Patents

Literature

282results about How to "Realize one-time molding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparation method of hollow-structure metal or ceramic part

InactiveCN102351542AShort cycleShorten the production cycleCeramic shaping apparatusAdhesiveCo injection

The invention relates to a preparation method of a hollow-structure metal or ceramic part, which comprises the following steps: selecting metal or ceramic powder as the raw material, mixing, and granulating to obtain a feed material; selecting a core material; injecting the core material into a die by co-injection molding to obtain a core in hollow shape, and injecting the metal or ceramic feed material to be completely coated on the core, thereby obtaining a green body; and carrying out solvent extraction and heating on the green body to remove the adhesive and core, and sintering to obtain the hollow-structure product. The invention implements one-step molding of the hollow metal or ceramic part; from the raw material to the product, the production cycle is short, and the automation degree of equipment is high, thereby greatly enhancing the efficiency and forming a randomly complex and completely hollow die cavity; and thus, the invention can be used for preparing a completely hollow part with no joint, greatly lowers the cost of the product, and is especially suitable for preparing hollow metal and ceramic parts.

Owner:CENT SOUTH UNIV

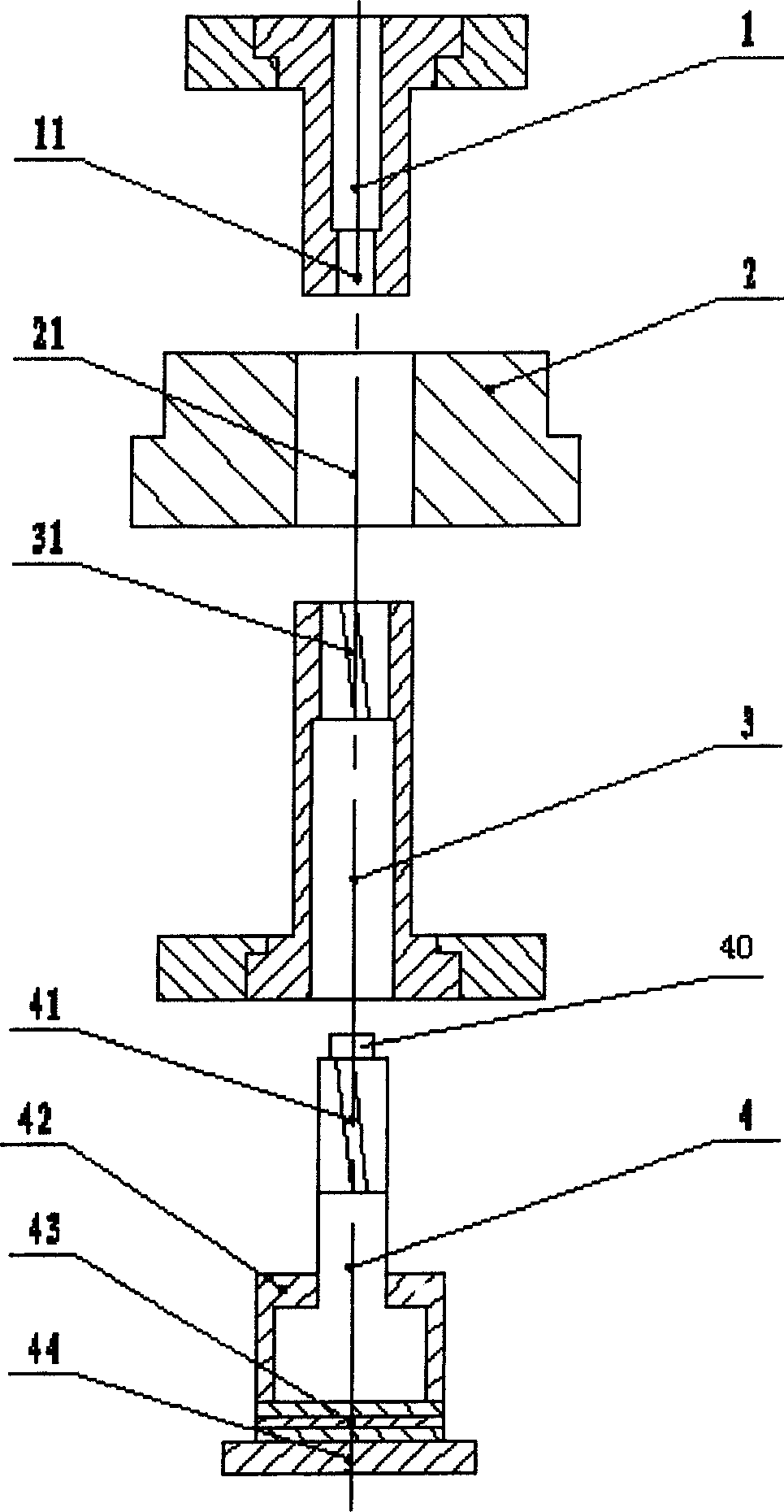

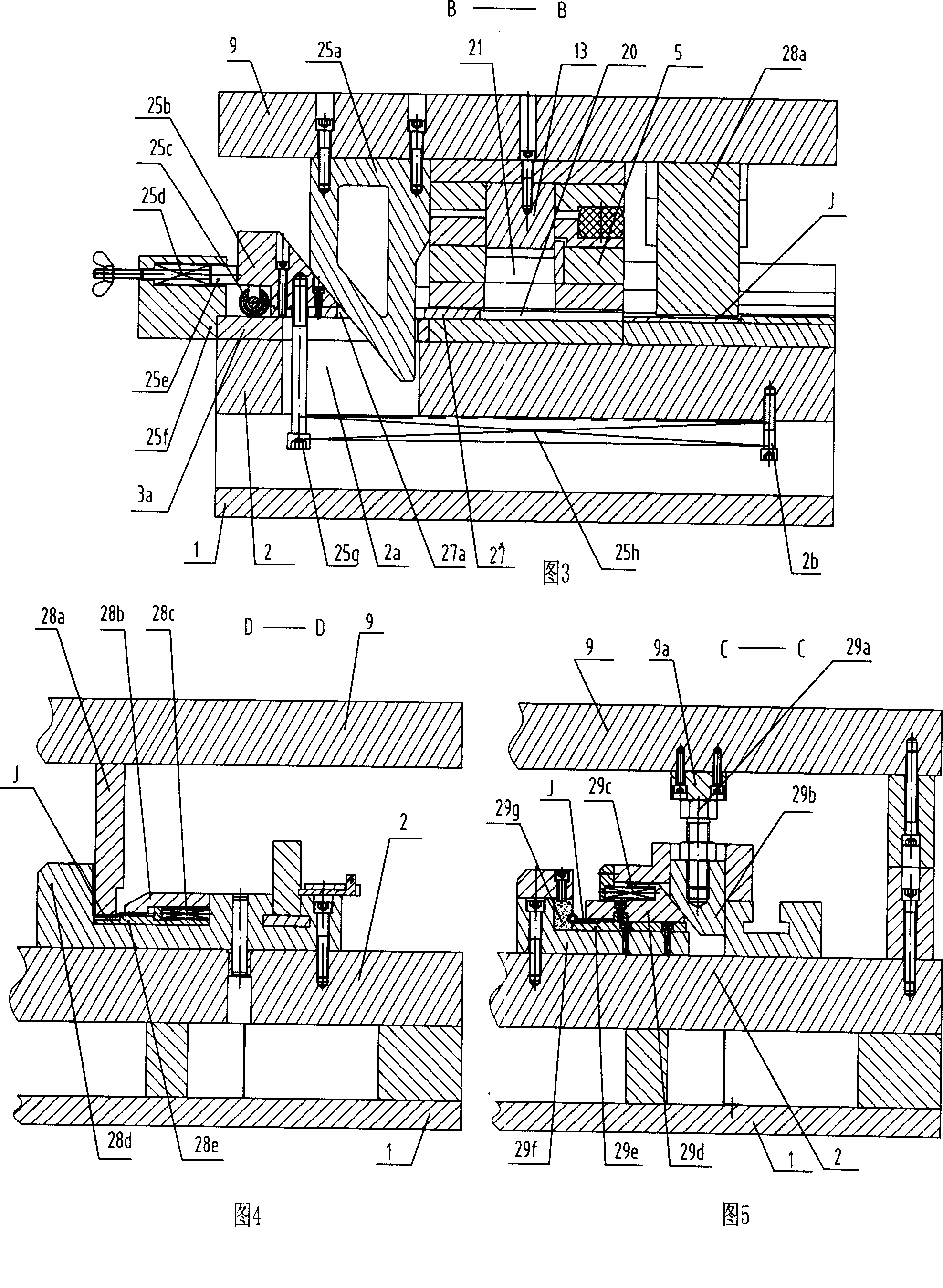

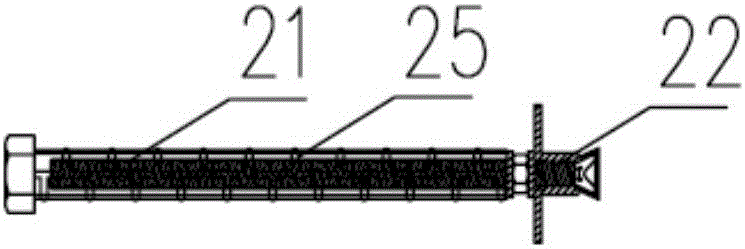

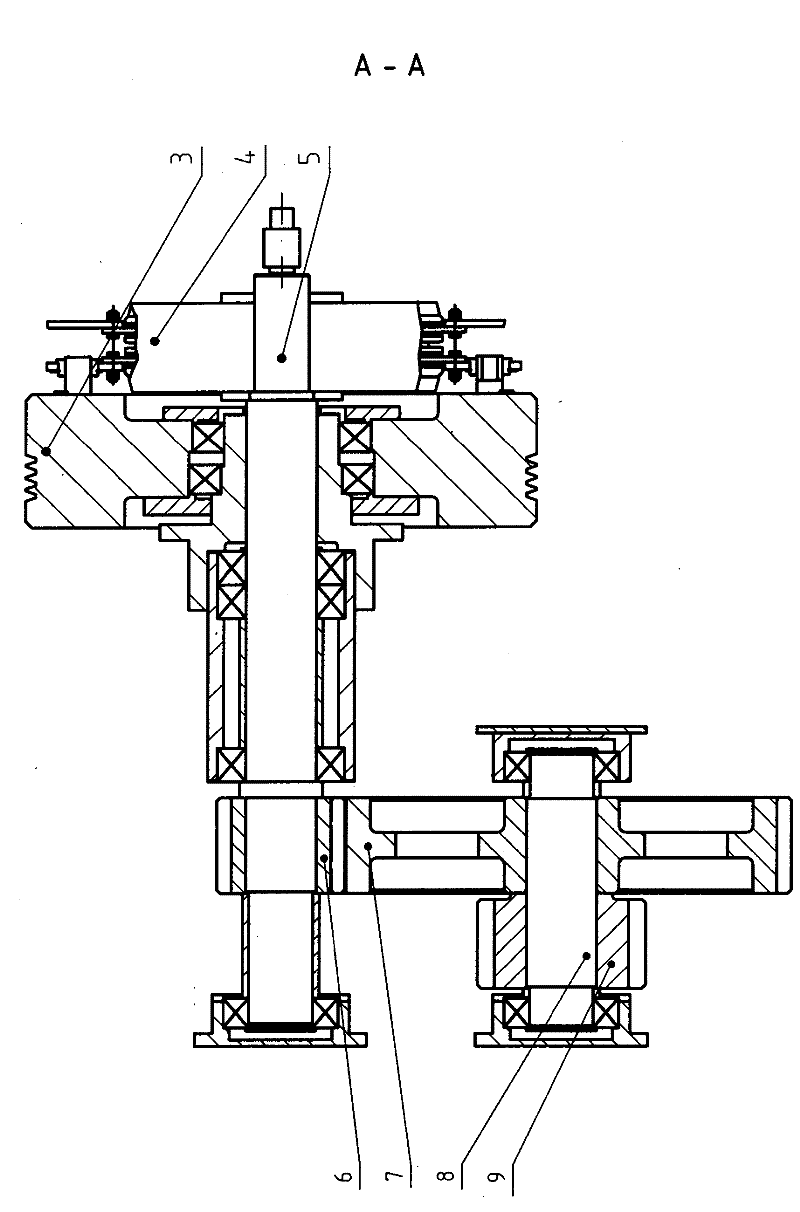

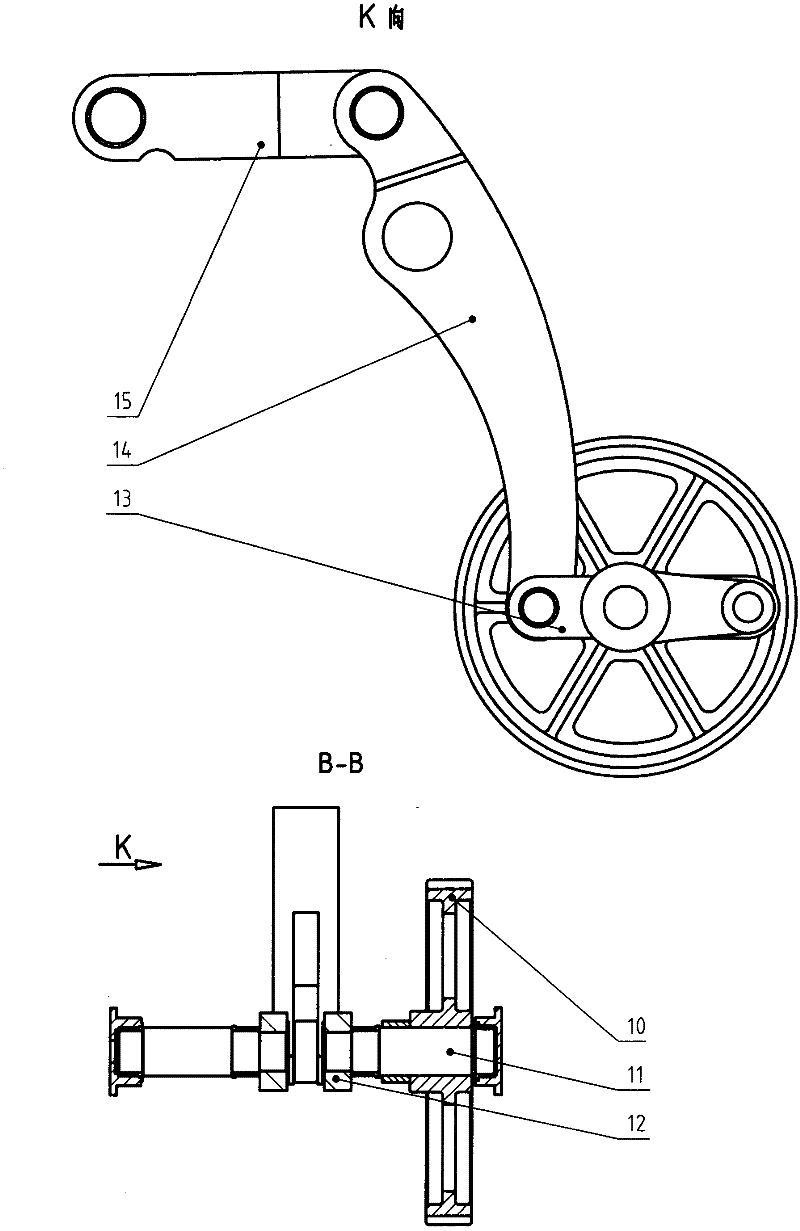

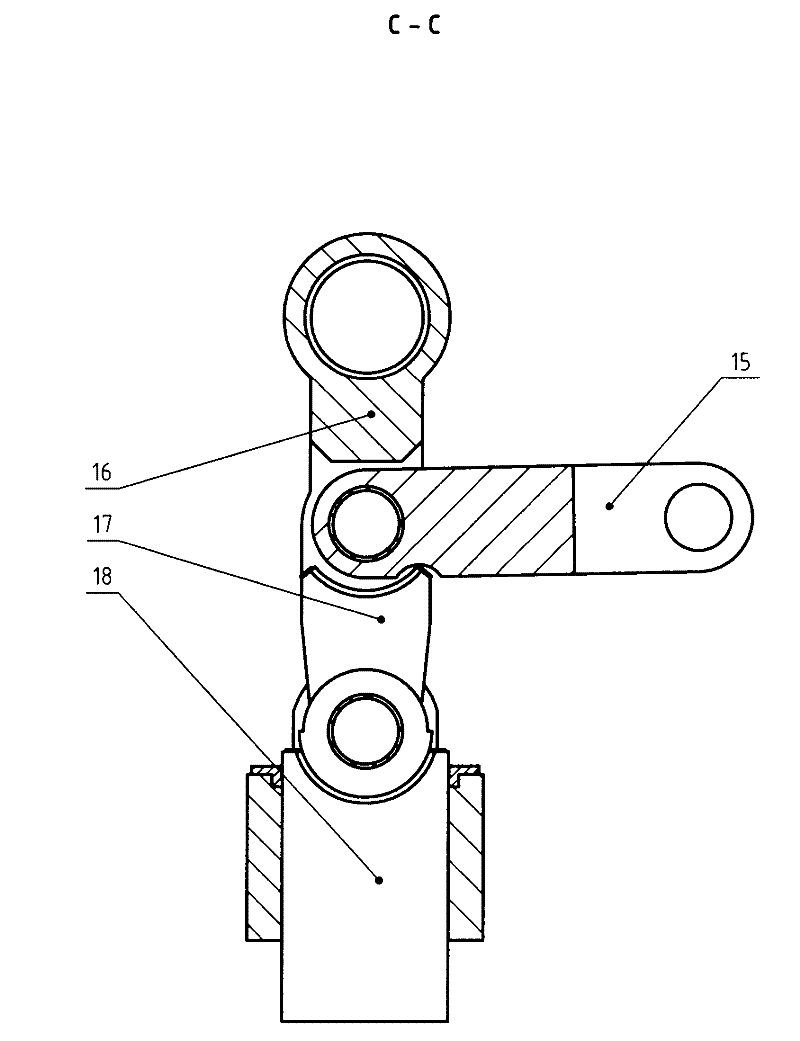

Manufacture method and die for powder metallurgy inside spin ratchet wheel

The invention relates to a method for producing powder smelt screw ratchet, which comprises: mixing the materials, compressing molding, sintering, compressing and shaping, to obtain the ratchet. The invention also discloses a relative mould, which is formed by a compressing upper punch, compressing middle mould, compressing lower punch; the upper part of lower punch has the inner screw tooth matched with the outer screw tooth; the upper punch is sliding matched with the middle mould; the middle mould is sliding matched with the lower mould; the compressing core rod has compressing core rod, friction plate, and rotation element; the upper part of compressing core rod has outer screw tooth; the lower end of core rod and the upper end of rotating element have friction plate between them, while their contact surface has lubricant. The invention, via the rotation of core rod, realizes the one-time molding and demoulding of inner screw ratchet, to improve the yield and reduce the cost.

