Patents

Literature

1663results about "Paper article packaging" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

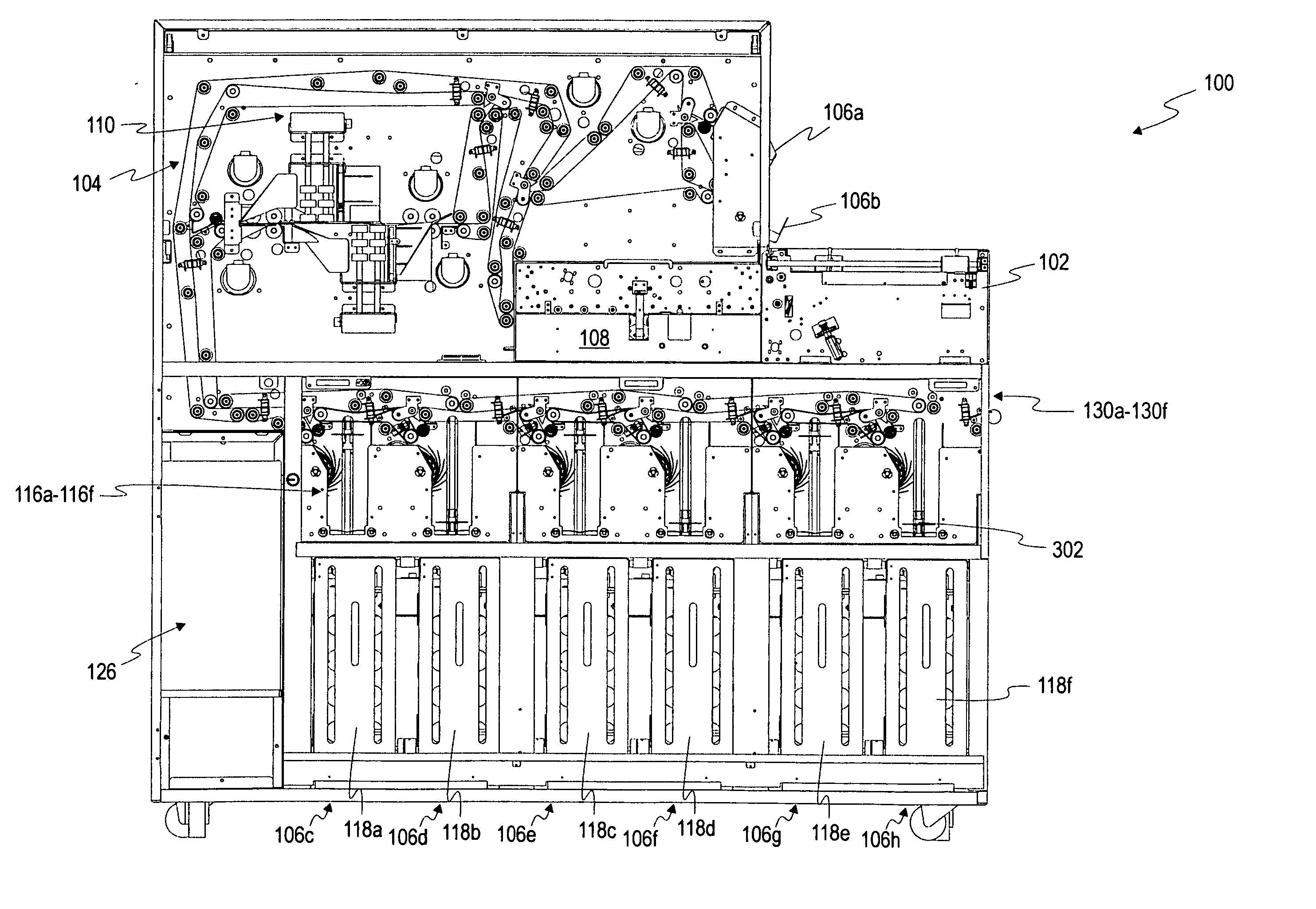

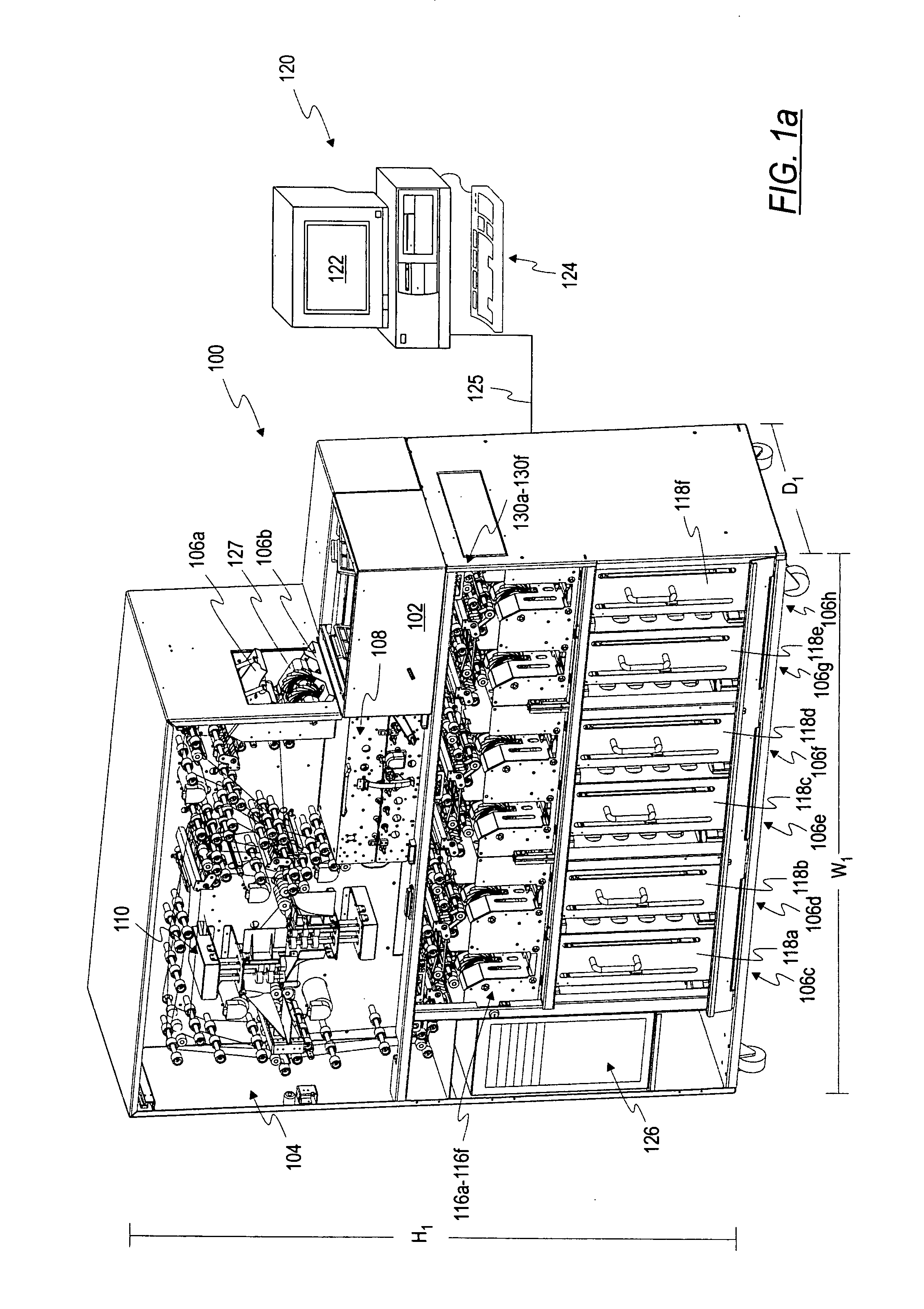

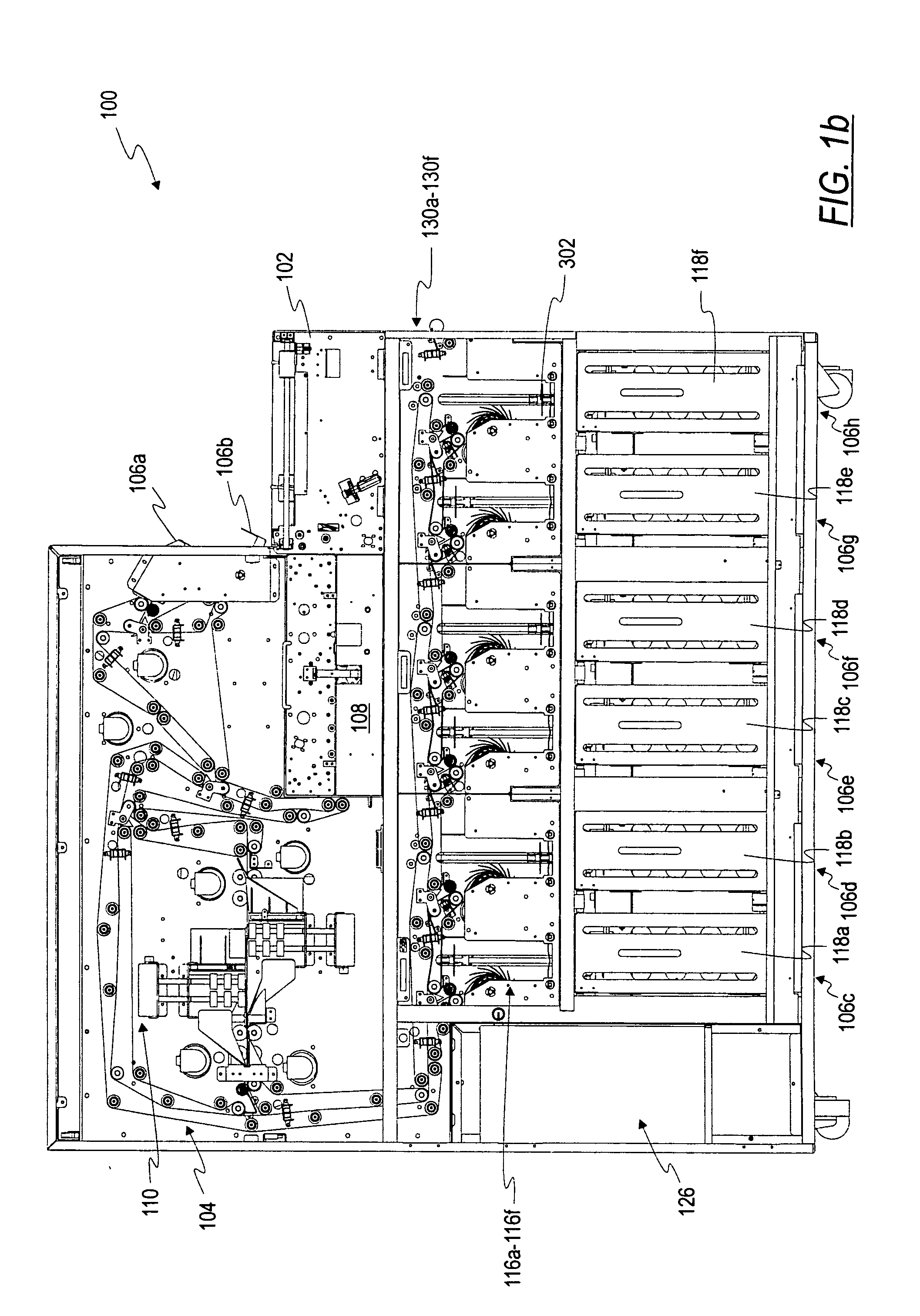

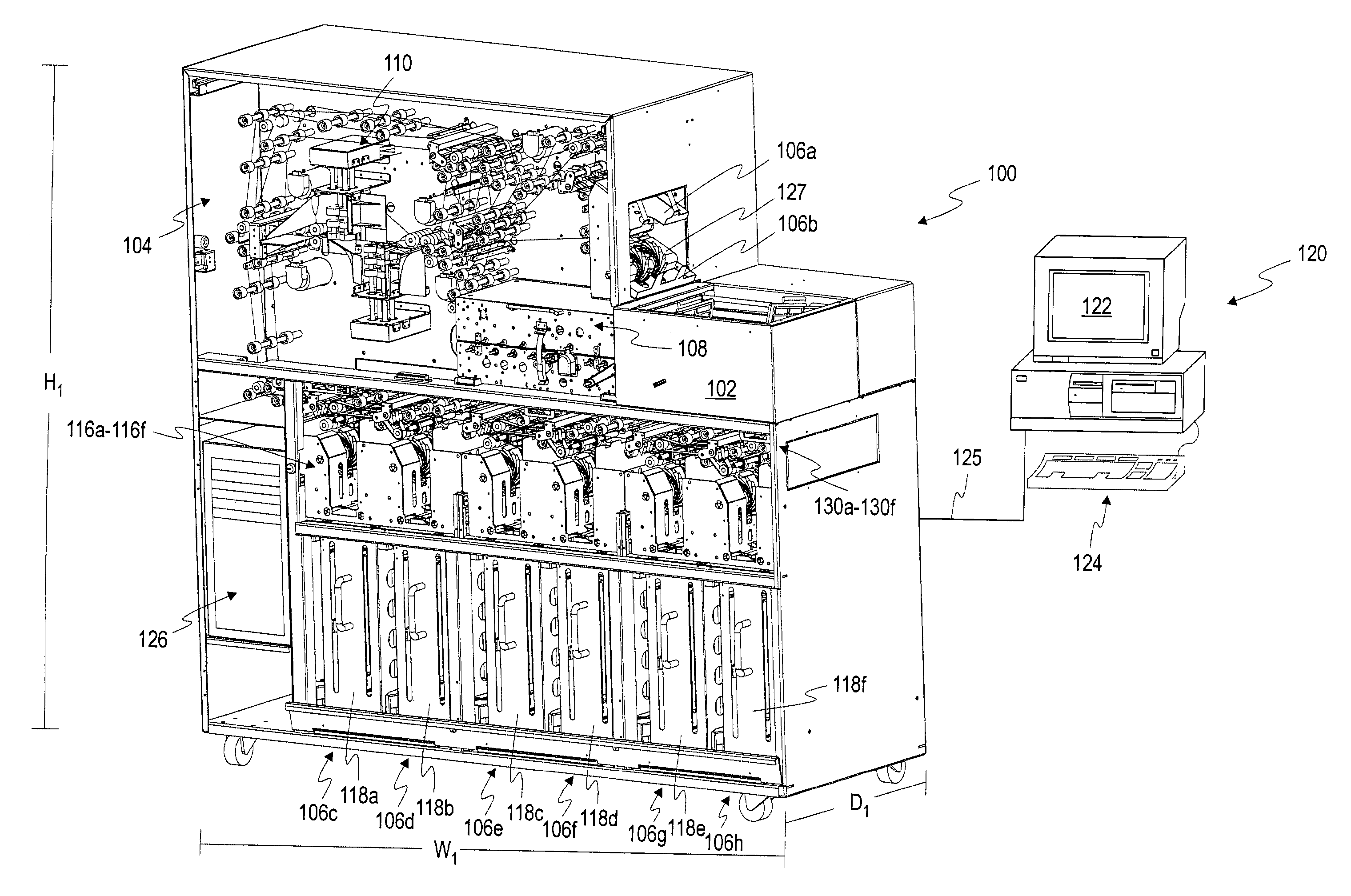

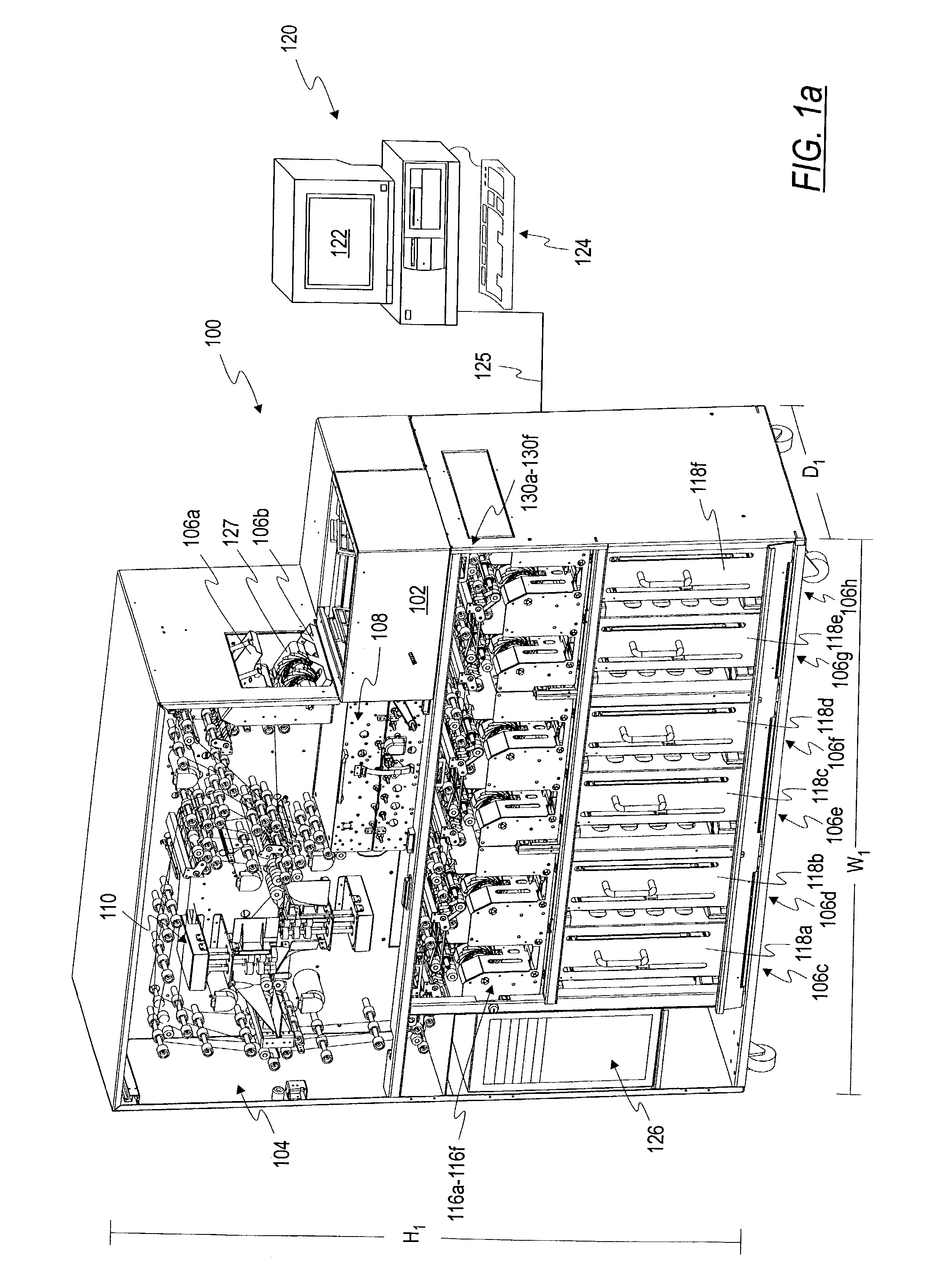

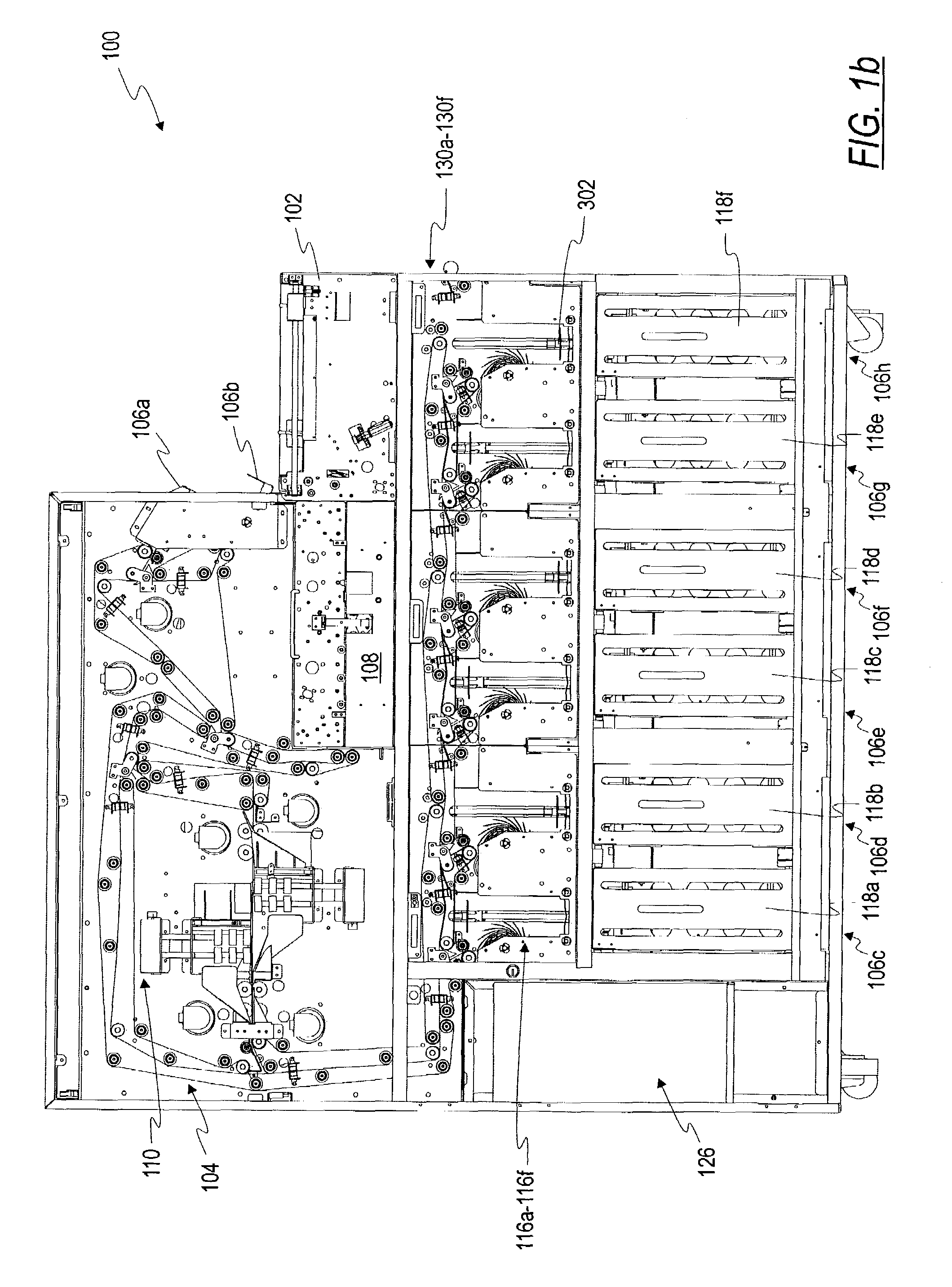

Currency processing and strapping systems and methods

A method and device for evaluating currency bills using a strapping unit that allows a currency evaluating device to automatically strap stacks of currency bills. Currency bills are placed in an input receptacle and an evaluating unit processes each currency bill one at a time. The currency bills are then transported to a plurality of output receptacles. A stack moving mechanism transports a stack of currency bills, which contains a predetermined number of currency bills, from each of the plurality of output receptacles to the strapping unit or a strapping position. Each stack of currency bills is strapped using strapping material.

Owner:CUMMINS-ALLISON CORP

Currency processing and strapping systems and methods

A method and device for evaluating currency bills using a strapping unit that allows a currency evaluating device to automatically strap stacks of currency bills. Currency bills are placed in an input receptacle and an evaluating unit processes each currency bill one at a time. The currency bills are then transported to a plurality of output receptacles. A stack moving mechanism transports a stack of currency bills, which contains a predetermined number of currency bills, from each of the plurality of output receptacles to the strapping unit or a strapping position. Each stack of currency bills is strapped using strapping material.

Owner:CUMMINS-ALLISON CORP

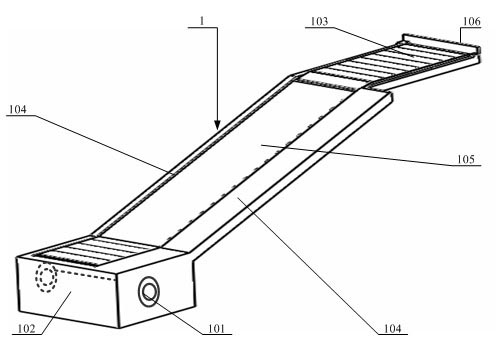

Full-automatic plastic bag folding and strapping machine

ActiveCN102167172AGuaranteed uptimeHigh degree of automationPaper article packagingBundling machine detailsEngineeringAutomation

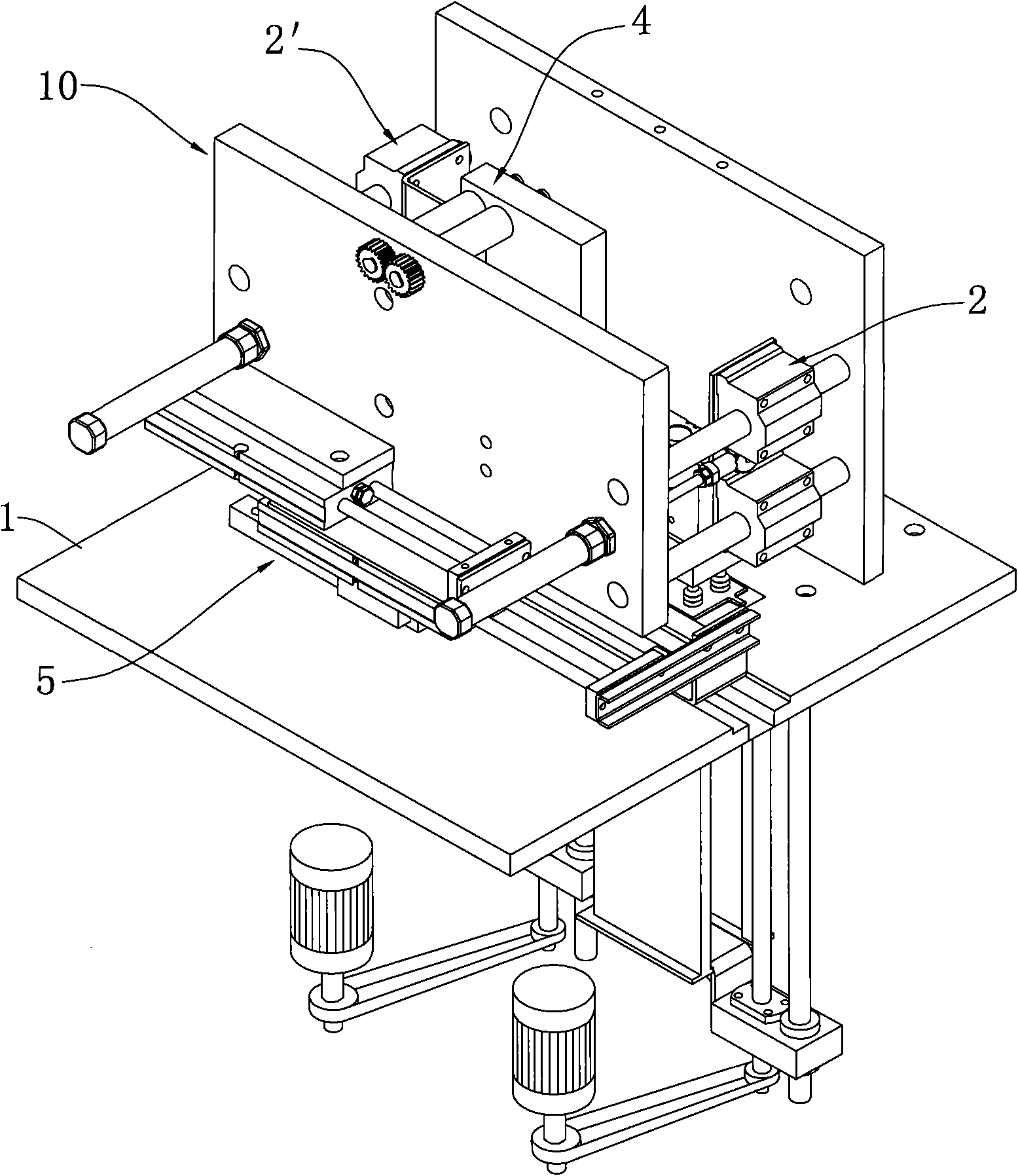

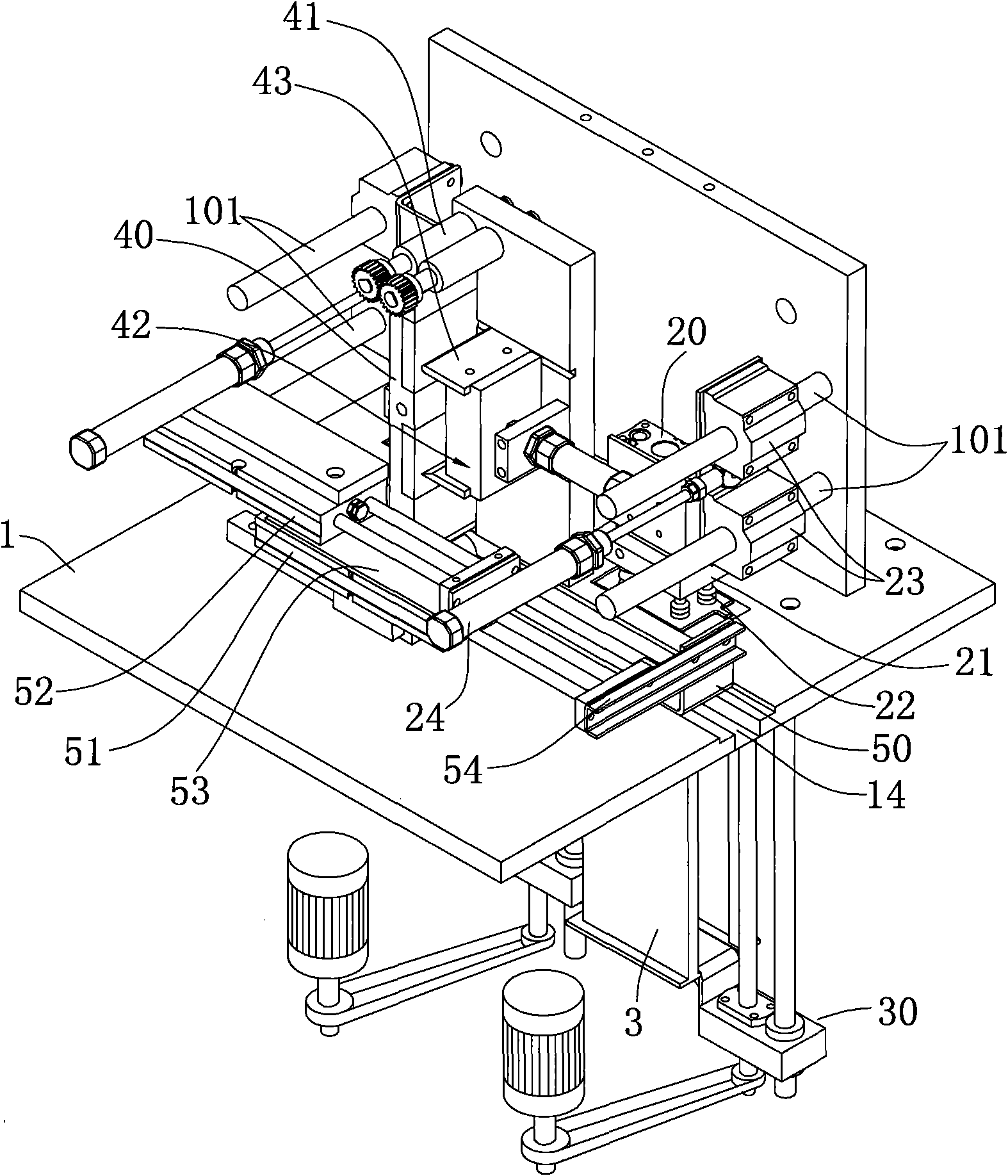

The invention discloses a full-automatic plastic bag folding and strapping machine. The machine comprises a frame, a plastic bag conveying device, a plastic bag folding device which is arranged behind a plastic bag lifting handle cutting device, and a plastic bag strapping device which is arranged below the plastic bag folding device and is used for strapping folded plastic bags with strapping tapes. After piled up, the bag materials of the plastic bags are conveyed to the plastic bag lifting handle cutting device by the plastic bag conveying device, lifting handle structures are processed, and the plastic bags are conveyed to the plastic bag folding device by the plastic bag conveying device to accomplish a required folding state, fed into the plastic bag strapping device and strapped by the strapping tapes. The invention has the advantages that: the full-automatic plastic bag folding and strapping machine has a high automation degree, high production efficiency and low processing cost and is reliably operated.

Owner:王秀来

Splitting system and splitting method of paper currency packaging bag production line

ActiveCN102627157AIncrease packet speedAvoid damagePaper article packagingWrappers shrinkageComputer control systemProduction line

The invention discloses a splitting system and a splitting method of a paper currency sealing bag production line. The splitting system is composed of a paper money bunch splitting system, a paper money bundle splitting system and a computer control system, wherein the paper money bunch splitting system is composed of a counting buncher, an automatic sealing mechanism, a paper money bunch splitting mechanism and a thin film paper money bundling machine; and the paper money bundle splitting system is composed of a loose bundle detecting and information collecting unit, an on-line weighing machine, a rejecting mechanism, a plastic seal shrinker, an automatic labeler and a paper money bundle splitting mechanism. The invention also relates to paper money bunch and paper money bundle splitting methods. The splitting method comprises the steps that the paper money bunch splitting mechanism for identifying the bundle variety splitting, a loose bundle detecting and information collecting unit for detecting whether the paper money bundle is loose and sealed and the paper money bundle splitting mechanism for identifying the bundle variety splitting, which are supported by conveyer belts (A and B) are used for sealing and splitting the paper money from the paper money bunch to the paper money bundle. The splitting system has the online use functions of multiple outlets of single or multiple counting and splitting machines and one outlet of different bundle varieties, and fully ideal paper currency sealing complete equipment in a banking system.

Owner:秦静 +3

Device for processing mail items in bundles

InactiveUS20090269173A1Processing bundles of mail items easily, reliably and cheaplyPaper article packagingOverturning articlesMechanical engineeringDelivery system

A device for processing mail items, having: at least one stacking device for forming a bundle of superimposed mail items and moving it from a forming position to a loading position; one or more robots for removing the bundles in the loading position and moving them into a covering position; one or more covering devices for placing upside down containers over the bundles in the covering position, so the bundles of mail items are housed inside the containers; a conveying system supplied by the covering devices with bundles of mail items covered with respective upside down containers; and a turnover device for turning the containers over through 180°, so the containers are positioned with their respective openings facing upwards.

