Patents

Literature

3485 results about "Piston ring" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A piston ring is a split ring that fits into a groove on the outer diameter of a piston in a reciprocating engine such as an internal combustion engine or steam engine.

Piston ring

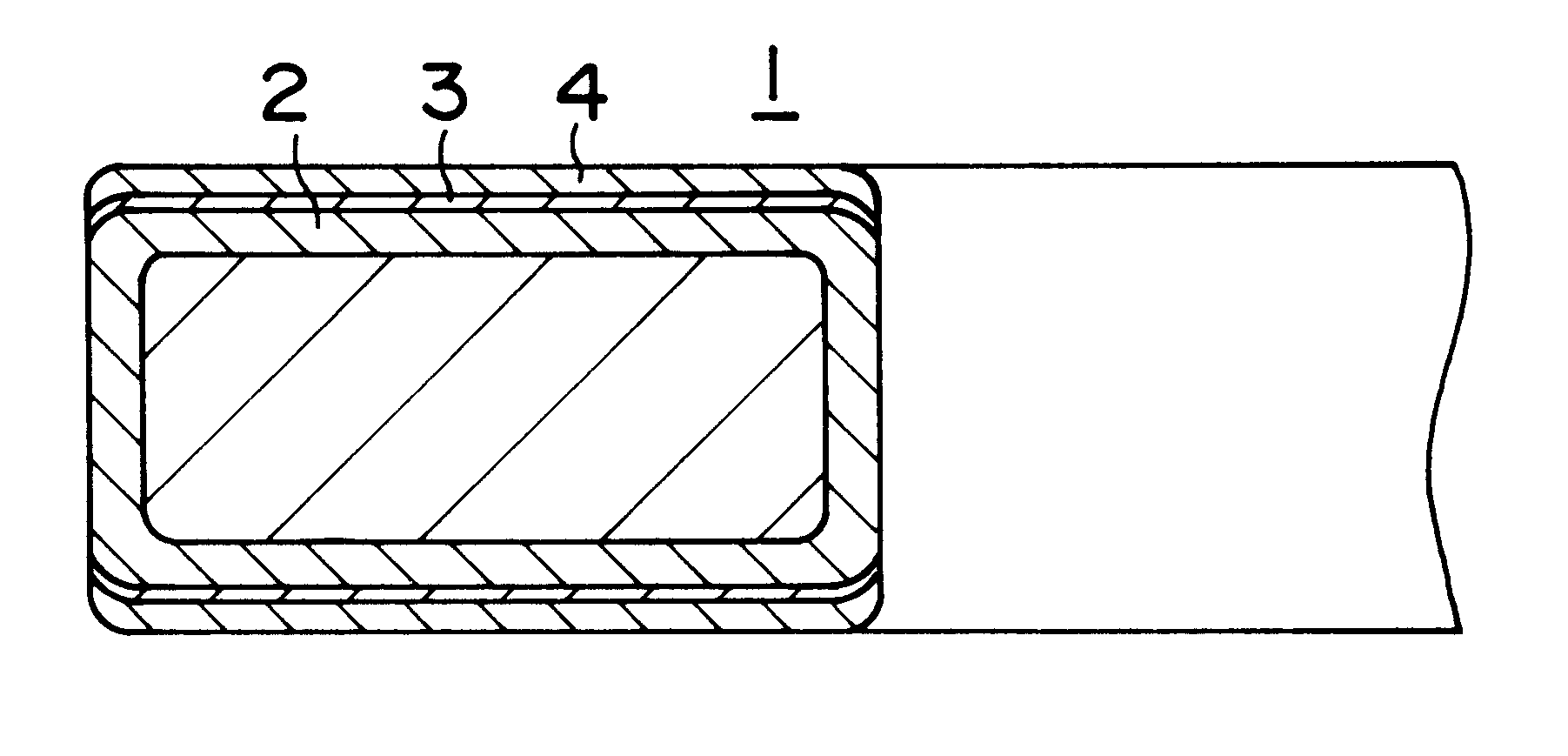

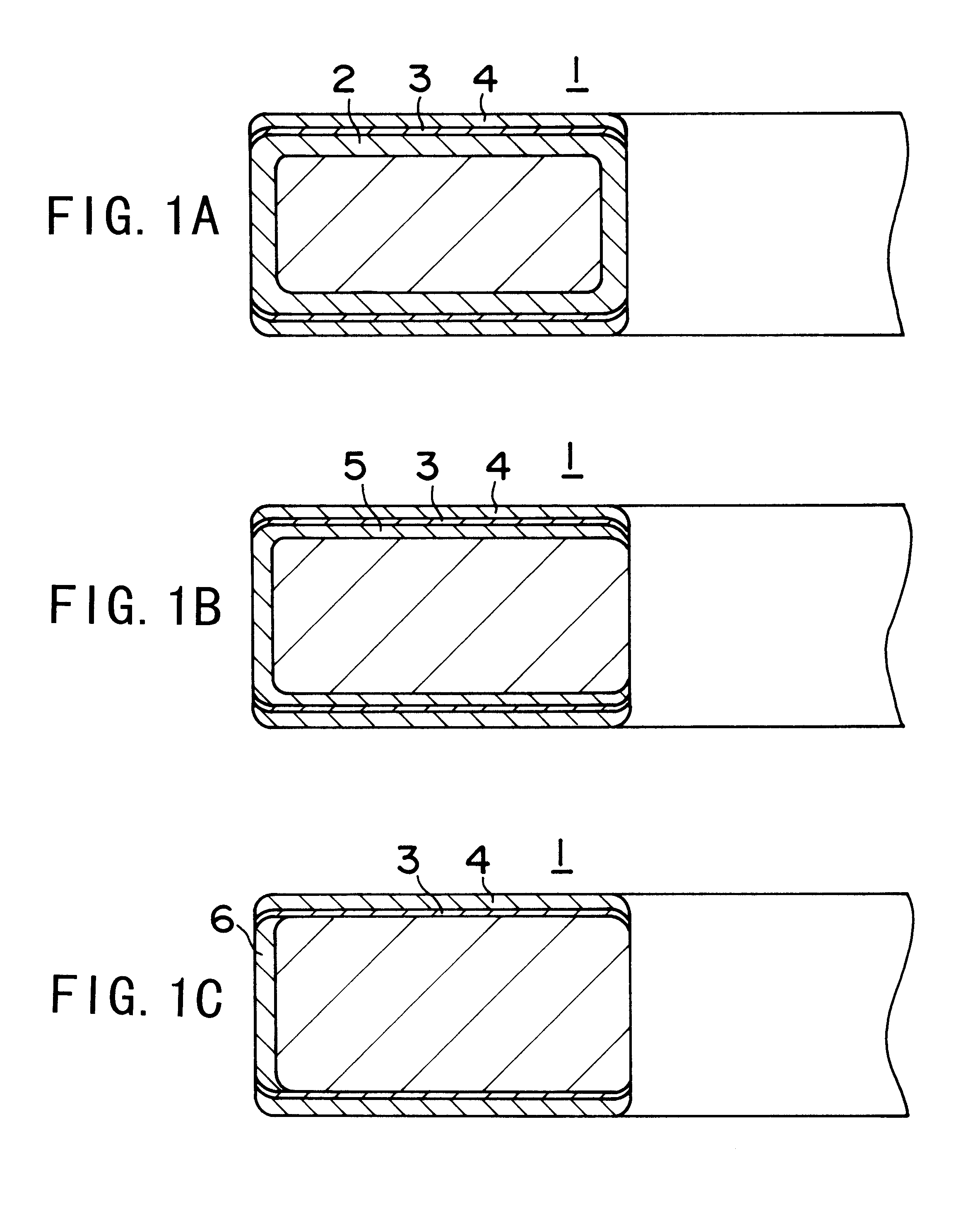

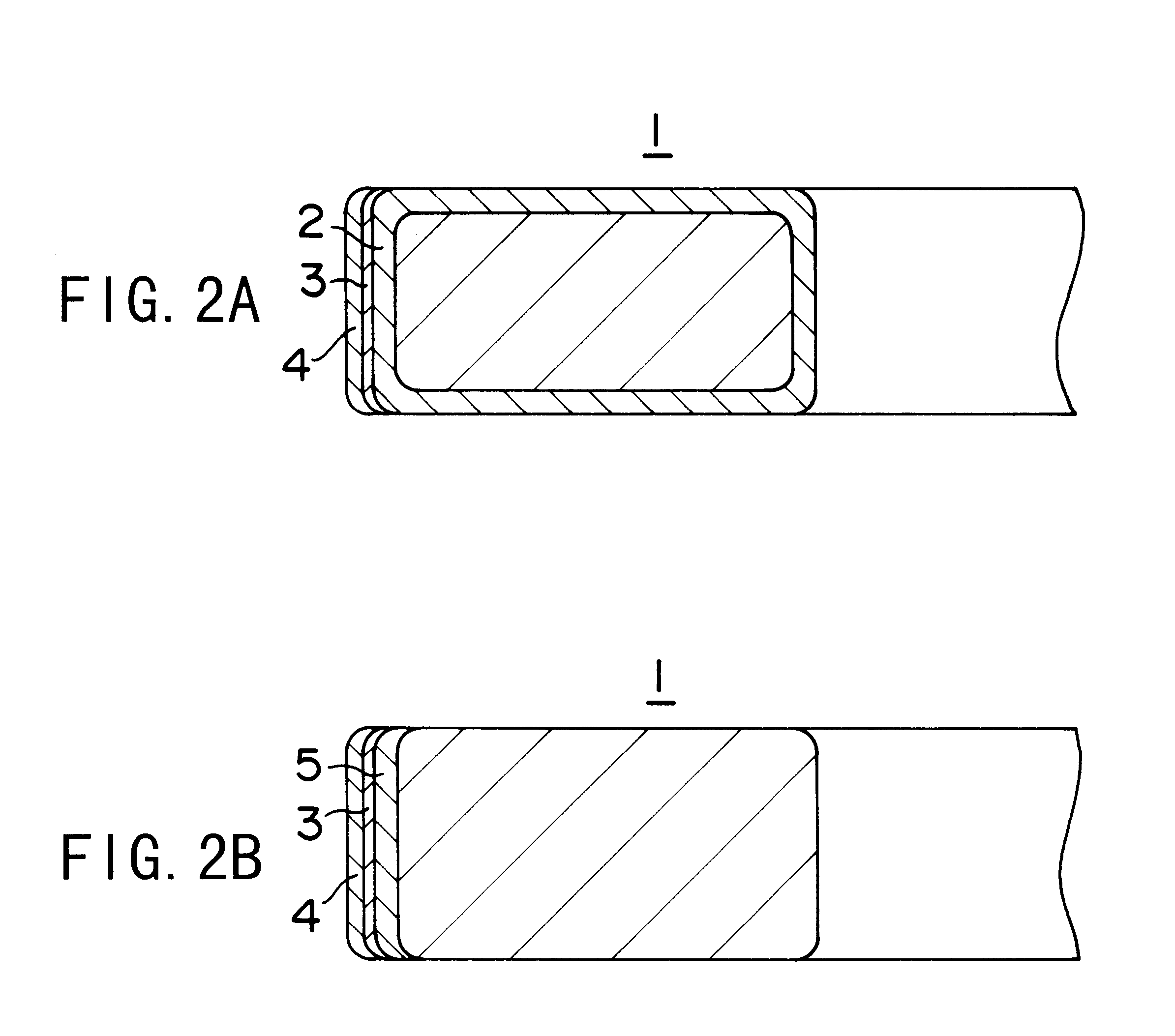

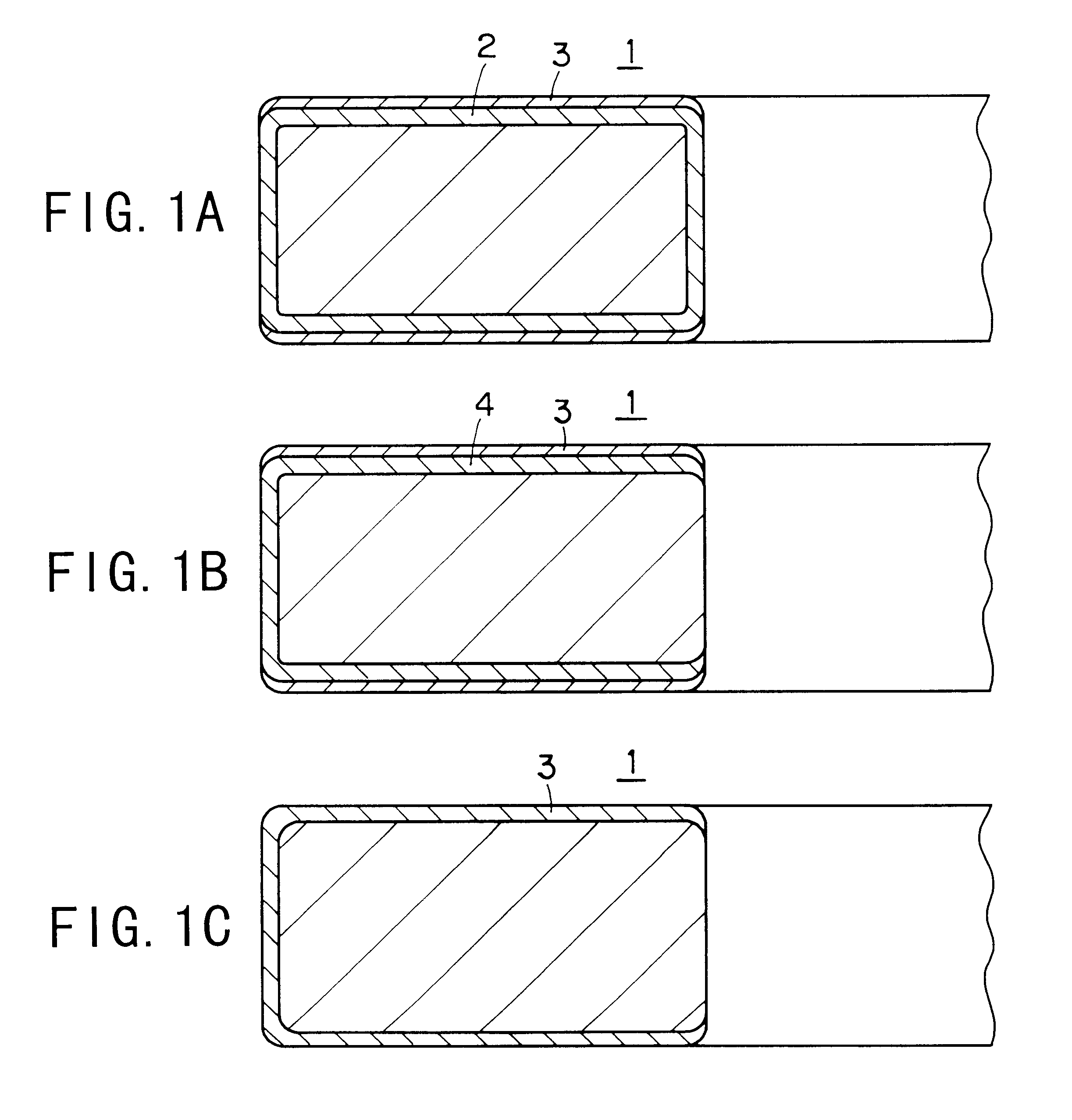

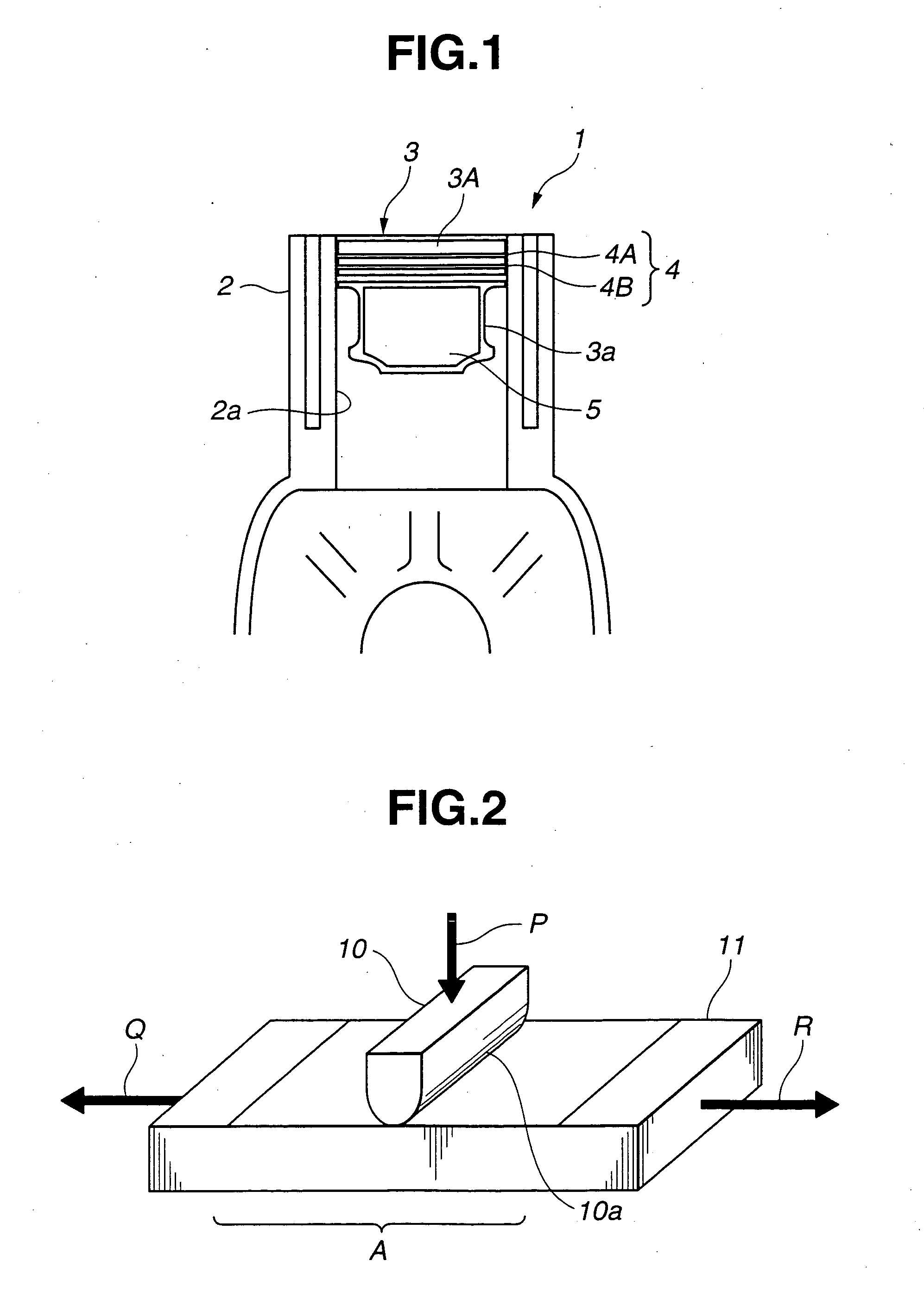

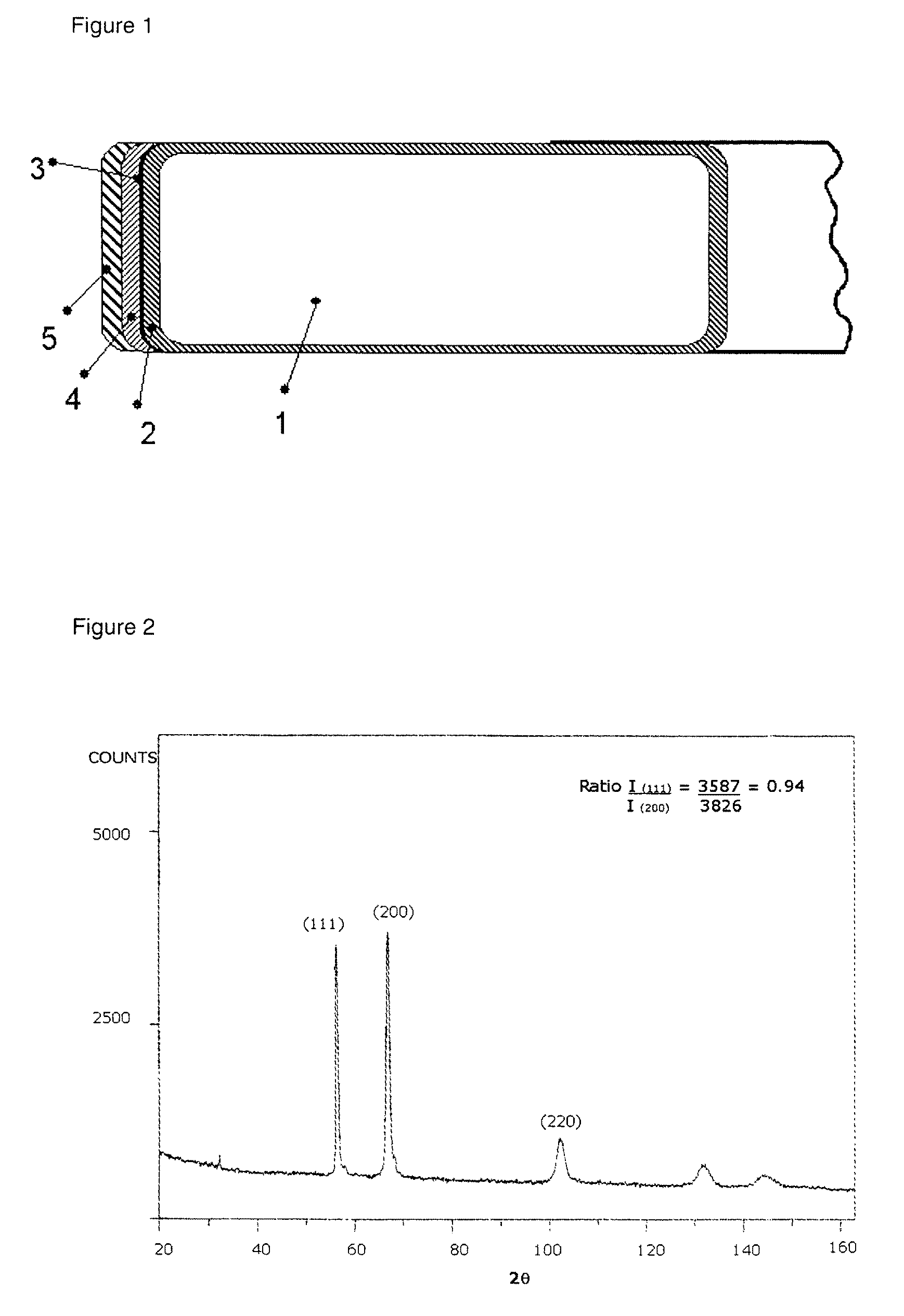

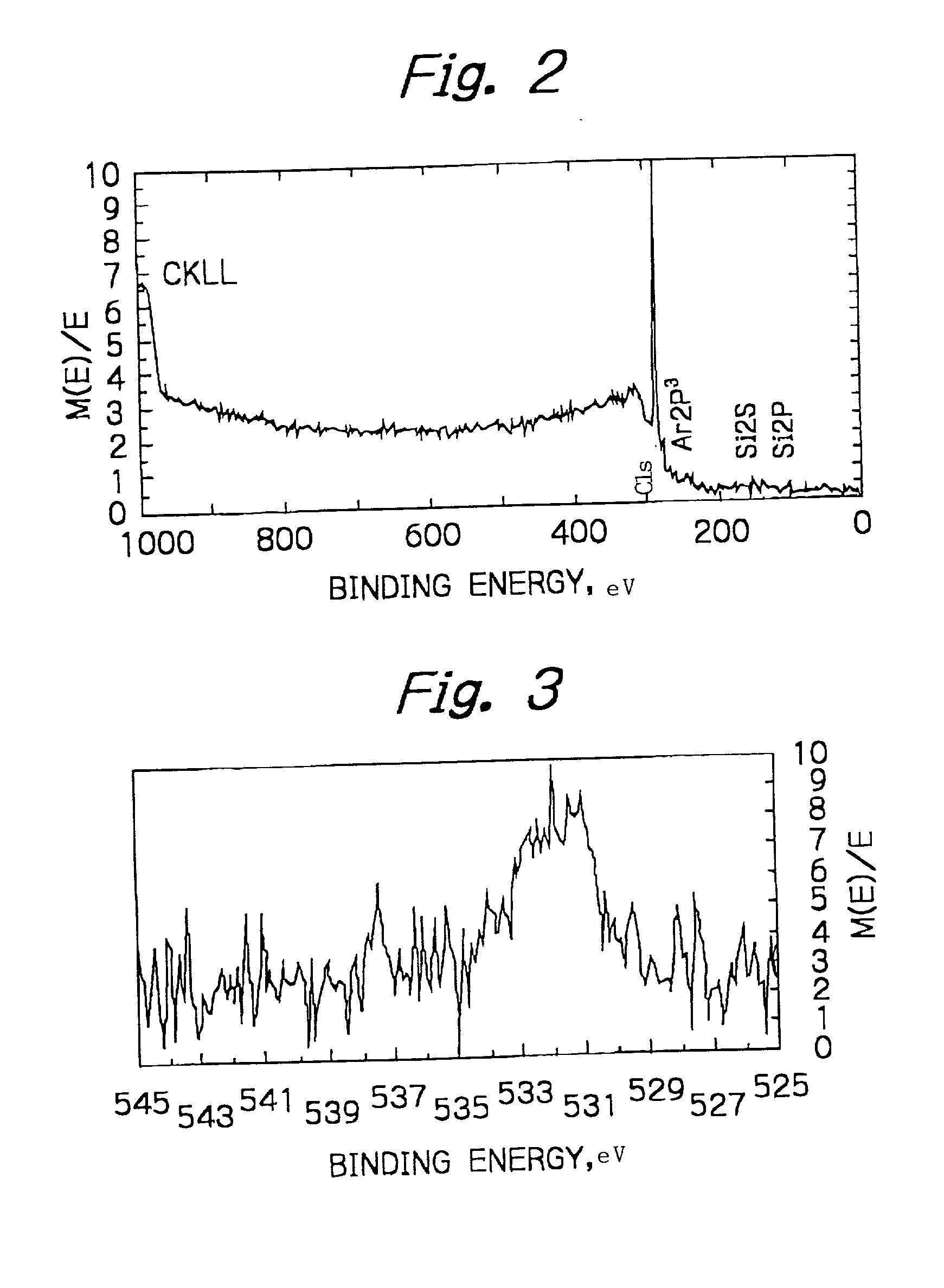

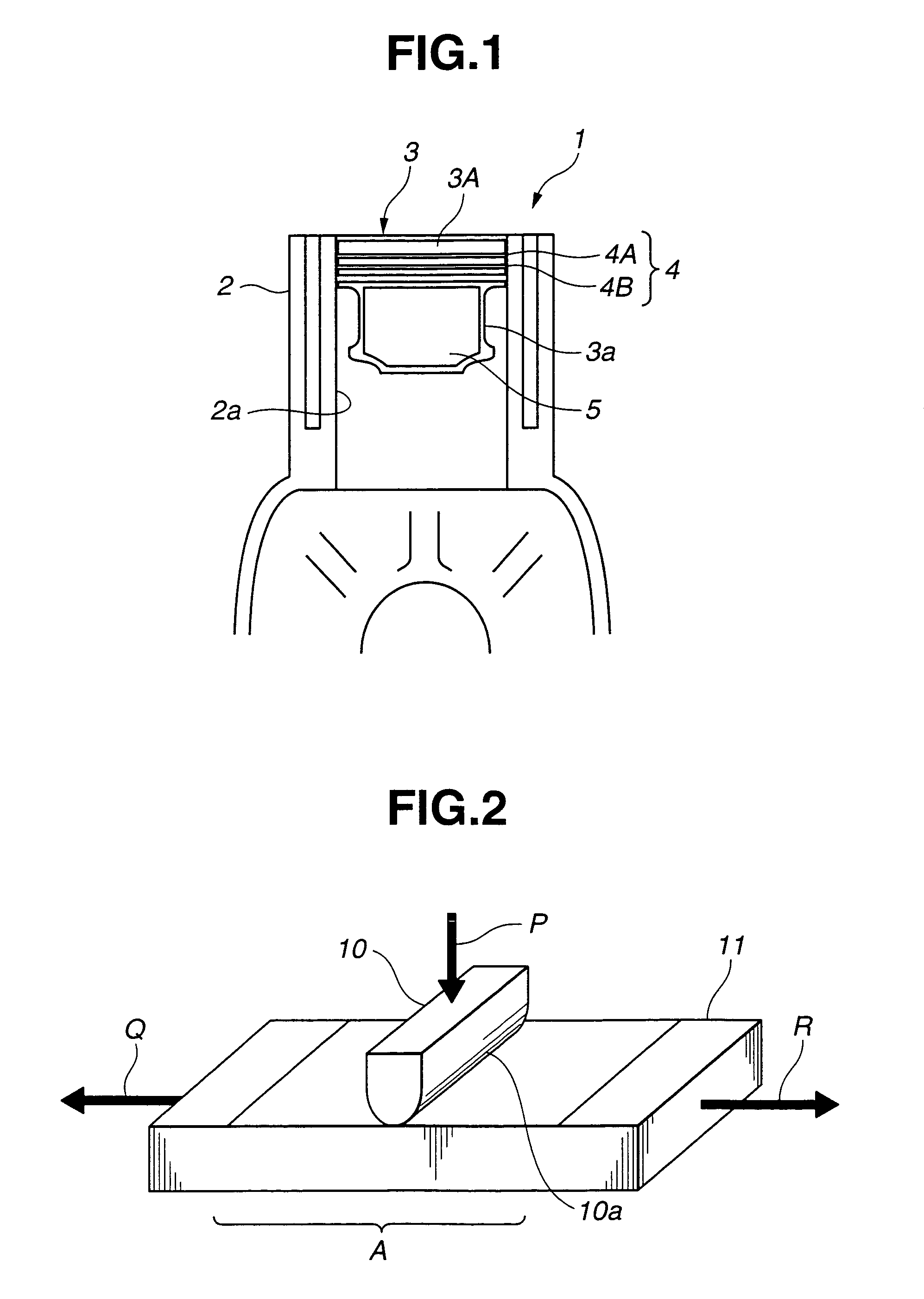

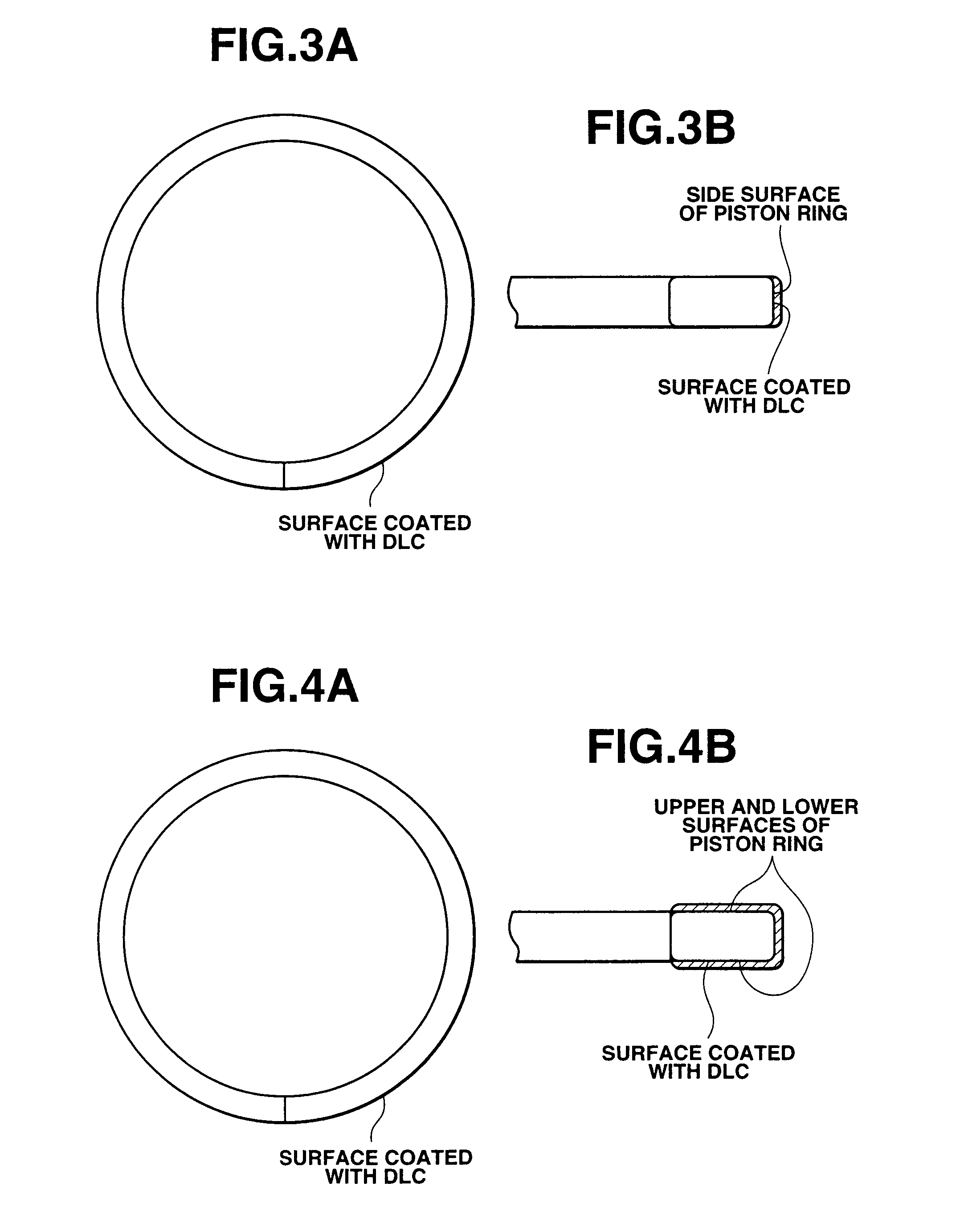

InactiveUS6325385B1Good sliding propertiesRelieve pressurePiston ringsBraking action transmissionCarbon filmDiamond-like carbon

Owner:TEIKOKU PISTON RING CO LTD

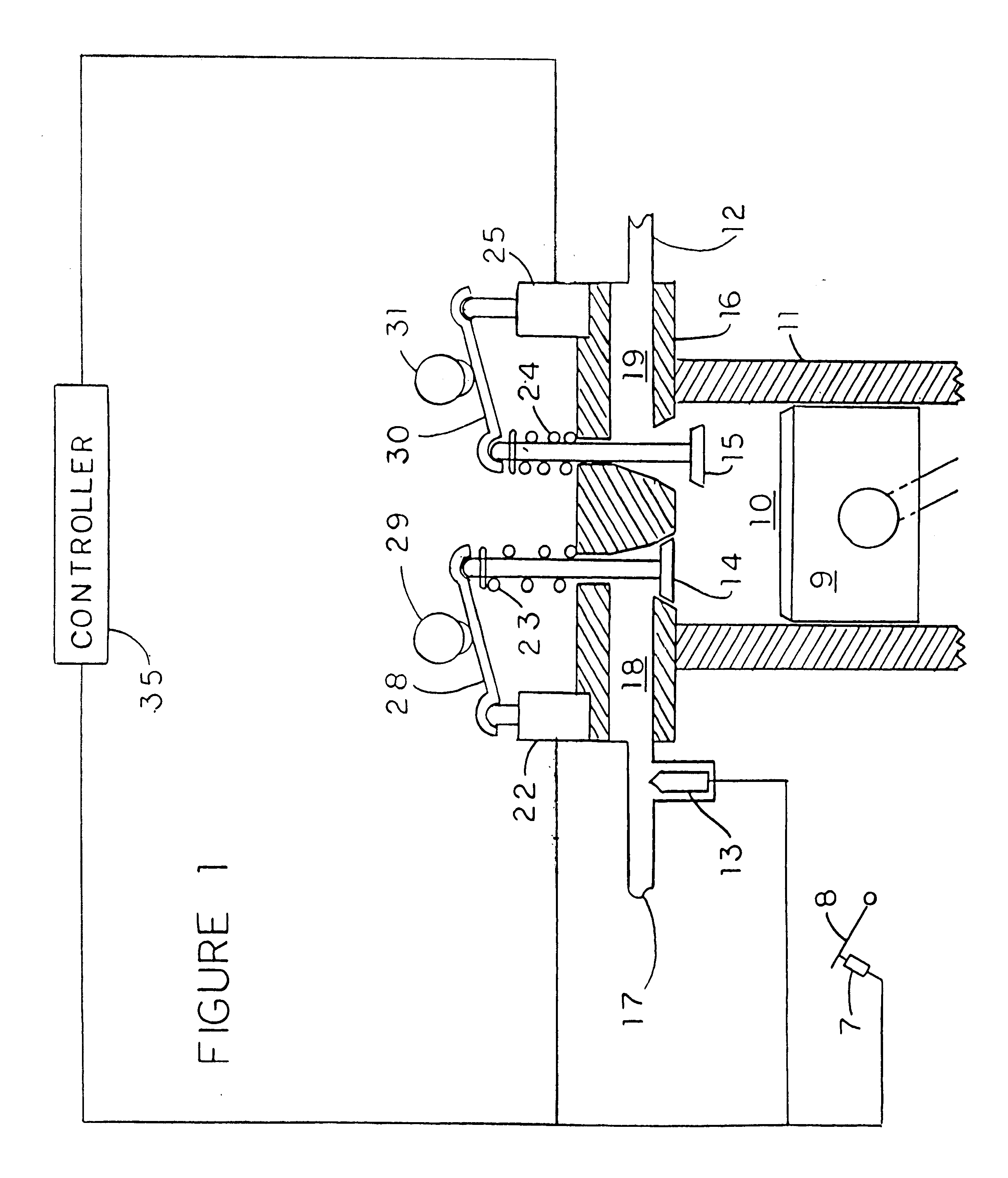

Engine valve disabler

A method for improving efficiency and reducing emissions of an internal combustion engine. Variable displacement engine capabilities are achieved by disabling engine valves during load changes and constant load operations. Active cylinders may be operated at minimum BSFC by intermittently disabling other cylinders to provide the desired net torque. Disabling is begun by early closing of the intake valve to provide a vacuum at BDC which will result in no net gas flow across the piston rings, and minimum loss of compression energy in the disabled cylinder; this saving in engine friction losses is significant with multiple disablements.

