Patents

Literature

150results about How to "Adjustable stroke" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

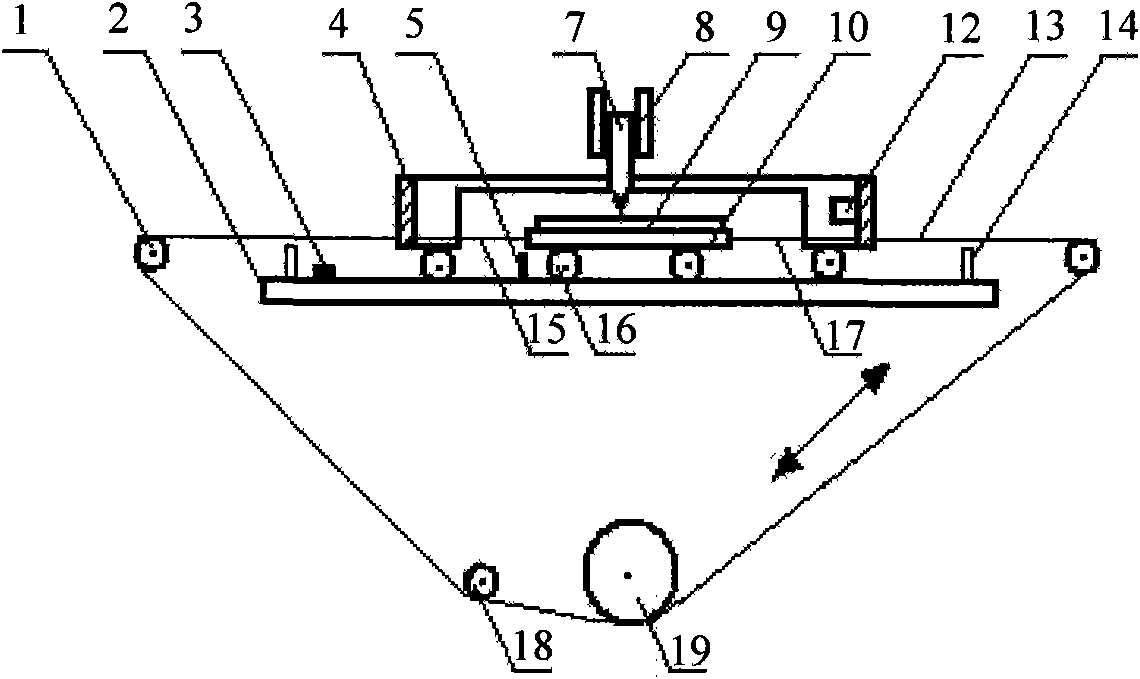

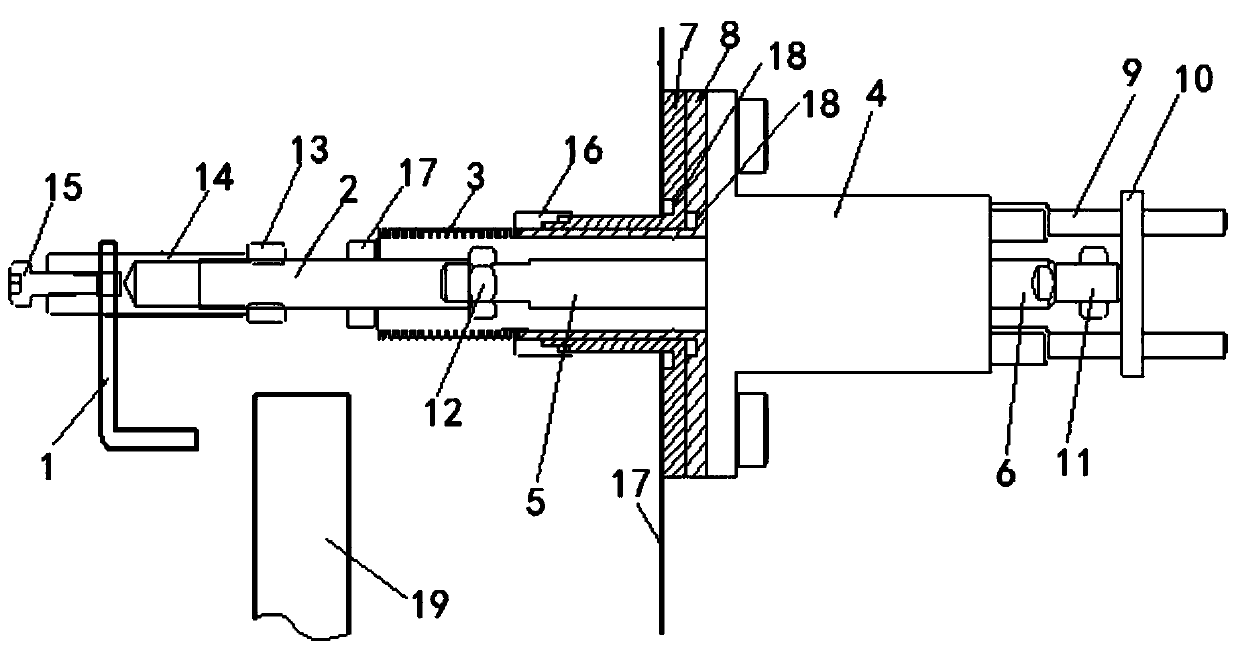

Device and method for testing linear reciprocating sliding friction and abrasion

InactiveCN101556238AAdjustable sliding speedAdjustable loadUsing mechanical meansMaterial weighingPositive pressurePeak value

The invention discloses a device and a method for testing linear reciprocating sliding friction and abrasion; the device consists of a transducer, a workbench, a sample table, a dragging frame, a force sensor, a changeover switch, a counter, a locking device, a guideway, a baffle, a cable wire, a reducer, a peak value stabilizer, a control part and an auxiliary component; the equipment can automatically complete the abrasion test of an arranged period and can manually complete the test to friction coefficient. The testing method comprises the following steps of: leading the friction block and the sample to reciprocate to slide horizontally with constant pressure, obtaining an abrasion weight loss rate after abrading, keeping a certain positive pressure and leading the sliding block to move from stillness to uniform movement, thus obtaining the maximum static friction coefficient and the sliding friction coefficient. The device and the method can realize uniformly linear and reciprocating relative sliding abrasion in long unidirectional journey, test the maximum static friction coefficient between two bodies and the maximum static friction coefficient, the speed, the load and the adjustable journey with other materials, and can be widely applied to the detection of various samples of different materials and different structural forms.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

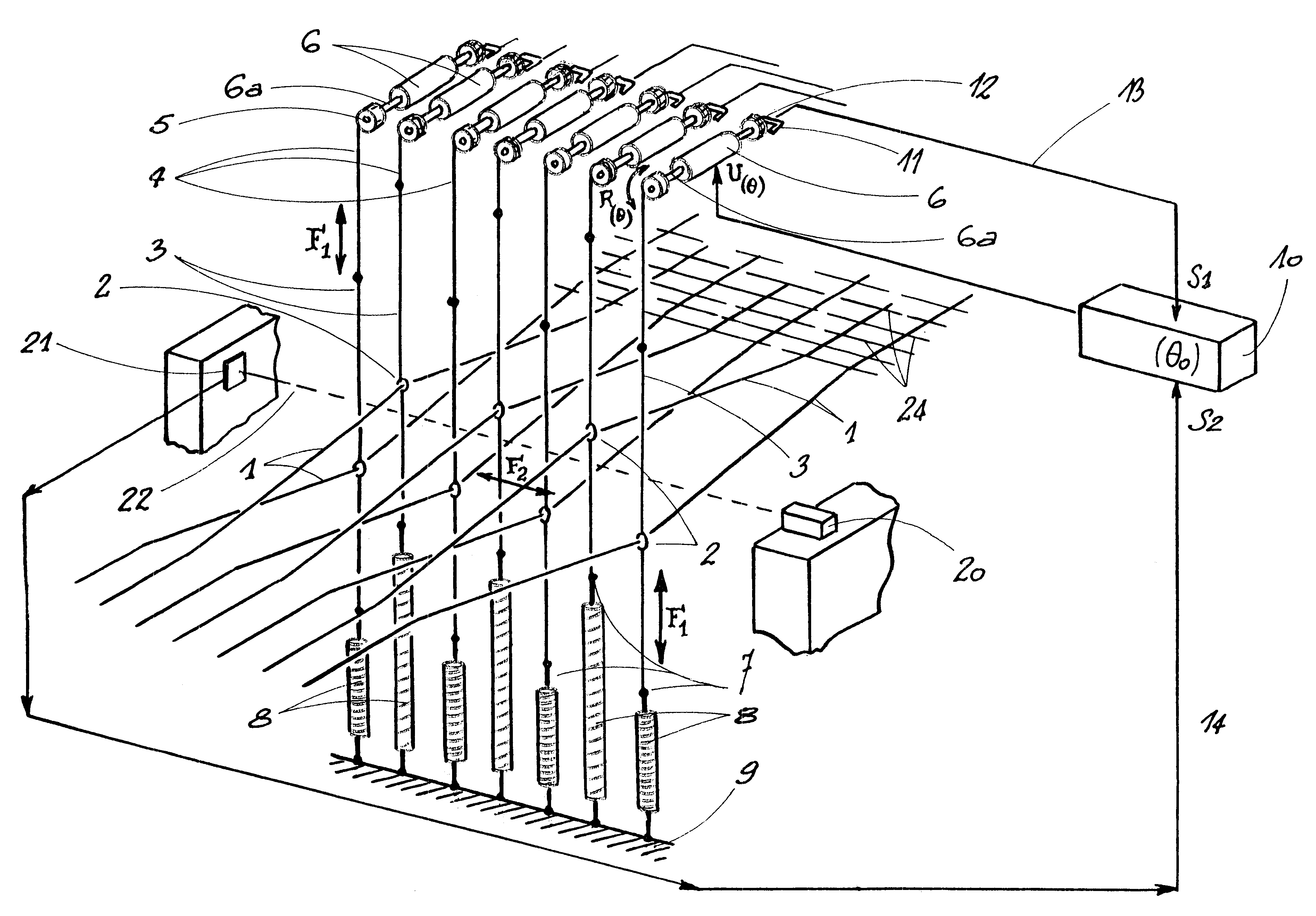

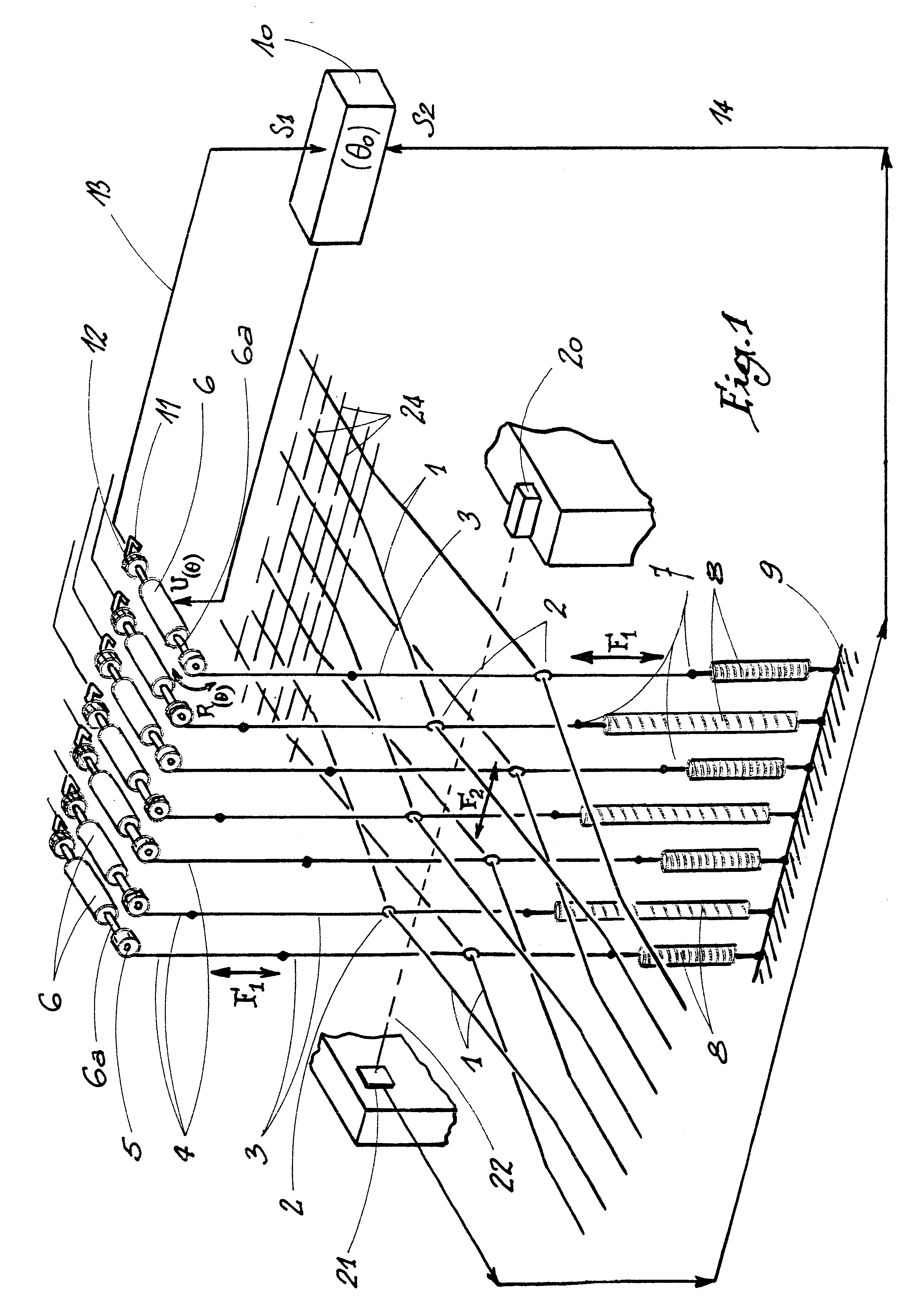

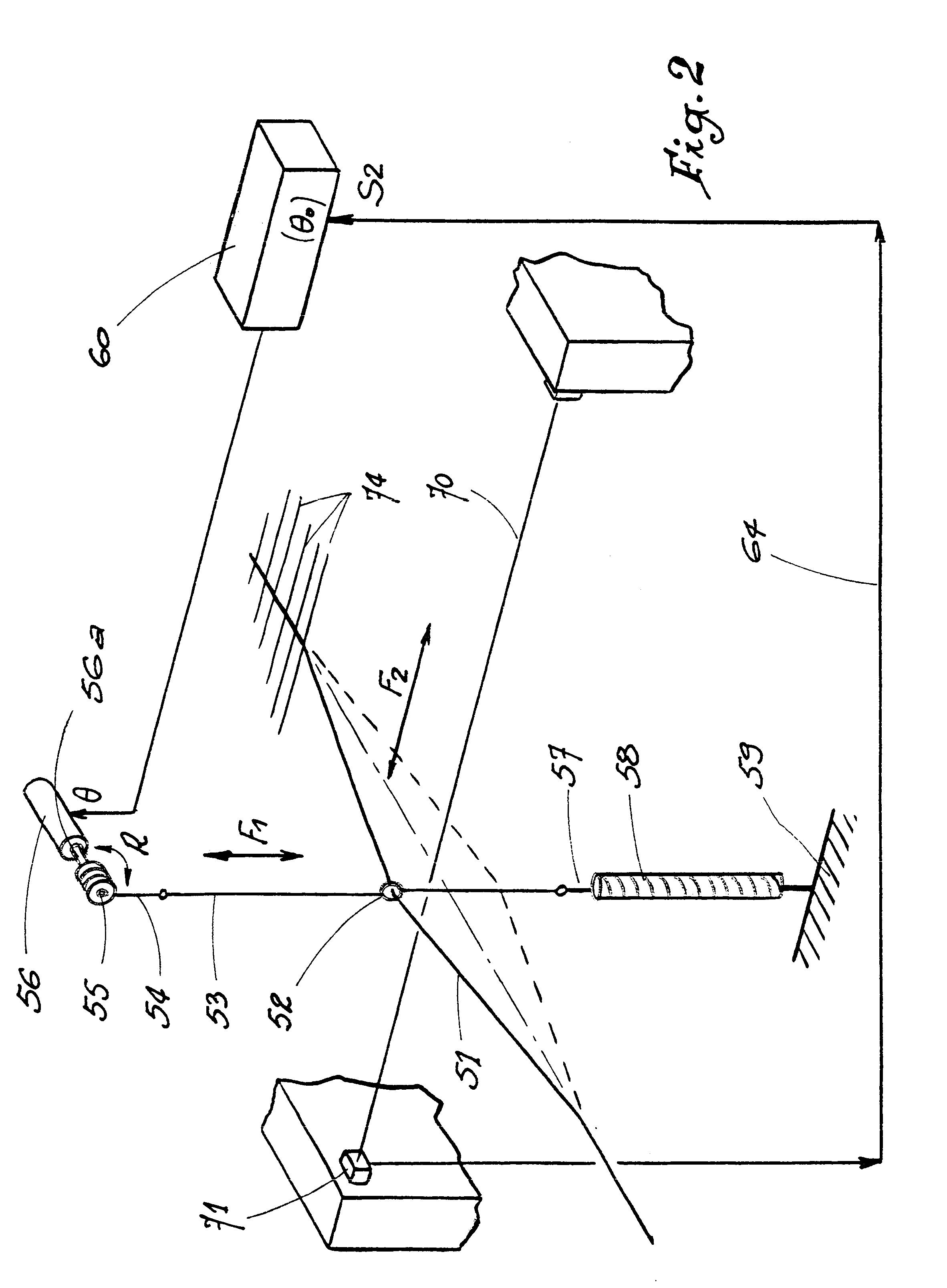

Process and device for positioning weaving loom warp yarns

InactiveUS6293315B1Adjustable strokePrecise positioningJacquardsOther shedding mechanismYarnEngineering

A device for positioning warp yarns of a weaving loom which are controlled by electrical actuators for forming a shed which includes a first detector common to the warp yarns driven by a plurality of different actuators for detecting the passage of at least one warp yarn into a predetermined position, and a second device for determining a value of a control parameter of an actuator for controlling movement of the at least one warp yarn upon passage into the predetermined position. The process consists in displacing a warp yarn and detecting its passage into a predetermined position and selecting a value of a control parameter of an actuator for the warp yarn upon passage of the warp yarn into the predetermined position and in using the selected value as a control point for controlling an actuator for the warp yarn.

Owner:STAUBLI FAVERGES SA

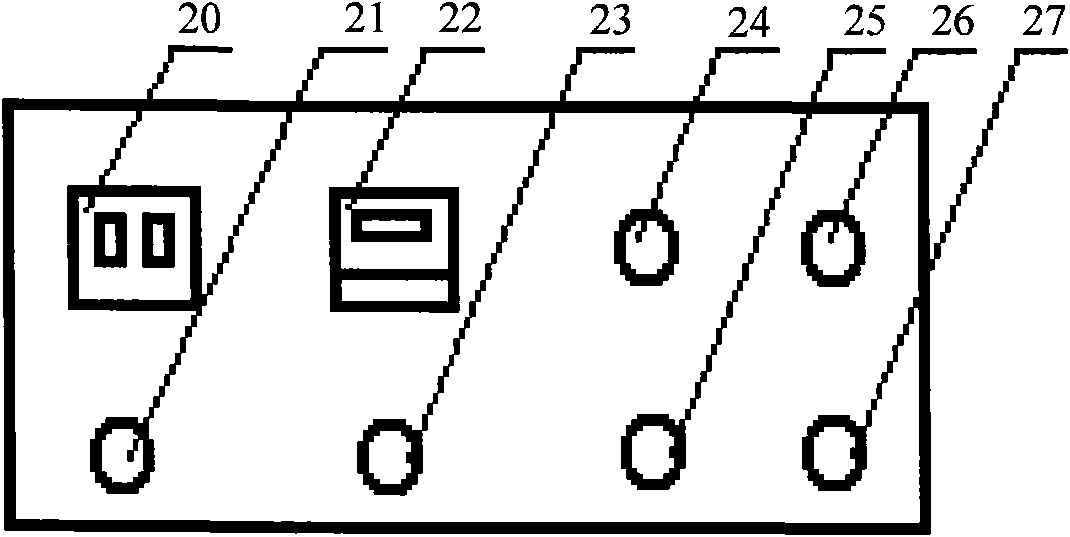

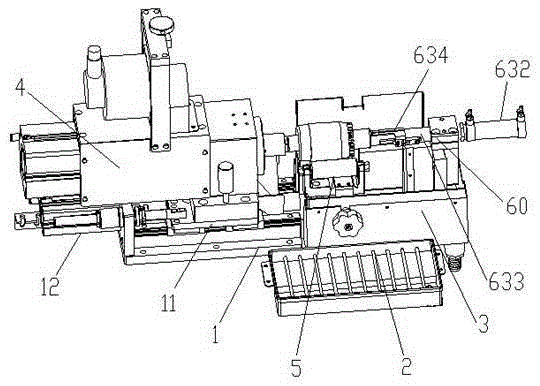

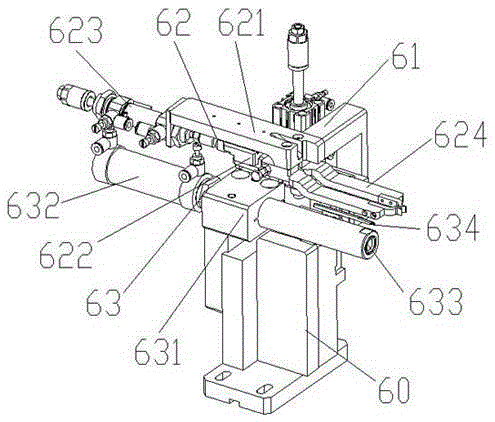

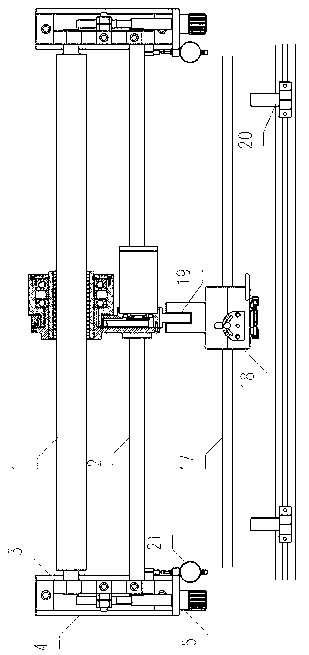

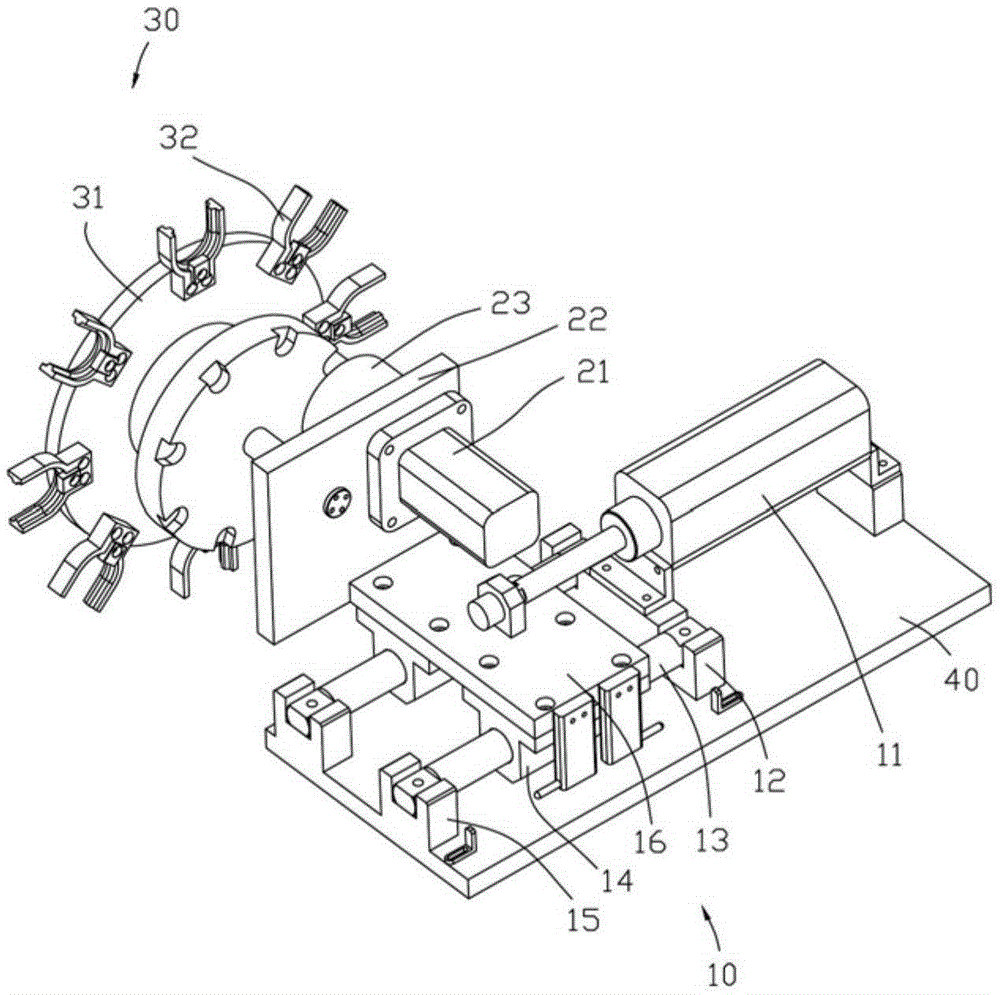

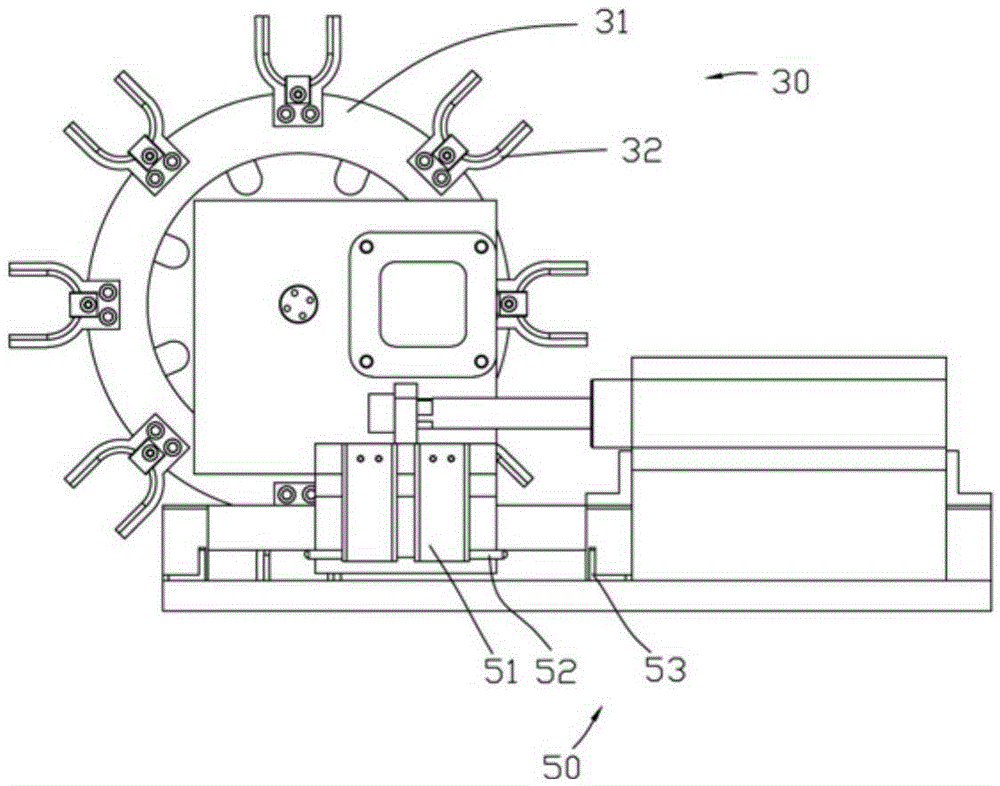

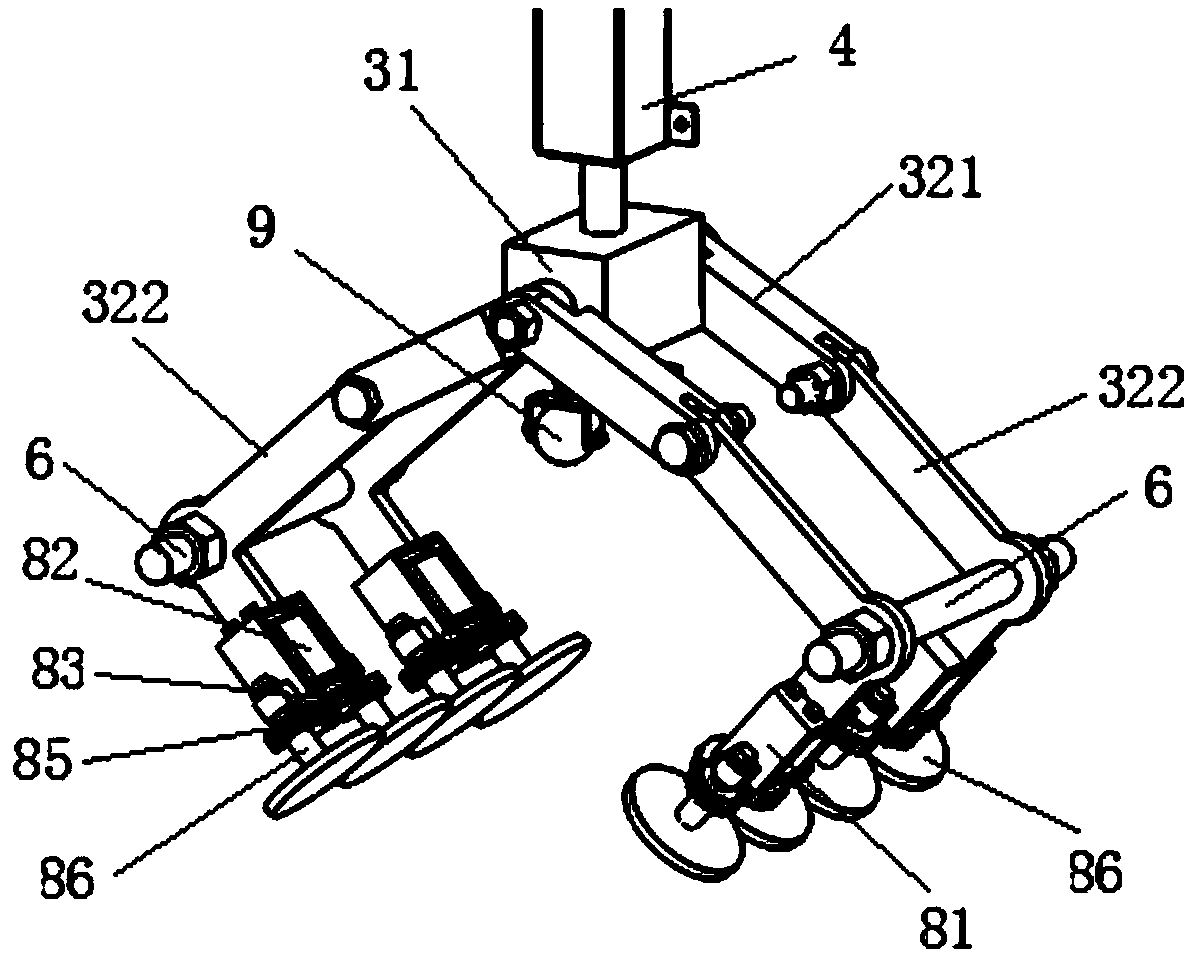

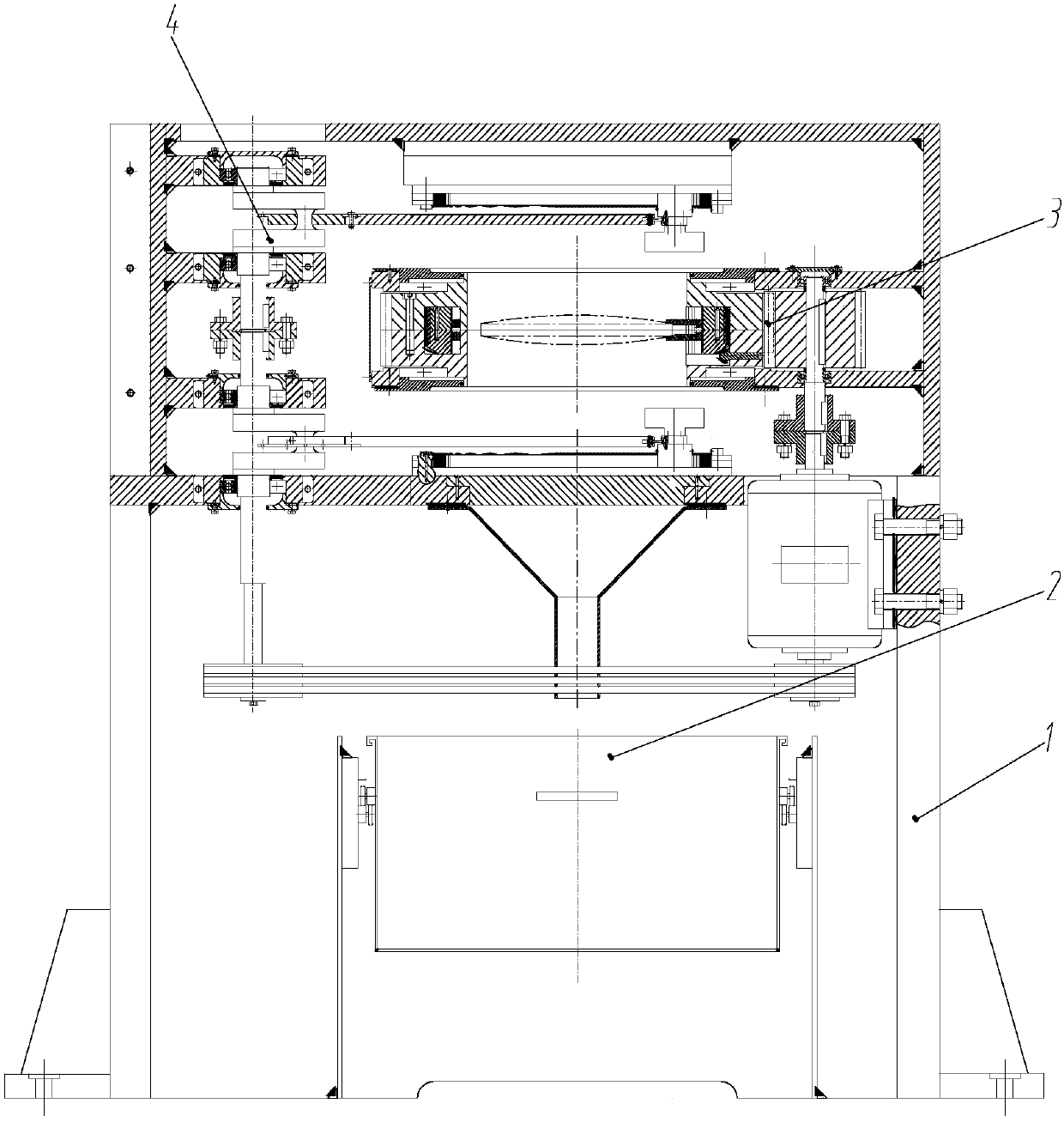

Wheel deburring device and deburring method

ActiveUS20160184958A1Small adjustmentAdjustable strokePolishing machinesRevolution surface grinding machinesEngineeringAutomation

The present invention provides a wheel deburring device, consisting of a frame, a motor, a guide rail, a swing plate, a cylinder, a servo electric cylinder and a hairbrush and the like. When in use, the device provided by the present invention can adjust the angle of the hairbrush according to the shape of the back cavity of the wheel spoke to adapt to hubs of any style, and the deburring effect is very ideal; and meanwhile, the device has the characteristics of high degree of automation, advanced process, safe and stable performance, etc.