Owner:ELSAG DATAMAT SPA

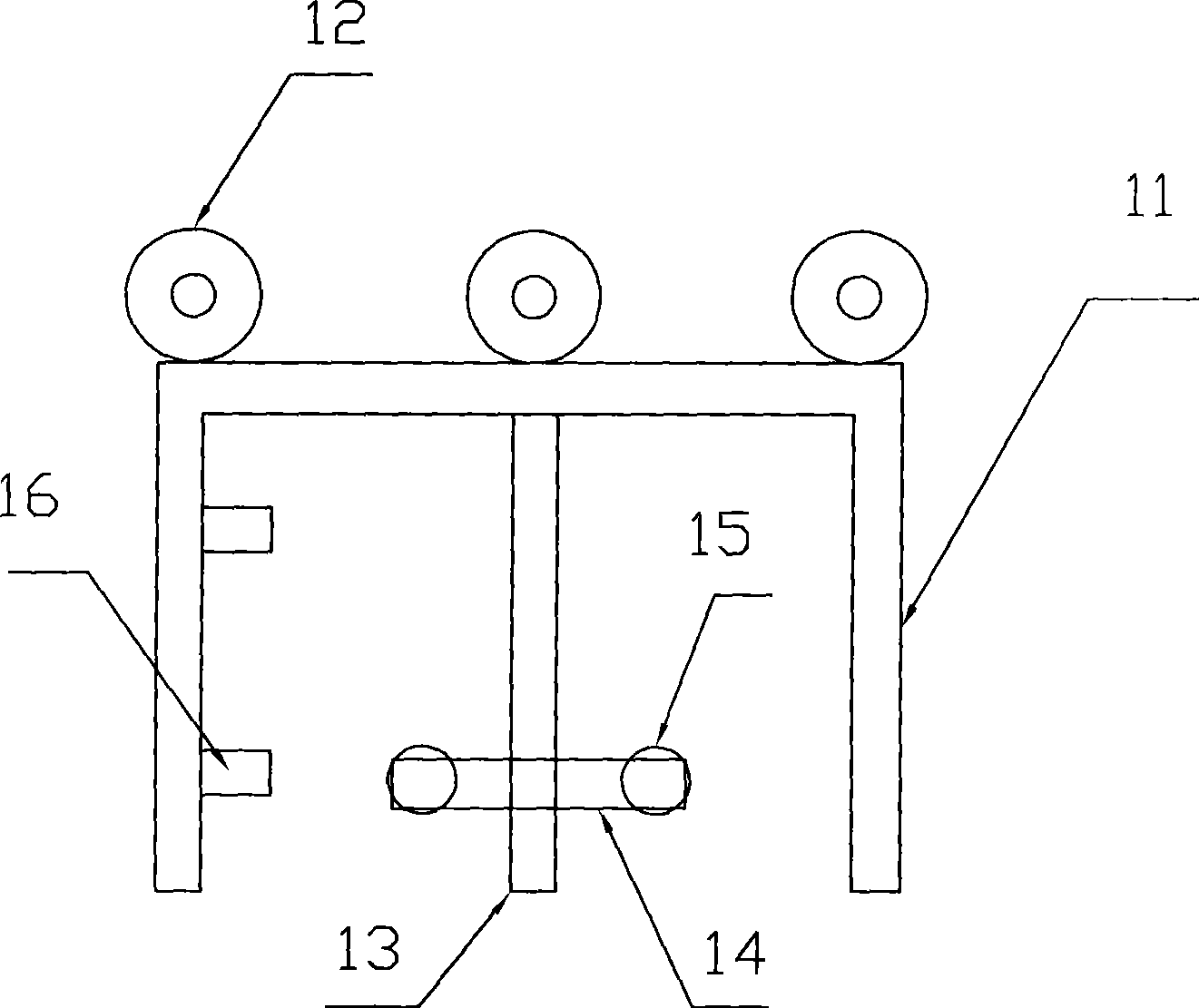

Device for stacking securities, in particular bank notes

ActiveUS20110052363A1Easy to disassemblePaper article packagingCoin/currency accepting devicesPaper documentEngineering

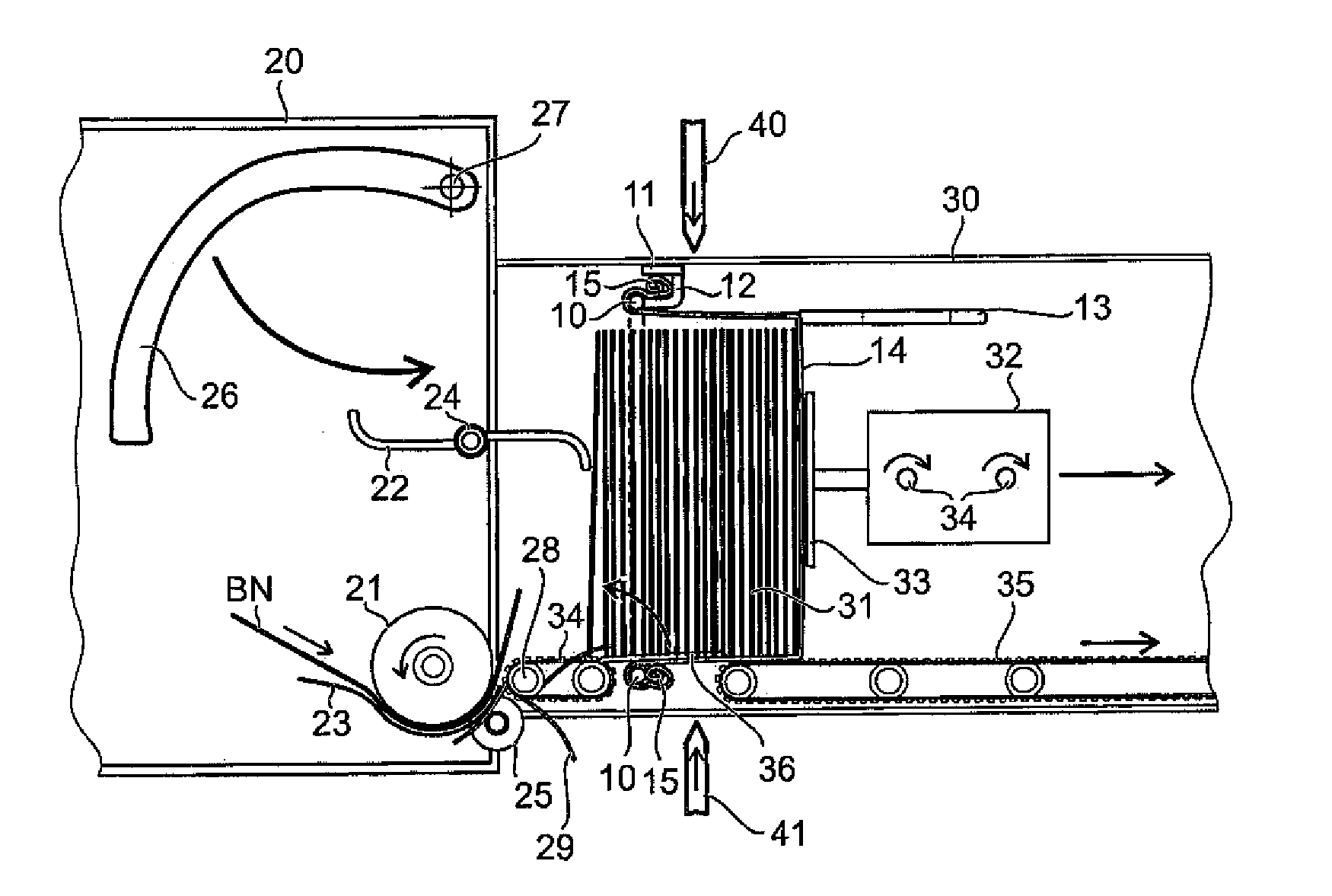

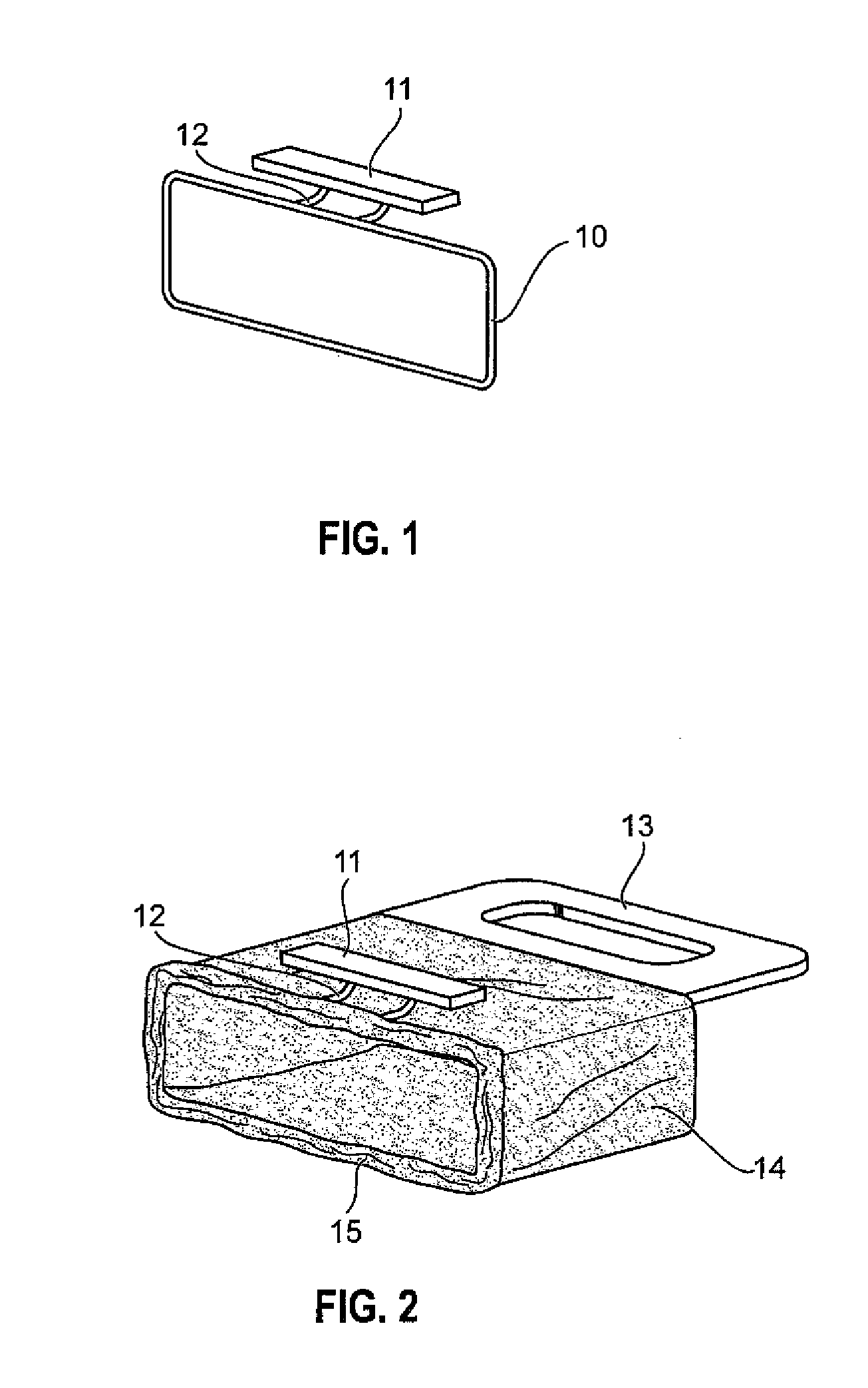

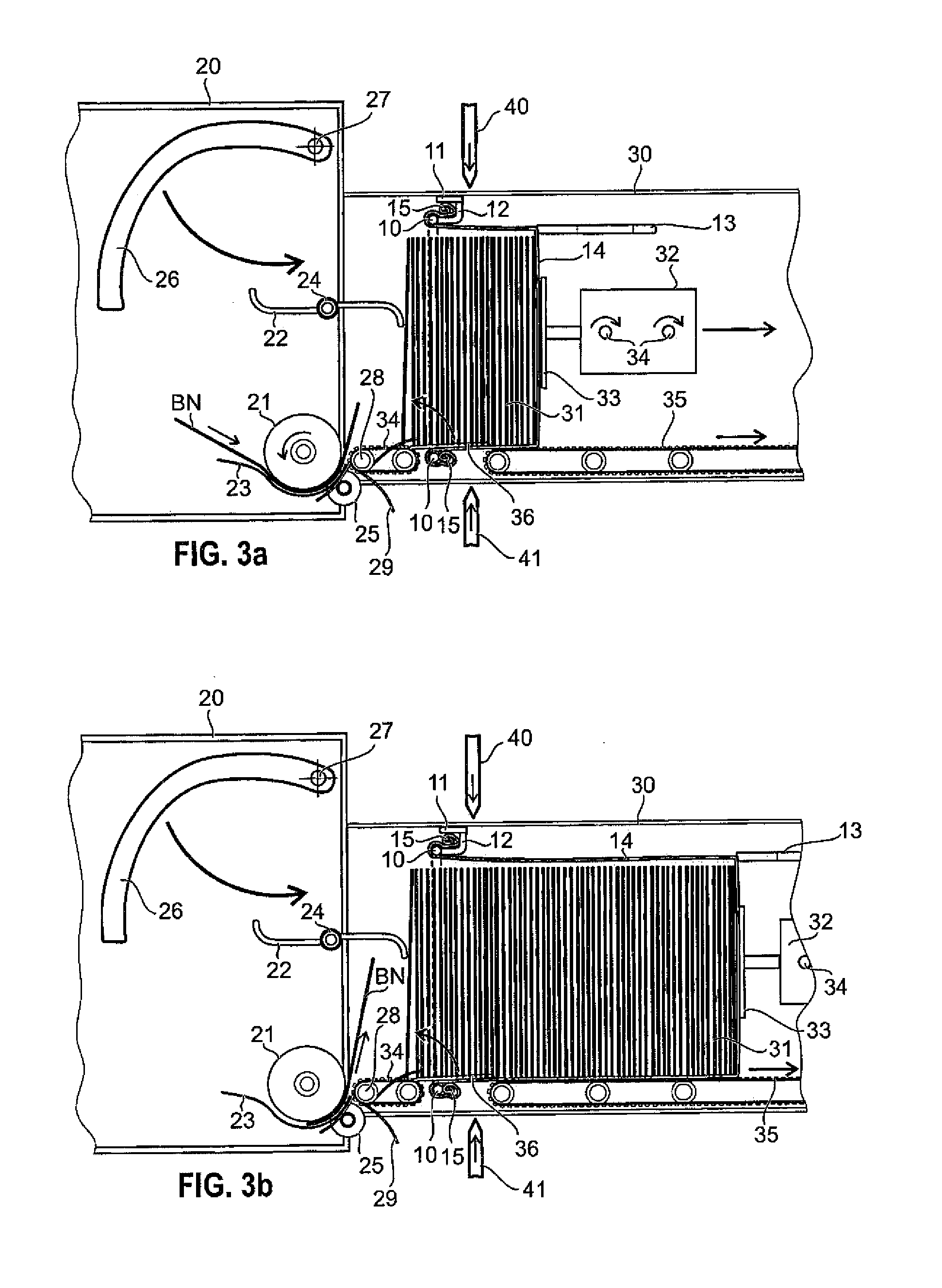

An apparatus for stacking financial documents, in particular banknotes. The financial documents (BN) are stacked upright in a stacking area on a stacking surface, and the stacking operation is terminated when a predetermined stack length is reached. The stack formation takes place in a receiving bag (14) which is stationarily held by a holding frame (10) in the entry area of the financial documents (BN) and which forms a stock (15) around the circumference of the holding frame (10). With increasing stack length, receiving bag material is automatically taken from the stock (15) so that the length of the receiving bag (14) continuously adapts to the length of the value note stack (31). At the end of the stacking operation the receiving bag (14) is closed at its opening, e.g. by welding, and can subsequently be removed from the stacking area and can be used as a transport container or, respectively, a security bag.

Owner:DIEBOLD NIXDORF SYST GMBH

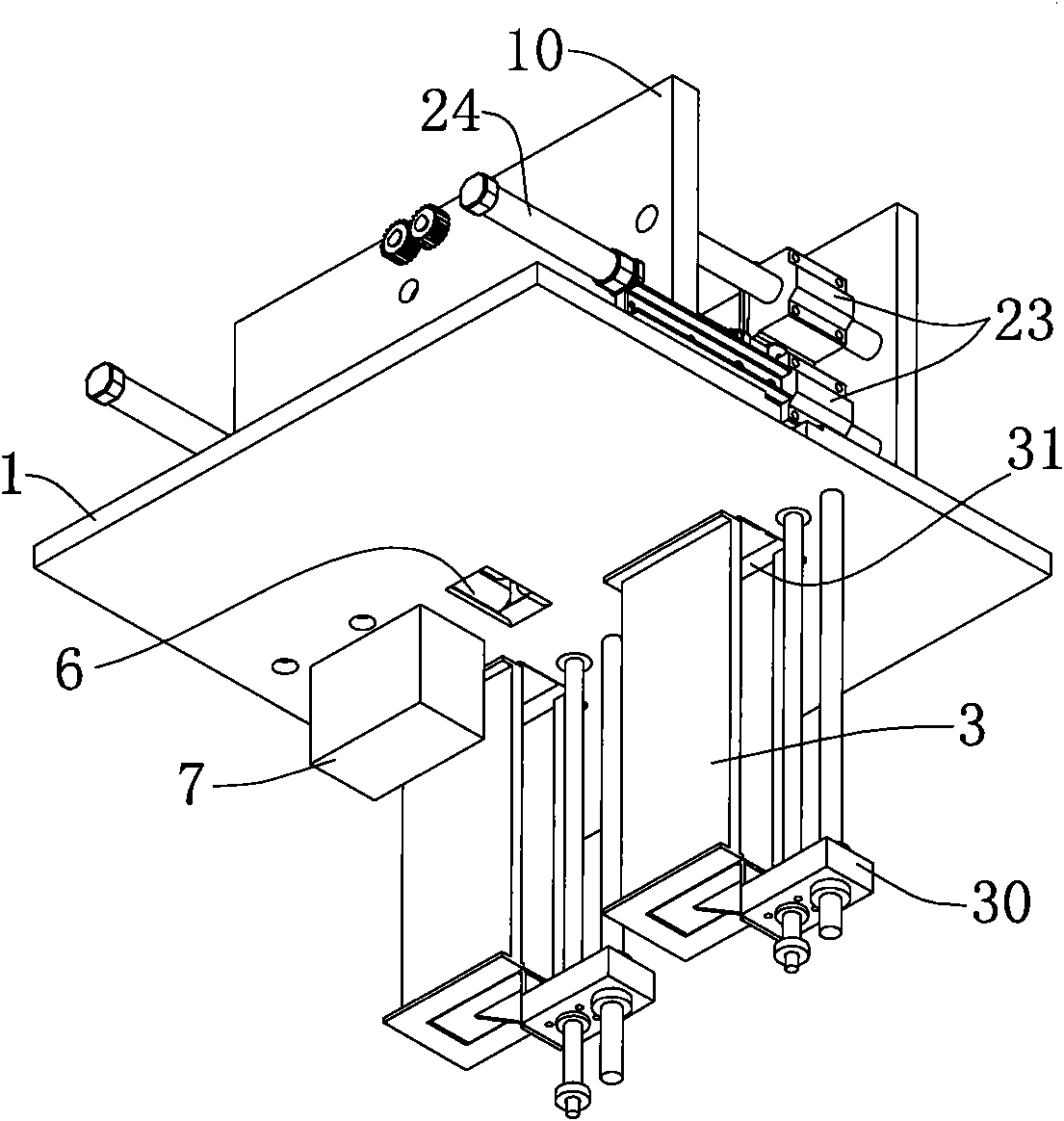

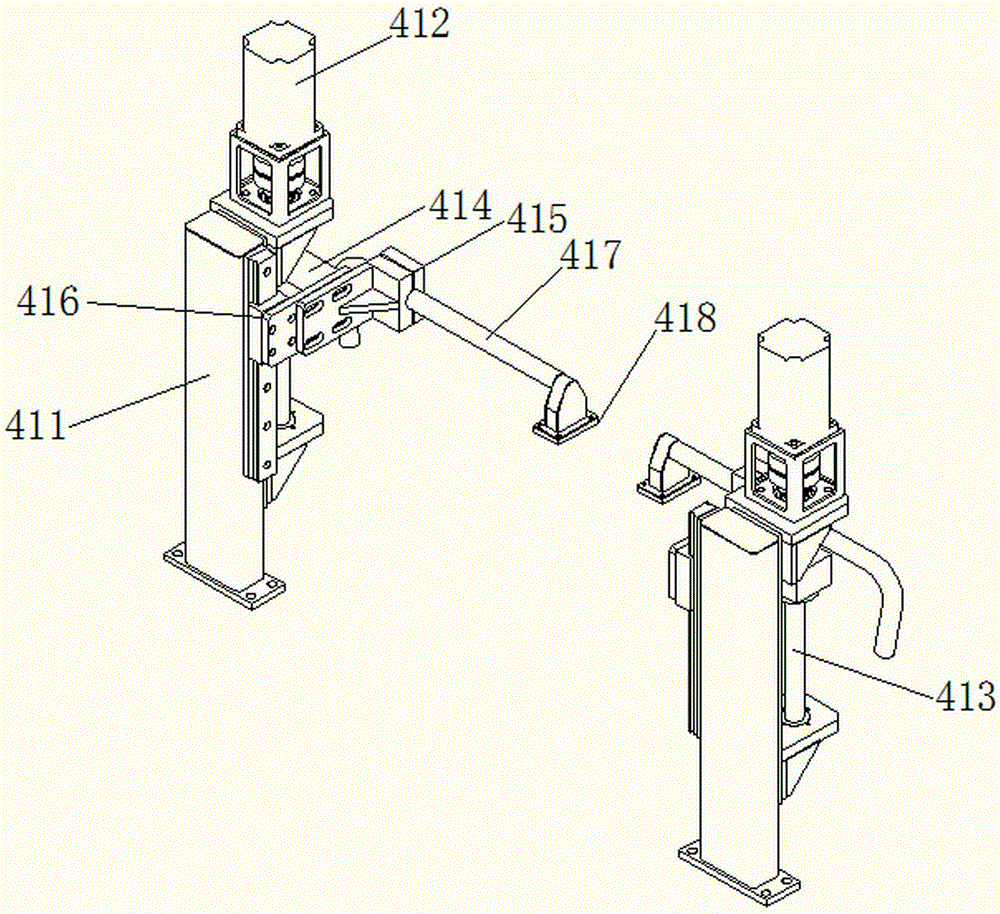

U-shaped automatic piece wrapping machine for pole pieces of storage batteries

InactiveCN101898646ARealize automatic feedingImprove efficiencyPaper article packagingWrapping material feeding apparatusPole pieceMechanical engineering

The invention discloses a U-shaped automatic piece wrapping machine for pole pieces of storage batteries, comprising a piece wrapping mechanism for wrapping a first pole piece, an assembly mechanism connected with the discharge end of the piece wrapping mechanism, a first piece supply mechanism for supplying the first pole piece to the piece wrapping mechanism and a second piece supply mechanism for supplying the second pole piece to the assembly mechanism, wherein the second pole piece and the wrapped first pole piece are piled up at intervals in the assembly mechanism to form a pole group. The machine realizes automatic feeding and automatic wrapping of the pole pieces and automatic assembly of the wrapped pole pieces, completes the whole operation process in a streamline manner in one step and improves the wrapping efficiency and quality of the pole pieces. Improvement of the degree of automation is conductive to correspondingly reducing the probability of manually contacting the pole pieces, thus greatly reducing the harm of lead dust to the operators.

Owner:ZHEJIANG HAIYUE AUTOMATIC MACHINERY

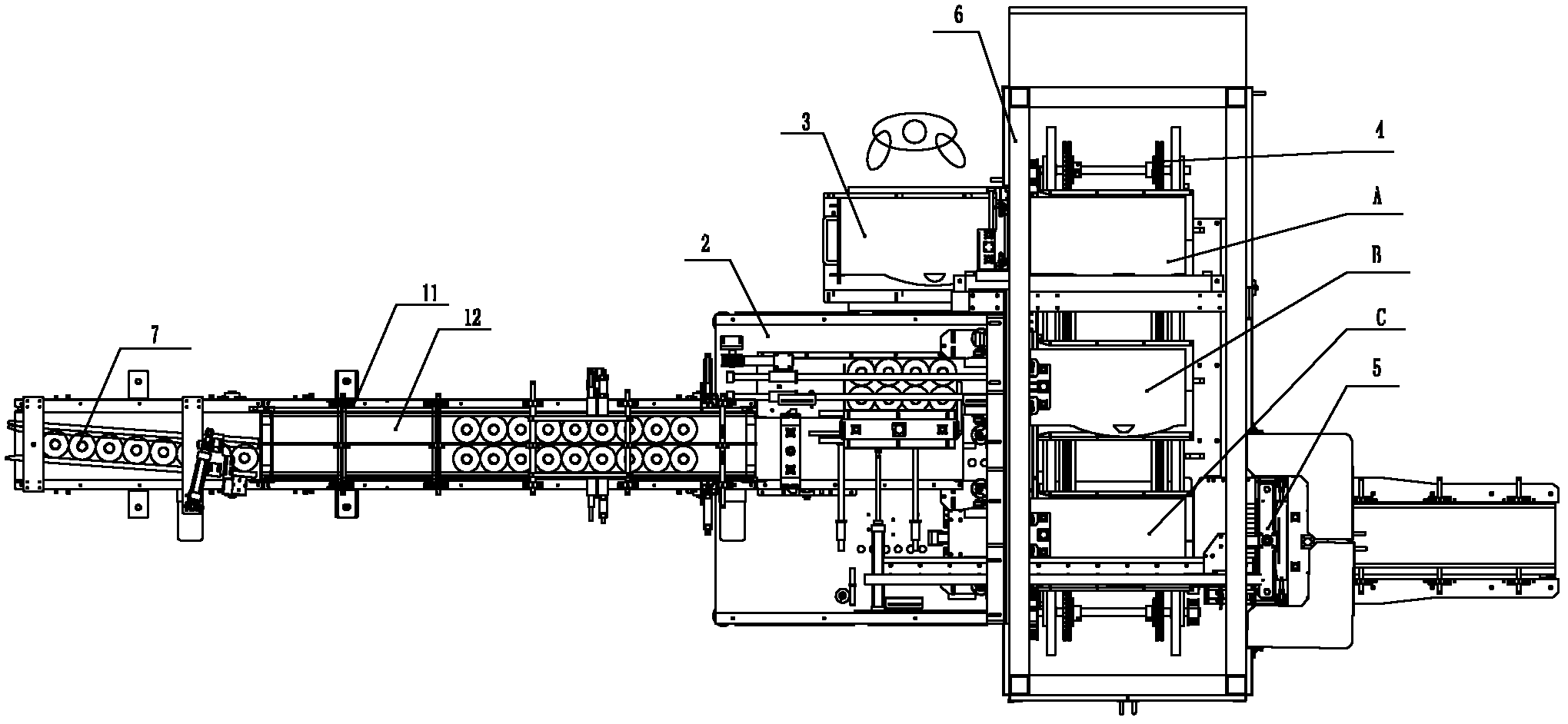

Roll paper packing machine

InactiveCN102556397AGuaranteed uniformityReduce labor costsPaper article packagingContinuous/uninterruptedRolling paper

The invention relates to a packing machine, in particular relates to a packing machine for packing roll paper. The roll paper packing machine is characterized by comprising a split conveying part, a feeding and managing conveying part, a bagging part, a packaging bag warehouse, a drag conveying part, a sealing output part and a frame part. The roll paper packing machine has the obvious advantages that: 1, the roll paper continuously enters the machine and forms the packaged finished products on sale finally, true whole assembly line operation is realized and true automatic operation is achieved; 2, labor cost is saved; and 3, a condition that the manual operation is influenced by different proficiency is avoided, and the automatic operation can fully ensure the unity of the final product quality.