Owner:MOYER DAVID F

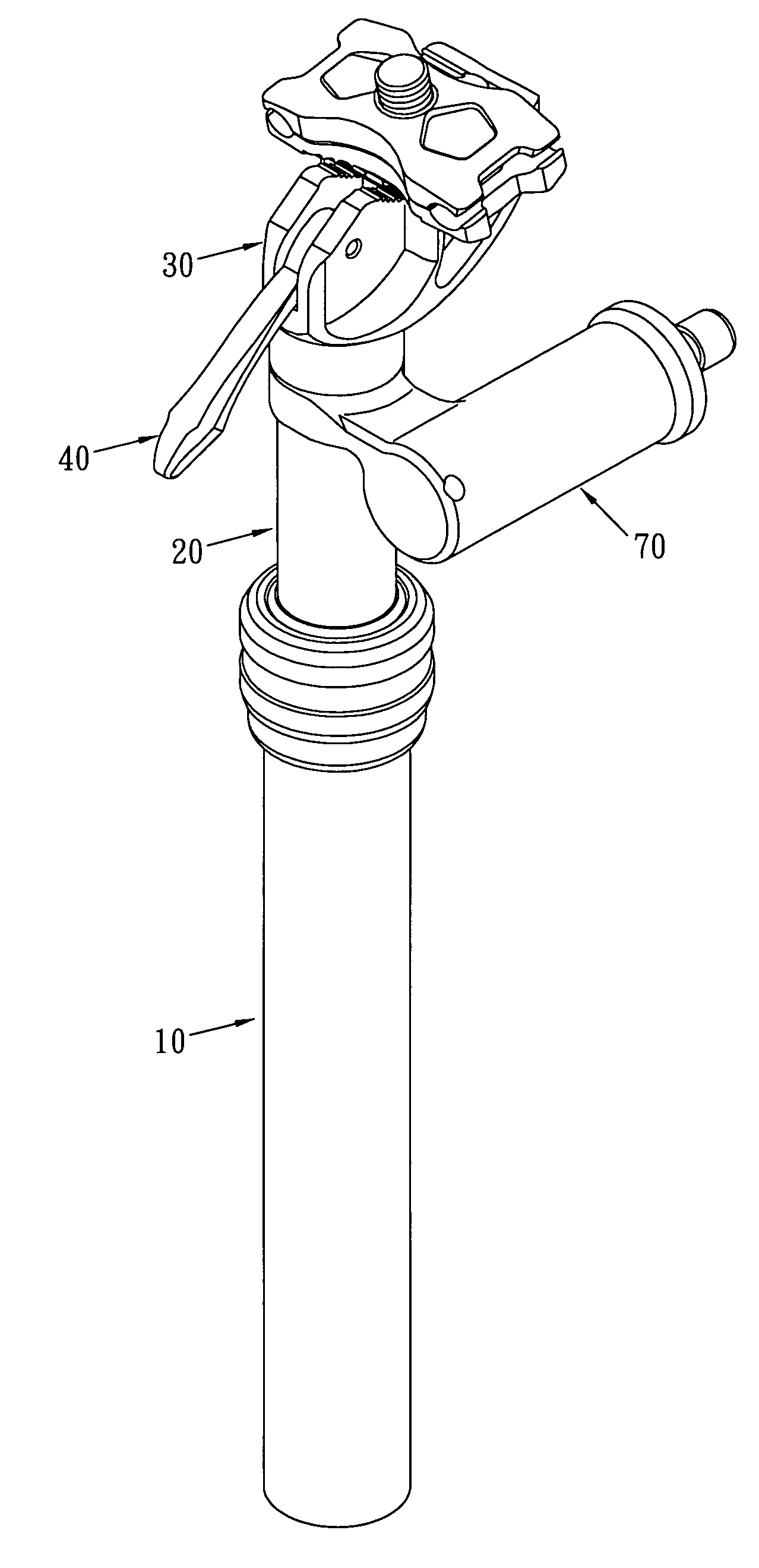

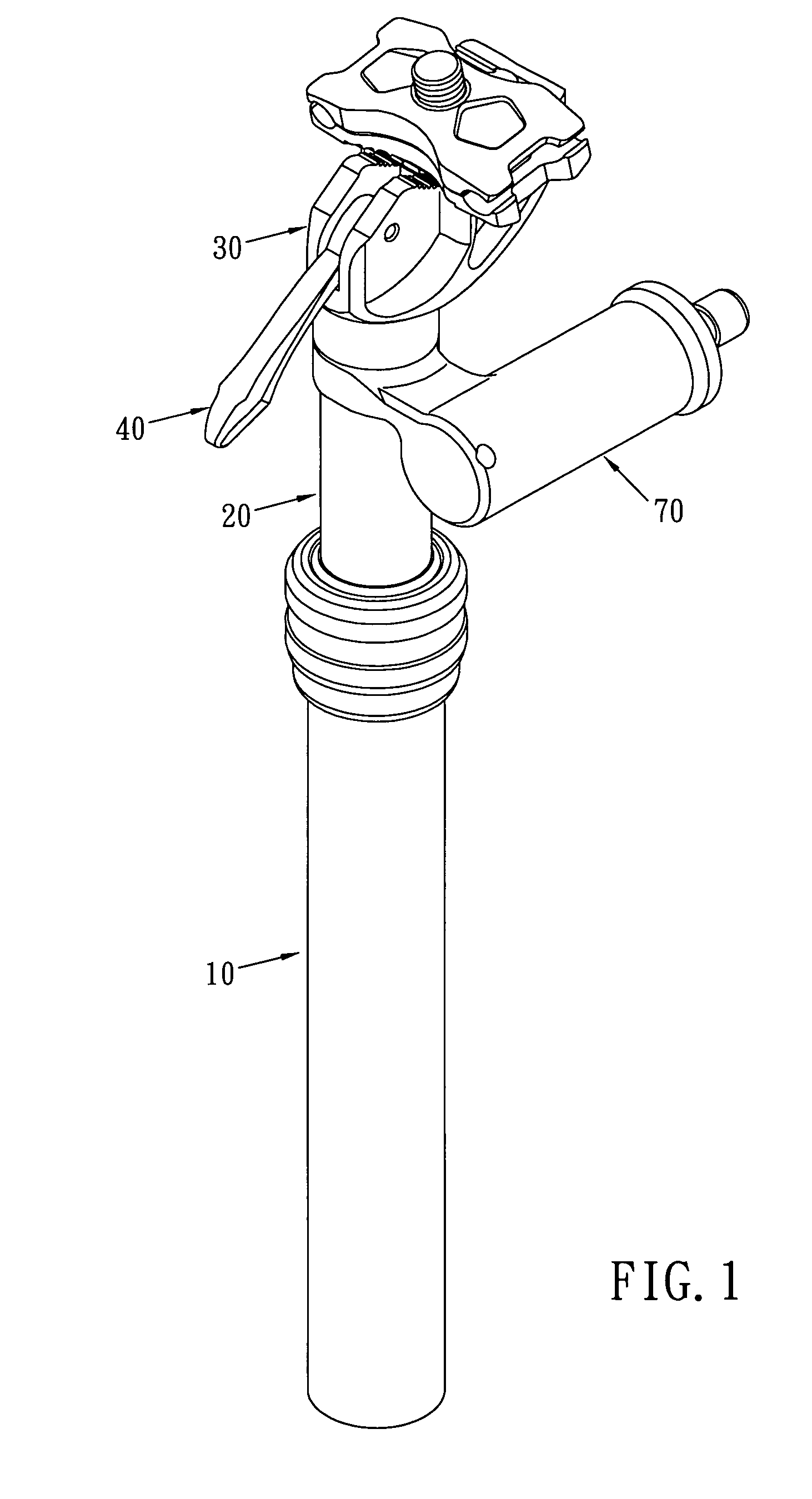

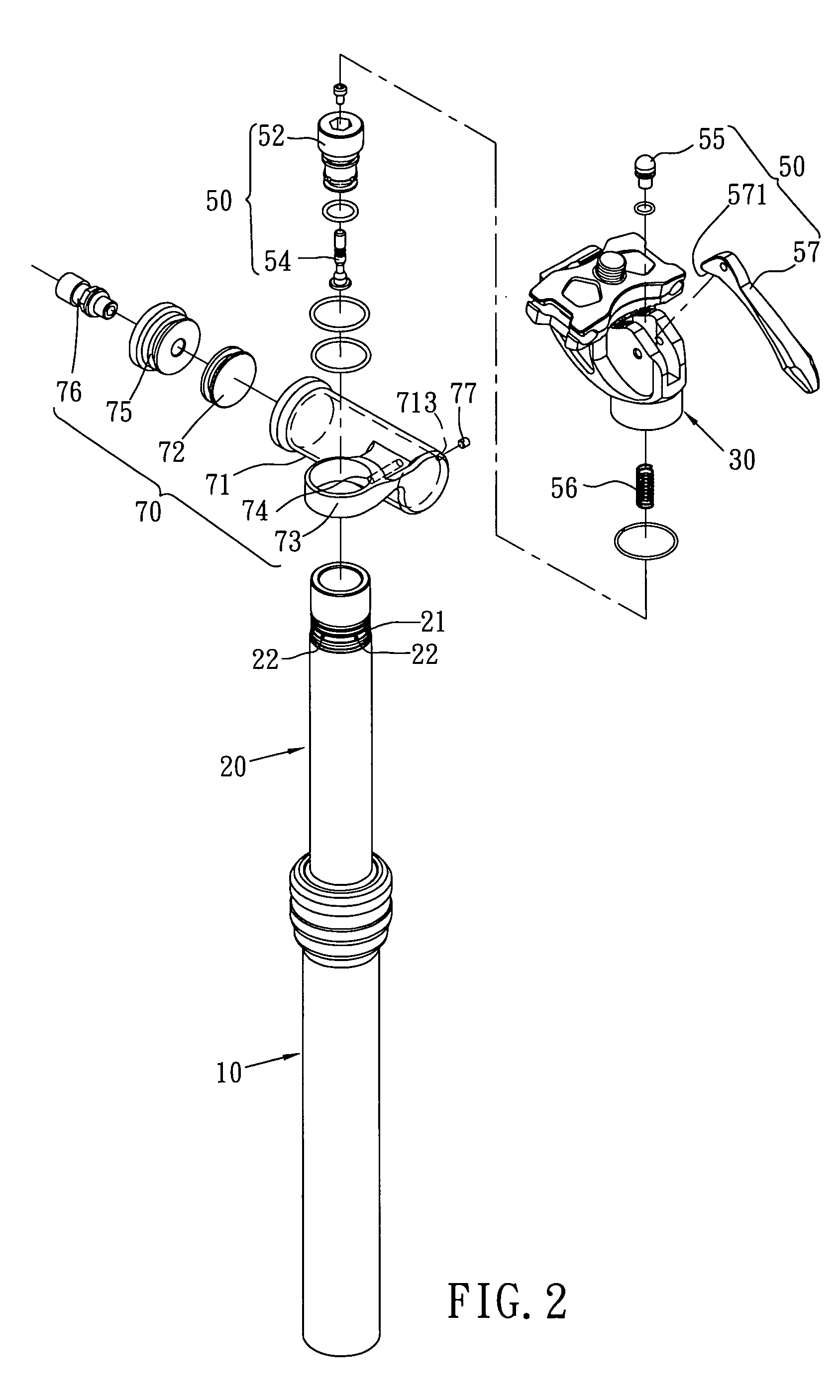

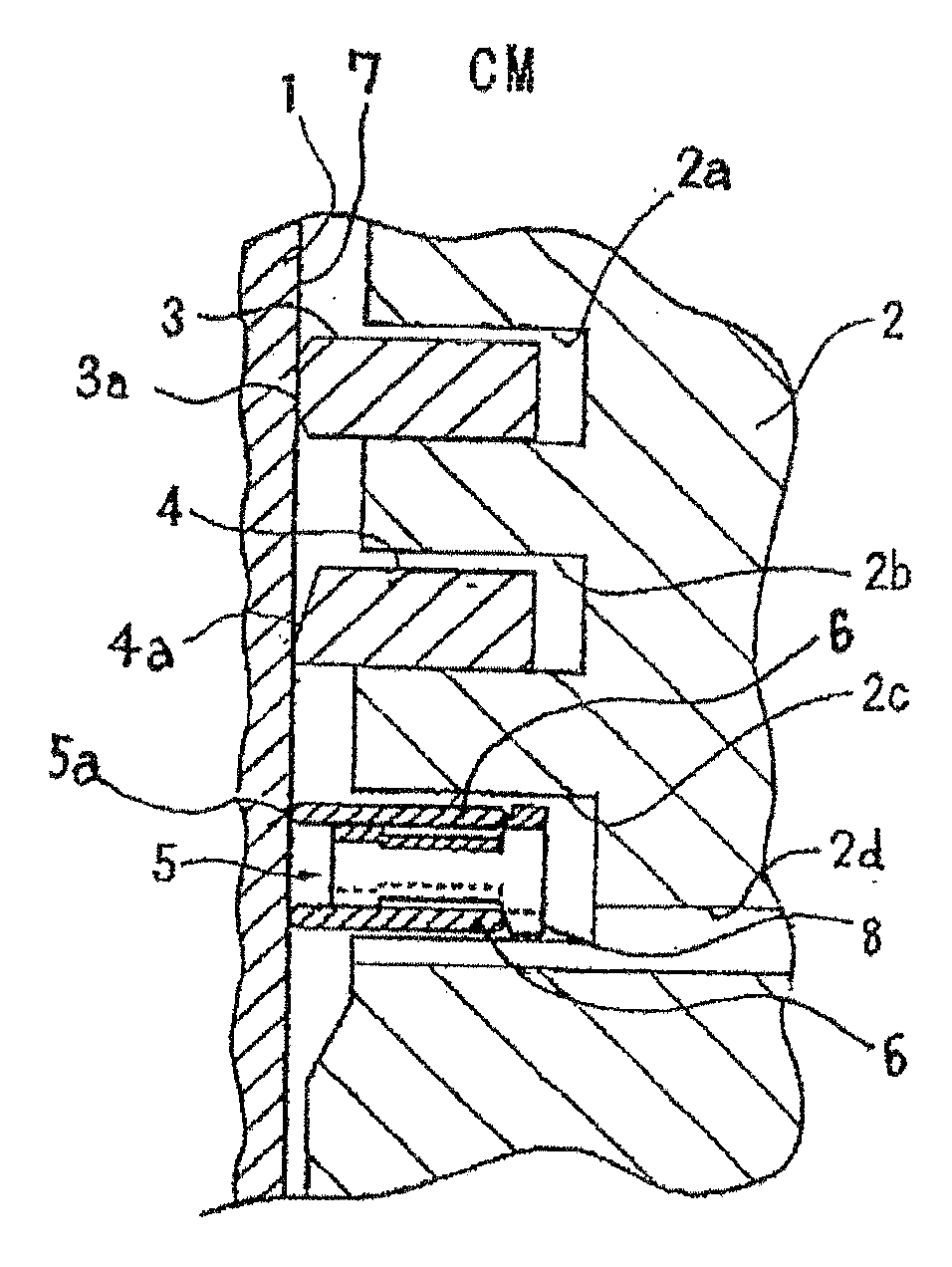

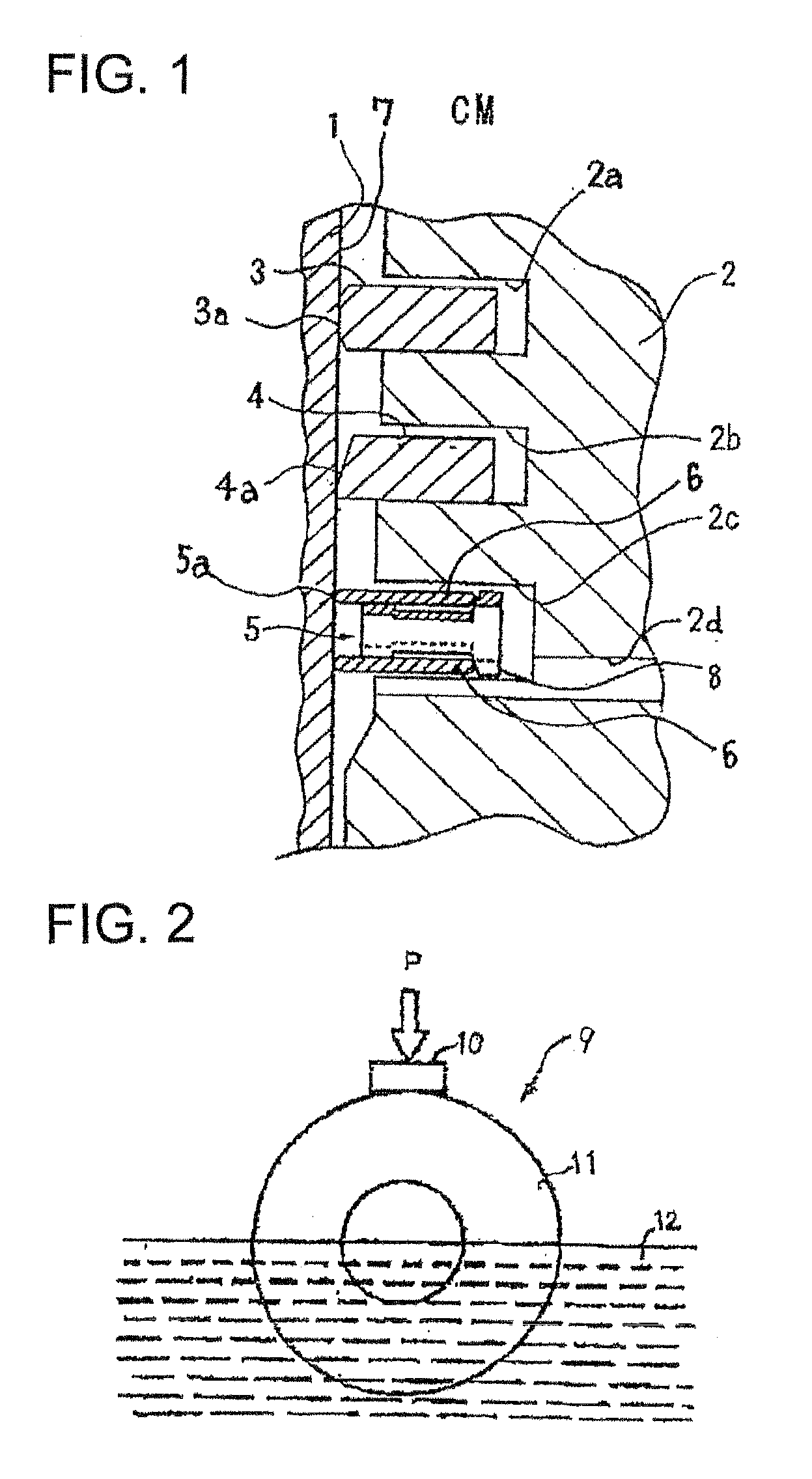

Adjustment device for bicycle seat

InactiveUS8191964B2Keep sizeLong travel distanceSeating furnitureCycle saddlesInterior spacePiston ring

An adjustment device for bicycle seat includes a connection portion located close to a top of the seat post and at least one through hole is defined through a wall of the connection portion. An adjustment device is located between the seat connector and the seat post so as to adjust the seat post relative to the seat tube. The adjustment device includes an adjustment path which can communicate with the at least one through hole or be sealed from the at least one through hole. A balance unit is connected to the connection portion and includes a cylinder and a piston ring is movably received in the cylinder to define an inner space of the cylinder into a liquid space and an air space. The cylinder includes a supply path which communicates with the liquid space and the at least one through hole.

