Patents

Literature

246results about How to "Solve easy peeling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

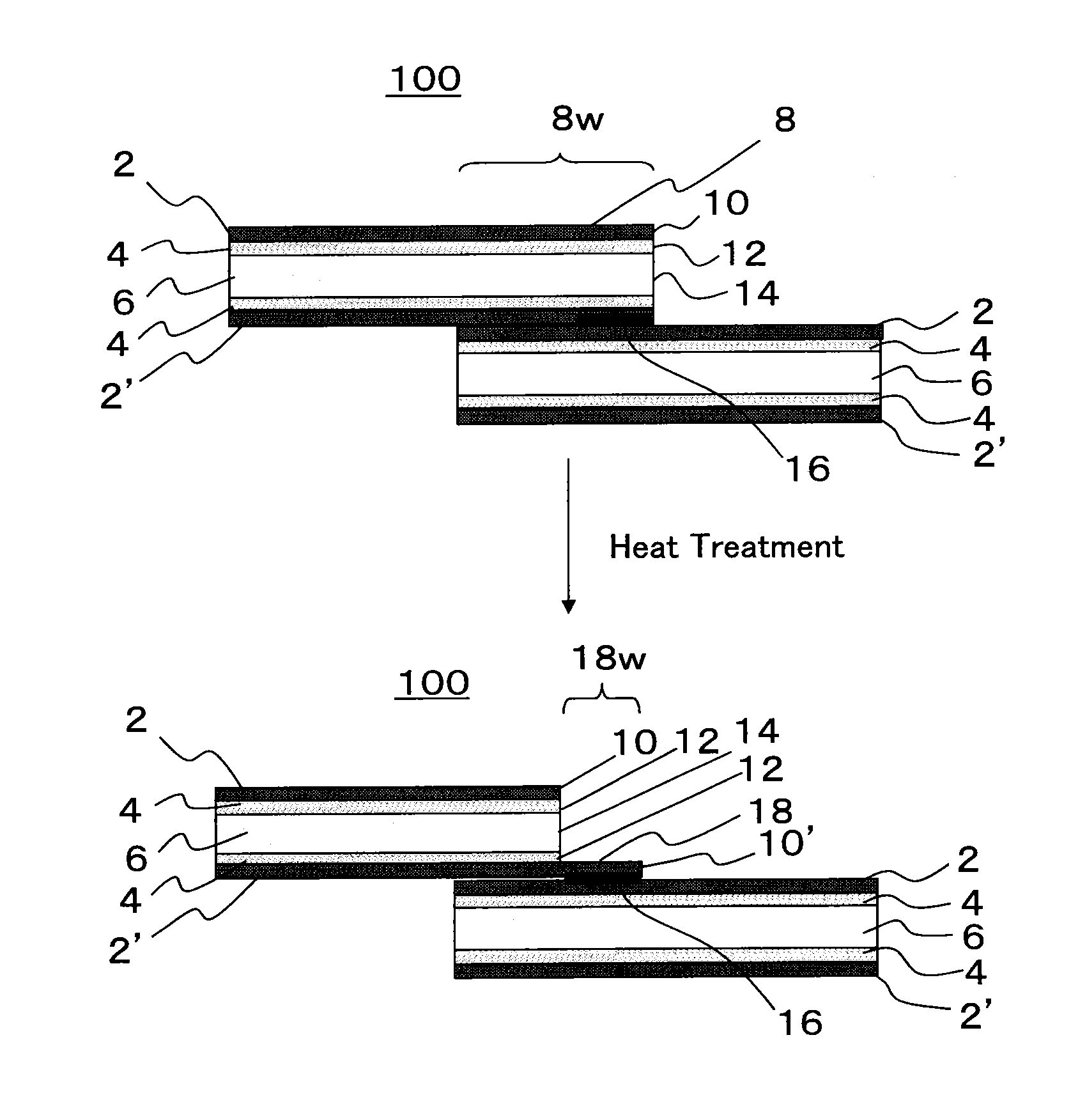

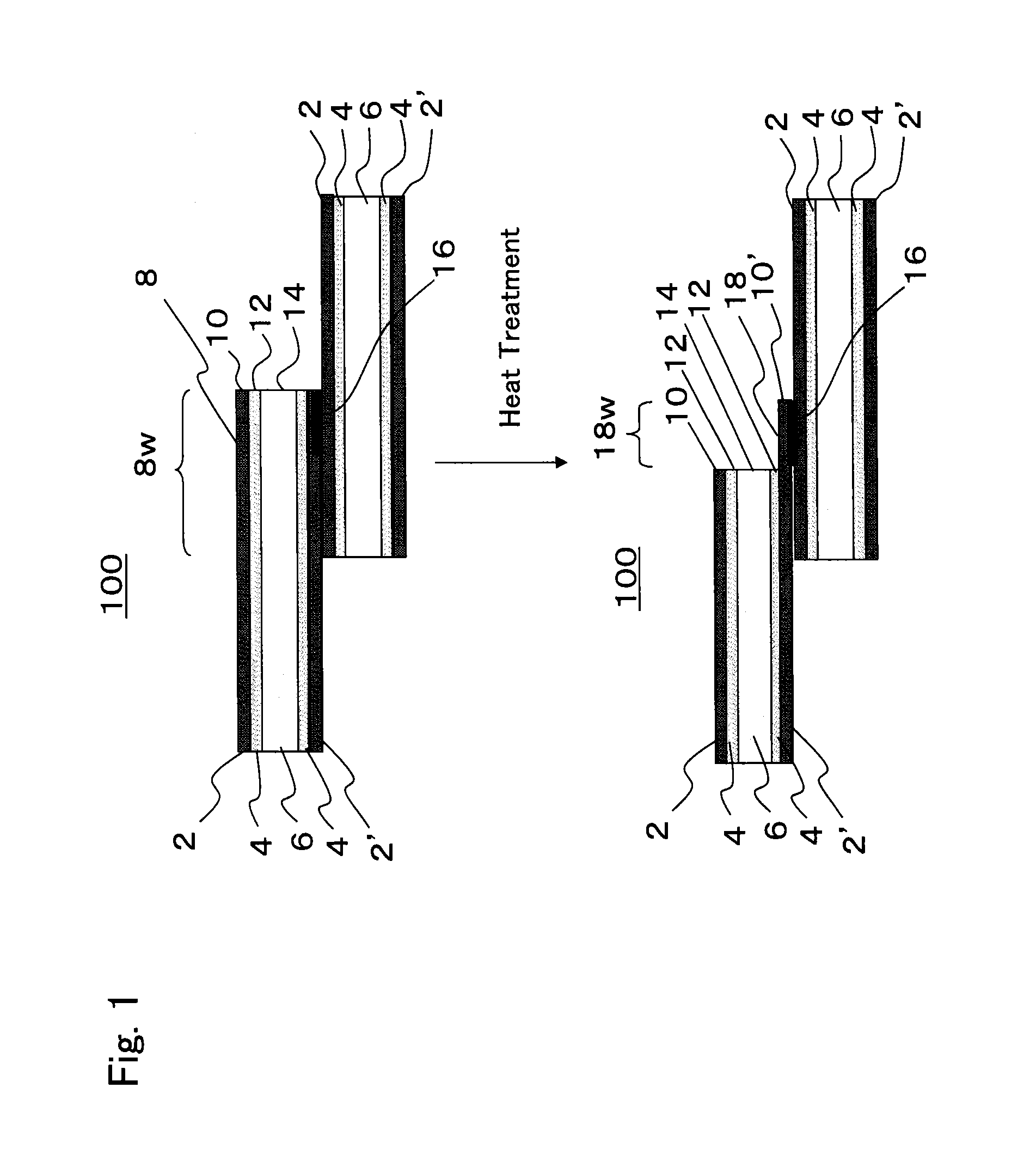

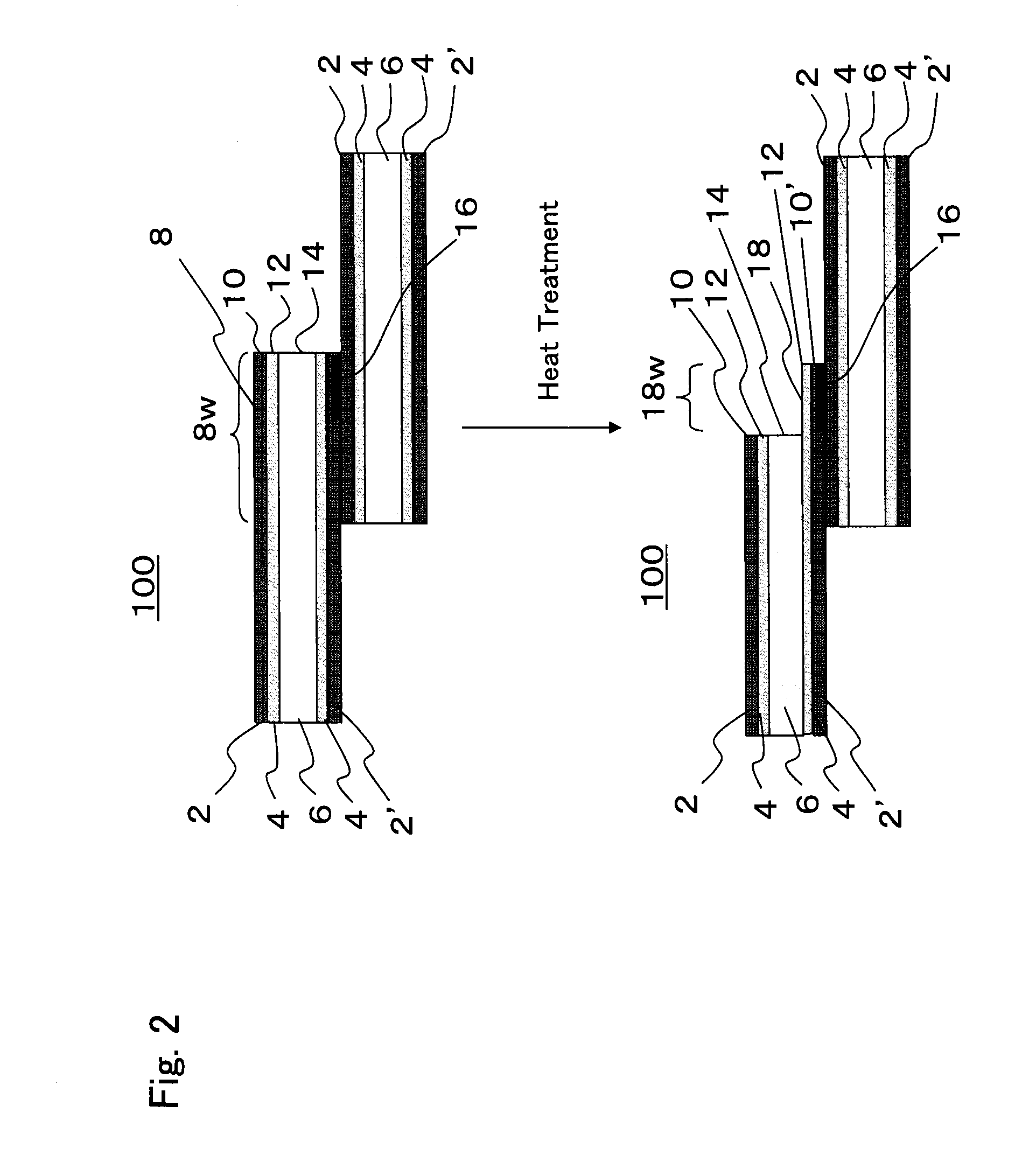

Heat-shrinkable laminated film, molded product and heat-shrinkable label comprising the film, and container

ActiveUS20130224412A1Good heat shrinkabilitySolve easy peelingBottlesSynthetic resin layered productsPolyesterRoom temperature

A heat-shrinkable laminated film having: (A) layer mainly having a polyester series resin; (C) layer mainly having a polystyrene series resin or mixture of polyester series and polystyrene series resins; and (B) layer mainly having polyester series and polystyrene series resins and disposed between (A) and (C) layers, the film having excellent heat-shrinkability, transparency, and interlayer-adhesiveness at room temperature, not easily peeled in a high-temperature treatment, inhibited from whitening when bent during processing, and suitable for shrinkage-packaging, shrink-bond-packaging, etc., with (B) layer having: a hard polyester series resin or mixture of hard polyester series and soft polyester series resins; and soft styrene series resin, hard styrene series resin, or mixture thereof, or with a content of the (B) layer polyester series resin smaller than that of the (A) layer one, and a content of the (C) layer polyester series resin smaller than that of the (B) layer one.

