Patents

Literature

4697results about "Perforating tools" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

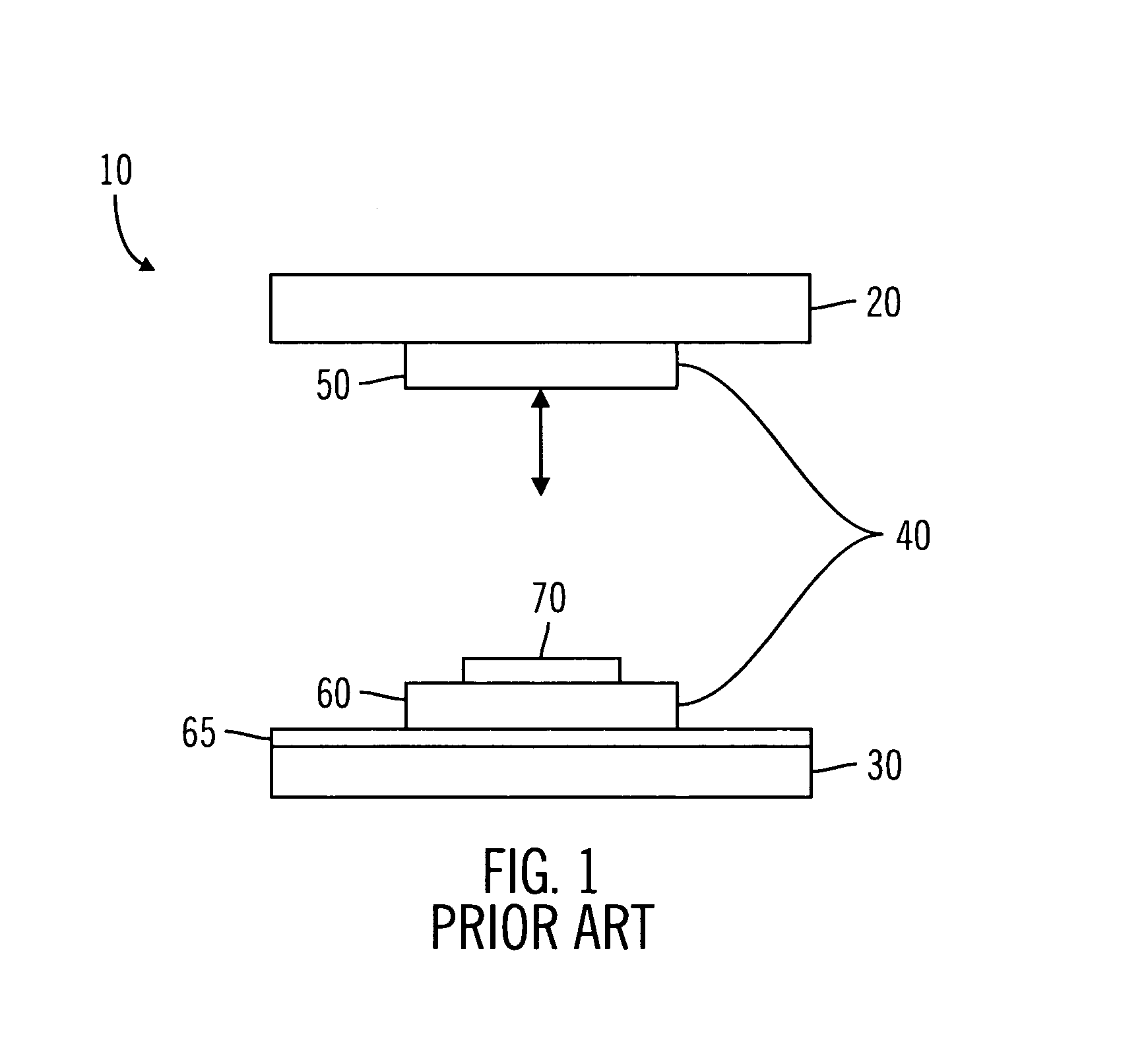

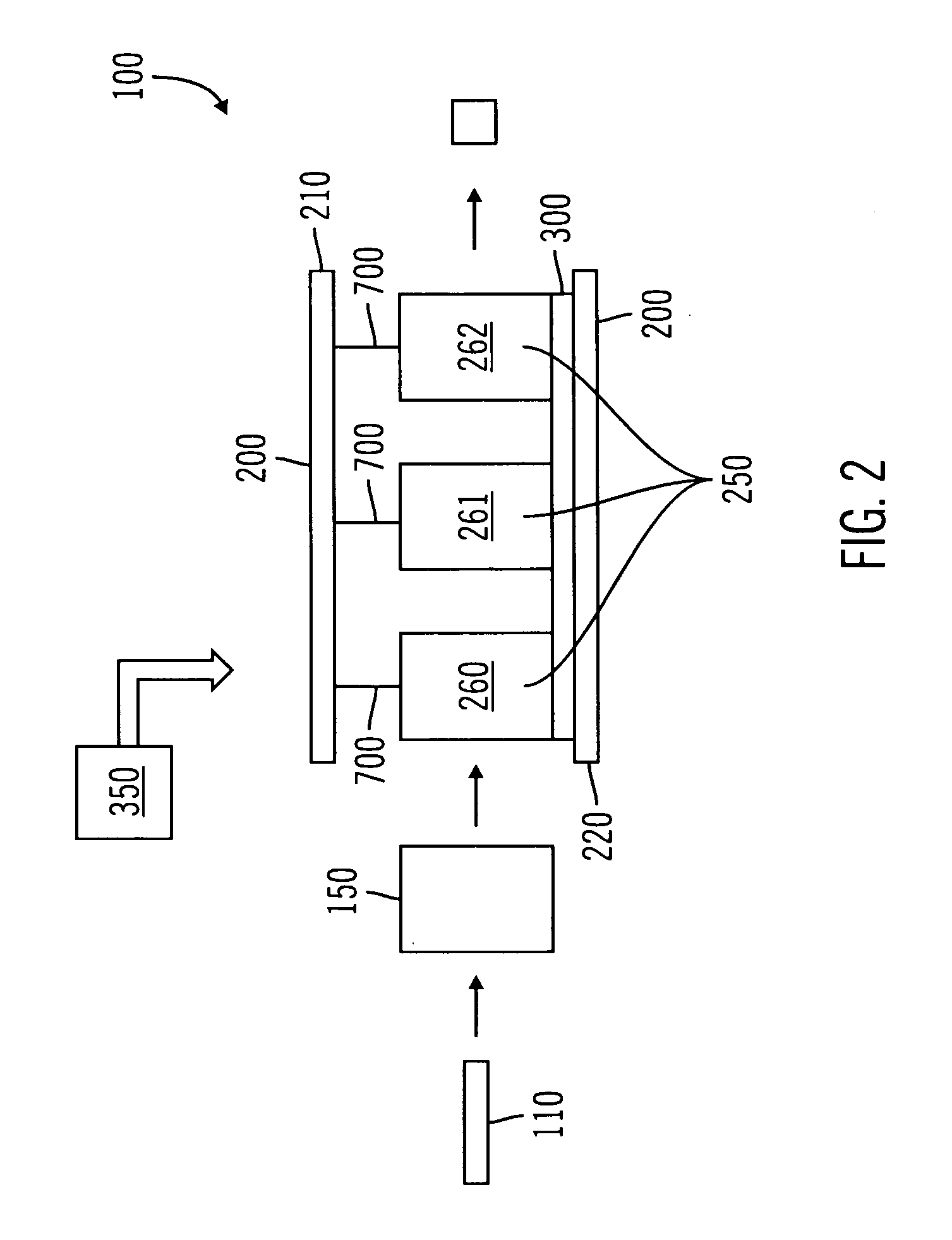

Stamping system for manufacturing high tolerance parts

ActiveUS7343770B2Minimize the numberTight toleranceShaping toolsPerforating toolsMachine pressStamping press

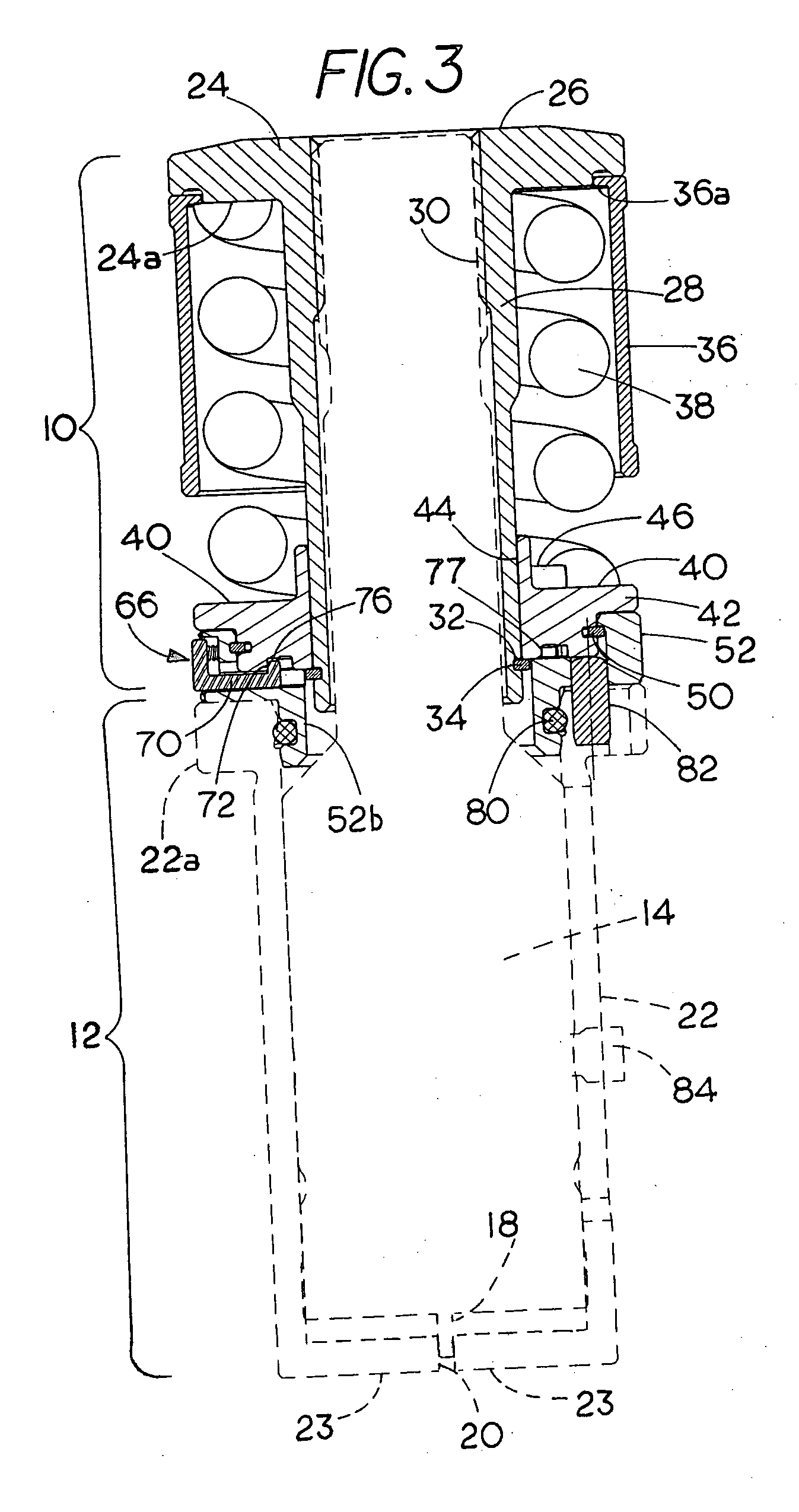

A system and process for stamping parts having tolerances below 1000 nanometers. The inventive system and process is particularly suited for producing optoelectronic parts. The system includes a stamping press and one or a progression of stamping stations for supporting a punch and die. The stamping stations are designed to maintain substantial alignment of the punch and die with minimal moving components. The stamping station includes a shaft for rigidly guiding the punch to the die. The stamping press is capable of providing the punch with the necessary force to perform the stamping operations. The system includes an interface system for interfacing the force of the press with the punch, while simultaneously structurally decoupling the press from the punch. The system also includes a locating sub-plate, for locating the stamping station in alignment relative to each other, and means for in-line machine stock material before entry into the stamping stations.

