Rotating feeding device capable of achieving clamping from interior of pipe end

A rotary feeding and clamping technology, applied in the field of internal clamping rotary feeding devices at the pipe end, can solve the problems of reducing work efficiency, difficult to complete manually, affecting the consistency of processing positions, etc., and achieves reasonable structure, convenient adjustment, and high processing accuracy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

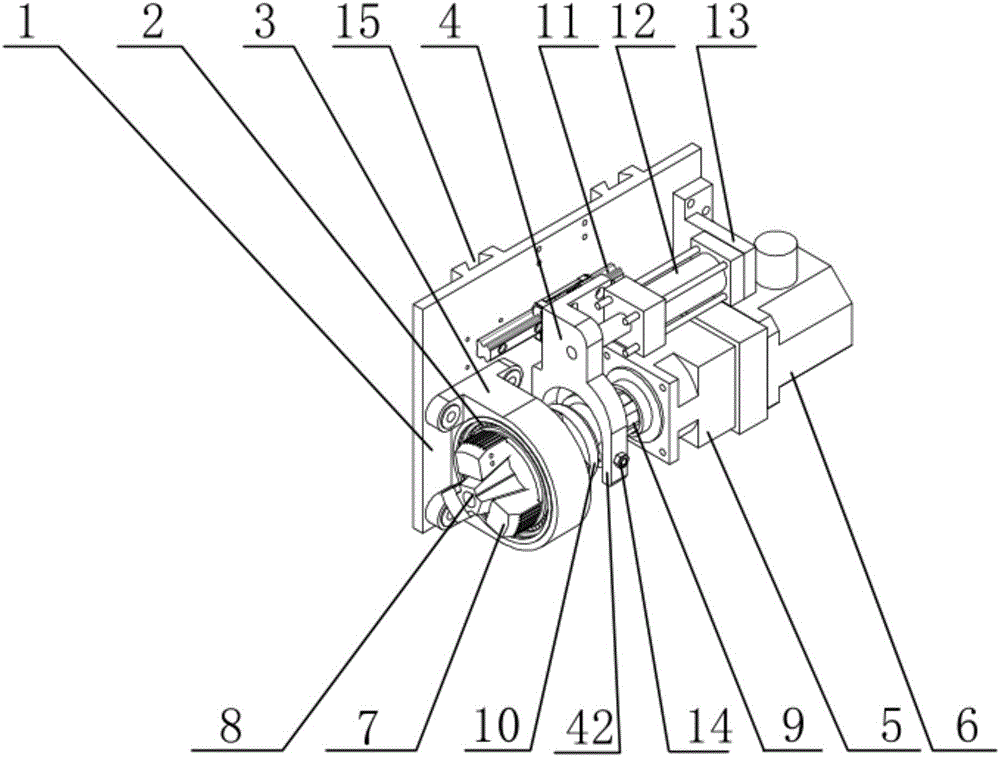

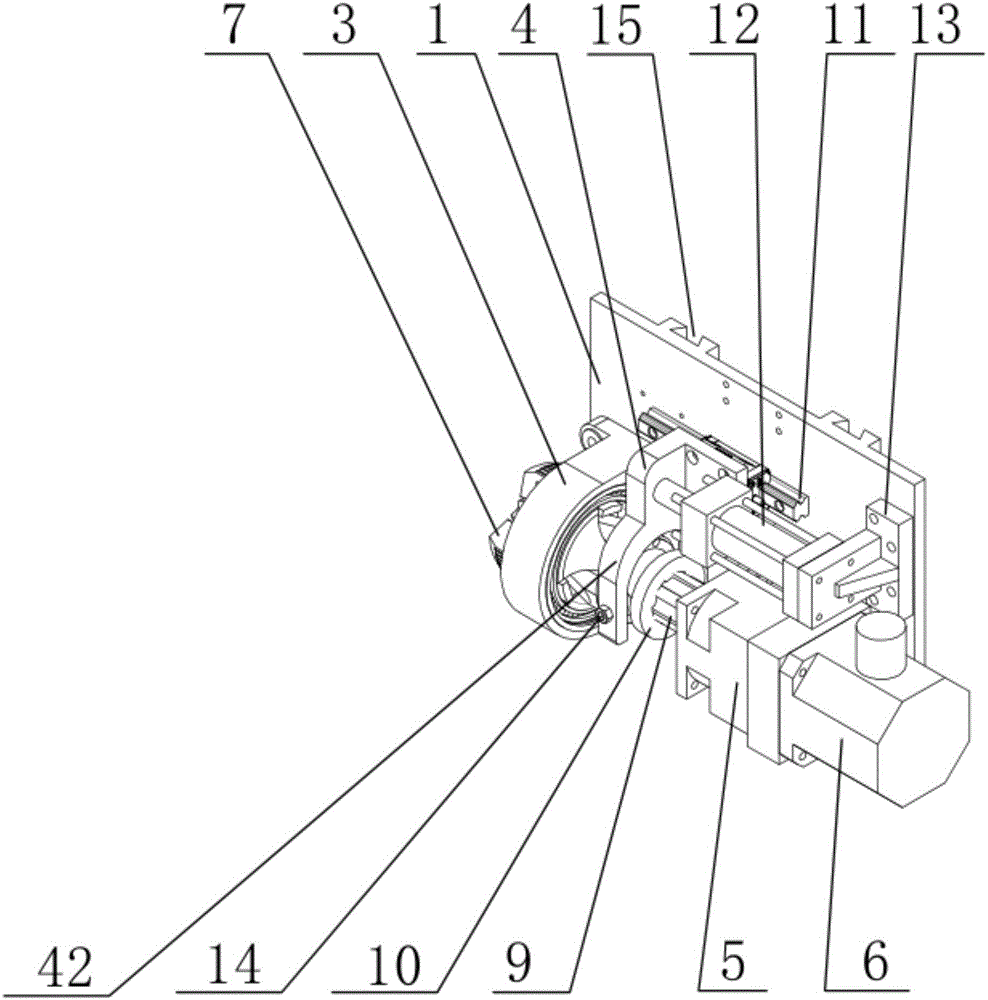

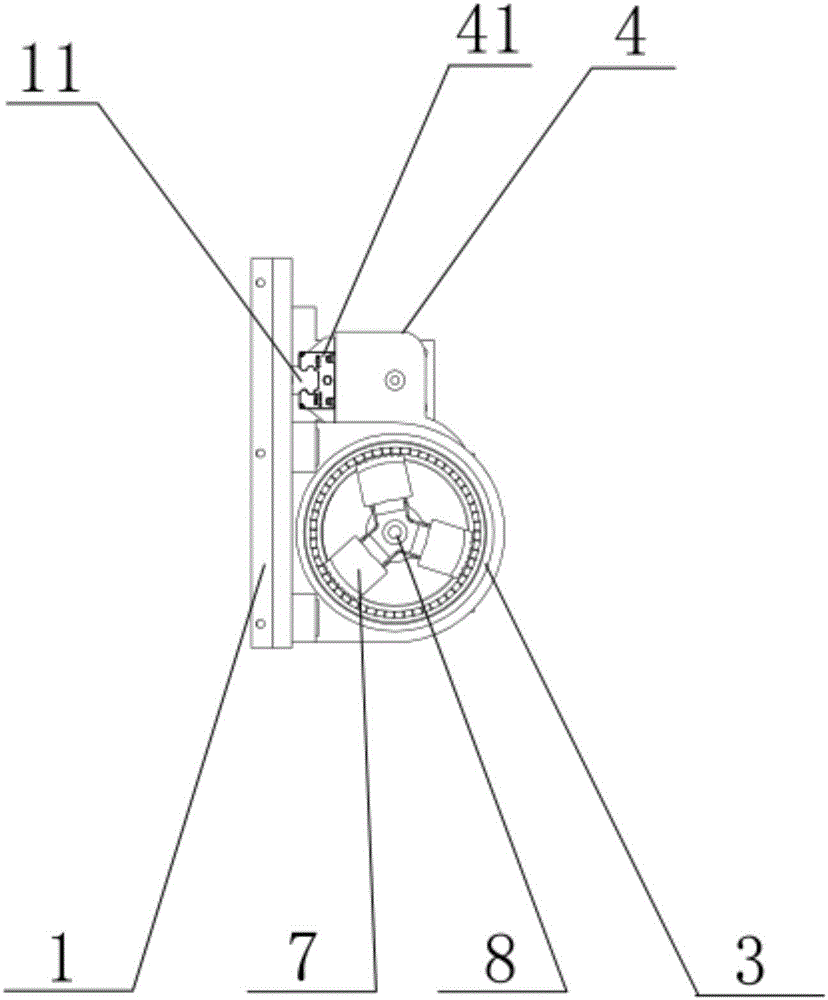

[0016] The technical scheme of the present invention will be further described below in conjunction with the accompanying drawings of the description:

[0017] Such as Figure 1~3 As shown, the present invention proposes a specific embodiment of a pipe end internal clamping and rotating feeding device, including a main shaft 9, an inner support block 8, an inner support three claws 7, a fork seat 4, and a tool for driving the main shaft 9 to rotate. Servo motor 6, servo reducer 5, and drive cylinder 12 for driving fork seat 4 to reciprocate inwardly and outwardly; servo reducer 5 is connected with main shaft 9, and drive cylinder 12 is connected with fork seat 4; The end is fixed in the machine base 3 through the deep groove ball bearing 2, and an annular groove is provided on the circular outer wall of the sliding block 10, and the roller on the roller needle roller bearing 14 is nested in the annular groove, and the roller rolls The needle on the needle bearing 14 is fixedl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com