Patents

Literature

566results about How to "Realize automatic clamping" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

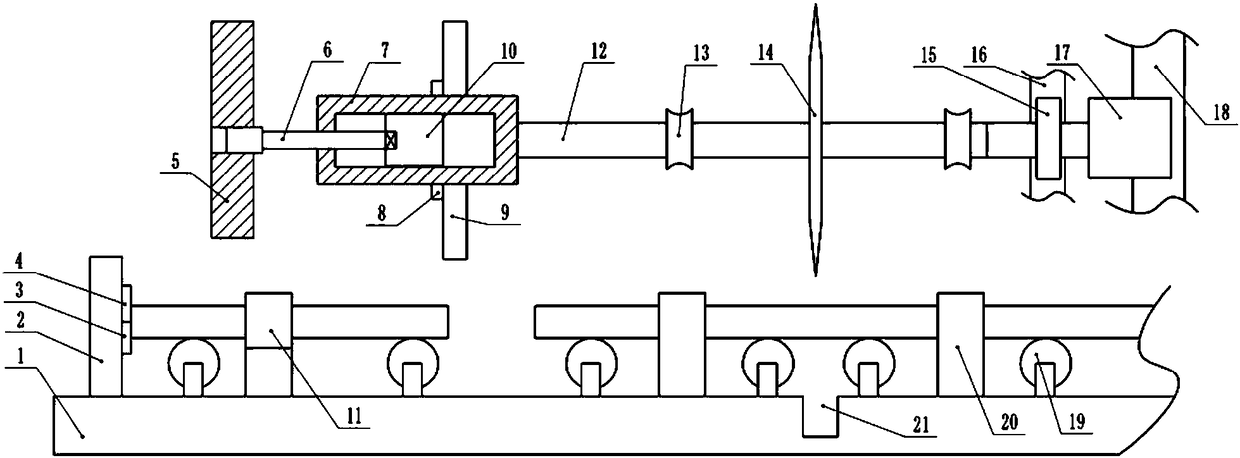

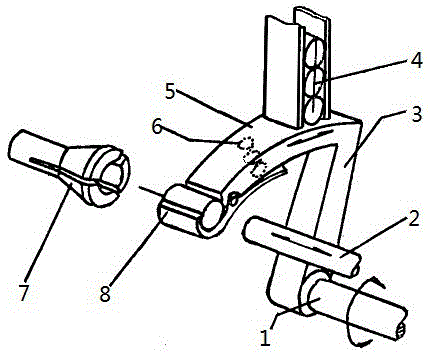

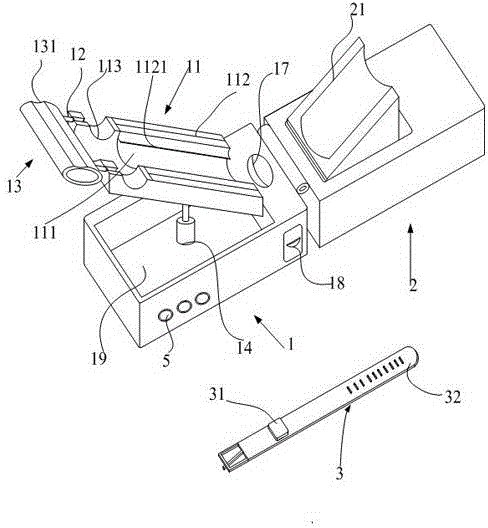

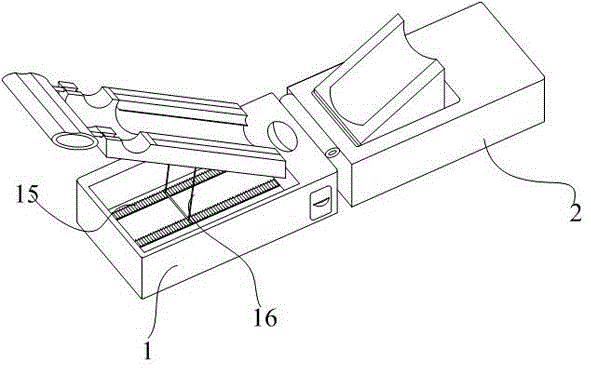

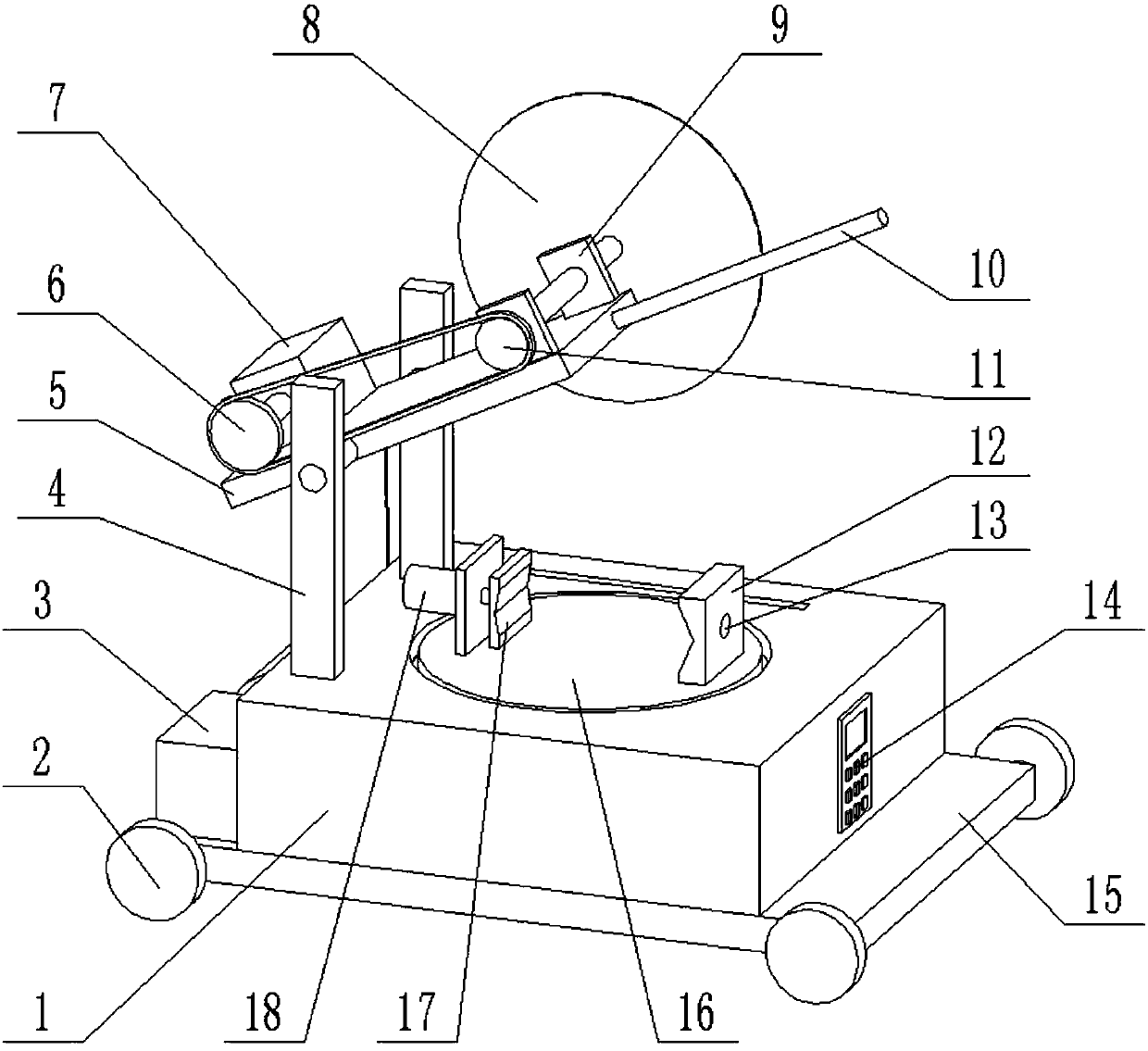

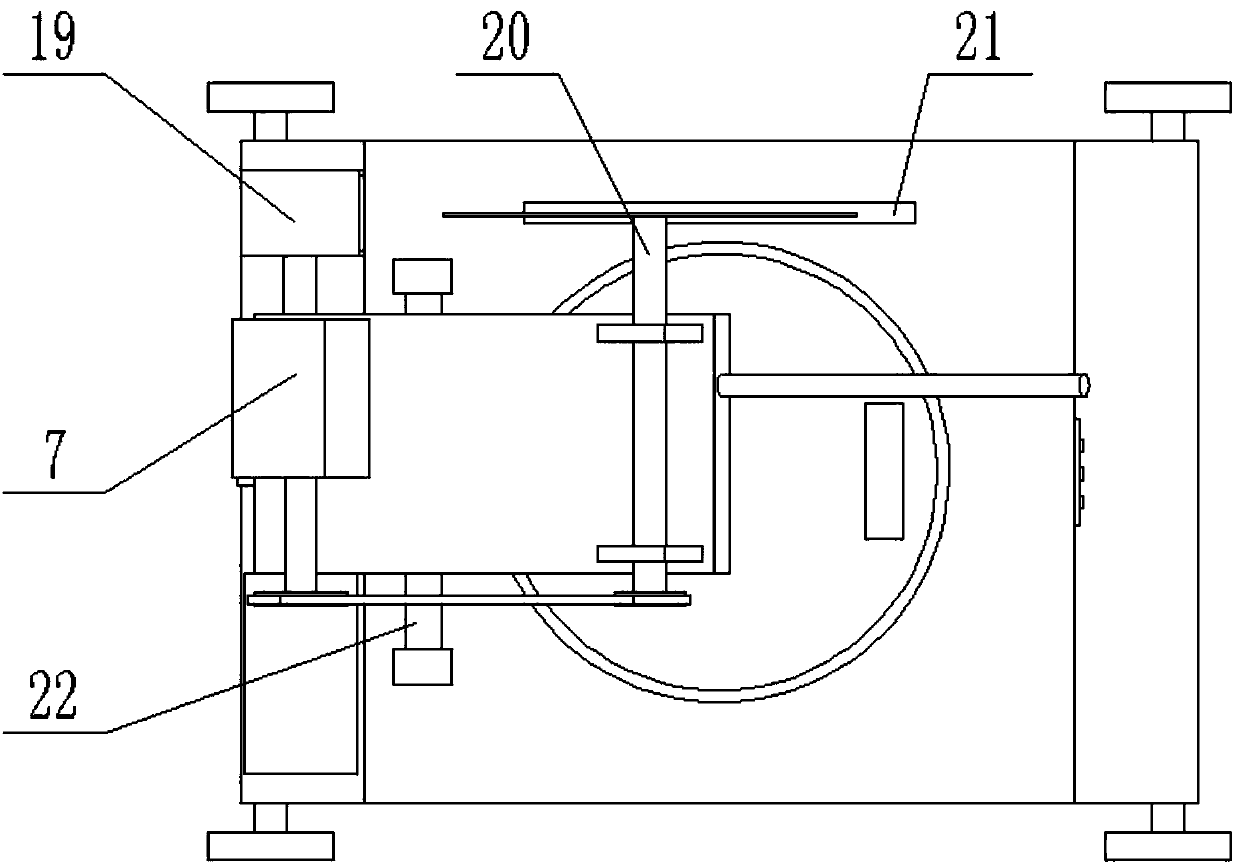

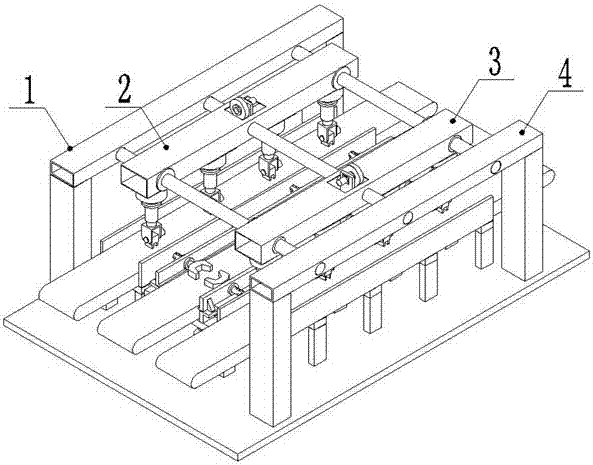

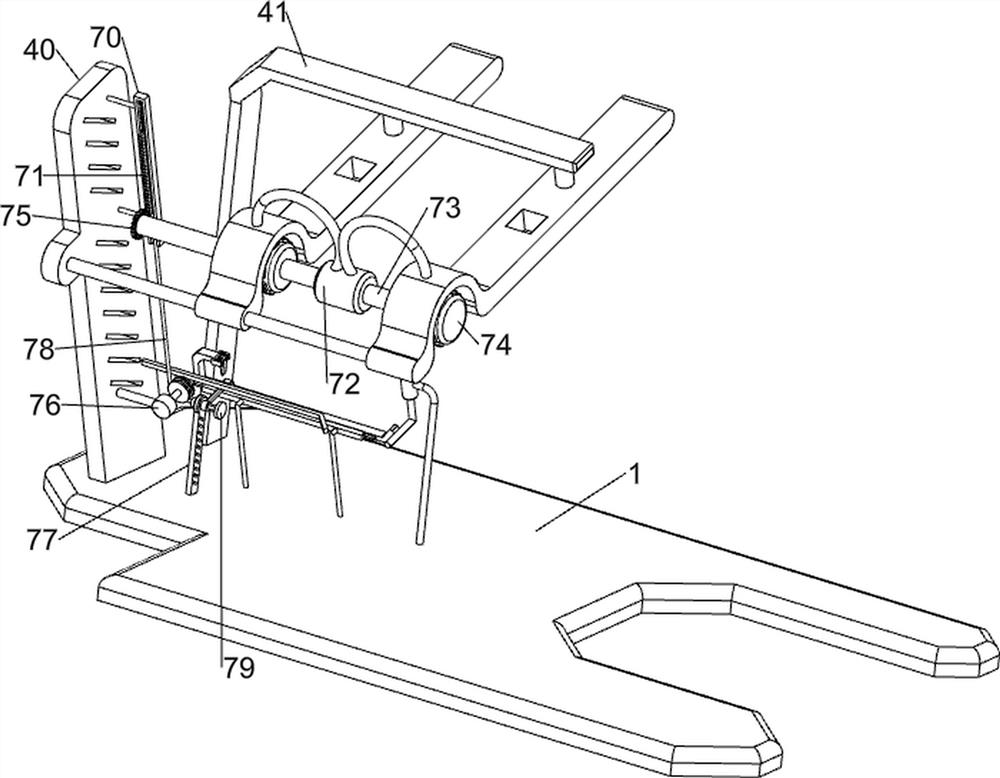

Pipe cutting and grinding device

ActiveCN108453508ARealize automatic clampingAchieve grindingEdge grinding machinesOther manufacturing equipments/toolsEngineeringSlide plate

The invention belongs to the technical field of cutting equipment, and specifically discloses a pipe cutting and grinding device. The pipe cutting and grinding device comprises a cutting mechanism anda grinding mechanism which are connected to the same rotating shaft, wherein a transmission gear and two fixed pulleys are arranged on the rotating shaft; a rack which is fixed to a machine frame isengaged with the transmission gear; the grinding mechanism comprises a rotating barrel which is fixed to the rotating shaft, and a grinding plate is arranged on the rotating barrel; a square shaft isin sliding connection with the interior of the rotating barrel, and a threaded rod which is in thread connection with the rotating barrel is rotatably connected to the square shaft; and the threaded rod is in sliding connection with a sliding plate, and the sliding plate is in sliding connection with the machine frame. The pipe cutting and grinding device further comprises a conveying roller, a first clamping mechanism and a second clamping mechanism; the first clamping mechanism comprises a clamping block and a fixing block; a sliding rope is connected between the clamping block and the corresponding fixed pulley; the second clamping mechanism is in sliding connection with a working platform; a baffle plate is arranged at the left end of the working platform; and magnetic parts which areattracted to and repelled by each other are arranged between the baffle plate and the second clamping mechanism. According to the scheme, the pipe cutting and grinding device has the advantages that anotch of a steel pipe can be ground while the steel pipe is cut, so that the working efficiency is improved.

Owner:苏州市振渭城镇建设发展有限公司

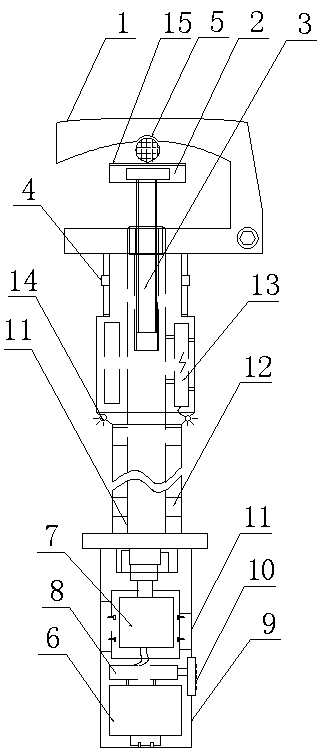

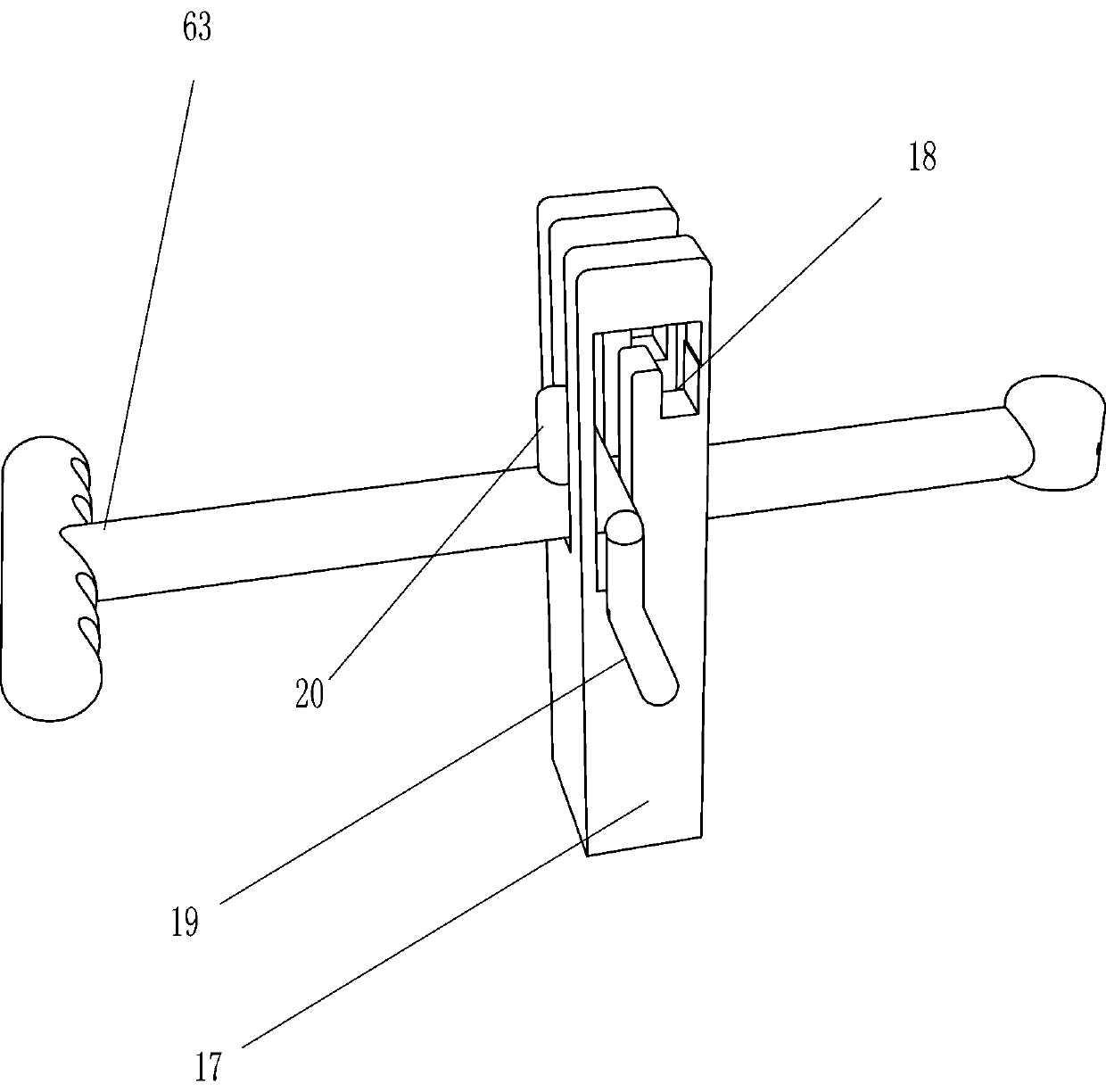

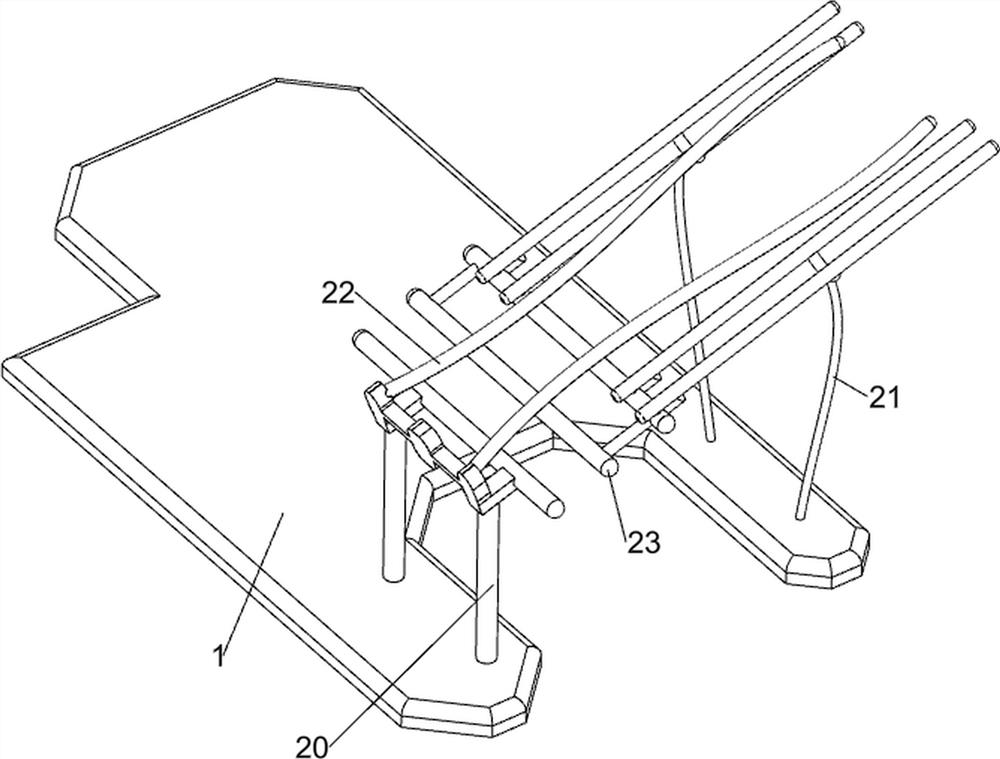

High voltage grounding tool for power maintenance

ActiveCN103531925AImprove securityAvoid safety hazardsLine/current collector detailsMulticonductor cable end piecesGround lineHigh pressure

The invention discloses a high voltage grounding tool for power maintenance, which comprises a grounding wire chuck and an operating rod, wherein the wire chuck comprises a C-shaped hanging frame, a wire clamp moving plate and a lifting rod; a connector connected with the C-shaped hanging frame is arranged at the top of the operating rod; the upper end of the lifting rod is connected with the wire clamp moving plate; a driving mechanism connected with the lifting rod is arranged in the operating rod; the operating rod is arranged in a multi-section insertion manner; locking rings are arranged among sections of the operating rod; reducer pipes are arranged among sections of a movable casing pipe; elastic pins or key structures matched with the movable casing pipe are arranged on the reducer pipes. According to the invention, the high voltage grounding tool is hung on a wire by utilizing the C-shaped hanging frame; the wire is clamped by adopting the lifting rod; the wire-off accident is prevented; the low-position safe operation is realized; the potential safety hazard caused by the climbing operation is avoided; the working difficulty is reduced; the working efficiency is improved; the sectional design concept is adopted; the flexible variation of the length of the operating rod is ensured; in the transmission link, the interchangeable connection can be carried out; the effects are obvious.

