U-shaped automatic piece wrapping machine for pole pieces of storage batteries

An automatic wrapping machine and storage battery technology, which is applied in the field of wrapping machines, can solve the problems of not getting rid of manual operation, etc., and achieve the effects of reducing hazards and improving wrapping efficiency and quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

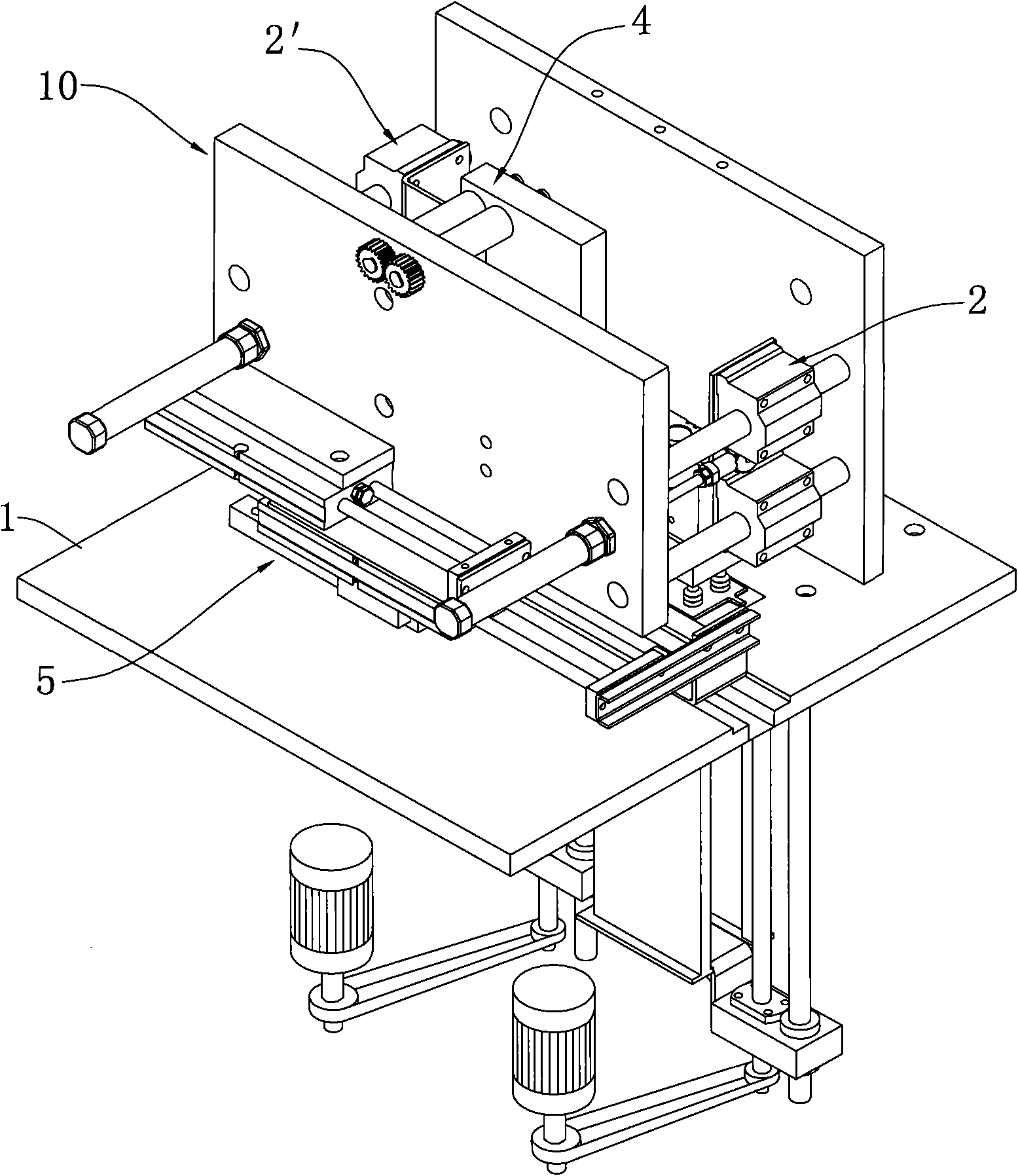

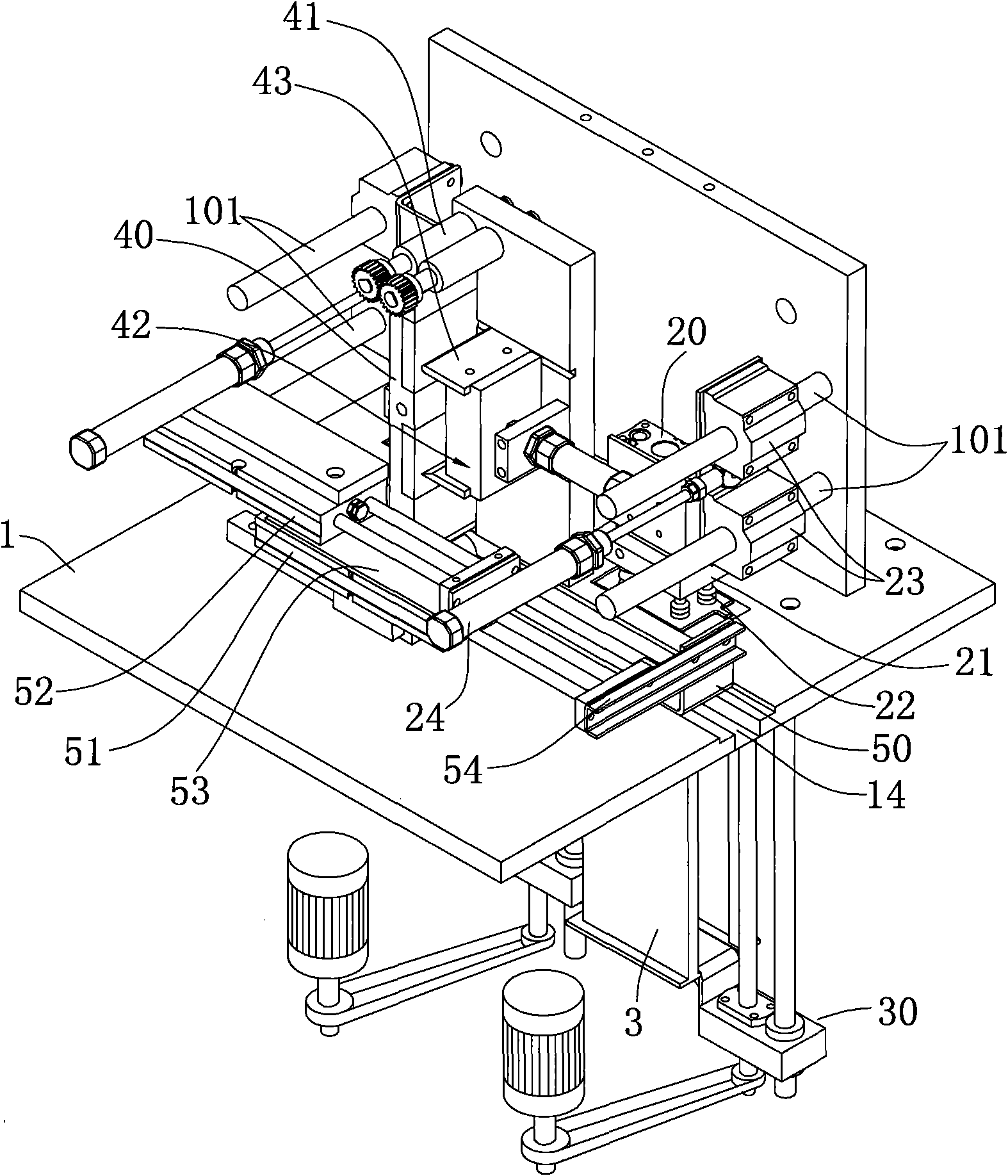

[0028] Embodiment 1: as Figure 5 , Image 6 As shown, the first film supply mechanism and the second film supply mechanism are arranged under the workbench 1, and the workbench 1 is provided with a bracket assembly 10, which communicates with the first film taking port 11 at the discharge end of the first film supply mechanism, and communicates with the second film feeder. The second sheet-feeding port 12 at the discharge end of the sheet-feeding mechanism, the first sheet-feeding mechanism 2 that transfers the first pole piece 7 from the first sheet-taking port 11 to the wrapping mechanism, and the second pole piece 7 are provided in the bracket assembly 10. The sheet 8 is transferred from the second sheet taking port 12 to the second sheet feeding mechanism 2' of the assembly mechanism; both the first sheet feeding mechanism and the second sheet feeding mechanism adopt a box-type feeding structure, and the box-type feeding structure includes a pole piece box 3, One end of ...