Owner:MITSUBISHI CHEM CORP

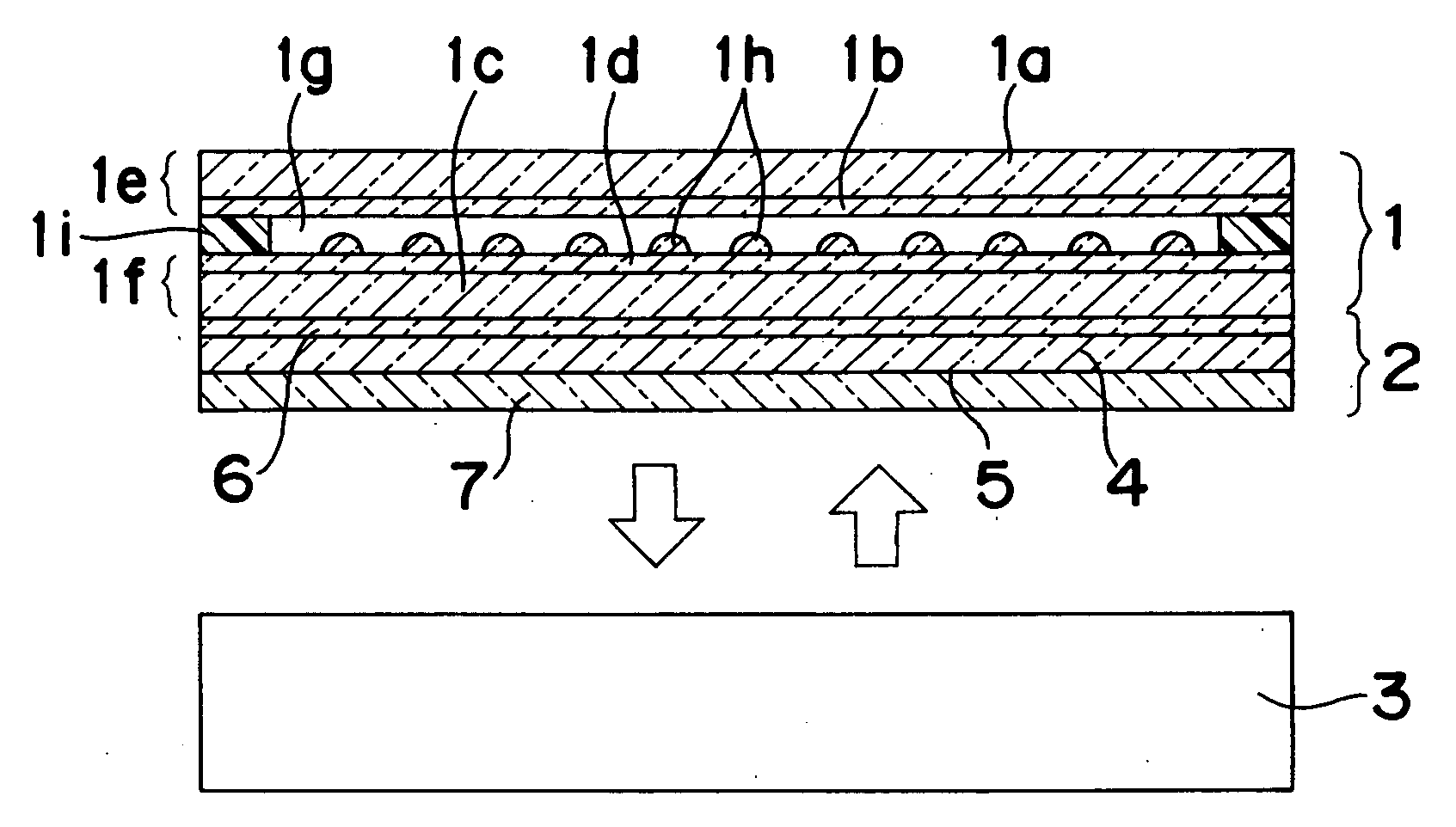

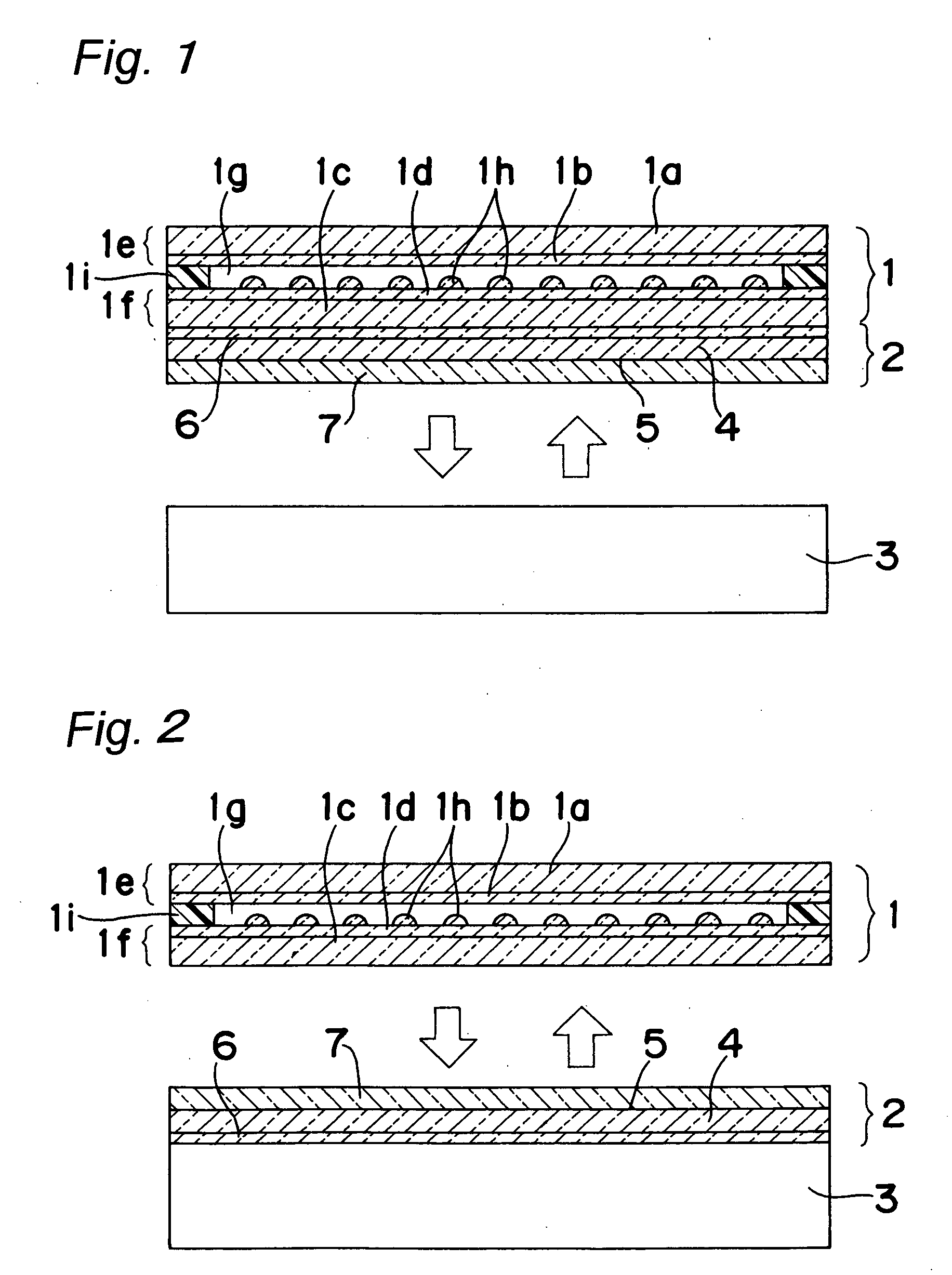

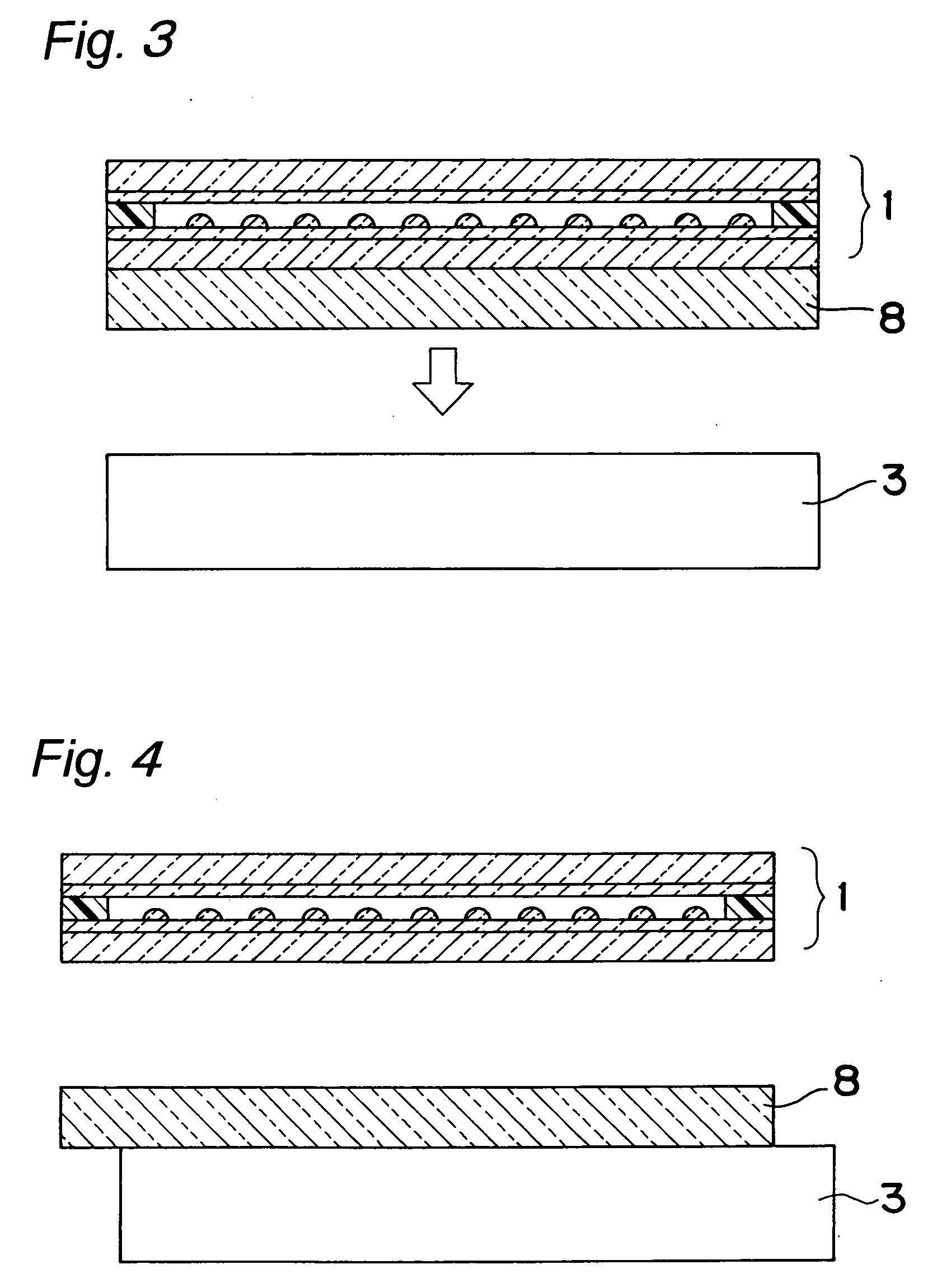

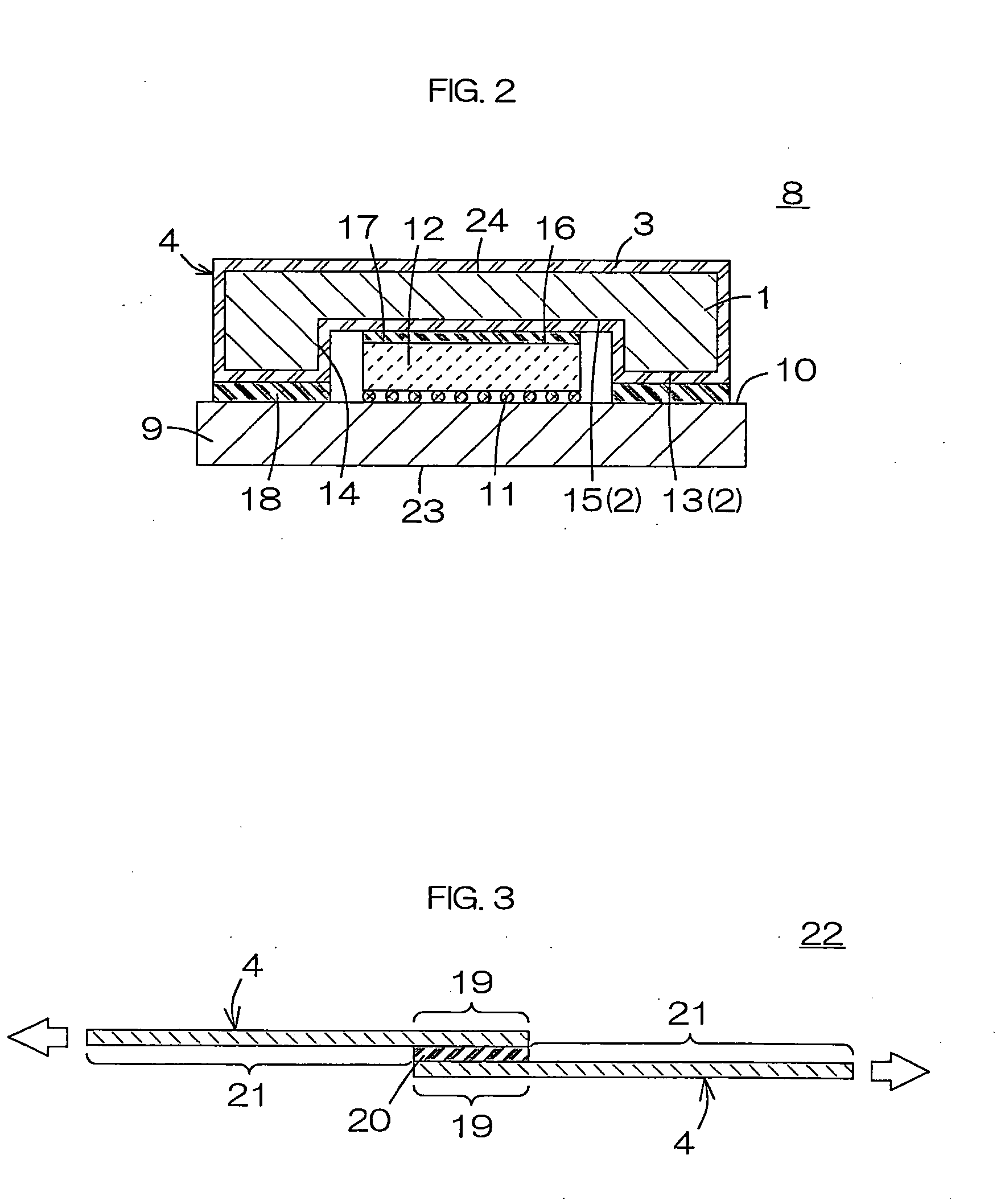

Mounting structure of re-peelable transparent touch panel and mounting sheet used for it

InactiveUS20040263481A1Improve adhesionSimple treatmentEmergency casingsDigital data processing detailsDisplay deviceEngineering

A transparent sheet for mounting that has an acrylic adhesive layer laminated on one surface of a core of plastic film and that has a silicone rubber sheet laminated on a primer-treated surface formed by primer treatment on the other surface is bonded overall onto a reverse face of a transparent touch panel with the acrylic adhesive layer, and the transparent touch panel provided with the sheet for mounting is mounted on a front surface of the display.

Owner:NISSHA PRINTING COMPANY

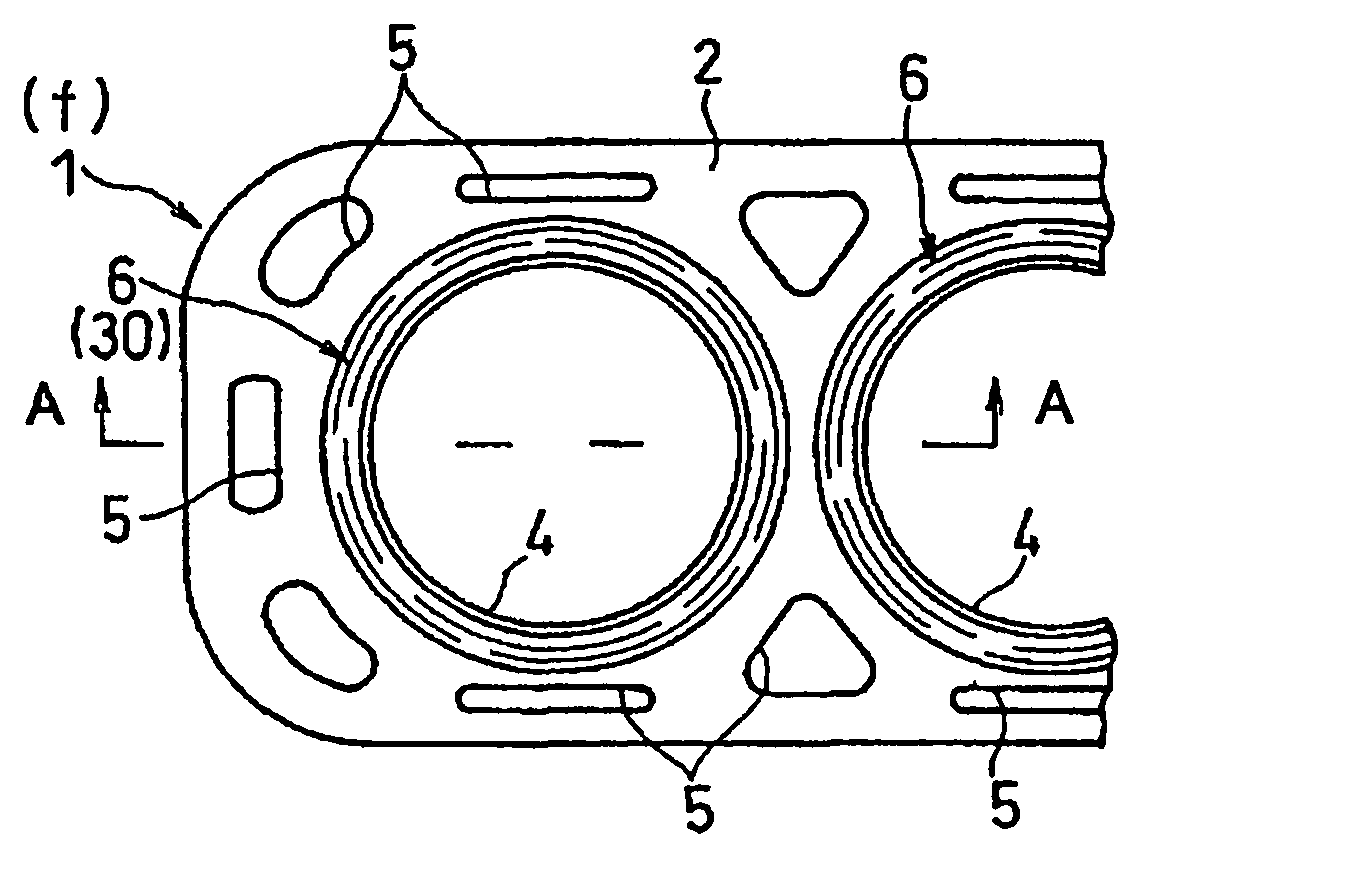

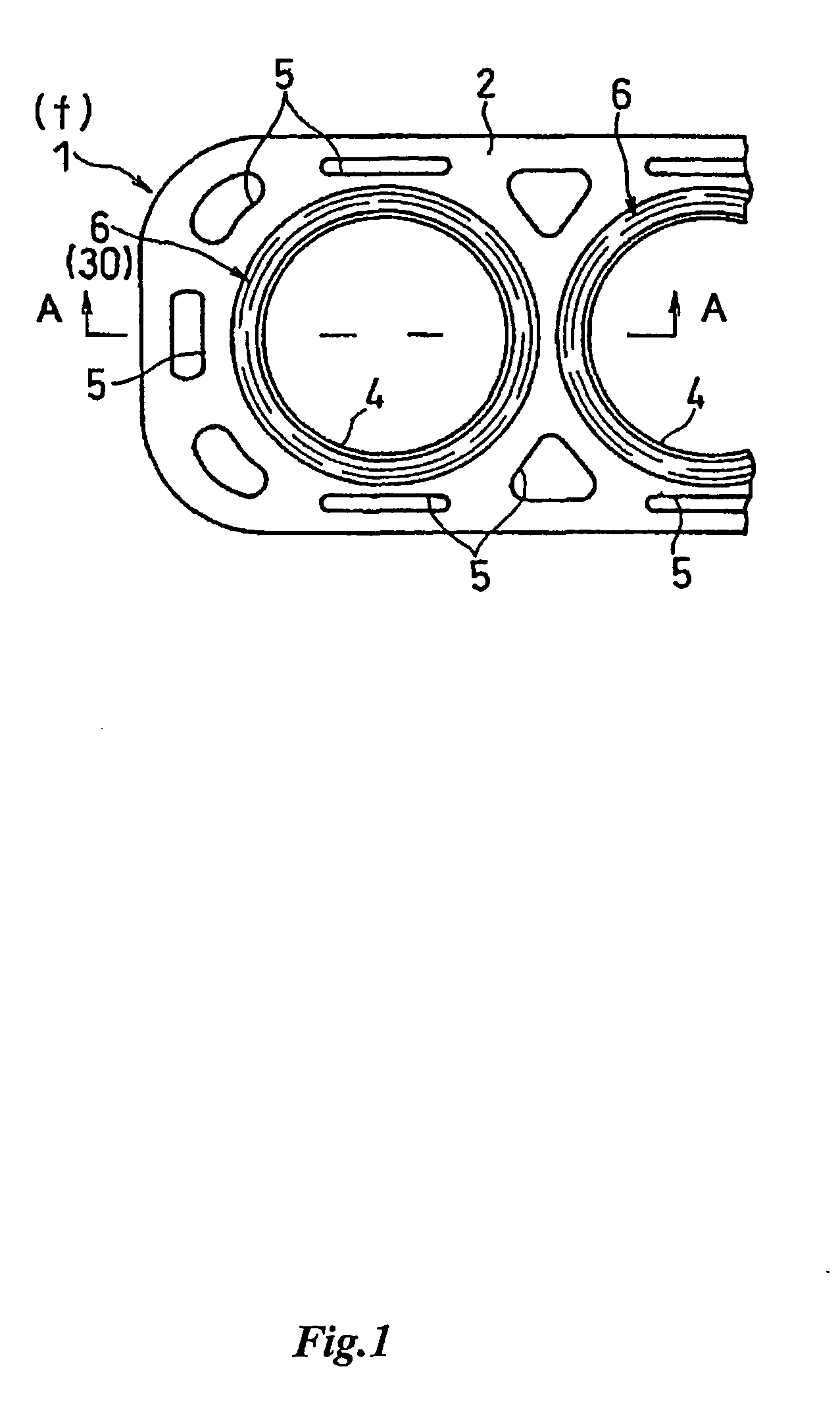

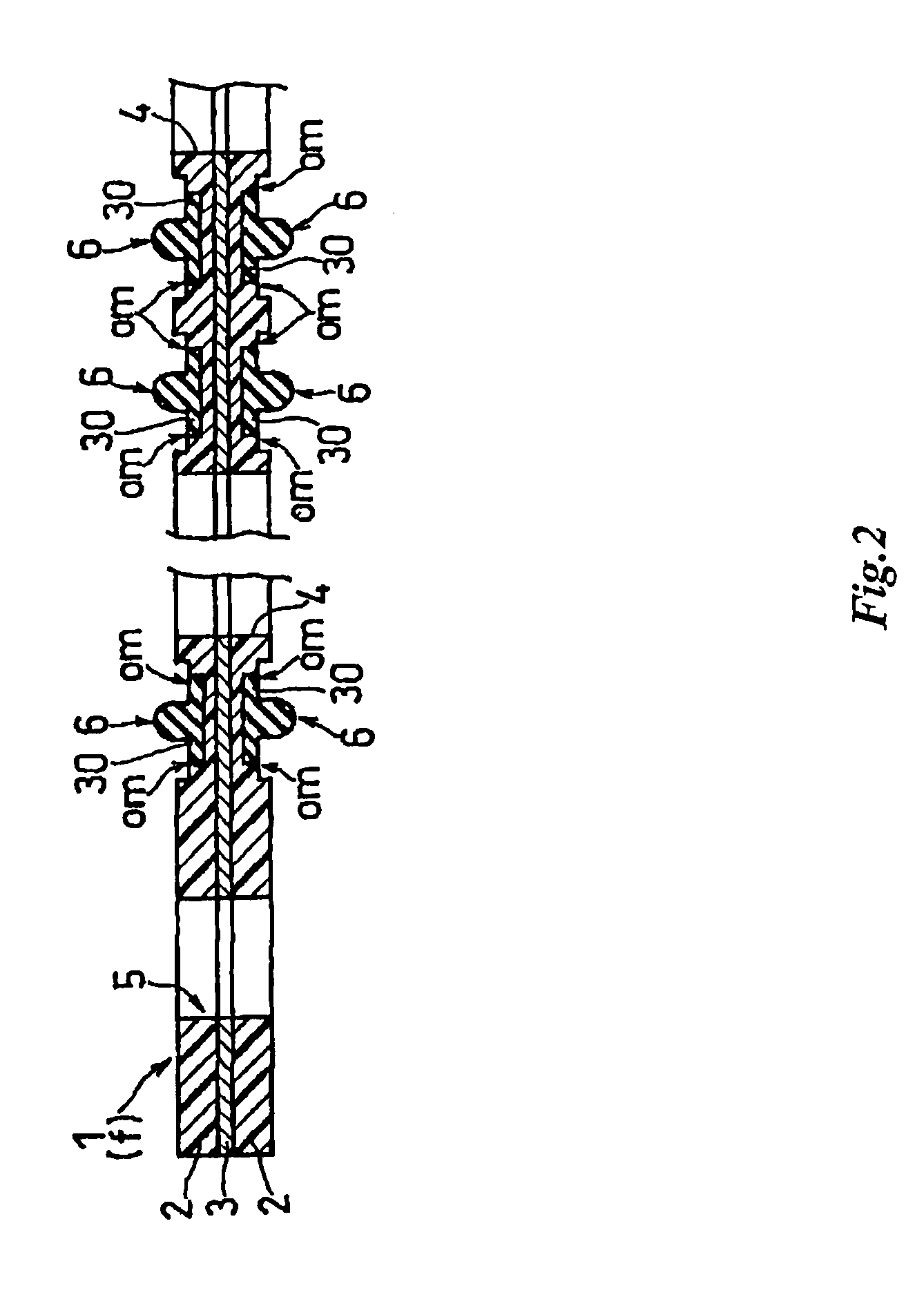

Cylinder head gasket

InactiveUS20050127615A1Facilitate productionSuperior processEngine sealsOther chemical processesEngineeringCylinder block

A cylinder head gasket for sealing between a cylinder block and a cylinder head, composed of a composite base plate, the composite base plate comprising a core material plate and a compound layer formed on the front and back surfaces of the core material plate, the compound layer being formed by coating compound materials which contain a rubber and a fiber material. The cylinder head gasket is comprised of an annular groove which is formed by pressing the corresponding region around the cylinder bore of the compound layer, and a bead projecting from the surface of the compound layer which is formed by inserting the rubber material into the annular groove.

Owner:UCHIYAMA MFG +2

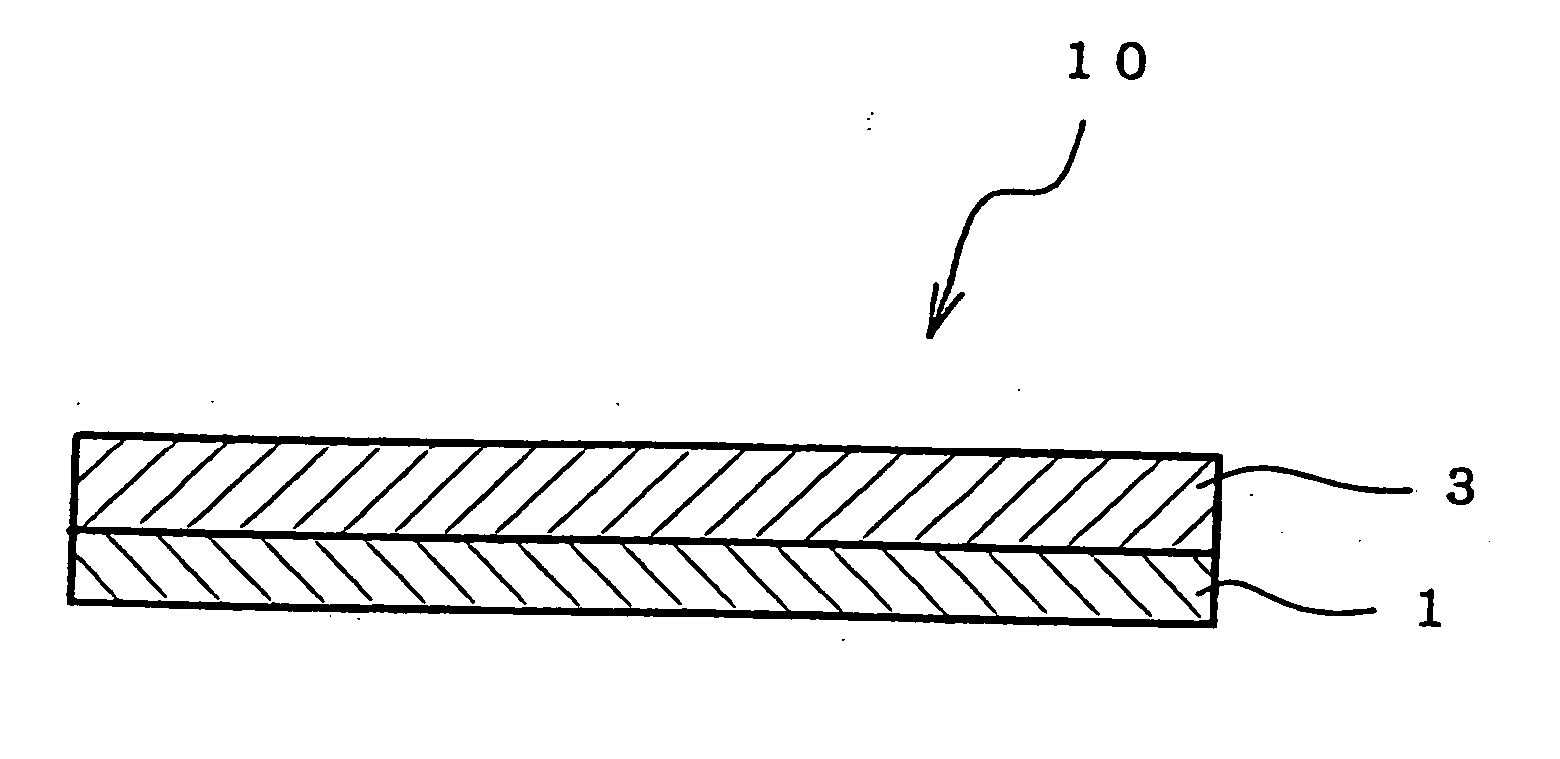

Adhesive preparation

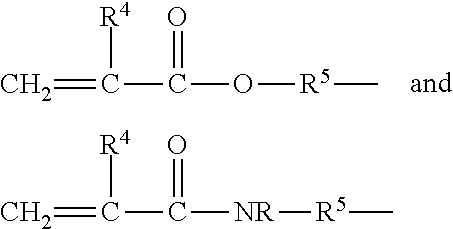

InactiveUS20060234581A1Improve adhesionSolve easy peelingSynthetic resin layered productsAdhesive dressingsStatic friction coefficientPressure sensitive

The present invention provides an adhesive preparation superior in adhesion property, which does not peel off or fall off easily and which can be adhered for a long time. An adhesive preparation 10 has a support 1 made of a cloth, and a pressure sensitive adhesive layer 3 formed on one surface of the support 1, which contains a pressure sensitive adhesive and a drug. The ratio (CW / AW) of a mass (CW) per unit area of the support 1 and a mass (AW) per unit area of the pressure sensitive adhesive layer 3 is 1.0-5.0, an adhesive layer-free surface of the support 1 has a static friction coefficient of 0.25-0.75, and a 20% modulus (AM) in one direction of the adhesive preparation 10 and a 20% modulus (EM) in the direction perpendicular to that direction are each 0.5-1.5 N / cm, and the ratio thereof (AM / EM) is 0.5-2.0.

