Patents

Literature

100results about How to "Stamping precision" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

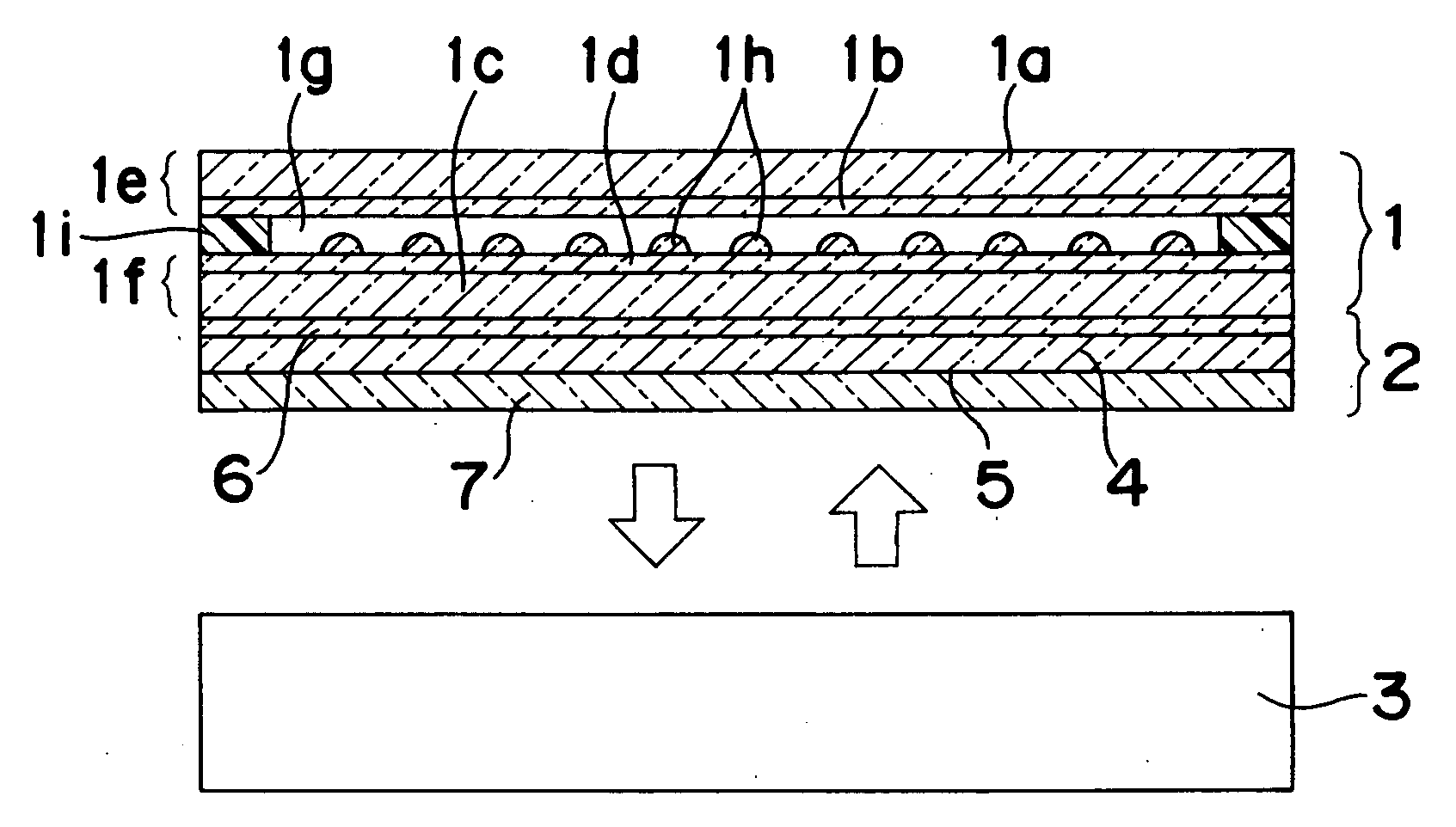

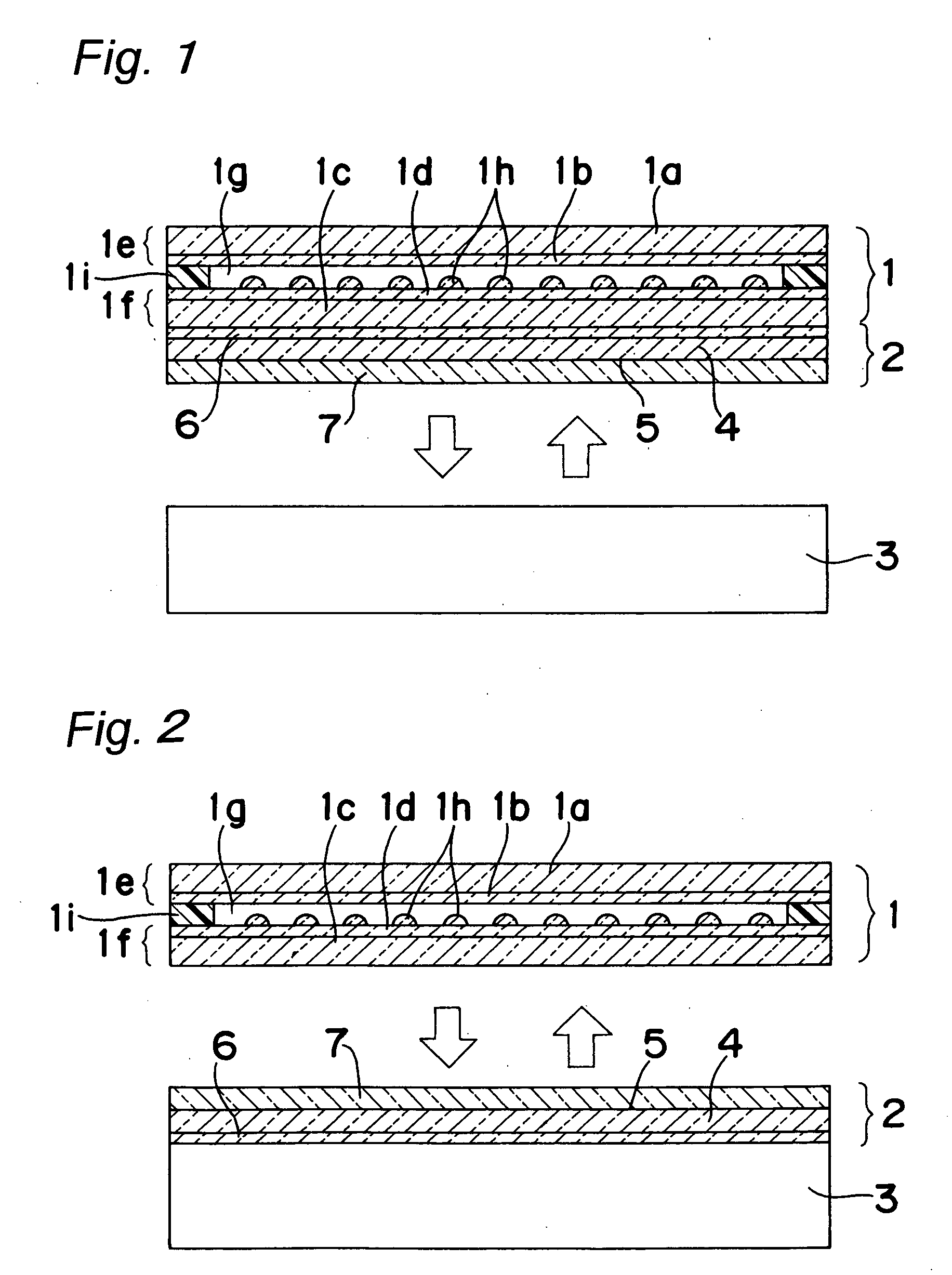

Mounting structure of re-peelable transparent touch panel and mounting sheet used for it

InactiveUS20040263481A1Improve adhesionSimple treatmentEmergency casingsDigital data processing detailsDisplay deviceEngineering

A transparent sheet for mounting that has an acrylic adhesive layer laminated on one surface of a core of plastic film and that has a silicone rubber sheet laminated on a primer-treated surface formed by primer treatment on the other surface is bonded overall onto a reverse face of a transparent touch panel with the acrylic adhesive layer, and the transparent touch panel provided with the sheet for mounting is mounted on a front surface of the display.