Owner:SENKO ADVANCED COMPONENTS

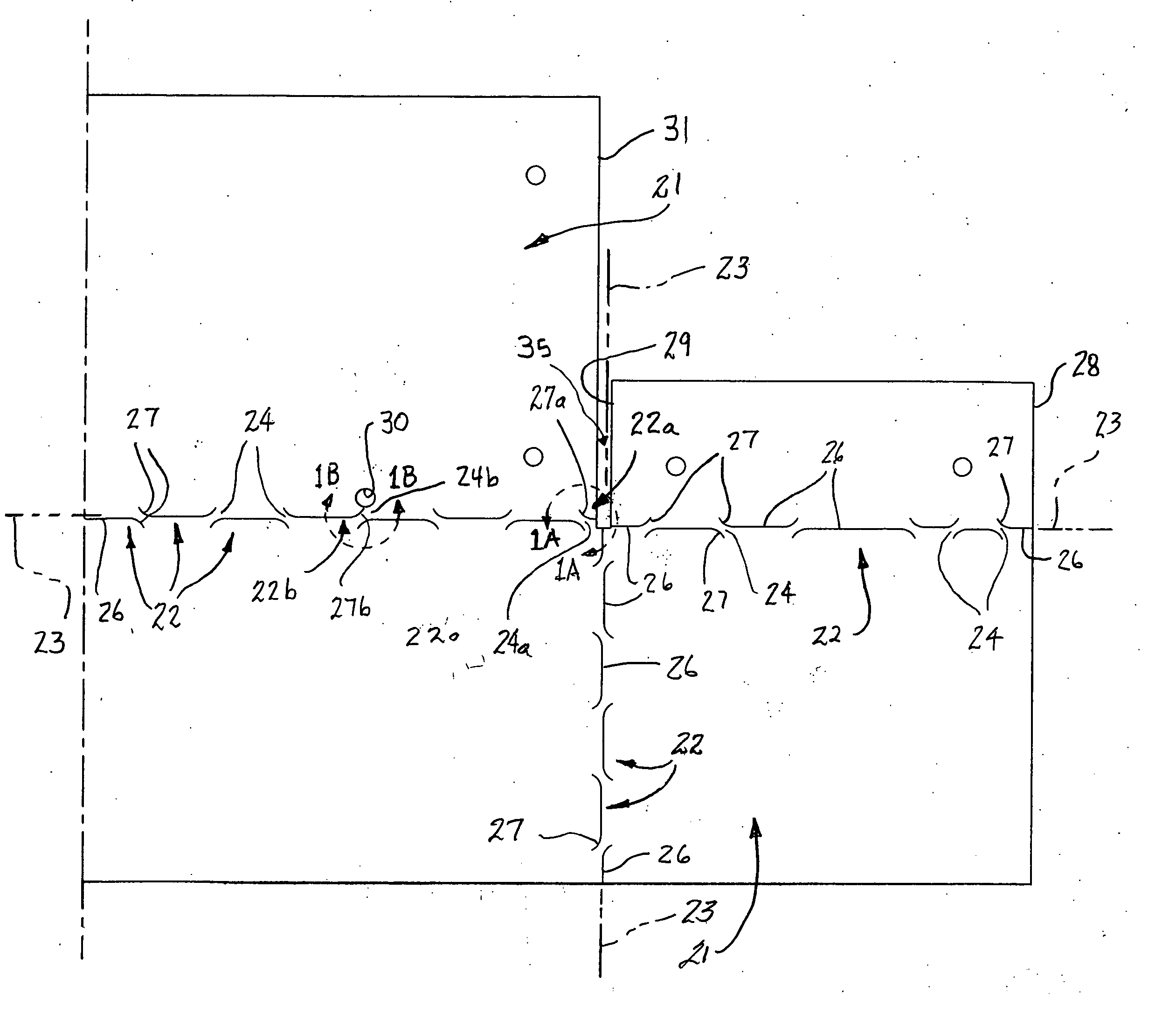

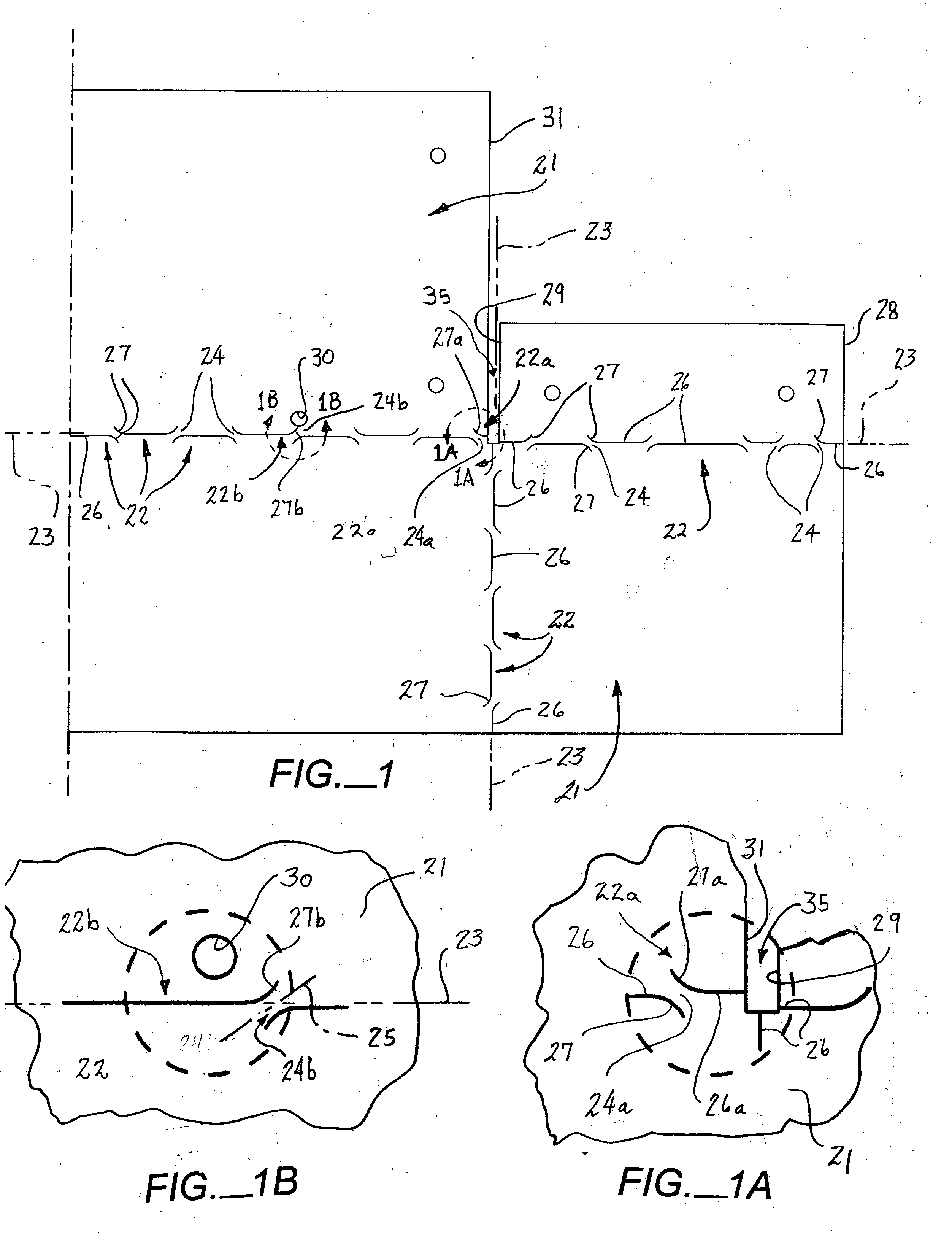

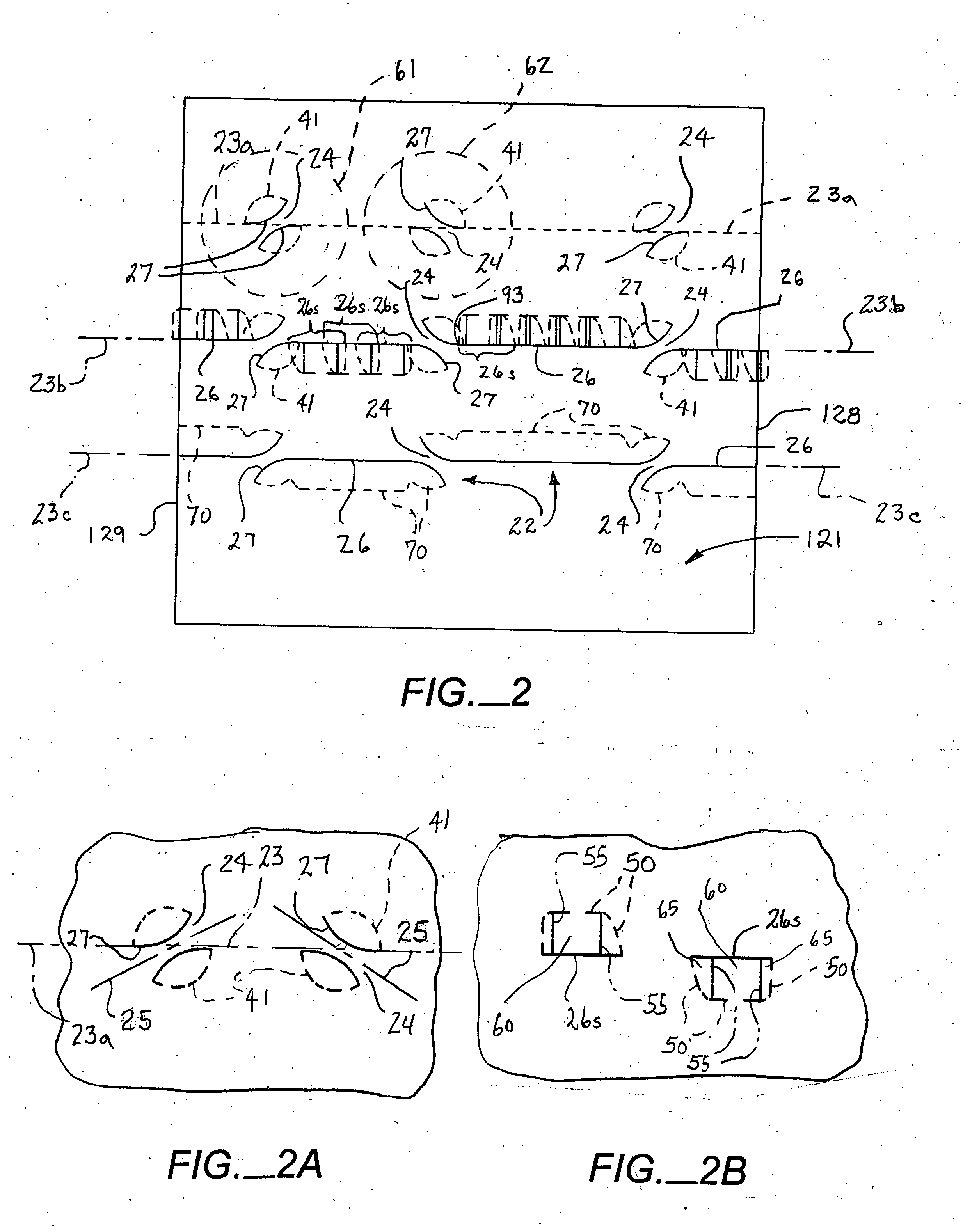

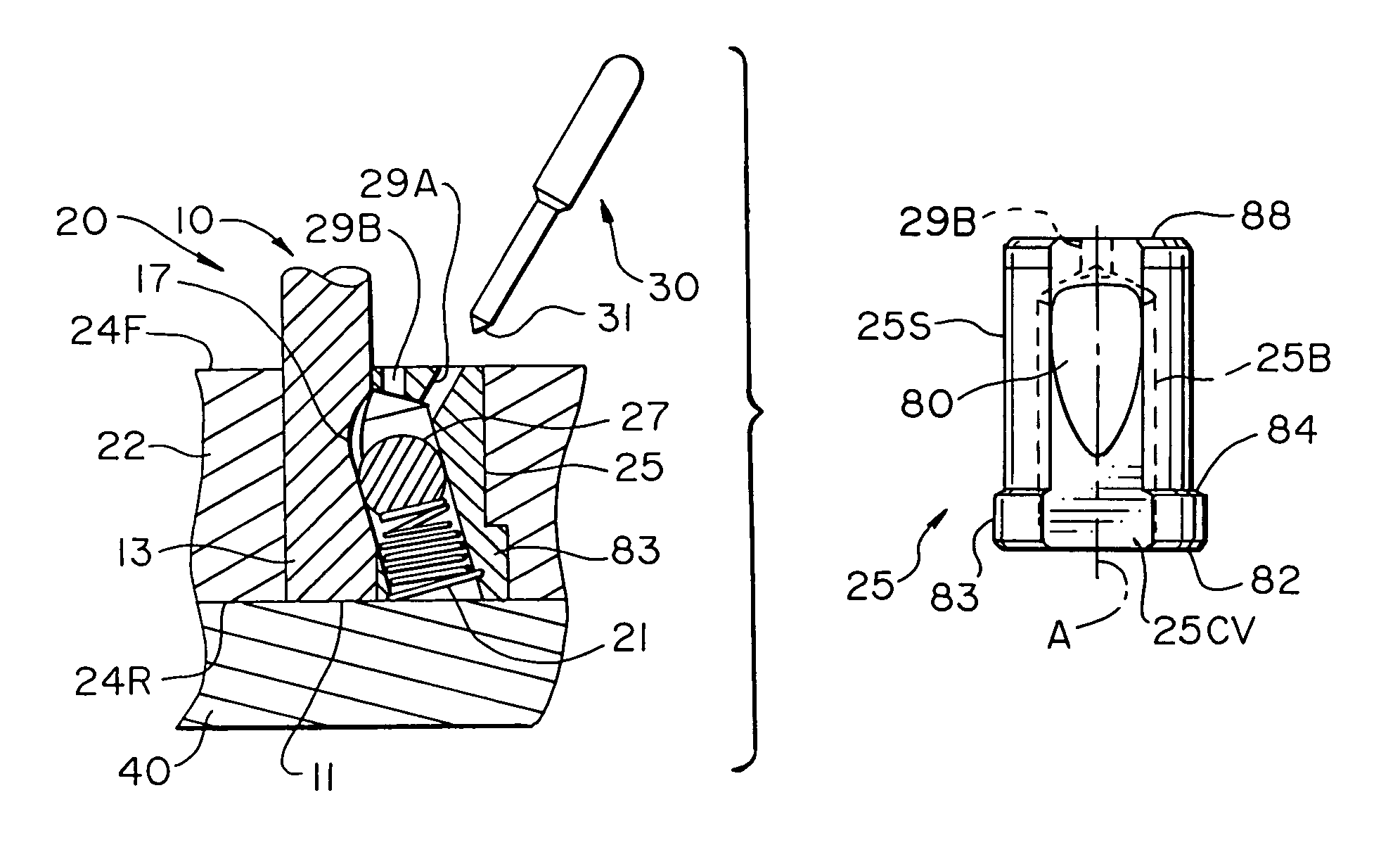

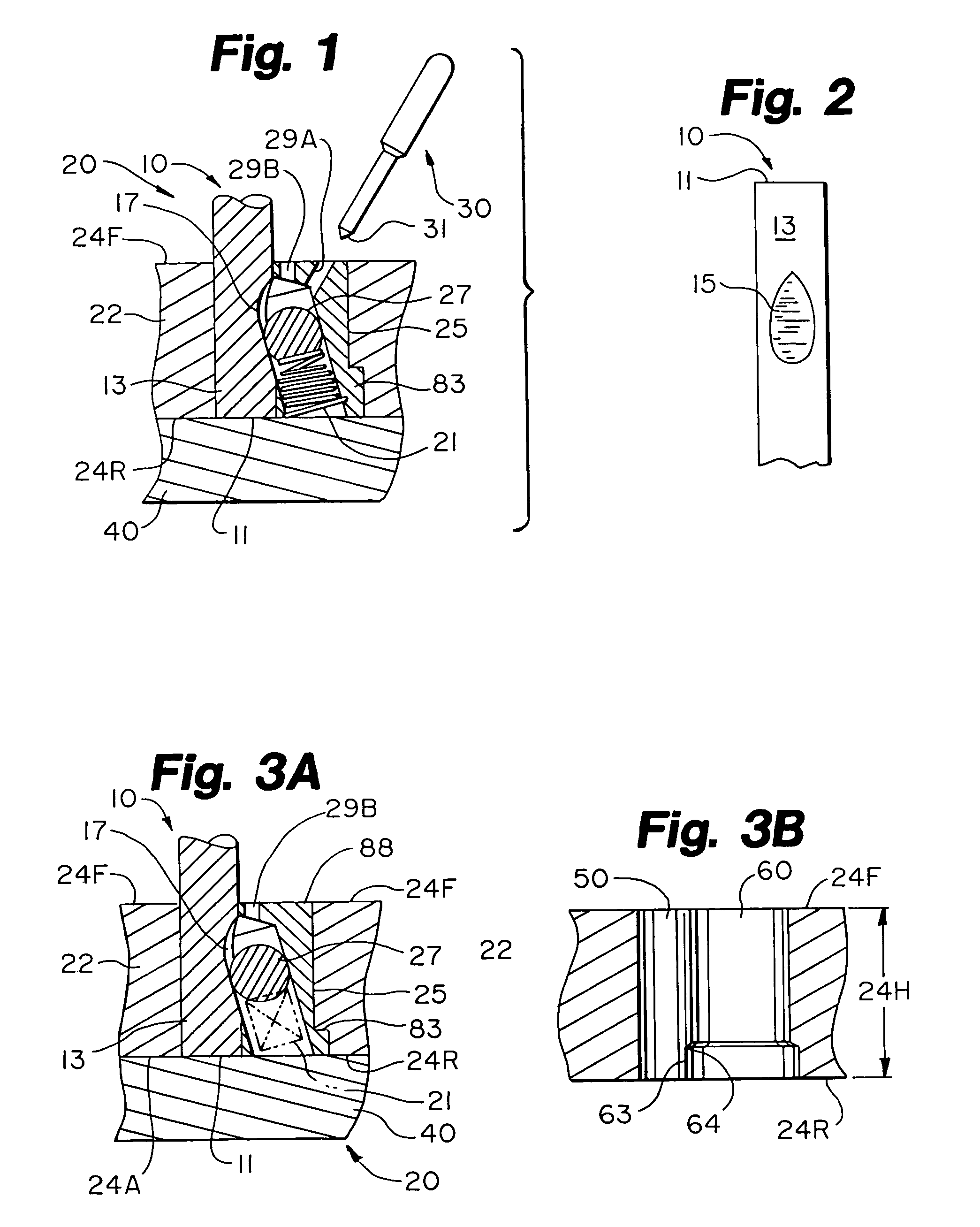

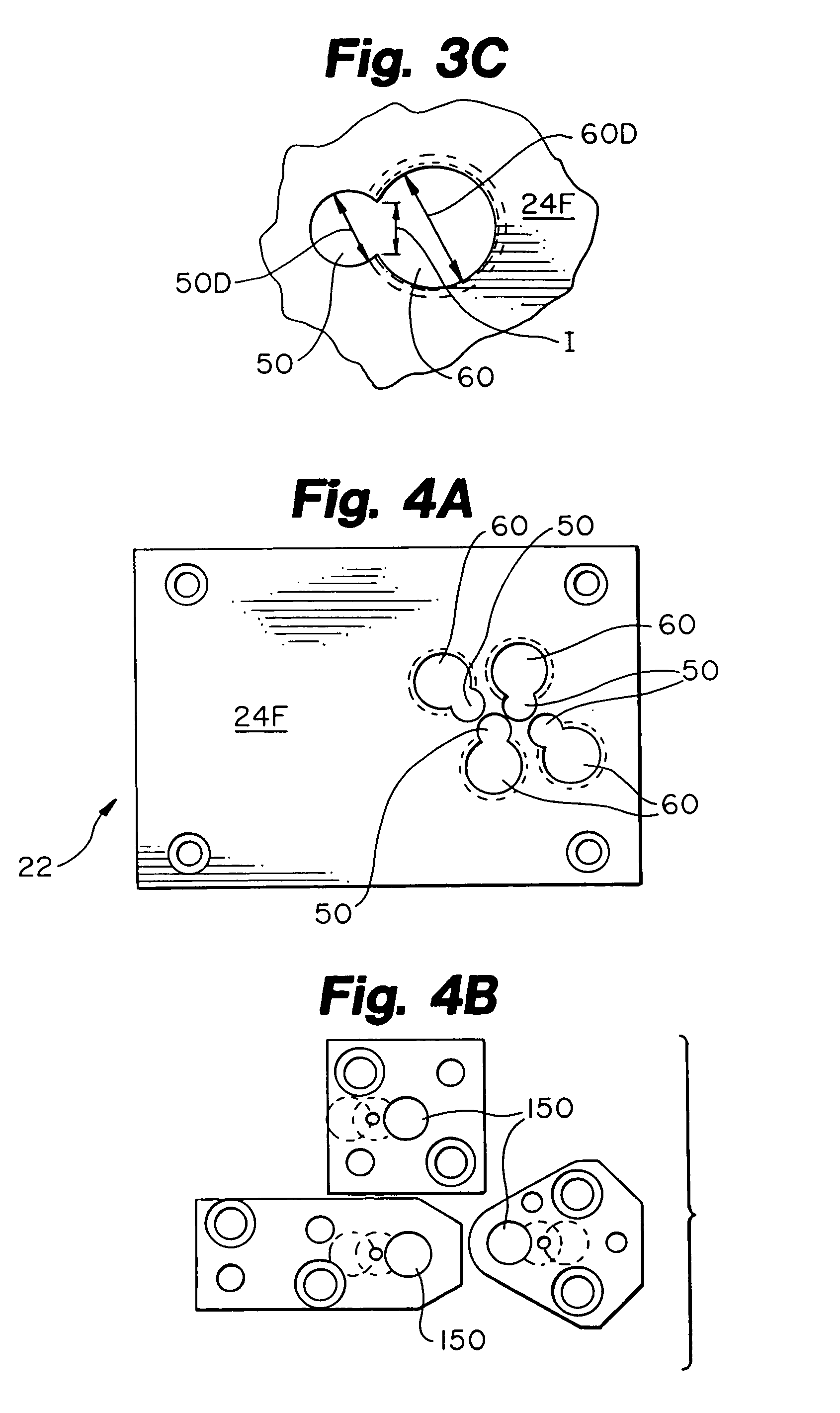

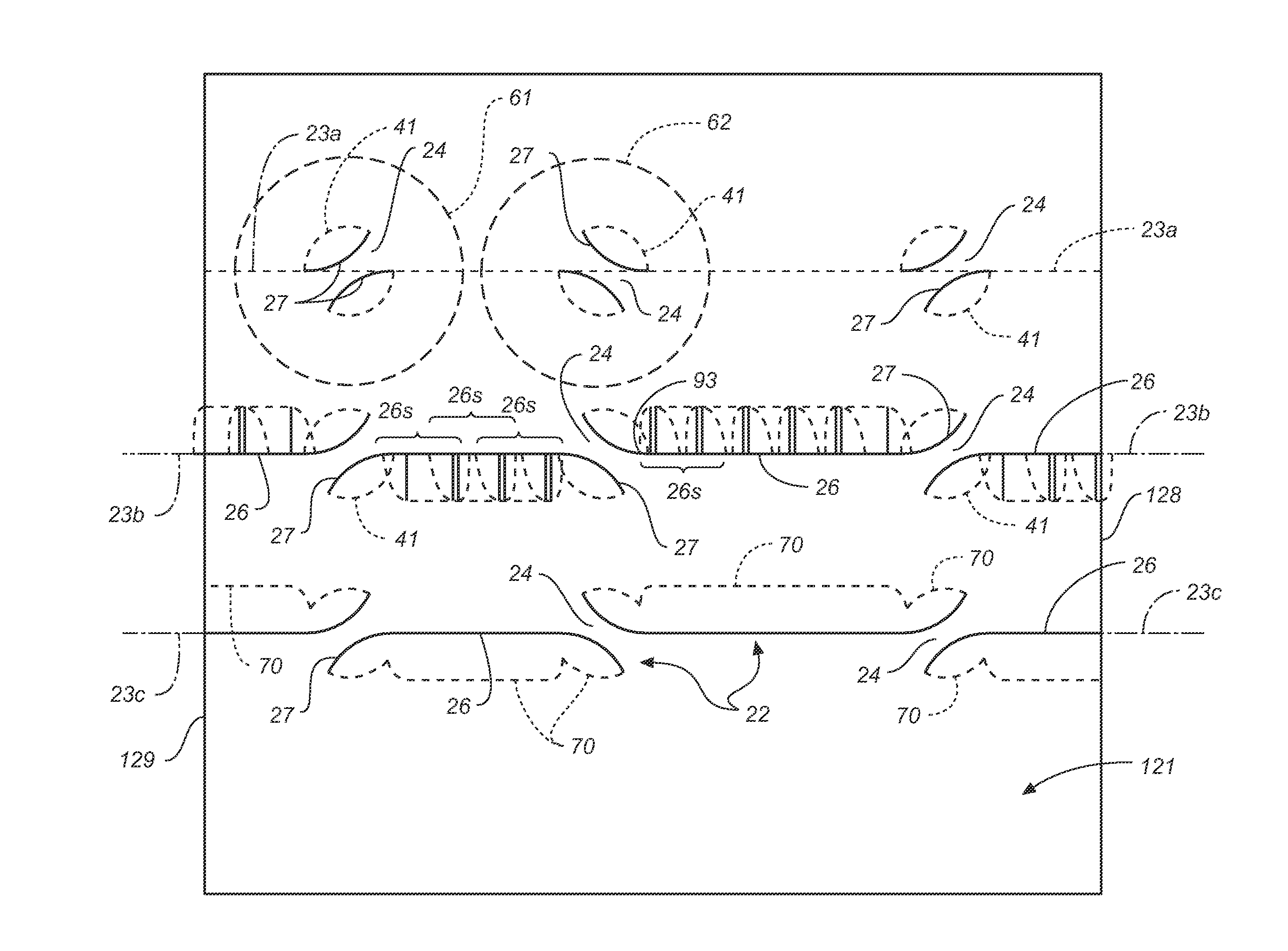

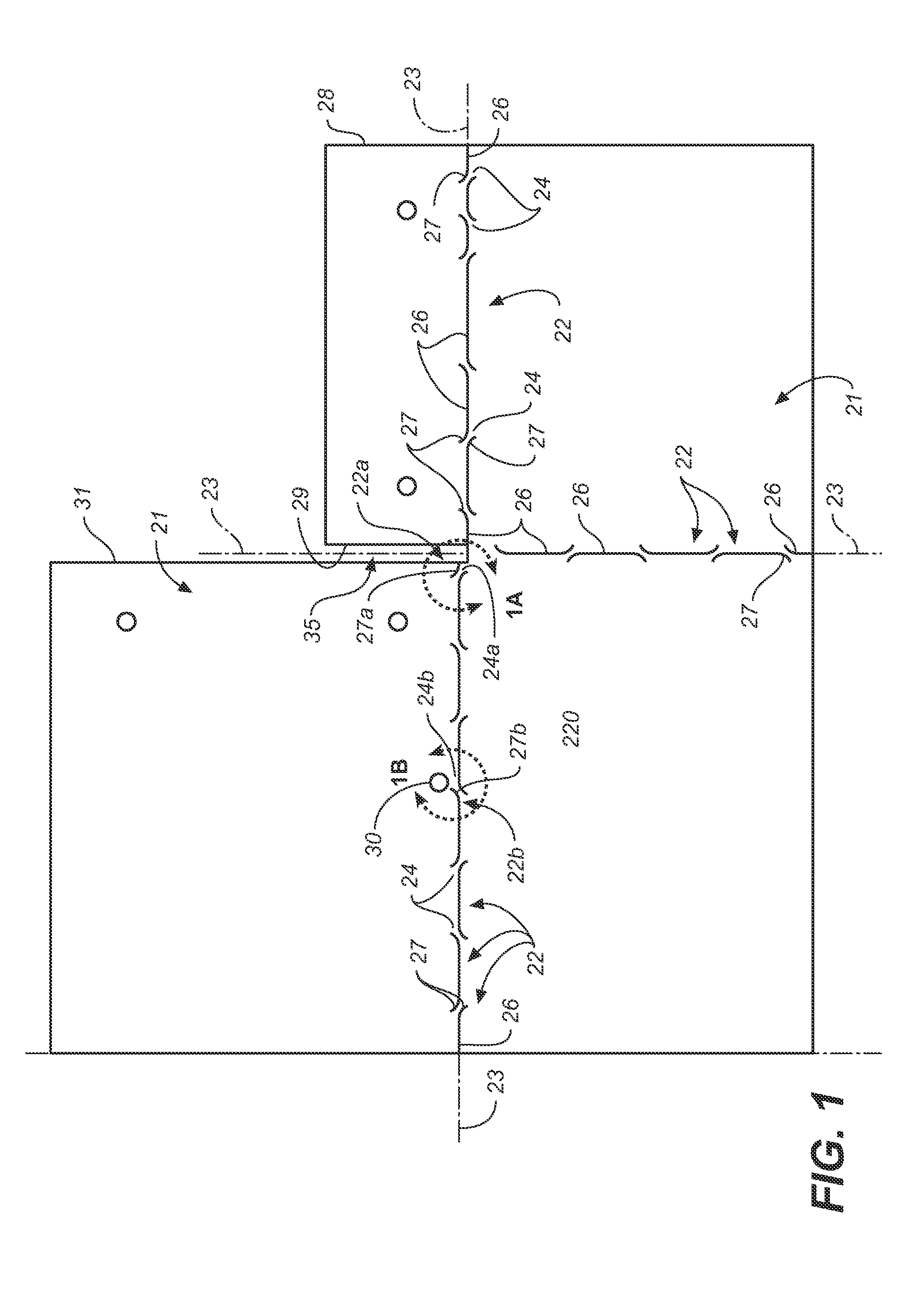

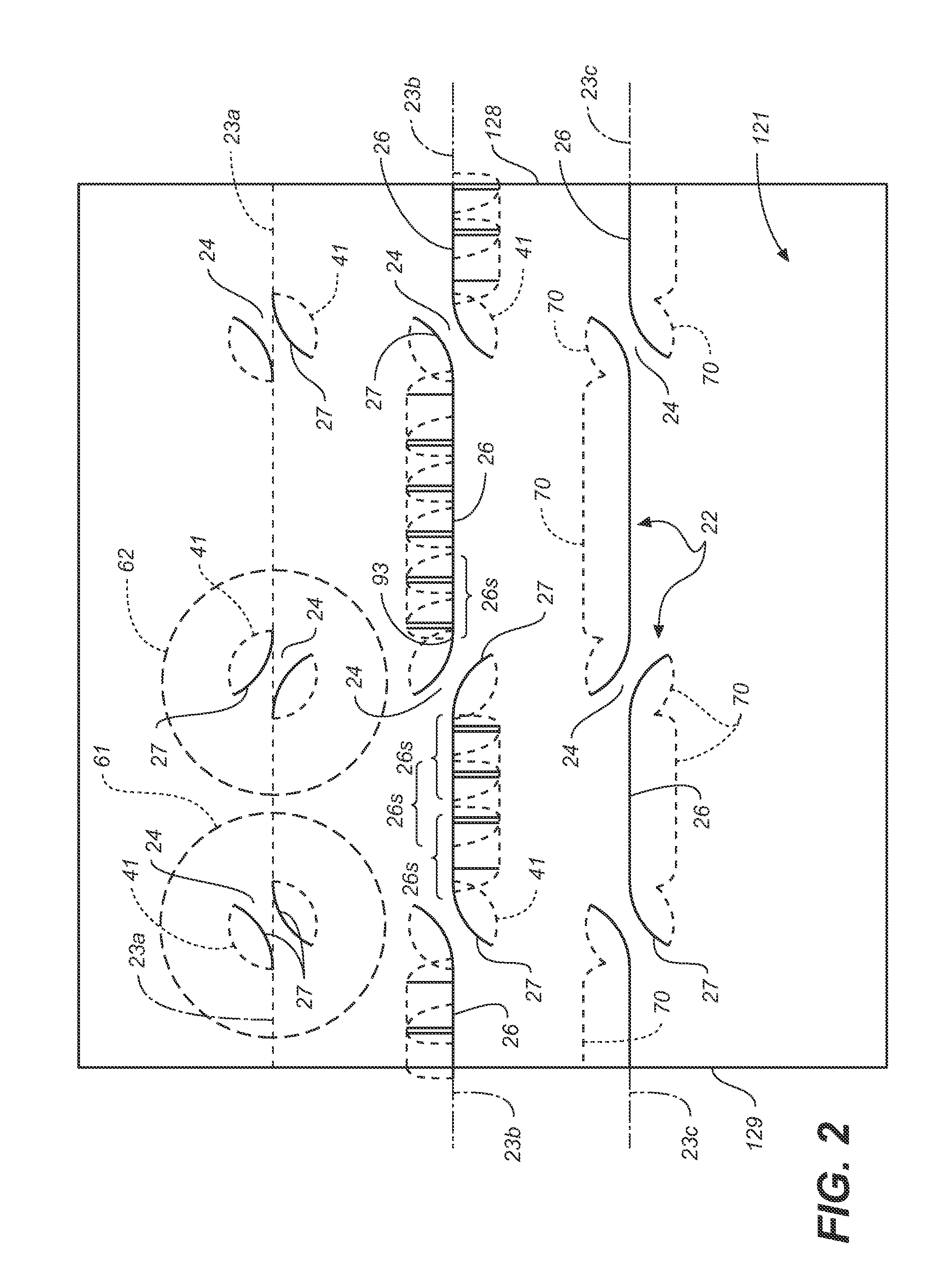

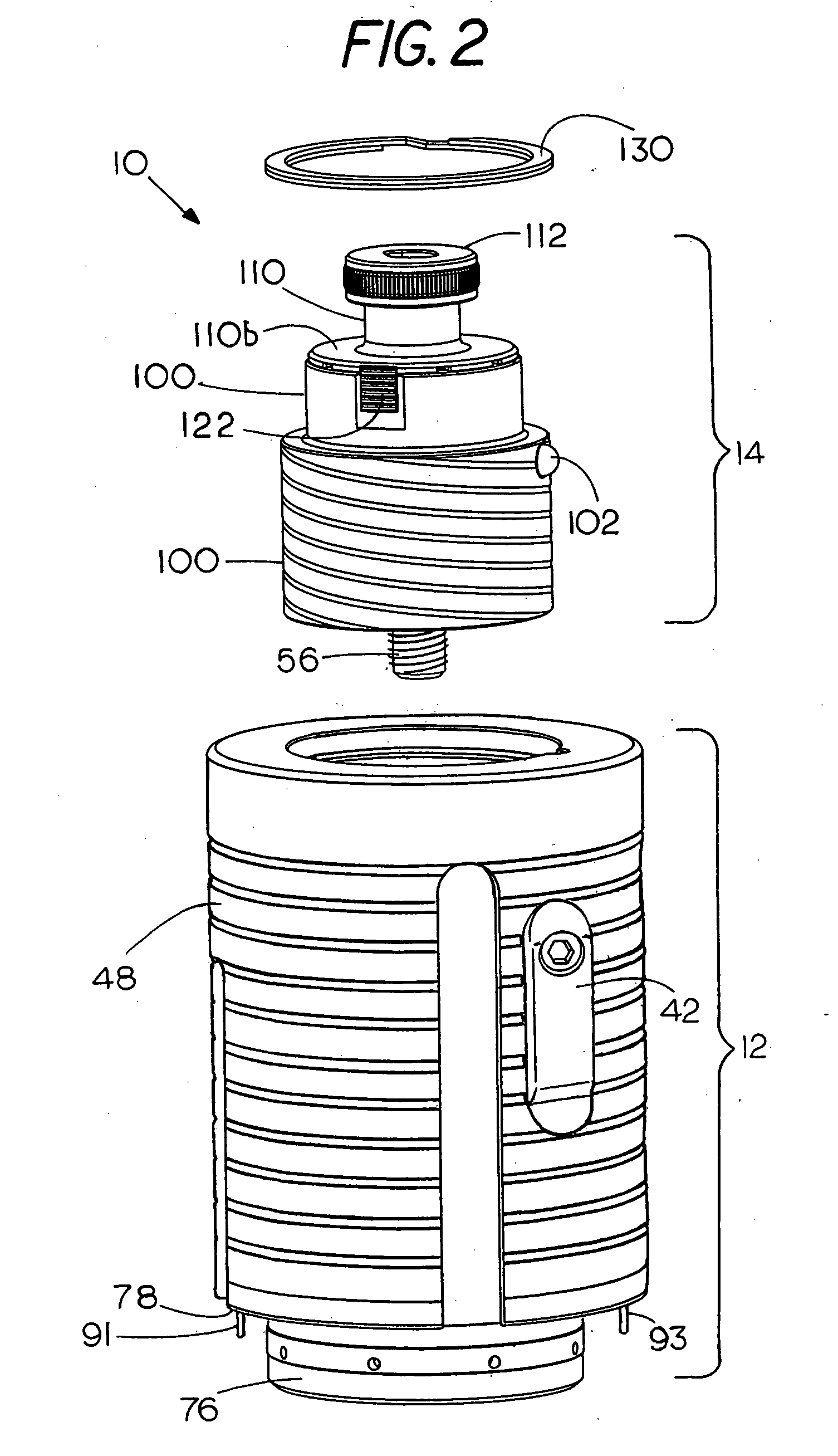

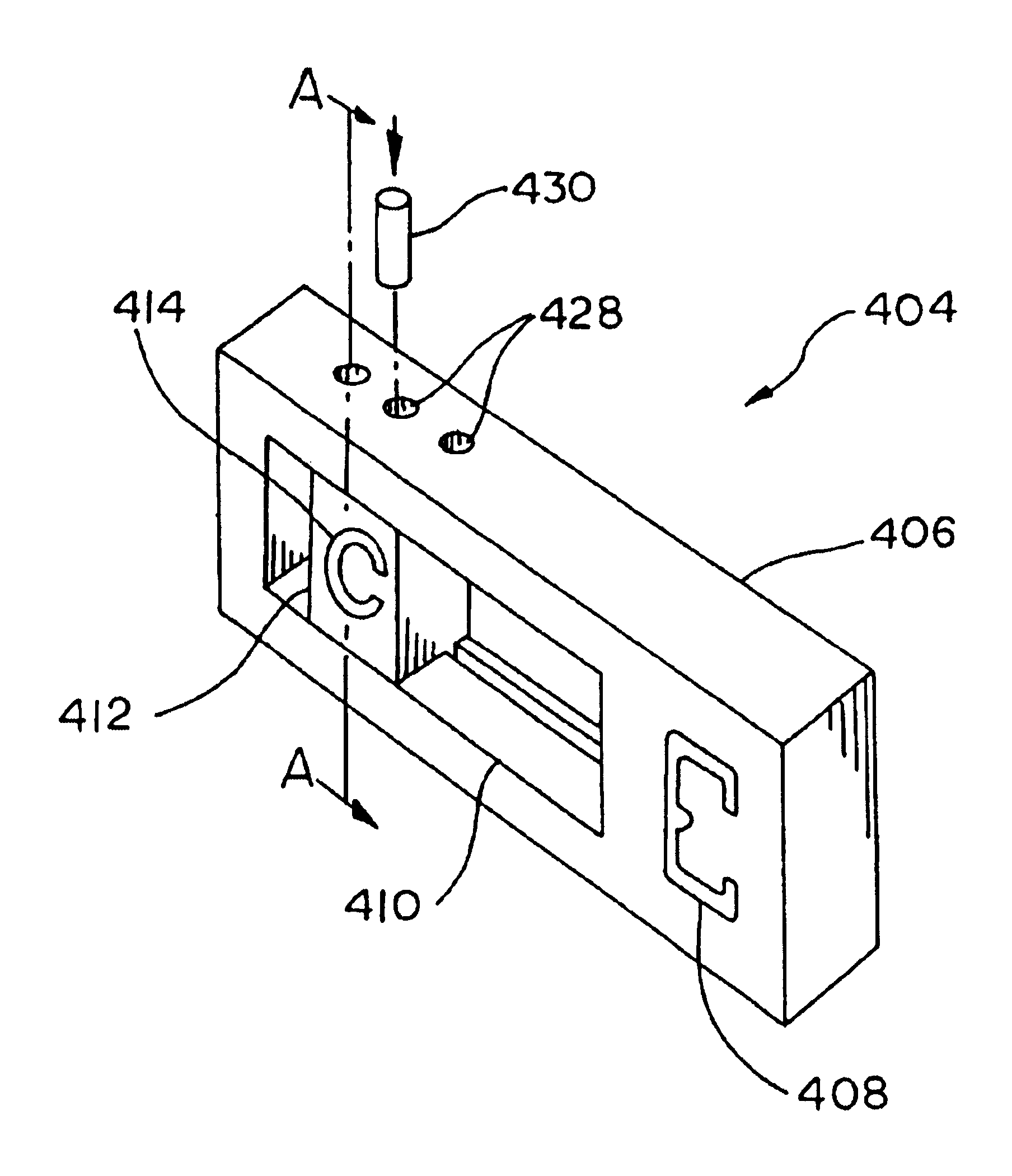

Process of forming bend-controlling structures in a sheet of material, the resulting sheet and die sets therefor

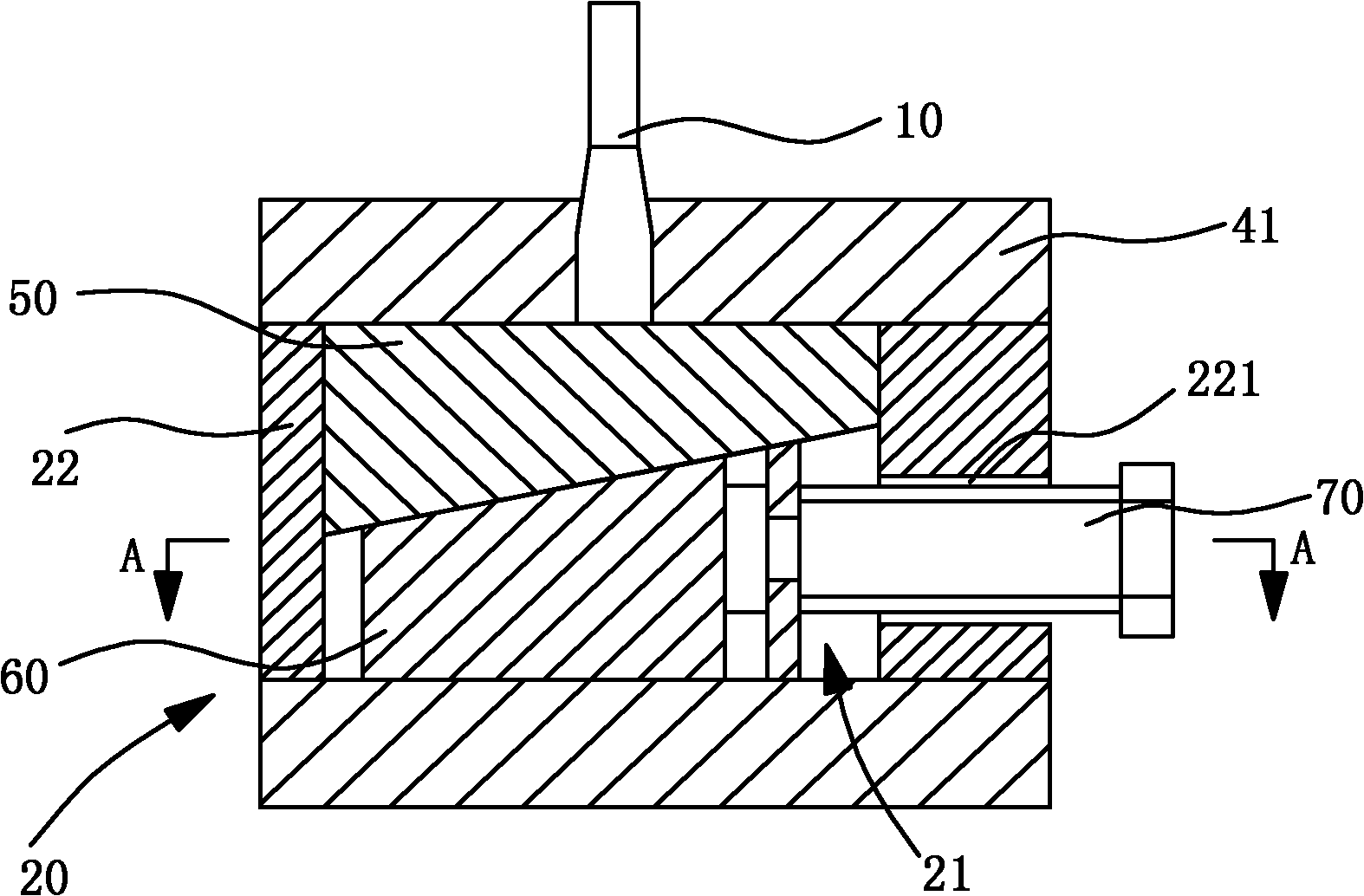

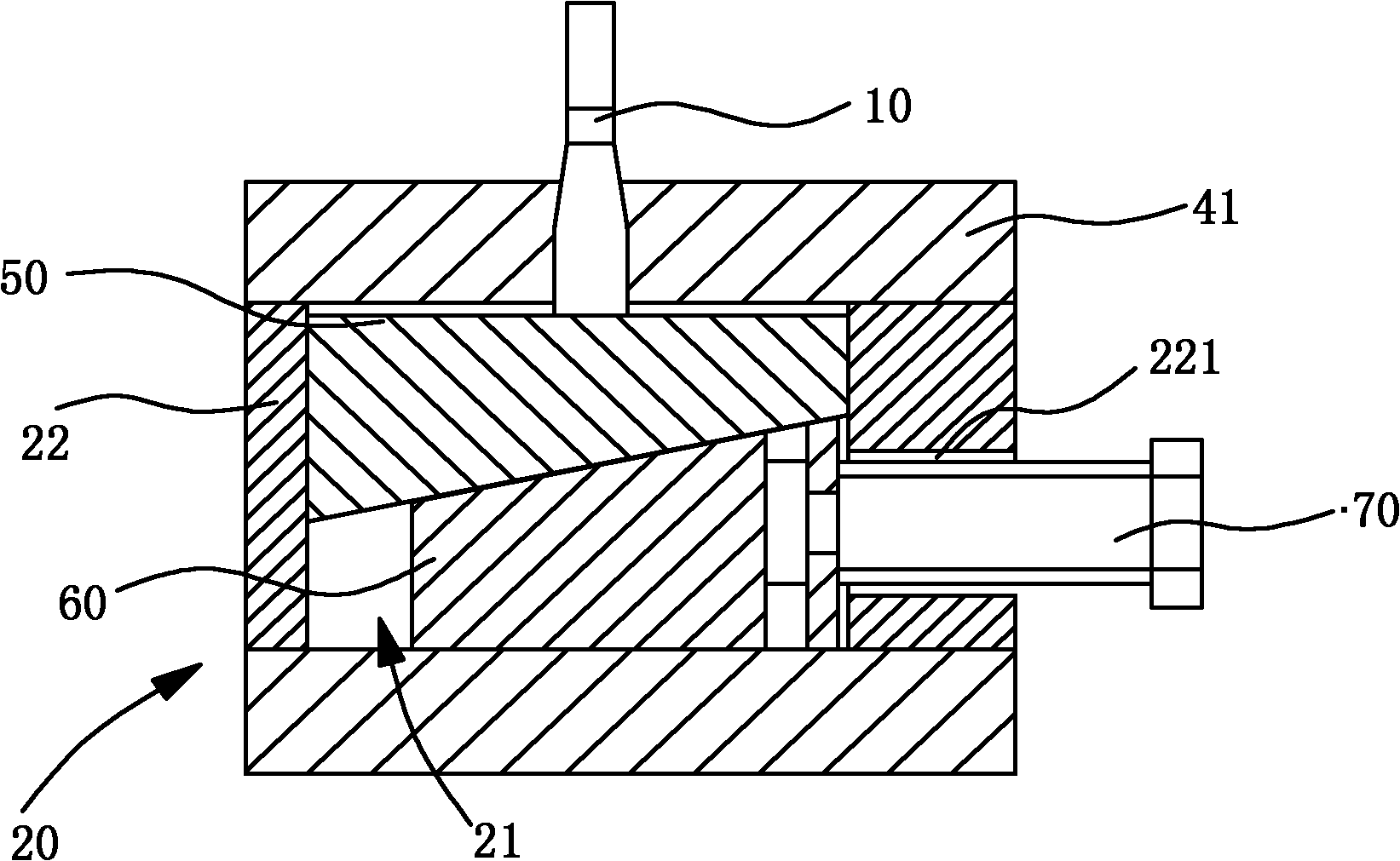

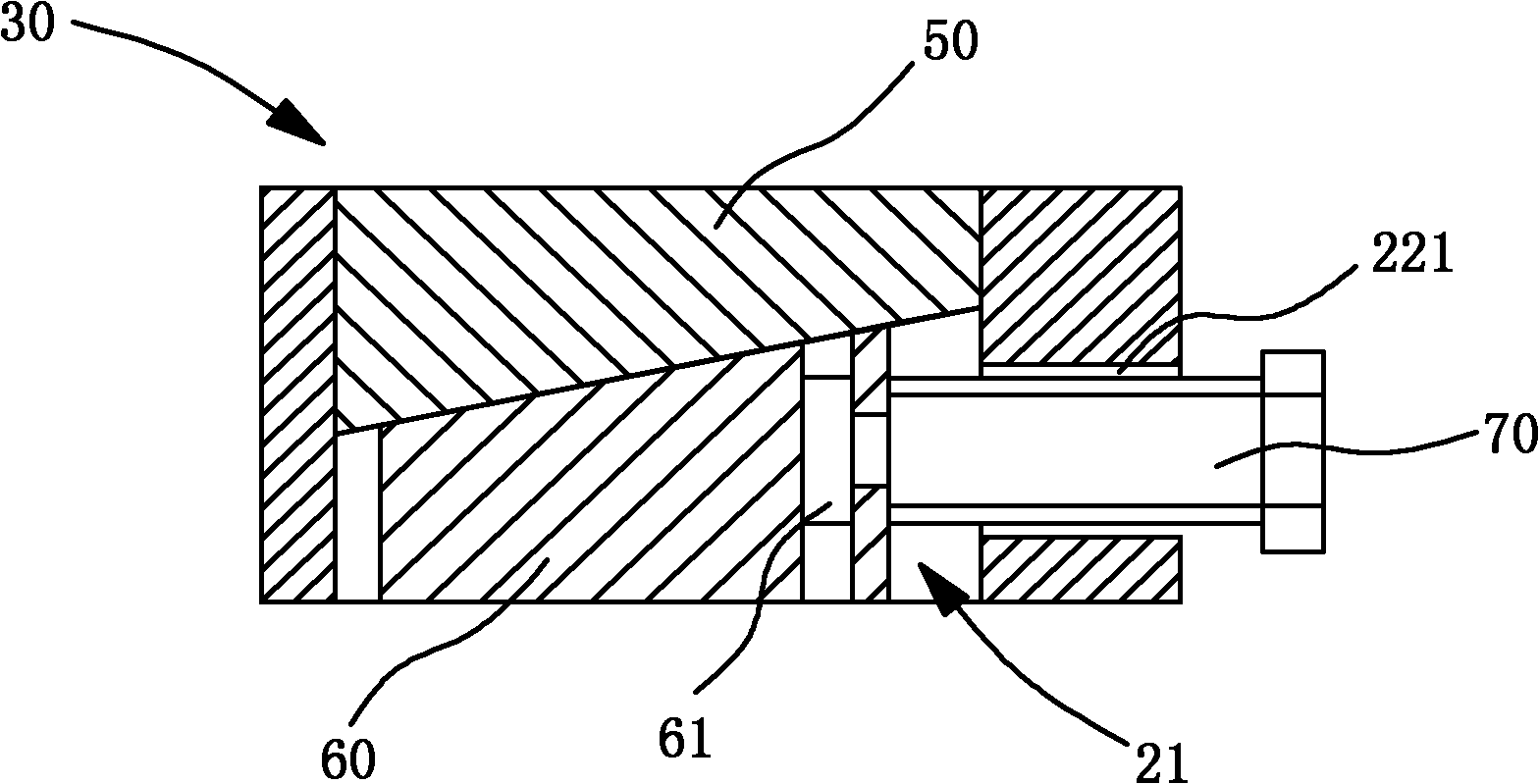

InactiveUS20050061049A1Optimize locationAchieved economicallyShaping toolsPerforating toolsMirror imageExtremity Part

A process of forming bend-controlling structures, such as slits, grooves or displacements (22), in a sheet of material (21, 121, 221, 321, 421, 521, 621,721). The bend-controlling structures (22) have central portions (26) extending substantially parallel to a desired bend line (23) on the sheet and end portions (27) which diverge away from the bend line (23). In one embodiment the process includes the step of forming the bending straps (24) between pairs of slit end portions (27) at a desired spaced apart distances along the bend line (23) with the straps (24) having a desired configuration, and the step of forming central portions (26) which connect the end portions (27) to complete the slits (22) using a separate die set. A plurality of end portion dies (51 / 54) can be used to produce end portions (27) of various shapes and straps (24) of various widths, and a single set of central portion forming dies (71 / 74) are used to connect the end portions (27). In other embodiments die sets producing a single end portion (27) or mirror image impressions (A,B) are used and preferably overlapped to produce the complete bend-controlling structure (22). A modular die assembly (500) also is disclosed in which the bend-controlling structures can be produced by modular die inserts (511-514, 611-614). Finally, a selection of die sets (722a, 722b, 722c) of differing length from a group of die sets can be made to position the bending straps (24) at desired locations along the bend line.

