Patents

Literature

97results about How to "Reduce human contact" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

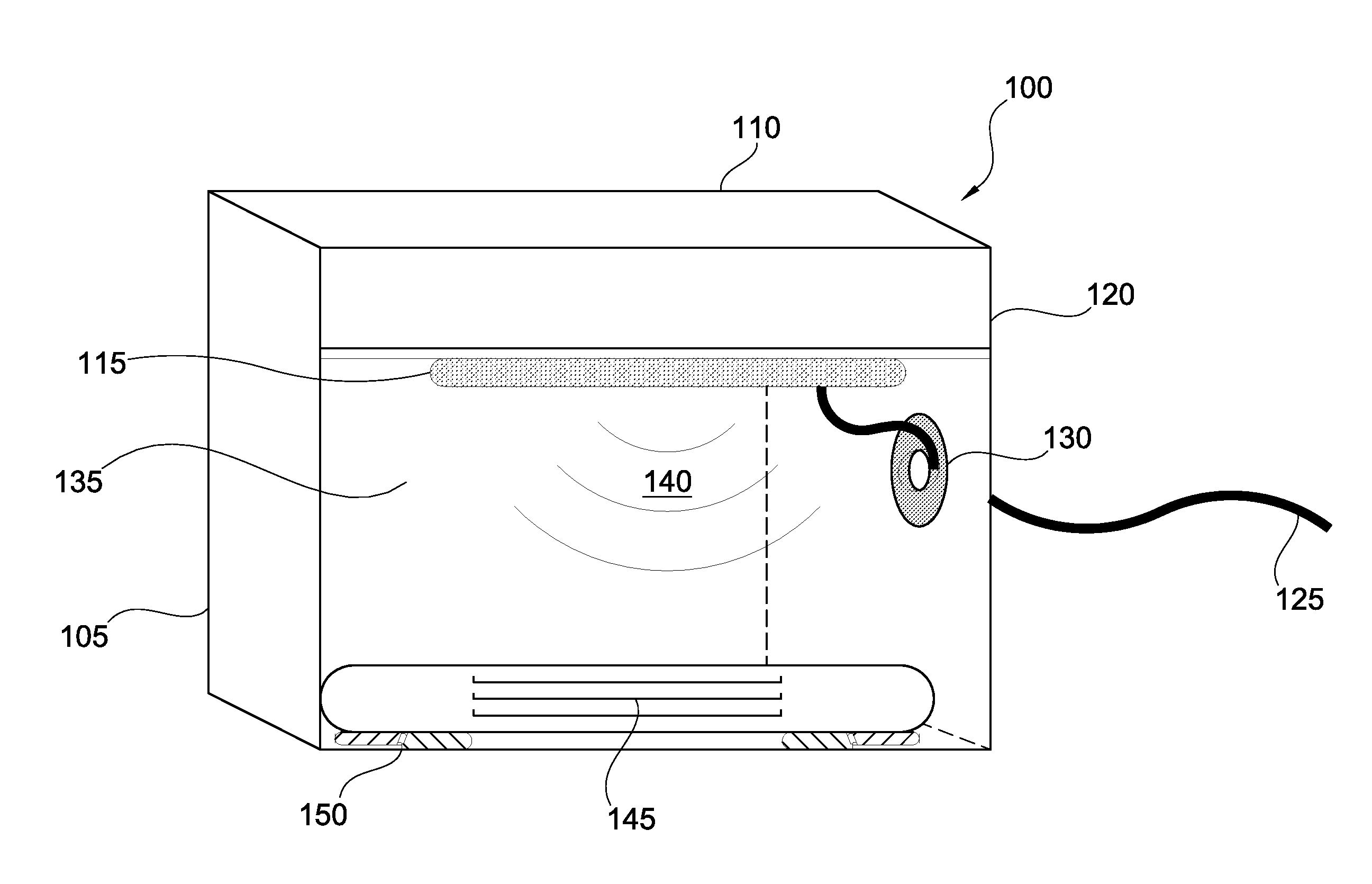

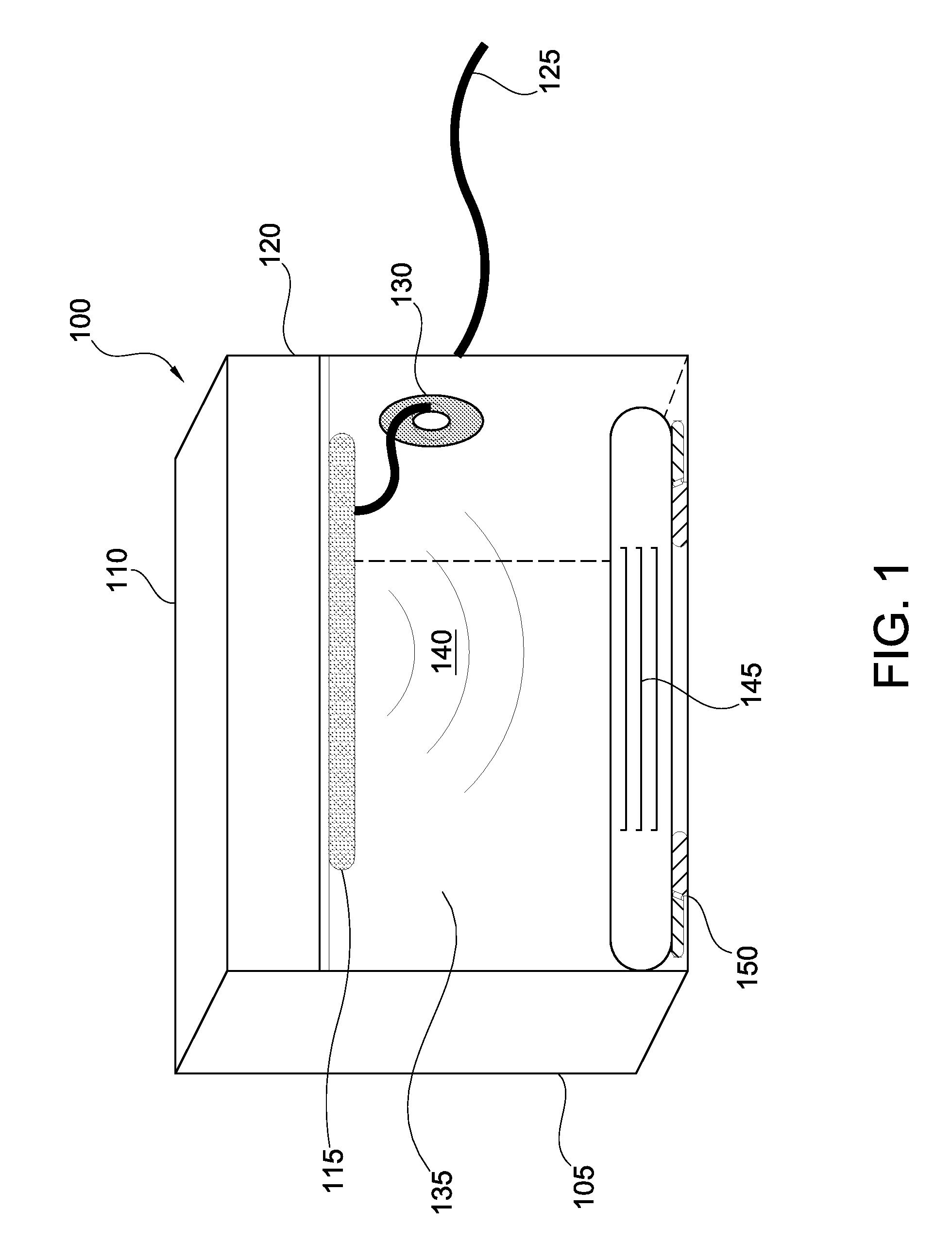

Smart instrument tray RFID reader

ActiveUS7362228B2Accurate and rapid trackingReduce processing costsSurgical furnitureDispensing apparatusEngineeringWorkstation

