Patents

Literature

1483 results about "Needle roller bearing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A needle roller bearing is a special type of roller bearing which uses long, thin cylindrical rollers resembling needles. Ordinary roller bearings' rollers are only slightly longer than their diameter, but needle bearings typically have rollers that are at least four times longer than their diameter. Like all bearings, they are used to reduce the friction of a rotating surface.

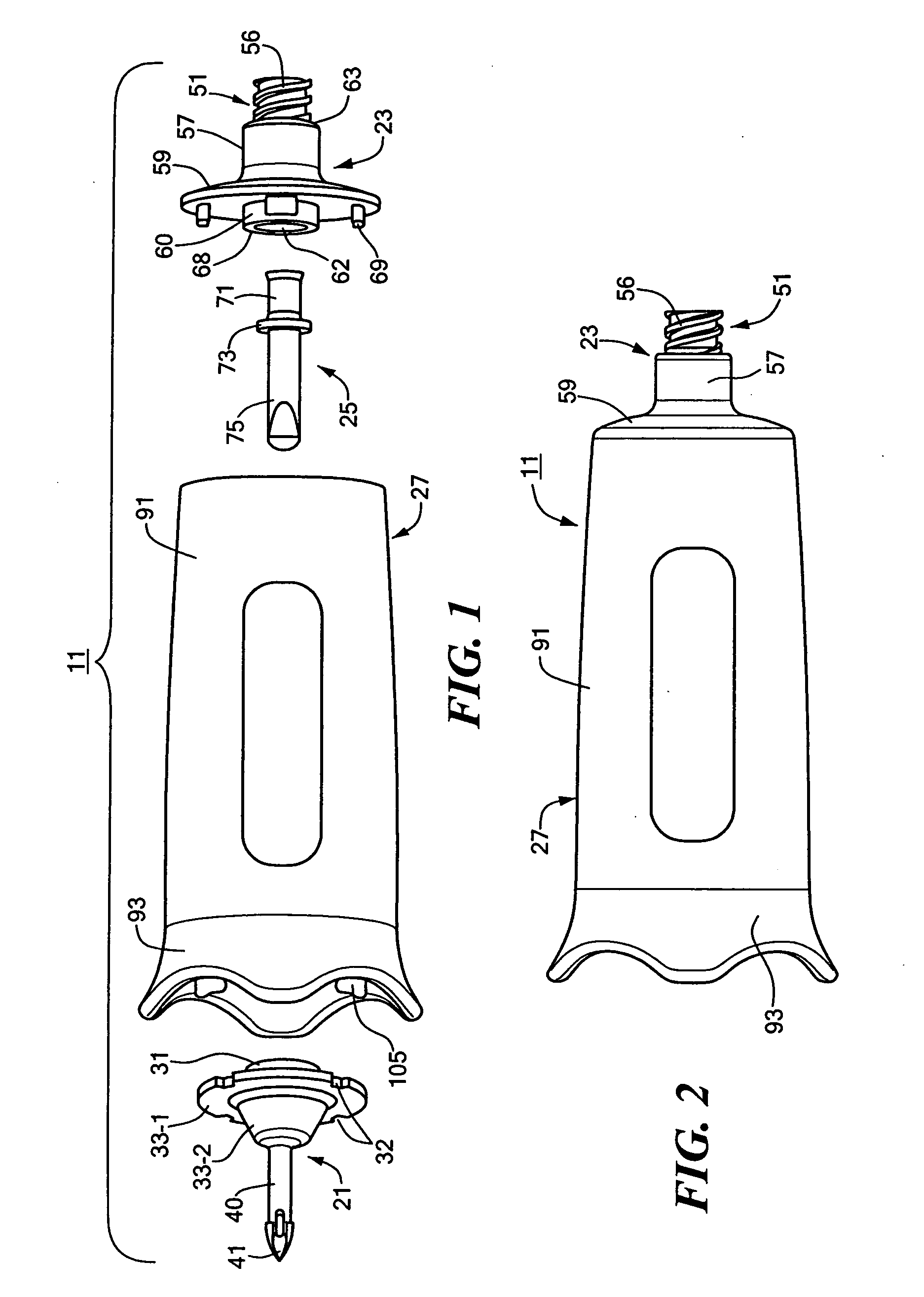

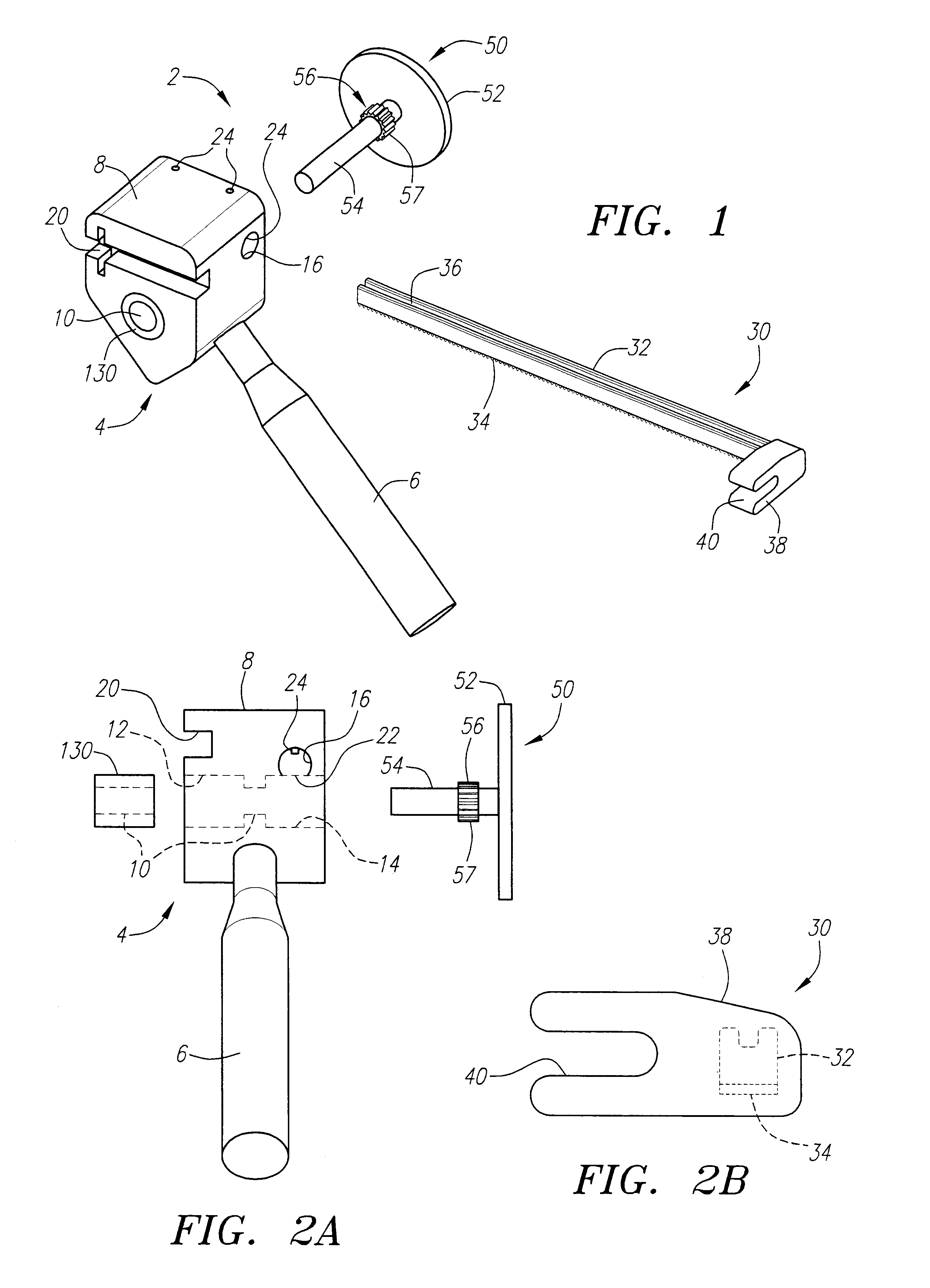

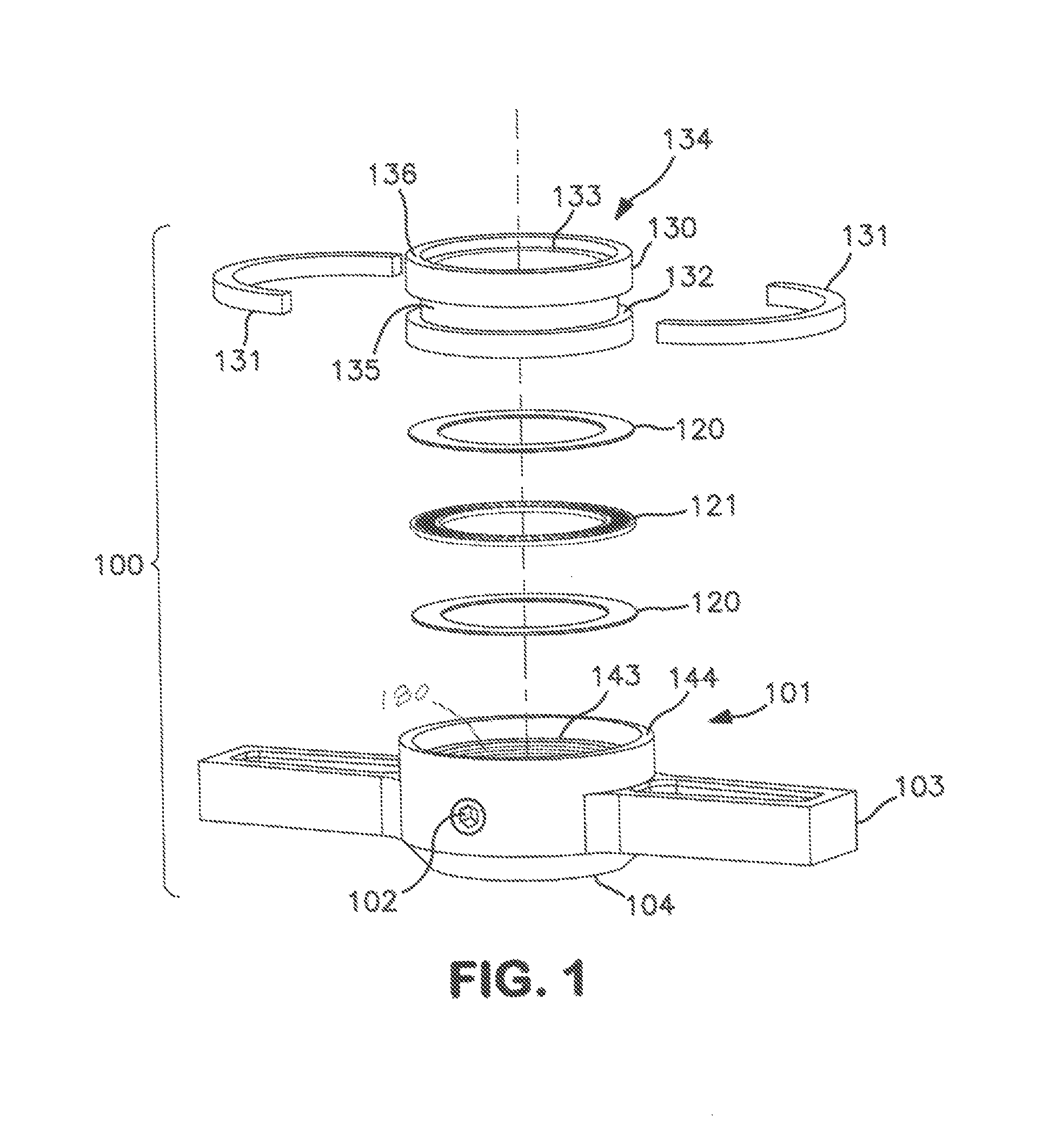

Vial adaptor

A vial adapter suitable for use in transferring fluid from a vial to a needleless syringe, the vial having a top end sealed with a septum. According to one embodiment, the vial adapter comprises (a) a body, the body having a top end, a bottom end and an inner cavity, the inner cavity being dimensioned to receive the vial, with the bottom end of the body extending below the bottom end of the vial; (b) a needle-bearing member mounted within the body, the needle-bearing member comprising a hollow needle extending downwardly into the inner cavity of the body for puncturing the septum of a vial disposed in the inner cavity; (c) a luer-lock-bearing member mounted on the top end of the body, the luer-lock-bearing member comprising a top portion and a bottom portion separated by a radial wall, the top portion being a female luer-lock, the bottom portion including a tubular structure in fluid communication with the hollow needle; and (d) a valve disposed within the luer-lock-bearing member for controlling fluid flow from the bottom portion to the top portion, the valve being opened by attachment of the needleless syringe to the vial adapter.

Owner:BOSTON SCI SCIMED INC

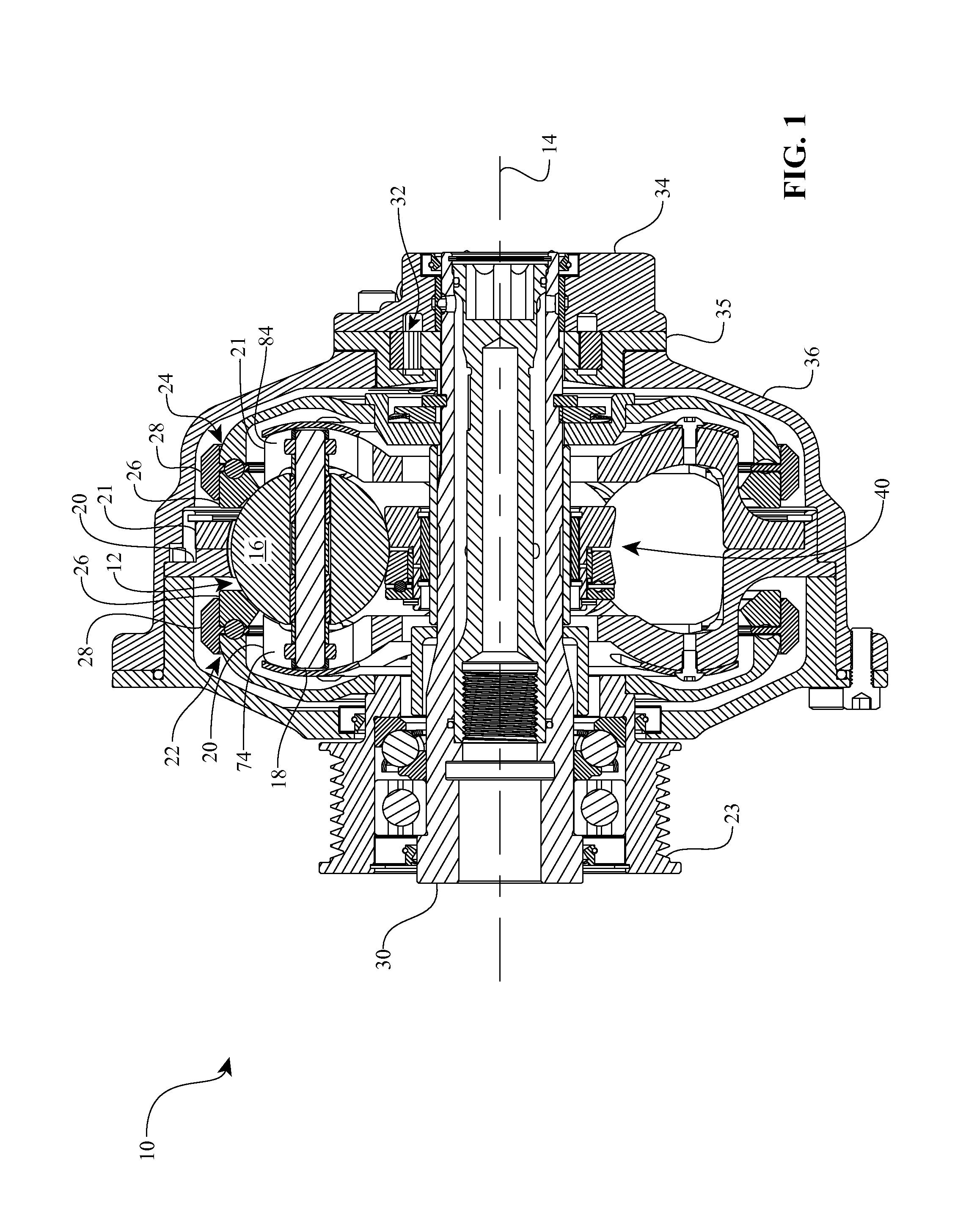

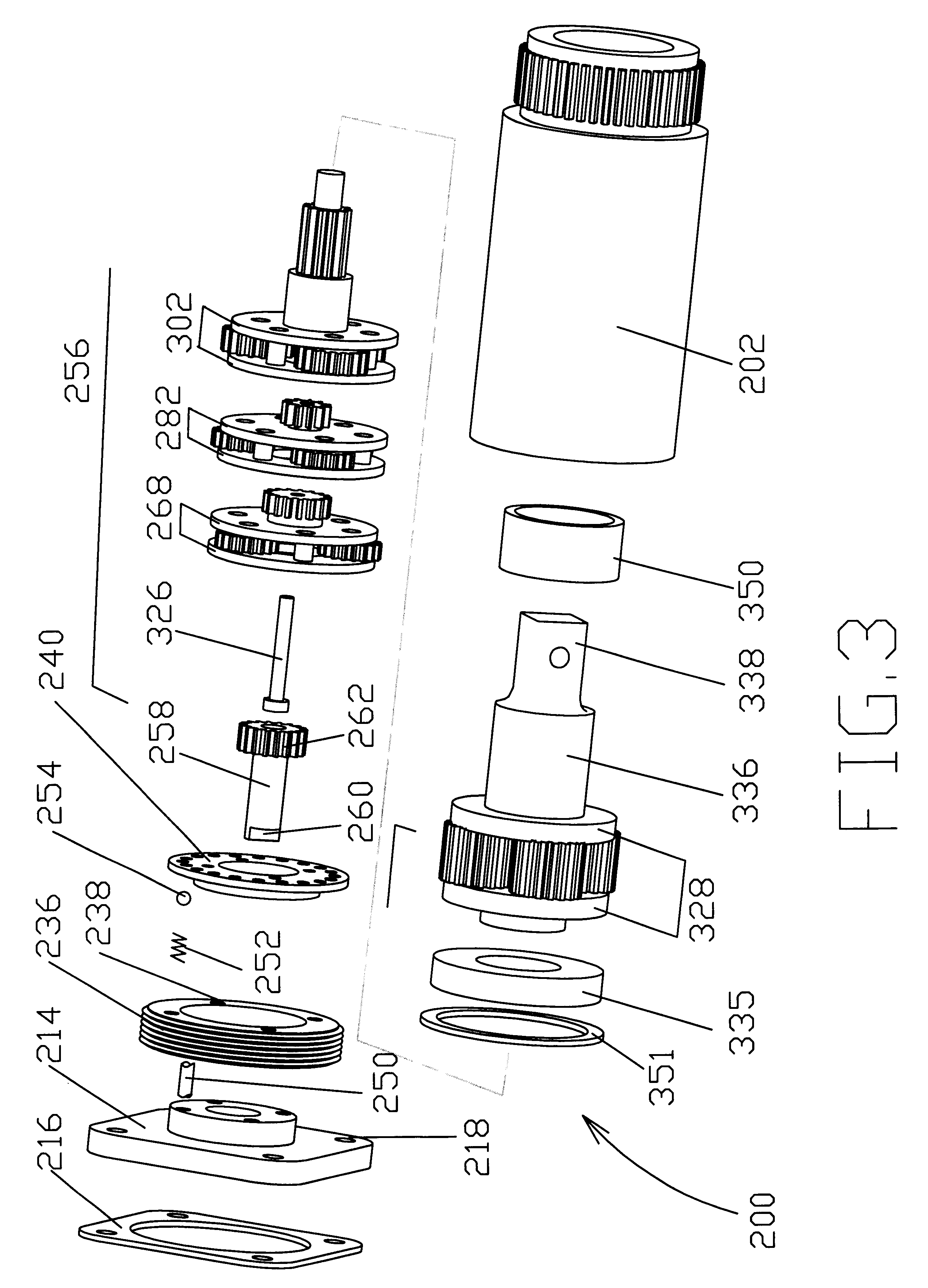

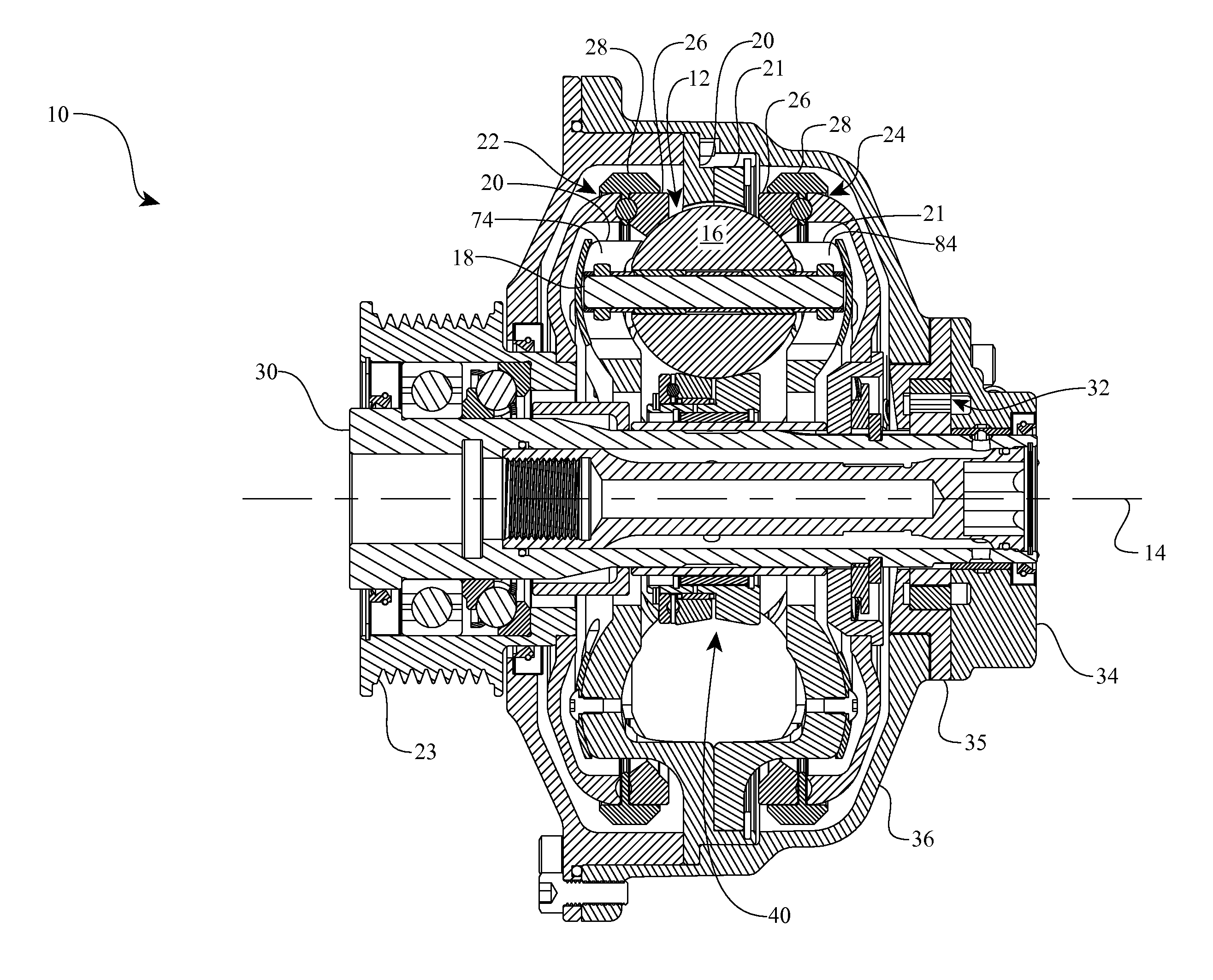

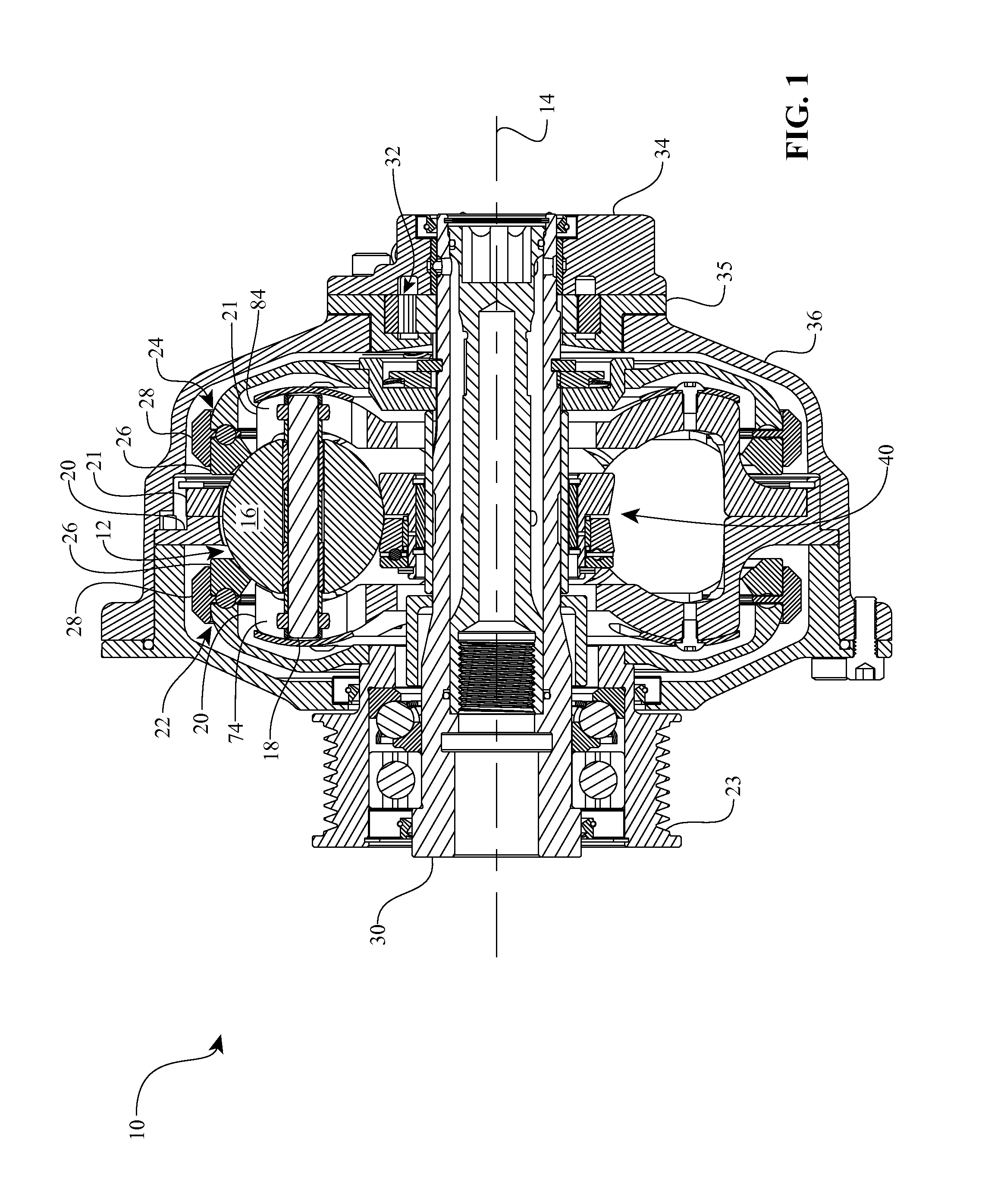

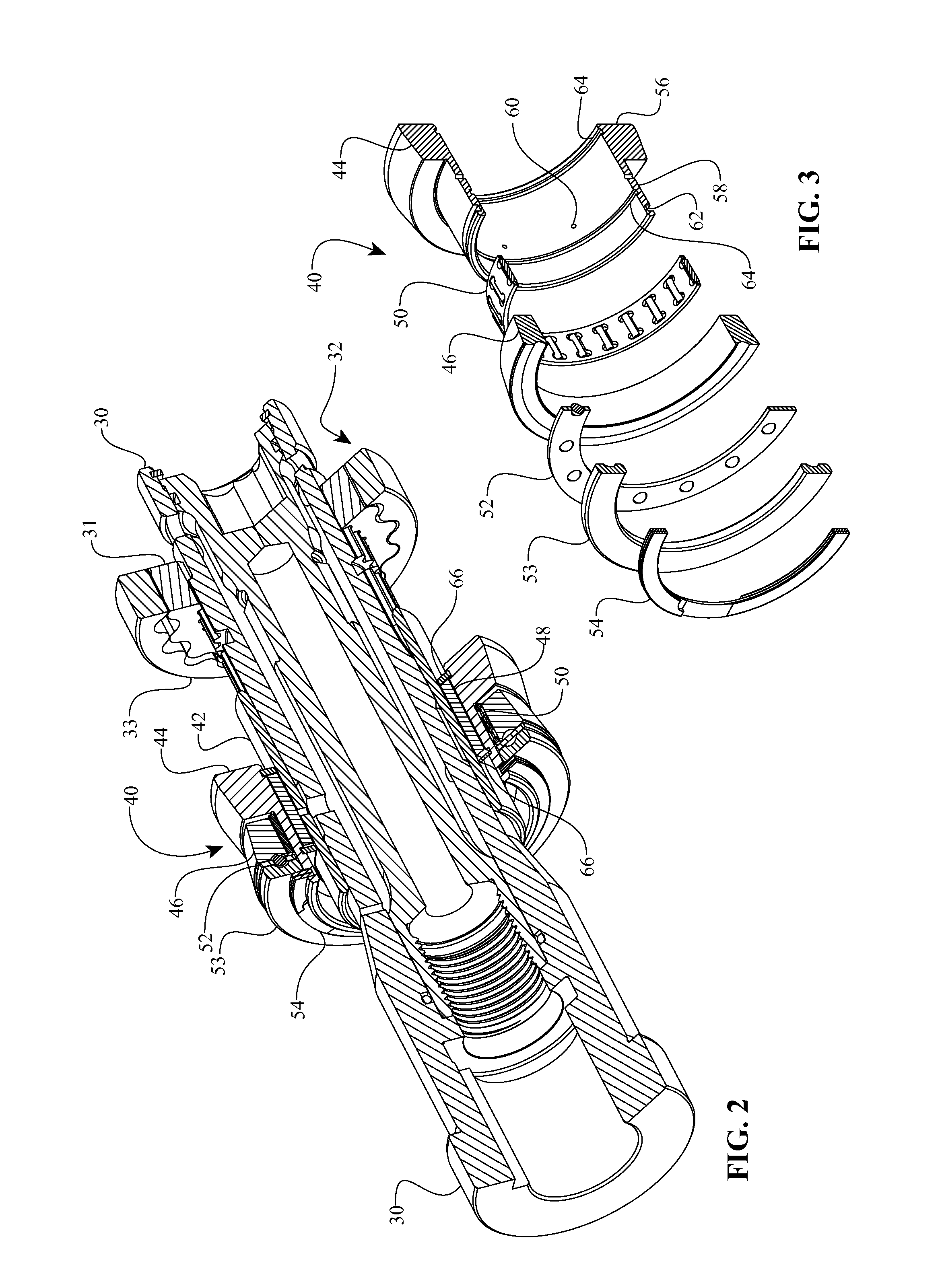

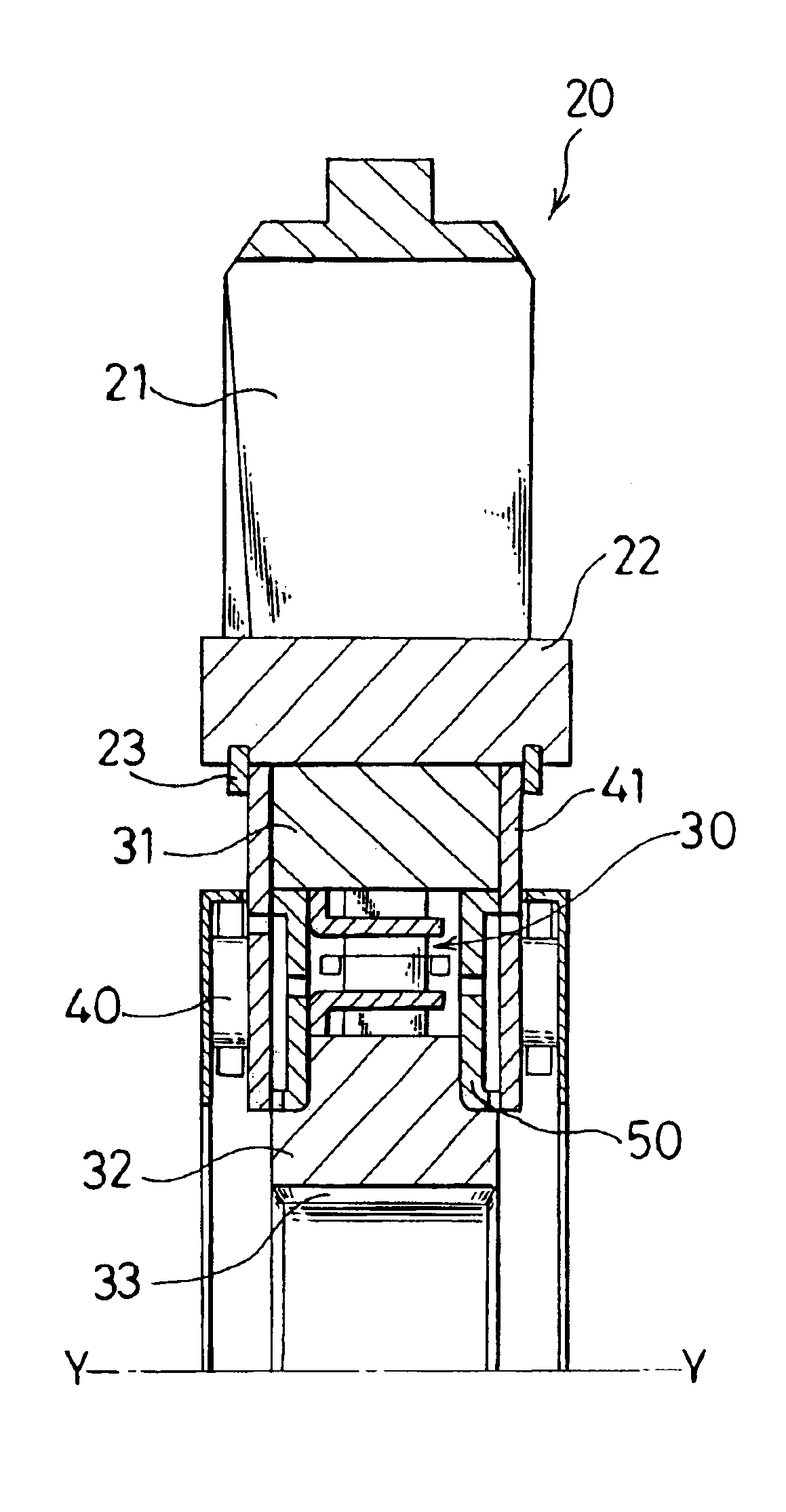

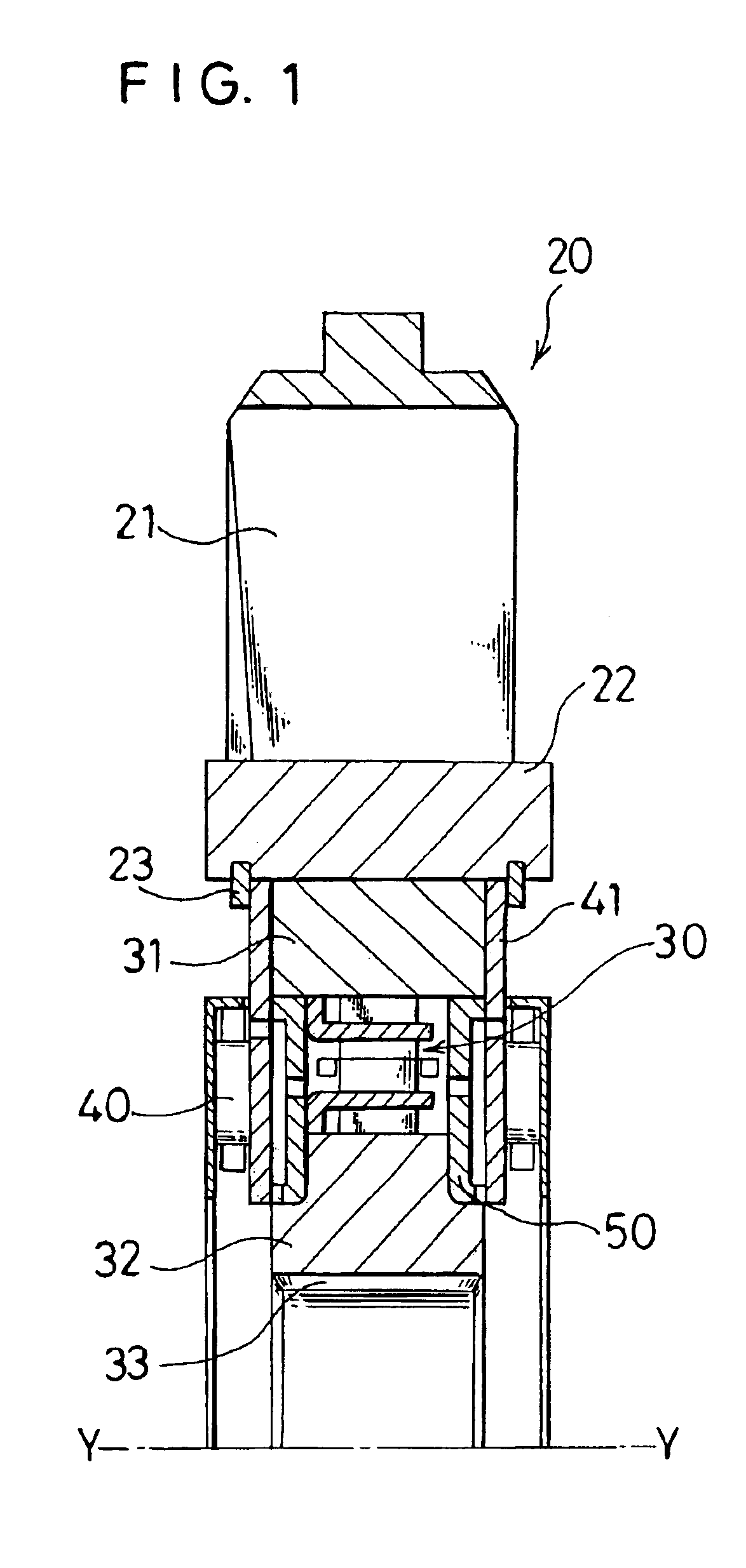

Continuously variable transmission

Owner:FALLBROOK INTPROP COMPANY

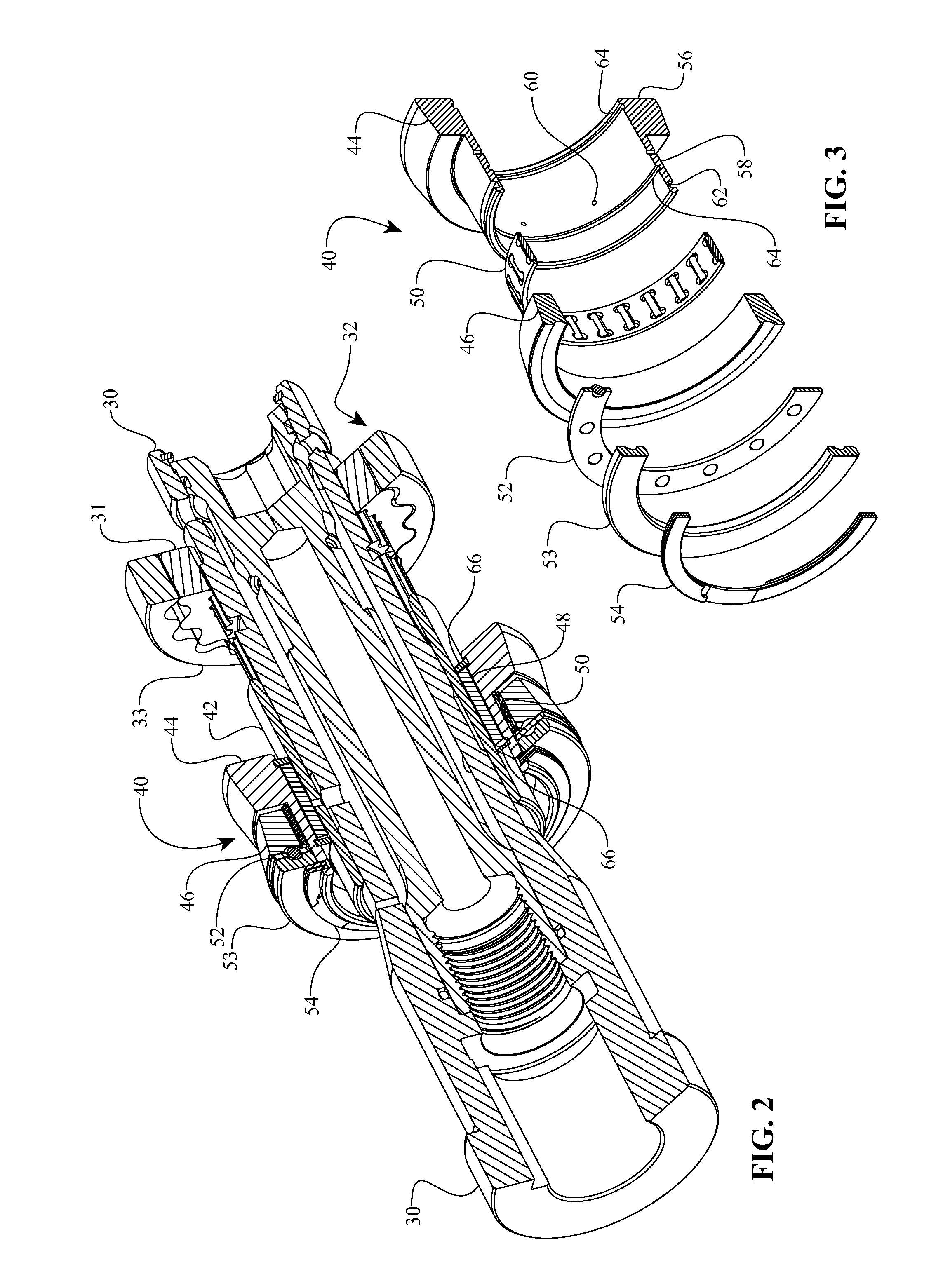

Torque tool

The torque tool comprises a torque converter including three planet carriers which encase three planetary gears. Each of the three planetary gears includes a sun gear and three planet pinions. Each of the three planet carriers has an input disc-shaped plate, directed towards an input shaft of the torque tool and an output disc-shaped plate directed towards an output shaft of the torque tool. The input and output shafts constitute the main shafts of the torque tool. Two of the three planet carriers, which are next to the input shaft, have their output disc-shaped plates extending into sun gears with which they form unitary structures. A stepped pin is centrally disposed in a needle bearing of a first sun gear adjacent the input shaft and extends through sliding bearings located in the following sun gears. A first large diameter of the stepped pin is commensurate with an interior diameter of the needle bearing and a second small diameter of the stepped pin is commensurate with interior equal diameters of the sliding bearings inserted in the following sun gears. The planet pinions of one of the three planet gears, which is adjacent to the output gear, arc each provided with a multiplicity of roll needles closely spaced together, the multiplicity of roll needles being inserted between each of the at least three planet gears and an axle for supporting.