Owner:IND ORIGAMI INC CA US

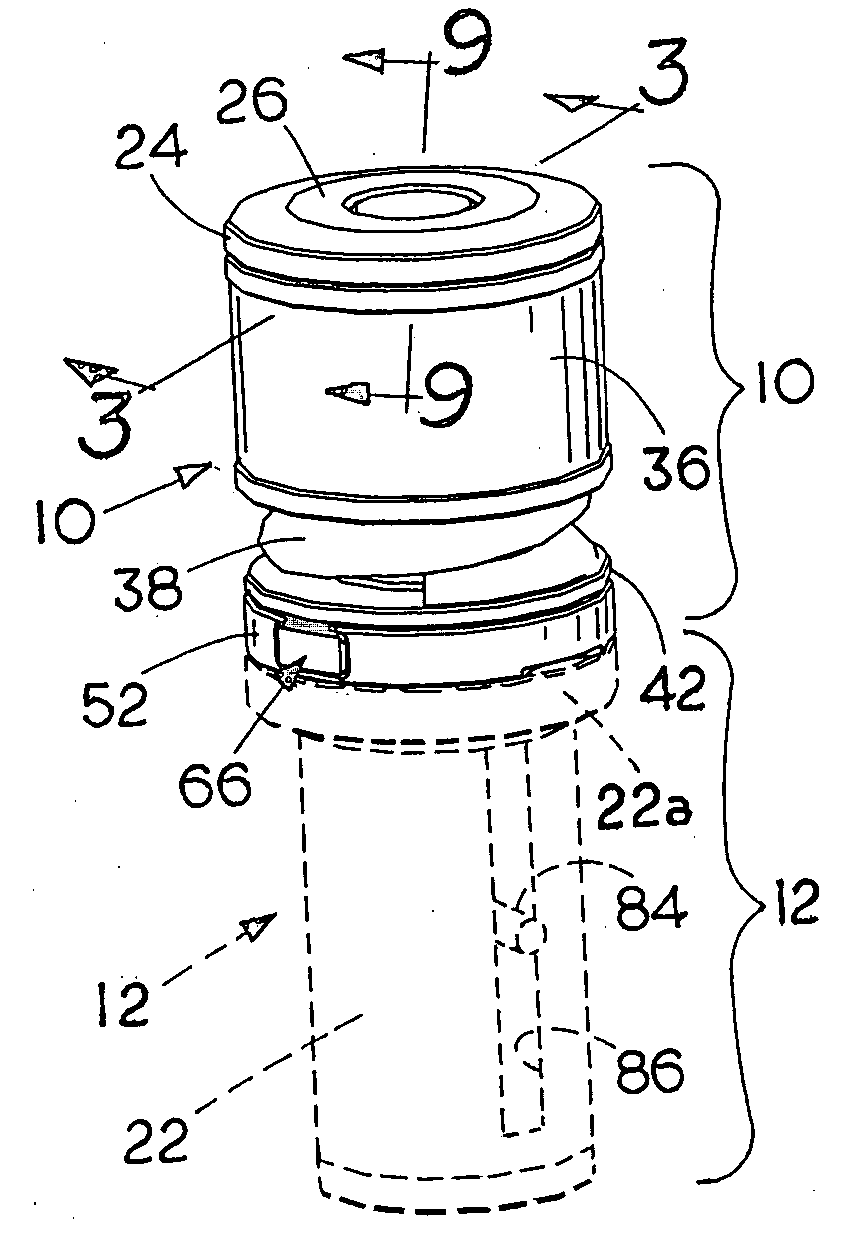

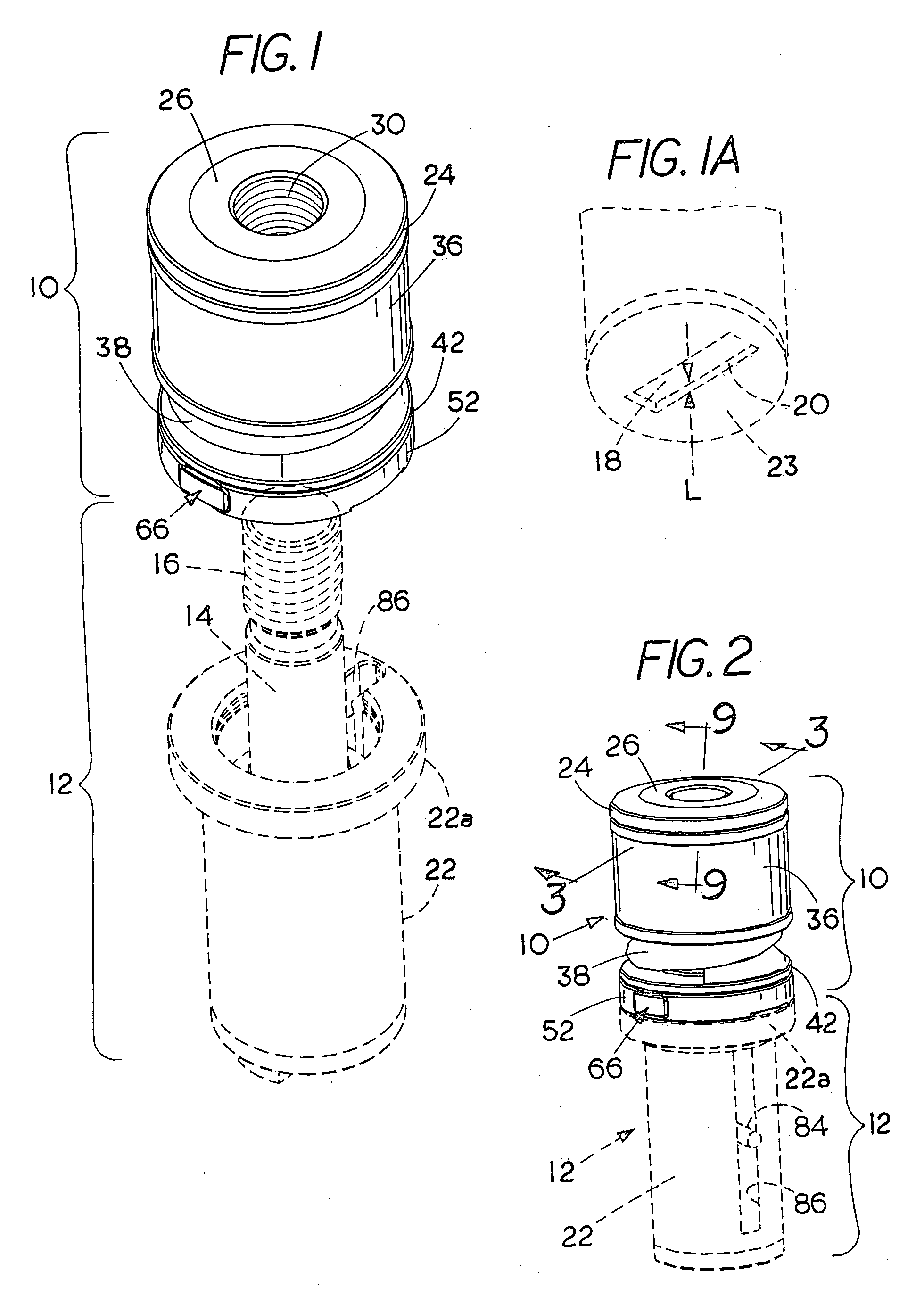

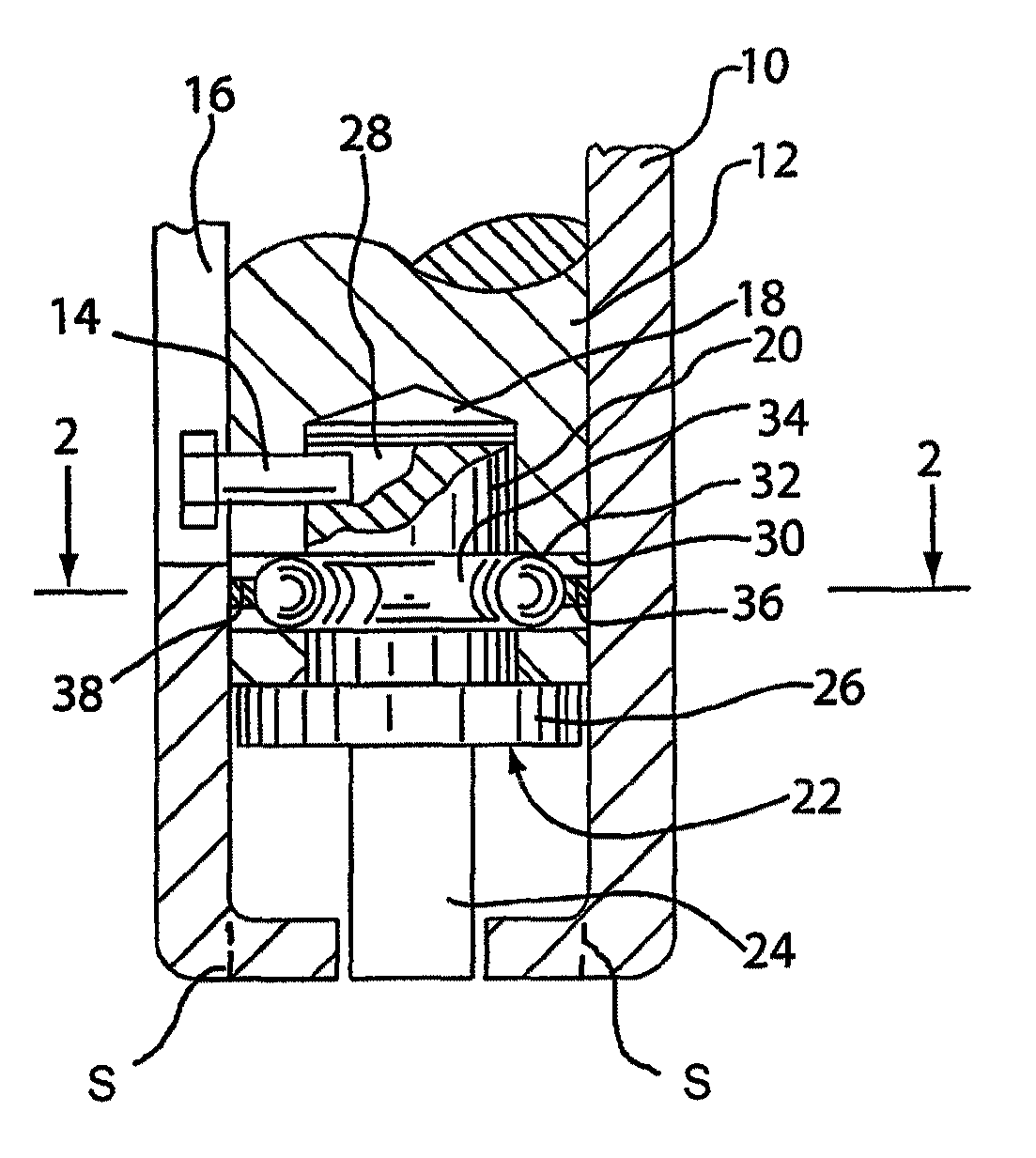

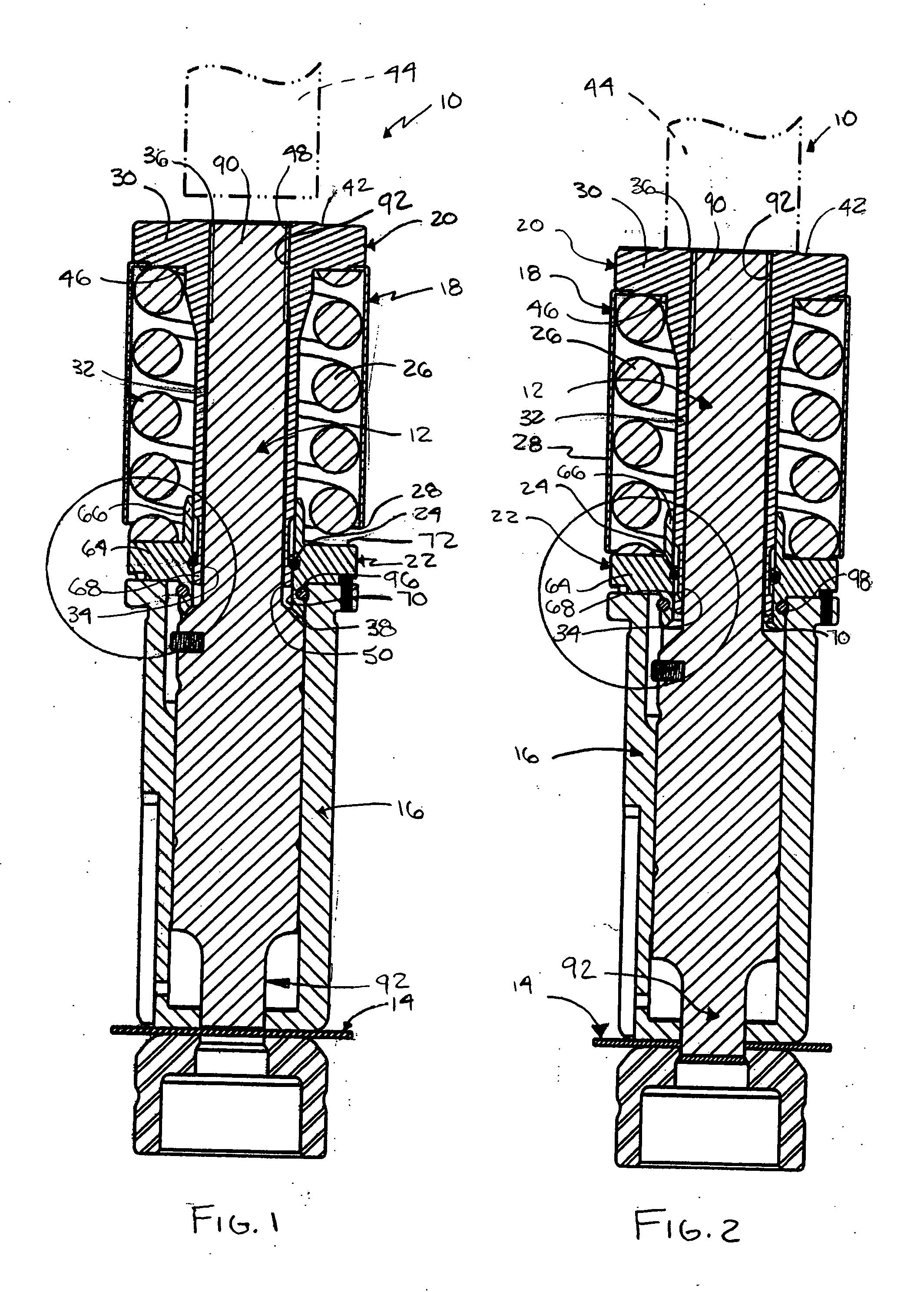

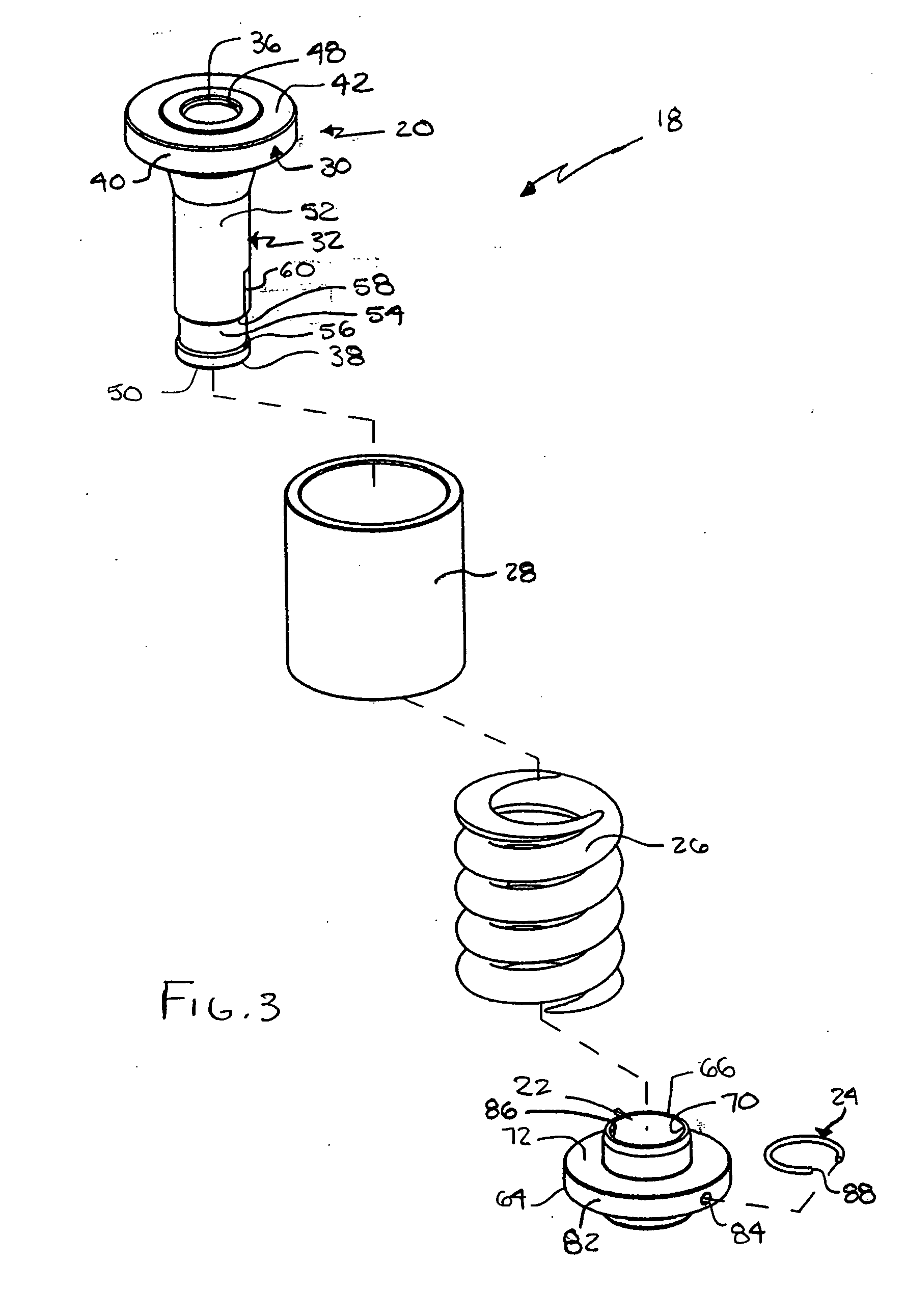

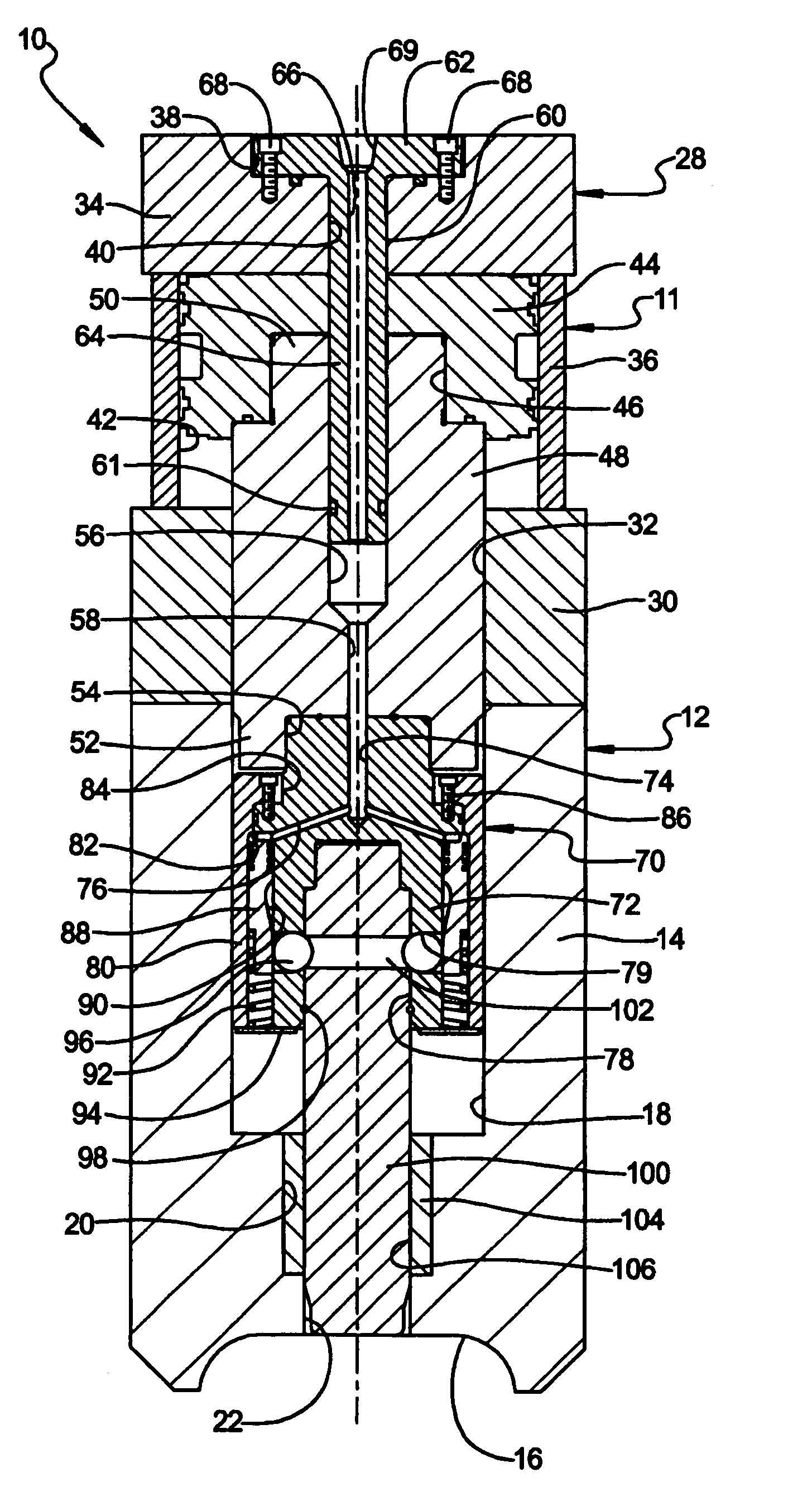

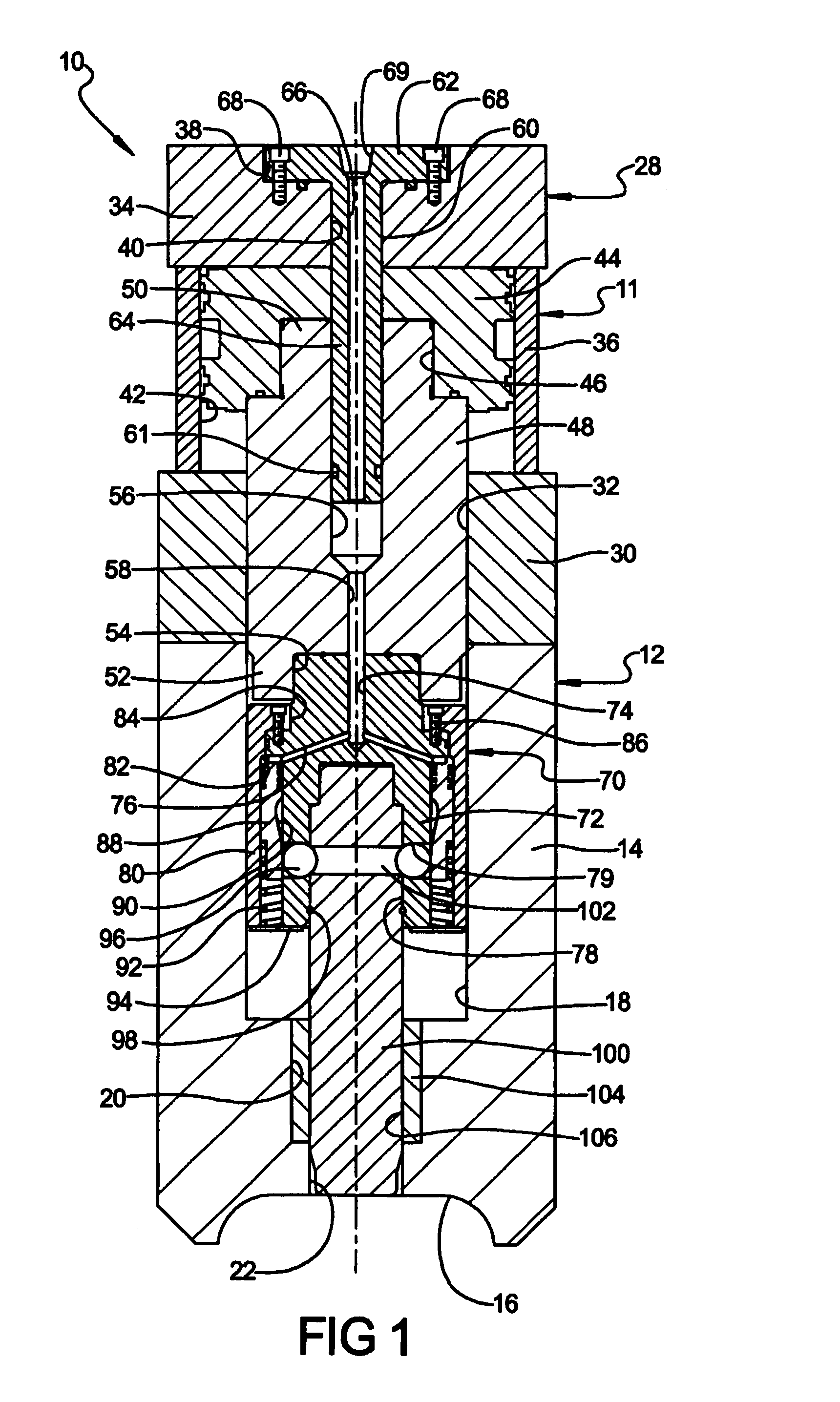

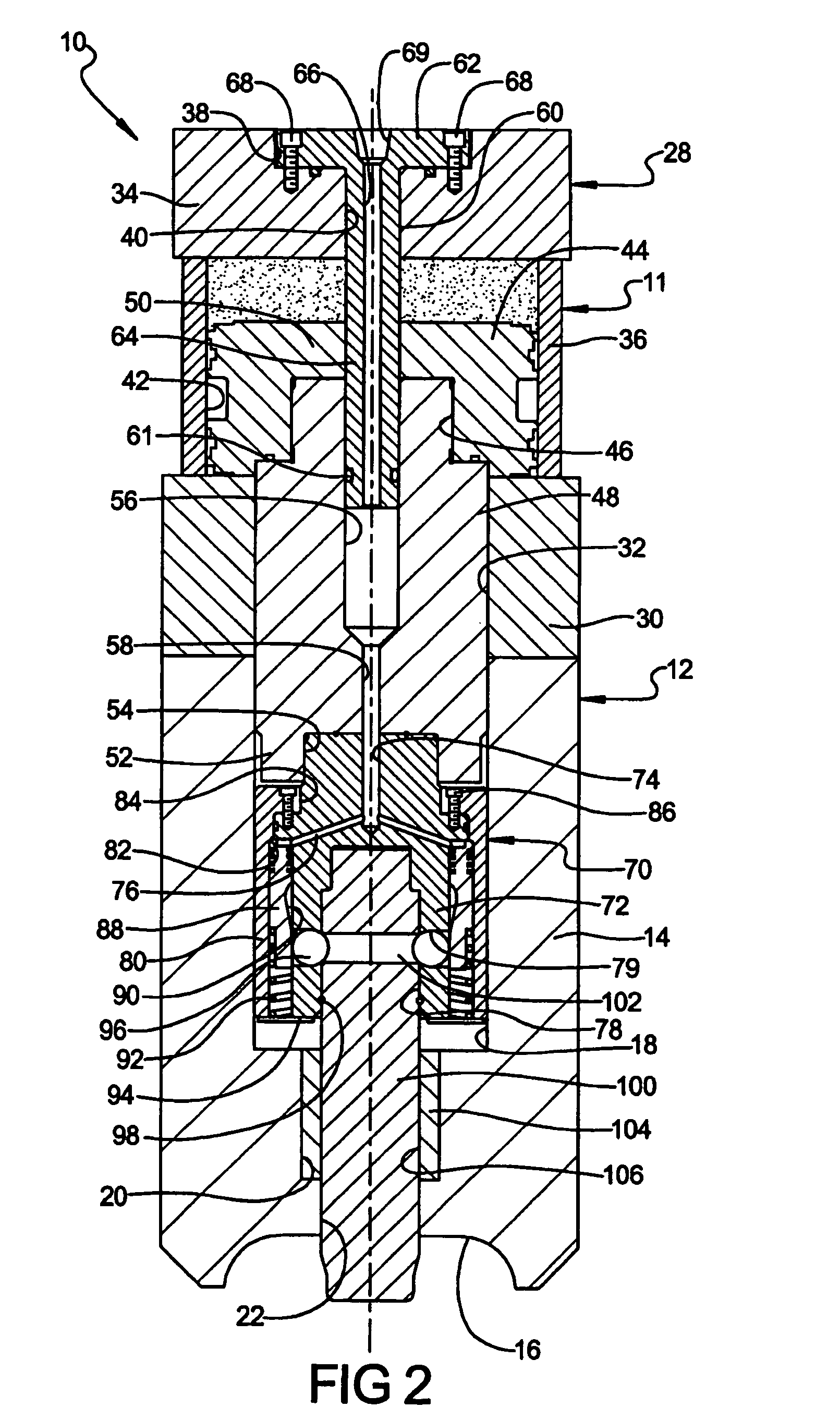

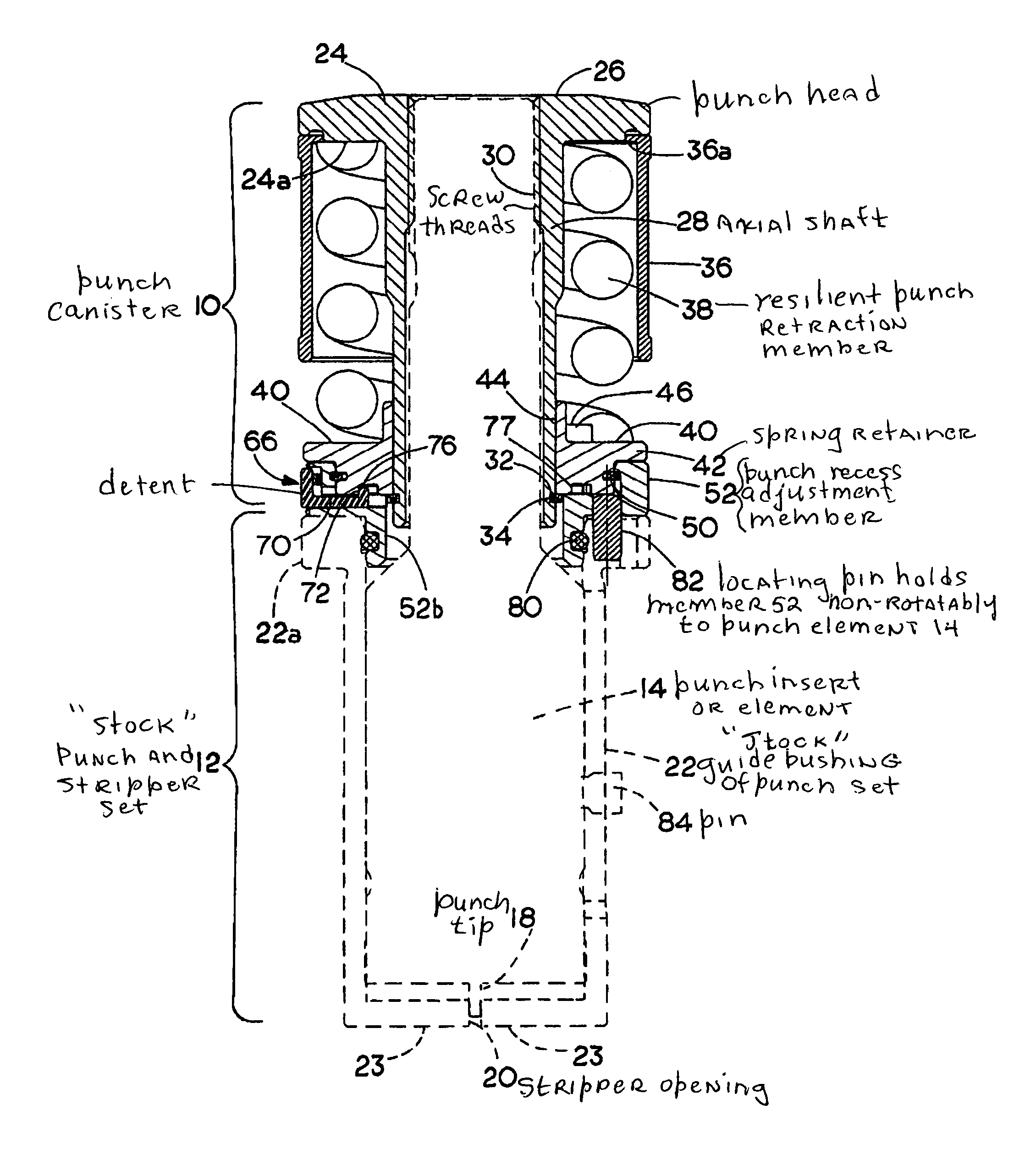

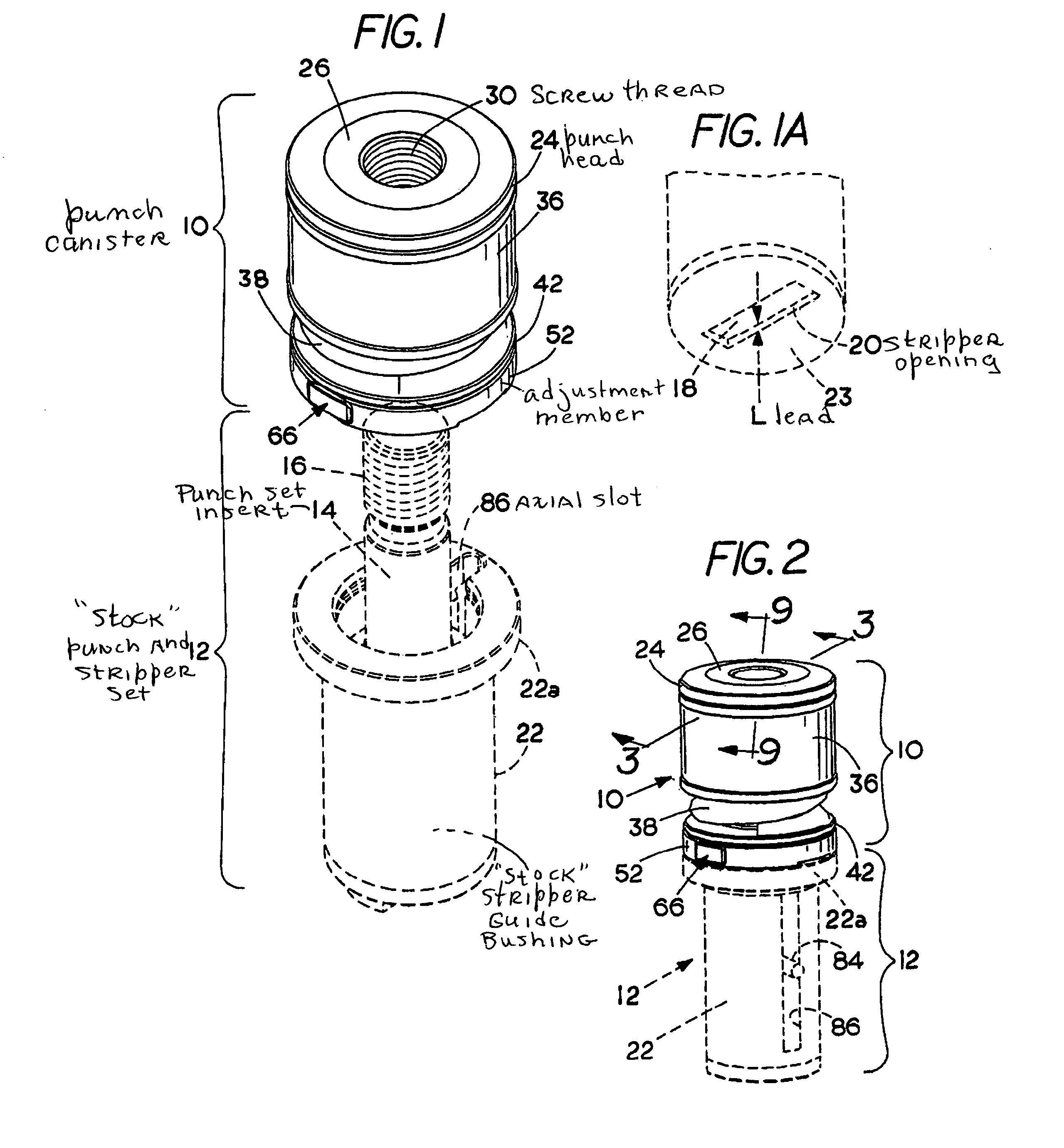

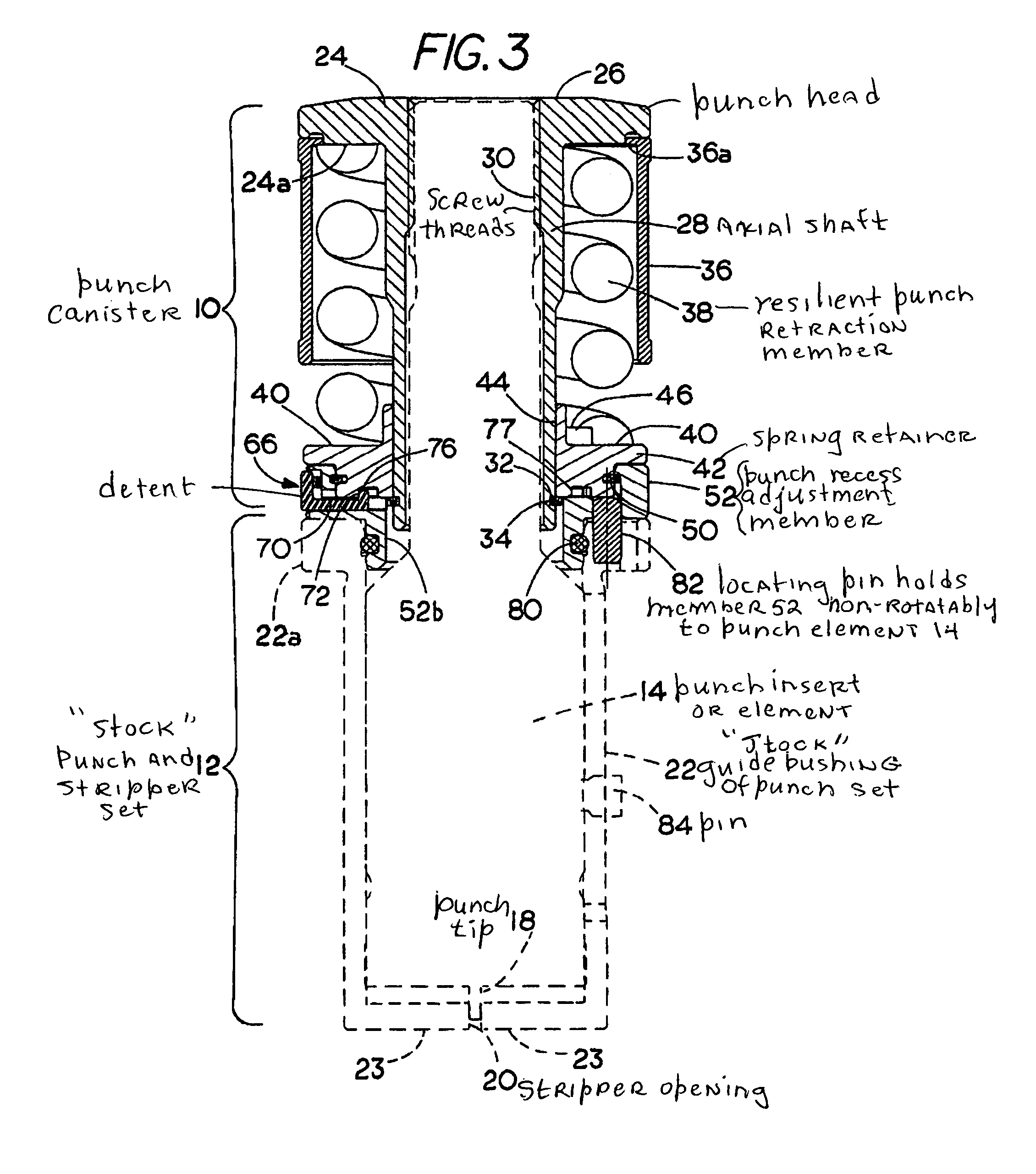

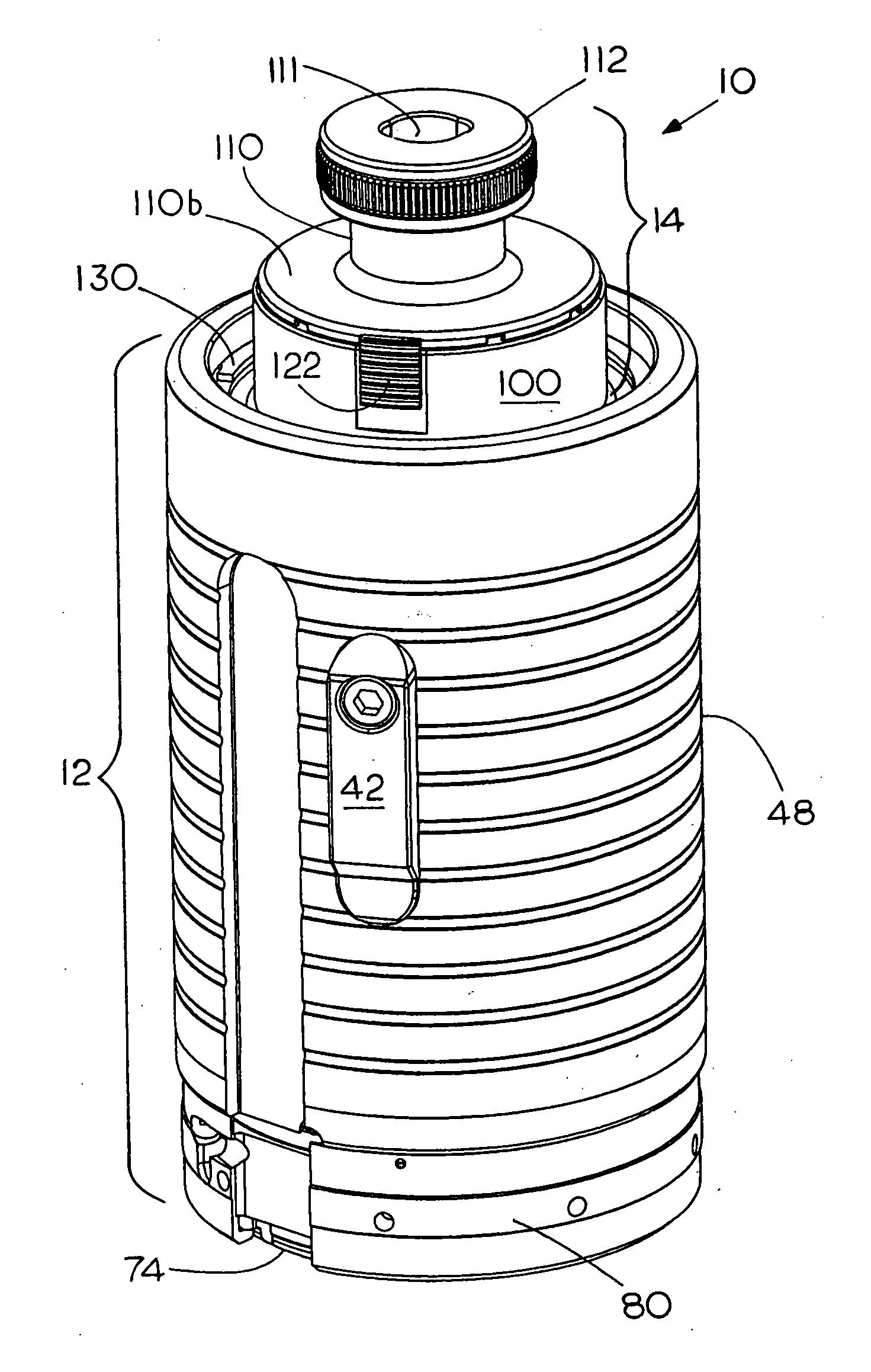

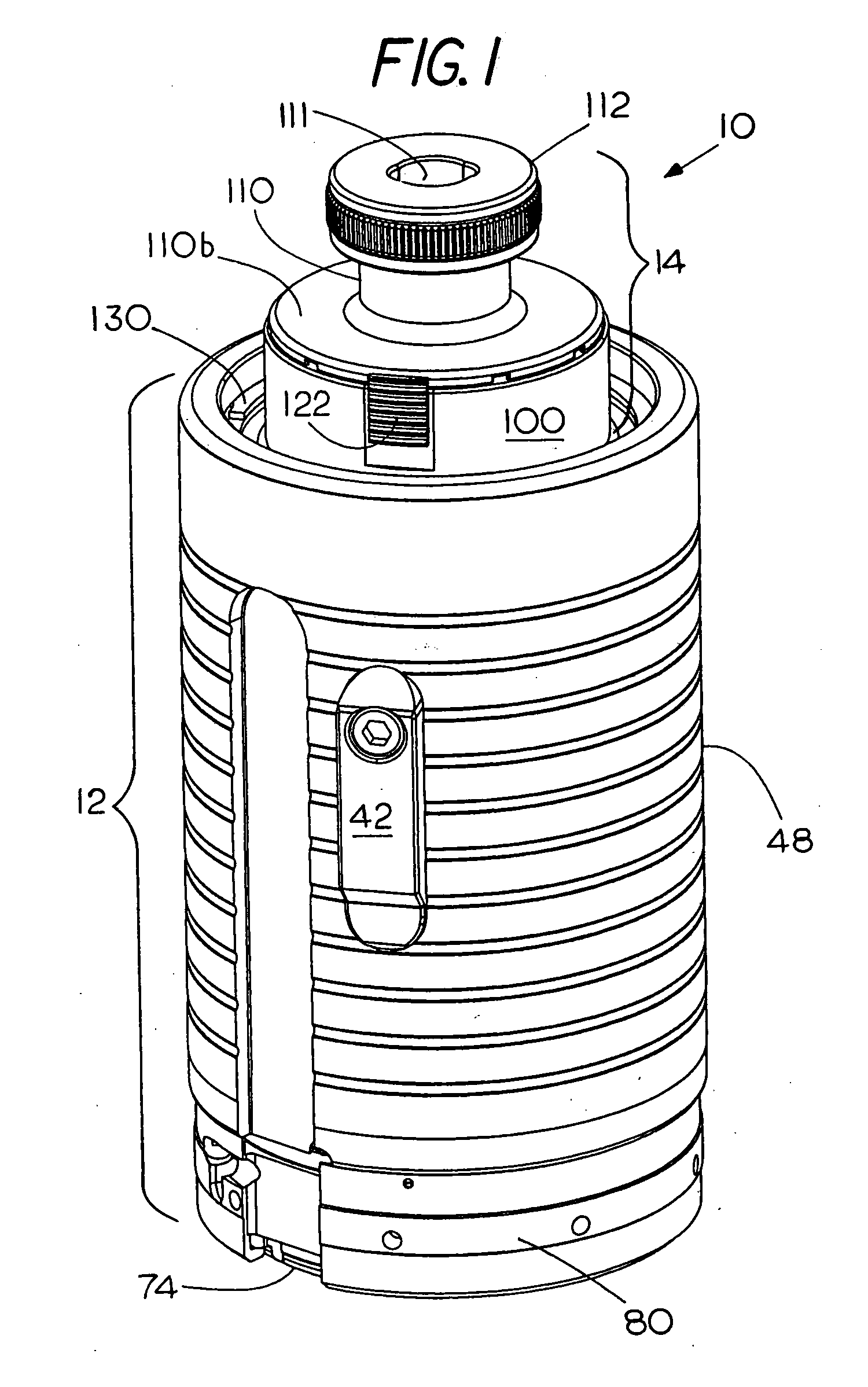

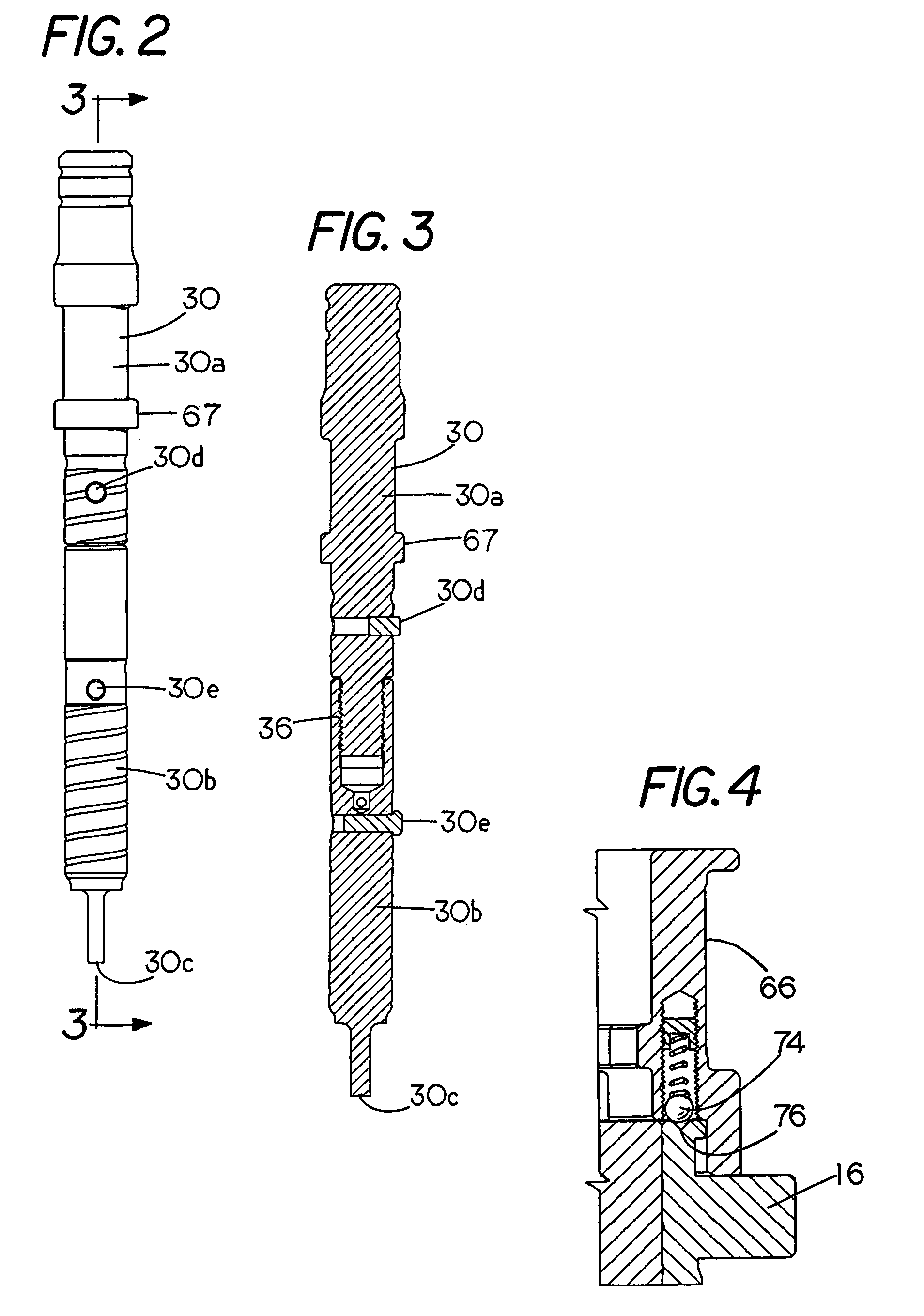

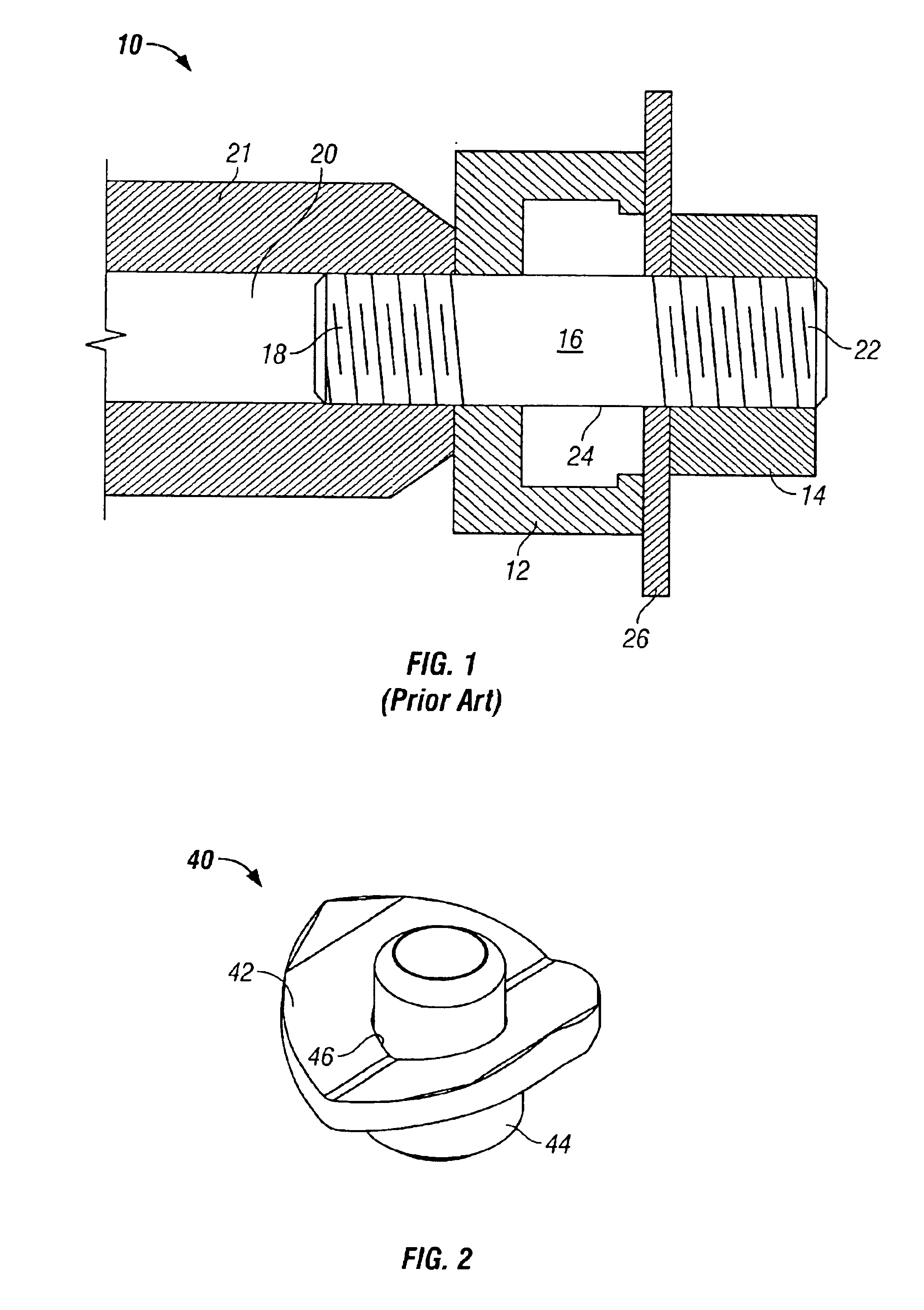

Punch with self-contained punch recess adjustment indexing

A punch canister includes a punch head with an axial shaft that has a screw thread which is adapted to be connected during use to the screw threads of a punch element that is slideably associated within a stripper bushing. A punch recess adjustment member is rotatably and slideably associated with the punch head. The adjustment member is adapted to the slideably but non-rotatably rotatably connected during operation to the punch element. A resilient retraction member, e.g., a spring, is located between the punch head and the adjustment member for biasing the adjustment member axially downward on the punch head. A manually releasable detent provided on the adjustment member is operatively associated with the punch head for retaining the adjustment member in any one of a plurality of selected circumferentially distributed angular positions on the punch head such that during operation disengagement of the detent allows the adjustment member and the punch element to be threaded axially on the punch head to control the distance that the punch element is recessed within the stripper bushing. In a preferred form, the detent is a lock that can be disengaged manually when the punch recess adjustment is to be made.

