Oil-free compressor used in locomotive

A technology for compressors and locomotives, applied in the field of air compressors, which can solve the problems of being unable to meet the operating conditions of locomotive compressors, achieve the effects of increasing the force-bearing area, simplifying operation and maintenance, and improving the force-bearing state

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

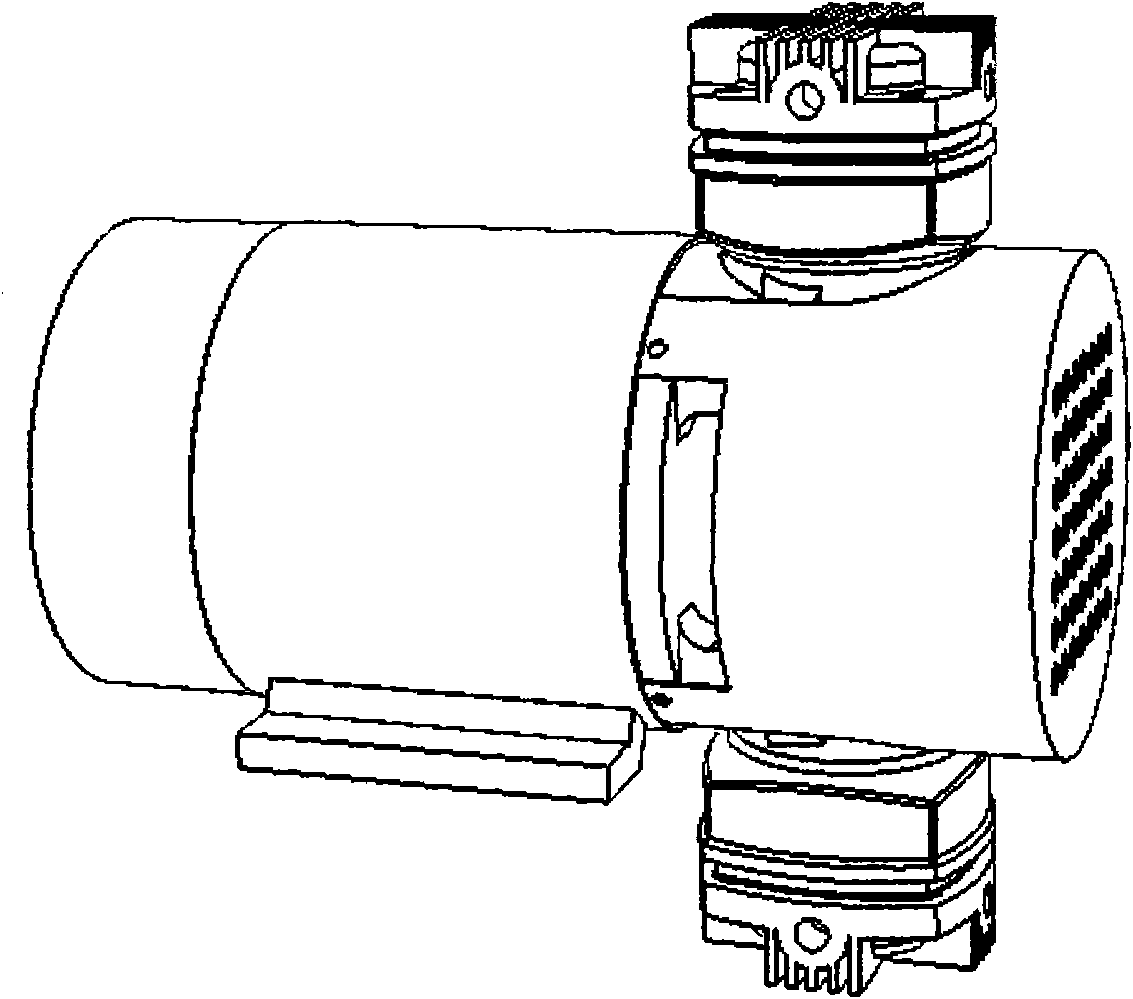

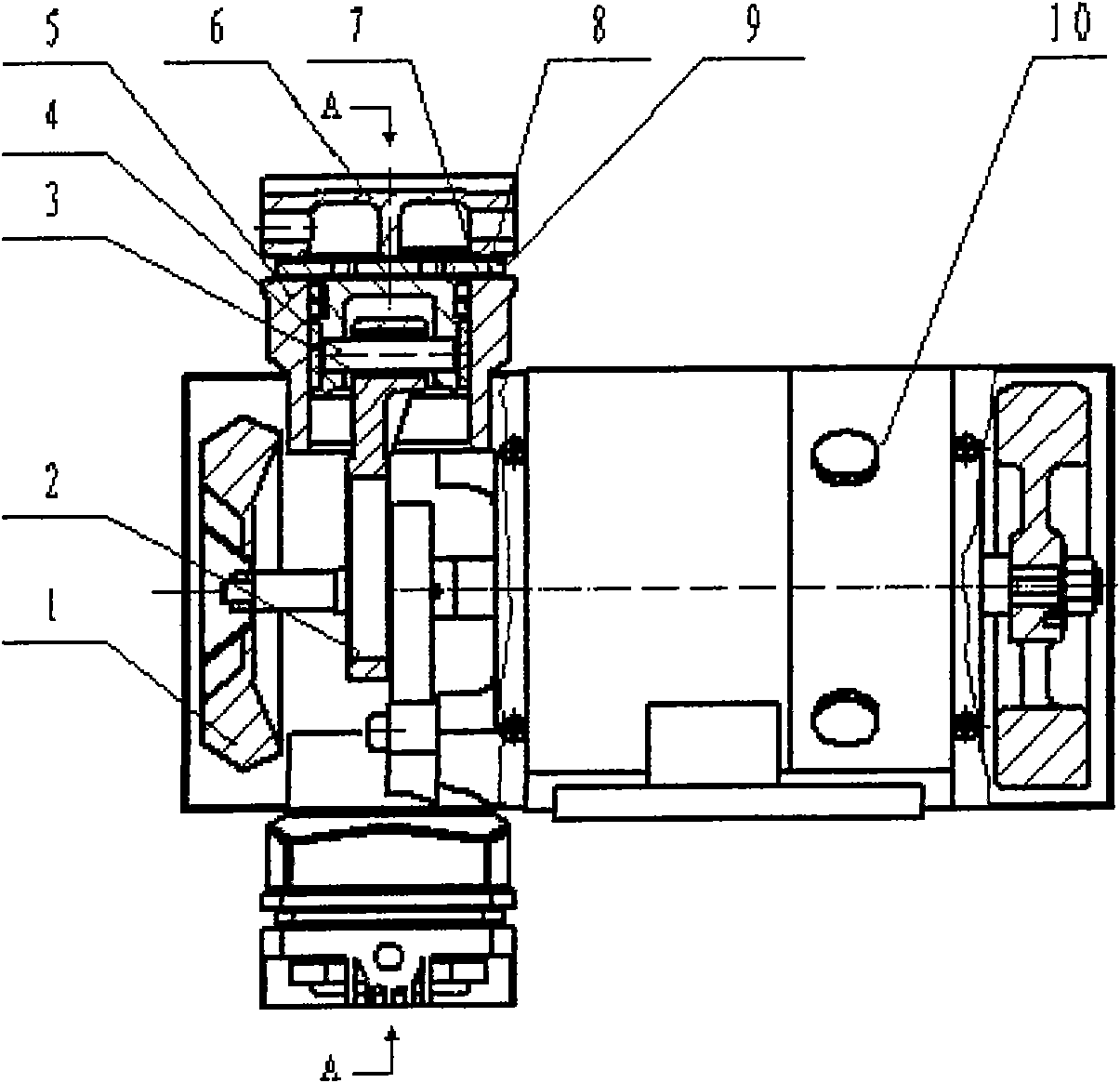

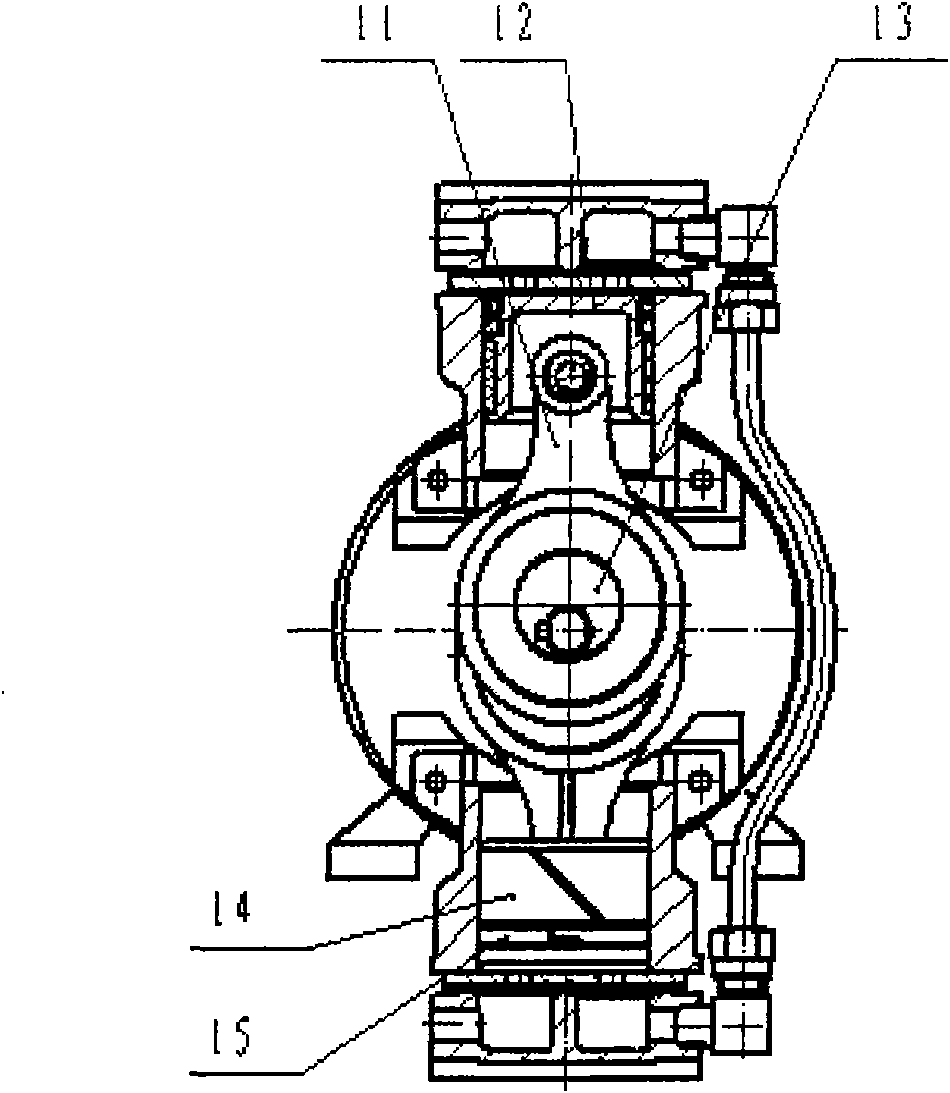

[0022] see figure 1 , 2 , 3, 4, oil-free compressor for locomotives, including components such as motor 10, cylinder 5, piston connecting rod assembly, air valve assembly, fan 1, wherein said piston connecting rod assembly consists of piston 12, piston ring 15, piston pin 4. It is composed of connecting rod 11 and other components. The small head of the connecting rod is connected to the piston 12 through the piston pin 4; two eccentric blocks 13 are set on the motor shaft, and the eccentric block 13 and the motor shaft pass through a centripetal valve with a sealing structure. The ball bearing 2 is connected with the large end of the connecting rod; the small end of the connecting rod is connected with the piston pin 4 through two inner ring-less needle bearings 3 with a single-side sealing structure assembled back to back. The motor 10 is a DC motor, and an AC motor can also be used. One end of the double extension shaft motor drives the flywheel, and the other end drives t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com