Owner:CITIC DICASTAL

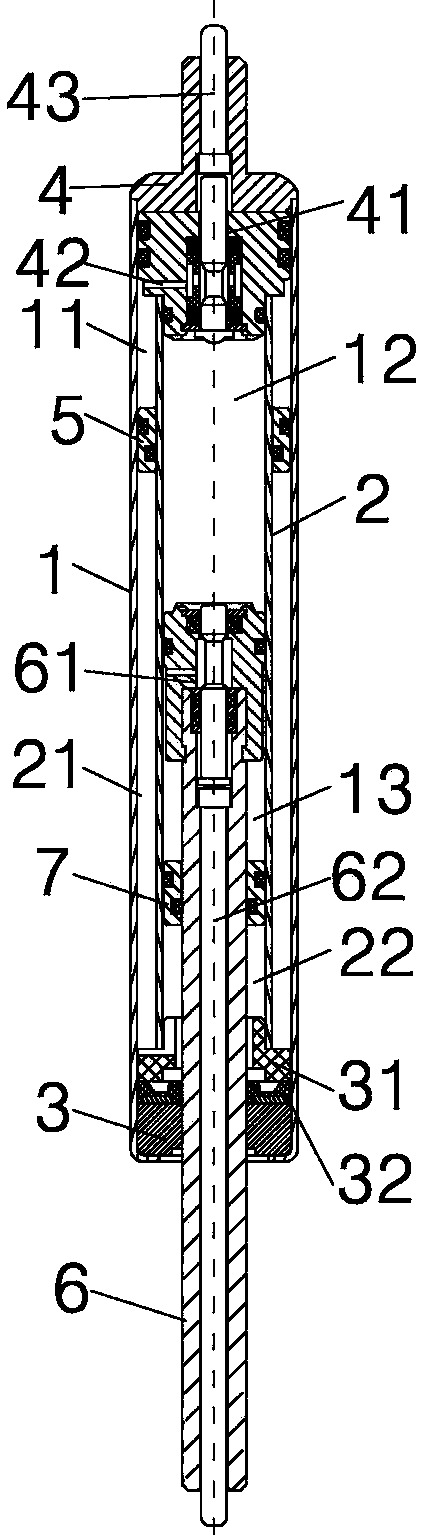

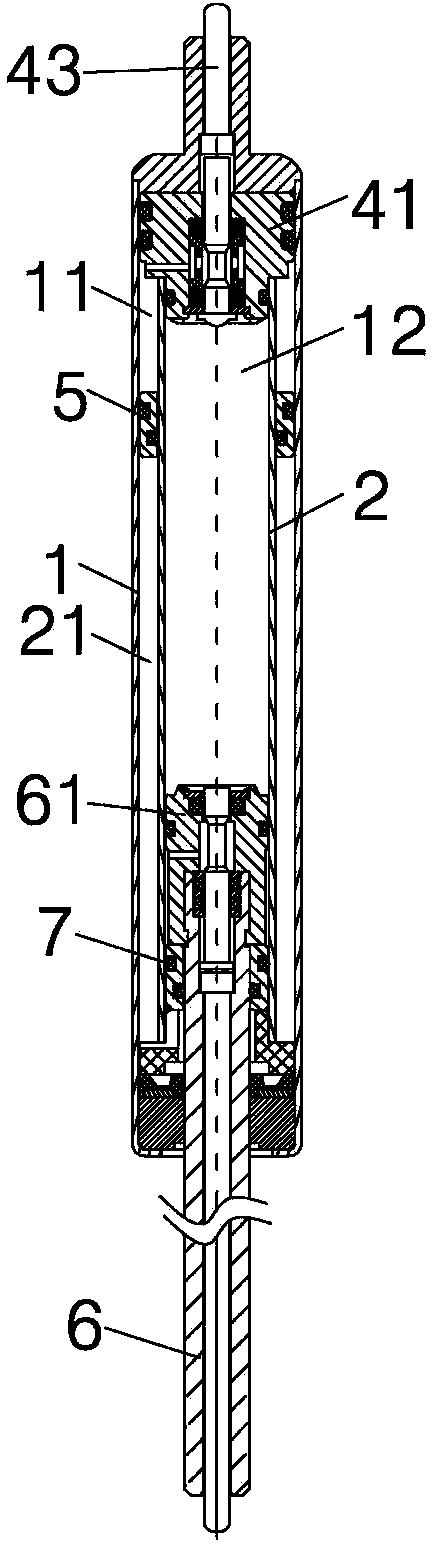

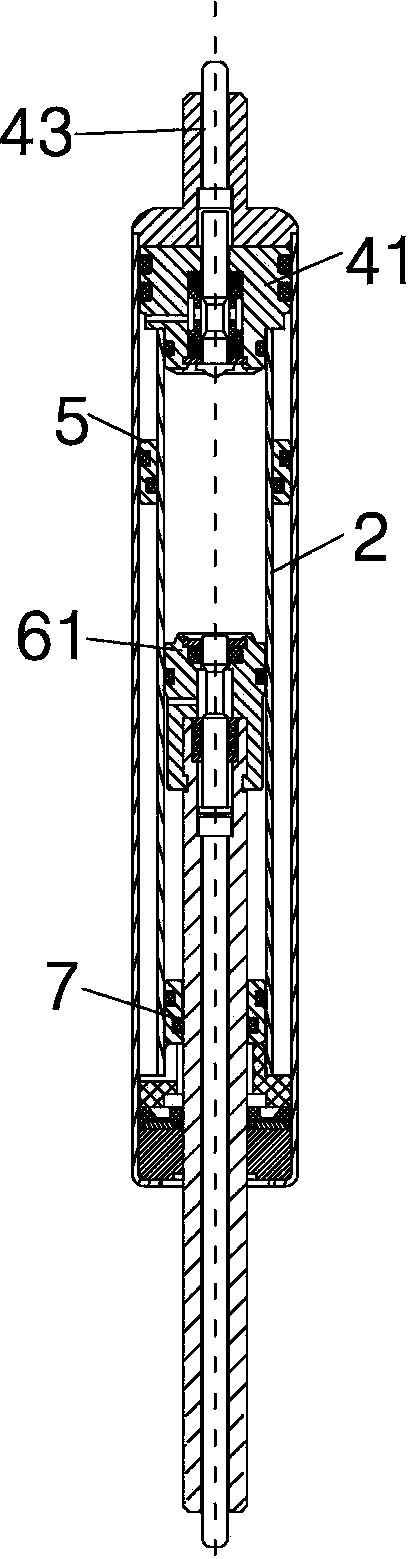

A double-barrel multi-chamber spring with an adjustable stroke

ActiveCN104235251AAdjustable strokeSimple structureSpringsGas and liquid based dampersGas springEngineering

A double-barrel multi-chamber spring with an adjustable stroke comprises an outer tube and an inner tube. A chamber is formed between the inner wall of the outer tube and the outer wall of the inner tube. A first floating piston is arranged in the cavity for dividing the chamber into a first oil chamber and a first air chamber. A small separation piston is arranged between the outer wall of the hollow piston rod and the inner wall of the inner tube. The inner wall of the inner tube is divided into a second oil chamber, a third oil chamber and a second air chamber orderly by a floating control valve and the small separation piston. A fixed control valve is arranged in a back block for conducting or blocking the first oil chamber and the second oil chamber through an oil passage. The fixed control valve is controlled by an operation actuating lever extending out from the back block. The floating control valve can conduct the second oil chamber and the third oil chamber through the oil passage. The double-barrel multi-chamber spring with an adjustable stroke of the invention has the following beneficial effects that the operation of the gas spring of the invention can be controlled by the fixed control valve at the tail end of the spring, so that it only needs to open the control valve when the spring needs to stretch, and the spring has controllable operation and can stop at any position.

Owner:陈月英

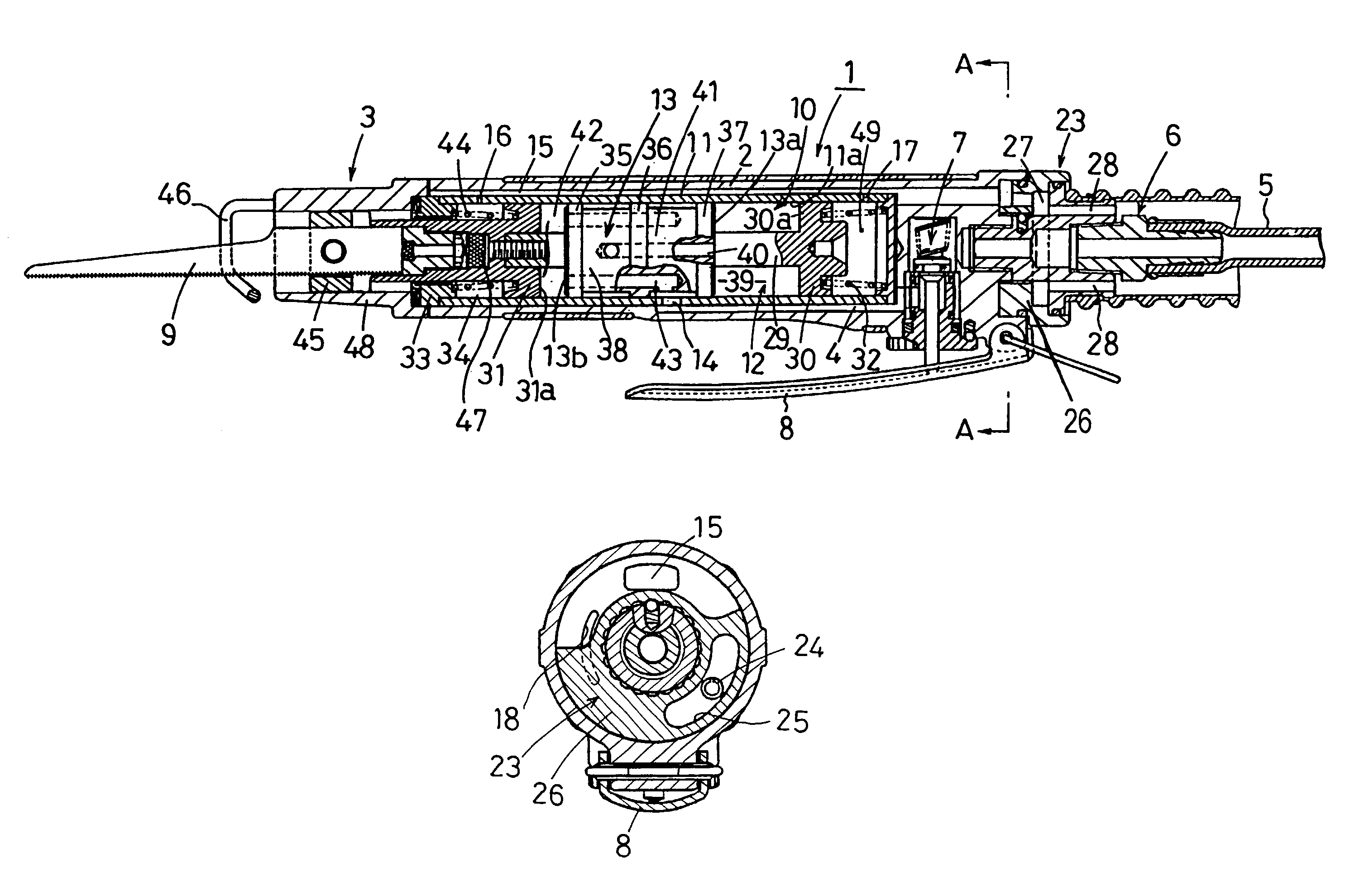

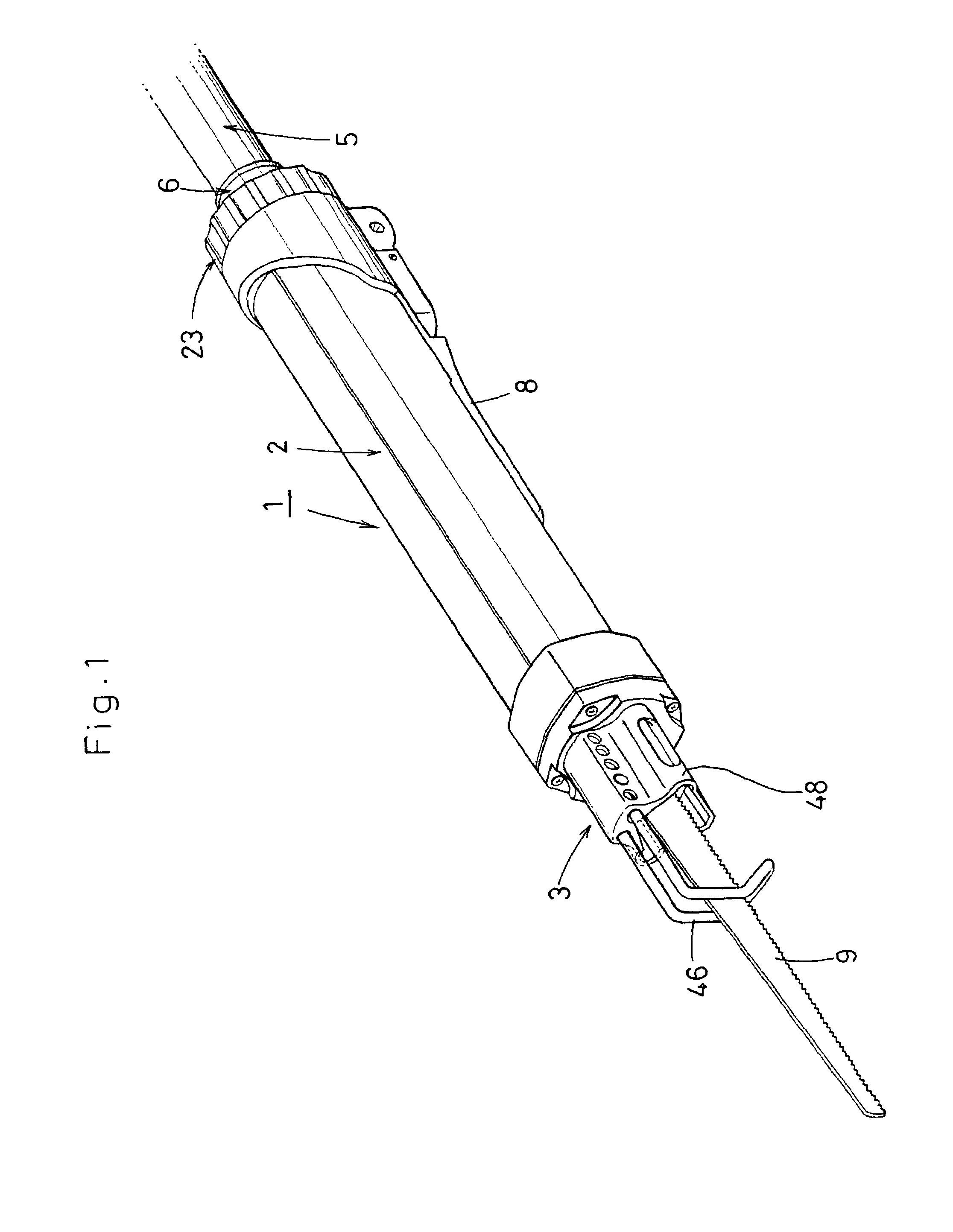

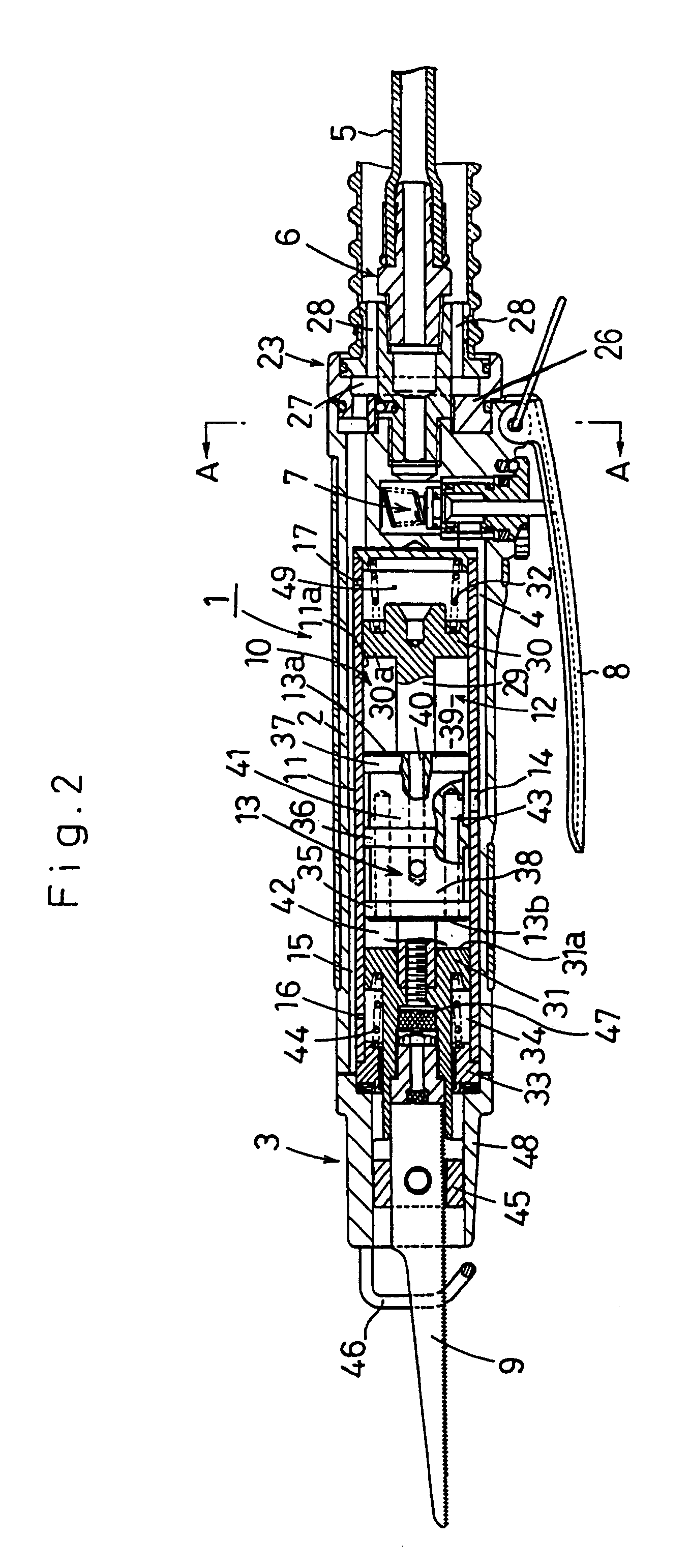

Air saw

InactiveUS7207116B2Prevent chatterIncreased durabilityMetal sawing devicesFeeding devicesReciprocating motionEngineering

A main spindle of an air saw is reciprocated by sliding a piston in a cylinder chamber with the pressure of air supplied to the cylinder chamber via an air supply path so as to alternately apply the air pressure to pressure-receiving surfaces of a back plate and a front plate, wherein a rear air-cushion chamber is formed in a portion for fixing a return spring for urging the back plate toward the center of a cylinder while a front air-cushion chamber is formed in a portion for fixing a return spring for urging the front plate toward the center of the cylinder, so that the front and rear balance is maintained.

Owner:KUKEN

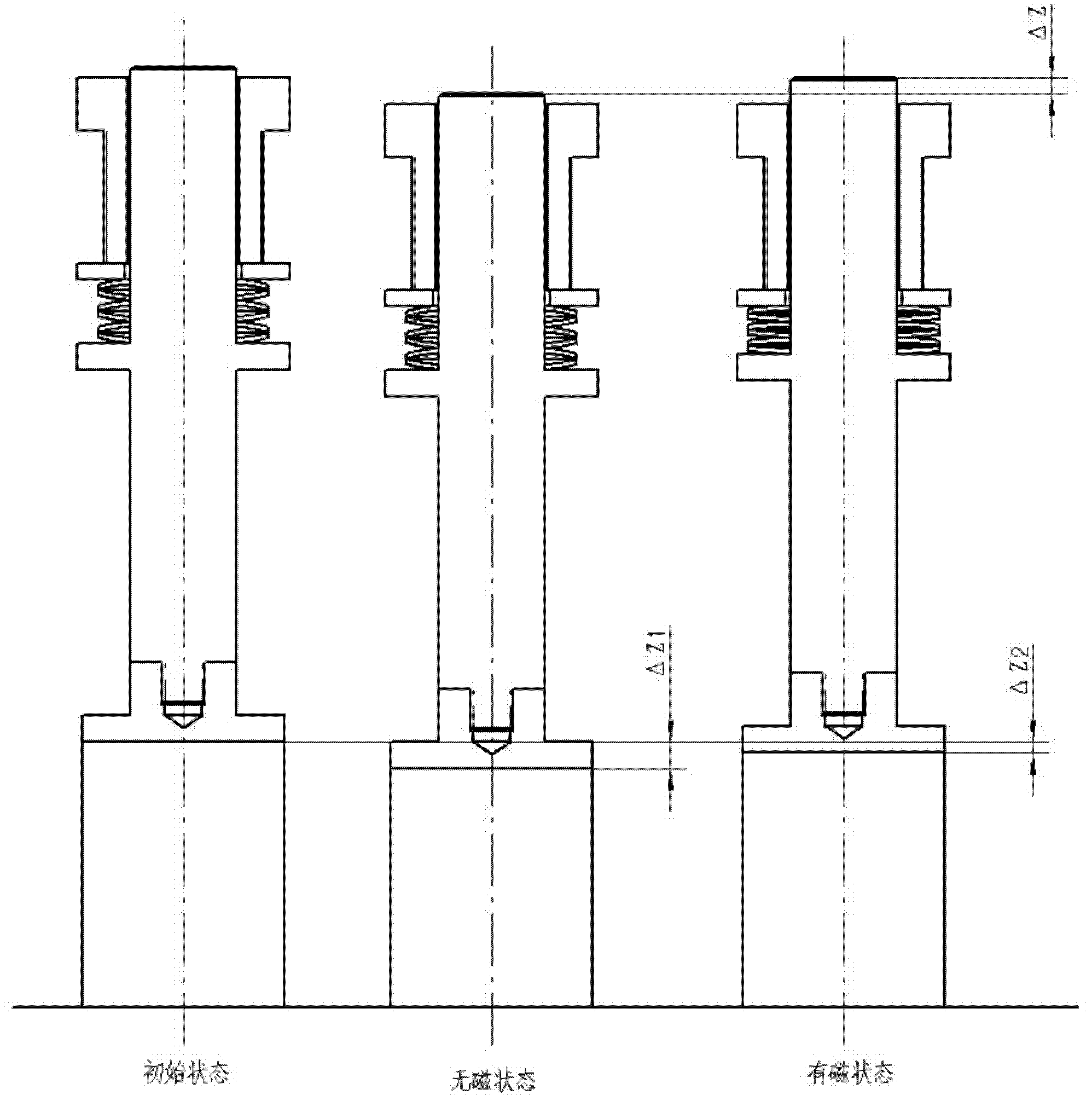

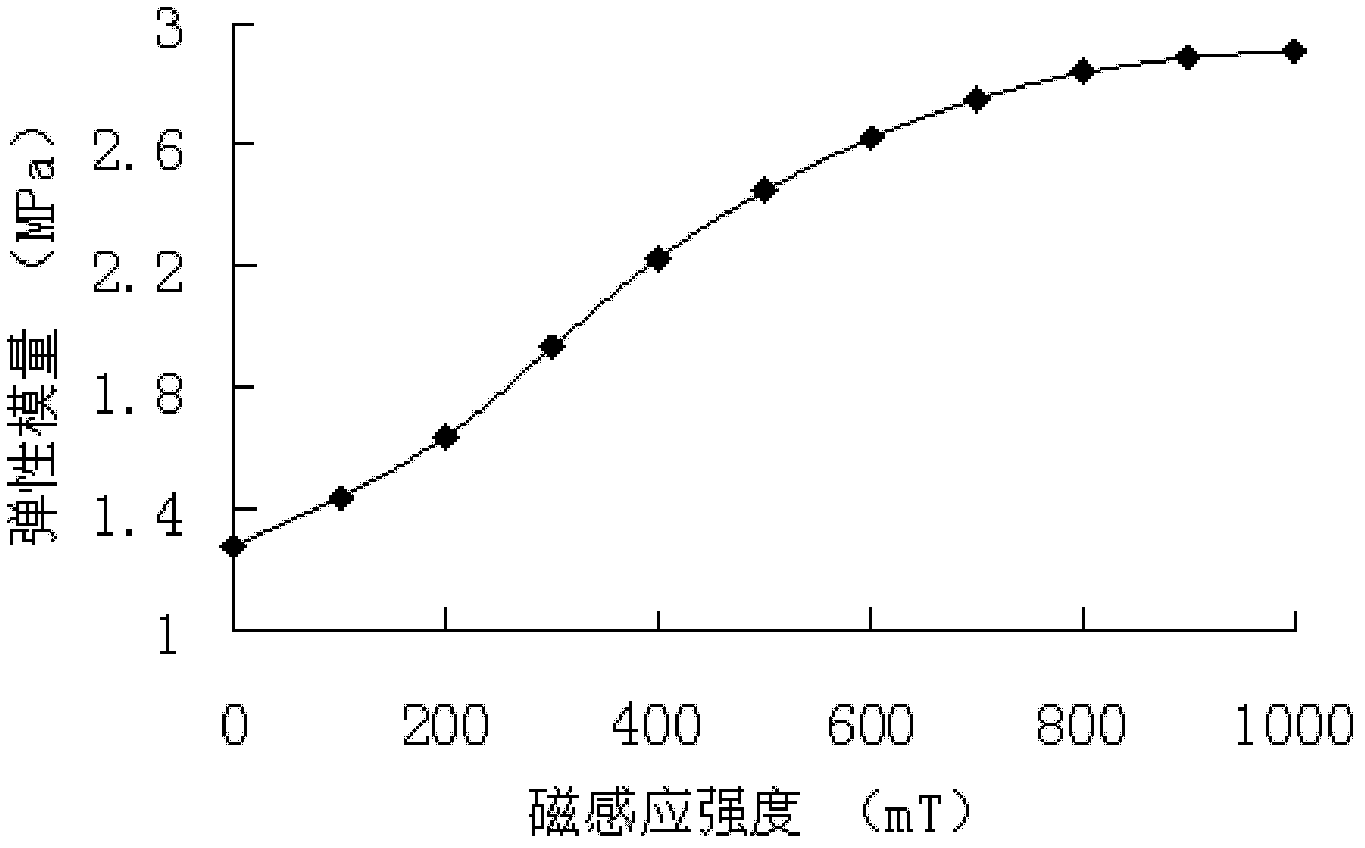

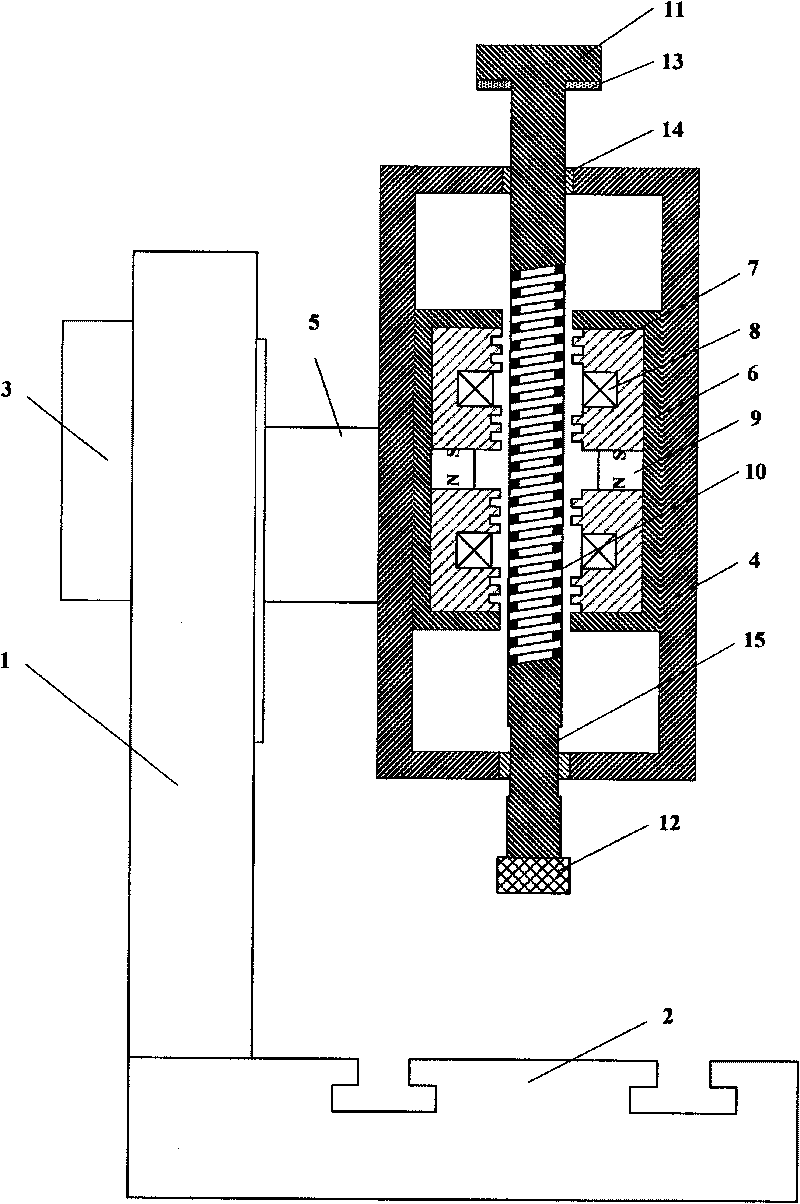

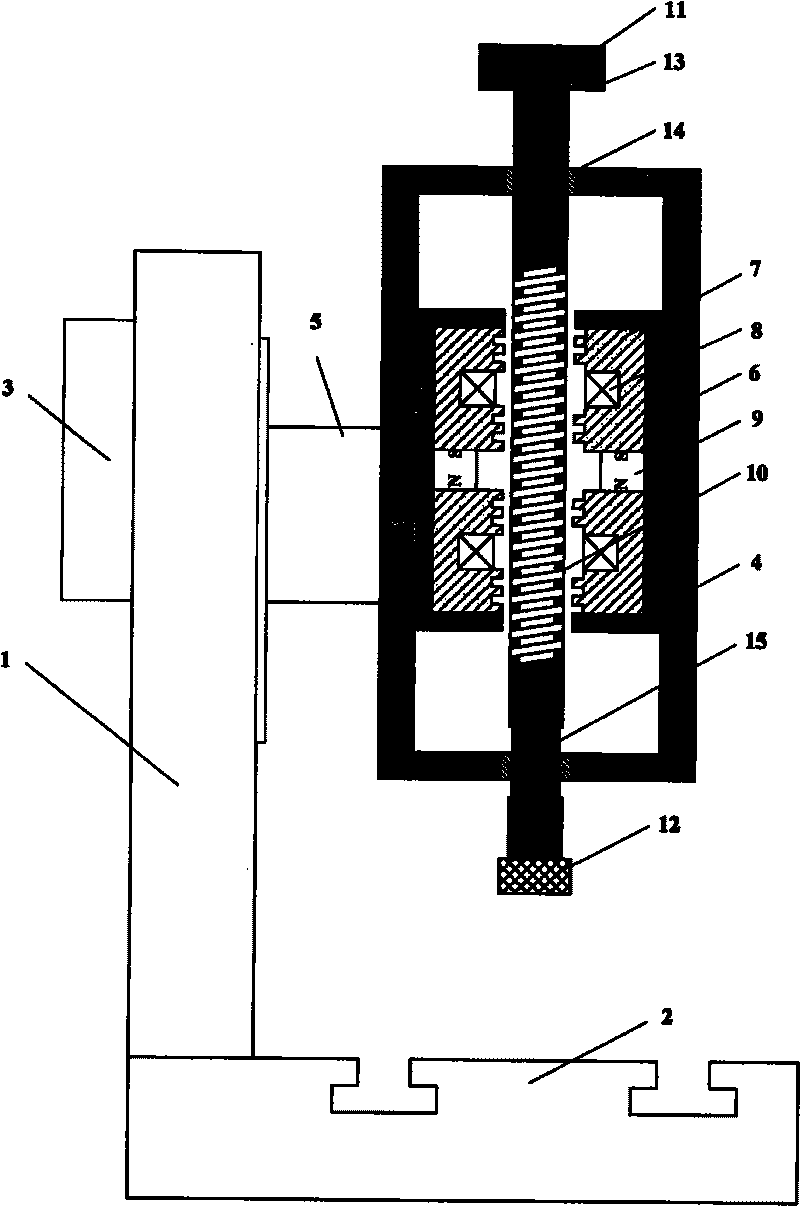

Squeezed micro-displacement actuator of magnetorheological elastomer

InactiveCN102437709AIncrease the itineraryAdjustable strokeDynamo-electric machinesMountingsMicro nanoElastomer

