Patents

Literature

73 results about "Tube (structure)" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In structural engineering, the tube is a system where, to resist lateral loads (wind, seismic, impact), a building is designed to act like a hollow cylinder, cantilevered perpendicular to the ground. This system was introduced by Fazlur Rahman Khan while at the architectural firm Skidmore, Owings & Merrill (SOM), in their Chicago office. The first example of the tube’s use is the 43-story Khan-designed DeWitt-Chestnut Apartment Building, since renamed Plaza on DeWitt, in Chicago, Illinois, finished in 1966.

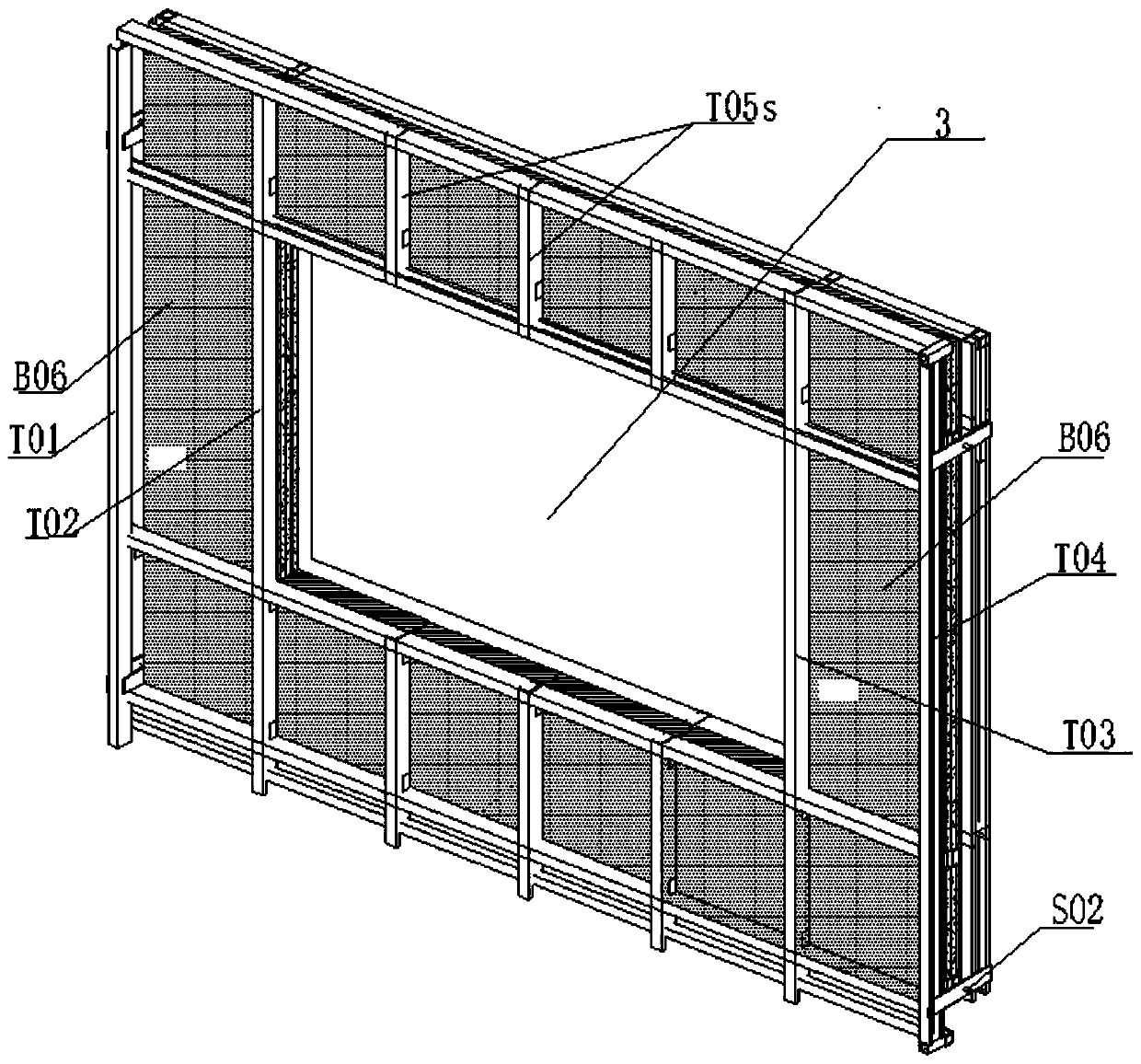

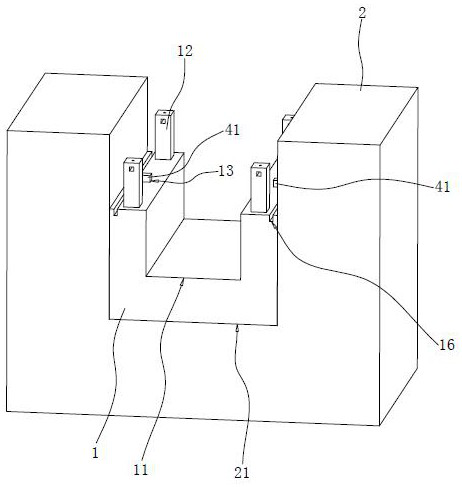

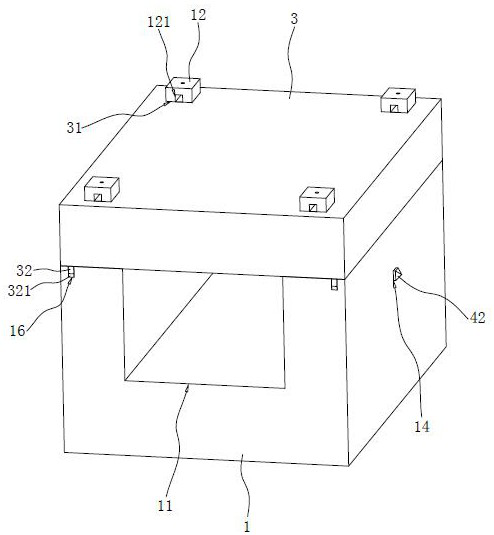

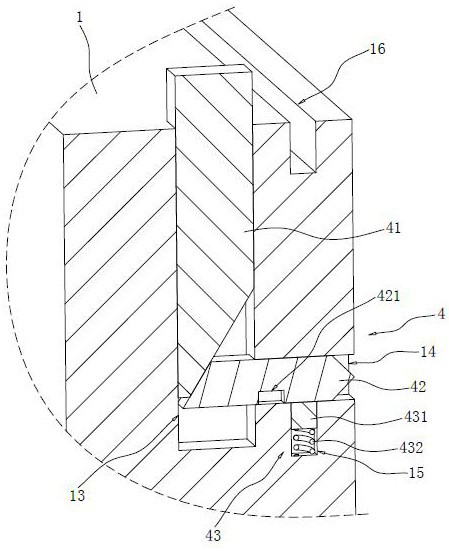

Method for constructing core tube wall through self-climbing formwork and adopted self-climbing formwork

InactiveCN104131703AGood climbing stabilitySmooth connectionForms/shuttering/falseworksBuilding material handlingTube (structure)Architectural engineering

The invention discloses a method for constructing a core tube wall through a self-climbing formwork and the adopted self-climbing formwork. The method comprises the steps that the core tube wall is constructed from bottom to top layer by layer; when a first-layer wall body is constructed, a first pre-buried component is pre-buried, and pouring of the first-layer wall body is completed; after construction of the first-layer wall body is completed, a second-layer wall body is constructed, and a second pre-buried component is pre-buried in the second-layer wall body; each pre-buried component is provided with a wall attachment device, after pouring of the second-layer wall body is completed, a guide rail is arranged between the first wall attachment device and the second wall attachment device, a self-climbing device on the formwork is connected with the guide rail, alternate mutual climbing of the formwork and the guide rail is achieved through the self-climbing device, a form board is arranged on the formwork, and the construction of the core tube wall is completed layer by layer through the form board. The method is suitable for core tube construction of a super high-rise building of a frame core tube structure of 200 m to 400 m, a wide platform is provided for operating personnel for construction, safety is guaranteed well, construction efficiency is greatly improved, and construction cost is lowered.