Owner:南通市海门常乐粉末冶金厂

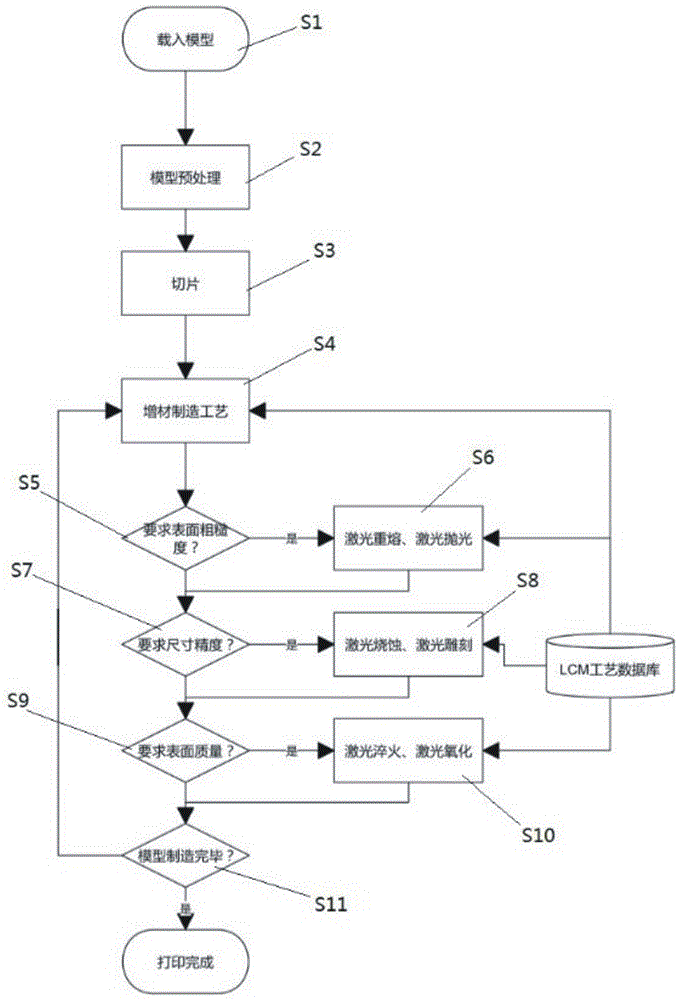

Laser composite manufacturing technology of parts

ActiveCN106756989AReasonable designHigh dimensional accuracyAdditive manufacturingIncreasing energy efficiencyPre treatmentSurface modification

The invention discloses a laser composite manufacturing technology of parts. The laser composite manufacturing technology comprises the following steps: S1, loading a model; S2, preprocessing the model; S3, slicing; S4, performing a material additive manufacturing technology; S5, judging whether surface roughness meets the requirement or not; S6, carrying out laser remelting and laser polishing; S7, judging whether dimensional accuracy meets the requirement or not; S8, carrying out laser ablation and laser engraving; S9, judging whether surface quality meets the requirement or not; S10, carrying out laser quenching and laser oxidation; S11, judging whether the manufacture of the model is finished. The laser composite manufacturing technology integrates the laser material additive manufacturing technology, a laser material subtractive manufacturing technology and a laser surface modification technology, thus being capable of effectively improving the dimensional accuracy, surface smoothness and compactness of the parts, improving the surface quality of the parts, and realizing one-time molding of the parts.

Owner:昆明七零五所科技发展有限责任公司

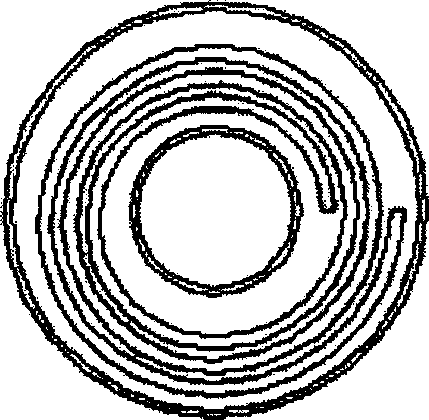

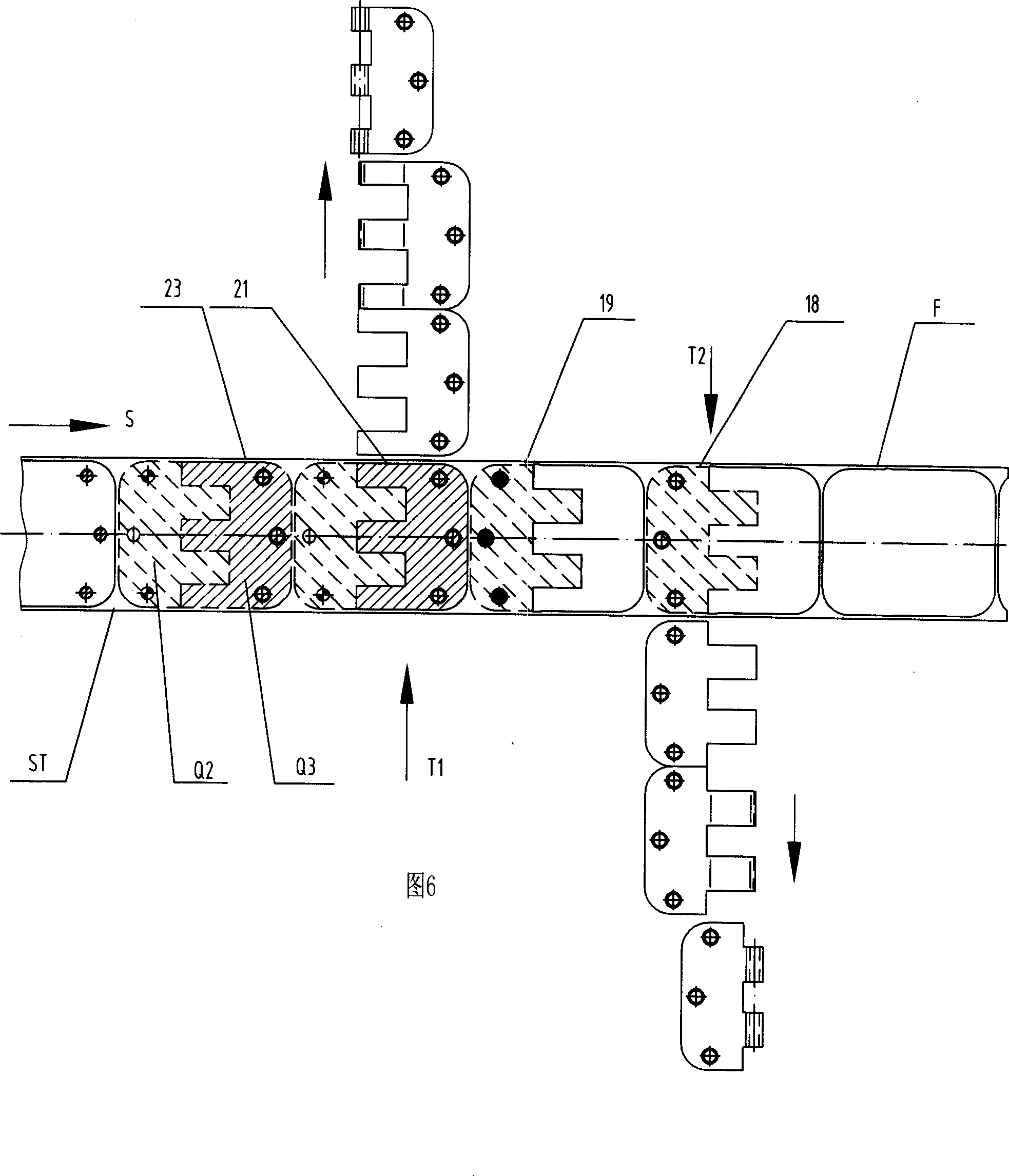

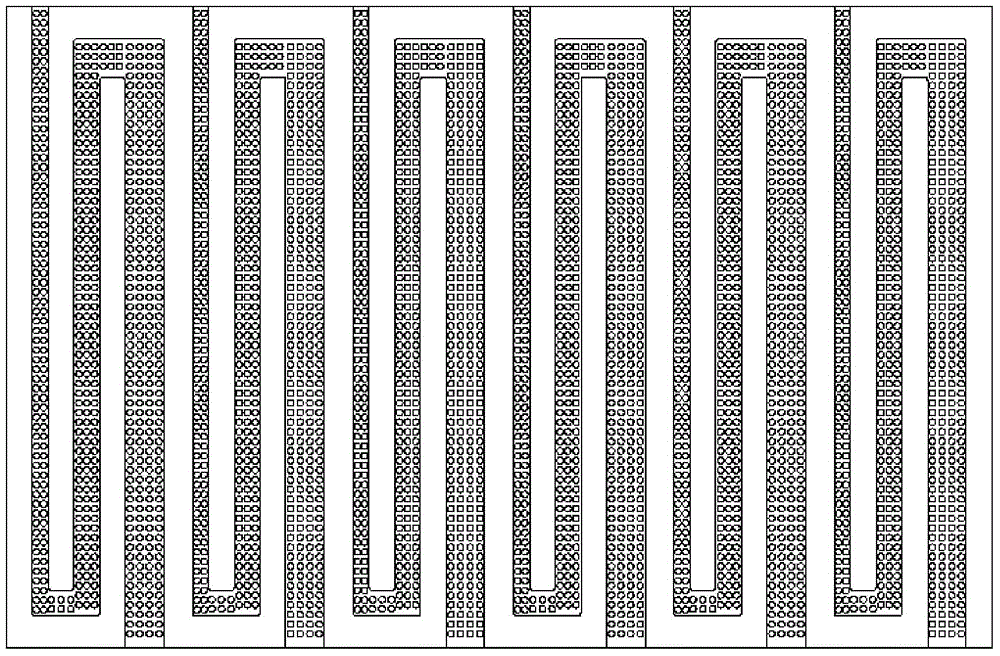

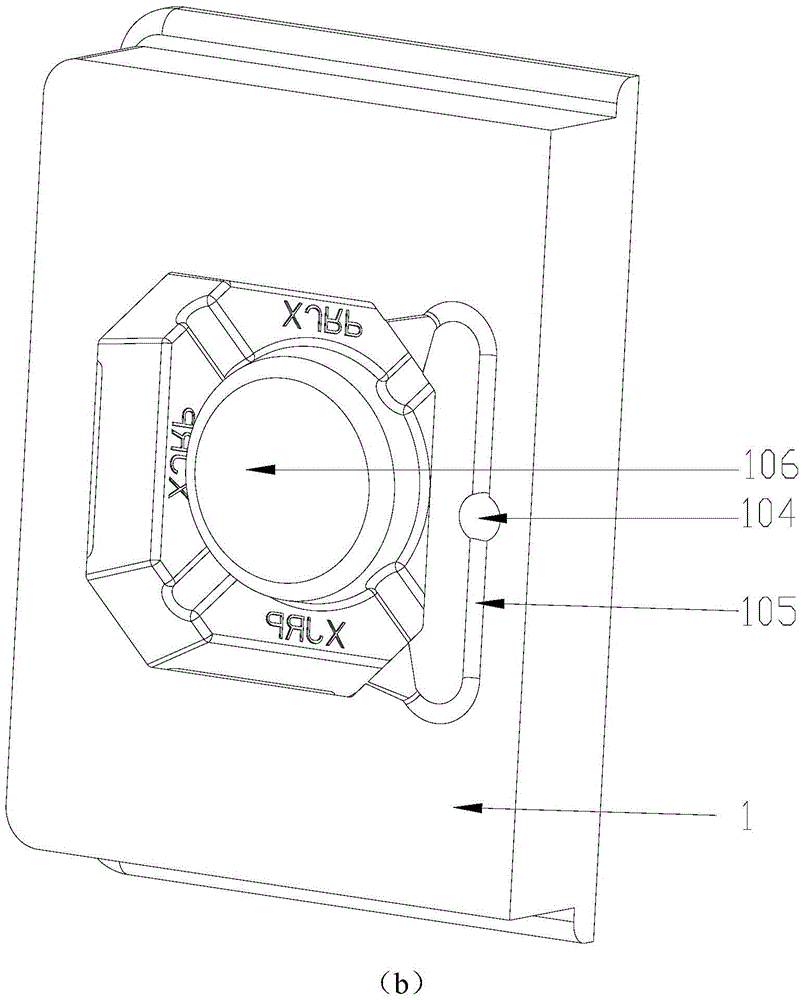

Complete cutting type belt coil pipe stepped mould for hinger

InactiveCN101011716AGuaranteed utilizationRealize one-time moldingShaping toolsMetal-working feeding devicesPunch pressStirrup

A hinge blade nest cutting winding progressive die comprises up die and bottom die and the connecting guide post, with the up die having stirrup punch head, three claw punch head and two claw punch head, with the bottom die having stirrup, three claw die and two claw die, with the later tow having a horizontal slide path, one side of which having a discharge device linked with the up die, bending die linked with the up die on the other side, and the winding die. It realizes the one time forming with the stirrup, shear cutting, bending and winding, with precision and improved production efficiency and reduced cost. One set of die, a punch machine and an operator will get everything done.

Owner:伟业重工(安徽)有限公司

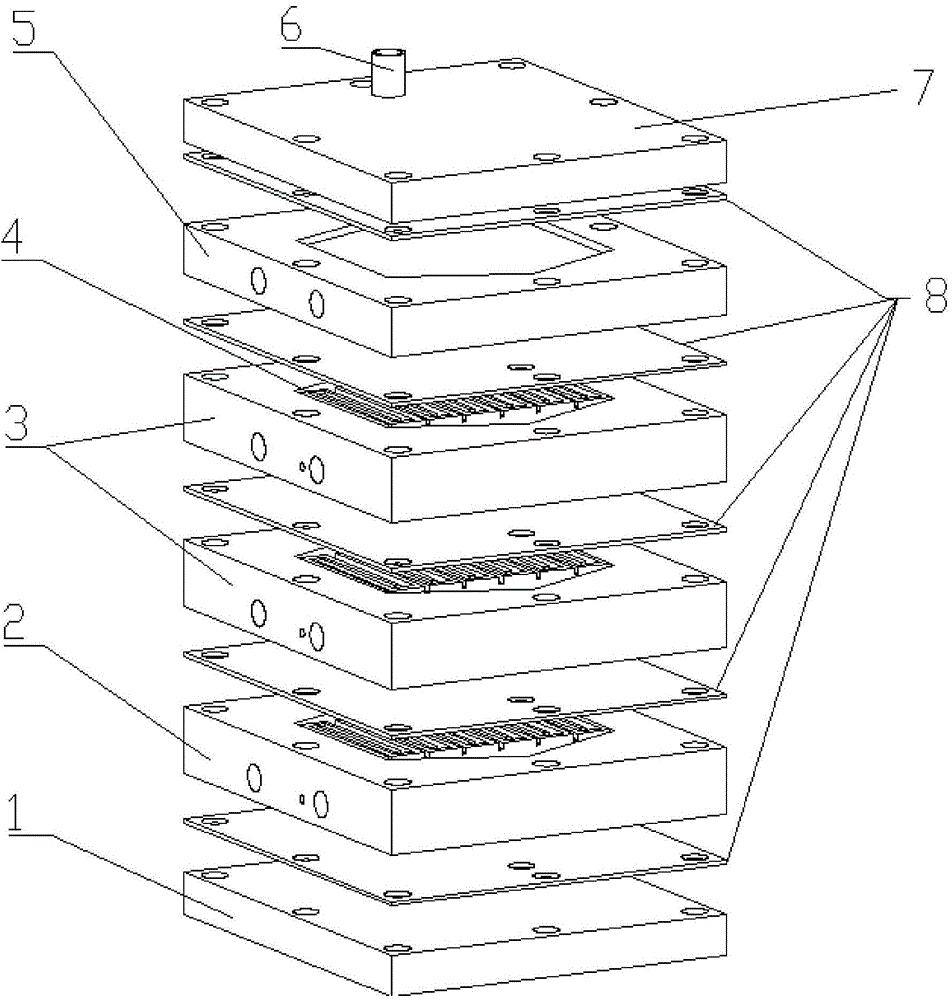

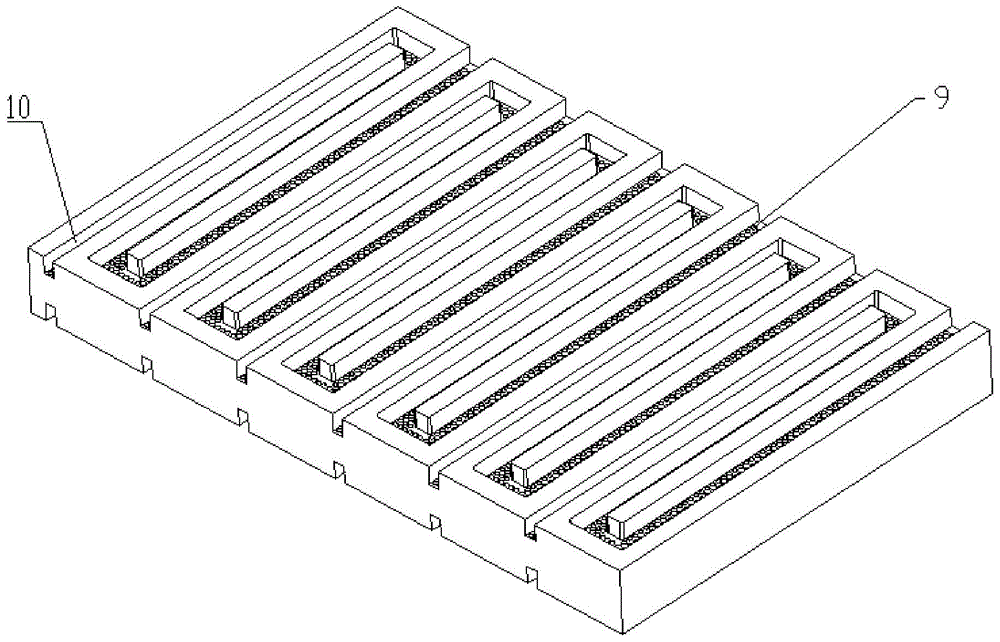

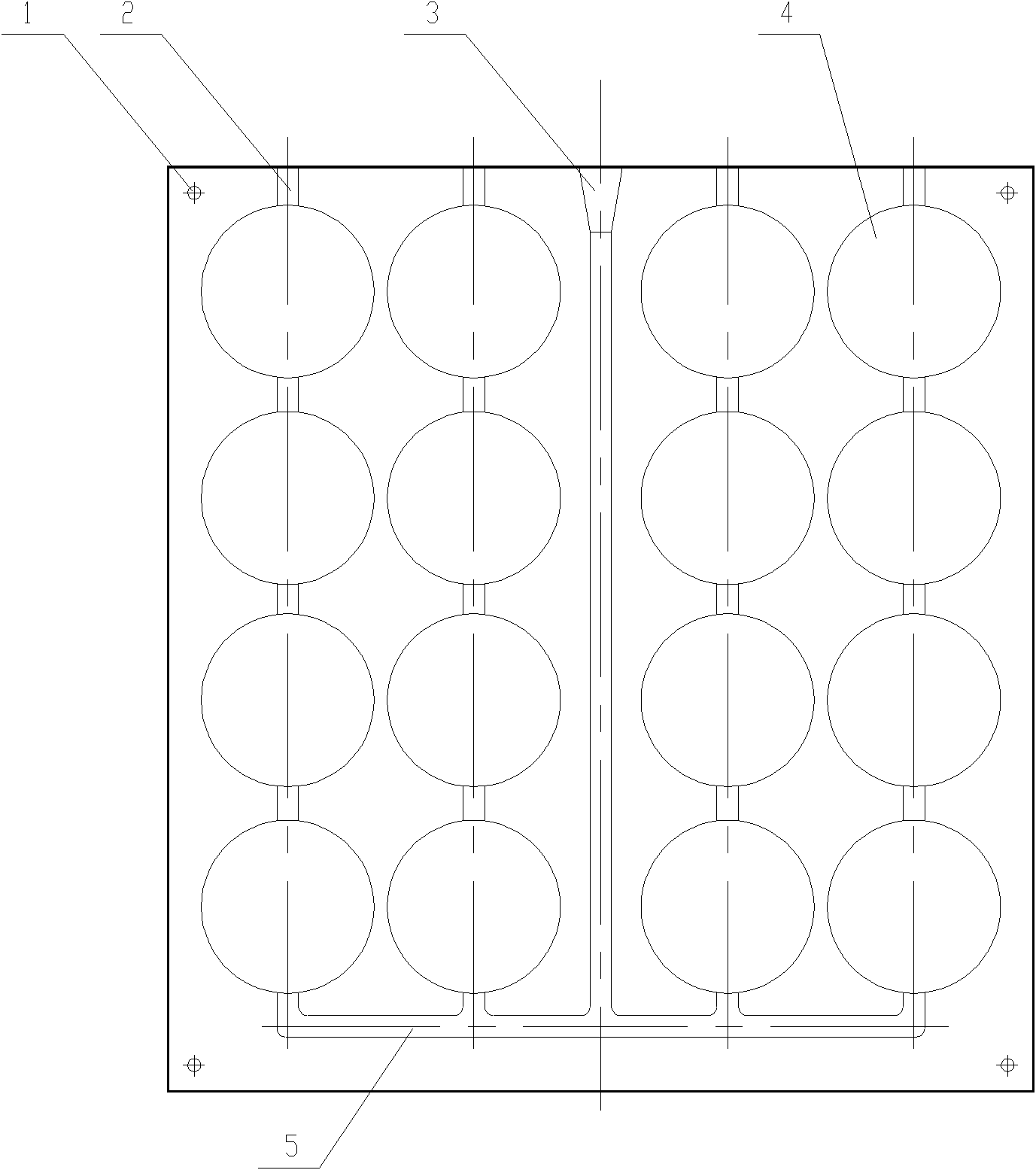

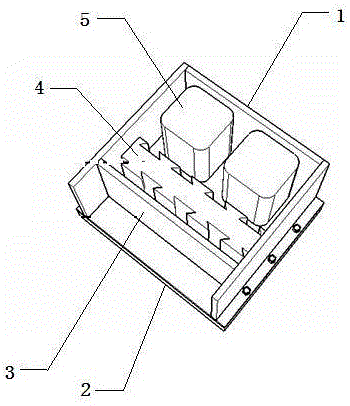

Laminated double-sided multi-serpentine microchannel reforming hydrogen production reactor