Owner:NEW WORLD TECH

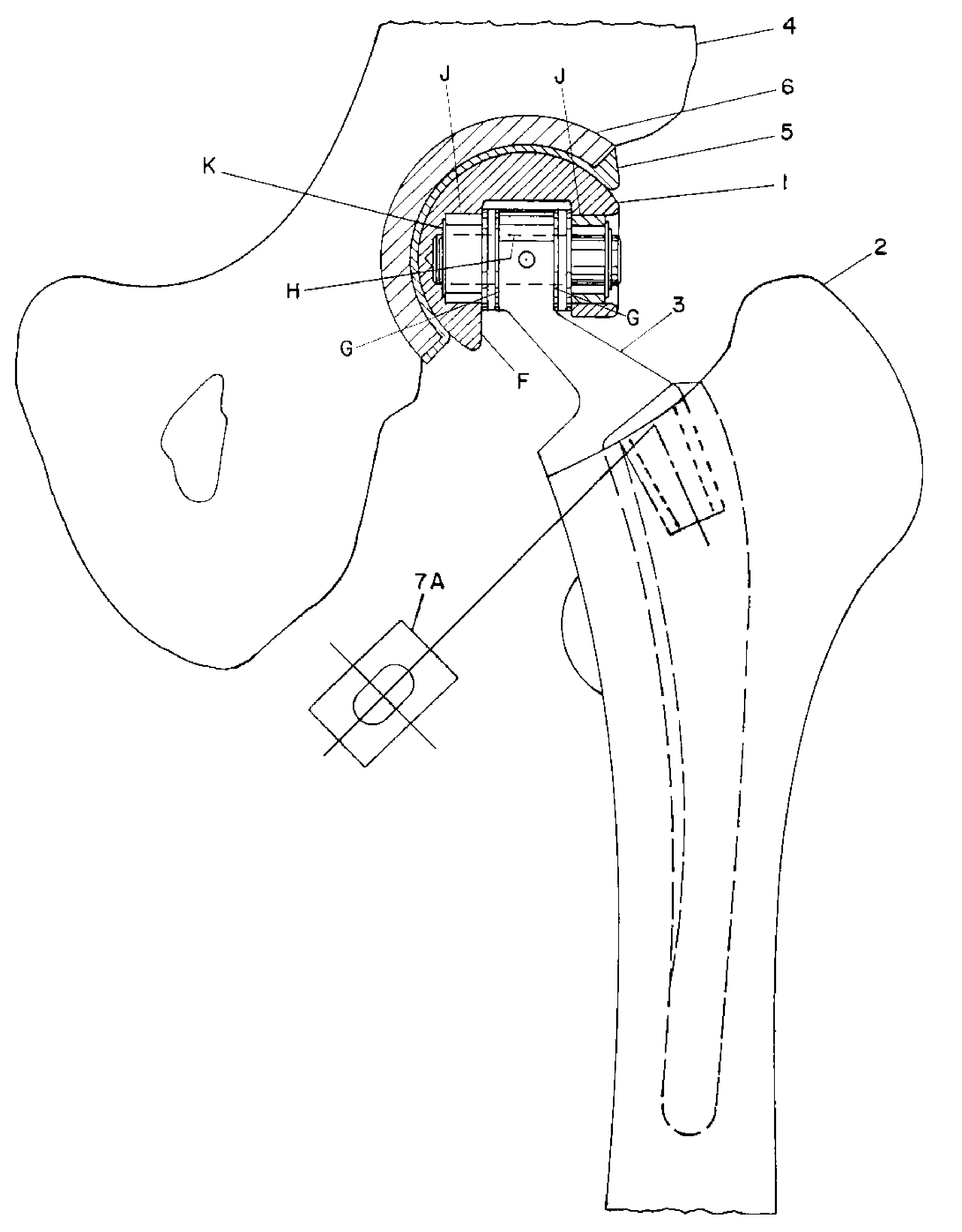

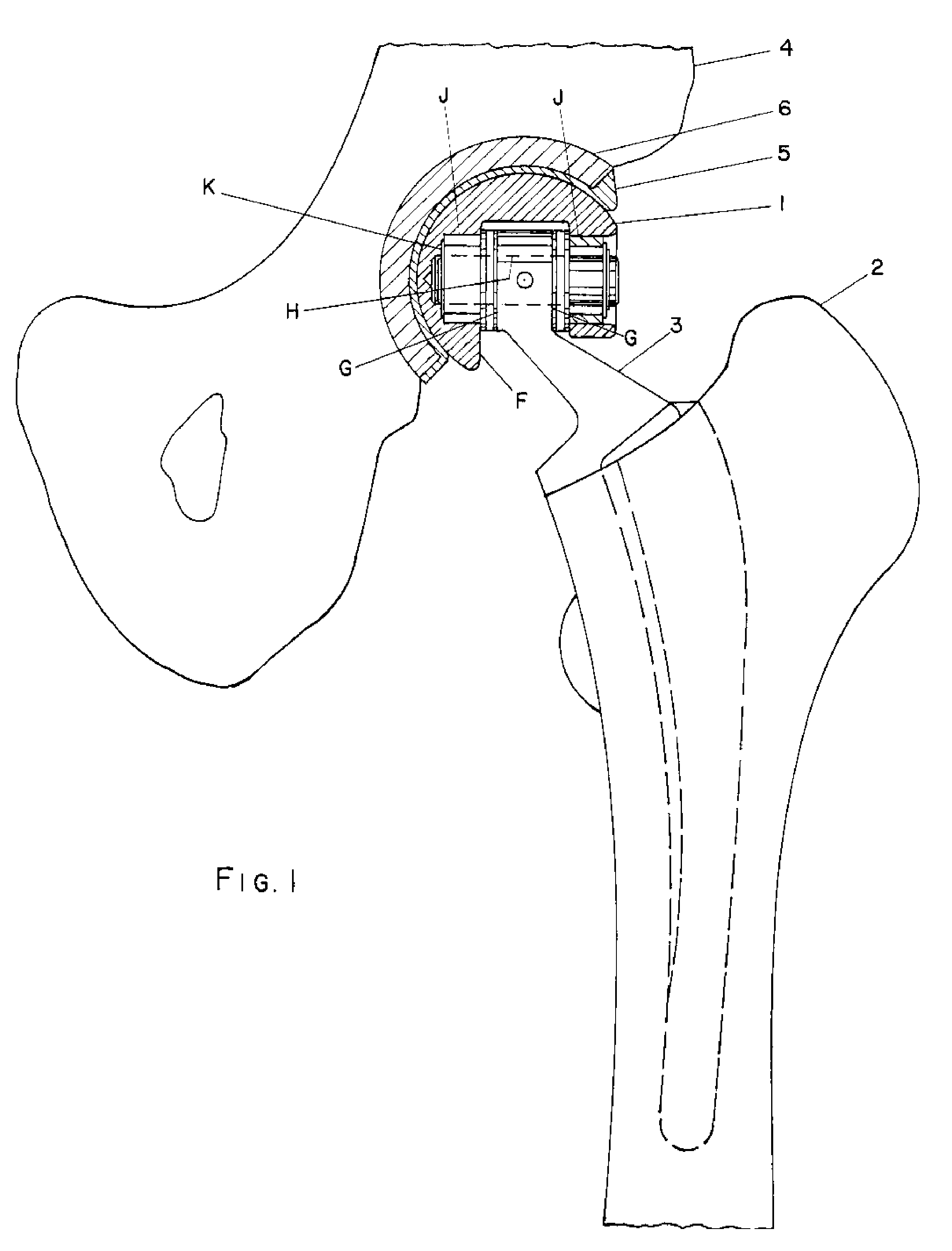

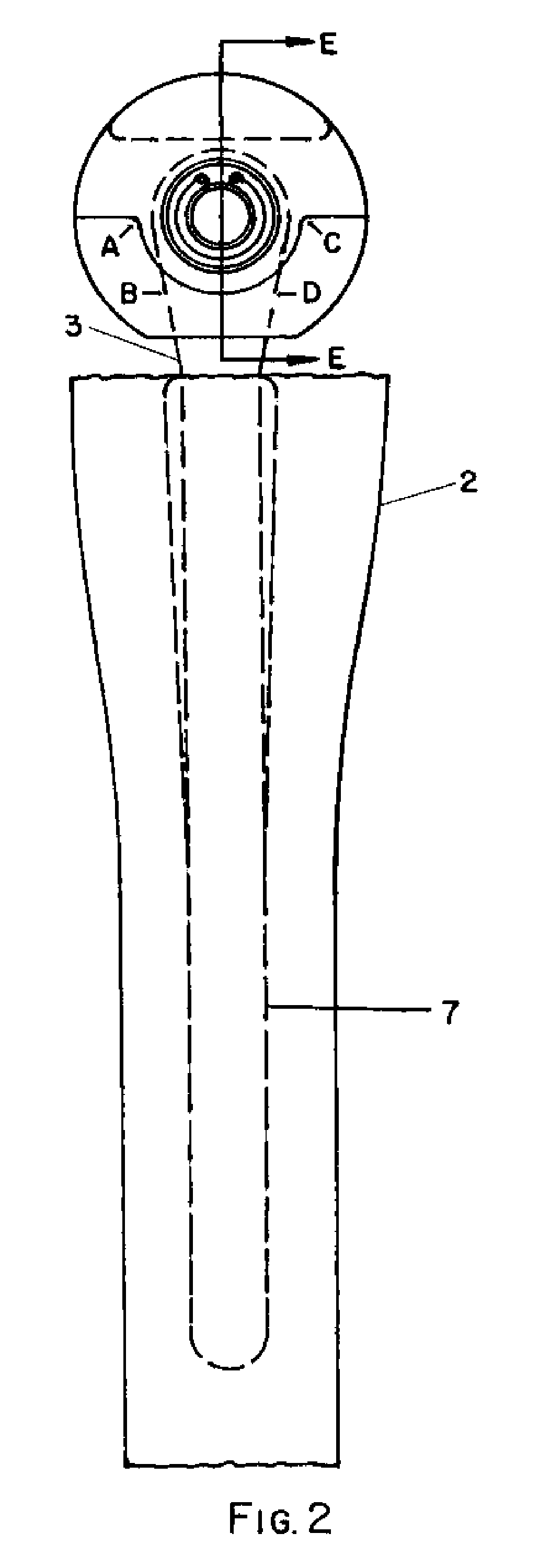

Hip prosthesis and the use thereof

InactiveUS7179298B2Reduce relative motionReduce wearJoint implantsFemoral headsNeedle roller bearingCoxal joint

Hip prosthesis. The femur side hip prosthesis includes both a ball and socket bearing and another (secondary) bearing system which facilitates motion of the type which is primarily in the forward and backward swinging of the leg. In certain embodiments of the invention, the secondary bearing system includes needle bearings and thrust bearings. That secondary bearing system lessens the motion of the ball and socket joint required during common activities such as walking. Certain embodiments of the invention include a modular connection between the stem for placement within the femur and the assembly that includes the secondary bearing.

