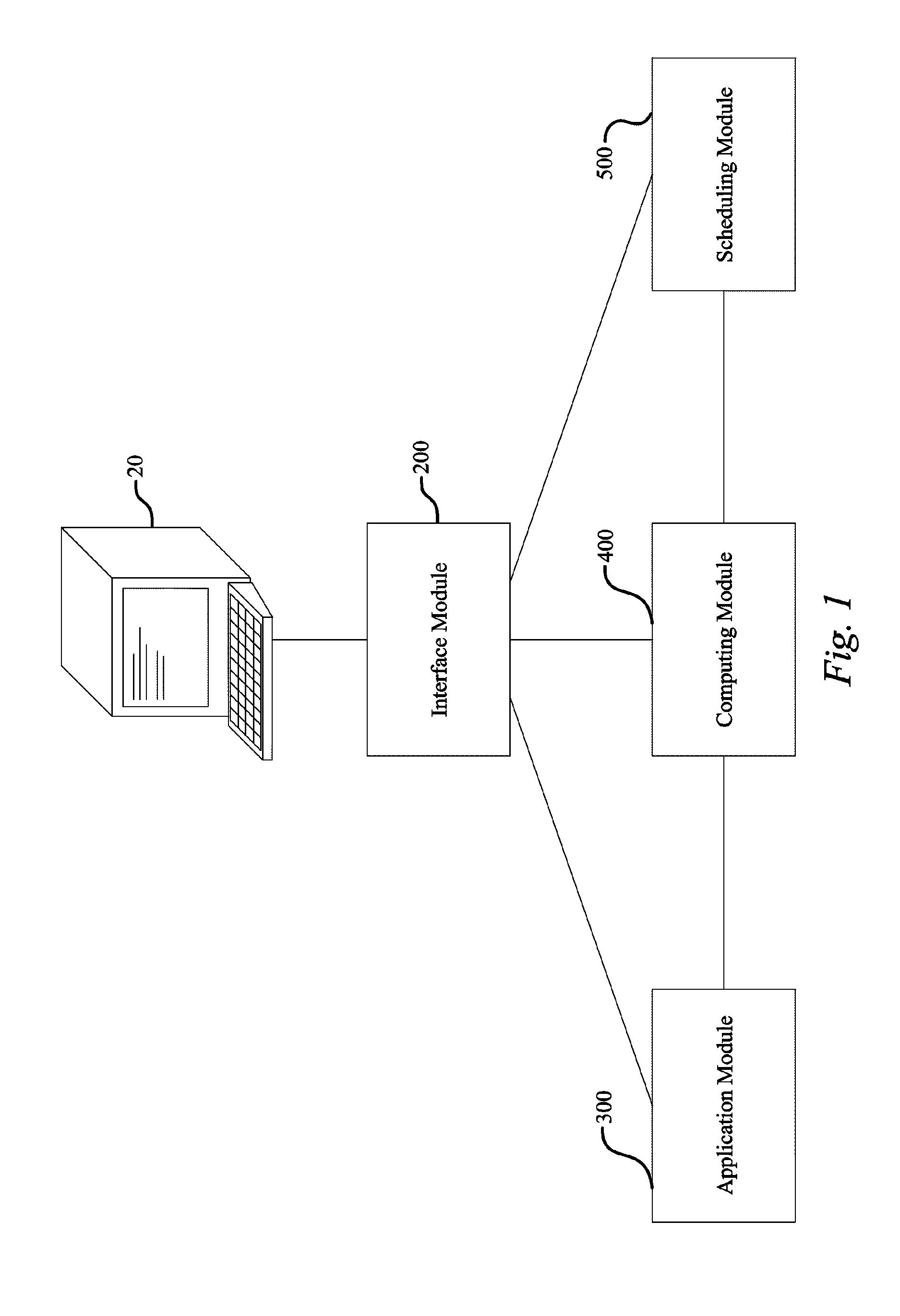

A remote high-performance computing material joining and material forming modeling system (100) enables a remote user (10) using a user input device (20) to use high speed computing capabilities to model materials joining and material forming processes. The modeling system (100) includes an interface module (200), an application module (300), a computing module (400), and a scheduling module (500). The interface module (200) is in operative communication with the user input device (20), as well as the application module (300), the computing module (400), and the scheduling module (500). The application module (300) is in operative communication with the interface module (200) and the computing module (400). The scheduling module (500) is in operative communication with the interface module (200) and the computing module (400). Lastly, the computing module (400) is in operative communication with the interface module (200), the application module (300), and the scheduling module (500).

Owner:EDISON WELDING INSTITUTE INC

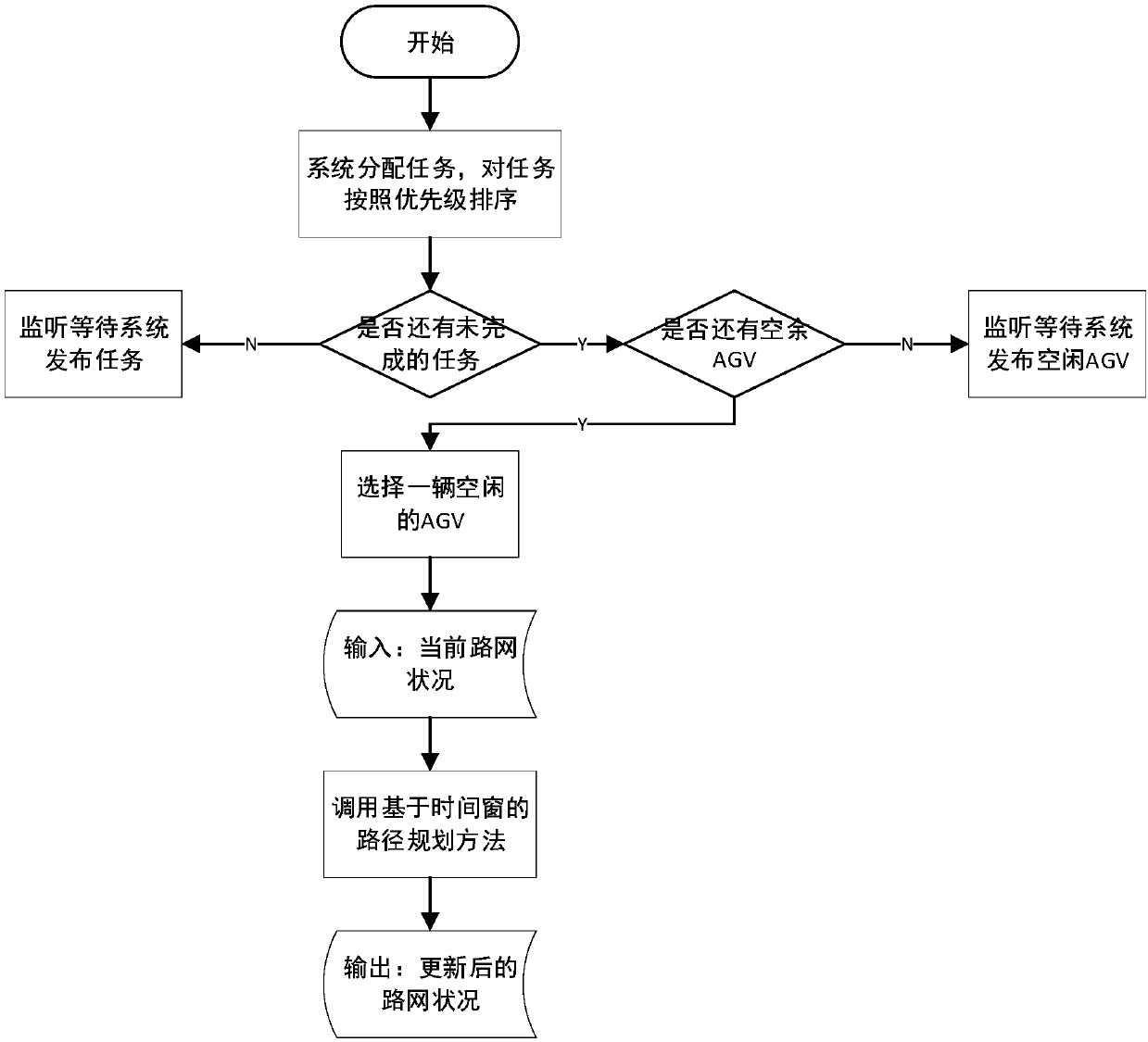

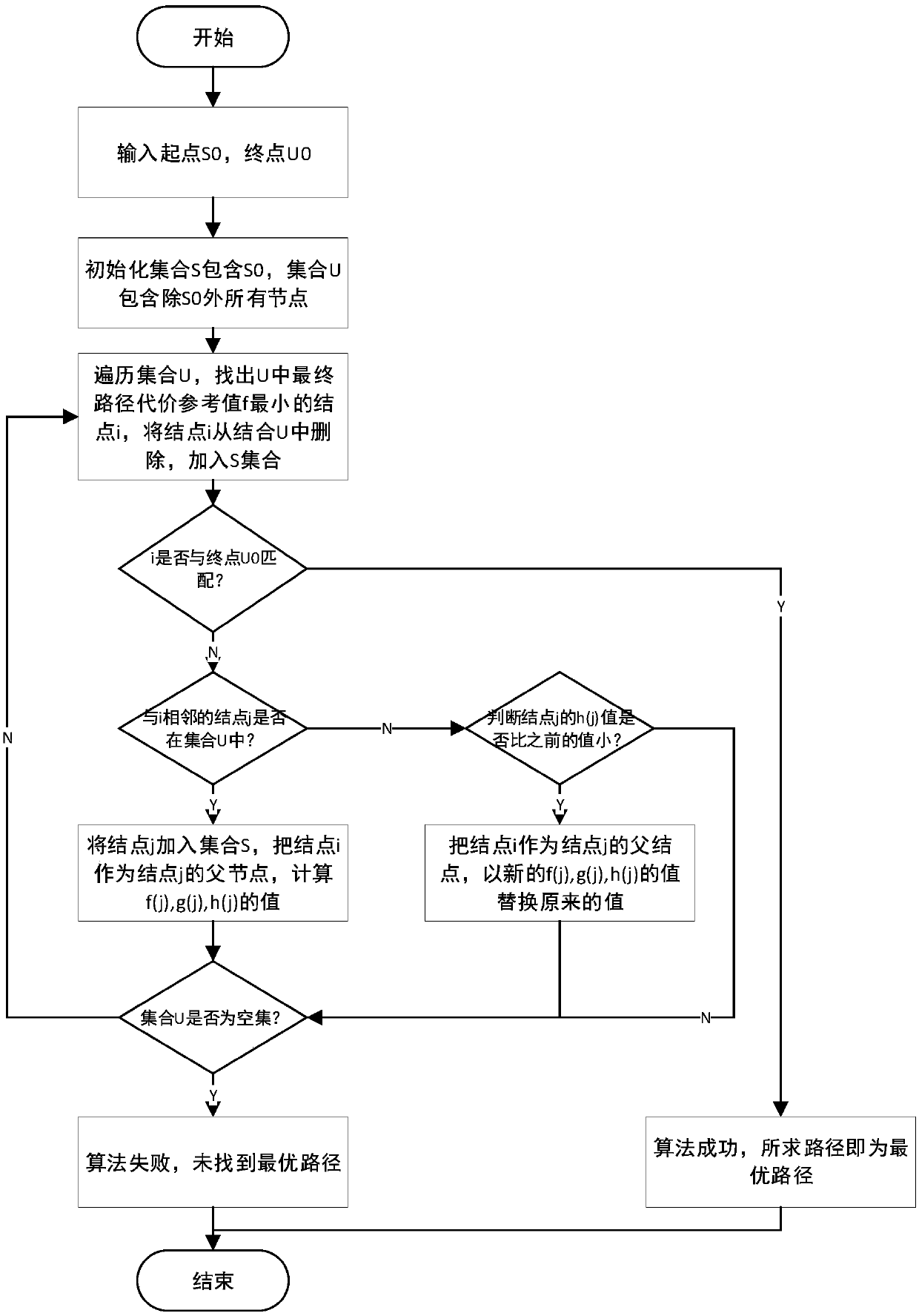

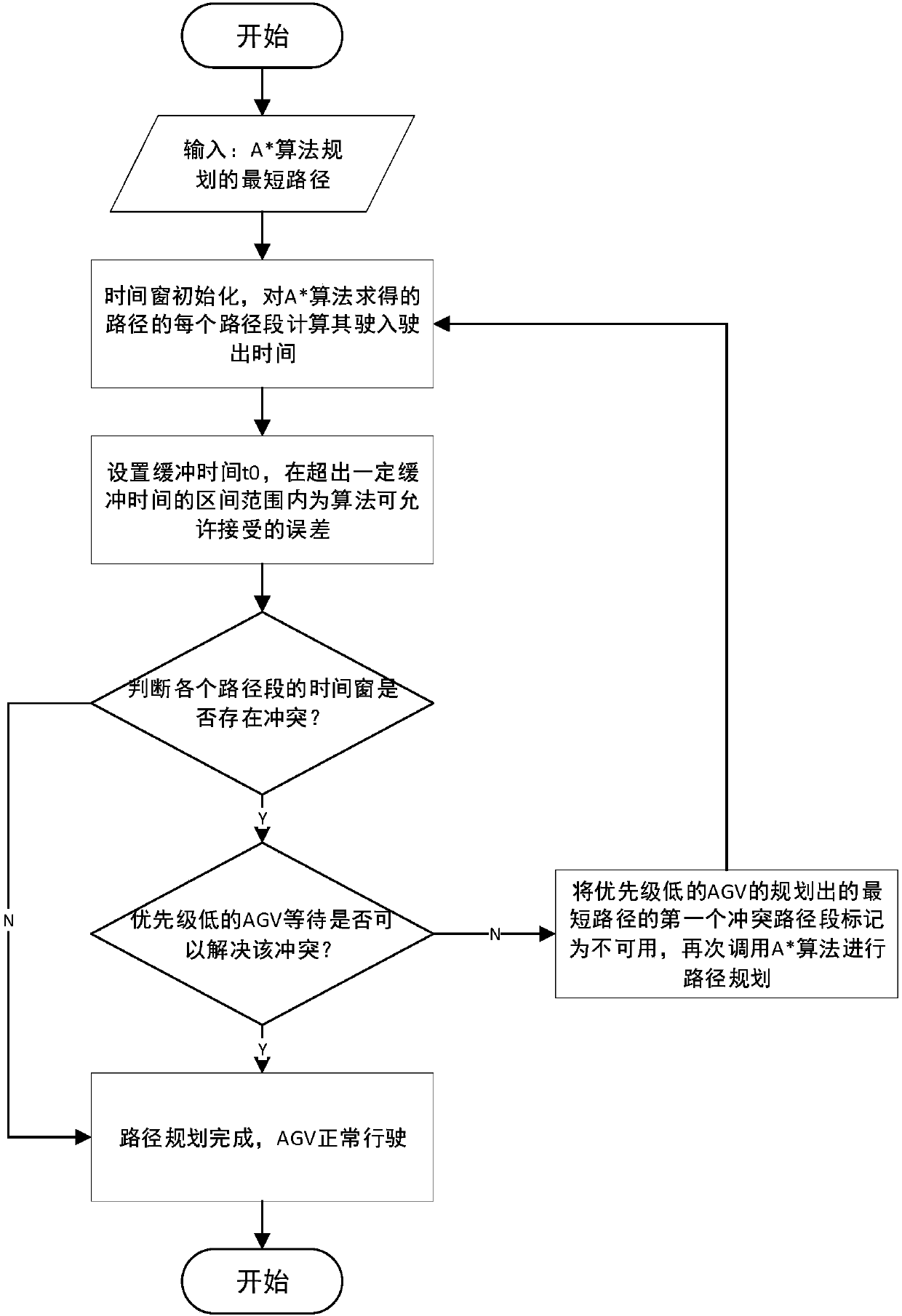

Dispatching and route-planning method for multiple AGVs used for material transportation in factory

PendingCN107727099AMake up for the shortcomings of not being able to get the optimal pathOptimal planning pathNavigational calculation instrumentsAlgorithmPlanning approach

The invention relates to a dispatching and route-planning method for multiple AGVs used for material transportation in a factory. The method comprises the following steps: (1) modeling material transportation scenes in a factory, including the travelling routes of AGVs, AGV charging points, loading and unloading points and standby zones for AGVs; (2) storing allocated tasks in a queue; (3) findingout one AGV closest to a current-task issuing site from a set of available AGVs; (4) calculating the shortest route from a current-task start point and a current-task stop point by using an A* algorithm; and (5) calling a time-window algorithm for maintenance of a time-window vector table of the shortest route obtained in the step (4). Compared with traditional A* algorithms, a heuristic functionin the A* algorithm used in the invention takes the traveling cost and turning cost of the AGVs on roads in a workshop into consideration, the time-window vector table of each route section is maintained, and whether conflicts exist in planned routes is determined by judging whether superposition exists; so the problems of collision conflicts, deadlock and the like of AGV route planning are effectively overcome.

