Patents

Literature

435results about "Sausage filling/stuffing machines" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

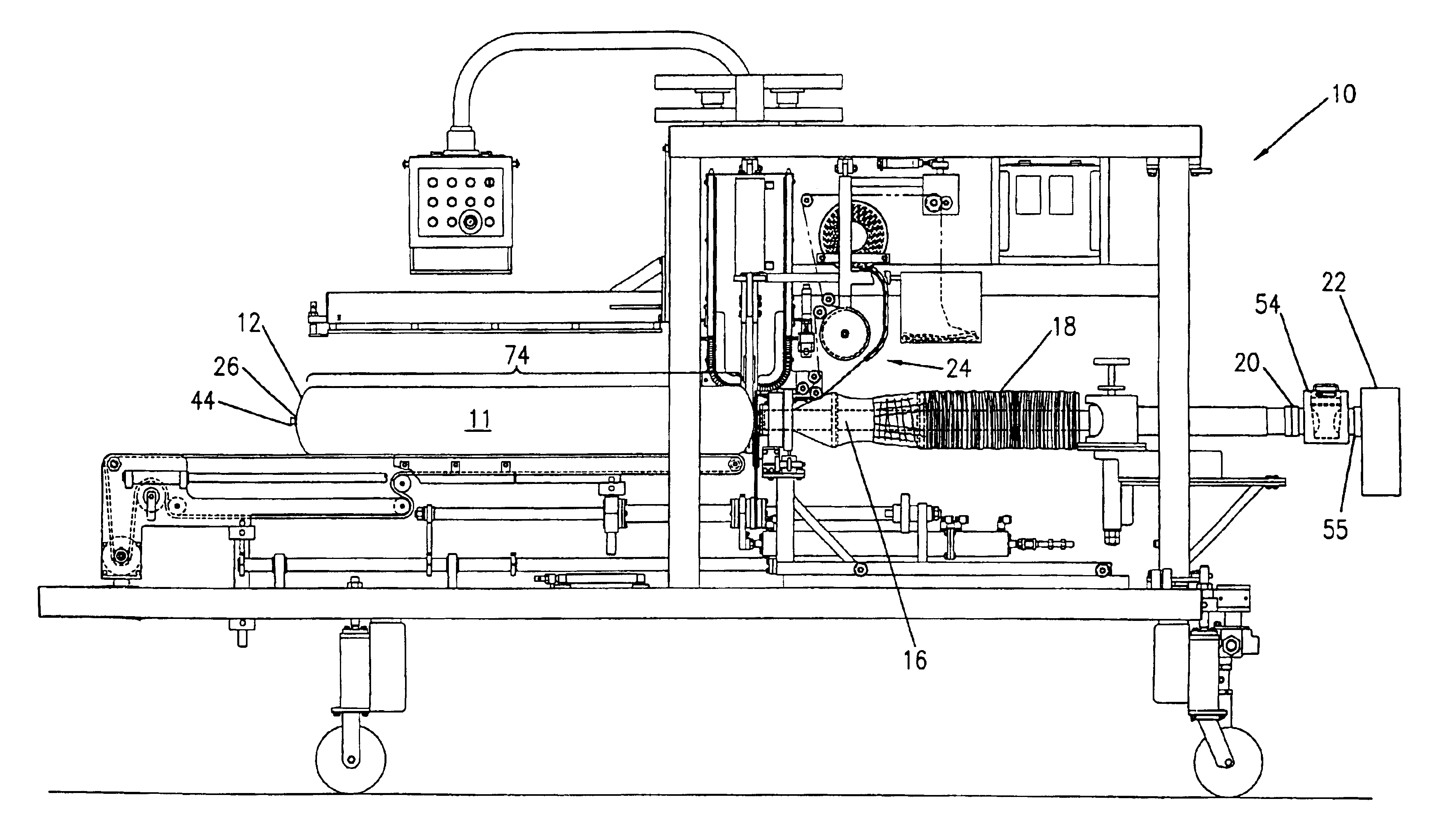

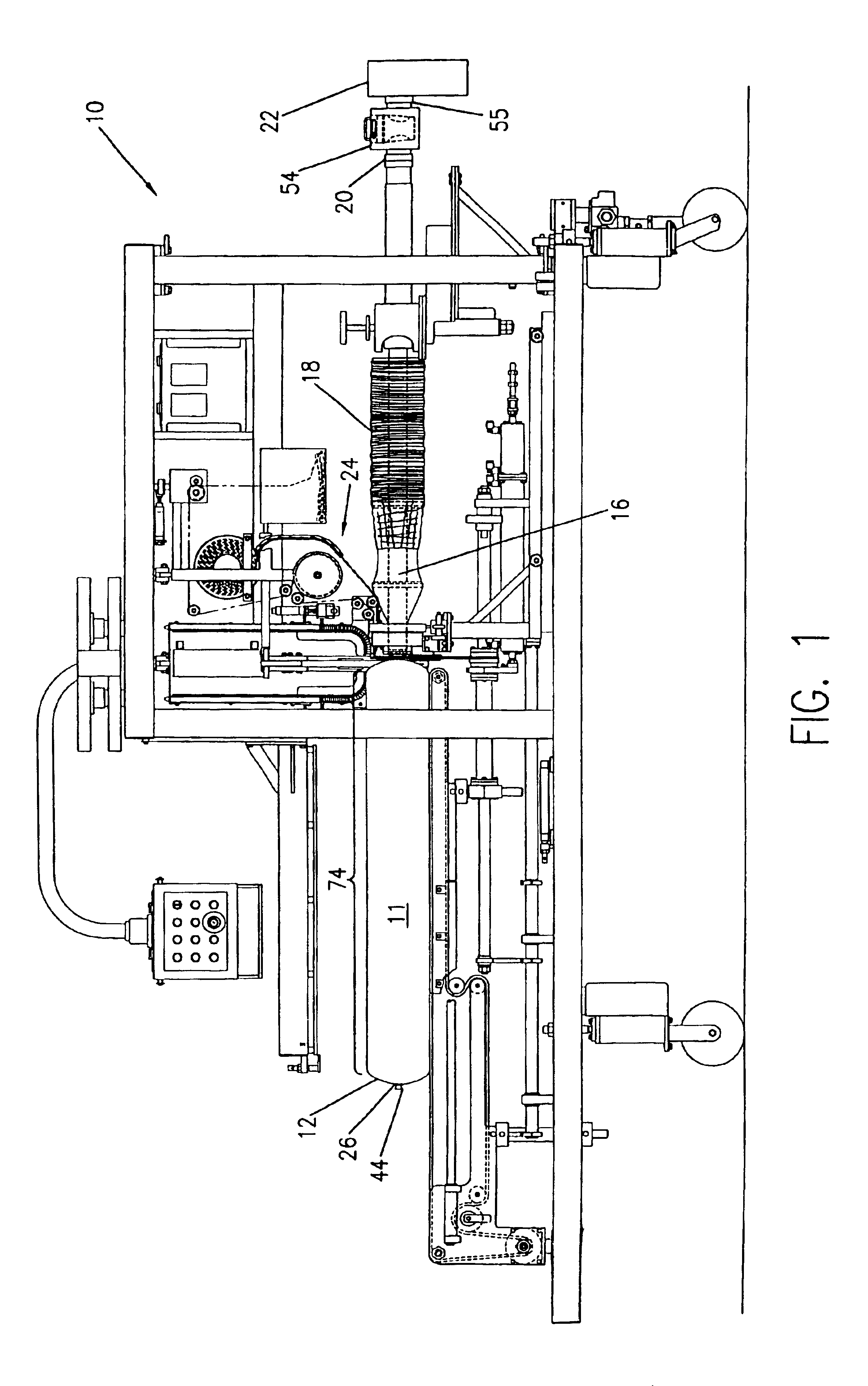

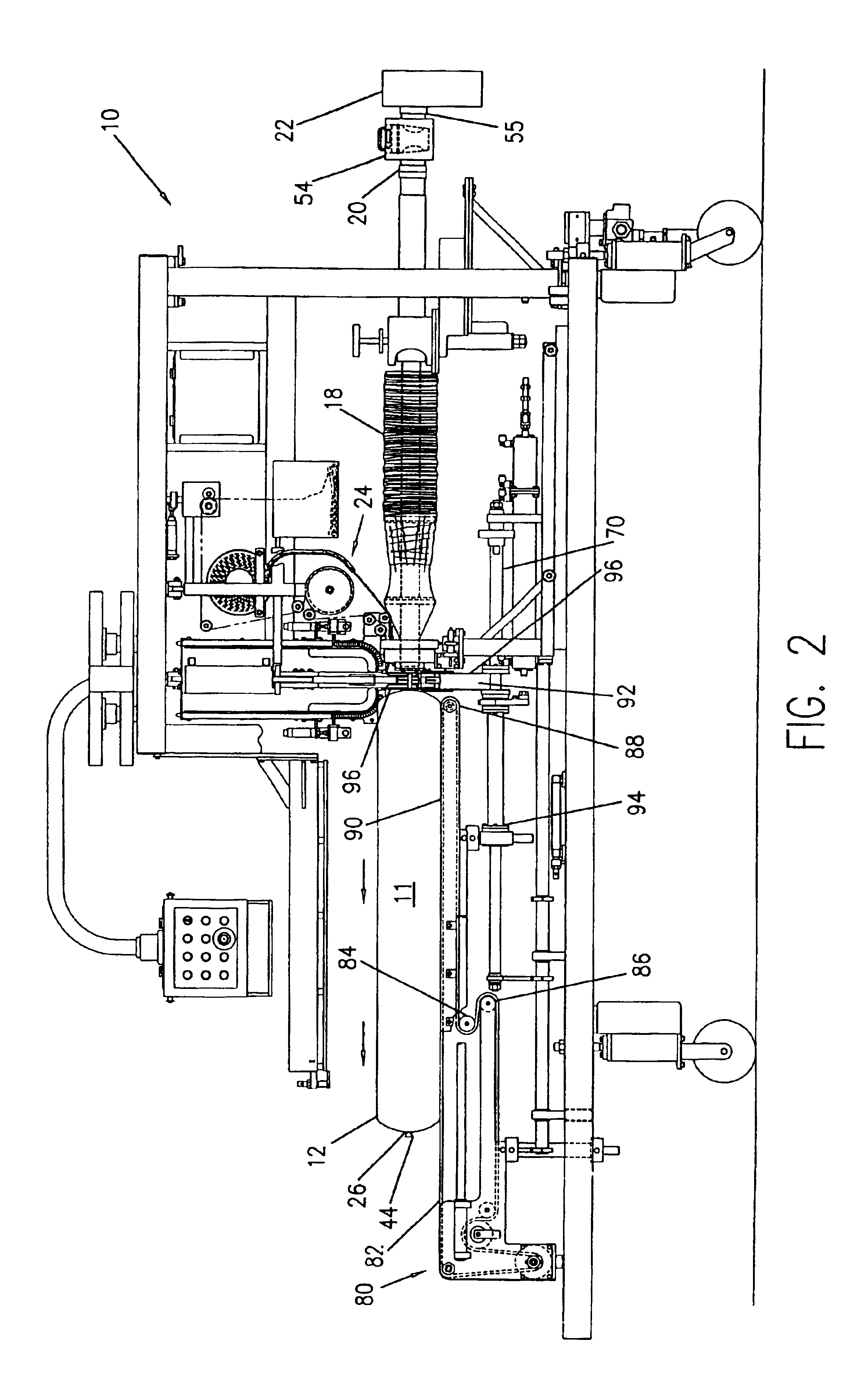

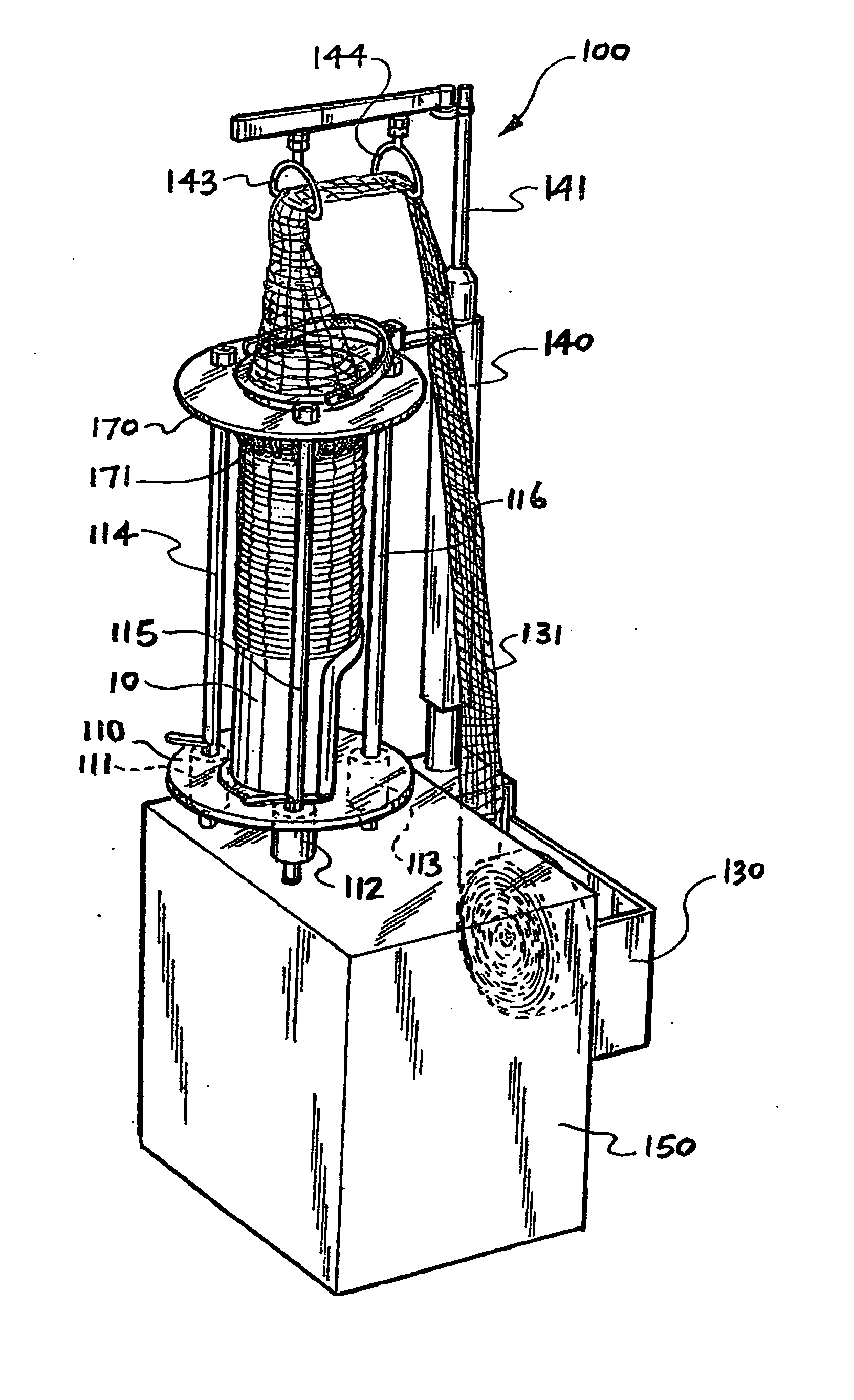

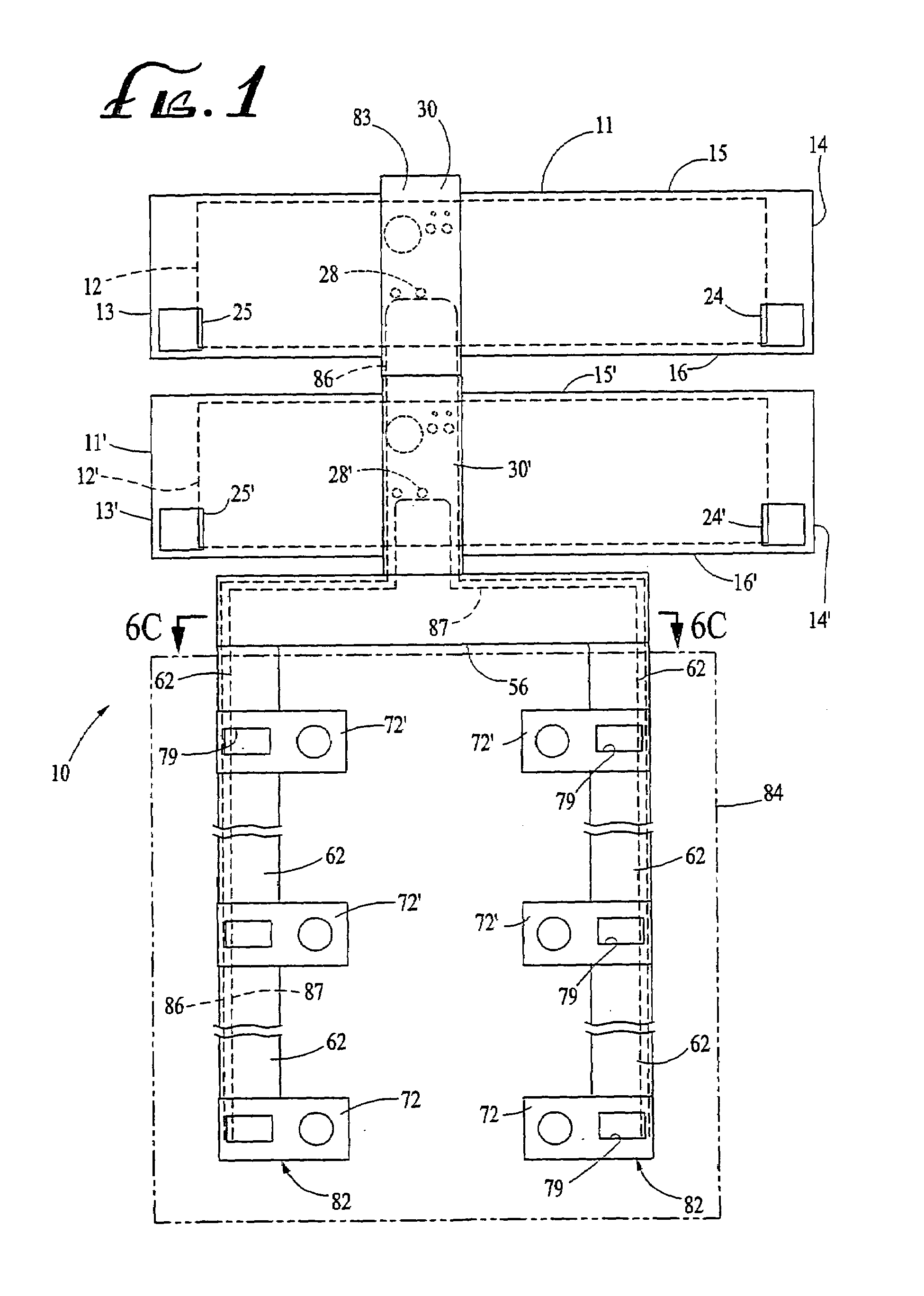

Apparatus for automatically stuffing food casing

InactiveUS6932688B2LengthReduce spacingSausage skin tying apparatusSausage filling/stuffing machinesBand shapeEngineering

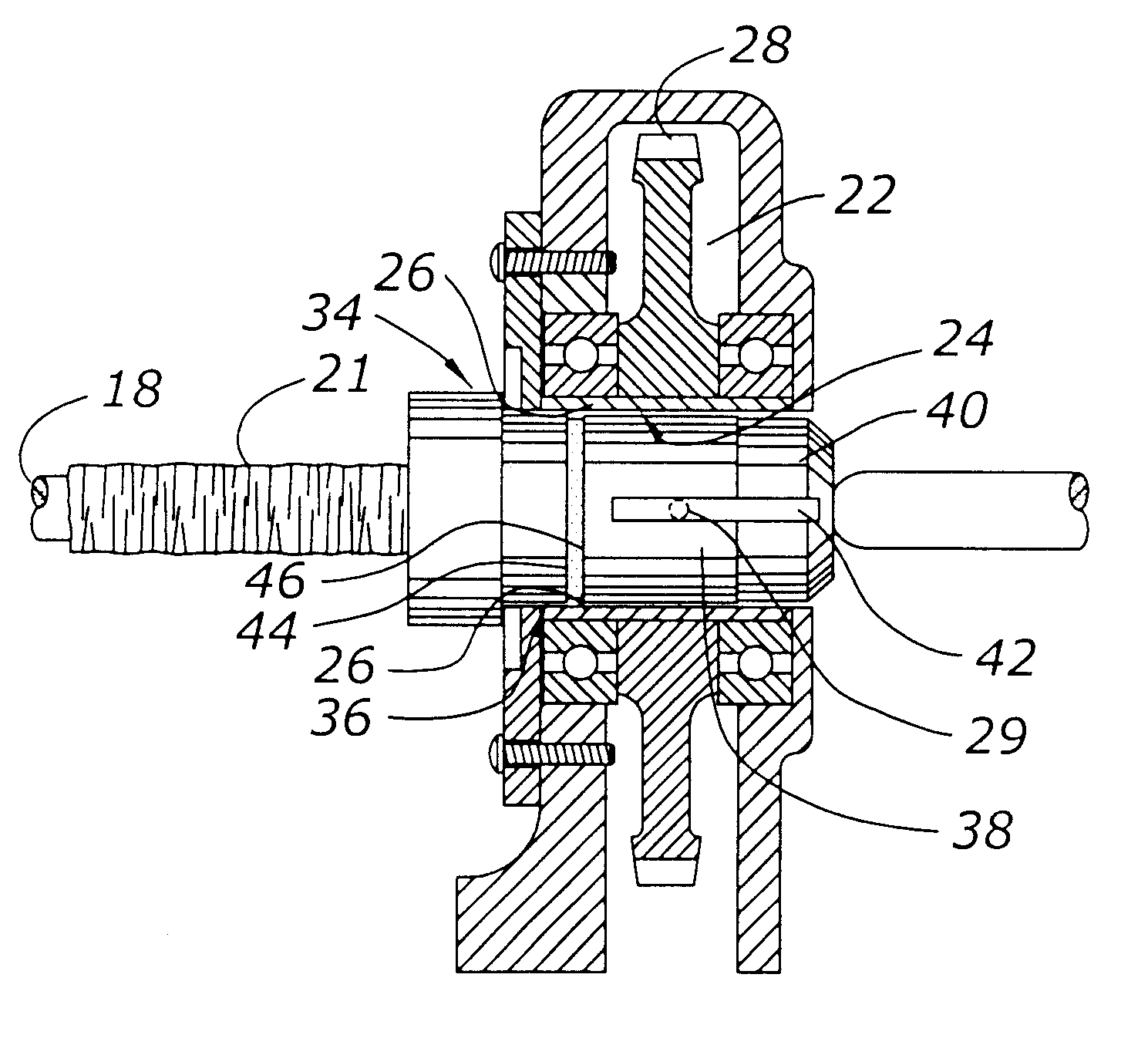

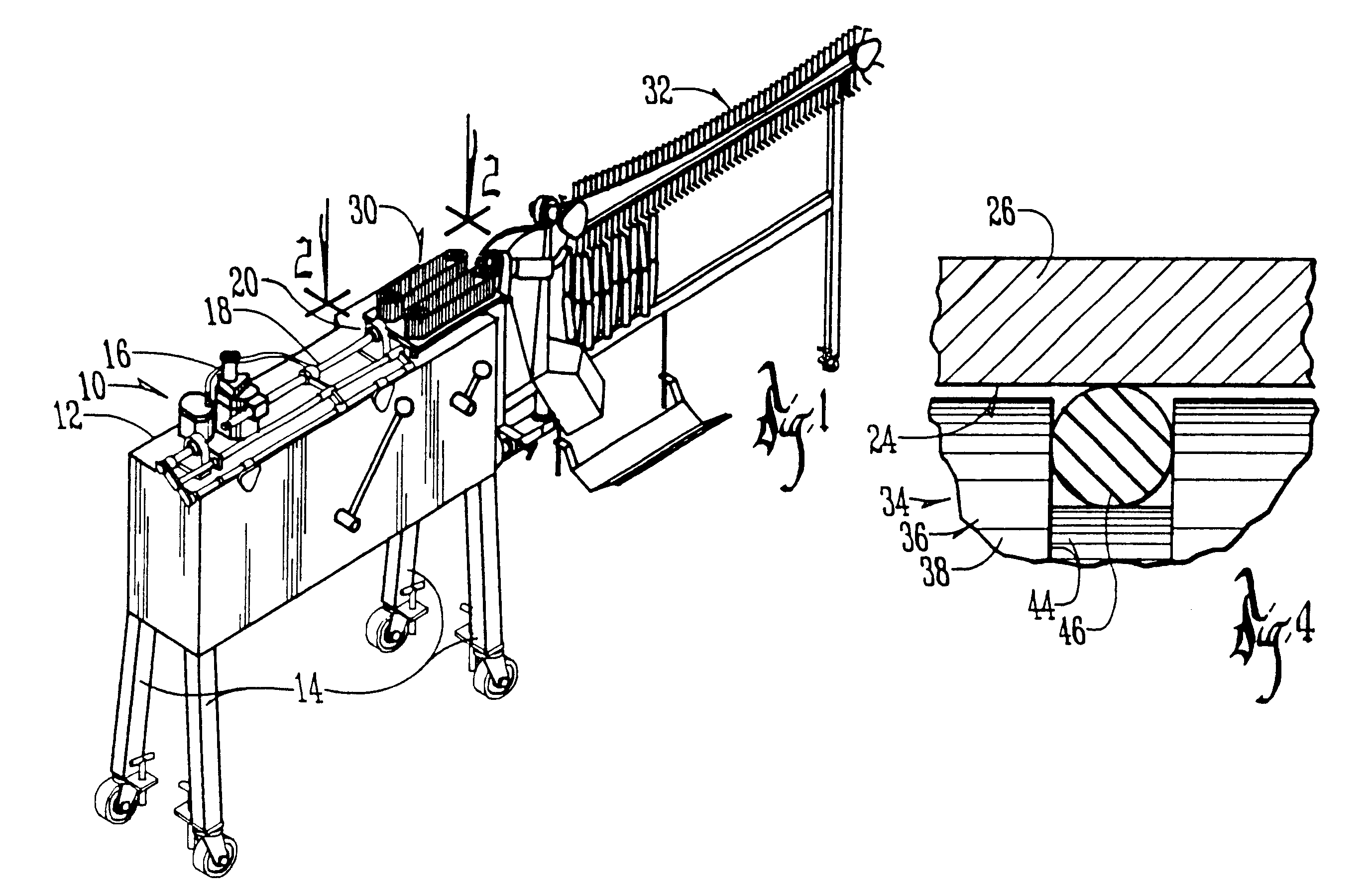

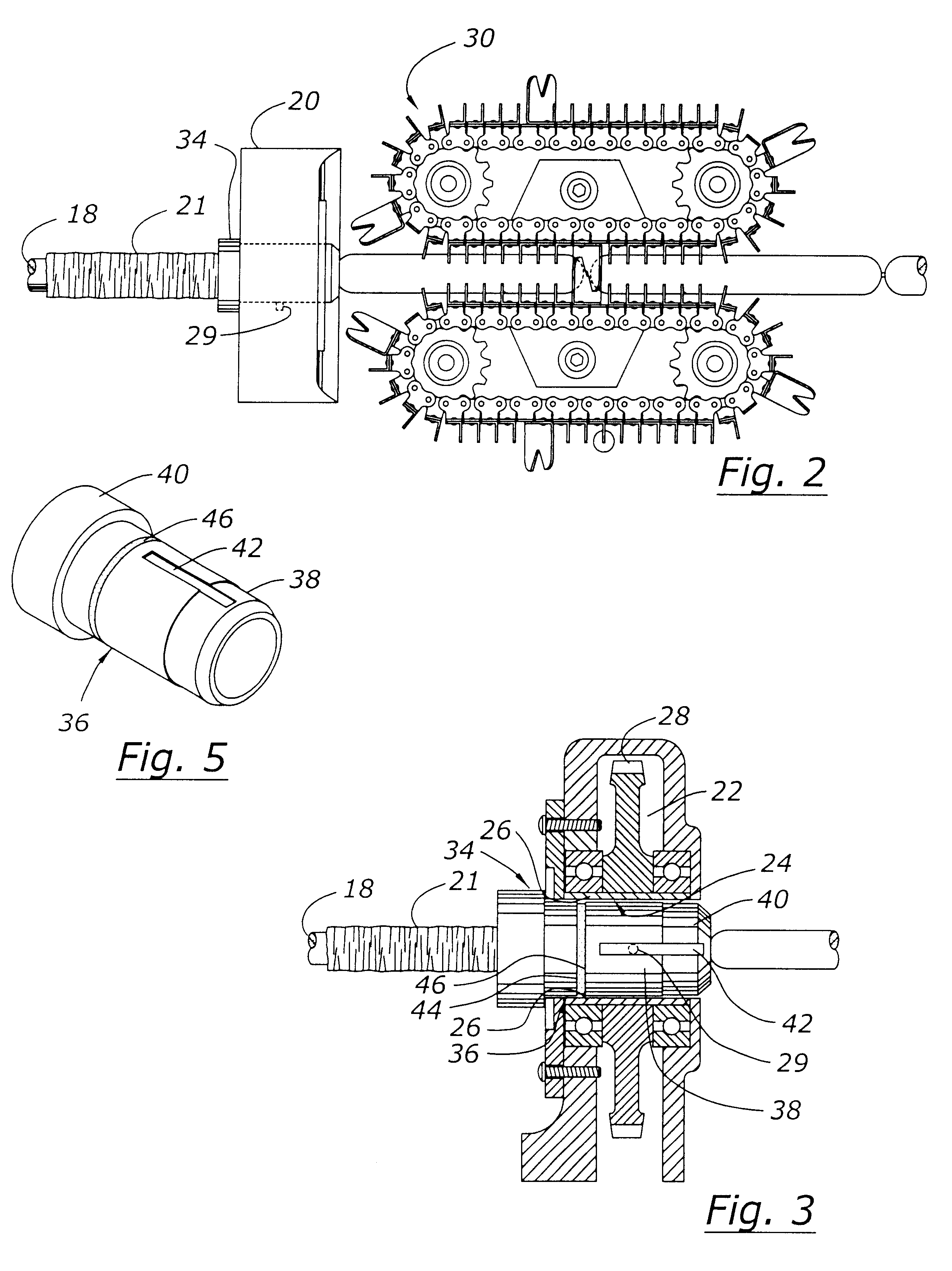

A clipping device is provided for closing stuffed food casing with a clip and an apparatus is provided for causing a taped, holding string loops, to be directed toward the clipping device for closing an end of the food casing so that a string loop is transferred directly from the tape into an entry into a channel in the clipping device. The clip draws the loop to the casing and holds the loop to the food casing. The stuffing apparatus preferably also includes a novel readily cleanable food flow cut-off valve. A punch and clip anvil is provided to apply clips bent around the casing in essentially mirror image helixes. An extending and retracting conveyor is provided to remove stuffed food product from the vicinity of the clipping device after stuffed food casing is closed.