The invention relates to a squeezed micro-displacement actuator of a magnetorheological elastomer and belongs to the field of precision mechanical devices. The actuator comprises a lower shell, a lower magnetizer, the magnetorheological elastomer, a magnet exciting coil, an upper magnetizer, a squeezing disc, an output rod, a linear bearing, a fixing flange, a pre-tightening mechanism and an upper shell. In the actuator, the output rod is used as micro-displacement output; one end of the output rod is connected with the magnetorheological elastomer through the squeezing disc while the other end of the output rod is positioned by the linear bearing; and the pre-tightening mechanism is used for applying a tightening force to the top end of the output rod. The tightening force is applied at working hours so that the magnetorheological elastomer is initially deformed, and the elastic modulus of the magnetorheological elastomer is changed through controlling a magnetic field after electrification, namely, the displacement at the end part of the output rod is changed, so that the purpose of micro-displacement output is achieved. The micro-displacement actuator provided by the invention has the advantages of large and adjustable stroke and simple structure, and can meet the requirement of micro-nano resolution.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

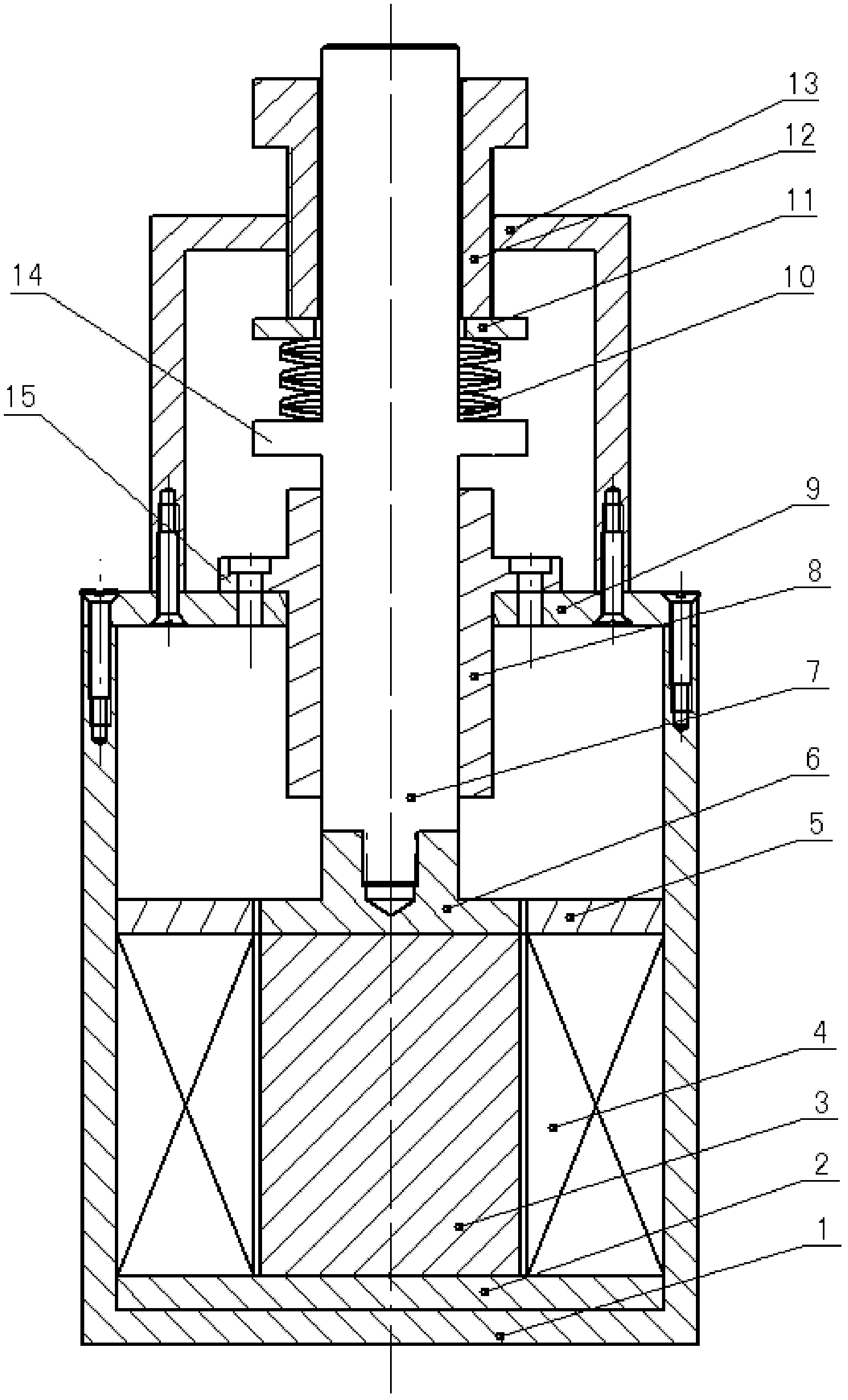

Electromagnetic lead screw driving type precise-punching presser

The invention discloses an electromagnetic lead screw driving type precise-punching presser which comprises a presser body, a working platform, a controller and a stand, wherein the presser body is fixed on the working platform; the stand is arranged above the working platform, and is movably connected with the stand through a connecting plate. The stand is provided with an electromagnetic lead screw system which comprises an electromagnetic nut and a punch shaft. The electromagnetic nut is fixed on the stand, and comprises two circular cores. Each circular core is divided into two parts by a coil. A circular permanent magnet is clamped between the two cores. The punch shaft penetrates through the stand and the electromagnetic nut, and has a gap with the electromagnetic nut. Threads which have the same pitch are processed at the inner hole side of the circular core and the part of the punch shaft. The controller is used for controlling the density, the frequency and the phase of the current in the coil. The invention has the advantages of adjustable speed and punch force, quick response, high guiding and positioning precision, simple structure, convenient control, less component consumption, low noise, convenient maintenance and long service life.