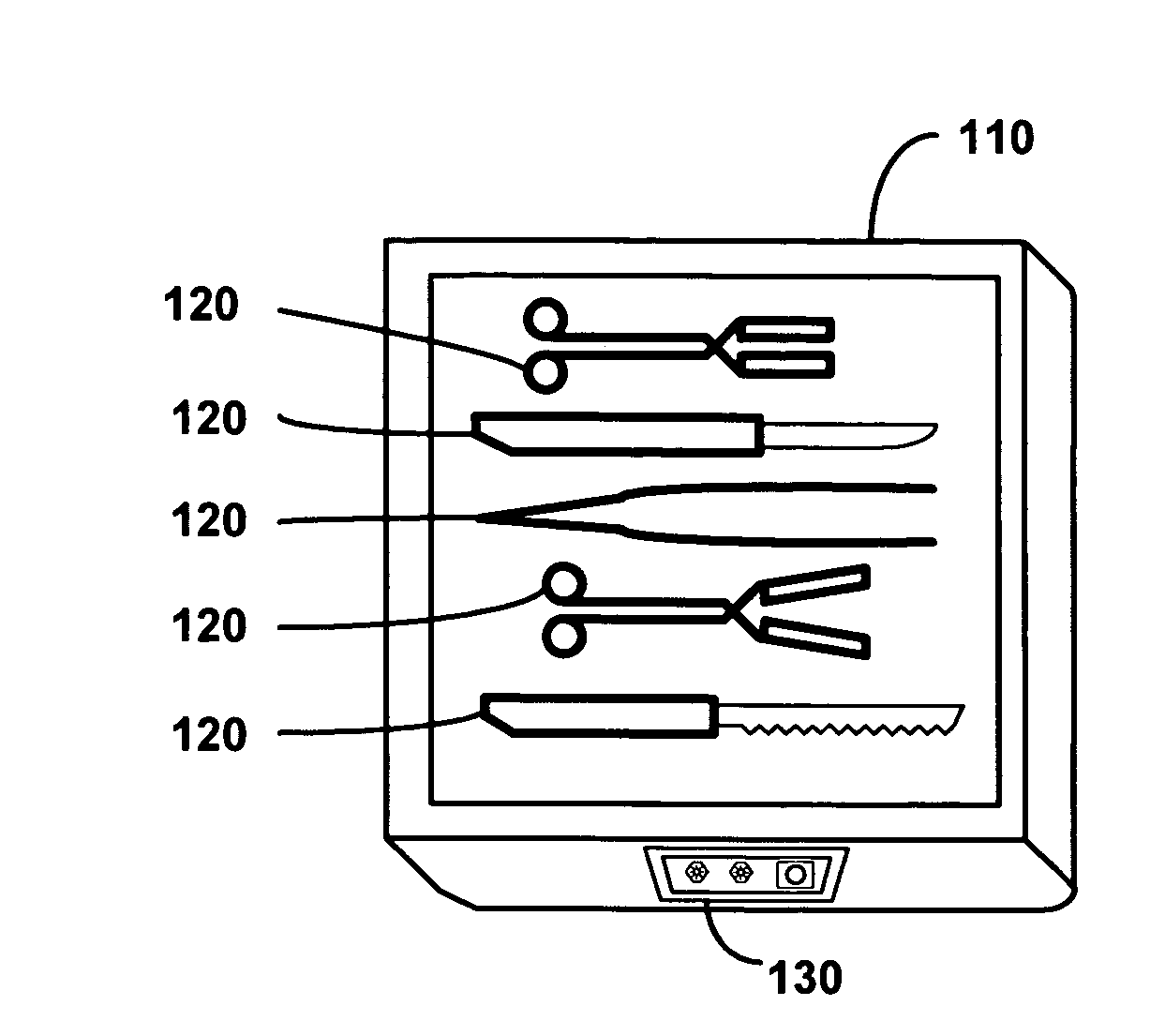

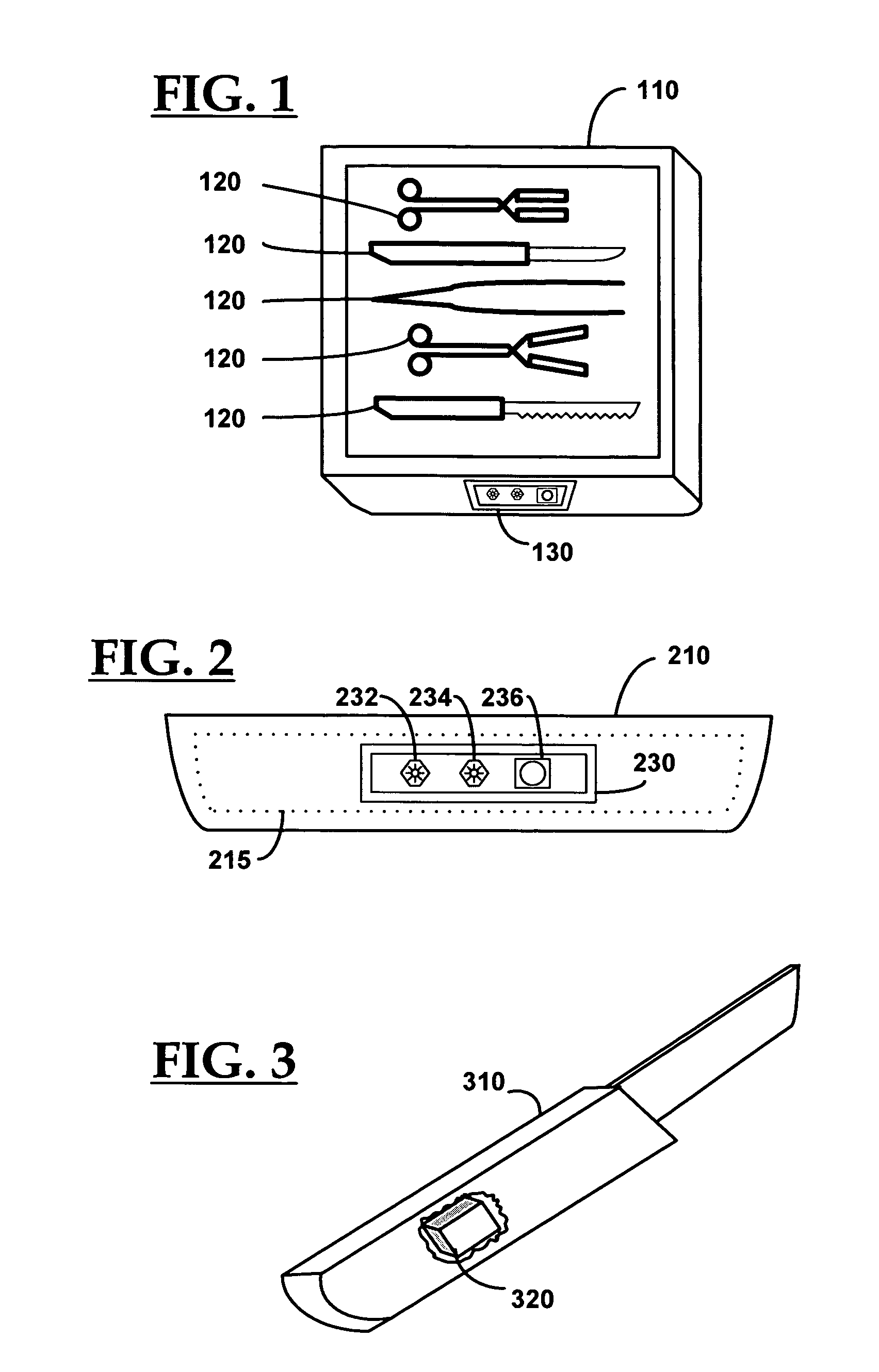

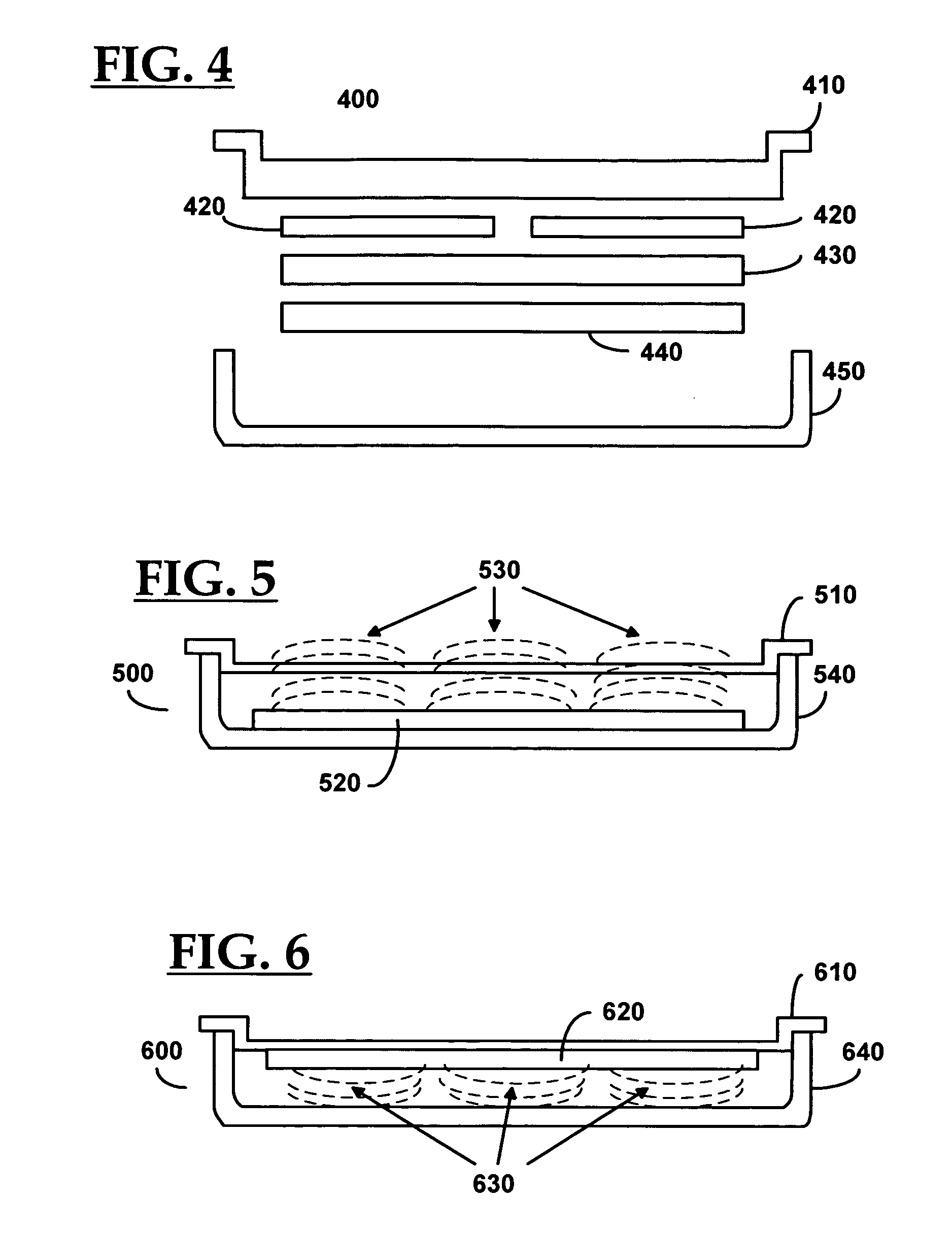

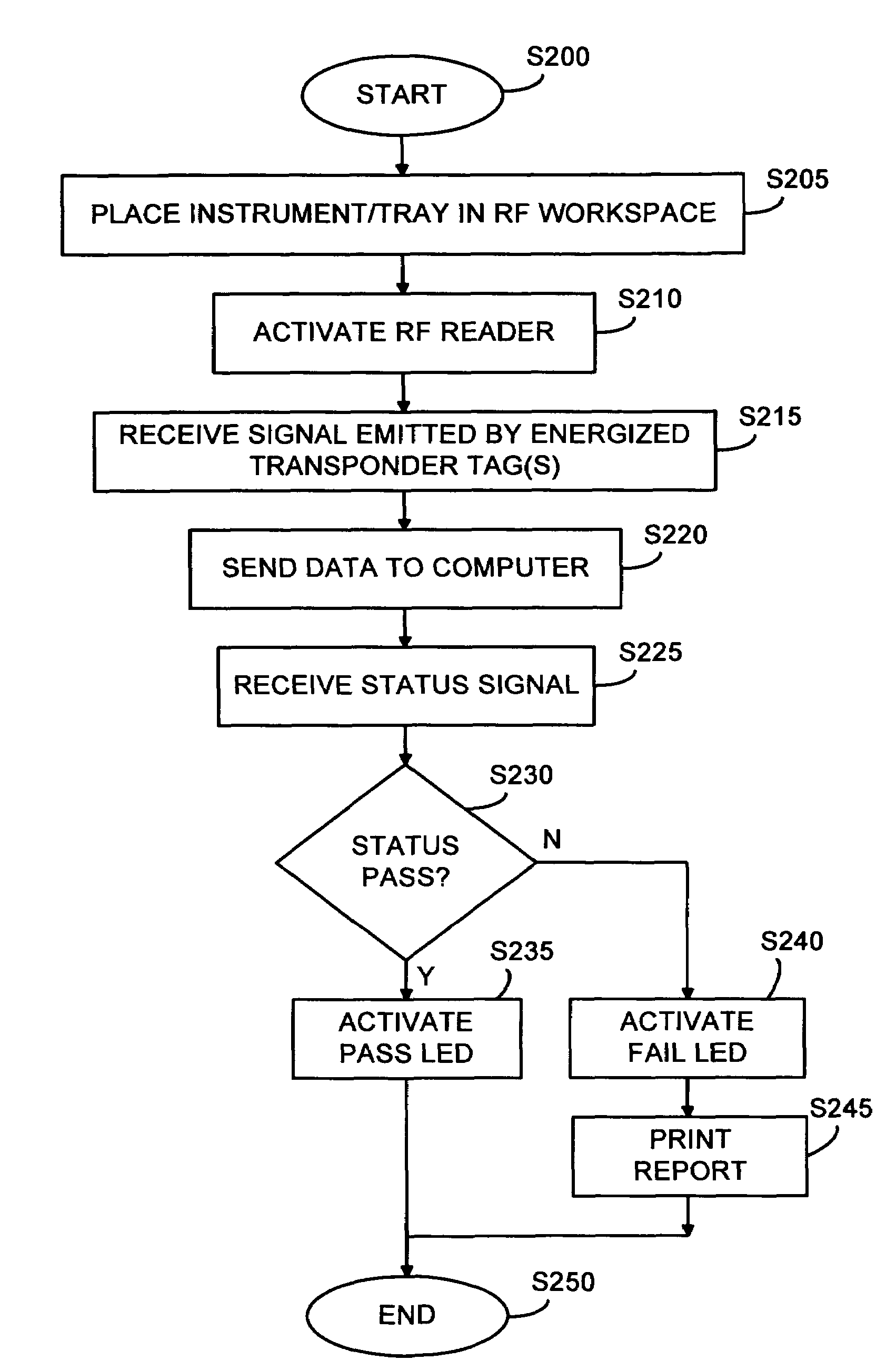

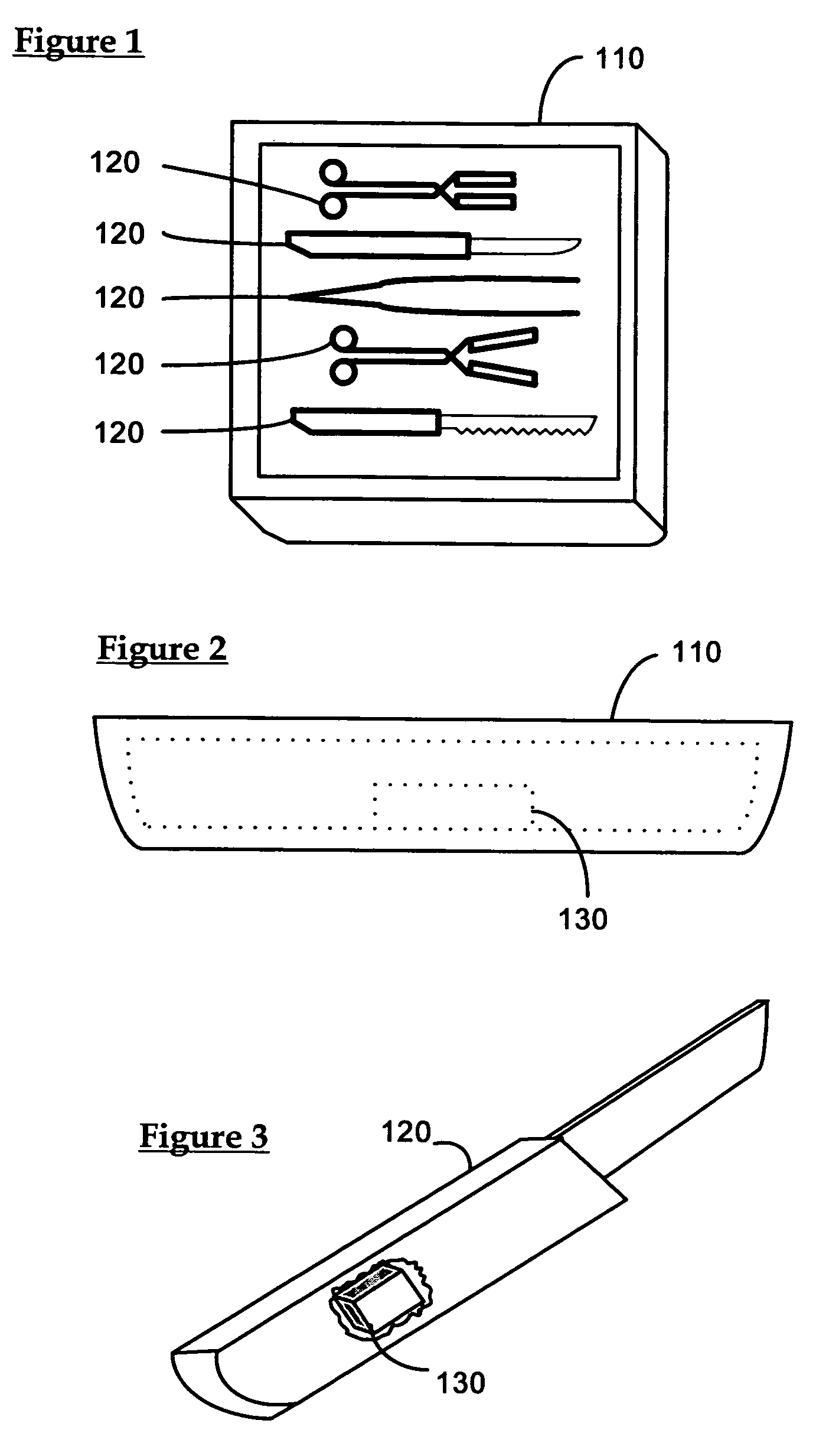

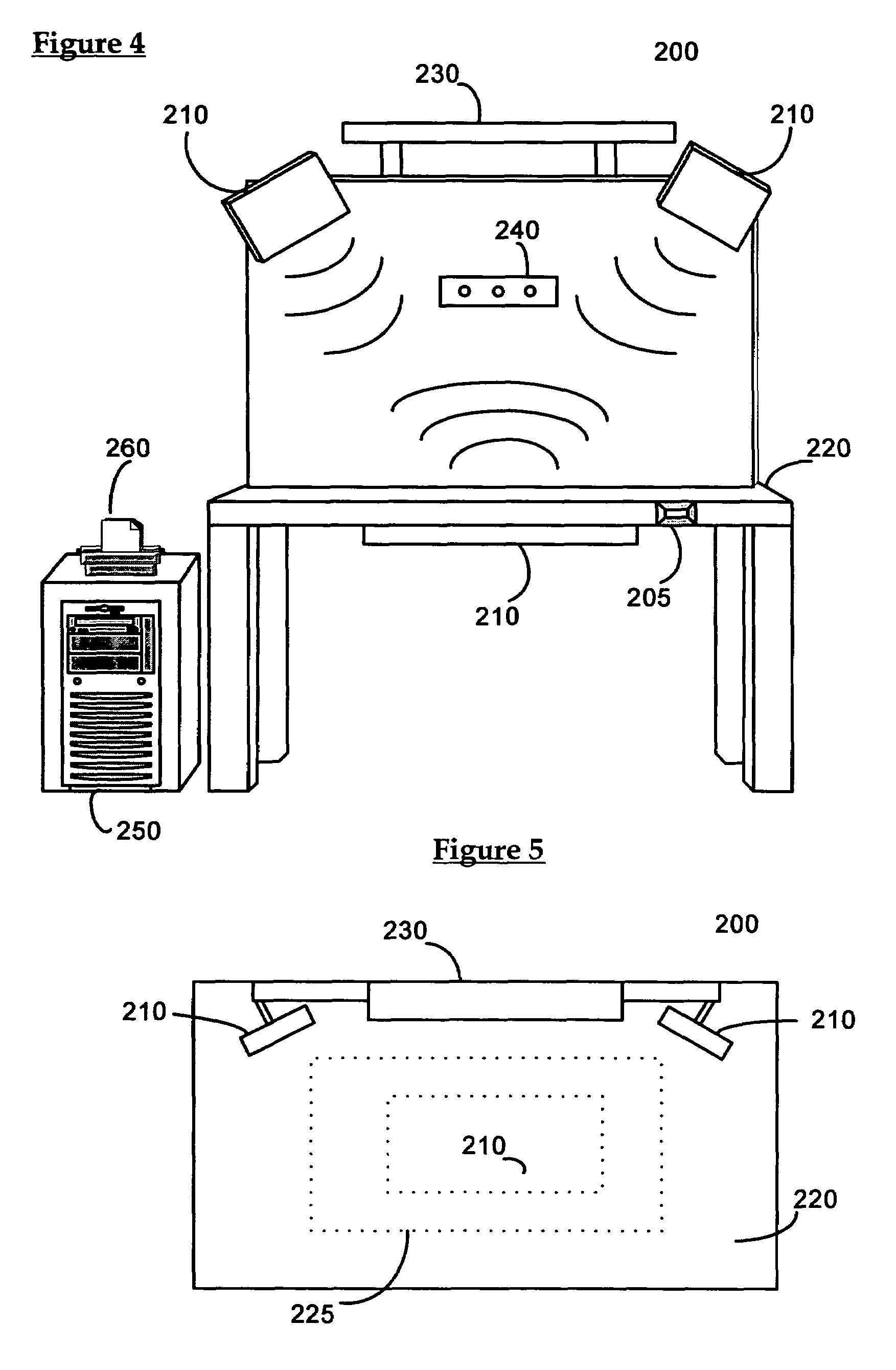

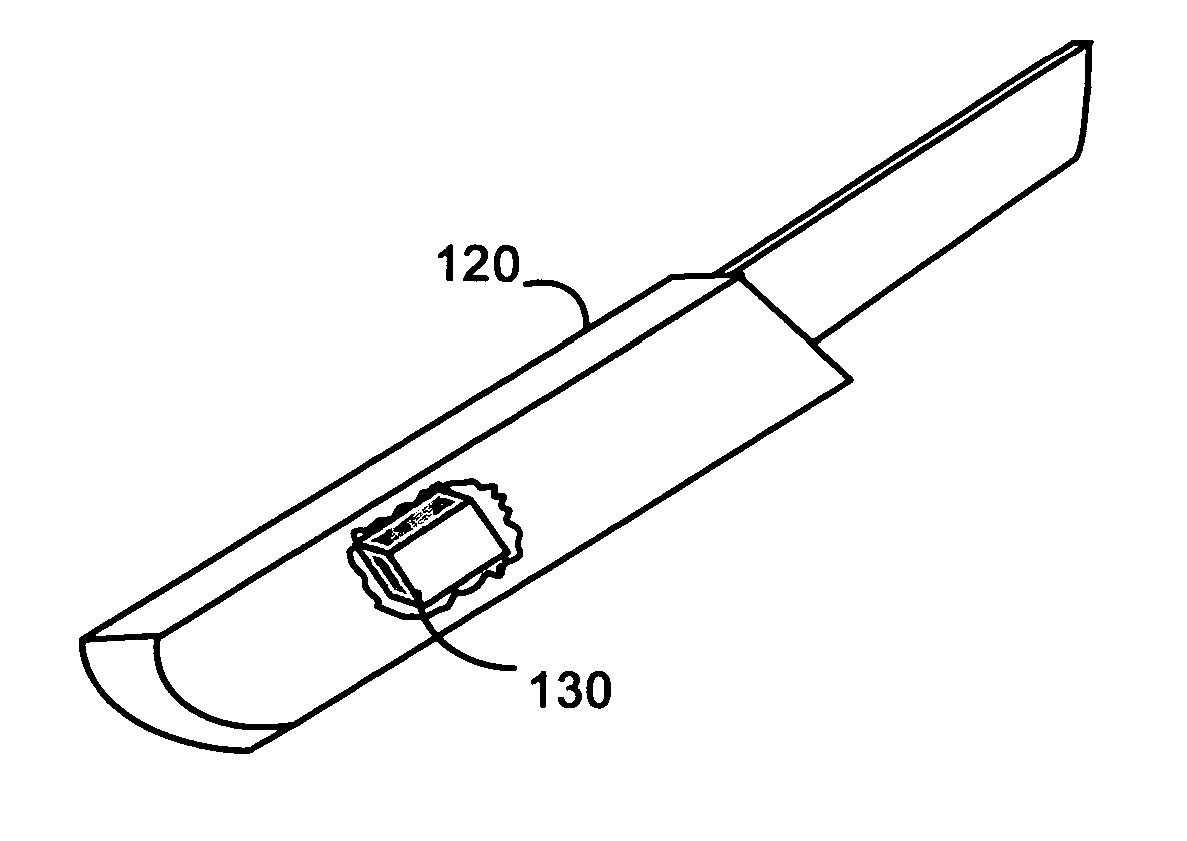

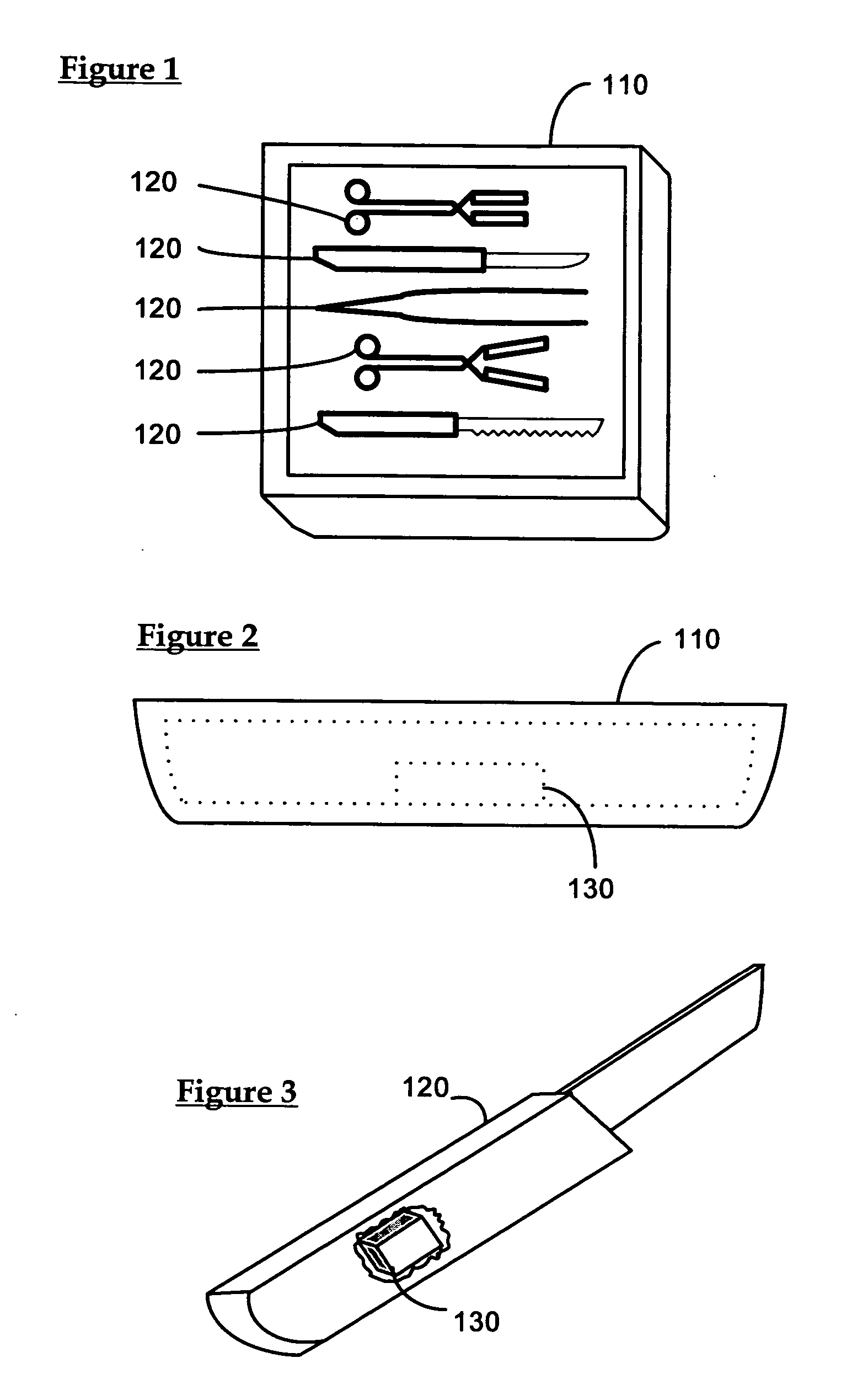

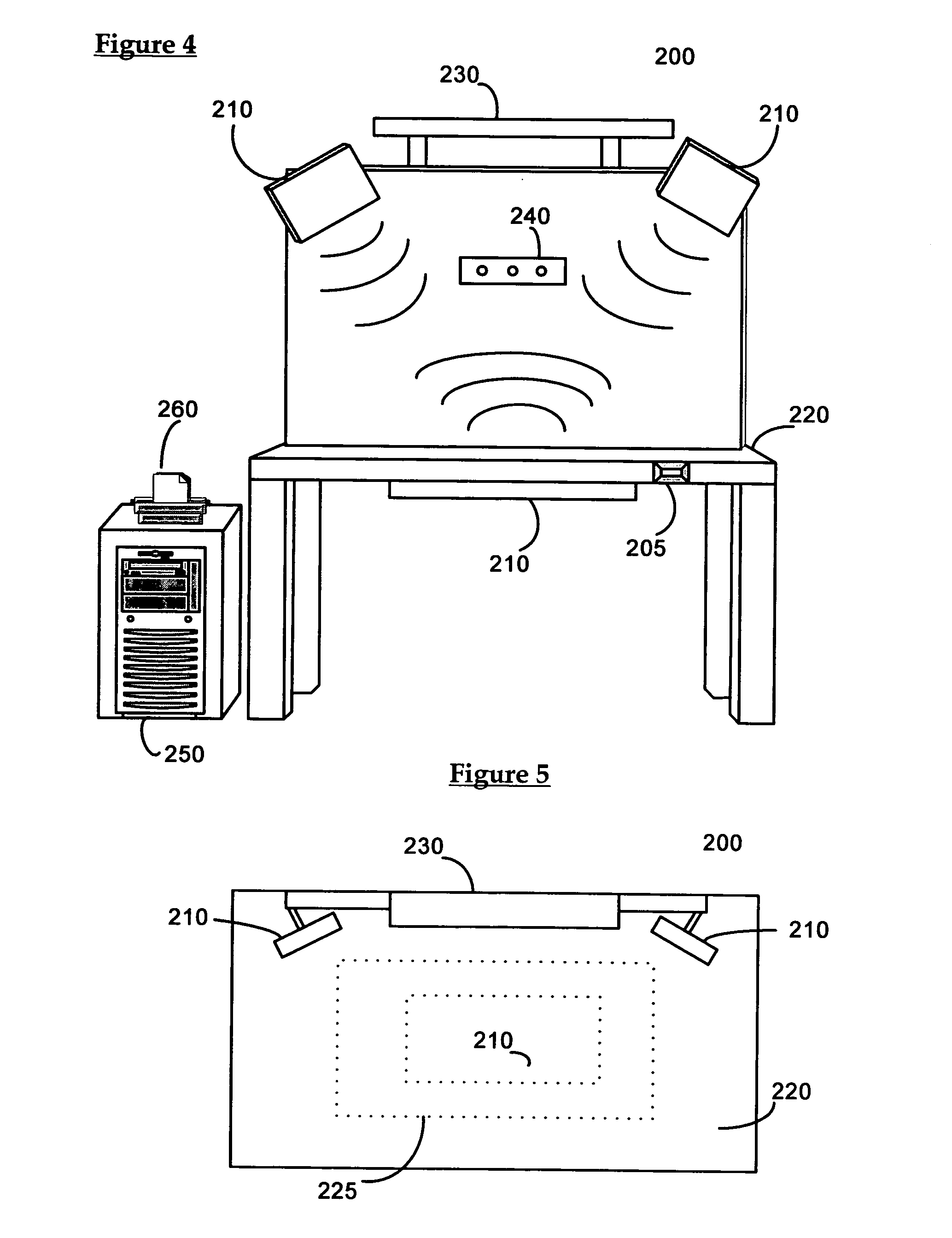

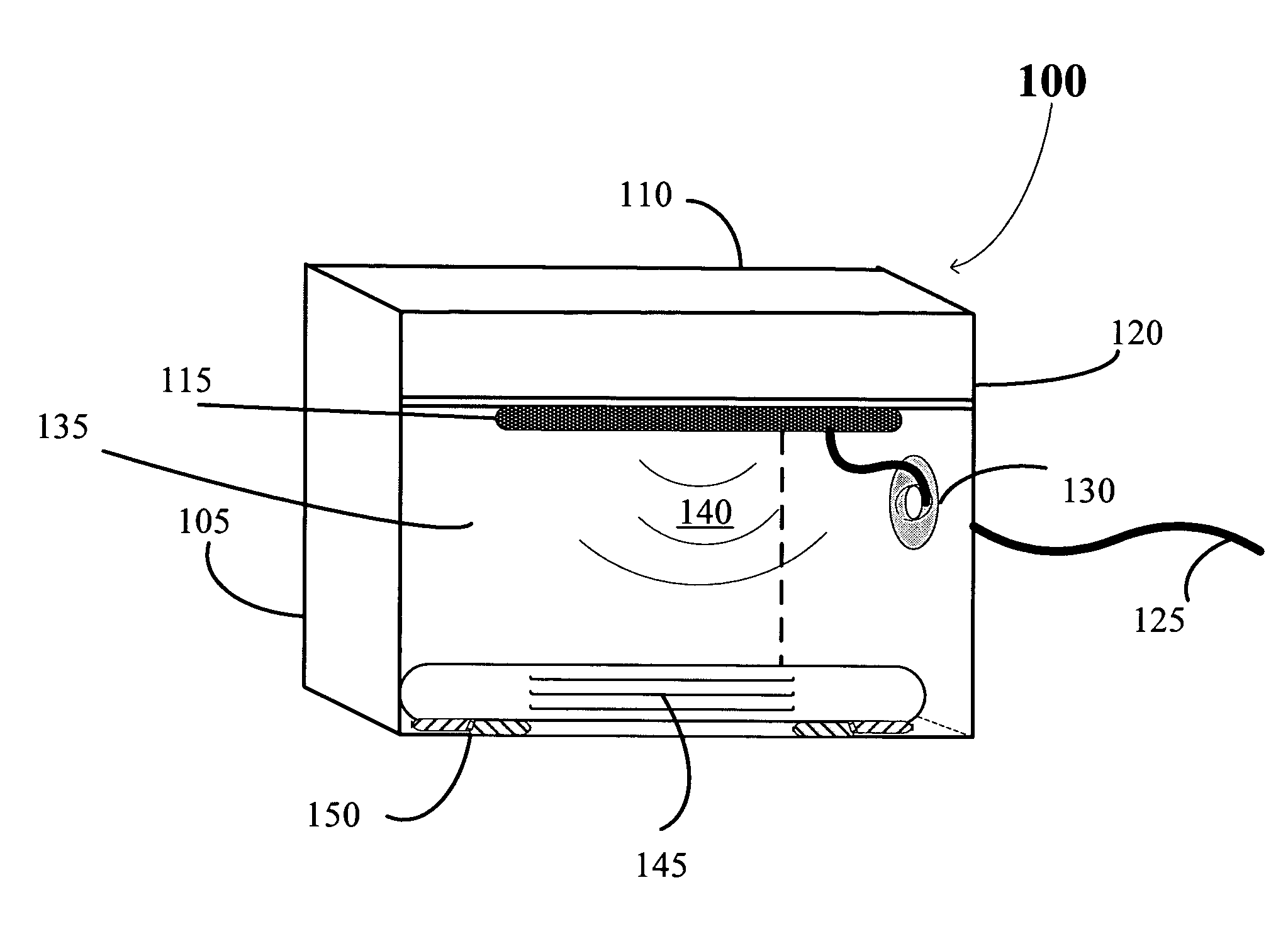

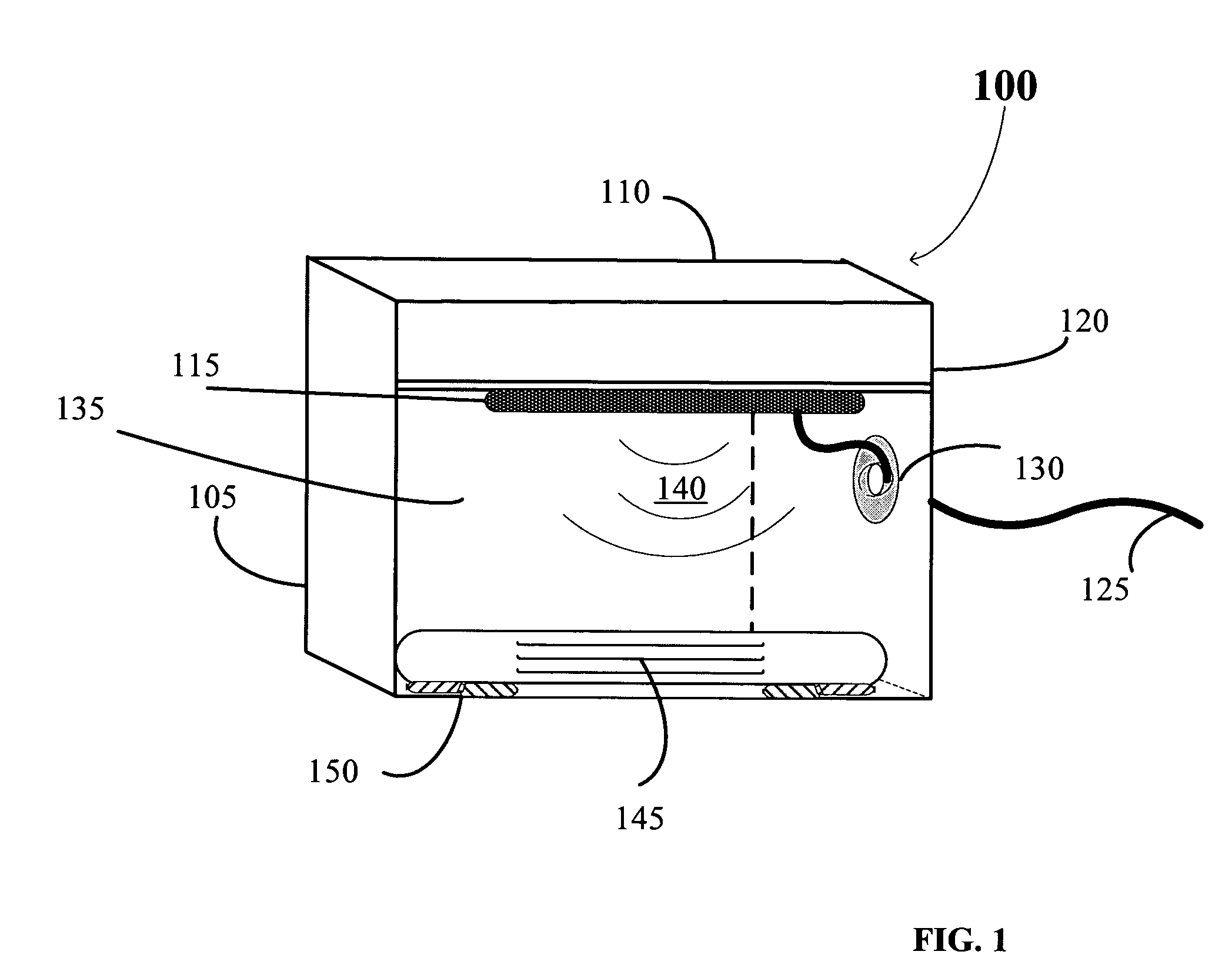

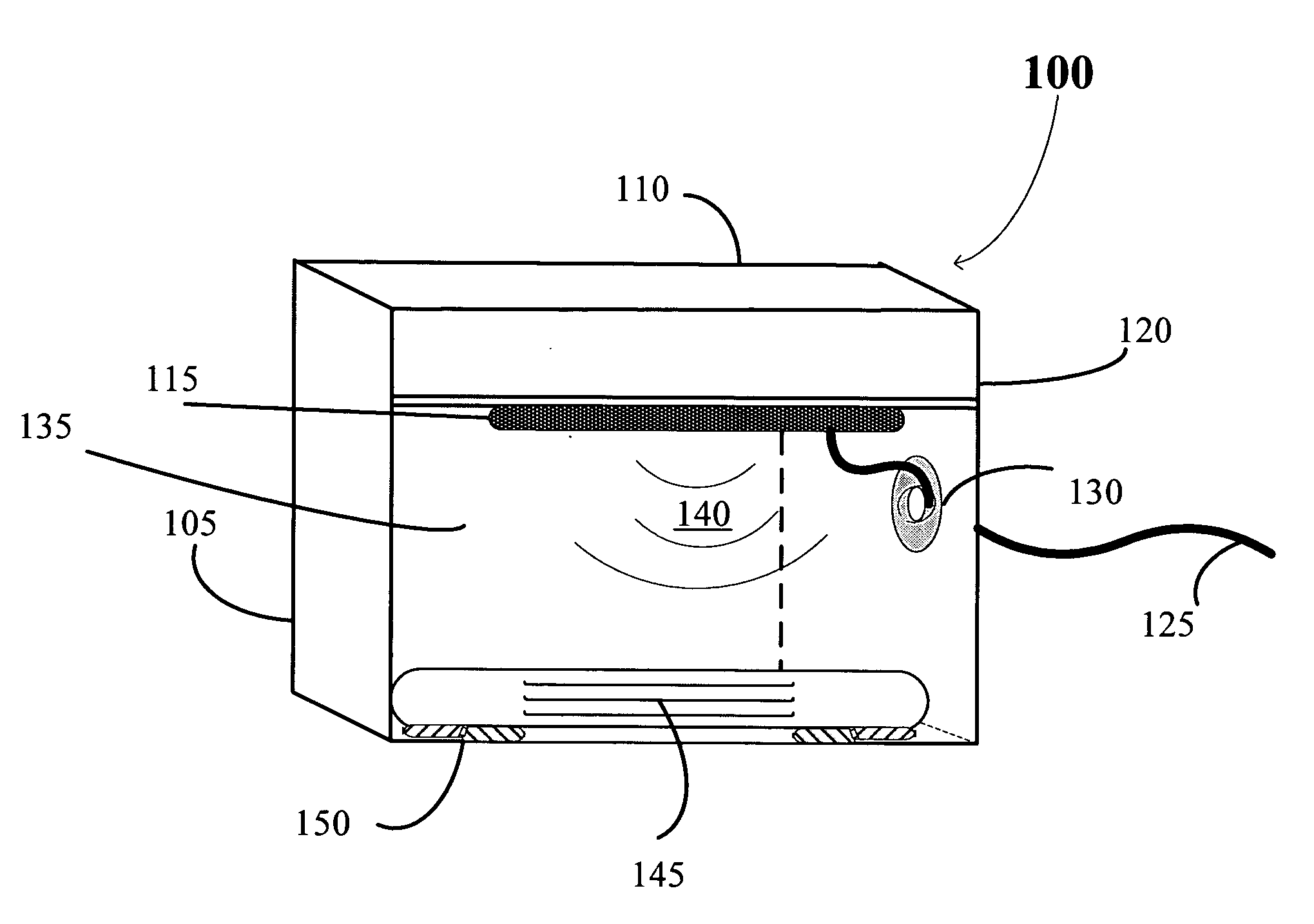

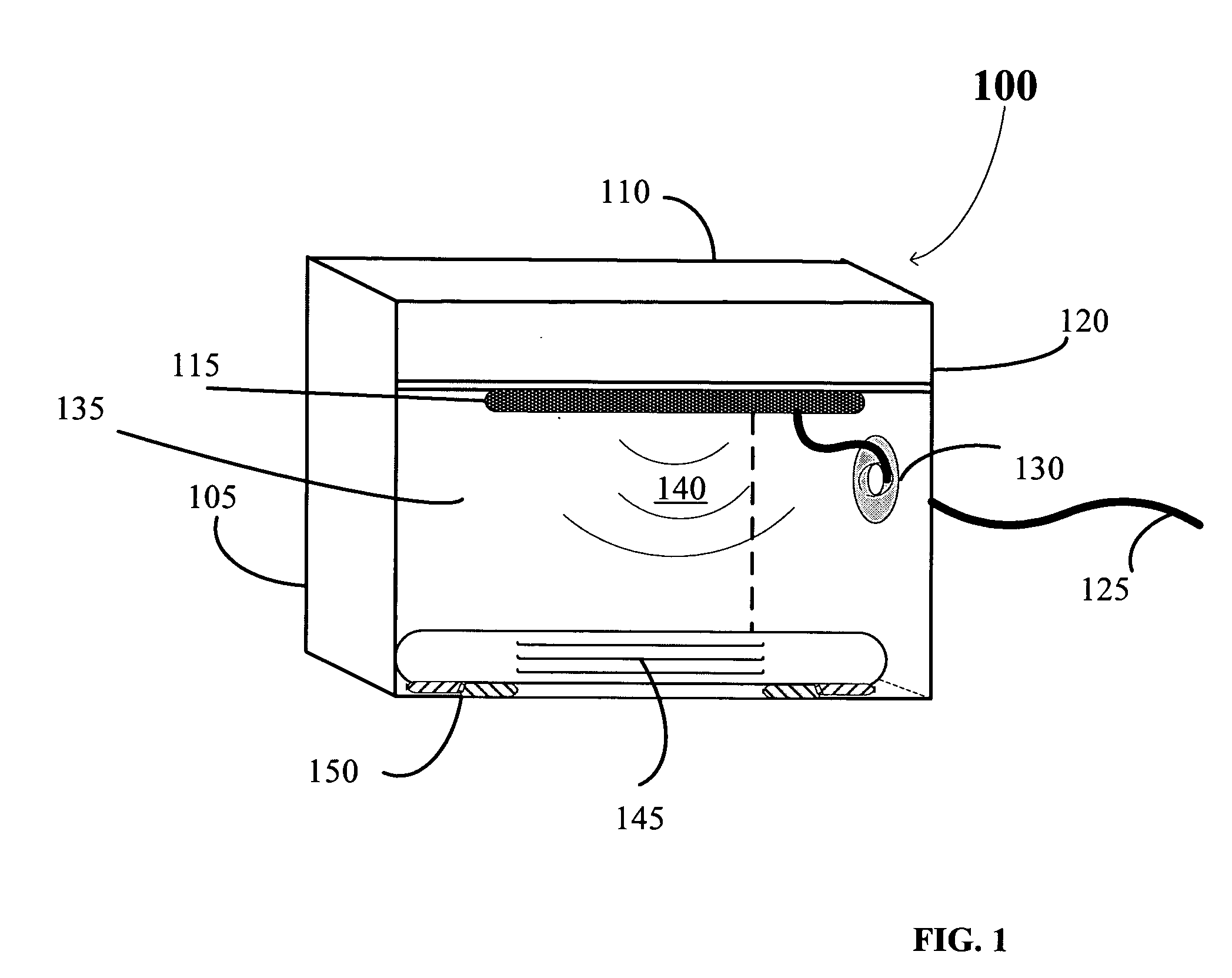

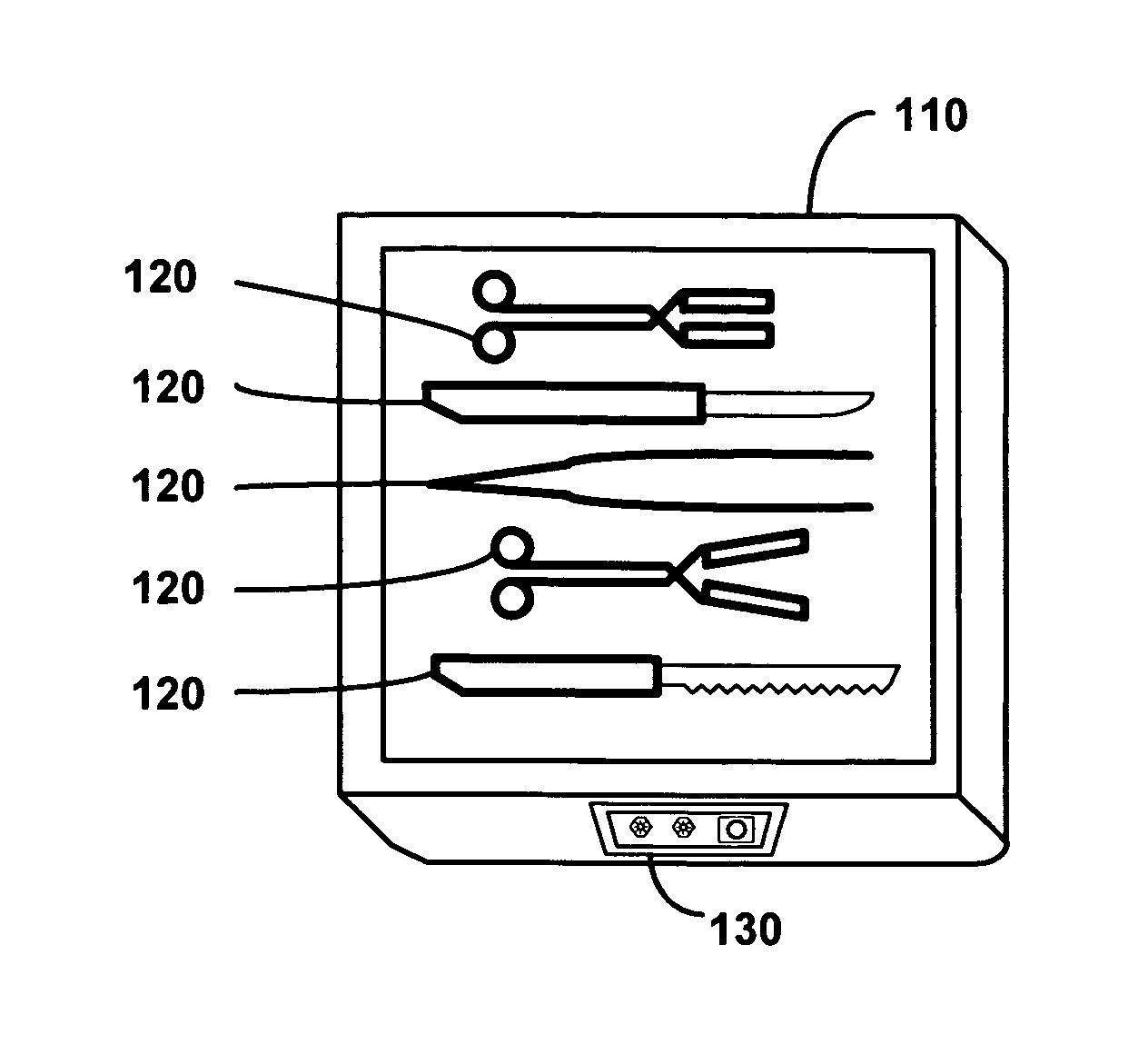

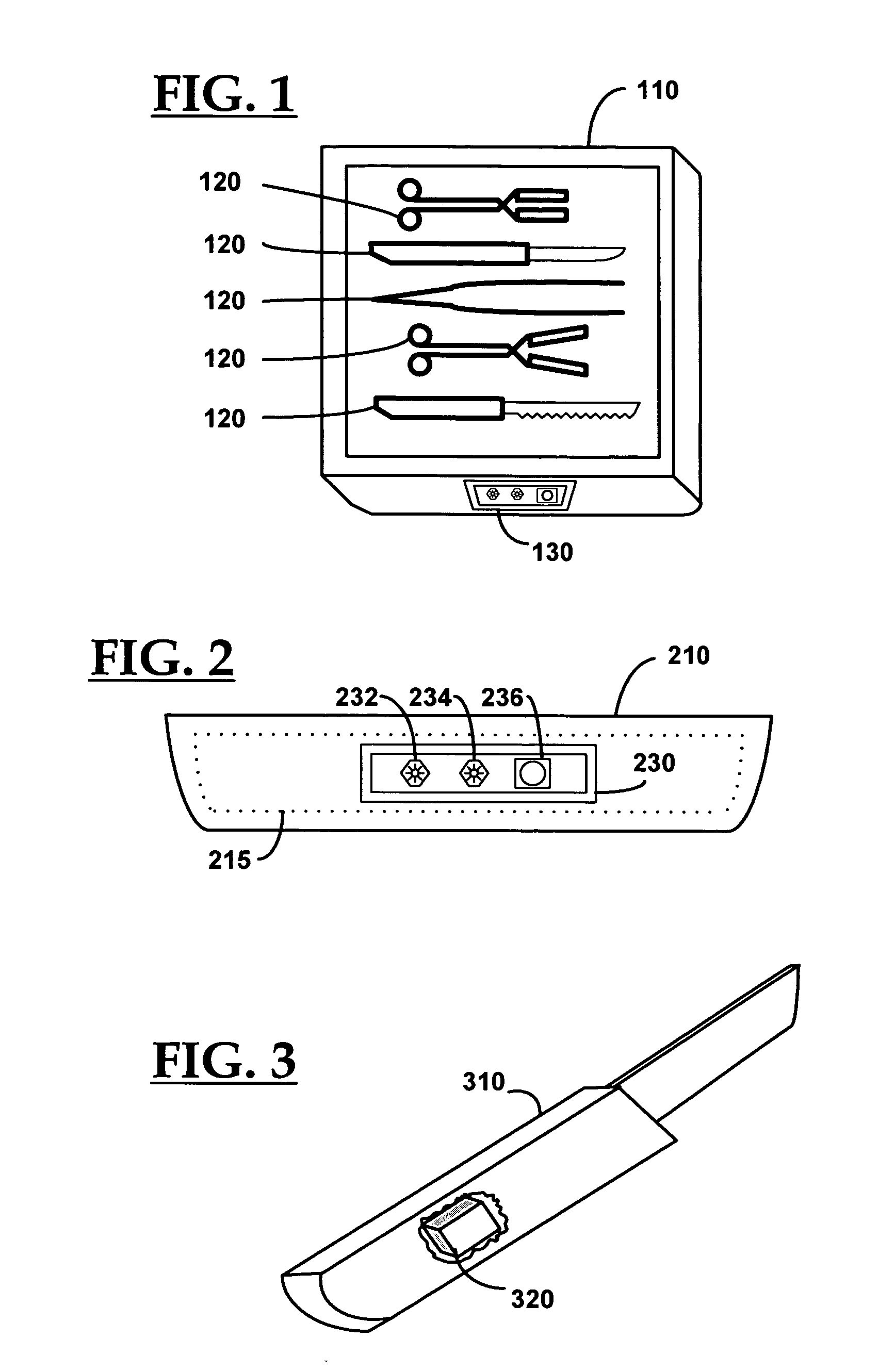

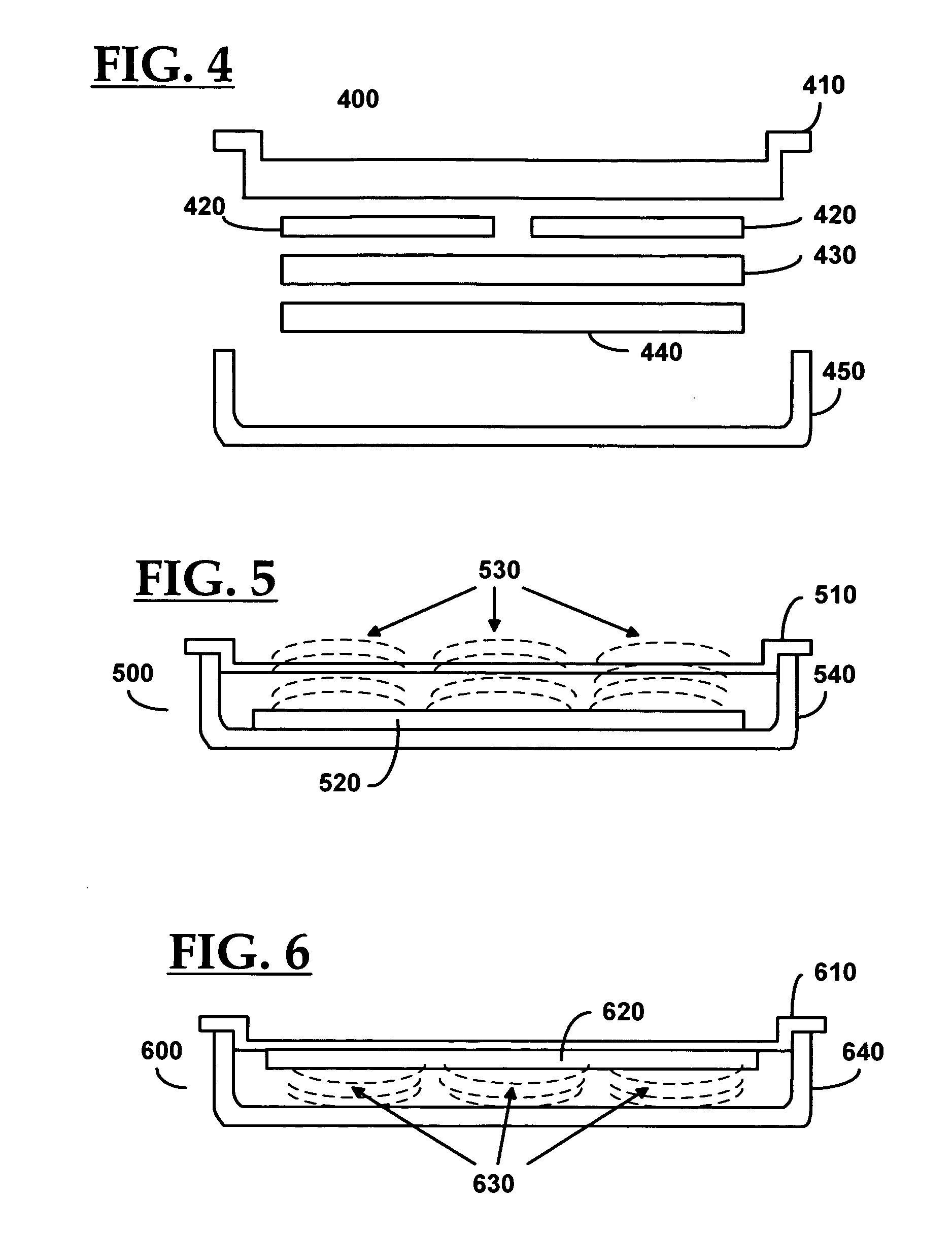

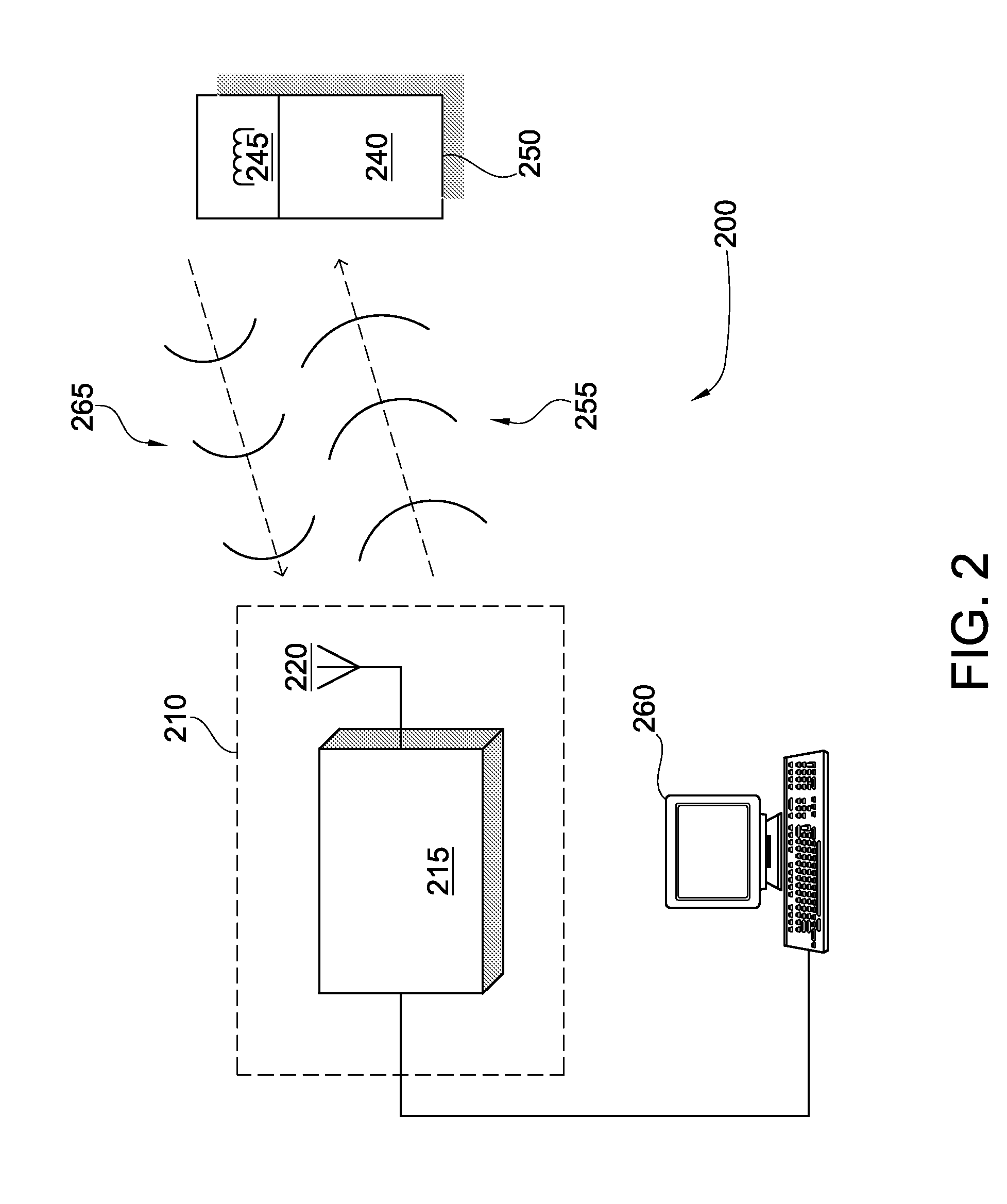

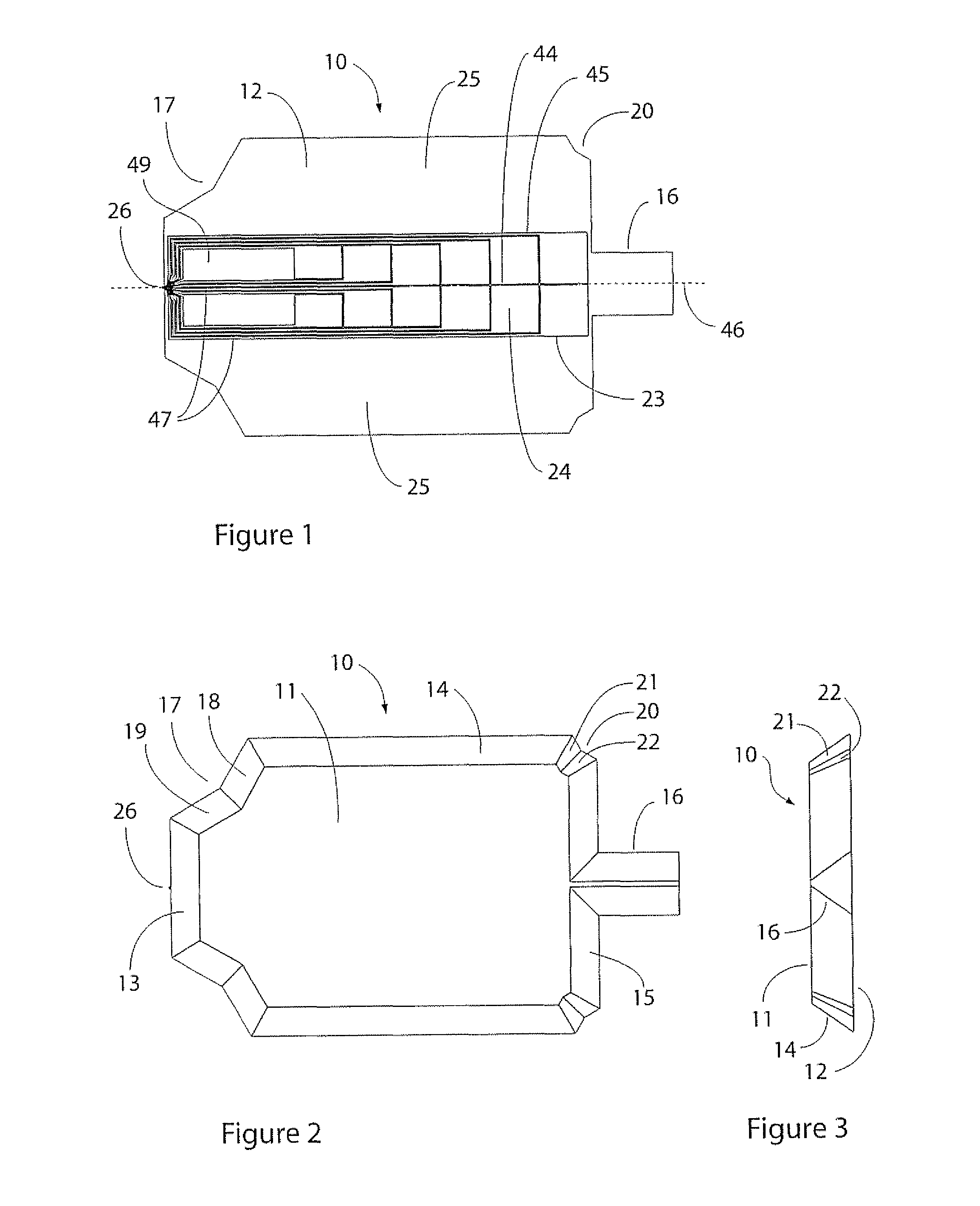

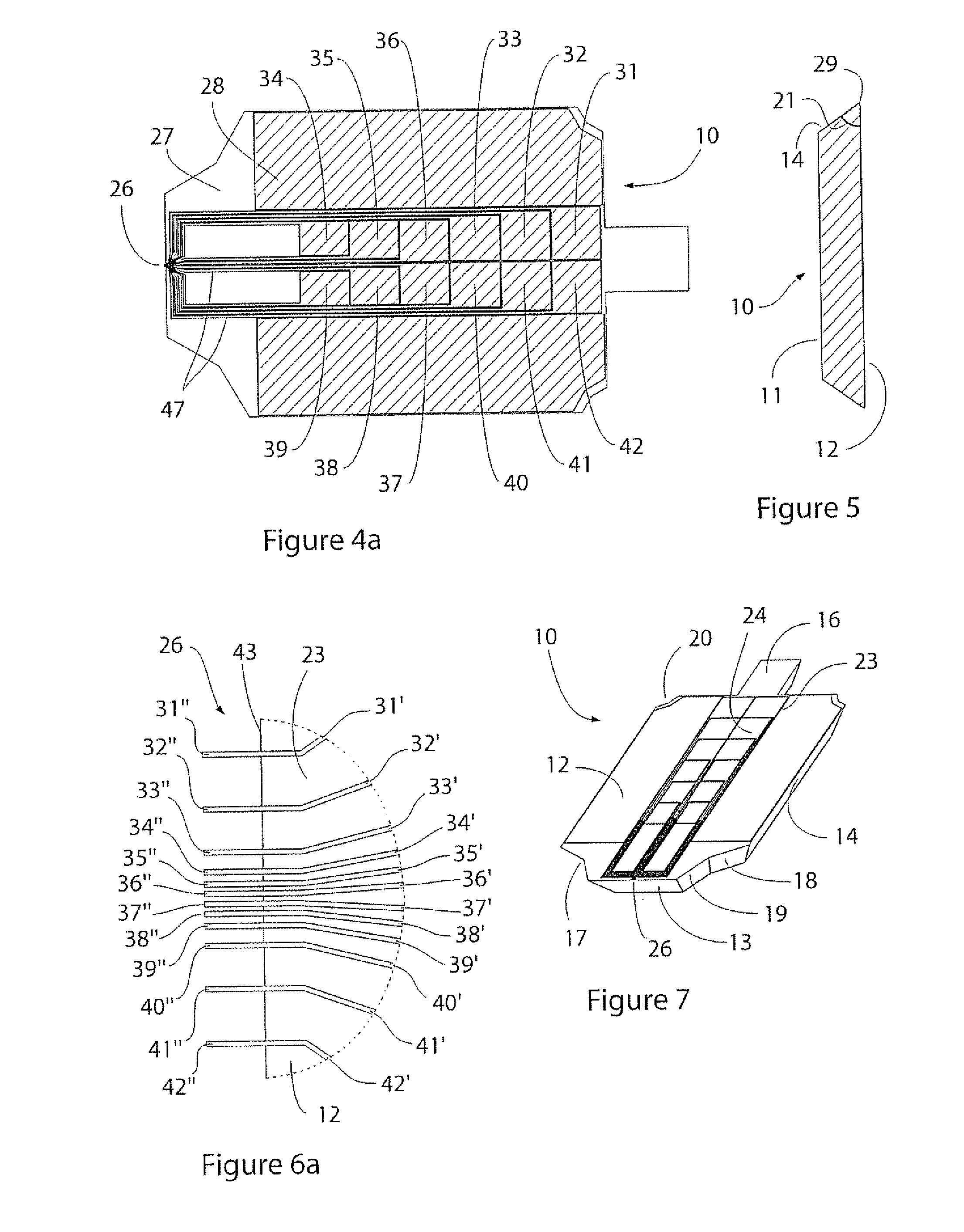

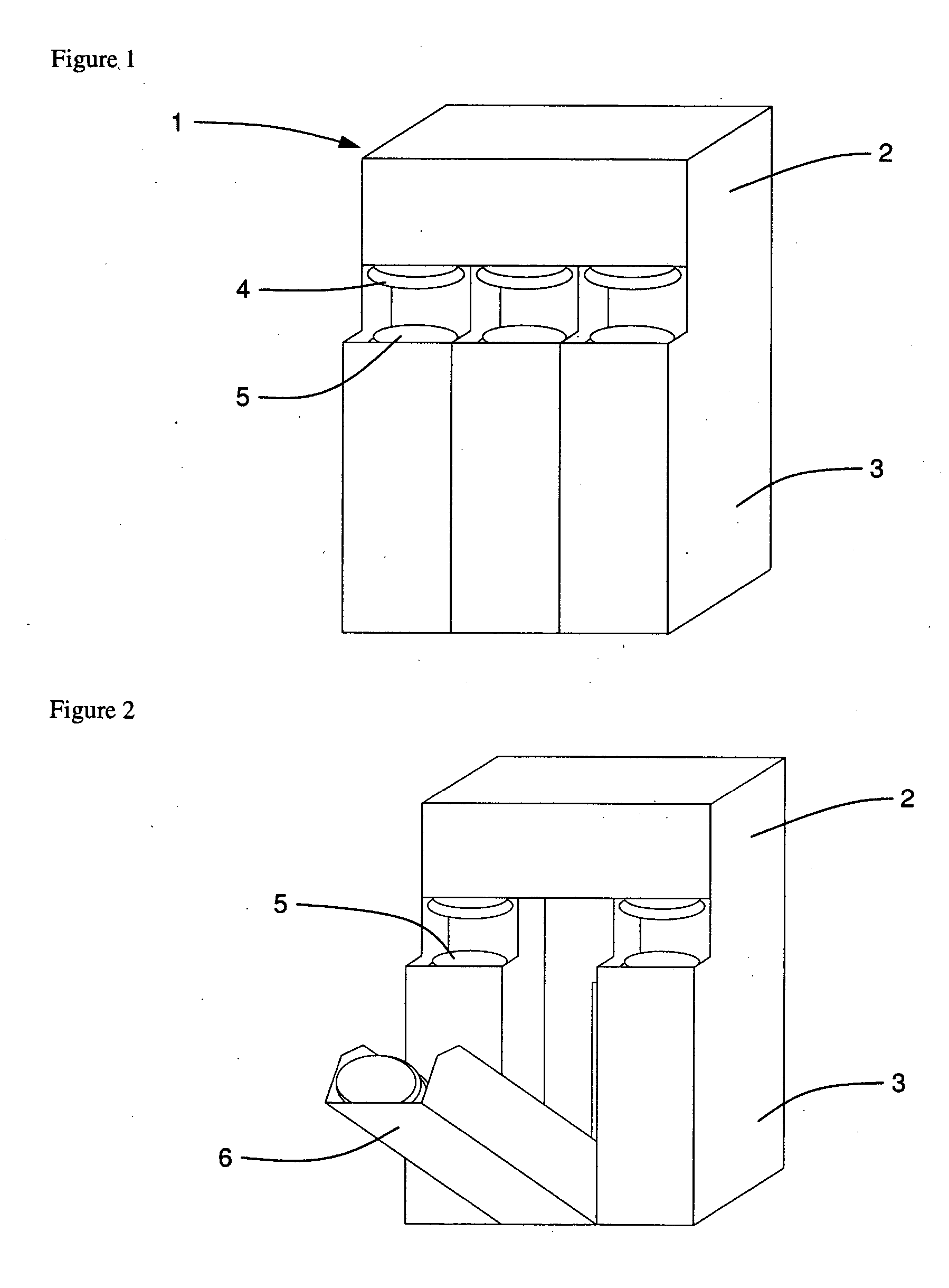

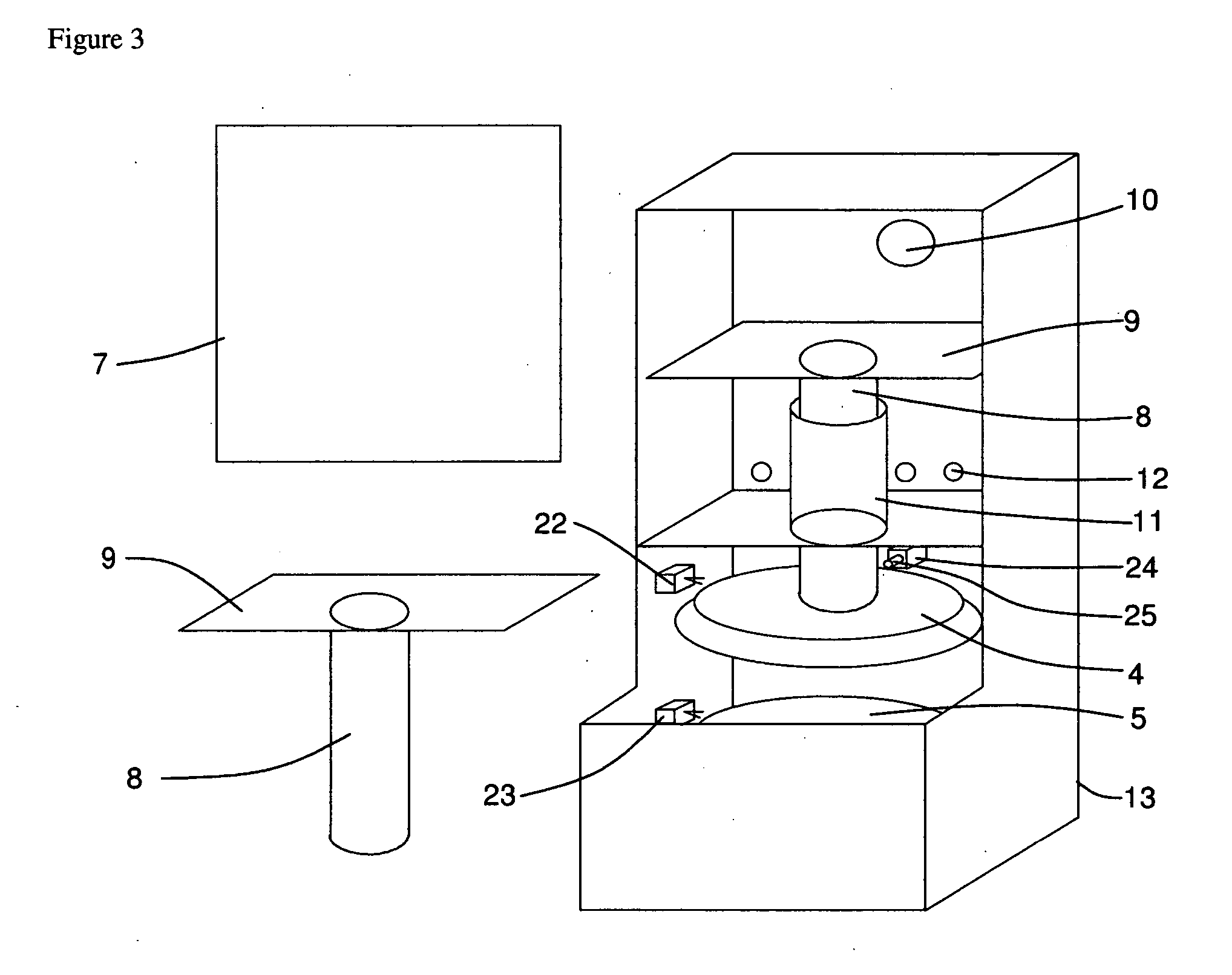

A radio frequency identification (RFID) workstation reader for RFID-enabled surgical instruments and surgical instrument trays and a method of using a RFID workstation reader to read RFID-enabled surgical instruments and surgical instrument trays is disclosed. The method, apparatus, and system enable individual instruments or a surgical instrument tray containing several surgical instruments to be quickly and efficiently inventoried and tracked. An instrument or instrument tray is placed on the workstation reader. An RF field generated by a plurality of antennae, causes RFID tags embedded in or attached to the instrument or instrument tray to emit a signal containing item specific identification information stored in the tags. The information is received by a control circuit and passed to a computer for data analysis. A status LED is illuminated on the workstation reader based on the results of the data analysis. The method, apparatus, and system can track, inspect, and verify inbound and outbound surgical instrument kits, and help to assess the surgical instruments' and trays' duty life cycle usage.

Owner:WARSAW ORTHOPEDIC INC

Workstation RFID reader for surgical instruments and surgical instrument trays and methods of using same

ActiveUS7268684B2Accurate and rapid trackingReduce processing costsSurgical furnitureDiagnosticsEngineeringWorkstation

A radio frequency identification (RFID) workstation reader for RFID-enabled surgical instruments and surgical instrument trays and a method of using a RFID workstation reader to read RFID-enabled surgical instruments and surgical instrument trays. The method, apparatus, and system enable individual instruments or a surgical instrument tray containing several surgical instruments to be quickly and efficiently inventoried and tracked. An instrument or instrument tray is placed on the workstation reader. An RF field generated by a plurality of antennae, causes RFID tags embedded in or attached to the instrument or instrument tray to emit a signal containing item specific identification information stored in the tags. The information is received by a control circuit and passed to a computer for data analysis. A status LED is illuminated on the workstation reader based on the results of the data analysis. The method, apparatus, and system can track, inspect, and verify inbound and outbound surgical instrument kits, and help to assess the surgical instruments' and trays' duty life cycle usage.

Owner:WARSAW ORTHOPEDIC INC

Workstation RFID reader for surgical instruments and surgical instrument trays and methods of using same

ActiveUS20060119481A1Reduce processing costsAccurate and rapid trackingSurgical furnitureDiagnosticsEngineeringWorkstation