Owner:HARRIS TRUST & SAVINGS BANK

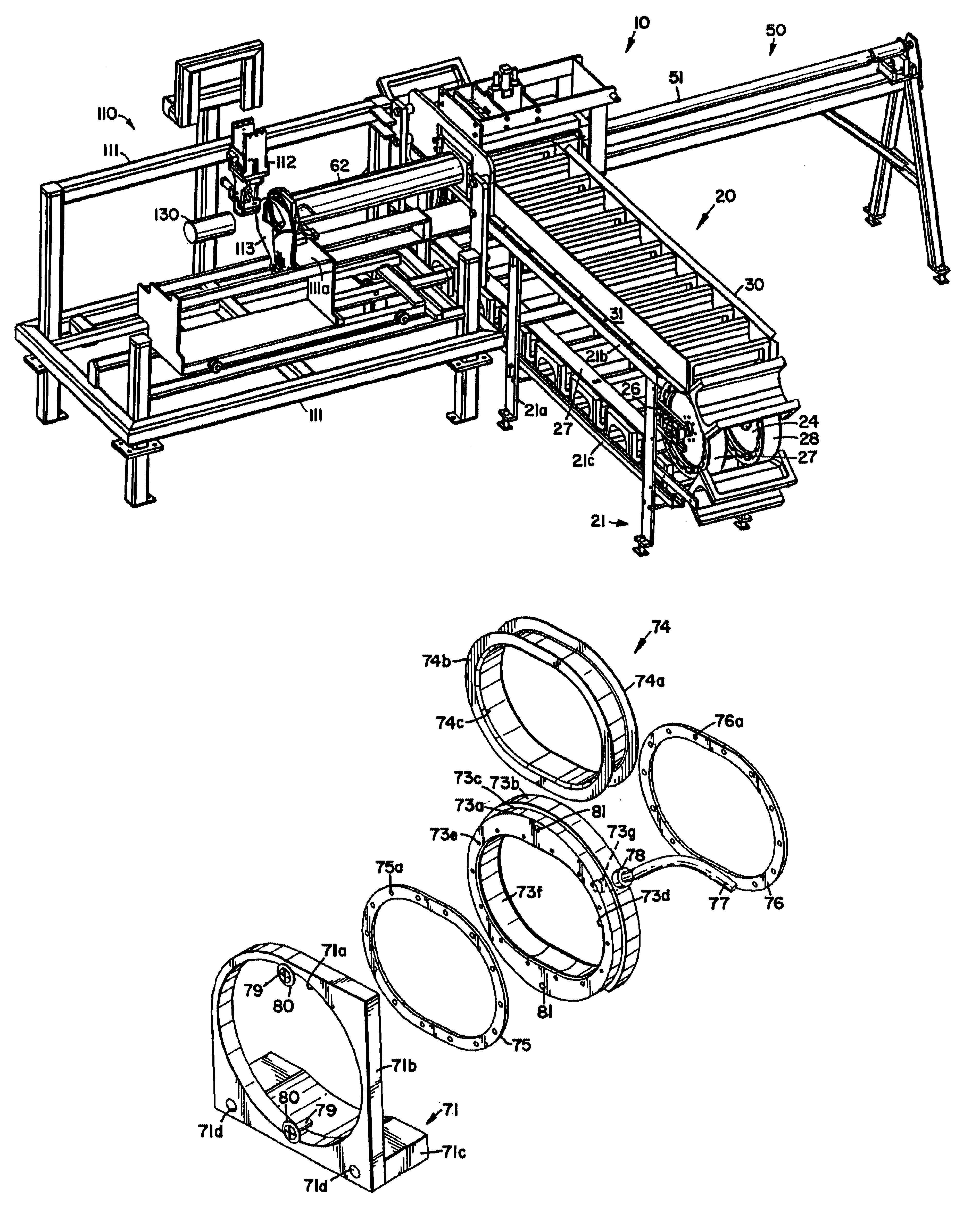

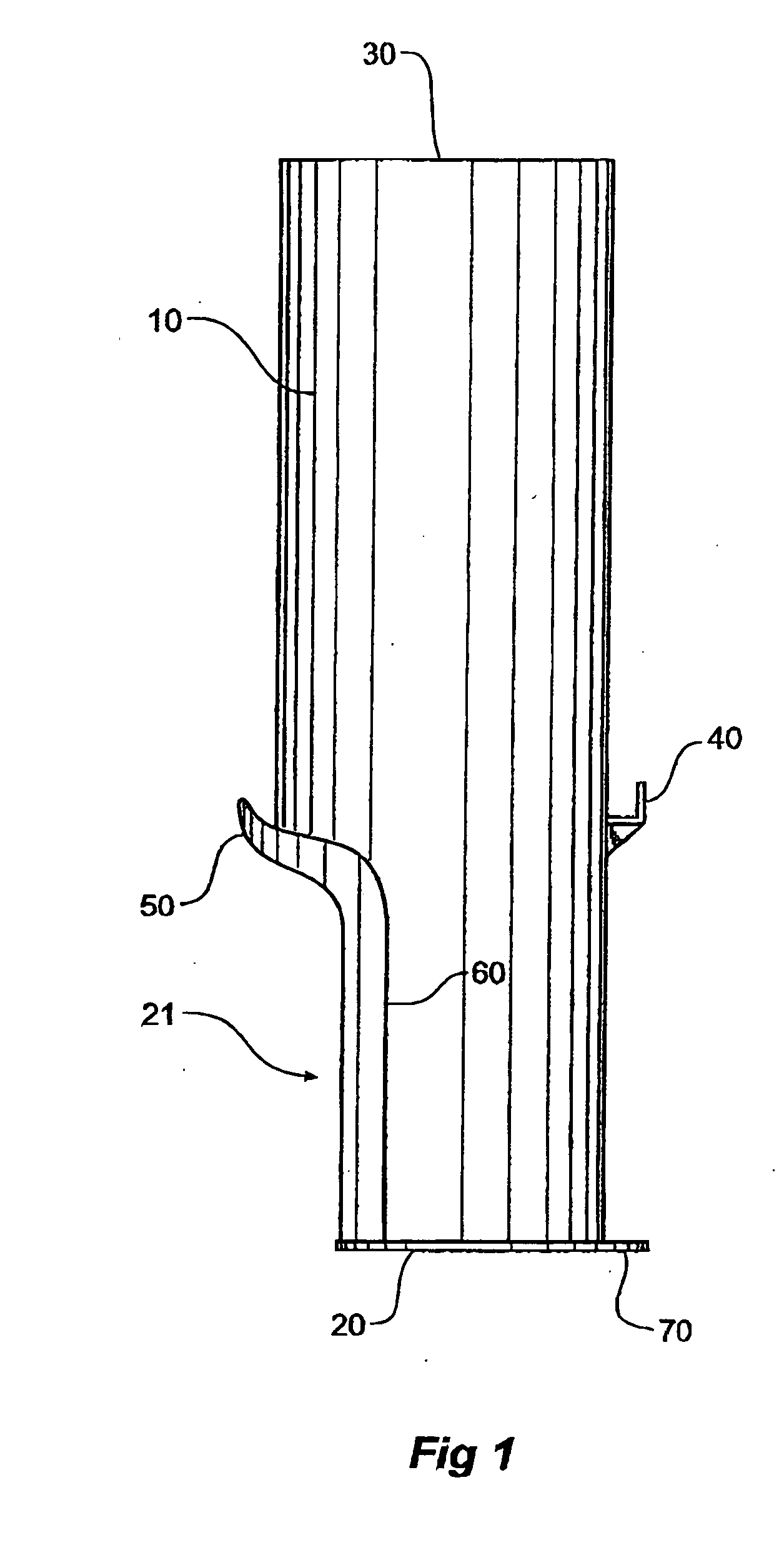

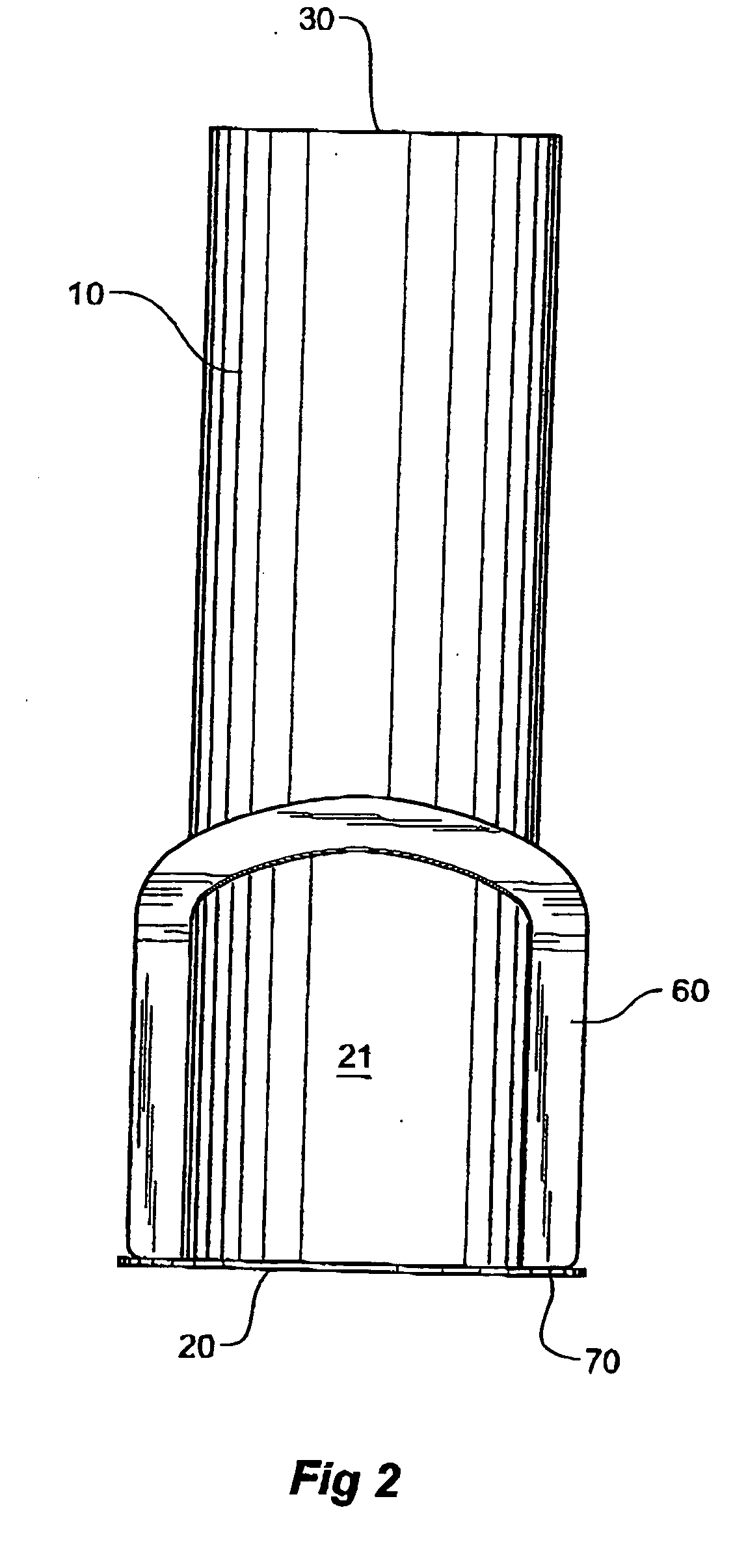

Method and apparatus for stuffing hams

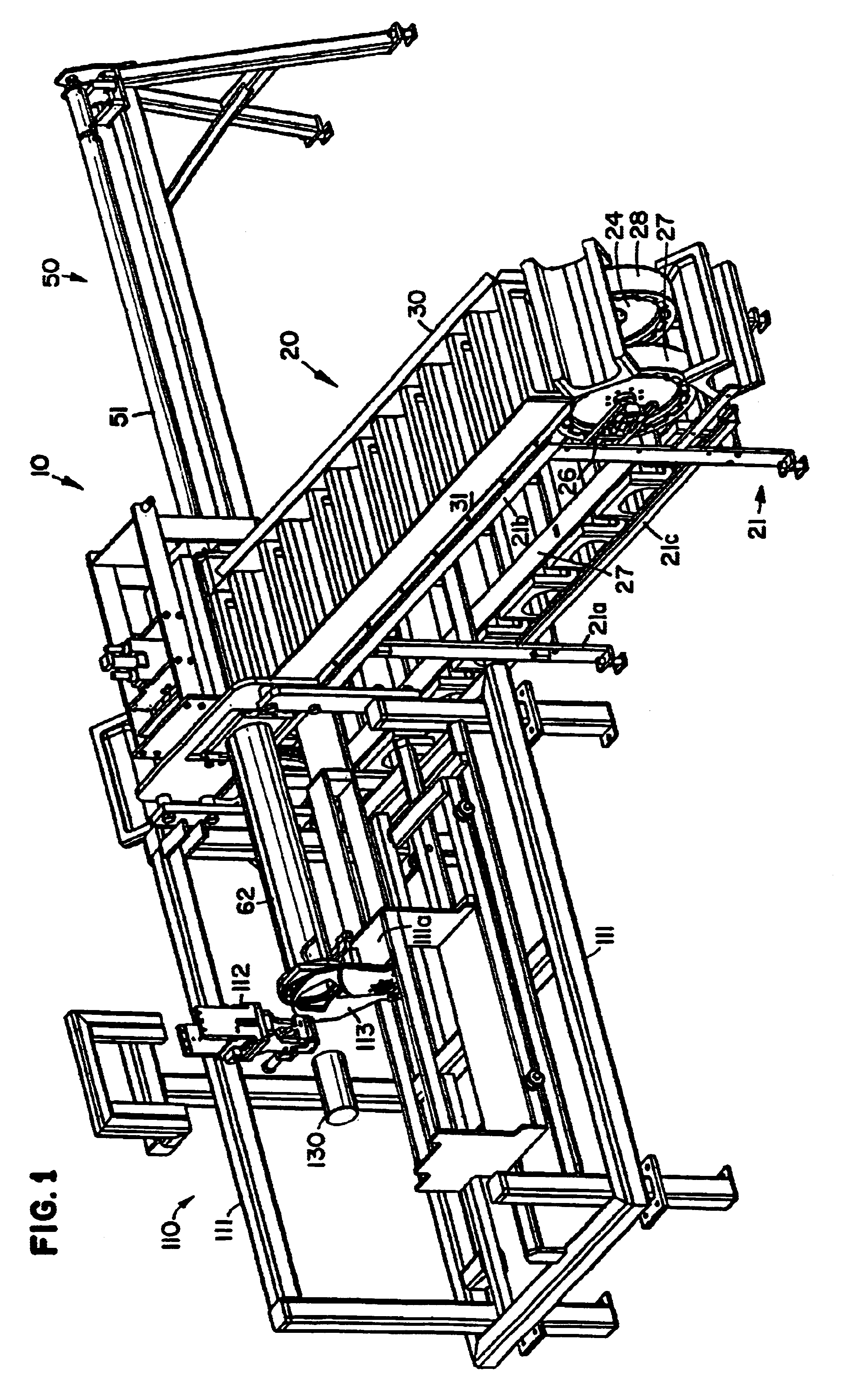

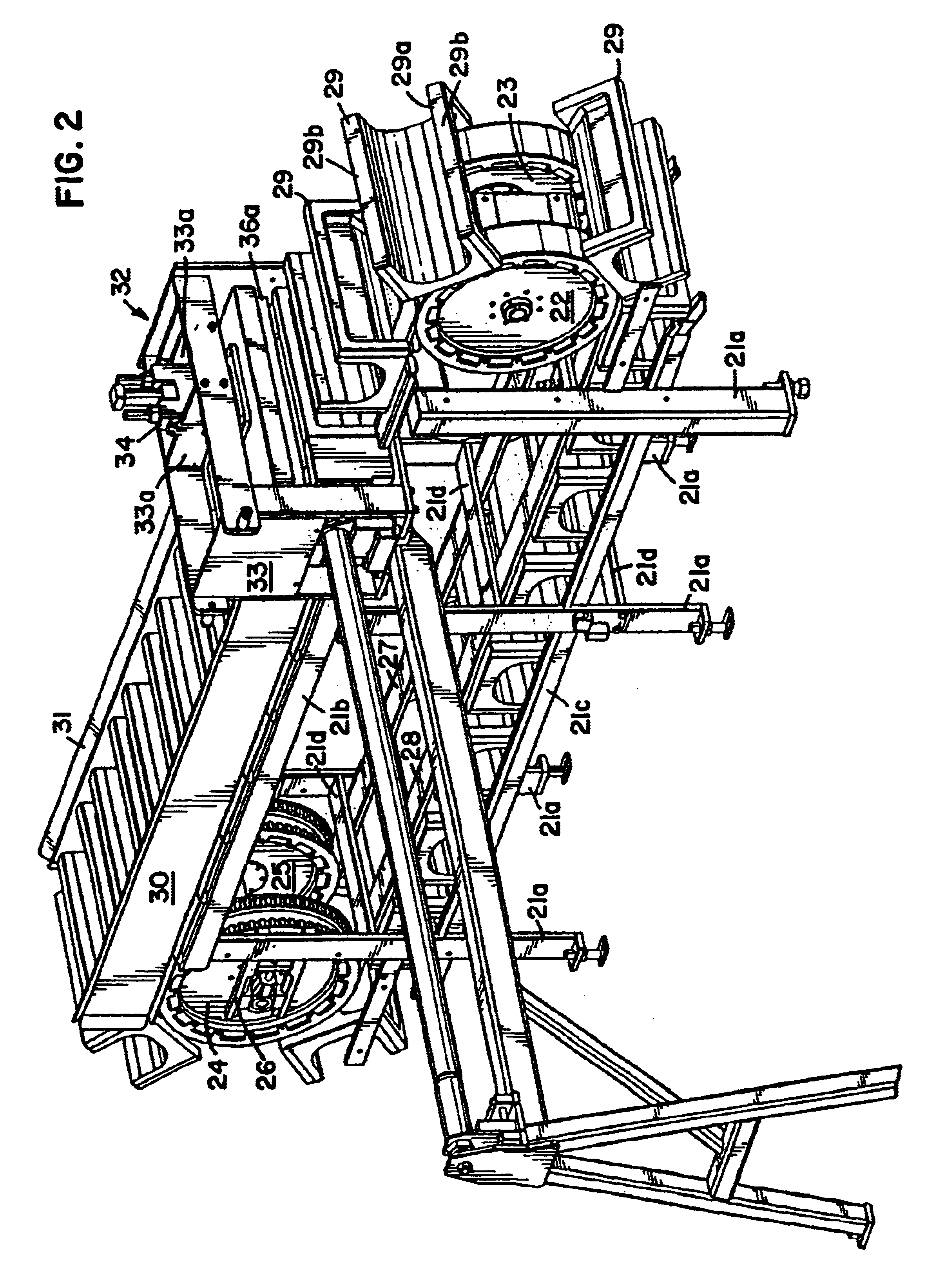

A combination stuffing horn (60) and skin brake (70) allows for a stuffing apparatus (10) for meat products (130) to be utilized. The stuffing horn (60) includes an elongate member (62) with a bore (62a) through which the meat product passes. The elongate member (62) has an outer cross section. The skin brake (70) has an inflatable bladder which is positioned around the elongate member. The bladder, when inflated, conforms to the outer cross section, wherein pressure is exerted on a shirred casing as the casing is being pulled over the horn (60) as the meat product (130) is stuffed into the casing.

Owner:HORMEL FOODS

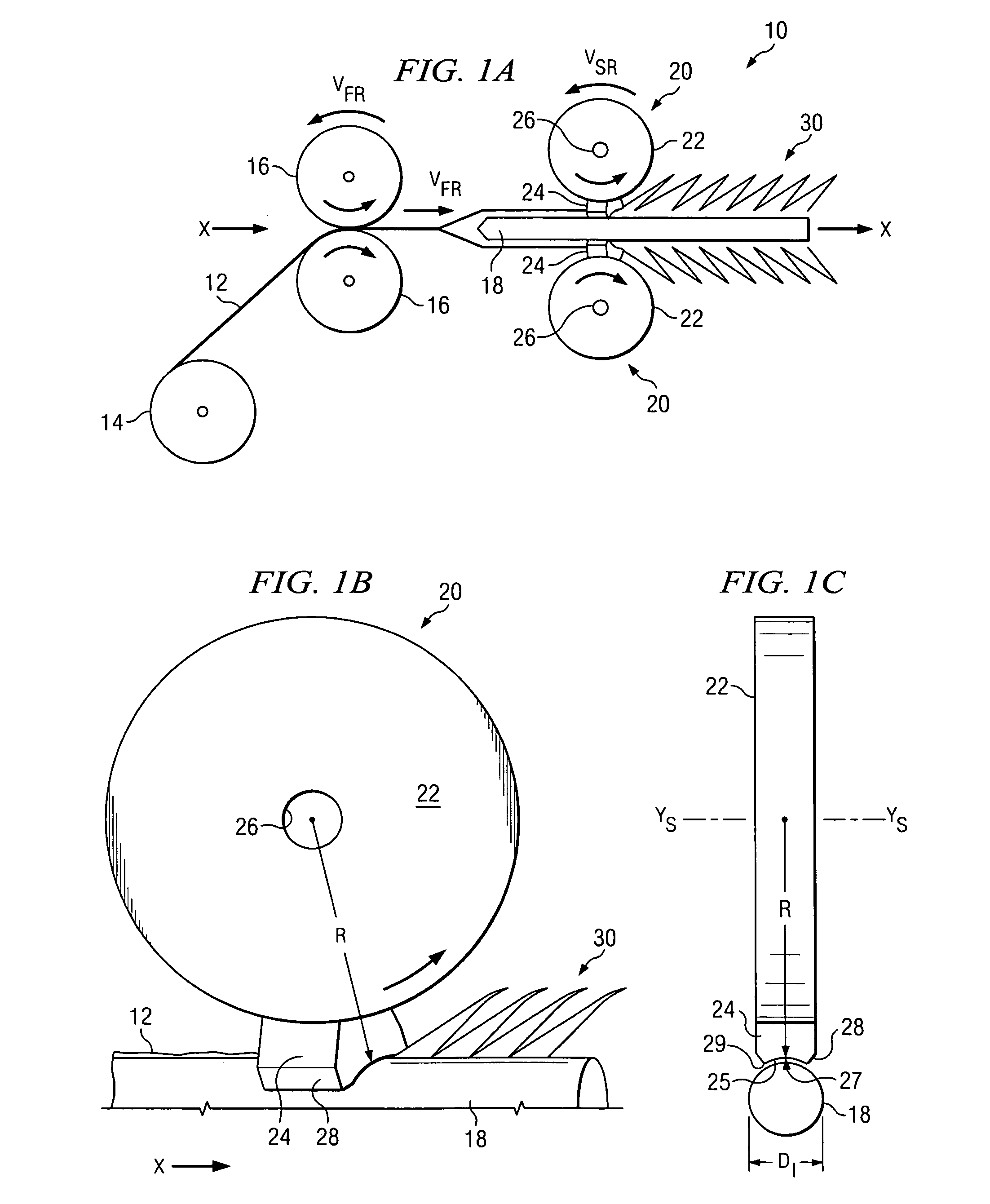

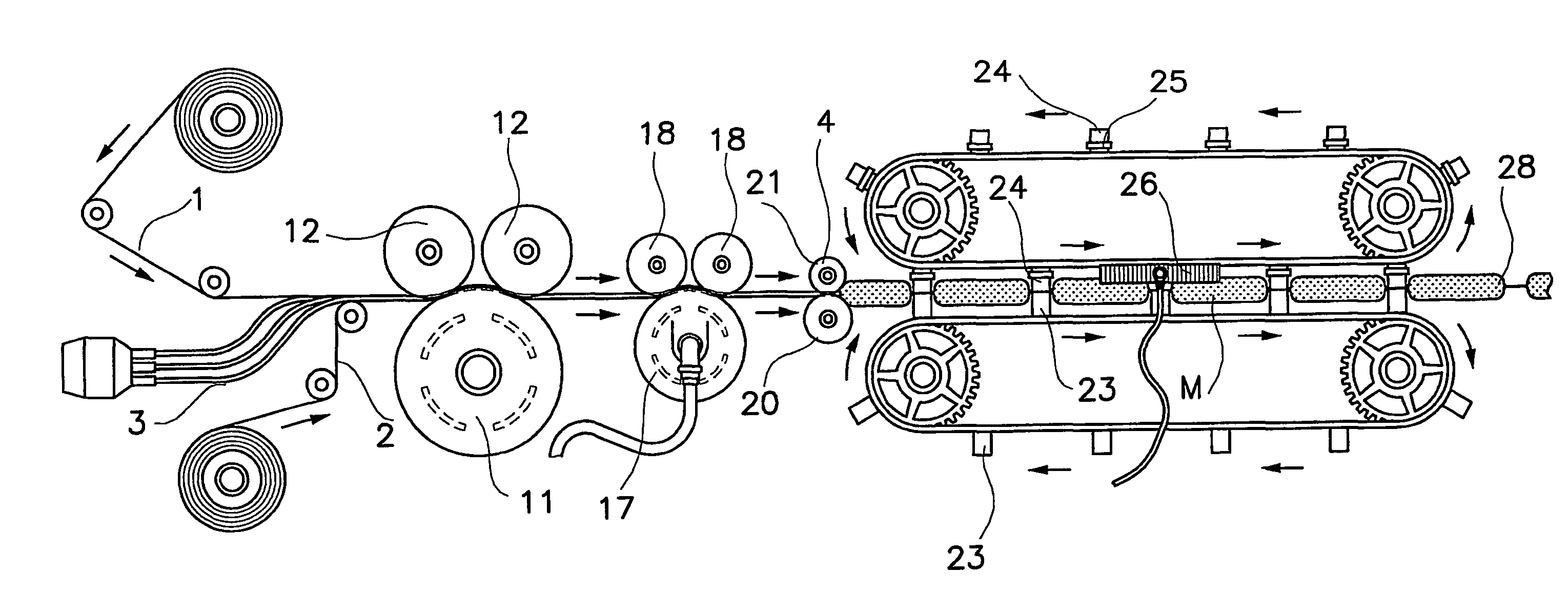

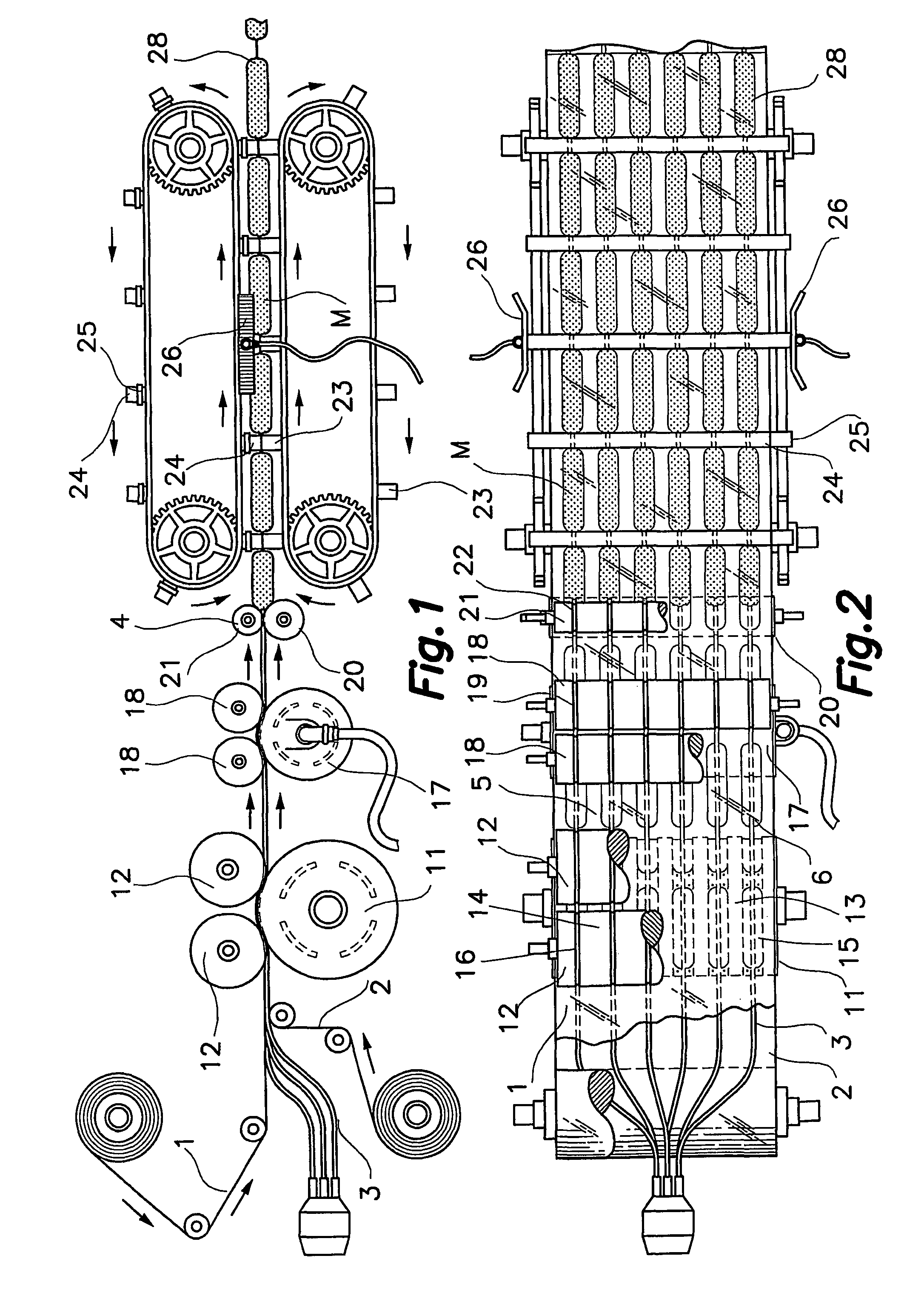

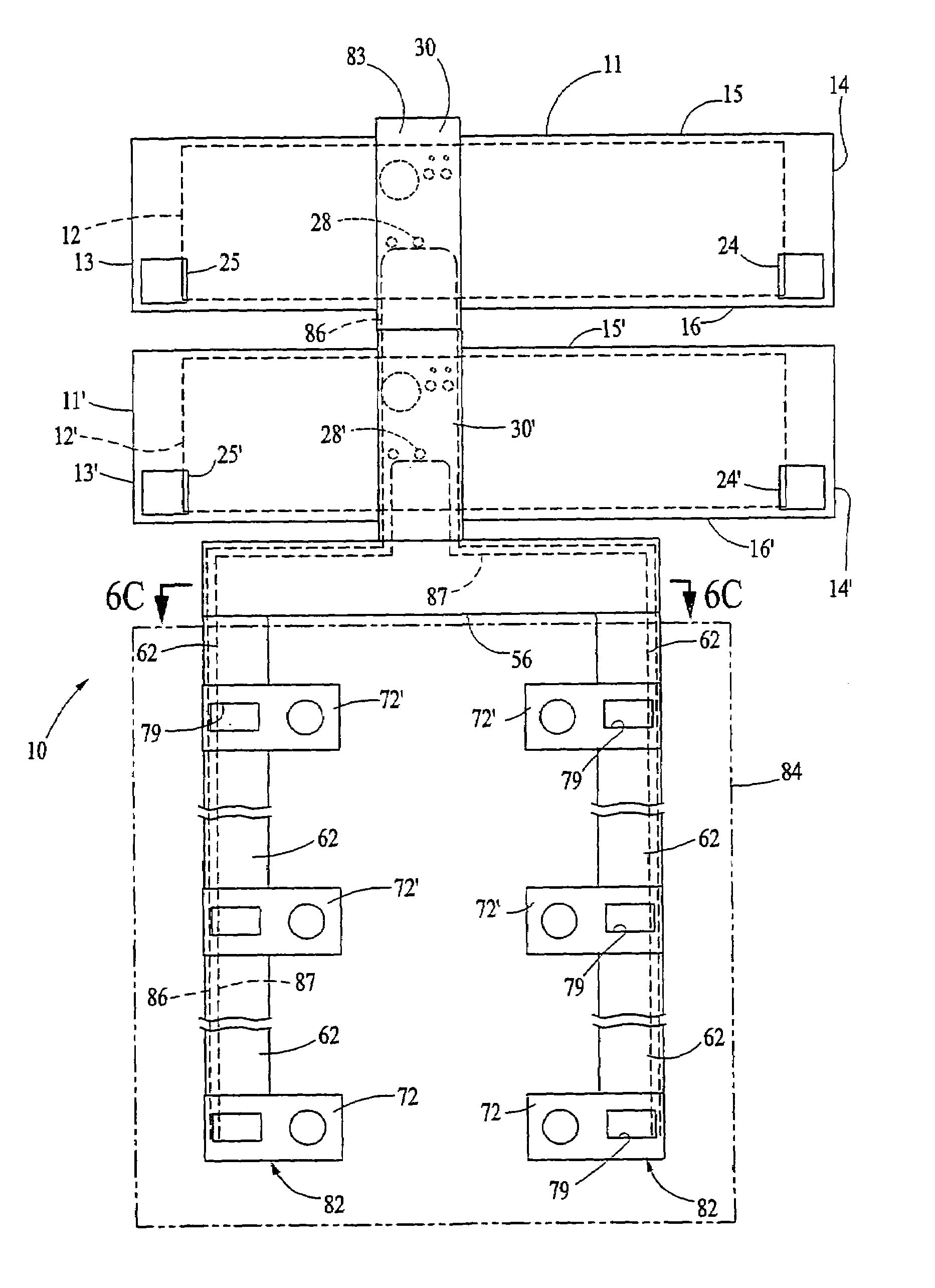

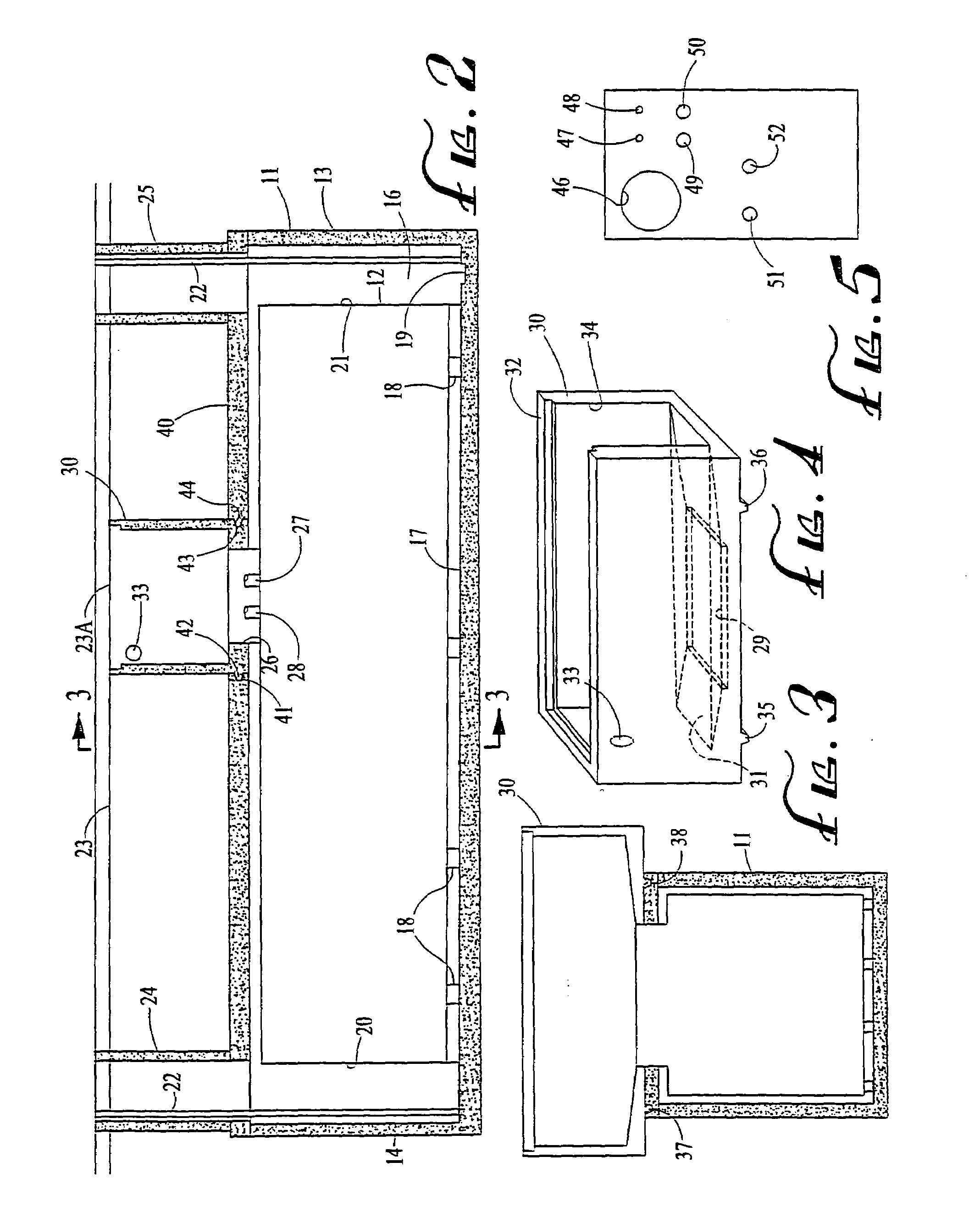

Process for the continuous manufacture of sausages

InactiveUS6135869ASkinless sausage makingPackaging under special atmospheric conditionsSynthetic resinGastric tube feeding

A process and apparatus for the continuous manufacture of food products such as sausages is provided which eliminates the need for intermediate stuffing of the food product into casings which are discarded prior to final packaging. The preferred apparatus of the invention includes first and second heated rollers (16, 17) each presenting a plurality of elongated, axially aligned channels or recesses (18,20) which are circumferentially and axially spaced on the corresponding rollers (16, 17); in addition, the second roller (17) includes a series of elongated, continuous, tube-receiving openings (22) extending between each series of aligned recesses (20). Mechanisms (28, 29) are associated with the rollers (16, 17) in order to continuously feed elongated synthetic resin sheets (34, 35) into the nip between the rollers (16, 17). Rollers (24, 27) are provided for forcing portions of the sheets (34,35) into the recesses (18,20) and openings (22) prior to passage of the sheets (34,35) between the rollers (16, 17) where they are longitudinally heat sealed together to continuously form elongated, aligned food-receiving cavities (48). A plurality of feeding tubes (11) extend through the rollers (16, 17) and are located within the corresponding openings (22) and recesses (20) during rotation of the rollers (16, 17). The tubes (11) continuously direct the flowing food material into the cavities (48), the latter being transversely heat sealed via transverse sealing bars (60, 60') to form complete, enclosed food packages.

Owner:ANDERSON ADAM

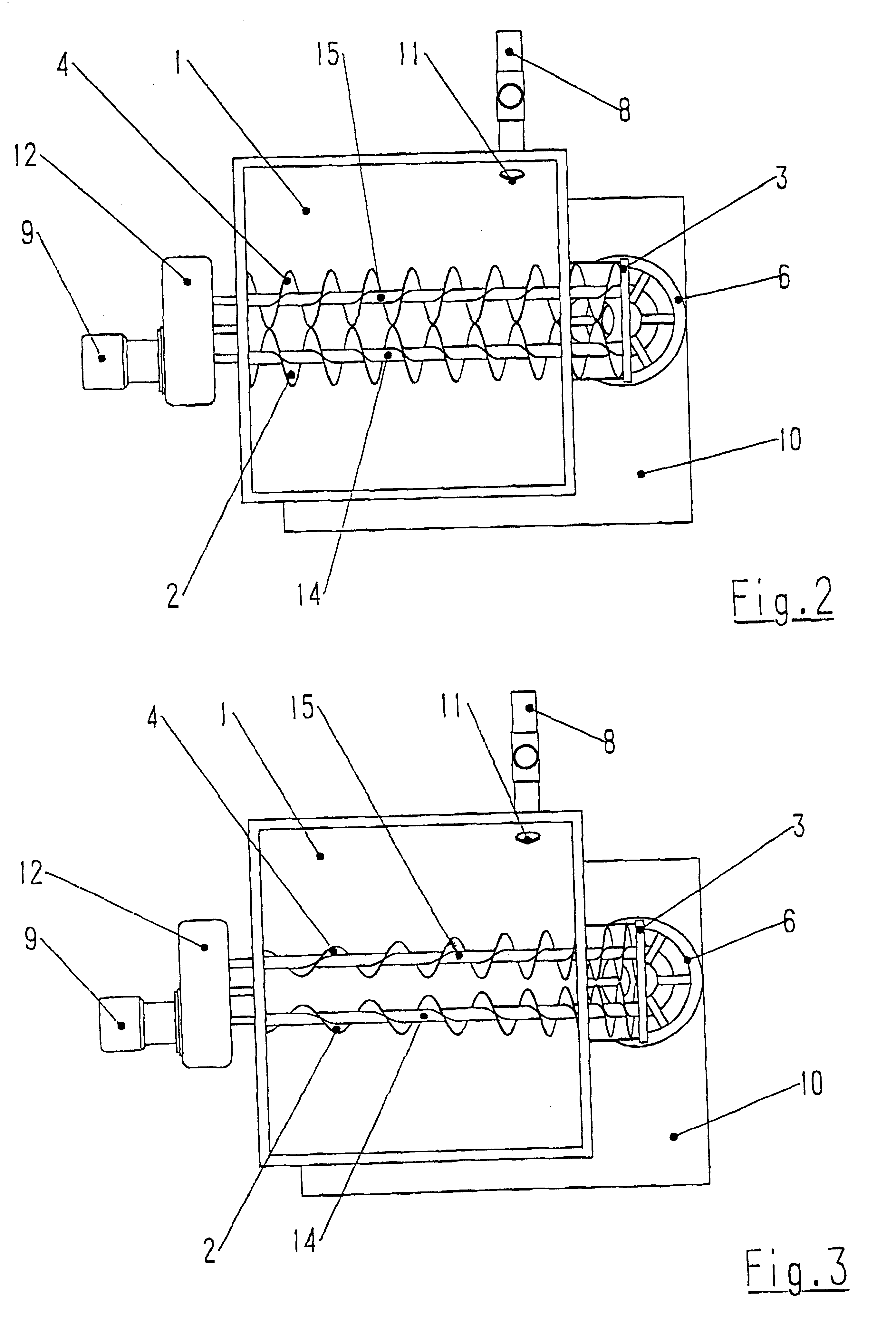

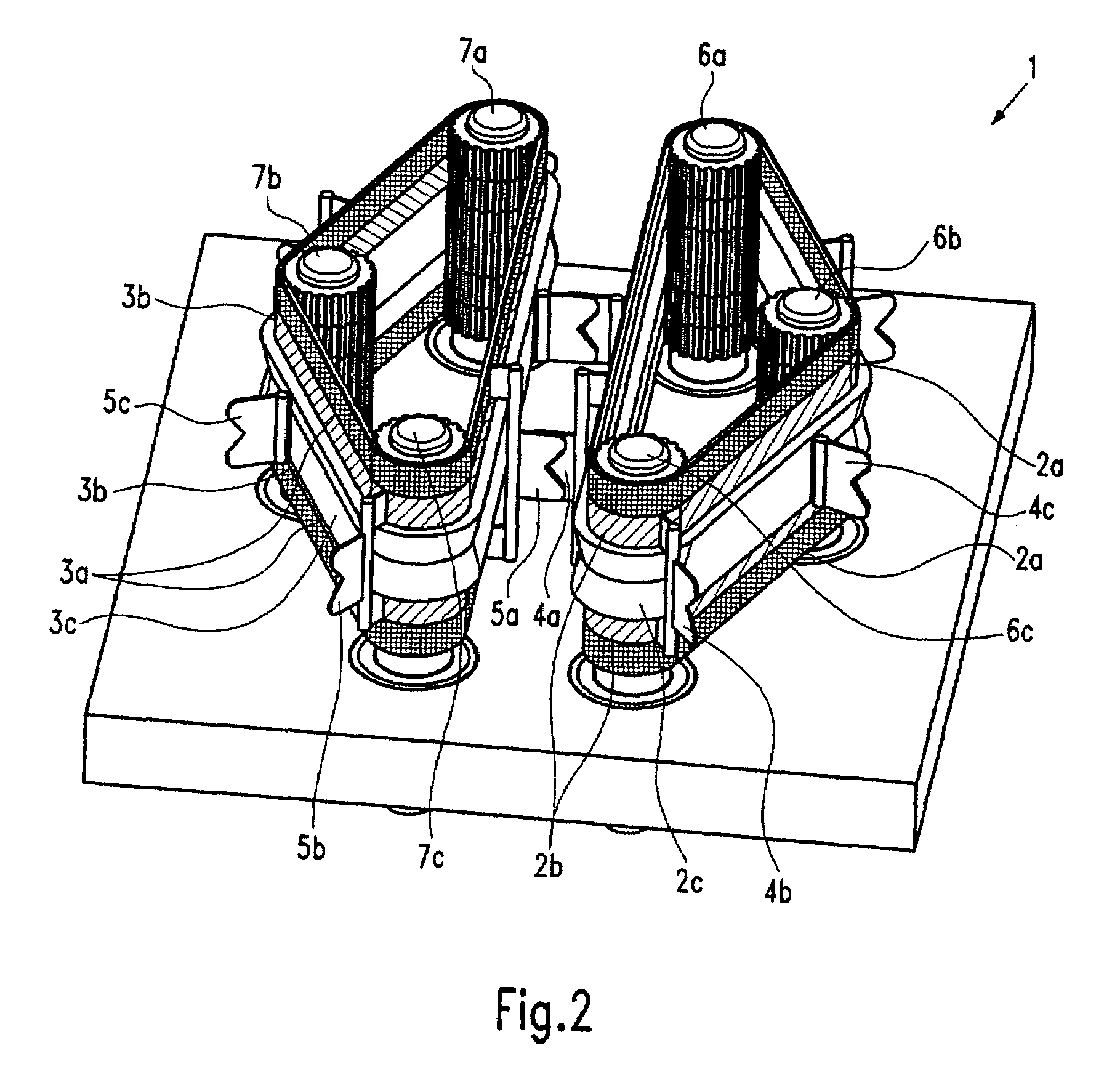

Feeding device of a stuffing machine; in particular for ground meats or the like

InactiveUS6287188B1Pleasant lookQuality improvementSausage filling/stuffing machinesMeat mixing apparatusEngineeringMechanical engineering

The invention relates to a feeding device for a stuffing and dosing pump of a vacuum stuffing machine for alimentary paste products, preferably ground or extruded meats.More specifically, the feeding device provides two elical scroll thrusting elements, facing each other and placed in the space under the hopper in order to operate continuously on the meat paste, thrusting and compacting it in the direction and toward the inlet of the stuffing pump.