Owner:HUMBOLDT STATE UNIVERSITY

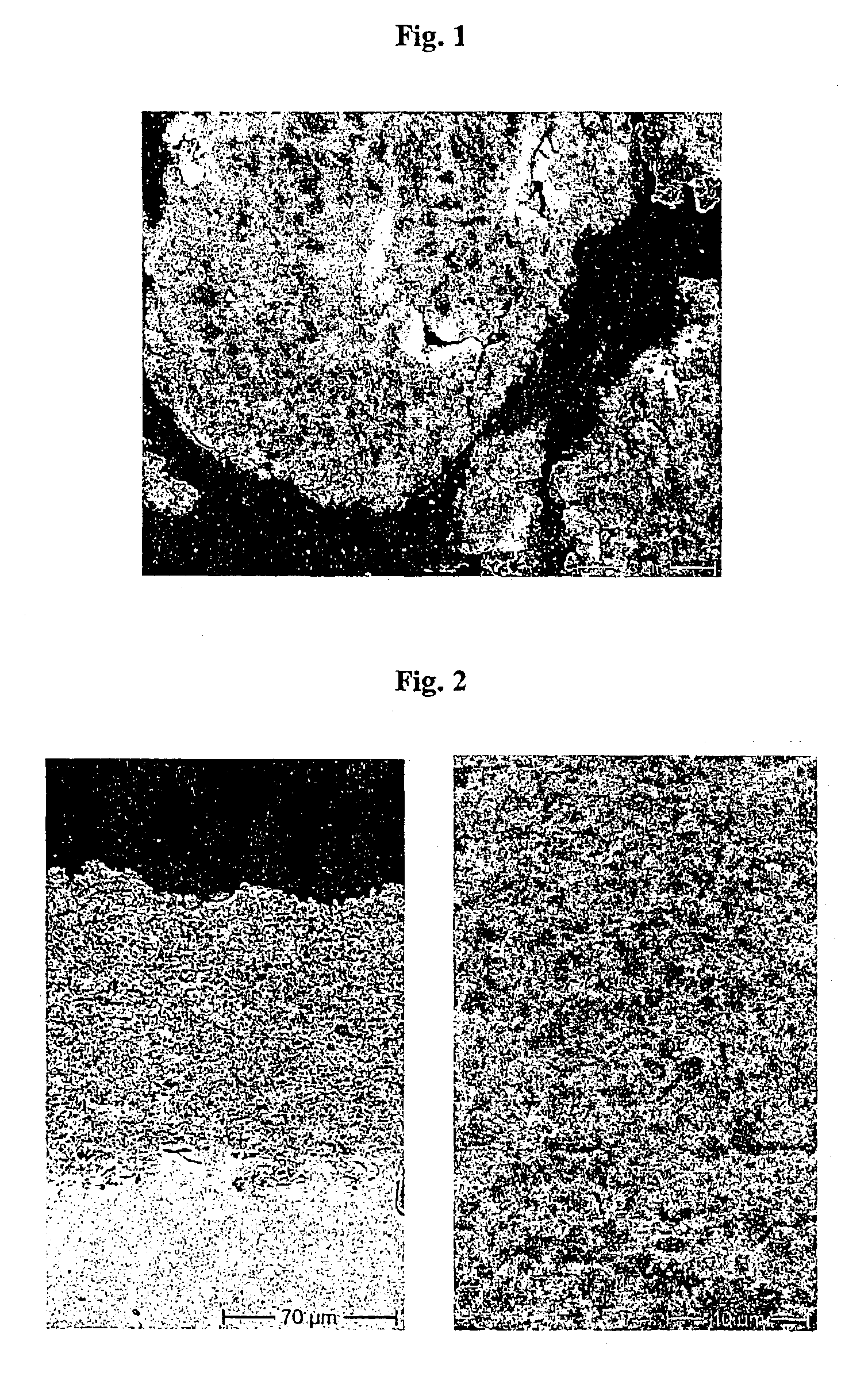

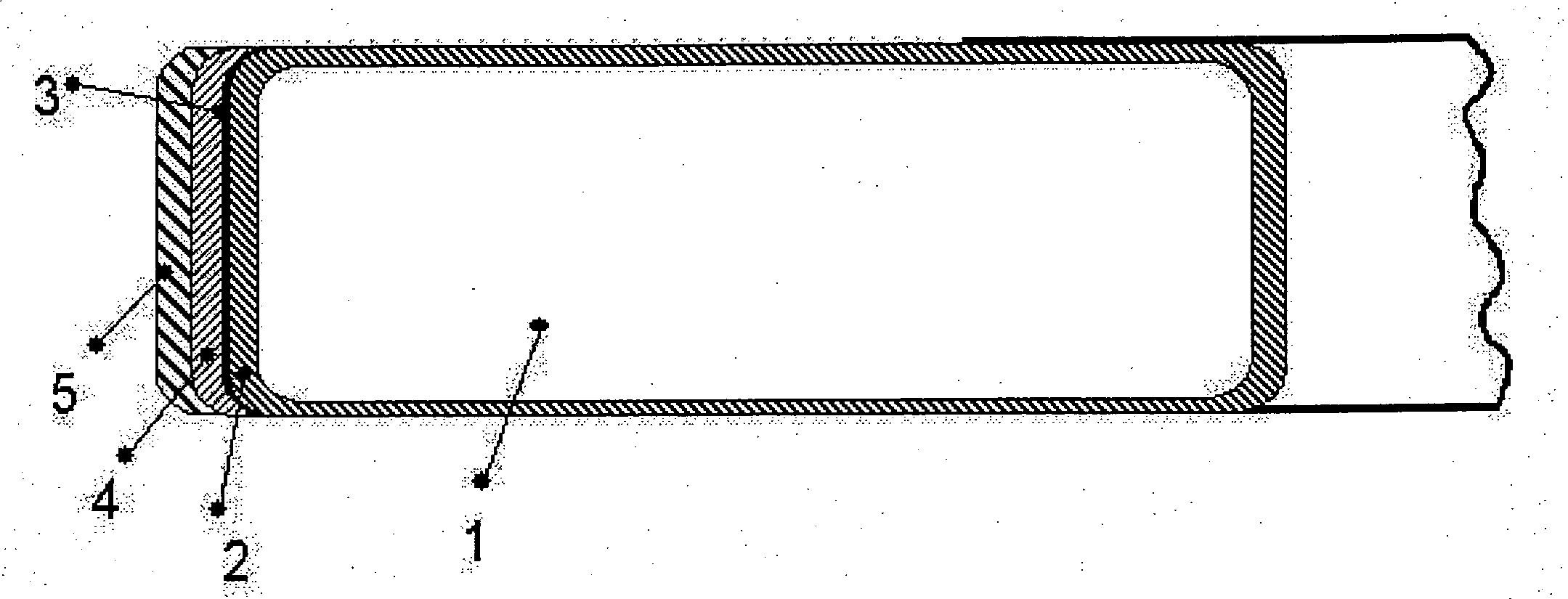

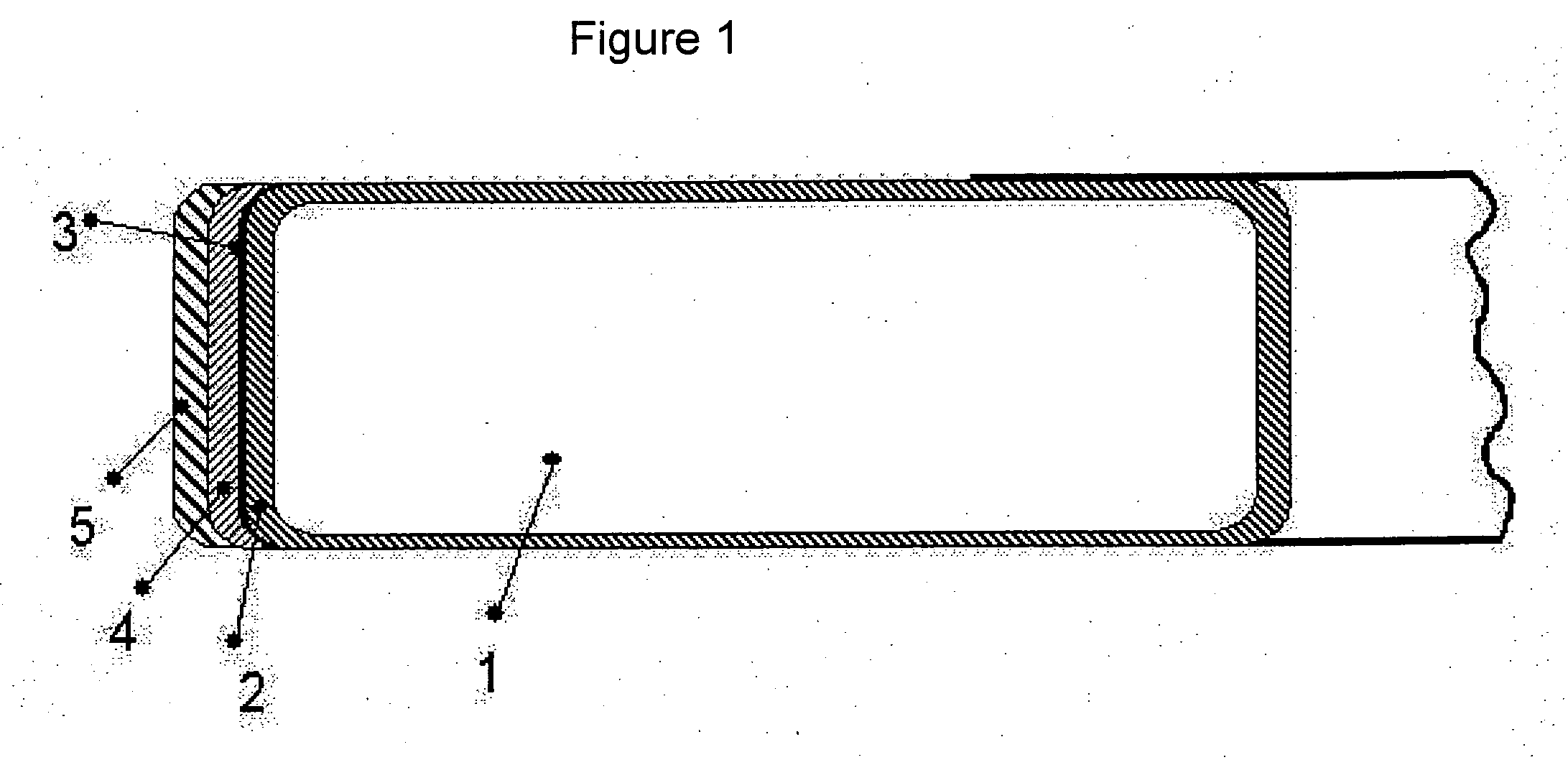

Thermally applied coating of mechanically alloyed powders for piston rings

InactiveUS6887585B2Improve the immunityTrend downMolten spray coatingPiston ringsCombustionWear resistant

The invention relates to a wear-resistant coating used for bearing surfaces and flanks of piston rings in internal combustion engines. The wear-resistant inventive coating is obtained by mechanically alloying powders which form a metallic matrix with hard material dispersoids and lubricant material dispersoids. The coating is then thermally applied to the workpieces, especially by means of high velocity oxygen fuel spraying (HVOF). The workpieces coated are bearing surfaces and parts of flanks pertaining to piston rings in internal combustion engines.

Owner:FEDERAL MOGUL BURSCHEID

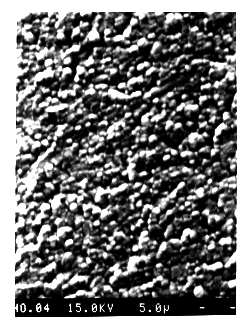

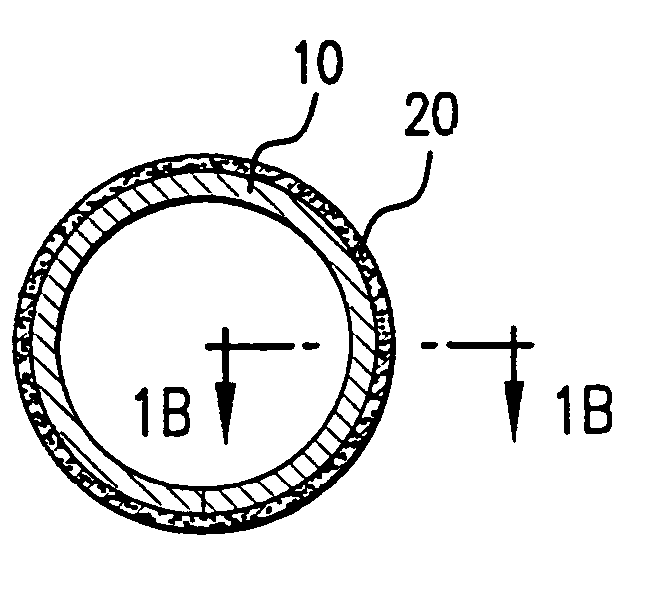

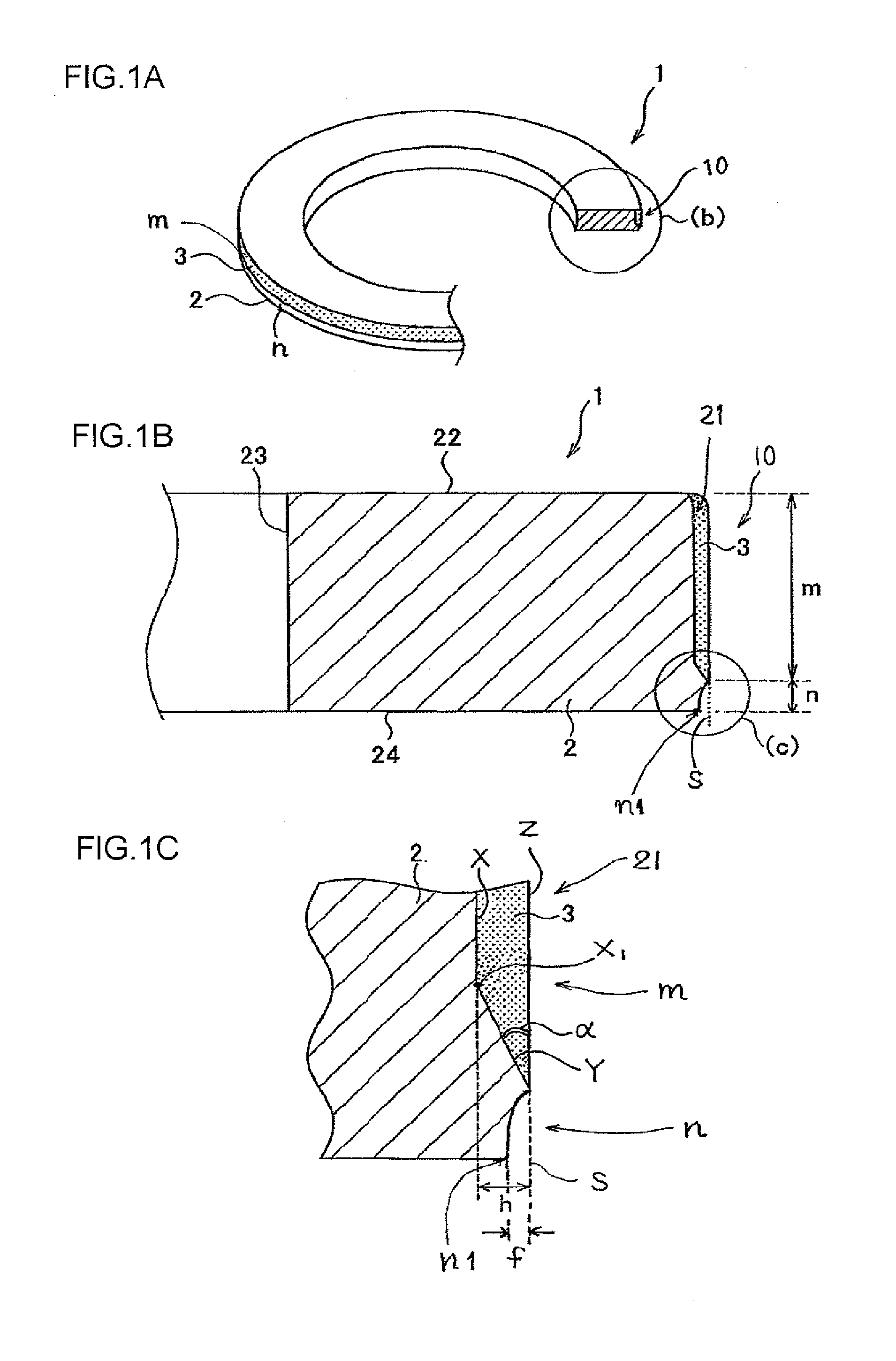

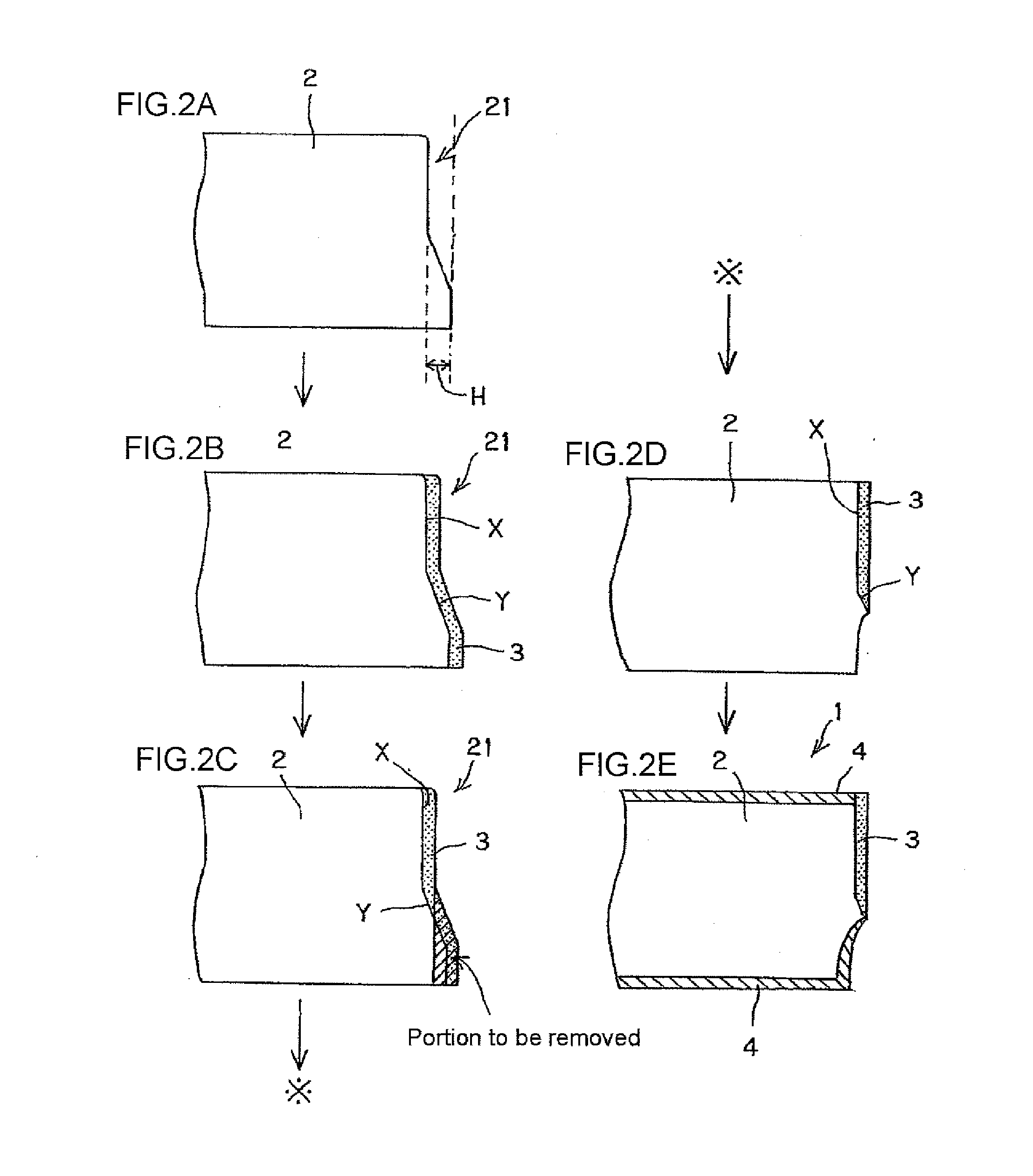

Sliding member and manufacturing method thereof

InactiveUS6279913B1Improve the immunityHigh bonding strengthPiston ringsBraking action transmissionCarbon filmDiamond-like carbon