Owner:NISSHA PRINTING COMPANY

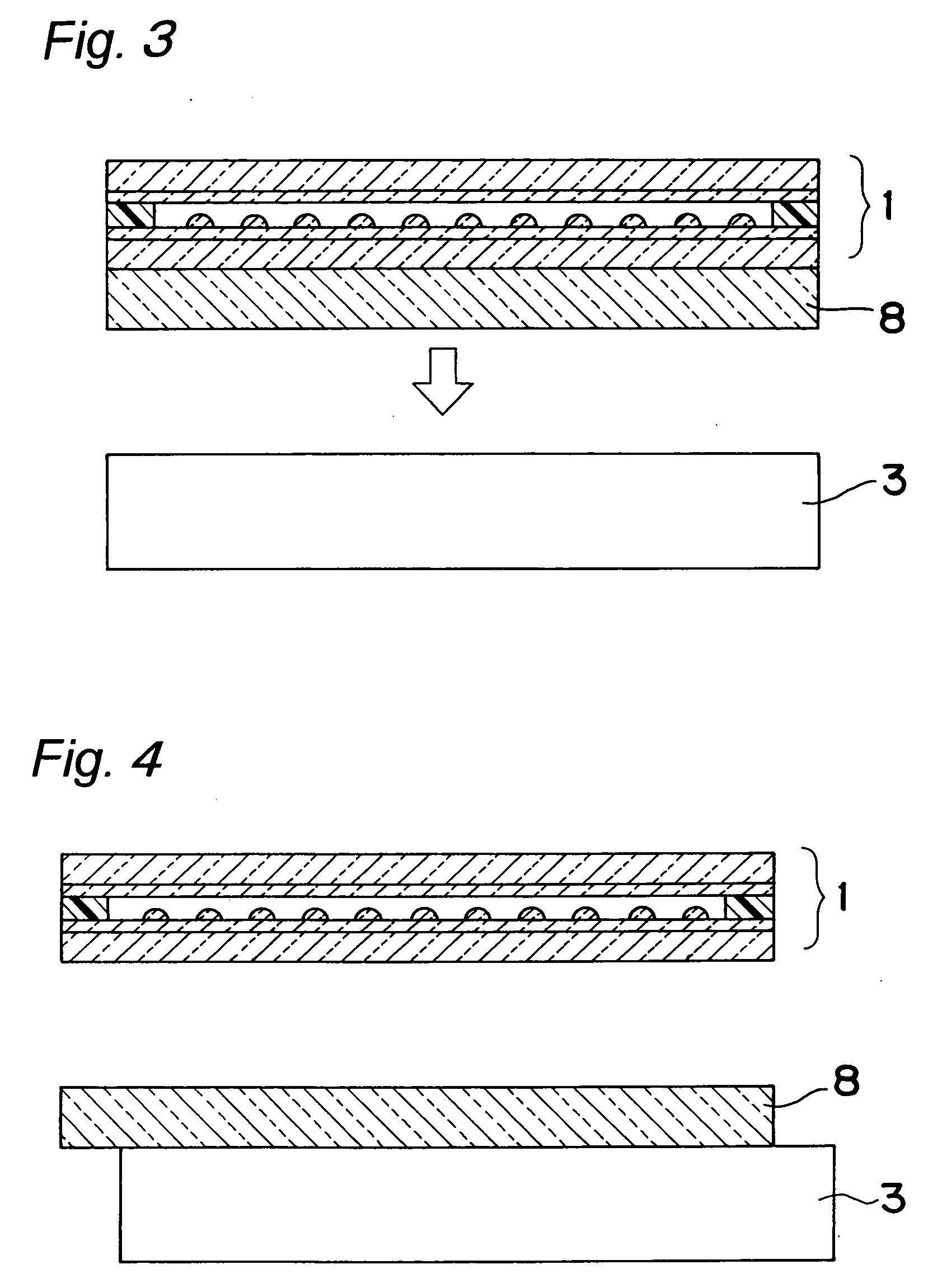

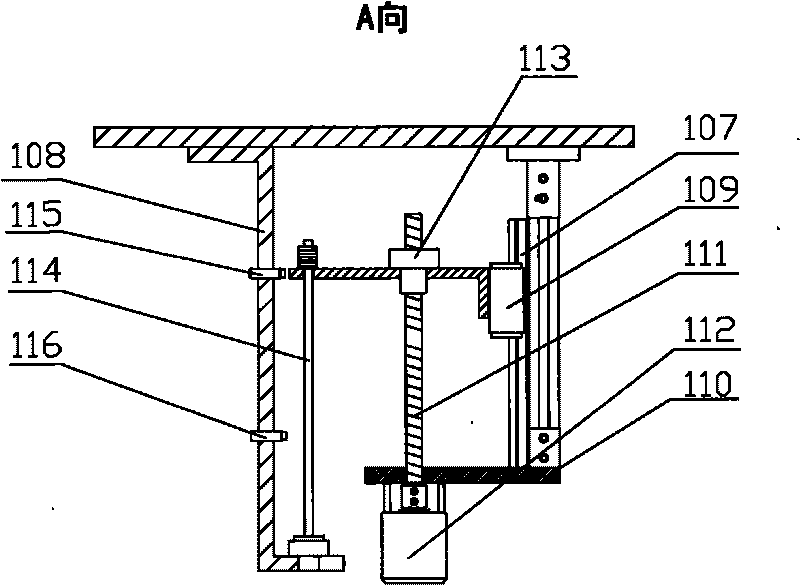

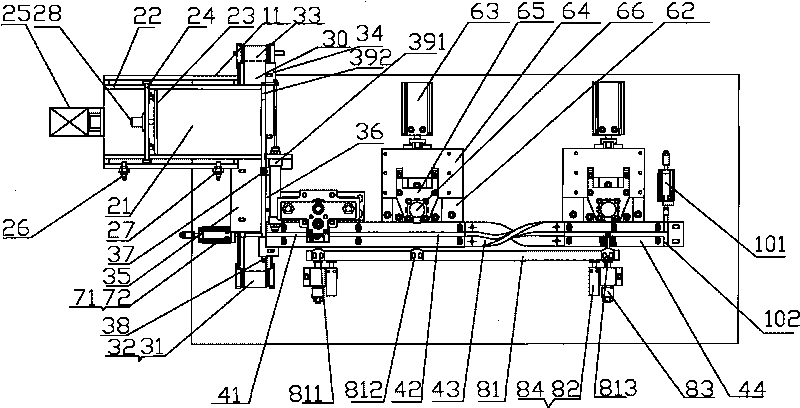

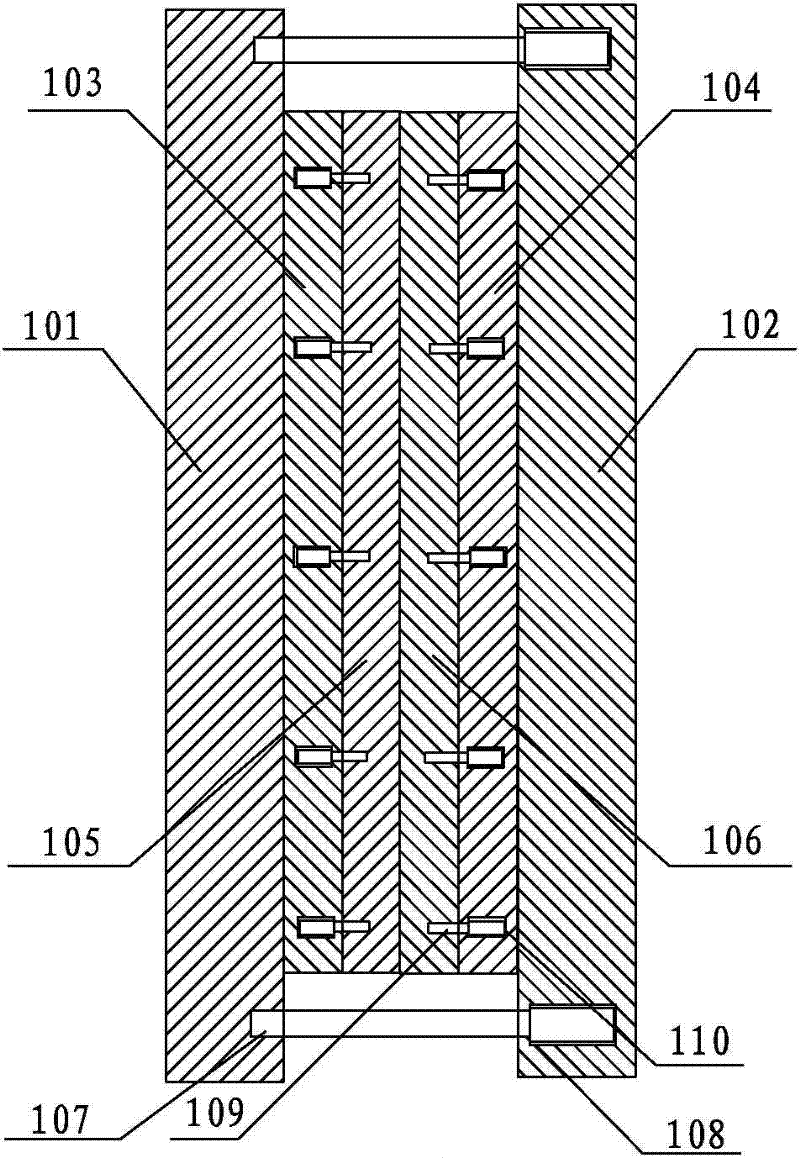

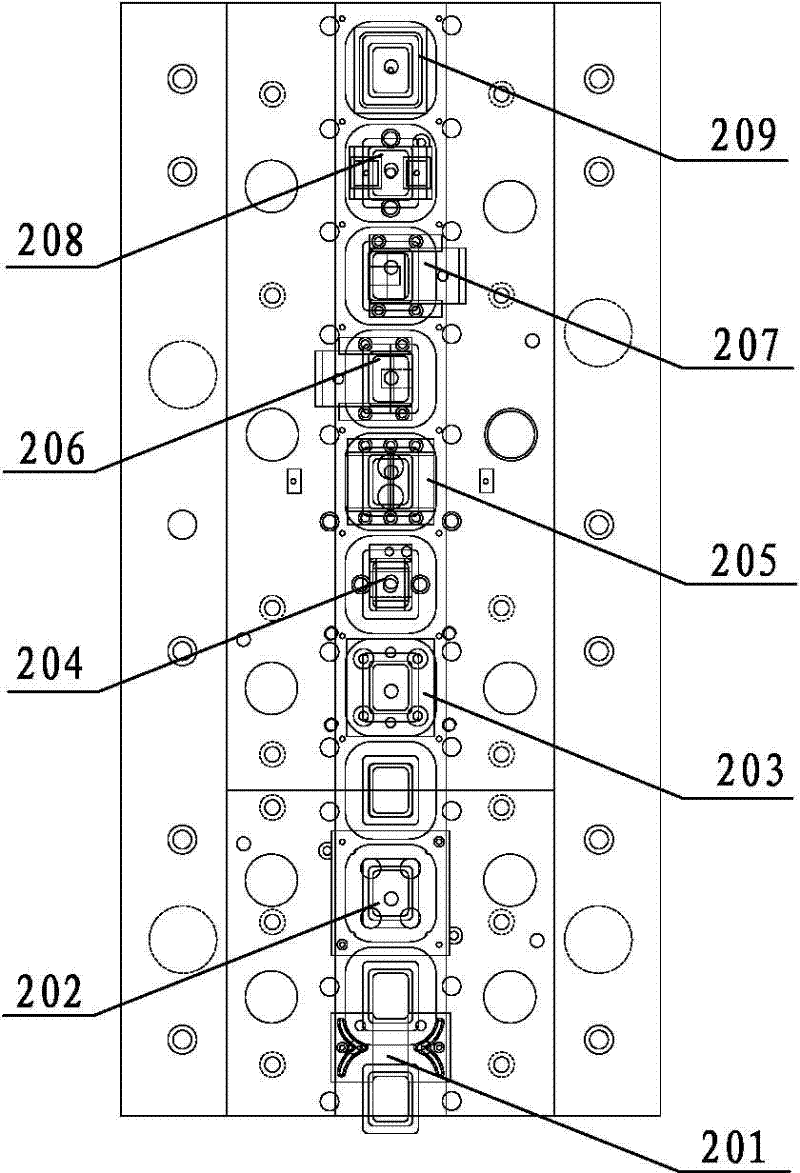

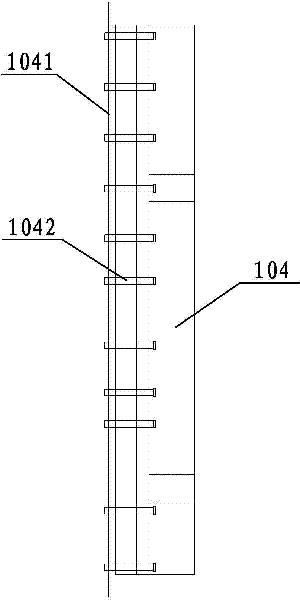

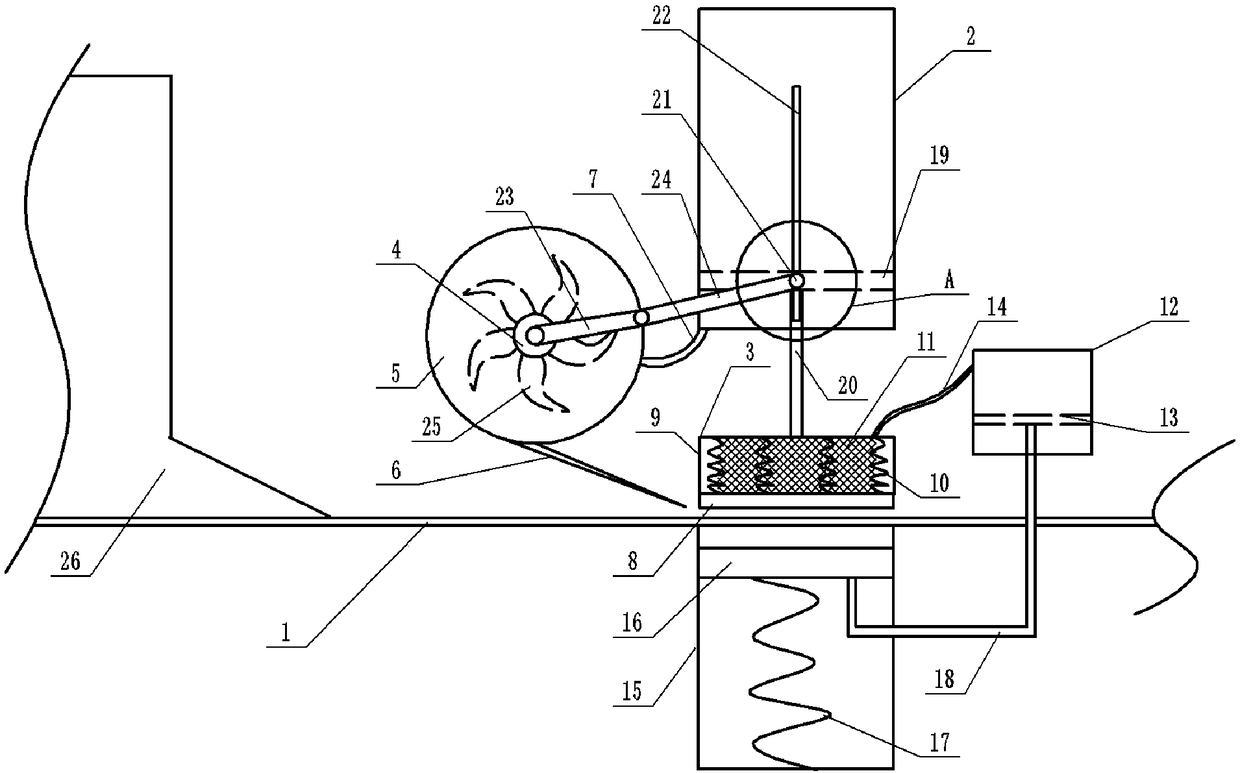

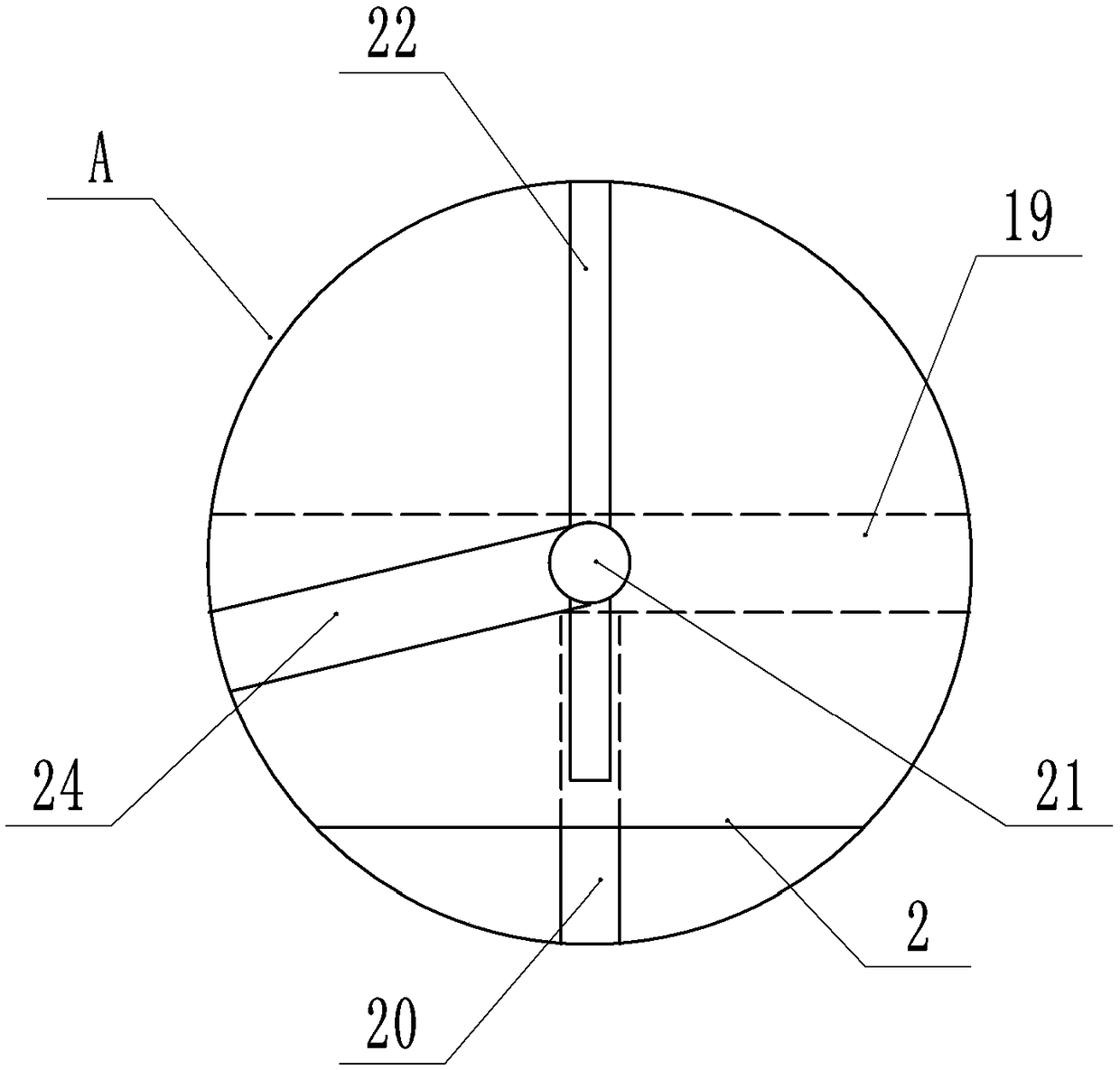

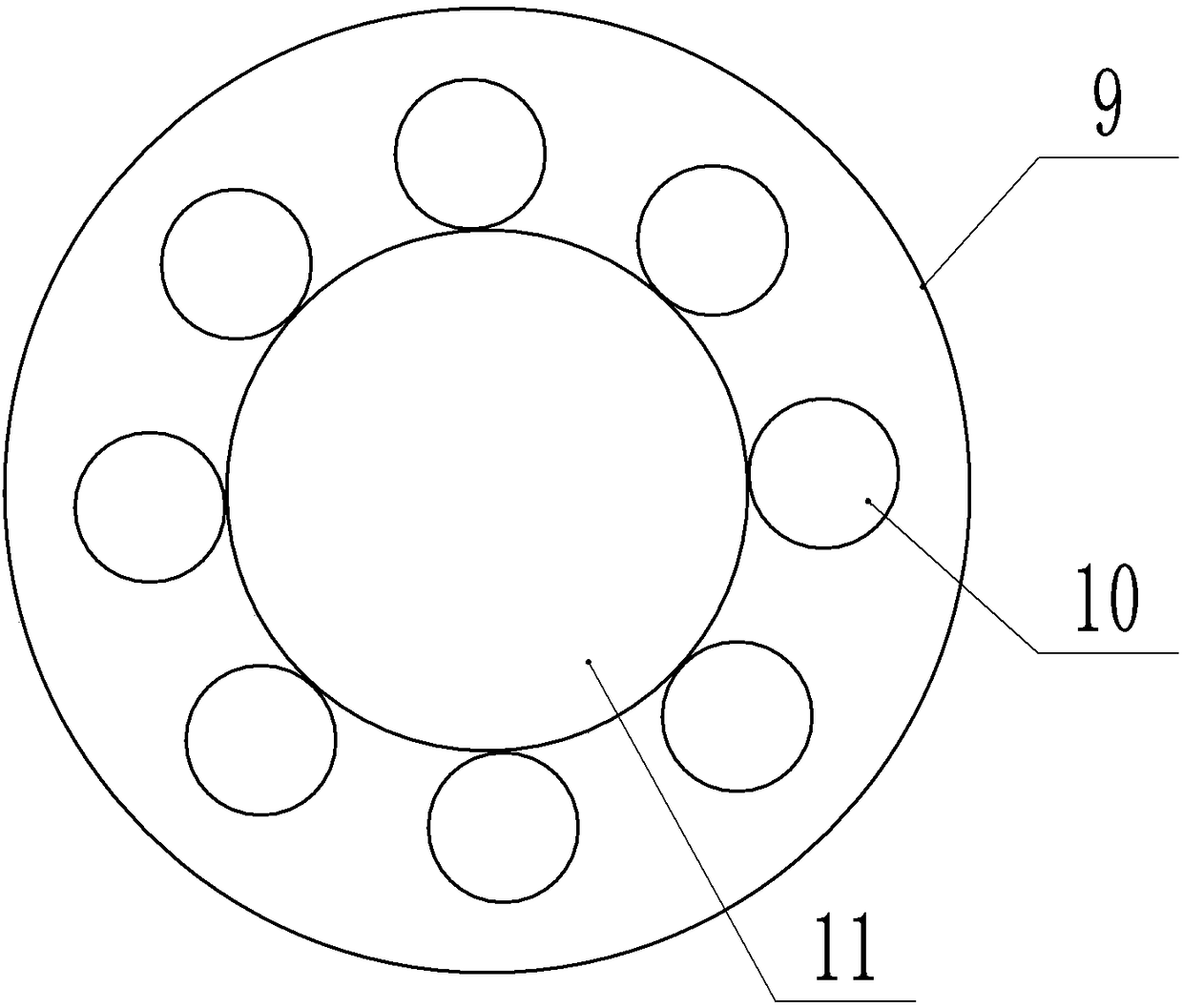

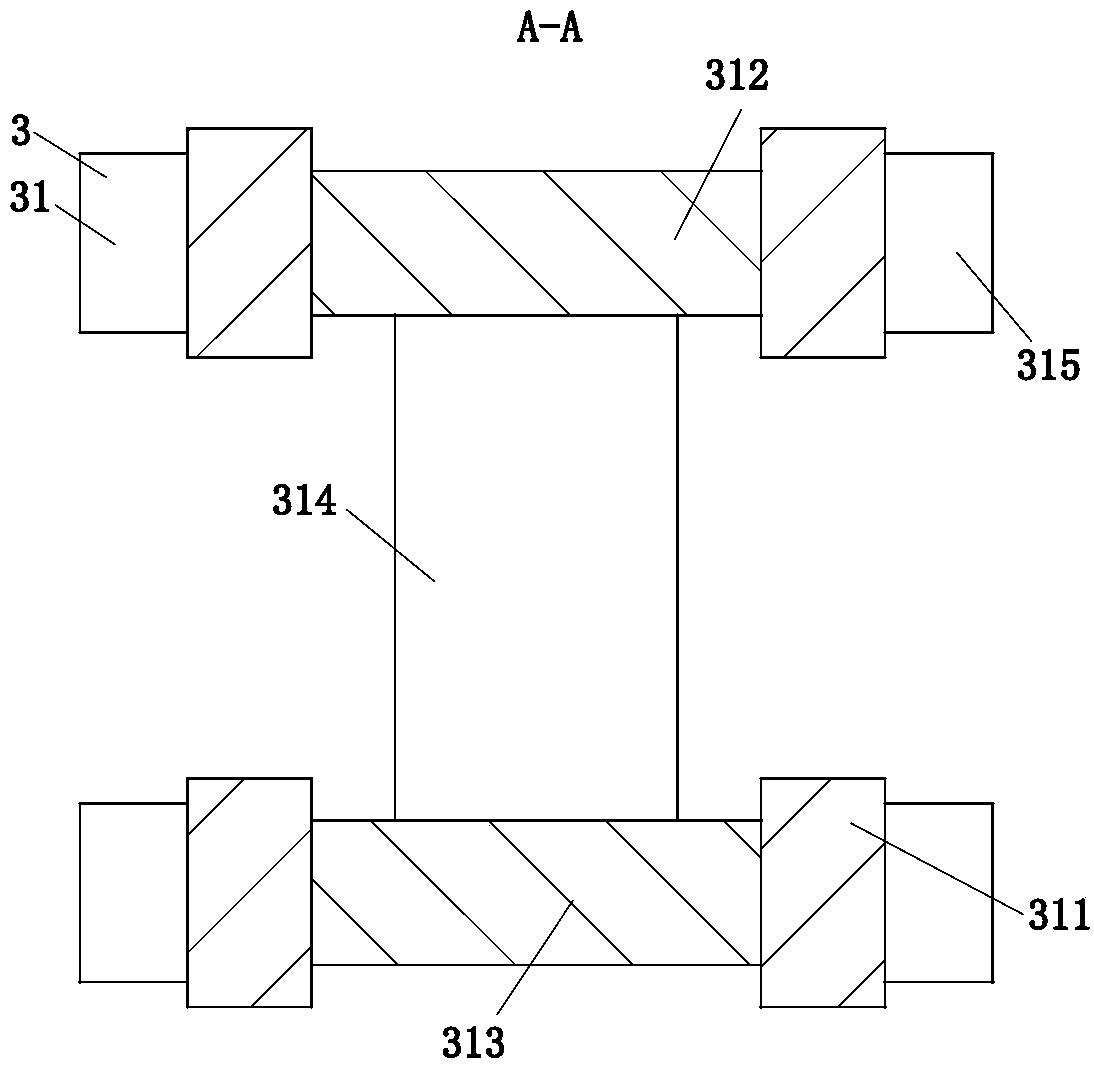

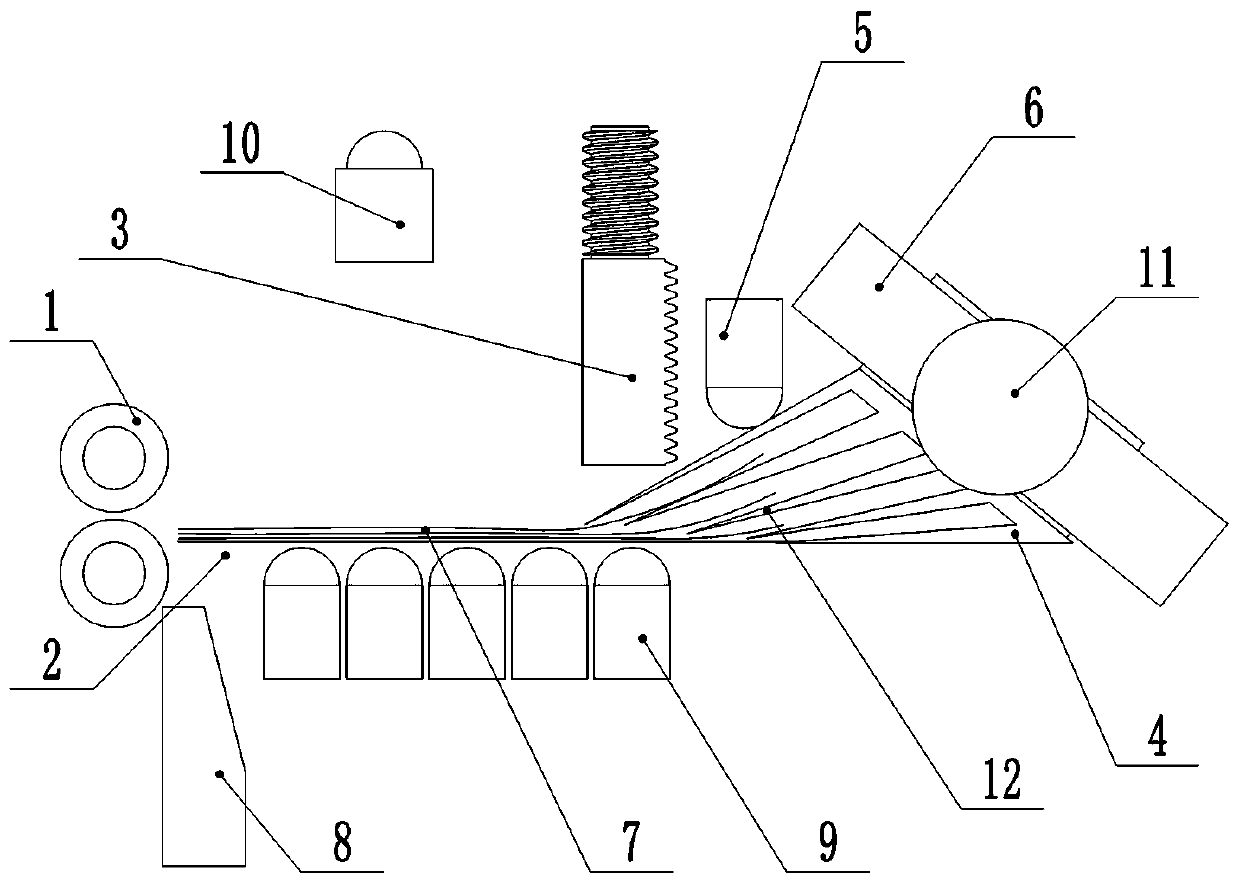

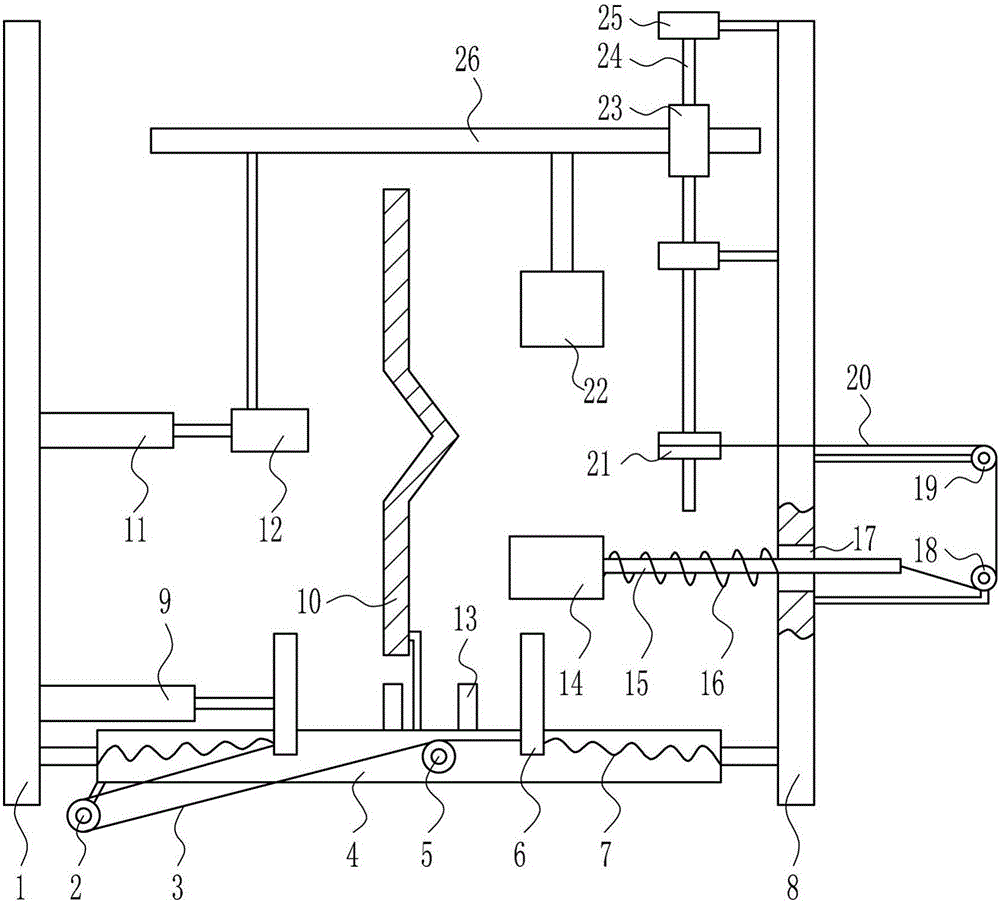

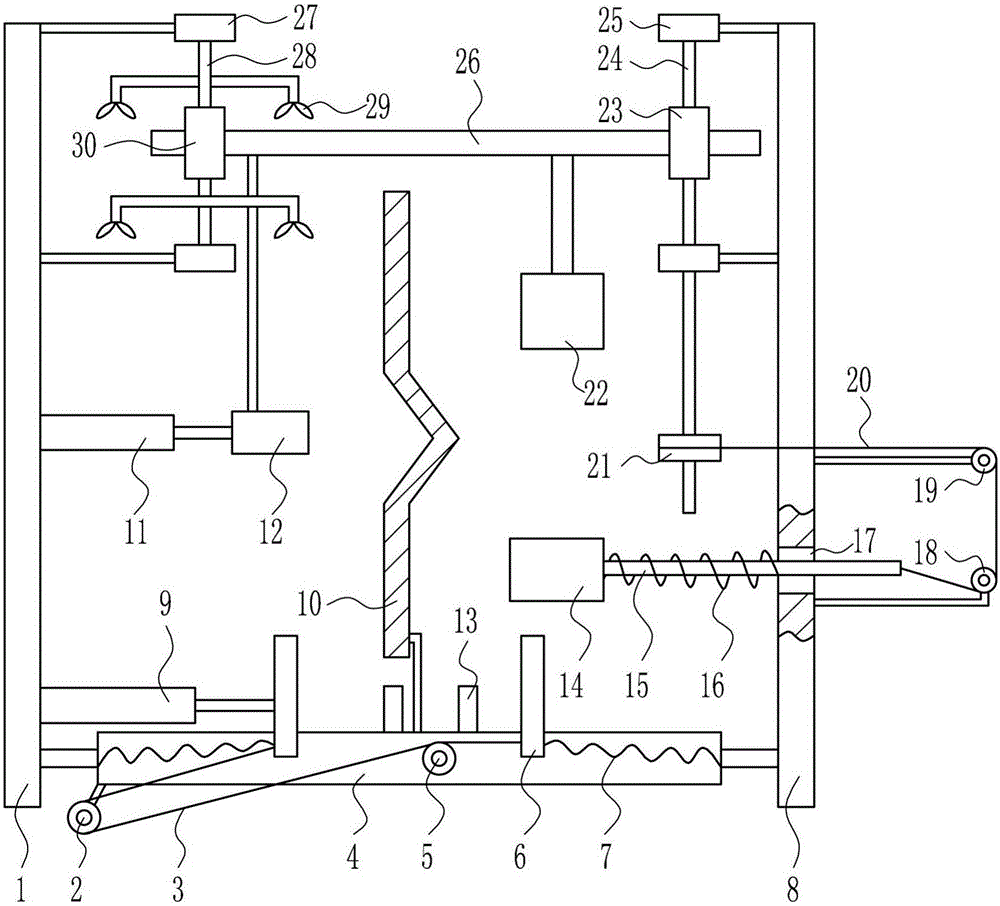

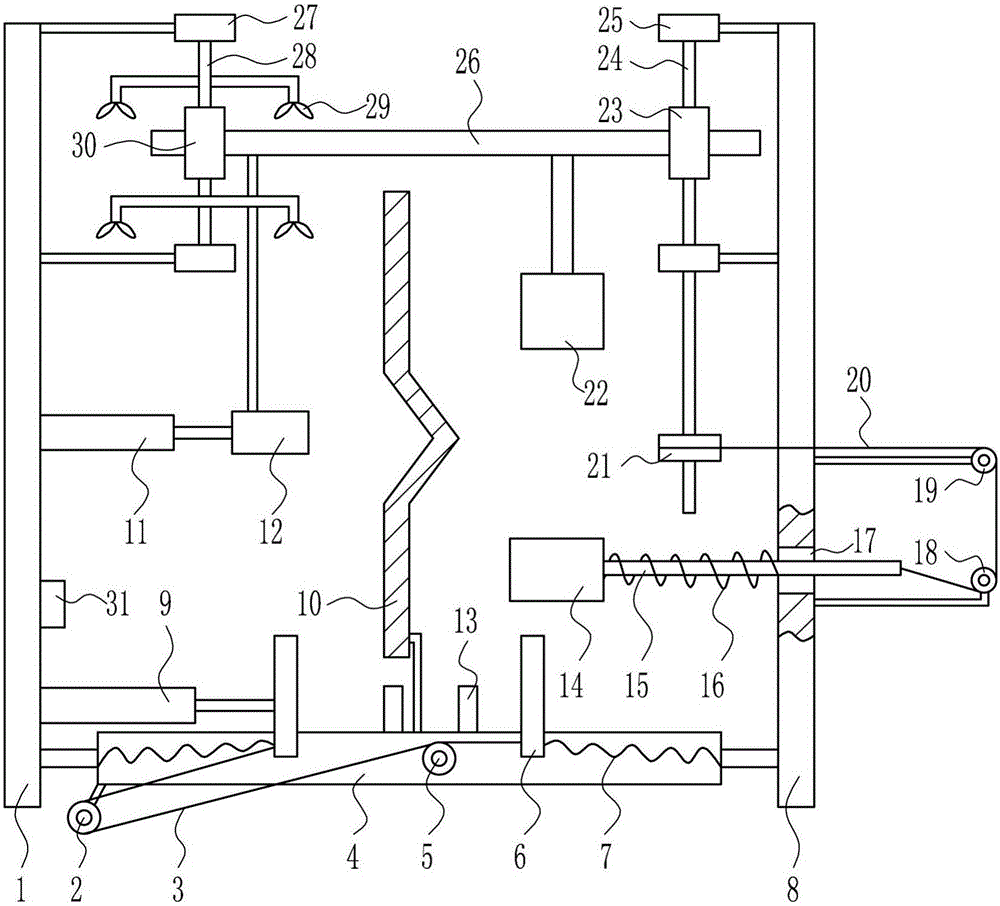

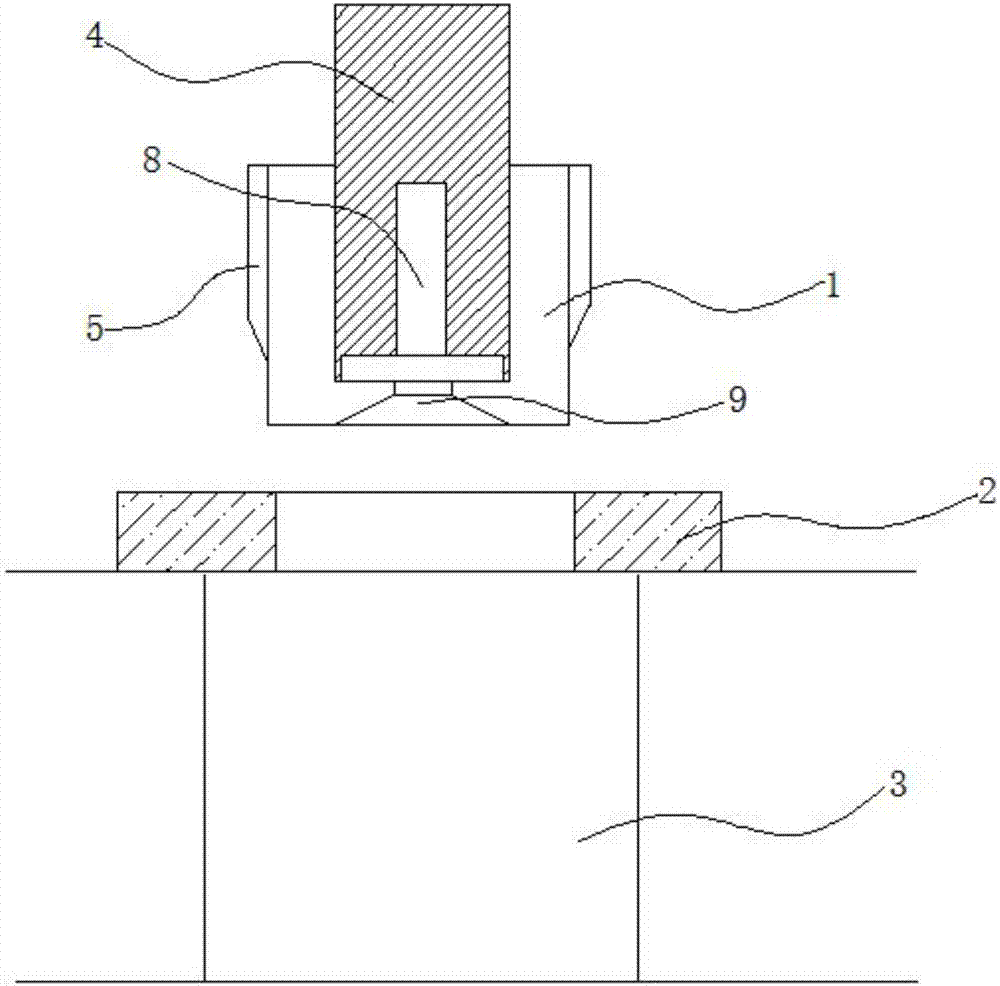

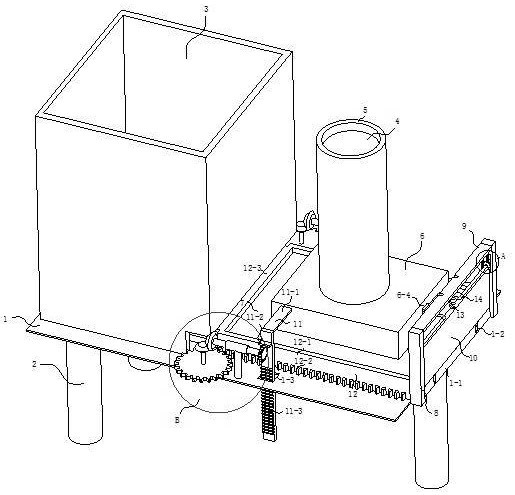

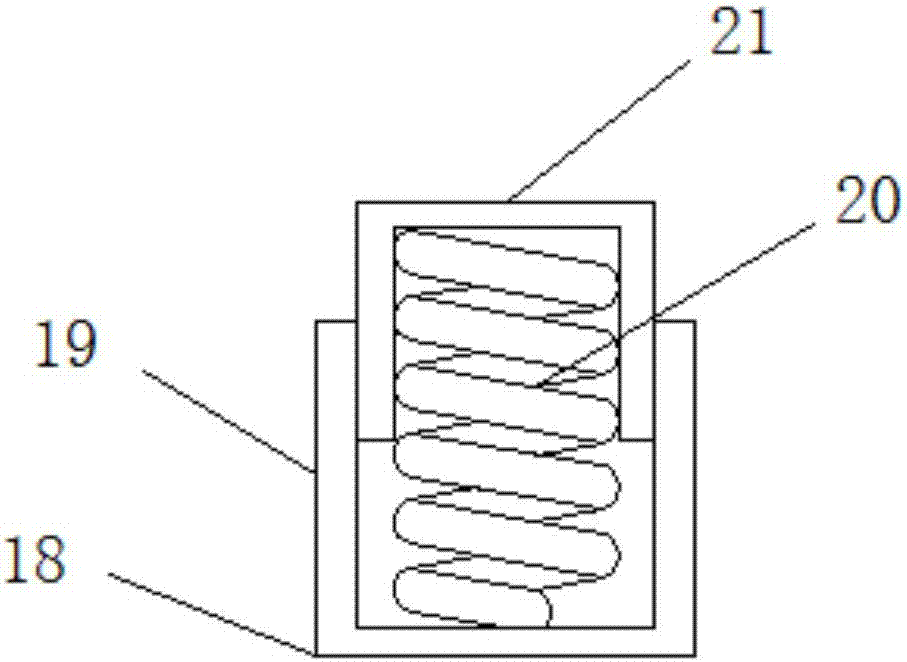

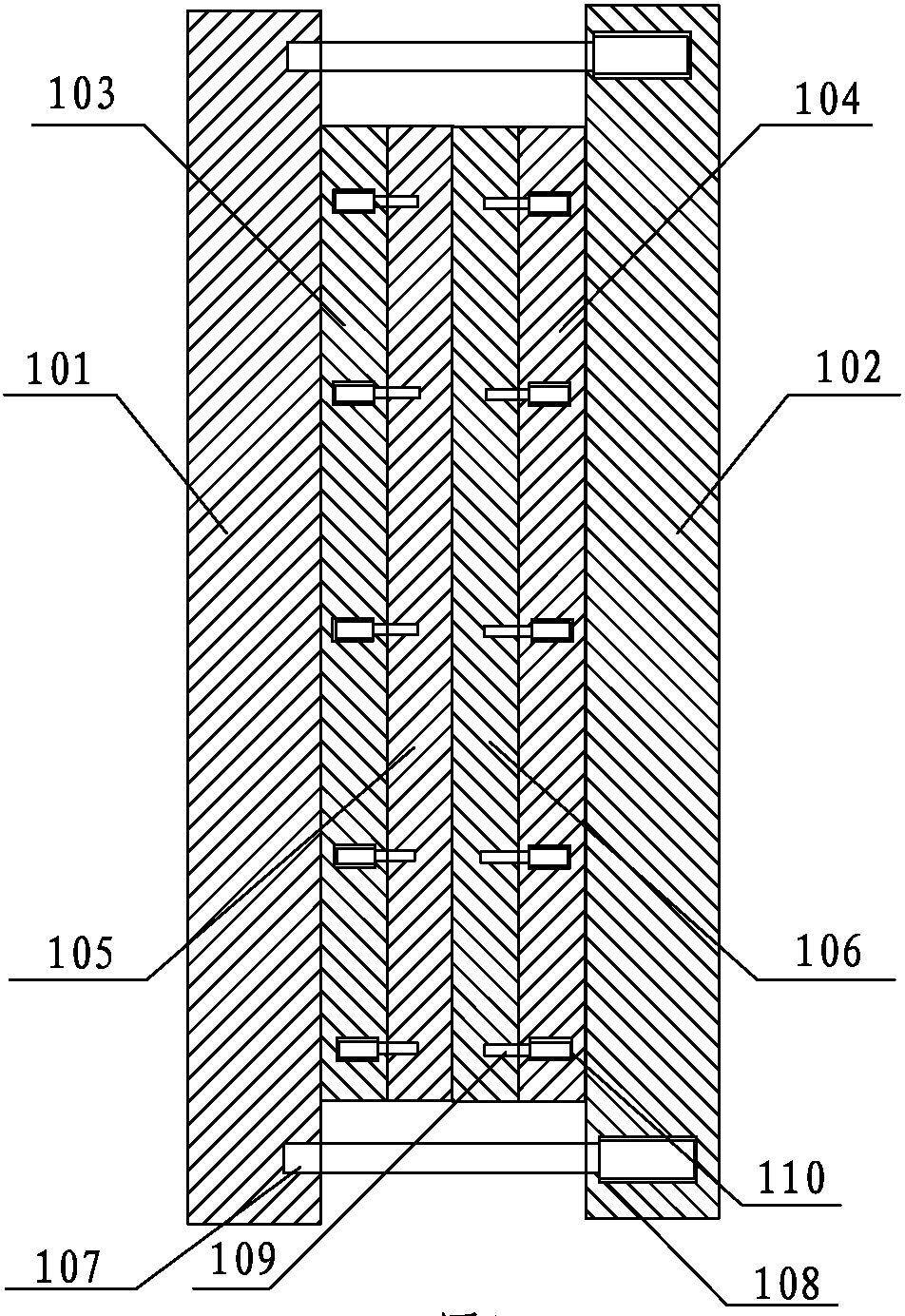

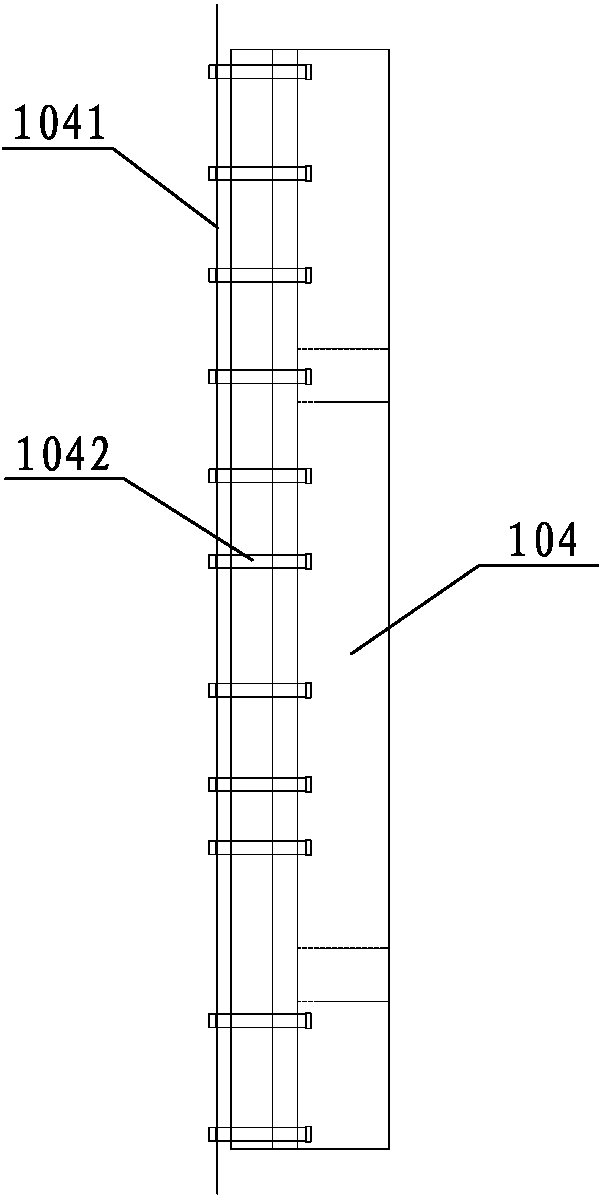

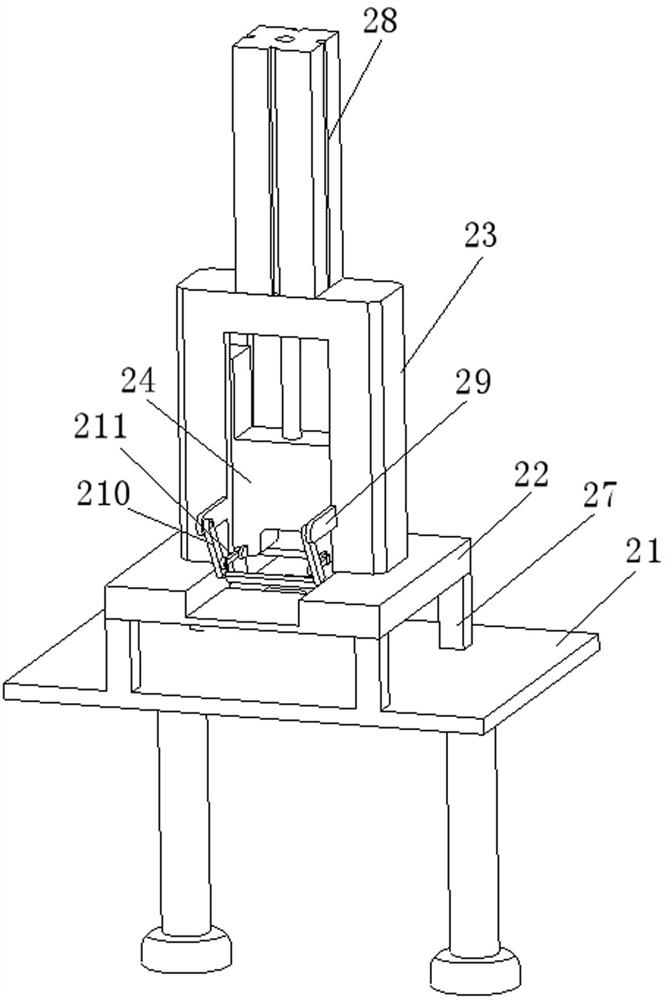

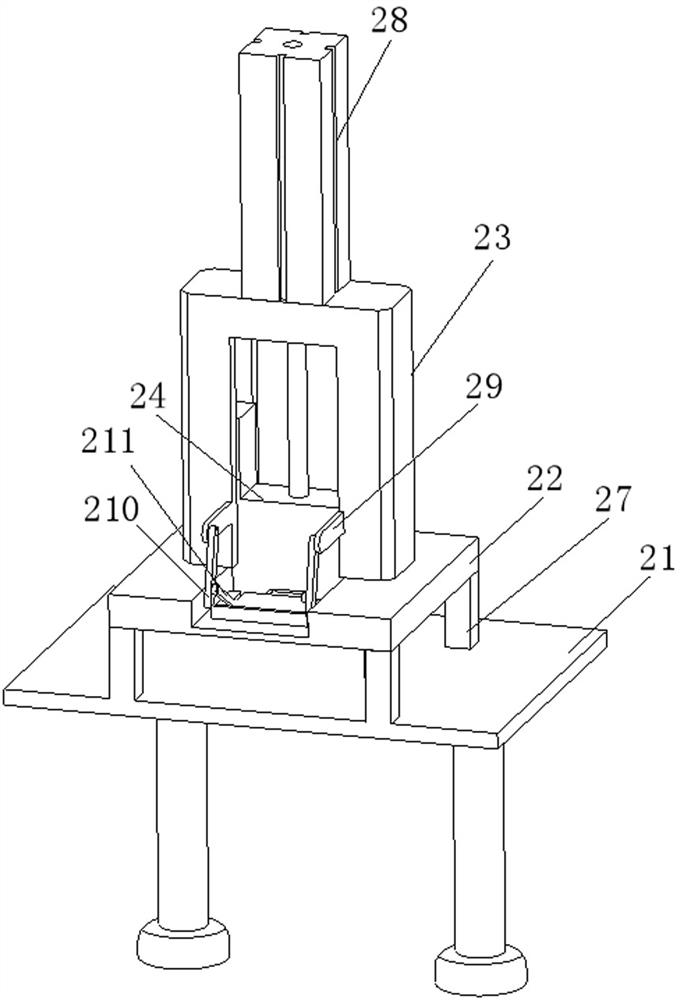

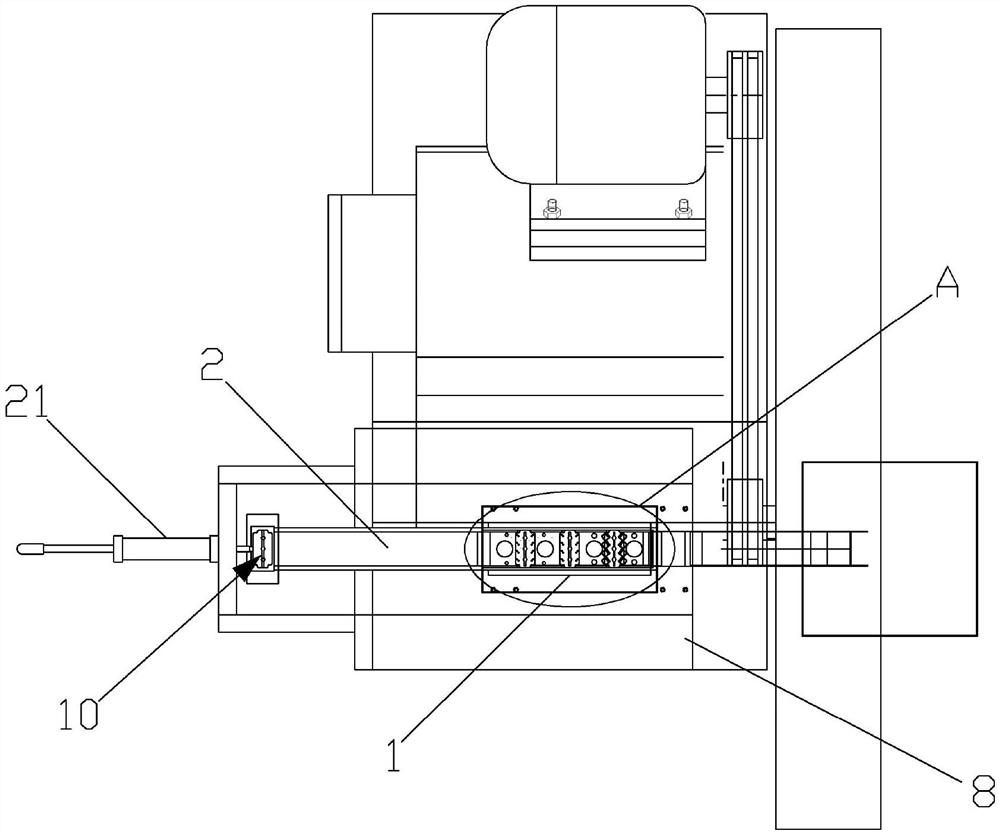

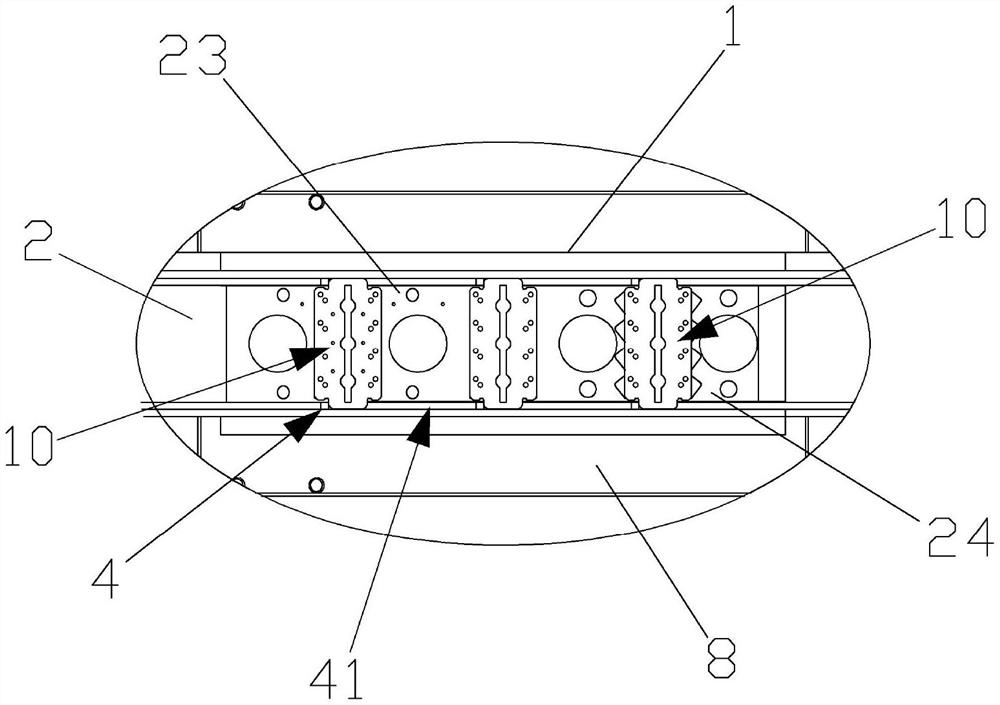

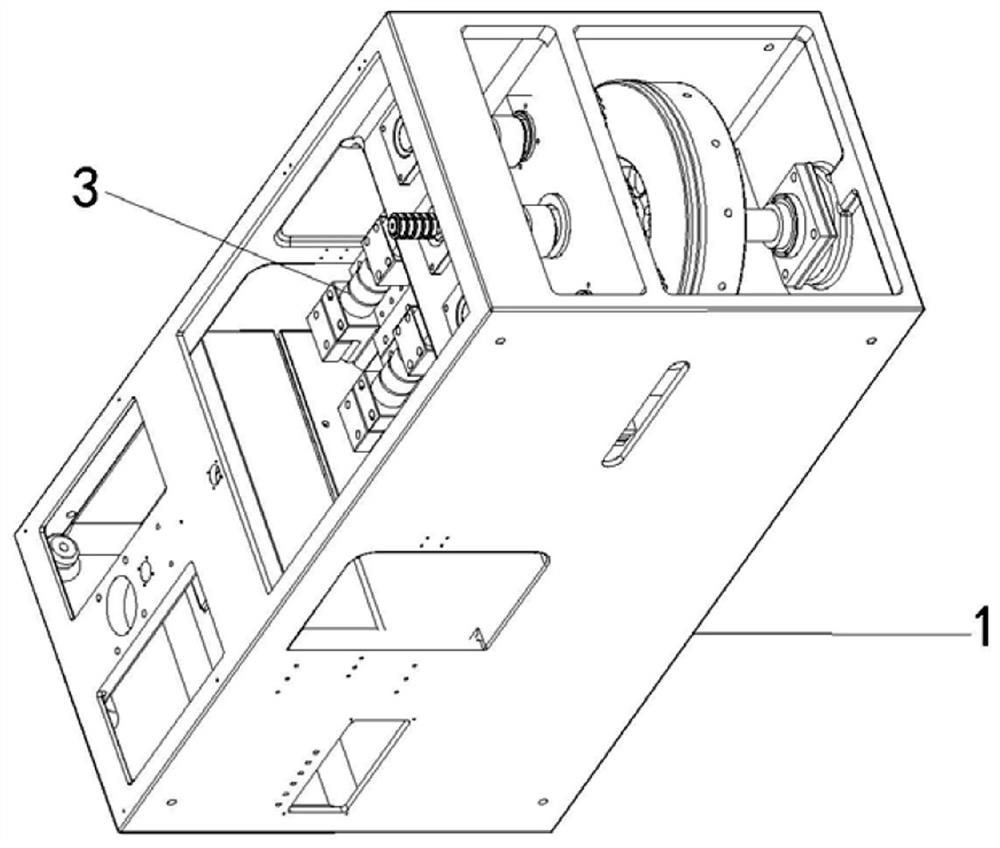

Full-automatic miniature bearing greasing gland method and device thereof

InactiveCN101718307AReduce processing timeSave energyBearing componentsMechanical engineeringSurface processing

The invention discloses a full-automatic miniature bearing greasing gland method and a device thereof; a miniature bearing to be processed is transported to a material arrangement device by a feeding device, so as to obtain the sequence of only one group of miniature bearings to be processed, and the miniature bearings are axially arrayed in parallel one by one, and then the miniature bearings to be processed are pushed in a material conveying channel one by one by a material pushing device and carry out greasing processing and single-surface gland processing by sequentially passing through the greasing device and the gland device on the material conveying channel, and then, the miniature bearings to be processed, which carry out single-surface processing, are turned with 180 degrees through a closed distorted material channel on the material conveying channel, and finally, the gland device is adopted again to carry out glad processing of a processing surface without a gland of the miniature bearings to be processed; therefore, the invention adopts a full-automatic mode to carry out greasing gland processing of the miniature bearings, every procedure is carried out automatically, the production efficiency is greatly improved, and the working efficiency is improved 10-15 times compared with the original manual operation.

Owner:南通山口精工机电有限公司

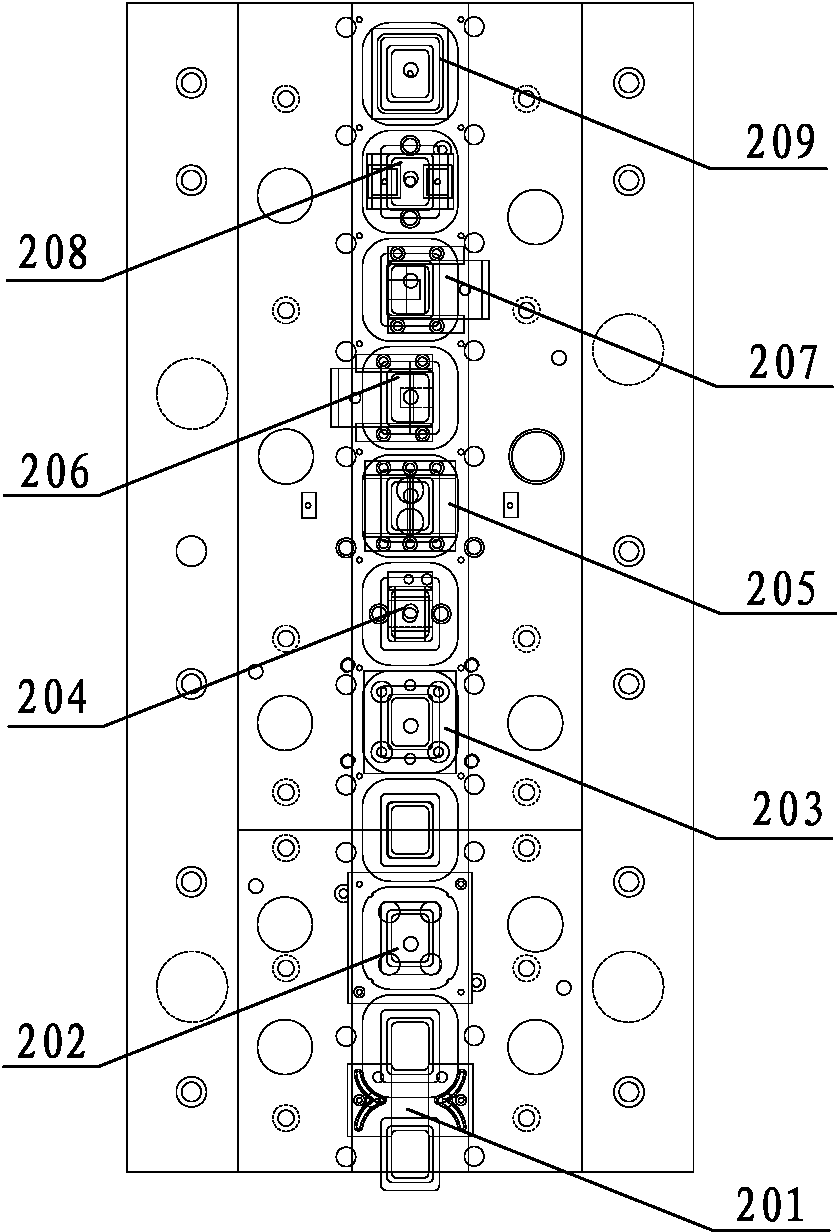

A Progressive Die for Double Hole Shielding Cover

The invention relates to the technical field of dies, in particular to a double-hole shielding cover progressive die. The double-hole shielding cover progressive die comprises an upper die holder, an upper die, a stripper plate, a lower die, a lower die holder, and a punching pilot hole station, a half sectioning station, a stretching station and a shielding cover punching-off station which are assembled correspondingly, wherein the upper die, the stripper plate and the lower die are correspondingly assembled with the punching pilot hole station, the half sectioning station, the stretching station, a double-side punching station, a bilateral hole turnup station, a first turnup flattening station, a second turnup flattening station, a punching side notch station and the shielding cover punching-off station which are formed sequentially. During actual production, production can be performed only by placing a material belt on the lower die, all the procedures are finished in the die, andfull automation of the whole flow is realized, so labor cost is reduced, the defective rate of the shielding covers is low, production efficiency is high, and the double-hole shielding cover progressive die is suitable for production of the shielding cover with side holes on the two sides.

Owner:DONGGUAN DAZHONG ELECTRONICS

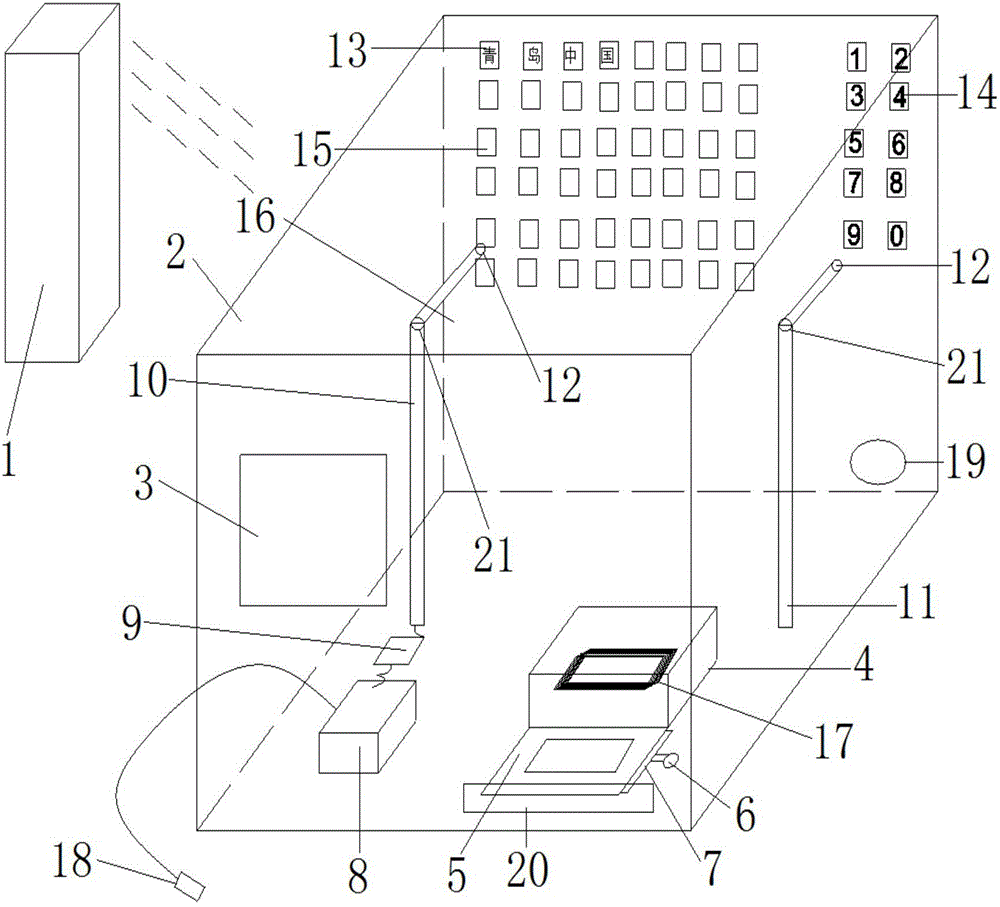

Self-service electronic invoice printing device

ActiveCN106447951AThe principle is simpleReasonable structureTypewritersApparatus for meter-controlled dispensingPaper invoiceApplication Context

The invention belongs to the technical field of electronic invoice printing equipment manufacturing, relates to equipment for converting an electronic invoice into a paper invoice, and in particular relates to a self-service electronic invoice printing device. Conversion of the electronic invoice to the paper invoice with real red stamps can be achieved through set word blocks and a mechanical arm together with an electronic invoice cloud platform in match. The main body structure of the self-service electronic invoice printing device comprises the electronic invoice cloud platform, a shell, a display touch screen, a printer, an invoice table, a motor, a sliding strip, a processor, a micro stepper motor, a word block mechanical arm, a stamp mechanical arm, an electromagnet, word blocks, digit blocks, word block holes, an inkpad plate, invoice paper, a code scanner, an ellipse stamp frame and an invoice outlet. Due to arrangement of the word blocks, the digit blocks and the ellipse stamp frame together with the mechanical arms, accurate pressing of the real red stamps can be achieved; due to arrangement of the touch display screen and the code scanner, rapid electronic invoice recognition and checking can be achieved; and the self-service electronic invoice printing device is simple in principle, reasonable in structure, high in printed invoice usability, accurate in real red stamp impression, and friendly in application environment.

Owner:BEIJING RUIYUN ARCHIVES MANAGEMENT CO LTD

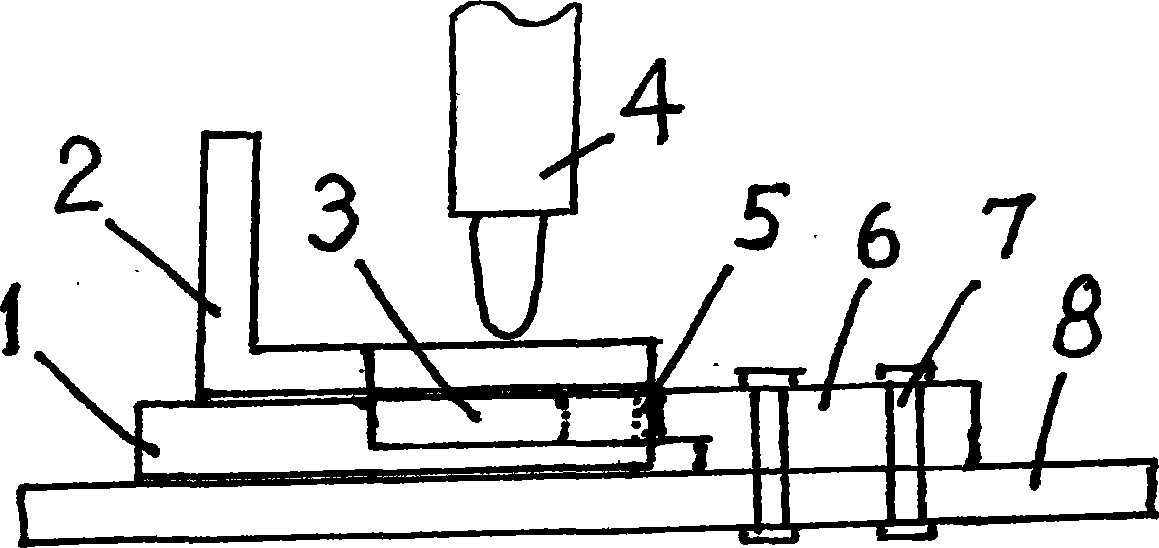

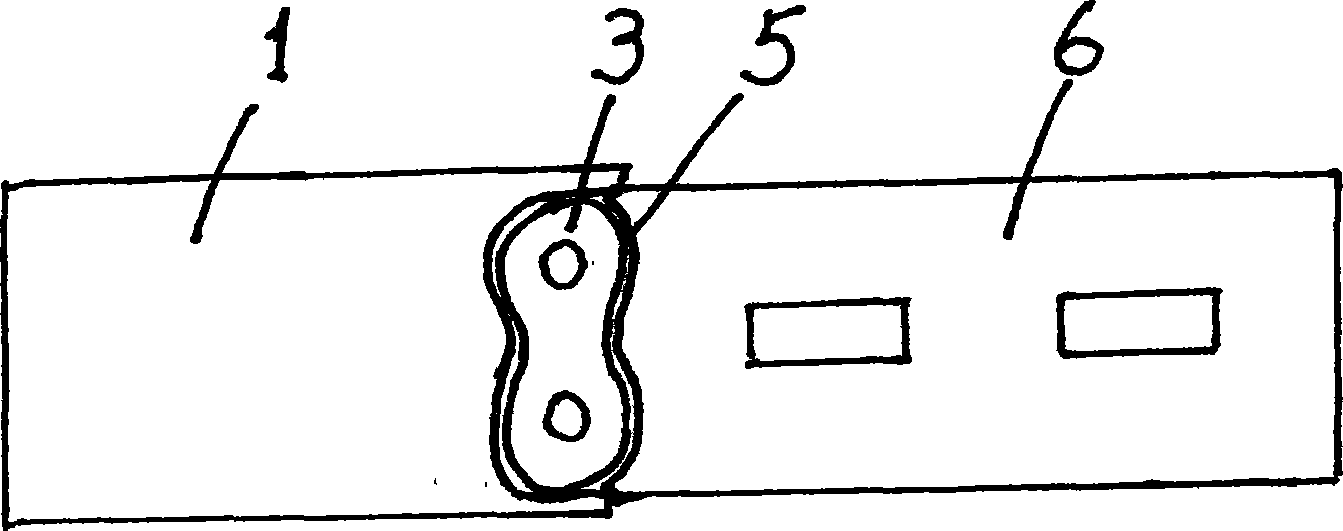

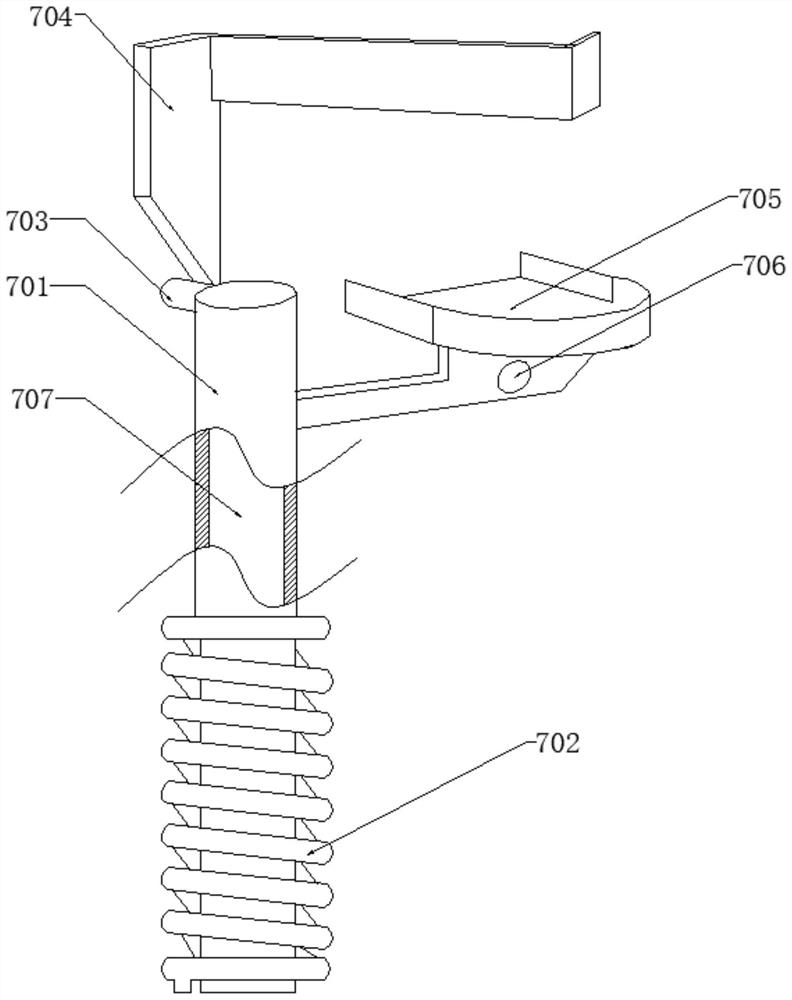

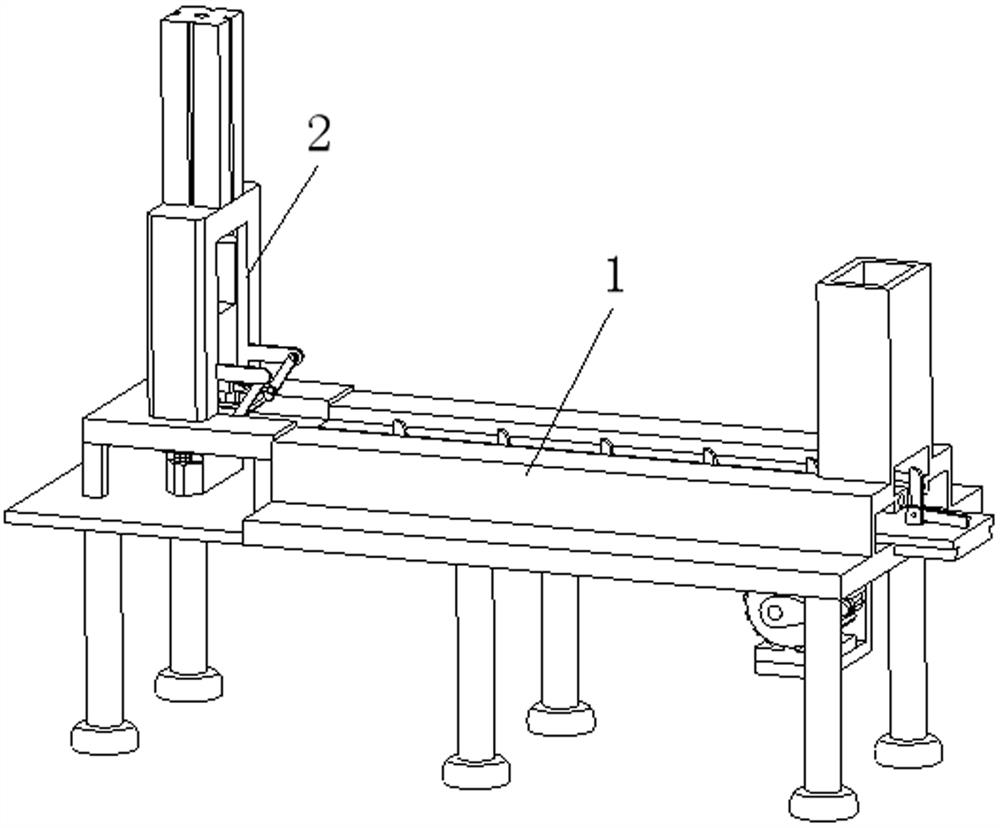

Outer plate post positioning baffle of chain assembly machine