Owner:STATE GRID CORP OF CHINA +1

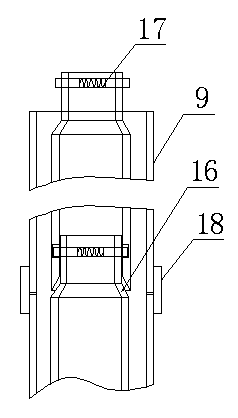

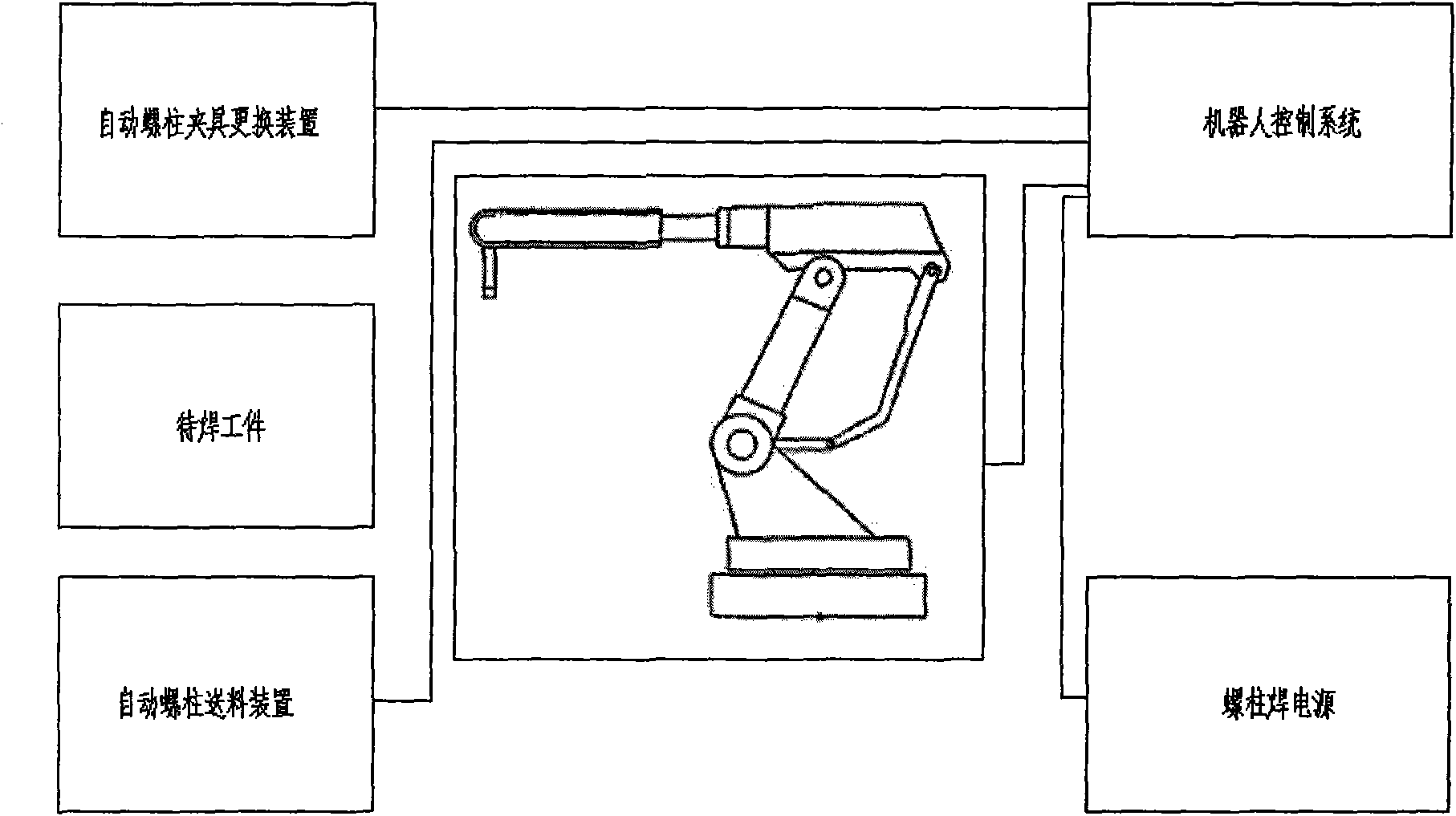

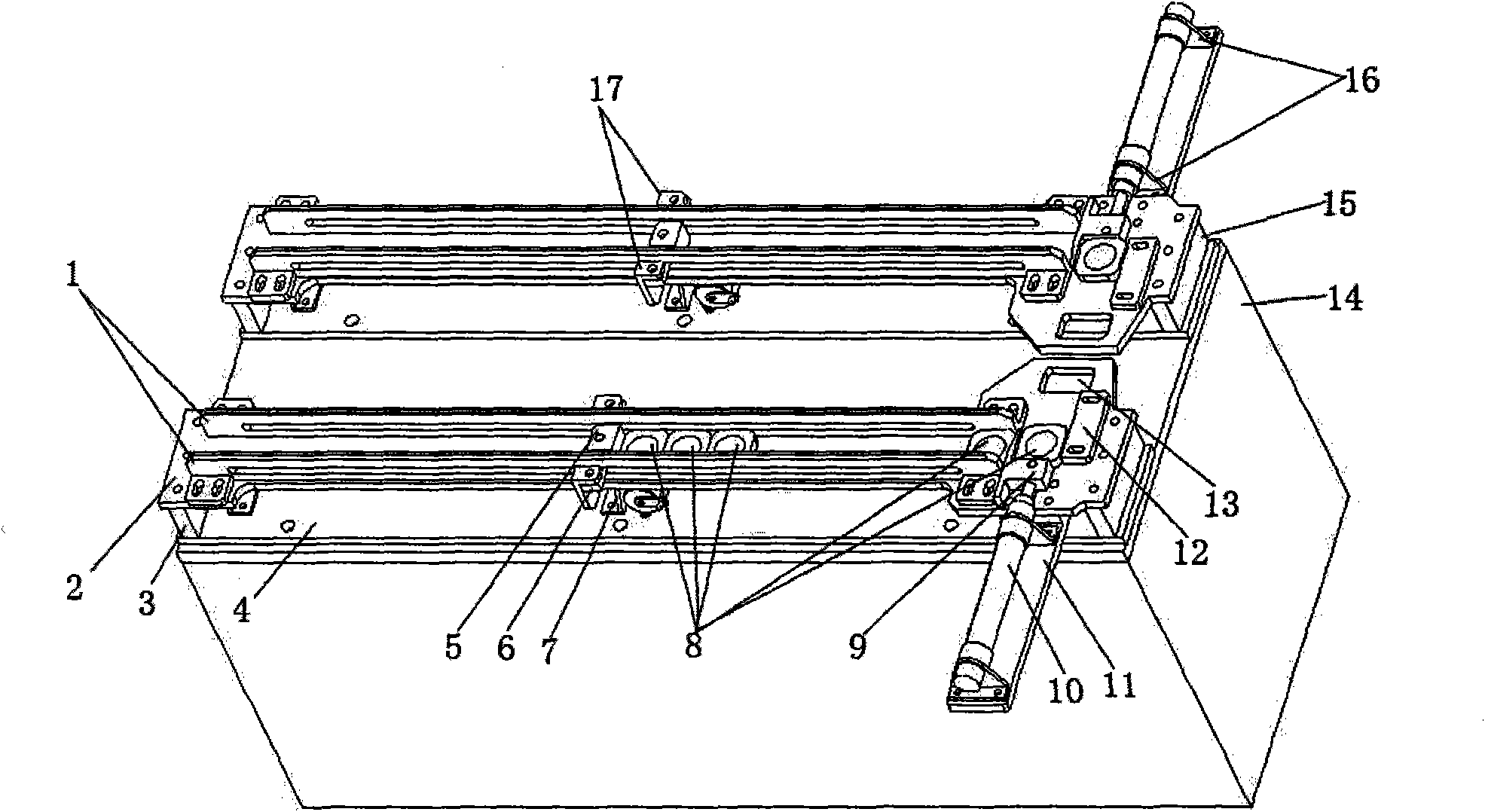

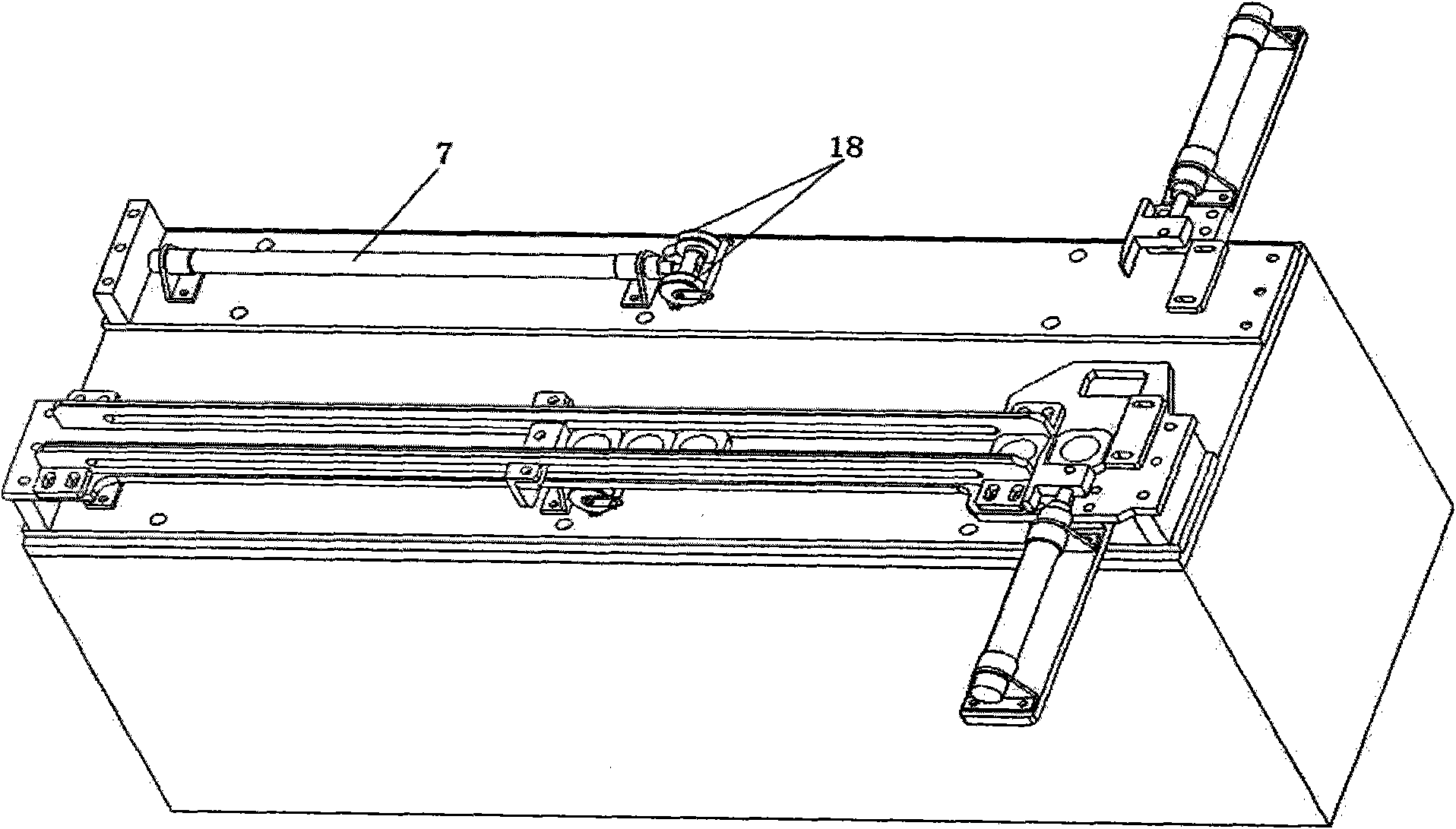

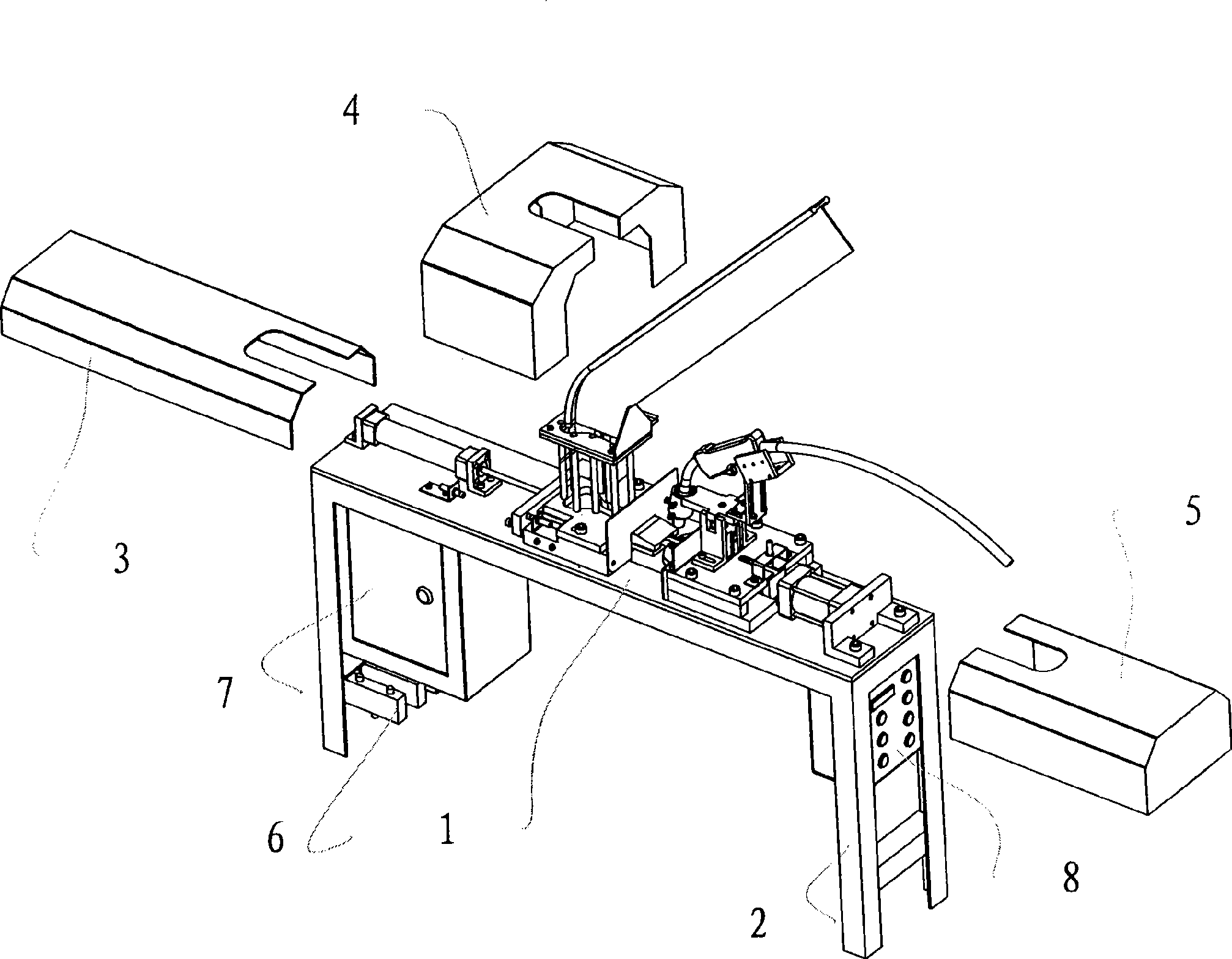

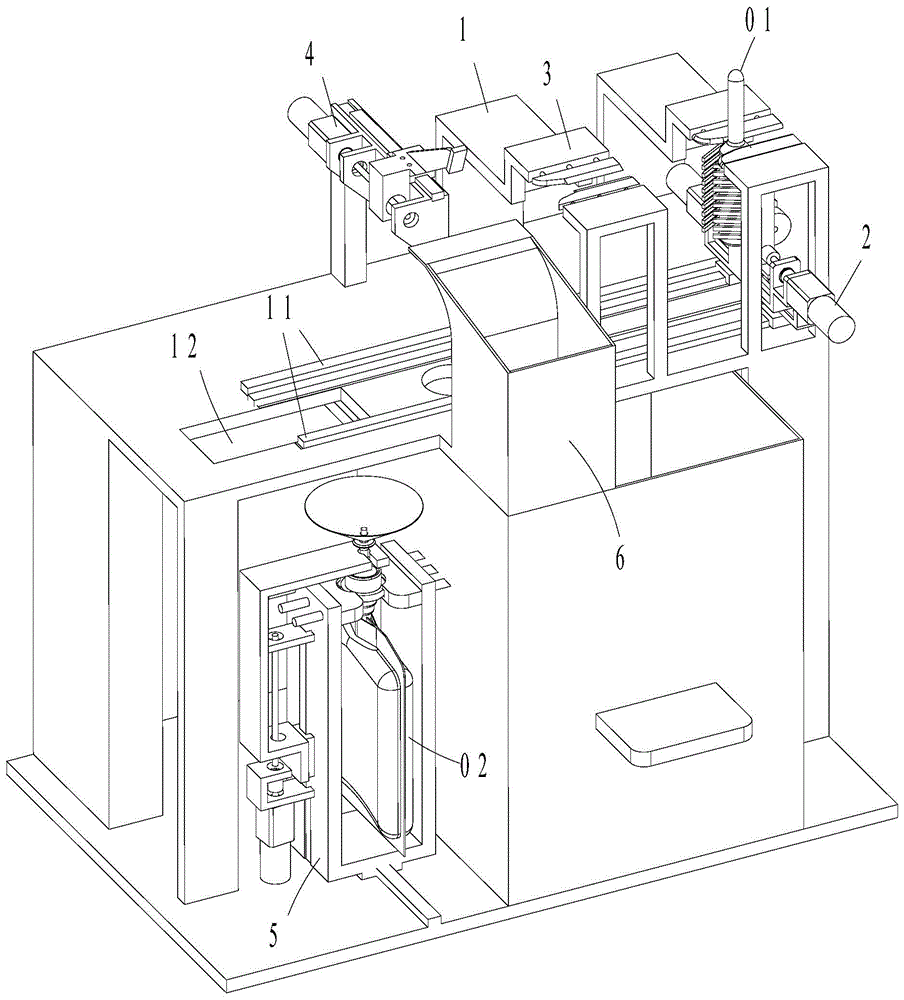

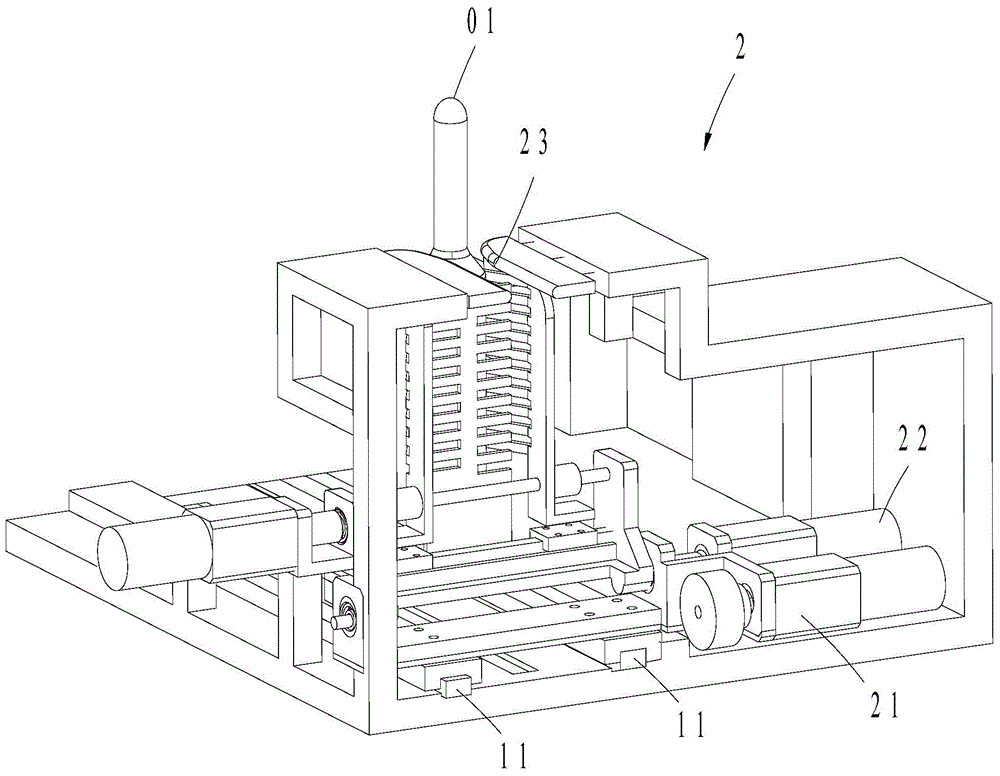

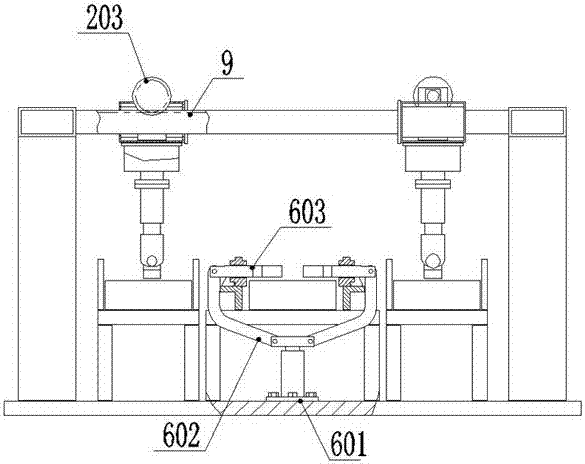

Stud flexible welding device and method

ActiveCN102114568ARealize automatic clampingLarge size spanArc welding apparatusControl systemControl signal

The invention discloses a stud flexible welding device and method. The stud flexible welding device comprises a welding robot, a robot control system, an automatic stud welding gun, an automatic stud feeding device, an automatic stud welding and clamping device and an automatic stud welding jig replacing device, wherein the welding robot, the automatic stud welding gun, the automatic stud feeding device, the automatic stud welding and clamping device and the automatic stud welding jig replacing device are connected with the robot control system to receive a control signal of the robot control system; the automatic stud feeding device is used for conveying studs; the automatic stud welding and clamping device is used for setting precompression amount required in an automatic clamping and welding process of studs and ceramic rings; and the automatic stud welding jig replacing device is used for assembling and disassembling the automatic stud welding and clamping device. The invention can be used for carrying out automatic feeding.