Owner:CHINA CONSTR FOURTH ENG DIV

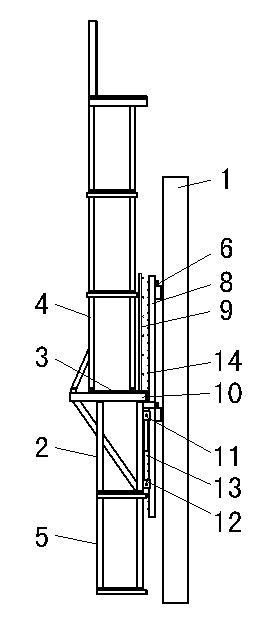

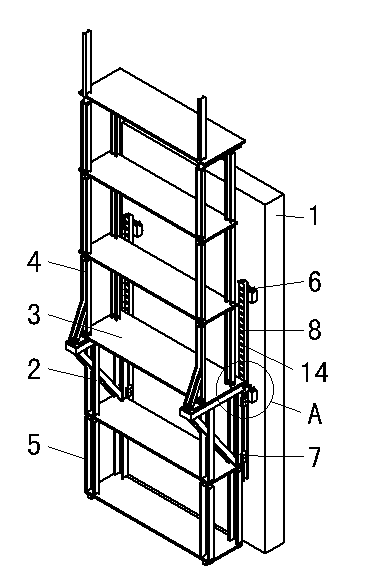

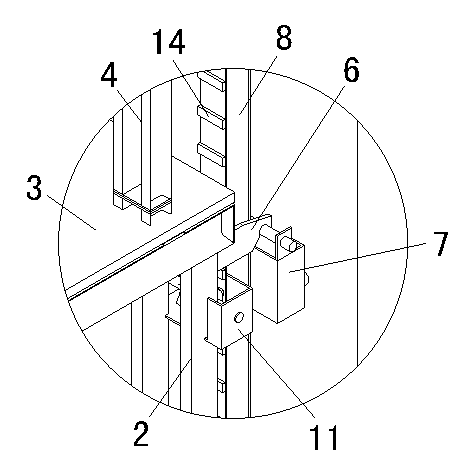

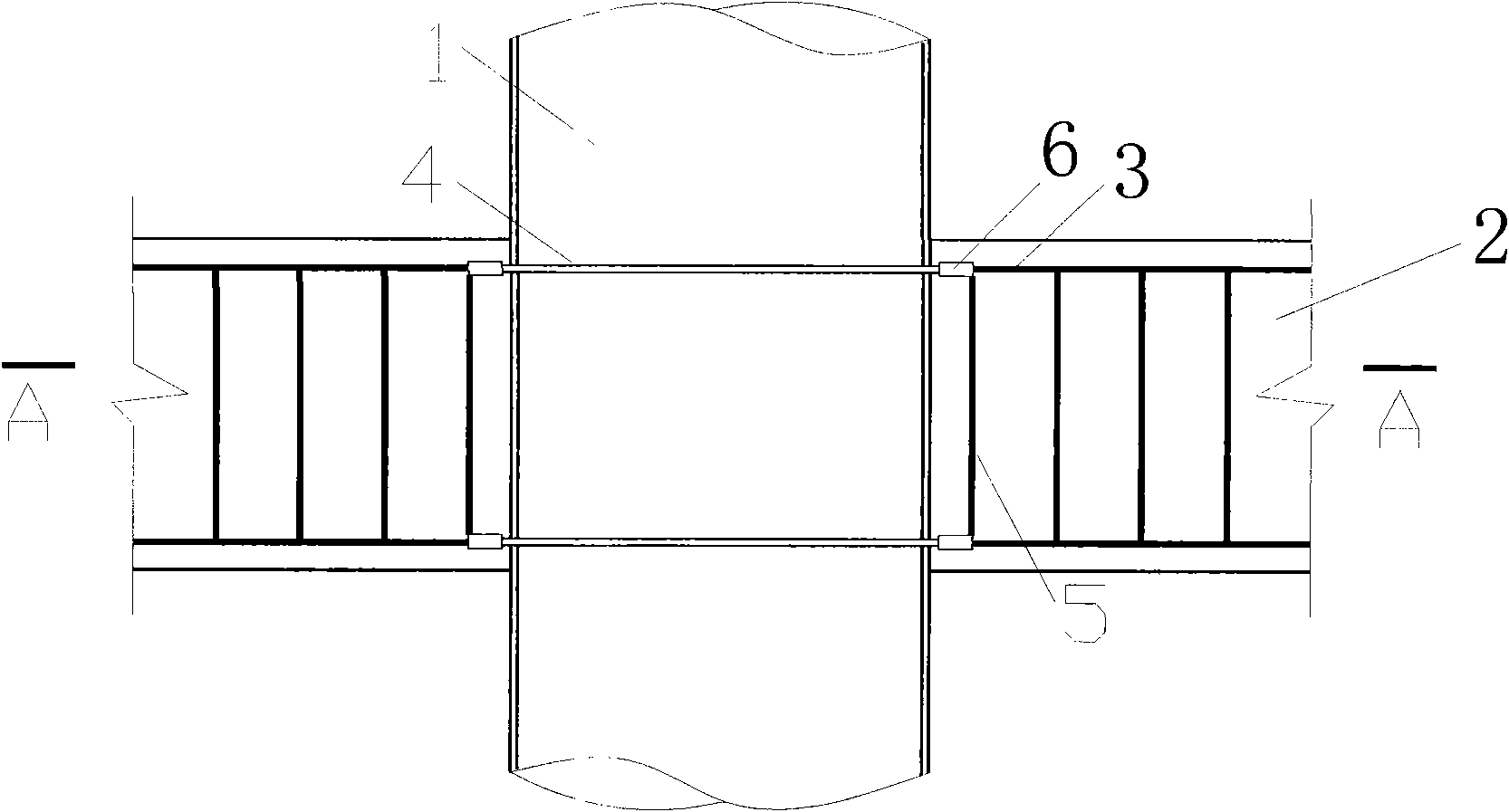

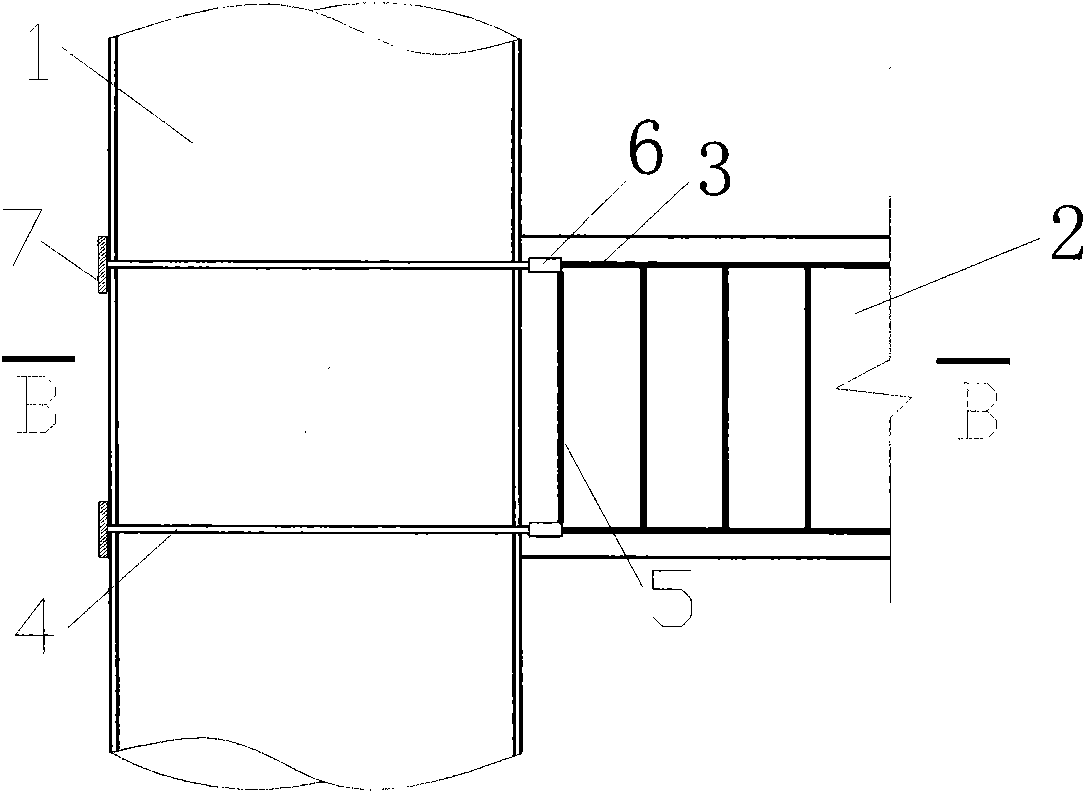

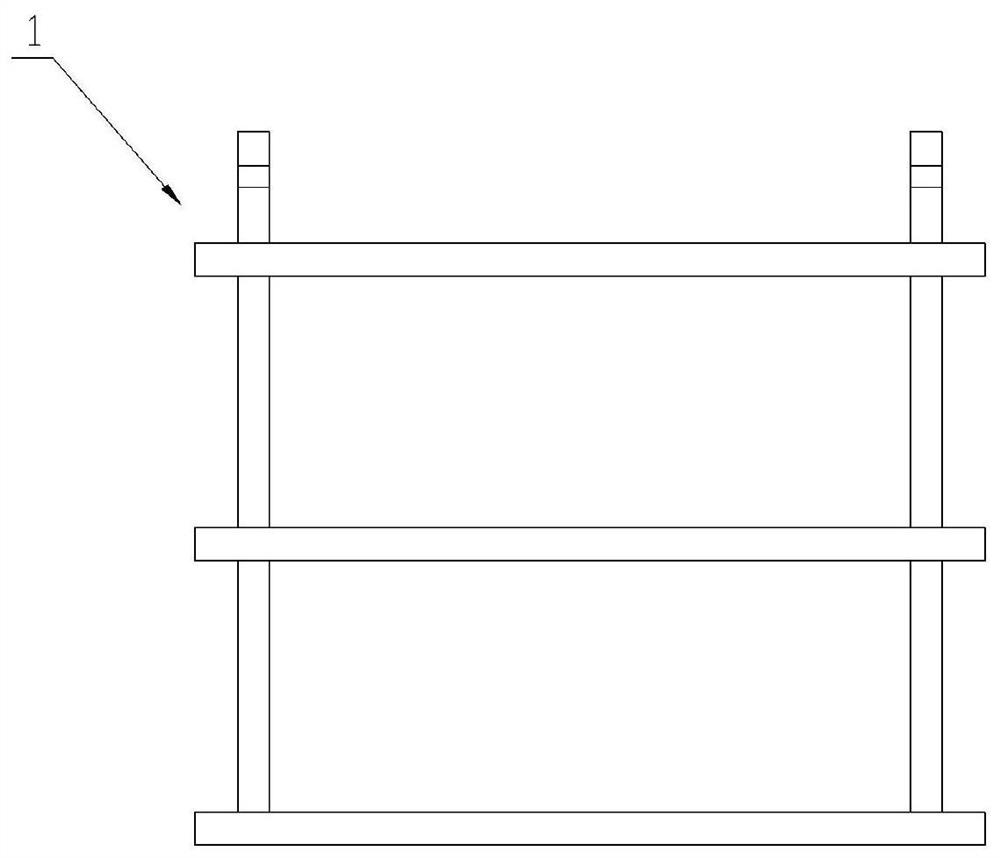

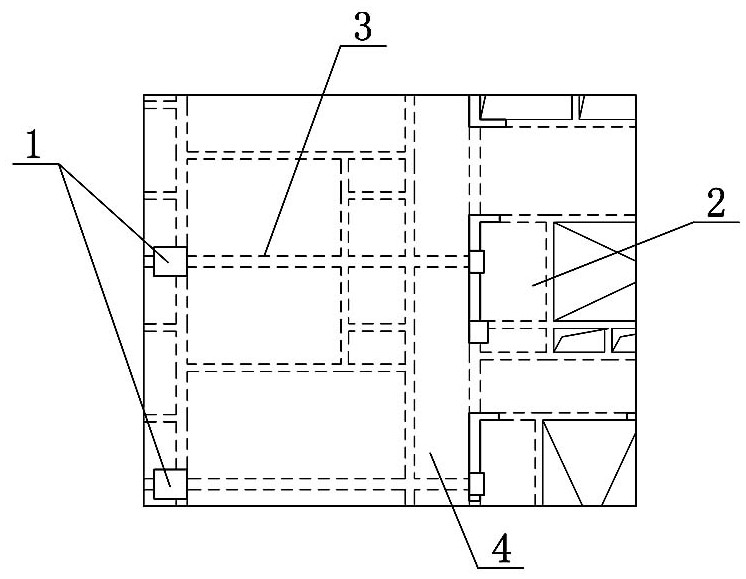

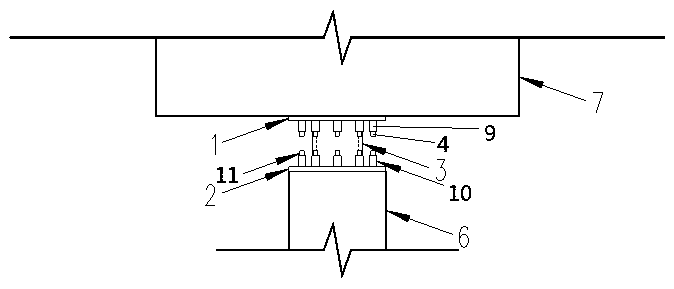

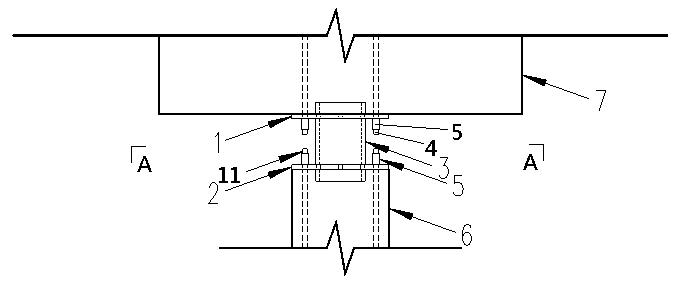

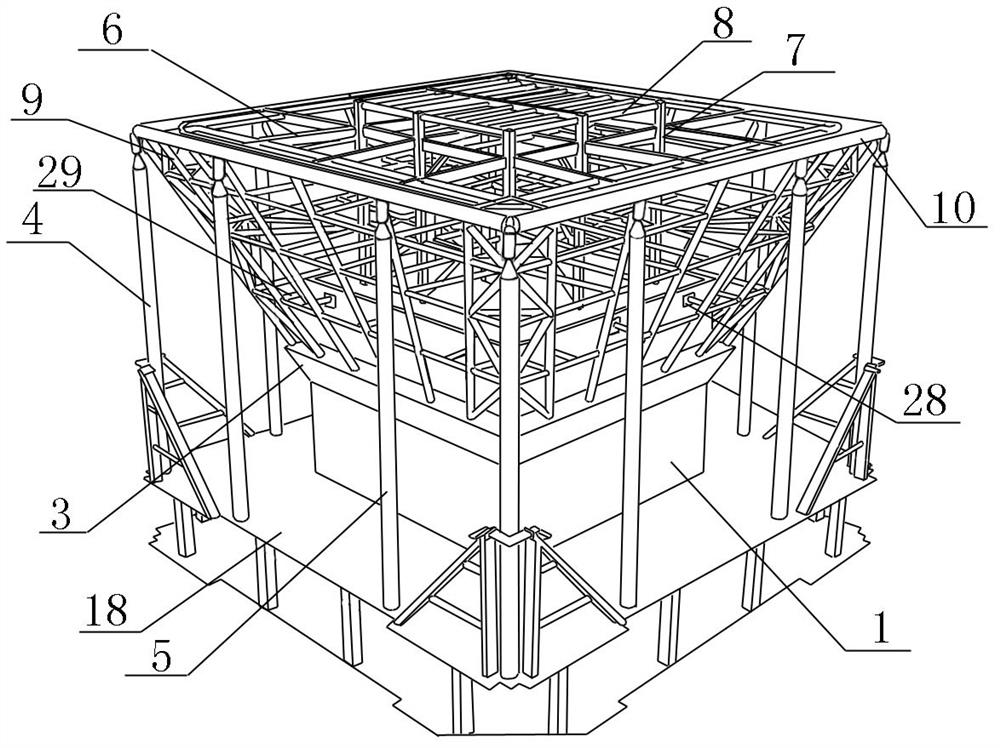

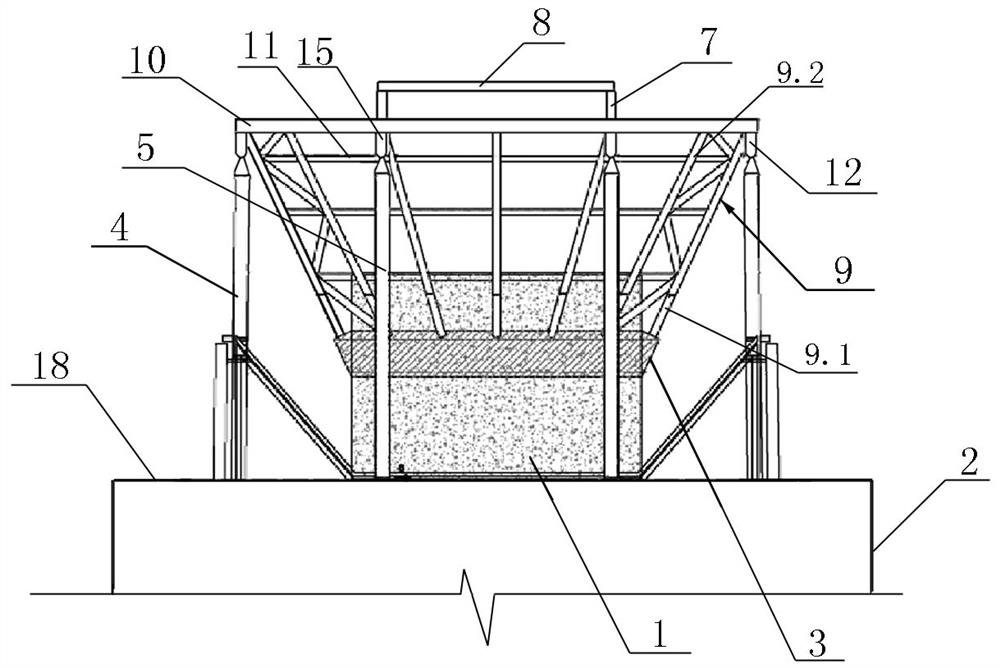

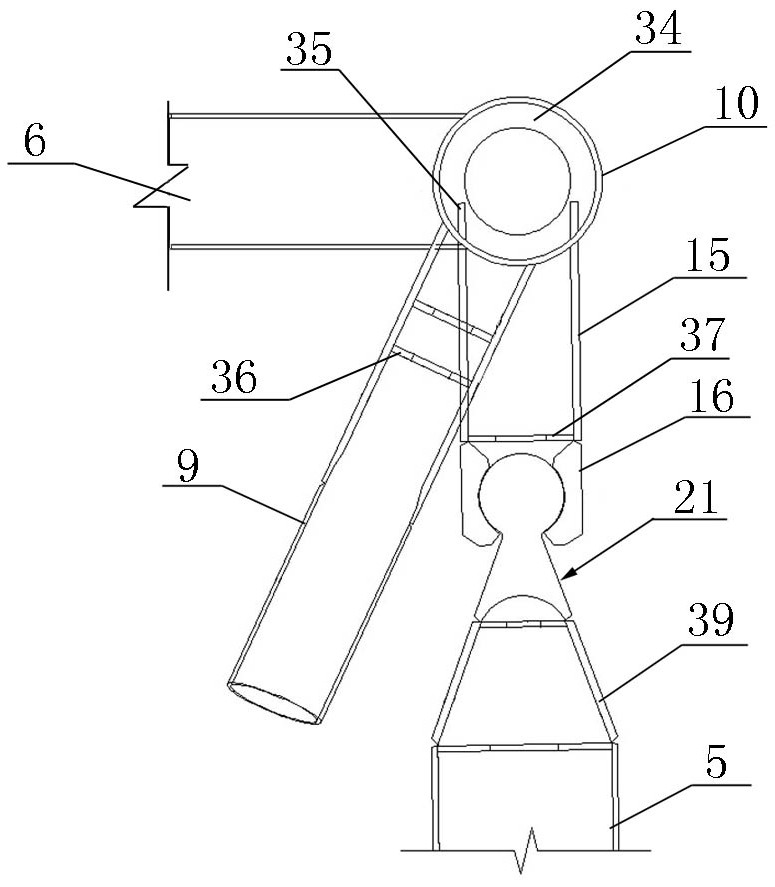

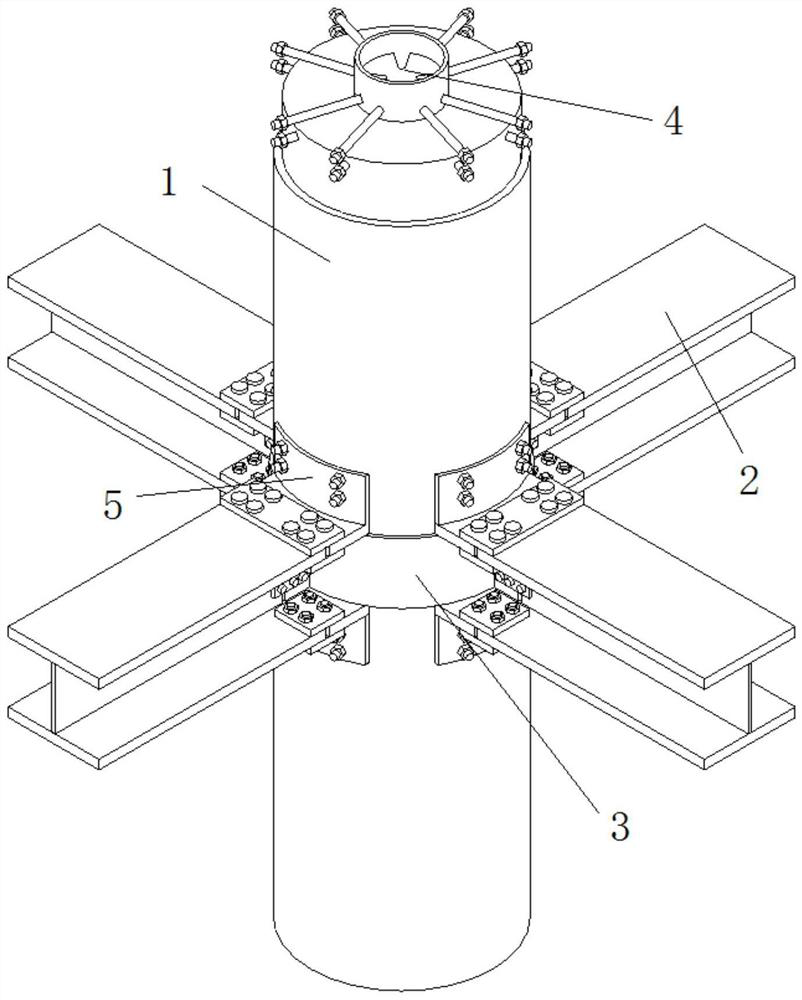

The nodes and construction method for concrete filled steel tubular column and in-situ reinforced concrete beam

InactiveCN101550728AImprove node connectionReduce construction difficultyBuilding constructionsReinforced concreteSteel bar

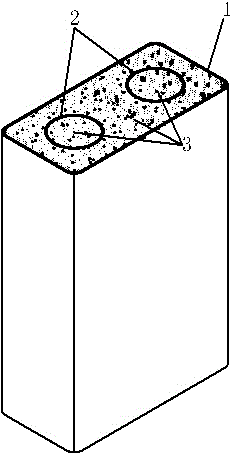

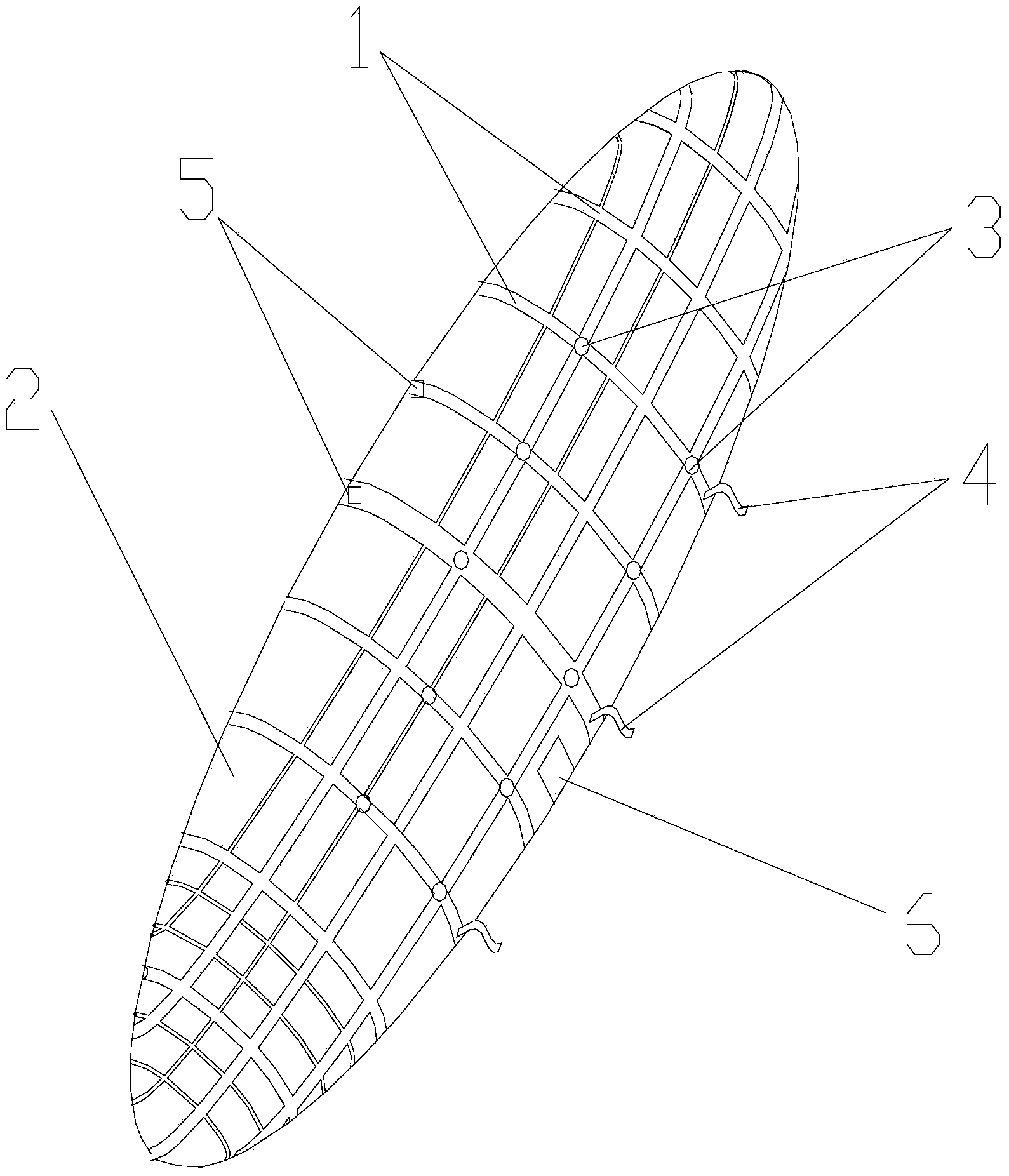

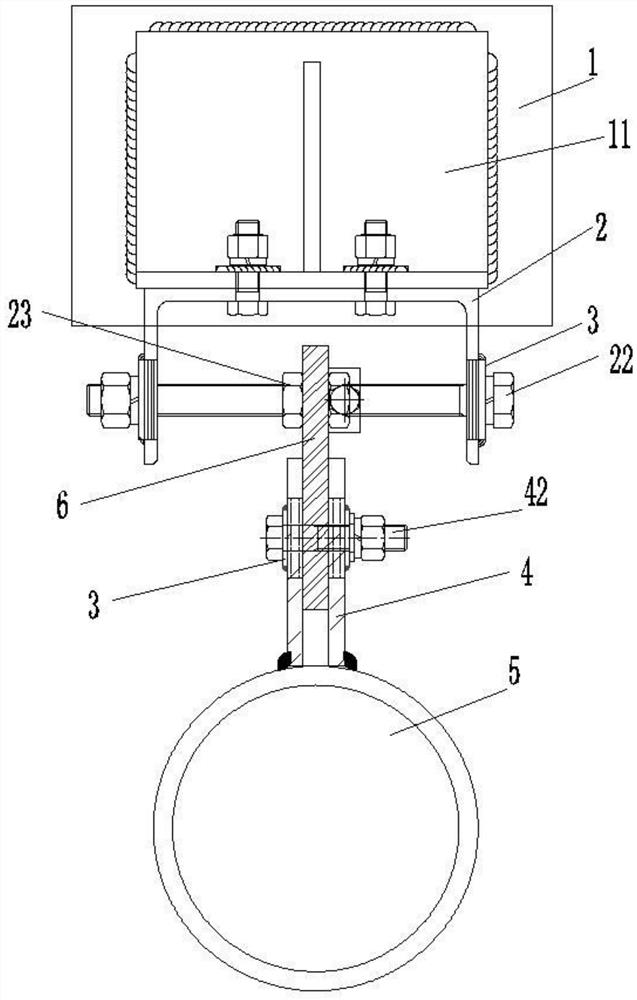

The nodes and construction method for concrete filled steel tubular column and in-situ reinforced concrete beam belong to the technical fields of architectural structure. The nodes consist of the concrete filled steel tubular column (1) and in-situ reinforced concrete beam (2); the characteristics are: that the beam longitudinal reinforcement (3) connects the concrete filled steel tubular column (1) through feedthrough rod (4), the steel sleeve tube (6) sets on both ends of the feedthrough rod (4) and connects the beam longitudinal reinforcement (3) through threaded connection, and the beam node areas is densely covered with stirrups (5) with the spacing of 50-80mm. As for the side-column node, one end of the feedthrough rod (4) is welded on the ring plate (7). The invention does not require on-site welding process to address the connection issue of the reinforced concrete and the concrete filled steel tube. With simple construction, it can be widely used for the building structure field and has broad application prospects.

Owner:CHINA STATE CONSTRUCTION ENGINEERING CORPORATION

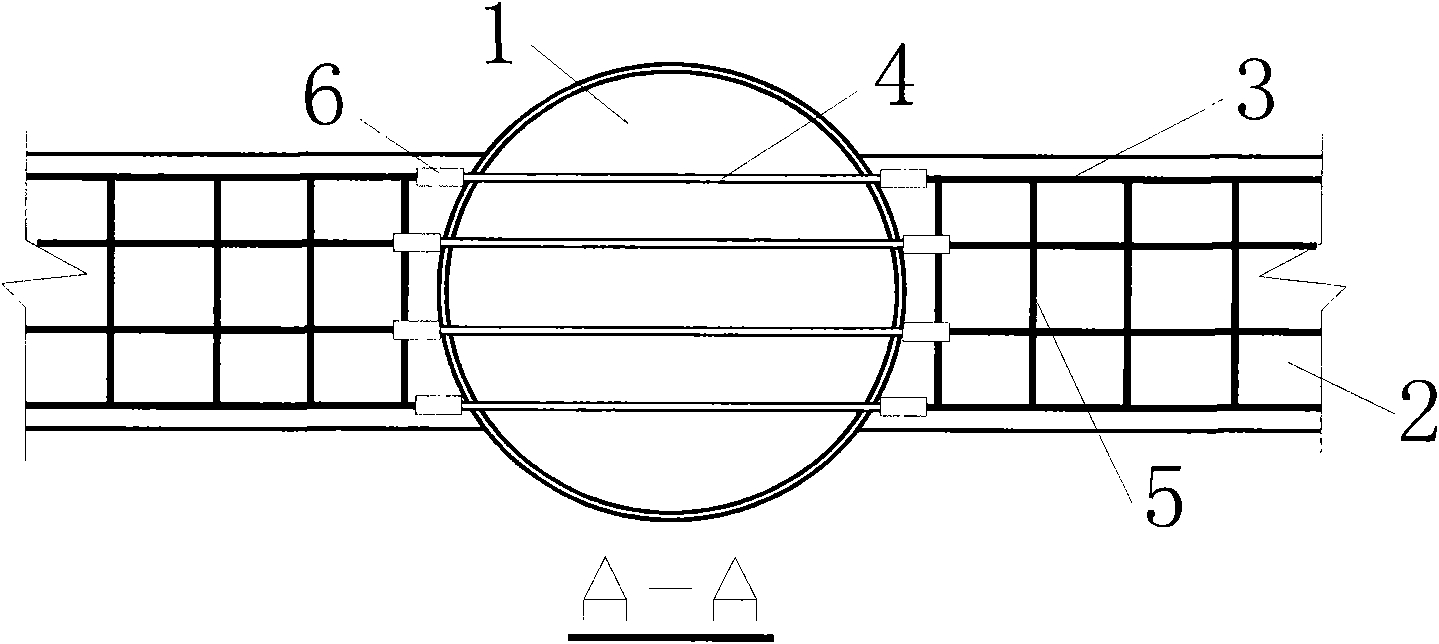

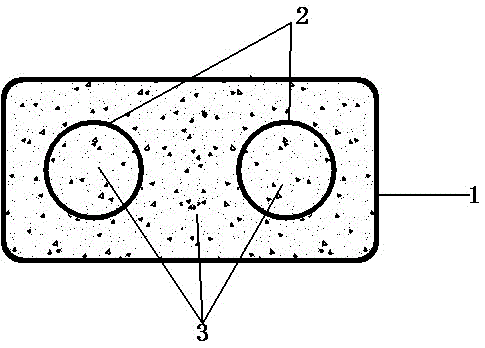

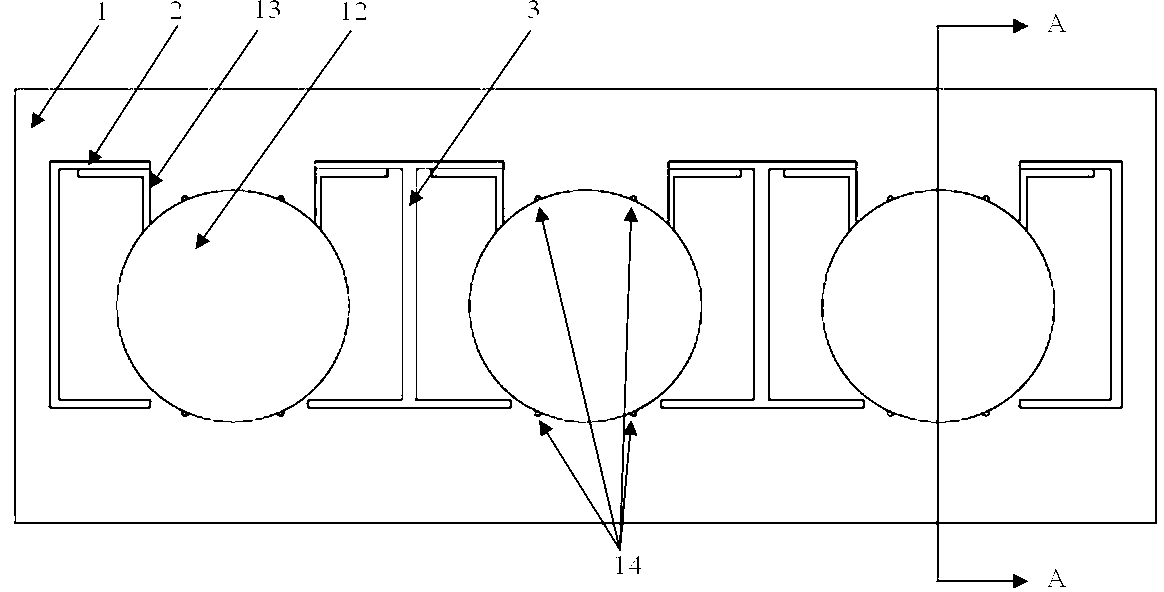

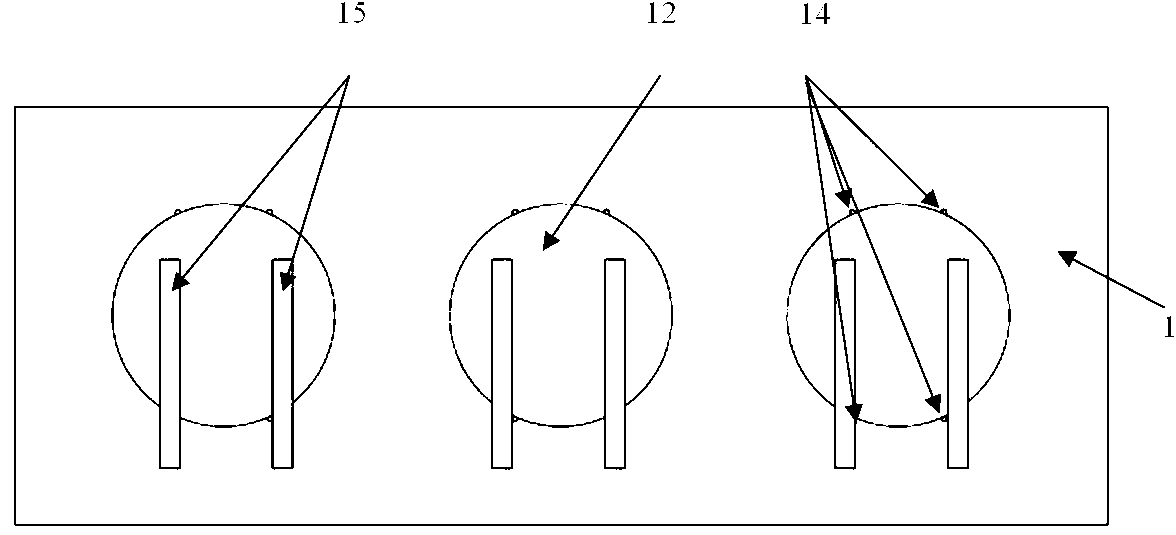

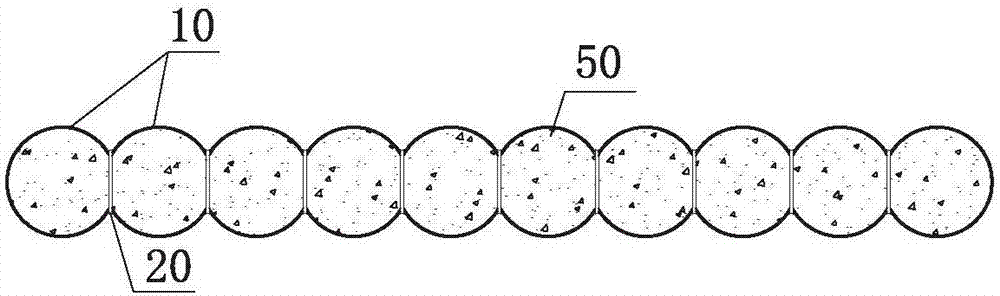

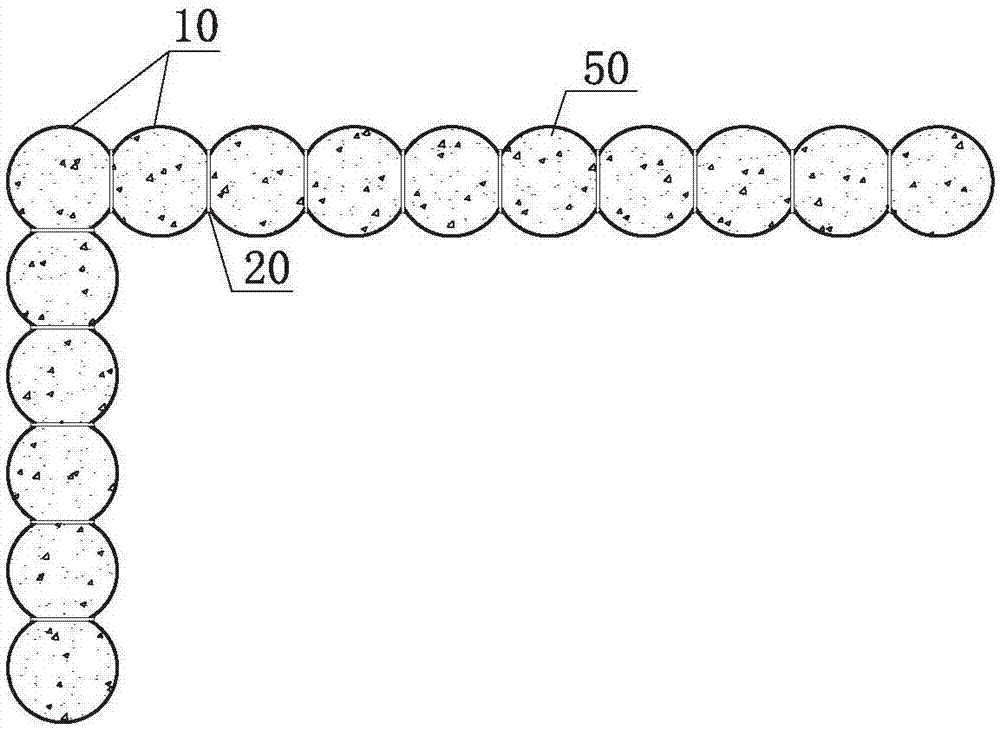

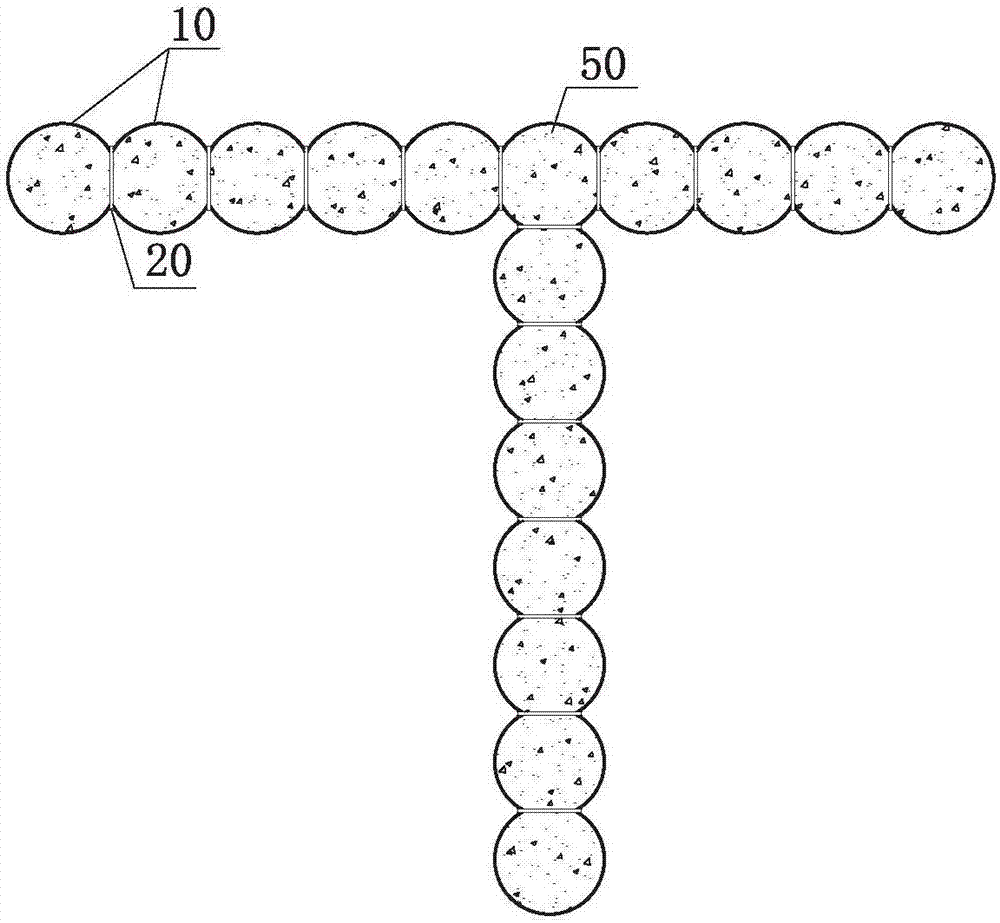

Novel multibarrel tube-confined concrete pier column

InactiveCN105648900AConvenient bindingOvercoming the shortcomings of poor restraint performance that cannot ensure that the concrete is in a three-dimensional stress stateStrutsBridge structural detailsEarthquake resistanceOperating energy

The invention discloses a novel multibarrel tube-confined concrete pier column which adopts a section form of a rectangular concrete-filled steel tube sleeving double circular steel tubes inside, the novel multibarrel tube-confined concrete pier column can have the advantage of good confining performance of circular steel tubes, overcome the defect that a rectangular concrete-filled steel tube poor in confining performance cannot ensure that concrete is in a three-direction stress state, and also have the characteristic of neat and attractive appearance of the rectangular concrete-filled steel tube, which facilitates construction. The pier column provided by the invention has high rigidity, high strength, good seismic performance and simple structure, can greatly lower the cost of structure construction and reduce difficulties in construction, and is suitable for large-diameter columns in bridge piers and buildings, as well as other related high-rising buildings or column components thereof.