The invention provides an outer plate rear-locating baffle of high-speed roller chain assembling machine. An outer plate presser is positioned below two stamping heads in the middle while an outer plate is transferred to the position for stamping by a delivery sheet, the outer plate is arranged below the outer plate presser, and is blocked by the delivery sheet on the left, in the front and the behind. The rear-locating baffle is characterized in that a rear-locating baffle is arranged on the right side of the outer plate. The rear-locating baffle is fixed on a bedplate by bolts. A semicircle-shaped concave block that slightly pulls forward on both sides and is hollow in the middle is arranged in the front of the rear-locating baffle. While the outer plate is transferred to the position for stamping by the delivery sheet, the outer plate just gets into the semicircle-shaped concave block, and the right side is blocked by the rear-locating baffle. The invention has the advantage of providing the outer plate rear-locating baffle of high-speed roller chain assembling machine, which can block the outer plate from the right side and prevent the outer plate from moving rightward, thereby assuring that stamping heads can stamp into the two round holes of the outer plate rightly, and significantly improving the speed and quality of chain assembling by assembling machine.

Owner:溧阳市超强链条制造有限公司

Intelligent seal selection and sealing examination control method

ActiveCN105711277AAvoid misuseQuick capClosed circuit television systemsStampingControl engineeringProcess engineering

The invention relates to an intelligent seal selection and sealing examination control method. The method comprises the following steps: (1) papers to be sealed are fed to the bottom of a chassis; (2) simulated seals corresponding to seals in a seal selecting module one to one are displayed on a display screen; and one of the simulated seals is selected; (3) the simulated seals are shifted to positions, needing to be sealed, in a shooting range; and (4) a sealing module shifts the sealed seal rightly above a paper sealing position to downwards move and seal to return. The method can randomly select the sealing position on the display screen, visually operates all the way to prevent operation errors, can select multiple seals to seal to widen the application range, dose not limit the paper feeding size to enable the fed papers with various sizes to be quickly and accurately sealed, can distinguish the truth from the false of the papers to improve the safety, and can set the operation authority of operators to improve the operation safety.

Owner:HANGZHOU RIMEI KAIKAI ELECTRONICS TECH CO LTD

Receipt printer with automatic stamping function

InactiveCN108544863AImprove stamping efficiencyThe seal is accurateTypewritersStampingReciprocating motionEngineering

The invention relates to the technical field of receipt processing and particularly discloses a receipt printer with an automatic stamping function. The receipt printer comprises a motor, a rack, a belt conveyor arranged at the paper discharge end of the printer, a stamping mechanism arranged at the position, above the belt conveyor, of the rack, and a bearing mechanism arranged at the position, below the belt conveyor, of the rack. The stamping mechanism comprises an inflator fixedly connected with the rack, a stamp structure slidably connected with the inflator, and a rotary shaft rotationally connected with the rack, wherein the inflator is provided with an air inlet, a one-way valve is arranged at the air inlet, a sliding plate is slidably connected in the inflator, a fixing rod is connected between the sliding plate and the stamp structure, and the rotary shaft can drive the stamp structure to make vertical reciprocating motion through the fixing rod. According to the receipt printer with the automatic stamping function, the stamp structure is driven by the rotary shaft to stamp a receipt, the receipt can be continuously and automatically stamped by cooperating with the belt conveyor and the printer, the stamping efficiency is high, and stamping is accurate.

Owner:重庆华康印务有限公司

Automatic automobile plate punching equipment and control circuit thereof

ActiveCN109290418AImprove stamping efficiencyExtended service lifeShaping safety devicesPressesPunchingEngineering

The invention belongs to the technical field of machining and particularly relates to automatic automobile plate punching equipment and a control circuit thereof. The automatic automobile plate punching equipment comprises a top plate, telescopic hydraulic cylinders, a male die, a female die and a cross frame, and further comprises supporting units, driving units, gas storage chambers and ejectionrods. Through cooperation of the supporting units, the driving units and the multiple ejection rods, on one hand, the cross frame can be moved left and right by adjusting first telescopic rods and second telescopic rods to adjusting the clearance between the cross frame and the driving units, so that the automobile plate punching efficiency is improved; on the other hand, an automobile plate is punched through the male die and the female die, the first telescopic rods and the second telescopic rods are squeezed to stretch and contract to buffer impact force of the male die and protect the male die and the female die against damage, and then the service life of the male die and the female die is prolonged.

Owner:ZHAOQING UNIV +1

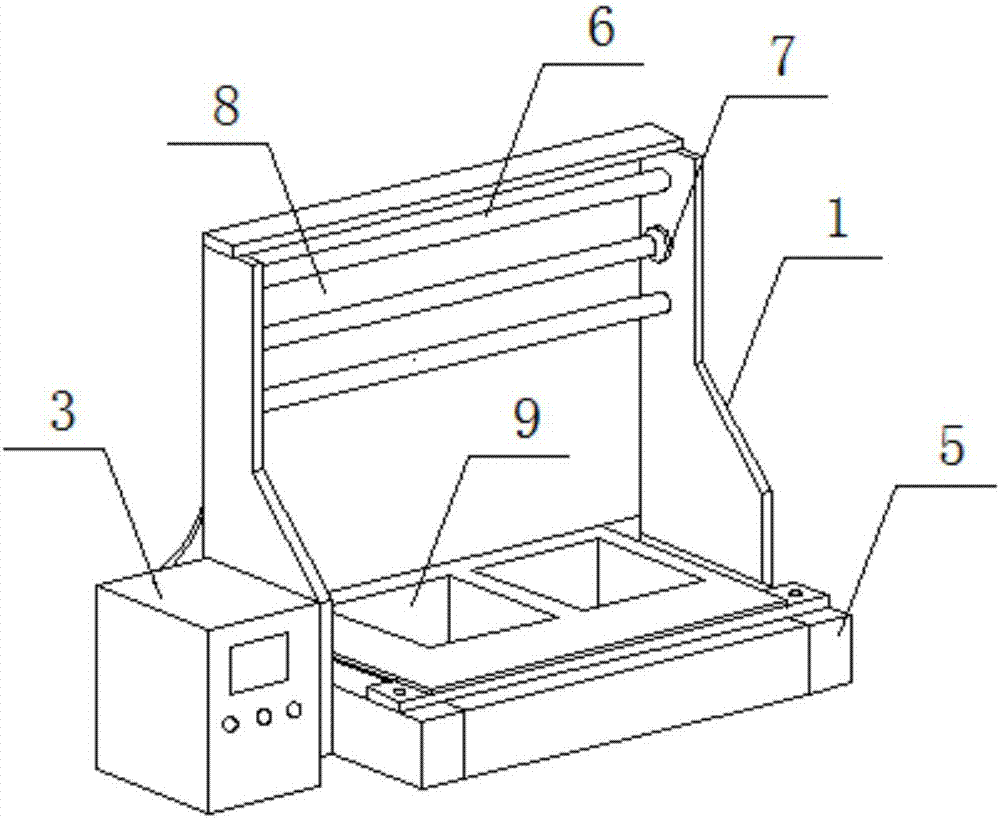

Paper feeding and positioning device for automatic stamping of cross-page seal and stamping machine using paper feeding and positioning device

The invention relates to a paper feeding and positioning device for the automatic stamping of cross-page seals and a stamping machine using the paper feeding and positioning device. The paper feedingand positioning device comprises paper feeding rollers, a paper pressing groove, limiting teeth, a layered elastic sheet, a sheet pressing rod and an elastic sheet frame; the paper feeding rollers cansequentially convey paper to the paper pressing groove one by one; the paper pressing groove is lower than the paper feeding rollers; a paper limiting block is arranged on one side, close to the paper feeding rollers, of the paper pressing groove, so that the paper can neatly fall into the paper pressing groove; a plurality of elastic feeler gauges are fixed together so as to be integrally manufactured into the layered elastic sheet, and the layered elastic sheet can rotate along with the elastic sheet frame; the limiting teeth are arranged near the layered elastic sheet, so that the feeler gauges deform to a certain extent and rotate to a position above the limiting teeth after the layered elastic sheet rotates forwards by a certain angle; after the layered elastic sheet reversely rotates by a certain angle, one end of each feeler gauge leans against the corresponding limiting teeth, so that the limiting teeth move or the feeler gauges are sequentially released and rotated into the paper pressing groove after being rotated; and the sheet pressing rod can move up and down and can extrude the layered elastic sheet at the lowest position, so that the paper can be pressed by the layered elastic sheet after entering the paper pressing groove.