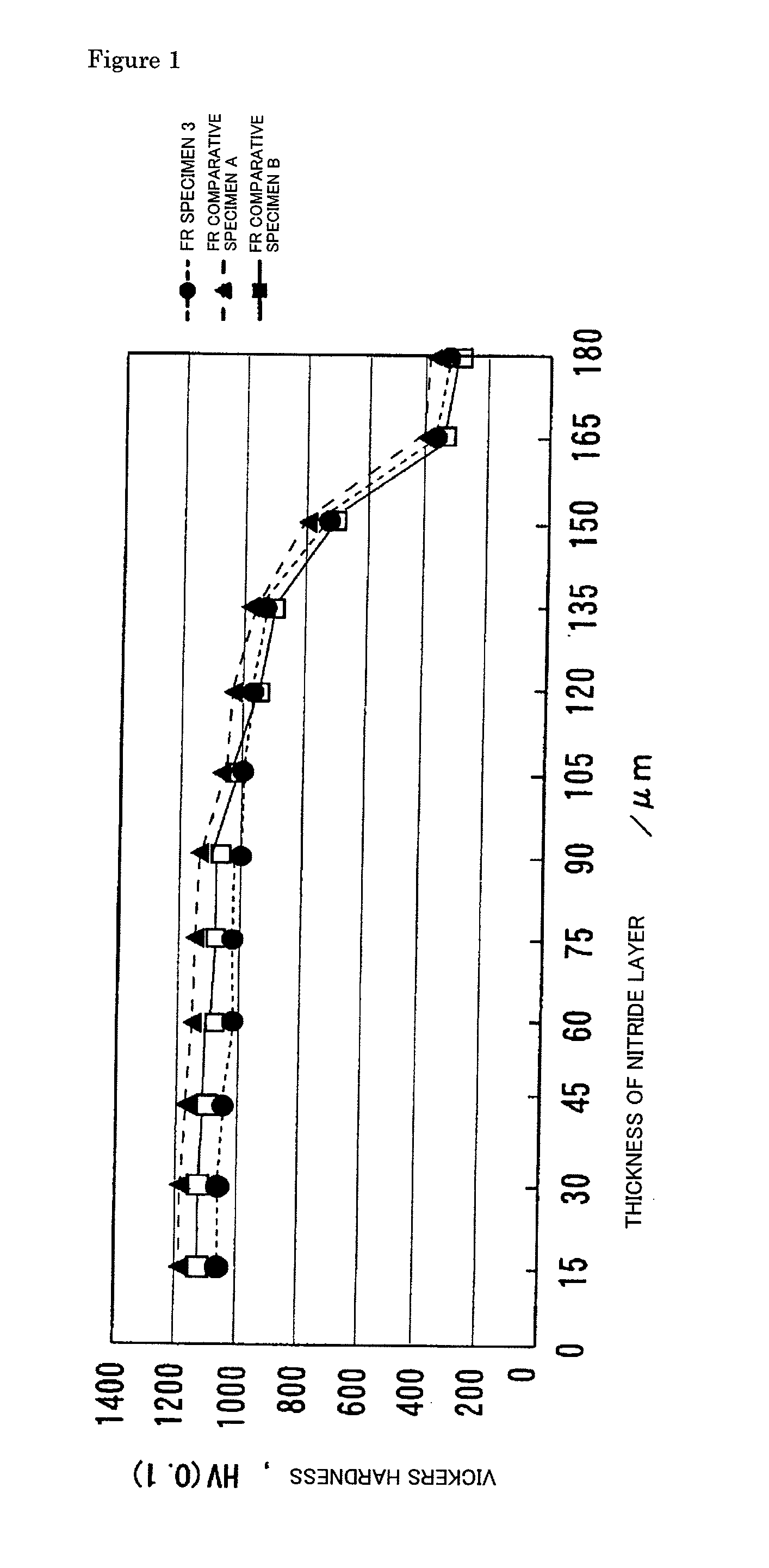

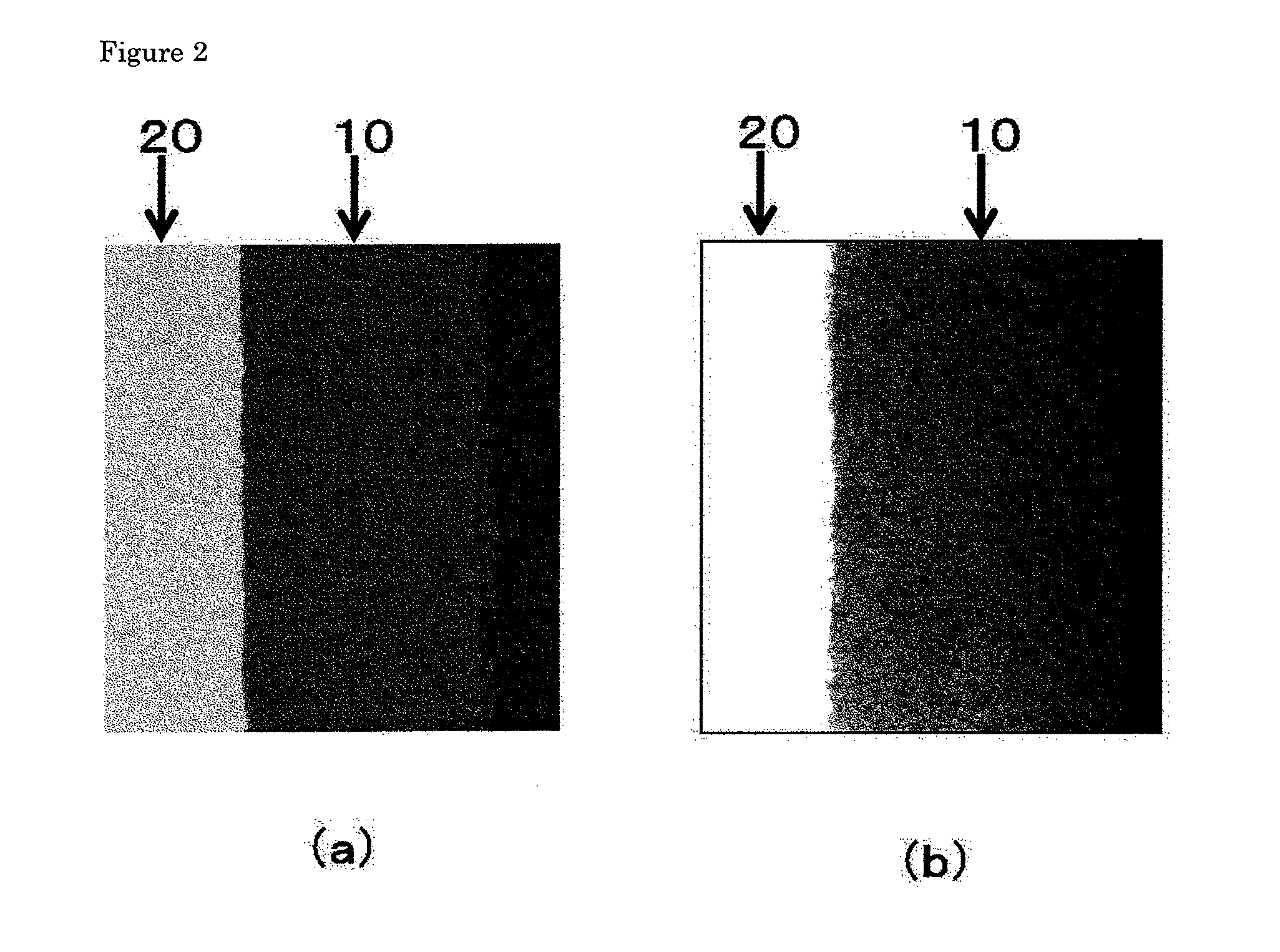

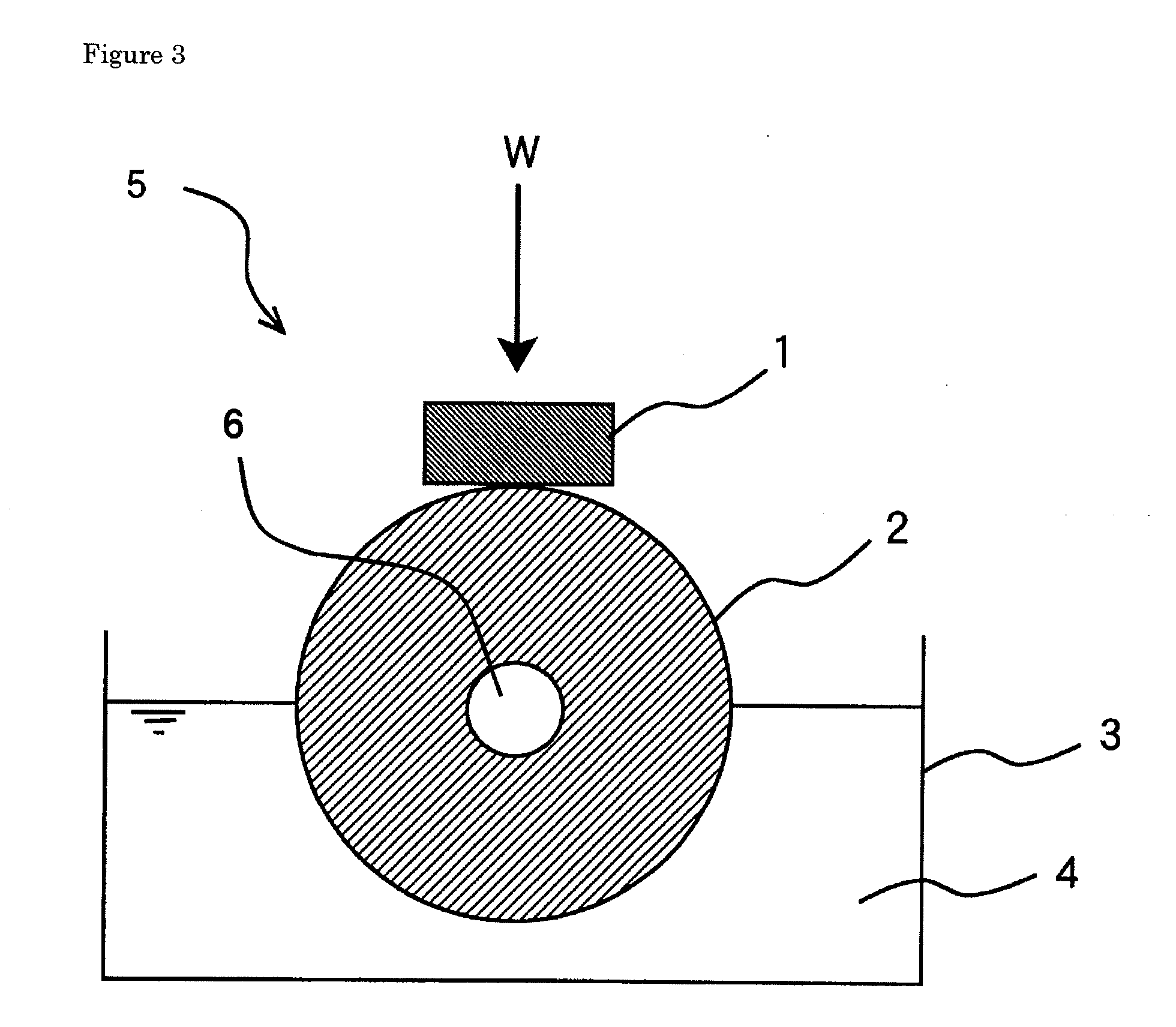

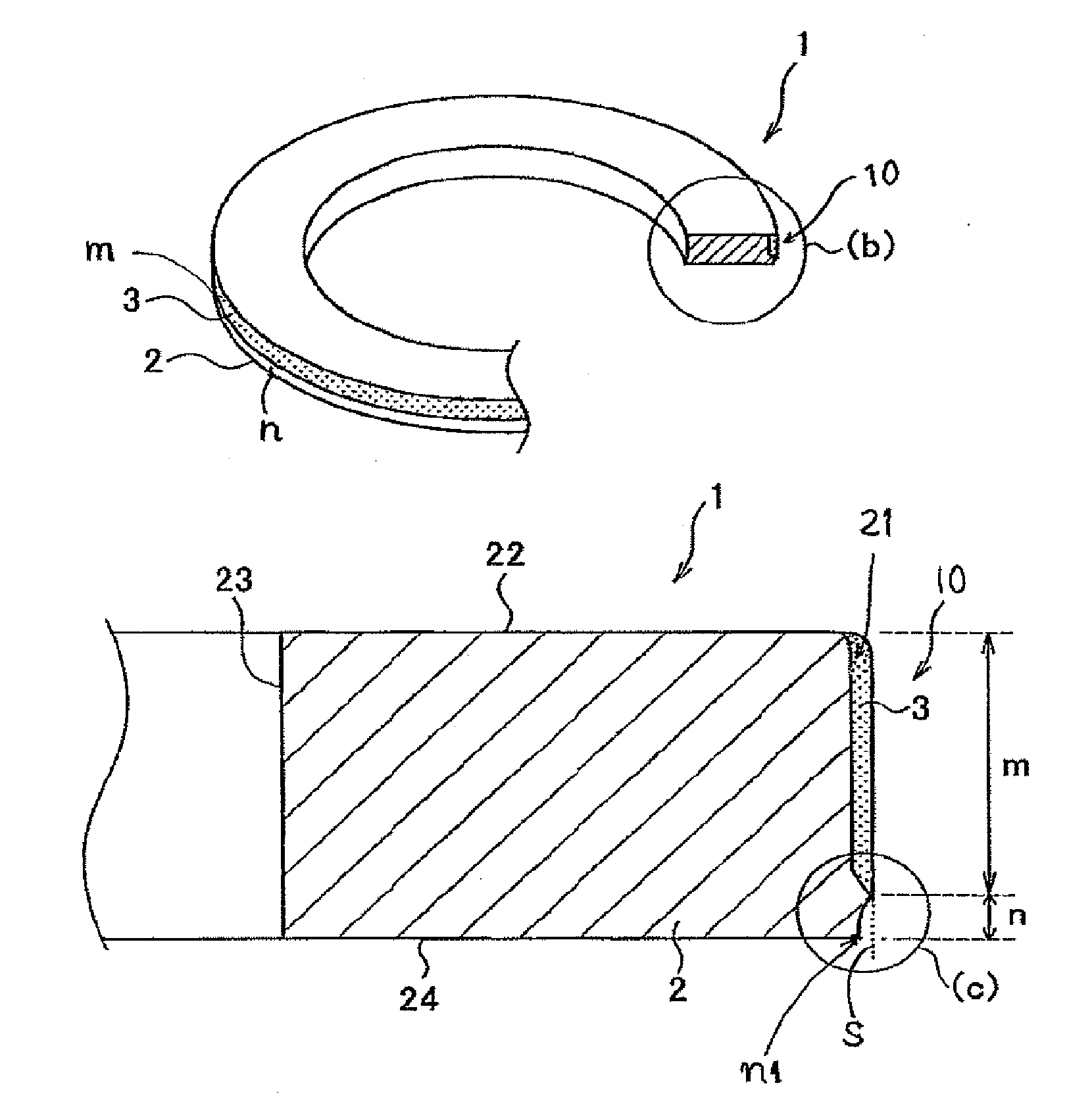

A piston ring is formed over the entire surface with a gas nitrided layer. A diamond-like carbon film is formed in a thickness of 0.5 to 30 micrometers over the gas nitrided layer at the upper and lower surfaces. The diamond-like carbon film has a surface structure in which diamond-like carbon has been deposited in nodular shapes in sizes of 0.5 to 5 micrometers. The diamond-like carbon is configured with any one of an amorphous carbon structure, an amorphous carbon structure having partly a diamond structure, or an amorphous carbon structure having partly a graphite structure.

Owner:TEIKOKU PISTON RING CO LTD

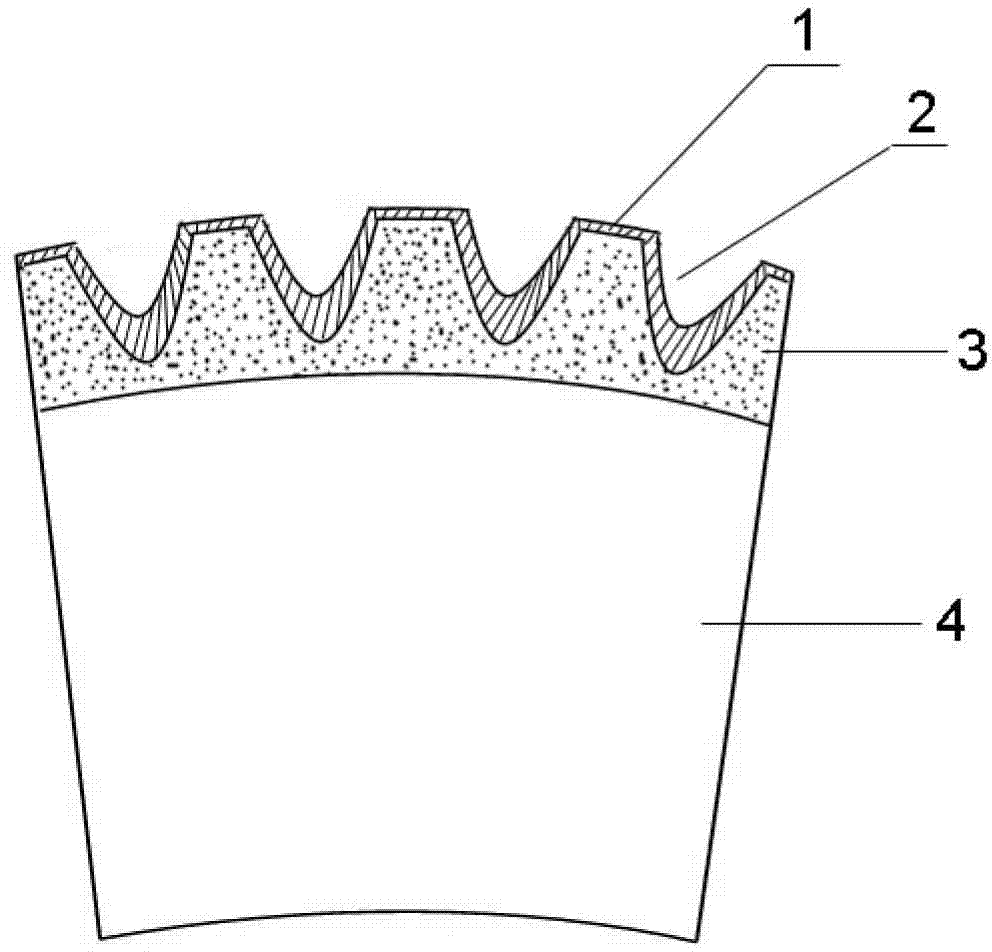

Wear-resisting piston ring with hard-soft composite coating and textured surface and wear-resisting piston ring manufacture method

InactiveCN103089479AImprove wear resistanceImprove wear and tearPiston ringsSolid state diffusion coatingChromium coatingDust particles

The invention discloses a wear-resisting piston ring with a hard-soft composite coating and the textured surface and a wear-resisting piston ring manufacture method. A hard coating like a chromium coating or a carburization / nitriding layer or a nickel base layer is deposited on an outer circle face of the piston ring, the hard coating is textured by pulse laser to achieve a regular and even micropore array, and a soft coating like a silver coating or a tin coating or a magnetic control sputtering MoS2 coating is prepared on the textured surface. The hard coating can serve as a hard support layer to improve wear resistance of the outer circle face of the piston ring. The surface micropore array can enhance fluid hydrodynamic effects of lubrication oil, can serve as a storage tank for lubrication oil / agent and can collect abrasive dust particles. The soft coating can serve as lubrication phase to achieve self lubrication and self repair of the friction surface.

Owner:NANJING UNIV OF SCI & TECH

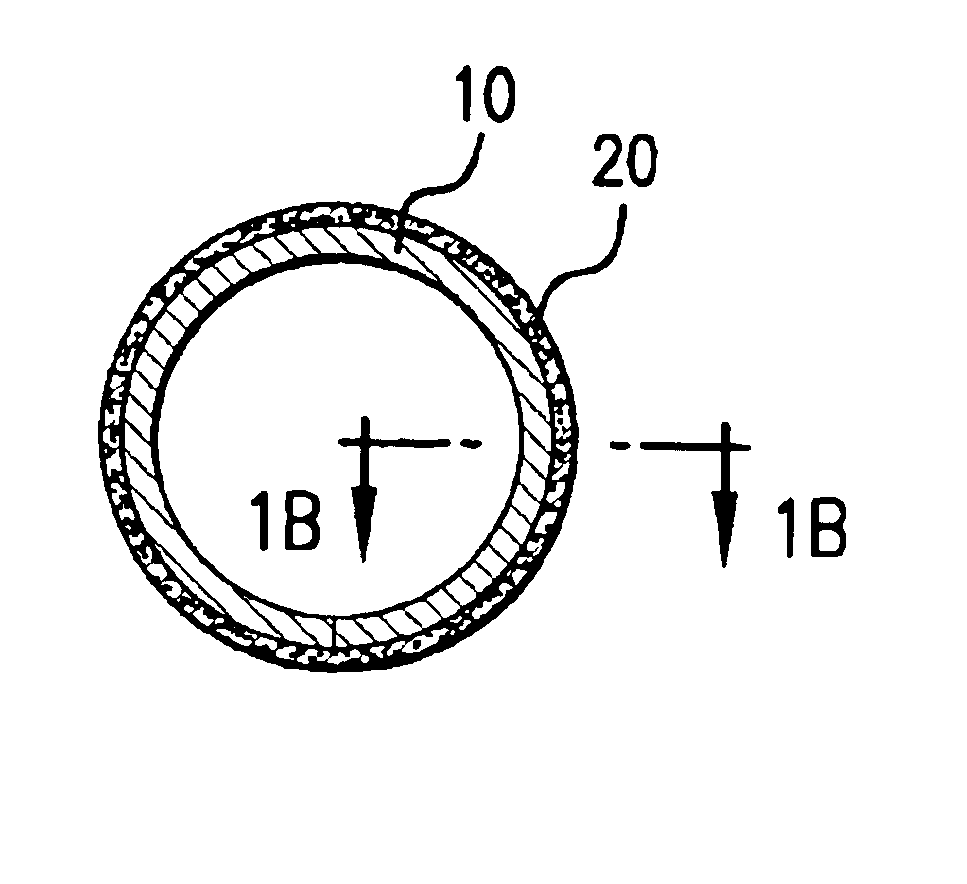

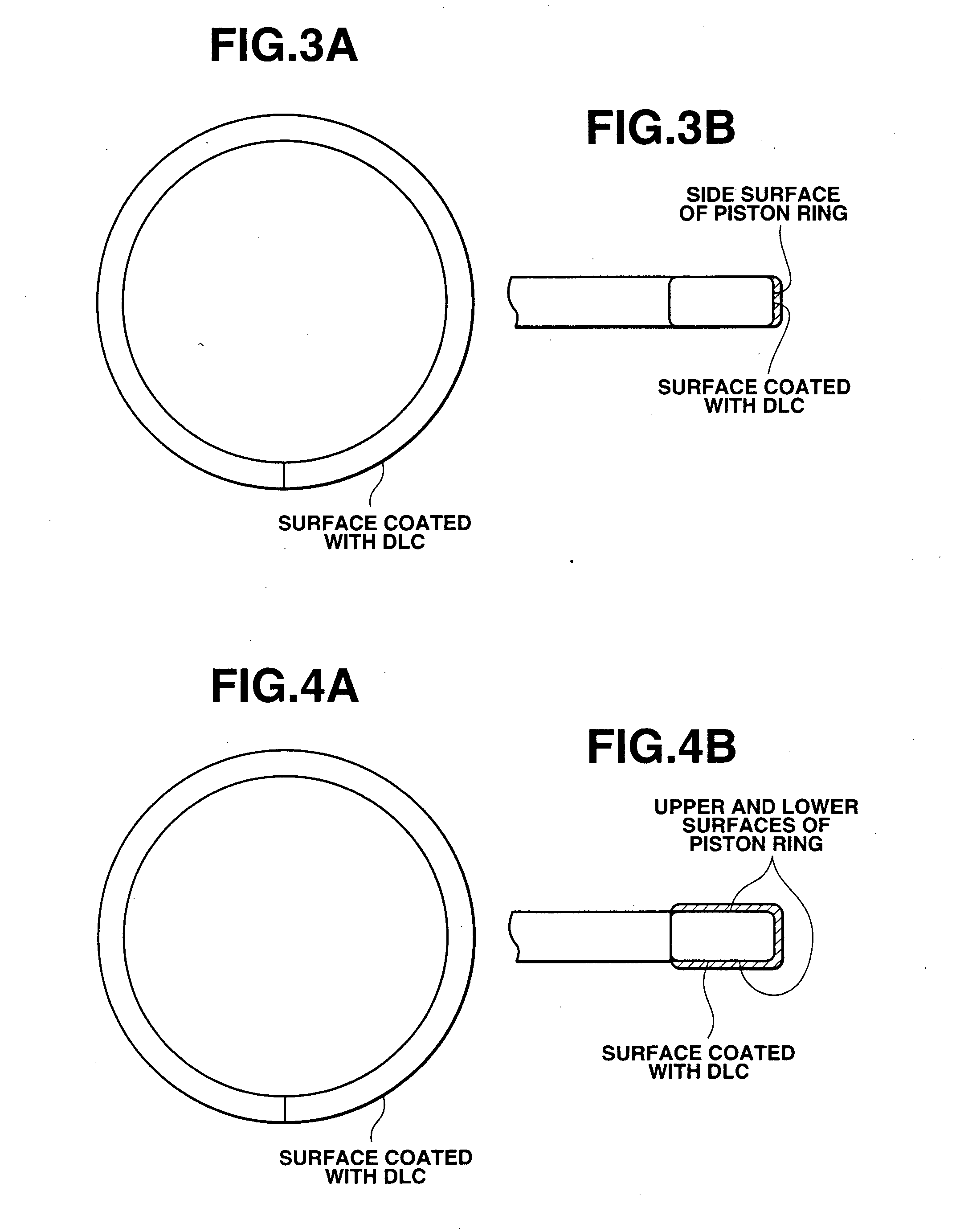

Sliding structure for automotive engine

InactiveUS6886521B2Preventing cracking and separationReduce coefficient of frictionPiston ringsMolten spray coatingCarbon filmPiston ring

A sliding structure for an automotive engine includes a sliding member with a sliding portion and a lubricant applied to the sliding portion so that the sliding portion can make sliding contact with a counterpart member via the lubricant. The sliding member is either of a piston ring, a piston pin, a cam lobe, a cam journal, a plain bearing, a rotary vane and a timing chain. The sliding portion has a base made of a steel or aluminum material and a hard carbon film formed on the base to coat the sliding portion. The hard carbon film has a thickness of 0.3 to 2.0 mum, a Knoop hardness of 1500 to 4500 kg / mm2, a surface roughness Ry (mum) satisfying the following equation: Ry<{(0.75-Hk / 8000)xh+0.07 / 0.8}, where h is the thickness (mum) of the film; and Hk is the Knoop hardness (kg / mm2) of the film.

Owner:NISSAN MOTOR CO LTD

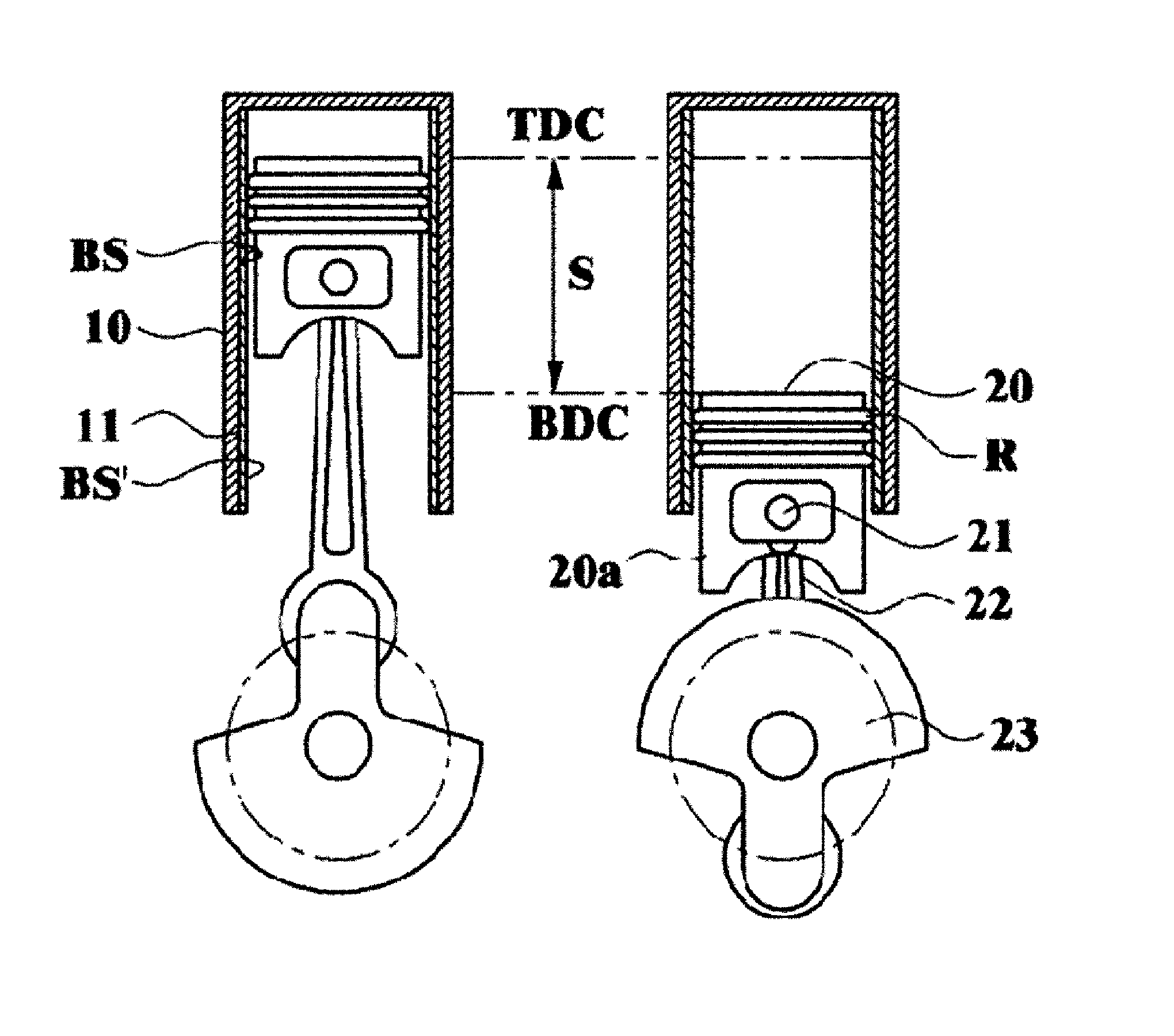

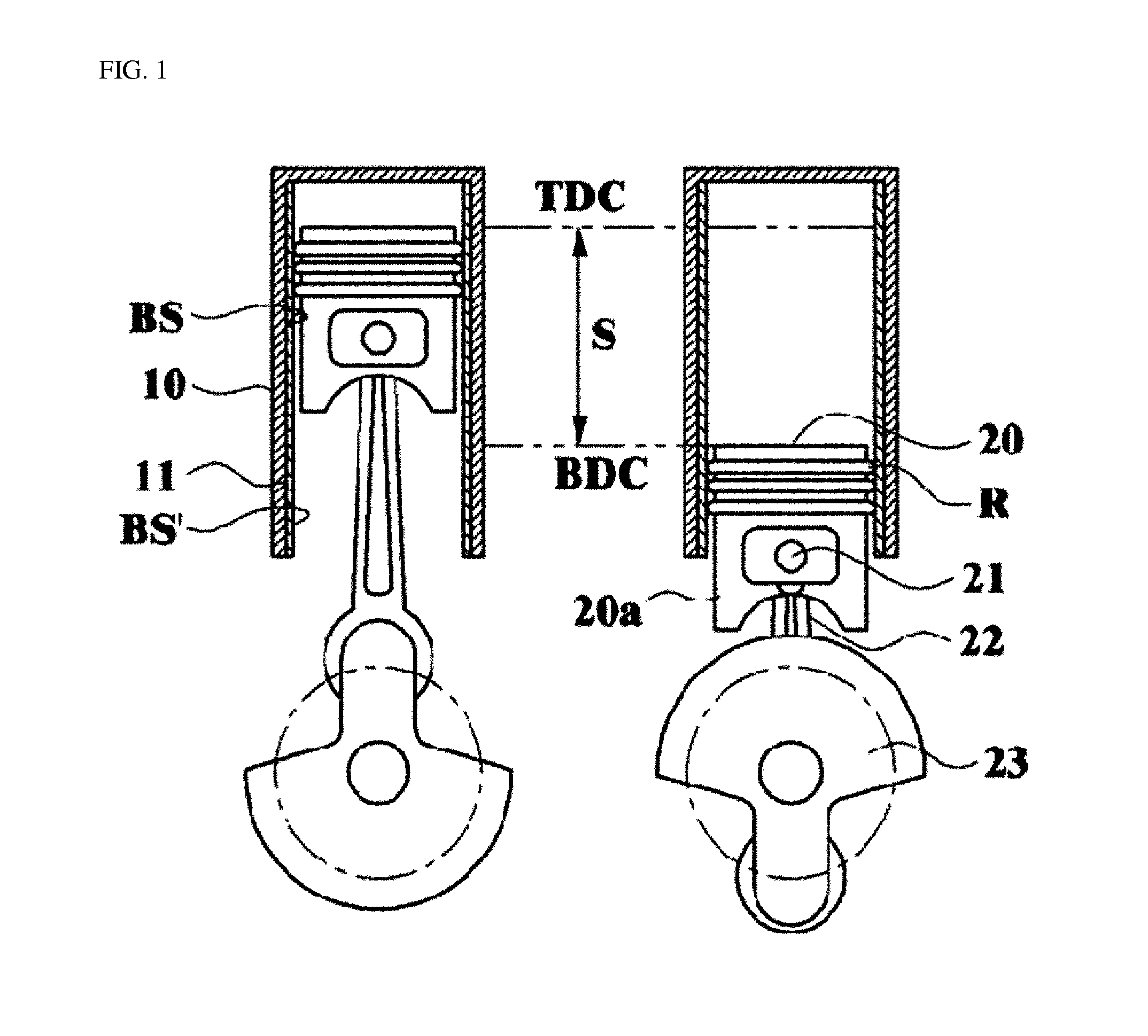

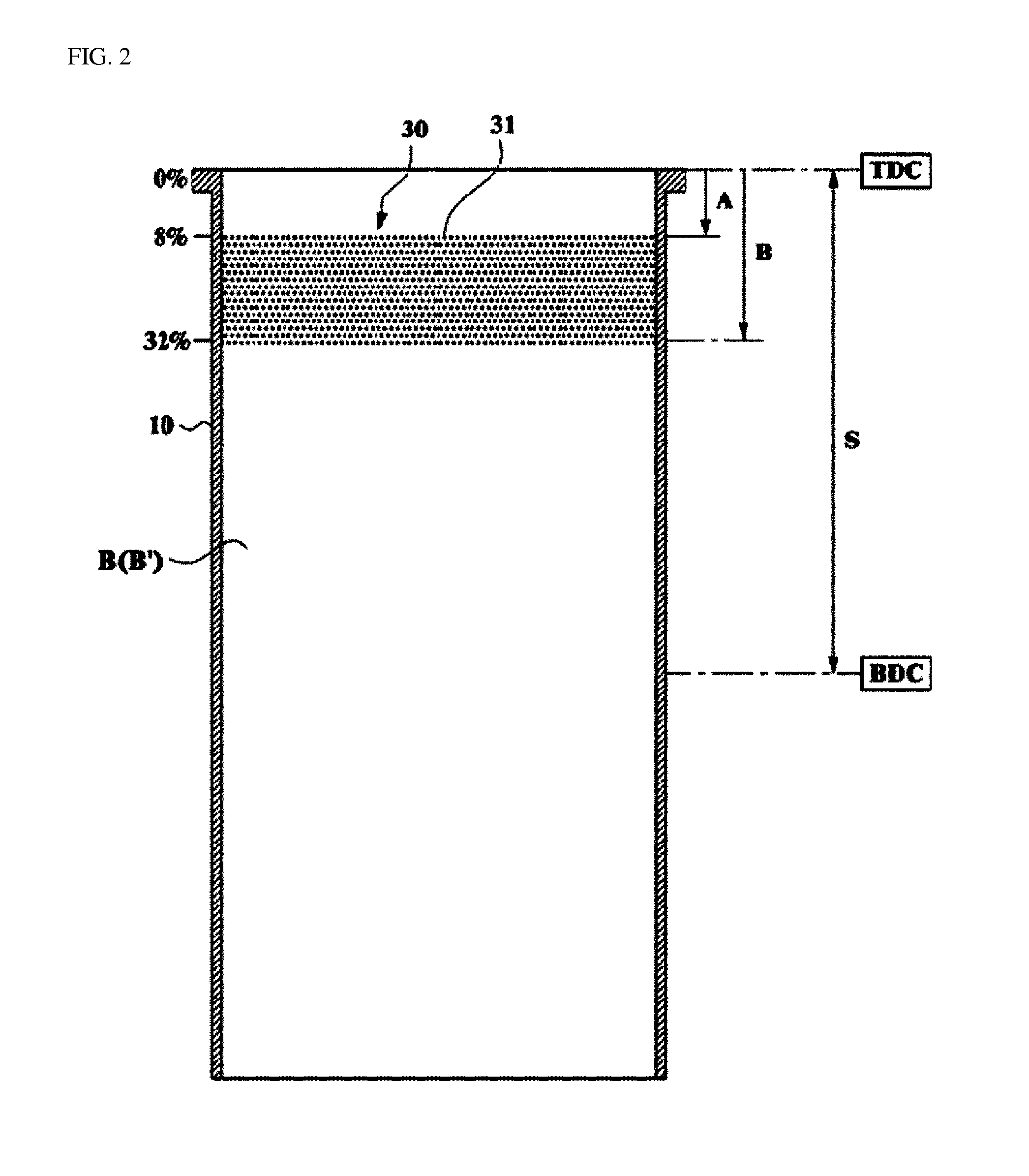

Cylinder device having improved wear resistance through optimal arrangement of fine textures

ActiveUS20140345453A1Reduce oil consumptionAvoid performance degradationCylinder headsCylindersPiston ringSurface roughness

There is provided a cylinder device having optimal arrangement of fine textures and optimal surface roughness capable of reducing wear of a cylinder bore side and a piston ring by processing fine textures in an optimal selection region of the cylinder bore side to improve lubrication characteristics between the piston ring and the cylinder bore side while reducing engine oil consumption by processing surface roughness of the cylinder bore side to an optimal status.