Owner:NANJING UNIV OF SCI & TECH

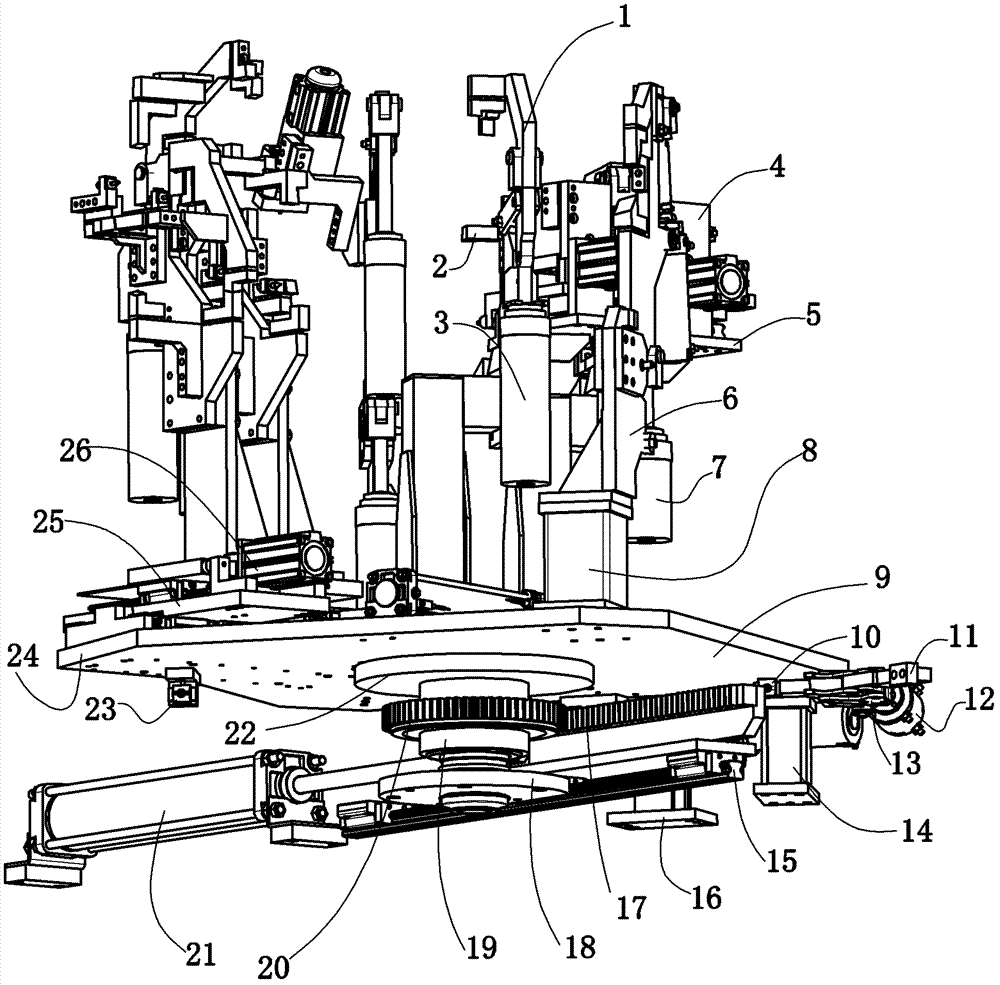

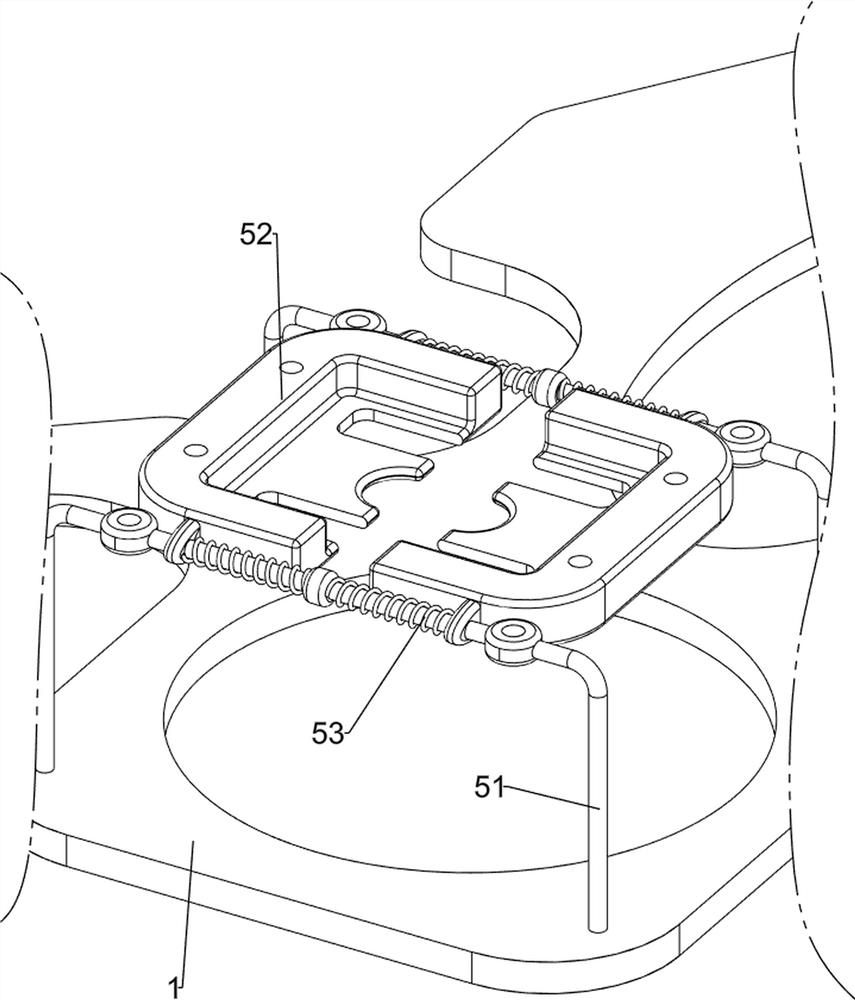

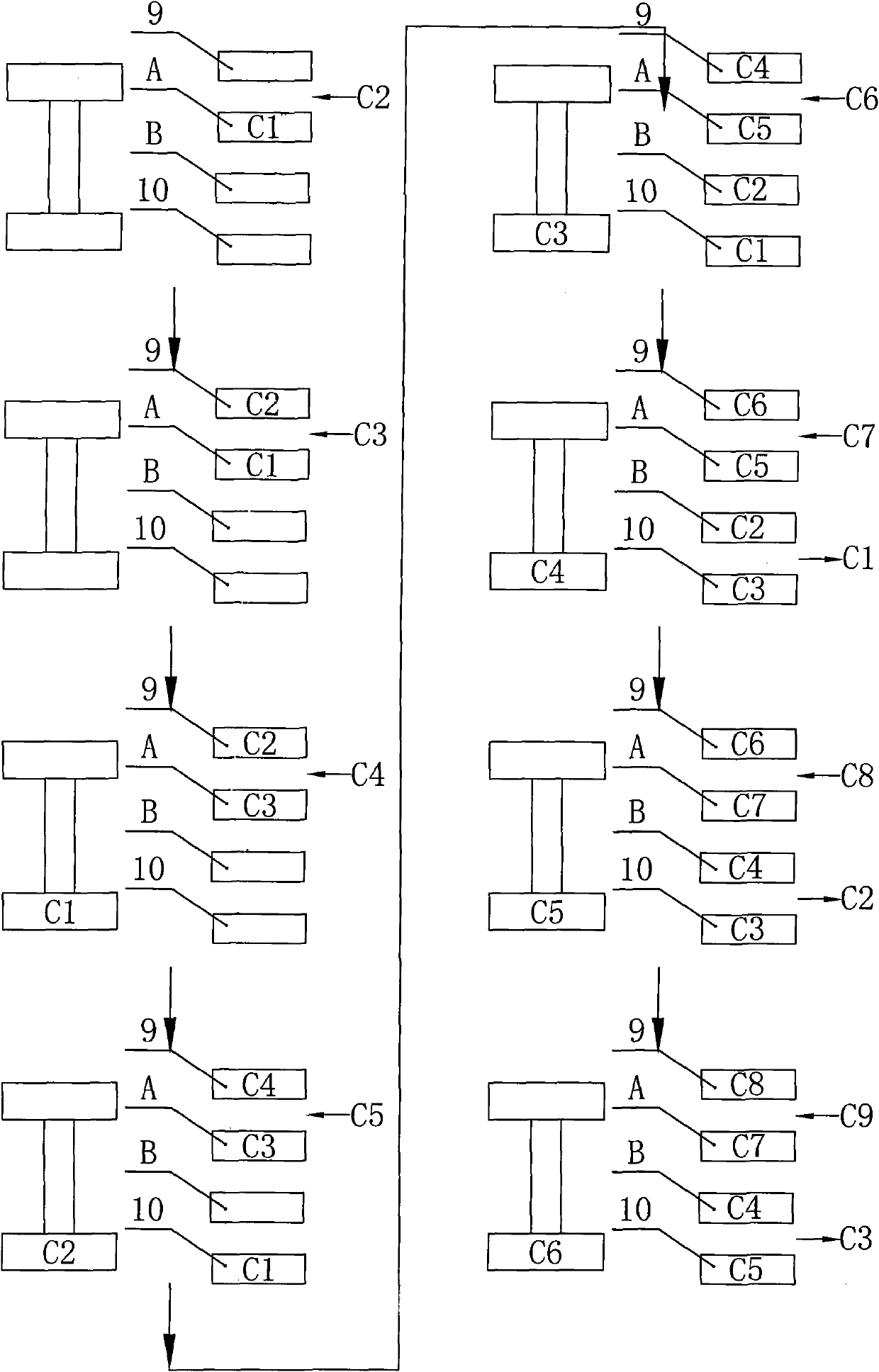

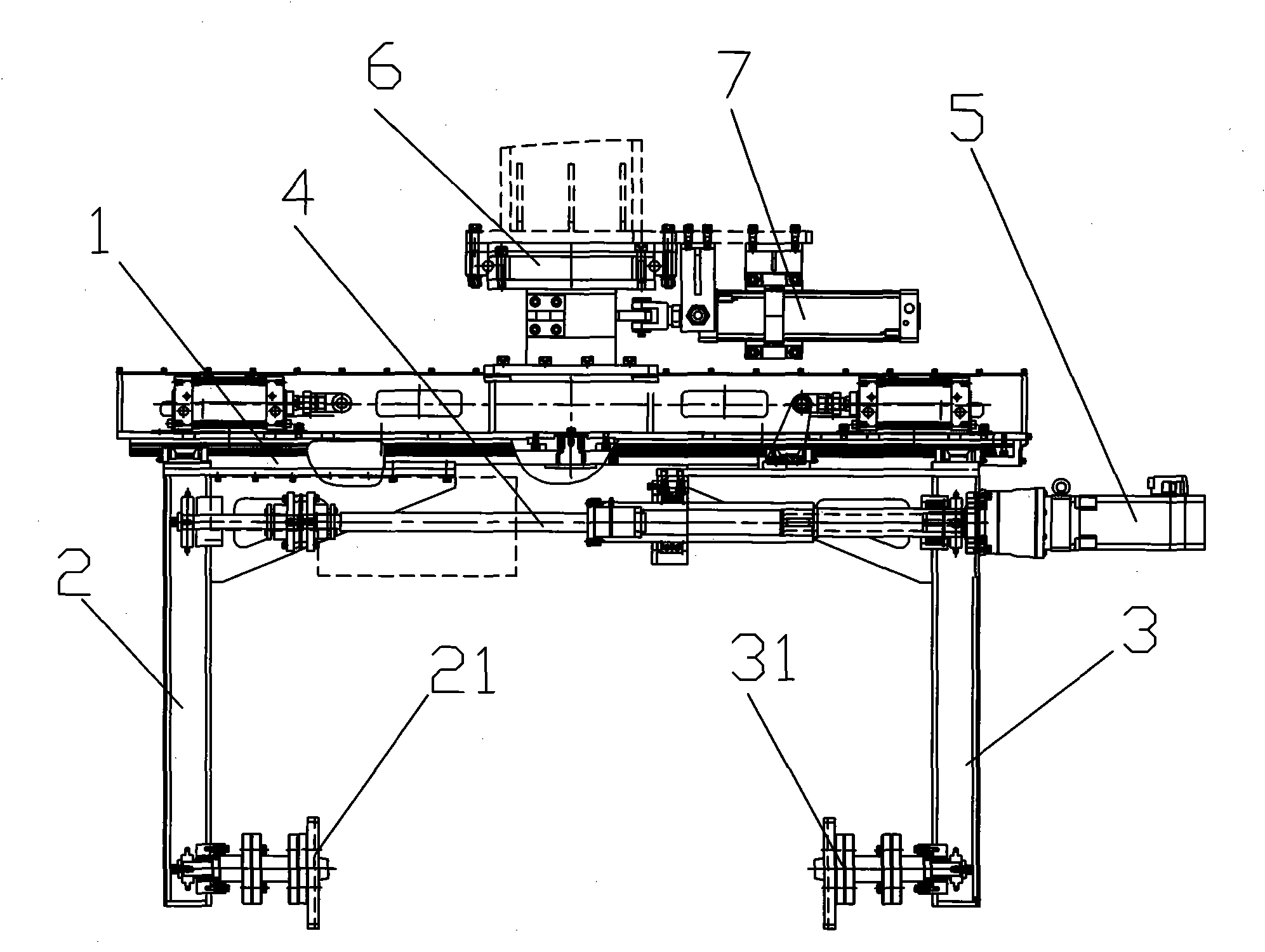

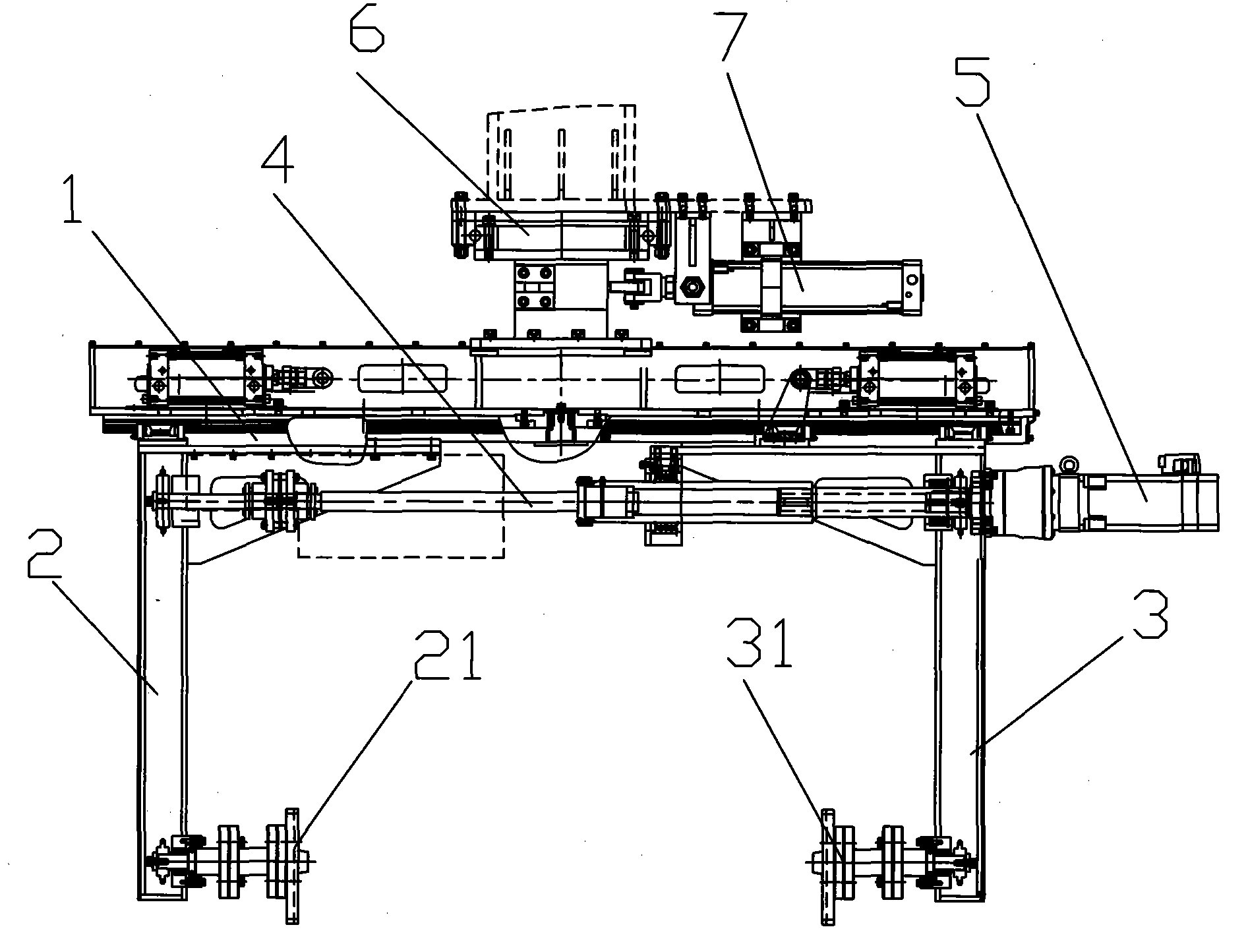

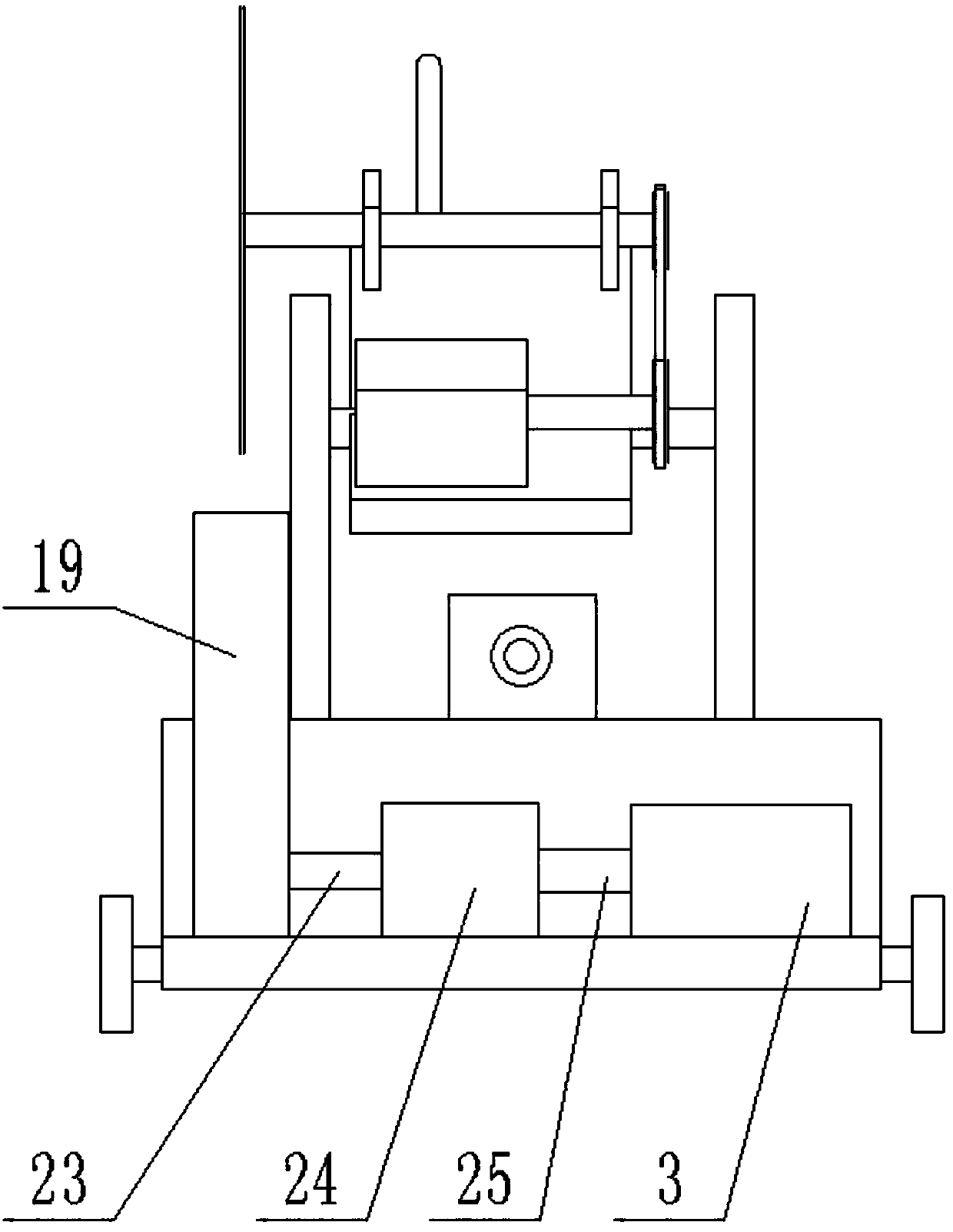

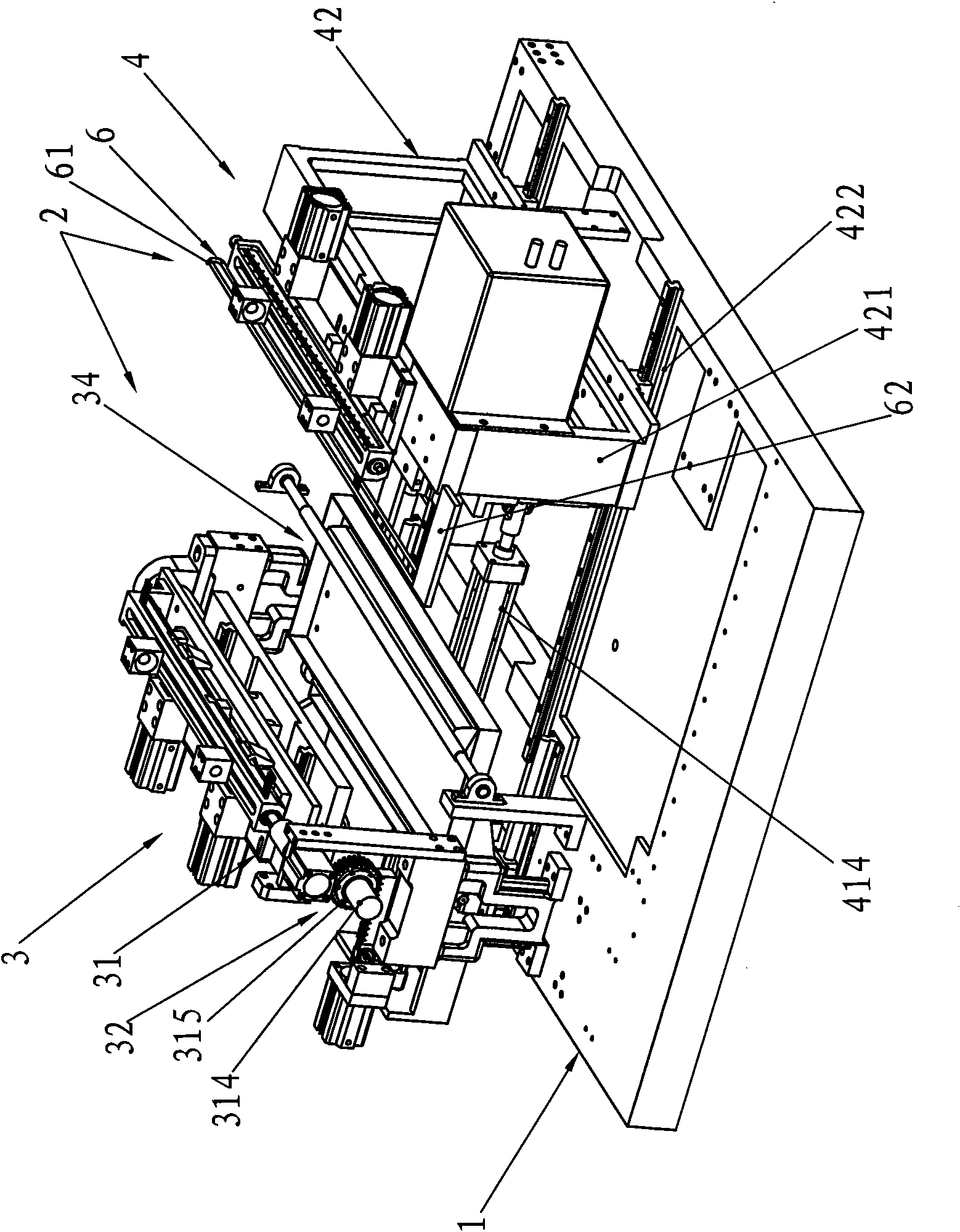

Automobile model switching mechanism of automobile production line

ActiveCN102873477ARealize automatic clampingQuick conversionWelding/cutting auxillary devicesAuxillary welding devicesProduction lineEngineering

The invention relates to an automobile model switching mechanism of an automobile production line, and solves the defect that in the prior art, one welding clamp only can correspond to one automobile model, so that the automobile model switching is inconvenient, the switching operation is troublesome and disordered, and the work efficiency is low. The automobile model switching mechanism comprises a rotating platform, at least two sets of clamping and positioning mechanisms on the rotating platform, and a rotary driving mechanism fixed under the rotating platform, wherein the clamping and positioning mechanisms comprise frame bodies, clamping arms, positioning arms and driving units; the clamping arms and the positioning arms are hinged to the frame bodies; the driving units correspond to the clamping arms and the positioning arms respectively; and the rotary driving mechanism comprises a rotating shaft and a driving gear meshed with outer teeth of the rotating shaft. As the clamping and positioning mechanisms are arranged on the rotating platform, and the lower part of the rotating platform is arranged on the production line, one set of rails is shared, and the rotary driving mechanism drives the rotating platform to rotate, the fast switching between two or three sets of the clamping and positioning mechanisms on the rotating platform is realized, the efficiency is high, the structure is simple, no transfer rail is required to be arranged additionally, and the cost is reduced.

Owner:ZHEJIANG JINGANG AUTOMOBILE +1

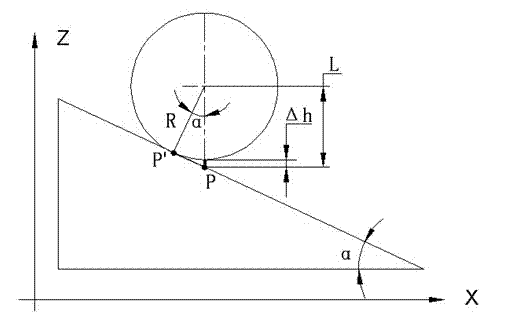

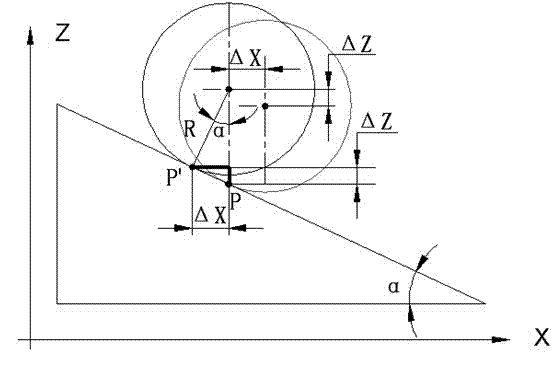

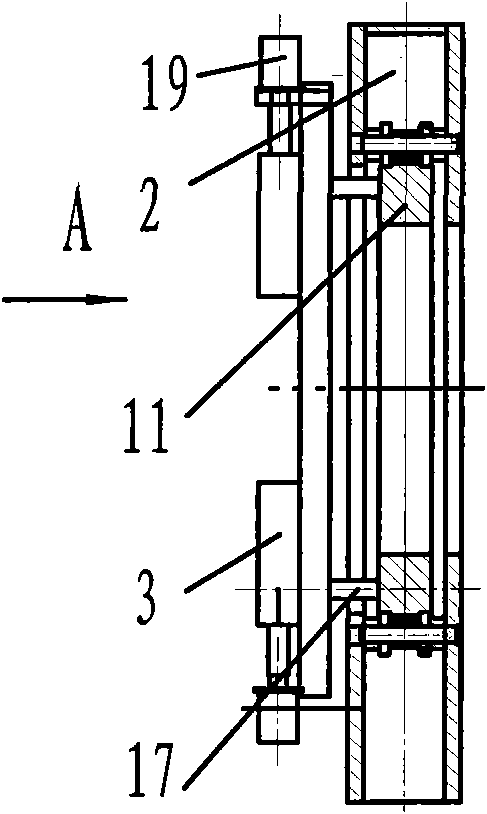

On-line measuring method for radials profile of compressor disc-like part of engine

InactiveCN102814512AAvoid errorsHas measurement limitationsAuxillary equipmentMeasurement/indication equipmentsReworkProcessing

The invention belongs to the field of automatic detection, particularly relates to an on-line measuring method for the radials profile of a compressor disc-like part of an engine. The method comprises the following steps that the measuring path of a measuring head is planned; the radius of sphere of the measuring head is corrected; characteristic points on the profile of a compressor disc are selected as measuring points; the motion program of the measuring head is edited; the motion track of the measuring head is optimized in virtual simulation software; the motion program of the measuring head is run; the measuring head traverses all the measuring points; the mean value of the measured values of the measuring points after errors are compensated is compared with the design theoretical value of the compressor disc part; when the measured values are within the design tolerance zone scope of the part, the processing size of the measured compressor disc part is considered to be qualified; otherwise, the processing and measurement are carried out again, until the size of the part is qualified. According to the method, a traditional manufacturing mode in the current industry that a design characteristic is matched with a set of measuring tooling is changed, so that the tooling manufacturing cost and the rework hours are saved, the one-time qualified rate of product processing is improved, the new product development cycle is shortened and the production cost is reduced.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

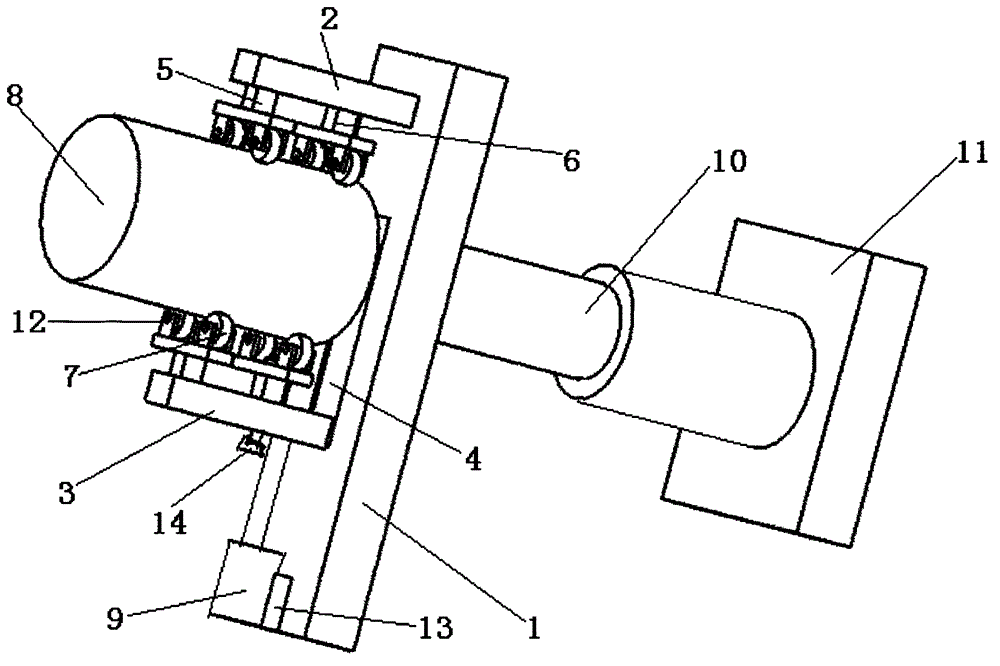

Machining tool for cylindrical workpieces

ActiveCN104985465AQuick clampingSmooth rotationWork clamping meansWelding/cutting auxillary devicesEngineeringMachine tool

The invention provides a machining tool for cylindrical workpieces. The machining tool comprises a bottom plate, a fixed support, a movable support, a first sliding groove, a fixed roller carrier, a sliding roller carrier, rollers, a first air cylinder, a second air cylinder and a locking bolt. By the adoption of the rollers, rapid workpiece clamping and accurate centering can be achieved, and workpieces can rotate conveniently in grinding or turning or welding or the like. By the adoption of the action of the air cylinders, automatic workpiece clamping can be achieved. By the arrangement of the first sliding groove and a second sliding groove, the distance between the fixed support and the movable support and the distance between the sliding roller carrier and the fixed roller carrier can be adjusted according to needs so that workpieces of different diameters can be clamped or different portions of workpieces can be clamped, and accordingly the universality and reliability of the tool are improved. The machining tool for the cylindrical workpieces is high in automation degree and clamping efficiency, greatly shortens the workpiece machining period, improves productivity and lowers the production cost.

Owner:ANHUI SCI & TECH UNIV

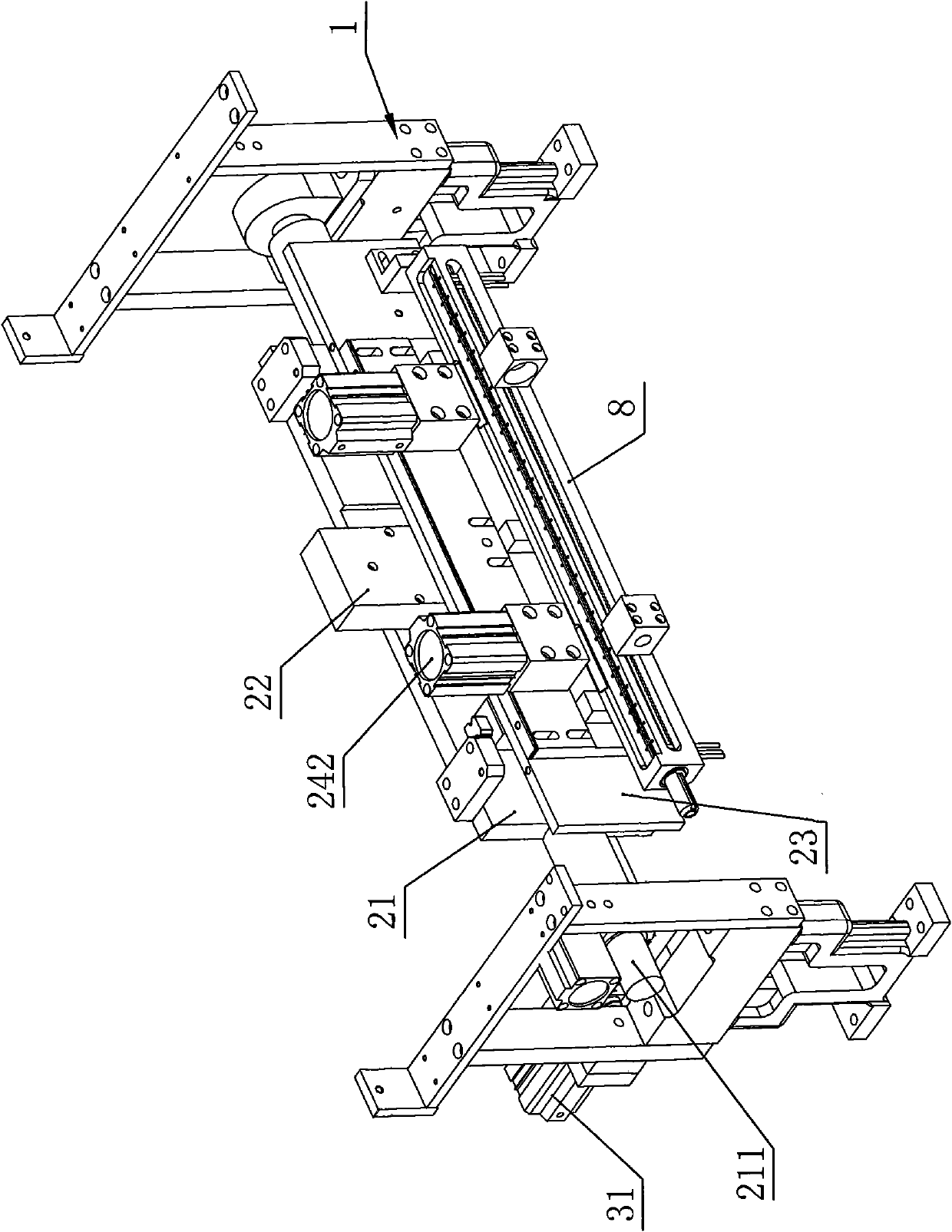

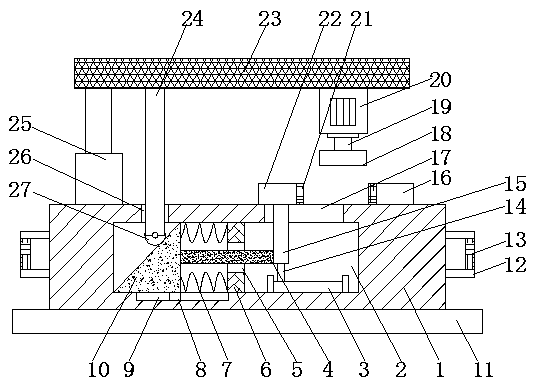

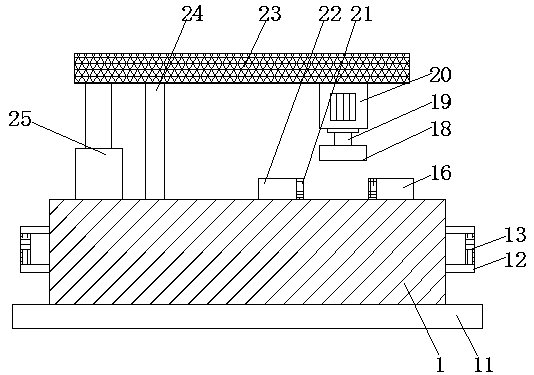

Programmable automatic welding system

ActiveCN101456107ARealize automatic feedingRealize automatic clampingWelding/cutting auxillary devicesAuxillary welding devicesSlide plateEngineering

The invention provides a programmable automatic welding system, which comprises a feed cylinder component, a main machine bedplate, a feeding component, a workpiece holding component, a welding gun holder, an electric control system, an air channel and a programmable controller, wherein the feed cylinder component comprises a feed cylinder and a T-shaped discharge oblique path for through which a workpiece enters the feed cylinder is arranged above the feed cylinder component; and the feeding component comprises a feeding bedplate and is fixed on the machine bedplate, two sides of the feeding component are provided feeding slide rails with a square notch respectively, and two sides of the feeding bedplate are fixed with feeding sliding plates which are matched with the slide rails respectively. The programmable automatic welding system can realize automatic feeding, automatic holding, automatic welling and automatic material retuning, sets free workers from complex manual labour, controls multi-direction operations and time through programs and is suitable for welding products of various sizes.