InactiveCN104671204ALarge specific surface areaFacilitate attachmentHydrogenProcess engineeringHydrogen production

The invention discloses a laminated double-sided multi-serpentine microchannel reforming hydrogen production reactor which comprises an upper cover board, a lower cover board, an evaporation plate, a plurality of upper reforming plates and lower reforming plates, wherein the plurality of upper reforming plates are arranged between the evaporation plate and the lower reforming plates; a flexible graphite pad is arranged between any two adjacent upper reforming plates; an evaporation cavity is formed in the upper surface of the evaporation plate; an inlet drainage cavity and an outlet drainage cavity, which are communicated with each other, are symmetrically connected with two sides of the evaporation cavity respectively; reaction cavities are formed in the centers of the upper reforming plates and the lower reforming plates; the inlet drainage cavity and the outlet drainage cavity, which are communicated with each other, are symmetrically connected with two sides of each reaction cavity respectively; reaction carrier sheets are arranged in the reaction cavities of the upper reforming plates and the lower reforming plates; and groove structures with a plurality of serpentine microchannels are symmetrically formed in the upper surfaces and the lower surfaces of the reaction carrier sheets respectively up and down. According to the laminated double-sided multi-serpentine microchannel reforming hydrogen production reactor, the specific surface area of the reaction carrier sheets can be significantly increased; adhesion of a catalyst is improved; and the reaction pressure drop can be effectively reduced, so that the alcohol conversion rate and the hydrogen production speed are improved.

Owner:ZHEJIANG UNIV

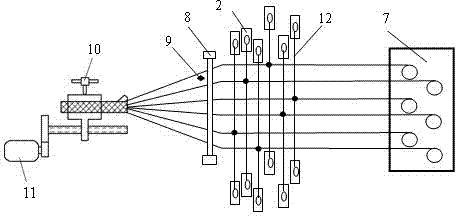

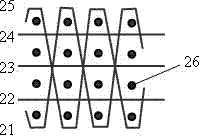

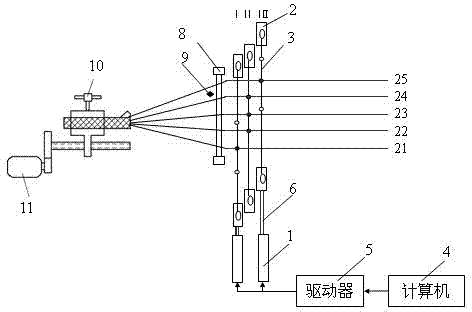

Opening device for stereo loom

InactiveCN102517741AReduce the number of pagesGood for weavingHealdsOther shedding mechanismYarnPalm fiber

The invention provides an opening device for a stereo loom. The opening device contains healed frames and is characterized in that at least one healed frame is connected with multi-hole palm fiber; at least one healed frame is connected with a push rod, which is connected with a servo electric cylinder; and the servo electric cylinder is connected with a driver, which is connected with a computer. By the adoption of the opening device, the number of heddles can be minimized and high-speed and digitalized control is carried out on the motion of the healed frames, thus greatly expanding types and specifications of fabrics and reducing abrasion of palm fiber to warp yarn.

Owner:DONGHUA UNIV

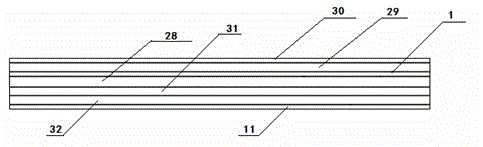

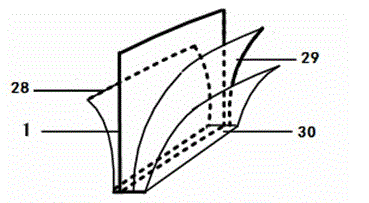

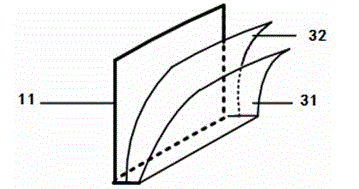

Perfumed aluminum-free composite inner liner paper for multi-coating cigarettes as well as preparation method and device of perfumed aluminum-free composite inner liner paper

The invention relates to a perfumed aluminum-free composite inner liner paper for multi-coating cigarettes as well as a preparation method and a device of the perfumed aluminum-free composite inner liner paper. The perfumed aluminum-free composite inner liner paper comprises two layers of raw paper, a blocking layer, two functional coatings, a perfuming coating and a surface layer, wherein the two sides of one layer of raw paper are respectively coated with the blocking layer and one functional coating, and the surface layer is attached on the functional coating; one side of the other layer of raw paper is sequentially coated with the other functional coating and the perfuming coating; the perfuming coating is combined with the blocking layer; the coating compound device comprises a double-sided coating part, a single-sided coating part and a compounding part. According to the perfumed aluminum-free composite inner liner paper for the multi-coating cigarettes as well as the preparation method and the device of the perfumed aluminum-free composite inner liner paper, the limitation of the original single-layer raw paper coating and single-physical-form functional blocking layer material is broken through; the perfumed aluminum-free composite inner liner paper has a damp-proof function, and is high in safety and barrier property as well as good in an anti-mould effect; therefore, a technical support is provided for the development of the novel and environment-friendly perfumed aluminum-free composite inner liner paper for the cigarettes.

Owner:CHINA TOBACCO YUNAN NEW MATERIAL

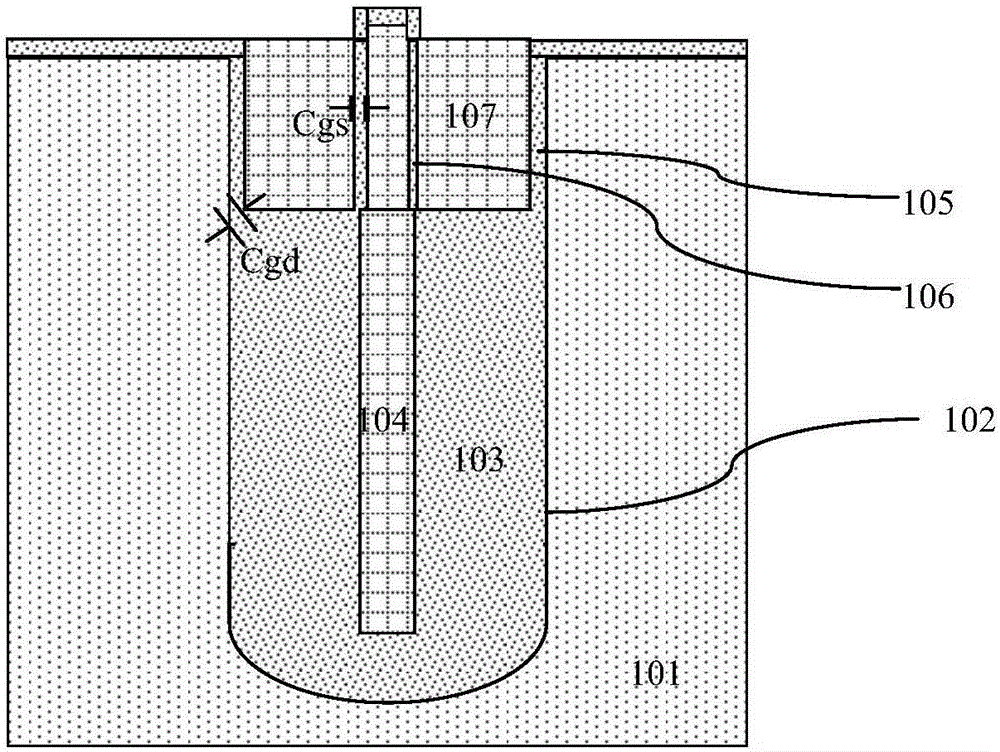

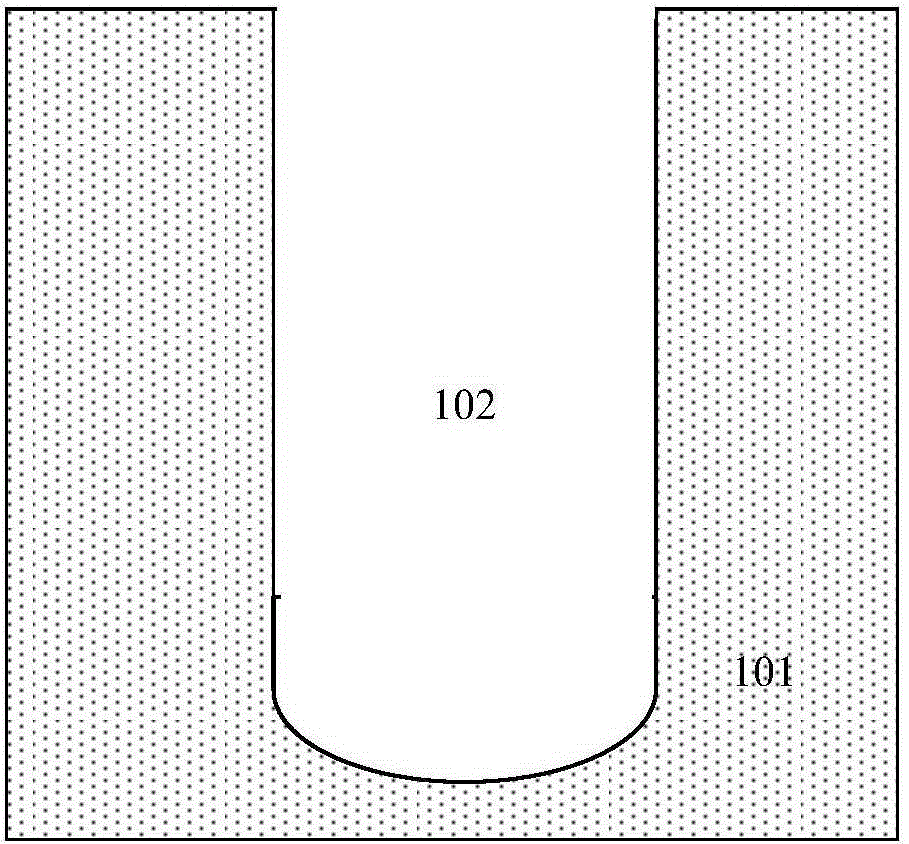

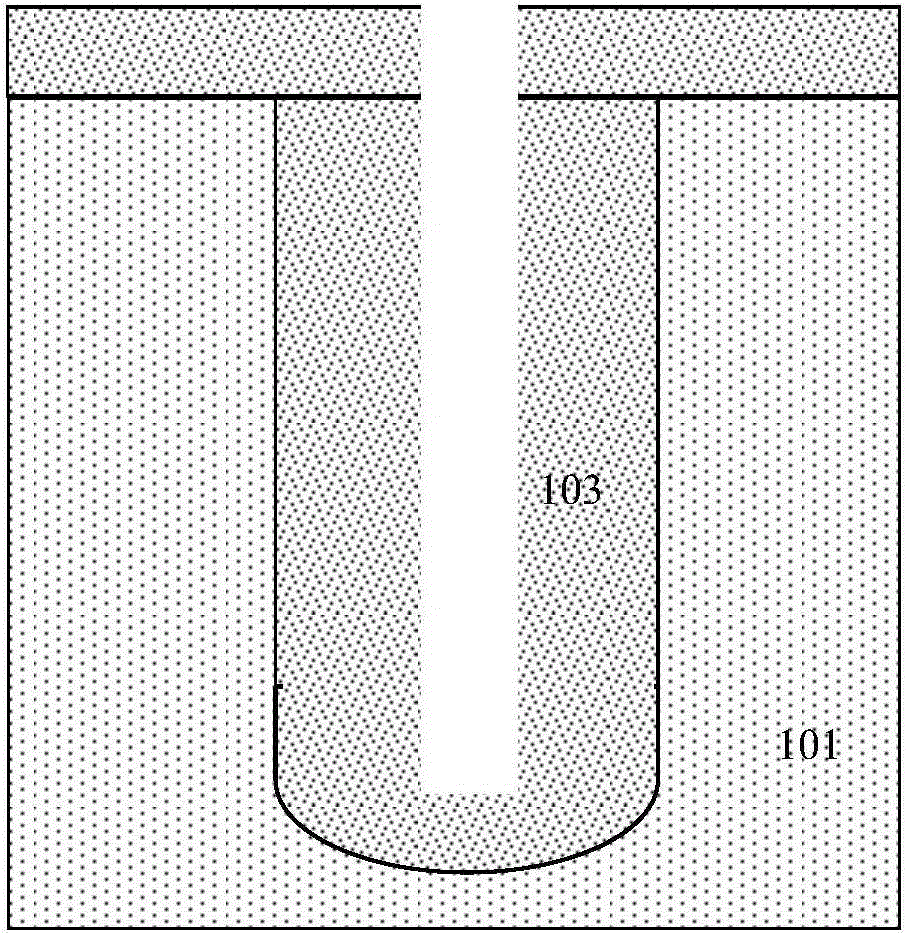

Trench gate structure with shielding gate and manufacturing method of trench gate structure

InactiveCN105225935AReduce parasitic capacitanceIncreasing the thicknessSemiconductor/solid-state device manufacturingSemiconductor devicesCapacitanceEngineering

The invention discloses a trench gate structure with a shielding gate. The trench gate structure comprises a trench, a thermal oxidation film layer, a nitridation film layer and a deposition and oxidation film layer, wherein the trench is formed in an epitaxial layer; the thermal oxidation film layer, the nitridation film layer and the deposition and oxidation film layer are formed on the inner side surface of the trench; the trench is completely filled with a first polysilicon layer; the deposition and oxidation film layer at the top of the trench is removed; the first polysilicon layer in the removal area is completely oxidized; the nitridation film in the removal area is also removed after being oxidized; the removal area is filled with a second polysilicon layer; a polysilicon gate comprises the second polysilicon layer; a gate oxidation layer comprises the thermal oxidation film layer isolated between the polysilicon gate and the epitaxial layer; and the shielding gate comprises the residual first polysilicon layer in the bottom of the trench. The invention further discloses a manufacturing method of the trench gate structure with the shielding gate. The stray capacitance between a gate and a source can be reduced; the withstand voltage between the gate and the source can be improved; the reliability of a device is improved; and the process cost can be reduced.

Owner:SHANGHAI HUAHONG GRACE SEMICON MFG CORP

Method for preparing high-density magnesia ceramic

The invention discloses a method for preparing high-density magnesia ceramic, and belongs to the technical field of structural ceramic application. A gel injection molding process is adopted. The method comprises the following steps of: preparing monomer solution for gel injection molding, adding pre-sintered high-purity magnesia ceramic powder into the monomer solution, and uniformly mixing to obtain stable slurry; adding a catalyst and an initiator, performing vacuum degassing, pouring the ceramic slurry into a die, and completely reacting a monomer with a cross-linking agent at an appropriate temperature to obtain a ceramic biscuit; and drying and sintering the biscuit to a magnesia ceramic product. The magnesia ceramic prepared by the method has the advantages of high mechanical strength, purity, density and thermal shock resistance and the like; meanwhile, the shape and size of the magnesia ceramic product can be controlled by the die; and a novel low-cost method for quickly and efficiently producing the high-density magnesia ceramic in batches is provided.

Owner:沈阳临德陶瓷研发有限公司

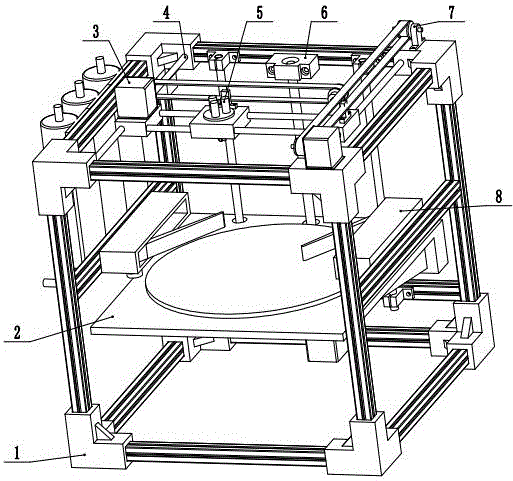

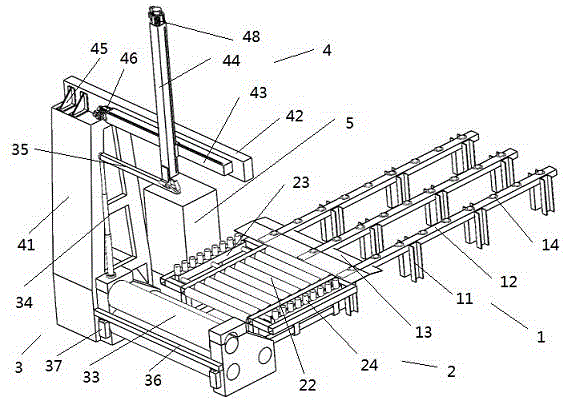

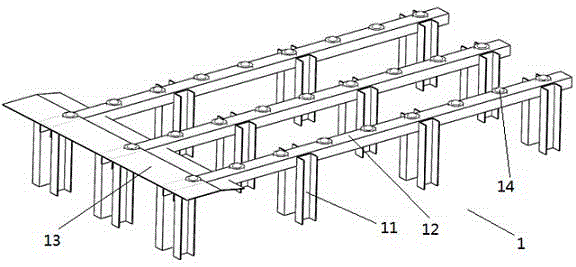

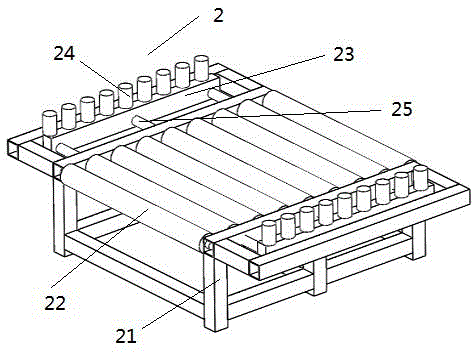

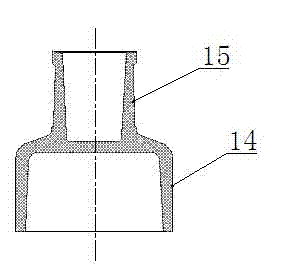

Robot used for manufacturing cakes

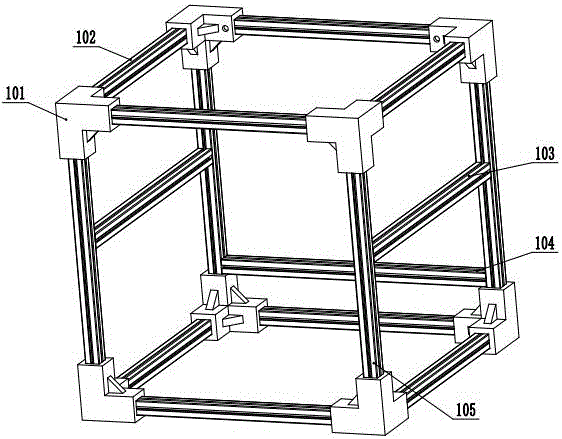

InactiveCN106035436ARealize one-time moldingImprove work efficiencyBaked articles handlingManipulatorNumerical controlOptical axis

The invention provides a robot used for manufacturing cakes. The robot comprises a rack, a workbench, an X-axis motion module, a Z-axis motion module, a Y-axis motion module, a movable scraper blade and the like, wherein the rack is of a square structure; two Y-axis guide optical axes are independently symmetrically installed at the round holes of angle joint blocks on the upper side of the rack; the X-axis motion module is installed on the Y-axis guide optical axes in a sliding way; the Y-axis motion module is fixedly installed on the upper side of the rack; the Z-axis motion module is fixedly installed on a first cross beam and a third cross beam on the rear side of the rack. The robot has the following advantages that the stable XYZ three-axis structure is adopted, numerical control programming control is adopted to be quick and accurate, one-time forming of the cake can be realized, working efficiency is greatly improved, working intensity is lowered, and cost is saved.