Owner:MATE PRECISION TOOLING

Adjustable length punch assembly

Owner:WILSON TOOL INT

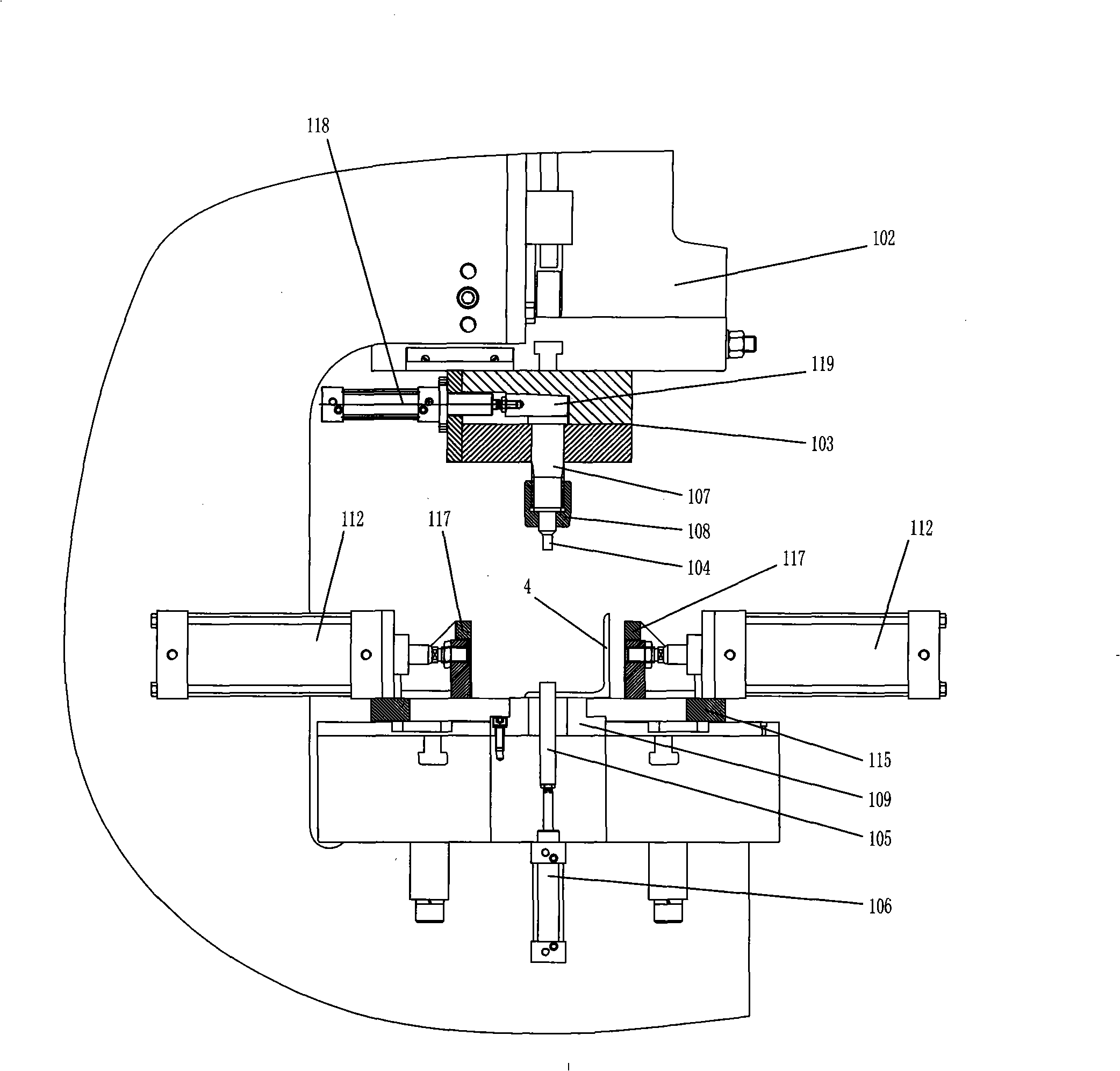

Multifunctional wiring-duct machining device and machining method thereof

InactiveCN105251878APerfect shapeConsistent processing shapeShaping toolsPerforating toolsEngineeringMachining

The invention relates to a multifunctional wiring-duct machining device and a machining method thereof. The machining device comprises a C-shaped base, an upper die rotary plate, a plurality of upper dies, a downward pressing device and a lower die. The upper die rotary plate is rotationally mounted at the upper end of the inner side of the C-shaped base, and the upper dies are mounted at the lower end of the upper die rotary plate in the radial direction. The downward pressing device is vertically mounted on the top of the C-shaped base and located on one side of the radial direction of the rotary plate. The lower die is fixedly mounted in the position, below the downward pressing device, of the upper end of the bottom of the C-shaped base. According to the multifunctional wiring-duct machining device and the machining method thereof, the problem that dies are frequently replaced during wiring-duct machining is solved; after integration, operation is convenient, batch machining can be achieved, work hours are shortened, and the manual labor intensity is relieved; in addition, after program control is added, automatic machining can be achieved, and the automation degree is increased.

Owner:TIANJIN RES INST OF ELECTRIC SCI

Punching tool

ActiveUS7975587B2Simple and rapid separationEasy to separatePerforating toolsMetal working apparatusPunchingPlunger

A punching tool has a guided, axially displaceable die plunger, which is fixed against relative rotation, in a guide bushing. In a bore in its front end a punching die is seated. During the punching stroke the punching die rests against a front face of the die plunger and is axially fixed in place by means of one or several snap-in balls each of which is seated in a transverse bore, which snap-in balls are maintained in engagement with an annular groove by means of a resilient ring in the die plunger. The outer diameter of the resilient ring is only slightly less in the engagement position than the inner diameter of the guide bushing and can be resiliently widened for releasing the punching die outside of the guide bushing.

Owner:MATE PRECISION TOOLING

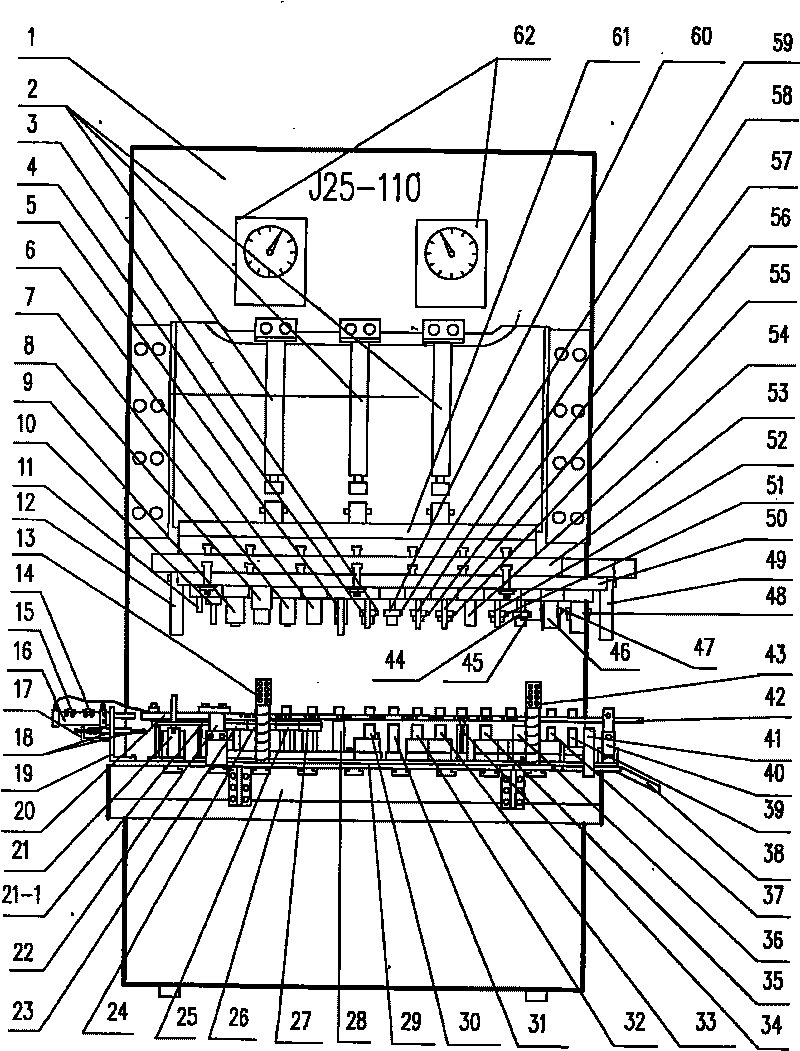

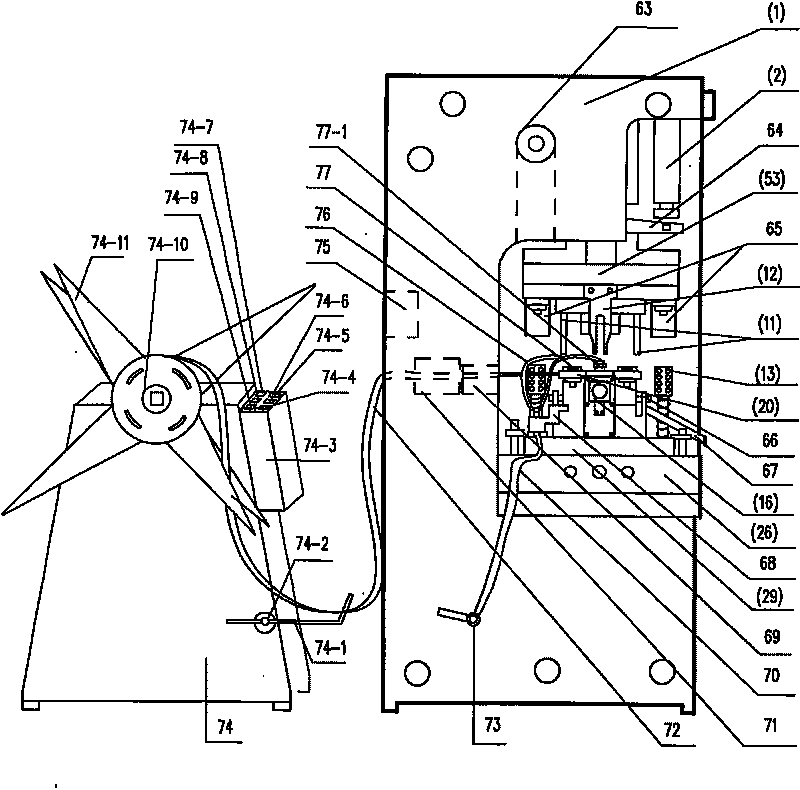

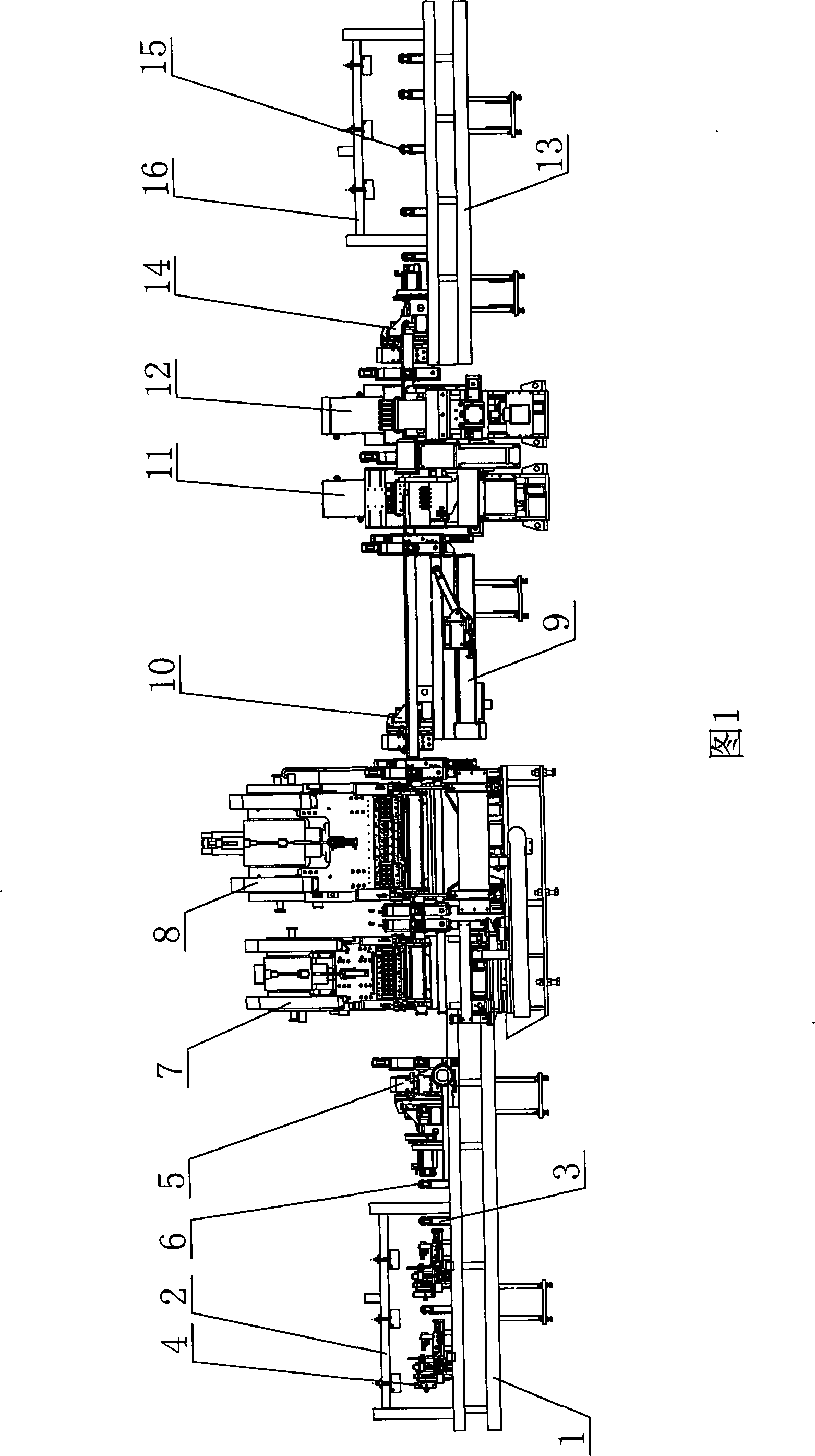

Automatic feed multi-station progressive die

ActiveCN101722229AReasonable structural designImprove ergonomicsShaping toolsPerforating toolsMachine pressAutomation

The invention relates to an automatic feed multi-station progressive die. The structure is as follows: a feed sectioning upper die, a feed sectioning lower die, a drawing upper die A, a drawing lower die A, a drawing upper die B, a drawing lower die B, a drawing upper die C, a drawing lower die C, a shaping upper die A, a gibbous shaping lower die, a top rush hole upper die, a top rush hole lower die, a material pressing upper die A, a profile four-hole punching die, a material pressing upper die B, a rotation die with a hole, a material pressing upper die C, a profile technology hole punching die, a material pressing upper die D, a profile U-shaped hole punching die, a shaping upper die G, a square hole shaping die, a sectioning upper die and a sectioning lower die are respectively fixed on an upper die and a lower die, wherein the upper die is connected with a pressure machine, and the lower die is fixed on a work table. Compared with the prior art, the automatic feed multi-station progressive die has reasonable structure and design, high work efficiency, low material cost, reliable performance, stable quality and high automation degree.

Owner:浙江人人集团有限公司

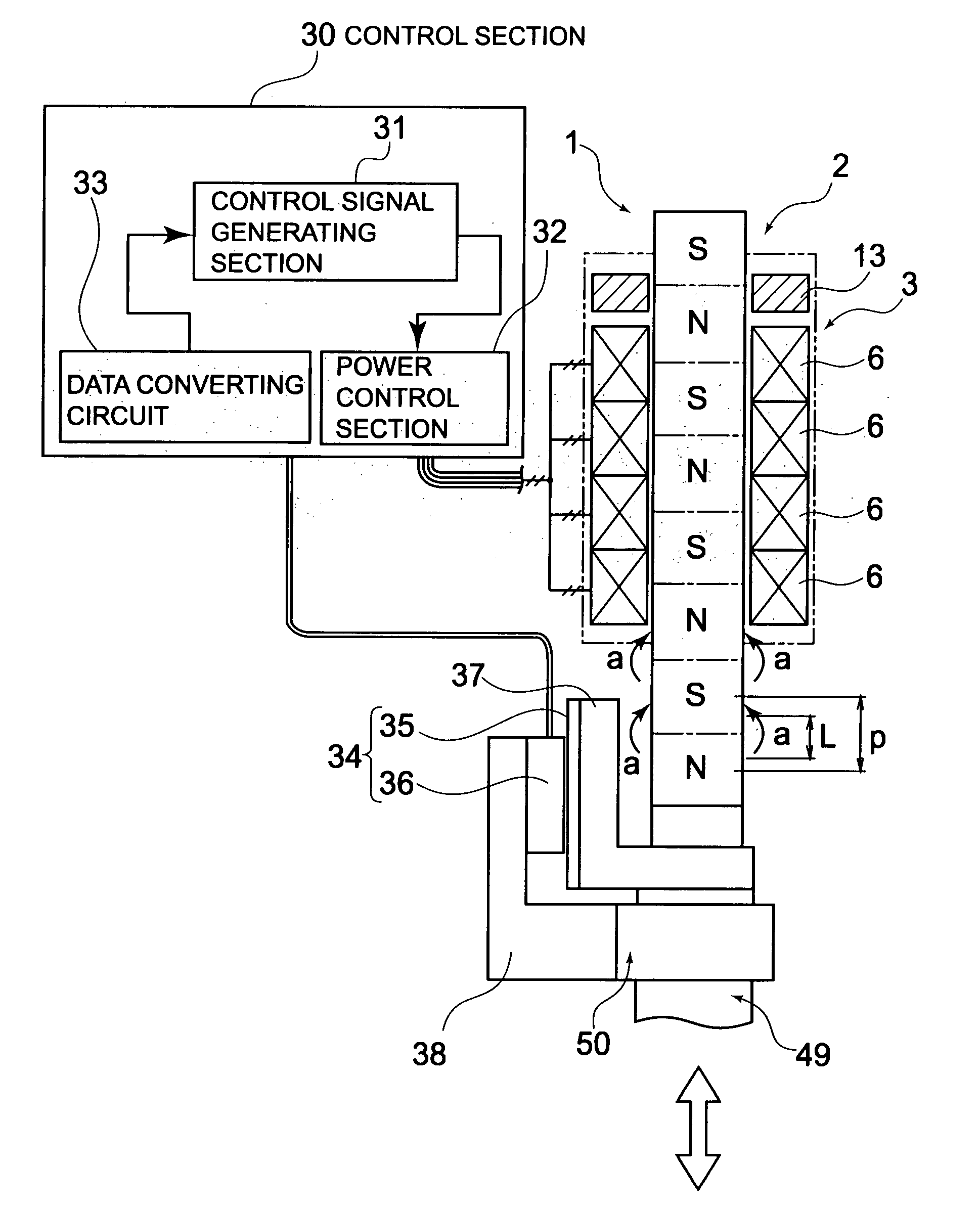

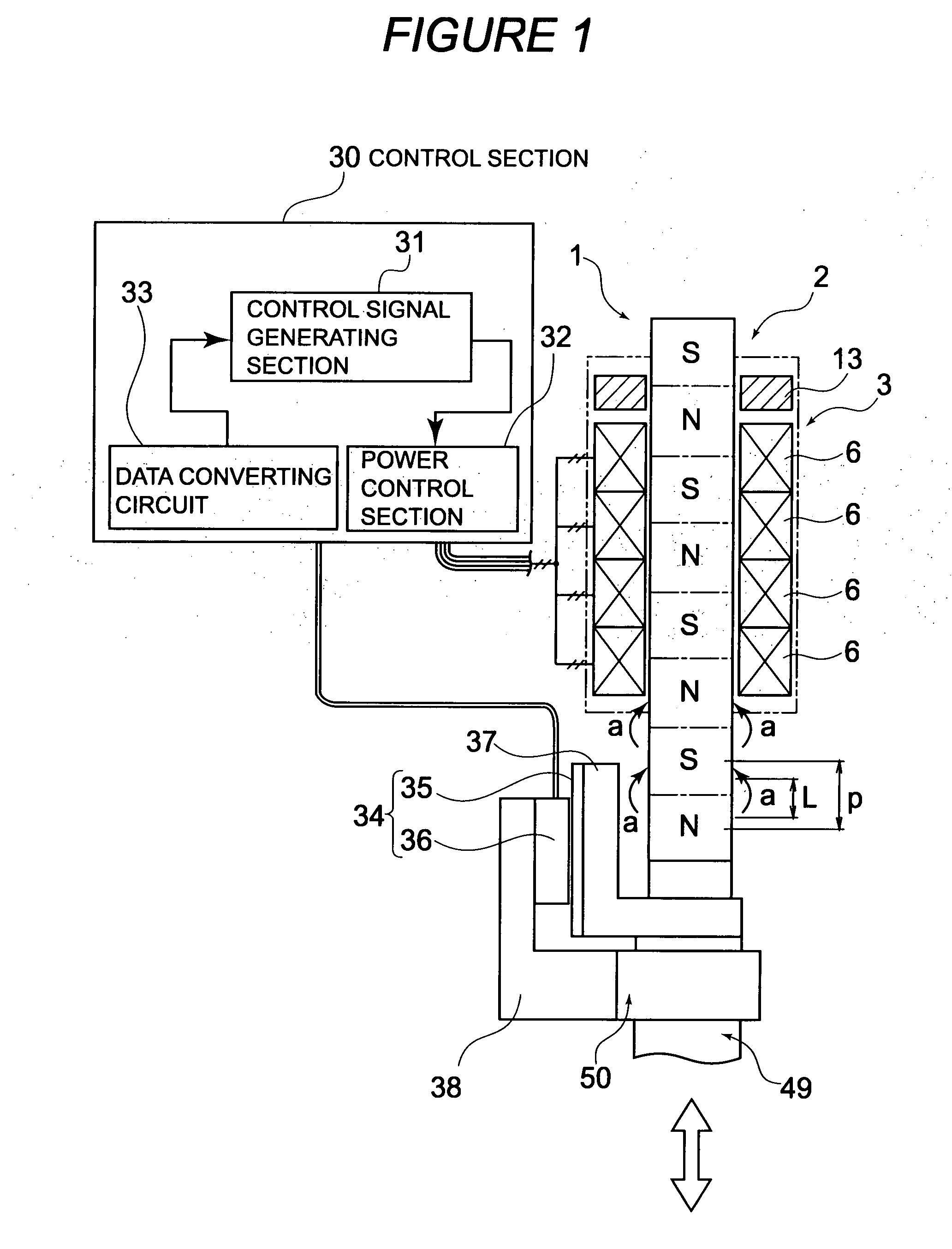

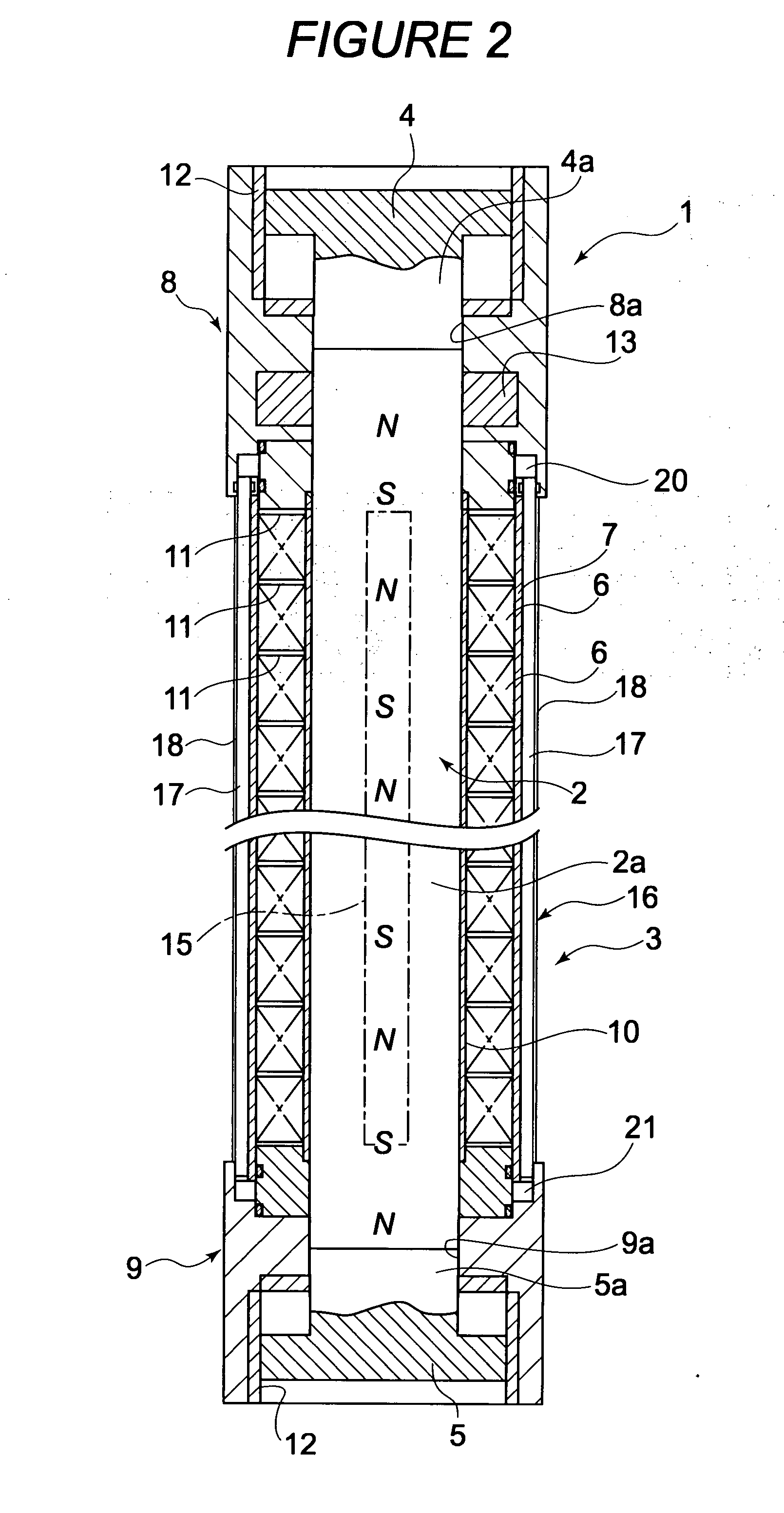

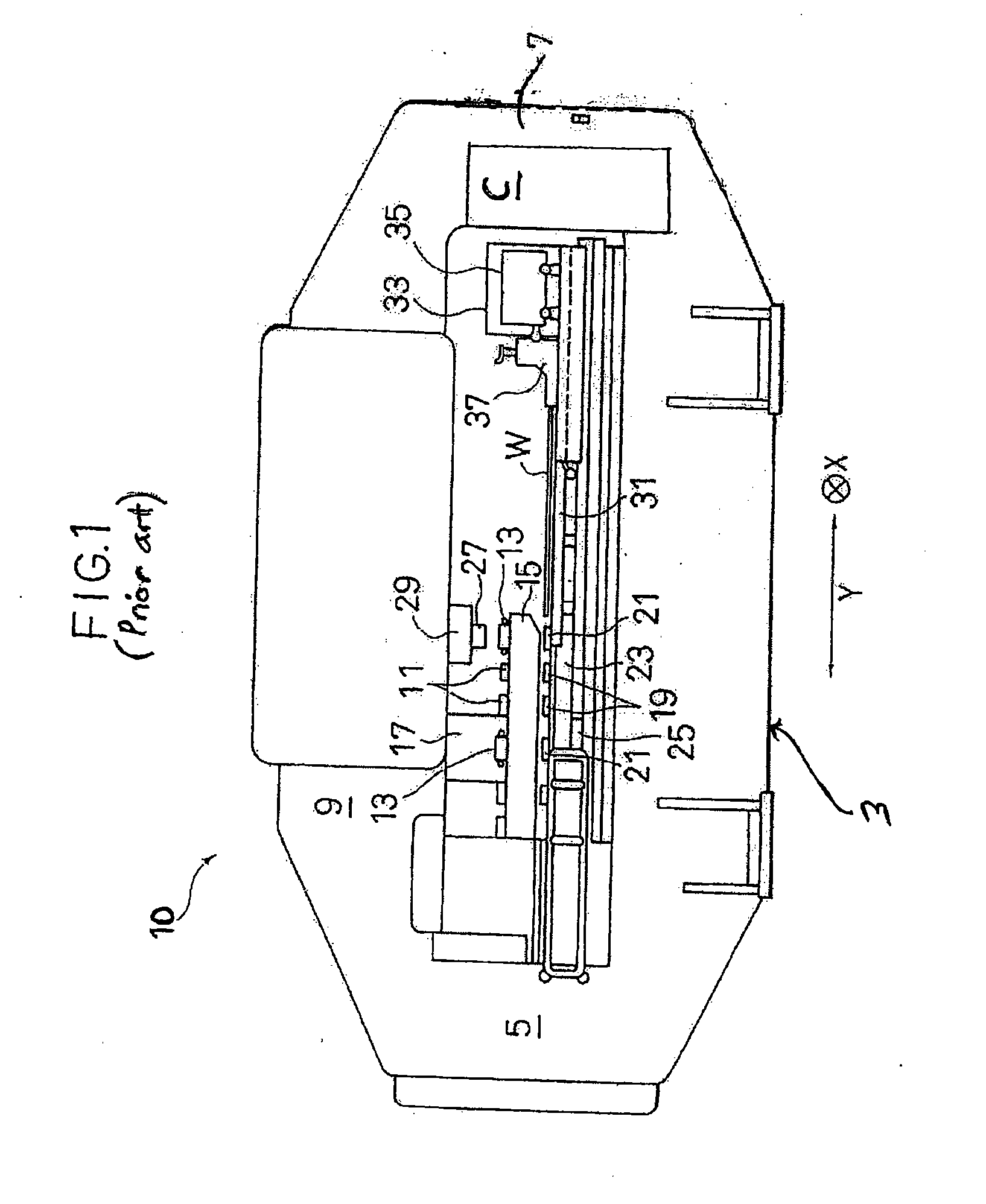

Linear motor device and machine tool having the same mounted thereon

InactiveUS20080079319A1Reduce variationAvoid loss of processing qualityPerforating toolsDynamo-electric brakes/clutchesReciprocating motionMagnetic poles

The present invention provides a linear motor device that can reduce a variation in thrust caused by a variation in attractive force. The linear motor device includes a linear motor 1 and a control section 30 that controls the linear motor 1. The linear motor 1 includes a magnet member 2 composed of permanent magnets having respective N poles and S poles alternately arranged in an axial direction, and a coil member 3 which is located orthogonally to the axial direction with respect to the magnet member 2 and through which the magnet member 2 is movable in the axial direction relative to the coil member 3. The control section 30 controls current conducted through the coil member 3 so that a moving one of the magnet member 2 and the coil member 3 reciprocates within a use range L corresponding to a part of a pitch p between the magnetic poles N and S in the magnet member 2.

Owner:MURATA MASCH LTD

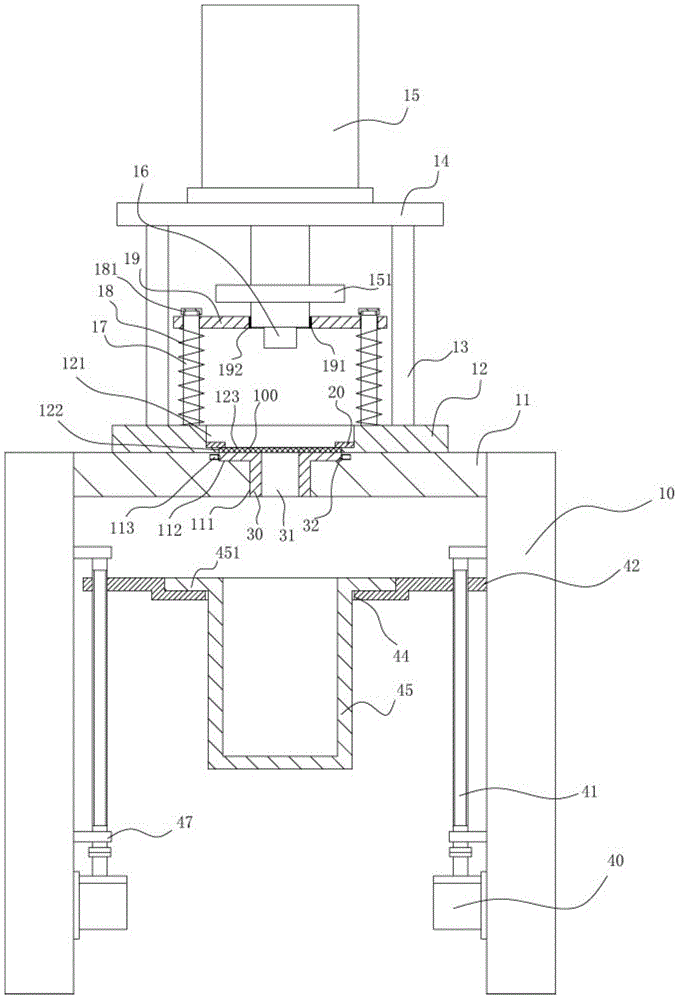

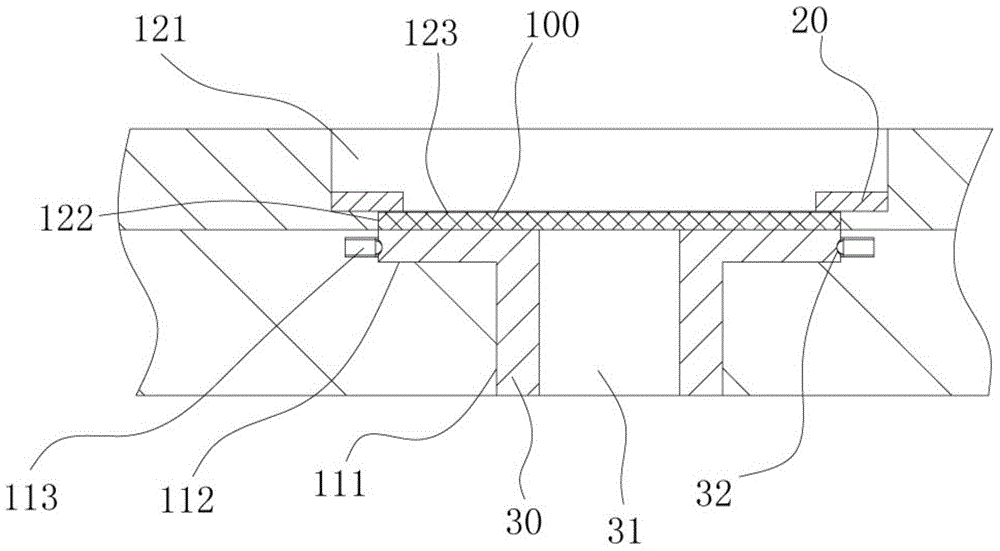

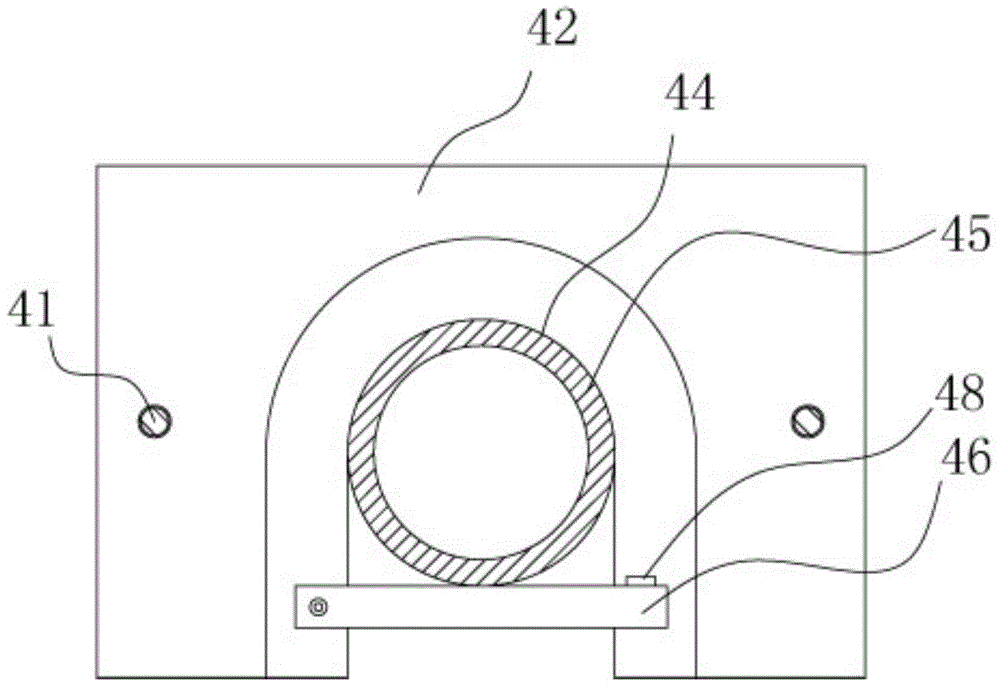

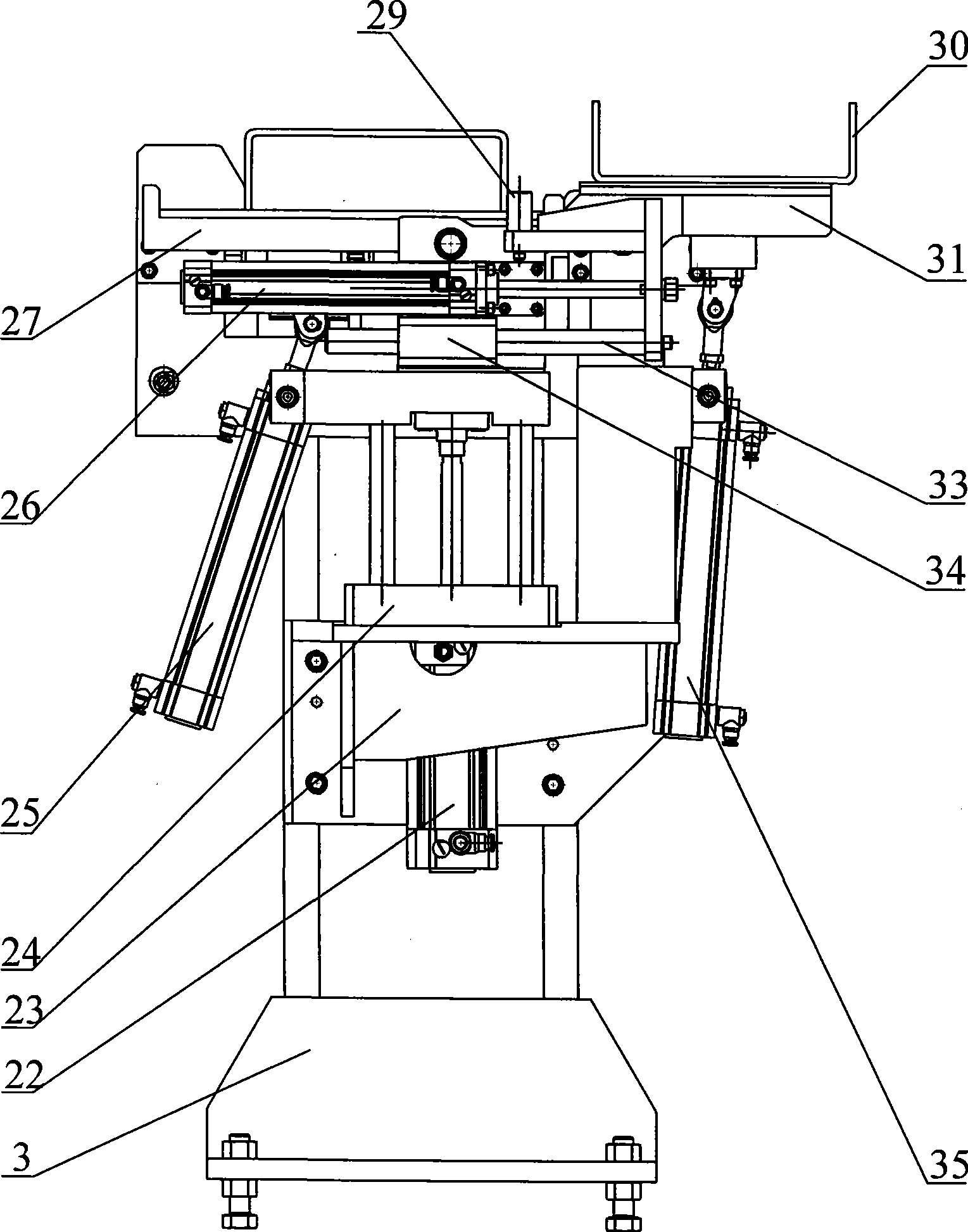

Punching device for electric wire threading slot punching

ActiveCN104889231AMeet punching requirementsRealize up and down adjustmentShaping toolsPerforating toolsPunchingEngineering

The invention discloses a punching device for electric wire threading slot punching. The punching device for electric wire threading slot punching comprises a rack, wherein an oil cylinder connecting bottom plate is fixedly arranged on the bedplate of the rack, a connecting strut is fixedly arranged on the top surface of the oil cylinder connecting bottom plate, an upper connecting plate is fixedly arranged at the upper end of the connecting strut, and a punching oil cylinder is fixedly arranged on the upper connecting plate; waste box adjusting motors are respectively fixedly arranged and vertical adjusting screws are hinged on the two sides plates of the rack, a waste box supporting plate is in threaded connection in the two vertical adjusting screws, the waste box supporting plate is provided with a stepped through hole, a waste box is inserted into the stepped through hole, the outer wall of the top portion of the waste box is provided with a radially extending supporting edge, and the radially extending supporting edge is inserted into the insertion section of the upper portion of the stepped through hole. The punching device for electric wire threading slot punching has the advantages that a wire threading slot plate can be automatically punched, the upward and downward adjustment of the waste box can be realized through the waste box adjusting motors, the waste can be collected in a unified manner and automatically falls down to the ground, and the waste box does not need to be manually lifted for discharging.

