Patents

Literature

396results about "Other shedding mechanism" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

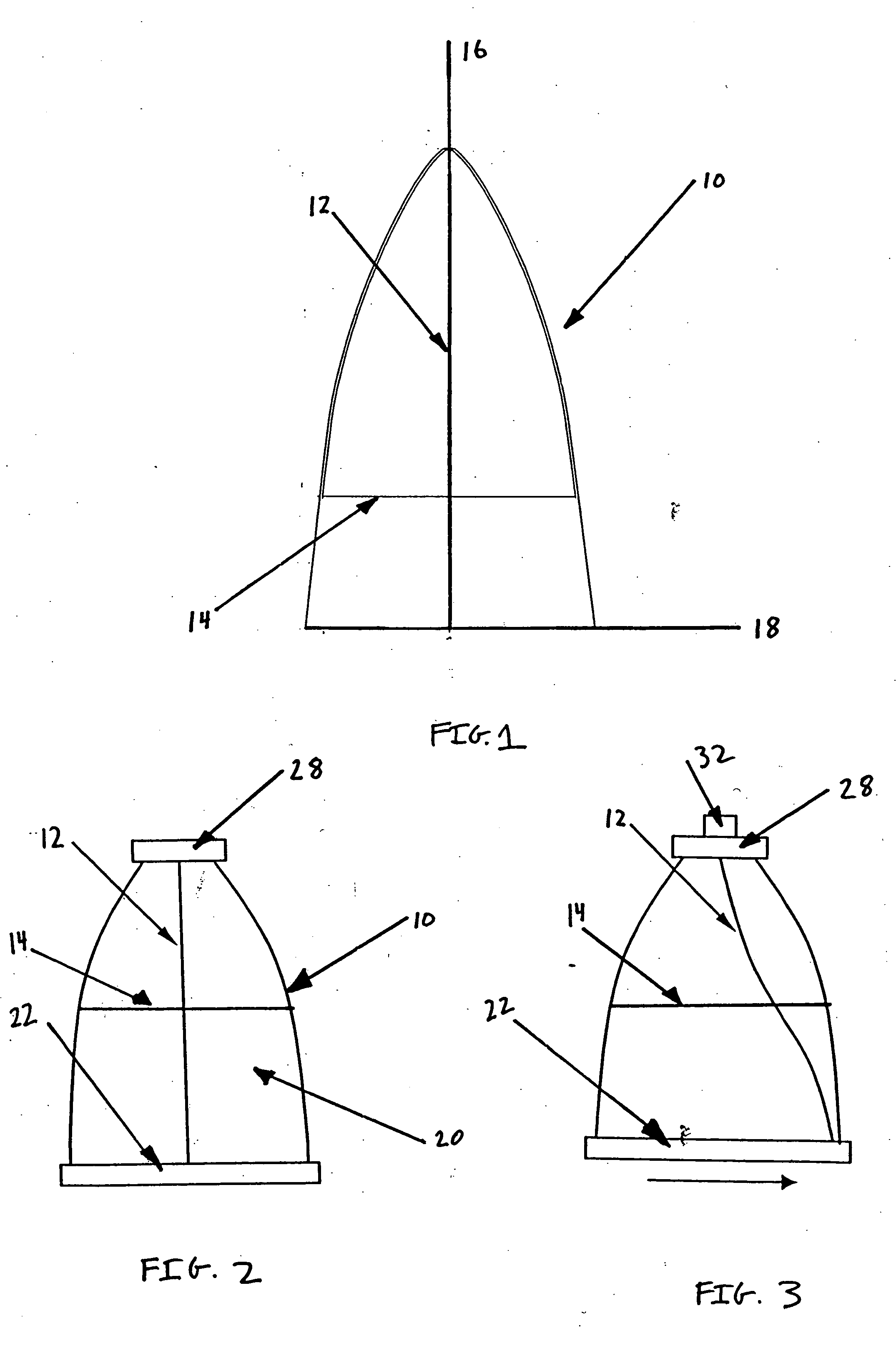

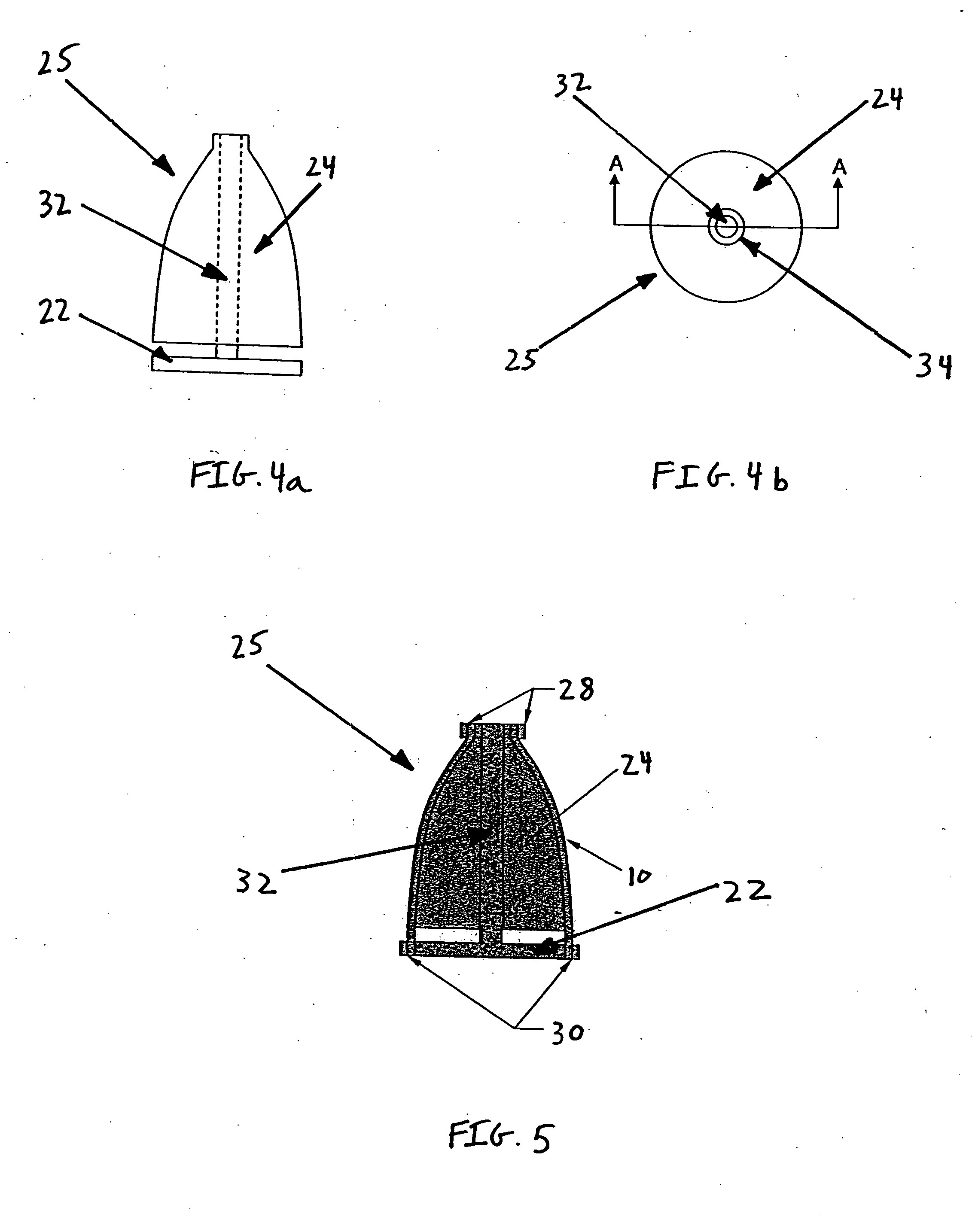

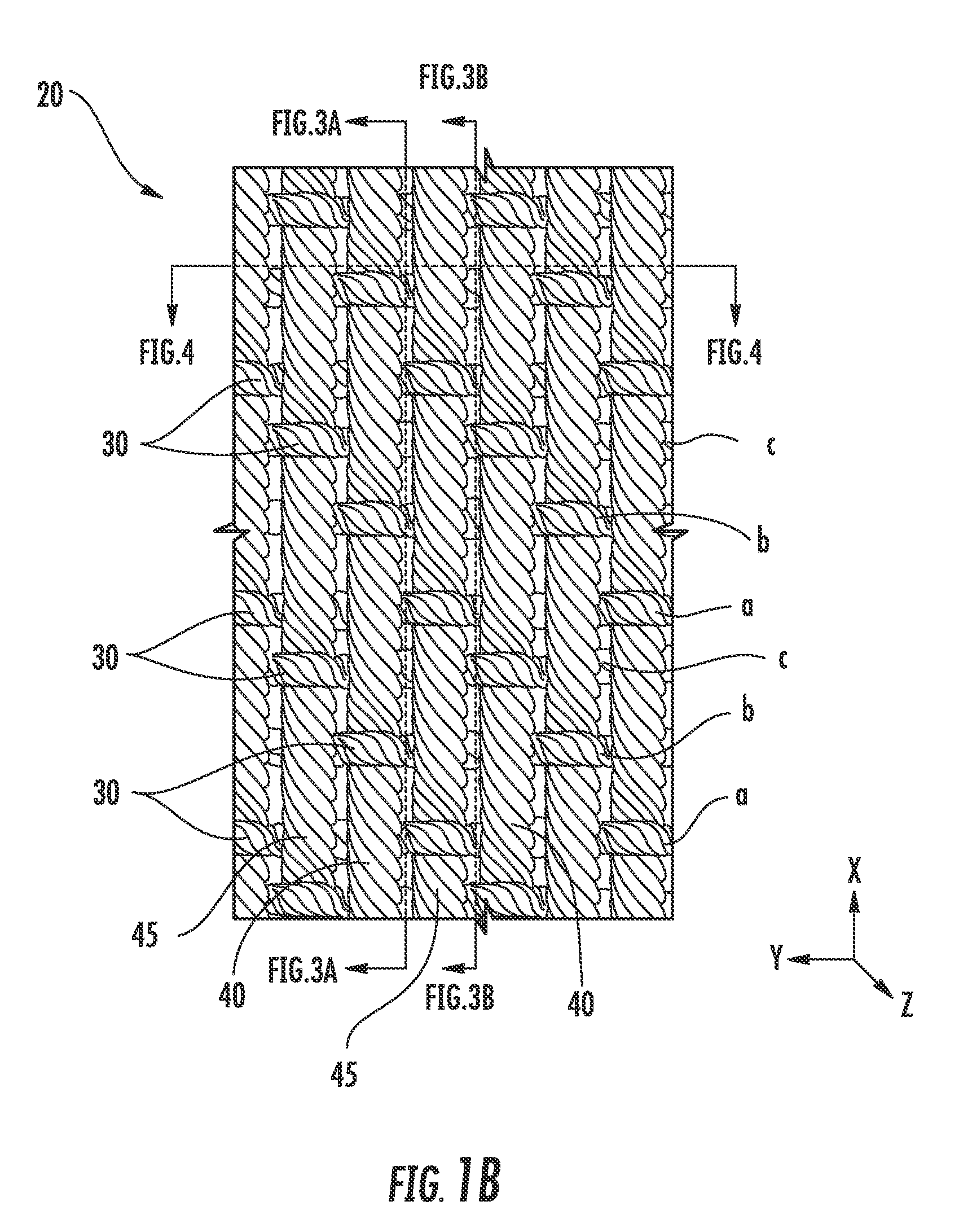

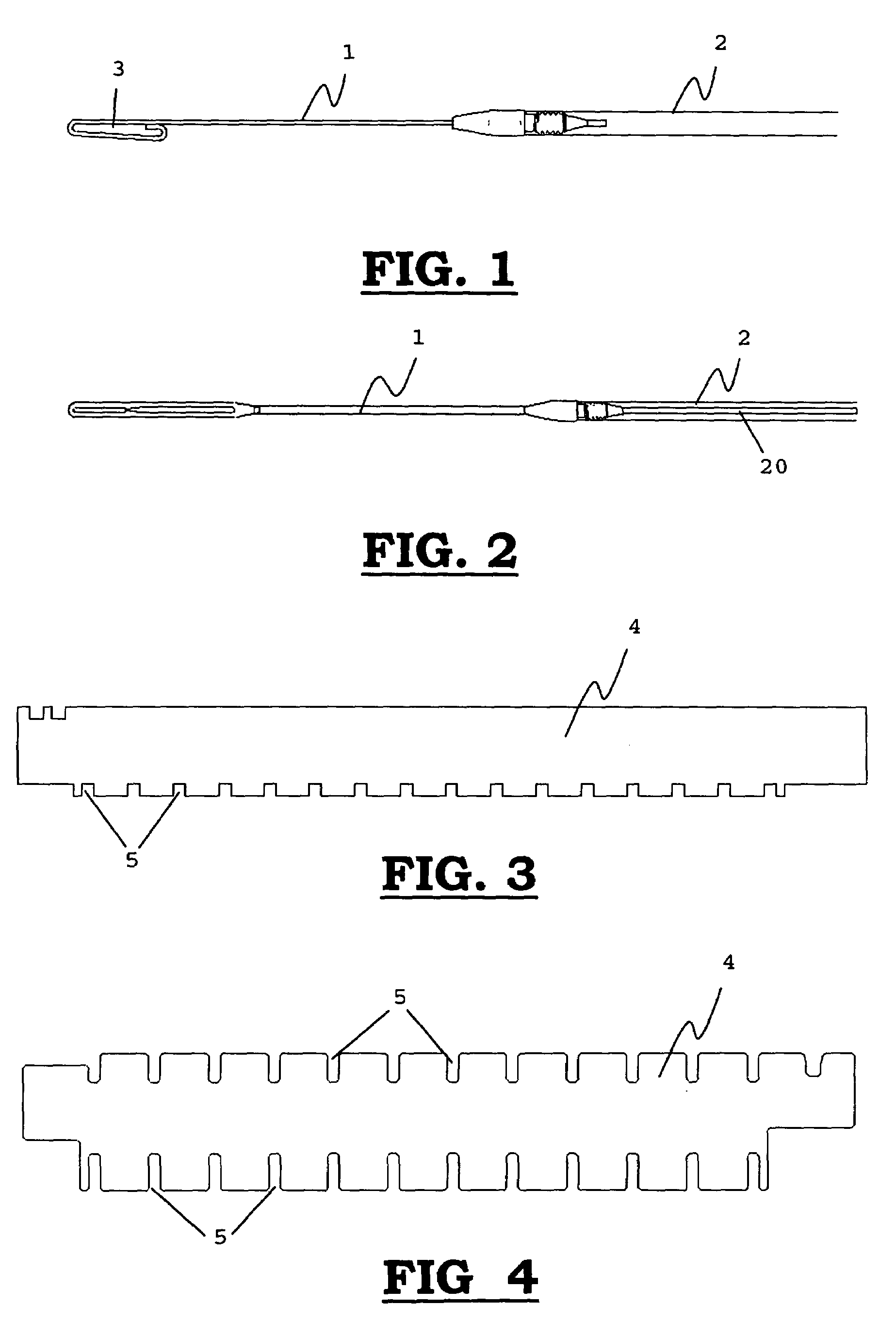

Full-fashioned weaving process for production of a woven garment with intelligence capability

A full-fashioned weaving process for the production of a woven garment which can accommodate and include holes, such as armholes. The garment is made of only one single integrated fabric and has no discontinuities or seams. Additionally, the garment can include intelligence capability, such as the ability to monitor one or more body vital signs, or garment penetration, or both, by including a selected sensing component or components in the weave of the garment.

Owner:GEORGIA TECH RES CORP

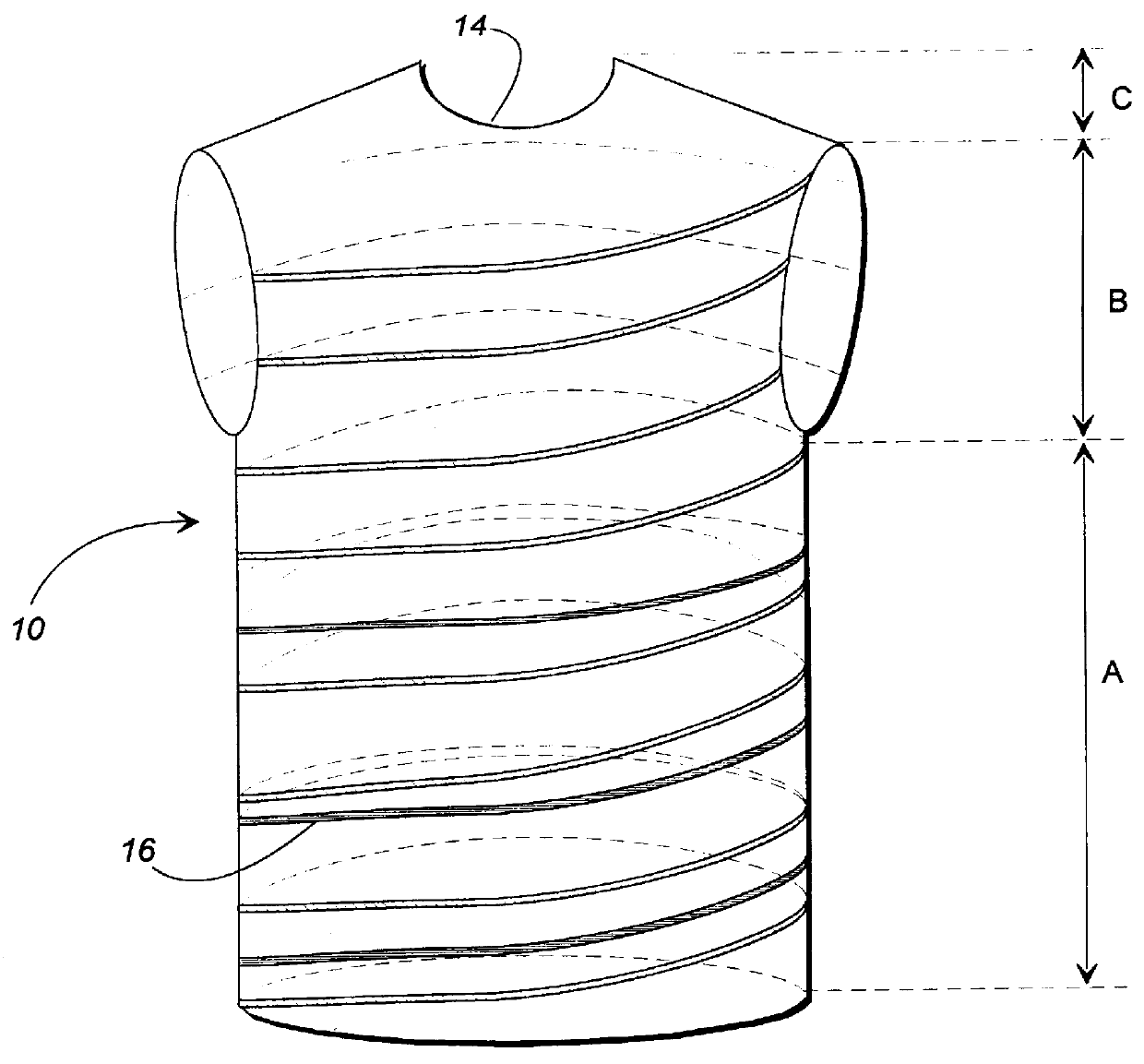

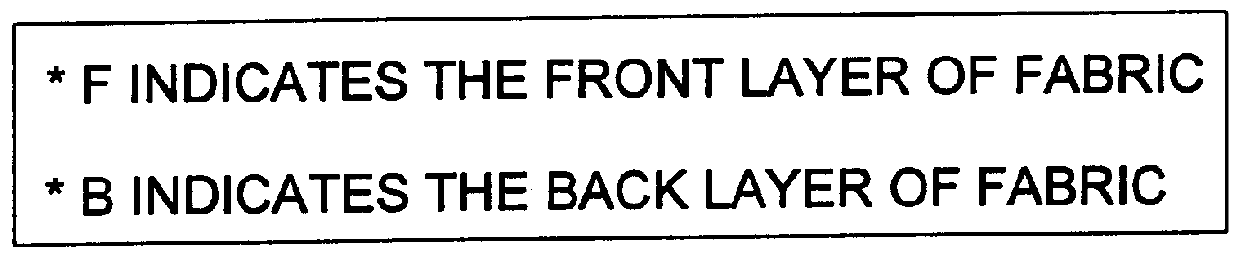

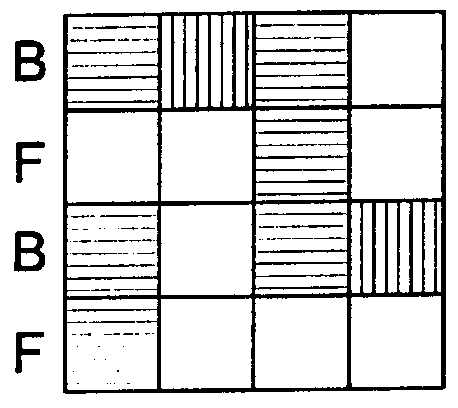

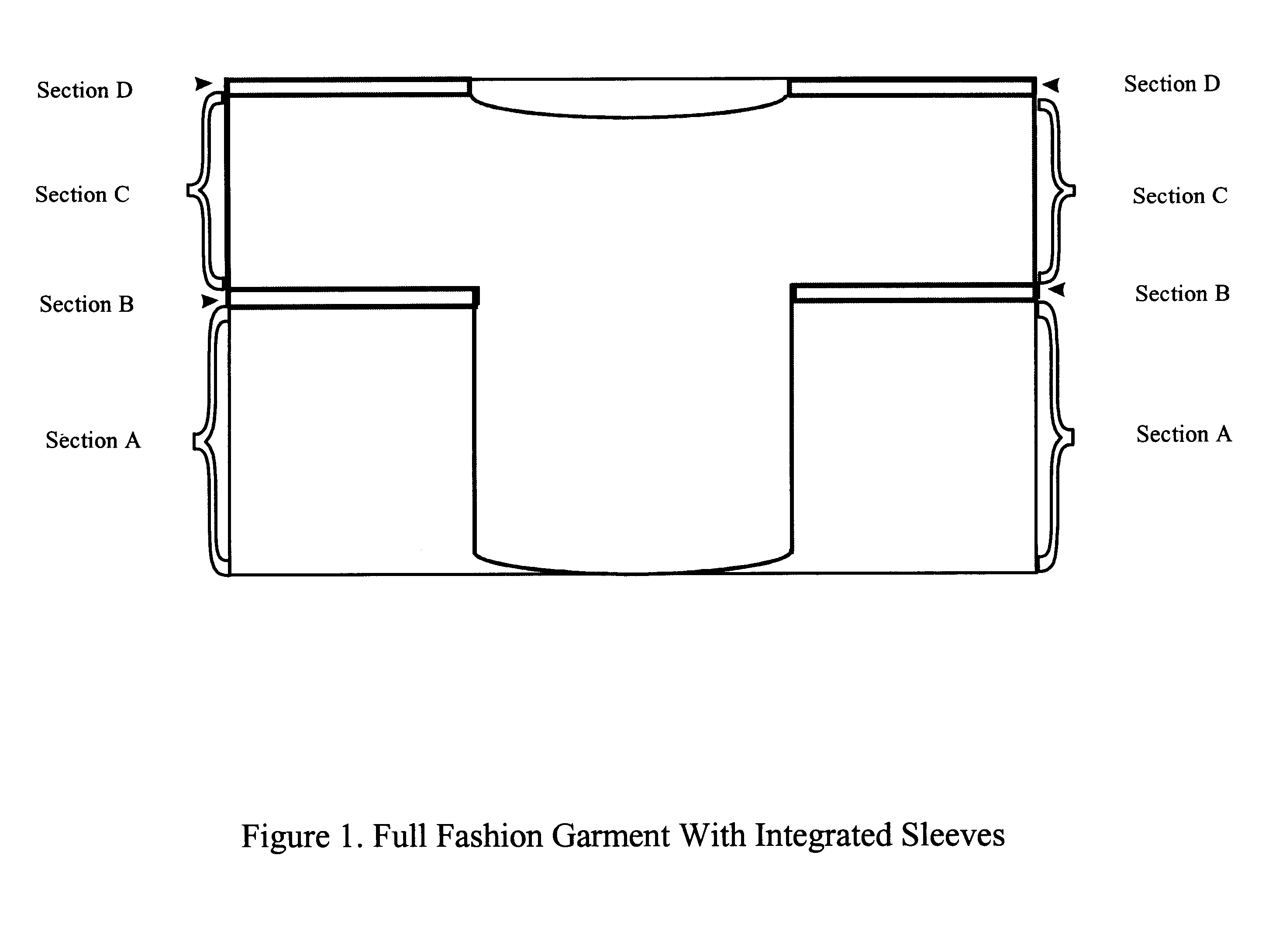

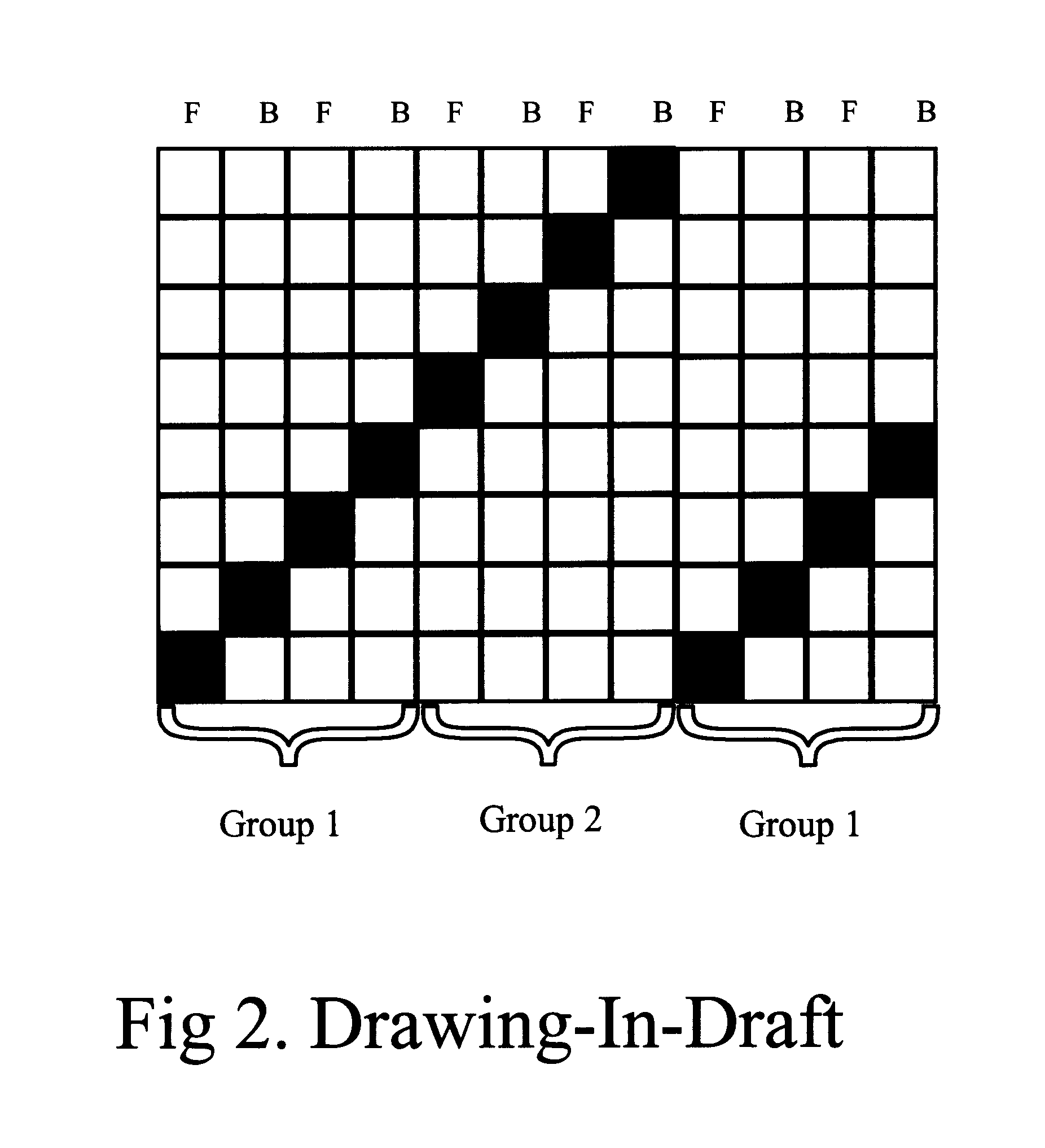

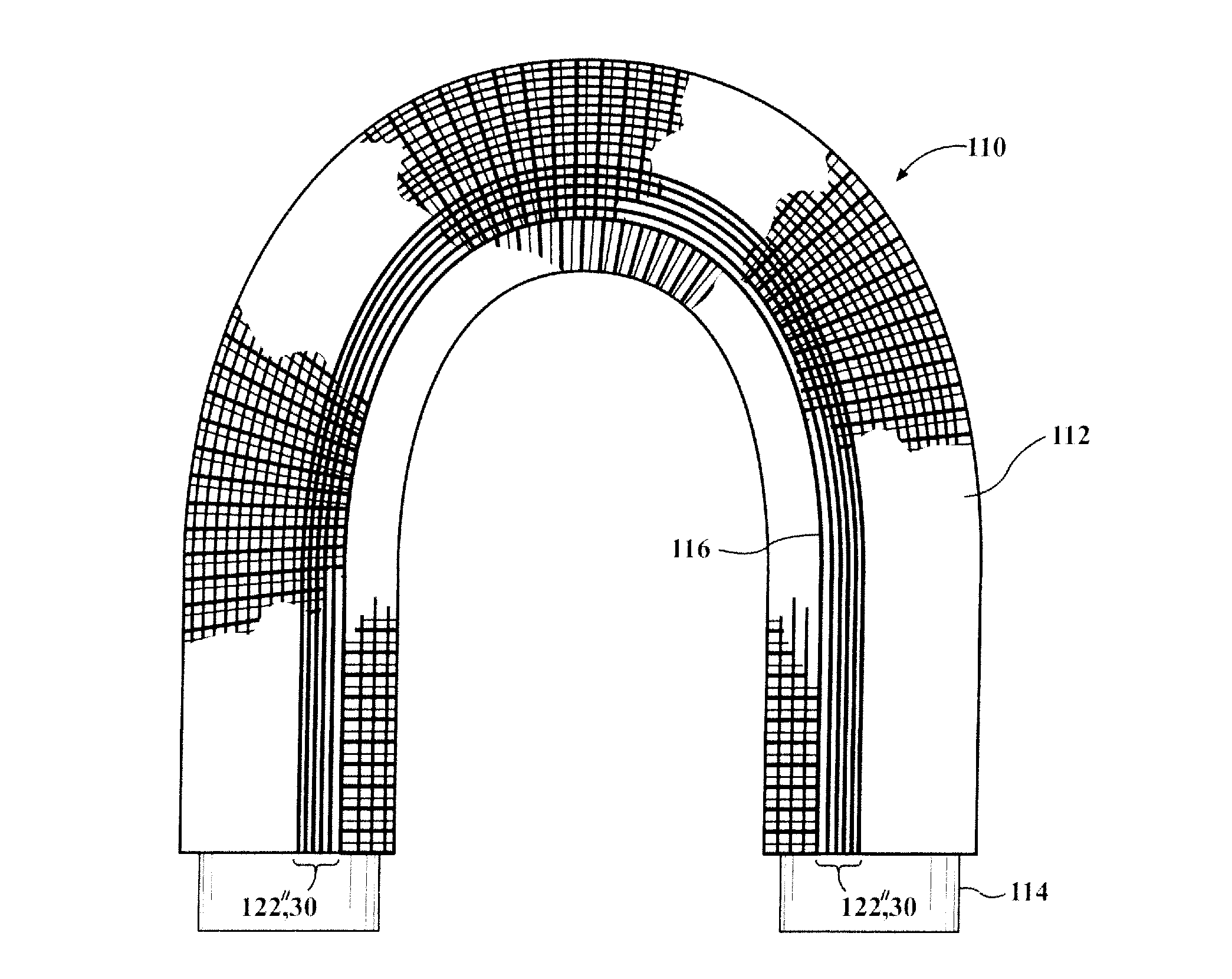

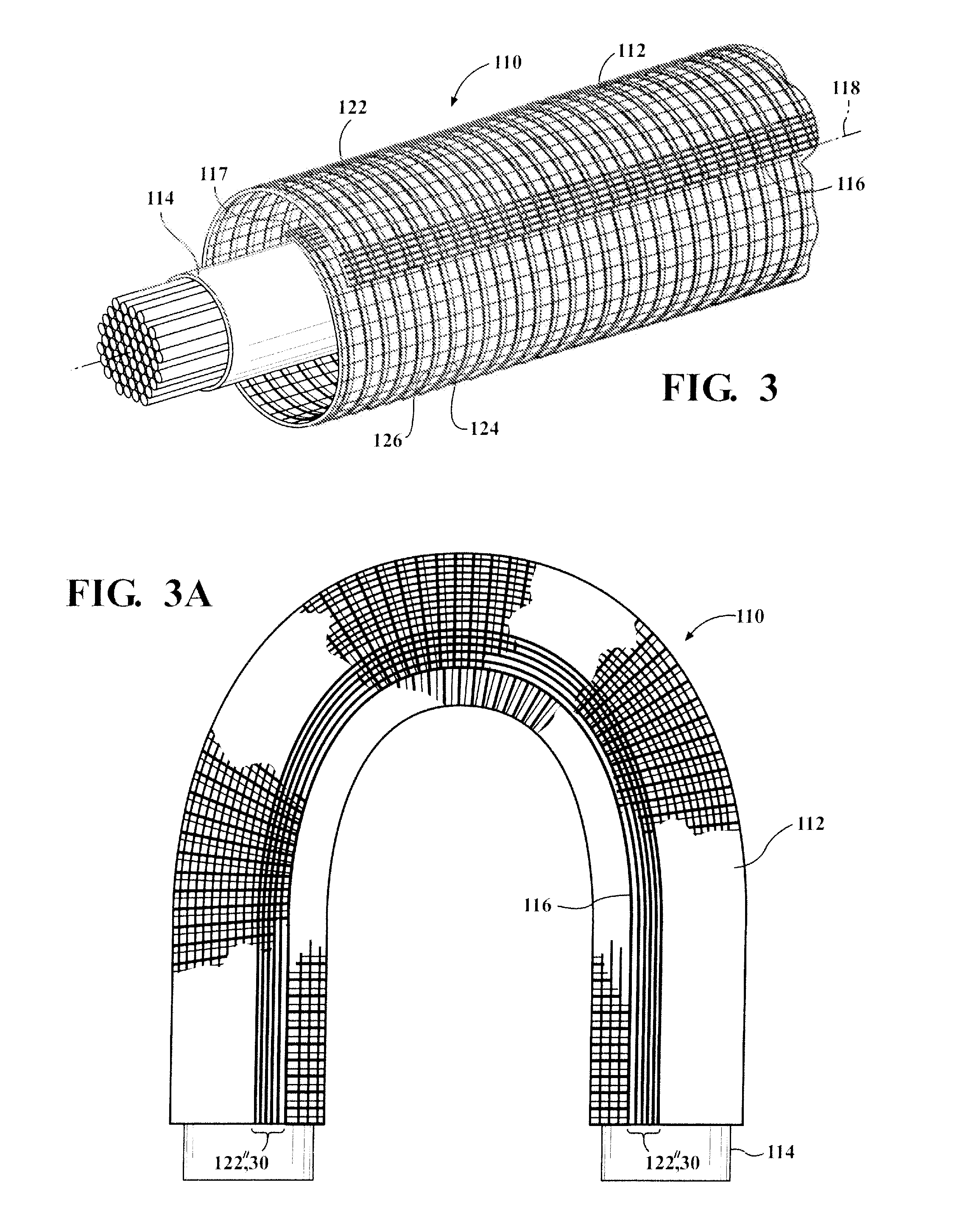

Full-fashioned garment with sleeves having intelligence capability

The invention comprises a full-fashioned weaving process for the production of a woven garment which can accommodate and include sleeves. The garment is made of only one, single integrated fabric and has no discontinuities or seams. Additionally, the garment can include intelligence capability, such as the ability to monitor one or more body vital signs, or garment penetration, or both, by including a selected sensing component or components in the weave of the garment.