Owner:NINGBO XULI METAL PROD

Lifting type centering clamping device and clamping method thereof

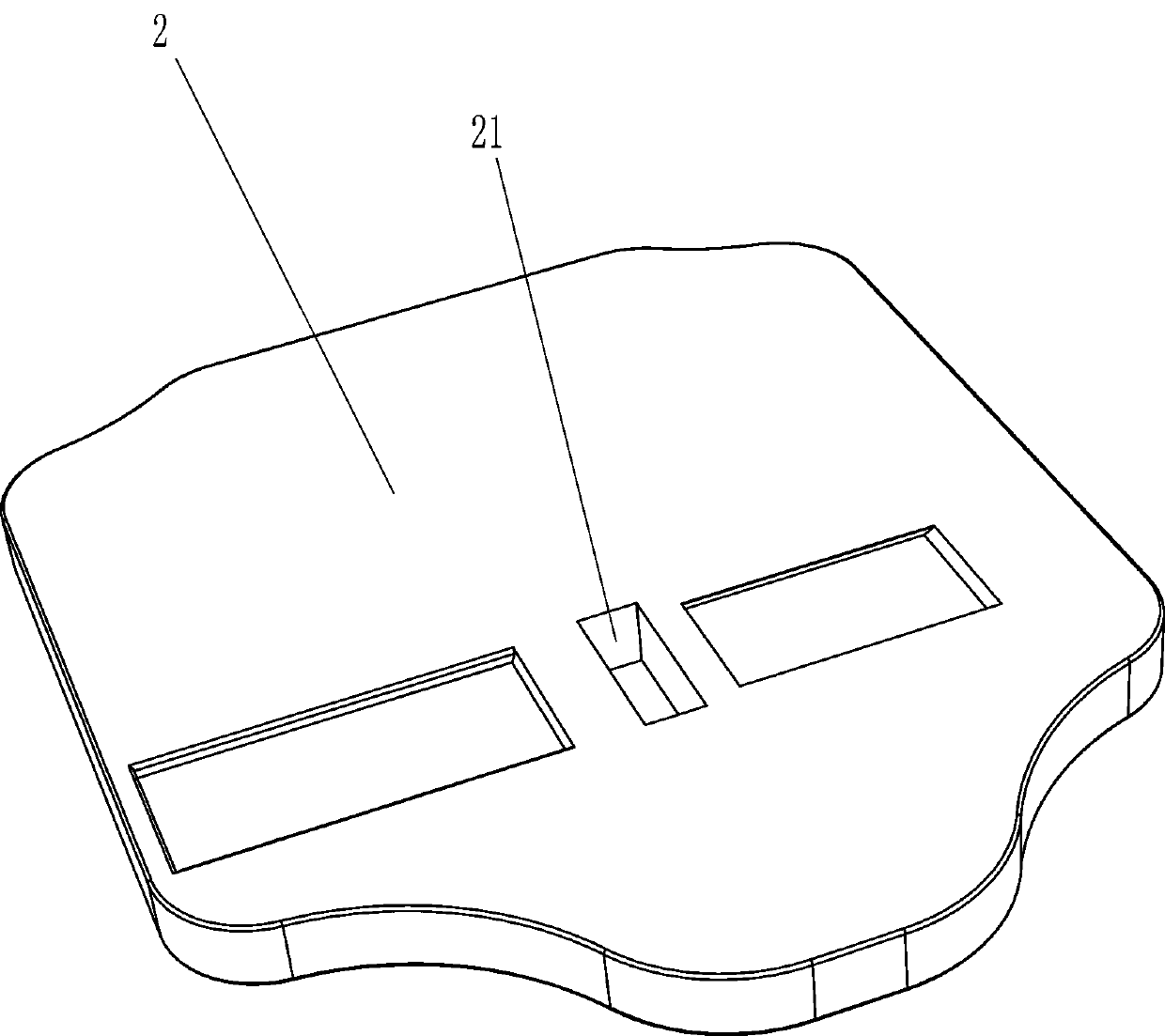

InactiveCN106975952AAchieve clampingAchieve releaseMetal working apparatusPositioning apparatusProduction lineLogistics management

A lifting type centering clamping device comprises a centering clamping mechanism and a lifting mechanism. The centering clamping mechanism comprises a bottom plate, a clamping air cylinder, a left connecting plate, a right connecting plate, a left clamping plate and a right clamping plate, wherein the left connecting plate, the right connecting plate, the left clamping plate and the right clamping plate are sequentially and symmetrically mounted on the left and right sides of the bottom plate; the left clamping plate and the right clamping plate are oppositely mounted to form an open-ring type clamping opening; the left connecting plate is connected with the left clamping plate through a screw rod; the right connecting plate is connected with a piston rod of the clamping air cylinder stretching into the right connecting plate; and the clamping air cylinder moves to drive the right clamping plate to move towards the left clamping plate to clamp or loosen a workpiece. The lifting mechanism comprises a base and a lifting air cylinder; a piston rod of the lifting air cylinder is connected with the bottom plate of the centering clamping mechanism; and the lifting air cylinder moves to push the bottom plate to lift and drop to realize lifting and dropping of the centering clamping mechanism. A clamping method of the centering clamping device comprises the steps of initial adjustment, clamping and loosening. The device is small in size, compact in structure and easy in operation of the clamping method, can meet the clamping machining requirement of longitudinally and transversely conveying the workpiece, and can be widely used in an automatic logistics production line.

Owner:LIUZHOU OVM MASCH CO LTD

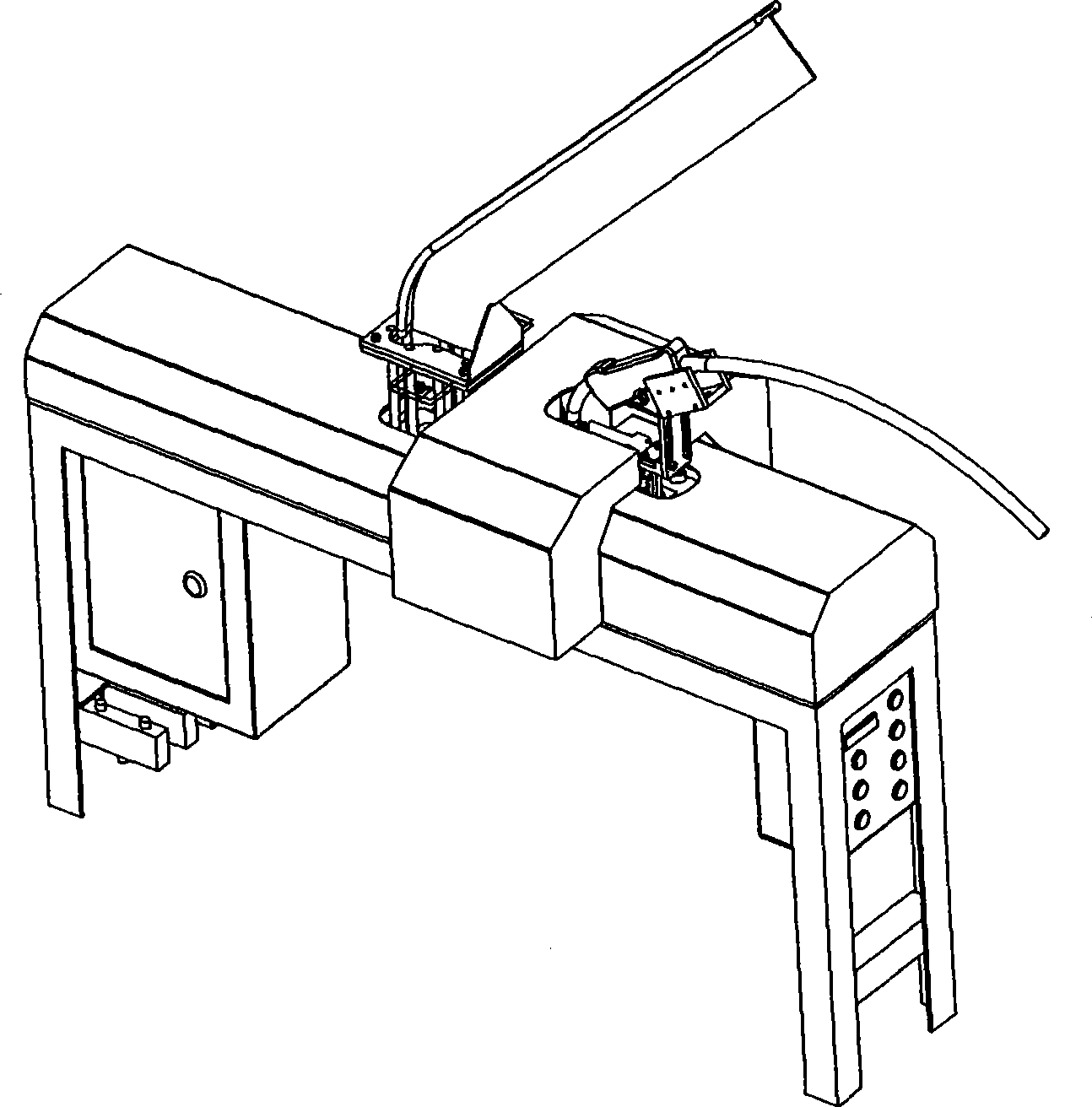

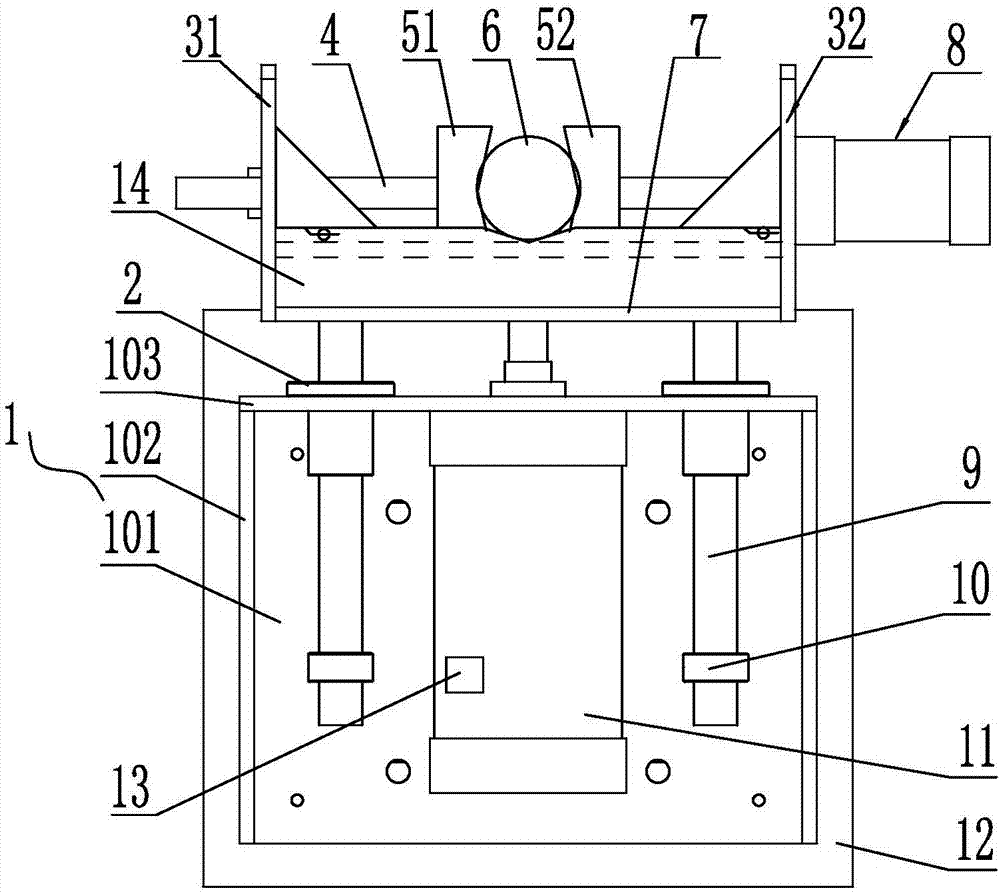

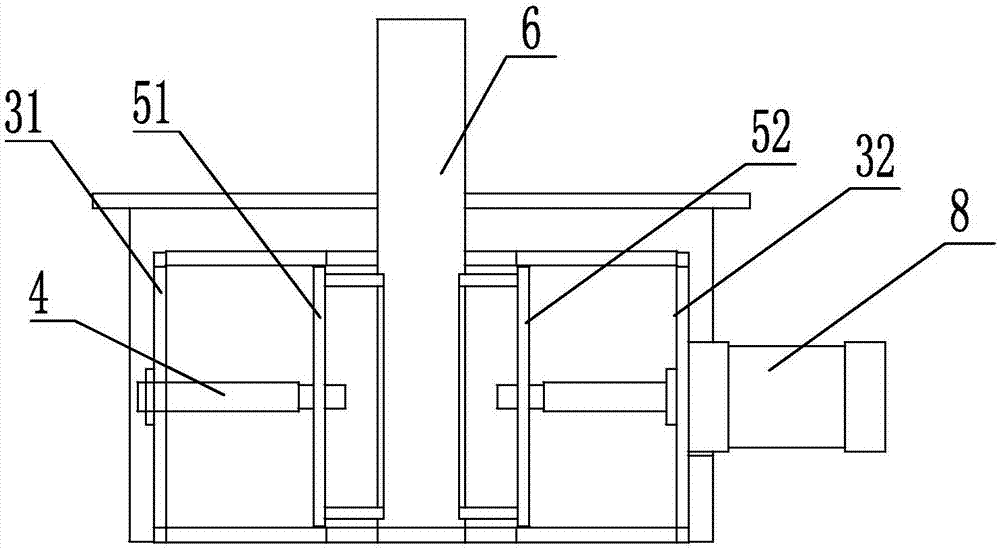

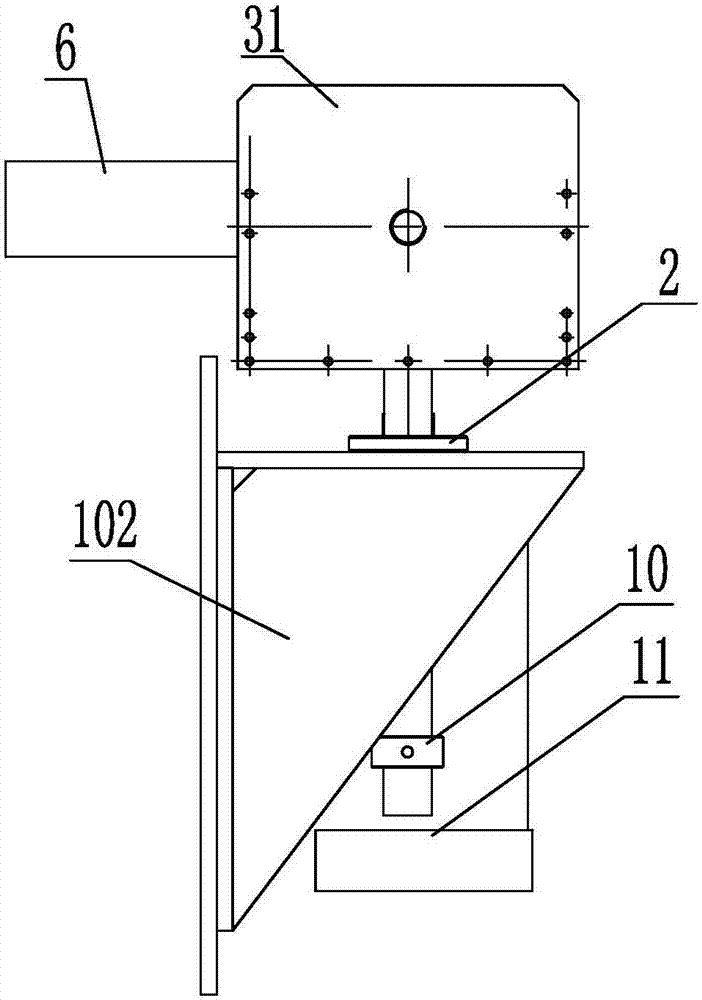

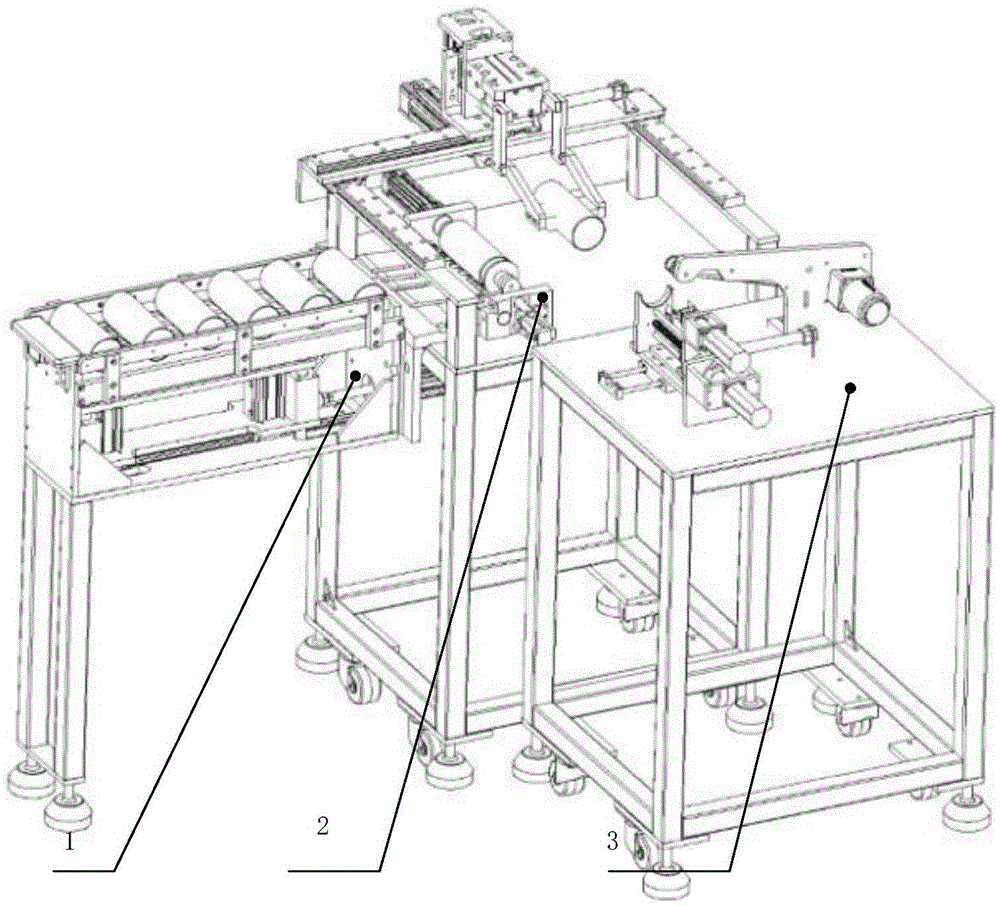

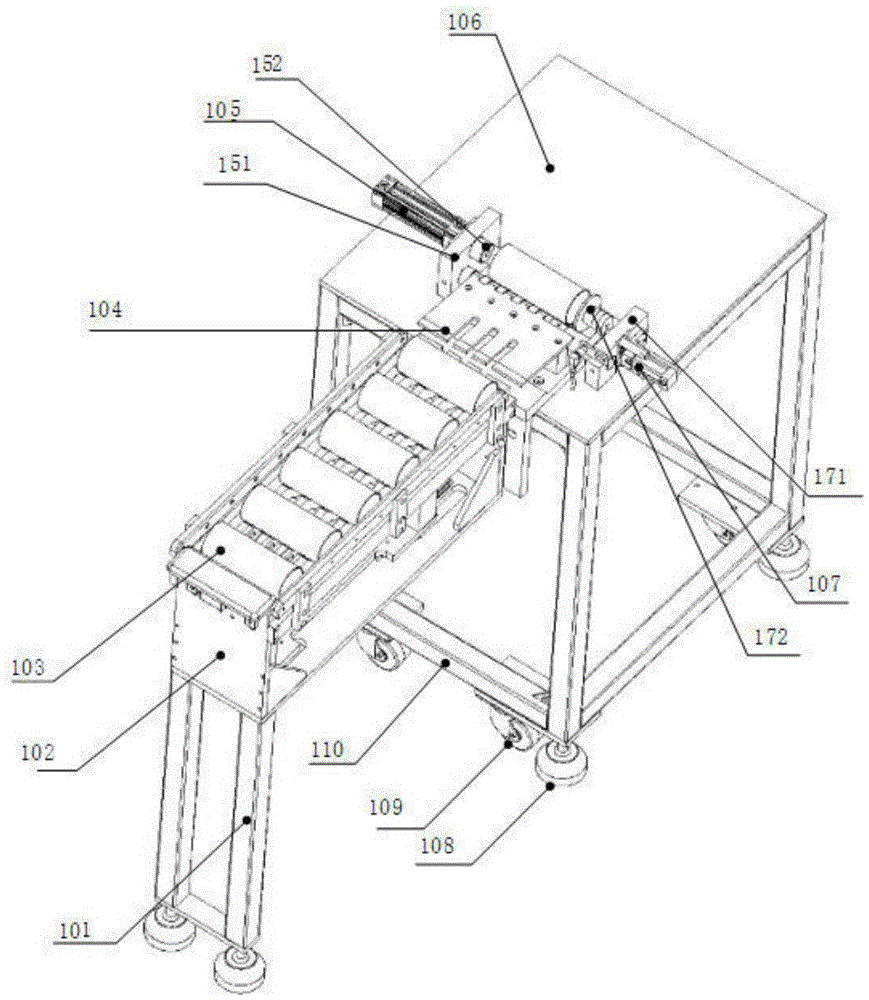

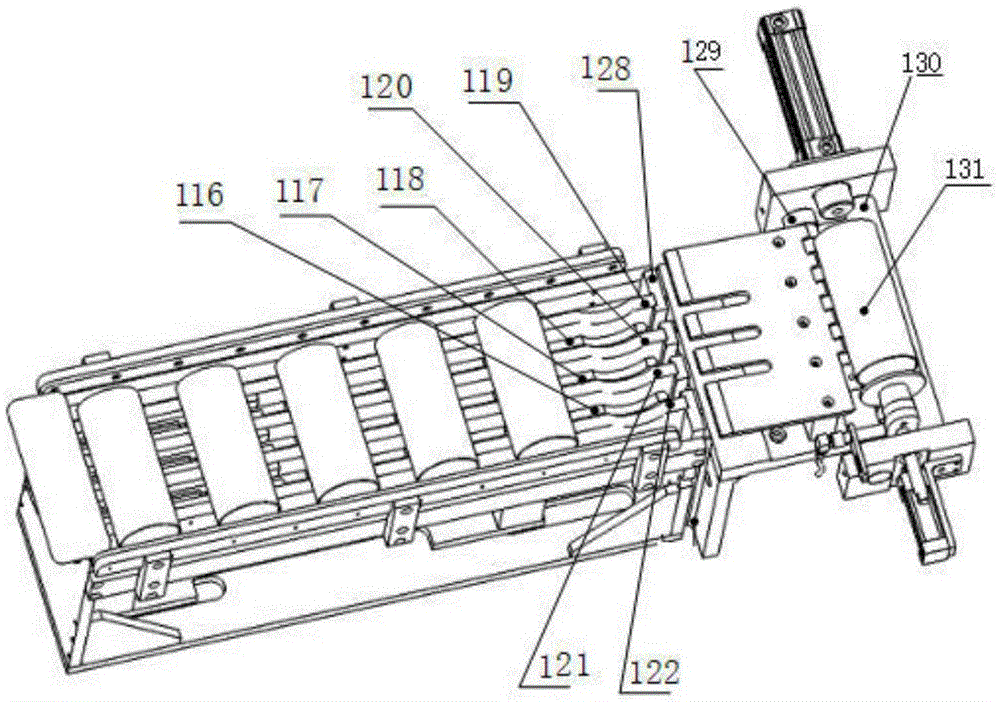

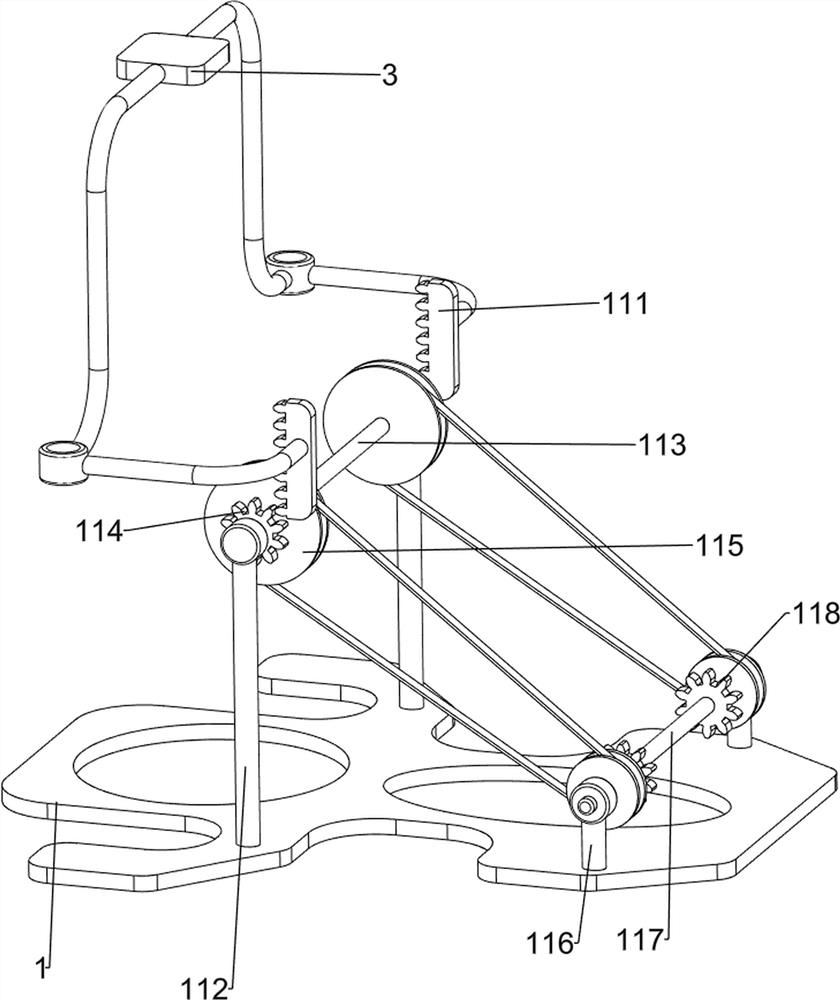

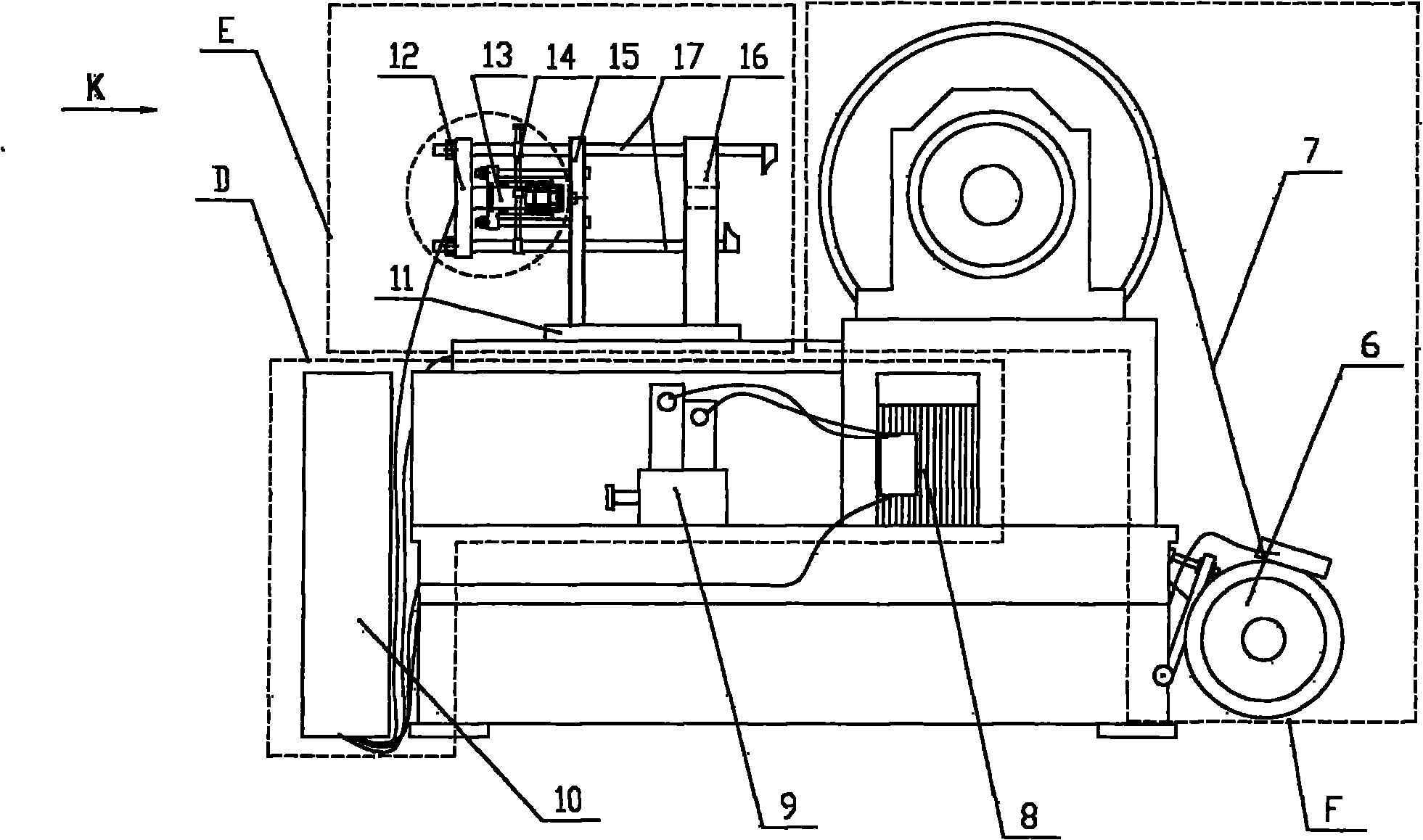

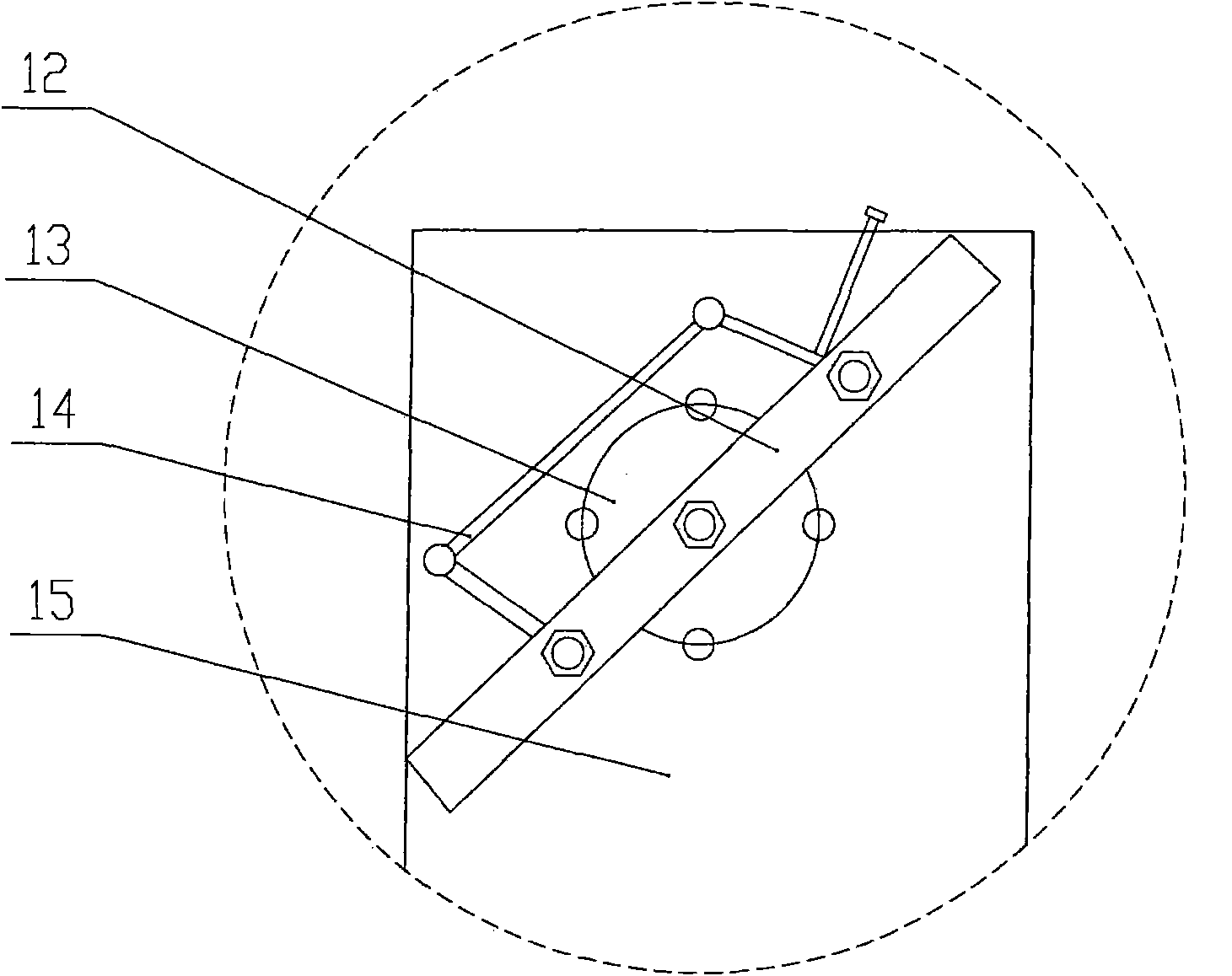

Automatic polishing system for stainless-steel cups

InactiveCN105619212ARealize automatic deliveryRealize automatic clampingGrinding drivesBelt grinding machinesEngineeringMotion control

The invention provides an automatic polishing system for stainless-steel cups, which comprises a conveying mechanism, a feeding mechanism and an external polishing mechanism, wherein the conveying mechanism comprises a conveying frame, a conveying table unit and a pressing unit; the conveying table unit and the pressing unit are mounted on the conveying frame; the feeding mechanism is mounted on a bracket faceplate of the conveying mechanism and comprises a feeding frame and a motion control unit mounted on the feeding frame; the external polishing mechanism comprises a polishing frame, an abrasive belt control unit and a part motion control unit; and the abrasive belt control unit and the part motion control unit are mounted on the polishing frame. The automatic polishing system for the stainless-steel cups can completely replace manual operation, remarkably improves the working efficiency, lowers the labor cost and increases the automation level of enterprises. Meanwhile, the automatic polishing system for the stainless-steel cups realize accurate control of polishing parameters and can achieve more stable and favorable polishing quality.