Owner:SHANDONG UNIV

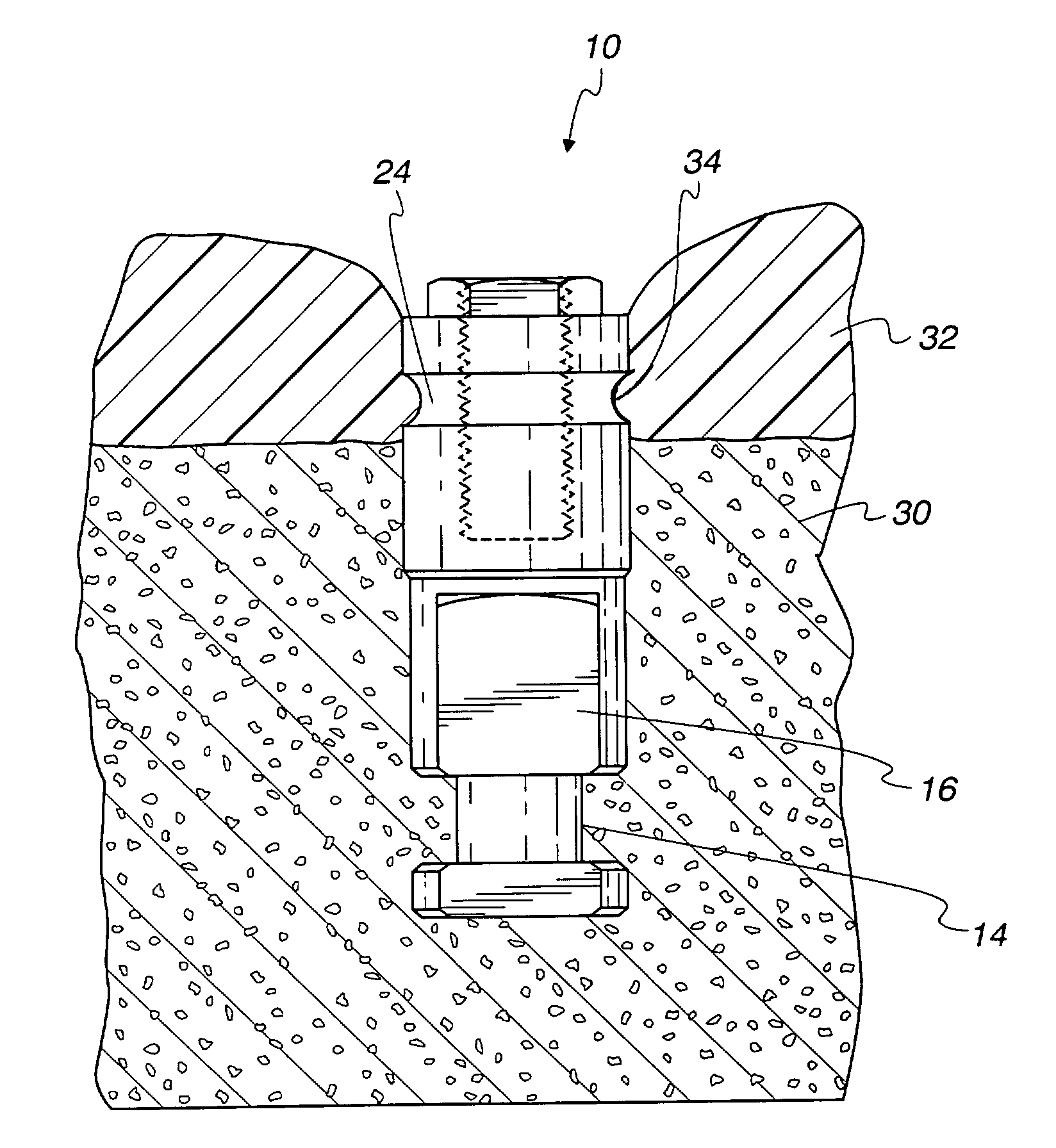

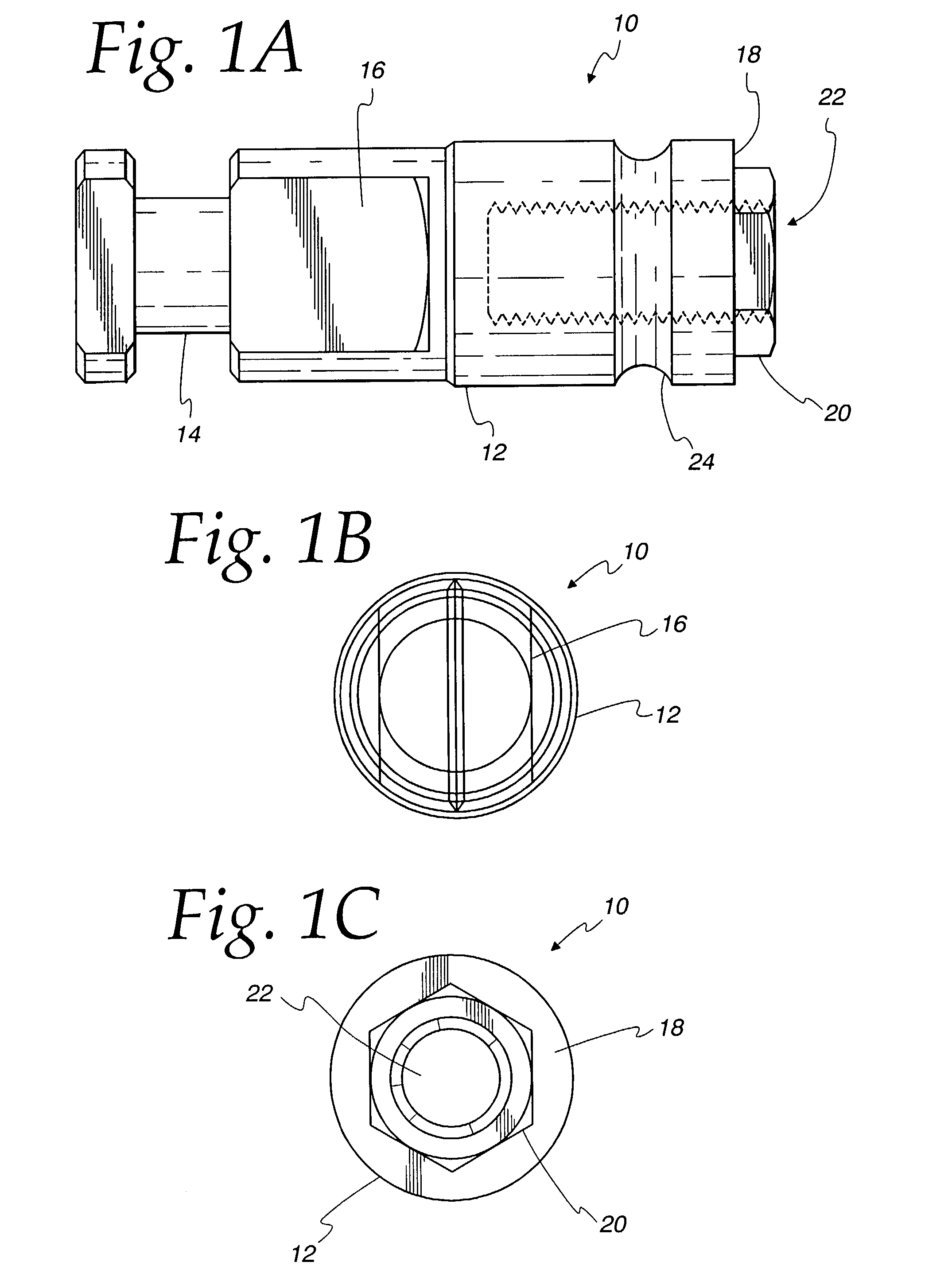

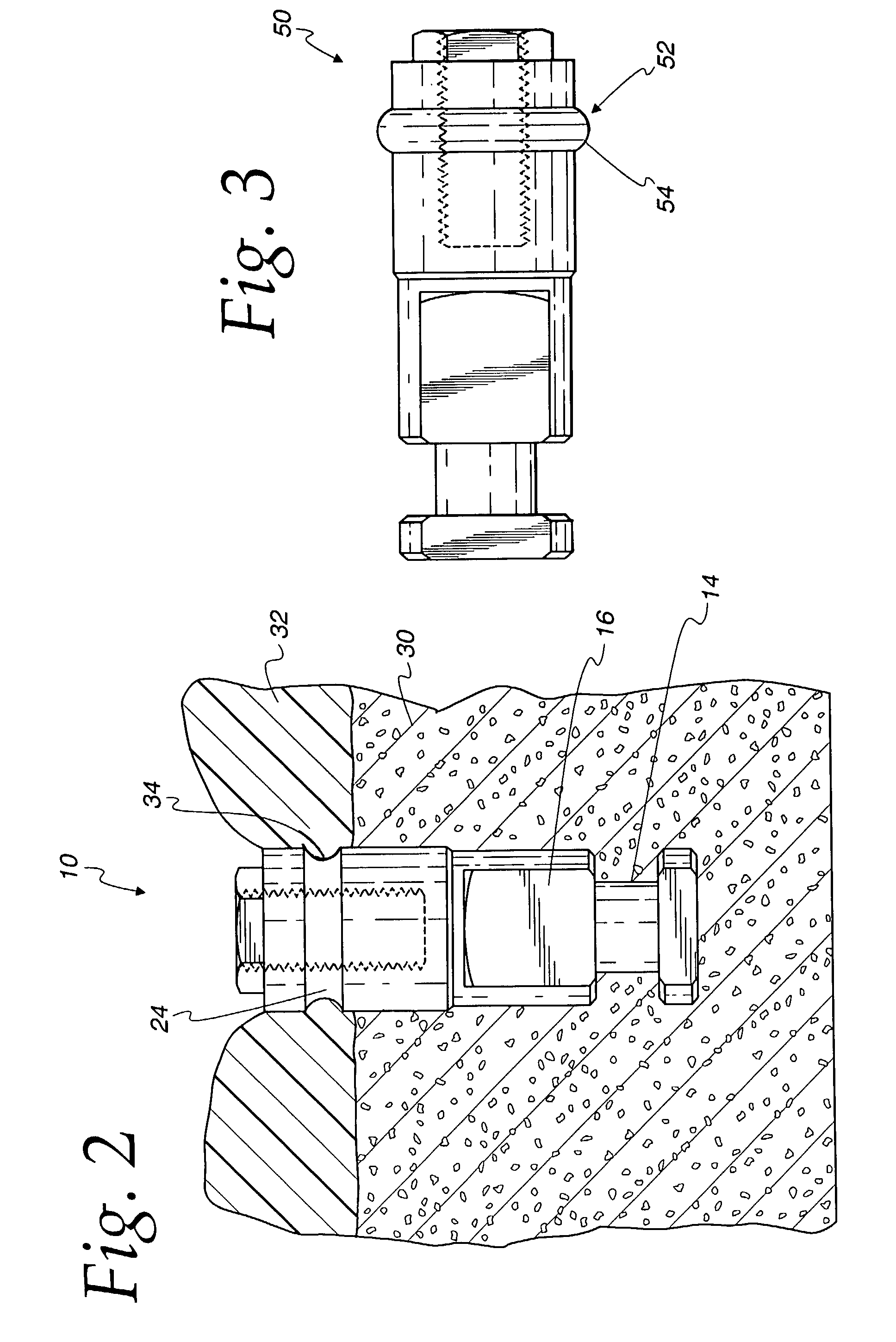

Dental implant analog having retention groove for soft tissue modeling

An implant analog is for supporting an article that is used to develop a dental prosthesis. The analog provides a main body for being anchored in a model of a mouth of a patient. The main body includes an upper surface for contacting the article that is used to develop a dental prosthesis. The analog includes a groove extending inward along a periphery of the main body below the upper surface for receiving a soft modeling material that replicates gingival tissue. Material for forming a soft tissue model flows into the groove to create a corresponding rib in the soft tissue model that allows the soft tissue model to be properly registered on the underlying stone model.

Owner:BIOMET 3I LLC

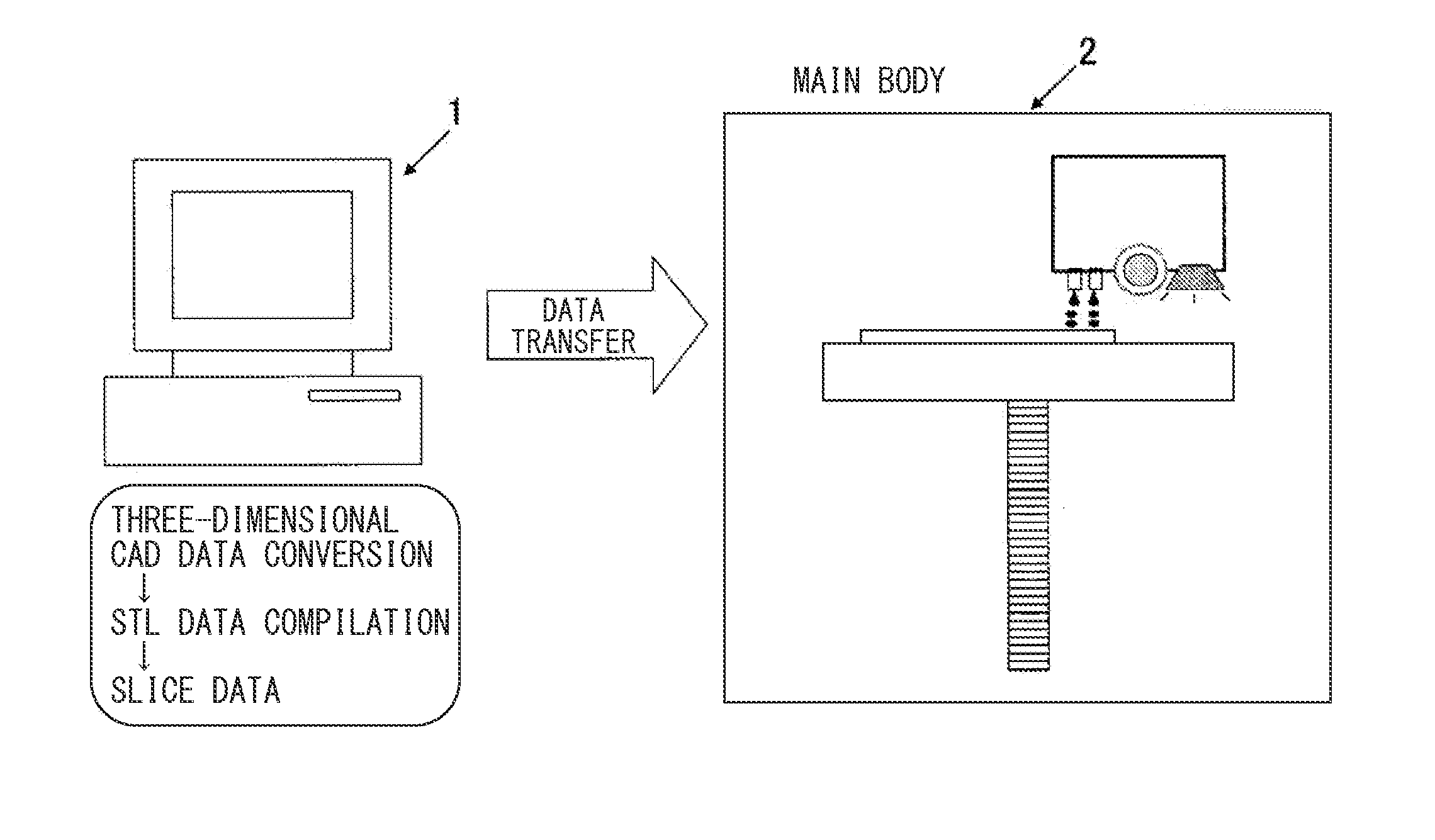

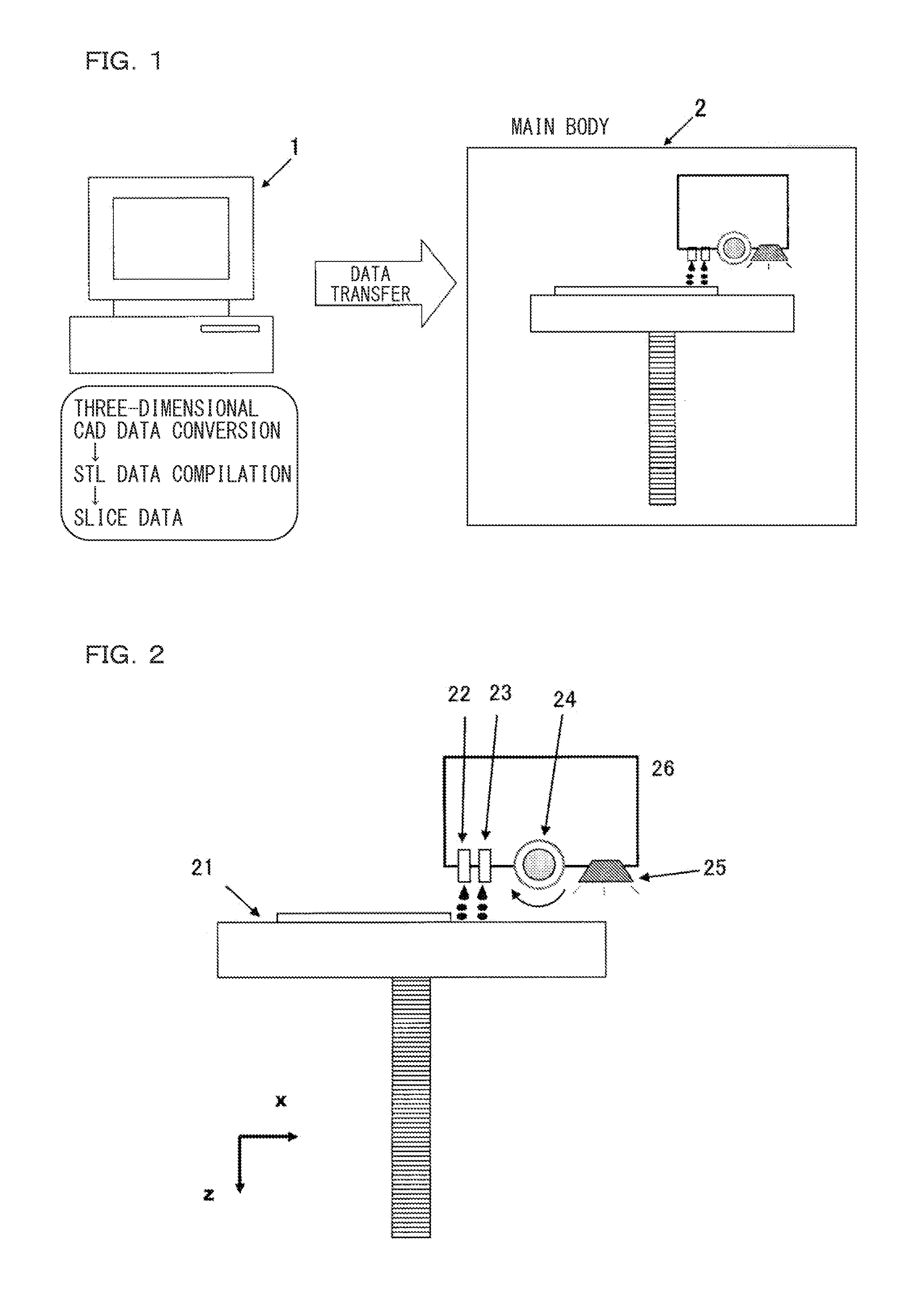

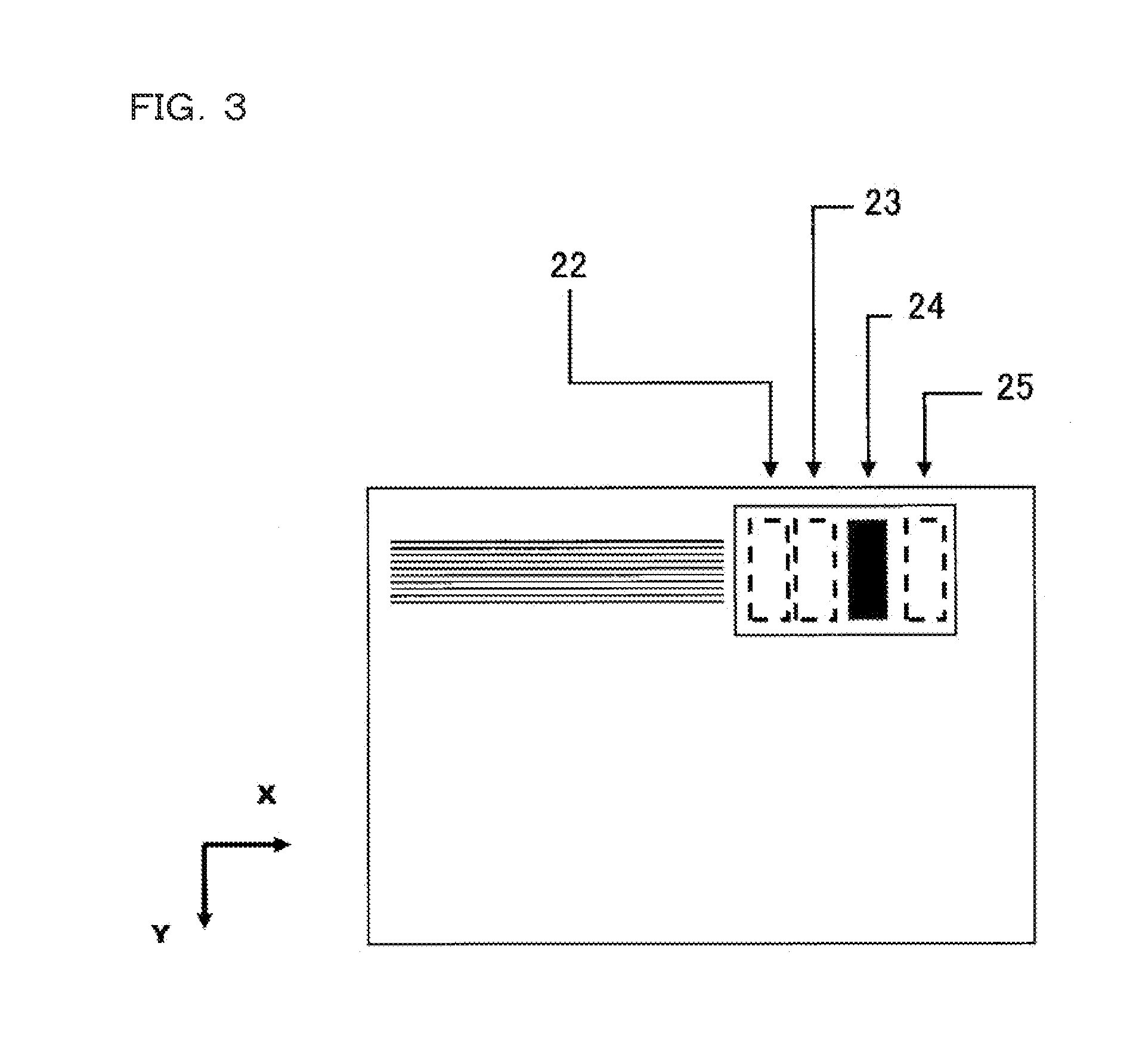

Modeling Material For Forming Photofabrication Model In Ink-Jet Three Dimensional Printing, Supporting Material For Supporting The Shape Of Photofabrication Model On Photofabrication And Production Method Of Photofabrication Model

ActiveUS20130234370A1Good water solubilityEasy to disassembleAdditive manufacturing apparatusInksSolubilityWater soluble

The present invention aims to provide a supporting material for supporting the shape of a photofabrication model on photofabrication in ink-jet three dimensional printing method in which the photocured product is excellent in solubility in water and is easy to remove after photofabrication, and the like. A modeling material for forming a photofabrication model in ink-jet three dimensional printing method containing a curable resin component with a weighted average of SP value of 9.0 to 10.3; and a supporting material for supporting the shape of a photofabrication model on photofabrication in ink-jet three dimensional printing method containing a water-soluble monofunctional ethylenically unsaturated monomer (F), polyoxypropylene glycol with a number average molecular weight of 100 to 5,000 and / or water (G), and a photopolymerization initiator (D).

Owner:KEYENCE

Creep resistance magnesium alloy and preparation method thereof

A kind of alloy, which is anti-squirming, and the components of it and the weight percent of them is: 1.5-10%Y, 0.15-2.0%Zr, 0.3-2.0%Nd, 2.5-8%Gd, and one kind or several kinds of components among Sm, Dy, Tb, Ho, Er, Tm and Eu is also contained, the other is Mg. the following steps are contained in the method: (1) To prepare material (2) To improve the temperature of warm-up stove and melting stove (3) To warm up the material (4) To melt the purified magnesium ingots in batches (5) To melt the other materials, which has been warmed up, in the Mg solution. (6) To distribute equably the alloy components in the Mg solution. (7) To make into casting ingot, cast, billet, board material, pipe material, model material, stick material, line material and all kinds of forged piece. The Mg alloy can fulfill the need owing a higher mechanics performance and anti-squirming performance under high temperate, and the anti-causticity performance is higher than the Mg in existence.