Owner:THE FIRST AFFILIATED HOSPITAL OF WENZHOU MEDICAL UNIV

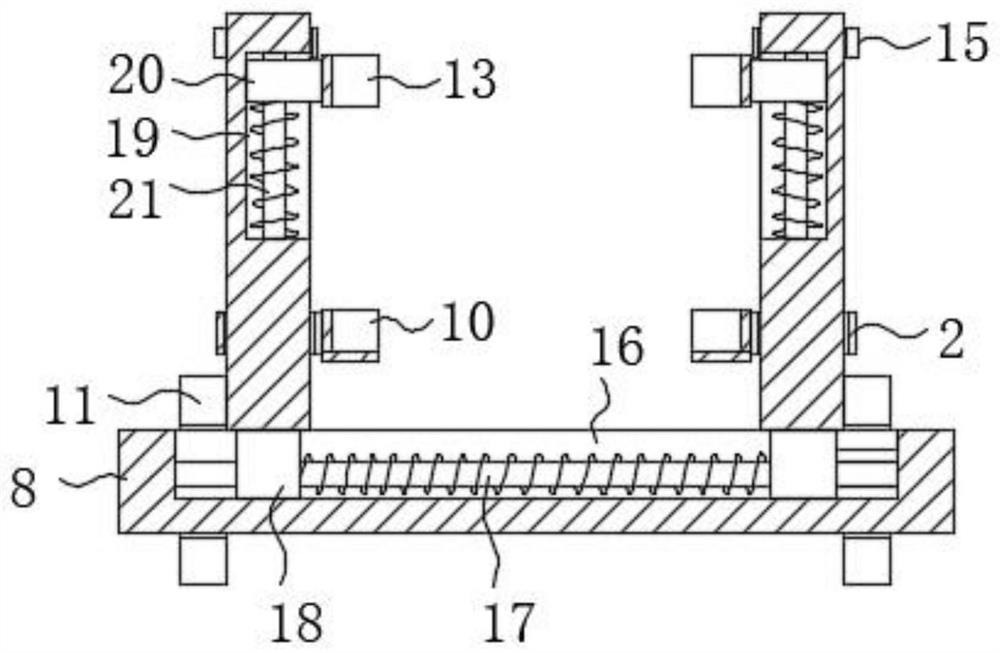

Stamping equipment for bus duct machining and fixing method of stamping equipment for bus duct machining

InactiveCN111531009AQuick fixEasy to fixShaping toolsMetal-working feeding devicesStructural engineeringMechanical engineering

The invention discloses stamping equipment for bus duct machining and fixing method of the stamping equipment for the bus duct machining. The stamping equipment comprises a stamping table, an L-shapedinstalling frame is fixedly connected to the middle of one side wall of the stamping table, an air cylinder is fixedly installed on one side wall of the top of the L-shaped installing frame, a connecting block is in transmission connection with the output end of the air cylinder, an upper mold is fixedly connected to the bottom end of the connecting block, a first lower mold is connected to the middle of the top end of the stamping table in a clamped mode, a storage box is connected to one side of the top end of the stamping table in a sliding mode, a sponge block is fixedly connected to themiddle of the inner wall of the bottom end of the storage box, and an installing plate is fixedly connected to one side of the bottom end of the stamping table. According to the stamping equipment forthe bus duct machining and the fixing method of the stamping equipment for the bus duct machining, a rotating plate is arranged, by means of cooperation of multiple connecting rods and multiple second lower molds, multiple stamping materials can be placed in the area outside the air cylinder, hands are prevented from being crushed by the air cylinder, safety is higher, and the multiple stamping materials can be rapidly and stably fixed by means of cooperation of multiple suction cups and multiple air guide pipes.

Owner:镇江西杰电气有限公司

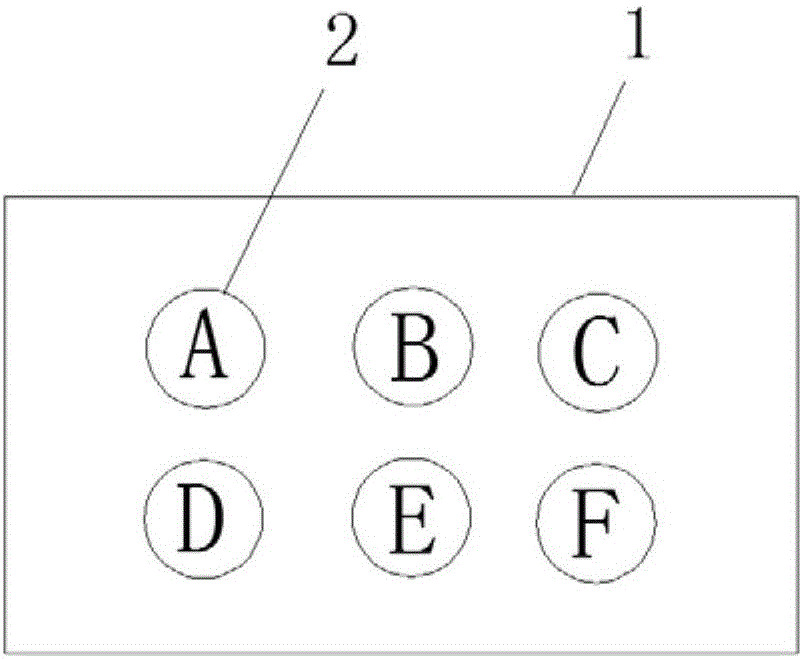

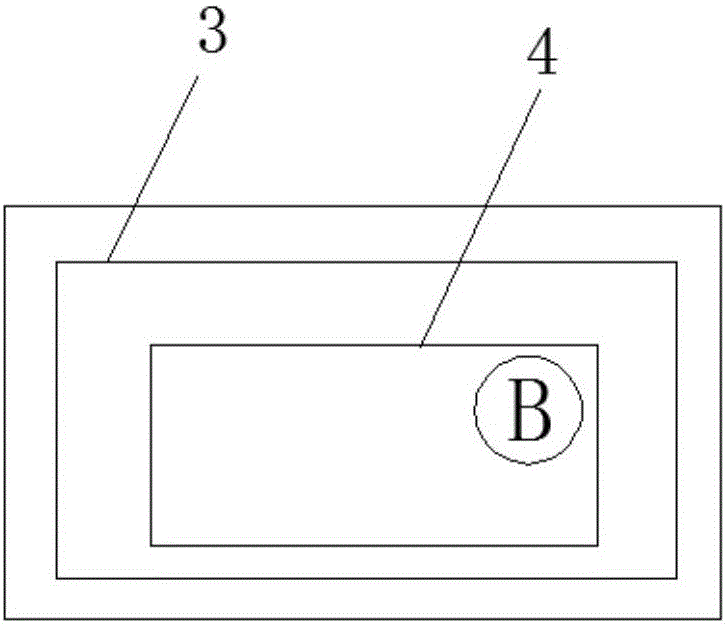

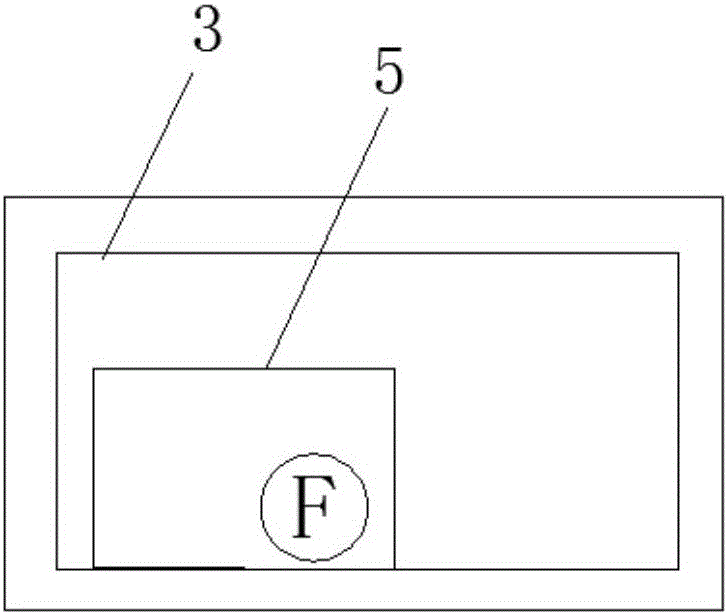

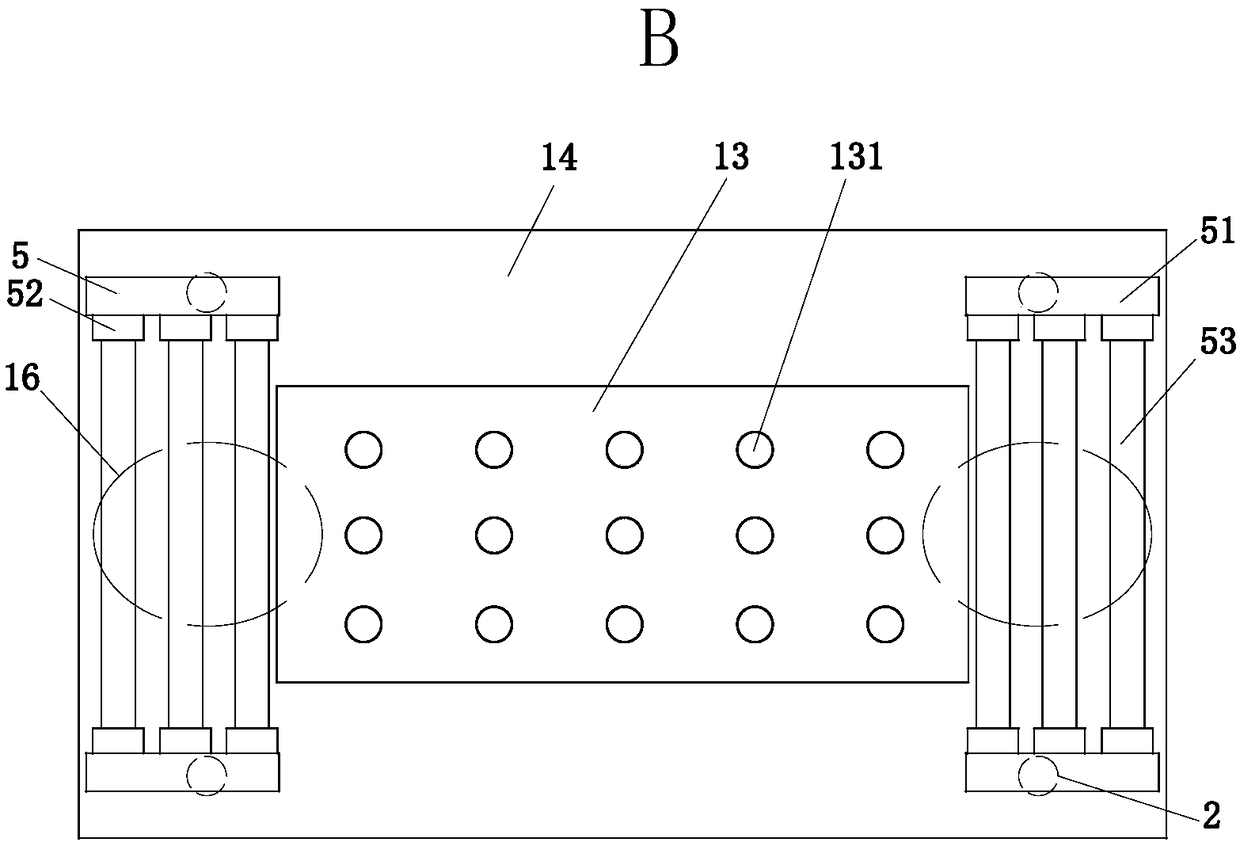

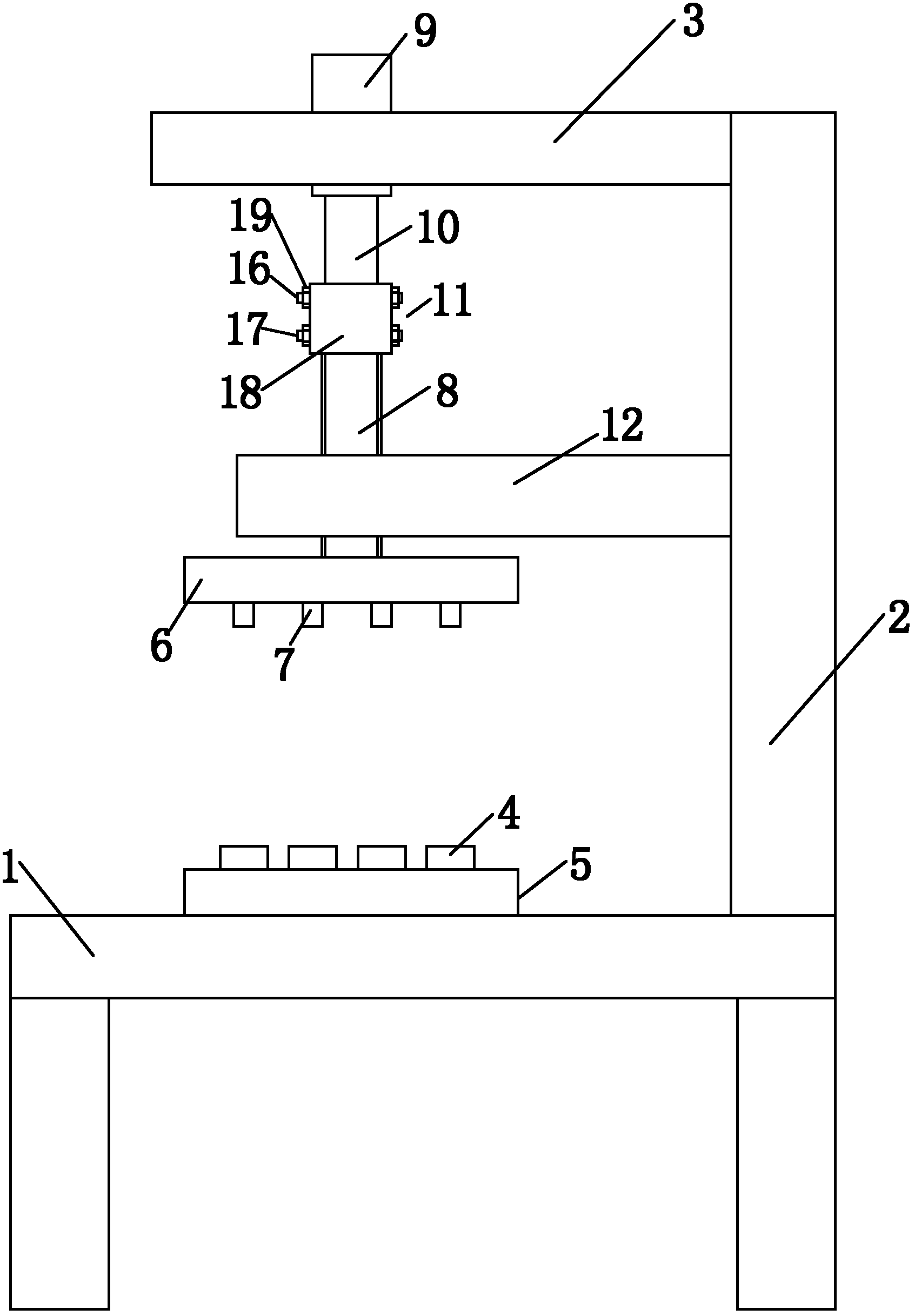

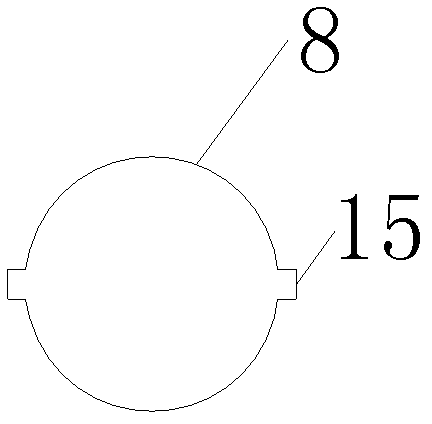

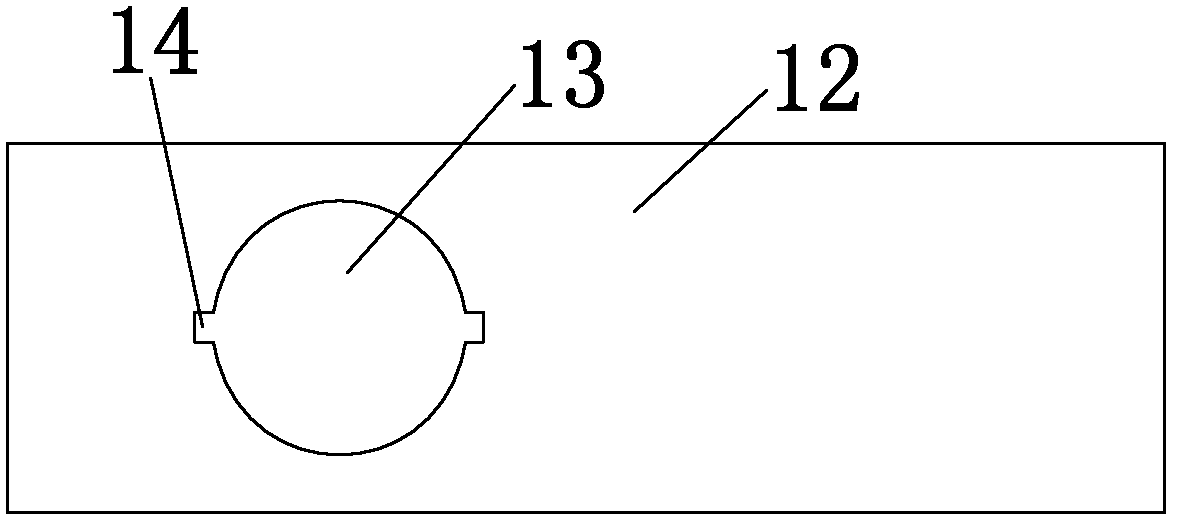

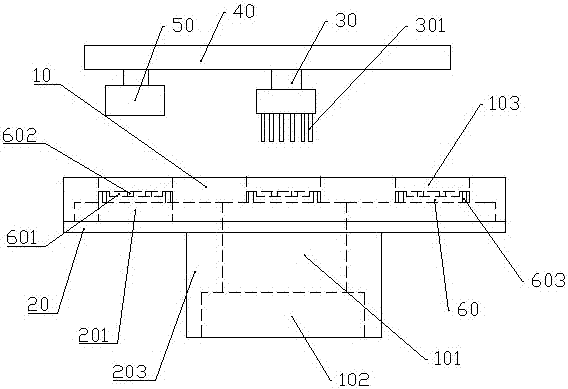

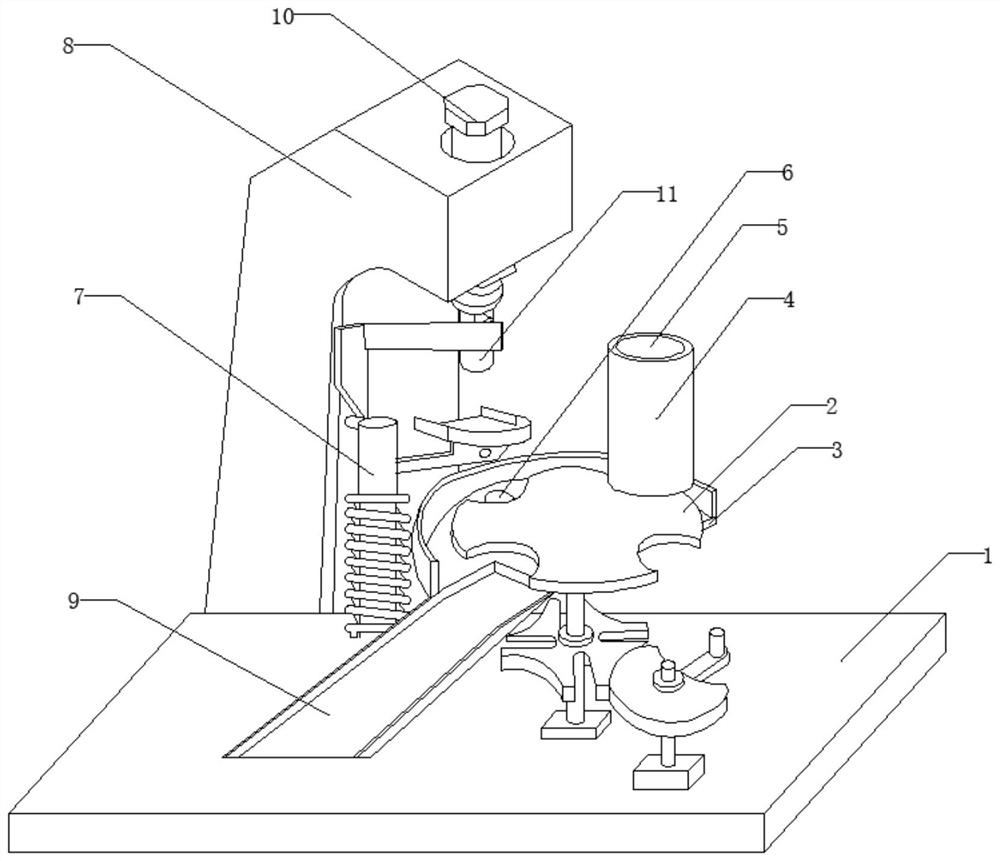

Plastic part punching machine

InactiveCN102490206AOrientation is accurateStamping precisionMetal working apparatusPunchingEngineering

The invention belongs to the technical field of punching machines, and particularly relates to a plastic part punching machine, which comprises a lower base, a support disposed vertically on the lower base and an upper base disposed at the upper end of the support. A lower punching disc provided with a plurality of punching dies is disposed on the upper end face of the lower base. An upper punching disc matched with a punching disc is disposed below the upper base. The lower end face of the upper punching disc is provided with punching heads which correspond to the punching dies on the lower punching disc one to one. A guide rod is fixedly arranged at the upper end of the upper punching disc, a punching cylinder is fixedly arranged below the upper base, and a piston rod of the punching cylinder is fixedly connected with the guide rod through a connector. During punching, a plurality of parts to be punched are correspondingly placed on the plurality of punching dies of the lower punching disc, the punching cylinder is started, the piston rod of the punching cylinder drives the upper punching disc downwards to enable the plurality of punching heads on the lower end face of the lower punching disc to correspond to the respective punching dies of the lower punching disc for punching, and accordingly a plurality of parts can be punched at one time and punching efficiency is improved.

Owner:常州鑫鹏工具制造有限公司

Hardware V-shaped plate bilateral stamping device

ActiveCN106270022APromote safe productionImprove lighting conditionsShaping toolsHydraulic cylinderEngineering

The invention relates to a bilateral stamping device, in particular to a hardware V-shaped plate bilateral stamping device. The invention aims to provide the hardware V-shaped plate bilateral stamping device which is accurate in stamping, simple to operate and provided with a heat sink. In order to solve the technical problem, the invention provides the hardware V-shaped plate bilateral stamping device comprising a left rack, a first roller, a first guy cable, a slide rail, a second roller, a slide block, a first spring, a right rack, a cylinder, a V-shaped stamping platform, a hydraulic cylinder, a first stamping block, a baffle block, a second stamping block, and the like; the right rack is arranged on the right of the left rack. The hardware V-shaped plate bilateral stamping device has the effects of being is accurate in stamping, simple to operate and provided with a heat sink; such design integrates the advantages of accurate stamping and simple operation, saves time, and improves the efficiency.

Owner:东台市汉友机械有限公司

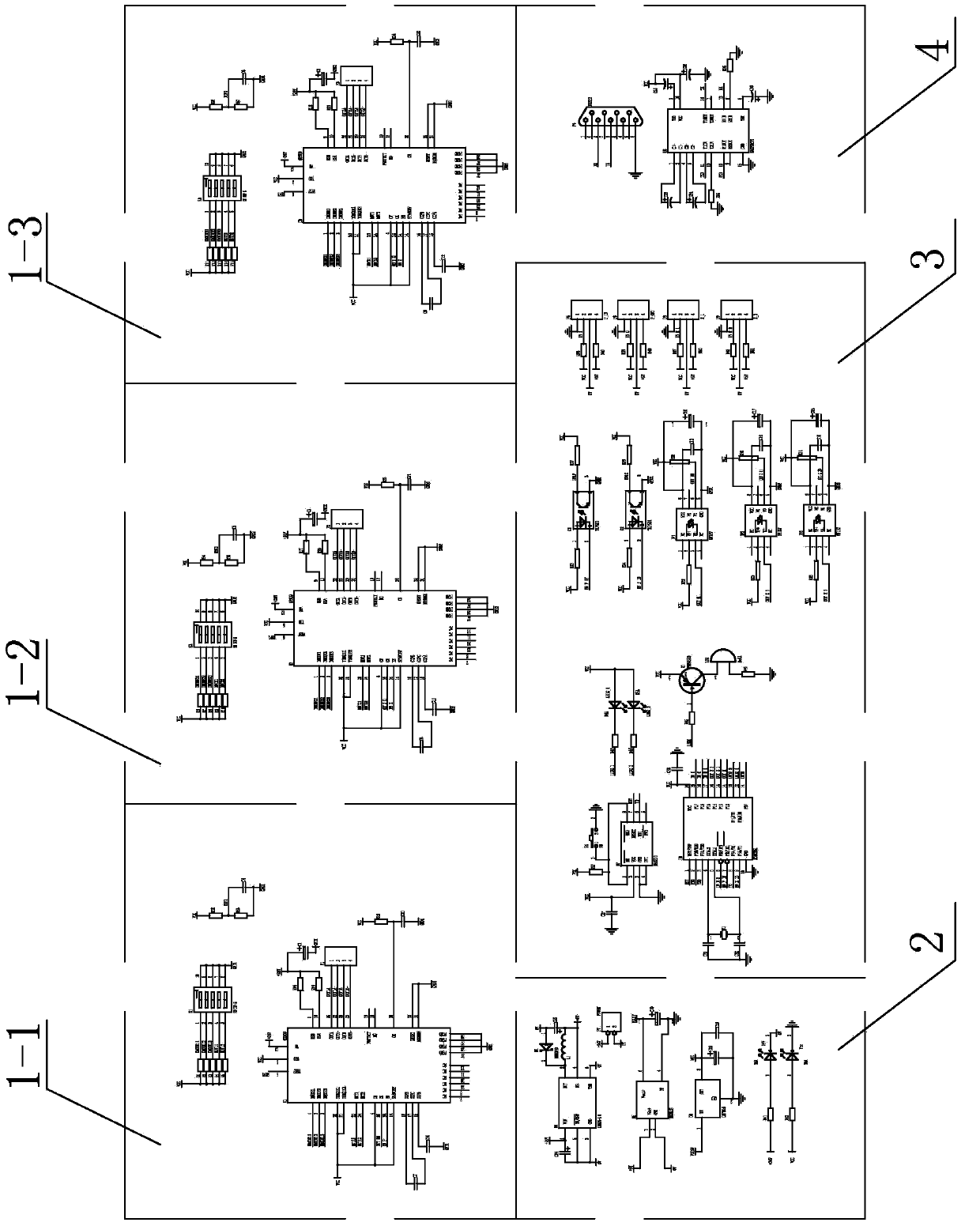

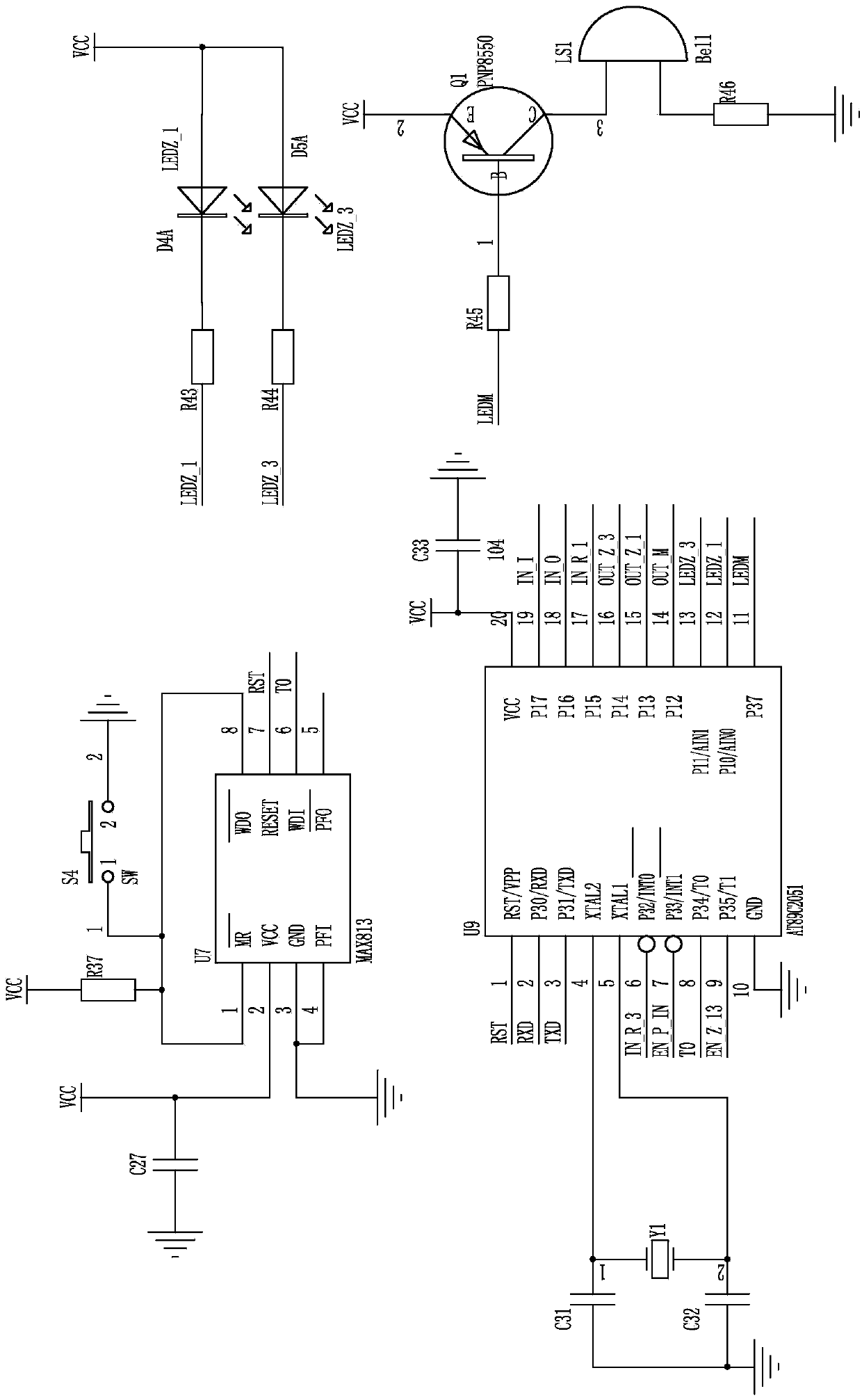

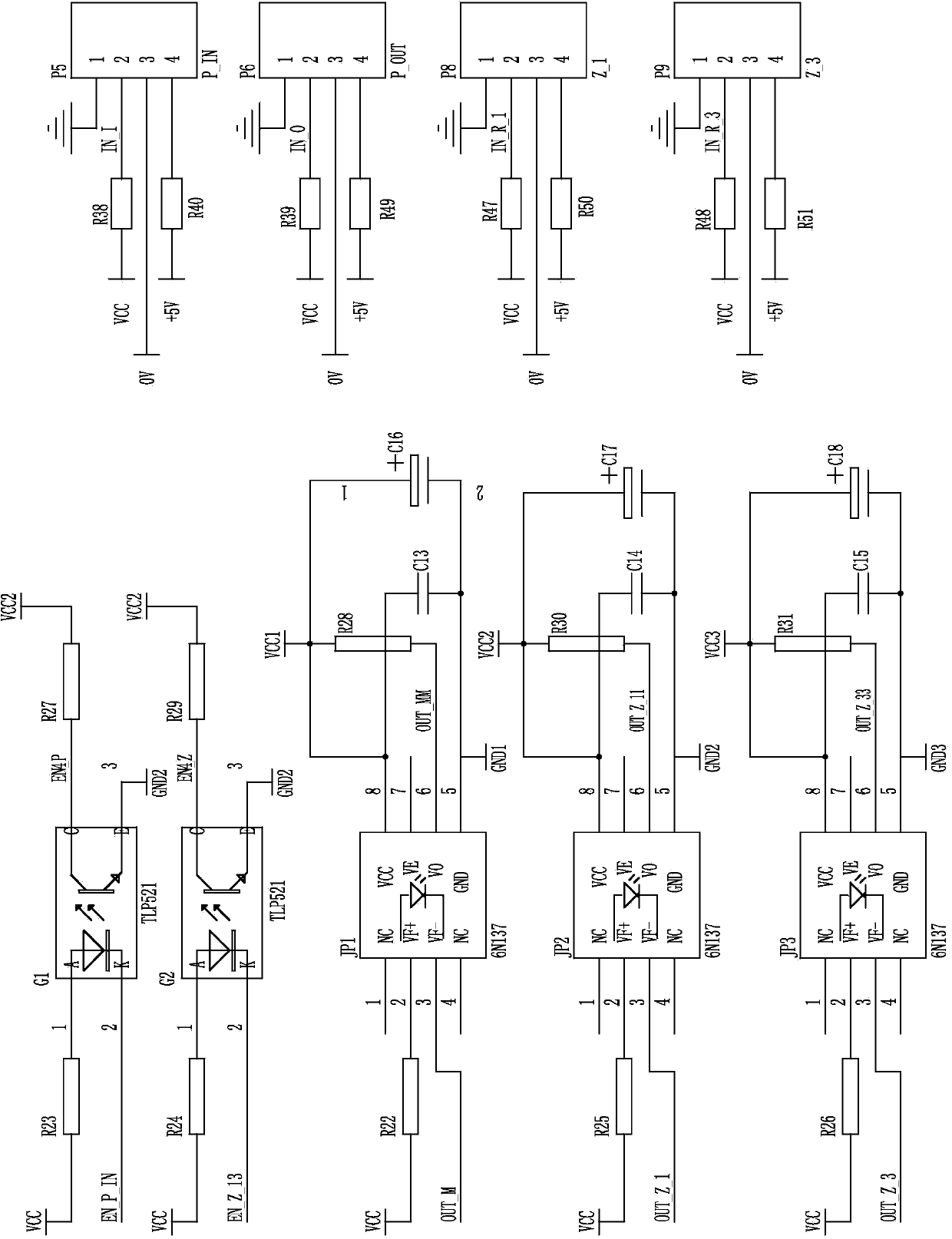

Controller for intelligent stamping mechanism

InactiveCN103995485ASimple structureLow costProgramme controlComputer controlControl engineeringElectric machinery

The invention relates to a controller for an intelligent stamping mechanism. The controller can control a paper advance mechanism and a stamping mechanism body of the intelligent stamping mechanism to work cooperatively. The controller has the advantages of being simple and reasonable in structure and accurate in control. According to the technical scheme, the controller for the intelligent stamping mechanism is characterized by being composed of a single chip microcomputer control circuit, a power source isolating circuit, a serial drive circuit and three stepping motor drive circuits.