Owner:REFIN

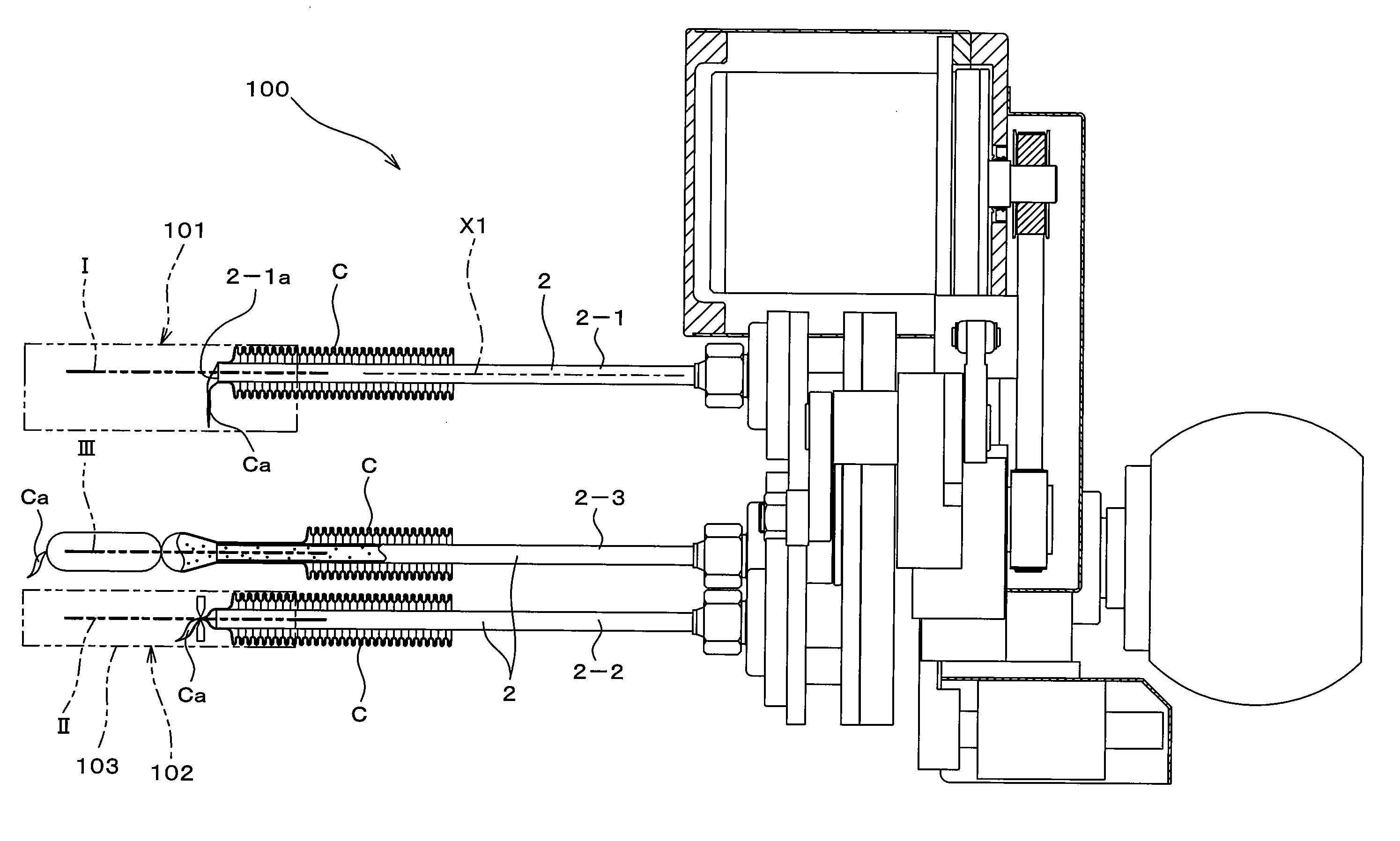

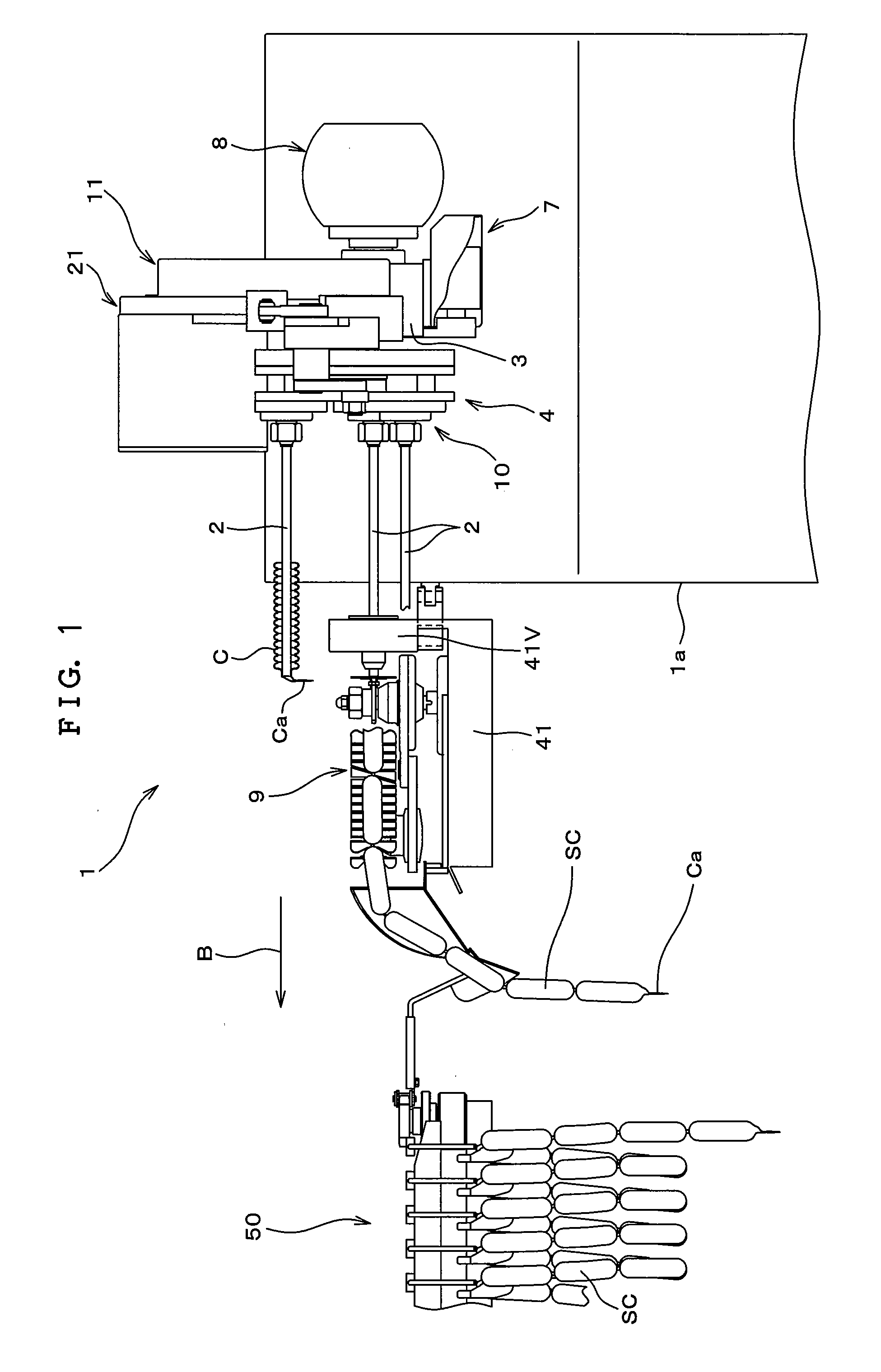

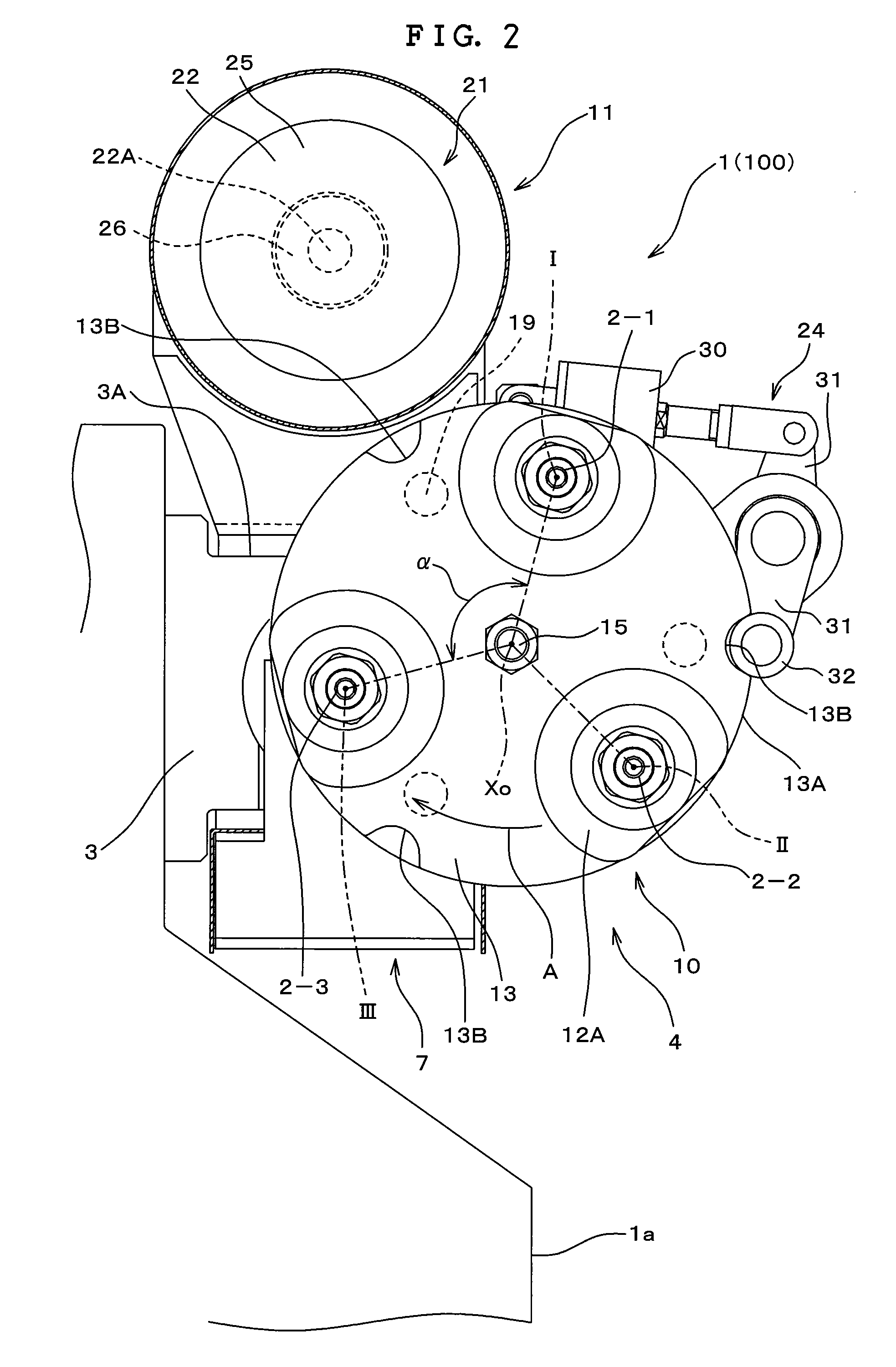

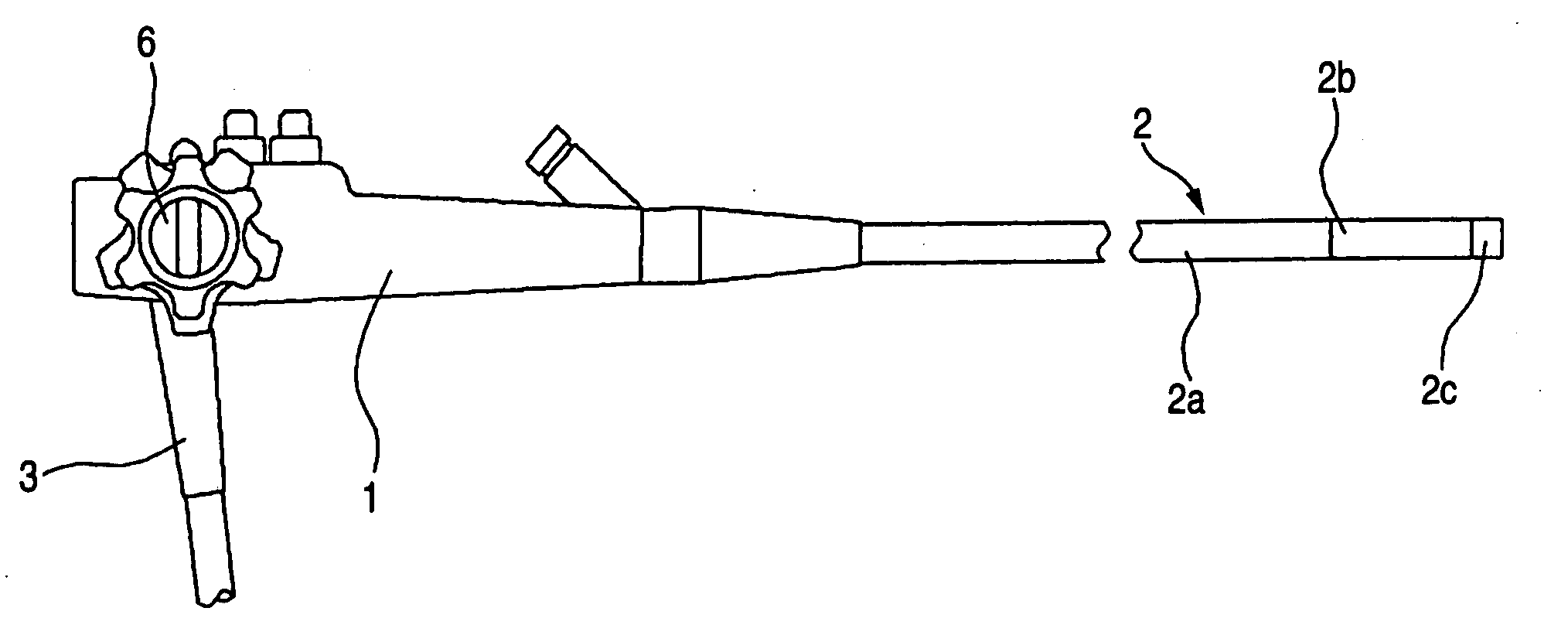

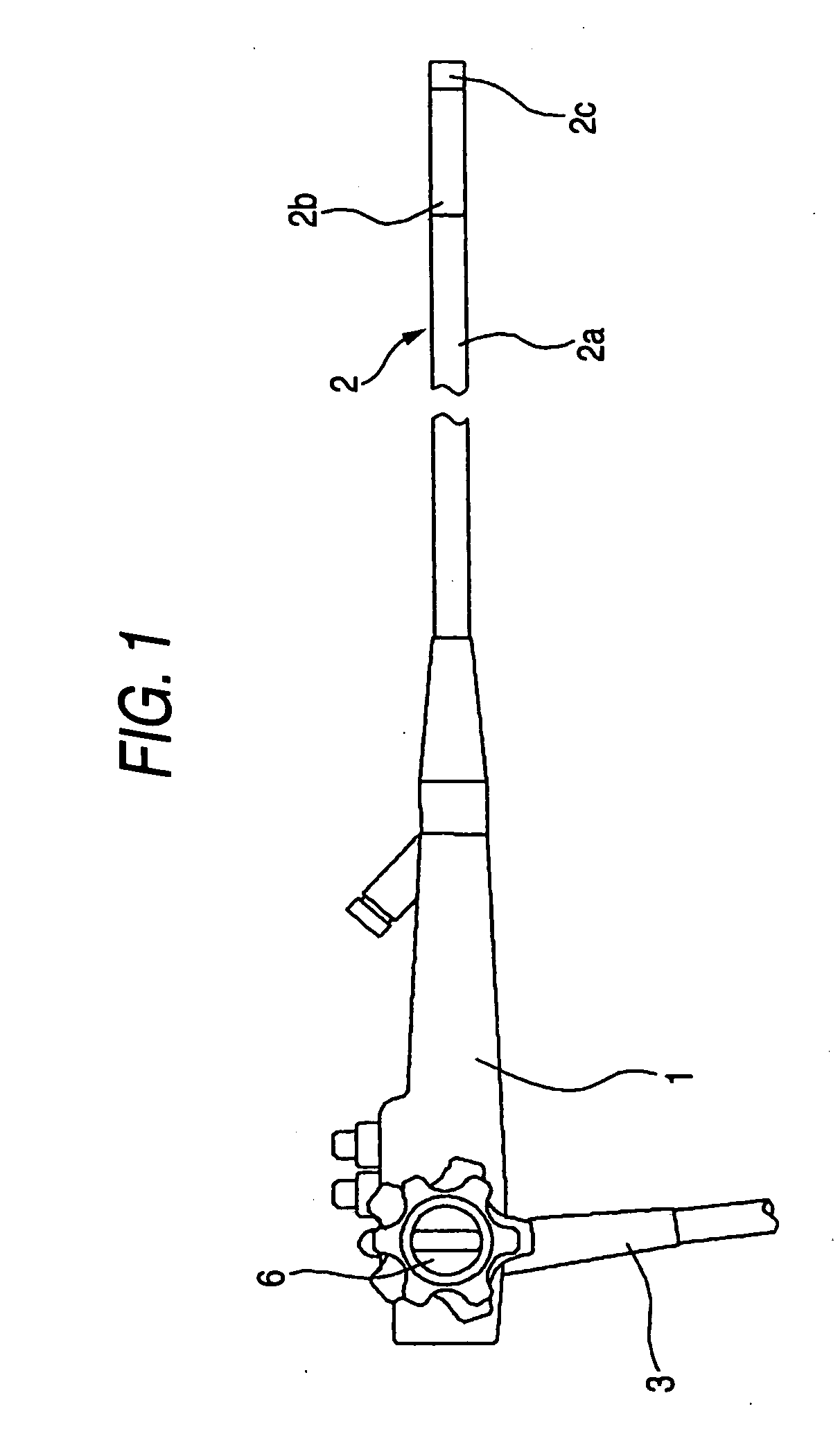

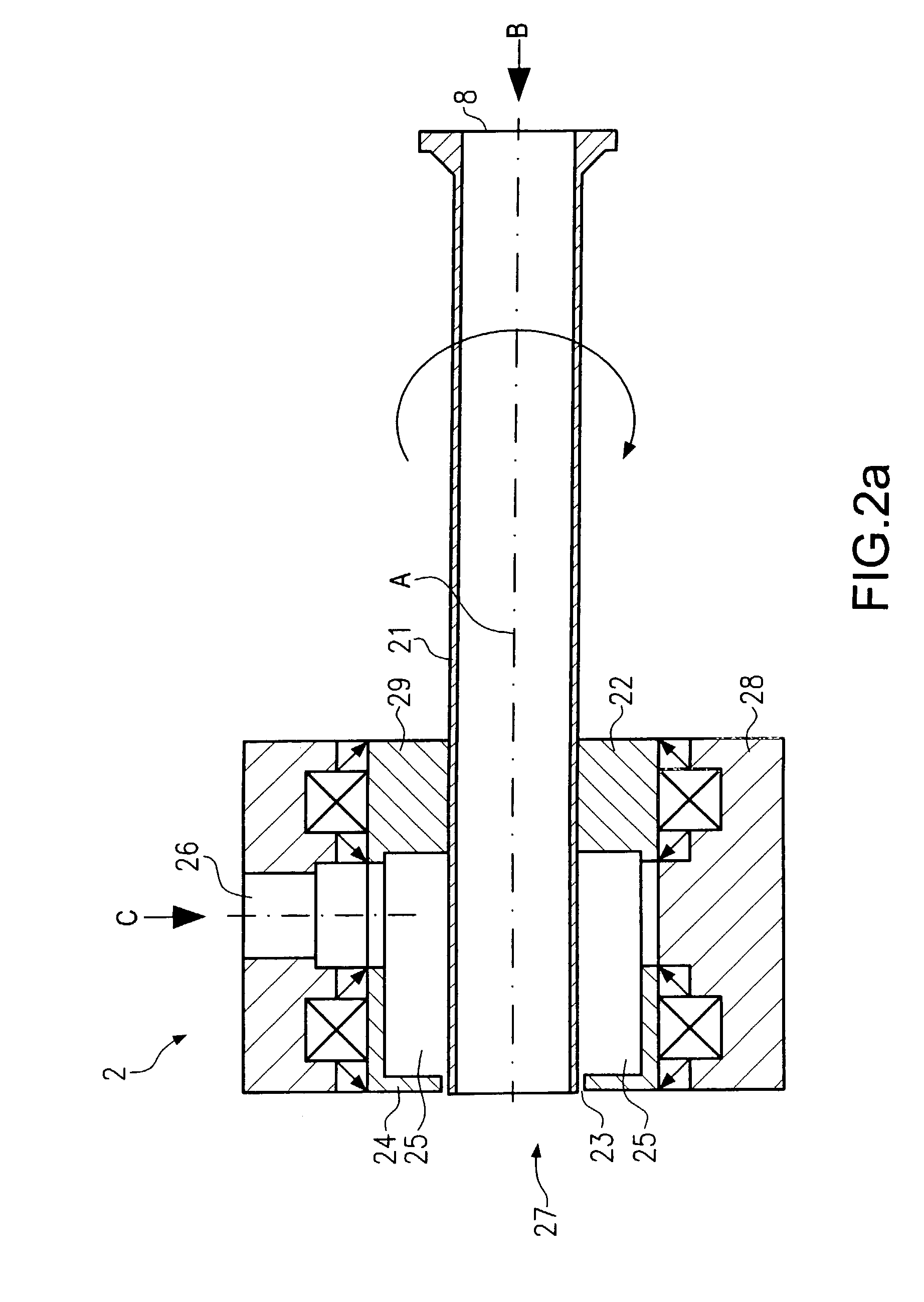

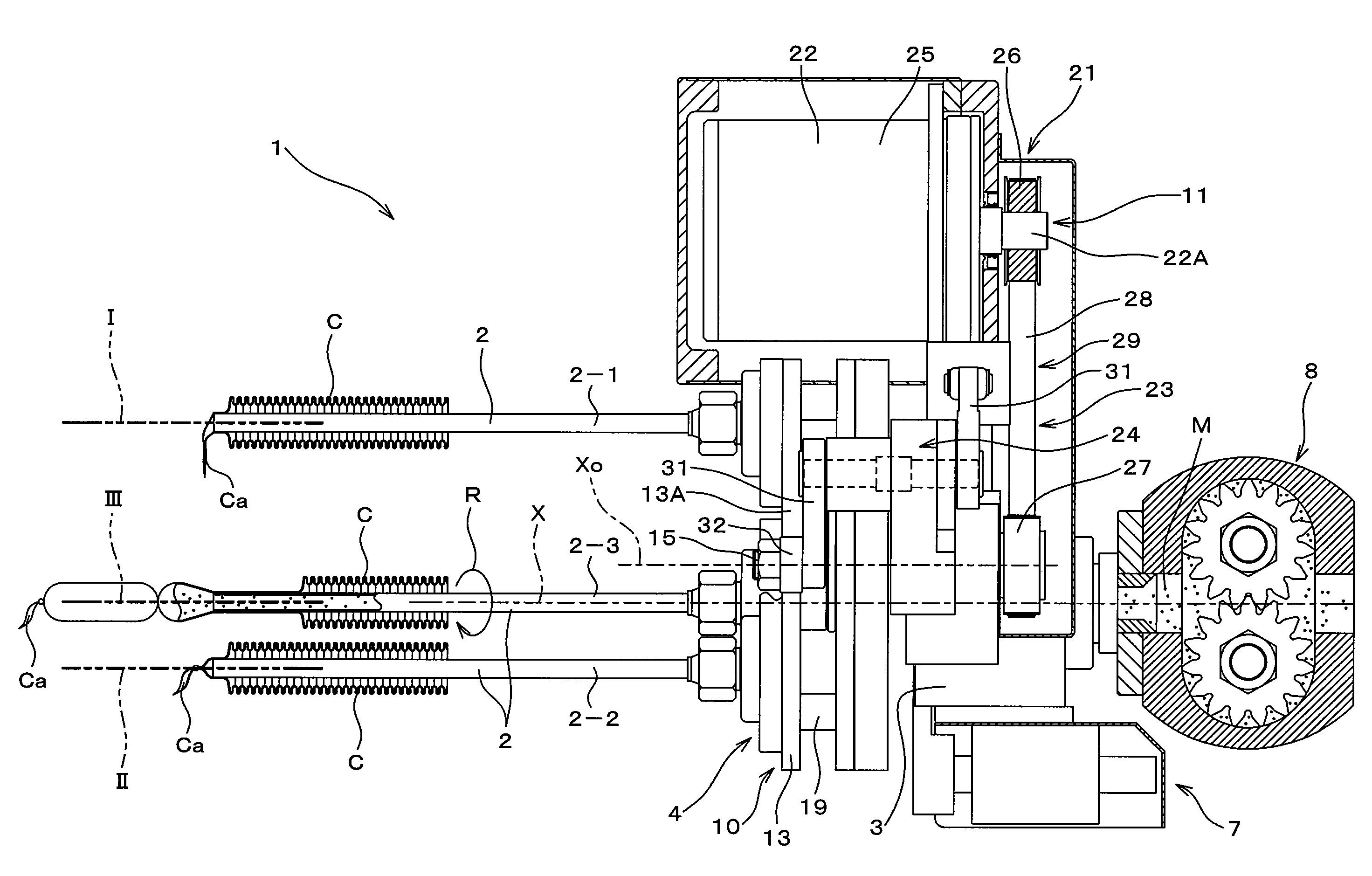

Apparatus and method for setting a casing to a nozzle feeding food-material of sausage or the like into the casing

ActiveUS20080311835A1Improve accuracyReduce idle timeSausage filling/stuffing machinesSausage twisting/linking machinesRotational axisFood material

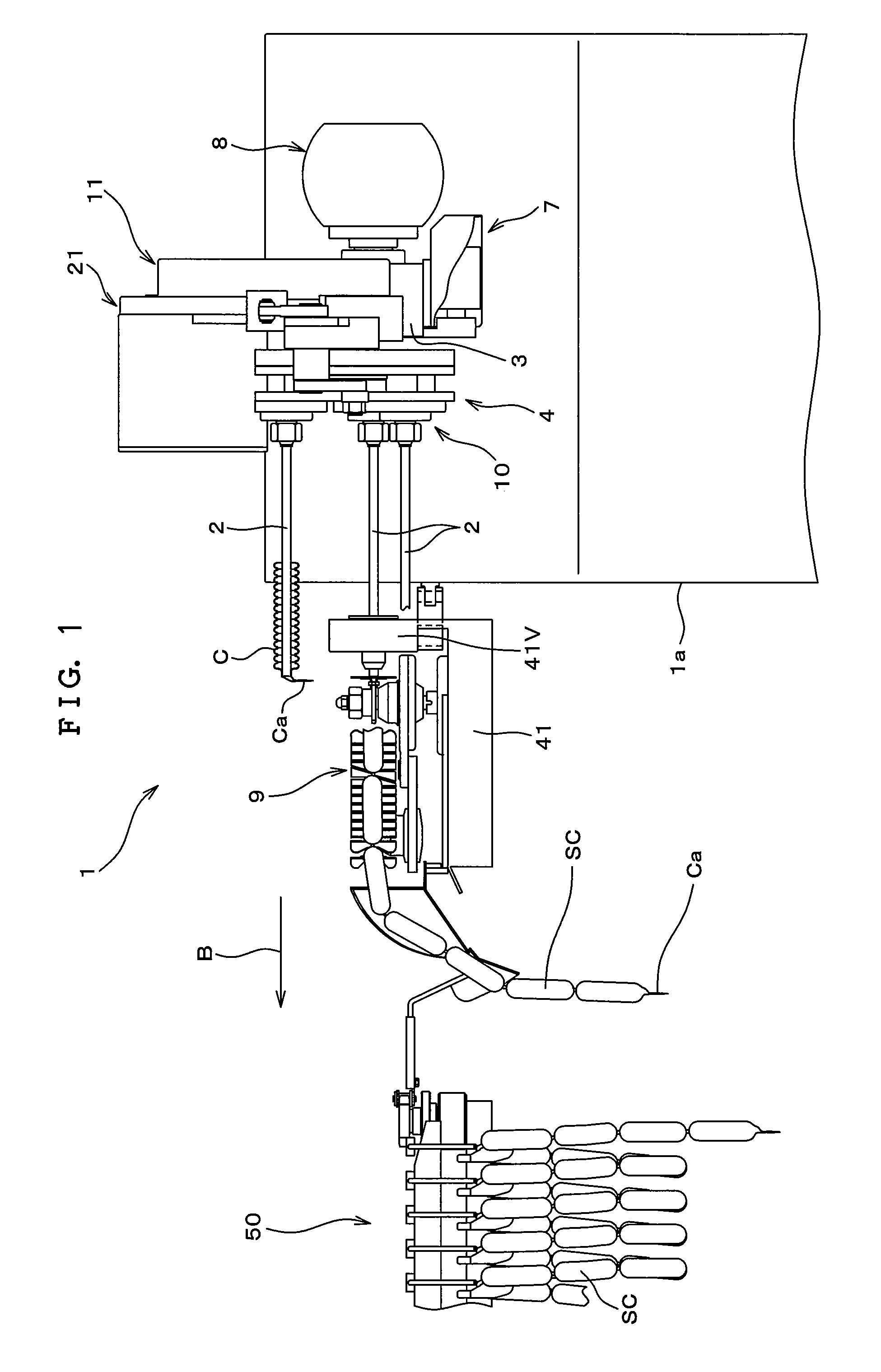

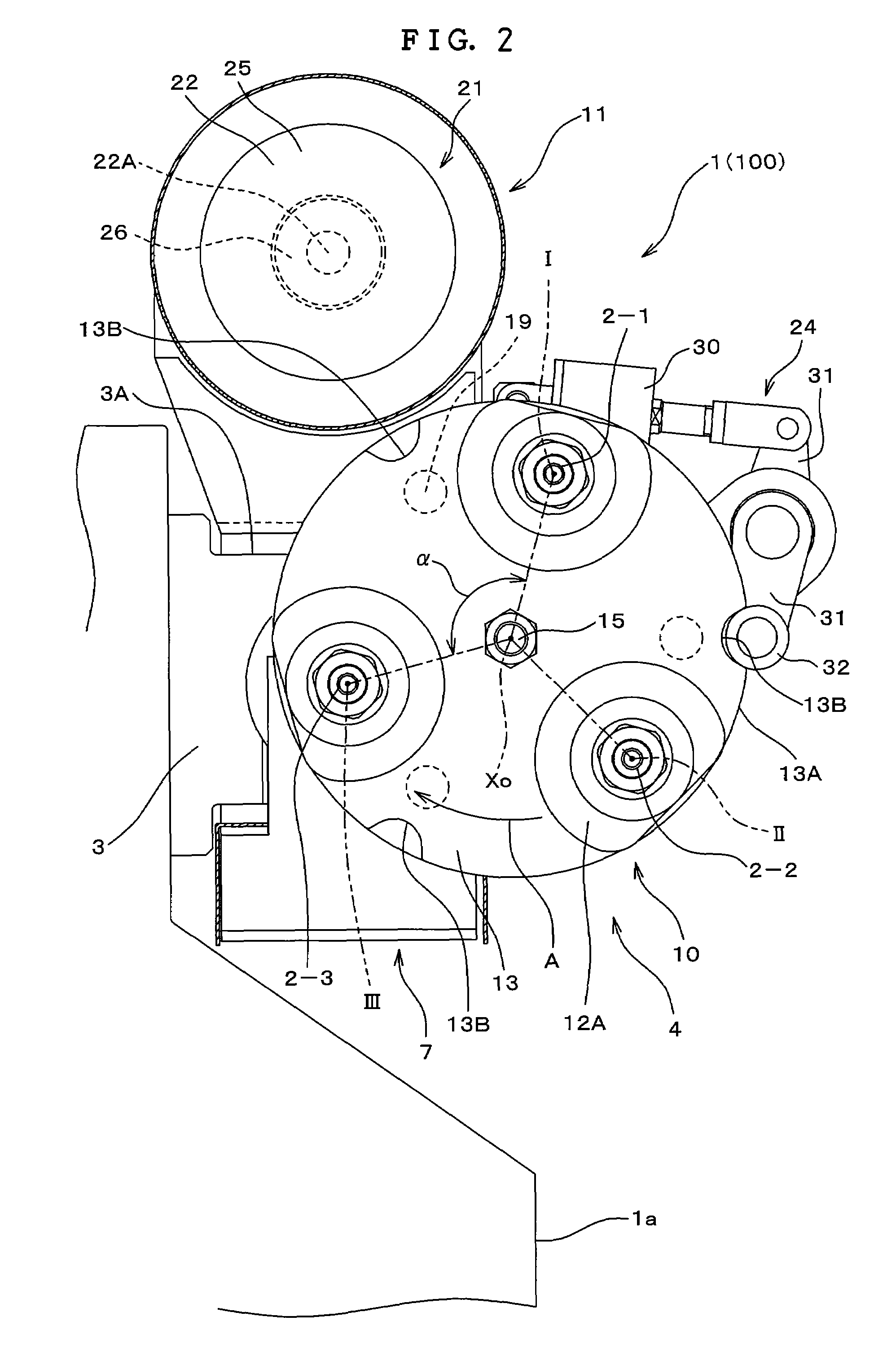

An apparatus for manufacturing chains of linked food products such as sausages with twisted portions and having a plurality of stuffing tubes, includes a plurality of stuffing tubes 2 provided at equal intervals about a rotational axis Xo; a stuffing tube moving body 4 which rotates through predetermined angles about the rotational axis Xo so that the respective stuffing tubes 2 sequentially move to a filling position III; and a stuffed casing conveying means 50 which conveys in a suspended state a stuffed casing C formed by the stuffing tube 2 positioned at the filling position III.

Owner:HITEC

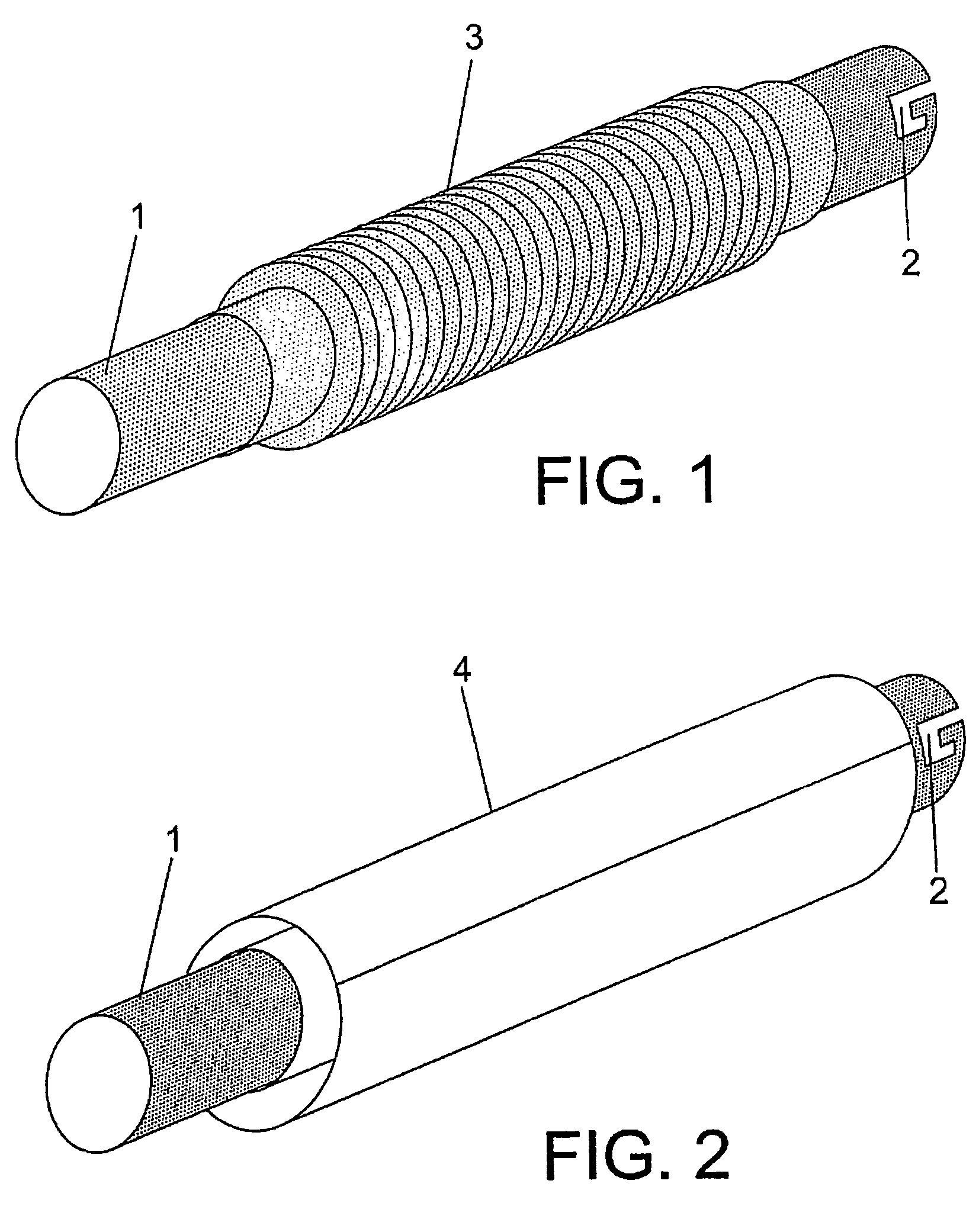

Double casing with netting for food products and production method therefor

InactiveUS7537514B2Prevents the costly operation of loading the netReduce operating costsFlexible coversLiving organism packagingCouplingEngineering

A casing is embodied as a hollow stiff cylindrical support provided with an attachment mechanism in its coupling to the stuffing horn, on which is placed a suitably shirred tube which in turn is coated with a separation sheet and finally by a tubular net, also compressed or shirred, and which together with the inner tube extends beyond the support tube and is clamped against the tube by a clip, staple or knot such that during the stuffing operation the shirred tube and the equally shirred net are axially extended, with a simultaneous yet independent extension of the two elements favored with the aid of the intermediate separation sheet.