Owner:GRIMAT ENG INST CO LTD

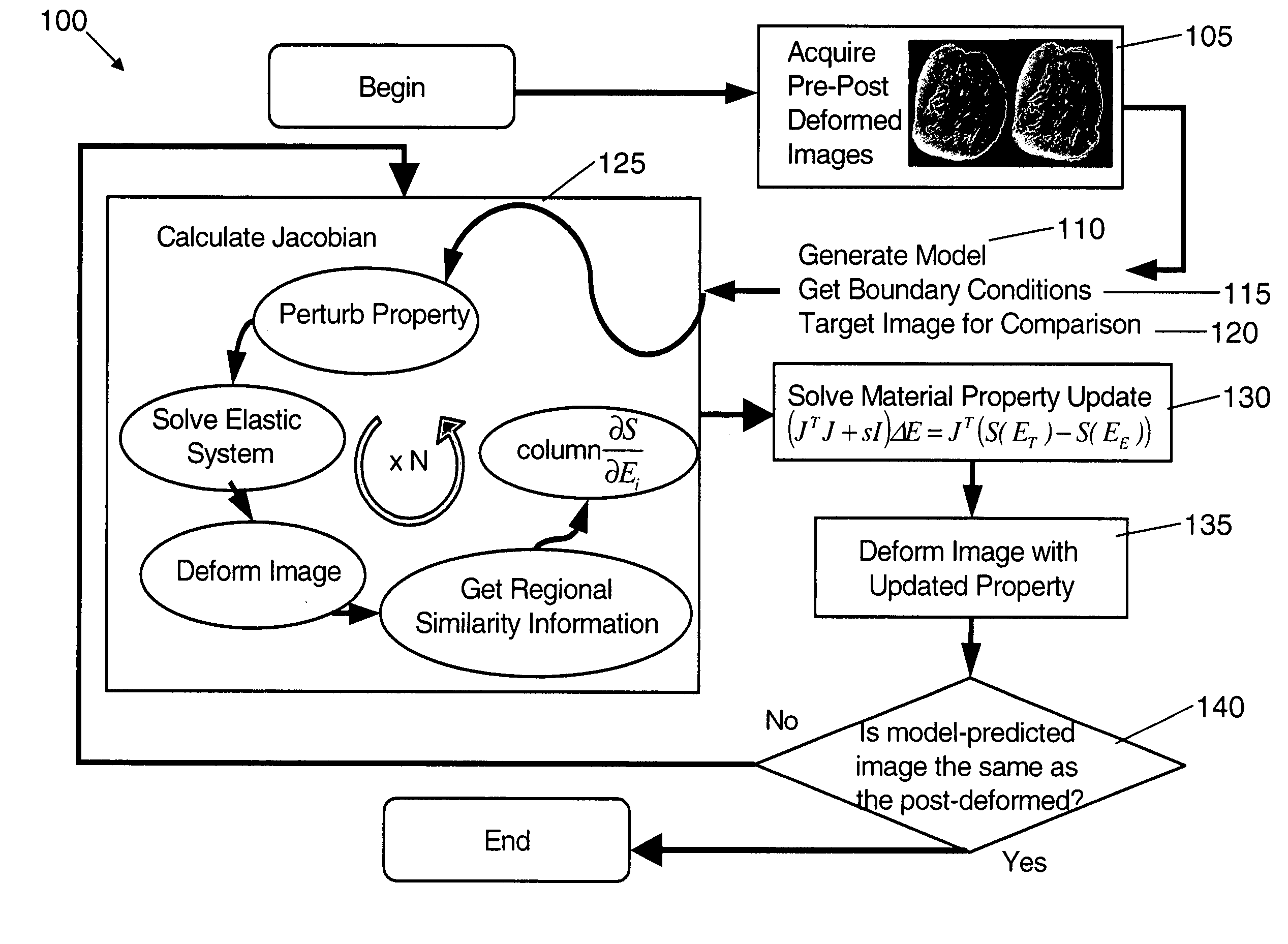

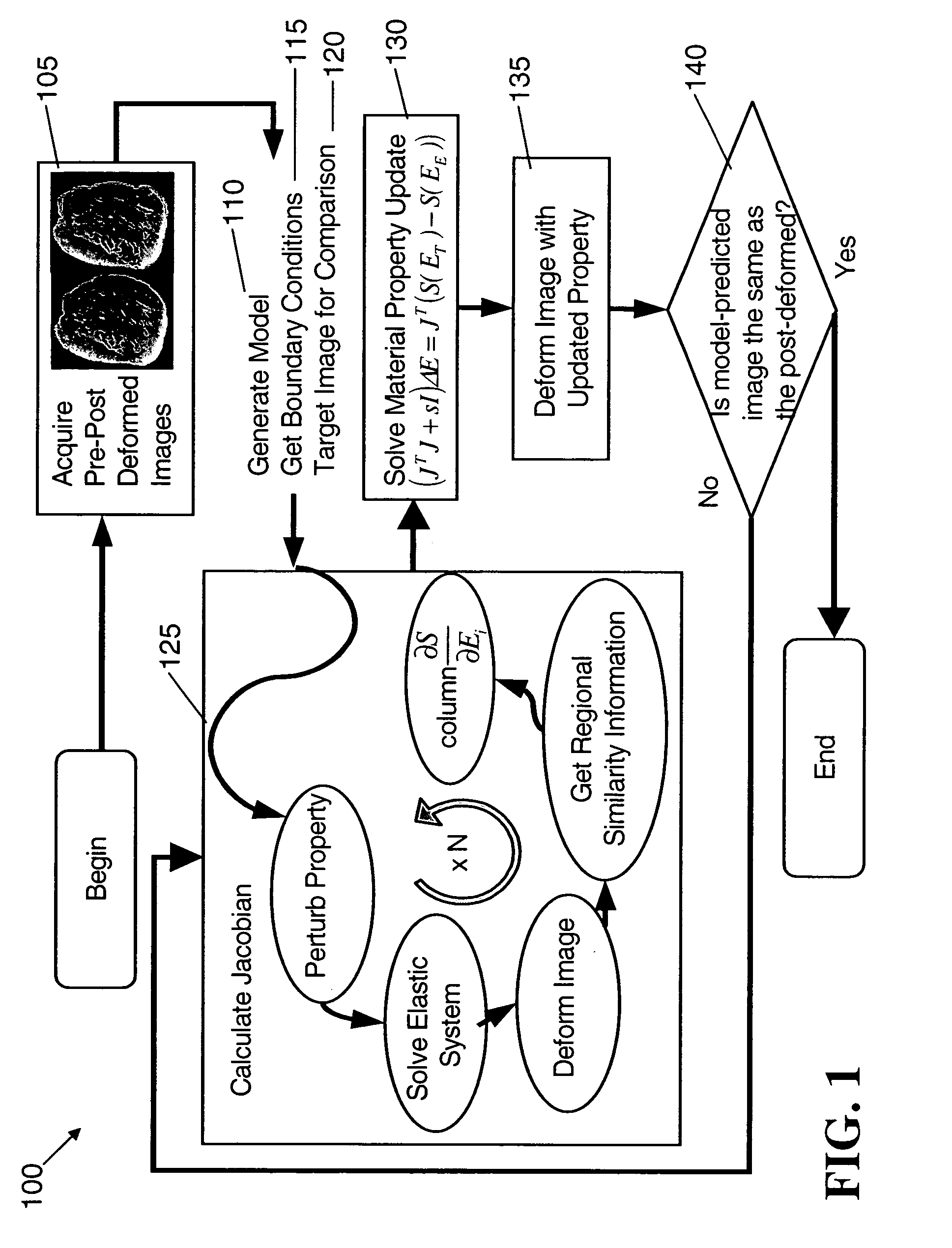

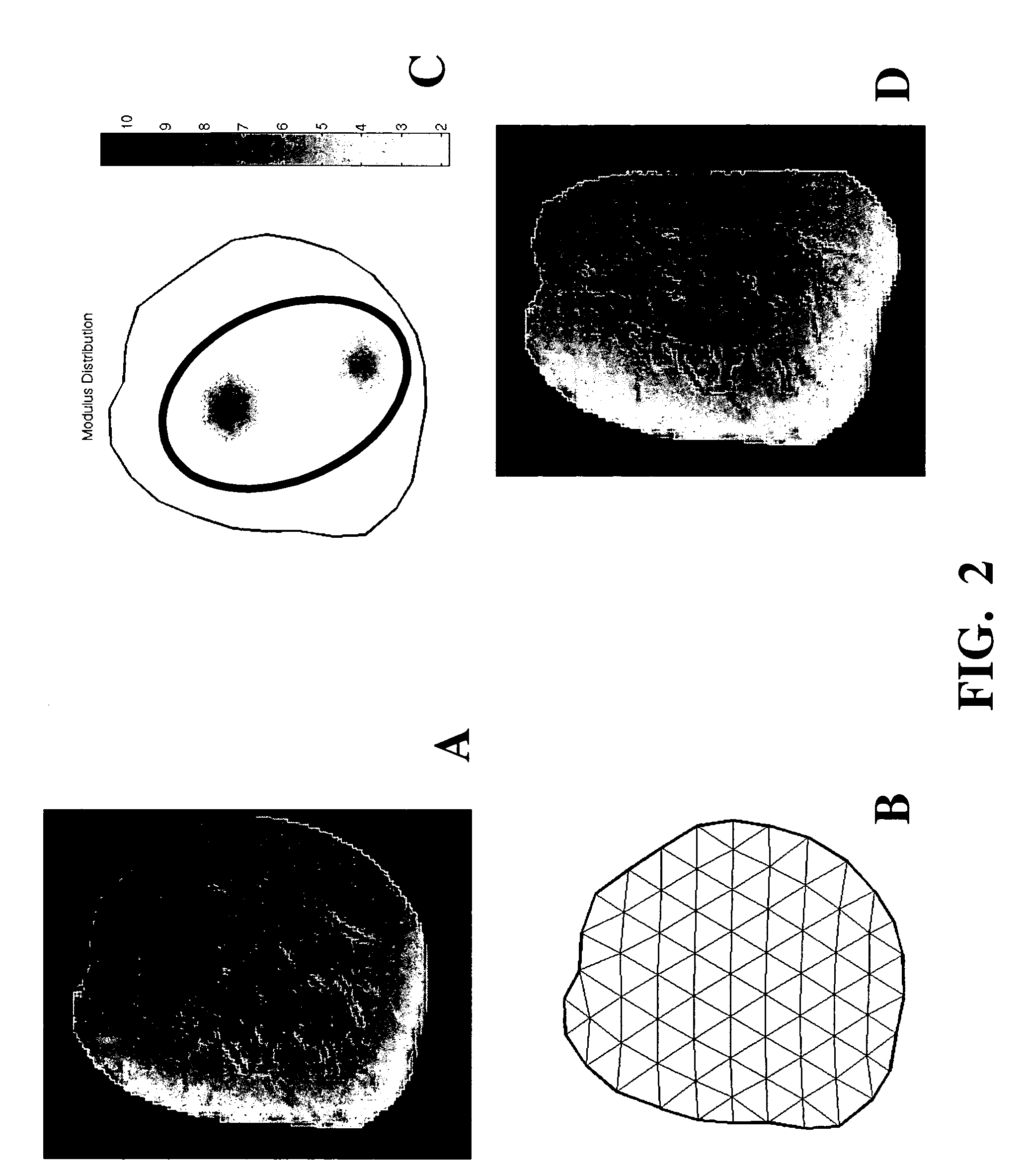

Elastography imaging modalities for characterizing properties of tissue

An image reconstruction algorithm begins with an initial acquisition of a preoperative imaging volume followed by a second imaging sequence subsequent to an applied deformation. A computational domain (model) is generated from the preoperative image series and boundary conditions are derived from a pre-post deformation comparison, as well as from information gathered from deformation source application (i.e., displacement and / or force). Using boundary conditions, a series of model-based image deformations is accomplished while varying model material properties. A calculation of a Jacobian matrix relating the change in regional mutual information is performed with respect to the change in material properties. Upon completion of this process, matrix regularization techniques are used to condition the system of equations and allow for inversion and subsequent delivery of model-property adjustments.

Owner:VANDERBILT UNIV

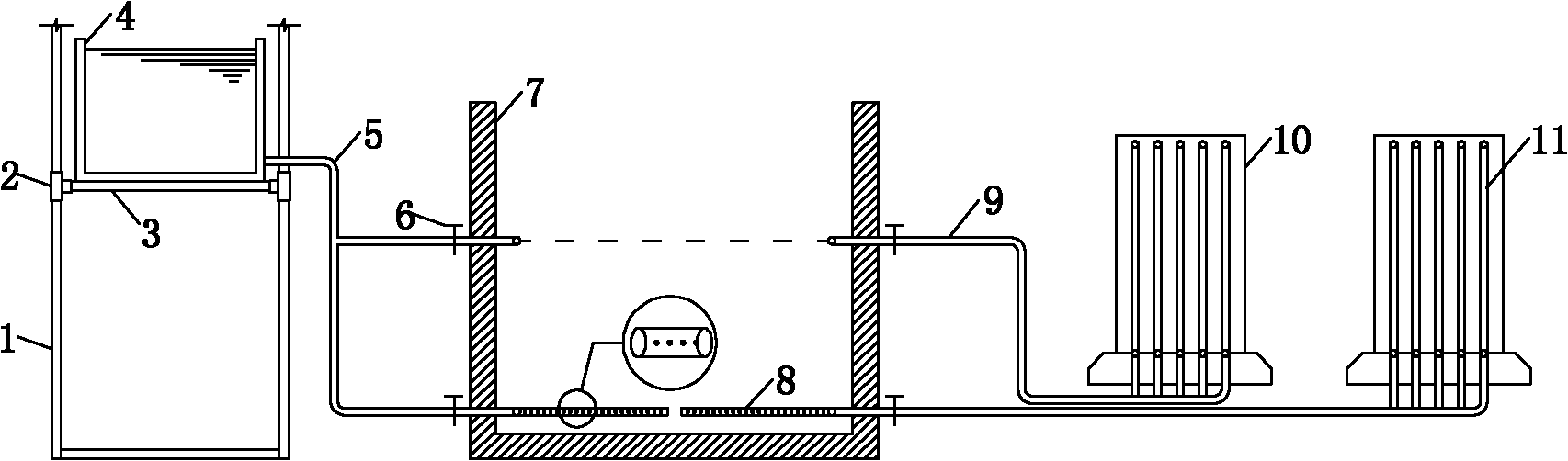

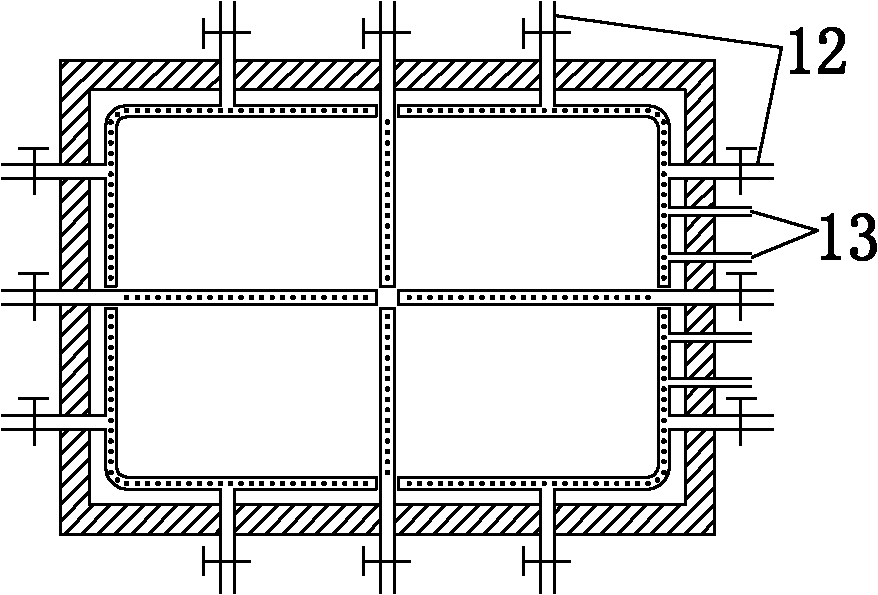

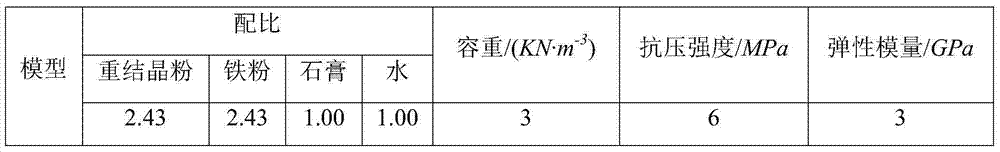

Model for causing ground setting due to engineering environment effect and test method thereof

The invention discloses a model for causing ground setting due to an engineering environment effect and a test method thereof. The model comprises a model casing, simulation materials, measuring equipment, data acquisition equipment and water pressure controlling equipment, wherein the simulation materials for simulating a research area are placed in the model casing; the measuring equipment is arranged in the model casing for measuring parameters; the data acquisition equipment is connected with the measuring equipment and is used for acquiring and processing the parameters measured by the measuring equipment; and the water pressure controlling equipment is connected with the model casing and provides water pressure for the model casing and is used for simulating a water table aquifer and an artesian aquifer on a practical soil layer. the test method comprises the following steps of: determining influence factors to be researched; considering the size and the distance of a simulationbuilding and the plane size of the model casing according to the consolidation principle; determining various similar constants by adopting a dimensional method; determining the simulation materials;simulating the early-stage preparations of the test; and carrying out a simulation test. According to the invention, the ground deformation due to the underground water level lifting and the ground setting due to the engineering environment effect can be researched.