Owner:NITTO DENKO CORP

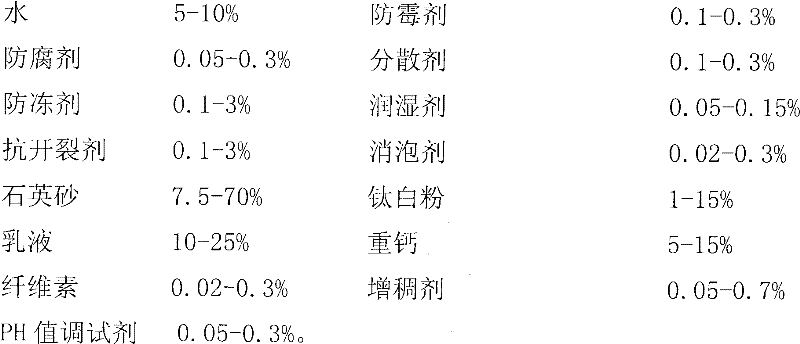

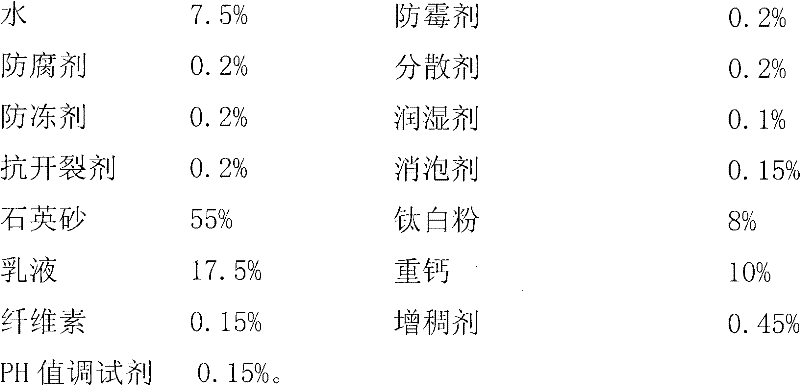

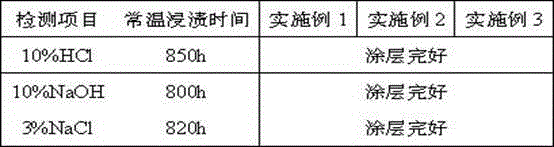

Special flexible texture coating for external heat insulating wall, and preparation method thereof

The invention discloses a special flexible texture coating for an external heat insulating wall. The coating is characterized by: 1) mixing water, an antimildew agent, a preservative, a dispersing agent, a wetting agent, a antifoaming agent, titanium pigment and calcium carbonate according to a mass ratio, followed by carrying out high speed dispersion to provide a spare use; 2) then mixing an emulsion, quartz sand and the antifoaming agent according to a mass ratio, followed by being added to the prepared mixed solution from the step 1), then carrying out medium-speed stirring; 3) mixing cellulose and the water according to a mass ratio, and carrying out stirring to prepare a mixed material of the cellulose to provide a spare use; 4) adding the mixture prepared through medium-speed stirring to the mixed material of the cellulose to carry out stirring, such that the mixed material of the cellulose can provide uniform thickening effect; 5) carrying out a color treatment for the finished product from the step 4). The coating provided by the present invention has characteristics of free of crack, high cohesional strength, effective prevention from coating deterioration, good water resistance, excellent penetration resistance, excellent flexibility. With the coating provided by the present invention, the fine cracks can be filled so as to prolong a service life of the external heat insulating wall and effectively protect buildings.

Owner:SHANDONG QINHENG TECH

Grass seed coating agent and coating process

The invention belongs to the technical field of seed coating, in particular relates to a grass seed coating agent and a grass seed coating process. The invention discloses the grass seed coating agent and the grass seed coating process. The coating agent contains a water-soluble mixture and water-insoluble solid particles. The weight of a grass seed prepared from the coating agent by the coating process can be increased by 15 to 100 percent, a coating layer is difficult to break, sowing performance can be improved, planting difficulty is reduced and the germination and growth state of the seed are improved. The process has the characteristics of convenient operation and short time.

Owner:SHANGHAI KEYUAN SEED

Polyvinylidene fluoride (PVDF) coating process for aluminum curtain wall

InactiveCN102139264ANot easy to peel offNot easy to stick offPretreated surfacesSingle-unit apparatusEngineeringPolyvinylidene difluoride

The invention relates to a polyvinylidene fluoride (PVDF) coating process for an aluminum curtain wall, which comprises a pretreatment flow and a spraying flow. The spraying flow comprises the following steps of: (1) making a pretreated aluminum plate go online; (2) manually spraying primer at a reverse side: spraying the primer at one side of a back automatic spraying system of the aluminum plate by using a hand spray gun; (3) automatically spraying the primer; (4) leveling the aluminum plate subjected to primer spraying; (5) drying the primer at the temperature between 180 DEG C and 250 DEG C, wherein the drying time is 10-20 minutes; (6) manually spraying a finishing coat at the reverse side; (7) automatically spraying the finishing coat; (8) leveling the aluminum plate subjected to finishing coat spraying; (9) manually spraying varnish at the reverse side; (10) automatically spraying the varnish; (11) leveling the aluminum plate subjected to varnish spraying; (12) drying the aluminum plate at the temperature between 230 DEG C and 250 DEG C for 10-20 minutes; (13) cooling the aluminum plate; (14) testing and appliqueing the cooled aluminum plate to form the aluminum curtain wall; and (15) going offline. The invention provides the PVDF coating process for the aluminum curtain wall of which a coating is not easy to peel off and fall off.

Owner:陈显忠

Preparation method of starch base paper packing adhesive

InactiveCN101838508AEasy to transportEasy to useNon-macromolecular adhesive additivesStarch derivtive adhesivesAdhesiveOxidizing agent

The invention belongs to the technical field of the adhesive, and particularly relates to a preparation method of starch base paper packing adhesive, which comprises the steps of mixing, oxidizing and modifying, wherein the mixing step is: water, Urea hydrogen peroxide and starch are added into a reactor to be uniformly mixed, and the mass ratio of the water, the Urea hydrogen peroxide and the starch is: 10 to 16 parts of water, 1 to 4 parts of Urea hydrogen peroxide and 8 to 12 parts of starch; the oxidizing step is: the pH value is adjusted to 8 to 10, catalyst is added to be mixed for 20 to 40 minutes, and then the mixture is statically held for1 to 2 hours; and the modifying step is: modifier and filler are added to be uniformly mixed. The Urea hydrogen peroxide is used as the oxidant of the starch, so not only the production cost is low, the glue consumption quantity is less, but also the production process is free from utilizing defoamer and is free from peculiar smell, and the environmental protection can be realized.

Owner:HUZHOU SIYI STARCH IND

Formula of putty coated on gypsum inner wall

The invention discloses a formula of putty coated on a gypsum inner wall. The putty comprises the following raw materials in parts by weight: 100 parts of desulfurized gypsum, 5-20 parts of French chalk, 0.3-5 parts of methyl cellulose, 0.1-1 part of polyvinyl alcohol, 0.01-1 part of sodium citrate and 0.01-1 part of redispersable gelatine powder. The raw materials are uniformly mixed and stirred to obtain the product. The initial setting time is 30-110 minutes, the final setting time is 45-125 minutes, the folding strength is 1.76-2.34 MPa, the compression strength is 3.55-5.05 MPa, and the bonding strength is 0.30-0.38 MPa. The invention has the advantages of strong adhesive force, high bonding strength, favorable air permeability, high water resistance, delicate hand feel of the wall surface, soft appearance and favorable tactile sensation.

Owner:河南省翔宇建材科技有限公司

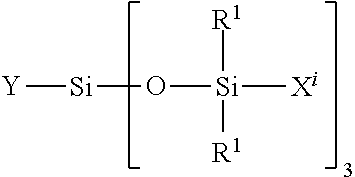

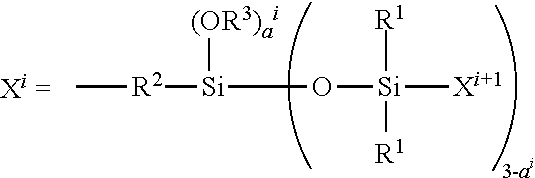

Skin perfecting cosmetic compositions and methods of use

PendingUS20200276093A1Good lookingImprove skin appearanceCosmetic preparationsMake-upSkin appearancePolymer science

The instant disclosure relates to cosmetic compositions that when applied to skin instantaneously and dramatically improve the appearance of the skin. The compositions include volatile hydrocarbon oil; mineral thickening agents; silicone elastomers; and hydrophobic film forming polymers; wherein the weight ratio of the total amount of hydrophobic film forming polymers to the total amount of mineral thickeners (film forming polymers:mineral thickening agent) is 1:1 to 8:1, and the weight ratio of the total amount of silicone elastomer to the total amount of mineral thickener (silicone elastomer:mineral thickening agent) is 1:1 to 5:1. Methods for improving the appearance of skin comprising application of the cosmetic compositions to the skin are also disclosed.

Owner:LOREAL SA

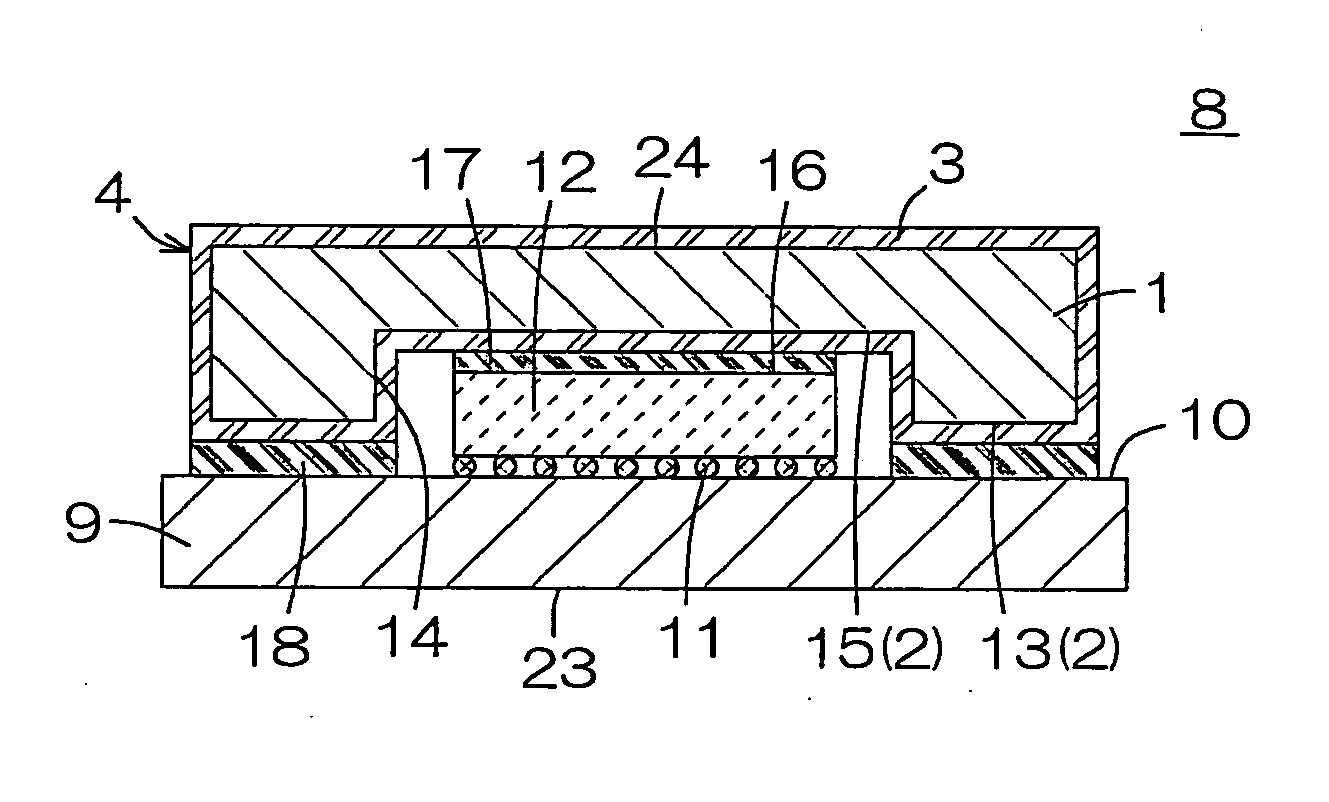

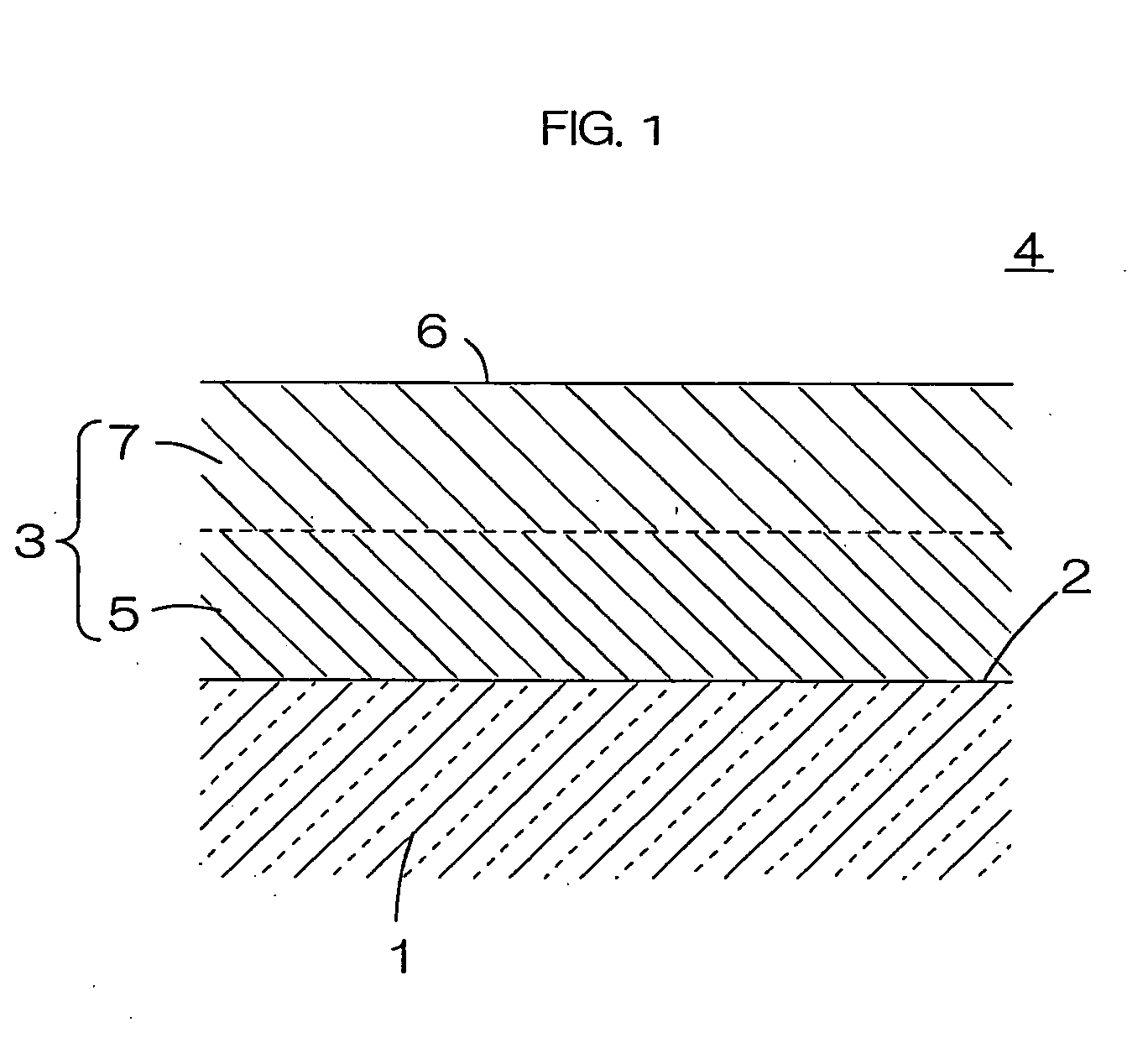

Heat spreader and method for manufacturing the same, and semiconductor device

InactiveUS20080298024A1Good reproducibilityEfficient preparationSemiconductor/solid-state device detailsSolid-state devicesDevice materialAdhesion strength

On a connection surface 2 of a base substrate 1 composed of a material including Cu, a heat spreader includes a Ni plating layer 3 having a high Cu region 5 where the content of Cu is not less than 1% by mass, in a range of not more than 2 μm in the thickness direction from an interface with a base substrate 1, and the content of Cu in a foremost surface 6 of the Ni plating layer 3 is less than 0.5% by mass, and the adhesion strength of the Ni plating layer 3 to the base substrate 1 is not less than 90 N / mm2. A semiconductor device includes a semiconductor element, and the heat spreader for removing heat generated when the semiconductor element is operated. In a manufacturing method, a first plating layer to form the high Cu region is formed on the connection surface 2 of the base substrate 1 and heat-treated at a temperature of more than 600° C., and a second plating layer is then formed thereon and heat-treated at a temperature of not more than 600° C.

Owner:ALLIED MATERIAL

Moisture-proof coating

InactiveCN105273543AGood film formingSpread evenlyLignin material coatingsEmulsionPhosphoric acid tributyl ester

The invention discloses moisture-proof coating which comprises following components according to content and proportion: 8 to 12 parts of chlorinated polypropylene resins, 13 to 15 parts of tributyl phosphate, 2 to 7 parts of fibrous wollastonite powder, 10 to 25 parts of acrylate copolymer emulsion, 12 to 14 parts of lignin, 4 to 7 parts of hydroxyethyl cellulose, 2 to 4 parts of thickening agents and 50 to 60 parts of ionized water. The moisture-proof coating can be adhered to various substrates, has excellent moisture resistance, and can not peel off or fade due to other external factors. Besides, the moisture-proof coating has good film forming effect, and is uniform in ductility and not easy to flake.