Owner:SHANGHAI SOONTRUE MACHINERY EQUIP +2

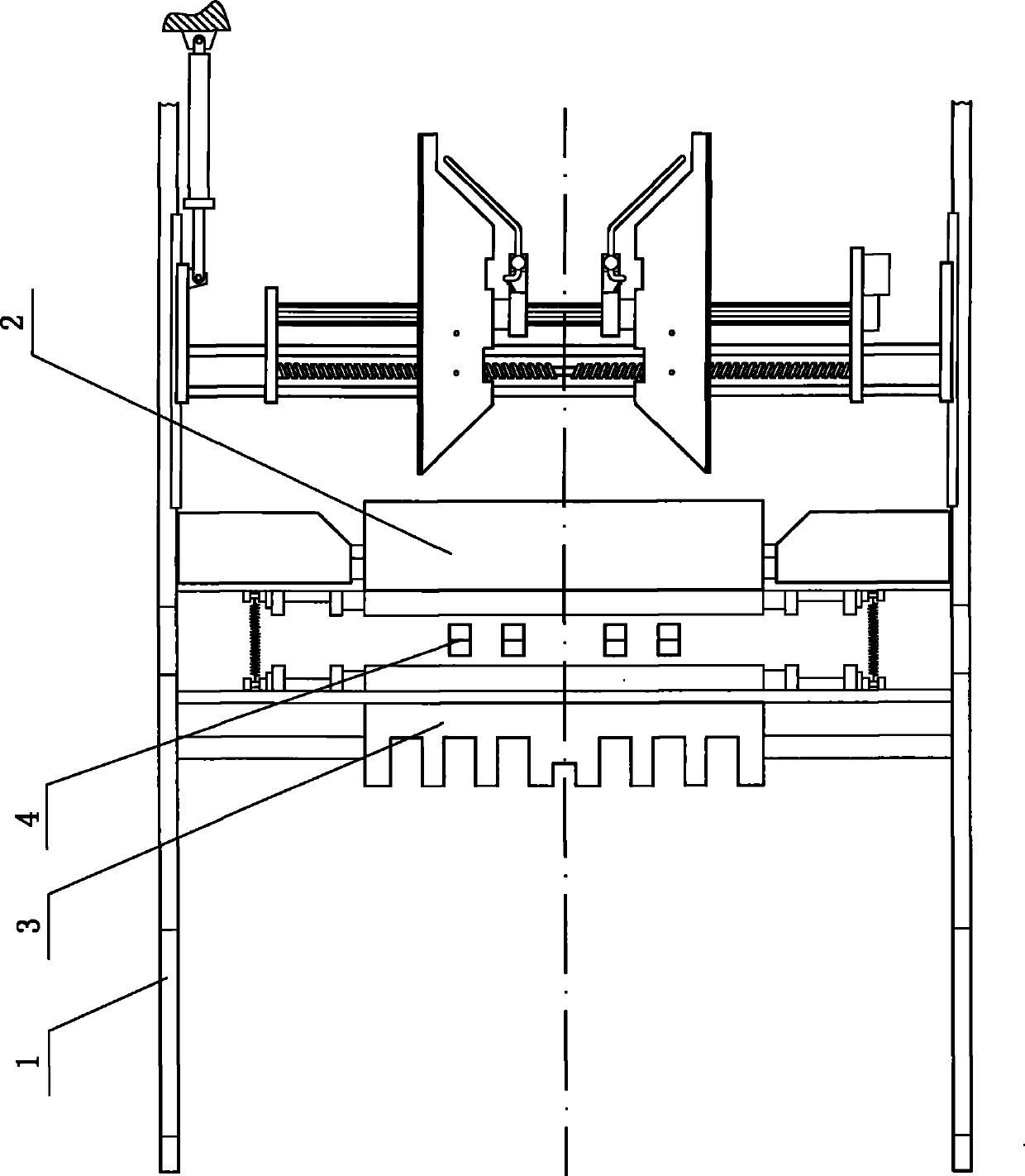

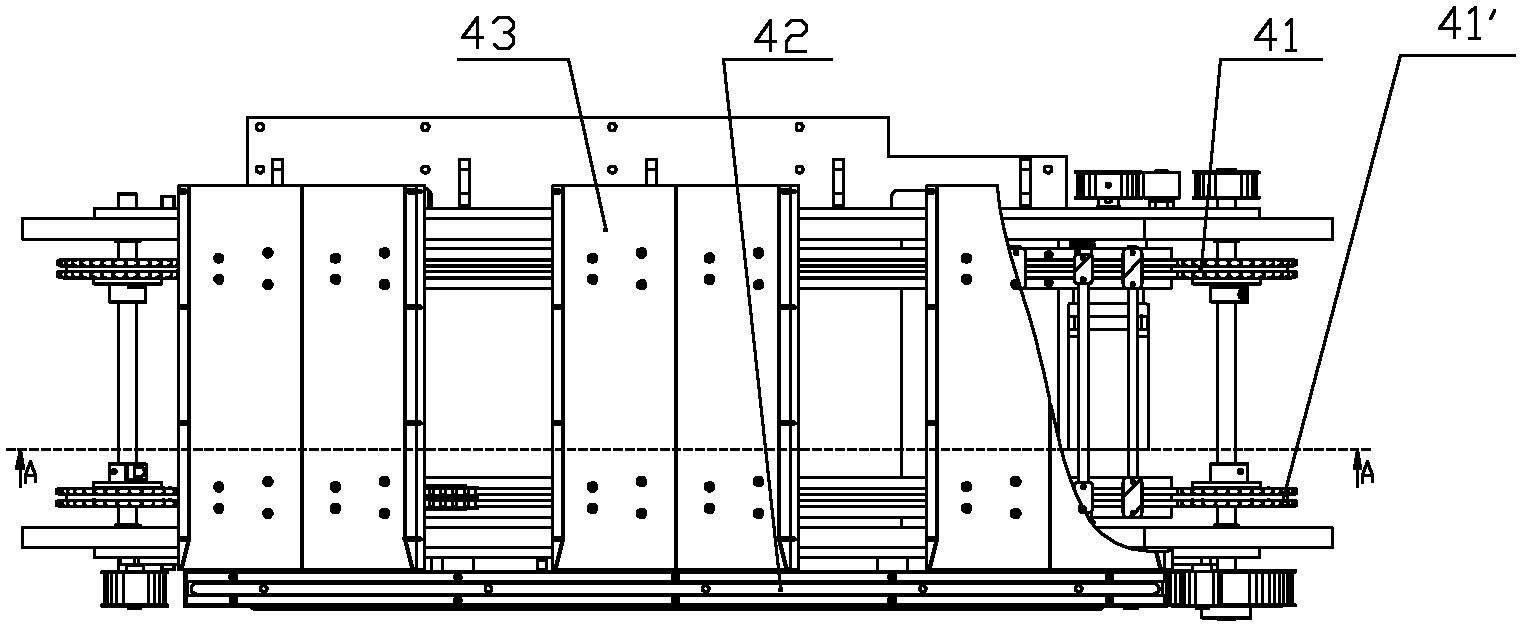

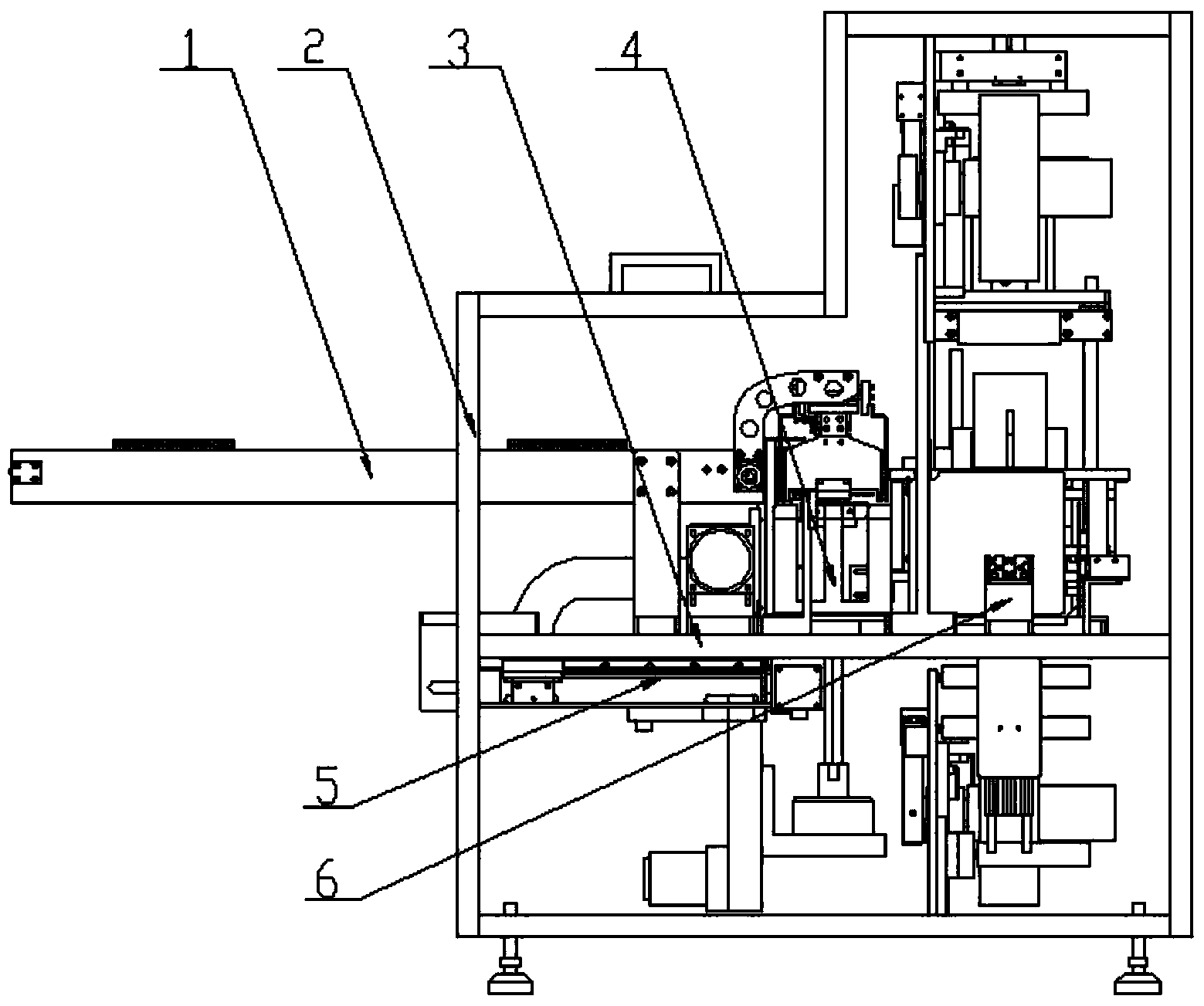

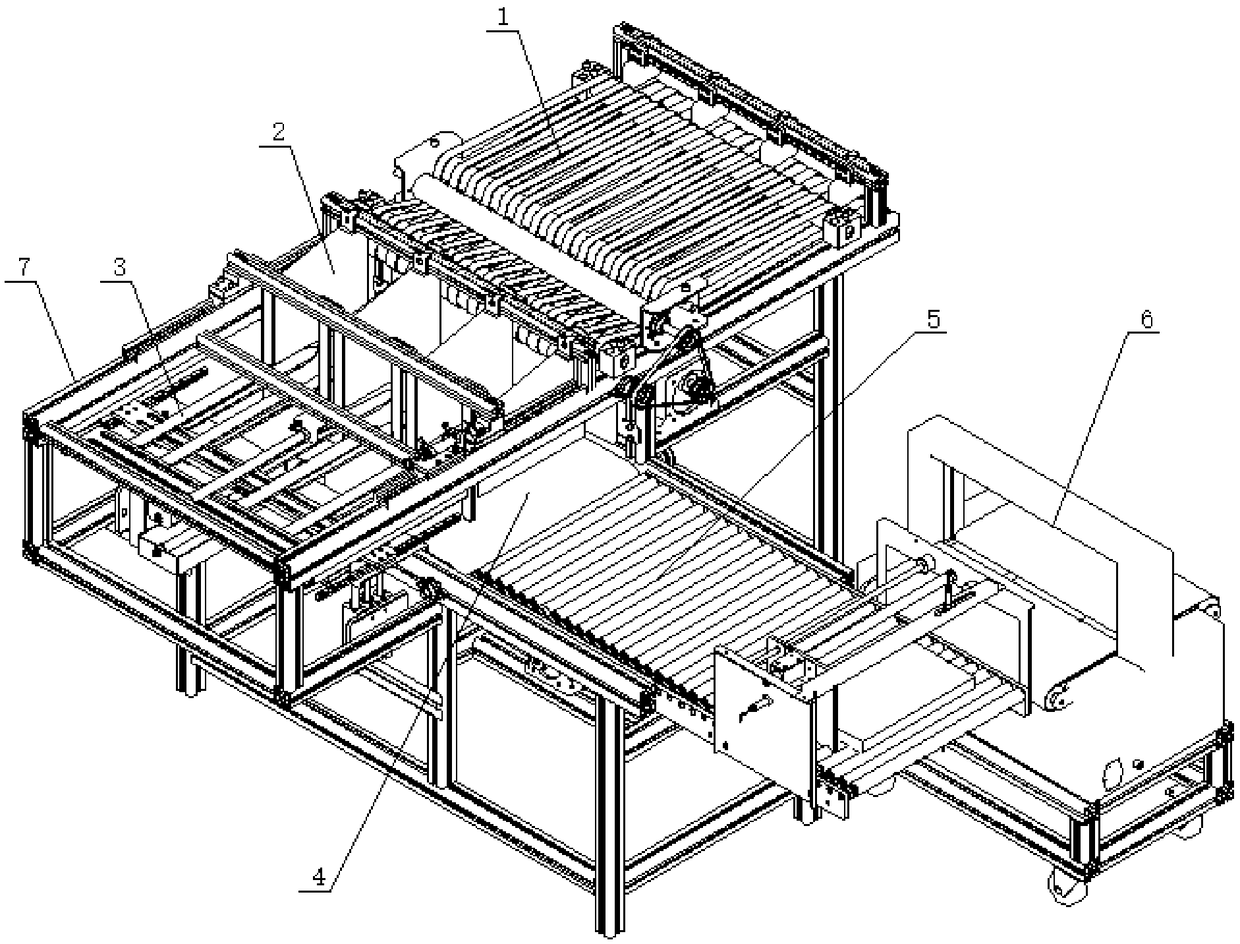

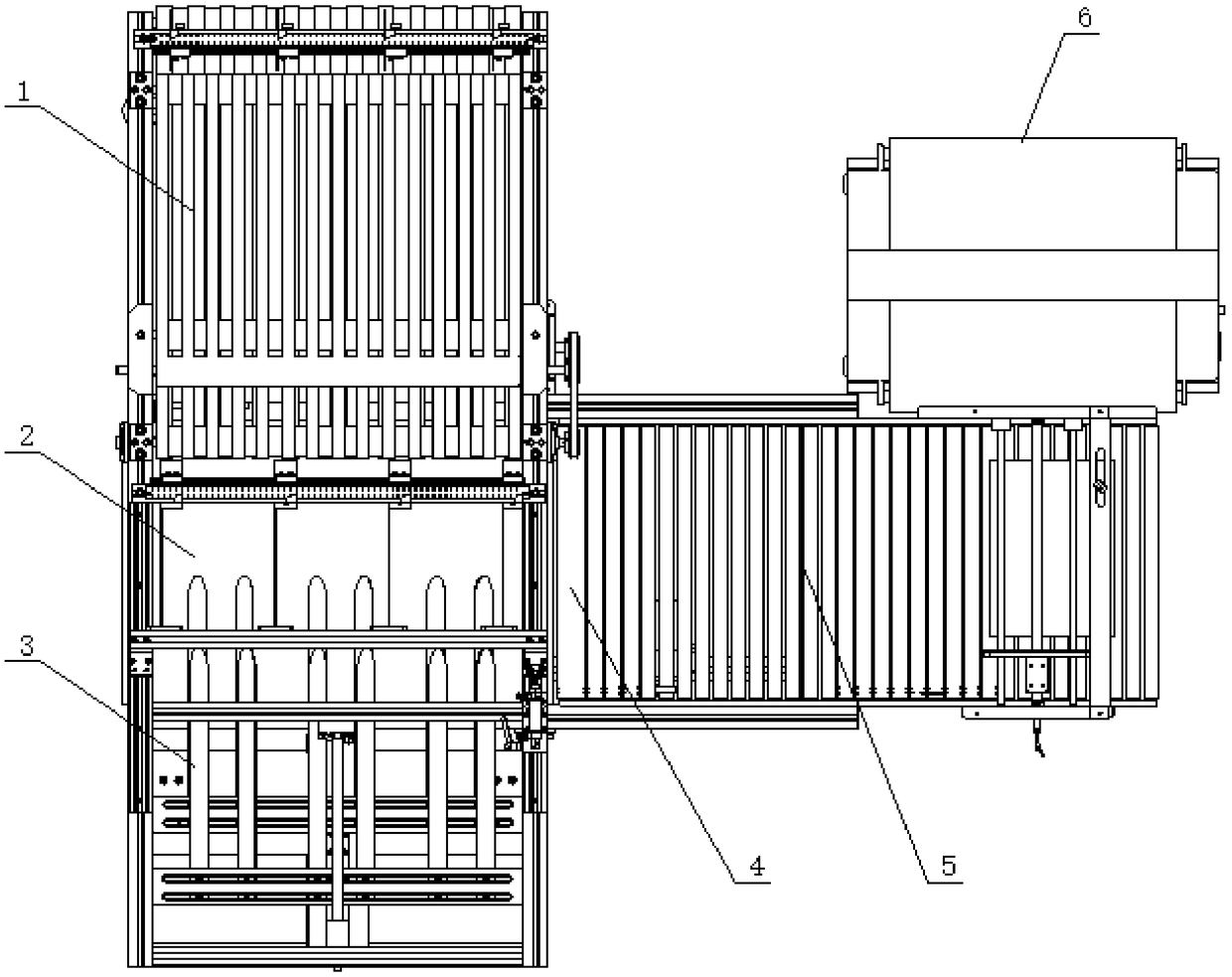

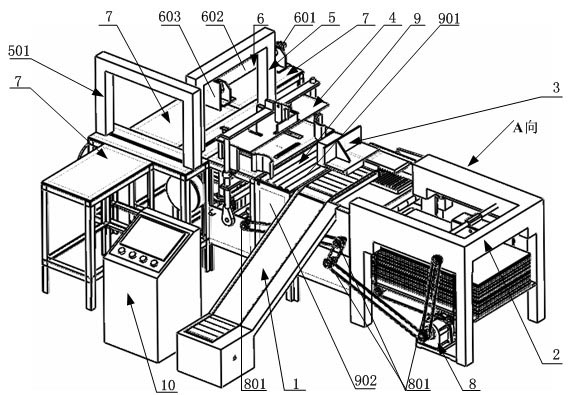

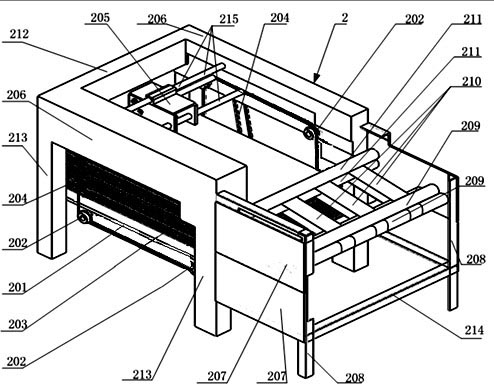

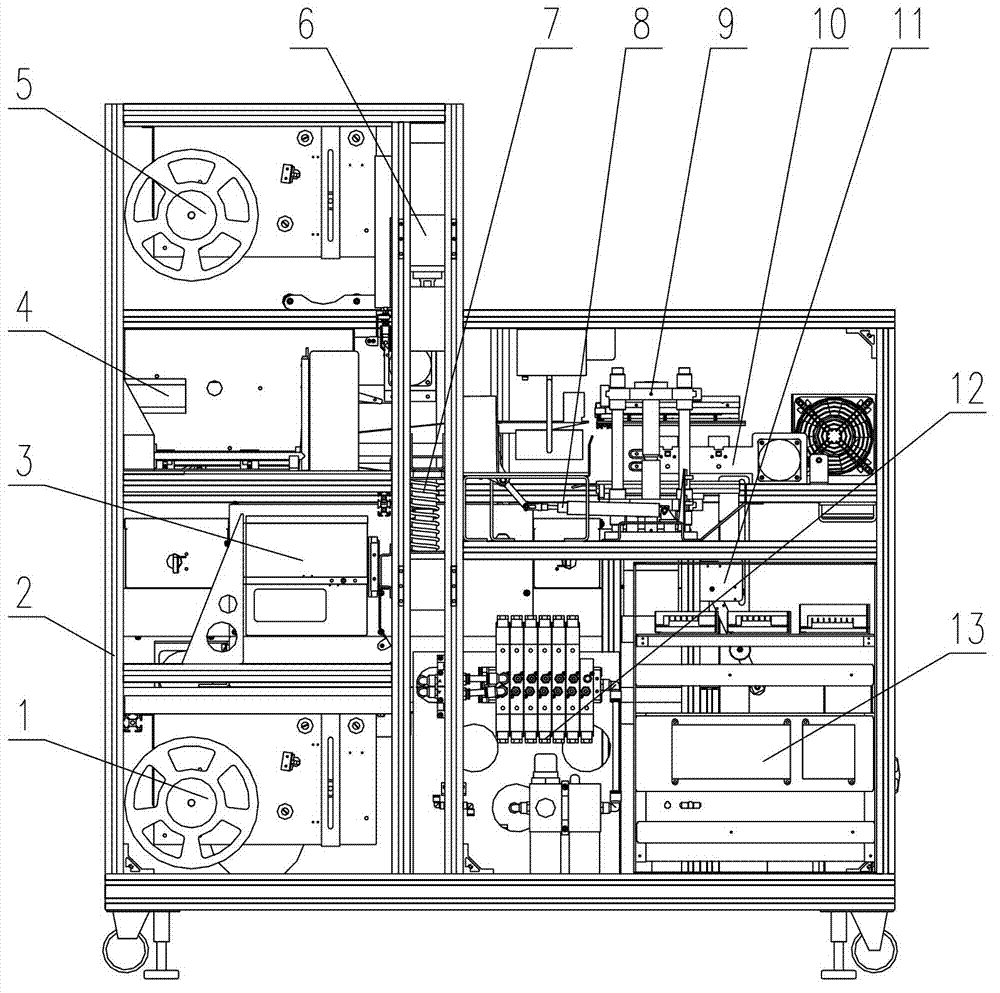

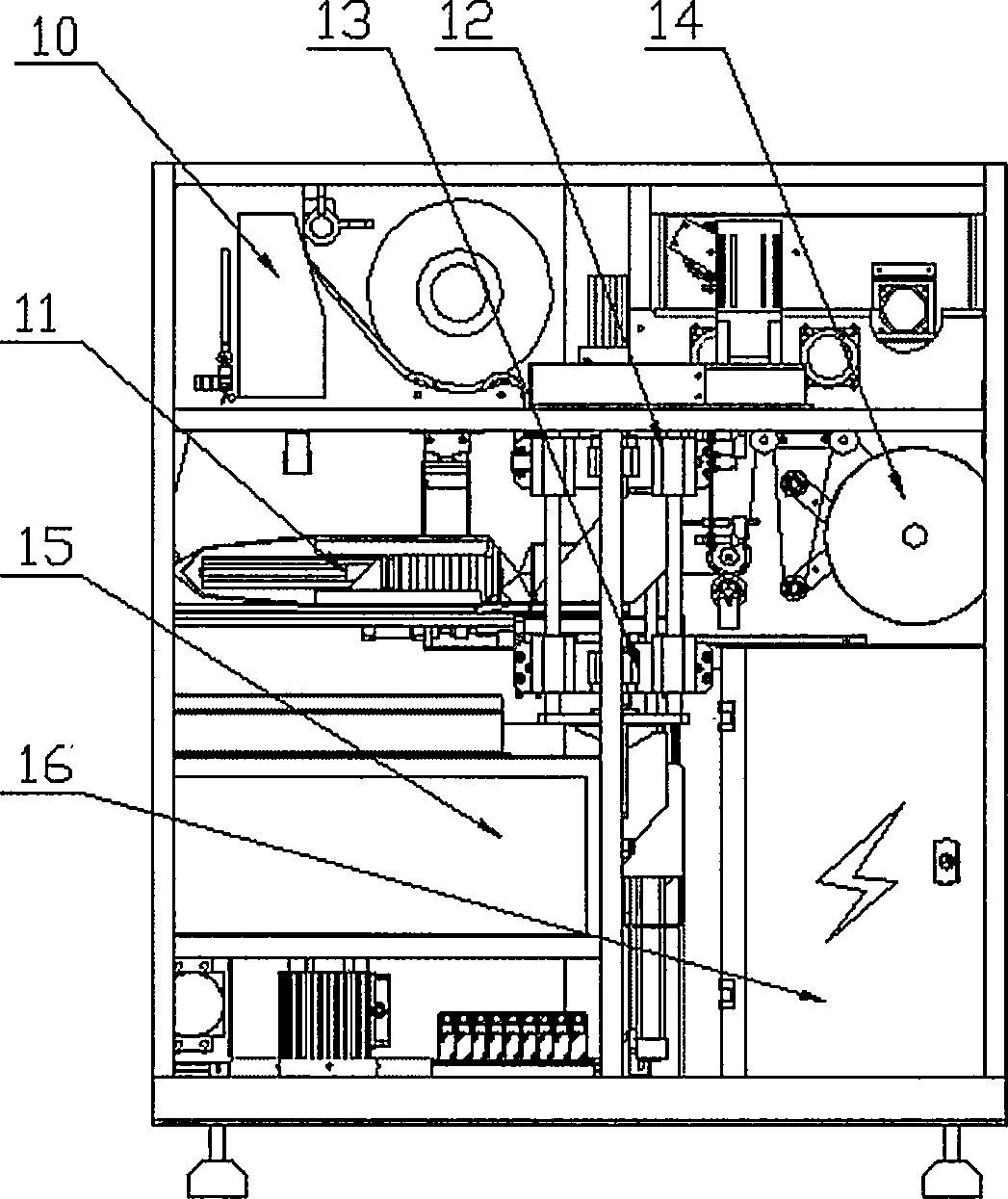

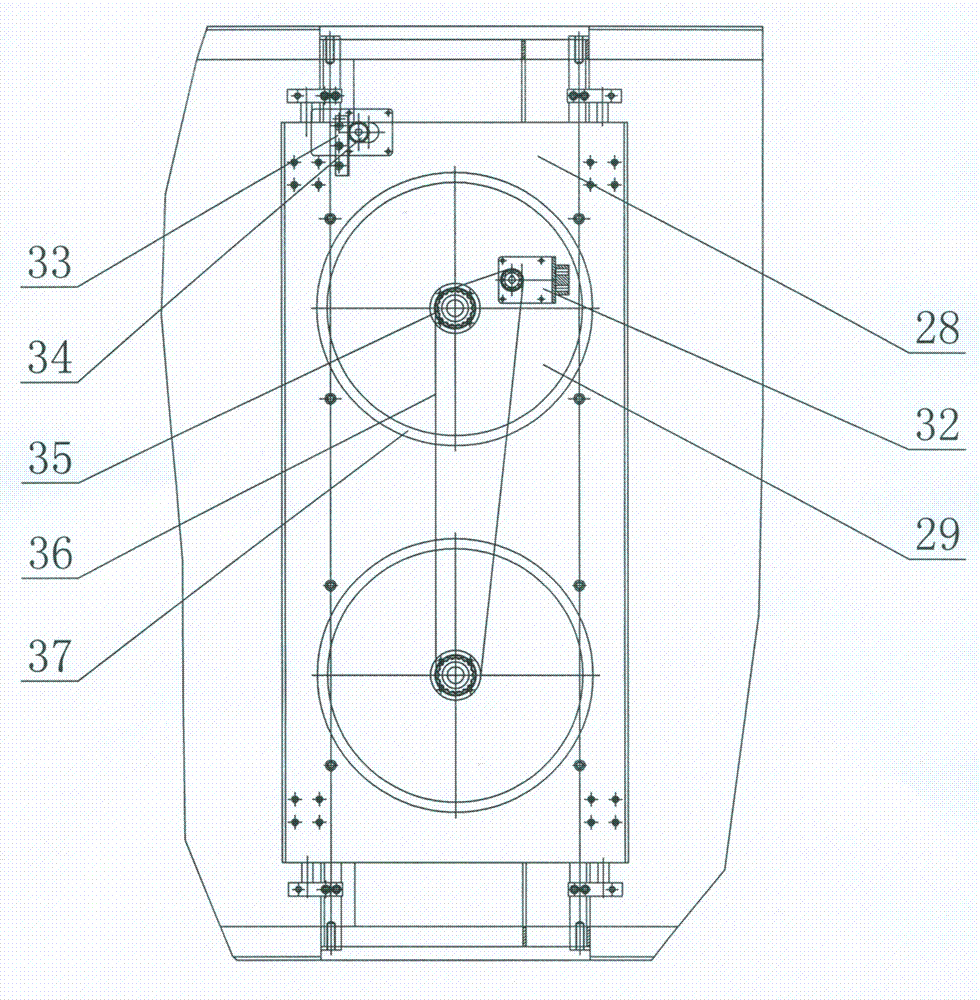

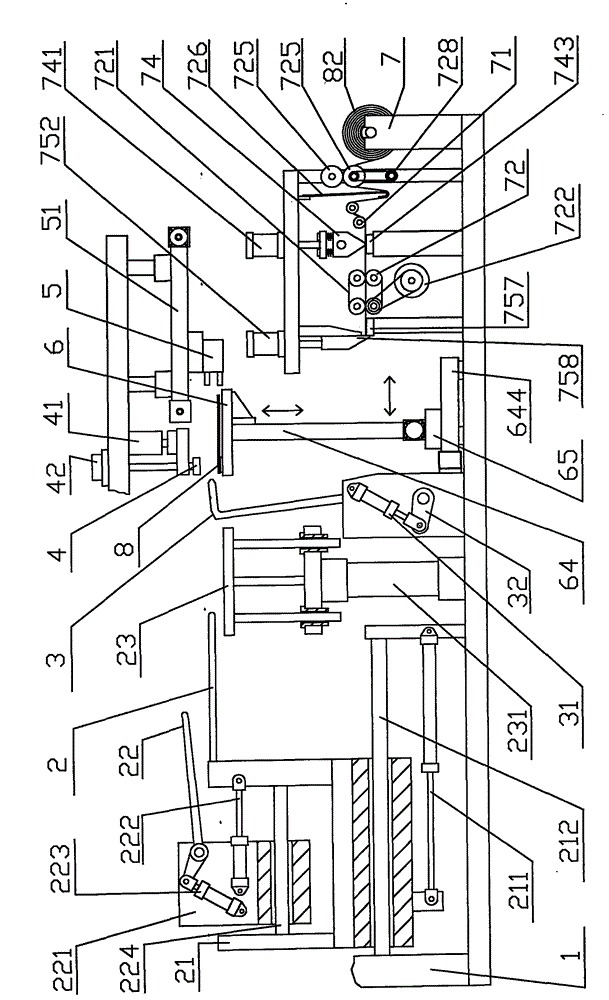

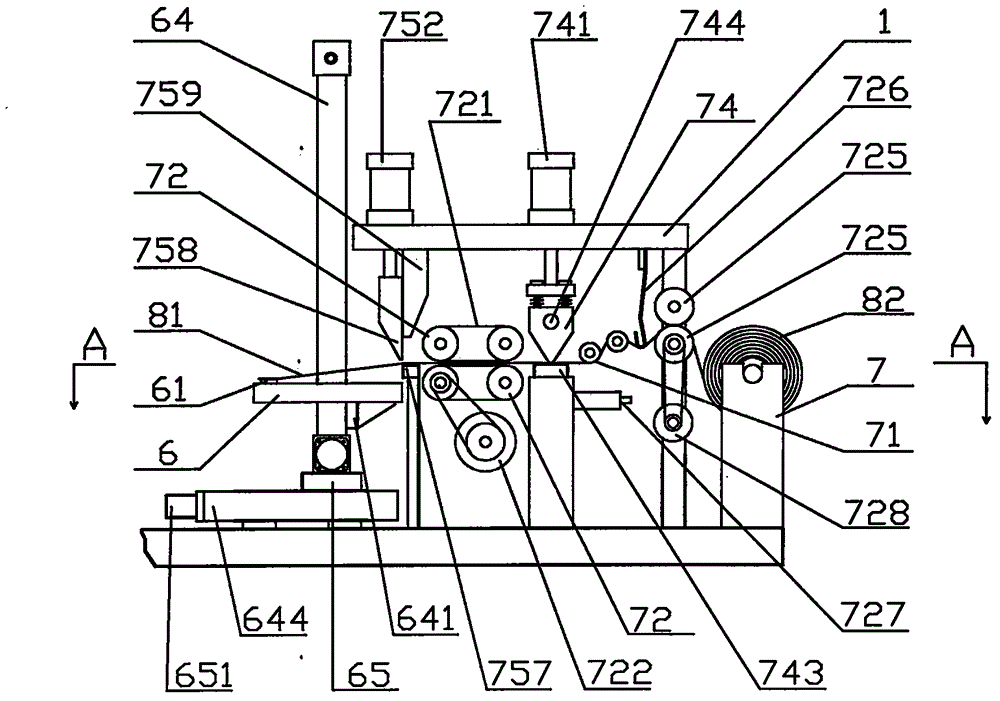

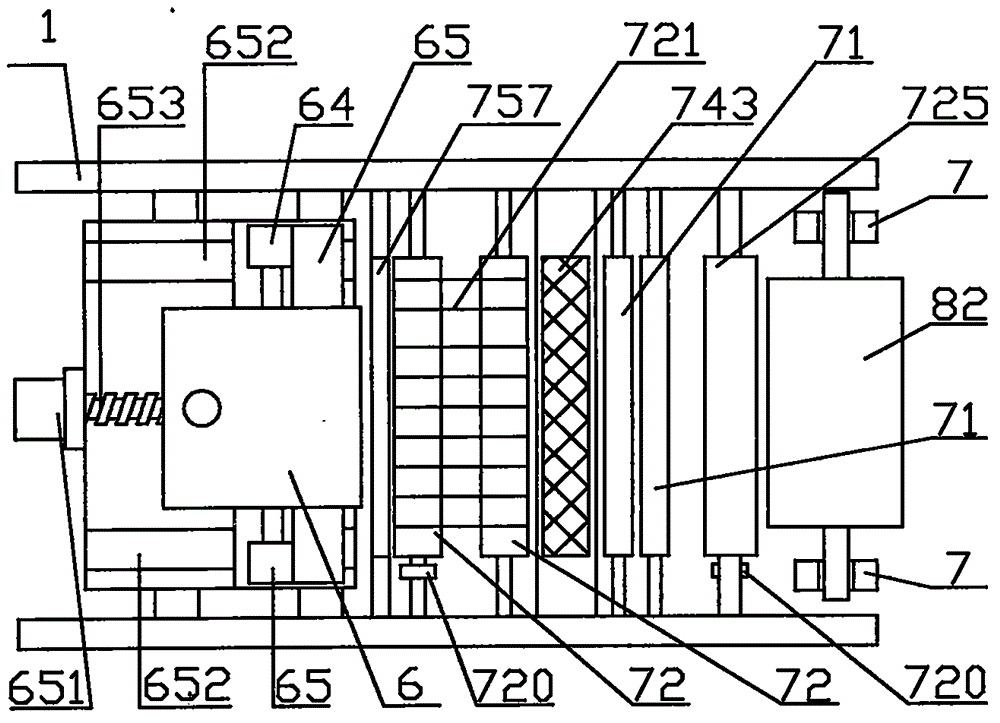

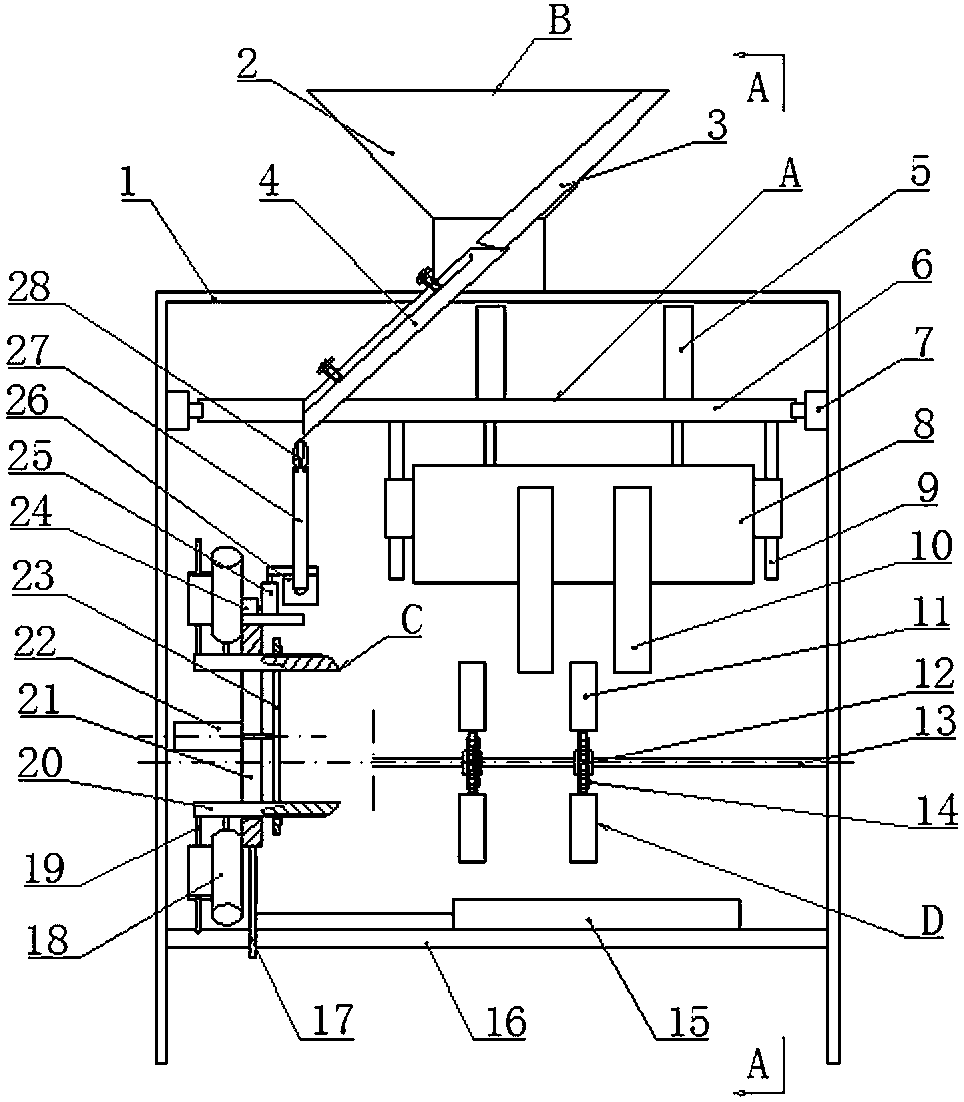

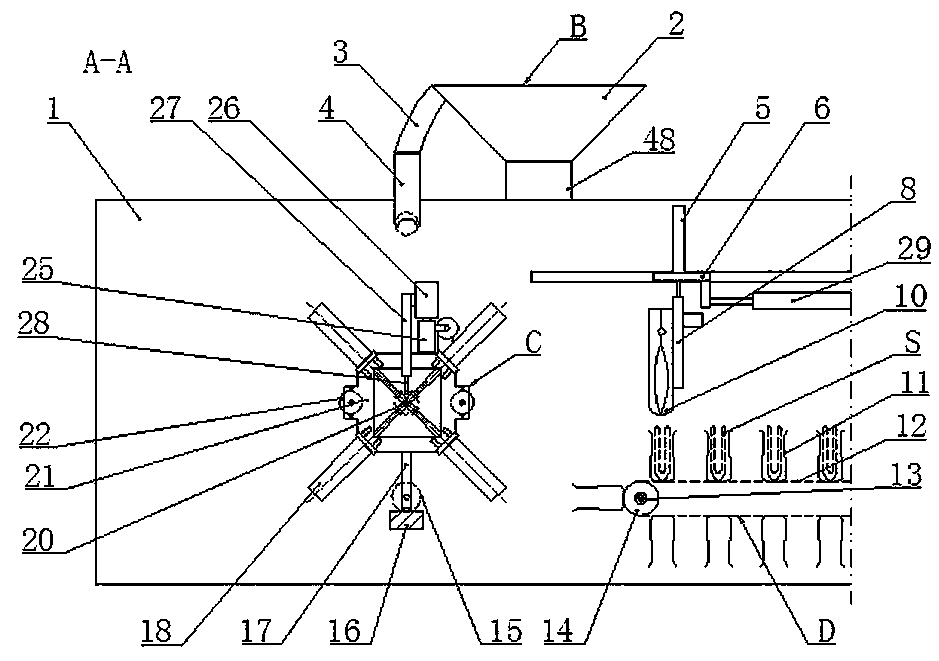

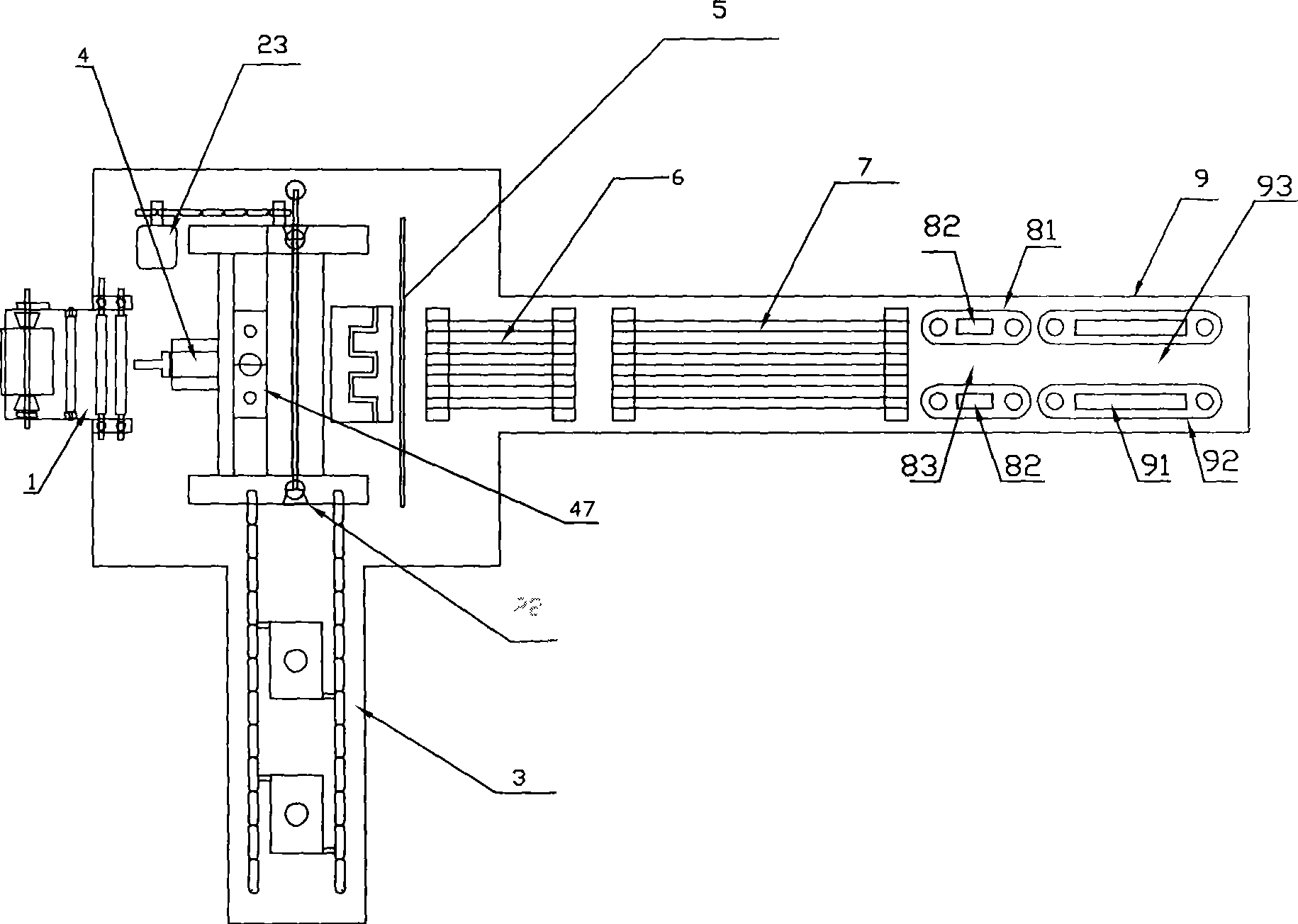

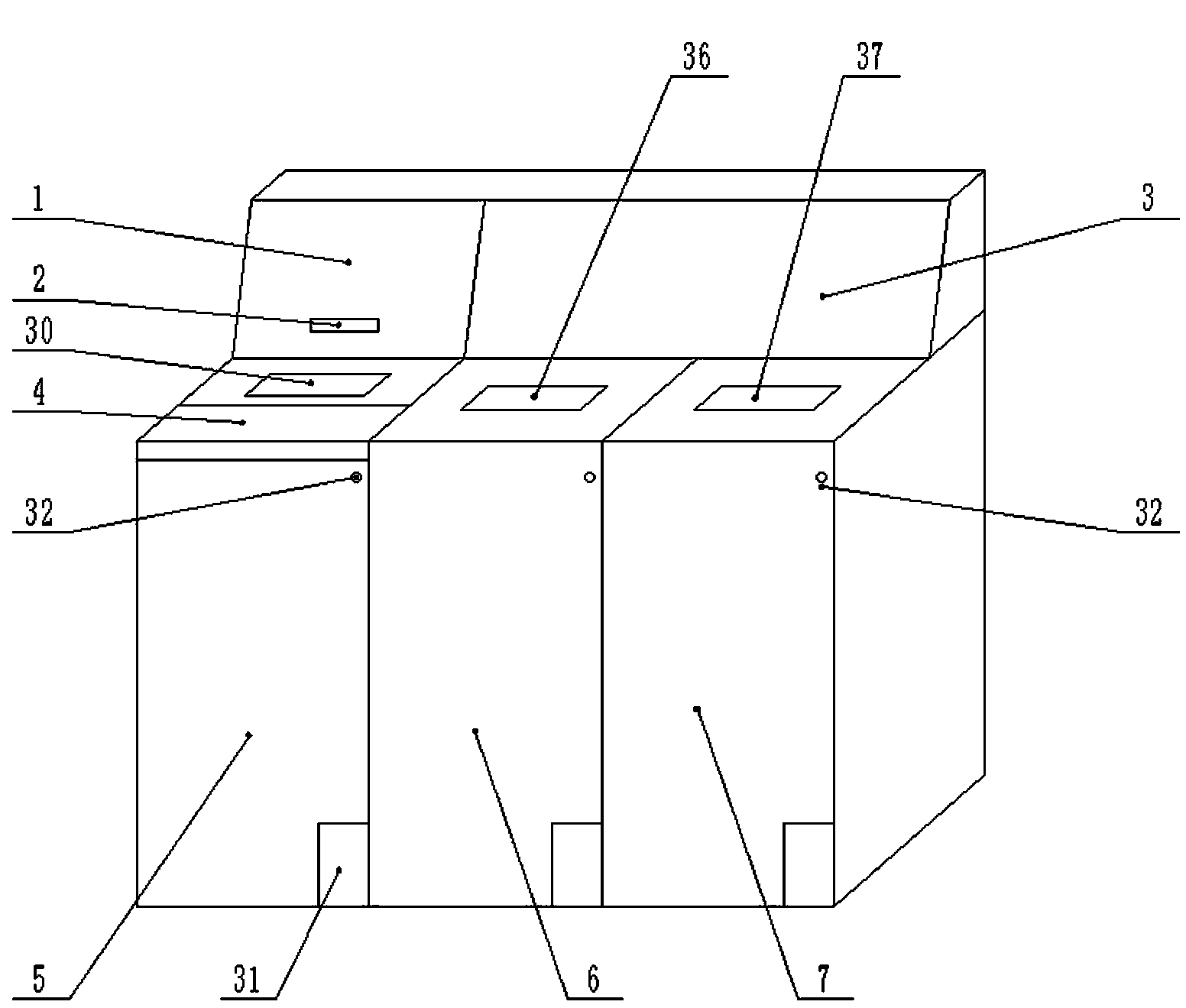

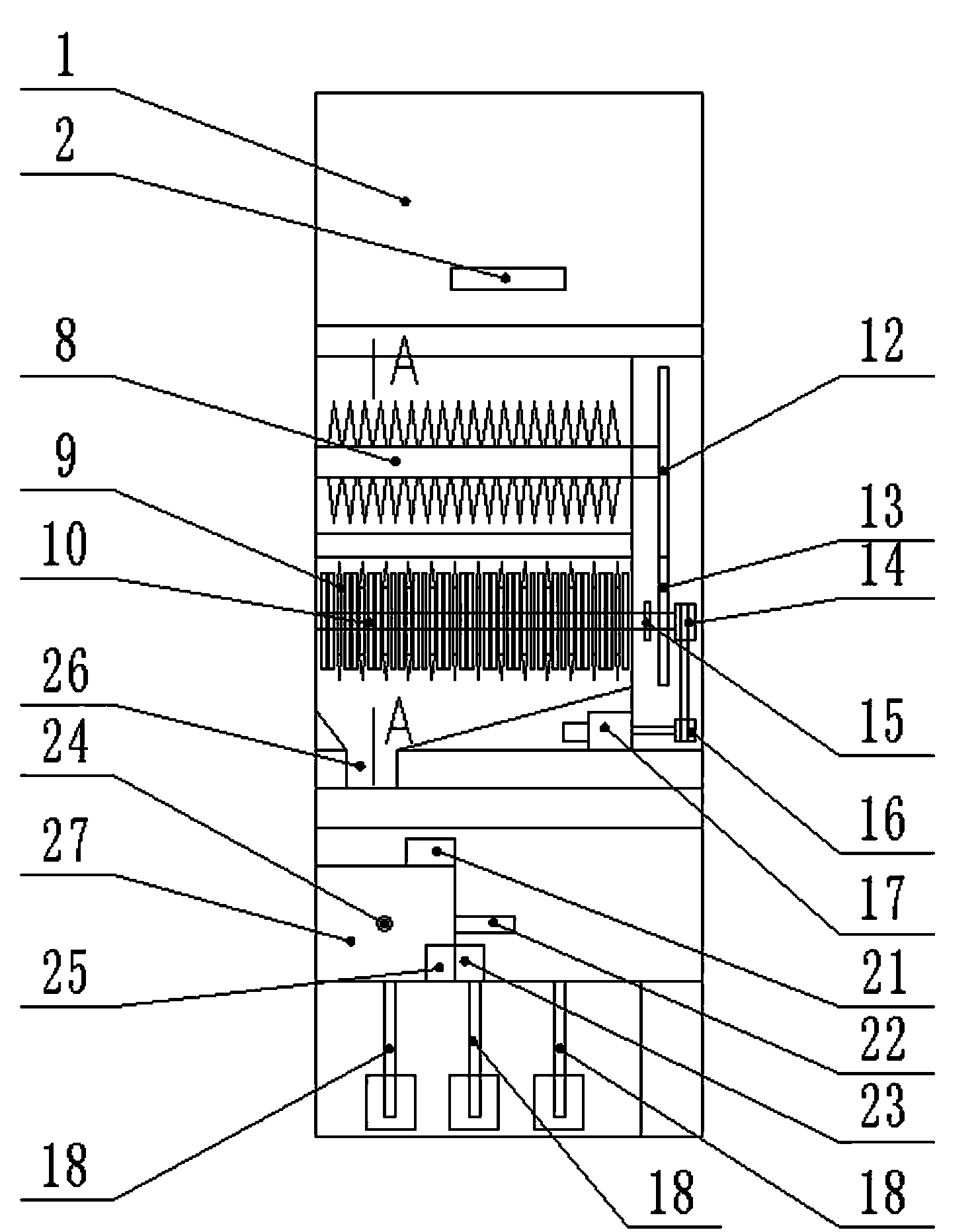

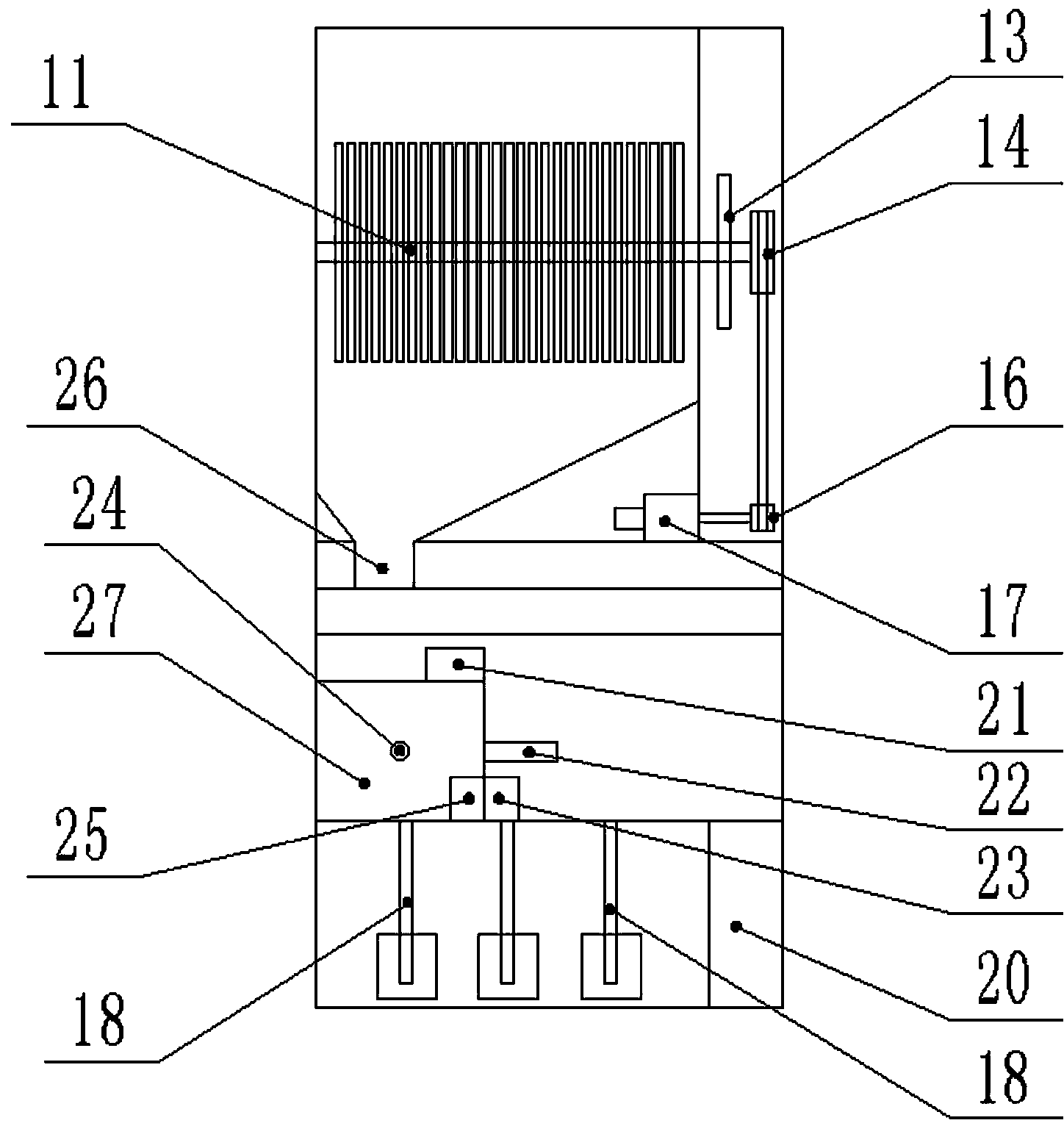

Automatic paper currency stacking and binding integrated machine

ActiveCN103625678AGuaranteed CompatibilityCompact structurePaper article packagingBundling machine detailsHeat sealerControl system

The invention discloses an automatic paper currency stacking and binding integrated machine for packing paper currency with different face values in the financial system. The machine comprises a conveying mechanism, a frame, a supporting base plate, an automatic stacking mechanism, a primary pushing mechanism, an arranging and jacking mechanism, a film packing mechanism, a secondary pushing mechanism, a heat-seal mechanism, a paper currency bundle turnover mechanism and a PLC (programmable logic control) control system, wherein paper currency is sorted and bound, and is fed into the conveying mechanism; the paper currency is fed into the automatic stacking mechanism by the conveying mechanism, and is subjected to pre-arrangement, counting, 5-bundle direction change and stacking; 10 bundles of paper currency is pushed into the arranging and jacking mechanism by the primary pushing mechanism after the paper currency bundles are stacked; the paper currency bundles are jacked to the secondary pushing mechanism after being arranged; the flat arranged paper currency bundles are pushed into the heat-seal mechanism by the secondary pushing mechanism, and are packaged; the paper currency bundles are moved out by the paper currency bundle turnover mechanism after the paper currency bundles are packaged. The automatic paper currency stacking and binding integrated machine has the advantages that paper currency can be automatically treated when the machine is used jointly with a sorting machine and a sealant shrinker, and the machine is compact in structure, stable and reliable, easy to operate and convenient to maintain.