Owner:TONGJI UNIV

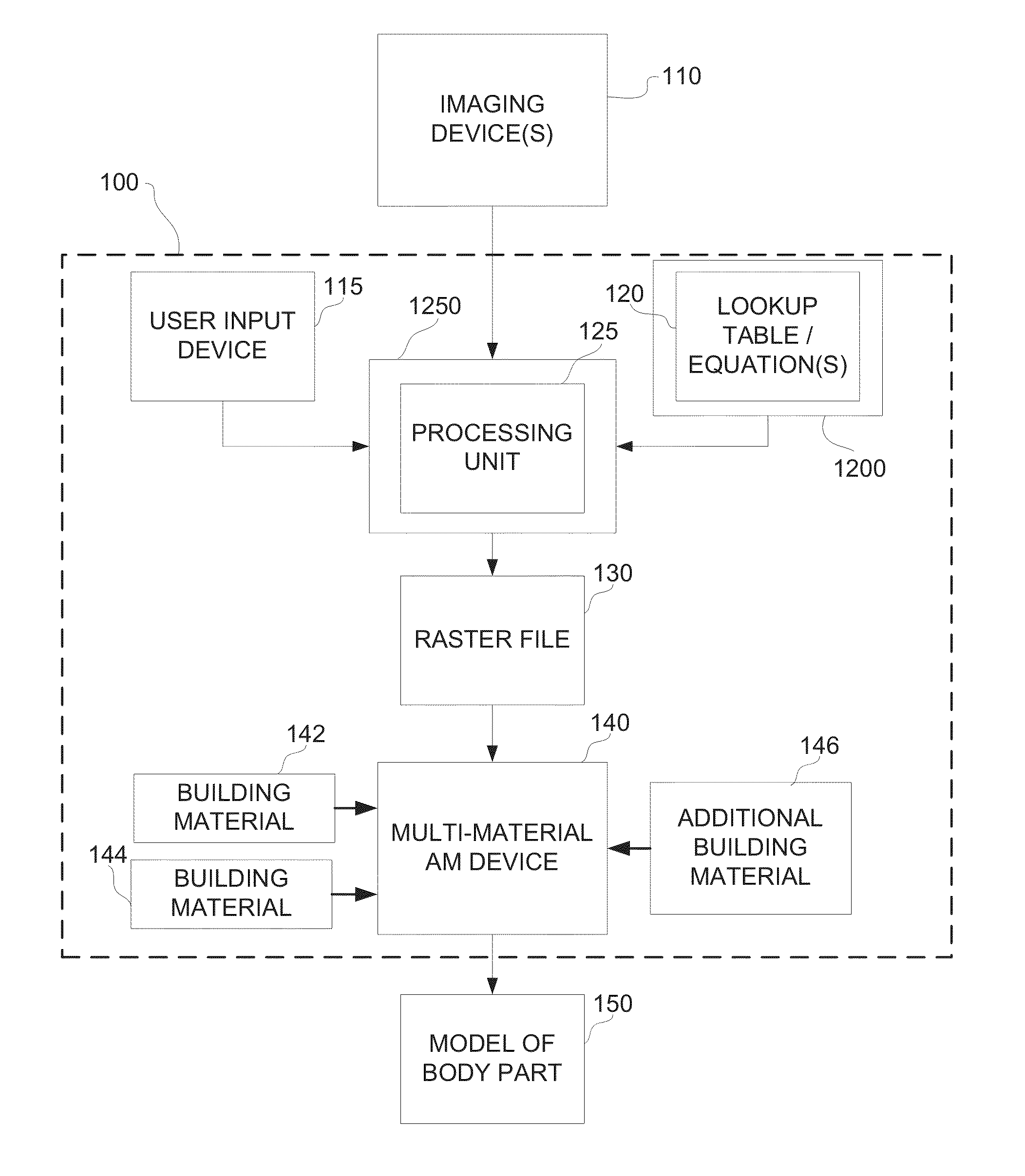

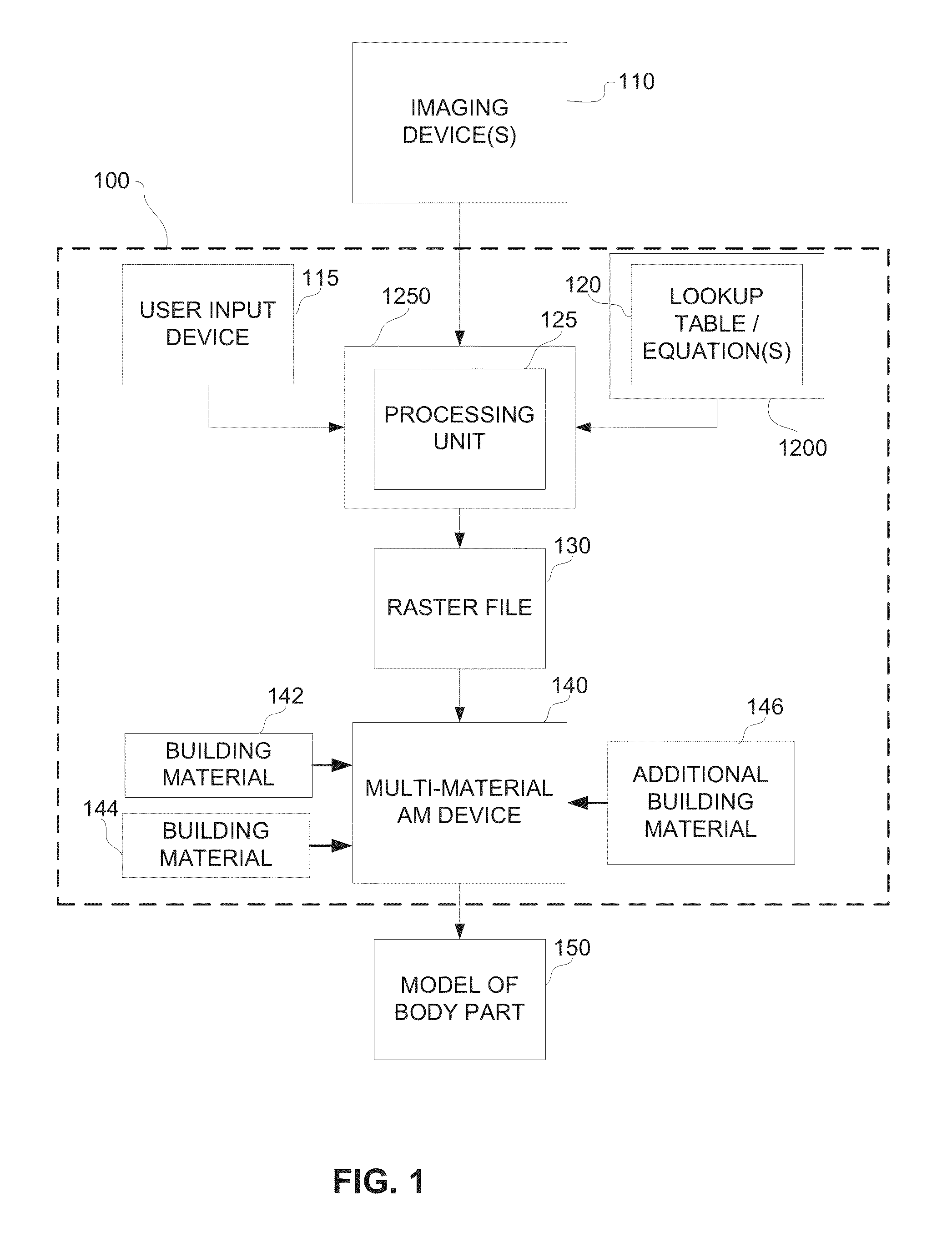

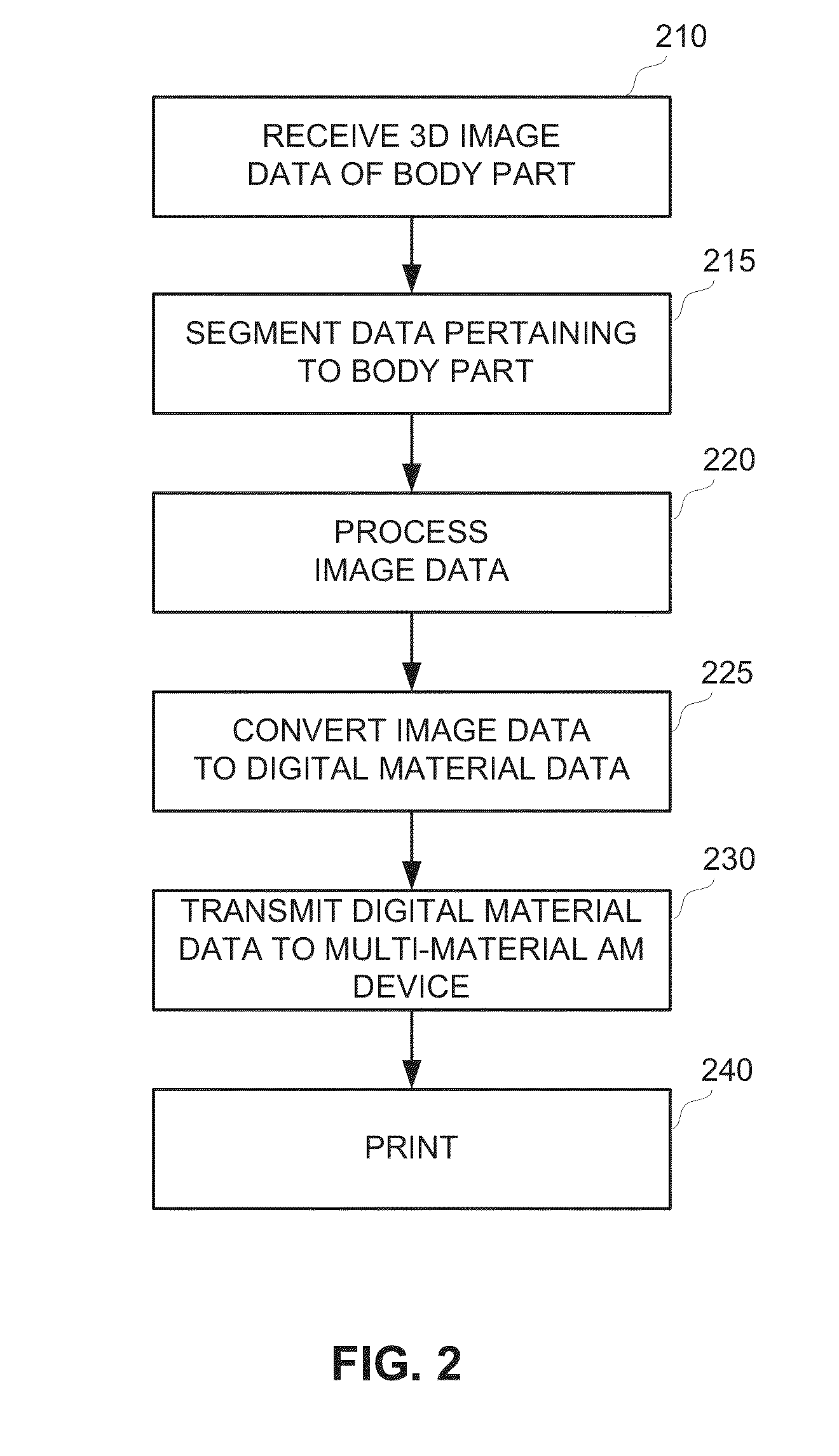

System and method for fabricating a body part model using multi-material additive manufacturing

ActiveUS20140312535A1Improve representationTurning machine accessoriesJoint implantsMulti materialVoxel

A method for physically reconstructing a body part using multi-material additive manufacturing includes receiving image data of the body part in the form of arrays of voxels, each array of voxels representing image data pertaining to cross-section of the body part, translating the image data in the arrays of voxels to printable bitmap images representing combinations of modeling materials for reconstructing the body part, and dispensing the combinations of modeling materials responsive to the bitmap images in a layerwise manner.

Owner:STRATASYS LTD

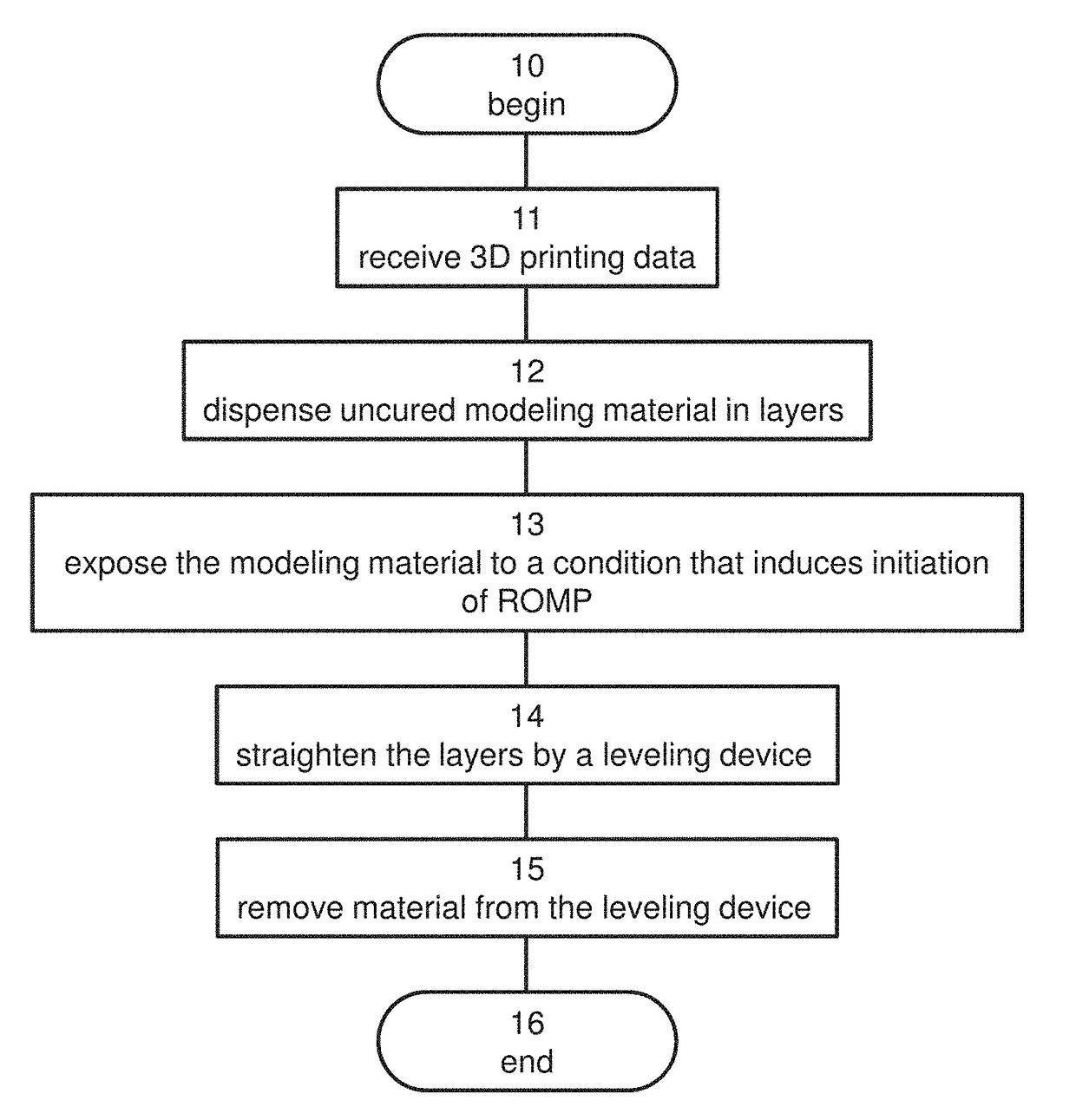

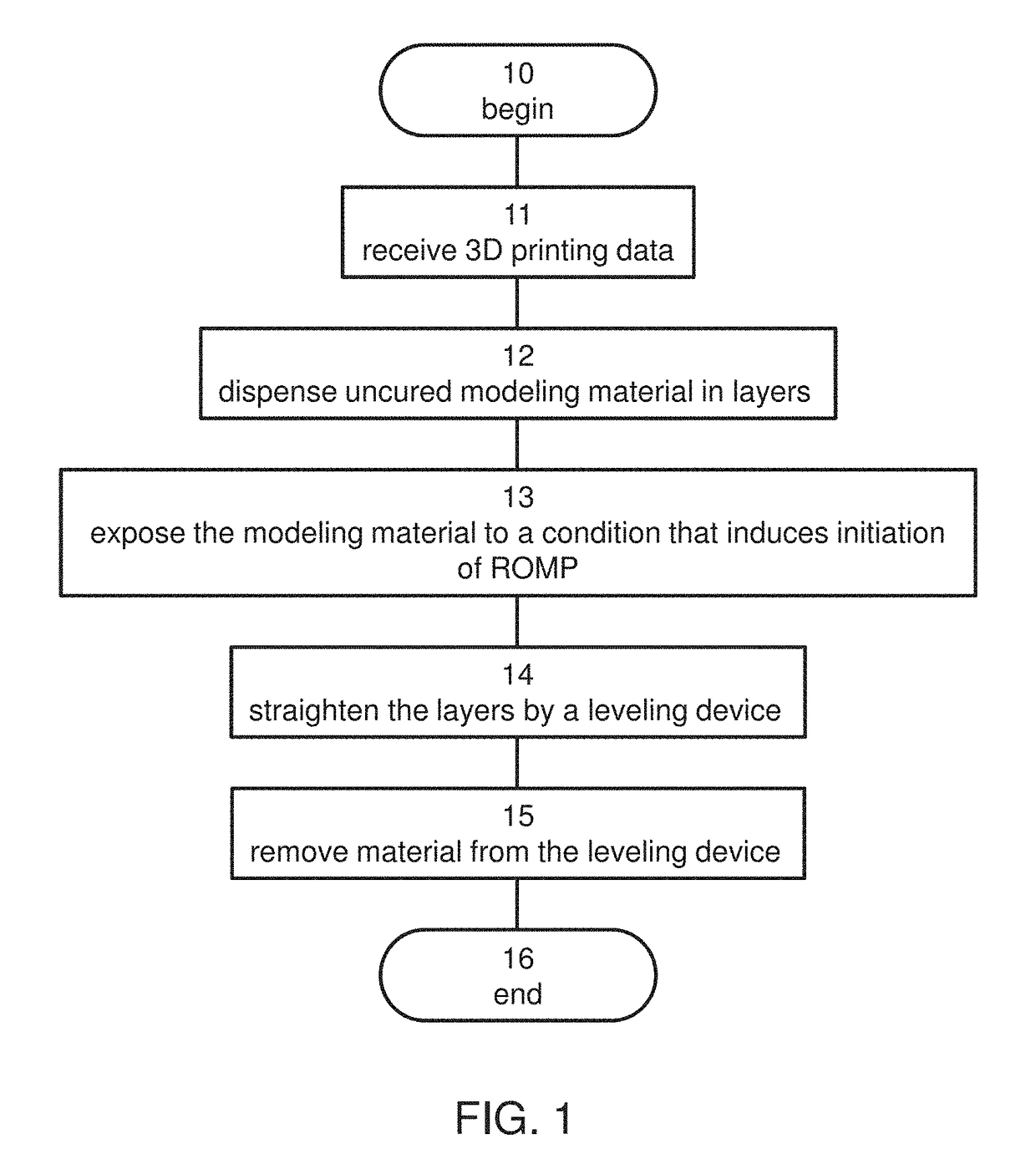

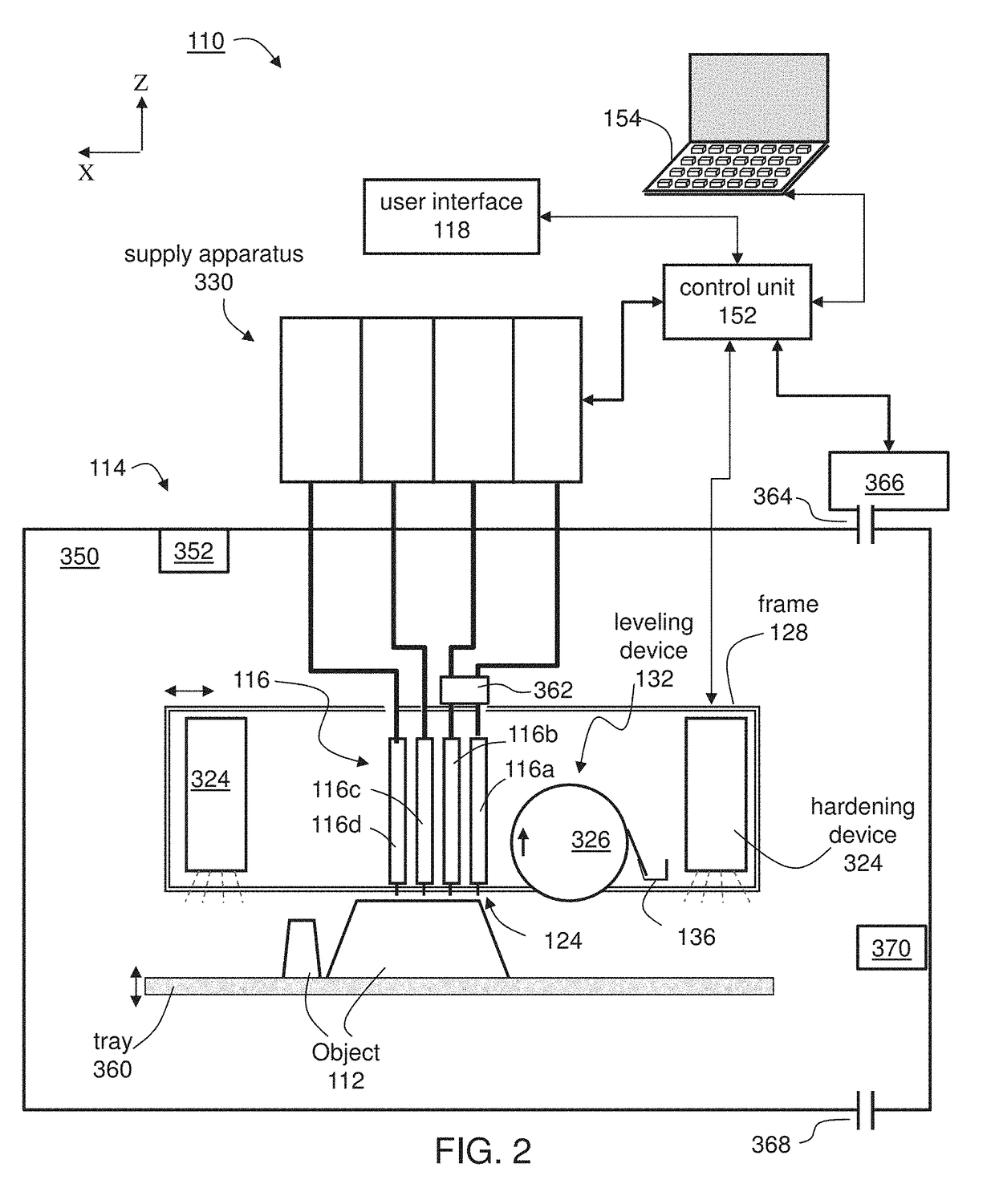

Three-dimensional inkjet printing using ring-opening metathesis polymerization

ActiveUS20170306171A1Improve mechanical propertiesImprove heat resistanceAdditive manufacturing apparatusInksPolymerizationChemistry

Methods for fabricating three-dimensional objects by 3D-inkjet printing technology are provided. The methods utilize curable materials that polymerize via ring-opening metathesis polymerization (ROMP) for fabricating the object. Systems suitable for performing these methods and kits containing modeling material formulations usable in the methods are also provided.