Owner:VISCOFAN

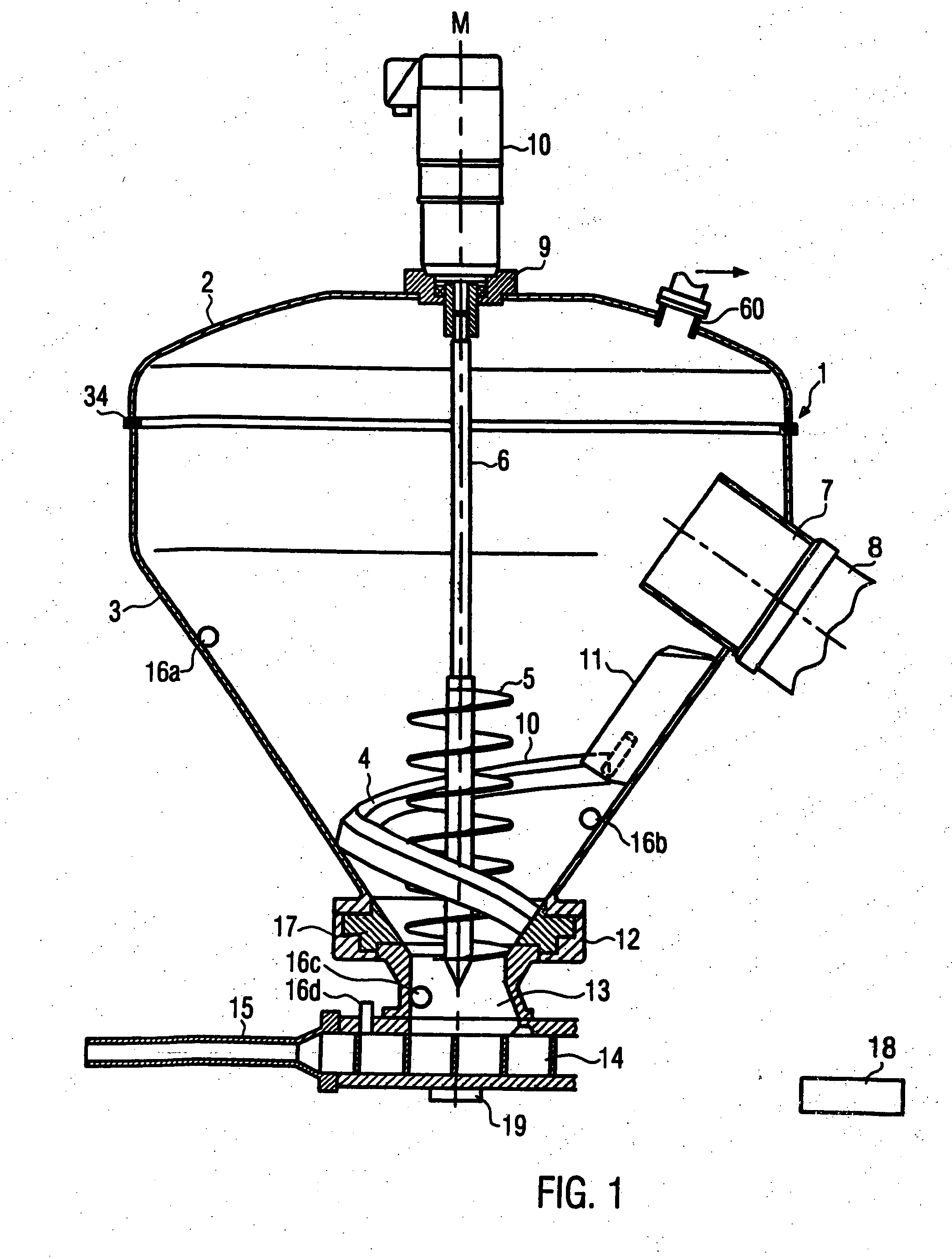

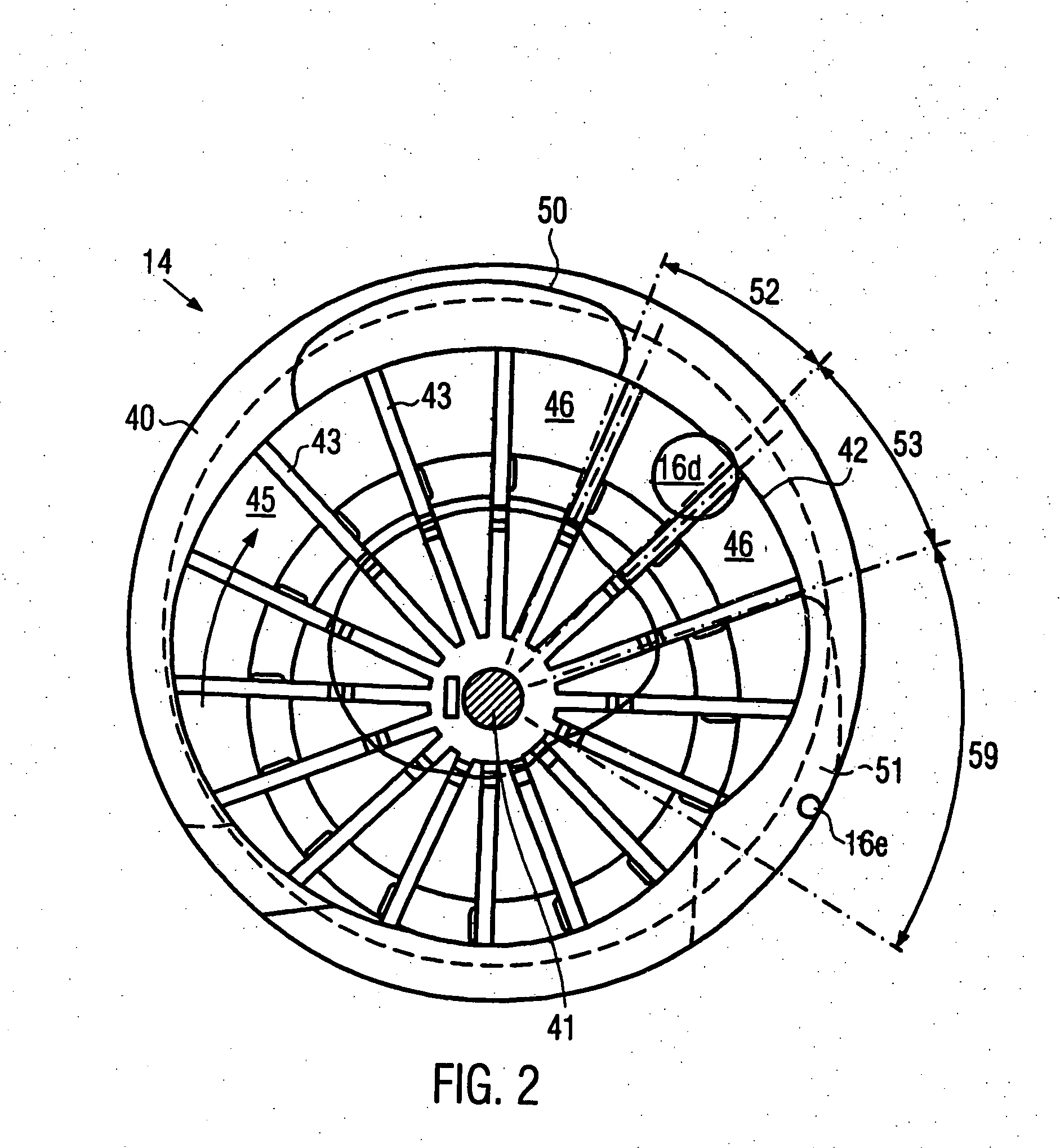

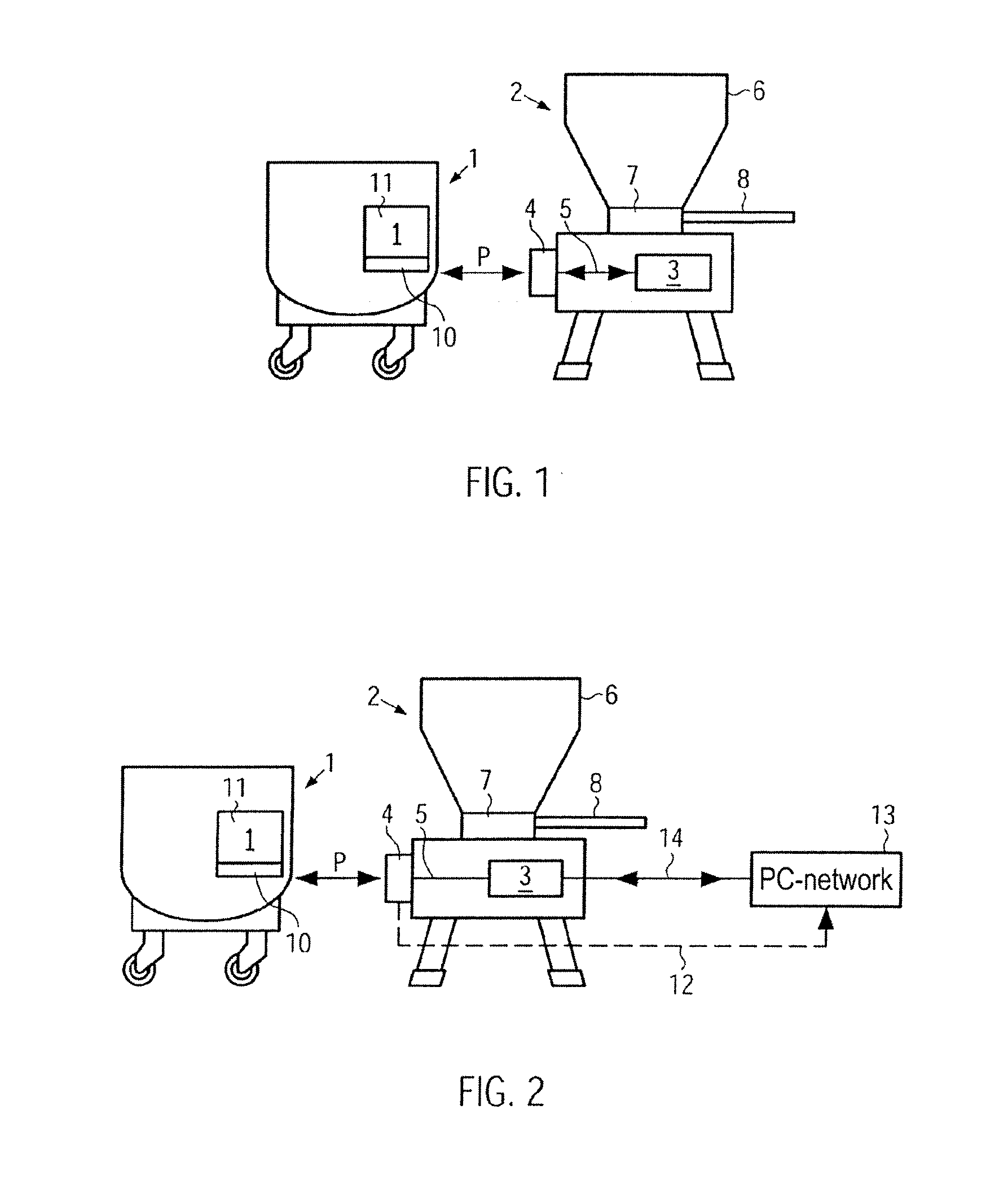

Filling machine and method of feeding paste masses from a hopper into a conveying mechanism

ActiveUS20070212994A1Easy and reliable chargingImprove accuracySausage filling/stuffing machinesEngineeringScrew conveyor

A method and a filling machine for charging paste mass, in particular sausage meat, with a conveying mechanism 14 arranged at the lower end 3 of the hopper 1 and a feed device 4, 5 for feeding the paste mass from the hopper into the conveying mechanism. To facilitate the charging of the conveying mechanism from the hopper 1 continuously and completely with paste mass, and namely independent of the degree of evacuation and the filling level of the paste mass, the feed device comprises a combination of a feeder curve 4 and a screw conveyor 5 arranged within the feeder curve.

Owner:ALBERT HANDTMANN MASCHFABRICK

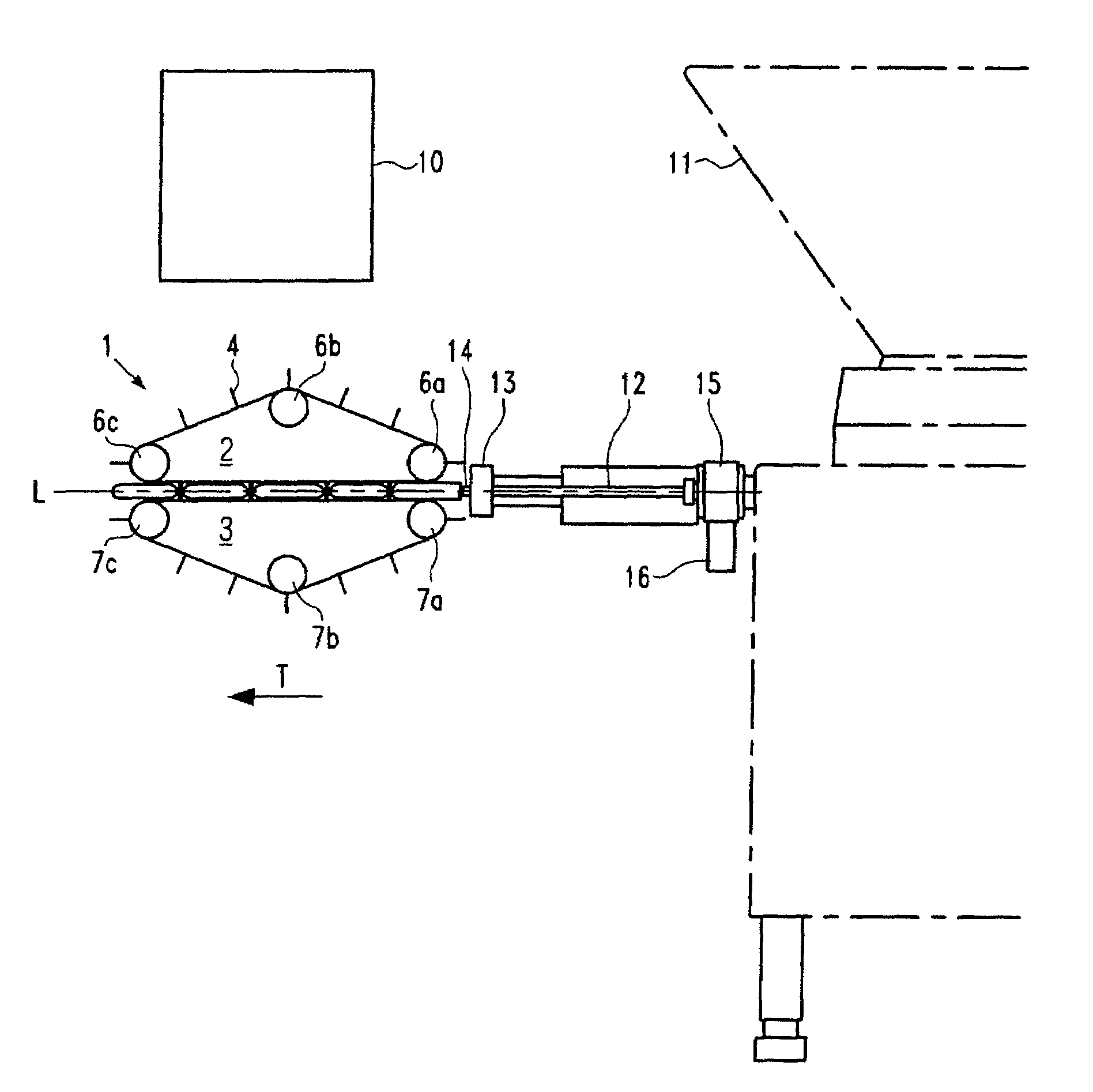

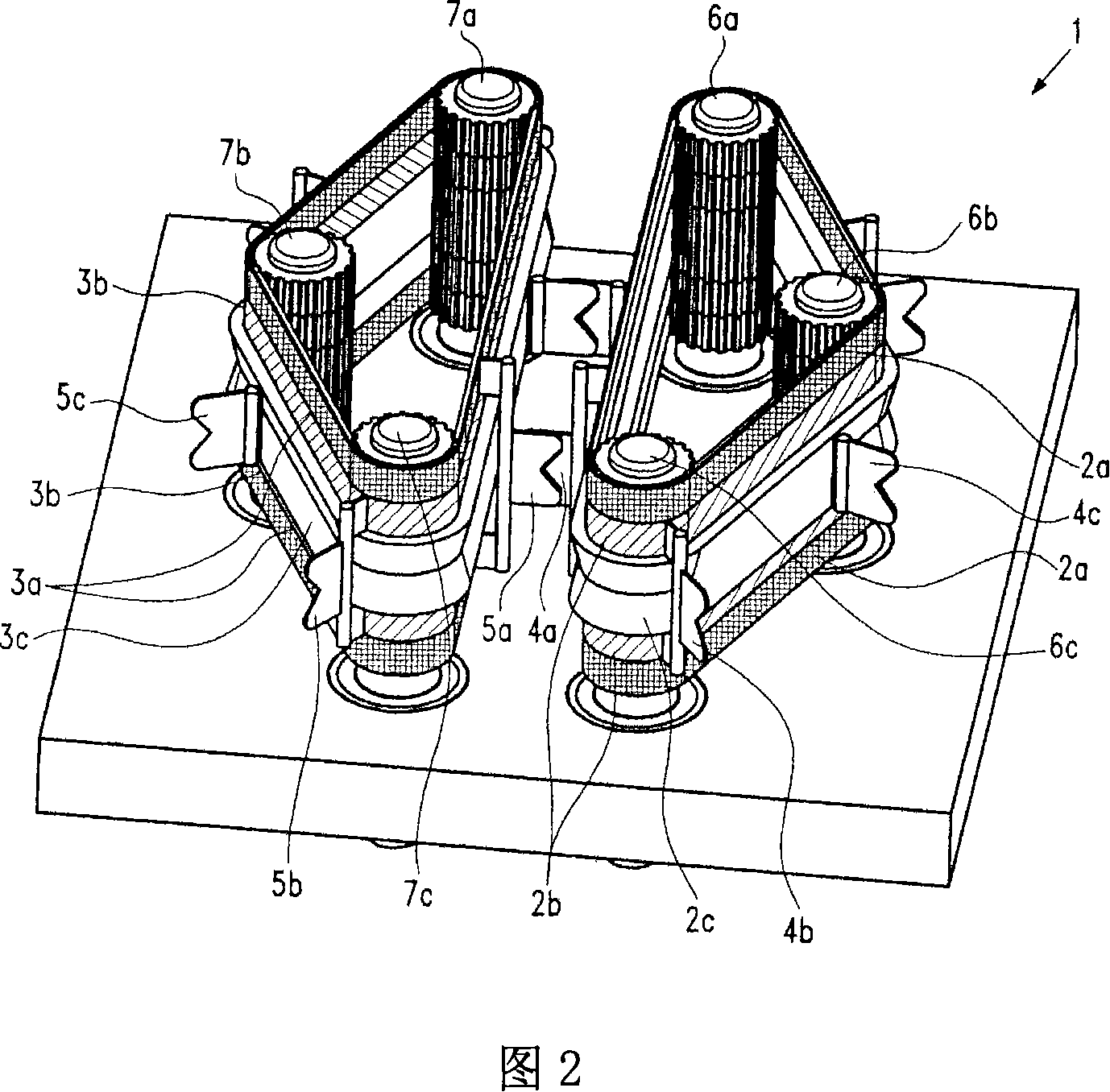

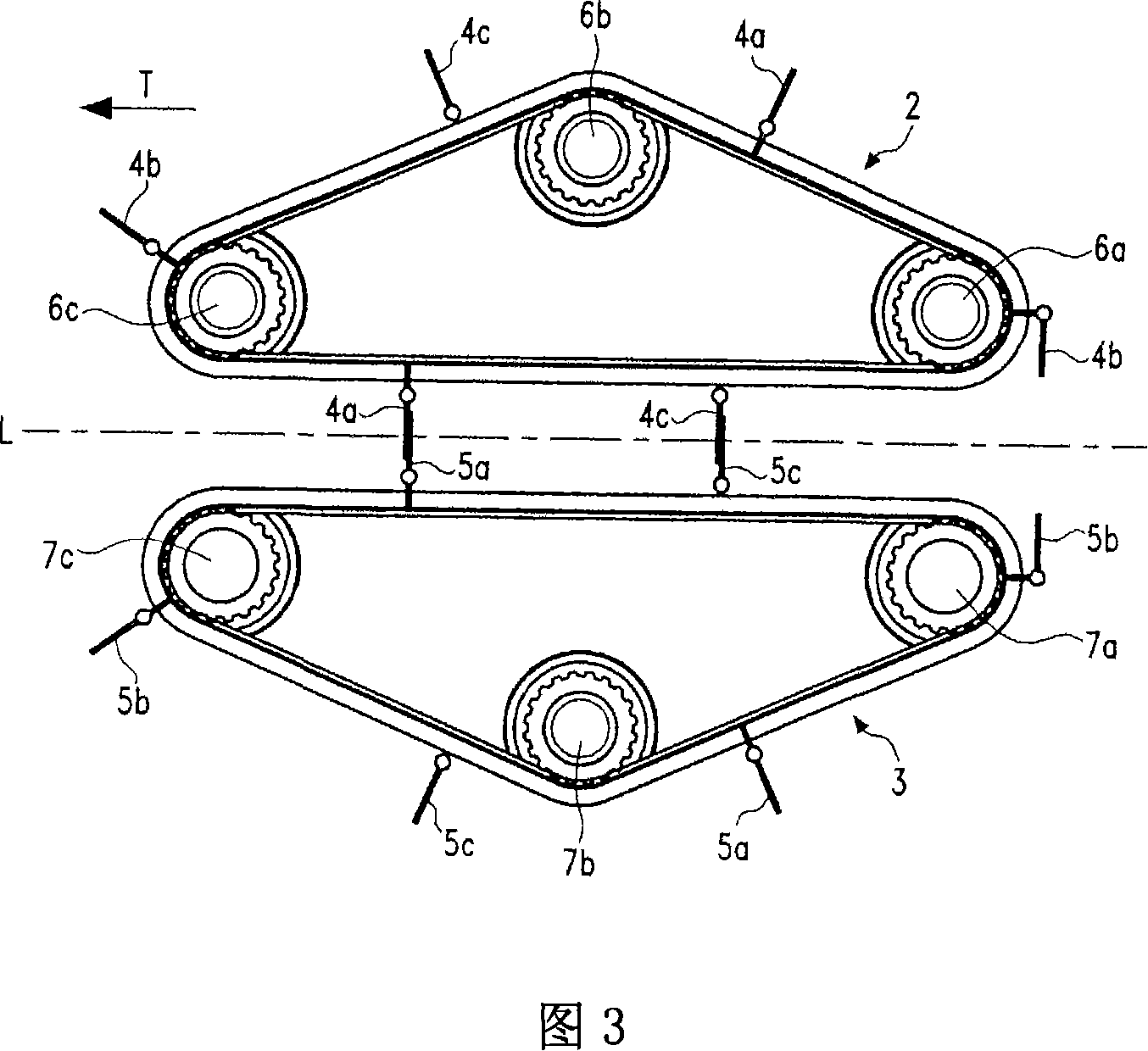

Apparatus and method for dividing a stuffed sausage skein

ActiveUS7381123B2Drawback can be obviatedFlexible configurationSausage filling/stuffing machinesEngineering

An apparatus and a method for dividing a stuffed sausage skein, wherein a transport element pair is provided, including rotating opposite transport elements between which the stuffed sausage skein is conveyed in a transport direction and each of which include at least one dividing element. To be able to configure the length of the portions flexibly without mechanical adaptation, the apparatus comprises several adjacently arranged transport element pairs drivable independently of each other with corresponding dividing element pairs. The speed of the transport element pairs is adjusted such that the spacing between the points of separation corresponds to a predetermined length of the divided sausage skein.

Owner:ALBERT HANDTMANN MASCHFABRICK

Shirred casing

A shirred fibrous food casing defines a shirred stick formed from a tubular fibrous casing. The shirred stick includes an average outside diameter at least 120% of the average inflated diameter of the deshirred casing. Additionally, the shirred stick includes an average inside diameter of at least 70% of the casing inflated diameter and a pleat pitch defined as the distance between adjacent apexes of major pleats measured on the casing after the shirred stick is deshirred.

Owner:VISKOTEEPAK BELGIUM NV

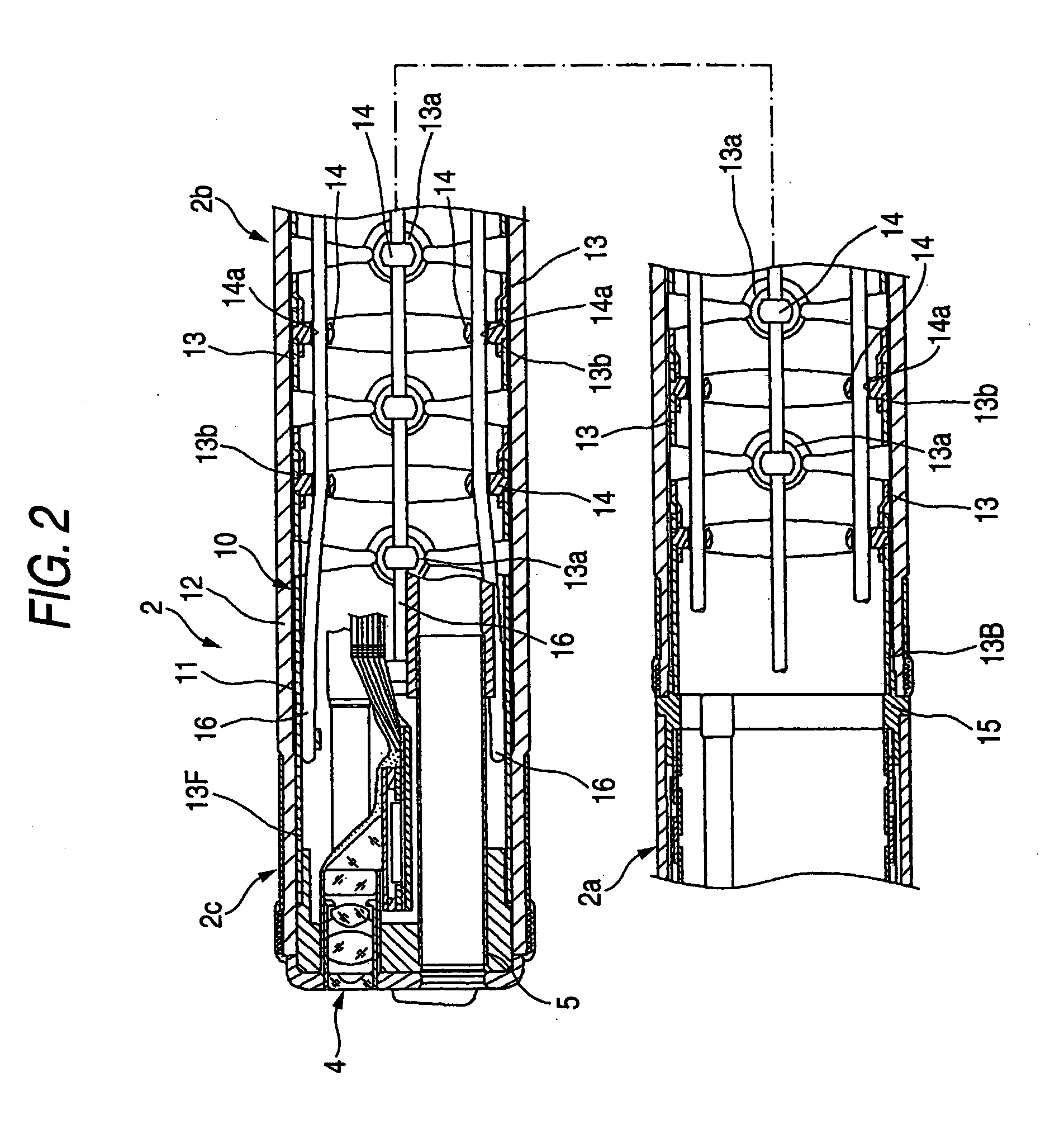

Endoscope angle portion

An endoscope angle portion comprises an angle portion structure. The angle portion structure includes angle ring units each of which comprises pivoting joint portions extending from its both ends and has a shape that is notched obliquely in directions away from the pivoting joint portions, and wherein adjacent ones of the angle ring units is pivotally joined to form the angle portion structure, wherein a first angle ring unit of the angle ring units has a larger length dimension than that of a second angle ring unit of the angle ring units, and the first angle ring unit has a smaller notch width of a notched portion than that of the second angle ring unit, the first angle ring unit being nearer a base end of the endoscope angle portion than the second angle ring unit.

Owner:FUJI PHOTO OPTICAL CO LTD

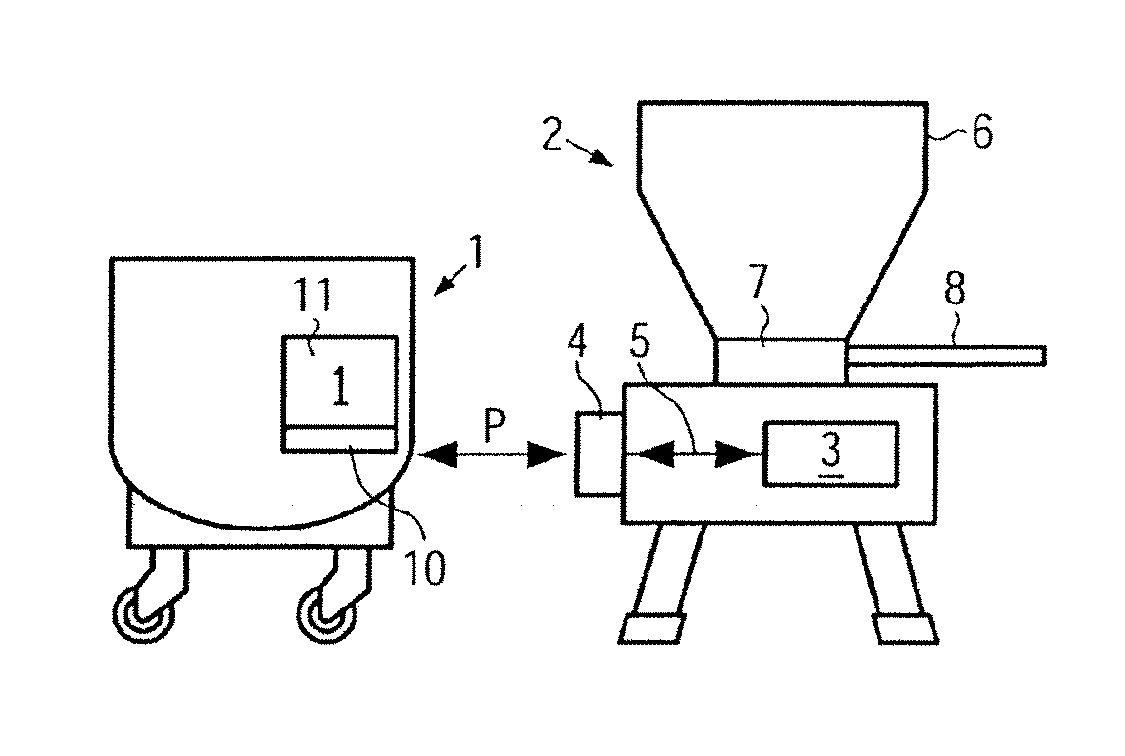

Filling machine and a filling method

InactiveUS20090130962A1Efficient fillingAvoid confusionWeighing indication devicesSausage filling/stuffing machinesMachine controlEngineering

A filling machine and a method of filling foodstuffs e.g. into sausage casings, with the filling machine having supplied thereto containers in which a foodstuff is stored, and a machine control unit. In order to guarantee a correct operation of the filling machine, a data reader receives container data stored in a storage means at the respective container, whereby the machine control unit is implemented such that the filling process is executed in dependence upon the container data read.

Owner:ALBERT HANDTMANN MASCHFABRICK

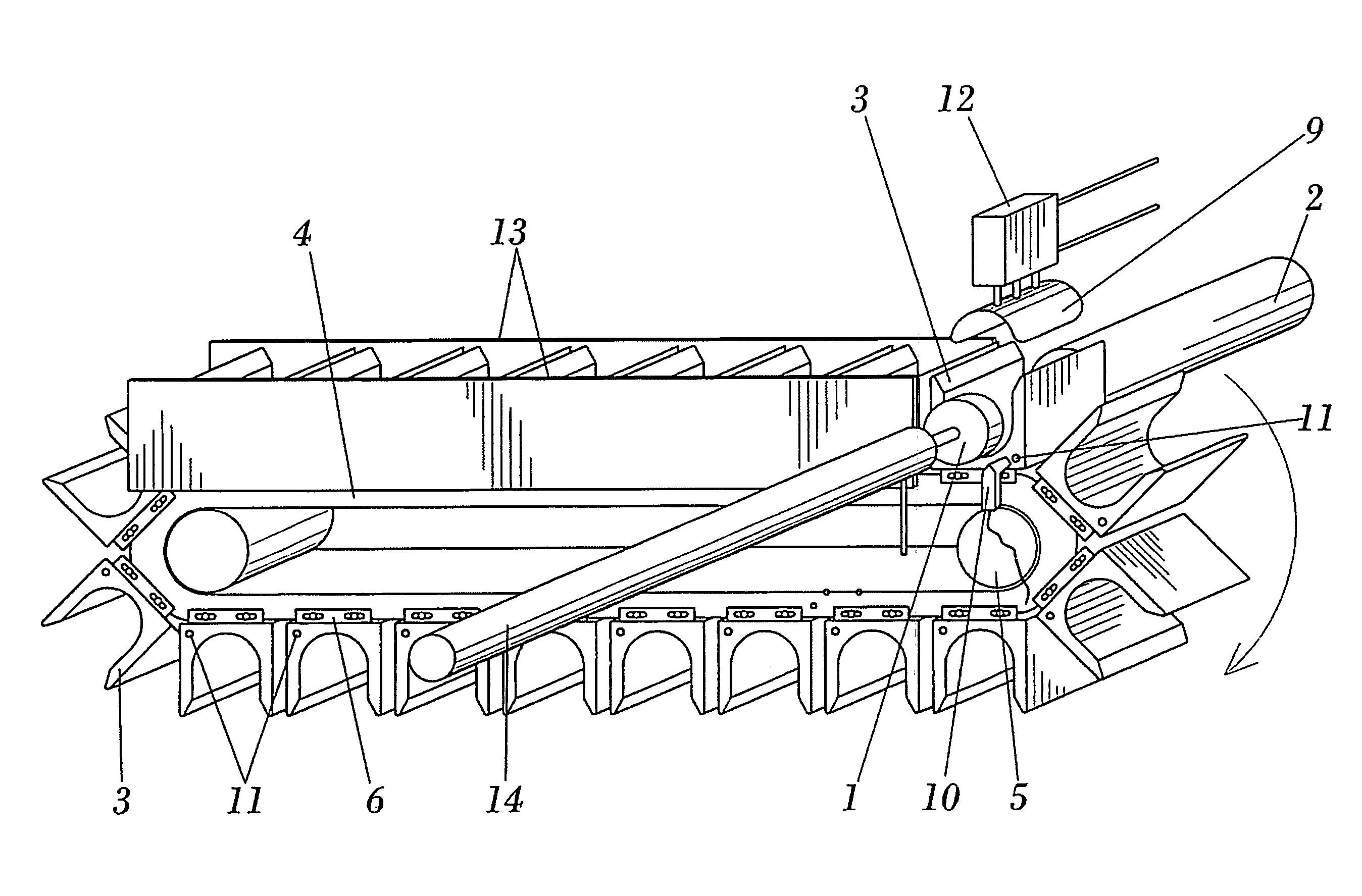

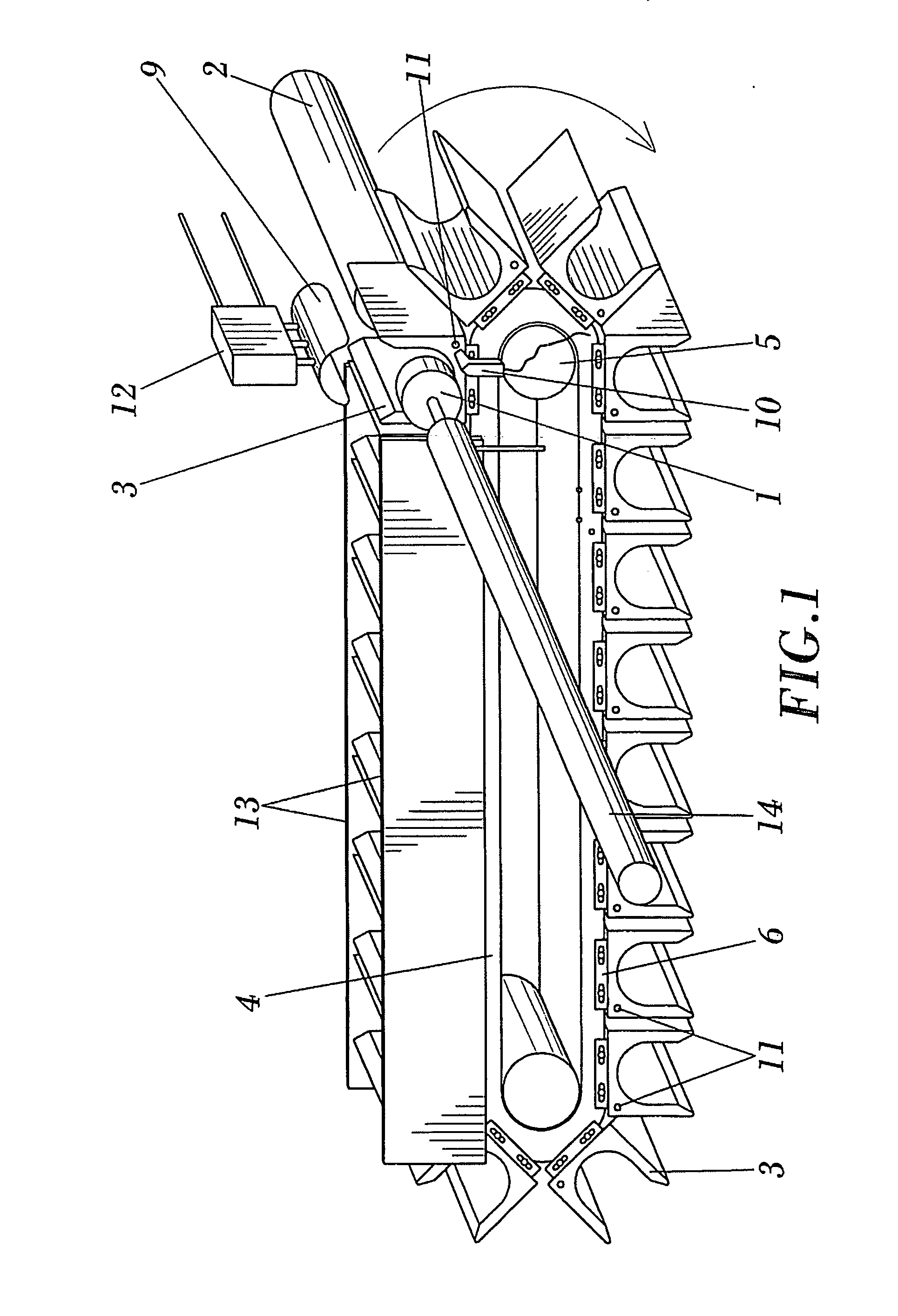

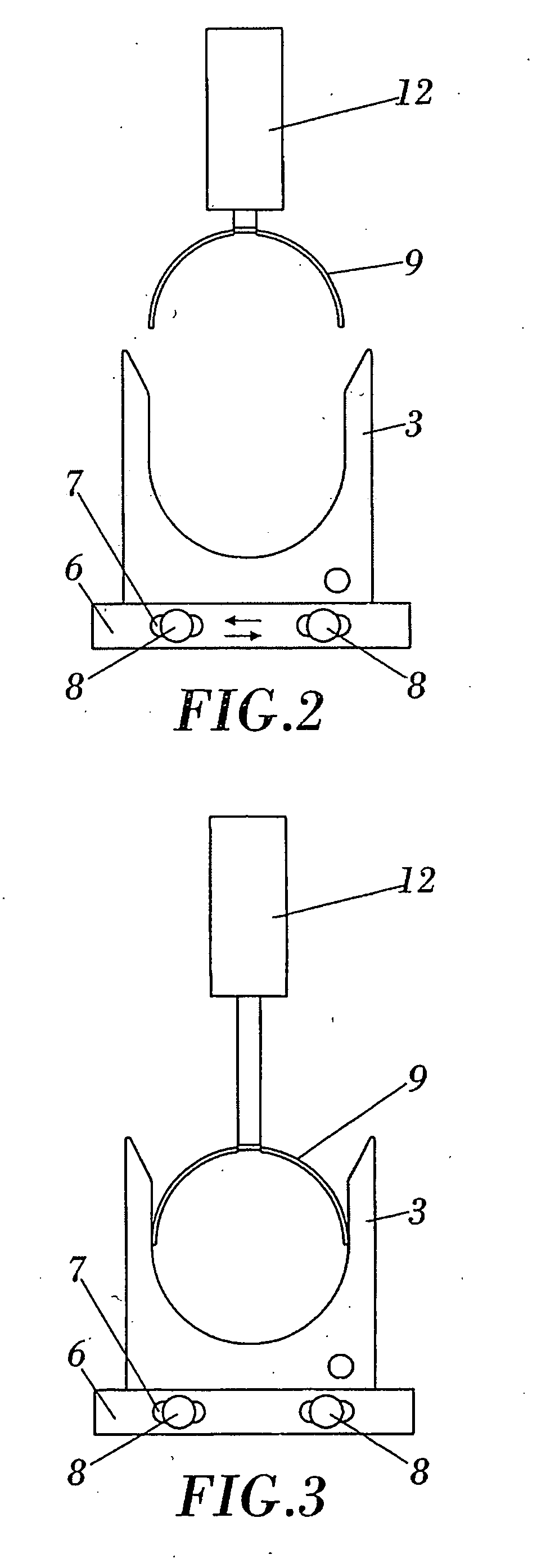

Feeder for meat pieces made of entire muscles for a piston stuffing machine

ActiveUS20060183413A1Meat/sausage hanging-upSausage filling/stuffing machinesClassical mechanicsEngineering

Incorporates buckets (3) open on their top in which the meat pieces are loaded, moving on traction means (4) that execute a step by step motion towards the feeding area located between the piston (1) and the body of the stuffing machine (2), where the meat piece is pushed by the piston (1) towards the body of the stuffing machine (2) for compacting and subsequently wrapping it. The buckets (3) have open front and rear faces to facilitate the run of the piston (1) and the exit of the meat piece towards the body of the stuffing machine (2). In addition, means are provided for facilitating the centred position of the bucket with respect to the position of the piston (1) in the feeding area.

Owner:VISCOFAN

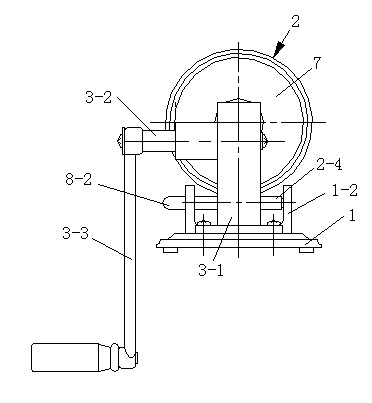

Net loader

InactiveUS20050048886A1Easy to manufactureEasy to cleanSkinless sausage makingSausage filling/stuffing machinesManual insertionEngineering

A device for filling tubular casings with edible material is disclosed. The device includes a tube upon which the casing can be shirred onto, a tube inlet, a tube outlet and tube support means. The support means allows the device to be supported for the manual insertion of edible material into the tube inlet and furthermore the manual forcing of this edible material through the tube and out of the tube outlet.