Owner:GREENLEE WILFRED E

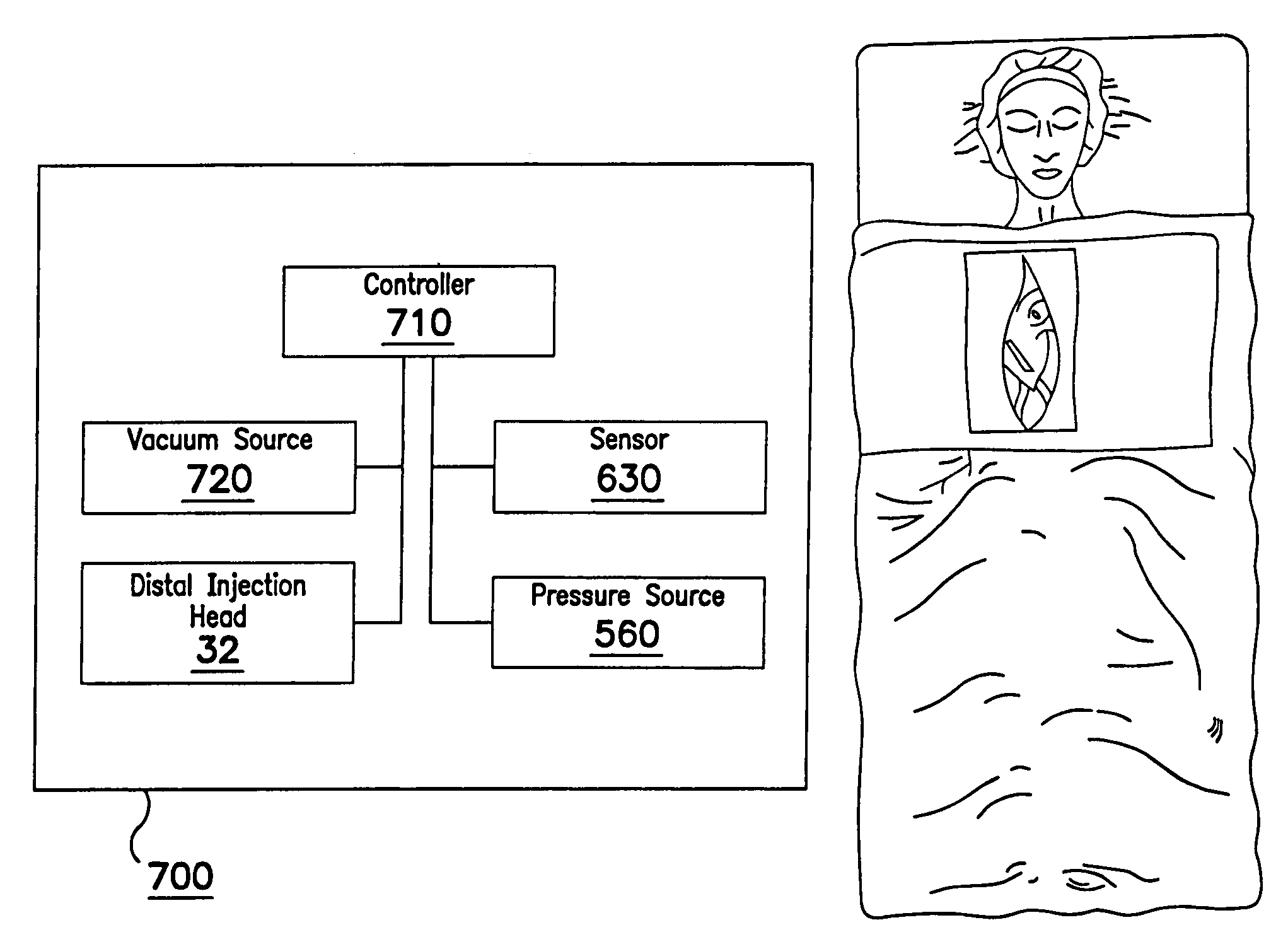

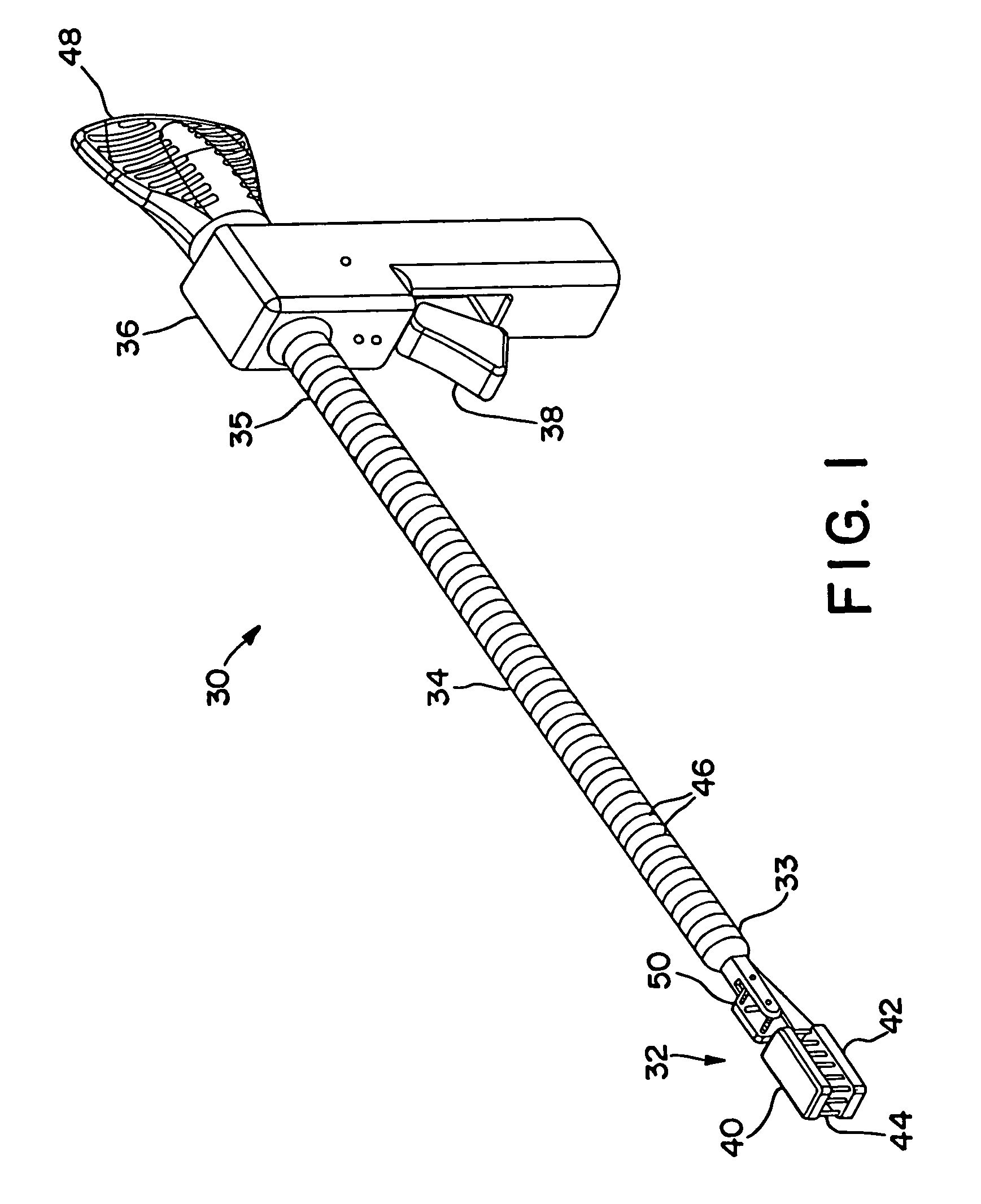

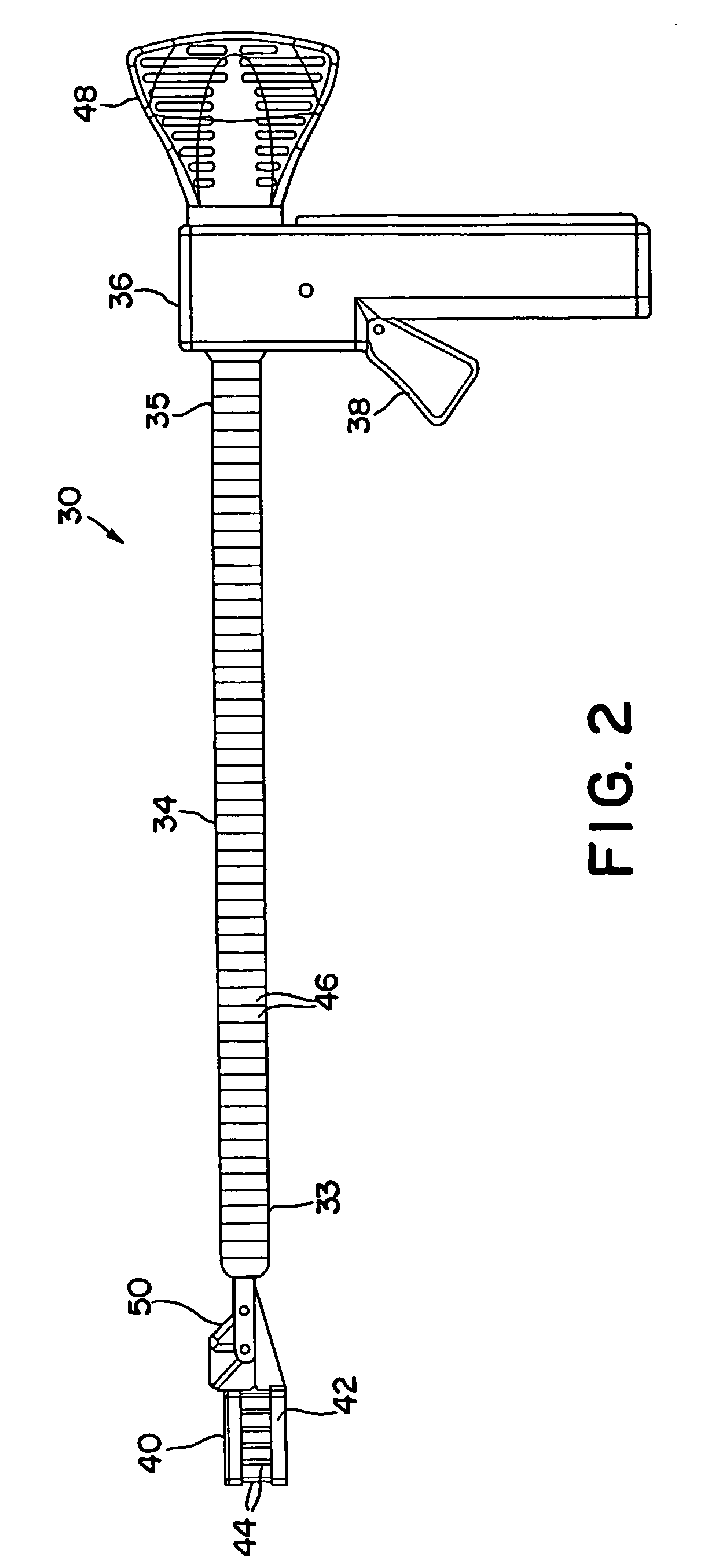

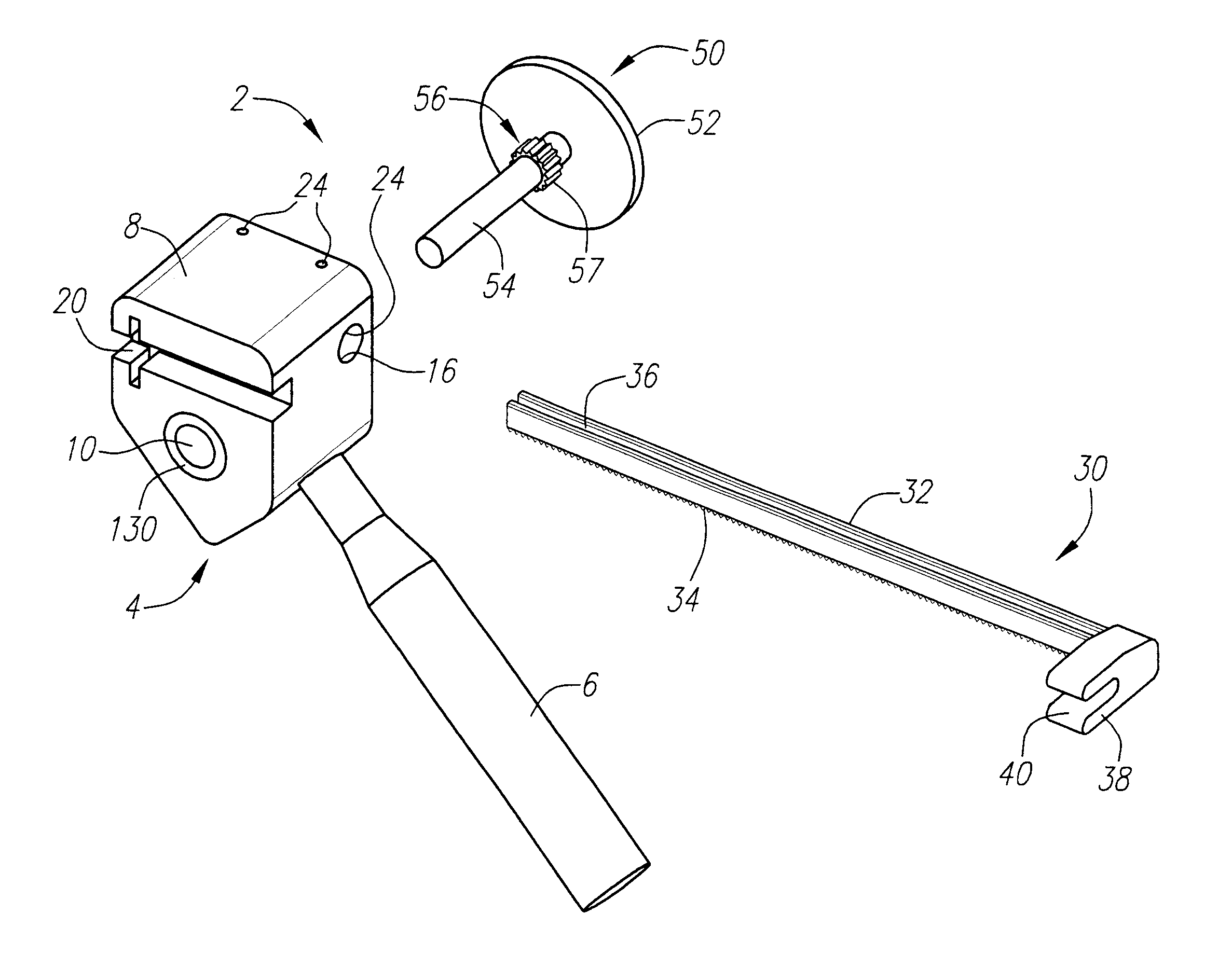

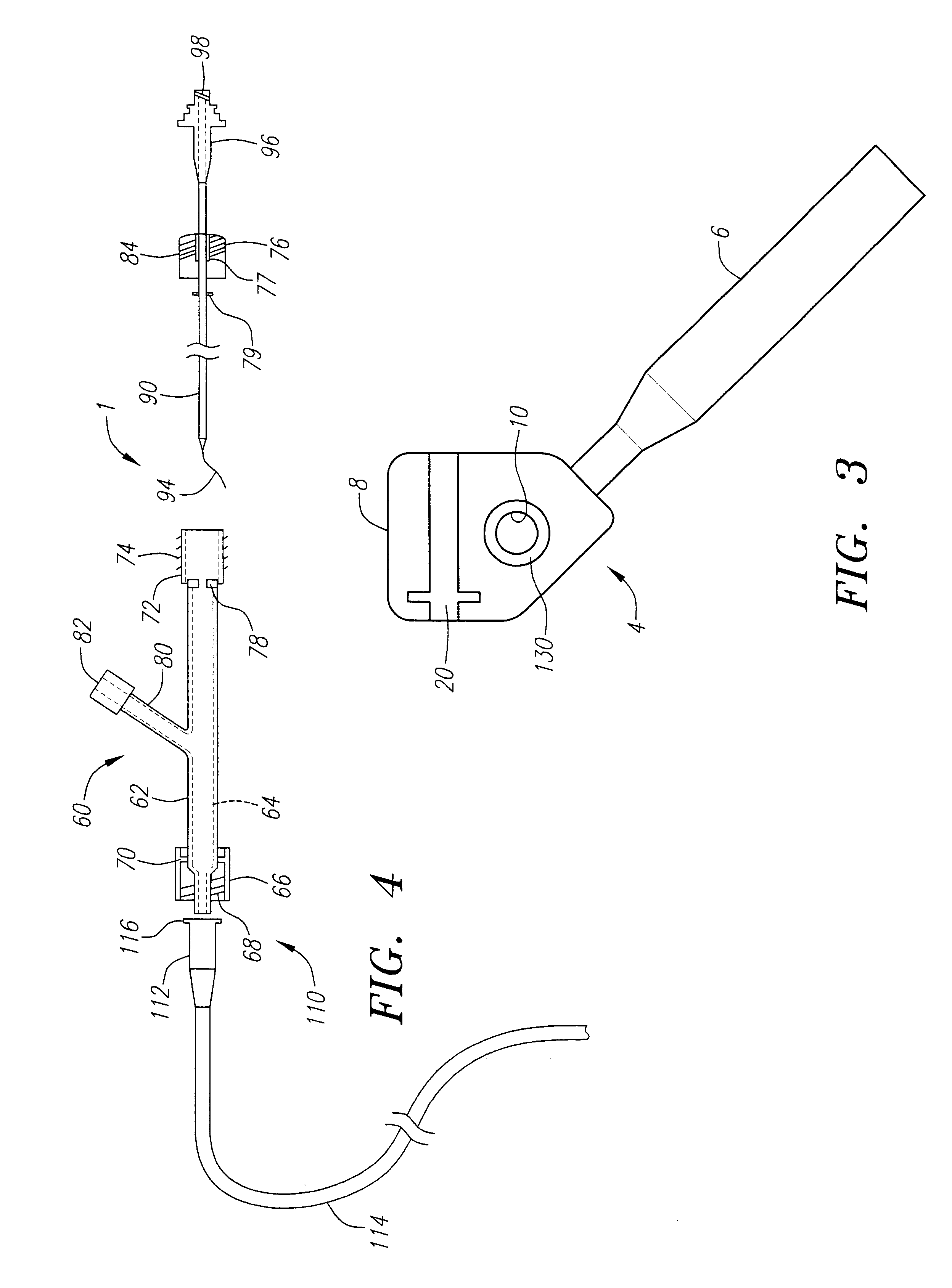

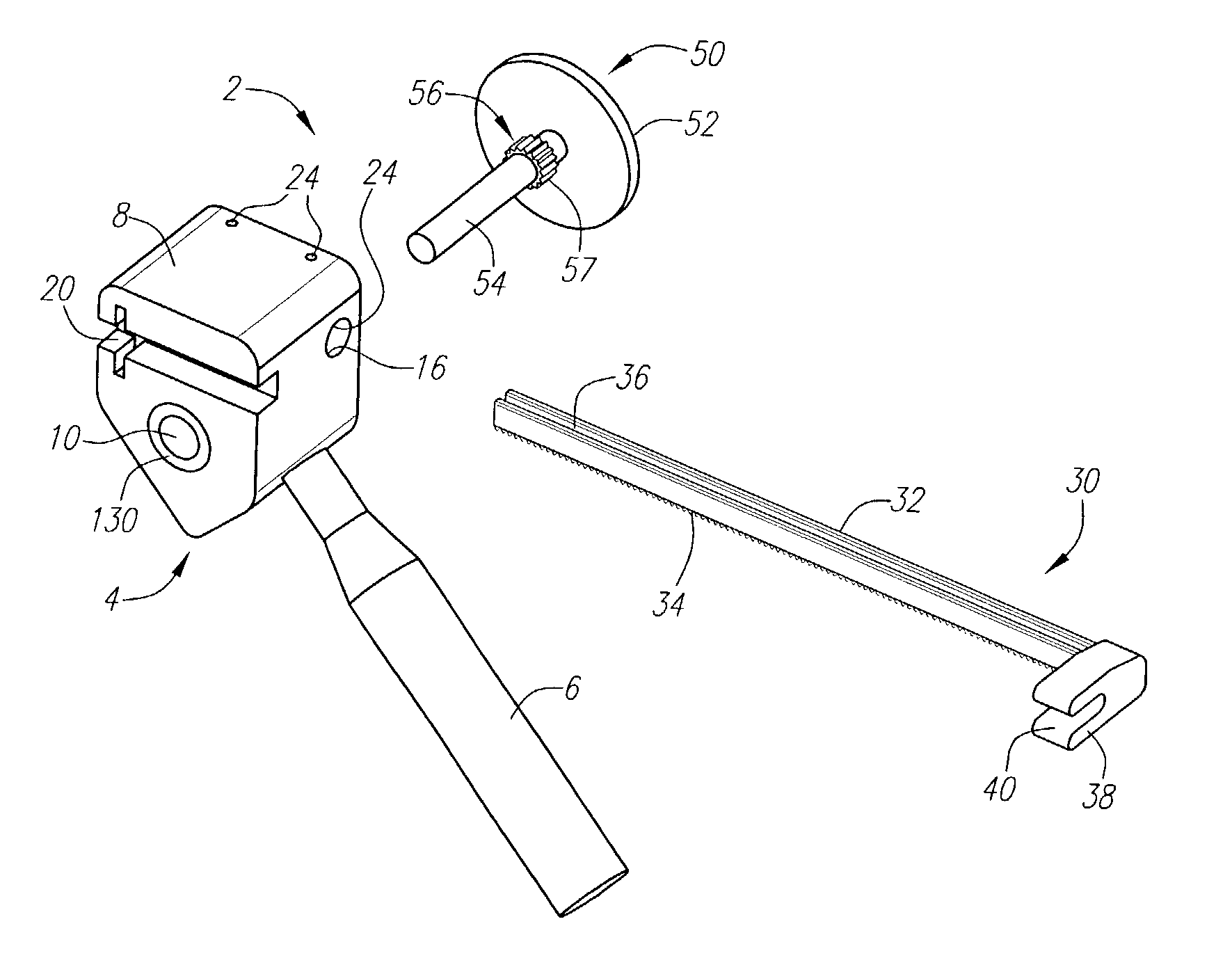

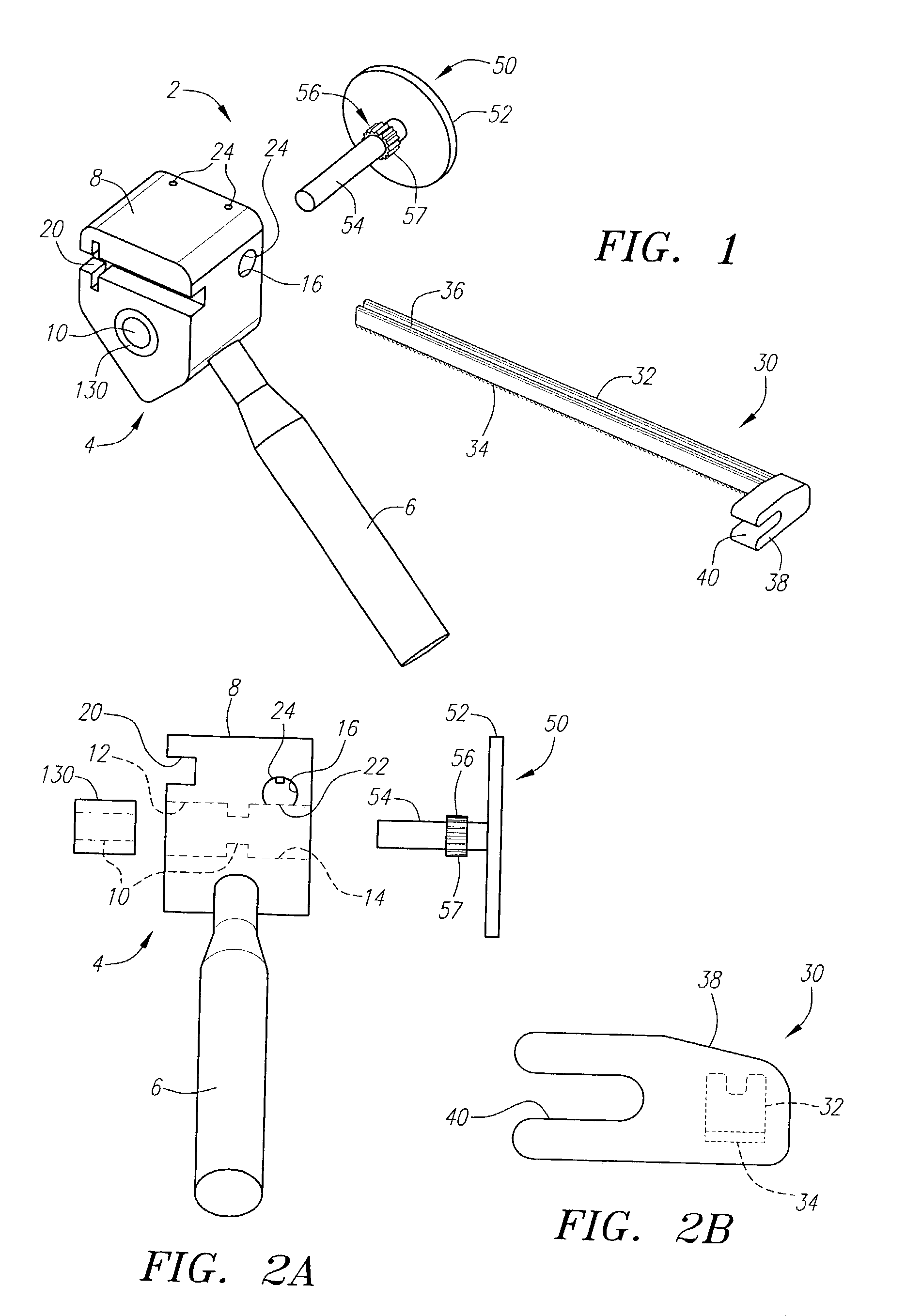

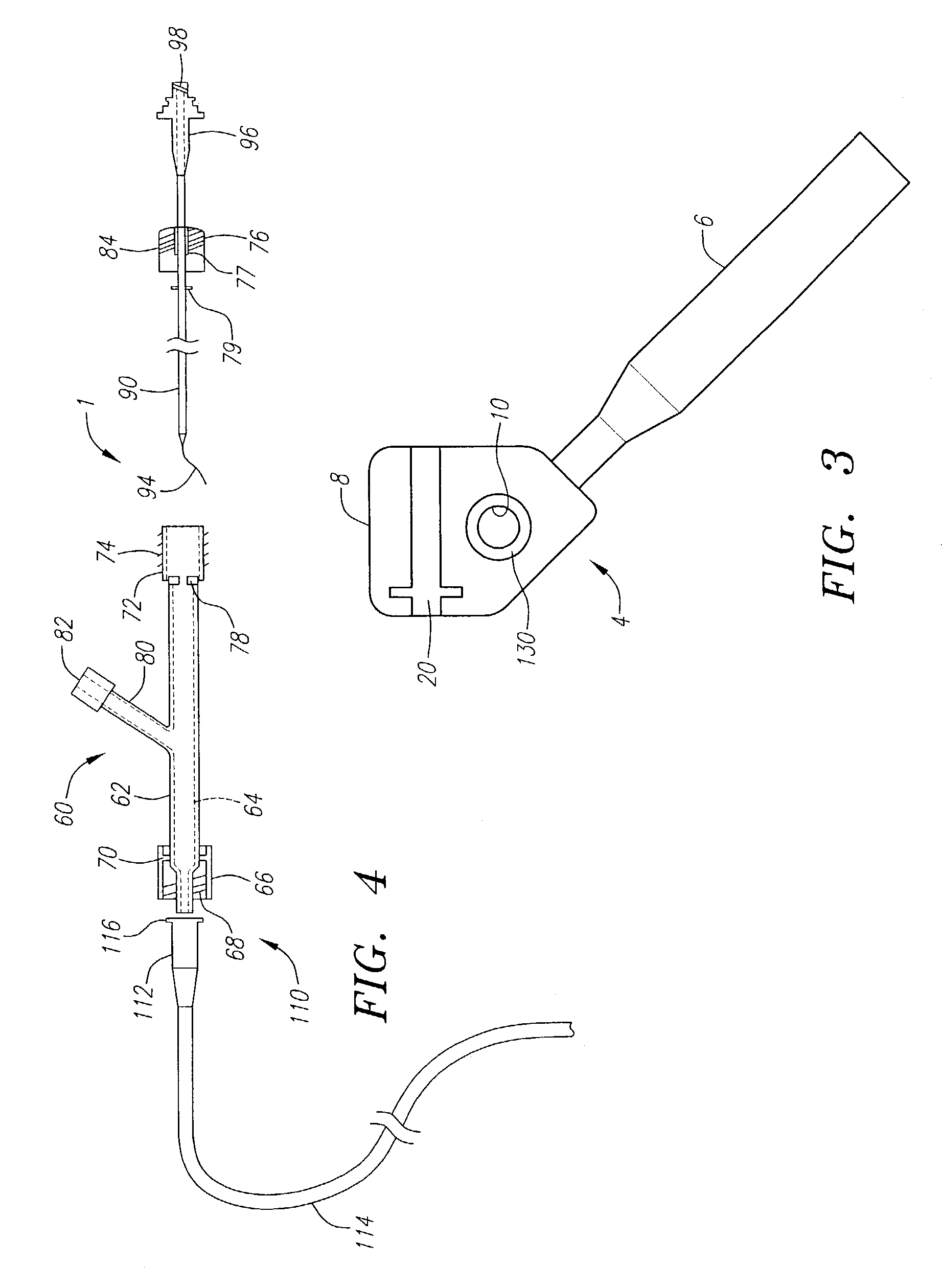

Stent delivery device

A unidirectional handle device for an endoluminal device includes an outer tubular member and an elongate inner member slidably received in the outer tubular member. The unidirectional handle includes a handle member, a needle bearing clutch disposed in the handle member, a control member guide, and shaft rotatable in a single direction disposed within the handle member. The shaft is rotatable in a single direction by its engagement with the needle bearing clutch. The shaft is in rotational engagement with the outer tubular member of the endoluminal device. The outer tubular member is slidable from a distal position to a proximal position when the shaft is rotated in the single direction. The unidirectional handle device provides substantially no backlash of the outer tubular member. In addition, the unidirectional handle device advantageously produces a tension-retaining effect during use.

Owner:ENDOTEX INTERNVENTIONAL SYST

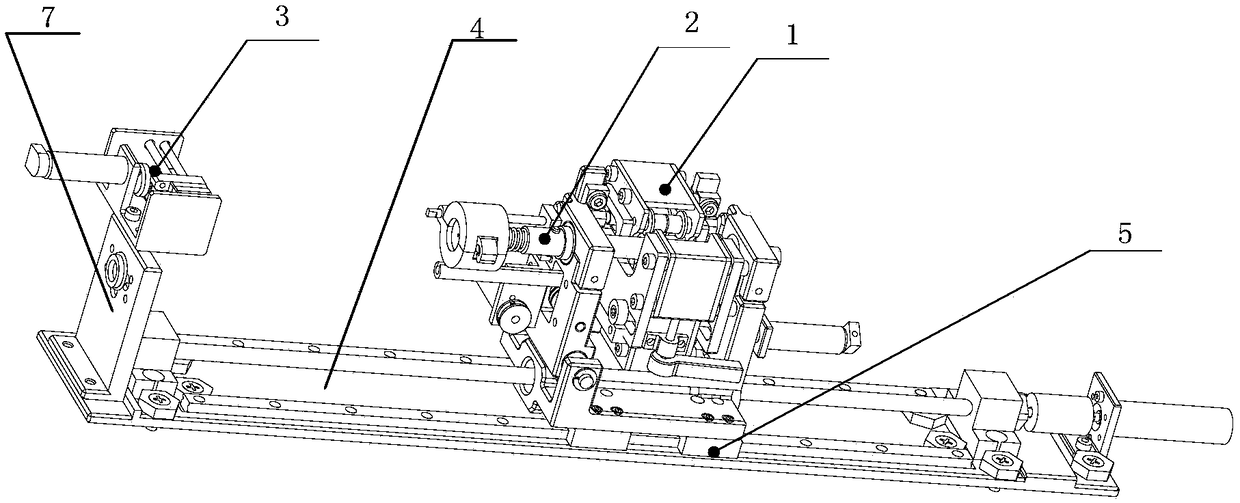

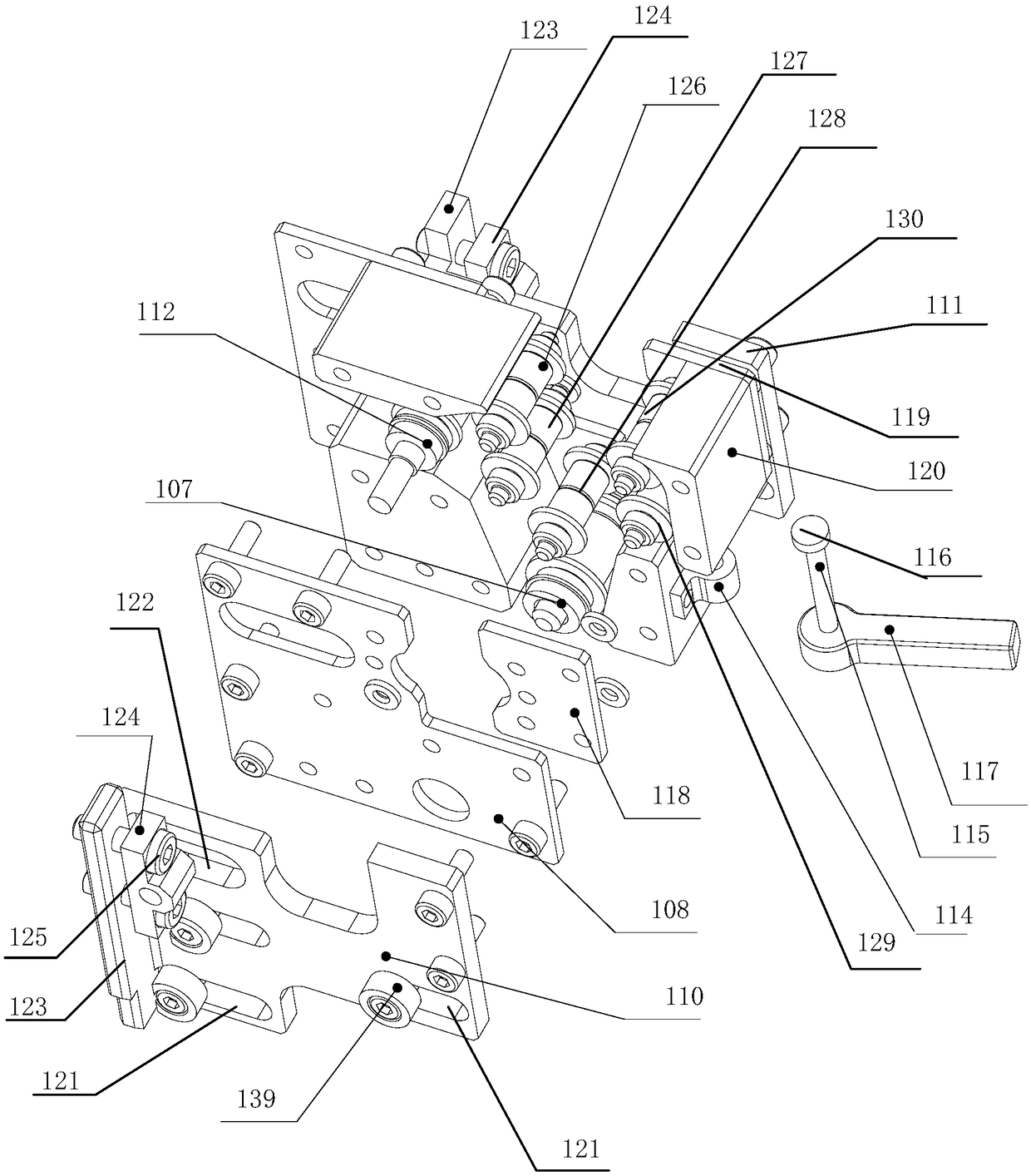

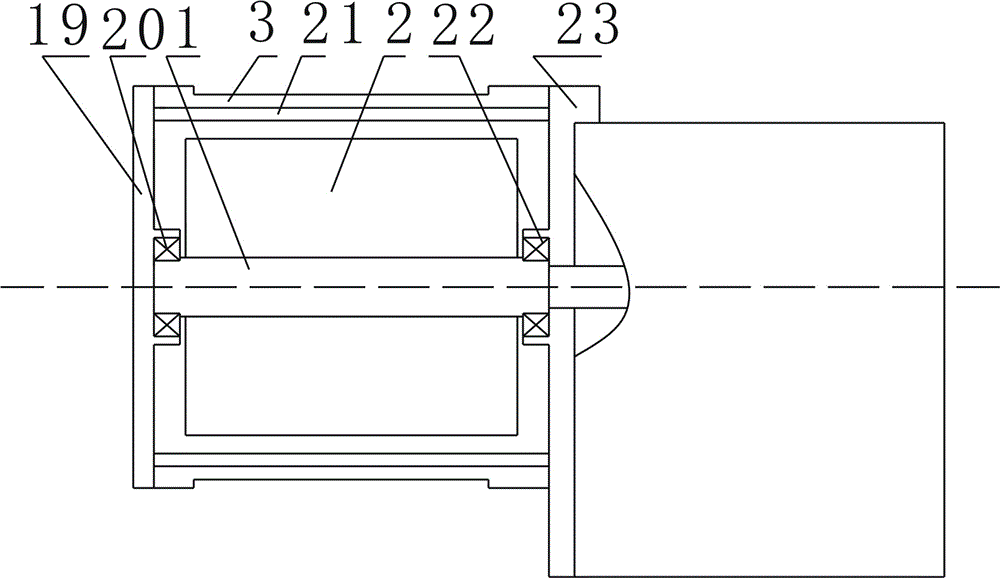

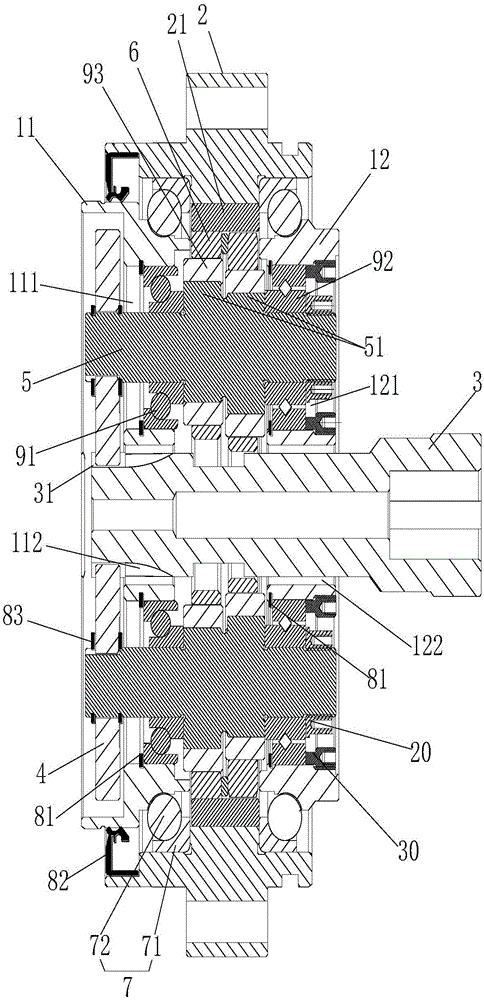

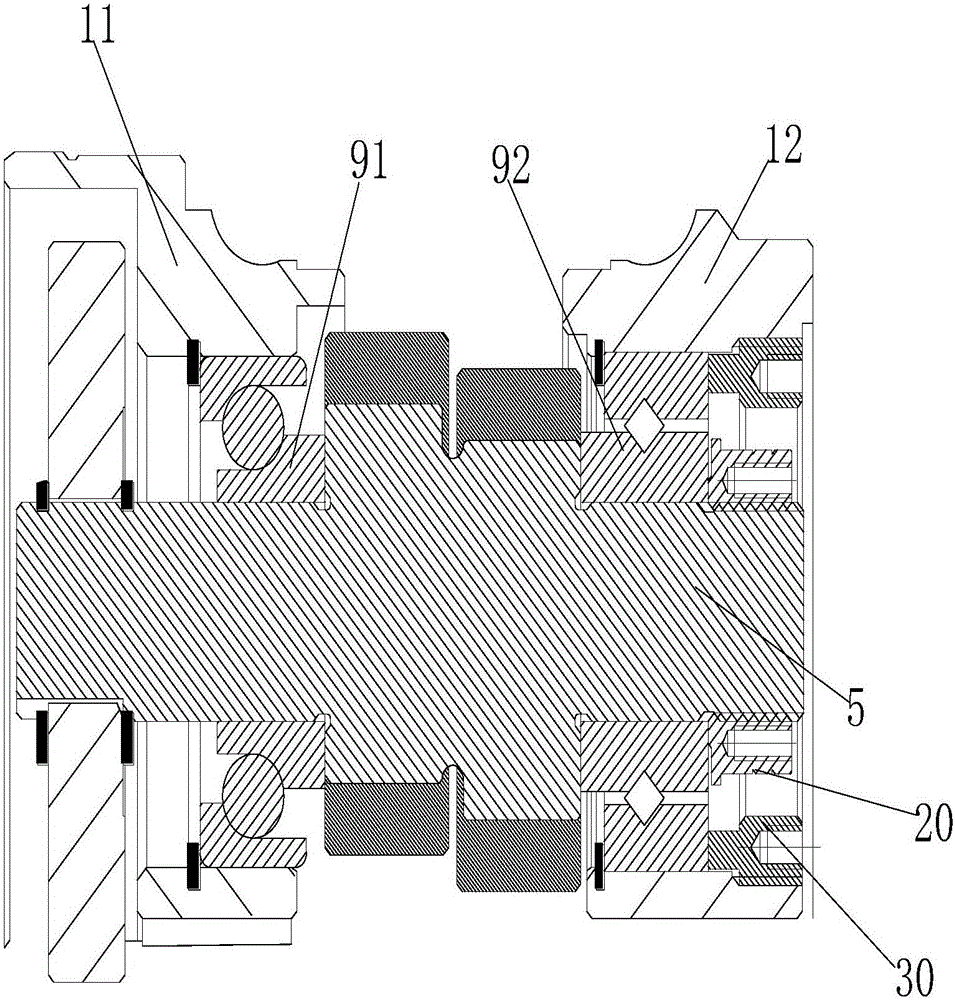

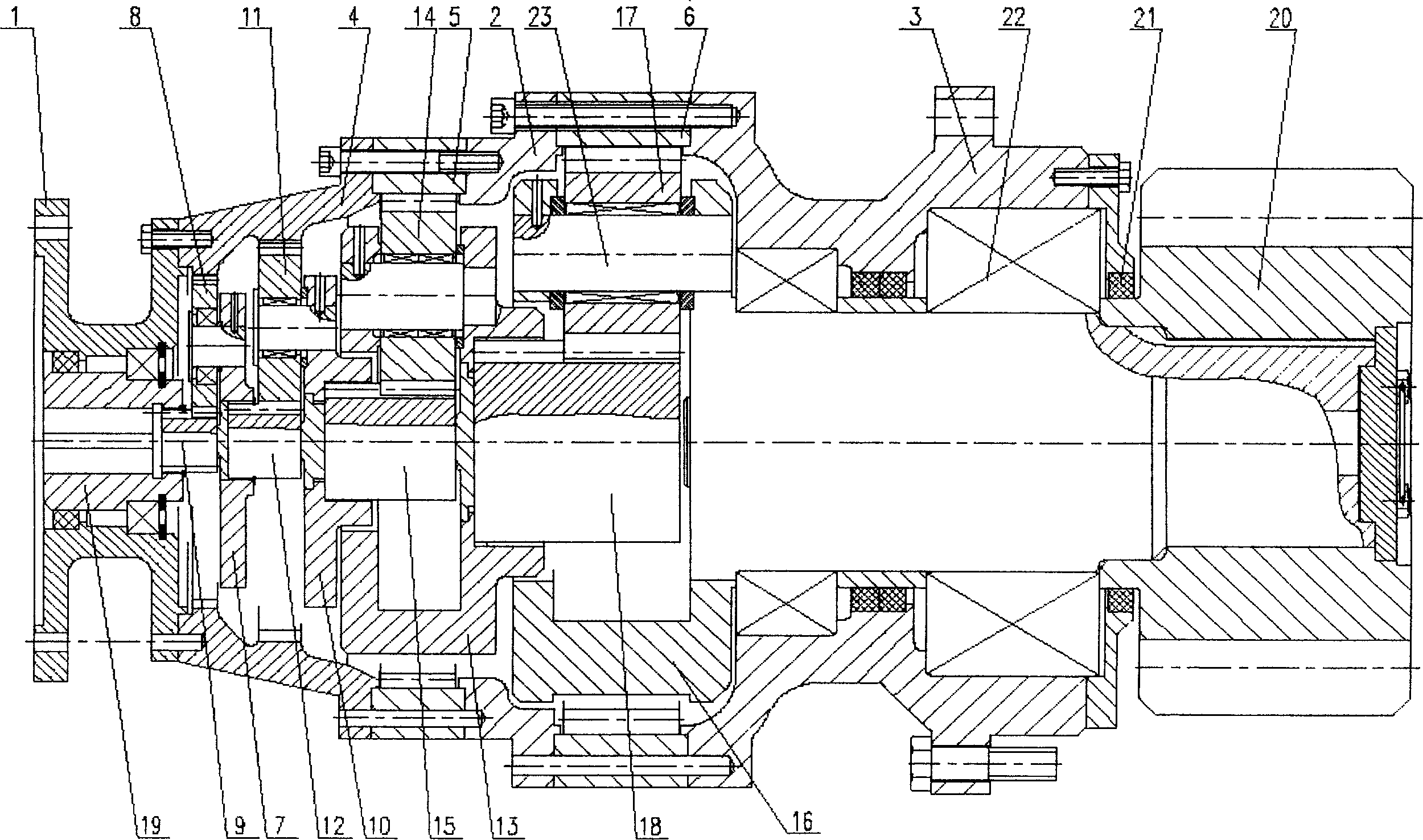

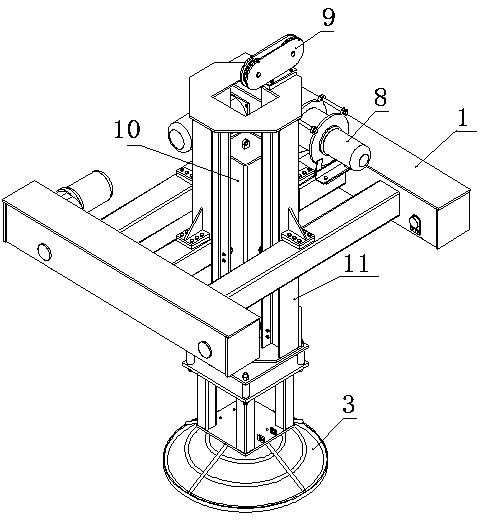

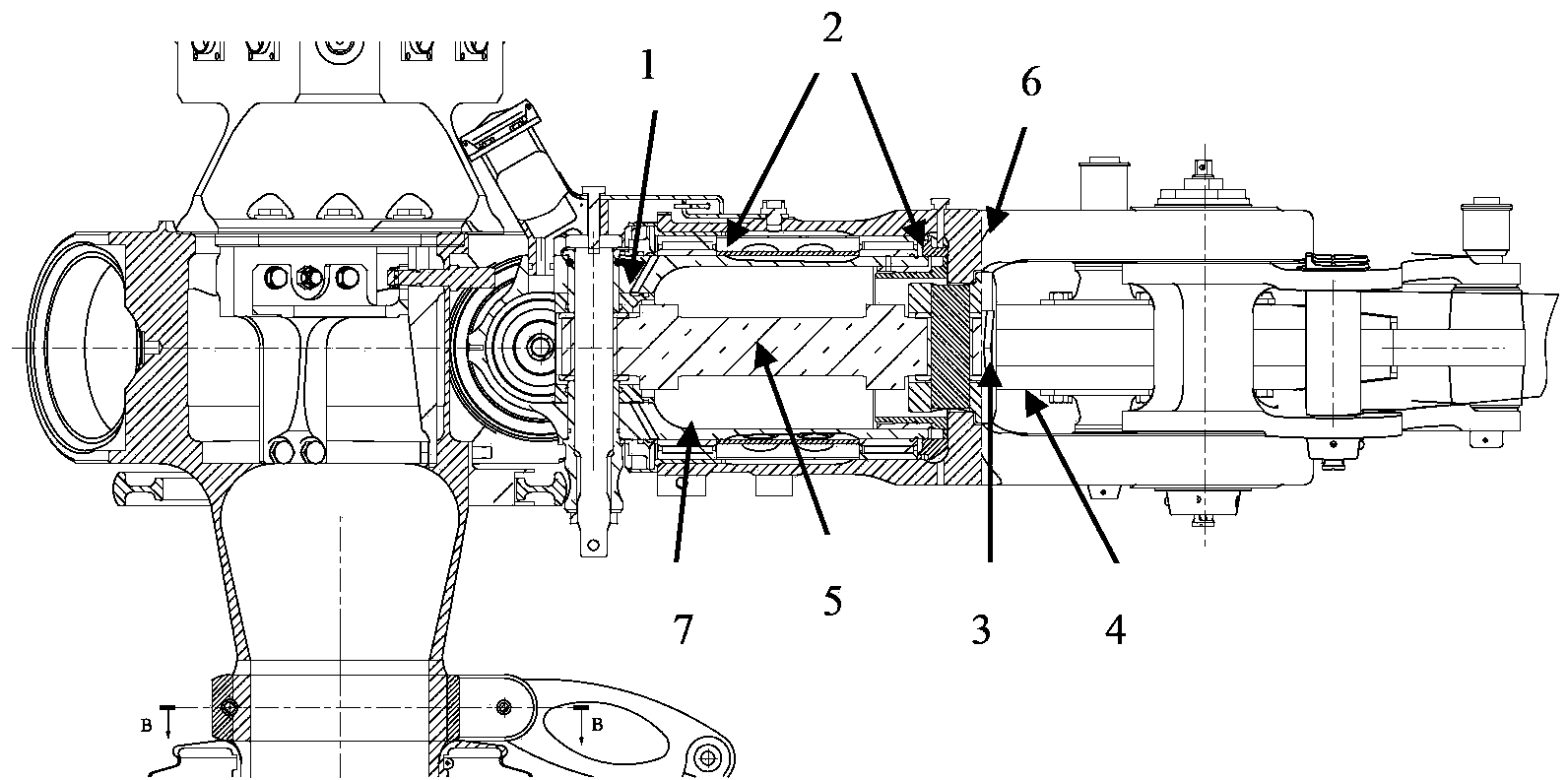

Catheter/wire rotating mechanism and propulsion device for minimally invasive vascular interventional surgery robot

ActiveCN108704214AEasy to installEasy to disassembleCatheterSurgical manipulatorsNeedle roller bearingMedical equipment

The invention relates to the technical field of medical equipment, in particular to a catheter / guide rotating mechanism and a propulsion device for a minimally invasive vascular interventional surgeryrobot. The propulsion device includes a rotating mechanism, a clamping mechanism, a fixing mechanism and a moving mechanism. The rotating mechanism includes a rotating motor, an active pulley, a tensioning pulley, a limiting eccentric wheel and five roller pin bearing components. The clamping mechanism includes a clamping rotating shaft, a clamping claw, a clamping claw sleeve and a clamping spring; the fixing mechanism includes a fixing finger guide rail, a fixing finger slide block, a fixing finger sliding base, a motor friction wheel guide base, a spring guide rod, a fixing finger motor, afixing finger eccentric wheel, a movable rubber block and a fixed rubber block; the fixing finger eccentric wheel drives the fixing finger sliding base to move so as to make the movable rubber blockand the fixed rubber block clamped or separated; the moving mechanism drives the rotating mechanism and the clamping mechanism to move close to or far from the fixing mechanism. According to the catheter / wire rotating mechanism and the propulsion device, the clamping body component of the clamping mechanism is convenient to disassemble and disinfect and the clamping claw does not slip.

Owner:YANSHAN UNIV

Stent delivery device

A unidirectional handle device for an endoluminal device includes an outer tubular member and an elongate inner member slidably received in the outer tubular member. The unidirectional handle includes a handle member, a needle bearing clutch disposed in the handle member, a control member guide, and shaft rotatable in a single direction disposed within the handle member. The shaft is rotatable in a single direction by its engagement with the needle bearing clutch. The shaft is in rotational engagement with the outer tubular member of the endoluminal device. The outer tubular member is slidable from a distal position to a proximal position when the shaft is rotated in the single direction. The unidirectional handle device provides substantially no backlash of the outer tubular member. In addition, the unidirectional handle device advantageously produces a tension-retaining effect during use.