Owner:望江县雷创科技有限公司

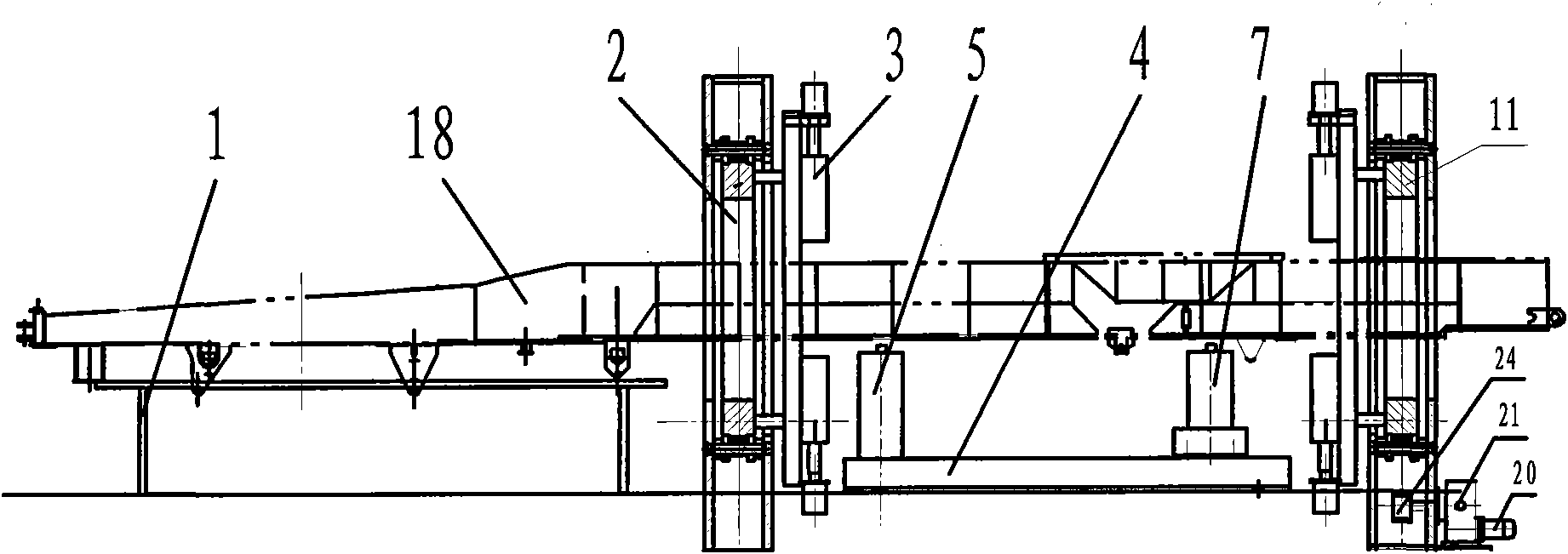

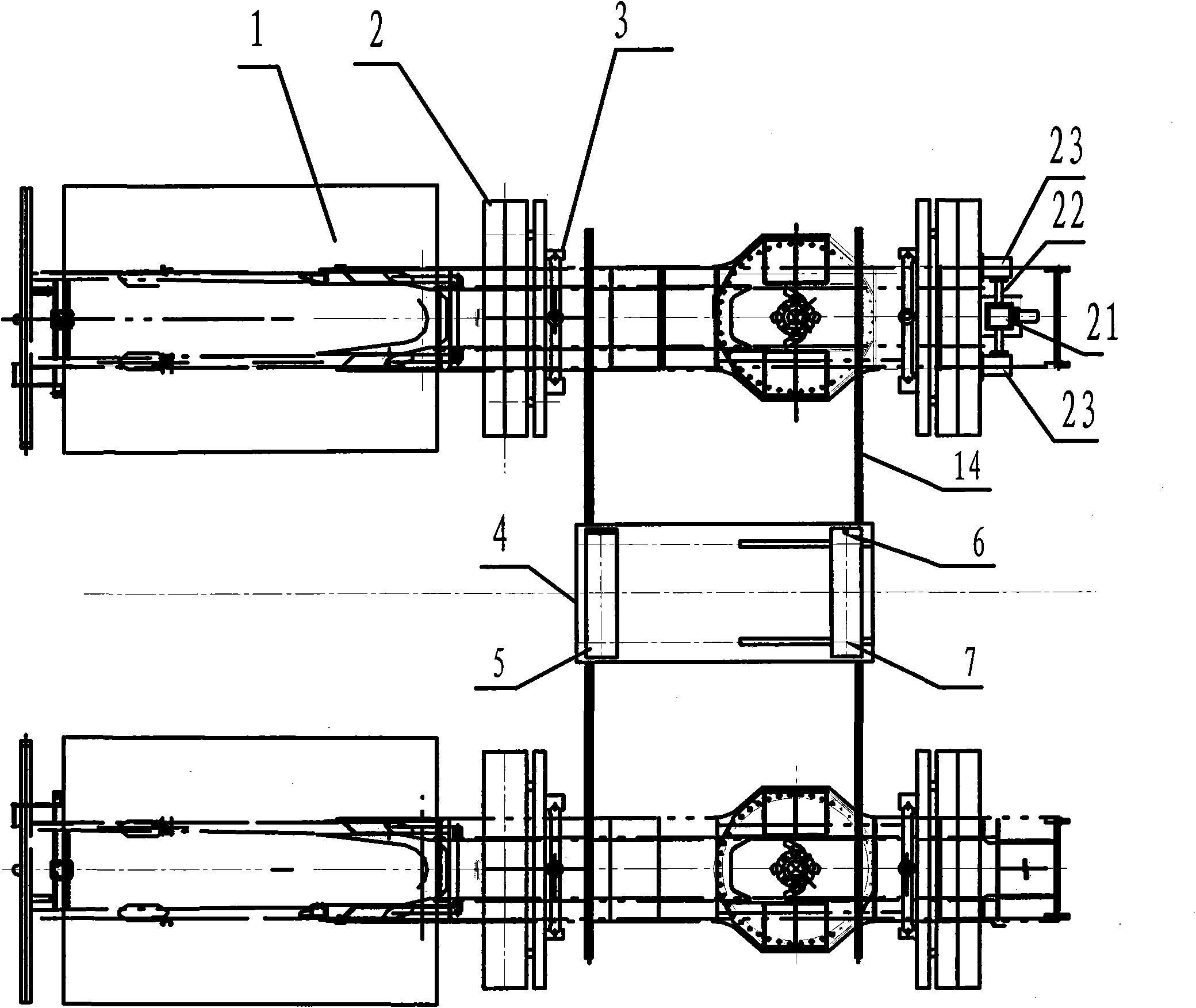

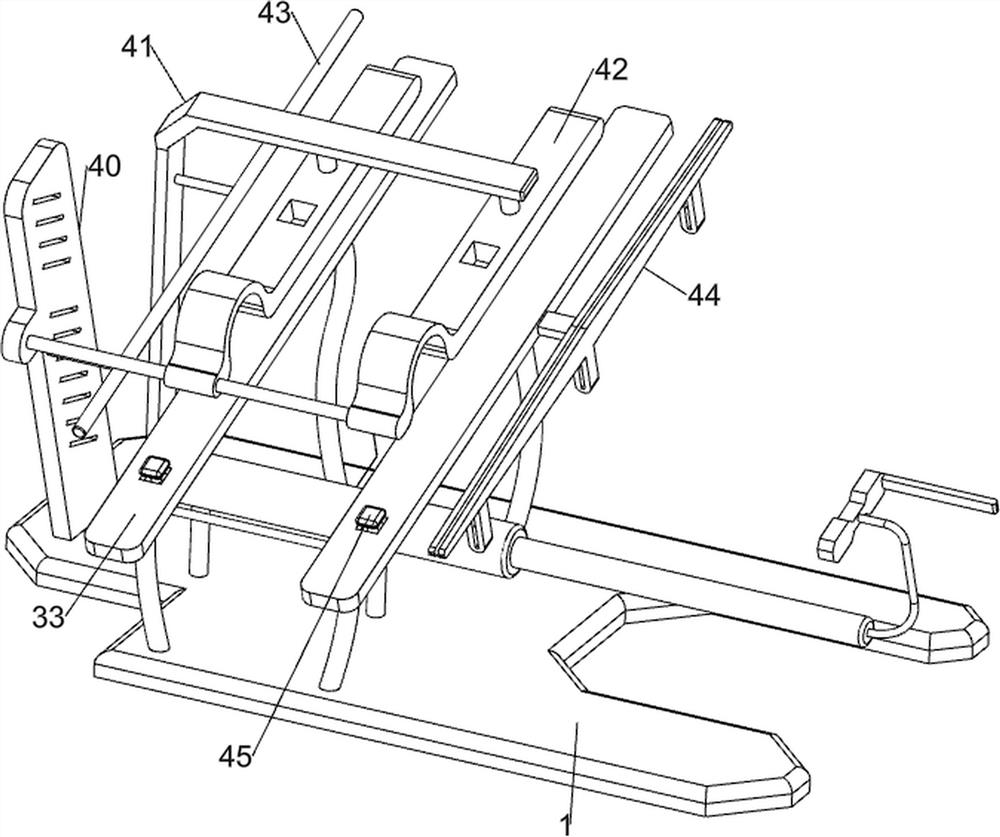

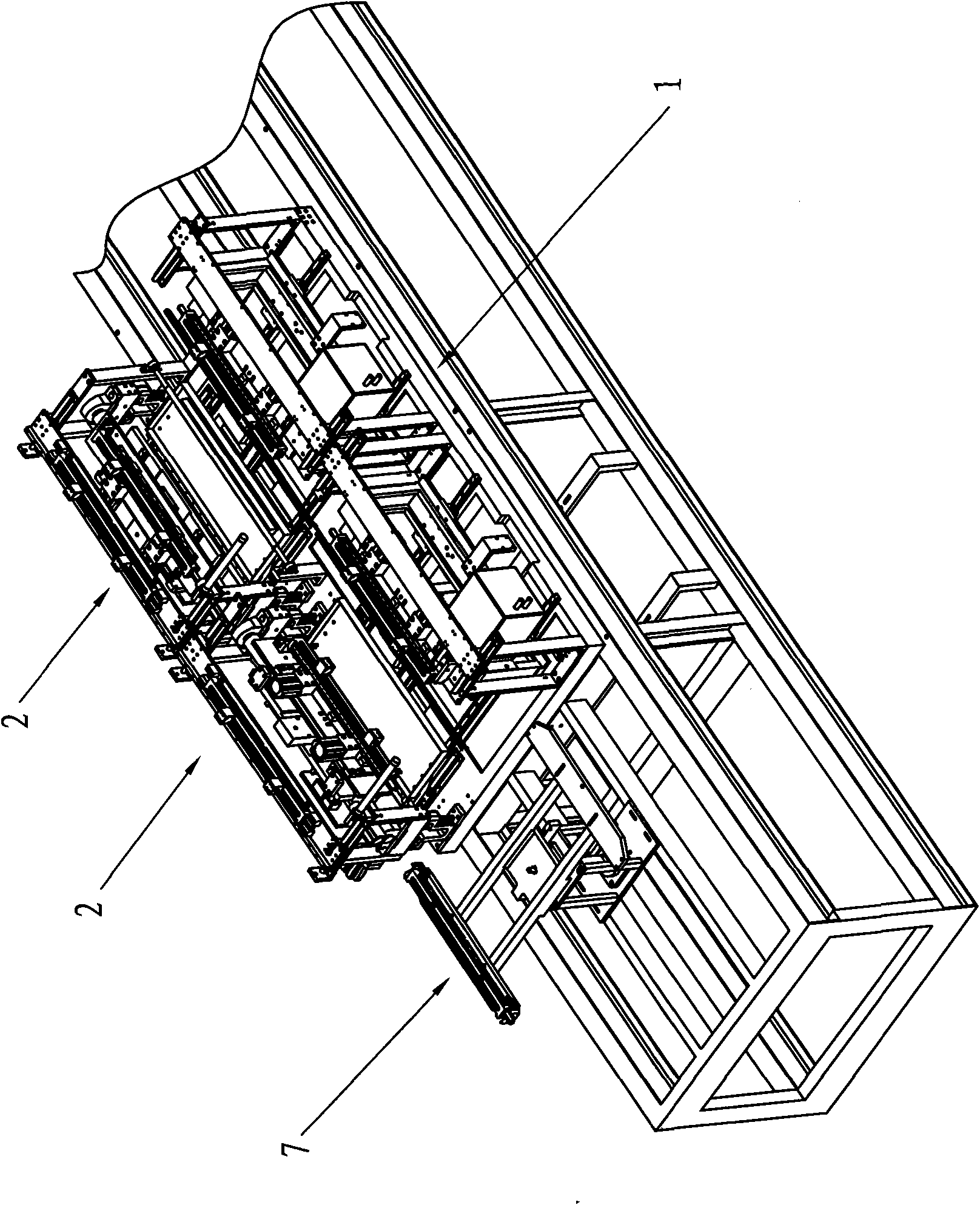

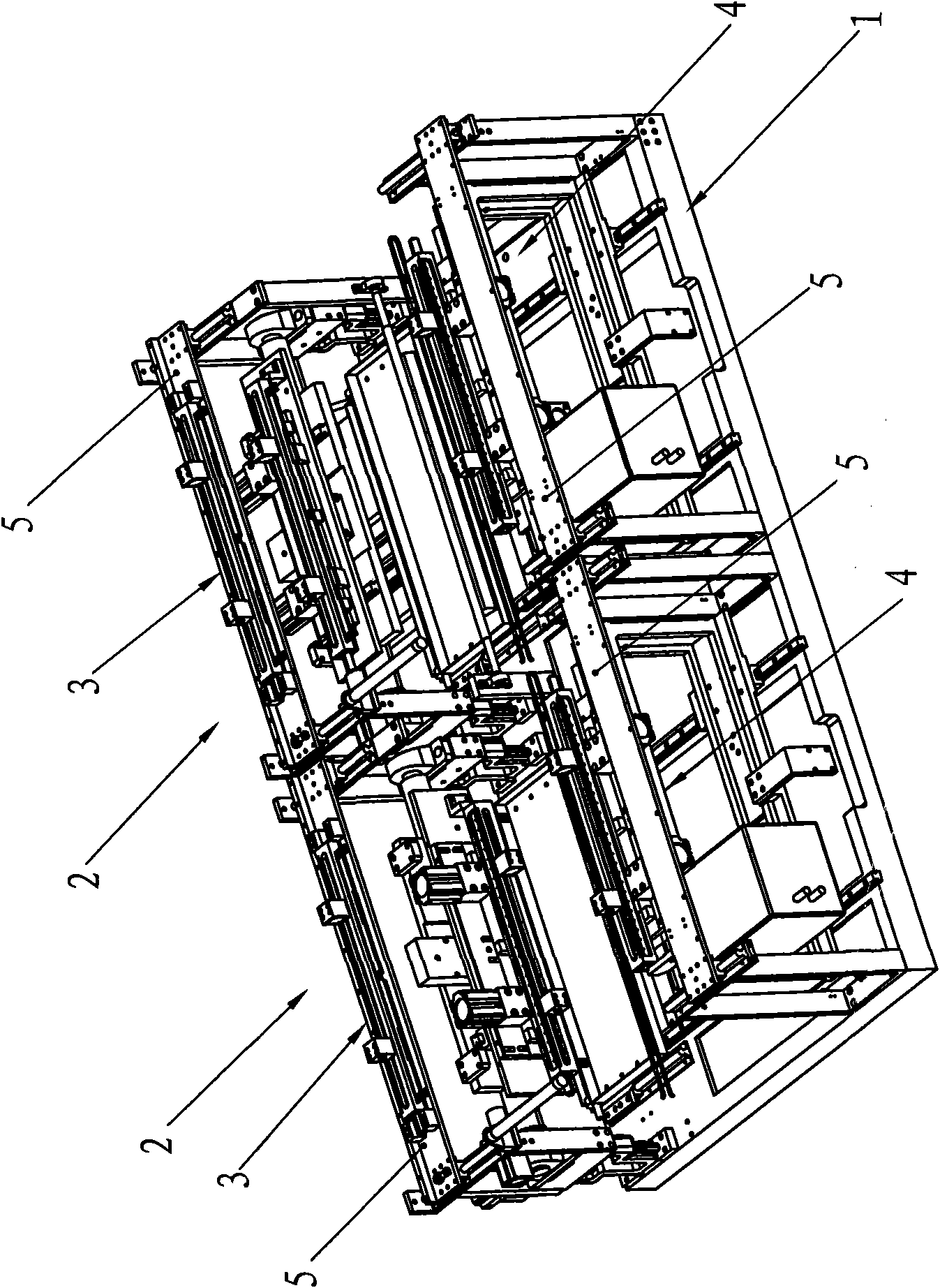

Side open type carriage welding turnover work center

InactiveCN101890608AConvenient welding operationGuaranteed coincidenceWelding/cutting auxillary devicesAuxillary welding devicesVehicle frameEngineering

The invention discloses a side open type carriage welding turnover work center belonging to automobile crane carriage welding displacement equipment. The turnover center comprises a side open welding positioner, a three-dimensional feeding trolley, a lifting platform and an electric control system, wherein the three-dimensional feeding trolley is located in the middle of the side open welding positioner, the lifting platform is arranged in front of the side open welding positioner, the three-dimensional feeding trolley is arranged on rails which are perpendicular to the side open welding positioner, and the electric control system is simultaneously connected with the three-dimensional feeding trolley, the lifting platform and the side open welding positioner. The side open type carriage welding turnover work center has the advantages that firstly, two side open tilters commonly use one feeding trolley, thus the turnover work center is compact in structure, secondly, the lateral faces of the tilters are open for realizing the positioning of work-pieces, thirdly, the work-pieces can be automatically clamped, and production efficiency are high, fourthly, 180-degree idle rotation can be realized in a turnover ring, which realizes the requirement that carriages are positively fed and reversely discharged, and fifthly, welding operations of workers are convenient.

Owner:XUZHOU HEAVY MASCH CO LTD

Tapping device convenient to clamp and adjust

InactiveCN112475486AAvoid shakingEasy loadingThread cutting feeding devicesThread cutting machinesCamDrill bit

The invention relates to a tapping device, in particular to a tapping device convenient to clamp and adjust. The tapping device convenient to clamp and adjust is easy to operate, high in efficiency and high in stability. The tapping device convenient to clamp and adjust comprises a base and first sliding rails, wherein the two first sliding rails are arranged on the base; a first supporting frame,wherein the first supporting frame is slidably connected between the upper portions of the two first sliding rails; a tapping mechanism, wherein the tapping mechanism is arranged in the middle of thefirst supporting frame and connected with the first sliding rails; and a fixing mechanism, wherein the fixing mechanism is arranged on the base and matched with the tapping mechanism. According to the tapping device convenient to clamp and adjust, a space cam is engaged with a shifting block, the space cam enables the shifting block to move up and down repeatedly, thus a tapping drill bit moves up and down repeatedly, after the tapping drill bit moves downwards to make contact with a steel plate, the tapping drill bit conducts tapping on the steel plate, thus the purpose of automatic downwardpressing is achieved, and operation is easy and convenient.