Owner:SUZHOU MINGXUAN FLOORING COATINGS

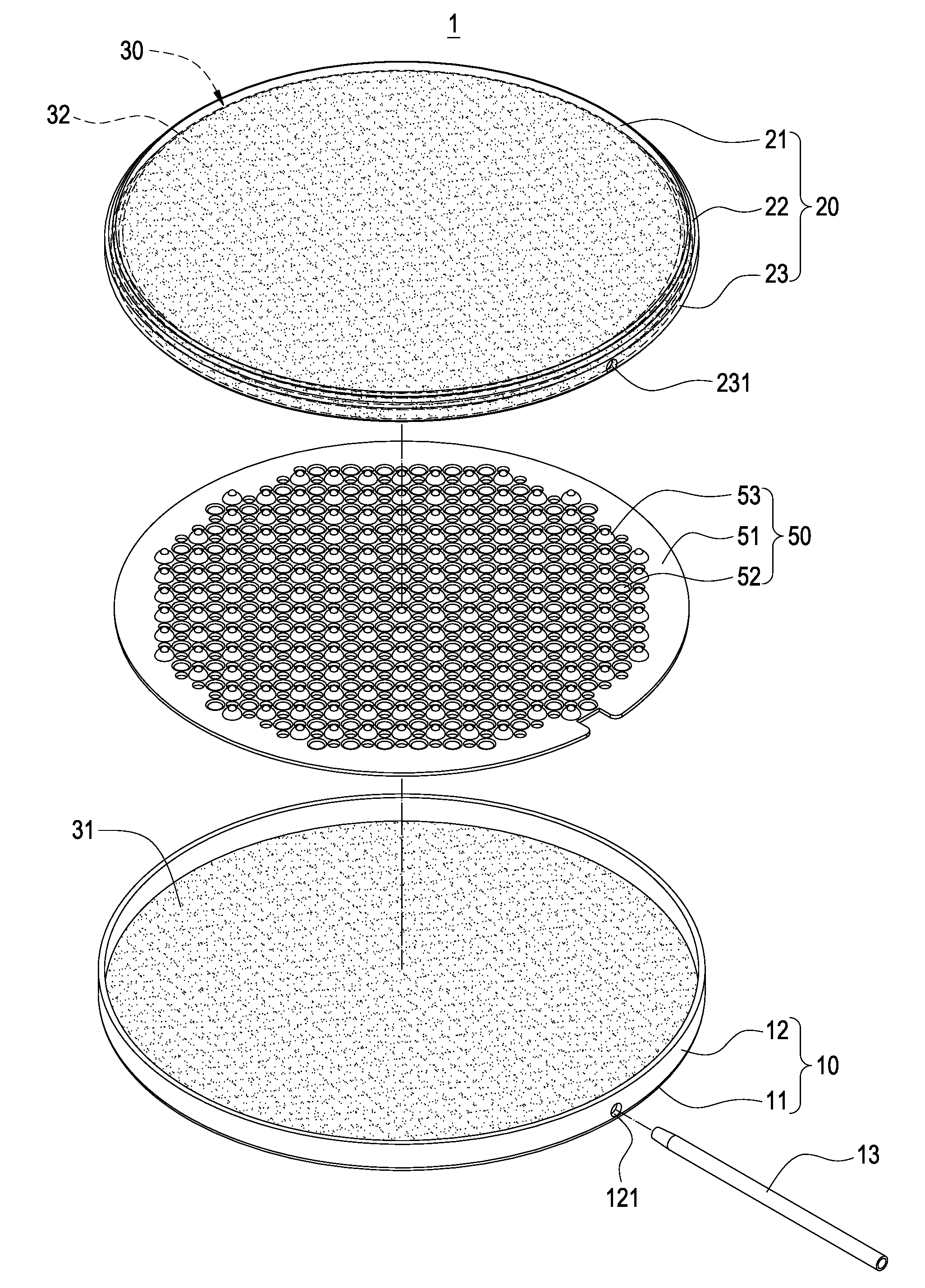

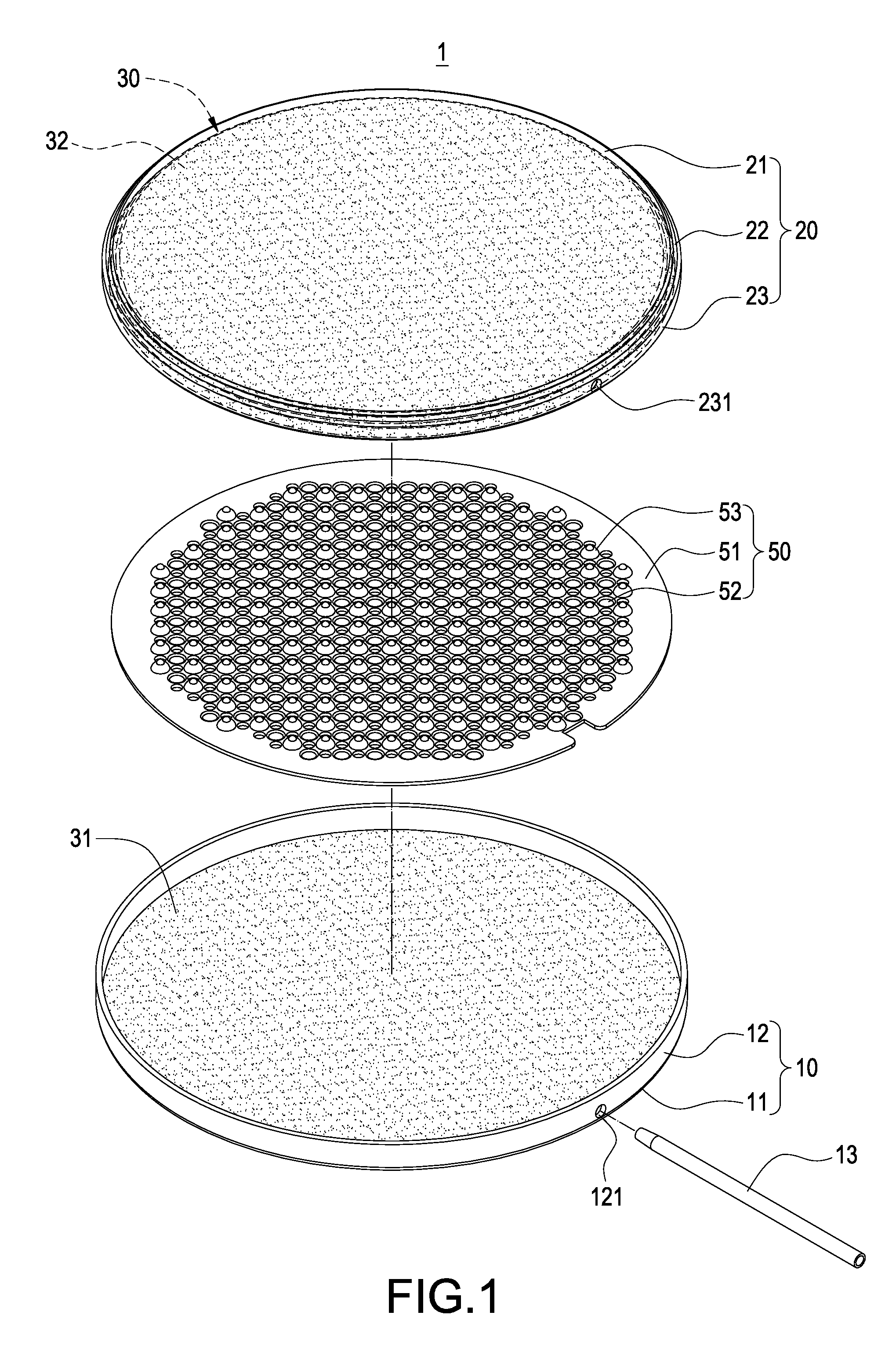

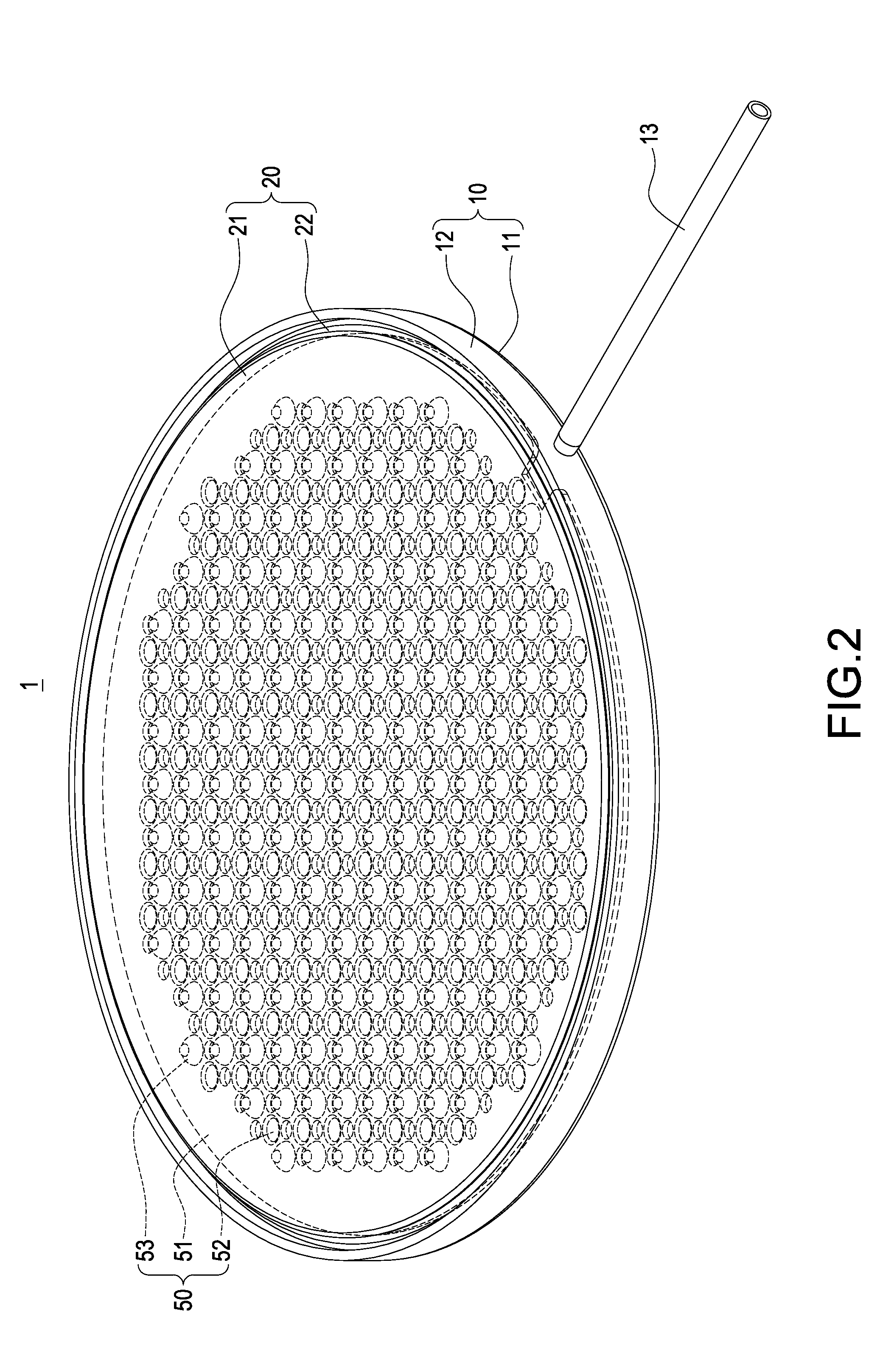

Vapor chamber and method of manufacturing the same

InactiveUS20140076995A1Guaranteed to workPrevent peelingSelf-acting watering devicesDigital data processing detailsWorking fluidEngineering

A vapor chamber and method of manufacturing the same are disclosed. The vapor chamber includes a lower shell, an upper shell, a wick structure and a working fluid. The lower shell has a bottom plate and a lower side plate extended from a periphery of the bottom plate. The upper shell has a top plate, an annular slot formed on the outer edge of the top plate, and an upper side plate extended from a periphery of the annular slot. The upper shell covers the lower shell so that the upper side plate abuts against the lower side plate, and a solder accommodating space is formed between the annular slot and the lower side plate.

Owner:WANG TZU +3

Casting method for steel-copper composite cylinder body

InactiveCN107096905AImprove corrosion resistanceImprove wear resistanceInternal combustion piston enginesCylindersCopper cylinderComposite cylinder

The invention discloses a casting method for a steel-copper composite cylinder body. The casting method comprises the steps of performing three-dimensional modeling, designing a casting technology and performing technology simulation and optimization, performing base steel heat treatment, performing machining, tool machining and welding, performing base steel surface treatment, performing pre-heating treatment before base steel production, smelting copper alloy, dipping the copper alloy, melting anhydrous borax, putting base steel into a borax solution, pouring the copper alloy into the base steel, putting the base steel into a water tank and cooling and solidifying the base steel to room temperature to obtain the steel-copper composite cylinder body. According to the casting method, the problems of the composite casting technology and the composite material composition of the steel-copper cylinder body can be solved; and the composite strength of the thermometal cylinder body can be high, the yield can be high, the cost can be low, the size of the cylinder body can not be limited, the forming process can be controlled easily, and the quality can be stable.

Owner:安徽恒利增材制造科技有限公司

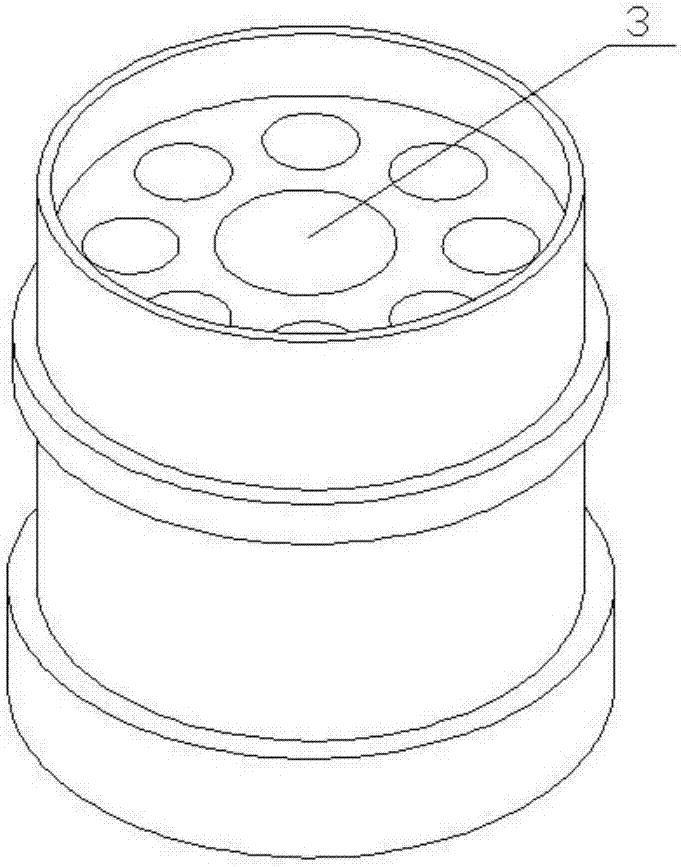

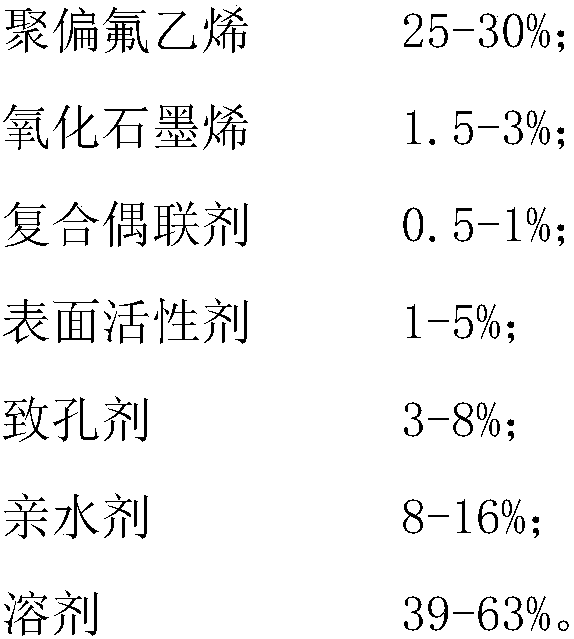

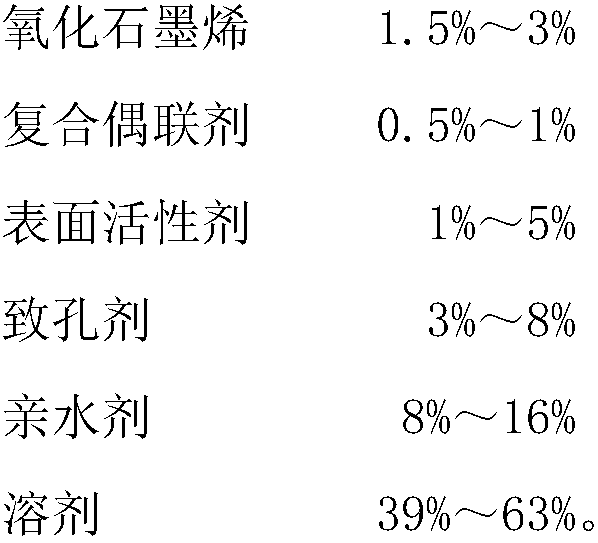

Antibacterial oxidized graphene modified PVDF (polyvinylidene fluoride) hollow fibrous membrane and preparation method thereof

InactiveCN108786495APlay a filtering rolePromote oxidative degradationSemi-permeable membranesMembranesPorosityFiber

The invention relates to an antibacterial oxidized graphene modified PVDF hollow fibrous membrane and a preparation method thereof. The antibacterial oxidized graphene modified PVDF hollow fibrous membrane is prepared from the following ingredients: polyvinylidene fluoride, oxidized graphene, a composite coupling agent, a surface active agent, a pore forming agent, a hydrophilic agent and a solvent. The preparation method comprises the steps that after oxidized graphene is subjected to vacuum drying, the composite coupling agent and polyvinylidene fluoride are added and mixed, and a dry powdery material is prepared; the dry powdery material is added into a mixed solution which is formed through blending of the surface active agent, the pore forming agent, the hydrophilic agent and the solvent to prepare spinning liquid, and the spinning liquid is subjected to membrane preparation through a solution spinning method technology and a membrane complexing technology. The prepared hollow fibrous membrane has the advantages that the porosity is high, the pores are distributed evenly and easy to control, the chemical property is stable, and the membrane has the catalytic and antibacterialfunctions, the membrane can achieve the effects of accelerating oxygenolysis of pollutants and preventing bacteria from proliferating on the surface of the membrane in the wastewater treatment process, and accordingly the anti-pollution property and the filtering effect of the membrane are improved.

Owner:NANTONG QIANGSHENG GRAPHENE TECH CO LTD

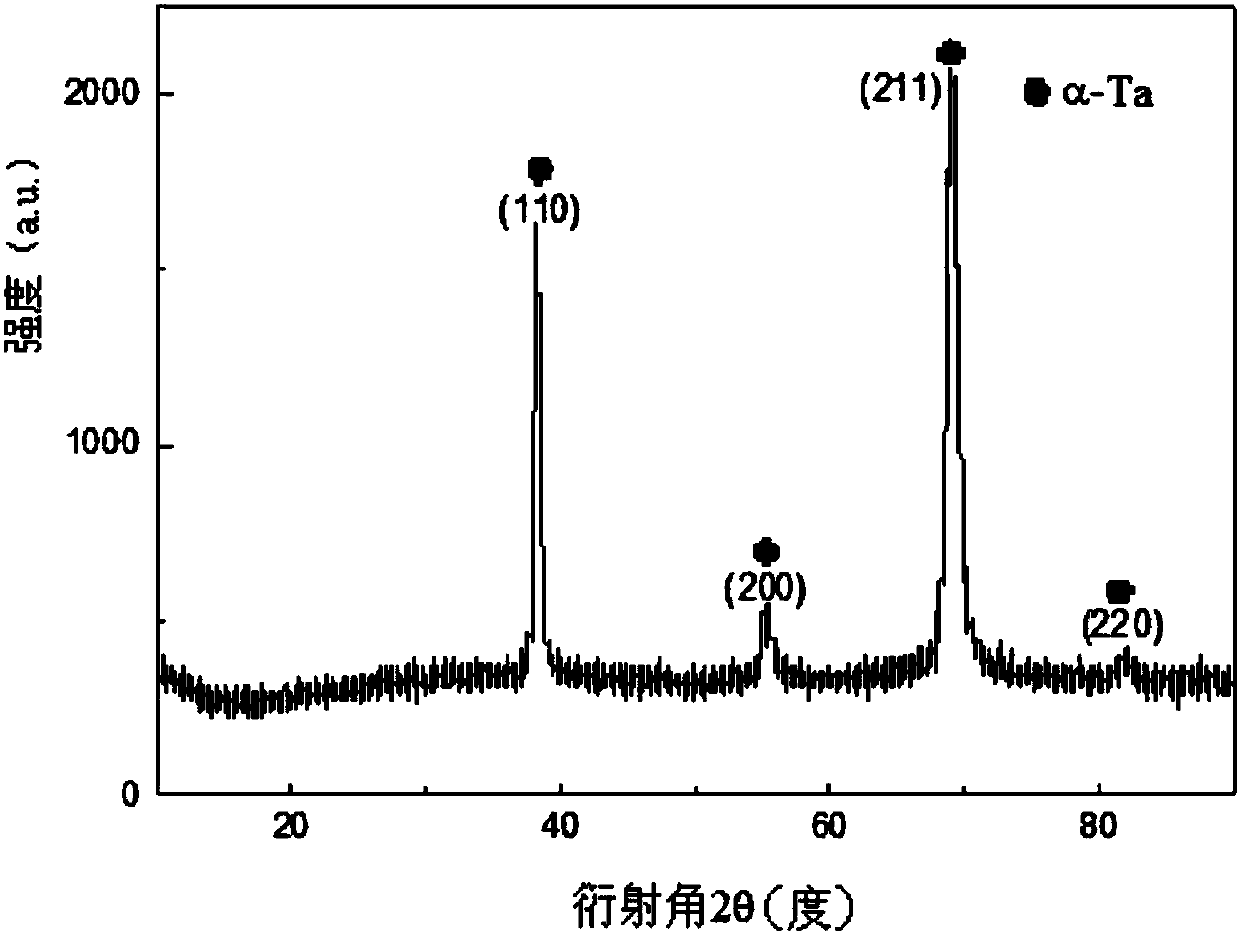

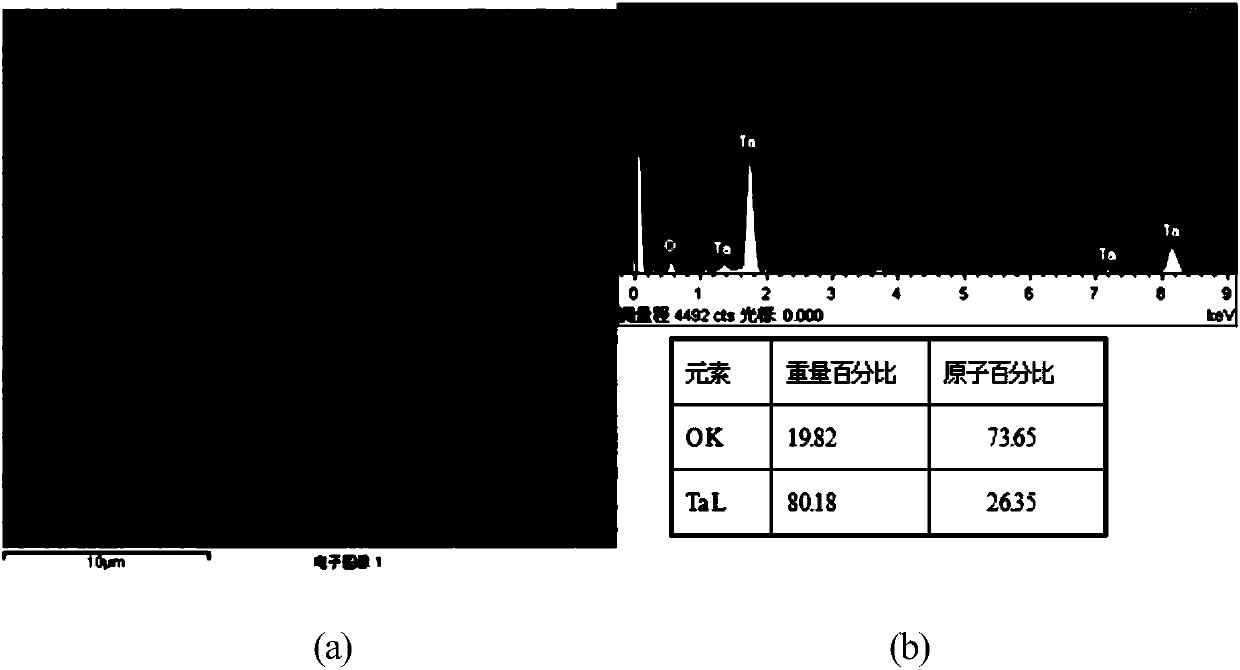

Preparation method of body-centered cubic Ta coating

ActiveCN108103463AImprove thermal shock resistanceAvoid pollutionVacuum evaporation coatingSputtering coatingPulse power supplyBinding force