Owner:ENDOTEX INTERVENTIONAL SYST

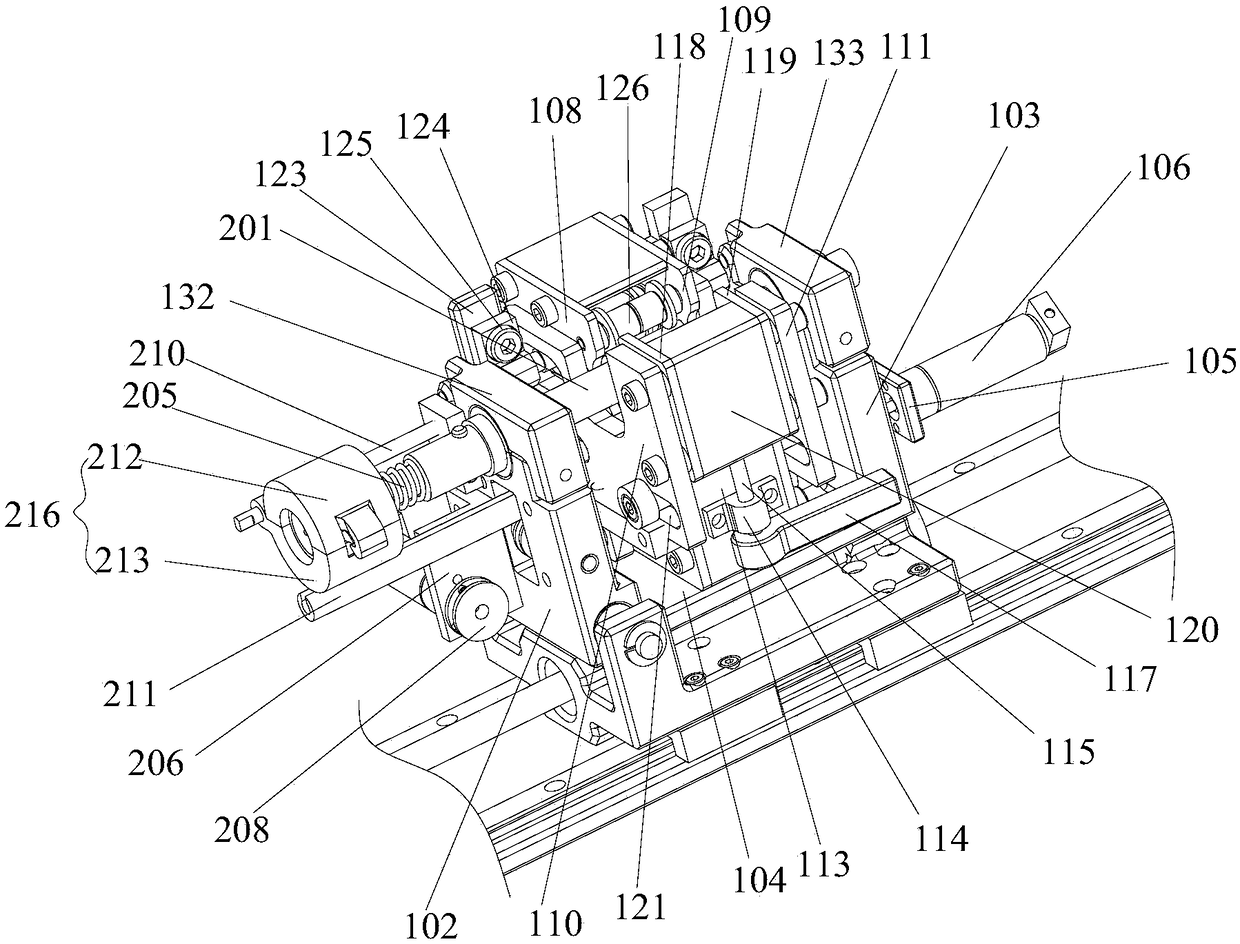

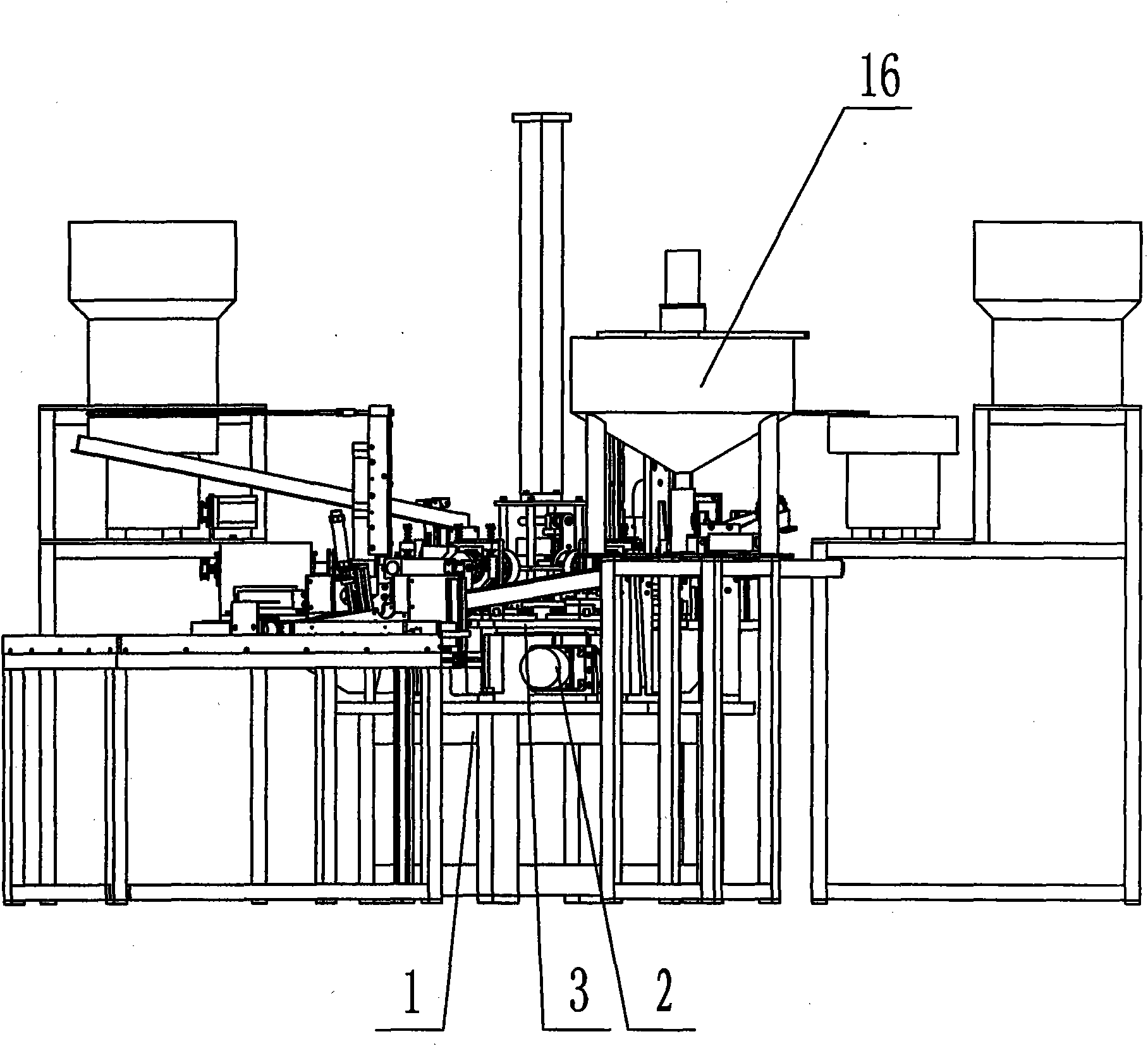

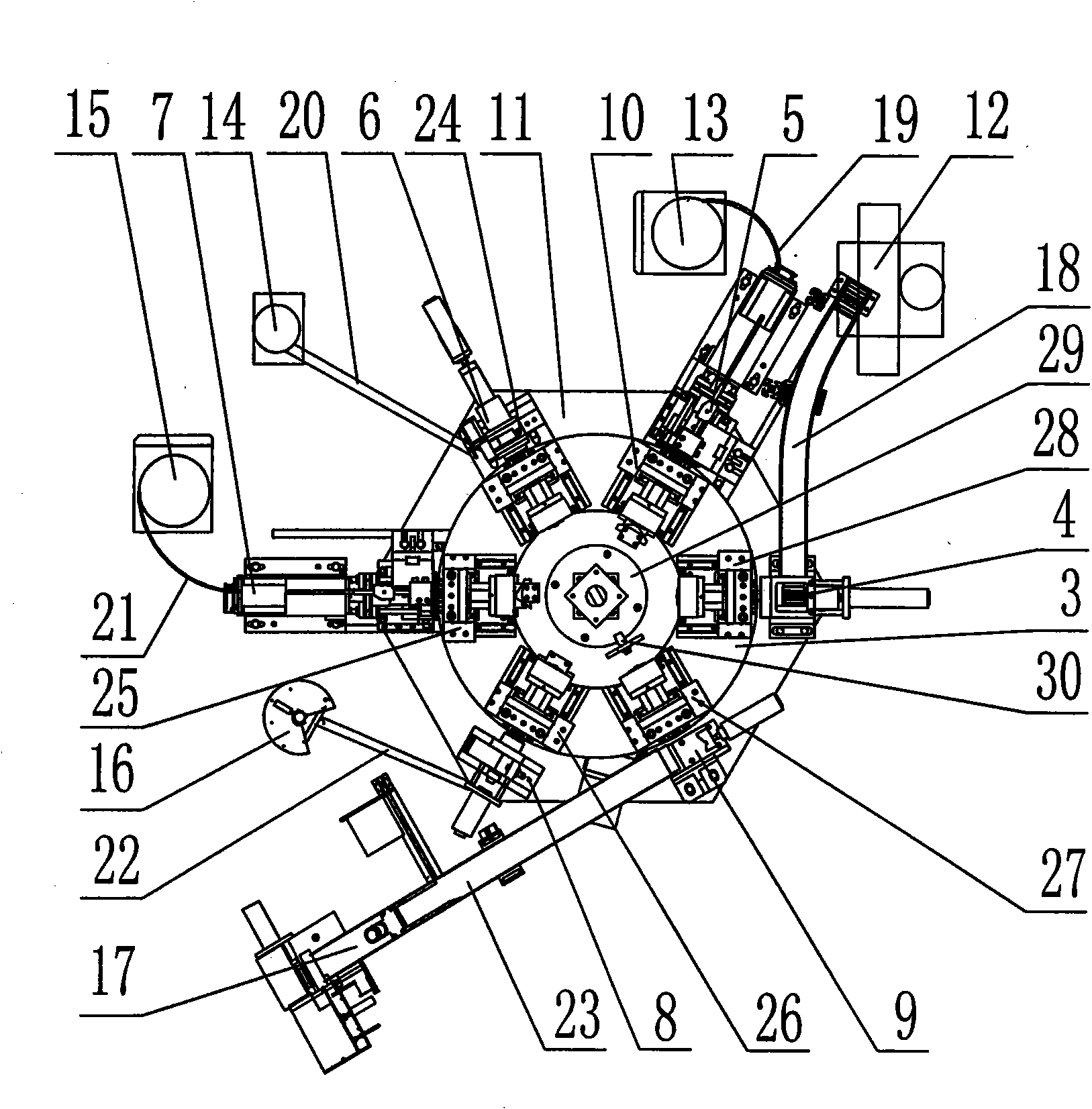

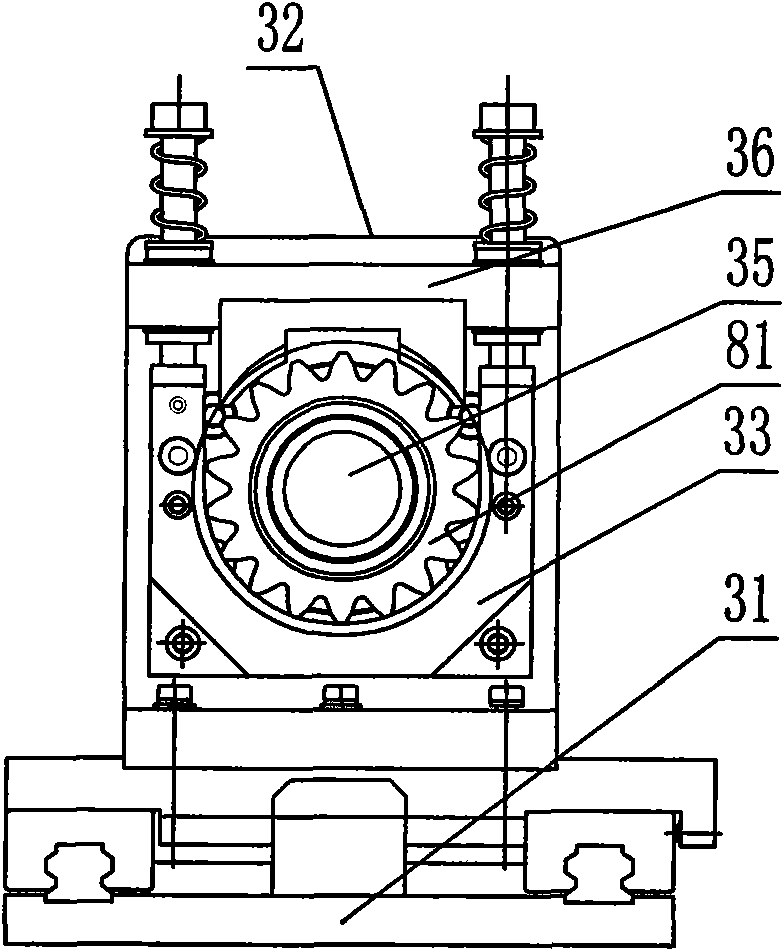

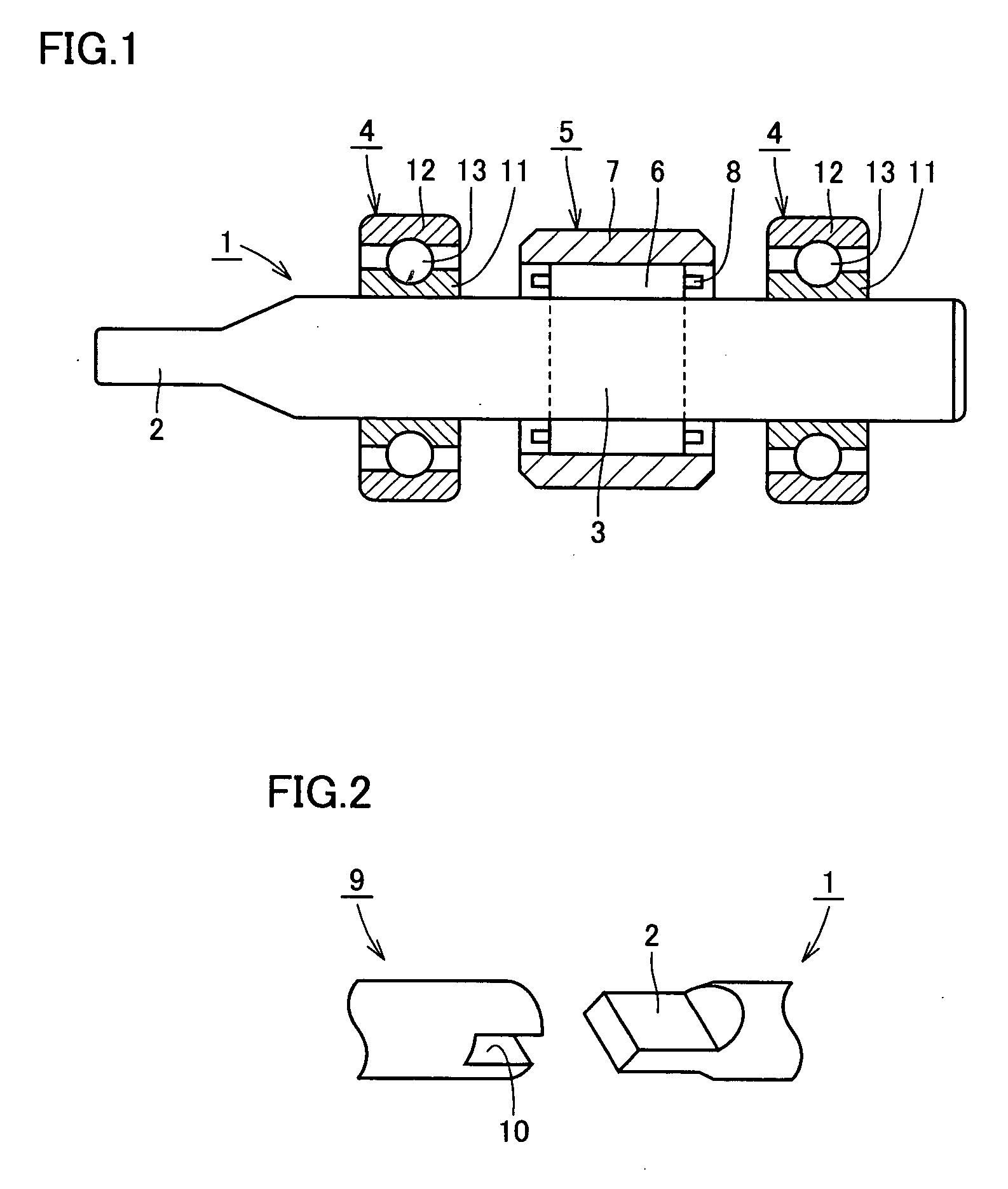

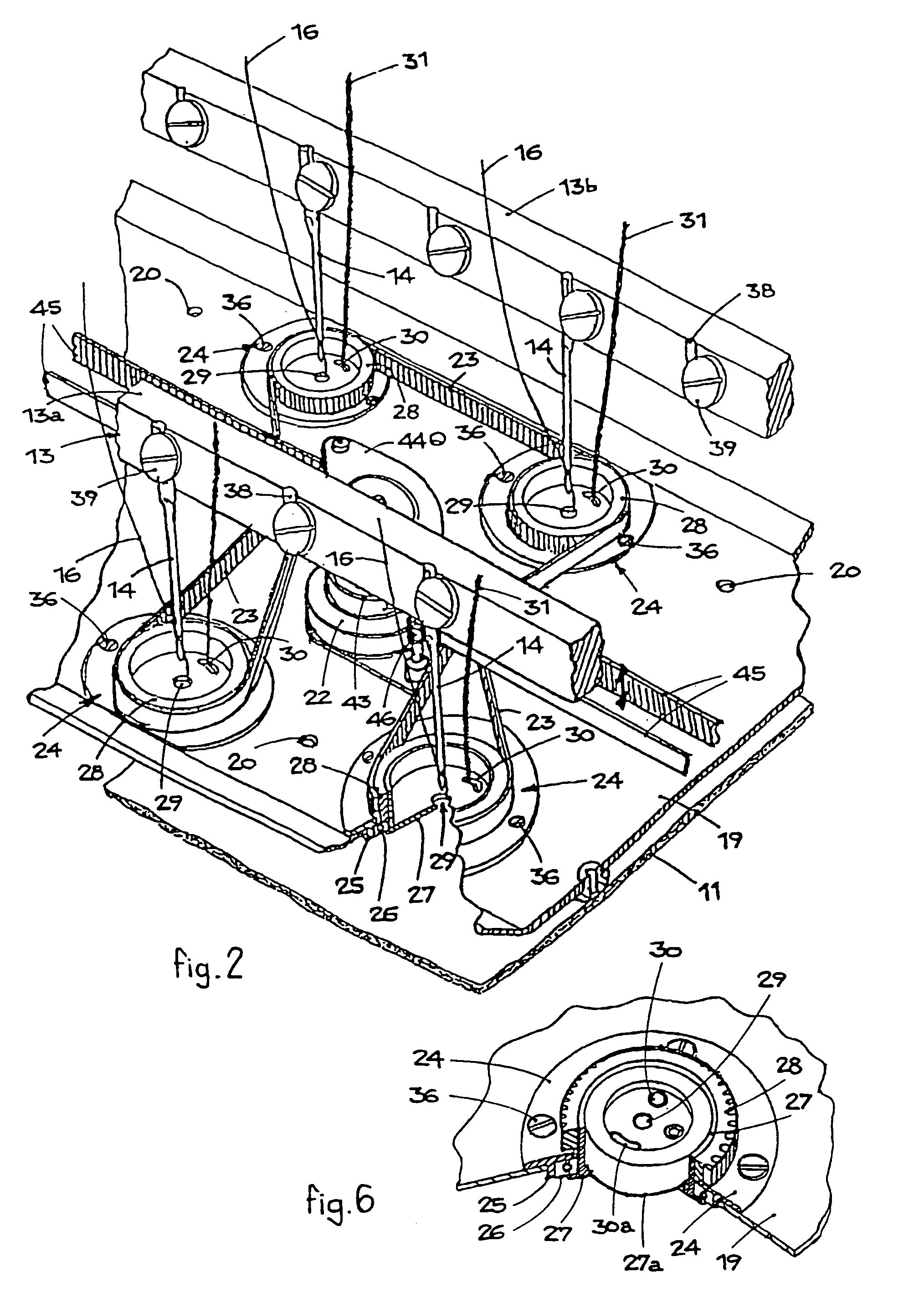

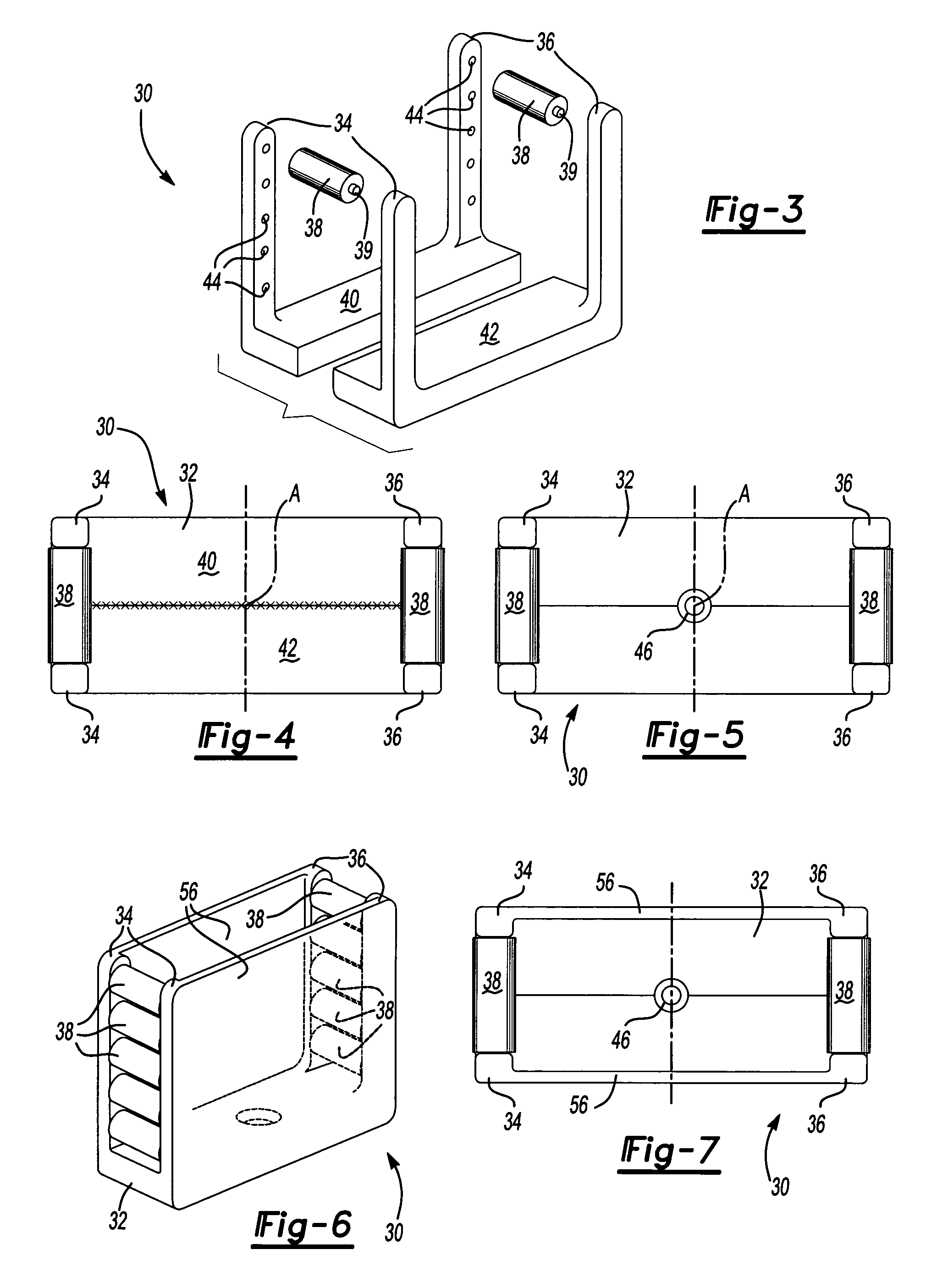

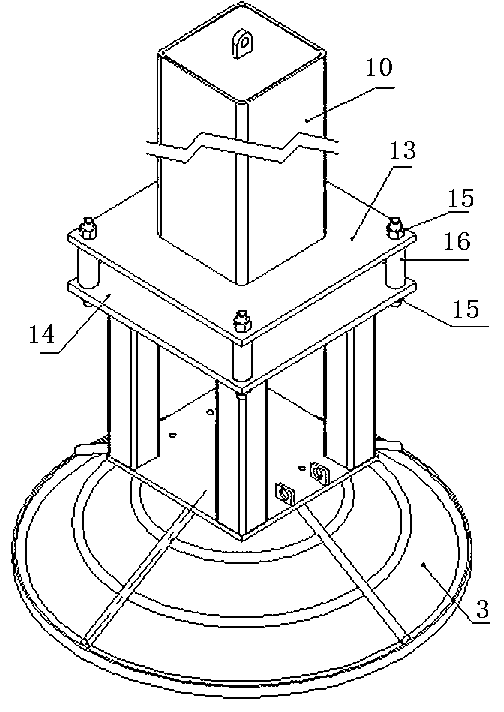

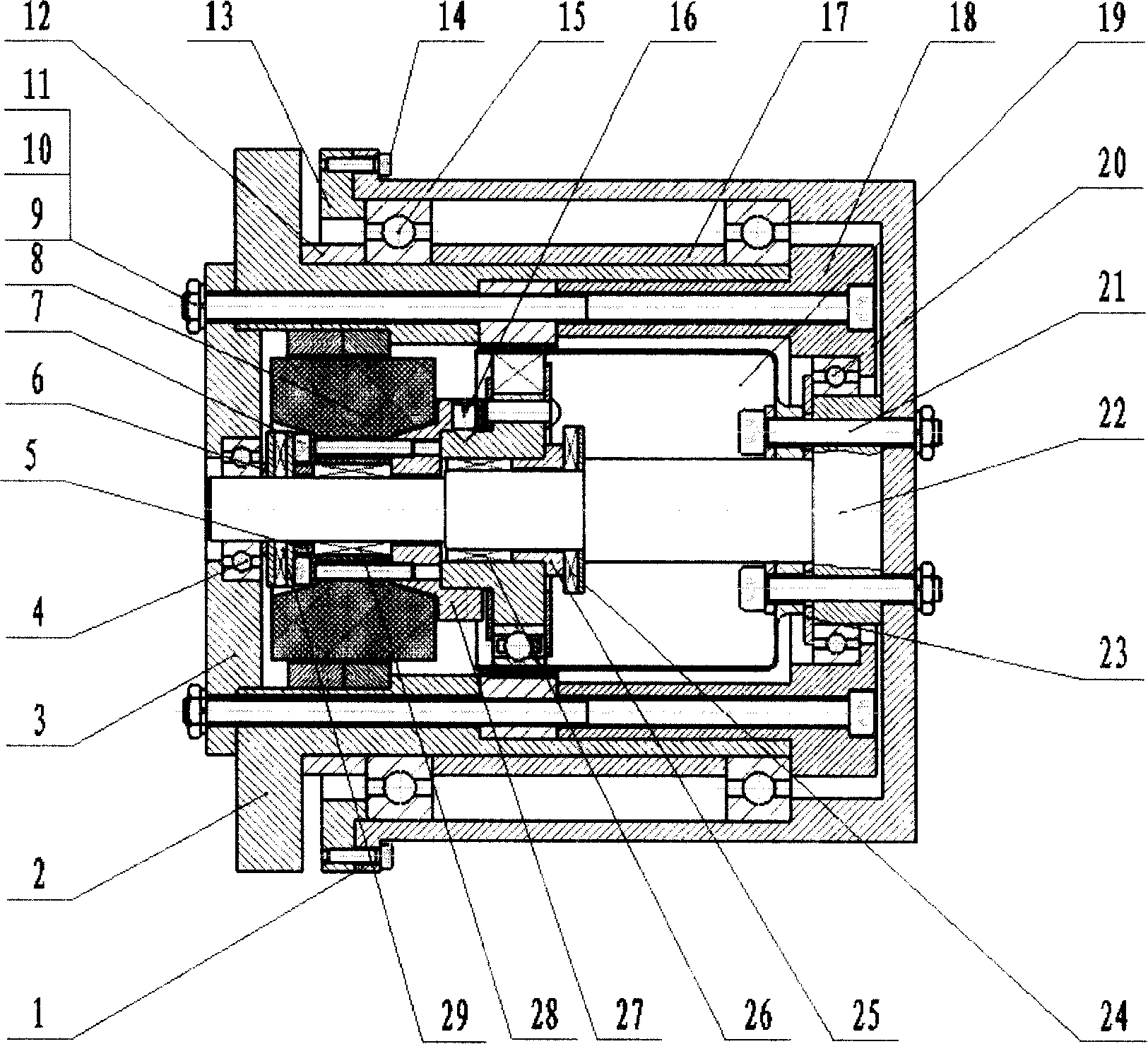

Automatic assembling machine of needle roller of planet wheel

ActiveCN102179688AReduce manpowerReduce material resourcesMetal working apparatusNeedle roller bearingProgrammable logic controller

The invention relates to an automatic assembling machine of a needle roller of a planet wheel, belonging to the technical field of automatic loading equipment of a needle roller bearing of a retainer. The automatic assembling machine comprises a stepping motor, an indexing disc, a first needle roller feeding device, an annular spacer feeding device, a second needle roller feeding device, a refillpart loading device, a planet wheel assembly part pushing-off device, and the like, wherein a fixed stand is provided with the indexing disc and the stepping motor; follower fixtures are uniformly distributed on the surface of the indexing disc; and a fixed installation plate positioned on the periphery of the indexing disc is provided with a planet wheel workpiece feeding device, the first needle roller feeding device, the annular spacer feeding device, the second needle roller feeding device, the refill part loading device and the planet wheel assembly part pushing device at intervals. In the invention, work units are controlled by a PLC (Programmable Logic Controller), and the automatic assembly of the needle roller of the planet wheel is realized, therefore, the assembling efficiency is enhanced and the problems that the traditional manual loading not only has low efficiency but also is easy to generate neglected loading and serious influences product quality are solved; and in addition, the production probability of unqualified products is reduced and the requirements on a product market are met.

Owner:HUBEI JINGCHUAN INTELLIGENT EQUIP

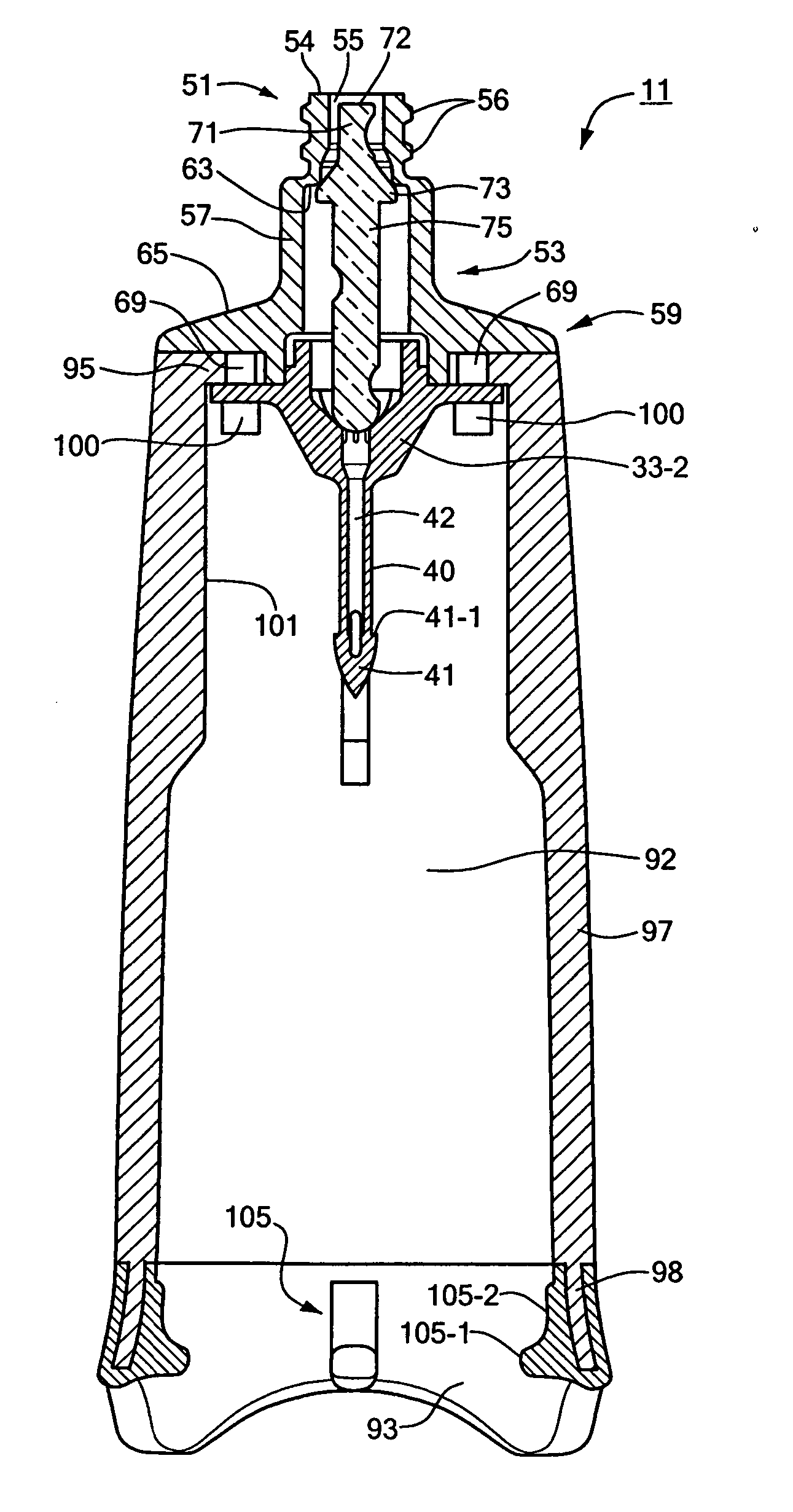

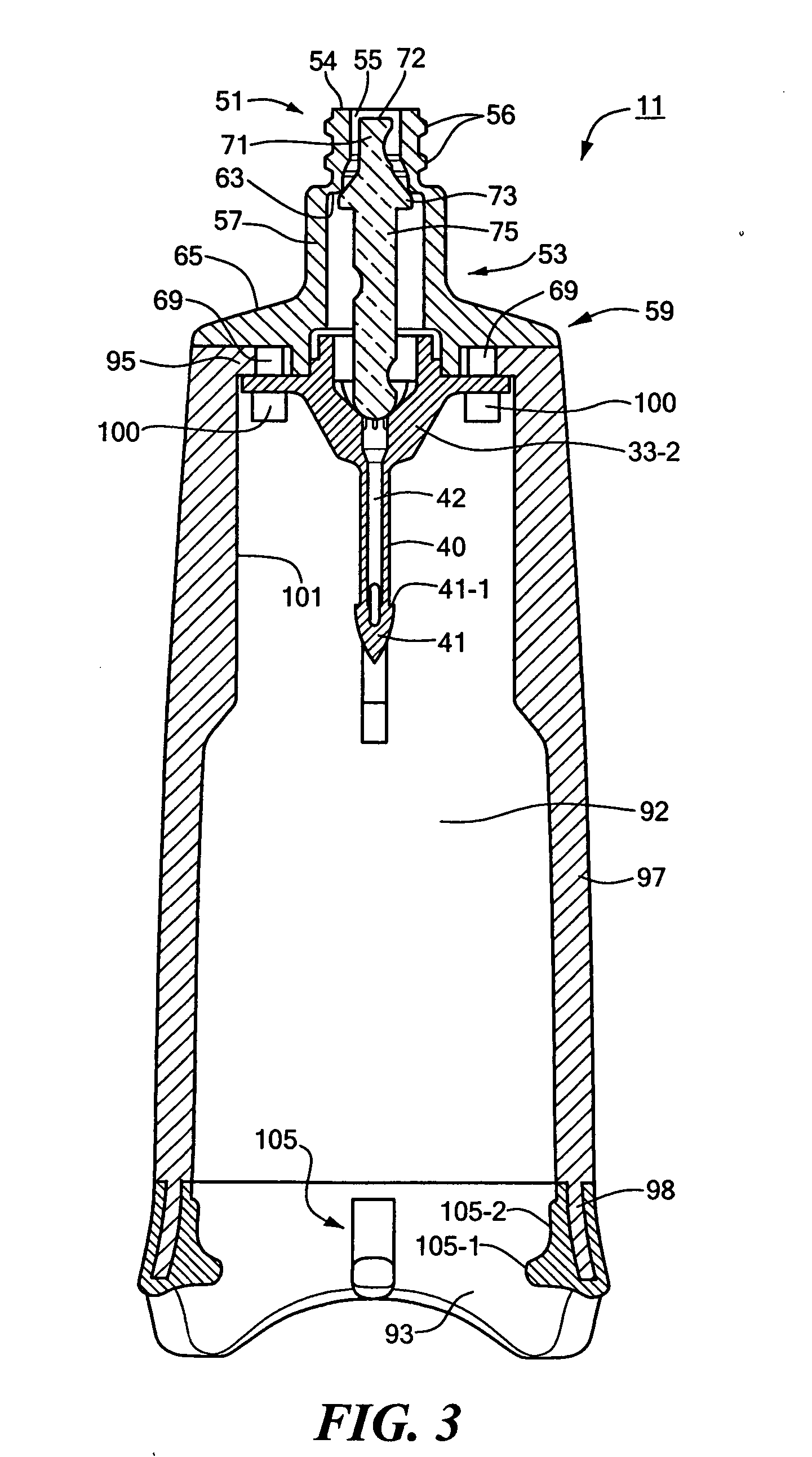

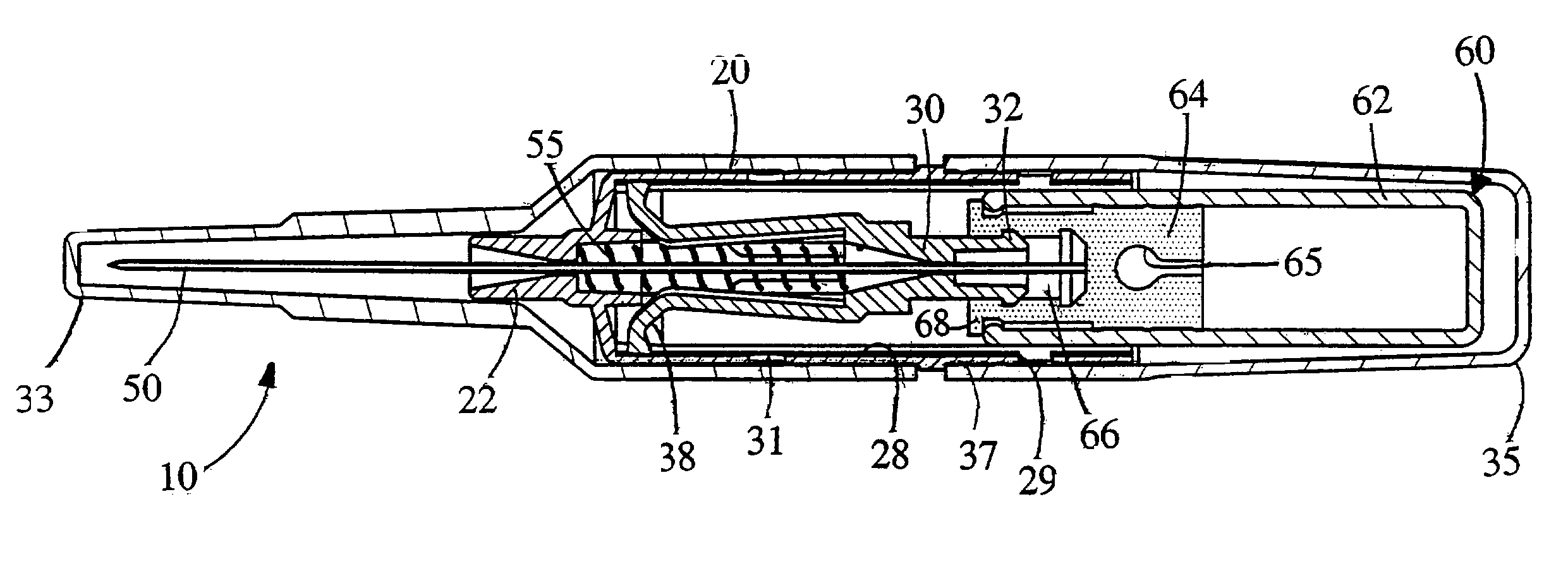

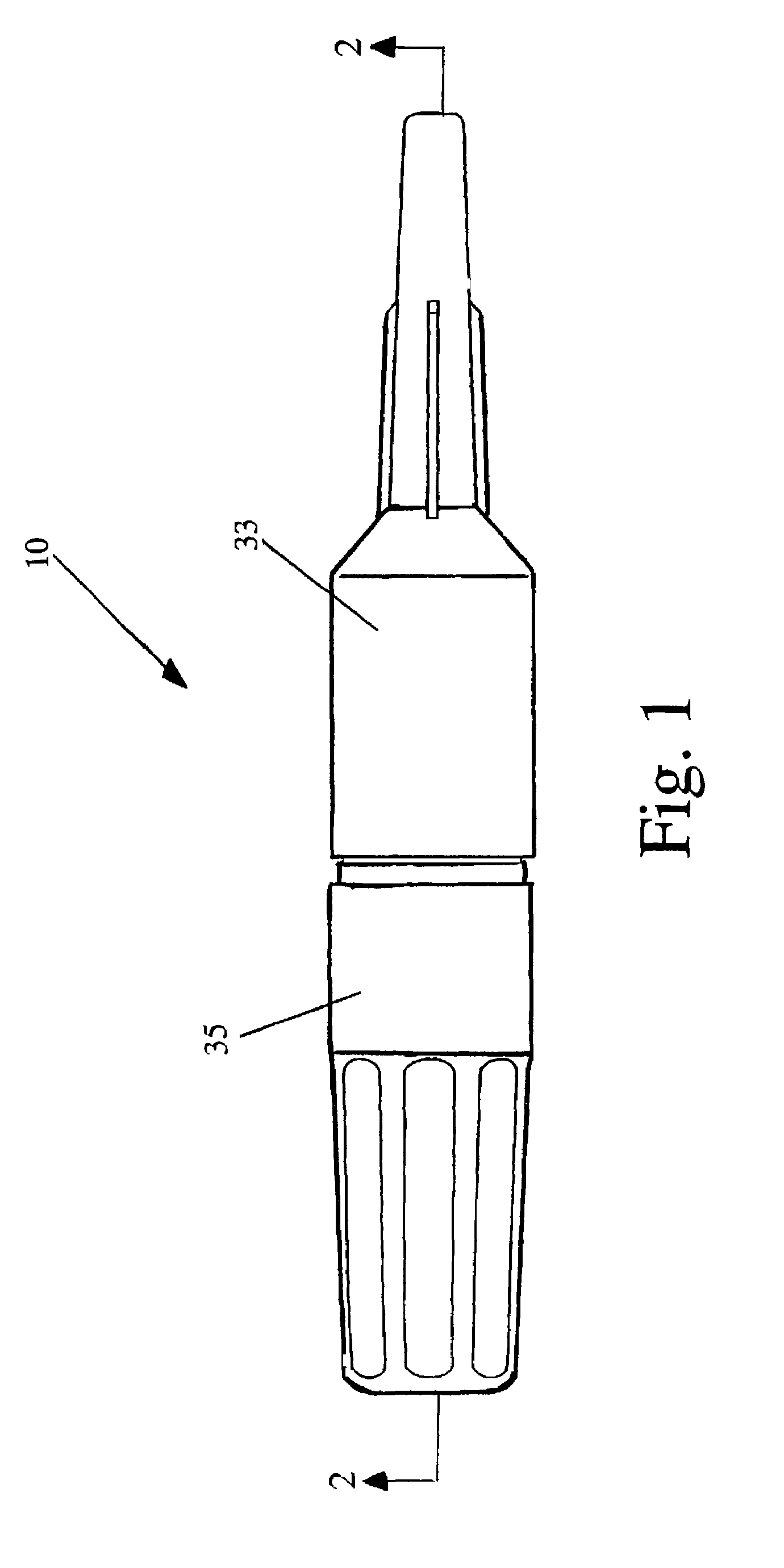

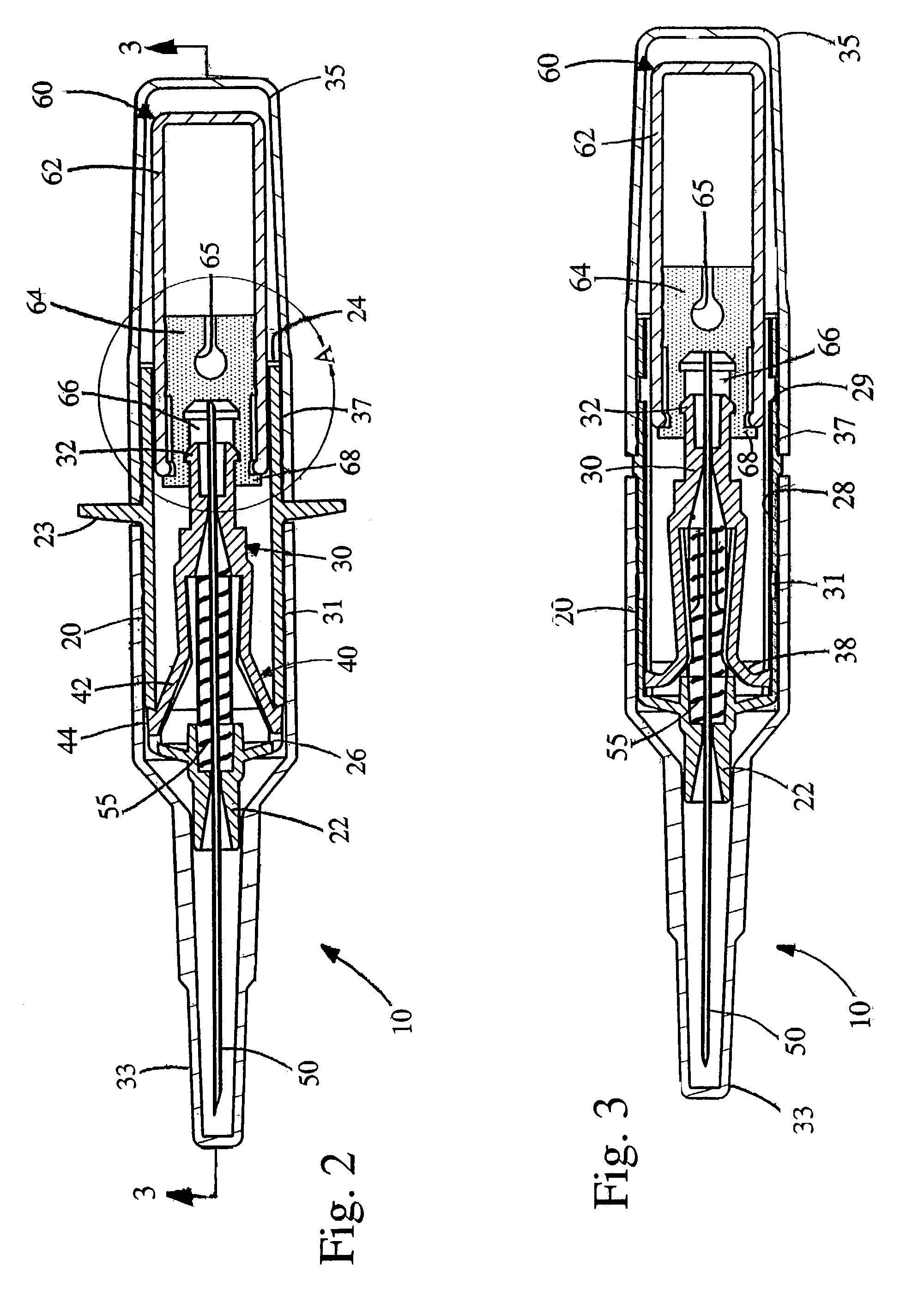

Pre-filled retractable needle injection device

A needle-bearing device for injecting medicinal fluid from a pre-filled vial is provided. After use, the needle is retracted into the body of the device to prevent inadvertent contact with the sharpened end of the needle. In one embodiment, the invention provides a manually actuable button that effectuates retraction of the needle after use. In another embodiment, retraction is effectuated automatically after the injection is complete.