Owner:张万香

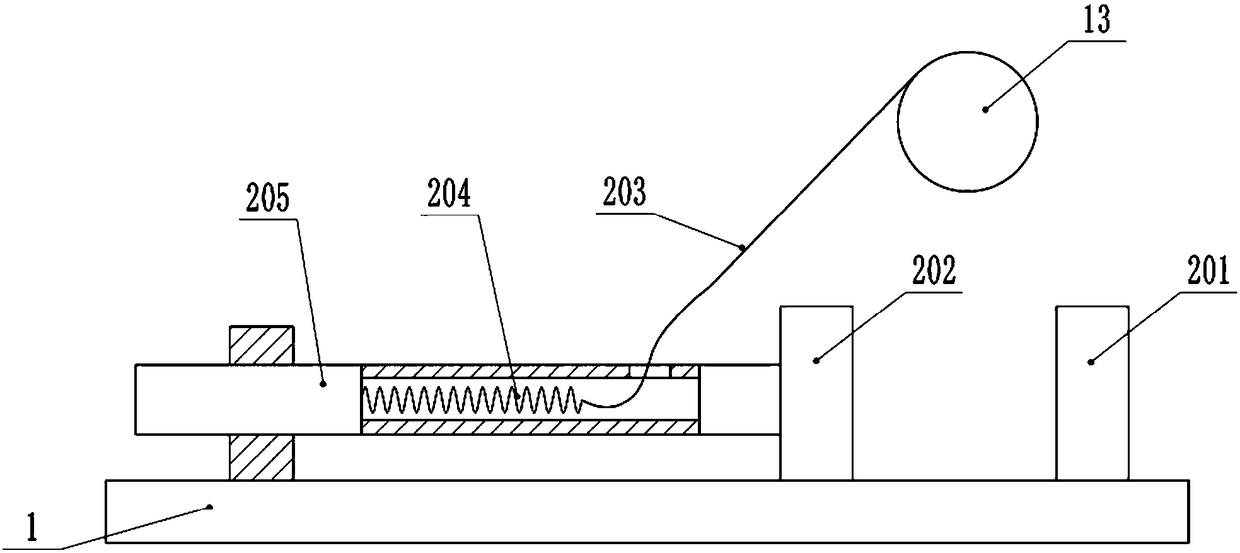

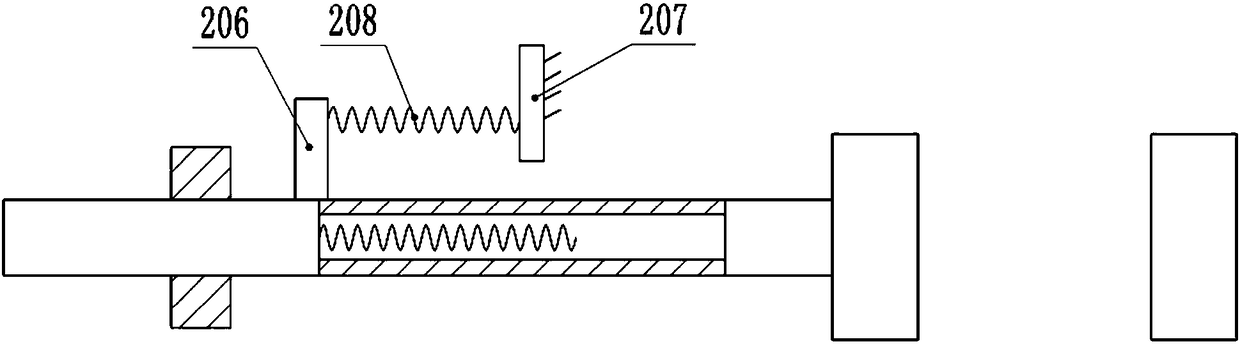

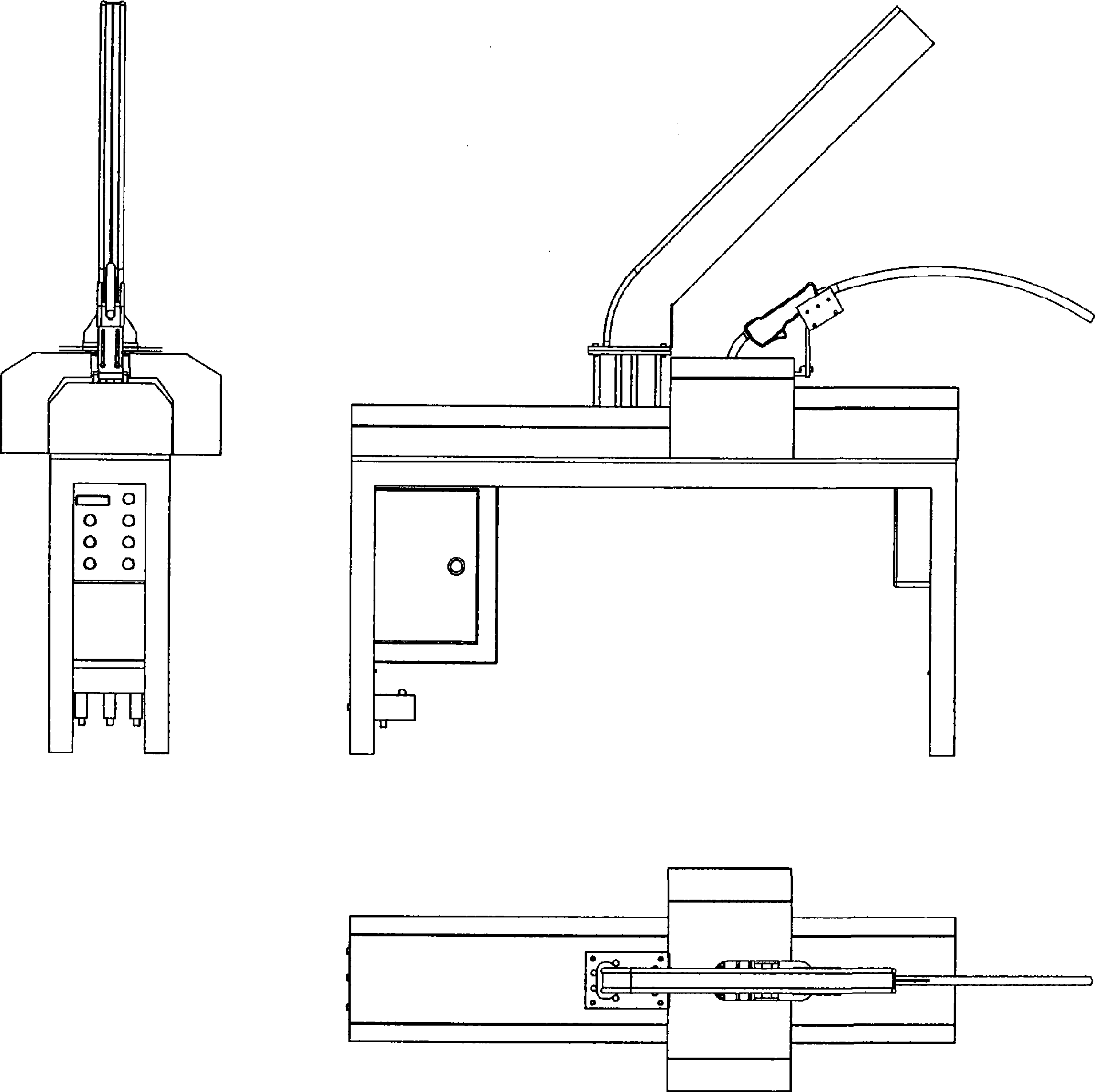

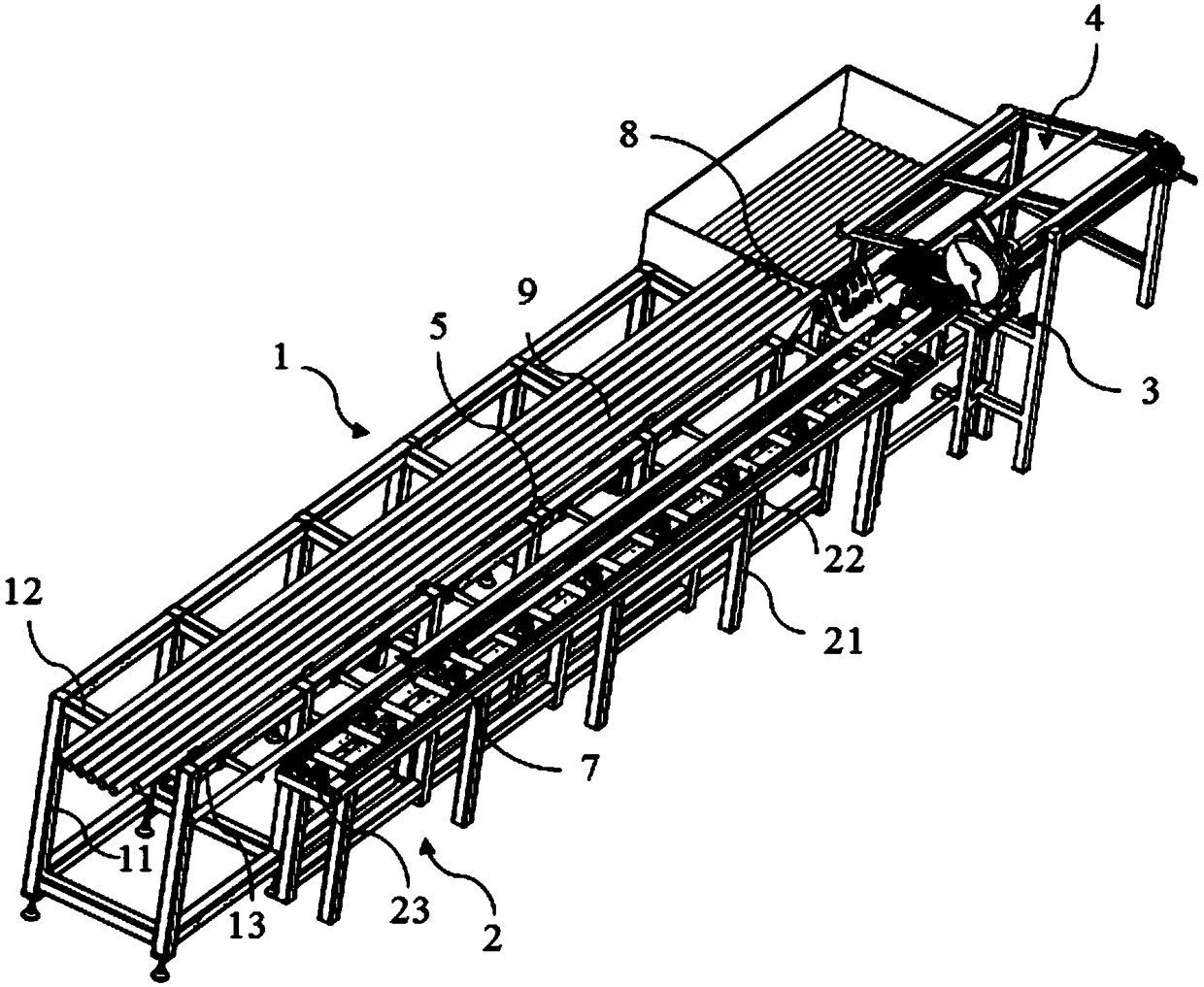

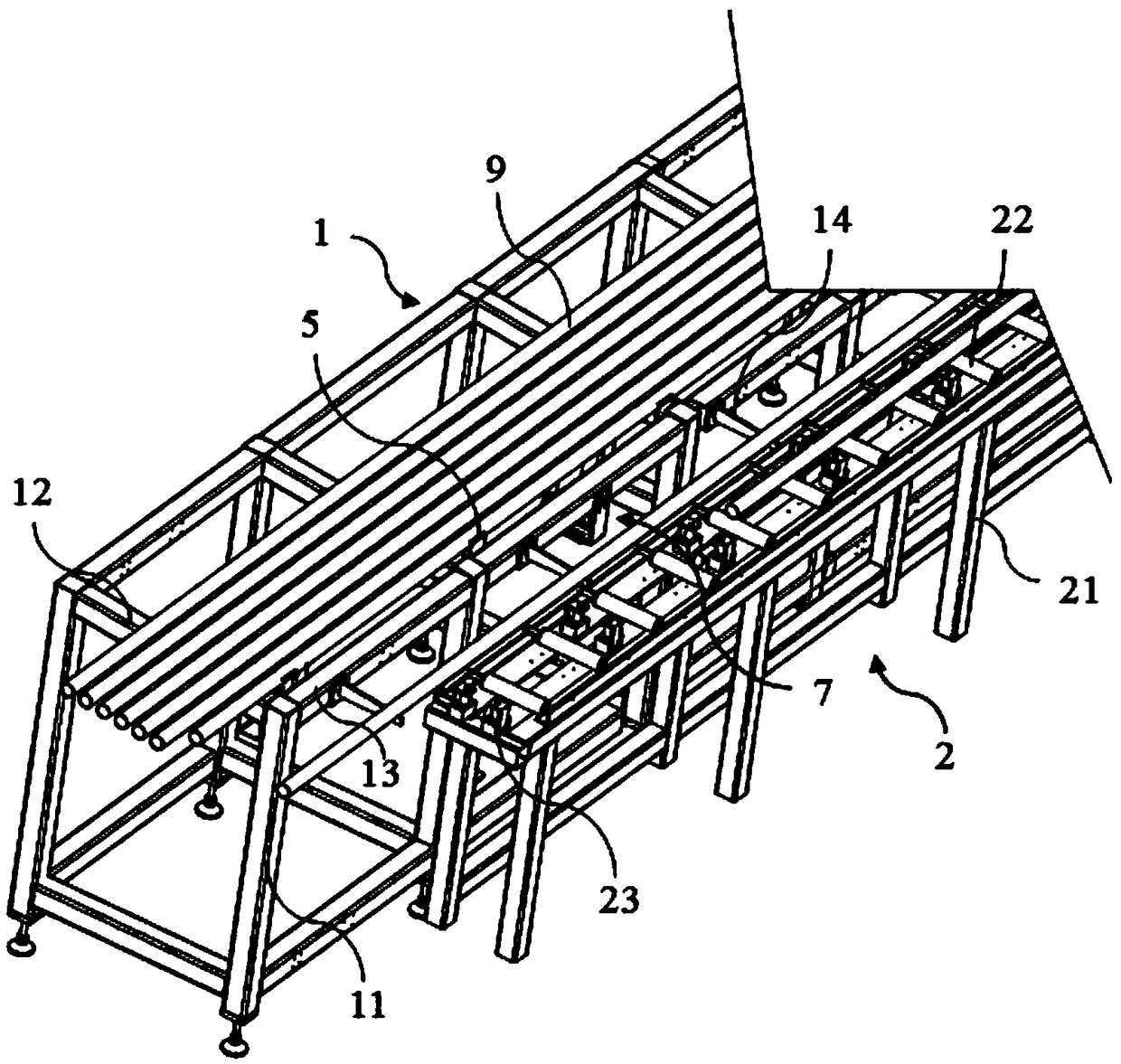

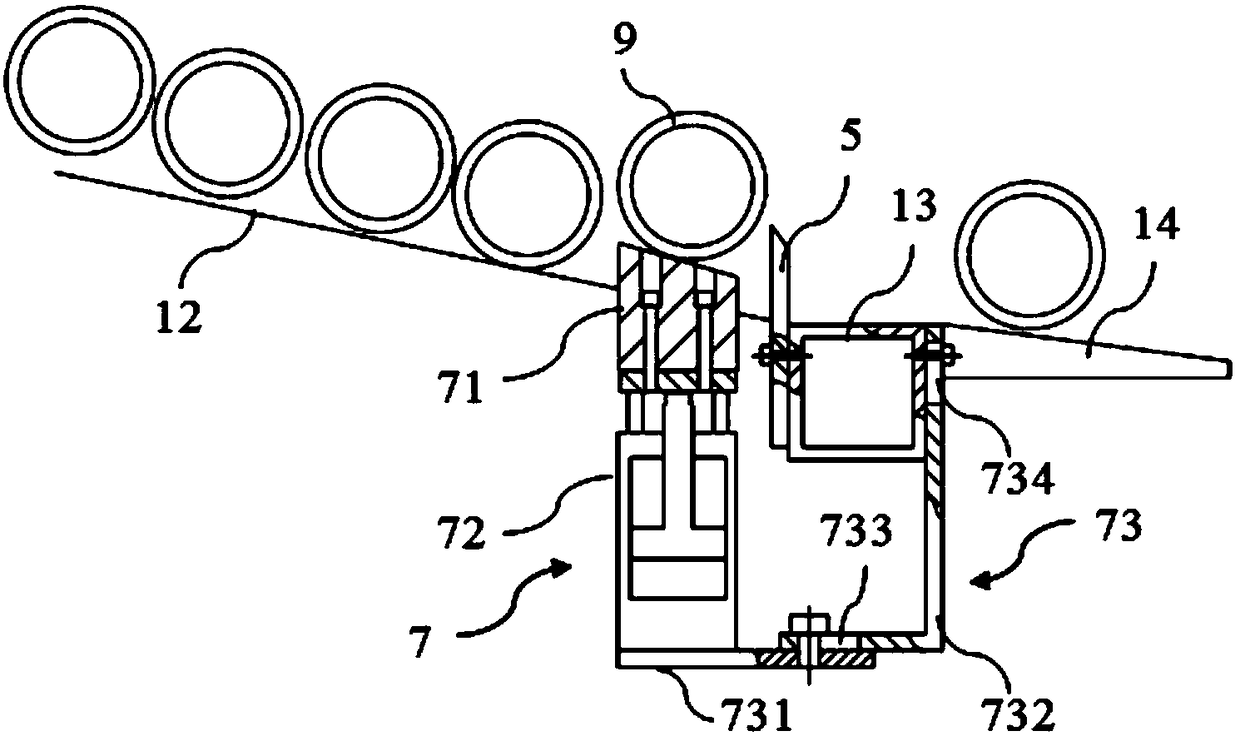

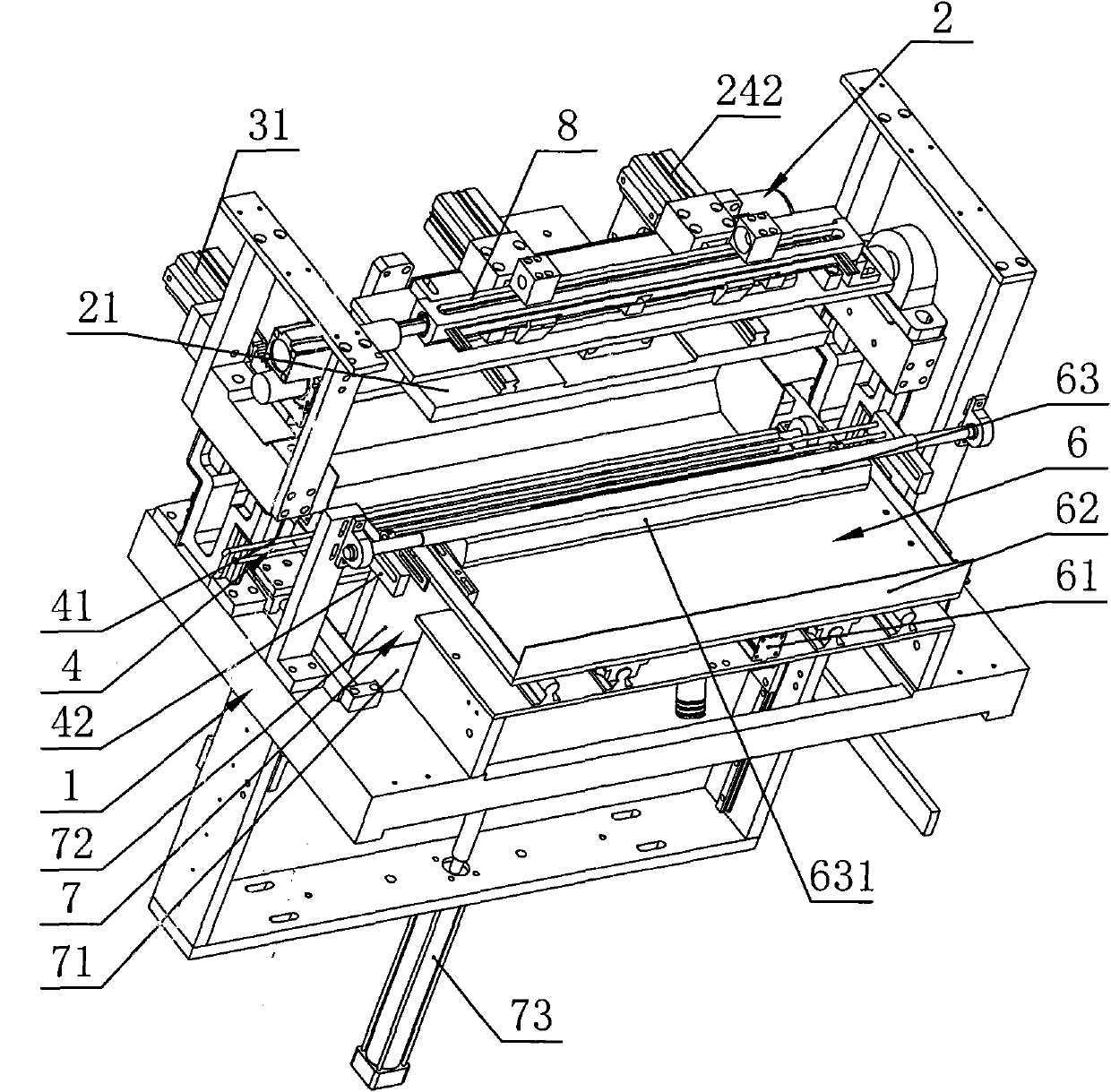

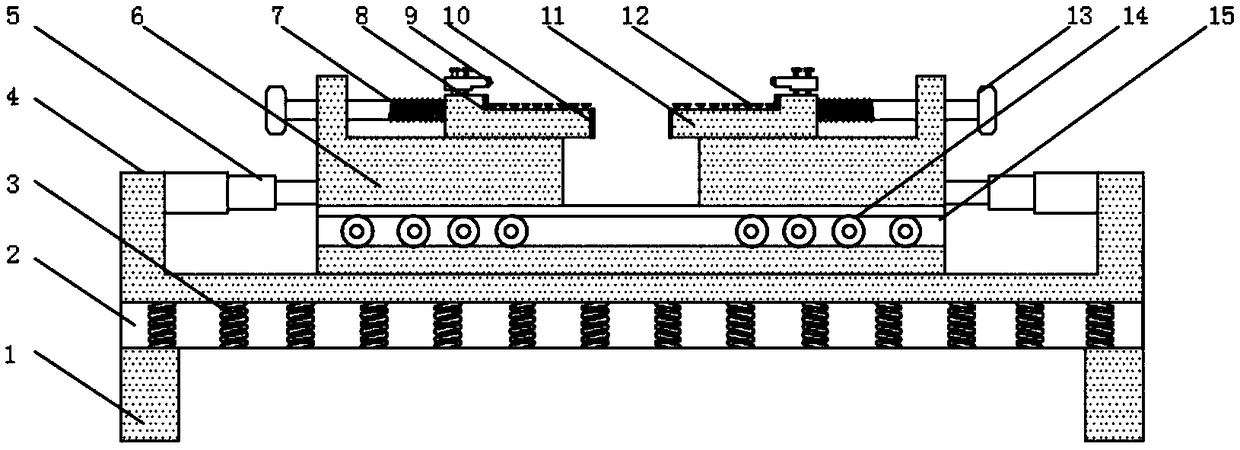

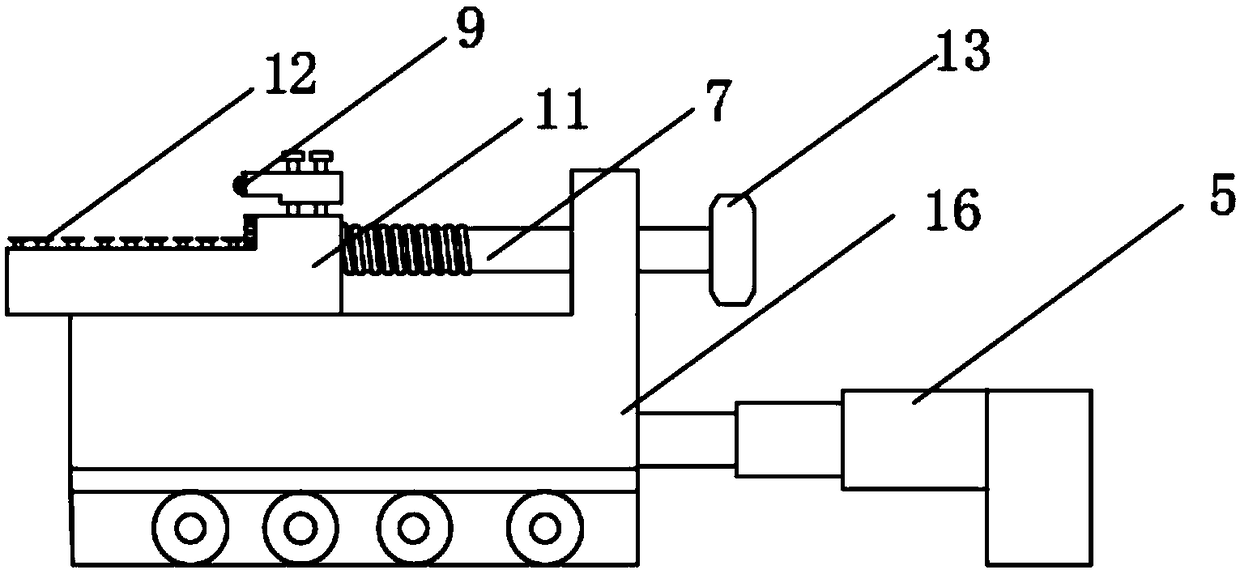

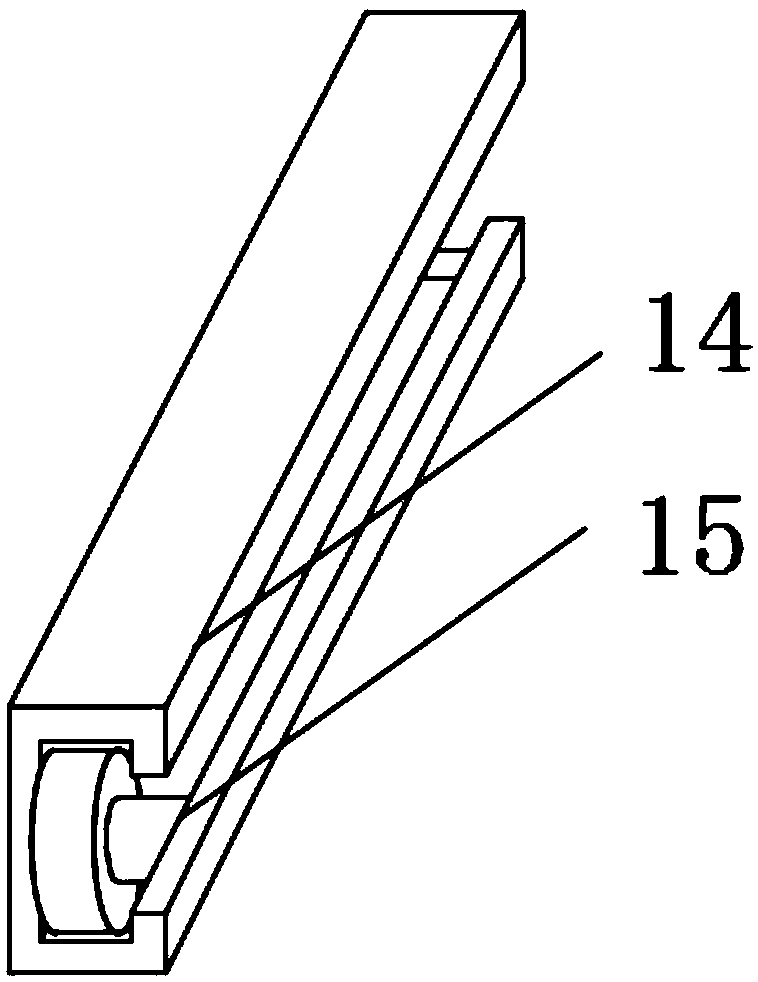

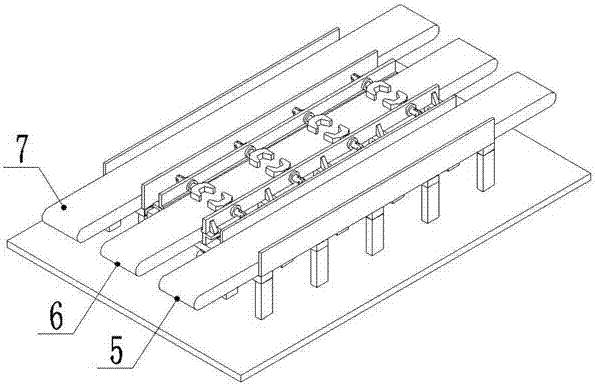

Automatic conveying and cutting equipment for pipes

PendingCN108705137AHigh degree of automationImprove cutting efficiency and cutting qualityTube shearing machinesShearing machine accessoriesEngineeringSlide plate

The invention discloses automatic conveying and cutting equipment for pipes. The automatic conveying and cutting equipment comprises a feeding mechanism, a conveying mechanism, a processing mechanismand a control mechanism, and the processing mechanism and the control mechanism are both arranged on a rack. The feeding mechanism comprises a feeding frame, a supporting frame and a square pipe. Thesupporting frame is provided with an inclined face, the outer side of the square pipe is fixedly provided with sliding plates, and the inner side of the square pipe is fixedly provided with blocking frames. Each jacking mechanism comprises a jacking block, a jacking air cylinder and a fixing bracket. The jacking air cylinders are installed on the square pipe through the fixing brackets, the jacking blocks are connected to the jacking air cylinders, the jacking blocks are provided with inclined faces, and the inclined direction of the inclined faces is consistent with that of the inclined faceof the supporting frame. At a first position, the inclined faces of the jacking blocks are located below the inclined face of the supporting frame; and at a second position, the jacking air cylindersare started through the control mechanism to jack the jacking block up, the inclined faces ascend, and the pipes arranged on the supporting frame pass over the blocking frames, led by the sliding plates and fall on the conveying mechanism. The adjustability of the jacking mechanisms is good, and the cutting efficiency and quality of the pipes are high.

Owner:ZHANGJIAGANG INST OF IND TECH SOOCHOW UNIV +1

Automatic loading mechanism of pin shaft

The invention discloses an automatic loading mechanism of a pin shaft to solve the problem of low manual loading efficiency in the prior art. The mechanism comprises a swing rod arranged below a bin, wherein an outlet of the bin is arched; the swing rod comprises a first support rod and a second support rod formed to an L shape and integrally molded; the first support rod is driven through power to perform the reciprocating rotation; the upper part of the second support rod is a convex arched slide table; the convex arched slide table and the outlet have the same curvature; the convex arched slide table can slide along the outlet when the first support rod swings; a groove is formed in the end part of the second support rod at the side of the convex arched slide table, and can swing below the outlet; a push rod capable of performing reciprocating linear motion is arranged at one side of the swing rod; the other side of the swing rod is a spring chuck; and the axles of the spring chuck, the groove and the push rod are on one straight line.

Owner:CHONGQING GANGQIAN MACHINERY

Electric clamping bracket and control system and control method thereof

ActiveCN106764289ARealize automatic clampingAchieve releaseStands/trestlesFriction gearingsControl systemDrive motor

The invention relates to an electric clamping bracket and a control system and a control method thereof. The electric clamping bracket comprises a shell and a clamping module. The electric clamping bracket further comprises a driving motor; the clamping module includes a left clamping frame and a right clamping frame; the left clamping frame and the right clamping frame extend to the front side, and are respectively arranged on two opposite sides of the shell; the left clamping frame or / and the right clamping frame is slidingly connected to the shell; and the driving motor drives the left clamping frame or / and the right clamping frame to enable the left clamping frame and the right clamping frame to oppositely approach or leave. The electric clamping bracket uses a motor for driving the clamping module to clamp or loosen mobile equipment so as to realize automatic clamping or loosening of the clamping bracket.

Owner:SHENZHEN BESTART TECH CO LTD

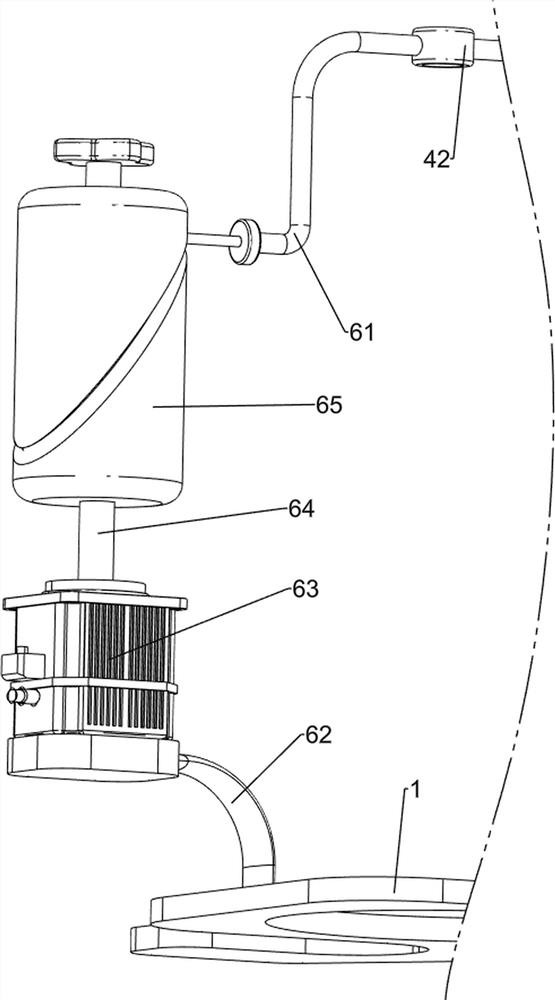

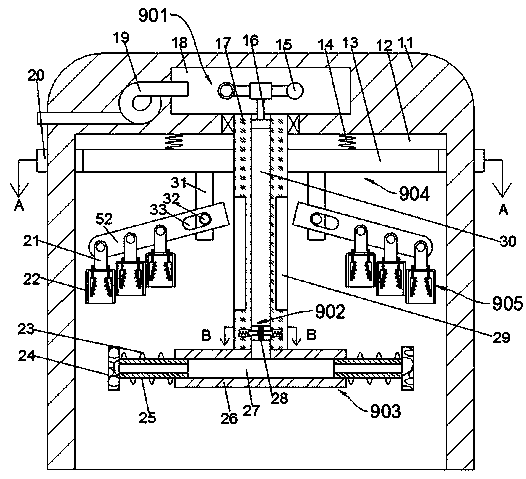

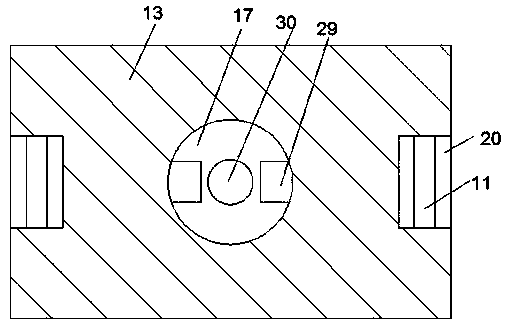

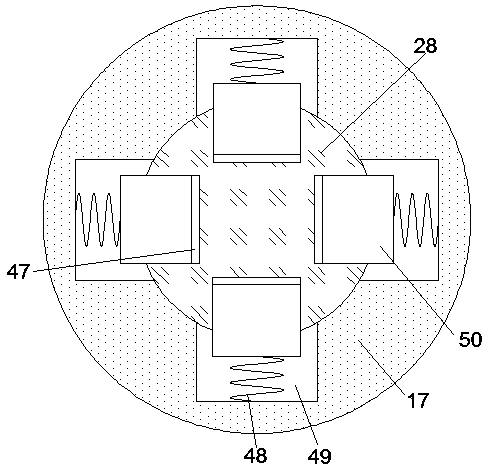

Medicine dispensing device and medicine dispensing method for ampoule bottle

ActiveCN104800912ARealize automatic clampingSimple structurePharmaceutical containersMedical packagingManual medicineBottle

The invention discloses a medicine dispensing device and a medicine dispensing method for an ampoule bottle. The medicine dispensing device for the ampoule bottle comprises a support, wherein a clamping part for clamping the ampoule bottle, a bottle cutting part for cutting the bottleneck of the ampoule bottle, a bottle hitting part for breaking the bottle head of the ampoule bottle, and a liquid receiving part for receiving medicine liquid of the ampoule bottle are arranged on the support; the clamping part comprises a translation mechanism for translating the ampoule bottle relative to the support, and a rotary mechanism for overturning the ampoule bottle; the liquid receiving part comprises a liquid bag and a funnel. According to the medicine dispensing device for the ampoule bottle, the clamping part comprises the translation mechanism for translating the ampoule bottle, and the rotary mechanism for overturning the ampoule bottle, so that the ampoule bottle is clamped automatically, the bottleneck of the ampoule bottle is cut automatically, the bottle head of the ampoule bottle is automatically broken, and the medicine liquid of the ampoule bottle is poured into the liquid bag automatically; the device is simple and compact in structure, less in occupied space, lower in cost, high in automation degree, and convenient to operate, the manual medicine dispensing intensity is reduced, and the medicine dispensing efficiency is greatly improved.