Owner:合肥哈工龙延智能装备有限公司

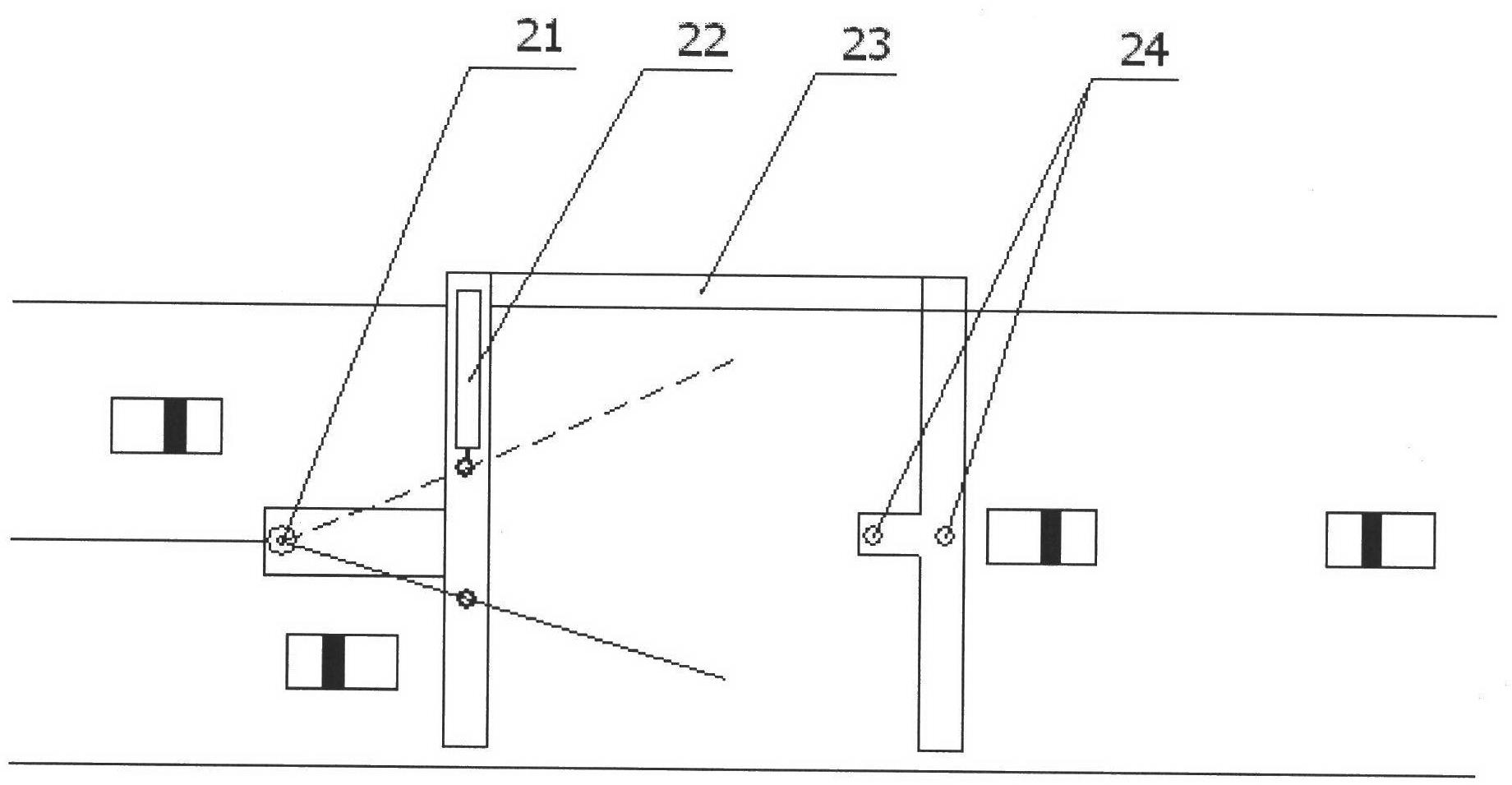

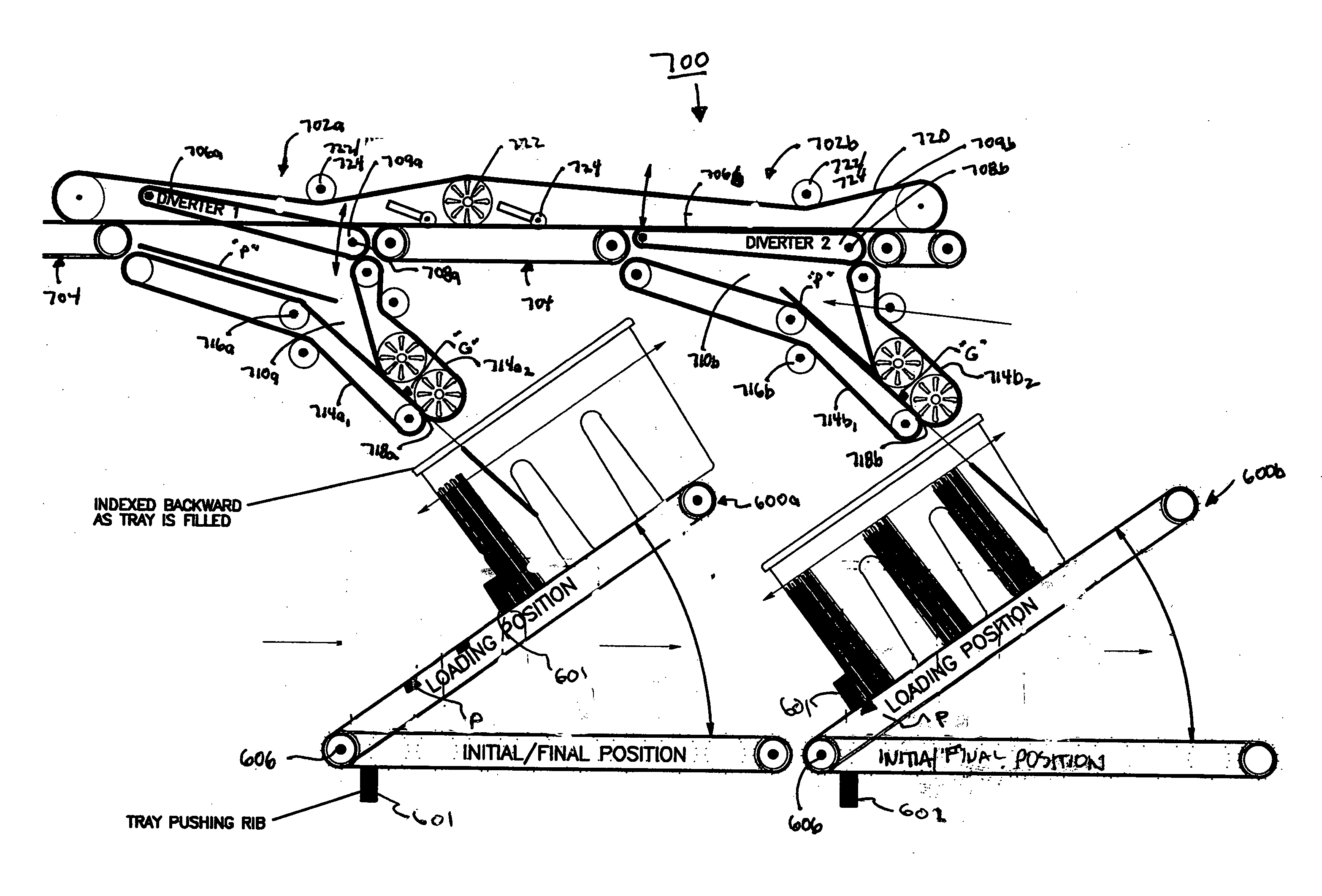

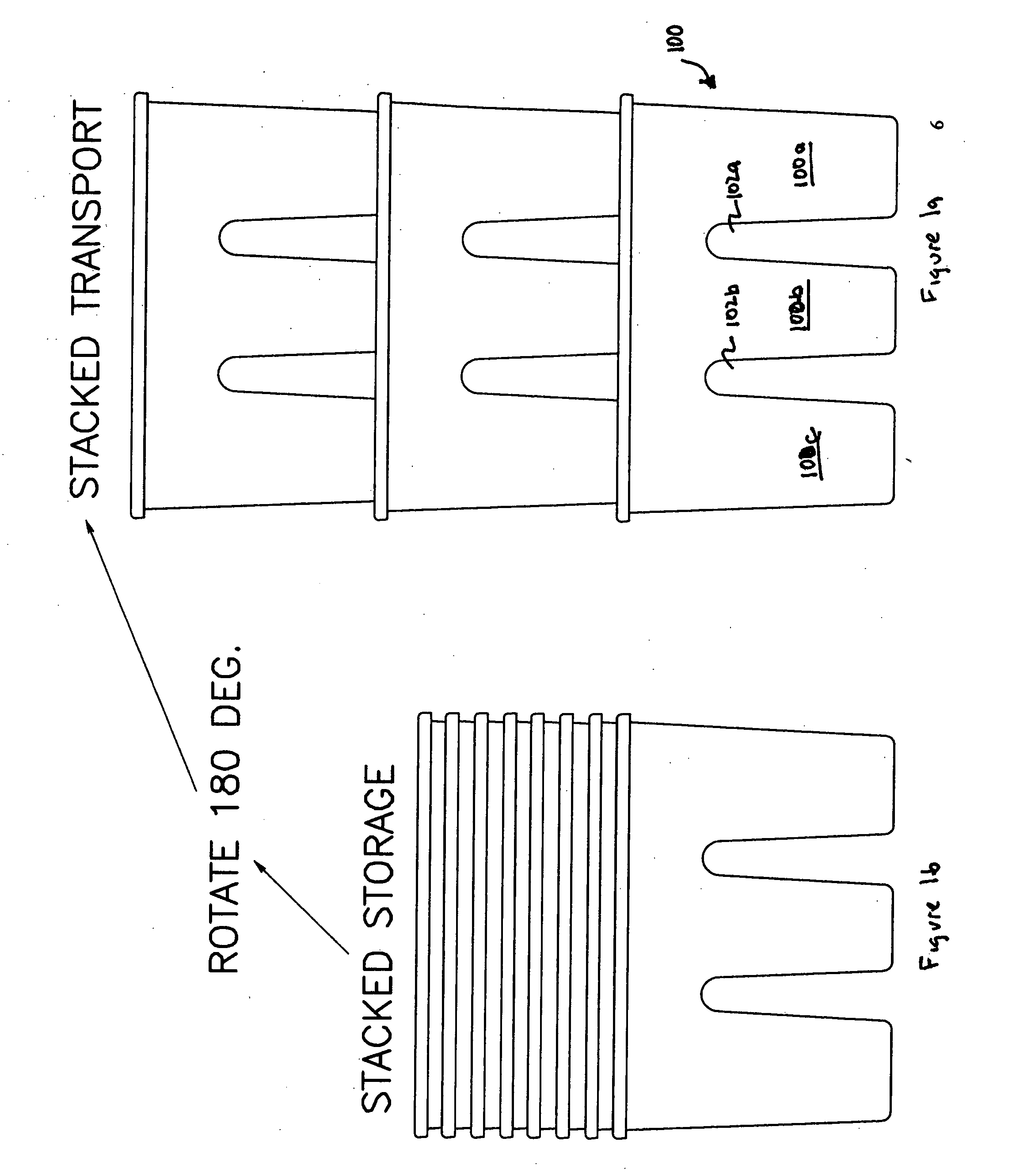

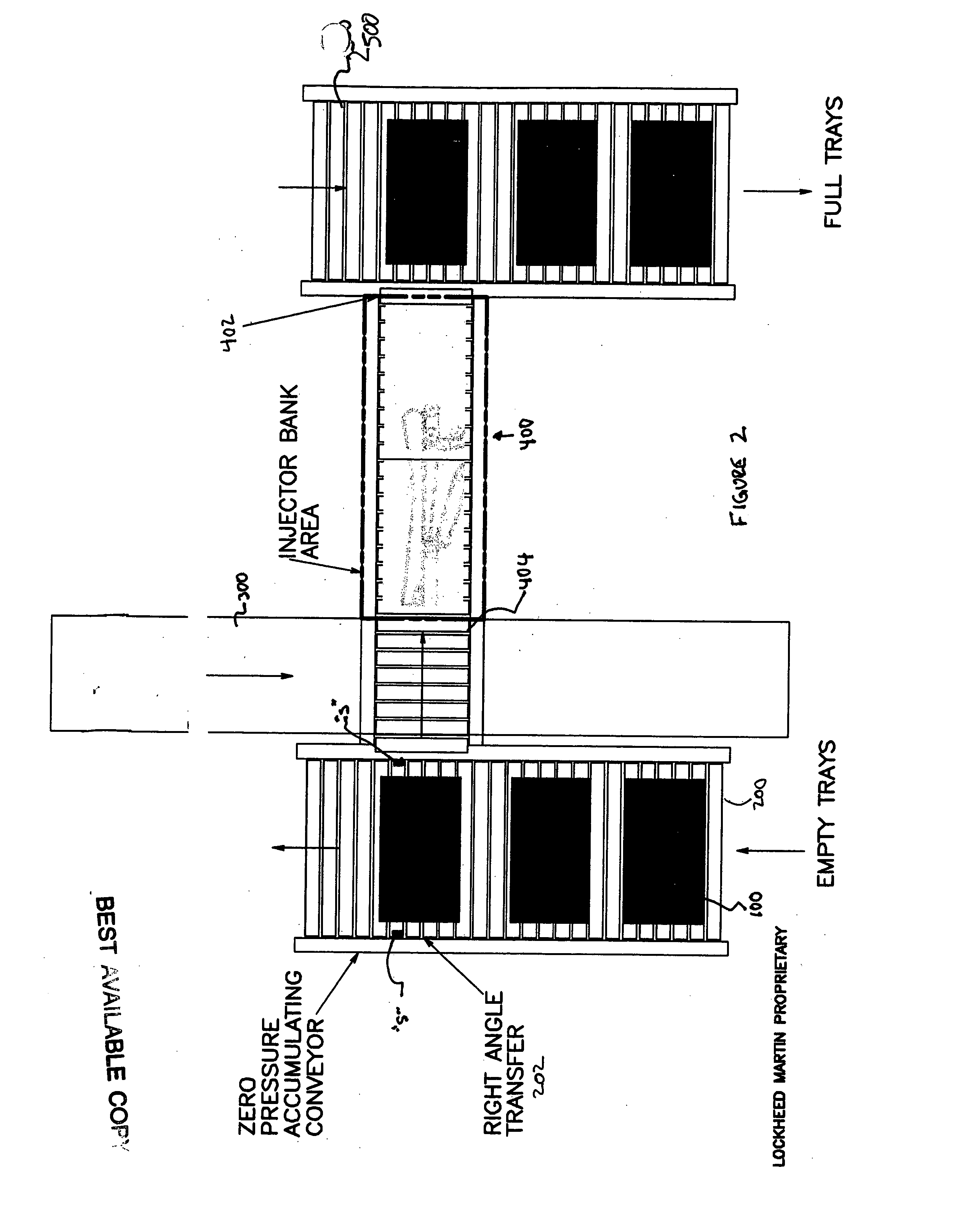

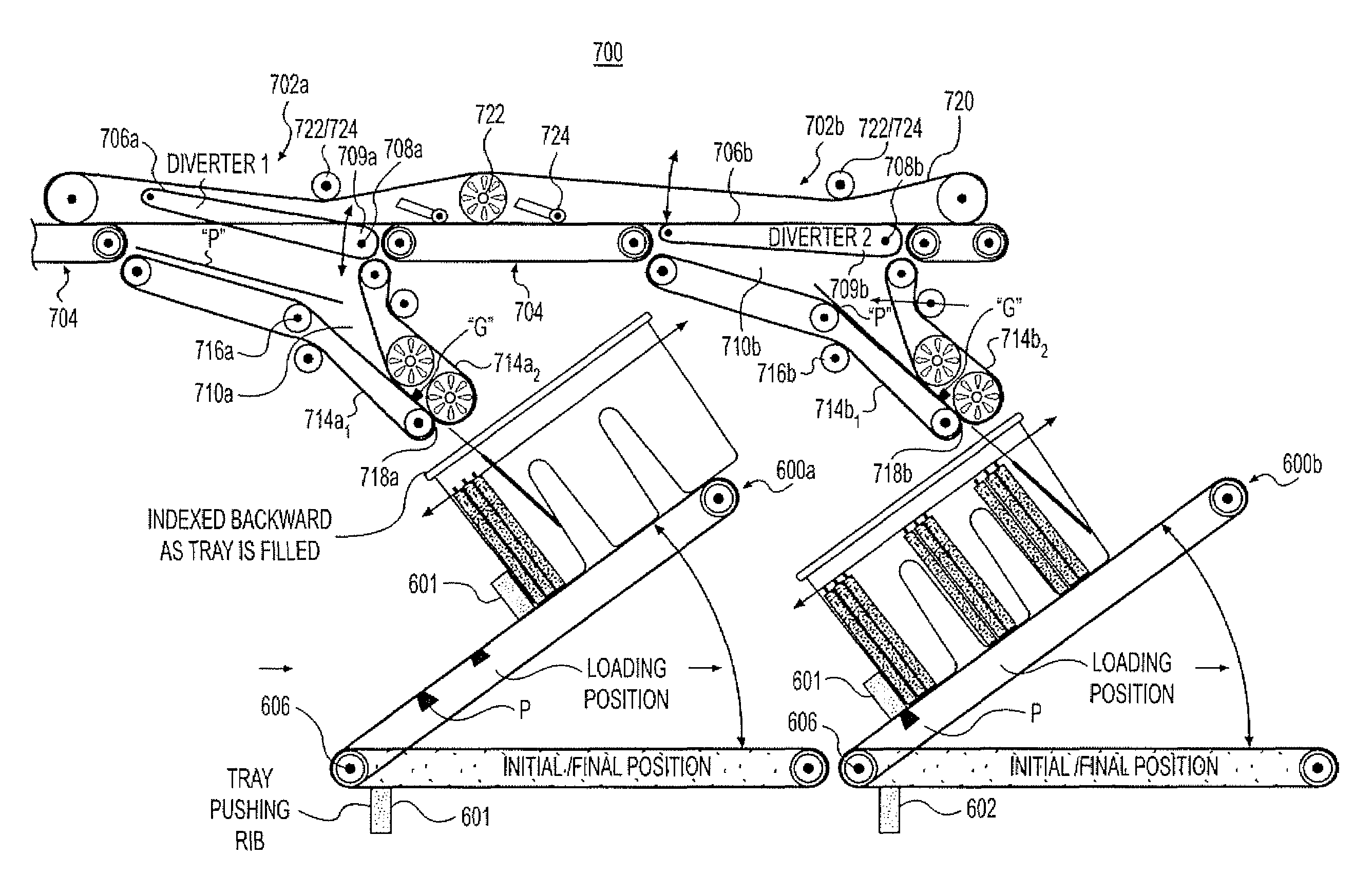

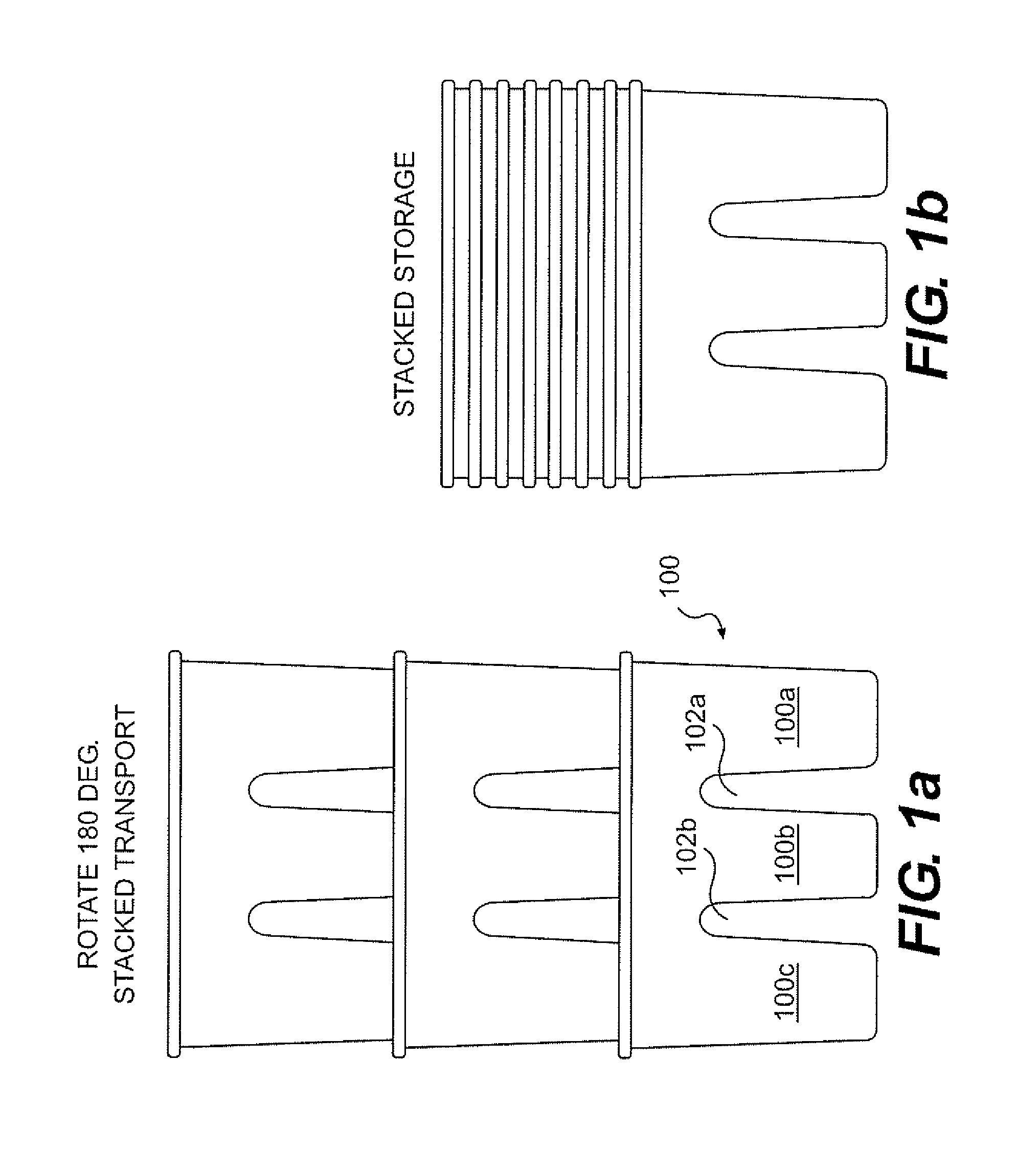

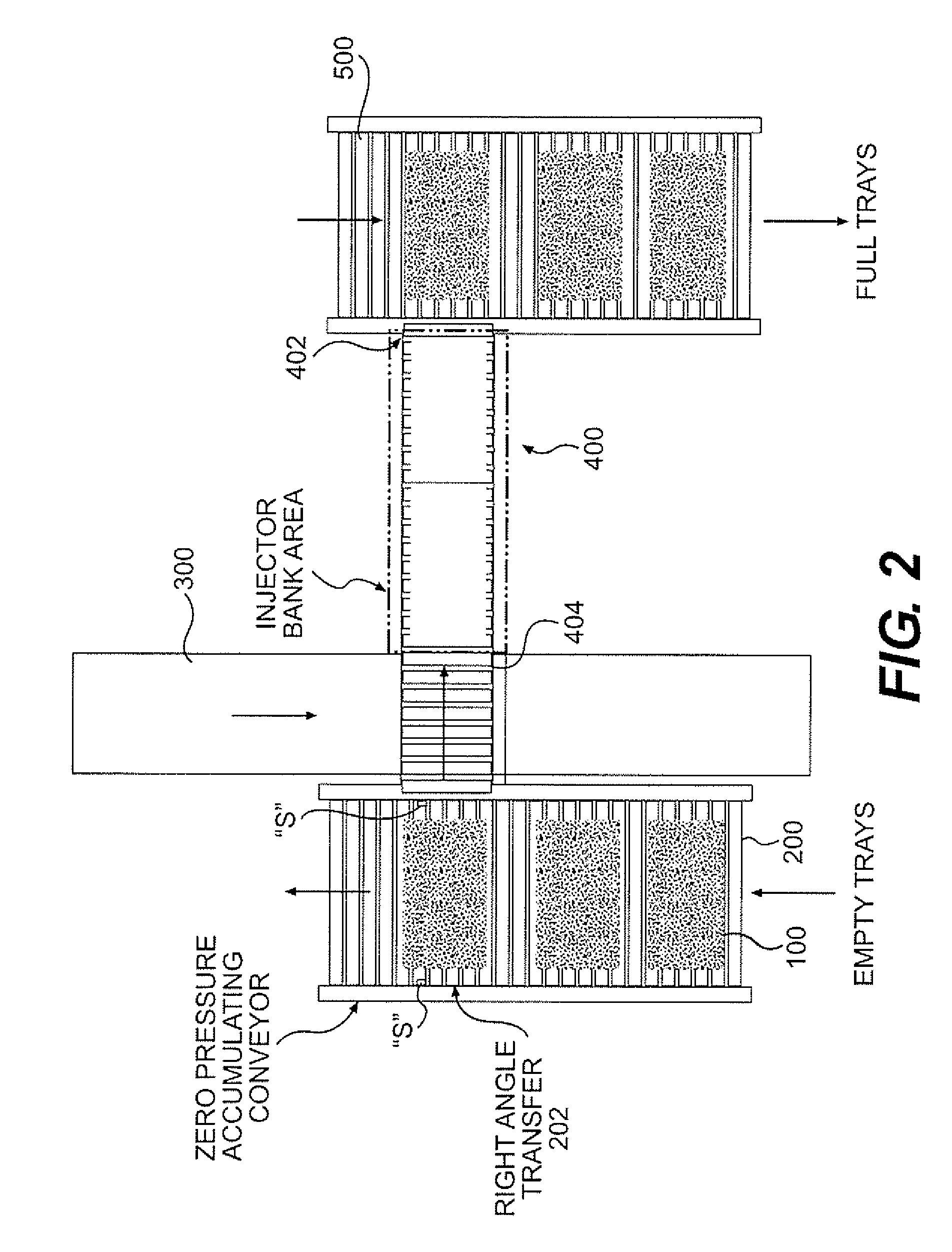

Vertical flat stacking apparatus and method of use

InactiveUS20040098948A1Paper article packagingPackaging automatic controlEngineeringVertical orientation

A device and method for stacking product into a container in a vertical orientation. The device includes at least one pivoting mechanism pivotable between a loading position and an initial / final position. The at least one pivoting mechanism retains a container thereon. The device may further include at least one corresponding diverting mechanism for injecting product into the container. The diverting mechanism includes a feeding area and a diverting arm swingable between an open position and a closed position. In the open position, the diverting arm allows product to enter the feeding area. An ejection station is positioned proximate to the feeding area and injects the product into the container after the product enters the feeding area via movement of the diverting arm. In one aspect the ejection station is provided by a pinch belt arrangement and is controlled by a control.

Owner:LOCKHEED MARTIN CORP

Vertical flat stacking apparatus and method of use

A device and method for stacking product into a container in a vertical orientation. The device includes at least one pivoting mechanism pivotable between a loading position and an initial / final position. The at least one pivoting mechanism retains a container thereon. The device may further include at least one corresponding diverting mechanism for injecting product into the container. The diverting mechanism includes a feeding area and a diverting arm swingable between an open position and a closed position. In the open position, the diverting arm allows product to enter the feeding area. An ejection station is positioned proximate to the feeding area and injects the product into the container after the product enters the feeding area via movement of the diverting arm. In one aspect the ejection station is provided by a pinch belt arrangement and is controlled by a control.

Owner:LOCKHEED MARTIN CORP

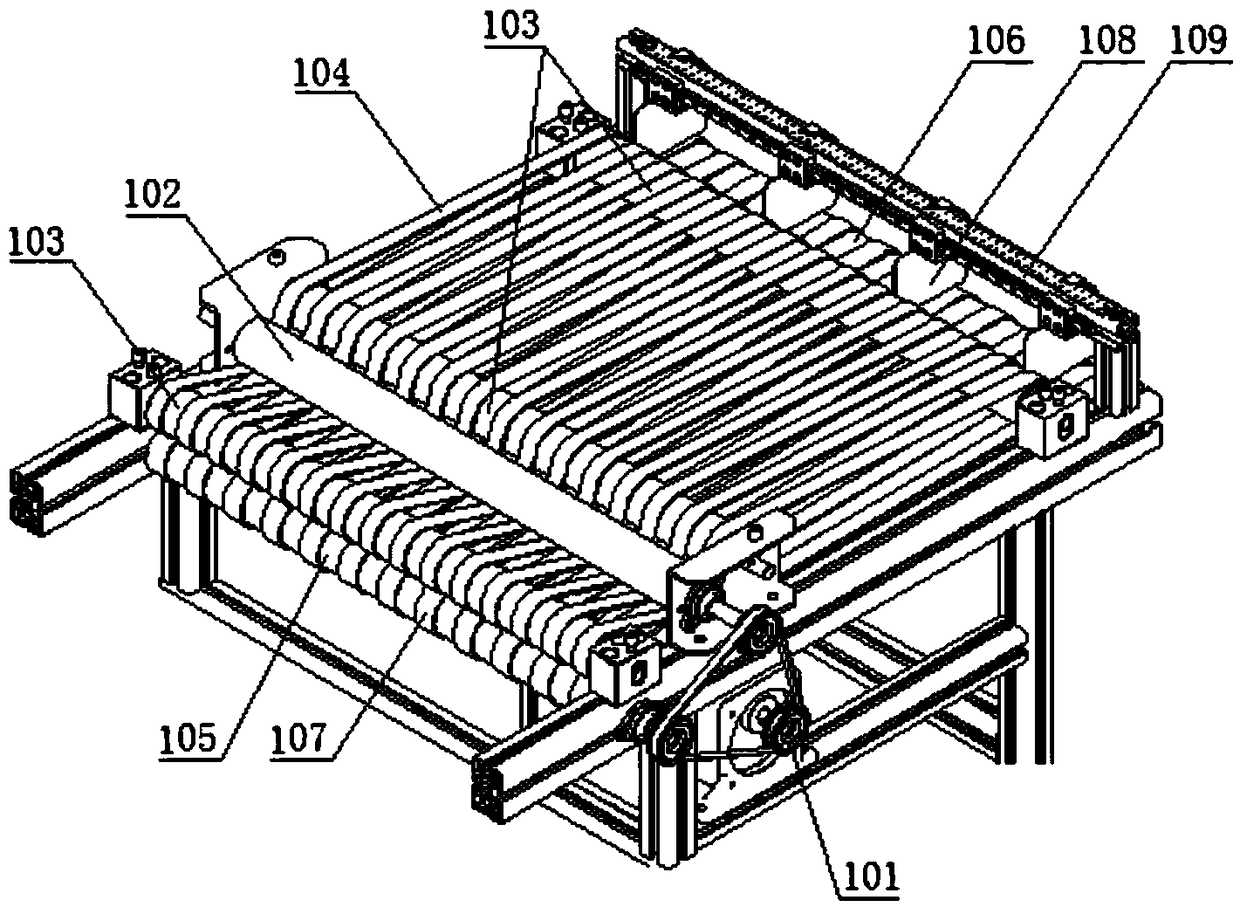

Continuous automatic neatening and bundling device and method

PendingCN108750180AFully automaticReduce manual operationsPaper article packagingPile receiversEngineeringMechanical engineering