Owner:STRATASYS LTD

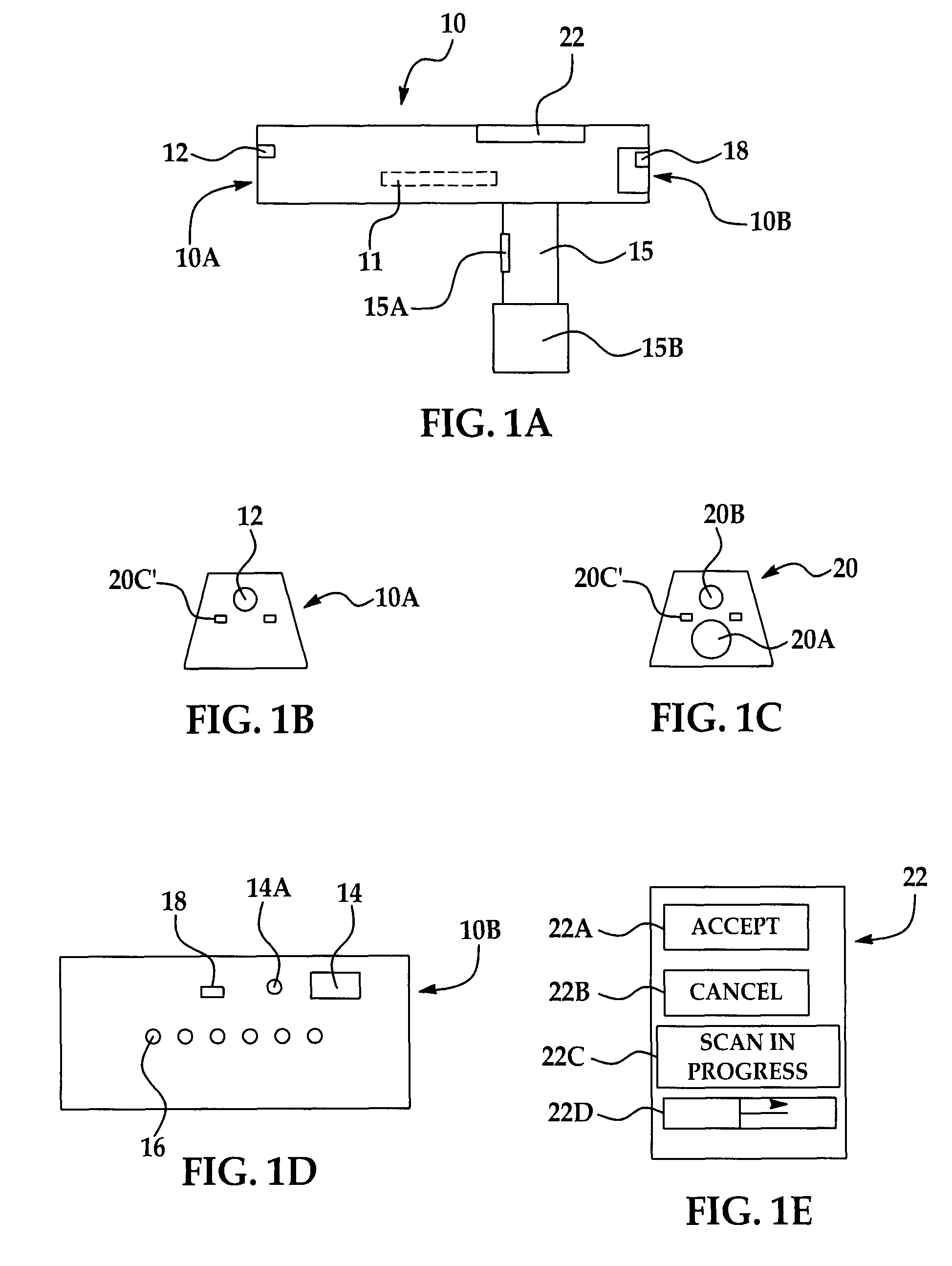

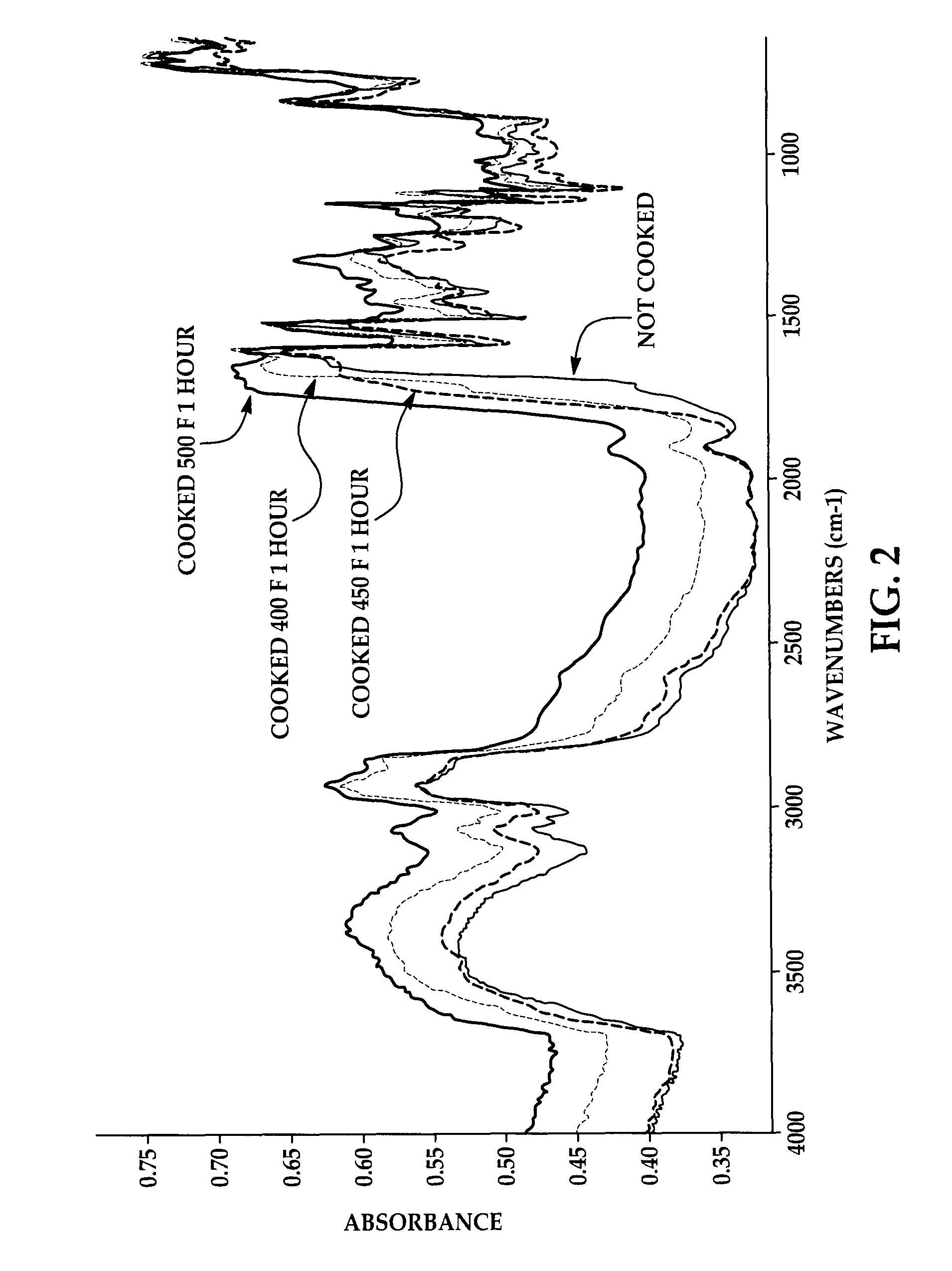

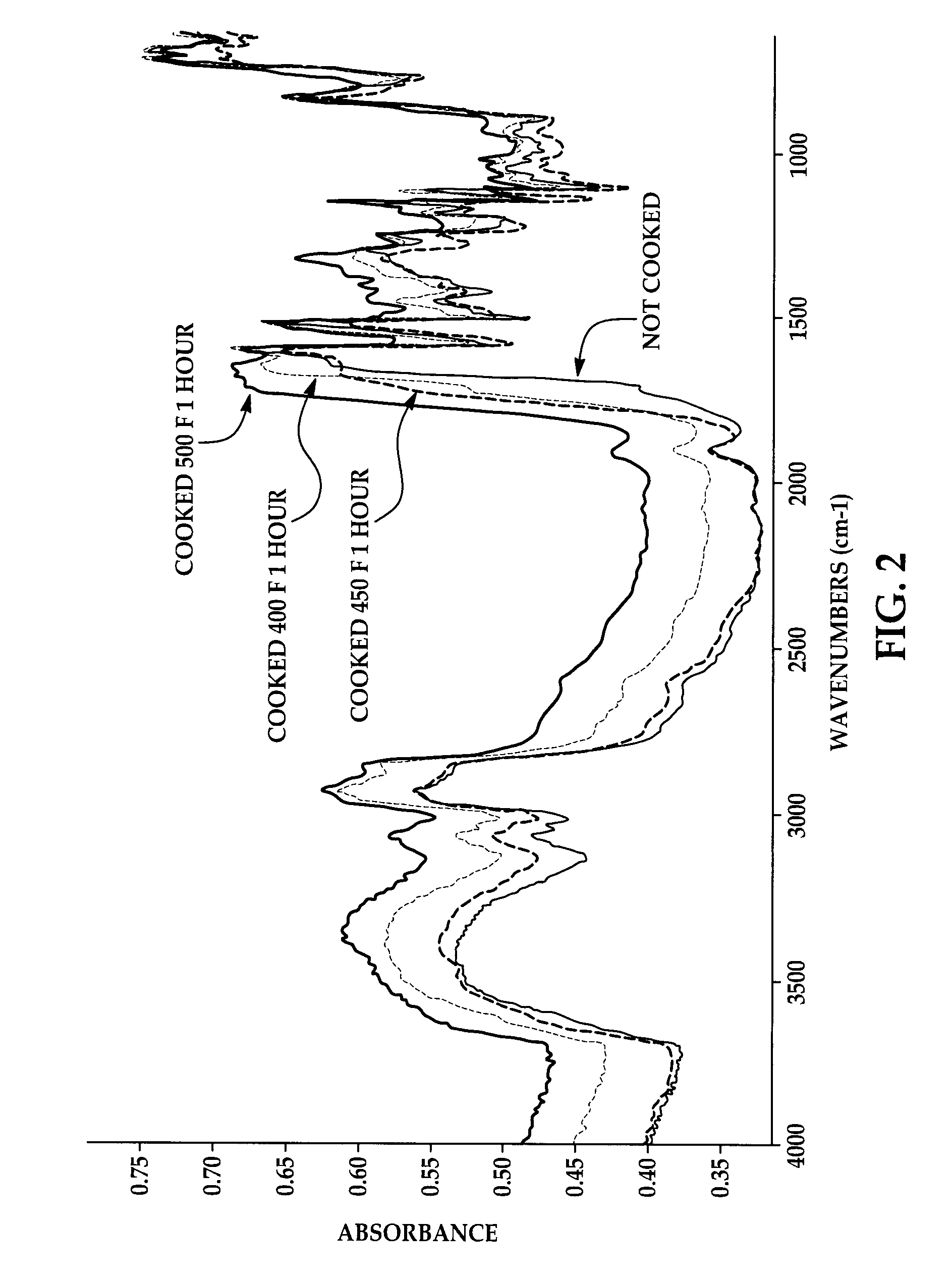

Sample preparation and methods for portable IR spectroscopy measurements of UV and thermal effect

A method of non-destructively determining the physical property of a material surface, the method including irradiating a surface with infrared energy over a spectrum of wavelengths; detecting said infrared energy reflected from said surface over said spectrum of wavelengths; performing multivariate calibration of said reflected infrared energy at a plurality of selected wavelengths including said spectrum of wavelengths; using results of said multivariate calibration to predict one or more physical properties of said model material; and, determining said one or more physical properties of said surface. Details are included for the case where uni-directional fiber CFRP materials are to be calibrated and predicted because special care must be taken for that material to insure the incident light from the spectrometer is at the proper orientation for calibration and for prediction of samples in question.

Owner:THE BOEING CO

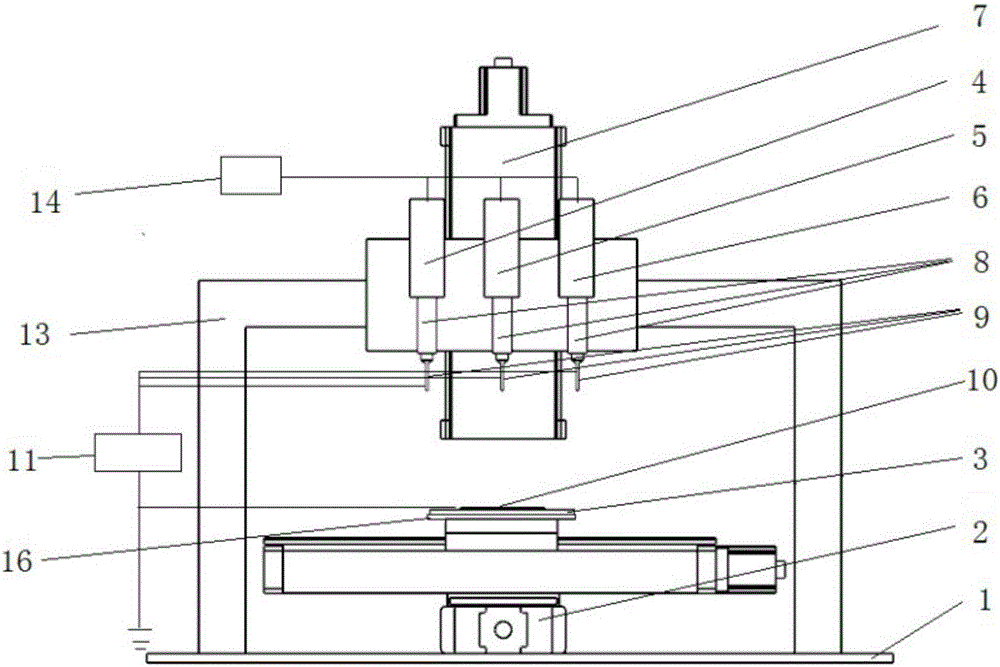

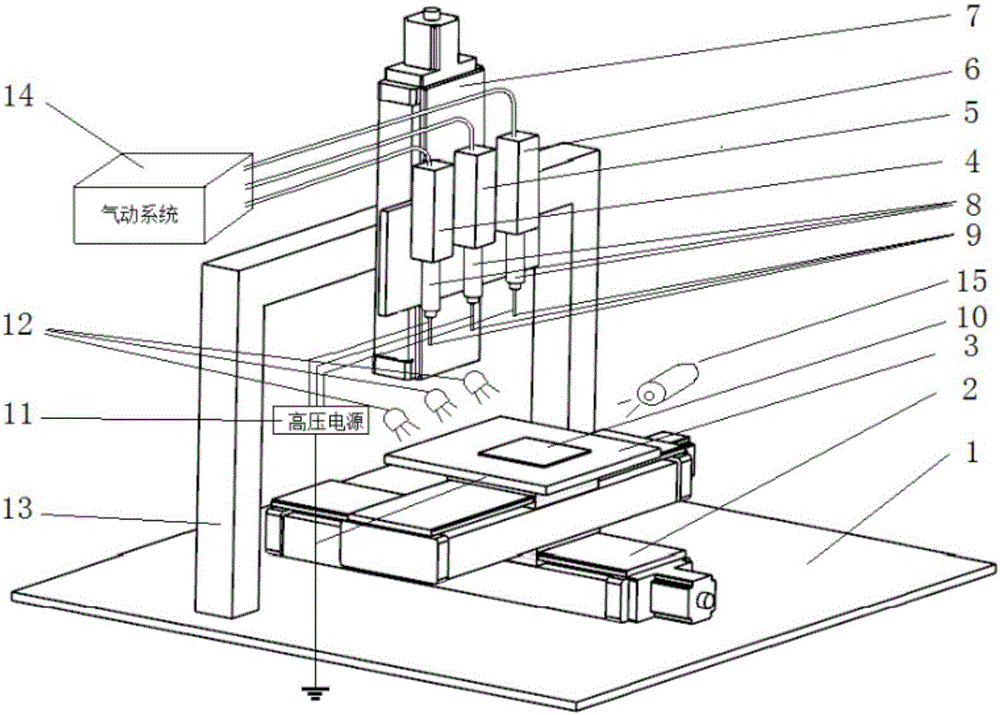

Micro-nano scale 3D printer and method

InactiveCN106738896AHigh resolutionLow costManufacturing driving means3D object support structuresMicro nanoSpray nozzle

The invention discloses a micro-nano scale 3D printer and a method. The 3D printer comprises a spraying head set, a printing tool, a controller and a three-dimensional movement mechanism. The spraying head comprises a plurality of spraying heads, and each spraying head applies a high-voltage pulse power supply between a corresponding electric conductive nozzle and an electric conductive base plate. Fluids are pulled from the nozzles by utilizing strong electric field force formed between the nozzles and the base plate to form Taylor Cones and stable conic jet flows. The controller controls the three-dimensional movement mechanism to drive the spraying head set and the printing tool to move relatively and meanwhile controls the movement of all the spraying heads to conduct micro-droplet spray printing on preset positions of the base material on the printing tool, and a model material, a release material and a supporting material are printed sequentially. Based on electrofluid power spraying printing (namely electric spraying printing), the micro-nano scale 3D printer solves the difficult problems that for micro-nano 3D printing, macro / micro cross-scale manufacturing cannot be achieved, the types of printable materials are few, and support is difficult to remove, and especially overcomes the deficiencies and the limitation, in the aspects of the cost, materials, resolution ratio, macro / micro cross-scale manufacturing, support removing and the like, of the of the current micro-nano scale 3D printing technology.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