Owner:DOOSAN INFRACORE CO LTD

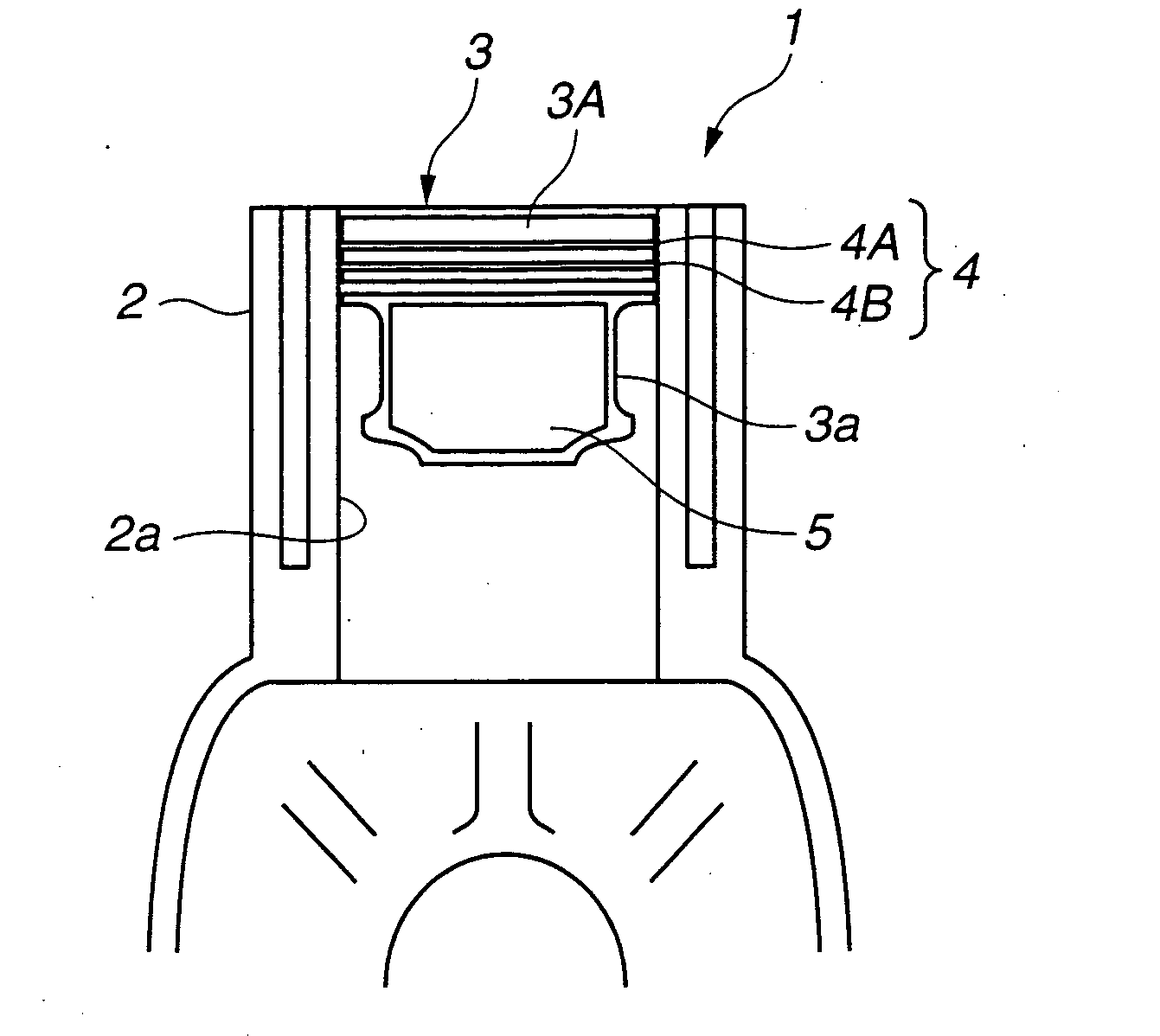

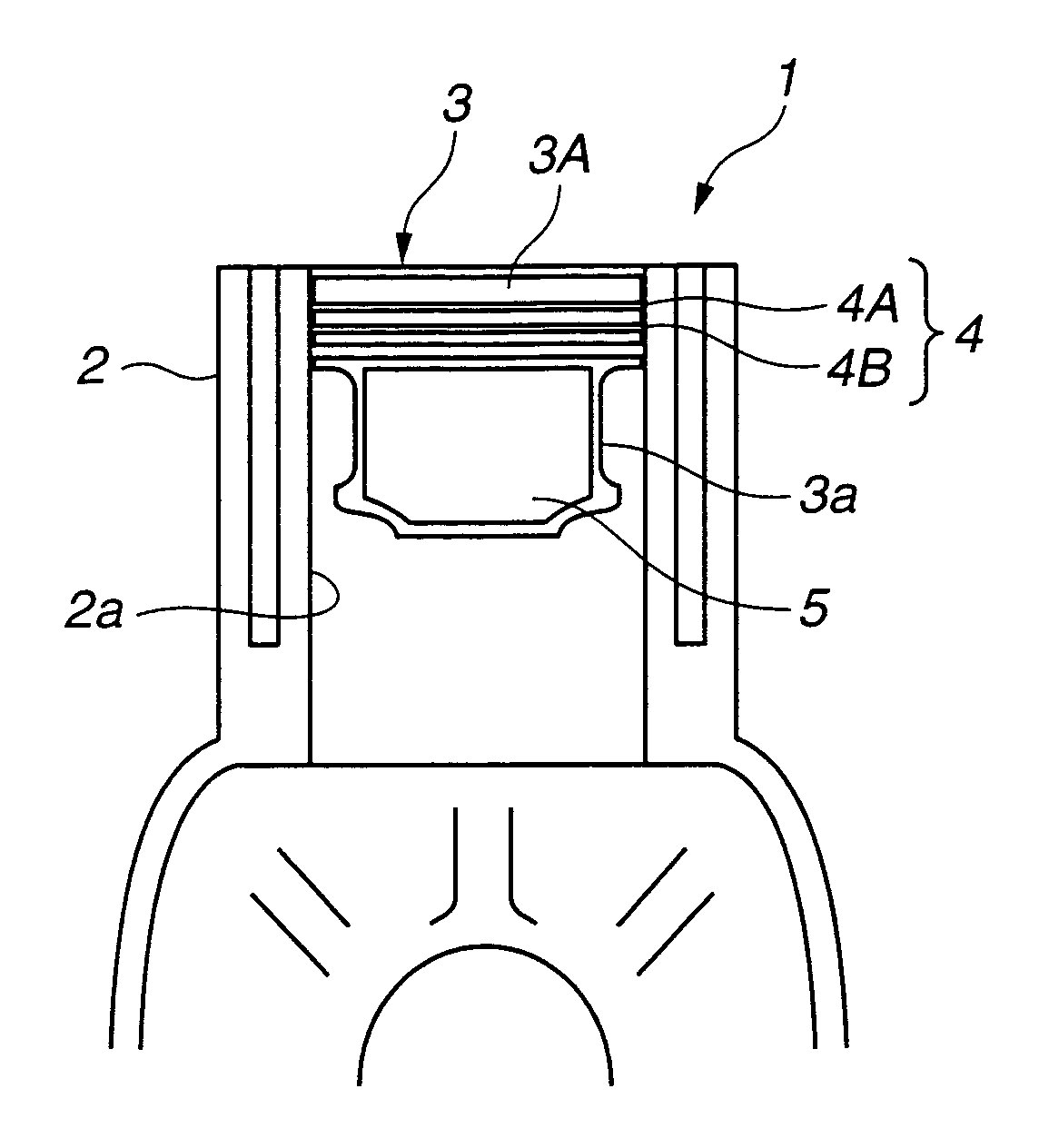

Piston for internal combustion engine

ActiveUS20050005892A1Excellent abrasion resistanceReduce coefficient of frictionCasingsPlungersPiston ringAliphatic amine

A piston for an internal combustion engine of an automotive vehicle. The piston has a piston ring and a piston skirt section each of which has a sliding section in slidable contact with a cylinder bore section of a cylinder block in presence of a lubricating oil. The cylinder bore section is formed of eutectic or hyper-eutectic aluminum alloy. Additionally, a hard carbon thin film is coated on the sliding section of the piston and contains hydrogen atom in an amount of not more than 1 atomic %. Here, the lubricating oil contains at least one selected from the group consisting of ashless fatty acid ester friction modifier, ashless aliphatic amine friction modifier, polybutenyl succinimide, derivative of polybutenyl succinimide, zinc dithiophosphate, and derivative of zinc dithiophosphate.

Owner:NISSAN MOTOR CO LTD

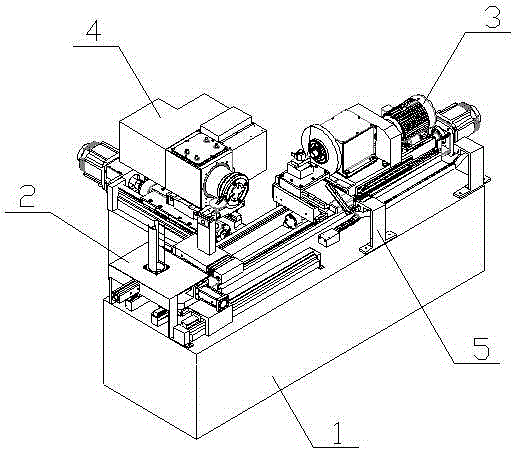

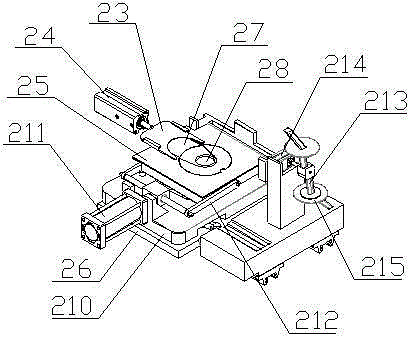

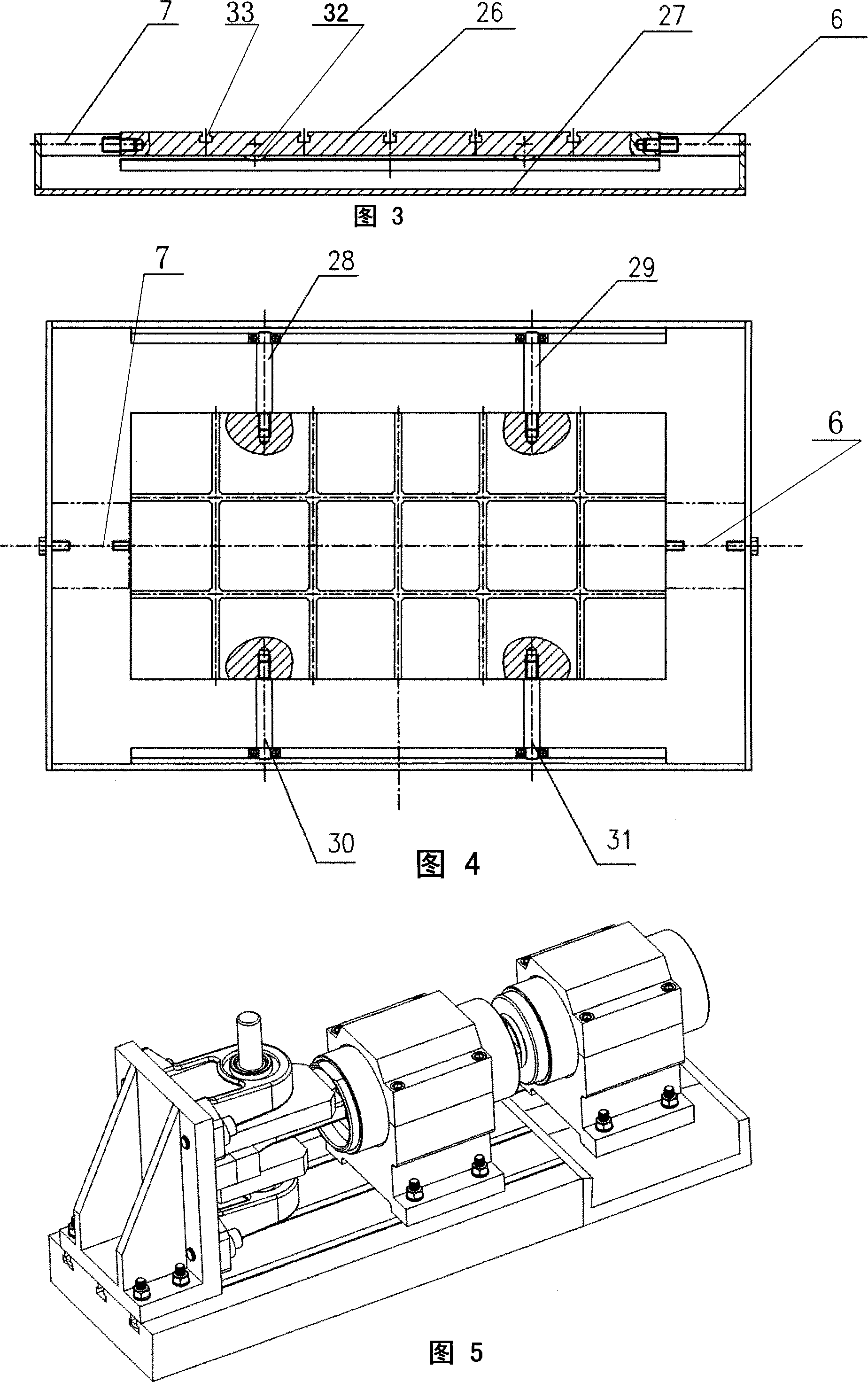

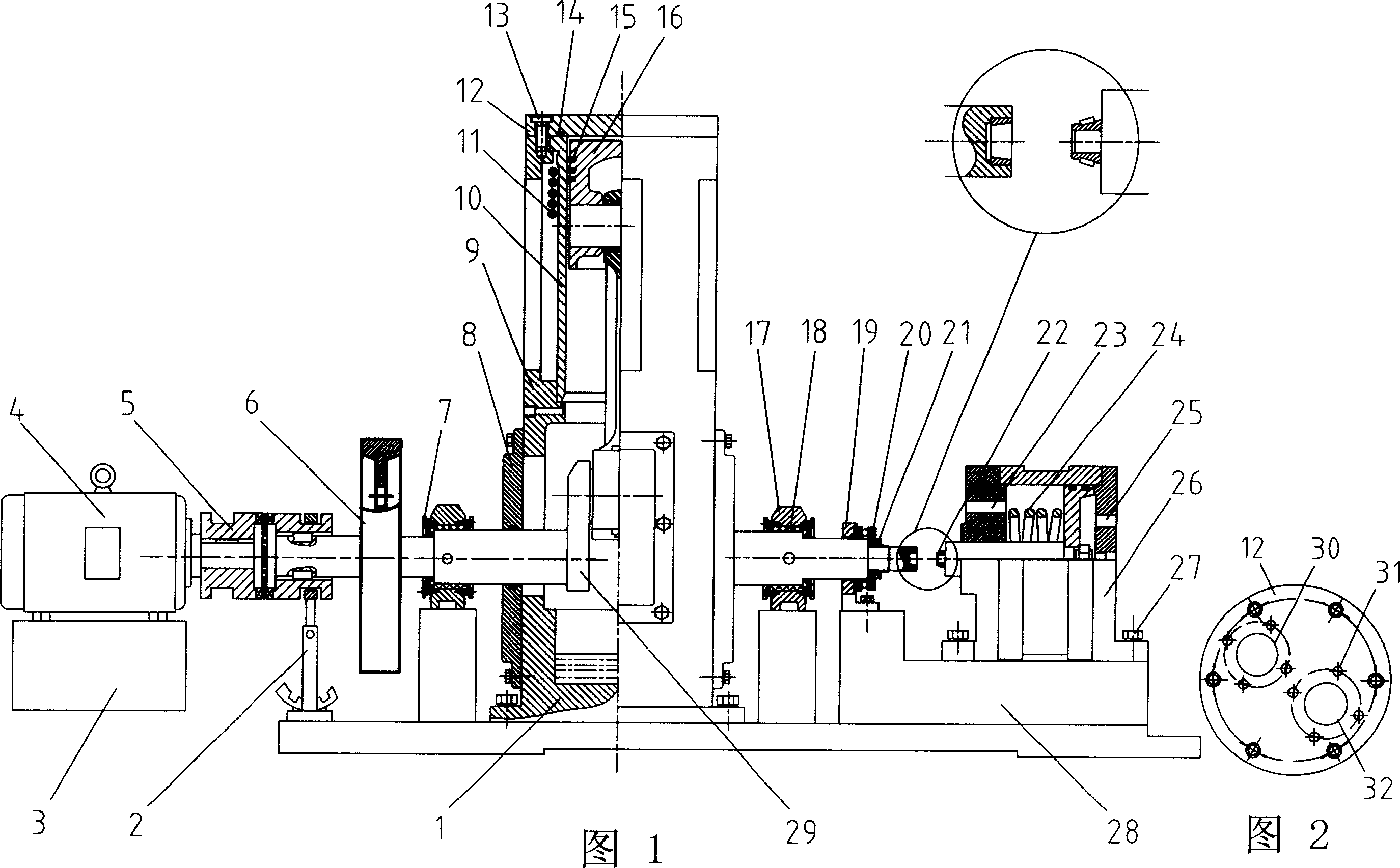

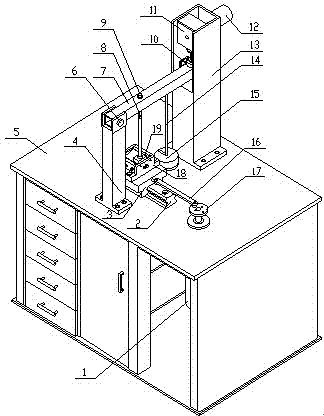

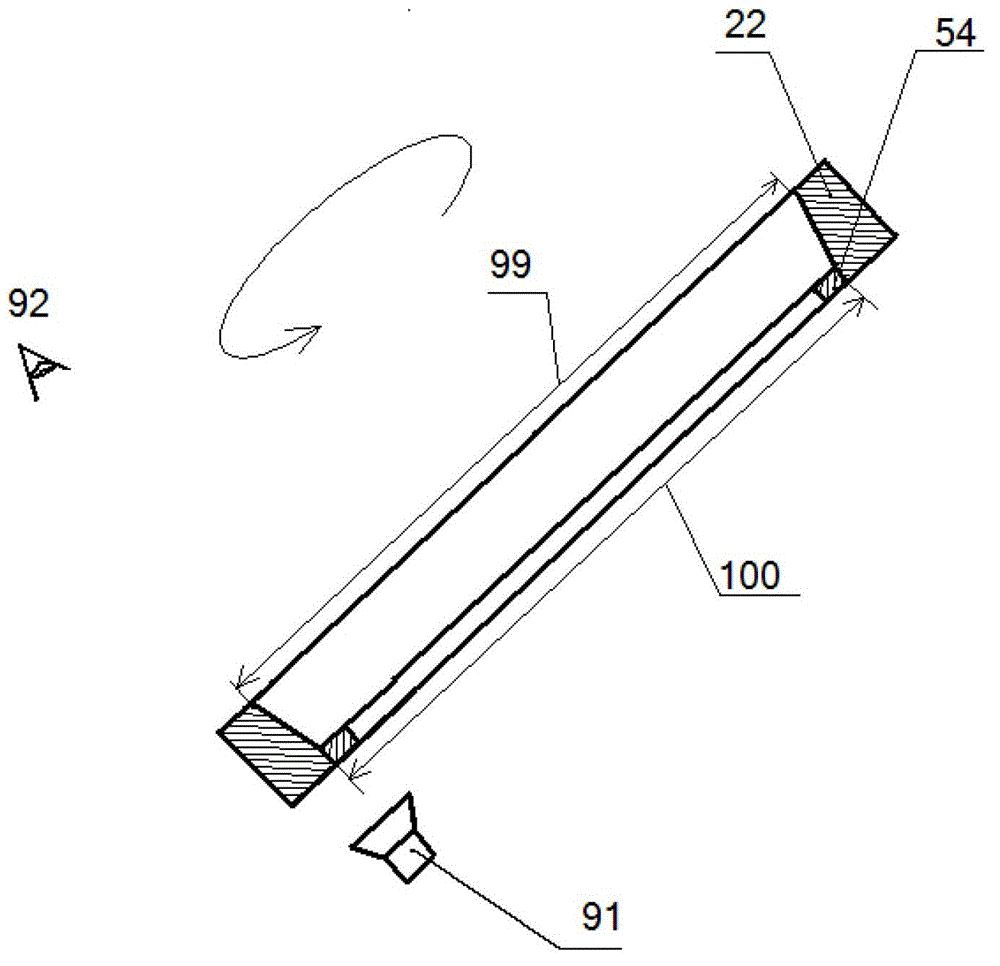

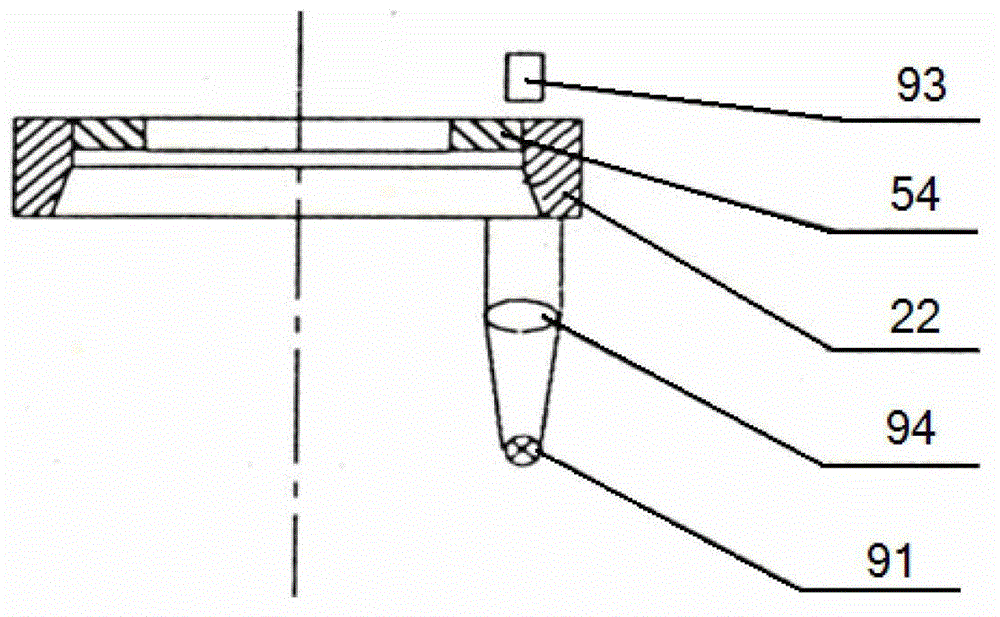

Full automatic grinding machine for piston ring inclined end surface

InactiveCN105171427AExtend your lifeReduce grindingFeeding apparatusOther manufacturing equipments/toolsPiston ringEngineering

The invention discloses a full automatic grinding machine for a piston ring inclined end surface. The full automatic grinding machine comprises a machine bed, an automatic loading and unloading rack, a composite processing table, a power head rack, a material collection rack and two parallel guide rails which are arranged on the machine bed, wherein the automatic loading and unloading rack and the composite processing table are arranged on the two ends of the two guide rails, the power head rack and the material collection rack are arranged on the two sides of the two guide rails; the automatic loading and unloading rack comprises a material storage rack, a material delivering slide table and a material delivering cylinder, the composite processing table comprises a processing slide table and a slide table displacement servo motor; the power head rack comprises a shell, a hollow axle pipe is arranged in the shell, an electromagnetic chuck and a positioning disk are sleeved on one end of the axle pipe near to the guide rail, and the material storage rack comprises a material storage rod, a guide rod and two inverted L-shaped connection racks. The piston ring inclined end surface is more simply processed, the processing precision is high and the processing efficiency is high.