Owner:HEBEI UNIV OF TECH

Building component sealing component and structure

PendingCN107829501AReduce mutual frictionExtended service lifeBuilding constructionsEngineeringStructural engineering

Owner:NENGCHENG GRP

Gas film building and buildings with same

The invention relates to a gas film building and buildings with the same, belongs to the field of building structural systems. The gas film building and the buildings with the same solve the potential safety hazard problem that partial failure of thin films can cause the whole gas film building to collapse in the prior art. The gas film building comprises a thin film, and gas charging tubes are arranged in the thin film. The invention further relates to the buildings which comprise walls and the gas film building. The internal pressure and the external pressure of the gas film building are identical, the whole architectural structure is connected through film sheets, maintenance is convenient to carry out, partial failure cannot cause the whole gas film building to collapse, and safety is guaranteed, needed aeration quantity is low, and power consumption is small, when the gas film building serves as a closed smelly source for treating stink gas, the needed gas exchanging amount and treating amount can be reduced greatly, a deodorization system is optimized, and the effects of energy conservation and environment protection are achieved. The gas film building is easy to inflate, dismount and move, and suitable for occasions with positions needing to be moved frequently.

Owner:深圳市利源水务设计咨询有限公司

Construction method of multi-line long span inverted trapezoidal space truss roof system

InactiveCN111851746AReasonable forceIncrease stiffnessBuilding roofsTube (structure)Architectural engineering

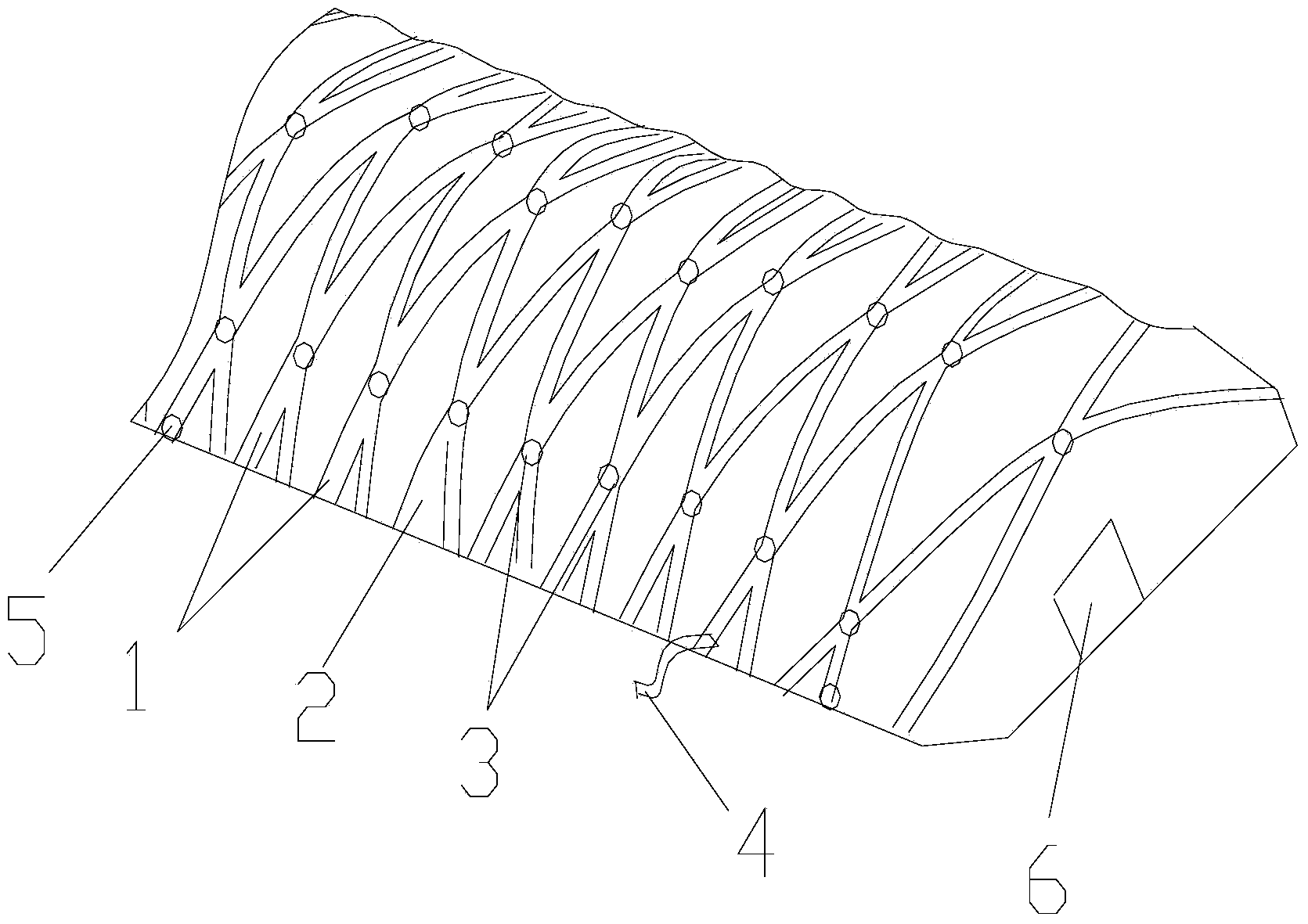

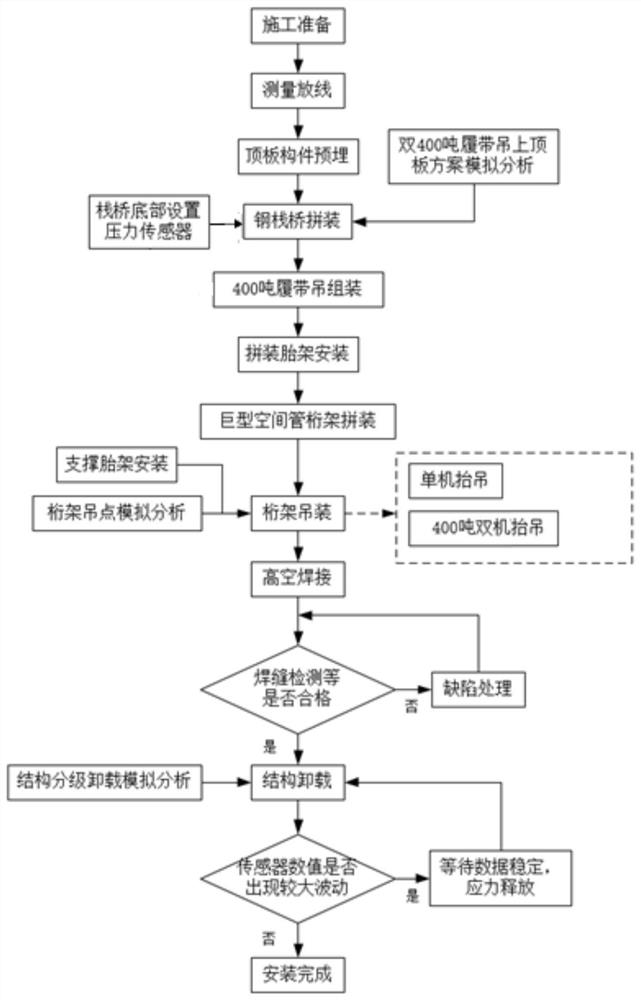

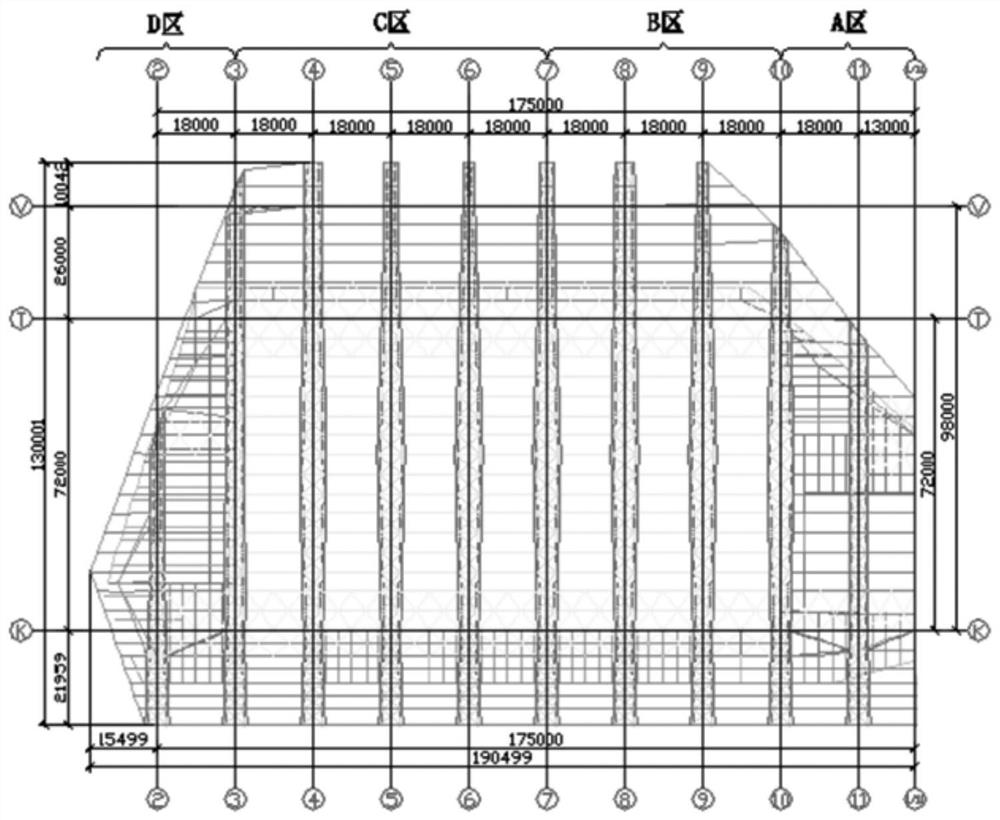

The invention provides a construction method of a multi-line long span inverted trapezoidal space truss roof system. The construction method comprises the steps of: S1, a construction preparation; S2,surveying and setting-out: a measurement of a steel trestle axis and a re-measurement of a scaffold position; S3, pre-embedding of roof components; S4, assembling of a steel trestle; S5, assembling of a hoisting machine; S6, installation of an assembling scaffold; S7, assembling of a giant space tube truss; S8, hoisting of the truss; S9, welding at high altitude; and S10, unloading of a structure. The construction method of the multi-line long span inverted trapezoidal space truss roof system has the characteristics of reasonable stress, high bearing capacity, large rigidity and convenient construction.

Owner:THE THIRD CONSTR OF CHINA CONSTR EIGHTH ENG BUREAU

Super high-rise building structure without inner tube

ActiveCN103362208AReduce steel consumptionReduce dosageBuilding constructionsReinforced concreteFloor slab

The invention relates to a building structure, in particular to a super high-rise building structure without an inner tube. The super high-rise building structure comprises a plurality of SRC (steel reinforced concrete) columns, a plurality of SRC window skirt beams, a plurality of vertical columns, a plurality of connection beams and a plurality of floors, wherein the SRC columns and the SRC window skirt beams are arranged at the periphery of the building structure and are used for forming an outer framed-tube structure; the vertical columns and the connection beams are arranged inside the building structure and are used for forming an inner frame structure; and the floors are used for connecting the outer framed-tube structure with the inner frame structure. The connection beams of the building structure are simpler in structural design, and the building structure can adapt to a more complicated and irregular structure, and is more material-saving and economic.

Owner:SHENZHEN GENERAL INST OF ARCHITECTURAL DESIGN & RES

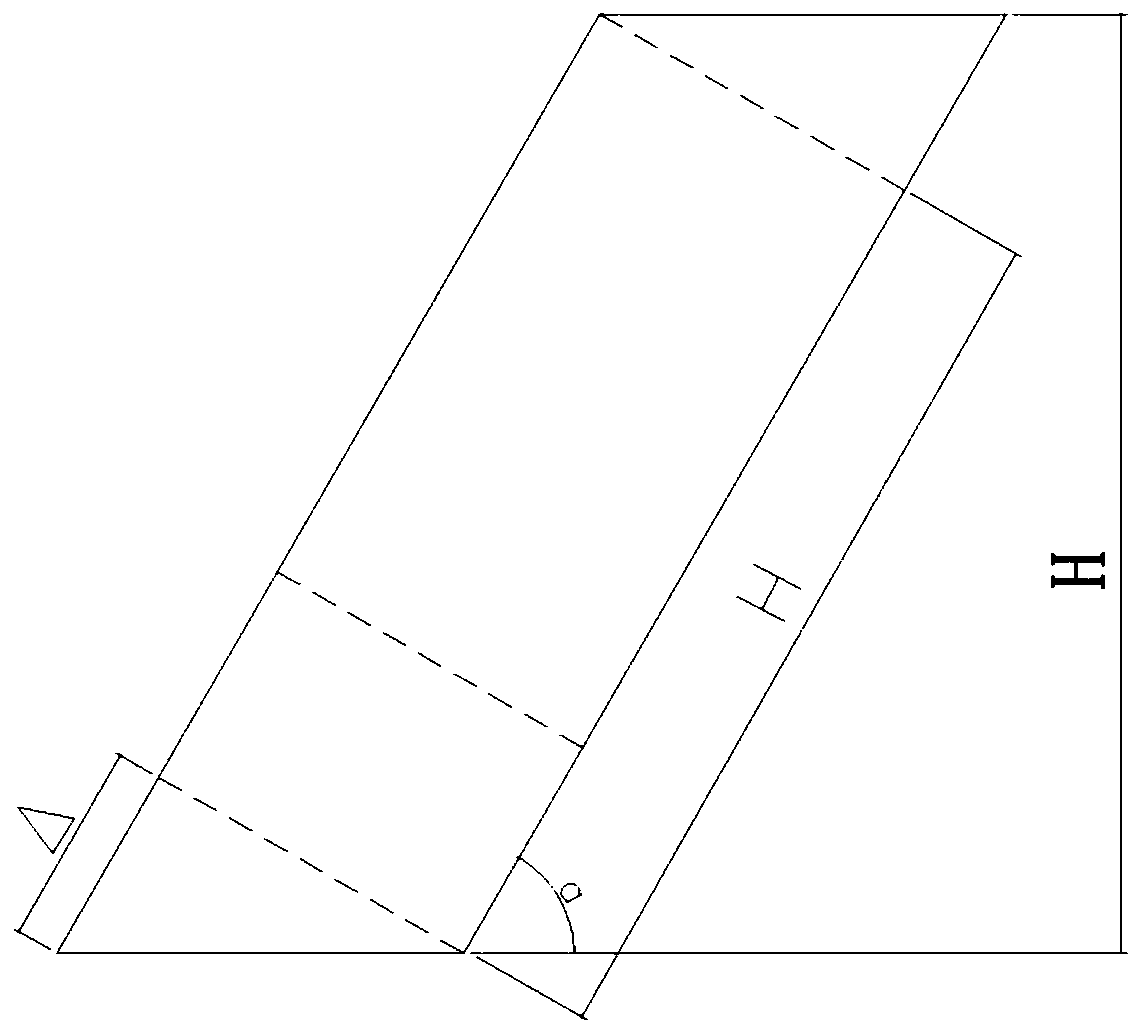

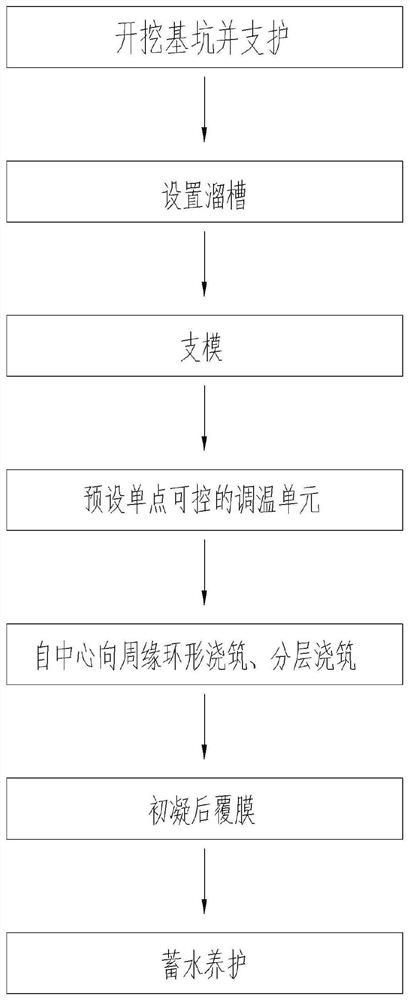

Construction method of cast-in-place concrete curve surface inclined tube body structure

InactiveCN110700570AEasy constructionEasy to manageForms/shuttering/falseworksFalseworkReinforced concrete

The invention provides a construction method of a cast-in-place concrete curve surface inclined tube body structure. The construction method is applicable to the construction of a cast-in-place reinforced concrete structure with great horizontal cross section curve surface dimension and with a vertical shaft inclined for a certain angle in industrial and civil buildings. The advantages that a multilayer plate can be easily processed and spliced, the building of a steel pipe scaffold is convenient, and the like are used; a polyhedron fitting curved surface body is spliced by formworks; by controlling the polyline width of a polyhedron horizontal cross section pattern, the chord height is about 2mm; the goal of smooth facade curve surface is achieved; the bare concrete requirement is met; for the formwork support, an inner rigid frame bent is built by a scaffold; and the formworks are supported and pulled from the inside in a single direction, so that the support problem of the tube bodyinclination is solved.

Owner:CHINA MCC17 GRP

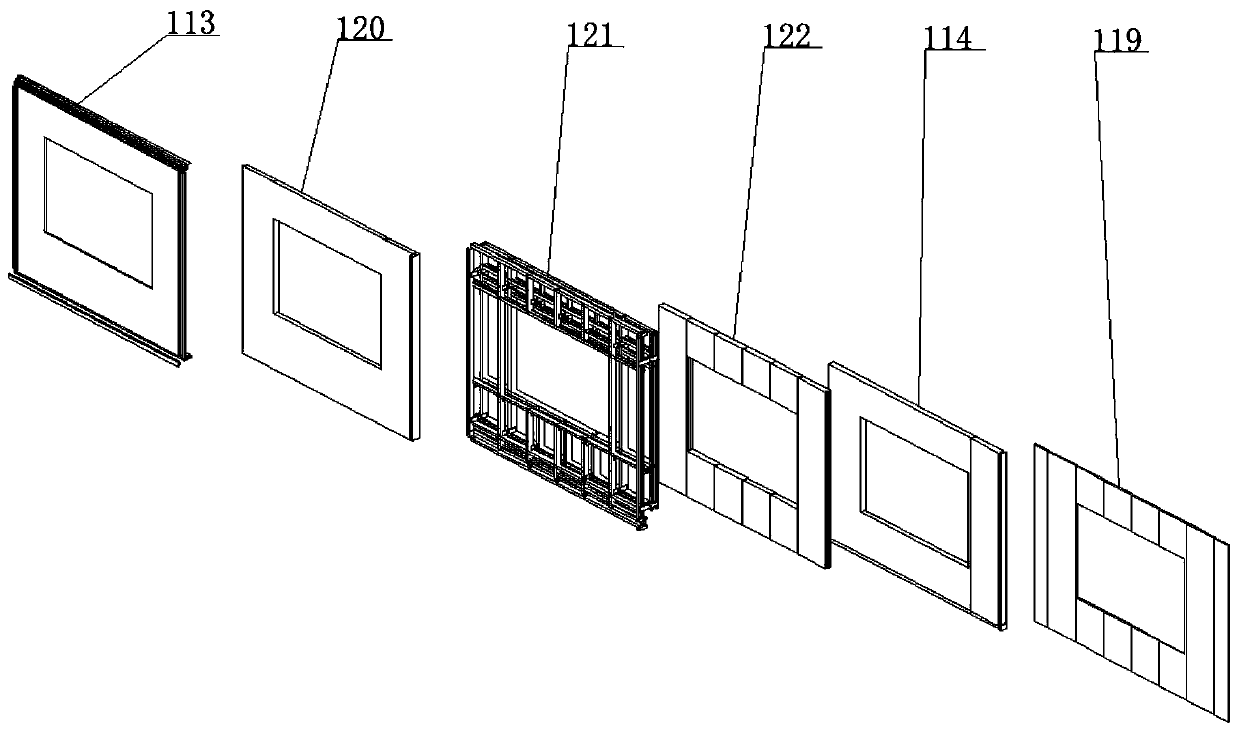

External enclosure system of fabricated steel structure house suitable for severe cold areas

ActiveCN110778016AReduce construction proceduresSimplified operational requirementsWallsInsulation layerTube (structure)

The invention belongs to the technical field of buildings, and particularly relates to an external enclosure system of a fabricated steel structure house suitable for severe cold areas. The system comprises a standard unit wallboard, a convex column unit wall plate and accessories, wherein the standard unit wallboard is composed of a truss type wall frame structure, an ALC strip plate core wall, an inner side filling wall body, a heat insulation layer and an outer wall decorative plate, and the convex column unit wall plate is composed of a cold-formed square tube framework, a heat insulationboard and an outer decoration panel. According to the system, the standardized wallboard and the convex column unit wall plate are adopted, so that standardized product design and industrial continuous production can be realized, technical requirements of site construction are reduced, production efficiency and assembly efficiency are greatly improved, assembly operation and construction difficulty are greatly simplified, the common problem that an existing external enclosure system of the fabricated steel structure building restricts the development of fabricated buildings is solved, a help force is provided for popularization and development of the fabricated buildings, and site construction become fabricated construction worthy of the name.

Owner:曲圣玉

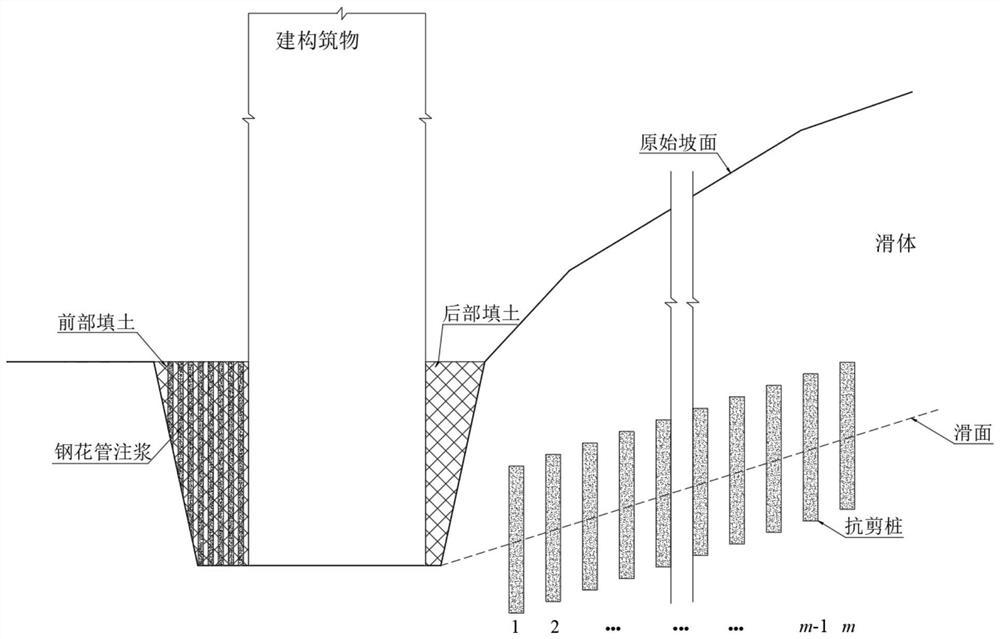

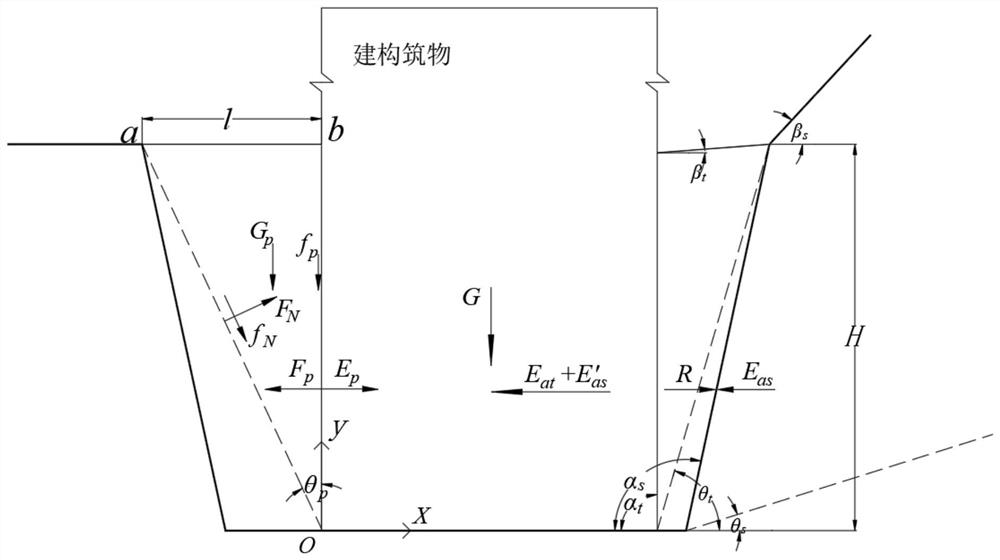

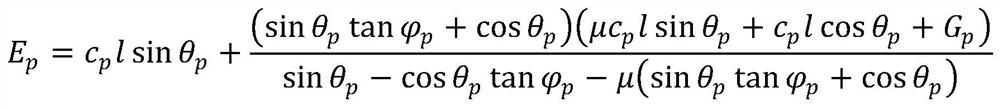

Overall reinforcement design method considering stability of building at bottom of landslide

PendingCN113204828AImprove physical and mechanical indicatorsReduce the possibilityGeometric CADDesign optimisation/simulationBasementTube (structure)

The invention discloses an overall reinforcement design method considering stability of a building at bottom of landslide. The method comprises the following implementation processes: determining that a building is located in a dangerous landslide front edge influence range, backfilling the front part and the rear part of the building with filling soil, and selecting a unit width landslide and the building as research objects; adopting a steel floral tube grouting reinforcement measure for a front fat groove of the basement of the building ti improve the physical and mechanical indexes of the composite soil body of the part, thus improving the passive soil pressure of the part on the building; adopting a deeply-buried shear-resistant pile supporting structure for the landslide on the rear portion of a building so as to resist sliding force generated by a sliding body; and finally, performing overall anti-sliding stability checking calculation on the building, so that the feasibility of the overall reinforcement design checking calculation method is verified.

