Four-die tool and forging press

A stamping tool and forging press technology, which is applied in the field of four-saddle stamping tools, can solve problems such as flattening of the workpiece, complex design structure of the four-saddle-forging device, cracks, etc., and achieve the effect of eliminating the drop

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

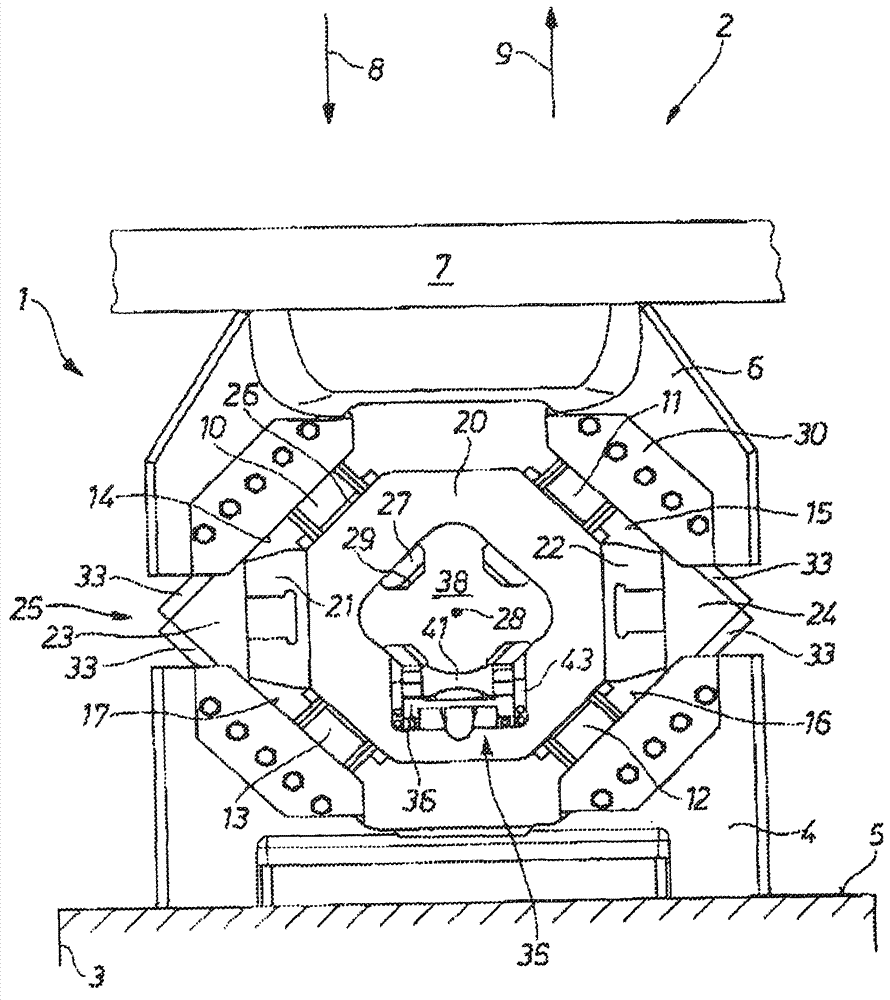

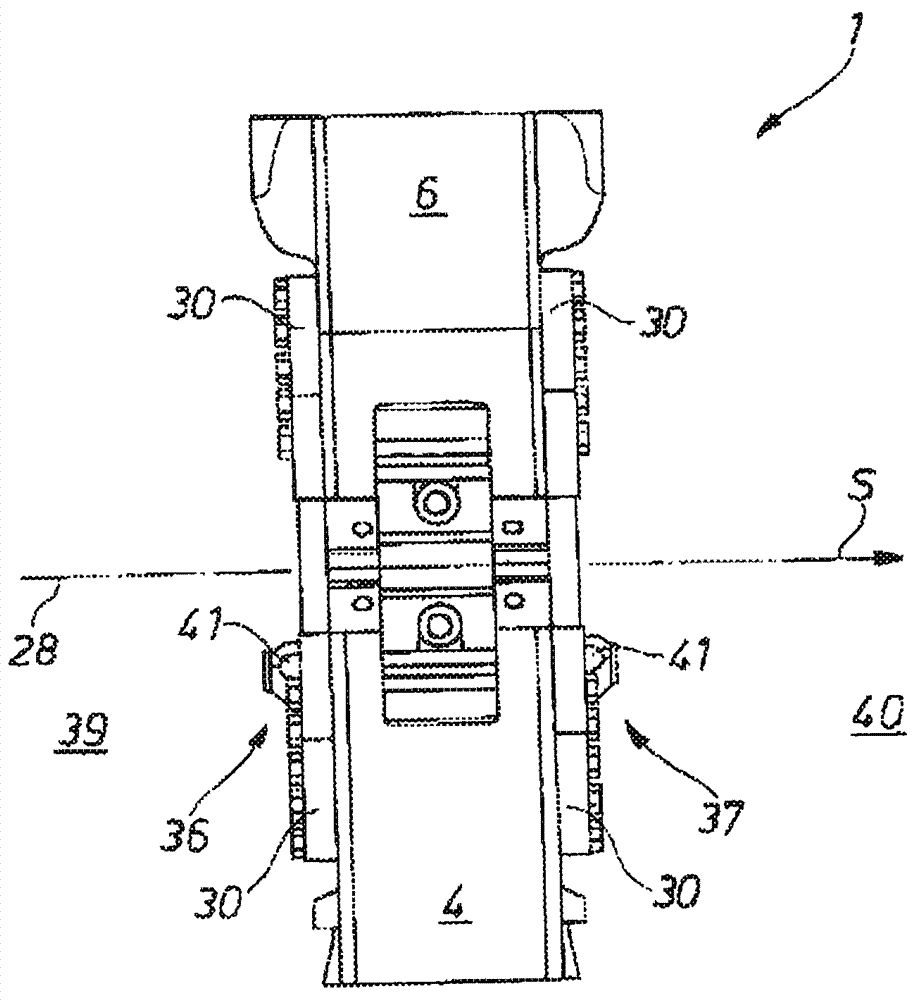

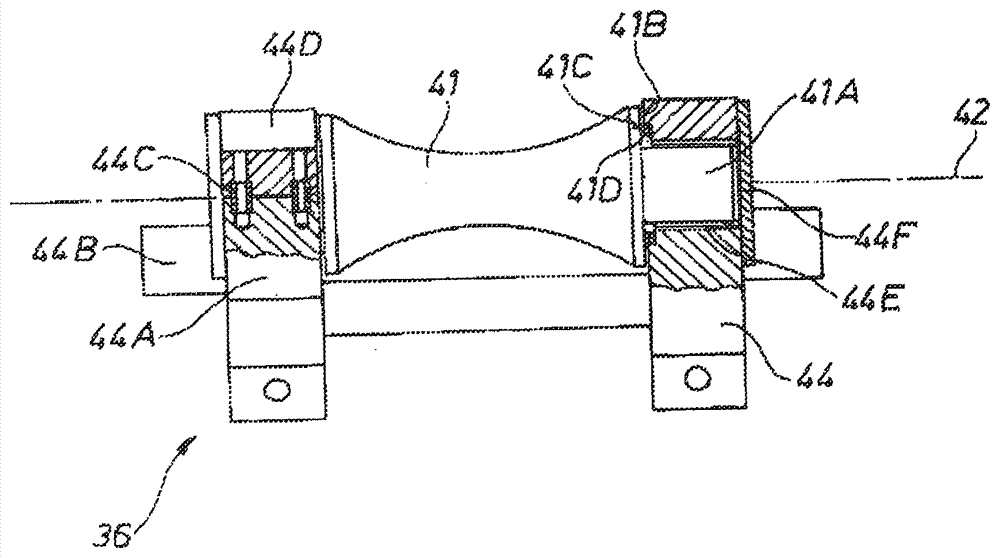

[0112] Forging Press 2 is equipped with figure 1 and 2 The four-saddle punching tool 1 shown in the forging press 2 is implemented in the design of a free forging press 3 .

[0113] The four-saddle stamping tool 1 has a lower saddle part 4 which is mounted stationary, ie immobile, on the stamping table 5 of the forging press 2 , and a displaceable, ie movable, part relative to the lower saddle part 4 . The upper saddle part 6 (which is arranged stationary on the moving beam part 7 of the forging press 2 ).

[0114] Here, the upper saddle part 6 of the four-saddle stamping tool 1 is fixed at the moving beam part 7 of the forging press 2 in such a way that the upper saddle part 6 can be moved downwards in a vertical forward movement 8 not only by means of the moving beam part 7 is moved towards the lower saddle part 4 to cause the forging process, as has hitherto been common. In addition, the upper saddle part can also be actively advanced from the lower saddle part 4 upwards...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com