Owner:GEORGIA TECH RES CORP

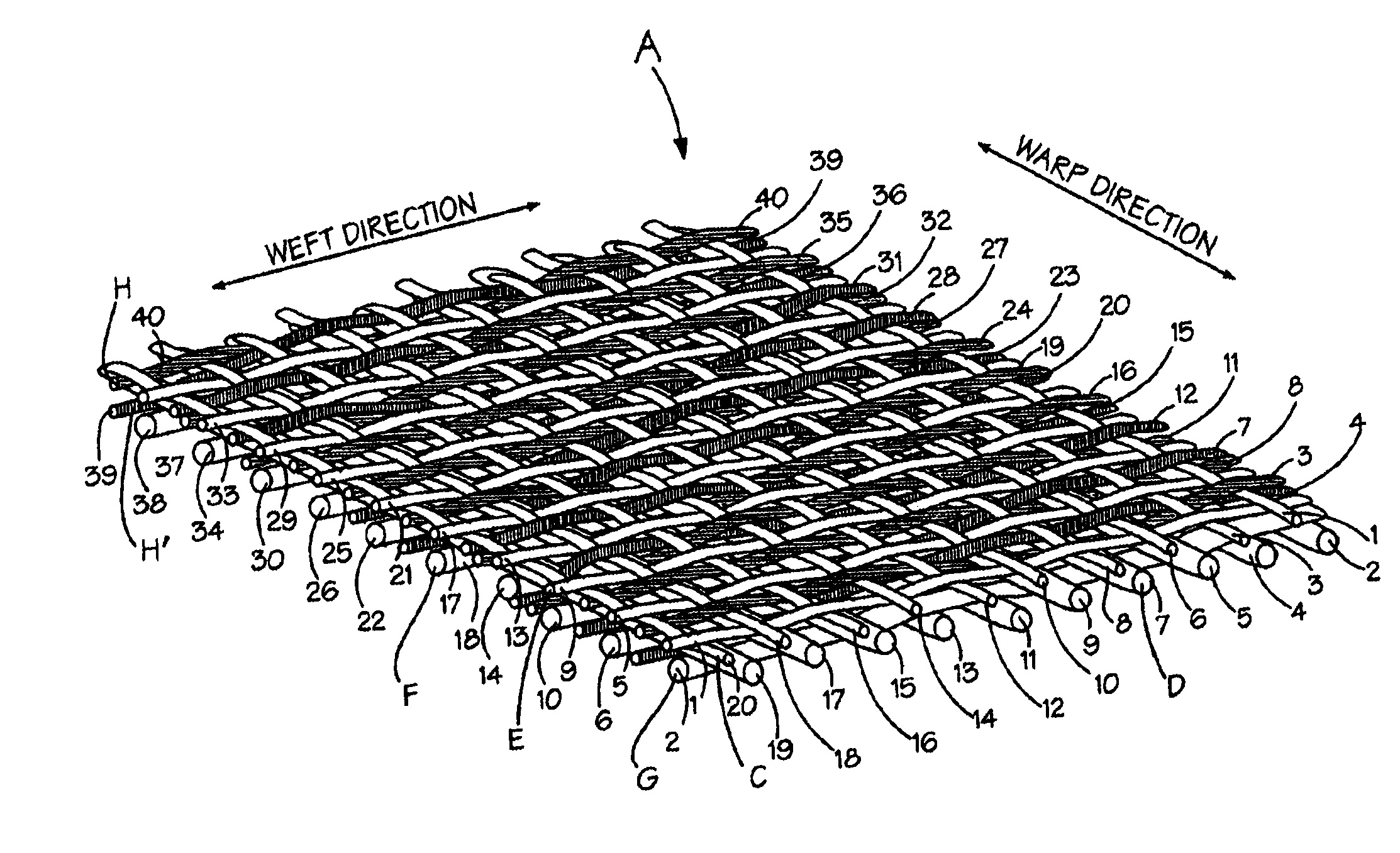

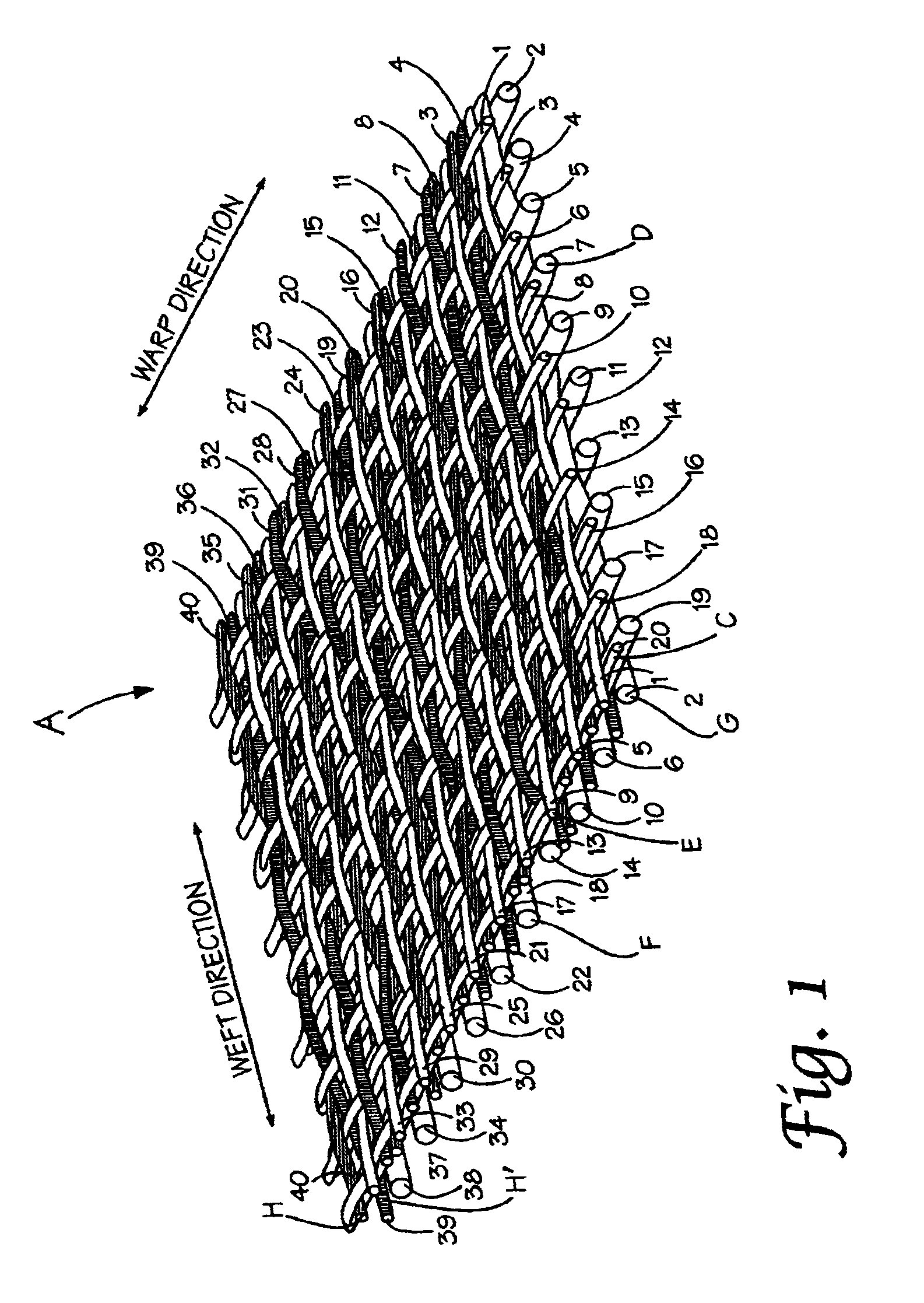

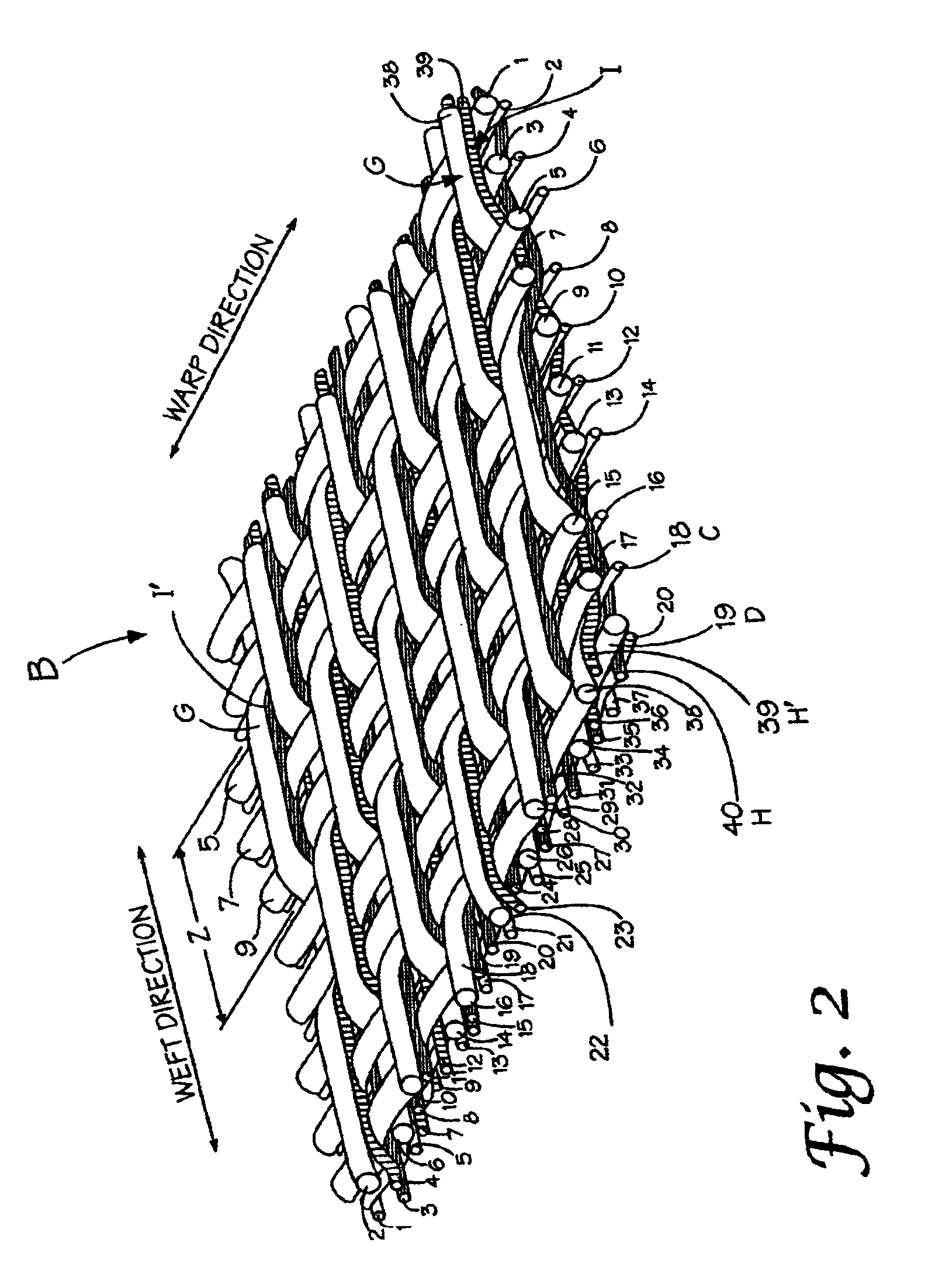

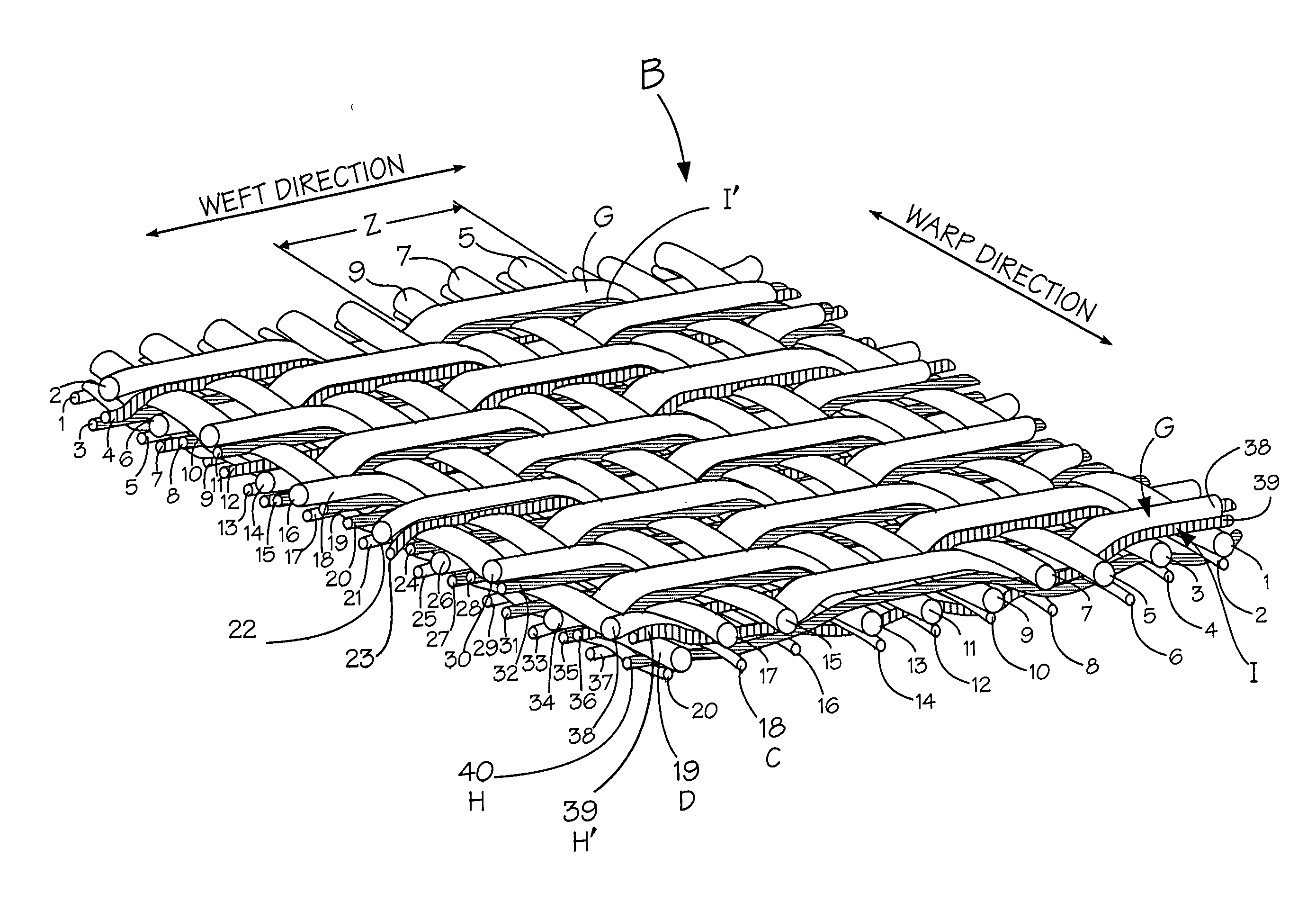

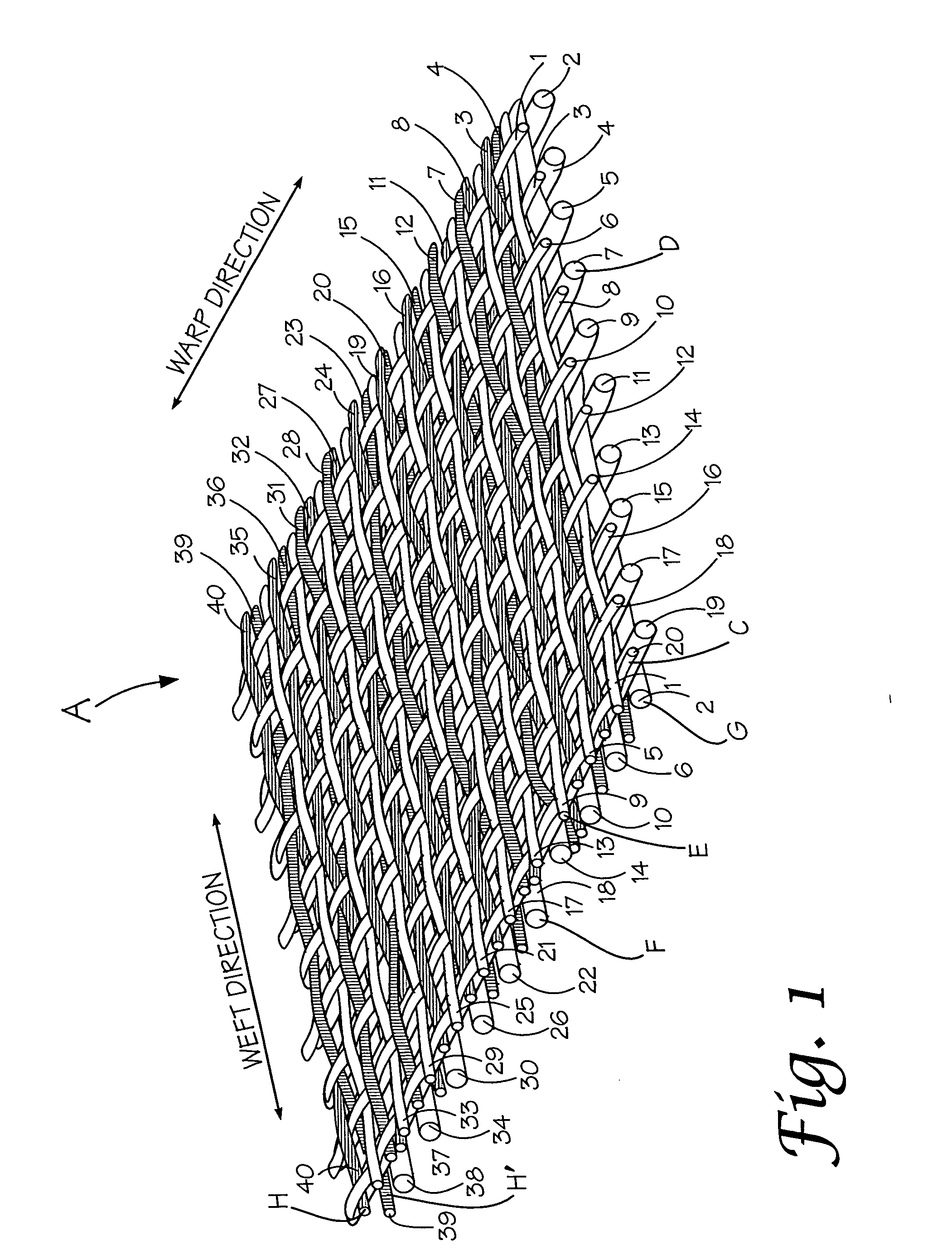

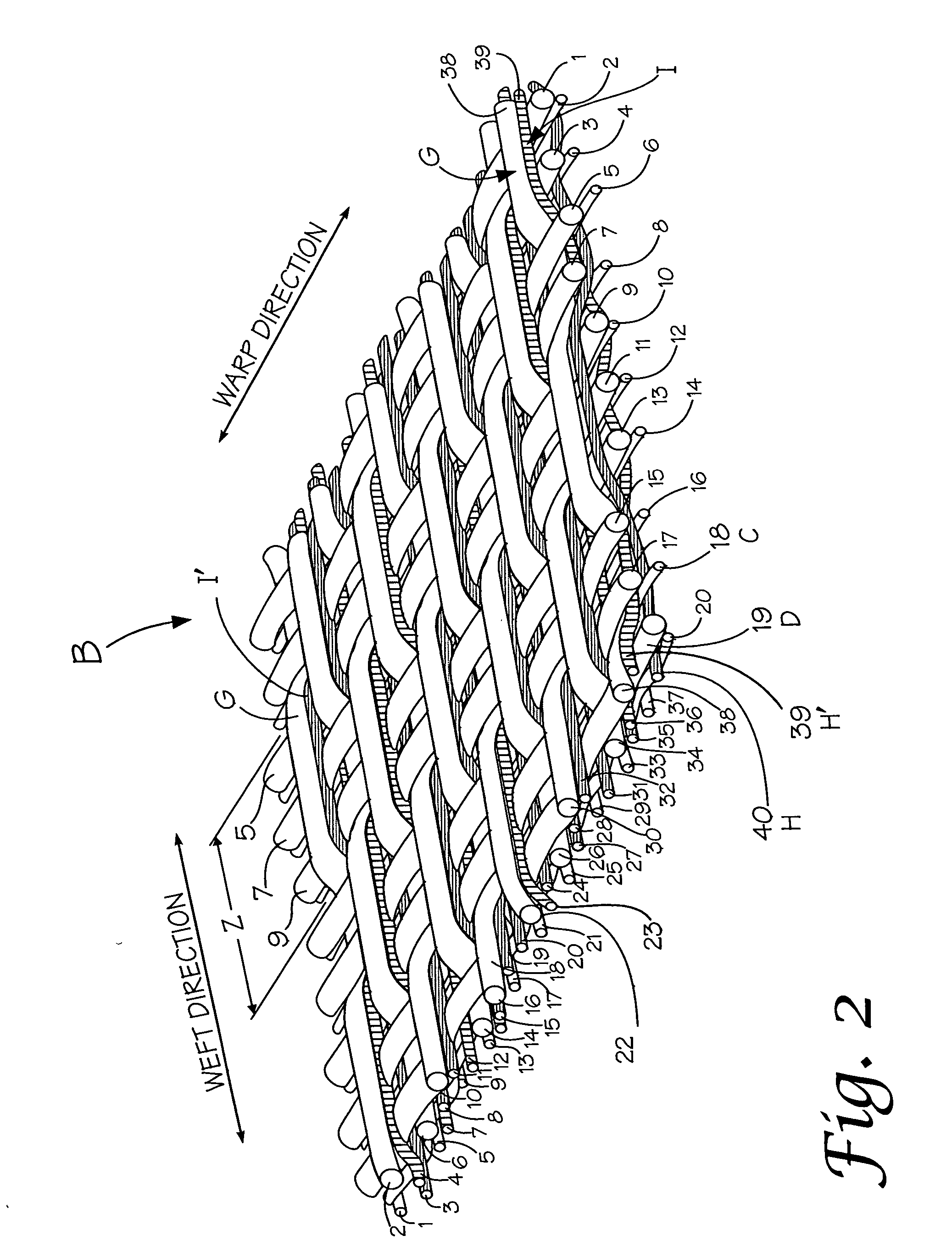

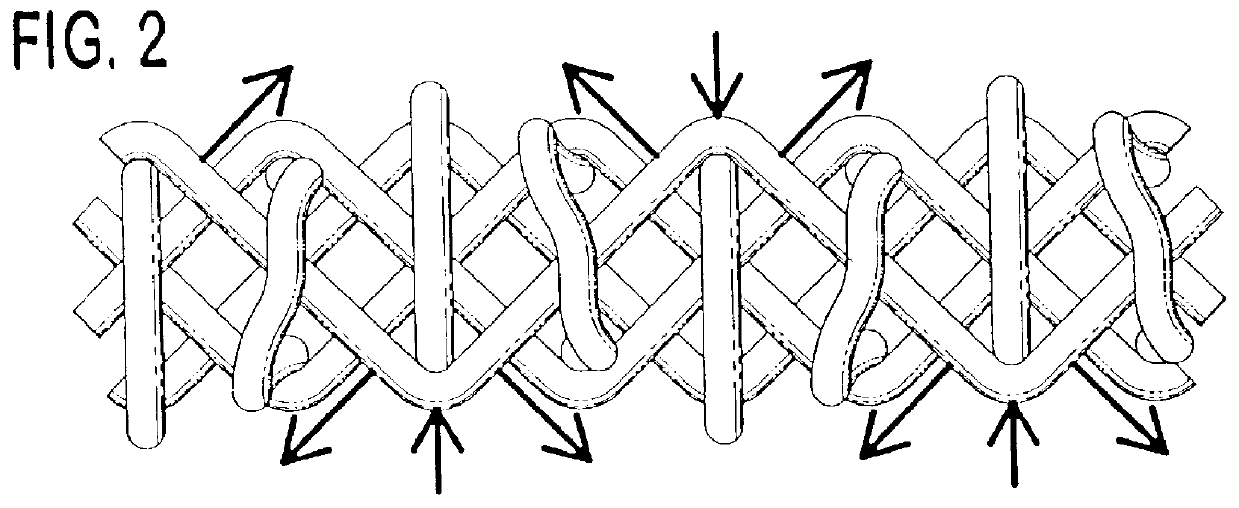

Composite papermaking fabric

A composite papermaking fabric having an upper support fabric including upper warp and weft yarns and a lower contact fabric including lower warp and weft yarns. The upper fabric is woven in a first weave pattern which forms a support surface and the lower fabric is woven in a broken twill weave pattern which forms the contact surface. The composite fabric includes paired binder yarns which weave in alternating sequences with the upper and lower fabrics binding them together. The broken twill weave pattern provides plural floats of cross-machine direction yarns passing outwardly of a plurality of adjacent lower warp yarns forming a plurality of adjacent cross-machine direction floats. Certain of the paired floats comprise a lower weft yarn and a binder yarn while others may comprise two lower weft yarns. The lower weft yarn floats are positioned to shield and protect the binder yarn floats along their entire length.

Owner:VOITH FABRICS

Composite papermaking fabric

A composite papermaking fabric having an upper support fabric including upper warp and weft yarns and a lower contact fabric including lower warp and weft yarns. The upper fabric is woven in a first weave pattern which forms a support surface and the lower fabric is woven in a broken twill weave pattern which forms the contact surface. The composite fabric includes paired binder yarns which weave in alternating sequences with the upper and lower fabrics binding them together. The broken twill weave pattern provides plural floats of cross-machine direction yarns passing outwardly of a plurality of adjacent lower warp yarns forming a plurality of adjacent cross-machine direction floats. Certain of the paired floats comprise a lower weft yarn and a binder yarn while others may comprise two lower weft yarns. The lower weft yarn floats are positioned to shield and protect the binder yarn floats along their entire length.