Owner:MDC INVESTMENT HLDG

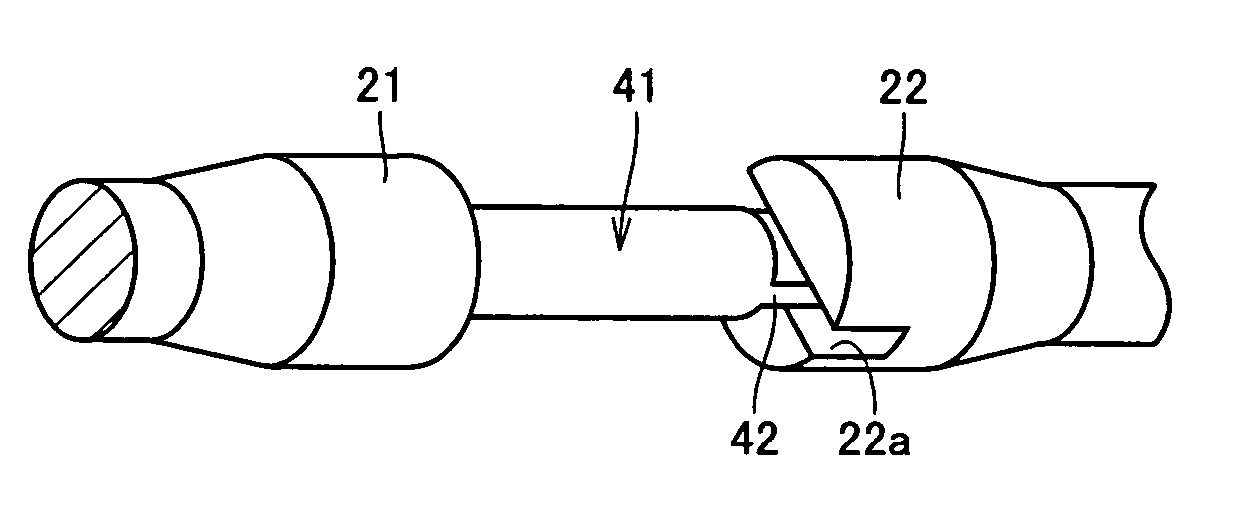

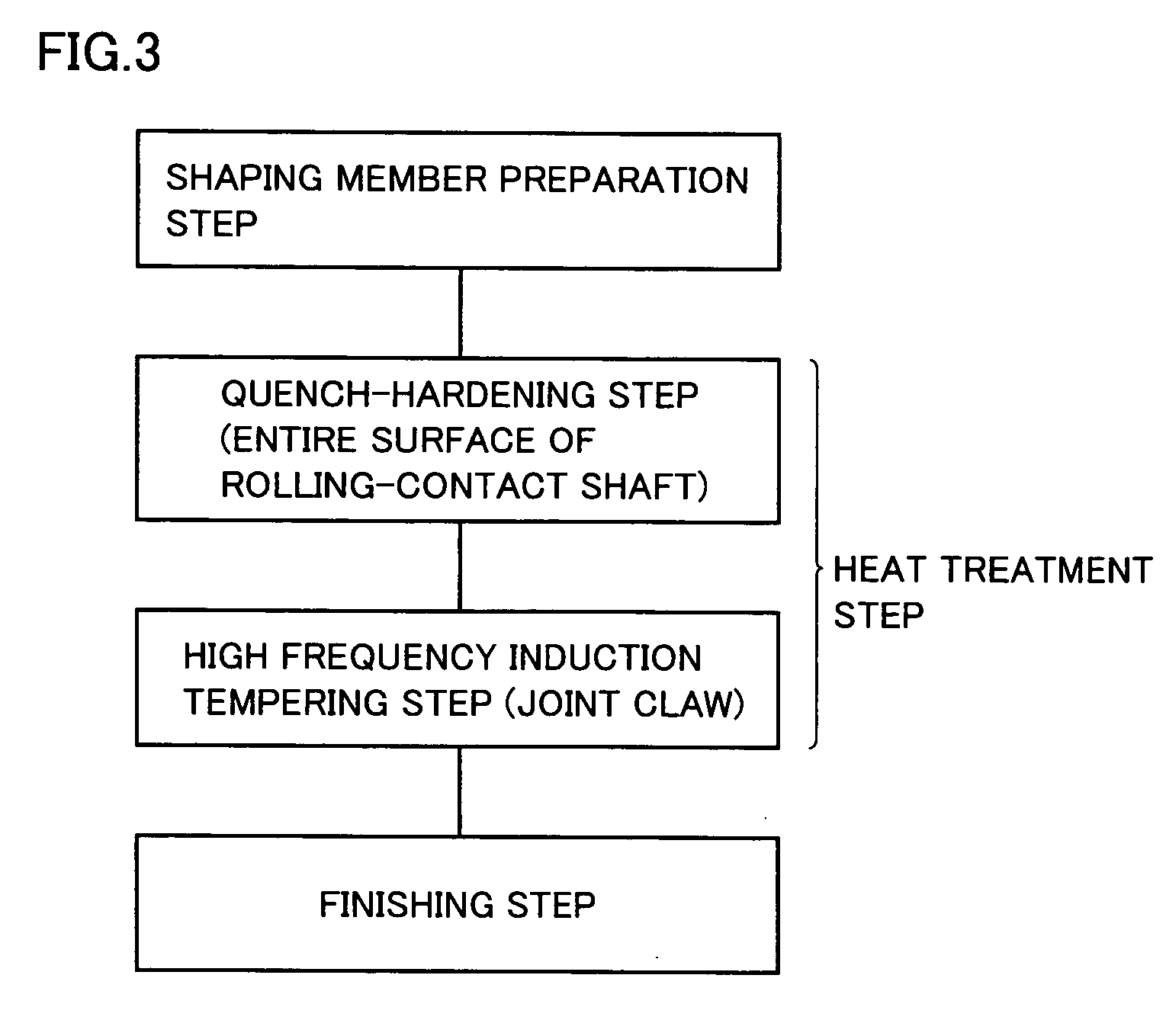

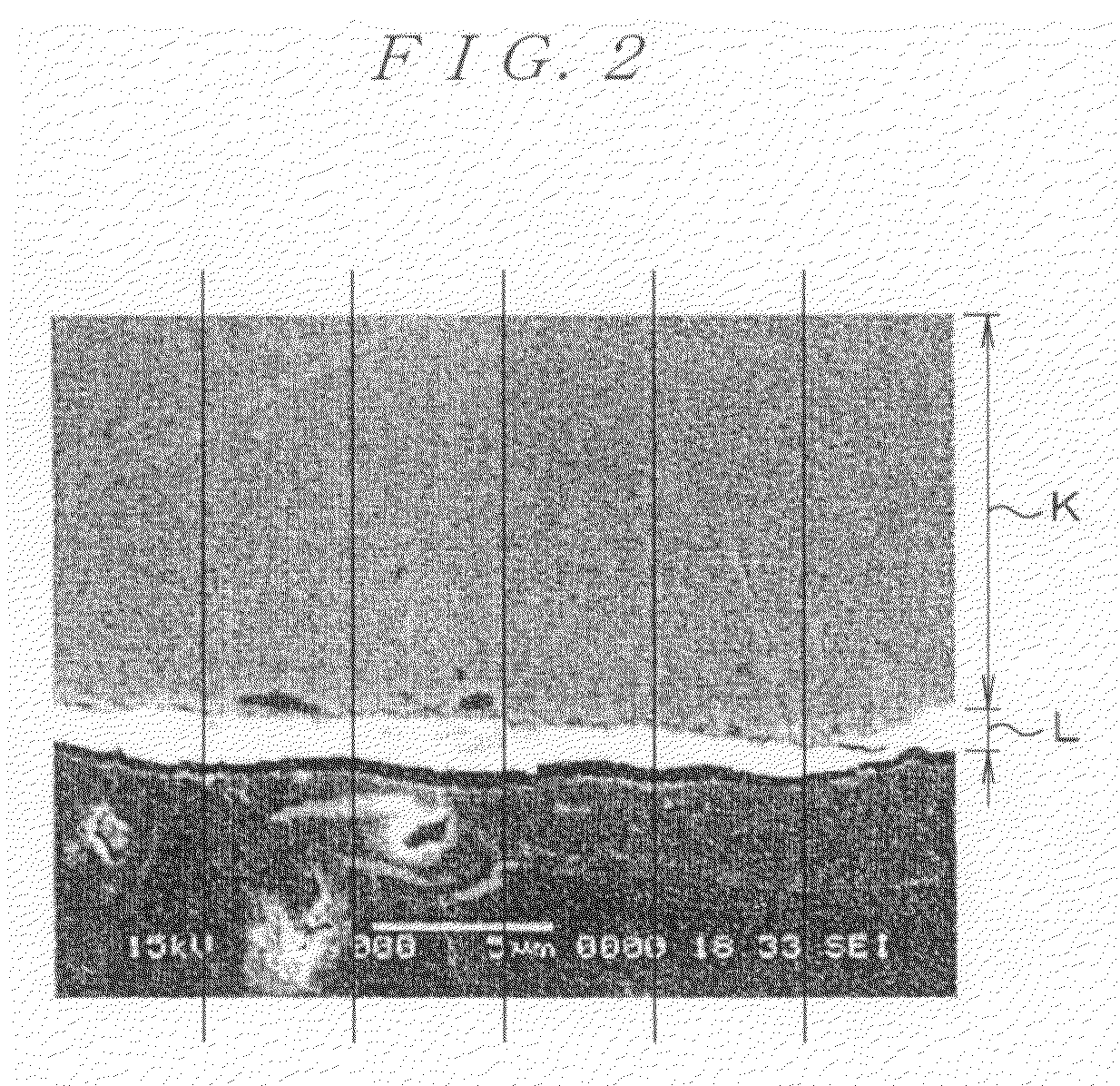

Rolling-contact shaft with joint claw

ActiveUS20070034301A1Improve contact fatigue lifeShaftsBearing componentsEngineeringMechanical engineering

A steel-made rolling-contact shaft with a joint claw improved in both the rolling contact fatigue life at the raceway and the static fracture strength (torsional strength) at the claw includes a joint claw at one end, and has a portion of the outer cylindrical surface functioning as a raceway of a needle roller qualified as a rolling element of a needle bearing. The joint claw is subjected to tempering by induction heating. A nitrogen-enriched layer is formed at the surface layer of the rolling-contact shaft with a joint claw. The grain size number of austenite grains in the nitrogen-enriched layer exceeds number 10. The hydrogen content of the rolling-contact shaft with ajoint claw is not more than 0.5 ppm.

Owner:NTN CORP

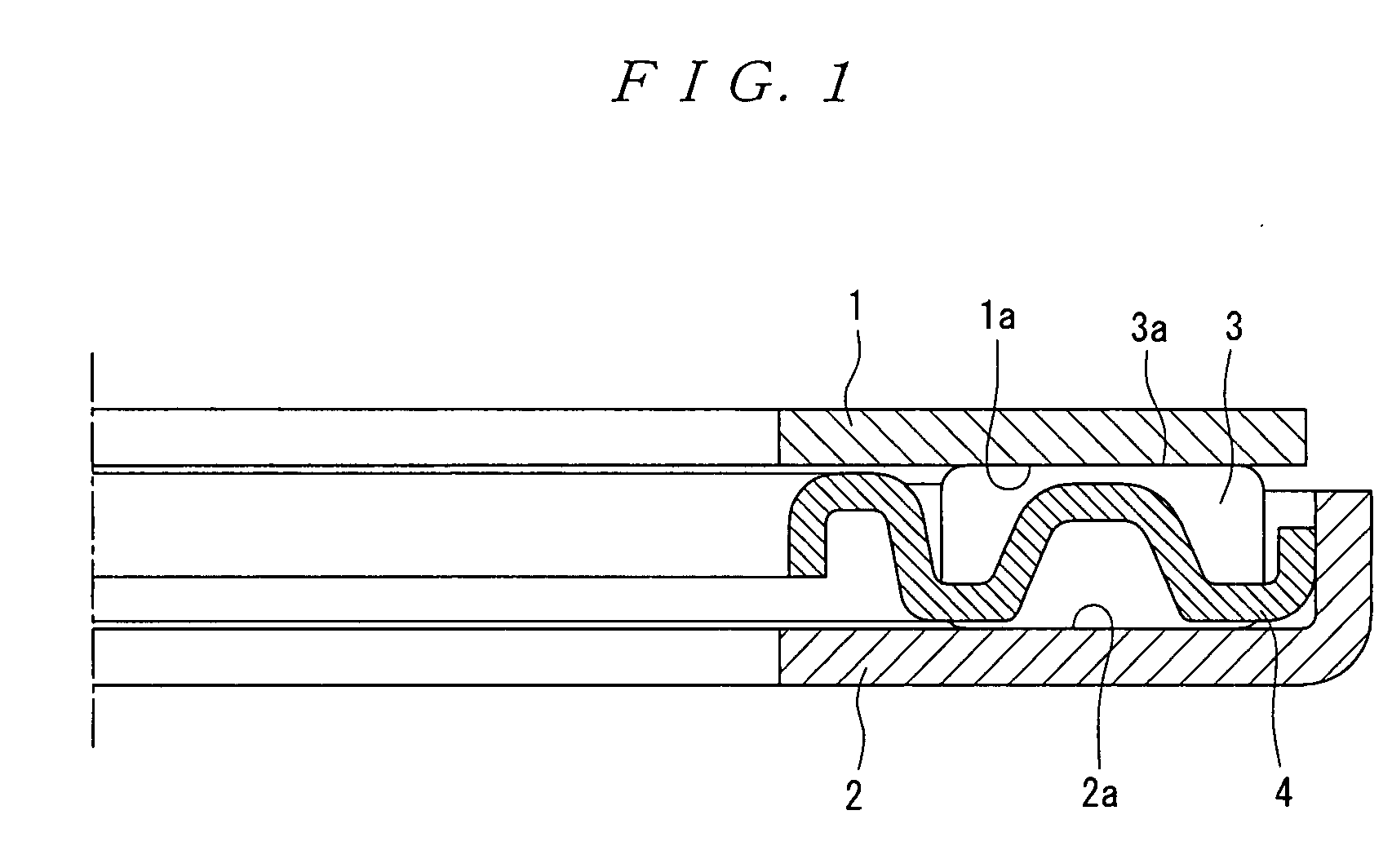

Rolling Device

InactiveUS20080107369A1Improve adhesionSolution to short lifeLighting applicationsRoller bearingsNeedle roller bearingEngineering

A rolling device in which damage such as seizure or wear is less liable to occur and which has a long life, even when used under severe conditions such as high speed, heavy load, high temperature and insufficient lubrication. A thrust needle roller bearing includes an inner ring 1, outer ring 2, and a plurality of rolling elements 3 rollably arranged between a raceway surface 1a of inner ring 1 and a raceway surface 2a of outer ring 2. A lubricant film consisting of a solid lubricant is coated over an area equivalent to an area ratio of 75% or more of at least one member of the group consisting of raceway surface 1a of inner ring 1, raceway surface 2a of outer ring 2, and a rolling contact surface 3a of rolling element 3. The thickness of the lubricant film is preferably 0.05 μm or more and 8 μm or less.

Owner:NSK LTD

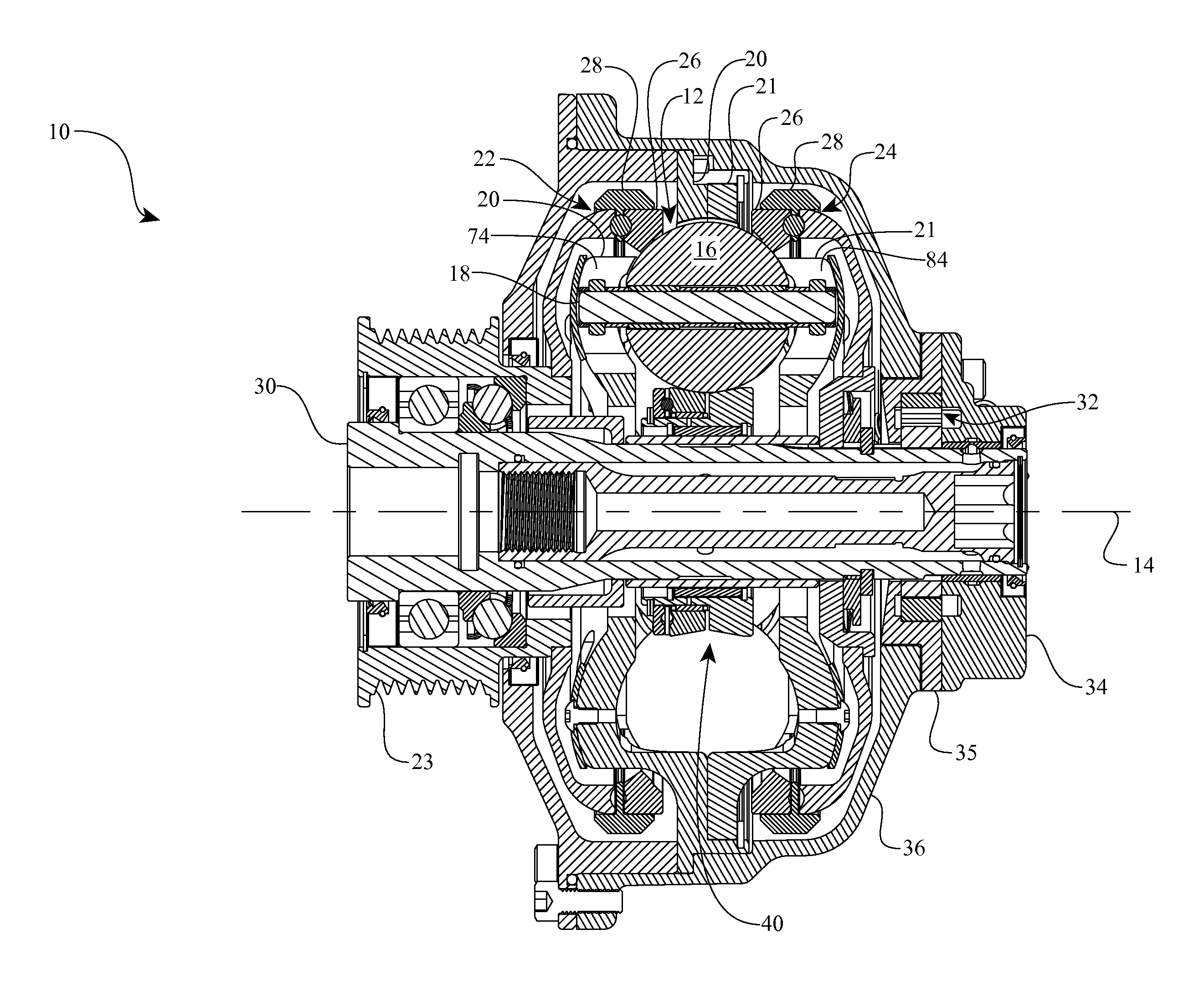

Continuously variable transmission

ActiveUS20120115667A1Wheel based transmissionRolling contact bearingsNeedle roller bearingBall bearing

Disclosed embodiments are directed to components, subassemblies, systems, and / or methods for continuously variable transmissions (CVT). In one embodiment, a CVT has a number of spherical planets in contact with an idler. Various idler assemblies can be used to facilitate to improve durability, fatigue life, and efficiency of a CVT. In one embodiment, the idler assembly has two rolling elements having contact surfaces that are angled with respect to a longitudinal axis of the CVT. In some embodiments, a bearing is operably coupled between the first and second rolling elements. The bearing is configured to balance axial force between the first and second rolling elements. In one embodiment, the bearing is a ball bearing. In another embodiment, the bearing is an angular contact bearing. In yet other embodiments, needle roller bearings are employed.

Owner:FALLBROOK INTPROP COMPANY

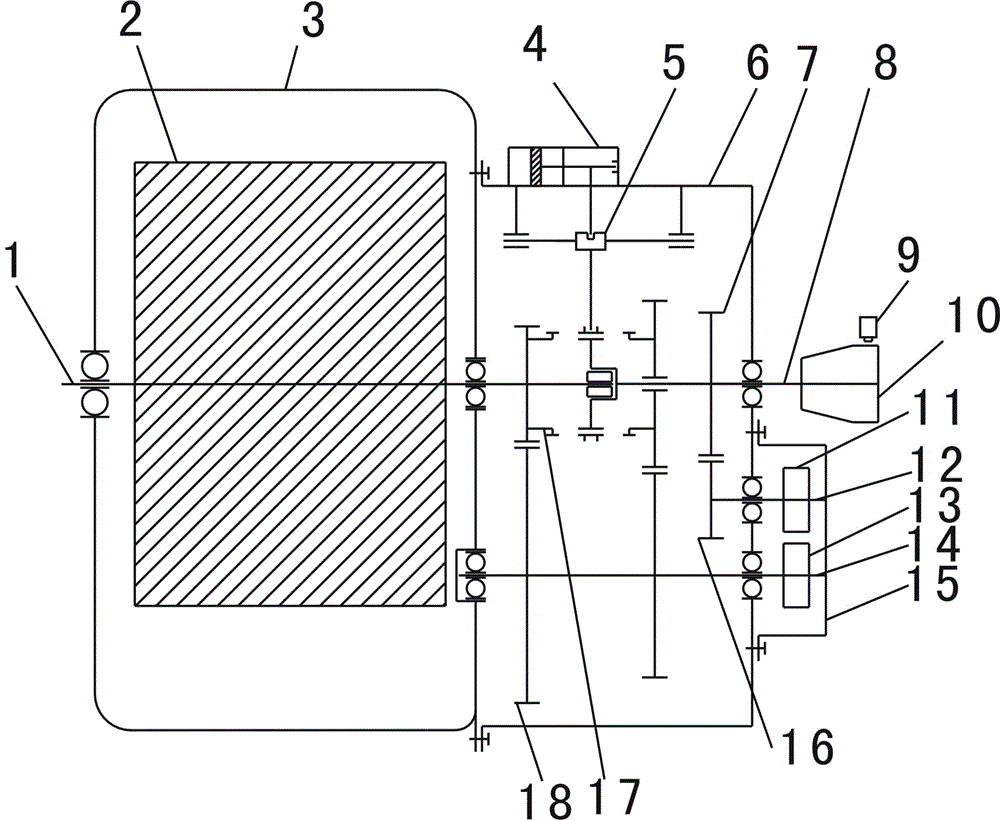

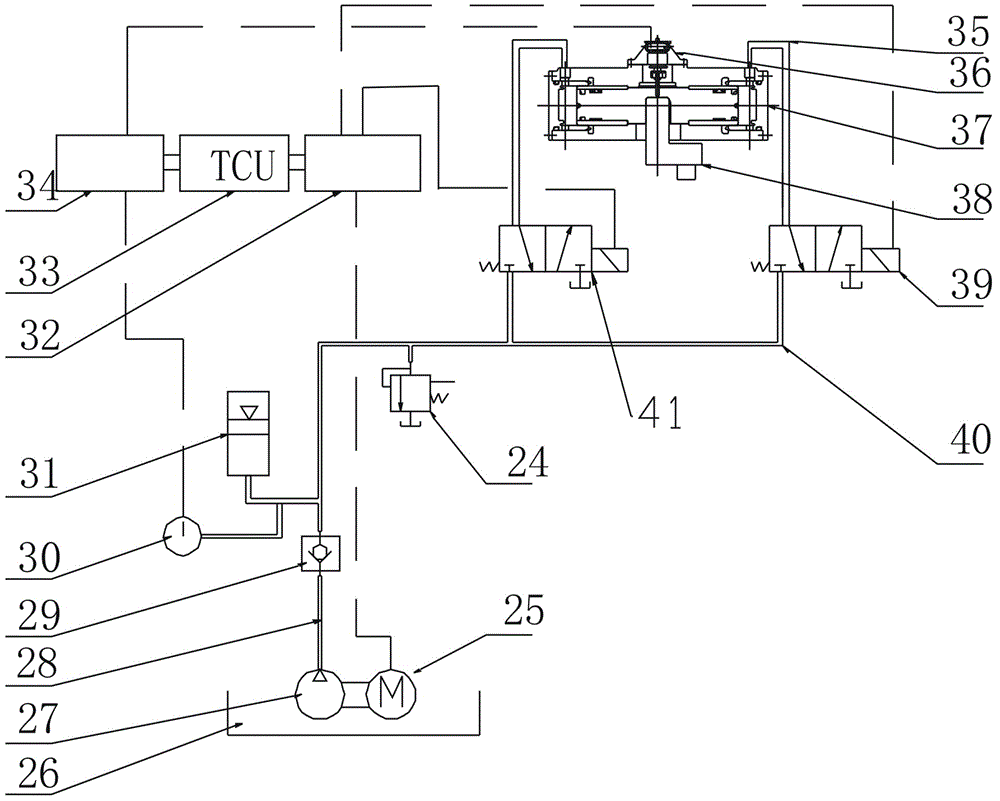

Two speed automatic transmission

ActiveCN102979862AImprove performanceImprove shift smoothnessToothed gearingsGearing controlAutomatic transmissionCoupling

The invention relates to a two speed automatic transmission which is characterized in that an electric motor and a transmission box are linearly integrated into a whole, a motor shaft is a transmission input shaft, the transmission input shaft is supported in a bearing of a transmission output shaft by a needle bearing or is connected with the transmission output shaft by splines, and a speed coupling shaft is arranged between a transmission intermediate shaft and the transmission output shaft; a transmission input shaft direct gear constant mesh gear is fixed on the motor shaft, and a transmission intermediate shaft direct gear constant mesh gear is meshed with the transmission input shaft direct gear constant mesh gear; an output shaft speed coupling gear fixed on the transmission output shaft and a coupling shaft speed coupling gear fixed on the speed coupling shaft are maintained meshed commonly; the speed coupling shaft is provided with an output shaft encoder, and an intermediate shaft encoder is arranged at the tail end of the transmission intermediate shaft. According to the two speed automatic transmission, the problem of power failure in the shifting process is solved, no obvious speed reduction is generated in the shifting process, the comfort in shifting is enhanced, the fuel economy is improved at the meantime, and the fuel consumption in the shifting process is reduced.

Owner:武汉理工通宇新源动力有限公司

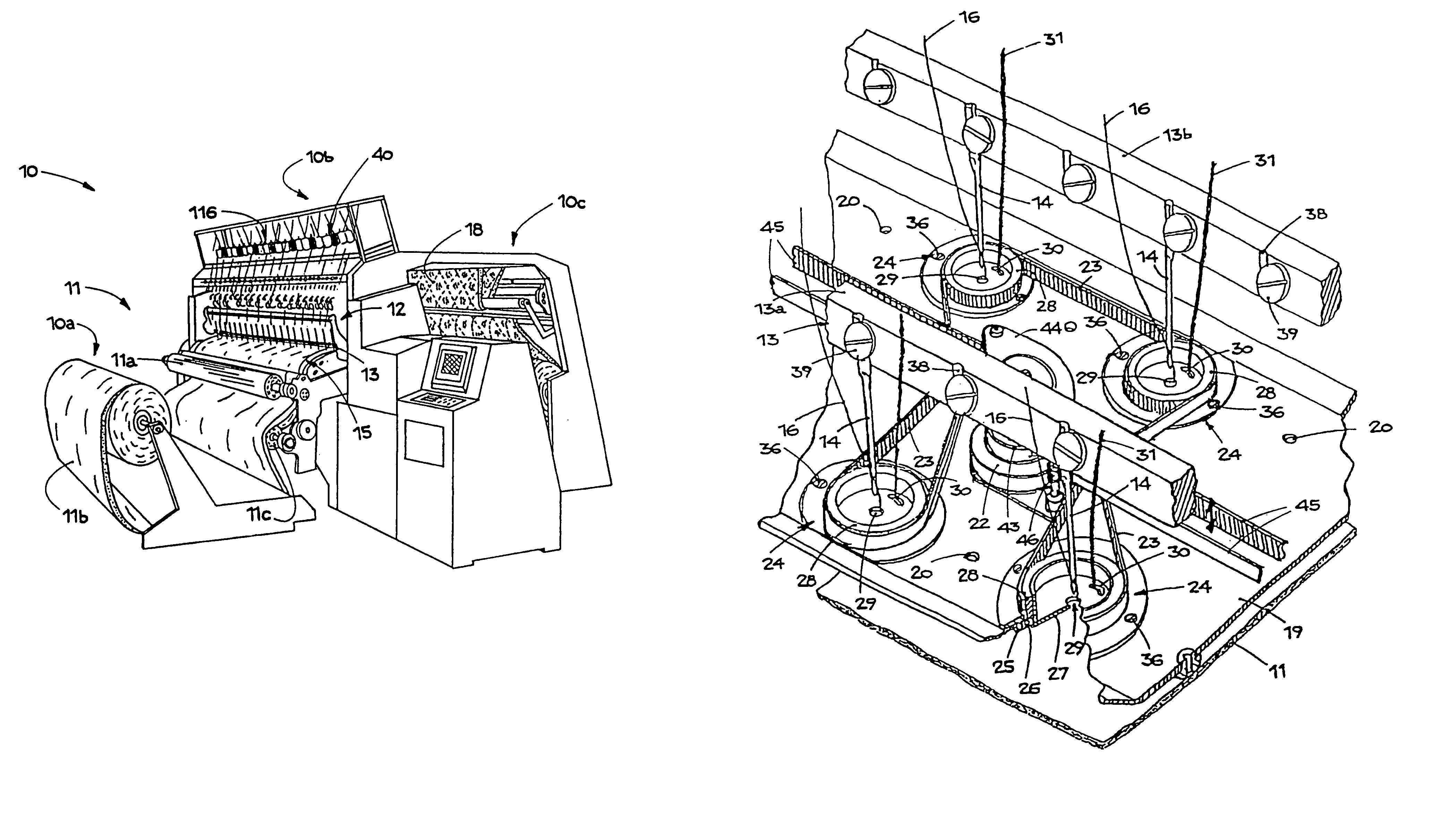

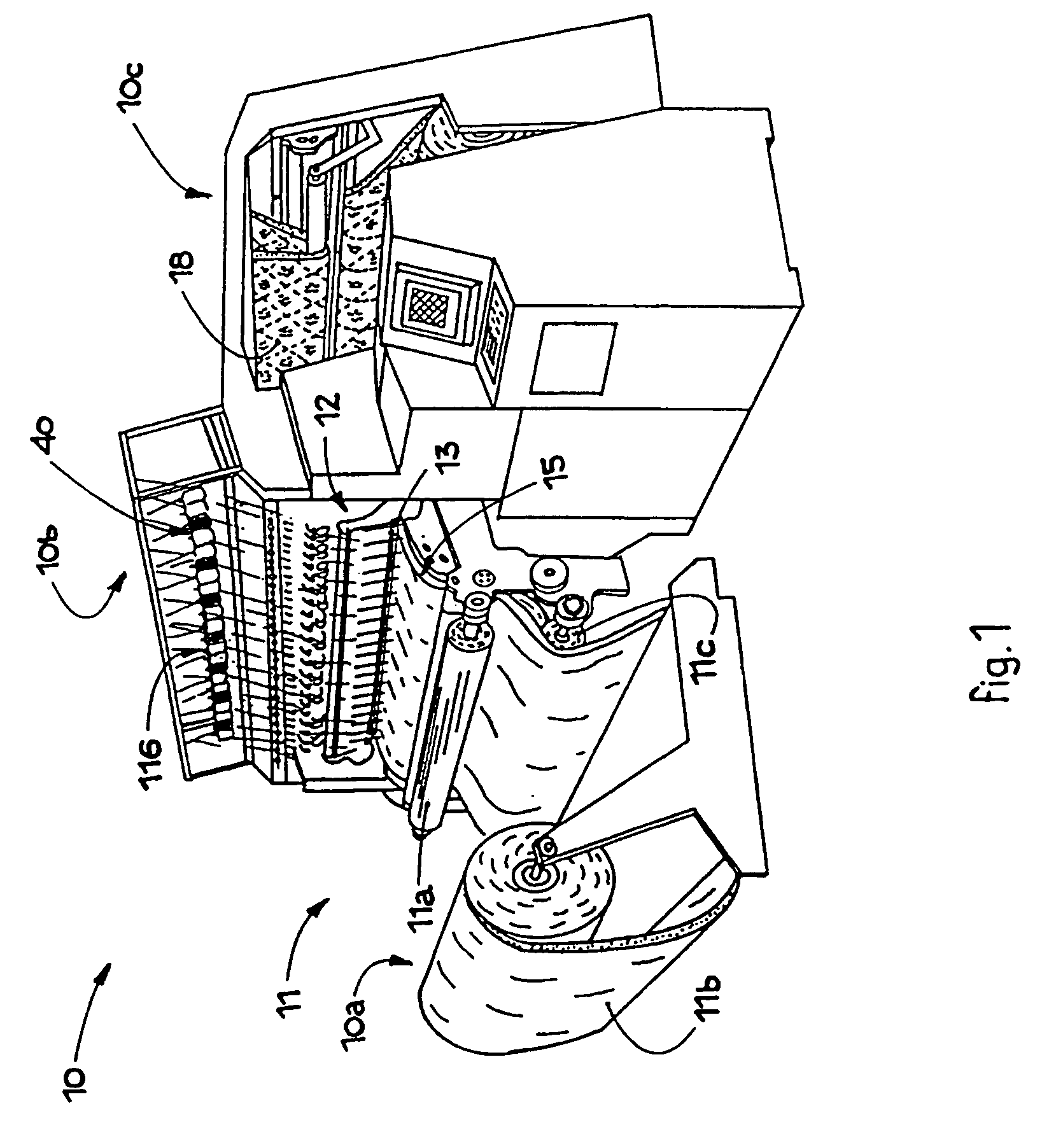

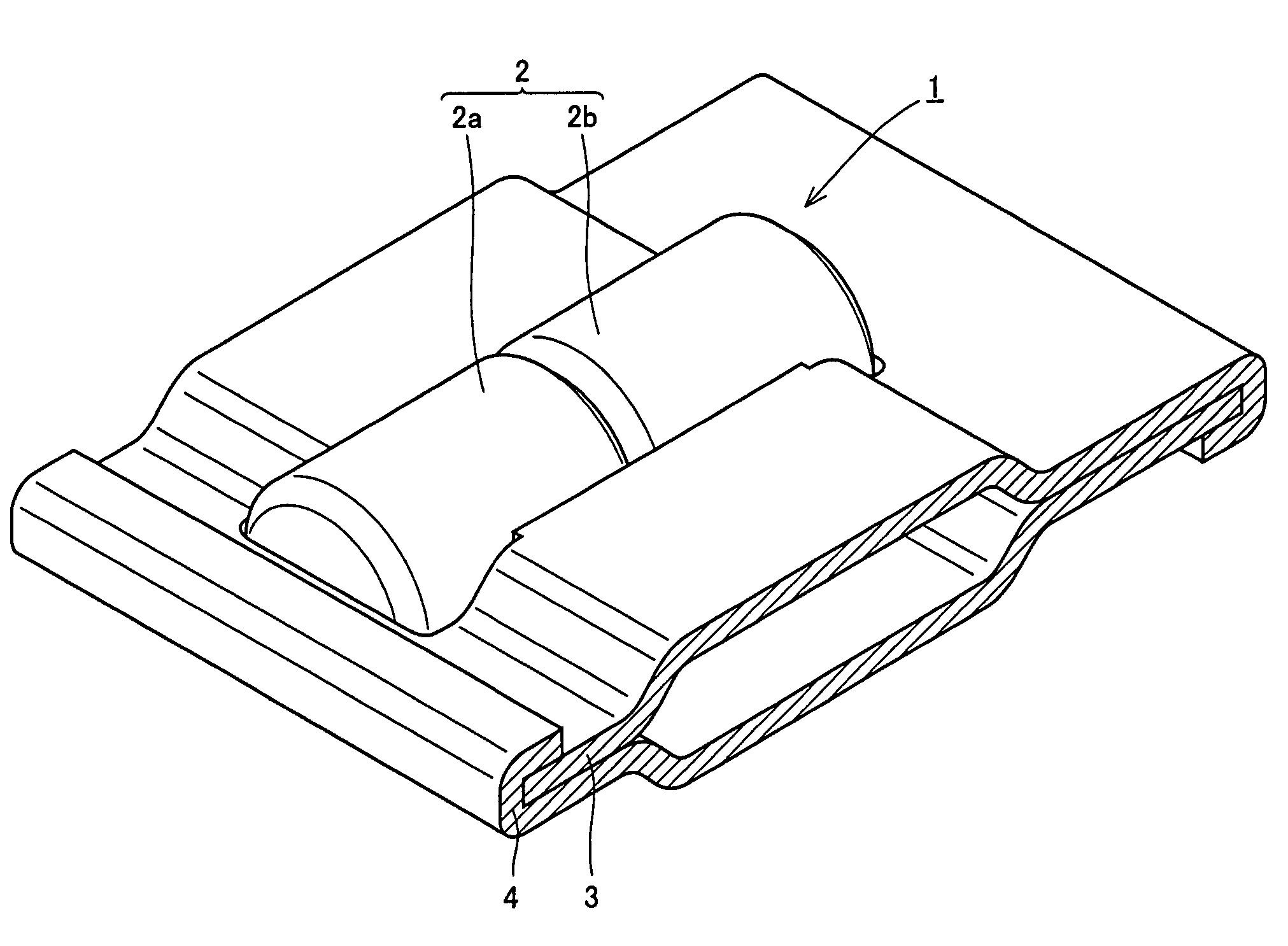

Method and device to apply cord thread or ribbons onto fabrics in a quilting machine

InactiveUS6957615B1Continuously workingMattress sewingAutomatic machinesNeedle roller bearingEngineering

A device for applying an embroidery material onto a textile fabric including a device for feeding the textile material; an upper sewing organ having a needle bearing bar and a plurality of needles; a lower sewing organ selected from the group consisting of shuttles, rotary crochets and moving hooks cooperating with the upper organ. At least one pressure plate for compressing the material and having embroidery devices thereon and a drive for providing rotational motion to the embroidery devices, wherein the drive device includes a hole for each needle to pass through and a second hole for the embroidery material to pass through, and wherein the rotational motion is in a single direction so as to direct the second hole in a position that is in front of the needle to obtain stitches on the textile fabric and to fix the embroidery material.