Owner:成都彼维仕科技有限公司

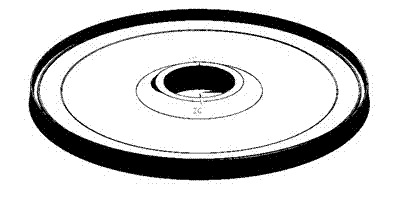

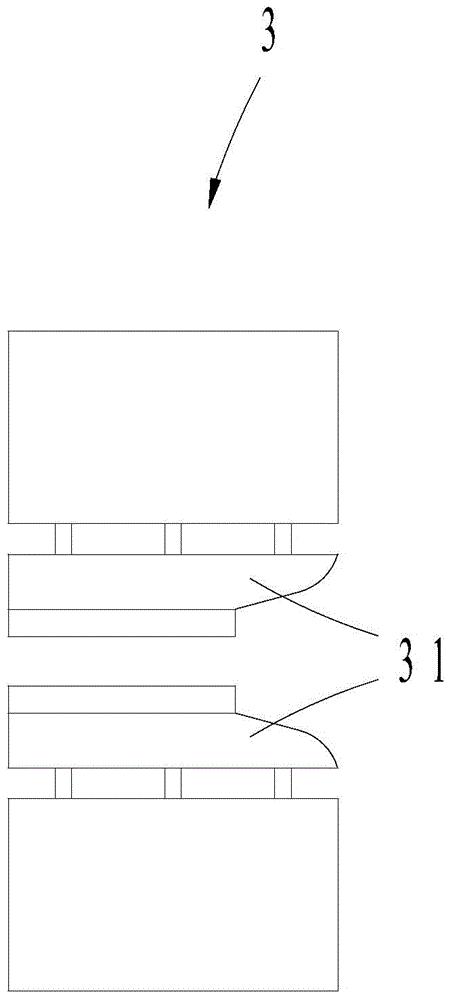

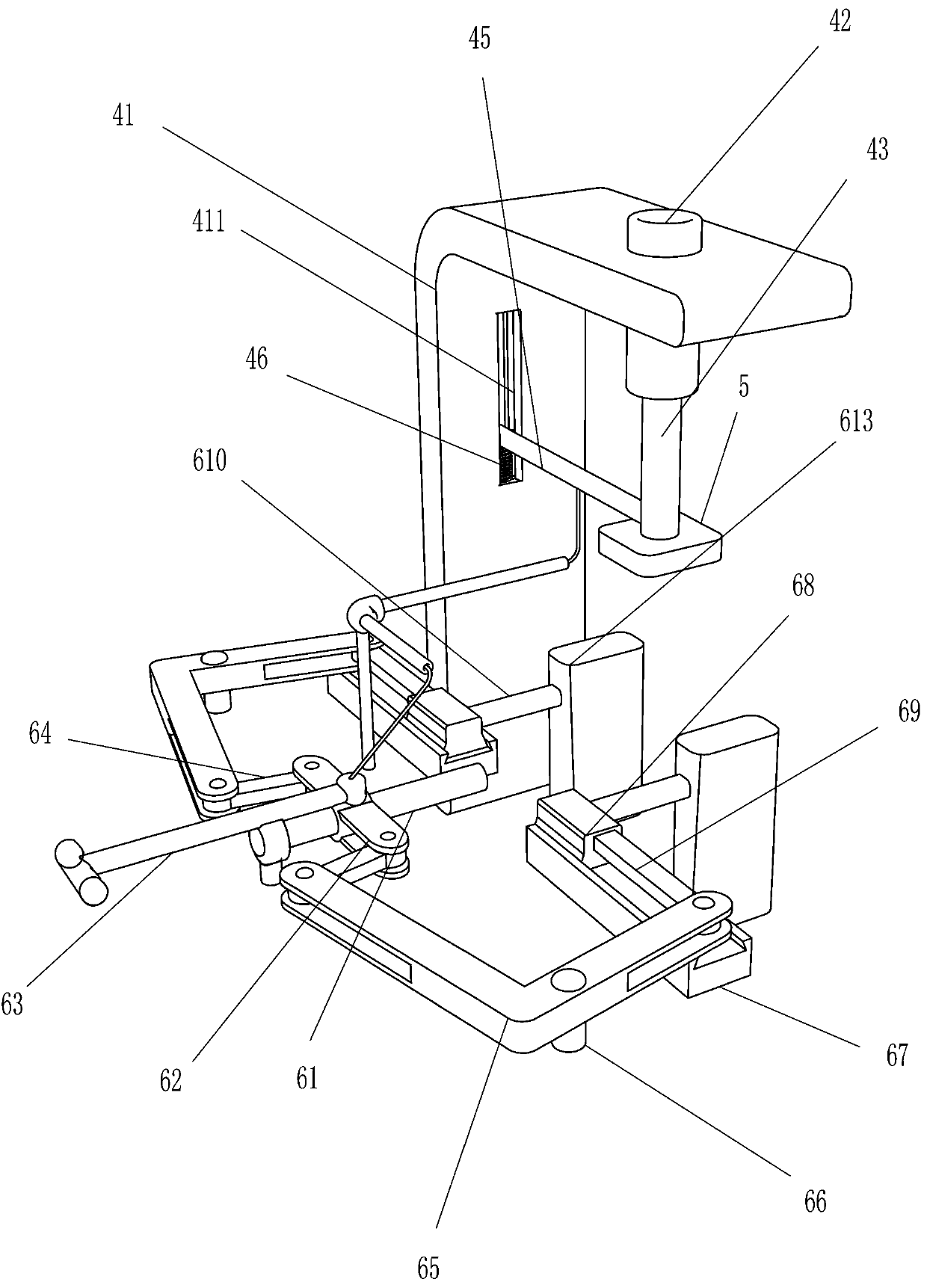

Blanking and loading mechanism of full-automatic diamond lapping and polishing machine and fixture switching mechanism thereof

InactiveCN101905437ARealize automatic clampingAchieve fixationEdge grinding machinesTransformation unitMechanical engineering

The invention relates to a diamond lapping and polishing machine, in particular to a blanking and loading mechanism of a full-automatic diamond lapping and polishing machine and a fixture switching mechanism thereof. The invention adopts the following technical scheme that the blanking and loading mechanism of the full-automatic diamond lapping and polishing machine and the fixture switching mechanism thereof are characterized by comprising a support, two sets of blanking and loading devices symmetrically arranged on the support and fixture switching devices arranged at the same side of the two sets of blanking and loading devices, wherein a baffle is respectively arranged above the two sets of blanking and loading devices, and the baffles are glidingly arranged on the support. Through adopting the technical scheme, the invention overcomes the defects of the prior art and provides the novel blanking and loading mechanism of the full-automatic diamond lapping and polishing machine and the fixture switching mechanism thereof, which can persistently finish the blanking and the loading in the same device, reduce the fixture transfer between the blanking and the loading, realize the automatic production and greatly improve the working efficiency.

Owner:陈哲

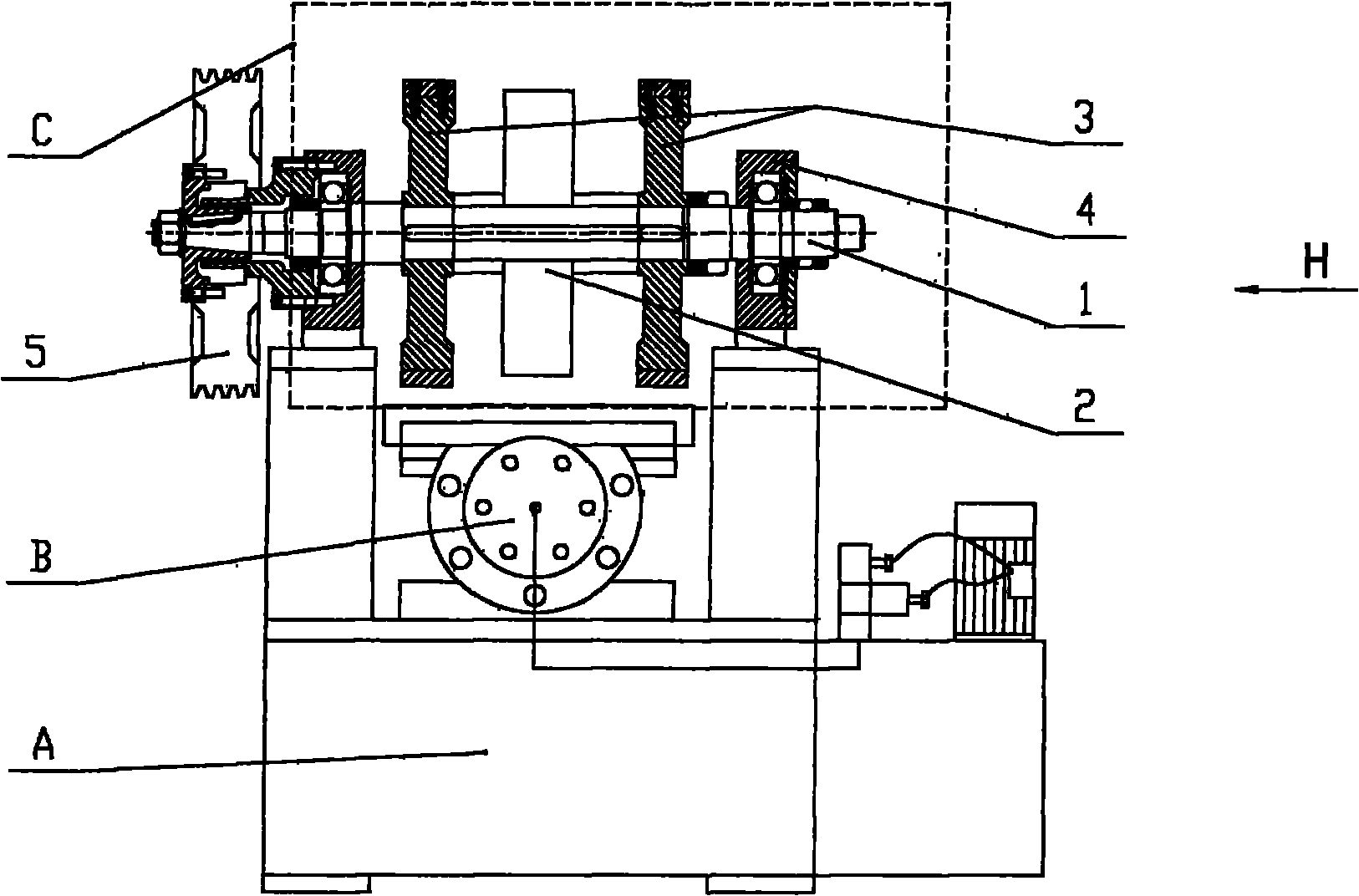

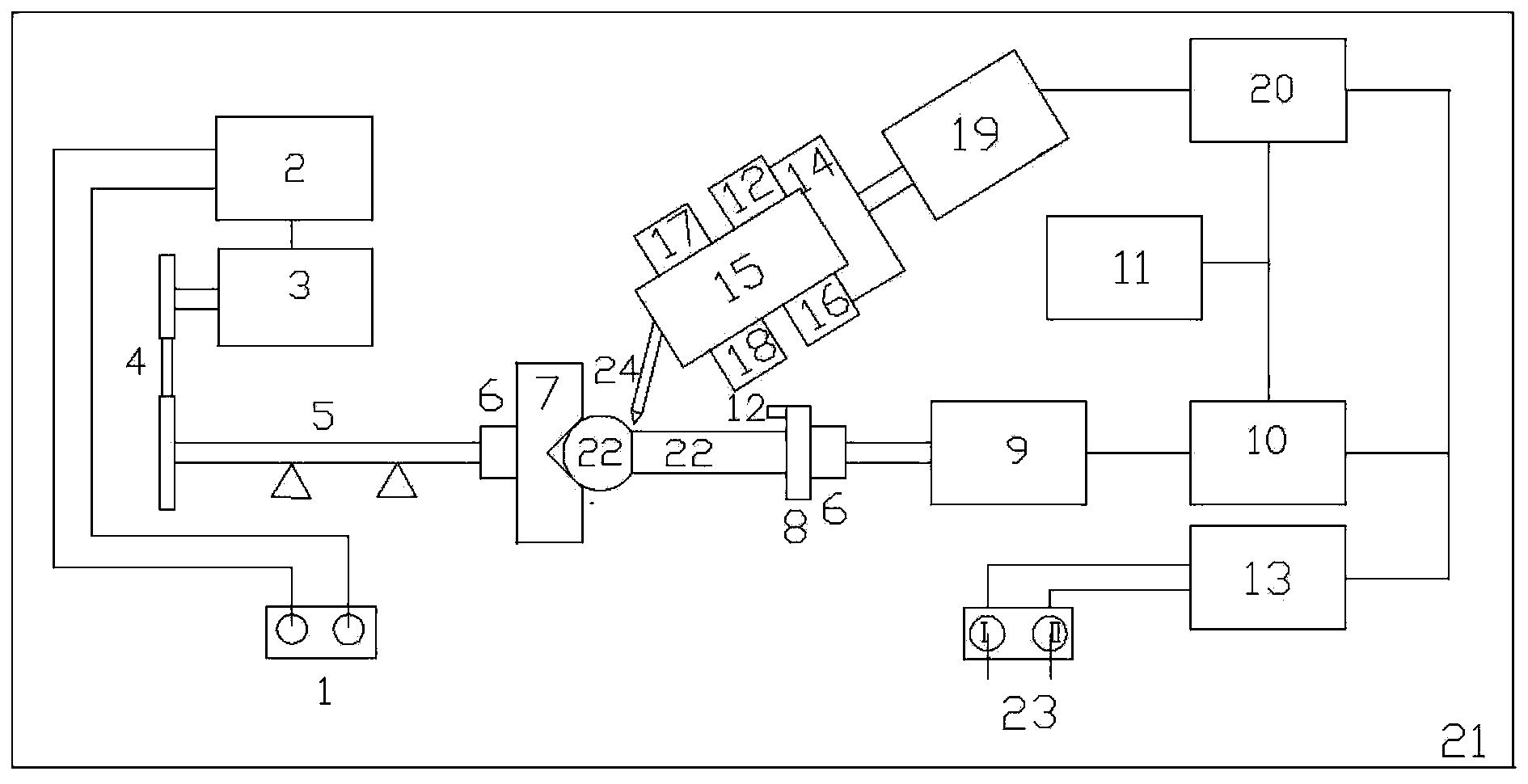

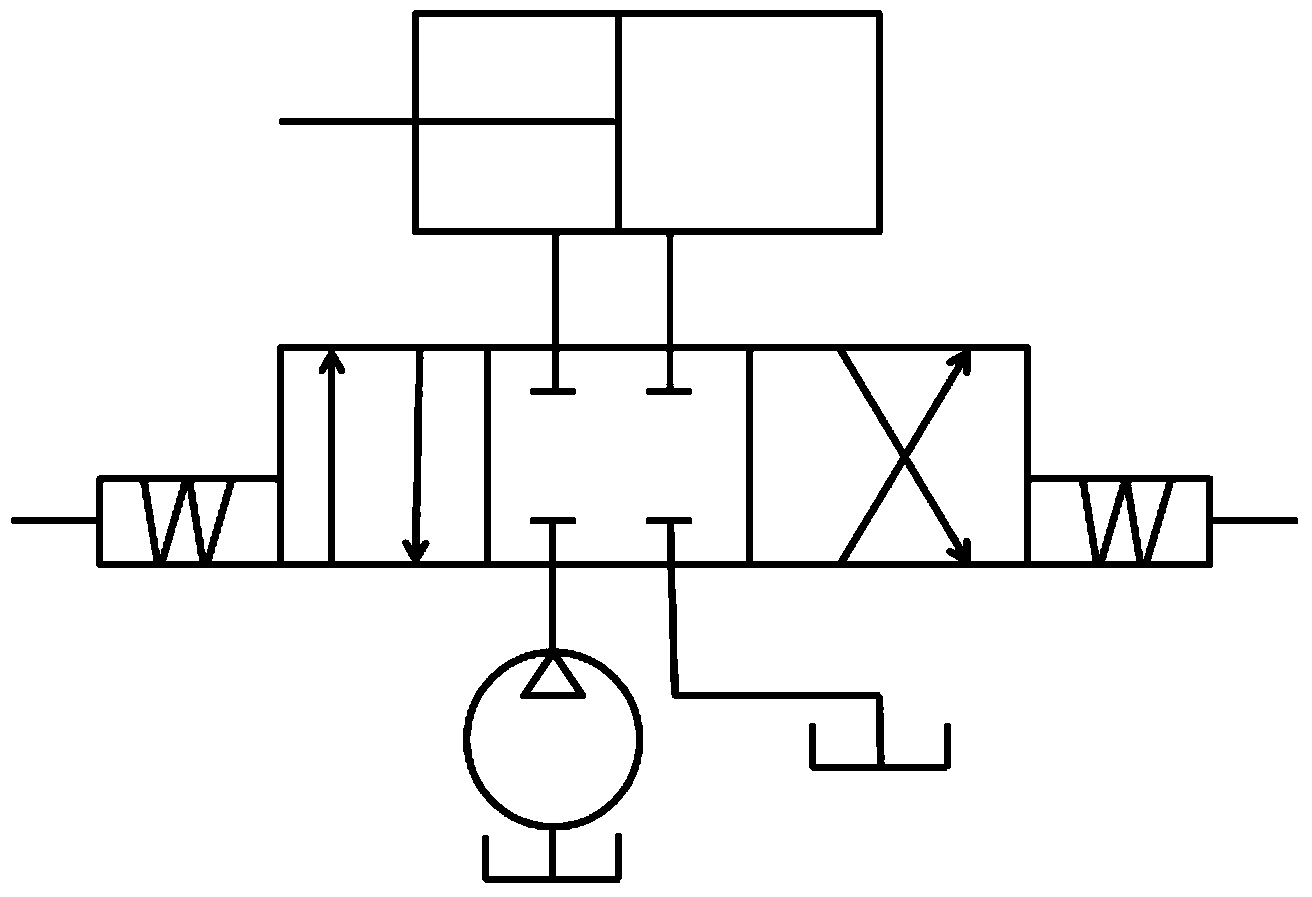

Multi-side milling machine and hydraulic clamp for same

InactiveCN102114550ARealize automatic clampingGuaranteed stabilityLarge fixed membersMilling equipment detailsMilling cutterHydraulic pump

The invention provides a multi-side milling machine and a hydraulic clamp for the same. The multi-side milling machine comprises a hydraulic sliding table (B), a hydraulic station (D), the hydraulic clamp (E) and a power head (C), wherein the hydraulic sliding table (B) is used for making the hydraulic clamp on the sliding table move forward and backward; the hydraulic station (D) controls the running of a motor, the movement of the sliding table and the clamping of the clamp; the hydraulic clamp (E) is used for clamping a work piece; and the power head (C) is arranged on a machine body. Power is supplied by the motor 6, and a belt wheel drives a main shaft of the power head (C) to rotate, so that the rotation of milling cutter disks arranged on the shaft is realized. The left and right milling cutter disks mill an external surface of a steering knuckle, and the middle three-blade milling cutter disk mills an internal surface and a bottom plane of the steering knuckle simultaneously. By the invention, the simultaneous processing of the four side faces and the bottom plane of parts of the steering knuckle is realized, and the work piece is clamped automatically; moreover, the production efficiency is high, the processing quality is high, the labour strength is low and production environment is also improved.

Owner:上海嘉仕久企业发展有限公司

Radial artery blood collection device

InactiveCN105310699ASimple structureEasy to carryDiagnostic recording/measuringSensorsBlood collectionEngineering

The invention belongs to the field of medical apparatuses and particularly relates to a radial artery blood collection device, comprising a front box and a rear box. The front box is provided with a front arm carrier receivable in the front box, lifting height of this carrier is adjusted through a lifting device, the carrier is provided with a recessed carrying cavity, and two sides of the carrying cavity are provided with clamping devices capable of moving transversely to clamp the arm. Compared with the prior art, the radial artery blood collection device has the front and rear boxes shafted, and the rear box can turn over the front box and fastens to the front box so that the whole device is simple in structure and convenient to carry; in addition, the clamping devices are disposed on two sides of the carrying cavity of the front arm carrier, the arm of a patient can be automatically clamped, clamping force of clamping sheets is controlled in a suitable pressure range, blood collection is achieved, and the discomfort in the patient caused by excess clamping of the clamping sheets for the arm is also avoided.

Owner:THE AFFILIATED HOSPITAL OF QINGDAO UNIV

Clamping device

The invention discloses a clamping device which comprises a supporting frame, the supporting frame is provided with a fixed clamping arm and a movable clamping arm, the lower ends of the fixed clamping arm and the movable clamping arm are respectively provided with a clamp plate, and the two clamp plates are arranged opposite to each other; and the fixed clamping arm is fixed at the supporting frame, the movable clamping arm is connected with a screw rod by a movable nut, the screw rod is connected with a drive motor, and the drive motor drives the screw rod to rotate. The clamping device disclosed by the invention has the advantages of simple structure and capability of realizing the automated clamping of sand cores, is easy to use, effectively improves the production efficiency, reduces the labor intensity, and effectively avoids the falling-off of sand cores in the process of coating the sand cores with paints by robots.

Owner:SUZHOU SUZHU FOUNDRY MACHINERY MFG

Chopping board side wall grooving equipment

ActiveCN111590143AConsistent depthRealize automatic clampingMetal working apparatusMaintainance and safety accessoriesStructural engineeringWorkbench

The invention relates to grooving equipment, in particular to chopping board grooving equipment. According to the technical scheme, the chopping board side wall grooving equipment which can groove theside wall of a chopping board, improve the grooving efficiency and guarantee that the depths of grooves formed by a cutting machine are consistent is provided. According to the technical scheme, thechopping board grooving equipment comprises a base, a groove and a lifting mechanism, wherein the top of the base is provided with a workbench, the groove is formed in the middle of the side portion of the workbench, a cylindrical containing box is arranged at the position, over the groove, of the side portion of the workbench, round holes are formed in the two sides of the cylindrical containingbox, and the lifting mechanism is arranged on the side part, close to one side of the cylindrical placement box, of the workbench. According to the chopping board side wall grooving equipment, throughthe lifting mechanism, the cutting machine can automatically move up and down and is tightly attached to the side wall of the chopping board, it is guaranteed that the cutting machine makes tight contact with the side wall of the chopping board all the time before grooving work is completed, and it is guaranteed that the depths of the formed grooves are consistent; and through a clamping and rotating mechanism, the chopping board can be automatically clamped and driven to rotate.

Owner:吴燕灵

Automatic clamping and positioning device for PCB

InactiveCN108811342AHigh degree of freedom of adjustmentHigh precisionPCB positioning during processingCircuit board tools positioningEngineeringPulley

The invention discloses an automatic clamping and positioning device for a PCB. The automatic clamping and positioning device comprises a U-shaped base and a sliding block. A damping layer is arrangedat the surface of the bottom of the U-shaped base; and a damping spring is arranged inside the damping layer. Telescopic rods are arranged at the surfaces of the sides of the U-shaped base; a slidingblock is arranged at one end of each telescopic rod in a pushing manner; a sliding rail is arranged at the bottom of the sliding block; and sliding pulleys are arranged at one side of the sliding block inside the sliding rail in a sliding manner. According to the invention, the telescopic rods arranged at the two sides of the U-shaped base push the sliding blocks to slide in the sliding rail; andclamping blocks are driven by the sliding blocks to clamp and fix a PCB. Moreover, infrared on-off calibration sensors are used for carrying out automatic on-off calibration; if fine adjustment is needed, rotary knobs are adjusted to screw fine-adjustment screw rods to carry out fine adjustment, so that the adjustment freedom of the PCB is improved substantially and automatic clamping is realized; and the precision of PCB clamping is improved.