Owner:VOITH FABRICS

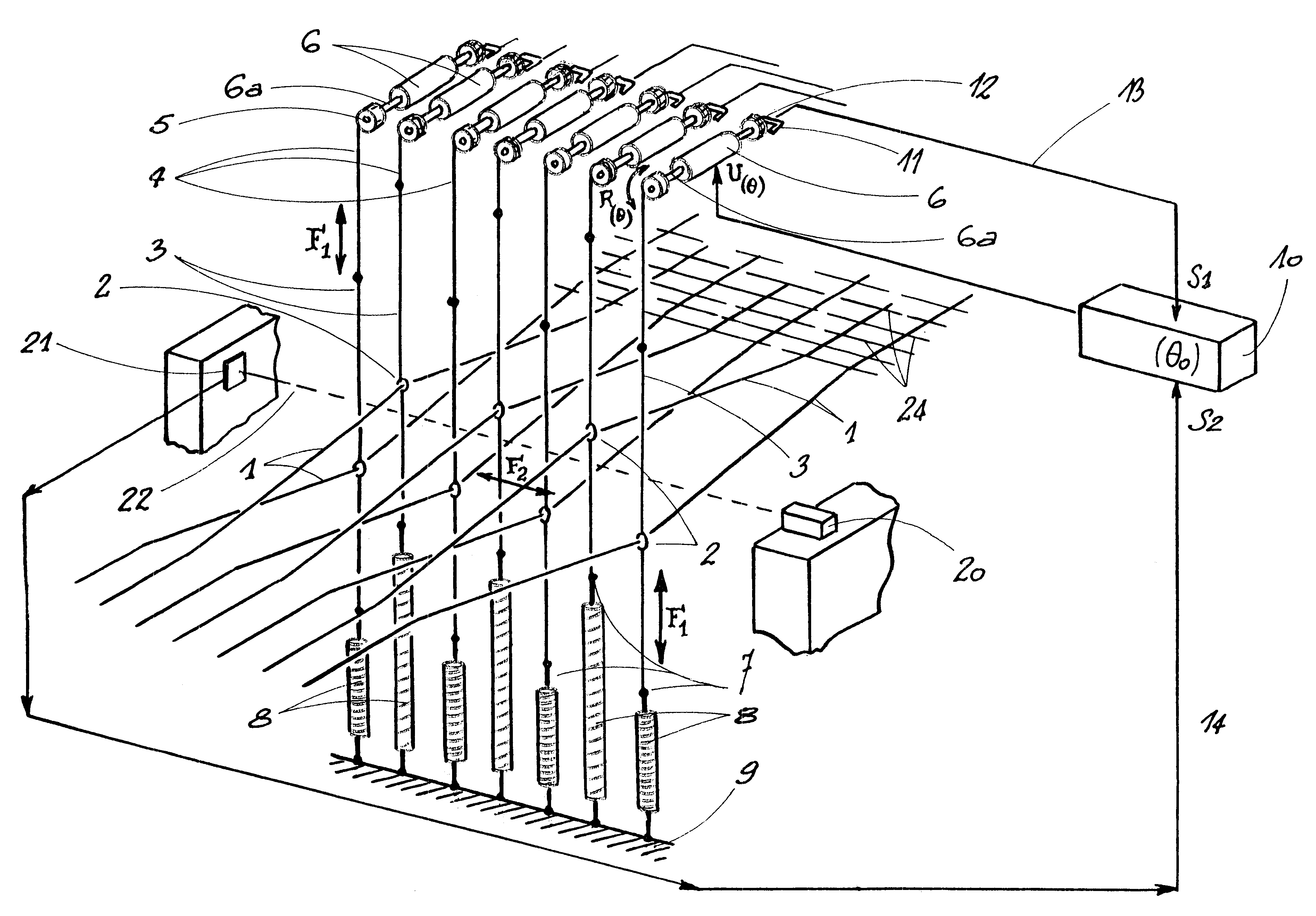

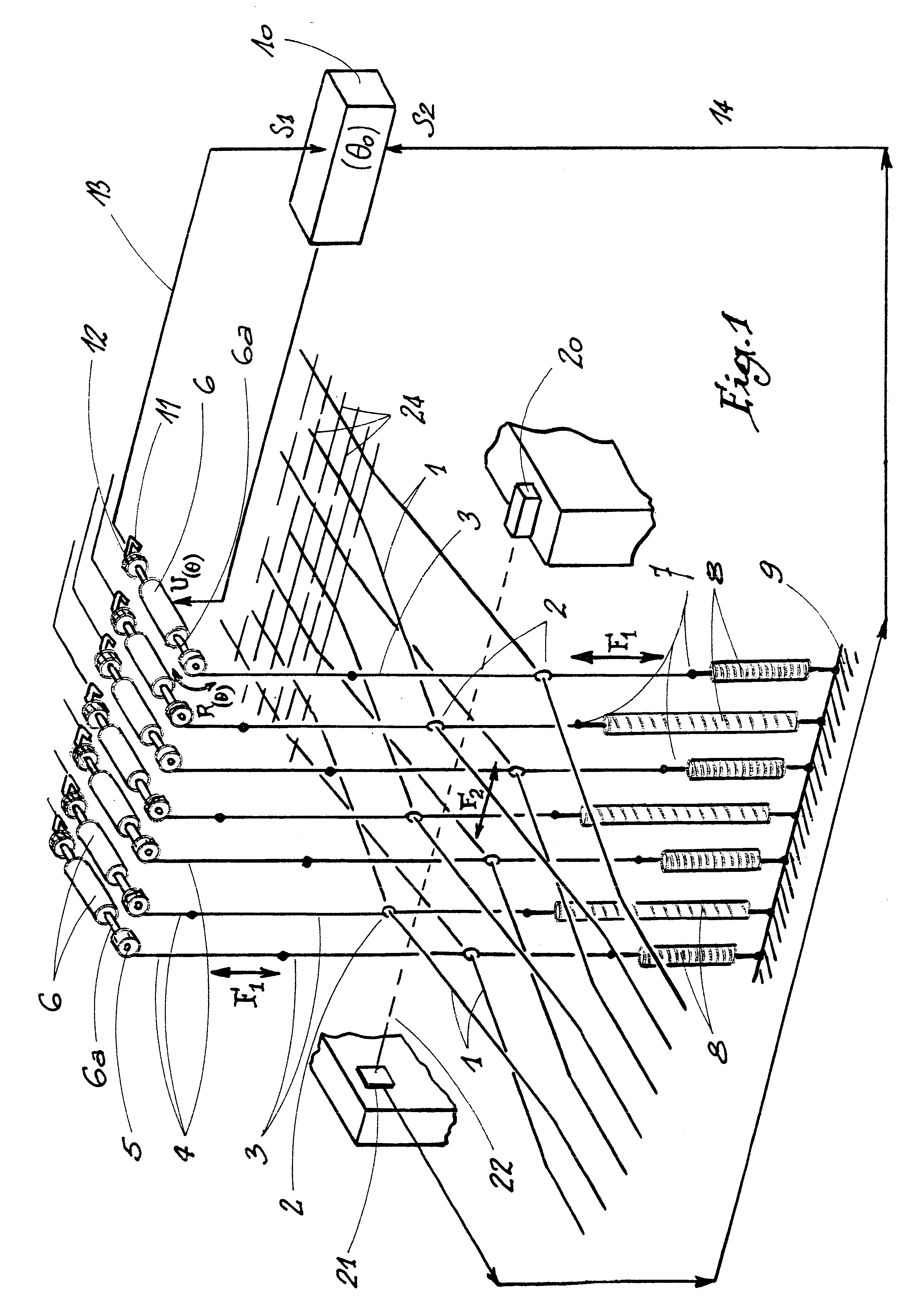

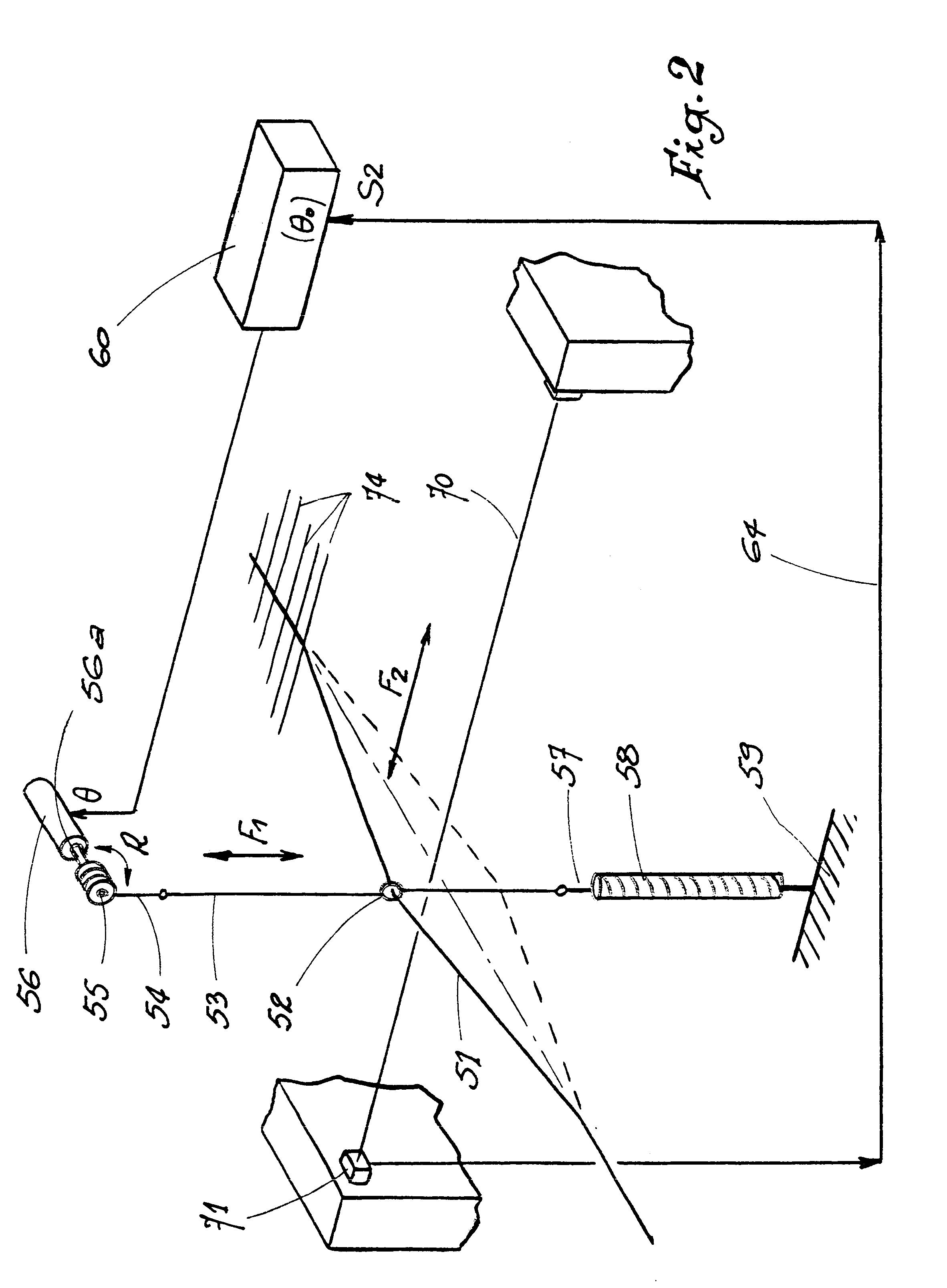

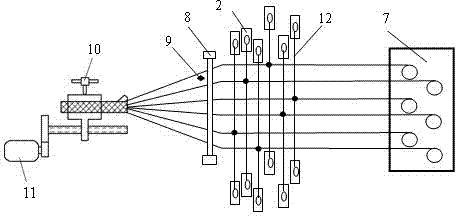

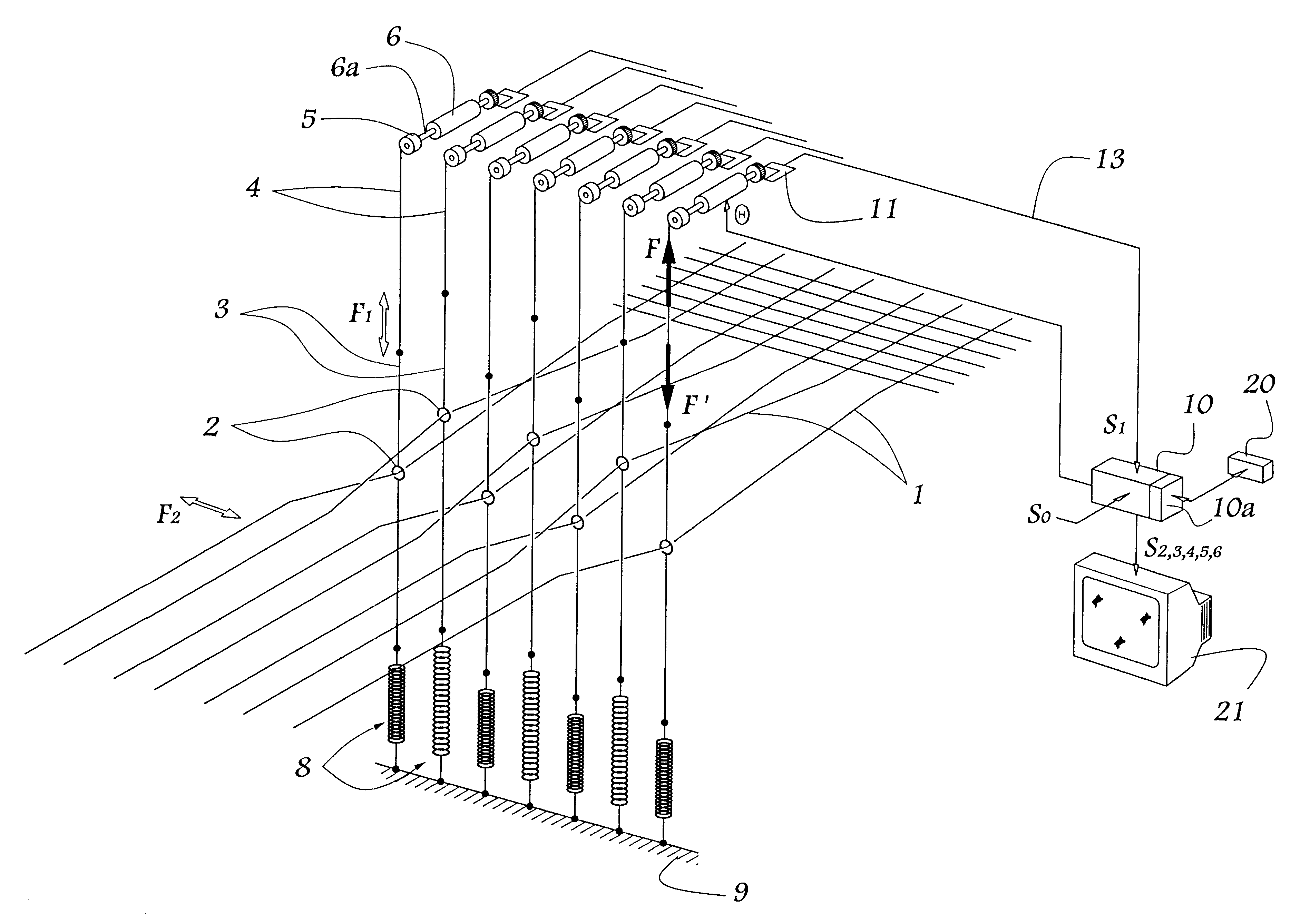

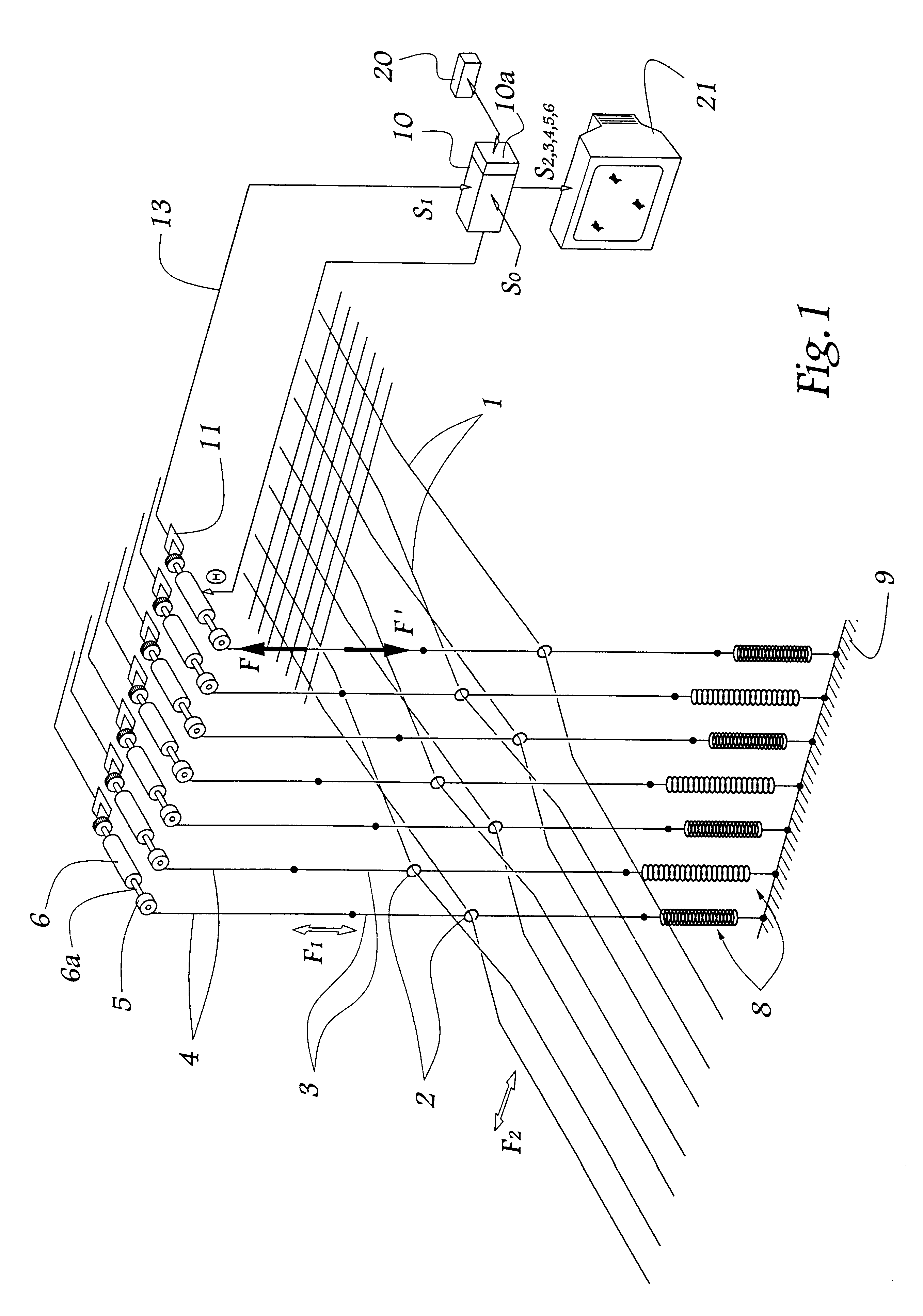

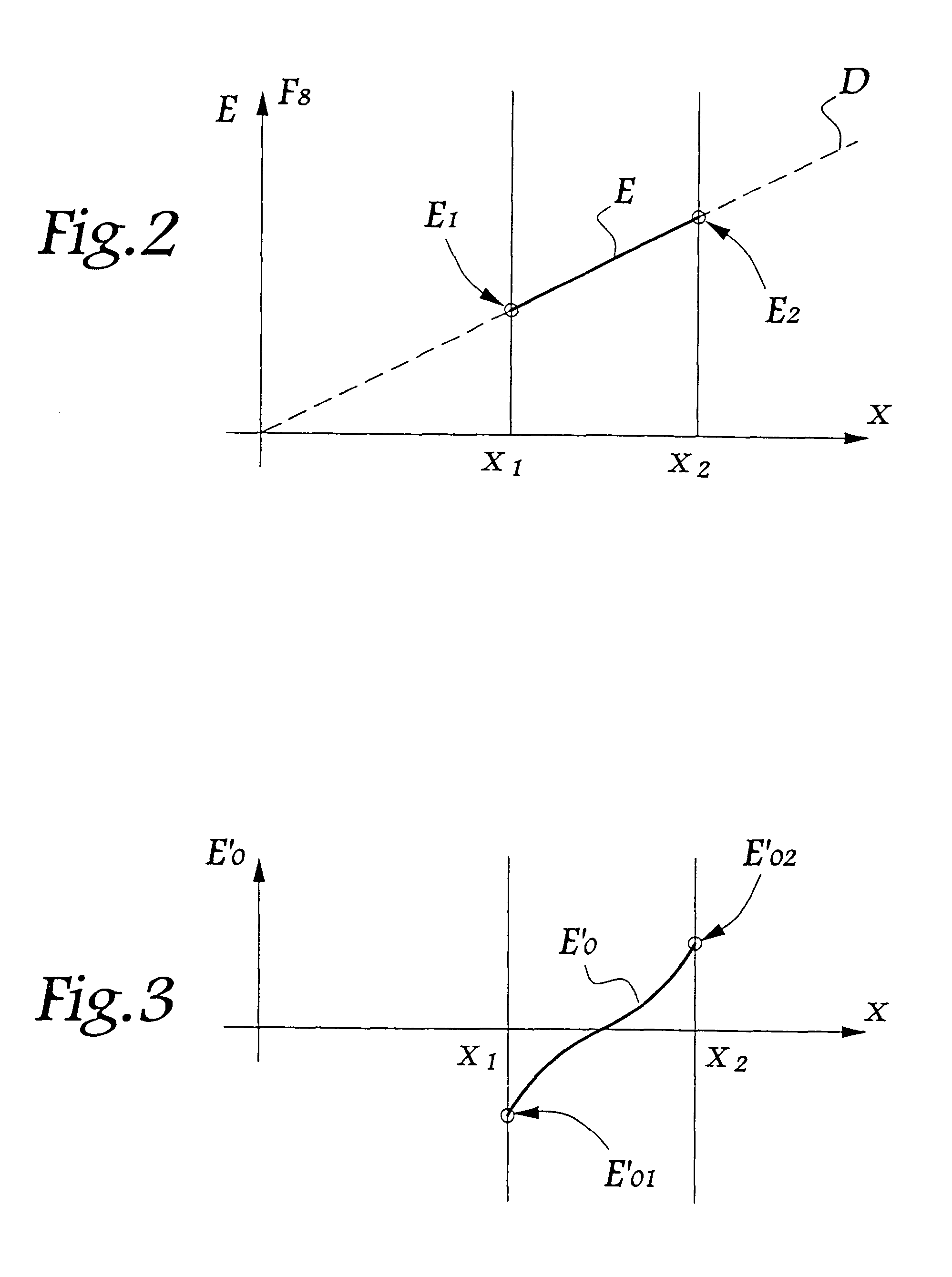

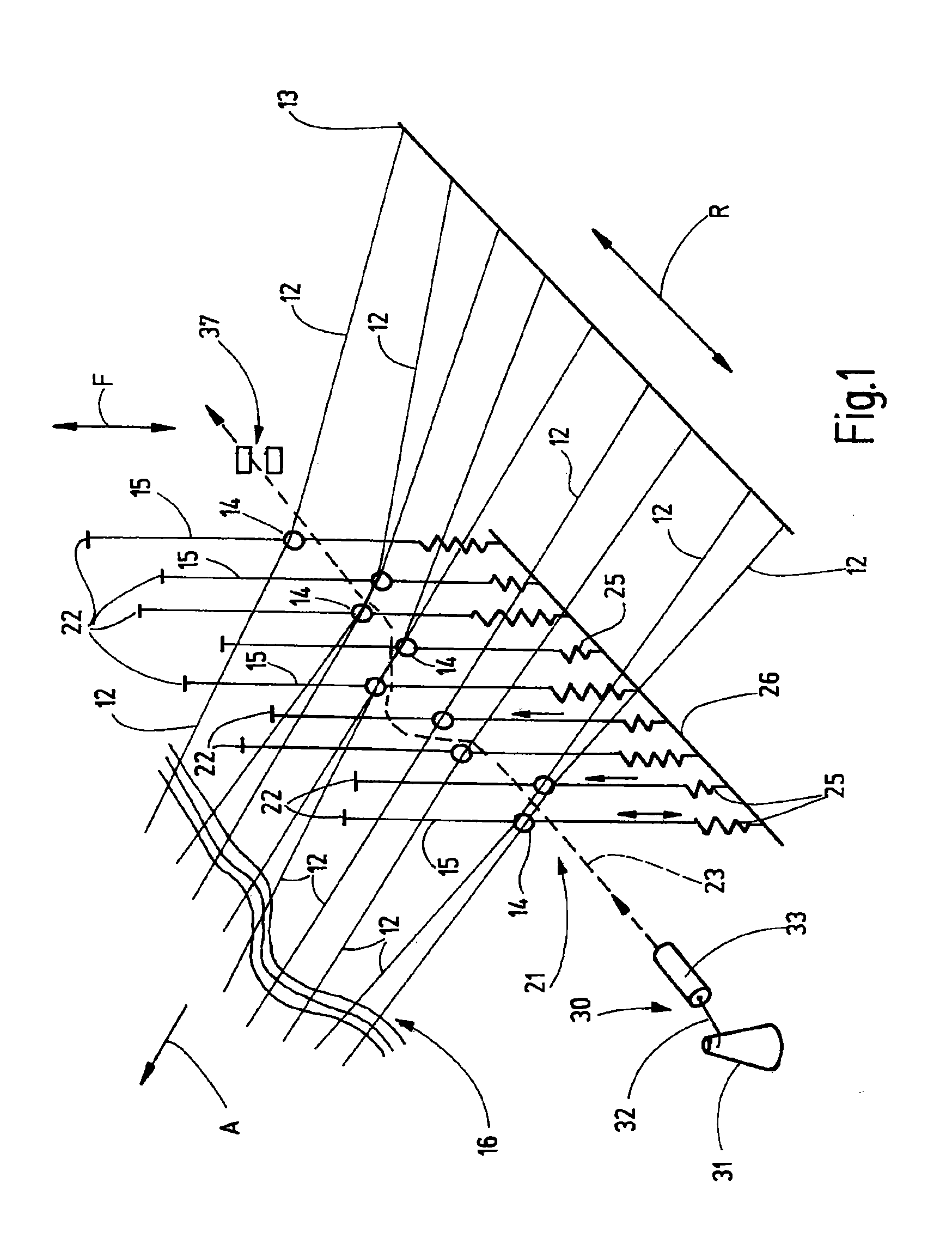

Process and device for positioning weaving loom warp yarns

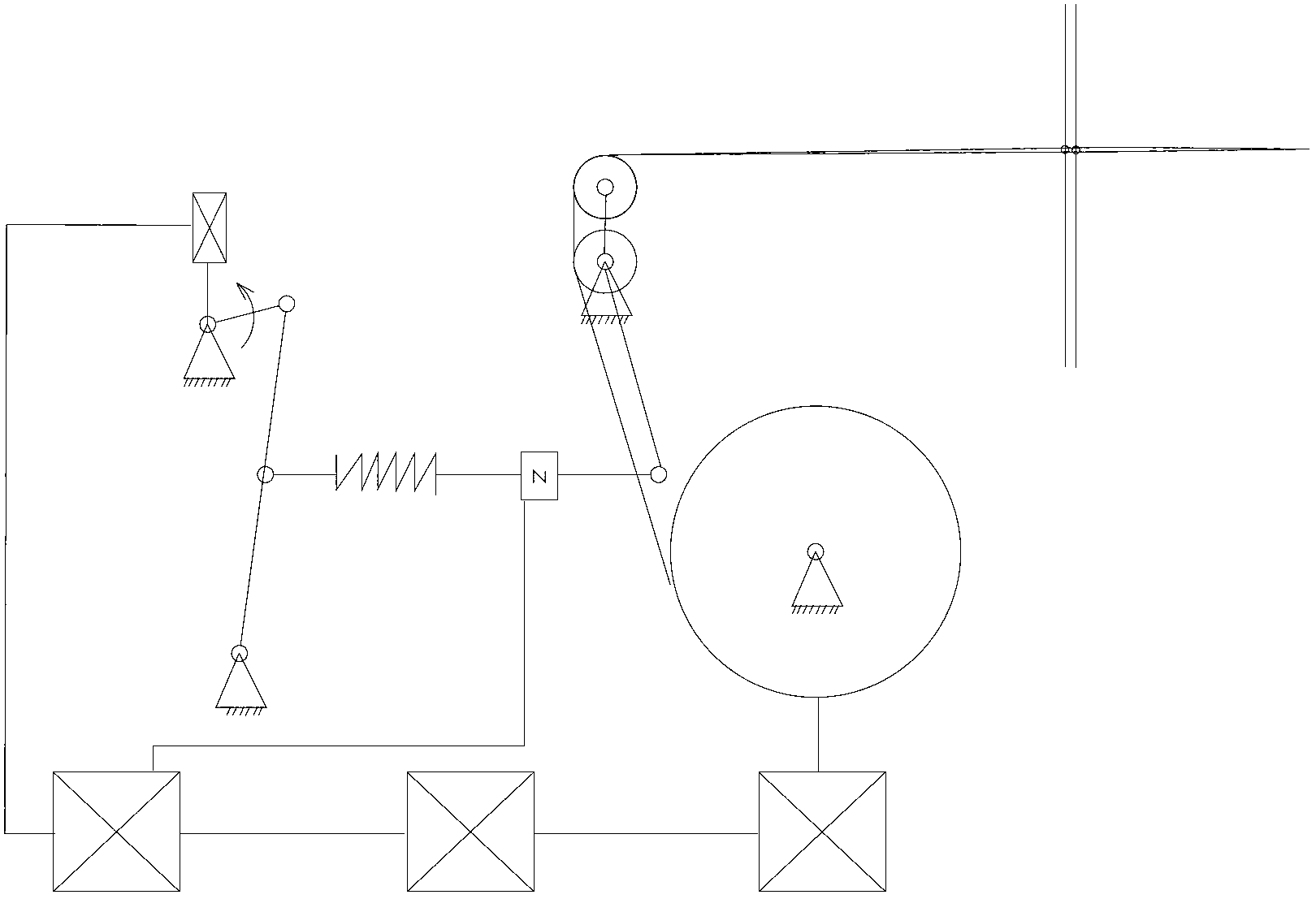

InactiveUS6293315B1Adjustable strokePrecise positioningJacquardsOther shedding mechanismYarnEngineering

A device for positioning warp yarns of a weaving loom which are controlled by electrical actuators for forming a shed which includes a first detector common to the warp yarns driven by a plurality of different actuators for detecting the passage of at least one warp yarn into a predetermined position, and a second device for determining a value of a control parameter of an actuator for controlling movement of the at least one warp yarn upon passage into the predetermined position. The process consists in displacing a warp yarn and detecting its passage into a predetermined position and selecting a value of a control parameter of an actuator for the warp yarn upon passage of the warp yarn into the predetermined position and in using the selected value as a control point for controlling an actuator for the warp yarn.