Owner:ZHENGYE ENG & INVESTMENT INC

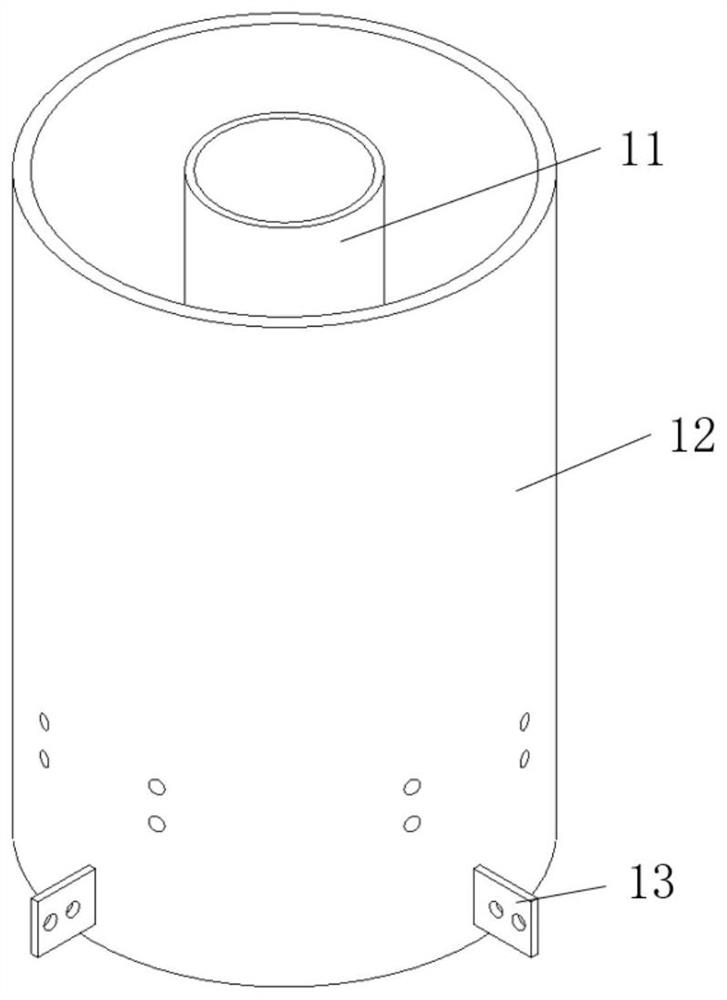

Novel composite floor system for super high-rise building

InactiveCN103321294ALarge spanReduce lossLoad-supporting elementsTube (structure)Architectural engineering

The invention provides a novel composite floor system for a super high-rise building and aims to overcome the defects that an existing high-rise building is small in span, large in self-weight, large in occupied space and the like. The novel composite floor system is characterized in that an interlayer composite floor system assembly is arranged on the top of each layer of the ground portion of the super high-rise building; each interlayer composite floor system assembly is composed of a core tube wall cap and a beam, wherein the core tube wall cap is a closed annular frame body; each beam is composed of a beam body and a wide and flat beam skeleton assembly. The novel composite floor system for the super high-rise building has the technological effects that the height of the beams in the novel composite floor system is only 8% to 15% of that of beams in a traditional technological structure, and therefore building space losses are saved; the usage amount of reinforcing bars and concrete in the beams is reduced due to the fact that hollow steel tubes are arranged internally, the self-weight of the structure is reduced, and structural stiffness is enhanced; in addition, due to the fact that the core tube wall caps and the beams are integrated, namely, the span of the beams is increased, therefore, labor and materials are saved, usable areas are increased, and firmness and durability of the building are improved.

Owner:CHINA CONSTR 4TH ENG BUREAU 6TH

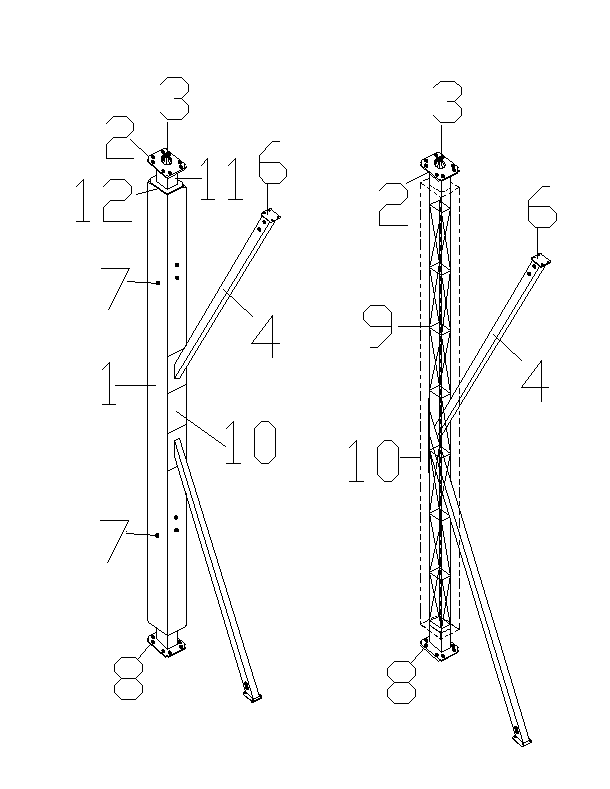

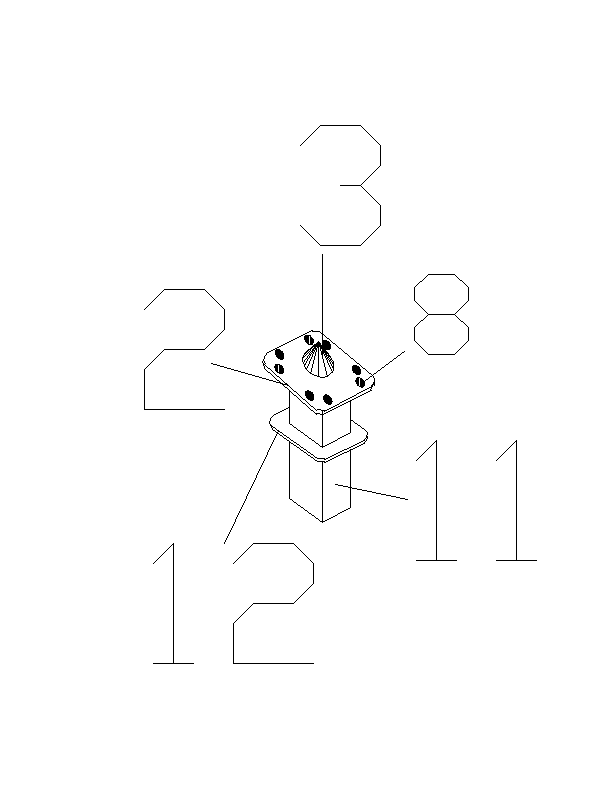

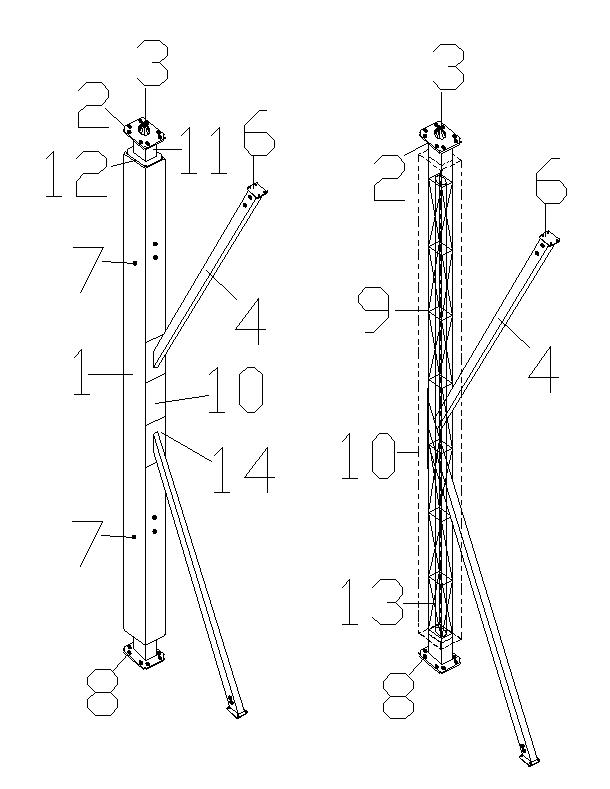

Unit combination with open structure

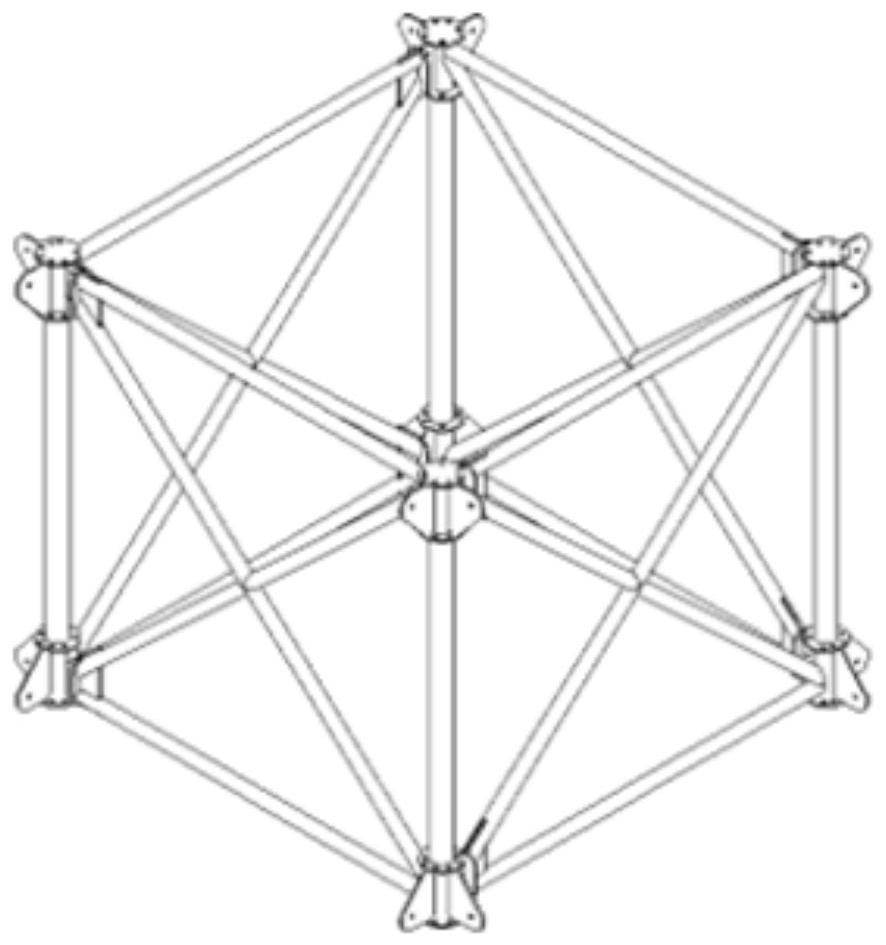

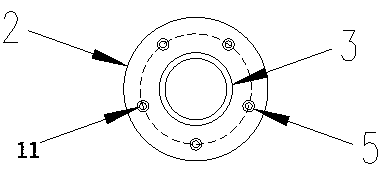

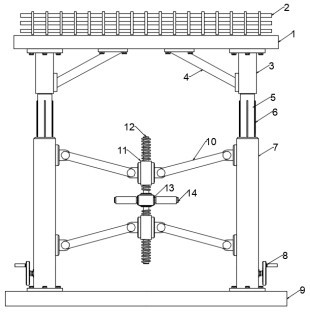

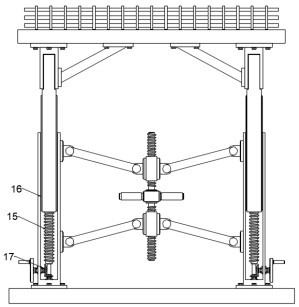

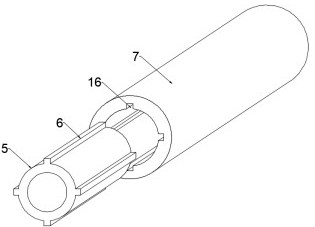

The invention discloses a unit combination with an open structure. The unit combination with the open structure is also called a unit combination with a K structure and mainly comprises unit column head connecting plates 2, unit strut head connecting plates 6, positioning bodies 3, strut members 4, column holes 7, mounting holes 8 for the column head connecting plates, assembly steel structural member or / and reinforcing bars 9 of a unit column 1, toughened concrete or reinforced concrete 10, column heads 11, column head barriers 12, a core tube 13, strut head barriers 14 and the like. The unit combination with the K structure is characterized in that the unit column head connecting plates 2 are connected to two ends of the unit column 1, the mounting holes 8 for the column head connecting plates are formed in the unit column head connecting plates 2, the strut members 4 are arranged to the middle of the unit column 1, the unit strut head connecting plates 6 are commonly arranged at the ends of the strut members 4, a K-shaped structural member is prefabricated after the components are combined with one another, and the unit combination with the K structure is formed. The unit combination with the open structure has the advantages that after being industrially manufactured in a modularized manner, the unit combination is applicable to buildings with steel structures in an assorted manner, so that the buildings with the steel structures can be quickly constructed.

Owner:金湖县综合检验检测中心

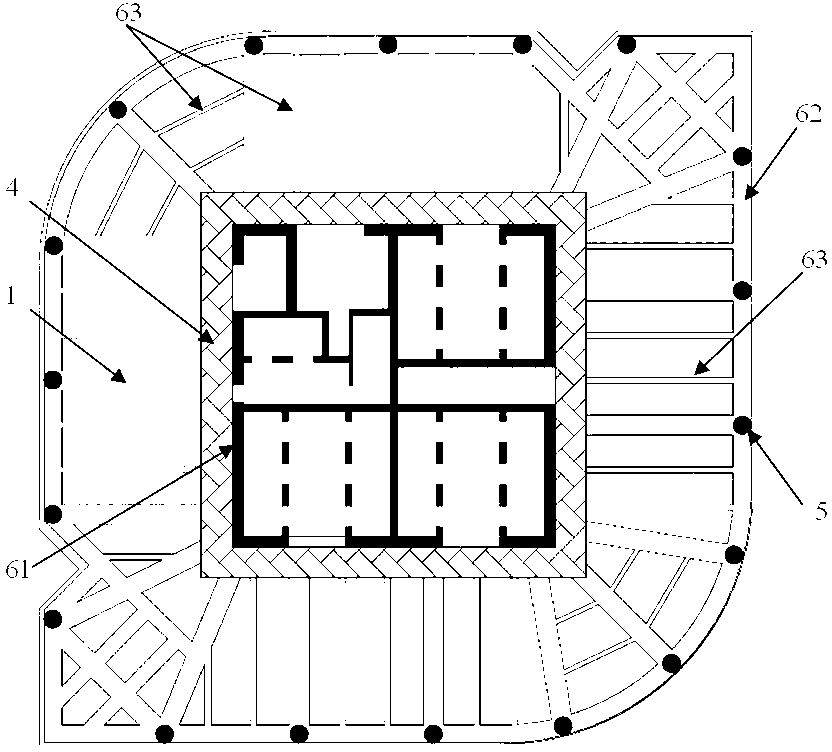

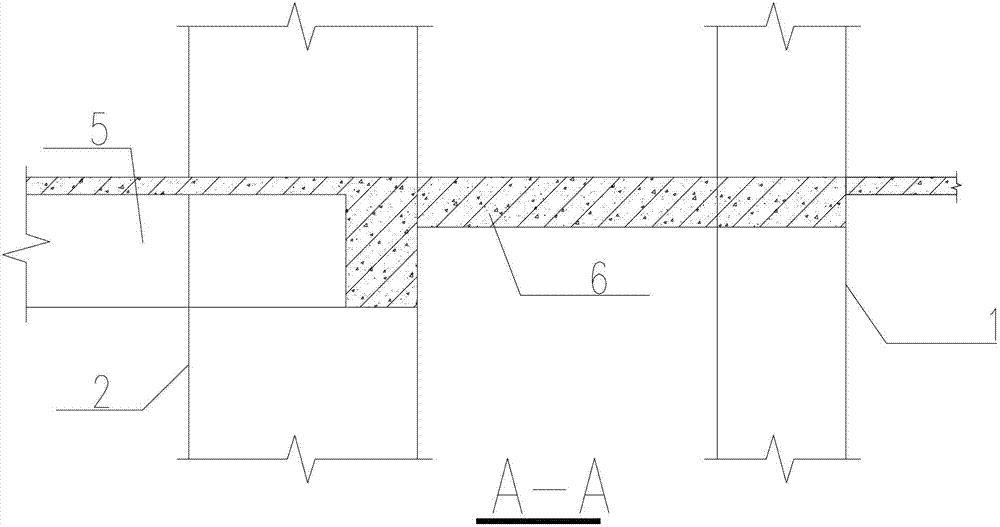

Plane connection construction for weakening influences of vertical deformation difference in high-rise building

InactiveCN103046643AMeet the bearing capacity requirementsReduce the influence of vertical deformation differenceBuilding constructionsThick plateTube (structure)

The invention discloses a plane connection construction for weakening influences of vertical deformation difference in a high-rise building. A vertical structure of the high-rise building comprises outer frame columns, inner frame columns and core-tube walls, and is characterized in that thick slabs serve as plane connection components among the inner frame columns and the core-tube walls and are concrete slabs with the thickness of 250-300mm, and concealed connecting beams are arranged in each thick slab. By the aid of the thick slabs serving as the plane connection components, the influences of the vertical deformation difference of the inner frame columns and the core-tube walls can be reduced effectively, and requirements of the plane connection components for bearing capacity are met after the concealed connecting beams are arranged on the construction.

Owner:TUS DESIGN GRP CO LTD

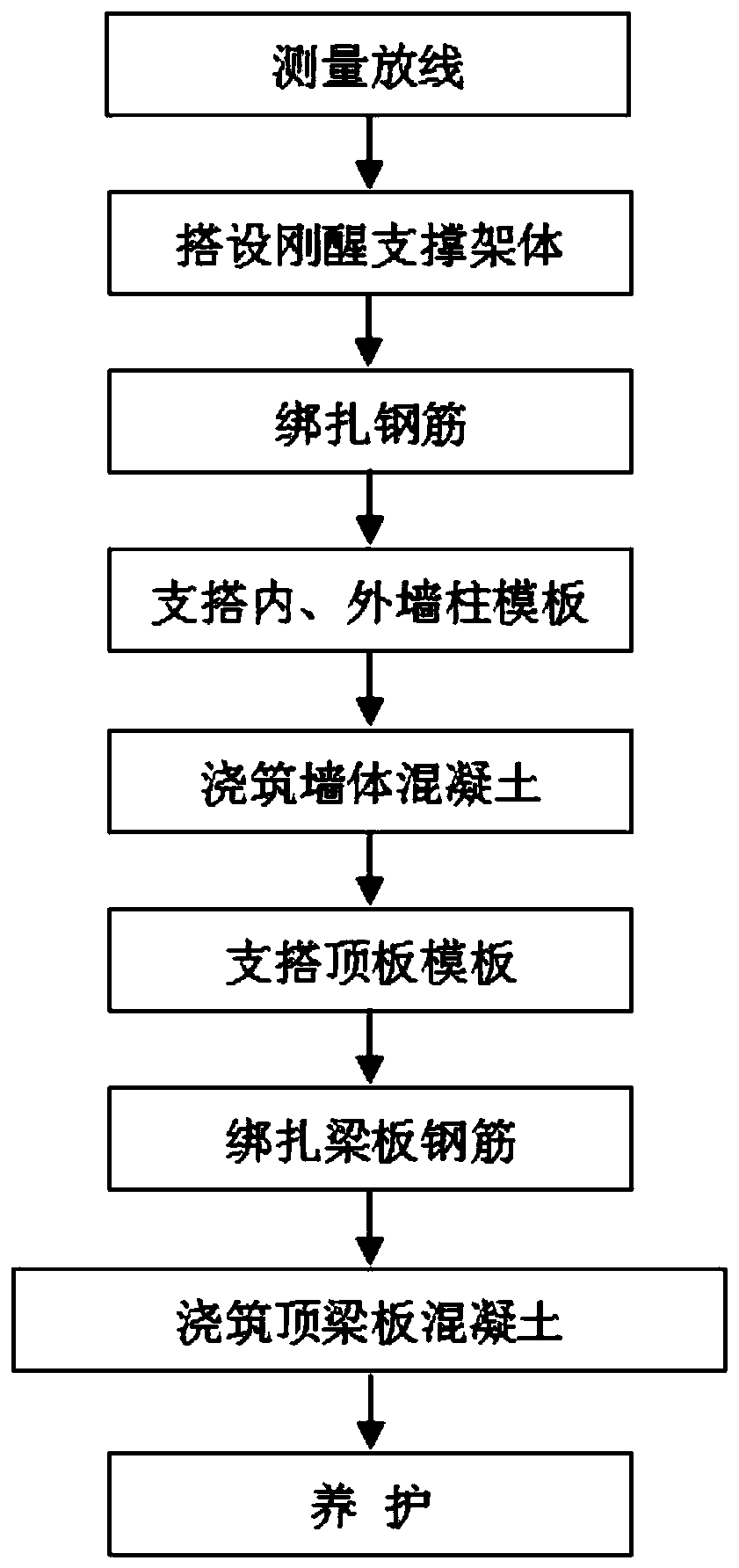

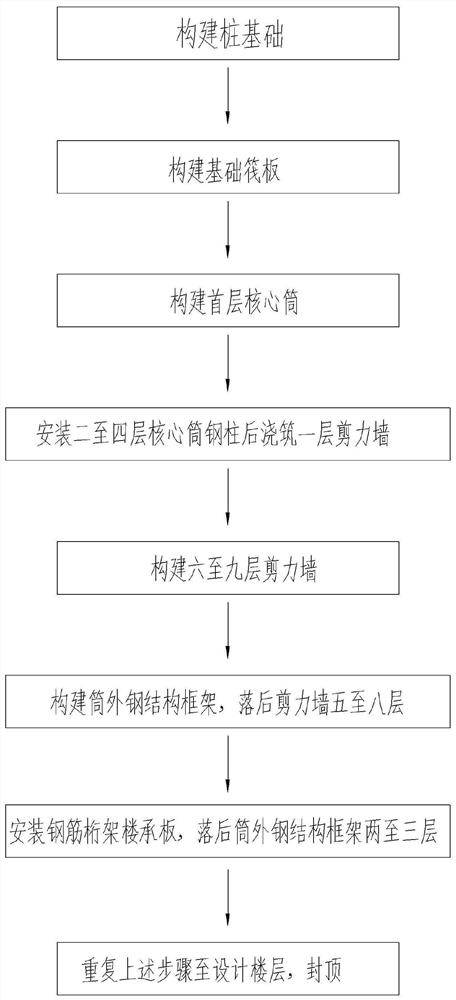

Construction method of super high-rise building main body structure

ActiveCN113374259AImprove convenienceImprove work efficiencyFoundation engineeringExtraordinary structuresTube (structure)Steel columns

The invention provides a construction method of a super high-rise building main body structure. The construction method comprises the following steps: constructing a main structure above a first floor according to a structure that a core tube steel column is earlier than a core tube shear wall by one to three floors, the core tube shear wall is earlier than a steel structure frame outside a tube by five to eight floors, and the steel structure frame outside the tube is earlier than a steel bar truss floor support plate by two to three floors. Therefore, deformation of different sections can be dynamically monitored in the construction process, deformation is corrected and supplemented when a next joint is constructed, the stability and safety of the whole structure are guaranteed, and the construction period of a whole building is shortened through segmented and partitioned construction. Meanwhile, all the parts of a waist truss are pre-assembled in an inserted connection mode and then fixedly connected, on one hand, the assembling convenience can be improved, the working efficiency can be improved, on the other hand, subsequent further fixed connection is facilitated, and the final connecting effect and strength are guaranteed.