Owner:ZHEJIANG UNIV

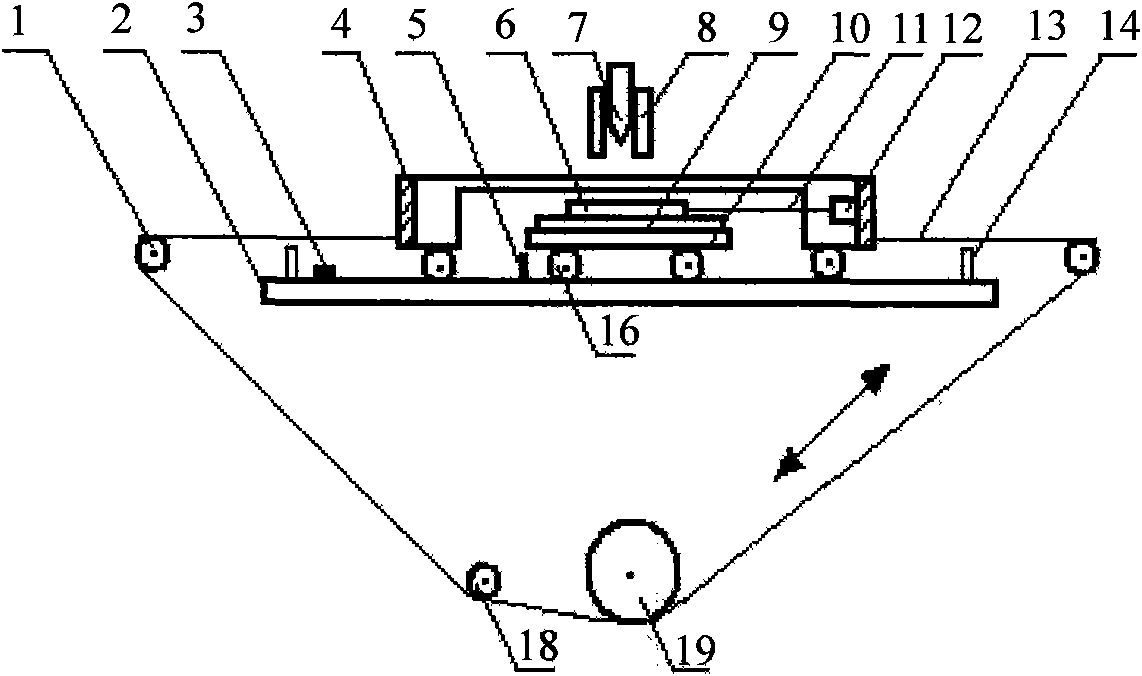

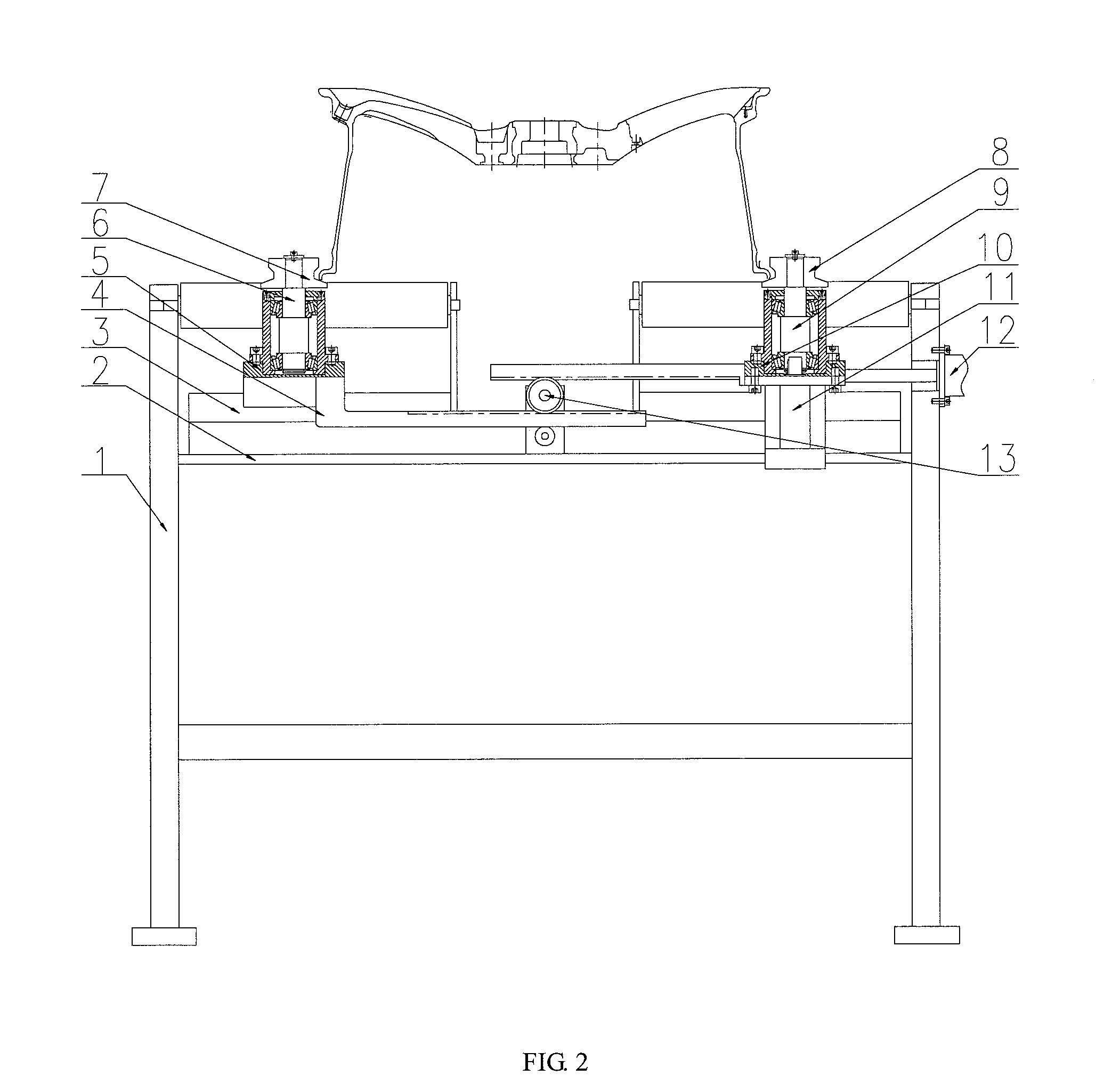

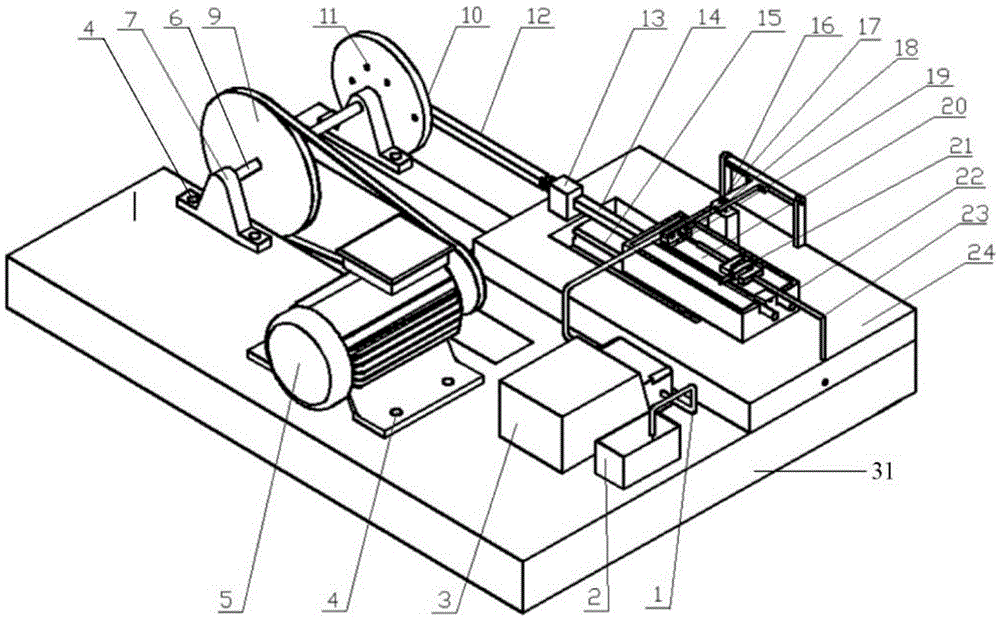

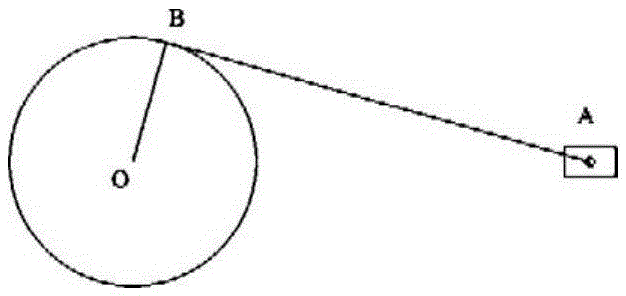

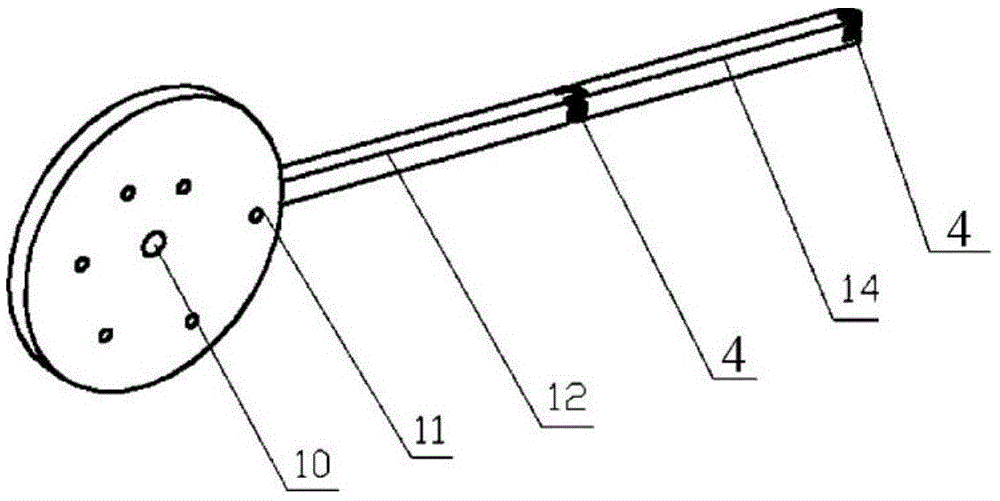

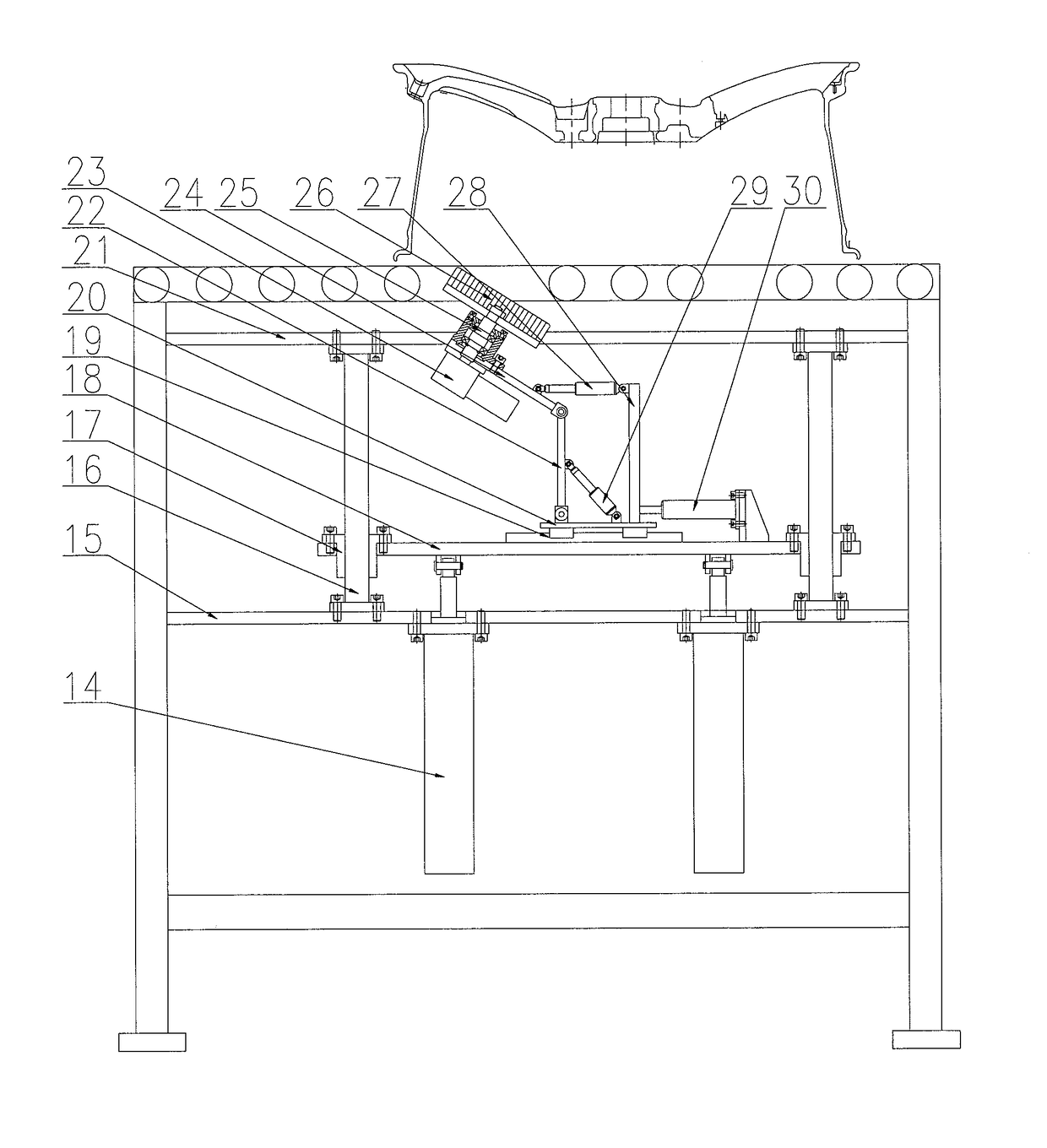

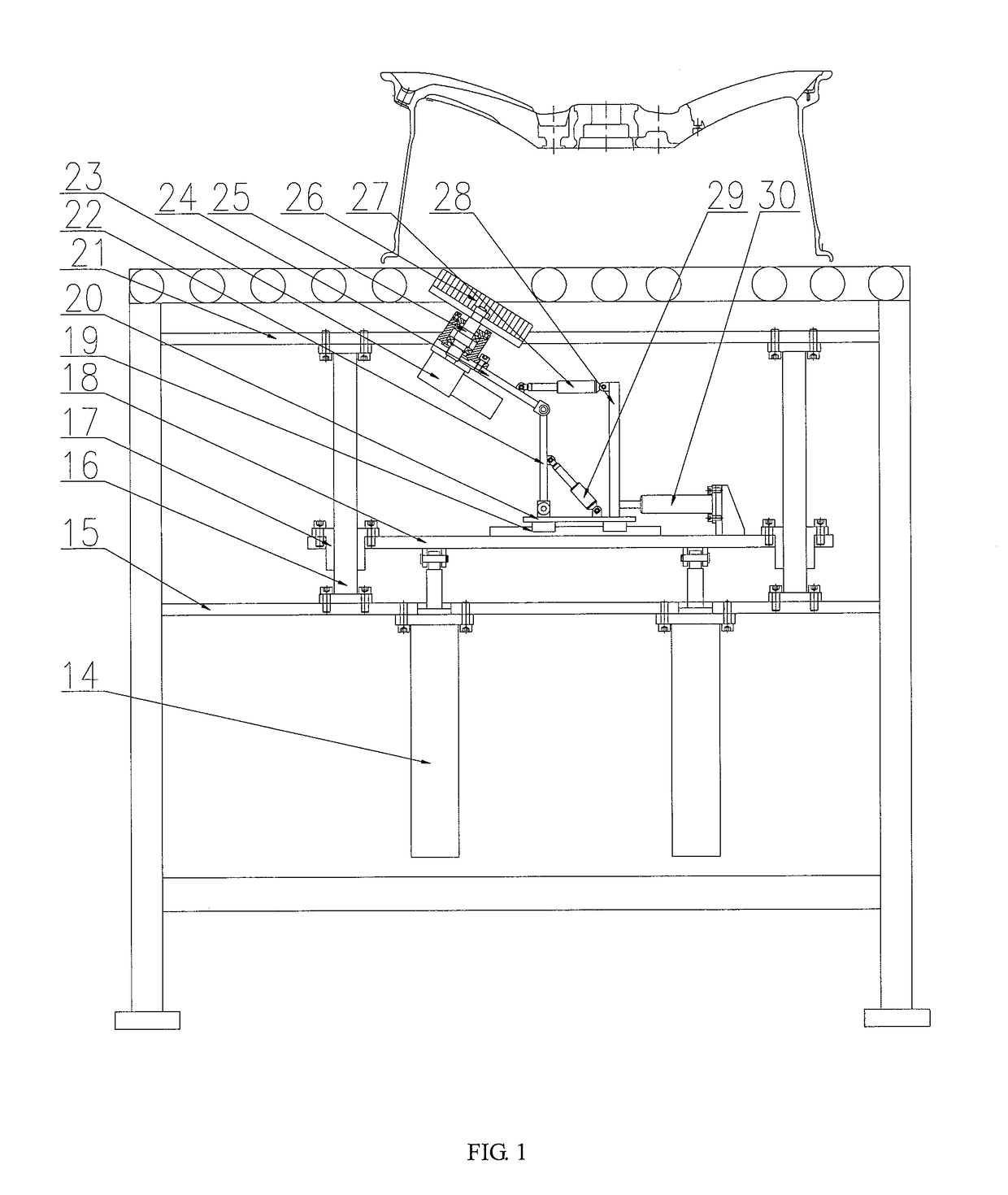

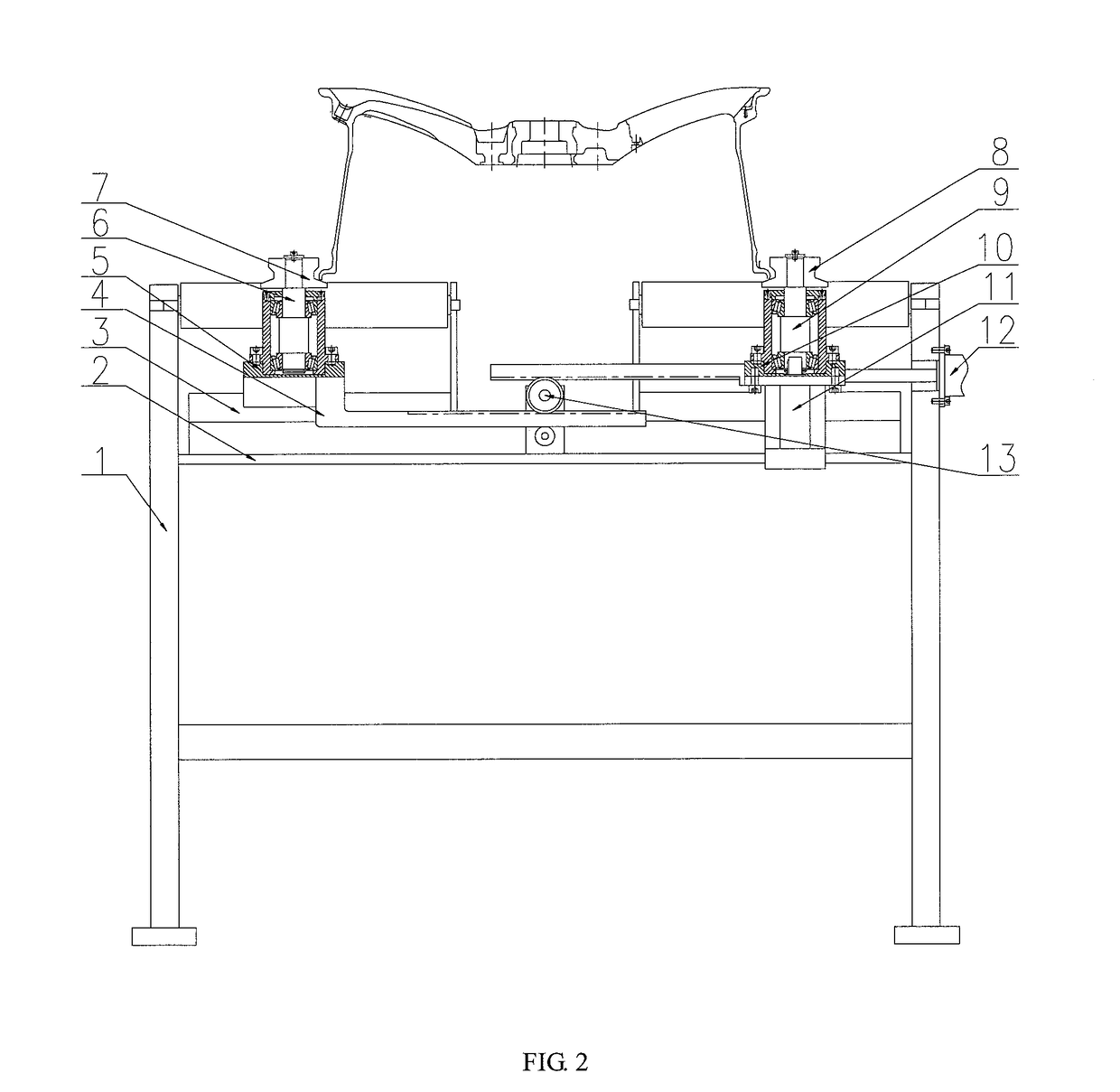

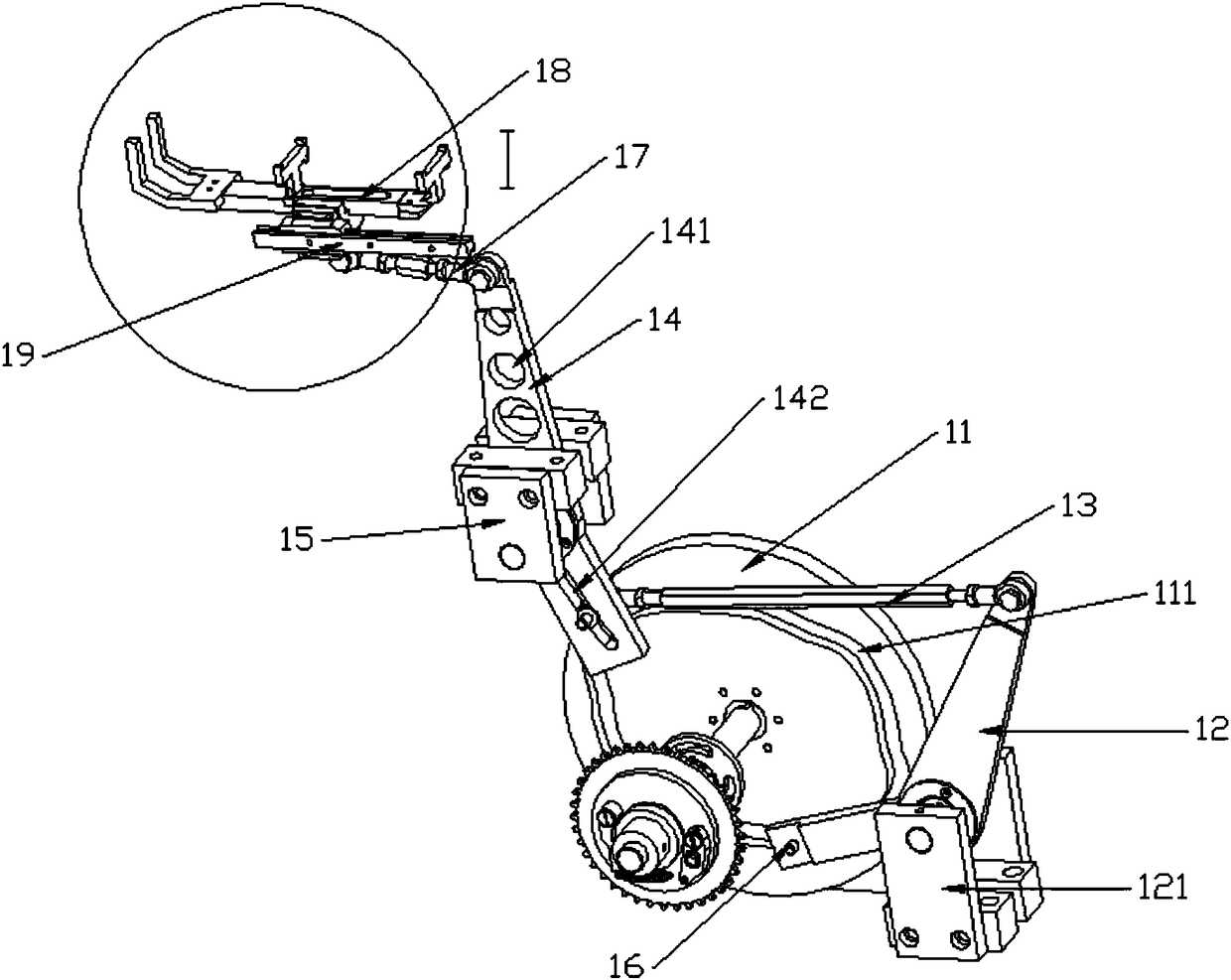

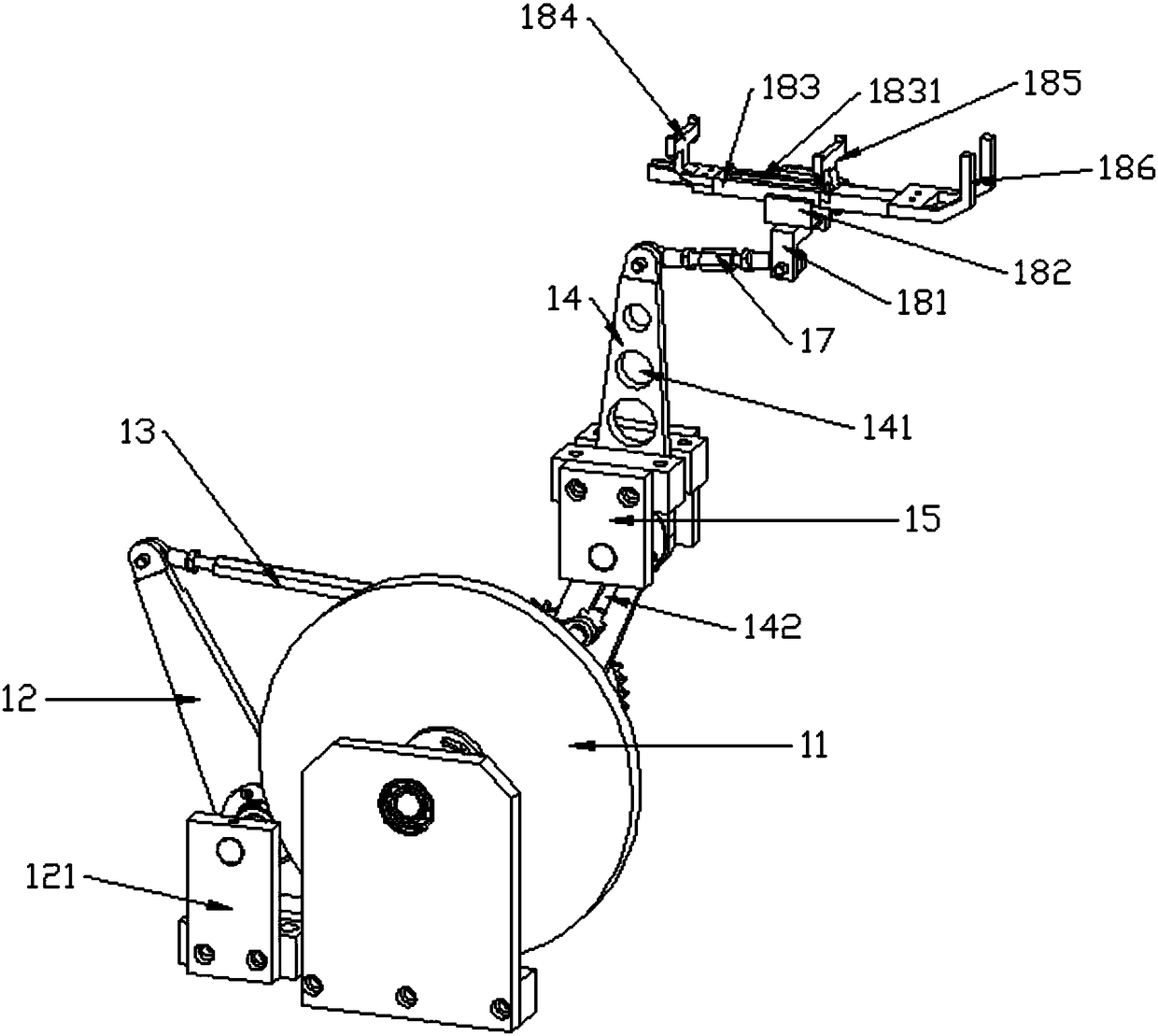

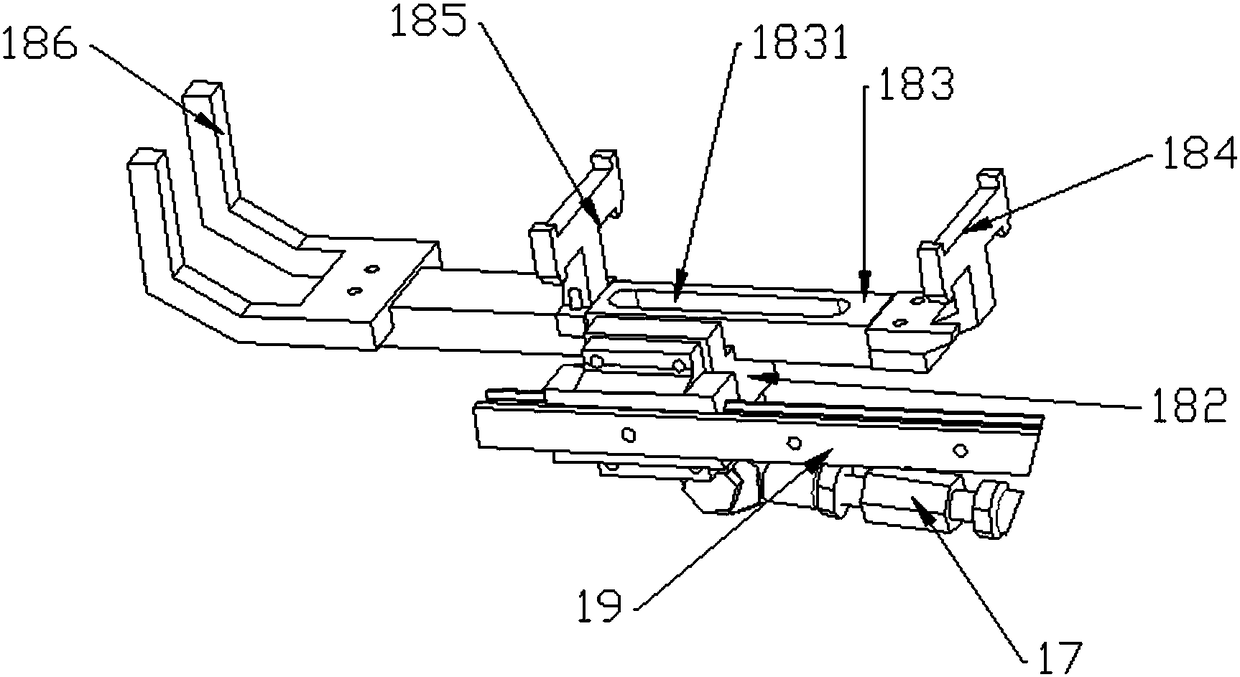

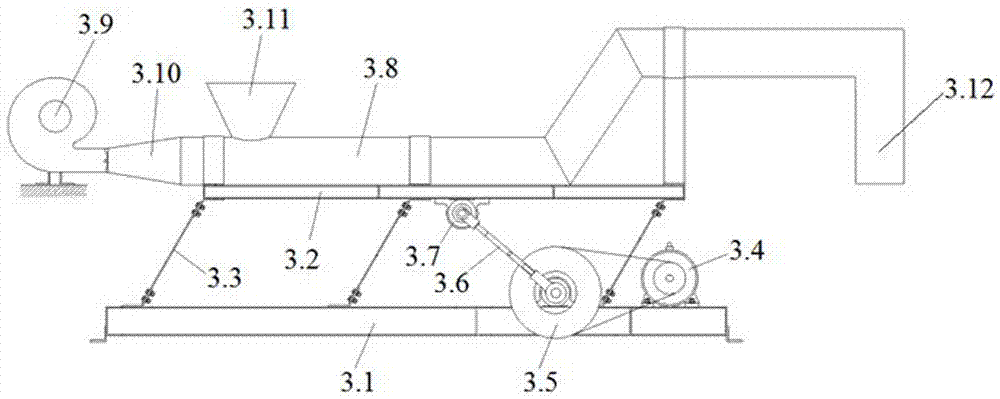

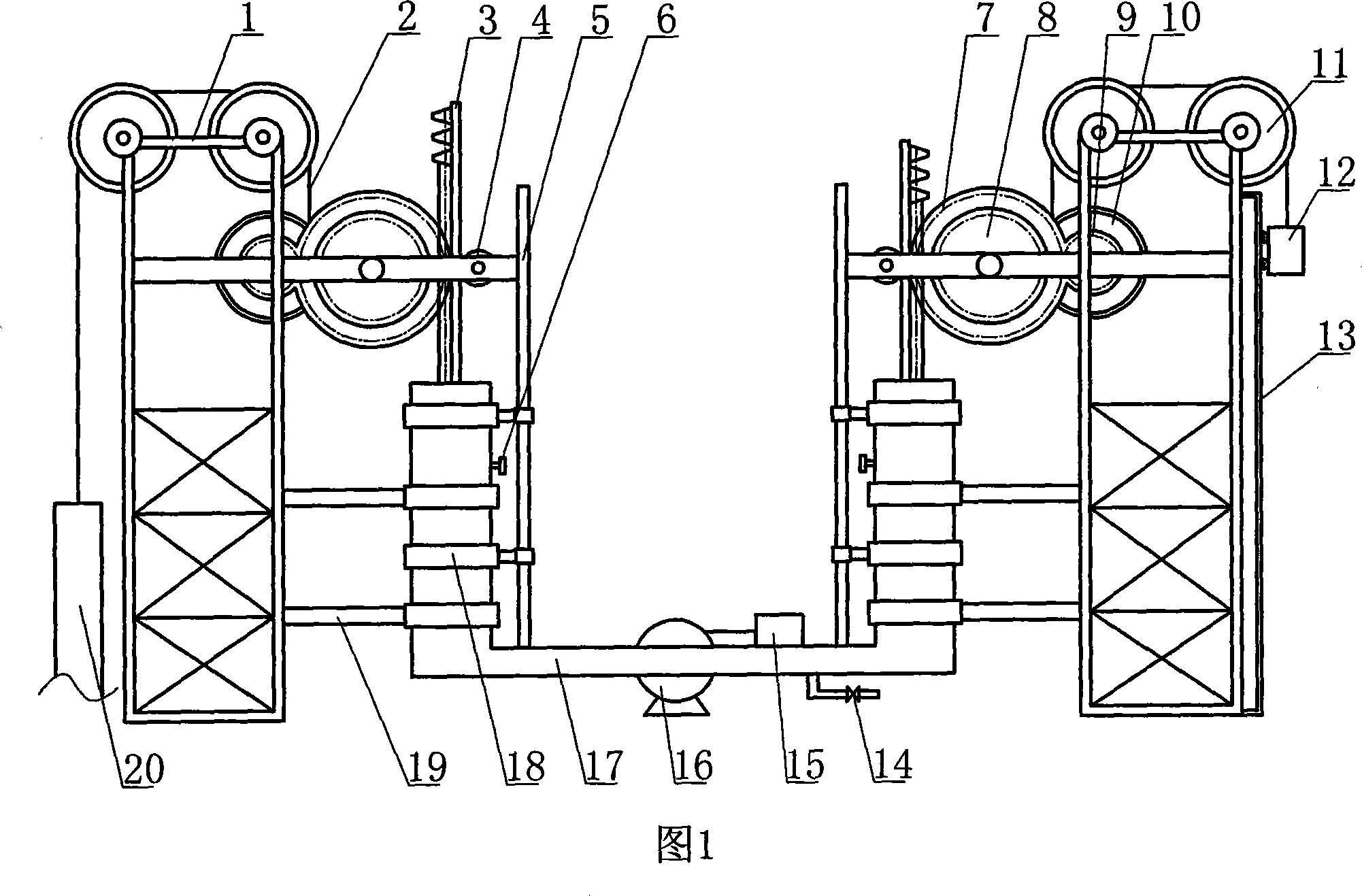

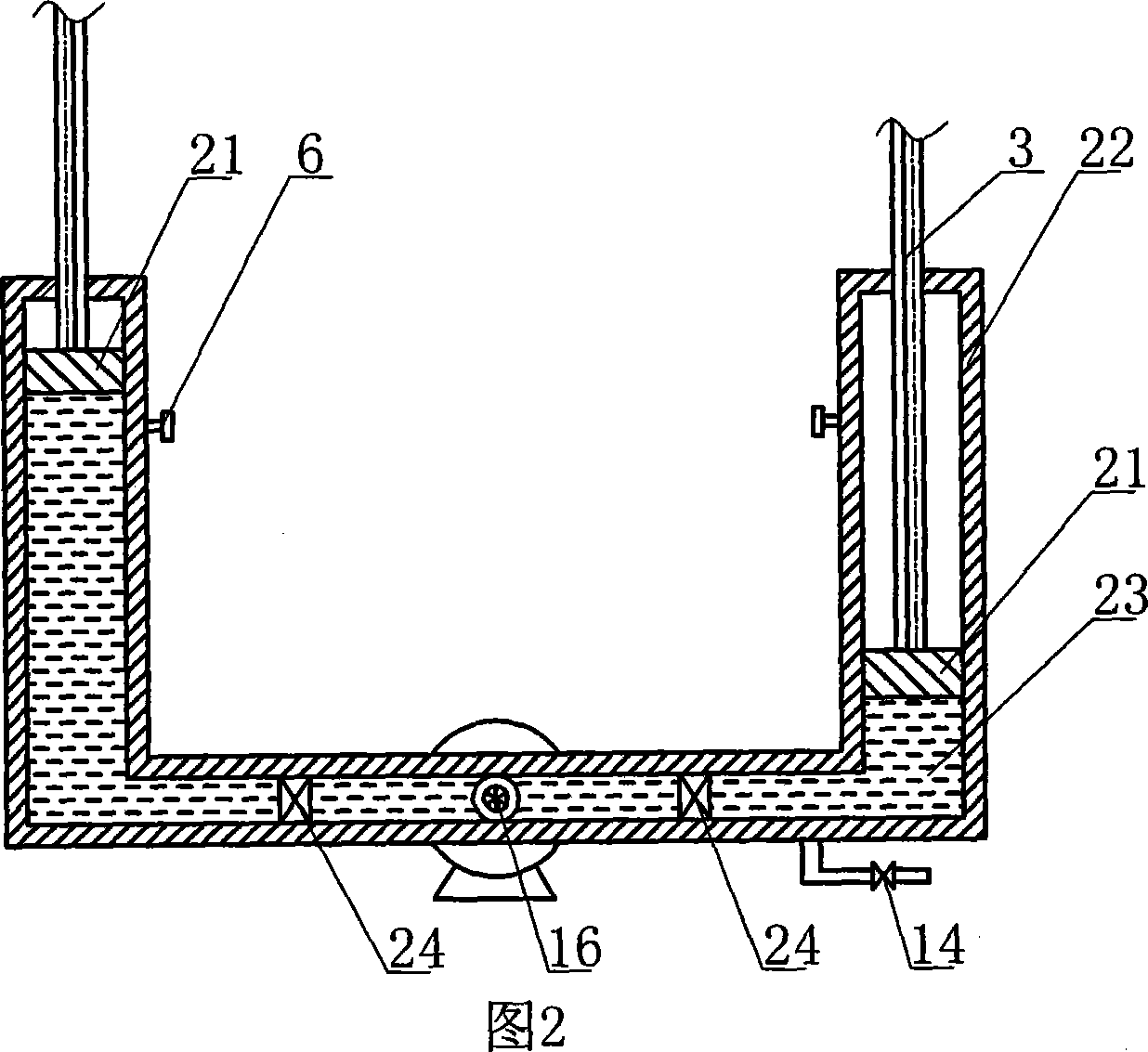

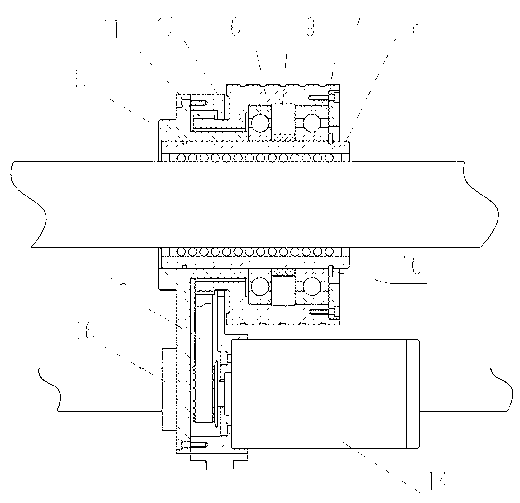

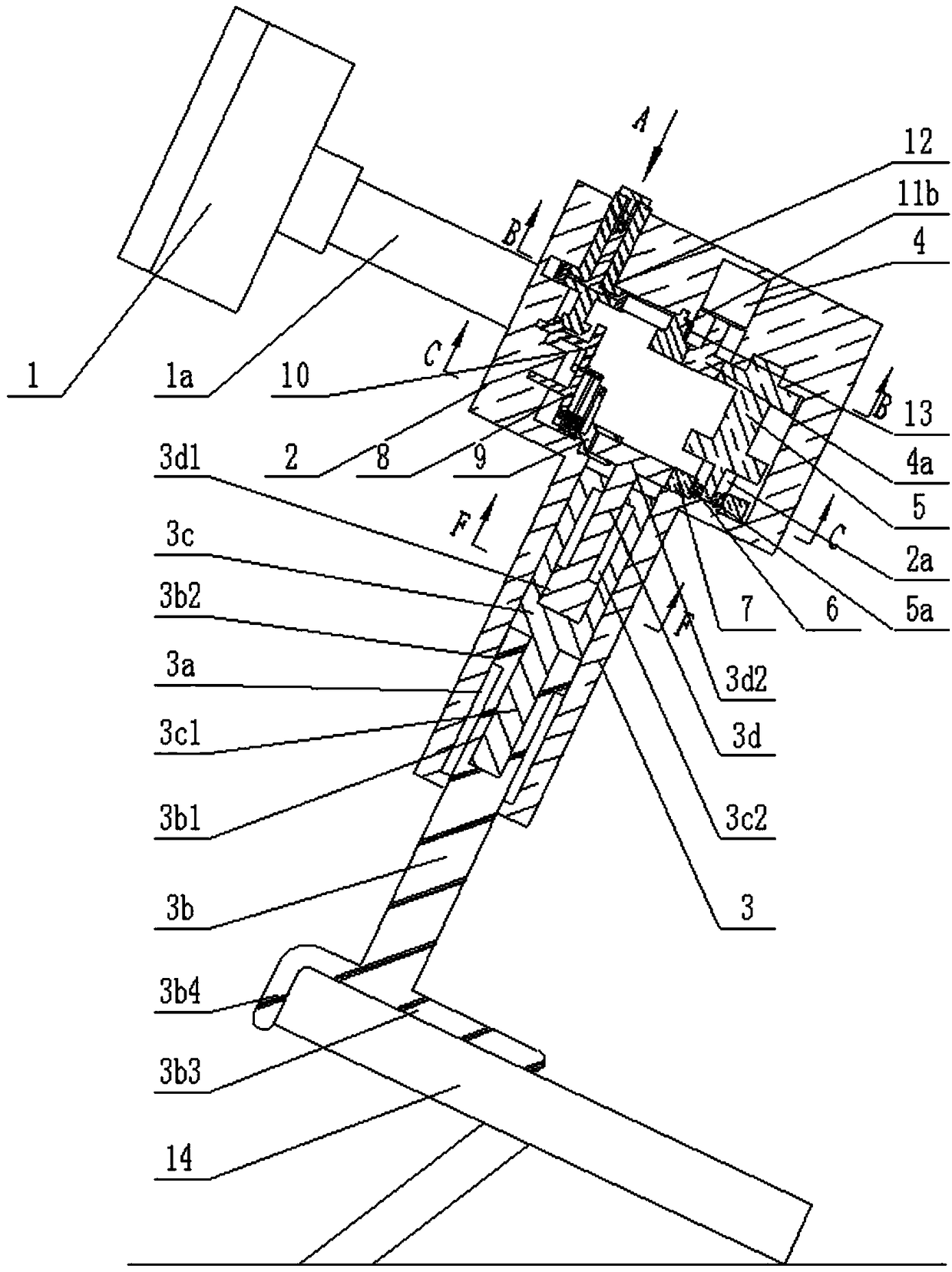

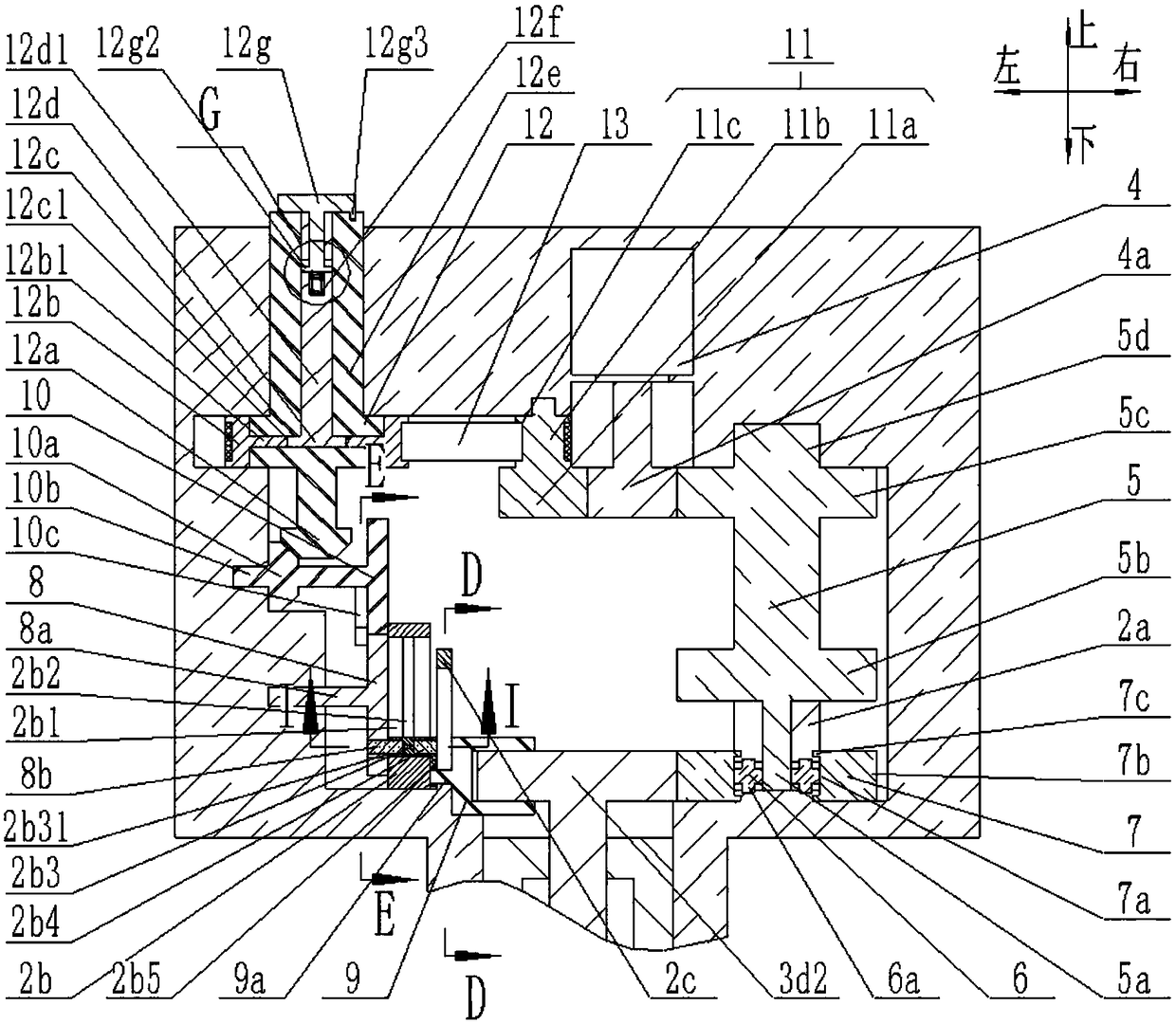

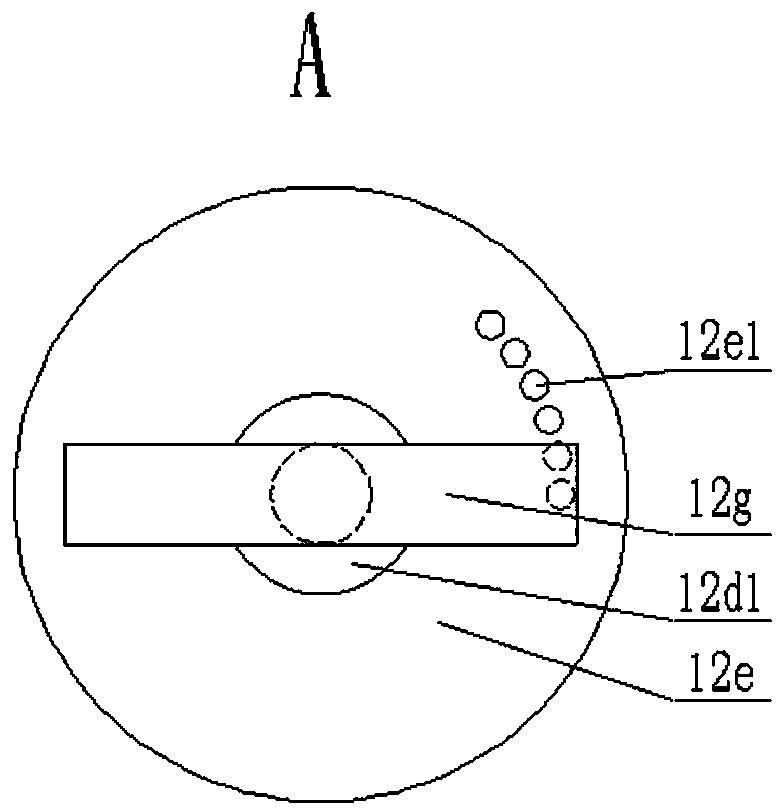

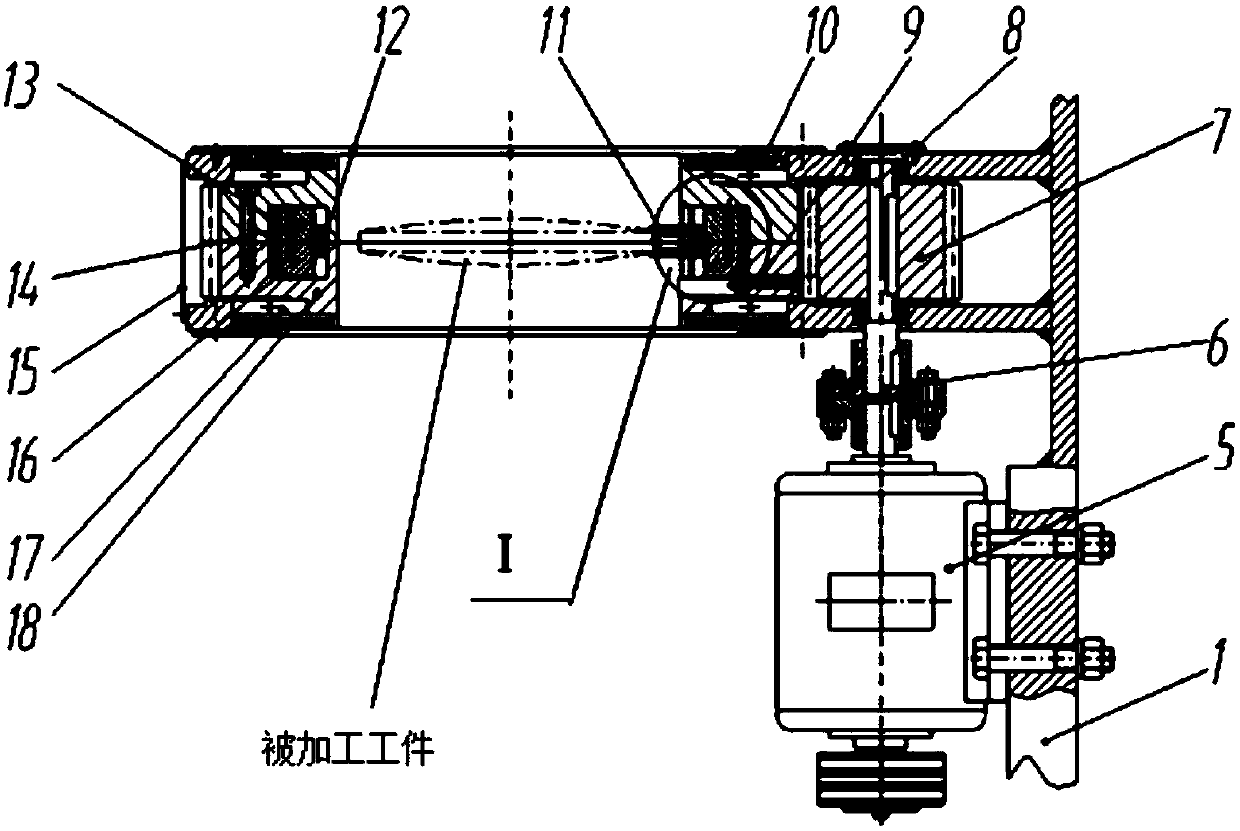

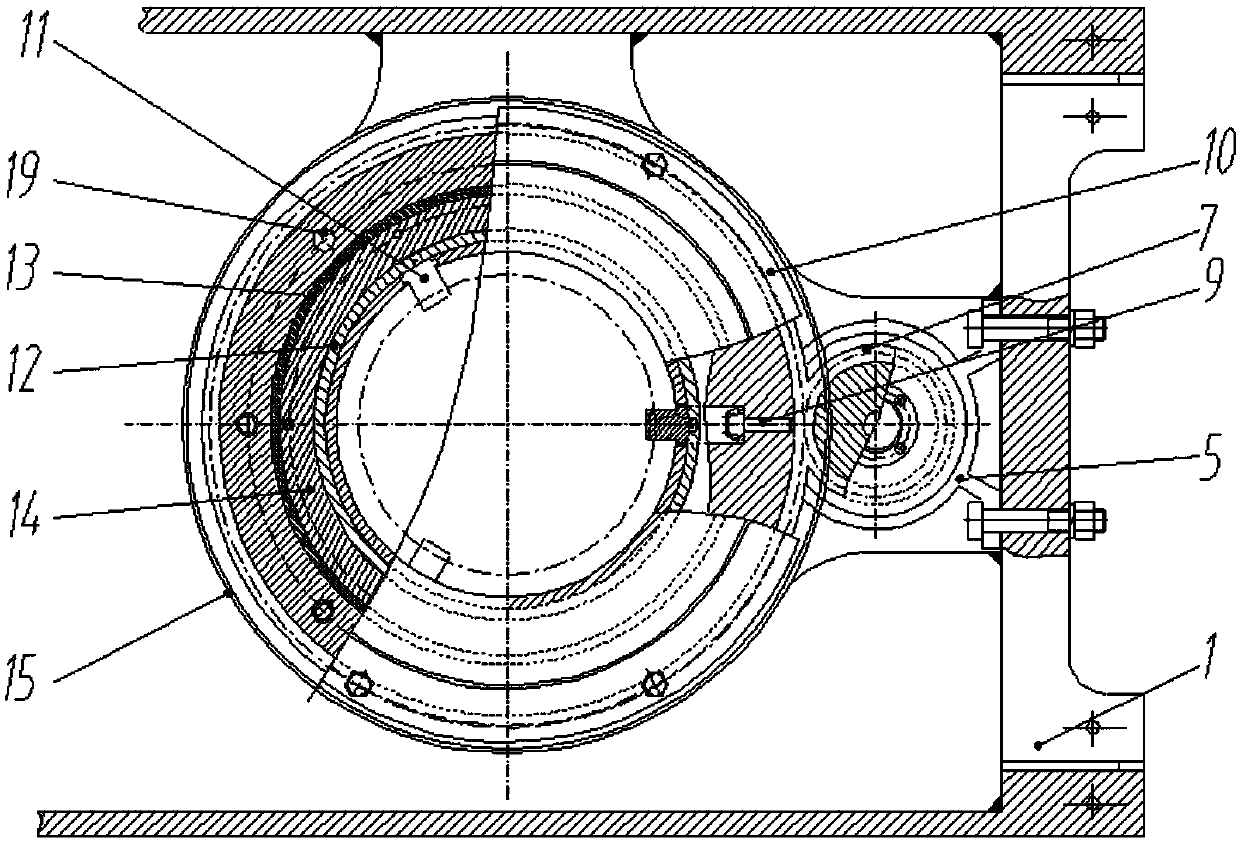

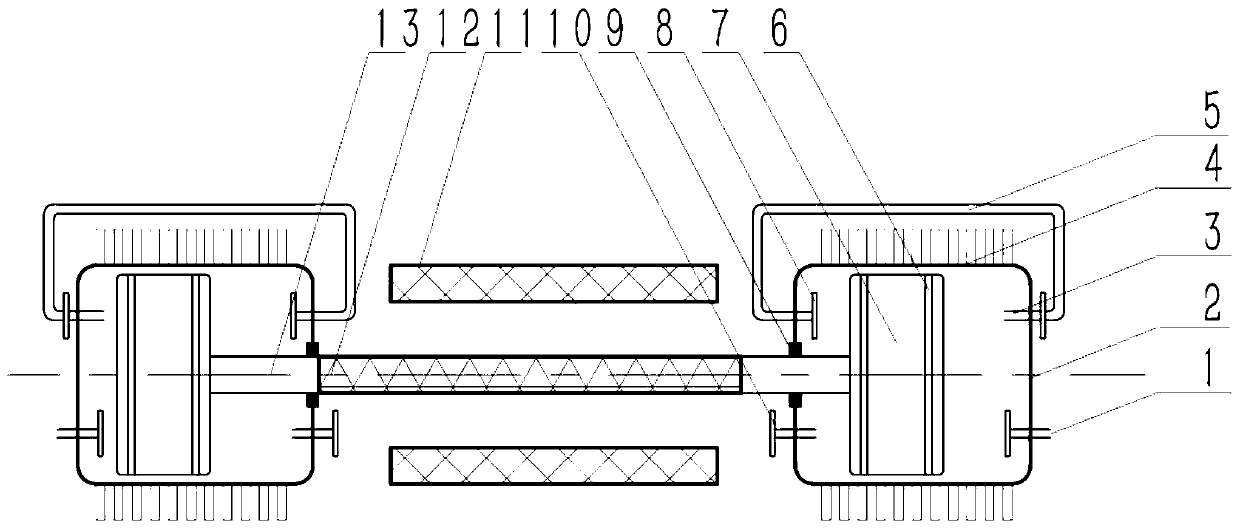

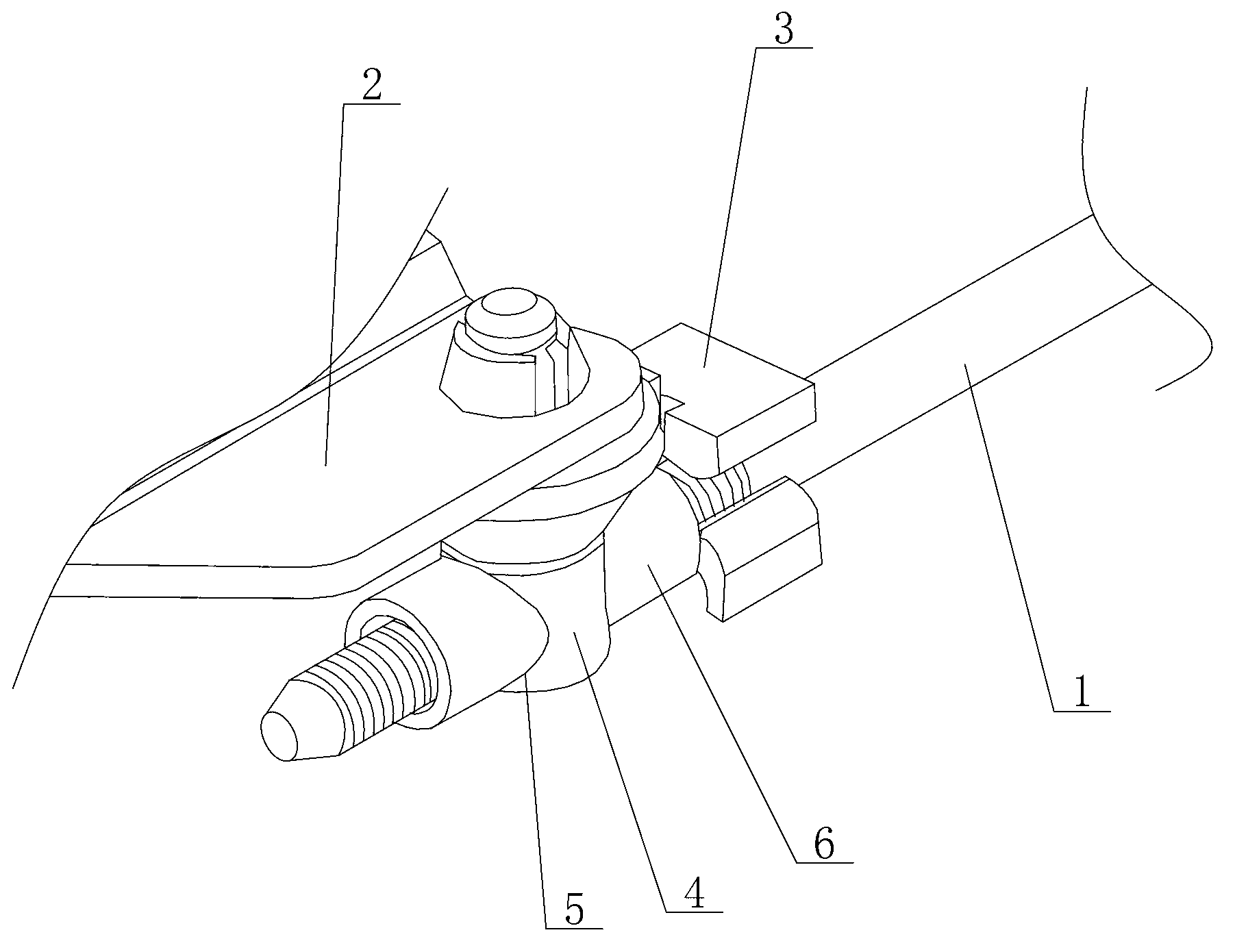

Internal combustion engine cylinder sleeve-piston ring friction performance testing machine with variable reciprocating stroke

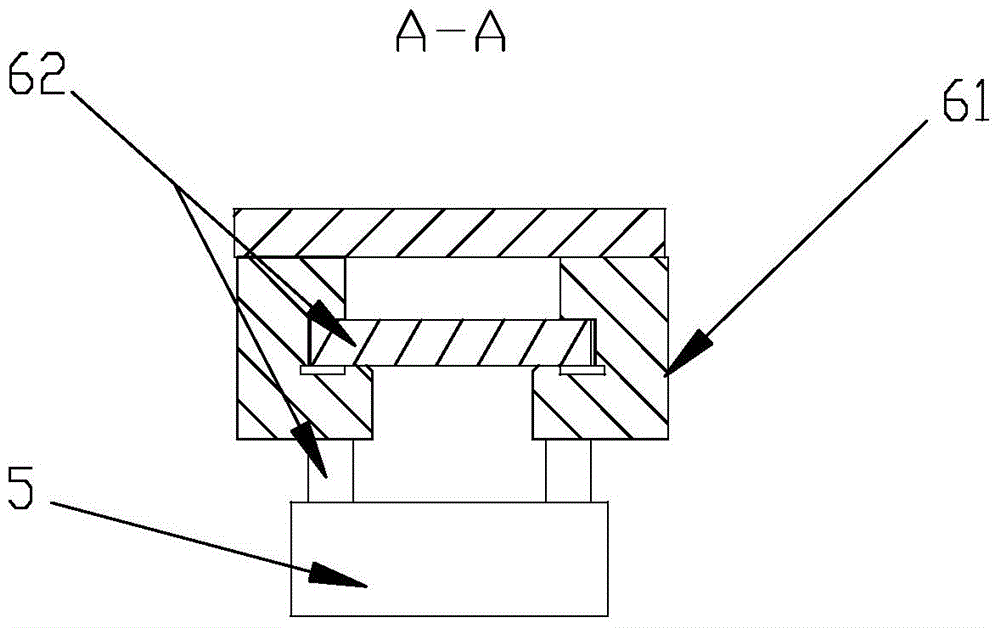

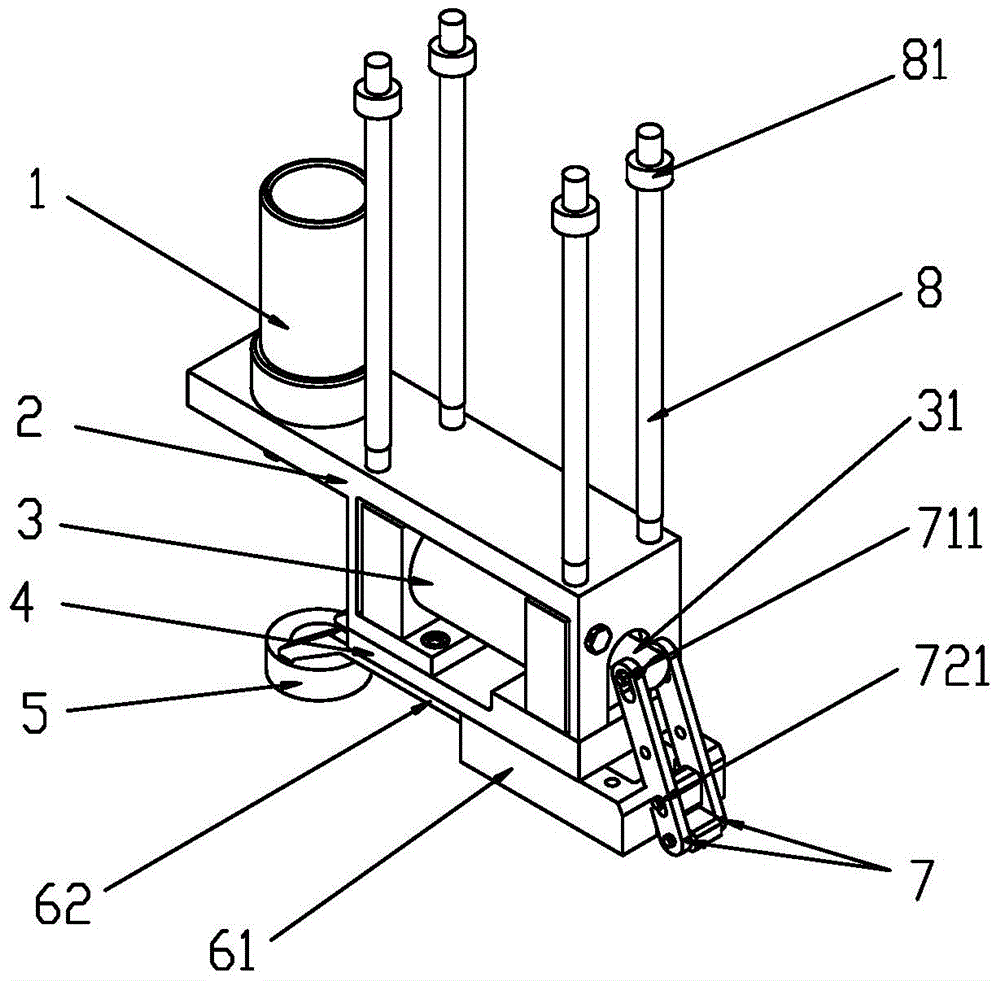

InactiveCN105628535ATest parameters are easy to controlGood repeatability of test resultsInvestigating abrasion/wear resistanceContact conditionSensor holder

The invention relates to a testing machine used for studying the mechanical power consumption of an internal combustion engine, in particular to an internal combustion engine cylinder sleeve-piston ring friction performance testing machine with the variable reciprocating stroke. The internal combustion engine cylinder sleeve-piston ring friction performance testing machine with the variable reciprocating stroke comprises a platform (24) and a bottom plate (31) and is characterized by further comprising a belt wheel axle (6), a support (7), a large belt wheel (9), a variable-radius crank disc (10), pin holes (11) for installing cylindrical pins, a connecting rod (12), an adjusting rod guide base (13), an adjusting rod (14), a guide rail (15), a loading hole (16), a cantilever beam (17), a piston ring clamp (18), a piston ring test piece (19), a cylinder sleeve test piece (20), a tension and pressure sensor (21), a cylinder sleeve base (22), a sensor support (23), a measuring rod (32) and the like. According to the internal combustion engine cylinder sleeve-piston ring friction performance testing machine with the variable reciprocating stroke, parameters are easy to control, the test pieces are easy to obtain, test data is high in precision, and contact conditions are easy to simulate.

Owner:TONGJI UNIV

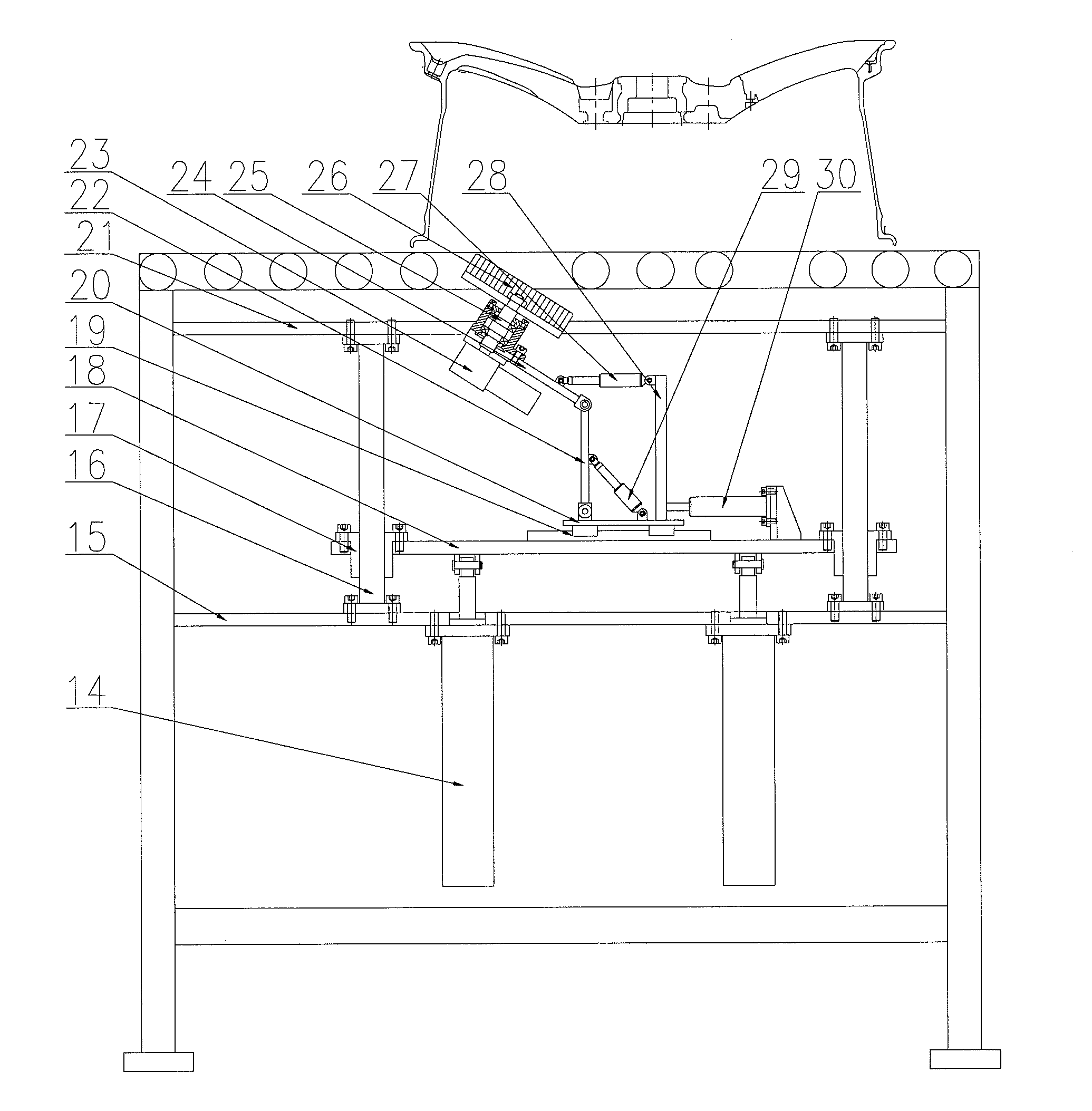

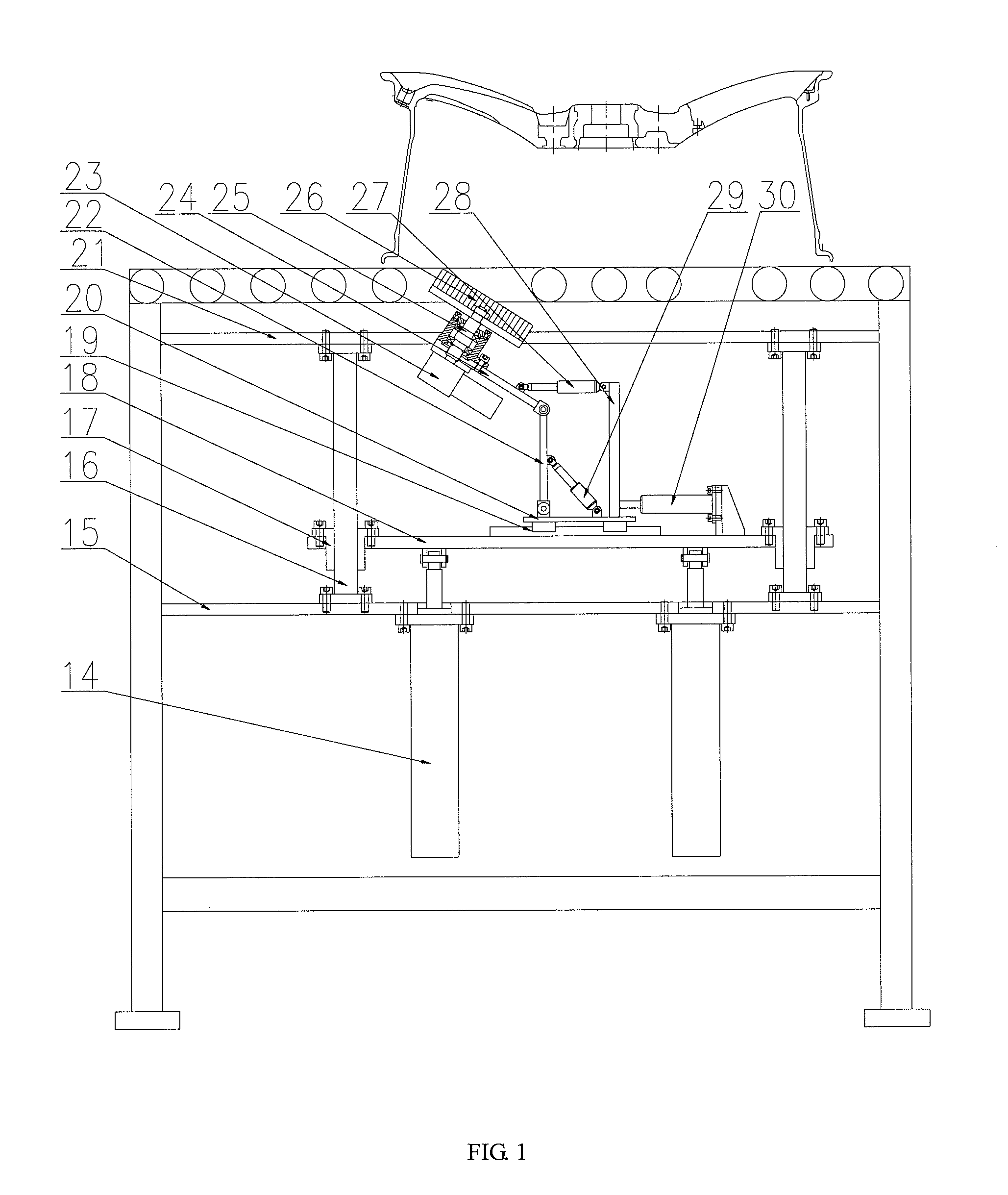

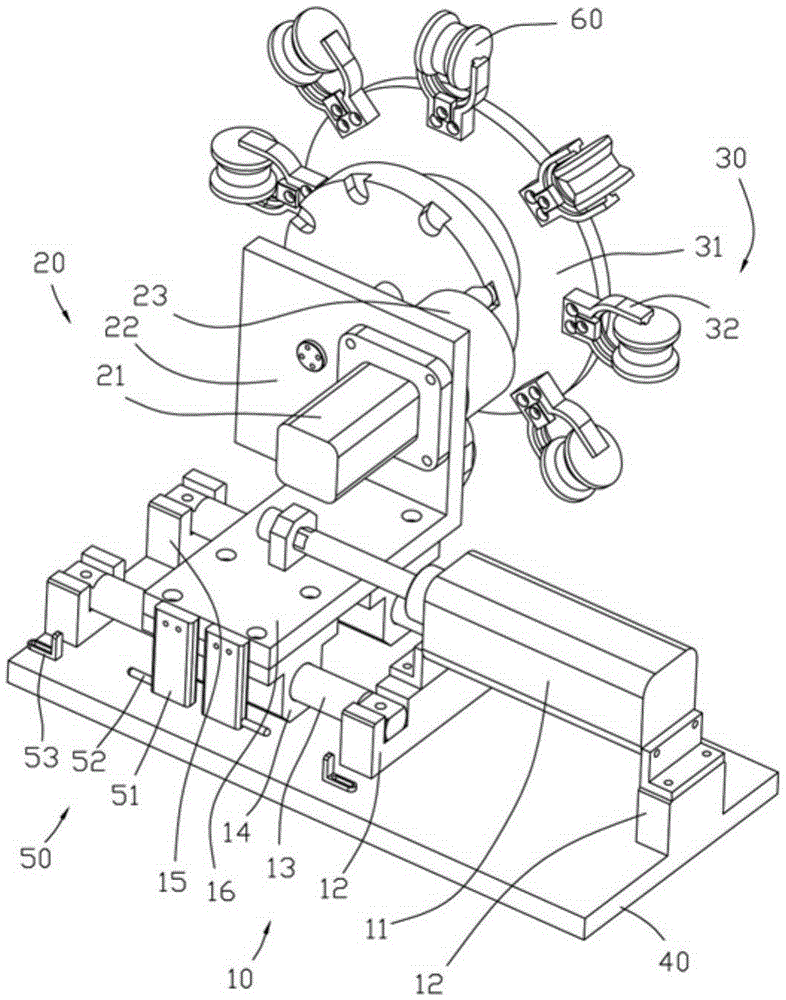

Wheel deburring device and deburring method

ActiveUS9833873B2Small adjustmentAdjustable strokeEdge grinding machinesPolishing machinesEngineeringAutomation

The present invention provides a wheel deburring device, consisting of a frame, a motor, a guide rail, a swing plate, a cylinder, a servo electric cylinder and a hairbrush and the like. When in use, the device provided by the present invention can adjust the angle of the hairbrush according to the shape of the back cavity of the wheel spoke to adapt to hubs of any style, and the deburring effect is very ideal; and meanwhile, the device has the characteristics of high degree of automation, advanced process, safe and stable performance, etc.

Owner:CITIC DICASTAL

Steel bar bending machine