Owner:STAUBLI FAVERGES SA

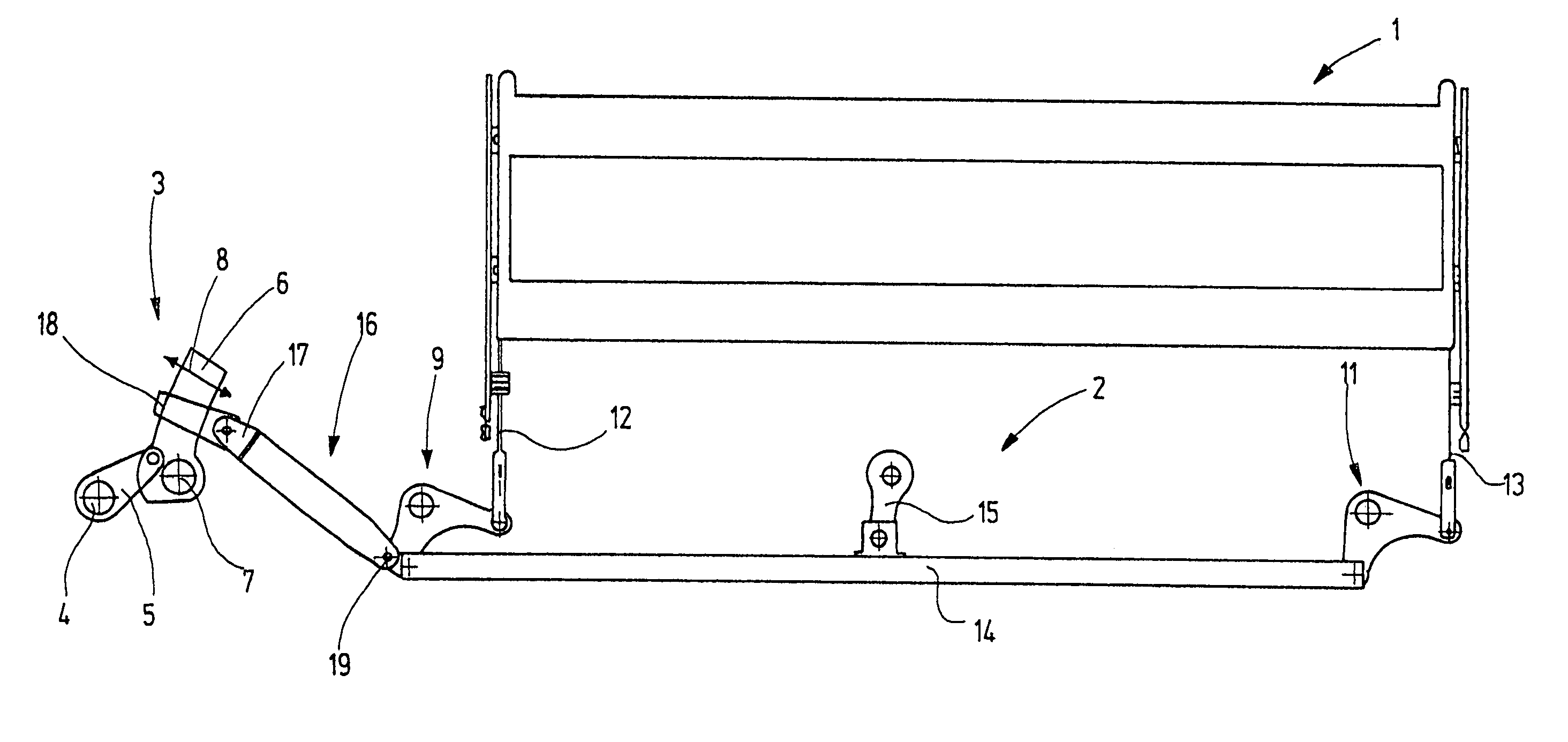

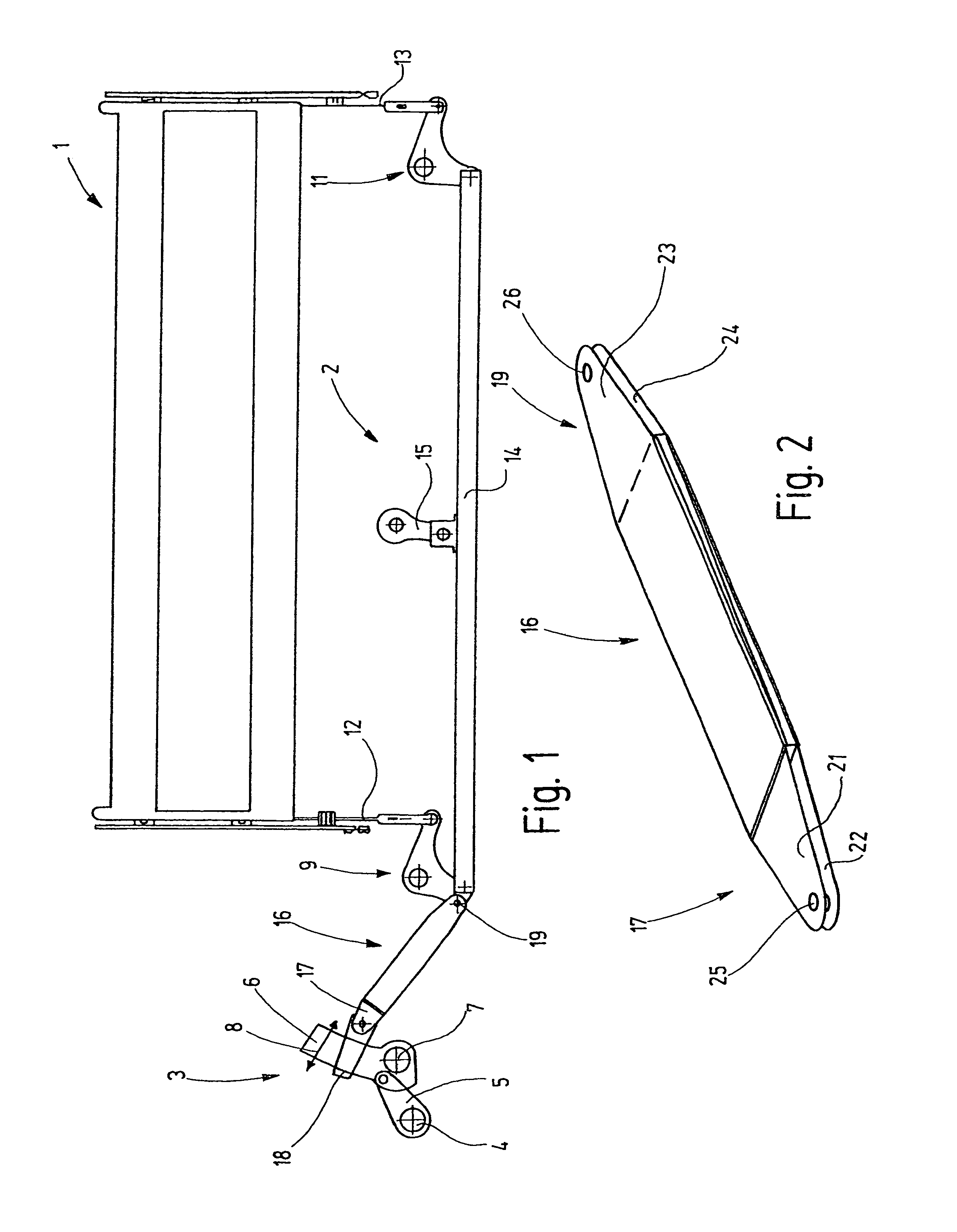

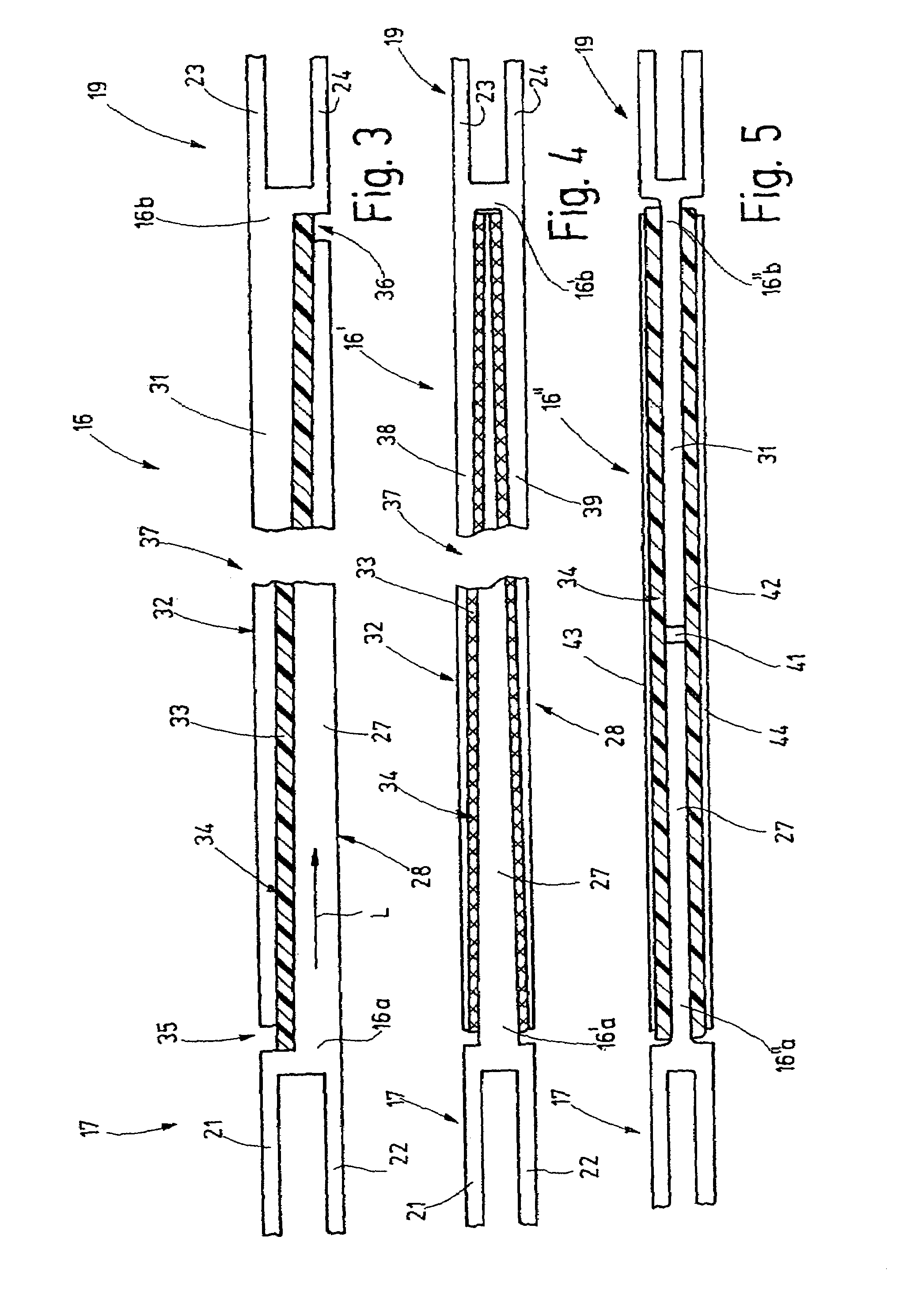

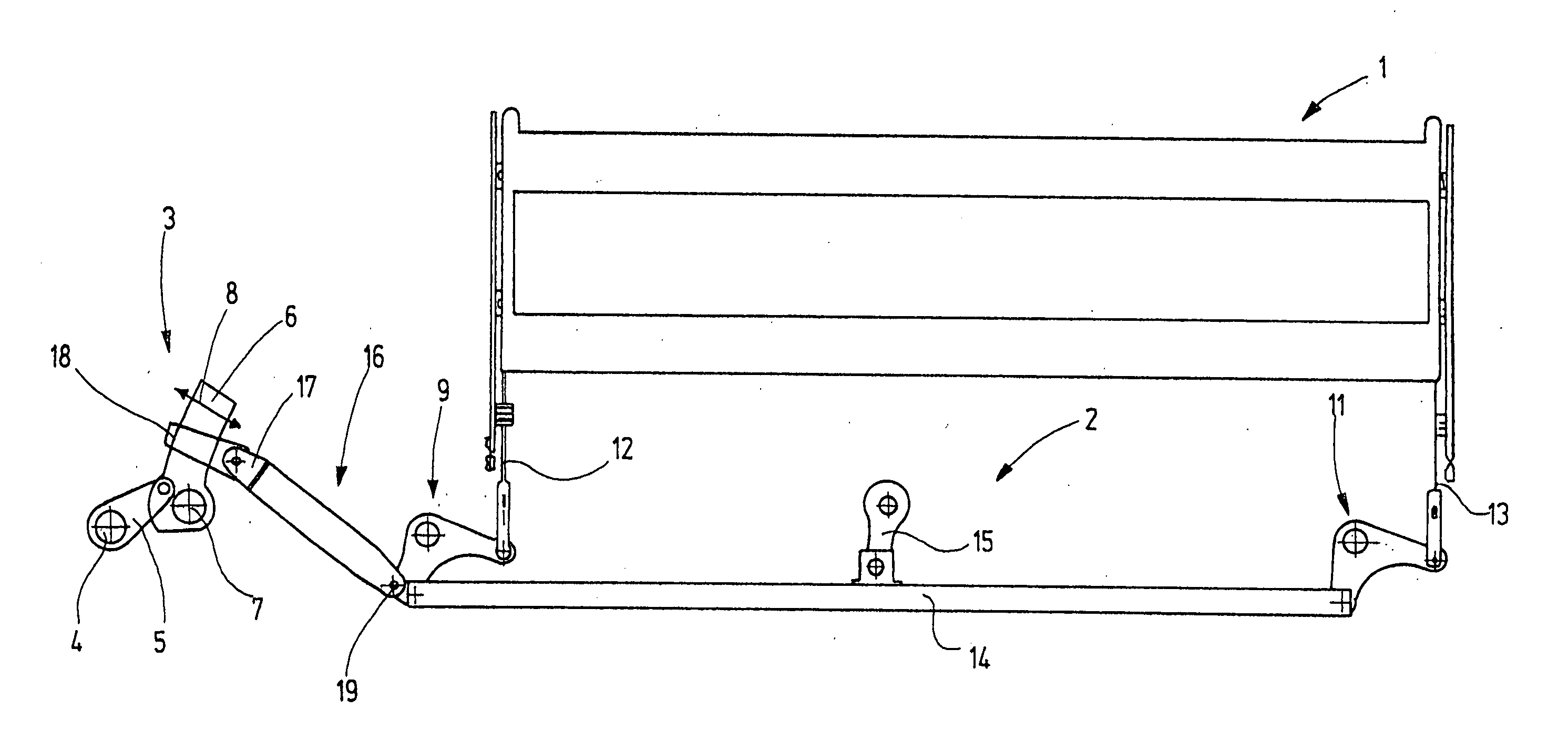

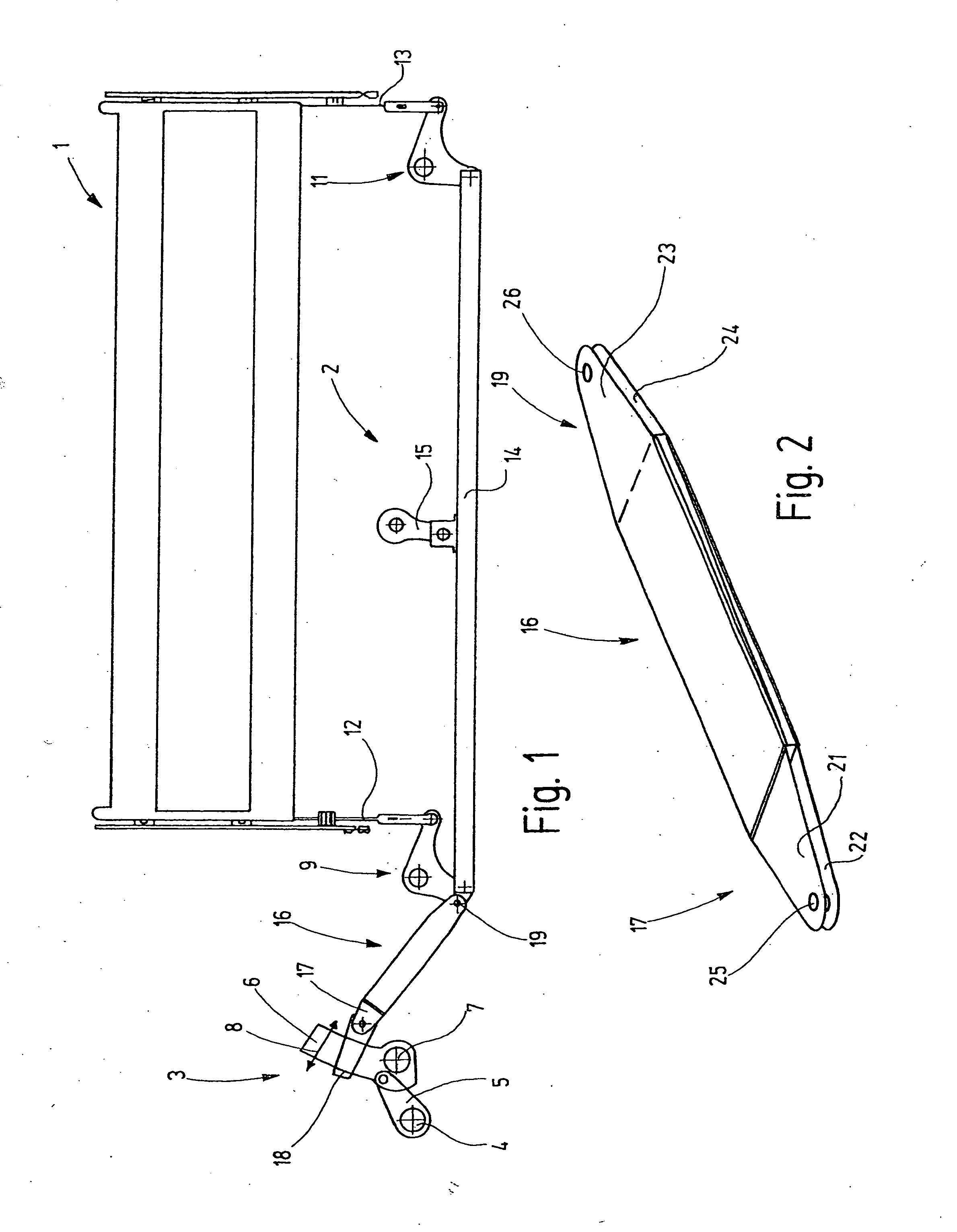

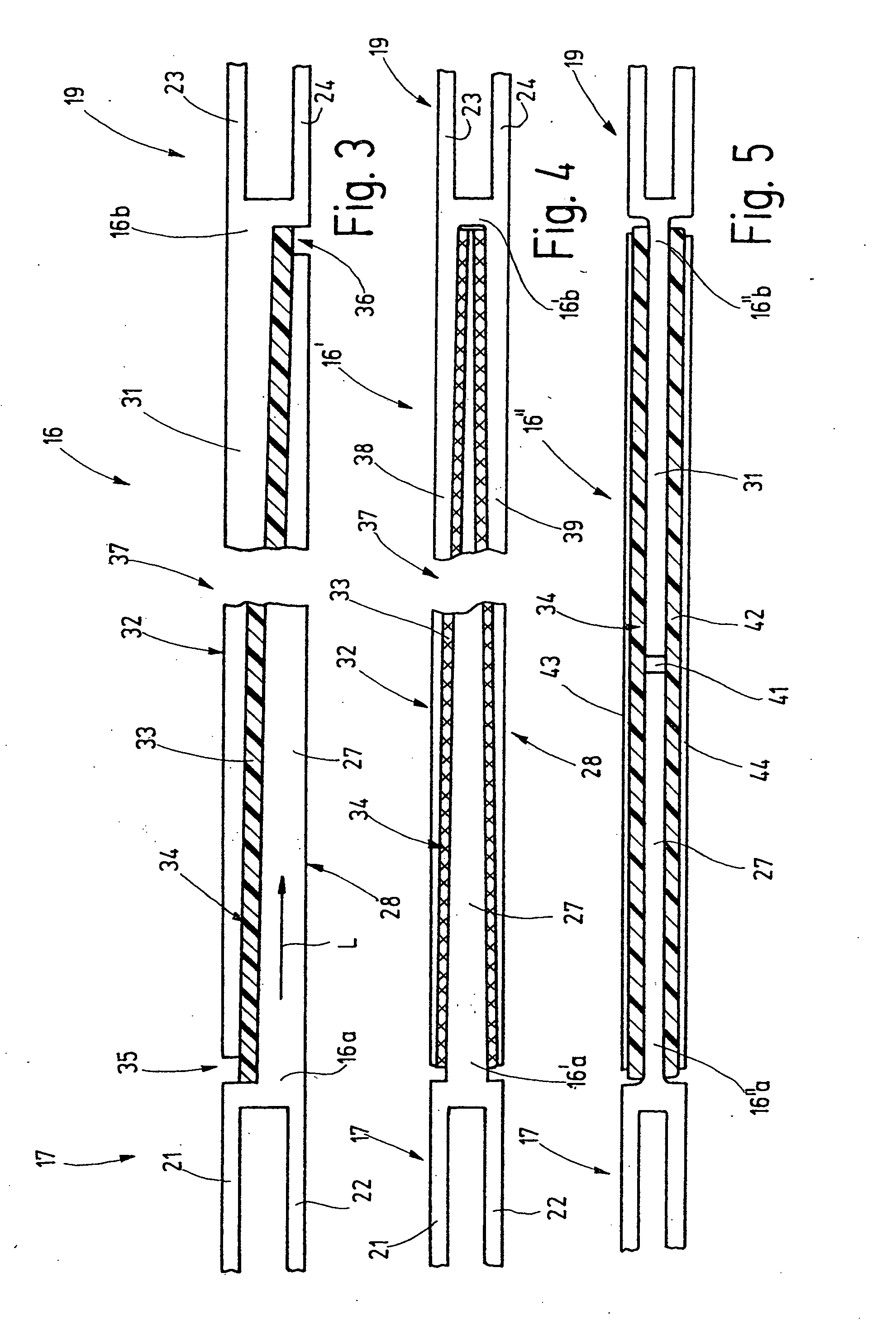

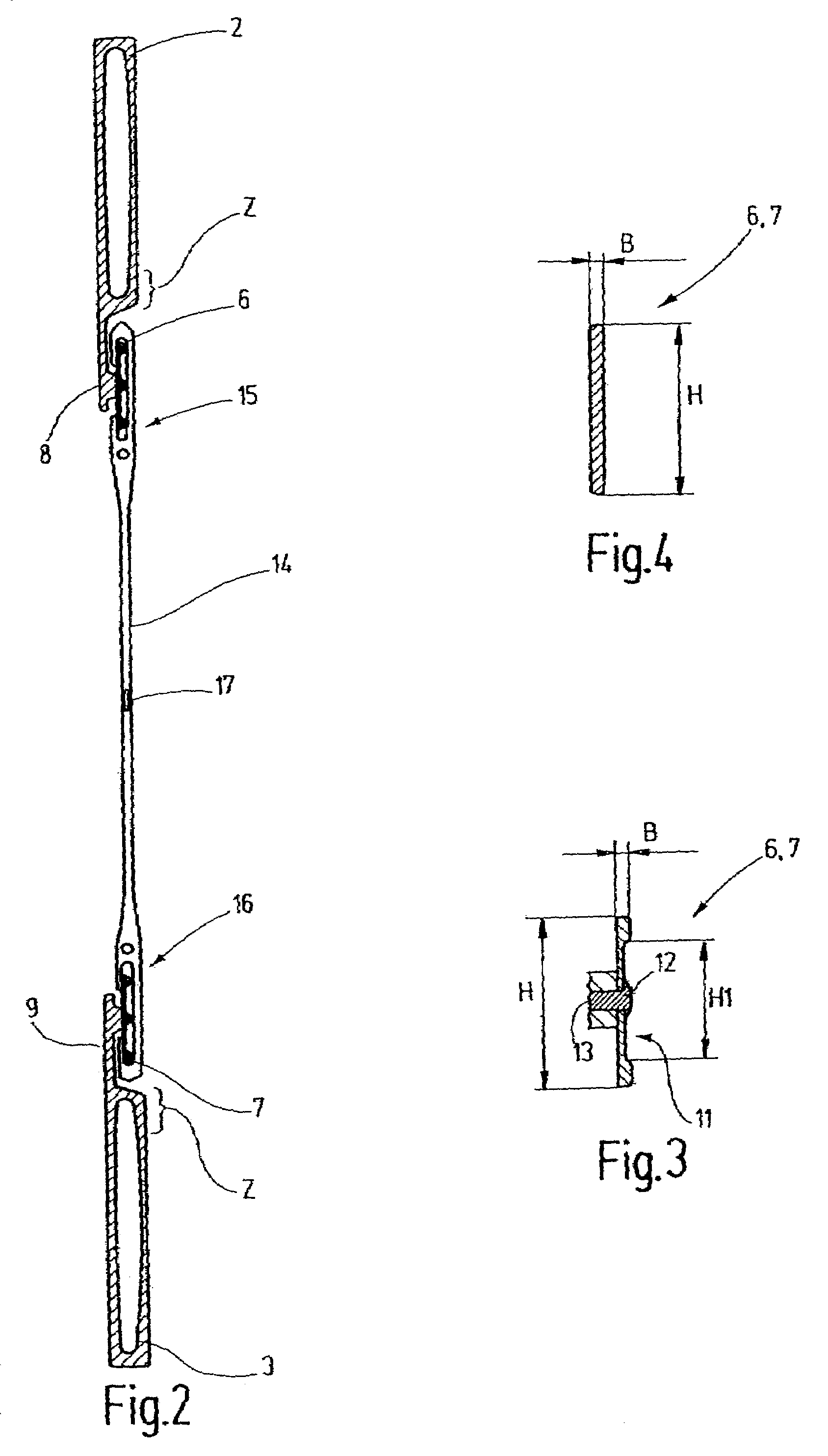

Low-vibration shedding system

A novel rod linkage for driving a heddle shaft includes at least one strap (16), which for damping oscillation has a sandwich structure (37) oriented in the longitudinal direction (L) of the strap assembly (16). The sandwich structure includes at least one rigid element (27), extending in the longitudinal direction, which is joined to one end (17) of the strap assembly (16); a second rigid element (31), likewise extending essentially in the longitudinal direction, which is joined to the other end (19); and a two-dimensional damping element (34), again extending in the longitudinal direction, disposed between the first two. The element (34) exclusively effects the mechanical connection of the two parts (16a, 16b) of the strap assembly (16). Preferably, no additional connecting elements, such as rivets, screws, or other rigid connections, between the rigid elements (27, 31) are provided. Preferably, the rigid elements (27, 31) are embodied as wedges pointing in opposite directions, which thus define a wave resistance that varies in opposite directions in the longitudinal direction. This wave resistance brings about an intentional coupling misadaptation with respect to the oscillation transmission. The element (34) disposed between them damps the oscillations additionally, so that the strap assembly (16) transmits driving motions like a filter and destroys or absorbs interfering oscillations.

Owner:GROZ BECKERT KG

Nonwoven fabrics containing yarns with varying filament characteristics

InactiveUS20040221436A1Good lookingIncrease stiffnessPaper/cardboardPaper/cardboard layered productsYarnPolymer science

The subject invention provides non-woven fabrics having yarns of varying characteristics. In a preferred embodiment the subject invention provides nonwoven fabrics that comprise yarns of different deniers or cross sections. The use of these yarns gives the nonwoven fabric a unique appearance and advantageous properties. The subject invention further pertains to the processes used to produce these fabrics.

Owner:CEREX ADVANCED FABRICS

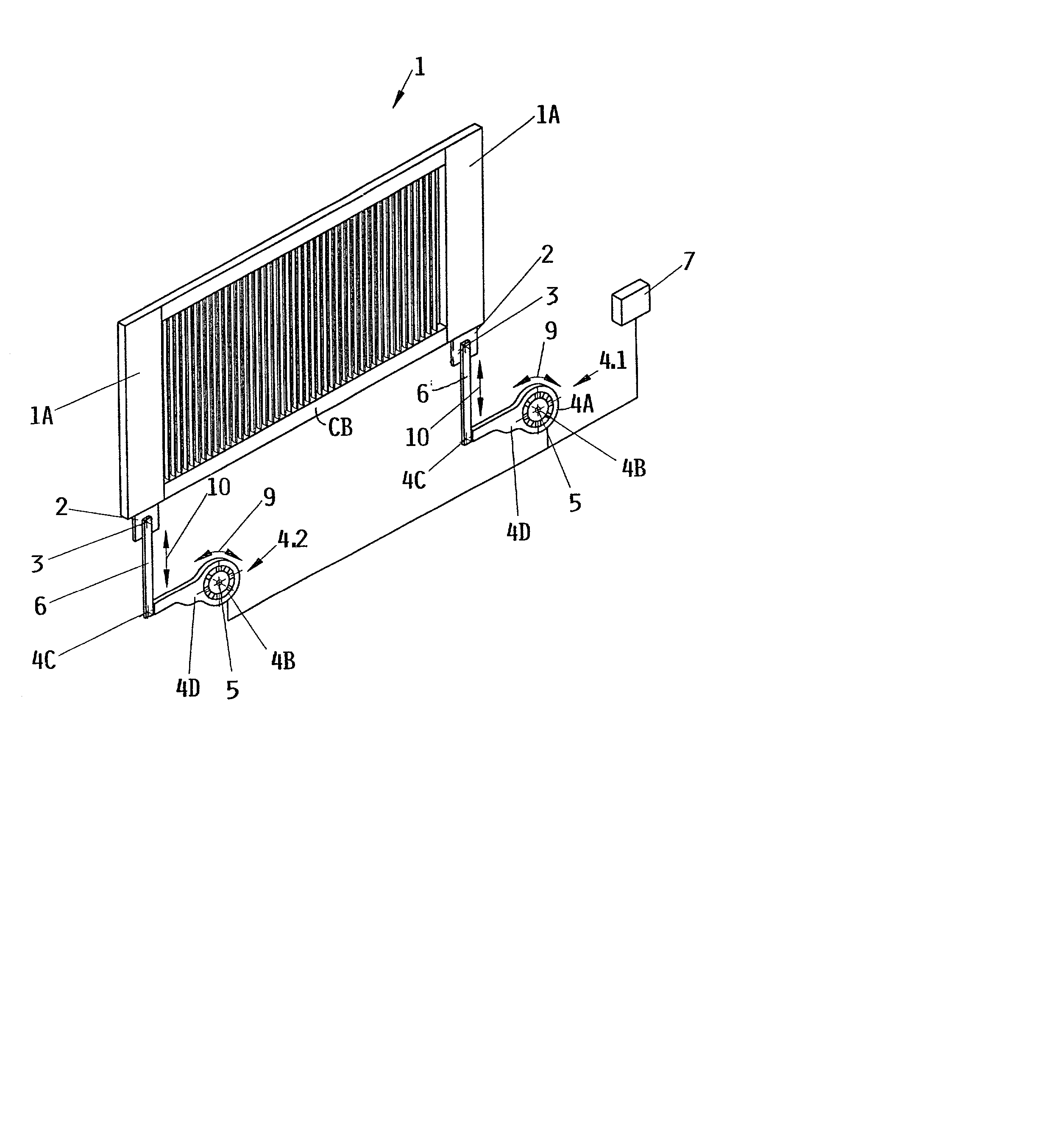

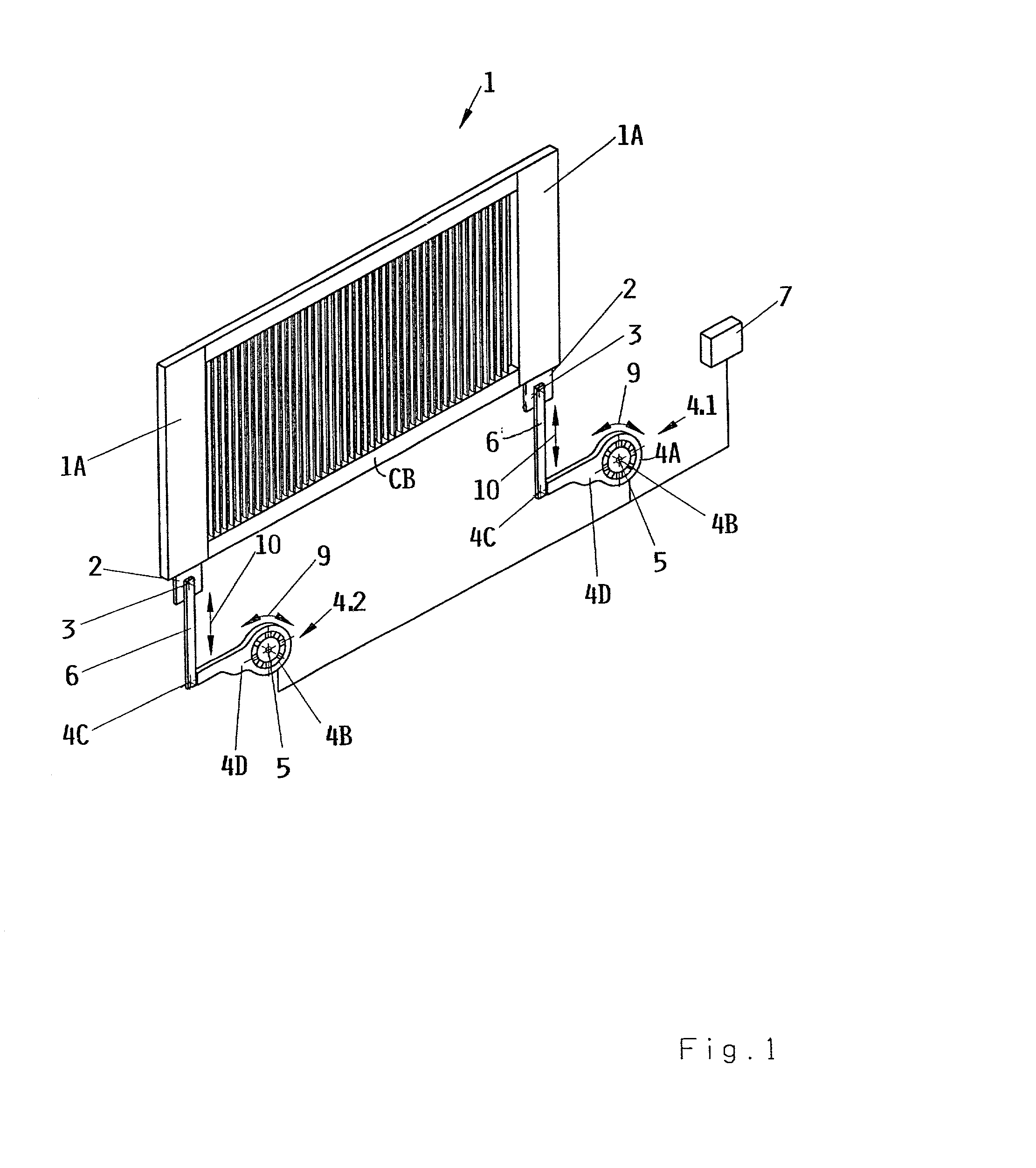

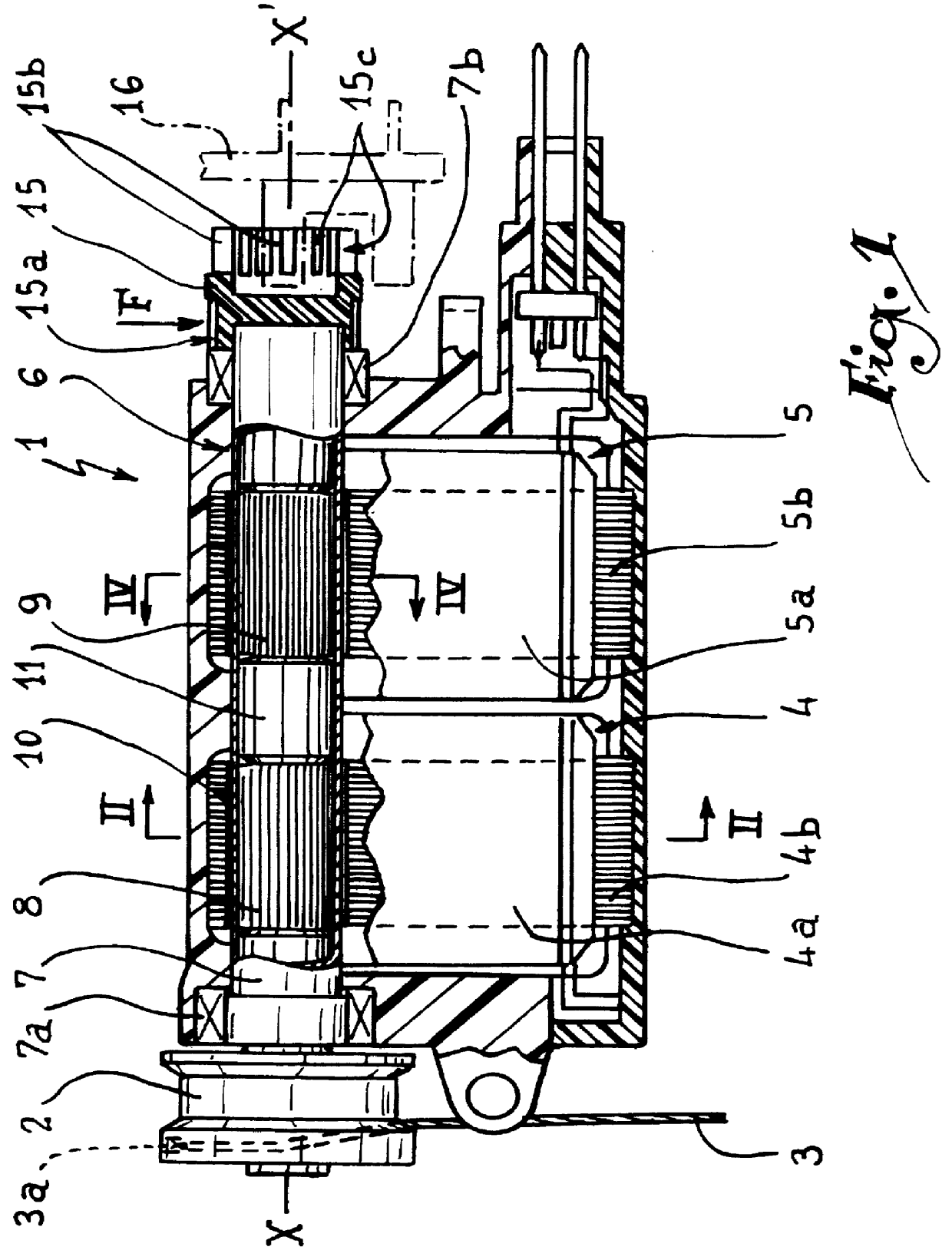

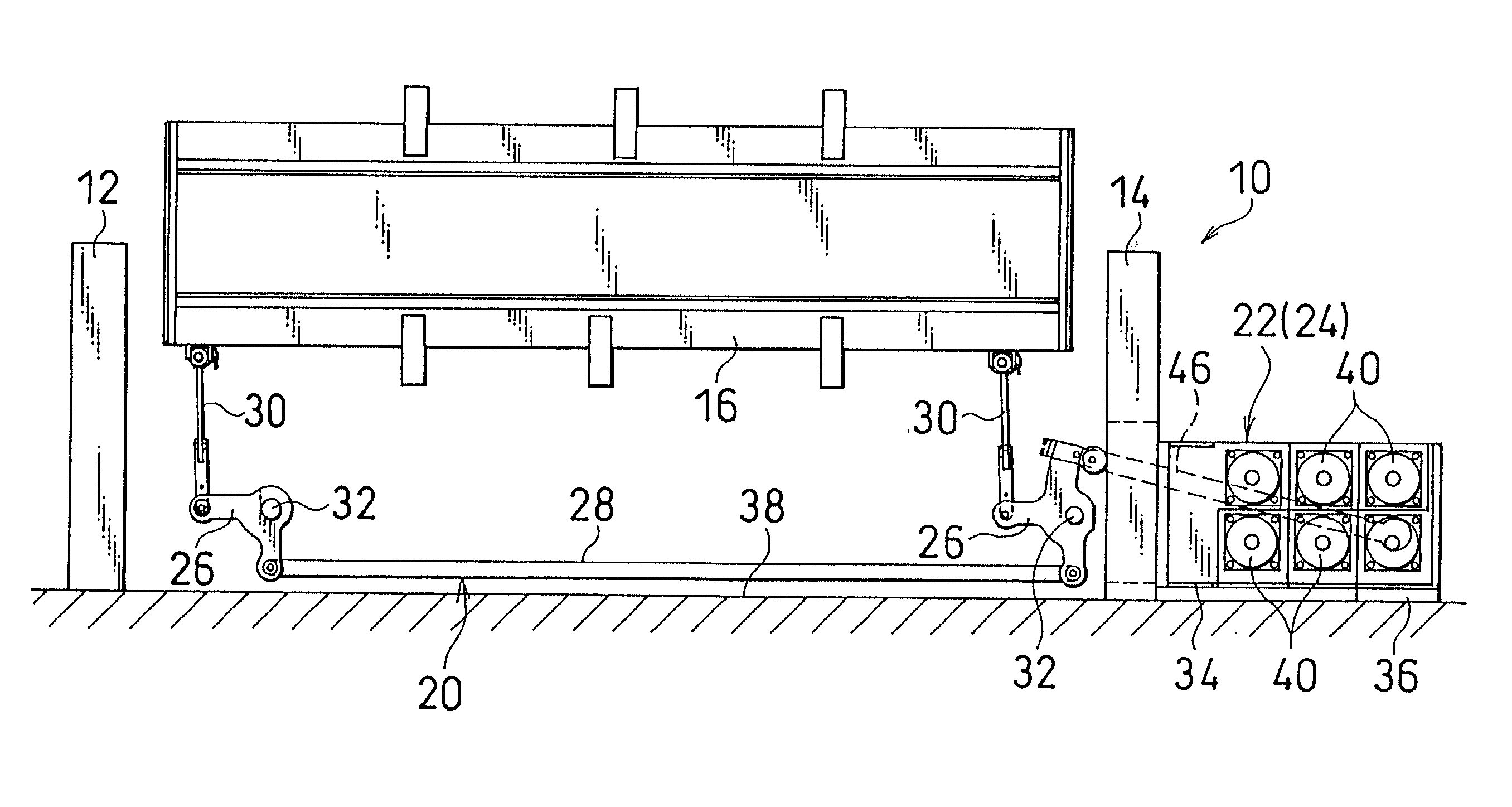

Drive mechanism for shed forming components of a loom

The heald shafts of a power loom are driven by electric D.C. or A.C. motors which have a external rotor or an armature connected to the respective heald shaft through two articulated couplings, for example snap locks, and a push-pull rod. The motors receive control signals from a computerized controller for reversing the motion direction of the external rotor or armature. The stators of the motors are rigidly mounted on a fixed axis secured to the loom frame.

Owner:LINDAUER DORNIER GMBH

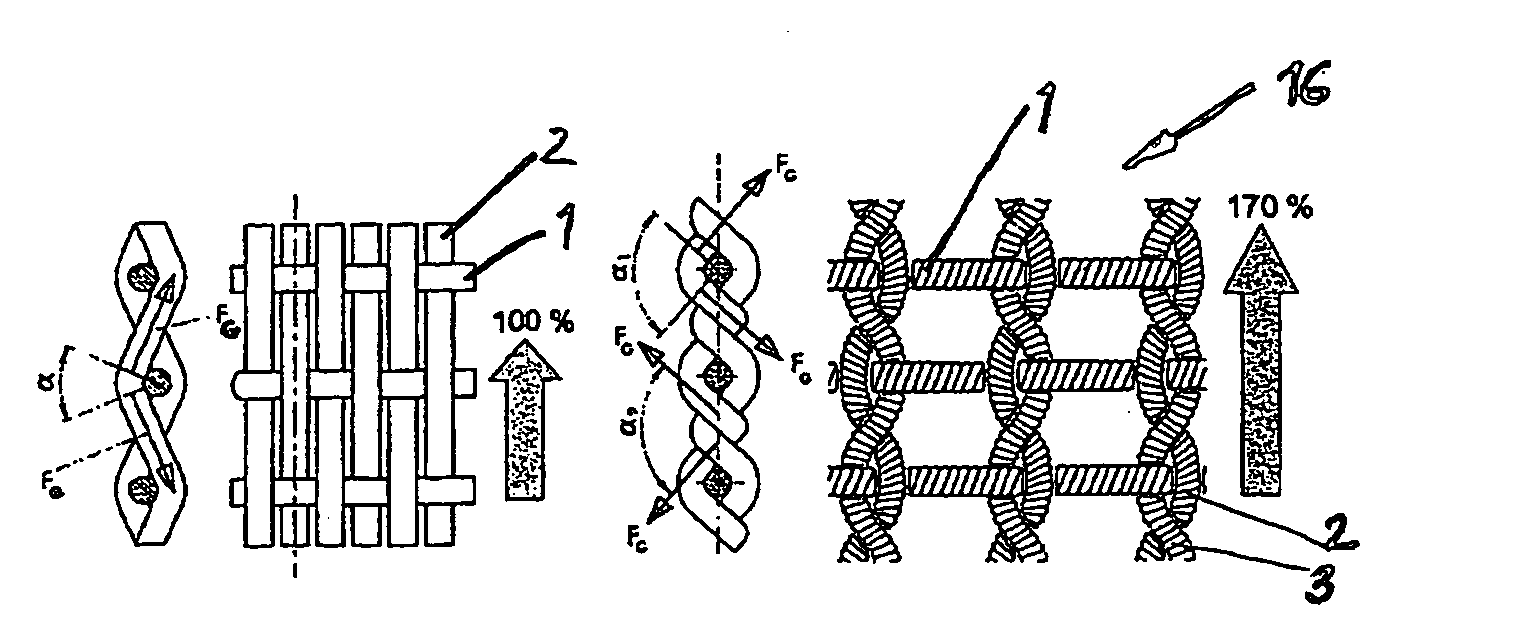

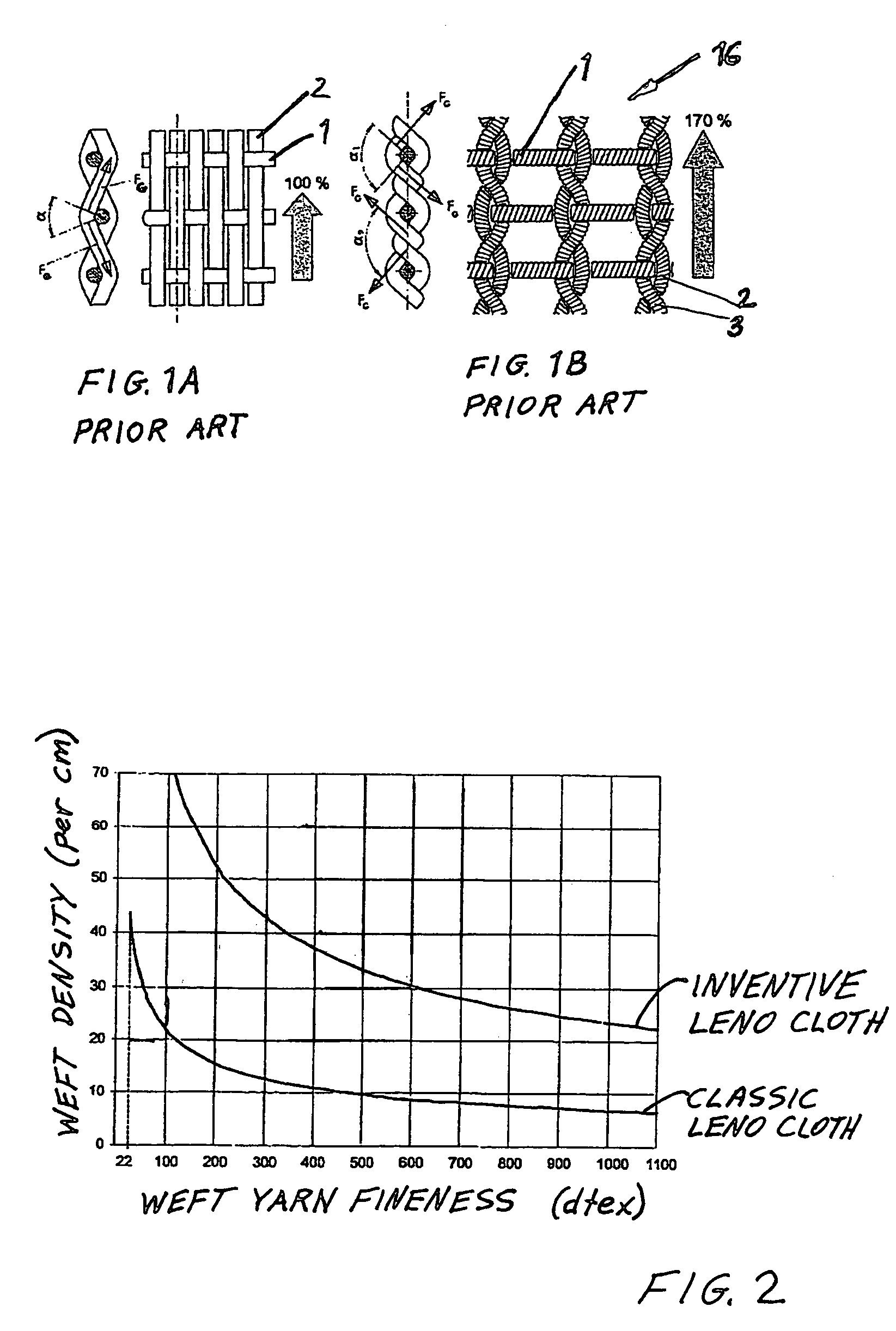

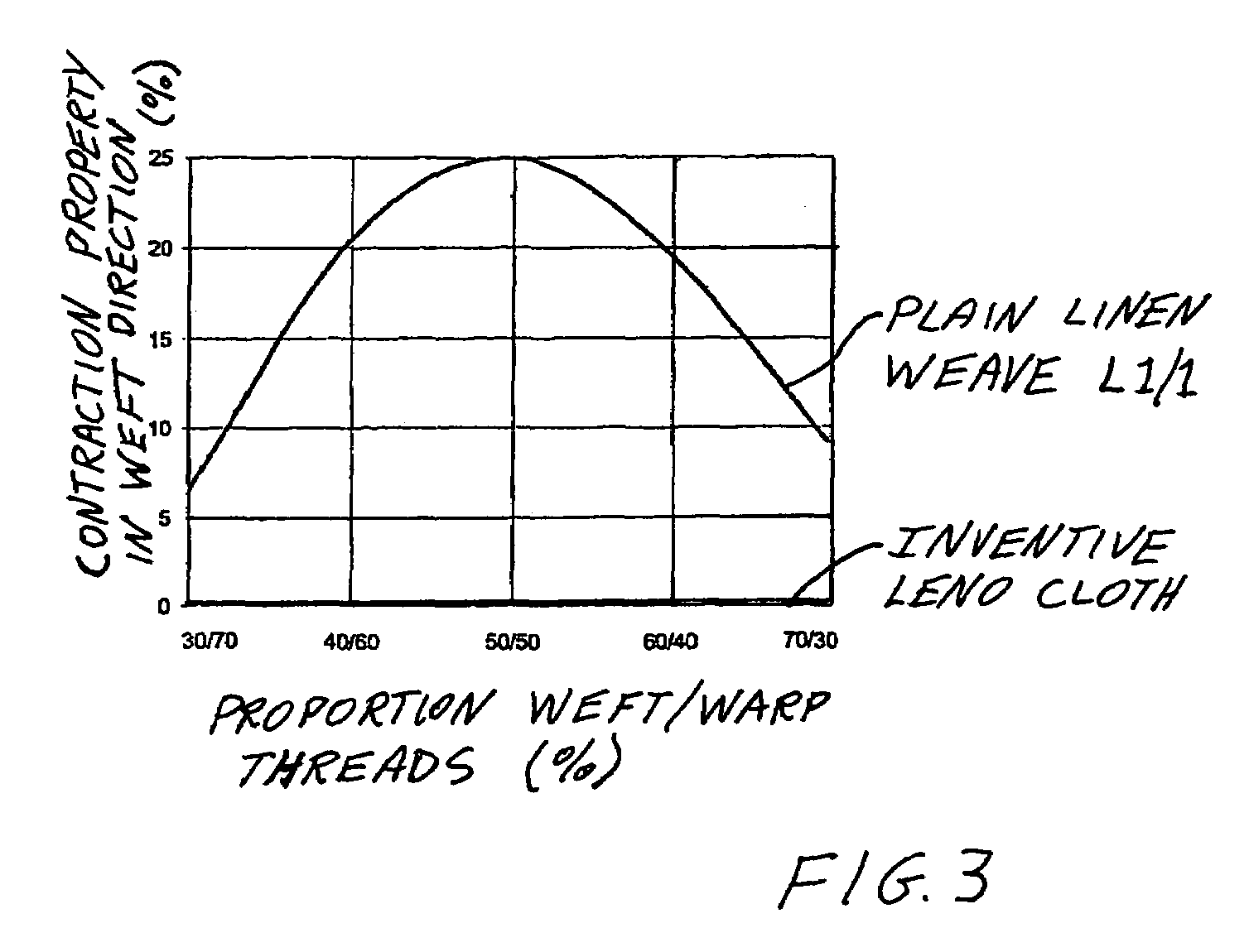

Leno cloth as well as method and weaving machine for production thereof

InactiveUS7287553B2Reduce tensionStronger working-in insertion or take-upOrnamental textile articlesLeno shedding mechanismYarnEngineering

A leno cloth is prepared, which comprises at least ground warp threads 1, leno warp threads 3 and weft threads 2, and in which the weft threads 2 and the ground warp threads 1 are arranged essentially interspace free. The weft threads are bound-off by means of the leno warp threads 3, which comprise a clearly lower titer relative to the ground warp threads 1, with such a lower tension relative to the ground warp threads, so that the crossings of the leno warp threads 3 with the ground warp threads 1 that are present due to the binding are arranged in a plane parallel to the plane of the maximum thickness of the weft threads. The leno warp threads 3 comprise a higher working-in or take-up into the woven cloth than the ground warp threads 1. According to a further aspect of the invention, a method for the production of a leno cloth as well as a loom for the carrying out of the method for the production of a leno cloth are described.