Owner:JIYUAN POWER SUPPLY COMPANY OF STATE GRID HENAN ELECTRIC POWER

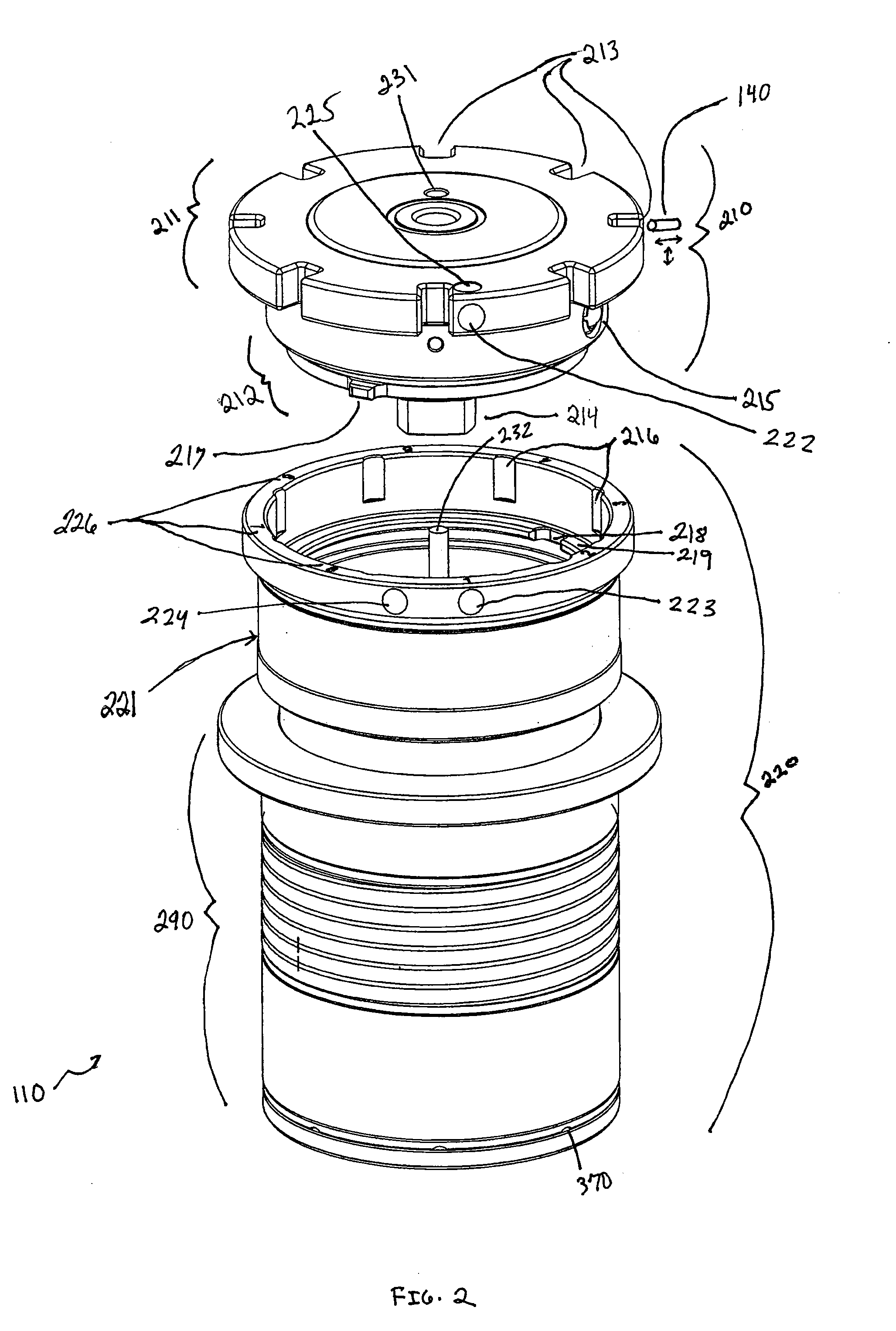

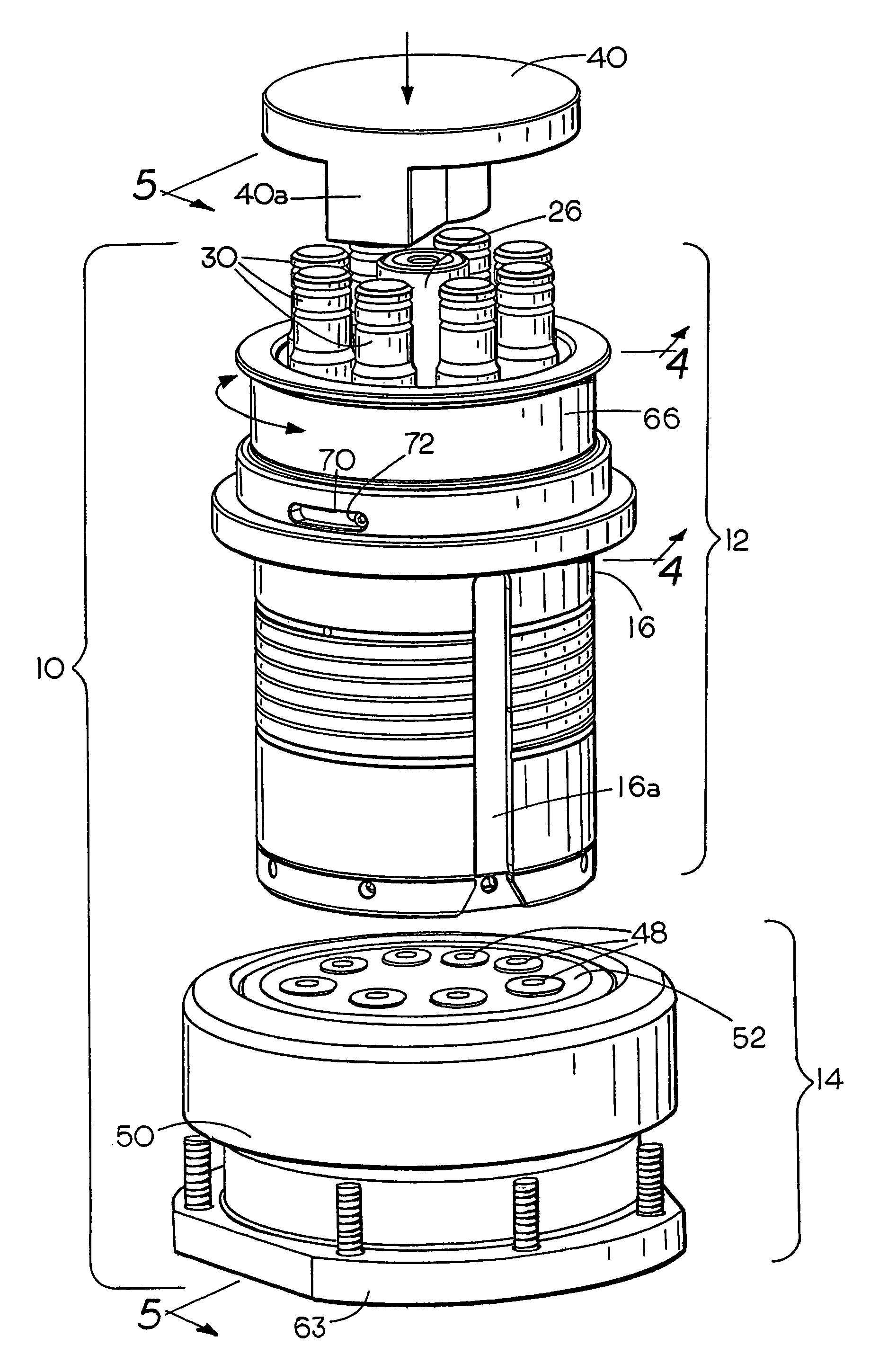

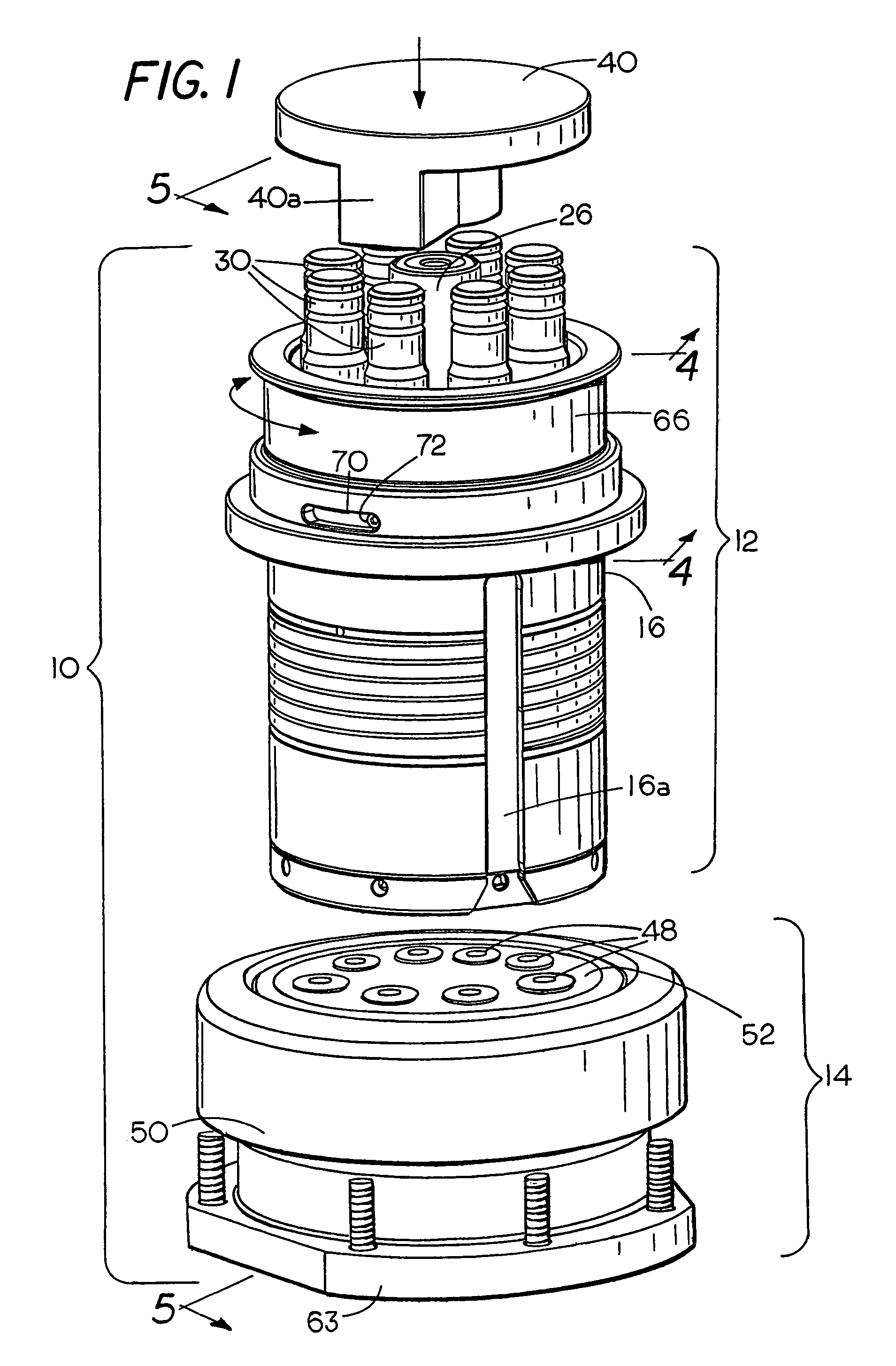

Ball-lock insert assemblies

The invention provides a ball-lock insert assembly adapted to be mounted axially in a mount opening formed in a holder plate having a desired thickness. The ball-lock insert assembly comprises an insert body having an axis and an elongated interior recess extending at an angle relative to this axis. The elongated interior recess is configured to house a resiliently-biased engagement member. The invention also provides retainer assemblies that include ball-lock assemblies, as well as methods of producing retainer assemblies, which methods include providing ball-lock assemblies.

Owner:WILSON TOOL INT

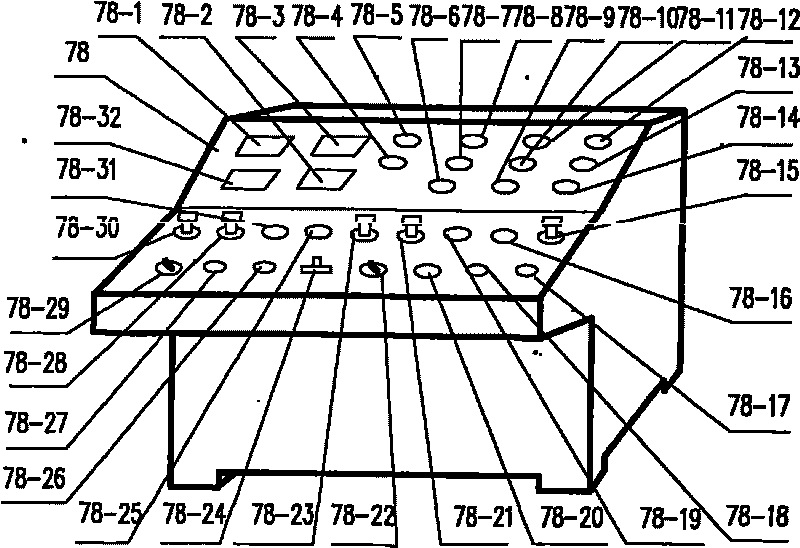

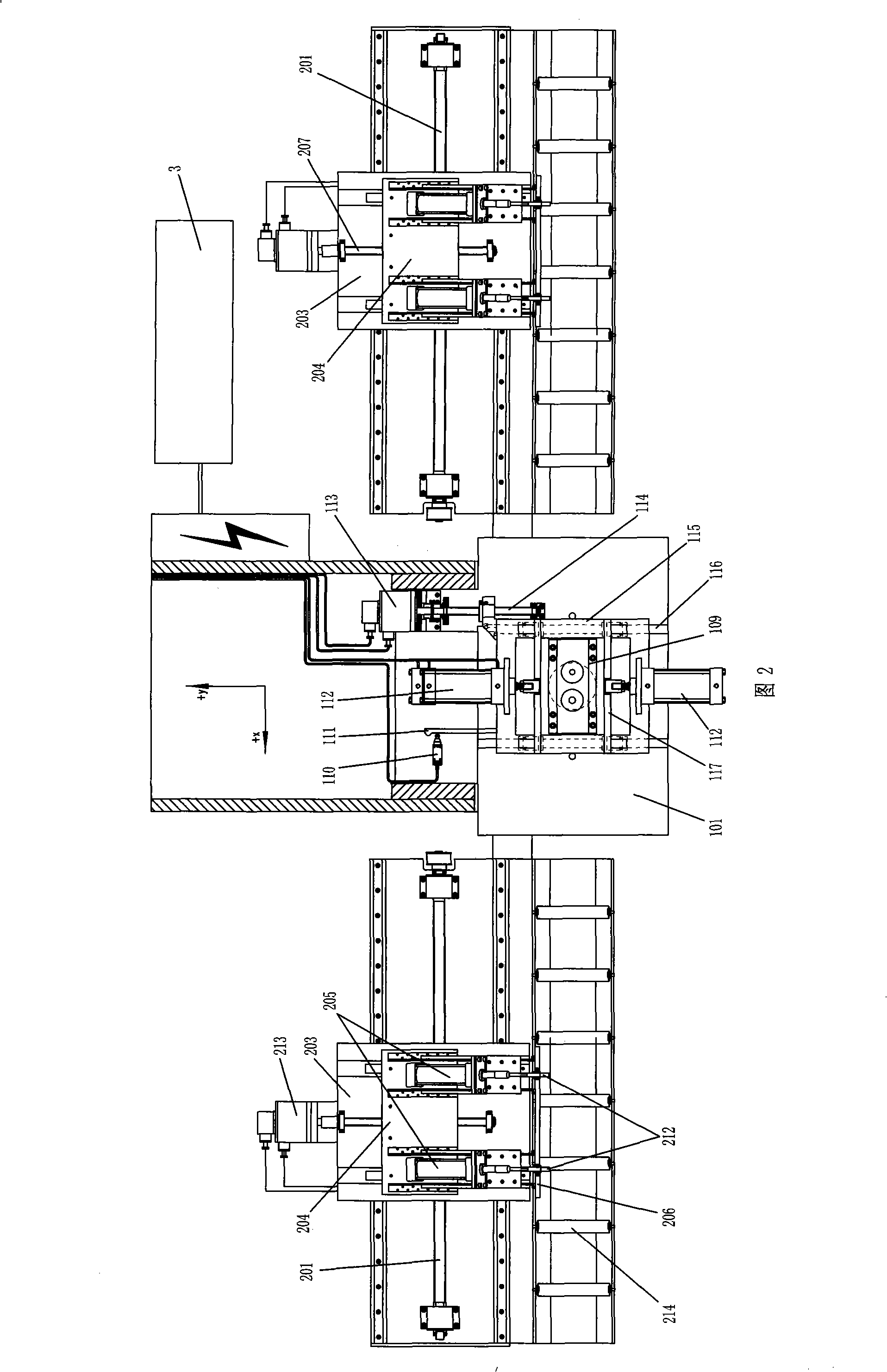

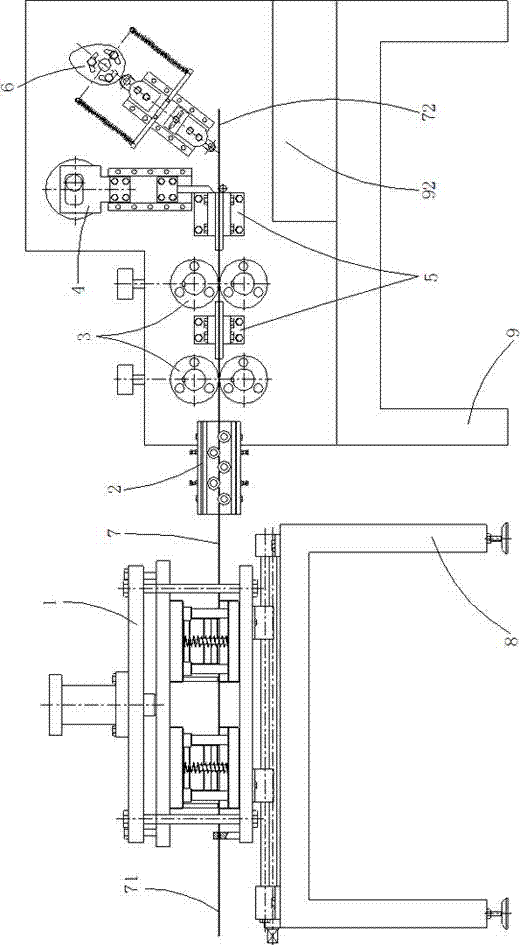

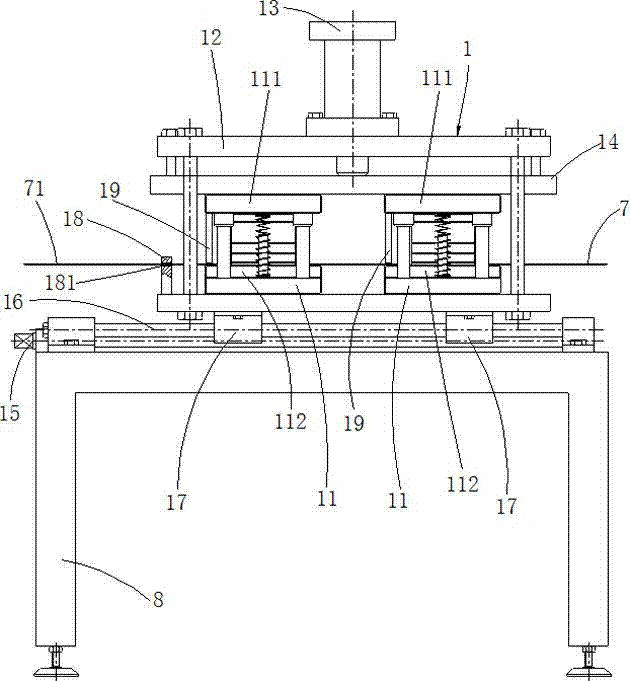

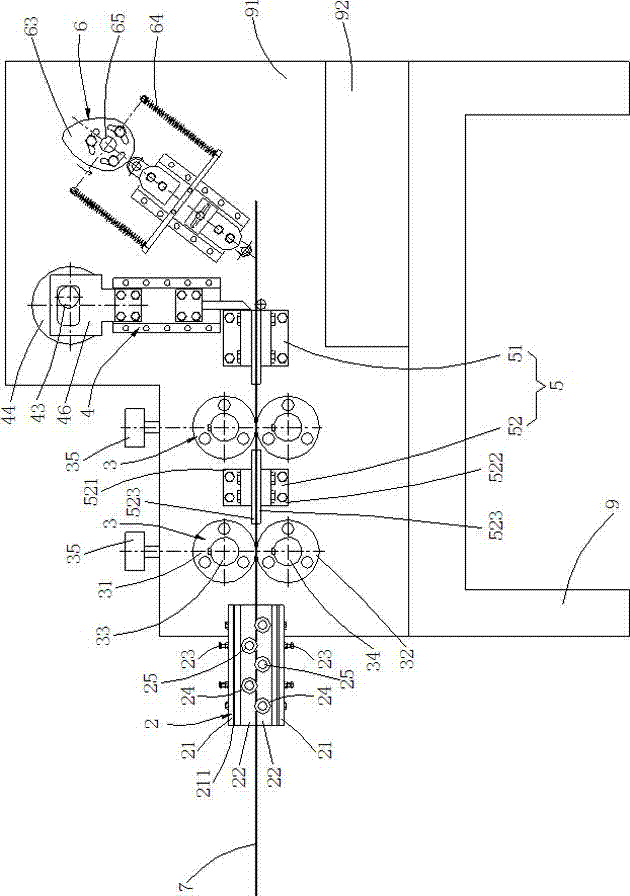

Angle steel eyelet work product line

InactiveCN101402118ARealize automatic clampingAchieve positioningPerforating toolsMetal-working feeding devicesProduction linePunching

The invention discloses a production line for punching angle iron. A transverse feed device and a transverse positioning device are used to realize the feed displacement and the positioning of an angle iron work piece along the transverse direction(the X axis); a vertical feed device, a vertical displacement device and a vertical positioning device which are matched with each other are used to realize the displacement and the positioning of the angle iron work piece along the vertical direction(the Y axis); and in the whole process of punching, after the angle iron work piece is put on the production line for punching, the clipping, feed, displacement, accurate positioning and punching are automatically realized, thereby not only realizing the automatic accurate positioning and continuous punching on any position of a punching face of the angle iron along the X and the Y axes, but also greatly improving the punching accuracy, production efficiency and processing stability and reliability.

Owner:浙江博雷重型机床制造有限公司

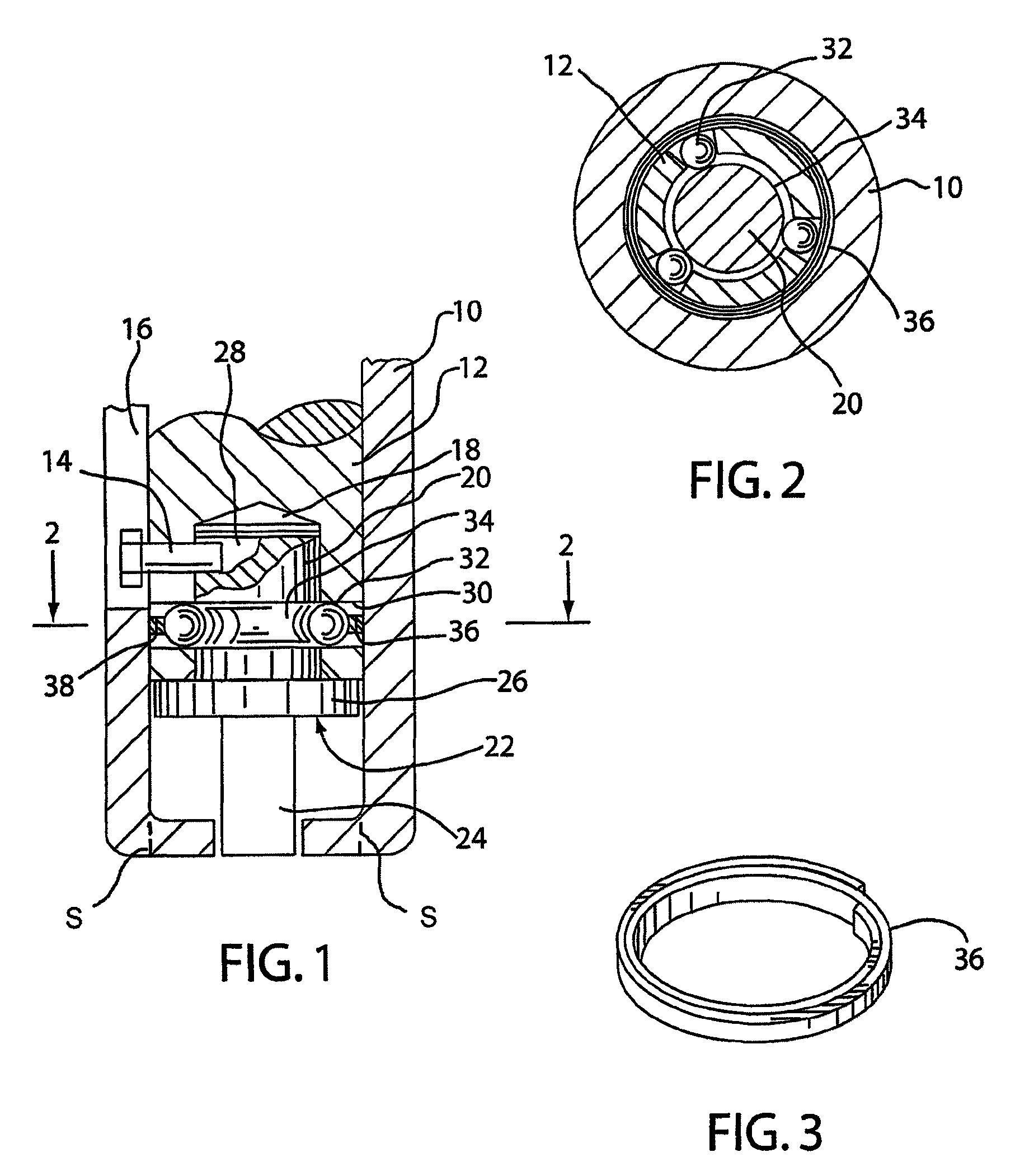

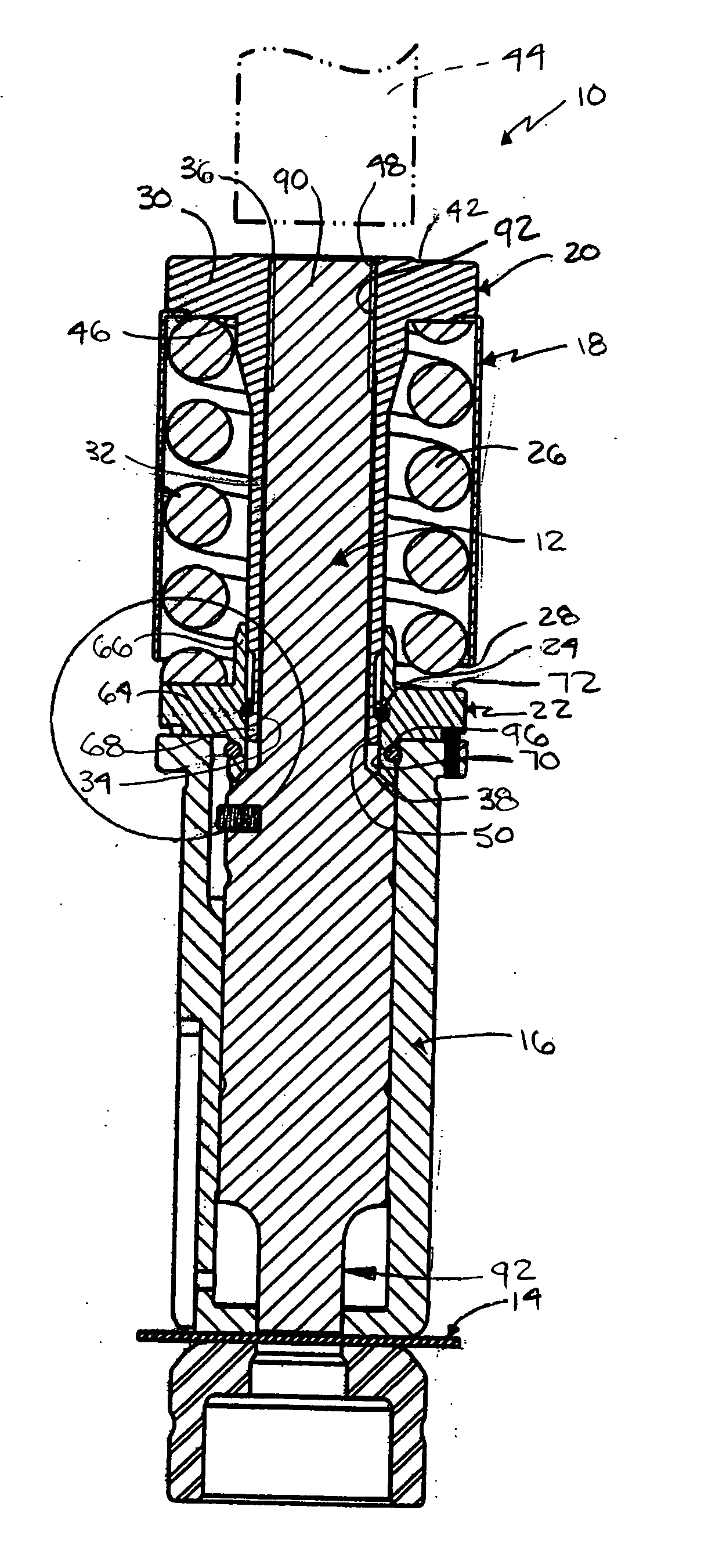

Biasing assembly for a punching device

ActiveUS20060060046A1Easy to adjustMinimal numberPerforating toolsStripping-off devicesPunchingEngineering

A biasing assembly for a punching device that includes a punch support member adapted to support a punch and including a head portion and a main portion extending from the head portion. The main portion has a recessed surface. A retaining member is coupled to the punch support member with the punch support member being slidable with respect to the retaining member. A coupling member is disposed between the main portion of the punch support member and the retaining member. A portion of the coupling member engages the recessed surface. A biasing member is supported between the head portion of the punch support member and the retaining member. The punch support member is movable between at least first and second positions with respect to the coupling member.

Owner:AMADA TOOL AMERICA

Automatic punching machine for steel strip

ActiveCN102825429ARealize continuous productionIncrease productivityPerforating toolsShearing machinesPunchingEngineering

The invention relates to an automatic punching machine for a steel strip; the automatic punching machine comprises a punching device, a shaping device, a driving device, a cutting device and a bending device; the punching device is arranged close to a steel strip feeding end; the bending device is arranged on a steel strip discharging end; the shaping device is arranged between the punching device and the driving device; the cutting device is arranged between the driving device and the bending device. The automatic punching machine further comprises a machine frame and a machine case; the punching device is fixed on the upper part of the machine frame; the shaping device, the driving device, the cutting device and the bending device are respectively fixed on the same side of the machine case. The automatic punching machine can automatically finish punching, bending and cutting processes of the steel strip, and also can realize continuous production, therefore, production efficiency is enhanced, and production cost is reduced.

Owner:浙江科朗汽车配件有限公司

Quick change assembly for hydroforming punches

InactiveUS7159426B1Good opening qualityReduce downtimePerforating toolsVehicle componentsEngineeringHydroforming

A punch assembly used with a hydroforming die includes a punch cylinder for mounting to the hydroforming die and having a movable rod. The punch assembly also includes a punch for piercing an opening in a tubular member disposed in the hydroforming die. The punch assembly further includes a quick change assembly interconnecting the rod of the punch cylinder and the punch for allowing the punch to be removably attached to the punch cylinder.

Owner:GM GLOBAL TECH OPERATIONS LLC

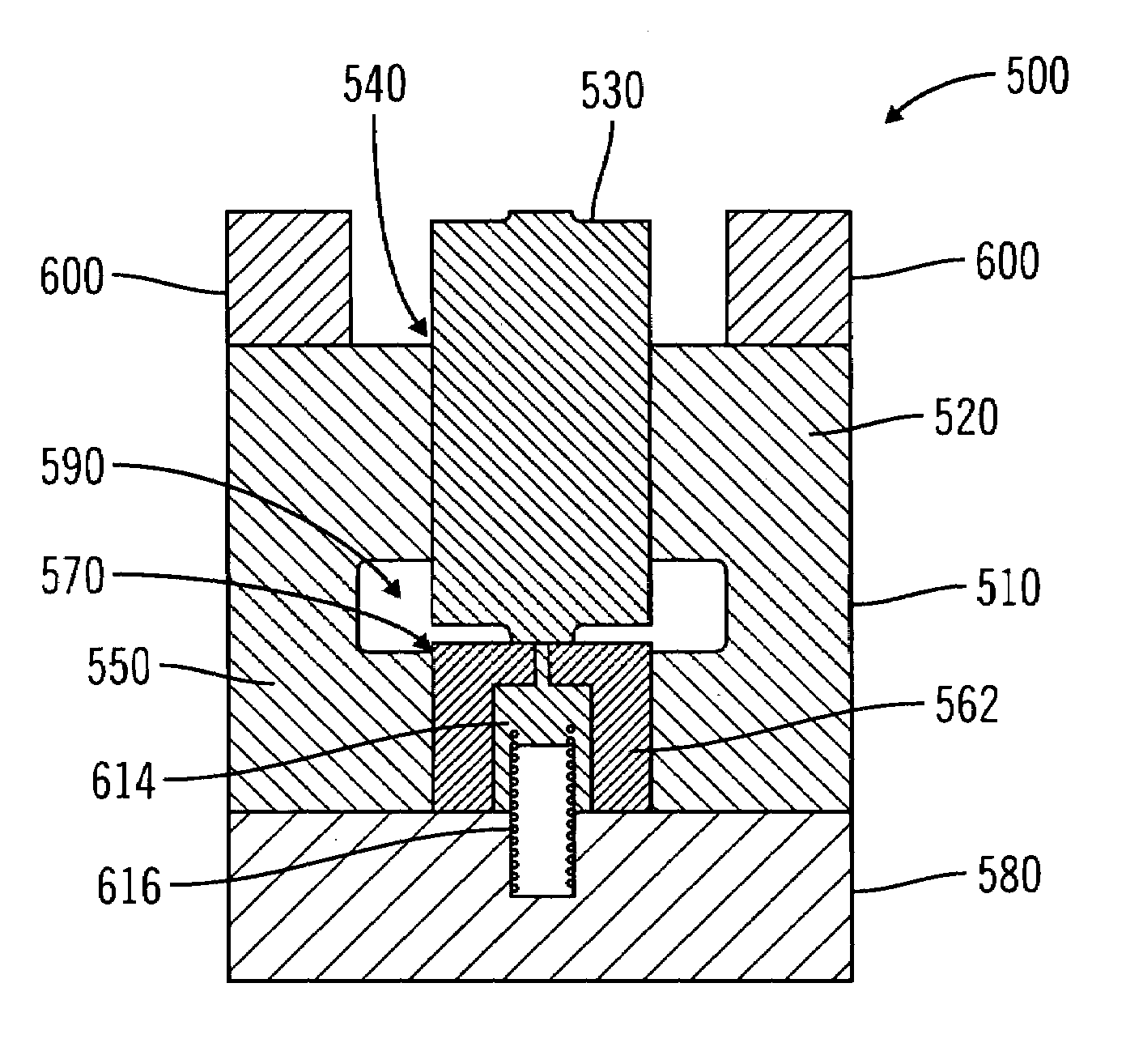

Process of forming bend-controlling structures in a sheet of material, the resulting sheet and die sets therefor

InactiveUS7222511B2Achieved economicallyBig advantageShaping toolsPerforating toolsEngineeringMirror image

A process of forming bend-controlling structures, such as slits, grooves or displacements (22), in a sheet of material (21, 121, 221, 321, 421, 521, 621, 721). The bend-controlling structures (22) have central portions (26) extending substantially parallel to a desired bend line (23) on the sheet and end portions (27) which diverge away from the bend line (23). In one embodiment the process includes the step of forming the bending straps (24) between pairs of slit end portions (27) at a desired spaced apart distances along the bend line (23) with the straps (24) having a desired configuration, and the step of forming central portions (26) which connect the end portions (27) to complete the slits (22) using a separate die set. A plurality of end portion dies (51 / 54) can be used to produce end portions (27) of various shapes and straps (24) of various widths, and a single set of central portion forming dies (71 / 74) are used to connect the end portions (27). In other embodiments die sets producing a single end portion (27) or mirror image impressions (A,B) are used and preferably overlapped to produce the complete bend-controlling structure (22). A modular die assembly (500) also is disclosed in which the bend-controlling structures can be produced by modular die inserts (511-514, 611-614). Finally, a selection of die sets (722a, 722b, 722c) of differing length from a group of die sets can be made to position the bending straps (24) at desired locations along the bend line.