A radio frequency identification (RFID) workstation reader for RFID-enabled surgical instruments and surgical instrument trays and a method of using a RFID workstation reader to read RFID-enabled surgical instruments and surgical instrument trays is disclosed. The method, apparatus, and system enable individual instruments or a surgical instrument tray containing several surgical instruments to be quickly and efficiently inventoried and tracked. An instrument or instrument tray is placed on the workstation reader. An RF field generated by a plurality of antennae, causes RFID tags embedded in or attached to the instrument or instrument tray to emit a signal containing item specific identification information stored in the tags. The information is received by a control circuit and passed to a computer for data analysis. A status LED is illuminated on the workstation reader based on the results of the data analysis. The method, apparatus, and system can track, inspect, and verify inbound and outbound surgical instrument kits, and help to assess the surgical instruments' and trays' duty life cycle usage.

Owner:WARSAW ORTHOPEDIC INC

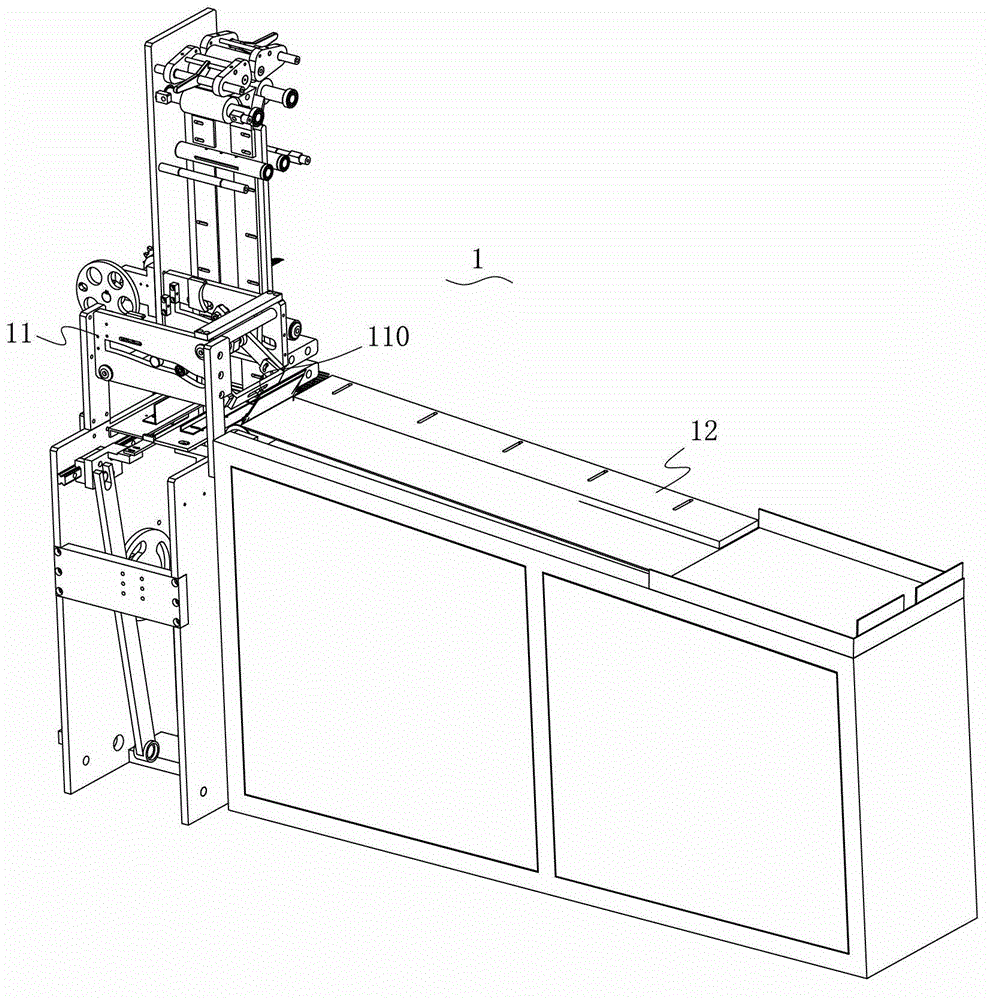

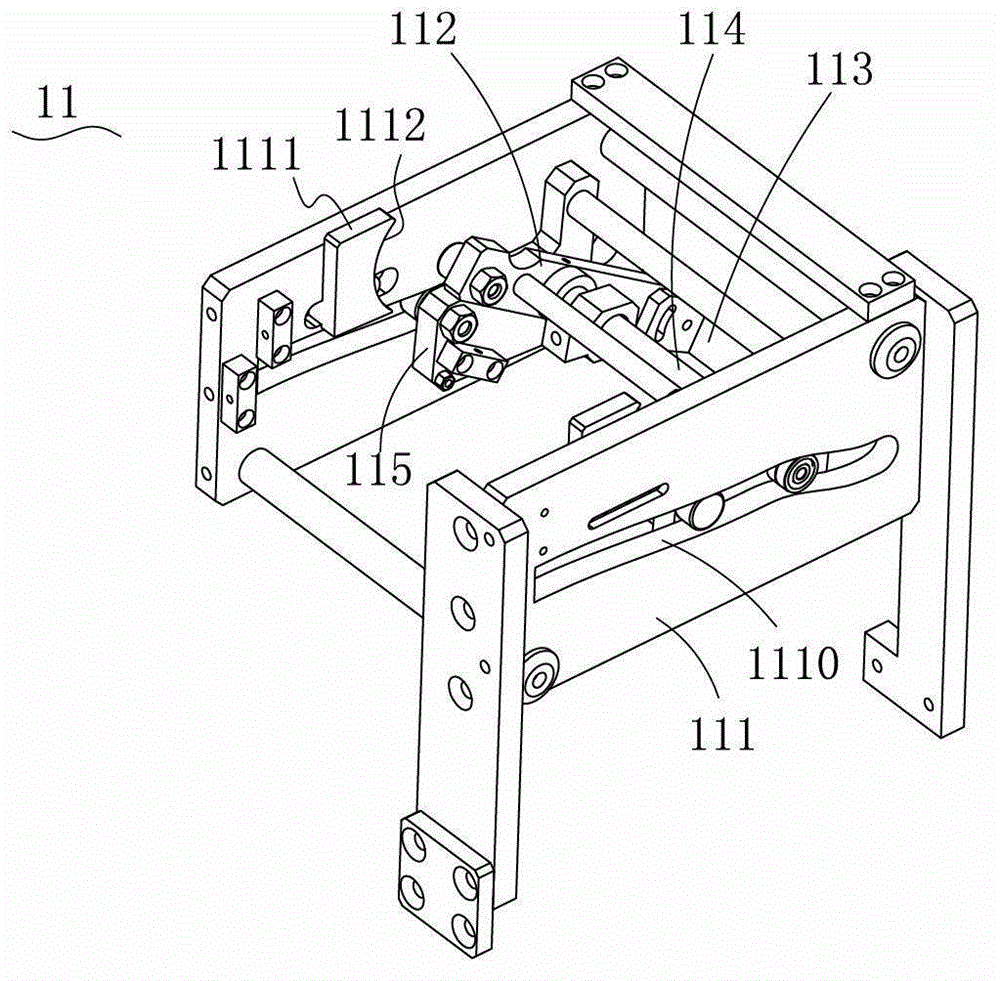

Automated pass-through surgical instrument tray reader

ActiveUS7644016B2Reduce processing costsEfficient collectionElectric signal transmission systemsSurgical furnitureData terminalEngineering

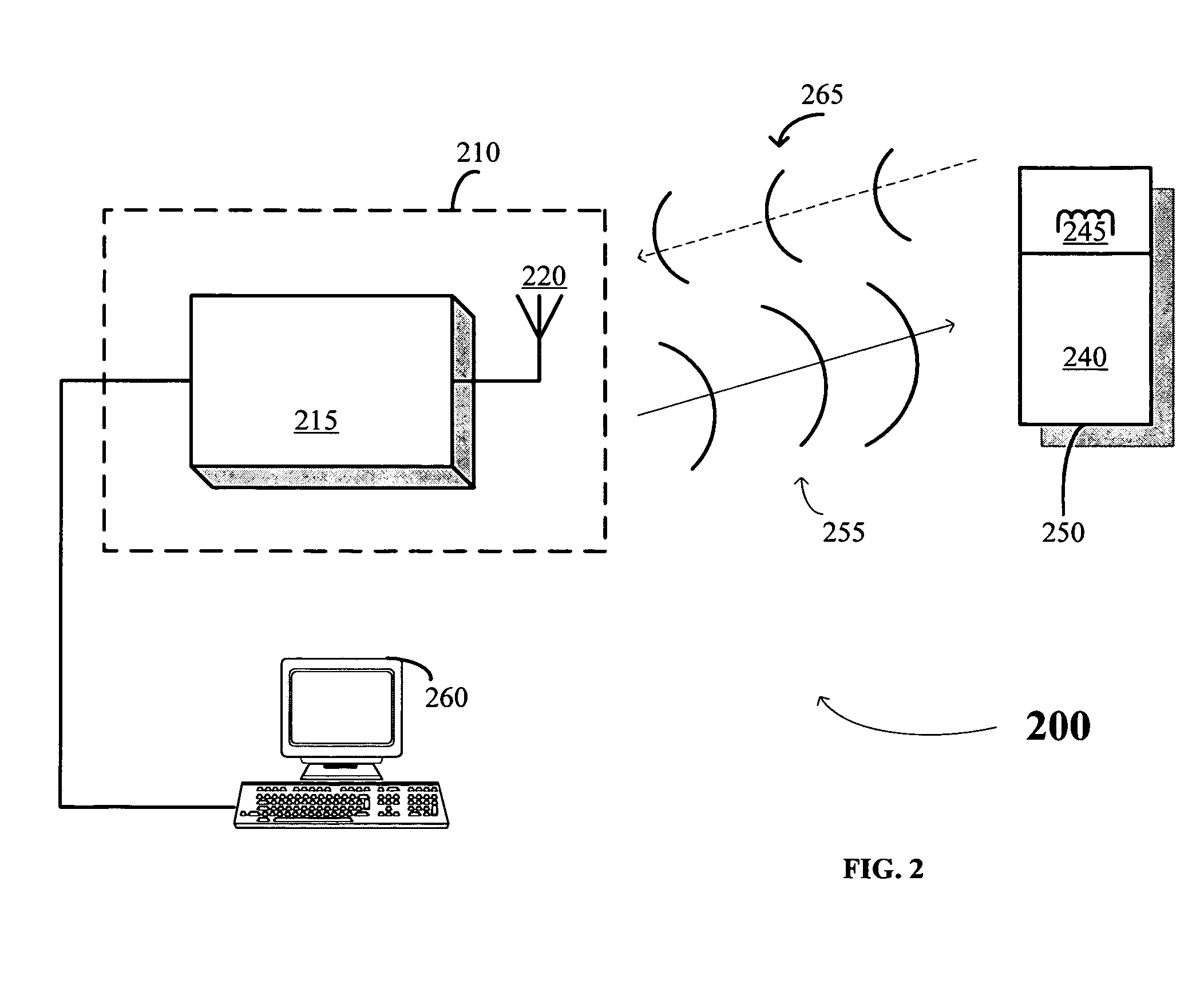

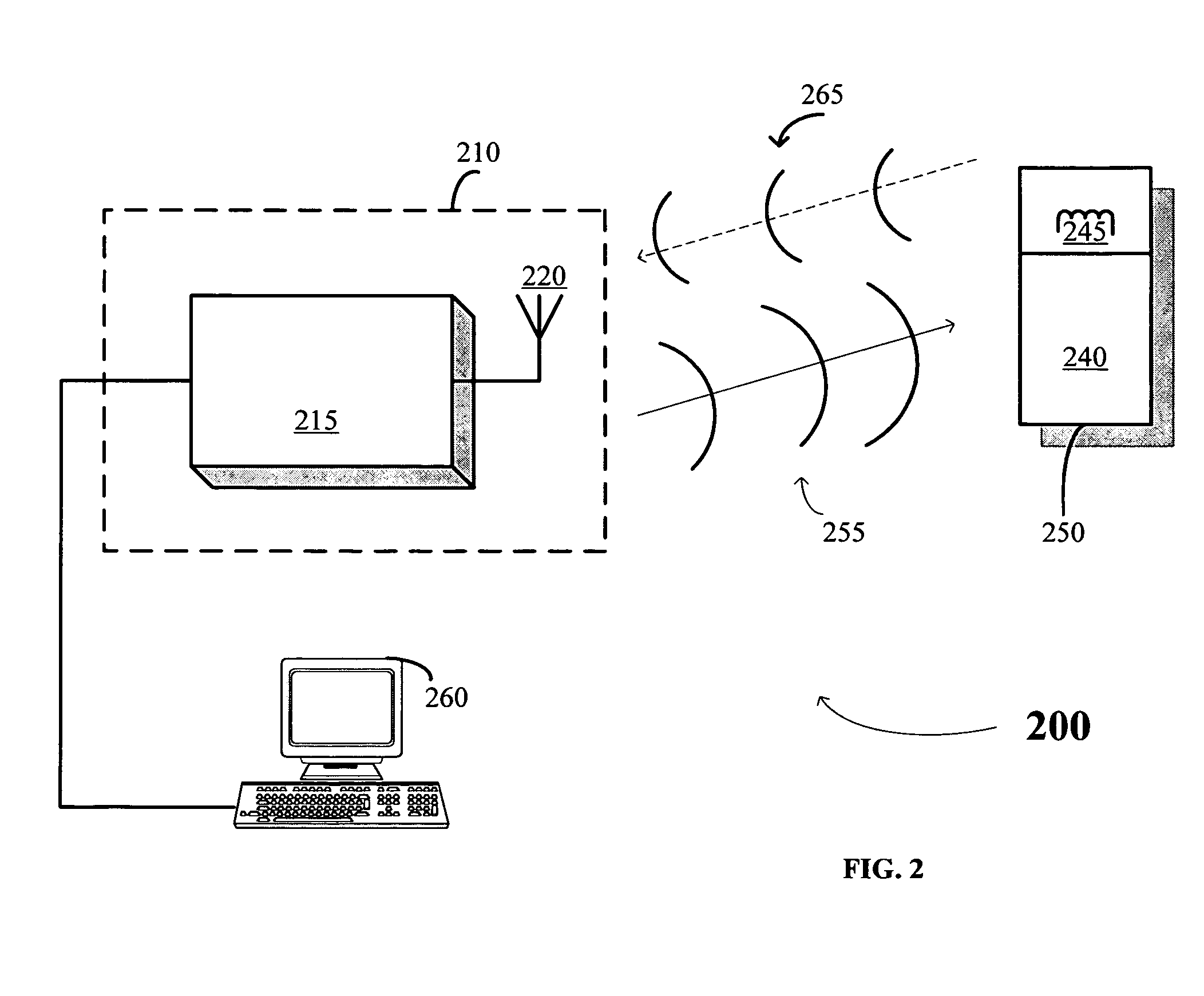

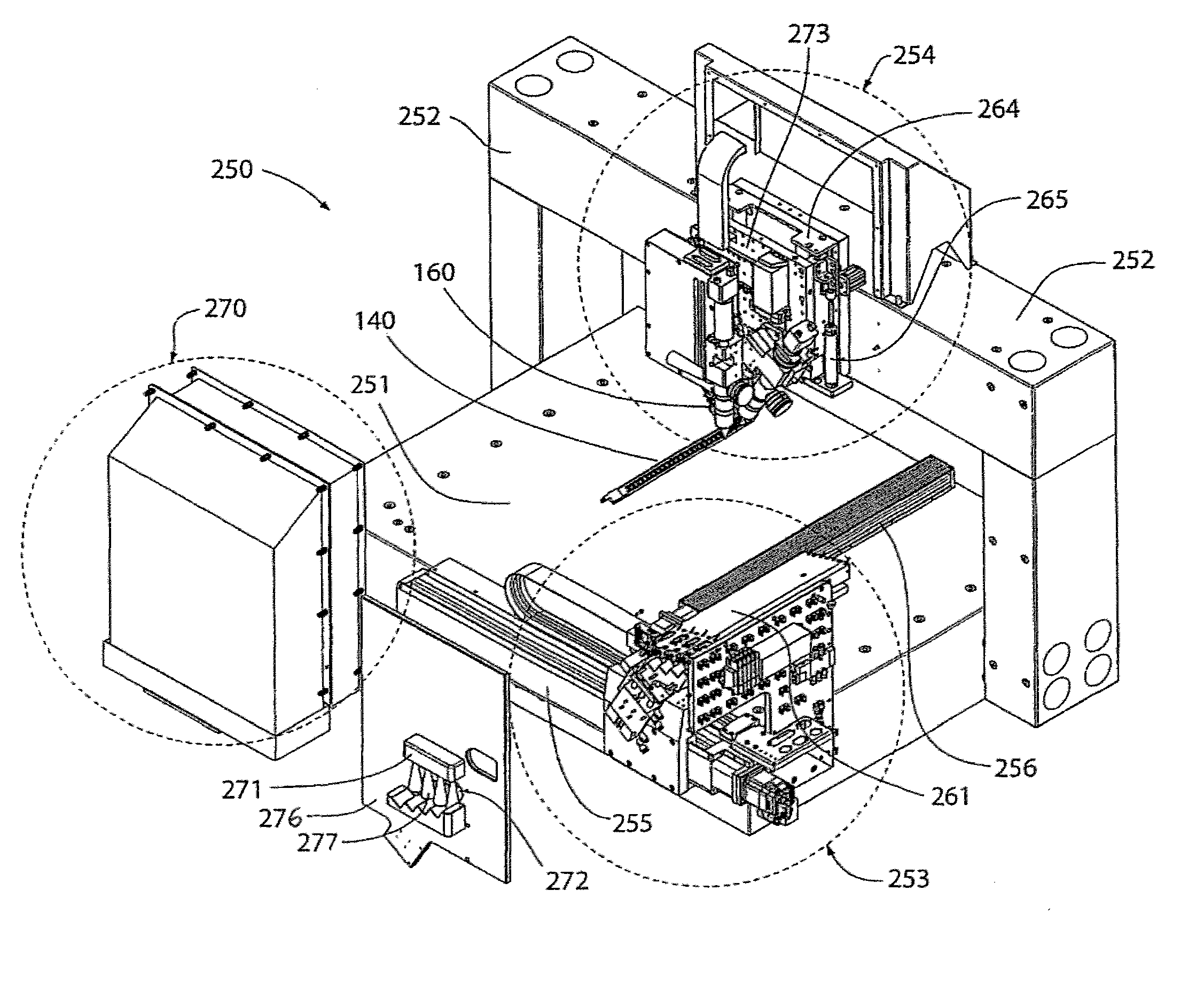

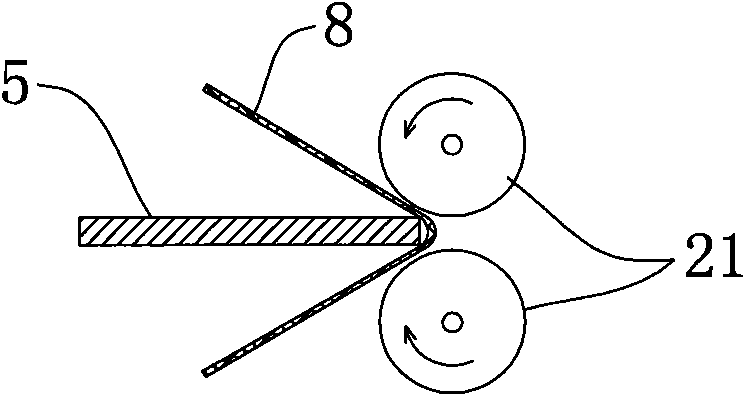

An apparatus and method for interrogating and automatically identifying a radio-frequency tagged surgical instrument tray and its contents of RFID-tagged surgical instruments are disclosed. The surgical instrument tray and its contents come into contact with an RF signal transmitted by the RFID reader, and as a result, the RFID tags affixed on the instrument tray and the surgical instruments respond by transmitting back to the RFID reader data pertaining to the history of the surgical instruments. A data terminal, which is connected to the RFID reader, may contain data pertaining to the radio frequency tagged surgical instruments during packaging, and during the return of the surgical instrument trays to the packager, identifies the surgical instruments.

Owner:WARSAW ORTHOPEDIC INC

Automated pass-through surgical instrument tray reader

ActiveUS20060043177A1Cost reductionReduce processing costsElectric signal transmission systemsSurgical furnitureRadio frequencyInstrument tray

An apparatus and method for interrogating and automatically identifying a radio-frequency tagged surgical instrument tray and its contents of RFID-tagged surgical instruments are disclosed. The surgical instrument tray and its contents come into contact with an RF signal transmitted by the RFID reader, and as a result, the RFID tags affixed on the instrument tray and the surgical instruments respond by transmitting back to the RFID reader data pertaining to the history of the surgical instruments. A data terminal, which is connected to the RFID reader, may contain data pertaining to the radio frequency tagged surgical instruments during packaging, and during the return of the surgical instrument trays to the packager, identifies the surgical instruments.

Owner:WARSAW ORTHOPEDIC INC

Smart instrument tray RFID reader

ActiveUS20060244593A1Reduce processing costsAccurate and rapid trackingSurgical furnitureDispensing apparatusEngineeringWorkstation

A radio frequency identification (RFID) workstation reader for RFID-enabled surgical instruments and surgical instrument trays and a method of using a RFID workstation reader to read RFID-enabled surgical instruments and surgical instrument trays is disclosed. The method, apparatus, and system enable individual instruments or a surgical instrument tray containing several surgical instruments to be quickly and efficiently inventoried and tracked. An instrument or instrument tray is placed on the workstation reader. An RF field generated by a plurality of antennae, causes RFID tags embedded in or attached to the instrument or instrument tray to emit a signal containing item specific identification information stored in the tags. The information is received by a control circuit and passed to a computer for data analysis. A status LED is illuminated on the workstation reader based on the results of the data analysis. The method, apparatus, and system can track, inspect, and verify inbound and outbound surgical instrument kits, and help to assess the surgical instruments' and trays' duty life cycle usage.