Owner:四川卡库机器人科技有限公司

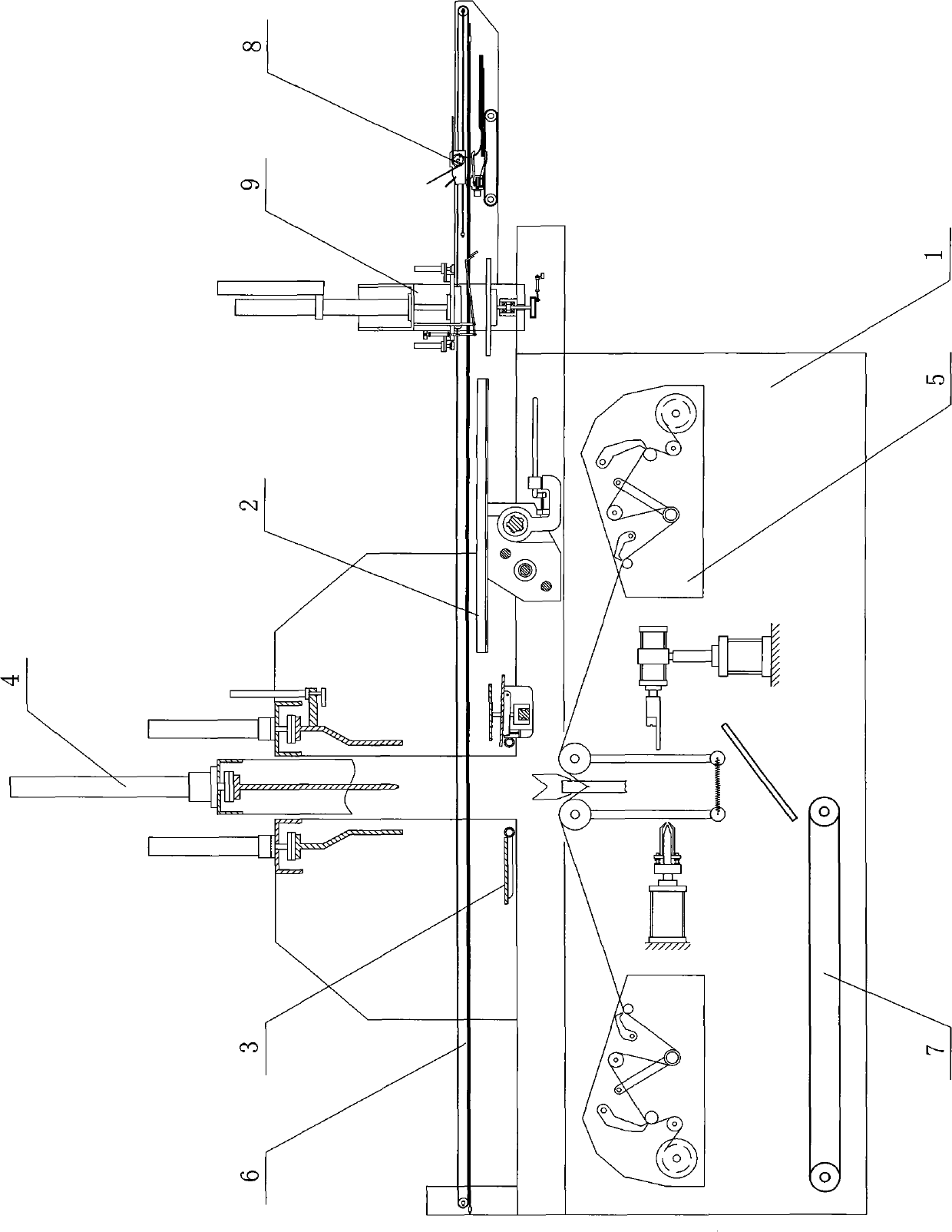

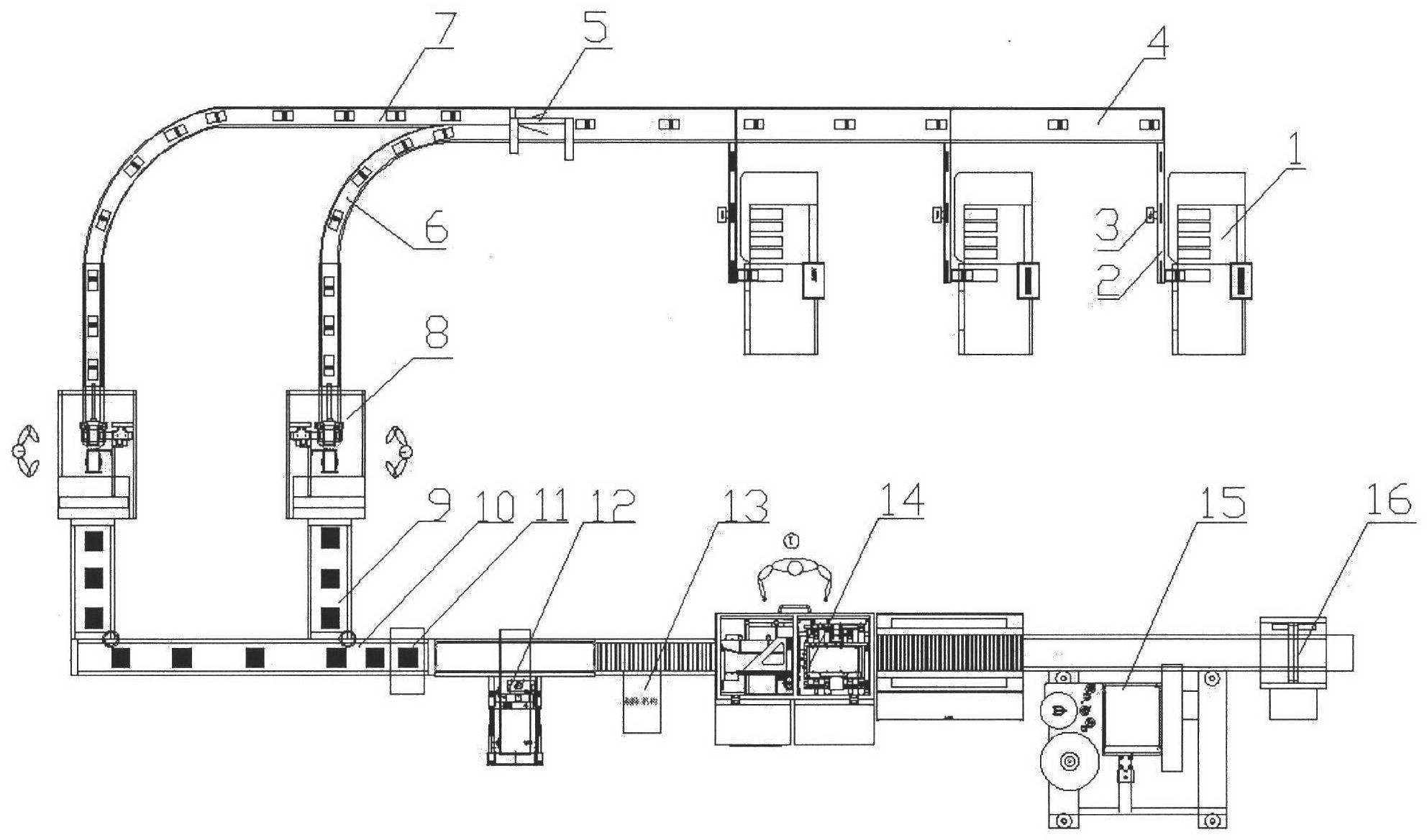

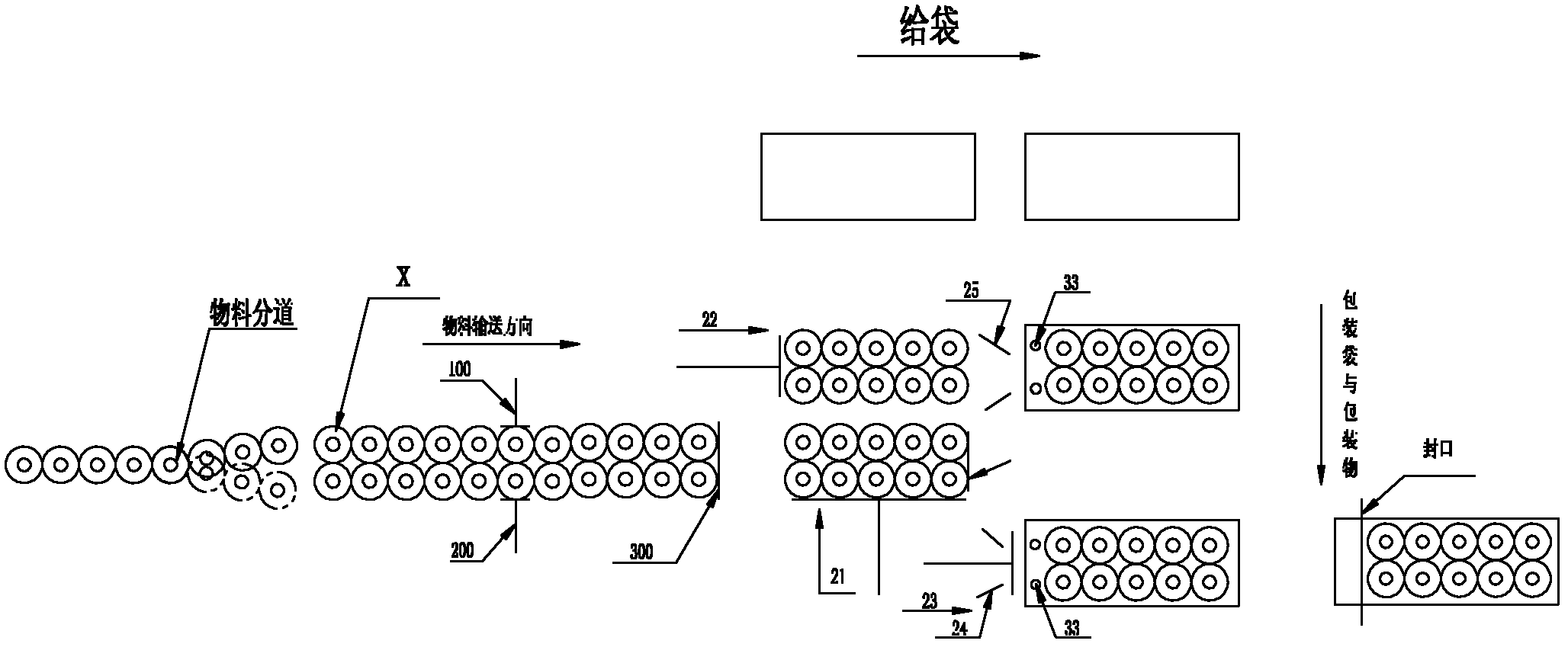

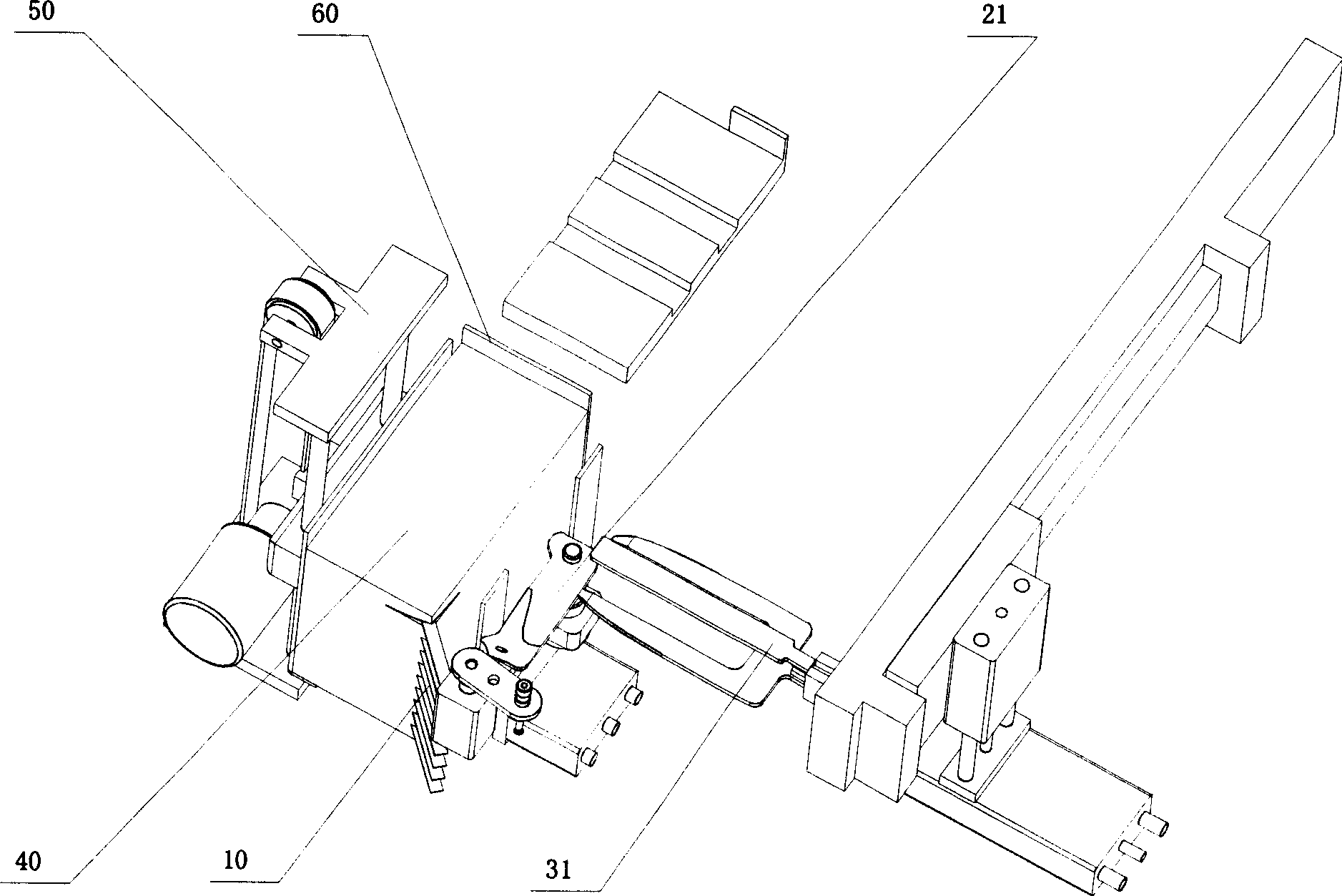

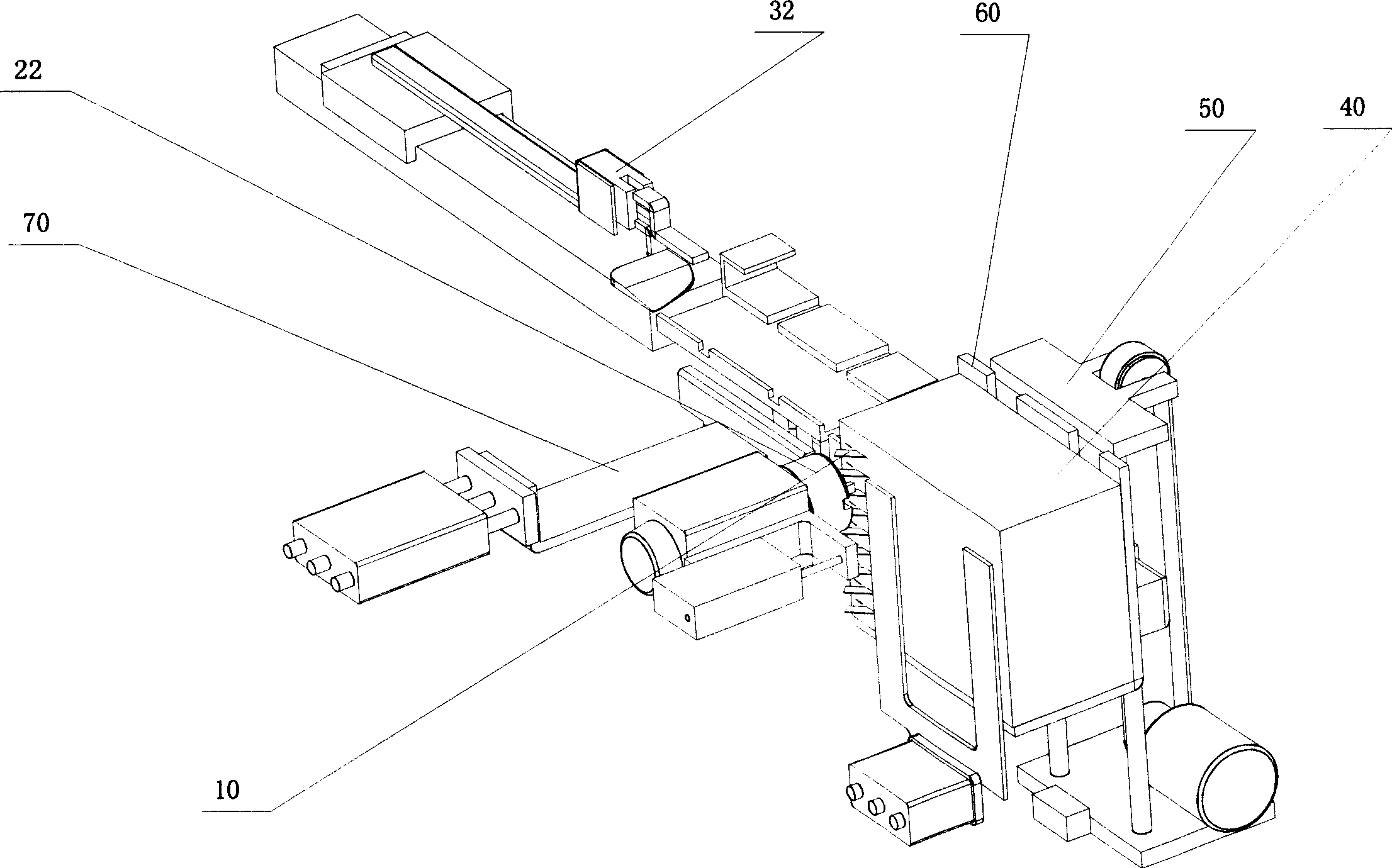

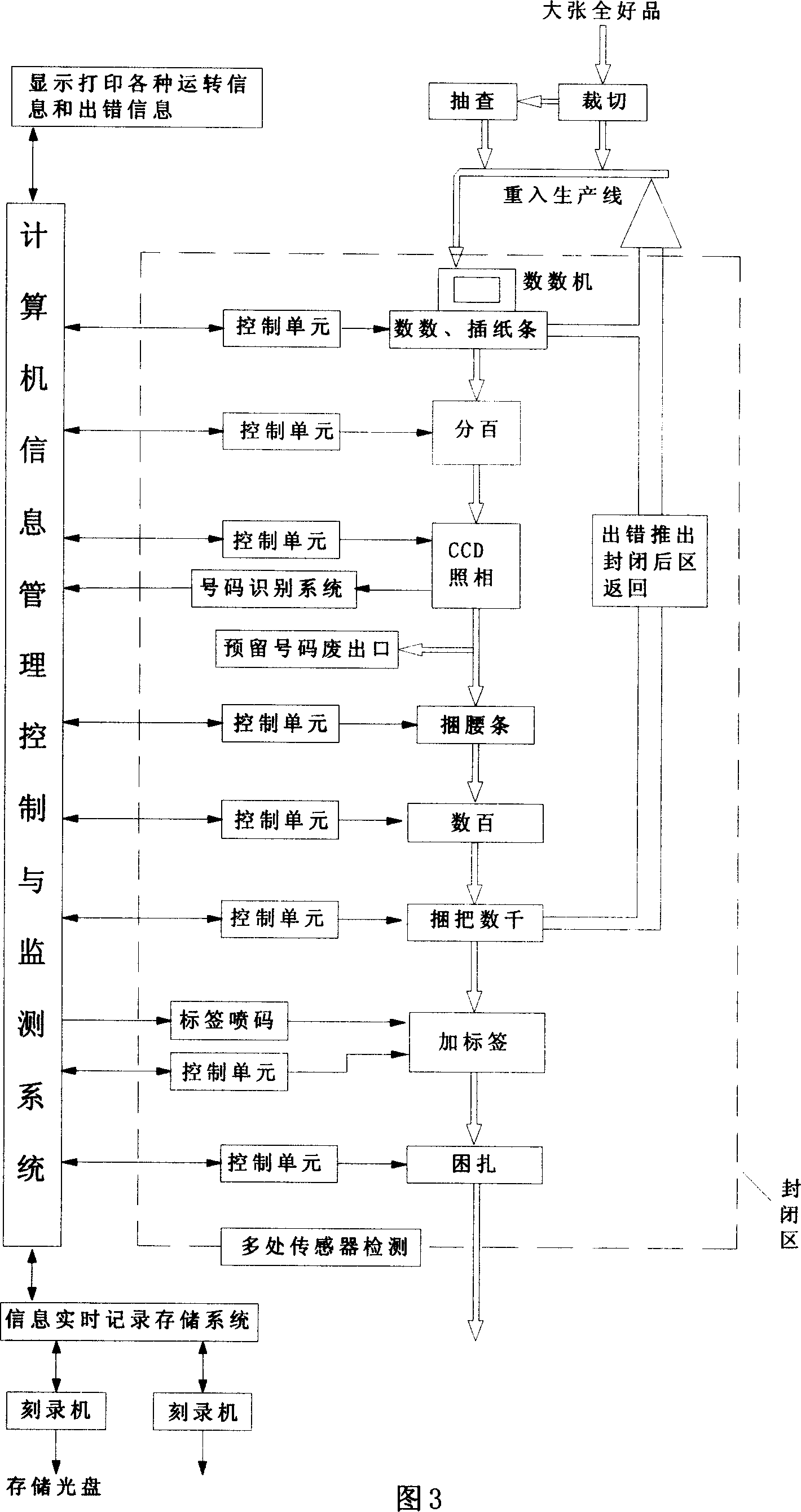

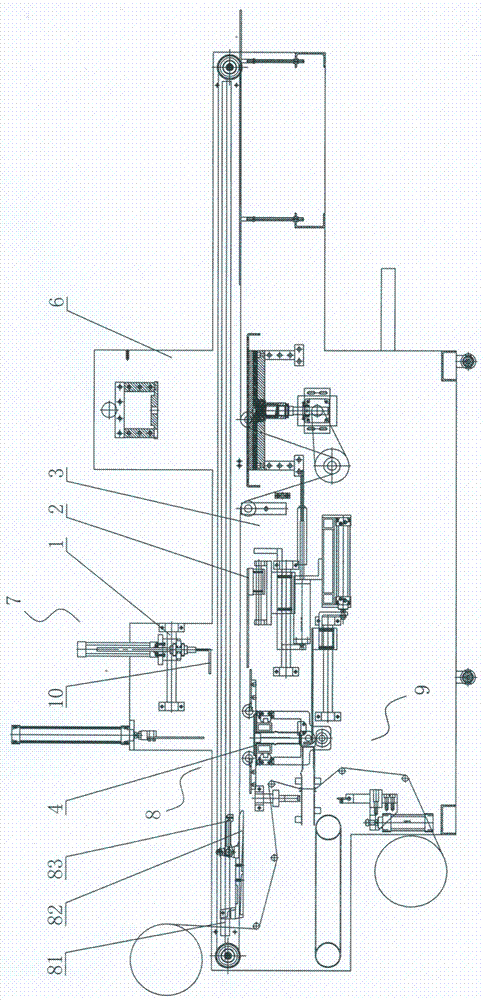

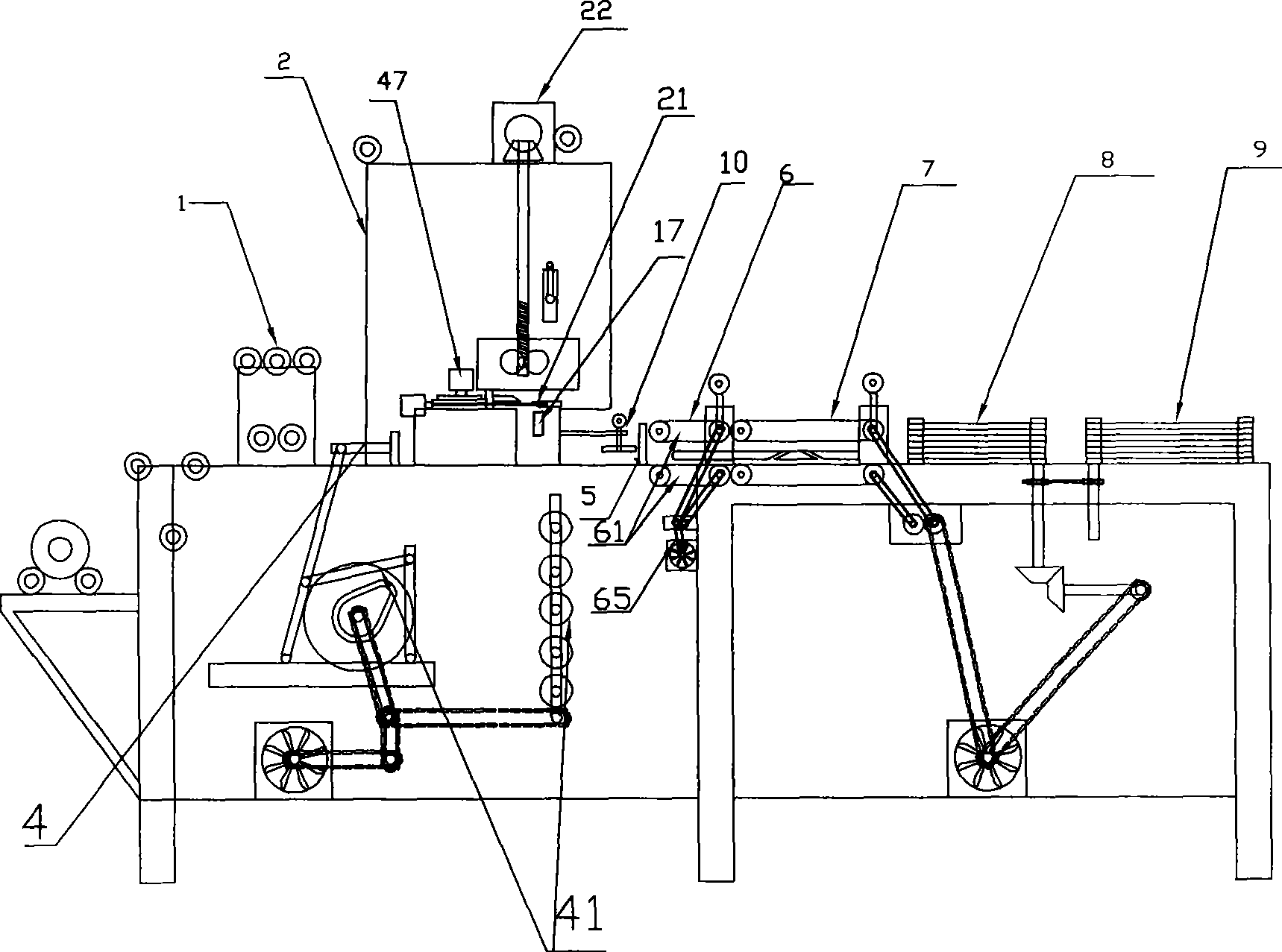

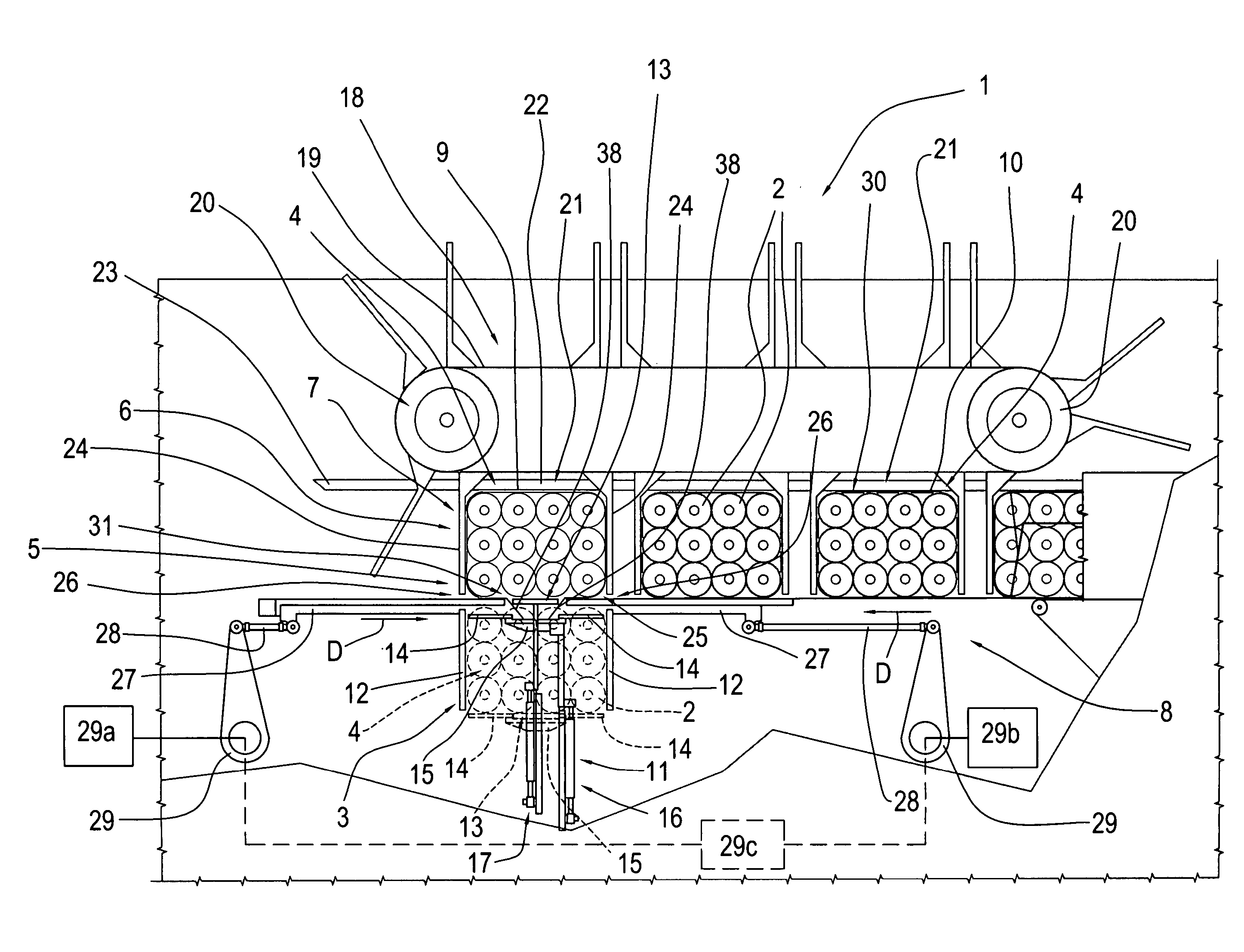

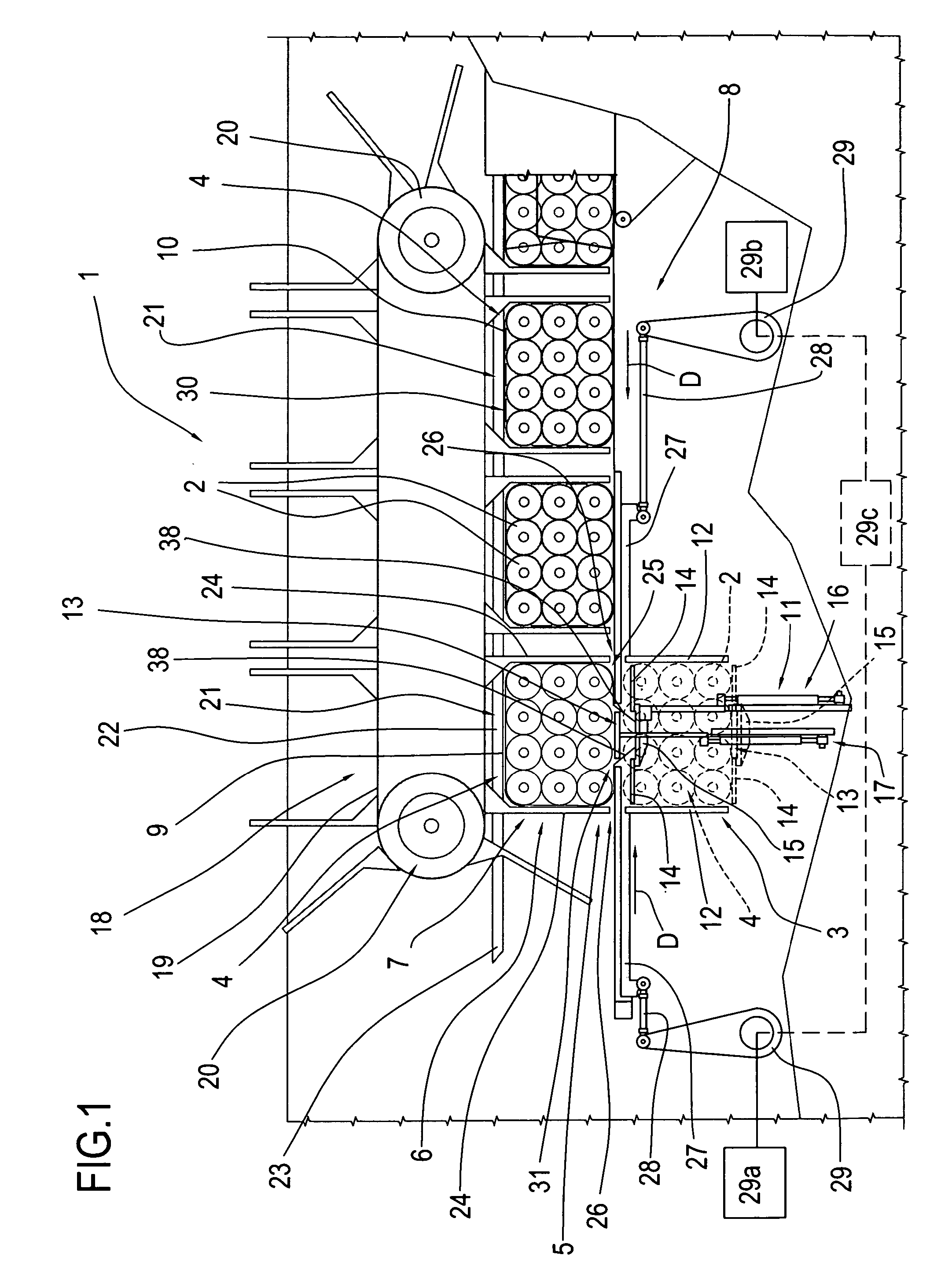

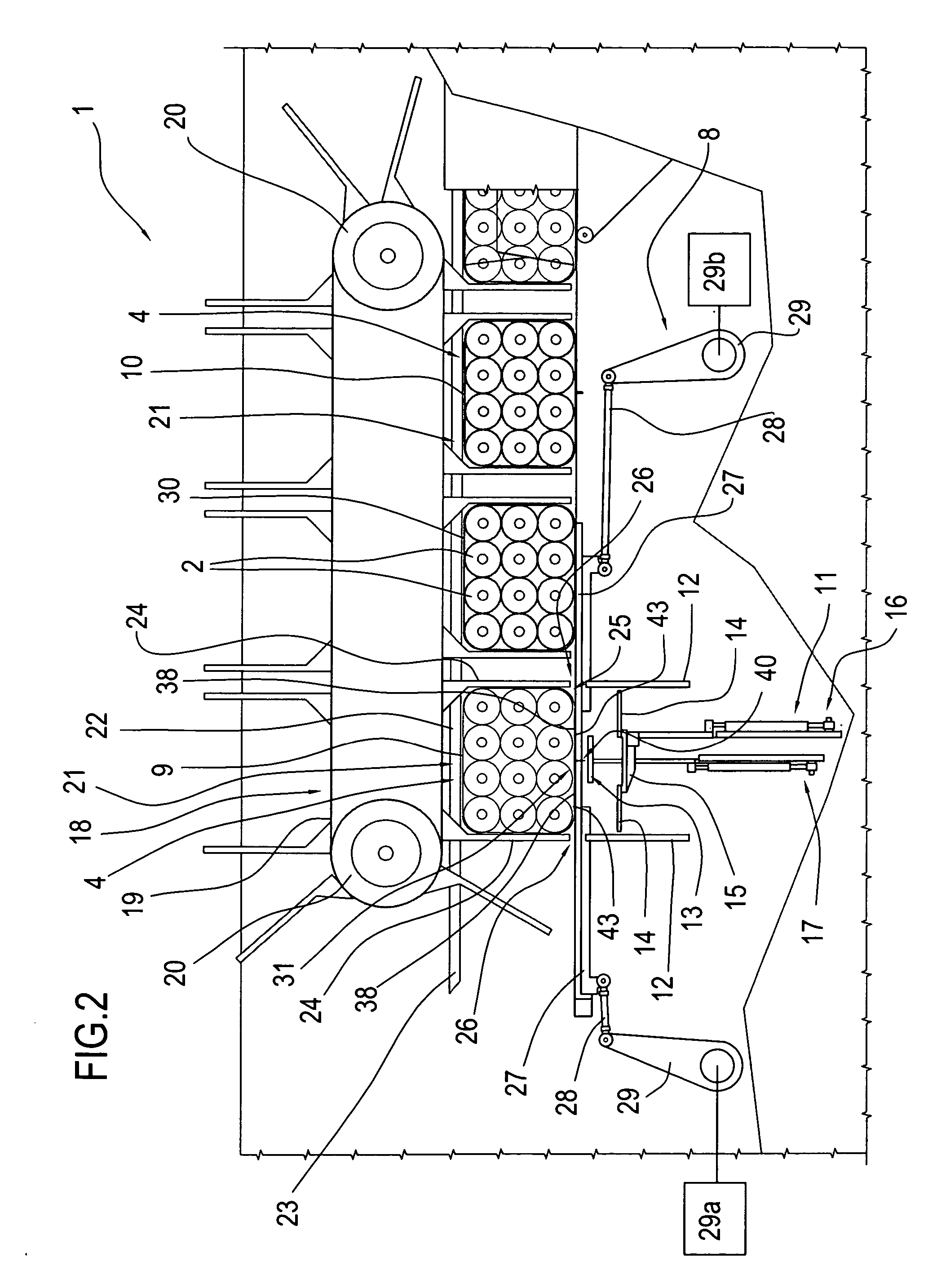

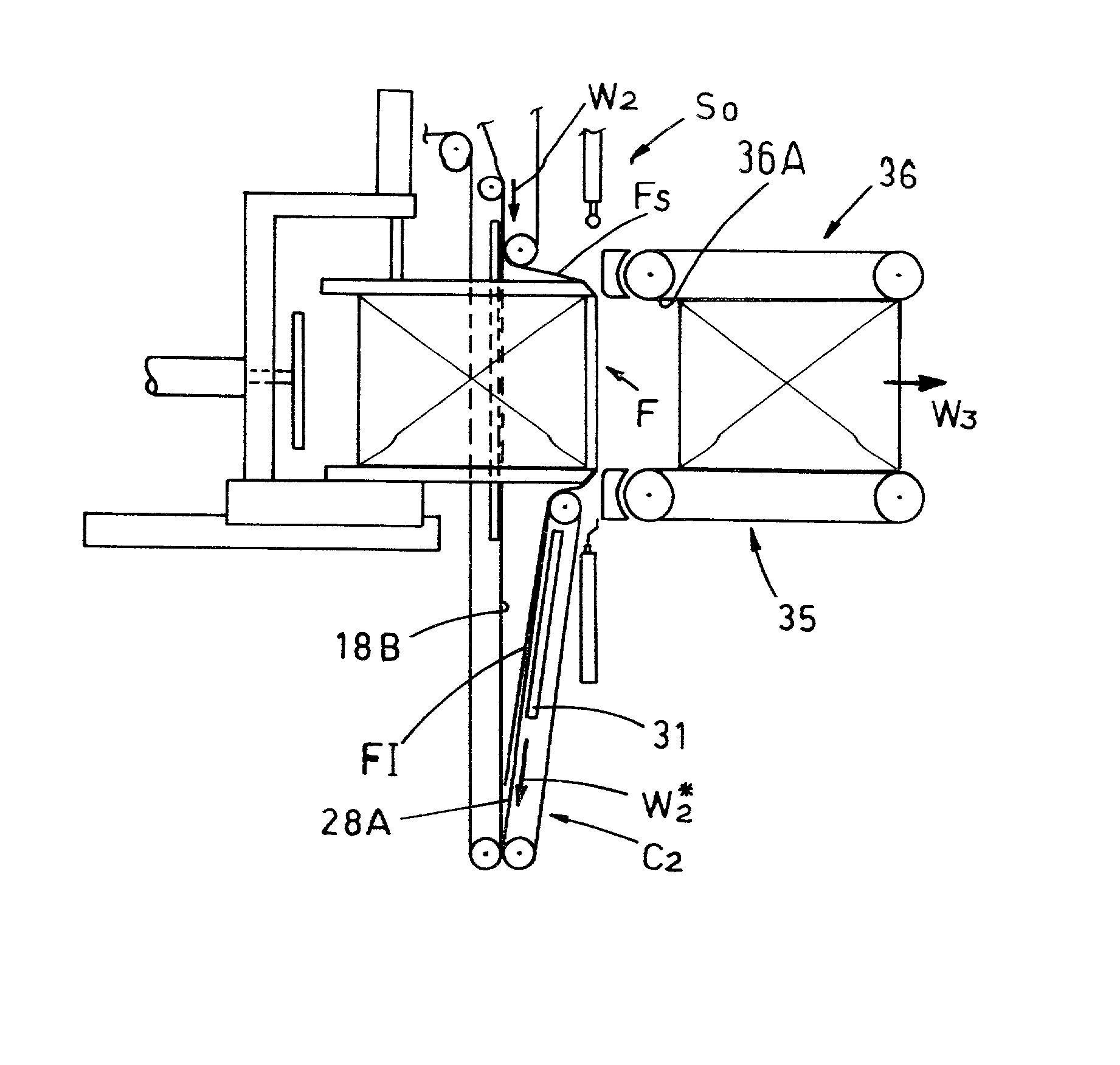

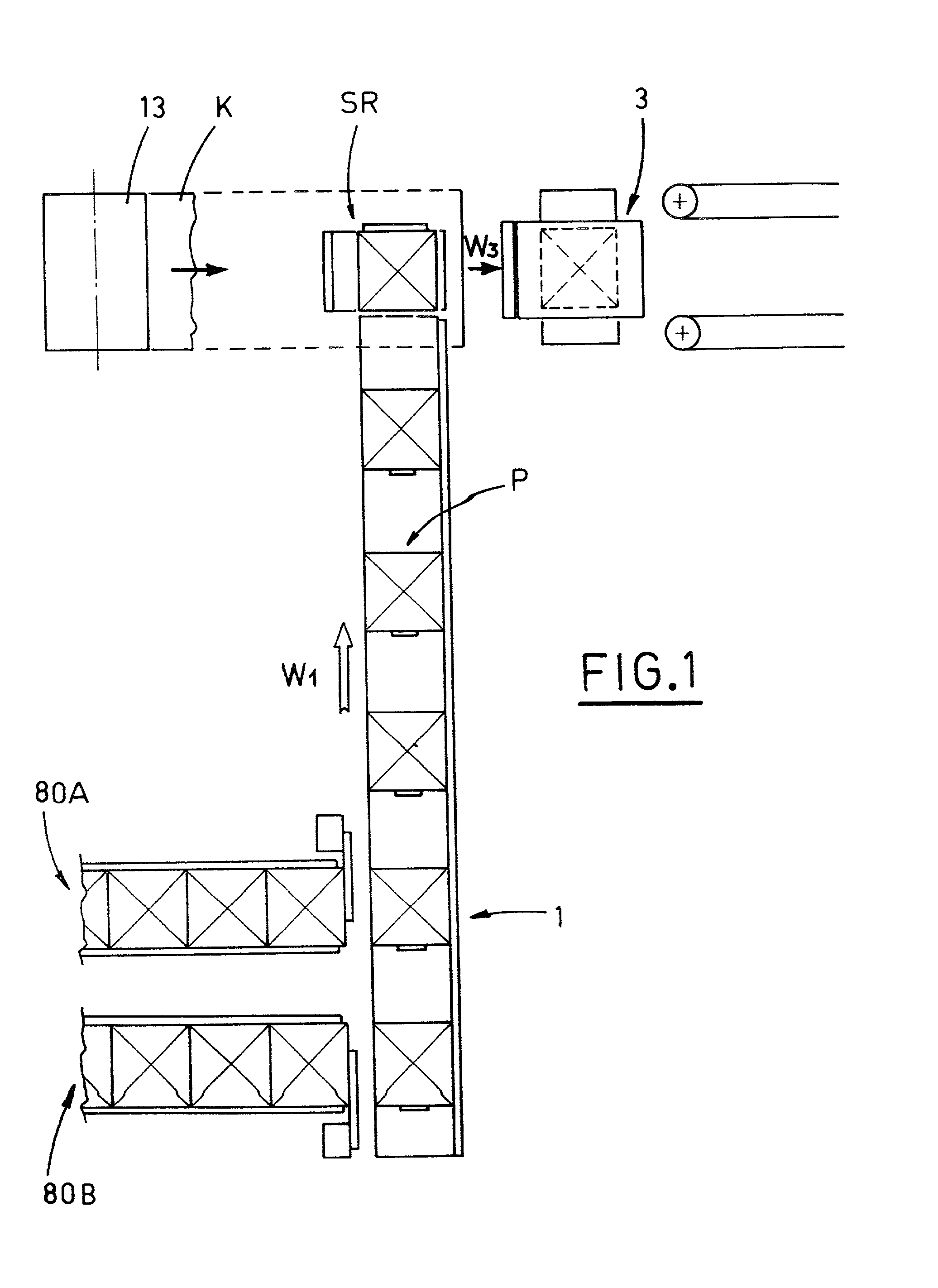

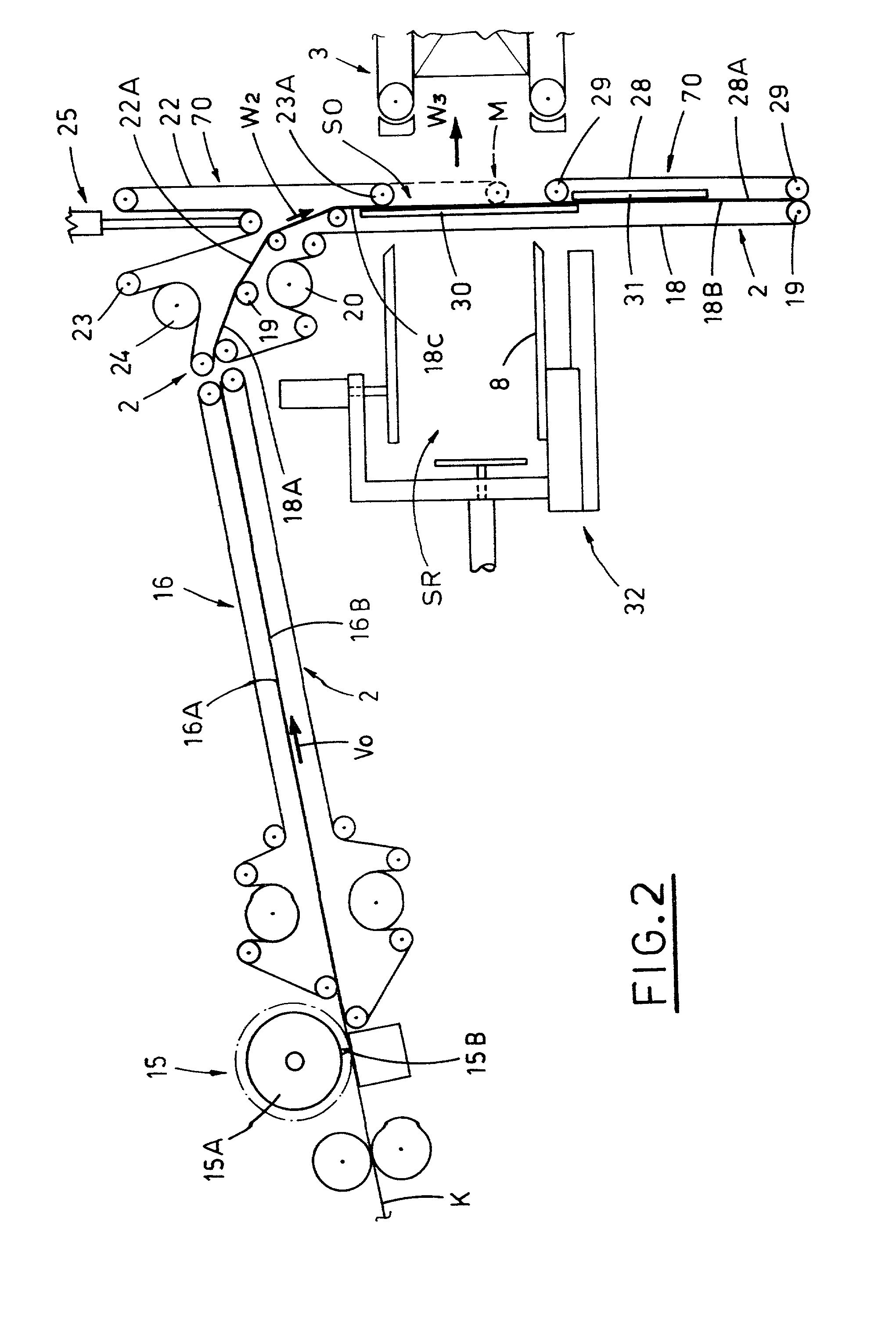

Automatic banknote counting, hundred separating, binding and packing method and production line in the said method

InactiveCN1673038AReduce the possibility of personal errorReduce labor intensityPaper article packagingProduction lineCounting Number

The present invention is automatic banknote counting, hundred separating, binding and packing method and production line in the said method. The method includes counting one thousand bills in a counting machine and inserting paper strips to separate every hundred bills, separating bills in automatic separator in hundreds, distinguishing every hundred bills, bundling in hundreds, re-counting in one other counting machine, stacking in ten bundles or one thousand bills, setting label, bundling and packing in one closed production line under the control with computer. The present invention has lowered labor strength, less error, high production efficiency and high bill safety.

Owner:CHINA BANKNOTE PRINTING & MINTING

Full-automatic book packing machine and method

InactiveCN102602557AReduce working noiseImprove working environmentPaper article packagingSoftware engineeringWorkbench

The invention discloses a full-automatic book packing machine and a method, which belong to the technical field of processing production equipment after printing. A paper delivery mechanism, a book feeding transmission platform and a book wrapping and corner folding mechanism are sequentially connected, the book wrapping and corner folding mechanism is connected with a binding machine A, a binding machine B is connected with another worktable, a book feeding mechanism is disposed on one side of the book feeding transmission platform, a delivery frame of the book feeding mechanism is mounted on a paper delivery mechanism platform, a book pushing mechanism is arranged on delivery rolls, a main motor is mounted below the paper delivery mechanism, a tabletop of the book feeding transmission platform, a tabletop of the book wrapping and corner folding mechanism and a tabletop of the worktable are sequentially connected, height of the three tabletops are consistent, and a main control device is independently arranged on one side of the book feeding transmission platform and connected with the main motor by an electric wire. Working noise of the full-automatic book packing machine is remarkably reduced, the full-automatic book packing machine is simple in structure and convenient in use, maintenance, popularization and application, and packing paper is saved.