Embodiment 2

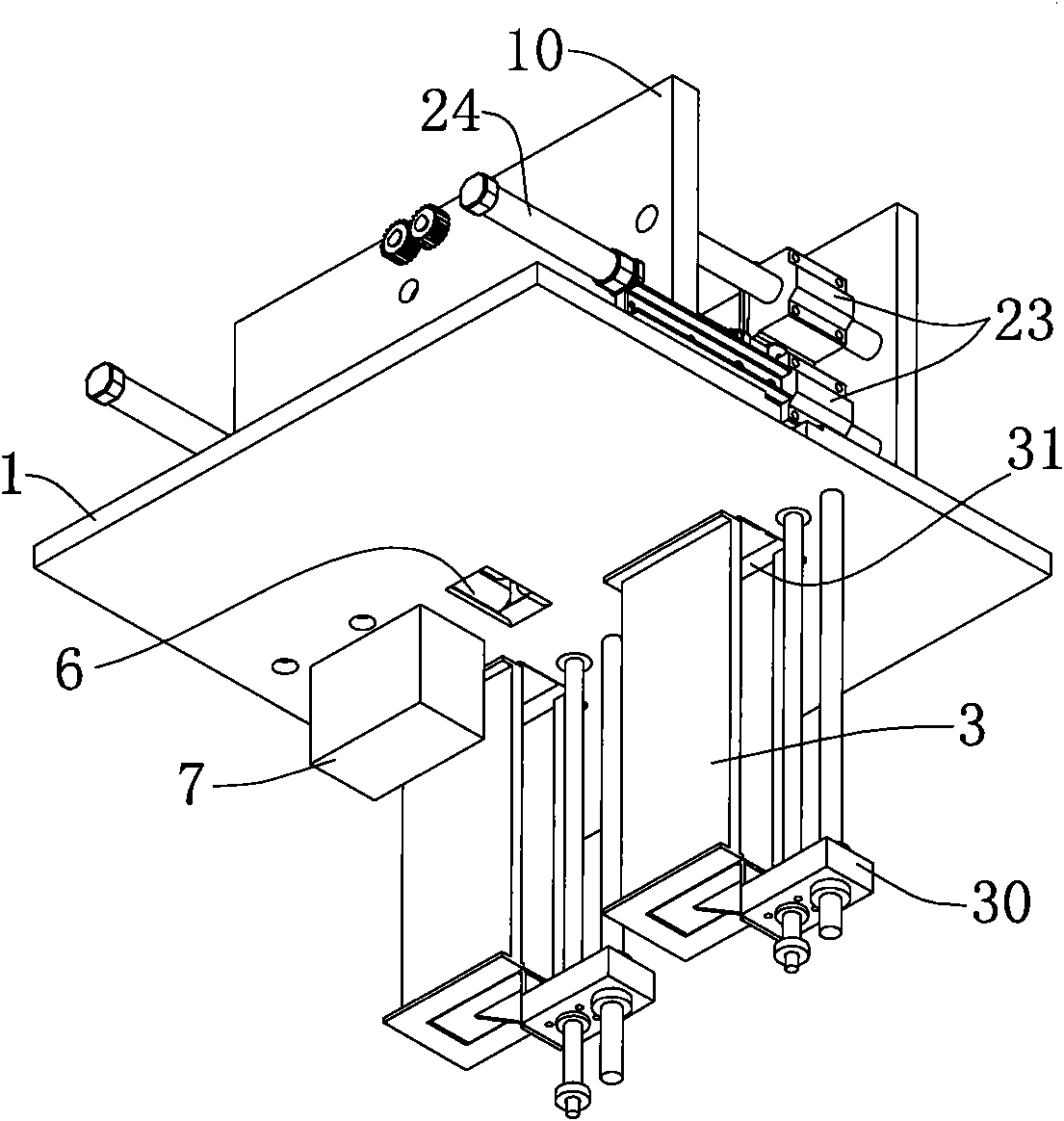

[0030] Embodiment 2: as Figure 7 As shown, the first sheet feeding mechanism and the second sheet feeding mechanism adopt a roller-type feeding structure and are arranged on the side of the worktable 1; the roller-type feeding structure includes a feeding table 3' and a set Conveyor belt 30' on the feeding table 3'; one end of the conveyor belt of the first film supply mechanism extends to the workbench 1 so that the first pole piece 7 is directly sent to the wrapping mechanism, and one end of the conveyor belt of the second film supply mechanism extends to the workbench 1, the second pole piece 8 is directly sent into the assembly mechanism.

[0031] The first sheet feeding mechanism and the second sheet feeding mechanism in this embodiment have adopted a roller belt feeding structure, which is simpler than Embodiment 1, but takes up a lot of space; the pole piece can be formed by the first sheet feeding mechanism and the second sheet feeding mechanism. The feeding mechanis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com