Owner:WARSAW ORTHOPEDIC INC

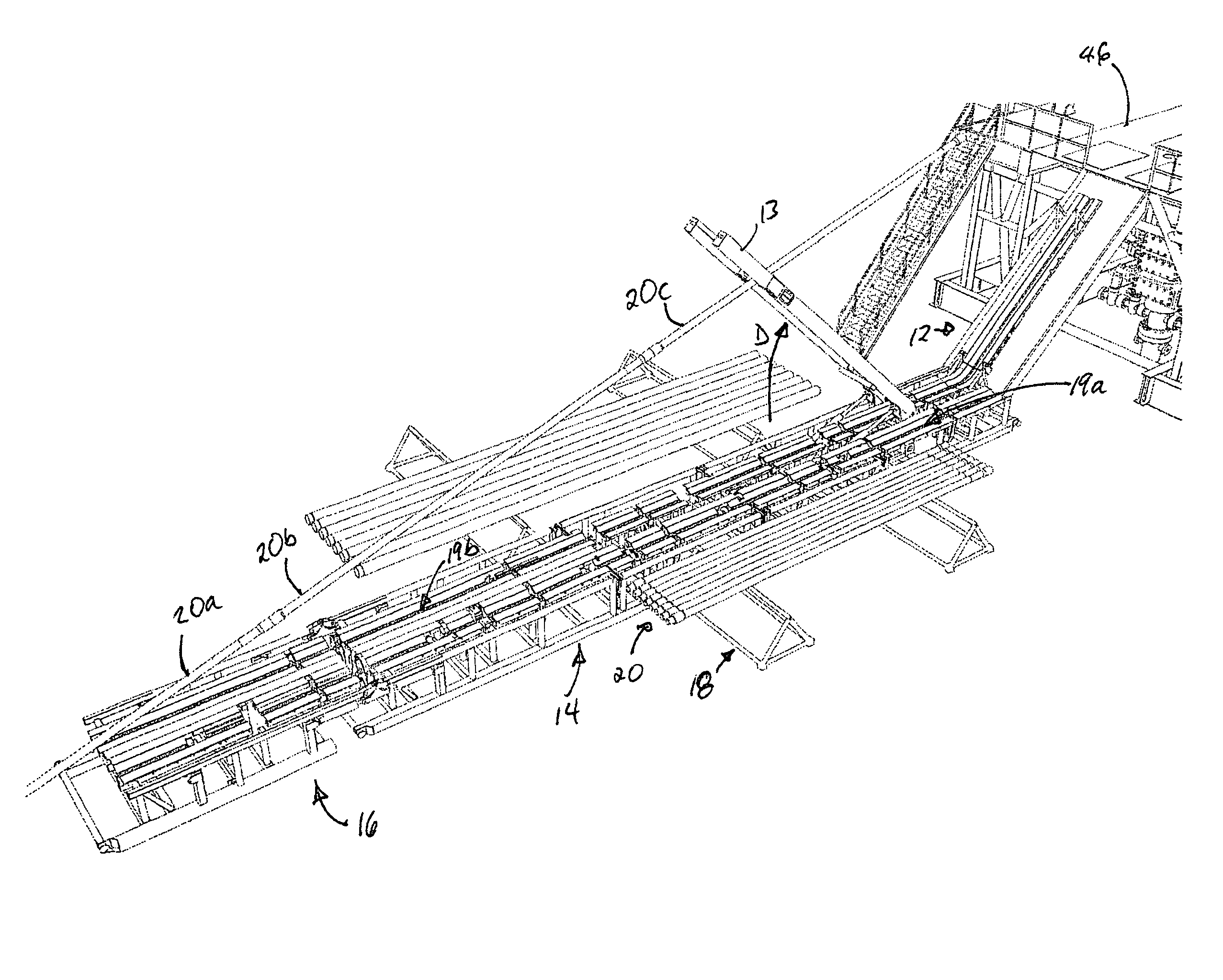

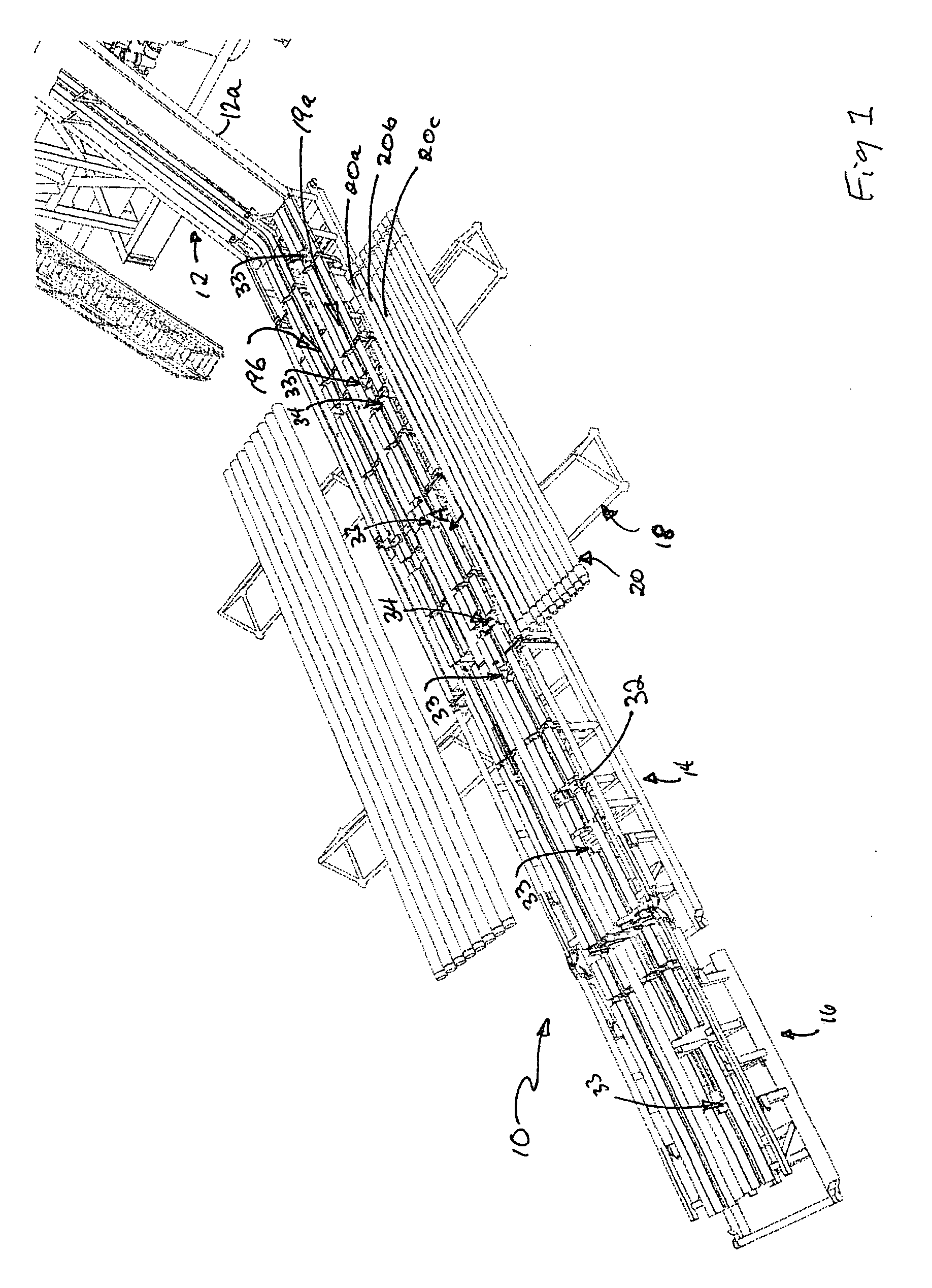

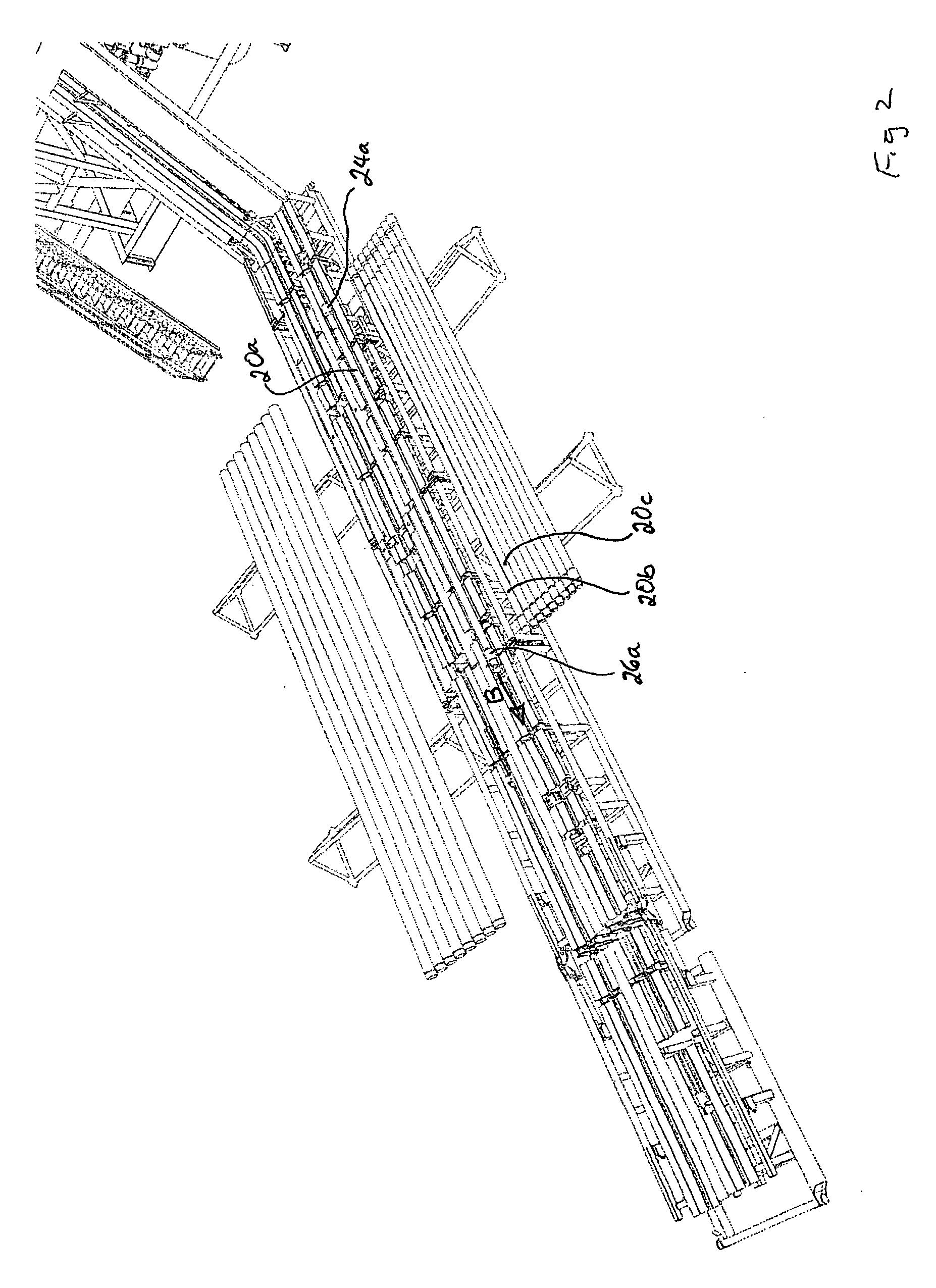

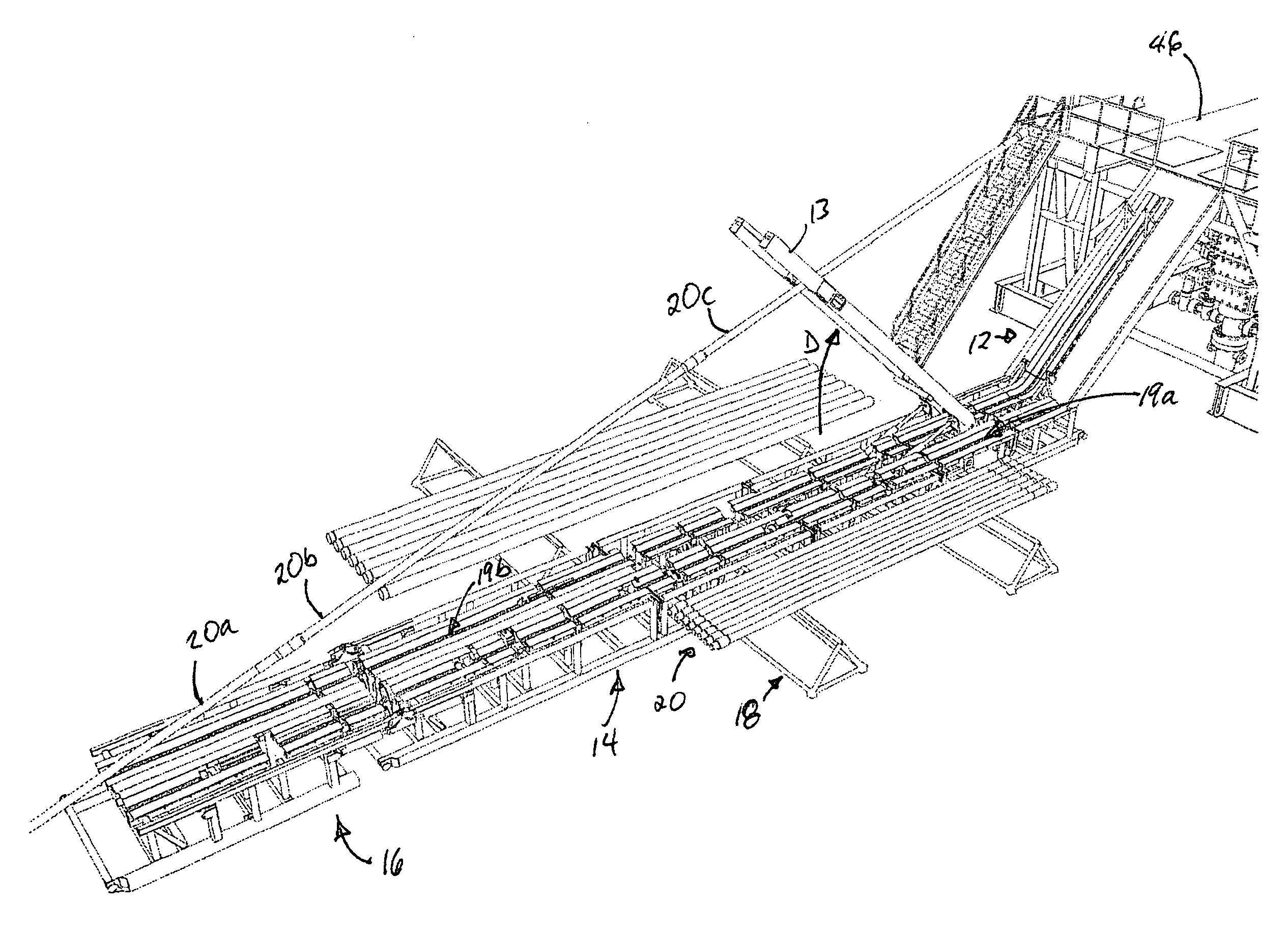

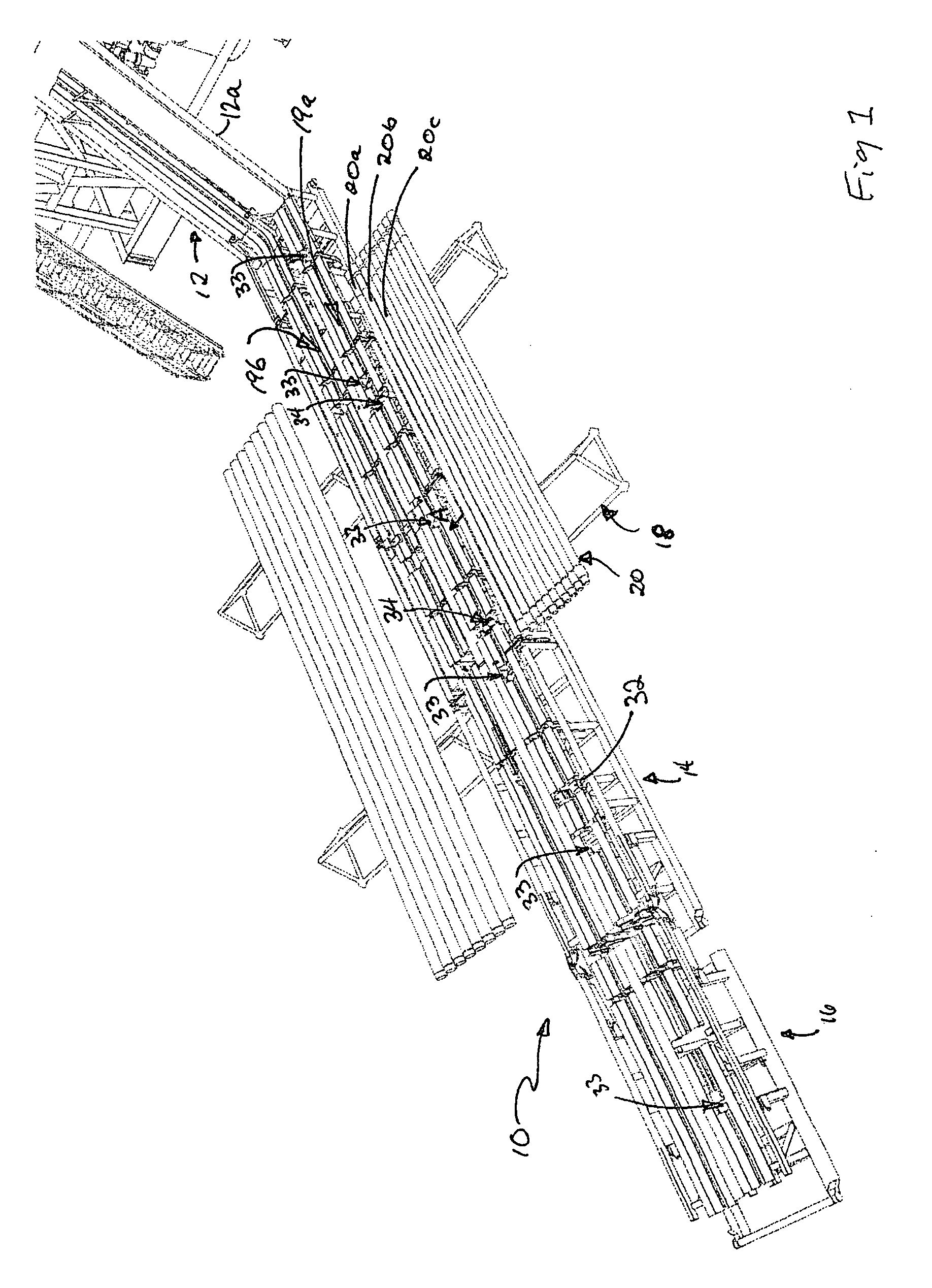

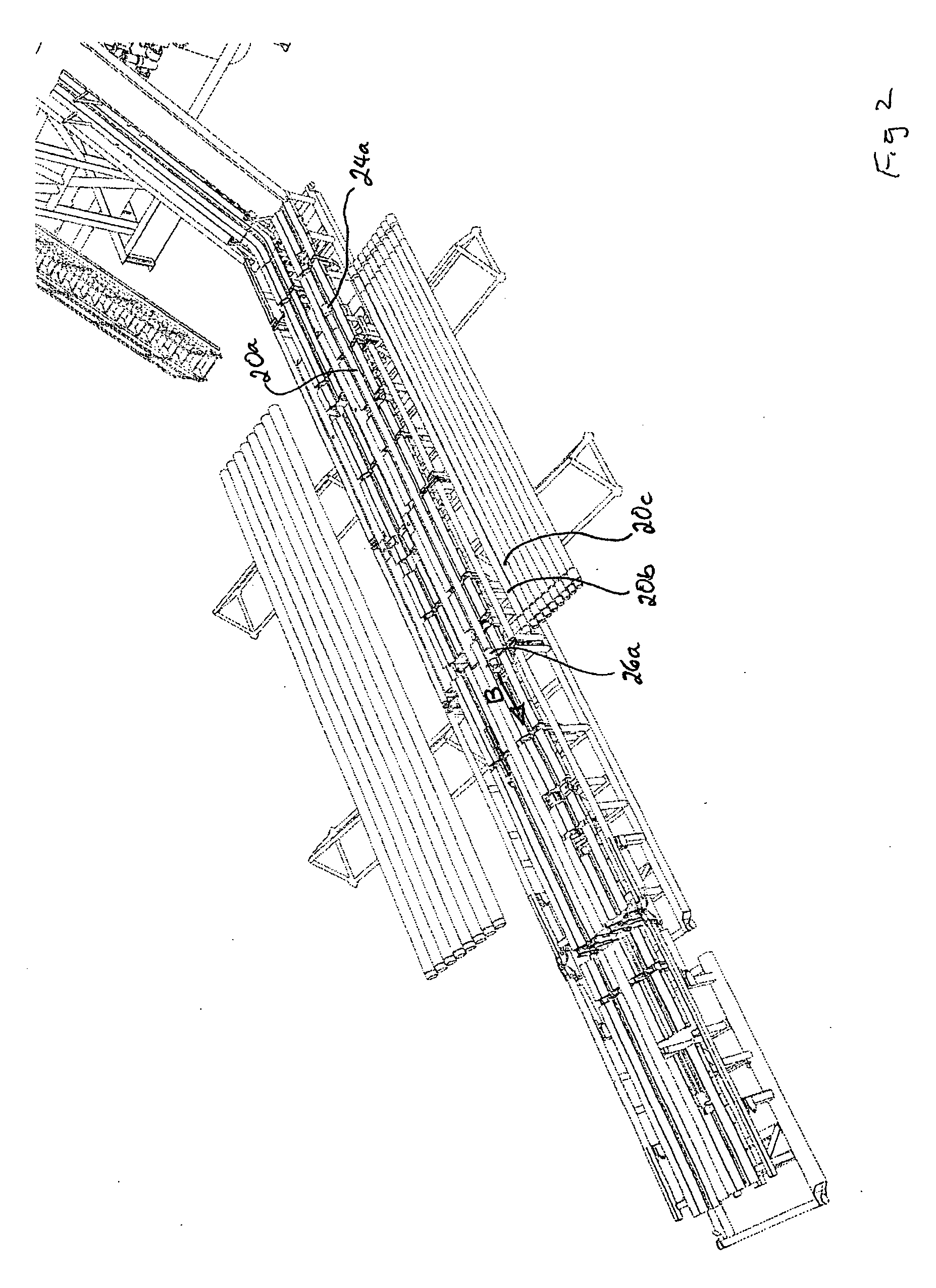

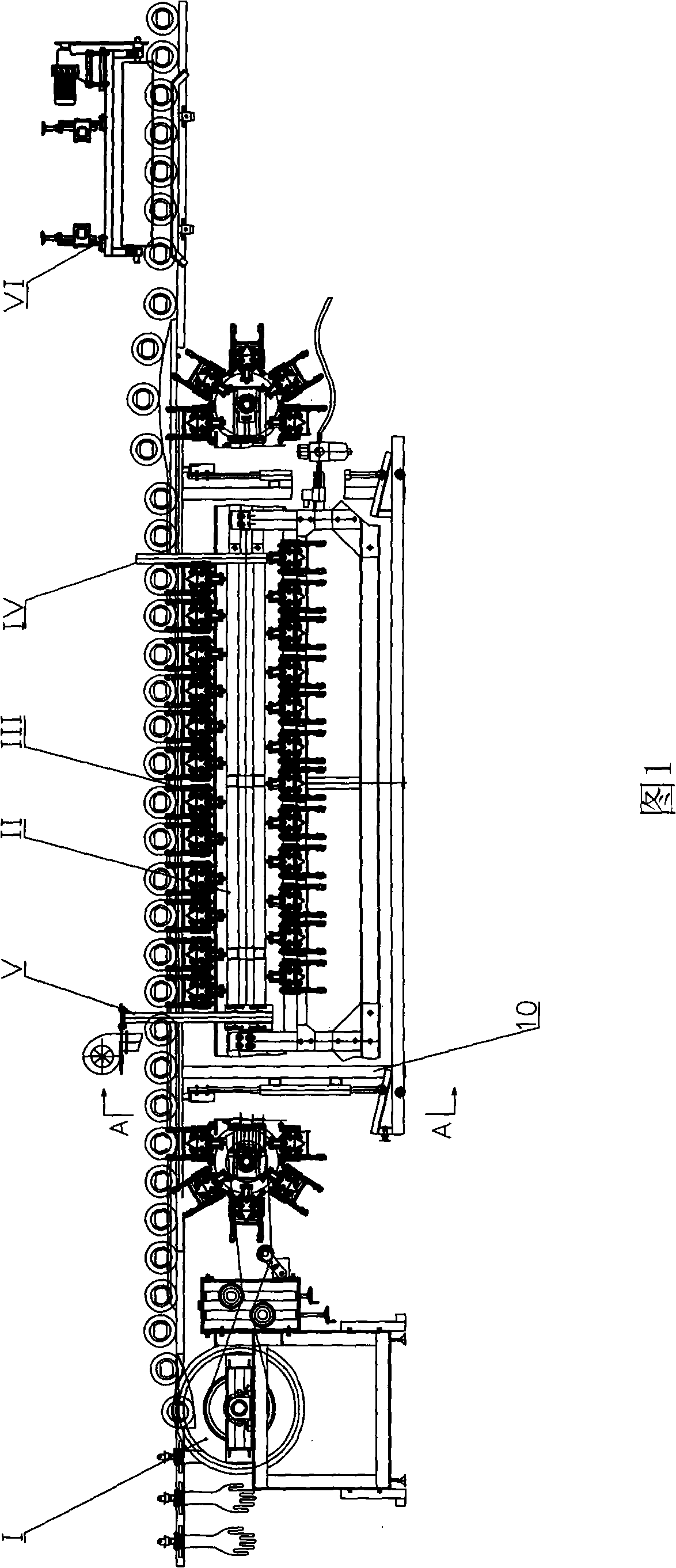

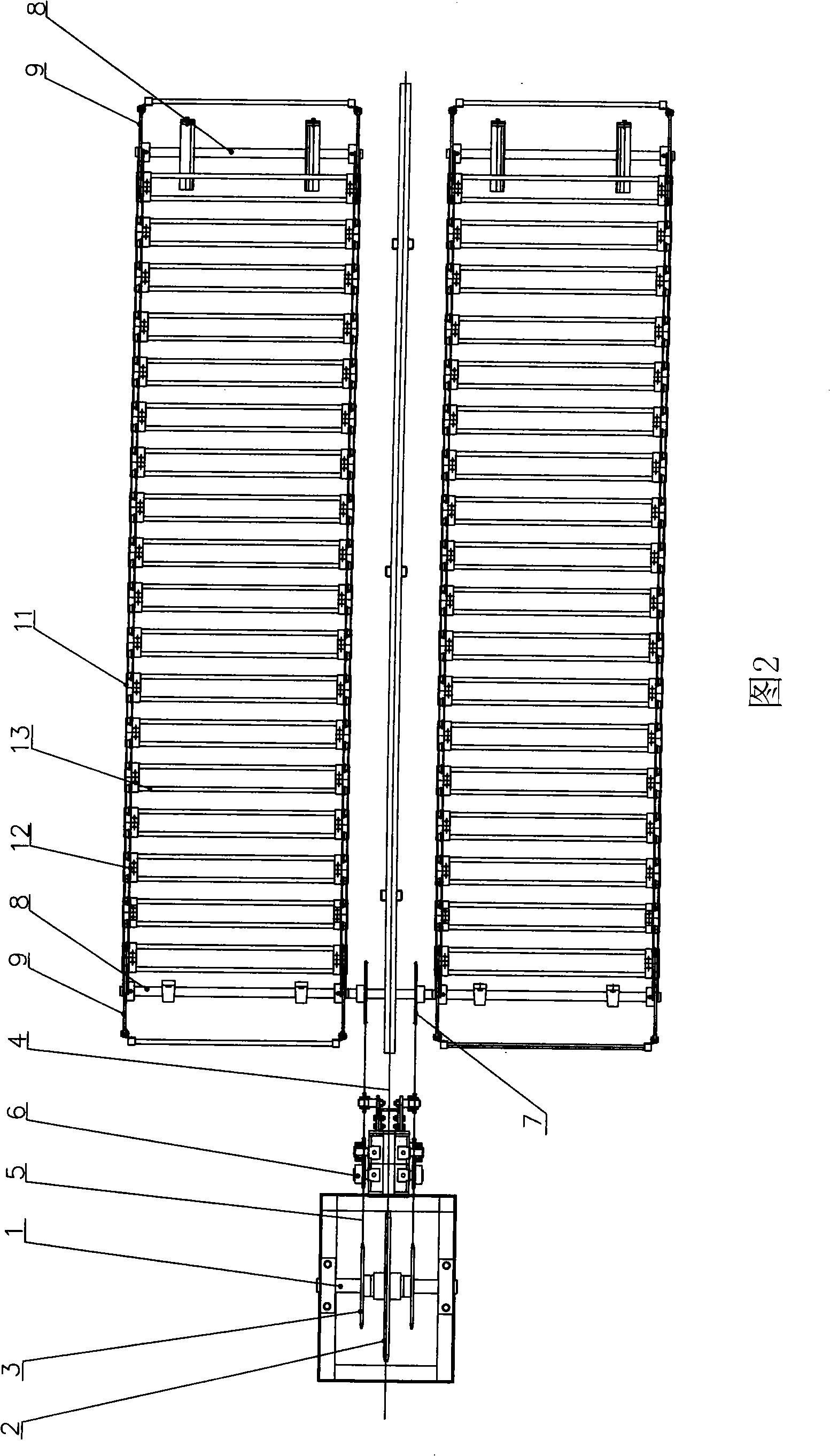

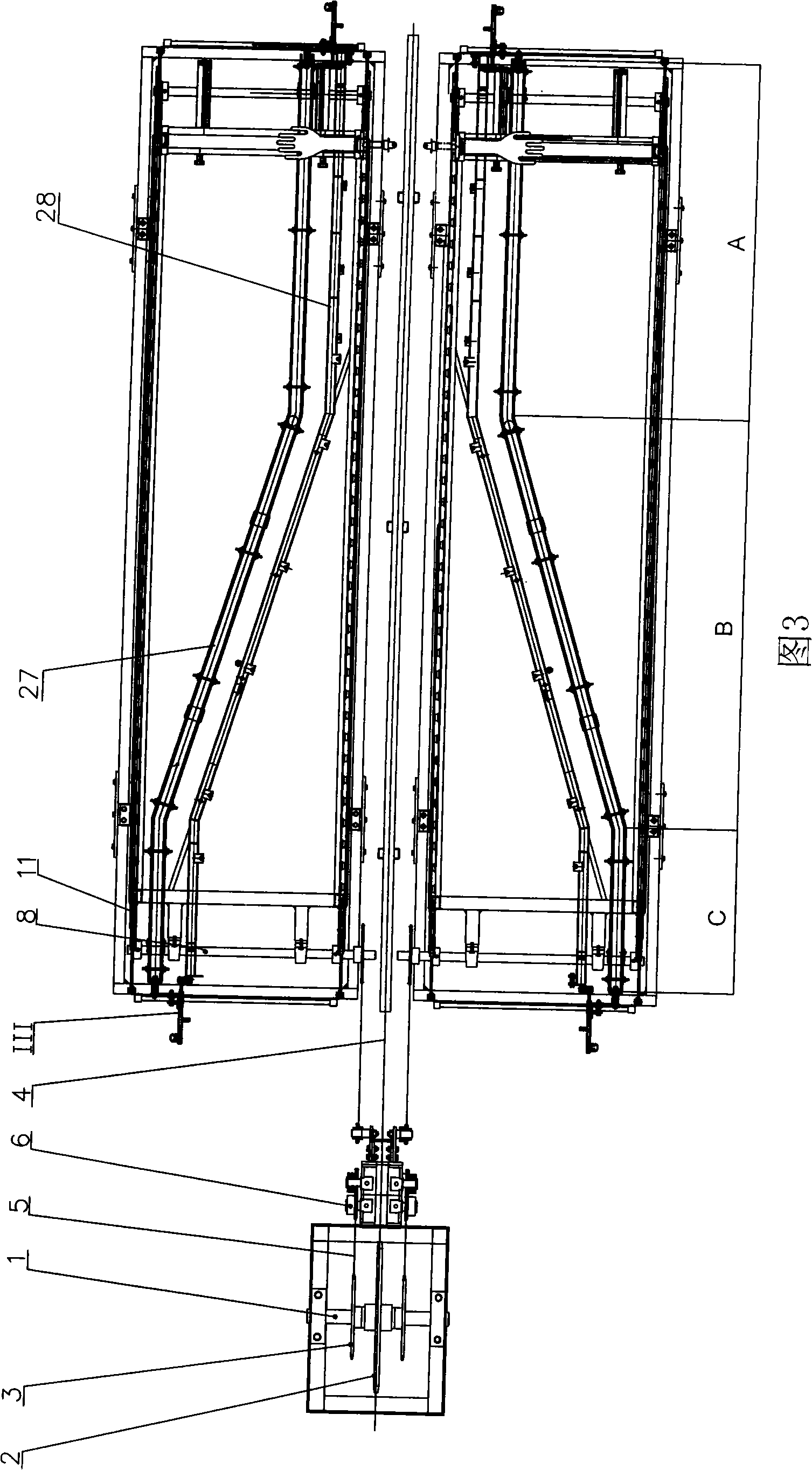

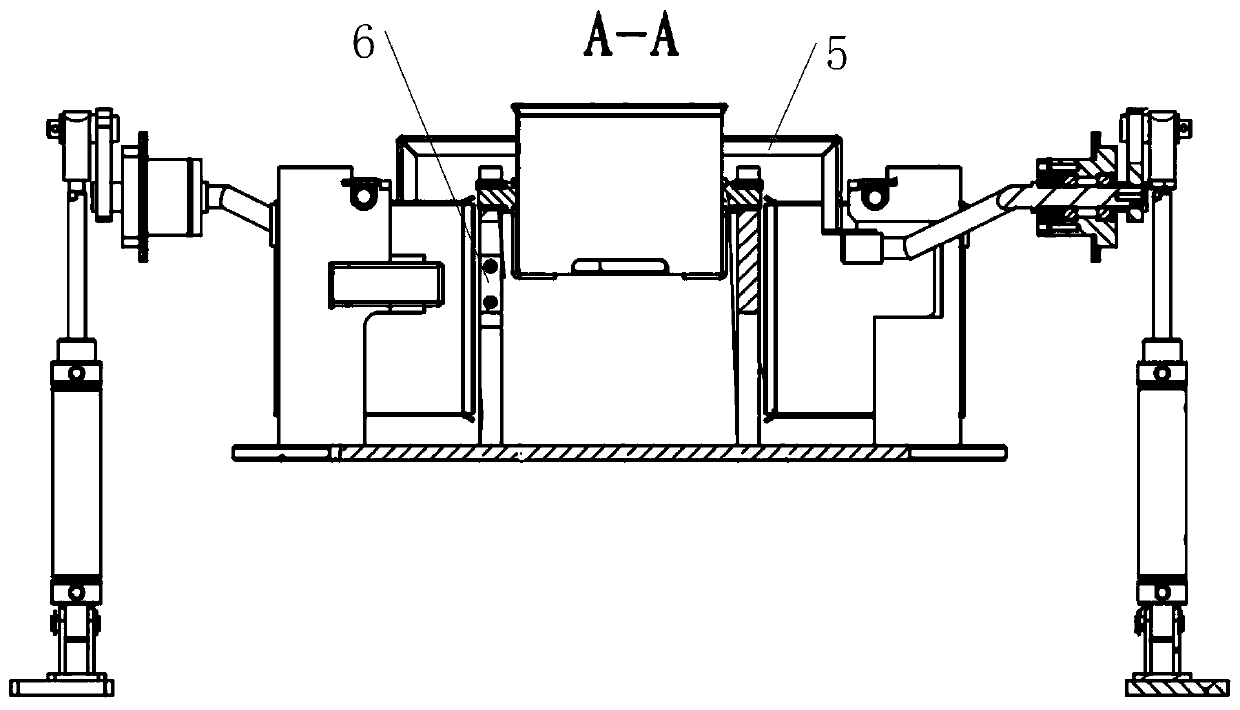

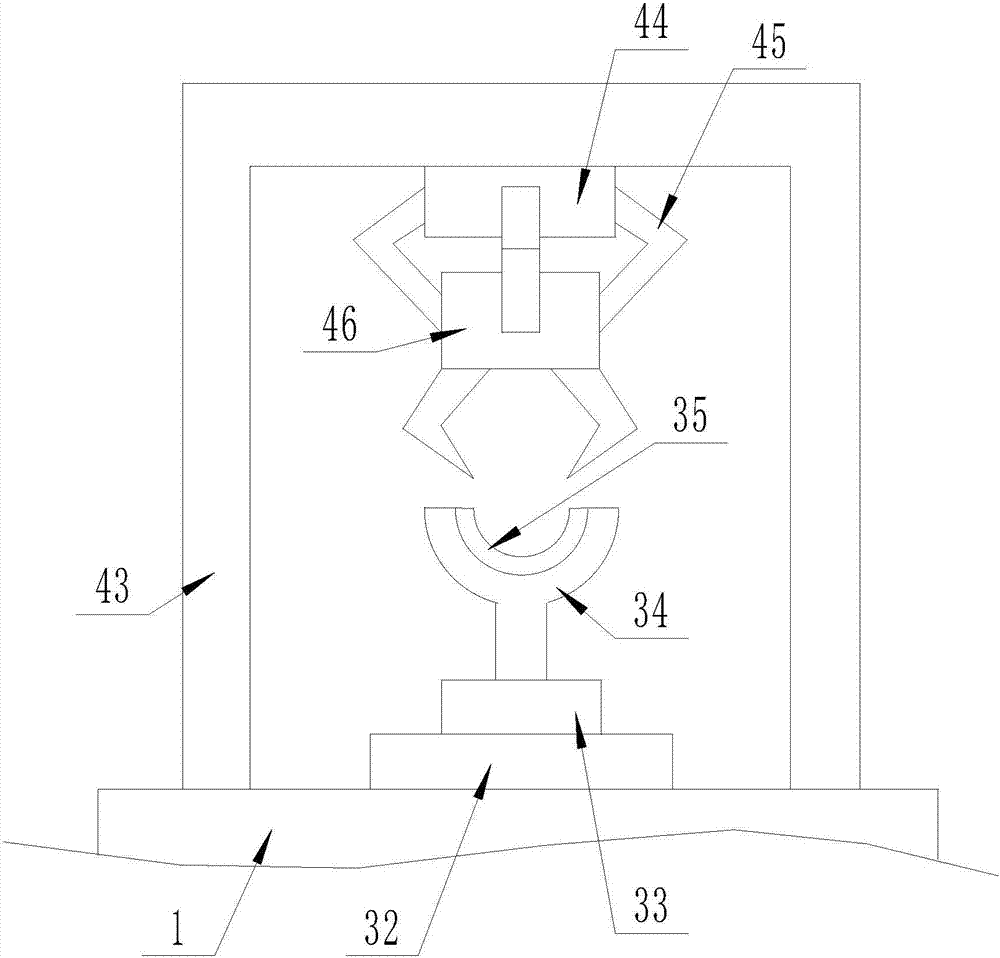

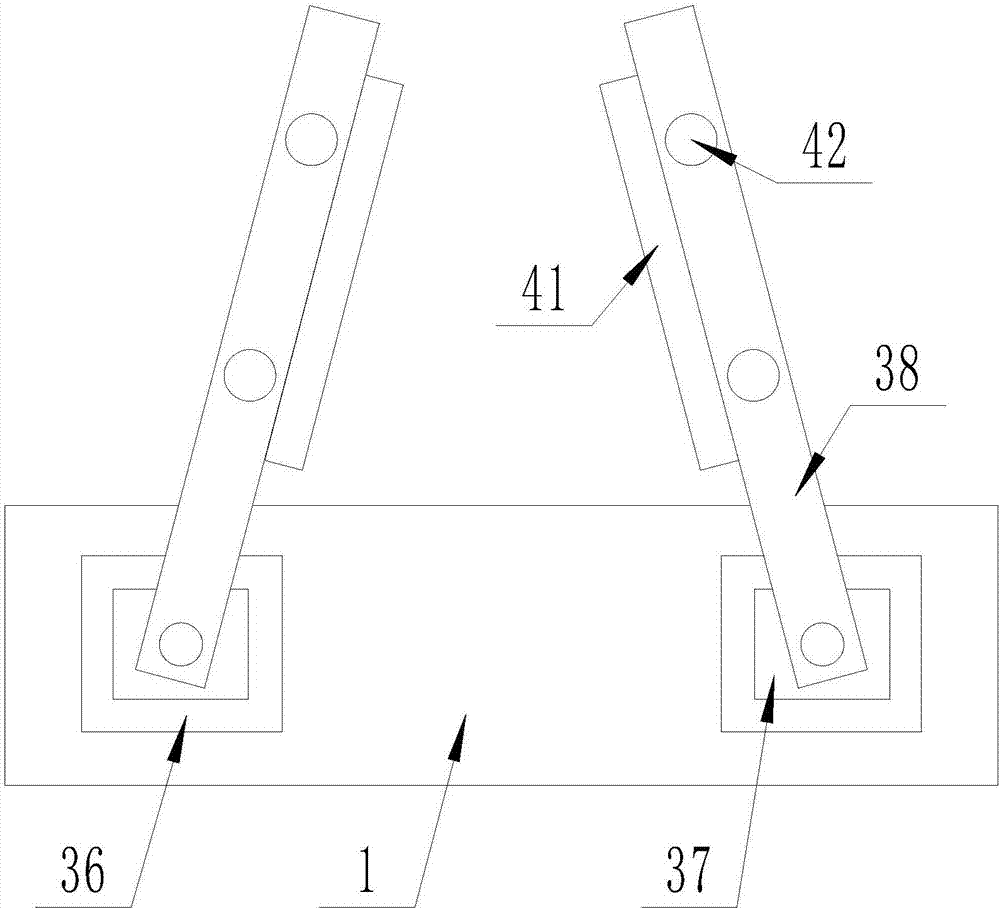

Horizontal offline stand building system

A horizontal offline stand building system includes a substantially horizontal, elongate catwalk having a frame and a stand lifting arm. The catwalk has a top surface adapted to receive at least two tubulars aligned coaxially along a linear path in a make-up channel on said top surface. The tubulars are threaded together to form preferably at least a triple pipe stand in the make-up channel. The completed stand is then transferred laterally to a delivery channel containing the stand lifting arm. The stand lifting arm is selectively actuable lifting arm for selectively elevating a rig end of a pipe stand from said top surface of the catwalk to the deck of a drilling rig, and then for supporting the mid and rear sections as the stand is hoisted from the delivery channel up the derrick of the drilling rig.