The invention discloses a steel bar bending machine. The steel bar bending machine comprises a conveying device and a bending mechanism. The bending mechanism comprises a cushion plate, a fixed block,a bending knife and an oil cylinder. The cushion plate is jointed with the side of steel bars in an abutting mode. The fixed block is fixedly arranged on the cushion plate. The fixed block is provided with through holes where the steel bars are inserted. The upper surface and / or the lower surface of the discharge end of the through-holes and / is arranged in an arc shape. The bending knife penetrates through the cushion plate and is jointed with surfaces of the steel bars in an abutting mode. The bending knife can slide in the steel bars and drive the steel bars to be bent matching the arc-shaped discharge end of the through holes. The bending knife is driven to slide by the oil cylinder. The stroke of the oil cylinder can be adjusted. The former method that a stepping motor is used to control a rotation angle of a bending machine to adjust a bending angle is omitted, and by changing the stroke of the oil cylinder, the displacement of the bending knife jointed with the steel bars in theabutting mode is controlled, so that the bending range of the steel bars is indirectly controlled. The structure of the whole bending machine is simplified, so that it is convenient for users to usein many occasions.

Owner:WUYI UNIV +1

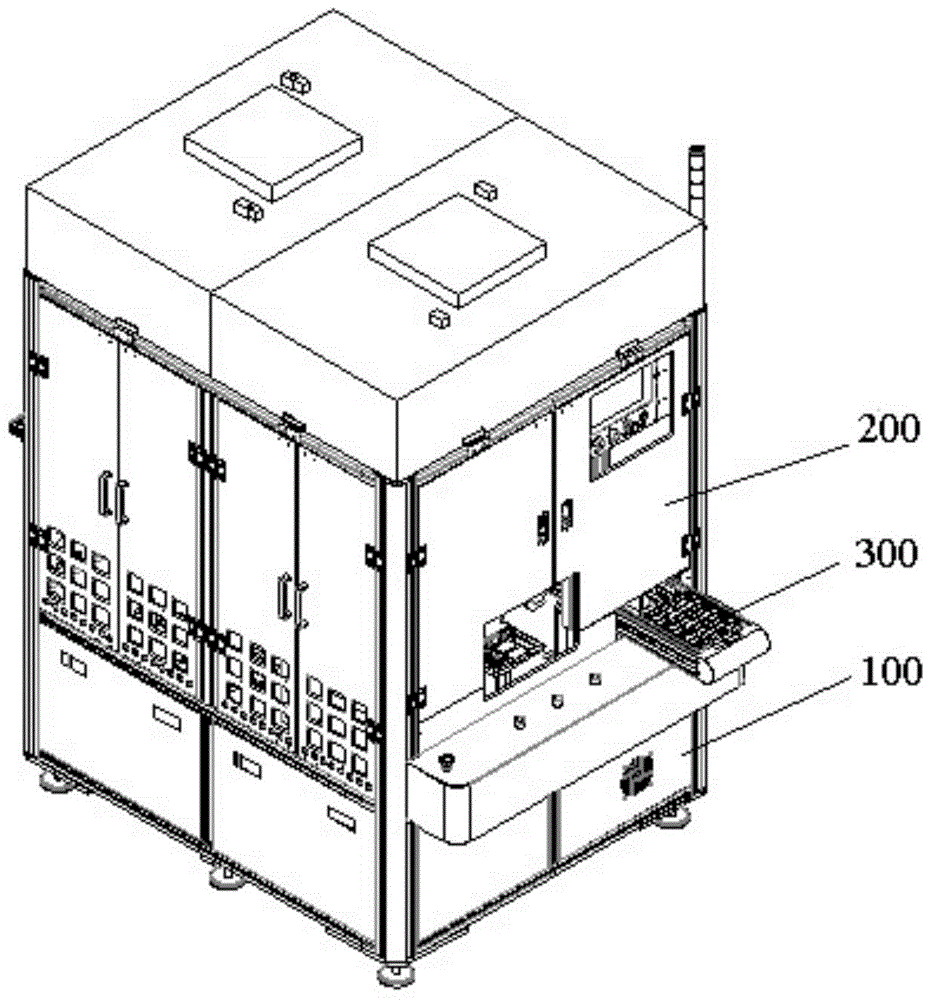

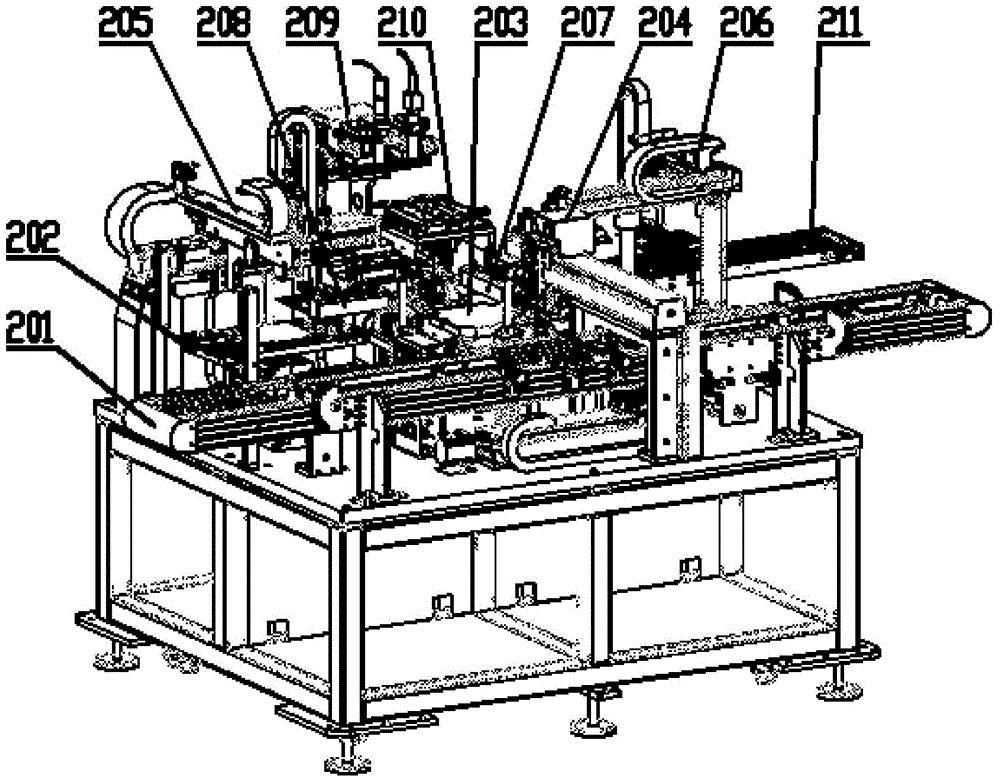

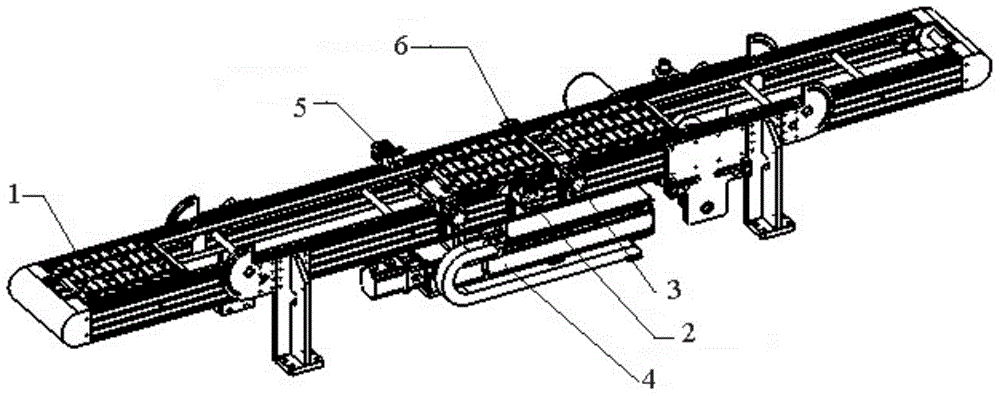

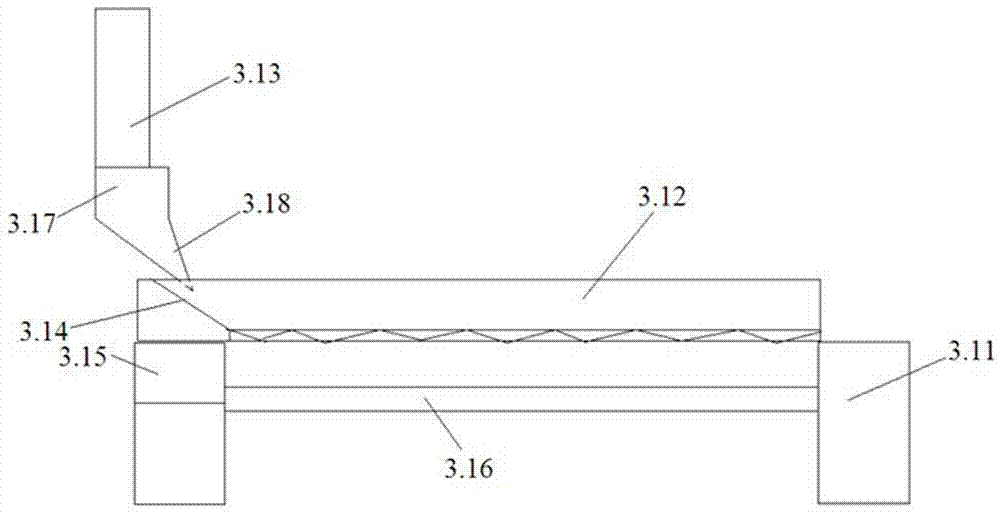

FPC light guide plate attaching machine

ActiveCN104816532ASolve the phenomenon of easy scratchesAdjustable pressureLaminationLamination apparatusLight guideEngineering

The present invention relates to the field of mobile phone backlight combination production equipment, particularly to an FPC light guide plate attaching machine, which comprises an upper cabinet and a lower cabinet, and comprises a first material feeding device fixedly arranged on the lower cabinet, a second material feeding device fixedly arranged on the lower cabinet, a third material feeding device fixedly arranged on the lower cabinet, a first material taking device fixedly arranged on the lower cabinet, a second material taking device fixedly arranged on the lower cabinet, a third material taking device fixedly arranged on the lower cabinet, a first destatic device fixedly arranged on the lower cabinet, a second destatic device fixedly arranged on the lower cabinet, a 2CCD image alignment device fixedly arranged on the lower cabinet, an FPC light guide plate attaching device fixedly arranged on the lower cabinet, a material discharge device fixedly arranged on the lower cabinet and an upper frame fixedly arranged on the lower cabinet, wherein the first material taking device, the second material taking device, the third material taking device, the 2CCD image alignment device, and the FPC light guide plate attaching device are positioned above the first material feeding device, the second material feeding device, and the third material feeding device. According to the FPC light guide plate attaching machine of the present invention, the technical disadvantages in the existing manual work can be overcome, and the productivity can be increased; the manual attaching is completely not required, the accurate parameters can be obtained, production switching is convenient, and the efficiency is high; and the problems of not high uniformity and low efficiency of the manual work can be solved.