Owner:LINDAUER DORNIER GMBH

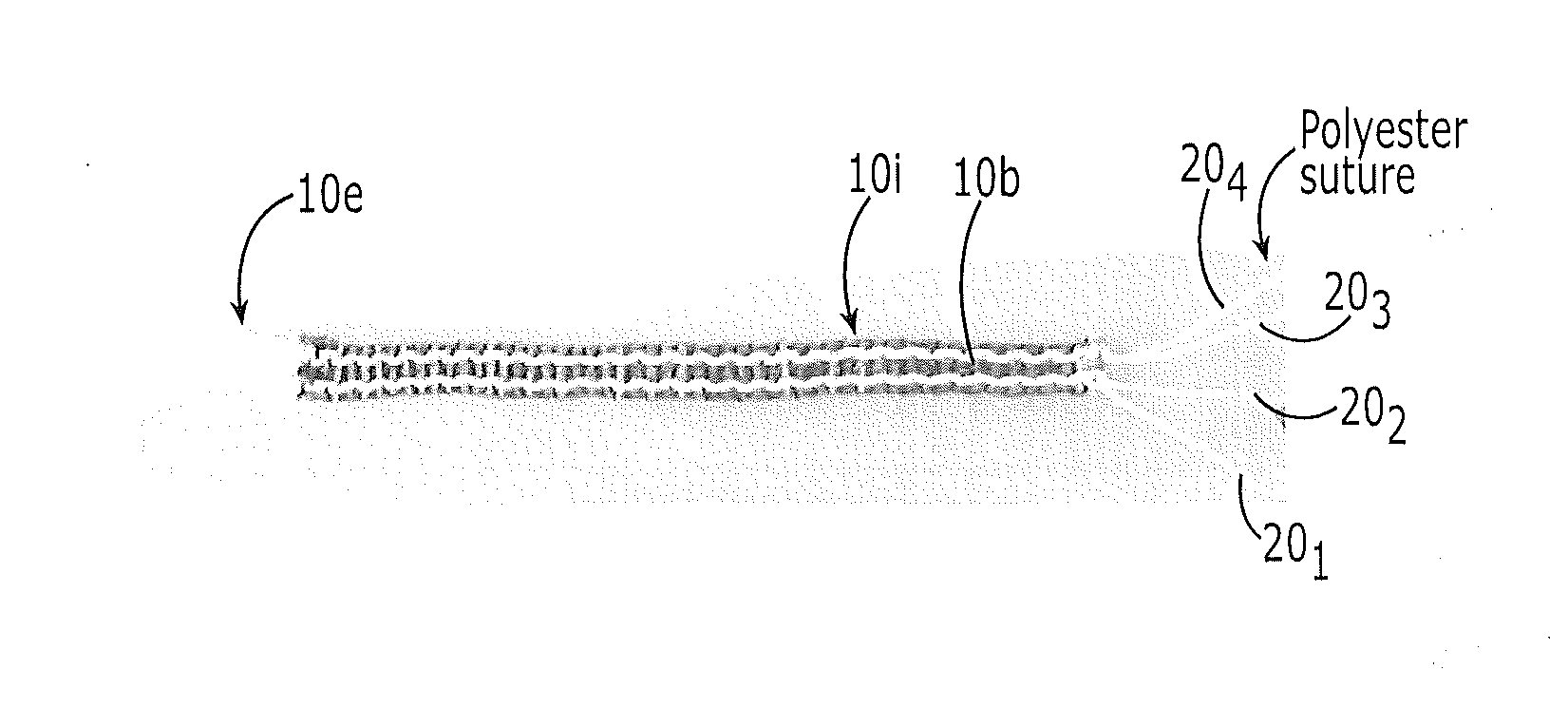

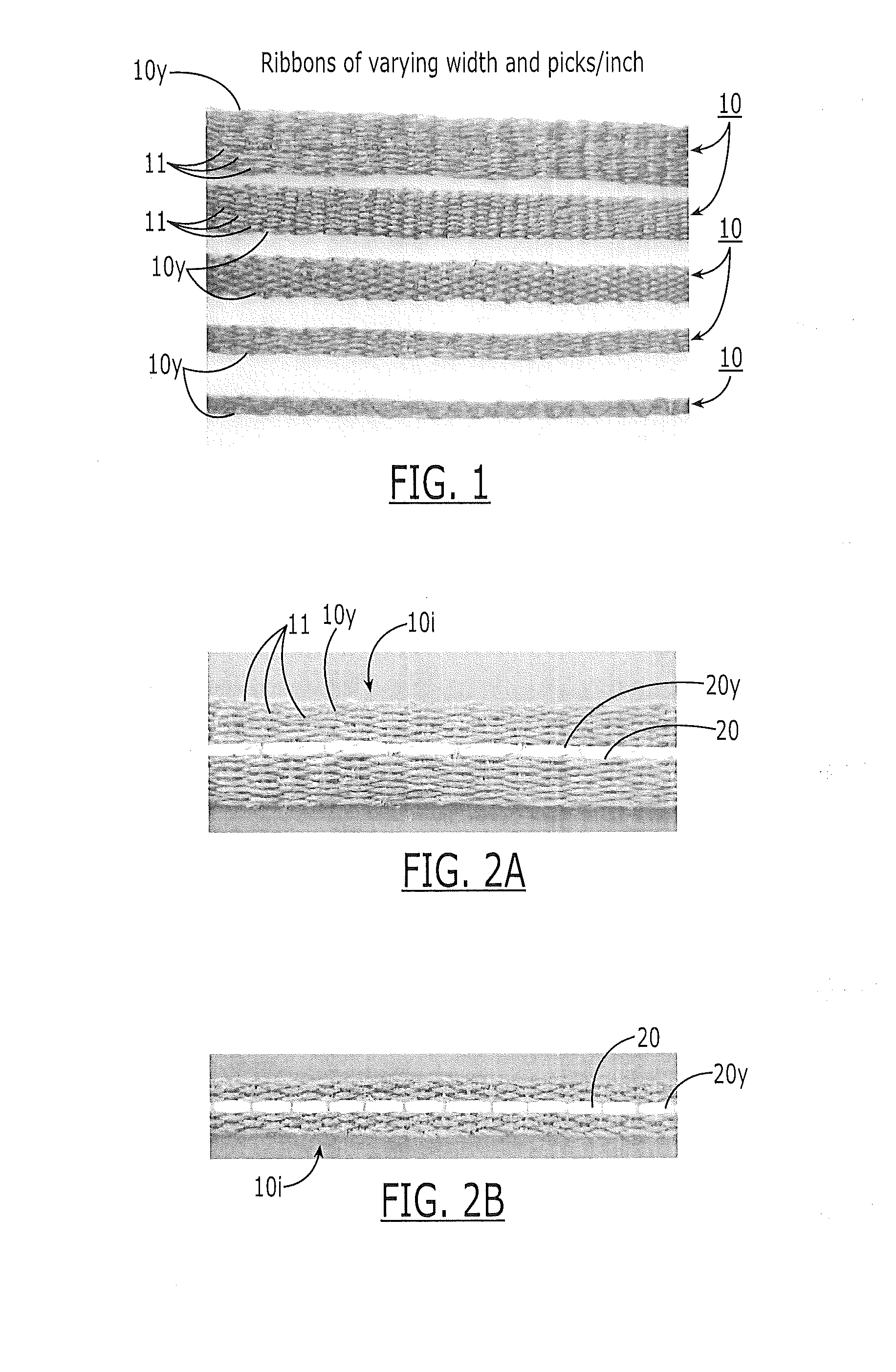

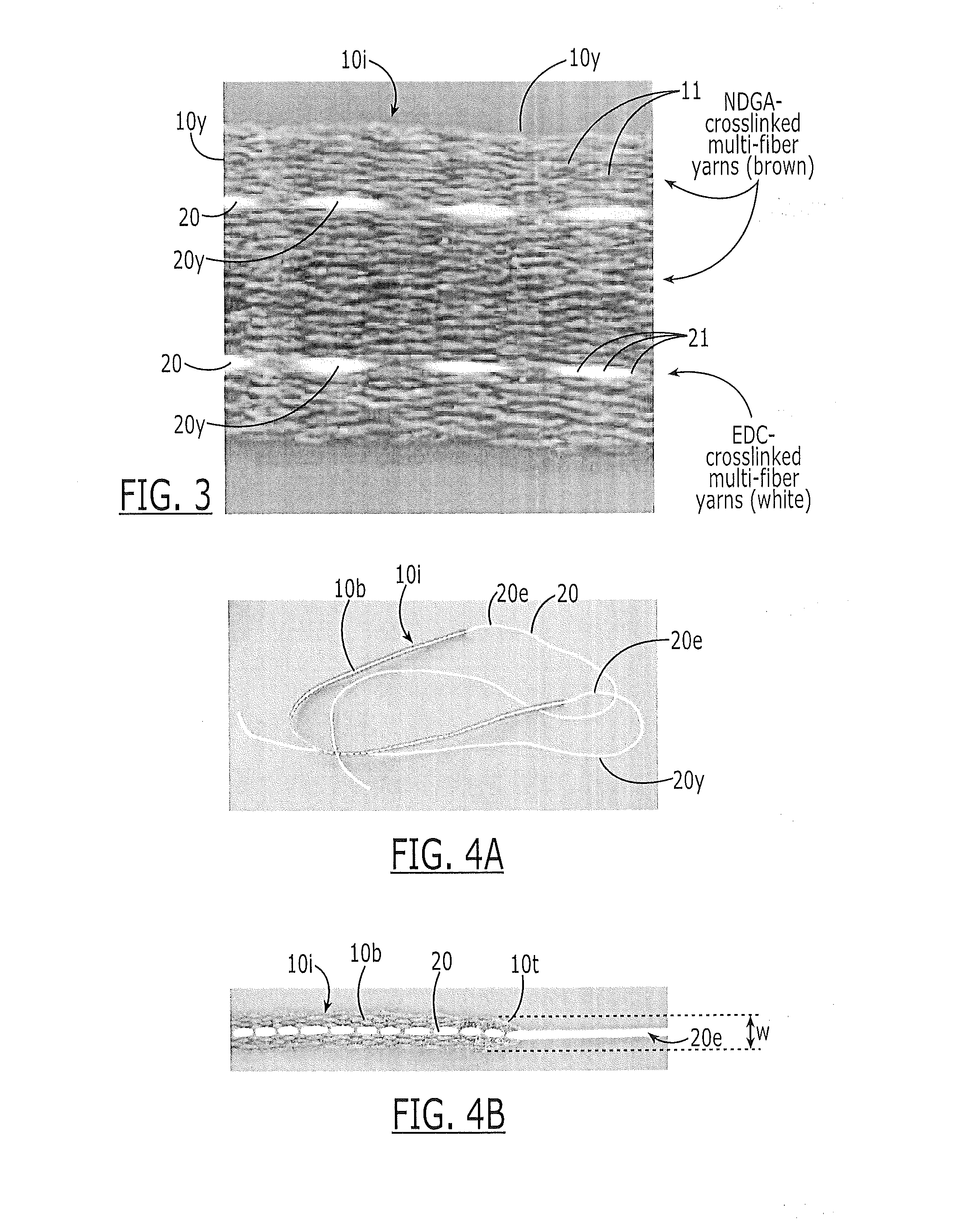

Collagen fiber ribbons with integrated fixation sutures and methods of making the same

ActiveUS20140172096A1Reduce probabilityDifferent fiber tensile strengthSuture equipmentsMonocomponent protein artificial filamentProsthesisCollagen fiber

Owner:MIMEDX GROUP

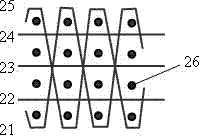

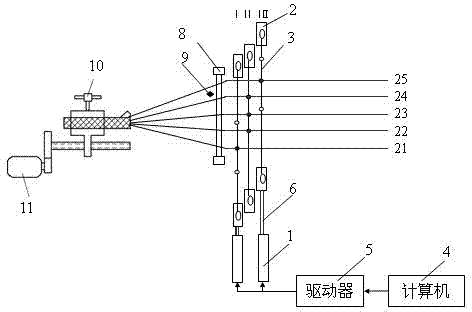

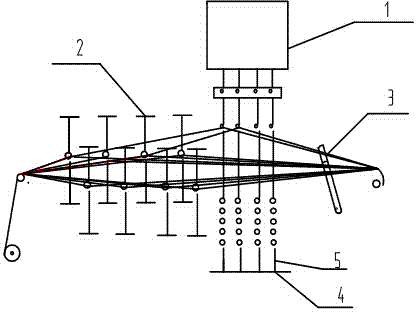

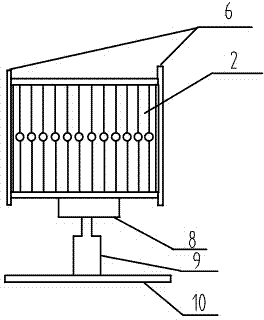

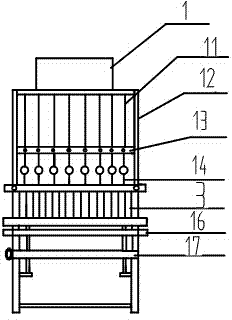

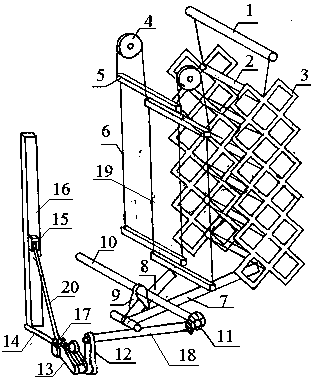

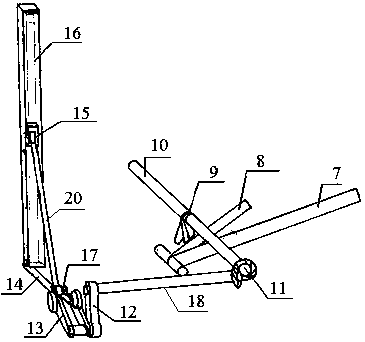

Opening device for stereo loom

InactiveCN102517741AReduce the number of pagesGood for weavingHealdsOther shedding mechanismYarnPalm fiber

The invention provides an opening device for a stereo loom. The opening device contains healed frames and is characterized in that at least one healed frame is connected with multi-hole palm fiber; at least one healed frame is connected with a push rod, which is connected with a servo electric cylinder; and the servo electric cylinder is connected with a driver, which is connected with a computer. By the adoption of the opening device, the number of heddles can be minimized and high-speed and digitalized control is carried out on the motion of the healed frames, thus greatly expanding types and specifications of fabrics and reducing abrasion of palm fiber to warp yarn.

Owner:DONGHUA UNIV

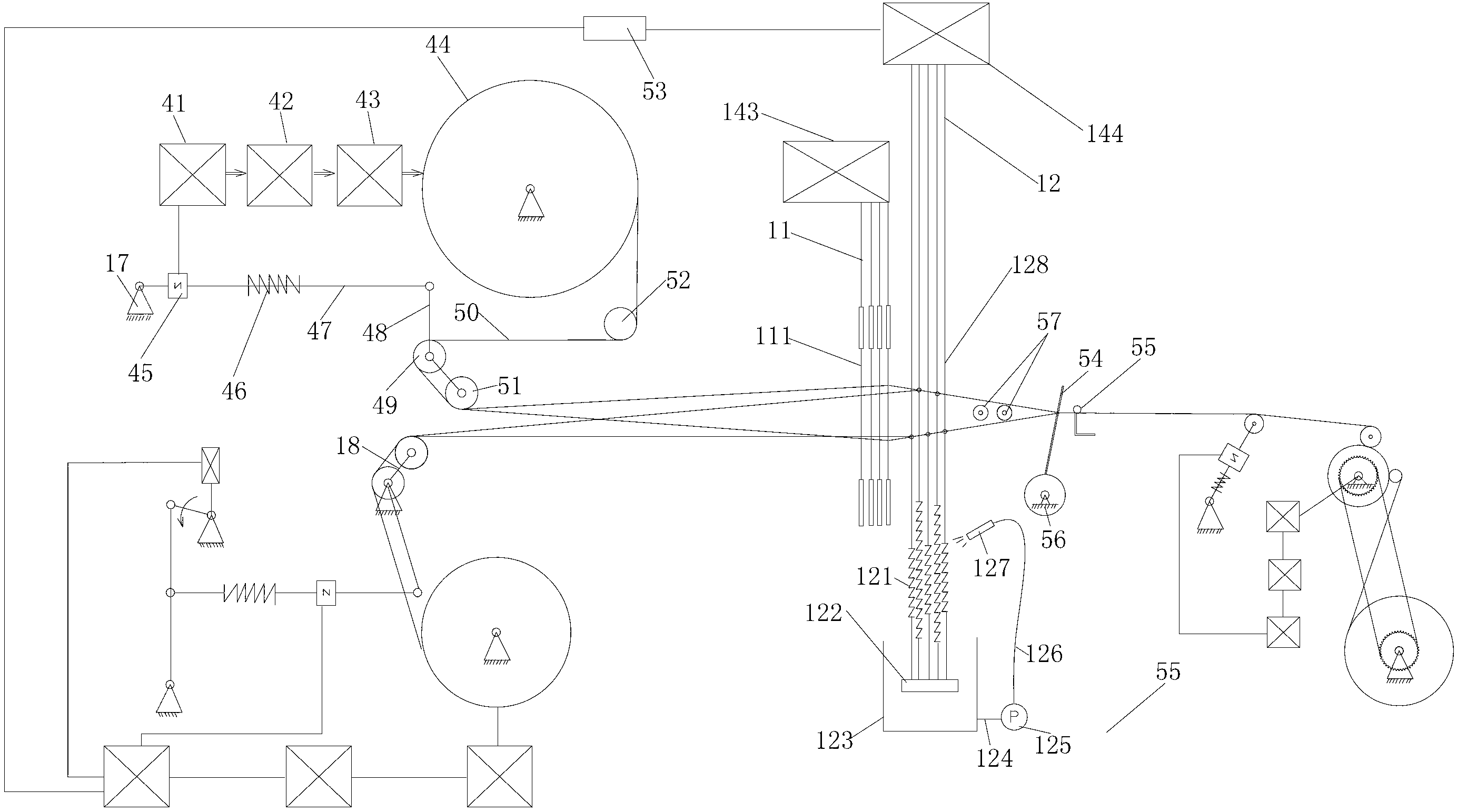

Double-let-off type composite shed water jet loom

InactiveCN103215733AGuaranteed stabilityAccurate and stable weft densityLoomsOther shedding mechanismVolumetric Mass DensityControl theory

The invention discloses a double-let-off type composite shed water jet loom, which comprises an active electronic let-off device, a passive electronic let-off device, a main shaft coder, a dobby, a jacquard machine, a reed, a shed stabilization device, a beating-up shaft, a nozzle and a passive take-up device. An active servo control system is actively adapted to the requirements of load variations of a shed according to pattern tissues, so that the stability of the shed is ensured; an active let-off take-up system is matched with a sensing device, so that responses to the requirements of tension variations of warps can be quickly made, positive compensation is realized, and the accuracy and the stability of weft density of cloth are ensured; due to the adoption of a composite shed time sequence difference manner, the problems of warp breakage and shed unclearness, which are caused by high warp density and excessive resistance, are solved; and beating-up stroke is improved, so that a shedding amount is reduced, the fluctuation range of the warps is narrowed, the warp breakage frequency is reduced, and the weaving efficiency and the quality of the cloth are effectively improved.

Owner:ZHEJIANG SANZHI TEXTILES +2

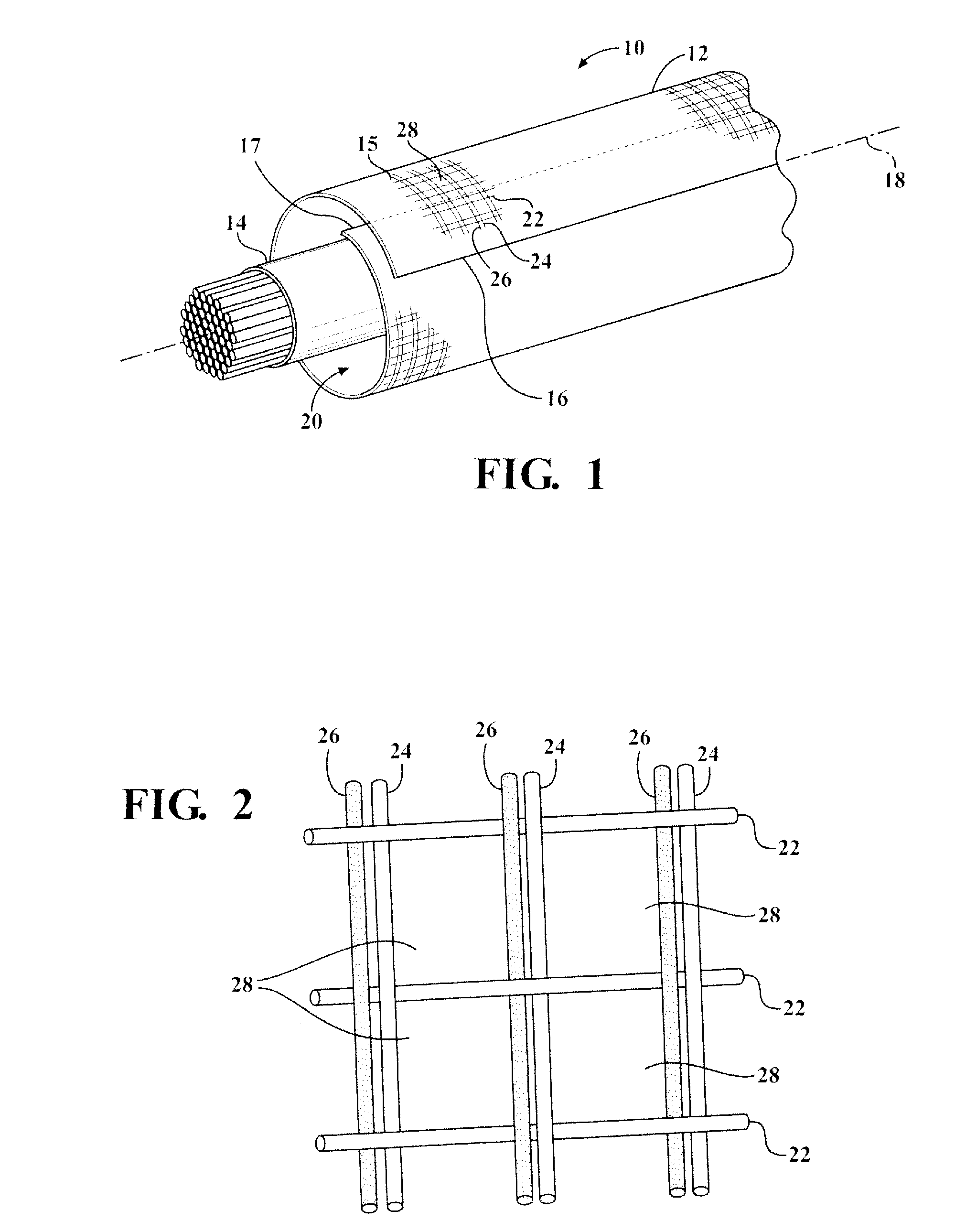

Flexible, abrasion resistant textile sleeve and method of construction thereof

ActiveUS8925592B2Large caliberEnhanced closing forceElectrical apparatusProtective fabricsYarnPliability

A textile sleeve for routing and protecting elongate members and method of construction thereof is provided. The sleeve includes an elongate wall having opposite edges extending parallel to a central axis of the sleeve. The wall is woven with warp yarns extending parallel to the axis and fill yarns extending transverse to the warp yarns. The warp yarns include monofilament yarns within an intermediate region of the wall and multifilament yarns within opposite edge regions of the wall to enhance abrasion resistance and curl, respectively, and the fill yarns include monofilament yarns larger in diameter than the fill monofilament yarns to provide further abrasion resistance, enhanced curl strength and multifilament yarns to provide increased coverage, maintain flexibility, and to maintain the warp monofilaments in their intended position.

Owner:FEDERAL MOGUL POWERTAIN LLC

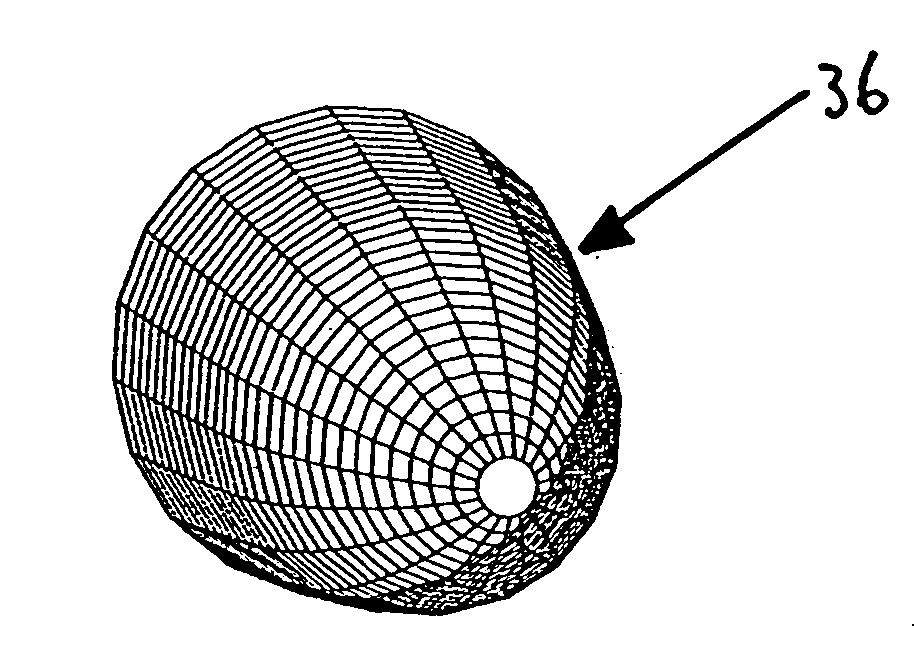

Fabricating symmetric and asymmetric shapes with off-axis reinforcement from symmetric preforms