Owner:MERCTECH

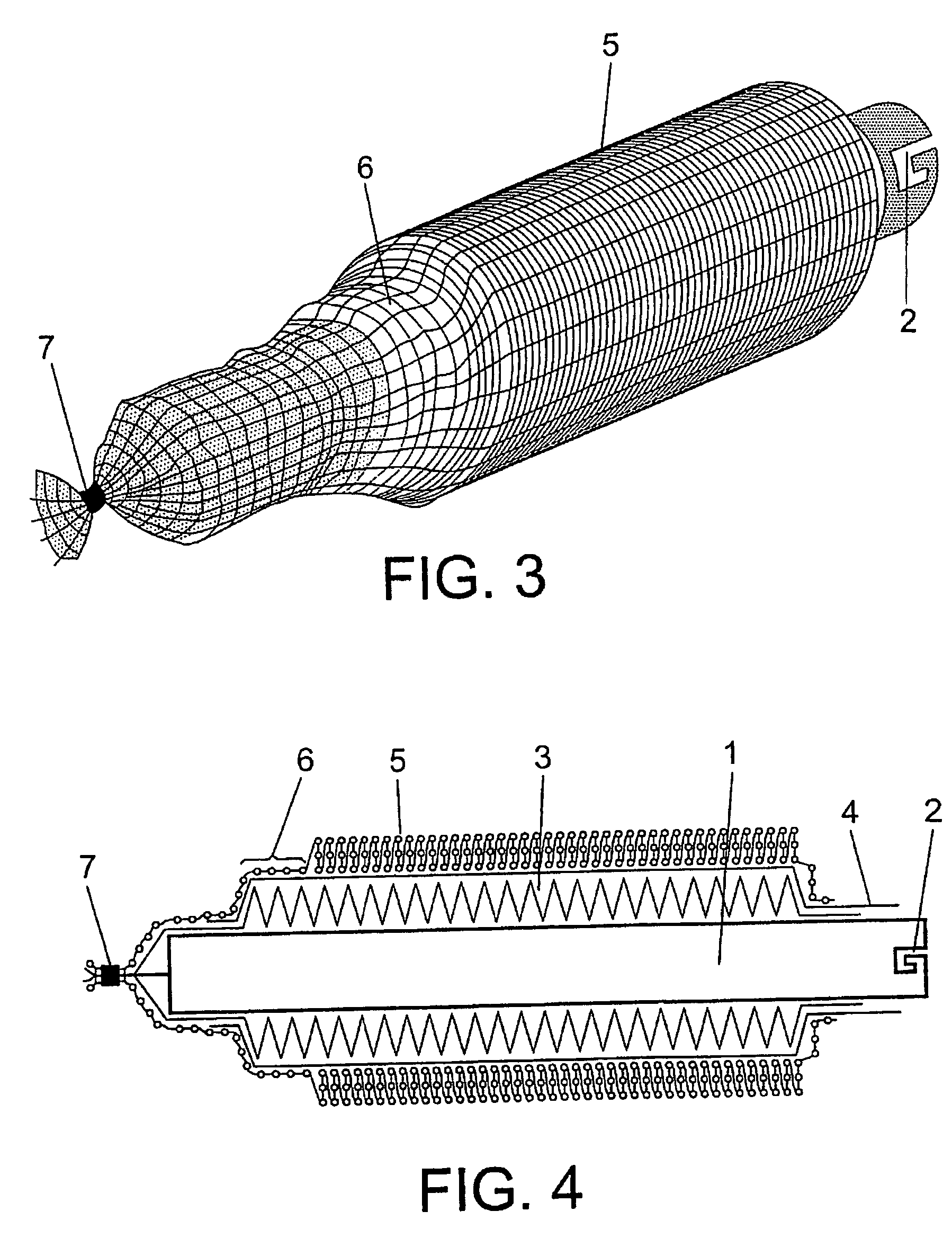

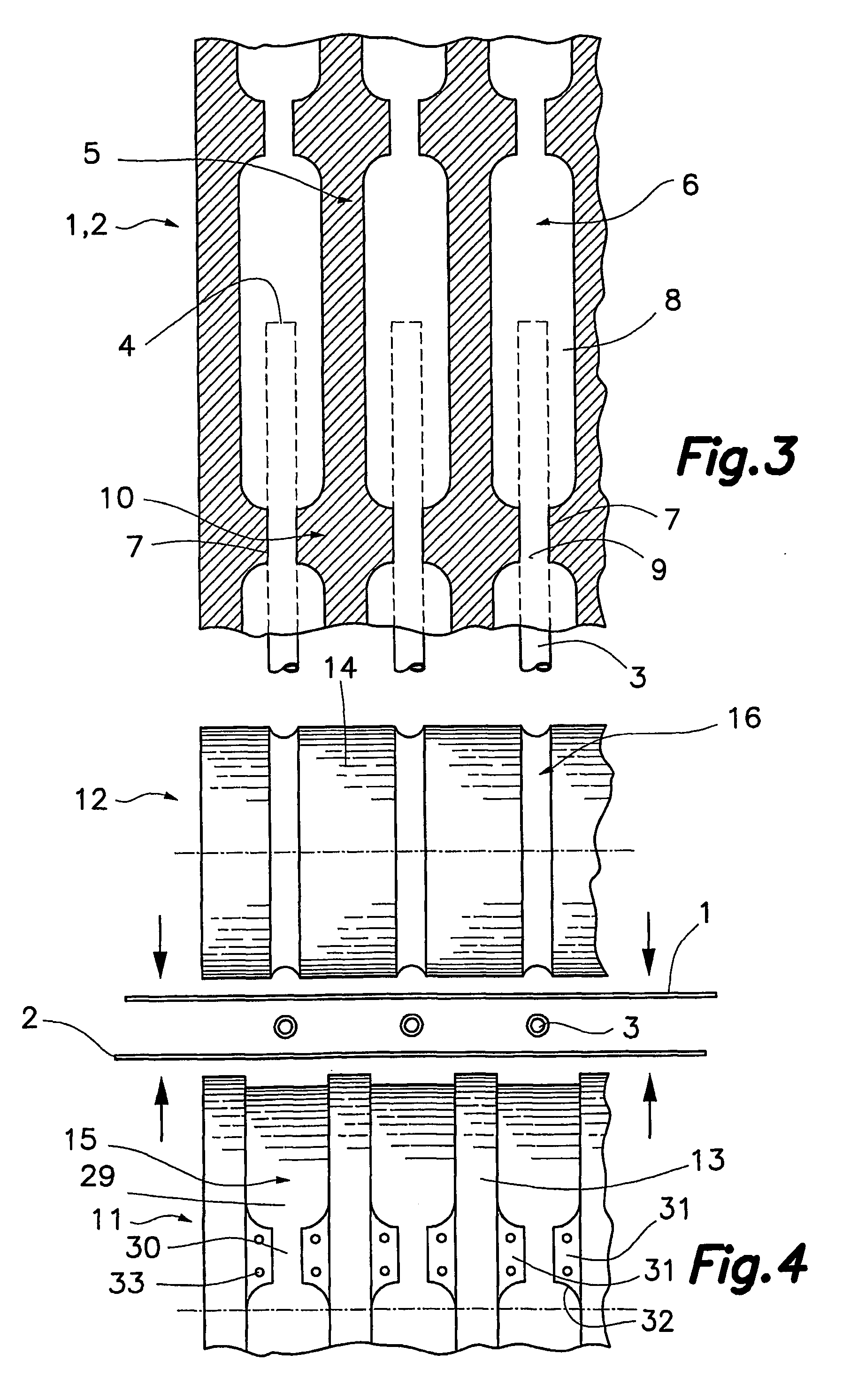

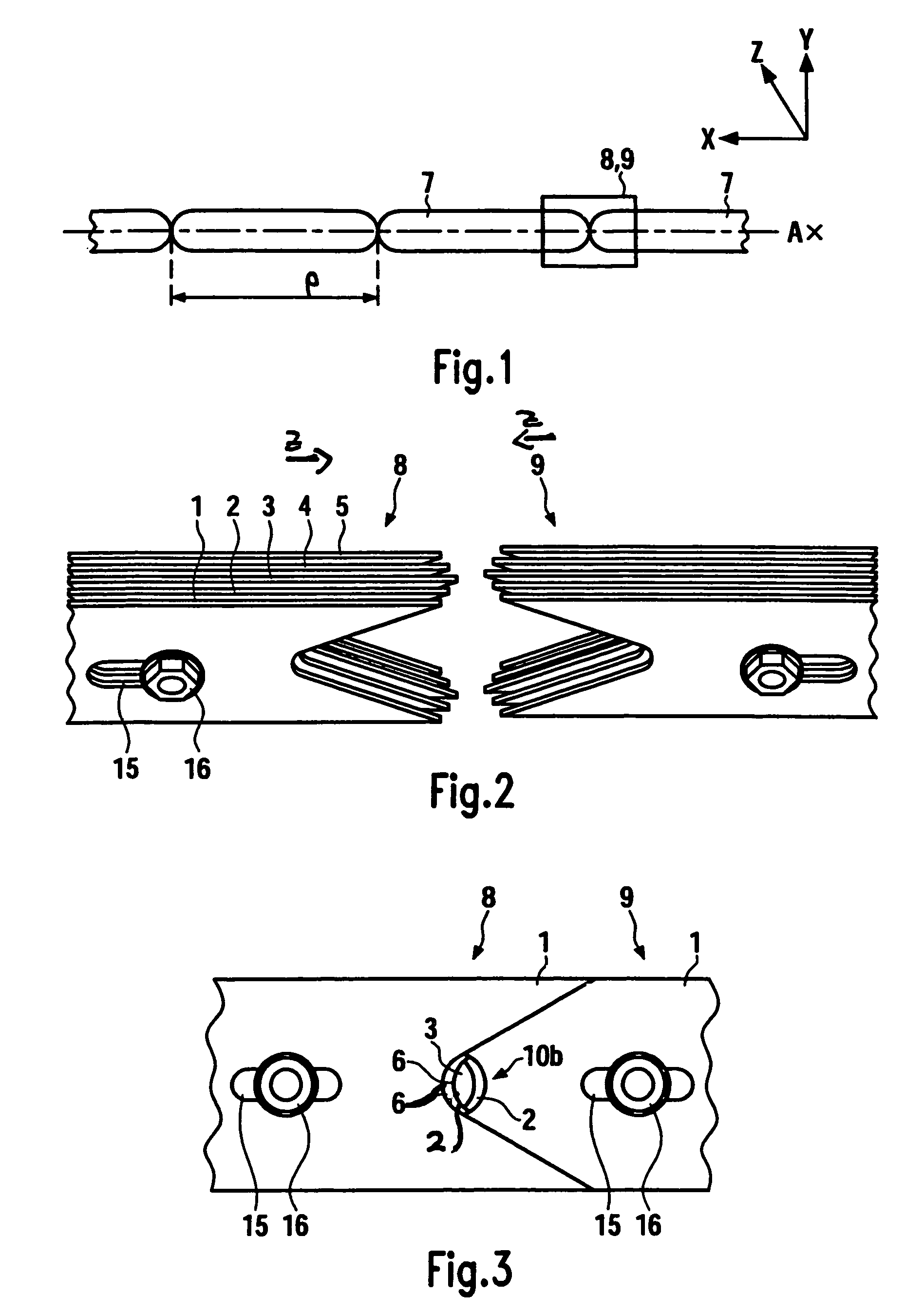

Process and machine for packing pasty, liquid or semiliquid products

InactiveUS7254929B1Accurate acquisitionSkinless sausage makingSausage casing manufactureLiquid productEngineering

Process and machine for packing pasty, liquid or semiliquid products comprising: nonstop feeding two sheets (1, 2) sandwiching ducts (3) ending in nozzles (4) feeding pasty, liquid or semiliquid products to be packed (M); nonstop longitudinally sealing the said sheets (1, 2) through longitudinal continuous beads (5) adjacent to the said continuous sleeves (6); forming through the said longitudinal sealing narrowings arranged at intervals longitudinally regular in the said sleeves (6) making possible the passage of the said ducts (3) and defining in the sleeves (6) long, wide lengths (8) and short narrow lengths (9); nonstop injecting with nozzles (4) material (M) within the said sleeves (6) which are inflated forming units (28) of material (M) with prior pressure closing of a narrow length (9) each sleeve advanced to each nozzle (4) while the sheets (1, 2) are moving forwards, and pressure closing and transversally sealing at regular intervals the said sleeves (6) filled with material (M).