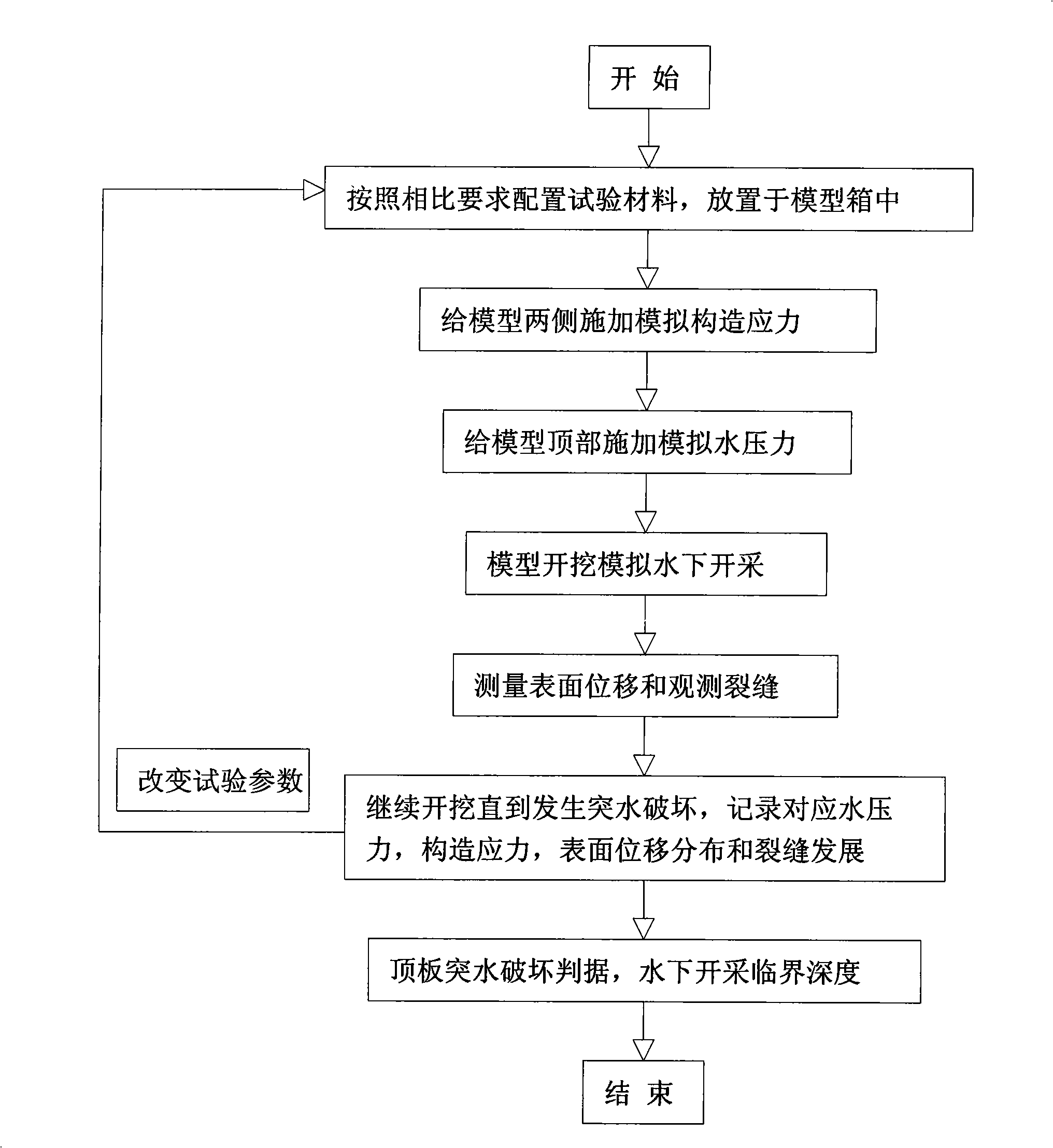

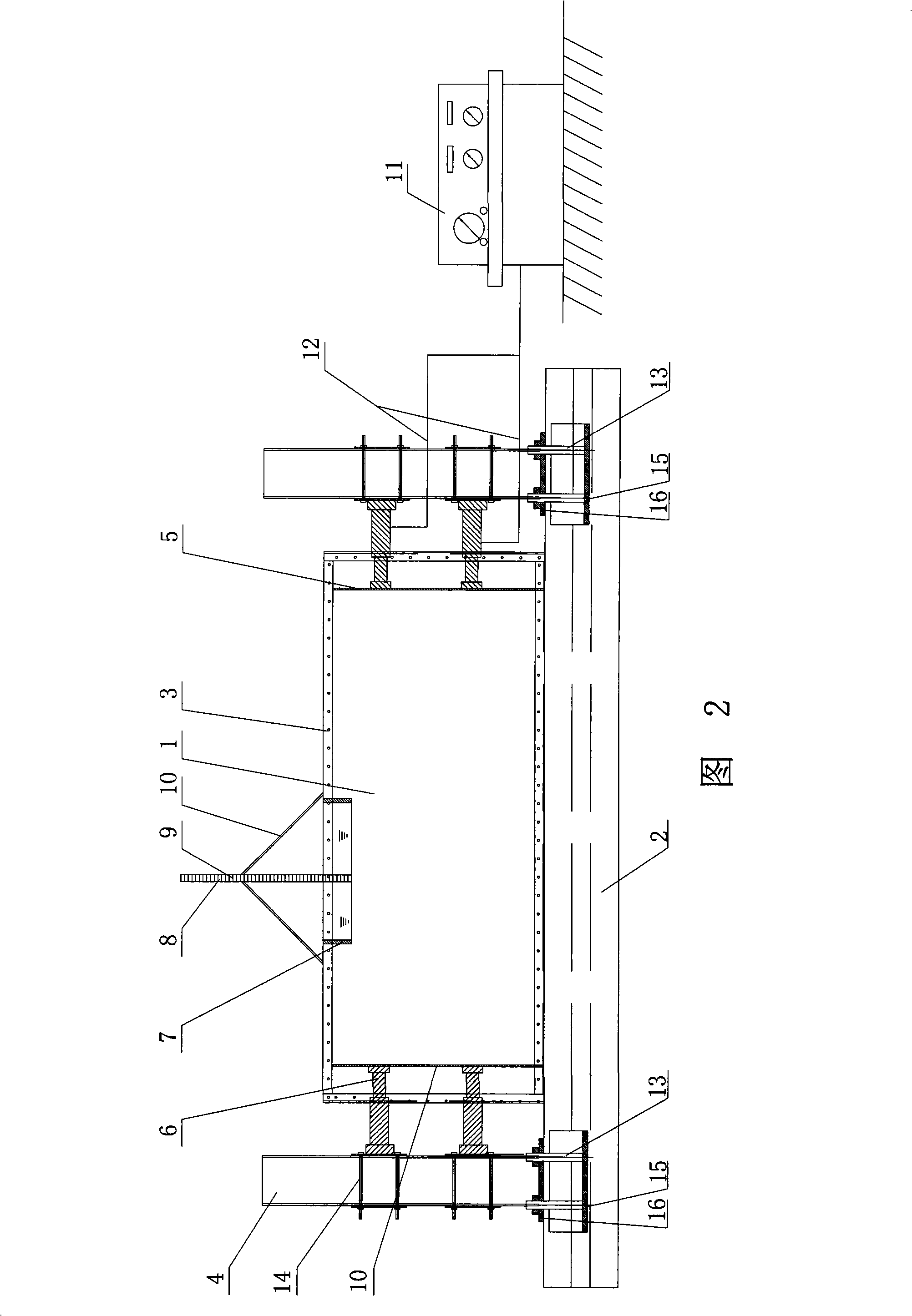

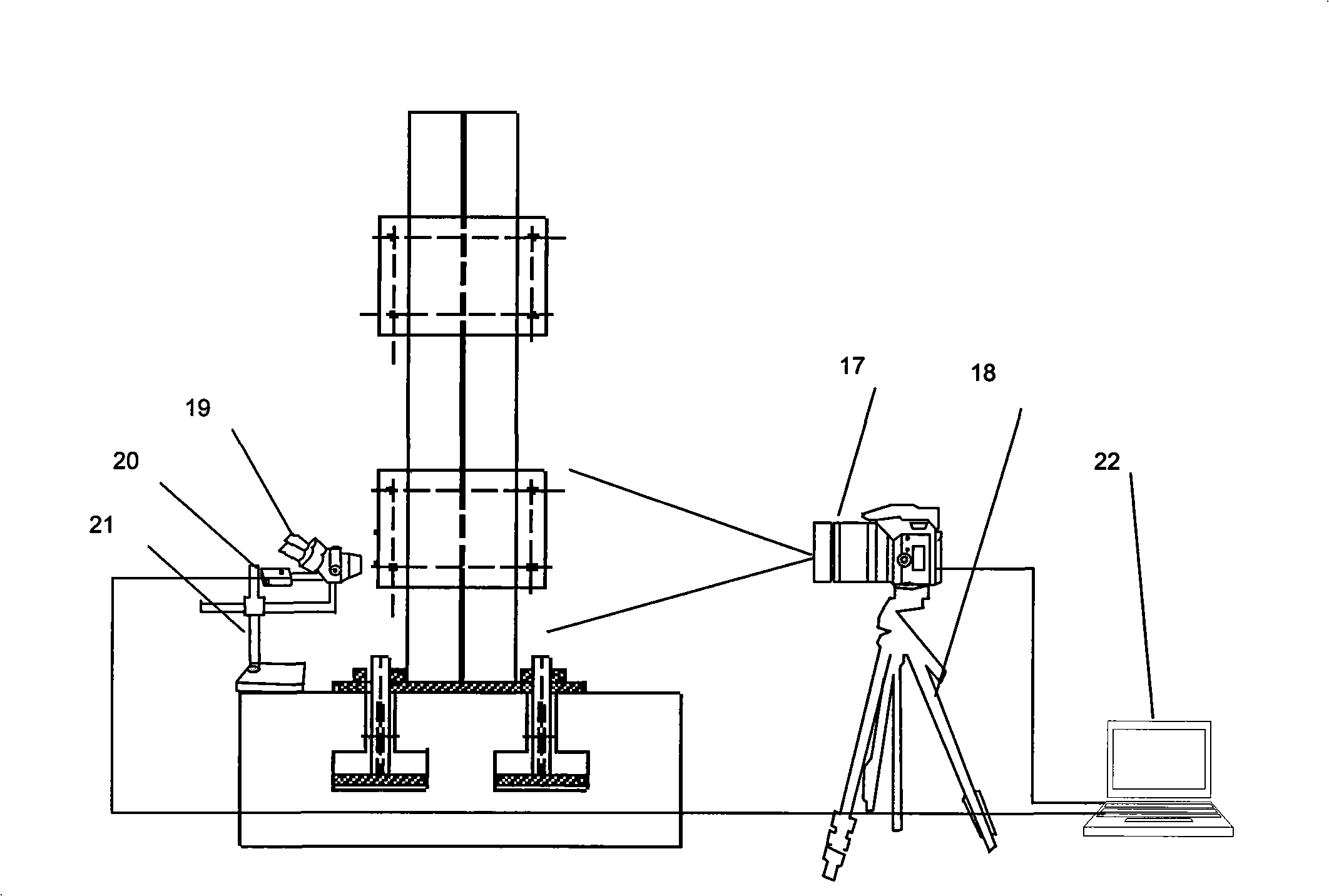

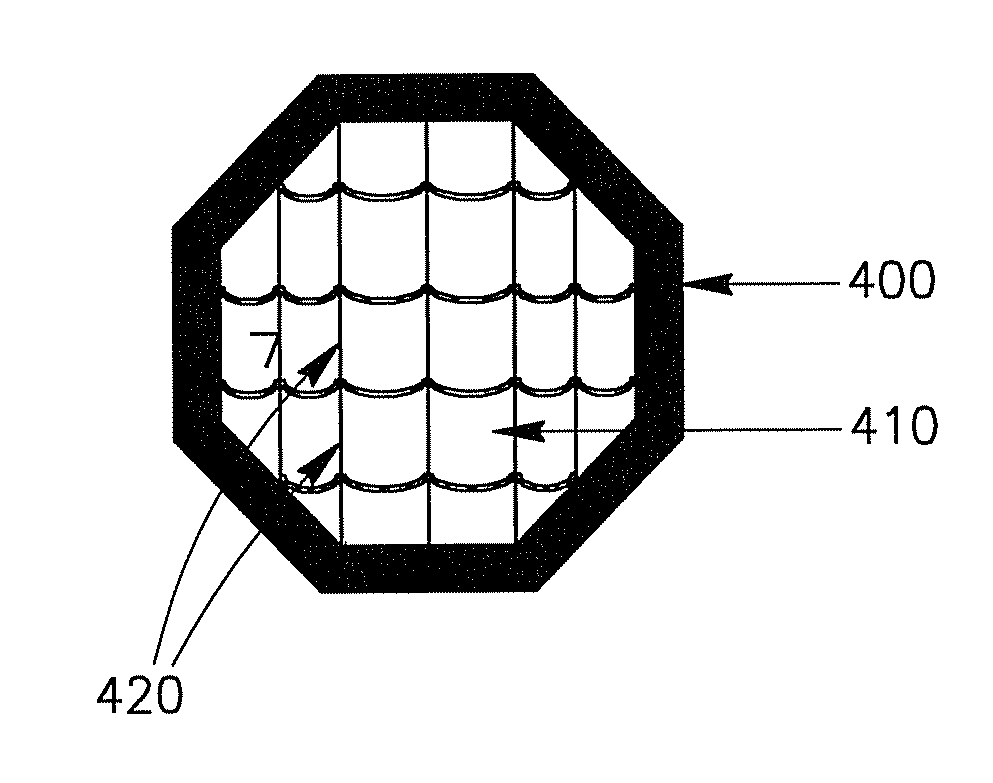

Offshore mining top board seepage flow sudden inflow test method and device

ActiveCN101308126ATo achieve the purpose of waterproofingWon't flow outMaterial analysisTectonic stressExperimental methods

The invention discloses an experimental method for top plate seepage and water inrush when in underwater exploitation as well as an apparatus thereof, comprising the steps of: (1) putting a configured experimental material in a model box according to the practical relative position; (2) exerting lateral pressure on the model material in the model box; (3) sealing the top part of the model box and exerting the stated water pressure on the top part of the model; (4) acquiring water pressure data, tectonic stress data, displacement digital photos and crack digital photos magnified by certain times at regular intervals in the exploitation process until the water inrush destruction takes place; (5) repeating the steps of (1), (2) and (3) to change lateral pressure and water pressure parameters, and repeating the step (4); and (6) obtaining the relation between the water pressure at the top part, the tectonic stress and the model surface displacement, model surface crack. The method and apparatus can embody the combined action of tectonic stress and water pressure at the top part and deadweight function of cover layer more factually, thereby improving the testing precision.

Owner:CENT SOUTH UNIV

Compositions and methods for use in three dimensional model printing

InactiveUS20080105818A1Similar elasticitySimilar strengthButtonsRecord carriersInvestment castingMaterials science

Embodiments of the invention are directed to a method of producing three-dimensional prototype molds for use in investment casting. The method includes dispensing modeling material and support material in a predetermined arrangement, in layers, to produce a three-dimensional mold having an outer shell. Generally, the out shell includes modeling material and the interior of the mold includes support material. Then the mold is cured.

Owner:OBJET GEOMETRIES

Remote high-performance computing material joining and material forming modeling system and method

InactiveUS8301286B2Arc welding apparatusDesign optimisation/simulationUser inputPerformance computing

A remote high-performance computing material joining and material forming modeling system (100) enables a remote user (10) using a user input device (20) to use high speed computing capabilities to model materials joining and material forming processes. The modeling system (100) includes an interface module (200), an application module (300), a computing module (400), and a scheduling module (500). The interface module (200) is in operative communication with the user input device (20), as well as the application module (300), the computing module (400), and the scheduling module (500). The application module (300) is in operative communication with the interface module (200) and the computing module (400). The scheduling module (500) is in operative communication with the interface module (200) and the computing module (400). Lastly, the computing module (400) is in operative communication with the interface module (200), the application module (300), and the scheduling module (500).

Owner:EDISON WELDING INSTITUTE INC

Preparation method for random crack test model

InactiveCN103674658AWide variety of sourcesRealize one-time moldingPreparing sample for investigationCouplingLarge size

The invention discloses a preparation method for a random crack test model. Different quantities of crack fragments with different thicknesses and different sizes are randomly doped into a continuous dielectric body model material, so that a test model capable of effectively simulating natural structural features such as cracks and joints of a rock body as well as the random structure feature distribution and a complicated dynamic environment of a rock body with a heterogeneity characteristic can be prepared, and a simulation test on the random crack rock body can be carried out. The model preparation process is simple and easy to operate; compared with the prior art, the preparation method has the advantages that the prepared rock body model is closer to an engineering rock body, and a test result is fitter to a real condition of the rock body. The preparation method for the random crack test model is applicable to large-size similar simulation tests and particularly relates to preparation of simulation test models which are used for similar simulation ore pressure observation, heterogeneous rock layer fluid and solid coupling simulation test, crushed coal rock body exploration simulation test and the like and have requirements on the structures of rock layers.

Owner:SHANDONG UNIV OF SCI & TECH

Polymer material for seismic physical model and its prepn

InactiveCN1772809ASatisfy the wave speed requirementsWave speed control range is largeEducational modelsEpoxyLongitudinal wave

The present invention belongs to the field of high molecular material technology, and is especially one kind of polymer material for seismic physical model and its preparation process. The polymer material consists of epoxy resin mixture comprising epoxy resin and assistant and silicone rubber mixture comprising silicone rubber and assistant in the weight ratio of 0-100. The polymer material is prepared through preparing epoxy resin mixture and silicone rubber mixture separately, mixing these two components in certain weight ratio inside some container via stirring to obtain model material, setting the container inside sealed box to vacuum pump for eliminating bubble, molding, curing inside the mold at 15-25 deg.c for 5-9 days, and demolding to obtain the seismic physical model. The model material has longitudinal wave speed regulating range of 1000-2850 m / s.

Owner:TONGJI UNIV

Water soluble ink-jet composition for 3D printing

ActiveUS9138981B1Additive manufacturing apparatusLiquid surface applicatorsChemical compositionWater soluble

The invention relates to a material composition, which may be a support material, for three-dimensional (3D) inkjet printing, comprising a glycol polymer, a low molecular weight polar substance and a surface active agent. The invention further provides a method for 3D inkjet printing comprising building a 3D object in layers, wherein at least one layer comprises a model material composition and a support material composition comprising PEG and a low molecular weight polar substance, wherein the layers are solidified before deposition of subsequent layers; and wherein, after solidification, the support material composition is removed by immersion of the solidified objet with the support in a liquid composition comprising a solvent.

Owner:STRATASYS LTD

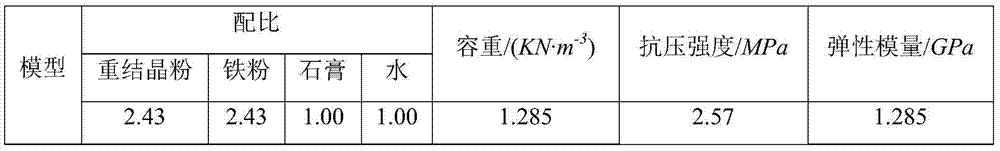

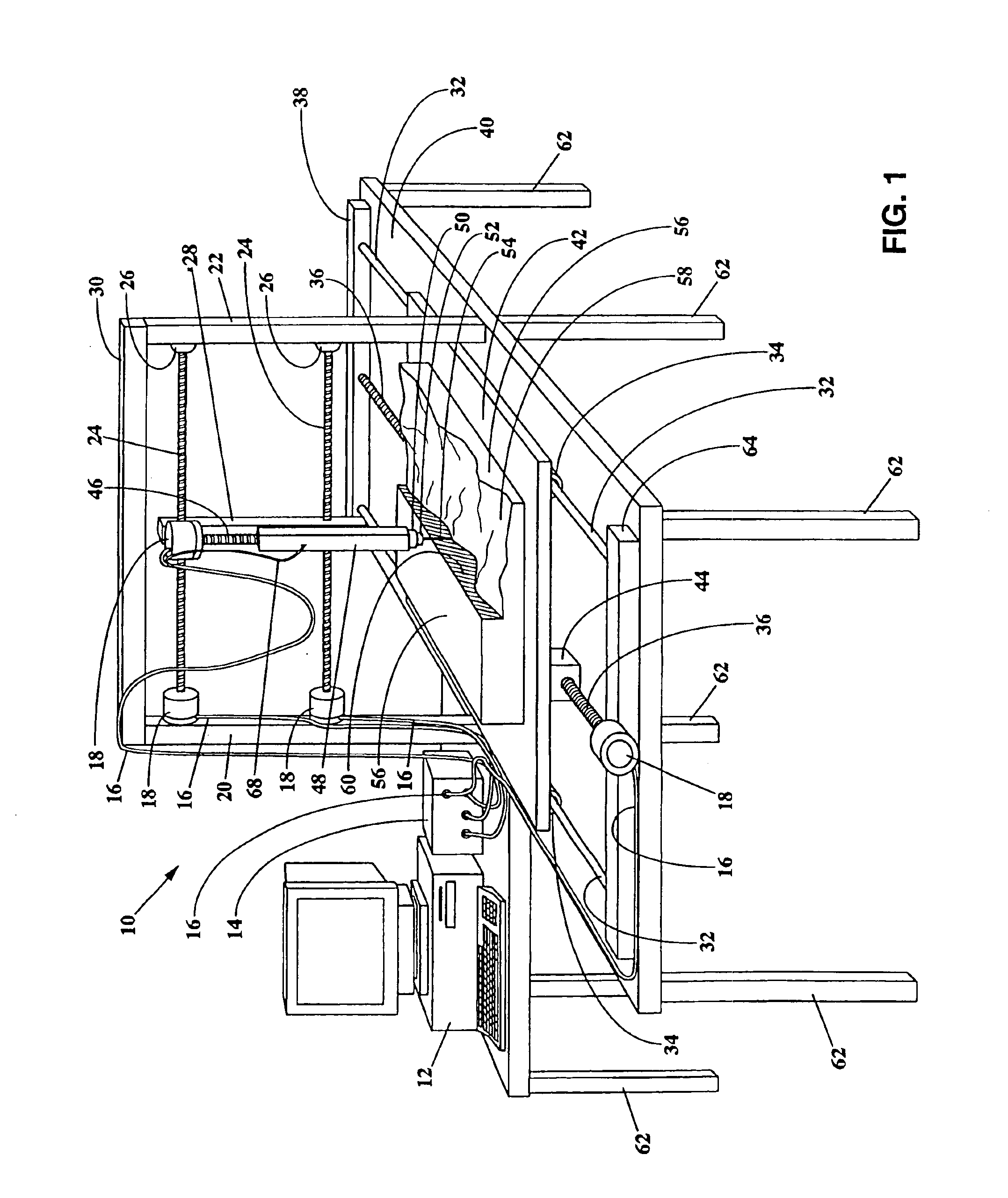

Hi-accuracy three-dimensional topographic modeling apparatus

InactiveUS7216003B2Accurate scaleSimple surfaceOrnamental structuresMilling machinesTerrainMaterial removal

A cutting apparatus includes a hi-accuracy three-dimensional cutting apparatus for topographic modeling that is electronically coupled with a computer. The computer has a central processor that executes instructions, a memory for storing instructions to be executed, and non-volatile storage for storing the messages. The executable computer instructions of the system include one or more algorithms for converting the complex and randomly-occurring contours found in natural terrain into an efficient series of modeling material removal swaths defined in simplified 2-axis cross-sections that are cut adjacent and parallel to one another. The swaths are defined in a simplified 2-axis surface contour-following rotation cutting device moved by the system's CPU, driver software, driver circuitry and / or logic circuitry. This multi-axis control of the system assures that each of the swaths are seamlessly rendered next to one another while also maintaining an optimal proximity between the upper surface of the 3D model and the rotation cutting device.

Owner:SOLID TERRAIN MODELING

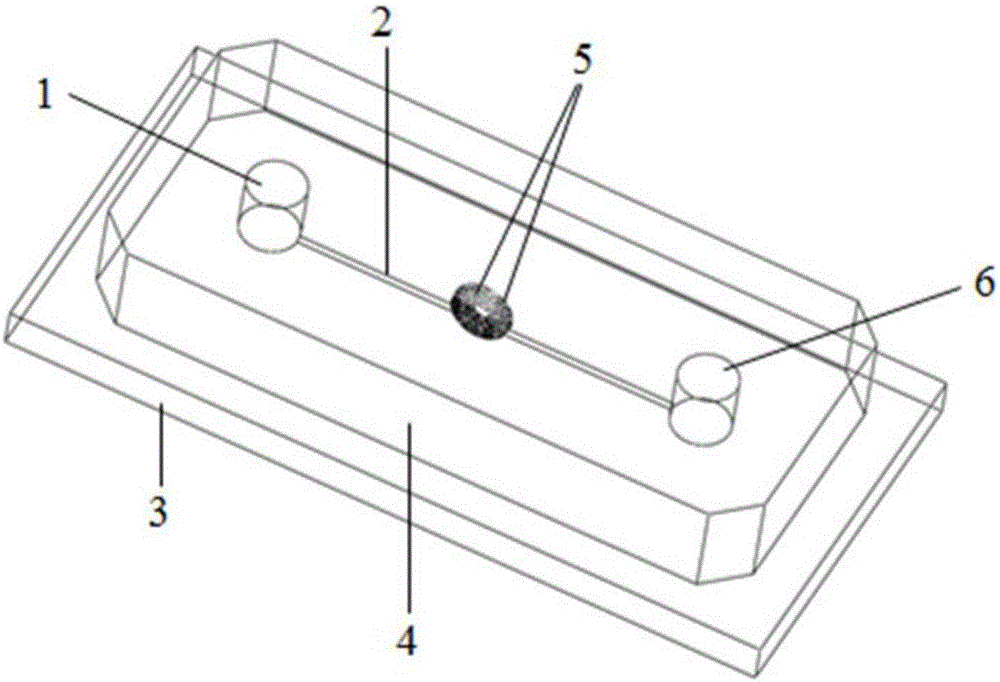

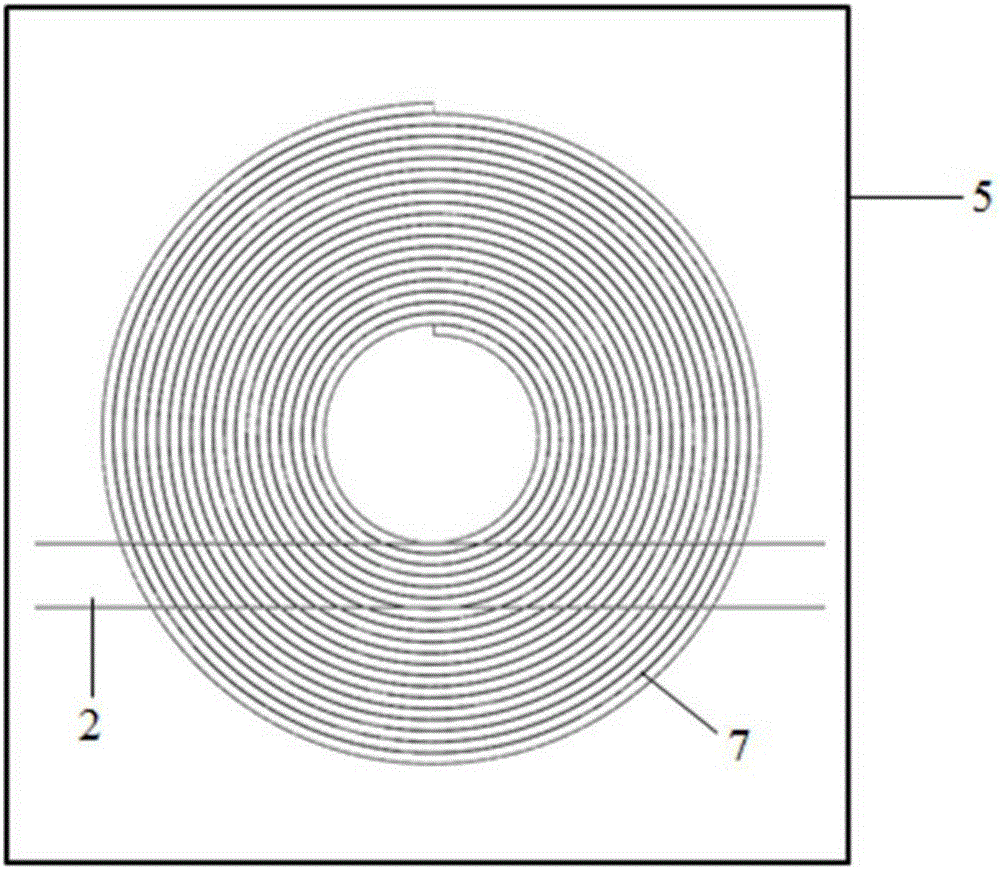

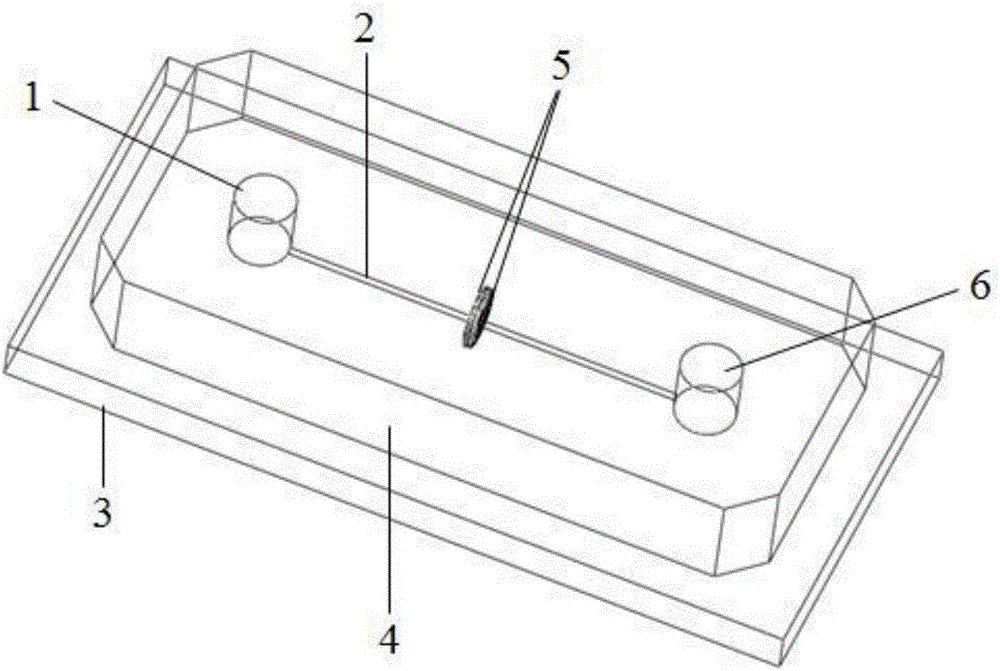

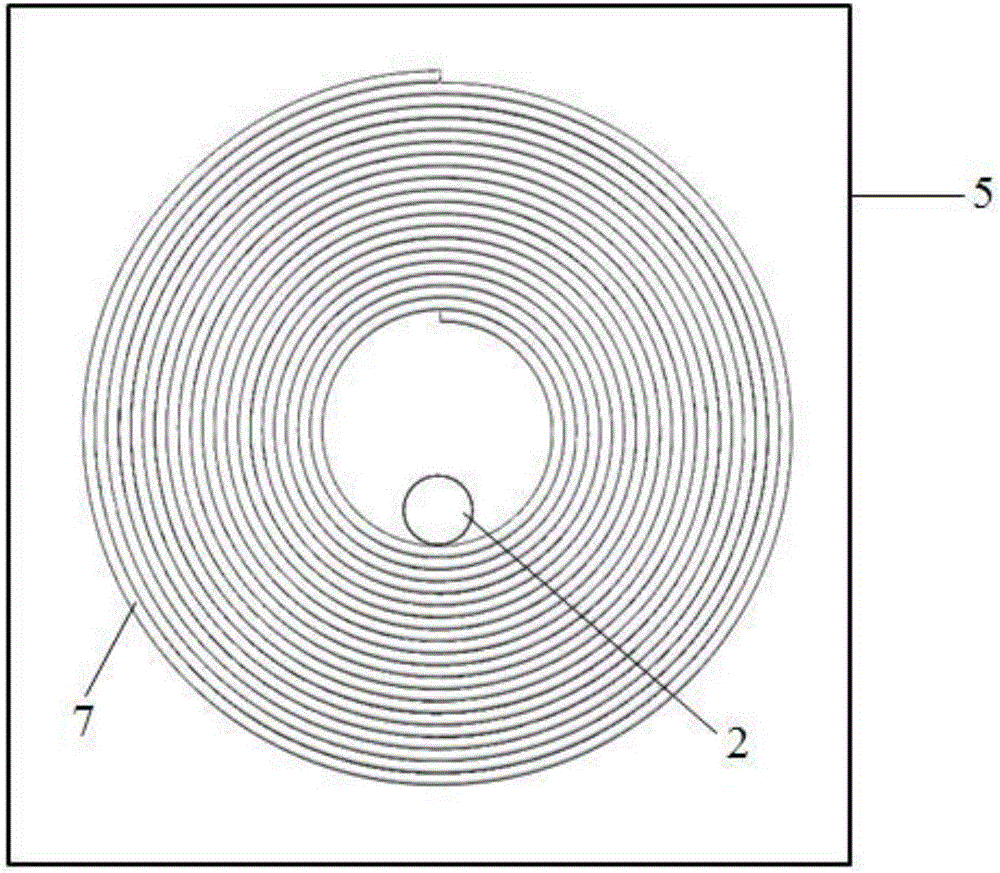

Capacitance-reactance oil detection system and manufacturing method thereof

The invention relates to the technical field of oil detection for mechanical equipment, and provides a capacitance-reactance oil detection system which comprises a detection device, a measurement mode switching unit and an excitation-detection unit, wherein the detection device comprises a microfluidic chip and a sensing unit; the microfluidic chip consists of a microchannel inlet, a microchannel, a substrate, a model material and a microchannel outlet; the sensing unit consists of two single-layer coils which are oppositely arranged on the two sides of the microchannel; the measurement mode switching unit is used for switching different measurement modes by changing different connection manners for four lead ends of the two single-layer coils; the excitation-detection unit is used for exciting the two single-layer coils with high-frequency alternating current to enable the two single-layer coils to serve as a capacitance detection device as well as an inductance-resistance detection device. By the chip, multiple parameters such as capacitance, inductance and resistance are measured by virtue of the same sensing unit, multiple particulate pollutants in oil can be discriminately detected, and a failure of mechanical equipment can further be diagnosed.