Owner:敖飞

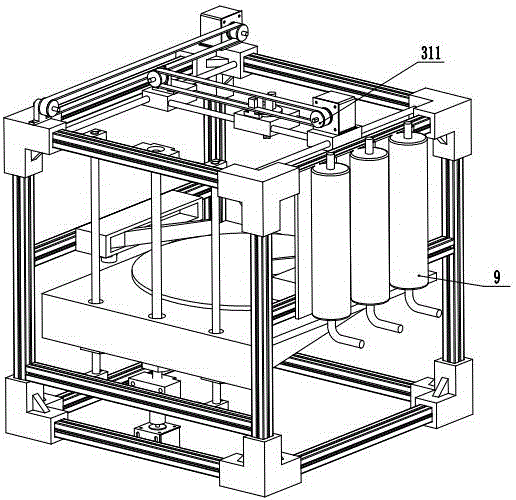

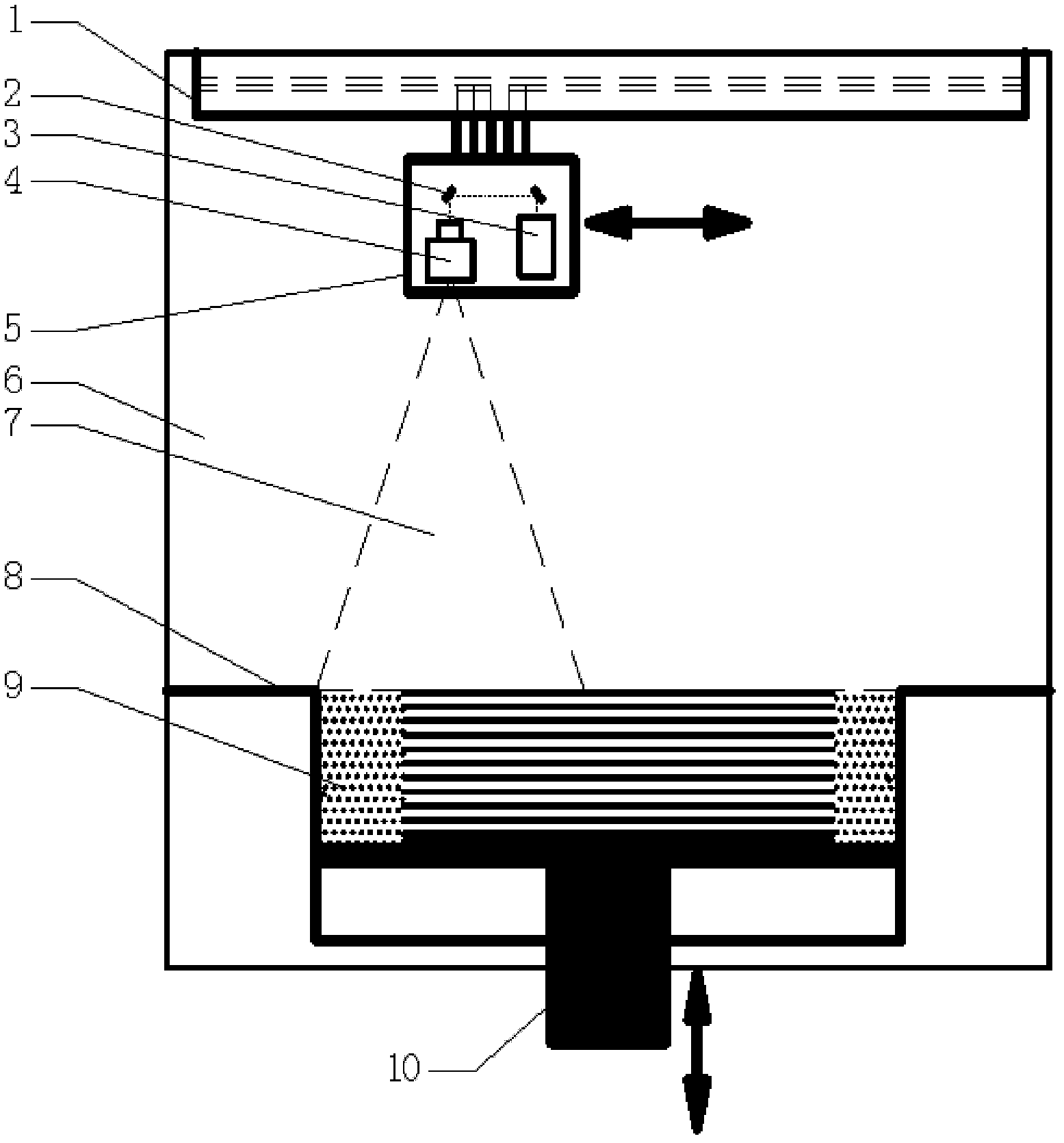

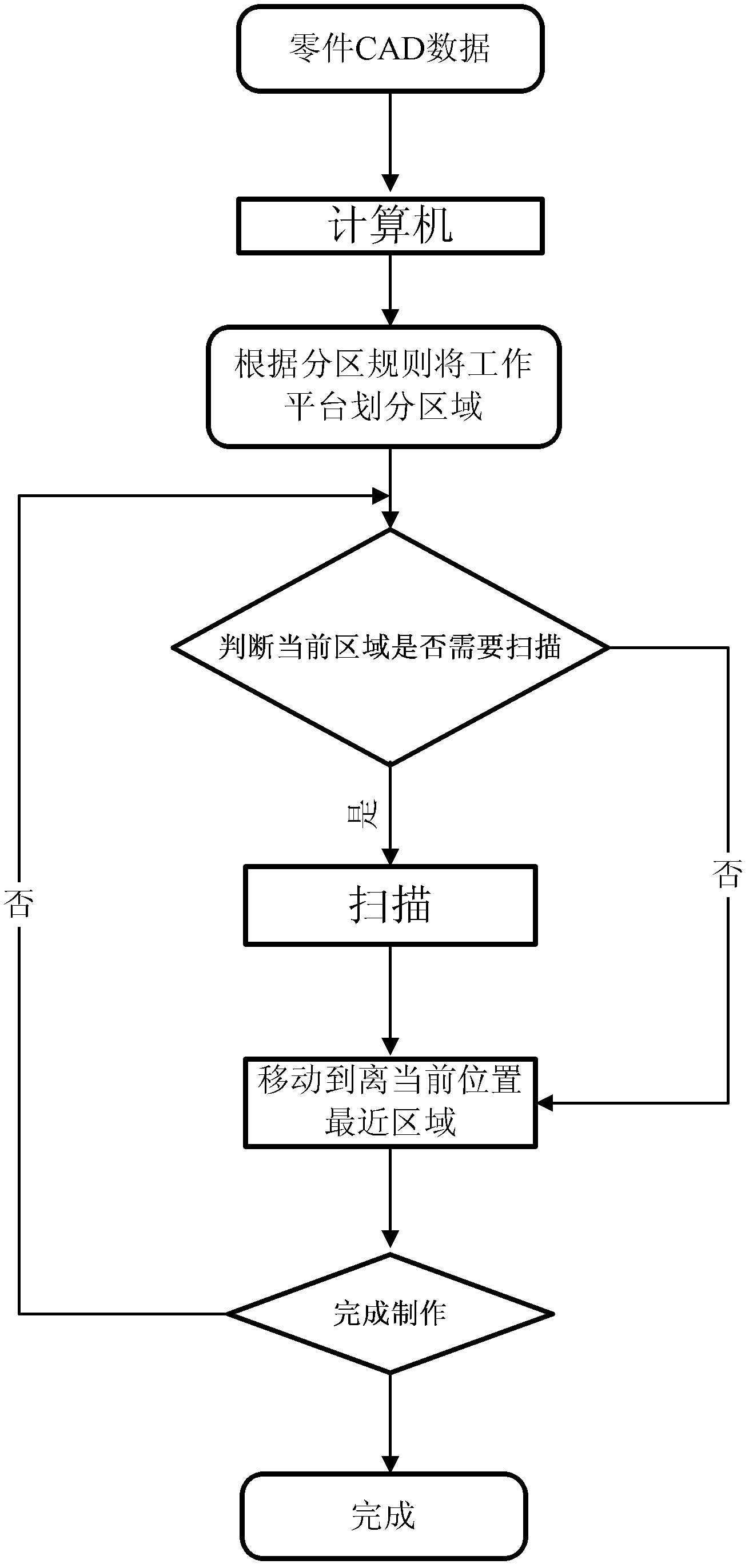

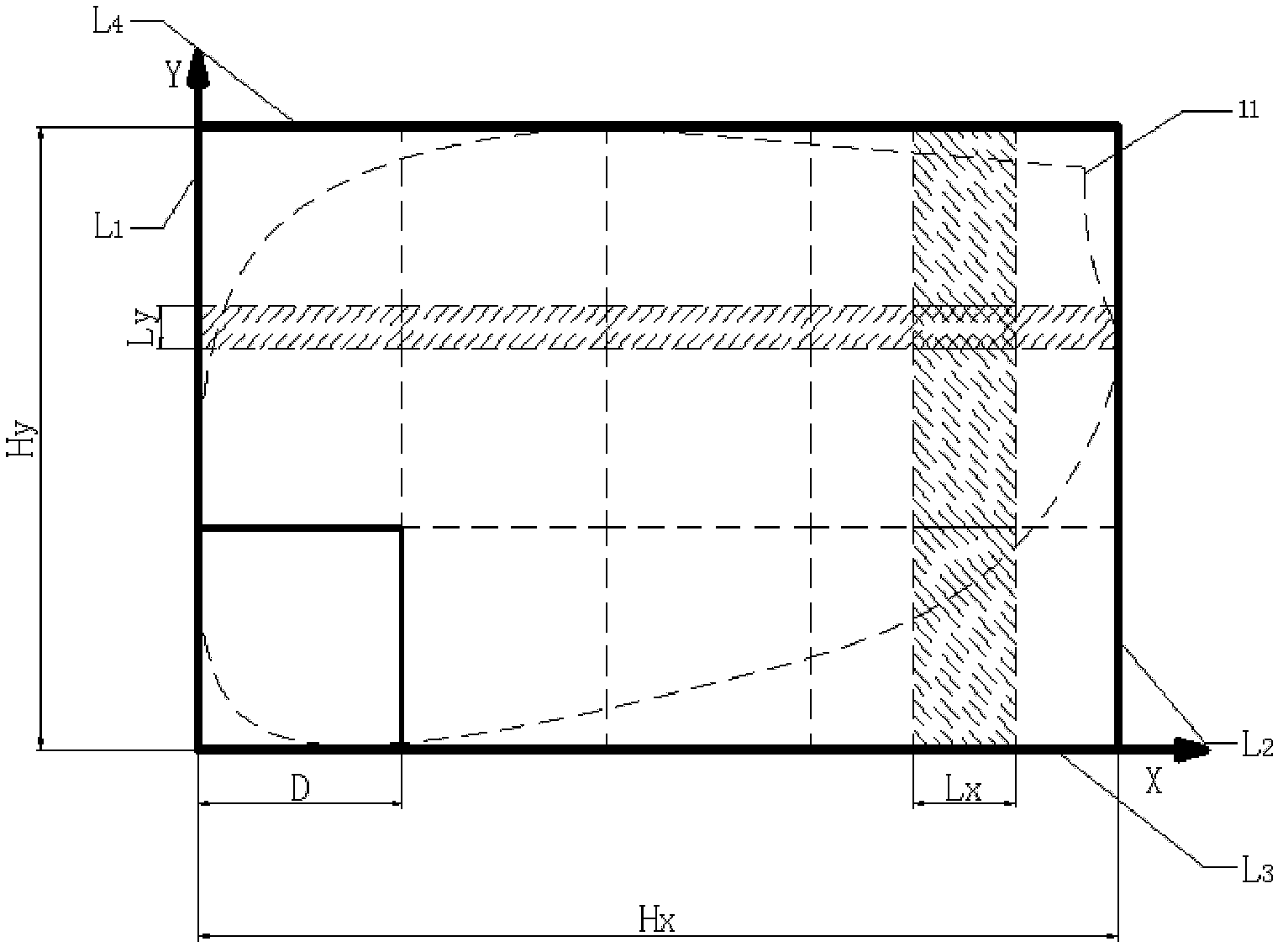

Regional mobile light source scanning system for laser rapid prototyping technology

InactiveCN102615281ARealize one-time moldingGuaranteed accuracyIncreasing energy efficiencyLaser beam welding apparatusOptoelectronicsLinear motor

The invention provides a regional mobile light source scanning system for a laser rapid prototyping technology. The system comprises a regional mobile platform, wherein the regional mobile platform is fixed in a working shell and arranged above a workpiece cavity; a linear motor platform of the regional mobile platform is suspended above the workpiece cavity through a connecting piece; a scanningplatform is fixed on the linear motor platform; a reflector of the scanning platform is positioned above a laser and a scanning mirror; the laser is positioned on the right of the scanning mirror; a computer with a scan control program is connected with the scanning platform through a mirror control card, and connected with the linear motor platform through a motion control card; before scanning,part data is input into the computer for partitioning, and is subjected to scan filling processing to determine whether a current region has data to be scanned or not, until all data are scanned. According to the regional mobile light source scanning system, the prototyping size of the laser rapid prototyping system is increased, and simultaneously high prototyping accuracy is maintained.

Owner:XI AN JIAOTONG UNIV

Automatic plate coiling and welding equipment

ActiveCN104647039AImprove mobilityRealize semi-automatic productionOther manufacturing equipments/toolsSemi automaticElectric control

The invention discloses automatic plate coiling and welding equipment, which comprises a material delivery device, a positioning mechanism, a plate coiling machine, a welding machine and an electric control cabinet, wherein the positioning mechanism is arranged at one end of the material delivery device, the plate coiling machine is arranged at one end of the positioning mechanism, the welding machine is arranged at one end of the plate coiling machine, and the electric control cabinet is arranged at one side of the welding machine. The automatic plate coiling and welding equipment has the advantages that the application range is wide, and the automatic plate coiling and welding equipment is suitable for coiling air pipes with various models; the traditional air pipe production equipment is replaced, the mobility of the air pipe production equipment is improved, the air pipe equipment is transferred to a customer site for producing the air pipe, and the transportation cost and production cost of an enterprise are reduced; the production procedure is reduced, the one-time forming is realized, the production time is shortened, and the production efficiency is improved; compared with the traditional full-manual air pipe coiling method, the automatic plate coiling and welding equipment is used for realizing the semi-automatic production of the air pipe.

Owner:FOSHAN GOOGOL AUTOMATION TECH

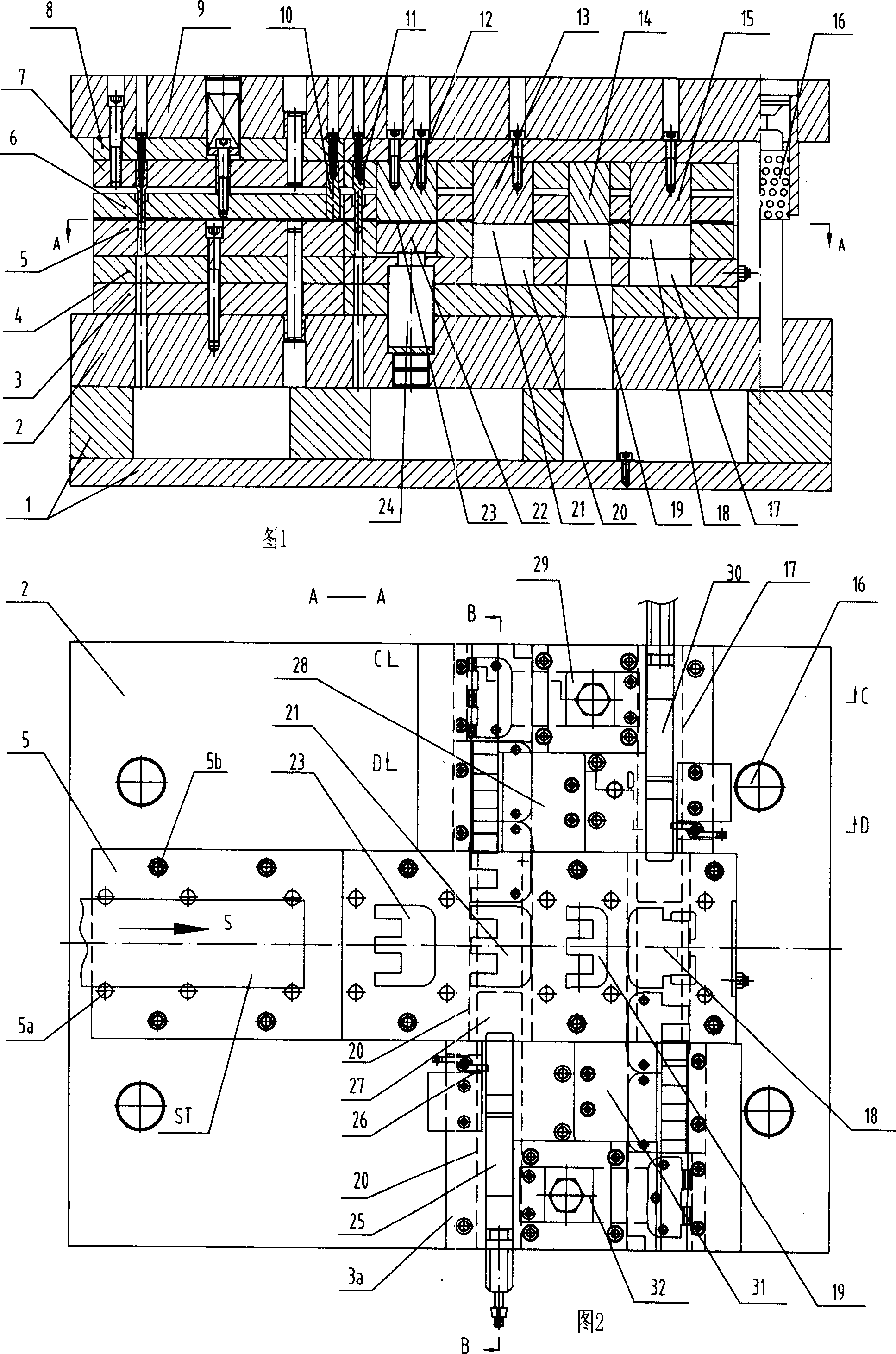

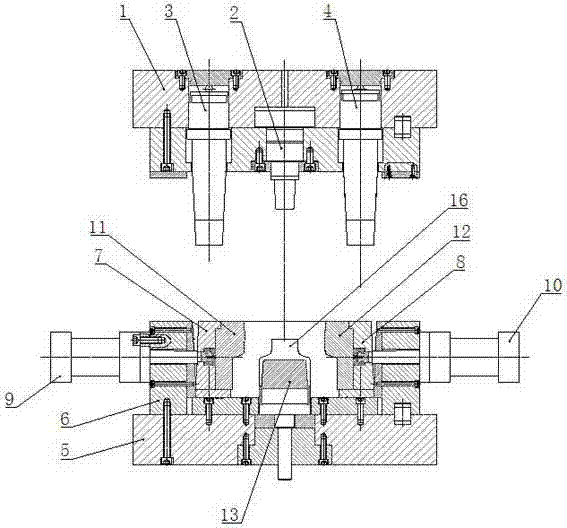

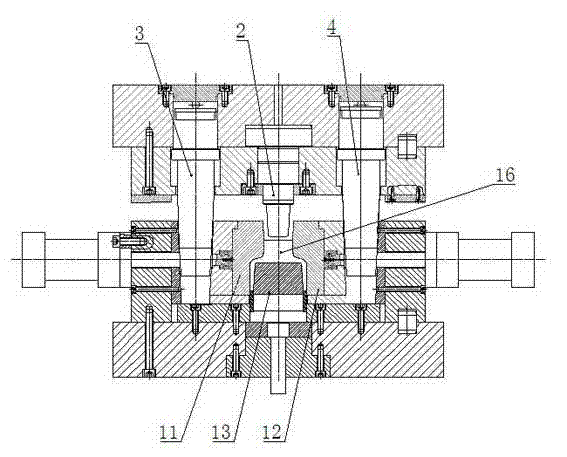

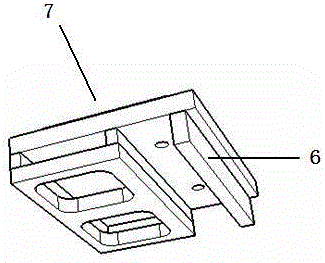

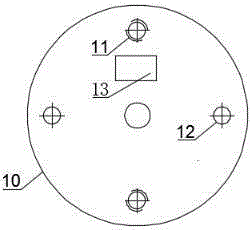

A molding die for rod-shaped insulator pillars for high-speed railways

ActiveCN102290169ARealize one-time moldingReduce processing stepsSupporting insulatorsPunchingEngineering