Owner:MECA

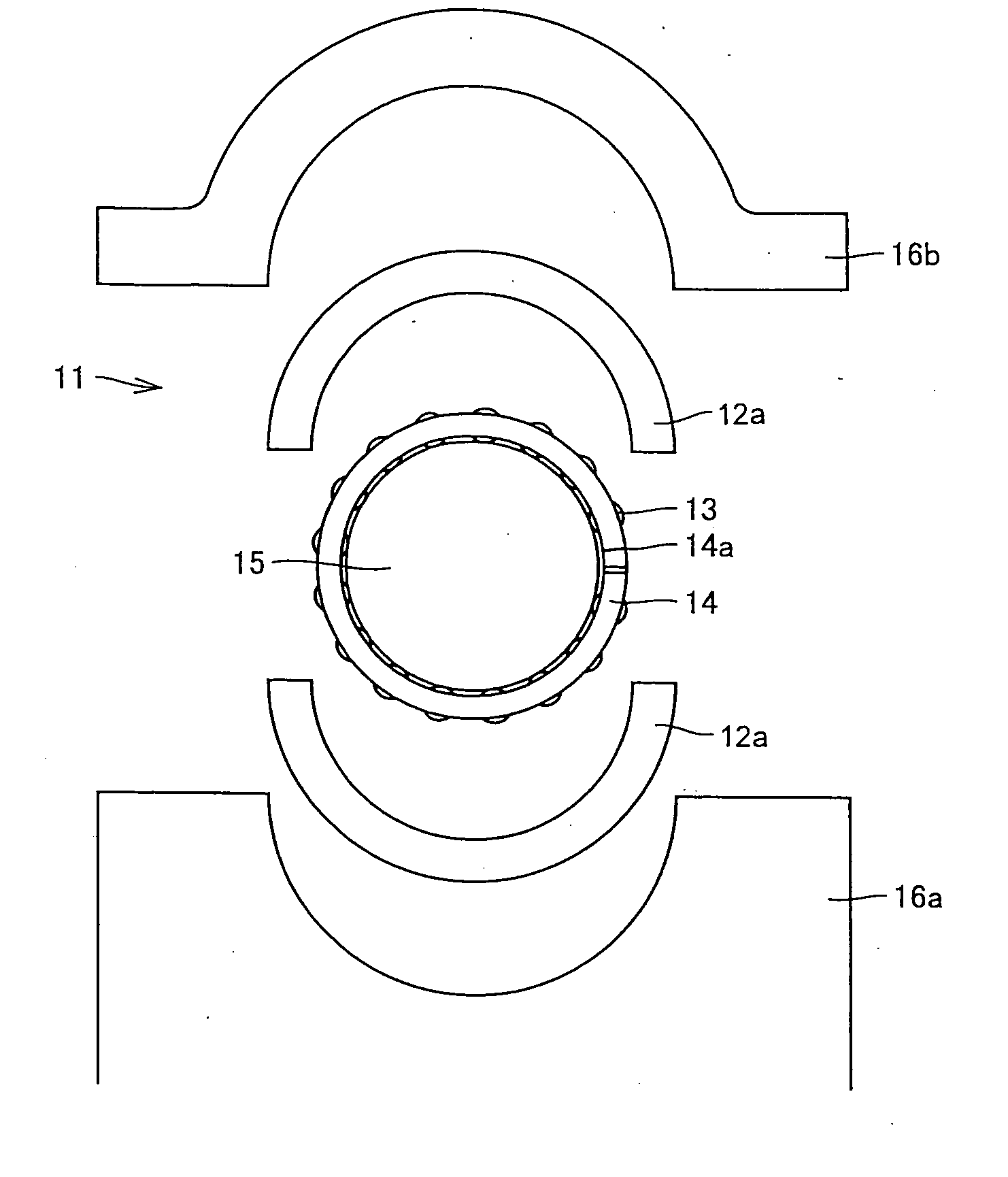

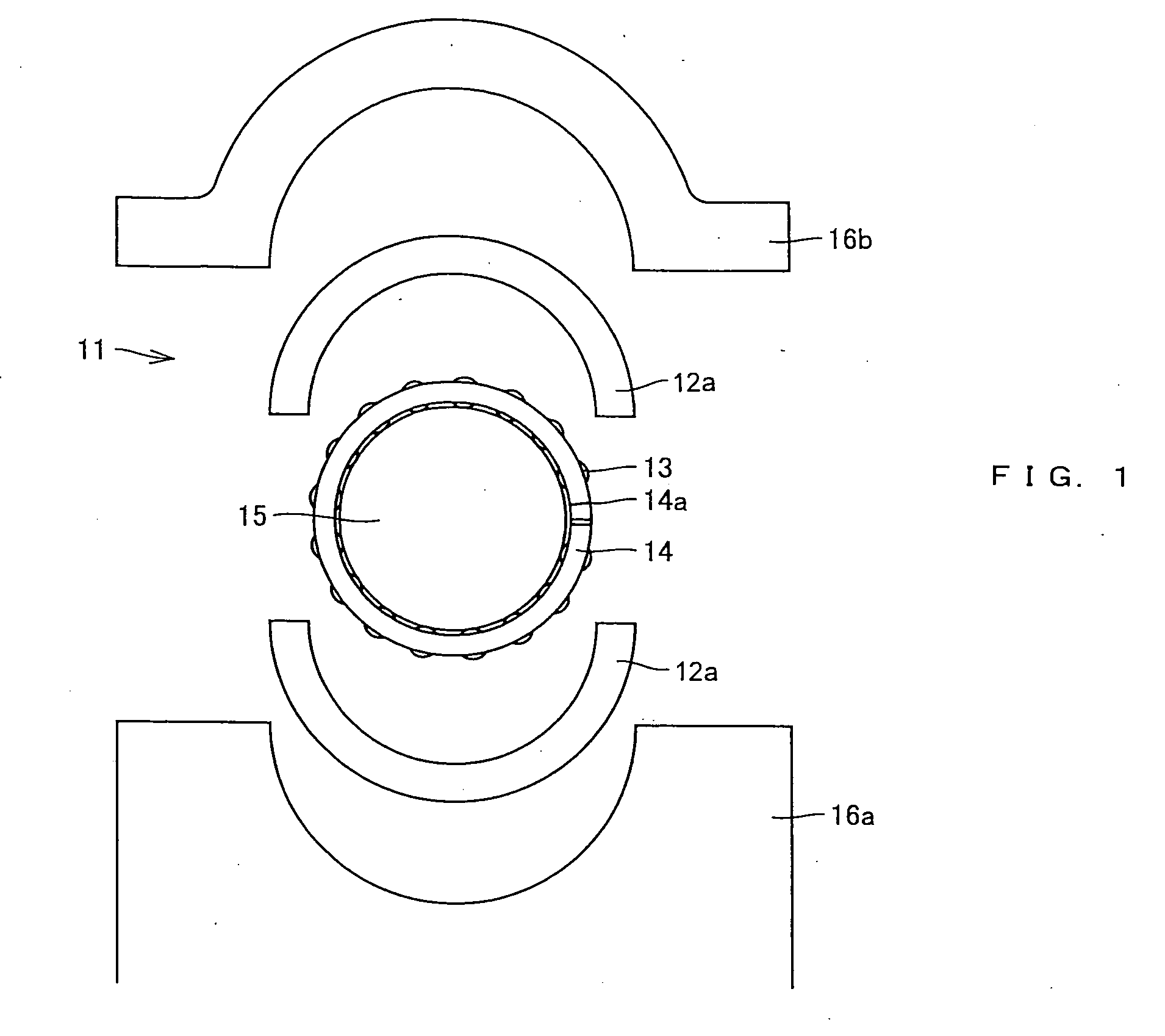

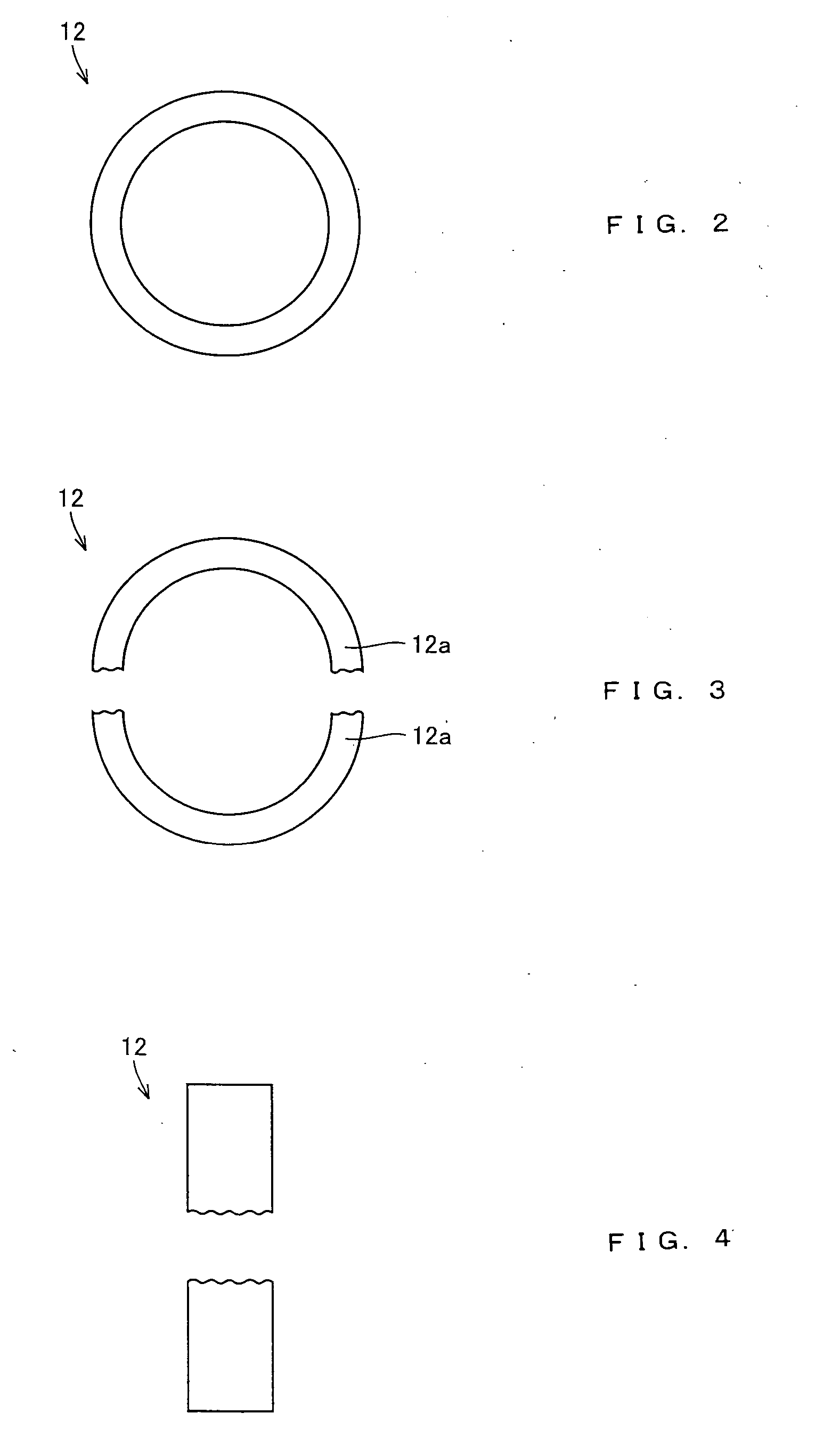

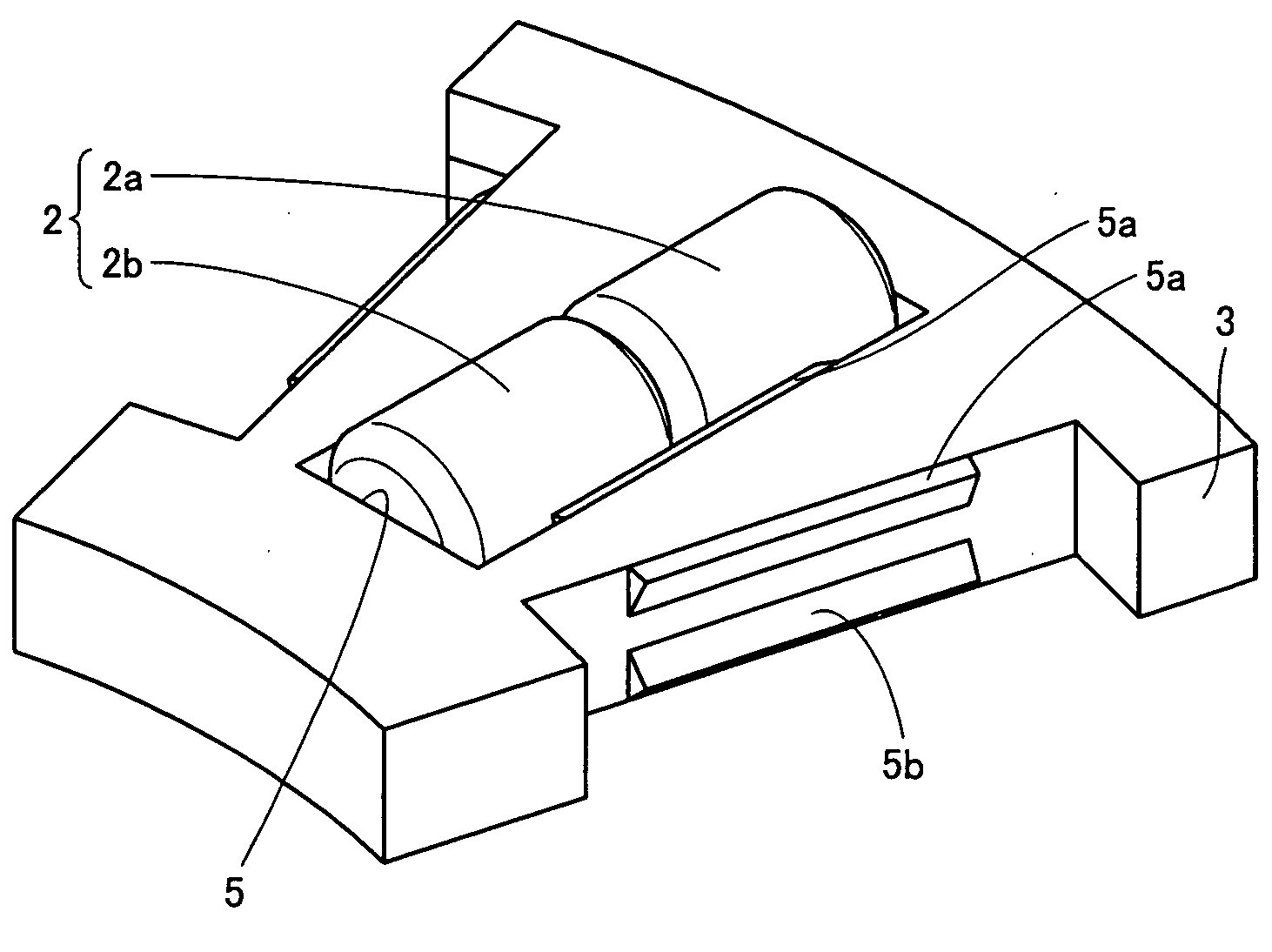

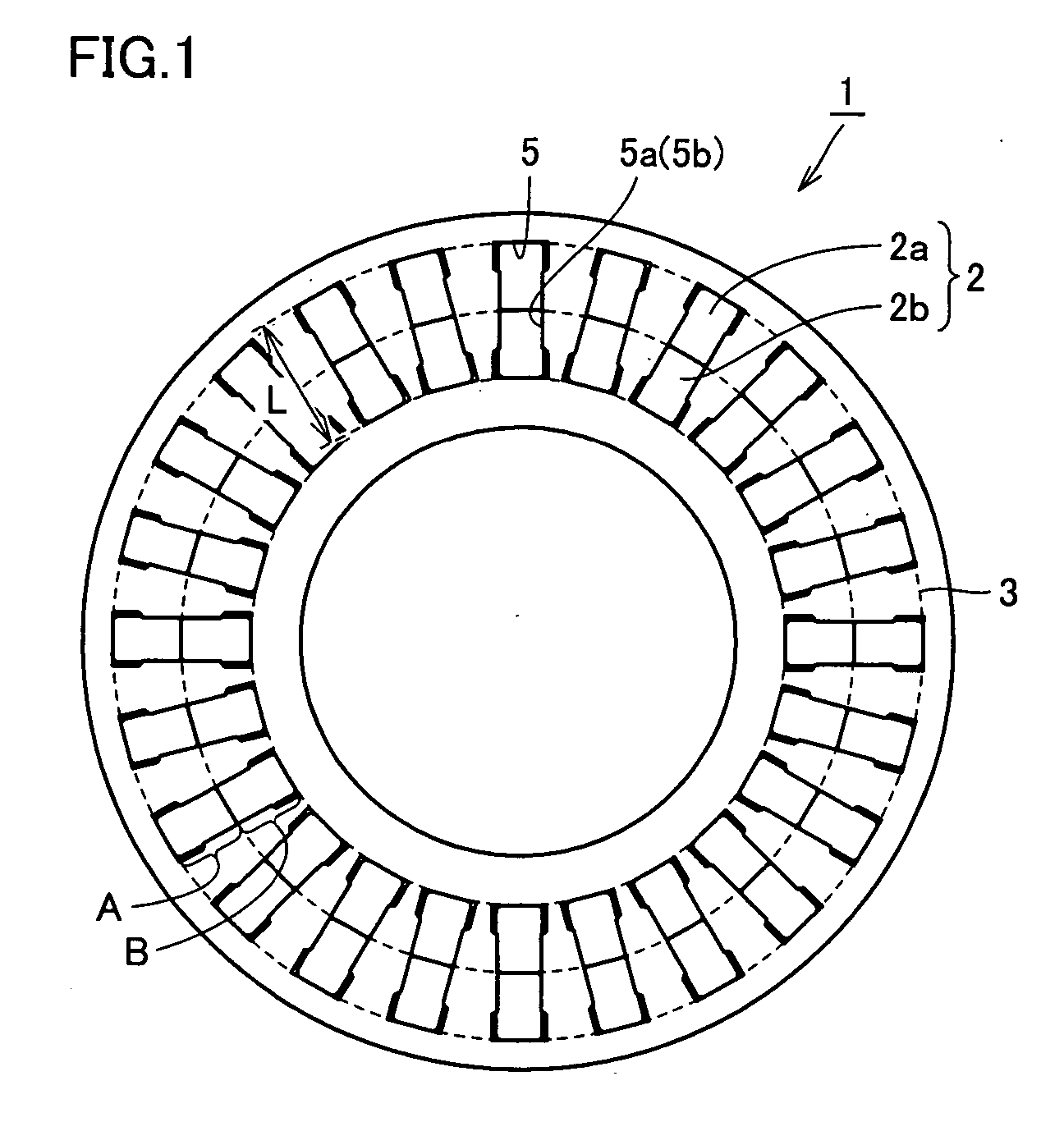

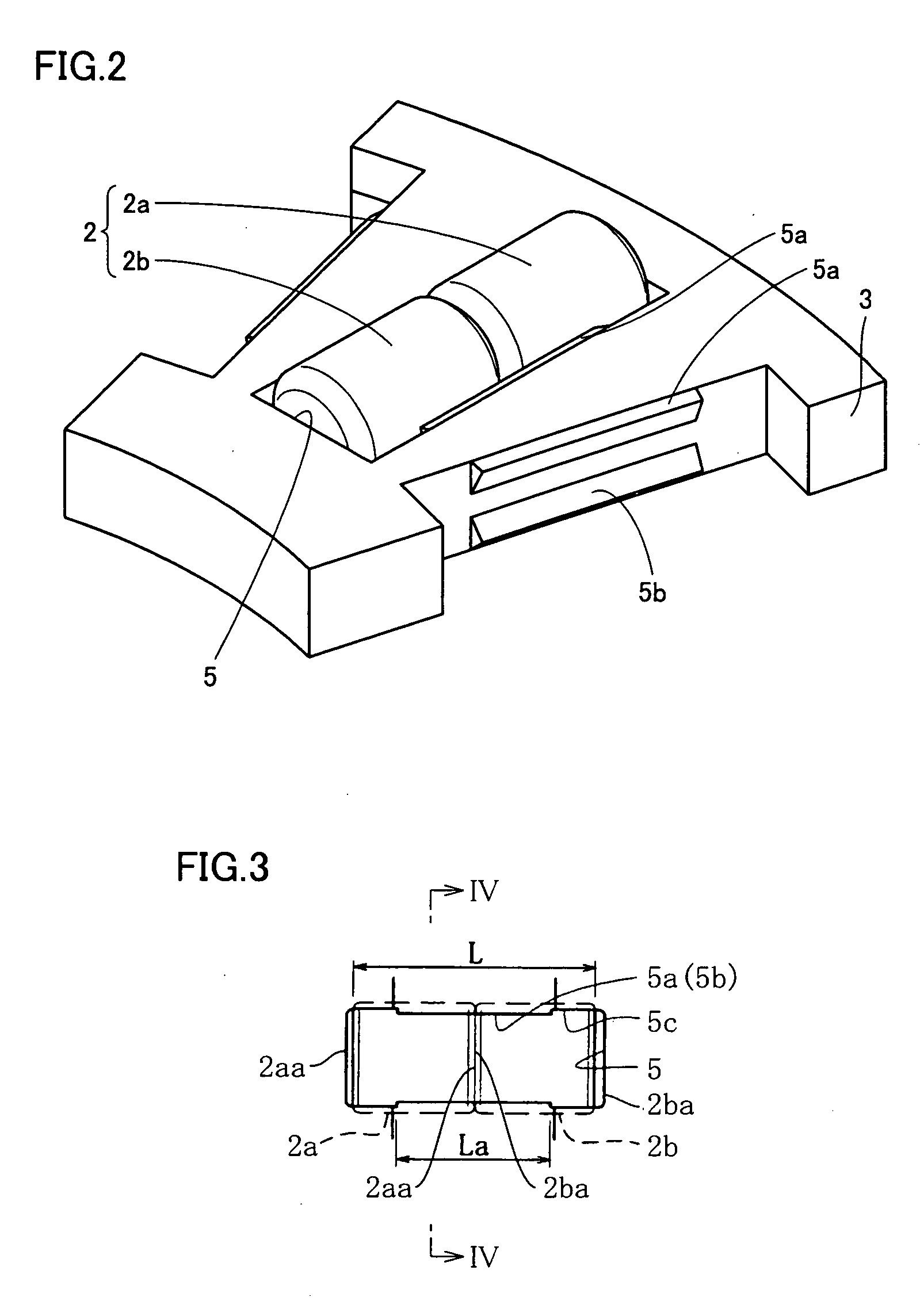

Needle roller bearing, crank shaft supporting structure, and split method of outer ring of needle roller bearing

InactiveUS20070116393A1Smooth rollingAvoid troubleCrankshaft bearingsShaftsNeedle roller bearingEngineering

A needle roller bearing comprises an outer ring having a plurality of outer ring members split by split lines extending in the axial direction of the bearing, and a plurality of needle rollers arranged on the track surface of the outer ring so that they can roll. The outer ring is split by a load applied to its end surface in the direction crossing the end surface.

Owner:NTN CORP

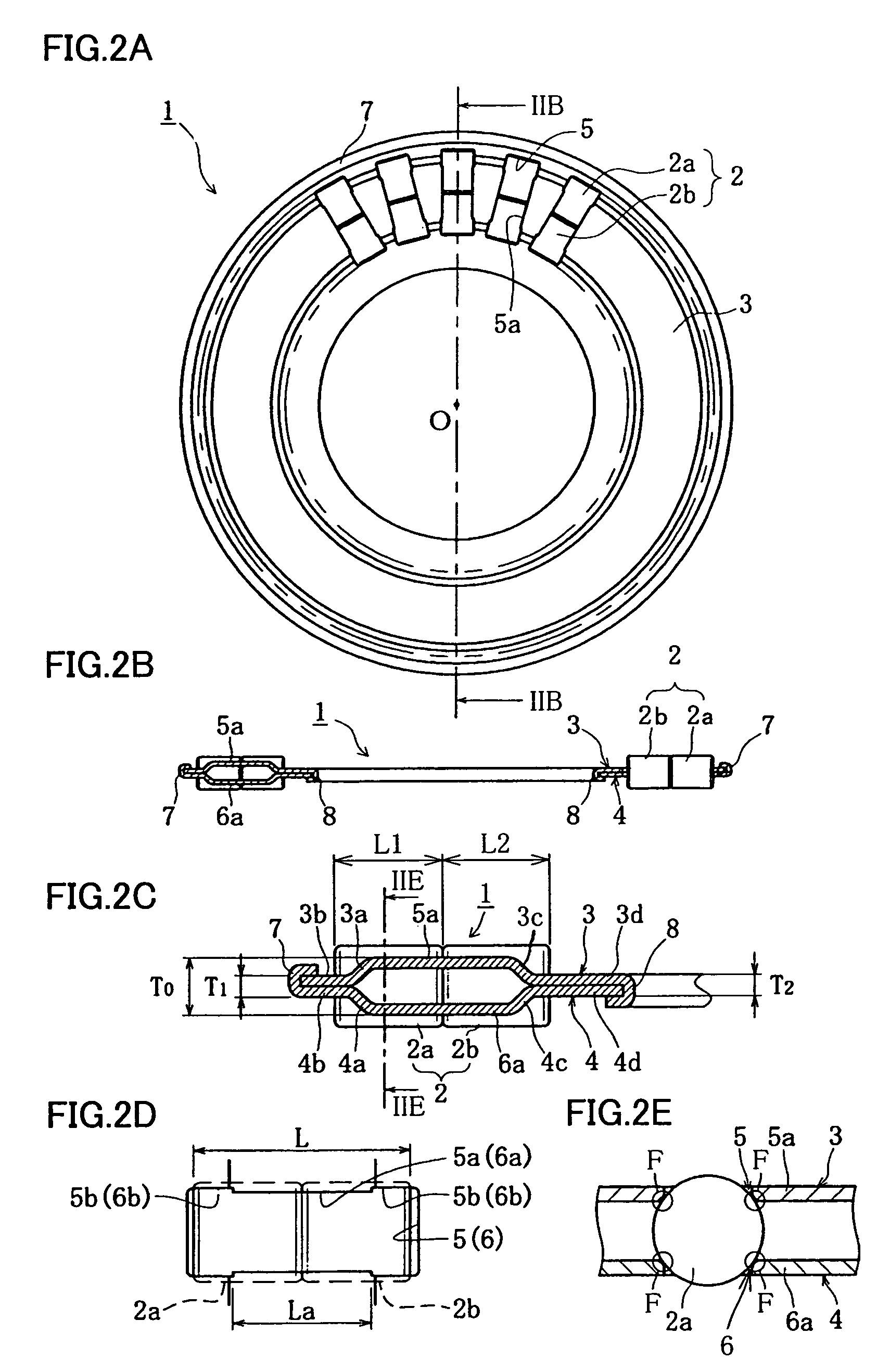

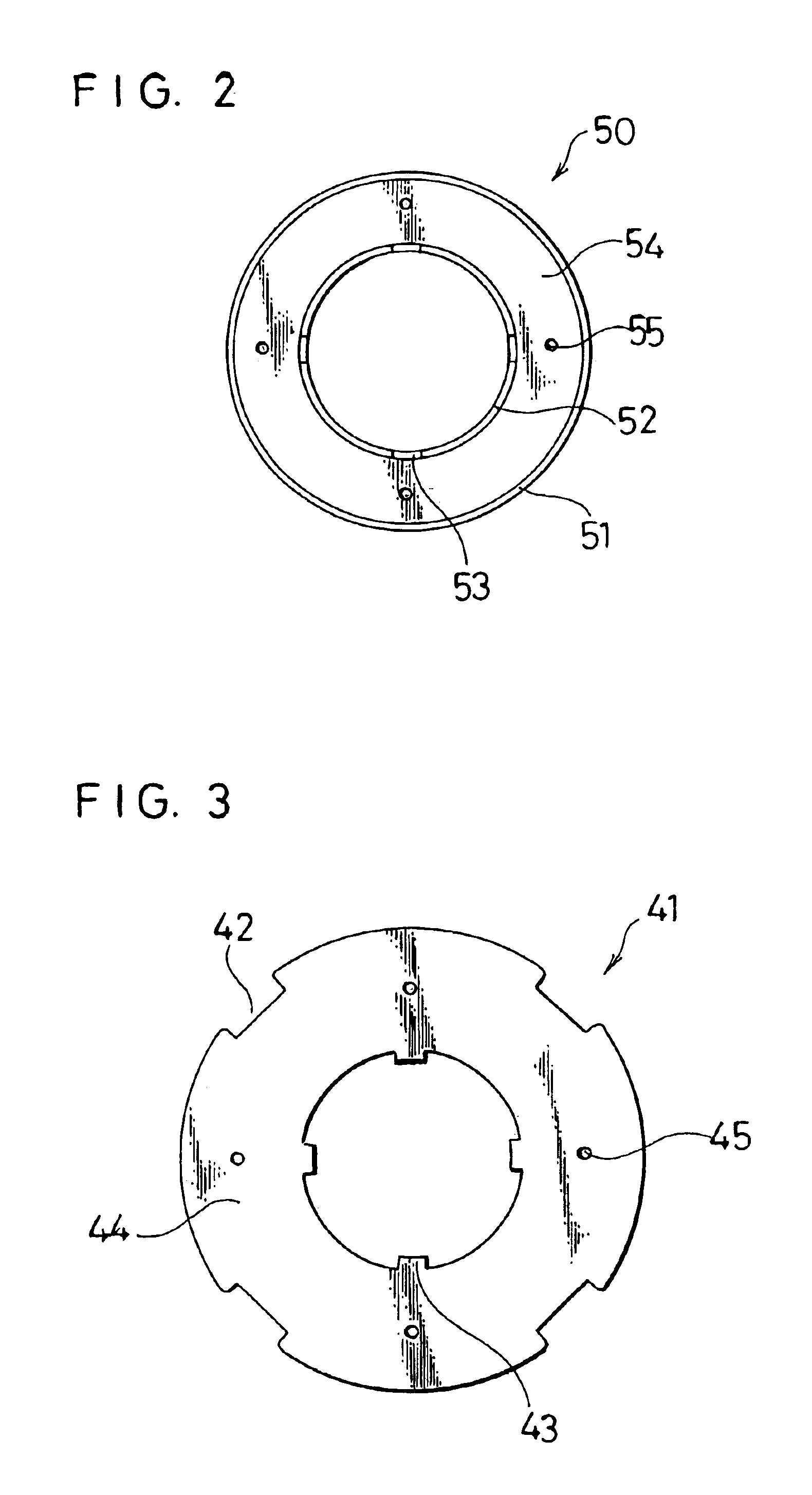

Thrust needle roller bearing

InactiveUS20050018940A1Reduce frictionIncreased durabilityShaftsBearing componentsNeedle roller bearingEngineering

A thrust needle roller bearing includes a plurality of needle rollers, and an annular retainer having a plurality of pockets for retaining the needle rollers. The plurality of pockets accommodate the needle rollers arranged in multiple rows shifted from each other in a radial direction of the retainer, and the retainer is made of synthetic resin. The thrust needle roller bearing is light, can reduce friction between the retainer and the needle rollers, and has high durability.