Owner:WEATHERFORD CANADA

Horizontal offline stand building system

InactiveUS20100163247A1Reduce human contactReduce the possibilityDrilling rodsFluid removalEngineeringPipe fitting

A horizontal offline stand building system includes a substantially horizontal, elongate catwalk having a frame and a stand lifting arm. The catwalk has a top surface adapted to receive at least two tubluars aligned coaxially along a linear path in a make-up channel on said top surface. The tubulars are threaded together to form preferably at least a triple pipe stand in the make-up channel. The completed stand is then transferred laterally to a delivery channel containing the stand lifting arm. The stand lifting arm is selectively actuable lifting arm for selectively elevating a rig end of a pipe stand from said top surface of the catwalk to the deck of a drilling rig, and then for supporting the mid and rear sections as the stand is hoisted from the delivery channel up the derrick of the drilling rig.

Owner:WEATHERFORD CANADA

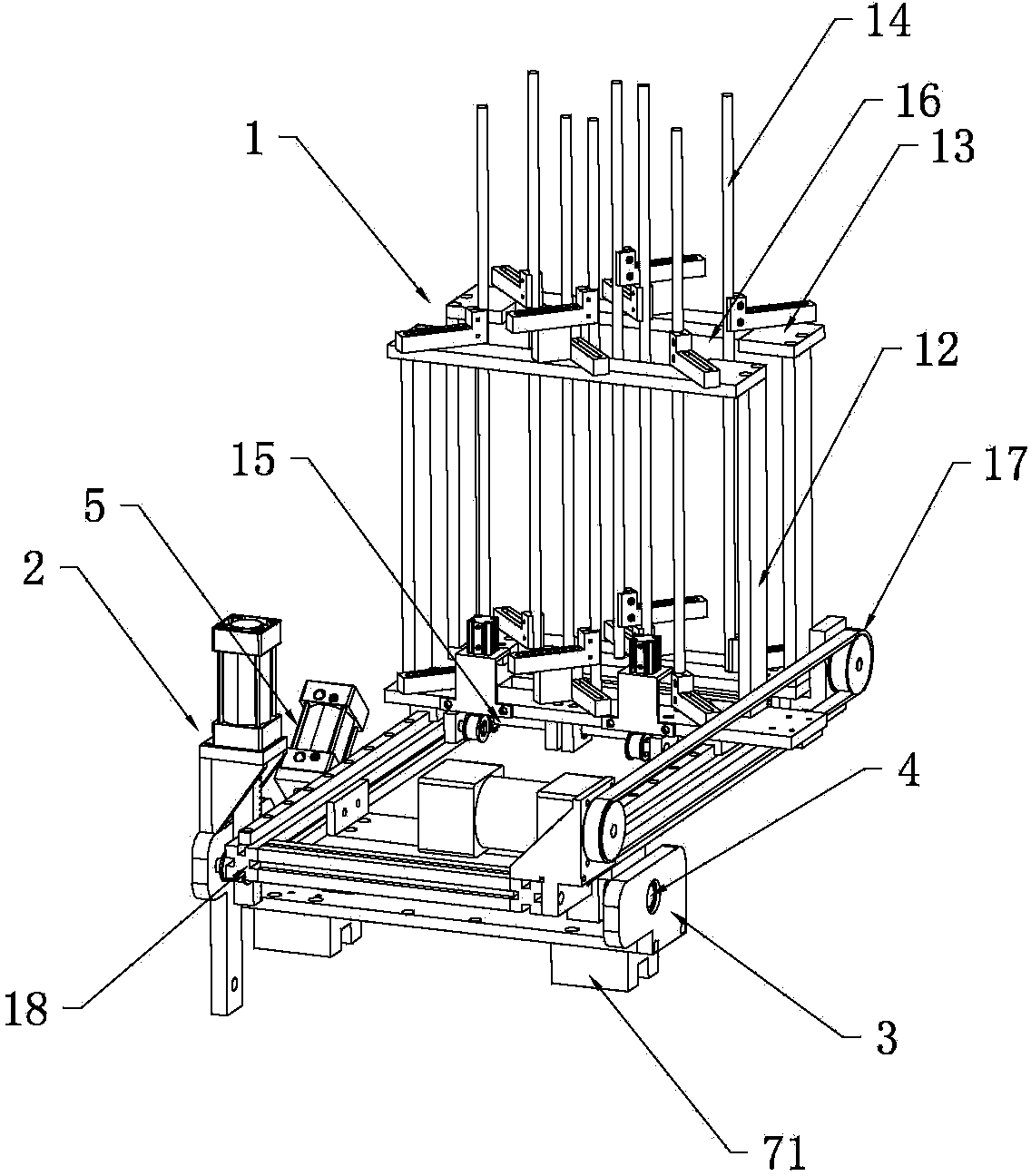

On-line automatic ingot stripper for glue gloves

The invention relates to a rubber glove online automatic demoulding machine, comprising a synchronous force grasping mechanism, a guide rail control mechanism, glove demoulding mechanisms, a glove blowing-aside mechanism and a glove blowing-down mechanism, wherein, a drive sprocket of the synchronous force grasping mechanism is engaged with a main drive chain for transmitting hand molds on a glove production line so as to transmit the power to the guide rail control mechanism; the glove demoulding mechanisms corresponding to the hand molds one by one are arranged on the guide rail control mechanism and can carry out circular movements of lengthwise synchronous moving, transverse separate moving and mechanical claw opening and closing, so as to complete the whole set of operations for glove demoulding; the glove blowing-aside mechanism and the glove blowing-down mechanism are respectively corresponding to the positions of initially grasping the hand mold and finally demoulding a glove by the mechanical claw, so that the glove can be blown to sleeve on the mechanical claw or blown down from the mechanical claw, thereby realizing full automation of glove demoulding. The rubber glove online automatic demoulding machine has quick demoulding speed, less operators, low cost, good product quality and high yield, and can completely replace manual operation.

Owner:杨志勇

Automatic piece coating machine

InactiveCN102867994AImprove efficiencyQuality improvementFinal product manufactureLead-acid accumulators constructionEngineeringAutomation

The invention discloses an automatic piece coating machine, which comprises a plate feeding track, wherein a first feeding station, a paper feeding station, a second feeding station, a supplementation station, a shifting device and a limiting block are sequentially arranged on the plate feeding track; a lifting and descending mechanism is arranged below the limiting block; a supporting plate which is used for supporting pole plates is arranged on the lifting and descending mechanism; a boxing mechanism and a box feeding mechanism are arranged at one end of the supporting plate; and a retainer plate which is connected with the supporting plate is arranged on the boxing mechanism. A pole plate which is fed by the first feeding station is coated on the paper feeding station, the coated pole plate is laminated with another pole plate on the second feeding station, a laminated pole plate group is shifted to fall into the lifting and descending mechanism under the action of the shifting device and the limiting block, the lifting and descending mechanism pushes the pole plate group to the boxing mechanism, the boxing mechanism boxes the pole plate group, the whole operation process is finished at one step in a pipeline mode, the coating efficiency and quality of a pole piece are improved, the possibility of manual contact with the pole piece is correspondingly reduced by improvement of automation degree, and the damage of lead dust on an operator is greatly reduced.

Owner:浙江长兴奥利尔科技股份有限公司

Automated Pass-Through Surgical Instrument Tray Reader

ActiveUS20100108761A1Reduce processing costsEfficient collectionElectric signal transmission systemsSurgical furnitureData terminalEngineering

An apparatus and method for interrogating and automatically identifying a radio-frequency tagged surgical instrument tray and its contents of RFID-tagged surgical instruments are disclosed. The surgical instrument tray and its contents come into contact with an RF signal transmitted by the RFID reader, and as a result, the RFID tags affixed on the instrument tray and the surgical instruments respond by transmitting back to the RFID reader data pertaining to the history of the surgical instruments. A data terminal, which is connected to the RFID reader, may contain data pertaining to the radio frequency tagged surgical instruments during packaging, and during the return of the surgical instrument trays to the packager, identifies the surgical instruments.

Owner:WARSAW ORTHOPEDIC INC

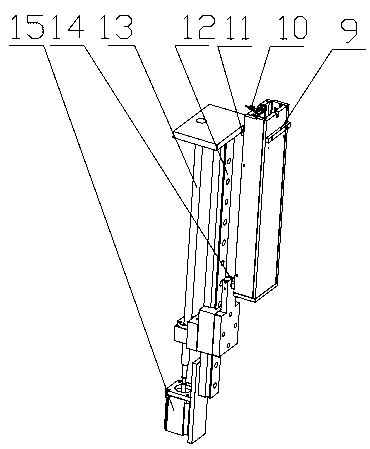

Automated multi-point probe manipulation

ActiveUS20120119770A1Accurately positionImprove accuracyElectrical measurement instrument detailsElectrical testingManipulatorBiomedical engineering

A multi-point probe particularly suitable for automated handling is disclosed. An automated multi-point measuring system including the multi-point probe and a probe manipulator head is also disclosed In addition, an automated multi-point probe gripping system including a probe holder and the probe manipulator head is revealed. Further, a loaded probe loader comprising a probe loader and a probe cassette for handling the multi-point probe is also revealed, where the probe cassette is provided with the probe holder for securing the multi-point probe.

Owner:CAPRES

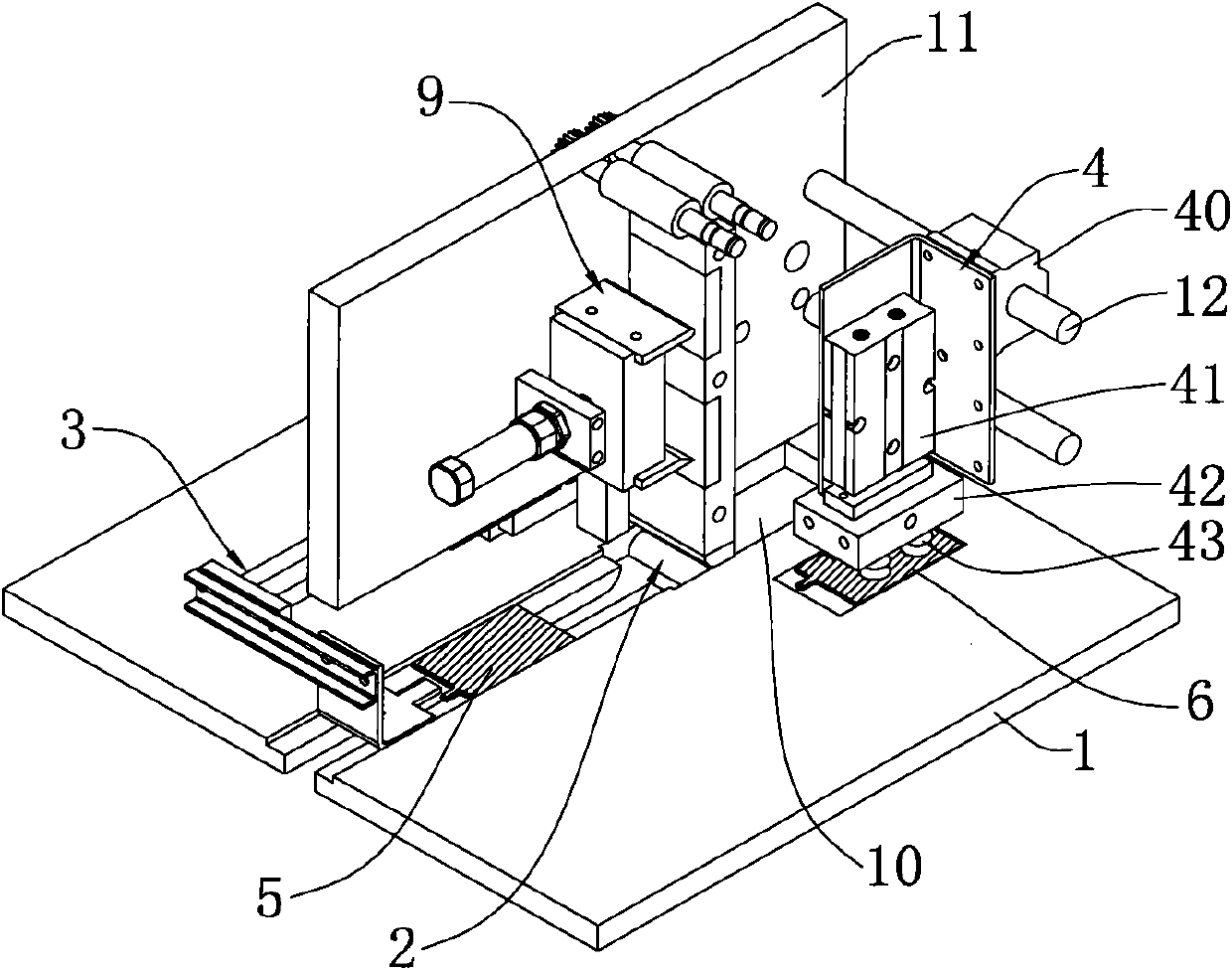

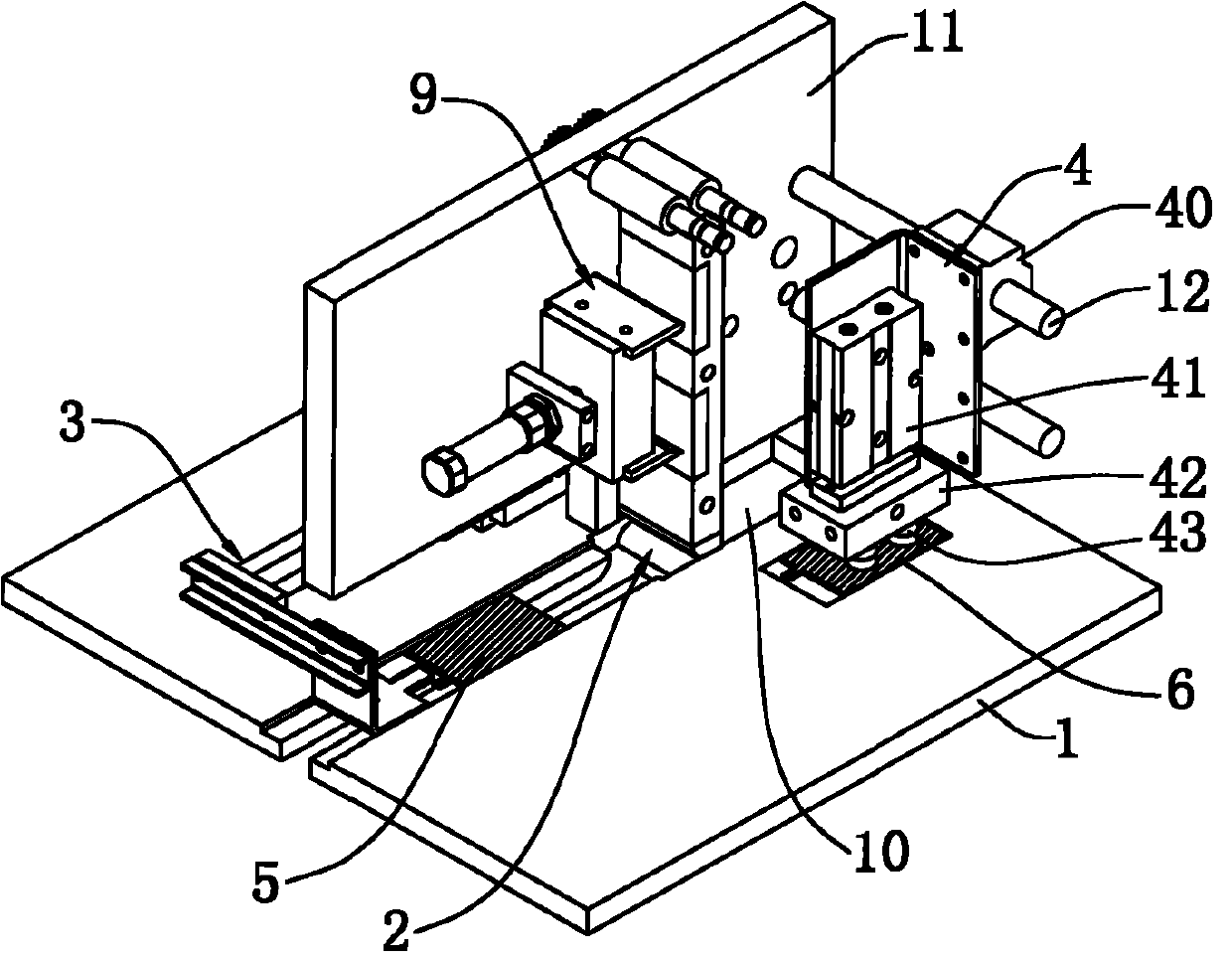

Wrapping assembly mechanism of storage battery wrapper

InactiveCN101908610AThe overall structure is compactReasonable structural designElectrode manufacturing processesEngineeringElectrical and Electronics engineering

The invention discloses a wrapping assembly mechanism of a storage battery wrapper, which comprises a wrapping device, an assembly mechanism and a delivering mechanism, wherein the wrapping device is used for wrapping first pole plates; the assembly mechanism is connected with the discharge end of the wrapping device; the delivering mechanism is used for delivering second pole plates to the assembly mechanism; and the wrapped first pole plates and the second pole plates are overlapped alternately in the assembly mechanism. When in work, the additional assembly mechanism and the delivering mechanism do not need manual operation, and the wrapping and assembly of the pole plates are finished in one step, thus the automation degree is greatly improved; and by reducing the chance for artificially touching the pole plates, the damage of lead dust on operators is also greatly reduced.

Owner:ZHEJIANG HAIYUE AUTOMATIC MACHINERY

Lid dispenser

InactiveUS20060226169A1Avoid failureAvoid interferenceCoin-freed apparatus detailsPackagingEngineeringElectric motor

Apparatus for dispensing lids and other articles such as plates, condiments, etc. comprising a threaded shaft powered by an electric motor which is used to raise a stack of items from the bottom of a storage hopper. A vacuum system, in a first embodiment comprised of a fan and a sliding tube, lifts the top most item from the stack, making it available to a user. A sensor at the top of the dispenser is used to detect the absence of an item in the dispensing position and again raises the stack of items, placing the top most item in position to be raised up by the vacuum system and again made ready for pick up by the user.

Owner:DAVIS MEGAN +1

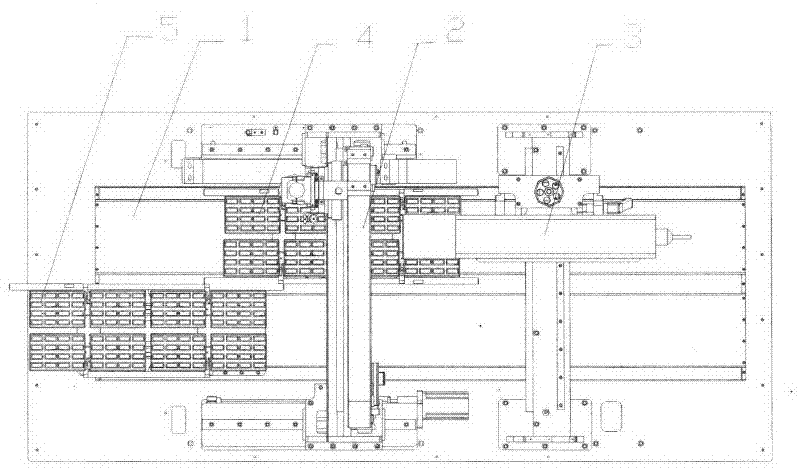

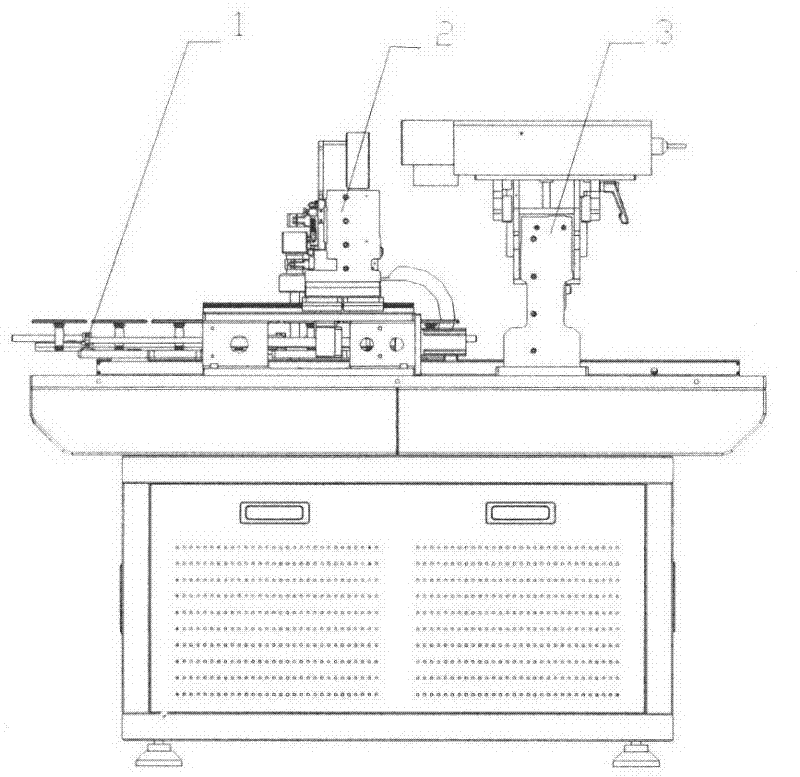

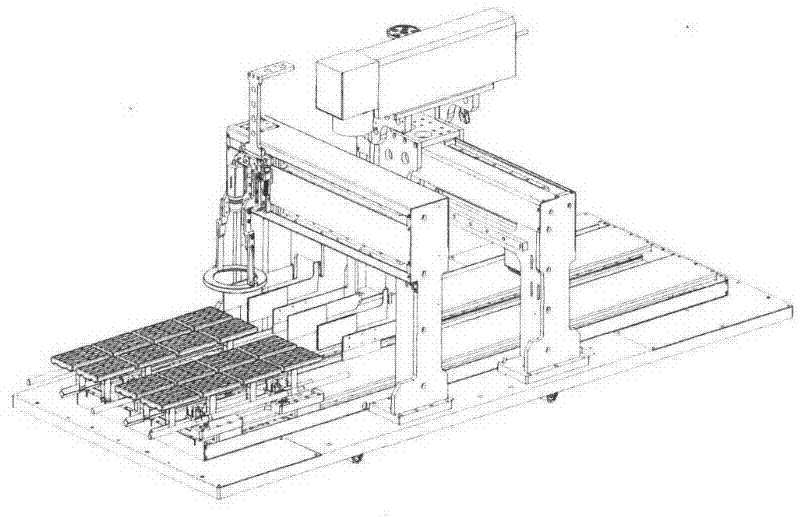

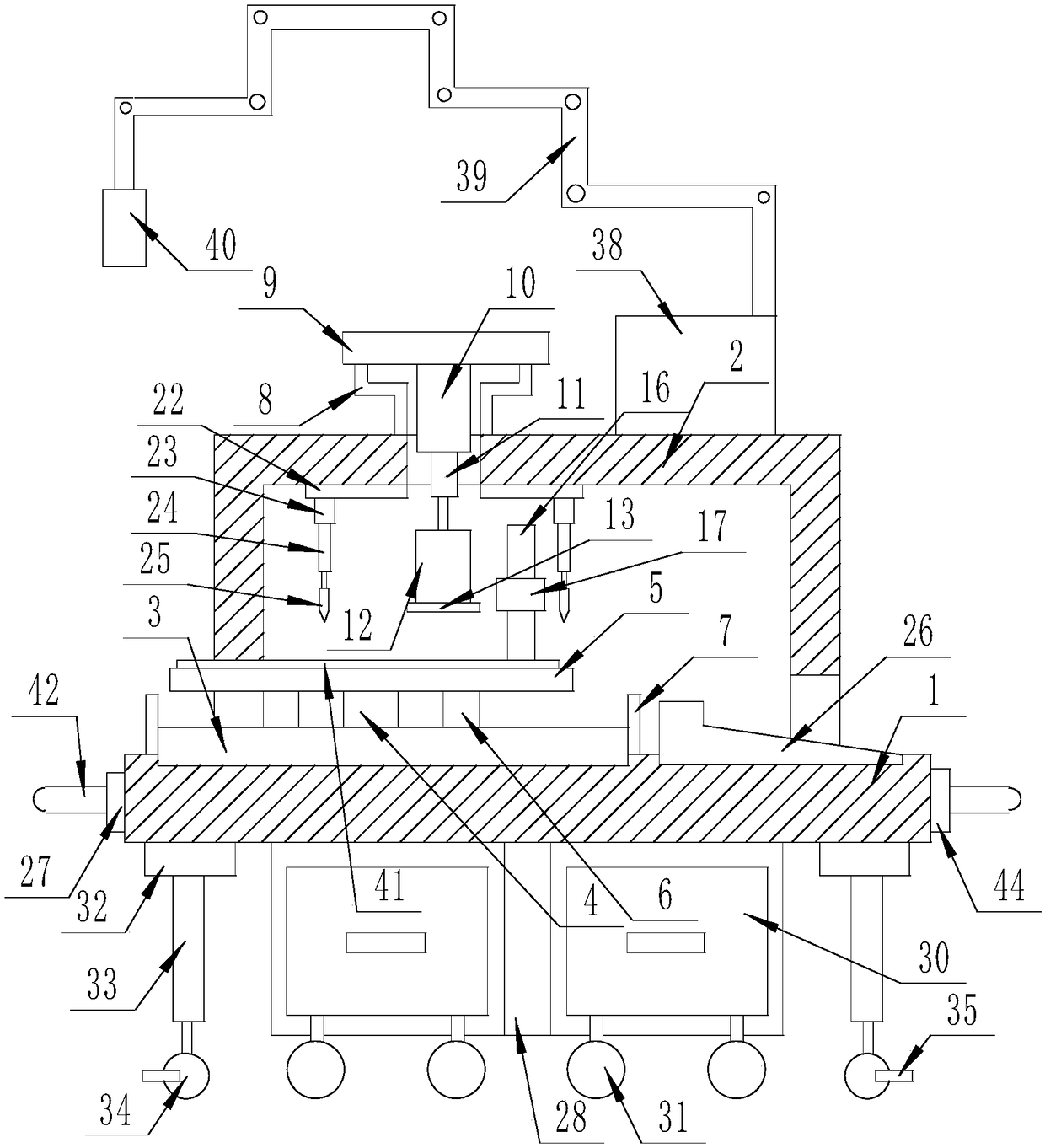

Full-automatic laser carving machine

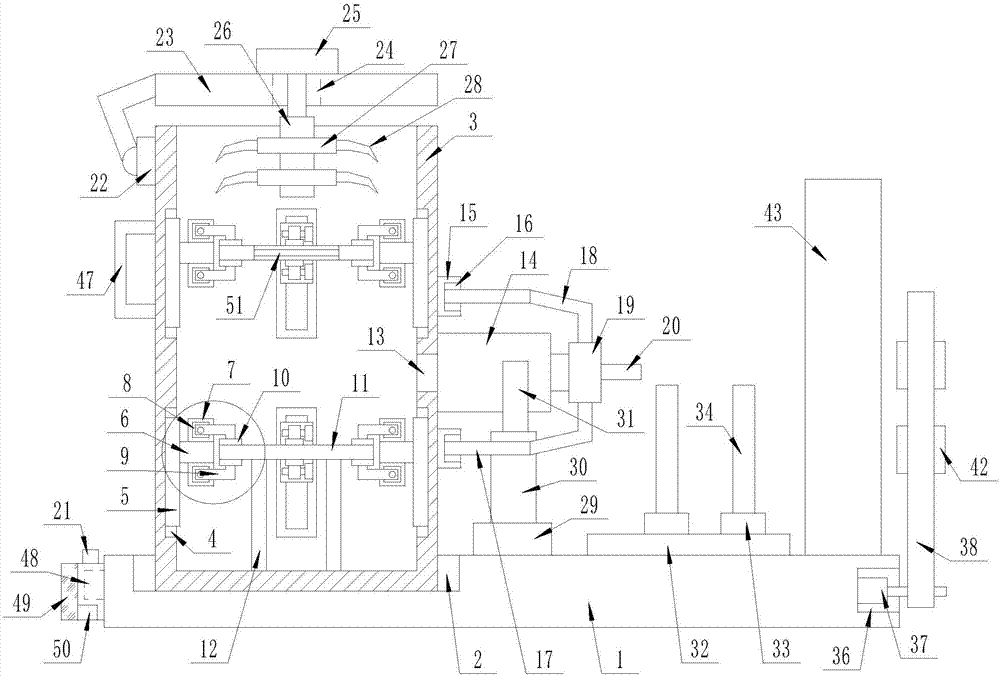

InactiveCN102343756AImprove pass rateSimple processModel makingEngravingMarine engineeringMachining system

The invention discloses a full-automatic laser carving machine, which comprises a workbench (1), a vision positioning system (2) and a laser carving machine system (3), wherein the workbench (1) comprises a material platform deck A (4) and a material platform deck B (5); the vision positioning system (2) and the laser carving machine system (3) can move between the material platform deck A (4) and the material platform deck B (5) through a motion guide rail; and when the laser carving machine system (3) is used for carving parts of the material platform deck A (4), the vision positioning system (2) can be used for shooting parts of the material platform deck B (5). The full-automatic laser carving machine is provided with two material platform decks, and the vision positioning system and the laser carving machine system are movable, so that parts can be continuously transported to the vision positioning system and the laser carving machine system by using the material platform decks, continuous work of vision and laser carving is ensured, and the working efficiency of equipment is increased.

Owner:SHENZHEN QIAOHUI PRECISION MACHINERY

Leftward and rightward movement receiving conveying system

The invention discloses a leftward and rightward movement receiving conveying system, which comprises two receiving conveying devices, two sliding driving devices and sliding rails, wherein the sliding rails are fixedly arranged on a rack; sliding blocks arranged on the sliding rails in a sliding way are respectively and fixedly connected to support frames of the two receiving conveying devices; each receiving conveying device is driven by the corresponding sliding driving device to slide along the corresponding sliding rail in a reciprocating manner. The system also comprises a controller, wherein the two receiving conveying devices and the two sliding driving devices are electrically connected with the controller respectively; under the control of the controller, materials can be alternately conveyed by the two receiving conveying devices, and during the distribution conveying of one receiving conveying device, the other receiving conveying device is in a receiving state. The system has the advantages that (1) the automation degree is high; (2) materials subjected to printing are alternately conveyed by the left and right receiving conveying devices, so that the working efficiency is high; (3) labors are less in contact with the materials subjected to printing, so that higher safety and reliability are ensured.

Owner:GUANGDONG LONGXING PACKAGING IND

Robot and grabbing mechanism

The invention discloses a robot and a grabbing mechanism. The grabbing mechanism comprises a cylinder seat, a material taking assembly and a material feeding assembly. The material taking assembly comprises a material taking cylinder, a mounting plate and at least two material taking needles. The material taking cylinder is fixed on the cylinder seat, and the mounting plate is arranged on a piston rod of the material taking cylinder. At least two mounting holes are formed in the mounting plate, the material taking needles are arranged in the mounting holes, and the material taking needles are arranged in a tilting mode relative to the vertical direction. The material feeding assembly comprises a material feeding cylinder and a material feeding plate, the material feeding cylinder is fixed on the cylinder seat, and the material feeding plate is fixed on a piston rod of the material feeding cylinder. The material feeding plate is arranged between two material taking needles, and the material feeding plate is arranged at the end close to the mounting plate. The robot and the grabbing mechanism are quick and convenient to operate and capable of grabbing minced fish meat and the like to be put at a specific position of a packaging machine, improves production efficiency, and lowers cost.