The invention relates to the field of material science, in particular to a preparation method of a body-centered cubic Ta coating. With adoption of a negative glow region magnetron sputtering method,a substrate part is placed in a negative glow region between an anode and a cathode, heating temperature of the substrate is 200-400 DEG C, a direct-current power supply or a pulsed power supply is used, pure Ta is taken as a target, Ar is taken as working gas, and sputtering power density is 3-15 W / cm<2>. With adoption of the method, the body-centered cubic lattice alpha-Ta coating can be deposited, and binding force and thermal shock resistance are remarkably better than those of an excellent conventional magnetron sputtered Ta coating. The Ta coating prepared with the method binds well withthe substrate when the thickness of the Ta coating reaches about 100 mu m, while the Ta coating prepared with the conventional magnetron sputtering method peels off when the thickness reaches 15 mu m. The thermal shock resistance of the Ta coating prepared with the method and having thickness of 100 mu m is 7 times higher than that of the Ta coating prepared with the conventional magnetron sputtering method and having thickness of 10 mu m.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI +1

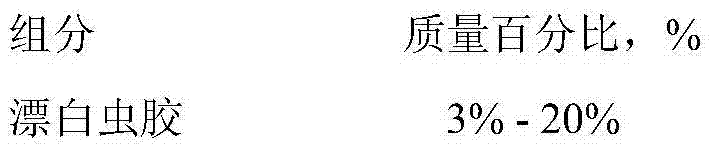

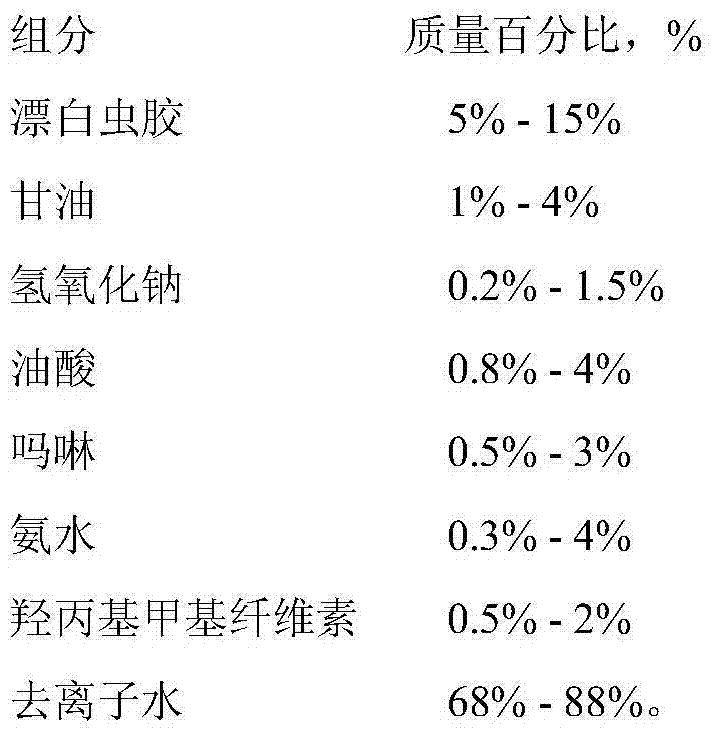

Preservative fruit wax containing bleached lac as well as preparation method and application thereof

The invention provides preservative fruit wax containing bleached lac as well as a preparation method and application thereof. The preservative fruit wax for fruits and vegetables is prepared by mixing bleached lac, glycerol, sodium hydroxide, oleic oil, morpholine, ammonia water, hydroxypropyl methyl cellulose and deionized water in a certain ratio and heating the mixture. By using the fruit wax to treat fruits and vegetables, fruit wax after film forming is not whitening, water-holding and preservative, good in flowability of fruit wax and hard to crust. Accumulation of substances with peculiar smells such as ethanol and acetaldehyde can be obviously reduced, the performance of prolonging the shelf life in quality maintaining aspect is superior to that of existing imported fruit wax, and the preservative fruit wax meets the environment-friendly safe demand of foods and mechanical waxing.

Owner:HUAZHONG AGRI UNIV

Rare earth aluminum alloy conductor and preparation method thereof

ActiveCN102994817AReduced peelingImpurities are easily removedMetal/alloy conductorsCable/conductor manufactureElectric propertiesAntimony

The invention provides a rare earth aluminum alloy conductor and a preparation method thereof. The rare earth aluminum alloy conductor comprises the following components in percentage by weight: 0.5-1% of Fe, 0.07-0.1% of Zn, 0.05-0.1% of Si, 0.02-0.04% of Sb, 0.02-0.05% of Sn, 0.15-0.30% of Cu, 0.01-0.02% of Sr, 0.01-0.03% of Te, 0.03-0.05% of rare earth and the balance of aluminum and inevitable impurities. The rare earth aluminum alloy conductor provided by the invention is excellent in electric property and can be used for producing a cable.

Owner:ANHUI PACIFIC CABLE CO LTD

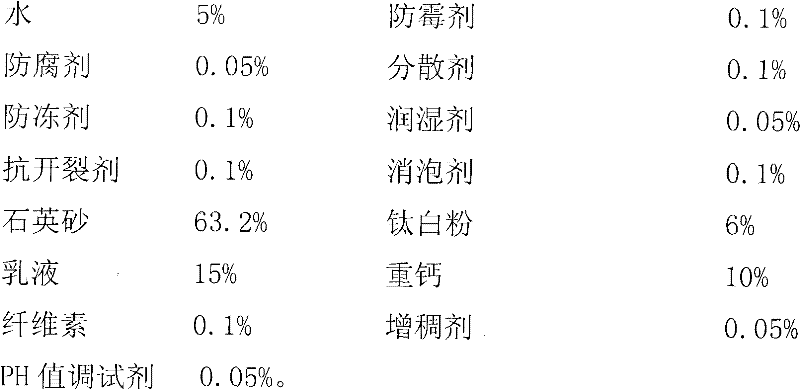

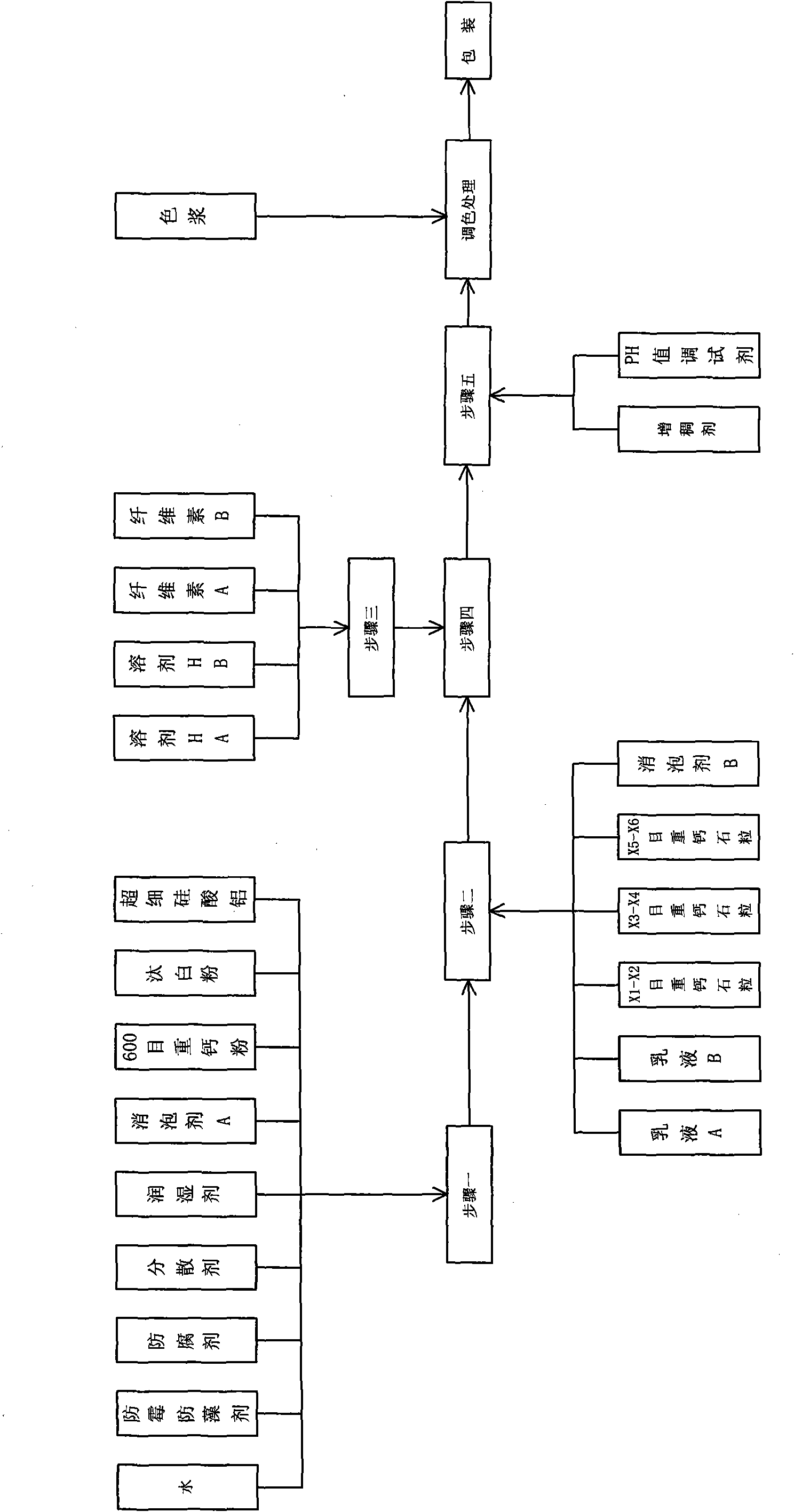

Flexible texture coating and preparation method thereof

InactiveCN101633812ASimple processGood value for moneyMulticolor effect coatingsSolventAluminium silicate

The invention discloses a flexible texture coating which comprises the following components according to percentage by mass: 5-10% of water, 0.1-0.3% of anti-mildew anti-algae agent, 0.05-0.15% of preservative, 0.1-0.3% of dispersing agent, 0.05-0.15 of wetting agent, 0.02-0.07% of defoaming agent A, 7.5-11.5% of 600-mesh heavy calcium carbonate power, 10-15% of titanium dioxide, 1.5-3.0% of ultra-fine aluminium silicate, 10-15% of emulsion A, 15-20% of emulsion B, 10-12% of X1-X2-mesh heavy calcium stone tablet, 10-12% of X3-X4-mesh heavy calcium stone tablet, 13-15% of X5-X6-mesh heavy calcium stone tablet, 0.05-0.1% of defoaming agent B, 0.5-0.15% of solvent HA, 1-3% of solvent HB, 0.2-0.3% of cellulose A, 0.1-0.2% of cellulose B, 0.5-0.7% of thickening agent and 0.05-0.15% of PH value adjusting reagent. The flexible texture coating of the invention has the advantages of bridging slight crack, rich forms and colors and environmental protection; the preparation method of the invention has simple, easy and fast process.

Owner:广东自然涂化工有限公司

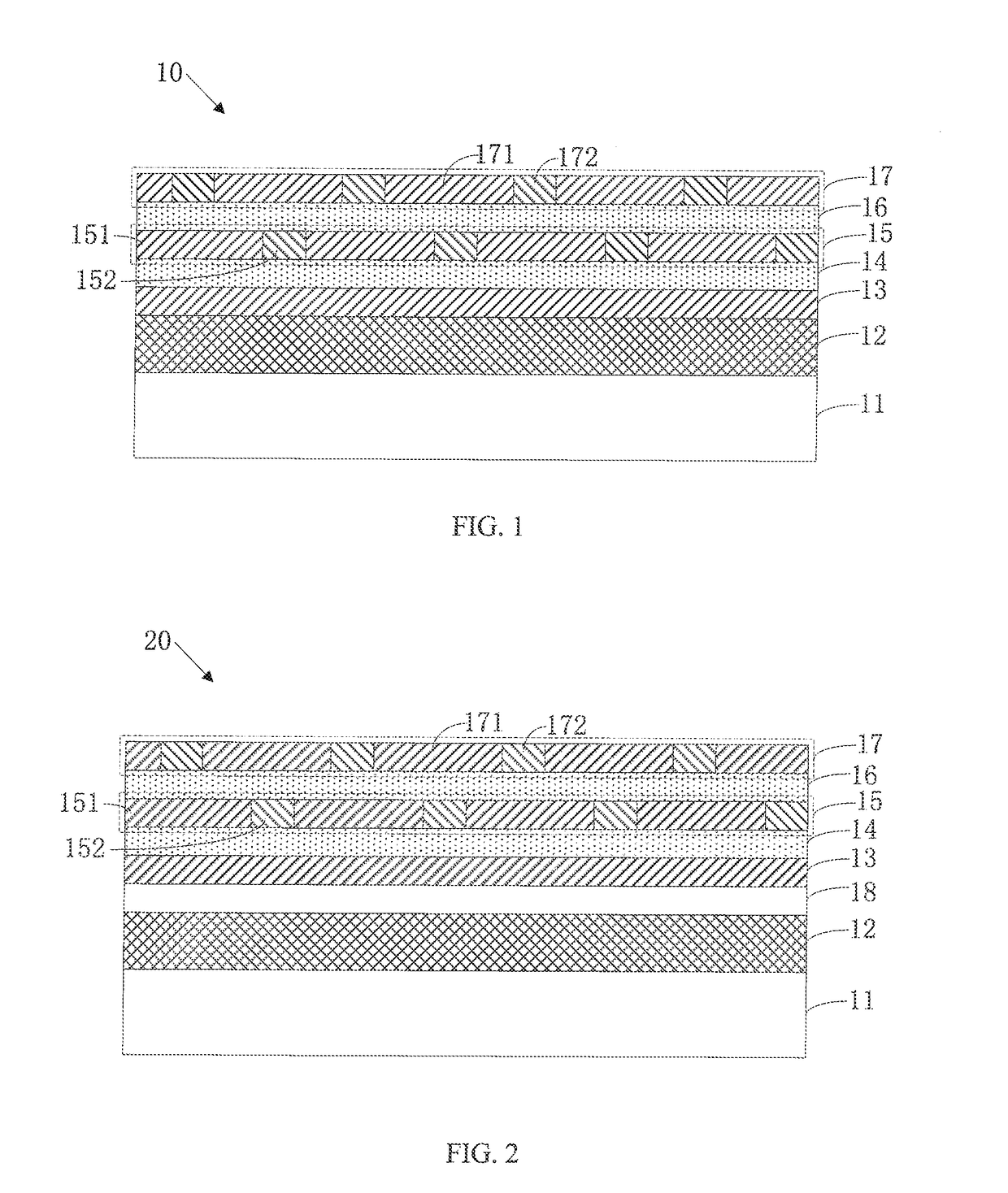

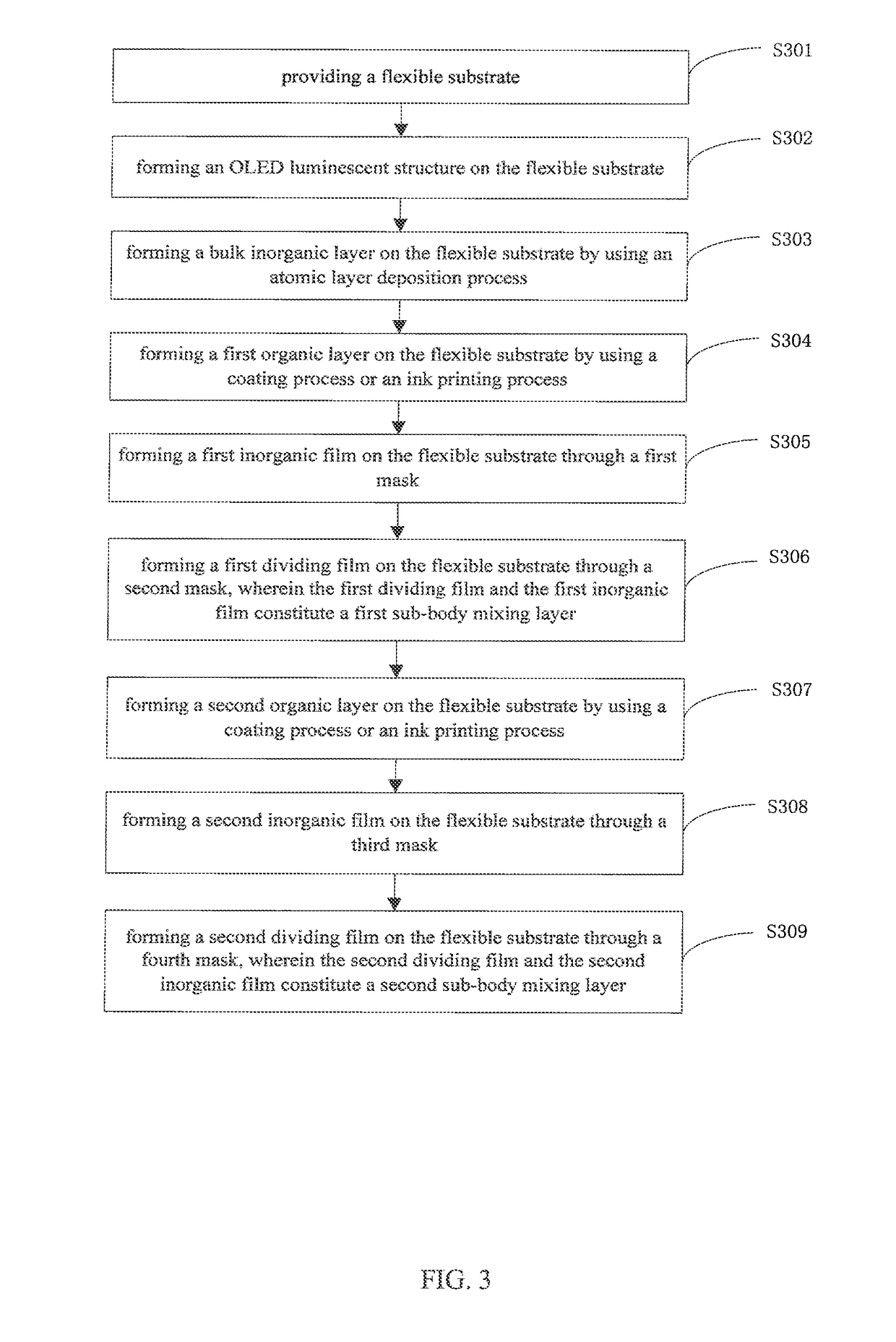

OLED flexible display panel and method for manufacturing the same

ActiveUS20190036076A1Avoid crackingSolve easy peelingFinal product manufactureSolid-state devicesFlexible displayLight-emitting diode

The present disclosure provides an organic light-emitting diode (OLED) flexible display panel, comprising a flexible substrate, an OLED luminescent structure, a bulk inorganic layer, a first organic layer, a first sub-body mixing layer, a second organic layer, and a second sub-body mixing layer. The first sub-body mixing layer includes a first inorganic film and a first dividing film that are alternately arranged, and the second sub-body mixing layer includes a second inorganic film and a second dividing film that are alternately arranged.

Owner:WUHAN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

Rust proof coating for machinery equipment and preparation method thereof

InactiveCN104130708AEffective protectionExtended service lifeAnti-corrosive paintsBituminous coatingsKaolin clayPhosphoric acid

The invention provides a rust proof coating for machinery equipment and a preparation method thereof. The coating contains the following components by weight: 30-45 parts of coal tar, 8-14 parts of maleic anhydride, 3-6 parts of modified phenolic resin, 10-20 parts of barium borate, 8-15 parts of molybdenum dioxide, 7-14 parts of aluminum tripolyphosphate, 1-3 parts of diatomite, 1-3 parts of kaolin, 1-3 parts of light calcium carbonate, 4-8 parts of propylene glycol, 0.6-1.1 parts of lead naphthenate, and 15-30 parts of deionized water. The coating provided by the invention has excellent rust resistance and wear resistance, hardly peels or blisters, has little environmental pollution, and can effectively protect the mechanical equipment, and prolong the service life of mechanical equipment.

Owner:SUZHOU JUKANG NEW MATERIAL TECH

Method for using stainless steel sleeve to coat large-diameter cylinder body

The invention discloses a method for using a stainless steel sleeve to coat a large-diameter cylinder body. The method for using the stainless steel sleeve to coat the large-diameter cylinder body includes that lathing the outer wall of the large-diameter cylinder body, and manufacturing the stainless steel sleeve in a clearance fit mode according to the size of the outer wall of the large-diameter cylinder body; processing triangular threads in the outer wall of the large-diameter cylinder body, and arranging the stainless steel sleeve at the outside of the large-diameter cylinder body under a normal temperature; rolling the stainless steel sleeve while heating. The method for using the stainless steel sleeve to coat the large-diameter cylinder body is convenient to construct and high in reliability, the restored upright surface is difficult to peel, and the life span is long.