Owner:DALIAN MARITIME UNIVERSITY

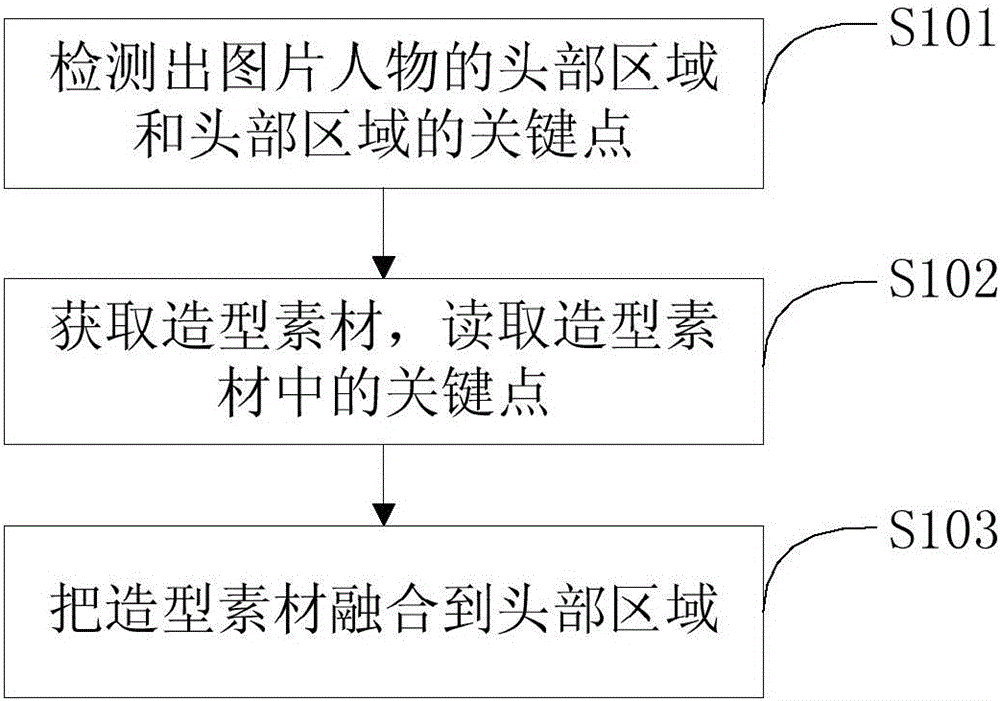

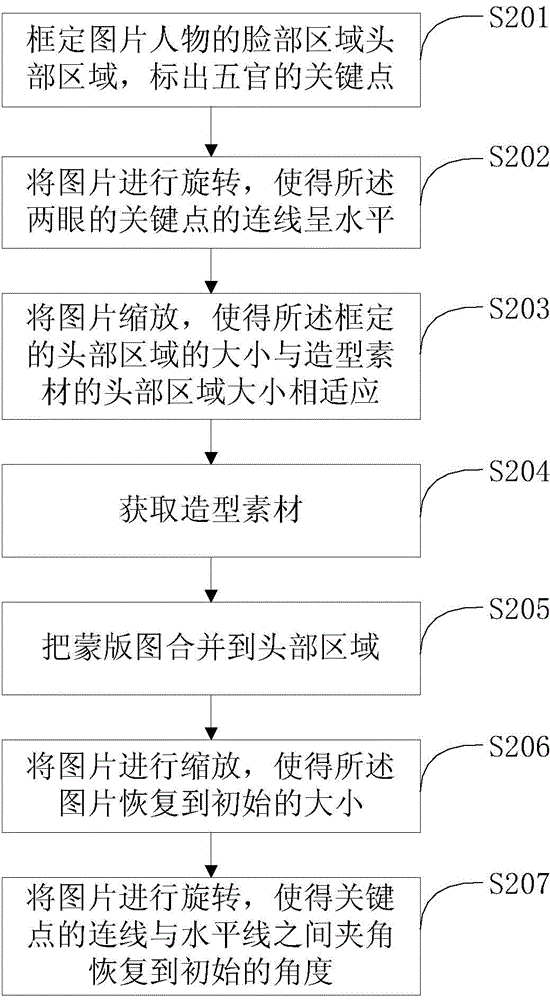

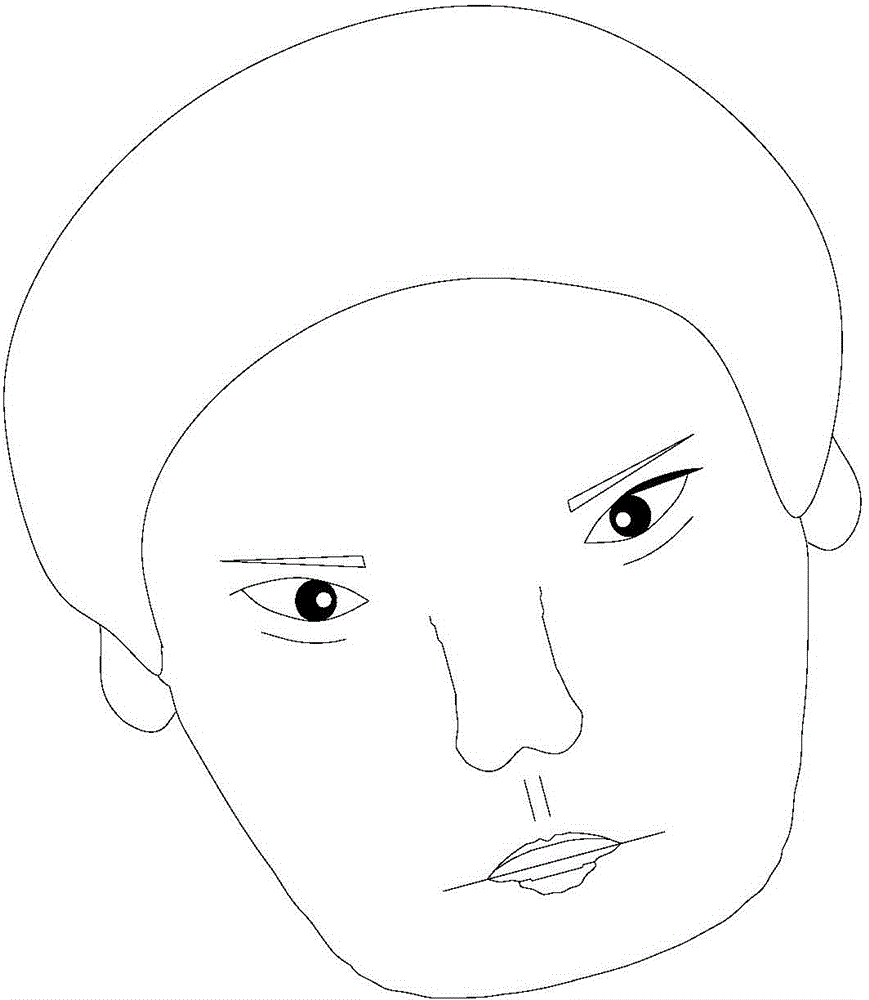

Method and device for modeling picture figure

ActiveCN104899825AEasy to operate and save timeGeometric image transformation2D-image generationComputer graphics (images)Computer vision

Owner:TENCENT TECH (SHENZHEN) CO LTD

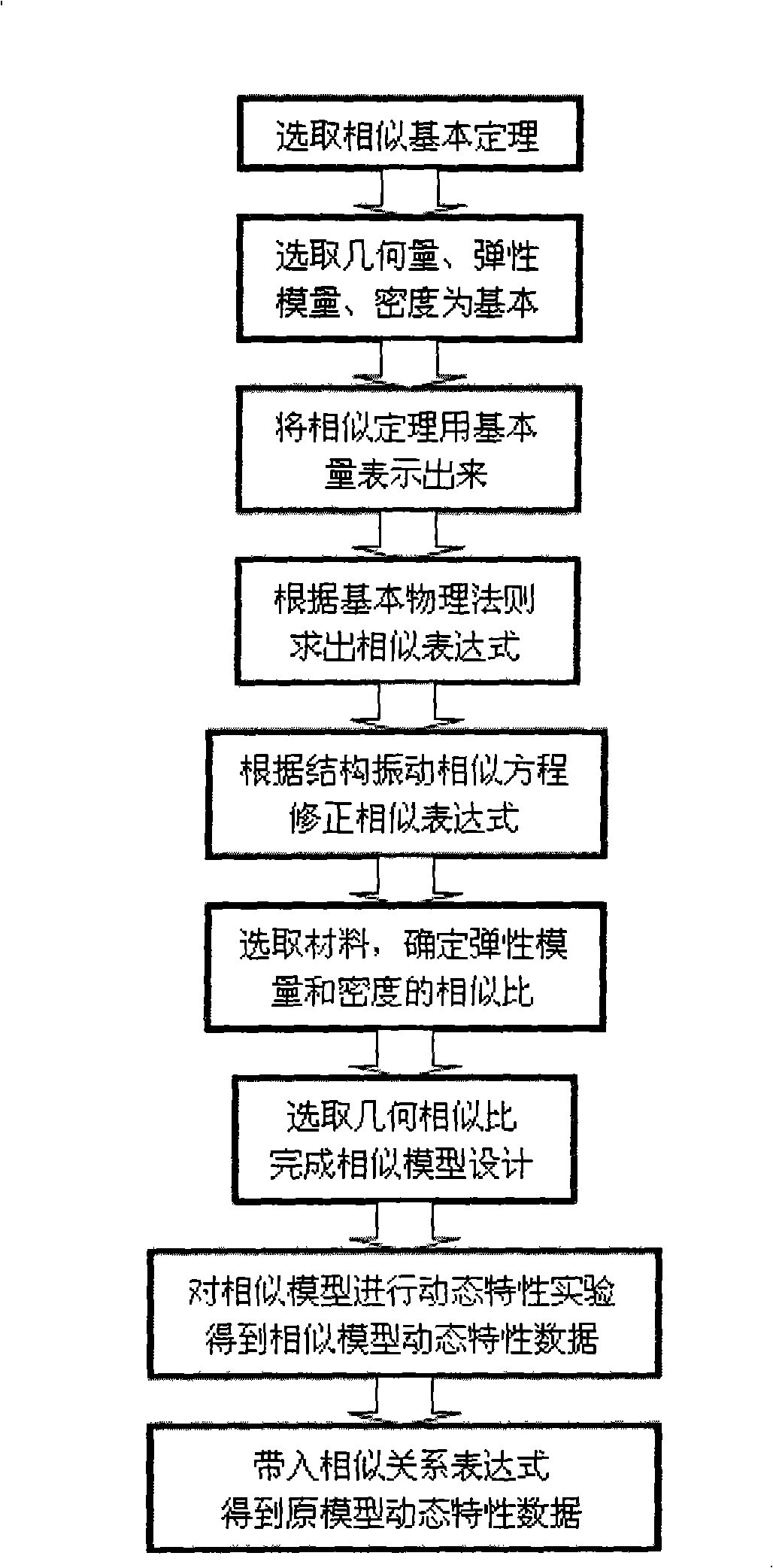

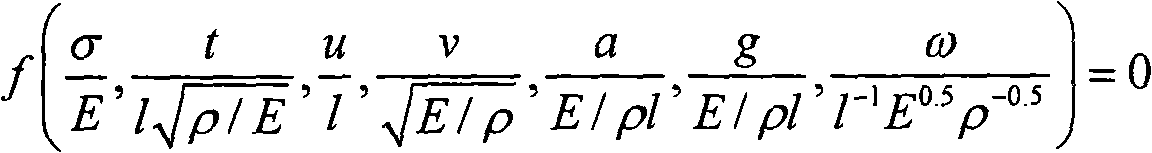

Large-sized mechanical equipment structure dynamic simulation test method

InactiveCN101261155ASmall scaleReduce testing costsSubsonic/sonic/ultrasonic wave measurementVibration testingElastic vibrationMechanical equipment

The invention provides a large mechanical equipment structure dynamic similarity test method, comprising the steps as follows: (1) a basic similarity theorem is adopted, all physical quantities are listed, geometrical quantity, density and elastic modulus are determined as basic physical quantities, and the similarity theorem is written into a dimensionless equation expressed by the basic physical quantity; (2) according to concerned basic physical principle, the similarity ratio of all physical quantities adopts similar relation expression, and the similar relation expression is modified according to a structure elastic vibration similarity equation; (3) similar model material is selected, density similarity ratio and elastic modulus similarity ratio are determined, geometrical quantity similarity ratio is determined, and the similar model design is then completed; (4) a structure dynamic test of the similar model is carried out so as to obtain the dynamic characteristic number which is substituted into the similarity relation expression so as to work out the dynamic characteristic data of the original model which is also the natural vibration frequency. The large mechanical equipment structure dynamic similarity test method realizes the conversion of ultra-large structure dynamic natural frequency with small model, effectively reduces the scales of dynamic test objects, simplifies the test instruments, and reduces the test cost.

Owner:BEIHANG UNIV

Sample Preparation and Methods for Portable IR Spectroscopy Measurements of UV and Thermal Effect

A method of non-destructively determining the physical property of a material surface, the method including irradiating a surface with infrared energy over a spectrum of wavelengths; detecting said infrared energy reflected from said surface over said spectrum of wavelengths; performing multivariate calibration of said reflected infrared energy at a plurality of selected wavelengths including said spectrum of wavelengths; using results of said multivariate calibration to predict one or more physical properties of said model material; and, determining said one or more physical properties of said surface. Details are included for the case where uni-directional fiber CFRP materials are to be calibrated and predicted because special care must be taken for that material to insure the incident light from the spectrometer is at the proper orientation for calibration and for prediction of samples in question.

Owner:THE BOEING CO

Inductive-reactance type oil detection system and manufacturing method thereof

ActiveCN106383146ARealize detectionMaterial impedanceMaterial resistanceCapacitanceMechanical equipment

The invention relates to the technical field of mechanical equipment oil detection and provides an inductive-reactance type oil detection system. The system comprises a detector, a measurement mode switching unit and an excitation-detection unit. The detector comprises a micro-fluidic chip and a sensing unit, wherein the micro-fluidic chip is composed of a micro-channel inlet, a micro-channel, a substrate, a model material and a micro-channel outlet; and the sensing unit is formed by two single-layer coils facing each other. The measurement mode switching unit switches different measurement modes by changing different connection modes of four lead terminals of the two single-layer coils. By supplying the two single-layer coils with high-frequency AC electric excitation, the excitation-detection unit can be used as an inductance-resistance detector as well as a capacitance detector. According to the chip, by the utilization of the same sensing unit, measurement of multiple parameters such as inductance, resistance and capacitance is realized, various particle pollutants in the oil can be distinguished and detected, and fault diagnosis of machinery equipment can be further carried out.