Owner:GUANGZHOU TECH LONG PACKAGING MACHINERY CO LTD

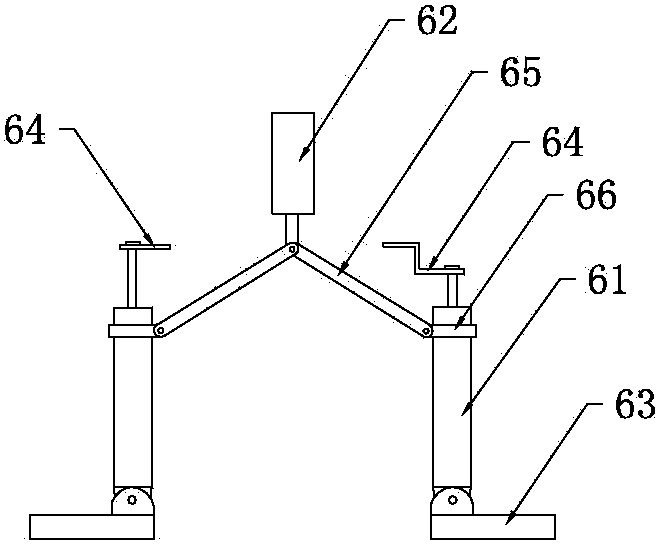

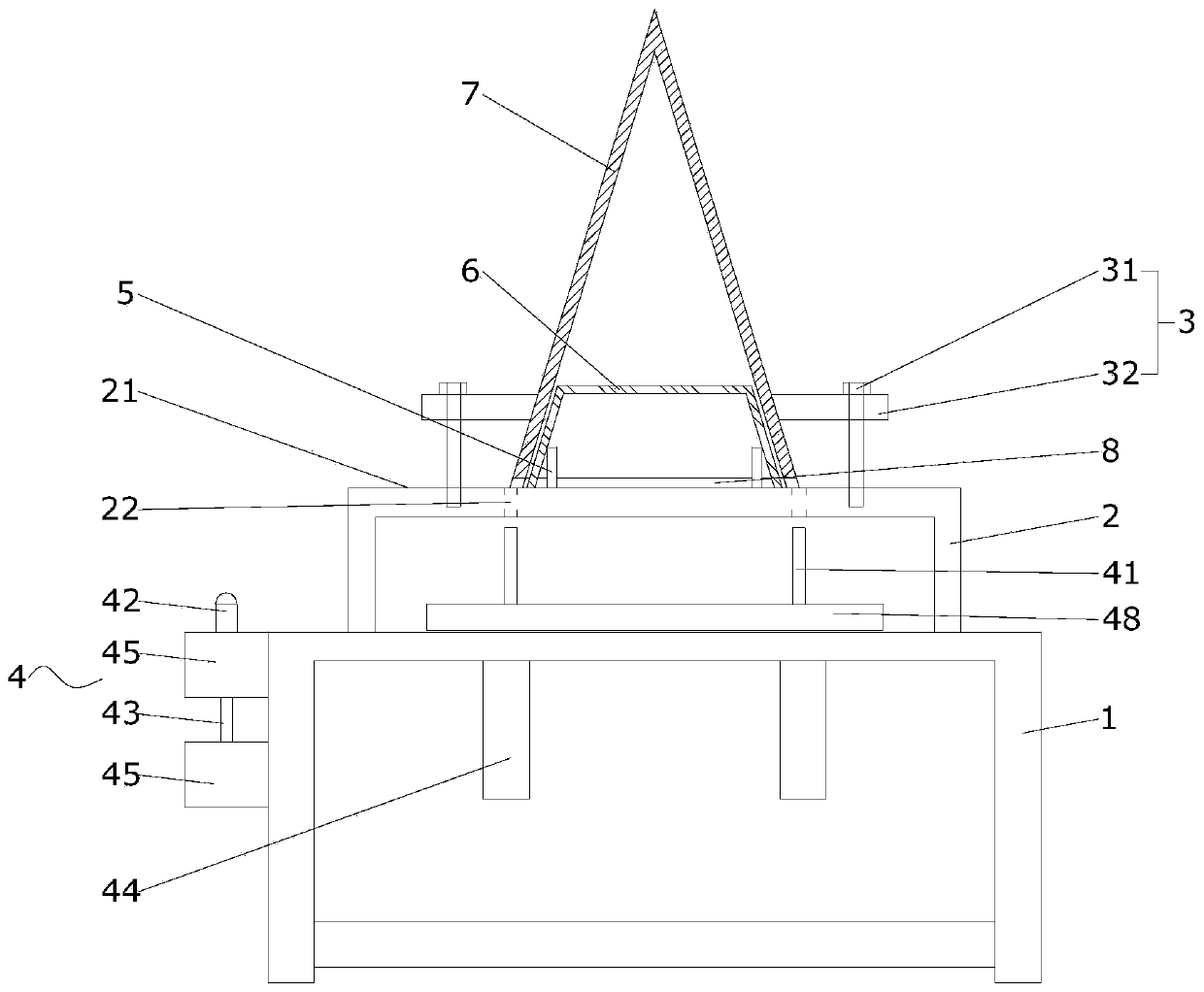

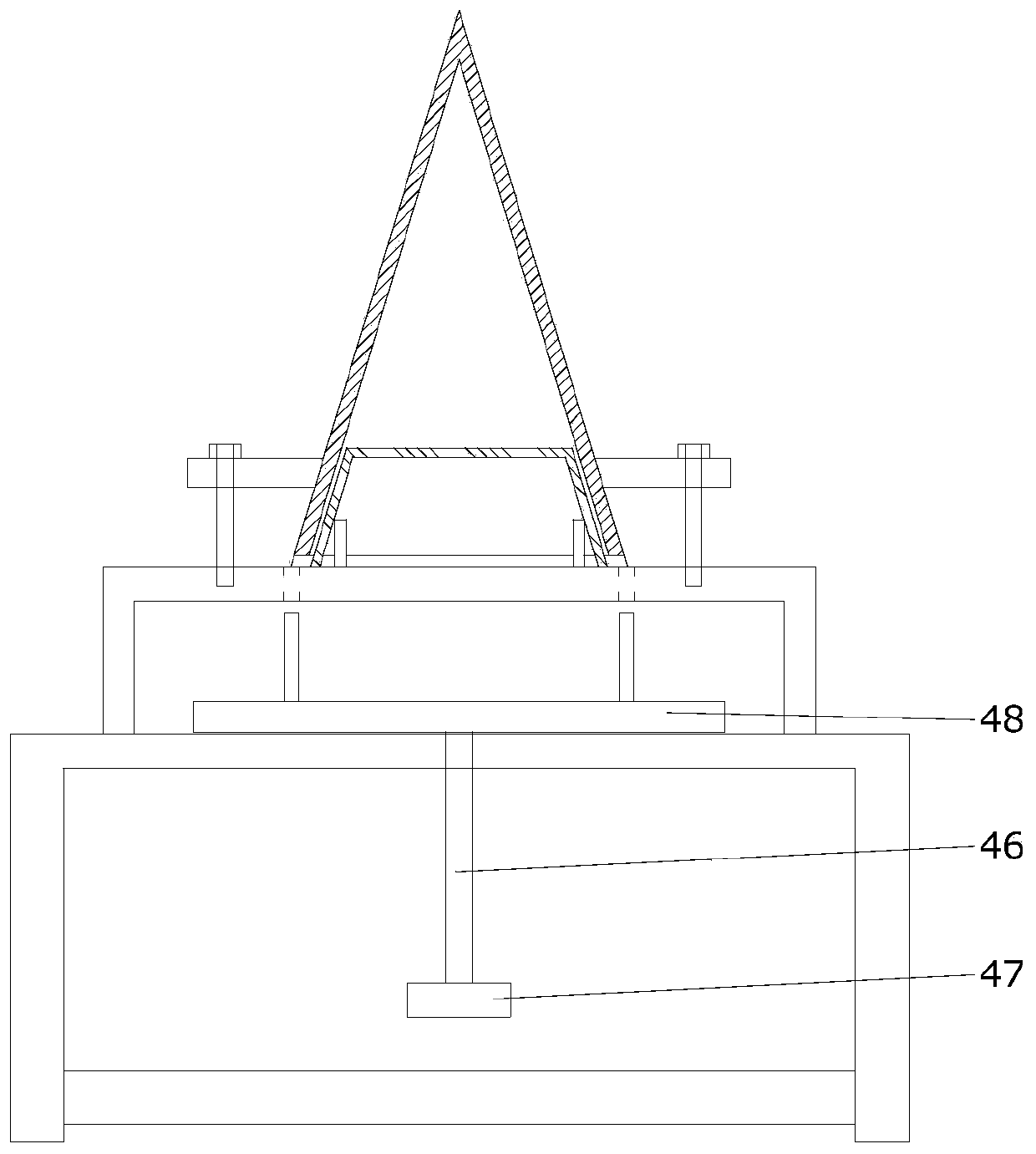

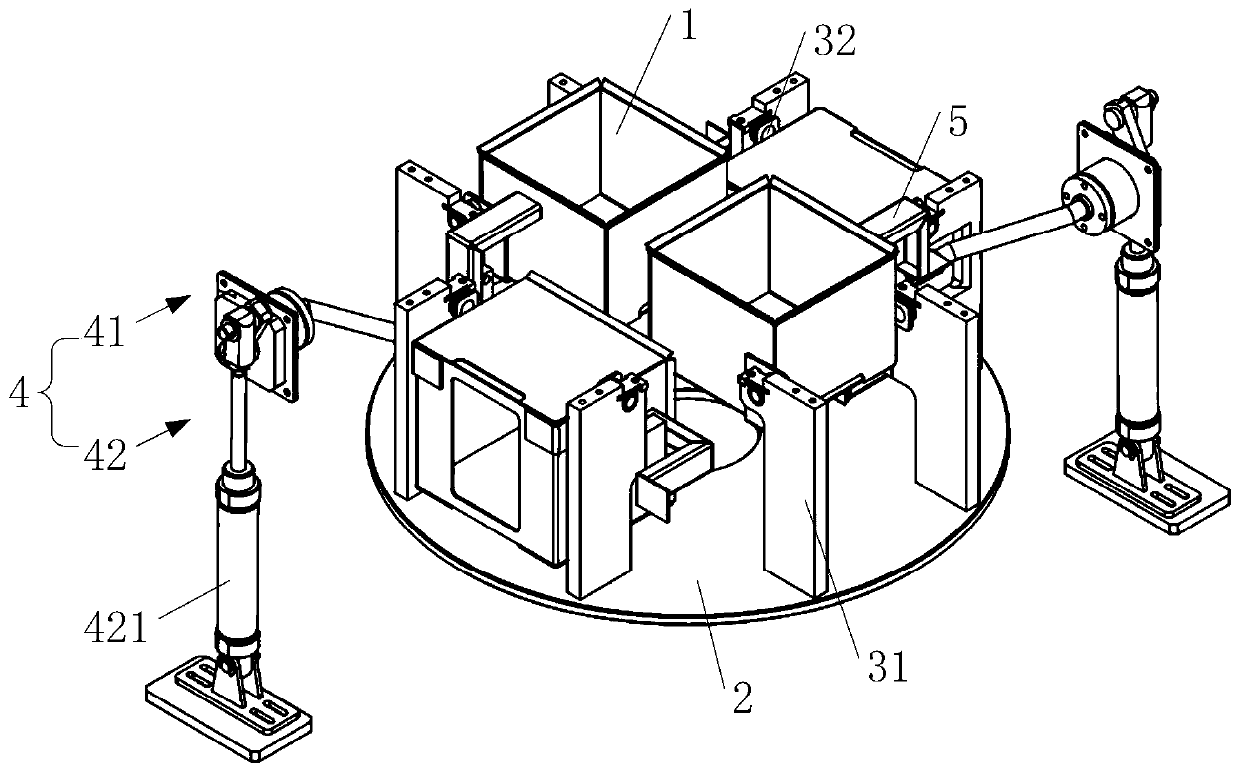

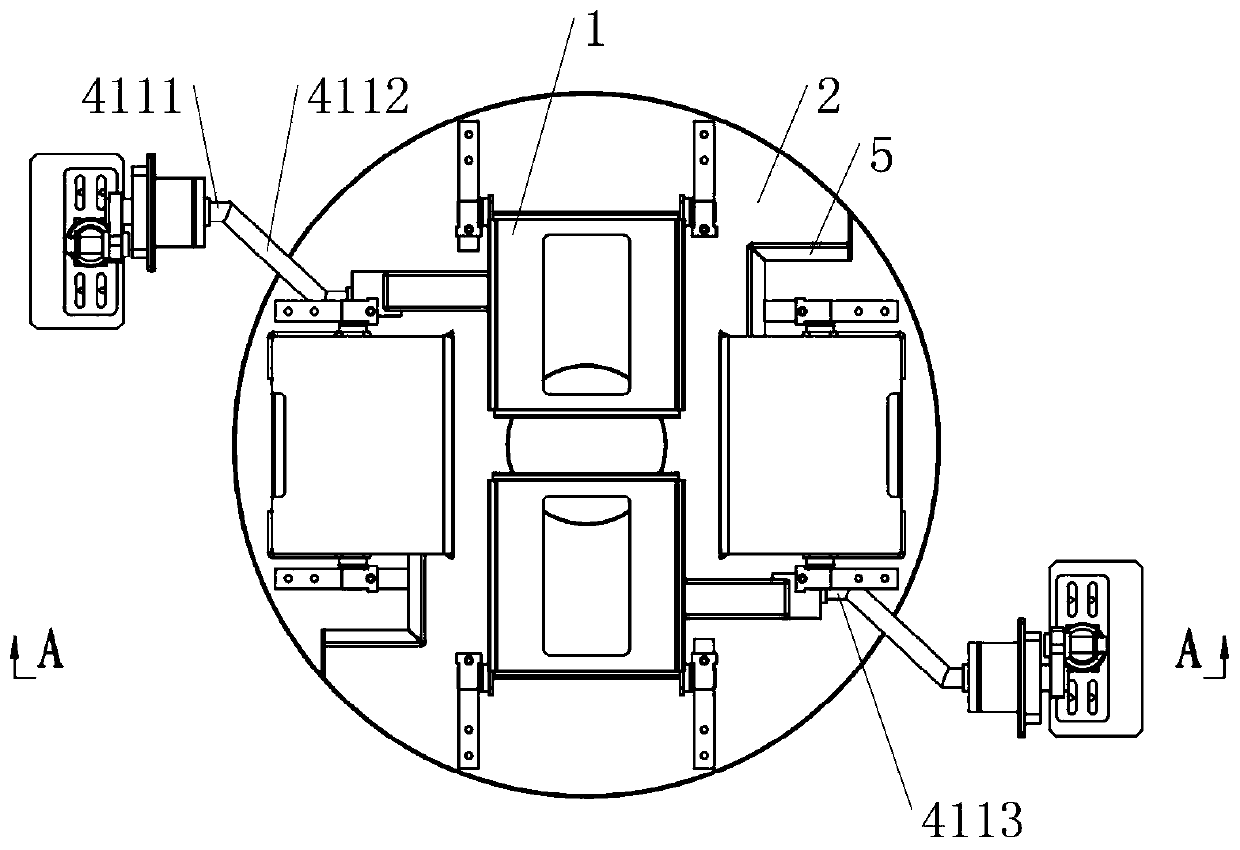

Radome bonding tool and bonding method thereof

The invention discloses a radome bonding tool. The radome bonding tool is characterized in that a bonding platform is installed on a base, a positioning piece is arranged on the working face of the bonding platform so as to position a metal ring, a lifting device is arranged below the bonding platform, the lifting device comprises jacking columns, the jacking columns are upwards lifted to penetrate through the bonding platform and support a radome placed over the metal ring, and a fastening device is installed on the bonding platform, is located around the radome and abuts against the radome.Meanwhile, the invention discloses a method for bonding the radome by using the bonding tool. Bonding is carried out through forward mounting of the radome, the bonding effect between the radome and the metal ring is excellent, the situation that an adhesive flows to the inner wall surface of the radome is avoided for a formed product, and the cost control optimization caused by the use of the adhesive is reduced; the bonding process shortens the curing period and is beneficial to mass production; and by using the bonding tool, manual contact with the radome is reduced, the human risk is reduced, the labor cost is reduced, and the mechanization level is improved.

Owner:FESHER AVIATION COMPONENTS ZHENJIANG

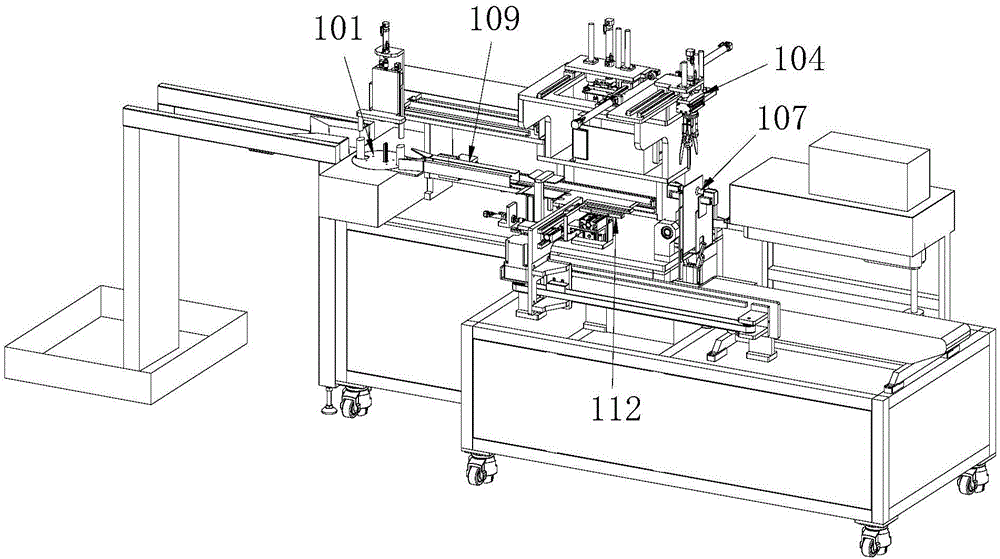

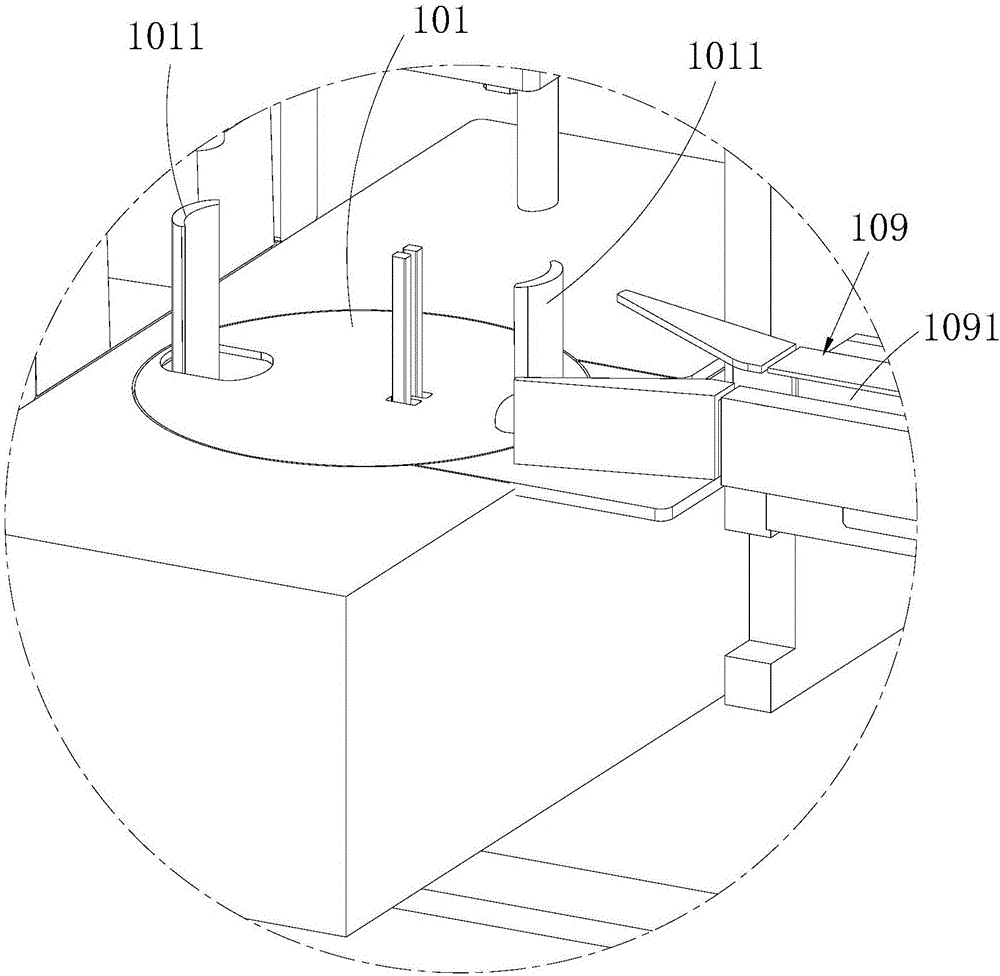

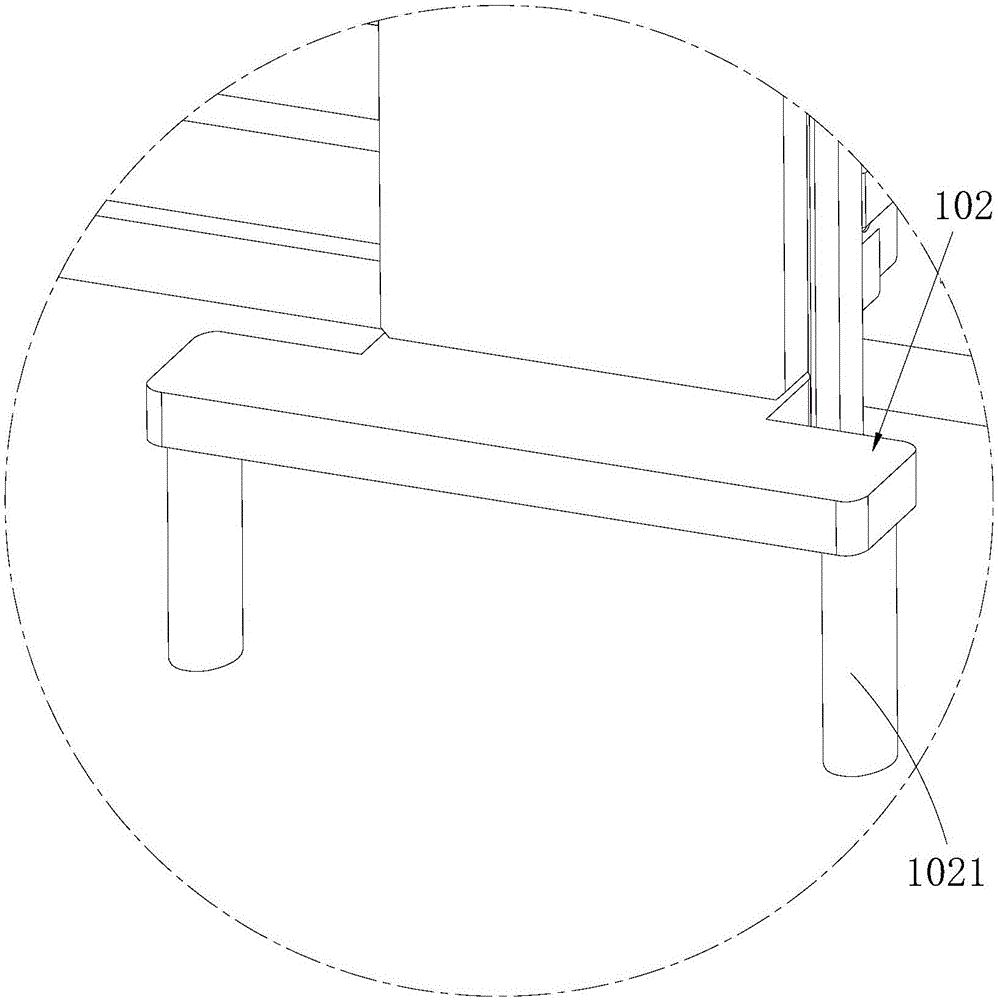

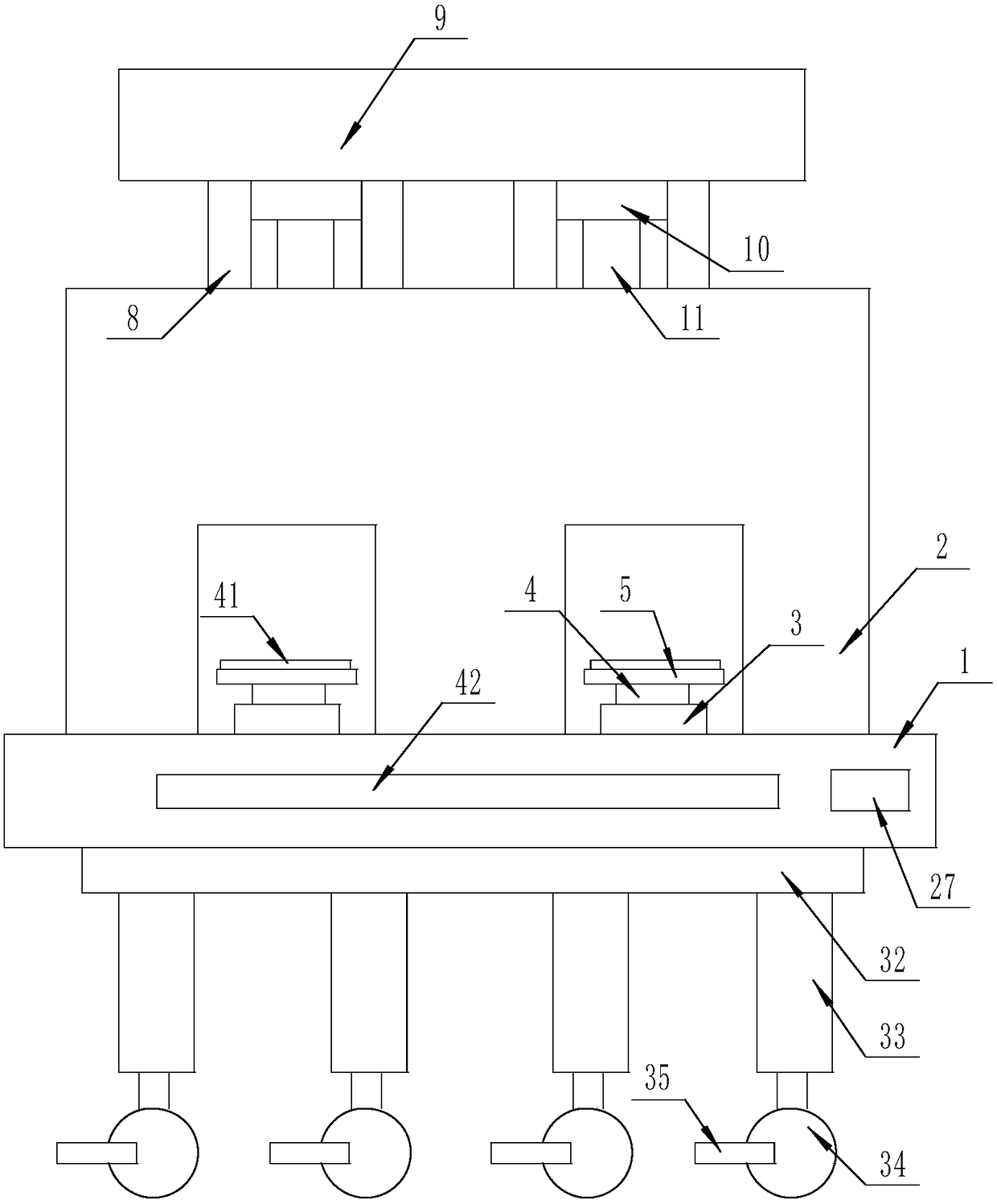

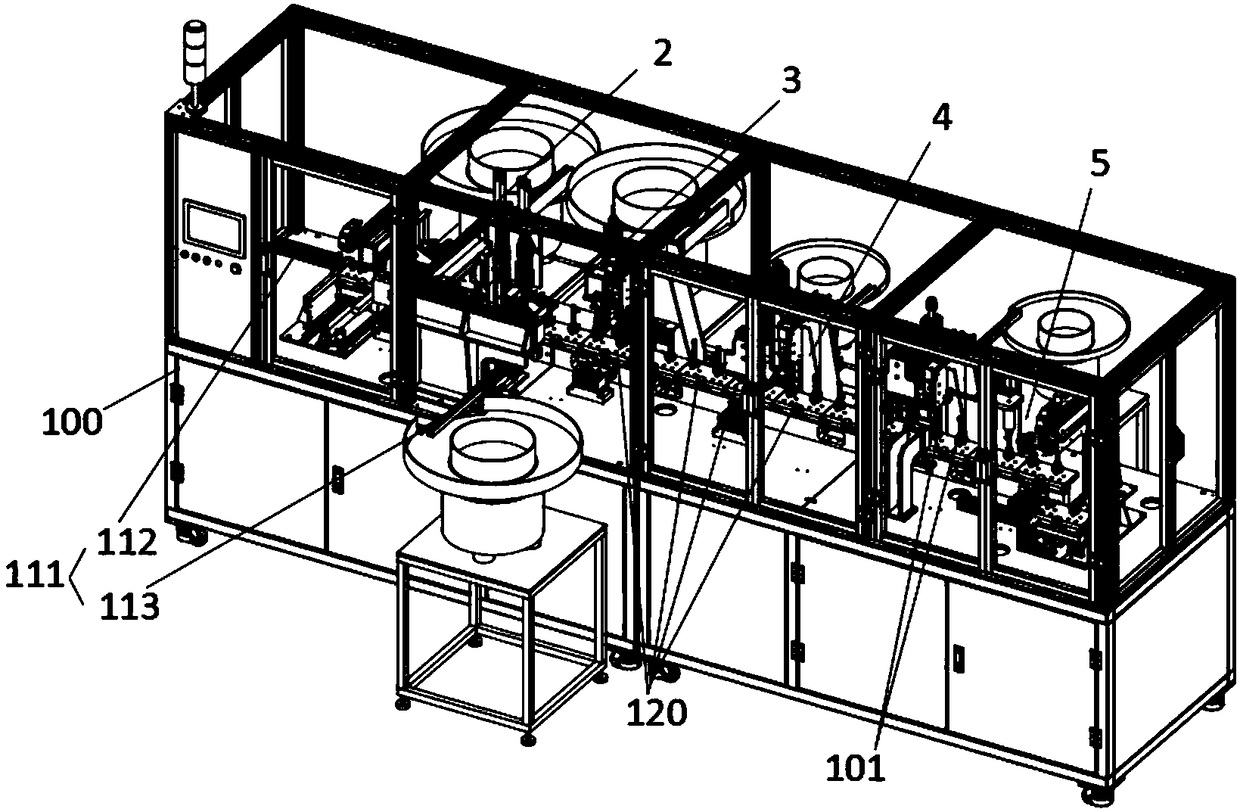

Automatic coiling and packaging equipment of consumable items such as catheters

ActiveCN106364753AReduce human contactReduce the probability of contaminationWrapper twisting/gatheringIndividual articlesCatheterEngineering

The invention relates to the technical field of packaging of consumable items such as catheters and discloses automatic coiling and packaging equipment of the consumable items such as the catheters. The equipment comprises a wire coiling table, a bag sucking and expanding mechanism expanding openings of bags, a bag sucking and rotating mechanism sucking the bags in the bag sucking and expanding mechanism and rotating the bags to the vertical state, a bag clamping mechanism clamping the bags sucked by the bag sucking and rotating mechanism, a bag closing mechanism closing the openings of the bags and a moving insertion strip packaging the consumable items such as the catheters into the bags and moving the bags containing the consumable items such as the catheters to the bag sucking and rotating mechanism; the wire coiling table is provided with two wire coiling heads for coiling the consumable items such as the catheters; and a moving strip moving the consumable items such as the catheters on the wire coiling table into the moving insertion strip is arranged above the moving insertion strip. Automatic packaging of the consumable items such as the catheters can be completed through sequential operation of the moving strip, the moving insertion strip, the bag sucking and expanding mechanism, the bag sucking and rotating mechanism, the bag clamping mechanism and the bag closing mechanism, the automation degree is high, the packaging efficiency is high, the cost is low, and the probability of polluting the consumable items such as the catheters is lowered.