Owner:BEIJING LANGDE COAL MINE MACHINERY +1

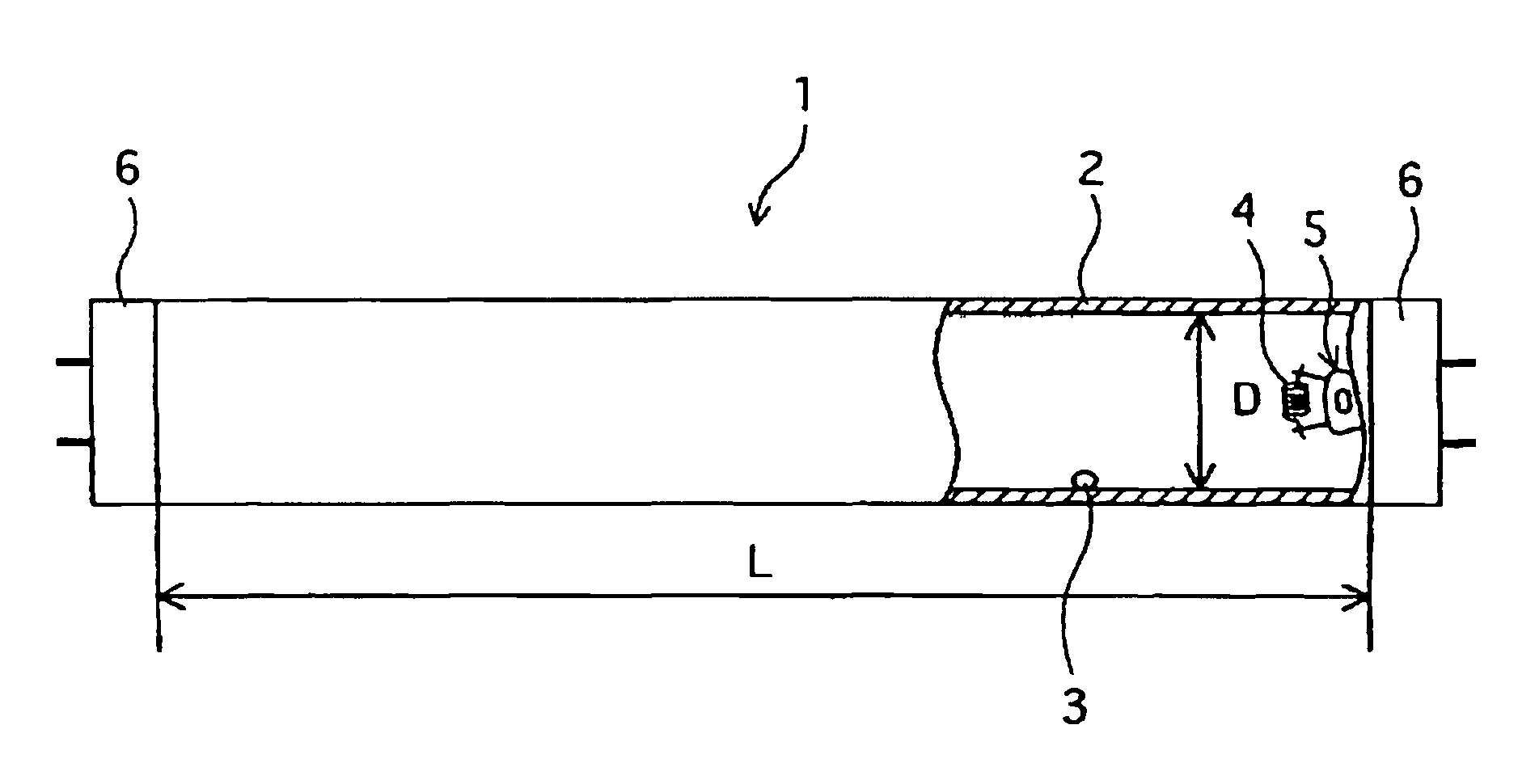

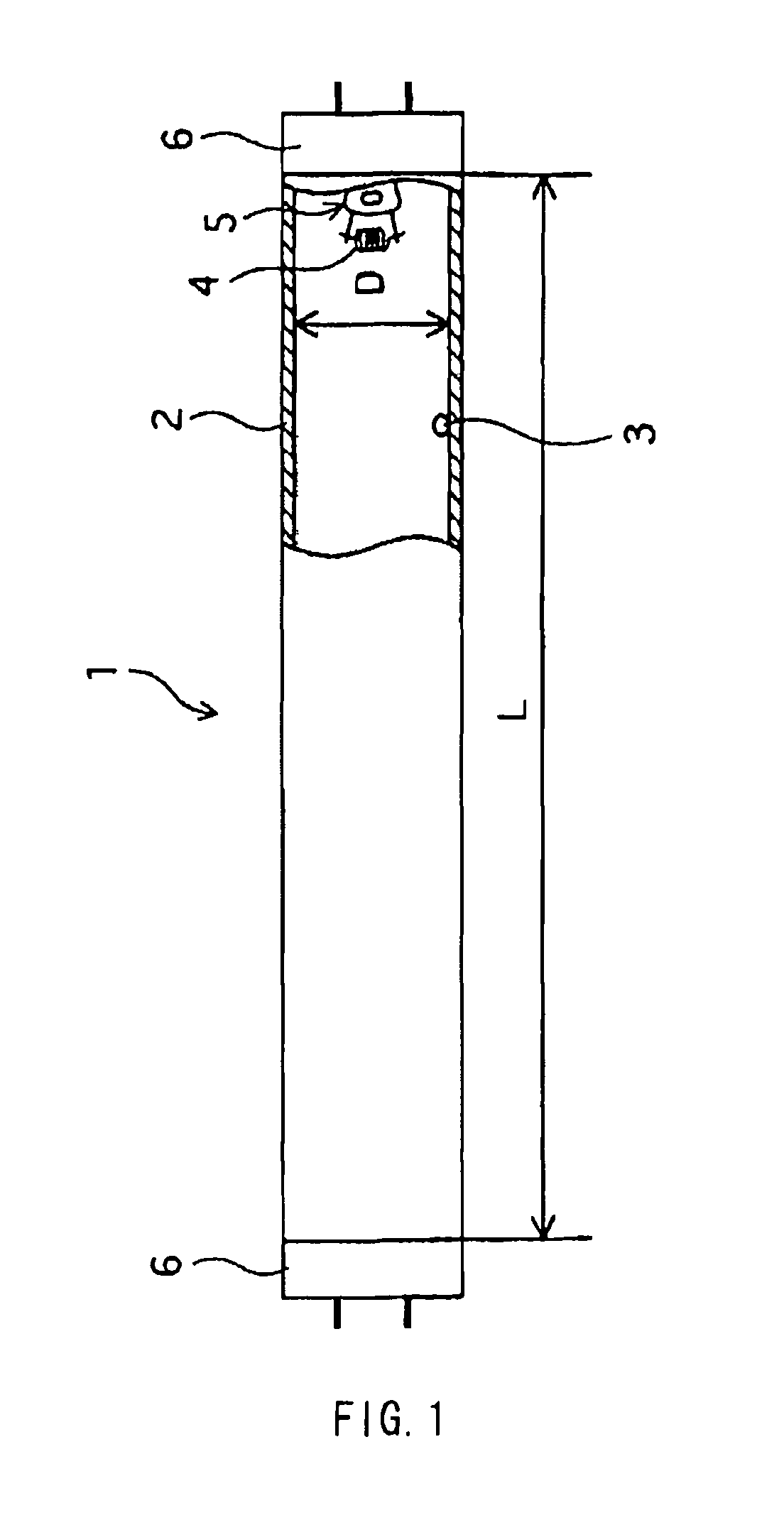

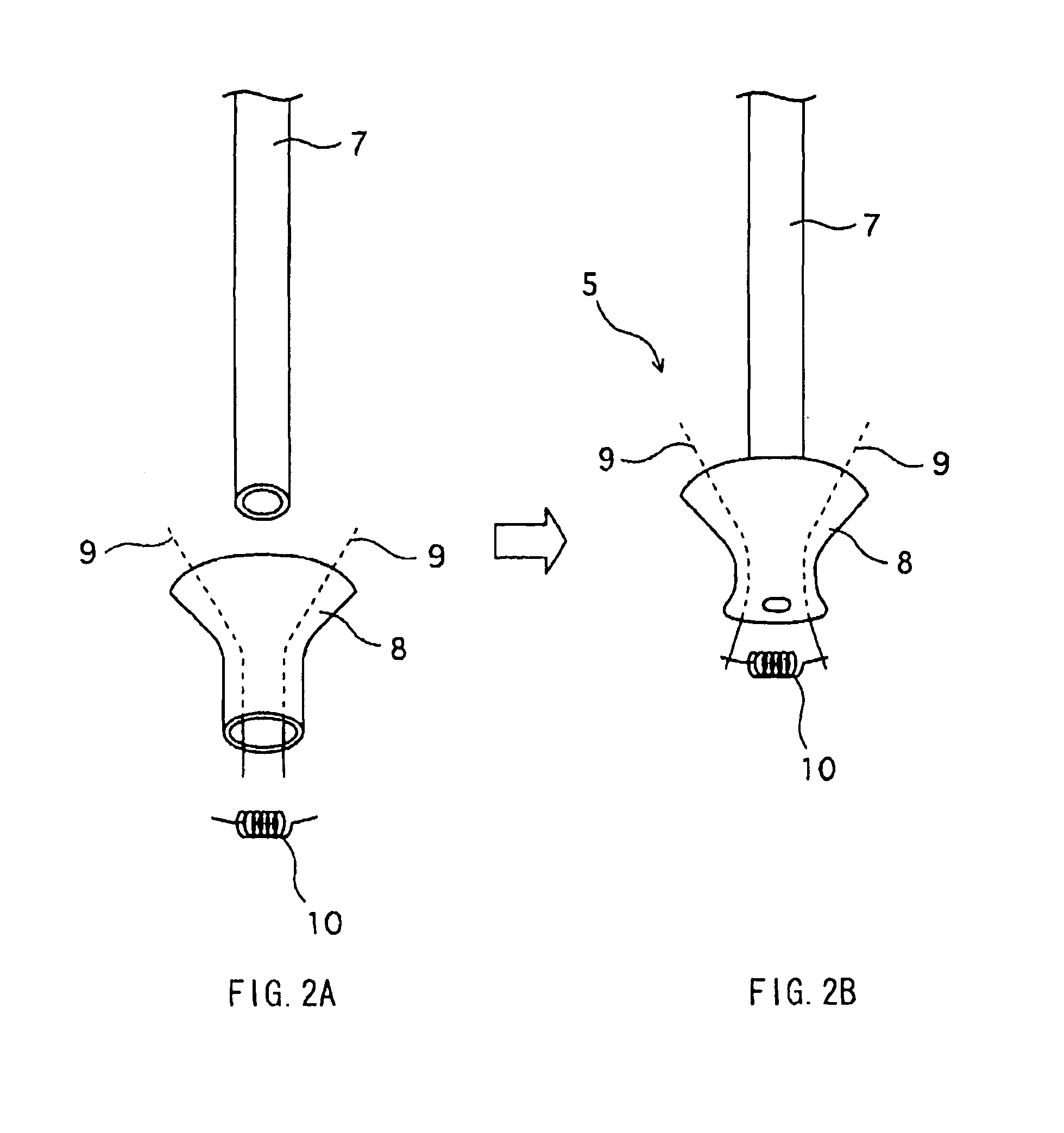

Fluorescent lamp, luminaire and method for manufacturing fluorescent lamp

InactiveUS7538479B2Solve easy peelingDischarge tube luminescnet screensElectroluminescent light sourcesNoble gasPhosphor

A fluorescent lamp is configured so that a glass bulb has a phosphor film formed on its internal face, and a rare gas and an amalgam pellet are enclosed therein. The amalgam pellet contains zinc, tin, and mercury as principal components, one amalgam pellet is enclosed in the glass bulb, and the amalgam pellet has a weight of not more than 20 mg. The fluorescent lamp satisfies the relationship expressed as: 45×(1−A)≦x≦55×(1−A), 75A≦y≦85A, 45−30A≦z≦55−30A, and x+y+z≦100, where x represents a content of zinc contained in the amalgam pellet in percent by weight, y represents a content of tin therein in percent by weight, and z represents a content of mercury therein in percent by weight. This configuration allows the fluorescent lamp to be characterized in that an amount of released mercury that is necessary for the first lighting of the fluorescent lamp is secured, and that the phosphor film is less prone to being peeled due to the amalgam.

Owner:PANASONIC CORP

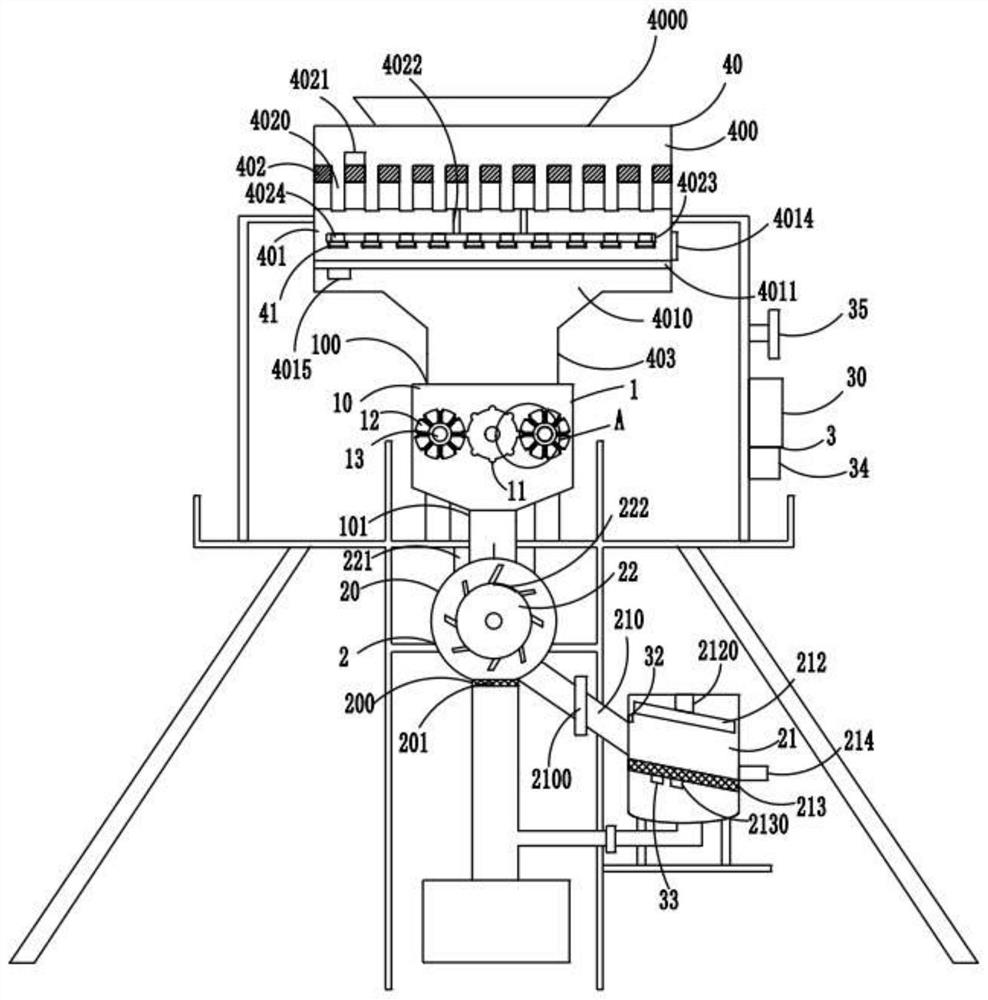

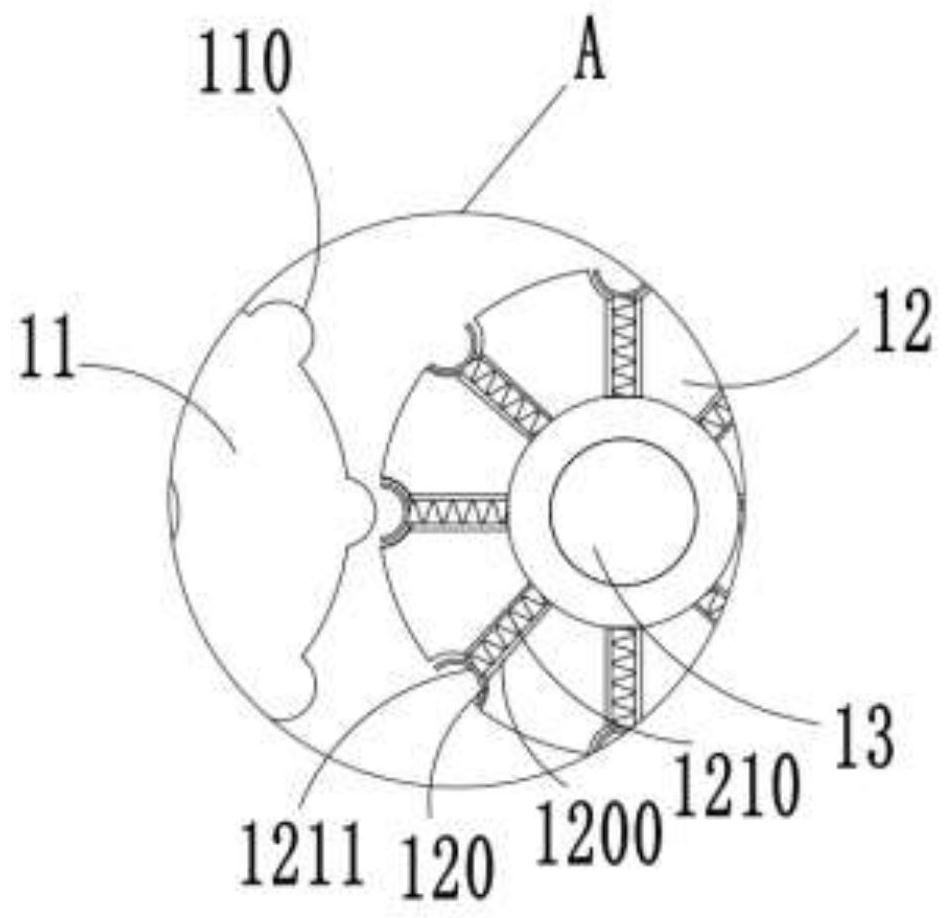

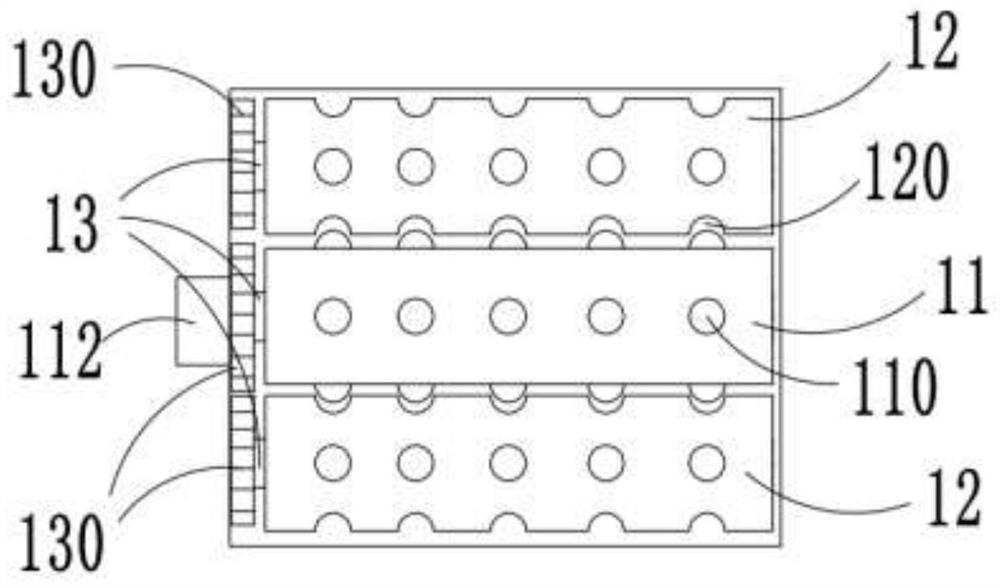

Deseeding and squeezing device for wine processing and production and processing method thereof

ActiveCN112175762AAvoid affecting post-cleaning workAvoid Interfering with Cleaning WorkJuice extractionWine preparationGrape seedProcess engineering

The invention provides a deseeding and squeezing device for wine processing and production and a processing method thereof, and belongs to the technical field of grape processing. The deseeding and squeezing device comprises a pulp squeezing element, a seed filtering element, a control element, a peeling element and a power supply. The deseeding and squeezing device has the advantages that the cleaned grape particles can be peeled, squeezed and deseeded, so as to meet the requirement of wine brewing; when the pulp squeezing element works, because a buffer press sheet is arranged on an auxiliary squeezing roller, the pressure between the auxiliary squeezing roller and a main squeezing roller can be partially buffered, so as to avoid the influence to the mouth feel of the brewed wine due tocrushing of grape seeds and difficulty in separation from grape juice; and when the seed filtering element works, the grape seeds can be quickly separated, and the pulp which is not thoroughly squeezed can be secondarily squeezed, so as to ensure the low content of grape juice in the filtered pulp, avoid the waste of grape juice, and increase the output of wine.