Owner:CHINA RAILWAY CONSTR ENG GROUP +1

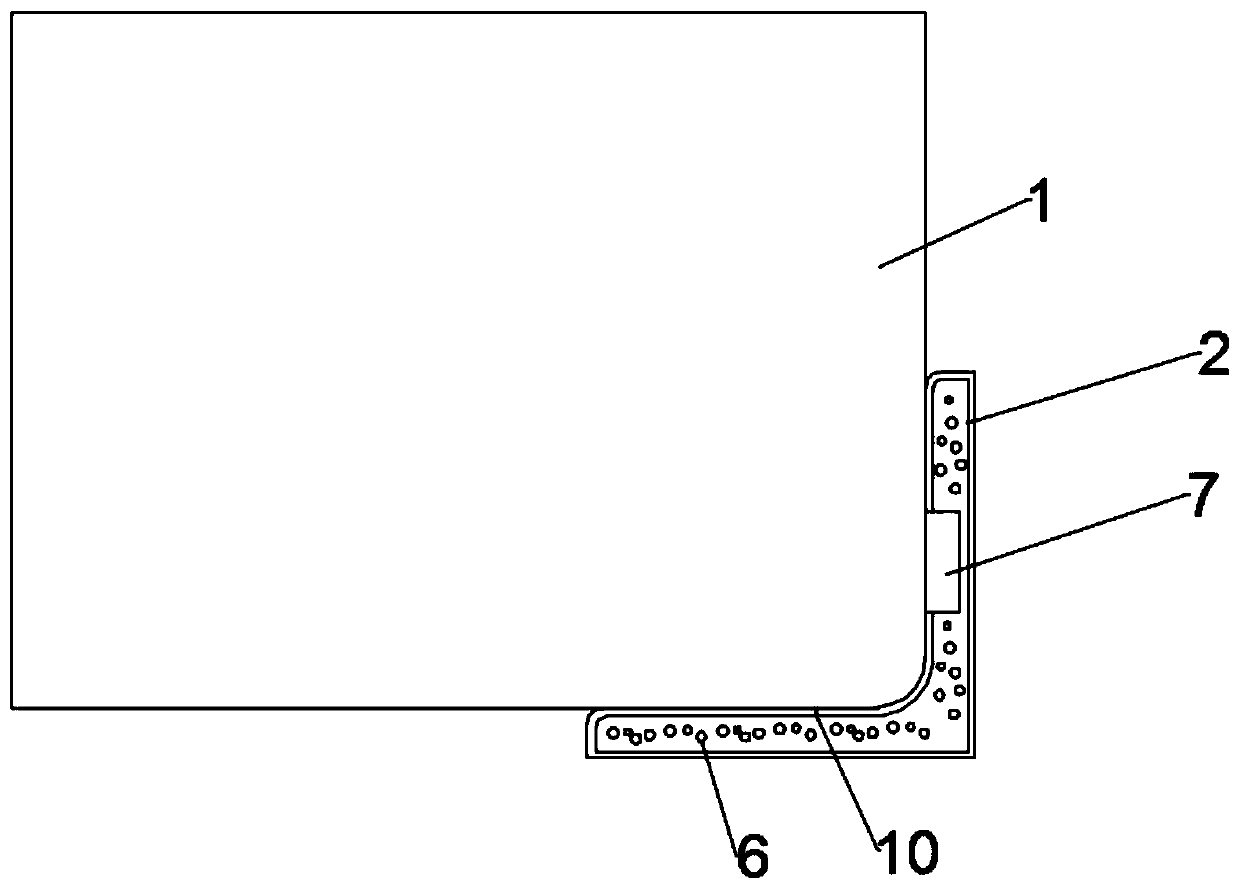

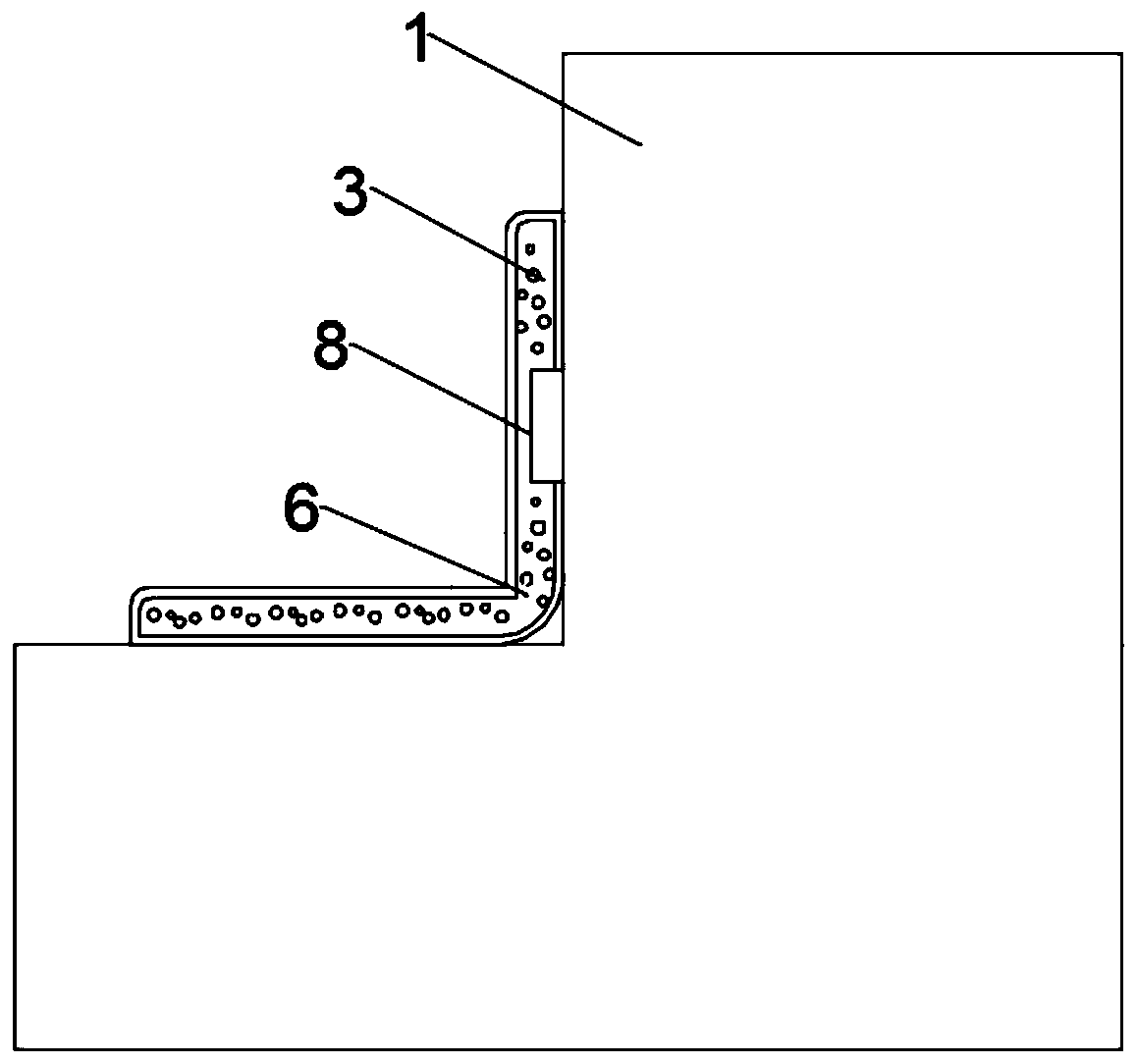

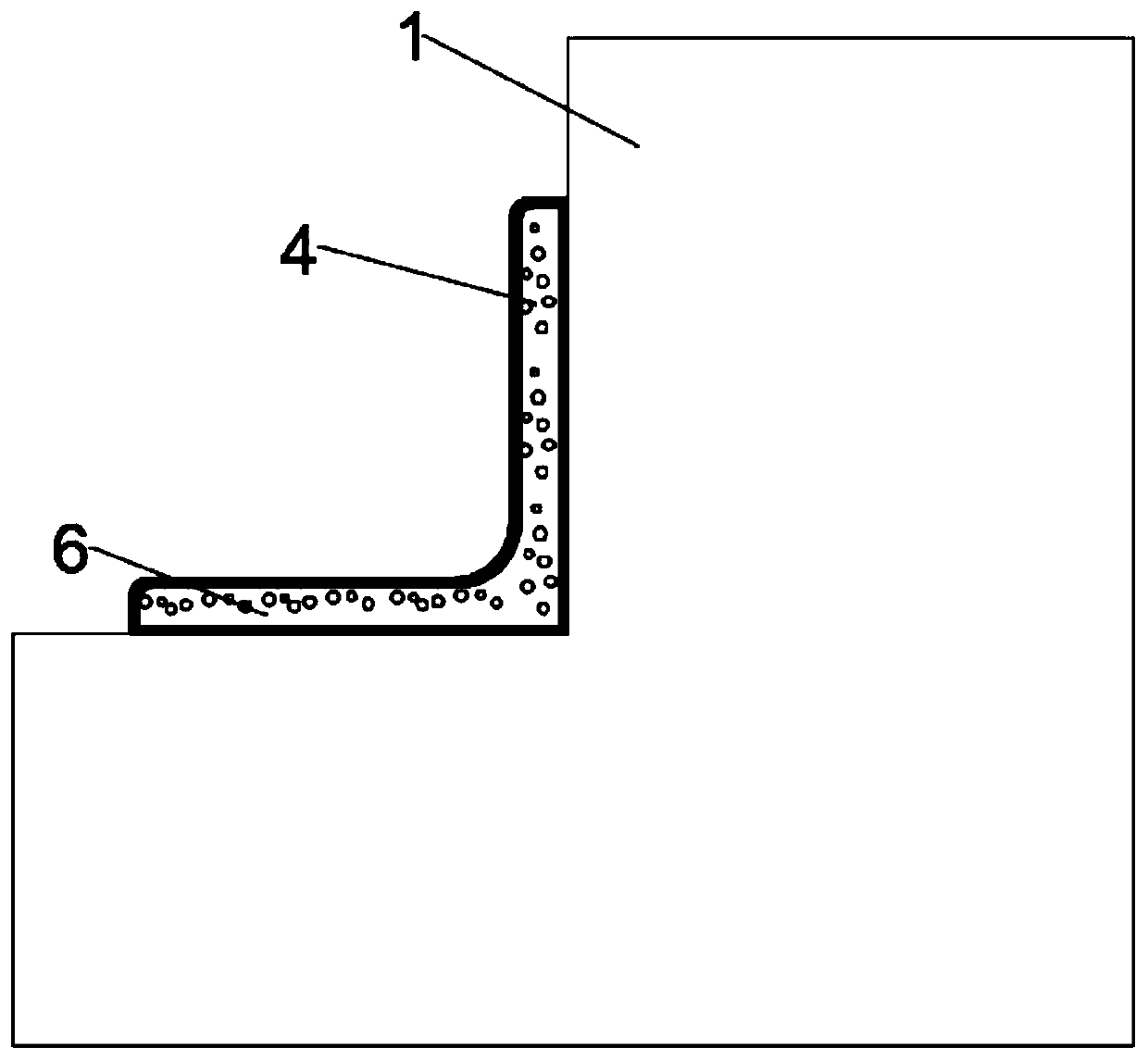

Light concrete internal and external corner structure in prefabricated building and installation method

InactiveCN111485700AAvoid shortened service lifeSolve maintenance difficultiesCovering/liningsFlooringTube (structure)Architectural engineering

The invention discloses a light concrete internal and external corner structure in a prefabricated building, and belongs to the technical field of prefabricated buildings. The problem that household wires cannot be preset inside concrete internal and external corners during installation and construction of the prefabricated building is solved. The light concrete internal and external corner structure in the prefabricated building is technically characterized by comprising a wall body, an inner wall external corner, an inner wall internal corner, an outer wall external corner and an outer wallinternal corner, wherein the inner wall external corner and the inner wall internal corner are installed on the inner wall of the wall body, and the outer wall external corner and the outer wall internal corner are installed on the outer wall of the wall body; and the inner wall external corner, the inner wall internal corner, the outer wall external corner and the outer wall internal corner are all installed on fixed clamps, and the fixed clamps are fixed on the wall body with expansion pipes in advance. The light concrete internal and external corner structure in the prefabricated building has the advantages of energy saving, environmental protection, non-toxicity and harmlessness, and can protect indoor wires, avoid difficult overhauling of pre-embedded wires in concealed tubes and avoid shortening of the service life of exposed wires due to exposure to the outside, and is simple in installation method operation and conducive to popularization and use in the prefabricated building.

Owner:河南天久装配式建筑有限公司

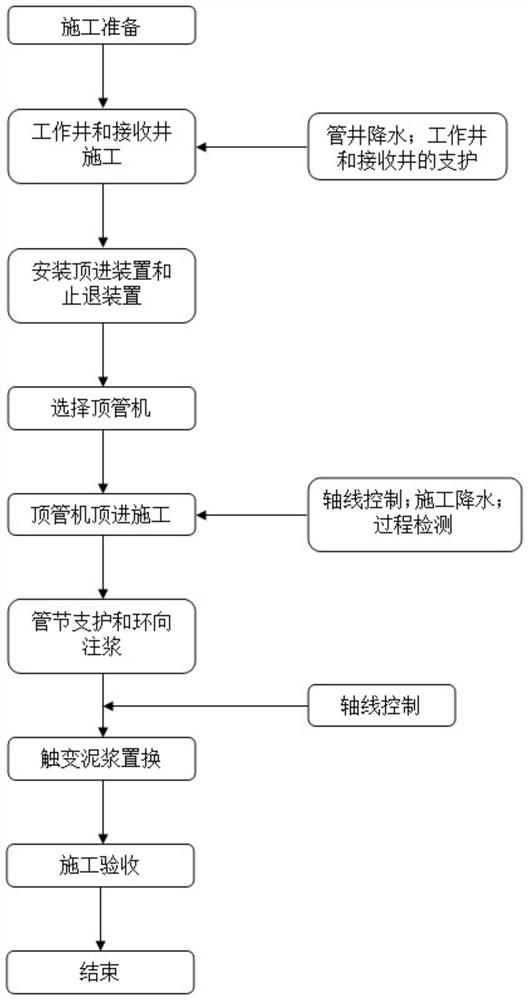

Earth pressure balance jacking construction method for water-rich shallow-buried large-section rectangular jacking tube

PendingCN113513322AEnsure safetyLow costUnderground chambersTunnel liningTube (structure)Architectural engineering

The invention relates to an earth pressure balance jacking construction method for a water-rich shallow-buried large-section rectangular jacking tube, and belongs to the technical field of underground passage construction. The earth pressure balance jacking construction method comprises the following steps of construction preparation; construction of a working well and a receiving well; installation of a jacking device and a retaining device; selection of a tube push bench; jacking construction through the tube push bench; tube joint supporting and circumferential grouting; and thixotropic slurry replacement. According to the earth pressure balance jacking construction method, by means of measures such as construction precipitation and manual sealing, water seepage in a construction space can be avoided, water gushing of a working face can be avoided, and the construction safety is greatly guaranteed; through a mechanical excavation method of the tube push bench and a tube joint prefabricating and supporting method, the construction excavation efficiency is improved, the construction period is greatly shortened, and meanwhile, the personnel cost is reduced; and through tube joint circumferential grouting, construction process settlement control and ground surface settlement monitoring, the ground surface settlement value can be effectively reduced, and normal operation of ground traffic and safety of ground surface buildings (structures) can be guaranteed. The earth pressure balance jacking construction method is suitable for complex geological conditions and environmental conditions.

Owner:THE SECOND ENG CO LTD OF CHINA RAILWAY 14TH CONSTR BUREAU CO LTD

A prefabricated underground pipe gallery structure and construction method thereof

ActiveCN113622463BEasy to layImprove stabilityArtificial islandsUnderwater structuresTube (structure)Architectural engineering

The present application relates to the field of building construction, in particular to an assembled underground pipe gallery structure, comprising a pipe gallery prefabricated body plugged into a placement slot provided on the ground, the upper surface of the pipe gallery prefabricated body is fixedly connected with At least four fixing rods, the fixing rods are all provided with hanging holes, the upper surface of the pipe gallery prefabricated body is lapped with a cover plate, and the upper surface of the cover plate is provided with a plurality of reserved holes for the fixing rods to be inserted into . The application also discloses a construction method for an assembled underground pipe gallery. The application has the effect that the process of laying the underground pipe gallery is relatively convenient.

Owner:中铁建设集团华北工程有限公司

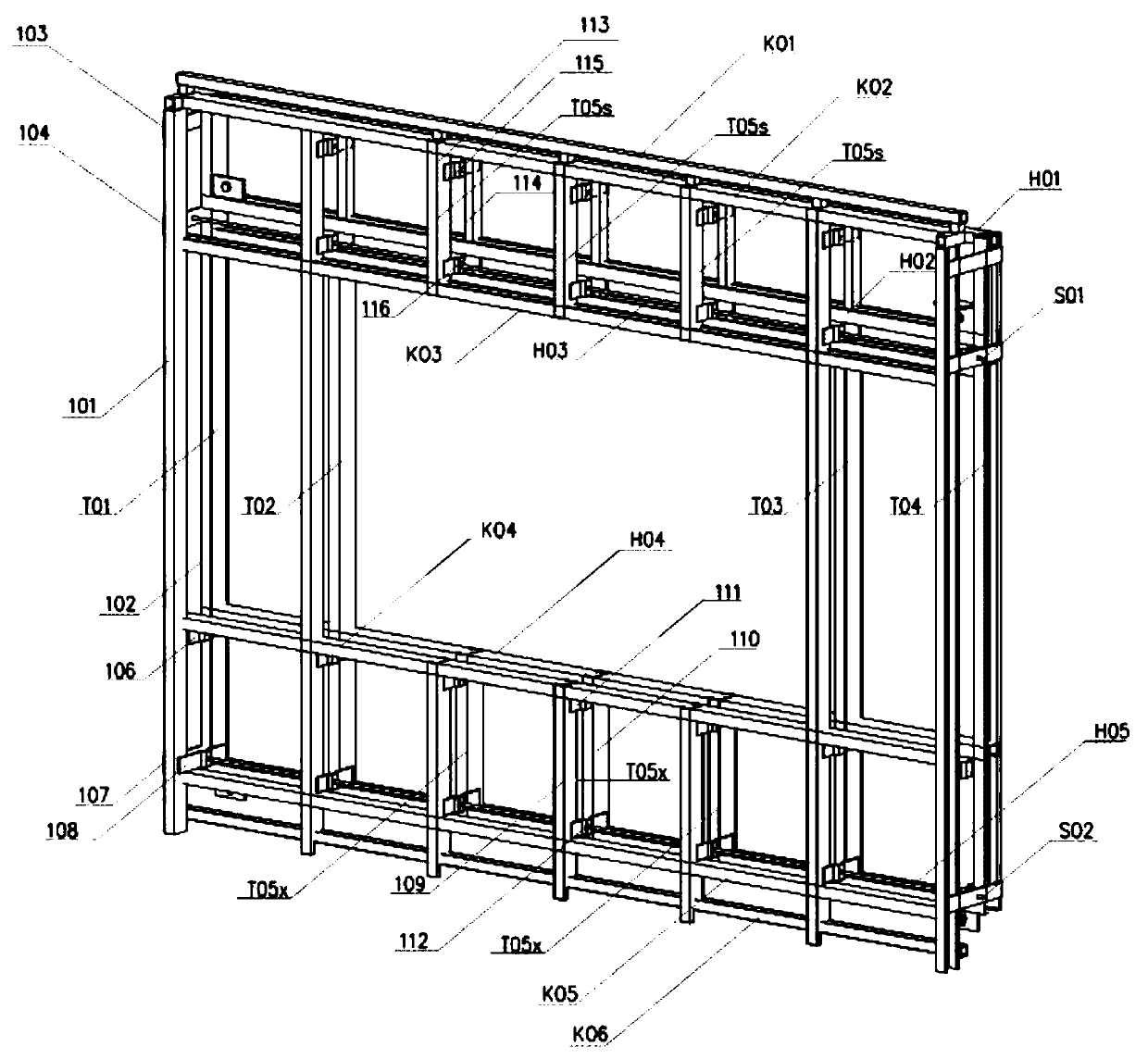

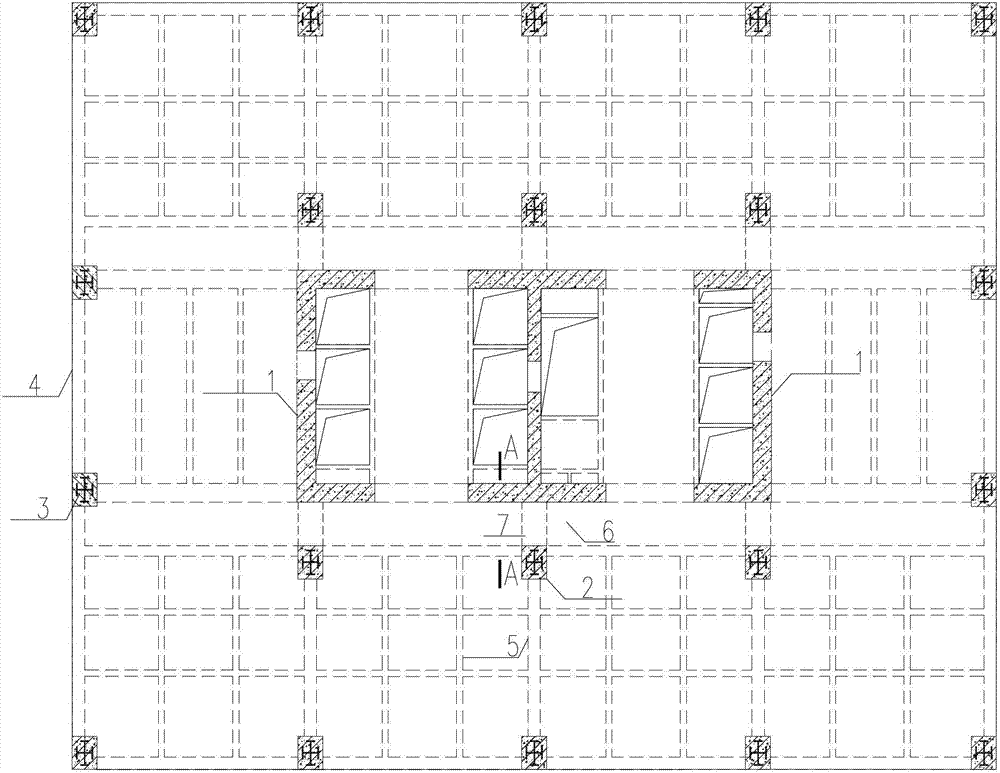

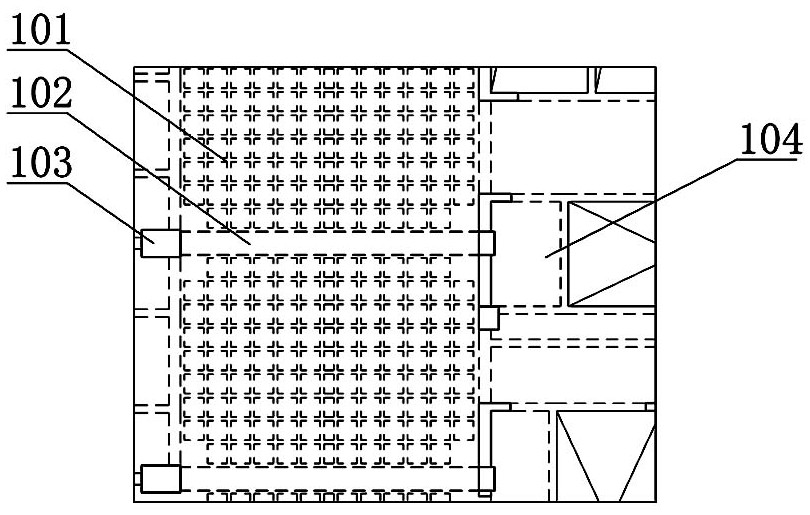

Application of ribbed floors and wide flat beams in frame-core tube structure system

InactiveCN113107094AAchieve connectionIncrease net heightFloorsExtraordinary structuresFloor slabTube (structure)