Owner:IND ORIGAMI INC CA US

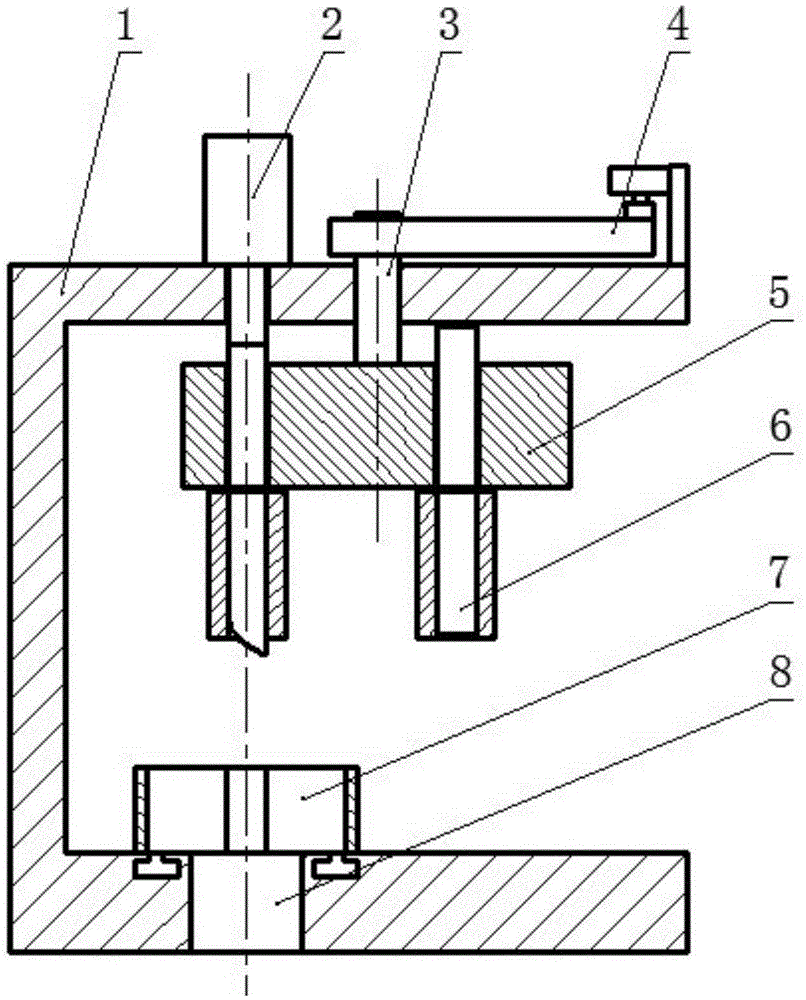

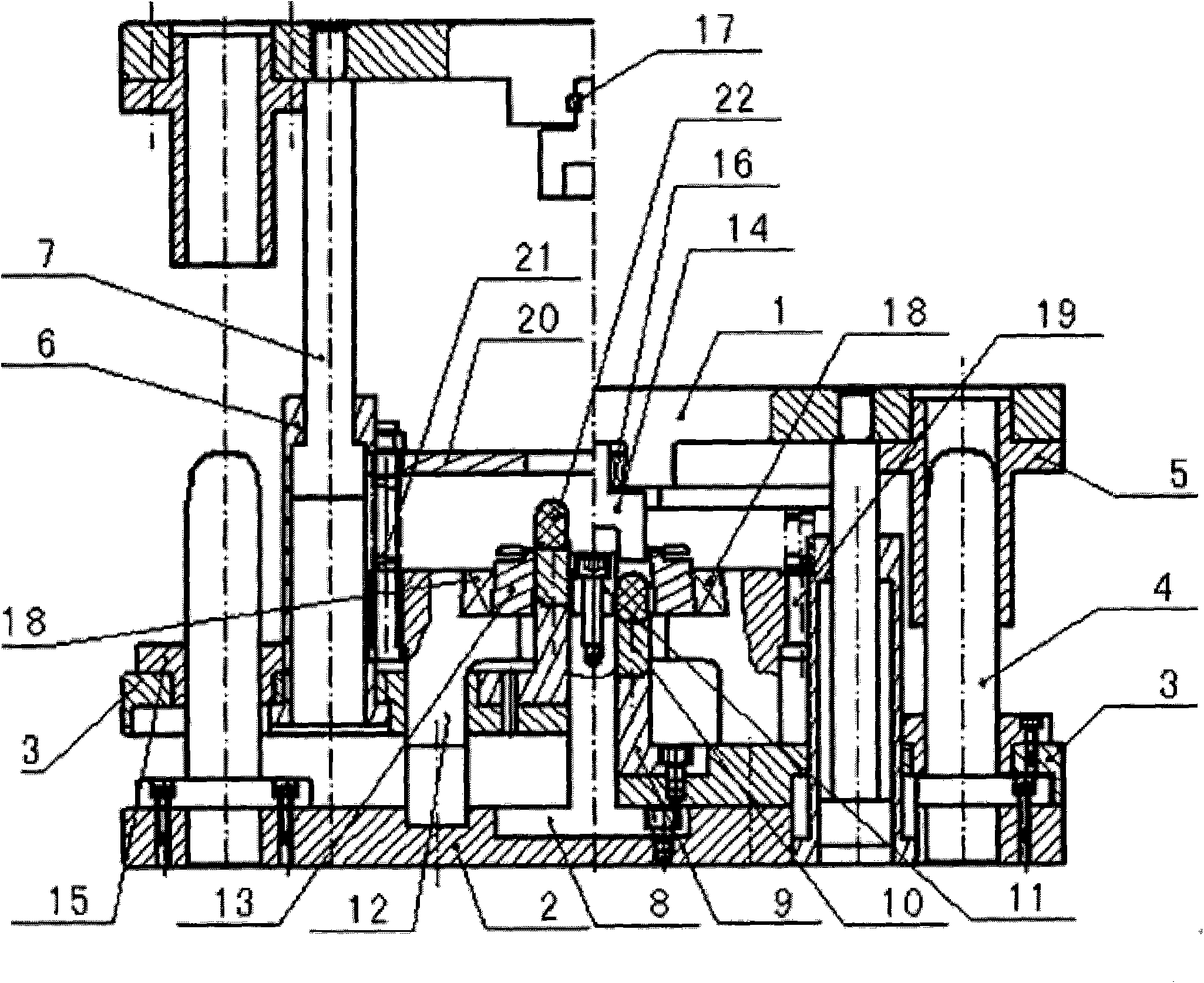

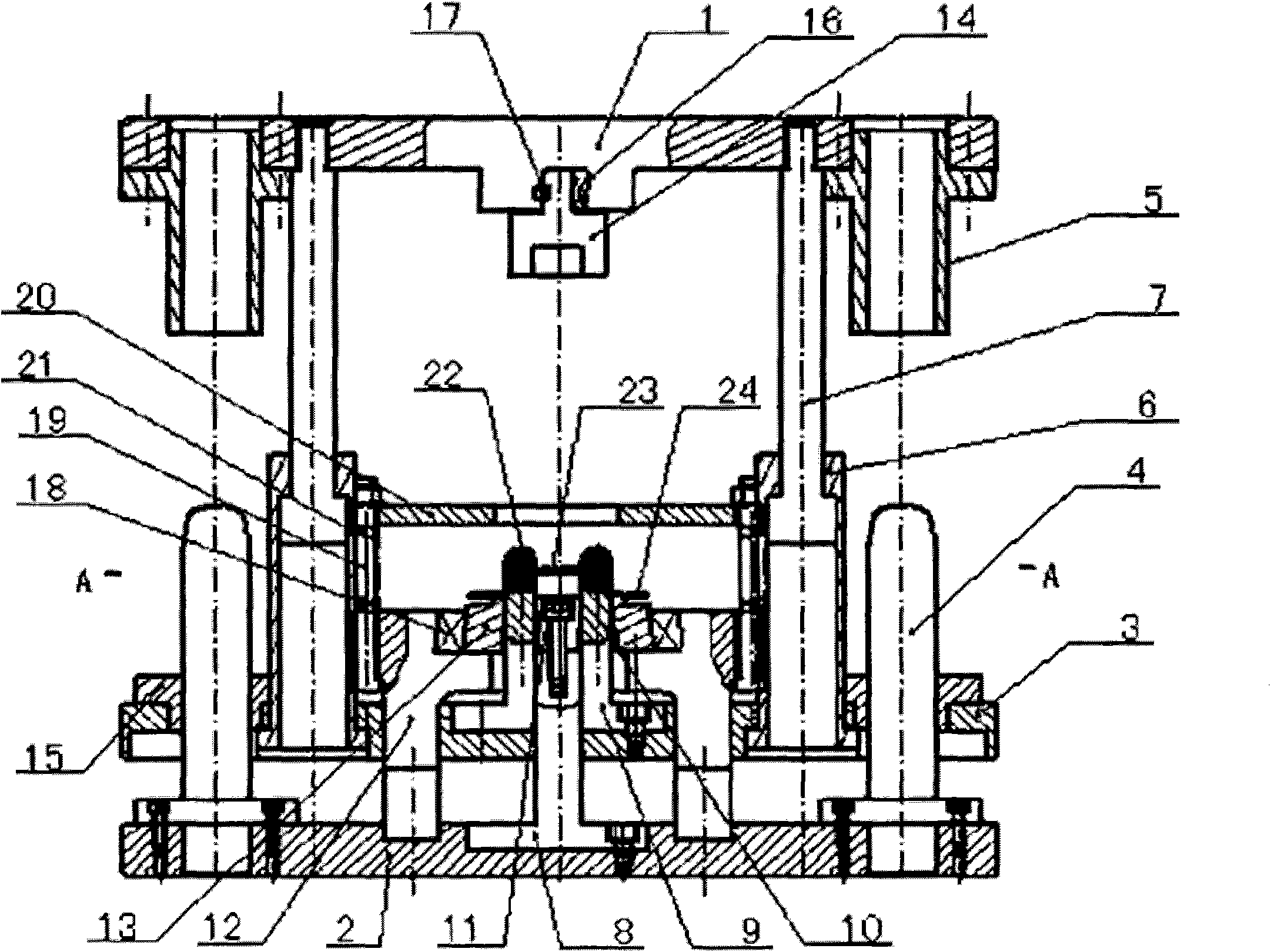

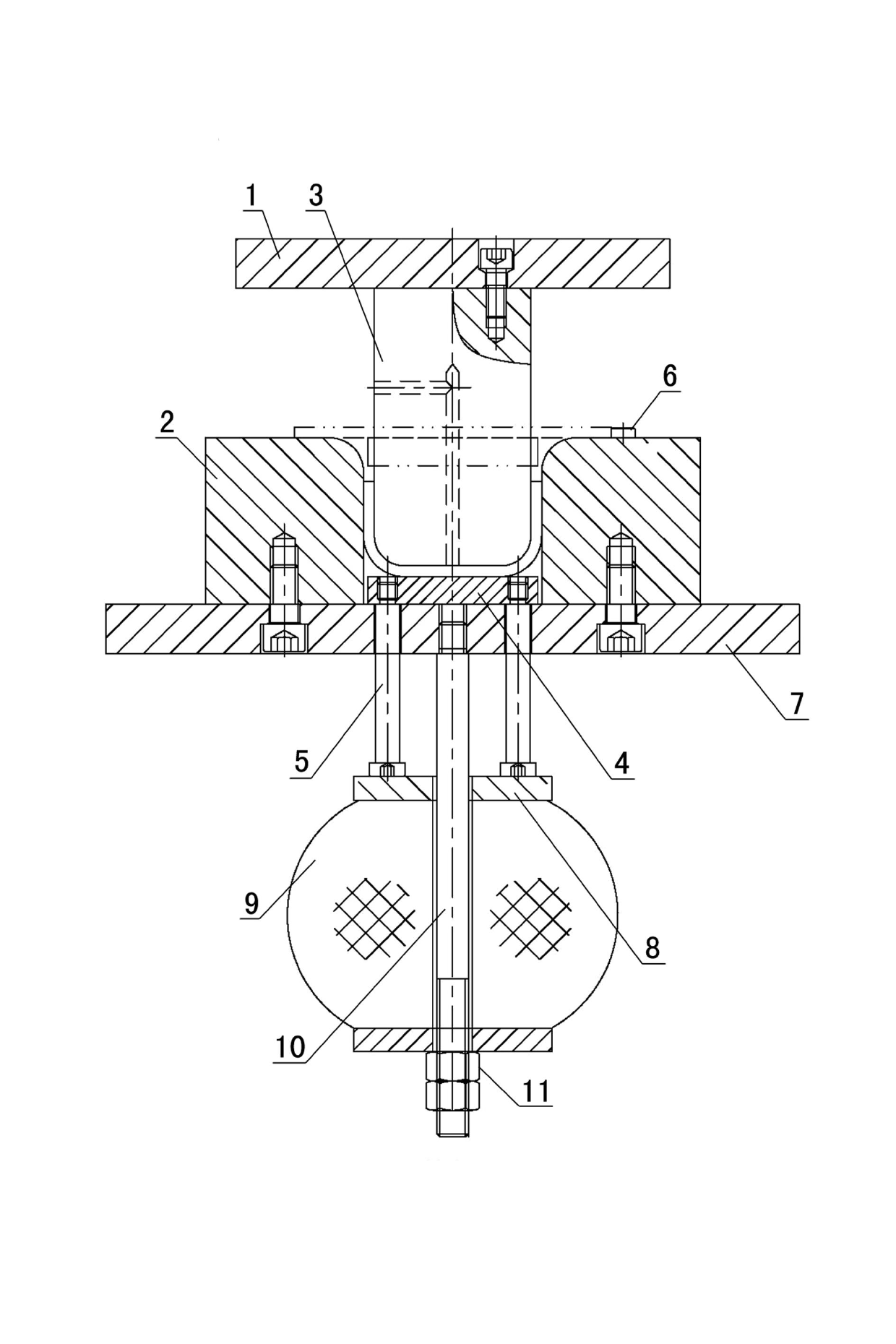

Ring forge piece punching and cutting composite type mould

ActiveCN102029323ACompact structureReasonable structureShaping toolsPerforating toolsPunchingEngineering

The invention relates to a ring forge piece punching and cutting composite type mould which is used on a mechanical press, in particular to the ring forge piece punching and cutting composite type mould. In the conventional mechanical manufacturing industry, inner hole punching and outer edge cutting in a forging and forming process of a forging ring of a transmission chain are performed in two steps, the production efficiency is low and the cost is high. The mould consists of an upper mould, an ejector, a lower mould and a material returning and outer burr removing part, wherein an upper mould plate is provided with a guide sleeve, connecting rods and an edge cutting punch head; a lower mould plate is provided with guide posts, an edge cutting female die seat, an edge cutting female die, a punching punch head seat and a punching punch head; a movable plate is provided with a connecting sleeve, an ejector seat and an ejector head and positioned and guided by two guide posts and the guide sleeve; and four connecting rods drive the connecting sleeve, the movable plate and the ejector part to rise so as to eject a finished punched workpiece. The composite mould is matched with a guide post guide sleeve structure, so accurate positioning of the upper mould, the lower mould and the ejector part is realized, the dimensional accuracy of a product is guaranteed, and the mould is suitable for simultaneous edge cutting and punching of a ring forge piece.

Owner:CHINA COAL ZHANGJIAKOU COAL MINING MACHINERY

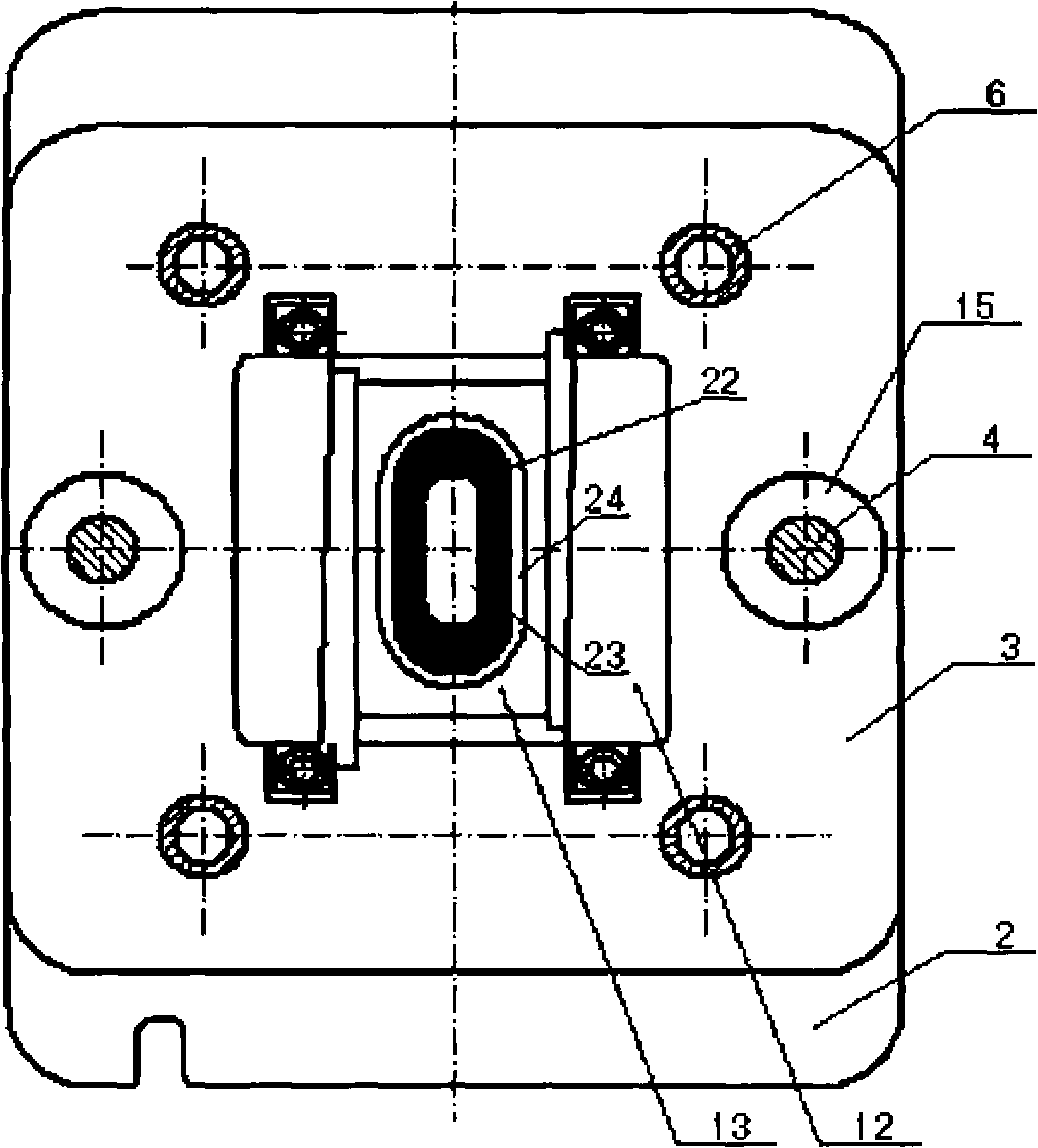

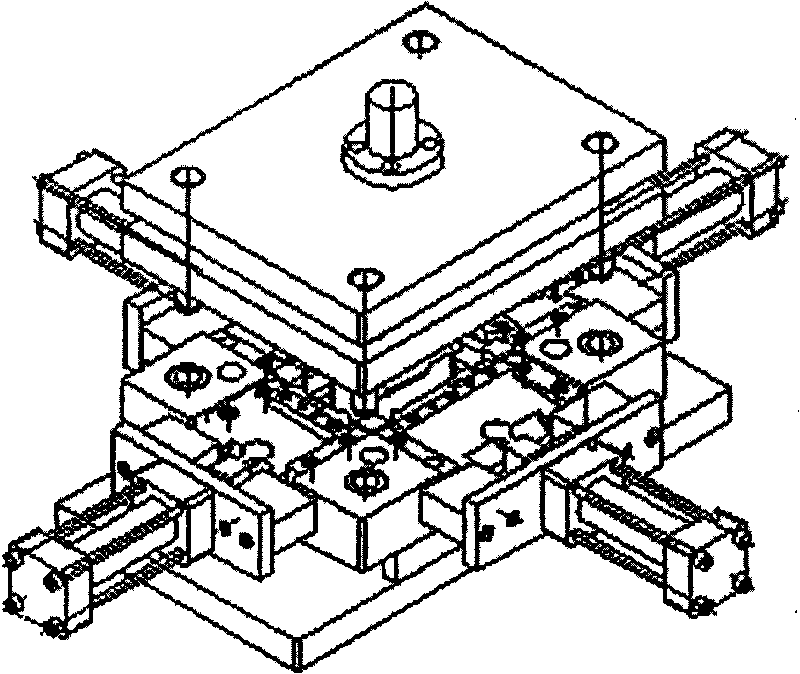

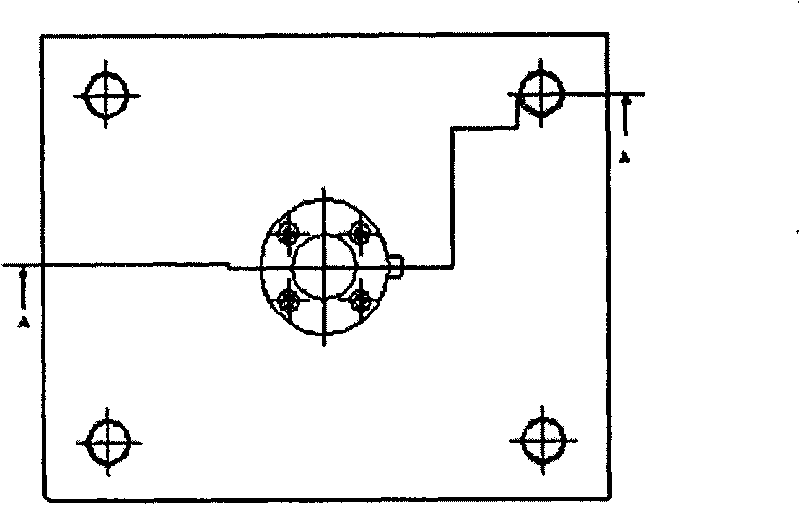

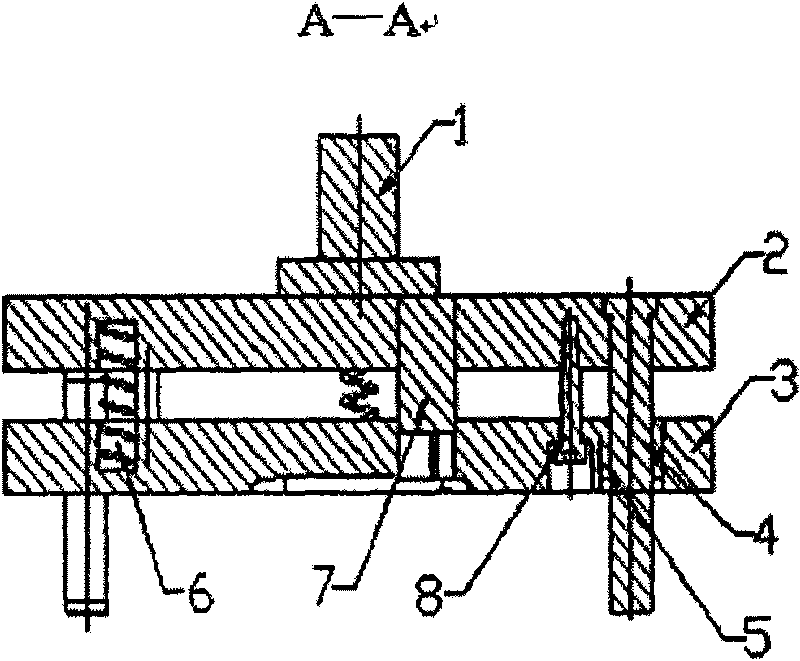

Multi-direction step-by-step tridimensional punching method of IML products and punching mould thereof

InactiveCN101698215AQuality assuranceGuaranteed stabilityShaping toolsPerforating toolsPunchingEngineering

The invention relates to a multi-direction step-by-step tridimensional punching method of IML products and a punching mould thereof, which is characterized in that a punching mould combing a direct punching mould and a lateral punching mould is adopted to dimensionally punch the cavern shapes and edge contours of IML product located on different surfaces step by step; the punching mould comprises an upper mould which comprises a punch (straight punching head) and a lower mould which comprises a die and air cylinder side cut assemblies; the punch of the upper mould and the die of the lower mould form a straight punching mode; the side wall of the die and four groups of air cylinder side cut assemblies of the lower mould form a side punching mode; a multidirectional step-by-step dimensional method is adopted to decompose the punching of the IML product with complex structure and shape into one-step punching with simpler shape, the power of one-step punching of side faces is provided by a straight air cylinder, thereby ensuring the quality and stability of quenching; in addition, the punching method has simple operation and accurate production orientation, the qualification rate can be above 90%, therefore, the method is applicable to large-scale batch production.

Owner:TIANJIN ZHONGHUAN HI TECH

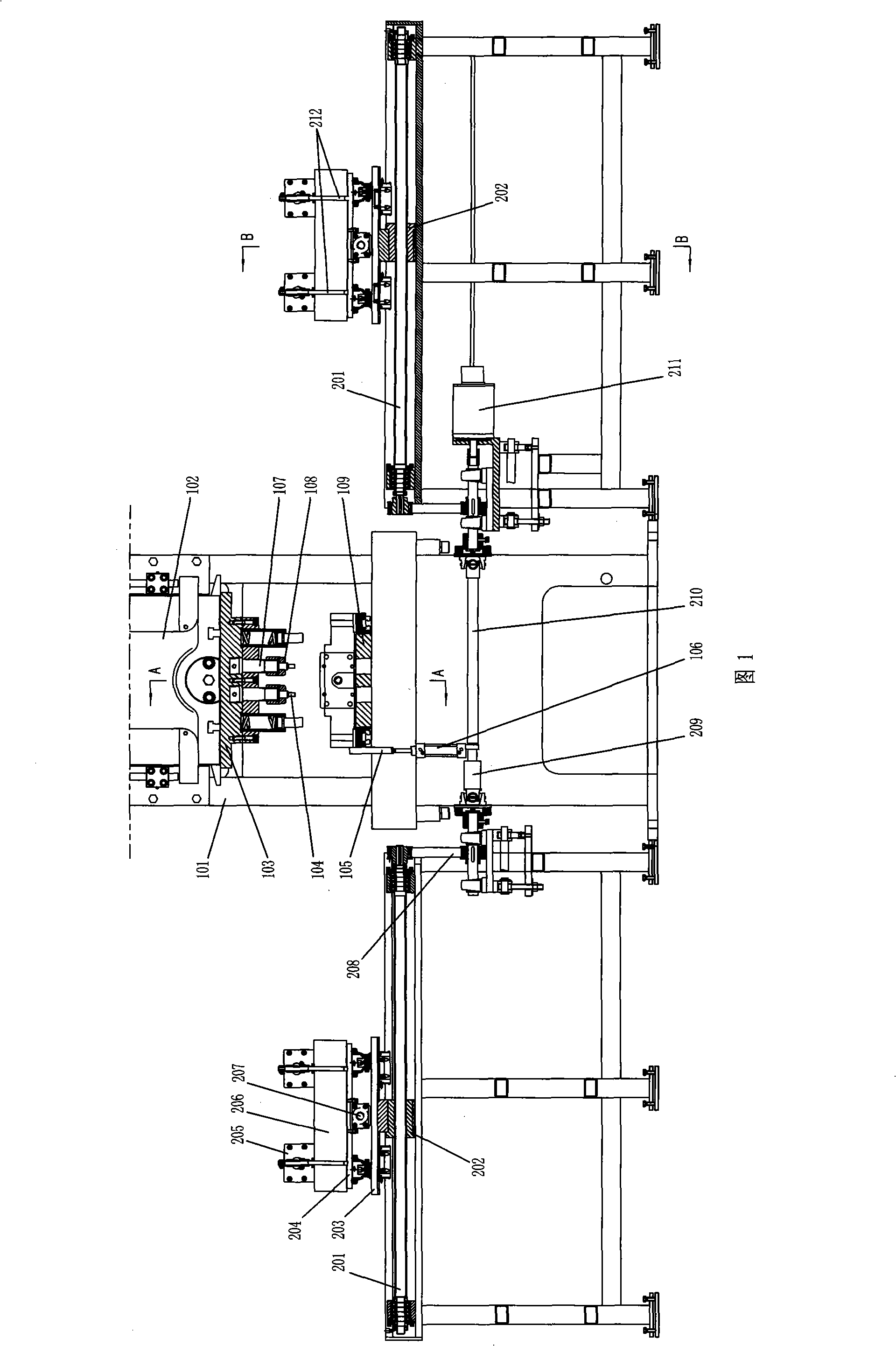

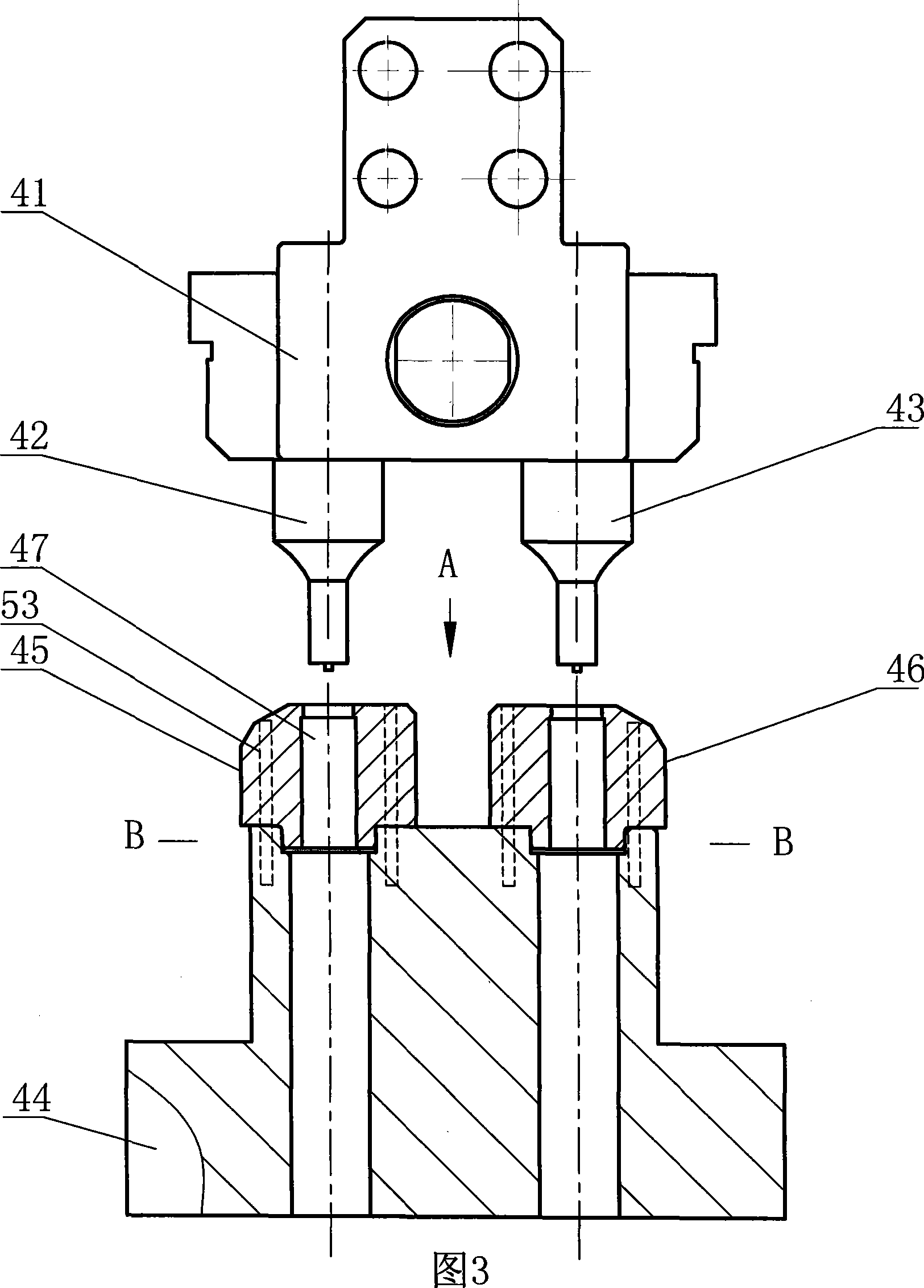

U shaped beam three-face punching technique and production device using the technique

InactiveCN101386046AThe punching position is accurateReduce manufacturing costShaping toolsPerforating toolsShaped beamPunching

The invention discloses a three-side-punch process of a U-shaped beam and a production device used in the process. The process comprises the following steps: the U-shaped beams are placed on a feeding platform, a feed picking device is adopted to successively pick up the spare U-shaped beams and hoist the beams to a support roller of the feeding end; a first feeding clamping device is adopted to clamp the U-shaped webs and feed the webs to working platforms of a ventral small punching machine which can move along the X / Y axis and a ventral large punching machine which can move along the Y axis; the ventral small punching machine which can move along the X / Y axis and the ventral large punching machine which can move along the Y axis punch the beams; a second feeding clamping device clamps the U-shaped beams and continuously feed the beams to the working platform of a left wing punching machine and a right wing punching machine; the left wing punching machine and the right wing punching machine punch the beams; the U-shaped beams are hoisted to a discharging platform after being fully punched. The invention has the advantages of simple process, high production efficiency, low cost and reasonable process arrangement; and the produced U-shaped beams have precise punching location.