Owner:ZUNYI NORMAL COLLEGE

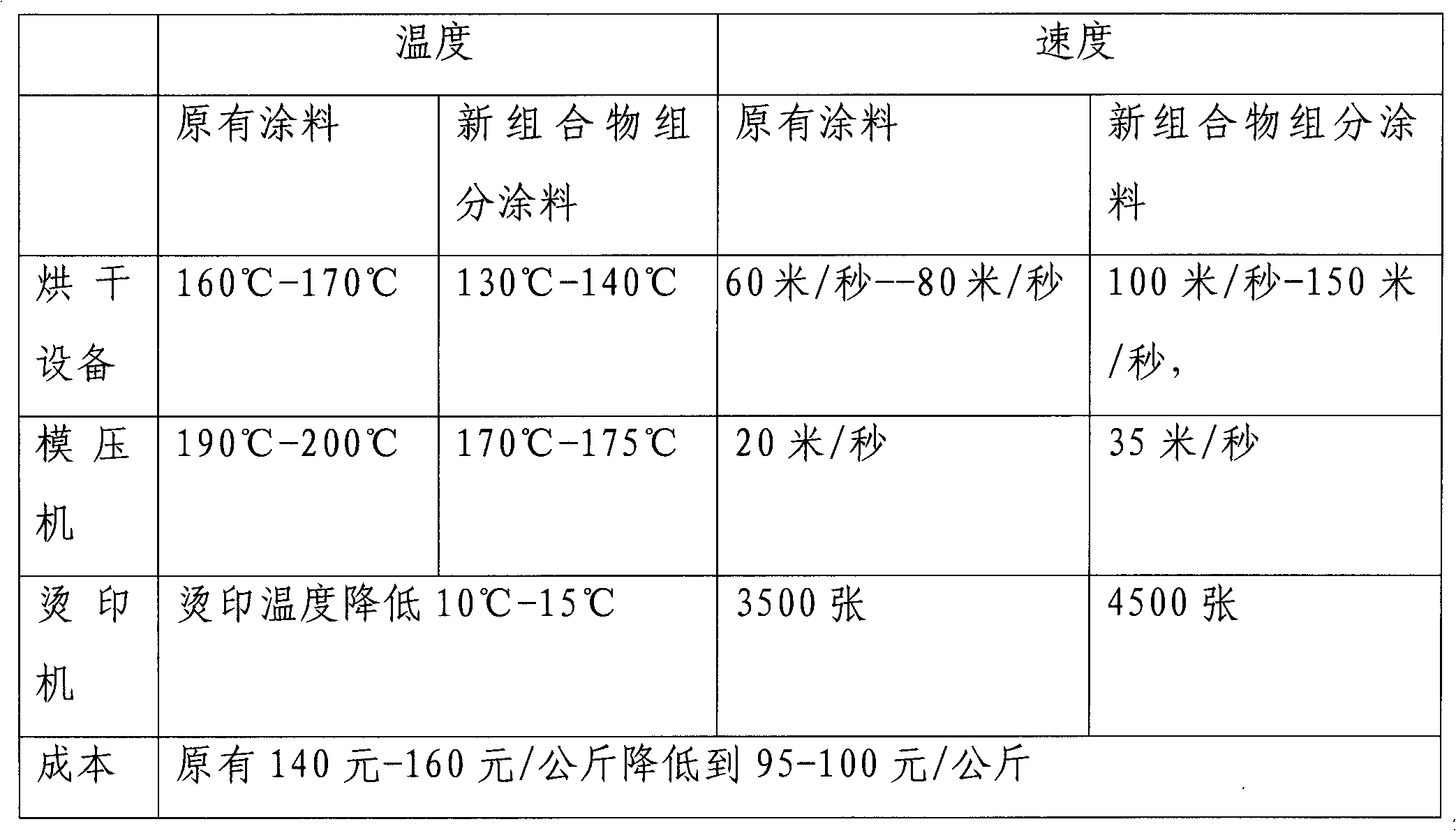

Cooling and energy saving type electrolytic aluminum imaging information layer paint and preparation method thereof

ActiveCN102417770ASolve pollutionReduce processing temperaturePolyurea/polyurethane coatingsInformation layerButyl acetate

The invention relates to a coating material of the holographic anti-counterfeiting printing industry, and in particular relates to a cooling and energy saving type electrolytic aluminum imaging information layer paint and a preparation method thereof, and provides a cooling and energy saving type electrolytic aluminum imaging information layer paint capable of reducing the processing temperature and increasing the processing speed. The paint composite comprises the following components in parts by weight: 30-40 parts of acrylic resin, 20-30 parts of polyurethane, 1-2 parts of organosilicon additive, 50-60 parts of butanone and 20-30 parts of butyl acetate; and the solid content of the paint composite is 35%-40%. By adopting the method, the processing temperature can be reduced, the processing speed can be increased, energy can be saved, the film-forming property of the product is excellent, the product is difficult to peel and stick, the application range of the product is wide, the paint is suitable for the heat printing of specific products, the pollution problem of the production to human and the environment can be solved; and the paint is a cooling and energy saving type electrolytic aluminum imaging information layer paint with better environmental friendliness and the production cost and use cost can be greatly reduced.

Owner:HUBEI LHTC ANTI COUNTERFEITING TECH CO LTD

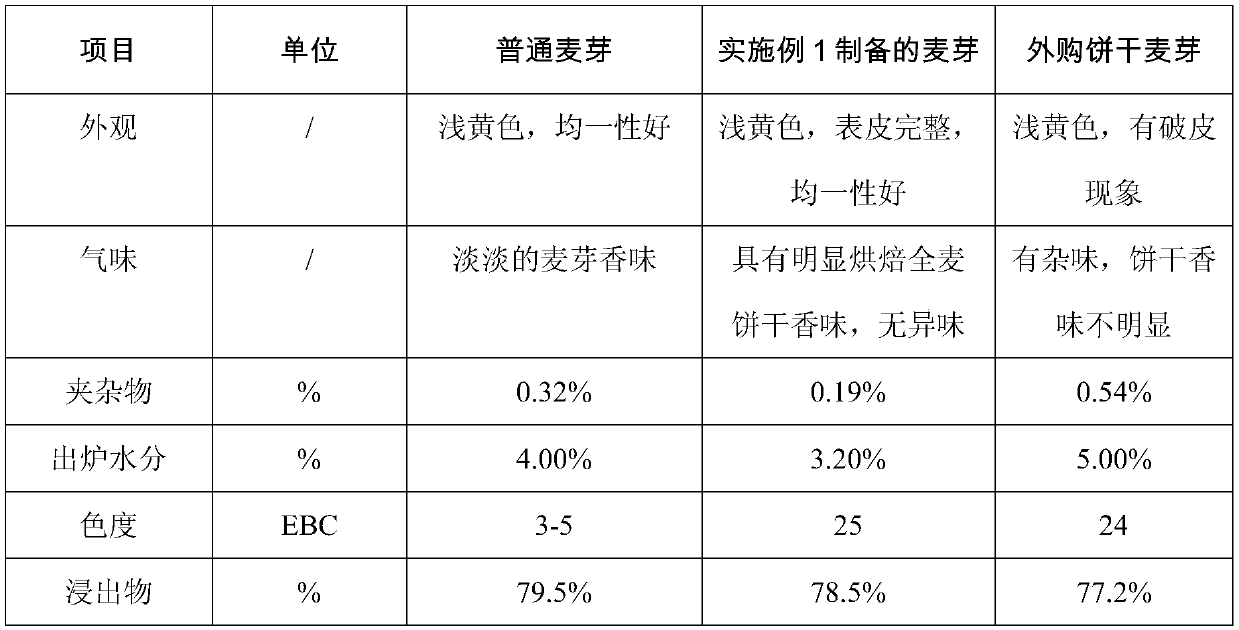

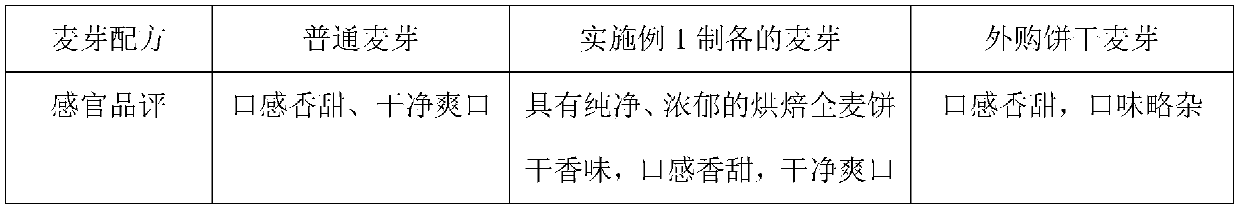

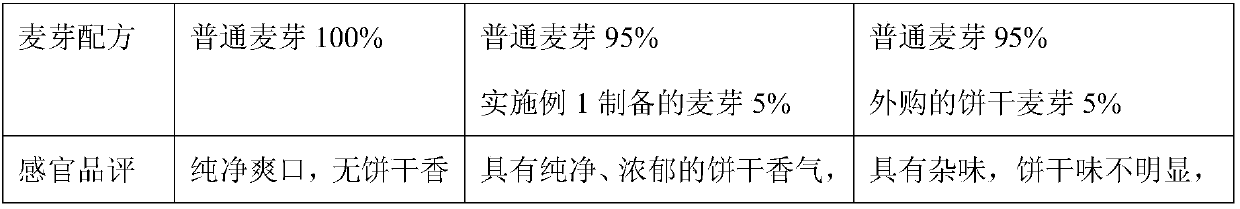

Preparation method of malt with biscuit aroma

The invention belongs to the field of malt manufacturing, and particularly relates to a preparation method of malt with a biscuit aroma. The method comprises the following steps: barley selection, barley raw material pretreatment, barley steeping, sprouting, green malt moisture removal, green malt kilning, root removal, malting baking and unloading. The biscuit malt obtained by the method is strong in biscuit flavor, rich in whole-grain biscuit taste, pure and strong in aroma, sweet in mouth feel and free from scorching smell and burning smell in sensory evaluation. Wort saccharified by the biscuit malt with high a biscuit aroma and beer brewed by the biscuit malt also have a significant biscuit aroma, and the typical flavor characteristics of a beer biscuit aroma are highlighted. The beerwith a biscuit aroma provided by the invention is only added with 5-10% of biscuit malt with a high biscuit aroma, so that the biscuit aroma of the beer can be significantly improved, and the plumpness and foam performance of the beer taste are improved. The beer is cool and transparent in appearance and free from significant change in chroma. All indicators of the beer reach the national standard of GB4927-2008 quality wine.

Owner:中粮麦芽(大连)有限公司

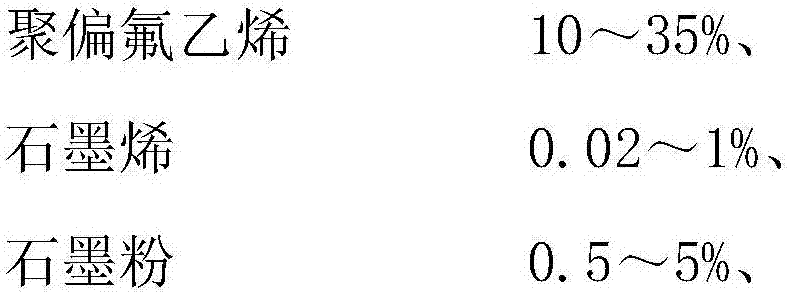

Reinforced graphene modified PVDF hollow fiber membrane and production method thereof

InactiveCN107349802APlay a filtering rolePromote oxidative degradationSemi-permeable membranesFiberSolvent

The invention discloses a reinforced graphene modified PVDF hollow fiber membrane and a production method thereof. The fiber membrane comprises, by mass, 10-35% of polyvinylidene fluoride, 0.02-1% of graphene, 0.5-5% of graphite powder, 0.2-0.5% of a composite coupling agent, 2-28% of a hydrophilic agent, 35-70% of a solvent and 5-25% of a pore forming agent. The whole production method of the fiber membrane comprises the following steps: the graphene and the graphite powder are pre-mixed and undergo microwave drying; the composite coupling agent and the polyvinylidene fluoride are added, and high-speed mixing is carried out; other raw materials are added to make a membrane producing material; and the membrane producing material is filtered, and the filtered membrane producing material is transferred into a spinning tank, and undergoes a high-temperature solvent phase conversion technology and a membrane laminating technology to produce the membrane product. The hollow fiber membrane produced in the invention has catalysis and antibiosis functions, and can accelerate the oxidative degradation of pollutants and prevent bacteria from breeding on the surface of the membrane in the sewage treatment process, so the anti-pollution performance and the sewage treatment effect of the membrane are improved; and crocheted network tubes are adopted to carry out reinforcement, so the tensile strength of the hollow fiber membrane is greatly improved, and filament fraction is avoided.

Owner:UNITED ENVIRONMENT TECH XIAMEN

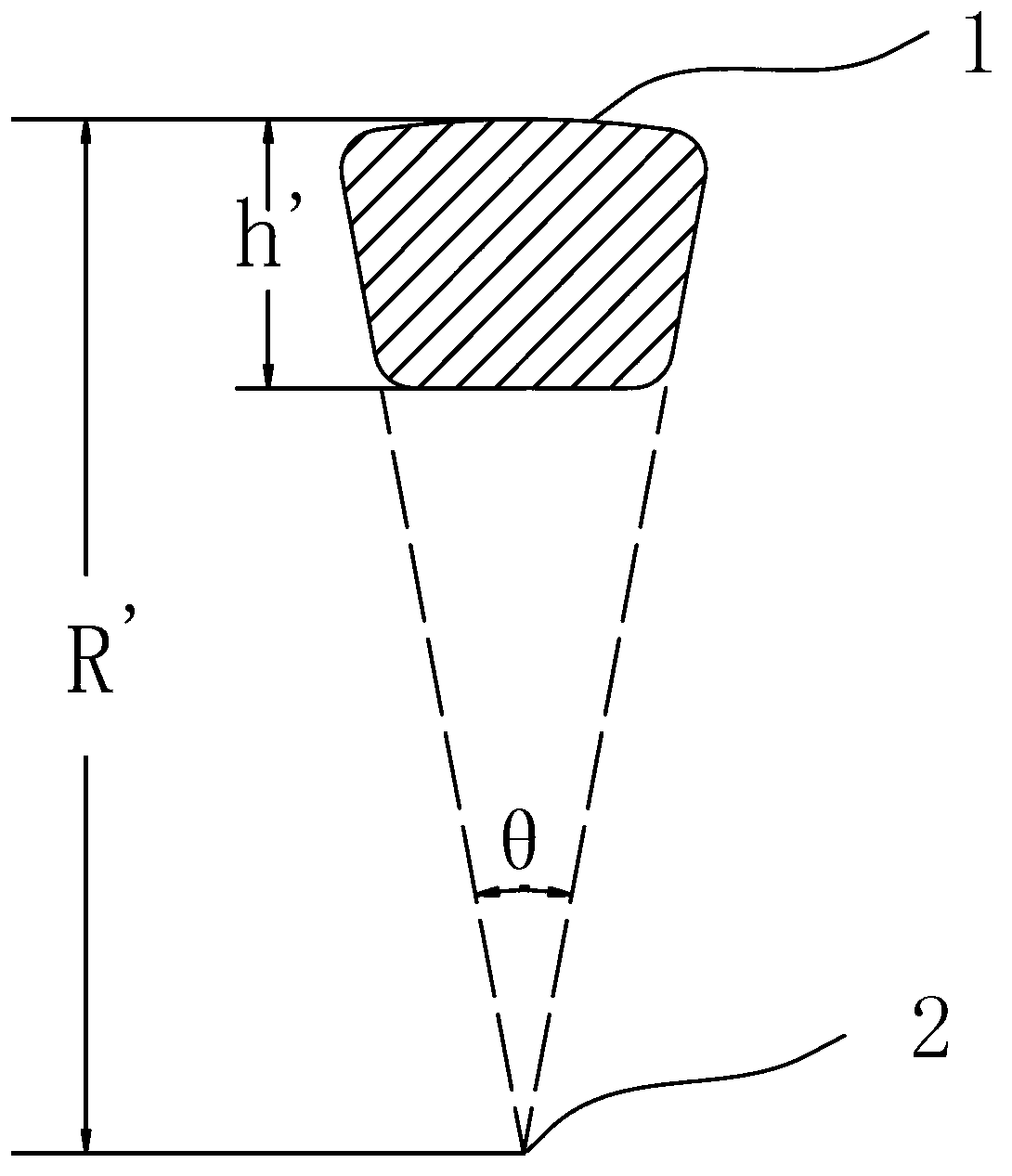

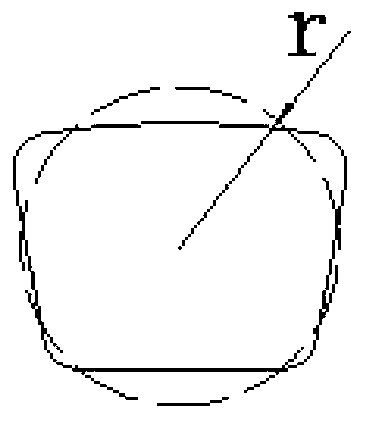

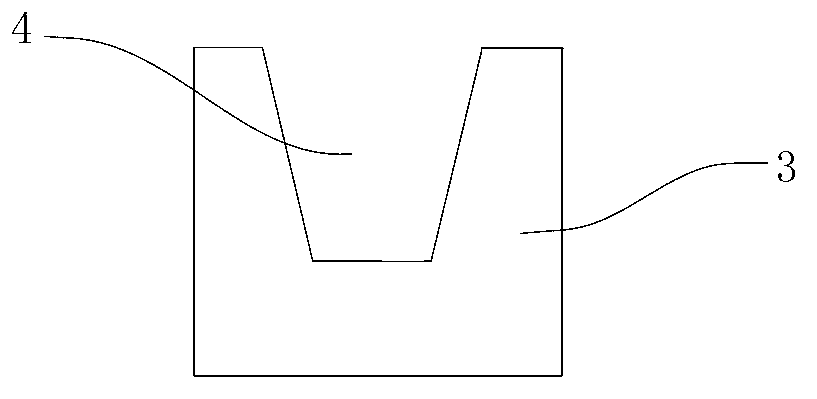

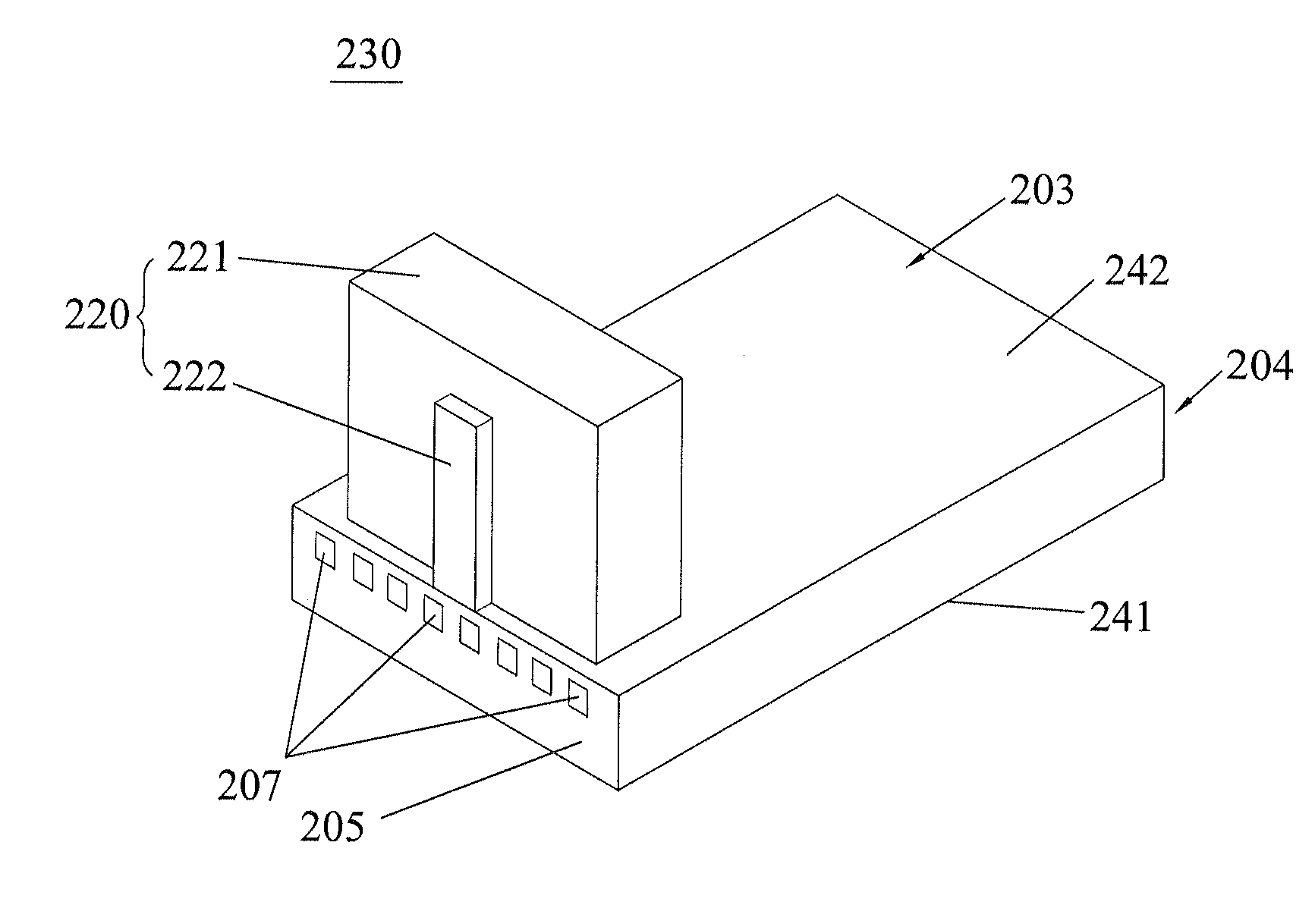

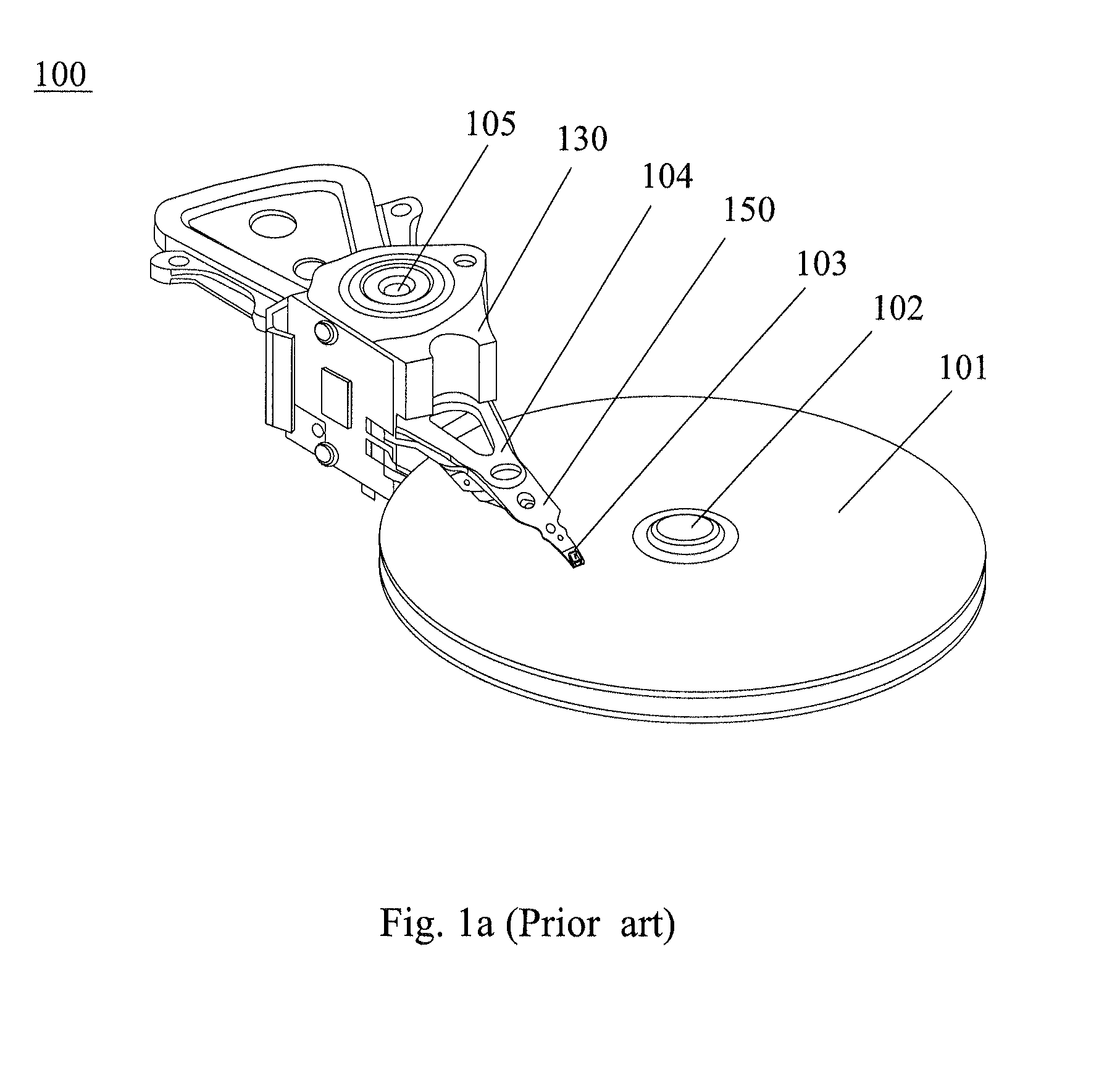

Light source chip and a thermally assisted head with the same, and manufacturing methods thereof

ActiveUS20130136885A1Smooth edgesImprove lighting effectsLayered productsOptical articlesOptoelectronicsLight source

A manufacturing method of a light source chip for a thermally assisted head comprises steps of (a) providing a light source bar with a surface coating formed thereon; (b) forming several blind holes on the predetermined positions of the light source bar by etching, the blind hole having a top hollowed on the surface coating and a bottom hollowed on the light source bar, and the blind hole having a first biggest width at its top; (c) cutting the light source bar along every two adjacent blind holes by a cutting machine. The cutting machine has a cutting means with a second biggest width that is smaller than the first biggest width of the blind hole, thereby cutting down an individual light source chip without contacting the side edges of the blind hole.