Owner:杭州杰马电子有限公司

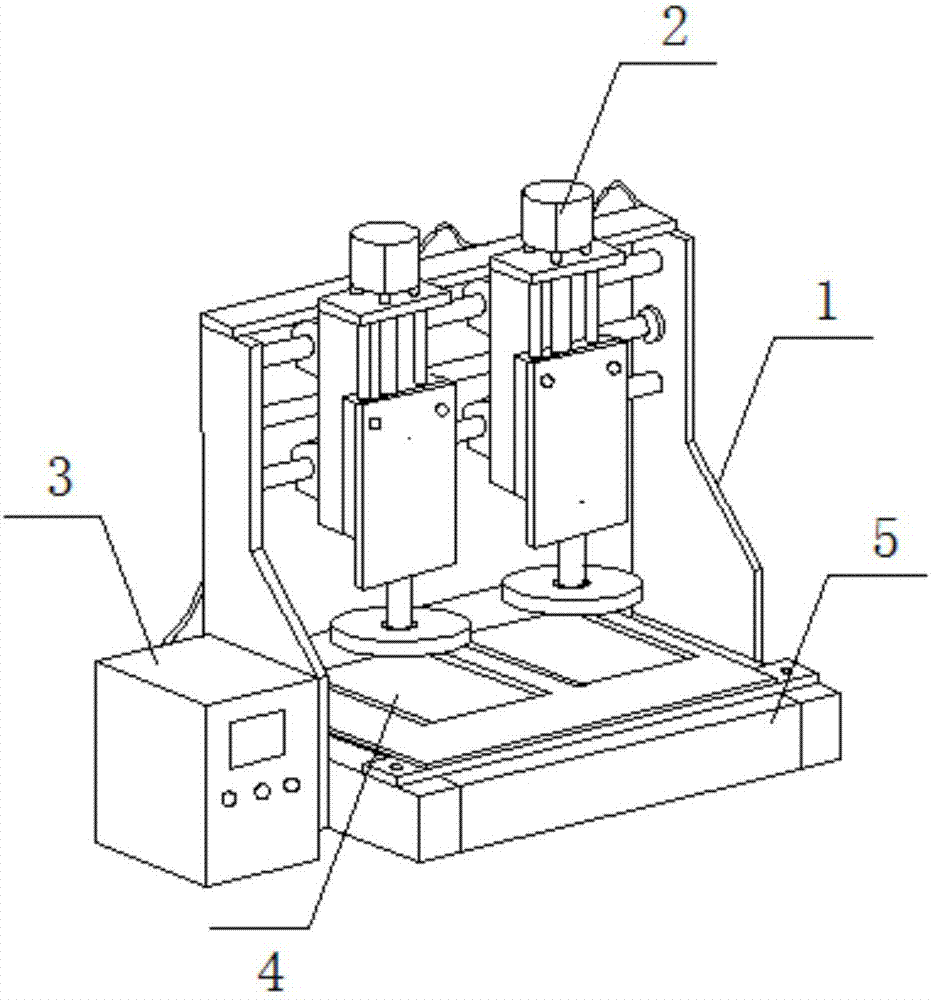

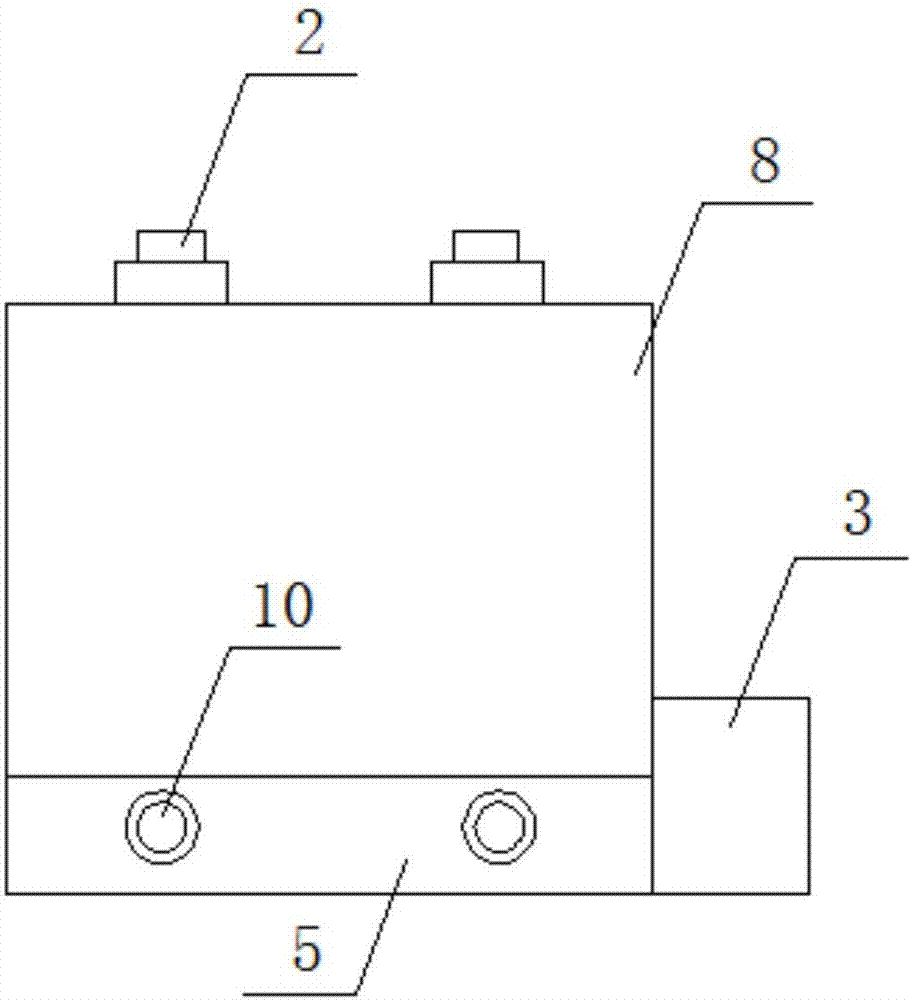

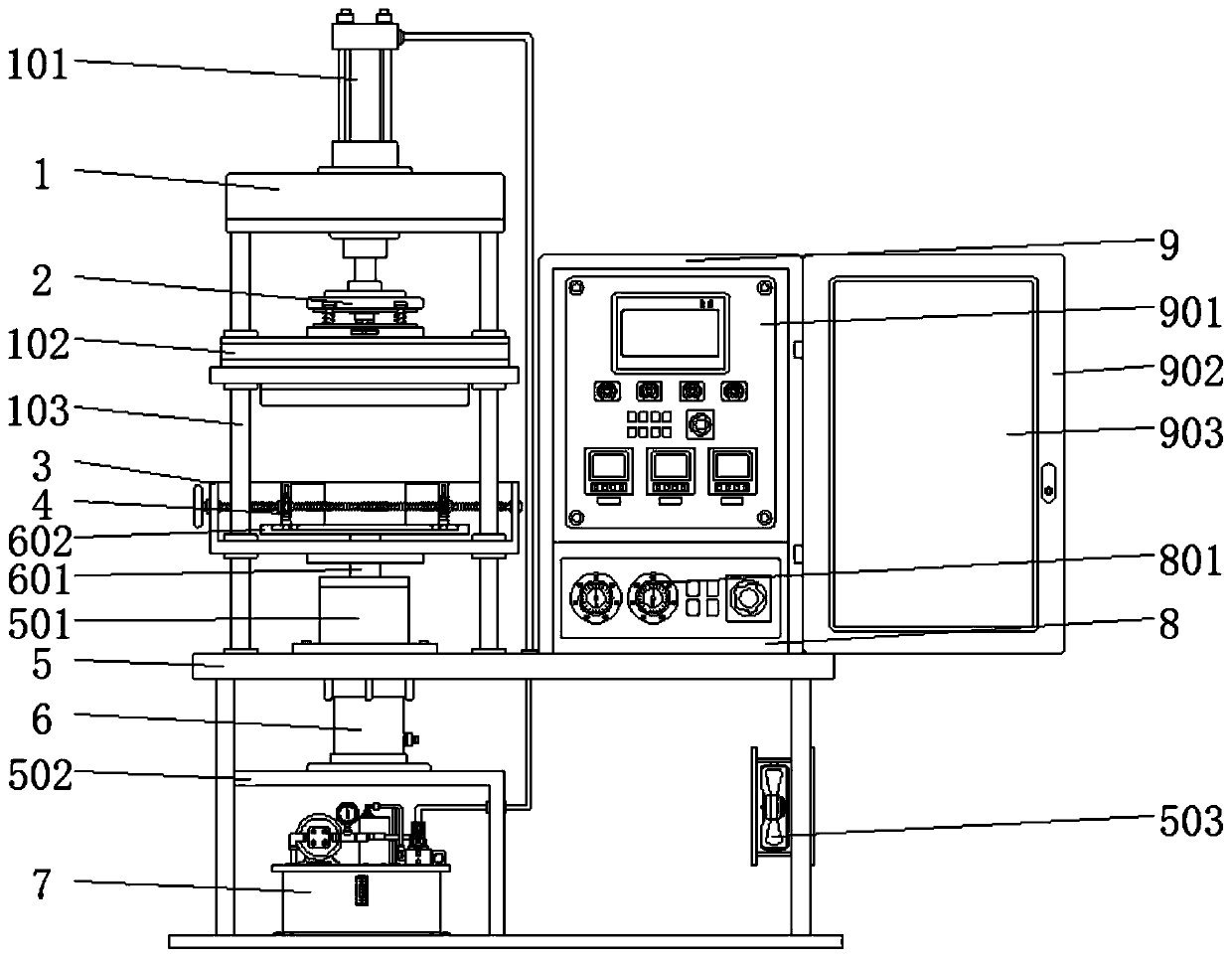

Stamping device for machining automobile stamping part

InactiveCN107262575AStamping precisionMetal-working feeding devicesVehicle componentsMechanical engineering

The invention discloses a stamping device for processing automobile stamping parts, which comprises a machine case, a stamping device, a control cabinet, a sealing plate, a bottom box, a sliding rod, a pole, a back plate, an inner groove, a shaping device, a sliding sleeve, a connecting Plates, pressure plates, pressure rods, plastic boxes, knobs, screws and movable rods. The beneficial effects of the present invention are: by installing two stamping devices inside the case, and the stamping devices are installed on the sliding rod on the top of the cabinet, the stamping device is installed on the sliding rod by using a sliding sleeve, so that the stamping device can slide on the sliding rod, so that The punching device can adjust its position by sliding the sliding sleeve before punching. By installing a bottom box at the bottom of the chassis, two inner slots are arranged inside the bottom box, a shaping device is installed inside the inner slot, and a slidable and replaceable plastic box is installed inside the shaping device, so that the stamping device can be replaced by different parts before stamping. The plastic box of the shape can stamp the stamping part into the desired shape, and the position of the stamping part can be defined by the plastic box.

Owner:无锡贺邦汽车配件有限公司

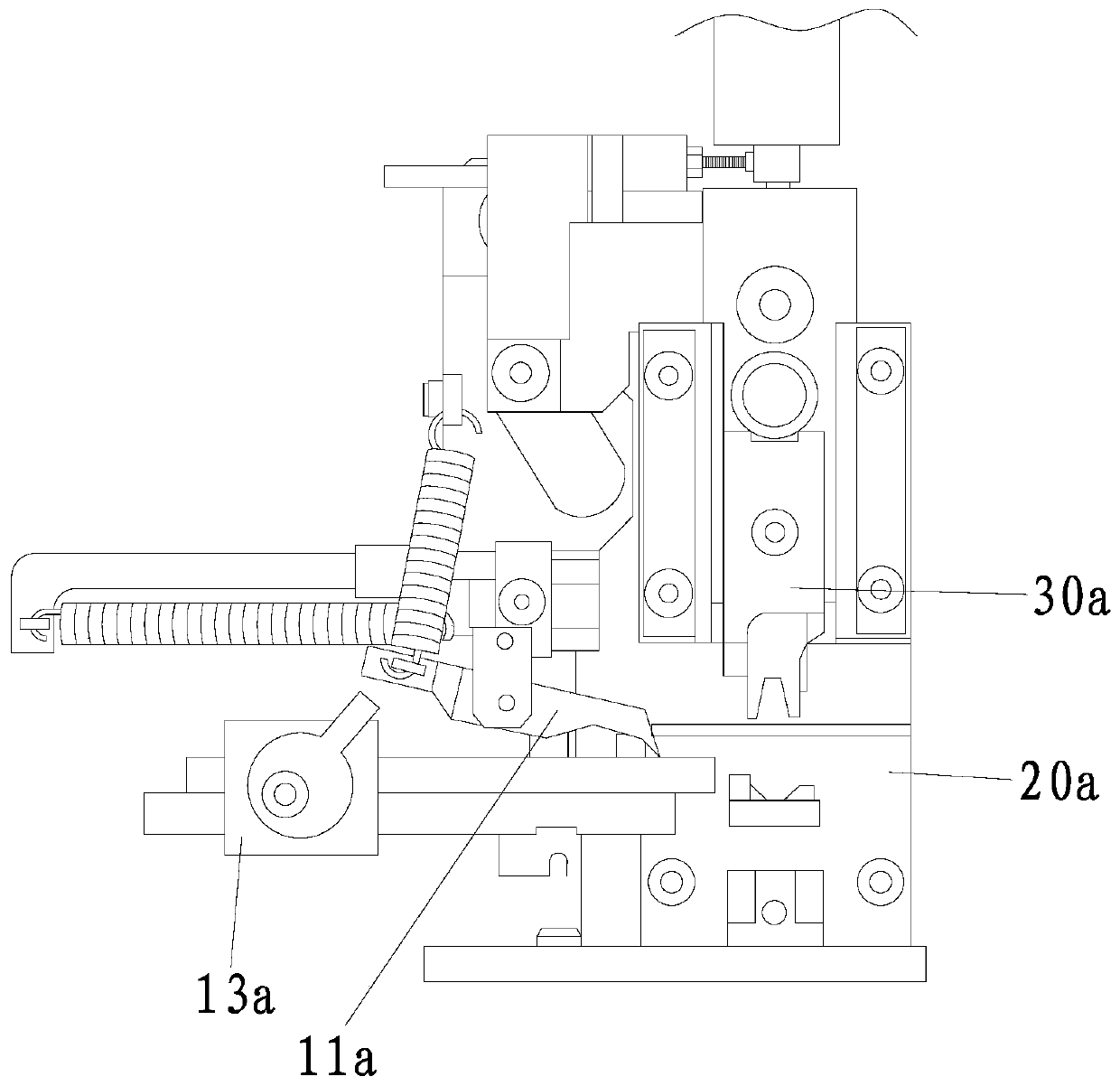

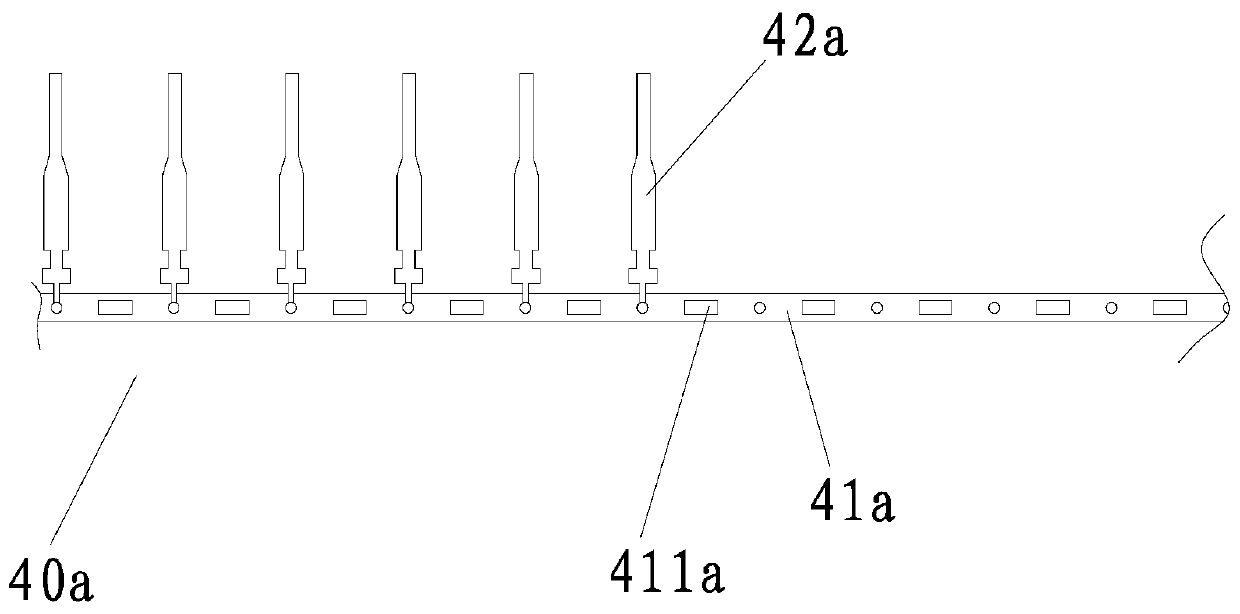

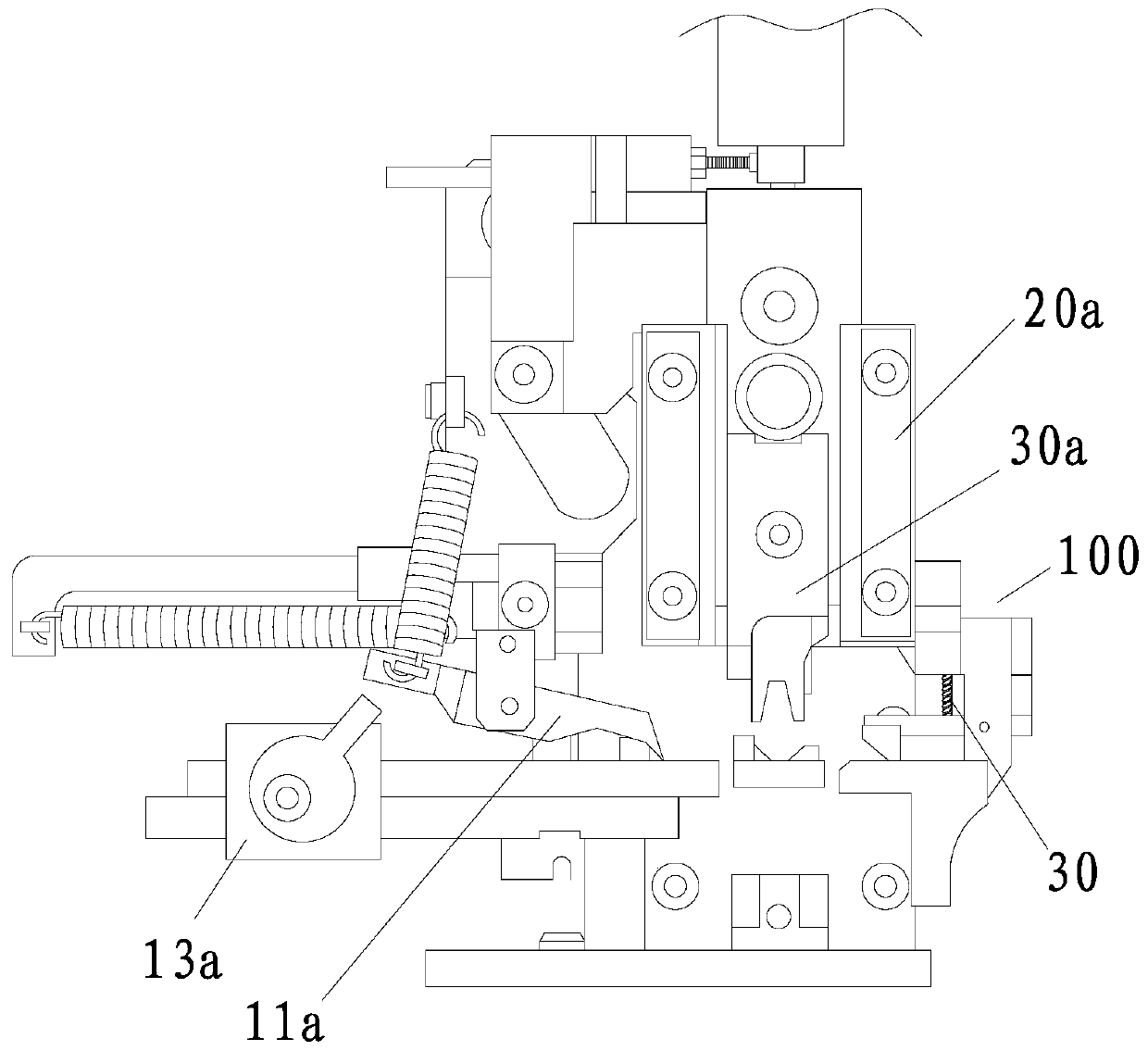

Terminal crimping die with material pressing mechanism

PendingCN111370967AAvoid wastingAvoid damageLine/current collector detailsStructural engineeringMechanical engineering

The invention discloses a terminal crimping die with a material pressing mechanism. The die comprises a material pressing mechanism. The material pressing mechanism comprises a seat body and a pressing claw used for extending into a process hole of a terminal material belt. The pressing claw is mounted on the seat body in a manner of swinging up and down. A telescopic spring is arranged between the seat body and the pressing claw. A conveying part is arranged on the seat body. The conveying part is located in the conveying direction of the terminal material belt, and an abutting part is arranged at one end of the pressing claw from back to front with the conveying direction of the terminal material belt as the conveying direction. The abutting part comprises an inclined section and a straight section located on the front side of the inclined section. The inclined section and the first end of the straight section are connected to form a tip, and the tip abuts against the conveying part.Compared with the prior art, when the material pressing plate cannot press the terminal material belt, the terminal material belt is positioned through the pressing claws, so that the terminal material belt is always in a crimping state, terminals in the whole disc of terminal material belt are effectively utilized, the utilization rate of the terminals in the terminal material belt is improved,and resource waste is avoided.

Owner:CYUANHUA(FUJIAN) ELECTRIC TECHNOLOGY CO.,LTD.