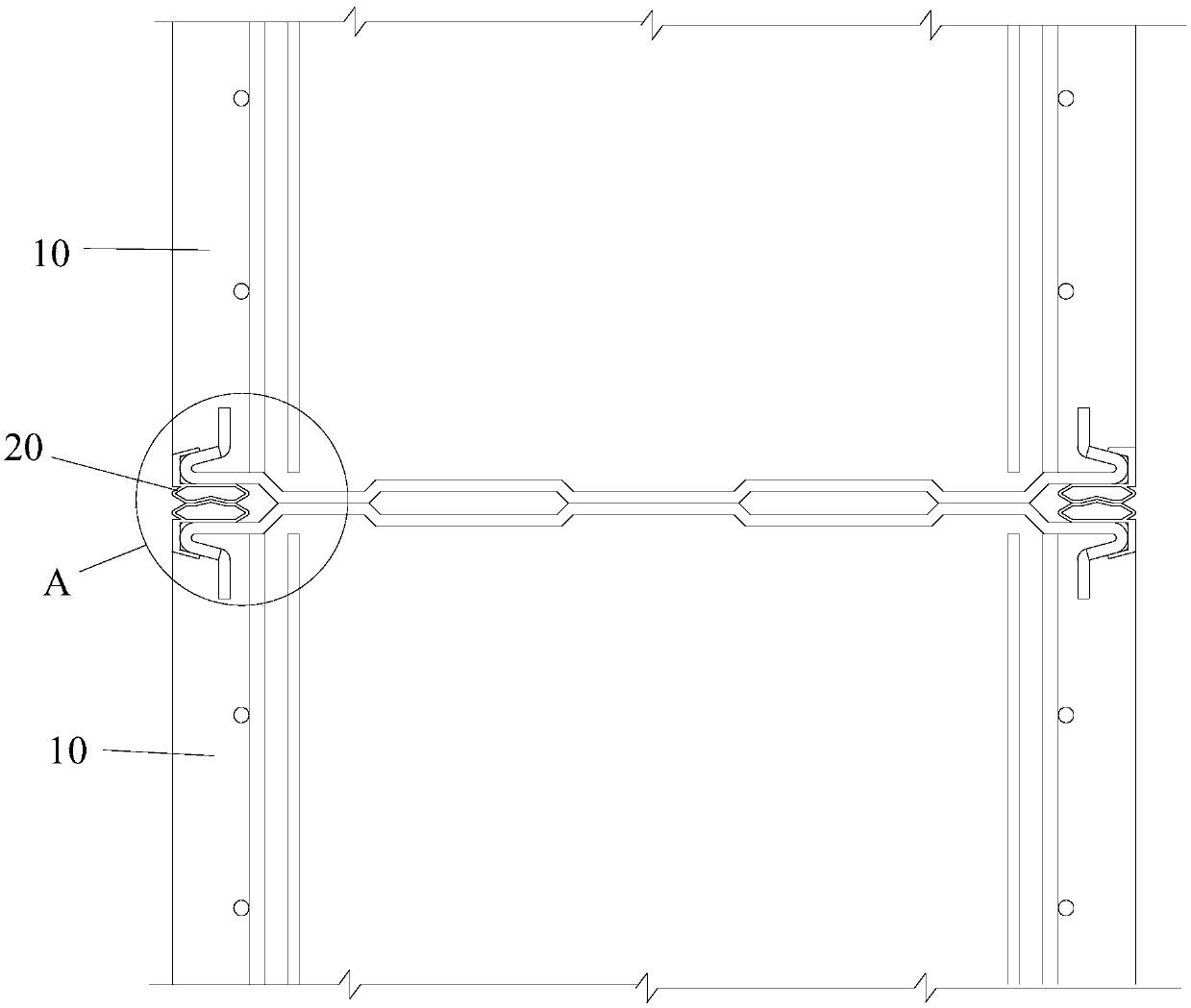

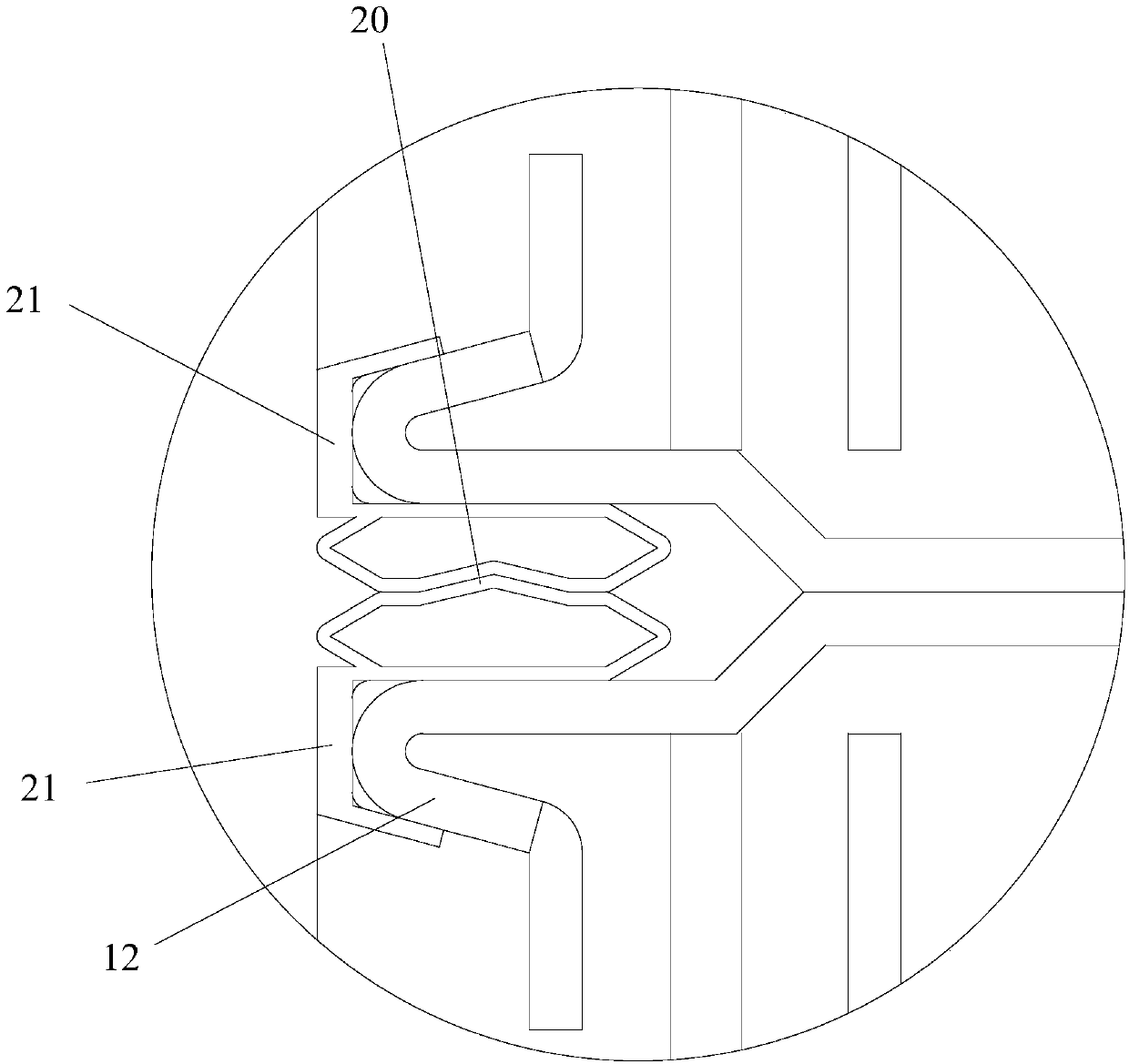

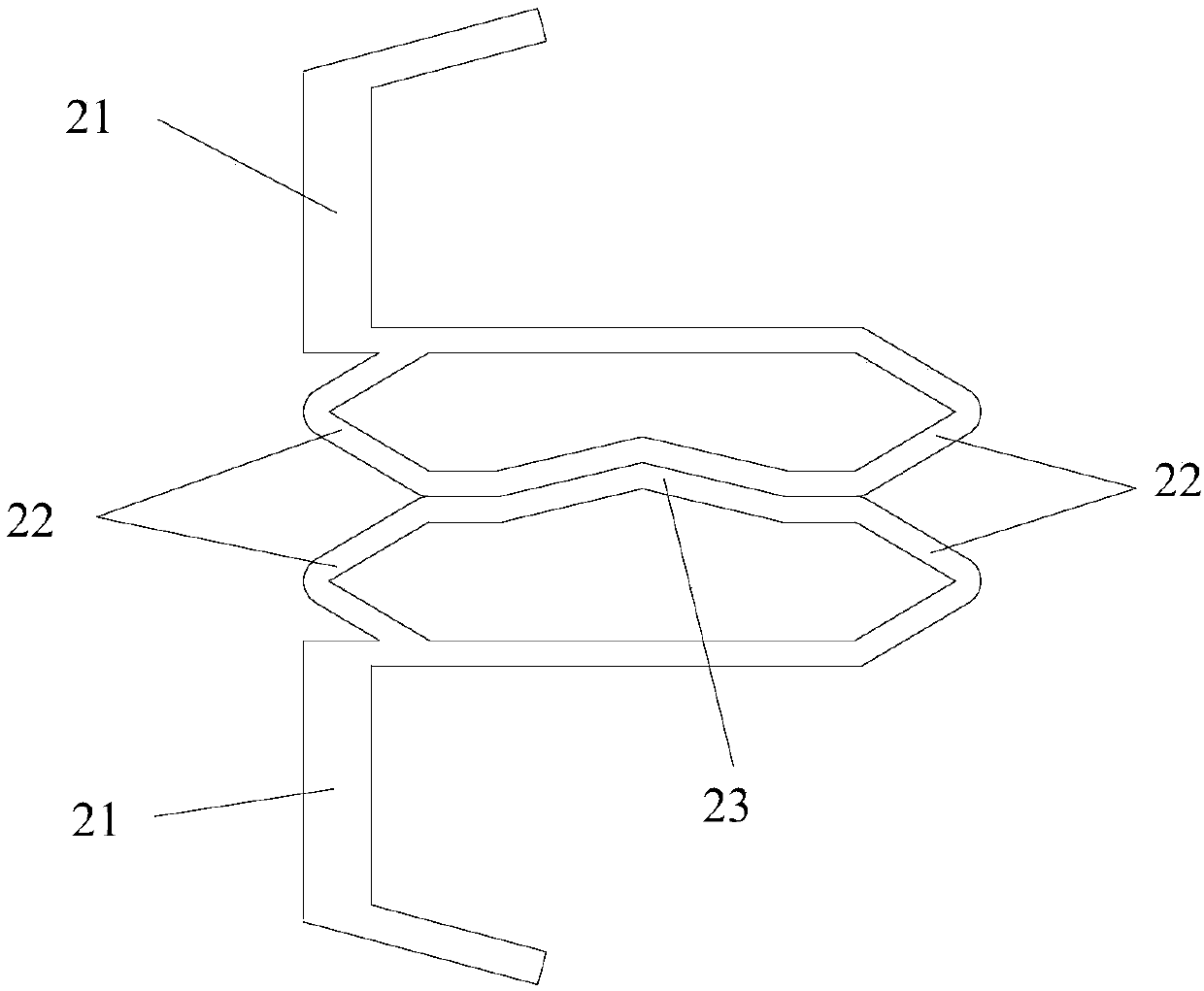

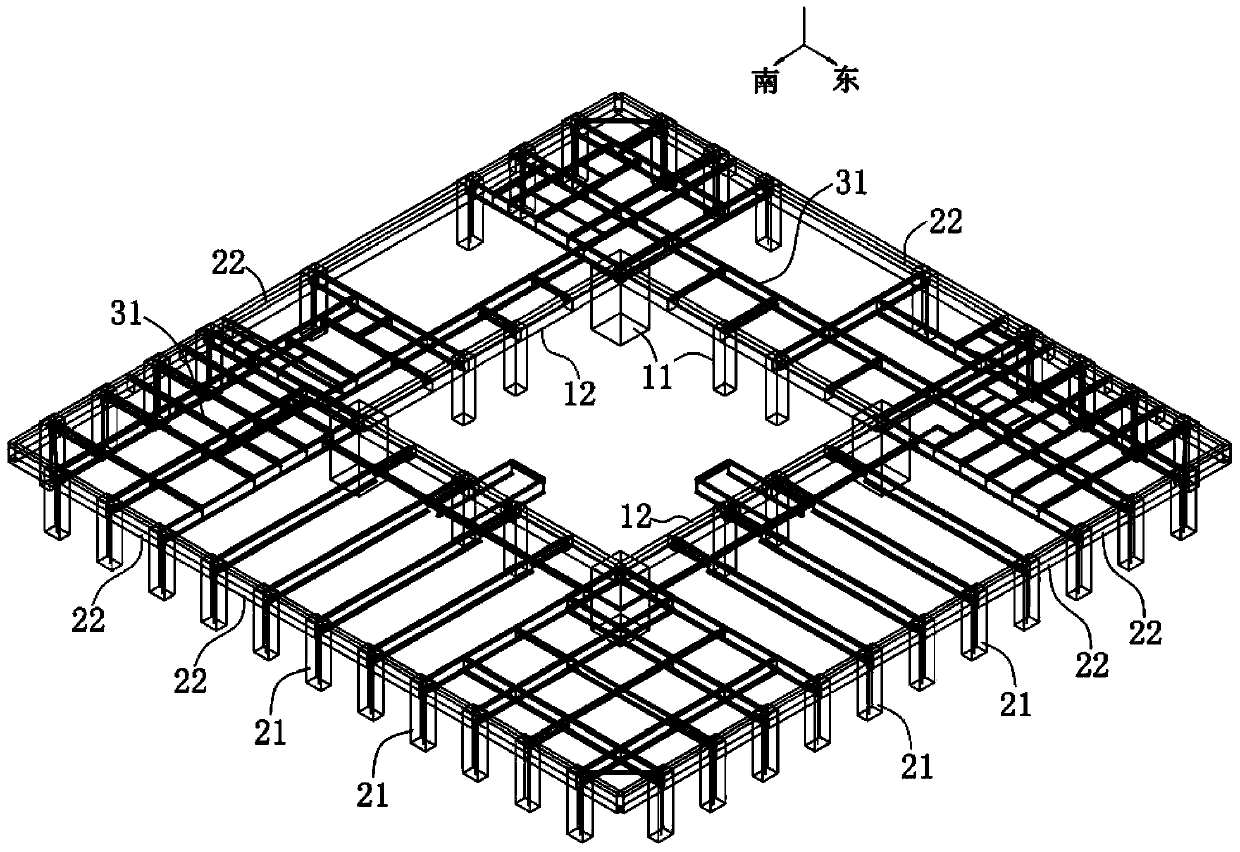

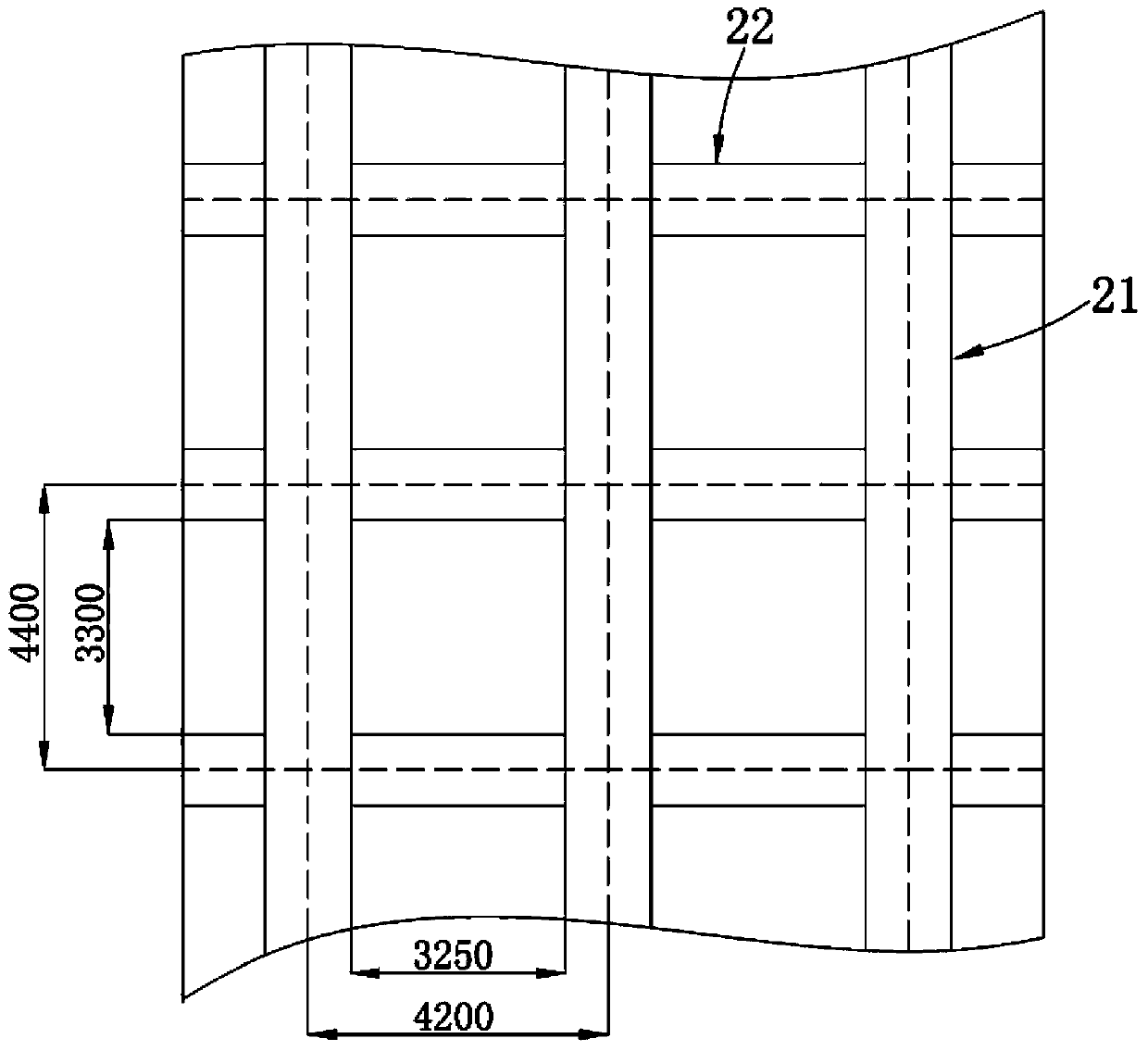

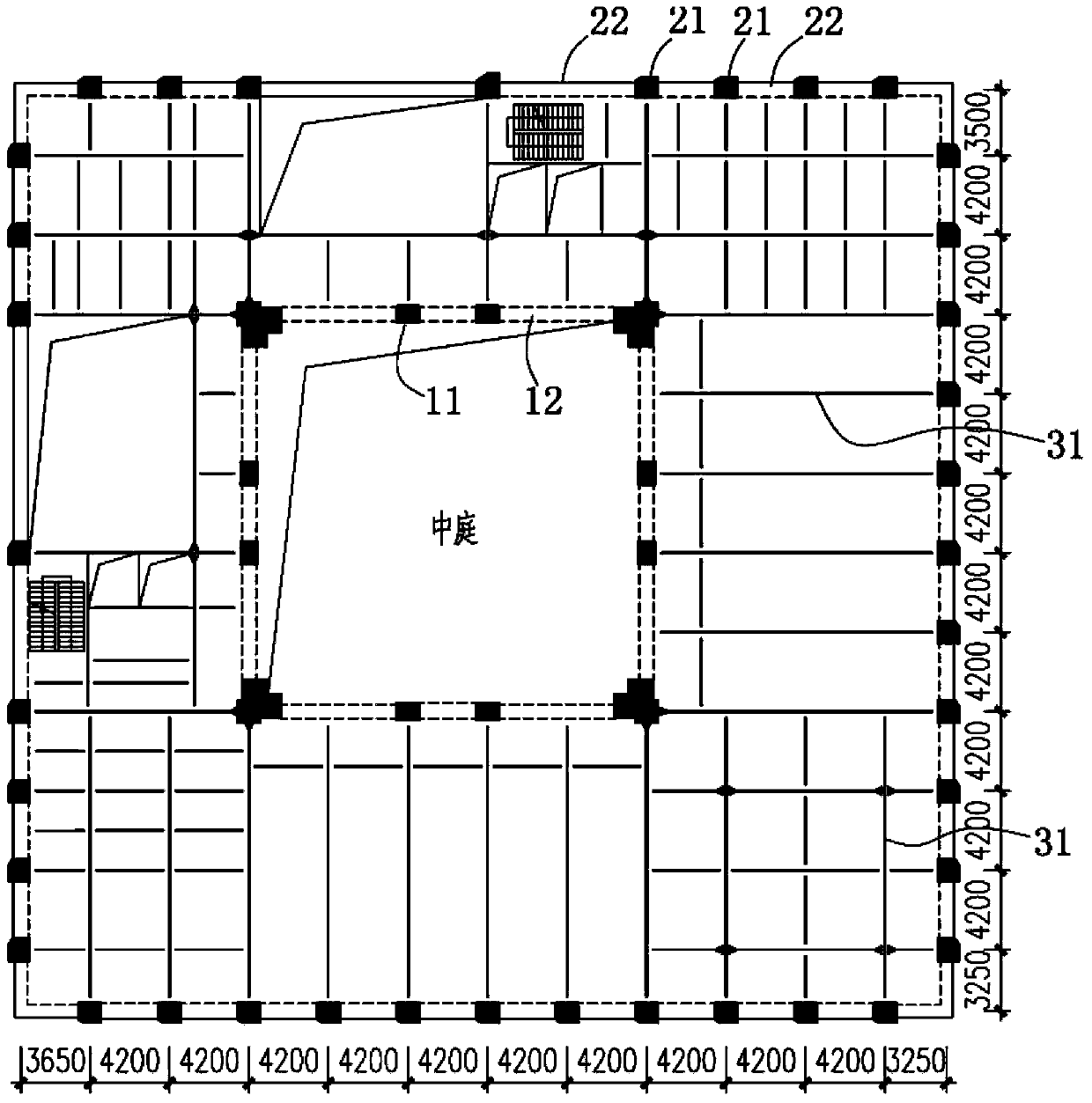

The invention discloses application of ribbed floors and wide flat beams in a frame-core tube structure system. According to the application of the ribbed floors and the wide flat beams in the frame-core tube structure system, the wide flat beams with the small section height are used for replacing traditional frame beams with the large section height, the floors outside a core tube are all the ribbed floors, connection of peripheral frame columns and the core tube is achieved, the clear height of a corridor is increased, the clear height of the corridor can be increased by at least 300 mm, and comfort is improved; meanwhile, the ribbed floors are used for replacing the traditional floors, formwork erecting can be reduced in the construction process, the construction difficulty is lowered, the construction efficiency is improved, and the construction period can be effectively shortened; and meanwhile, the ribbed floors are adopted to replace the traditional floors, the wide flat beams are adopted to replace the traditional frame beams, the frame-core tube is improved, the main body structures of frame columns and the core tube are not changed, and the shock strength of a building can be effectively improved.