Owner:SHENZHEN BEICHENG AUTOMATION EQUIP

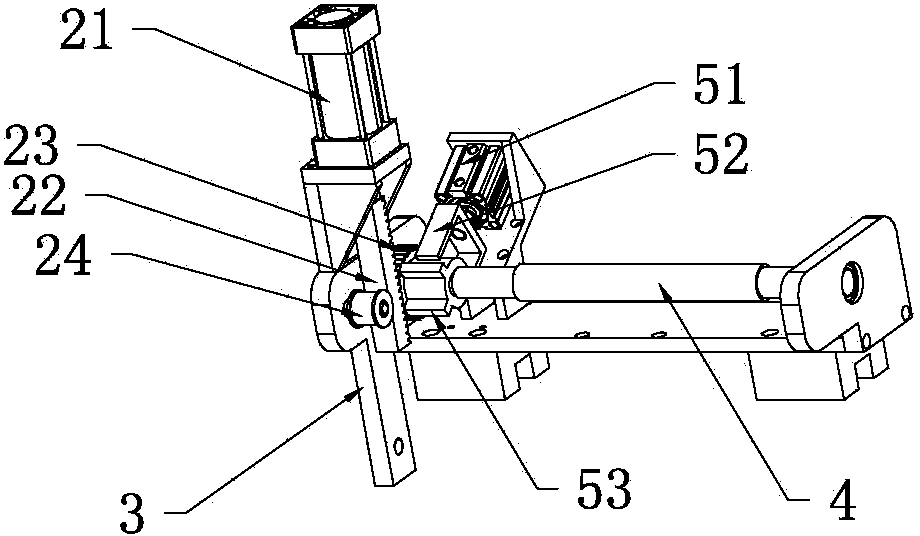

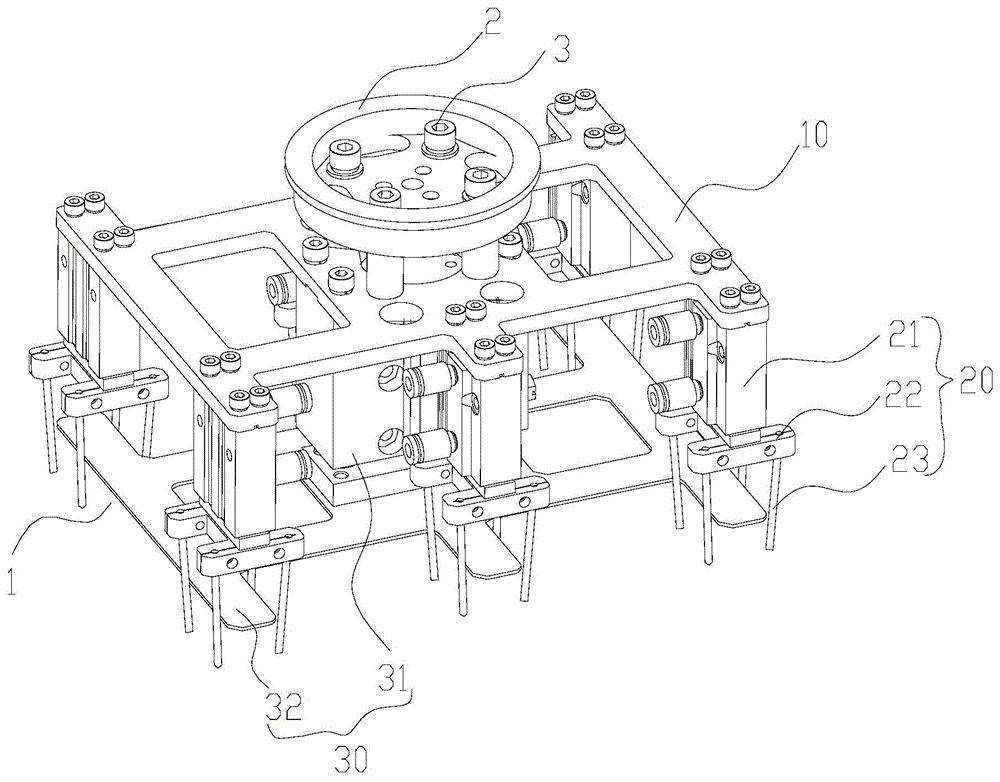

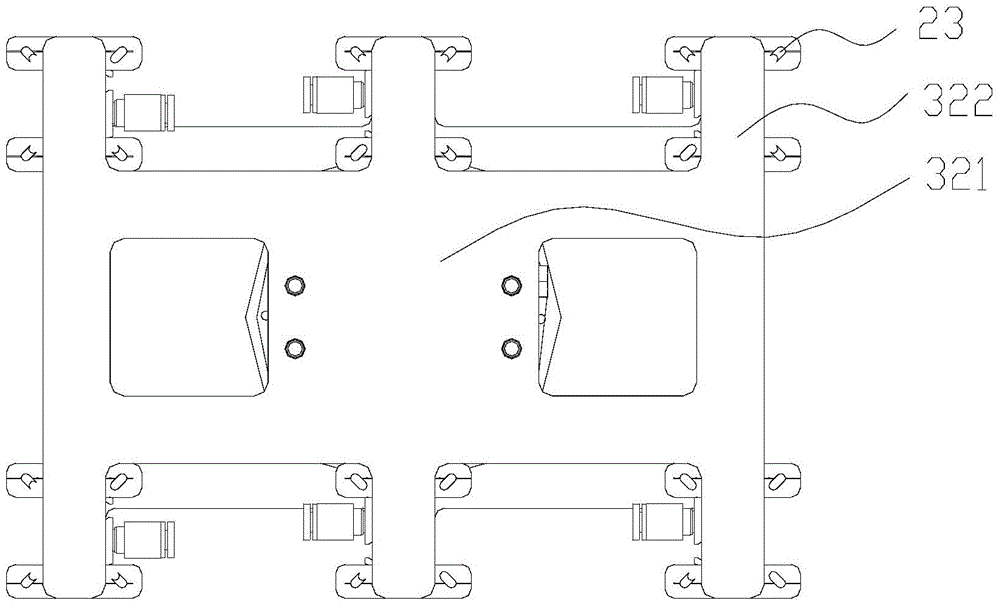

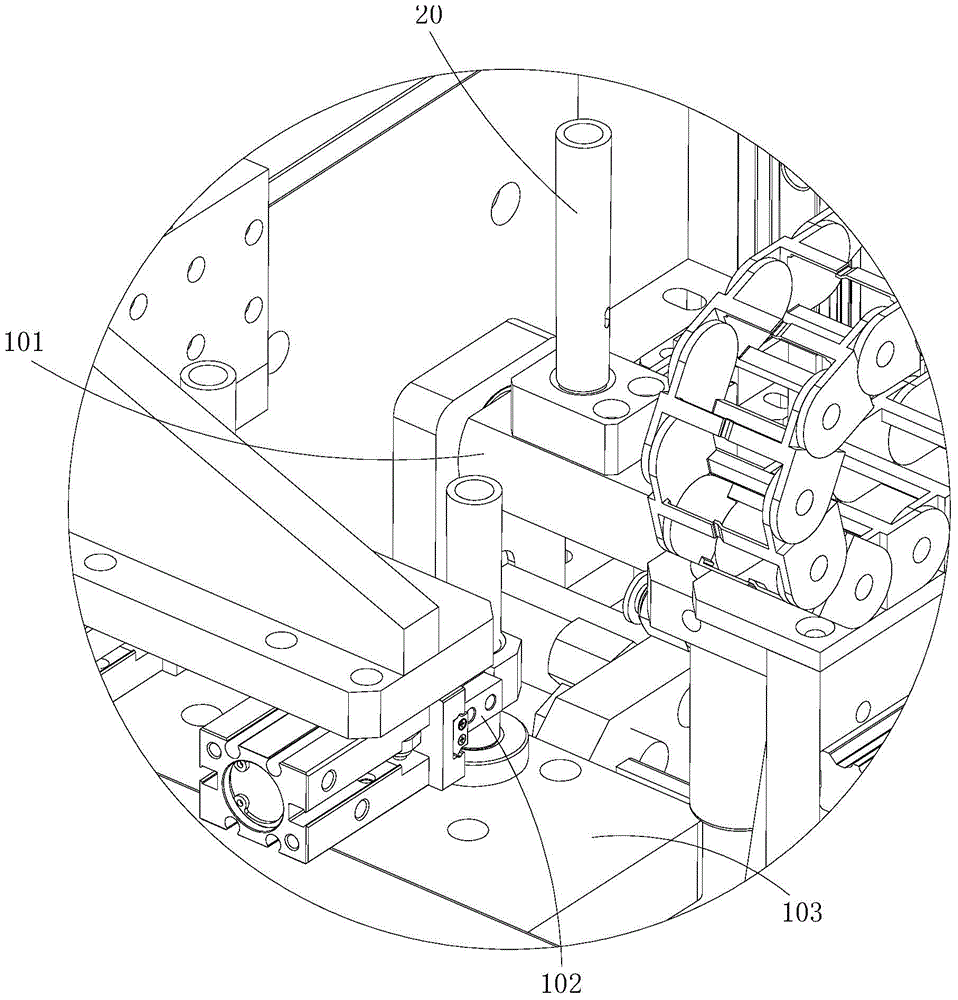

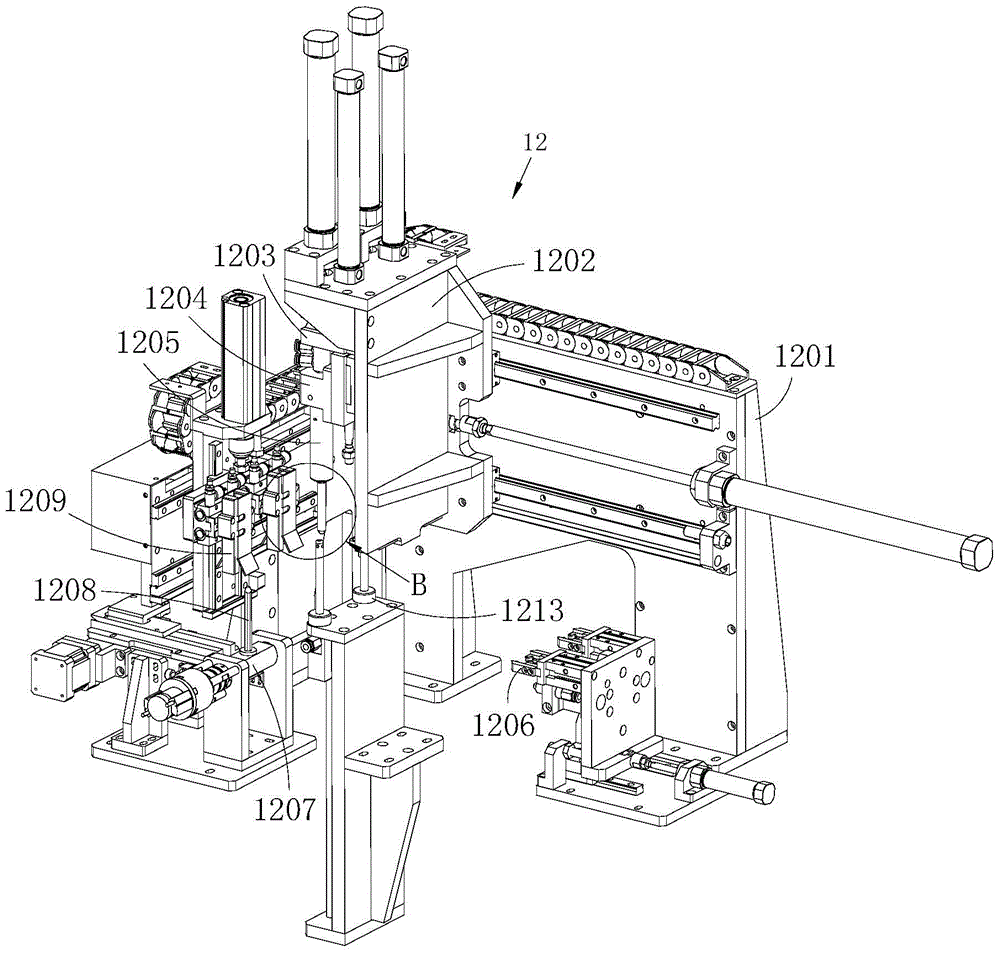

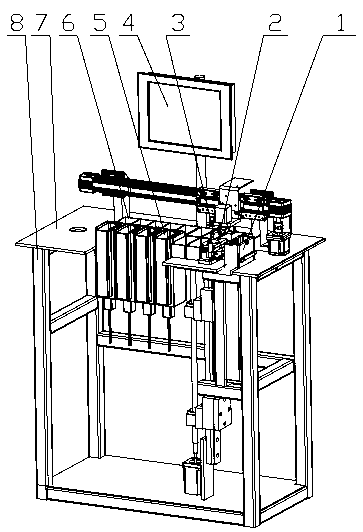

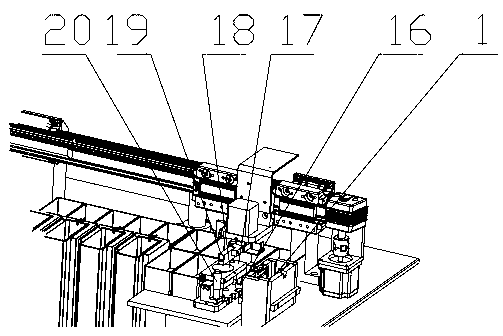

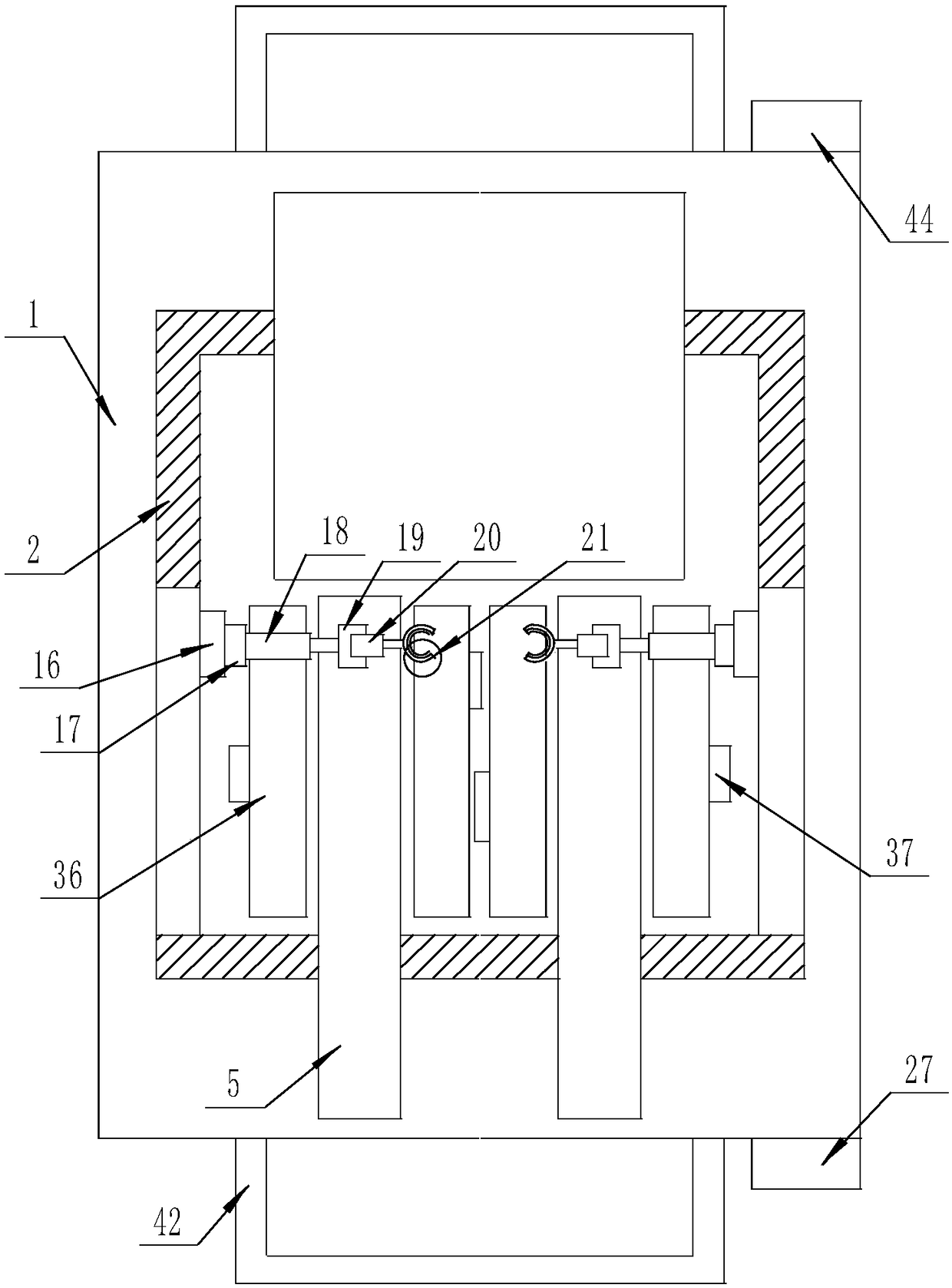

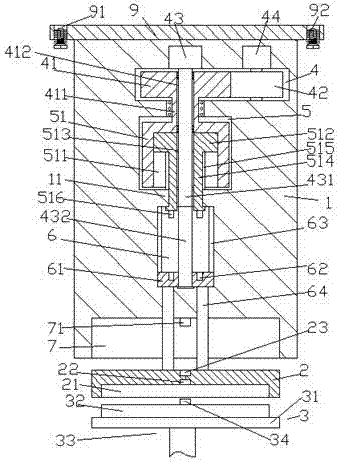

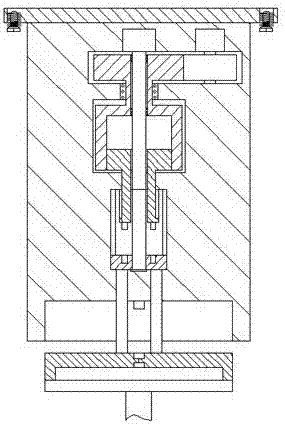

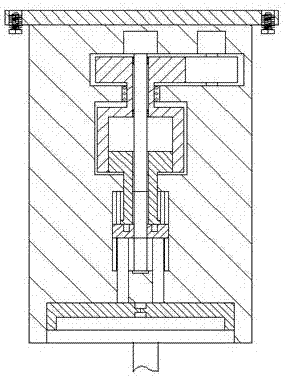

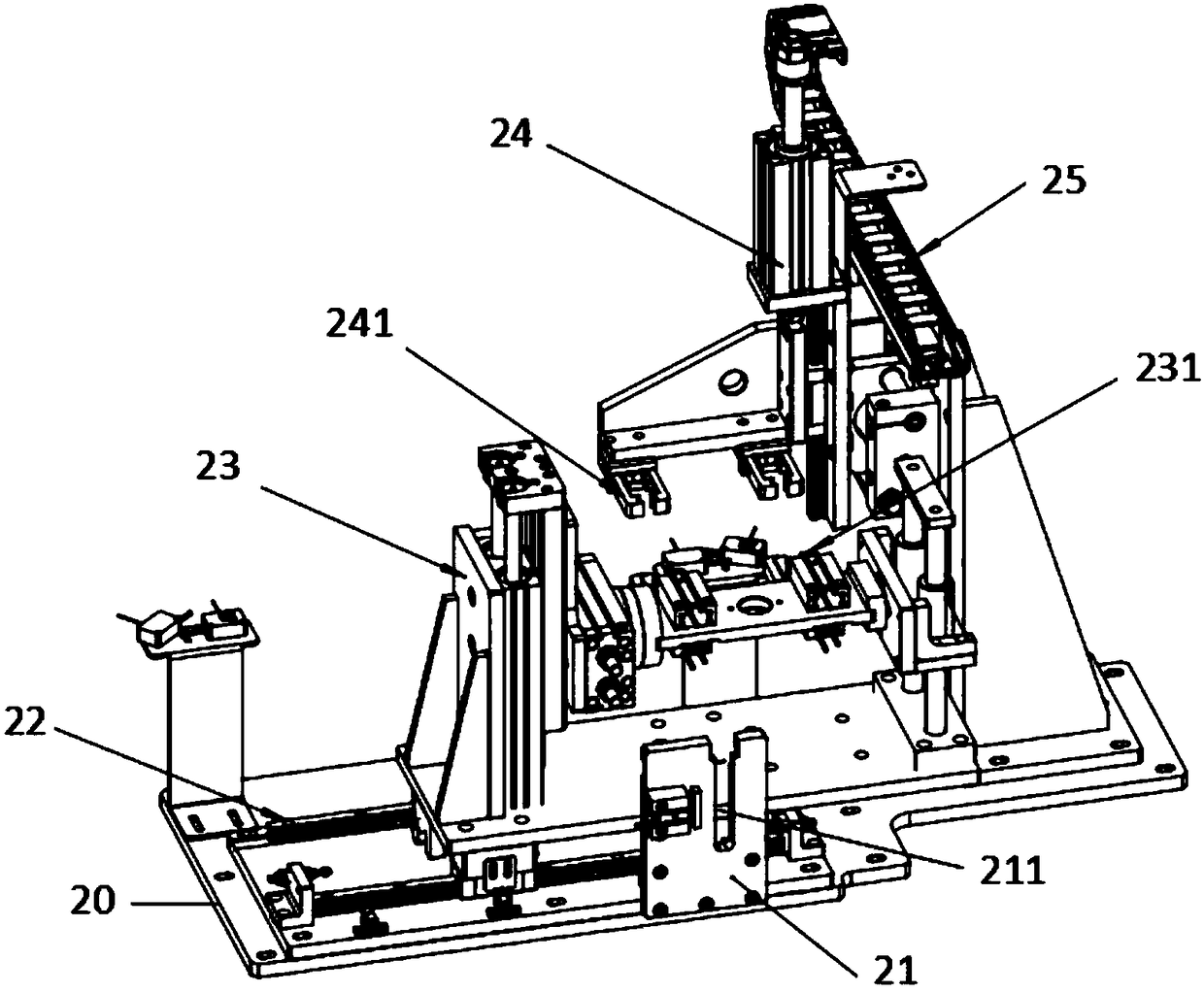

Automatic assembly equipment for infusion pump core

ActiveCN104786057AImplement automatic assemblyReduce human contactAssembly machinesRubber ringAutomatic test equipment

The invention relates to the technical field of infusion pump core assembly, and discloses automatic assembly equipment for an infusion pump core. The automatic assembly equipment is used for automatically assembling a guide pillar, a guide bar, a rubber sleeve and two rubber rings into the infusion pump core and comprises a horizontal guide rail and a moving base used for fixing the guide pillar. A rubber sleeve sleeving structure, a guide bar inserting structure and a rubber ring sleeving structure are sequentially arranged in the extension direction of the horizontal guide rail, wherein the rubber sleeve sleeving structure is used for sleeving the guide pillar with the rubber sleeve, the guide bar inserting structure is used for inserting the lower end of the guide bar into the guide pillar from top to bottom with the upper end of the guide bar exposed out of the guide pillar and making the end of the guide bar sleeved with the rubber sleeve, and the rubber ring sleeving structure is used for sleeving the periphery of the lower end and the periphery of the upper end of the rubber sleeve with the two rubber rings respectively. By means of the automatic assembly equipment for the infusion pump core, the whole infusion pump core can be automatically assembled without manual operation, so that time consumption is low, and efficiency is high; besides, contact between workers and the infusion pump core is reduced, so that it is avoided that the infusion pump core is contaminated, and potential safety hazards in use are avoided.

Owner:SHENZHEN BEICHENG AUTOMATION EQUIP

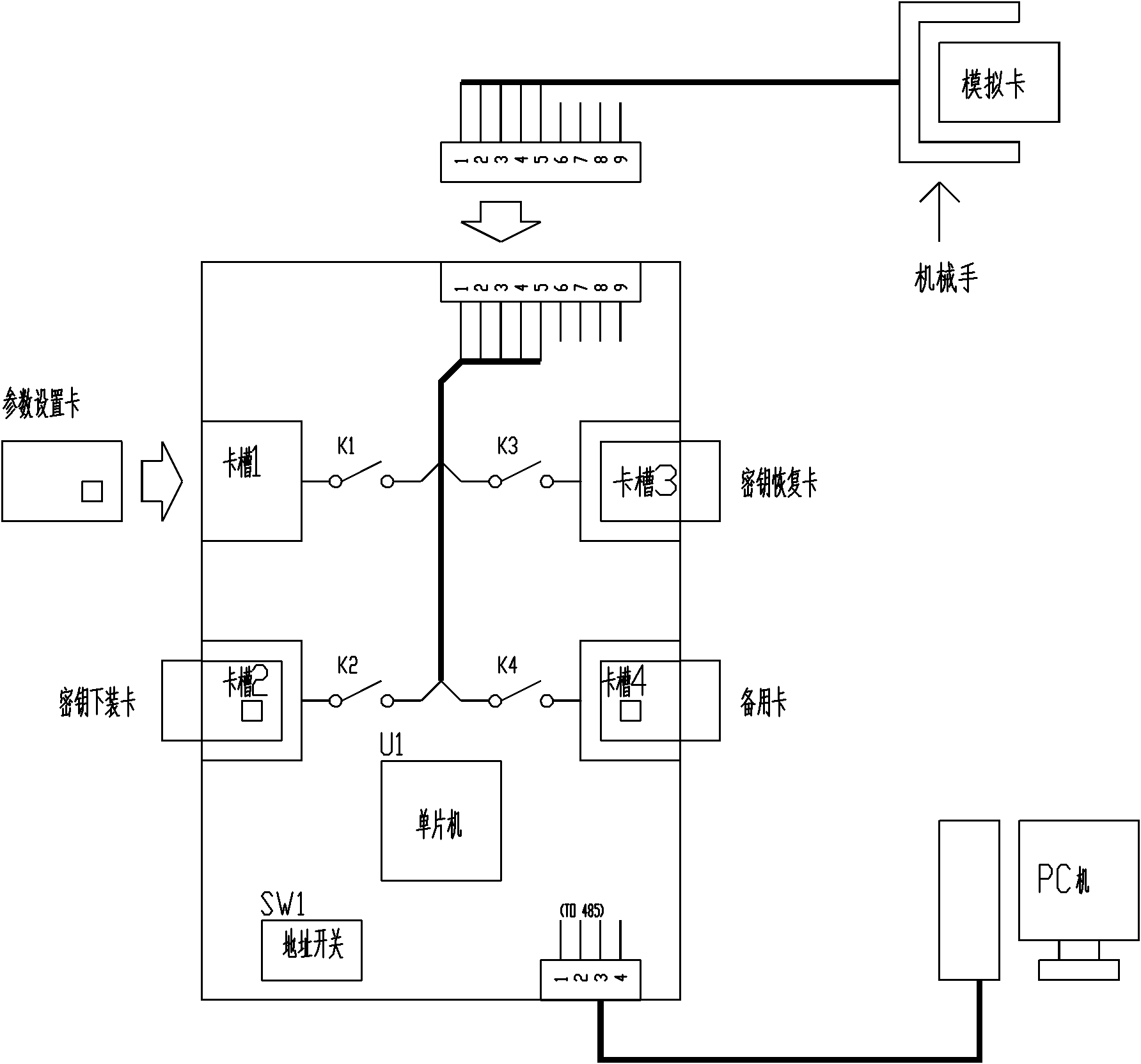

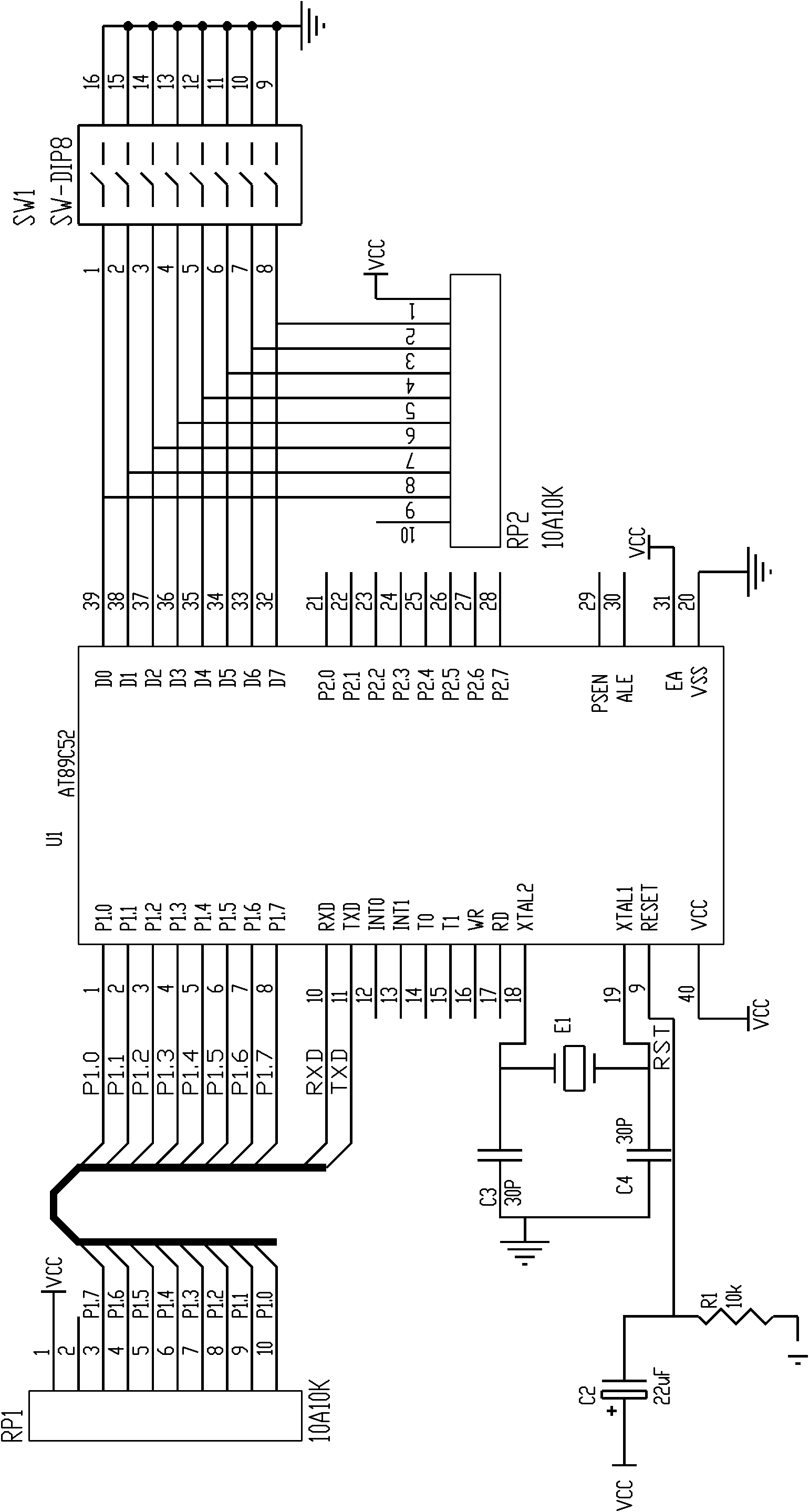

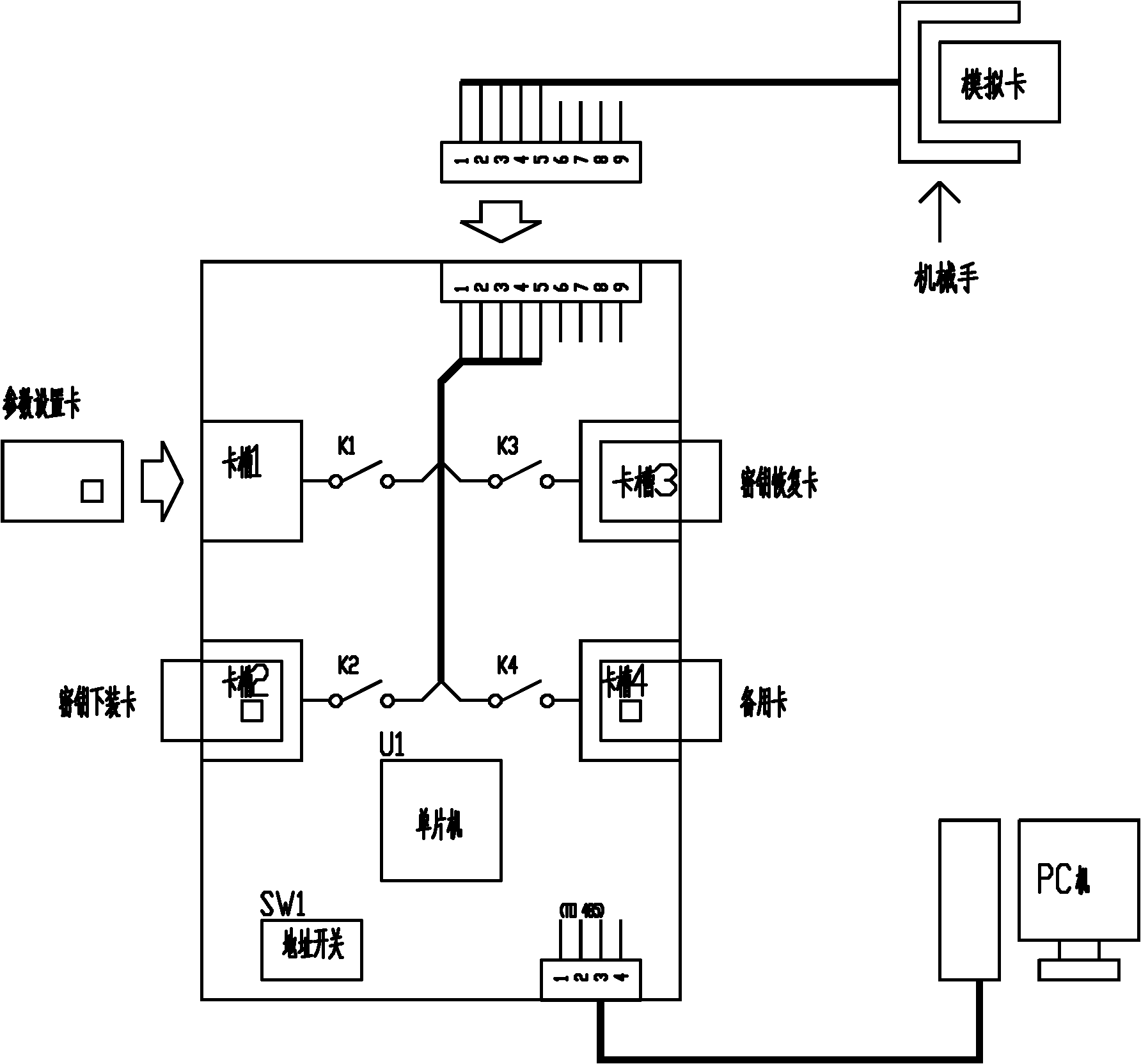

Automatic card inserting device and method for detecting electric energy meter

InactiveCN102121980AImprove personal safetyRealize fully automatic operationElectrical measurementsApparatus for hiring articlesMicrocontrollerComputer module

The invention relates to an automatic card inserting device and method for detecting an electric energy meter, relating to an automatic card inserting device and method. At present, the functions, such as presetting and zero clearing of parameters of an electric energy meter, local secret key downloading, and the like, of an intelligent electric energy meter are fulfilled by inserting, extracting and replacing a card manually, therefore labor intensity is high, time and energy are wasted, efficiency is lower, and error possibility is higher. The automatic card inserting device is characterized by comprising a master control computer, a master control module and an analog card, wherein the master control module comprises a singlechip, a switching unit, a plurality of card slots and functional cards, wherein the switching unit is connected with an I / O (Input / Output) port of the singlechip, the plurality of card slots are connected with the switching unit, and the functional cards correspond to the card slots; the master control module is connected with the analog card in a communication way through a data line; and the master control computer is provided with a card reading module, an analog card contact judgment module and an automatic card replacement control module. The invention realizes the full-automatic operation without inserting, extracting and replacing the card manually, so that the manpower is decreased and the work efficiency, the reliability and the personal safety of workers are enhanced.

Owner:STATE GRID ZHEJIANG ELECTRIC POWER +1

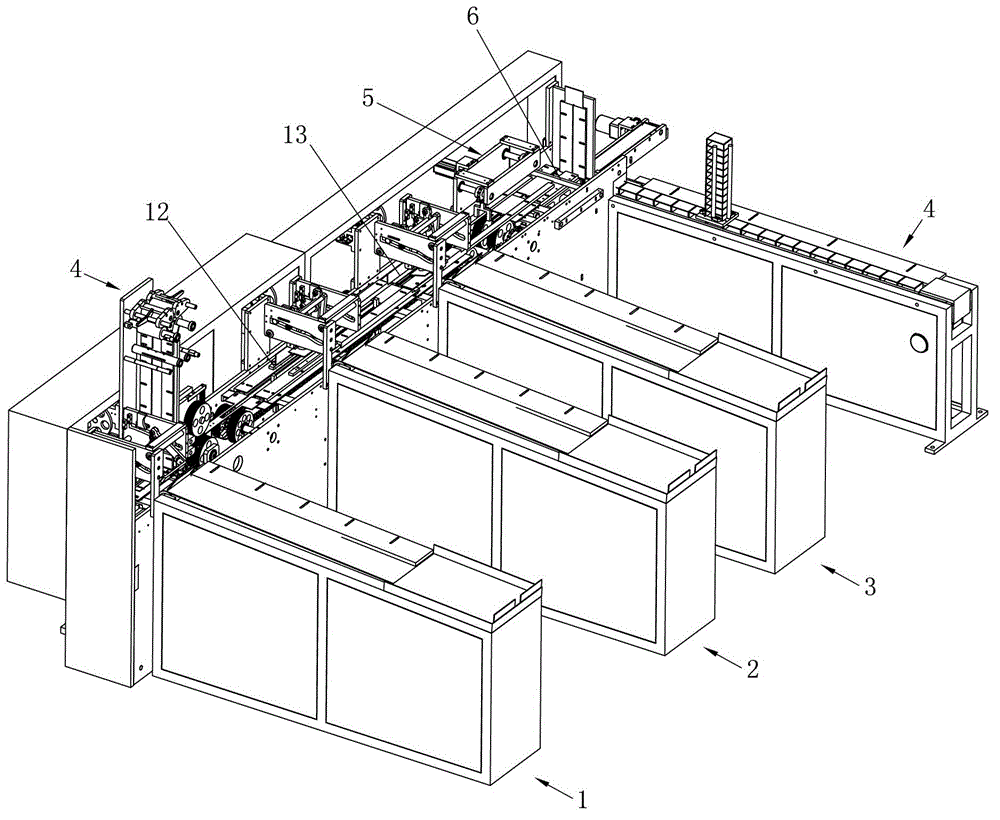

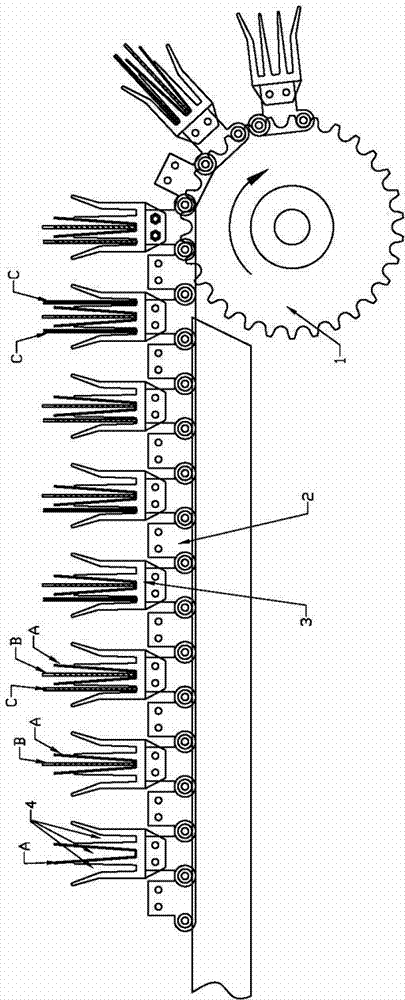

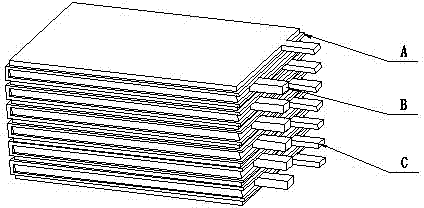

Group distribution streamline of lead storage battery plate wrapping machine

InactiveCN103165944AAvoid interferenceGuaranteed accuracyFinal product manufactureLead-acid accumulators constructionSprocketEngineering

The invention relates to relates to a lead storage battery manufacture device, and concretely relates to a group distribution streamline of a lead storage battery plate wrapping machine used for the lead storage battery plate wrapping machine. the group distribution streamline comprises an annular chain driven by a sprocket wheel and moved in a cycle mode, the annular chain has a horizontal conveying segment used for conveying a group part; a plurality of carriages capable of synchronously moving with the chain are successively arranged on the annular chain, three slots with parallel arrangement are provided on the carriage, a plugboard station used for inserting a separator plate, a positive plate and a negative plate is arranged outside the horizontal conveying segment; and a removal station used for removing a group part on the carriage is arranged at the end of the horizontal conveying segment. According to the invention, the separator plate, the positive plate and the negative plate of the lead storage battery group are distributed and combined in order according to the requirement, the lead storage battery manufacture device is in favor of raising production efficiency, the phenomenon that staff contacts with harmful metal can be reduced.