Owner:SHENZHEN JIYIN TECH

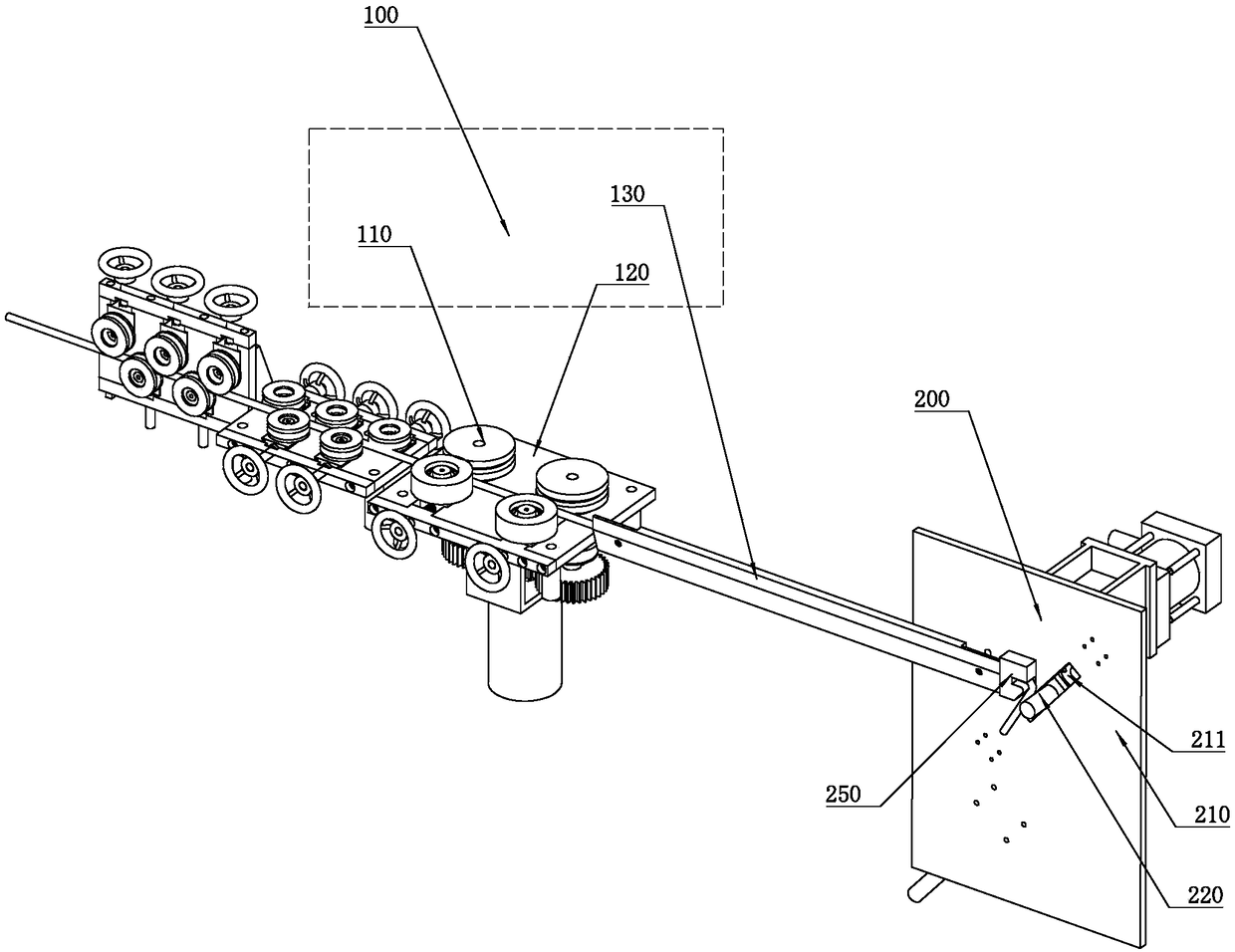

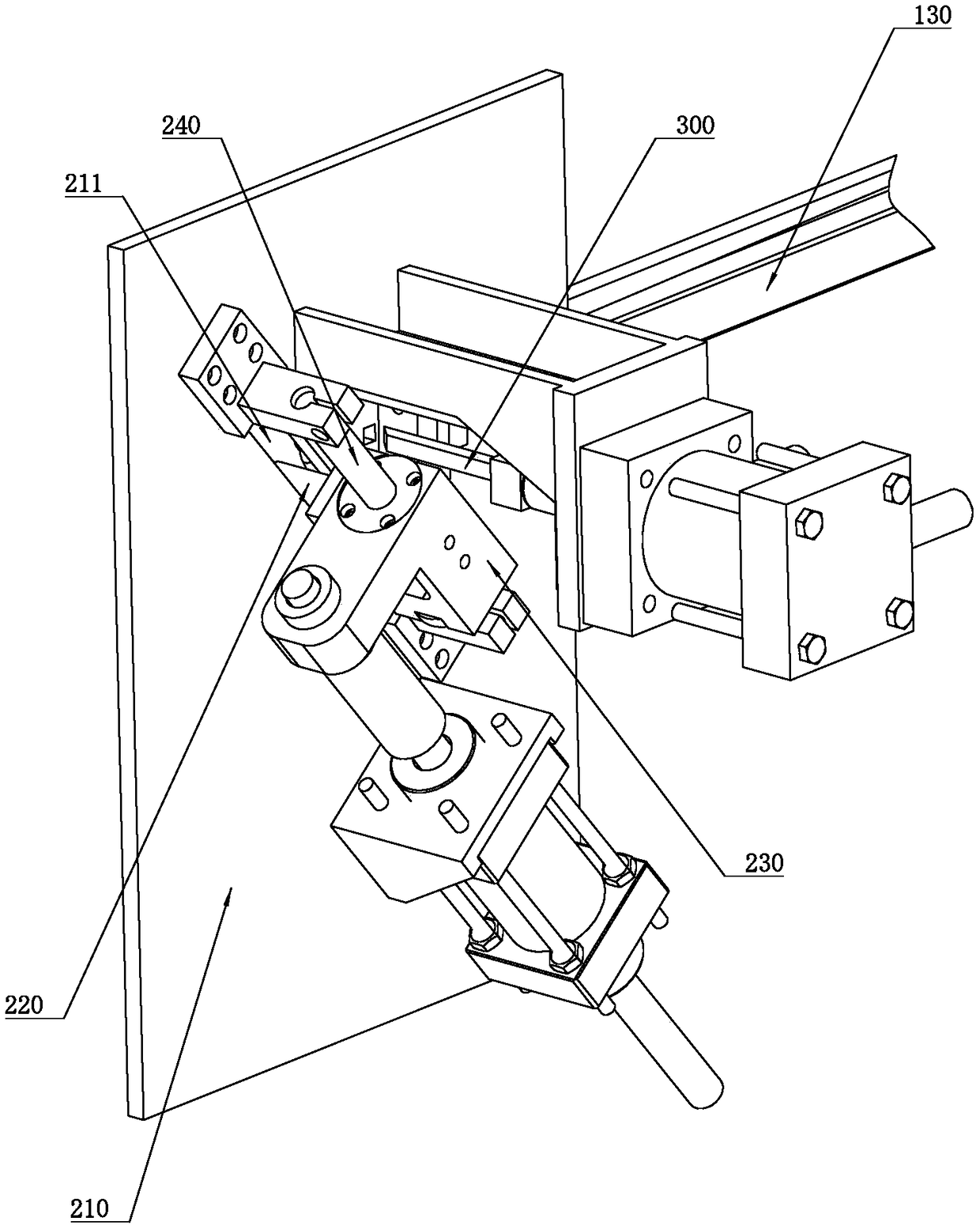

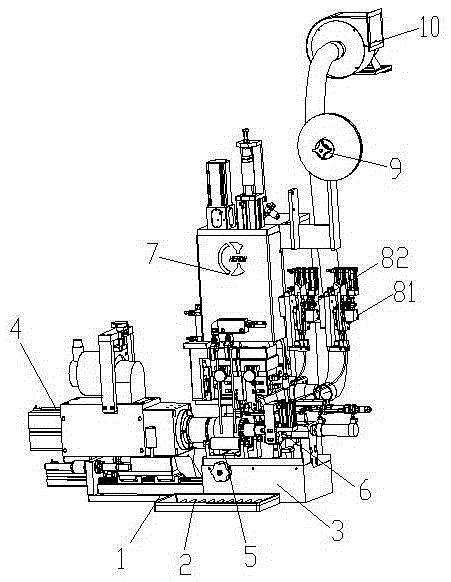

Inverse armature brazing machine with double feeding of brazing wire belts and welding technology thereof

ActiveCN105397229ANo consumptionRealize automatic alignmentMetal working apparatusSolder feeding devicesEngineeringFiller metal

The invention discloses an inverse armature brazing machine with double feeding of brazing wire belts and a welding technology thereof. The inverse armature brazing machine comprises an armature preparation plate, a machine base, a loading supporting base, a servo clamping and indexing mechanism, an armature loading supporting roller mechanism, an armature supporting rectification mechanism, a wire pressing and welding mechanism, a first brazing wire belt feeding mechanism, a second brazing wire belt feeding mechanism, a brazing filler metal plate and a smoke absorption mechanism. According to the machine, the brazing wire belts can be fed to the welding areas between outer-layer wires and inner-layer wires and the welding areas between the inner-layer wires and a commutator segment at the same time so as to be located in the middle of a conducting loop in welding and become the largest heat emission spot, and therefore the problem that a commutator emits heat excessively and then becomes expanded and deformed in the traditional lateral brazing wire belt feeding and welding process is solved, and the problems that temperature rise is excessive and the service life is short due to the small sectional area of arc welding connection and welding spot connection caused by single feeding of the brazing wire belts are solved; two wire processes of argon arc welding are eliminated in the armature welding process, the welding efficiency is high, welding is more reliable, less brazing filler metal is used, and the welding benefit is better.

Owner:HERON INTELLIGENT EQUIP CO LTD

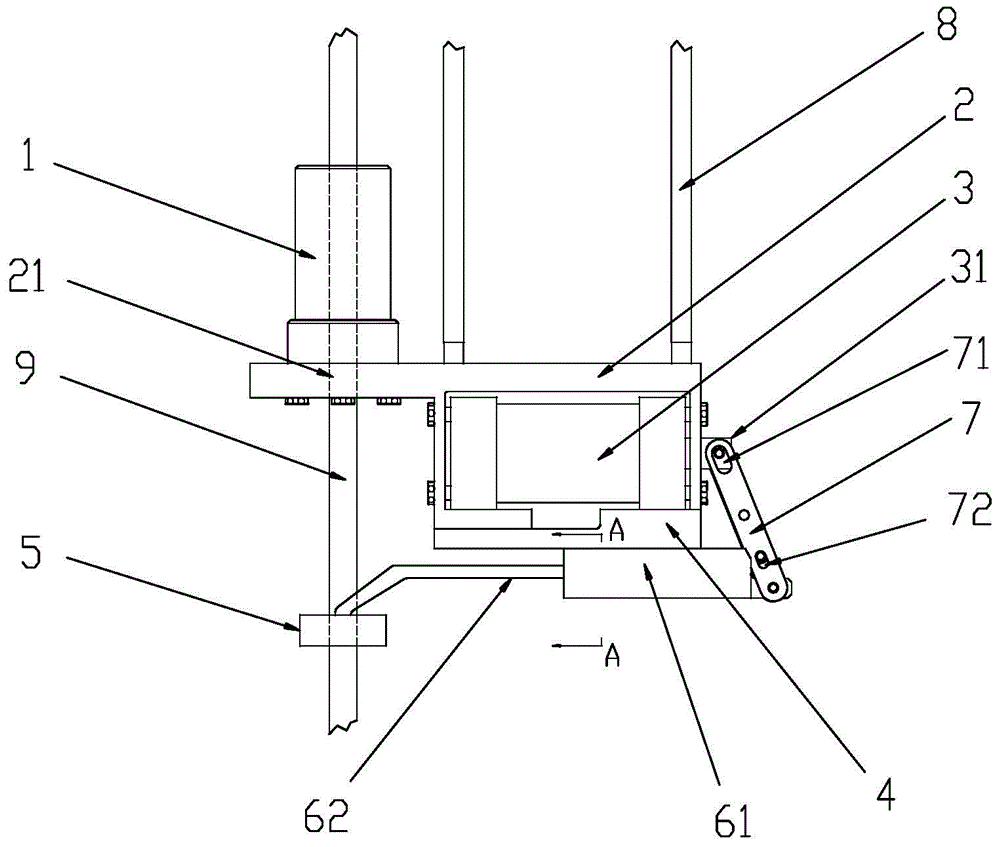

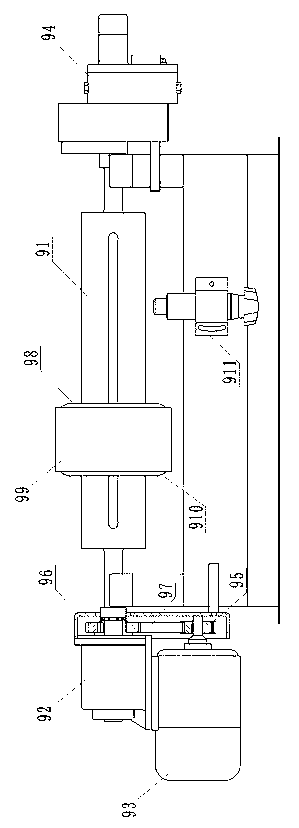

Lift system

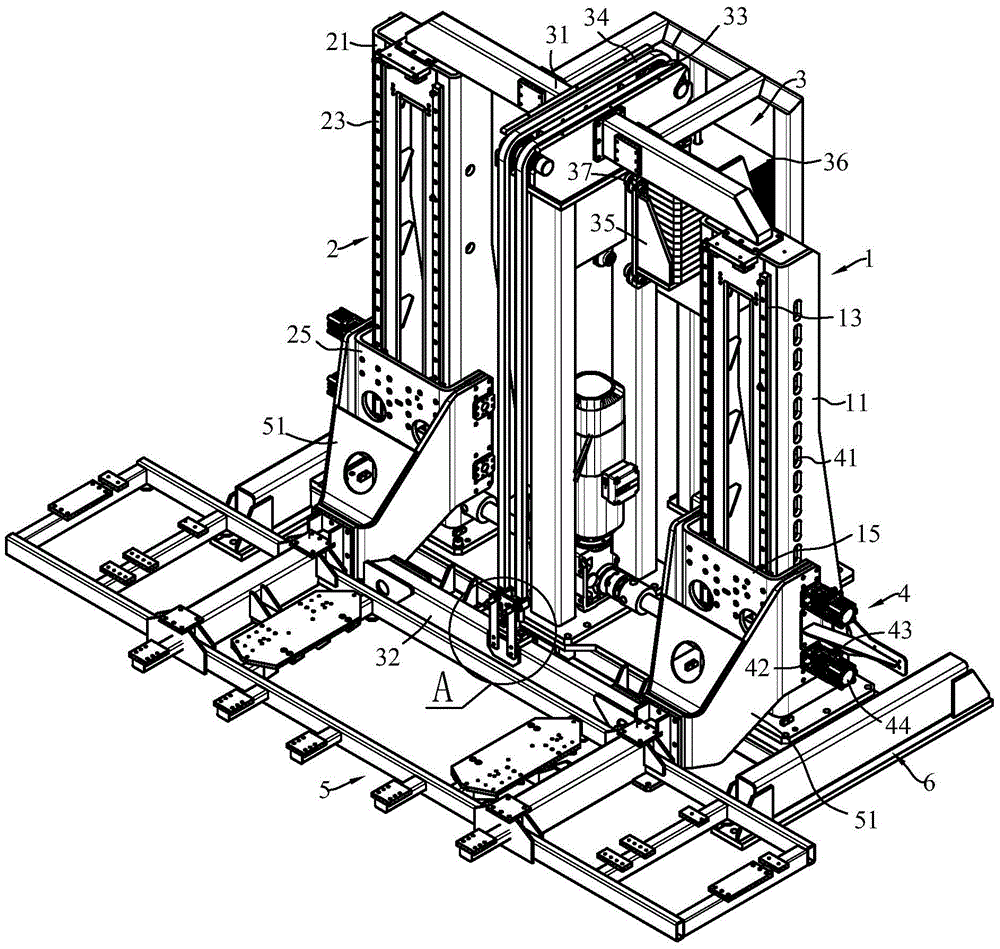

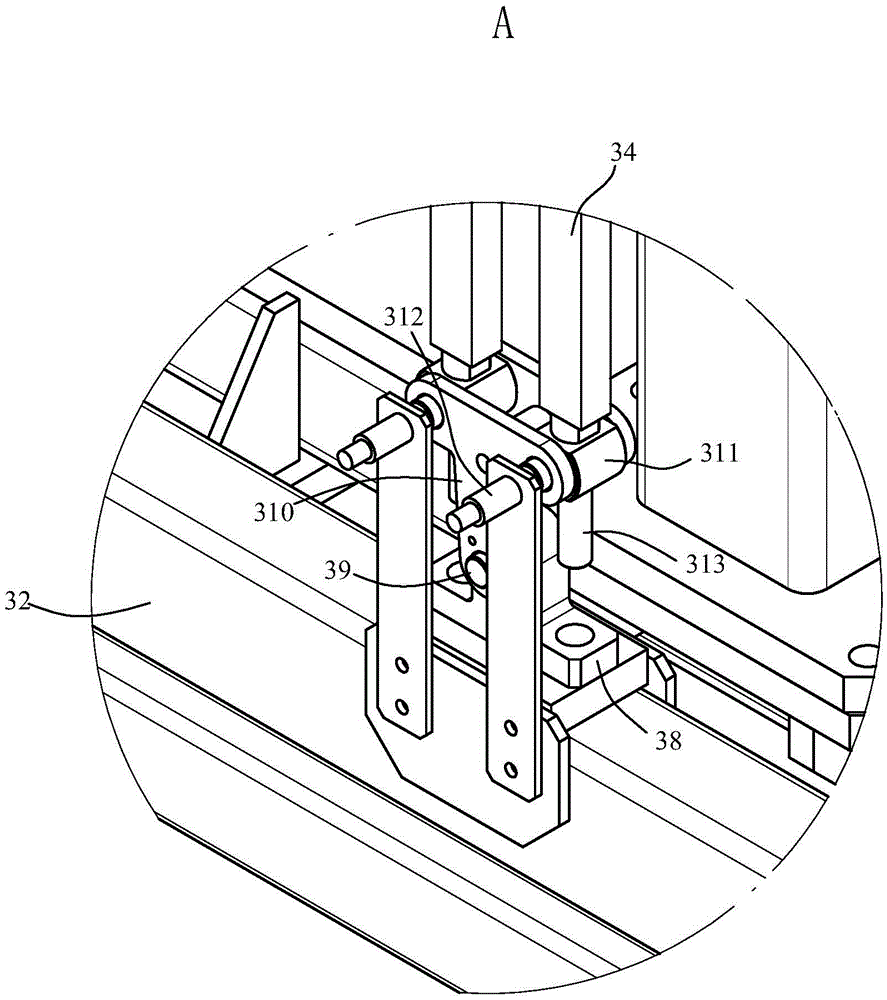

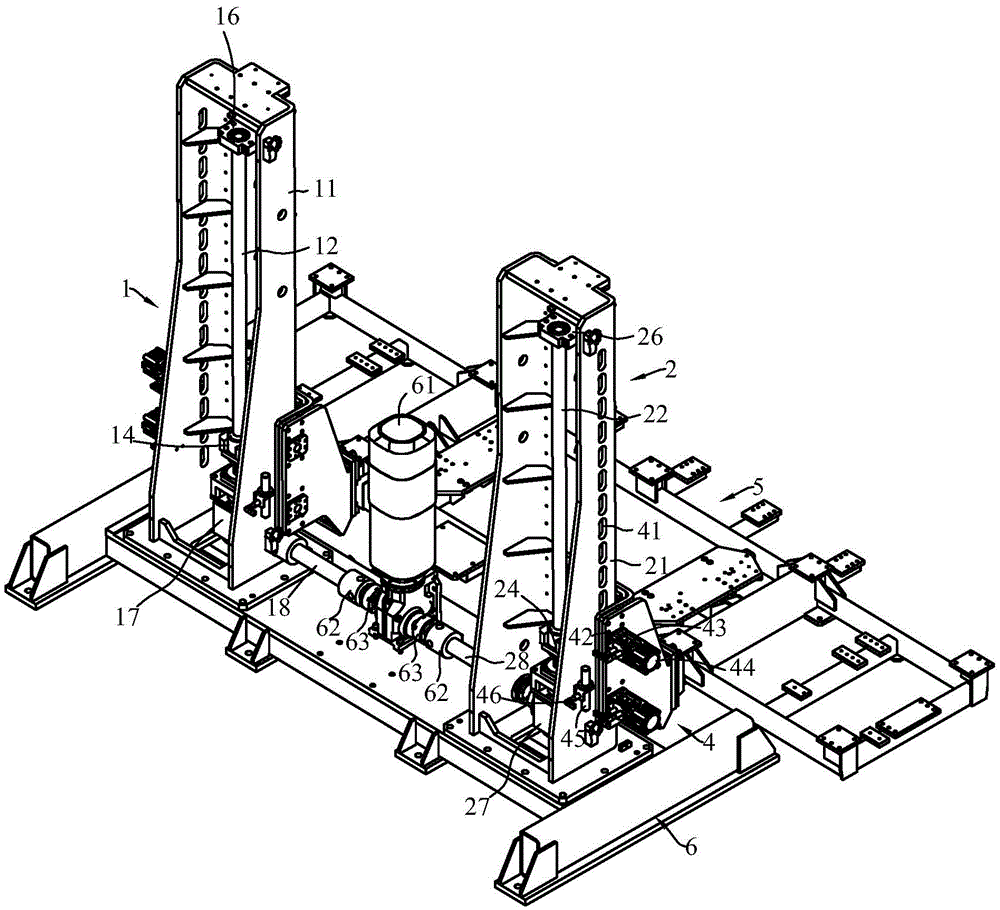

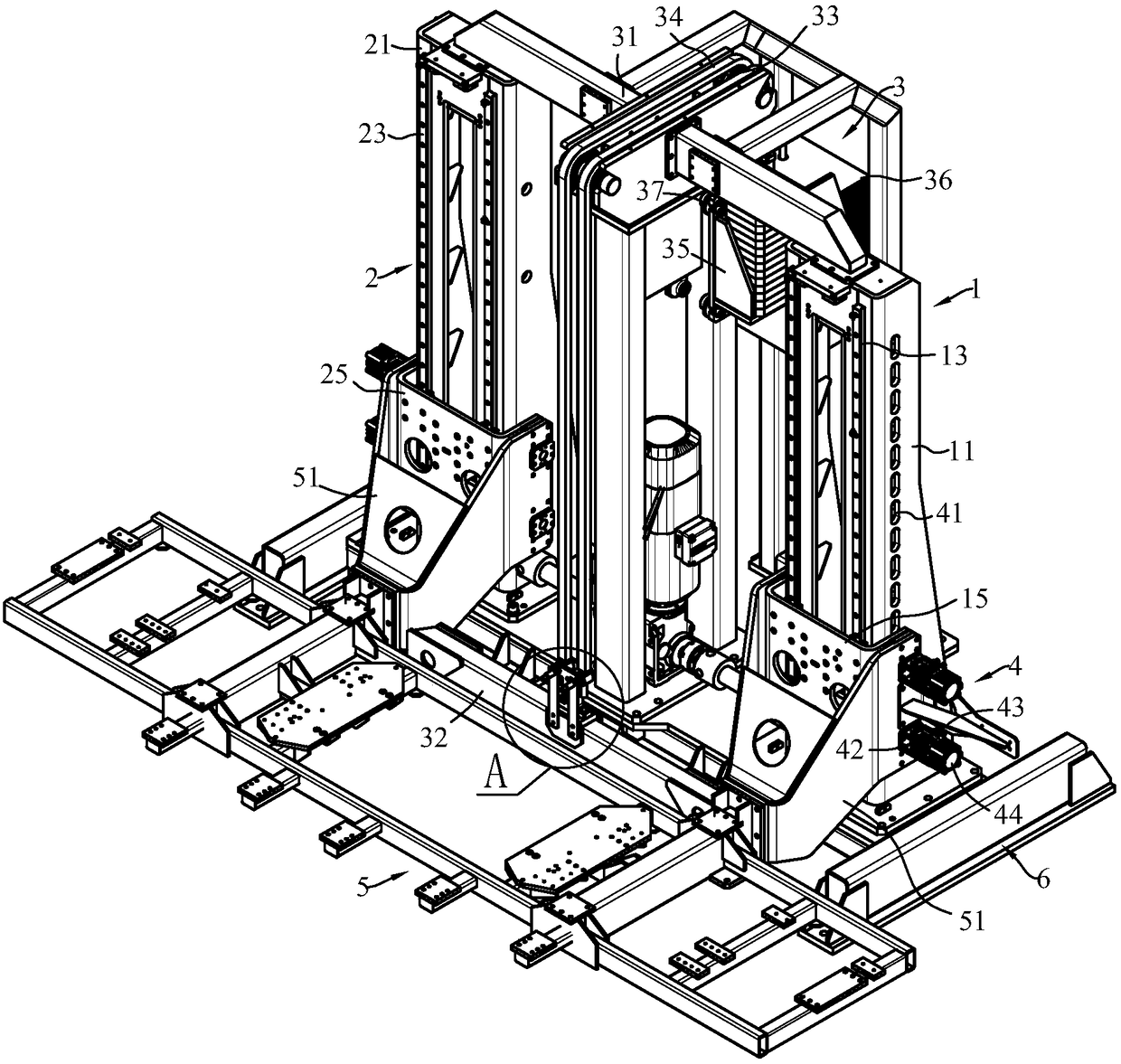

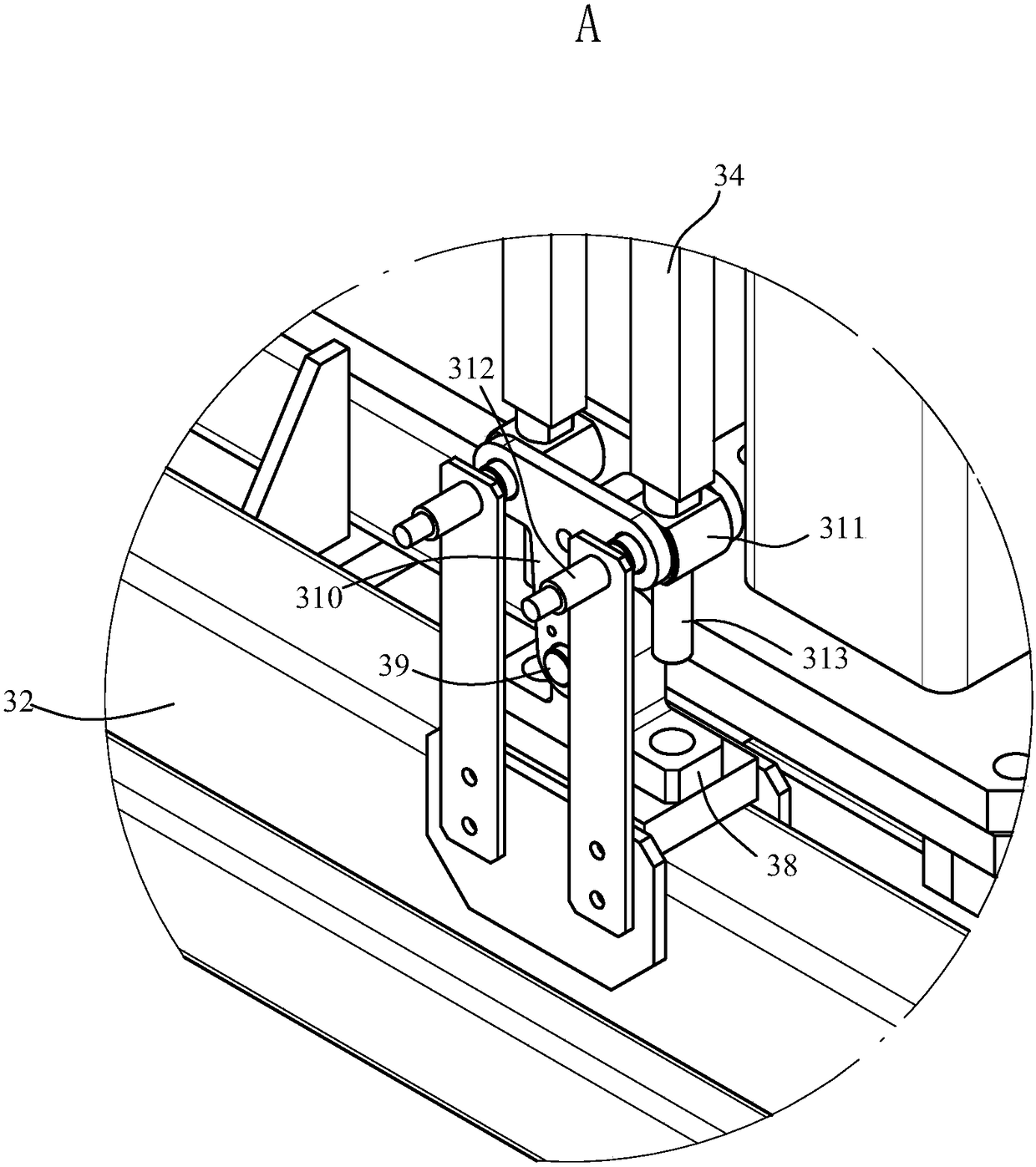

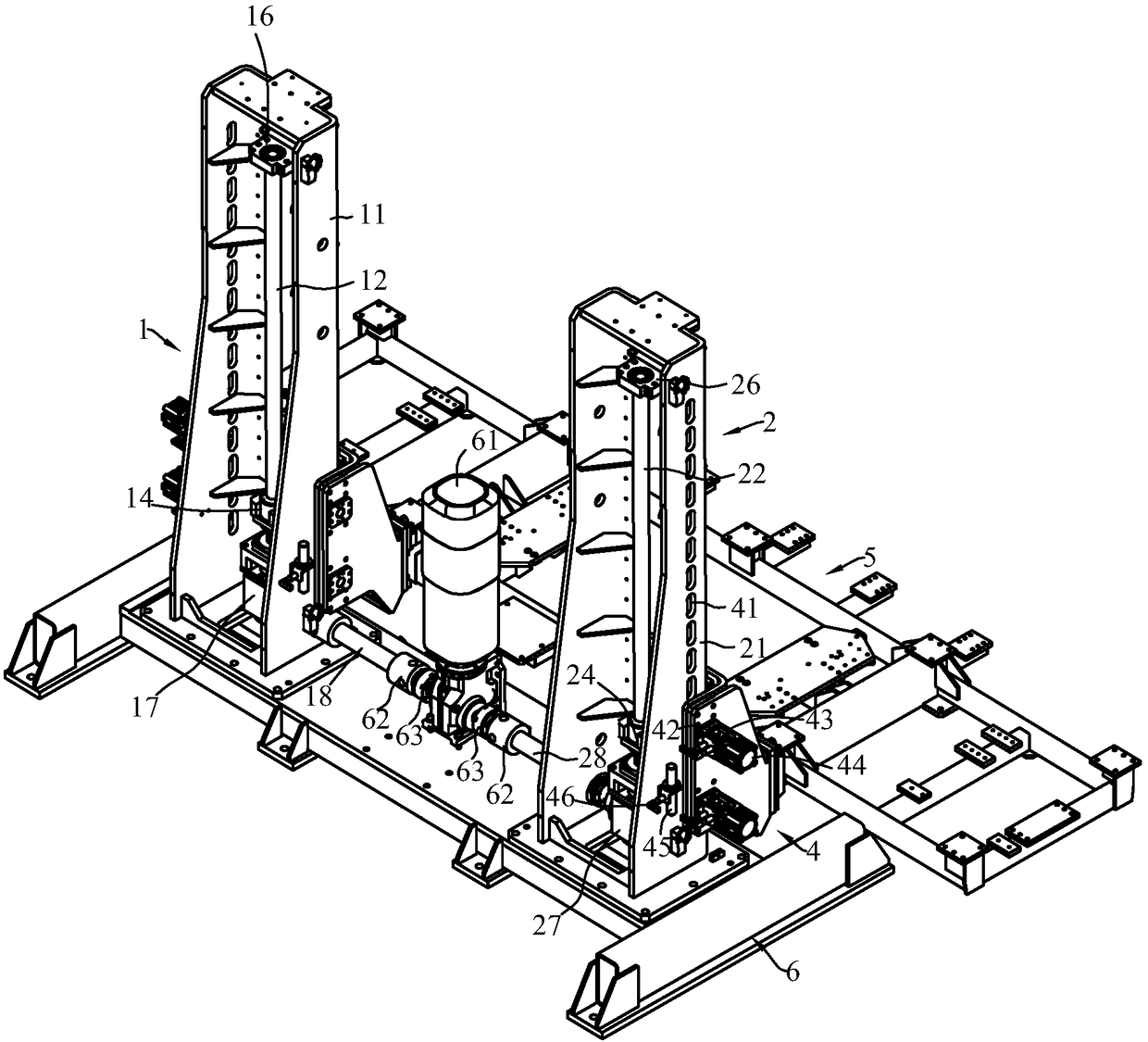

ActiveCN105668457AAdjustable strokeSolve the problem of high-speed and high-precision dockingSafety devices for lifting equipmentsLifting framesButt jointElectric machinery

The invention discloses a lift system. The lift system comprises a tray, a machine base, a left lifting unit and a right lifting unit; the left lifting unit comprises a left vertical column, a left screw, left linear guide rails, a left screw connection block and a left loading base; the right lifting unit comprises a right vertical column, a right screw, right linear guide rails, a right screw connection block and a right loading base; the machine base is provided with a motor capable of synchronously driving the left screw and the right screw to rotate synchronously for lifting the left loading base and the right loading base synchronously, and the tray is fixedly connected to the left loading base and the right loading base through tray bases. When a conveyance load is located on the tray, the motor rotates forwards and reversely, and therefore the conveyance load can be switched between upper-layer stations and lower-layer stations. According to the lift system, the screws and the linear guide rails are combined, the stroke of a lift is adjustable, high-speed and high-accuracy butt joint between fixed stations and stations of the lift is realized, the left lifting unit and the right lifting unit are synchronously driven by the motor, and transmission synchronism of the two sides of the lift system is realized.