The invention relates to a bar-shaped insulator support post molding die for a high-speed railway. The bar-shaped insulator support post molding die comprises an upper template and a lower template, wherein an upper punching head is arranged in the center of the upper template; a left vertical female die locking cylinder and a right vertical female die locking cylinder are arranged on both sides of the upper template respectively; a die seat is arranged on the lower template; a left female die and a right female die are arranged in the die seat, and are driven to move horizontally by a left side cylinder and a right side cylinder respectively; the end parts of piston rods of the left female die locking cylinder and the right female die locking cylinder have conical or wedged structures; and the outer side faces of the left female die and the right female die are provided with conical or wedged structures which are matched with the piston rods of the left female die locking cylinder and the right female die locking cylinder respectively. After the left side cylinder and the right side cylinder are used for driving die assembly of a left die kernel and a right die kernel, and the left female die locking cylinder, the right female die locking cylinder and the upper punching head descend quickly, the piston rods of the two female die locking cylinders are embedded into gaps between the left and right female dies and the die seat, and the piston rods are matched with the conical or wedged structures of the left and right female dies to drive the left and right die kernels to belocked, so that one-step molding of a small compression joint part is realized, the molding efficiency is improved, turning is avoided, and materials are saved.

Owner:RUGAO DASHENG LINE EQUIP

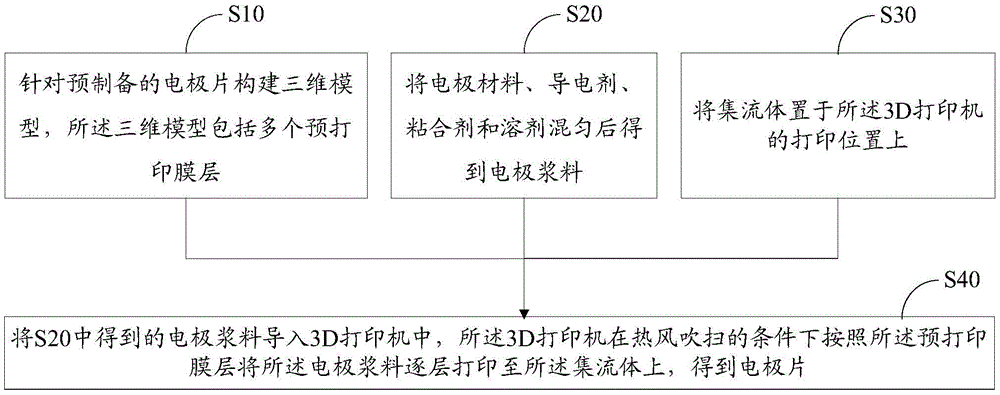

Preparation method of electrode slice

InactiveCN105609328ARealize one-time moldingIncreasing the thicknessHybrid/EDL manufactureSolventThree dimensional model

The invention discloses a preparation method of an electrode slice. The preparation method comprises the steps of: constructing a three-dimensional model, which comprises a plurality of pre-printed film layers, for a pre-made electrode slice, mixing electrode materials, a conductive agent, an adhesive and a solvent to obtain an electrode slurry, and placing a current collector on a printing position of a 3D printer; and guiding the electrode slurry into the 3D printer which prints the electrode slurry layer by layer onto the current collector according to the pre-printed film layers under the condition of hot air purging, so that the electrode slice is obtained. According to the preparation method of the electrode slice, since the electrode slurry is printed onto the current collector layer by layer in the form of mixed slurry, the uniformity between coatings of the electrode slice can be effectively improved; and the electrode slurry is printed onto the current collector layer by layer under the condition of hot air purging, the printed film layers can be dried quickly, the process of film layer curing is omitted, and the one-time forming of the electrode slice is achieved.

Owner:GUANGDONG FENGHUA ADVANCED TECH HLDG

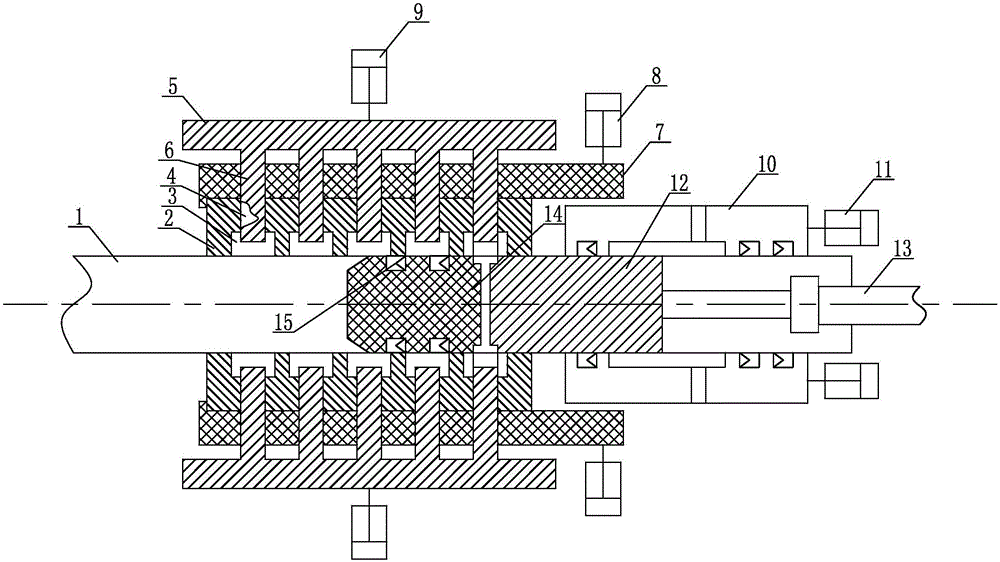

Multi-corrugation one-time forming device of EGR pipe and forming technology of multi-corrugation one-time forming device of EGR pipe

The invention discloses a multi-corrugation one-time forming device of an EGR pipe. The one-time forming device comprises two corrugation forming half cylinders surrounding the EGR pipe. The two corrugation forming half cylinders are correspondingly provided with forming half-cylinder mold combining devices respectively. Corrugation forming half grooves and corrugation top forming holes are formed in the inner walls of the two corrugation forming half cylinders. Corrugation top limiting molds are oppositely arranged on the outer sides of the corrugation forming half cylinders. Corrugation top limiting inserting pieces corresponding to the corrugation forming holes are arranged on the inner walls of the two corrugation top limiting molds respectively. The two corrugation top limiting molds are each connected with a limiting drive device. Forming half cylinder ejecting devices are arranged at the side portions of the two corrugation forming half cylinders respectively. A corrugation pressure forming device is arranged between the two corrugation forming half cylinders. One-time forming of multiple independent corrugations is achieved, consistency of the sizes such as the corrugation outer diameter, the corrugation outer outline and the length is effectively guaranteed, and the reliability of the EGR pipe is improved. Meanwhile, the production efficiency of the EGR pipe is greatly improved. The rejection rate and the assembling stress of the EGR pipe are greatly reduced.

Owner:十堰市倍力汽车管业有限公司

Method for preparing large-sized ceramic grinding balls

The invention discloses a method for large-sized ceramic grinding balls, which belongs to the technical field of grinding media. The method comprises: firstly, preparing monomer solution for gelcasting; secondly, adding ceramic powder into the monomer solution, stirring the solution uniformly to obtain stable slurry, adding a catalyst and an initiator into the slurry, stirring the slurry under vacuum to exhaust air; and finally, pouring the slurry into a mold, keeping the temperature of the slurry till the monomer reacts with a crosslinker completely to obtain a ceramic grinding ball biscuit, and drying and sintering the biscuit to obtain the ceramic grinding ball. The ceramic grinding ball manufactured by the method has high strength, hardness, wear resistance, corrosion resistance and high-temperature stability; meanwhile, the size of the ball can be controlled by the size of the ball mold cavity of the mold; and the method is particularly suitable for forming large-sized ceramic grinding balls, is low in cost and makes industrial production easy.

Owner:SHANGHAI JIAO TONG UNIV

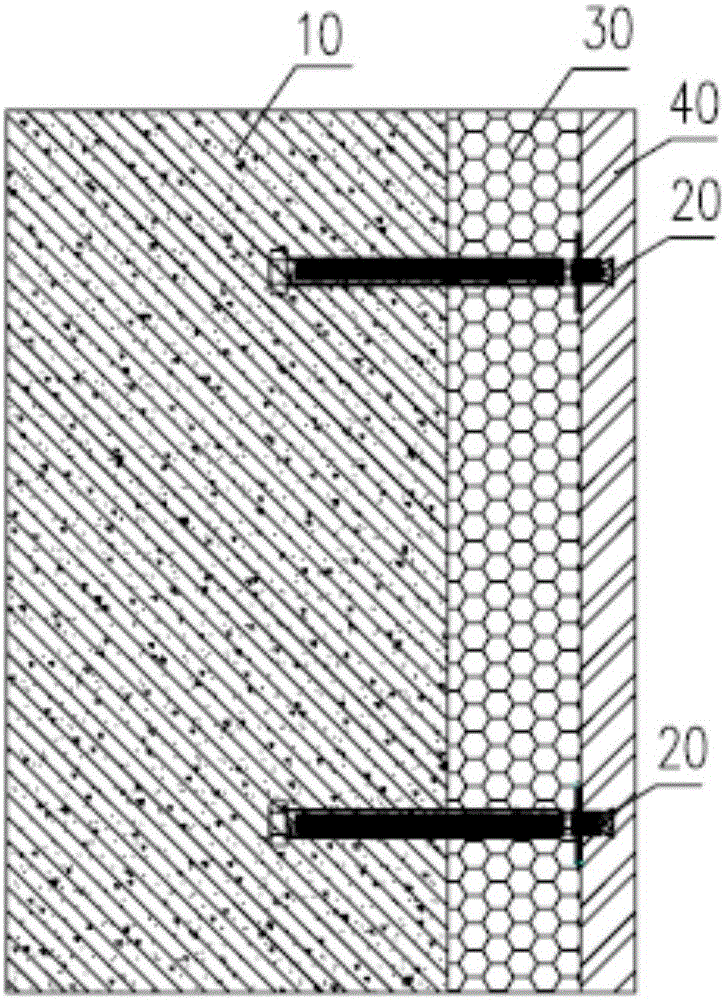

Manufacturing method and structure of integrated prefabricated thermal-insulation wallboard and wallboard connecting assembly

ActiveCN106223498AImprove insulation effectFirmly connectedCeramic shaping apparatusHeat proofingThermal insulationEngineering

The invention discloses a manufacturing method and structure of an integrated prefabricated thermal-insulation wallboard and a wallboard connecting assembly. The manufacturing method of the integrated prefabricated thermal-insulation wallboard comprises the following steps: S10: stacking a thermal-insulation material and an outer decorative finish layer; S20: connecting the thermal-insulation material and the outer decorative finish layer through a connecting assembly, wherein the connecting assembly stretches out of the thermal-insulation material; S30: flatly laying the thermal-insulation material and the outer decorative finish layer into a member mold; and S40: pouring concrete wall body on one side, stretching out of the thermal-insulation material, of the connecting assembly. The structure of the integrated prefabricated thermal-insulation wallboard comprises a concrete wall body, the thermal-insulation material and the outer decorative finish layer, wherein the connecting assembly is pre-buried in the concrete wall body and the connecting assembly stretches out of the concrete wall body; the thermal-insulation material is stacked with the concrete wall body through the connecting assembly; and the outer decorative finish layer is stacked with the thermal-insulation material through the connecting assembly. The manufacturing method of the integrated prefabricated thermal-insulation wallboard, disclosed by the invention, has few machining links and high accelerating speed; and the manufactured wall body has good quality and a good thermal-insulation effect, and the replacement of the thermal-insulation wallboard and the outer decorative finish layer at a later period is convenient to realize.

Owner:SHANGHAI JOHNSON ARCHITECTURAL & ENG DESIGN CONSULTANTS

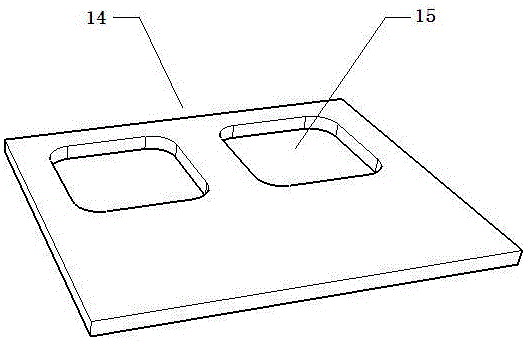

Self-insulation concrete hollow building block mold and manufacturing method of building blocks

ActiveCN105799047ARealize one-time moldingQuality improvementDischarging arrangementMouldsMaterials science

Owner:JINLING INST OF TECH

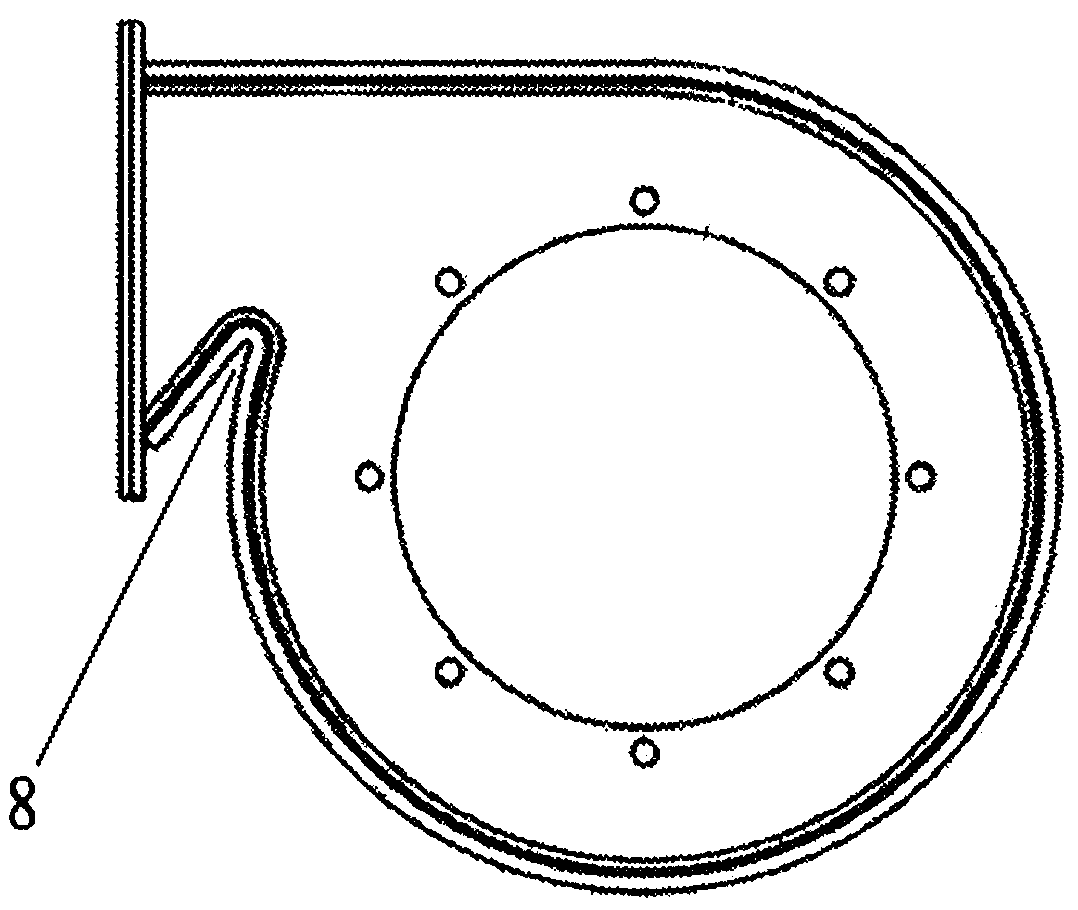

Kitchen ventilator volute edge folding and rolling device

The invention relates to the field of kitchen ventilators, in particular to a kitchen ventilator volute edge folding and rolling device which comprises an upper pressing plate and a lower pressing plate. The upper pressing plate and the lower pressing plate can rotate. The edge of the upper surface of the lower pressing plate and the edge of the lower surface of the upper pressing plate are provided with limiting edges. The overall shape of the limiting edges is consistent with the shape of the outer edges of an upper side plate and a lower side plate of a volute. Groove extruding blocks capable of horizontally moving are arranged on one side of the upper pressing plate and one side of the lower pressing plate and correspond to grooves of volume surrounding plates. Rolling pieces capable of horizontally moving are arranged on the other side of the upper pressing plate and the other side of the lower pressing plate. When the upper pressing plate and the lower pressing plate rotate, therolling pieces roll the edges of the lateral sides of the volute along the upper edge of the lower pressing plate and the lower edge of the upper pressing plate. According to the scheme, the kitchen ventilator volute edge folding and rolling device is specially used for edge folding, rolling and assembling of the upper side plate, the lower side plate and the surrounding plates of the kitchen ventilator volute, and compared with traditional welding, the kitchen ventilator volute edge folding and rolling device is high in assembling efficiency, good in sealing performance and high in surface finish degree.