Owner:NANCHANG HANGKONG UNIVERSITY

Soft tissue packing machine

ActiveCN103950590AGuaranteed uniformityReduce labor costsPaper article packagingWrapping material feeding apparatusEngineeringSoft tissue

The invention discloses a soft tissue packing machine, and relates to the technical field of tissue packing machinery. The soft tissue packing machine comprises a path division conveying component, a material sorting conveying component, a membrane supporting and conveying component, a bag opening and strutting component, a negative pressure conveying component, a bag pushing component and a cutter seal component. The soft tissue packing machine disclosed by the invention has the advantages that the bag opening and strutting component, a membrane conveying mechanism and a membrane conveying mechanism are improved, according to the soft tissue packing machine, the bag opening size of packing bags can be regulated, the soft tissue packing machine is suitable for the package of products in any specifications, the soft tissue packing machine adopts integral operation, the efficiency is improved, the cost is reduced, and the packing quality can also be unified.

Owner:上海松川峰冠包装自动化有限公司

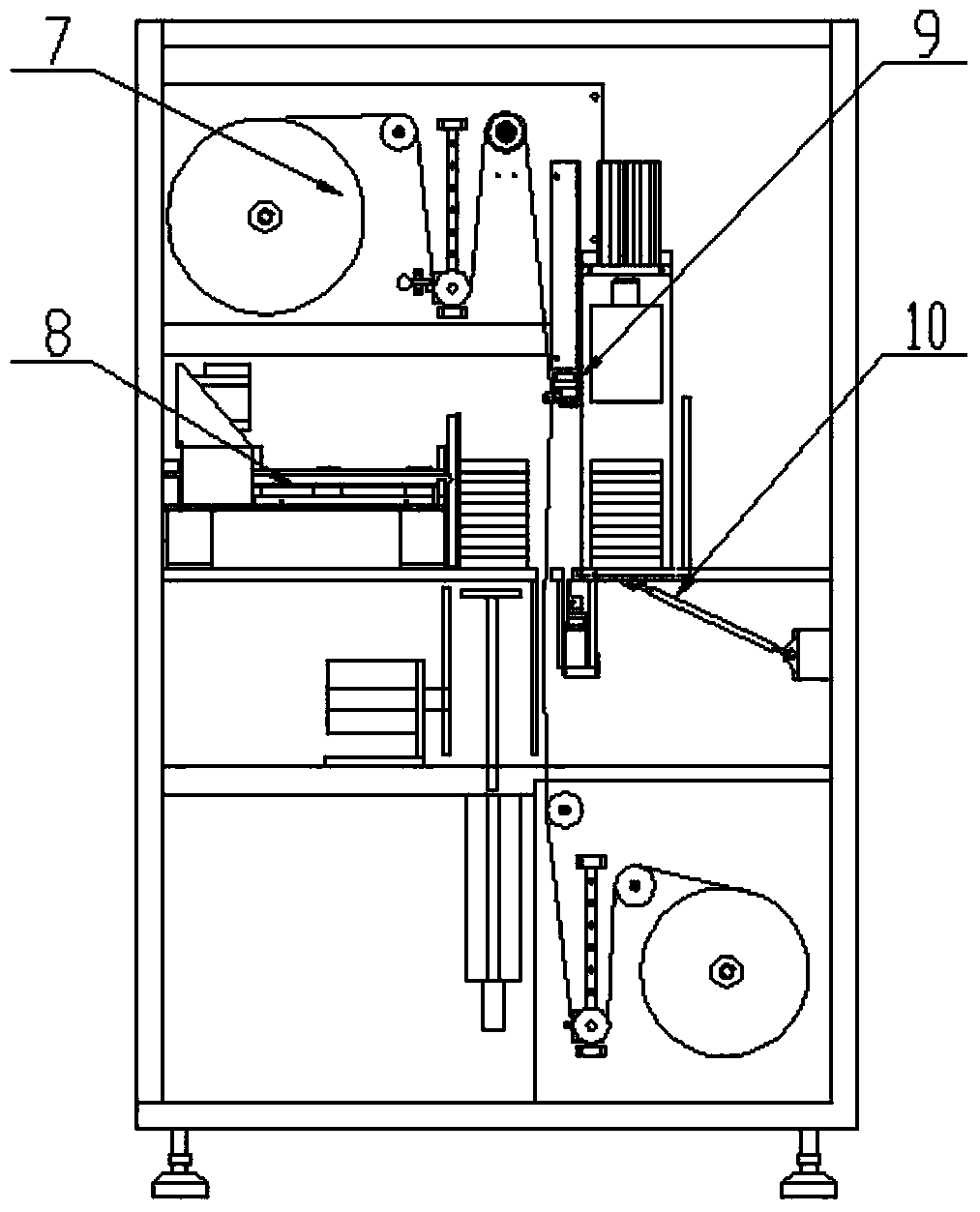

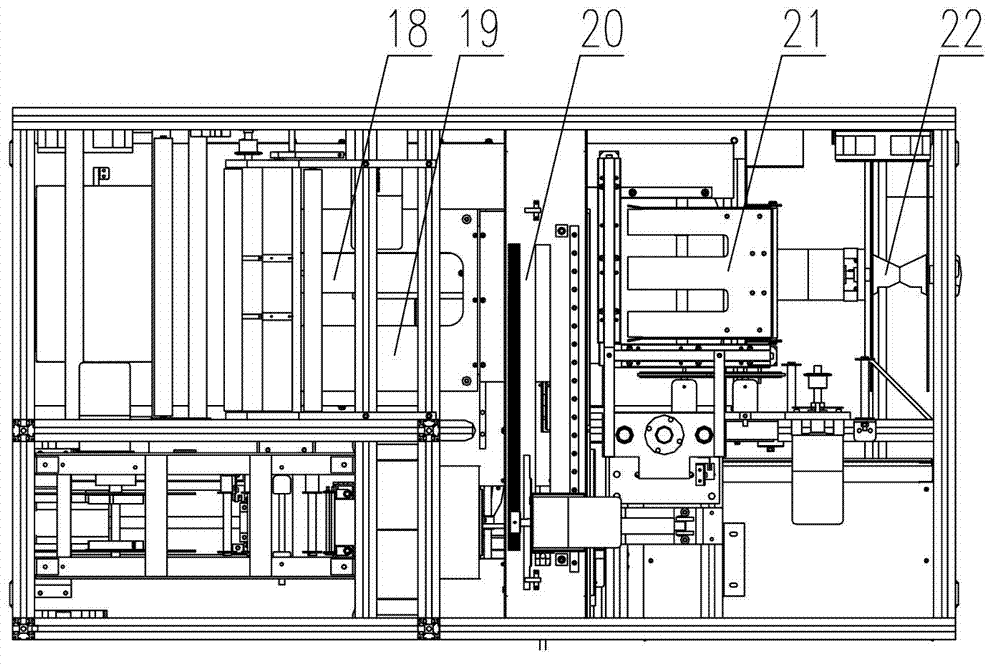

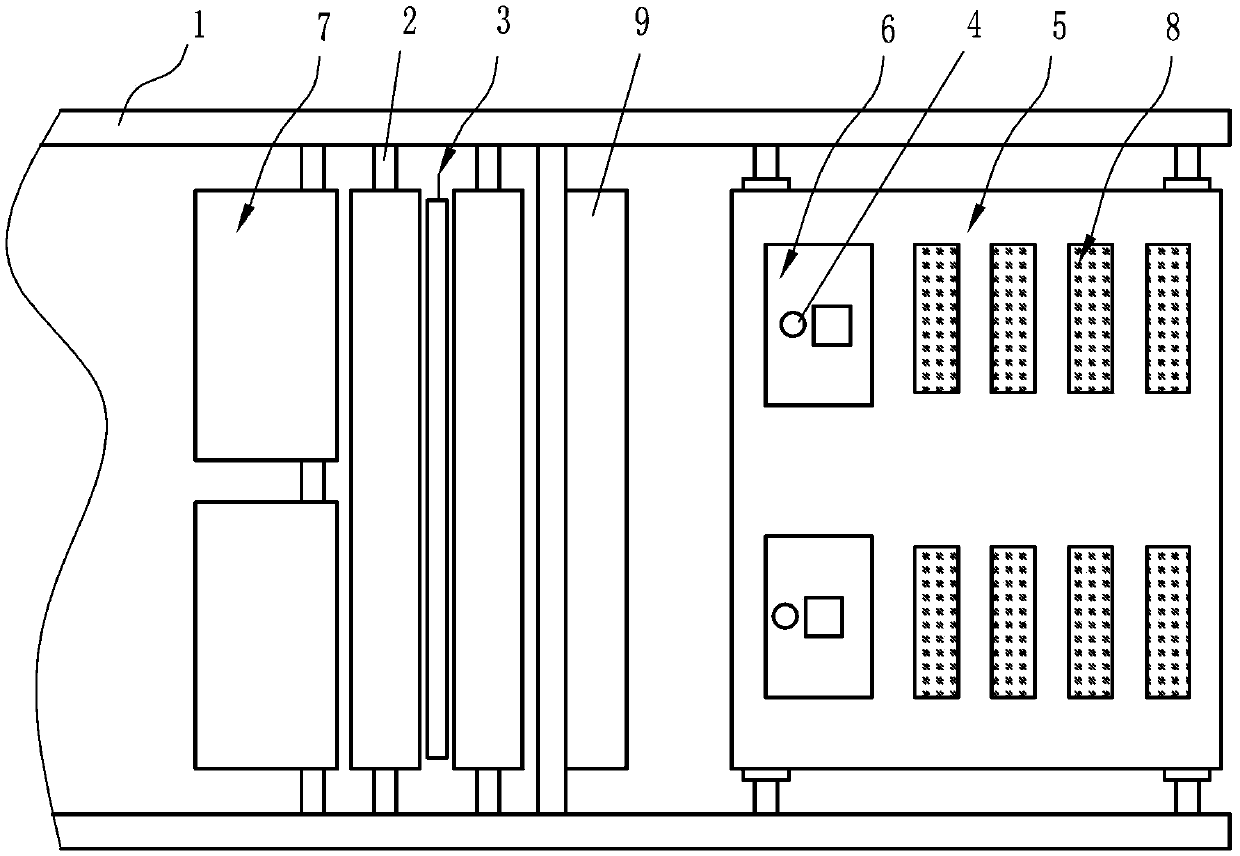

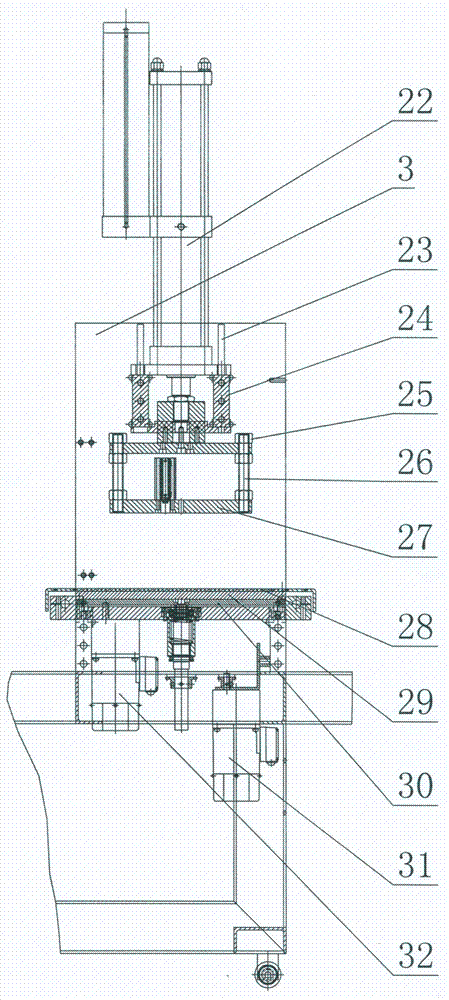

Banknote plastic packaging machine and banknote packaging method

ActiveCN102897340AImprove packaging qualityImprove preservation qualityPaper article packagingWrappers shrinkagePlastic packagingControl system

The invention provides a banknote plastic packaging machine and a banknote packaging method. The banknote plastic packaging machine comprises a frame, an upper plastic film frame, a lower plastic film frame, a lifting mechanism, a driving system and a control system, wherein the frame is divided into a plurality of layers of mounting areas from top to bottom by a plurality of baffle plates; a primary plastic package unit is arranged in the mounting area between the upper plastic film frame and the lower plastic film frame and used for conducting primary plastic package on plastic packaged banknotes by a plastic film, and the secondary plastic package unit is parallel to the primary plastic package unit and is used for conducting the secondary plastic package on the plastic packaged banknotes by heat shrinkage films; the lifting mechanism is arranged in front of an L-shaped banknote pushing mechanism and used for conveying the plastic packaged banknotes subjected to secondary plastic package to a heat shrinkage furnace, and the heat shrinkage furnace is arranged below the lifting mechanism and used for conducting heat shrinkage treatment on the plastic packaged banknotes subjected to secondary sealing and cutting. According to the banknote plastic packaging machine, the banknote damaging rate is reduced, the banknote drawing can be avoided, the banknote storage quality is improved, the environment of the banknote storage warehouse is improved, the logistics management of the banknotes is facilitated, the volume of the machine is small, and the degree of automation is high.

Owner:ZHEJIANG ZHONGDA PACKAGING EQUIP +1

Plastic body folding machine

InactiveCN103359339ANot easy to deform and disperseNeatly foldedPaper article packagingRelative motionEngineering

The invention discloses a plastic folding machine which is used for folding plastic bags. The plastic bag folding machine comprises a rack, a plastic bag conveying device, a handle folding device, a final folding device, a clamping plate device, and a discharge output device. Piles of plastic bags produced on a bag making machine are conveyed to corresponding processing positions through the conveying device. Handles of the bags are folded through the handle folding device, and then the plastic bags are folded through the final folding device and are conveyed into the clamping plate device. The clamping plate device rotates 90 degrees in a swinging mode and then moves onto a bag discharge device. The bag discharge device moves downward and is inserted into clearance of the clamping plate device so as to block or pinch the plastic bags. When the clamping plate device and the bag discharge device are in relative motion, the plastic bags are discharged onto an output device. Folding package of the plastic bags is finished after manual banding. The plastic folding machine can meet requirements of diversified markets of nylon cord banding, rubber band banding or plastic film packaging, and is simple in structure and capable of folding neatly.

Owner:王秀来

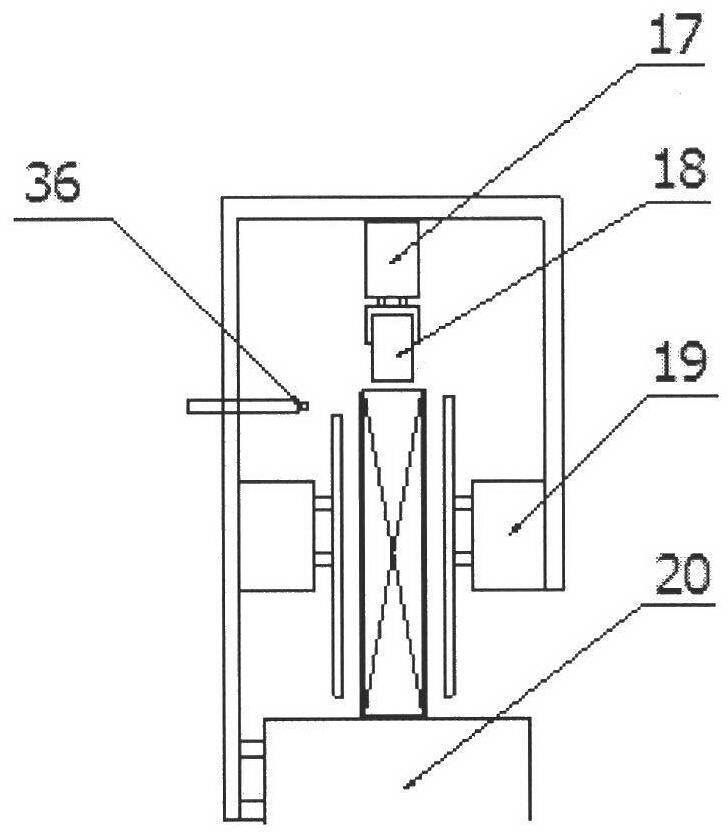

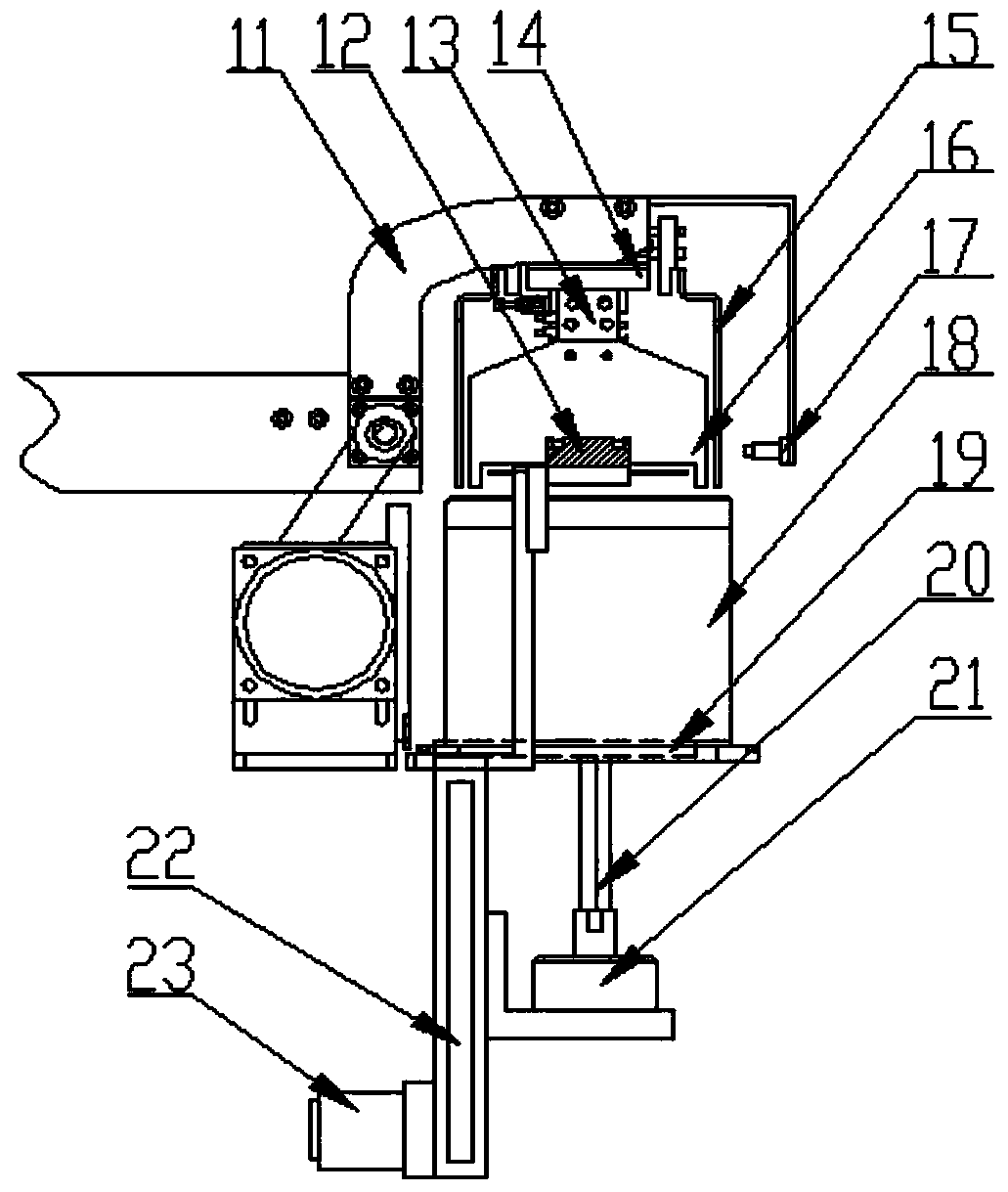

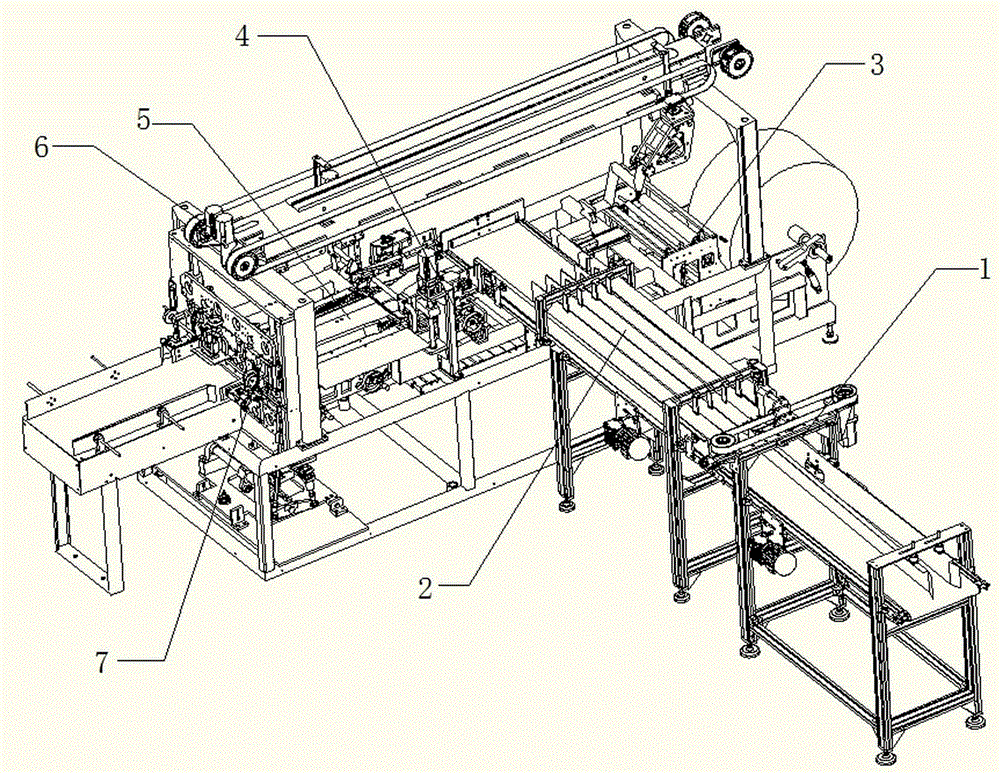

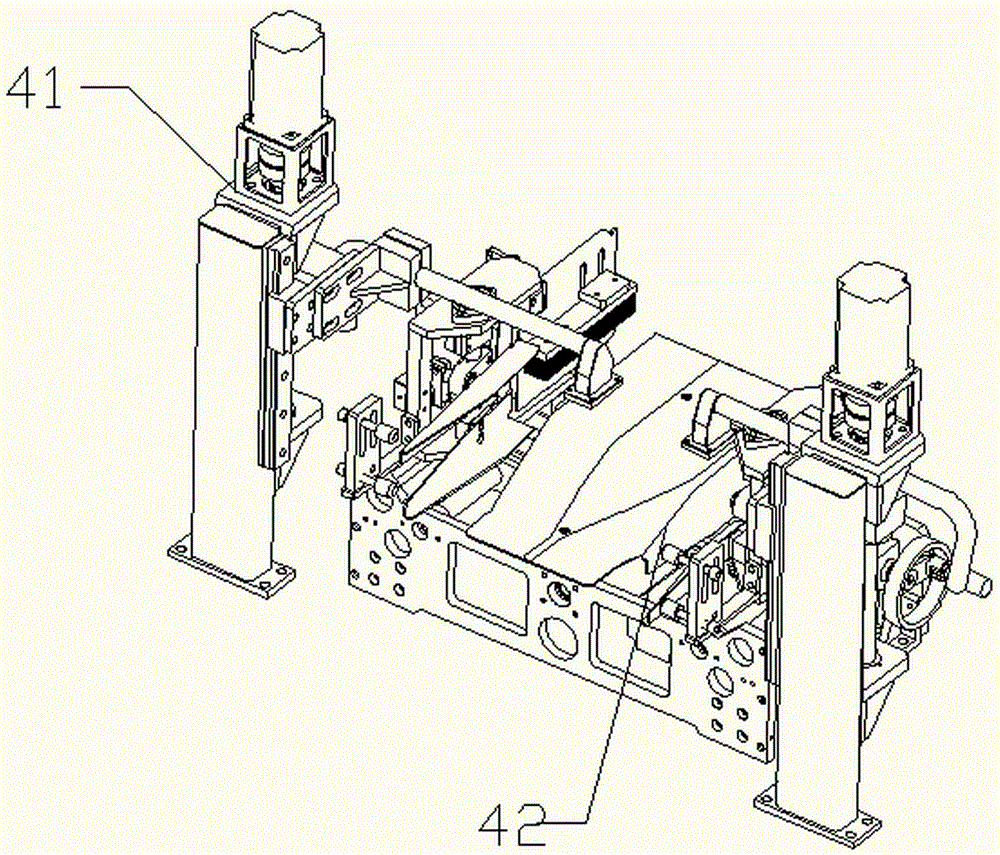

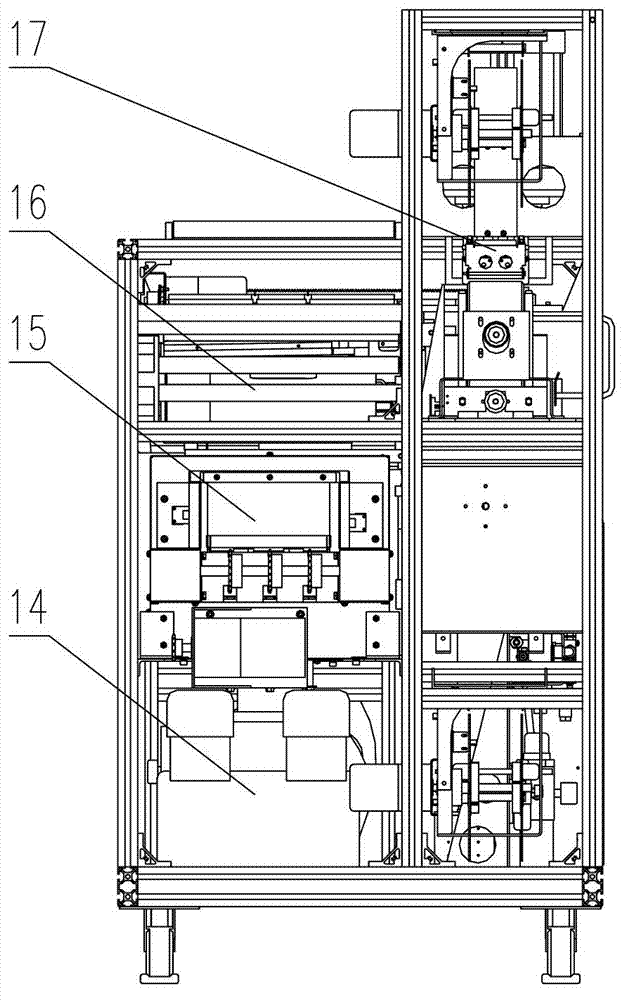

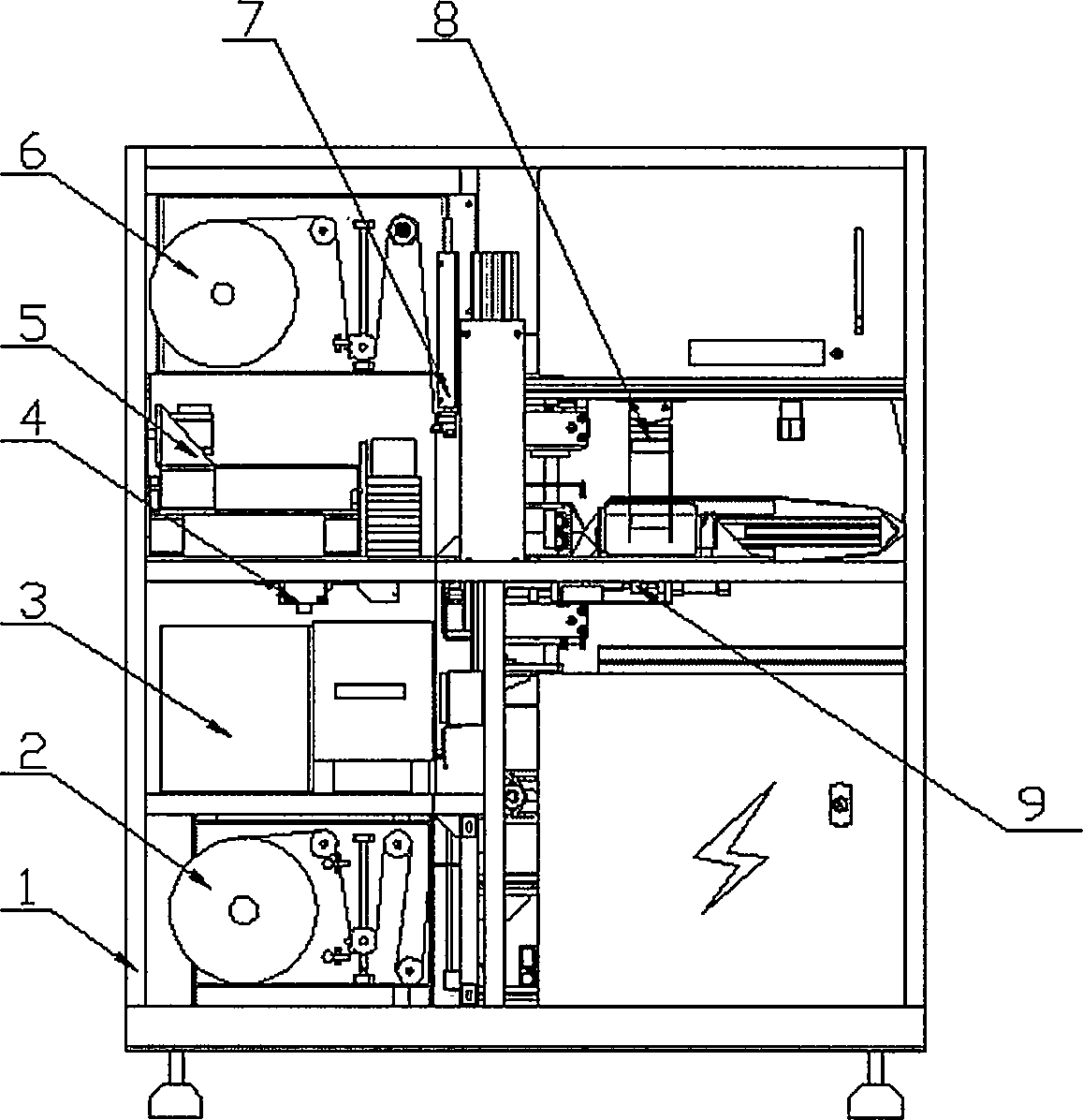

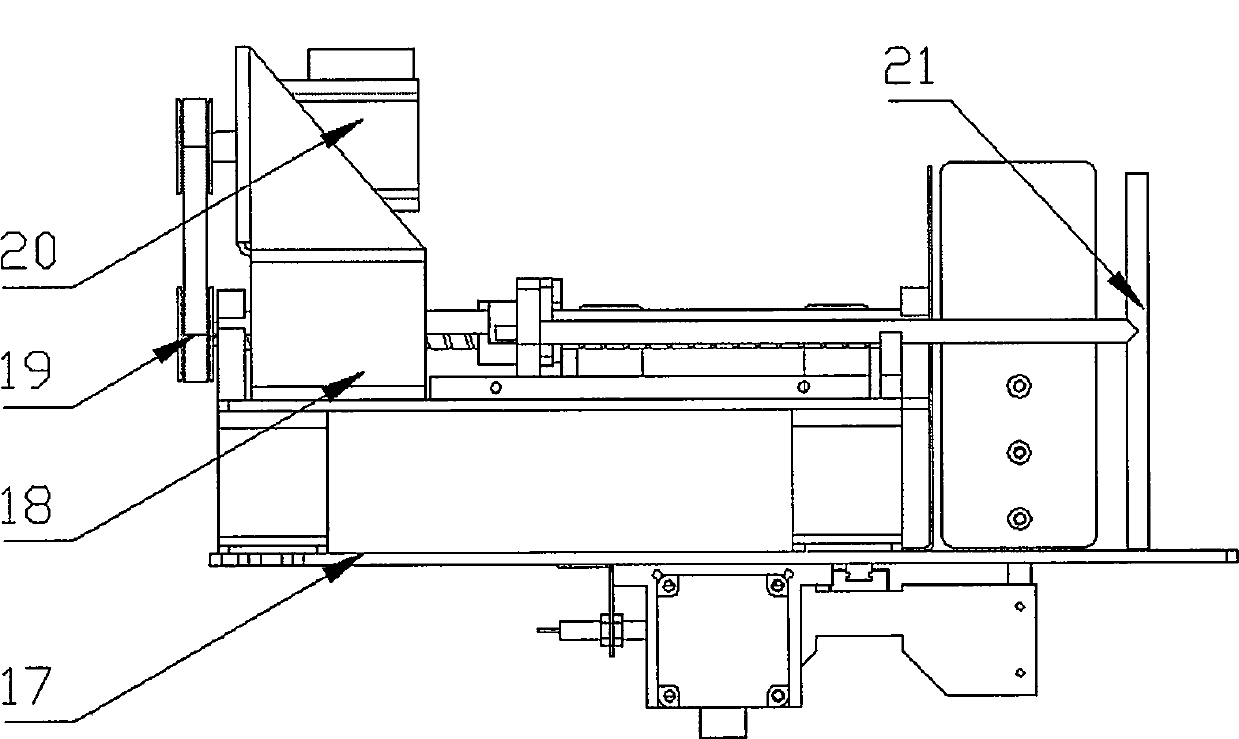

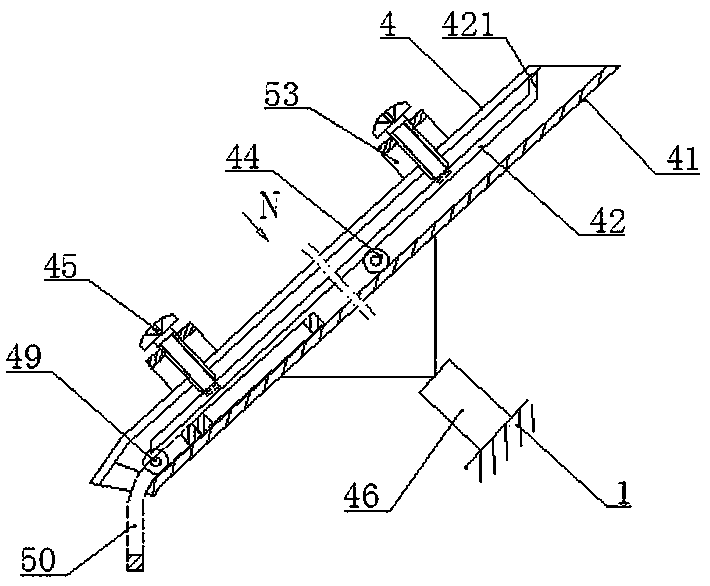

Bundling and plastically-enveloping AIO (all-in-one) machine for paper currency

InactiveCN103738523AMoisture-proofWith dustproofPaper article packagingWrappers shrinkageControl systemProgrammable logic controller

The invention discloses a bundling and plastically-enveloping AIO (all-in-one) machine for paper currency used for automatically bundling and plastically-enveloping the paper currency, aiming at the different face values of paper currency in a financial system. The AIO machine mainly comprises an automatic bundling unit and an automatic plastically-enveloping unit, and is composed of a lower film rolling mechanism, a heat transfer printing printer, a paper currency adjusting mechanism, a primary pushing mechanism, an upper film rolling mechanism, a heat-seal bundling mechanism, a side pushing mechanism, an overturning mechanism, a film plastically-enveloping mechanism, a forming mechanism, a U-shaped sealing mechanism, a lifting mechanism, a material receiving mechanism, a thermoshrinking furnace mechanism and a PLC (Programmable Logic Controller) control system. The working principle of the AIO machine is that a start button is pressed and the primary pushing mechanism is controlled to push the paper current into the bundling mechanism for bundling through the PLC after 10 bundles of paper currency are placed into a paper currency entrance, and the paper currency is sent to a side push position through the overturning mechanism, the paper current is sent into the U-shaped sealing mechanism for plastically enveloping by the side pushing mechanism, and a packaging film is shrunk by the thermoshrinking furnace after the plastic envelope. The AIO machine has the advantages of being reasonable in structure, compact in mechanism, simple to operate, convenient to maintain, and realizing stability and reliability.

Owner:YEE FOO PACKAGING SHENZHEN CO LTD

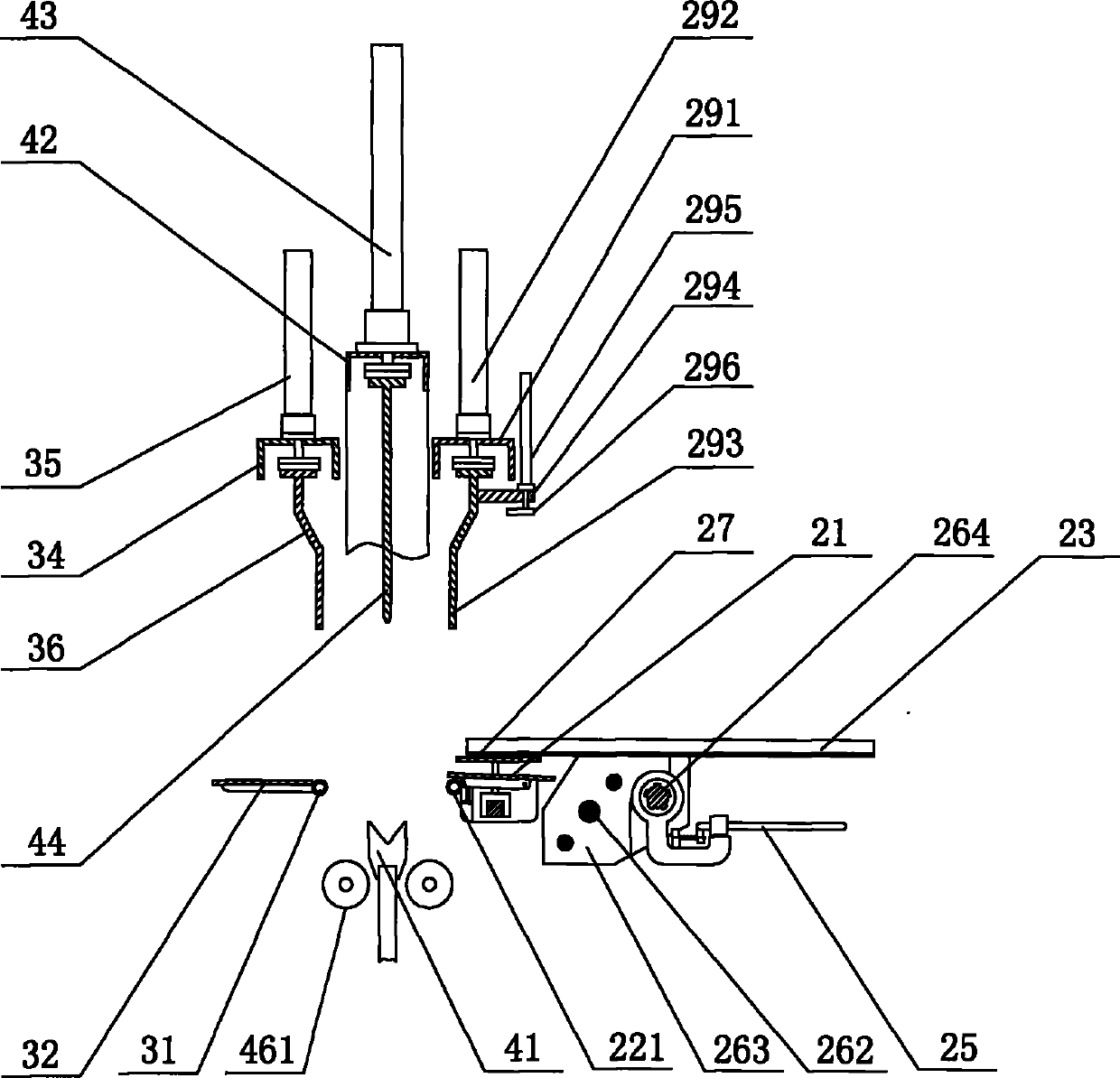

Folding and bundling integrated machine for packaging bag

ActiveCN106864886AImprove folding efficiencyTied up firmlyPaper article packagingBinding material applicationEngineeringMachining

The invention discloses a folding and bundling integrated machine for a packaging bag. The folding and bundling integrated machine comprises a machine frame, a bag body folding mechanism and a bundling mechanism, and is characterized in that the bag body folding mechanism comprises a supporting plate, a center positioning device, a front folding device for folding the bottom of a bag body backwards, and a rear folding device for folding a bag opening part of the bag body forwards. The front folding device and the rear folding device are arranged in front of and behind the supporting plate correspondingly. The center positioning device comprises positioning pressing plates, lifting parts driving the positioning pressing plates to rise and fall, and adjustment parts used for adjusting the transverse positions of the positioning pressing plates. The positioning pressing plates include the left pressing plate and the right pressing plate. The left pressing plate and the right pressing plate are arranged over the supporting plate and arranged on the two sides of the supporting plate correspondingly. Under the folding working condition, the bag body is arranged on the supporting plate, a front pressing plate and a rear pressing plate. According to the folding and bundling integrated machine, folding of the bag body is achieved in a center positioning and frontward-backward folding manner, the structure is simple, the machining cost is low, and the bag body folding efficiency is high.