Owner:GUANGZHOU MINO AUTOMOTIVE EQUIP CO LTD

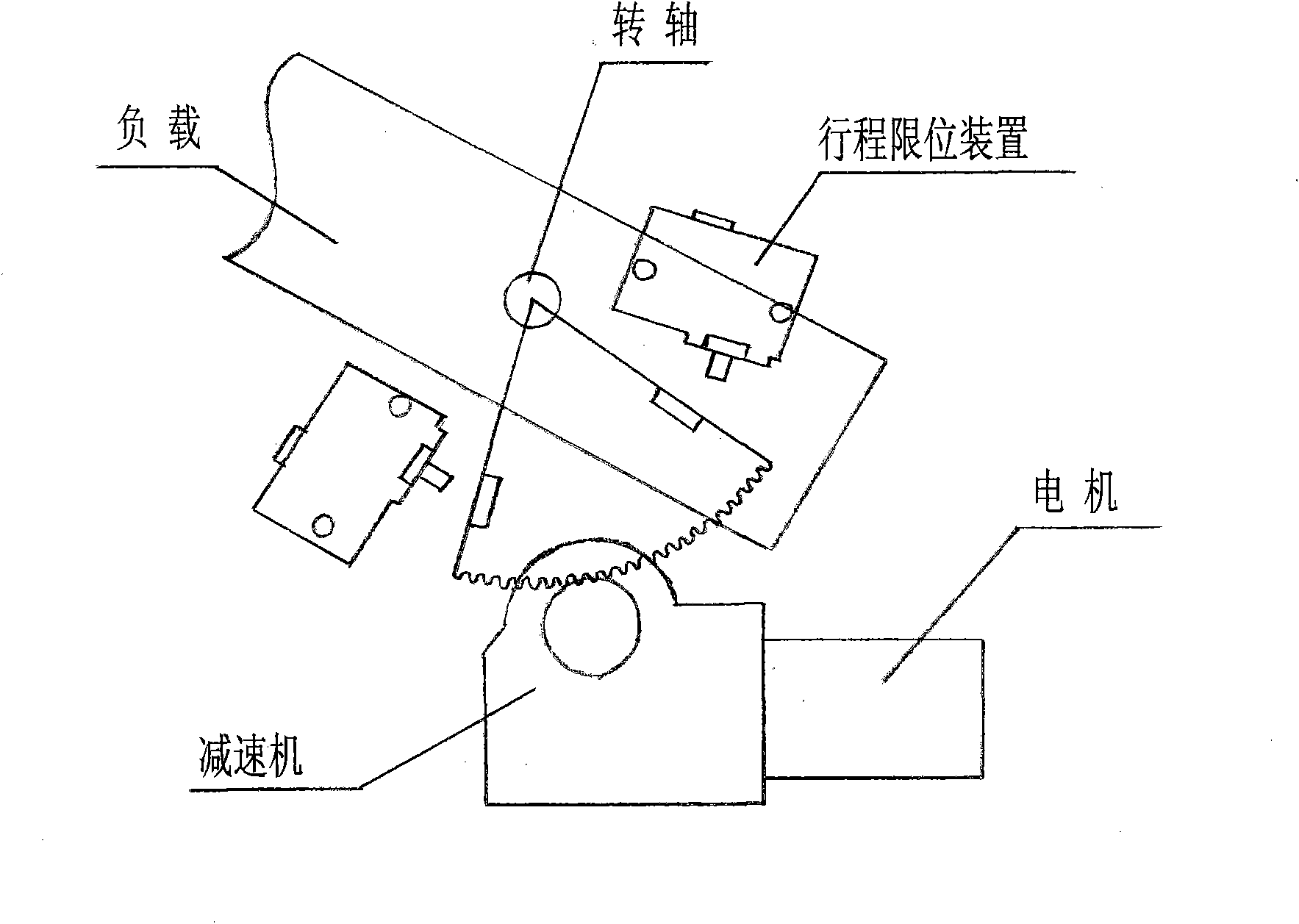

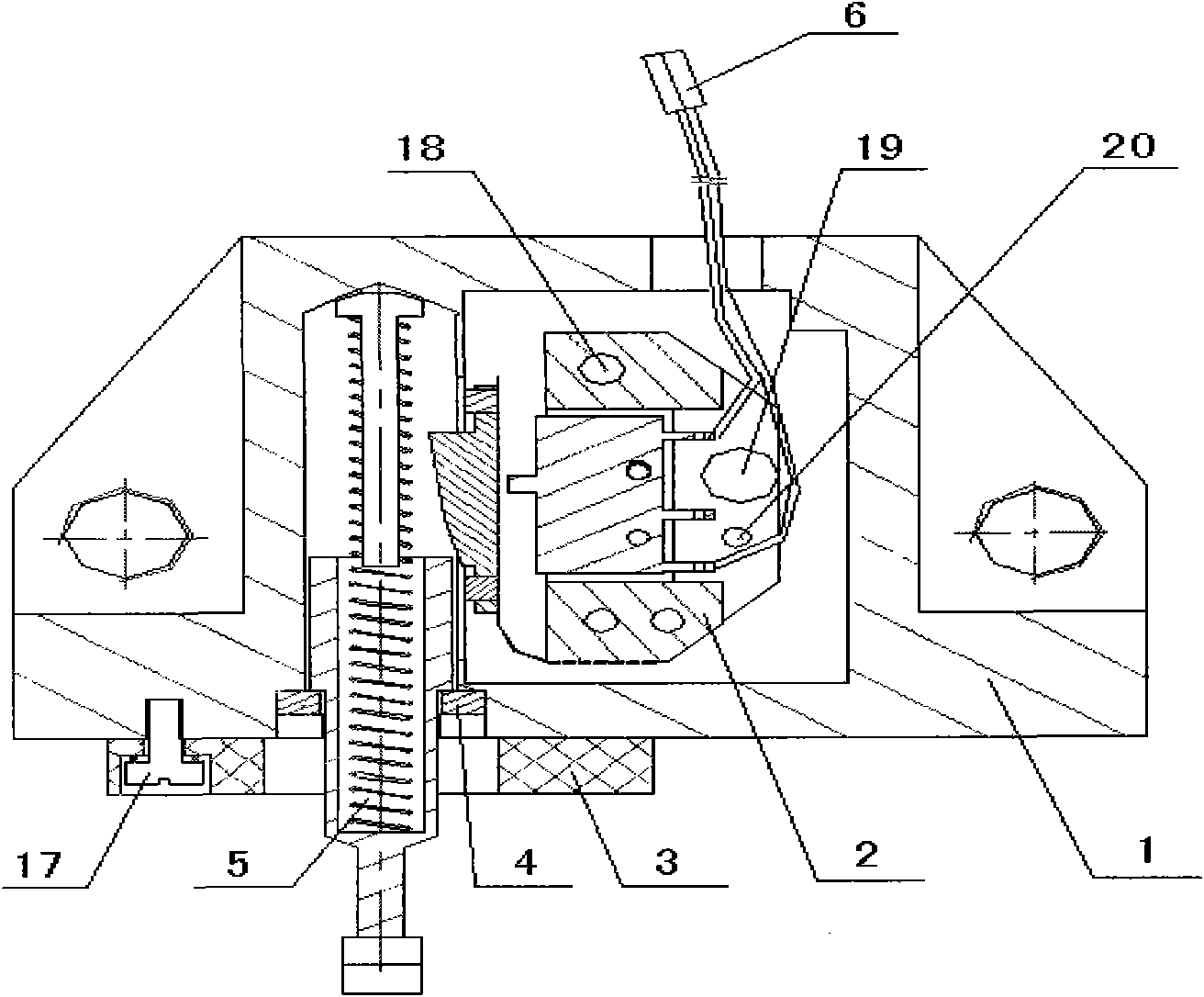

Travel limiting device

The invention relates to a travel limiting device, which is characterized in that: all components of the system are arranged in a limit switch box; a working face of the limit switch box is provided with rubber plates meeting the requirements on thickness and materials so as to reasonably buffer inertial impact force applied during mechanical limit; the working face of the limit switch box is inwards provided with cylindrical cavity holes serving as access ways of a spring travel shaft; the spring travel shaft comprises a spring, a hollow shaft of which an inner cavity at one end is provided with holes, two adjusting nuts and a spring guiding shaft; and in the limit switch box, the right side of the spring travel shaft is provided with a travel control switch which comprises four components, namely a substrate, a spring piece, a flange plate and a micro switch, wherein the flange plate is arranged on the spring piece; and the micro switch and the spring piece are arranged on the substrate. The device provides effective measures for electrical limit and mechanical limit, and simultaneously effectively realizes the accurate adjustment of the positions of the electrical limit and themechanical limit by adopting the travel-length mechanical structure adjustment technology.

Owner:CHINA NORTH VEHICLE RES INST

Material pushing device capable of moving bi-directionally and simultaneously

The invention provides a material pushing device capable of moving bi-directionally and simultaneously, and belongs to the field of card packaging equipment. The material pushing device comprises a bottom frame, a horizontal moving assembly and an up-down moving assembly. The horizontal moving assembly further comprises a lower swing arm, an upper swing arm and a pushing assembly. A driving grooveis formed in the side face of a horizontal cam, a guiding wheel is arranged in the driving groove, the guiding wheel is fixedly locked at one end of the lower swing arm, the middle of the lower swingarm is hinged to a first fixed seat, the end, away from the guiding wheel, of the lower swing arm is hinged to the lower end of the upper swing arm through a large connection rod, the middle of the upper swing arm is hinged to a second fixed seat, the second fixed seat is arranged above the horizontal cam, the upper end of the upper swing arm is hinged to the lower end of the pushing assembly through a hinged small connection rod, and a guiding linear rail which is horizontally arranged is arranged on the side face of the pushing assembly. The material pushing device is driven by adopting thehorizontal cam and a vertical cam, moving in the horizontal direction and vertical direction can be achieved simultaneously, and moving is stable and reliable.

Owner:TIANJIN JINSHUDA MACHINERY

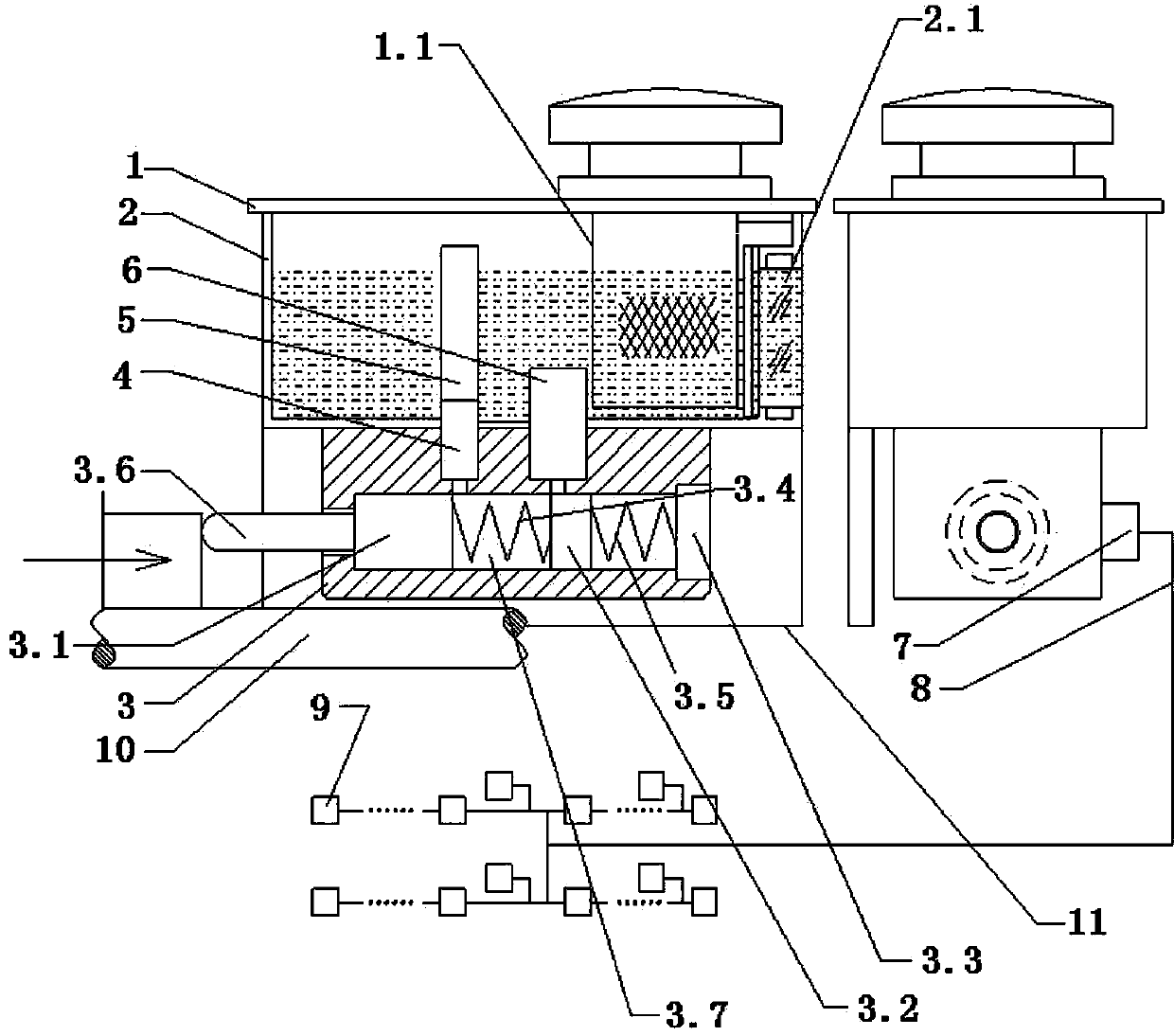

Mechanized tea brick production system

ActiveCN107494801AImprove air delivery efficiencySolve easy blockagePre-extraction tea treatmentBrickAgricultural engineering

The invention relates to a mechanized tea brick production system. The system comprises a raw tea leaf feeding device, a tea leaf pressing mold, a tea-leaf-conveying, dust-removing and surface-smoothing device, a hydraulic tea leaf pressing device, a tea brick pushing-off device and a circulating conveyer belt, wherein the raw tea leaf feeding device, the tea leaf pressing mold and the tea-leaf-conveying, dust-removing and surface-smoothing device are arranged on the front section of the circulating conveyer belt; the raw tea leaf feeding device is arranged on the upper part of the tea leaf pressing mold; the tea leaf pressing mold is arranged on the circulating conveyer belt; the tea-leaf-conveying, dust-removing and surface-smoothing device is arranged on one side of the tea leaf pressing mold; the hydraulic tea leaf pressing device is arranged on the middle section of the circulating conveyer belt; the tea brick pushing-off device is arranged on the back section of the circulating conveyer belt; and one side of the tea-leaf-conveying, dust-removing and surface-smoothing device is provided with a tea leaf returning conveyer belt. The system provided by the invention basically realizes mechanization and automation of tea processing, greatly enhances processing efficiency, and powerfully guarantees production of sanitary tea products conforming to a unified standard.

Owner:普洱市布朗茶业有限公司

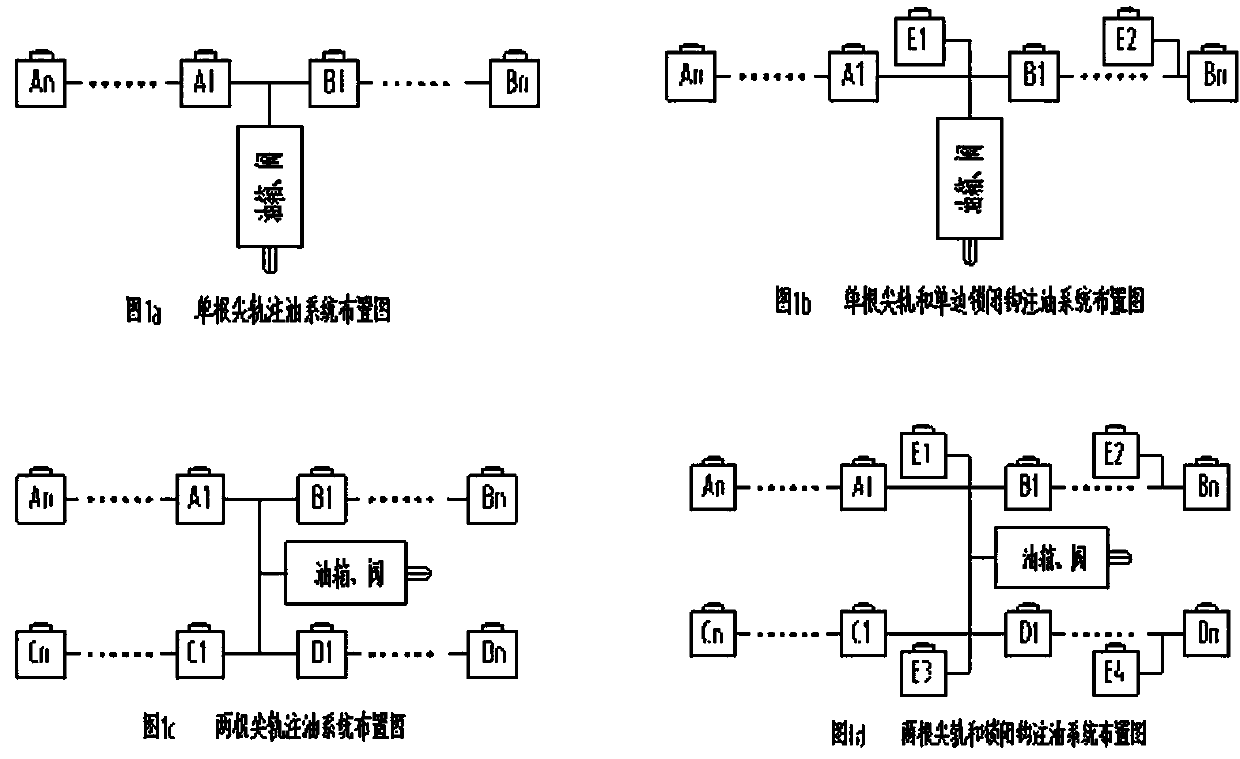

Multipoint automatic oil filler of railway turnout

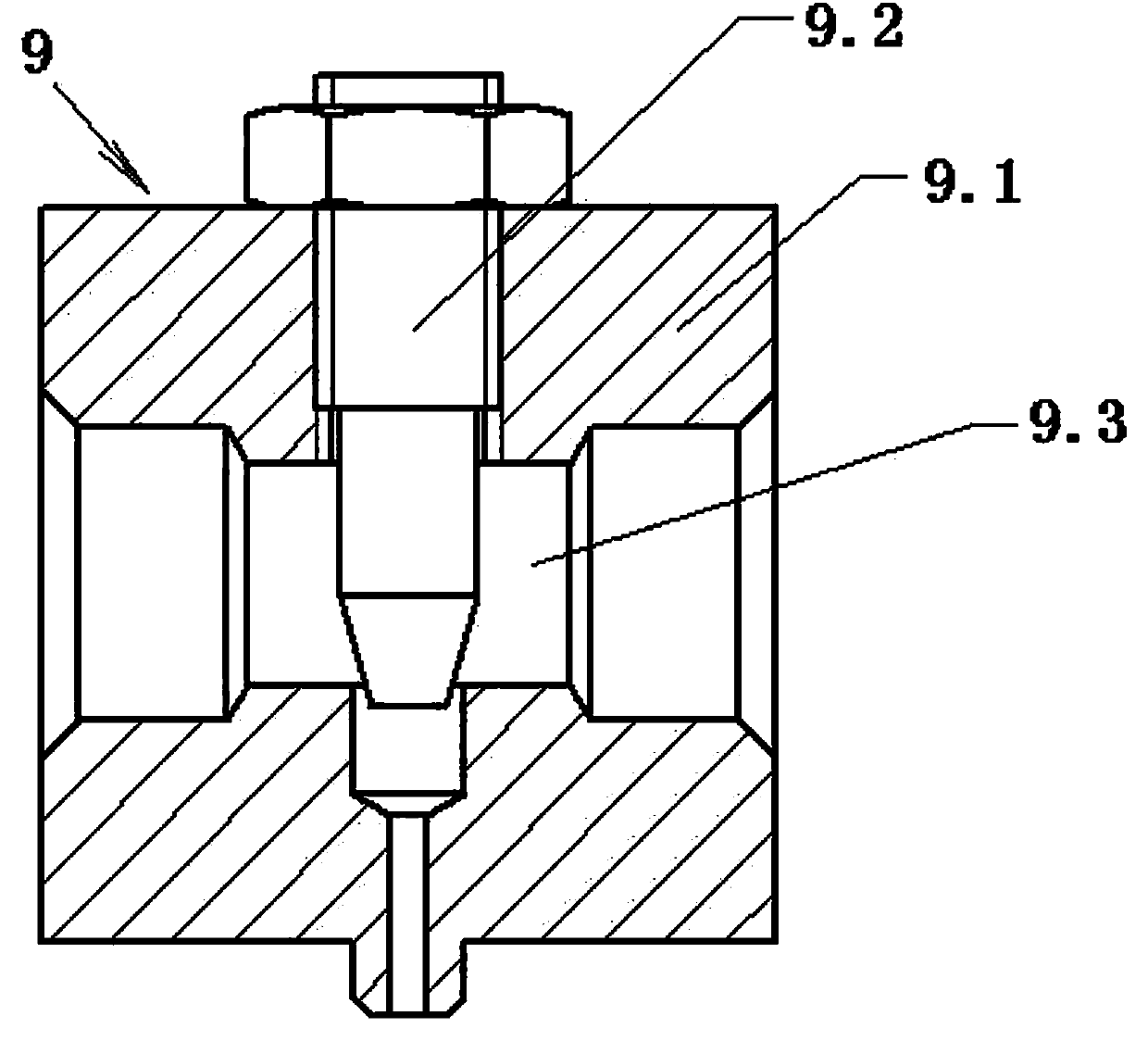

InactiveCN104197179AAdjustable strokeMany lubrication pointsRail lubricationRail wetting/lubricationSpool valveMarine engineering

A multipoint automatic oil filler of a railway turnout comprises an oil tank, an oil tank cover and a support supporting the oil tank and is characterized in that a valve body is arranged at the bottom of the oil tank, the valve body is provided with a cavity, a valve core and a plug are respectively arranged at two ends of the cavity, a slide valve is arranged between the valve core and the plug, and the valve core, the slide valve and the plug are connected through a first elastic part and a second elastic part respectively. One end of a pushing rod is connected with the valve core, the other end of the pushing rod extends out of the valve body, the cavity is communicated with the oil tank through an oil inlet pipe, an exhaust pipe and an oil gas valve, a hole is formed in the middle of the cavity, and an oil outlet valve is arranged in the hole and connected with a series of oil filling ports through oil pipes. The multipoint automatic oil filler of the railway turnout has the advantages that the multipoint automatic oil filler is driven by power produced by a switch machine in work, does not need an external power supply, is simple in structure and covers multiple lubricating points.

Owner:李祺

Stroke adjustable energy-saving hydraulic pumping unit

InactiveCN101078340AAdjustable strokeAdjustable stroke timesFluid removalFluid gearingsPunchingHydraulic pump

The invention relates to an energy-saving hydraulic oil pumping unit with adjustable stroke used in oil field, comprising frame, gear group, hydraulic transmission mechanism, rack, head sheave, suspended-weight rope and oil pumping bar. Two frames are set at two sides of hydraulic transmission mechanism symmetrically. A gear group and two head sheaves are set on each frame. Two gear groups are mated with racks set at two ends of hydraulic transmission mechanism respectively. The gear group draws the oil pumping bar through the suspended-weight rope and the head sheave. Thereinto, the hydraulic transmission mechanism comprises communicating vessel, piston and hydraulic pump. A hydraulic pump is fixed in the communicating vessel and two pistons are set in cavities at two ends of communicating vessel respectively. Driving liquid is poured between two pistons in cavities of communicating vessel. The invention is provided with simple structure, scientific and reasonable design, adjustable stroke and punching time, convenient maintenance, dismounting and use, safe operation, high liquid production volume, little energy consumption and low operating cost. It is also provided with higher innovation.

Owner:丁长良

Eddy current detection device for fuel rod

ActiveCN103559922AAdjustable strokeSave operating timeNuclear energy generationNuclear monitoringEddy currentEngineering

The invention provides an eddy current detection device for a fuel rod. The eddy current detection device for the fuel rod comprises a guide cylinder, an installation plate, a driving device, a telescopic mechanism and an eddy current probe, wherein a through hole is formed in the installation plate; the guide cylinder is arranged at the upper end of the installation plate and is coaxial with the through hole; the driving device is arranged at the lower end of the installation plate and is connected with the telescopic mechanism; a movement direction of the telescopic mechanism is perpendicular to the axis of the guide cylinder and is positioned on the radial extension line of the guide cylinder; the end of the telescopic mechanism is connected with the eddy current probe; under the driving of the telescopic mechanism, the eddy current probe horizontally moves between a working position and a non-working position; when being at the working position, the eddy current probe is coaxial with the guide cylinder. The eddy current detection device for the fuel rod is connected with a fuel rod replacement device through the guide cylinder and can be used for detecting the fuel rod on line on the fuel rod replacement device; if the detected fuel rod is defective, the fuel rod can be directly repaired or replaced, so that the operation time is shortened, and the operation difficulty is reduced; moreover, the eddy current detection device for the fuel rod is reliable to move and high in accuracy.

Owner:STATE NUCLEAR POWER PLANT SERVICE

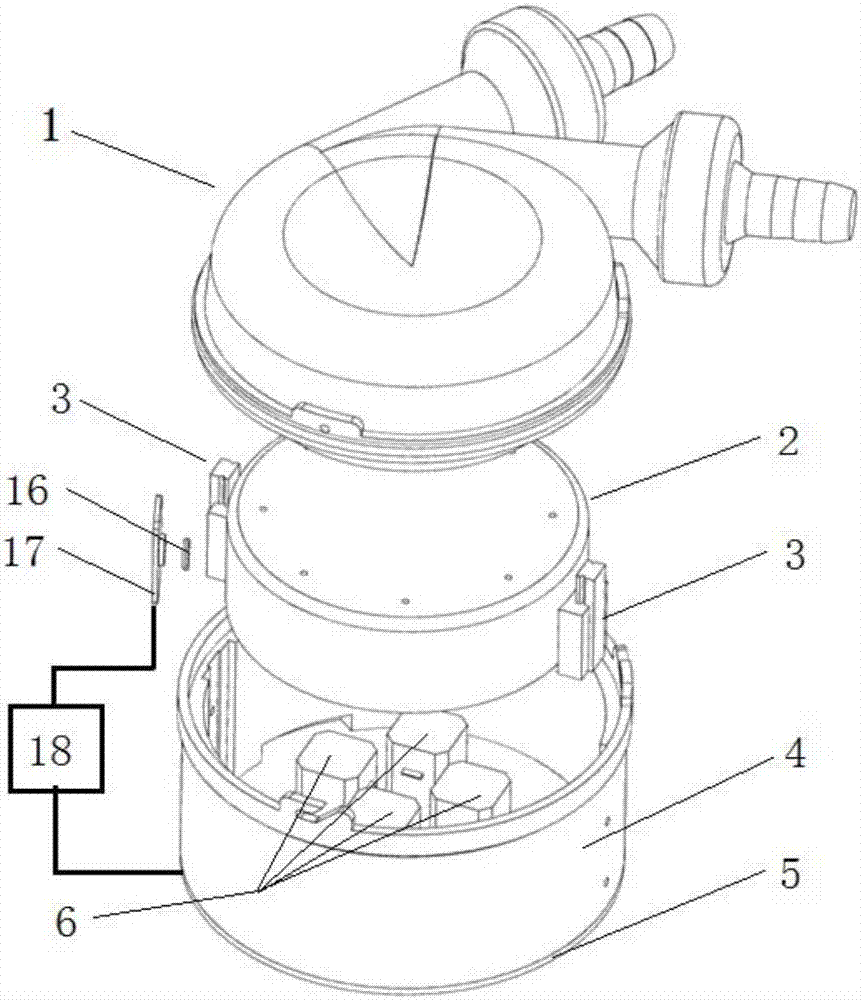

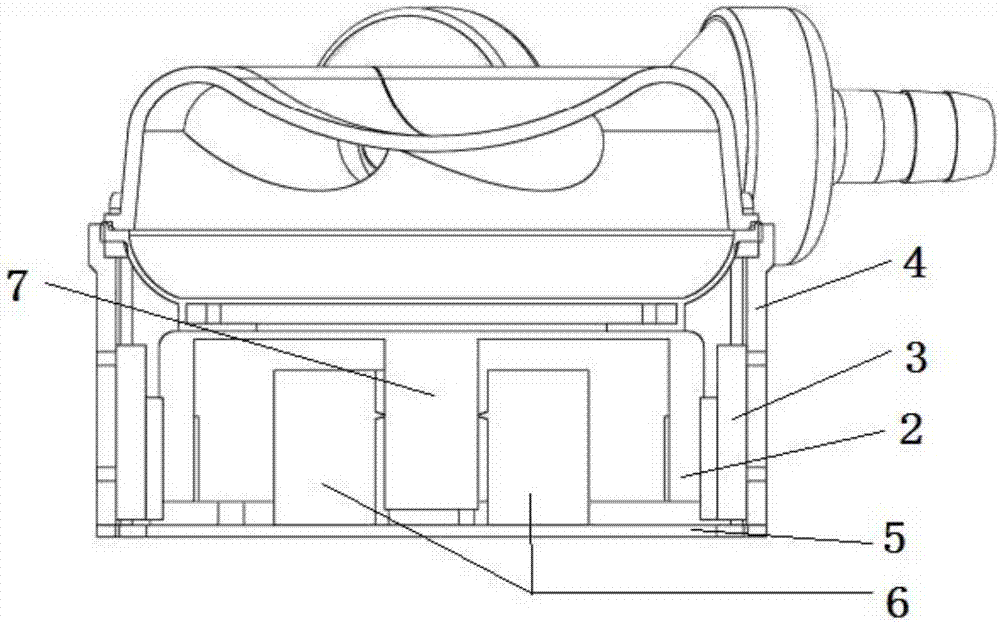

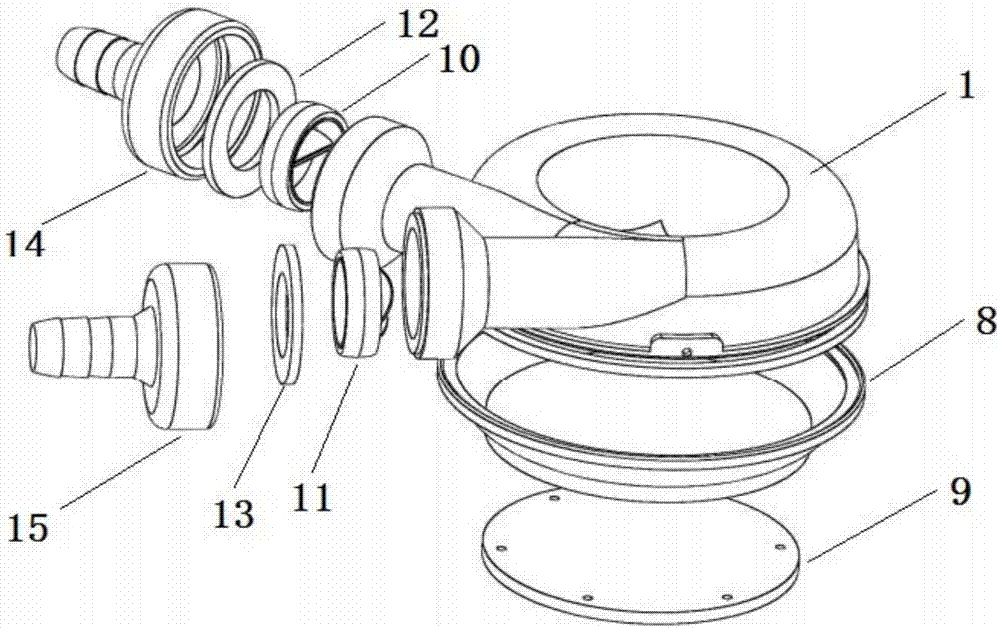

Implantable pulsating blood pump driven by ultrasonic linear motor

ActiveCN107007894ACompact structureSmall sizeMedical devicesIntravenous devicesUltrasonic linear motorPower transmission

The invention discloses an implantable pulsating blood pump driven by an ultrasonic linear motor. The implantable pulsating blood pump comprises a blood cavity, a driving part, a sensing module, a control module, a shell 4 and a base 5. The driving part is connected with the blood cavity, the sensing module and the control module, the driving part is arranged in the shell 4, and the blood cavity, the shell 4 and the base 5 are sequentially connected. The sensing module collects relevant information of the driving part and transmits the collected information to the control module, the control module controls the driving part to move, and the driving part drives the blood cavity to generate deformation. The driving part comprises a linear guide rail 3 and the ultrasonic linear motor, and the ultrasonic linear motor provides power for the pulsating blood pump. The ultrasonic linear motor is adopted as a pump body power source, a complex motion conversion structure is avoided, the power is directly transmitted to the elastic blood cavity, the volume of the blood cavity is changed, pulsating flow is formed and output, a pump body can be miniaturized, reliability is improved, and the ultrasonic linear motor is adjustable in stroke and rapid in response.