Owner:嵊州市英格电器有限公司

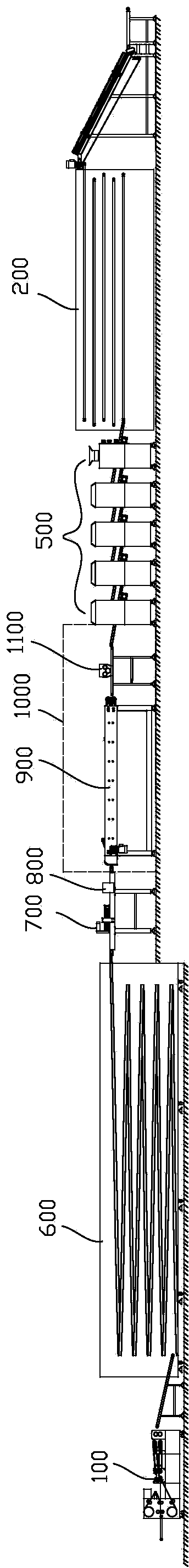

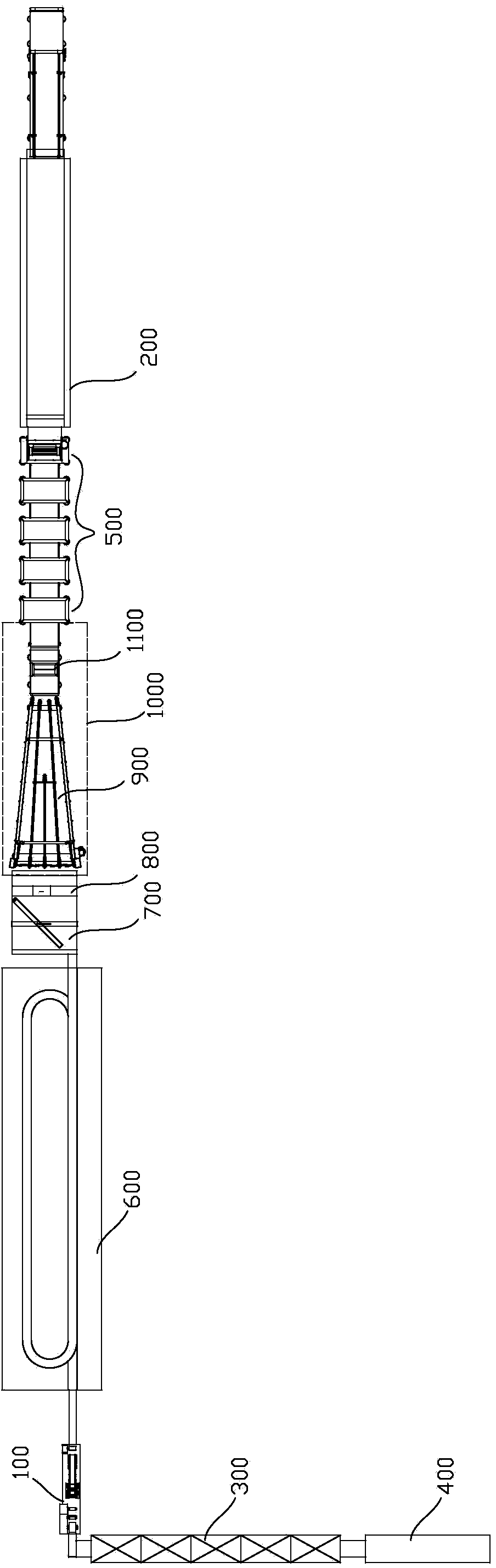

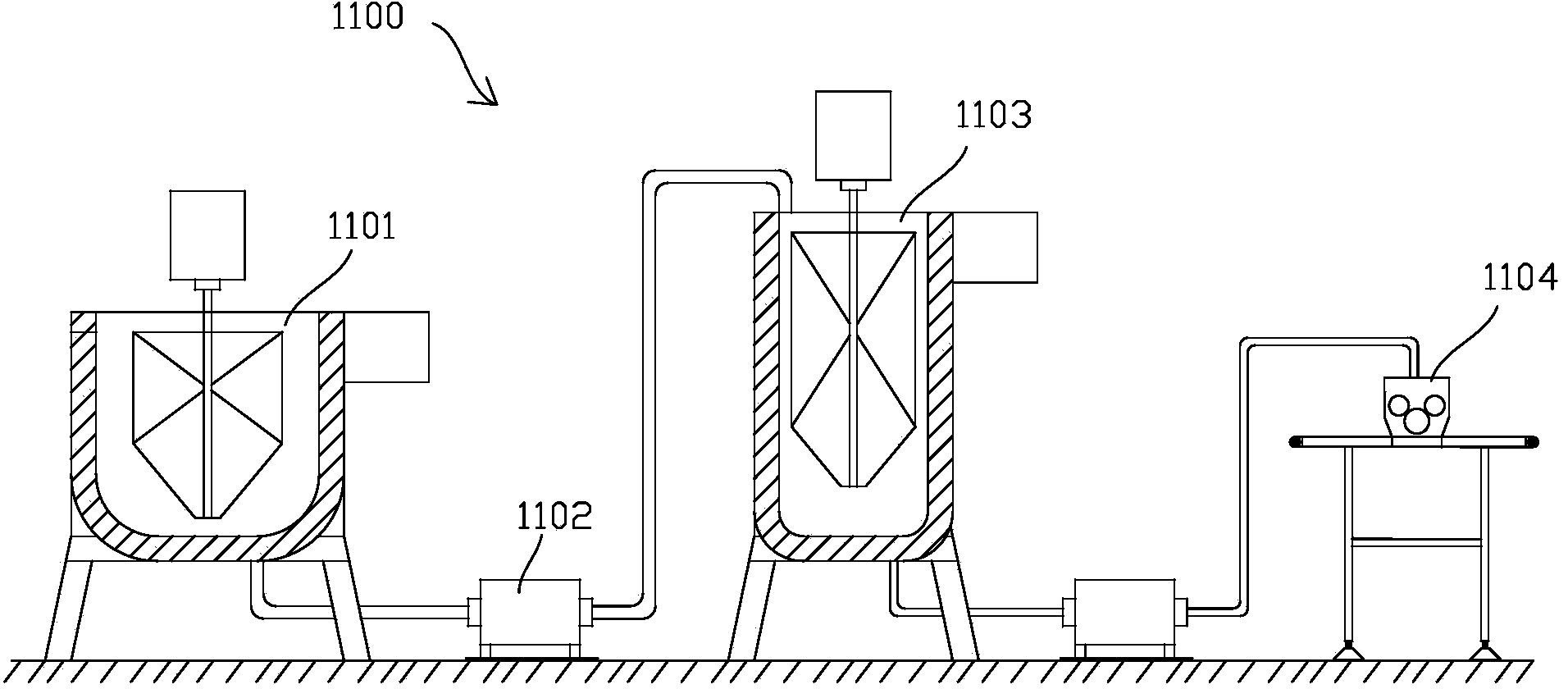

Industrial automation fried flour cake production line

ActiveCN103891827ARealize industrializationAchieve standardizationBakery productsDough extruding machinesProduction lineThinning

The invention belongs to the technical field of food processing equipment and particularly relates to an industrial automation fried flour cake production line. The industrial automation fried flour cake production line comprises a mobile constant-temperature soft flour drawing conveying system, a wrapper forming system, a wrapper oil applying system, an oil-applied wrapper thinning system, an oil-applied wrapper condiment adding system, a stuffing filling system, a mobile constant-temperature cylindrical flour roll drawing conveying system, a traction type flatting-filming system, a metering dividing and cutting system, a tunnel quick-freezing system and a packaging system, which are sequentially arranged. The industrial automation fried flour cake production line can realize industrialization, standardization, large scale and industrial production of Chinese special snacks and can promote industrialized development and commercialized operation of the Chinese special snacks. The industrial automation fried flour cake production line can not only be applied to production of friend flour cakes but is widely applicable to industrial production of various Chinese special snacks, such as multi-layer pies, multi-layer steamed bread, roti cina and shredded cakes and is wide in application range.

Owner:杨明德

Device and method for continuously manufacturing metal powder through multi-electrode plasma arcs

ActiveCN105252012AFacilitate mechanized productionReduce powder manufacturing costsPhysicsElectric arc

The invention relates to a device and method for continuously manufacturing metal powder through multi-electrode plasma arcs. The device and method are characterized in that raw material rods enter a plasma arc generator electrode inner cavity of a heating area through a feeding opening in a feeding device; three electrodes of the plasma arcs are used for evaporating the metal raw material rods into fogging plasma bodies, namely, rods, wires or ceramic rods with the same powder materials are manufactured, wherein the raw material rods are located in the center, and the arcs are located on the periphery; and inert gas flow is used for blowing fogging metal fog into a collecting device, and the fogging metal fog is rapidly cooled and solidifies into powder along with rapid reduction of the temperature and the air pressure. Convenience is brought to mechanized production, and the powder manufacturing cost is greatly reduced. Through adjustment of parameters such as the plasma arc output heat and the protection gas pressure, the powder granularity can range from 0.1 micrometer to 100 micrometers. One-time molding of powder manufacturing is achieved.

Owner:CHANGCHUN UNIV OF TECH

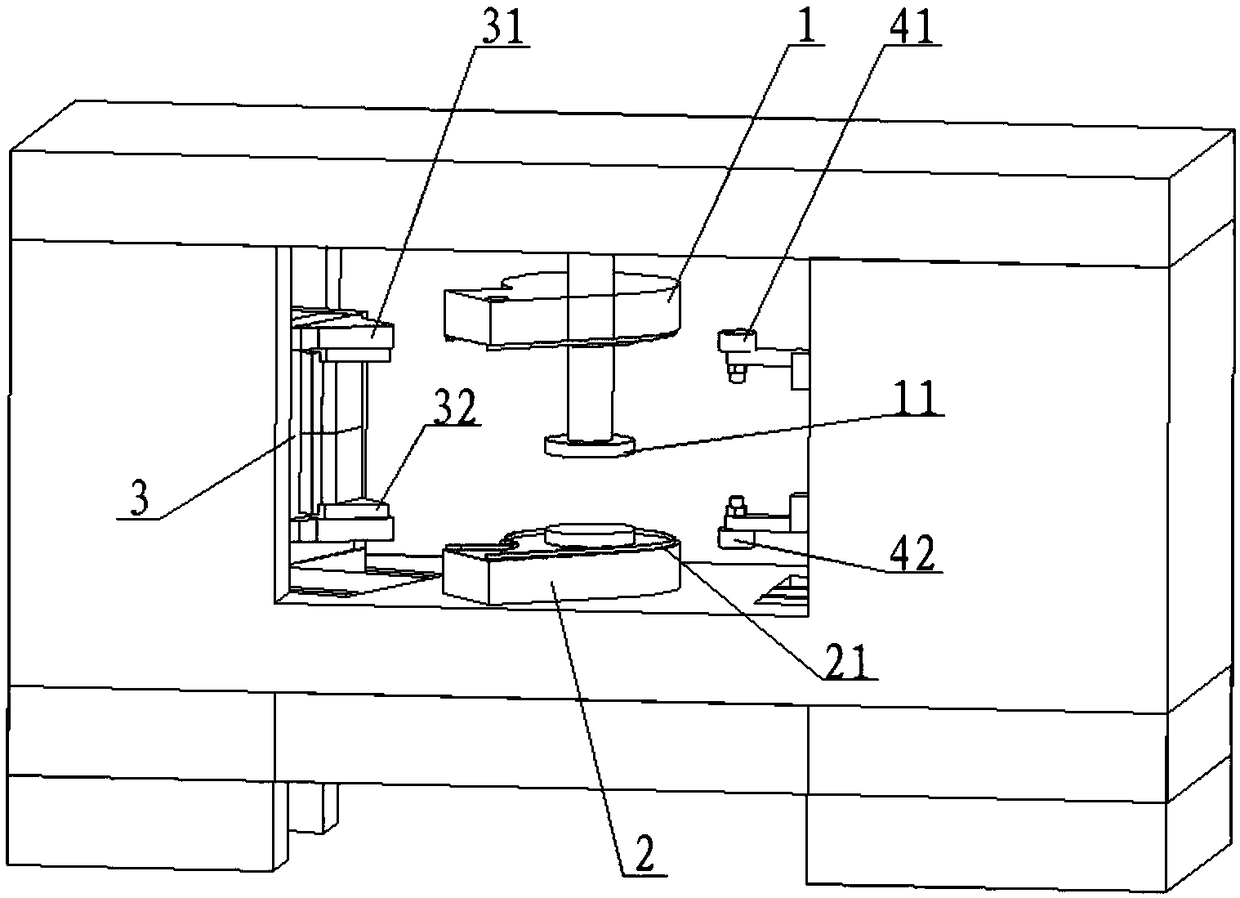

High-temperature adhesive tape solder preparation device and method

InactiveCN106141508AAdjustable thicknessAvoid Roll StickingWelding/cutting media/materialsSoldering mediaAdhesiveExtrusion

The invention discloses a high-temperature adhesive tape solder preparation device and method. The preparation device comprises release paper trays 1, a material extruding machine 2, a roller rolling machine 3 and a material collecting disc 4. The preparation method comprises the following steps: firstly mixing a high-temperature welding powder and an adhesive to form a paste; secondly loading the paste into the material extruding machine 2 and extruding strip-shaped paste on a release paper by the material extruding machine 2, rolling the mixed paste isolated by the release paper by the roller rolling machine 3, and finally placing the material collecting disc 4 which has collected the strip-shaped solder in a constant-temperature drying chamber provided with ventilation facilities, and carrying out drying treatment. According to the invention, the extrusion action force of the double-roller rolling mill is utilized, so that the mixed paste of the adhesive and the high-temperature welding powder flows in the two-dimensional space of the release paper, the gap and the rotating speed of the roller are controlled to obtain the high-temperature adhesive tape solder which is flat in surface, compact in the overall density and uniform in thickness. The method is simple and easy to operate and the industrial production is easy to achieve.

Owner:ZHEJIANG ASIA GENERAL SOLDERING & BRAZING MATERIAL

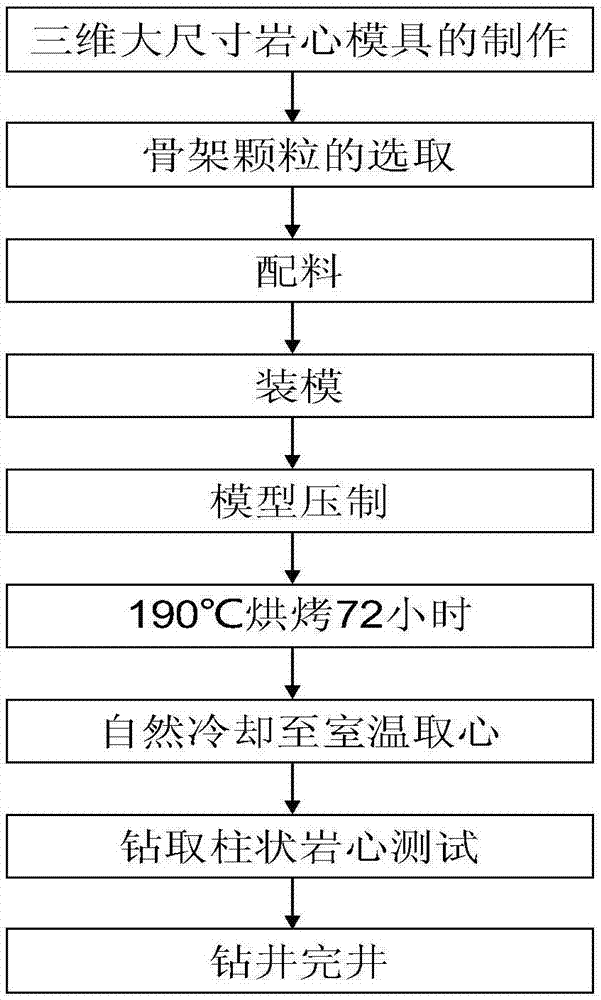

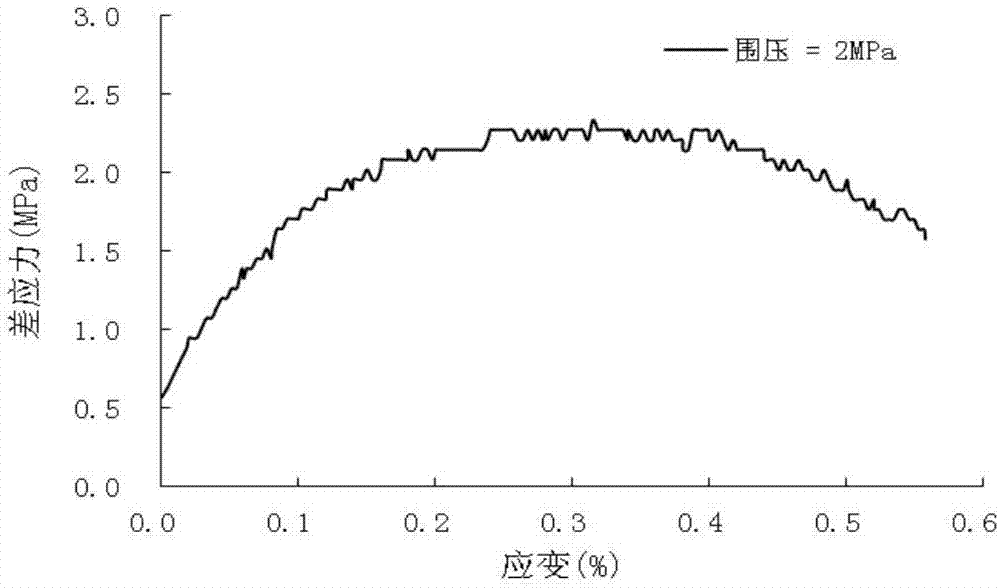

Manufacturing method of three-dimensional large-sized artificial rock core

ActiveCN107063826ARealize one-time moldingNo secondary processing requiredPreparing sample for investigationPorosityExperimental research

The invention discloses a manufacturing method of a three-dimensional large-sized artificial rock core. The manufacturing method comprises the following steps: (1) producing a mold according to a size of a prefabricated three-dimensional large-sized artificial rock core; (2) filling the mold with a mixture of skeleton particles, formation water and a cementing agent, wherein the granularity distribution of the skeleton particles is consistent with that of the natural rock core; (3) pressing the mixture in the mold; and (4) roasting the pressed mold, and shaping. The granularity distribution, porosity, permeability, cementing degree and pore throat characteristics, mechanical properties and the like of the rock core are approximate to the natural rock core; and the manufactured rock core can substitute a reservoir core to perform the macro experimental research. The rock core manufactured by the invention can simulate a sedimentary rhythm and structural configuration of a real reservoir. The rock core manufactured by the invention can simulate different completion conditions and well pattern modes and can realize the indoor experiment under the high pressure condition.

