Steel structure roof structure of tower building and construction method thereof

A steel structure and roof technology, applied in special structures, roofs, building components, etc., can solve the problems of unsatisfactory construction and inability to ensure the safety of the installation process, and achieve the effect of novel structure, beautiful appearance, and safe operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

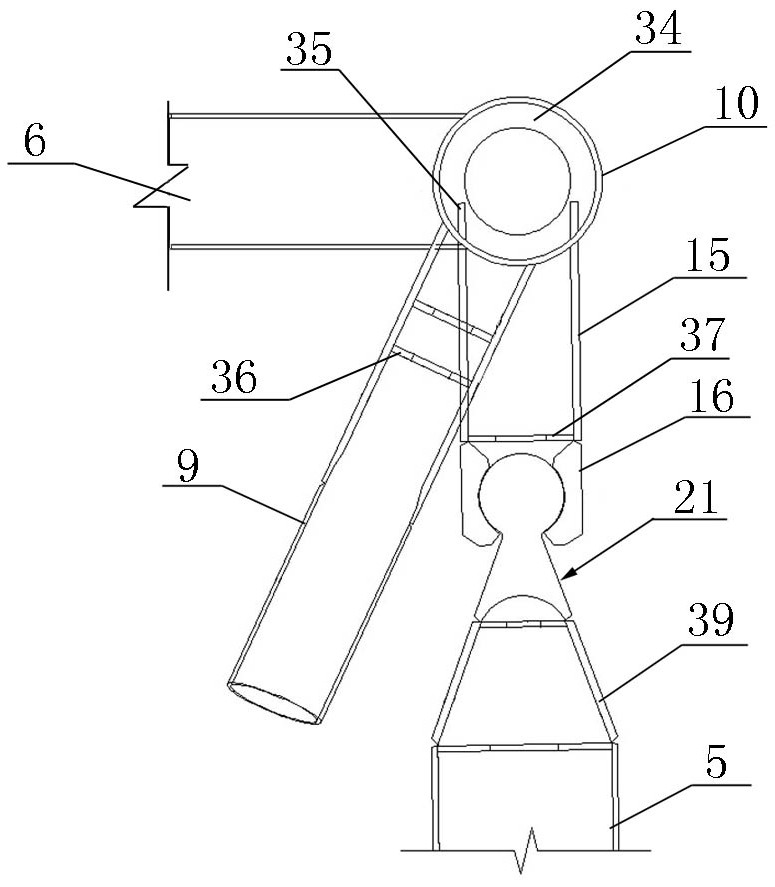

[0051] The corner hanging column 4 and the side hanging column 5 of the steel structure roof structure in this embodiment are constructed by temporarily fixing the lower end. The hanging column is installed from top to bottom, and the top of the corner hanging column 4 is installed first. The corner post connects the ball end 19 and the side post connection ball end 21 at the top of the side hanging post 5, and then installs the side post connecting seat 22 and the corner post connecting seat 20 at the bottom of the corner hanging post 4 and the bottom of the side hanging post 5; Hanging post 4 is temporarily just connected with corner post connecting seat 20, and side post connecting seat 22 is temporarily just connected with side post hanging post 5.