Owner:CHONGQING UNIV OF TECH

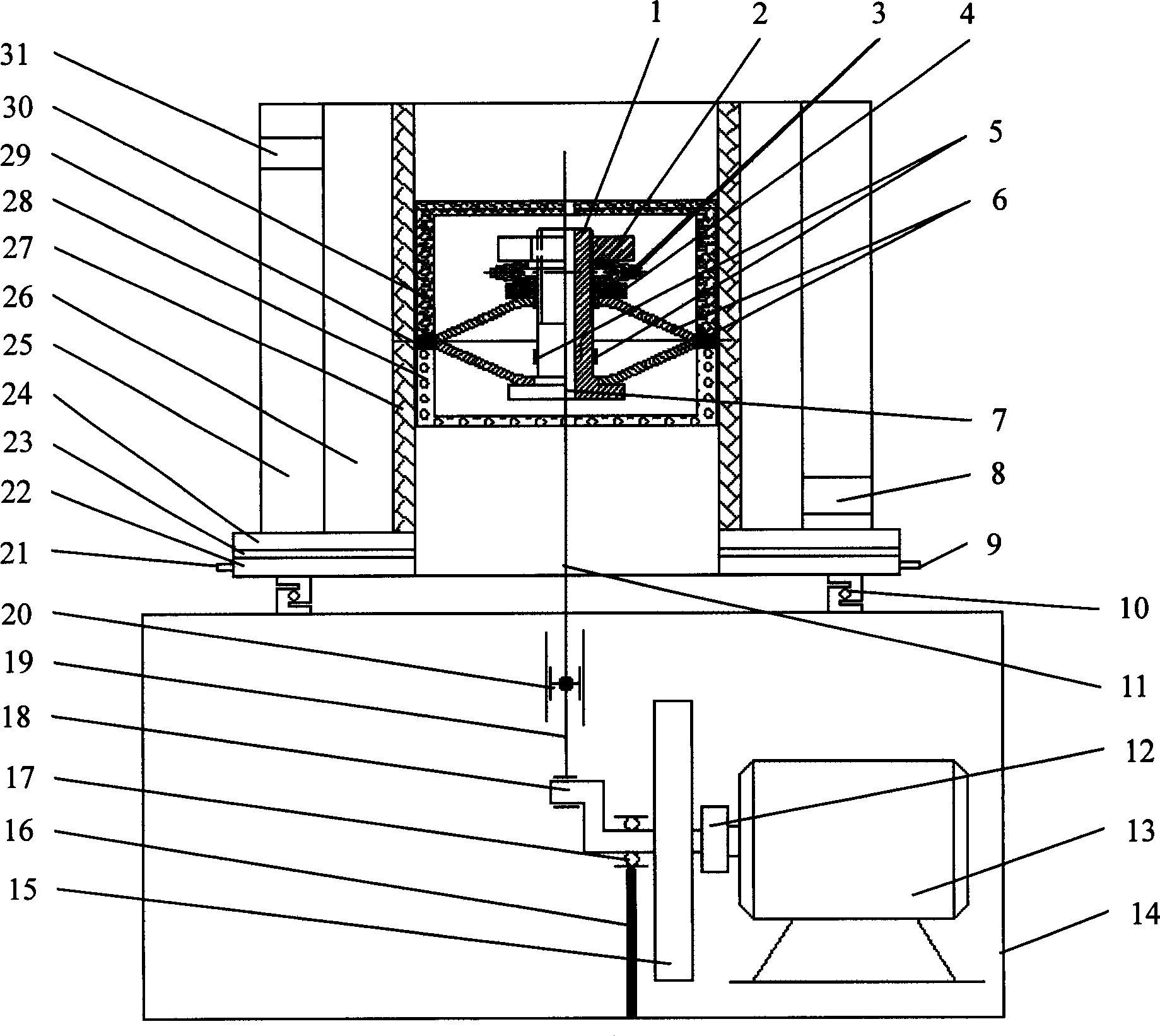

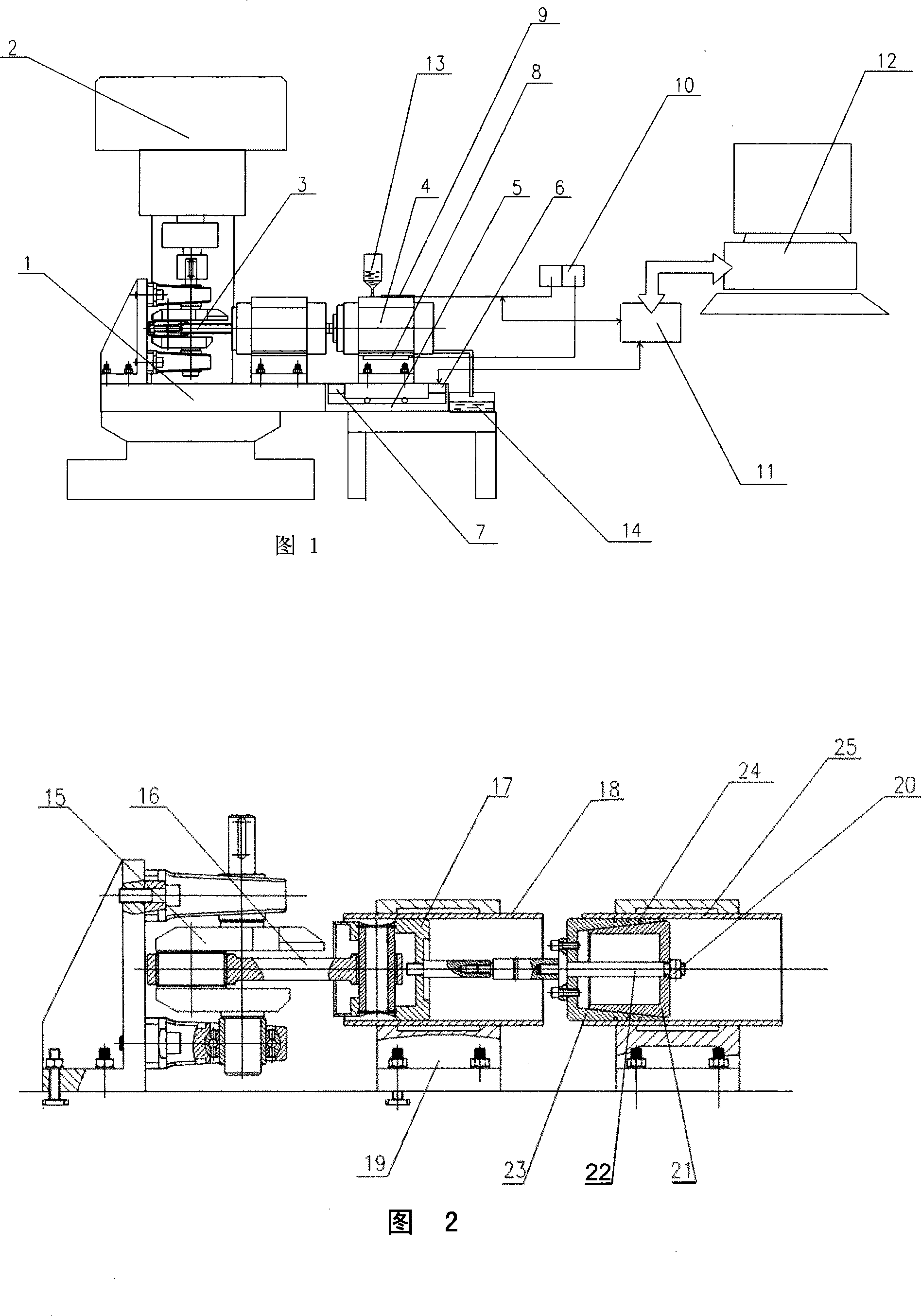

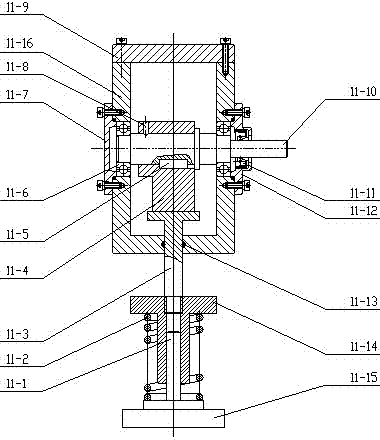

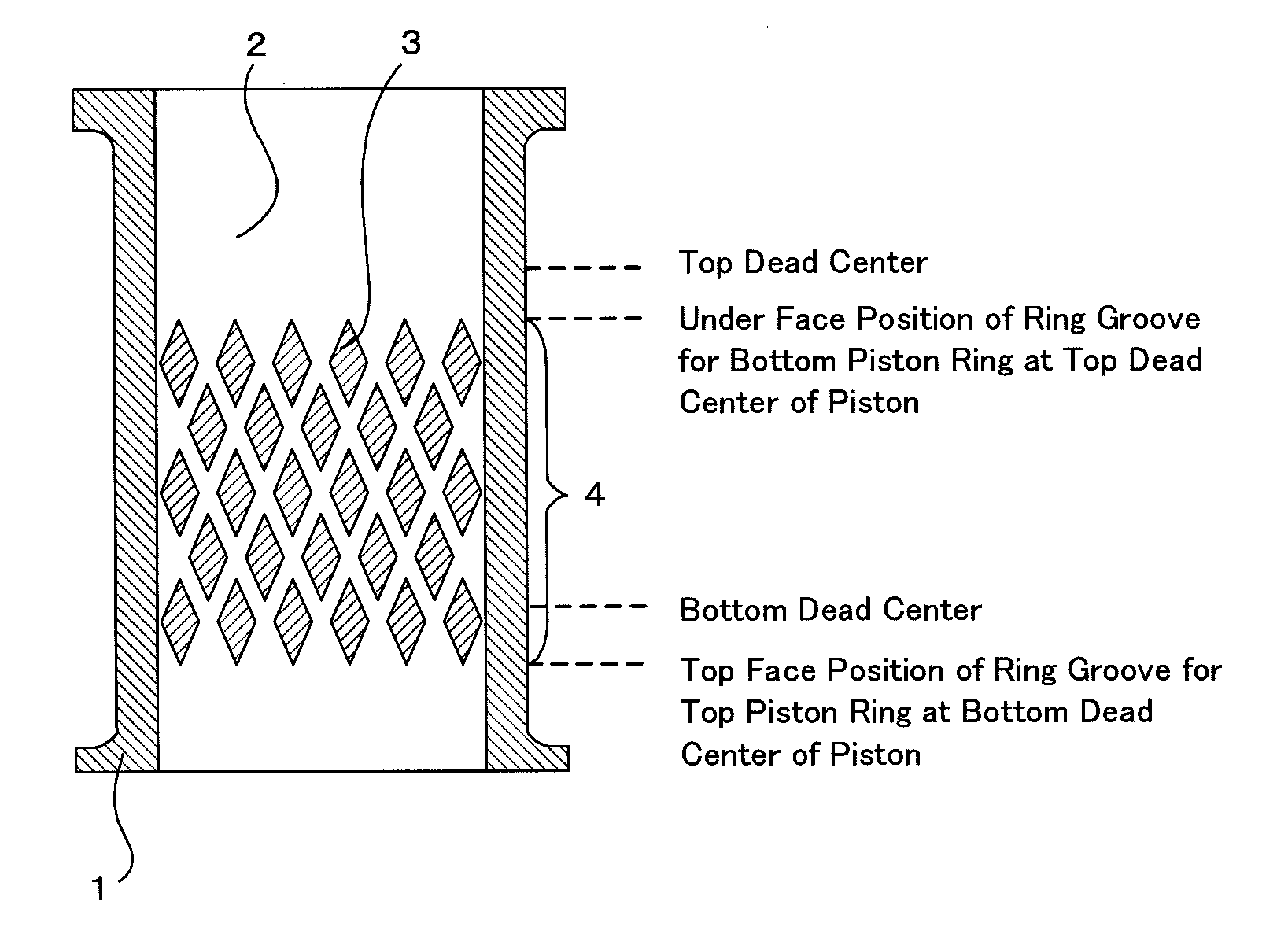

Friction wear test method and apparatus for cylinder liner piston ring component

InactiveCN1789963AEliminate the effects ofPrecise frictionMachine part testingInvestigating abrasion/wear resistanceThermal insulationPiston ring

The invention discloses a friction and abrasion testing method and equipment of cylinder piston ring element in the friction and abrasion testing technique domain, which is characterized by the following: adapting mechanic radial loading construction method and equipment to test the cylinder and piston ring element; adding liquid through heating the cylinder cavity to keep thermal; fixing the friction force sensor on the test machine rack directly; eliminating the measuring result influence of friction force by inertia force of moving component to gain more precise friction force; segregating the friction force sensor and cylinder through thermal-insulation material; setting the cooler to prevent the rack temperature from elevating and the temperature of friction force sensor from exceeding the highest working temperature. The invention is used as the rapid assessment method in the lab developing procedure of cylinder piston ring.

Owner:DALIAN MARITIME UNIVERSITY

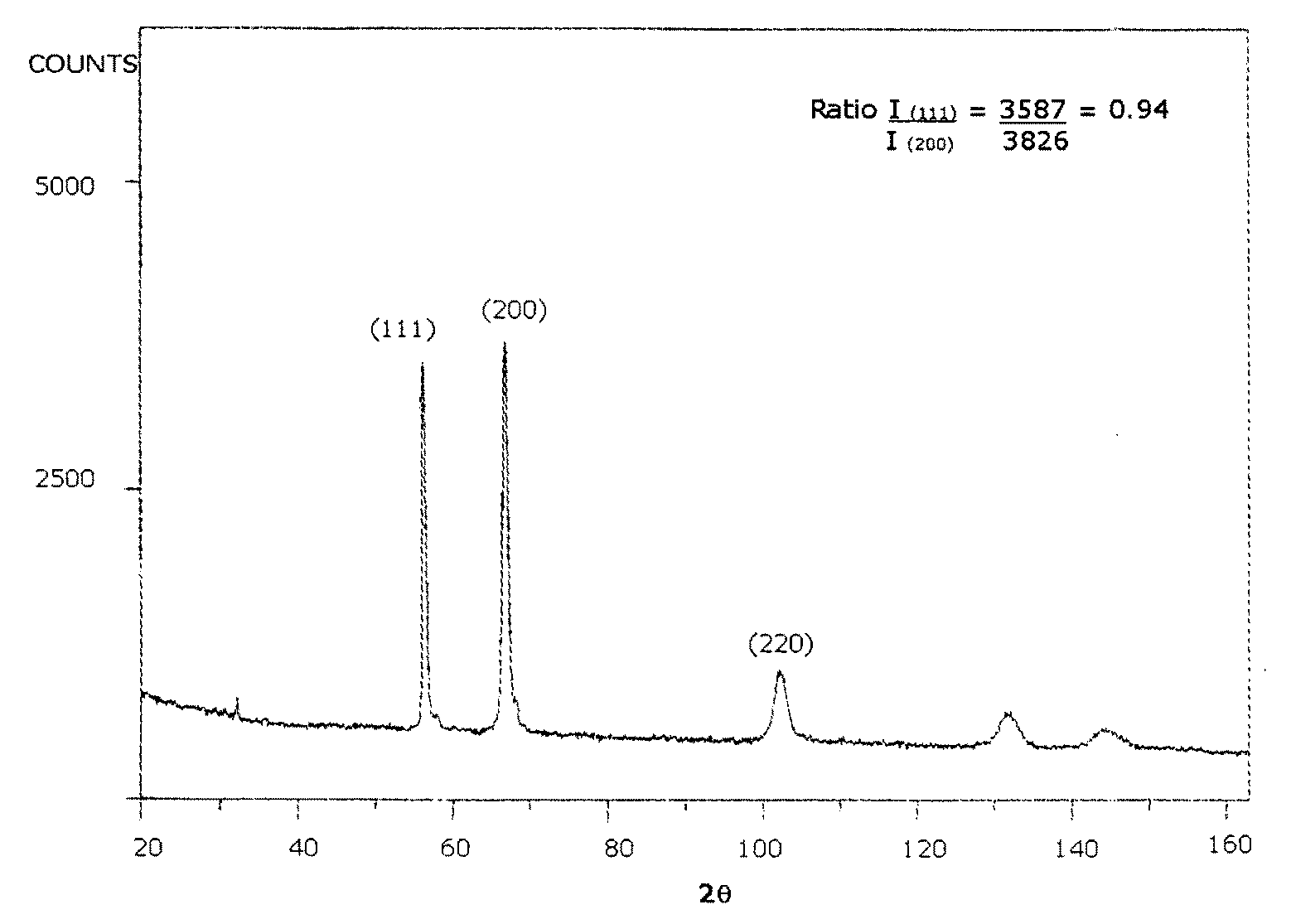

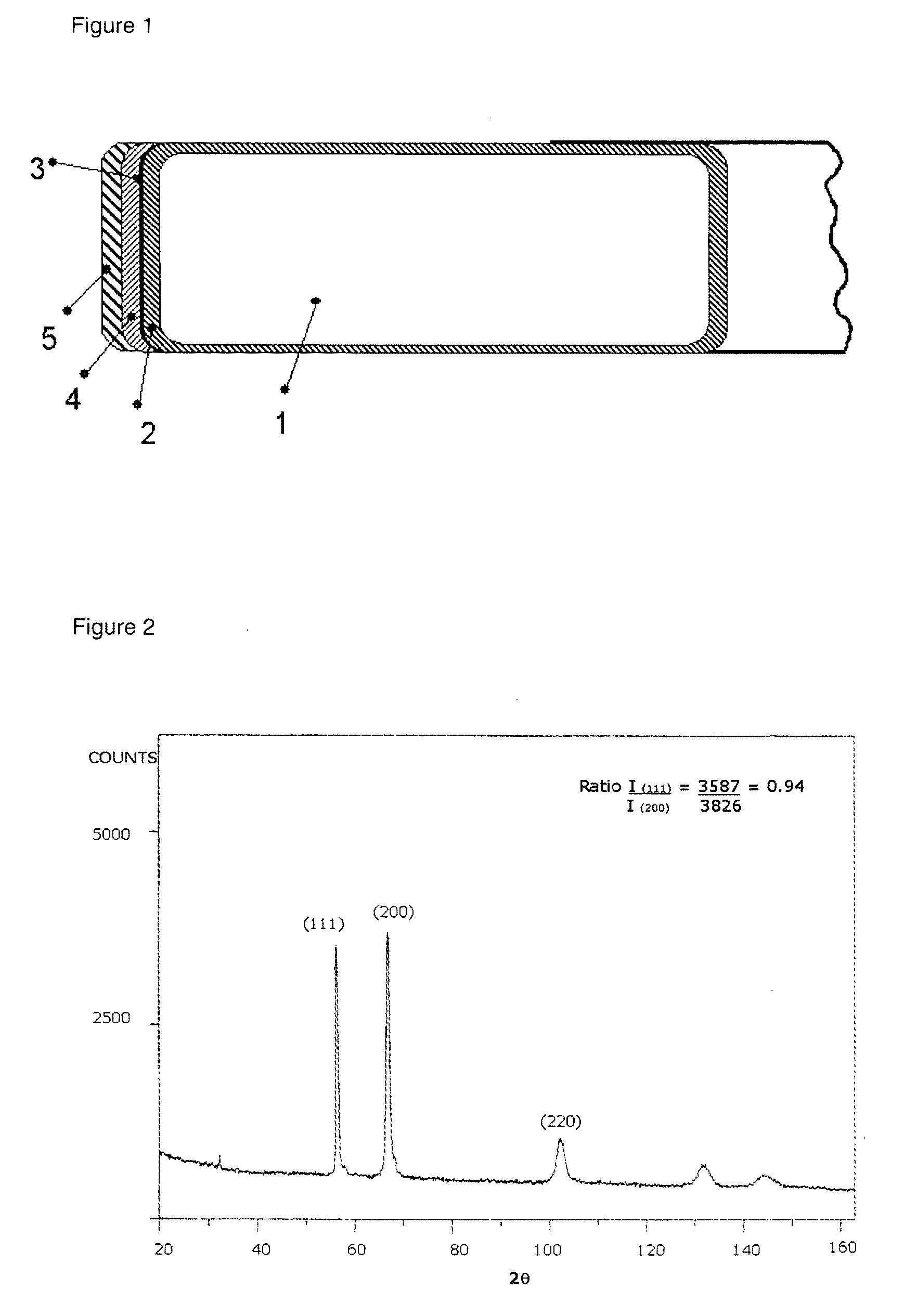

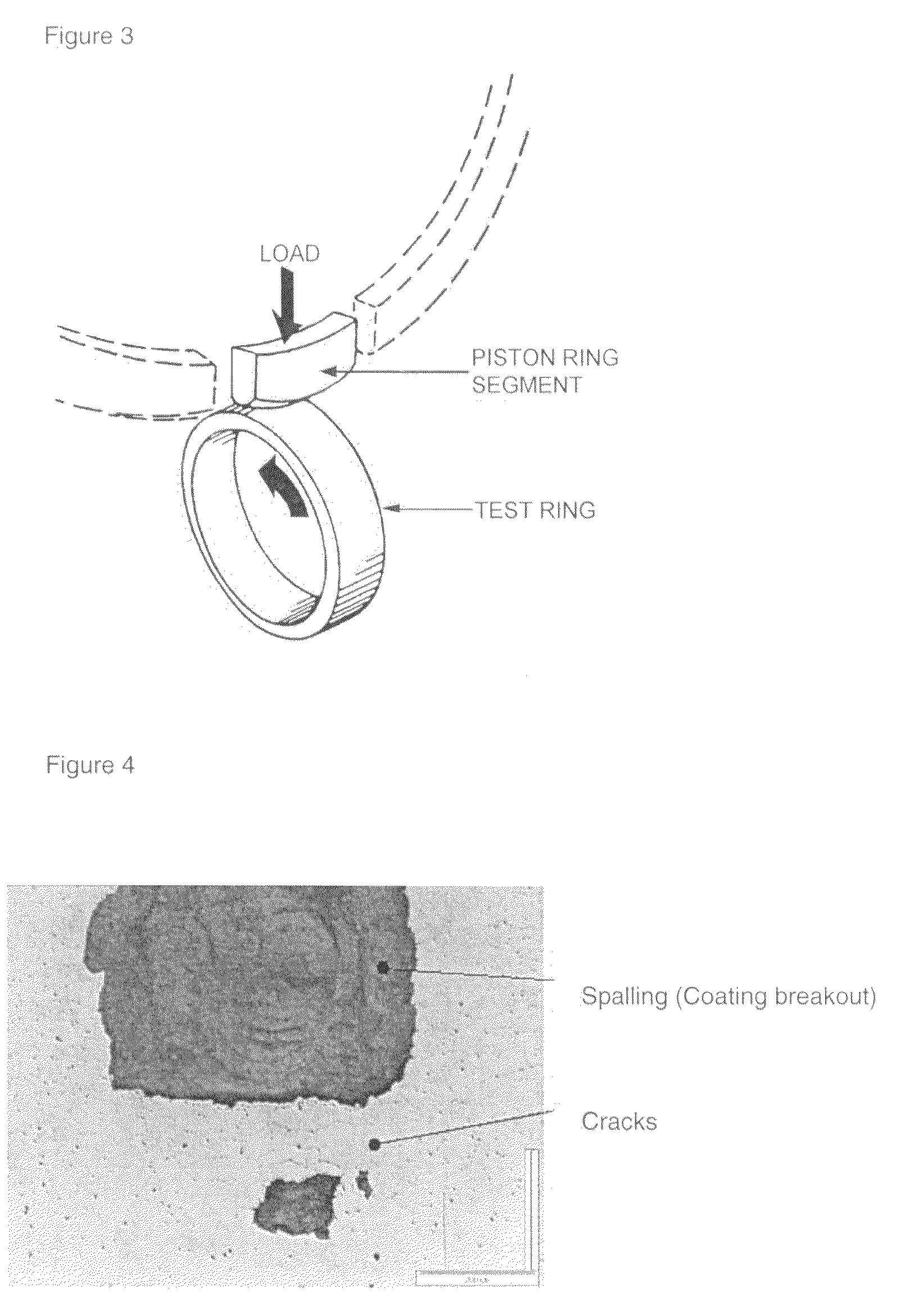

Piston ring for internal combustion engines

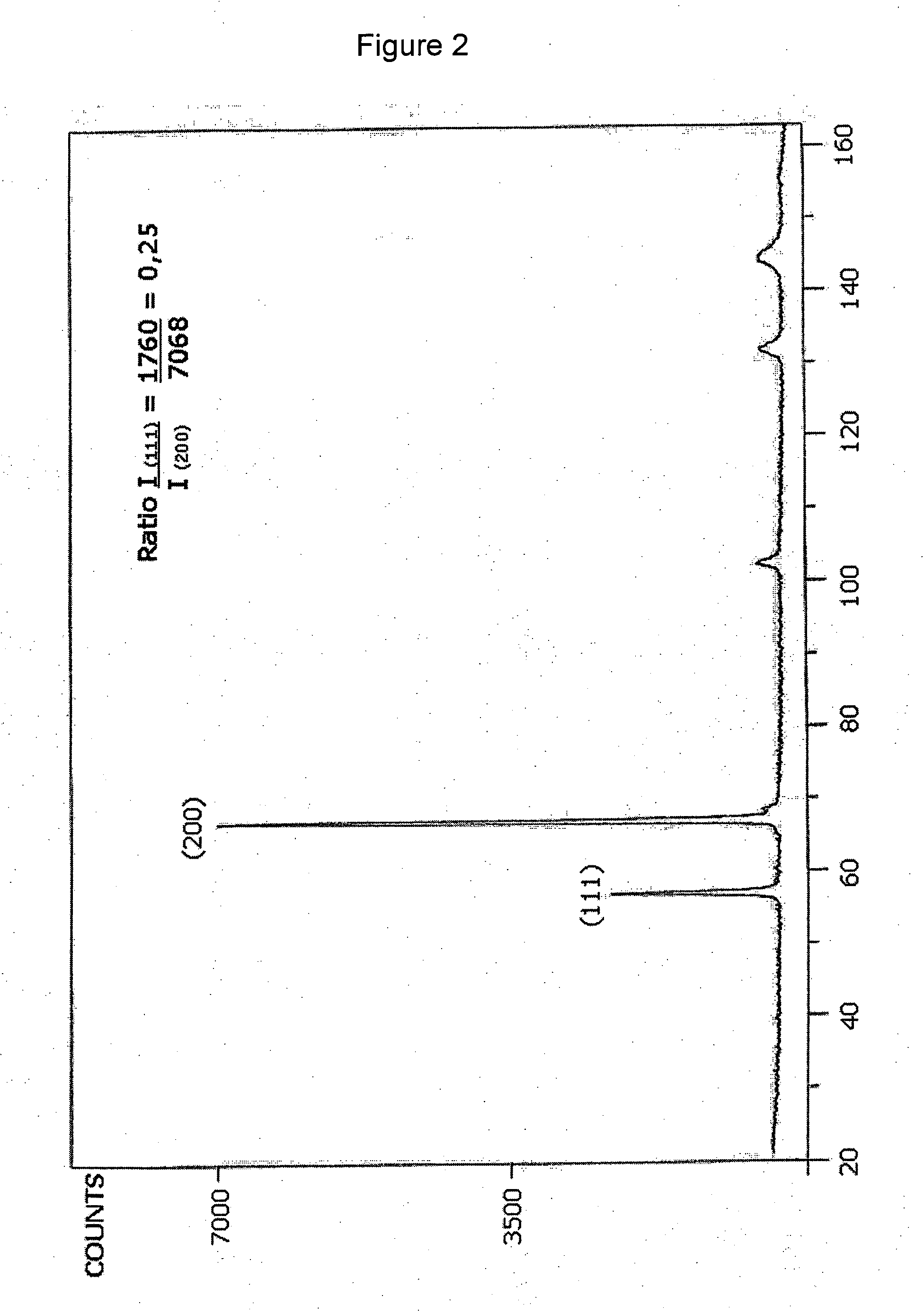

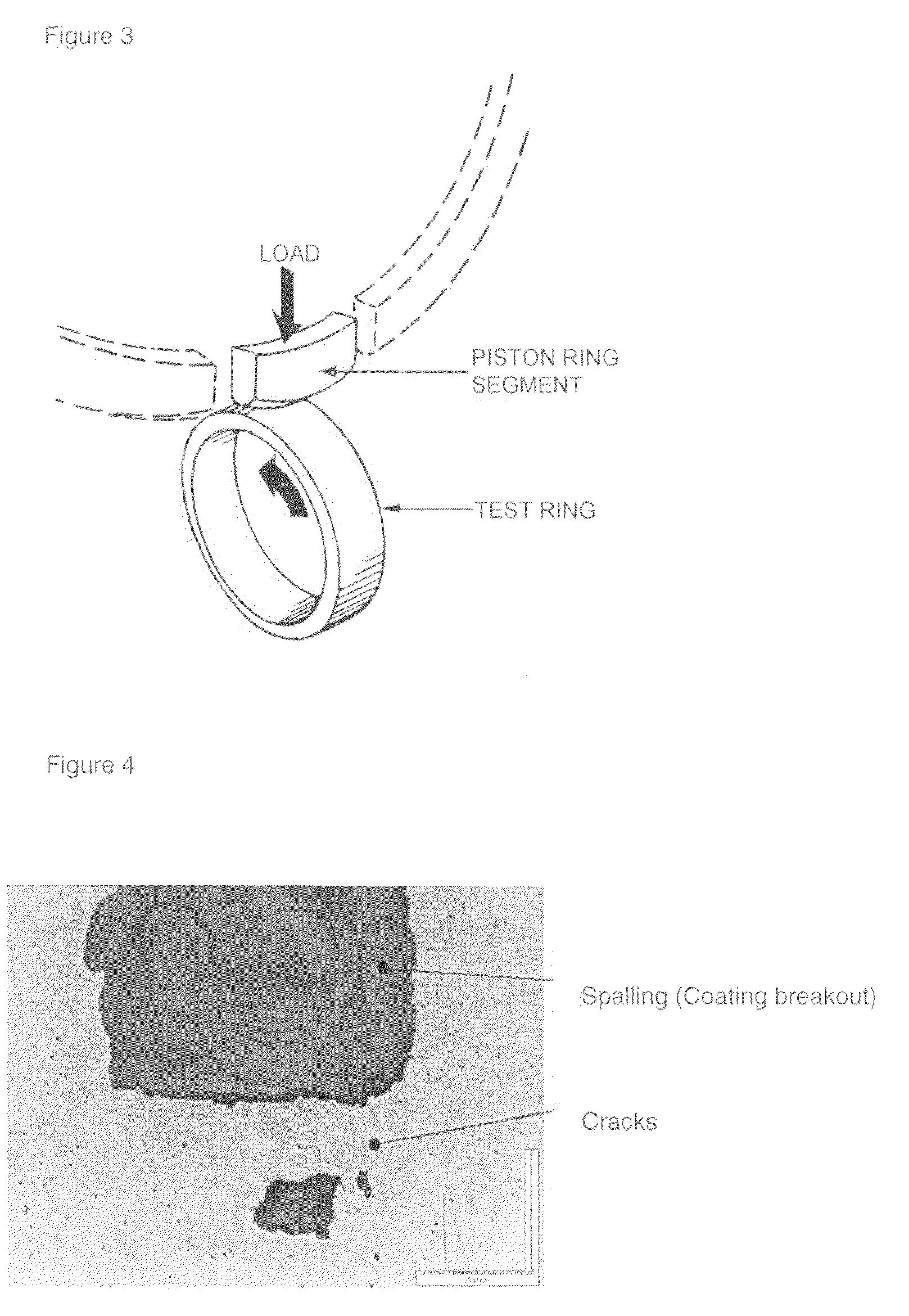

InactiveUS20060269790A1Promote absorptionReduce toughnessPiston ringsVacuum evaporation coatingCrazingEngineering

A piston ring for internal combustion engines with a coating of Chromium nitride (CrN) deposited by a physical vapor deposition process on a sliding surface with a typical crystal structure of CrN phase, has a high wear resistance and superior resistance to the generation of micro-cracks and consequent localized loss of pieces of the coating. The coating is a columnar crystalline coating of CrN having a dispersed pore content lower than 10% in volume and ratio of intensities, measured through x-ray diffraction, between the crystal planes (111) and planes (200), parallel to the surface, in the range of 0.40 to 0.70. This crystalline distribution is obtained through an oxygen content impregnated in the CrN coating between 1.0% in weight to 7.0% in weight. The Vickers hardness of the film ranges from 1,500 to 2,200 HV.