Owner:SIPPR ENG GROUP

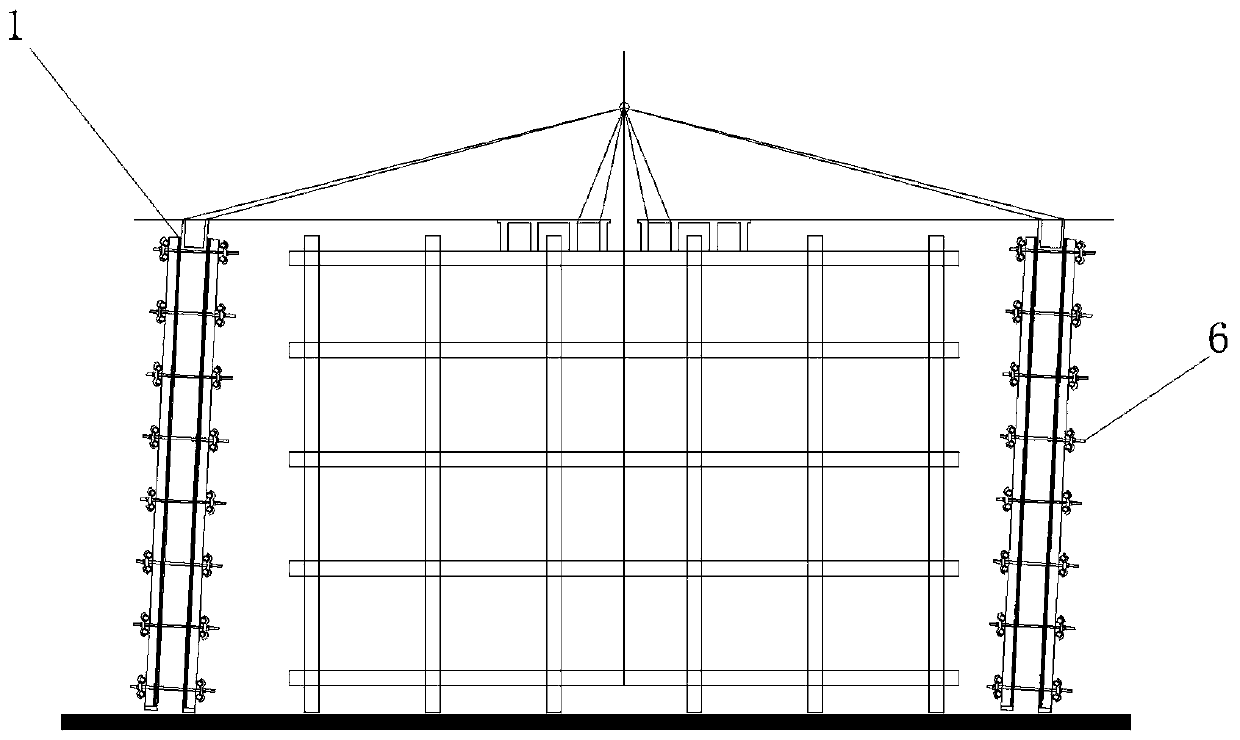

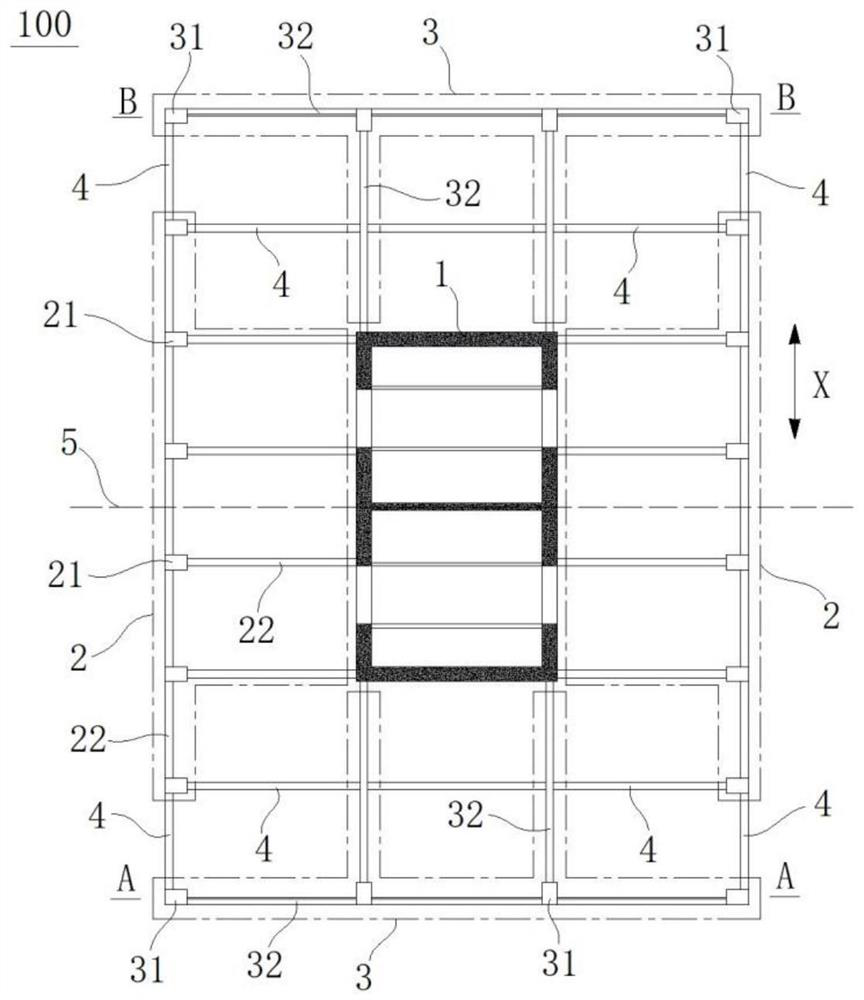

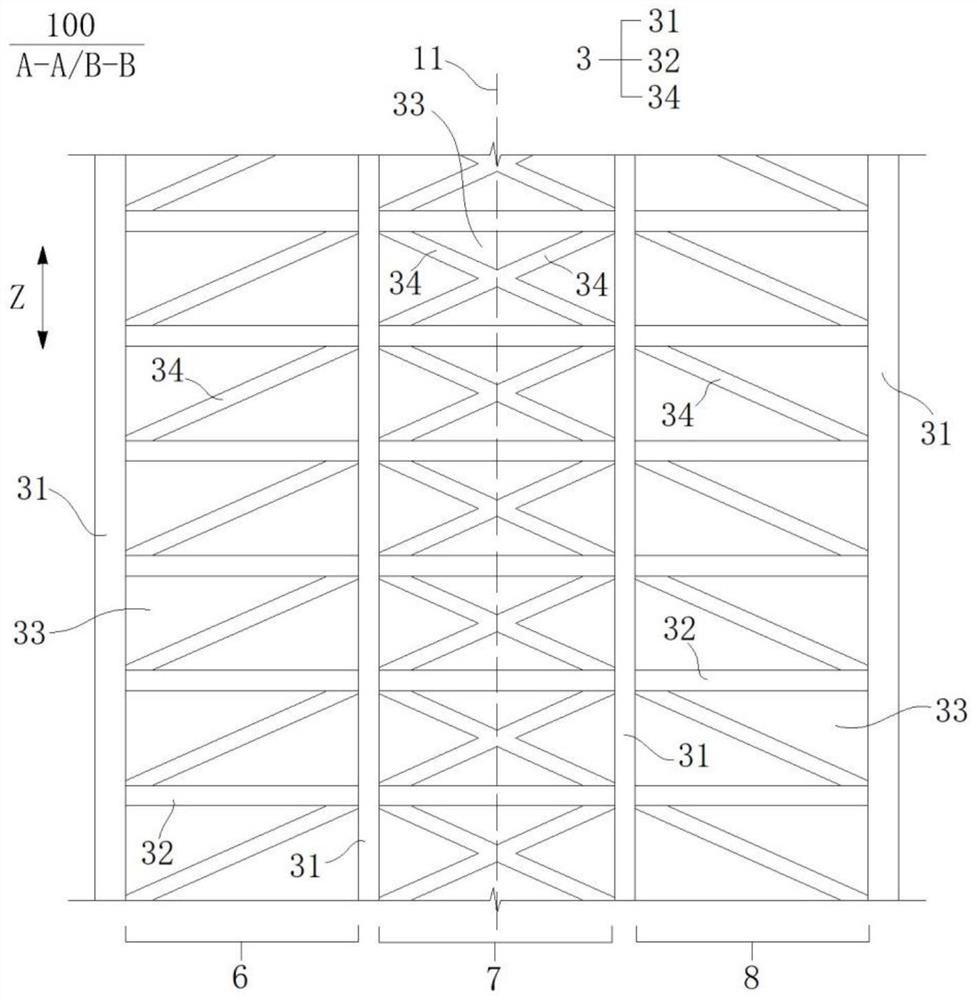

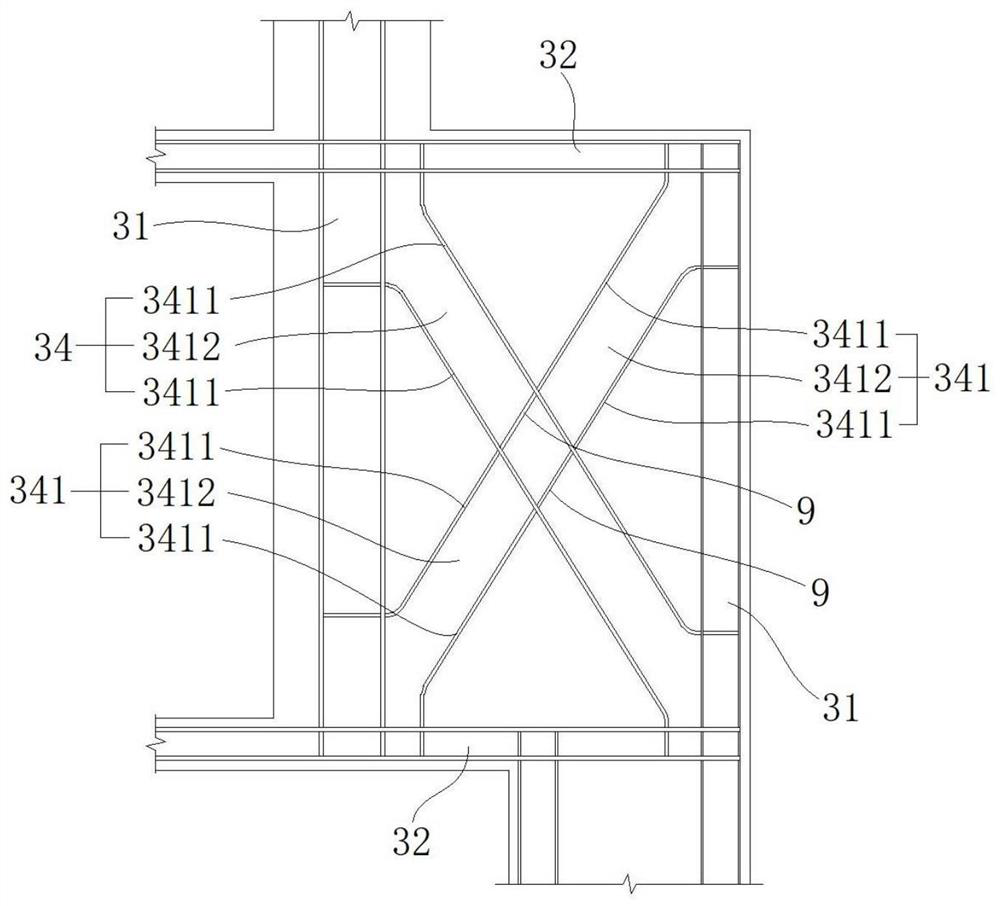

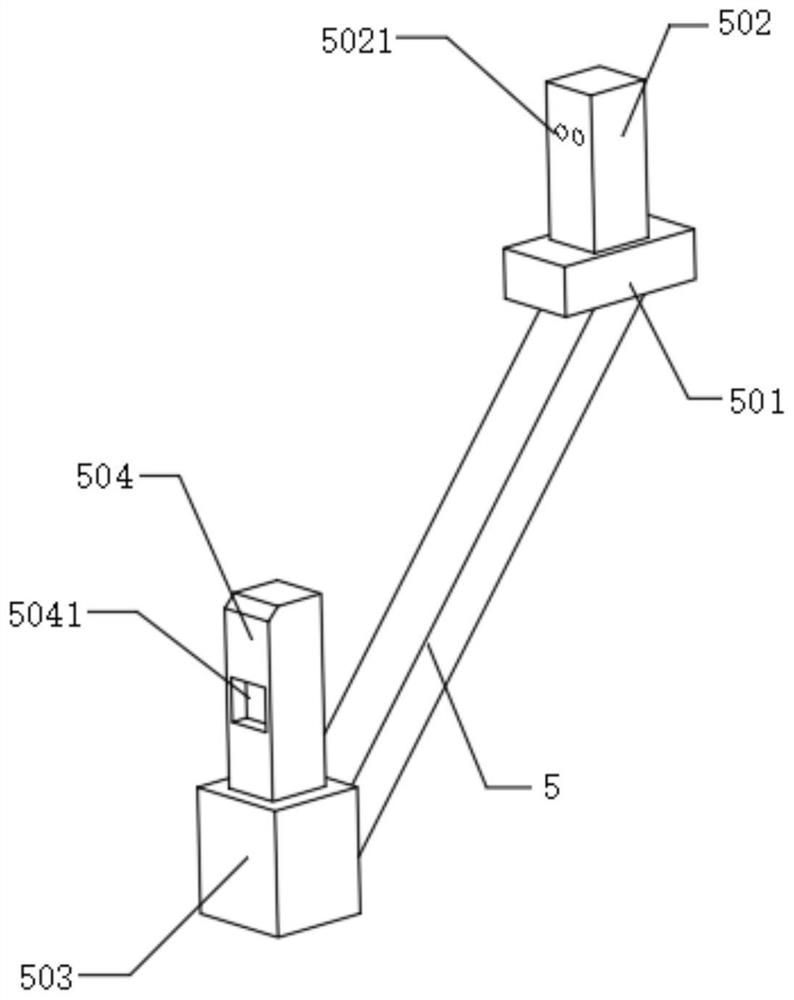

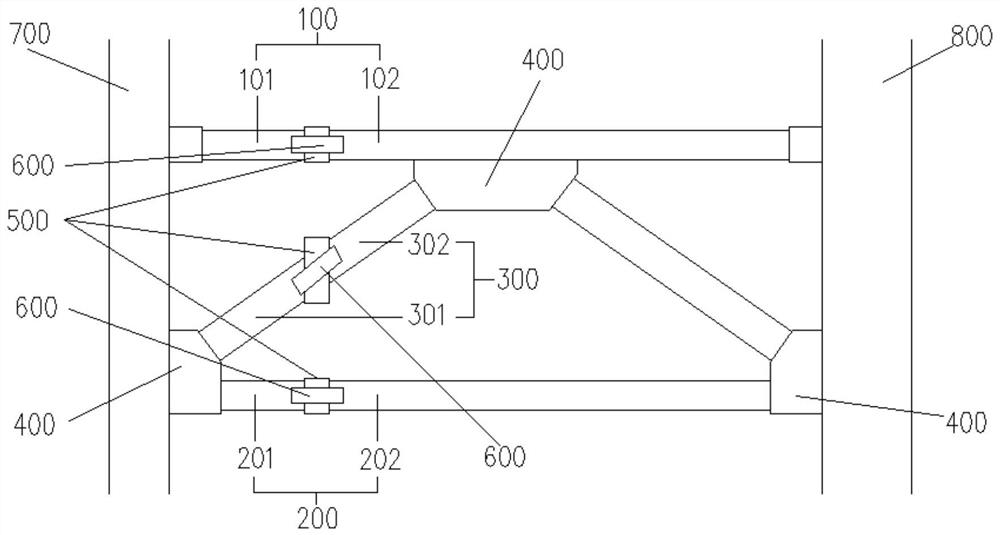

Braced frame-core tube building structure and construction method thereof

PendingCN113445628AAvoid loss of ability to resist lateral forcesExtraordinary structuresBraced frameTube (structure)

The invention discloses a braced frame-core tube building structure and a construction method thereof, and relates to the technical field of buildings, which aims to solve the problem that in the prior art, a frame-core tube building structure, a shear wall building structure and the like cannot meet the high anti-seismic requirement of a high-intensity area. The braced frame-core tube building structure comprises a core tube structure, an outer frame structure and a braced frame structure, wherein the outer frame structure comprises a first frame column and a first frame beam; the braced frame structure comprises at least one second frame column and further comprises second frame beams which are arranged between the adjacent second frame columns and / or between the second frame columns and the core tube structure; the adjacent second frame columns and the adjacent second frame beams enclose to form first sashes, and / or the second frame columns, the core tube structure and the adjacent second frame beams enclose to form second sashes; and inclined struts are arranged in the first sashes and the second sashes. The braced frame-core tube building structure can be suitable for the high-intensity area.

Owner:CCDI INT SHENZHEN DESIGN CONSULTANTS

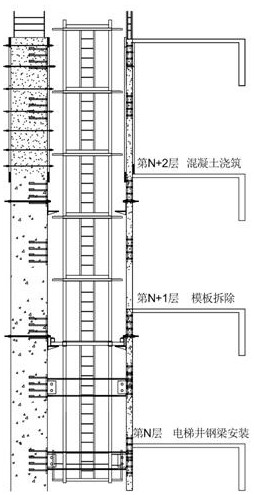

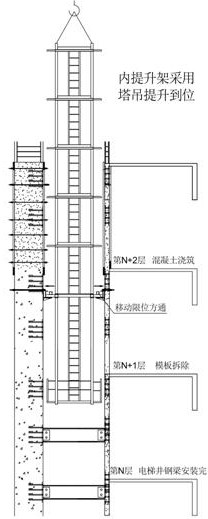

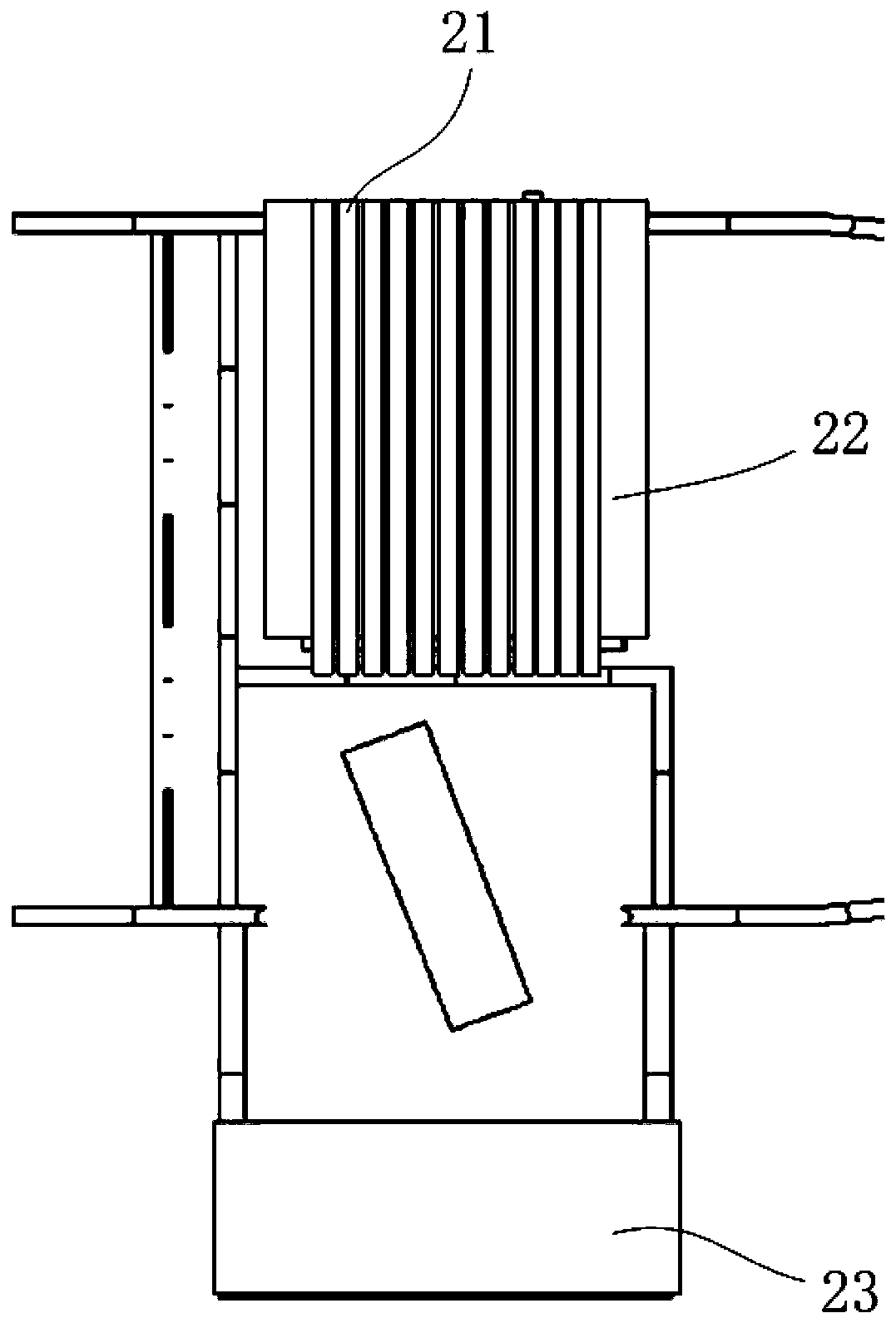

Hoistway inner hoisting frame for core tube elevator shaft steel beam installation and steel beam construction method

InactiveCN112627543AReduce the risk of attackReduce the cost of construction measuresBuilding material handlingVertical ductsTube (structure)Classical mechanics

The invention relates to a hoistway inner hoisting frame for core tube elevator shaft steel beam installation. A hoisting frame body is arranged in an elevator shaft of a core tube shear wall, and the hoisting frame body is a rectangular frame and comprises six layers; the bottommost layer is used for elevator steel beam installation, and the floor height of the bottommost layer is the standard floor height of a building; and the upper five layers are used for concrete structure construction, steel bar binding and form erecting and removing are sequentially conducted from top to bottom, and the layer height of each of the upper five layers is half of that of the bottommost layer. According to the hoisting frame, the construction measure cost is effectively reduced; and the construction progress is quickened, elevator steel beams and an elevator shaft concrete structure are synchronously constructed, and waiting for elevator shaft capping is not needed.

Owner:中冶(上海)钢结构科技有限公司

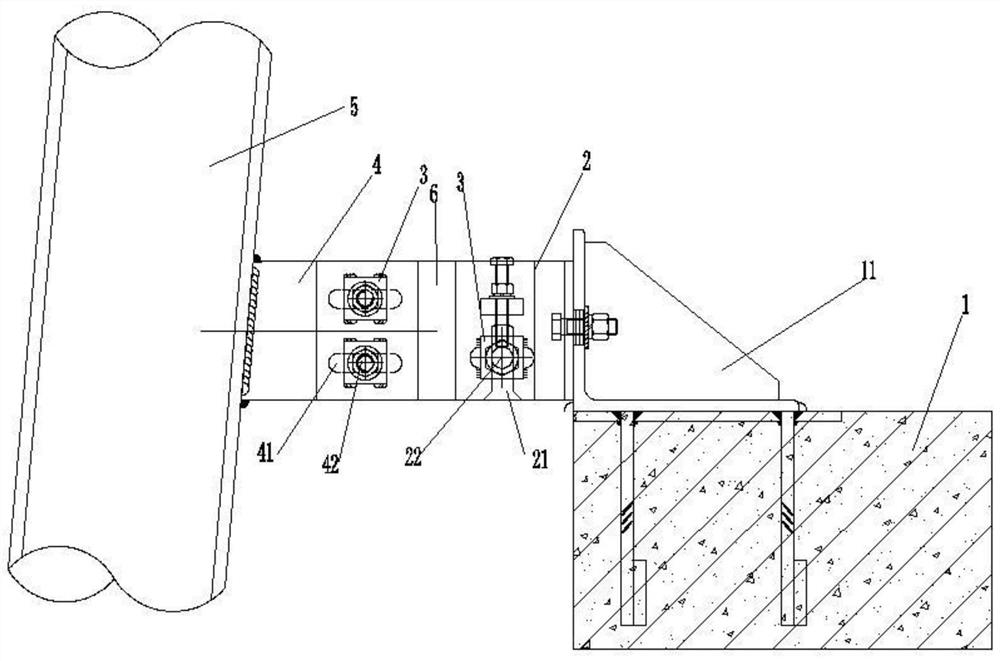

Precast pile and bearing platform fabricated type foundation tenon type flange connecting structure and construction method

ActiveCN110904986AReasonable structureSimple and fast operationFoundation engineeringTube (structure)Architectural engineering

The invention relates to a precast pile and bearing platform fabricated type foundation tenon type flange connecting structure and a construction method. The precast pile and bearing platform fabricated type foundation tenon type flange connecting structure comprises a tube pile and a bearing platform. Supporting steel tubes are arranged between the tube pile and the bearing platform, a lower flange disc attached to the end face of the tube pile is arranged at the lower ends of the supporting steel tubes in a sleeving mode, an upper flange disc attached to the end face of the bearing platformis arranged at the upper ends of the supporting steel tubes in a sleeving mode, upper deformed steel bars are arranged on the upper flange disc, one end of each upper deformed steel bar is inserted into the bearing platform, an upper fastening nut is arranged at the other end of each upper deformed steel bar, and the upper fastening nuts are used for locking the upper flange disc to the lower endface of the bearing platform. An upper fastening mechanism is arranged on the lower flange disc in a penetrating mode, one end of the upper fastening mechanism is inserted into the tube pile, a lowerfastening mechanism is arranged at the other ends of lower deformed steel bars, and the lower fastening mechanism is used for locking the lower flange disc to the end face of the tube pile. The precast pile and bearing platform fabricated type foundation tenon type flange connecting structure is reasonable in structure and easy and convenient to operate, field welding is not needed when the tube pile and the bearing platform are connected, manual cost is greatly reduced, field operation is reduced, fire disaster risks of a construction site are reduced, the construction speed is improved, andmeanwhile the structure is stable, reliable and high in safety.

Owner:STATE GRID FUJIAN ELECTRIC POWER CO LTD +2

Post-cast strip supporting structure used for civil house building

InactiveCN111719894AAchieve reuseGuaranteed stabilityShoresTube (structure)Architectural engineering

The invention relates to a post-cast strip supporting structure used for civil house building. The post-cast strip supporting structure used for civil house building comprises a formwork arranged in apost-cast strip, a reinforcement cage is arranged on the formwork, at least two fixing tubes are detachably installed on the side, away from the reinforcement cage, of the formwork, and a telescopicsupport is arranged on the inner side of each fixing tube in an inserted manner. Telescopic adjusting mechanisms are installed on the telescopic supports, and the telescopic adjusting mechanisms are used for adjusting the length of the telescopic supports. A supporting mechanism used for conducting horizontal supporting on the telescopic supports is arranged between every two adjacent telescopic supports, and the supporting mechanisms can be adjusted. Due to the arrangement of the telescopic adjusting mechanisms, length adjustment of the telescopic supports can be achieved, and the fixing tubes fixed to the formwork are matched for achieving supporting; and due to the arranged supporting mechanisms, horizontal limiting of the telescopic supports can be achieved, the supporting stability can be effectively ensured, the number of occupied steel pipes is small, subsequent demounting is facilitated, repeated use of supporting parts can be achieved, and practicability is high.

Owner:NANYANG NORMAL UNIV

Steel structure roof structure of tower building and construction method thereof

ActiveCN111749384ANice appearanceNovel structureBuilding roofsExtraordinary structuresTube (structure)Architectural engineering

The invention discloses a steel structure roof structure of a tower building and a construction method thereof. The steel structure roof structure comprises a roof body, corner hanging columns and side hanging columns. The roof body is in the shape of an inverted pyramid and comprises a tower crown structure, a peripheral structure and a connecting net frame. The tower crown structure is arrangedat the top of a core tube. The peripheral structure comprises oblique columns and a frame beam. The rectangular frame beam is connected to the tops of the oblique columns. The connecting net frame isconnected between the tower crown structure and the peripheral structure. The corner hanging columns are mounted on a top plate of a frame tube and positions corresponding to four corners of the framebeam. The bottoms of the corner hanging columns are connected with the top plate through corner column connecting seats correspondingly. The side hanging columns are arranged on the top plate of theframe tube and positions corresponding to connecting short columns of the upper side portion of the frame beam. The bottoms of the side hanging columns are connected with the top plate through side column connecting seats correspondingly. According to the steel structure roof structure of the tower building and the construction method, the technical problems that a traditional steel structure roofis simple in modeling and hard to stand out in building groups, a traditional construction method fails to meet construction requirements of steel structure roof structures with a complex structure,and the safety of the mounting process fails to be guaranteed are solved.

Owner:中建二局阳光智造有限公司 +1

Structure of constraining faced wall for building

PendingCN107882211ASimple structureReduce material usageWallsProtective buildings/sheltersMaterial consumptionAspect ratio

The invention provides a structure of constraining a faced wall for a building. The structure of constraining the faced wall for the building includes a plurality of column units, and cross section length-width ratio of each of the column units is more than 4. The column units include arc-shaped plates at least. The arc-shaped plates are flexibly connected with slab connecting pieces, circular tubes, polygon tubes and other arc-shaped plates in a fit mode to form the column elements. All the column units or some of the column units are filled with filler. The structure of constraining the faced wall for the building is simple and useful, the material utilization amount is low, the constraining of the quasi-circular structure to the filler is high, the structural bearing and the anti-seismic functions are good, the consumption of resource and energy is low, and the template is not required; and the weight of all components is light, transportation, lifting and installation are convenient and fast, the operation is convenient and fast, the speed of the operation is high, the labor intensity of workers is low, the construction efficiency is high, and the construction cost is low.

Owner:赵建敏 +2

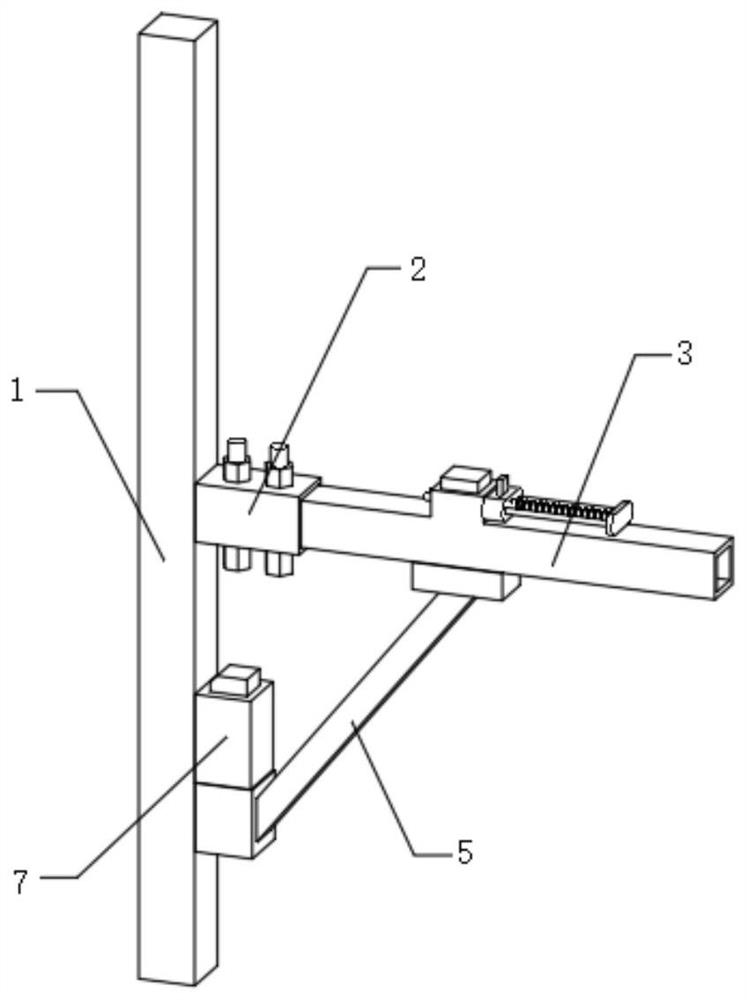

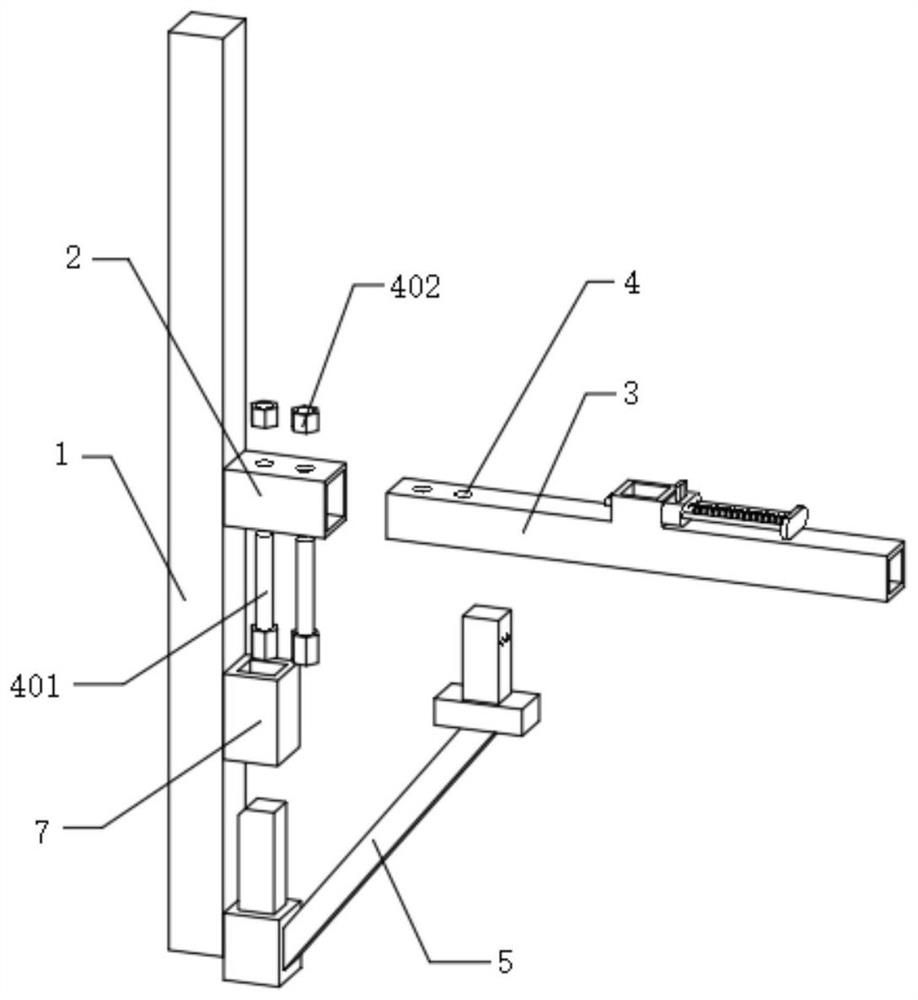

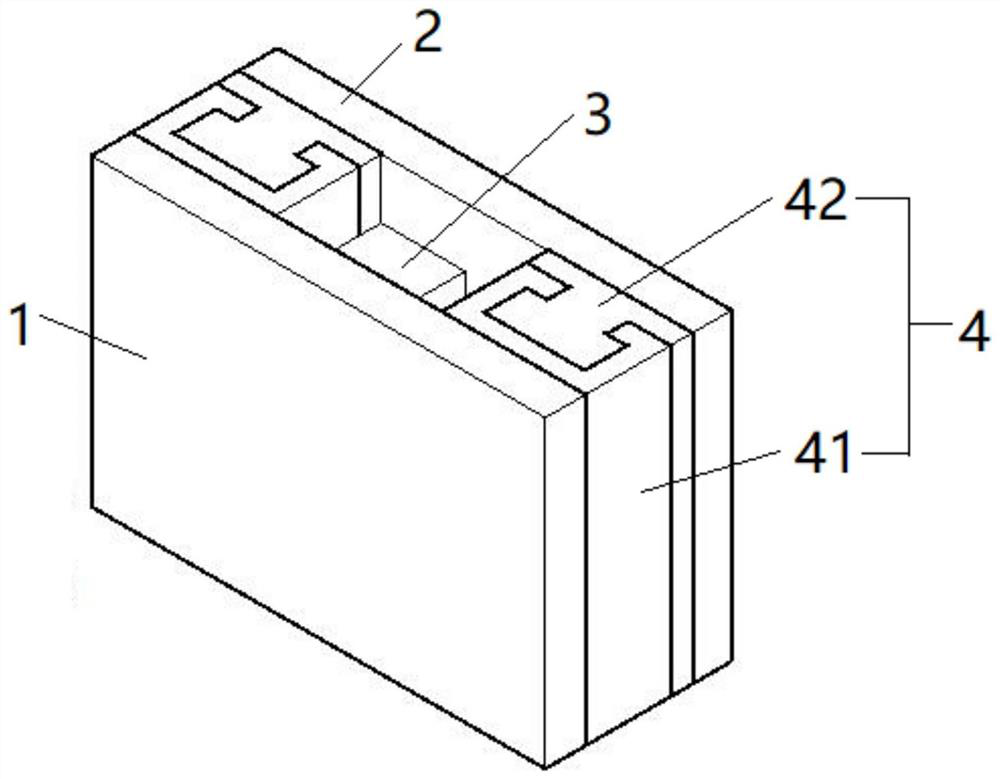

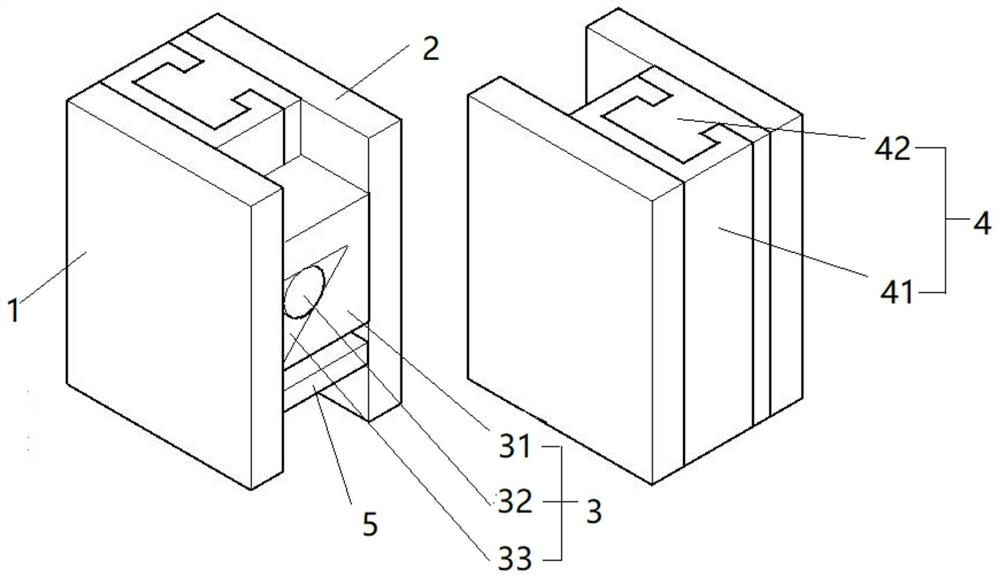

Node connecting device for prefabricated building structures

ActiveCN112922156BStable supportHigh strengthBuilding constructionsTube (structure)Architectural engineering

The invention discloses a node connection device used for a prefabricated building structure, and relates to the field of prefabricated buildings. The node connection device for prefabricated building structure comprises a column, the side wall of the column is fixedly connected with a square tube seat, the tube cavity of the square tube seat is movably inserted with a cross bar, and the top of the cross bar is provided with two sets of fixing holes. A fixing bolt is movably inserted in the fixing hole. The fixing bolt extends upward through the square tube seat and the fixing hole and is threadedly connected with a fixing nut. A reinforcing rib is fixedly installed between the column and the cross bar, and a top block is fixed on the top of the reinforcing rib. A first insertion post is fixed on the top of the top block, and two sets of locking holes are opened on the side wall of the first insertion post. When the node connecting device for prefabricated building structure is in use, it is convenient to assemble and connect the nodes of the prefabricated building structure. When assembling, it saves time and effort and realizes quick assembly.