Owner:浙江晨宇科技股份有限公司

Plastic bag packer

InactiveCN105109750AGuaranteed length accuracyCompact structurePaper article packagingWrapper twisting/gatheringEngineeringPlastic bag

The invention discloses a plastic bag packer used for packing low-cost plastic bags produced by a bag making machine. The plastic bag packer mainly comprises a rack, a feeding device, a support plate swinging device and a lifting sucking disc device, and is characterized by further comprising a bag conveying device and a bag making device; the bag making device is characterized in that an output mechanism is used for inputting package films on film rolls to the operation position of a thermal sealing mechanism and the operation position of a cutting mechanism, then the package films are thermally sealed and cut to form package bags, the package bags are output to a bag storage disc of the bag conveying device; the bag storage disc is used for conveying the package bags to a predetermined operation position of the packer along with a bag-conveying operation mechanism; a suction disc is arranged on the bag storage disc, is used for fixing the bottom layers of open ends of the package bags, and cooperates with the lifting sucking disc to open the openings of the bags. The plastic bag packer has the advantages that the structure is simple and compact, the bags are fed and conveyed stably and reliably in sequence, the technical problem that the bags are taken unstably in sequence of the plastic bag packer in the prior art is solved, the plastic bag packer also has a function of automatically making the bags, and the package cost is saved.

Owner:王秀来

Automatic bundling device of plastic bag making machine

PendingCN108773518ARealize automatic strappingPrevent accumulation and cloggingPaper article packagingBinding material applicationEngineeringTransfer mechanism

The invention provides an automatic bundling device of a plastic bag making machine. The automatic bundling device comprises a plastic bag feeding mechanism, a rubber band arranging and output mechanism and a bundling mechanism. The bundling mechanism comprises an opening device and a rubber band transfer mechanism. The rubber band transfer mechanism is used for transferring rubber bands output bythe rubber band arranging and output mechanism to the opening device. The opening device is used for opening each rubber band and sleeving the rubber band onto a stack of plastic bags. The automaticbundling device has the advantages that the automatic bundling device can implement automatic bundling of soft thin film products and improves the working efficiency; through arranging of a lower rubber band output channel of the rubber band arranging and output mechanism, the rubber bands can be prevented from getting accumulated and blocked and can be conveyed smoothly; through the combination effect of band release convex heads of band release plates arranged on the outer side of a band release plate of the opening device and brace rod grooves formed in the circumferential surfaces of rubber band brace rods, the situation that rubber bands cannot be kept away from the rubber band brace rods can be effectively prevented, and the working reliability of band release is improved.

Owner:王根乐

Napkin packing machine

ActiveCN101439767AHigh degree of automated packagingReduce labor intensityPaper article packagingWrapping material feeding apparatusPaper towelElectric machinery

The invention discloses a paper towel packing machine, which comprises a film feeding device, a paper towel conveying device, a wrapping device, a side sealing device, an end face forming device and an end face closing device, wherein the film feeding device and the paper towel conveying device are positioned before the wrapping device; the side sealing device, the end face forming device and the end face closing device are arranged behind the wrapping device sequentially; the film feeding device comprises a rear film feeding device and a front film feeding device behind the rear film feeding device; the rear film feeding device comprises a film feeding positioning rack and two groups of rollers which are arranged on the top end and the bottom end of the positioning rack respectively; the front film feeding device comprises two lateral plates and a supporting rack, the lateral plates are provided with an adjusting device, a step motor, a color code photoelectronic tracking device and a dashed hole punching device, and a pedestal is fixed on the middle part of the supporting rack; and the pedestal is provided with two retaining plates which are provided with two large rollers and two small rollers. The paper towel packing machine has the advantages of having high automation packing degree, causing no secondary pollution, improving the packing efficiency, and reducing the cost.

Owner:广东爱美高智能设备有限公司

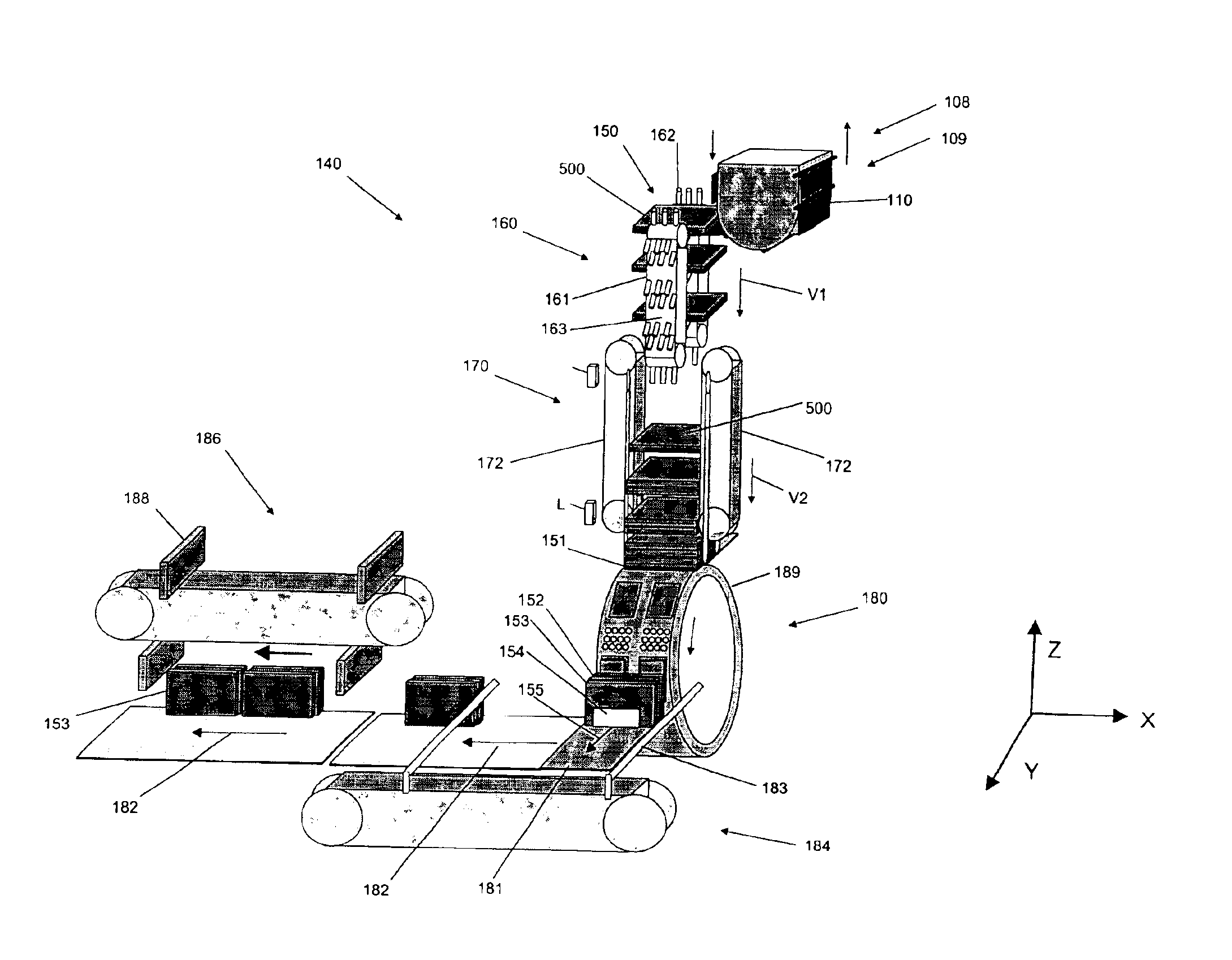

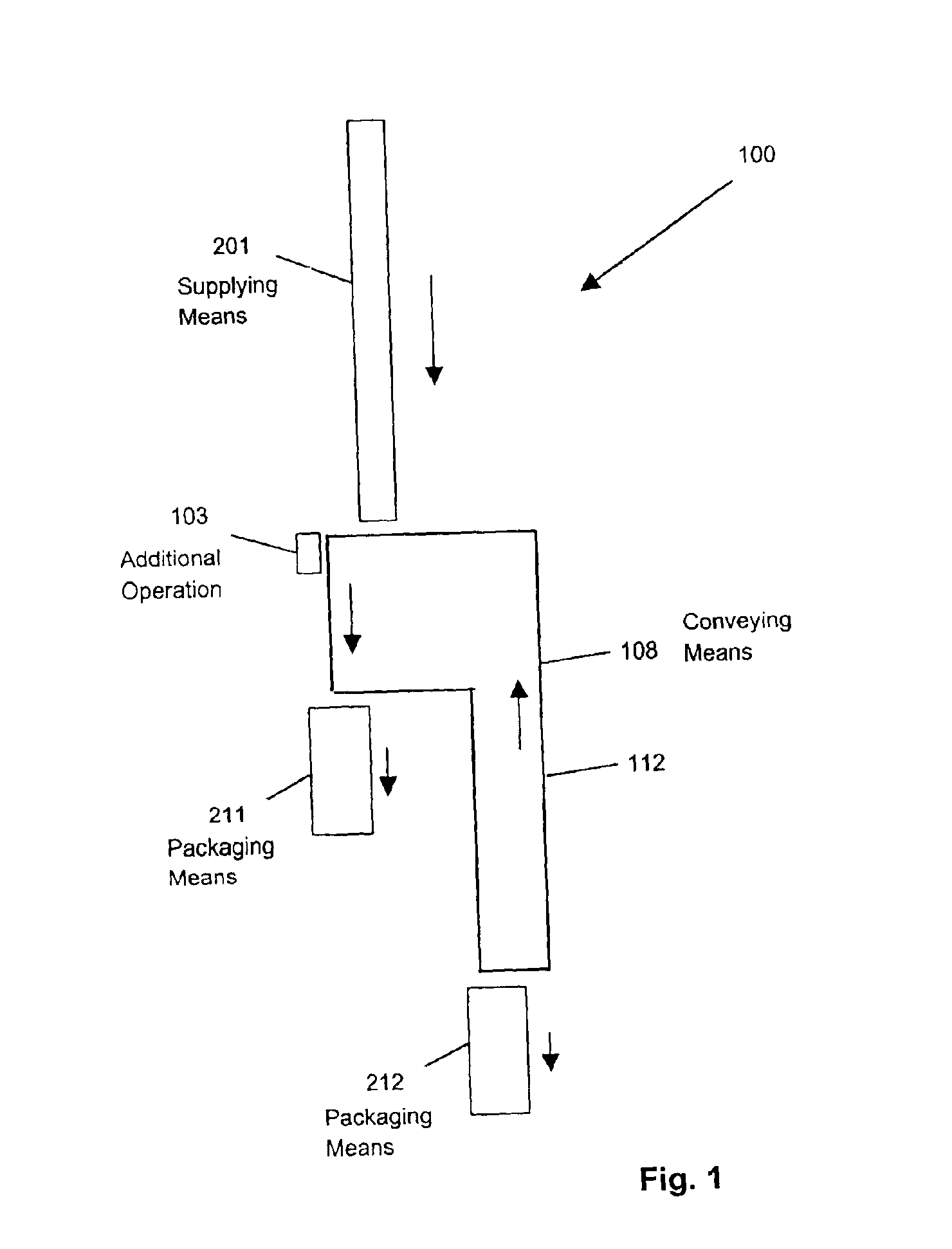

Flexible manufacturing system for consumer packaged products

InactiveUS6925784B2Paper article packagingOral administration deviceFlexible manufacturing systemFlexible manufacture system

A flexible manufacturing system for producing and packaging consumer products into different packages is disclosed. The system includes one or more supplying means for providing the consumer products, and a multiplicity of packaging means for packaging the consumer products into different packages. The system further includes one or more conveying means for conveying the consumer products from the supplying means to the packaging means. The conveying means forms a continuous path linking the supplying means with the packaging means. The continuous path includes a multiplicity of receptors capable of accepting, carrying, and discharging the consumer products. Further, the system includes one or more stacking means for arranging the consumer products into separate stacks of products prior to packaging.

Owner:THE PROCTER & GAMBLE COMPANY

Method and system for packaging rolls of products

InactiveUS20050229546A1Simple and economical systemPaper article packagingWrapper folding/bending apparatusEngineeringMechanical engineering

A method and system for packaging rolls of products, in particular rolls of toilet and / or kitchen paper, in which a wrapping sheet is wrapped in a “U” shape around a group of products so that its two end flaps project from the group, each of the end flaps then being folded in an “L” shape so that one portion adheres to the group and the remaining end portion extends transversally to the group and adheres, at the point where they meet, to the end portion of the other flap; the flaps then being sealed to one another at their end portions to form a tubular wrapper.

Owner:TISSUE MACHINERY

Machine for packaging stacks of multiply paper articles or the like into wrappings obtained from a wrapping sheet

InactiveUS20020073649A1Avoids curling and stretchingPaper article packagingWrapping material feeding apparatusEngineeringPaper sheet

In a machine for packaging stacks of multiply articles of paper into wrapping sheets, a first line conveys stacks of multiply articles of paper to a a wrapping station while a second feeds wrapping sheets to the wrapping station. Each sheet is kept vertically in a waiting position in the wrapping station until one stack is moved towards the sheet, so that the sheet gradually folds around the stack with overlapping parallel edges to be heat-welded. In the said second line there are first endless belts and second endless belts for a wrapping sheet received from conveying means situated upstream. The sheet is pulled up to the wrapping station and is clamped in the wait position by suction.

Owner:C G BRETTING MFG

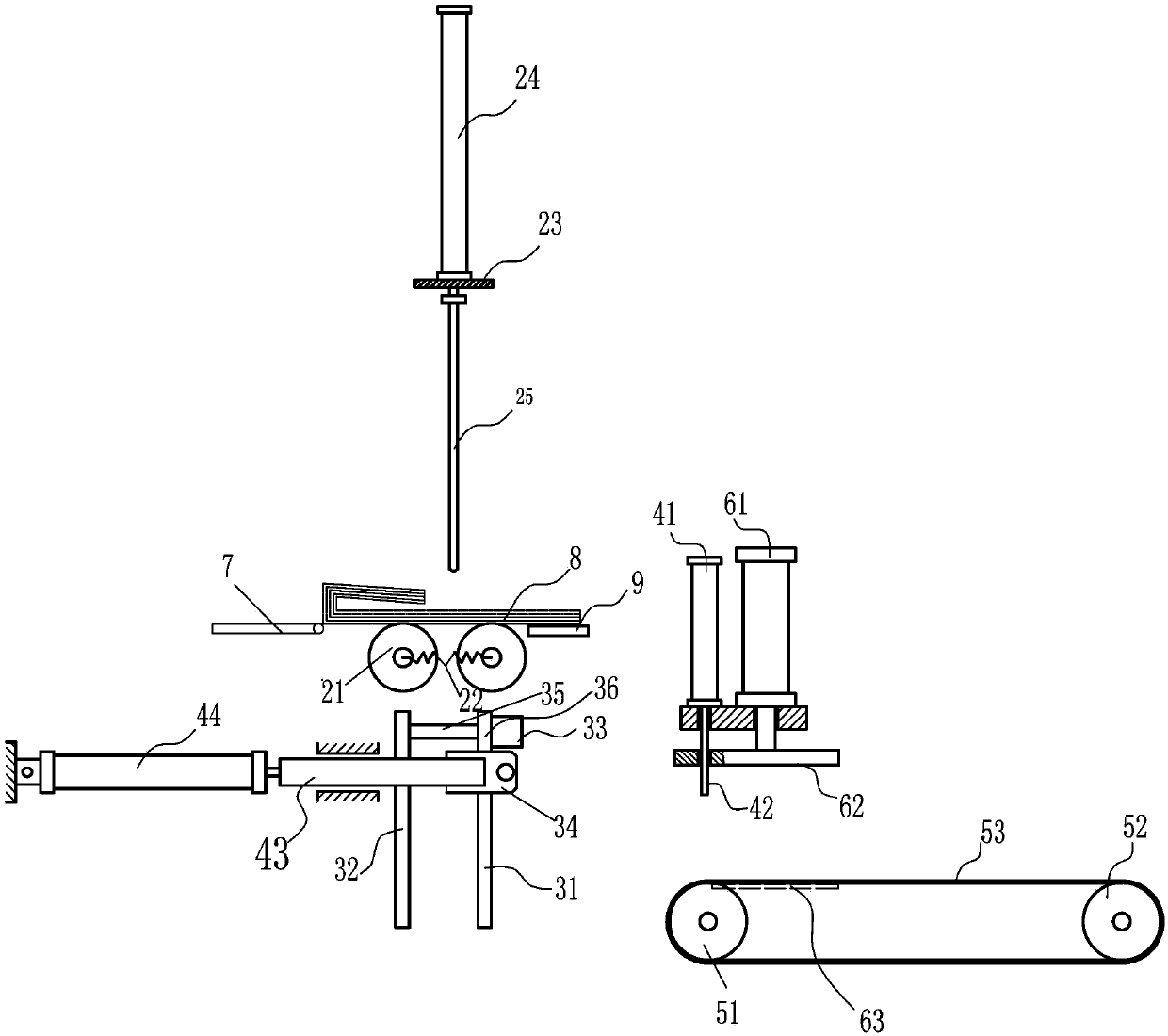

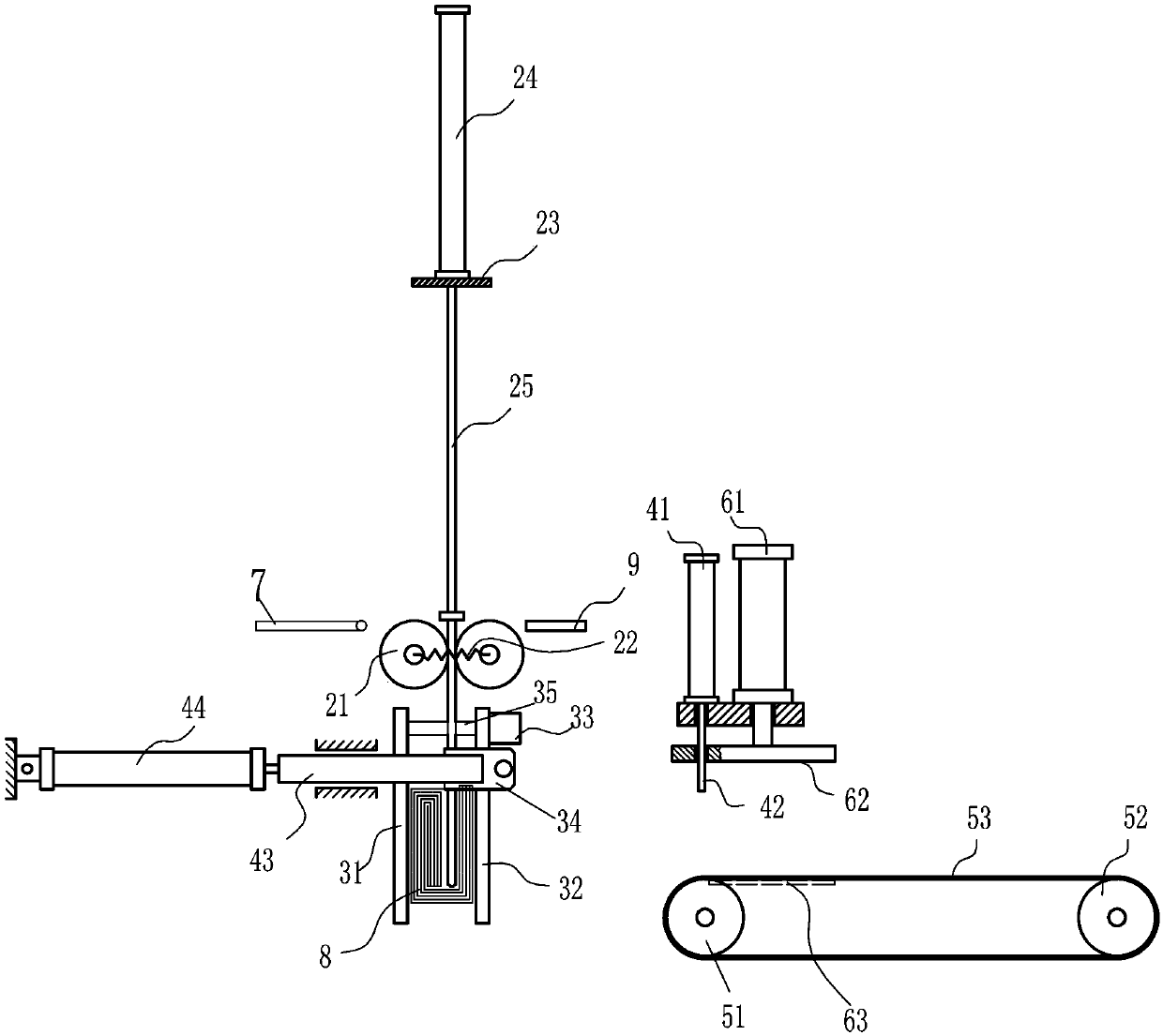

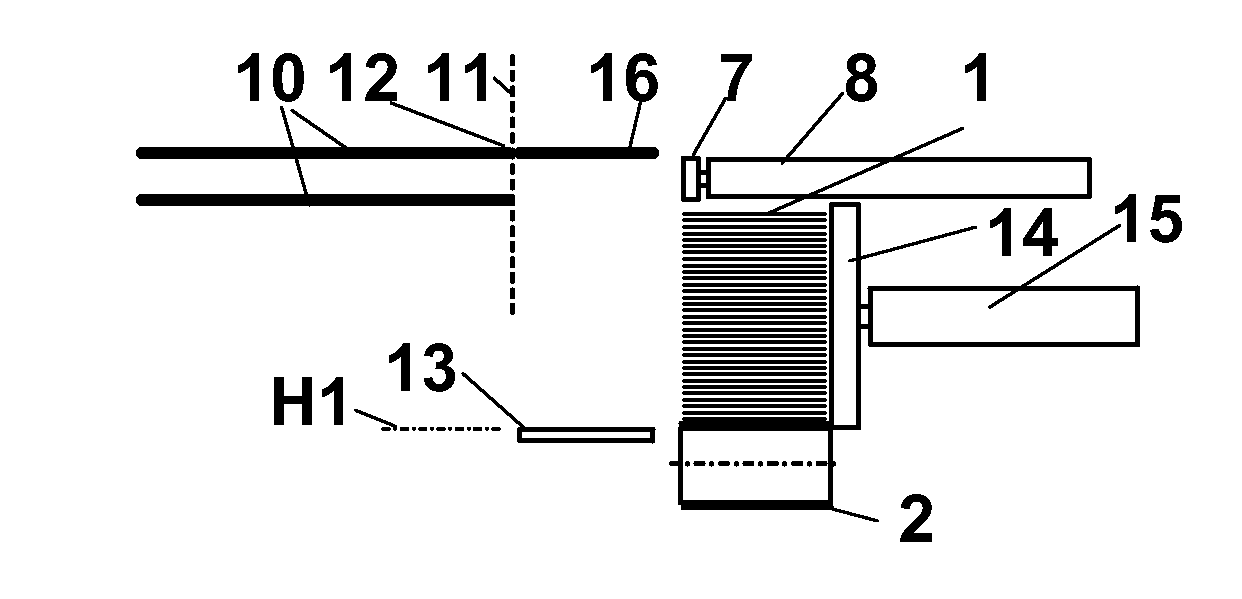

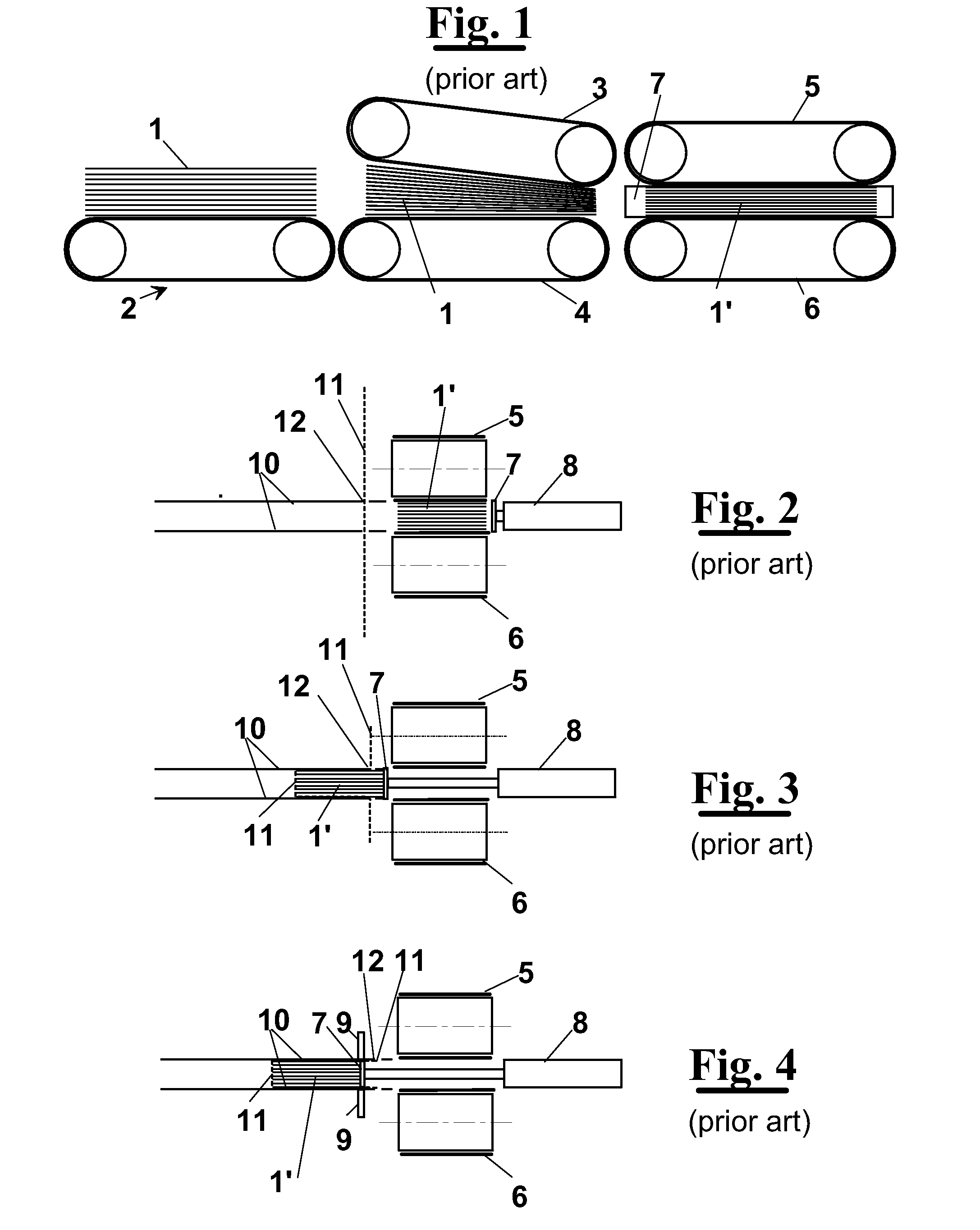

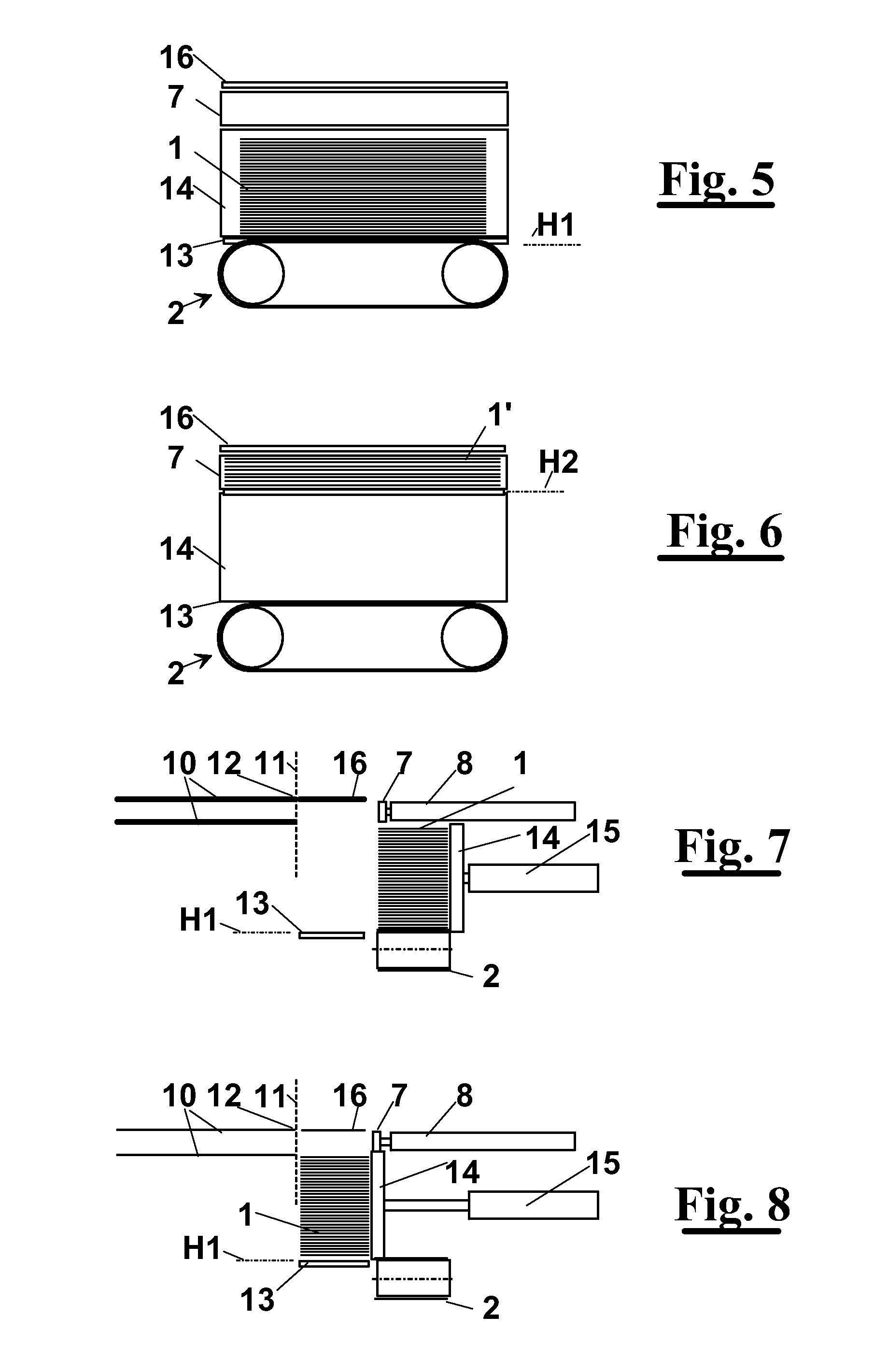

Banding machine for logs of sheet material

InactiveUS20070271872A1Improve productivityPaper article packagingWrapper folding/bending apparatusEngineeringSheet material

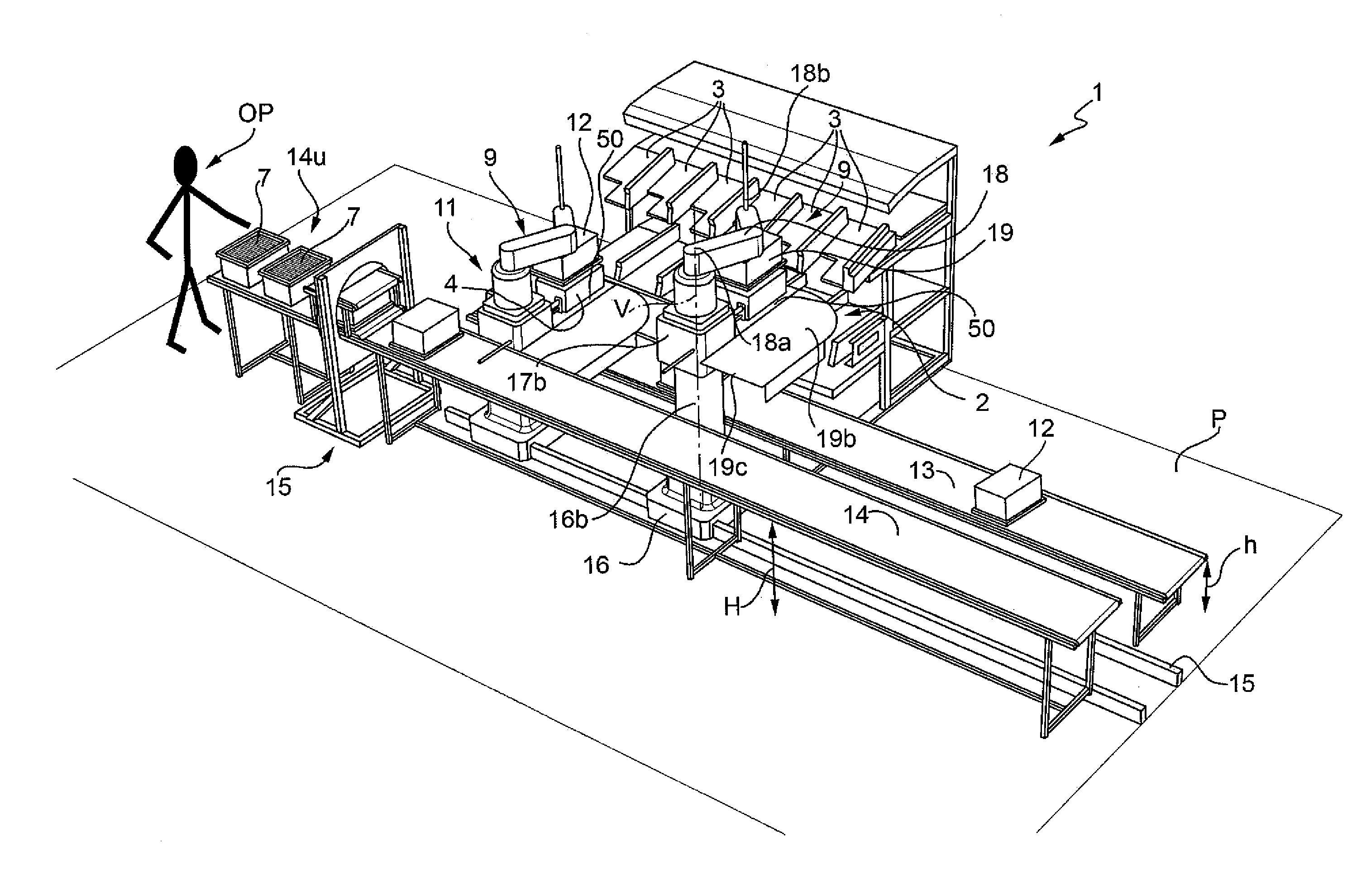

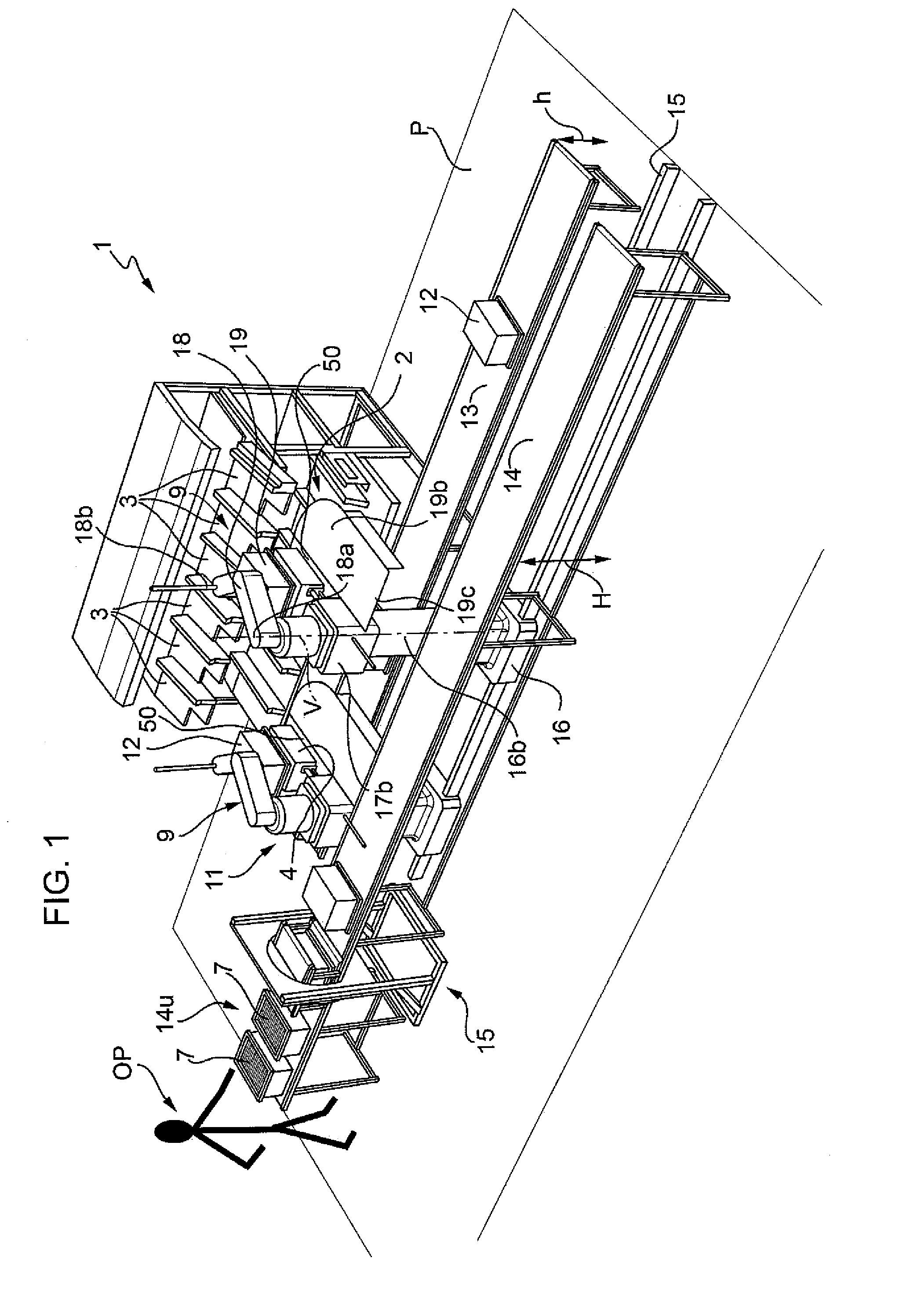

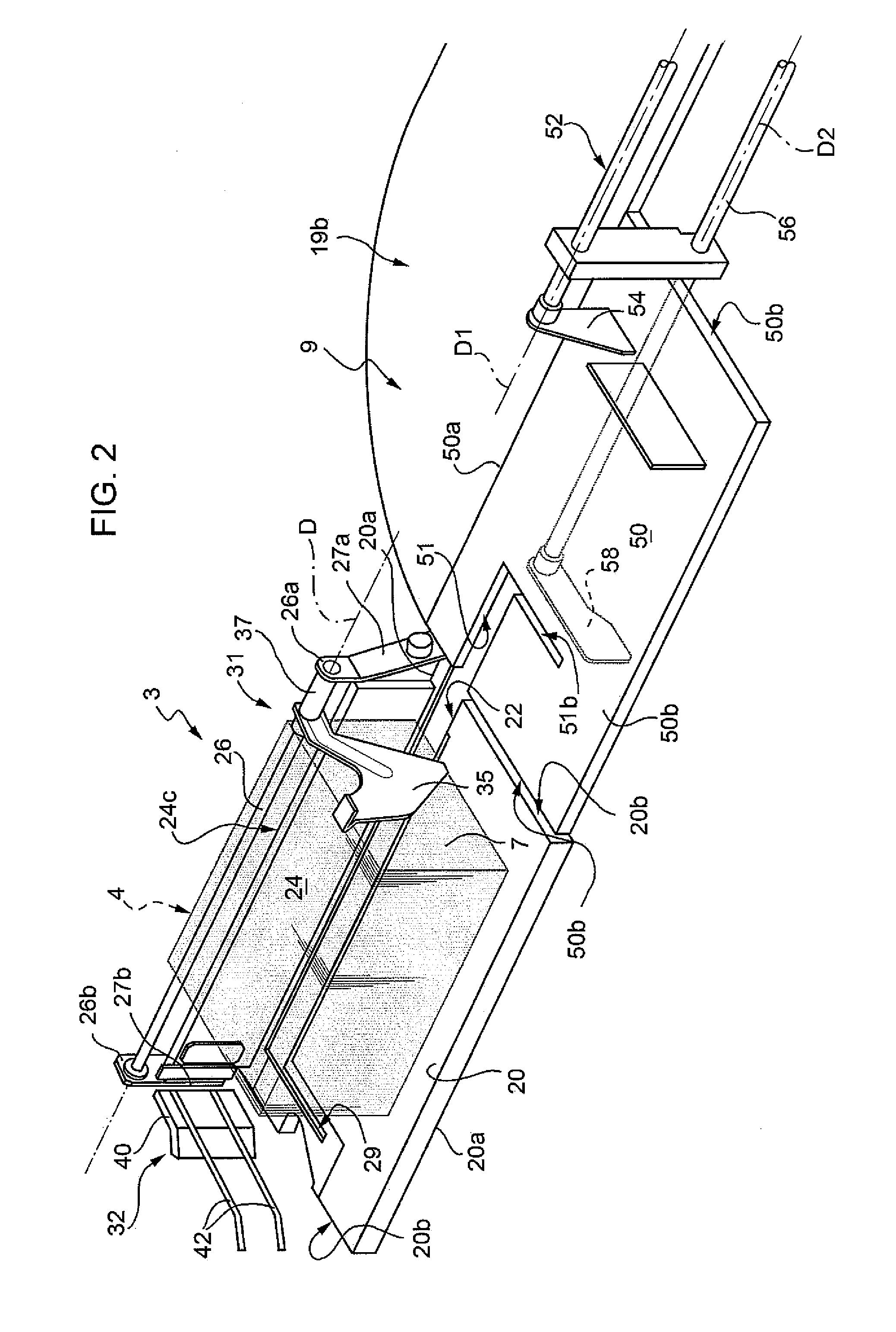

Banding machine for logs (1) of sheet material fed by a conveyor belt (2) to a packaging apparatus adapted to band it with a banding web (11) up to form a tubular wrapper around it. The packaging apparatus of the banding machine comprises a pusher (7) operated by an actuator (8), which pushes the log (1) in a channel (10) where a packaging sheet (11) is arranged stretched in front of the log, as an obstacle, along all the length of the machine through a passage (12). According to the invention, the conveyor belt (2) and the packaging apparatus (7) are arranged at different heights, respectively at a first and a second height (H1 and H2). Another pusher (14) can be provided, operated by a cylinder piston (15) at a first height (H1), in addition to the pusher (7) at the second height (H2), independent from each other. Furthermore, a lifting member (13) is provided, which receives the log (1) from the first pusher (14) and moves from the first height (H1) to the second height (H2). At its inlet in the banding machine the log (1) can be not compressed and is compressed up to reaching a compact shape indicated as (1′) when passing from the first height (H1) to the second height (H2). In particular, the lifting member (13) while lifting the log compresses at the same time the log (1) against a fixed wall (16), up to causing the log to achieve a compact configuration (1′).