Owner:JINAN CASTING FORGING MACHINERY INST

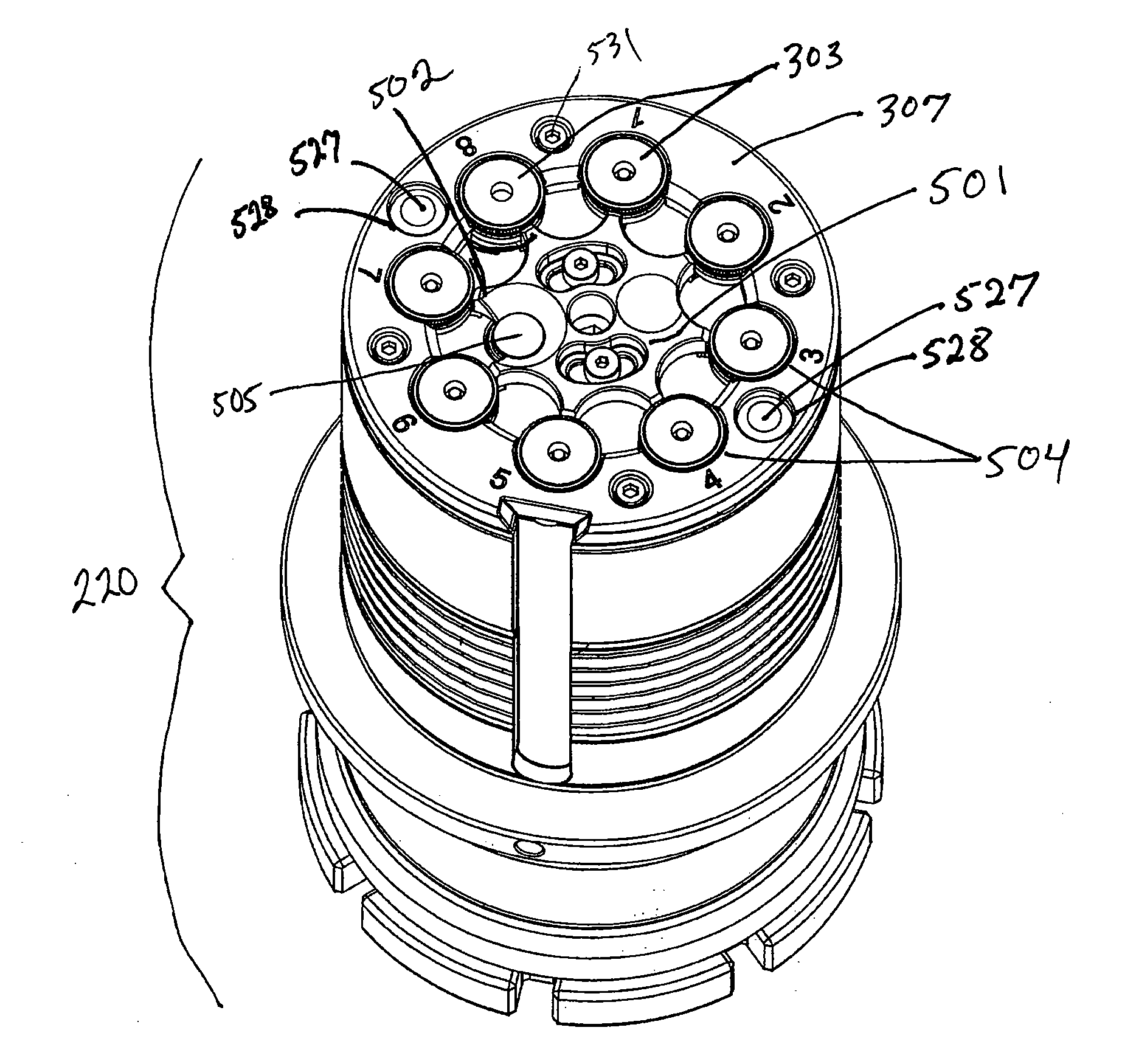

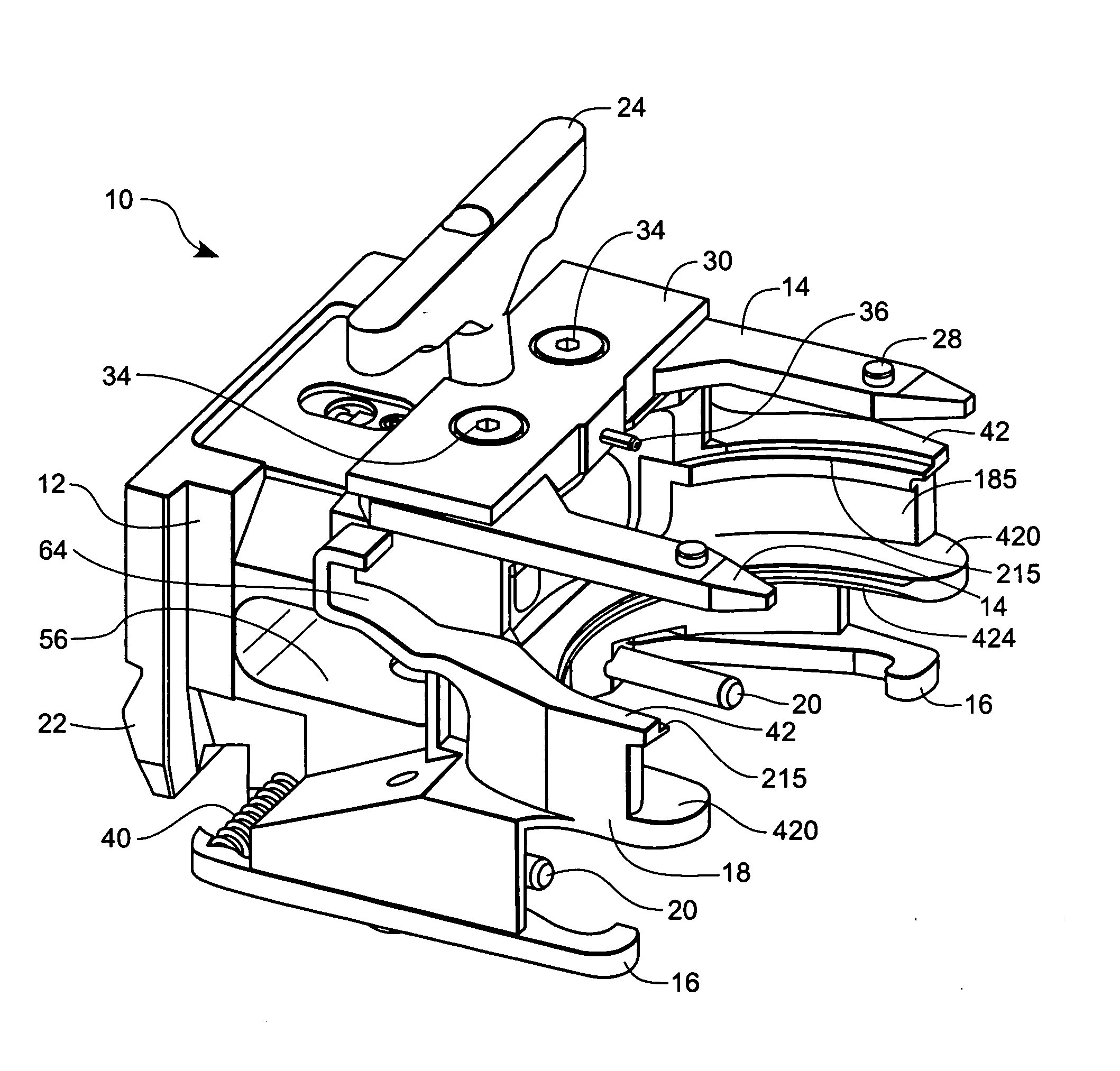

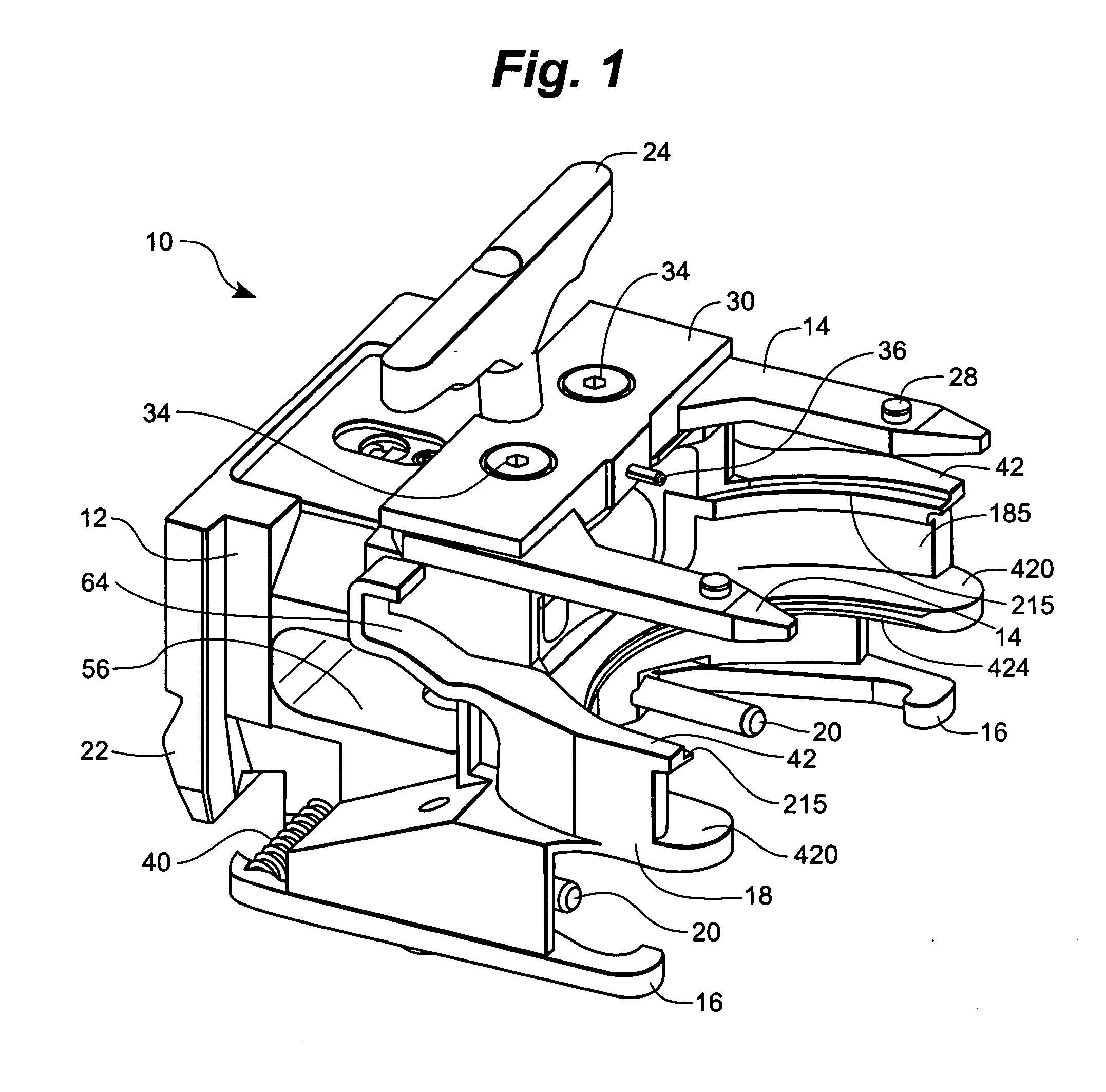

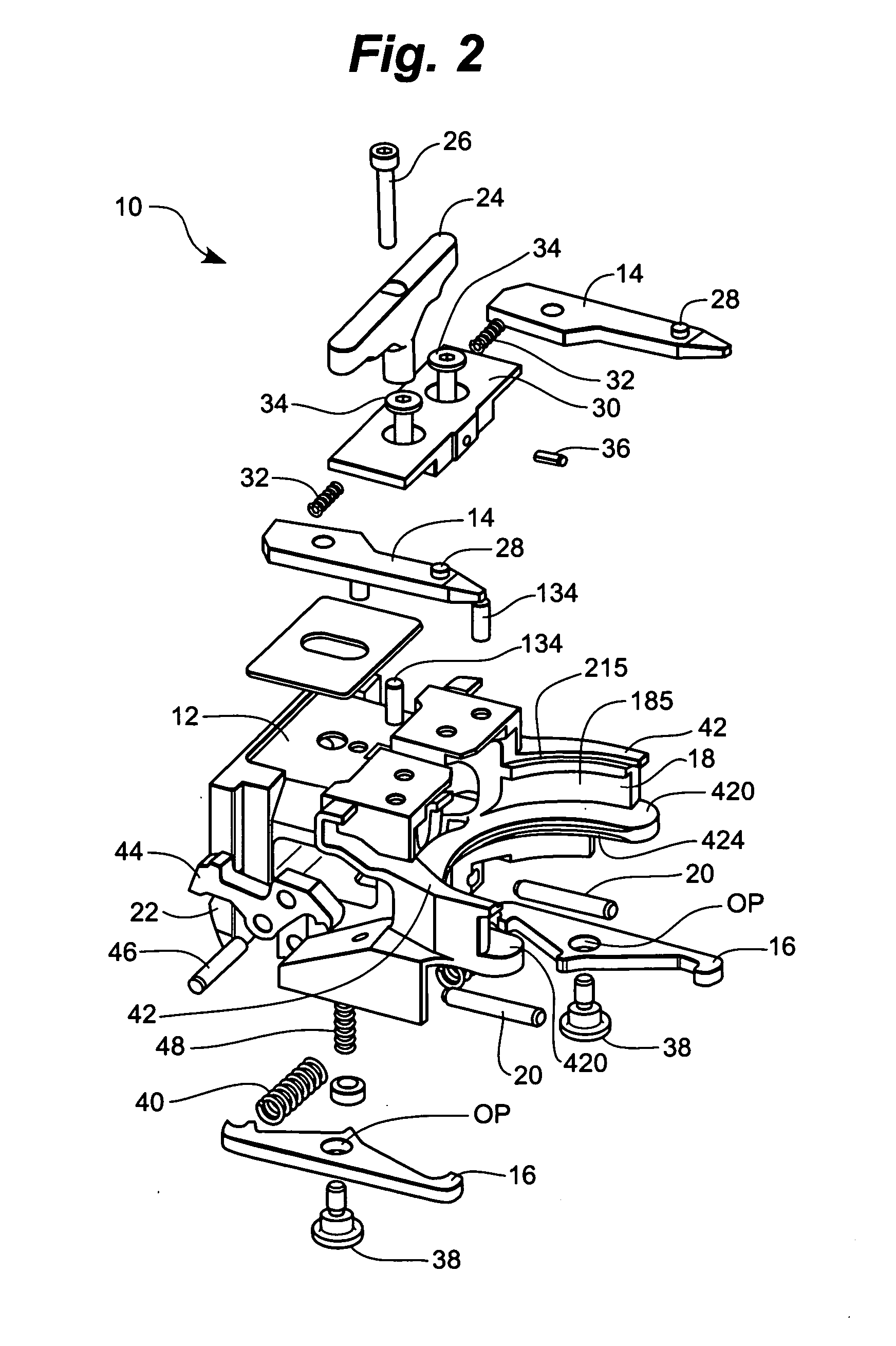

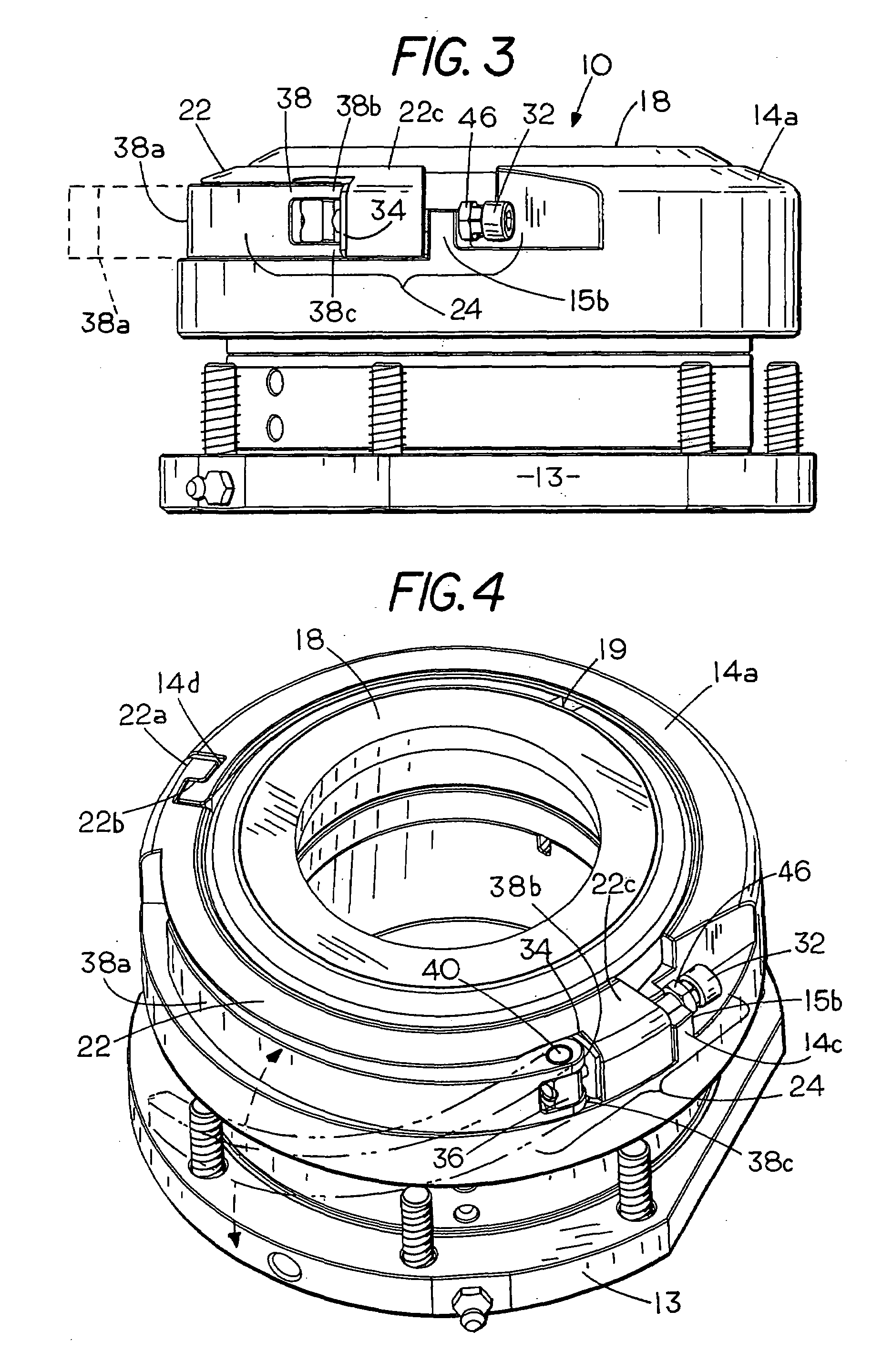

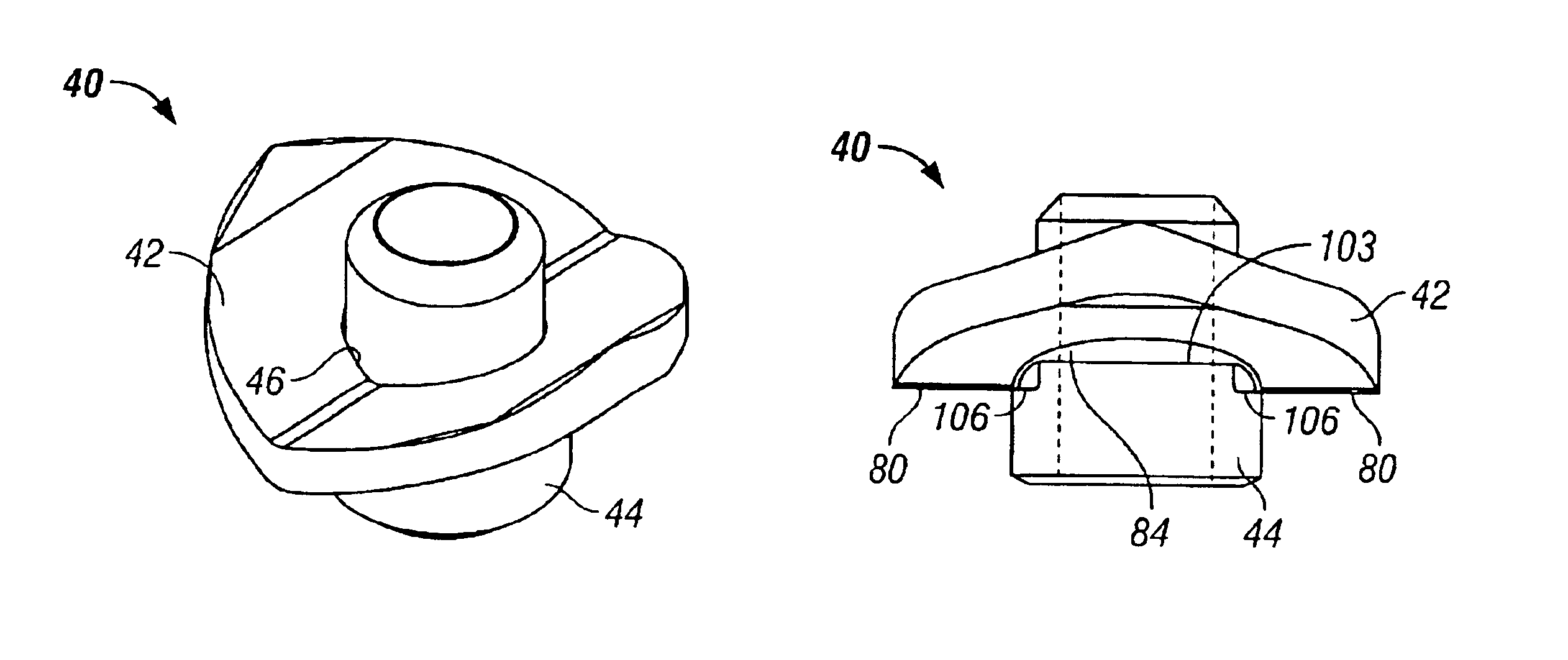

Multiple Punch and Die Assembly

ActiveUS20110107888A1Prevent movementAutomatic/semiautomatic turning machinesShaping toolsIndependent motionPunch press

A multiple punch and die assembly adapted to be placed in a punch press having a punch ram for imparting movement to a selected punch assembly for carrying out a punching or forming operation comprises a punch assembly for holding a plurality of selectively operable punches mounted for independent movement in the punch assembly so as to selectively engage a workpiece. The punch assembly has a punch carrier for reciprocal motion within a punch guide and a striker body engaging the punch carrier, said striker body being selectively, toollessly connectable to the punch carrier by a pair of tabs located on a lower circumference of the striker body, said pair of tabs located on a lower circumference of the striker body with a radial separation other than 180 degrees. A circumferential lip in the punch carrier receives the pair of tabs and has corresponding radially separated reliefs for allowing the pair of tabs to pass the circumferential lip, the engagement of the pair of tabs by the circumferential lip thereby locking the striker body to the punch carrier while permitting relative rotation of the striker body and punch carrier to select a punch for engagement by the striker. A detent means releasably positions the striker body in one of a plurality of operating positions, at which a punch is positioned for being struck selectively by the ram via the striker body such that one punch is driven to an operating position when at least one other punch is in inactive. In another embodiment the assembly has a stripper retainer that has precision pockets for holding strippers corresponding to the selectively operable punches.

Owner:MATE PRECISION TECH INC

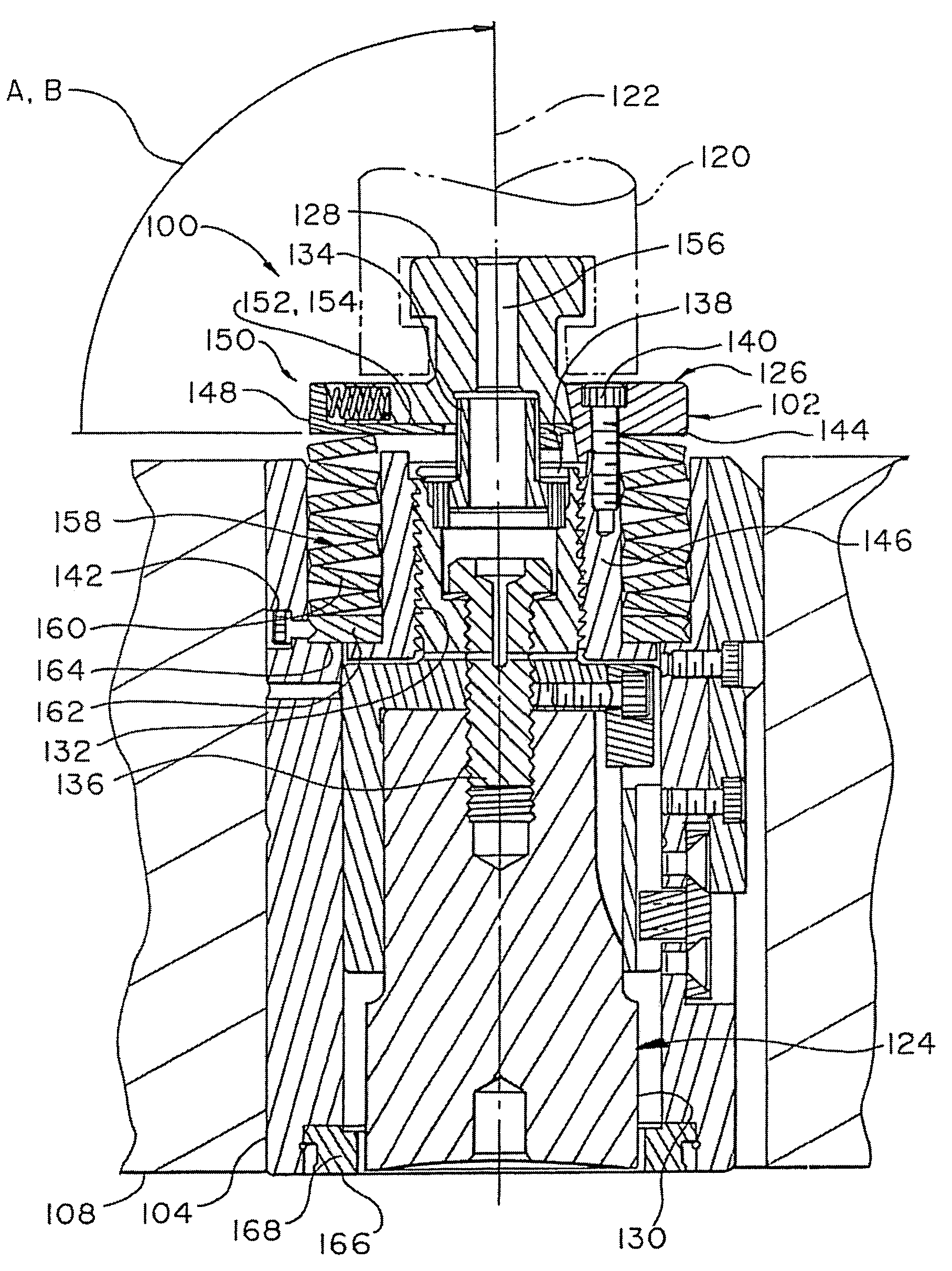

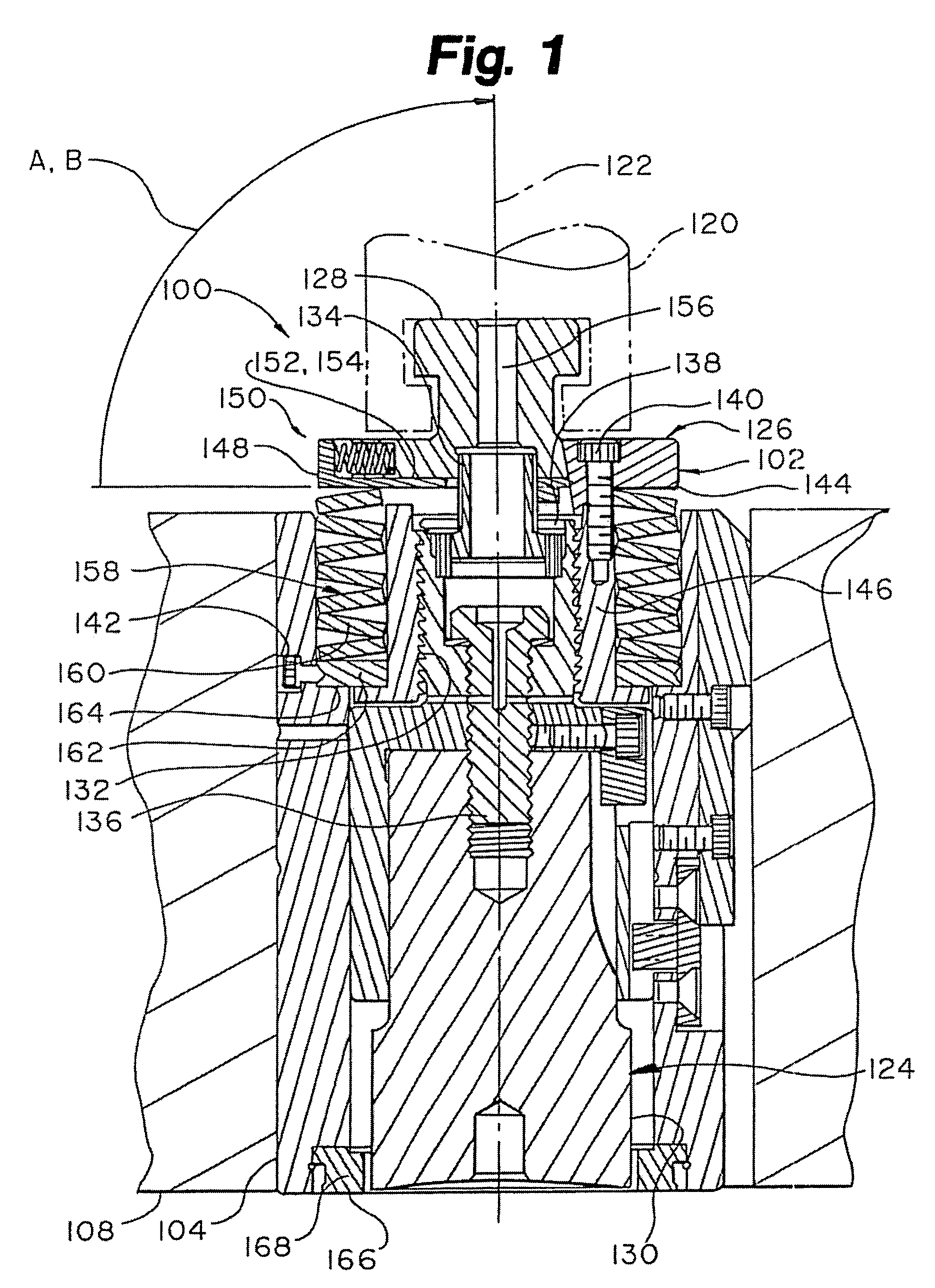

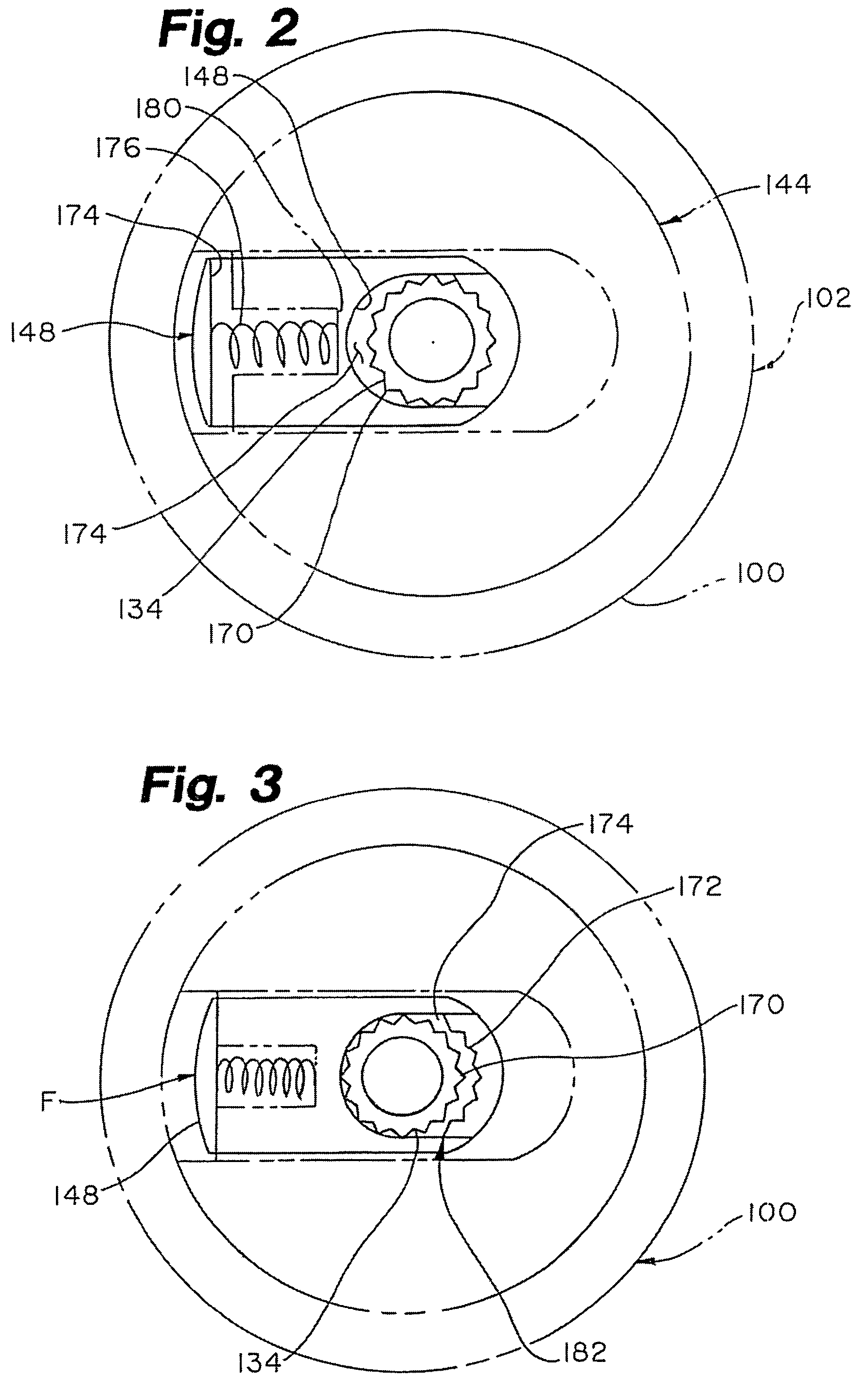

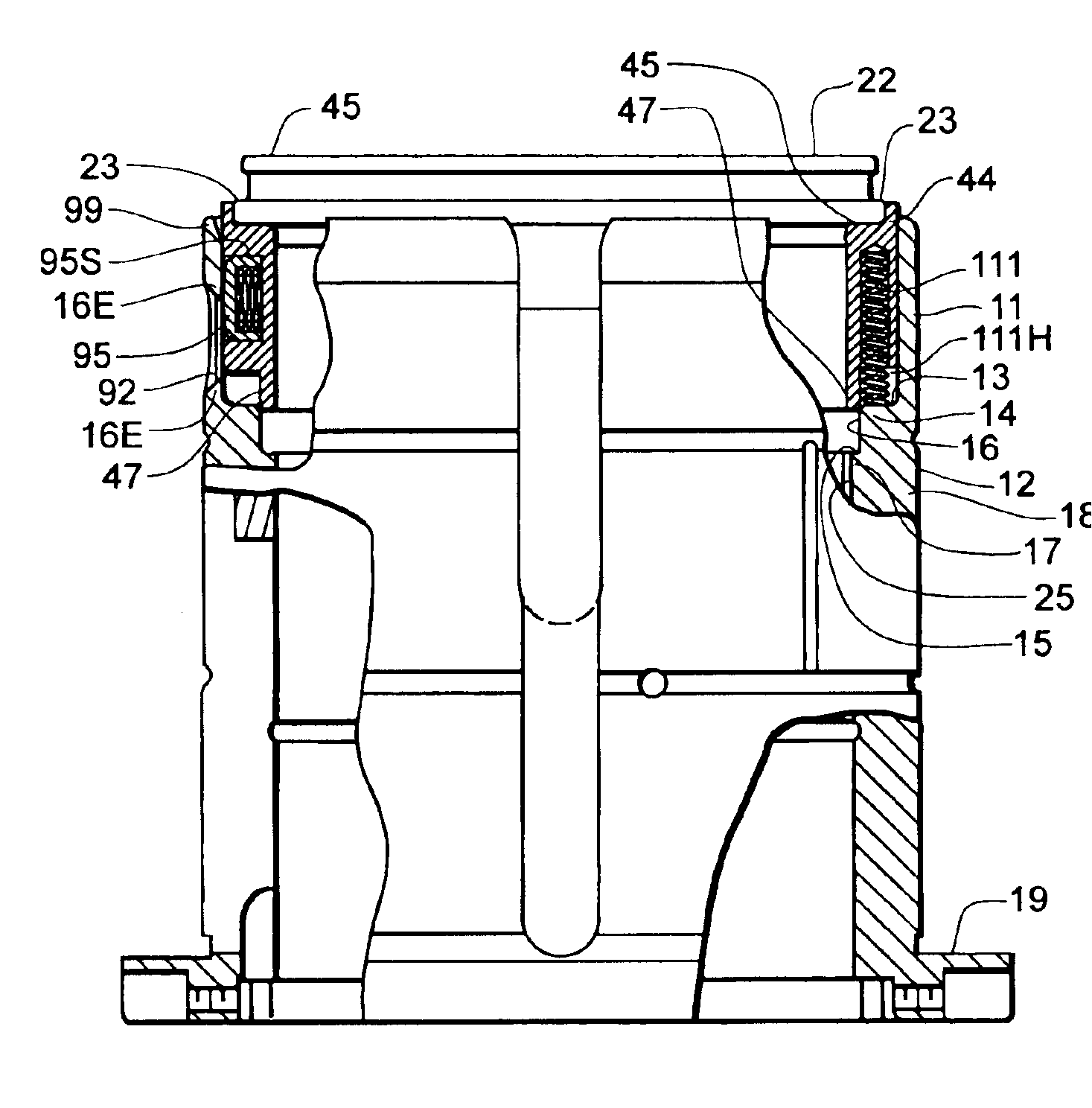

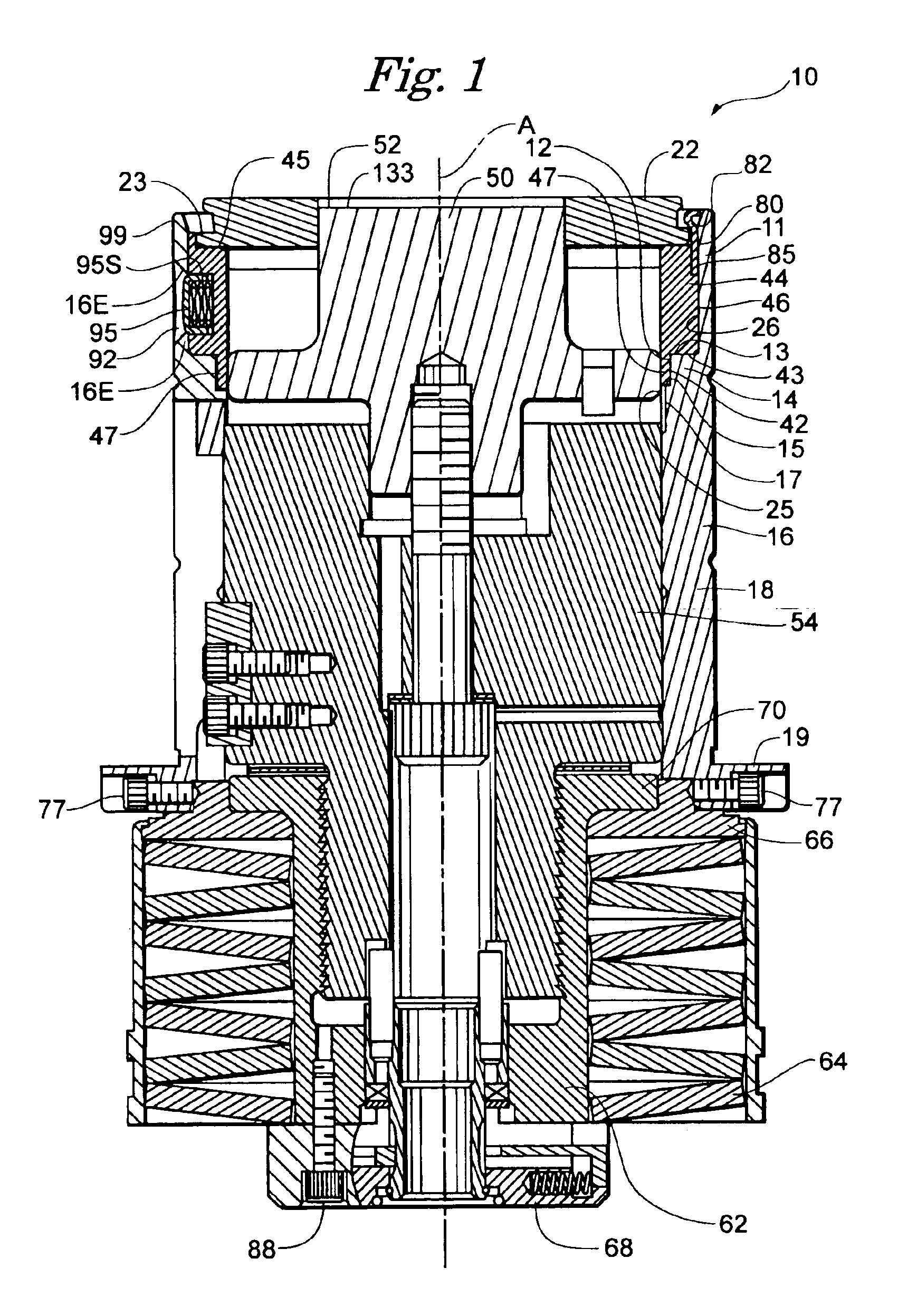

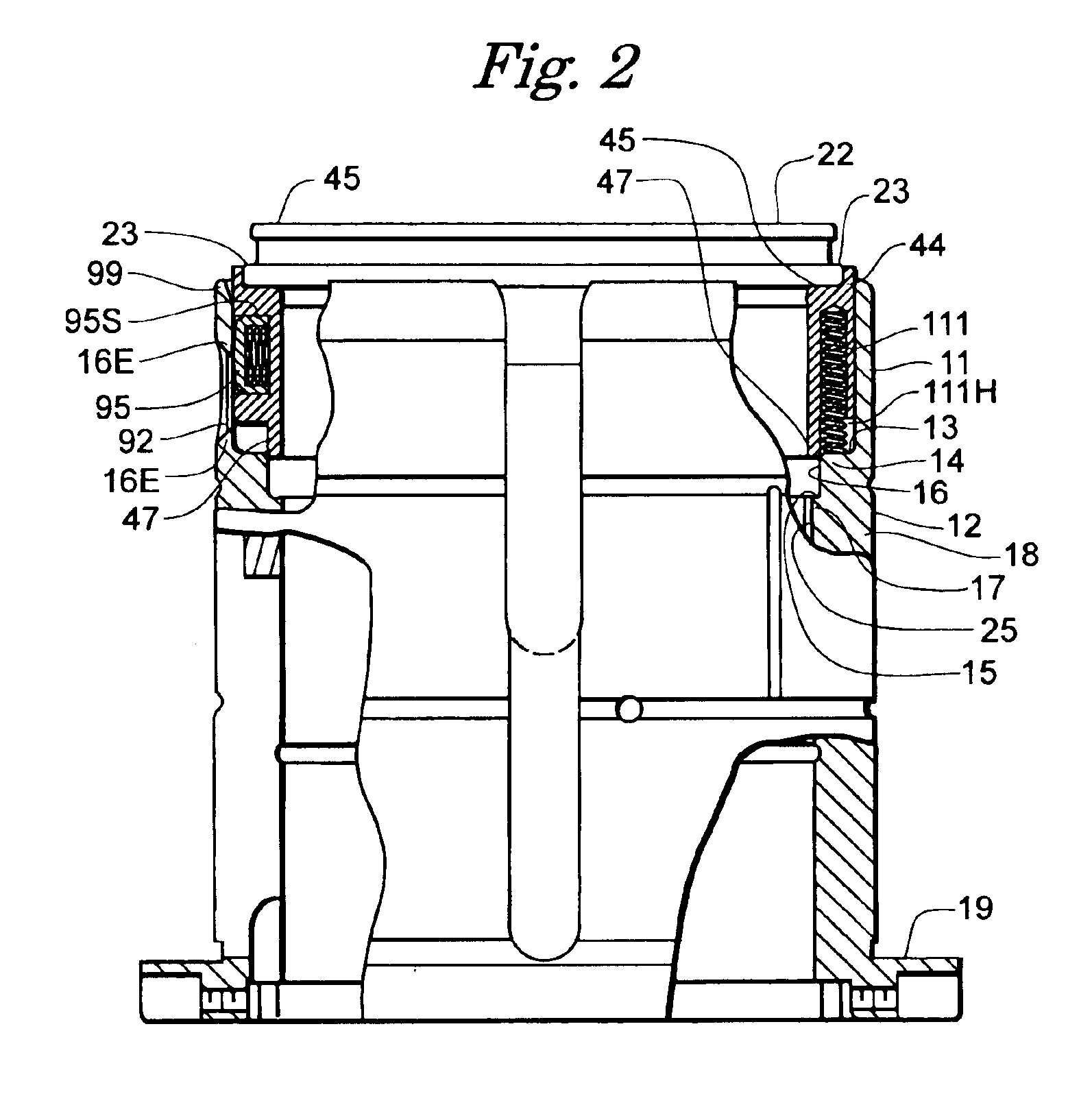

Punch with self-contained punch recess adjustment indexing

A punch canister includes a punch head with an axial shaft that has a screw thread which is adapted to be connected during use to the screw threads of a punch element that is slideably associated within a stripper bushing. A punch recess adjustment member is rotatably and slideably associated with the punch head. The adjustment member is adapted to the slideably but non-rotatably rotatably connected during operation to the punch element. A resilient retraction member, e.g., a spring, is located between the punch head and the adjustment member for biasing the adjustment member axially downward on the punch head. A manually releasable detent provided on the adjustment member is operatively associated with the punch head for retaining the adjustment member in any one of a plurality of selected circumferentially distributed angular positions on the punch head such that during operation disengagement of the detent allows the adjustment member and the punch element to be threaded axially on the punch head to control the distance that the punch element is recessed within the stripper bushing. In a preferred form, the detent is a lock that can be disengaged manually when the punch recess adjustment is to be made.

Owner:MATE PRECISION TOOLING

Cartridge for machine tool

A cartridge for a machine tool is provided. The cartridge has a main body, two punch-retention arms, and two die-retention arms. Preferably, the two punch-retention arms are spaced apart and at least generally parallel to each other. Likewise, the two die-retention arms preferably are spaced apart and at least generally parallel to each other. In some cases, the main body is formed of a first metal, and the punch-retention arms and die-retention arms are formed of metal(s) different than the first metal. In one group of embodiments, the invention provides a cartridge having a weight of less than 3 pounds.