Owner:SCHUTZ ALEJANDRO JAVIER +1

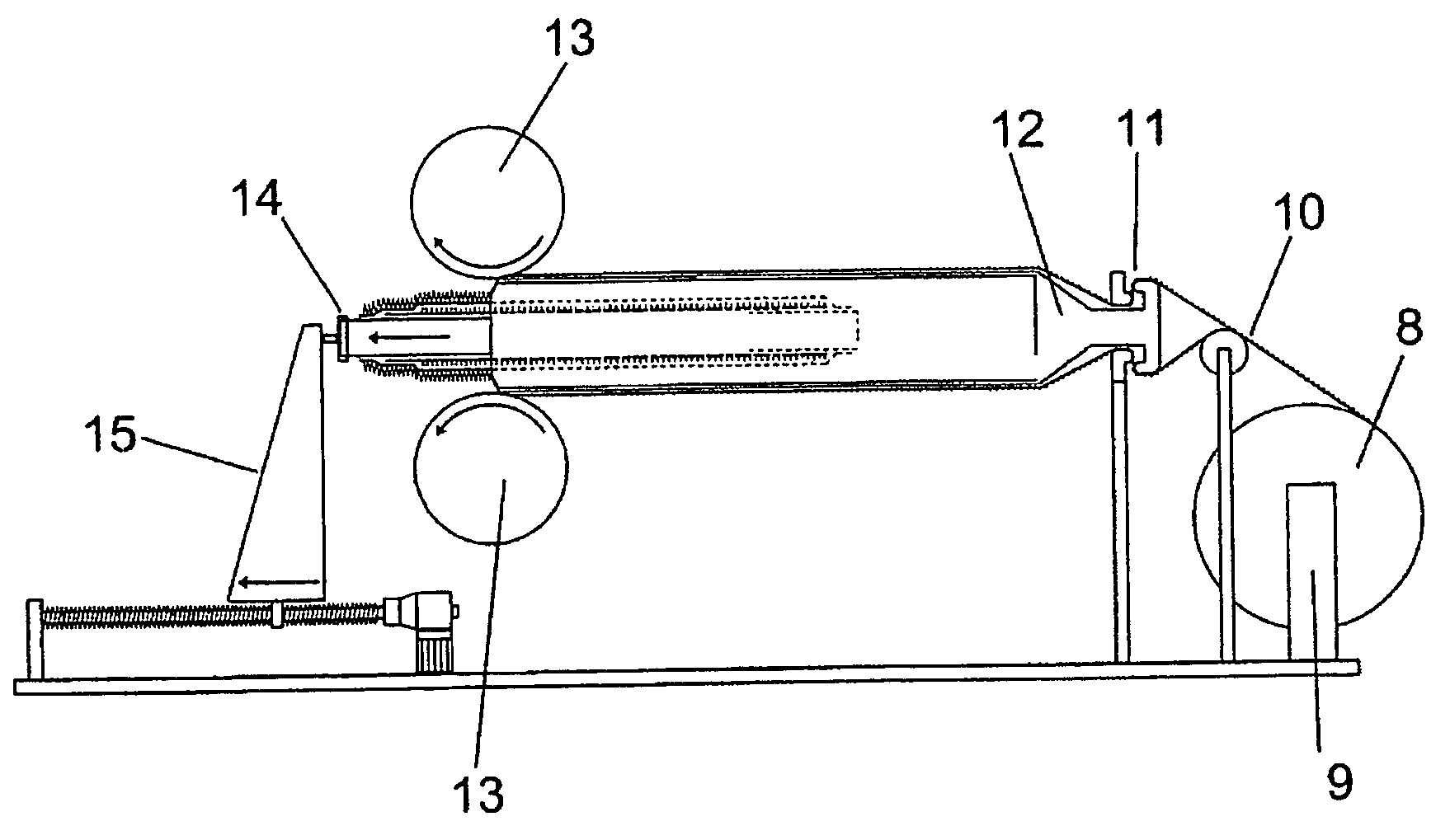

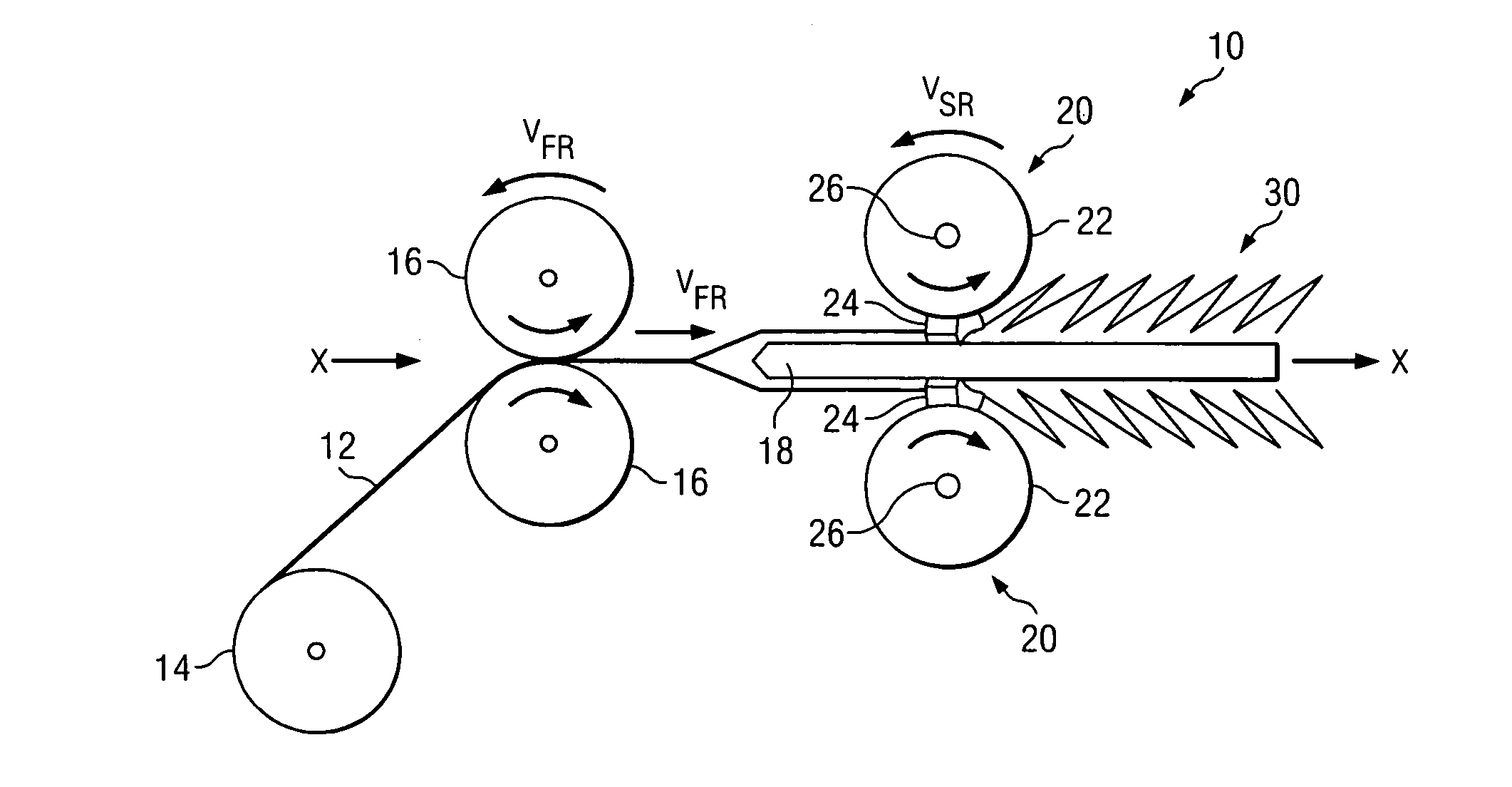

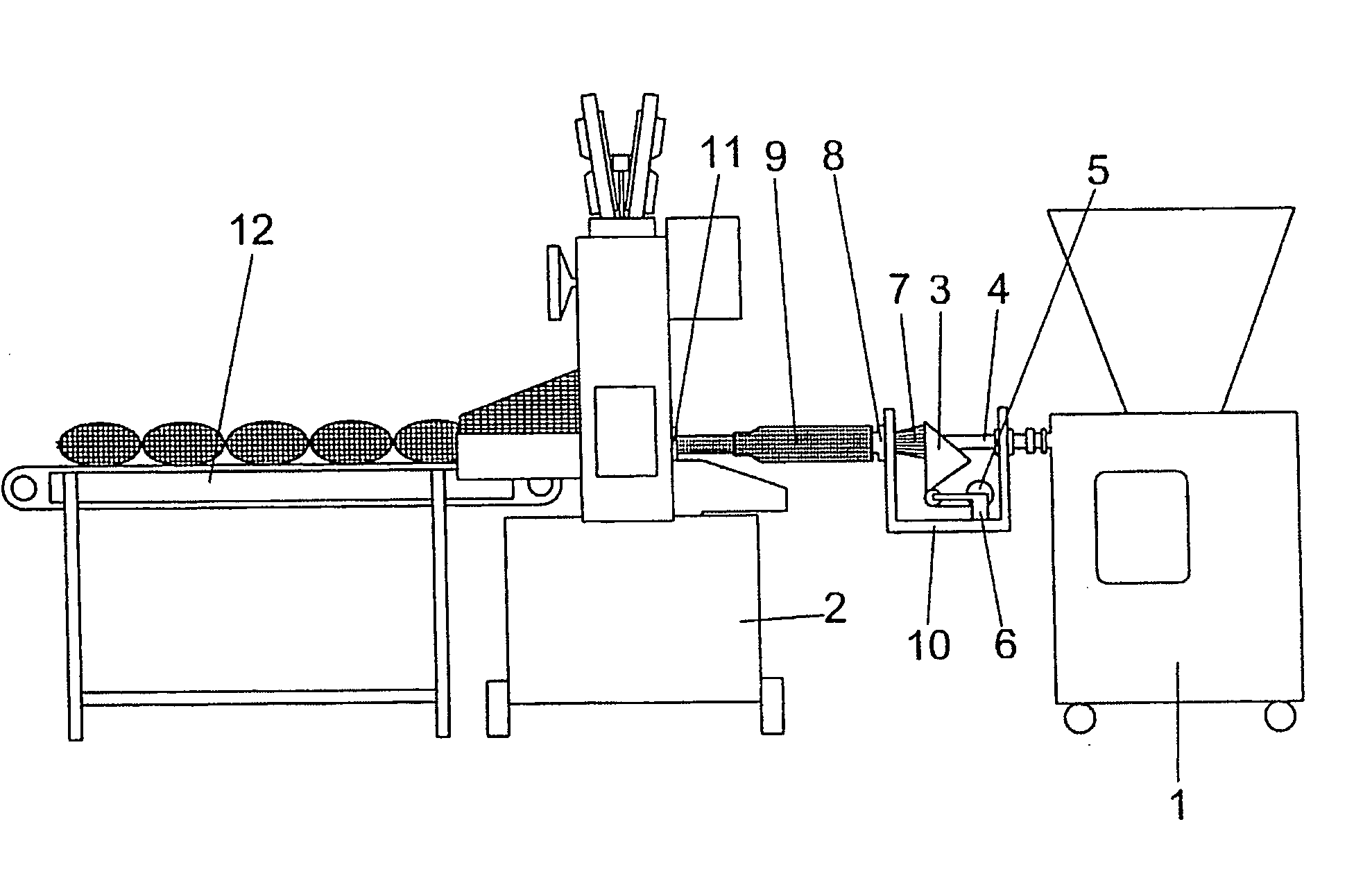

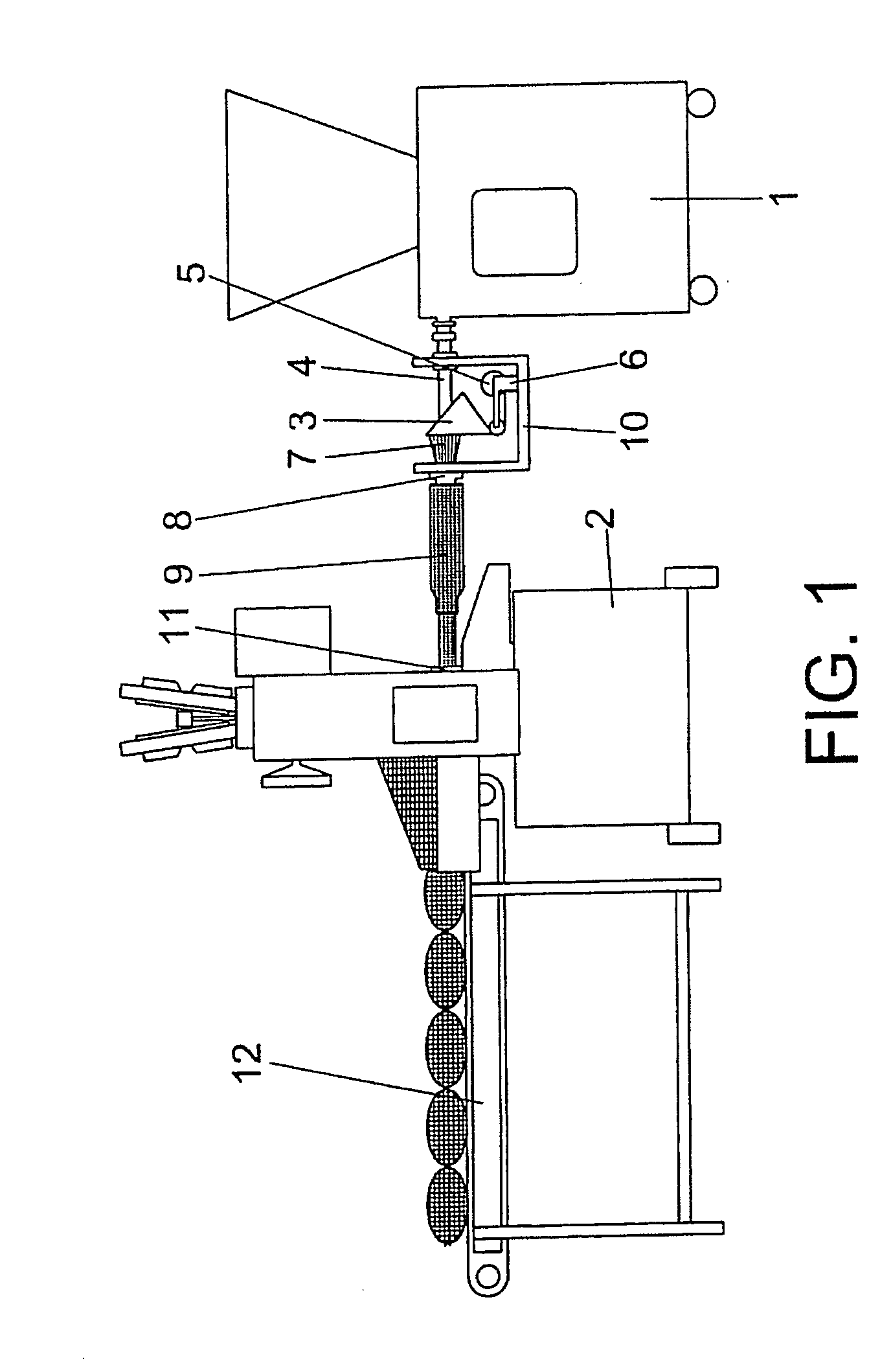

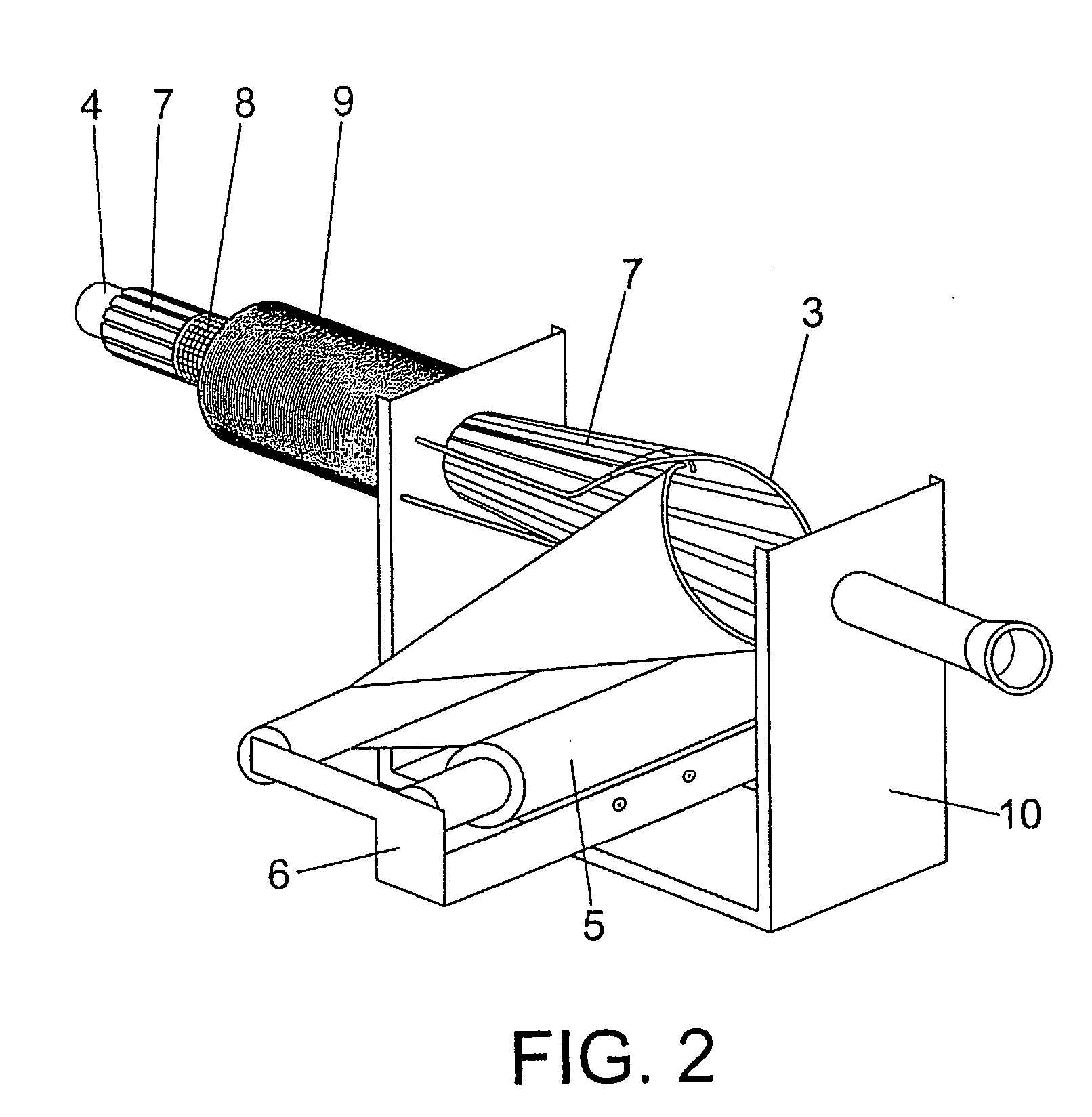

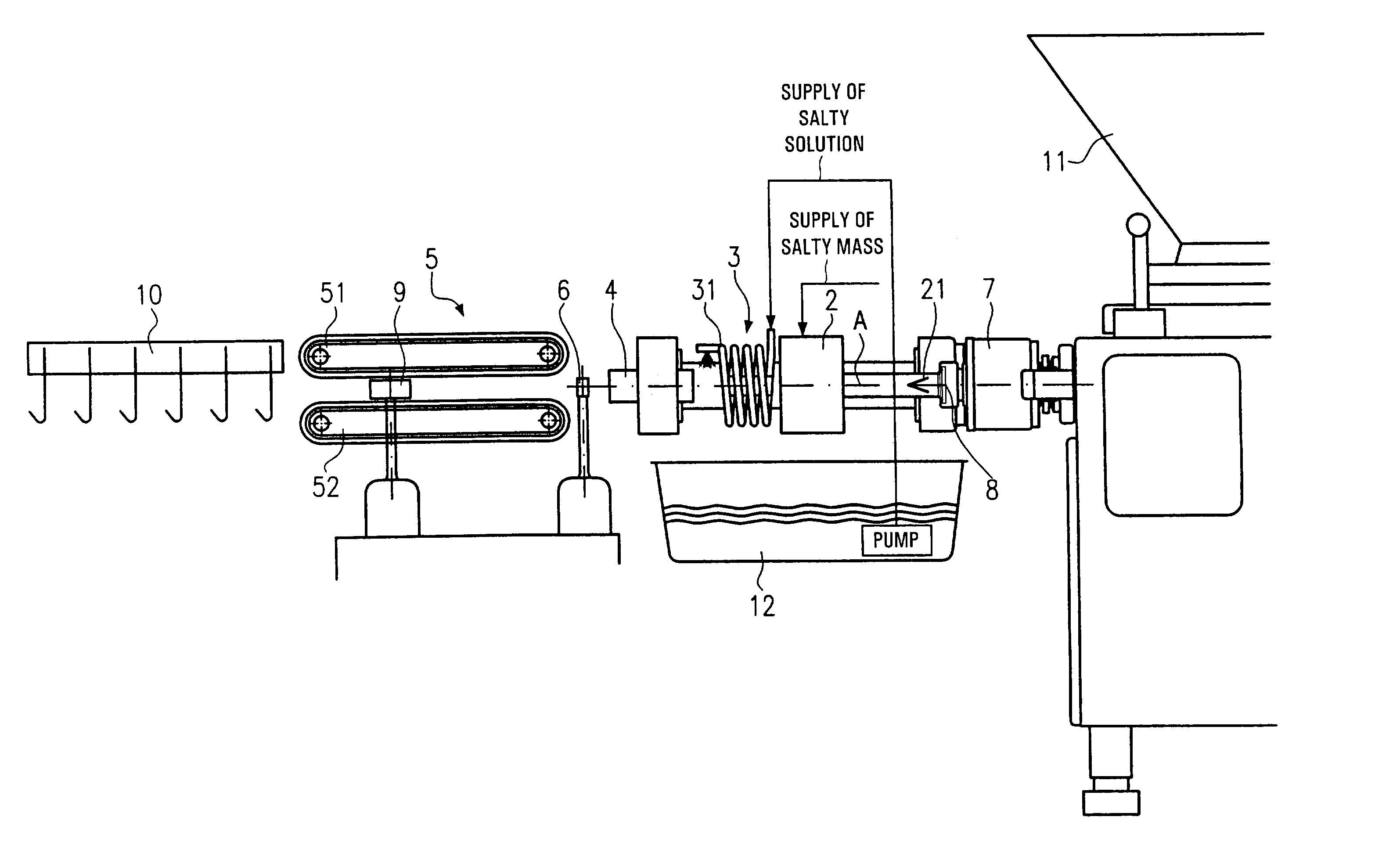

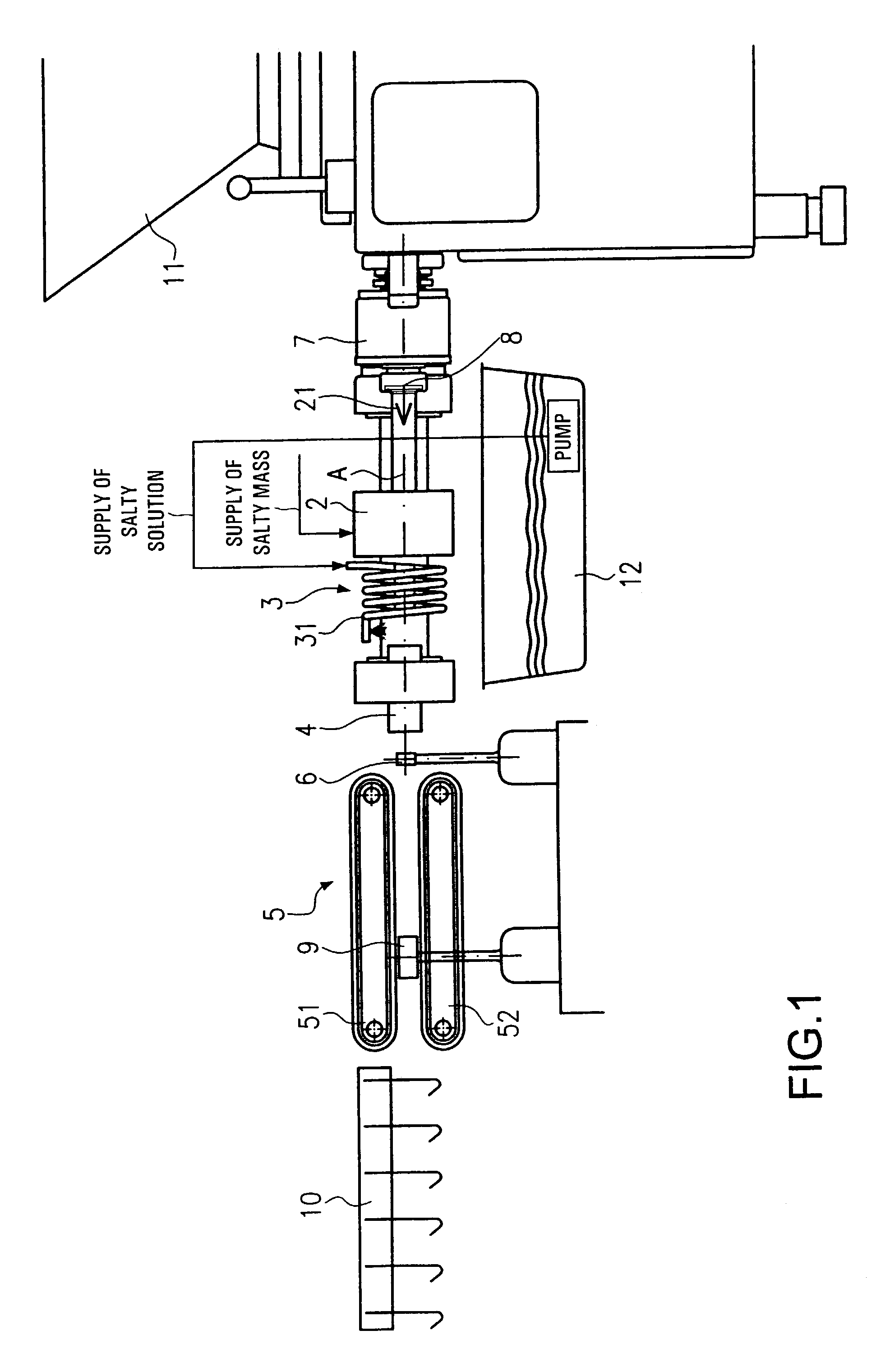

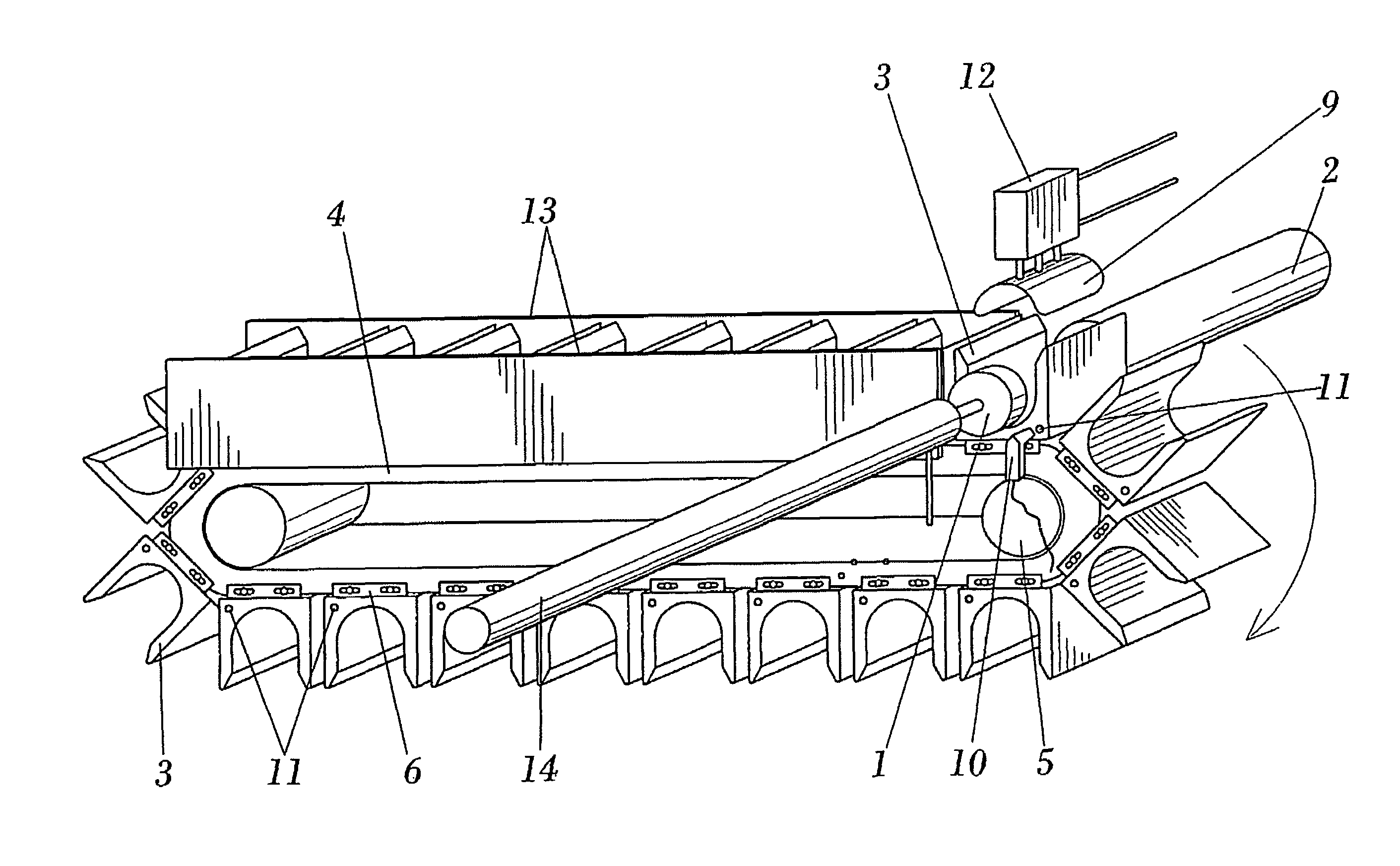

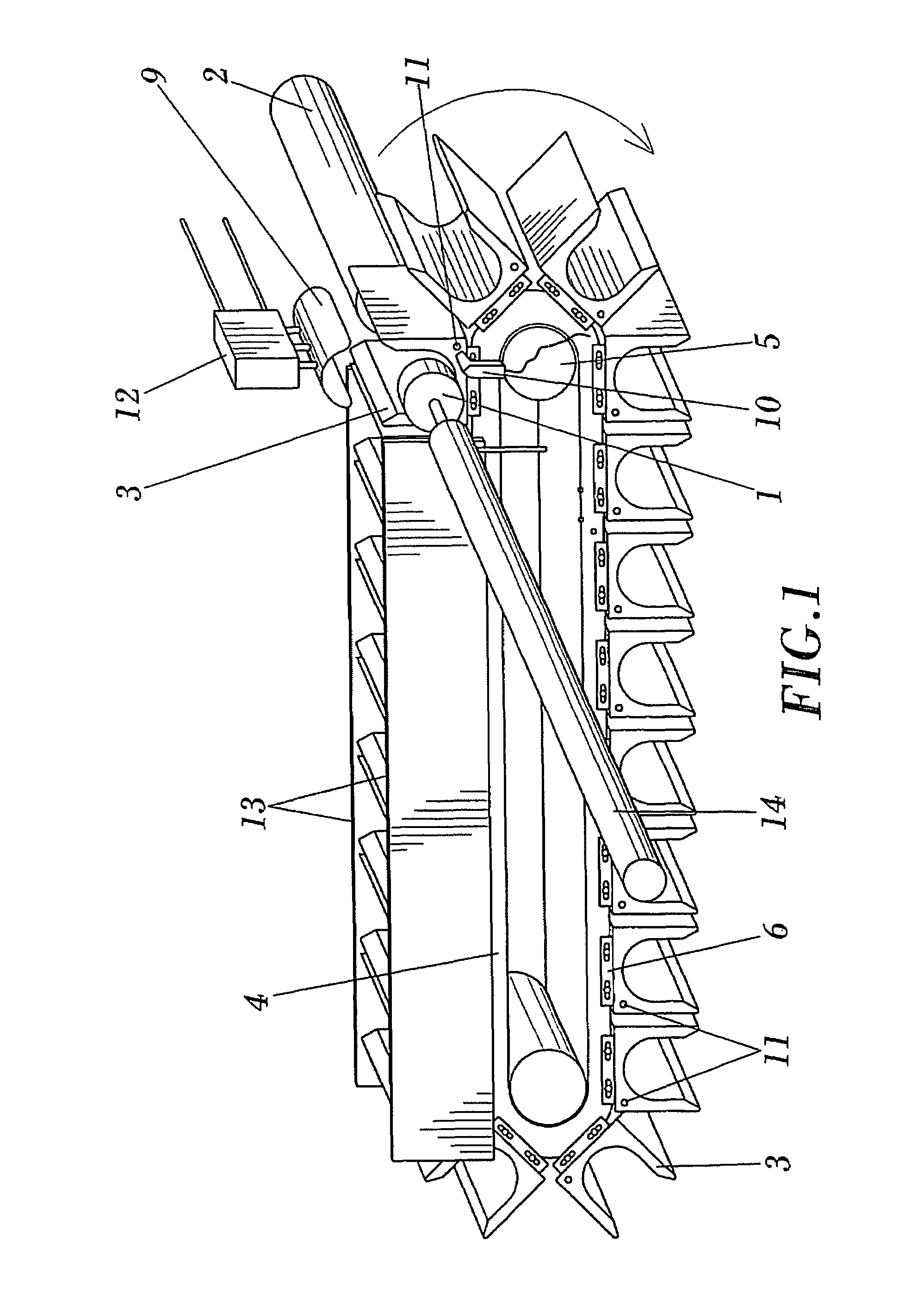

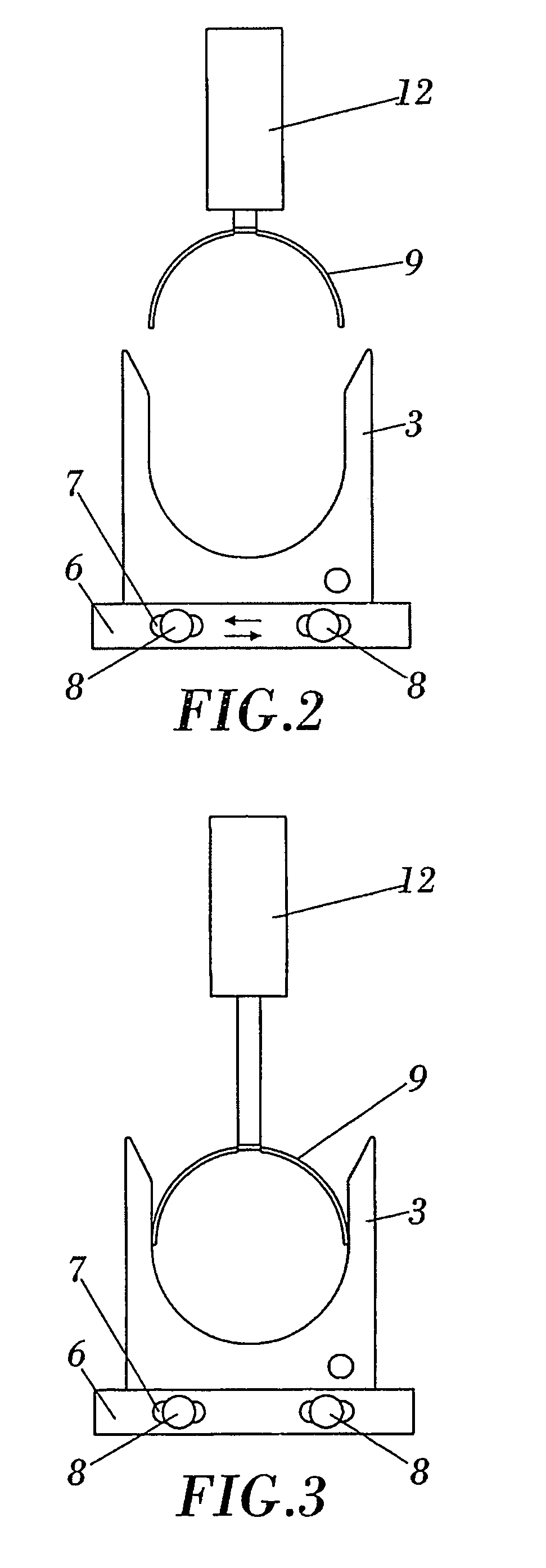

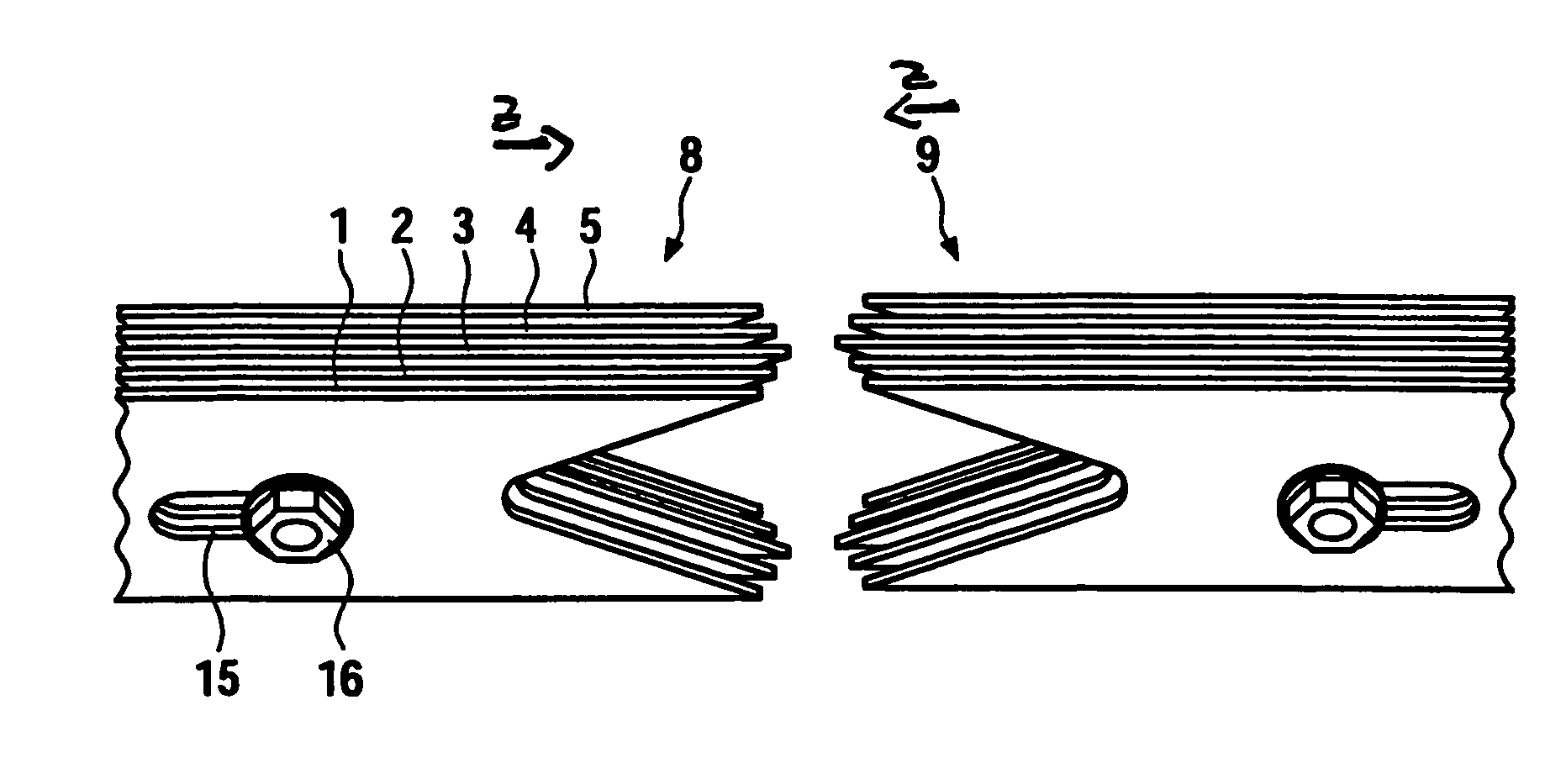

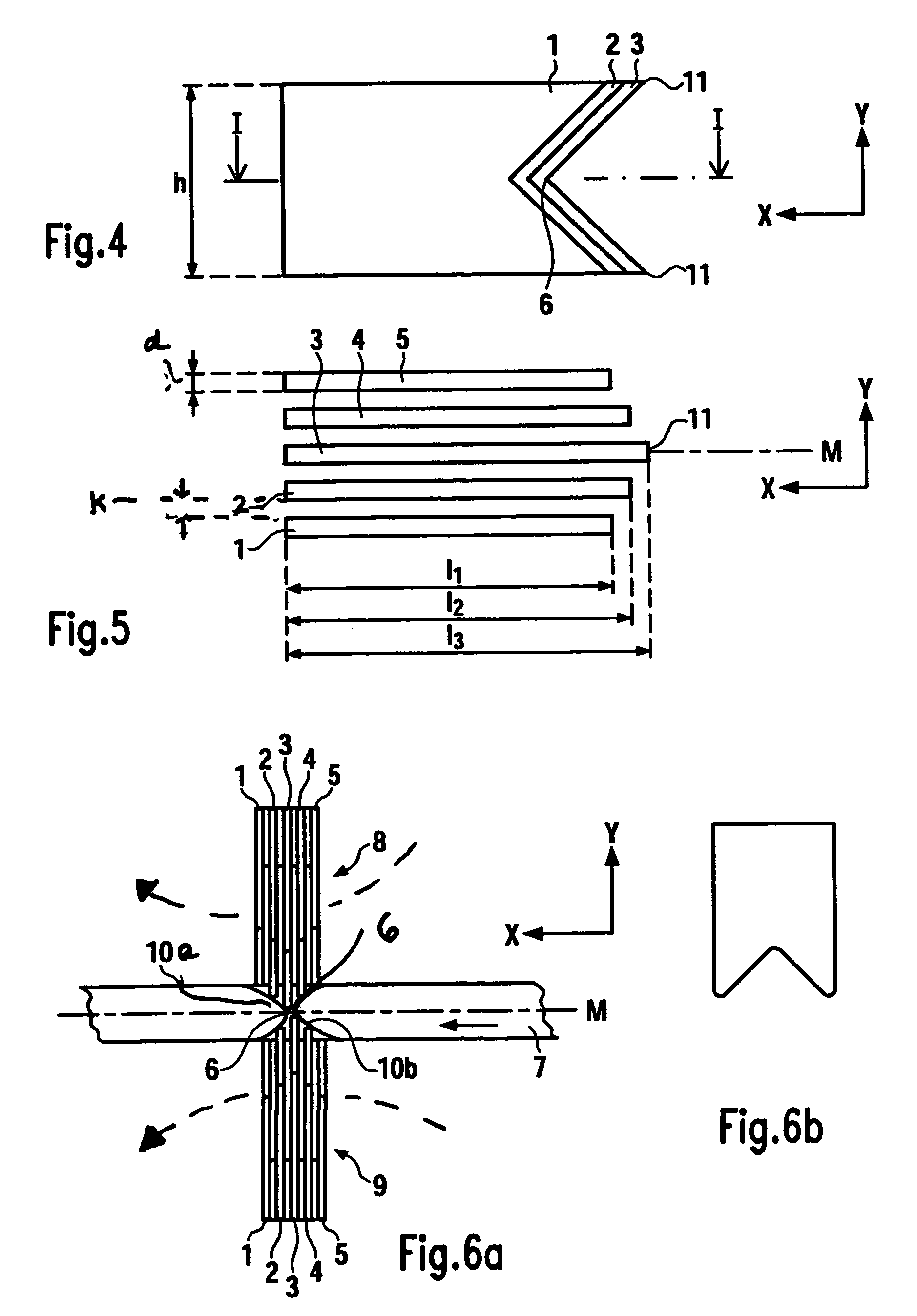

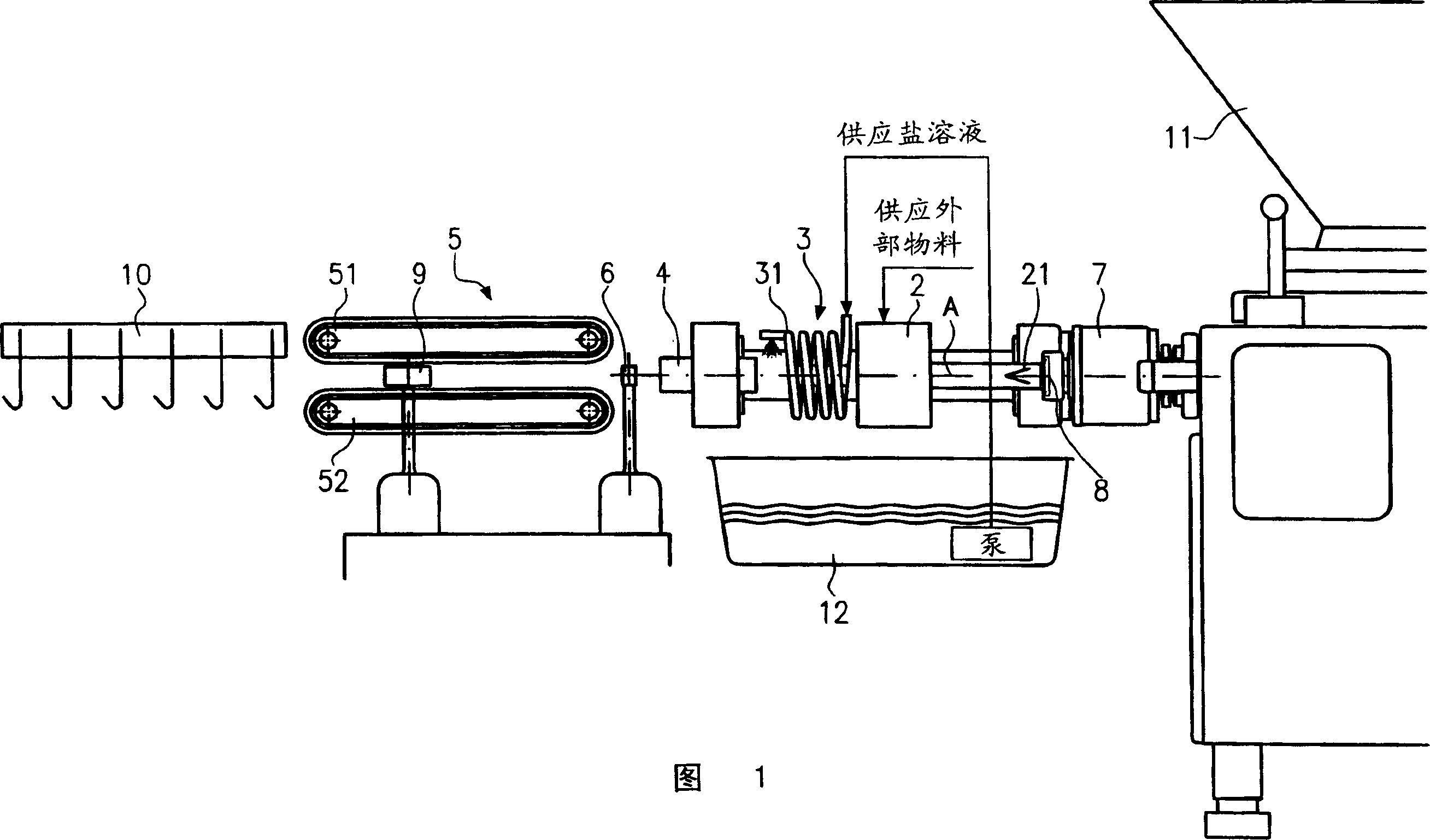

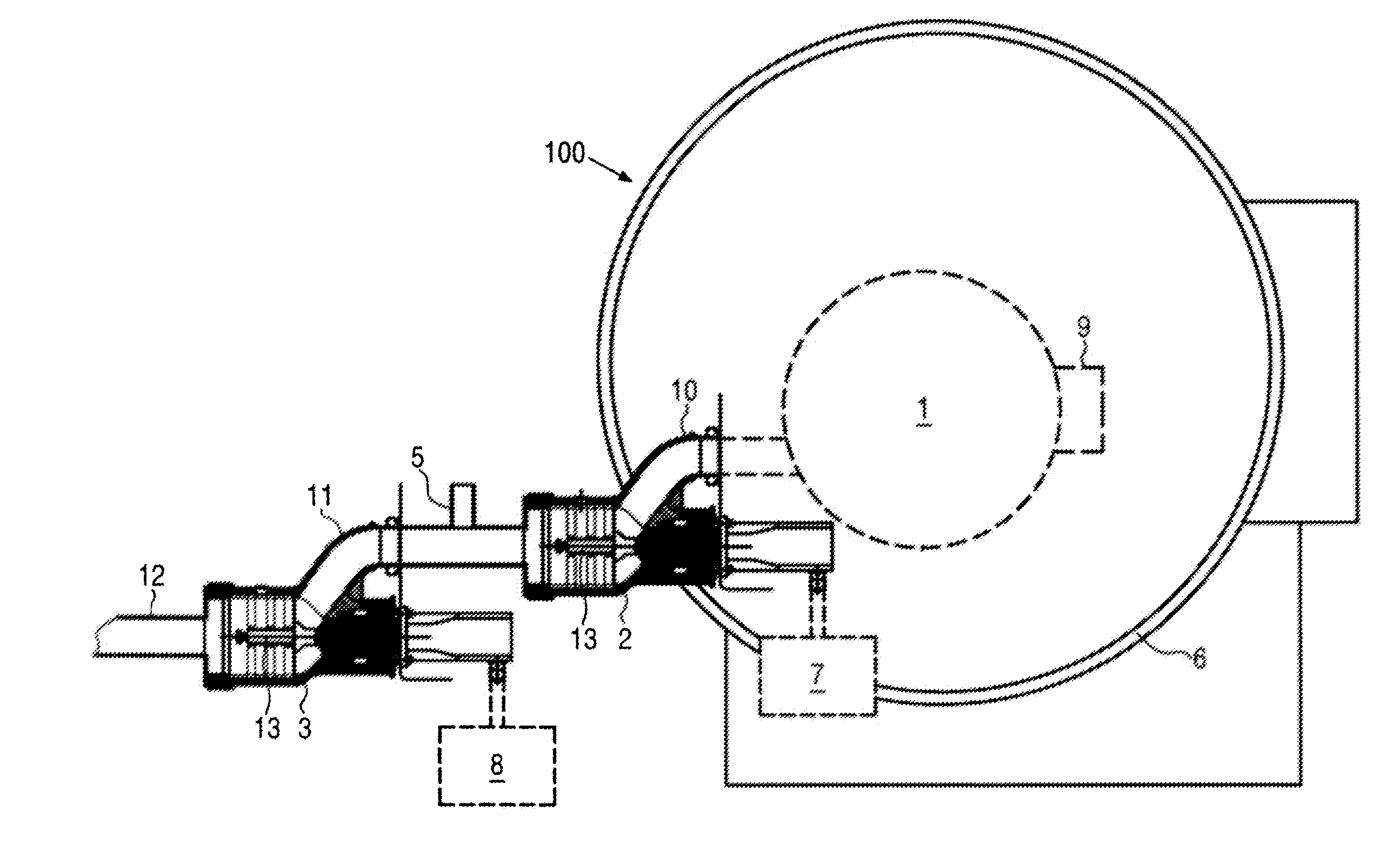

Method and apparatus for the automatic stuffing of meat products into a double casing comprising a sheet and a net

ActiveUS20050126403A1Increase speedImprove load effectMultilayer sausage casingsSkinless sausage makingAutomatic testingFood products

Based on a conventional installation including a stuffing-portioning machine (1) and a fast clipper (2), duly synchronised, between which is established a shaping device (3) that converts the film (5) meant to wrap food products that is supplied in the form of a coil into a tubular element that can be coupled to the stuffing tube (3), on which is coaxially mounted a second tube (8) bearing an external casing (9) based on a tubular net, the invention consists of using tubes (4) and (8) with a small diameter, much smaller than that of the finished product, so that the film (5) is adapted to the tube (4) after the former is profusely folded longitudinally, while the small diameter of the tube (8) allows the multilayer shirring of the tubular net (9), using the pressure provided by the pumping system of the stuffing machine (1) to achieve the radial expansion of the film (5) and the tubular net (9) to obtain the final diameter of the finished product, which will vary according to the speed with which it is separated from the double clipper (2) carried by a conveyor belt (12) with an adjustable speed.

Owner:VISCOFAN

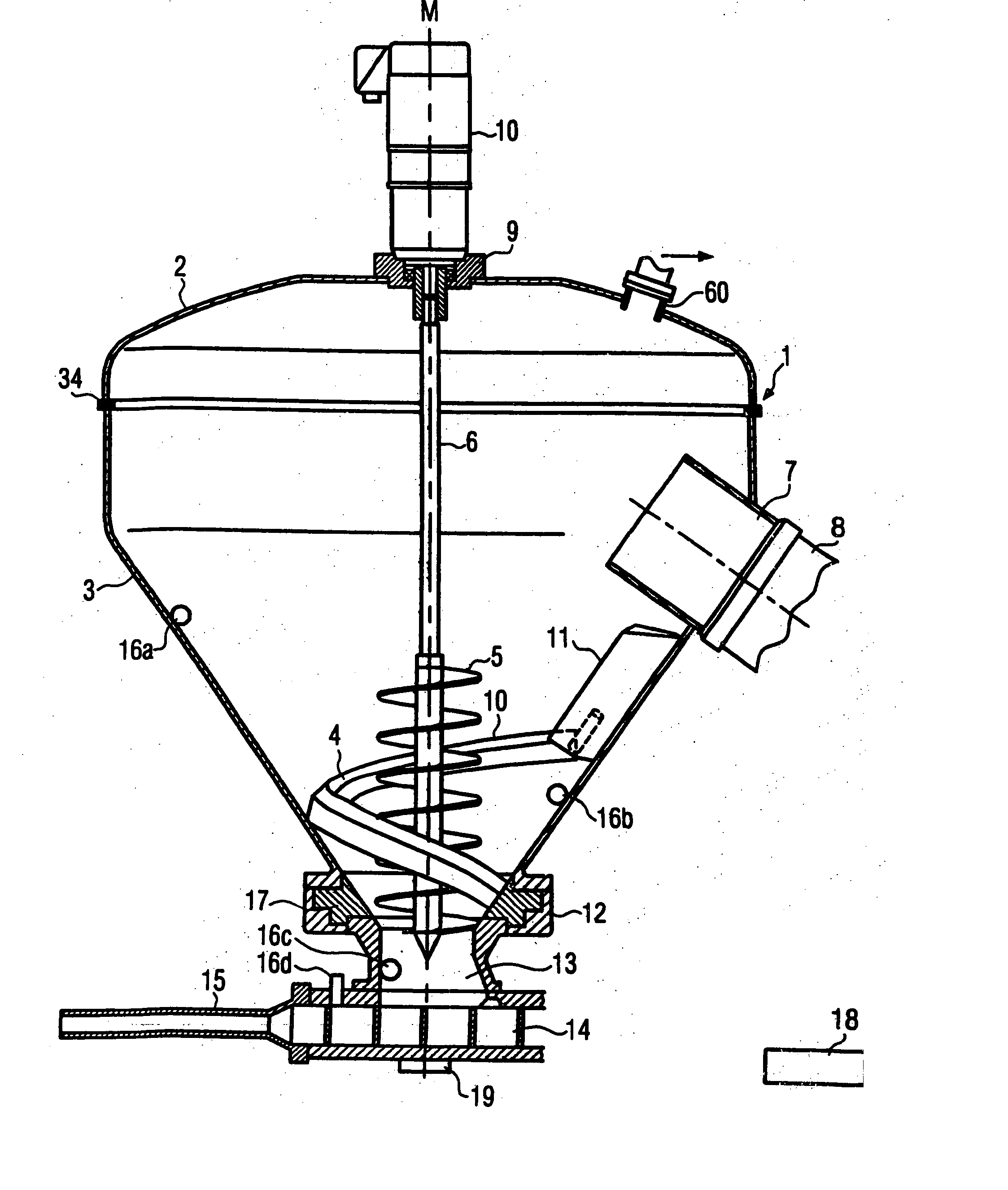

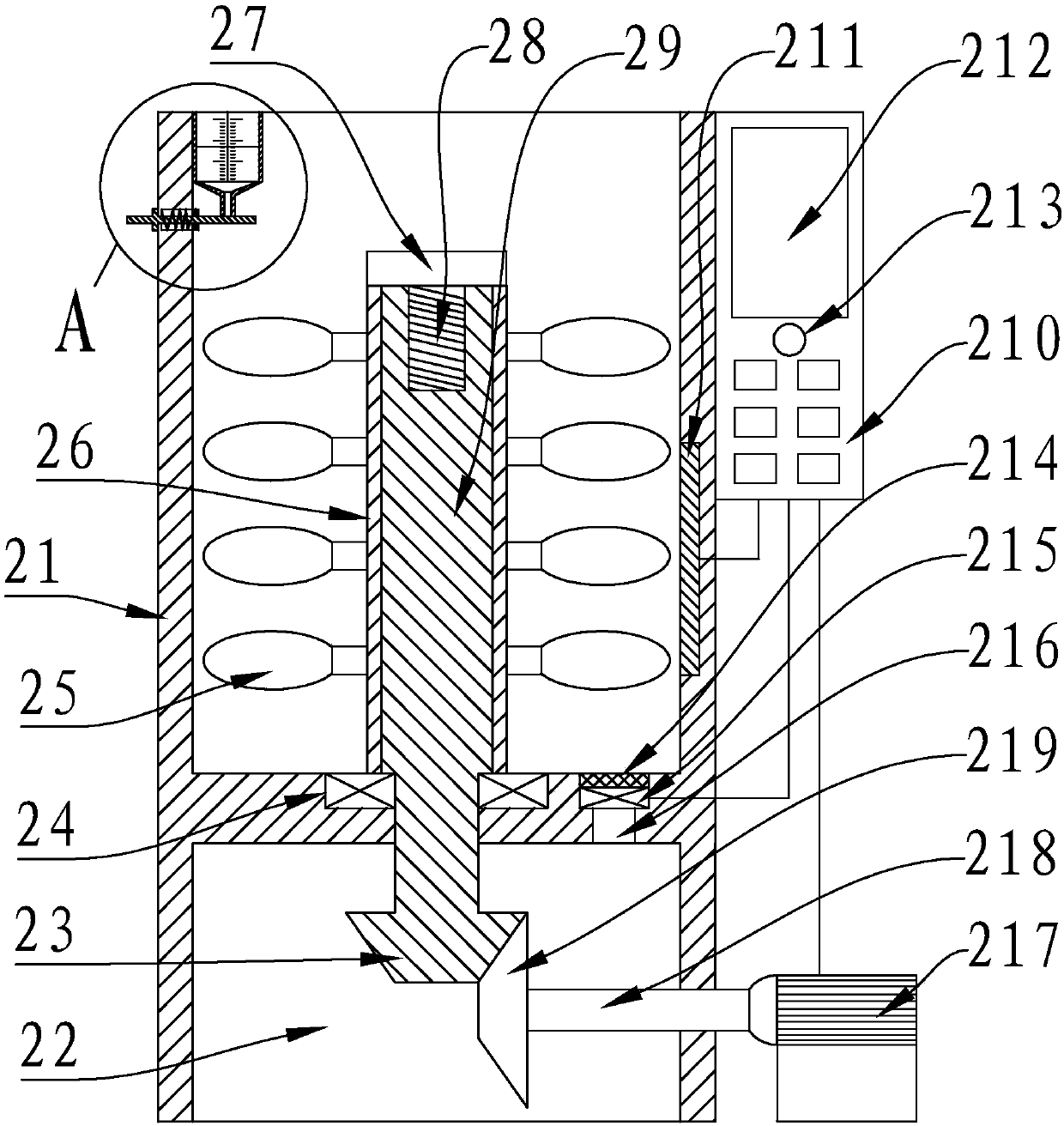

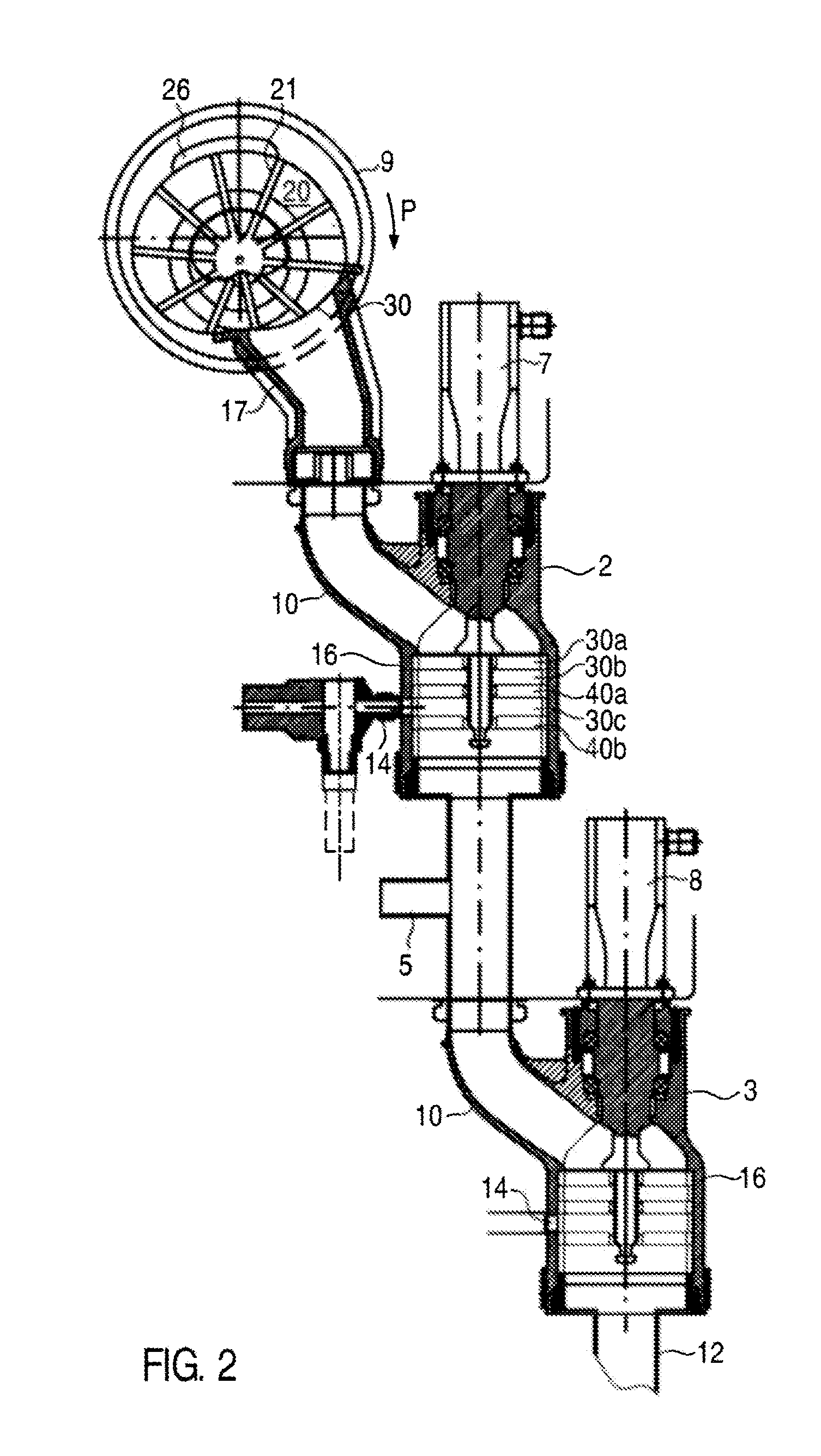

Device and method for the manufacture of a strand of a pasty mass and extrusion head for such a device and method, respectively

ActiveUS6988943B2Increase productivityCompact structureSausage casing manufactureSausage filling/stuffing machinesBiomedical engineeringExtrusion

The invention relates to a device for the manufacture of a strand of a pasty mass, in particular sausage meat, with an extrusion head 2, comprising a device 27 for coextruding the pasty mass and a casing surrounding the pasty mass, a solidification device 3 for solidifying the casing, and a wring-off device 4. The invention is characterized in that a conveyor device 5 is arranged downstream of the wring-off device 4, the coextrusion device 27 and a strand guide 41 of the wring-off device 4 on the one hand and the conveyor device 5 on the other hand can be rotated relatively to one another.