Owner:MAHLE METAL LEVE +1

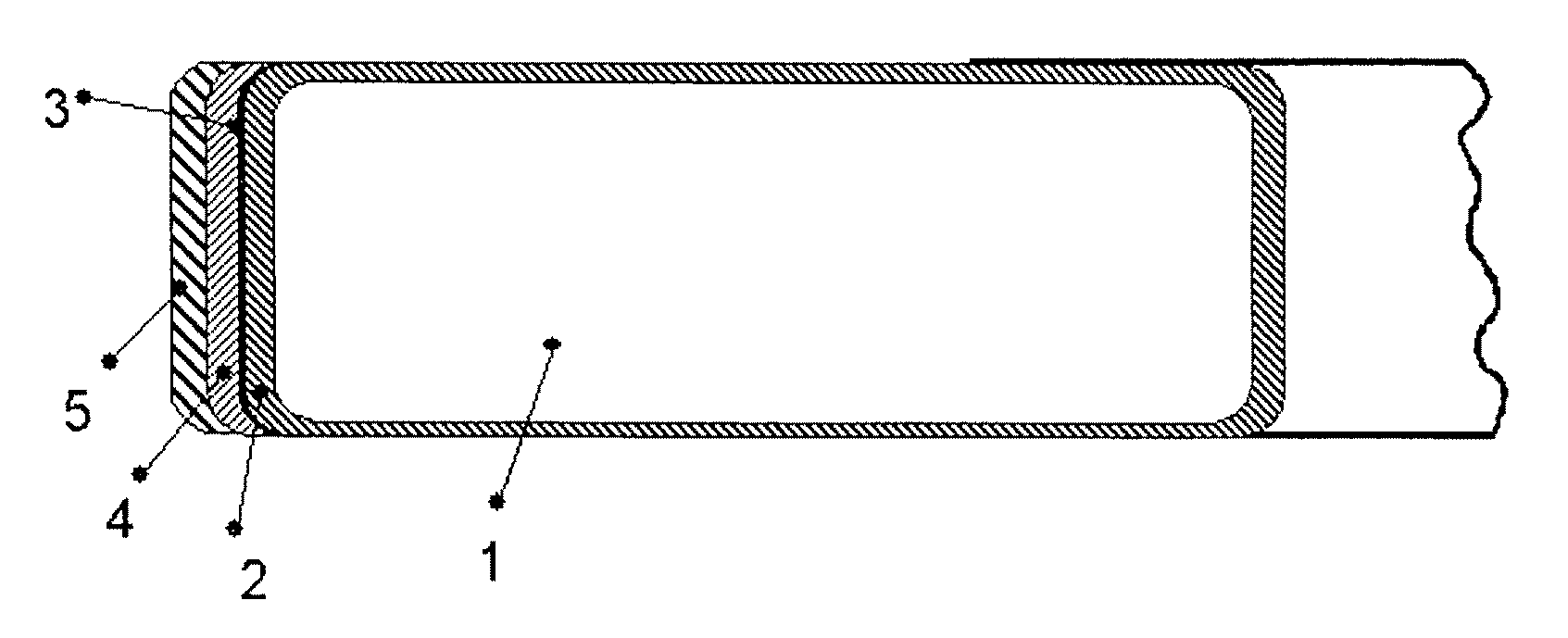

Sliding element, in particular piston ring, having a coating and process for producing a sliding element

ActiveUS20130140776A1Increase valueProducibilityPiston ringsBraking action transmissionPiston ringMetal

A sliding element, in particular piston ring, has on at least one running surface, from the inside outwards, a coating having a metal-containing adhesive layer and a ta-C type DLC layer with a thickness of at least 10 μm.In a process for the production of a sliding element, in particular a piston ring, coating with a metal-containing adhesive layer and a ta-C type DLC layer in a thickness of at least 10 μm is carried out.

Owner:FEDERAL MOGUL BURSCHEID

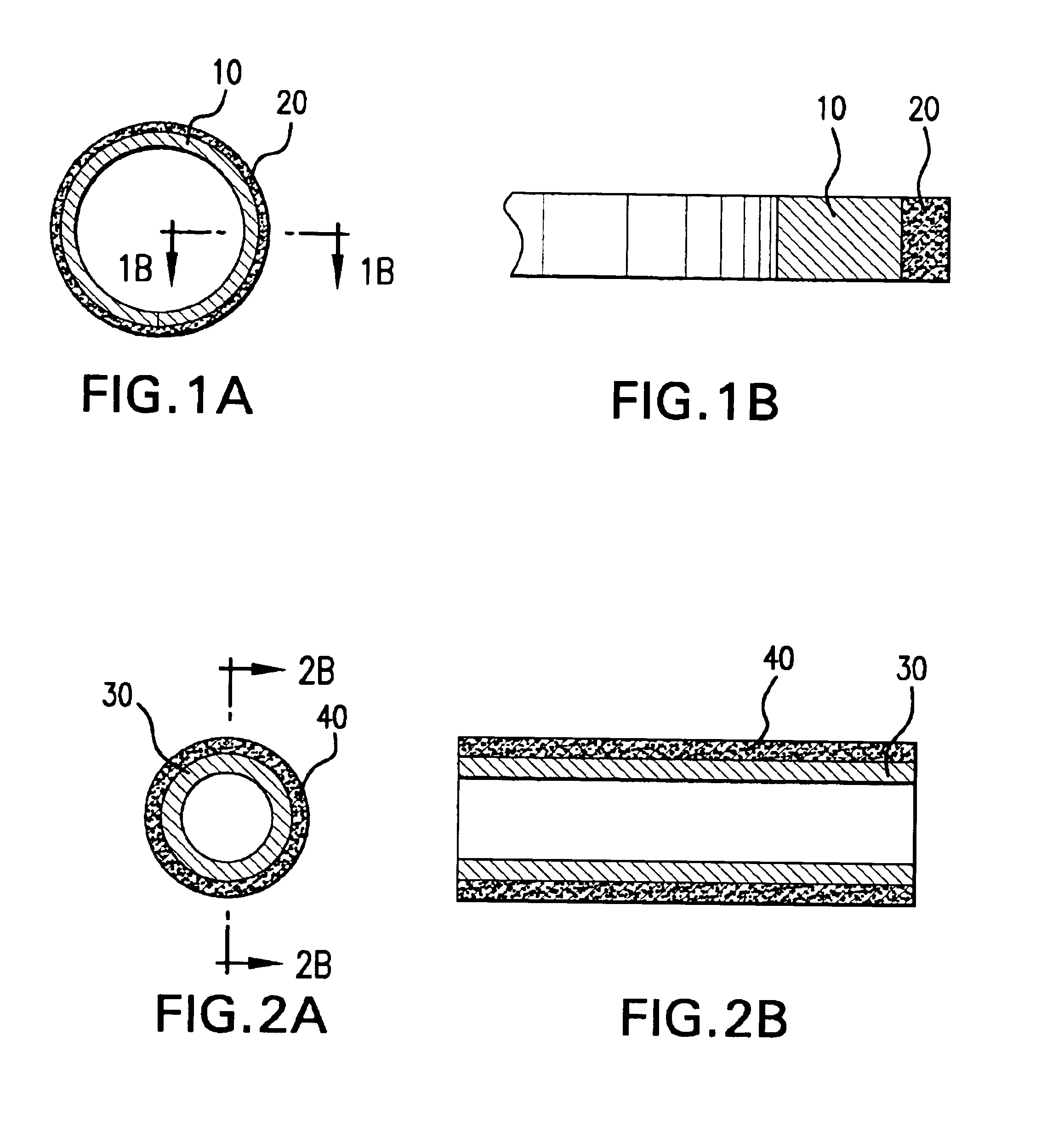

Combination of a cylinder liner and a piston ring

InactiveUS20080053396A1Reduce wearImprove the immunityPiston ringsCylinder headsPiston ringSurface roughness

The disclosed is a combination of a cylinder liner and a piston ring which contacts to a inner circumference surface of the cylinder liner at the pressure of 0.03 to 0.2 MPa, wherein the composition of the cylinder liner includes, silicon: 23.0 to 28.0% by weight, magnesium: 0.80 to 2.0% by weight, copper: 3.0 to 4.5% by weight, iron: 0.25% by weight or less, nickel: 0.01% by weight or less, and the rest: unavoidable impurities and aluminum, and wherein surface roughness profile of the inner circumference surface has Rz 0.5 to 1.0 μm, Rk=0.2 to 0.4 μm, Rpk=0.05 to 0.1 μm, Rvk=0.08 to 0.2 μm, meanwhile, wherein the composition of a piston ring includes carbon: 0.6 to 0.7% by weight, chrome: 13 to 14% by weight, molybdenum: 0.2 to 0.4% by weight, silicon: 0.25 to 0.50% by weight, manganese: 0.2 to 0.5% by weight, and the rest: unavoidable impurities and iron, and wherein carbides with the diameter of 5.0 μm and less are contained at the area rate of 4 to 10%, and the surface roughness of an outer circumference sliding surface is Rz=0.8 μm or less, and RPk=0.15 μm or less.

Owner:NIPPON PISTONRING CO LTD

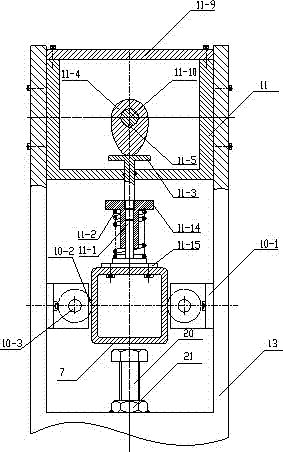

Reciprocating type piston ring-cylinder sleeve friction wear testing machine

InactiveCN101158619ATemperature monitoringMonitor frictionMachine part testingInternal-combustion engine testingEngineeringInternal combustion engine

The invention provides a friction and abrasion tester for reciprocating piston ring-cylinder liner. The invention relates to the technical field of mechanism friction and abrasion, in particular to a friction and abrasion tester for reciprocating piston ring-cylinder liner as a friction paring element practically applied in an internal-combustion engine. A motor driven crankshaft connecting rod mechanism of the tester moves in linear reciprocation through a slide block and a guide sleeve of a guide mechanism, a loading system adopts extrusion-high strength bolting structure to change the pressure from a piston ring of the high strength bolting to the cylinder liner, a lubricator and an oil collector of a lubricating device are positioned on the loading mechanism corresponding to the position of the cylinder liner, sensors of a friction tester and a temperature measurement and a control device are connected to a data collecting card of a data collecting and monitoring device and a computer through interfaces. The invention adopts the practically applied piston ring-cylinder liner of an internal-combustion engine as a friction paring element, load, speed, temperature, lubricant supply experimental parameters can be changed; the invention can monitor temperature, friction experimental data and process experimental data.

Owner:KUNMING UNIV OF SCI & TECH

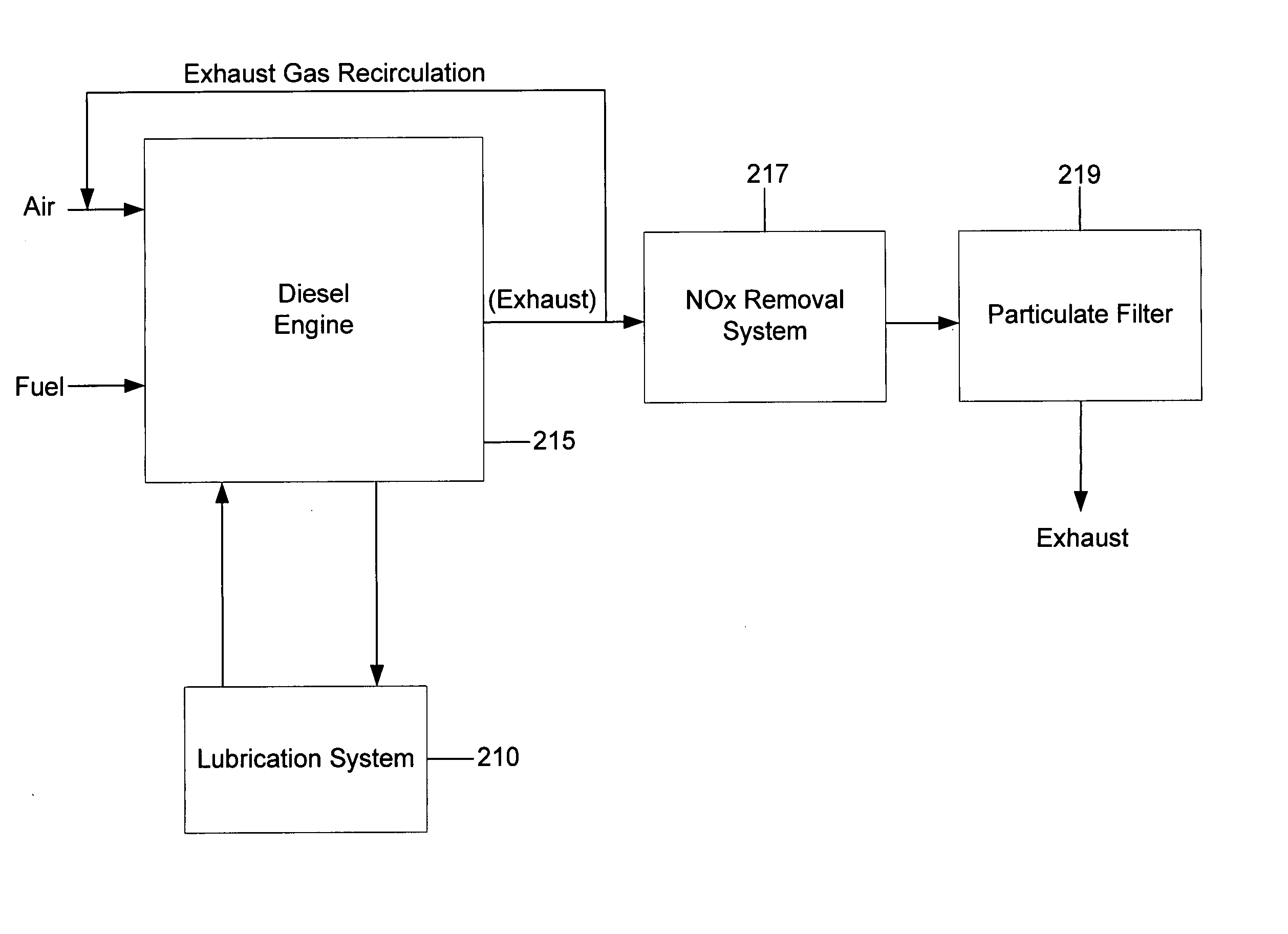

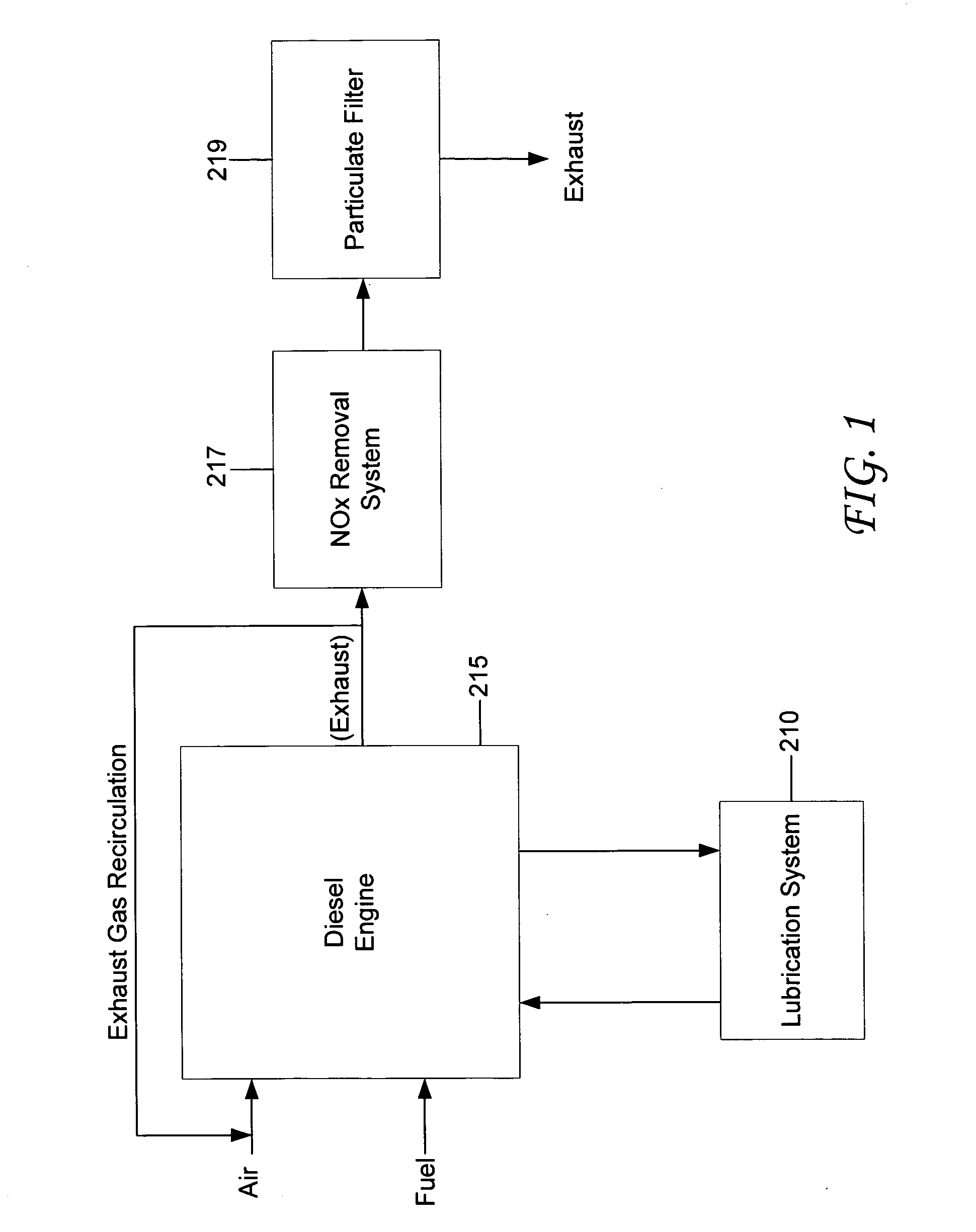

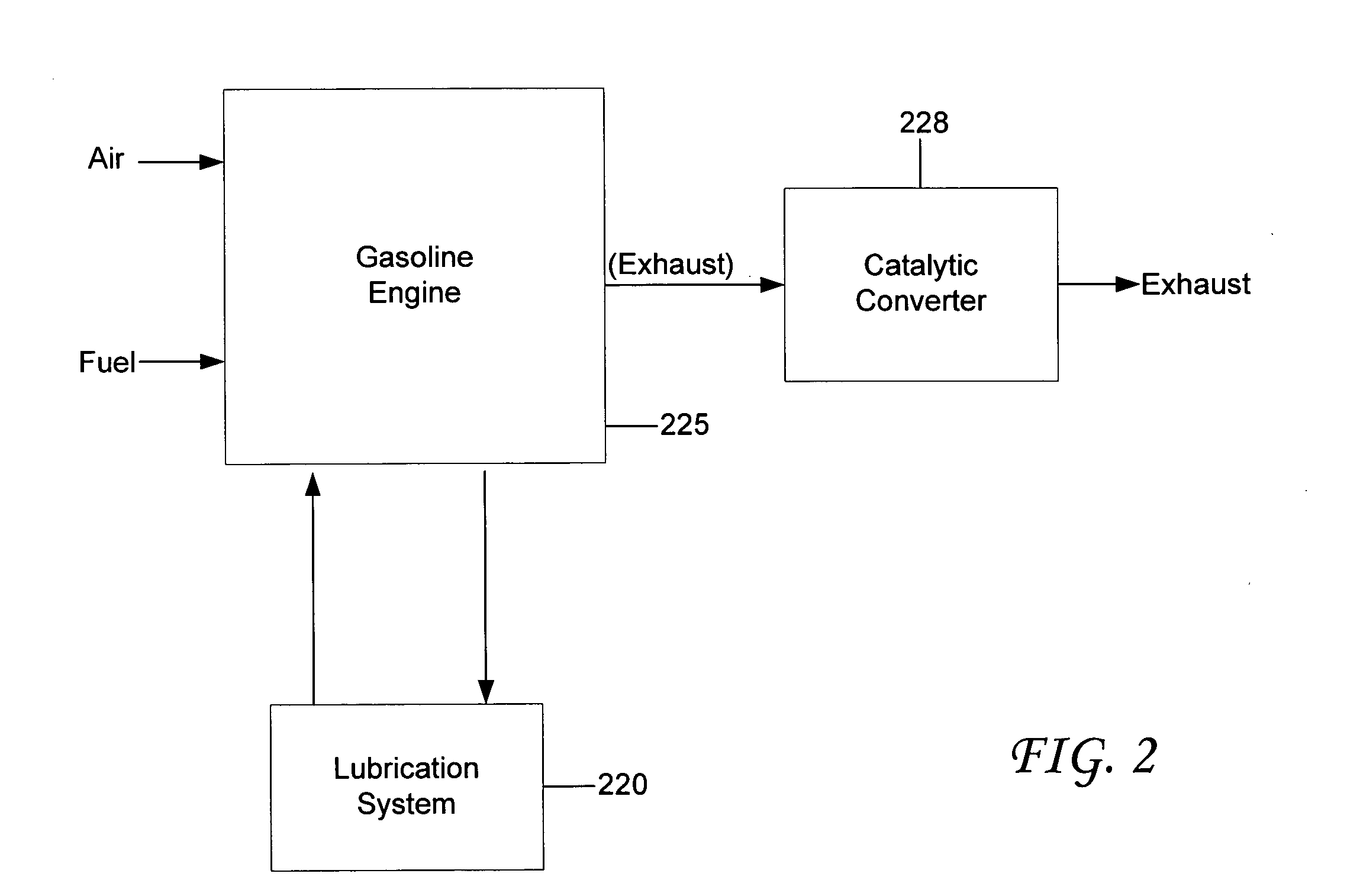

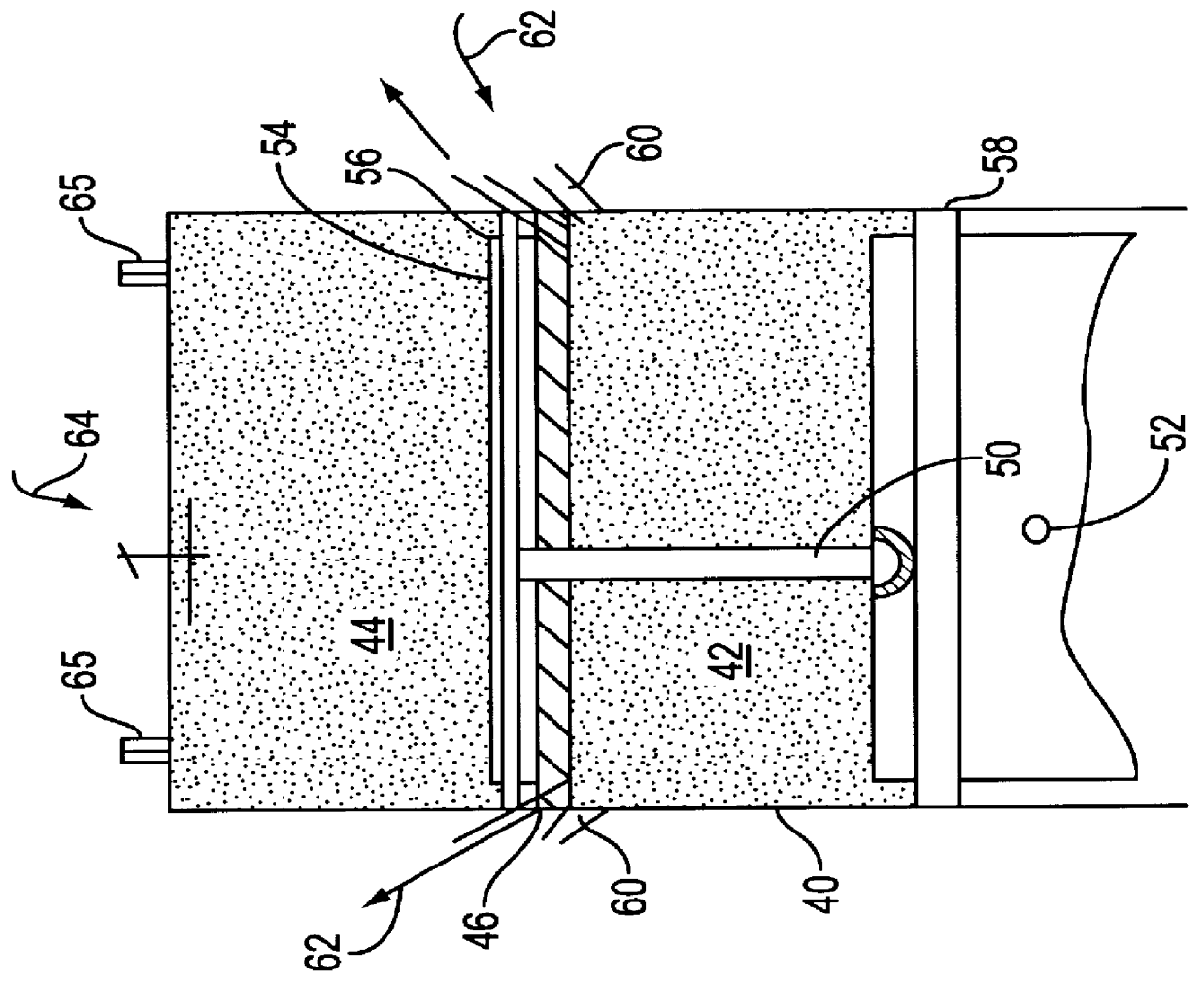

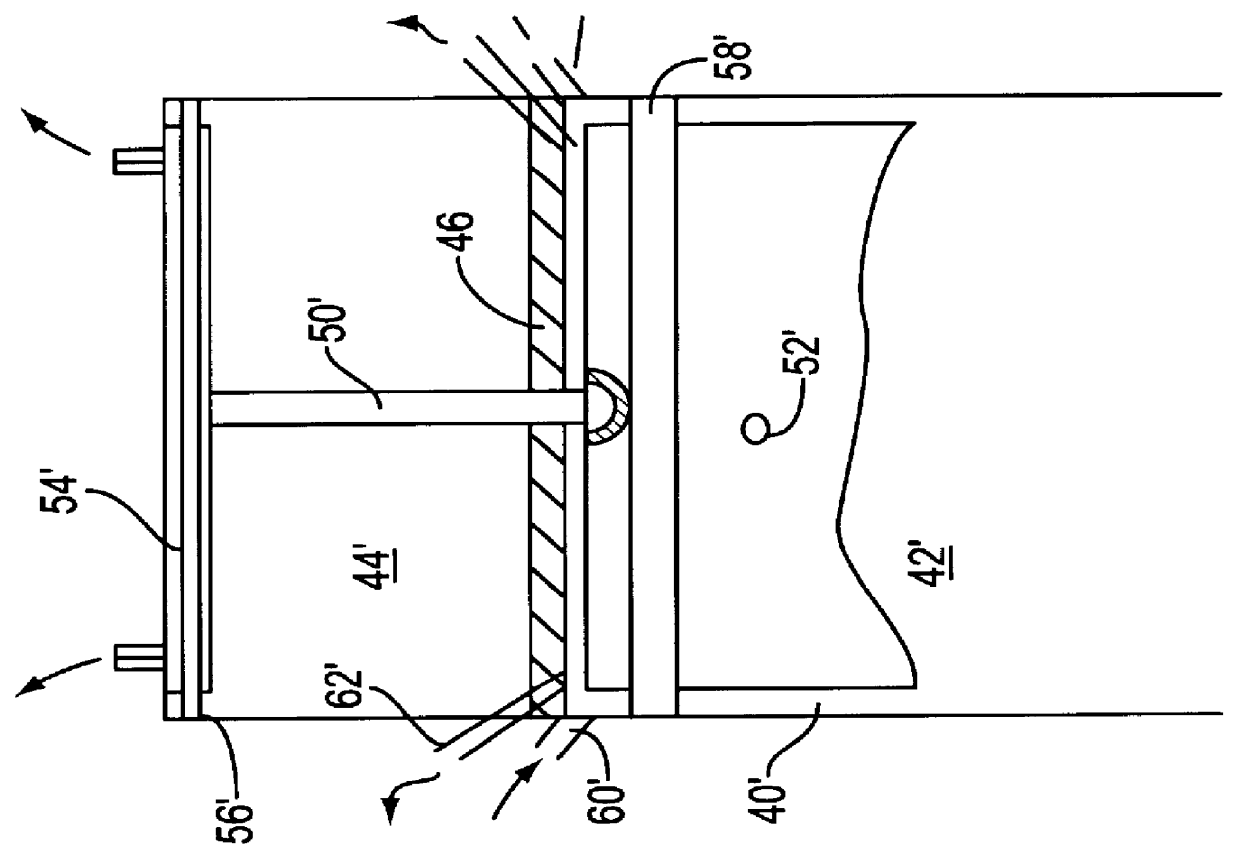

Materials and processes for reducing combustion by-products in a lubrication system for an internal combustion engine

InactiveUS20060260874A1Minimizes engine depositEfficient emissionsMachines/enginesLubricant mounting/connectionSolubilityExternal combustion engine

A lubrication system having an oil filter modified to replace or supplement the performance of lubricant additives that may be used within an internal combustion engine to increase the performance of a lubricant. The formulation of the lubricant is changed in accordance with the chemicals placed in the oil filter. For example, when the oil filter contains a strong base, the lubricant concentration of detergent will decrease, in some cases to zero, while the dispersant concentration in the lubricant will increase. The dispersant is the ideal weak base to neutralize combustion acid at the piston ring zone, carry the resultant weak base-combustion acid complex to the strong base in the oil filter, undergo ion exchange with the strong base, immobilize the acid in the oil filter and recycle back to the piston ring zone for reuse as an acid neutralization agent. The reduction or elimination of detergent from the lubricant will reduce the fouling of the emission filter and of deposit formation on engine parts such as the piston. The oil filter may also contain an additive which is slowly released into the lubricant. For example, a ZnDDP anti-wear additive may be slowly released from the oil filter to the lubricant. Because the ZnDDP has low molecular weight alkyl groups it has limited solubility in the lubricant. The rate of release is limited by the equilibrium concentration of the additive in the lubricant. As a result, a relatively constant concentration of the additive may be maintained in the lubricant. The resultant closed system allows the oil drain intervals to be significantly extended.