Owner:DALIAN MARITIME UNIVERSITY

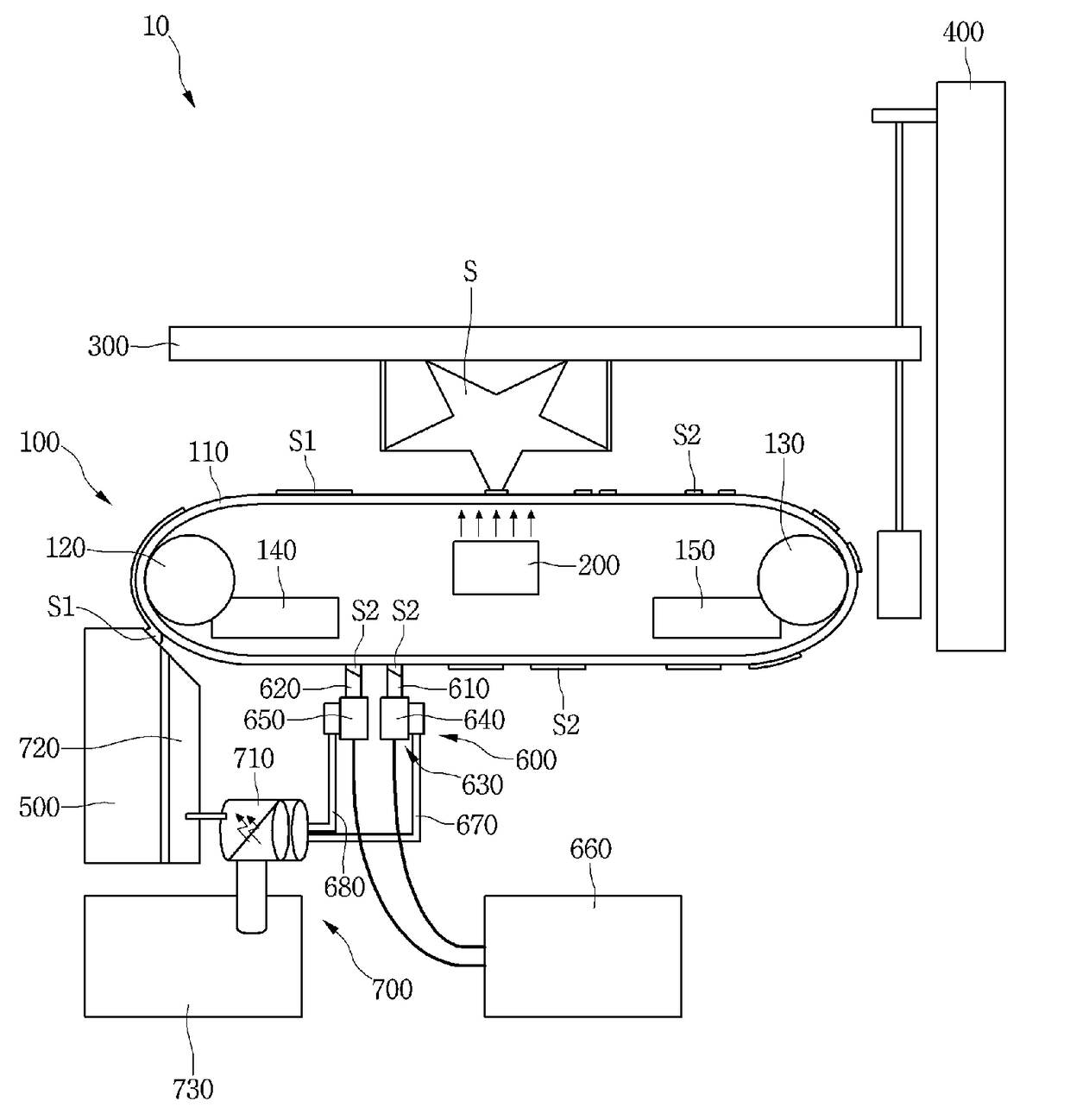

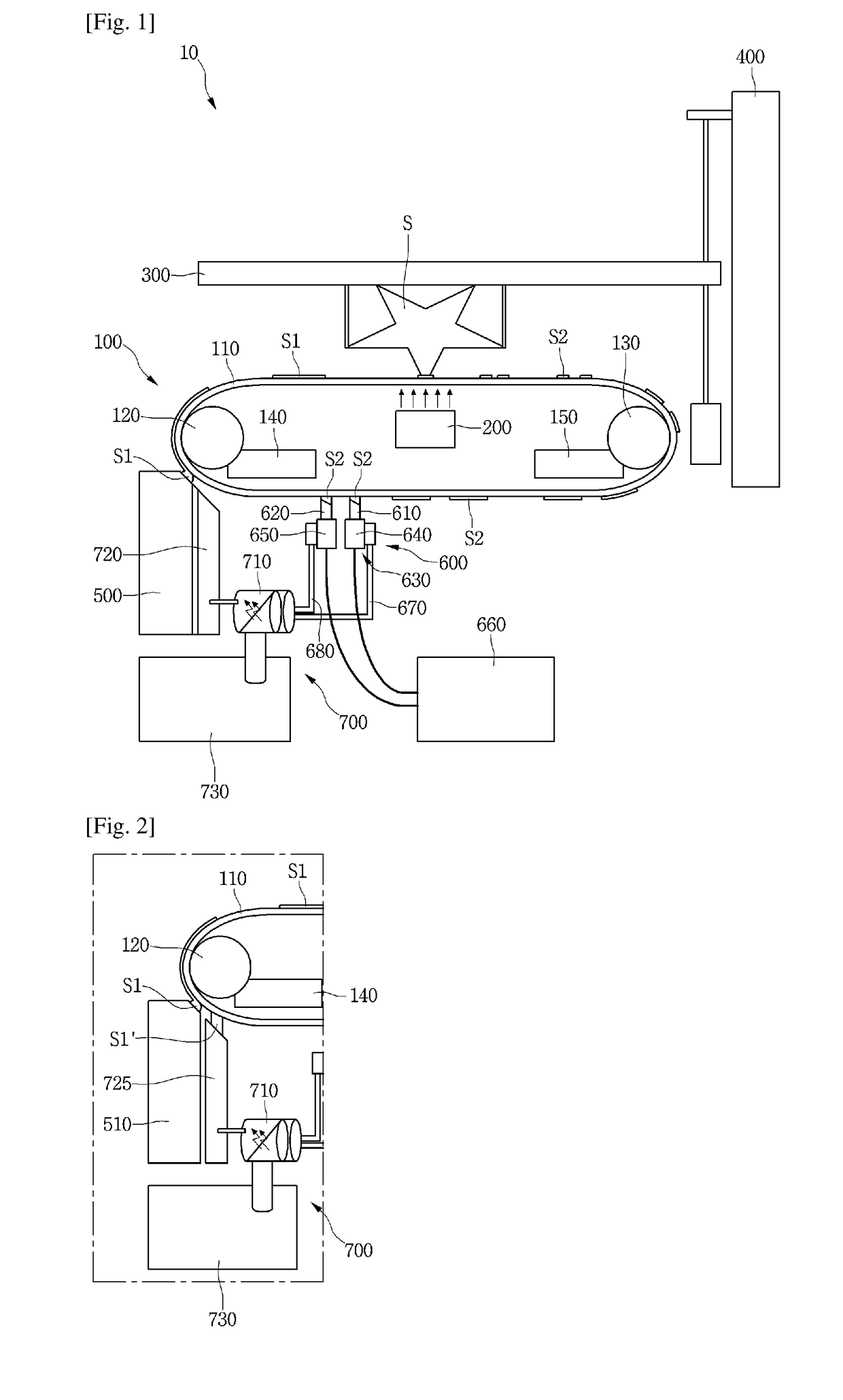

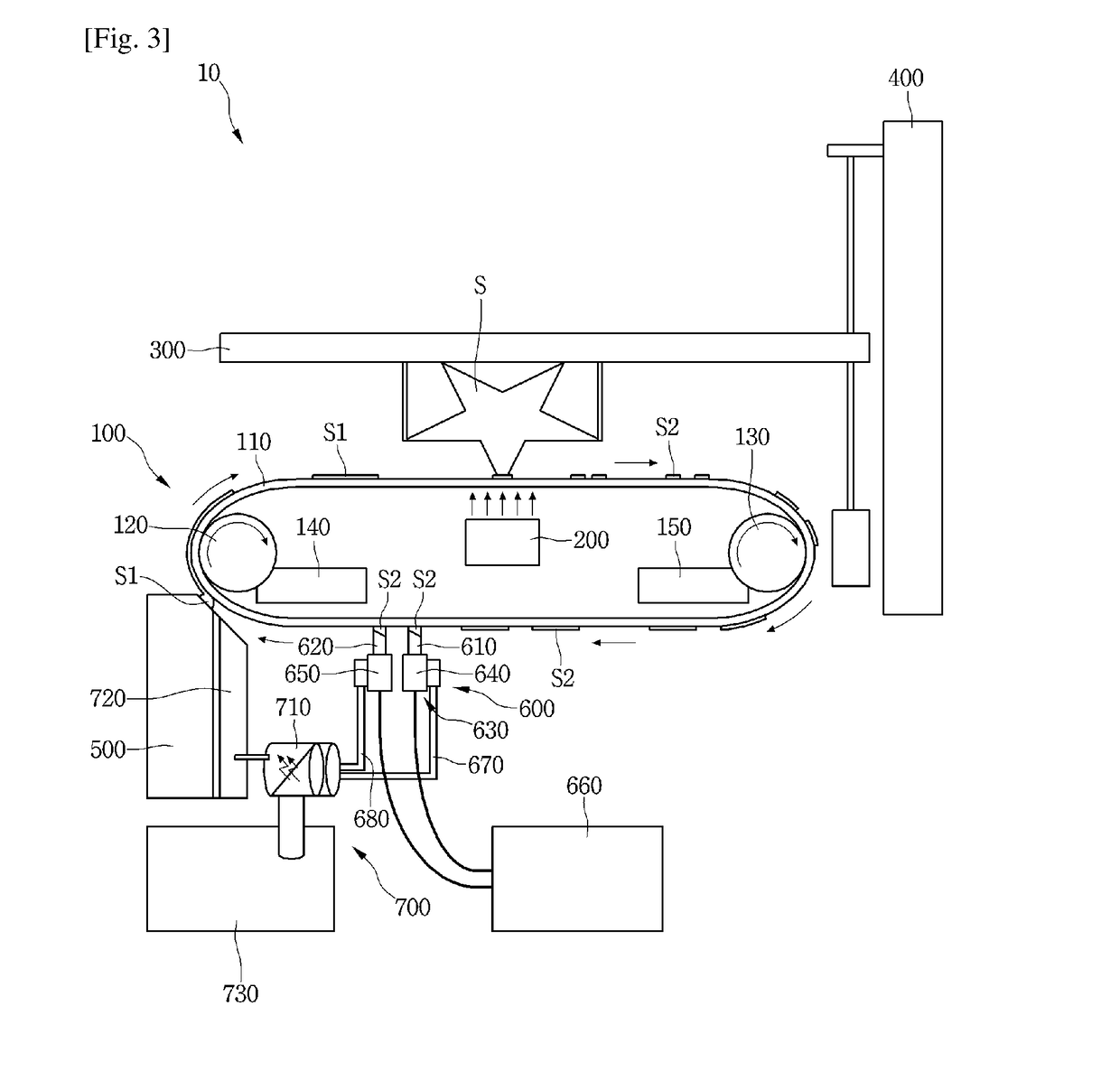

3D printing apparatus

InactiveUS20180043619A1Low costManufacturing platforms/substratesManufacturing driving meansEngineeringMaterial supply

A three-dimensional (3D) printing apparatus is provided. The 3D printing apparatus includes a modeling material circulating part for circulating a modeling material for modeling a 3D model, a light source unit disposed on one side of the modeling material circulating part to supply light toward the modeling material so that the modeling material is cured, a stage on which the modeling material cured through the light source unit is seated, the stage being disposed to face the modeling material circulating part, a stage driving part connected to the stage to provide a driving force for moving the stage, a modeling material supply part for supplying the modeling material to the modeling material circulating part, a modeling material collecting part for collecting the modeling material, which passes through the light source unit, of the modeling material circulating by the modeling material circulating part, and a modeling material recycling part connected to the modeling material collecting part to filter the collected modeling material to resupply the filtered modeling material to the modeling material circulating part.

Owner:LG ELECTRONICS INC

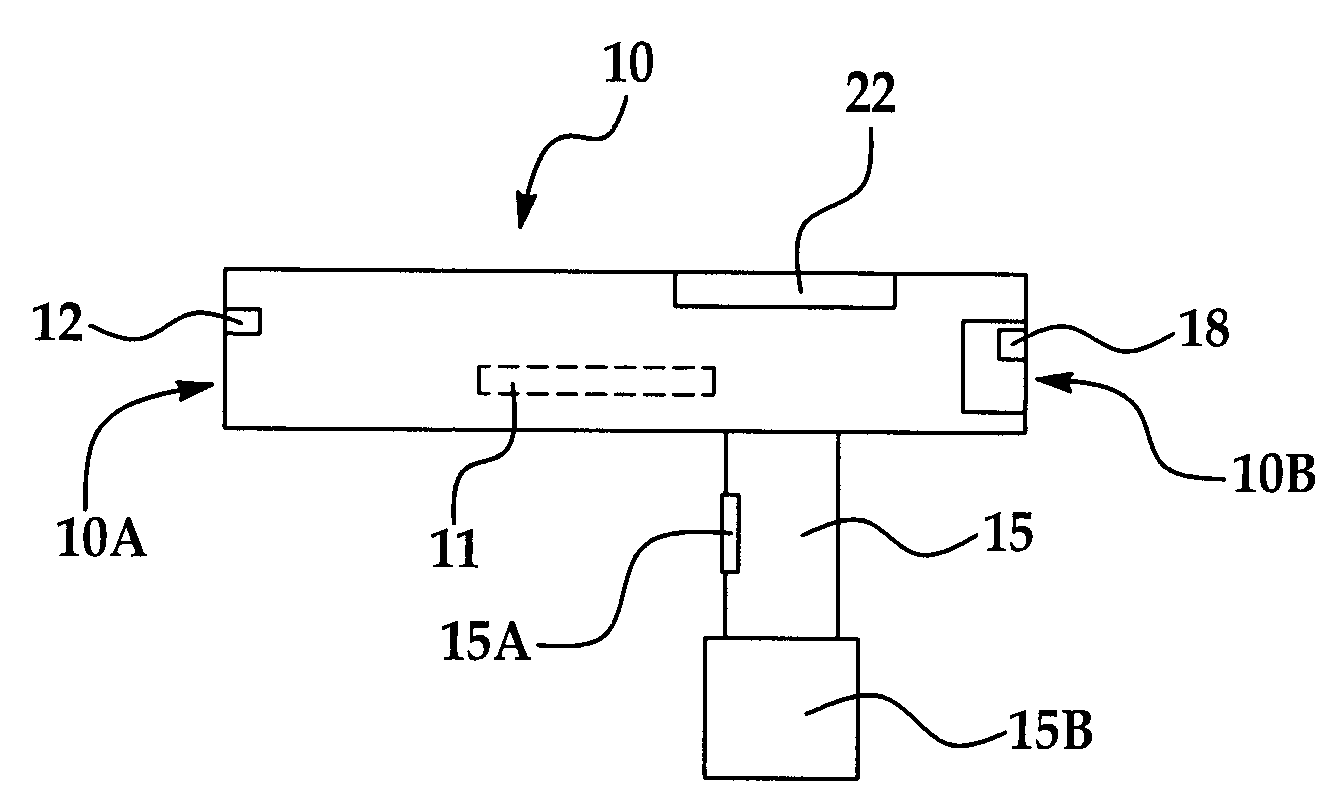

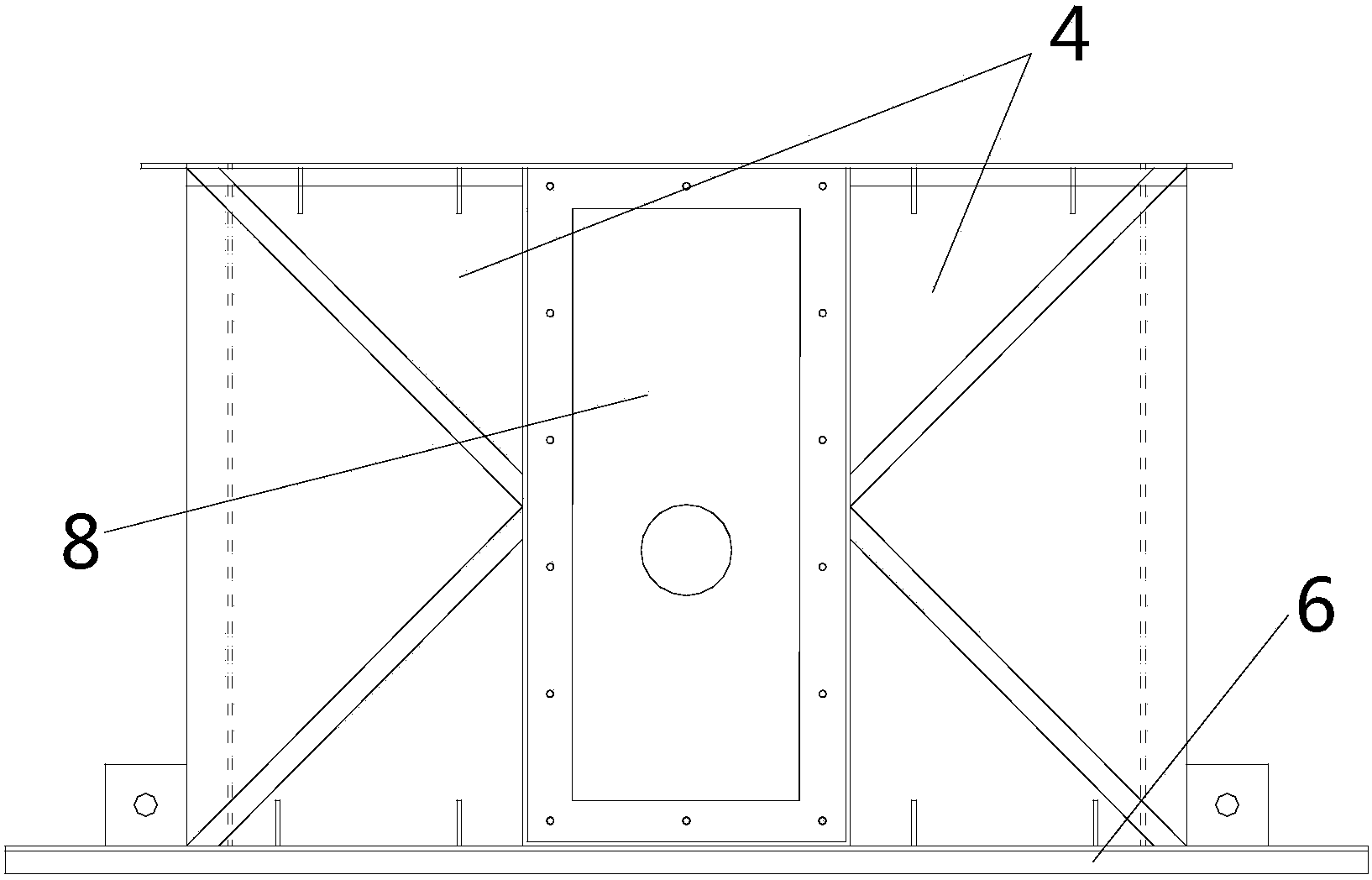

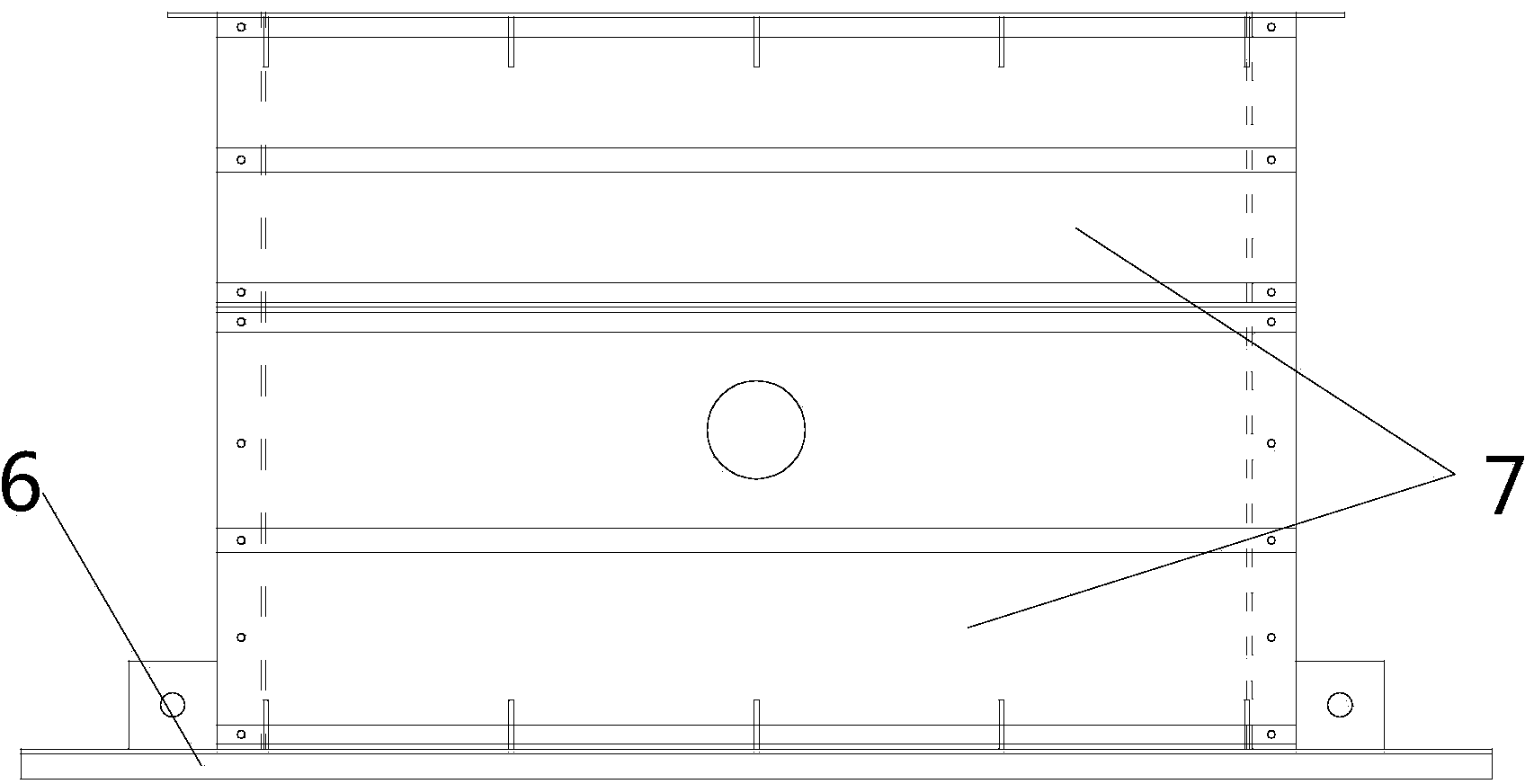

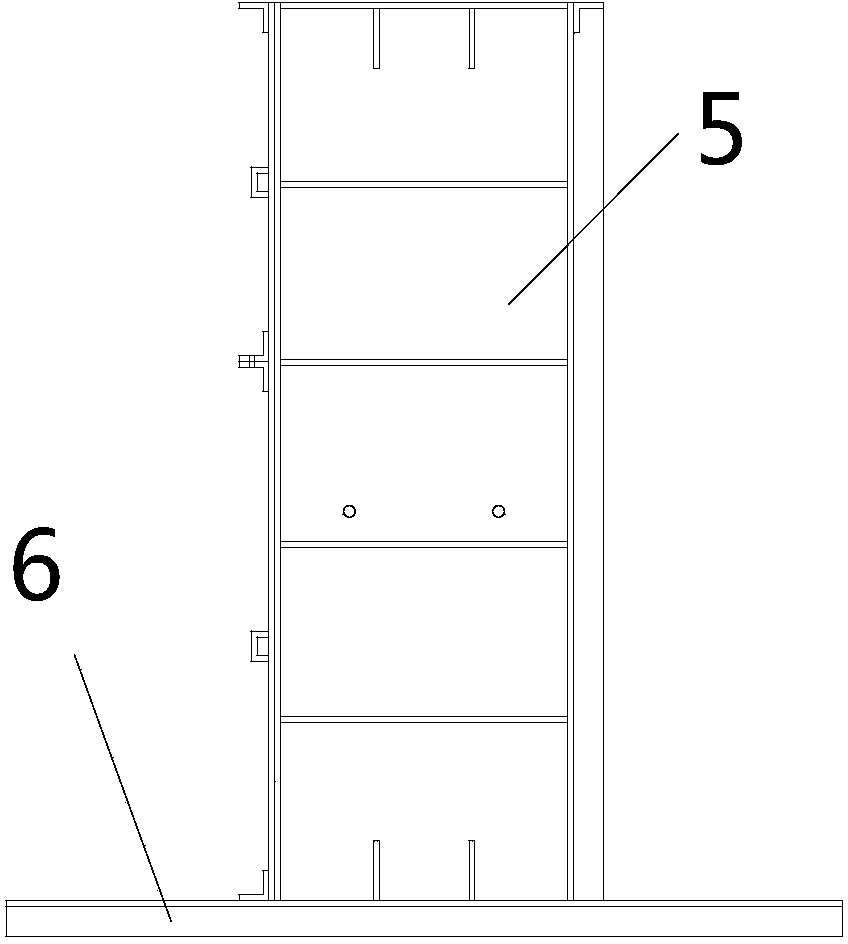

Shake table test real-time loading device for simulating different burial depths of rock tunnel

InactiveCN103969012AReal-time loadingReduce weightMaterial strength using tensile/compressive forcesVibration testingData acquisitionRock tunnel

The invention relates to a shake table test real-time loading device for simulating different burial depths of a rock tunnel. The shake table test real-time loading device comprises a model case, a real-time loading device body and a data acquisition system. The model case is used for containing test model materials and providing counter force for the real-time loading device body. The loading device body comprises a loading system and a sliding loading plate and used for achieving real-time loading of the test model materials in the ground shake application process. The acquisition system is used for monitoring real-time soil pressure of the test model materials in the real-time loading process. The device is used for solving the simulation problem of surrounding rock stress fields under the different burial depths in the shake table test process and can conduct loading when a test model shears and deforms in the vibration process, true real-time loading is achieved, the loading situation is monitored, and convenience is brought to research on power reaction of the tunnel under different burial depths. An air bag loading mode is adopted, shake table test loading can be conducted and meanwhile the mass of the model case can be reduced to the maximum degree.

Owner:BEIJING UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com