Owner:ALBERT HANDTMANN MASCHFABRICK

Feeder for meat pieces made of entire muscles for a piston stuffing machine

ActiveUS7314405B2Meat/sausage hanging-upSausage filling/stuffing machinesEngineeringMechanical engineering

Owner:VISCOFAN

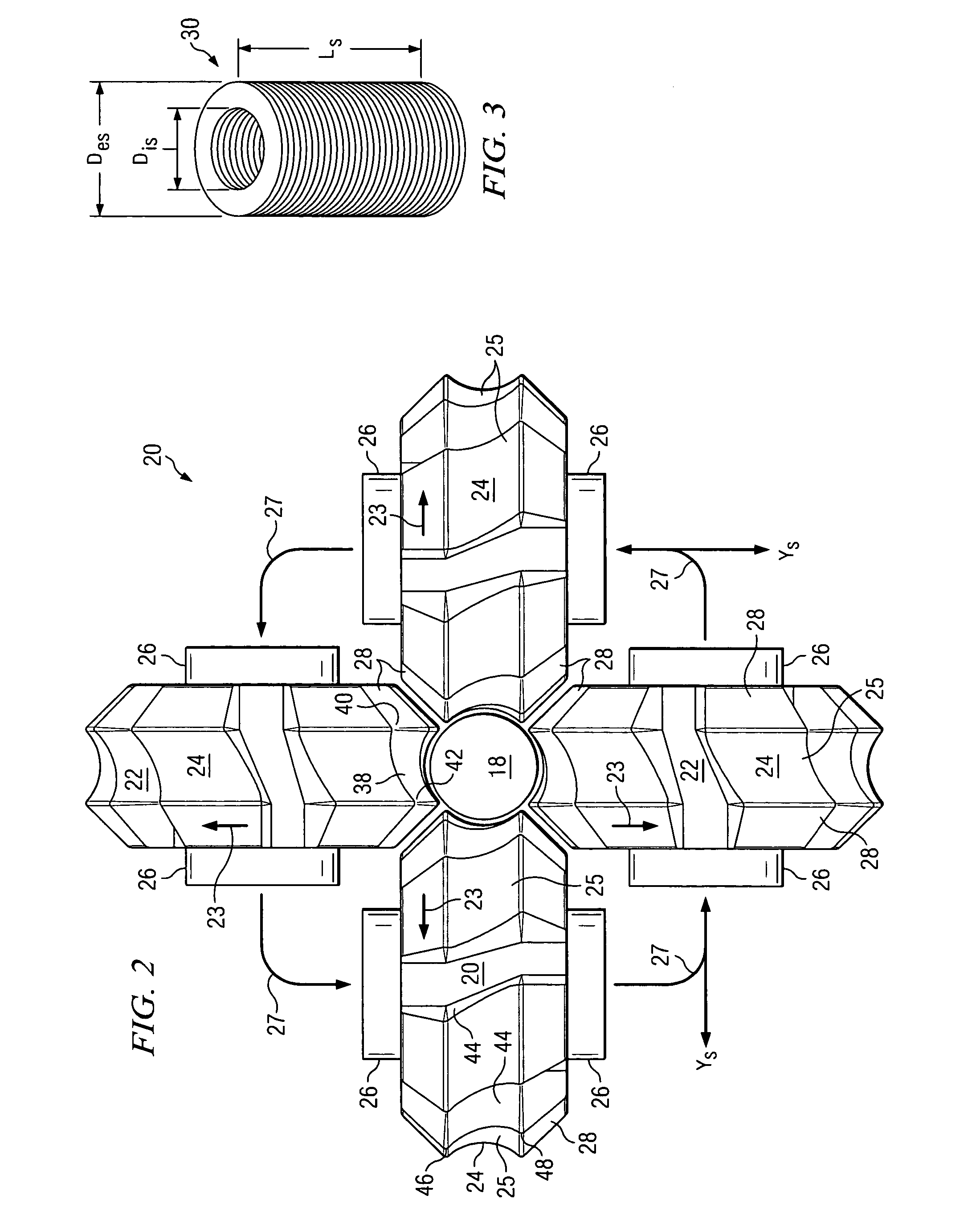

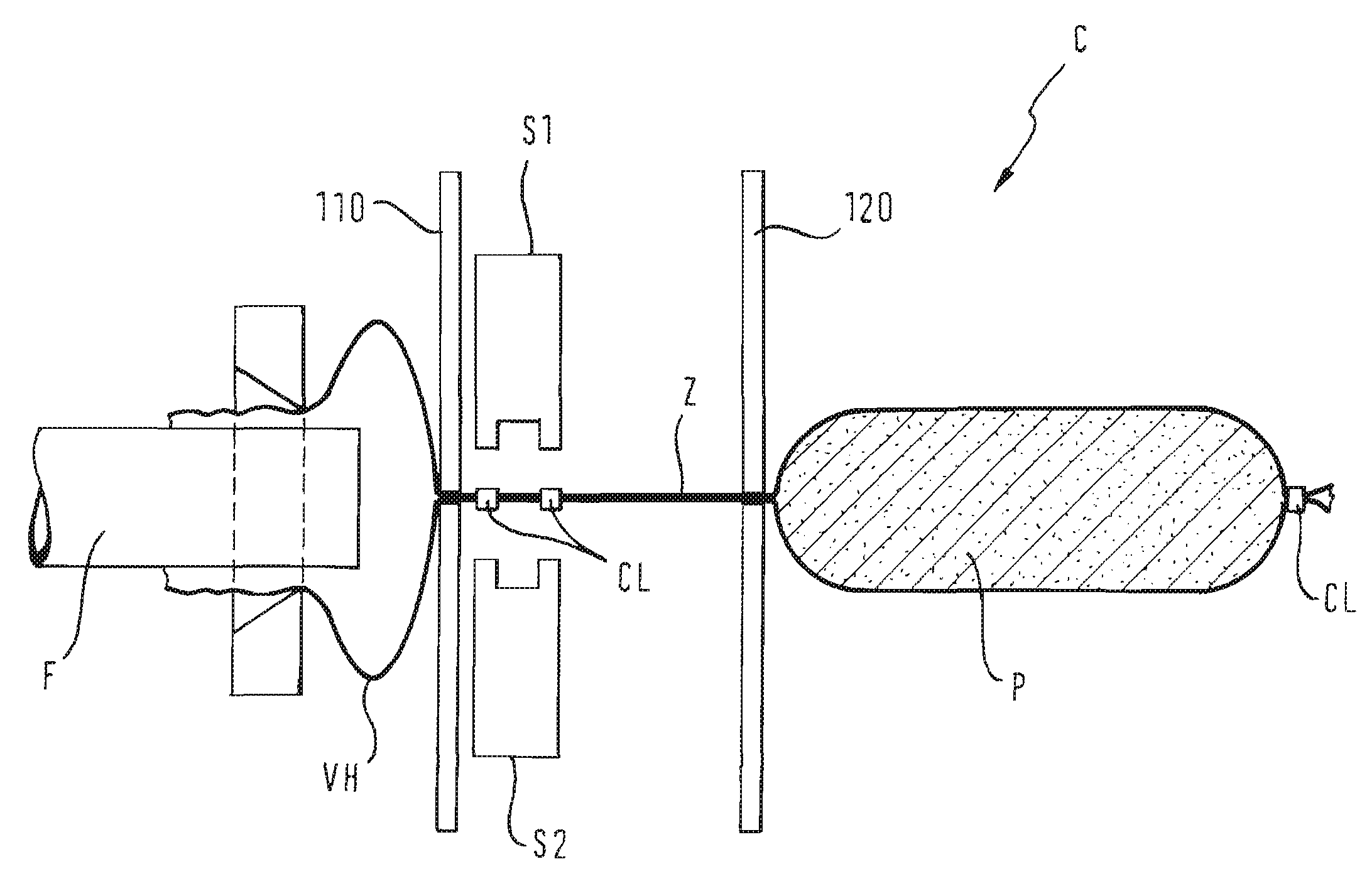

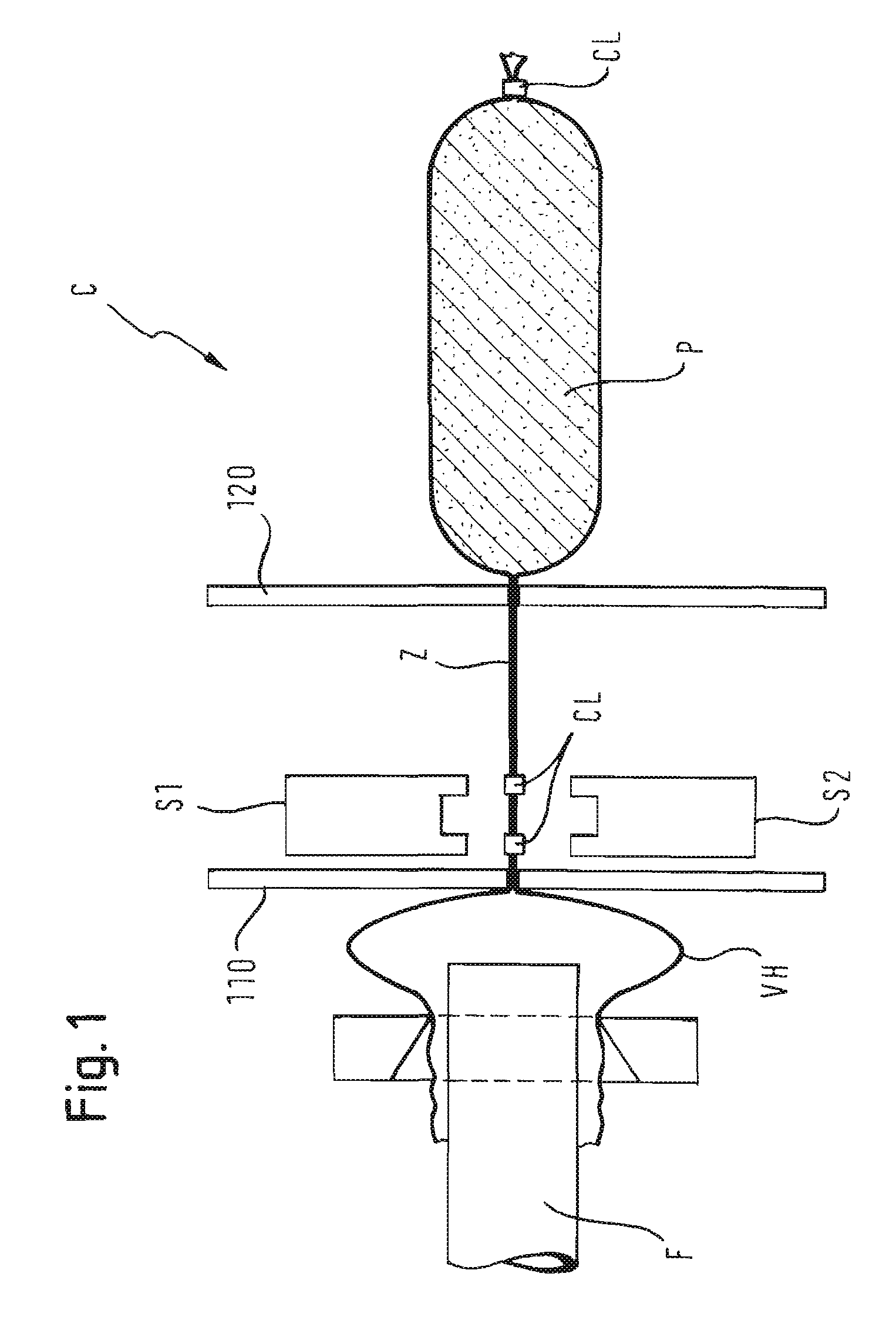

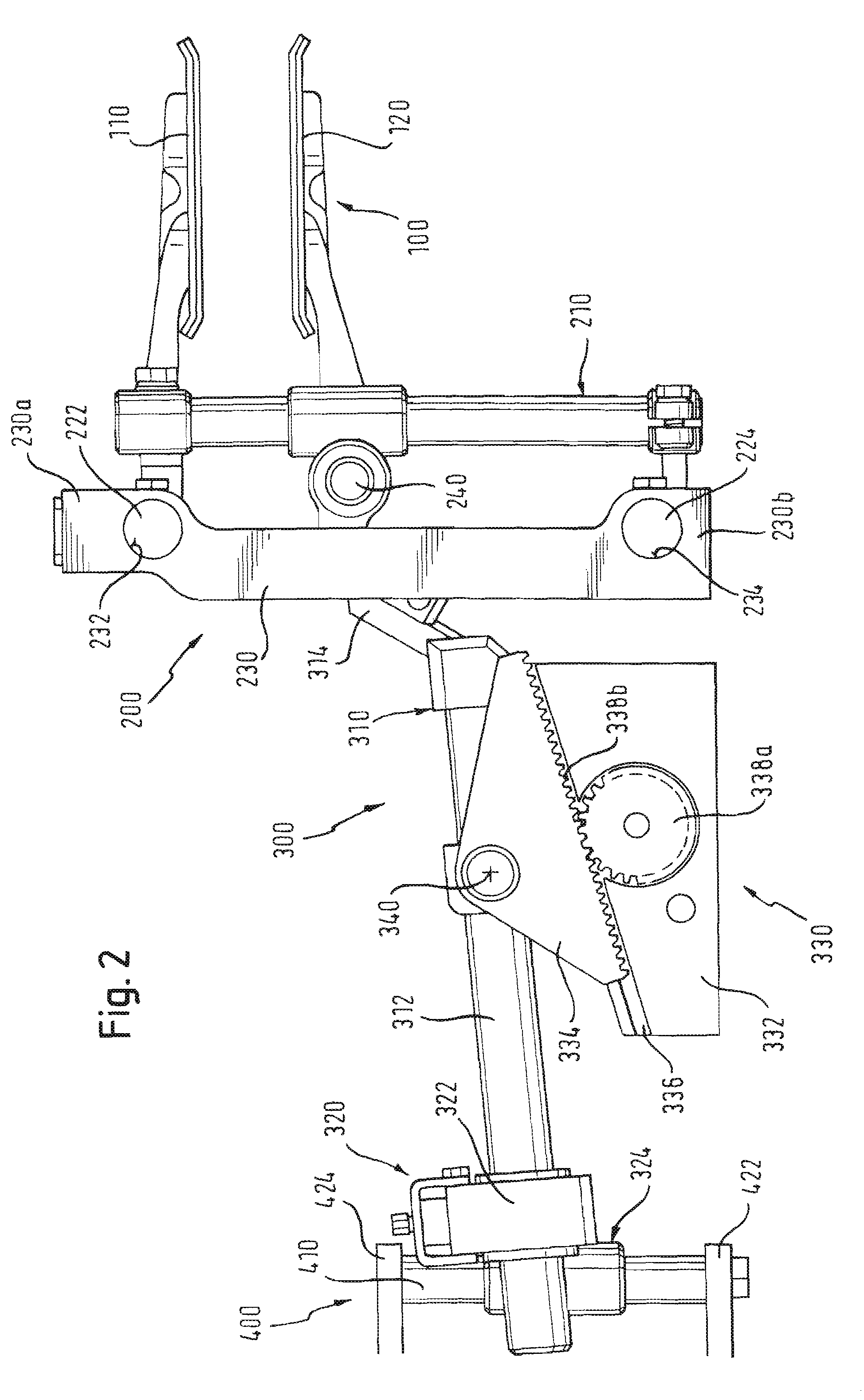

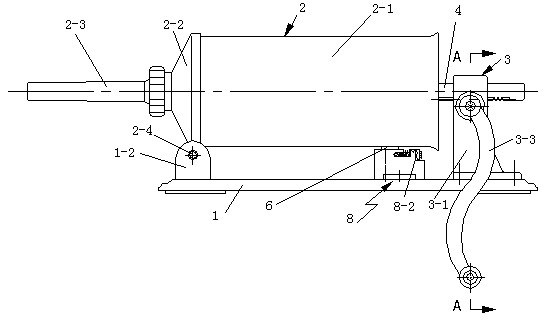

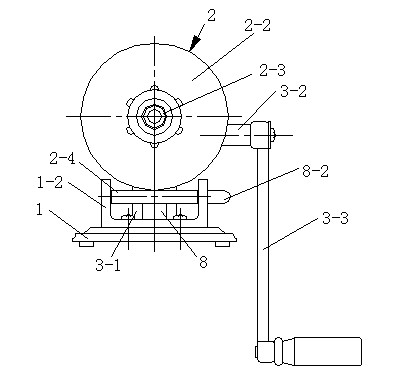

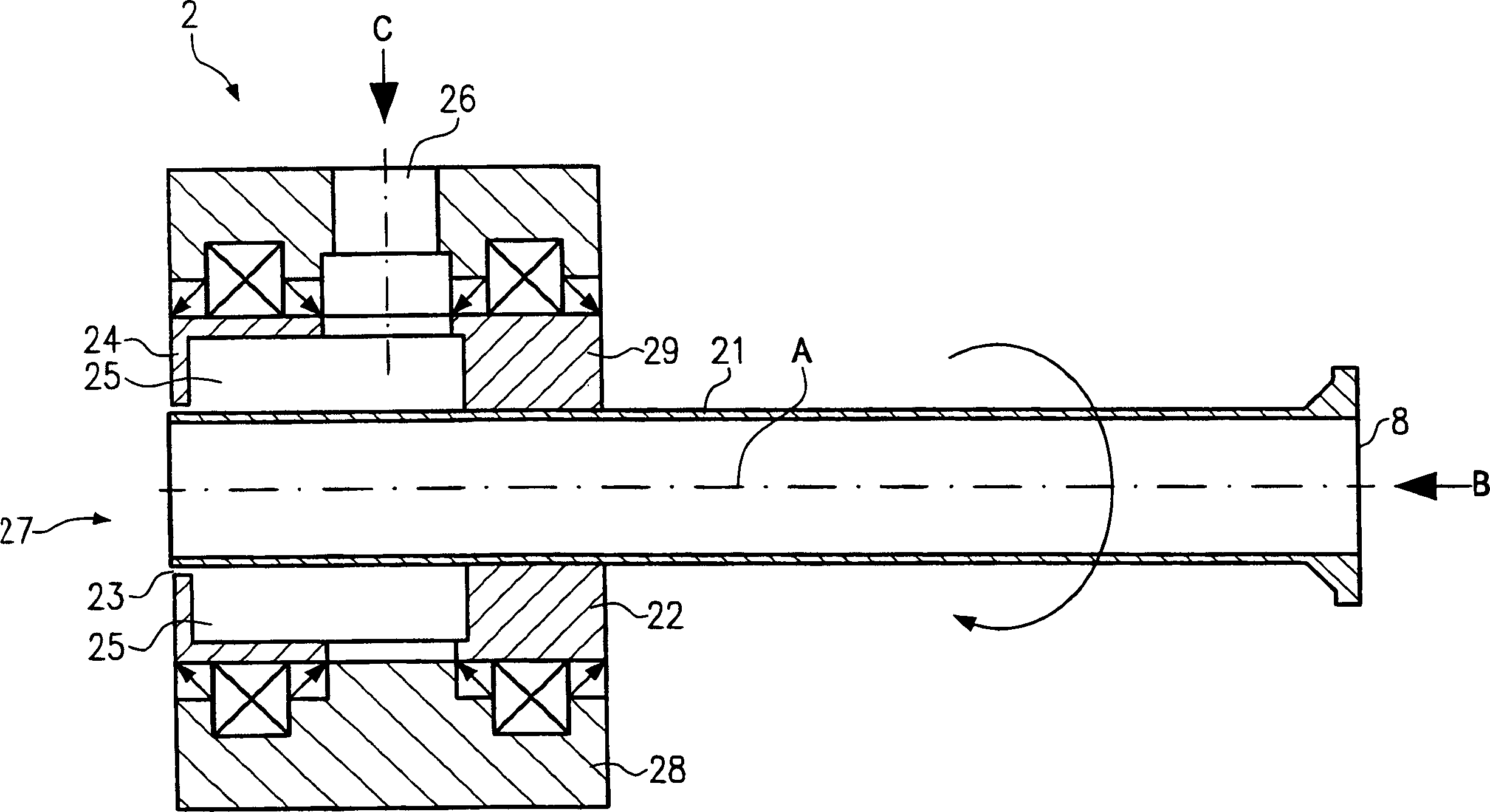

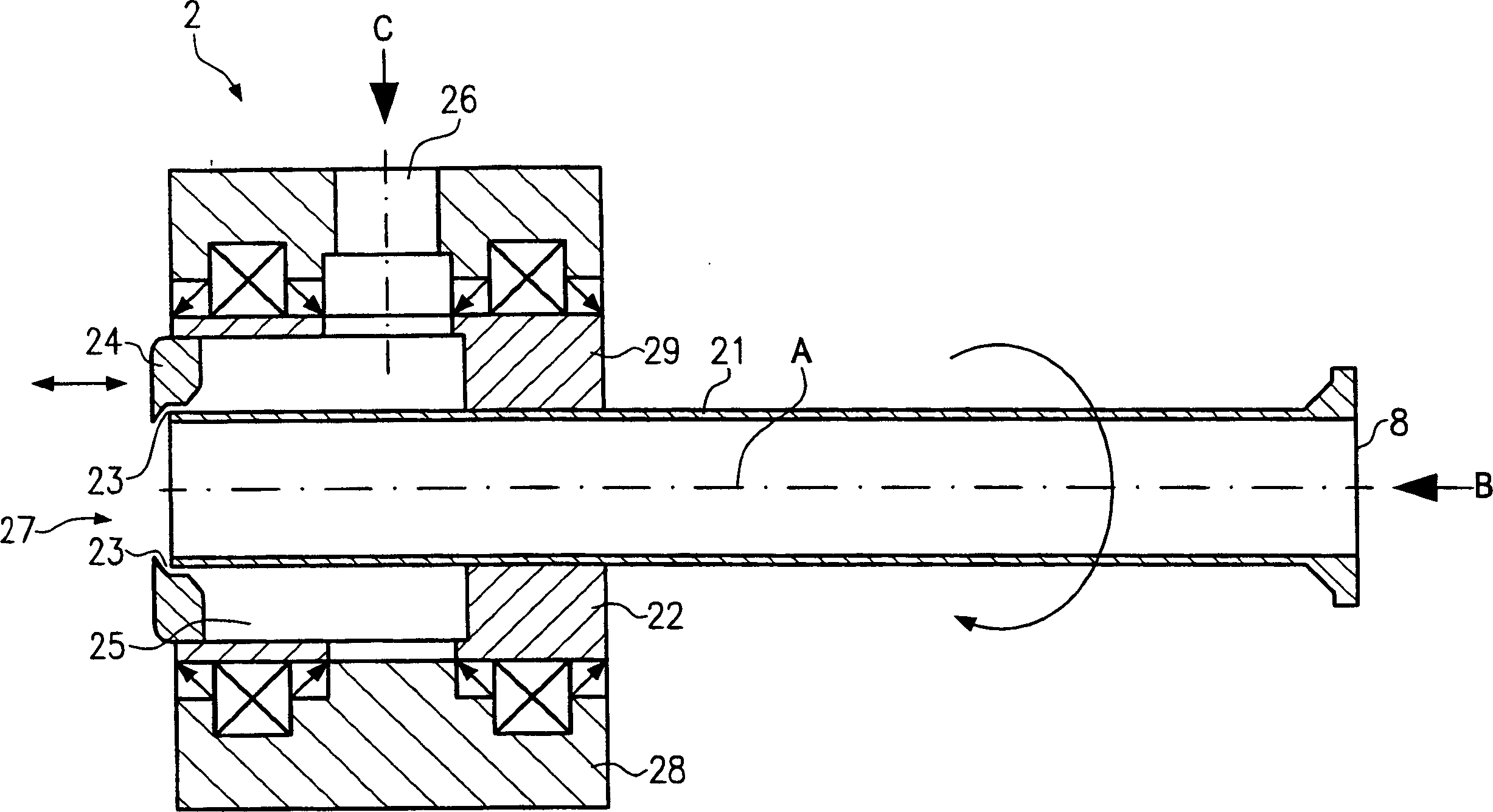

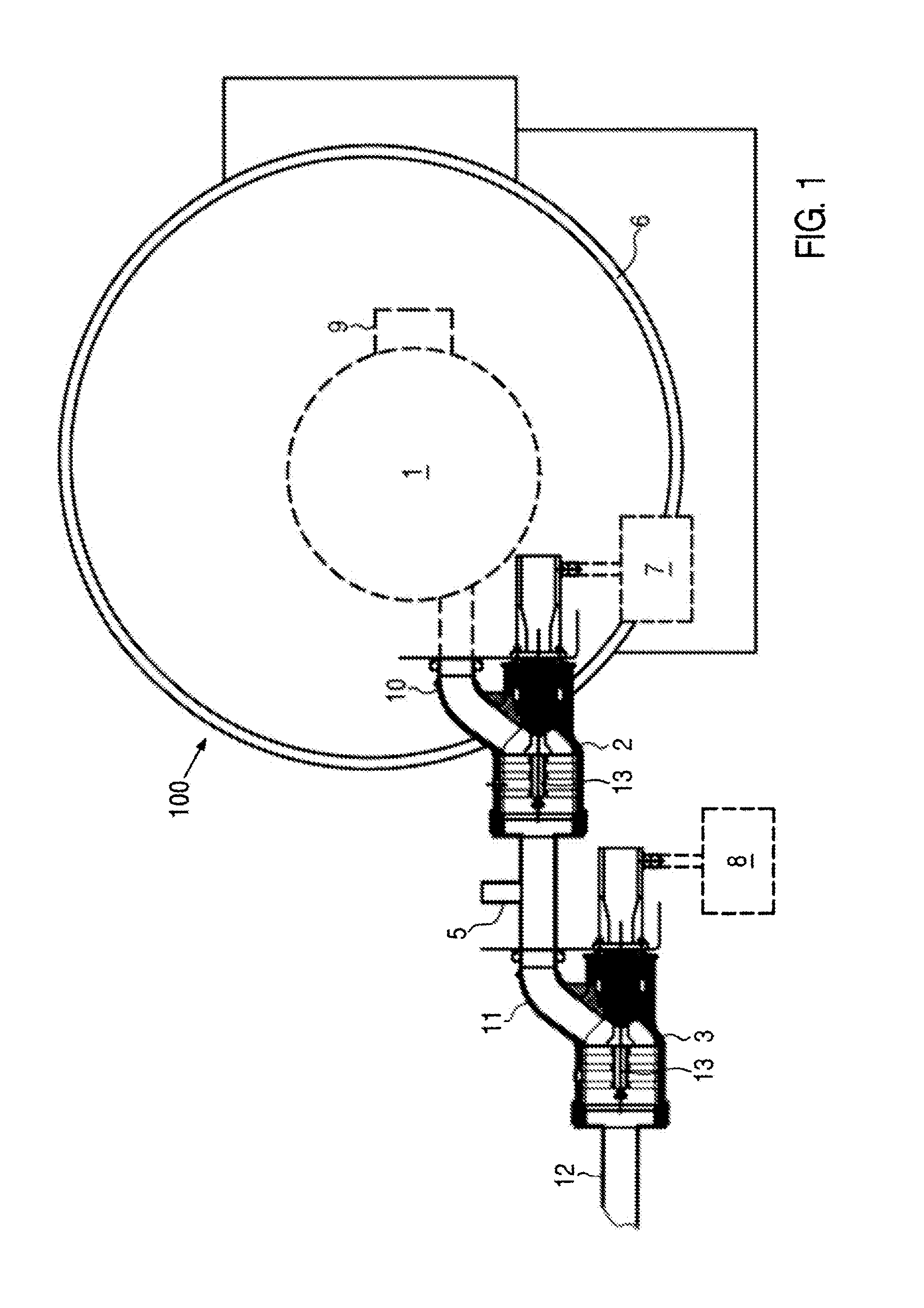

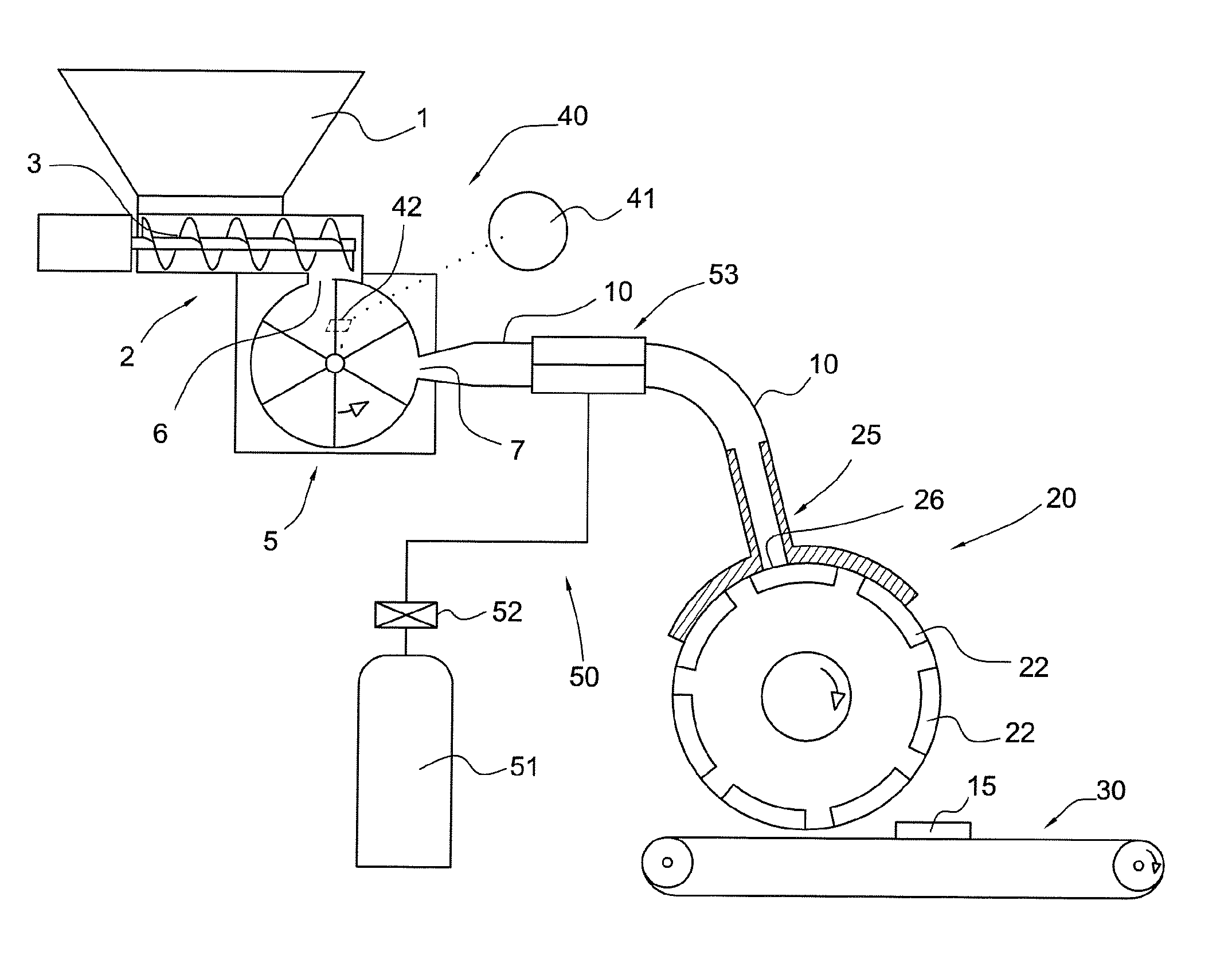

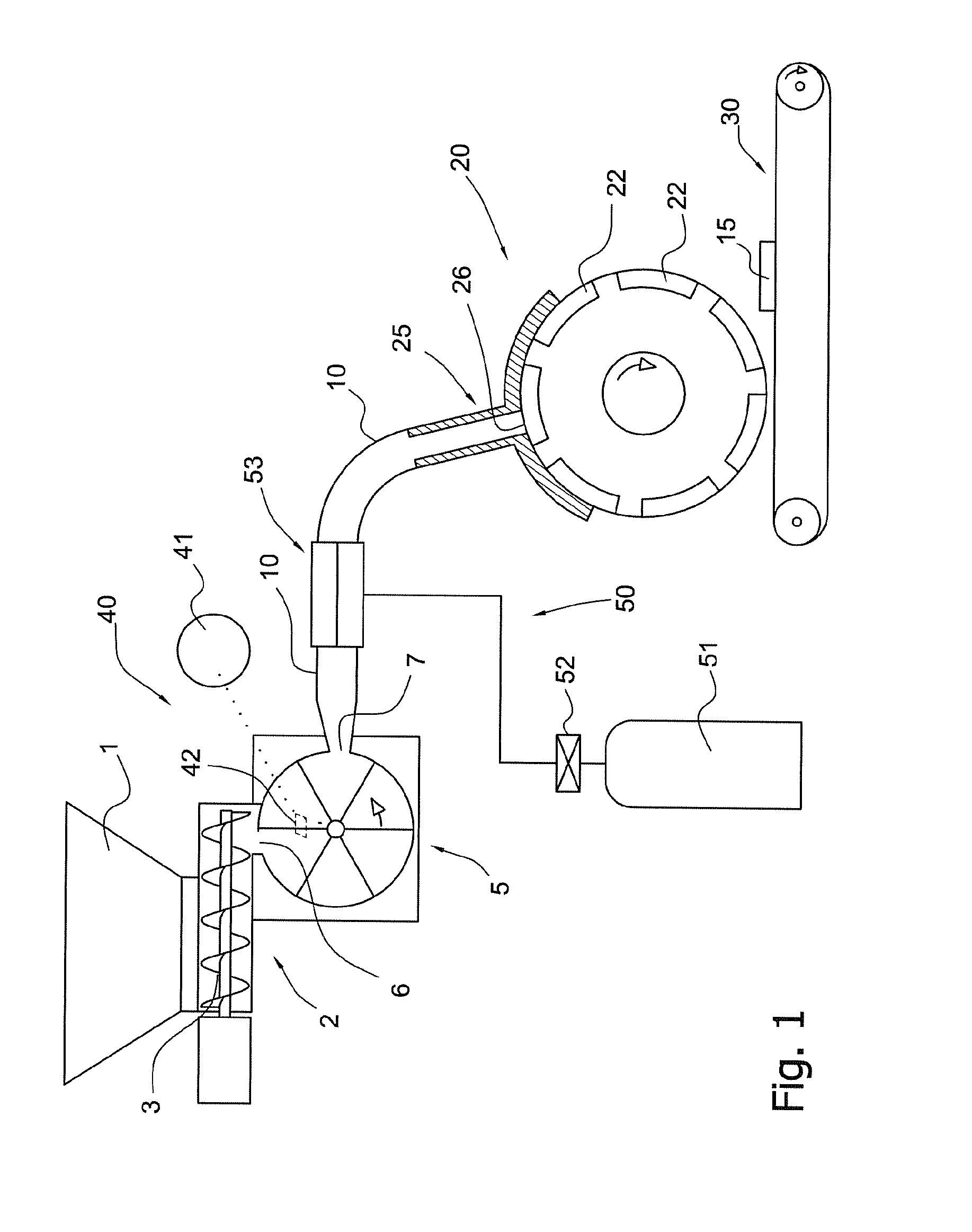

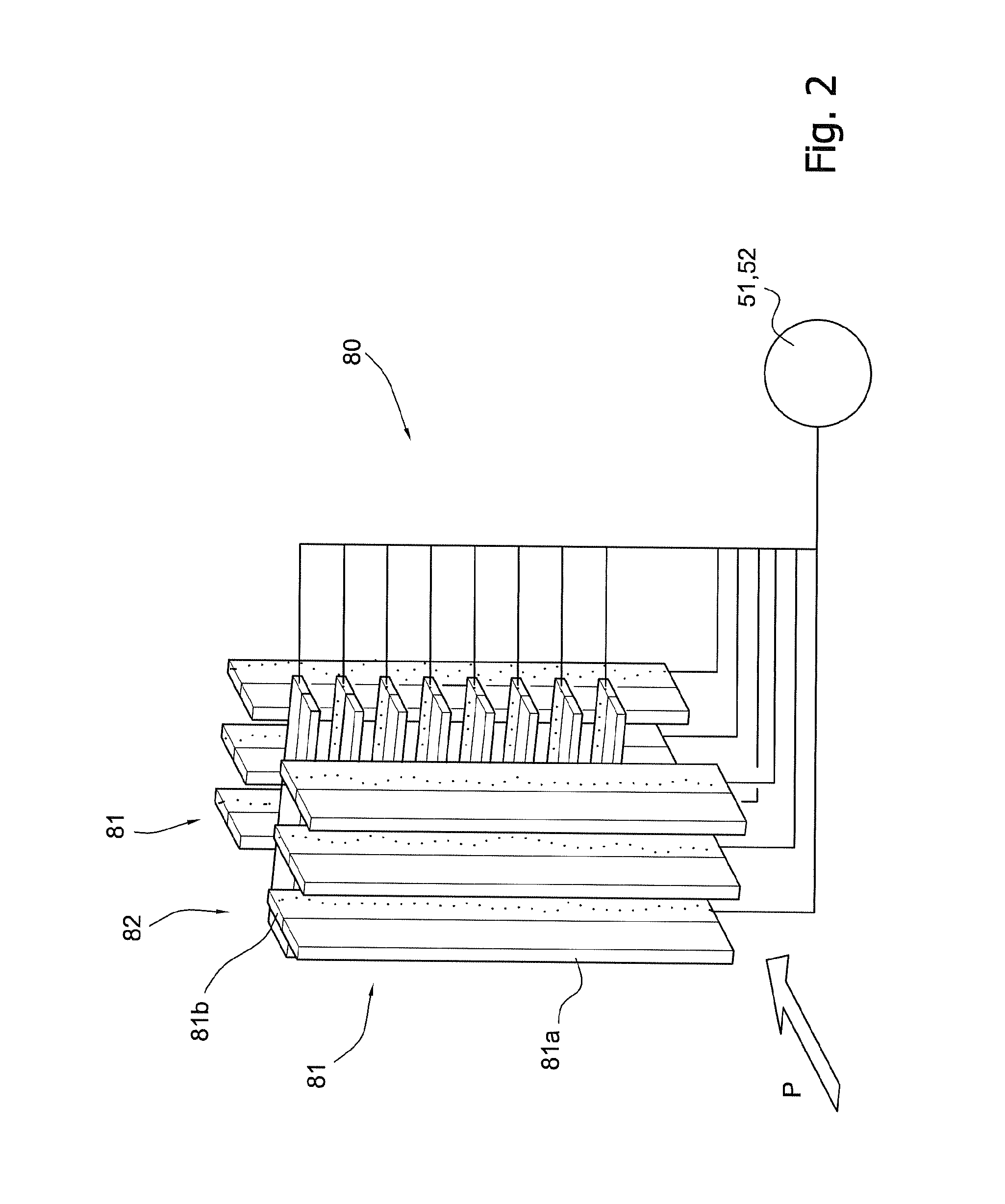

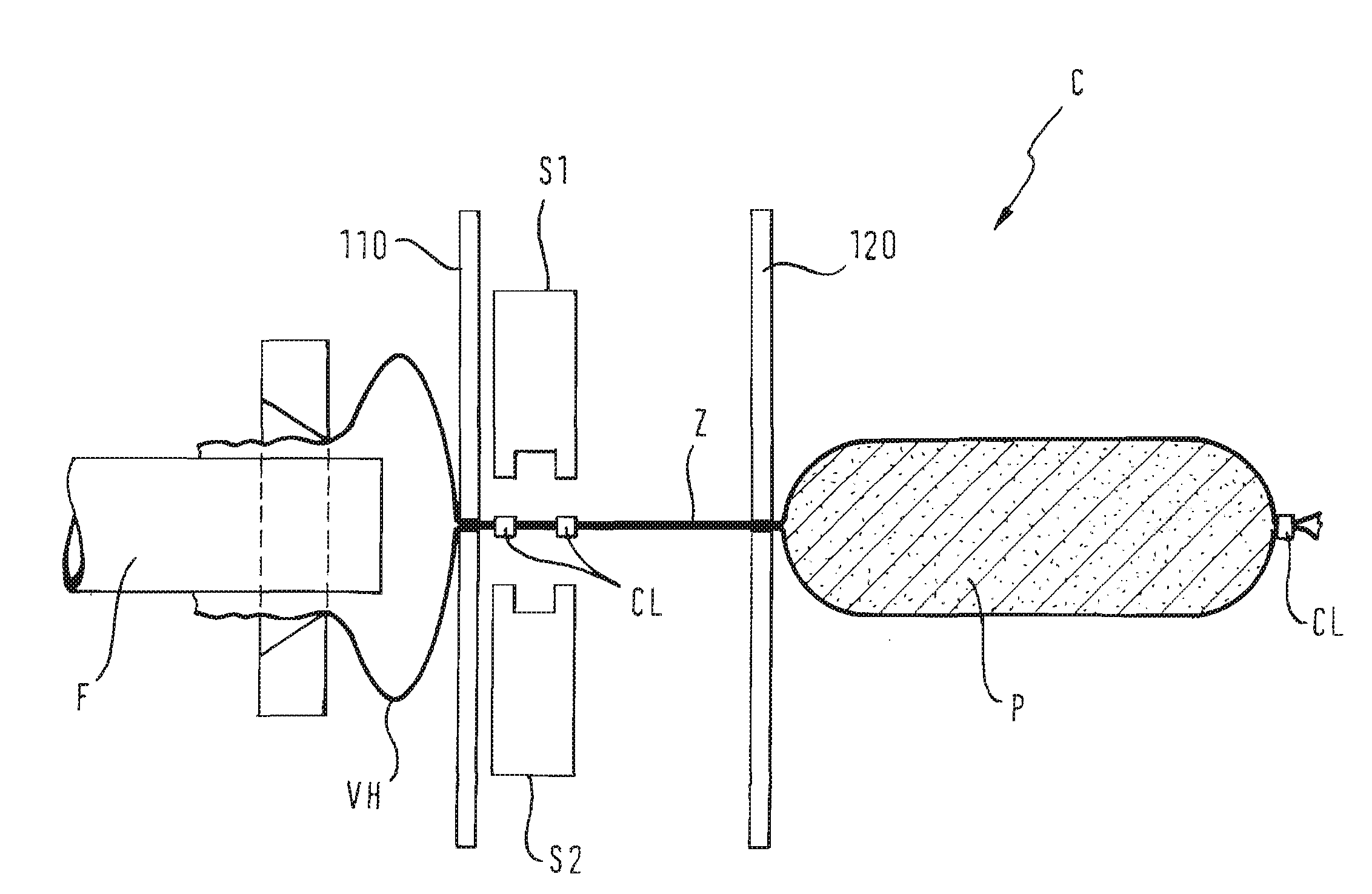

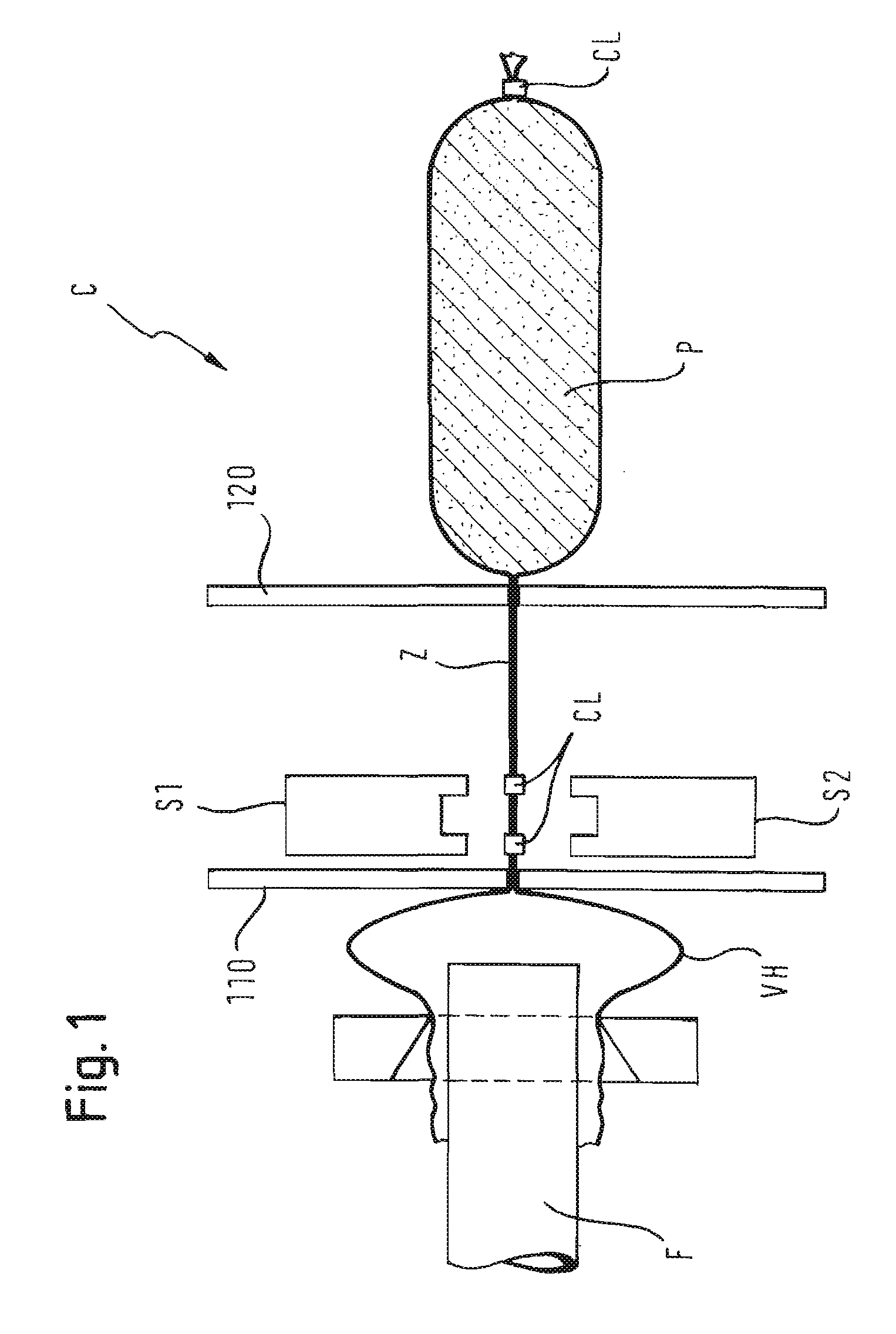

Apparatus for manufacturing chains of linked food products such as sausages with twisted portions and having a plurality of stuffing tubes and method of manufacturing the same

ActiveUS7666071B2Reduce idle timeSignificant differenceSausage filling/stuffing machinesSausage twisting/linking machinesRotational axisEngineering

An apparatus for manufacturing chains of linked food products such as sausages with twisted portions and having a plurality of stuffing tubes, includes a plurality of stuffing tubes 2 provided at equal intervals about a rotational axis Xo; a stuffing tube moving body 4 which rotates through predetermined angles about the rotational axis Xo so that the respective stuffing tubes 2 sequentially move to a filling position III; and a stuffed casing conveying means 50 which conveys in a suspended state a stuffed casing C formed by the stuffing tube 2 positioned at the filling position III.