Owner:ALBANY ENGINEERED COMPOSITES

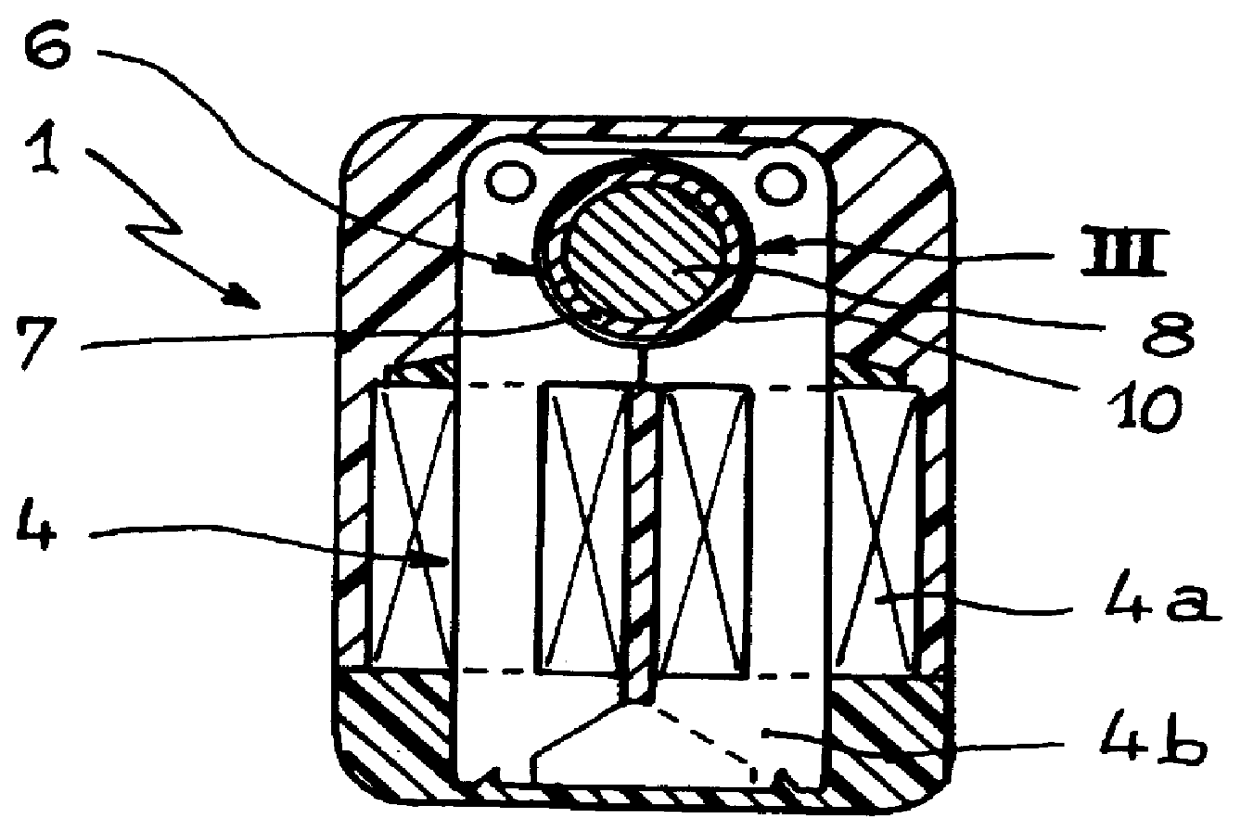

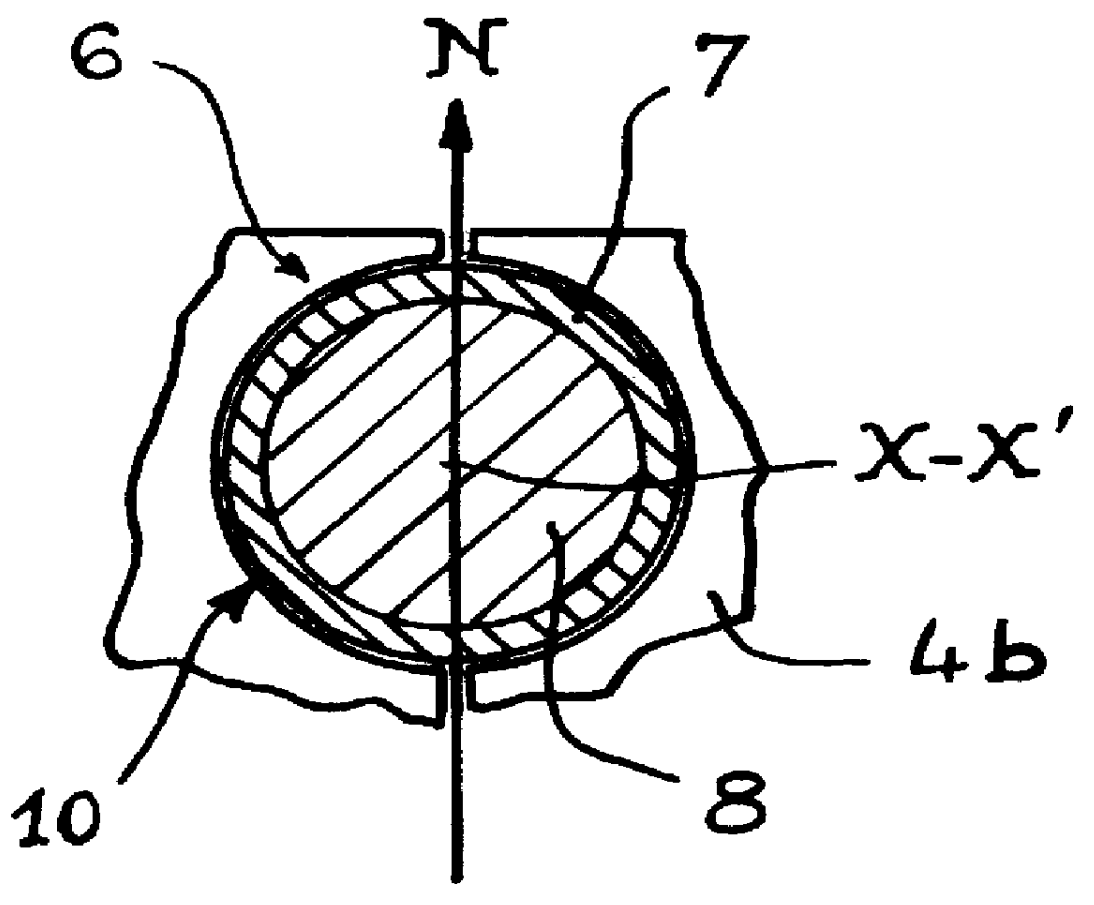

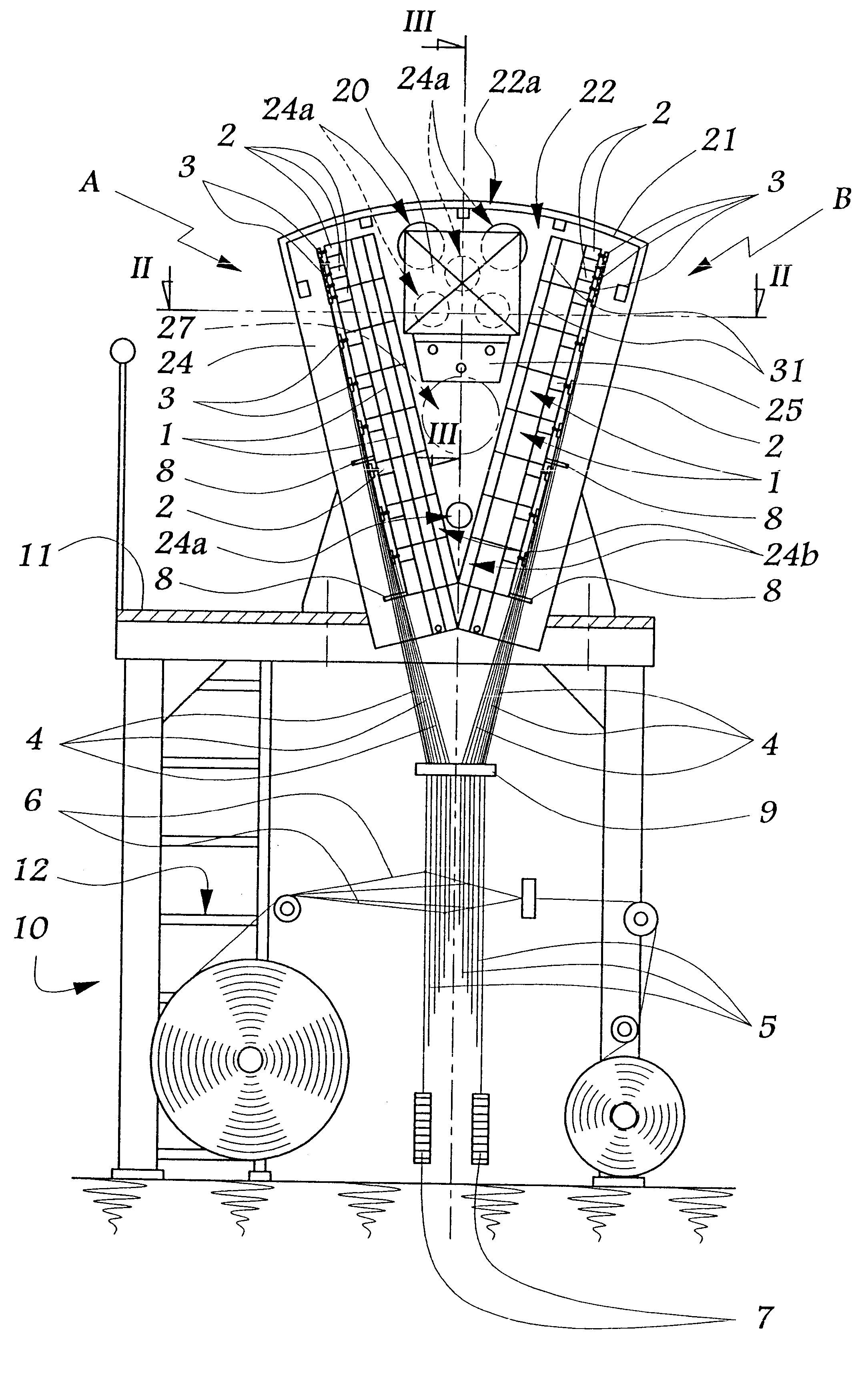

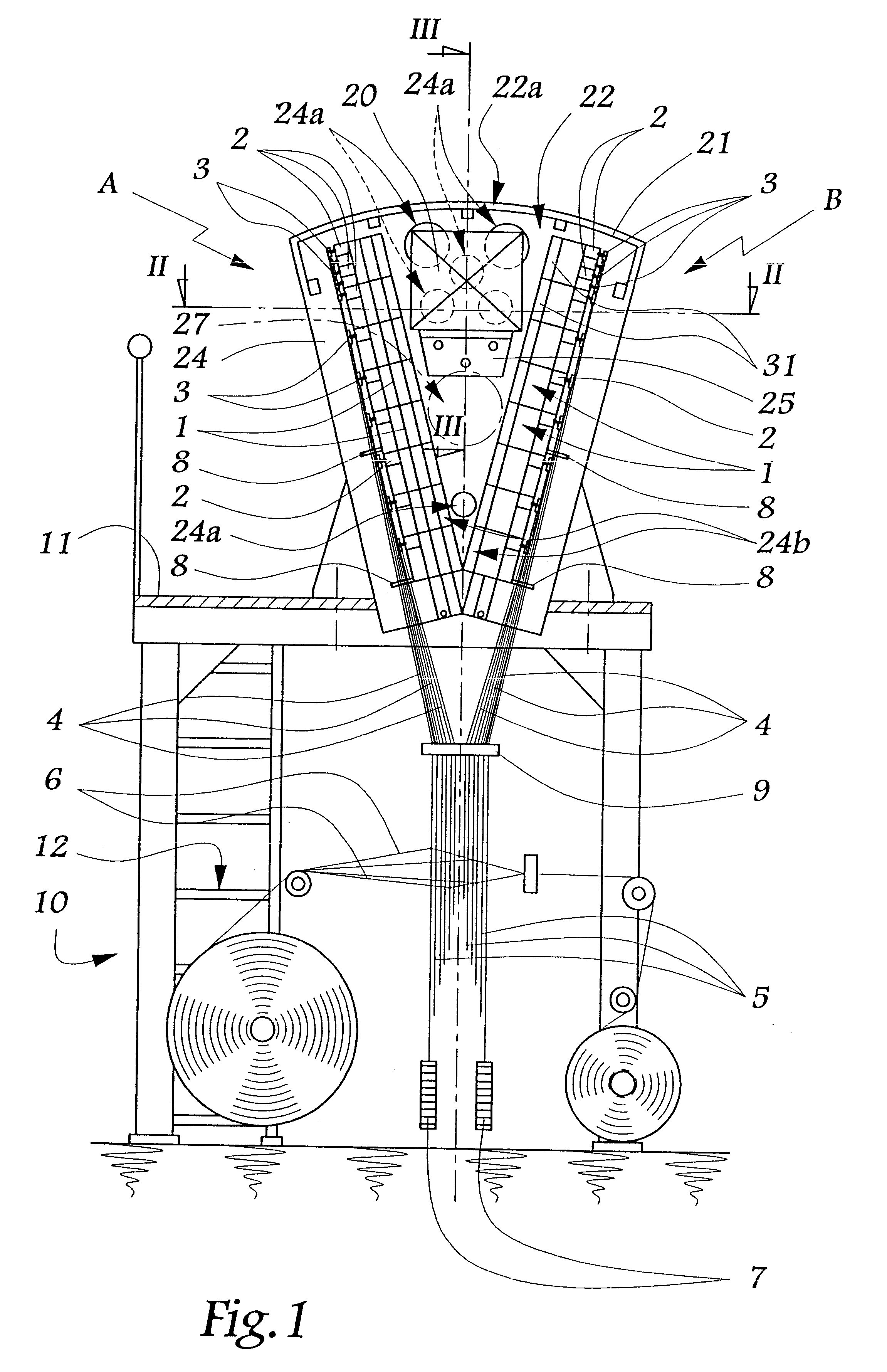

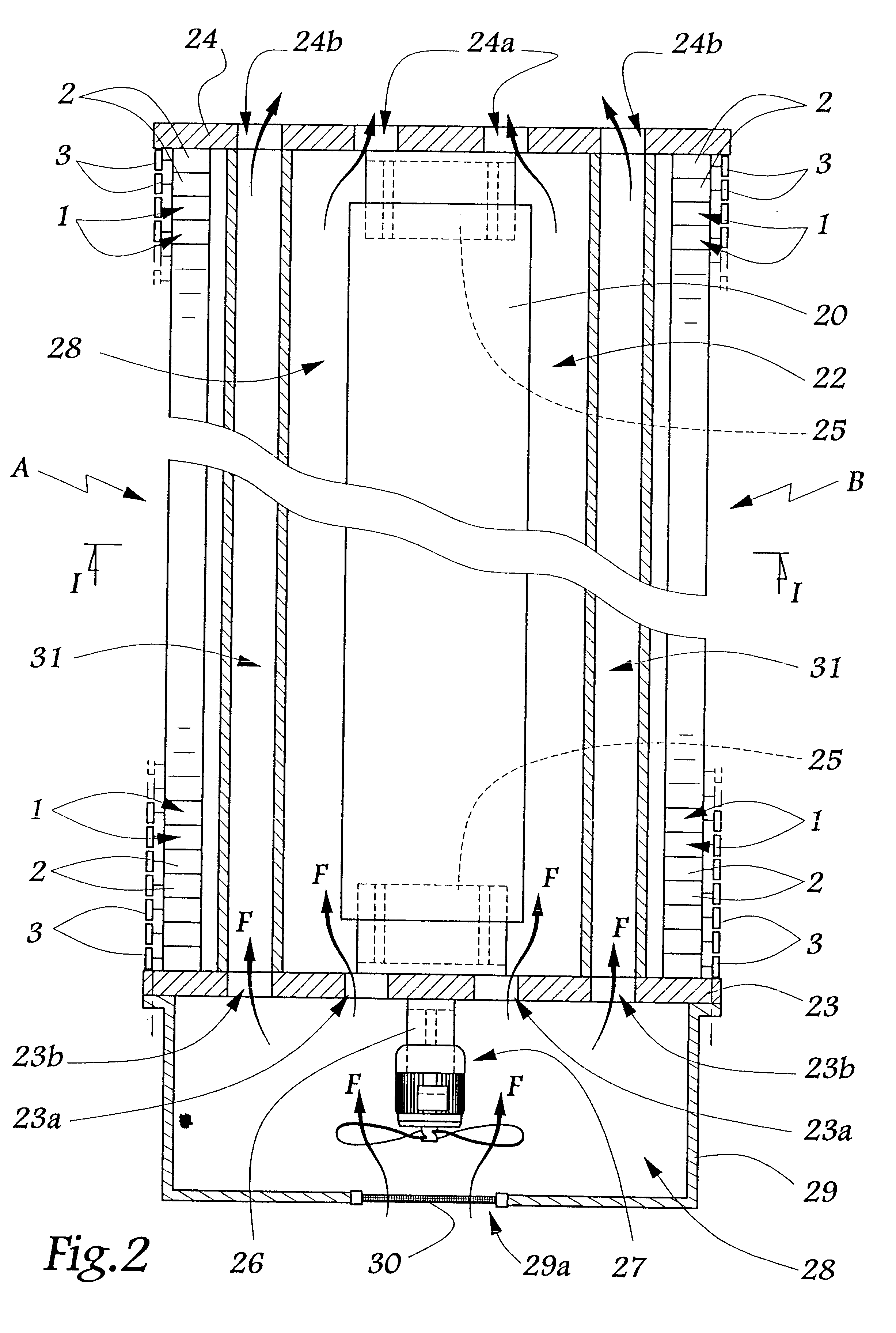

Electrical rotating actuator for forming a weaving loom shed

InactiveUS6105630AEasy to manufactureReduce the overall diameterJacquardsDobbiesElectrical polarityEngineering

An electrical rotating apparatus for controlling a harness cord associated with the shed of a weaving loom which includes an actuator including a rotor and a stator. The rotor is formed of at least two permanent magnets which are mounted within a tube so as to be spaced axially with respect to one another and wherein a plurality of stator elements are also provided offset axially relative to an axis of rotation of the rotor such that each of the plurality of rotors corresponds with a separate one of the plurality of stators. The polarities of one or the other of the permanent magnets or the stator elements are offset angularly relative to the axis of rotation.

Owner:STAUBLI FAVERGES SA

Stretchable fabric

First warp yarns and second warp yarns are each interwoven with weft yarns to produce a one-layer, lightweight, stretchable fabric. The first warp yarns include stretchable yarns that are activatable to achieve a contracted state, and the second warp yarns include non-stretchable yarns. The first warp yarns may include a stretchable core yarn with non-stretchable wrap yarn wrapped around the stretchable core yarn. The first warp yarns may be in an alternating arrangement with the second warp yarns. When the yarns are woven together, the first warp yarns are in an extended state and the second warp yarns are in an unbunched state. The fabric then undergoes a finishing procedure during which the first warp yarns are activated to achieve a contracted state. The second warp yarns thus achieve a bunched state, and the resulting fabric is stretchable in the warp direction.

Owner:JB MARTIN

Low-vibration shedding system

InactiveUS20050051228A1Good oscillation absorptionImprove axial rigidityWeft knittingDobbiesCouplingEngineering

A novel rod linkage for driving a heddle shaft includes at least one strap (16), which for damping oscillation has a sandwich structure (37) oriented in the longitudinal direction (L) of the strap assembly (16). The sandwich structure includes at least one rigid element (27), extending in the longitudinal direction, which is joined to one end (17) of the strap assembly (16); a second rigid element (31), likewise extending essentially in the longitudinal direction, which is joined to the other end (19); and a two-dimensional damping element (34), again extending in the longitudinal direction, disposed between the first two. The element (34) exclusively effects the mechanical connection of the two parts (16a, 16b) of the strap assembly (16). Preferably, no additional connecting elements, such as rivets, screws, or other rigid connections, between the rigid elements (27, 31) are provided. Preferably, the rigid elements (27, 31) are embodied as wedges pointing in opposite directions, which thus define a wave resistance that varies in opposite directions in the longitudinal direction. This wave resistance brings about an intentional coupling misadaptation with respect to the oscillation transmission. The element (34) disposed between them damps the oscillations additionally, so that the strap assembly (16) transmits driving motions like a filter and destroys or absorbs interfering oscillations.

Owner:GROZ BECKERT KG

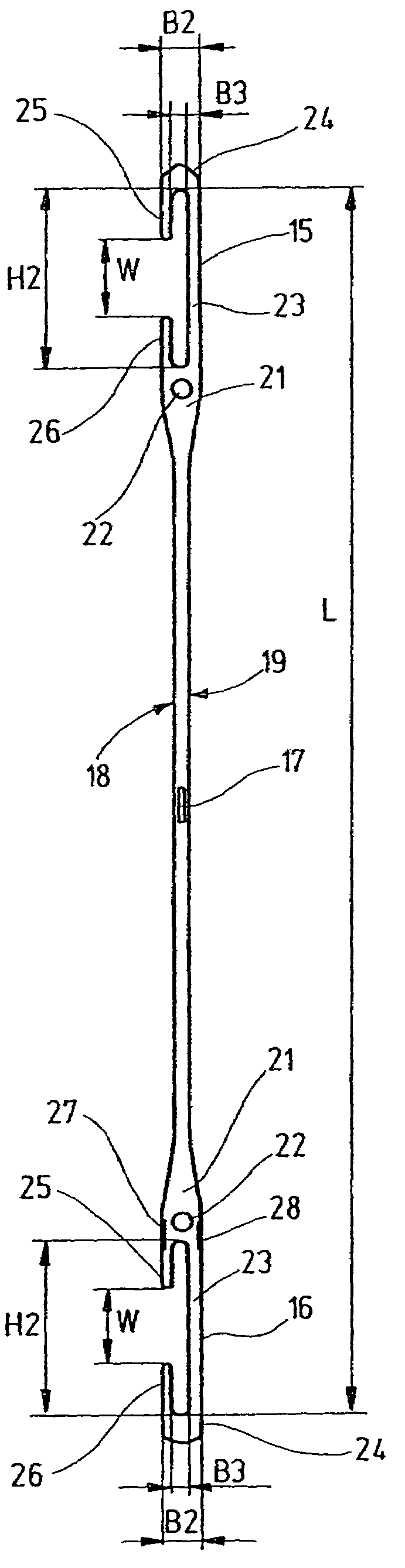

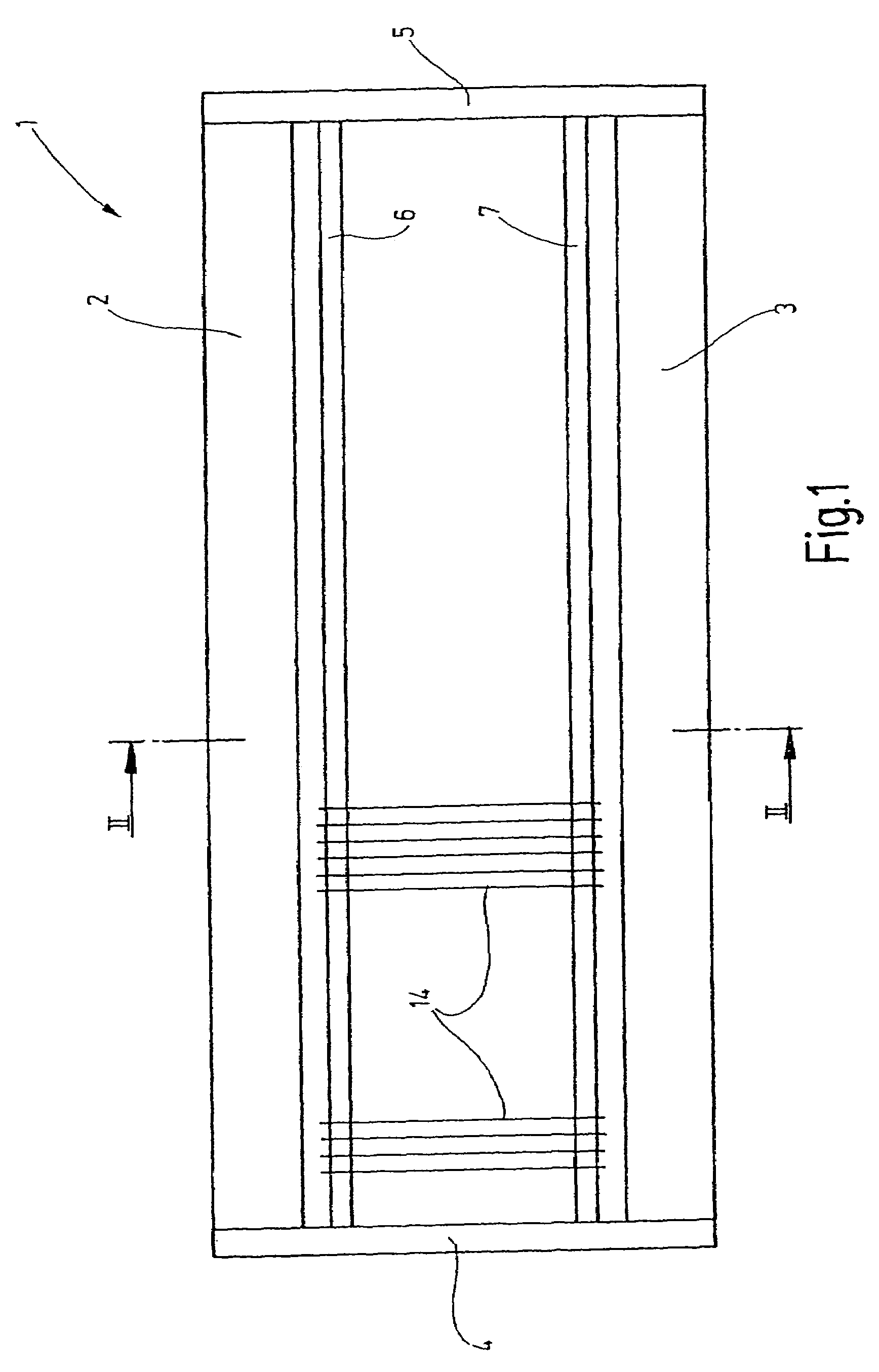

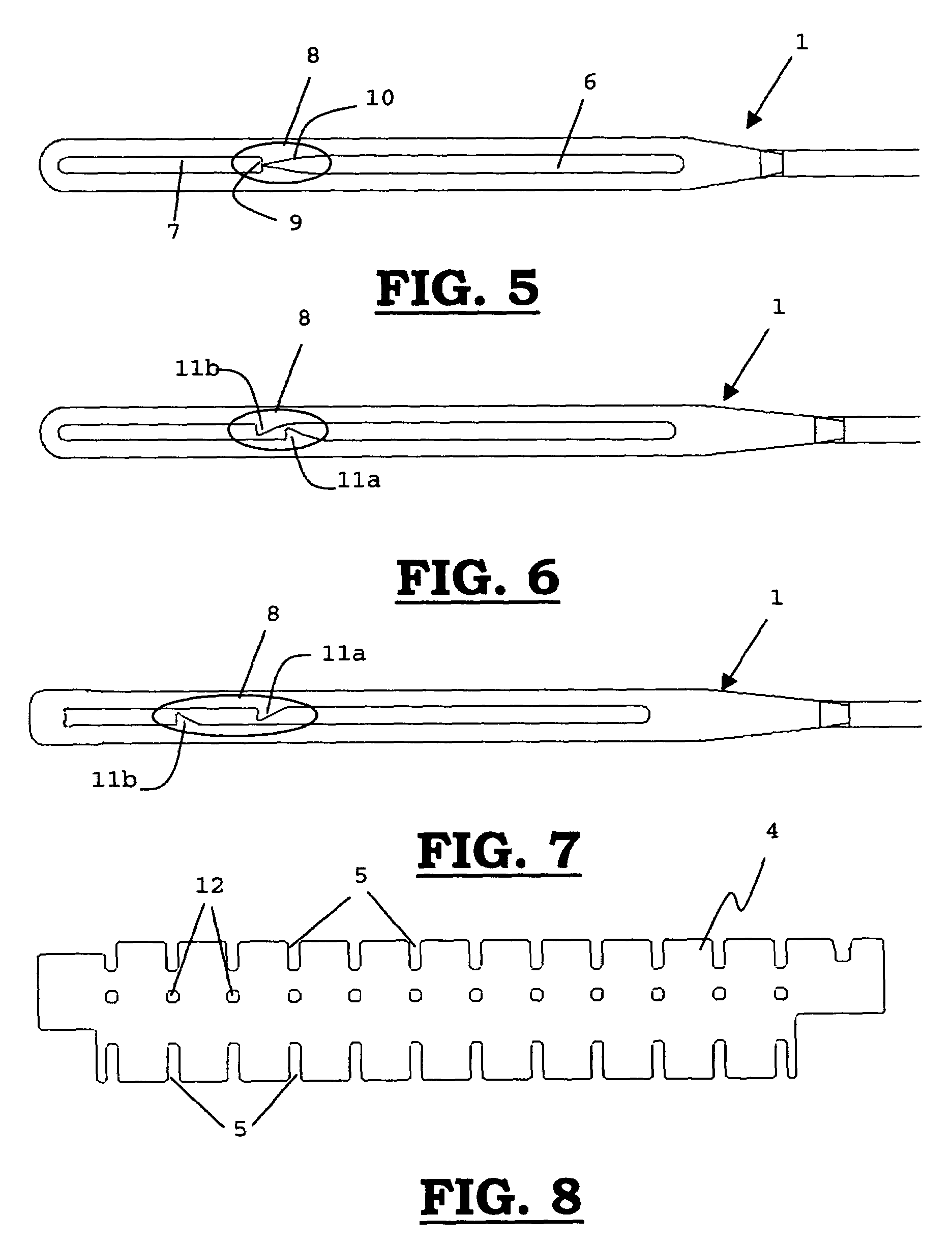

Heddle with reduced play

A heddle (14) of the invention is distinguished by end eyelets (15, 16) of reduced size, with which heddle support rails (6, 7) of reduced cross section are associated. The axial play of the heddles on the heddle support rails (6, 7) is limited to from 0.5 mm to 1.5 mm. The lateral play is in the range of 0.2 mm to 0.5 mm. This system formed of heddle support rails and heddles is especially suitable for particularly rigid heddle shafts for power looms with an extremely high operating speed.

Owner:GROZ BECKERT KG

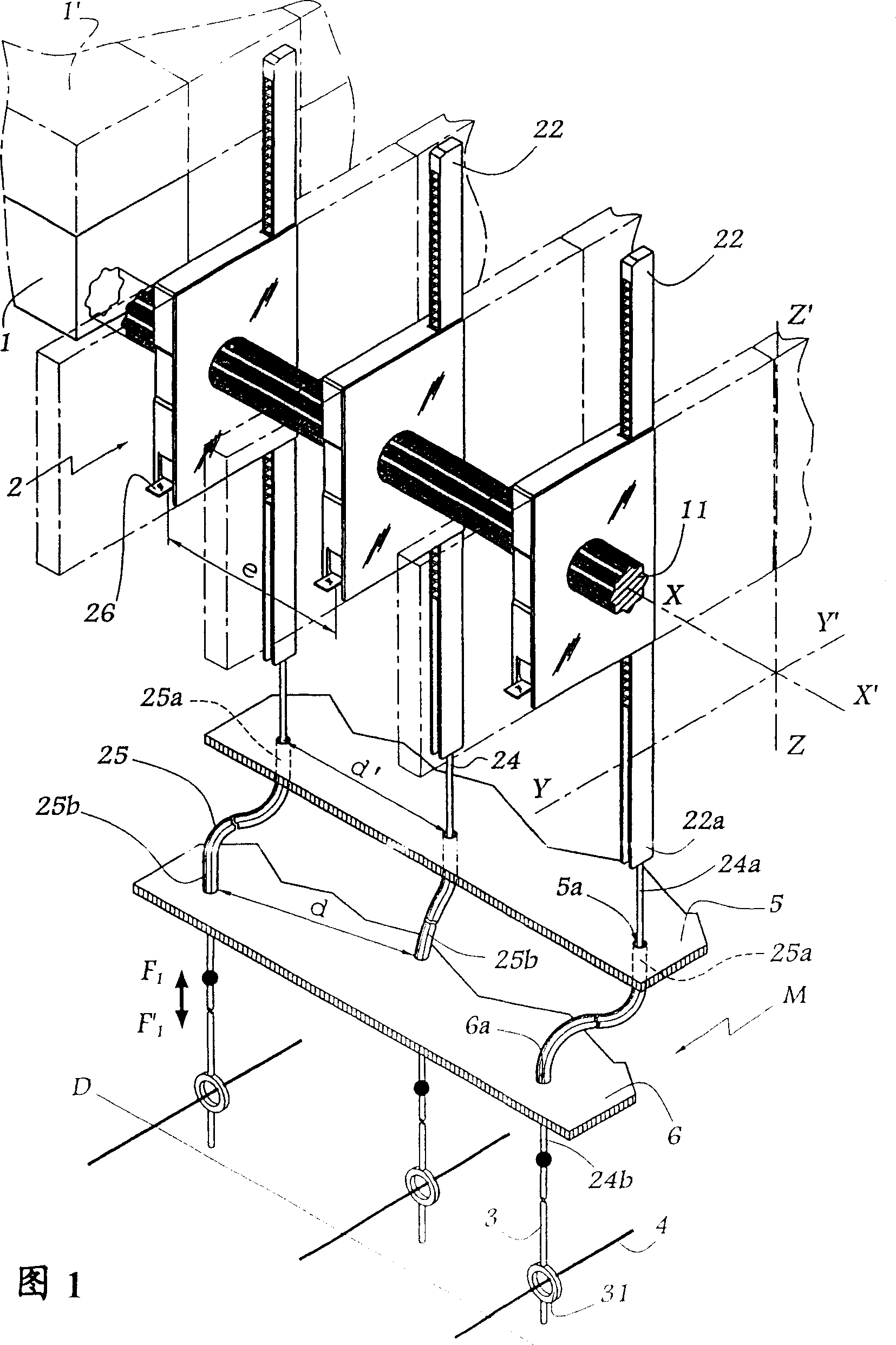

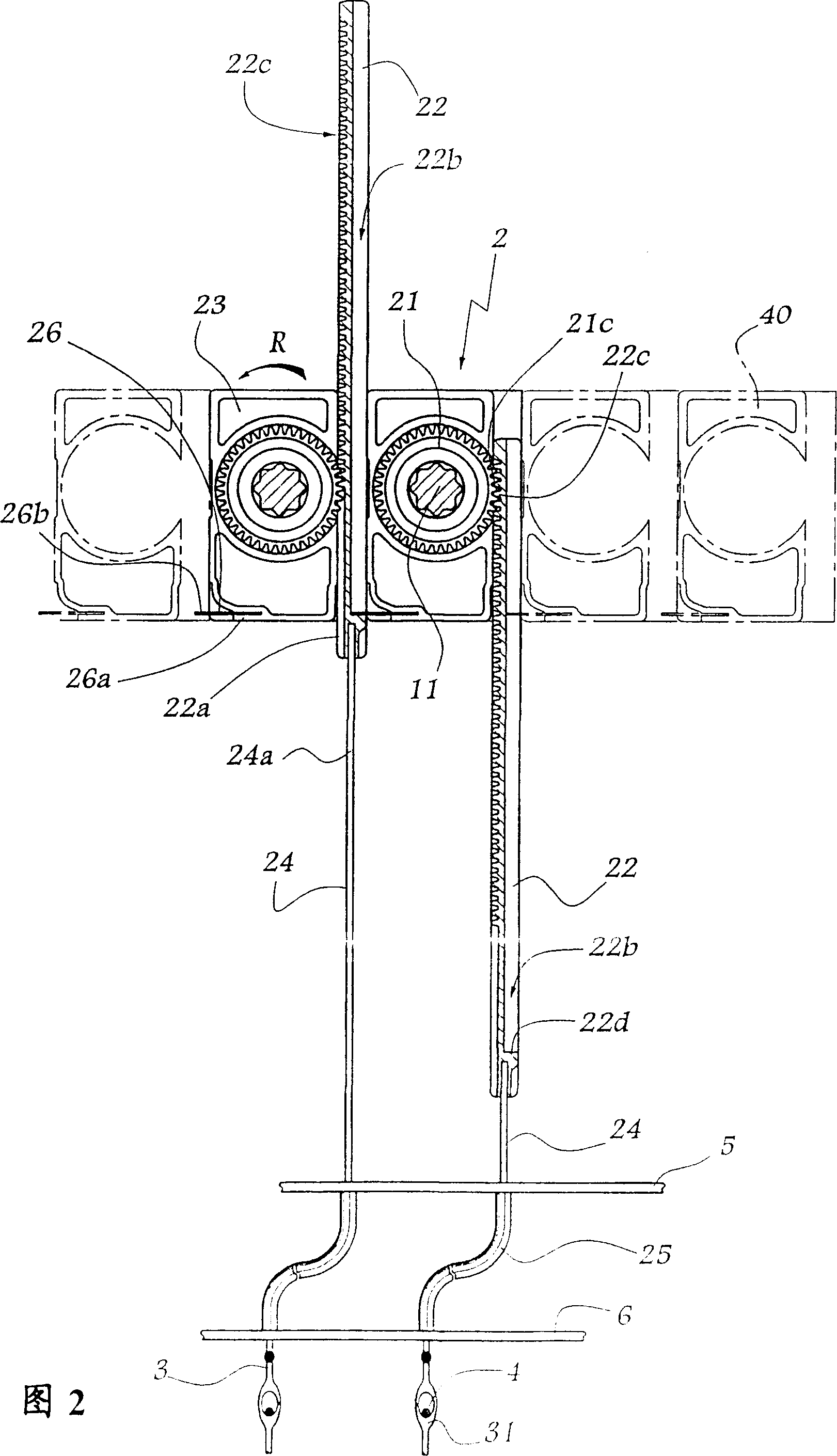

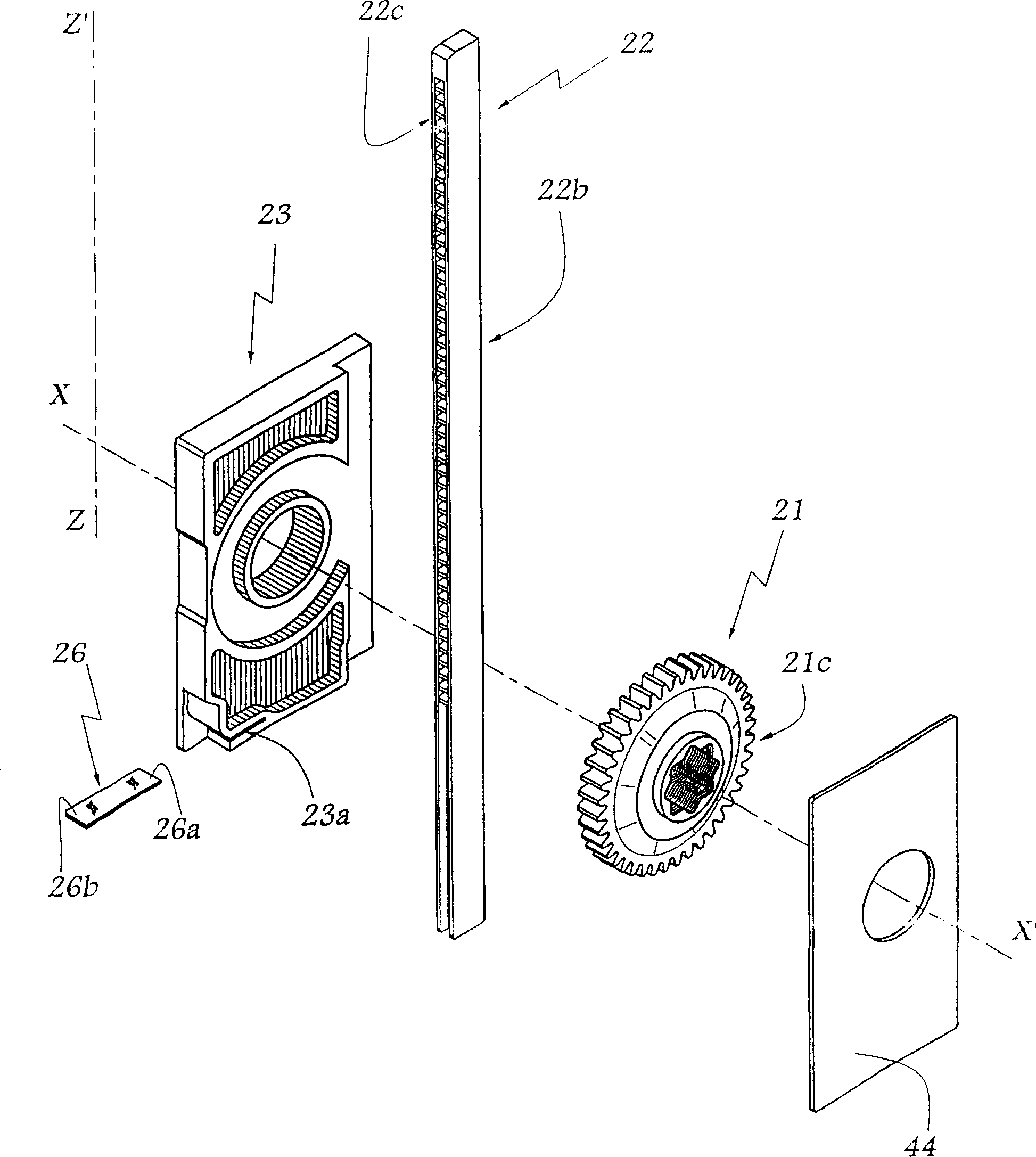

Device for forming shed in weaving loom of jacquard type

InactiveCN1520475ASave spaceAlignment is quick and accurateJacquardsOther shedding mechanismEngineeringRotary actuator

The invention relates to a shedding device comprising at least one electric rotary actuator having an output shaft ( 11 ) that is designed to rotate a pinion ( 21 ) which is engaged with a rack ( 22 ), said rack being connected to a control heald ( 3 ) of a warp end ( 4 ) by means of a load transfer element ( 24 ).