Owner:NTN CORP

Transmission for vehicle

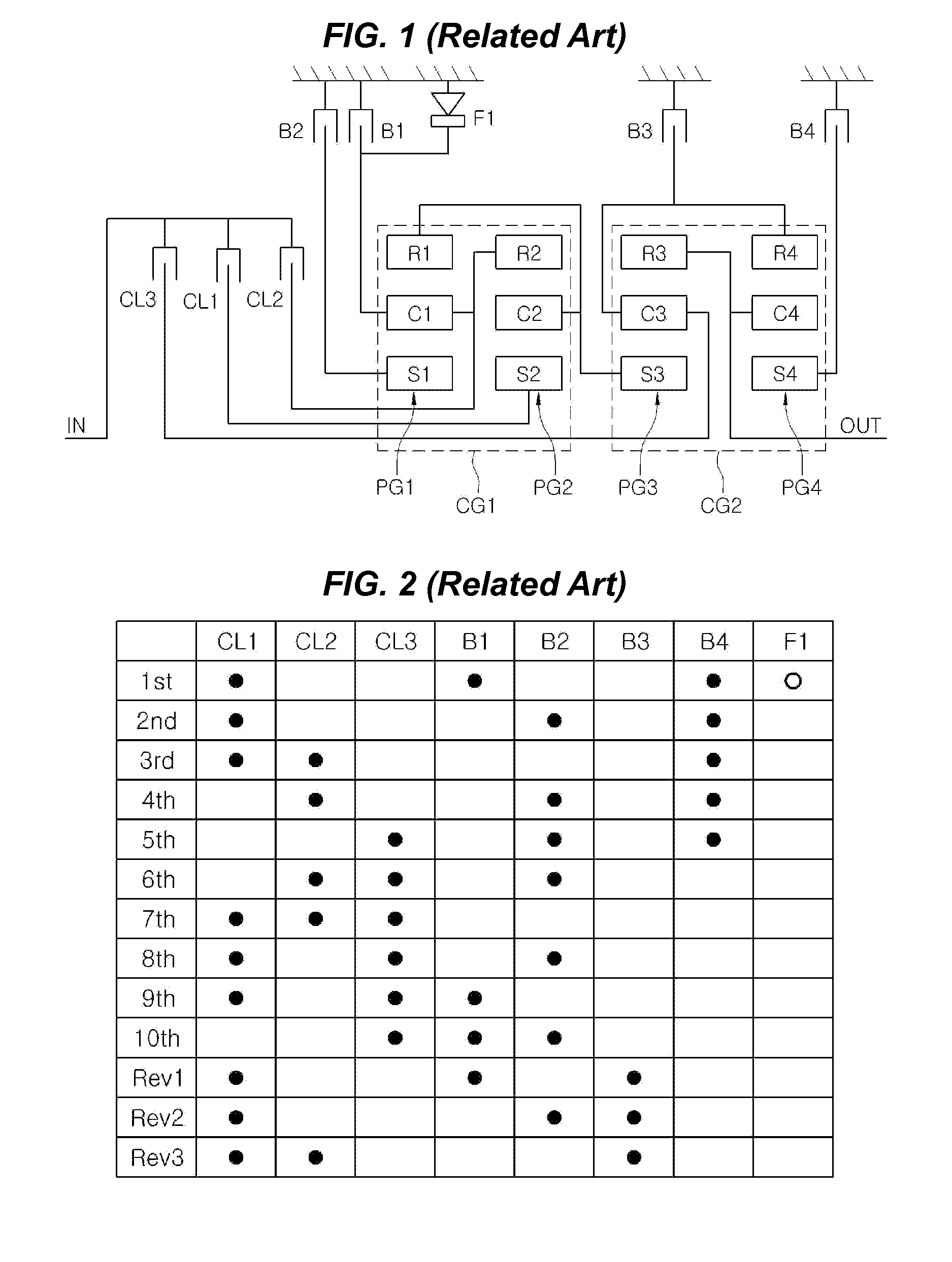

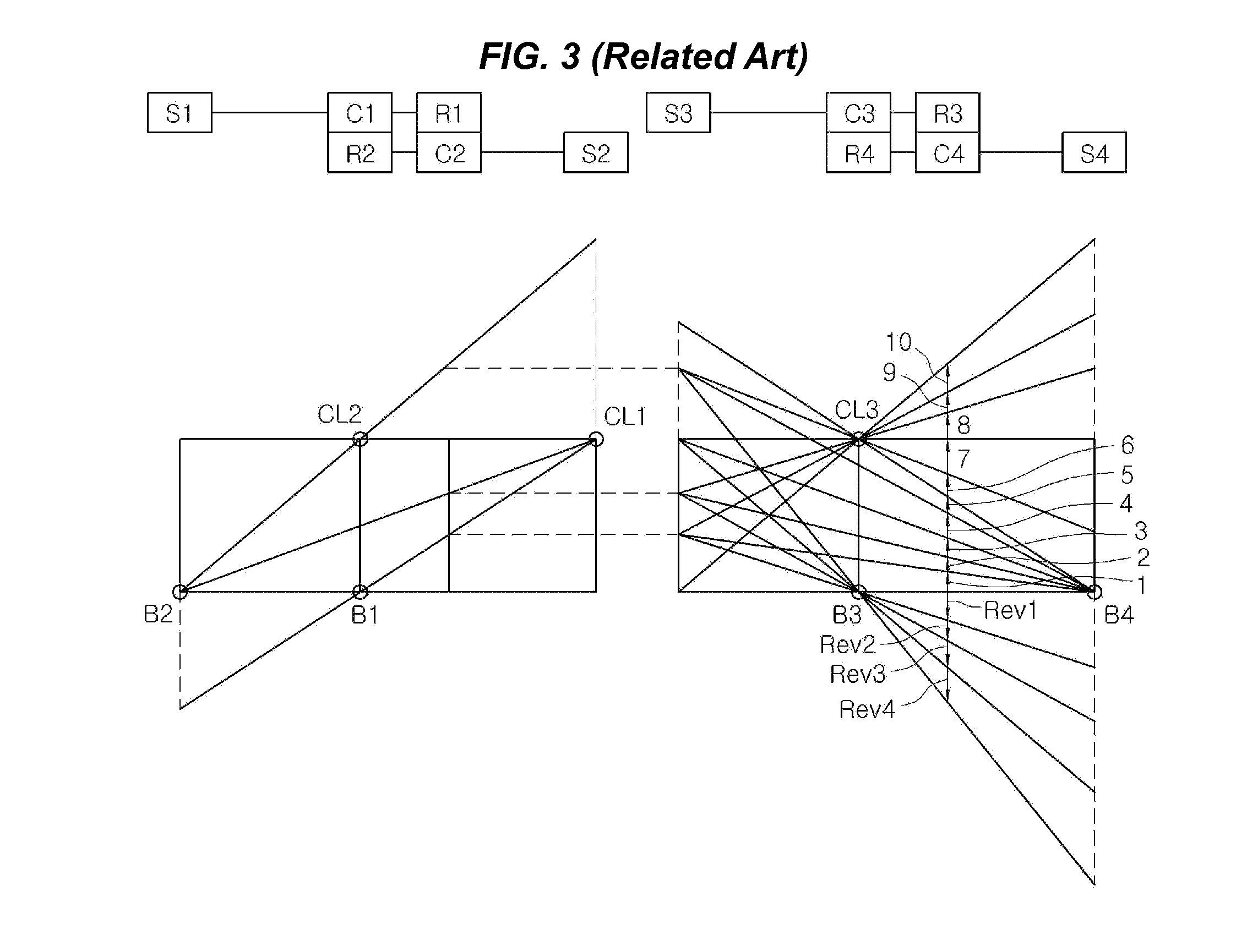

ActiveUS8517885B2Improve efficiencyExtend your lifeToothed gearingsTransmission elementsNeedle roller bearingGear wheel

A transmission for a vehicle employs four planetary gear trains to realizing at least forward 10-speed and reverse 3-speed gear ratios, thereby reducing the number of rotations of a second sun gear of a second planetary gear train so as to increase the efficiency of power transmission and to improve the longevity of related components of the second planetary gear train, such as a pinion gear, a pinion shaft, and a needle roller bearing.

Owner:HYUNDAI MOTOR CO LTD

RV speed reducer with crossed roller bearings

InactiveCN106015468AImprove rigidityReduce the difficulty of assemblyToothed gearingsGearing detailsNeedle roller bearingBall bearing

The invention discloses an RV speed reducer with crossed roller bearings. The RV speed reducer comprises a planet carrier assembly, a pin gear housing, an input shaft, planet gears, crankshafts and cycloidal gears. The planet carrier assembly comprises an output disc and a supporting flange. A plurality of gear pins are installed on the inner side wall of the pin gear housing. A first gear is arranged at one end of the input shaft. The two planet gears are externally meshed with the first gear. One end of each crankshaft is installed in a left crankshaft installation hole through an angular contact ball bearing or a conical roller bearing, and the other end of each crankshaft is installed in a right crankshaft installation hole through the corresponding crossed roller bearing. Each crankshaft is provided with two eccentric parts. A through hole of each cycloidal gear is connected with the corresponding eccentric part through a needle bearing. Each cycloidal gear is internally meshed with the corresponding gear pin. The RV speed reducer has the advantages of being good in transmission performance and convenient to machine, disassemble and assemble; meanwhile, the assembly difficulty is lowered, the production cost is reduced, and the rigidity of the speed reducer is improved through the crossed roller bearings.

Owner:GUANGZHOU HAOZHI ELECTROMECHANICAL

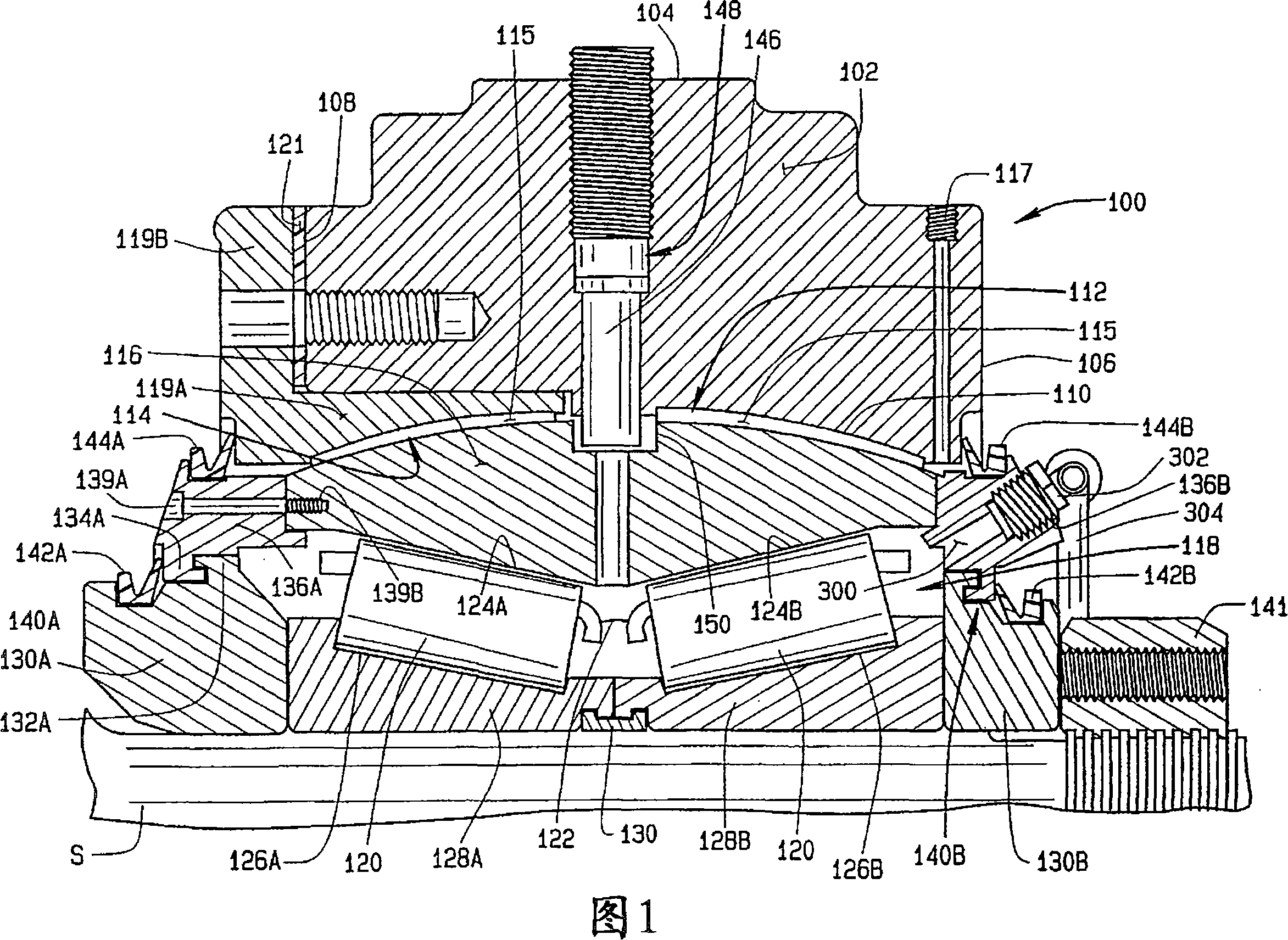

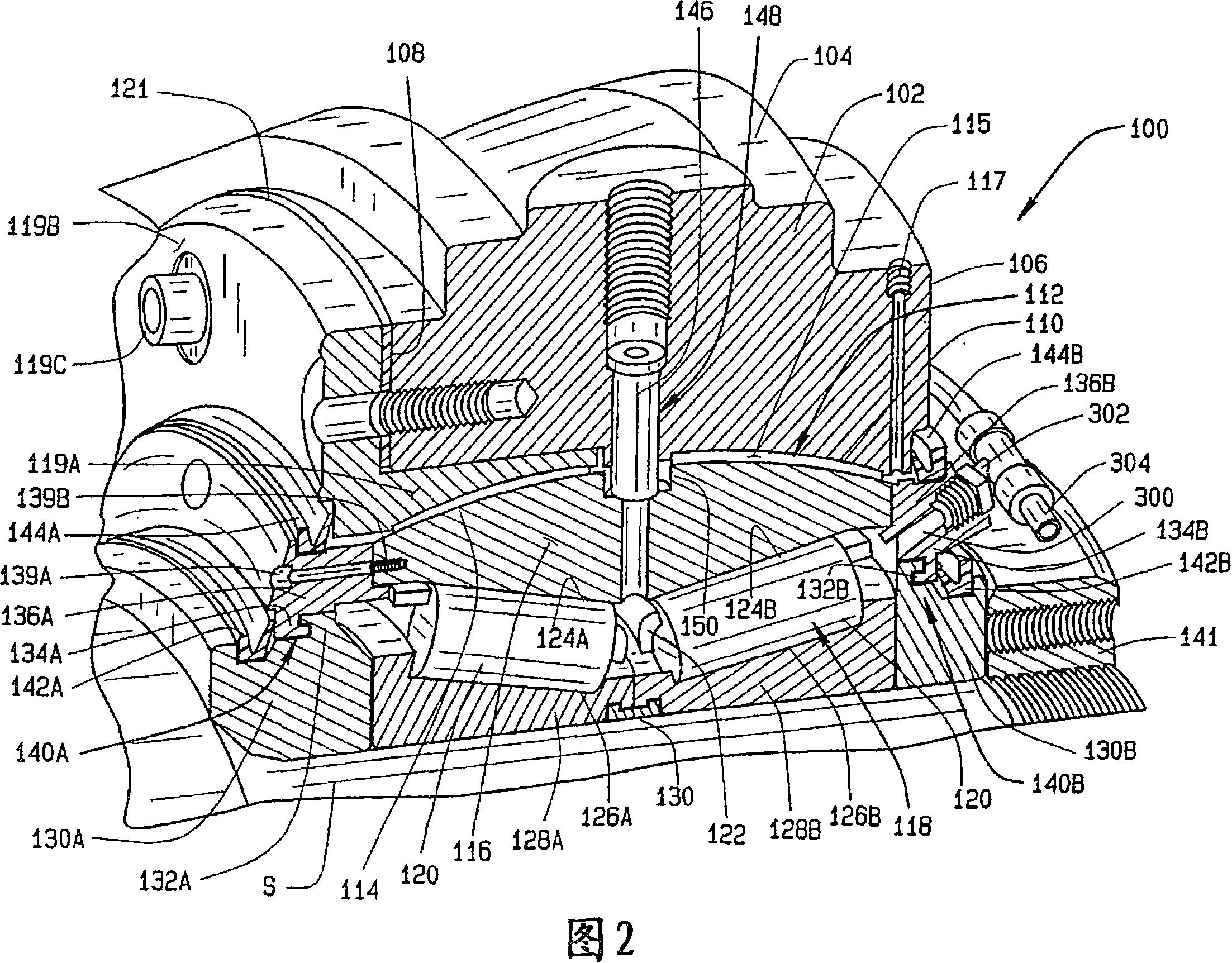

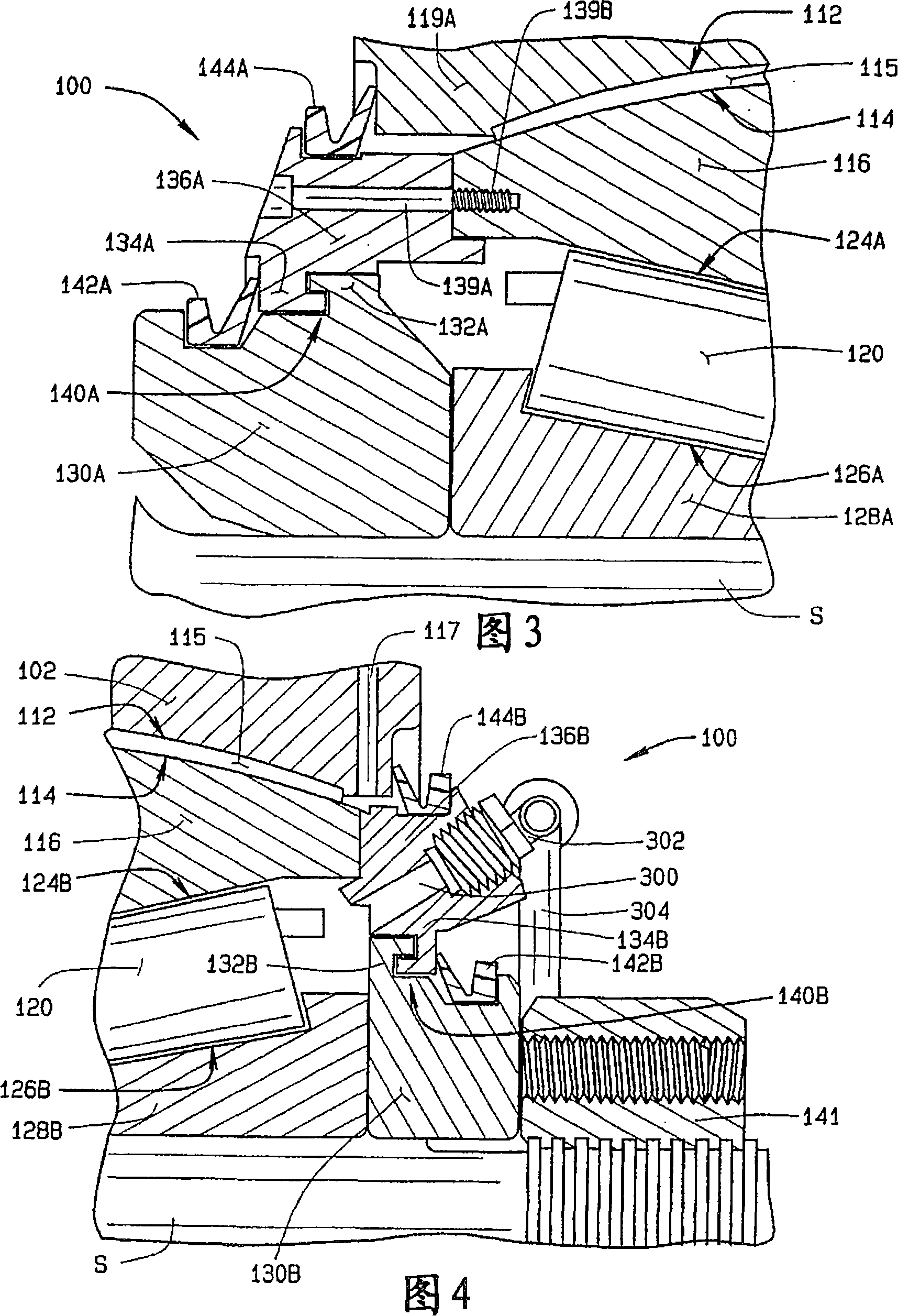

Pillow block system with tapered roller bearings

A spherical outer diameter tapered roller bearing pillow block system (100) for supporting the rotating main shaft of a wind turbine. The bearing system is configured with a unitized construction and factory set preload bearing settings to facilitate installation and setup. A spherical outer diameter surface (114) is formed on the outer race (116) of a tapered roller bearing assembly disposed about the rotating main shaft of the wind turbine. The bearing assembly is secured to a stationary support structure of the wind turbine through a pillow block housing assembly (102) providing a matching spherical housing seat (112) to form a ball and socket interface between the tapered roller bearing assembly (118) and the pillow block housing assembly (102). The ball and socket interface accommodates static and dynamic misalignments between the wind turbine main shaft and the supporting structure, while the bearing assembly (118) accommodates radial and axial loads.

Owner:THE TIMKEN CO

Yaw gearbox for wind power generator

ActiveCN1587681AReduce weightCompact structureToothed gearingsMachines/enginesNeedle roller bearingWind driven

The invention relates to a kind of off-course gear box of wind-driven generator. Between the flange and the middle box body there are the first-grade and the second-grade inner gear cluster, and the third-grade and fourth-grade inner gear circles. On the first and the second grade inner gear cluster there are inner gear circles. Input shaft, planet frames and solar wheels at all levels, output gear shaft axis, the input shaft of connected to the first-grade solar wheel, the planet frames at all levels are connected to the next grade solar wheel. The fourth grade planet frame is fixed on the back box body by the bearing. The end of the frame goes through the back box body and connects with the output gear. Each-grade planet frame has planet wheel, between the input shaft and flange, between the fourth grade planet frame and back box body, there is oil-sealing. Advantages of the invention: take the first and second inner gear circule cluster as a component and make the structure compact; take the gear circle cluster and the inner gear circles at all levels, as a part of the box, reduce the weight, and it is easy to process, convenient to dismantle and fix.

Owner:NANJING HIGH SPEED & ACCURATE GEAR GRP

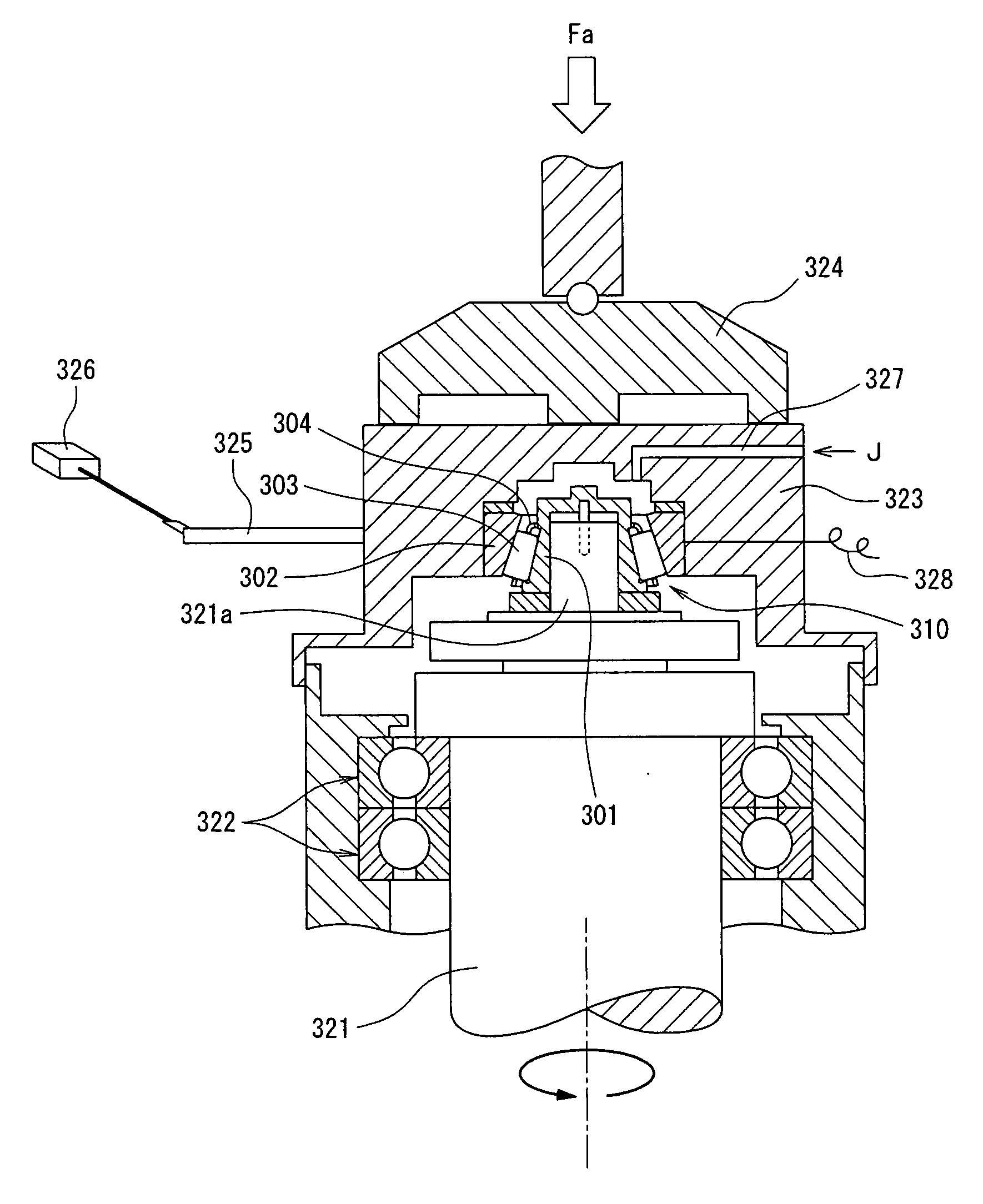

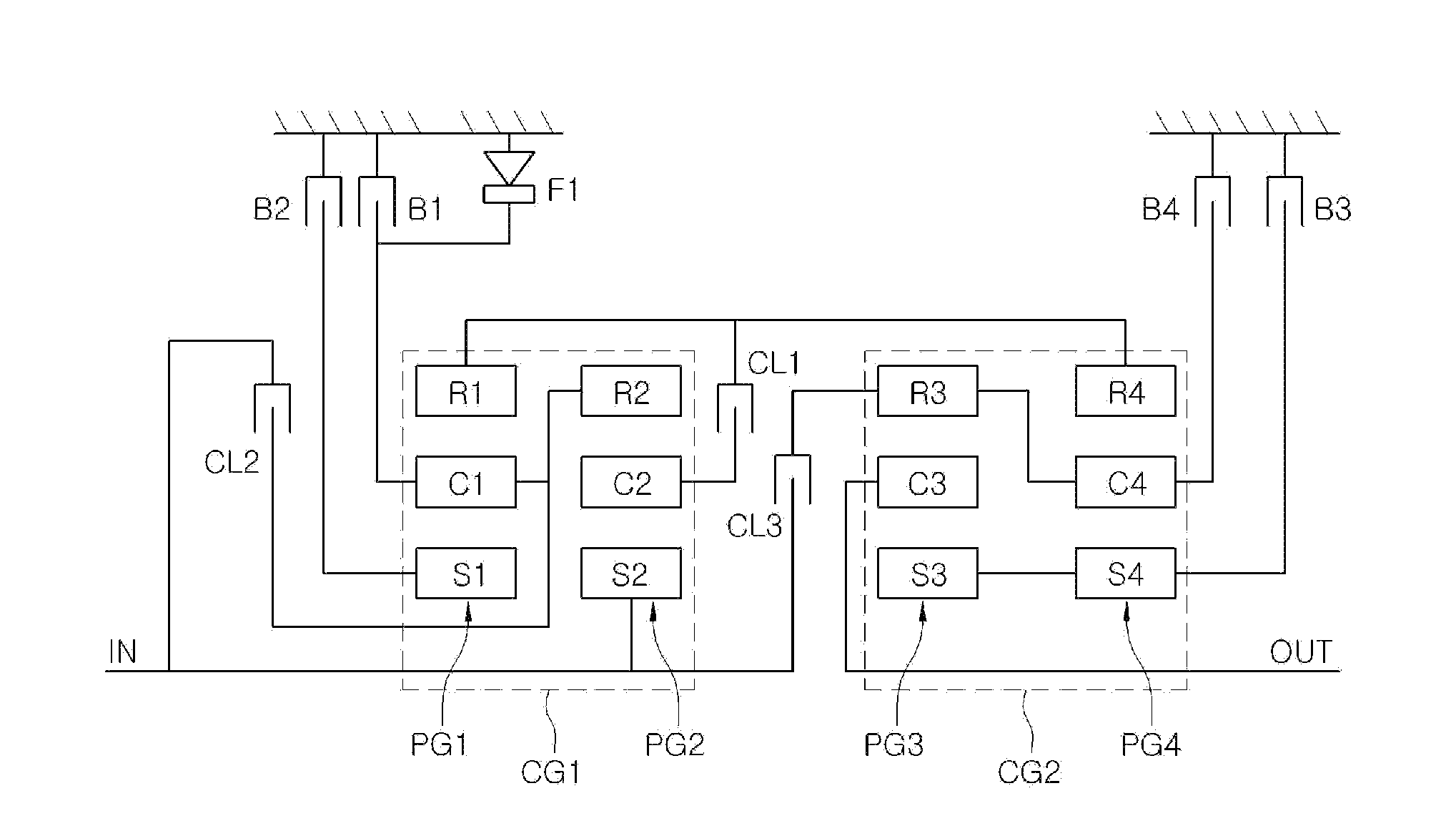

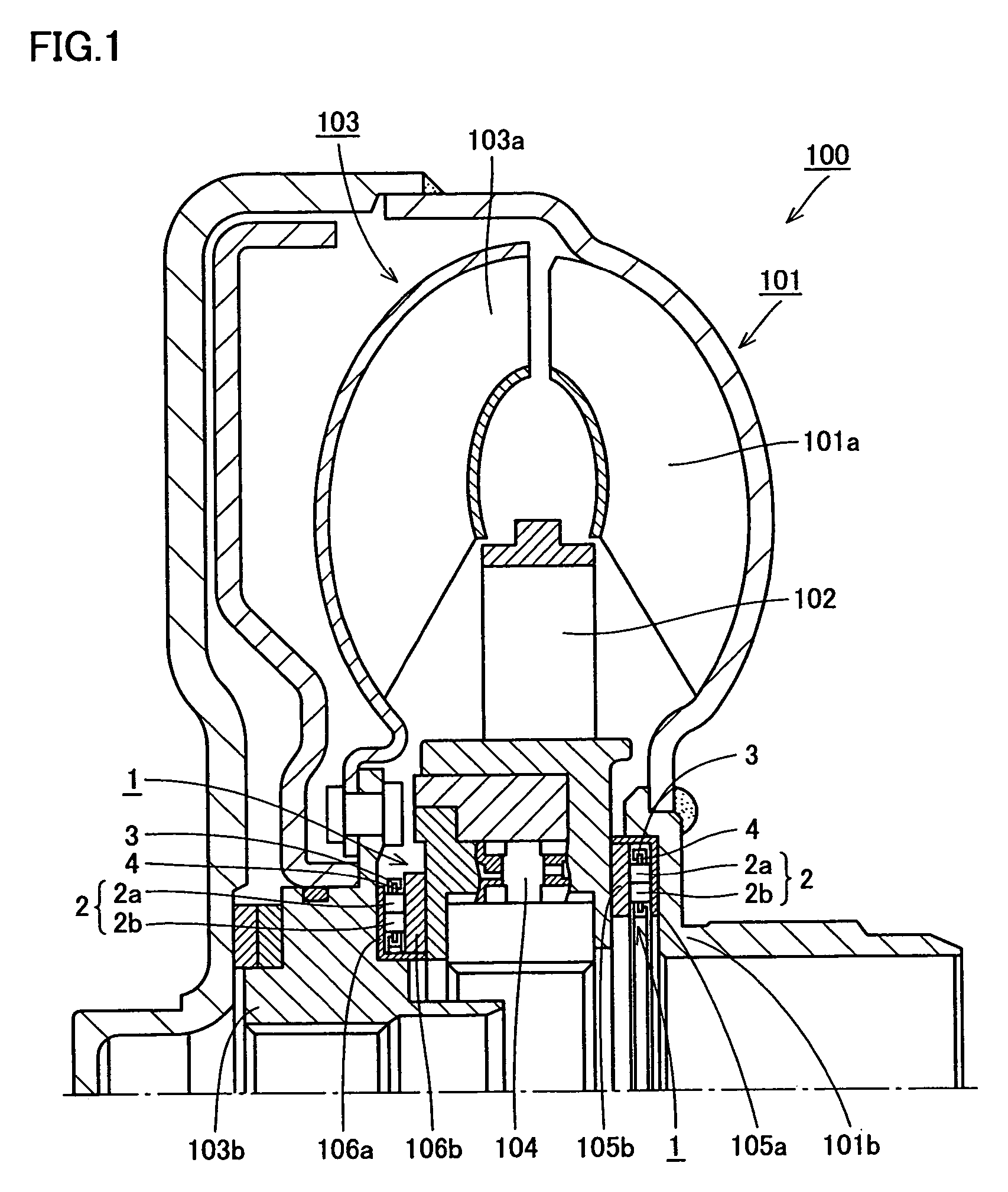

Support structure carrying thrust load of transmission, method of manufacturing thereof and thrust needle roller bearing

ActiveUS7033083B2Reduction of differential slipImprovement of the inflow and outflow of a lubricating oilRoller bearingsToothed gearingsImpellerNeedle roller bearing

A support structure carries a thrust load of a transmission which includes a torque converter having an impeller and a turbine opposite to each other with a stator therebetween. A thrust needle roller bearing having needle rollers arranged in two rows is provided at, at least one of places respectively between the stator and the impeller and between the stator and the turbine. The support structure carrying a thrust load of the transmission, a method of manufacturing the support structure and the thrust needle roller bearing are thus obtained, with an improvement in inflow and outflow of a lubricating oil, a reduction of the differential slip of the needle rollers, and an improvement in strength durability.

Owner:NTN CORP

Stator with one-way clutch

InactiveUS6814203B2Reduced dimensionLow costRotary clutchesBearing componentsImpellerNeedle roller bearing

A stator is provided with an impeller and a one-way clutch. The stator includes at least one plain bearing and at least one side plate. The plain bearing is arranged adjacent to and on an axially outer side of a side portion of the one-way clutch and between an inner ring and an outer ring of the one-way clutch, and on its inner and outer peripheries, has flanges with bearing tracks formed thereon. The side plate is arranged on an axially outer side of the plain bearing and at a position adjacent to the plain bearing such that the side plate serves not only as a stopper for the plain bearing but also as a bearing track for a needle bearing. The plain bearing and side plate are provided with engageable portions, respectively, and are maintained in engagement with each other via the engageable portions.

Owner:NSK WARNER

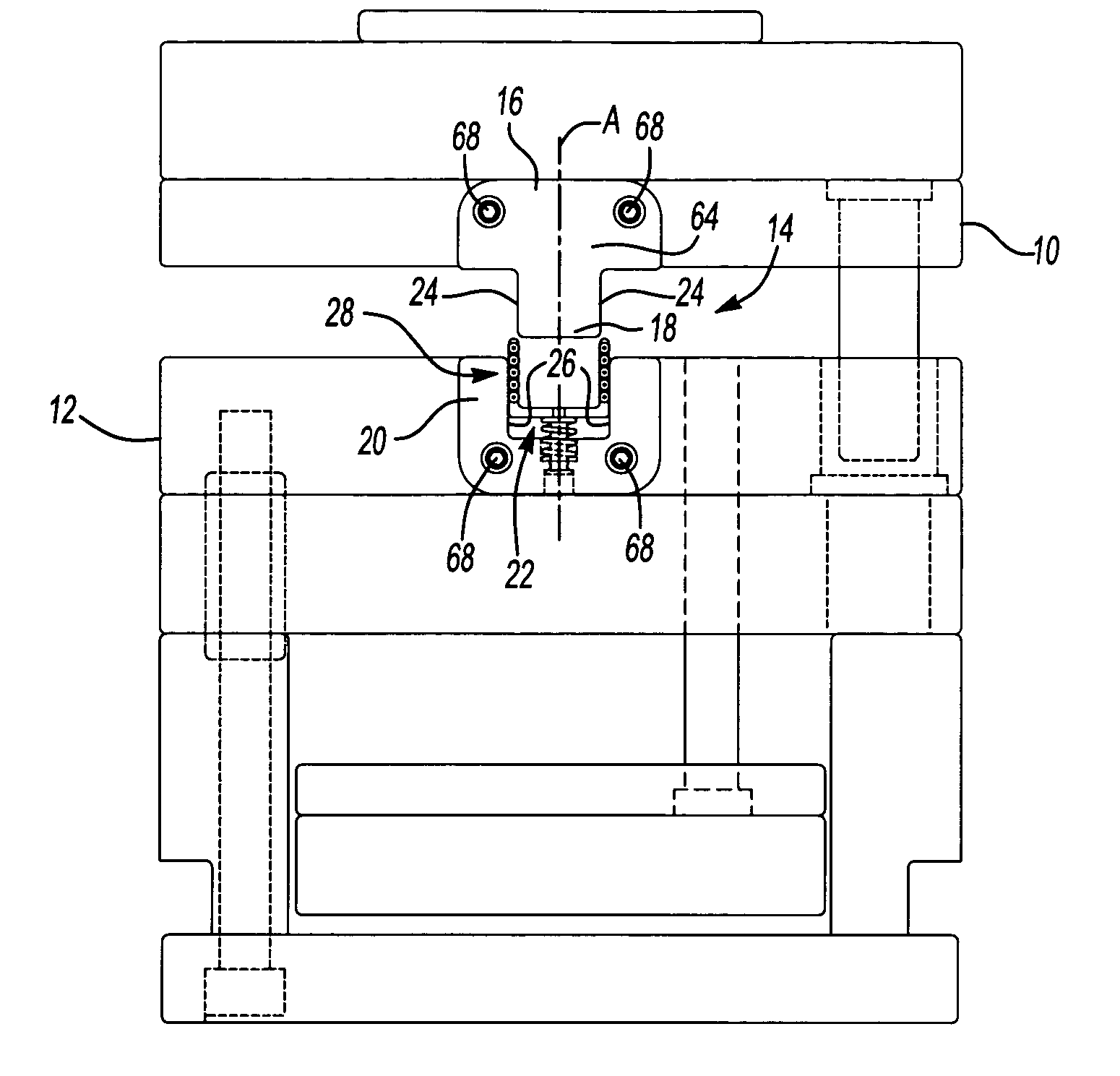

Positioning device with bearing mechanism

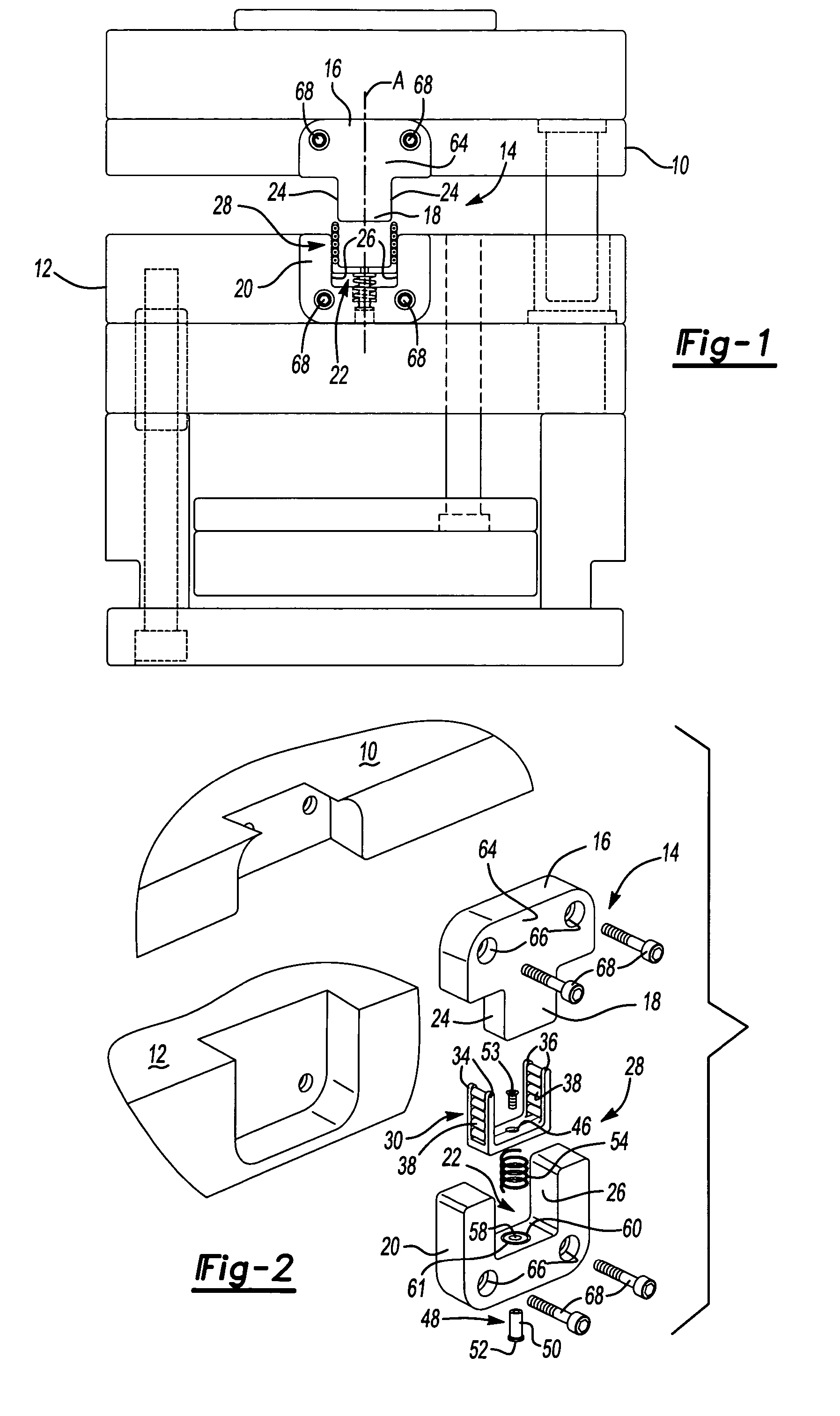

ActiveUS6953331B2Reduce frictionExtended operating cycleLinear bearingsConfectioneryNeedle roller bearingBearing surface

A positioning device for aligning and guiding first and second mold halves together is provided. The positioning device includes a first member defining an alignment axis and having a male portion. The first member is mounted to the first mold half. A second member is separable from the first member and defines a female portion for mating with the male portion along the alignment axis to align the first and second mold halves together. The second member is mounted to the second mold half. The male portion presents a first bearing surface and the female portion presents a second bearing surface. A cage that rotatably supports a plurality of needle bearings reduces friction along the bearing surfaces when mating the members together along the alignment axis. A spring resiliently supports the cage.