Owner:HITEC

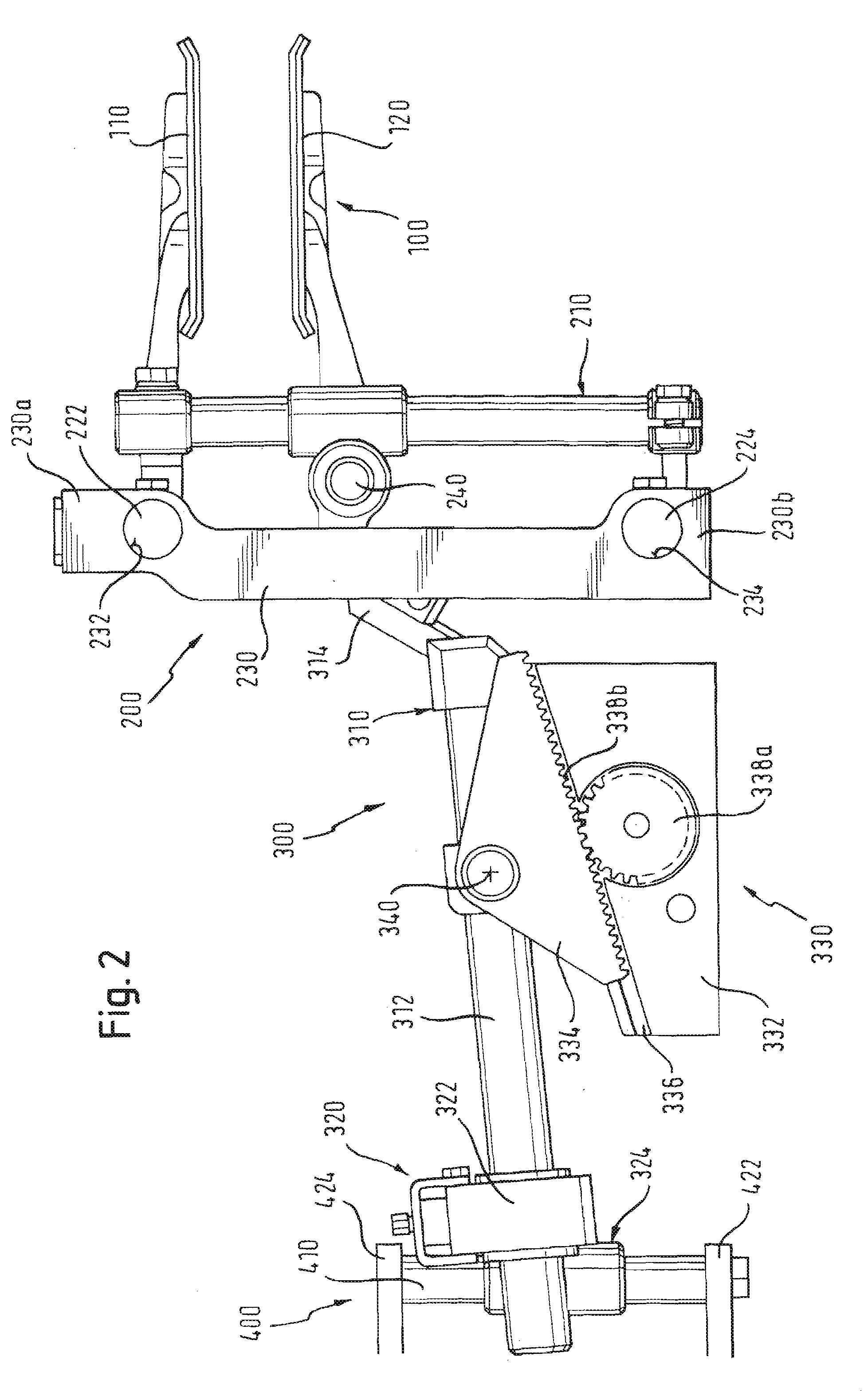

Shaping device and shaping method for forming rounded tips on the ends of sausages

ActiveUS7762874B2Facilitates the tying off and/or partingUniform formatSausage skin tying apparatusSausage filling/stuffing machinesEngineeringMechanical engineering

Owner:ALBERT HANDTMANN MASCHFABRICK

Automatic spreading adjustment

ActiveUS7575506B2Simple structureSimple of stroke movementSausage filling/stuffing machinesSausage twisting/linking machinesLinear motionFilling materials

Owner:POLY CLIP SYST

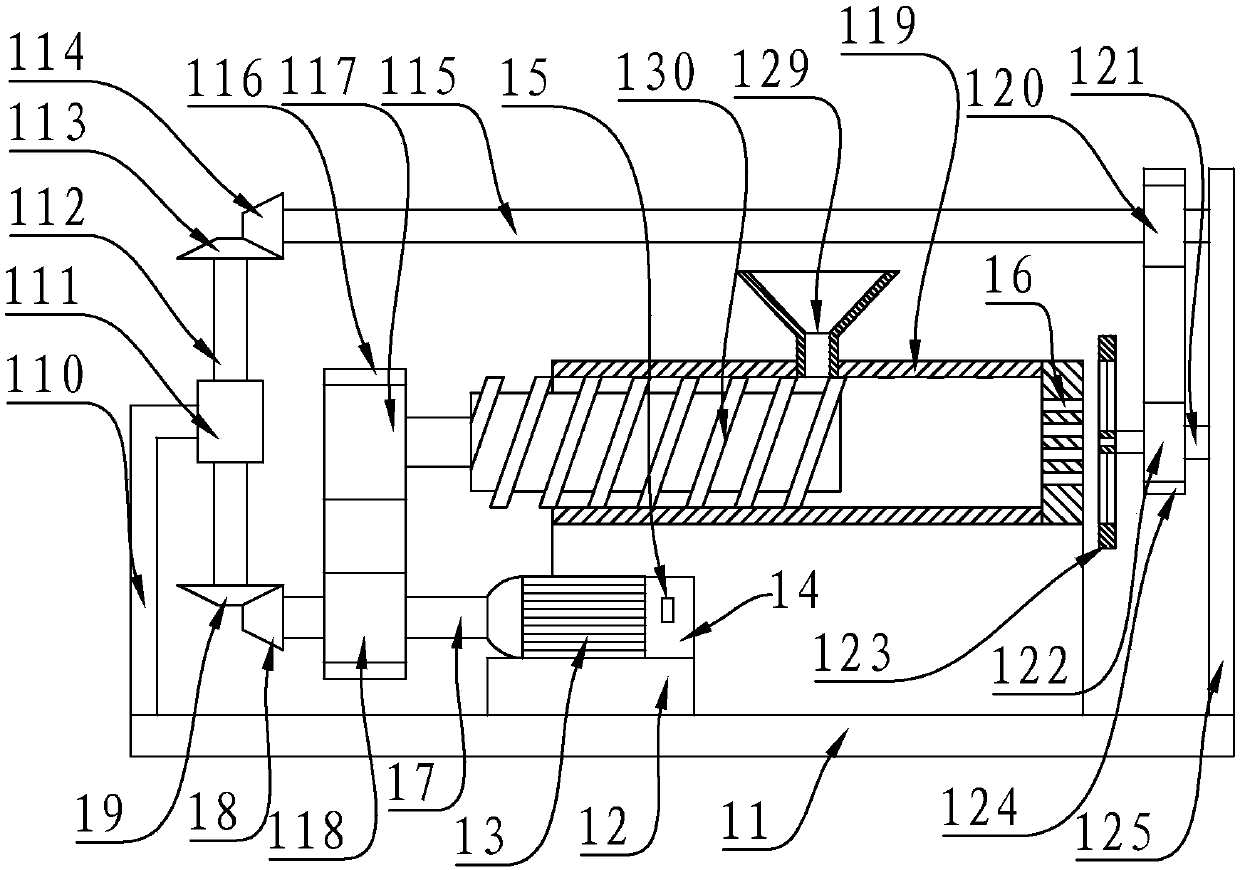

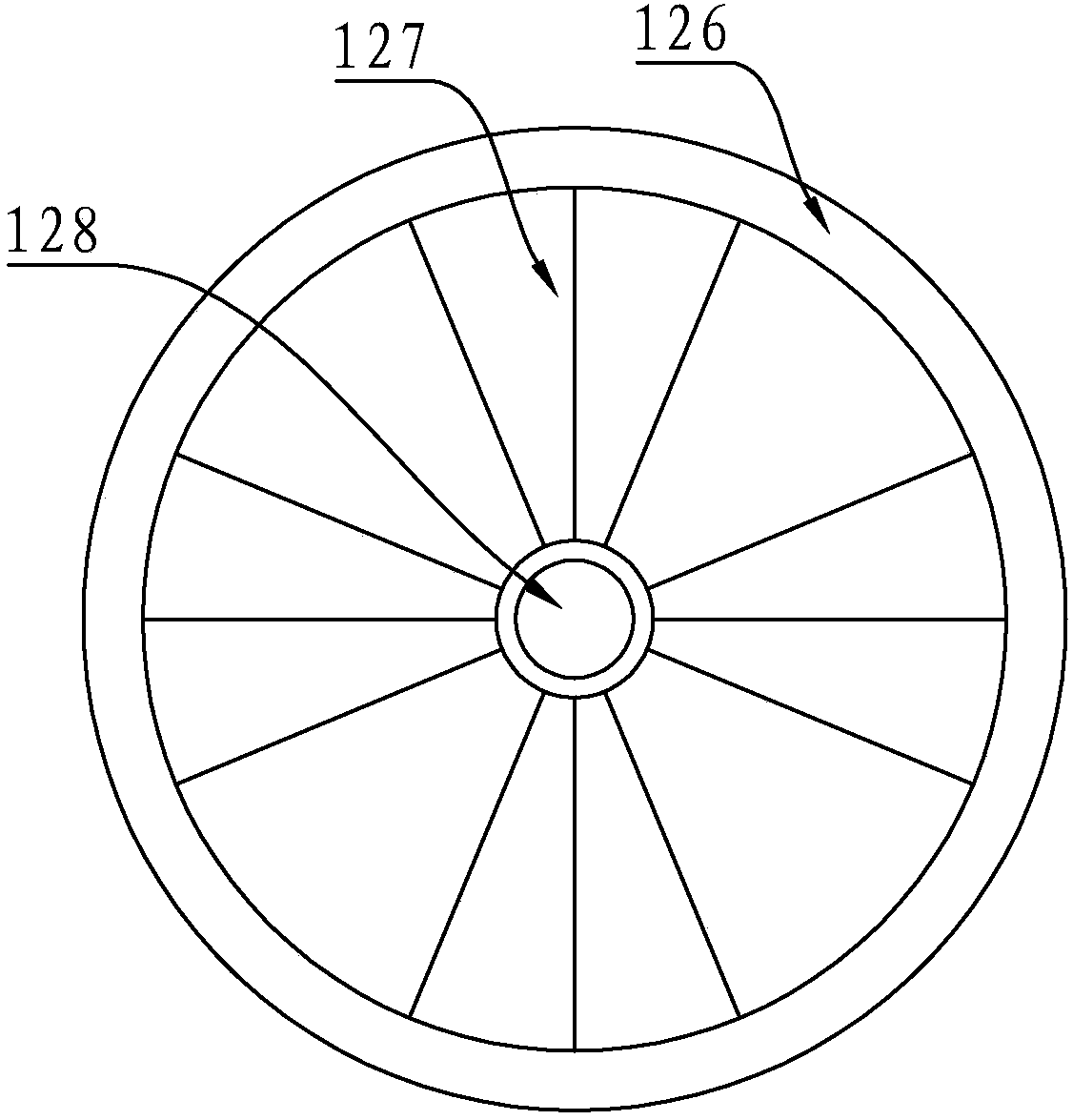

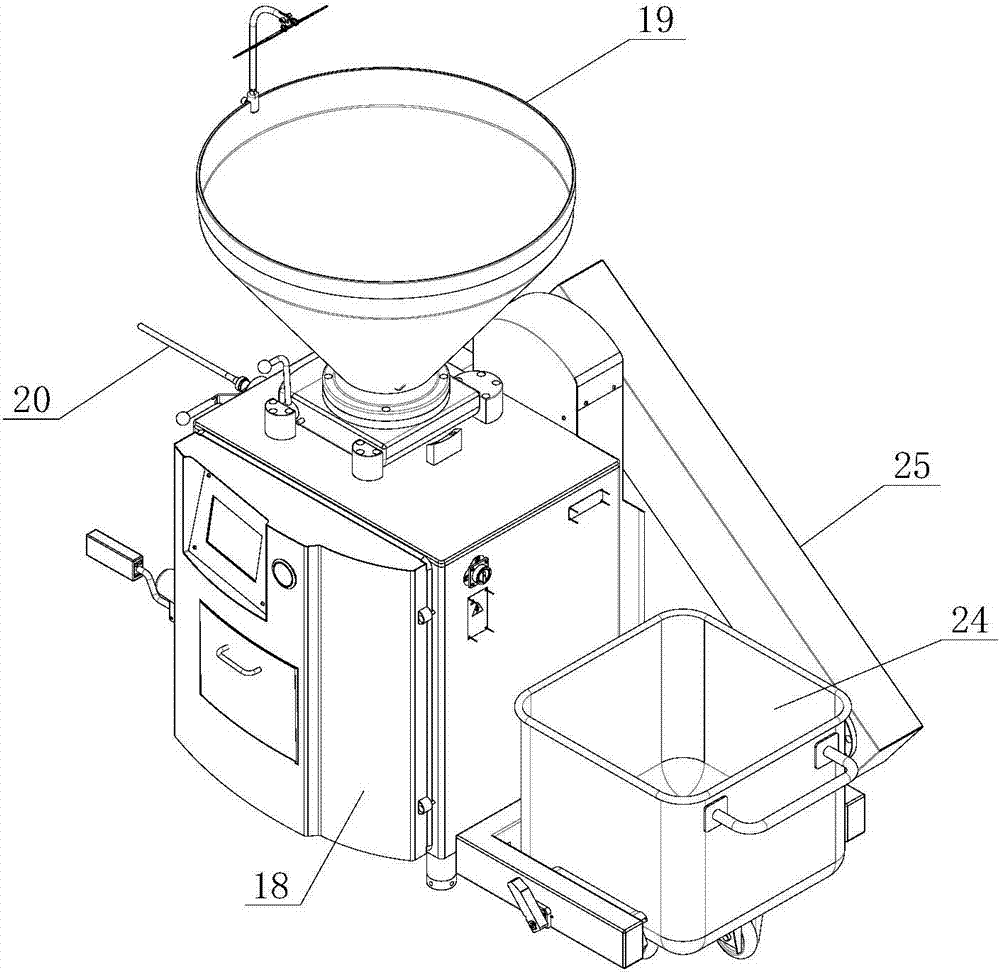

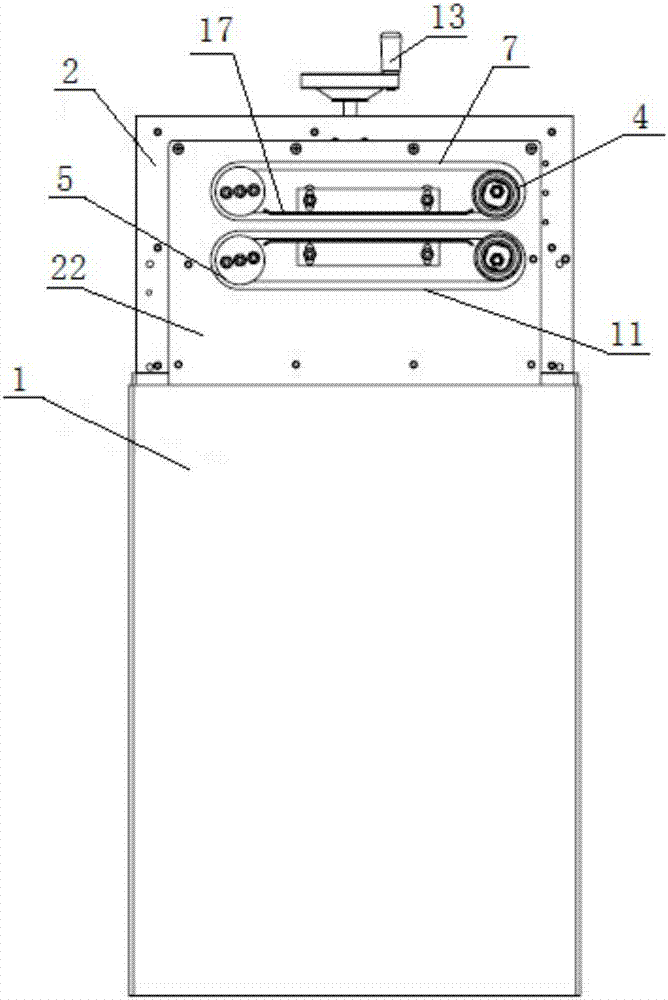

Energy-saving environment-friendly production process of sausages and production device of sausages

ActiveCN107897743AThe production process is simple and applicableSteady improvement in qualityLinked sausage separationSausage filling/stuffing machinesElectric machineryAutomation

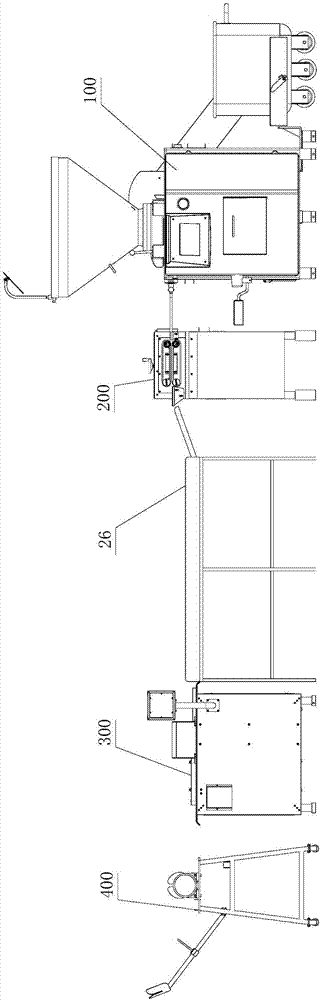

The invention provides an energy-saving environment-friendly production process of sausages and a production device of the sausages. The device comprises a weighing and stirring system, a sausage filling system, a smoking system, an air exhaust cooling and shaping system and a cutting system; a meat mincing system comprises a screw cylinder and a first screw rod which are matched with each other;the outer end of the first screw rod is provided with a first belt pulley; a rinsing system comprises a rinsing barrel made of a transparent material, a second motor, a first stirring sleeve and a second controller; a pickling system comprises a top cover and a pickling barrel; and a third rotating shaft is transversely arranged inside the pickling barrel. According to the invention, all importantdevices in sausage production process are improved, the automation degree of the production process is further improved, more mechanized operations are adopted, labor cost is reduced, production efficiency is improved at the same time, the error rate is lower, and the quality of the sausage is improved stably.

Owner:福建舜洋食品有限公司

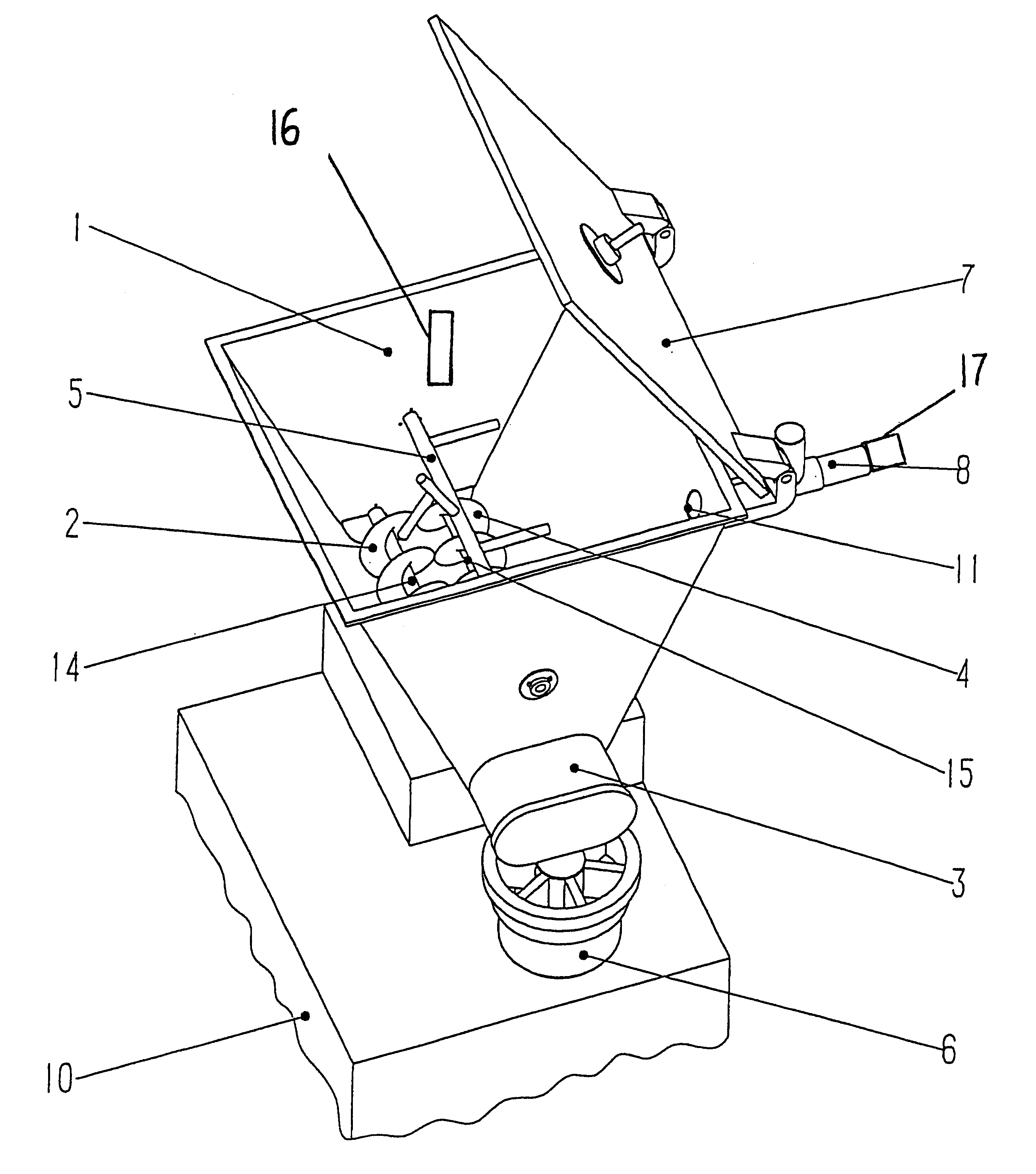

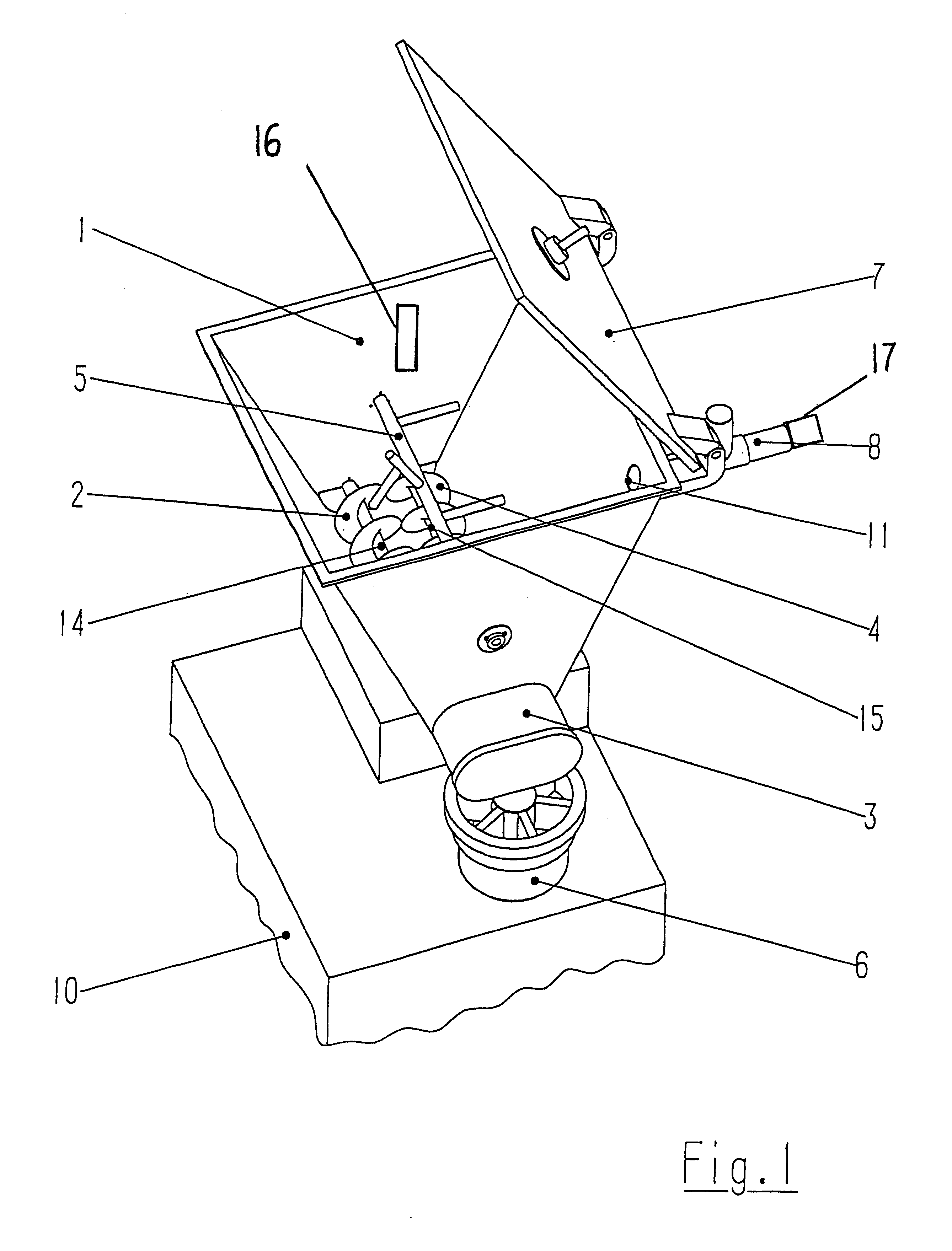

Fuel dispensing and containment assembly

A modular fuel dispensing and containment assembly for storing fuel in at least one fuel tank and for pumping the fuel to a group of fuel dispensers. The assembly has a reinforced concrete vault located underground which contains a fuel tank within its interior. The fuel tank is separated from the interior walls of the vault. The fuel tank has a turbine corridor on its lid, which corridor has an interior volume which leads from the fuel tank to a series of piping corridors. The turbine corridor and the piping corridors are all underground and the piping corridors lead to dispensing modules which are located under the dispensers or gas pumps. The dispenser modules and piping corridors are all sufficiently large to permit the entry of service personnel to their interiors. The interiors of the various corridors and modules form a single interconnected air volume. The result is a fuel dispensing and containment assembly wherein the vault and corridors and dispensing modules act as a secondary containment against any contaminant leaking from the primary piping or tanks. It also permits complete visual inspection of the primary containment and physical access to all its parts at any time.

Owner:GROPP STEVEN M

Sausage filler

The invention discloses a sausage filler used for making sausage, and the sausage filler provided by the invention comprises a charging barrel, a piston, a piston rod, a base and a piston rod driving device, wherein the barrel body of the charging barrel is provided with a locking insert which is provided with a locking groove; the base is fixedly provided with a locking pop-up device which comprises a locking box, an operating lever, a locking spring shaft, a locking spring, a locking piece, a pop-up spring and a pop-up shaft; the locking groove or locking hole of the locking insert can be blocked and jointed with the locking piece of the locking pop-up device; and the bottom of the locking insert props against the pop-up shaft of the locking pop-up device. The sausage filler ensures the charging barrel to be rapidly locked and disassembled, and is convenient to operate, convenient for batch production and high in efficiency.

Owner:常州市开源工具制造有限公司

Apparaus and method for producing paste material and extrusion head separately used for the apparatus and method

InactiveCN1468540AHigh normal sclerosisIncrease distanceSausage skin tying apparatusSausage casing manufactureMechanical engineeringExtrusion

Owner:ALBERT HANDTMANN MASCHFABRICK

Device and method of manufacturing and filling up fine sausage meat, in particular an emulsion

ActiveUS20110248105A1Continuous operationShorten the timeCocoaSausage filling/stuffing machinesEmulsionEngineering

A device and a method of manufacturing and filling up product in the form of fine sausage meat, in particular an emulsion, with a feed means for the product, a feed pump for transporting the product, at least one downstream fine mincer as well as a filling and / or portioning means arranged downstream of the fine mincer for filling up the produced fine sausage meat or the emulsion, respectively.

Owner:ALBERT HANDTMANN MASCHFABRICK

Apparatus and method for dividing a stuffed sausage skein

An apparatus and a method for dividing a stuffed sausage skein, wherein a transport element pair is provided, including rotating opposite transport elements between which the stuffed sausage skein is conveyed in a transport direction and each of which include at least one dividing element. To be able to configure the length of the portions flexibly without mechanical adaptation, the apparatus comprises several adjacently arranged transport element pairs drivable independently of each other with corresponding dividing element pairs. The speed of the transport element pairs is adjusted such that the spacing between the points of separation corresponds to a predetermined length of the divided sausage skein.

Owner:ALBERT HANDTMANN MASCHFABRICK

Processing a mass of pumpable foodstuff material

ActiveUS20140212558A1Good dispersionPackaging under vacuum/special atmosphereCheese manufacturePump chamberFood material

A method and installation for processing a mass of pumpable foodstuff material, for example a ground meat mass. The installation comprises a hopper and a positive displacement pump having an inlet and an outlet. A tube structure connects to the outlet of the pump and has a mouth, e.g. leading to a moulding device or a sausage machine. A controllable vacuum assembly is provided to cause controlled evacuation of air from the mass in the trajectory of the mass from and including the hopper to and including a pump chamber at a position where it is in communication with the pump inlet. A controllable aeration assembly is provided to cause controlled introduction of a gas into the mass at one or more locations in the trajectory of the mass between the pump outlet and the mouth. The assembly comprises a source of pressurized gas and a gas pressure control device to introduce said gas into the mass at a controlled pressure that is at least equal to the actual pressure of the mass at the location of introduction of the gas into the mass. An aeration member is disposed in the path of the mass between the pump outlet and the mouth of the mass feed member. The aeration member is connected to the source and has one or more orifices from which said gas is emitted.

Owner:MAREL TOWNSEND FURTHER PROCESSING

Automatic spreading adjustment

ActiveUS20080220704A1Simple structureSimple of stroke movementSausage filling/stuffing machinesSausage twisting/linking machinesEngineeringMechanical engineering

Owner:POLY CLIP SYST

Chuck for meat encasing machines

InactiveUSRE37883E1Sausage filling/stuffing machinesSausage twisting/linking machinesMechanical engineering

A chuck for a meat encasing machine has an elongated body having an inlet end and a discharge end. The body has an elongated hollow bore extending therethrough and an exterior cylindrical surface. A plurality of radially extending flutes are in the bore of the body for purposes of grasping and imparting rotational motion to a filled meat casing. An annular groove extends around the exterior cylindrical surface of the body member. A resilient O-ring is mounted in the groove and slightly projects outwardly from the groove to frictionally engage a socket into which the chuck is inserted.

Owner:STORK TOWNSEND BV

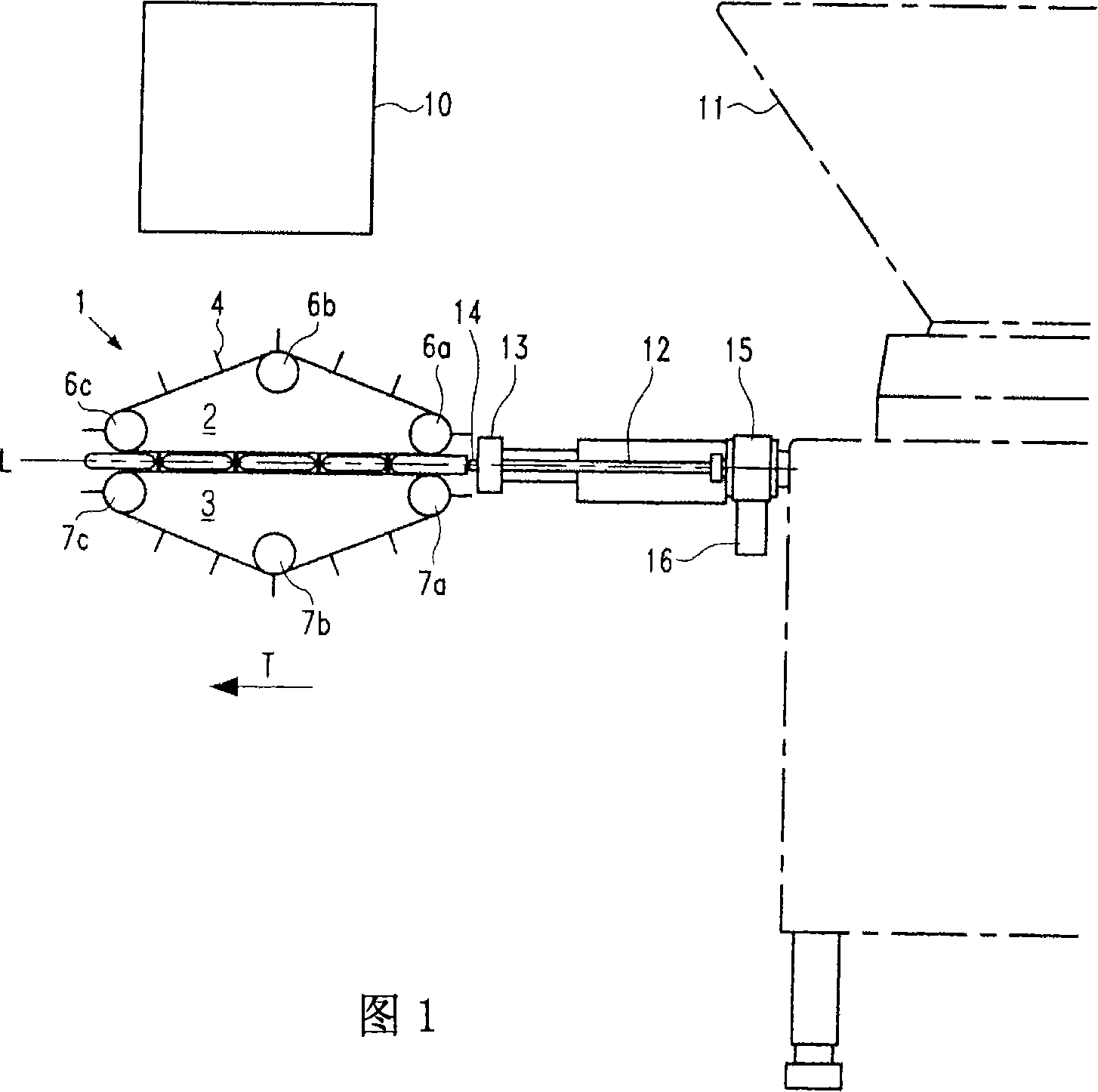

Production line for producing sausage product

ActiveCN107041413AReduce manufacturing costSmall footprintSausage skin tying apparatusSausage filling/stuffing machinesProduction lineEngineering

The invention relates to the field of sausage product processing, and discloses a production line for producing a sausage product. The production line comprises a filling device, a drawing device, a working table, a thread binding device and a thread removing device, wherein the filling device is used for automatically filling a casing; the drawing device is used for guiding and transmitting forwards the casing filled with sauce; the working table is used for temporarily storing a sausage product to be subjected to thread binding; the thread binding device is used for carrying out length determination, segmentation and thread binding on the sausage product; the thread removing device is used for removing cotton threads on segments of the fumigated or cooked sausage product subjected to thread binding; the thread binding device comprises a segment clamping mechanism for carrying out pre-constriction on the sausage product, a thread binding mechanism for winding and binding the sausage product at constricted positions by adopting the cotton threads so as to segment the sausage product, and a fixed-length drawing mechanism for drawing an initial position of the sausage product at a set drawing distance so as to enable the sausage product to be segmented at a fixed length. The integral production line for producing the sausage product, which is disclosed by the invention, is small occupied space, simple operation, convenience in maintenance, low production cost, high production efficiency, uniformness of the filled sausage product and high quality.

Owner:佛山市奥楷机械科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com