Owner:施托布利里昂公司

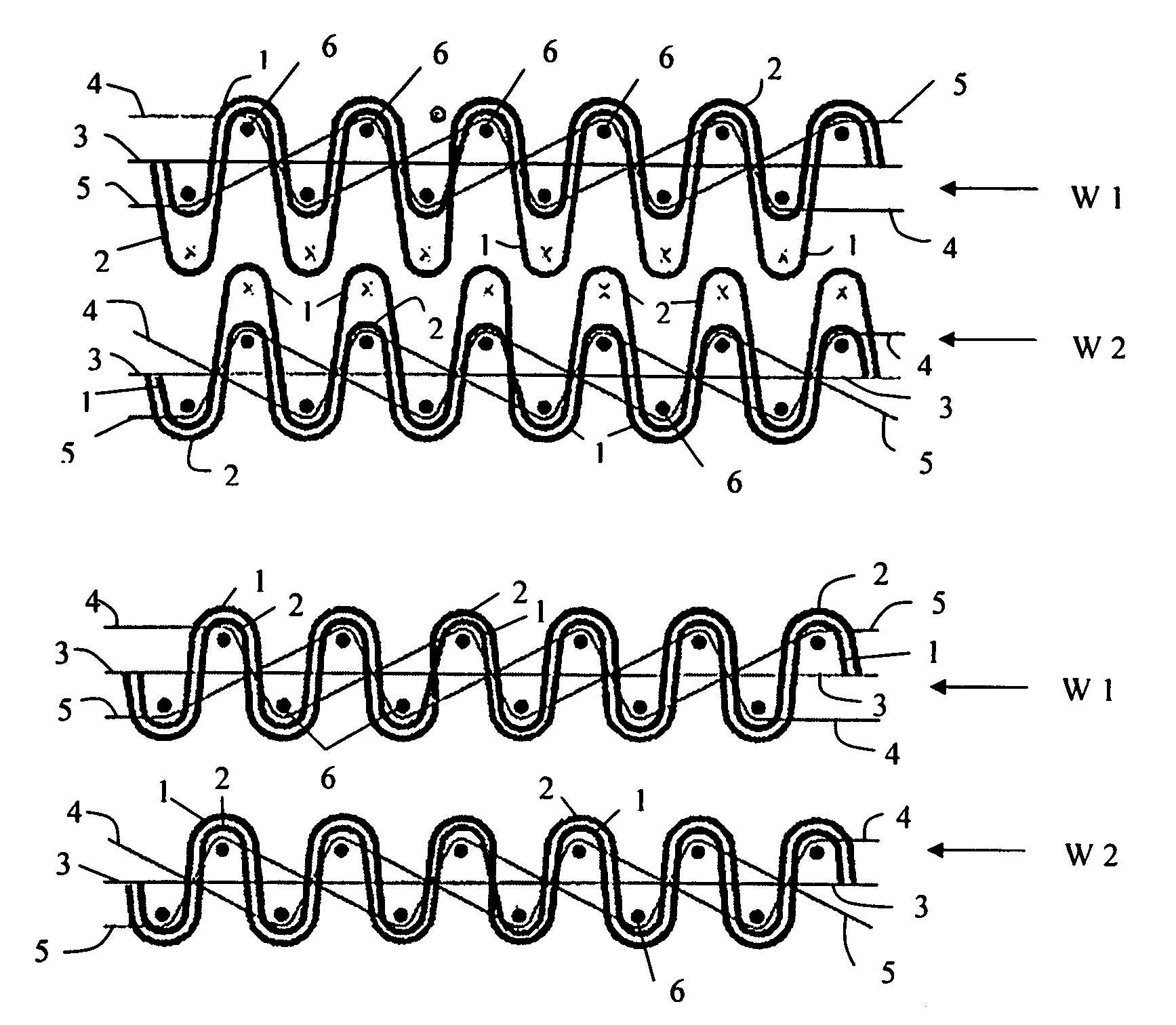

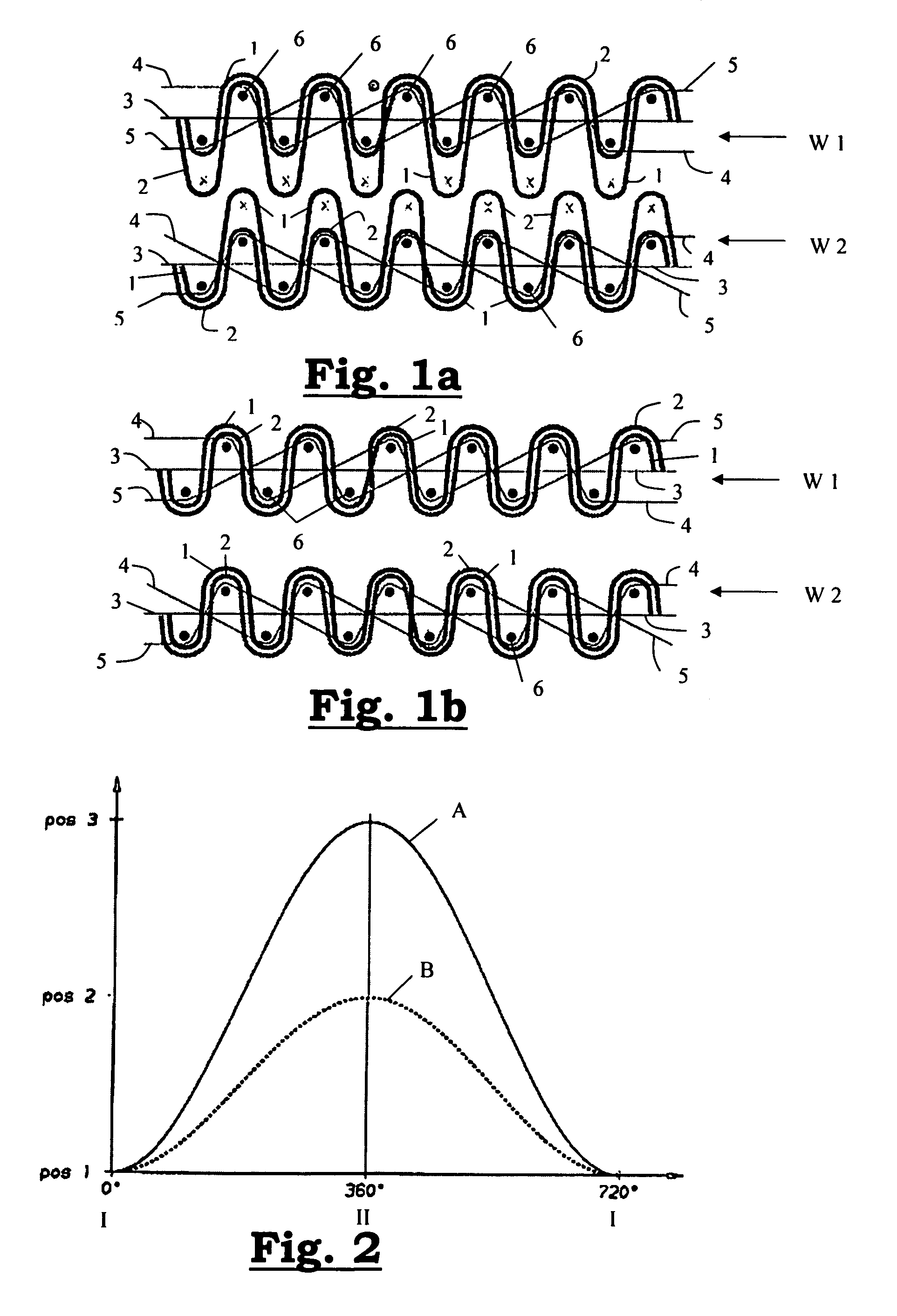

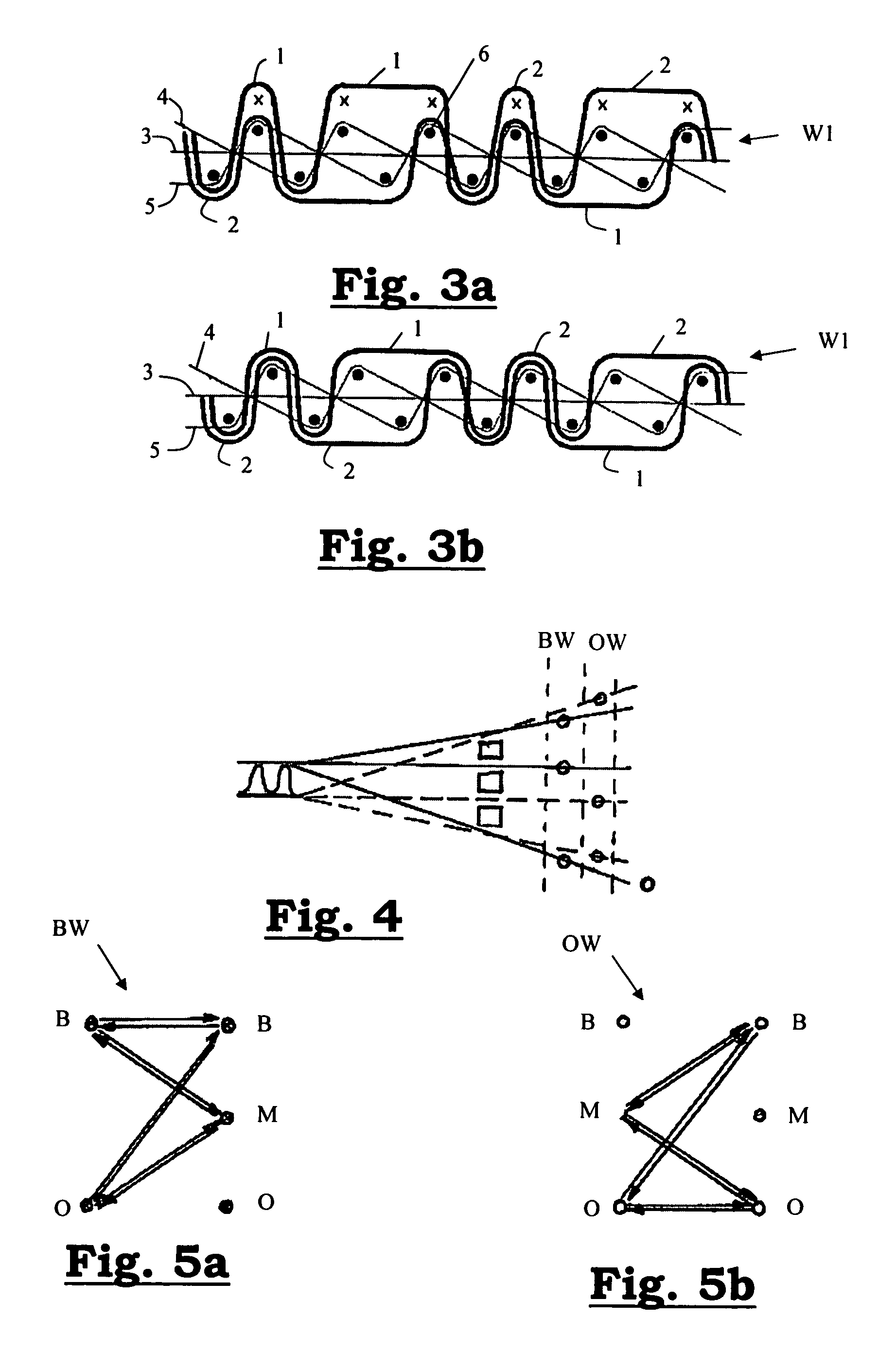

Method and system for weaving fabrics with two useable sides

This invention relates to a method and to a system for weaving fabrics with two useable sides (W1), (W2), in which per operating cycle one weft thread (6) is inserted, and in which each fabric comprises a first figure warp thread (1) and a second figure warp thread (2) that, in a number of operating cycles, are positioned together alternately above and below the weft insertion level, so that, at both fabric sides, these figure warp threads (1), (2) are bound over the same weft threads (6), while running above one another, and in which the mutual position (upper or lower position) taken up by the first figure warp thread (1) and the second figure warp thread (2) in each fabric (W1), (W2) during the weaving process is determined selectively according to a previously defined figure pattern, preferably by positioning the first (1) and second figure warp threads (2) in a first shed (I) at a first level (POS. 1) at one side of the weft insertion level and in a second shed (II), selectively on a different second level (POS. 2) and third level (POS. 3), at the other side of the weft insertion level. The invention also relates to fabrics (W1), (W2) woven according to such method.

Owner:VAN DE WIELE MICHEL

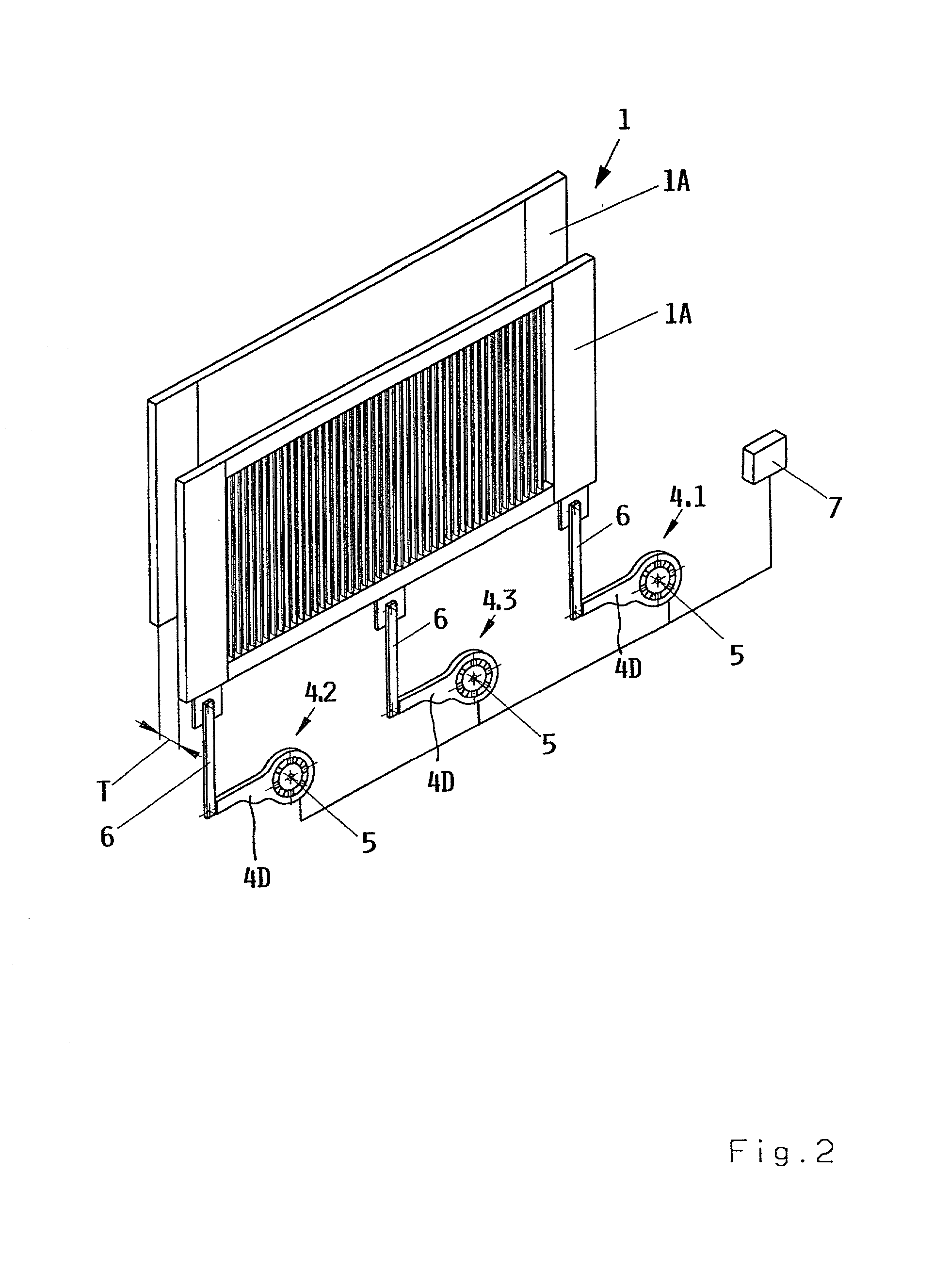

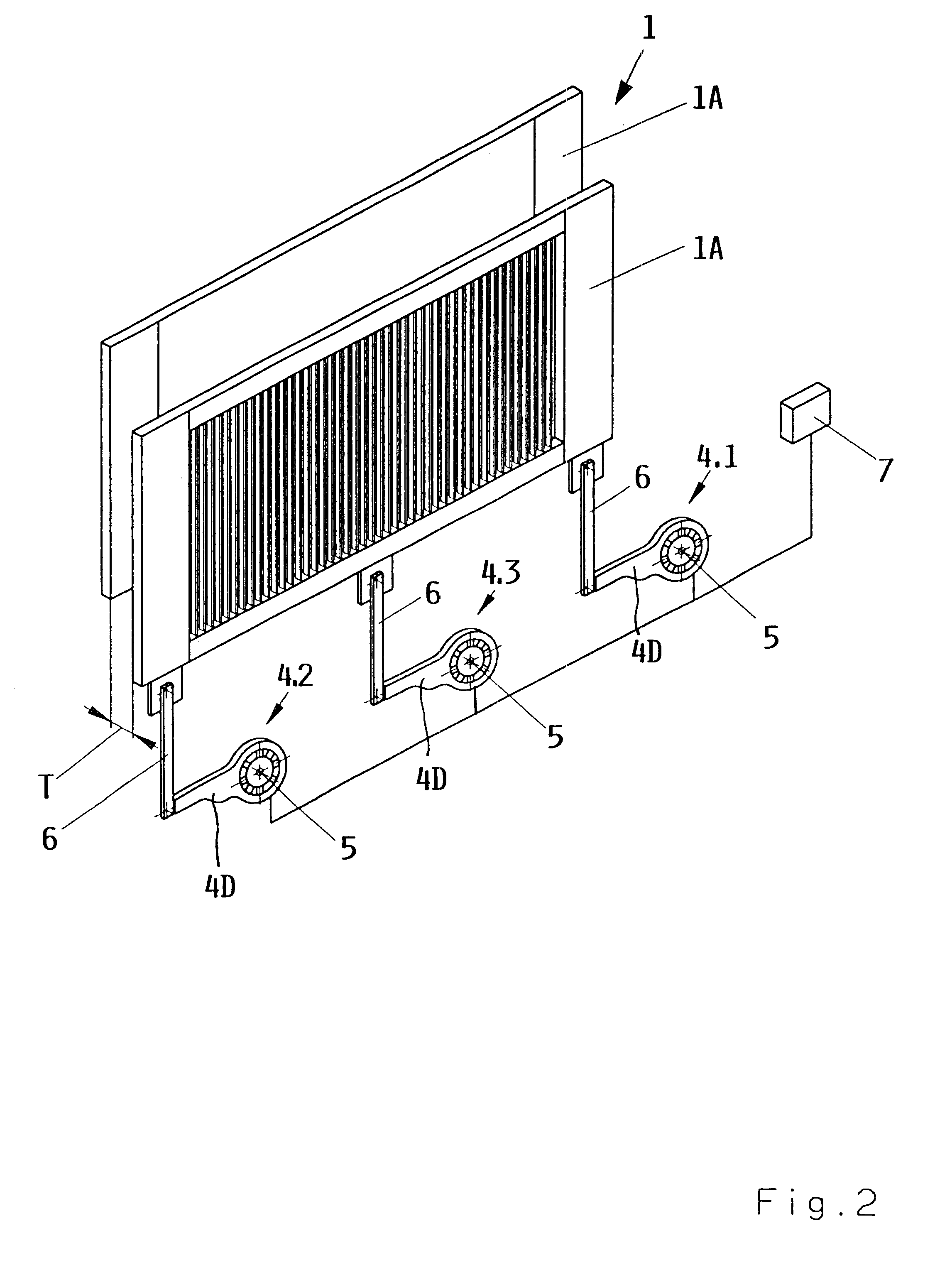

Weaving loom panel support structure for jacquard selectors

A loom and a weaving mechanism of the Jacquard type for forming the shed in the loom wherein the weaving mechanism is associated with a harness including harness cords secured to heddles. The harness cords are controlled by electric actuators mounted to two panels extending above the heddles and between which a compartment is formed in which a control unit for supplying and monitoring the operation of the actuators is housed.

Owner:STAUBLI FAVERGES SA

Method and device for detecting jacquard shed anomalies

InactiveUS6357486B2Reduce operating costsQuick and accurate identificationJacquardsLoomsYarnEngineering

In a weaving loom of the Jacquard type comprising electrical actuators for displacing heddles controlling the position of the warp yarns, the following steps are carried out:a so-called "normal effort" is determined, exerted by at least one actuator on at least one harness cord in order to displace, between two positions of its normal stroke, at least one heddle connected to a normally taut warp yam;from this normal effort, at least one threshold value representative of a limit of a range of values of normal weaving effort is determined;while the loom is in operation, a so-called "operational effort" exerted by this actuator on the harness cord is determined;at least one value representative of this operational effort is compared with the threshold value, anda first, so-called "anomaly signal" is generated when the value representative of the operational effort is outside the afore-mentioned range.The device comprises a logic unit incorporating a comparator and associated with a memory and a display means.

Owner:STAUBLI FAVERGES SA

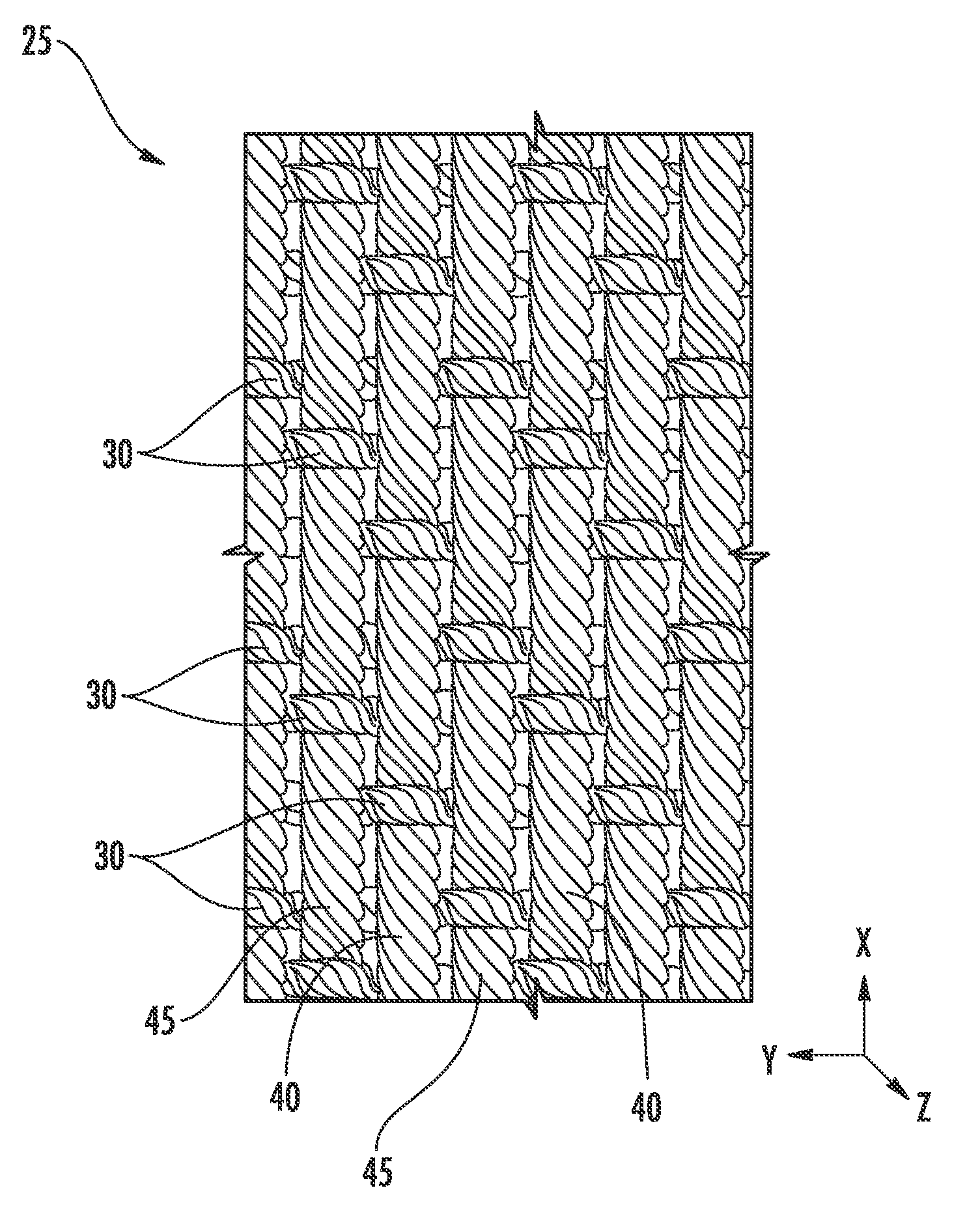

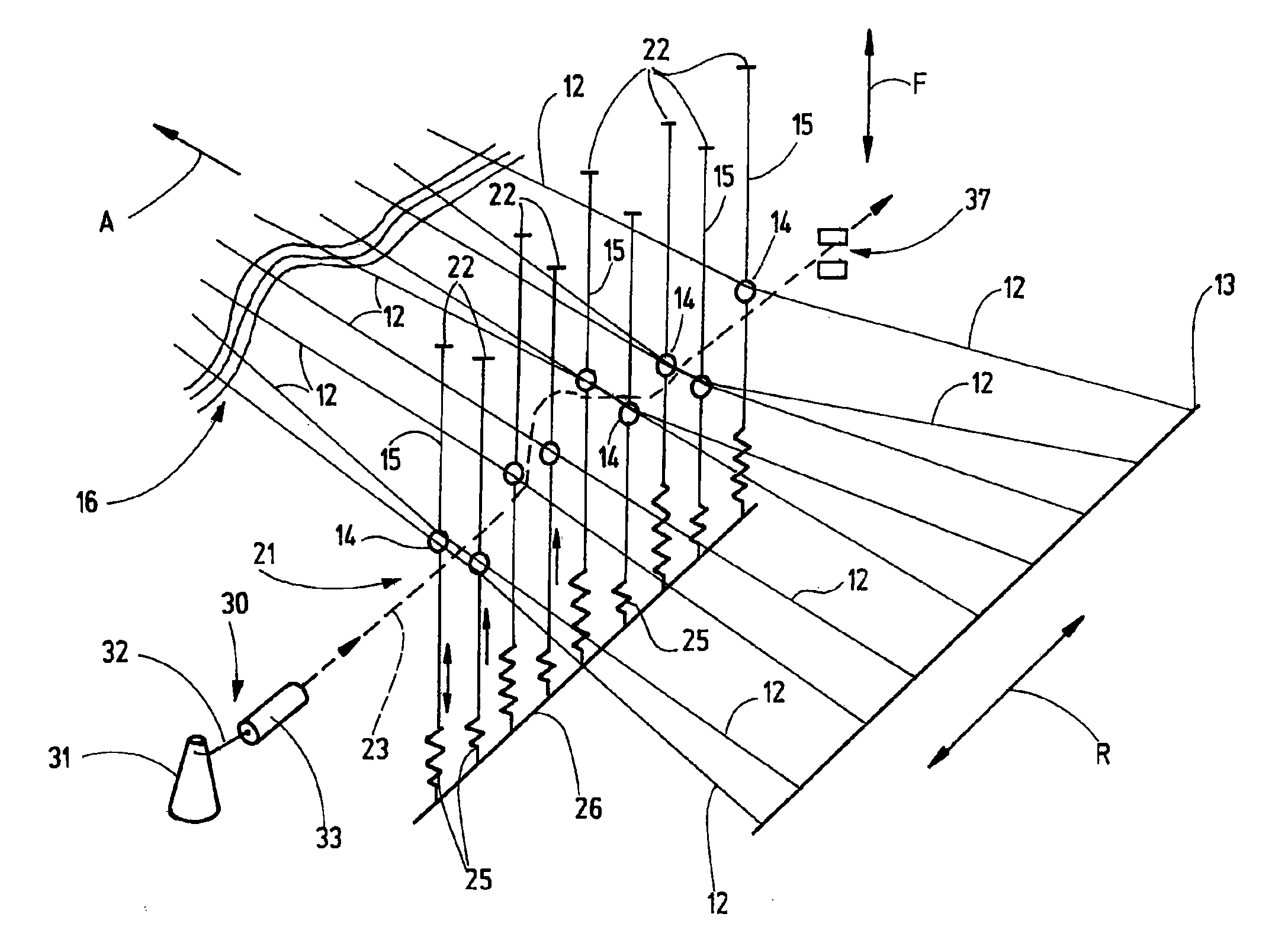

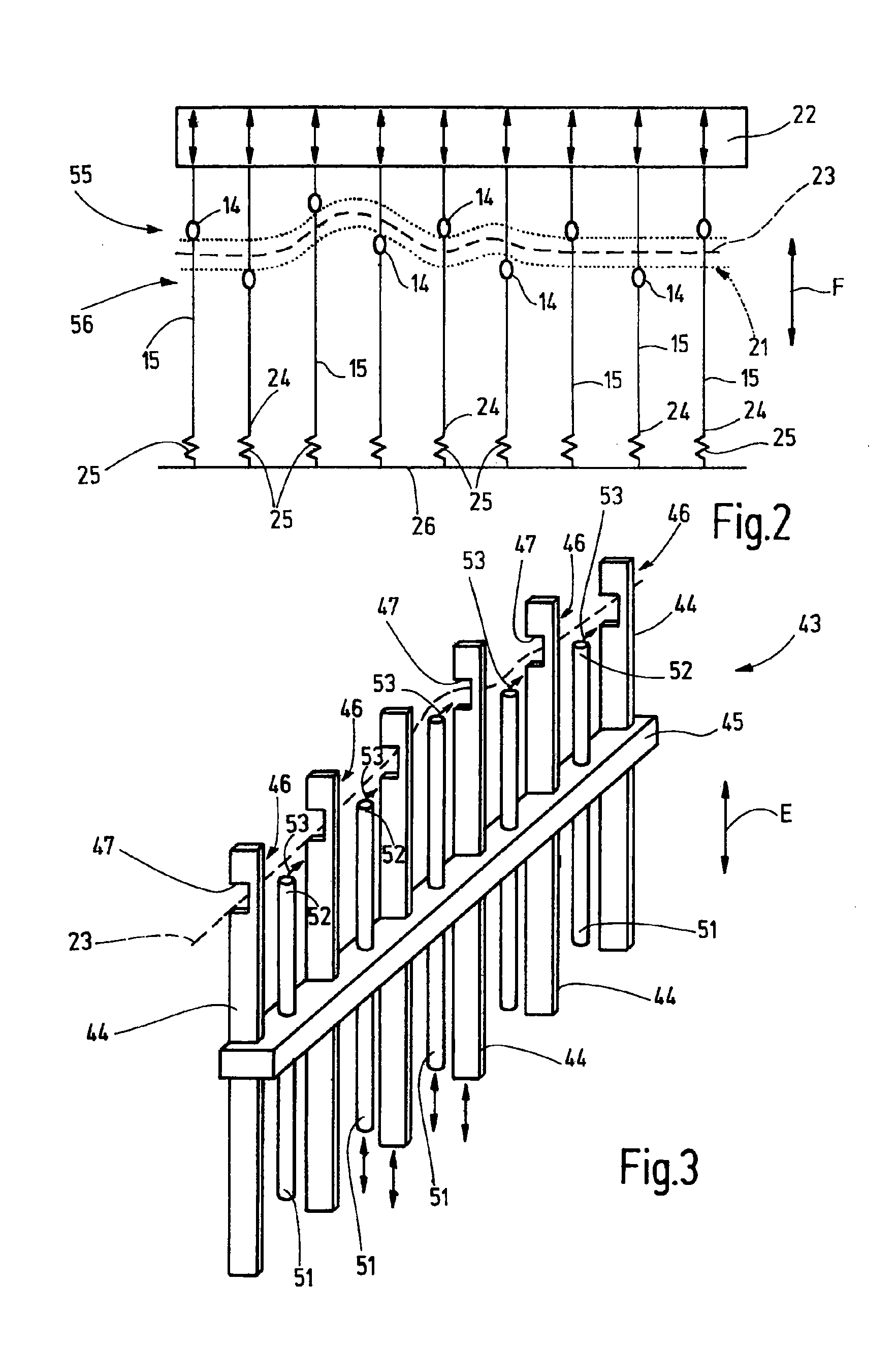

Weaving Machine and Method for Three-Dimensional Weaving

a weaving machine and a weaving method for direct three-dimensional weaving, wherein the weft thread (32) is imparted with its desired two-dimensional course already when the weft thread is being input. The position of the warp threads (12) is adapted to the weft thread path (23). The weft thread path (23) is defined by the lamellae (44) that extend into the shed (21) in between the warp threads (12). The lamellae (44) are arranged on a common bar (45) so that they can be individually adjusted, thus enabling the adjustment of the desired weft thread path (23) by positioning the lamellae (44). The lamellae (44) and the bar (45), at the same time, form the reed (43) that is used for casting on the weft thread (32) at the fabric edge (16).

Owner:GROZ BECKERT KG

Tapestry weaving semi-automatic sample weaving machine

ActiveCN104727001AIncrease productivityReduce labor intensityJacquardsSmallware loomsSemi automaticUltimate tensile strength

The invention designs a tapestry weaving semi-automatic sample weaving machine. The semi-automatic sample weaving machine comprises a weft insertion device, a beating-up device, a let-off device and a take-up device and is characterized by further comprising a pneumatic opening device and an electronic jacquard opening device. The electronic jacquard opening device is fixed between the let-off device and the take-up device. The pneumatic opening device is fixed in front of the electronic jacquard opening device. The semi-automatic sample weaving machine has the advantages that the pneumatic opening device and the electronic jacquard opening device are effectively combined with a traditional sample weaving machine, a traditional purely-manual tapestry weaving machine is changed into the semi-automatic tapestry weaving machine, equipment automation level is further increased, labor intensity of operators is relieved, and production efficiency is increased effectively.

Owner:IANGSU COLLEGE OF ENG & TECH

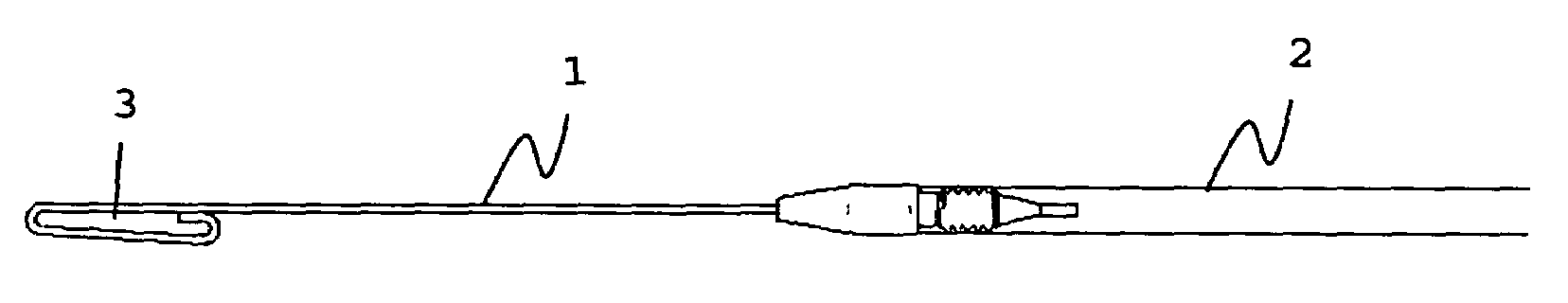

Device for attaching return springs in a harness of a Jacquard weaving machine

On the one hand, the invention relates to a device for exerting a return force on at least one harness element of the harness of a Jacquard weaving machine, comprising at least one return spring (2) provided with means of attachment (1) for attaching the return spring (2) to retaining means (4) being immovably provided, said means of attachment (1) being provided with a positioning opening (6) for positioning the means of attachment (1) with respect to the retaining means (4), and a fixing opening (7) for fixing the means of attachment (1) to the retaining means (4), a spring connection (8) being provided between the positioning opening (6) and the fixing opening (7), in such a manner that the means of attachment (1) are able to move from positioning opening (6) to the fixing opening (7) with respect to the retaining means (4), but after having been fixed will be unable to move back from the fixing opening (7) to the positioning opening (6) with respect to the retaining means during operation or transport of the Jacquard machine.On the other hand, the invention relates to a device for immovably installing the retaining means (4) of one or several return springs (2) of a Jacquard weaving machine, the device being provided with at least two fixed installing elements (13) for installing the retaining means (4), the said installing elements (13) being provided with one or several recesses to apply the retaining means (4).