Owner:EXTREME COMPONENTS

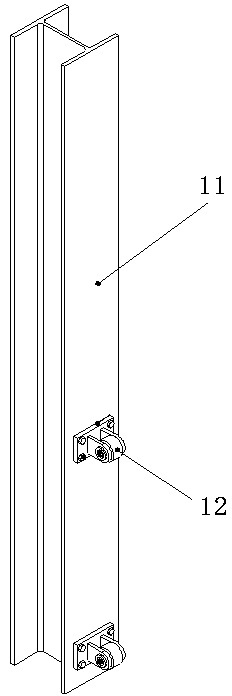

Trowelling machine

ActiveCN103182733AImprove production line efficiencyImprove surface qualityCeramic shaping apparatusNeedle roller bearingProduction line

The invention provides a trowelling machine comprising a transition carriage, a walking mechanism, a cutter head assembly, an electric control cabinet, a rail and an operation platform, wherein the rail is fixedly mounted on a ground; the walking mechanism is in a bridge type structure; the bottoms of two side arm frames of the bridge type structure are provided with walking mechanism double-flange walking wheels to walk in a vertical direction of the rail; an upper transverse beam of the bridge type structure is provided with a transverse beam rail; the bottom of a frame of the transition carriage is provided with transition carriage double-flange walking wheels to transversely move on the transverse beam rail; the cutter head assembly comprises a lifting device, a guide device and a trowelling plate; the lifting device is connected with the trowelling plate through an electric lifting machine; the guide device is in guide connection with a cutter head vertical column by respectively mounting two needle bearings at inner sides of four guide frame stand columns; and the electric control cabinet and the operation platform are mounted on the walking mechanism. According to the trowelling machine disclosed by the invention, the efficiency of a production line and the surface quantity of a cement board are greatly improved, the manpower is saved, the cost is reduced and the performance is good.

Owner:XIANGTAN YUANDA RESIDENTIAL IND CO LTD

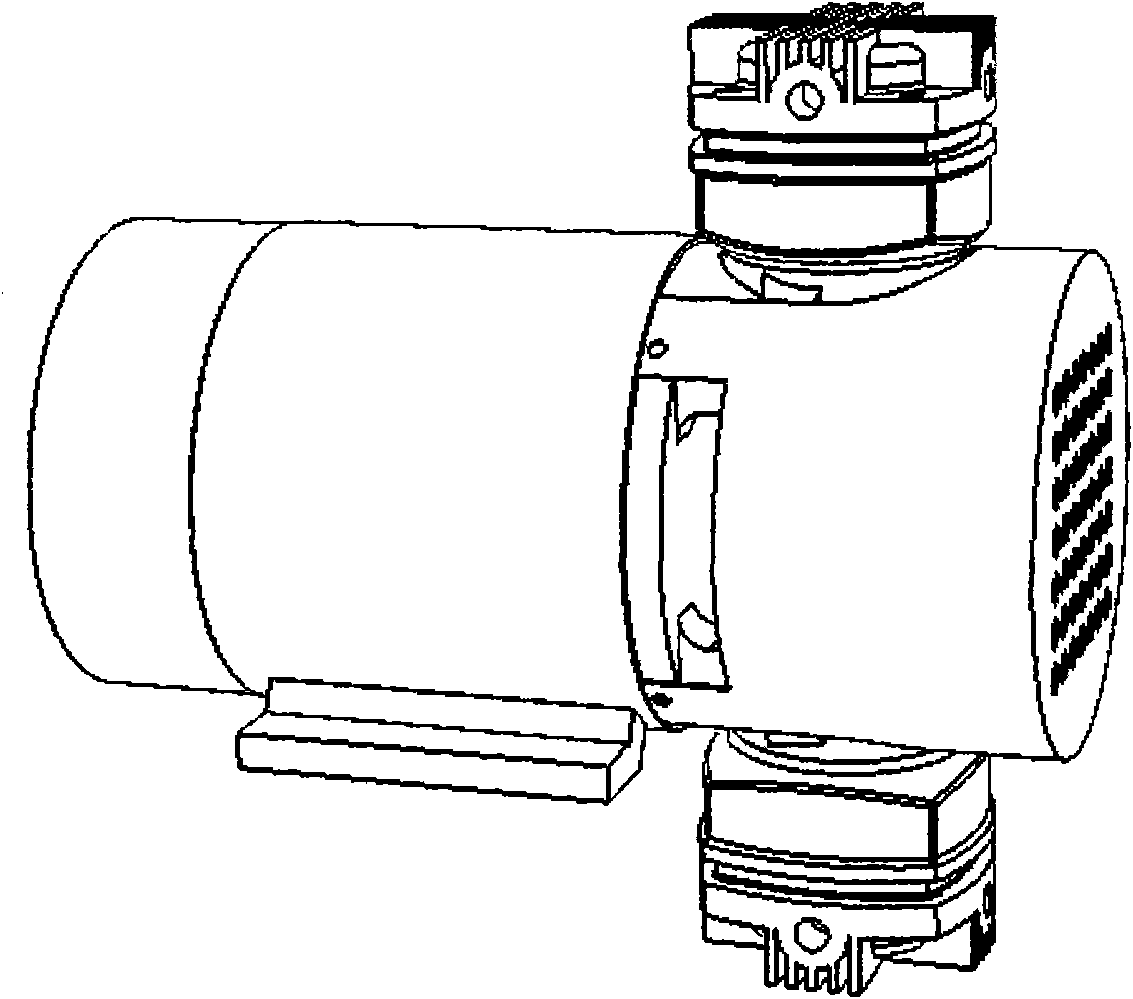

Oil-free compressor used in locomotive

InactiveCN101614200AIncrease the bearing areaImprove the state of stressPositive displacement pump componentsPiston pumpsNeedle roller bearingBall bearing

The invention belongs to the technical field of air compressors, relates to an oil-free compressor used in a locomotive, in particular to an eccentric block-connecting rod reciprocating piston total oil-free lubricated compressor. The oil-free compressor comprises a motor, cylinders, a piston connecting rod assembly, an air valve assembly, cooling fan and the like, wherein, two cylinders are symmetrically arranged above and below a motor shaft, and can also be arranged at the left and the right of the motor shaft, and the two cylinders are coaxial. Connecting rods are sheathed on the motor shaft by a radial ball bearing and an eccentric block, small top end of each connecting rod is provided with two needle roller bearings with an one-side sealed structure, and a crank-connecting rod mechanism drives a piston to realize reciprocating motion in the cylinders. An air inlet valve, a valve plate and an air outlet valve are arranged between the cylinders and cylinder caps, and the valve plate is of a flat-sheet structure, and is provided with an inlet flow channel and an outlet flow channel. The cylinder caps are provided with air inlet chambers and air outlet chambers. The oil-free compressor has the advantages of oil saving, environmental protection, and simple operation and maintenance.

Owner:HEFEI GENERAL MACHINERY RES INST

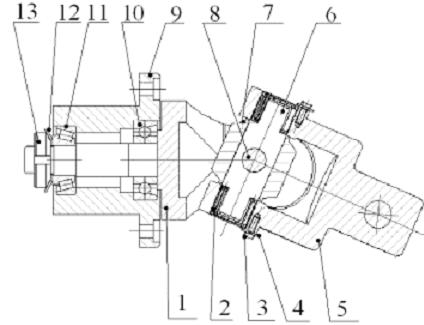

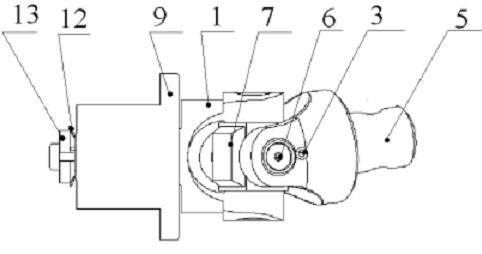

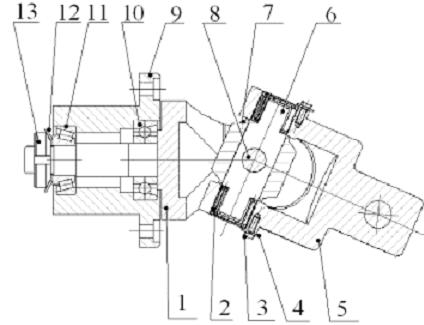

High-precision spherical hinge structure for parallel machine tools

InactiveCN102518689AWide range of independent cornersHigh tensile strengthYielding couplingNeedle roller bearingThree degrees of freedom

A high-precision spherical hinge structure for parallel machine tools comprises a lock nut, a washer, a spherical joint lower fork bearing block, a cylindrical pin, a cross, a pin roll, a spherical hinge upper fork, a large washer, a screw, a needle roller bearing, a spherical hinge lower fork and the like, wherein the spherical hinge upper fork rotates around the pin roll positioned in the cross, the spherical hinge lower fork rotates around the cylindrical pin transversely inserted into the pin roller, and the spherical hinge lower fork is fitted to the spherical hinge lower fork bearing block through the lock nut and two pairs of bearings. The high-precision spherical hinge structure is simply a three-degree-of-freedom hinge structure capable of substituting a spherical hinge. Compared with the traditional spherical hinges, the high-precision spherical hinge structure has the advantages that the independent rotational angle range is wide, tensile strength is high, mounting and regulation are convenient, machining precision is easy to guarantee and the like. The high-precision spherical hinge structure is mainly applied to parallel machine tools to replace spherical hinges.

Owner:JIANGSU UNIV

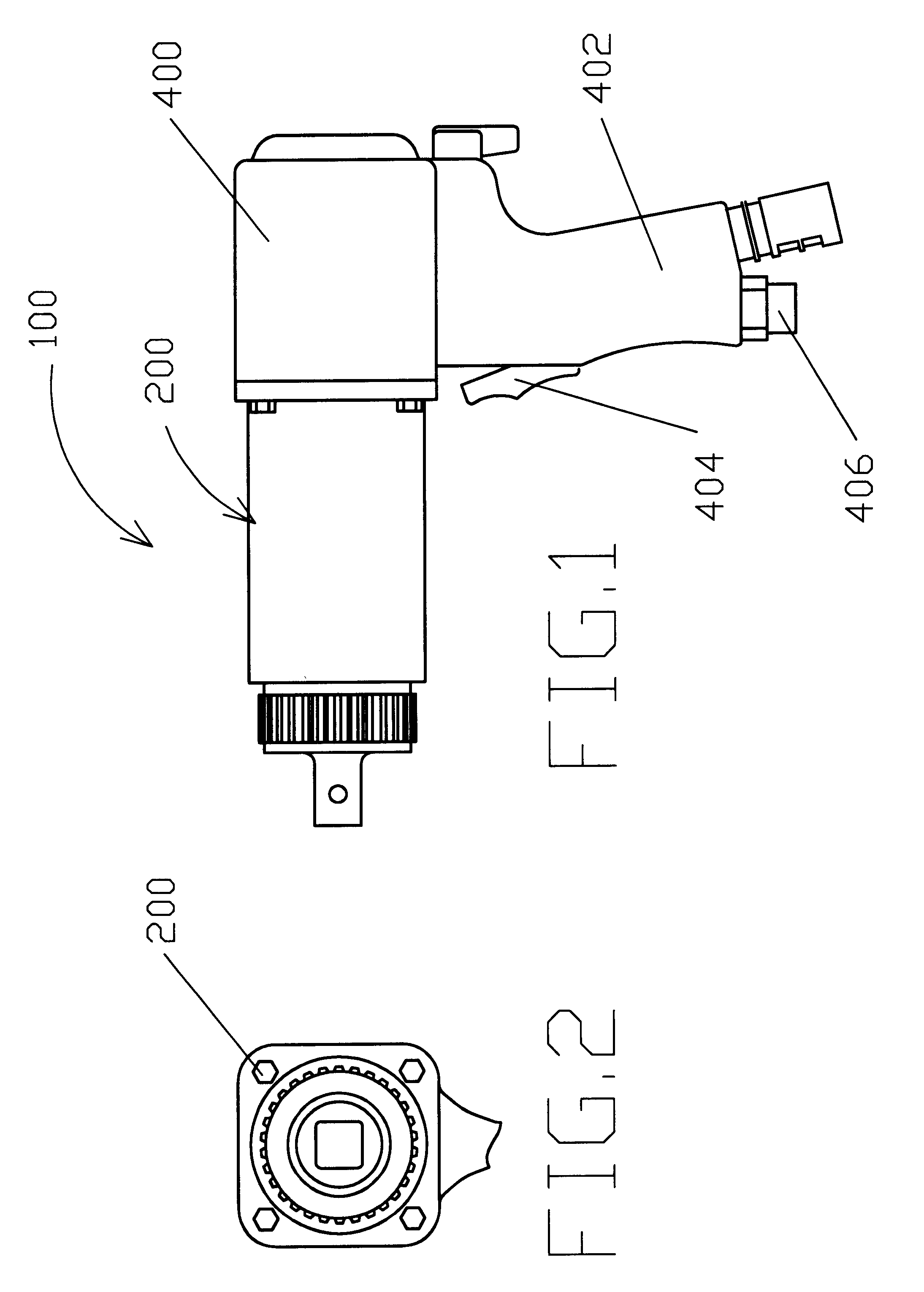

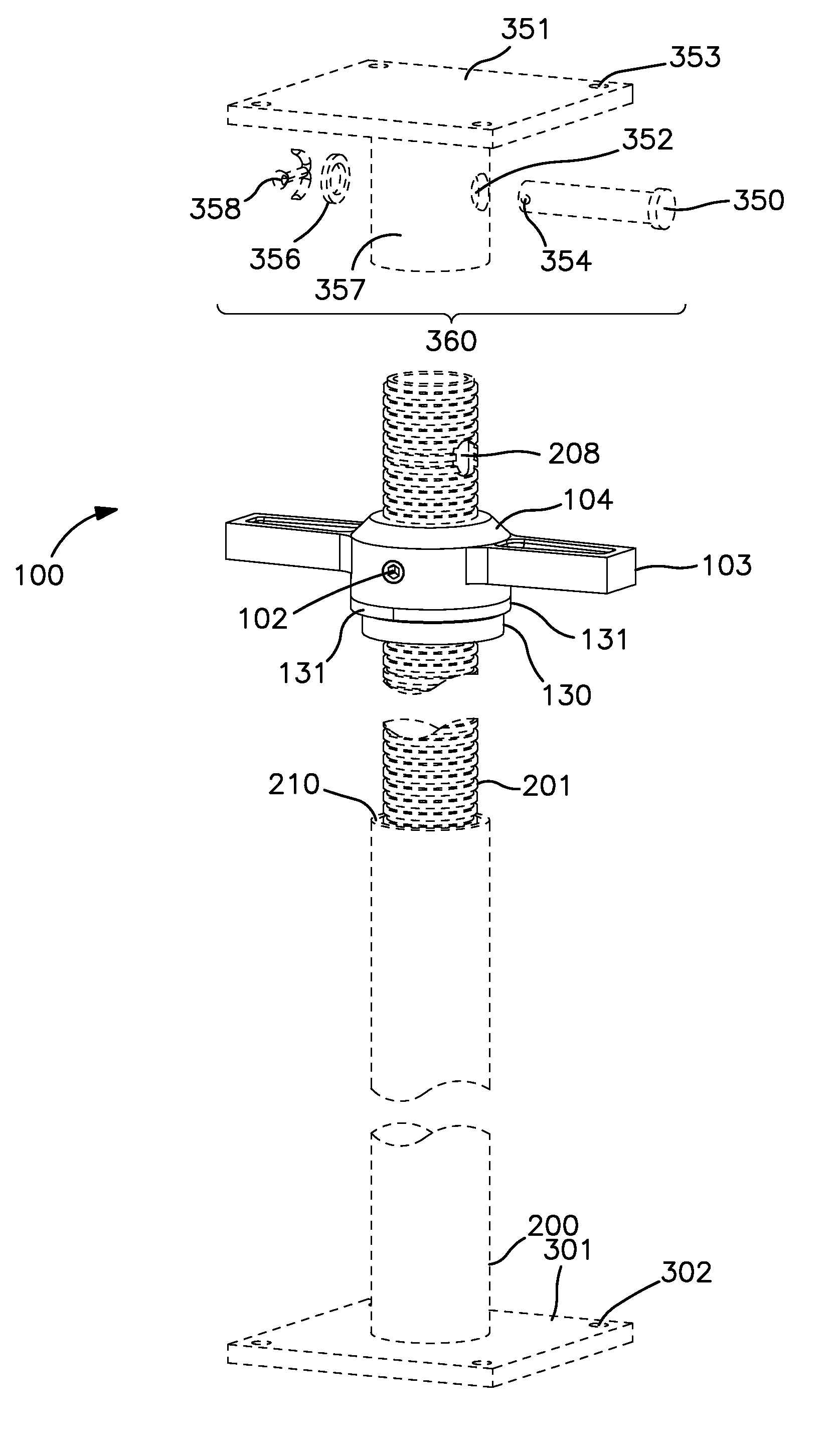

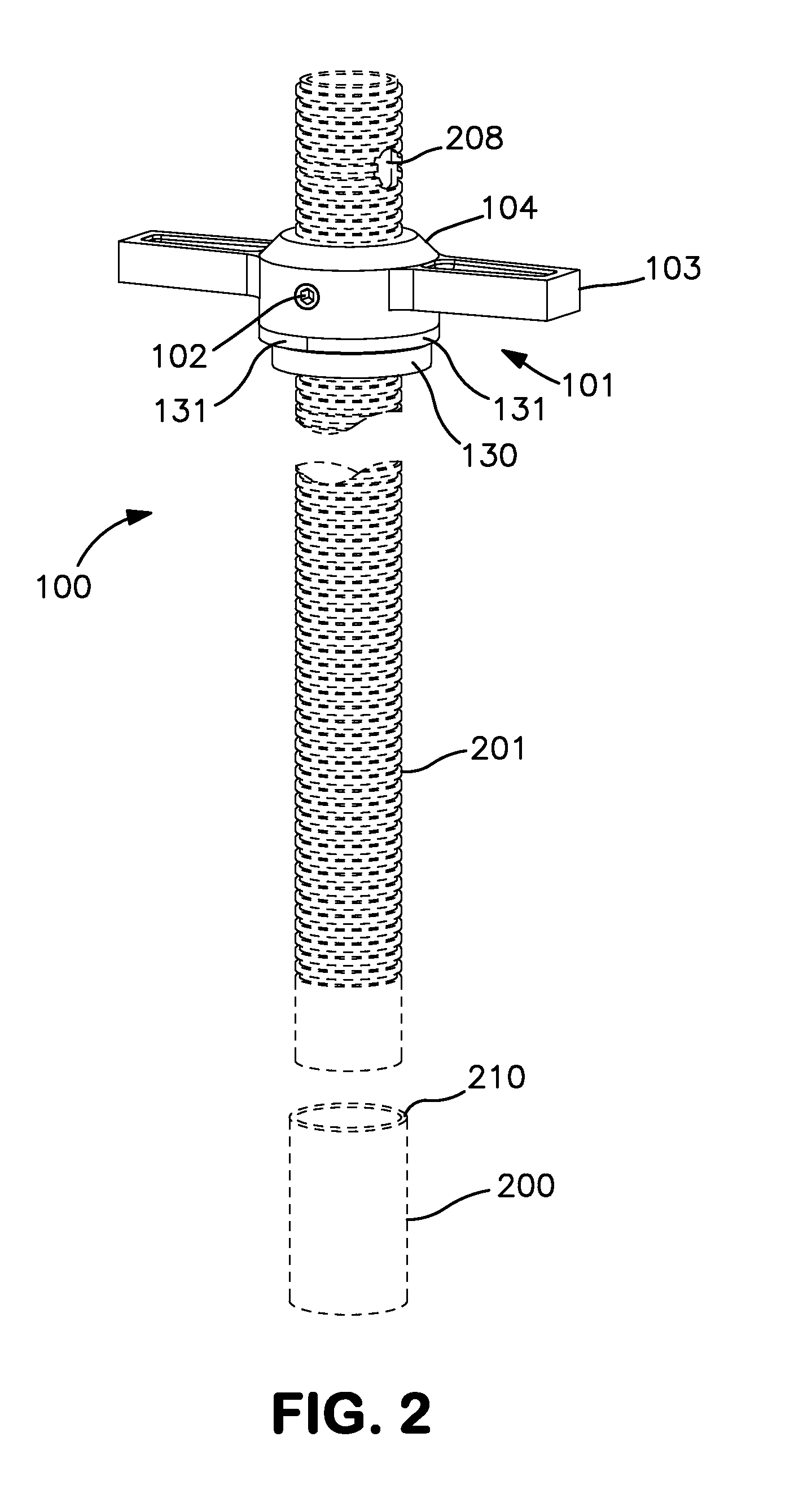

Shoring apparatus with roller bearing

ActiveUS9027898B1Easy to useImprove securityStands/trestlesKitchen equipmentNeedle roller bearingEngineering

The present general inventive concept teaches a shoring apparatus with roller bearing to facilitate ease of use and inhibit undue wear on the apparatus. The apparatus is expandable and retractable and is releasably secured via a tightening assembly. In some embodiments, the tightening assembly includes a nut, at least one flat washer, a roller bearing, at least two split rings, and a rotator. The tightening assembly—featuring the roller bearing—serves to decrease friction, increase safety, and enhance both ease of positioning and ease of stabilization with respect to the shoring apparatus.

Owner:HOLMBOE BRENT

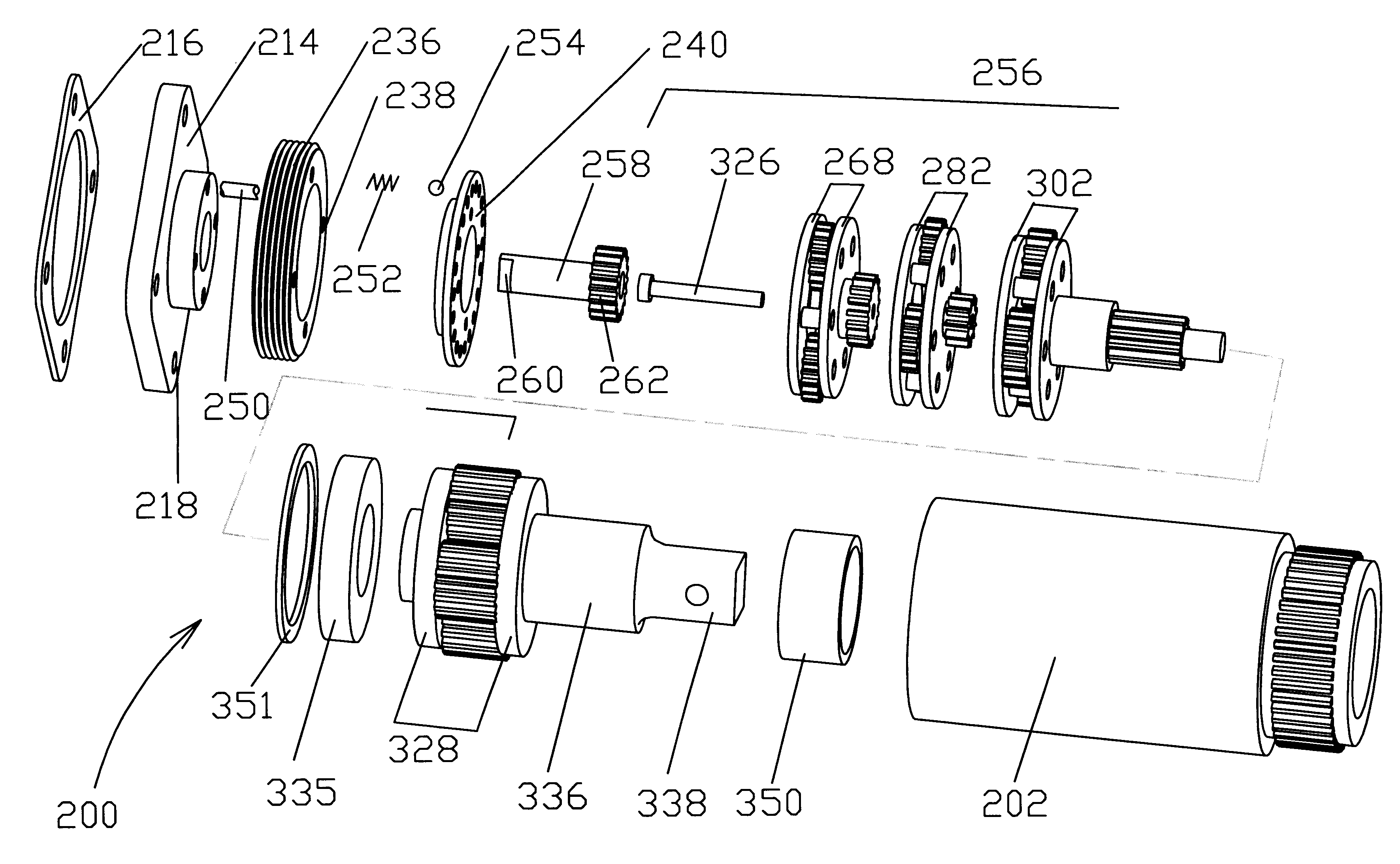

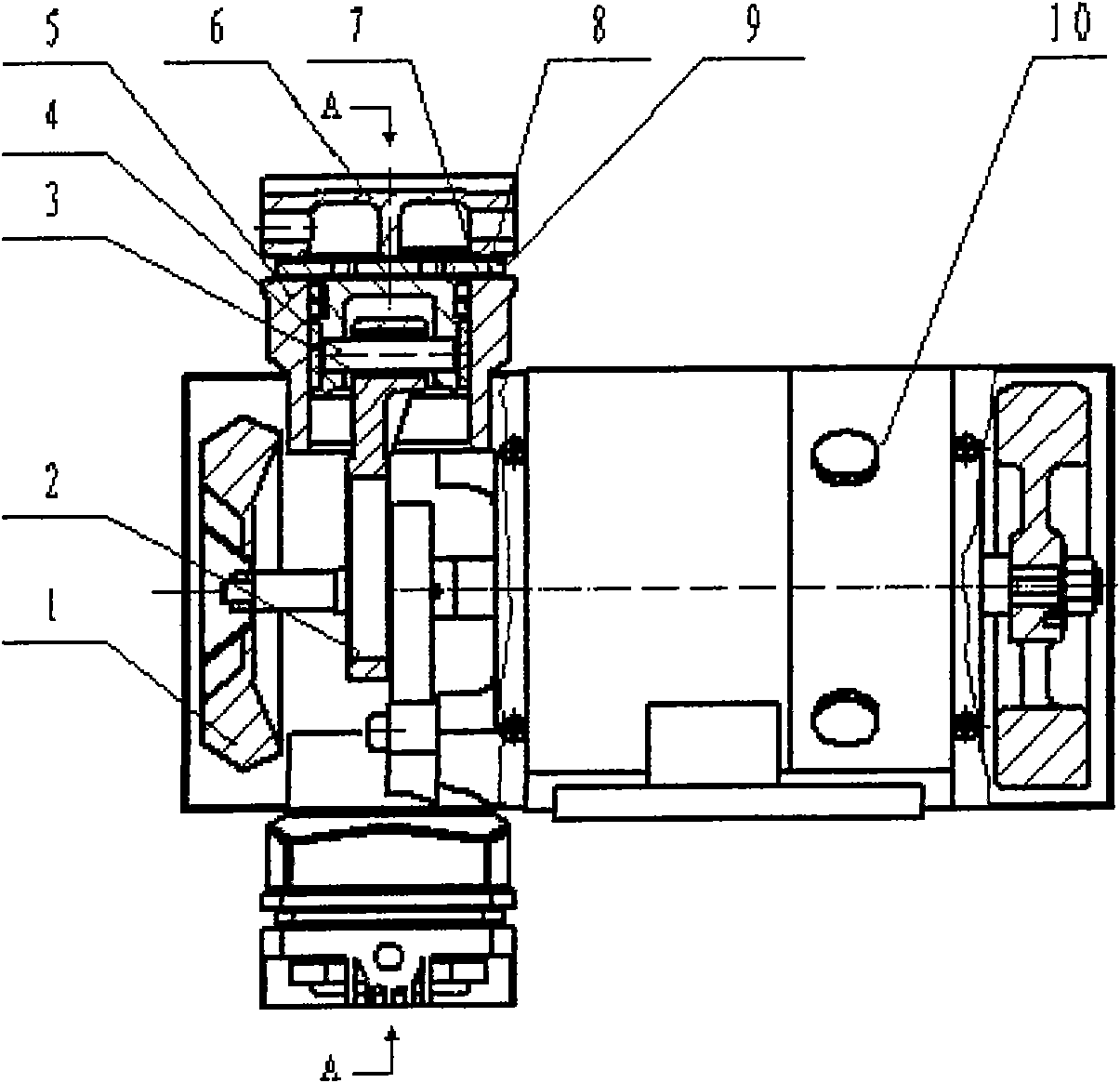

Robot smart arm joint drive and reduction device thereof

InactiveCN101209556AEasy to controlSimple structureJointsToothed gearingsNeedle roller bearingBall bearing

The invention provides a robot smart arm joint driver and a decelerating device thereof, consisting of a flange, a motor fixed frame, an end cover, a deep ditch ball bearing, a permanent magnetic DC moment motor, a hexagon thin nut, a spring washer, a sleeve 1, a bearing retaining cover, a second sleeve, a harmonic reducer, a through shaft, a rolling needle bearing, a thrust rolling needle bearing and a connecting flange. The permanent magnetic DC moment motor is fixed on the motor fixed frame; the rotor of the motor is connected with the connecting flange which is connected with the harmonic generator of the harmonic reducer; the steel wheel of the harmonic reducer is fixed on the motor fixed frame by a screw; the flexible wheel of the harmonic reducer is connected with the through shaft and the flange; the rolling needle bearing is arranged between the rotor of the motor and the harmonic generator and the through shaft; the deep ditch ball bearing is arranged between the flange and the motor fixed frame. The joint driver and the decelerating device have the advantages of compact structure, smart motion, simple control, good application effect and great implementation value.

Owner:ZHEJIANG UNIV OF TECH

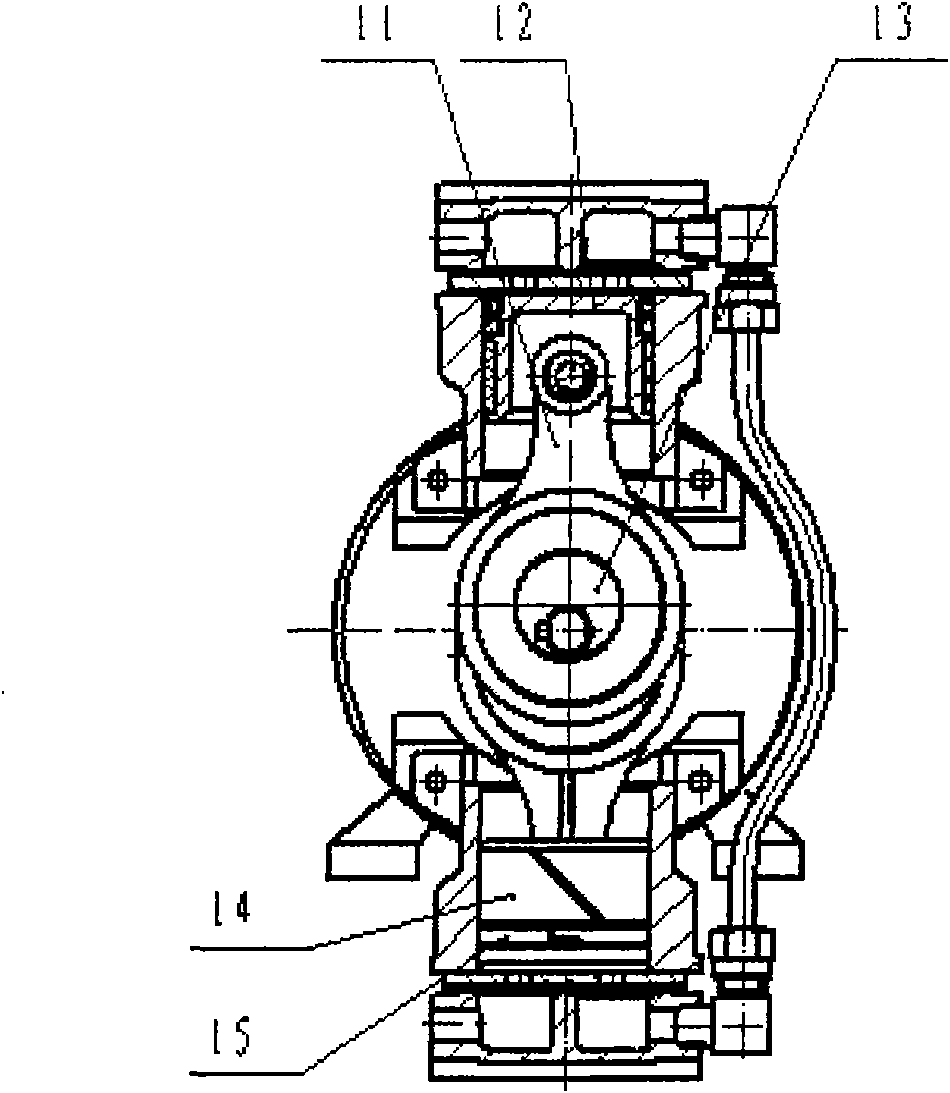

Rotor head pulling and twisting strip type propeller hub for helicopter blade dynamic balance test table

InactiveCN104344931AThe structure can be designed to be simple and compactReduce frictionStatic/dynamic balance measurementNeedle roller bearingDynamic balance

The invention relates to the technical field of helicopter test, in particular to a rotor head pulling and twisting strip type propeller hub for a helicopter blade dynamic balance test table. The propeller hub comprises a pin shaft (1), a needle bearing (2), a shaft pin (3), a variable-pitch hinge casing end cover (4), a pulling and twisting strip (5), a variable-pitch hinge shaft casing (6) and a variable-pitch hinge shaft neck (7), wherein the first end of the tubular element variable-pitch hinge shaft neck (7) is connected with a test table center element through a swinging hinge, the variable-pitch hinge shaft neck (7) is arranged inside the variable-pitch hinge shaft casing (6) through the needle bearing (2) in a sleeving way, one end of the pulling and twisting strip (5) is fixedly connected with the first end of the variable-pitch hinge shaft neck (7) through the shaft pin (1), and the other end of the pulling and twisting strip (5) is connected with the variable-pitch hinge shaft casing (6) and the variable-pitch hinge casing end cover (4) through the pin shaft (3). The structure can be designed to be simpler and more compact. The needle bearing (2) does not bear the centrifugal force, so the service life of the needle bearing can reach the limitless service life, and higher-precision blade hinge moment measurement can be realized.

Owner:HARBIN

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com