Owner:SAE MAGNETICS (HK) LTD

Anti-cracking exterior wall putty

InactiveCN103351695AImprove crack resistanceImproves resistance to crack formationStarch coatingsFilling pastesFiberCarboxymethyl cellulose

The invention discloses anti-cracking exterior wall putty. The anti-cracking exterior wall putty comprises the following components in percentage by weight: 15-17% of pure acrylic elastic emulsion, 10-12% of silicone-acrylate elastic emulsion, 0.5-1% of carboxymethyl cellulose, 2-3% of polyacrylonitrile fiber with the length of 2-6mm, 0.4-0.6% defoaming agent, 0.5-1% of preservative, 0.8-1.2% of thickening agent, 14-16% of white cement, 4-6% of cassava gelatinized starch, 10-12% of heavy calcium carbonate, 5-7% of talcum powder and the balance of water. After being subjected to heat and cold circulation for many years in cold regions, the anti-cracking exterior wall putty disclosed by the invention does crack; tests at minus 40 DEG C to 40 DEG C show that the anti-cracking exterior wall putty has a very good anti-cracking effect; after the anti-cracking exterior wall putty is scraped, other overcoat agents do not need to be sprayed; the anti-cracking exterior wall putty is not weathered, does not peel and has high bonding strength.

Owner:ANHUI KAILIN ADVANCED MATERIAL CO LTD

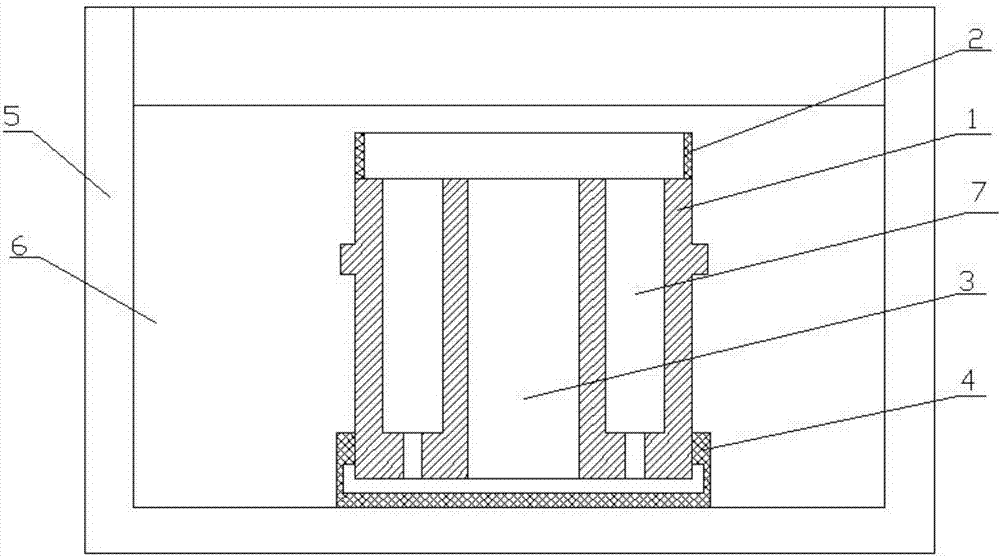

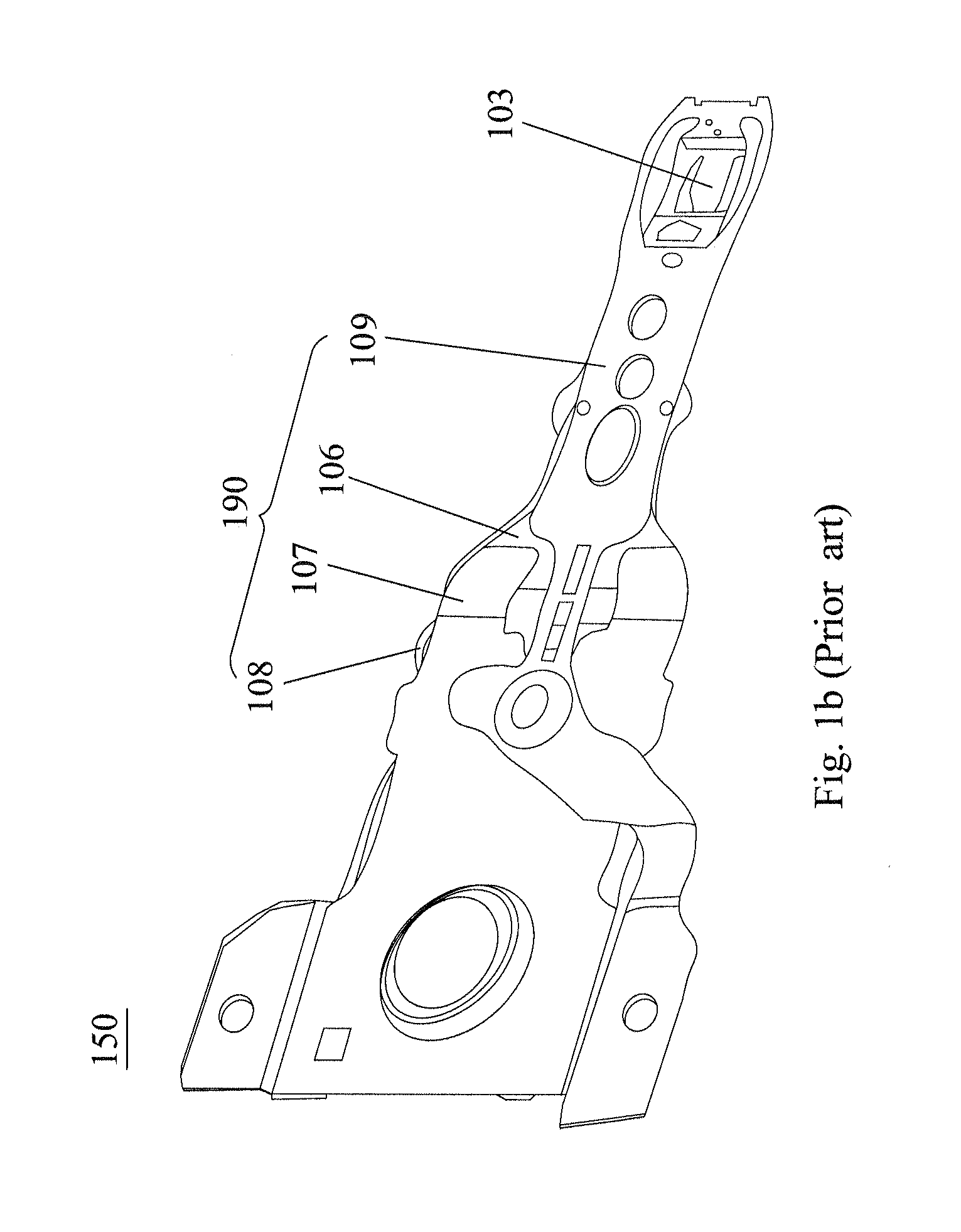

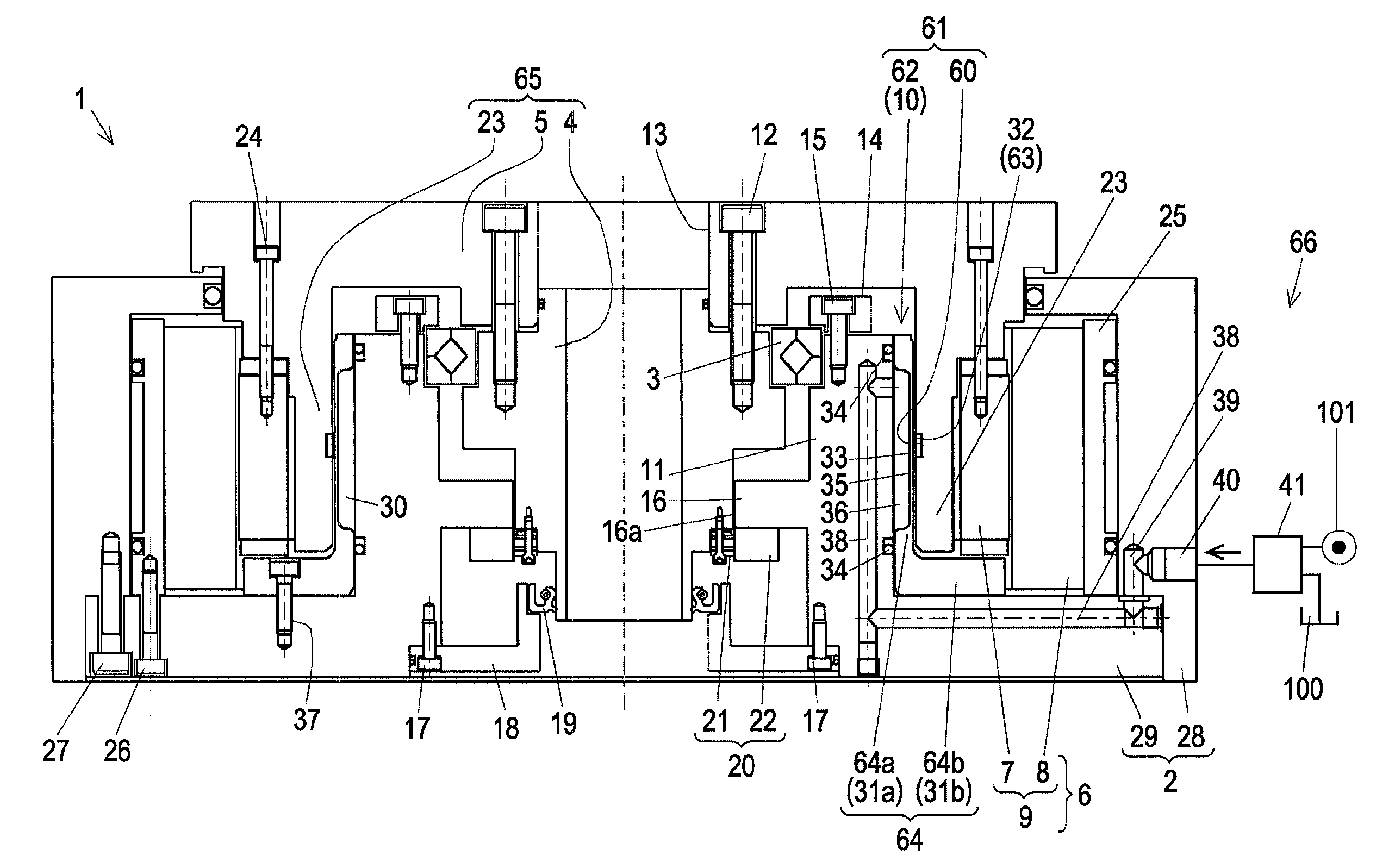

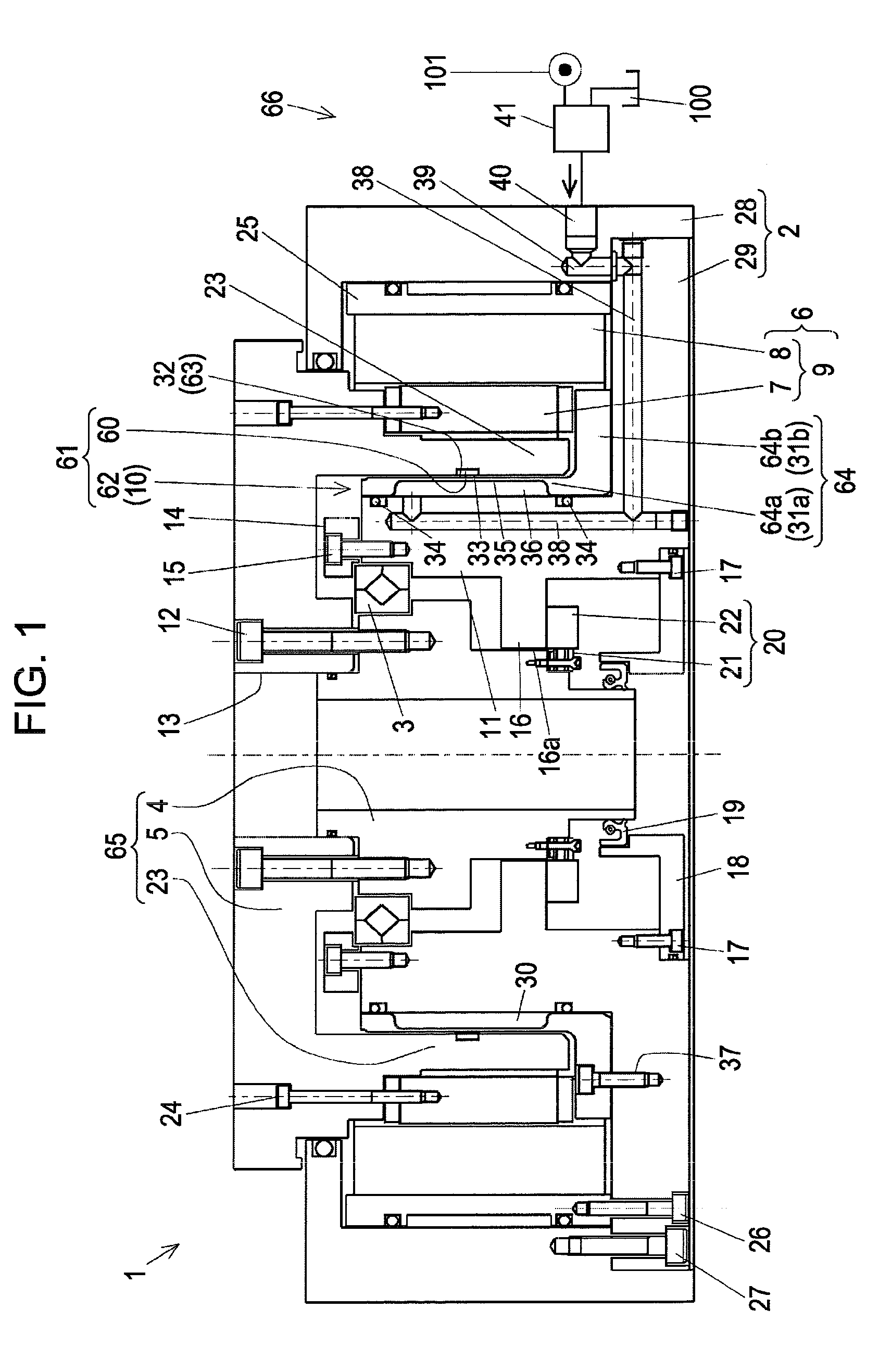

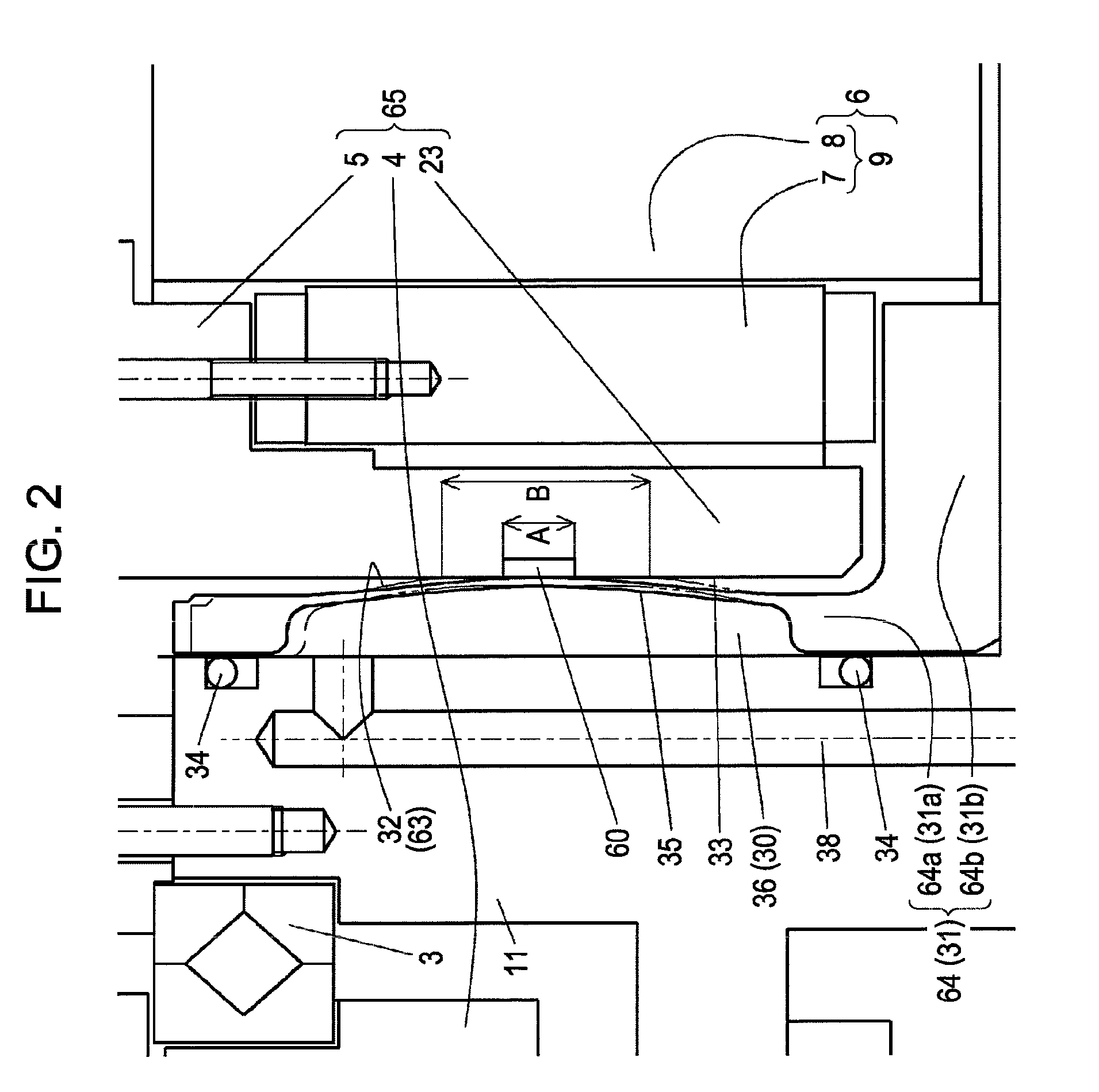

Rotation-resistance device for main shaft drive of machine tool

InactiveUS20110023655A1Uniform and stableAvoid low process precisionFluid actuated brakesPrecision positioning equipmentEngineeringMachine tool

When a finishing operation is performed while rotating a workpiece at a main shaft drive of a machine tool, pulsation occurring in a rotation of the main shaft drive is restricted and the rigidity of a main shaft is increased without increasing the size of a bearing. A rotation-resistance device of a main shaft drive in a machine tool has the following structure in the main shaft drive including a main shaft 4, a rotating body 65, and a driving device 6, the main shaft 4 being supported so as to be rotatable with respect to a frame body 2, the rotating body 65 being secured to an end of the main shaft 4, the driving device 6 rotationally driving the rotating body (65). The rotation-resistance device includes a damping device (10) including a damping member, which is provided at the frame body 2 or the rotating body 65 and which includes a resiliently deformable damping section, a pressing-force applying device 66, which applies a pressing force to the damping member by operating fluid, and a damping surface 32, provided at a side of the frame body 2. The damping device 10 causes the pressing force to act upon the damping section to flex the damping section, so that the damping surface 32 and a sliding surface 33 are pressed against each other, and a rotation resistance that allows rotation is applied to the rotating body 65. A low-friction coefficient member 60 is secured to at least one of the damping surface 32 and the sliding surface 33.

Owner:TSUDAKOMA KOGYO KK

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com