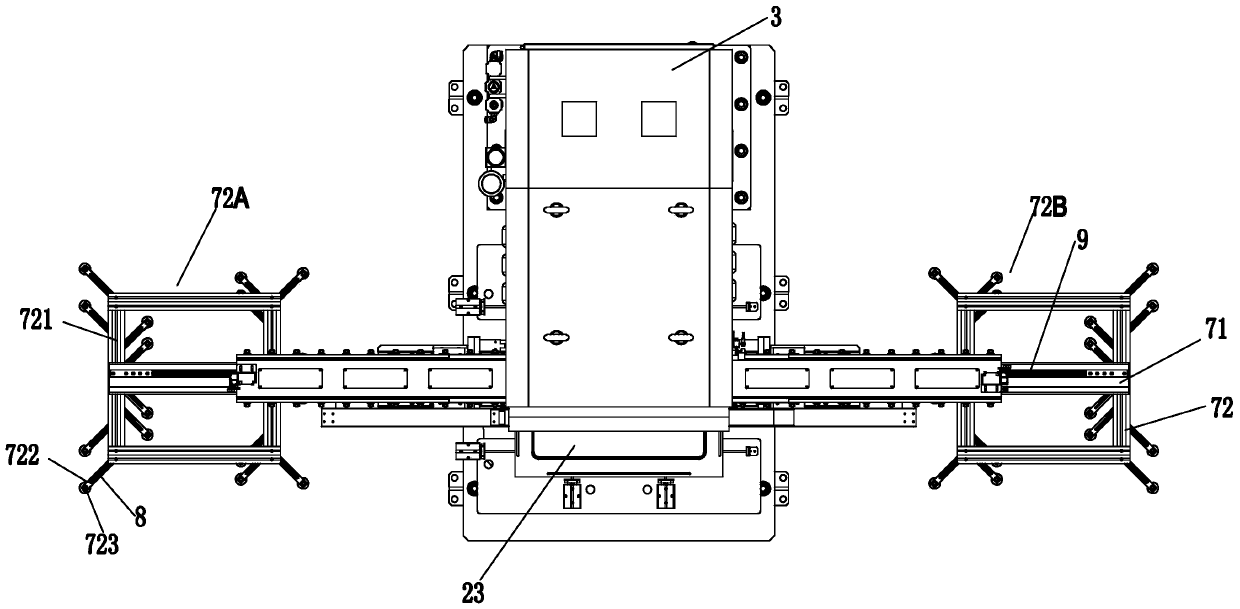

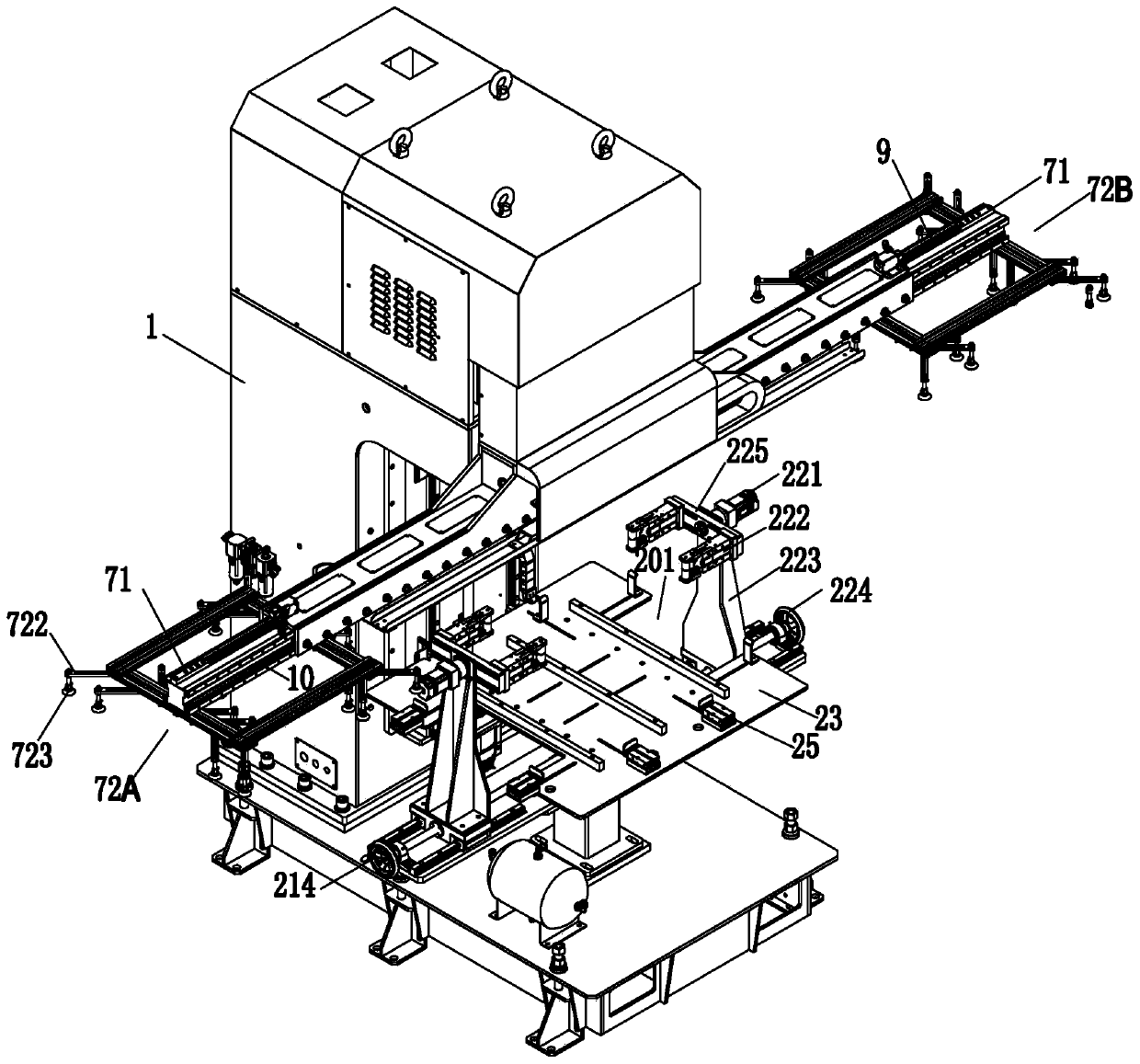

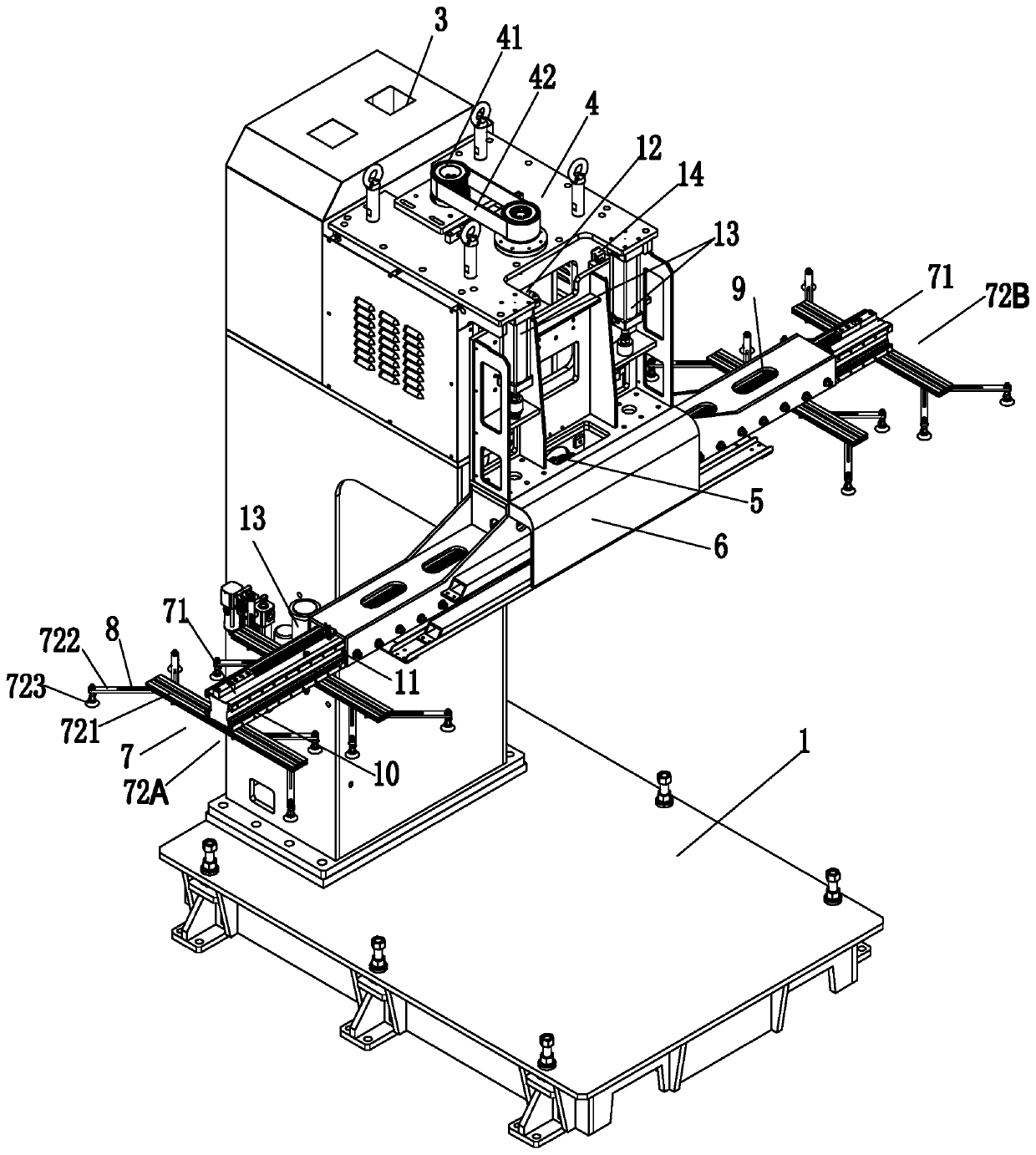

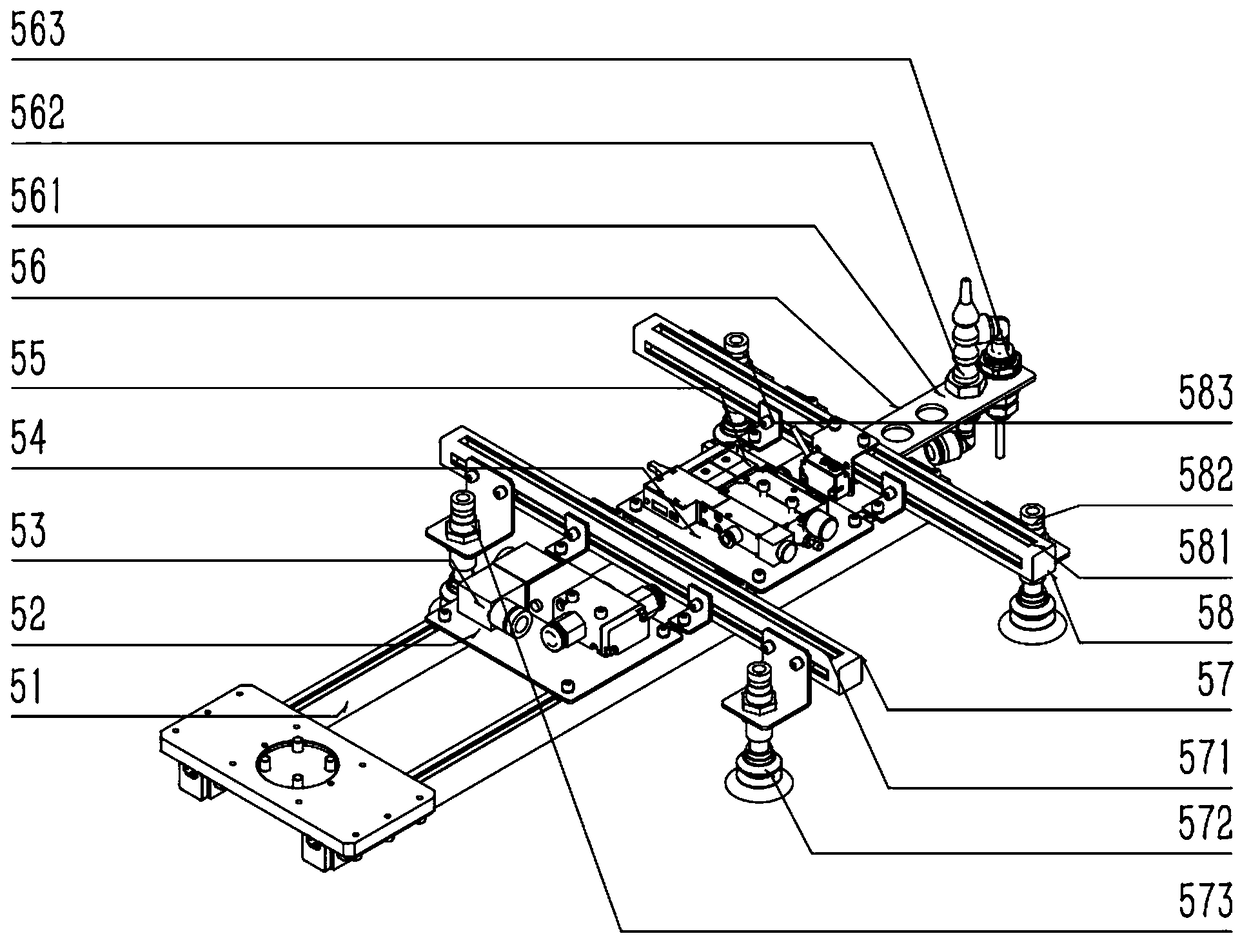

Intelligent multifunctional independent type wired mechanical hand

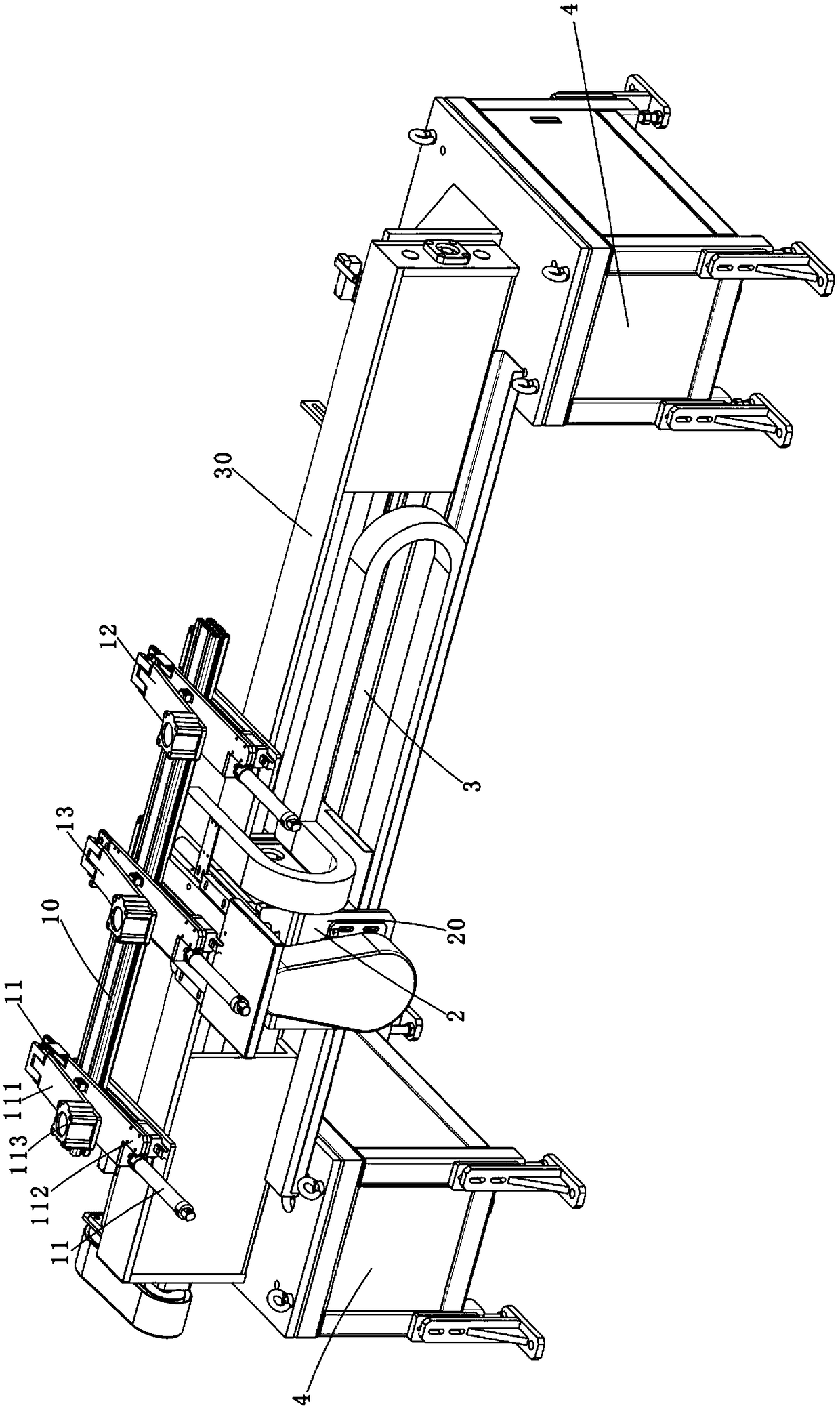

PendingCN110000300AImprove transmission efficiencyMeet mass production requirementsMetal-working feeding devicesPositioning devicesPunchingEngineering

The invention relates to an intelligent multifunctional independent type wired mechanical hand. The intelligent multifunctional independent type wired mechanical hand comprises a machine base, an electric control box, a connecting base, a mechanical arm, a lifting transfer table, a transfer table lifting mechanism, a left workpiece turnover mechanism, and a right workpiece turnover mechanism; theconnecting base is mounted on the machine base through the lifting mechanism, the mechanical arm is arranged on the connecting base through a horizontal transfer mechanism, the mechanical arm comprises a horizontal transfer guide rail and at least two sets of sucking arms, the horizontal transfer guide rail connected with the horizontal transfer mechanism, the lifting transfer table is arranged onthe machine base in a lifting and sliding manner and is located below the mechanical arm, the transfer table lifting mechanism is arranged on the machine base and is in driving connection with the lifting transfer table, and the left workpiece turnover mechanism and the right workpiece turnover mechanism are arranged on the machine base and are located on the left side and the right side of the lifting transfer table correspondingly. The independent type wired mechanical hand is provided with the left workpiece turnover mechanism, and the right workpiece turnover mechanism, the left workpieceturnover mechanism and the right workpiece turnover mechanism can turn over the workpiece on the lifting transfer table by 180 degrees, and a punching device in the rear working procedure can punch the other face of the workpiece conveniently.