Owner:黄永锋

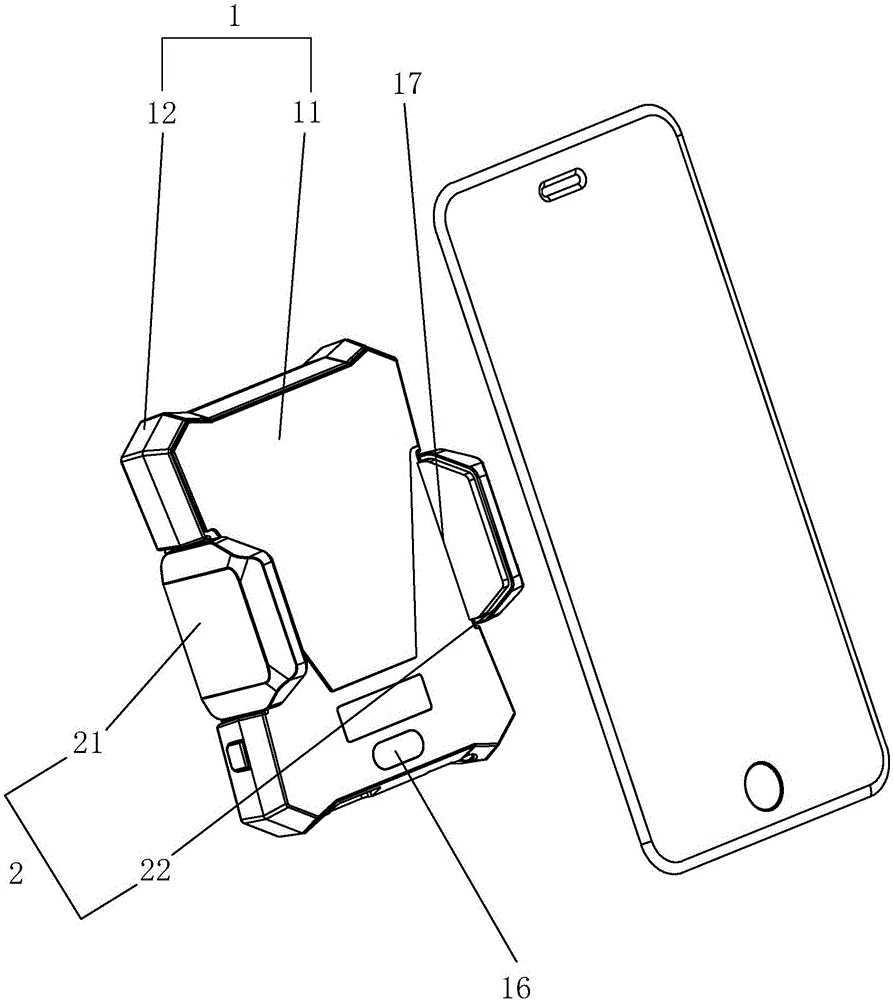

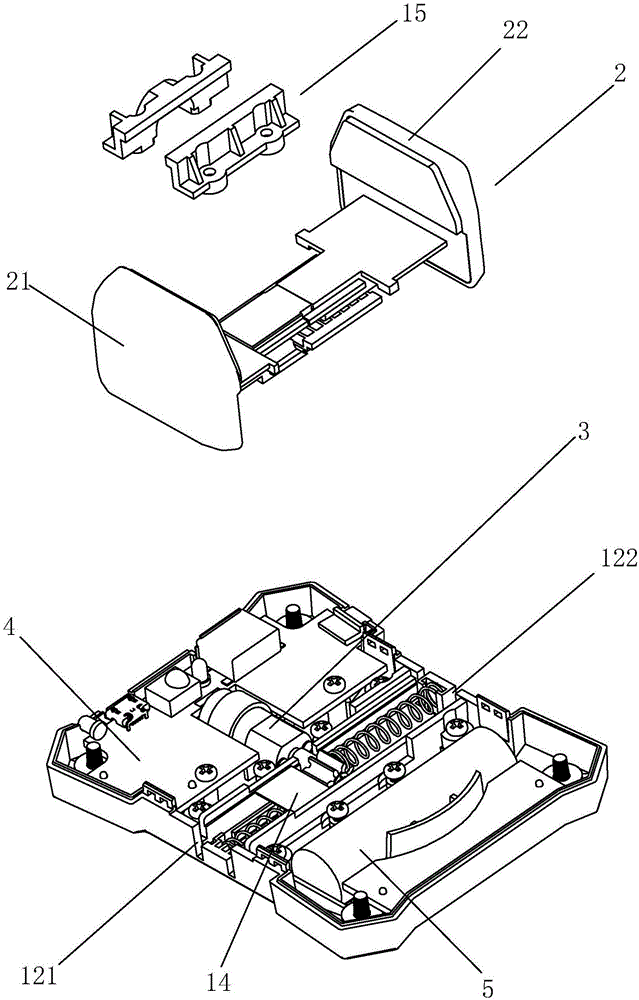

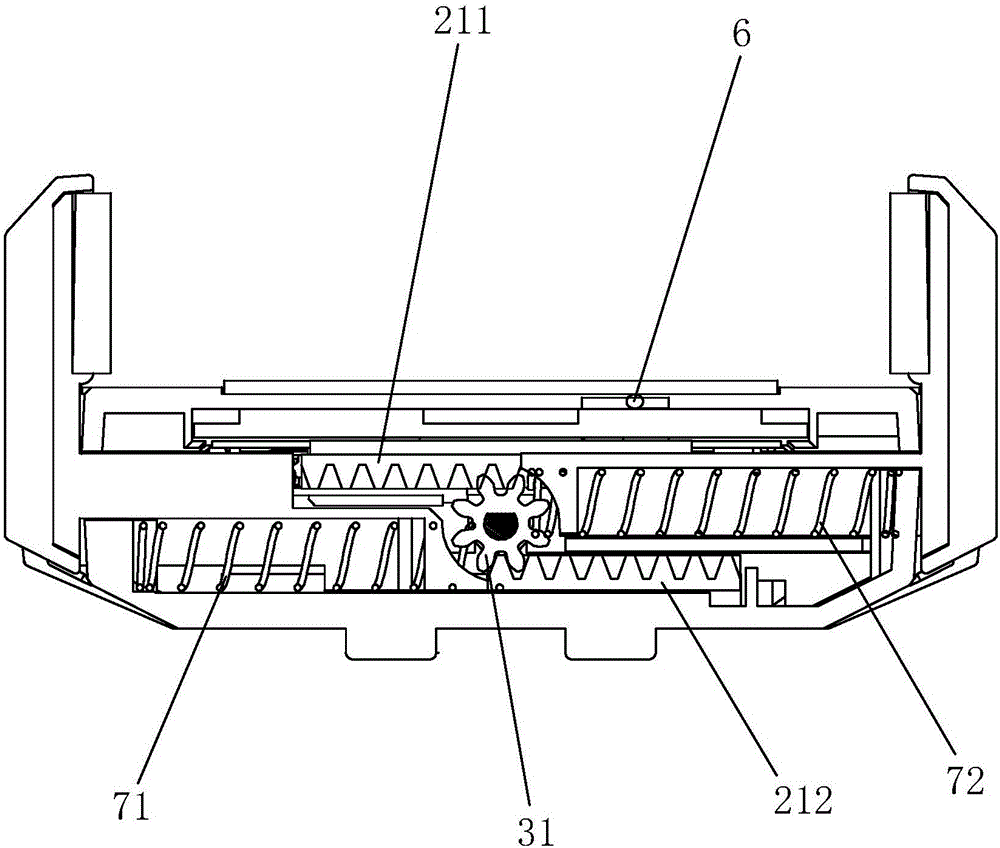

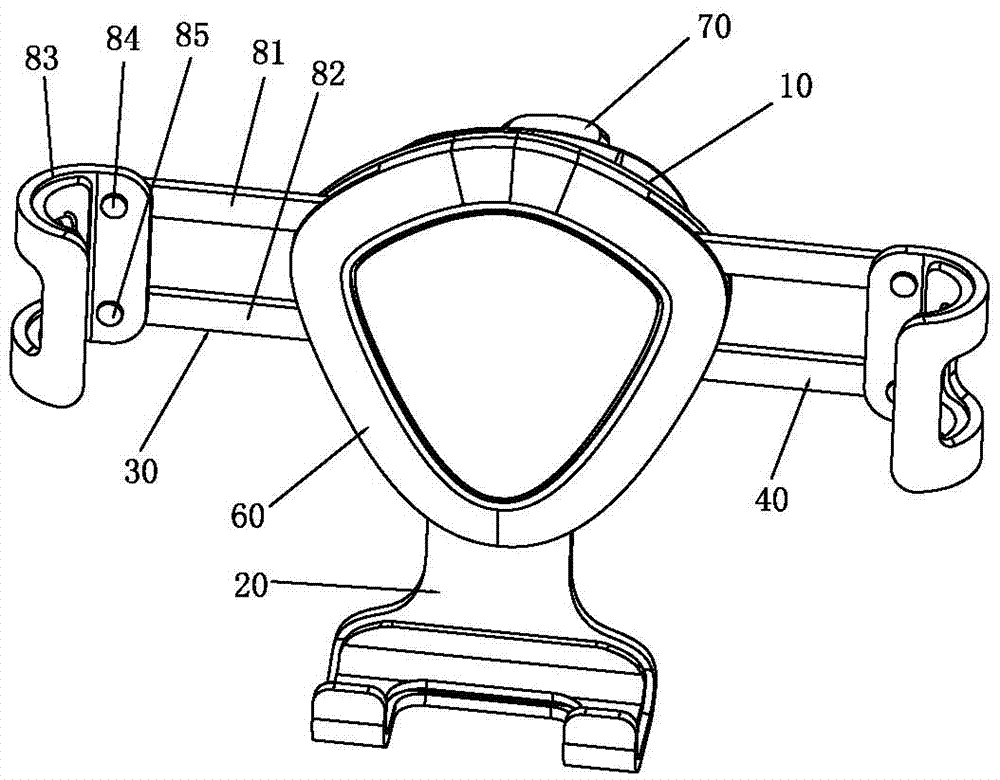

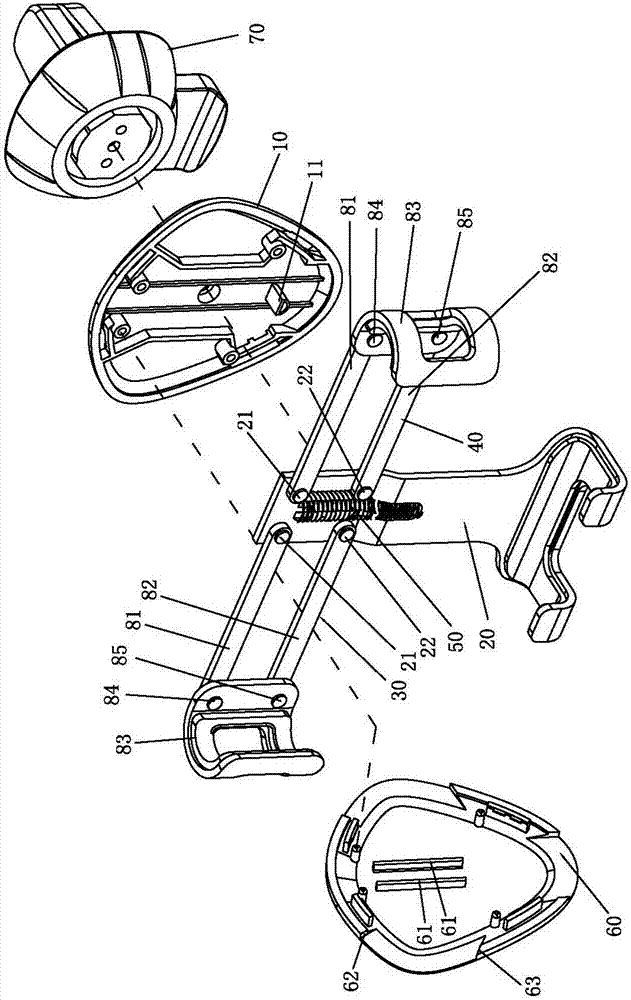

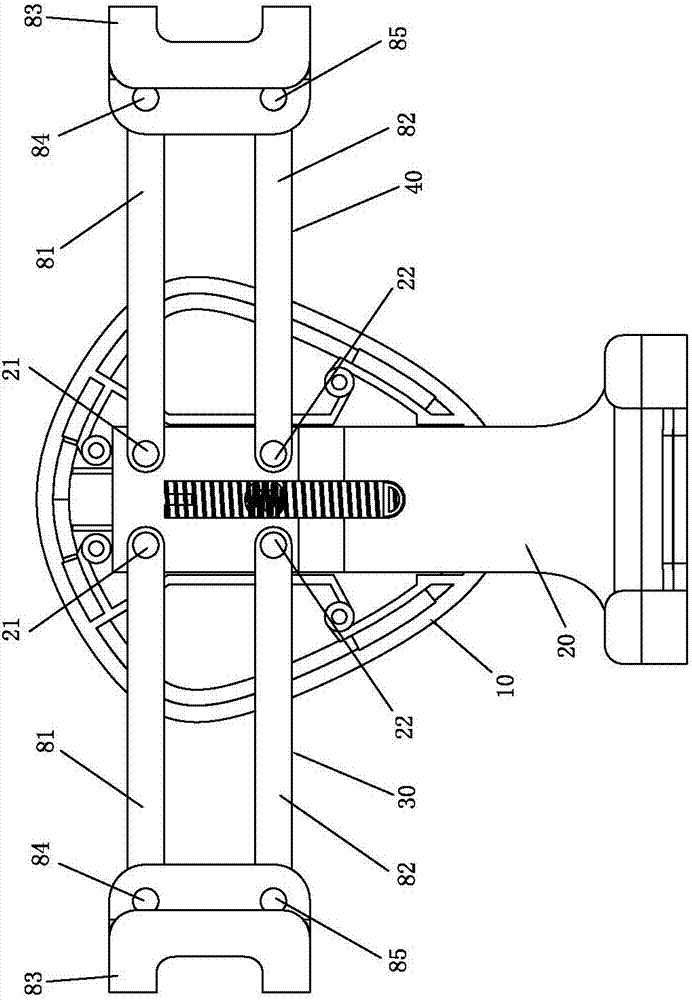

Parallelogram connecting rod type automatic clamping bracket

ActiveCN106961500AIncrease contact surfaceImplementing Angle ChangesPassenger spaceRacks dispositionEngineeringSupport point

The invention discloses a parallelogram connecting rod type automatic clamping bracket. The parallelogram connecting rod type automatic clamping bracket comprises a back side base, a bottom support arm, a left side clamping arm, a right side clamping arm and a reset elastic element, wherein both the left side clamping arm and the right side clamping arm comprise clamping parts, first connecting rods and second connecting rods; a first rotating support point and a second rotating support point are arranged one above the other at an interval on the bottom support arm specific to the left side clamping arm and the right side clamping arm; a third rotating support point and a fourth rotating support point are arranged one above the other on the clamping part; inner and outer ends of a first connecting rod are pivoted to the first rotating support point and the third rotating support point respectively; inner and outer ends of a second connecting rod are pivoted to the second rotating support point and the fourth rotating support point respectively; and the first, second, fourth and third rotating support points are connected in sequence to form a parallelogram structure. The bottom support arm is pressed downwards under the gravity of a mobile phone, and the mobile phone is clamped automatically through inward obliquely-upward displacement of the clamping part by means of the deformation principle of a parallelogram, so that angular change of a clamping surface on the clamping part is prevented, and good contact clamping of the mobile phone is ensured.

Owner:BENZHI (SHENZHEN) INFORMATION TECH CO LTD

Self-dust-suction pipe cutting tool with adjustable cutting angle

InactiveCN107695422ARealize automatic adjustmentAvoid damageTube shearing machinesShearing machine accessoriesEngineeringPressure controlled ventilation

The invention discloses a self-dust-suction pipe cutting tool with the adjustable cutting angle. The tool comprises a bottom plate, a controller, an angle adjusting motor and a clamping motor; the angle adjusting motor is arranged in the middle of the upper end of the bottom plate, the shaft end of the angle adjusting motor is provided with an angle adjusting plate, a motor supporting plate is arranged on one side of the upper end of the angle adjusting plate, a fixed clamping plate is arranged on the other side of the upper end of the angle adjusting plate, the clamping motor is arranged on one side of the motor supporting plate, a dust suction pump is arranged in the middle of one side of the upper end of the bottom plate, a dust collection box is arranged on the front side of the one side of the upper end of the bottom plate, a protection box is arranged at the upper end of the bottom plate, and the controller is arranged on one side of the protection box. The self-dust-suction pipecutting tool has the beneficial effects that automatic adjustment of the cutting angle can be achieved, cutting of different angles can be conveniently achieved, automatic clamping is achieved, detection and clamping pressure control can be achieved at the same time, the pipe surface can be prevented from being damaged, self dust suction is achieved, and dust pollution is prevented.

Owner:ZHEJIANG KAICHEN IND & TRADE CO LTD

Casting polisher having automatic clamping function

InactiveCN108436667AImprove stabilityAvoid overall shakingGrinding machinesGrinding work supportsEngineeringFriction force

The invention discloses a casting polisher having an automatic clamping function. The casting polisher comprises a polishing table; the polishing table is internally provided with a cavity; the internal bottom wall of the cavity is provided with a sliding chute; an oblique block is placed at the internal bottom wall of the cavity; the bottom surface of the oblique block is fixedly connected with aslider which is matched with the sliding chute; the slider is clamped inside the sliding chute; the inside of the cavity is fixedly connected with a partition plate which is matched with the cavity;the left side surface of the partition plate is provided with a first through hole; and the right side surface of the oblique block is fixedly connected with two symmetric springs. The overall castingpolisher having the automatic clamping function can be used for automatically clamping objects, is convenient and quick, can effectively improve the stability of the overall polisher, prevents shake,caused by external force in a use process, of the overall polisher, is convenient to move by a user, can effectively increase the friction force between a hand and a handle when being moved by the user, can meet the requirements of enterprises and is beneficial for wide popularization.

Owner:蔡敬东

Electronic watch automatic assembling mechanism

ActiveCN107203123AImprove assembly efficiencyIncrease productionAssembly machinesRepair toolsEngineeringElectrical and Electronics engineering

Owner:YIWU CITY ZHUOYUE ELECTRONICS

Automatic boxing equipment for biological capsule production

ActiveCN112478296AReduce labor costsEasy to take outIndividual articlesBiological glueProcess engineering

The invention relates to boxing equipment, in particular to automatic boxing equipment for biological capsule production. The automatic boxing equipment for biological capsule production can limit medicine boxes, and achieve automatic boxing and automatic discharging. The automatic boxing equipment for biological capsule production comprises a base, a placing mechanism and a pushing mechanism, wherein the placing mechanism is arranged on one side of the base, and the base is provided with the pushing mechanism. Through the cooperation of the placing mechanism and the pushing mechanism, capsules can be automatically boxed and can be automatically conveyed, and therefore the labor cost can be saved; through the cooperation of a limiting assembly and a downward pressing assembly, the boxes can be automatically moved forwards, and people can conveniently take out the boxes; and meanwhile, the medicine boxes can be limited, and therefore the medicine boxes do not need to be manually fixed.

Owner:中芝堂药业(山东)有限公司

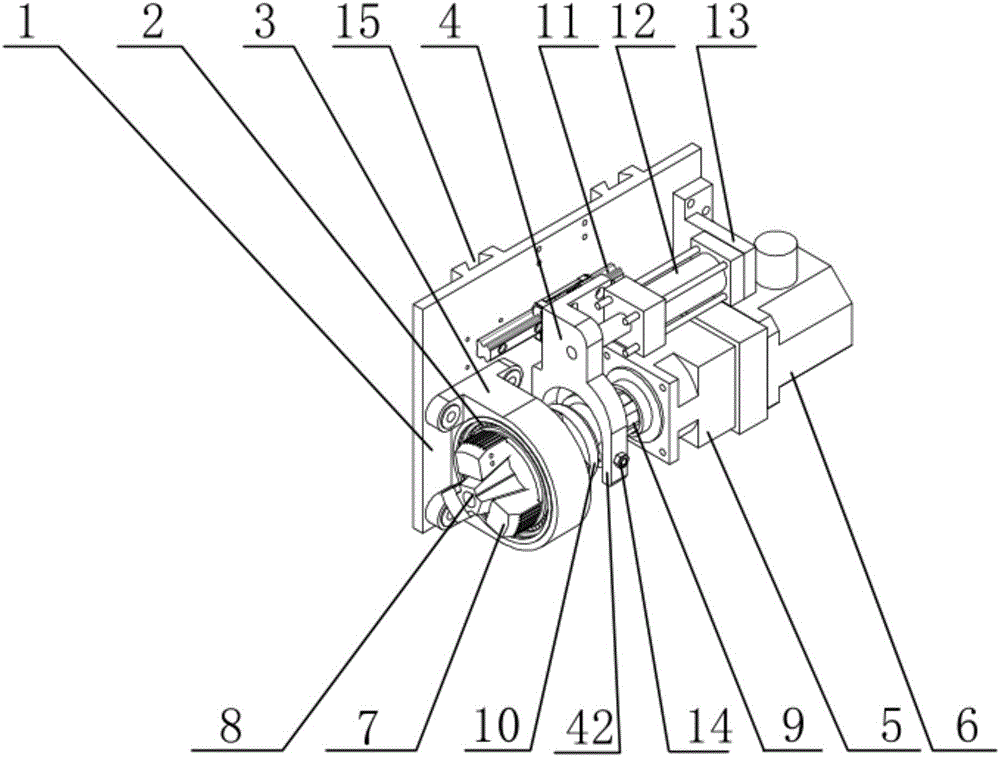

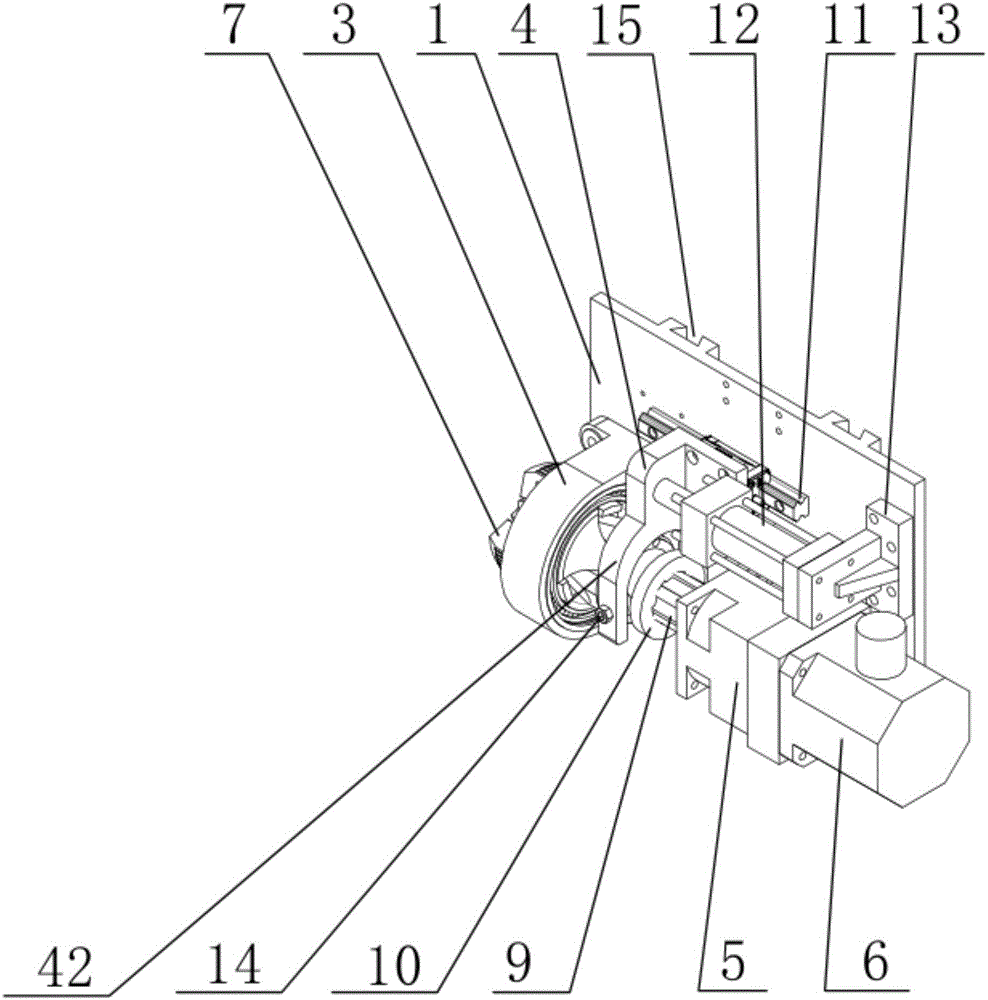

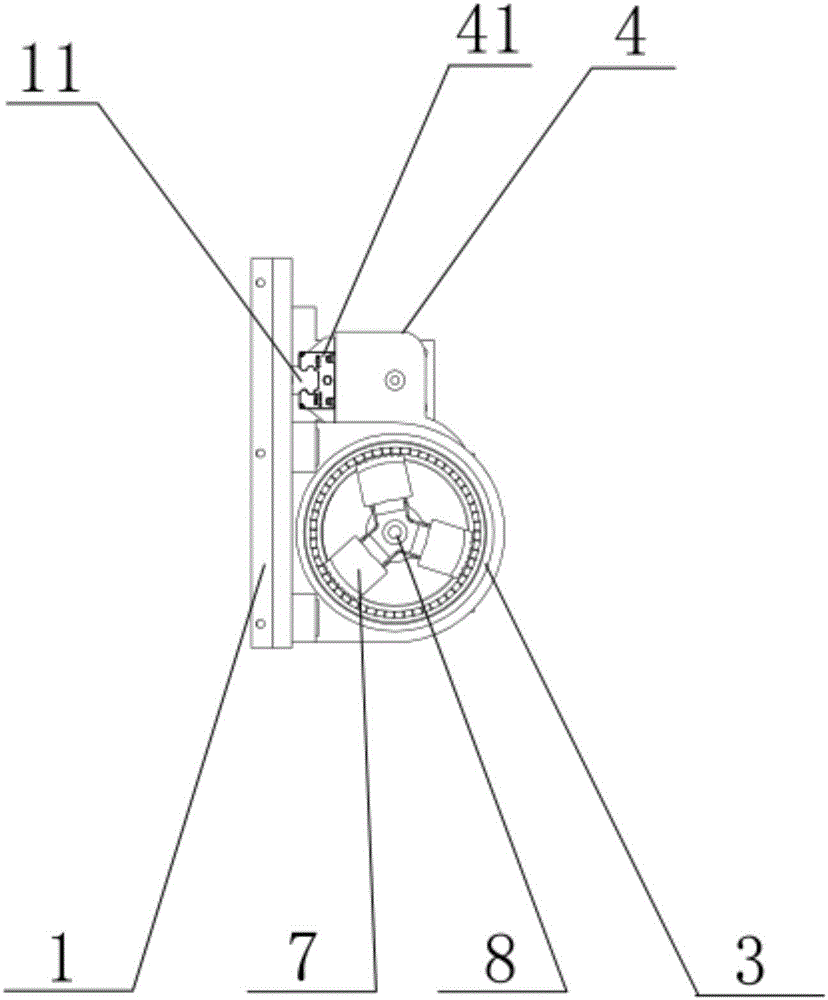

Rotating feeding device capable of achieving clamping from interior of pipe end

InactiveCN106312627AWith concentric rotation functionWith longitudinal feeding functionPrecision positioning equipmentMetal working apparatusReciprocating motionElectric machinery

The invention provides a rotating feeding device capable of achieving clamping from the interior of a pipe end. The device comprises a main shaft, a servo motor, a servo reduction machine, a shifting fork seat, a driving air cylinder, an inner strutting block and an inner strutting triple-jaw, wherein the servo motor is used for driving the main shaft to rotate, and the driving air cylinder is used for driving the shifting fork seat to perform reciprocating motion. The shifting fork seat drives a sliding block to be capable of performing inward-and-outward reciprocating motion in the axial direction of the main shaft while performing inward-and-outward reciprocating motion,. The inner strutting block and the sliding block are arranged on the main shaft from outside to inside and both can perform inward-and-outward reciprocating motion in the axial direction of the main shaft. The inner strutting triple-jaw is in limited-fit connection with a machine base. When performing outward movement in the axial direction of the main shaft, the inner strutting block can drive the inner strutting triple-jaw to perform outward expansion in the axial direction of the main shaft and the radial direction of the machine base, so that the inner strutting triple-jaw props the inner pipe wall, and the effect that the interior of the pipe end is clamped and fixed through the inner strutting triple-jaw is achieved. The rotating feeding device has the beneficial effects of being reasonable in structure, high in machining precision, good in stability, reliable in operation, convenient to adjust and the like.

Owner:ZHEJIANG KING MAZON MACHINERY

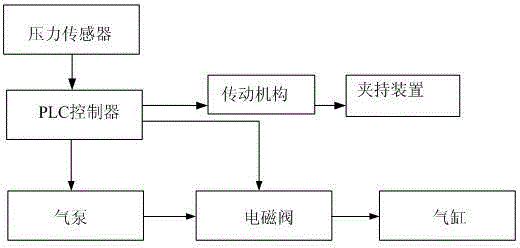

Semi-automatic welding device for circumferential welds

InactiveCN103521979AAvoid deformationUniform feedWelding/cutting auxillary devicesAuxillary welding devicesWeld seamAir pump

The invention relates to a semi-automatic welding device for circumferential welds. The semi-automatic welding device comprises a motor controller, an electromagnetic speed adjusting motor, a locating mechanism, a clamping mechanism, a first air cylinder, a first electromagnetic control valve, an air pump, a travel switch, a control mechanism, a second air cylinder, a second electromagnetic control valve and the like. The control mechanism controls the amount of air pumped to the first air cylinder through the first electromagnetic control valve, the first air cylinder pushes the clamping mechanism to move in the direction towards the locating mechanism through a rotary disc mechanism, and after signals for triggering the travel switch are detected, the clamping mechanism stops moving towards the locating mechanism. The motor controller controls the rotation speed of the electromagnetic speed adjusting motor, the locating mechanism and the clamping mechanism synchronously rotate, the control mechanism controls the amount of air pumped to the second air cylinder through the second electromagnetic control valve, the second air cylinder pushes a welding gun to move, and when the welding gun moves to a limiting block, the travel switch is triggered, and the welding gun stops moving. The semi-automatic welding device is prone to guaranteeing the welding quality, high in welding efficiency, low in cost and simple in structure.

Owner:XUZHOU BAISHILI ELECTRIC VEHICLE +1

Adaptation of full-automatic diamond grinding and polishing machine and clamp adapting unit thereof

InactiveCN101941168ASimple structureEasy to operateEdge grinding machinesEngineeringMechanical engineering

The invention relates to a diamond grinding and polishing machine, in particular to the adaptation of a full-automatic diamond grinding and polishing machine and a clamp adapting unit thereof. The full-automatic diamond grinding and polishing machine comprises a bracket and two sets of adapters, wherein the adapters are arranged on the bracket and adjacent to each other; one side of the two sets of adapters is provided with a clamp conversion device; each set of adapters comprises a feeding and powder-delivery unit and a collection unit; two baffles, which form a slide fit with the bracket, are respectively arranged above the feeding and powder-delivery unit and the collection unit; the feeding and powder-delivery unit comprises a clamp fixing mechanism, a rotating mechanism for driving the clamp fixing mechanism to rotate, a waste brushing mechanism and a powder-delivery mechanism; and a heating mechanism is arranged between the feeding and powder-delivery unit and the collection unit. By using the technical scheme, the invention has the advantage of quick adaptation, and enhances the machining speed and efficiency.

Owner:陈哲

Chemical metal barrel recovery terminal

InactiveCN110180845ARealize automatic clampingAvoid consumptionHollow article cleaningWater resourcesMetal

The invention discloses a chemical metal barrel recovery terminal. The chemical metal barrel recovery terminal comprises a suspension frame, wherein a cleaning cavity with a downward opening is arranged in the suspension frame; a hydraulic driving cavity is arranged at the upper end of the cleaning cavity; the inner wall of the lower end of the hydraulic driving cavity is rotationally connected with a threaded column extending into the cleaning cavity; clamping rod structures synchronously rotating according to a rod are started by utilizing a spiral groove at the open end of a metal barrel toachieve automatic clamping, so that a metal barrel is suspended in the air, friction consumption between the metal barrel and the ground in subsequent rotary cleaning is avoided; meanwhile, the plurality of groups of clamping structures distributed at equal intervals and an interval adjustable cleaning structure are adopted, so that cleaning of chemical barrels with different diameters is met; and a valve structure opened and closed according to a centrifugal effect is adopted, so that water resources are saved, internal structures of the chemical metal barrel recovery terminal are driven tooperate after pressurizing water and cost is reduced.

Owner:XINCHANG COUNTY MAIDI ENVIRONMENTAL PROTECTION TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com