Owner:WILSON TOOL INT

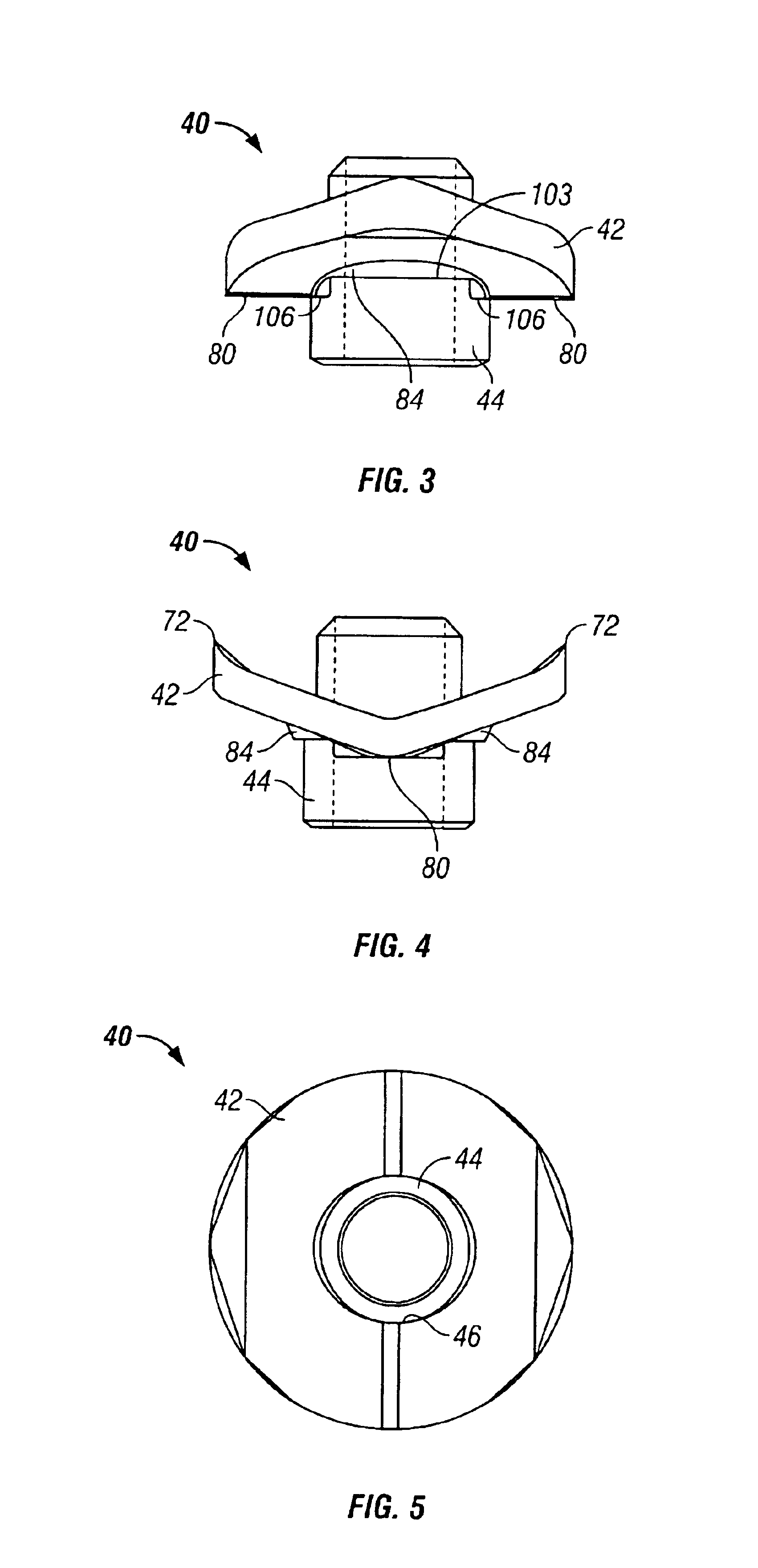

Punch device with adjustment subassembly as retrofit insert or as original equipment

ActiveUS20090266209A1Prevent misalignment and uneven wearPrevent rotationPerforating toolsMetal working apparatusPunch pressReciprocating motion

A punch assembly for a punch press has a punch housing with a punch that is slideably mounted for reciprocation along punch axis within the punch housing and at least one resilient member in the housing for yieldably biasing the punch upwardly in the housing along the punch axis. A punch length adjustment subassembly is provided in the punch housing. The subassembly has a base member that is slideable axially but non-rotatably mounted within the housing and a punch head member having an upper end that is positioned to be struck by a punch ram of a punch press for driving the punch downwardly to an operating position. The punch head is mounted for rotation on the punch axis relative to the base member but is held against axial movement relative to the base member. The punch head is operatively associated by a threaded length adjustment connection to the punch and a releasable stop member is connected between the punch head and the base member for preventing rotation of the punch head relative to the base member while the punch assembly is in operation on the punch press. The invention is also directed to the punch head subassembly per se as a retrofit insert to update existing punch assemblies for manual tooless punch length adjustment and tooless punch removal.

Owner:MATE PRECISION TOOLING

Adjustable blind cutting device

A method and apparatus for sizing window coverings slidably extendable from a bay into an aisle of a retail outlet. The method includes the steps of locating the center of the window covering relative to a cutting station utilizing a half scale for removing a portion of the window covering from each of its ends.

Owner:HUNTER DOUGLAS INDS SWITZERLAND

Multiple punch and die assembly providing hand disassembly, punch length adjustment and replacement

ActiveUS7726554B2Eliminate scoring and marking of sheet materialReduce impact stressDigitally marking record carriersPerforating toolsStress boneEngineering

A multiple punch and multiple die assembly has a workpiece protector which is a punch lifter that is operatively associated with each punch for supporting each of the punches in an inactive position as an active punch is moved by the ram to the active, i.e. operating position to thereby eliminate scoring or marking of the sheet material or other workpiece that is being punched. To eliminate the need for hand tools and hand assembly or disassembly, a manually moveable retainer on the punch assembly is provided that can be moved by hand between a punch-releasing and punch-retaining position for holding the punches within the multi-punch assembly during operation. To prevent stress fractures that formerly occurred in die carriers, support of each die is distributed between two different die components thereby reducing impact stress on the carrier as the ram drives the punch through the workpiece.

Owner:MATE PRECISION TOOLING

Lifting punching device

The invention relates to the field of automobile manufacturing, in particular to a lifting punching device which realizes effective switching to or not to punch without removing a mould. The technical scheme adopted by the invention is as follows: in a lifting punching device, a punch is arranged on a mould seat, and an adjusting mechanism for adjusting the height of the punch and a limit mechanism for limiting the moving direction of the punch are arranged in the mould seat. Through the technical scheme, the adjusting mechanism can realize the lifting movement of the punch, and the limit mechanism can ensure that the punch always moves in the vertical direction during the lifting. The device is simple to operate, convenient to use and low in manufacturing cost, and can effectively save the mould development cost and improve the production efficiency.

Owner:CHERY AUTOMOBILE CO LTD

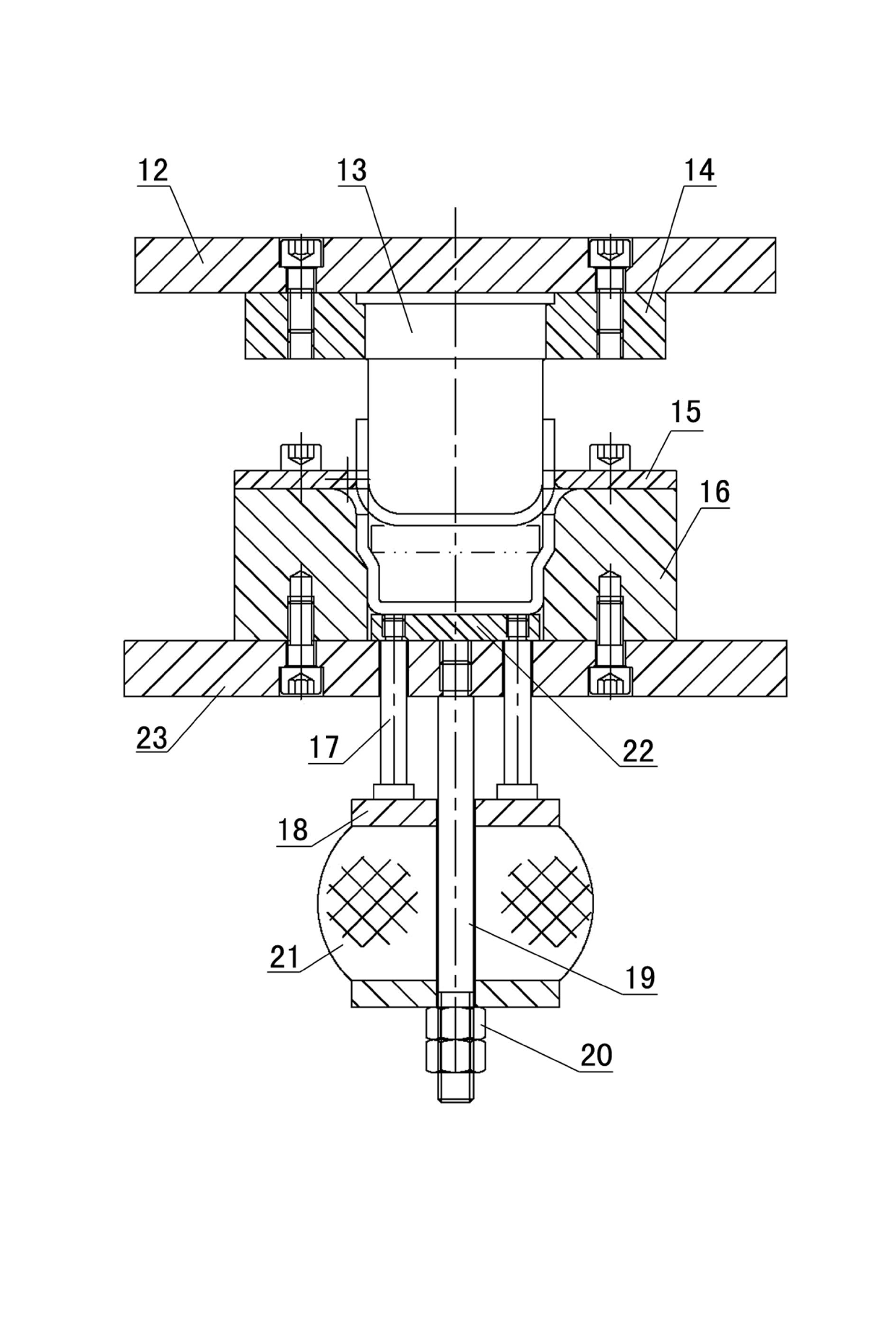

Stepped cylindrical component die for medium plate

InactiveCN101767154ASimple structureEasy to manufactureShaping toolsPerforating toolsEngineeringScrew thread

The invention relates to a stepped cylindrical component die for a medium plate, which consists of a primary drawing die, a drawing dressing die and a punch die. The primary drawing die consists of an upper drawing die, a lower drawing die and a drawing die material returning device. The drawing dressing die consists of an upper dressing die, a lower dressing die and a dressing die material returning device. The punch die consists of an upper punch die, a lower punch die and a punch die guide pair. Only three sets of the stepped cylindrical component dies for the medium plate can press a die plate with middle thickness into a stepped cylindrical component. The three sets of dies have the advantages of simple structure, simple and easy manufacturing, convenient maintenance, reasonable layout, stable performance and long service life. The design standardization degree of the three sets of dies is high. Connecting bolts, material returning bolts, discharge rods and the like are all selected from standard components easily purchased on the market. The three sets of dies all adopt threaded connection and do not adopt the non-removable mode such as riveting, welding and the like so as to be convenient for later maintenance and convenient disassembling.

Owner:BEIJING SANXING AUTOMOBILE

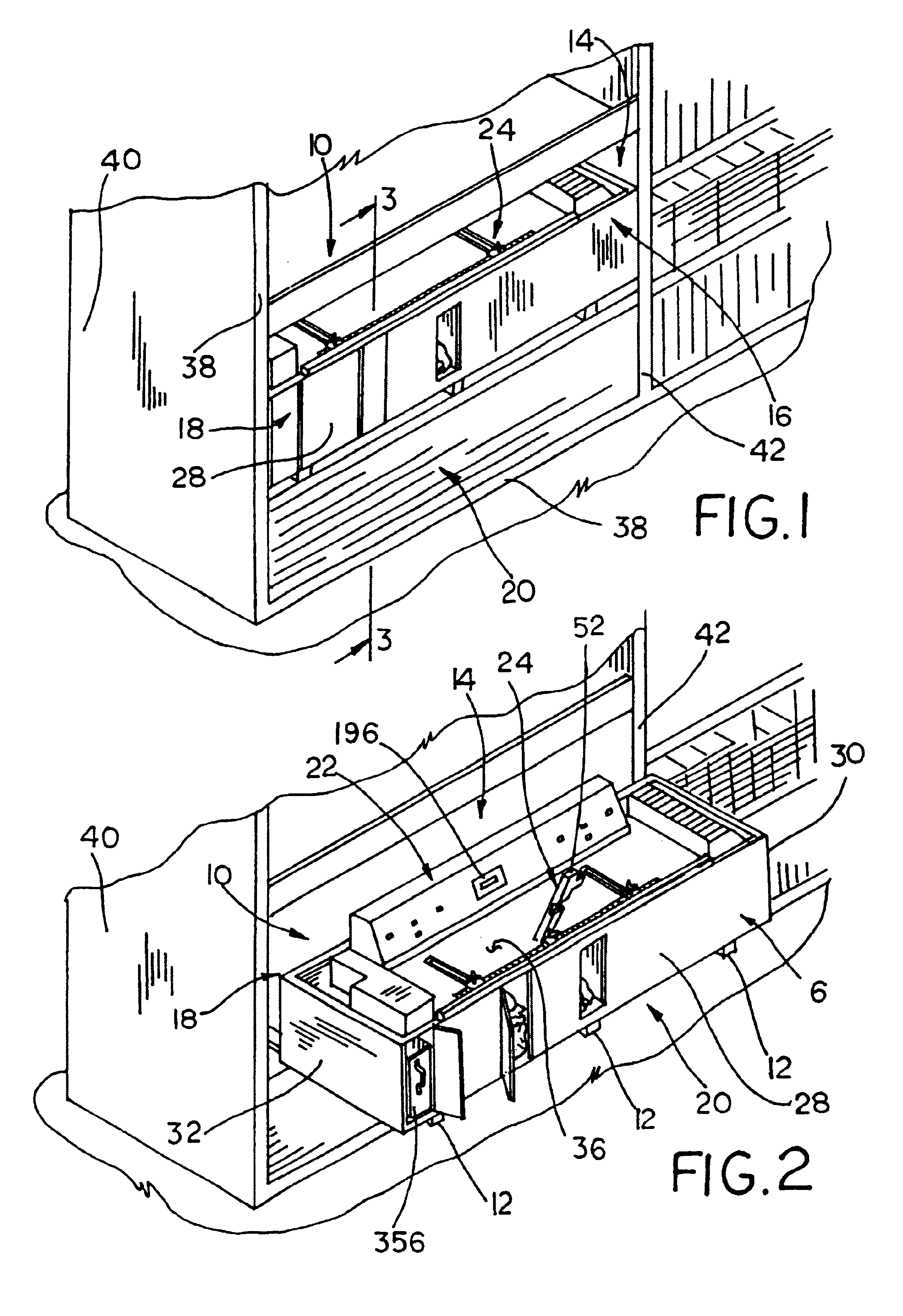

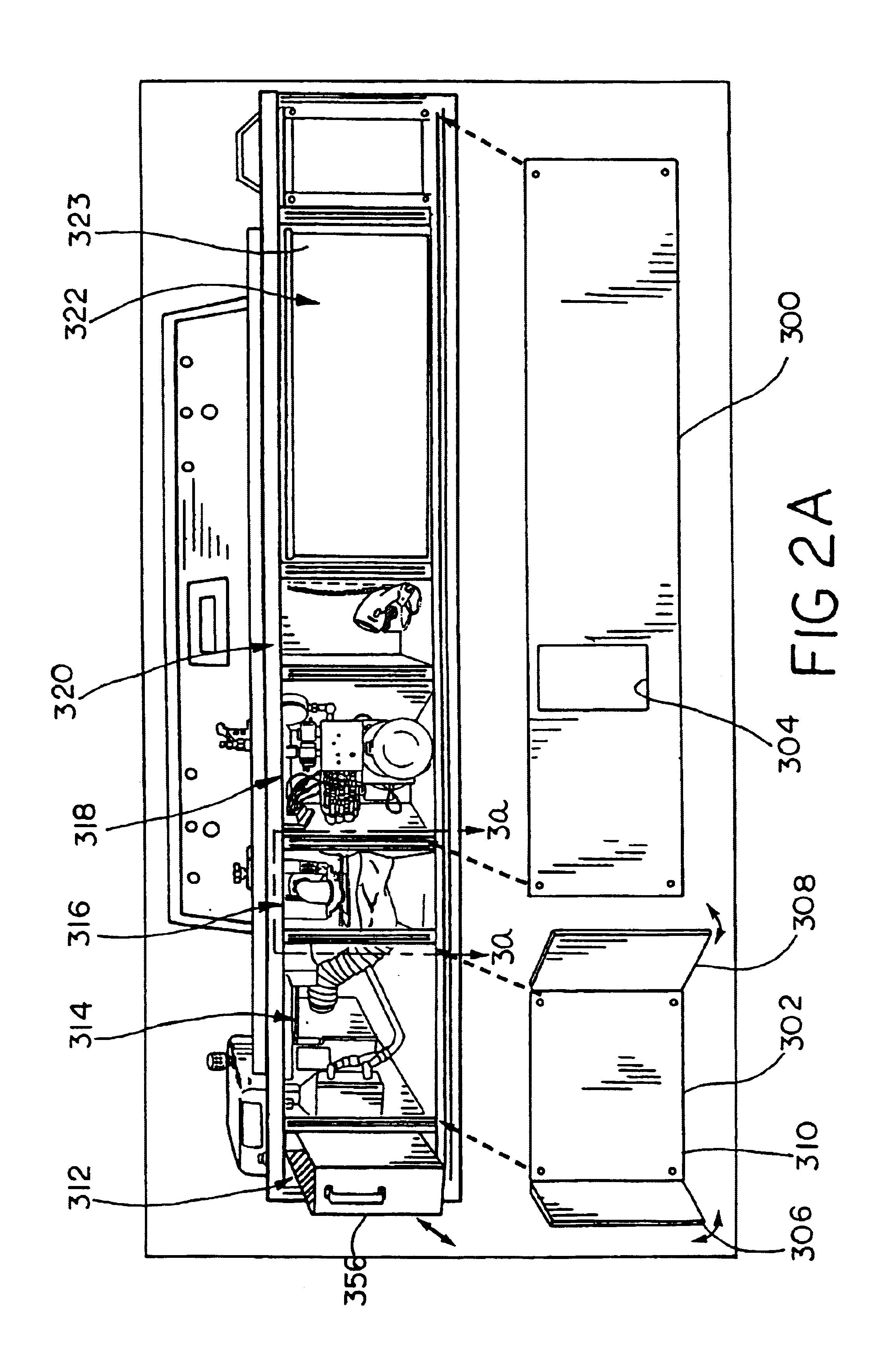

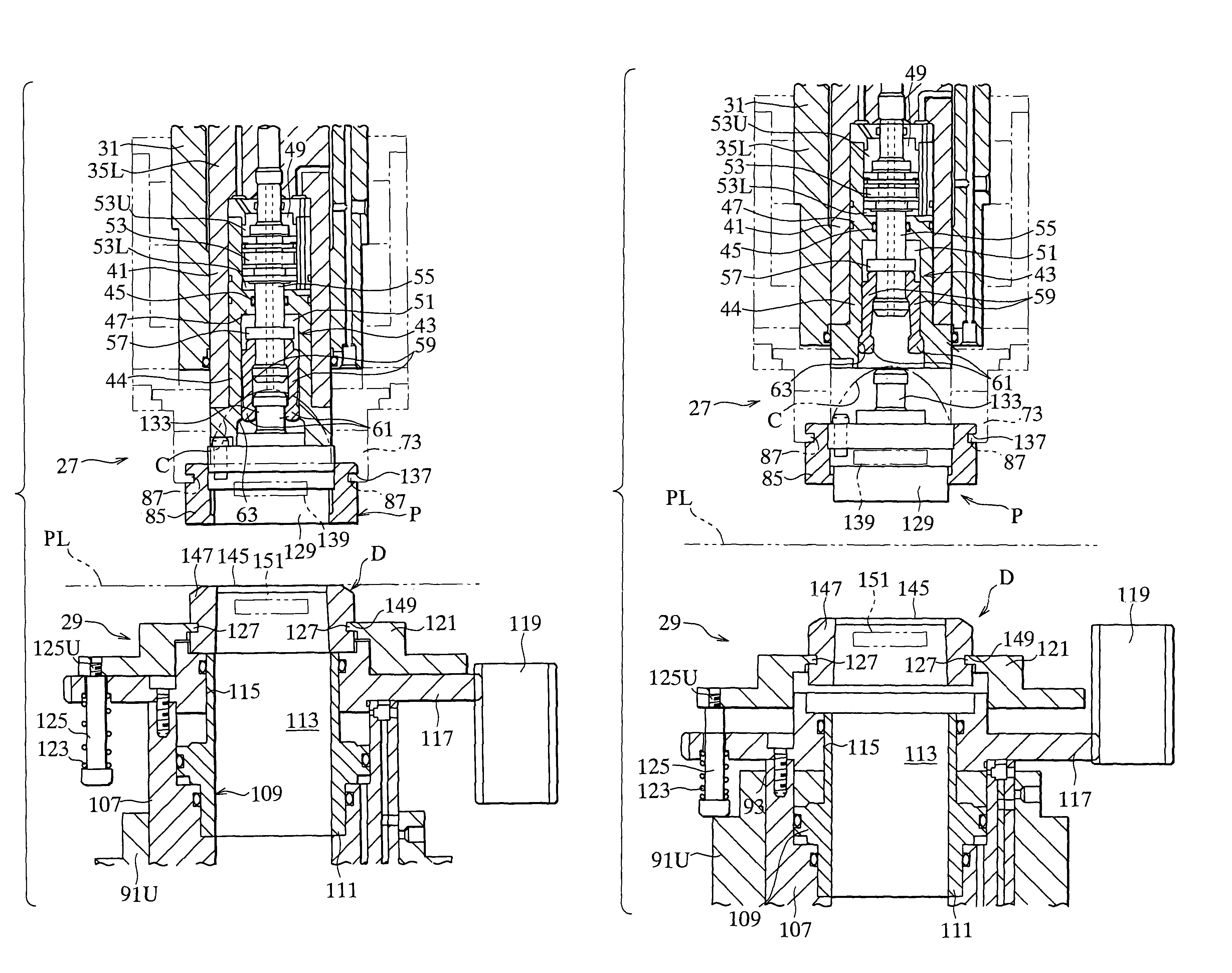

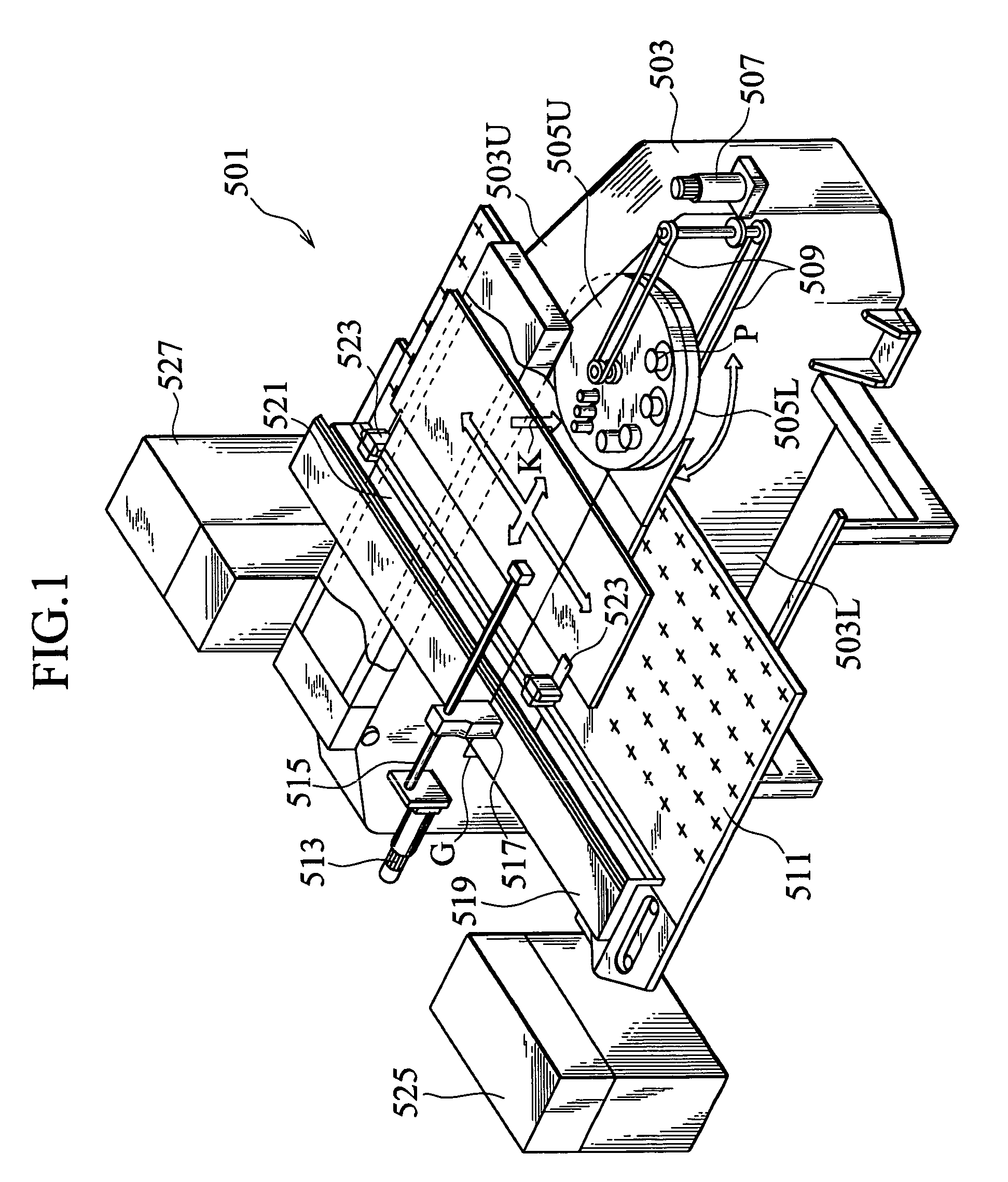

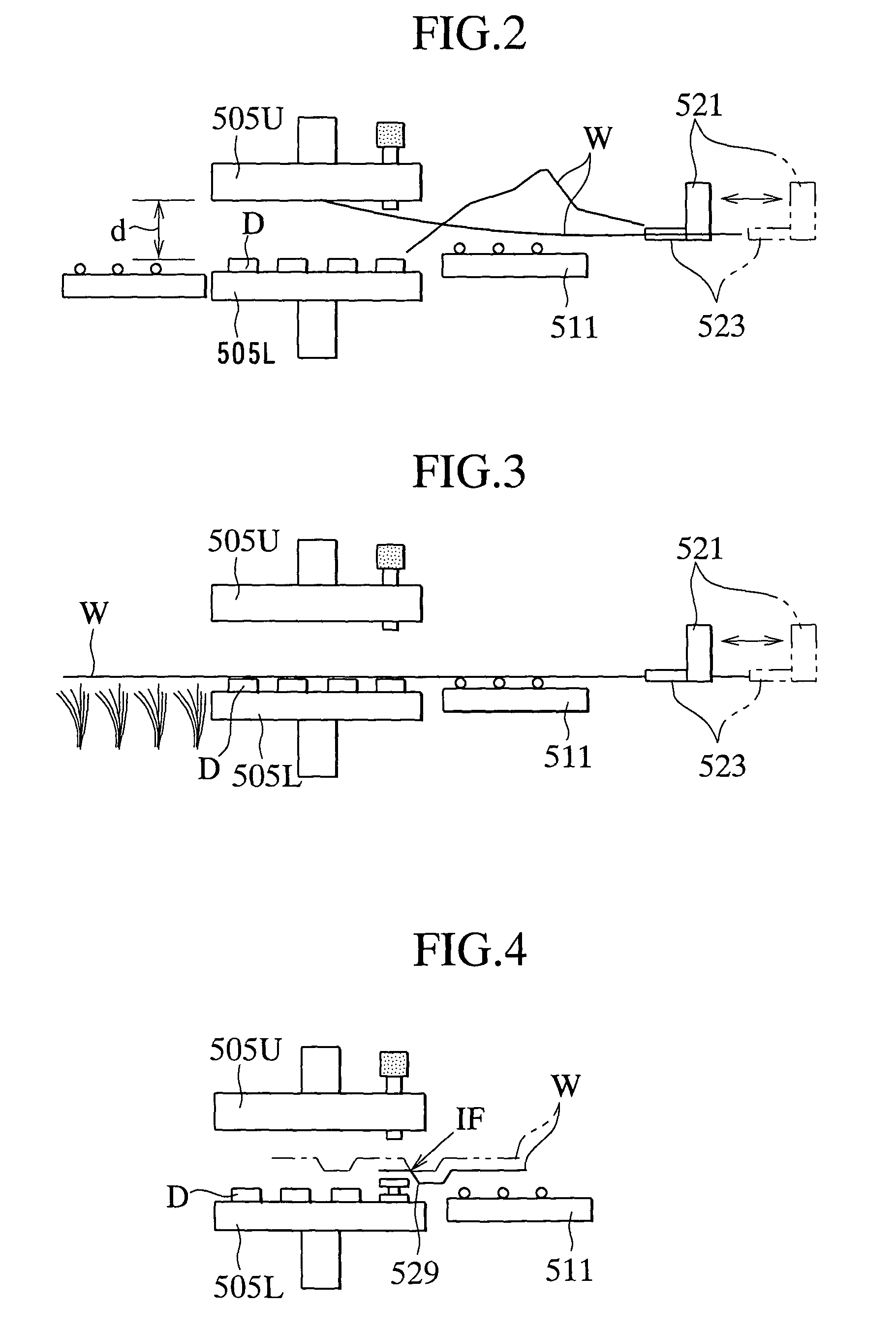

Punch press, method of replacing punch and die for punch press, and punch system

A punch press provided with a punch and die set taking-out / taking-in apparatus 291; a punch taking-out / taking-in arm 367 for performing taking-out / taking-in of a punch P; and a die taking-out / taking-in arm 369 for performing taking-out / taking-in of a die D, wherein taking-out / taking-in of many punches P, dies D accommodated in a punch and die set accommodating portion 282 of a rack 283 is performed by pivoting a punch holding arm 279 which holds a punch P and a die holding arm 281 which holds a die D in a punch and die set exchanging apparatus 23 forward or backward; and delivery of a die is performed between the punch and die set taking-out / taking-in apparatus 291 and the punch and die set exchanging apparatus 23.

Owner:AMADA CO LTD

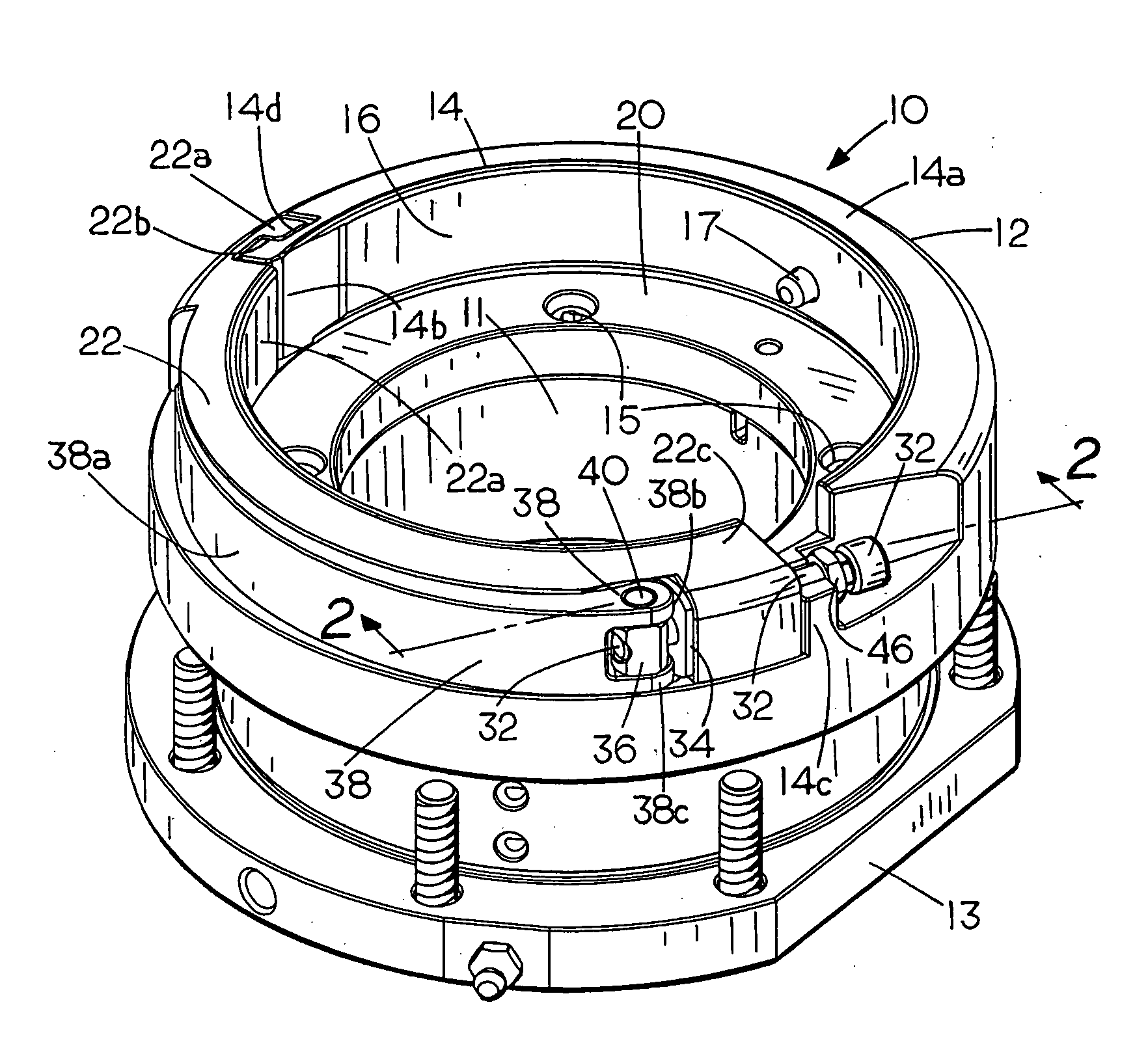

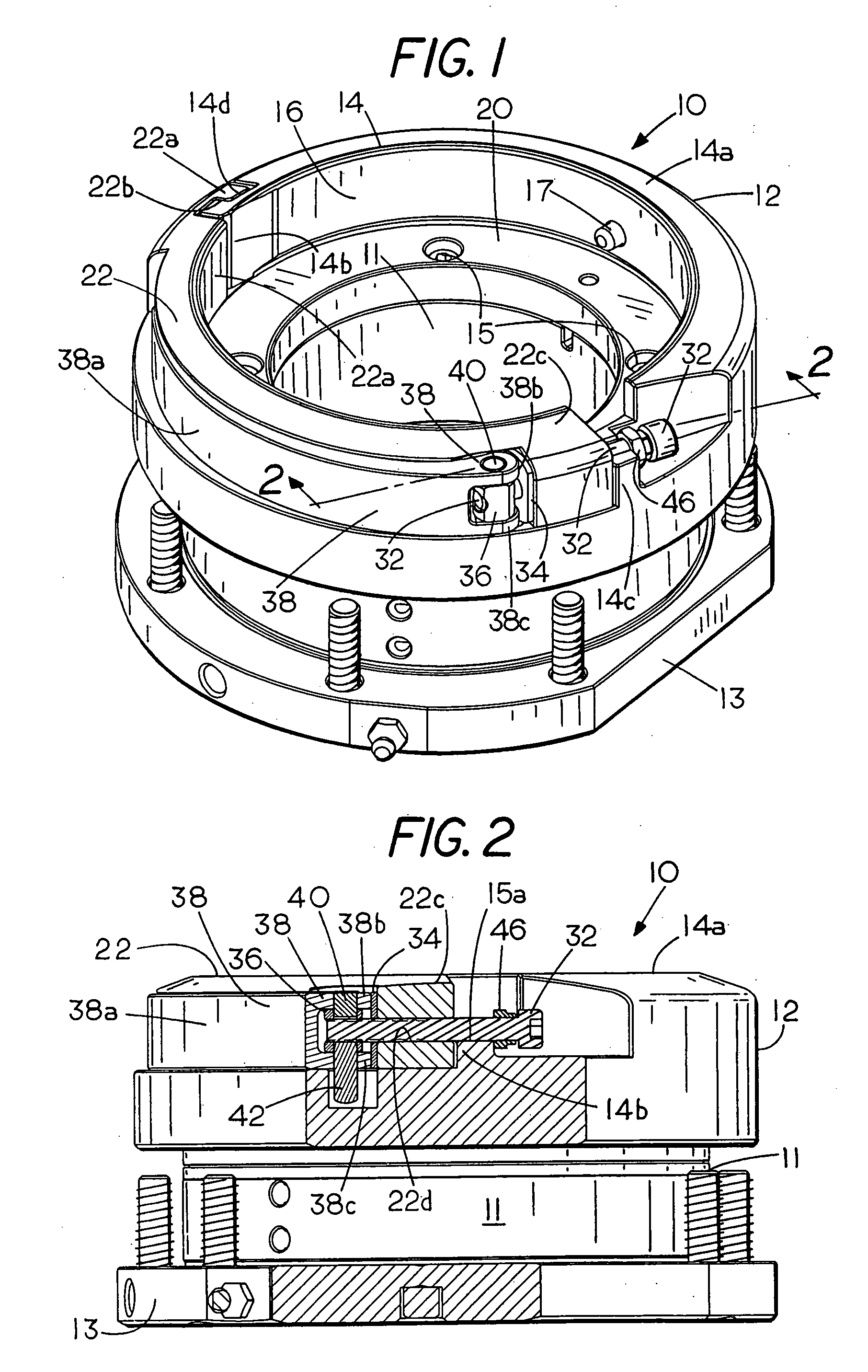

Punch press die holder with hand-operated retaining clamp

A punch press die holder assembly includes a die holder body with a fixed rim which partially surrounds an upwardly opening die receptacle within the die holder. The receptacle is dimensioned to receive a punch press die, especially of any various circular dies now in commercial use. Cooperating with the fixed rim portion of the die holder is a moveable clamp member that is a portion of the rim that has a centrally directed surface which contacts the die when the die is in place within the receptacle. A manually operable fastener is operatively connected to the moveable clamp member to hold the clamp member in a closed position for restricting the movement of the die and the fastener is movable by hand to an open position for releasing the clamp member and the die from the die holder so that the die can then be removed and replaced from one side by sliding it horizontally out of the die holder.

Owner:MATE PRECISION TOOLING

Two piece punch with pilot hole locator

A two piece punch is provided for use in a punch assembly. The punch includes a generally disc shaped cutter and a cylindrically shaped nut. The punch is assembled by passing a portion of the nut through an aperture in the cutter. The punch is mounted to the remainder of the punch assembly by fastening the nut to the draw stud. As the punch becomes worn, use of the nut continues while the cutter is removed and replaced.

Owner:GREENLEE TEXTRON

Stripper plate retention system

A punch guide assembly is provided for removably carrying a stripper plate. The punch guide assembly comprises a punch guide and a stripper plate guide movable axially with respect to the punch guide. The stripper plate guide has a locked position wherein the stripper plate is secured to the punch guide assembly and an unlocked position wherein the stripper plate can be readily removed from the punch guide assembly. The stripper plate guide is resiliently biased axially toward its unlocked position yet is restrained against axial movement relative to the punch guide when in its locked position.

Owner:WILSON TOOL INT

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com