Owner:FOSHAN SHUNDE KAISHUO PRECISION MOLD AUTOMATION TECH CO LTD

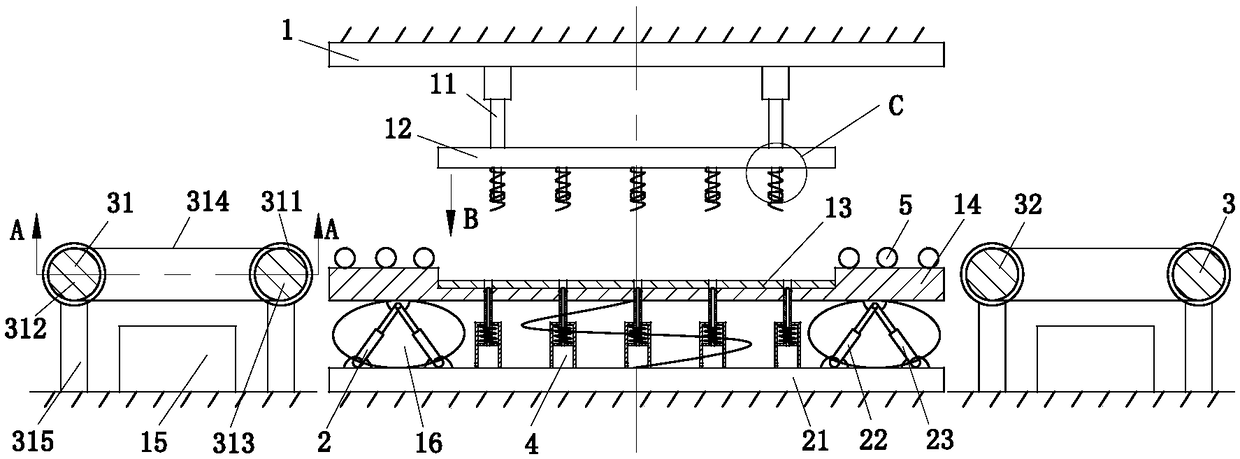

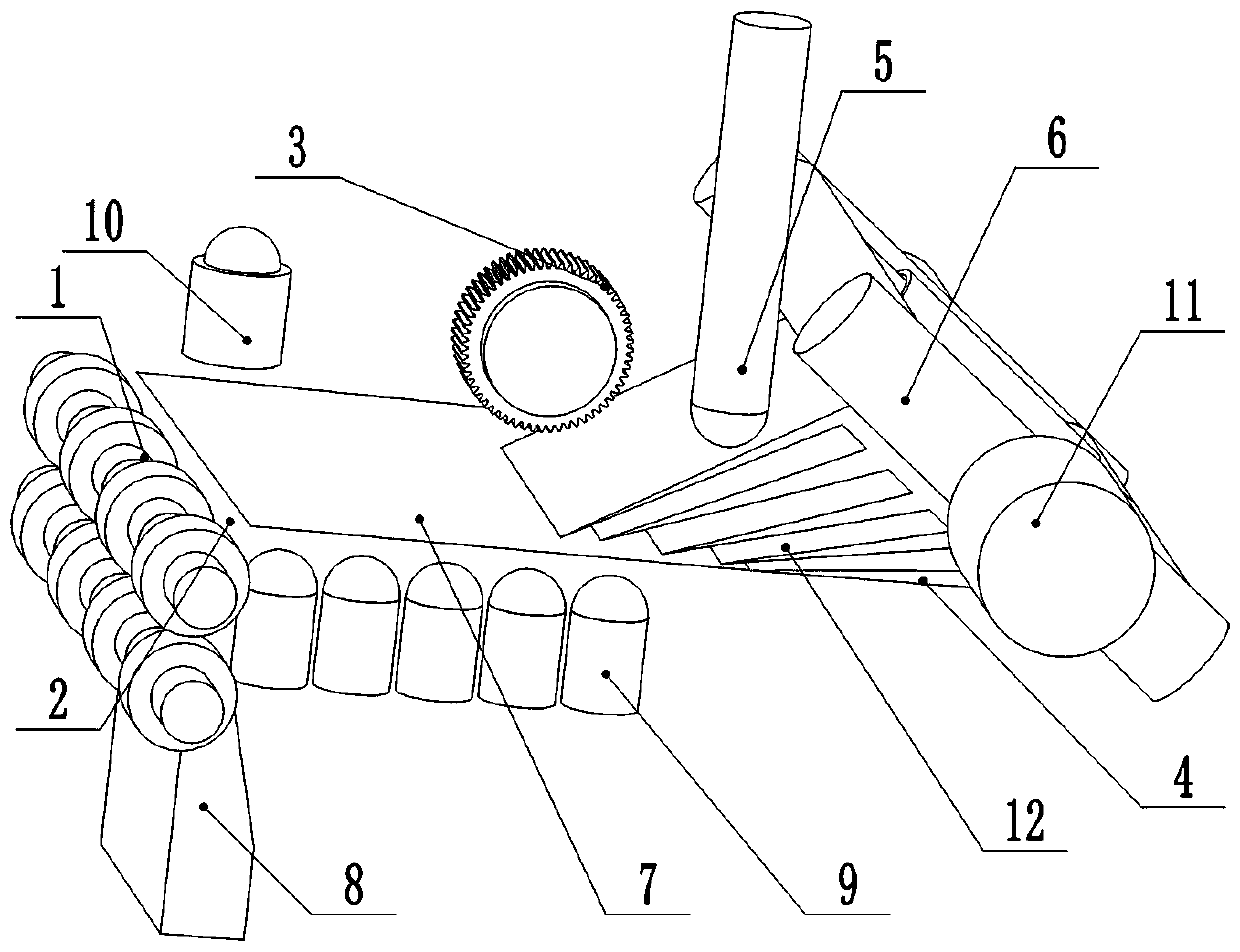

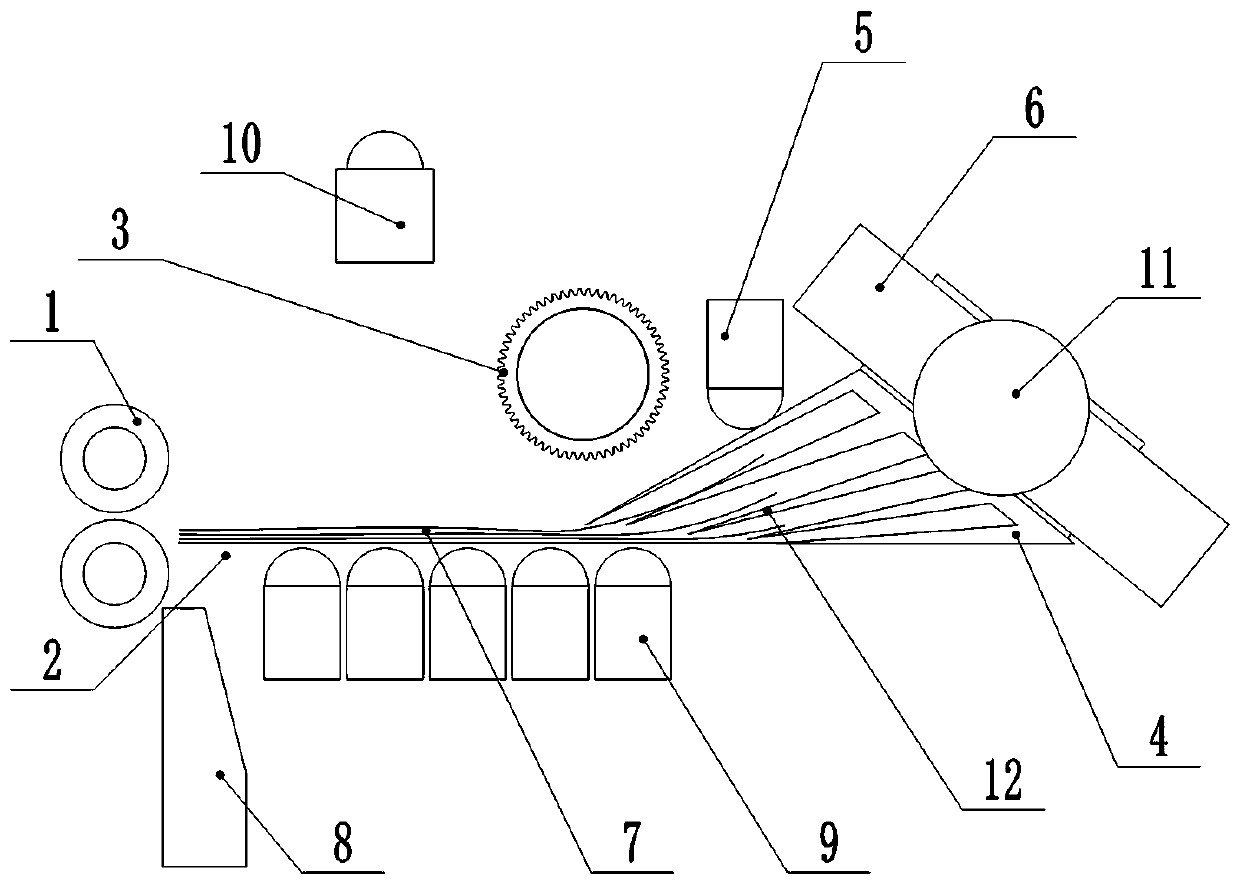

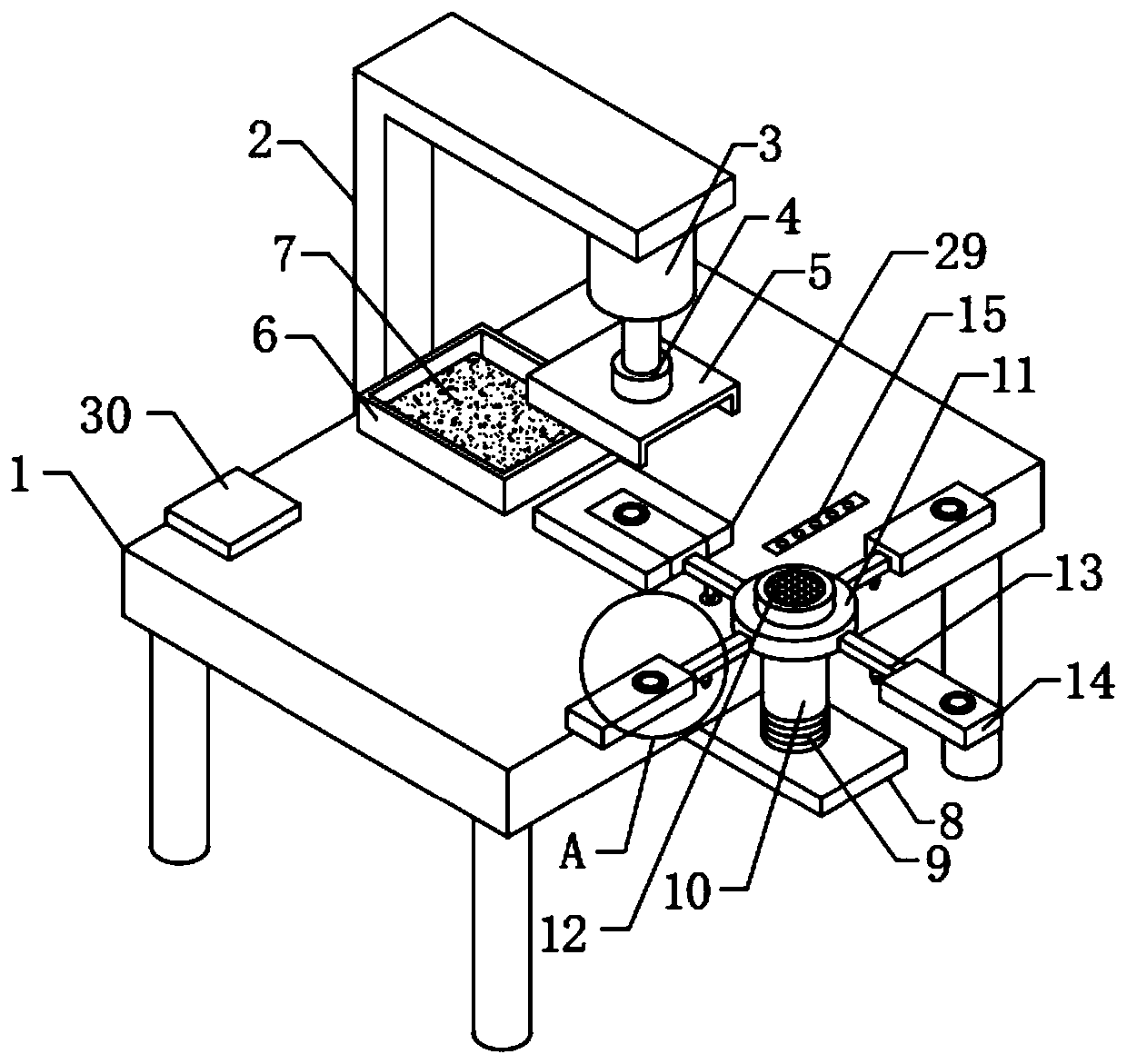

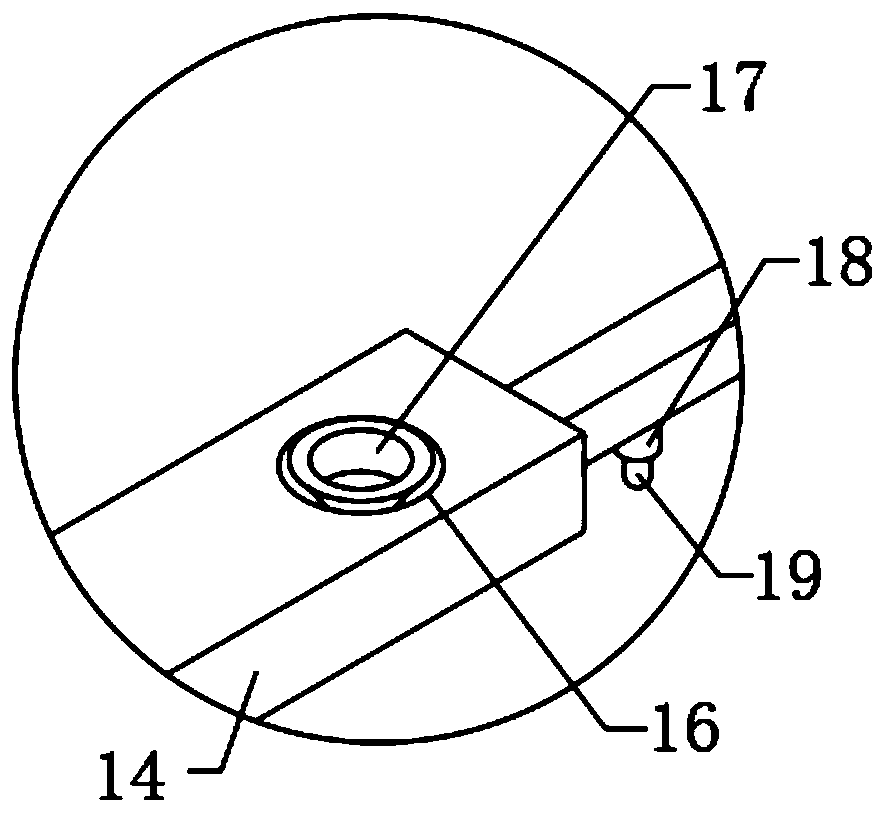

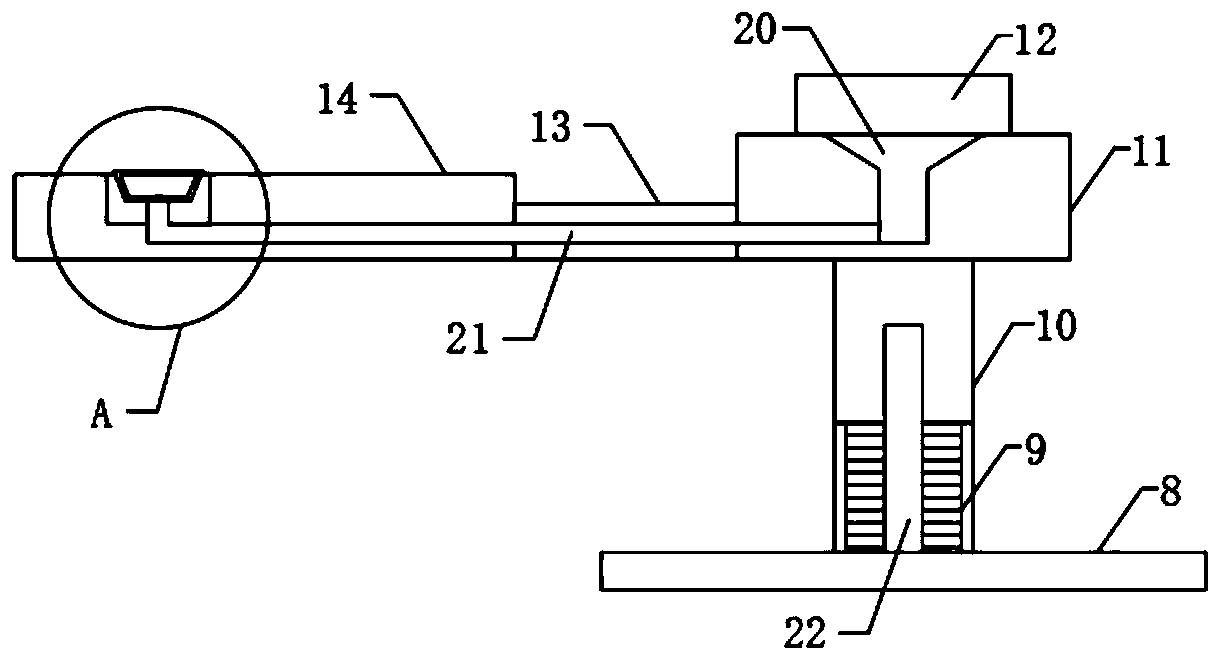

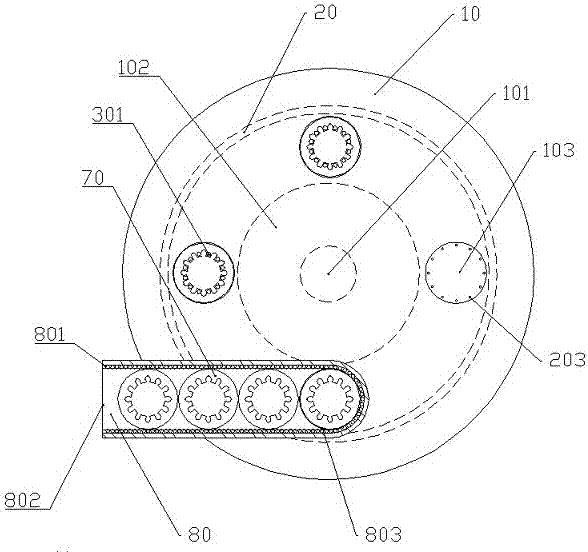

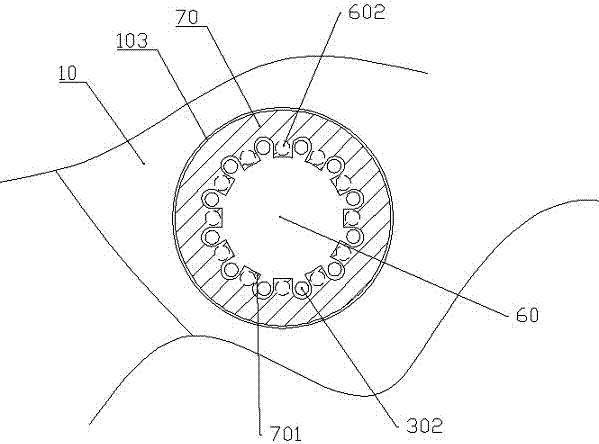

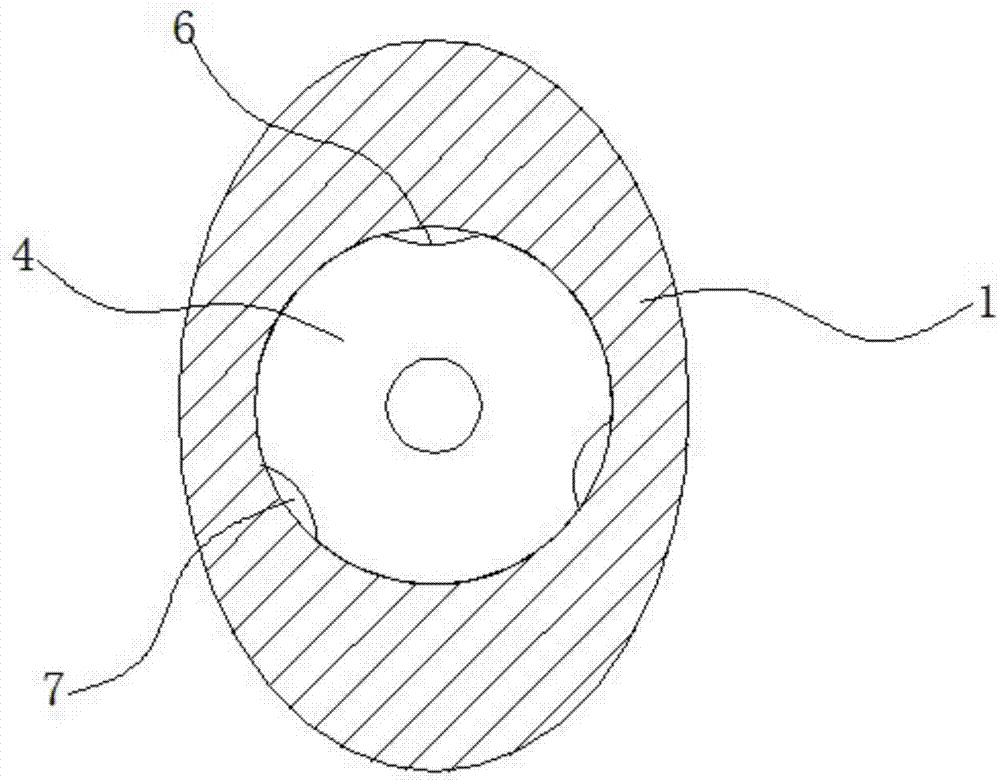

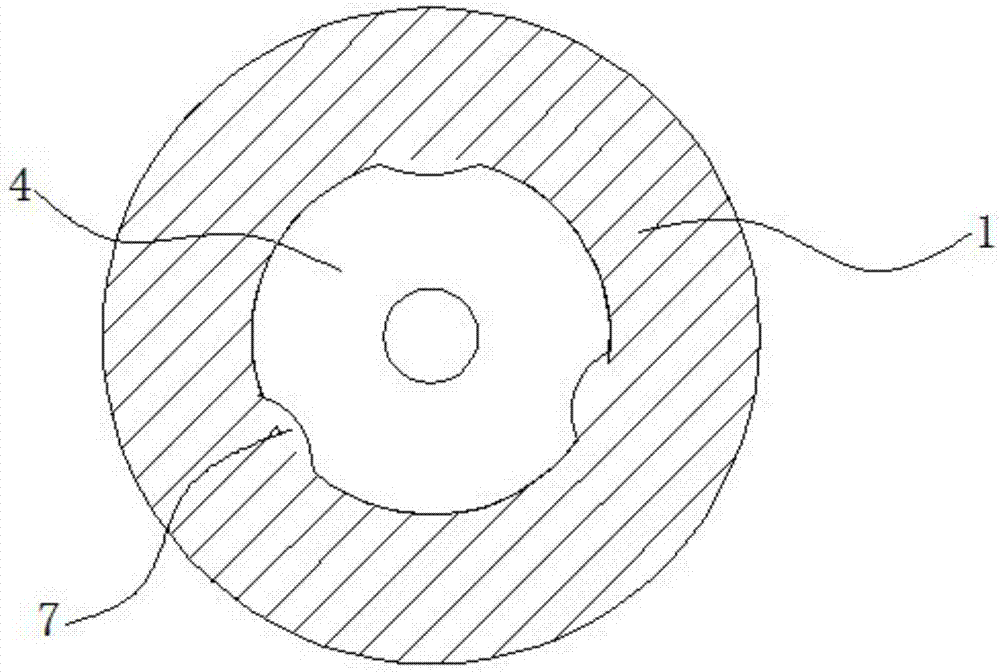

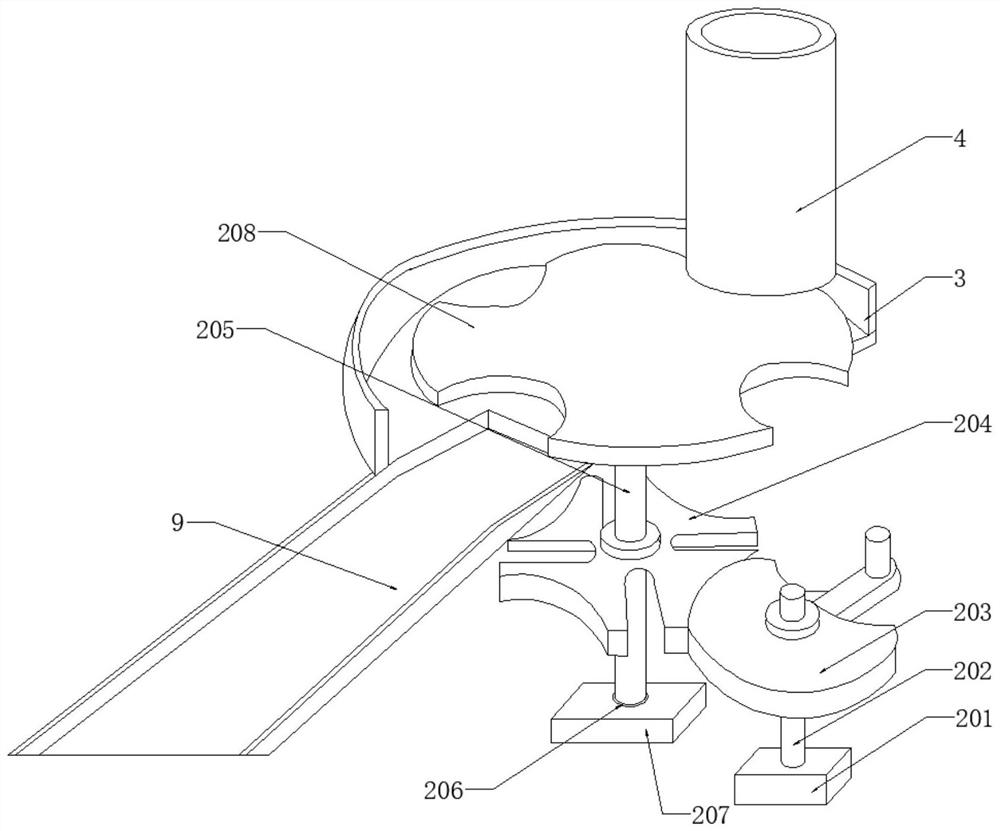

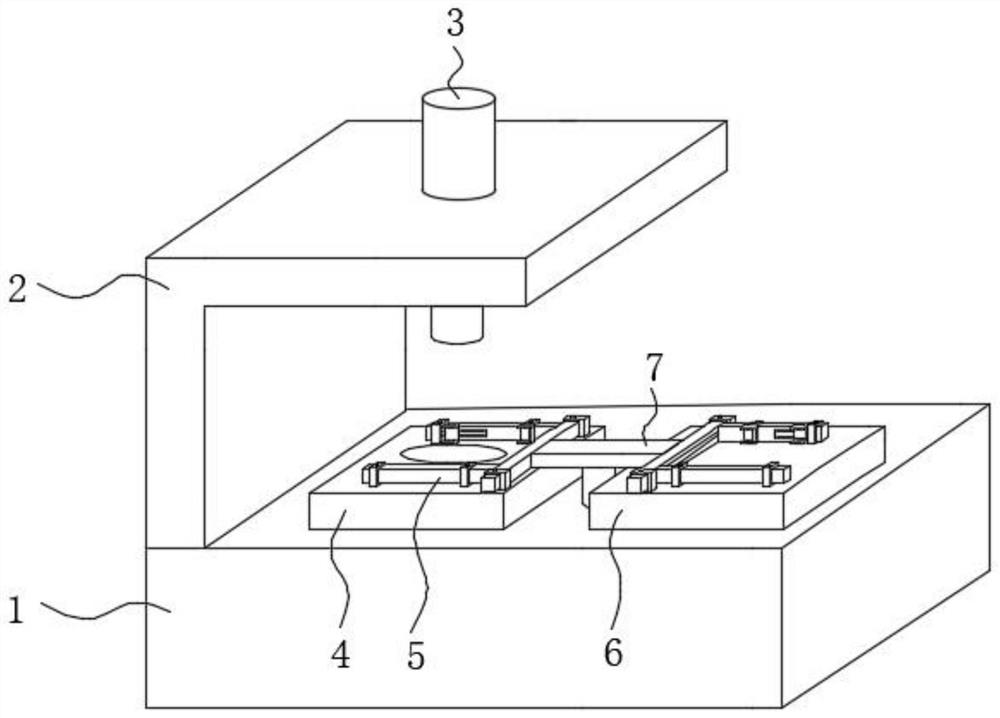

Method for stamping washers

ActiveCN107282738AImprove stamping qualityReduce stamping defective rateMetal working apparatusEngineeringMachining

The invention relates to the field of part processing, and in particular discloses a method for stamping washers. When internal teeth lock washers are stamped, machining through grooves on a turntable are rotating, so that four steps, namely feeding, calibration, stamping and pick-up, are conducted on the internal teeth lock washers in the four machining through grooves in sequence so as to achieve cycle machining of the internal teeth lock washers and improve the stamping efficiency of the internal teeth lock washers; meanwhile, before the internal teeth lock washers are stamped, the positions of the internal teeth lock washers can be calibrated through a calibration stamping mechanism so as to ensure that stamping parts of the internal teeth lock washers can be accurately stamped, and the stamping defective rate of the internal teeth lock washers is reduced. According to the method for stamping washers, the internal teeth lock washers can be aligned with a stamping head and a kicker pin, so that the stamping efficiency of the internal teeth lock washers is improved.

Owner:YANCHENG TONGJI AUTO PARTS CO LTD

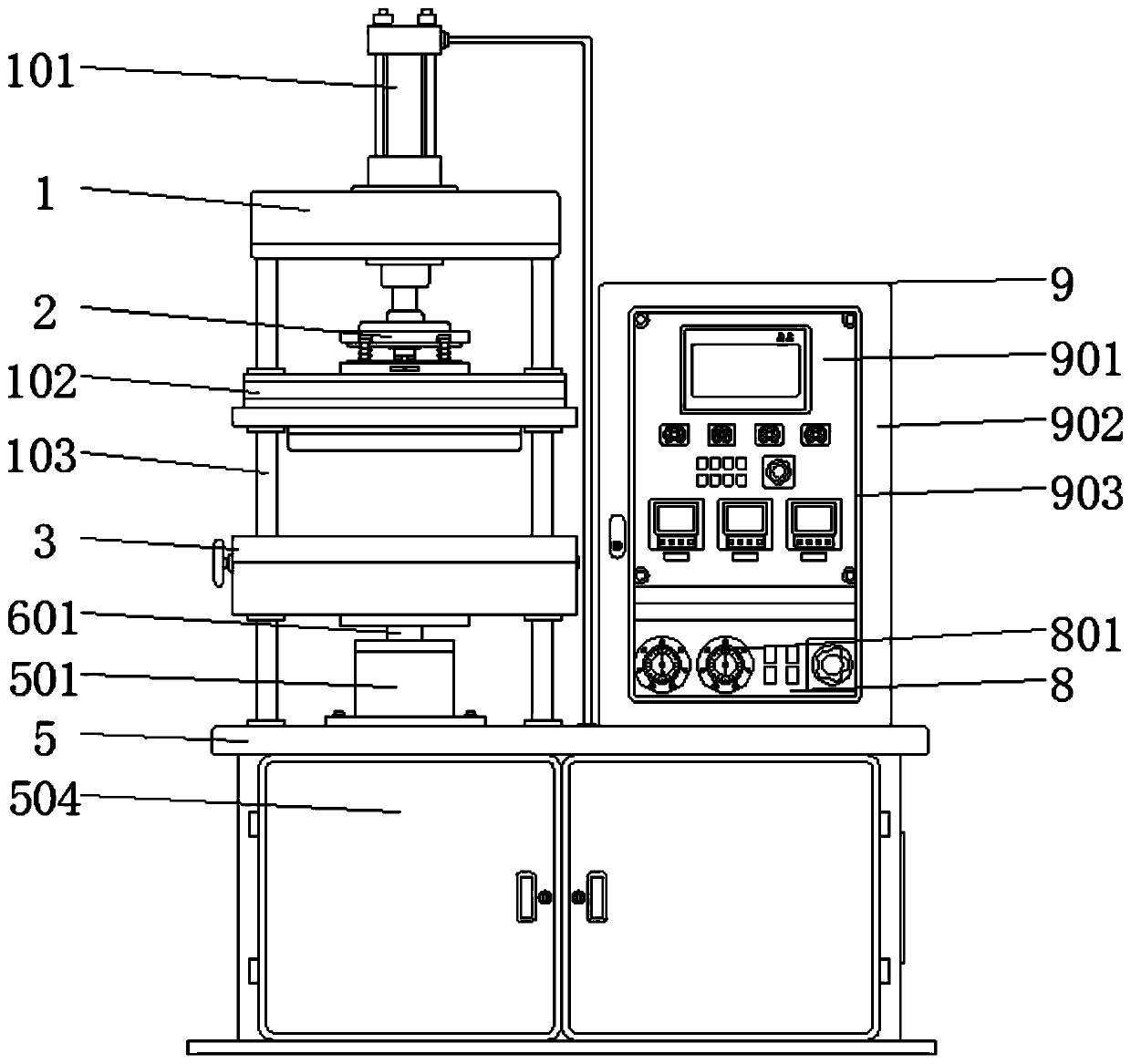

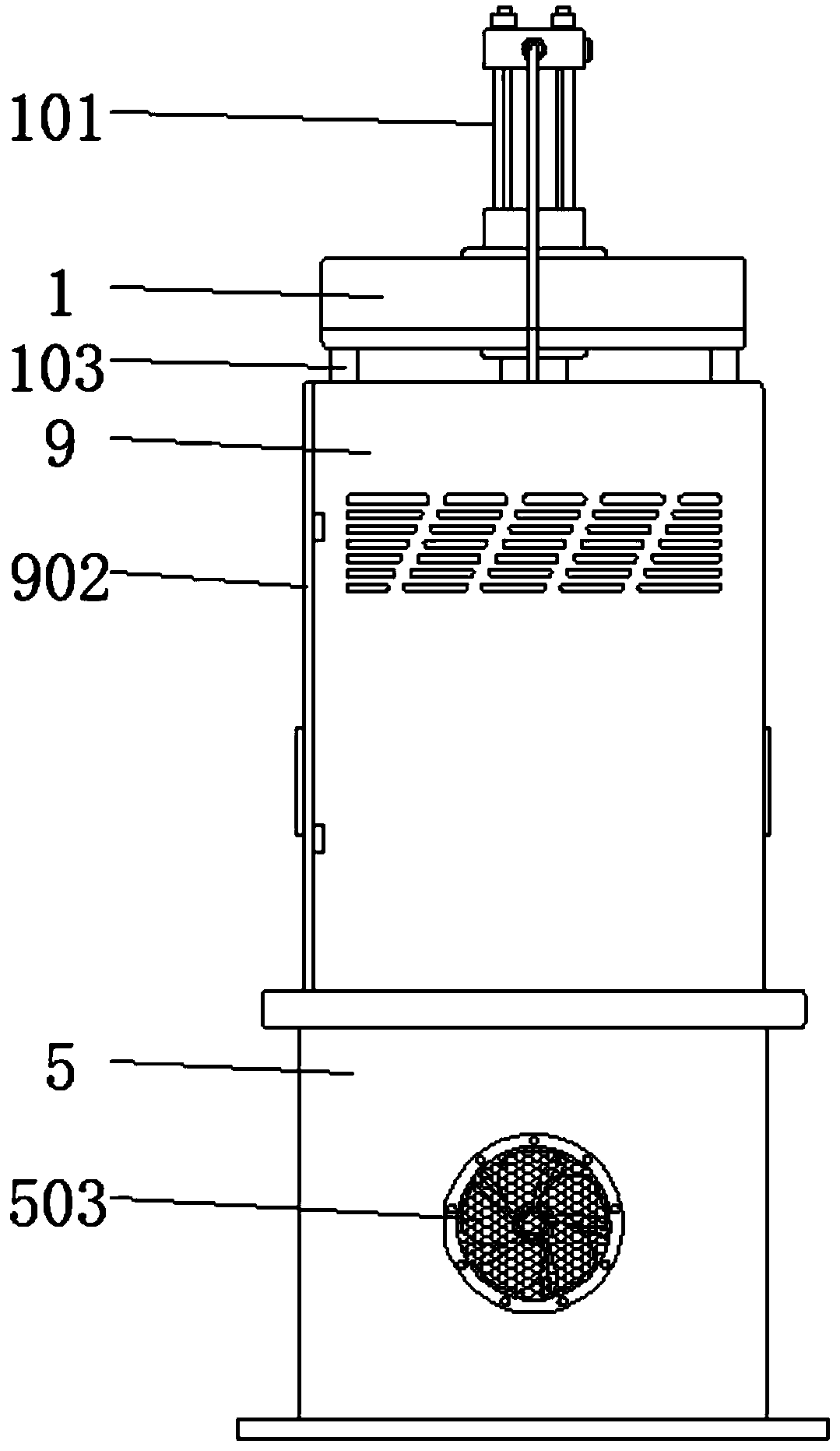

Stamping device for processing automobile parts

InactiveCN111515283AQuality improvementGuaranteed accuracyMetal-working feeding devicesPositioning devicesStructural engineeringMechanical engineering

The invention discloses a stamping device for processing automobile parts. The stamping device comprises an adjusting frame, a bottom cabinet and a control box, a top frame is installed on one side ofthe top of the bottom cabinet through two groups of guiding rods, an operation box is movably installed on the outer sides of the guiding rods, an installation table is welded into the bottom cabinet, a hydraulic rod is fixedly installed at the top of the installation table, a piston rod extending into the operation box is installed in the hydraulic rod, an adjusting plate is fixedly installed atthe top of the piston rod, and the adjusting frame is movably installed at the top of the adjusting plate through a sliding chute. According to the stamping device for processing the automobile parts, the adjusting frame is installed in the operation box, the adjusting frame can adjust the shapes required by the automobile parts, so that the stamping device is suitable for stamping processing theautomobile parts with different shapes, and thus application ranges of the device are extended; and meanwhile, the position of a stamping piece can be limited through the adjusting frame, so that thestamping is accurately carried out, the precision of the stamping piece is ensured, and the stamping quality of the automobile parts is improved.

Owner:合肥惠开车科技有限公司

Punching equipment

InactiveCN107335716ASimple structureStamping precisionPerforating toolsMetal working apparatusPunchingEngineering

A stamping equipment, including a punch, a stamping die and a support seat, the stamping die is installed on the support seat, the punch is located above the support seat, a groove is arranged in the center of the stamping die, and the punch can be pressed into the middle of the stamping die In the groove of the punch, the central section of the punch is circular, the punch is nested at the bottom end of the main shaft, and the outer wall of the punch is provided with a wear-resistant sleeve, which is installed at the middle and upper end of the punch; The equipment makes its structure simple, and can punch round holes and non-round holes, and can process a variety of materials with accurate punching. After punching, the punch can rotate under the action of the main shaft, and the wear-resistant sleeve on the punch can be removed by rotation. The burr on the edge of the punching part of the stamped workpiece improves work efficiency and quality.

Owner:JIASHAN RUIYI ELECTRONICS TECH

Steel plate straightening and stamping integrated equipment for rolled steel

InactiveCN111790809AEasy to unloadPrecise positioningMetal-working feeding devicesPositioning devicesSteel platesStamping

The invention discloses steel plate straightening and stamping integrated equipment for rolled steel, and relates to the field of rolled steel stamping. The equipment comprises a lower die plate, supporting columns, a stamping die column, a straightening pressing plate and a connecting sleeve; the lower die plate is fixedly connected with the ground through the supporting columns, the straightening pressing plate is connected with the stamping die column through the connecting sleeve, and the stamping die column and the straightening pressing plate are externally connected with a driving piece; and a feeding device, a material returning device, a reversing structure and a sealing plate are fixedly arranged on the lower die plate, the reversing structure is connected with a straightening pressing plate through a transmission plate, a lifting structure is arranged on the sealing plate, and a telescopic traction structure is arranged on the straightening pressing plate. The steel plate straightening and stamping integrated equipment for the rolled steel solves the technical problems that a traditional device is discontinuous in stamping and low in precision.

Owner:北京康乾白祥商贸有限公司

Rough blank stamping device of Longquan sword

The invention provides a preparing process of the Longquan sword. The process comprises following steps that archaized low-sulfur white iron is selected to serve as a raw material, a rough blank stamping device is adopted to stamp the archaized low-sulfur white iron to form the early form of the Longquan sword, and rough hammering, fine hammering, shaping, quenching, polishing, tempering, carving,shaving and assembling are carried out. The traditional Longquan sword making process is improved, the performance of pig iron is changed, the archaized low-sulfur white iron raw material is adopted,the Longquan sword suitable for a dance studying person with the sword for keeping health for use, and the Longquan sword has the beneficial effects that the sword body has strength and toughness; the rear tail of the sword body is elastic, and free in stretching; thirdly, the sword body is bright; fourthly, t he archaized low-sulfur white iron raw material is adopted, and it is ensured that themade Longquan sword is resistant to wear and oxidation and not prone to rusting.

Owner:浙江精龙刀剑有限公司

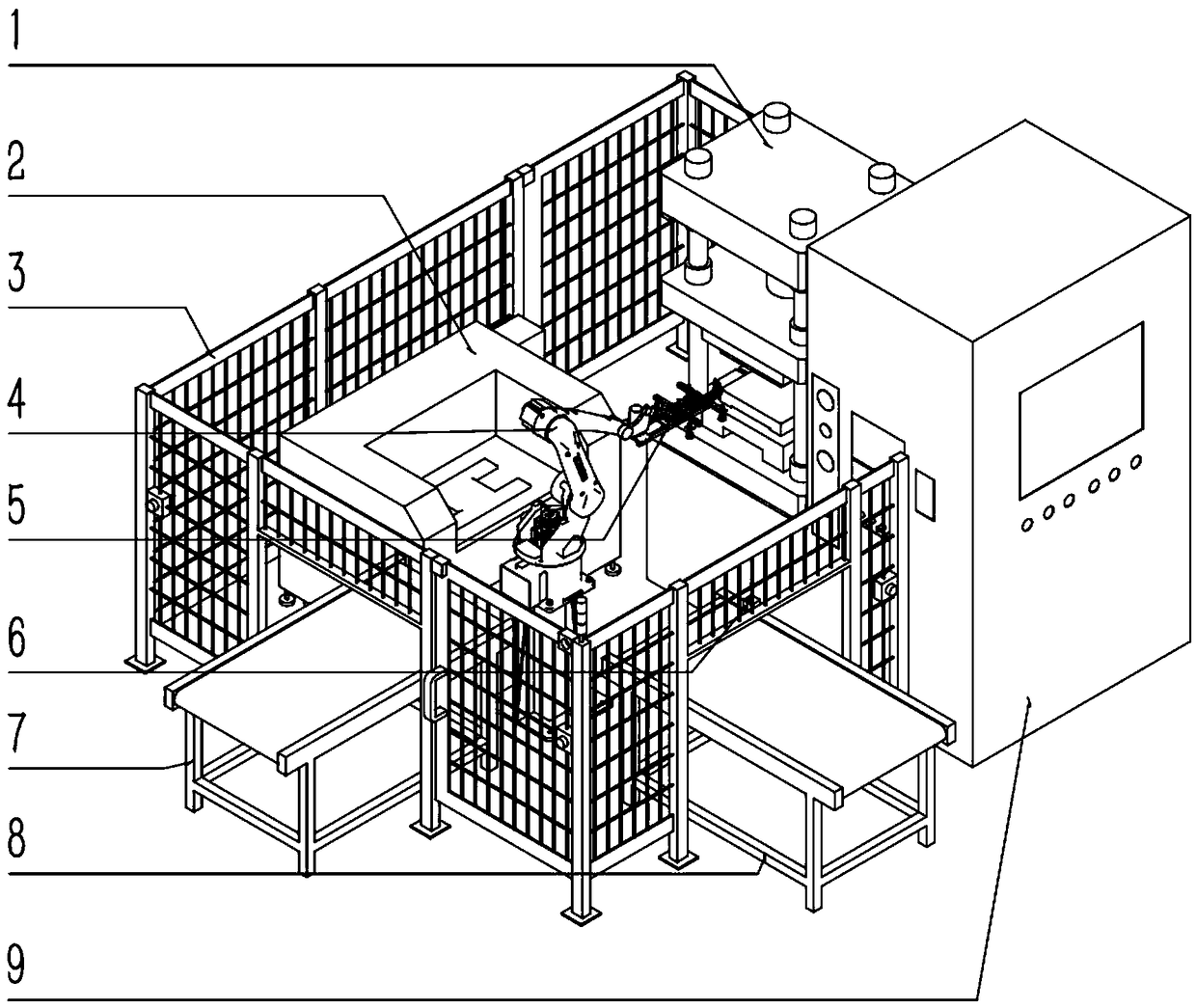

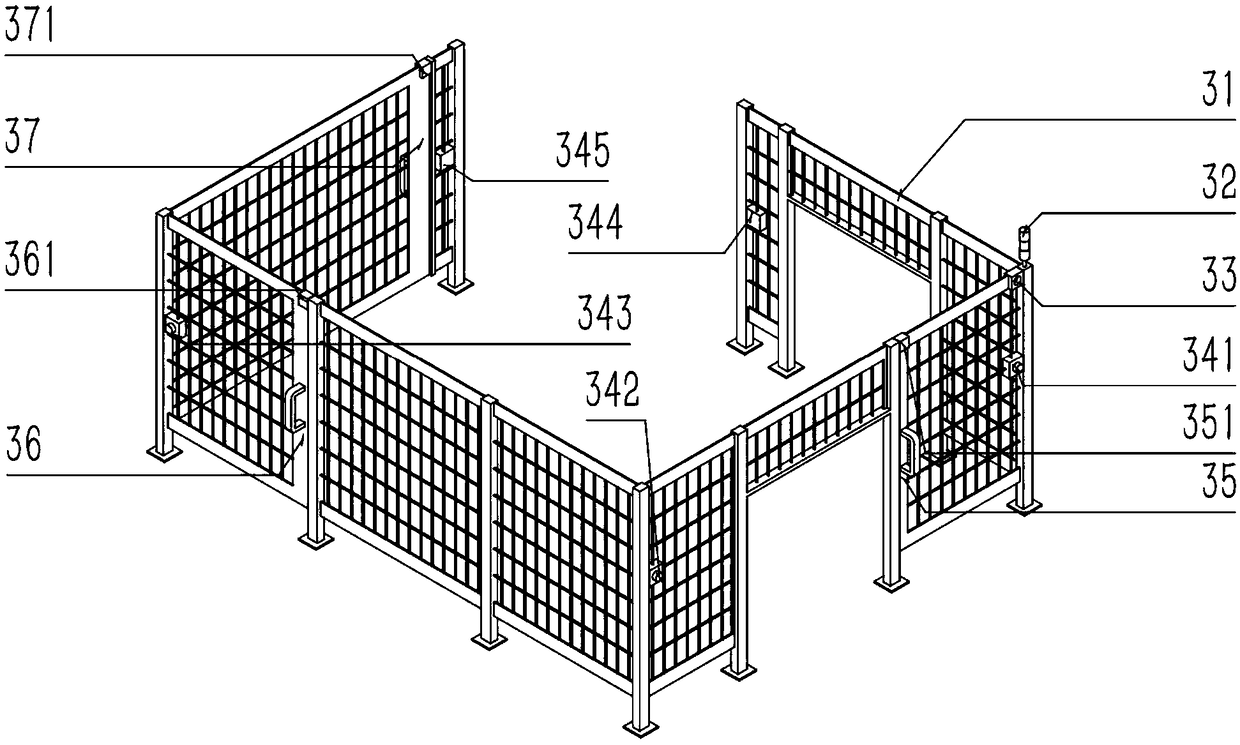

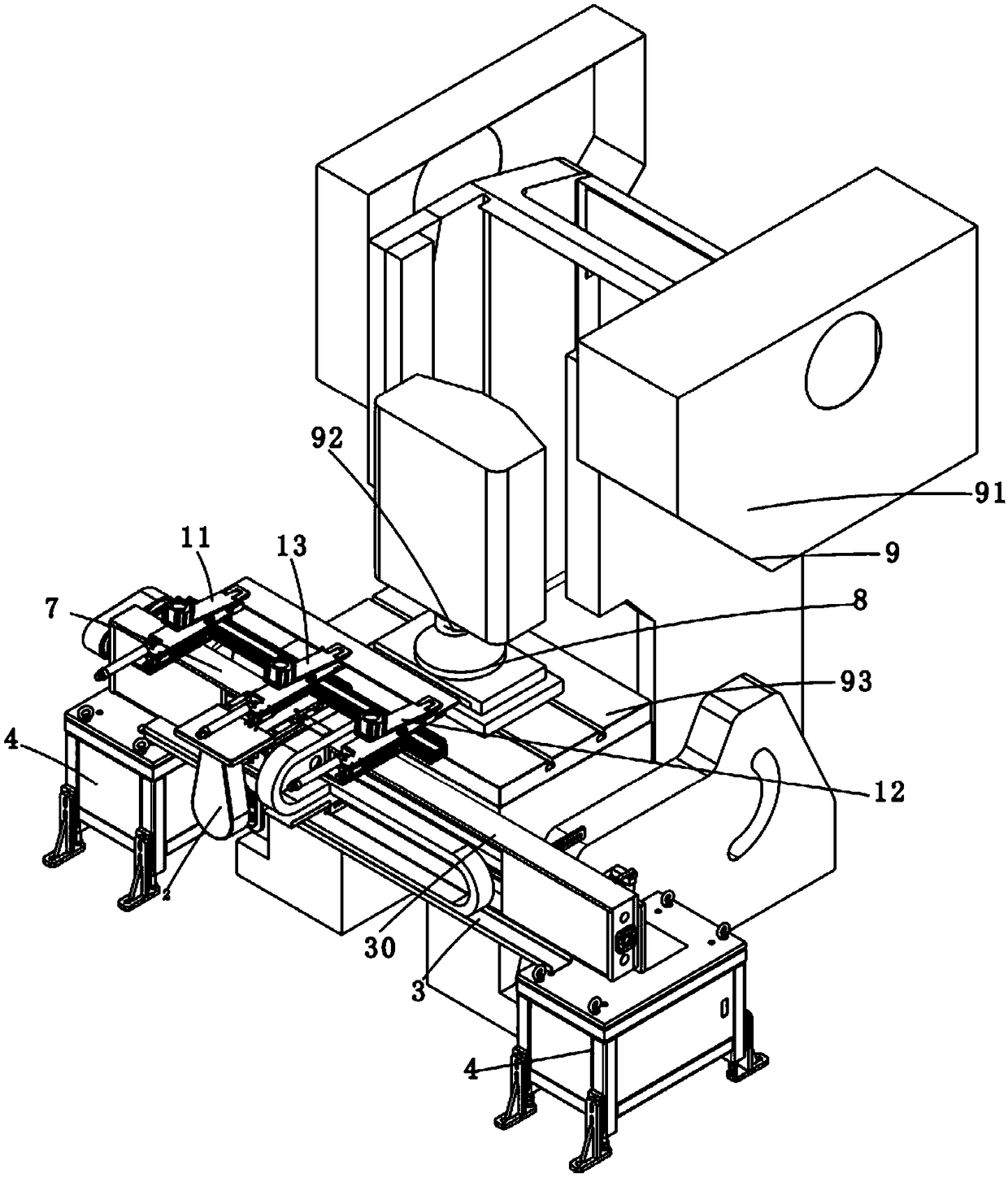

Multi-station flexible stamping workstation

PendingCN109261776AQuality improvementHigh degree of automationMetal-working feeding devicesShaping safety devicesProduction linePunch press

The invention discloses a multi-station flexible stamping workstation which comprises a punching machine, safe protective guards, a multi-joint industrial robot, a discharged material conveying line,a fed material conveying line and a stamping die library. The safe protective guards are connected with two side surfaces of the stamping die library, the safe protective guards and the stamping die library limit flexible working space, the punching machine, the multi-joint industrial robot and a visual camera are arranged in the working space, the discharged material conveying line and the fed material conveying line extend and penetrate the working space, the punching machine, the discharged material conveying line and the fed material conveying line are arranged on the peripheral side of the multi-joint industrial robot, and the stamping die library is arranged on the side surface of the punching machine. According to the workstation, high quality of a stamping product is ensured, the workstation is high in automation degree and production efficiency, safe and reliable, production management is facilitated, and zero-clearance connection and real-time control are achieved after a production line is changed.

Owner:GSK CNC EQUIP

Automobile part stamping device

PendingCN112893590AHigh precisionGood effectMetal-working feeding devicesCleaning using gasesStructural engineeringStamping press

The invention discloses an automobile part stamping device which comprises a bottom plate, an adjusting mechanism is arranged at the top end of the bottom plate, a feeding disc is arranged on one side of the top end of the adjusting mechanism, a discharging groove is formed in the top end of the feeding disc, a feeding port is formed in the top end of the discharging groove, a lower die is arranged at the top end of the feeding disc, and a sweeping mechanism is arranged on one side of the adjusting mechanism. A punching machine is arranged on the side, away from the adjusting mechanism, of the sweeping mechanism, the sweeping mechanism and the punching machine are arranged at the top end of the bottom plate, and a discharging plate is arranged at the bottom end of the feeding disc. The automobile part stamping device has the beneficial effects that under the action of the adjusting mechanism, the discharging groove can evenly discharge materials at a constant speed, so that the working efficiency is improved, an obtained die can be directly discharged from the discharging plate under the action of a punching head of the punching machine and the lower die, and therefore collection of automobile parts is completed, and under the action of the sweeping mechanism, and after each time of stamping is finished, the sweeping mechanism is used for blowing and cleaning the surface of the lower die, so that sweeps of the lower die are cleaned away.