Owner:CHINA NAT OFFSHORE OIL CORP +1

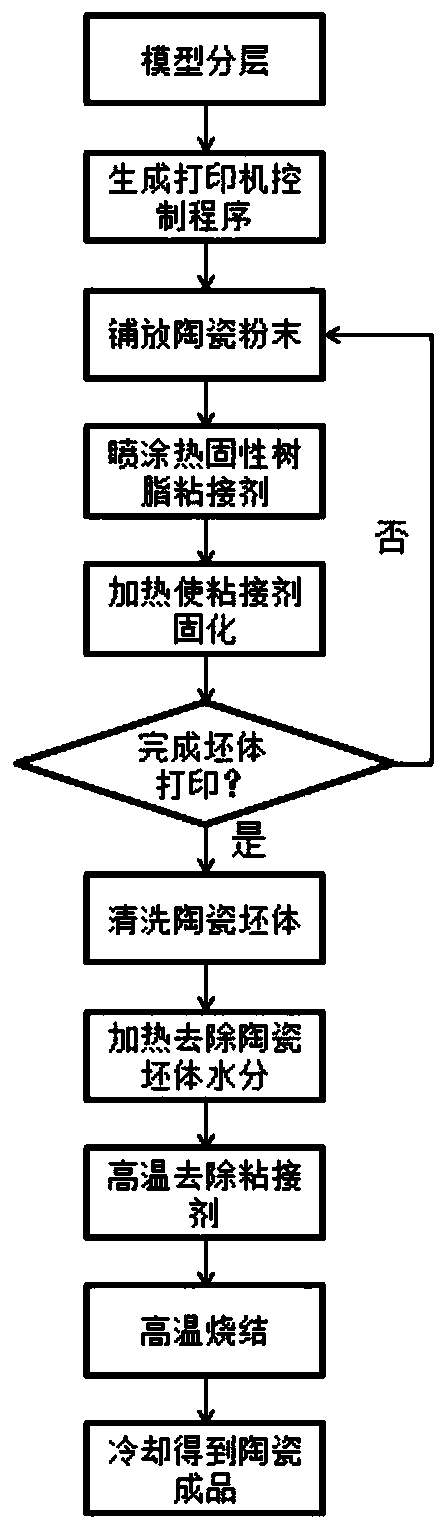

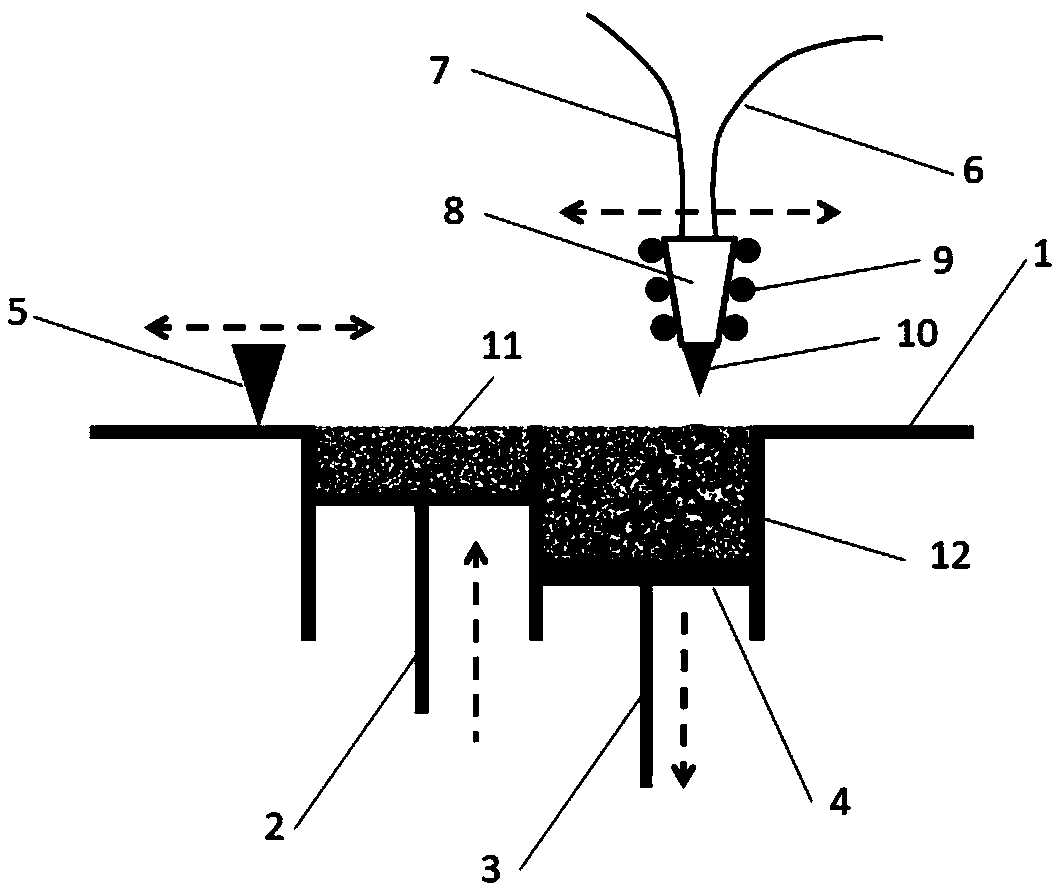

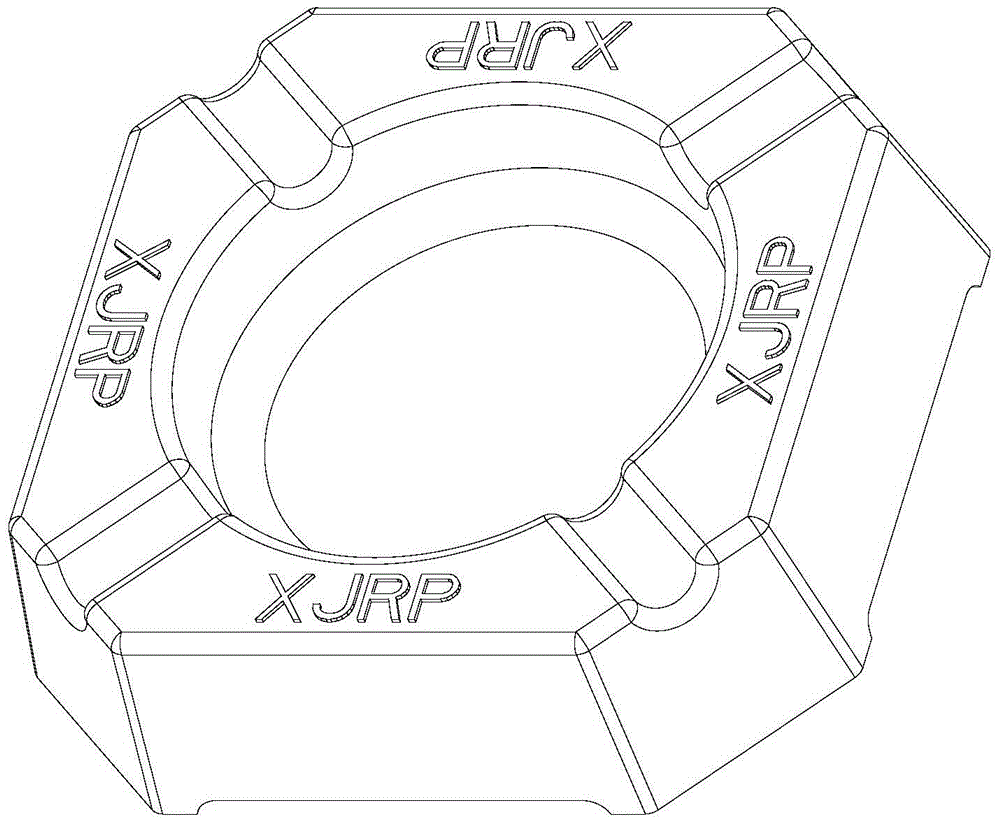

Ceramic material additive manufacturing method

PendingCN108947494ASmall molecular weightEffective bondingAdditive manufacturing apparatusEpoxyMetallurgy

The invention relates to a ceramic material additive manufacturing method. The method includes performing layering on a ceramic part model to be printed, and determining areas where each layer needs to be bonded; laying a layer of ceramic powder on a work tray; spraying a thermosetting resin adhesive in the area where the layer needs to be bonded by using a nozzle, the thermosetting resin adhesiveincluding an epoxy resin monomer and a hardener; heating the thermosetting resin adhesive on the layer of the ceramic powder by using a heating device to be in thermal curing cross-linking polymerization so that the layer of the ceramic powder can be bonded; performing layer by layer printing until a complete ceramic body can be formed; cleaning the ceramic body; and putting the cleaned ceramic body into a sintering furnace to perform calcining so that a compact ceramic part finished product can be formed. Equipment which can realize the manufacturing method is also provided.

Owner:TIANJIN UNIV

Light curing injection mold cores and manufacturing method thereof

InactiveCN105599178AReduce the amount of subsequent processingShorten the production cycleAdditive manufacturing apparatusMaterials scienceRapid manufacturing

The invention discloses light curing injection mold cores and a manufacturing method thereof. The light curing injection mold cores comprise a fixed mold core and a movable mold core. The manufacturing method includes the following steps that firstly, layering is conducted on the designed fixed mold core or the movable mold core which is subjected to shelling and comprises a pouring system and a conformal cooling channel with layering software, the layered fixed mold core or movable mold core is loaded to a rapid light curing forming machine, and a shell of the fixed mold core or the movable mold core is manufactured; then a backfilling material is manufactured, vacuum stirring processing is conducted on the backfilling material with a vacuum casting machine, a shell pouring cavity of the fixed mold core or the movable mold core is filled till the shell pouring cavity is fully filled, curing is conducted at the room temperature for 10-24 hours, and the light curing injection mold cores are obtained. The light curing injection mold cores which are manufactured in a light curing mode and provided with the conformal cooling channel and subjected to backfilling are short in manufacturing cycle, low in manufacturing cost and applicable to rapid manufacturing of medium or small batches of injection products and rapid trial-manufacture and performance detection of new products and the like.

Owner:XI AN JIAOTONG UNIV +1

Energy-saving precise press with multiple connecting rods

The invention discloses an energy-saving precise press with multiple connecting rods, which is different from an eccentric-shaft type press and an eccentric-wheel type press. With the improvement on the awareness of environment protection and energy conservation and the fast development of precision industries, such as precision electronics, automobile parts and the like, requirements on an energy-saving precision press are increased daily. The invention aims to solve technical problems of saving energy sources, particularly electric energy; increasing a nominal travel; prolonging the residence time of a sliding block at a bottom dead center; and applying the press in a lignite fine-press molding process. The technical scheme provided by the invention is as follows: the press realizes low-input high-output by utilizing a double-level structure according to the lever principle; the energy source is saved by more than 80%; the usage amounts of materials, such as bearing steel materials, nonferrous metals and the like, are further reduced, and the domestic energy-saving and exhaust-reducing call is responded; the nominal travel can reach more than 40mm through the utilization of the double-lever structure, a running curve of the sliding block close to the bottom dead center tends to gentle, the residence time of the sliding block at the bottom dead center can reach as long as 1 / 12 of period and the difficulty of the press as a lignite fine-press molding device is solved.

Owner:张士友 +1

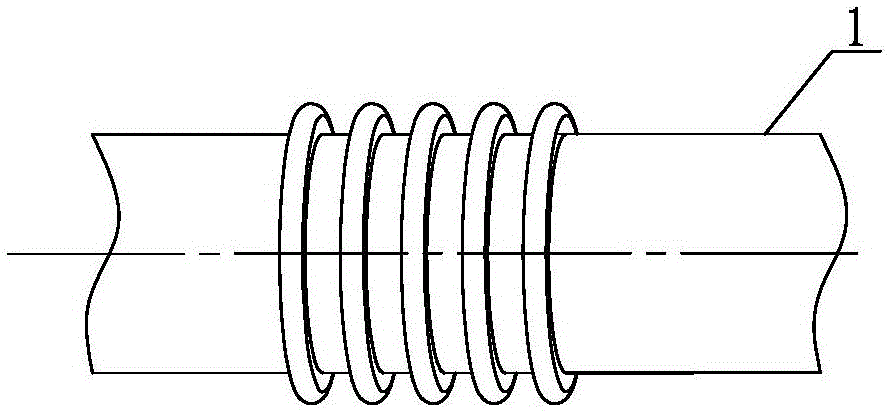

Brazing method for cable shielding layer and shell

InactiveCN102350552ARealize one-time moldingUniform and stable shapeSoldering apparatusEngineeringConductor Coil

The invention discloses a brazing method for a cable shielding layer and a shell, wherein wire branching holes are formed in two ends of the shell; a cable passes through the wire branching holes; and the brazing method comprises the following steps of: winding, namely winding brazing wires on parts, opposite to the wire branching holes, of the cable shielding layer; fixing, namely fixing the cable, the shell and the brazing wires by a clamp; heating, namely, putting a brazing part into an induction coil and heating the brazing part by induction heating equipment; and cooling, namely stopping heating until the brazing part is cooled. By the brazing method, one-time molding of joints at two ends of the shell can be realized, the shape of the shell is uniform and stable, the brazing quality is easy to guarantee, and efficient and automatic production requirements can be met.