Owner:SHANGHAI JIAO TONG UNIV

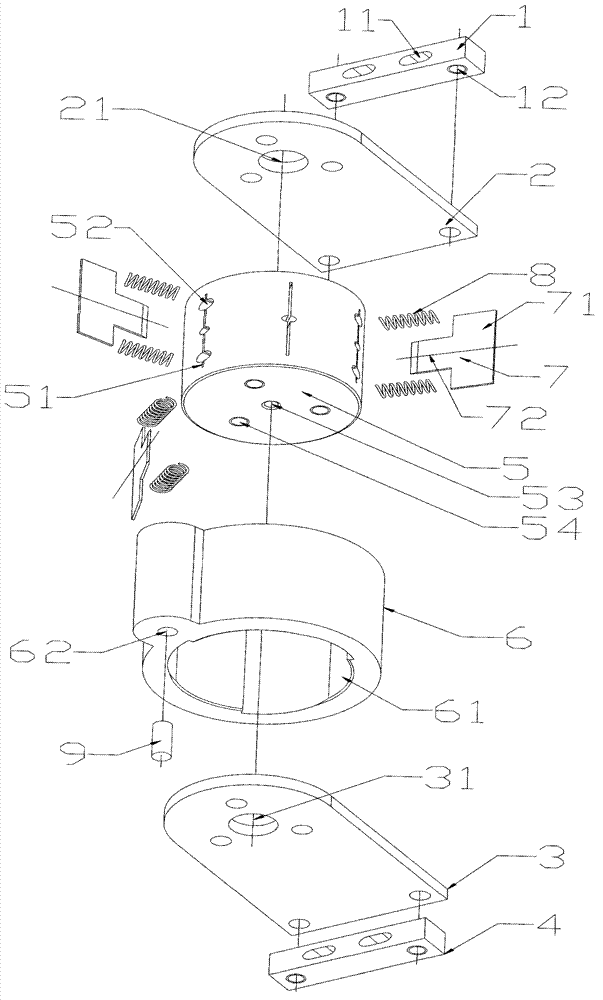

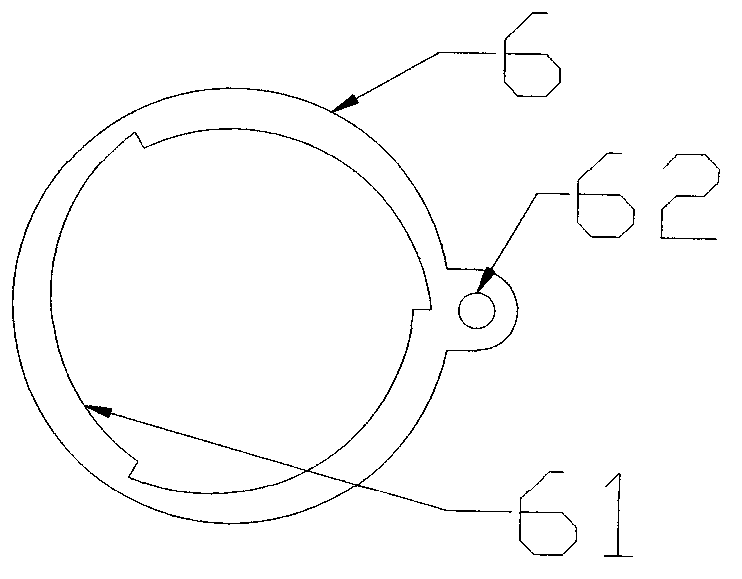

Straight knife edge wire cutting mechanism applied to peeling-wire machine

InactiveCN102761081AAccurate travelAdjustable strokeApparatus for removing/armouring cablesFixed frameWire cutting

The invention discloses a straight knife edge wire cutting mechanism applied to a peeling-wire machine, which consists of a driving device and a knife rest, wherein the driving device is provided with a cylinder, a cylinder fixing frame and a mounting fixing frame; and the driving device mainly uses the cylinder fixed on the panel of the peeling-wire machine as a power source. The knife rest is provided with a stator, a rotor, a knife blade set, a spring set and a fixing frame; the knife blade set is arranged in the stator, the knife edge of the knife blade keeps off from a wire hole III inside the stator under the action of the reaction force of the spring set, and the knife blade moves towards the wire hole III under the action of the rotary pushing action force of the rotor so as to achieve the wire cutting effect. The straight knife edge wire cutting mechanism applied to a peeling-wire machine has the advantages of accurate travel range, adjustable travel range, large driving force, high peeling speed, no damage to a cable core, stable performance, long service life, simple structure and low cost.

Owner:ZHONGSHAN YATAI MACHINERY

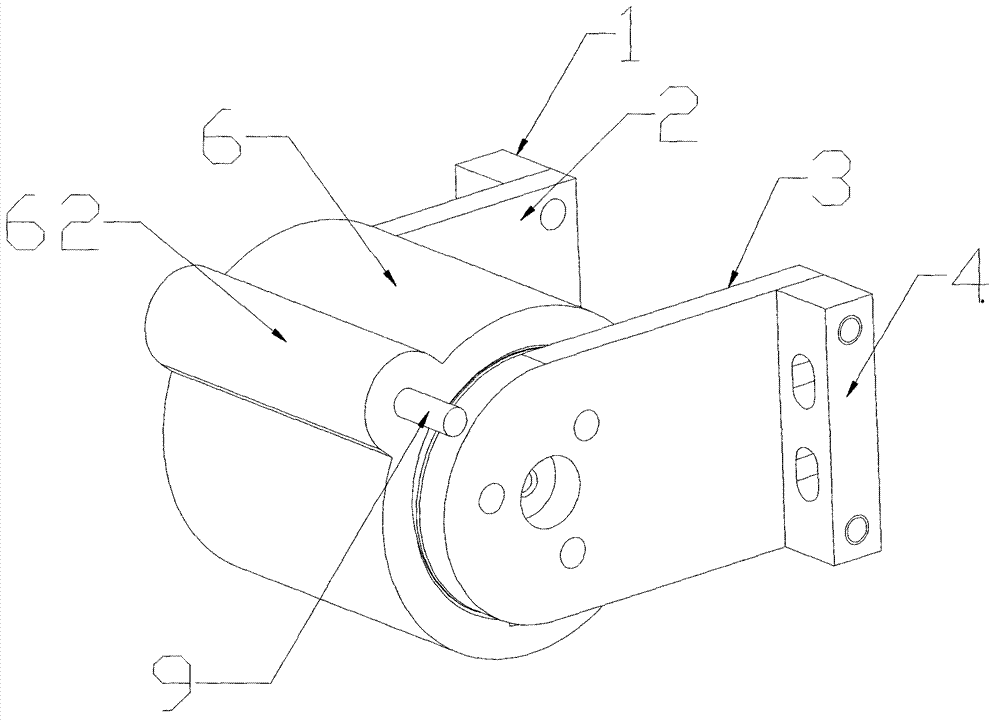

Grinding device of licker-in grinding and covering machine

ActiveCN103264326AHigh rotation accuracyImprove grinding qualityRevolution surface grinding machinesGrinding drivesFailure rateBall bearing

The invention discloses a grinding device of a licker-in grinding and covering machine. The grinding device comprises a grinding head unit, a roller unit and a power device, wherein the roller unit comprises a main roller, a guide rod, a grinding roller support and a grinding roller seat bottom plate; the main roller is in parallel to the guide rod; both ends are respectively arranged on the grinding roller seat bottom plate through the grinding roller support; the grinding head unit comprises a grinding head, a high-precision ball bearing, a high-precision linear bearing and linear bearings; the grinding head unit is arranged on the main roller and the guide rod through the two linear bearings, and is driven by the power unit to perform reciprocating motion along the main roller and the guide rod; the grinding head is directly arranged on the high-precision ball bearing; the high-precision ball bearing is also directly arranged on the high-precision linear bearing, and is driven by the power unit so that rotary motion is performed on the grinding head by taking the main roller as an axle center. The grinding device has the beneficial effects that the equipment is high in precision during rotary motion and reciprocating motion, adjustable in stroke, smooth in reversing and extremely low in failure rate; and the whole equipment is high in grinding quality, simple in structure and convenient to operate, and is free of amending a grinding wheel during the using process.

Owner:无锡立达纺织机械器材有限公司

Arc striking device for ion plating and ion plating device

PendingCN110565055AImprove sealingSame itineraryVacuum evaporation coatingSputtering coatingEngineeringVacuum chamber

The invention discloses an arc striking device for ion plating and an ion plating device, and relates to the technical field of ion plating. The arc striking device comprises an arc striking hook, a connecting rod, a corrugated pipe, a drive device and a sealing insulating part. A mounting hole is formed in the side wall of a vacuum chamber of the ion plating device, the sealing insulating part isfixed into the mounting hole and connected with the mounting hole in a sealed manner, an output shaft of the drive device penetrates through the sealing insulating part to be fixedly connected with one end of the connecting rod, the drive device can drive the connecting rod to reciprocate in the axial direction, one end of the corrugated pipe is fixedly connected with one end of the sealing insulating part, the other end of the corrugated pipe fixedly sleeves the connecting rod and is connected with the connecting rod in a sealed manner, and the connecting rod penetrates through the corrugated pipe to be fixedly connected with the arc striking hook. The ion plating device comprises the vacuum chamber and the arc striking device for ion plating. The drive device drives the arc striking hook to move, acting force is large, hook adhesion is not easily caused, the corrugated pipe is arranged for static sealing, the sealing performance of the vacuum chamber is good, and vacuum is not easily damaged.

Owner:BEIJING TECHNOL SCI

Using method of control device for automobile in idle state for long time

The invention relates to a using method of a control device for an automobile in an idle state for a long time. The control device for the automobile in the idle state for a long time comprises a base, a driver, a lower end column and a speed adjusting rod. The base is fixed to the side wall of a cockpit; the driver is arranged at the front end of the base; and the lower end column is arranged below the driver and is internally provided with the telescopic speed adjusting rod. According to the using method of the control device for the automobile in the idle state for a long time, operation isconvenient, the control device can be fixed in the cockpit, the rotating speed of an engine is linearly adjusted, and fuel oil consumption is reduced.

Owner:ZIBO VOCATIONAL INST

Steering mechanism of glue sprayer for polyurethane rollers

The invention discloses a steering mechanism of a glue sprayer for polyurethane rollers. The steering mechanism comprises a base plate, wherein an air cylinder transmission assembly is mounted on the base plate and comprises an air cylinder and a sliding plate, and a moving rod of the air cylinder is fixedly connected with the sliding plate; two limiting assemblies are arranged on one side of the sliding plate, and a motor transmission assembly is arranged on the other side of the sliding plate; the sliding plate is connected with a motor base of the motor transmission assembly, and the motor base is vertically arranged; a rotary plate of a roller carrier assembly is mounted on the motor base, and roller carriers are arranged on the rotary plate. According to the steering mechanism, polyurethane is applied in the mode that a glue spraying gun is fixed and the rollers are moved, so that the problem that the temperature and the flow of polyurethane in the glue spraying gun are influenced in the adjustment process of a traditional glue spraying gun can be avoided, and polyurethane can be better applied to the rollers.

Owner:SUZHOU PINFA ELECTROMECHANICAL TECH CO LTD

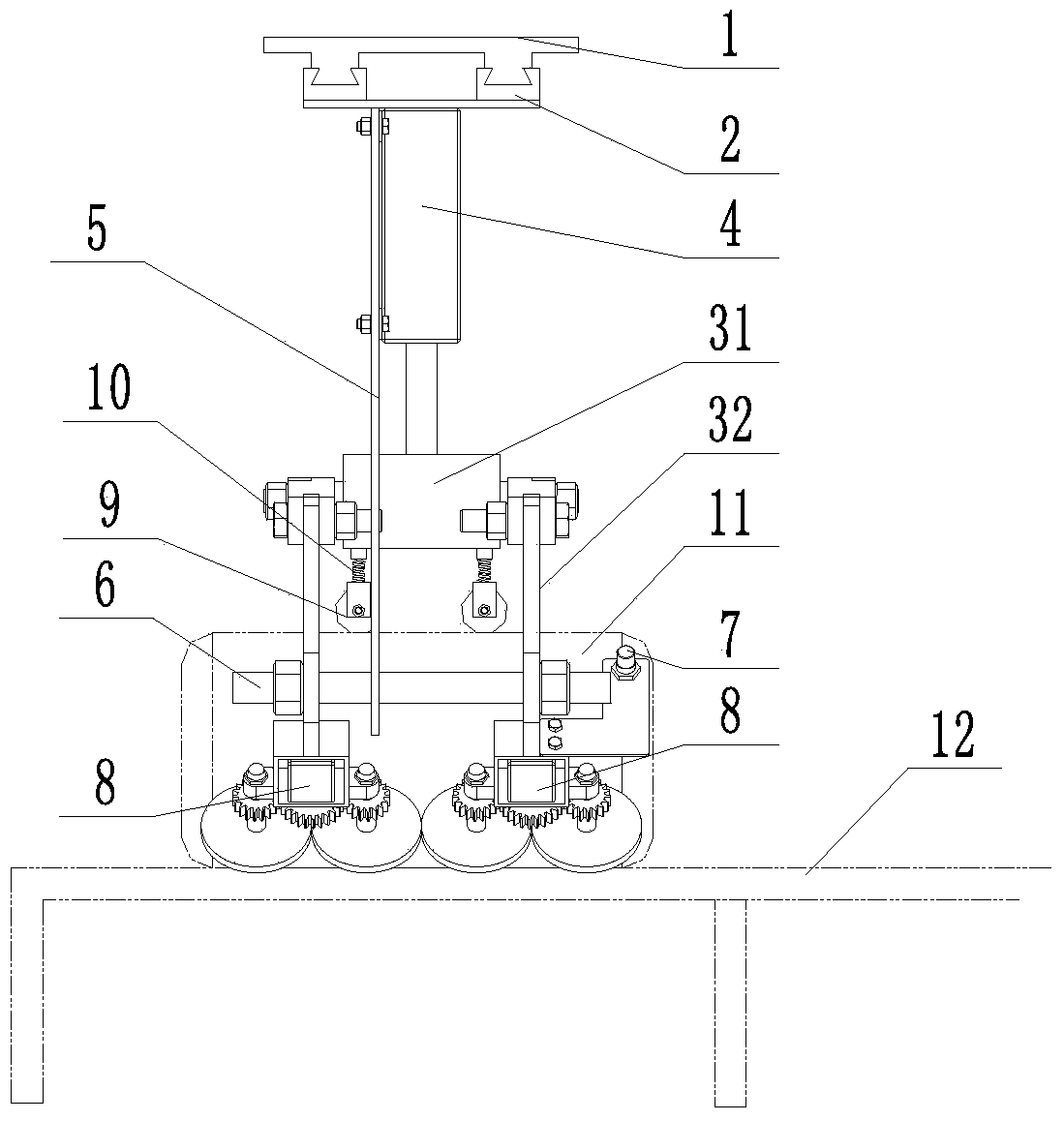

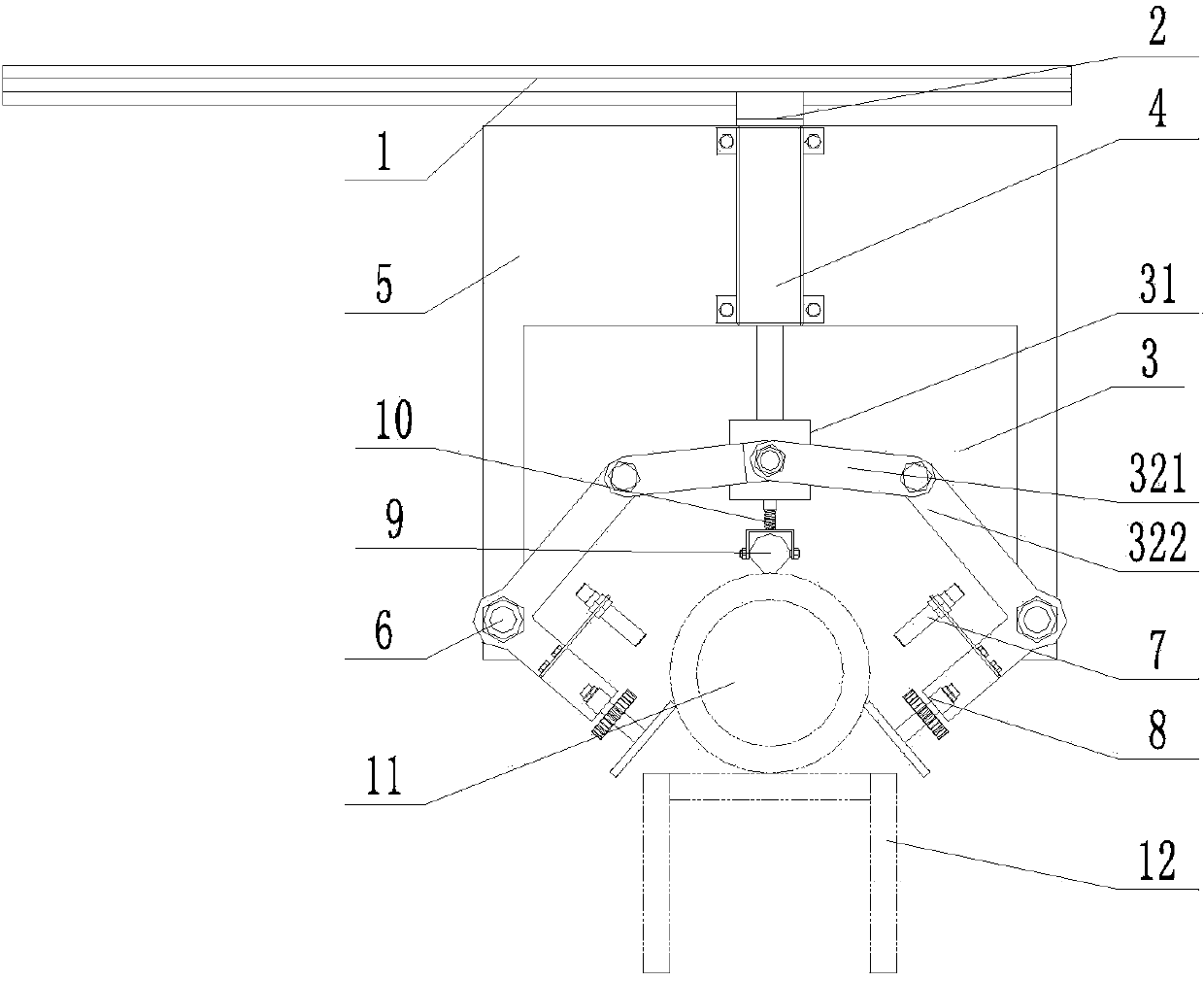

Positioning and clamping device for LNG gas bottle production line

ActiveCN103803298ASolve difficult-to-grip problemsImprove clamping stabilityConveyor partsProduction lineGas cylinder

The invention discloses a positioning and clamping device for an LNG gas bottle production line. The positioning and clamping device comprises a moving base, at least one bottle clamping mechanism arranged on the moving base and used for clamping gas bottles in the radial direction, and a driving mechanism for driving the bottle clamping mechanism. A position adjusting mechanism is arranged at the clamping end of the bottle clamping mechanism and comprises a motor support. A bottle moving motor is arranged on the motor support. A driving gear is arranged on an output shaft of the bottle moving motor. Driven shafts parallel to the output shaft of the bottle moving motor are arranged on the portions, on the two sides of the output shaft of the bottle moving motor, of the motor support and provided with driven gears matched with the driving gear. Bottle moving rotating discs used for moving the gas bottles in the axial direction are arranged at the ends of the driven shafts.

Owner:TIANCHUANG ZHIKU CULTURE PROPAGATION SUZHOU CO LTD

Magnetic grinder for two-sided disc small-curvature-surface component

PendingCN107617932AImprove processing qualityImprove processing efficiencyGrinding work supportsLinear motionEngineering

The invention discloses a magnetic grinder for a two-sided disc small-curvature-surface component. The magnetic grinder comprises a workpiece rotating mechanism, a workpiece clamping mechanism, a magnetic grinding head reciprocating linear motion mechanism and a magnetic grinding material collecting device. When the whole magnetic grinder is driven by a double-shaft output motor, a workpiece can rotate through gear transmission, and double-eccentric-crankshaft sliding blocks can be driven through belt transmission to assist a magnetic grinding head in reciprocating linear motion; the transmission ratio of the gear transmission to the belt transmission is 1:1, that is, the magnetic grinding head performs the reciprocating linear motion once when the workpiece rotates in a circle; under theaction of a magnetic brush, machining tracks on the workpiece can be uniformly distributed on the whole machining surface through the matching between the rotating motion and the reciprocating linearmotion; in the above process, the grinding material is collected by the magnetic grinding material collecting device, thereby improving the workpiece machining quality and efficiency; and accordingly,the magnetic grinder can be utilized for the finishing grinding of a high-precision large-diameter lens, and has an extensive application prospect in the field of high-precision machining.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

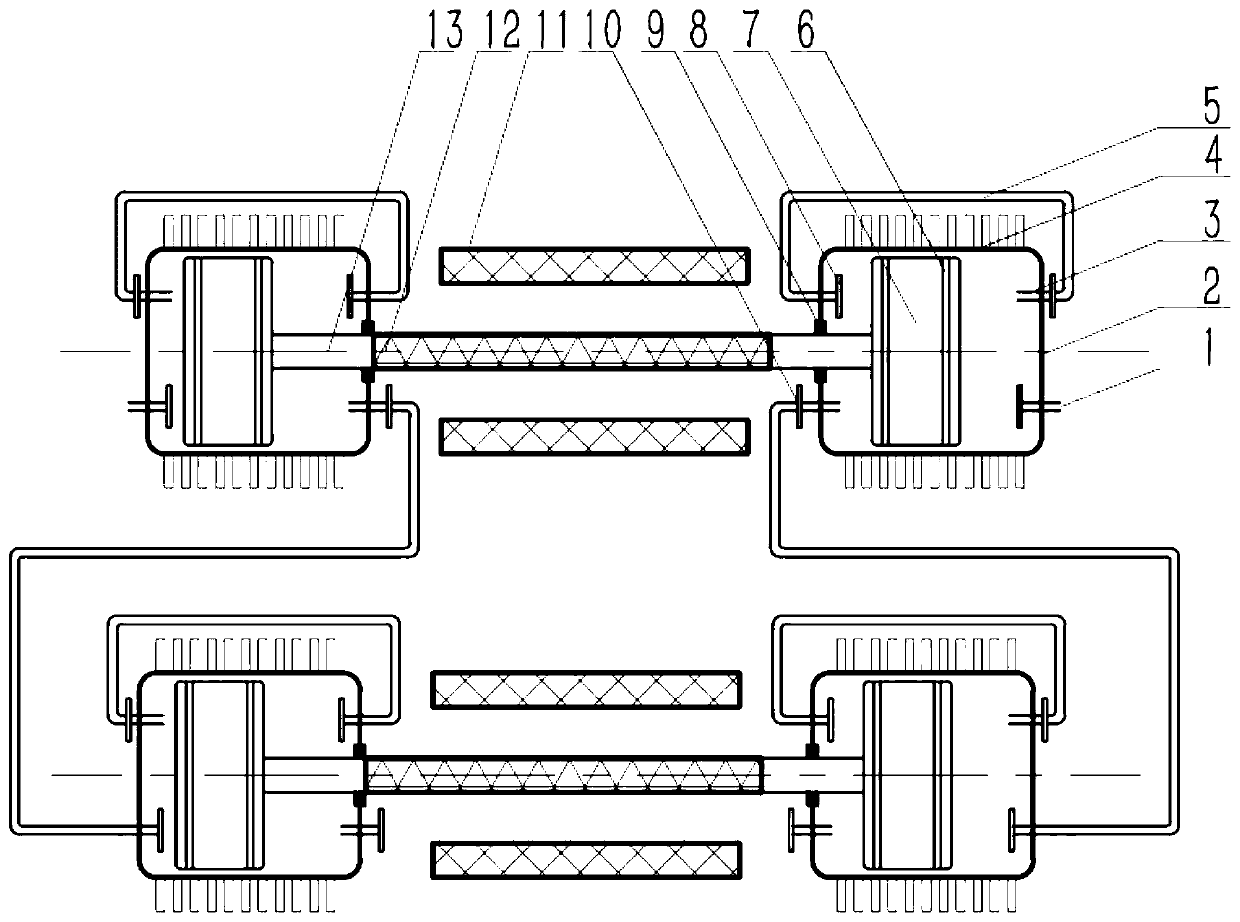

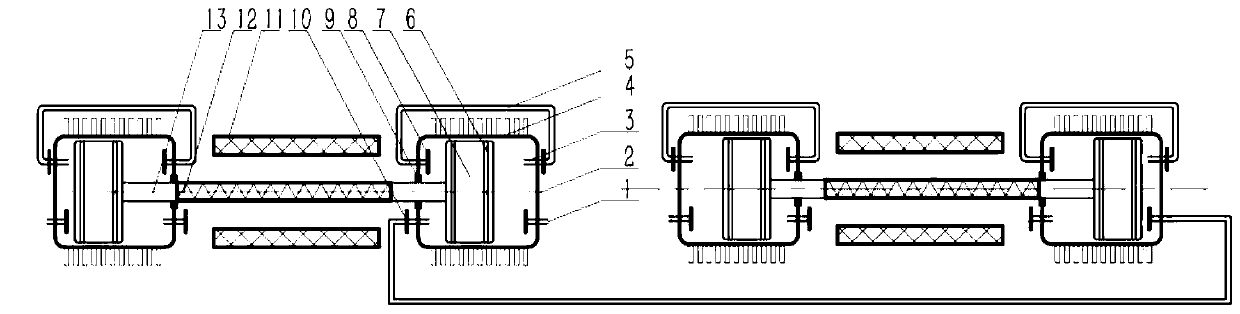

Multi-cascaded double-cylinder linear compressor

ActiveCN110094319AIncrease profitSimple structurePositive displacement pump componentsPiston pumpsLinear compressorEngineering

The invention relates to a multi-cascaded double-cylinder linear compressor, and belongs to the field of energy power. The multi-cascaded double-cylinder linear compressor comprises double-cavity compression cylinders, a linear motor and cascading pipes. Each cylinder is composed of a cylinder cover and a cylinder body and is divided by a double-sided piston into two air cavities (a first-stage compression cavity and a second-stage compression cavity), wherein the two air cavities communicate with each other through the corresponding cascading pipe; and the double-sided piston is driven by thelinear motor to reciprocate to continuously change the volumes of the two air cavities, so that first-stage compression and second-stage compression are completed. Series connection and parallel connection of the multi-cascaded double-cylinder linear compressor are completed through different connection manners of the cascading pipes, and thus, variable-pressure ratio and variable-displacement output is achieved. According to the multi-cascaded double-cylinder linear compressor, the structure of the high-pressure compressor is simplified; and a multi-cascaded reciprocating-type linear compressor system is a resonant system, so that the energy utilization rate is increased.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Adjustable automobile door lock connection rod structure

The invention discloses an adjustable automobile door lock connection rod structure which comprises a connection rod, a connection rod joint and a lock body outer outside-the-open rocker arm, wherein one end of the connection rod joint is clamped in a hole of the lock body outer outside-the-open rocker arm, the other end of the connection rod joint is clamped onto the connection rod, a first connector is rotatably arranged in the hole of the lock body outer outside-the-open rocker arm, and one end of the first connector and one end of the connection rod joint are coaxially connected in the hole of the lock body outer outside-the-open rocker arm. A threaded hole is formed on the first connector, outer threads are arranged at the end of the connection rod, and the connection rod is connected into the first connector through a threaded structure. The adjustable automobile door lock connection rod structure fixes an outside-the-open pull rod through the first connector and the connection rod joint, the first connector can rotate freely, the outside-the-open connection rod and a jacket are in threaded connection, trouble shooting is achieved by adjusting the connection rod, and therefore the product progress is led to be as scheduled.

Owner:无锡忻润汽车安全系统有限公司

a lift system

ActiveCN105668457BAdjustable strokeSolve the problem of high-speed and high-precision dockingSafety devices for lifting equipmentsLifting framesButt jointEngineering

The invention discloses a lift system. The lift system comprises a tray, a machine base, a left lifting unit and a right lifting unit; the left lifting unit comprises a left vertical column, a left screw, left linear guide rails, a left screw connection block and a left loading base; the right lifting unit comprises a right vertical column, a right screw, right linear guide rails, a right screw connection block and a right loading base; the machine base is provided with a motor capable of synchronously driving the left screw and the right screw to rotate synchronously for lifting the left loading base and the right loading base synchronously, and the tray is fixedly connected to the left loading base and the right loading base through tray bases. When a conveyance load is located on the tray, the motor rotates forwards and reversely, and therefore the conveyance load can be switched between upper-layer stations and lower-layer stations. According to the lift system, the screws and the linear guide rails are combined, the stroke of a lift is adjustable, high-speed and high-accuracy butt joint between fixed stations and stations of the lift is realized, the left lifting unit and the right lifting unit are synchronously driven by the motor, and transmission synchronism of the two sides of the lift system is realized.

Owner:GUANGZHOU MINO AUTOMOTIVE EQUIP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com