Owner:JIANGSU RONGWEI ENVIRONMENTAL PROTECTION TECH

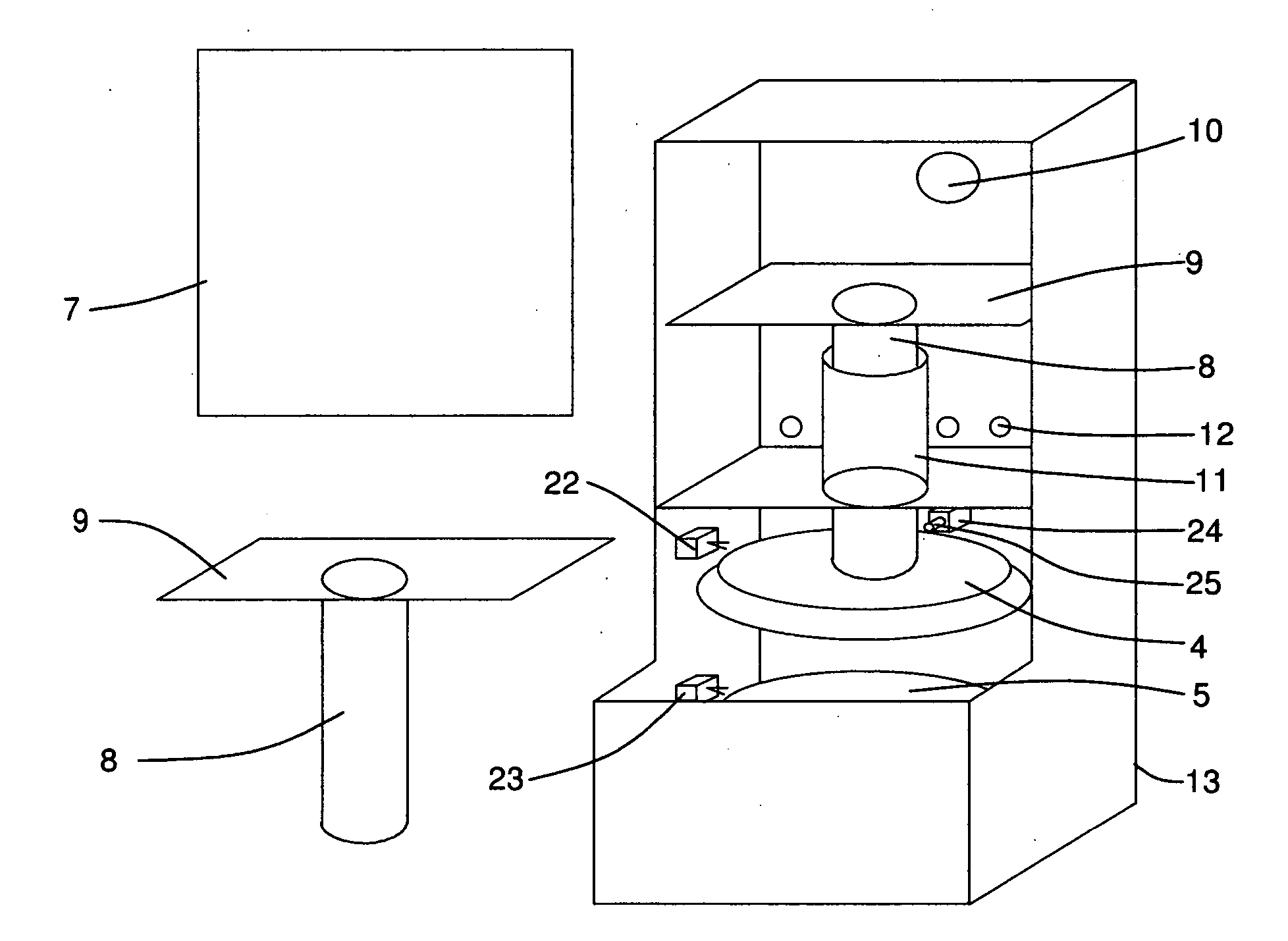

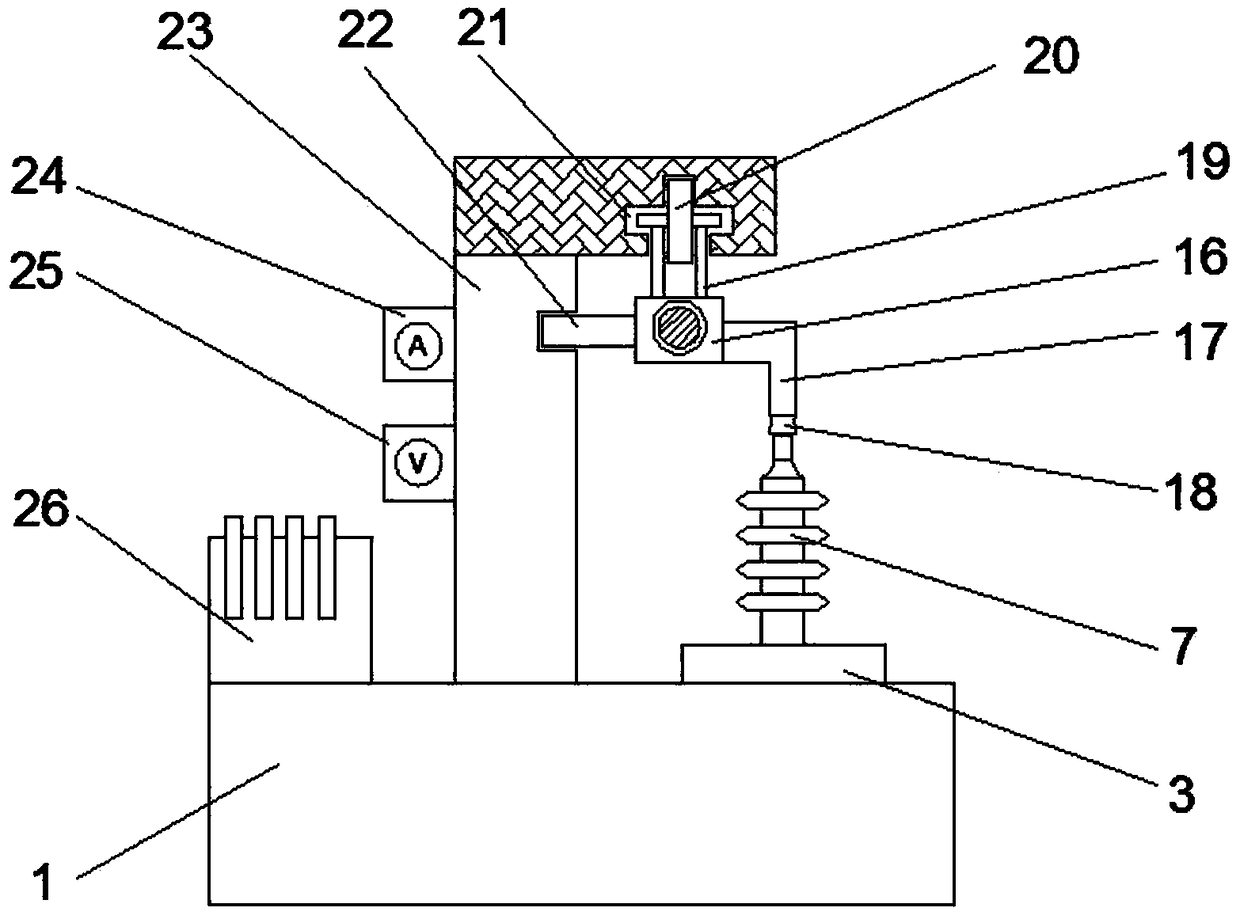

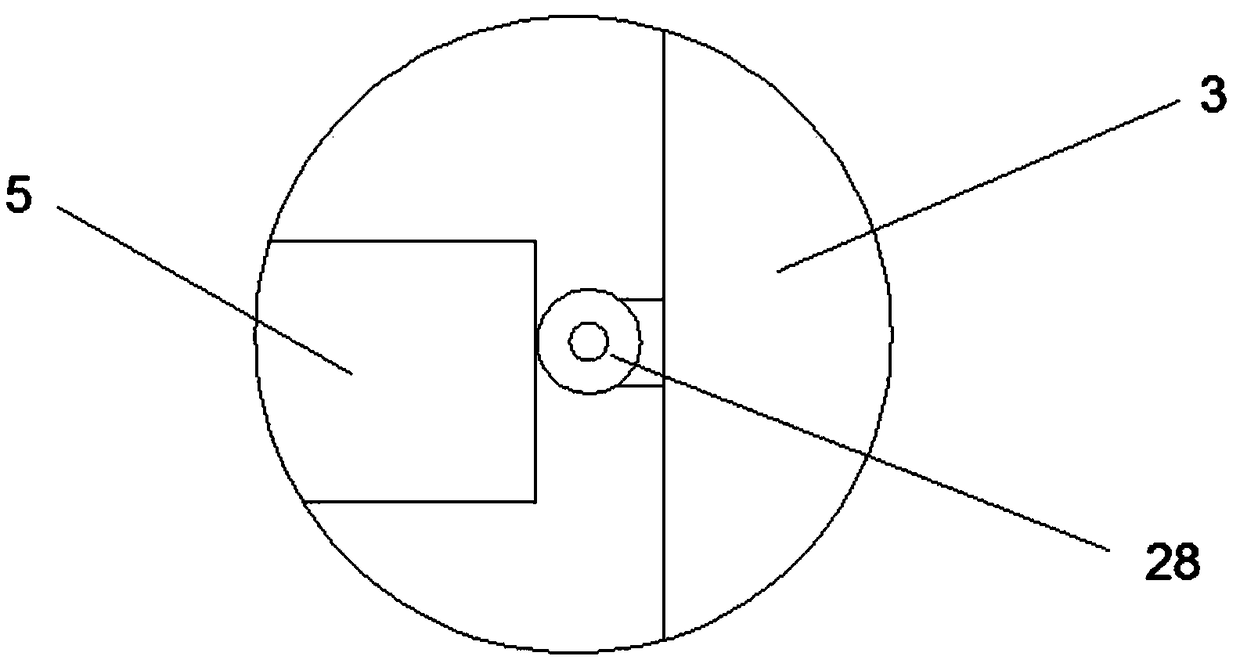

Quartz crystal wafer thickness sorting machine with wafer arranging function and sorting and wafer arranging method

The invention discloses a quartz crystal wafer thickness sorting machine with a wafer arranging function. The quartz crystal wafer thickness sorting machine comprises a feeding module, a thickness measuring module, a sorting module and a discharging module. The feeding module delivers crystal wafers in place, and the crystal wafers are transferred by an upper electrode to the thickness measuring module to be subjected to thickness measurement. The sorting module sorts the crystal wafers into different material boxes according to measurement results of the thickness measuring module. A part of material boxes is connected with the discharging module. The crystal wafers in the part of material boxes are discharged through the discharging module. The quartz crystal wafer thickness sorting machine can achieve quartz crystal wafer full-automatic sorting and discharging functions, feeding, measurement, sorting and wafer arrangement are controlled by independent motors, the wafer thickness measuring speed can be remarkably improved, the quartz crystal wafer thickness sorting machine has the wafer arranging function after sorting, man-made wafer contact probability can be reduced, and wafer damage rate is reduced. The invention further discloses a quartz crystal wafer thickness sorting and wafer arranging method.

Owner:RES INST OF ZHEJIANG UNIV TAIZHOU

Turnover structure and wafer spin-drying equipment

ActiveCN110034051AMitigation efficiencyAlleviate waste of manpowerSemiconductor/solid-state device manufacturingState of artEngineering

The invention relates to the technical field of semiconductor wafer processing devices, in particular to a turnover structure and wafer spin-drying equipment. The turnover structure is applied to thewafer spin-drying equipment, and comprises a bearing box, a rotary disc and a turnover device; the bearing box is rotationally connected to the rotary disc; and the turnover device is in driving connection with the bearing box and can drive the bearing box to turn over on the rotary disc. The wafer spin-drying equipment comprises the turnover structure. According to the turnover structure and thewafer spin-drying equipment, the technical problems that in the prior art, the wafer spin-drying equipment is relatively low in efficiency, wastes labor and easily causes pollution to wafers are relieved.

Owner:BEIJING SEMICON EQUIP INST THE 45TH RES INST OF CETC

Full-automatic fruit processing device

The invention discloses a full-automatic fruit processing device. The full-automatic fruit processing device comprises strip bearing plates, wherein a full-automatic fruit processing device body is arranged on the upper surfaces of the strip bearing plates; a supporting and travelling mechanism is arranged at edges of the lower surfaces of the strip bearing plates; and a fruit bearing mechanism isarranged on the inner side of the supporting and travelling mechanism, on the lower surfaces of the strip bearing plates. The full-automatic fruit processing device disclosed by the invention has thebeneficial effects that the using is very convenient; fruits of different sizes are convenient to automatically peel and remove kernels, and are also convenient to perform sheet-form cutting throughcontrolling to perform appropriate processing, so that manual contact is reduced, bacteria carried by fruits are reduced, and the edible health of people is guaranteed.

Owner:徐文斌

Novel electric-power power supply apparatus

ActiveCN106877050AReduce human contactPrevent looseningLive contact access preventionEngineeringElectric motor

The invention discloses a novel electric-power power supply apparatus. The novel electric-power power supply apparatus comprises a socket part and a plug part which is inserted and connected below the bottom of the socket part; a first accommodating cavity, a second accommodating cavity and a third accommodating cavity are formed in the socket part from top to bottom in sequence; a combining groove is formed in the bottom end plane of the socket part; a first tooth-shaped wheel is arranged in the first accommodating cavity; the right side of the first tooth-shaped wheel is connected with a second tooth-shaped wheel in an occlusion manner; the top of the second tooth-shaped wheel is connected with a first electric motor; a rotary shaft which penetrates through the wall body of the socket body and enters the second accommodating cavity is arranged at the bottom of the first tooth-shaped wheel; a sleeve shell, the top of which is fixedly connected with the rotary shaft, is arranged in the second accommodating cavity; an inner spiral whorl cavity is formed in the sleeve shell; a telescopic block is matched and connected in the inner spiral whorl cavity in an inner spiral whorl manner; a first through groove, which is formed in an up and down penetration manner, is formed in the telescopic block; a second through groove, which is formed in an up and down penetration manner, is formed in the first tooth-shaped wheel and the rotary shaft; a rotary pin shaft, which is arranged in an up and down extension manner, is arranged in the second through groove; the top end of the rotary pin shaft is connected with a second electric motor; an extension section at the bottom of the rotary pin shaft passes through the second through groove and the inner spiral whorl cavity to enter the third accommodating cavity.

Owner:江苏凯顺电气有限公司

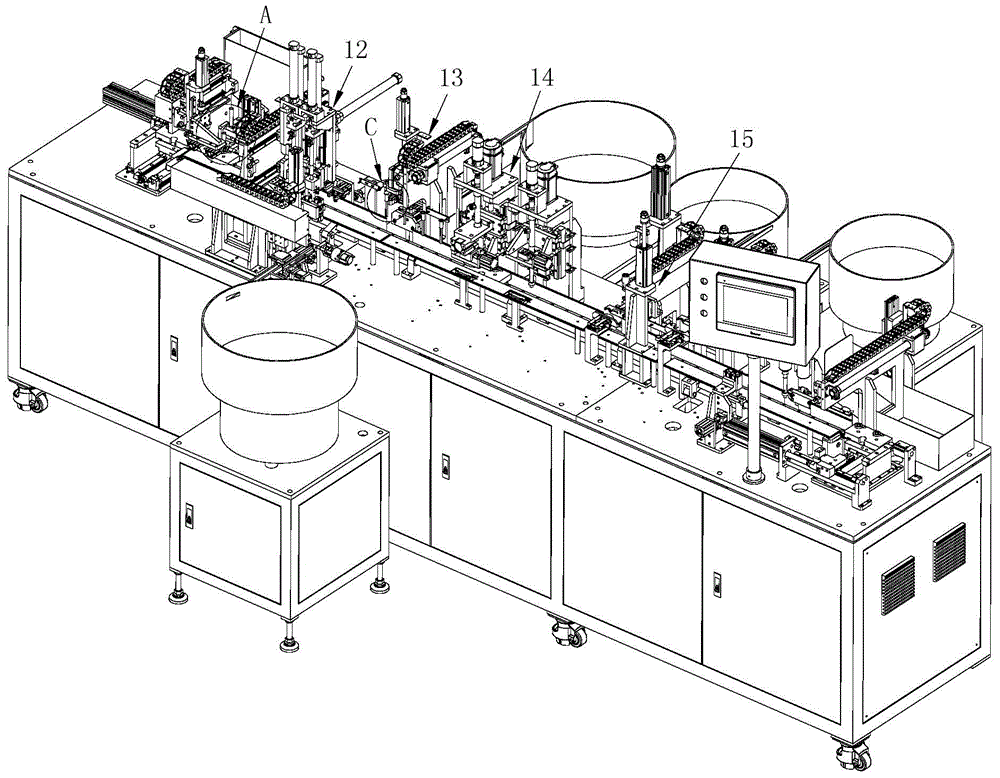

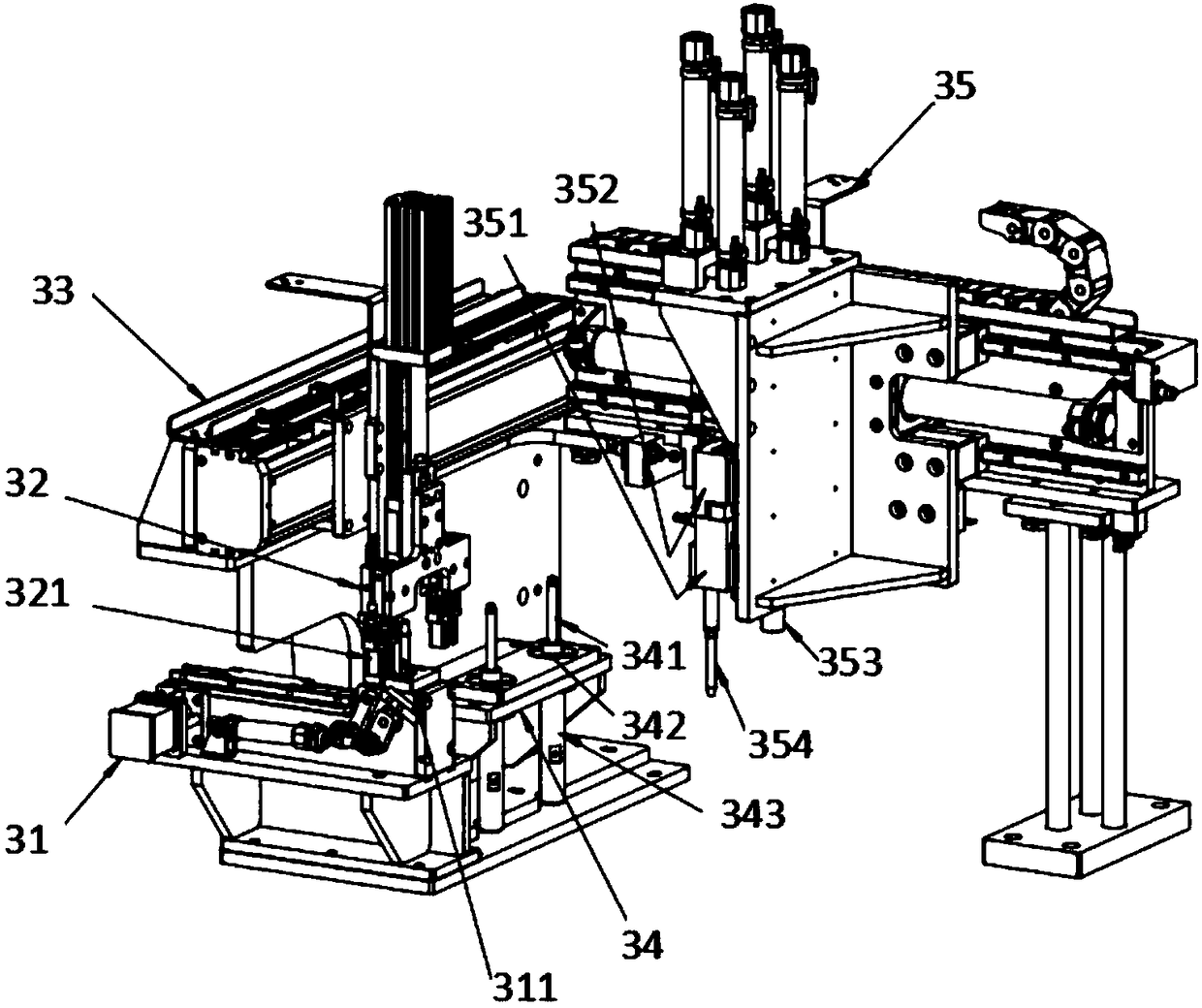

High-quality automatic assembly equipment for pump core of infusion pump and assembly method of automatic assembly equipment

PendingCN108161431AImplement automatic assemblyReduce human contactAssembly machinesAutomatic test equipmentSilica gel

The invention discloses high-quality automatic assembly equipment for a pump core of an infusion pump and an assembly method of the high-quality automatic assembly equipment. The high-quality automatic assembly equipment comprises a horizontal sliding rail; moving and carrying jig plates which move along the horizontal sliding rail and are used for locating bases are arranged on the horizontal sliding rail; a base charging mechanism, a silicone tube assembly mechanism, a top rod assembly mechanism and a silicone ring assembly mechanism are sequentially arranged on the two sides of the horizontal sliding rail along the horizontal sliding rail; the base charging mechanism takes out, lifts, and turns over the bases and then puts the bases onto the moving and carrying jig plates; the siliconetube assembly mechanism allows silicone tubes to sleeve the bases; the top rod assembly mechanism inserts top rods into the bases from top to bottom; the tips of the upper ends of the top rods are exposed out of the bases and thus the silicone tubes sleeve the tips of the bases; and the silicone ring assembly mechanism allows two silicone rings to sleeve the peripheries of the upper end and the lower end of the silicone tubes. With the utilization of the high-quality automatic assembly equipment, complicated work by artificial assembly can be replaced, the assembly quality problem is solved, the locating accuracy, the assembly precision and the assembly efficiency are improved, and the assembly automation is realized.

Owner:苏州泽尔塔自动化有限公司

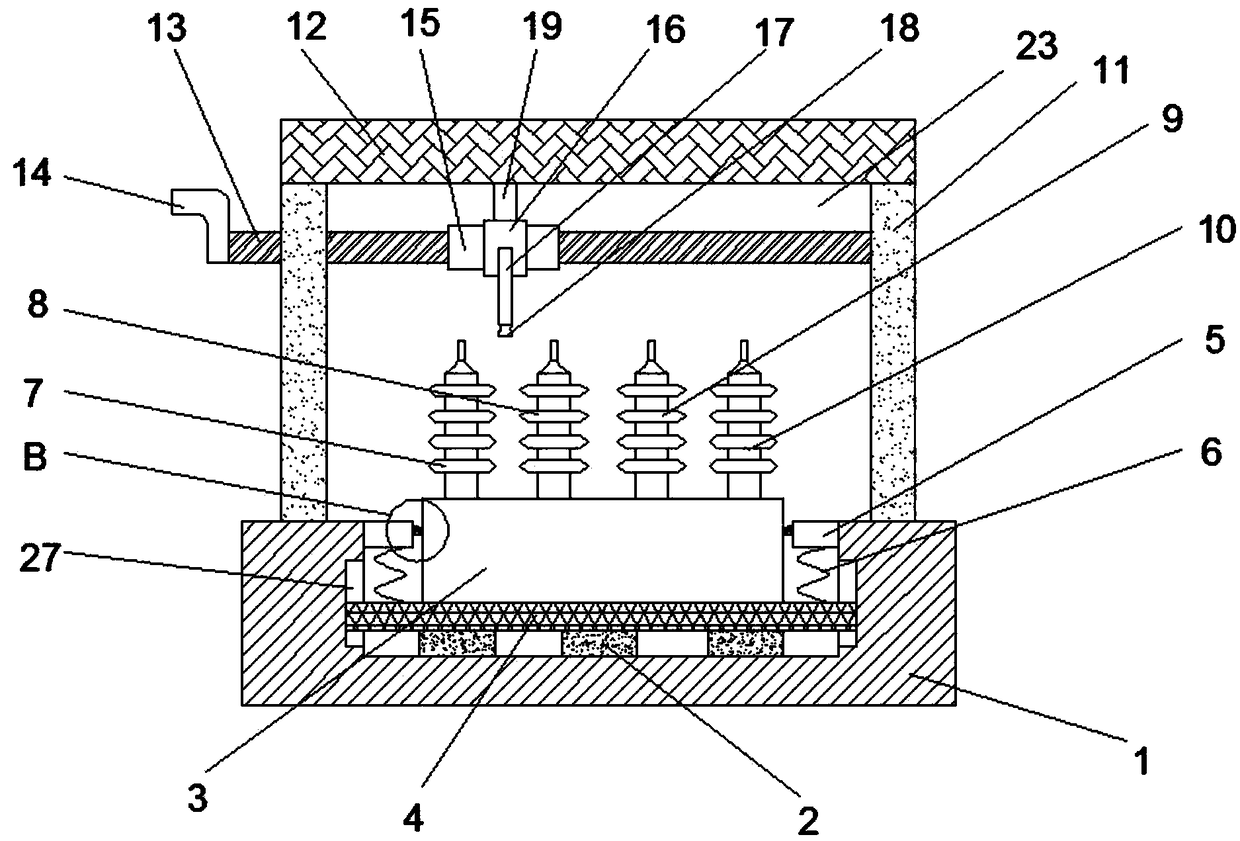

Experimental device for distribution line overvoltage protector

InactiveCN109142921AAccelerateImprove experimental efficiencyElectrical testingEngineeringSlide plate

The invention discloses an experimental device for a distribution line overvoltage protector. The experimental device comprises a bottom disc, wherein a box body is sleeved in the bottom disc, the lower end of the box body is provided with a sliding plate, the left and right sides of the upper part of the bottom disc are provided with anti-dropping plates, a buffer spring is arranged between the sliding plate and each of the two anti-dropping plates, a first terminal is arranged at the left side of the upper end of the box body, a second terminal is arranged at the right end of the first terminal on the upper end of the box body, a third terminal is arranged at the right end of the second terminal on the upper end of the box body, and a fourth terminal is arranged at the right side of theupper end of the box body. During operation, a screw rod rotates in a vertical plate and drives a cylinder to move leftwards and rightwards, and a contact at the lower end of a connecting rod can be in contact with the plurality of terminals in sequence, thereby accelerating the speed of the experiment and improving the efficiency of the experiment. A travelling wheel slides in a top slot, the contact moves more steadily, and the screw rod can save manual contact with the contact, thereby avoiding a safety accident caused by electric leakage, and improving the usage safety of equipment.

Owner:ANHUI SHUORI PHOTOELECTRIC TECH

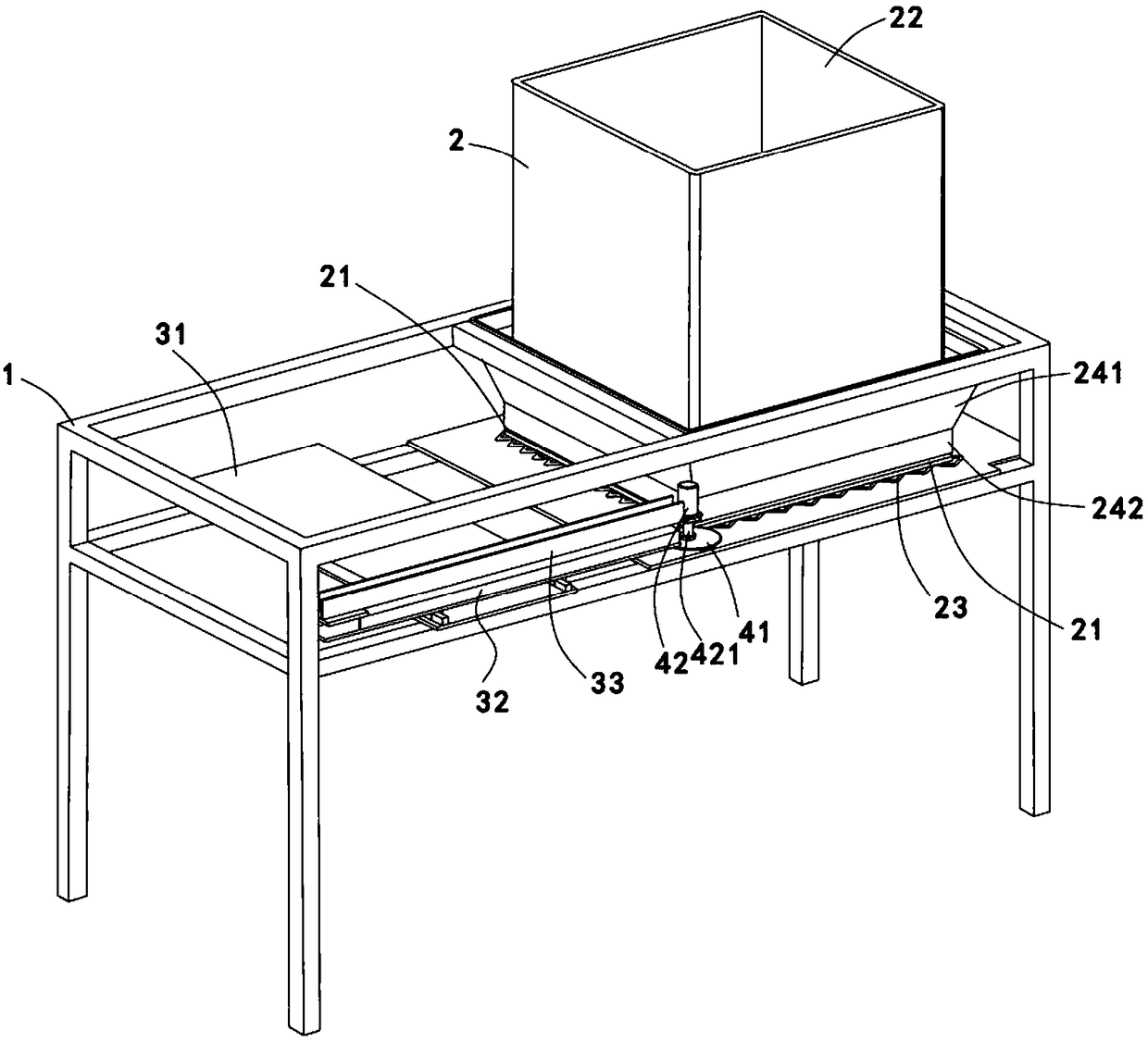

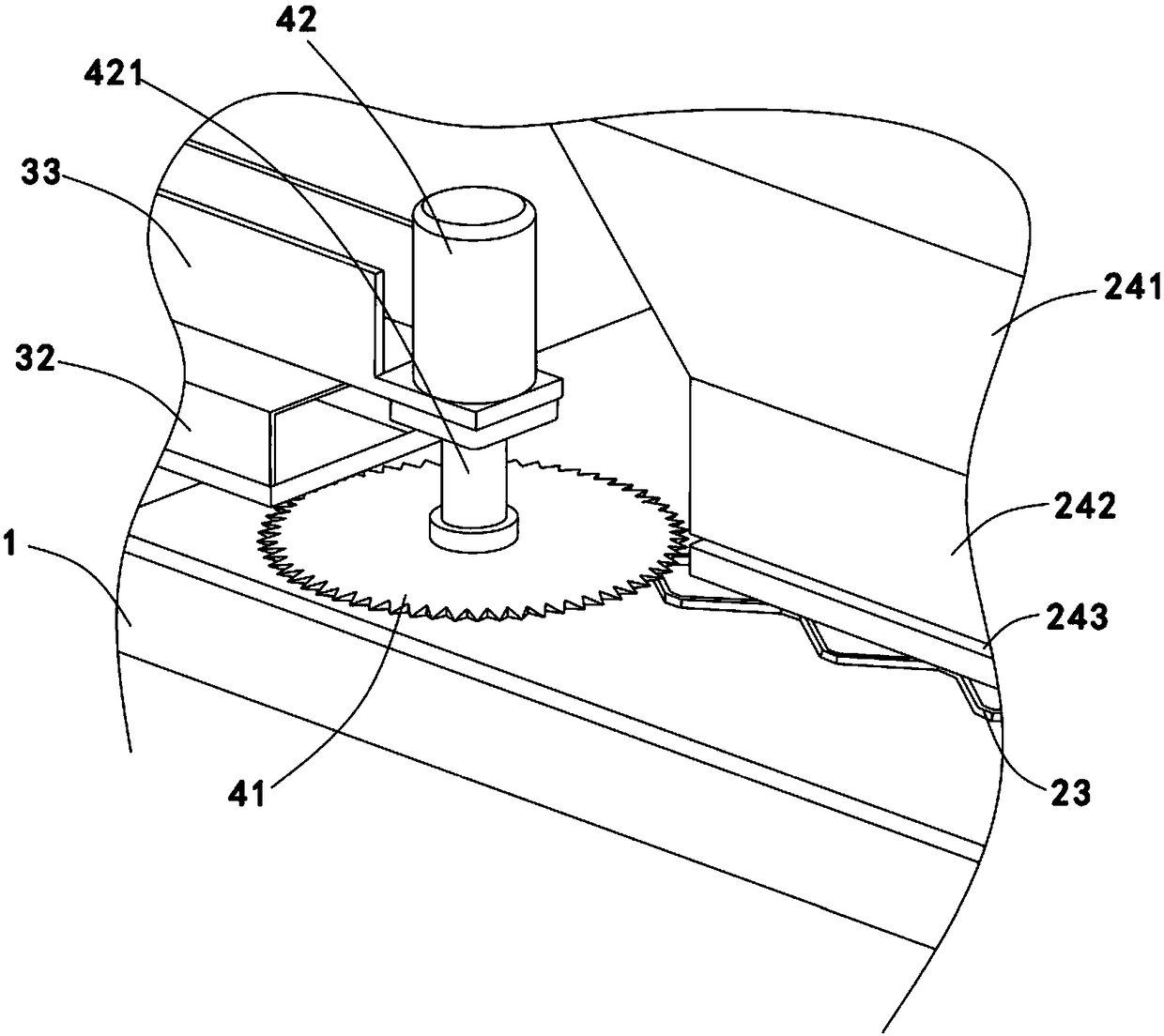

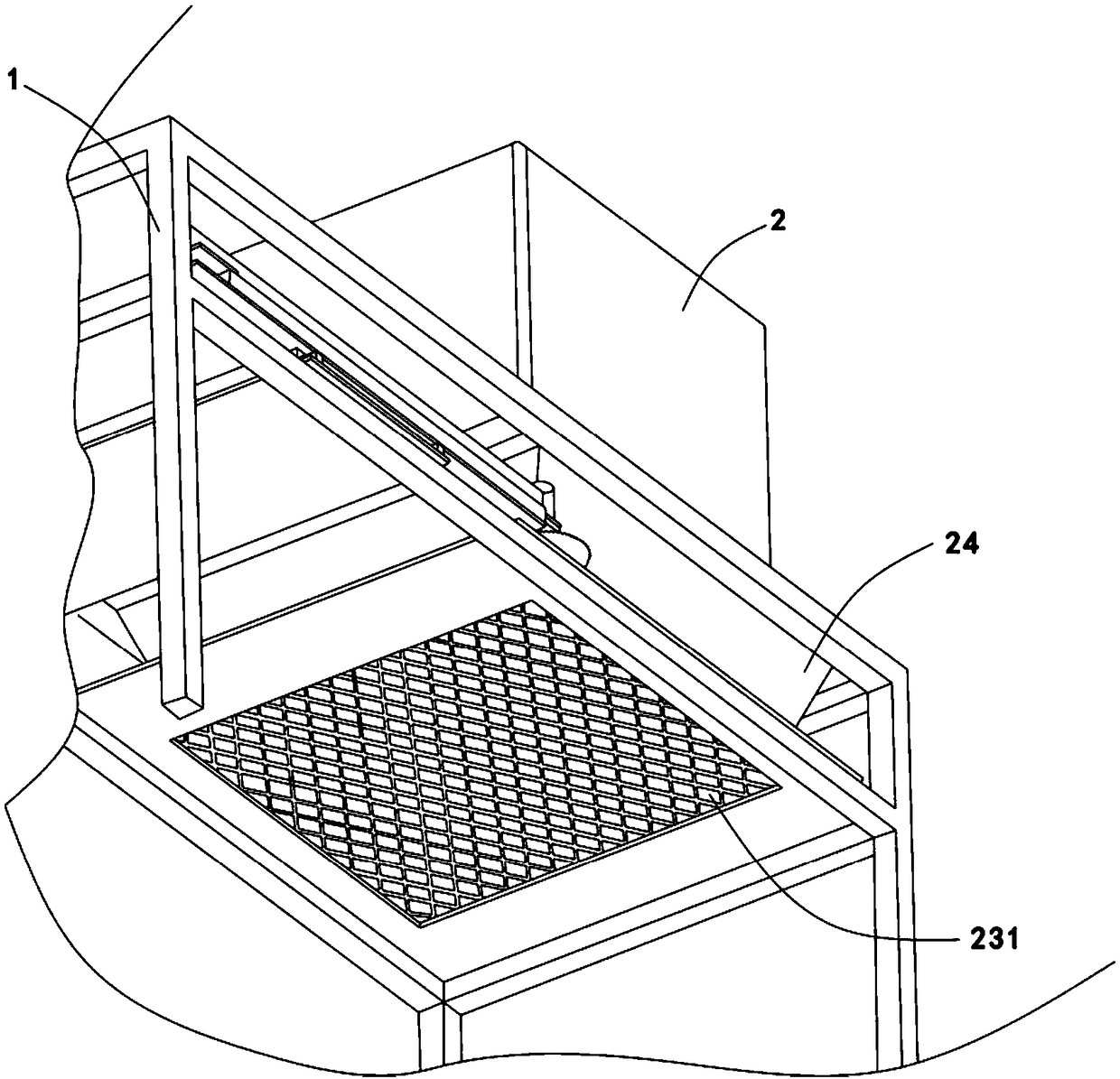

Automatic bag cutting device and hazardous waste cooperative treating system of cement kiln

PendingCN109229674AReduce the time spent in close contact with hazardous wasteImprove work efficiencyBags openingLoading/unloadingEngineeringMechanical engineering

The invention discloses an automatic bag cutting device. The automatic bag cutting device comprises a rack, a track mechanism, a containing cavity and a cutter assembly; the track mechanism comprisesa first track, a second track and a telescopic part, wherein the second track can conduct reciprocating movement along the first track, the telescopic part can move along the second track, and the cutter assembly is arranged at the end of the telescopic part; an open groove is formed in the side wall of the containing cavity, a feeding port is formed in the top of the containing cavity, and a discharging port is formed in the bottom of the containing cavity. The invention further discloses a hazardous waste cooperative treating system of a cement kiln. The hazardous waste cooperative treatingsystem comprises a crane lifting mechanism, a material bin, a power feeding mechanism, a metering mechanism and a conveyor belt machine, wherein the material bin is located below the discharging portin the automatic bag cutting device, the power feeding mechanism is located below the material bin, the metering mechanism is arranged at the end of the power feeding mechanism, and the conveyor beltmachine is connected with the metering mechanism and used for conveying materials into the cement kiln. Automatic bag cutting is realized, the probability that during bag cutting treatment, workers make contact with hazardous waste is lowered, potential safety hazards are reduced, safety is higher, bag cutting speed is high, and labor costs are reduced.

Owner:ZHEJIANG HUANLI ENVIRONMENTAL PROTECTION TECH

Sausage loading and cutting device

ActiveCN106852363ASimple structureEasy to operateSausage filling/stuffing machinesEngineeringFixed length

The invention discloses a sausage loading and cutting device. The device comprises a bar-shaped pedestal, a No. circular groove is arranged in the upper surface of the bar-shaped pedestal, a circular raw material stirring barrel is embedded in the No.1 circular groove, a position, positioned at the right side of the No.1 circular groove, on the upper surface of the bar-shaped pedestal is fixedly connected with a supporting mechanism, a position, positioned at the right side of a loading mechanism, on the upper surface of the bar-shaped pedestal is provided with a fixed length snapping mechanism, the side surface of the bar-shaped pedestal is provided with a cutting mechanism overlapped with the fixed length snapping mechanism, an extruding and loading mechanism is arranged in the circular raw material stirring barrel, the side surface of the circular raw material stirring barrel is provided with a rotary stirring mechanism, and the side surface of the bar-shaped pedestal is provided with a controller. The device has the advantages of simple structure and high practicality.

Owner:TIANJIN SHUNHECHENG FOOD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com