Owner:N V MICHEL VAN DE WIELE

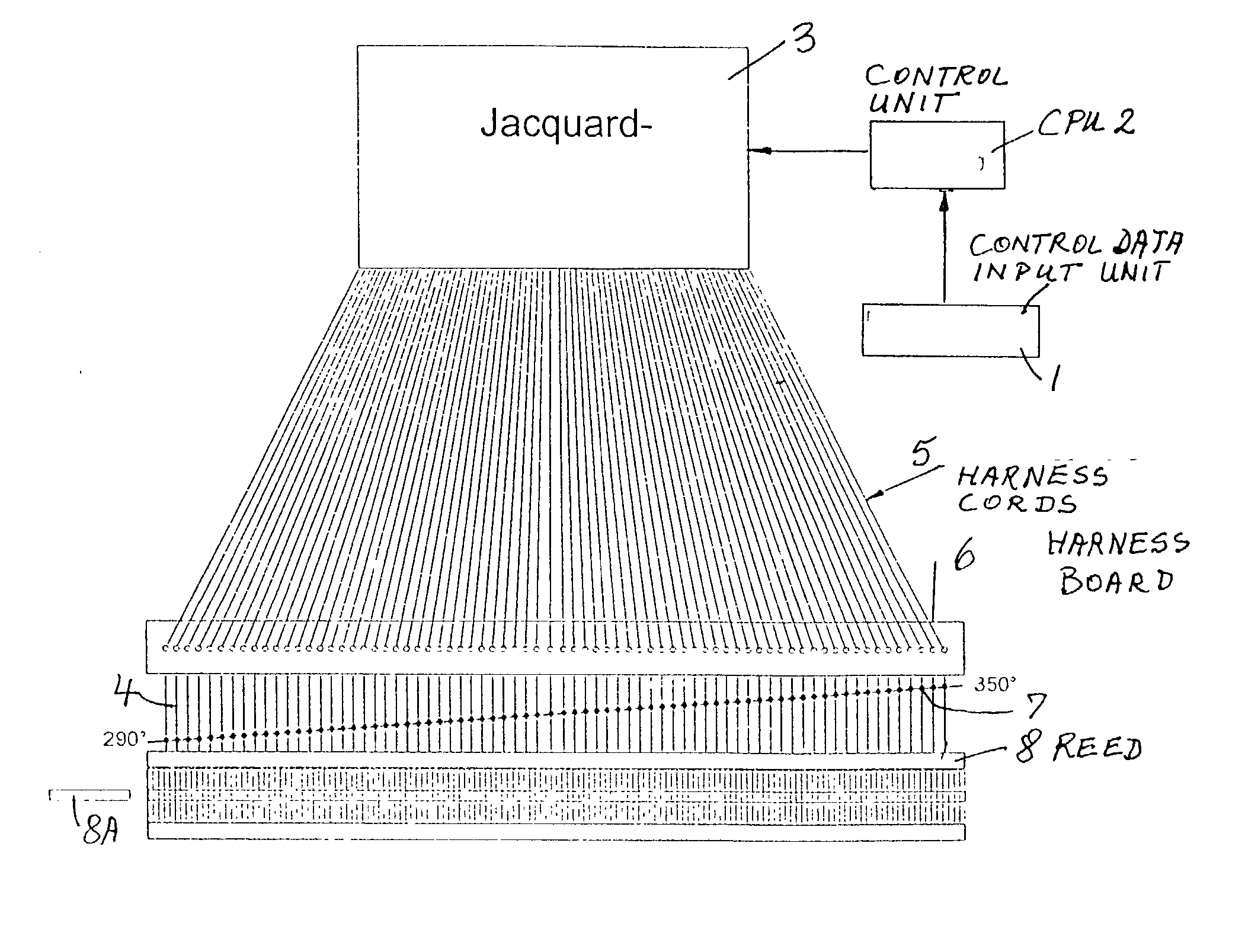

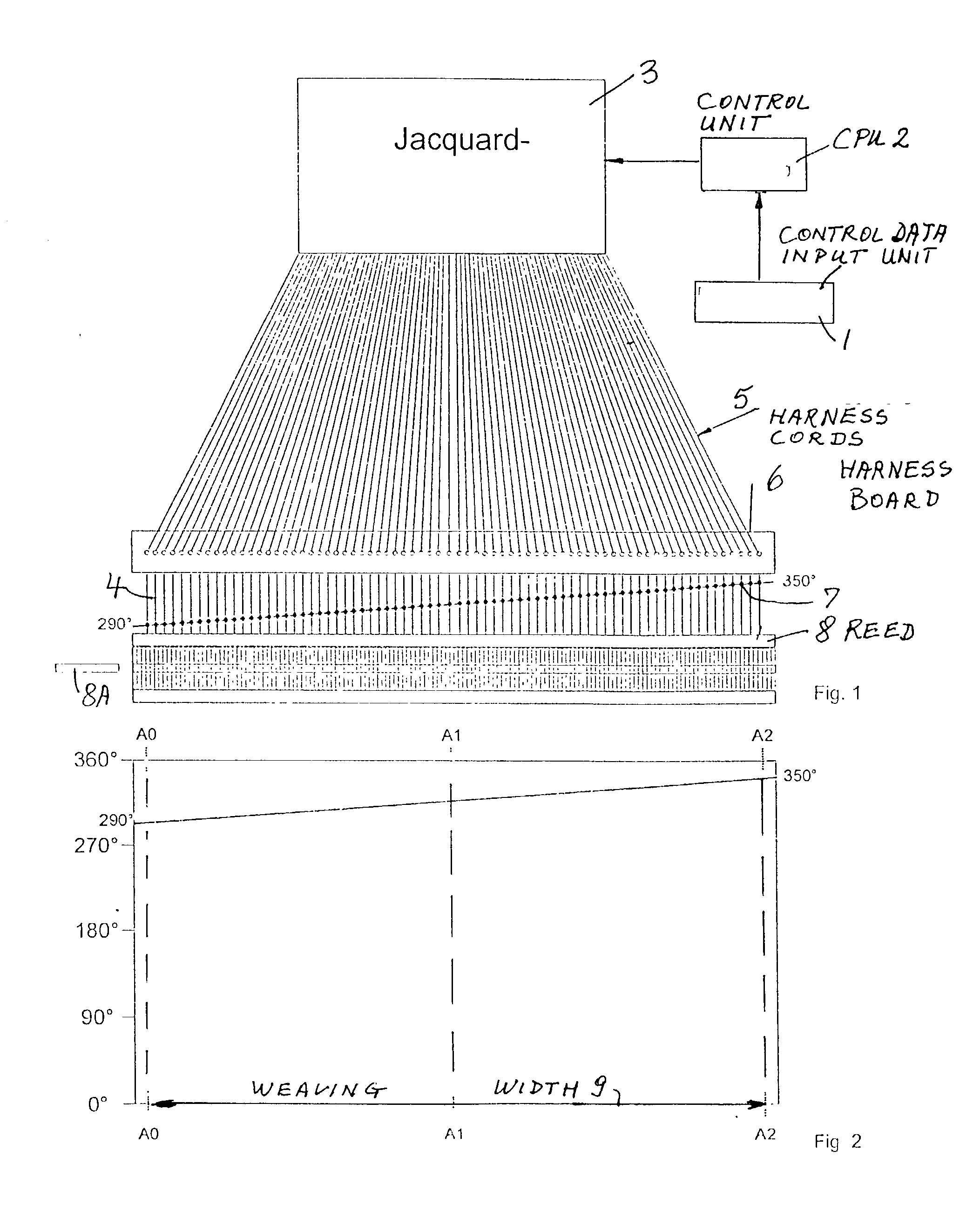

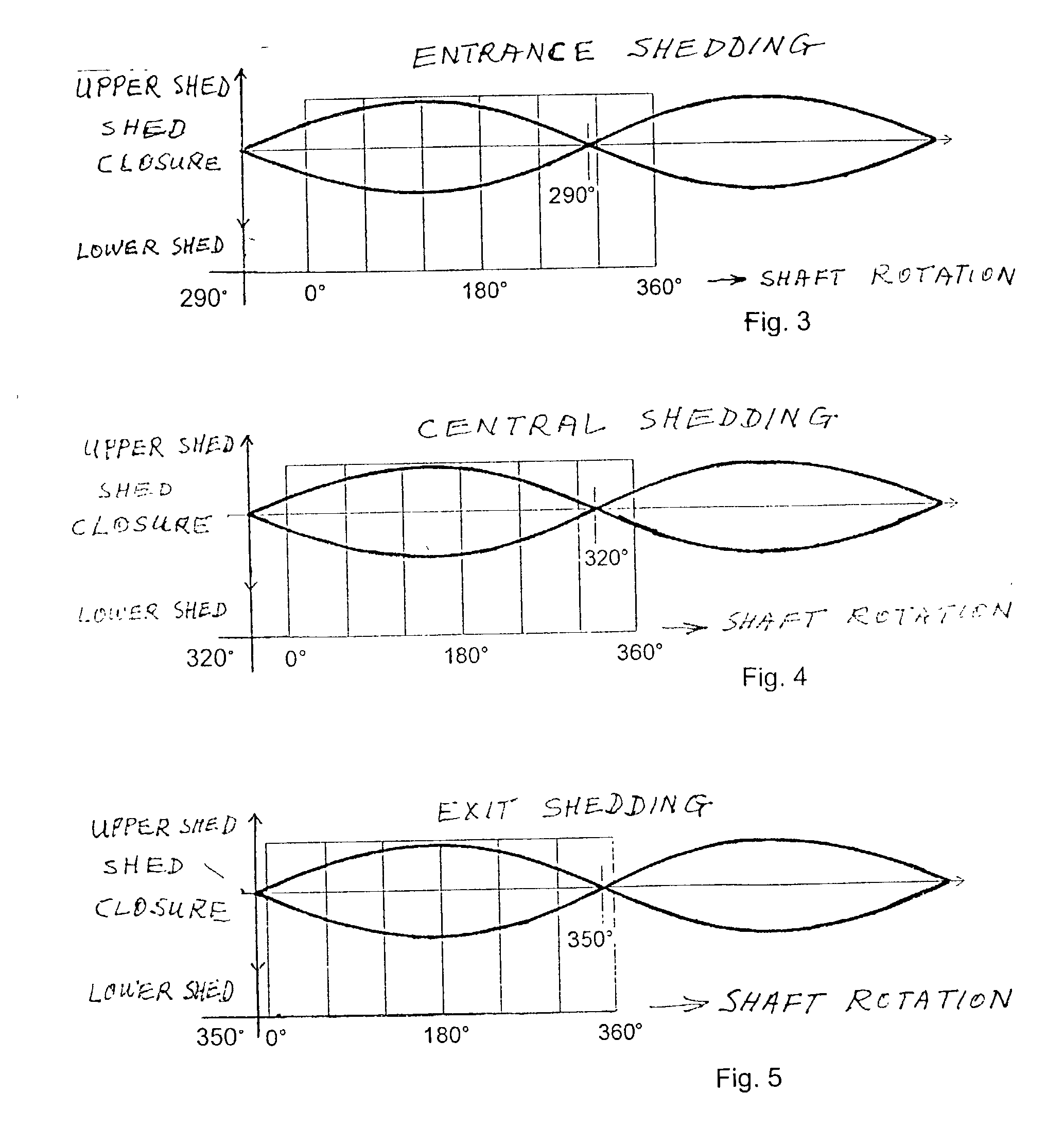

Method for controlling the shed in a loom with fluidic weft insertion

InactiveUS20030070721A1Operational securityExtended time intervalJacquardsLoomsHelical lineEngineering

The shed of a fluidic weaving loom is not changed simultaneously for all warp threads, but rather continuously starting at the weft entrance and continuing helically, so to speak, to the exit of the warp shed. This sequential shed closure takes place with a so-called domino effect along a helical line curved in space, whereby additional time is gained for stretching the inserted weft thread and temporarily stopping the shed formation or shedding is avoided.

Owner:STAUBLI FAVERGES SA

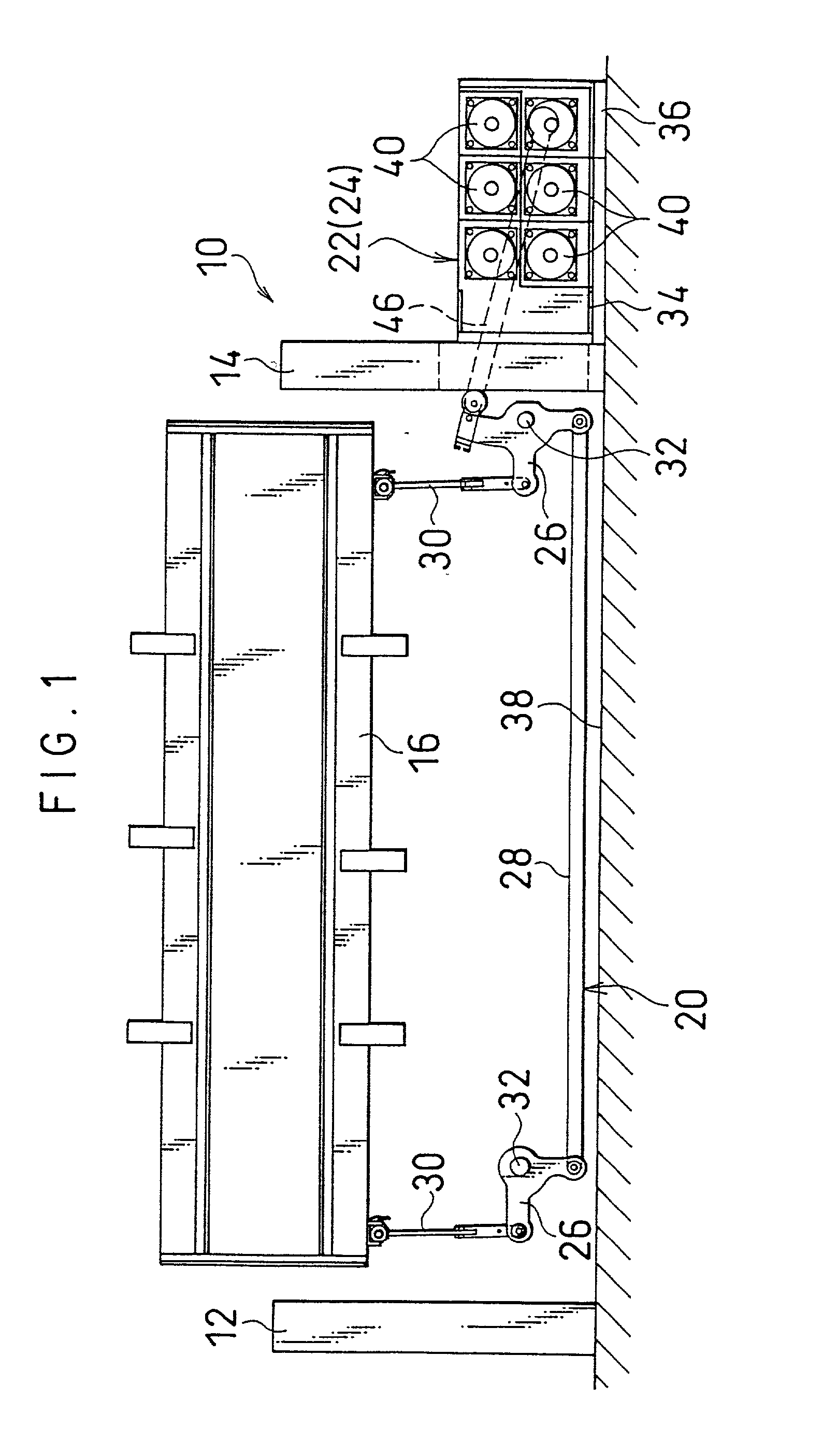

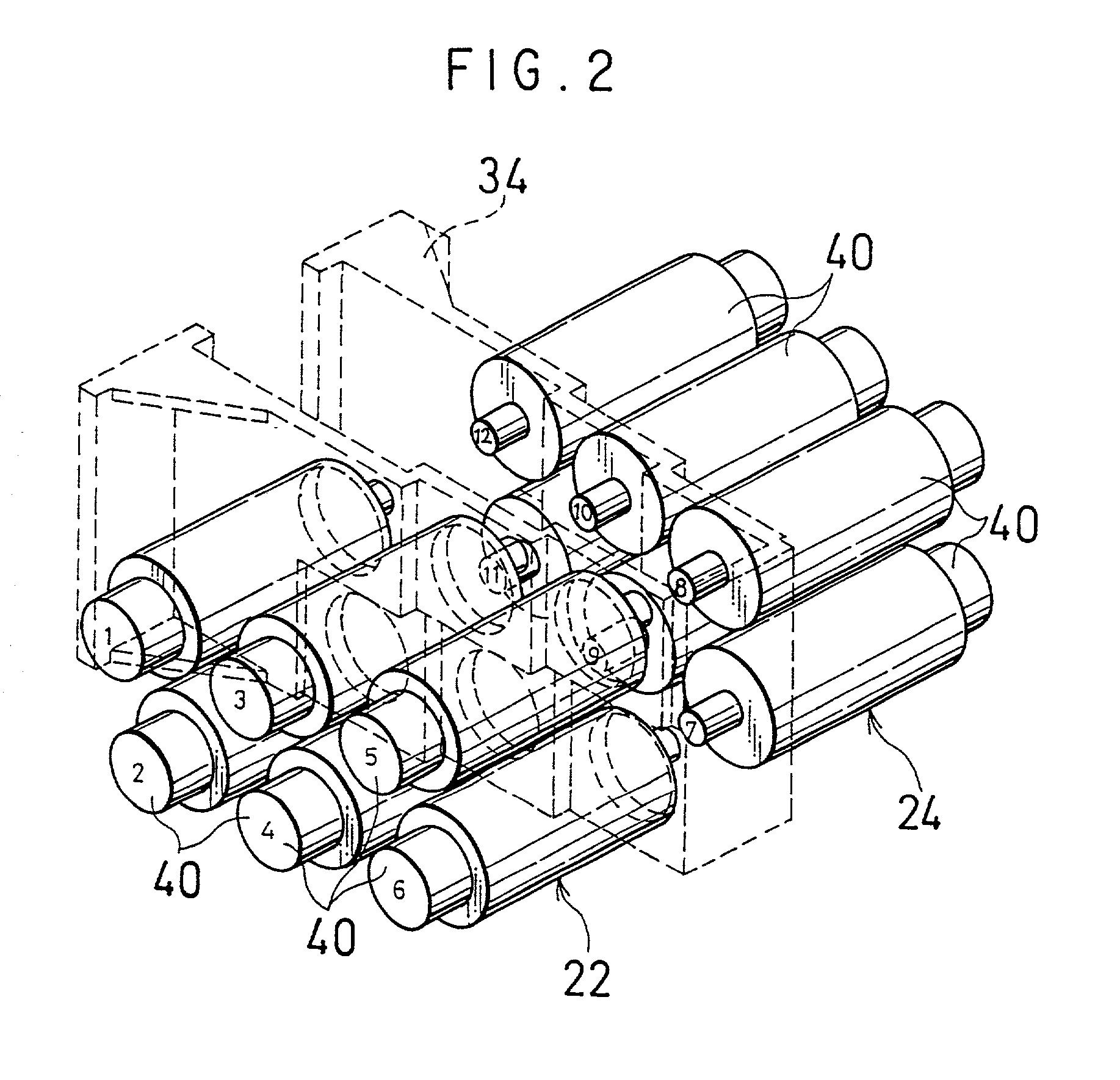

Shedding device in weaving machine

InactiveUS20020046777A1Improve directionIncrease distanceCam shedding mechanismOther shedding mechanismMarine engineeringElectric motor

A shedding device in a weaving machine comprises one or more motor groups including a plurality of motors provided in every heald frame and directing their output shafts in the forward and backward direction of the weaving machine. The motors of each motor groups are arranged in the upward and downward, rightward and leftward directions, and two or more motors operating as at least part of the motor group are arranged in the longitudinal direction of a connecting member connecting the motors with support mechanisms of the heald frames to form one or more motor rows opposing to one or more connecting members, and adjoining motors in the motor row or rows are related to non-adjoining heald frames among the heald frames corresponding to the support mechanisms.

Owner:TSUDAKOMA KOGYO KK

Electric motor drive mechanism for shed forming components of a loom

The heald shafts of a power loom are driven by electric D.C. or A.C. motors which have an external rotor or an armature connected to the respective heald shaft through two articulated couplings, for example snap locks, and a push-pull rod. The motors receive control signals from a computerized controller for reversing the motion direction of the external rotor or armature. The stators of the motors are rigidly mounted on a fixed axis secured to the loom frame.

Owner:LINDAUER DORNIER GMBH

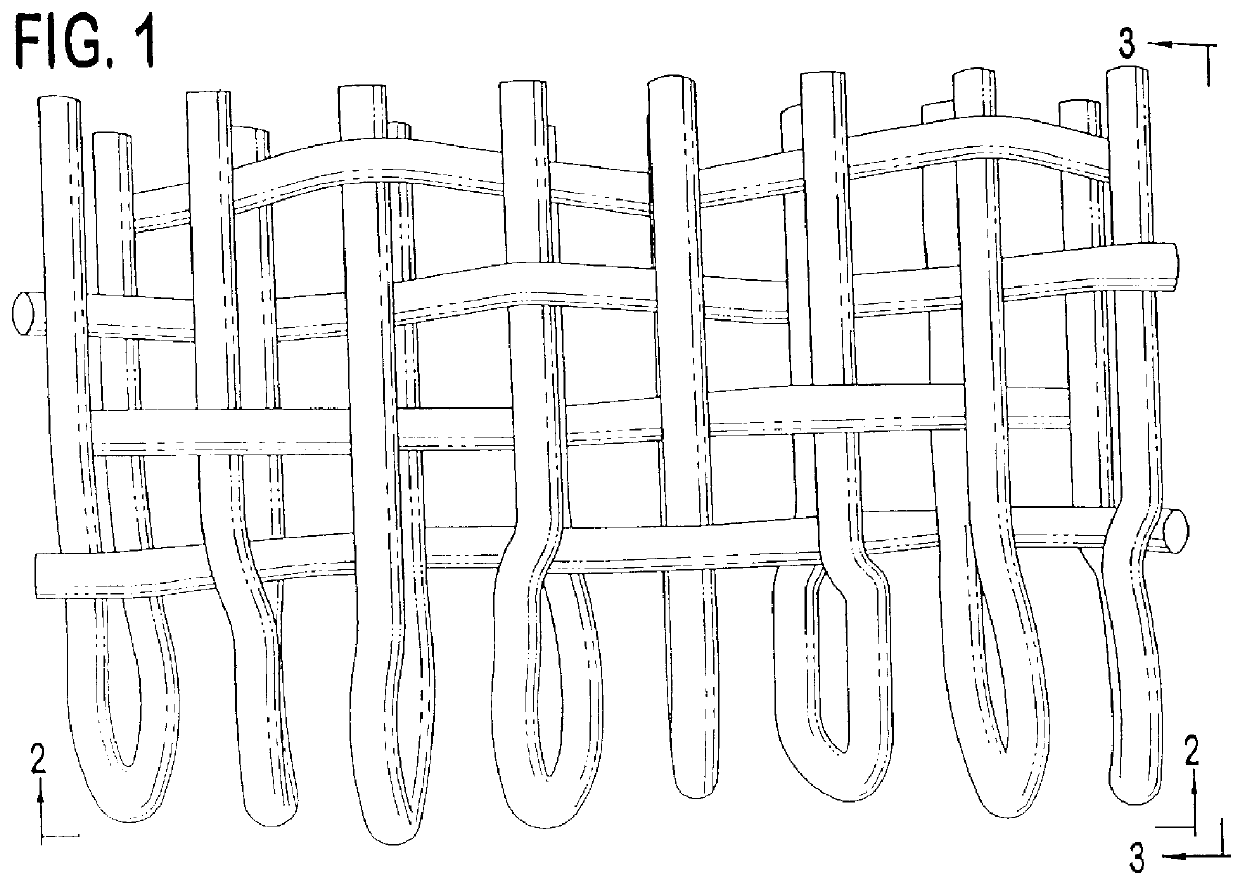

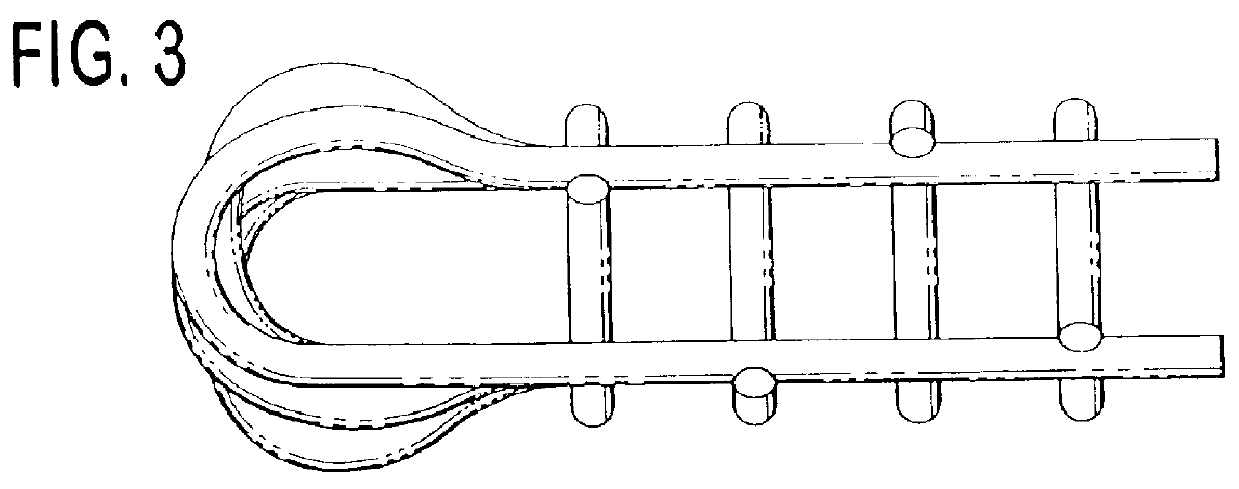

Woven loop press base fabric having high density top layer

A papermaker's fabric having a system of primary machine direction yarns which form seaming loops at each end of the fabric and a system of secondary machine direction yarns. A system of cross-machine direction yarns are interwoven with the primary and secondary systems of machine direction yarns in a weave pattern that provides adjacent balancing yarns that maintain the seam loops in substantially vertical alignment.

Owner:ASTENJOHNSON

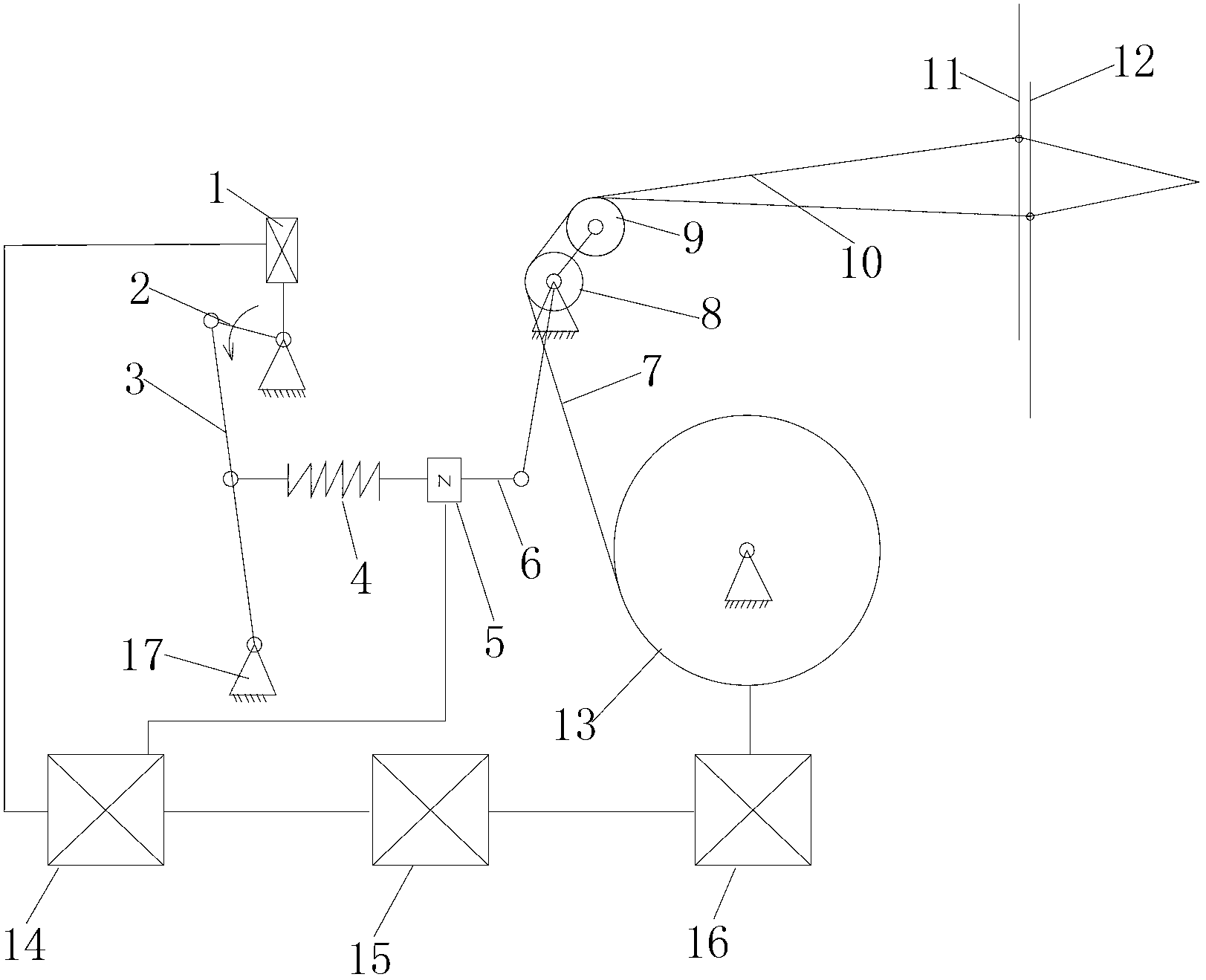

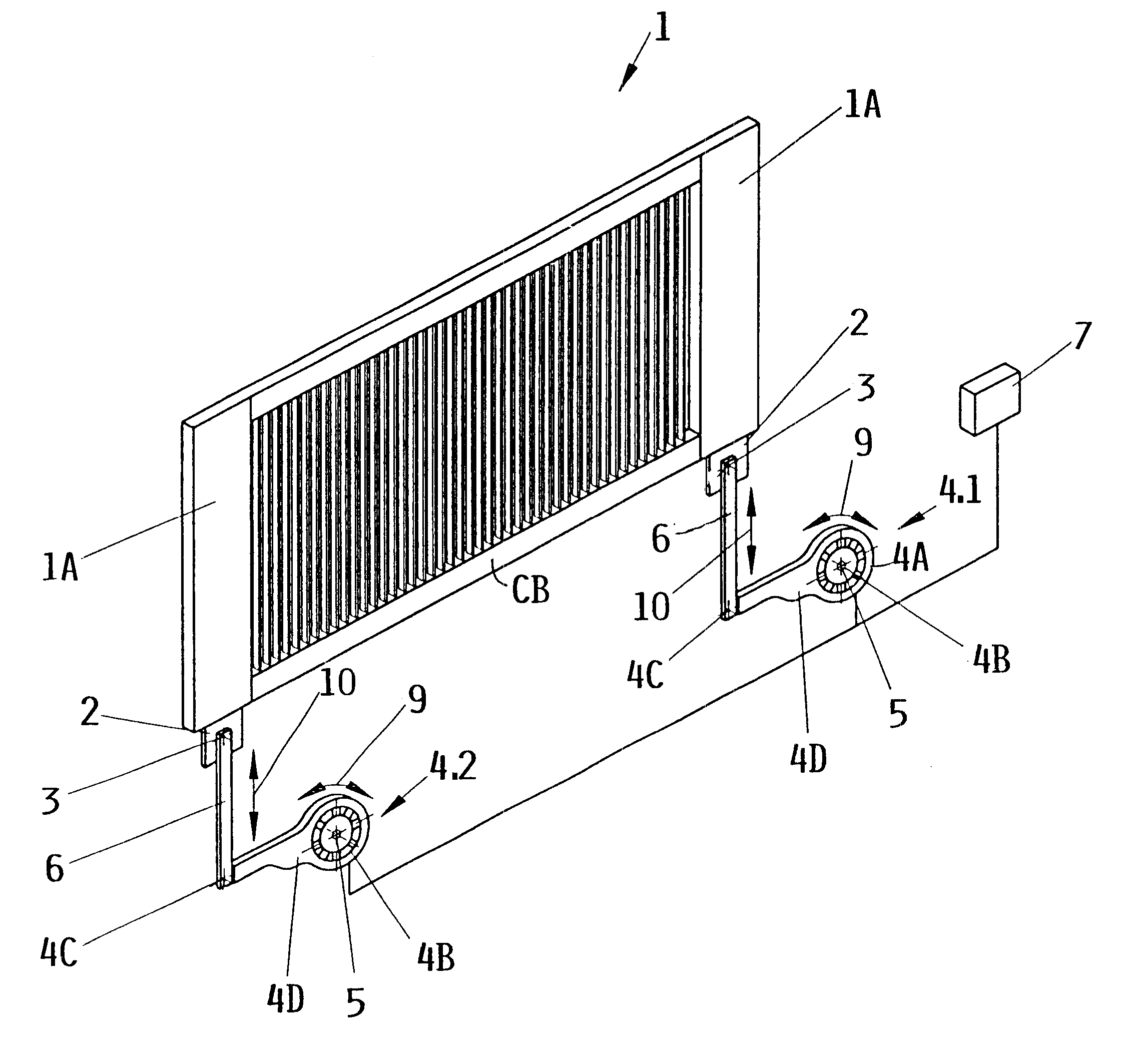

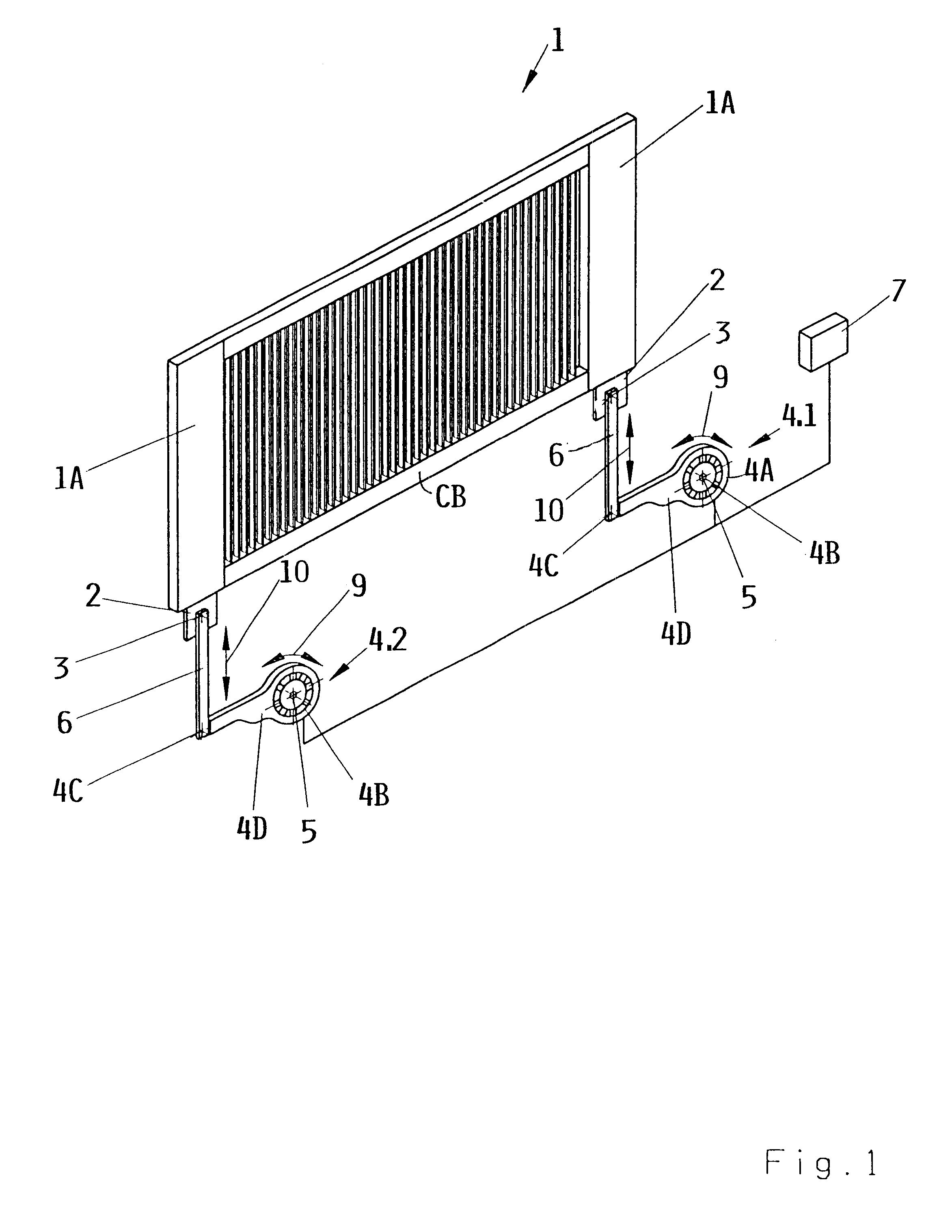

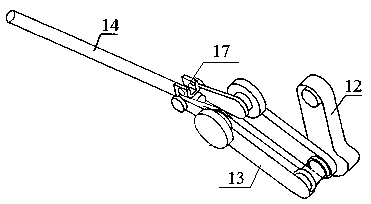

Opening weft insertion mechanism applicable to multilayer fabric weaving

ActiveCN103849974AFavorable weft insertionIncrease varietyLoomsOther shedding mechanismStructural engineeringIndustrial engineering

The invention relates to textile machinery for multilayer fabric weaving, and particularly relates to a loom opening weft insertion mechanism for producing multilayer fabrics with thickness of over 10mm, belonging to the technical field of textile machinery. The opening weft insertion mechanism comprises a heald frame, an opening device and a weft insertion device in a loom, wherein the opening device consists of more than two layering rollers and two rhombus lifting mechanisms. The opening weft insertion mechanism provided by the invention has the advantages that in a lifting opening mechanism consisting of multiple groups of movable hinges, with more hinge points and more layers, the layers and thickness of a fabric can be increased; by the rhombus lifting mechanism, pages of the heald frame can be saved, and the varieties of the multilayer fabrics are expanded; the lifting opening mechanism and the weft insertion mechanism are in cooperation and linkage, the opening action is finished once for guiding each weft yarn, and the up-down movement of the weft insertion mechanism in the vertical direction can be realized; meanwhile, the up-down displacement of the lifting mechanism can be adjusted through the rotation amplitude of a spindle, and the bending abrasion and breakage of warp yarns are avoided.

Owner:广东世纪金海复合材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com