Owner:王敏辉

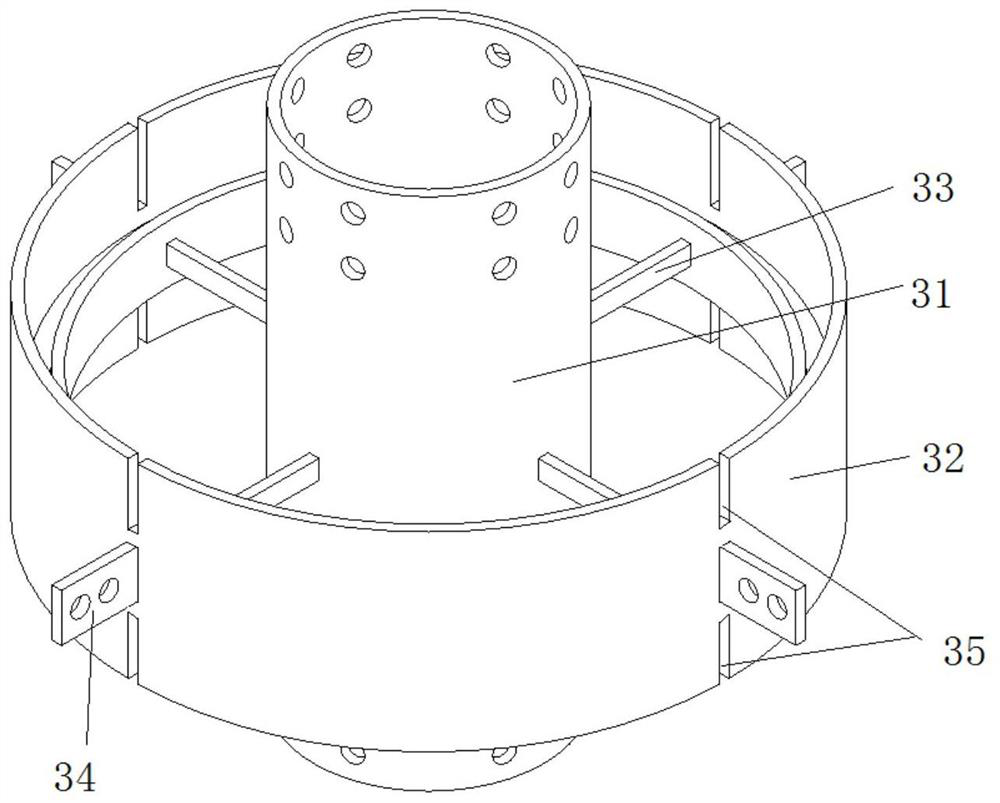

Double steel pipe concrete beam-column joint with built-in frp bar connection device and its installation method

ActiveCN111733986BPrevent bucklingHigh strengthStrutsBuilding reinforcementsConcrete beamsTube (structure)

The invention relates to the field of building structures. The double steel pipe concrete beam-column node with a built-in FRP tendon connection device of the present invention includes double steel pipe columns, I-beams, node connectors, inner braces and outer ring plates; the double steel pipe columns include inner steel pipes and the outer steel pipe; the node connectors include connecting the inner pipe and connecting the outer disk, both of which are round steel pipes; the inner support is a columnar structure, and bolt holes are evenly distributed along the circumference at both ends; the outer ring plate includes mutual The vertical horizontal part and the ring part; the upper and lower double steel pipe columns are connected by node connectors and inner supports. The inner pipe and the inner steel pipe are fixed in the bolt holes of the inner support. The invention utilizes the superior tensile performance and fatigue load resistance capacity of FRP tendons to effectively improve the seismic energy dissipation capacity of nodes and enhance the safety and bearing capacity of the structure.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

A construction method of outrigger truss structure

ActiveCN112081244BExtraordinary structuresBuilding material handlingTube (structure)Architectural engineering

In order to release the "additional stress of the outrigger truss" and solve the problem of "the outrigger truss cannot be fastened in time during the construction of the overall building structure", eliminate the influence of the outrigger truss on the construction process, and improve construction efficiency. Construction method of outrigger truss structure. The invention relates to a construction method of an outrigger truss structure, which is used for connecting an outer frame column structure and a core tube structure. When stress is generated due to differential deformation between different building structures, the vertical sliding device for one-way control of displacement can make the two sides of the outrigger truss structure slide against each other, thereby releasing the stress and ensuring the construction quality.

Owner:SHANGHAI CONSTRUCTION GROUP +1

Steel circular tube single-column universal multi-dimensional special-shaped curtain wall construction structure and method

ActiveCN111997246AAdjustable and controllable installationImprove work efficiencyGeometric CADWallsTube (structure)Architectural engineering

The invention relates to the technical field of buildings, in particular to a steel circular tube single-column universal multi-dimensional special-shaped curtain wall construction structure and method. The method can be applied to the conditions of super complex building modeling and very short construction period. Under the condition that a civil engineering main body is not constructed, detaildrawings of a multi-dimensional special-shaped curtain wall skin, keels and connecting parts are exported from a BIM model; the multi-dimensional special-shaped curtain wall skin is subjected to production blanking in advance and then is assembled and constructed; and then the multi-dimensional special-shaped curtain wall skin and the main body structure are synchronously assembled and installed during construction. The construction period is greatly shortened, it is guaranteed that multi-dimensional different-direction curved surface curtain wall construction is completed within the shortestconstruction period, the working efficiency is greatly improved, the position of the multi-dimensional special-shaped curtain wall component is adjusted through the keels, the connecting parts and thecivil engineering main body structure,the installation of the multidimensional special-shaped curtain wall skin can be adjusted and controlled within a certain error range after the civil engineeringmain body structure is completed, the working process is simplified, the construction precision is effectively improved, and therefore the engineering progress and quality are guaranteed.

Owner:SUZHOU HOLLY MATE DECORATION CO LTD

Construction method for constructing underground structures under buildings

ActiveCN109555155BReduce loadHigh strengthArtificial islandsExcavationsTube (structure)Architectural engineering

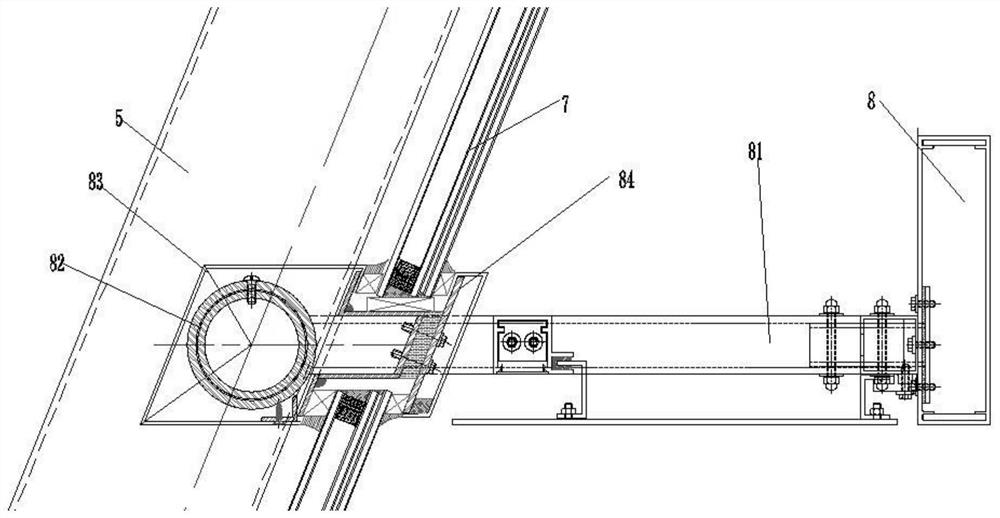

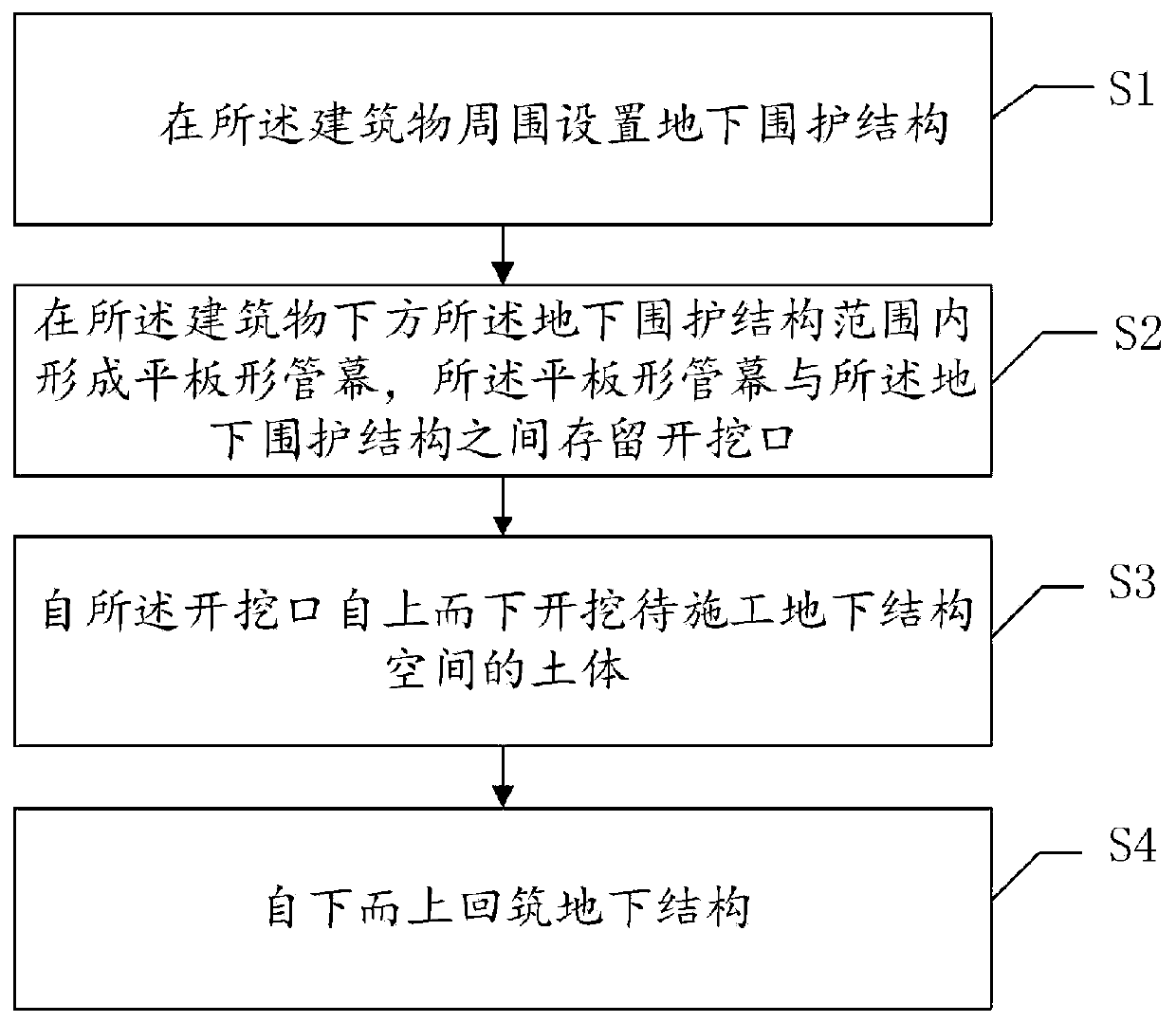

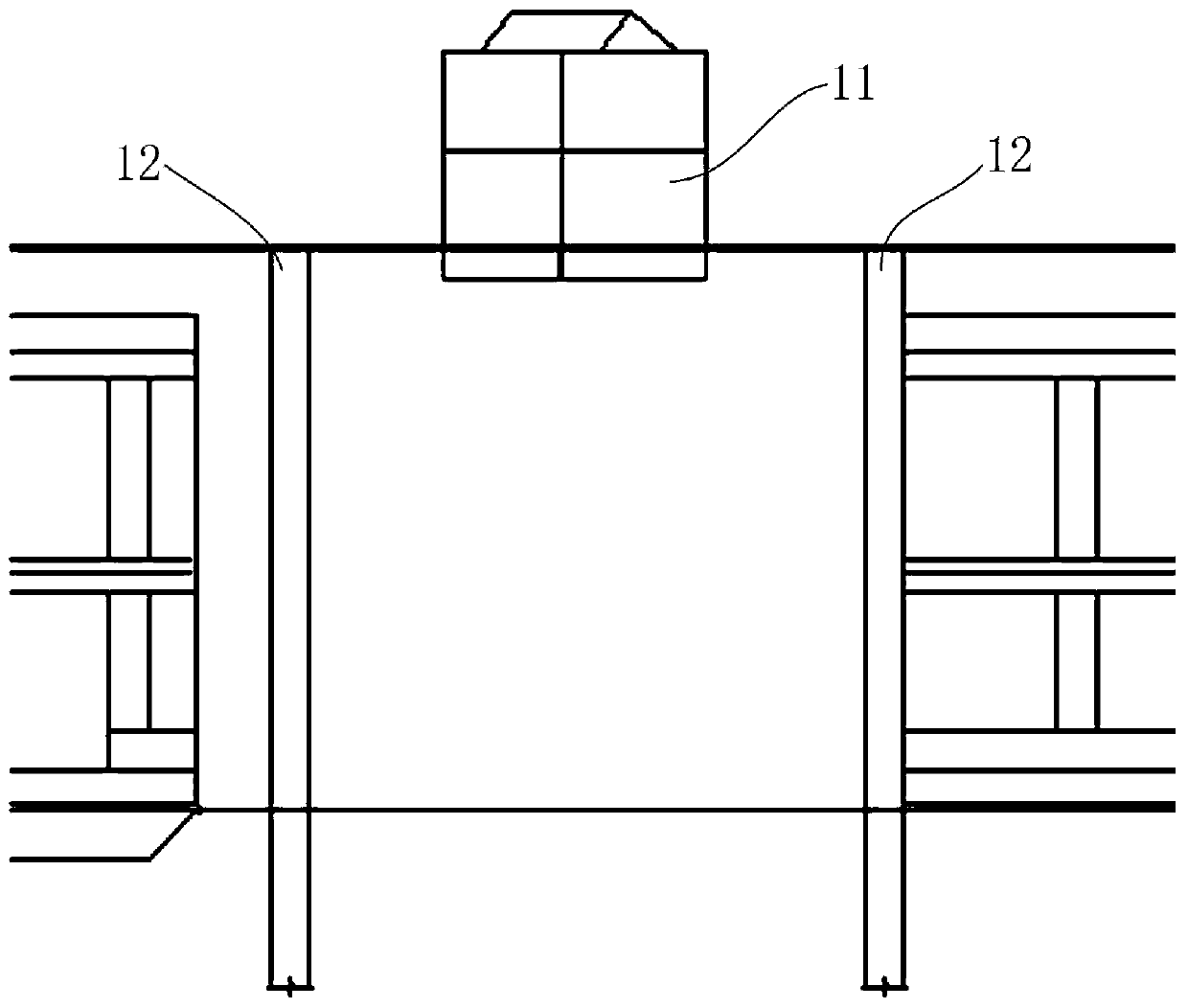

The invention provides a construction method for constructing an underground structure under a building. The construction method comprises the steps that underground enclosing structures are disposedaround the building; a plate-shaped tube curtain is formed in the position, within the scope of the underground enclosing structures, below the building; excavation openings are left between the flat-plate-shaped tube curtain and the underground enclosing structures; a soil body in the underground structure space to be constructed is excavated from top to bottom from the excavation openings; and back-building of the underground structure is performed from the bottom up. The construction method utilizes the formed flat-plate-shaped tube curtain, and the load on the tube curtain is reduced due to higher strength, rigidity and water-stop properties and fewer requirements on the soil body thickness on the lower part of the building; and better support are provided for the soil body on the upper part of the tube curtain and the soil body on the lower upper part of the building while expanding the underground structure space to be constructed. The structure formed by the method of forming the underground structure smoothly form bottom to up can be rich and complicated, the back-building structural quality can be guaranteed as a ground structure, and the construction efficiency is high and the speed is high.

Owner:SHANGHAI MECHANIZED CONSTR GRP

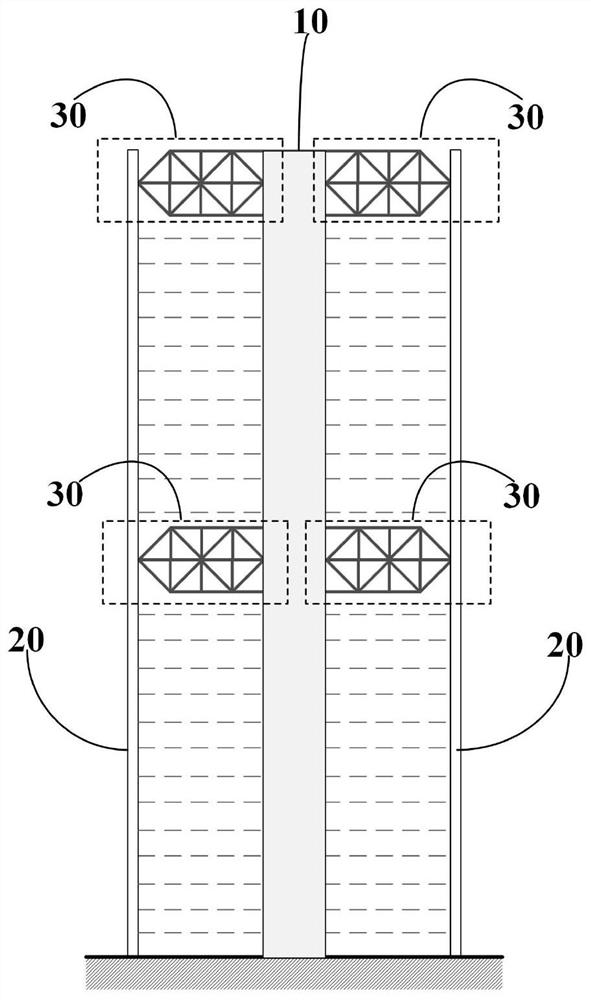

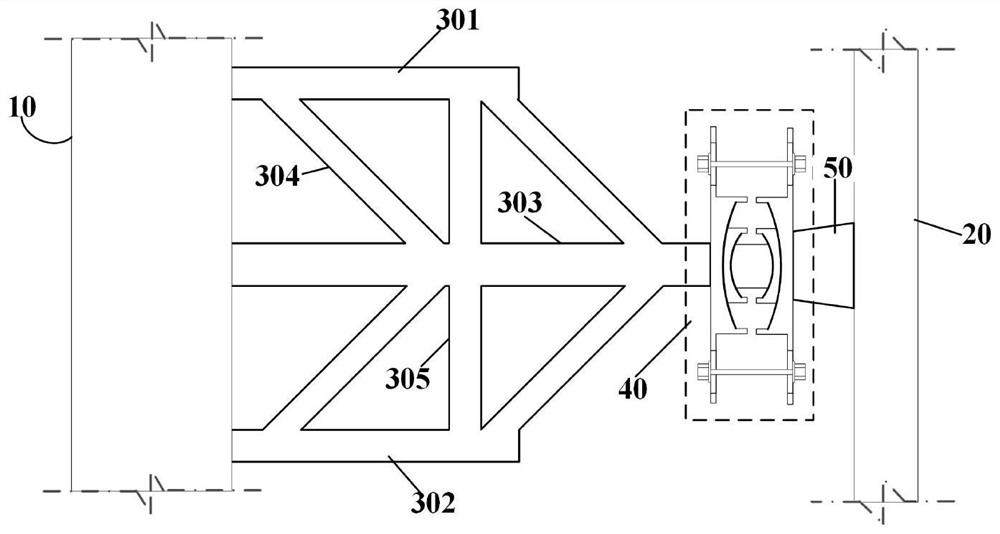

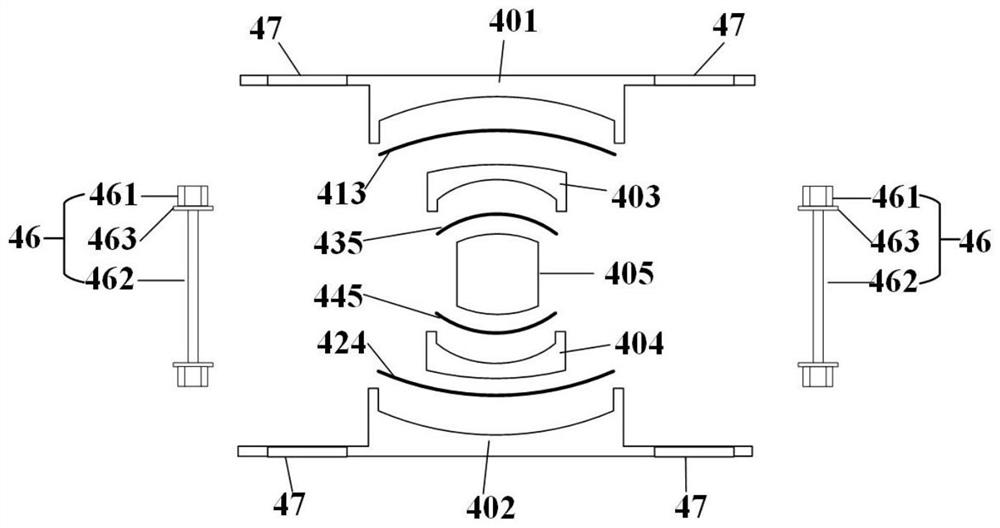

Super high-rise building structure self-adaptive friction energy dissipation extending arm system capable of resisting multiple catastrophe

ActiveCN114150913AMeet the performance requirements of vibration reduction (shock)Reducing the Impact of Multiple HazardsProtective buildings/sheltersShock proofingTube (structure)Architectural engineering

The invention discloses a super high-rise building structure self-adaptive friction energy dissipation outrigger system capable of resisting multiple catastrophe. The super high-rise building structure self-adaptive friction energy dissipation outrigger system comprises a building core tube, a peripheral huge column, an outrigger truss, a supporting bracket and a self-adaptive friction energy dissipation device. One end of the outrigger truss is fixedly supported on a building core tube, and the other end of the outrigger truss is connected with a bracket arranged on a peripheral huge column through a self-adaptive friction energy dissipation device; the self-adaptive friction energy dissipation device is provided with a pair of outer supports, a pair of middle sliding discs, a convex sliding block and four corresponding friction interfaces. A slotted hole is formed in a wing plate of the external support, and a split bolt is arranged to provide normal stress needed by friction for the self-adaptive friction energy dissipation device. The rigidity and the energy dissipation capacity of the device can be adjusted in a self-adaptive mode, the requirement for the vibration reduction performance of a super high-rise building structure under multiple disasters such as static average wind, fluctuating wind / small earthquakes, medium earthquakes and large earthquakes can be met at the same time, and the purpose of reducing influences of multiple disasters is achieved.

Owner:BEIJING UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com