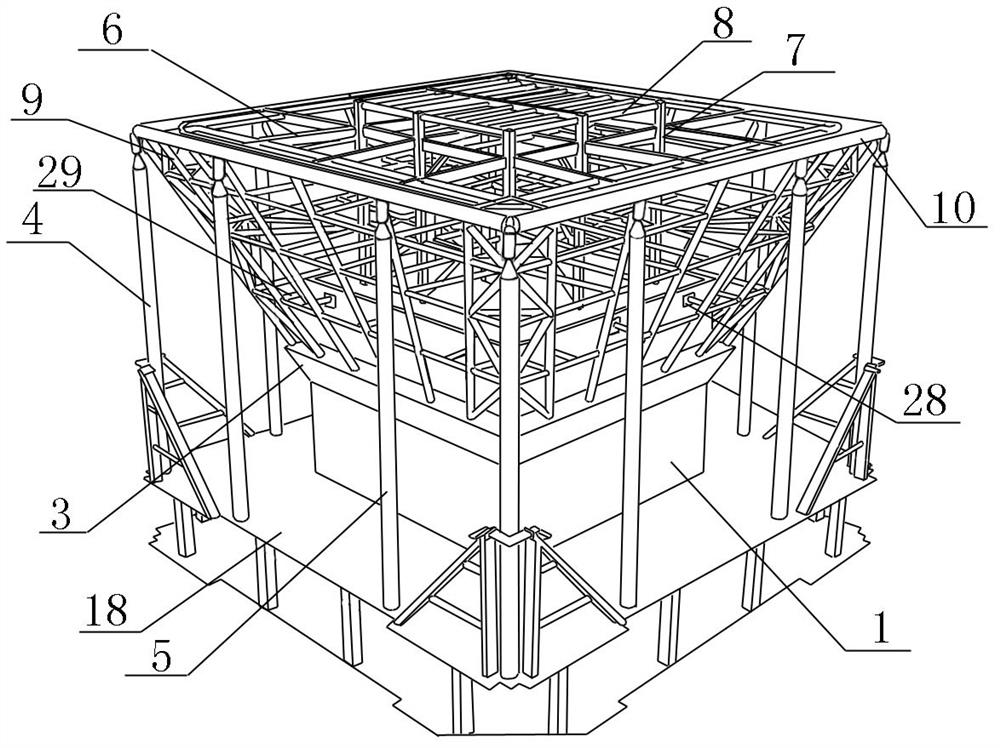

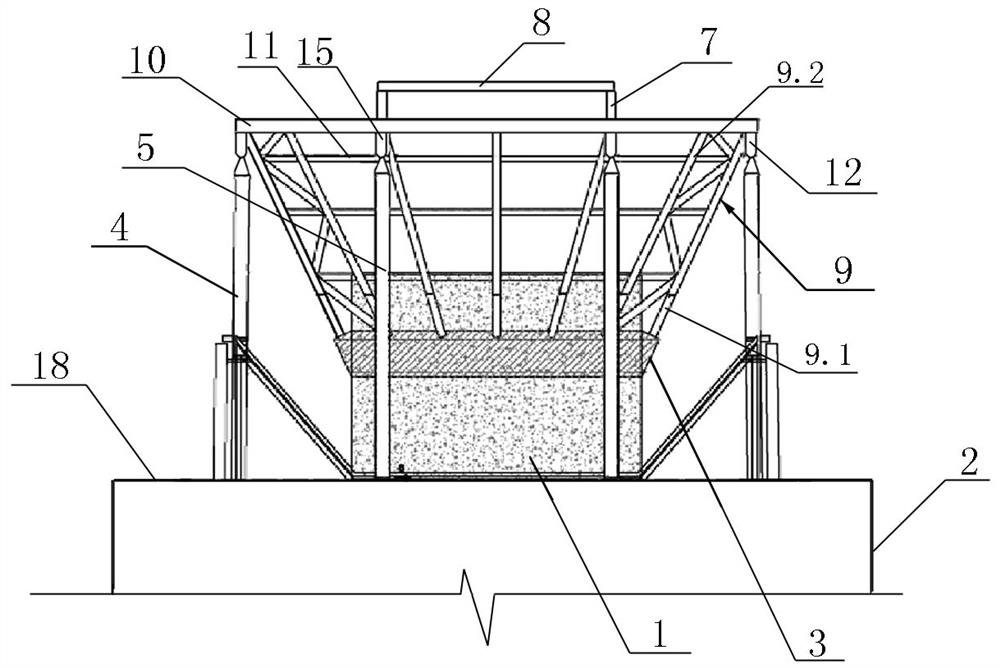

[0052] Such as Figure 1-18 As shown, the steel roof structure of the tower is installed on the top of the tower; the tower includes an inner core tube 1 and an outer frame tube 2; the top of the core tube 1 exceeds the outer ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com