Owner:MTC MACCINE TRASFORMAZIONE CARTA SRL

Paper brick classifying and recycling machine

ActiveCN104069927AReduce the frequency of manual cleaning of outbound shipmentsEasy to usePaper article packagingGrain treatmentsResidential areaBrick

The invention relates to a waste paper treatment machine, and in particular relates to a paper brick classifying and recycling machine. When newspaper and periodicals are smashed, the newspaper and the periodicals are weighed, and corresponding money is calculated, and then is discharged through a coin discharging opening, so that people can be encouraged to protect the environment; after weighing is finished, the paper is smashed; the smashing comprises coarse smashing and fine smashing; the coarse smashing is implemented by a screwdriver for mincing the paper into sheets; the fine smashing is implemented by a strip-shaped cutter and the screwdriver which are used for smashing the paper into small segments; furthermore, the paper is subjected to vacuumized compression and packaging in a paper compressing and packaging cavity; after being packaged, the paper is stored in equipment. The paper brick classifying and recycling machine can be used in residential areas or offices. The paper brick classifying and recycling machine is provided with an electronic screen which can be used for environment protection advertising or commercial advertising.

Owner:TAIYUAN UNIV OF TECH

Apparatus for forming cartons from blanks and for simultaneously filling the cartons

InactiveUS6357212B1Easy to adjustPrecise positioningPaper article packagingBox making operationsCartonEngineering

A box folding and article packaging apparatus has a lower tool section positioned below a work support surface and several upper tool sections positioned above the work support surface. The lower tool section includes four modular corner units each with folding flaps and a fixed support element. The four support elements together define the work support surface. The four corner units are displaceable relative to each other for adapting the apparatus for handling blanks of different sizes. A precut and precreased blank is first placed on the work support surface. The article to be packaged is then placed on the blank whereupon folding begins. One upper tool section also includes folding elements for folding a cover portion of a box and closing the box. Another upper tool section includes either adhesive applicators or staplers or the like for fastening folded blank sections to one another to complete the carton around the article or articles.

Owner:WINKLER DUNNEBIER GMBH

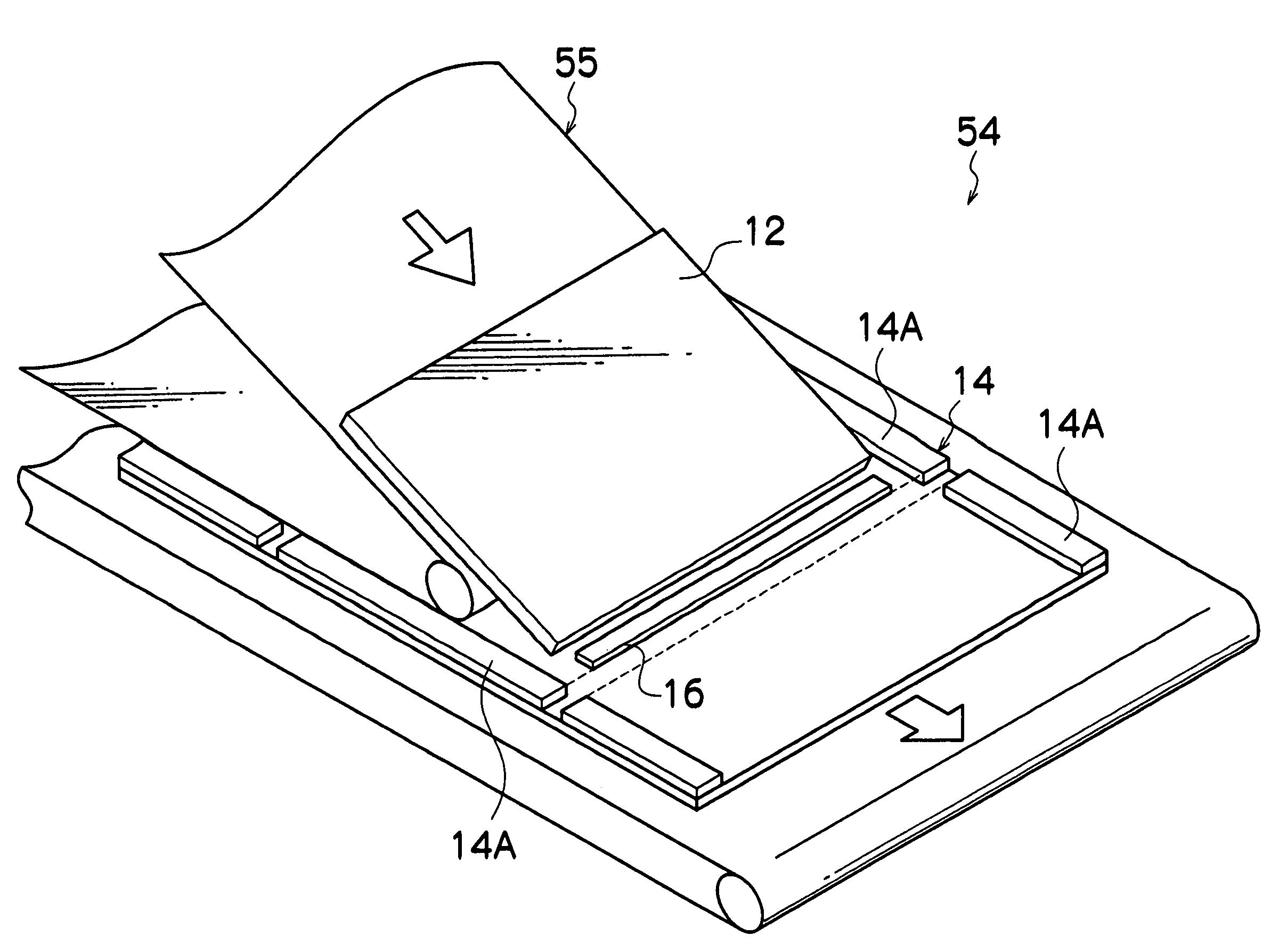

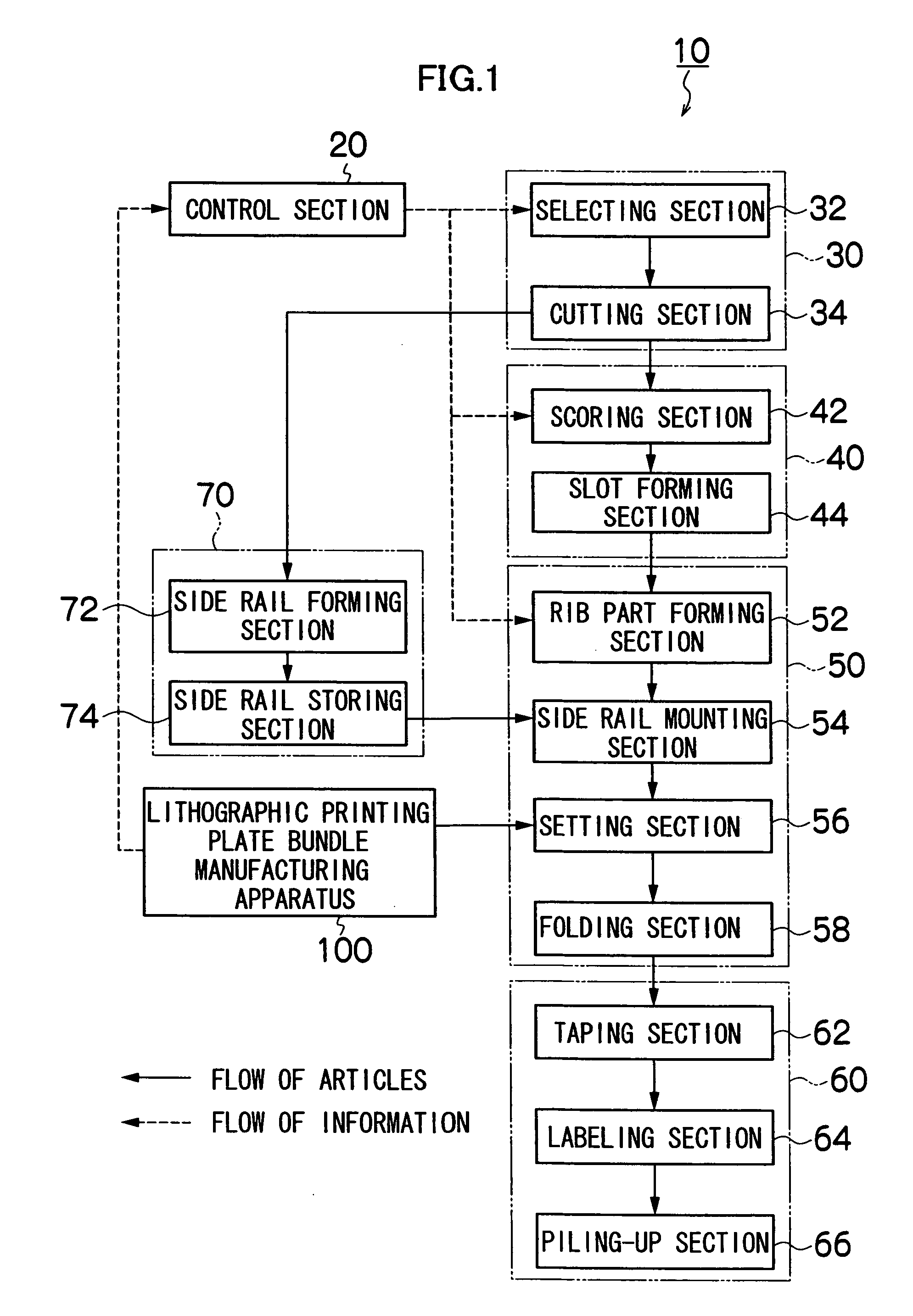

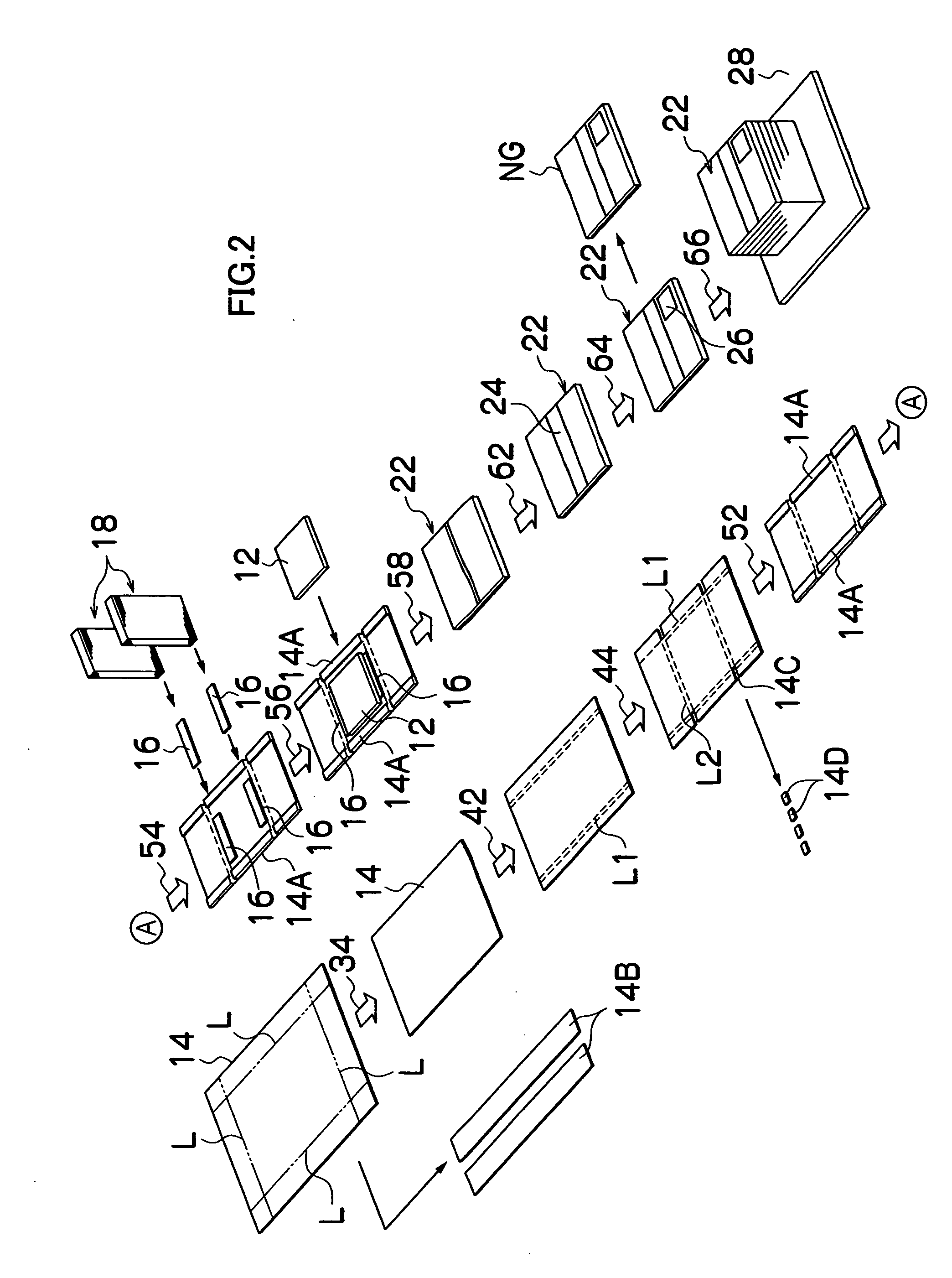

Packaging method and apparatus

InactiveUS20080073235A1Easy to transportReduce packaging materialsPaper article packagingOther accessoriesMaterials processingMaterial supply

The method of packaging an article by folding a sheet-shaped packaging material includes: a determining step of determining a size of the packaging material and a packaging pattern of the packaging material in accordance with information about the article; a packaging material supplying step of performing at least one of selecting and cutting operations on the packaging material so as to match the size determined in the determining step, and then supplying the packaging material; a packaging material working step of forming a score line on the packaging material supplied in the packaging material supplying step in accordance with the packaging pattern determined in the determining step; and a packaging body forming step of conveying and placing the article onto a predetermined position of the packaging material on which the score line has been formed in the packaging material working step, and then folding the packaging material along the score line to form a box-shaped packaging body.

Owner:FUJIFILM CORP

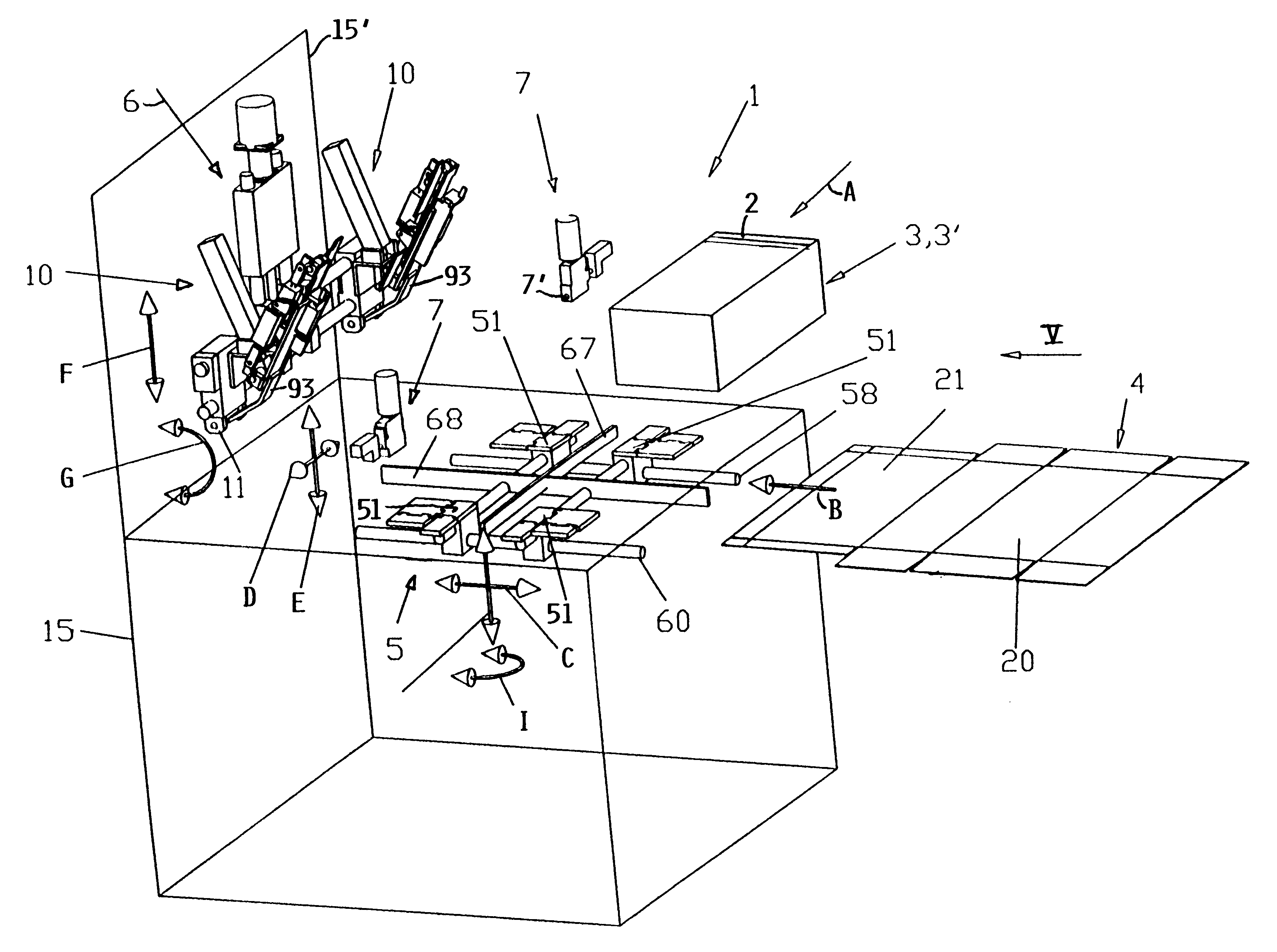

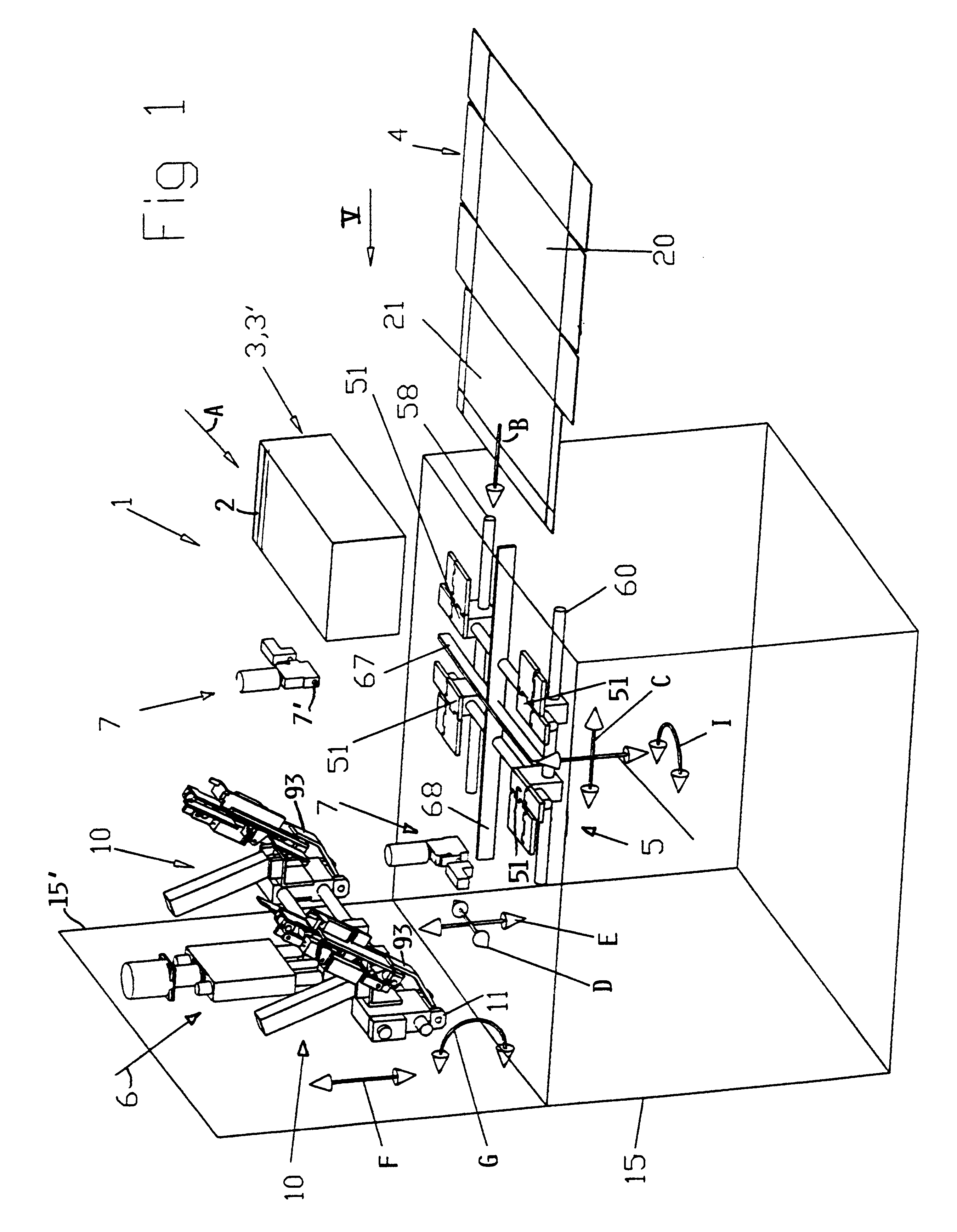

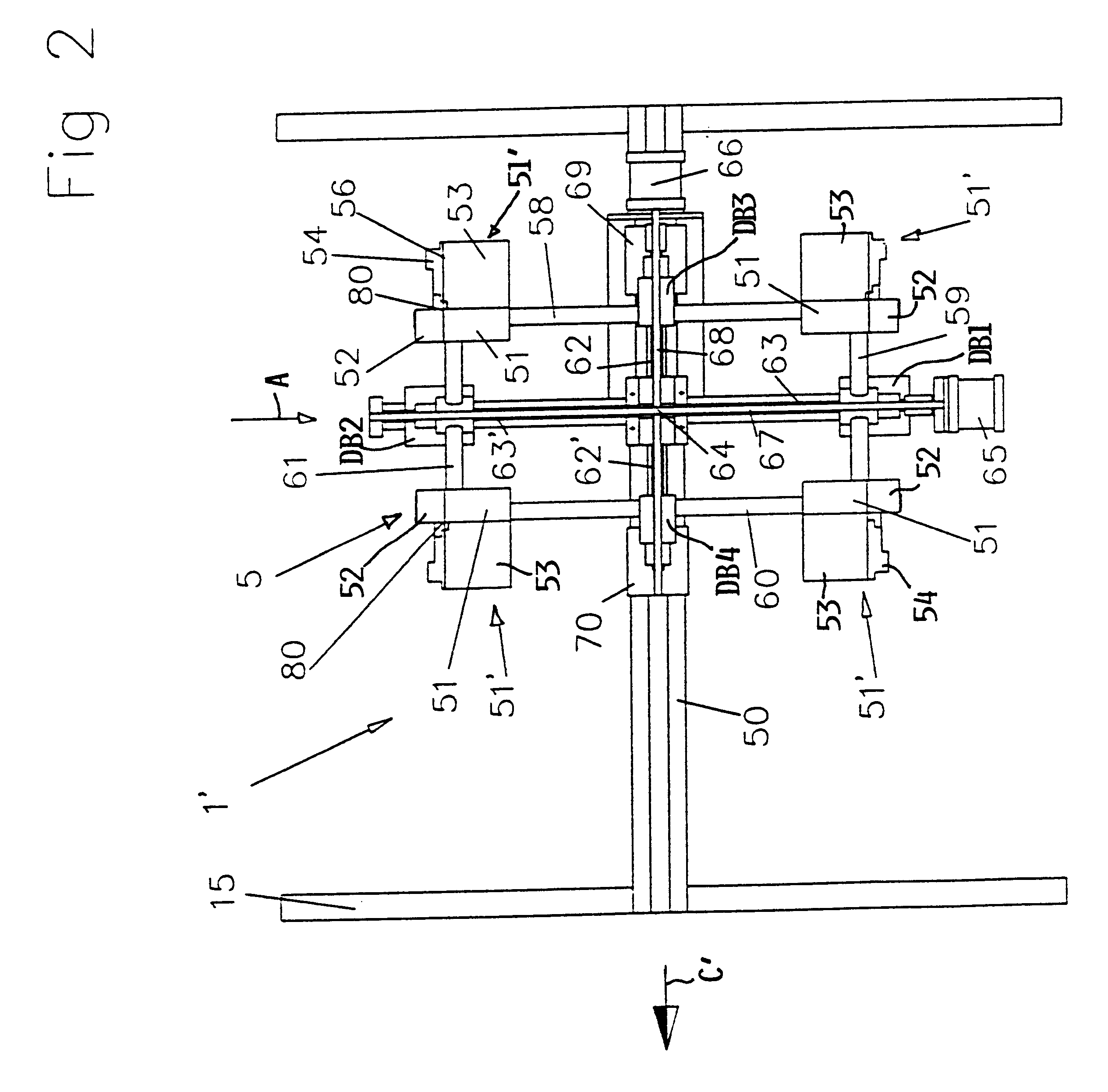

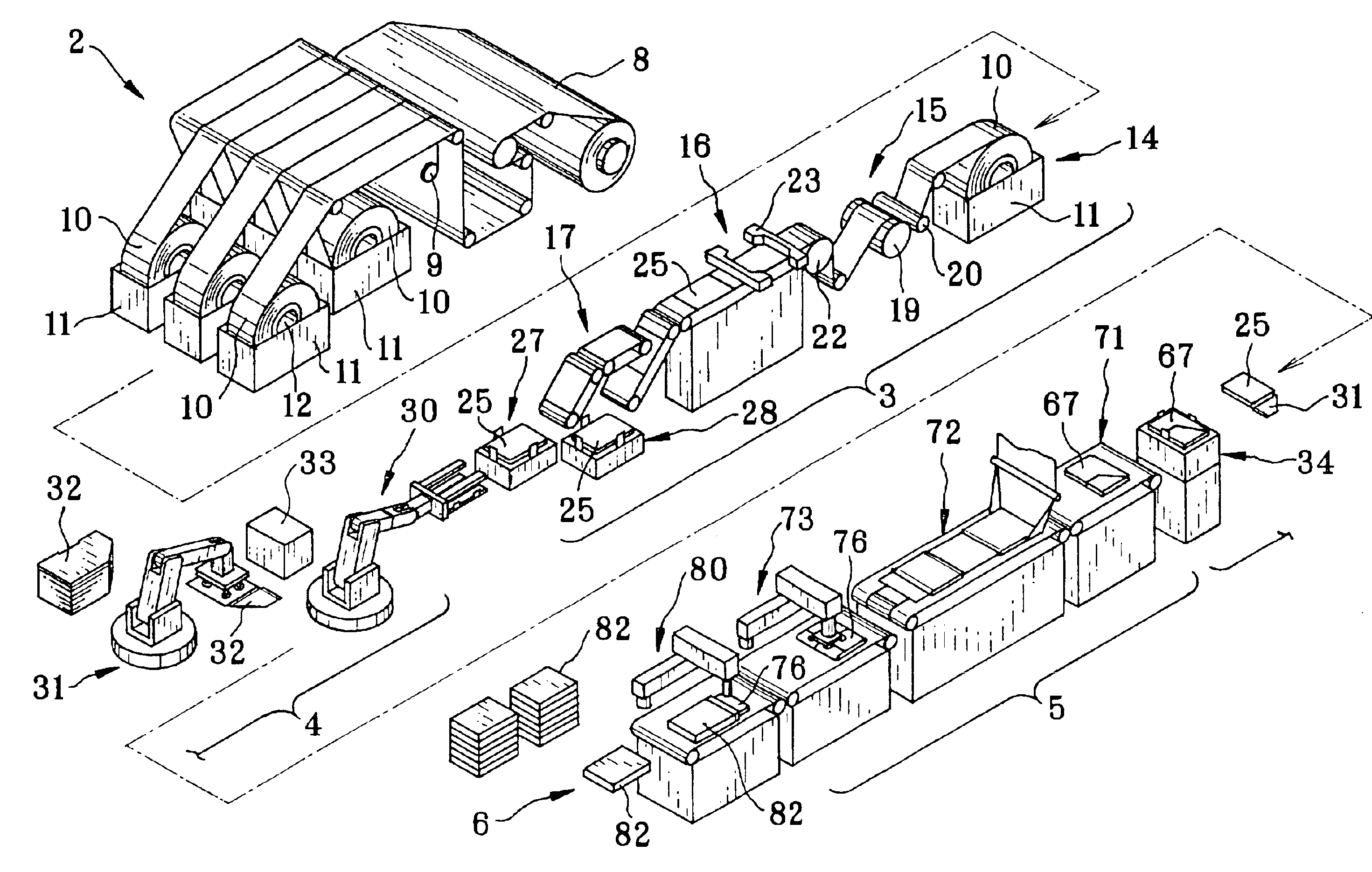

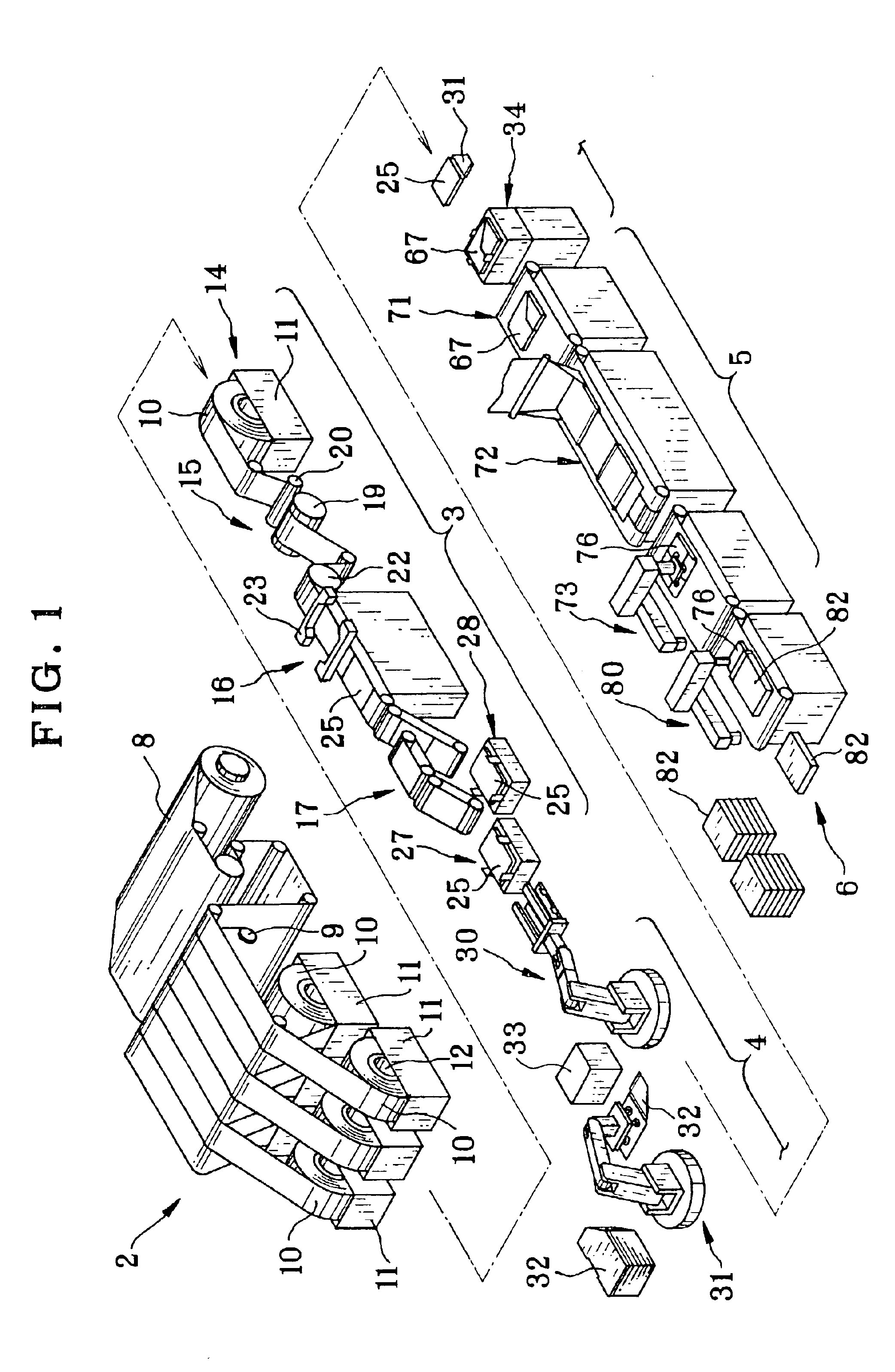

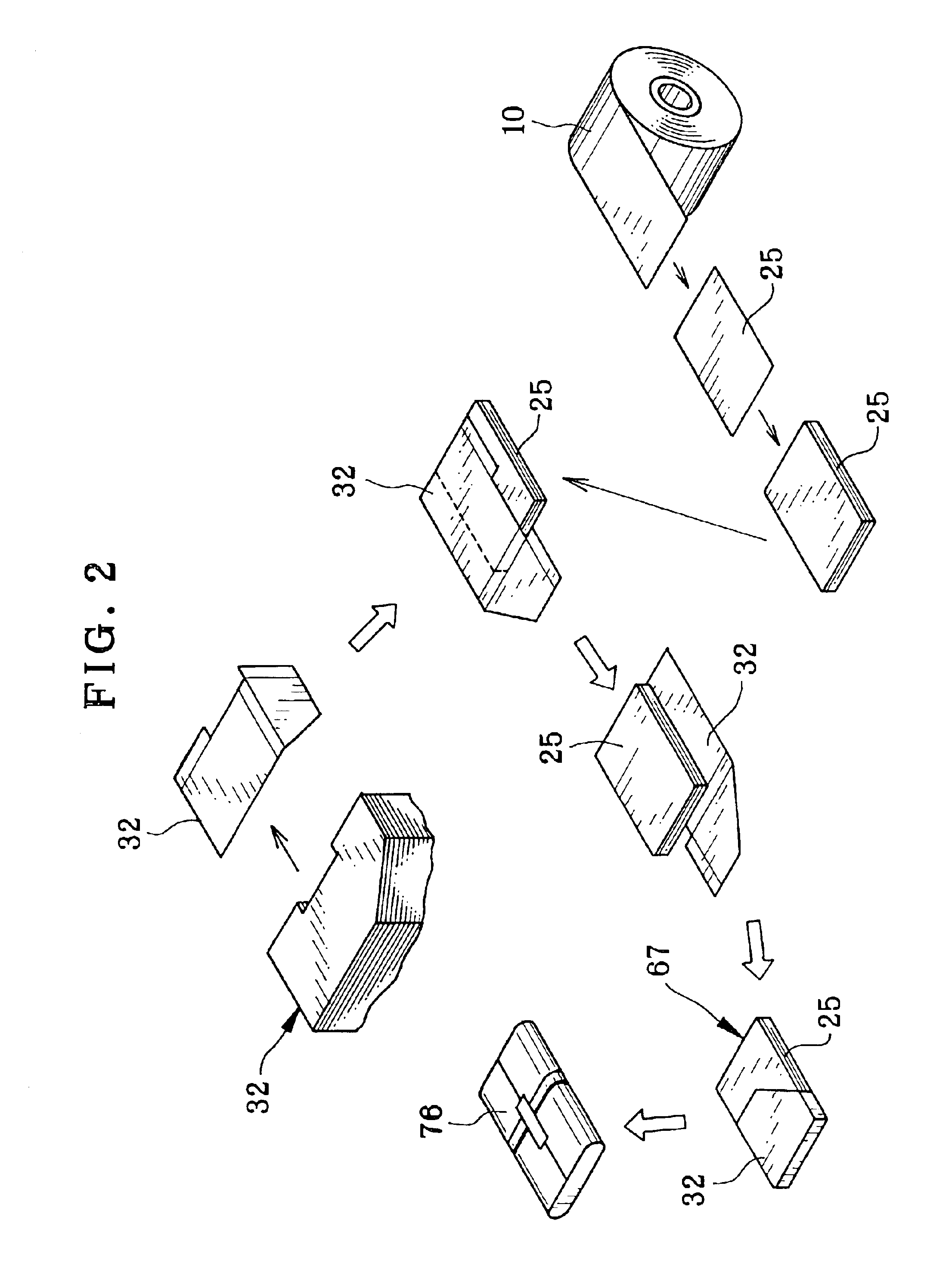

Sheet package producing system, sheet handling device, and fillet folding device

InactiveUS6907711B2Efficient productionImprove efficiencyPaper article packagingCapsSynchronous controlThin membrane

A sheet package producing system includes at least a cutter module and a packaging module. The cutter module has a cutter blade, for producing X-ray films by cutting a continuous sheet material. The packaging module has packaging robots, for producing a sheet package by packaging the X-ray films stacked on one another. In the sheet package producing system, a first module control unit is incorporated in the cutter module, for controlling the cutter blade. A second module control unit is incorporated in the packaging module, for controlling the packaging robots. A CPU is connected with the first and second module control units removably by a component network, for controlling the cutter module and the packaging module in synchronism.

Owner:FUJIFILM HLDG CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com