Owner:HARBIN INST OF TECH SHENZHEN GRADUATE SCHOOL

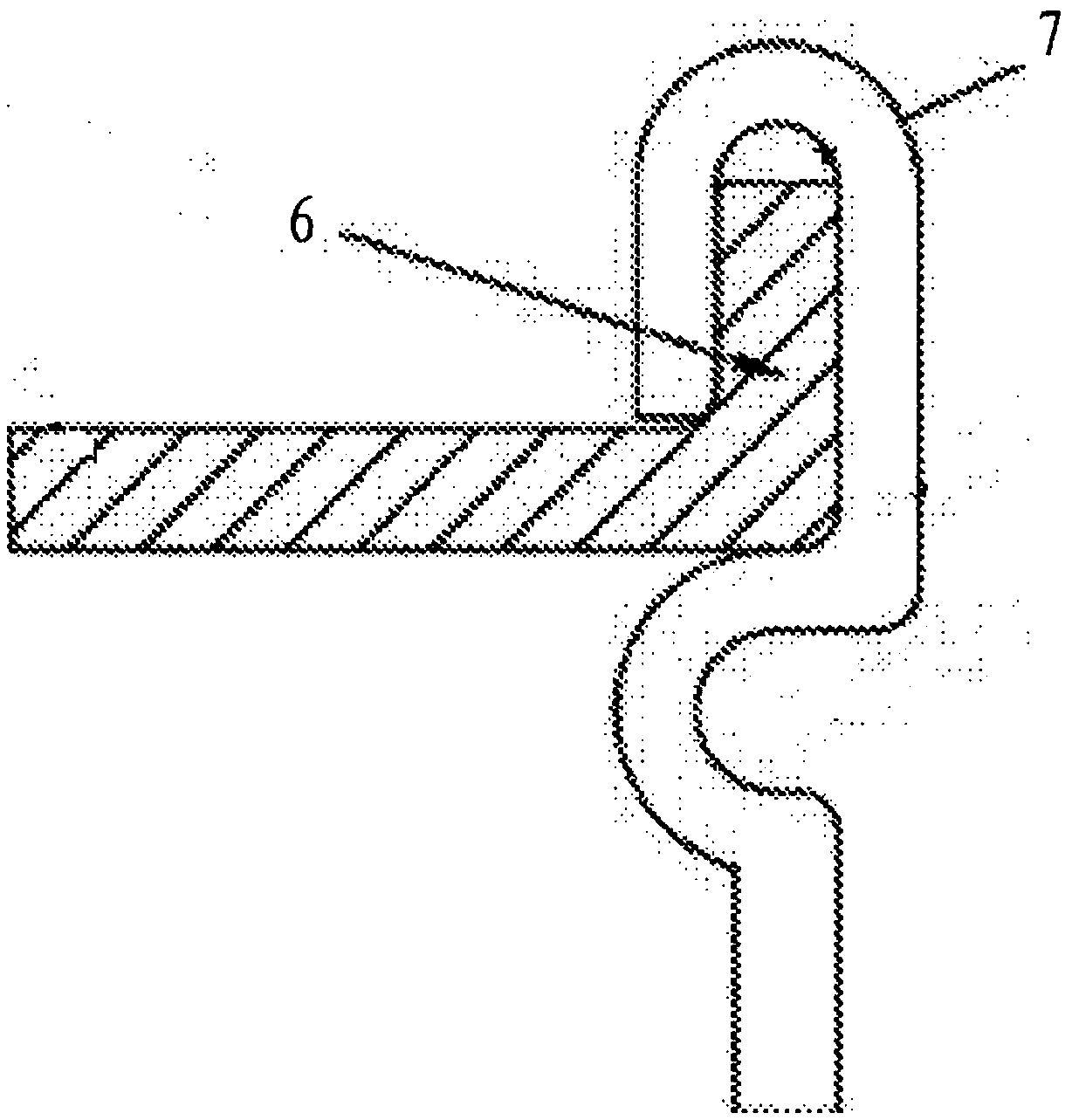

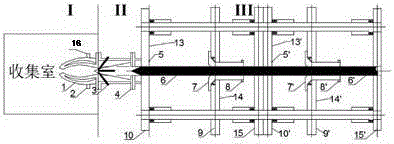

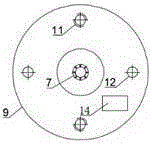

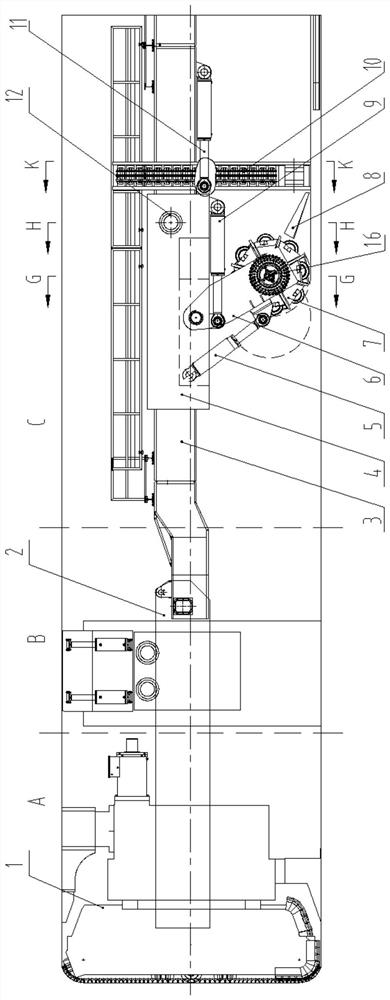

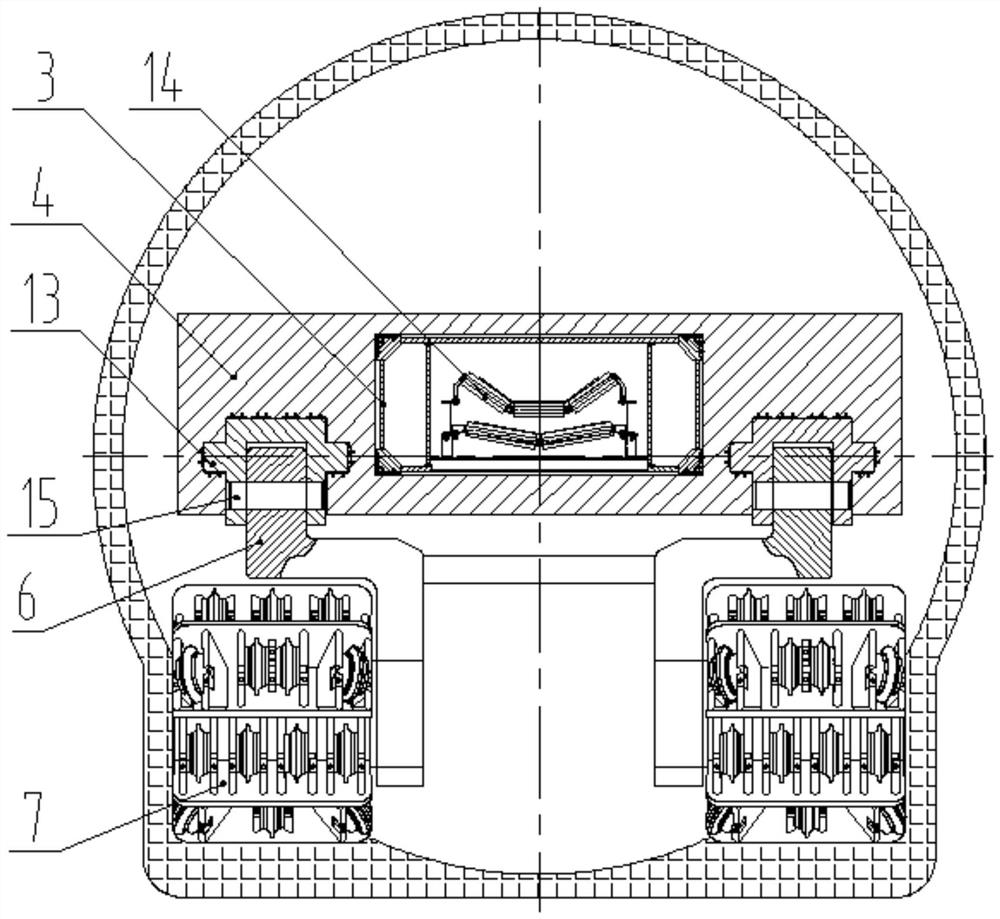

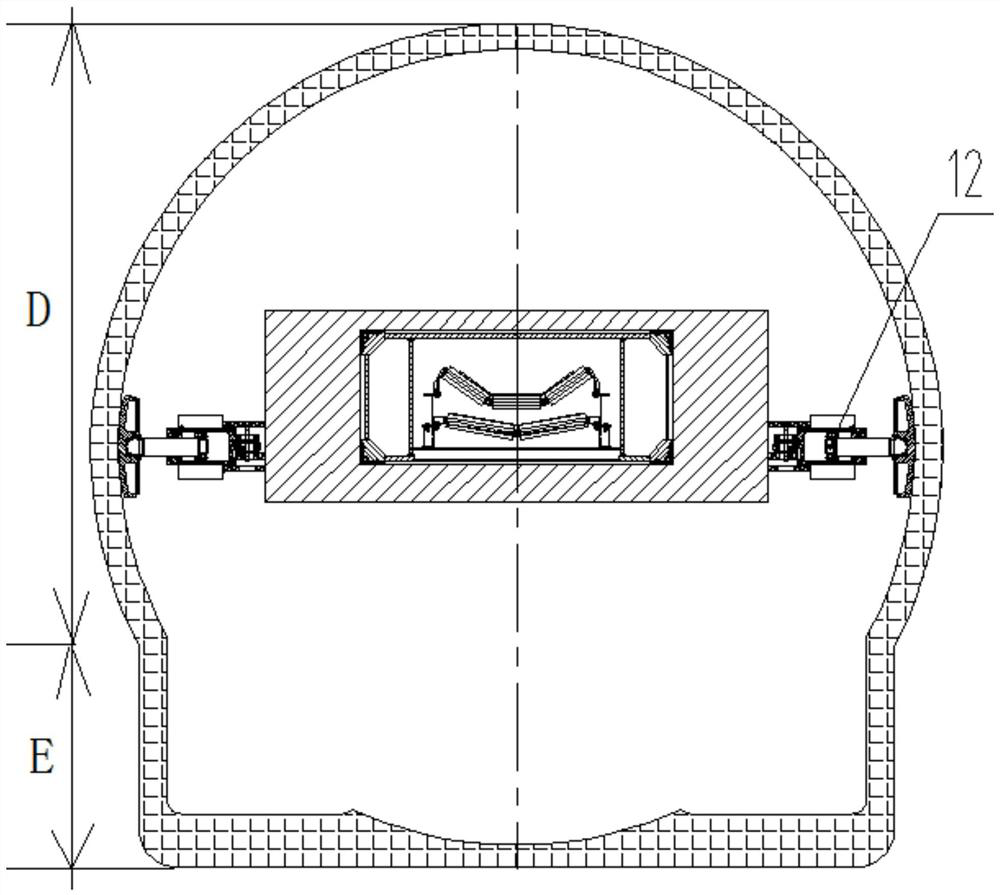

Continuous excavation device and full-face heading machine

PendingCN113586073ARealize one-time moldingImprove tunnel space utilizationTunnelsShield machineShield tunneling

The invention discloses a continuous excavation device and a full-face heading machine. The continuous excavation device comprises a rear main beam (3) and a sliding box (4) which are sleeved inside and outside, the rear main beam (3) extends in a front-back direction, the sliding box (4) can move in the front-back direction, excavation mechanisms are arranged on the left side and the right side of the sliding box (4), each excavation mechanism comprises supporting arms (6) and wheel type cutter heads (7), and the supporting arms (6) and the wheel type cutter heads (7) are arranged up and down. A wheel type cutter head (7) is connected with a supporting arm (6) through a cutter head shaft (16), and the axis of the cutter head shaft (16) is arranged in a left-right direction. According to the continuous excavation device, the continuous excavation device can be conveniently carried on an existing circular shield tunneling machine or a TBM shield tunneling machine, one-time excavation forming of the section of a special-shaped tunnel (similar to a city gate opening shape or a horseshoe shape) is achieved, the quality of the formed section is good, and the continuous excavation device has the advantages of being safe, stable, high in efficiency, capable of integrating excavation and supporting and the like.

Owner:CHINA RAILWAY ENGINEERING EQUIPMENT GROUP CO LTD

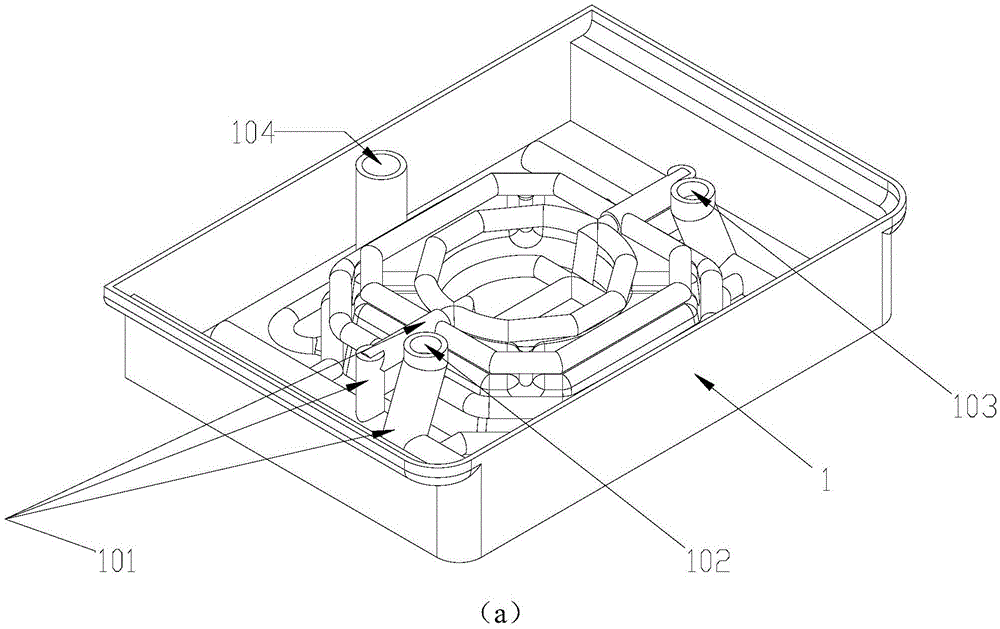

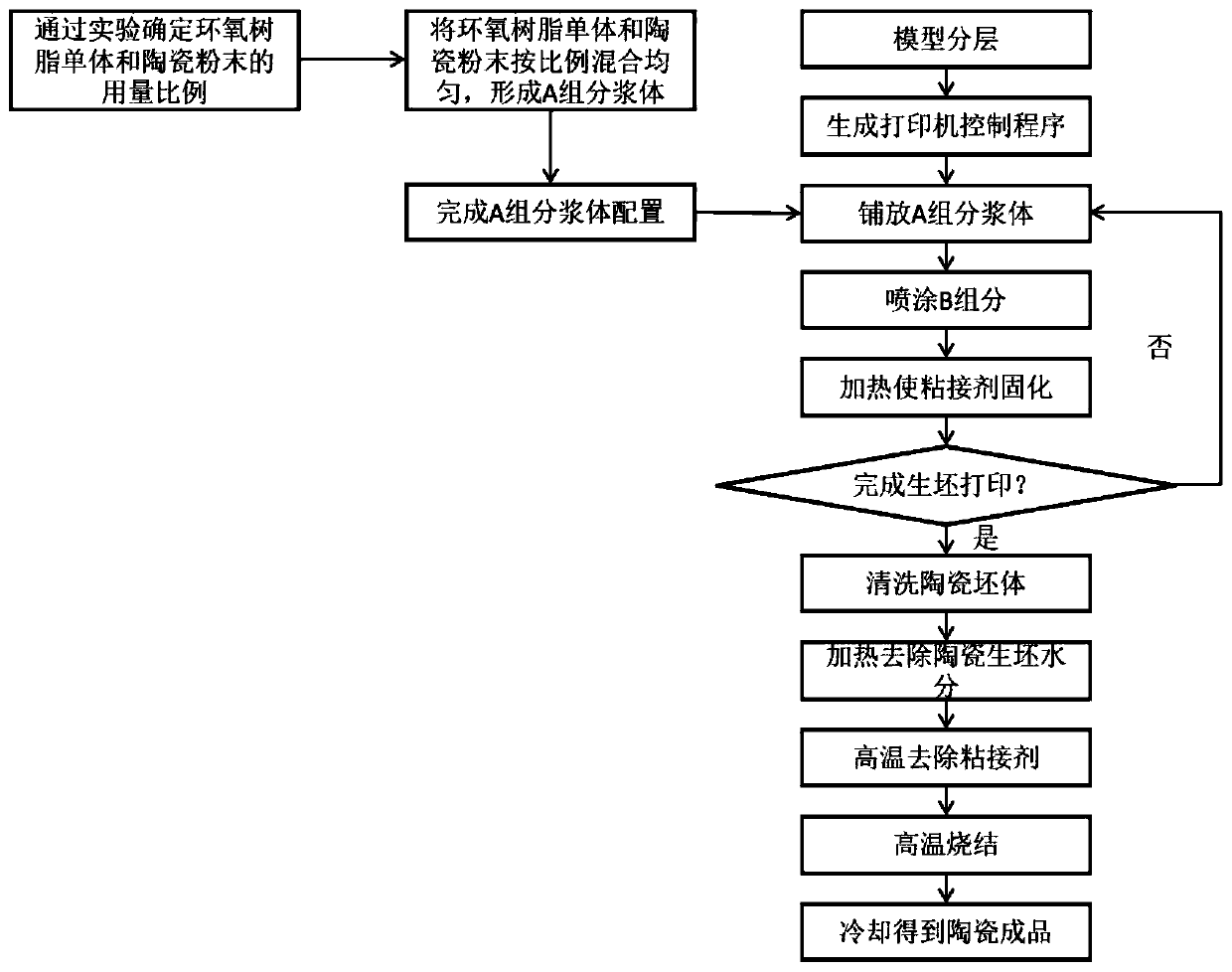

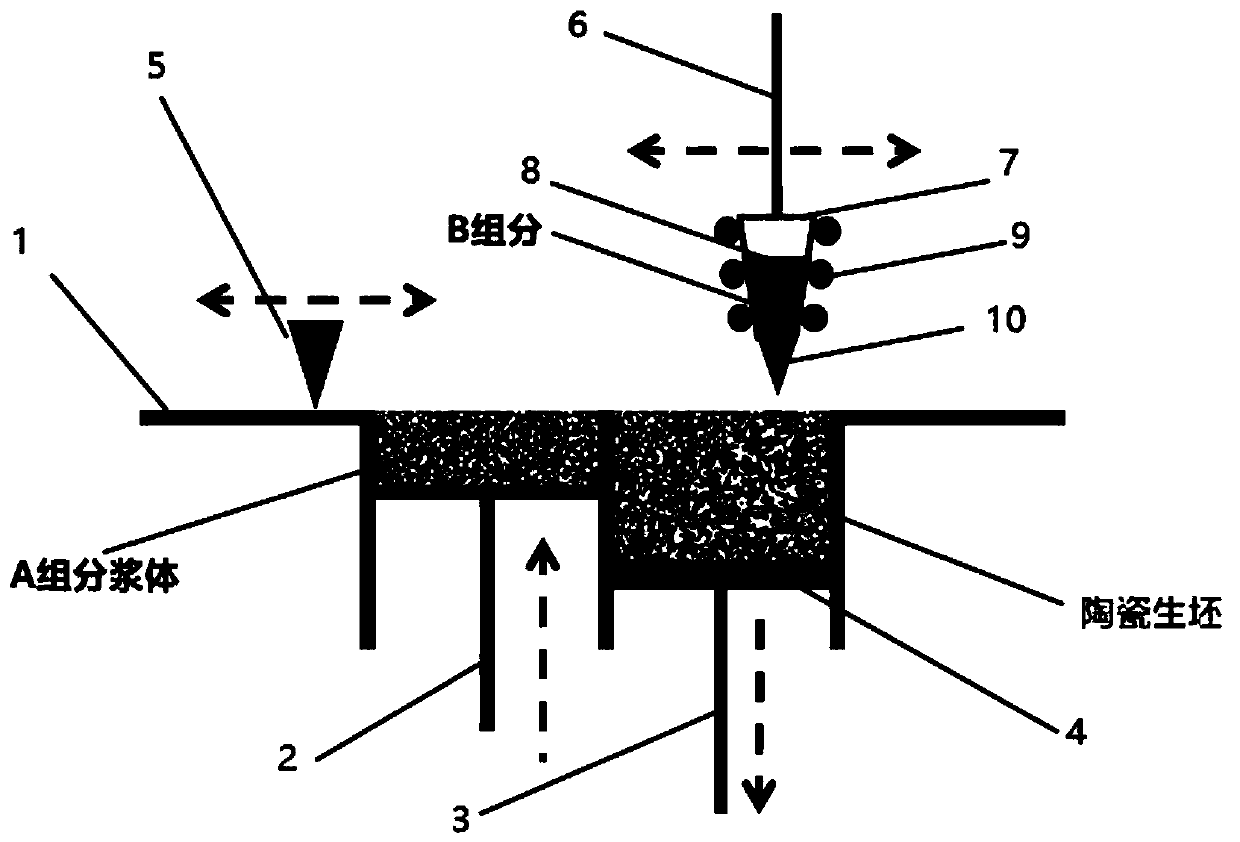

Thermosetting bonding based ceramic additive production method and equipment

PendingCN110240485ASmall molecular weightReduce stickingAdditive manufacturing apparatusCeramic shaping apparatusEpoxyMetallurgy

The invention relates to a thermosetting bonding based ceramic additive production method. The method comprises the steps: layering a mold for ceramic parts required to be printed, determining an area required to be bonded of each layer, and creating a printer control program; uniformly mixing an epoxy resin monomer with ceramic powder to form slurry with relatively good fluidity as component A slurry, wherein for a consumption ratio of the epoxy resin monomer and the ceramic powder, the proportion of the ceramic powder in the component A slurry should be as high as possible on the premise of meeting the requirements on fluidity so as to achieve that a final ceramic finished product is high in compactness and low in shrinking percentage; laying a layer of component A slurry on a working tray; spraying a hardener of epoxy resin as a component B to the area required to be bonded of the corresponding layer with a sprayer according to the program; heating the ceramic powder of the corresponding layer with a heating device; carrying out printing layer by layer until a complete ceramic green body is formed; carrying out washing clean; and carrying out high-temperature calcination. The invention simultaneously provides equipment achieving the method, i.e., a ceramic powder bonding printer.

Owner:TIANJIN UNIV

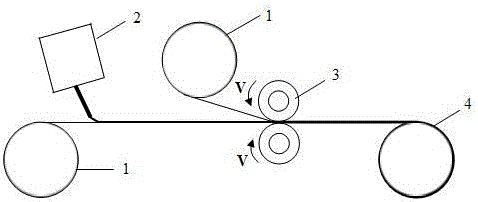

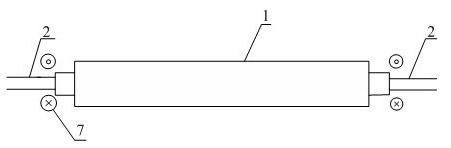

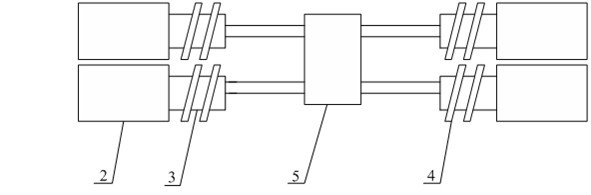

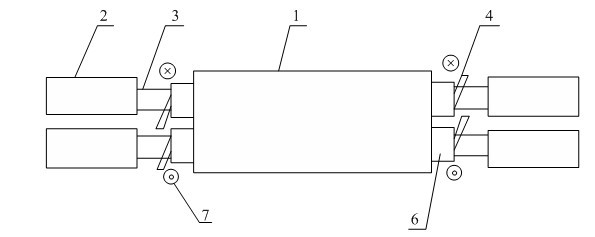

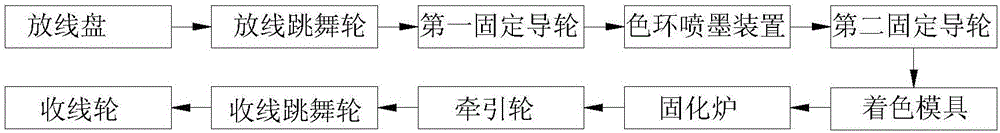

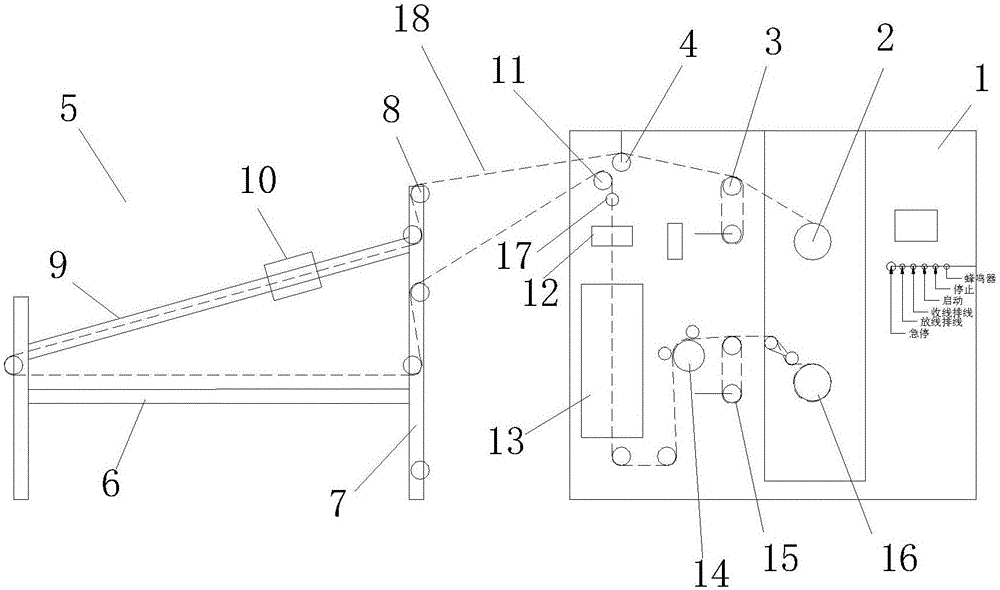

Color ring printing and coloring one-step forming technology and device for optical fibers

InactiveCN106517824ARealize one-time moldingAvoid the risk of fiber cutCladded optical fibreOptical waveguide light guideEngineeringFiber breakage

The invention discloses a color ring printing and coloring one-step forming technology and device for optical fibers. According to the technology, a color ring ink-jetting device and a coloring die are simultaneously arranged on a base, so that color ring ink-jetting and optical fiber coloring can be simultaneously carried out on the optical fibers, and the production efficiency of the optical fibers is increased. Color ring printing and coloring one-step forming is perfectly realized on the optical fibers, the processing efficiency is greatly increased, equipment is simplified, and the risk of fiber breakage in the two-step production process of the optical fibers is effectively avoided.

Owner:ZHEJIANG DONGTONG IOT TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com