Owner:重庆大江国立精密机械制造有限公司

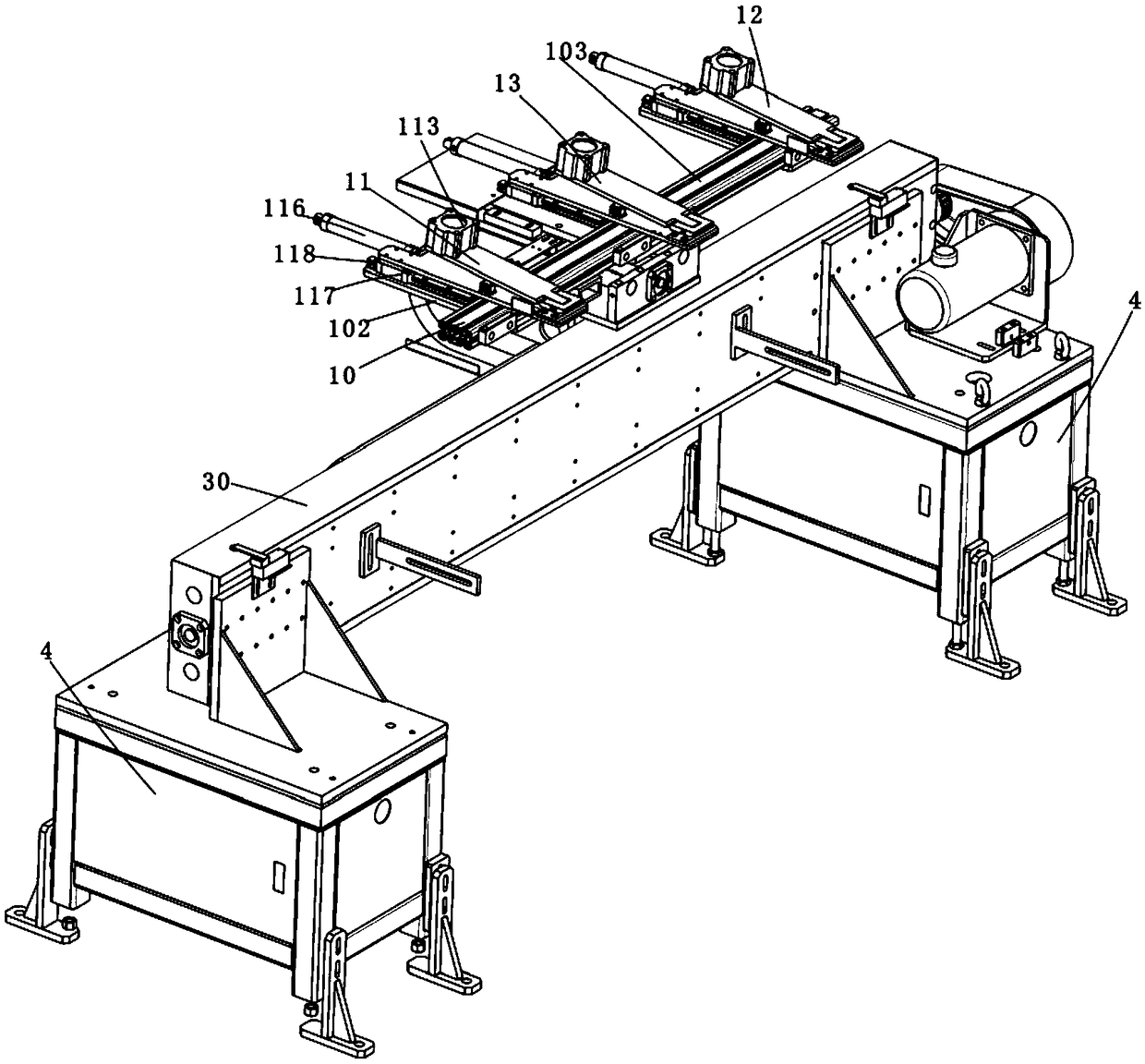

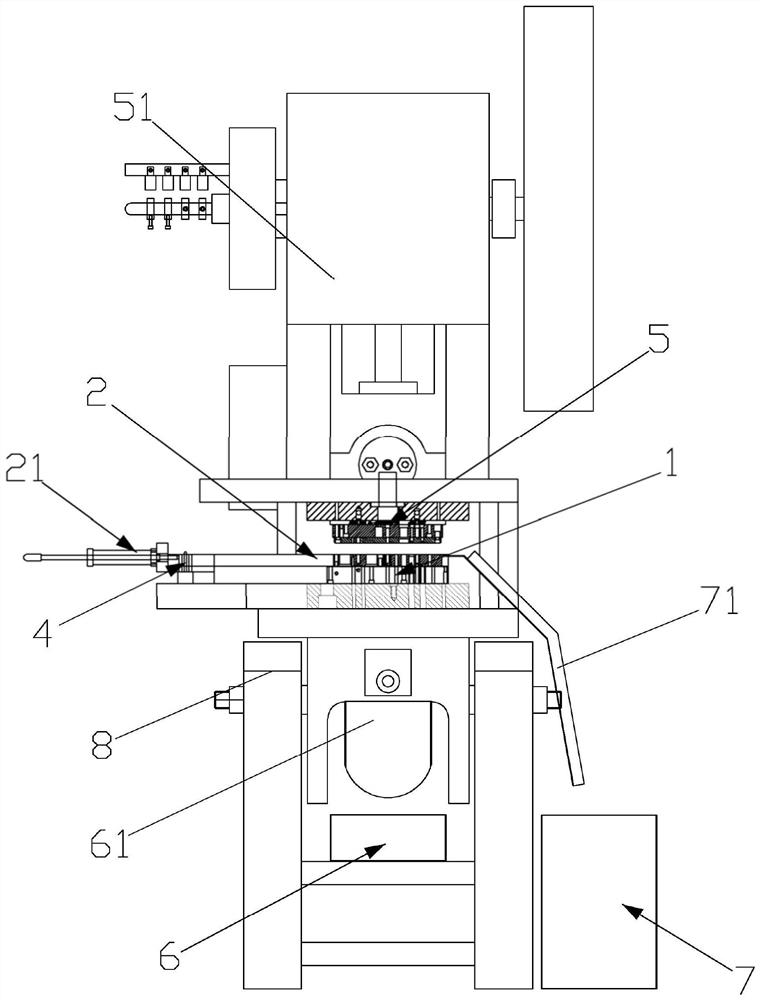

Side-punching system for short strip materials

InactiveCN109261827AAvoid wastingIncrease profitMetal-working feeding devicesPositioning devicesPunch pressEngineering

The invention discloses a side-punching system for short strip materials. The side-punching system comprises punching equipment, a die arranged on the punching equipment and a feeding device arrangedon a front side of the punching device. The feeding device comprises a first frame, a first clamping device, a second clamping device and a third clamping device, the first clamping device is used forclamping one end of a material, the second clamping device is used for clamping the other end of the material so as to cooperate with the first clamping device, the third clamping device is arrangedbetween the first clamping device and the second clamping device and used for clamping a middle portion of the material, and when the third clamping device clamps the middle portion of the material, the first clamping device or the second clamping device unclamps the material and move backwards. The side-punching system for the short strip materials has the advantages that a use ratio of the integral material is increased, the amount of waste is decreased, production cost for same yield is reduced, comprehensive automatic feeding is realized, manual moving or overturning during material punching is omitted, labor intensity and labor cost of workers are reduced, punching efficiency of a punching machine is improved, and production efficiency is improved.

Owner:HANGZHOU KINGNET ELECTROMECHANICAL

Stamping system for pneumatic liquid pump production

InactiveCN113182411AImprove processing efficiencyEasy to fixShaping toolsMetal-working feeding devicesPunchingMachining

The invention relates to the technical field of pneumatic liquid pump production, in particular to a stamping system for pneumatic liquid pump production, and aims to solve the problems that a stamping device for pneumatic liquid pump production in the prior art is prone to being limited after parts are fixed, and the parts are deformed. According to the technical scheme, the stamping system comprises a machining table of a hollow structure, wherein the top of the machining table is provided with a die and a punching head matched with the die; and a feeding mechanism, wherein the feeding mechanism comprises a connecting plate and fixing mechanisms installed at the two ends of the connecting plate, each fixing mechanism comprises a transverse plate fixed to one end of the connecting plate, two movable plates installed on one side of the transverse plate, a positioning frame and a fixing frame, and the positioning frames and the fixing frames are installed on the sides, close to each other, of the two movable plates. The stamping system for pneumatic liquid pump production is reasonable in structure and easy to operate, parts can be conveniently fixed during stamping, the parts cannot be restrained when the parts deform during stamping, and therefore part stamping is more accurate, and the stamping system is easy to use and popularize.

Owner:安徽士必达液压器材有限公司

Double-hole shielding cover progressive die

The invention relates to the technical field of dies, in particular to a double-hole shielding cover progressive die. The double-hole shielding cover progressive die comprises an upper die holder, an upper die, a stripper plate, a lower die, a lower die holder, and a punching pilot hole station, a half sectioning station, a stretching station and a shielding cover punching-off station which are assembled correspondingly, wherein the upper die, the stripper plate and the lower die are correspondingly assembled with the punching pilot hole station, the half sectioning station, the stretching station, a double-side punching station, a bilateral hole turnup station, a first turnup flattening station, a second turnup flattening station, a punching side notch station and the shielding cover punching-off station which are formed sequentially. During actual production, production can be performed only by placing a material belt on the lower die, all the procedures are finished in the die, andfull automation of the whole flow is realized, so labor cost is reduced, the defective rate of the shielding covers is low, production efficiency is high, and the double-hole shielding cover progressive die is suitable for production of the shielding cover with side holes on the two sides.

Owner:DONGGUAN DAZHONG ELECTRONICS

Automobile buckle stamping device

ActiveCN112893681ARealize automatic stampingStamping precisionMetal-working feeding devicesVehicle componentsStructural engineeringIndustrial engineering

The invention discloses an automobile buckle stamping device, and belongs to the technical field of stamping equipment. The automobile buckle stamping device comprises feeding equipment and stamping equipment, wherein the feeding equipment is arranged on the right side of the stamping equipment, and the stamping equipment comprises a stamping base, a stamping plate, a stamping shell, an upper stamping die, a lower stamping die and a feeding plate; when the feeding equipment conveys buckle raw materials to the stamping plate, a stamping machine works to drive the upper stamping die to slide upwards in the stamping shell, and at the moment, the feeding plate works to push the buckle raw materials on the stamping plate to the top of the lower stamping die; and the stamping machine reversely works to drive the upper stamping die to move downwards to be matched with the lower stamping die to complete stamping, at the moment, the feeding plate is reset, during repeated work, the feeding plate drives the next buckle raw material to move to the top of the lower stamping die, the stamped automobile buckle is extruded out of the lower stamping die, and automatic stamping is achieved.

Owner:湖北天成汽车配件有限公司

Blade punching forming device of thin cutter

PendingCN114850293AImprove pass rateReduce wastePerforating toolsMetal-working feeding devicesMoulding deviceKnife blades

The invention discloses a thin cutter blade punching forming device which comprises a die base, a sliding seat, a pair of suction nozzles, a plurality of positioning blocks, a stamping die and a material receiving box, a sliding groove is formed in the middle of the die base, the sliding seat is arranged on the sliding groove of the die base in a sliding mode, and the sliding seat is driven by a sliding driving device to horizontally move along the sliding groove. The suction nozzle is arranged at the head end of the sliding seat in a liftable mode and used for sucking a metal sheet and placing the metal sheet on the sliding seat, gaps are formed between the inner side face of the sliding groove and the two sides of the sliding seat respectively, and the multiple positioning blocks are arranged in the gaps in a liftable and spaced mode and used for limiting movement of the metal sheet. The punching die is used for punching the metal sheets on the sliding base, a guide groove is formed in the sliding base in an up-down penetrating mode, the blade is formed under punching of the punching die and pushed into the guide groove, and the formed blade is guided into the receiving box through the guide groove. The device is simple in structure and high in automation degree, and equidistant conveying and automatic punch forming of the blades are achieved.

Owner:广东奕源塑胶有限公司

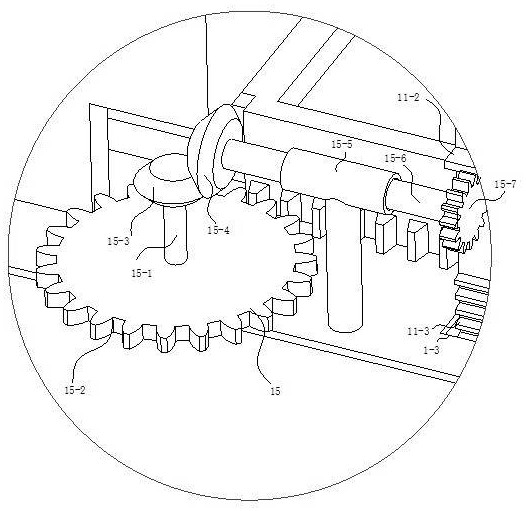

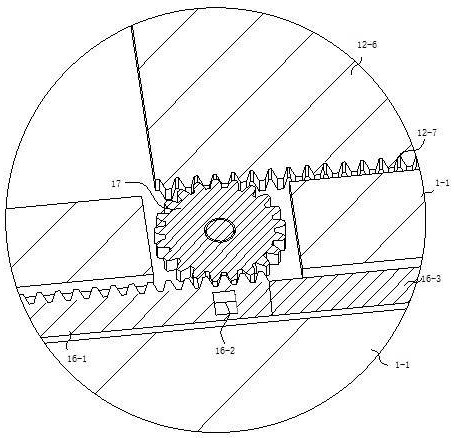

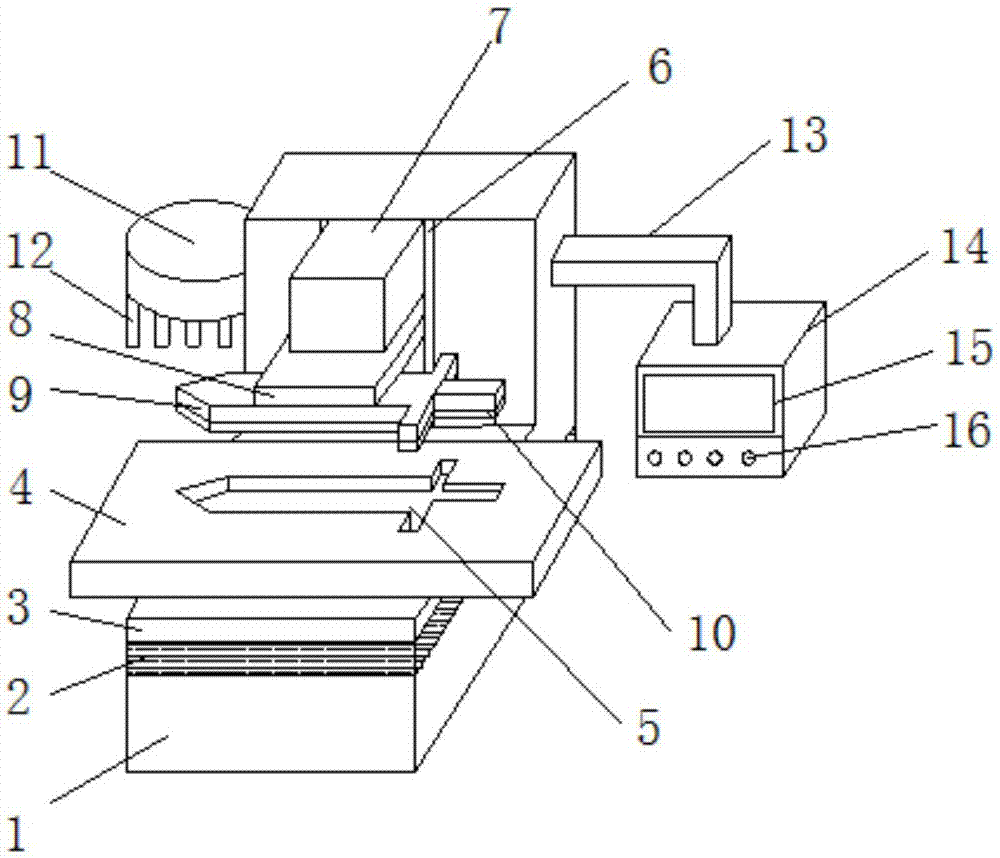

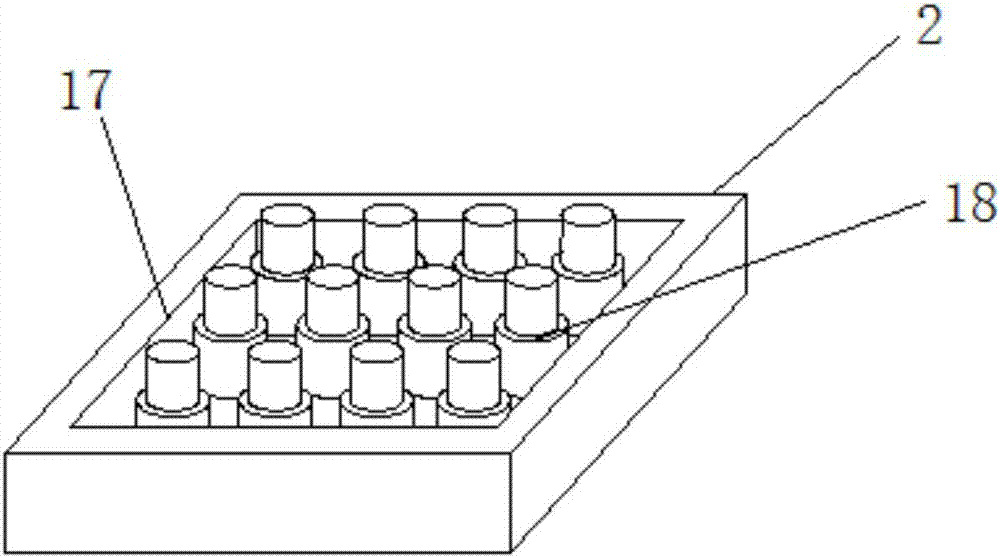

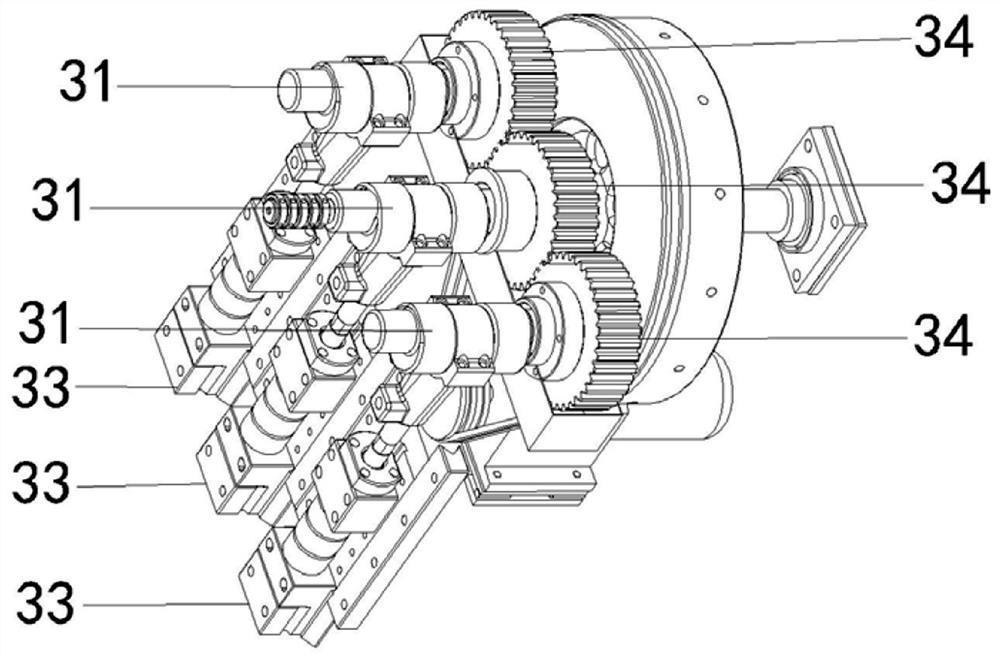

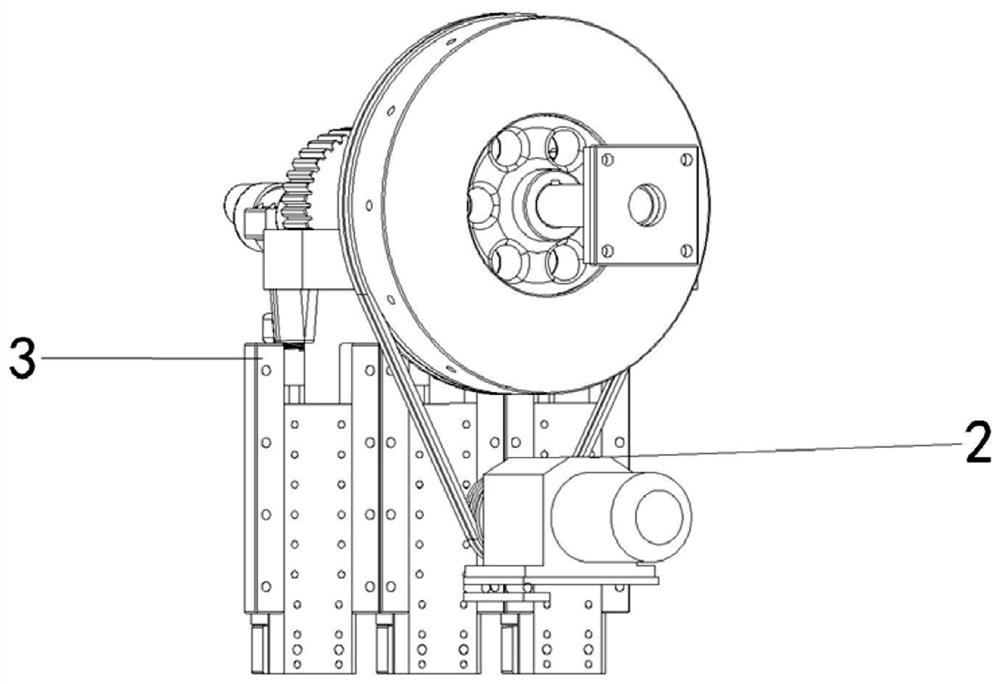

Multi-station punching machine

The invention relates to a multi-station punching machine. The multi-station punching machine comprises a punching machine frame, a power input mechanism and a plurality of punching mechanisms, the punching mechanisms are arranged on the punching machine frame and are in mutual meshing transmission through gears, the power input mechanism is in transmission connection with one punching mechanism,the punching mechanisms conduct different punching machining on workpieces to be machined, each punching mechanism comprises a crankshaft, a connecting rod and an adjusting assembly, a gear is arranged on each crankshaft, each connecting rod is in transmission connection with the corresponding crankshaft, each adjusting assembly is connected to the lower portion of the corresponding connecting rod, and an upper die is connected to the lower portion of each adjusting assembly. Through driving of the single power input mechanism and meshing transmission of the gears among the multiple punching mechanisms, simultaneous operation work of multiple stations is achieved, a product is bent multiple times, the machining efficiency is improved, the occupied space is reduced, and the cost is reduced.

Owner:东莞市铲能多自动化设备有限公司

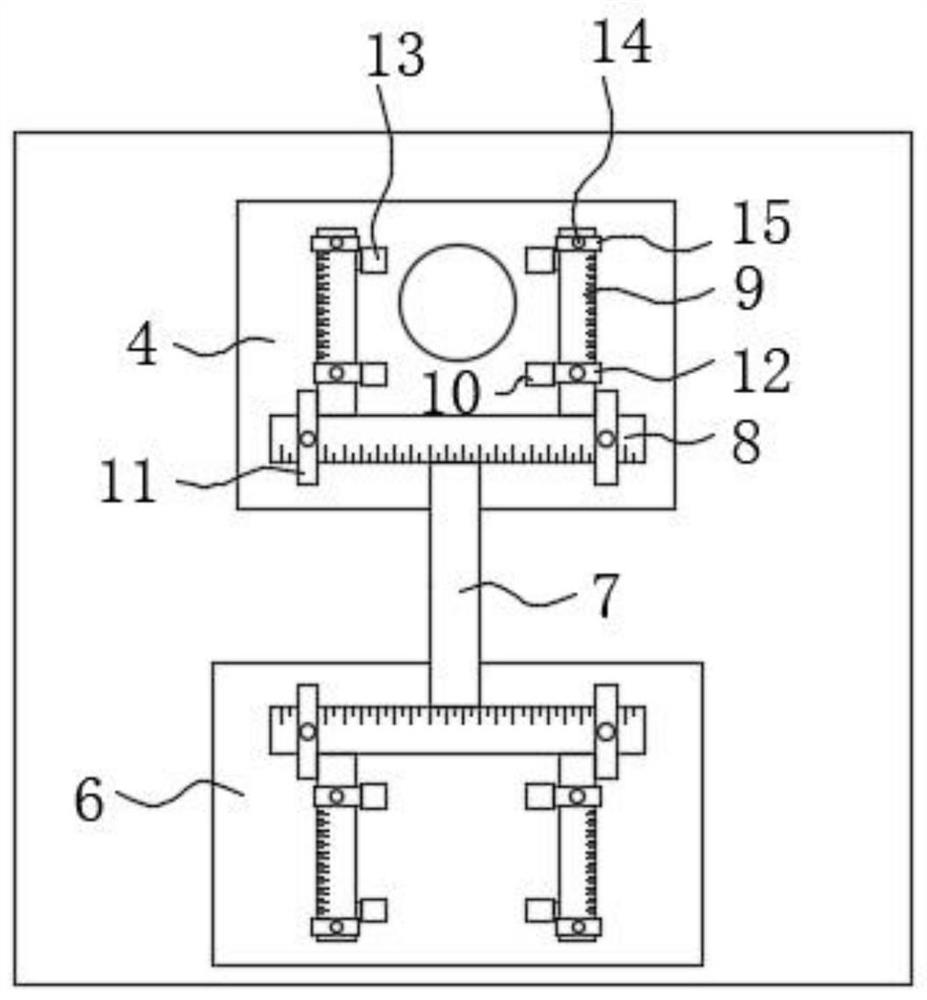

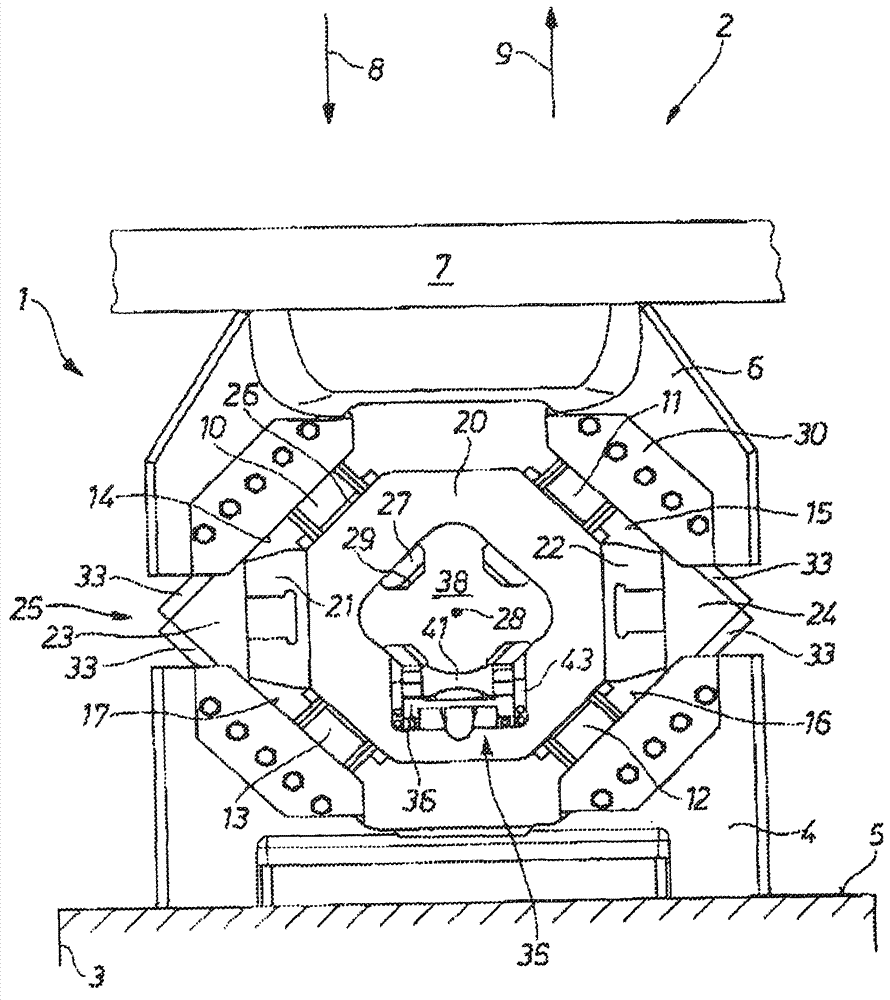

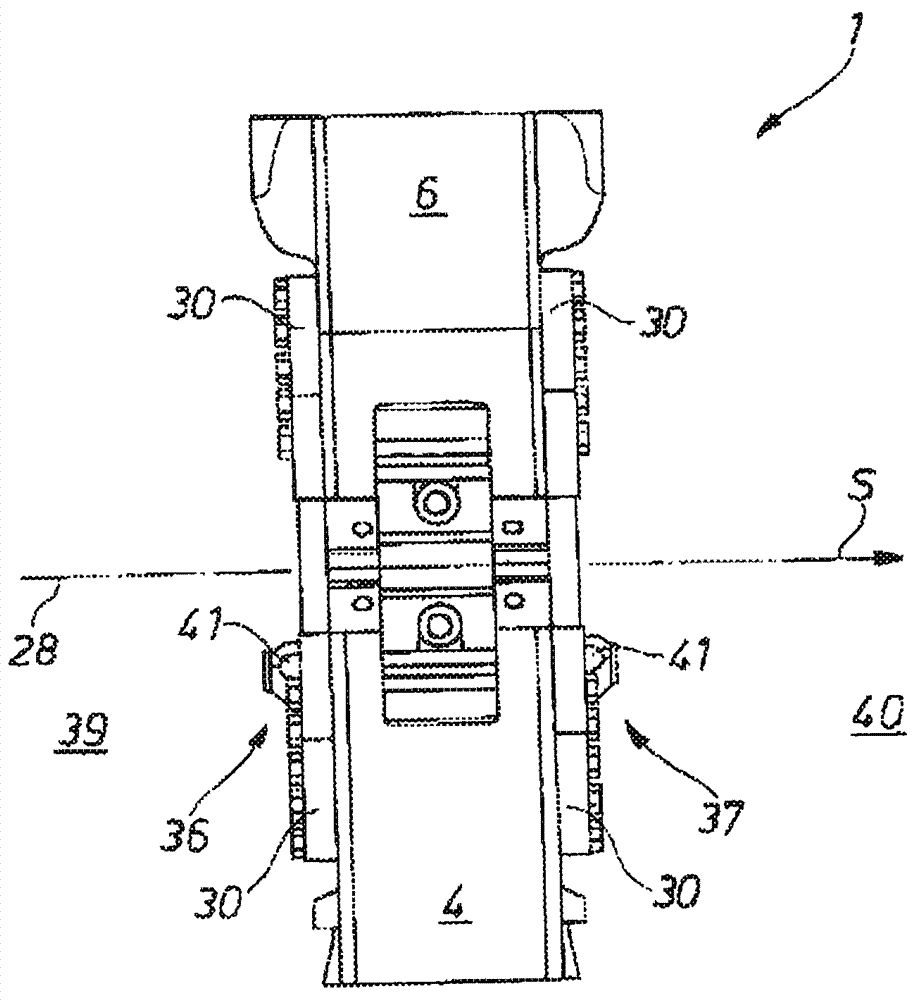

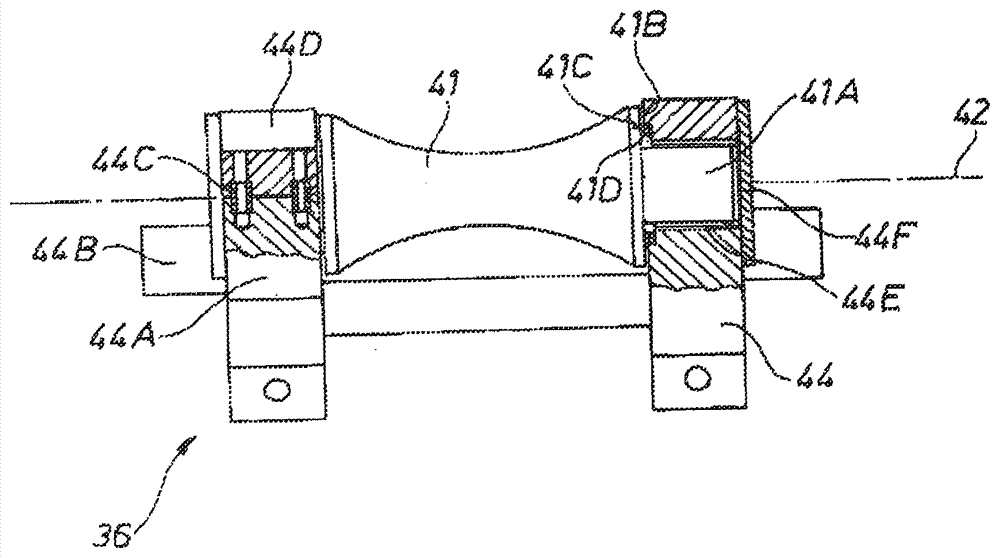

Four-die tool and forging press

ActiveCN104325054AStamping precisionAvoid broadeningForging hammersUpsetting pressesEngineeringManipulator

The invention relates to a four-die press tool (1), comprising a lower die assembly (4) and an upper die assembly (6) displaceable relative thereto, comprising four rams (10, 11, 12, 13) spaced apart and supported on the lower die assembly (4) or the upper die assembly (6) and carrying forging dies (29), and a ring (20) on which are mounted the four rams (10, 11, 12, 13) concentrically around the central press axis (28) of the four-die press tool (1) in such a way that they can be displaced relative to the central press axis (28) whenever the upper die assembly (6) is moved relative to the lower die assembly (4), wherein protecting means (35) are mounted on the ring (20) to secure a workpiece in a centered position on a central predetermined position of the workpiece relative to the central press axis (28) independently of a workpiece manipulator.

Owner:SMS MEER

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com