Owner:LUTEK

Friction-loss and vibration analog experimental equipment for main motion components of IC engine

InactiveCN1940523AMonitor temperature in real timeReal-time monitoring of abrasive compositionInternal-combustion engine testingInvestigating abrasion/wear resistancePiston ringFriction loss

A tester used for simulating wear-out and vibration of main movable parts on internal combustion engine consists of master driving system formed by air cylinder, piston ring, piston, crankshaft, inlet and outlet of high pressure air; state monitoring system formed by pressure transducer and vibration transducer on bearing base, oil monitoring transducer and temperature transducer as well as vibration transducer on machine rack, and dynamic transducer on crankshaft. It is featured as utilizing high pressure air to simulate explosion pressure in air cylinder and to simulate operation condition causing wear-out and vibration of cylinder sleeve and piston ring pair in said engine.

Owner:WUHAN UNIV OF TECH

Piston ring with chromium nitride coating for internal combustion engines

ActiveUS20090278320A1Improve the immunityHigher absorption of internal compressive stressesPiston ringsBraking action transmissionGas phaseX-ray

The invention relates to a piston ring for internal combustion engines, the piston ring comprises a steel or cast iron base material with a coating of chromium nitride deposited by a physical vapor deposition process on a sliding surface of the piston ring, wherein the coating is composed of a columnar crystal structure of CrN with the following features:(a) an oxygen content in solid solution of 0.5 to 2.5 wt %;(b) a content of uniformly dispersed micro-pores of less than 10% in volume of the coating; and(c) an X-ray diffraction intensity ratio of (111) planes to (200) planes parallel to the surface in the range of 0.80 to 1.20.

Owner:MAHLE INT GMBH +1

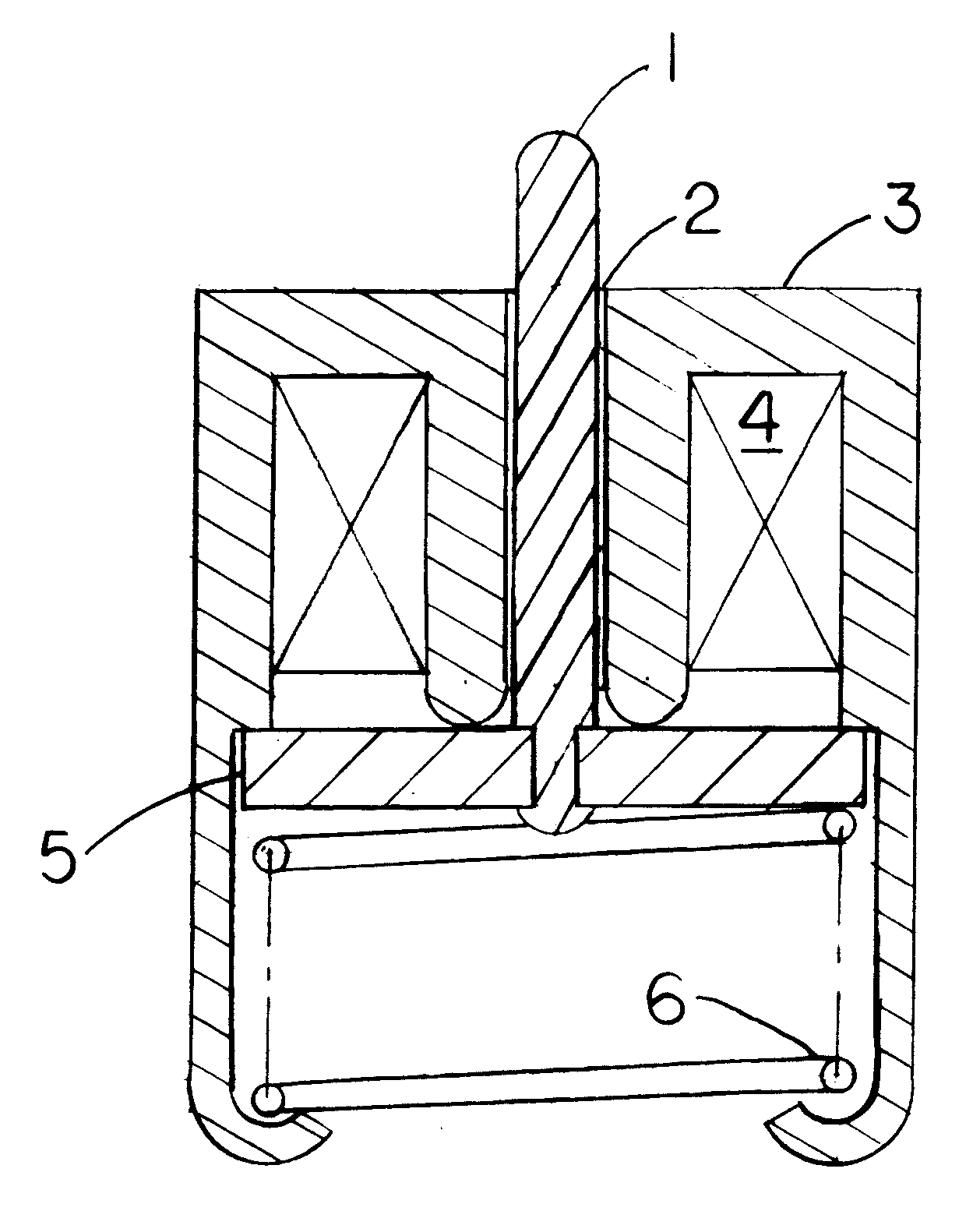

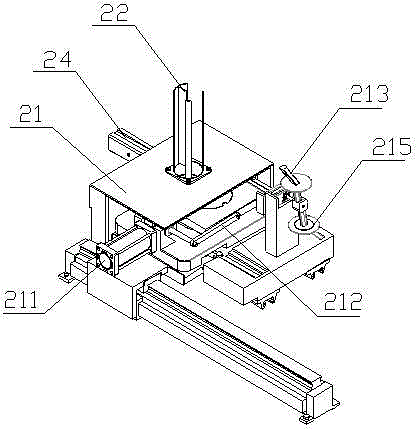

Friction and wear test device for variable load cylinder liner and piston ring

InactiveCN102288502ASimulation is accurateNot subject to assembly errorsInvestigating abrasion/wear resistanceWear testingPiston ring

A variable-load cylinder-sleeve piston-ring frictional wear testing device is mainly composed of a main shaft motor, a guide rail, a sliding table, left and right uprights, a work table, a lever, a loading rod, a swing limiter, a load changer, an inner concave cambered-surface lower clamp and an outer convex cambered-surface upper clamp. An alternating force is generated by the load changer, and then is amplified by the lever to act on a test piece, thereby realizing radial loading of a piston ring to a cylinder sleeve; a variable load is measured in real time by a pressure sensor between theload changer and the lever; friction is measured by a foil gauge on the loading rod; the swing amplitude of the lever is reduced by the swing limiter; the loading rod comes into contact with the outer convex cambered-surface upper clamp through a ball pair to guarantee that the loading direction is vertically downward; the rotating speed of the motor is controlled by means of a program so as to carry out frictional wear tests at different speeds. The testing device is simple in structure, various in testing functions and high in accuracy.

Owner:CHINA UNIV OF MINING & TECH

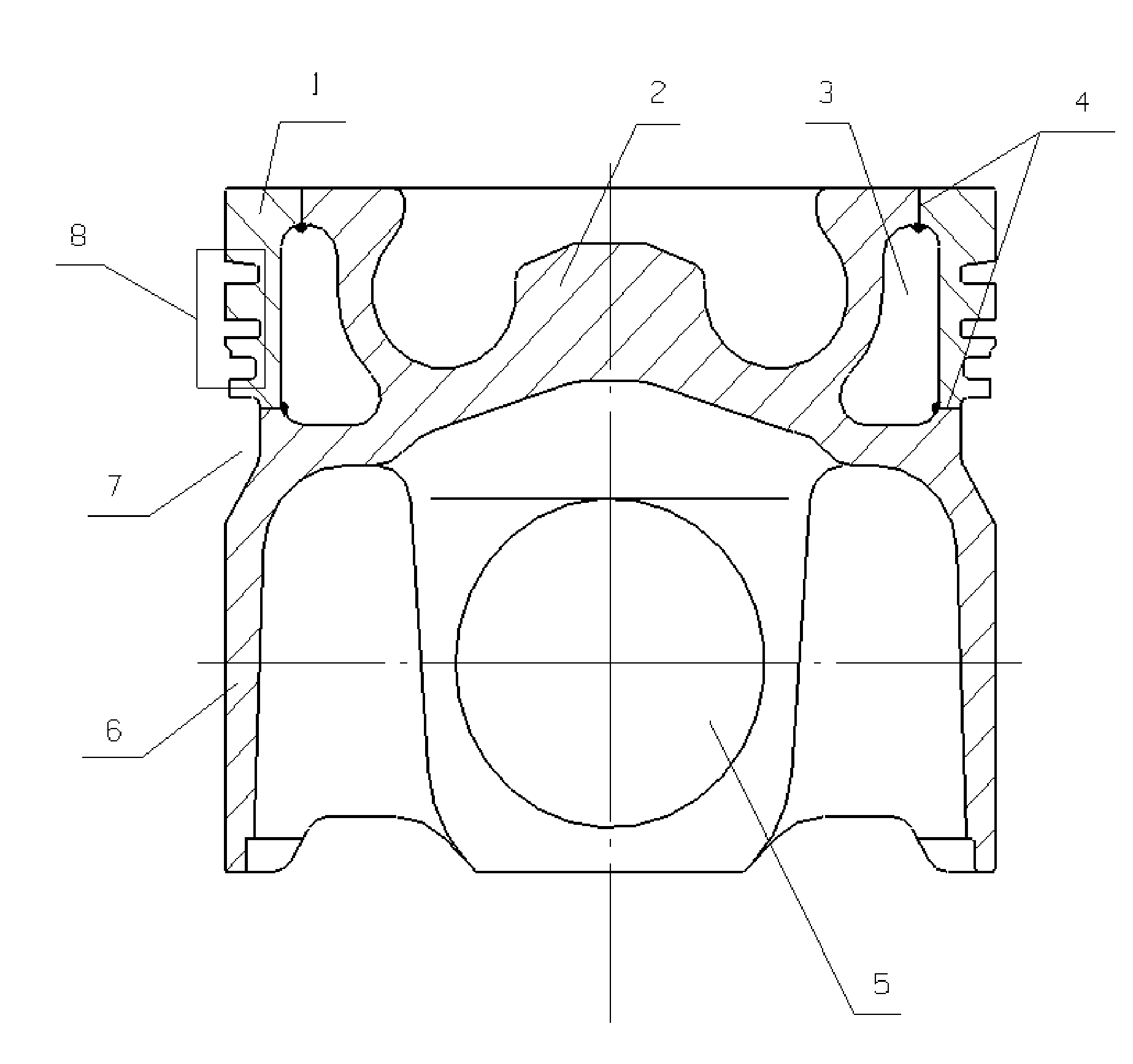

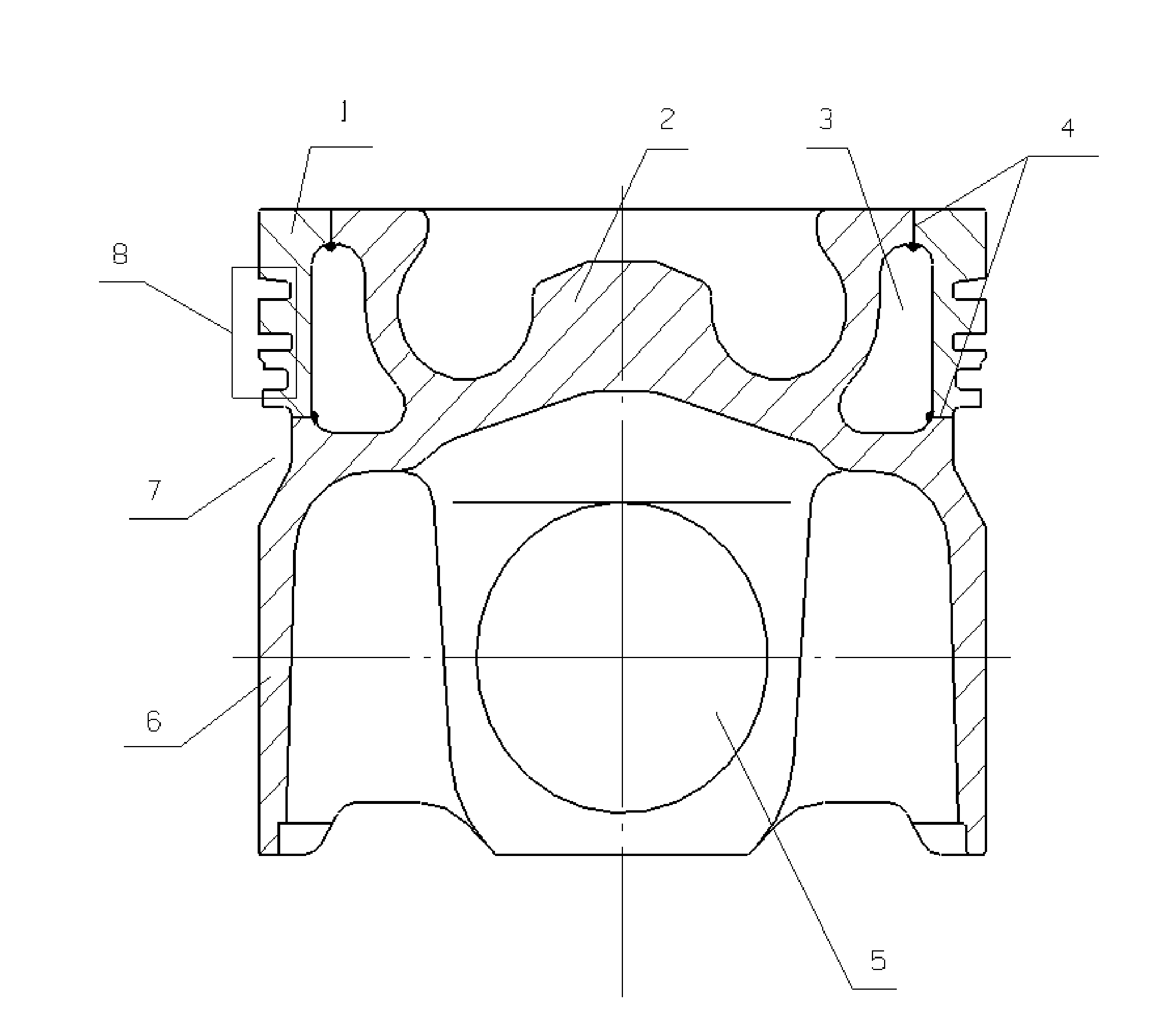

Single-piece forged-steel piston with inner oil cooling chamber and a method for manufacturing thereof

InactiveUS20090020007A1Simple structureEasy to makeValve arrangementsPlungersPiston ringCooling chamber

A laser-welded single-piece forged-steel piston with an enclosed inner oil cooling chamber having the advantages of simple structure and easy manufacturing process, and capable of satisfying the requirement of engines for high power, high rigidity, and low discharge development, and its manufacturing process. The laser-welded single-piece forged-steel piston of the invention comprises a piston body member and a piston ring member, wherein the piston body member is welded together with the piston ring member through laser welding procedure, an enclosed inner oil cooling chamber is formed between the piston body member and the piston ring member, and is connected with the piston inner cavity by means of at least two oil inlet / outlet holes, and a pin hole is opened at the lower portion of the piston body member.

Owner:LIN FENGHUA +3

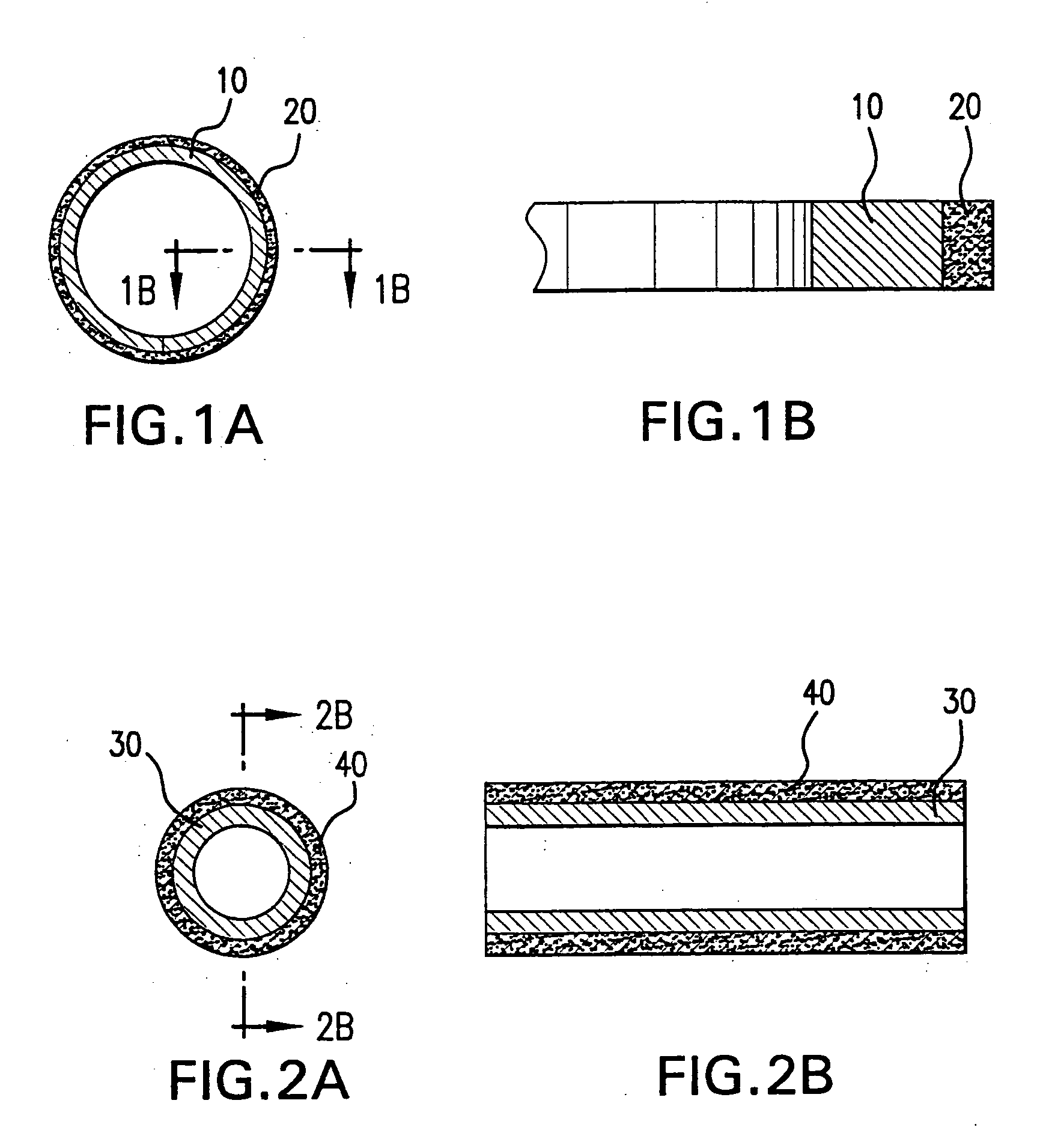

Sliding structure for automotive engine

InactiveUS20050188942A1Reduce coefficient of frictionIncreased durabilityMolten spray coatingPiston ringsCarbon filmPiston ring

A sliding structure for an automotive engine includes a sliding member with a sliding portion and a lubricant applied to the sliding portion so that the sliding portion can make sliding contact with a counterpart member via the lubricant. The sliding member is either of a piston ring, a piston pin, a cam lobe, a cam journal, a plain bearing, a rotary vane and a timing chain. The sliding portion has a base made of a steel or aluminum material and a hard carbon film formed on the base to coat the sliding portion. The hard carbon film has a thickness of 0.3 to 2.0 μm, a Knoop hardness of 1500 to 4500 kg / mm2, a surface roughness Ry (μm) satisfying the following equation: Ry<{(0.75−Hk / 8000)×h+0.07 / 0.8}, where h is the thickness (μm) of the film; and Hk is the Knoop hardness (kg / mm2) of the film.

Owner:NISSAN MOTOR CO LTD

Piston ring with chromium nitride coating for internal combustion engines

ActiveUS7891669B2Improve the immunityPiston ringsBraking action transmissionExternal combustion engineGas phase

The invention relates to a piston ring for internal combustion engines, the piston ring comprises a steel or cast iron base material with a coating of chromium nitride deposited by a physical vapor deposition process on a sliding surface of the piston ring, wherein the coating is composed of a columnar crystal structure of CrN with the following features:(a) an oxygen content in solid solution of 0.5 to 2.5 wt %;(b) a content of uniformly dispersed micro-pores of less than 10% in volume of the coating; and(c) an X-ray diffraction intensity ratio of (111) planes to (200) planes parallel to the surface in the range of 0.80 to 1.20.

Owner:MAHLE INT GMBH +1

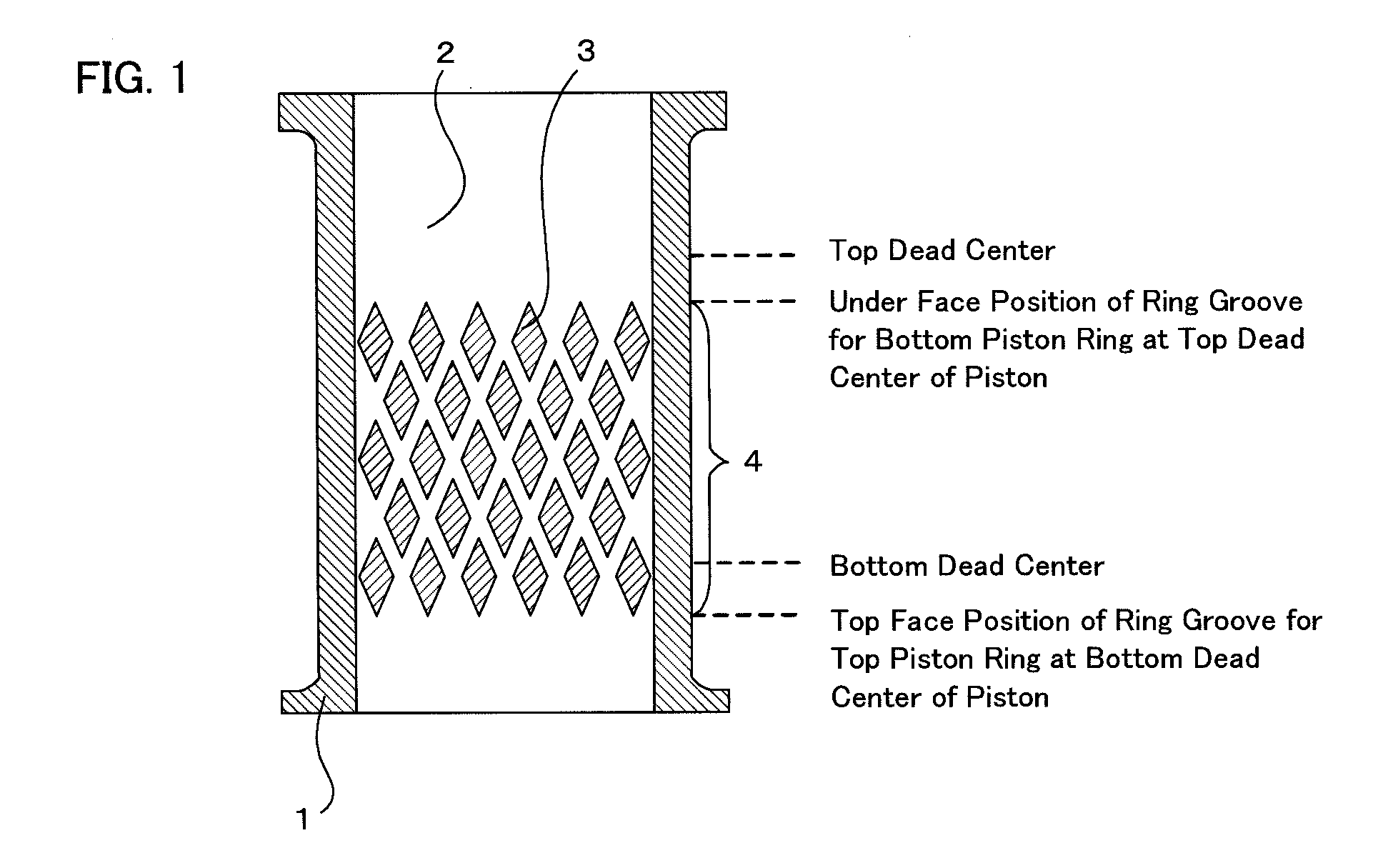

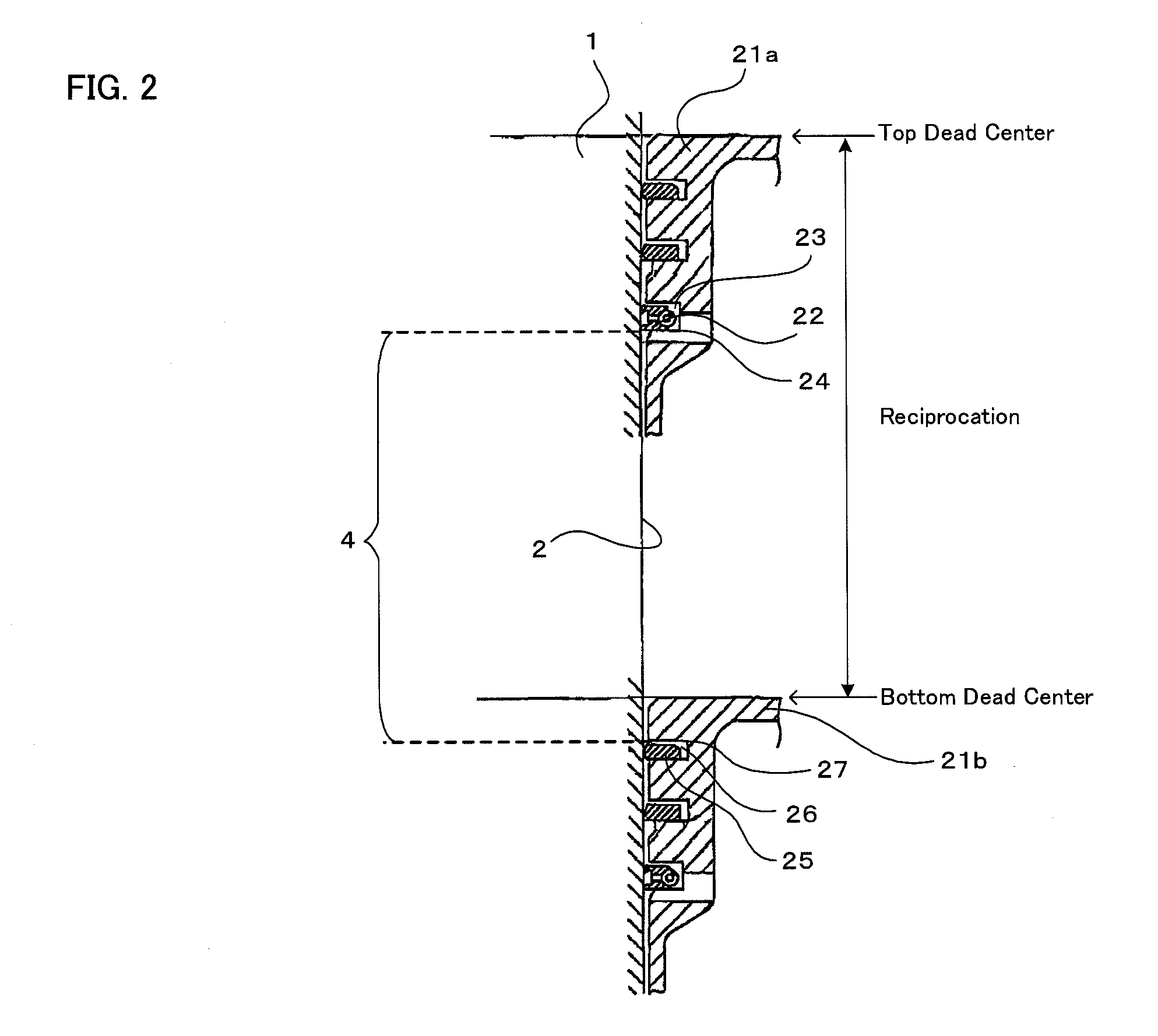

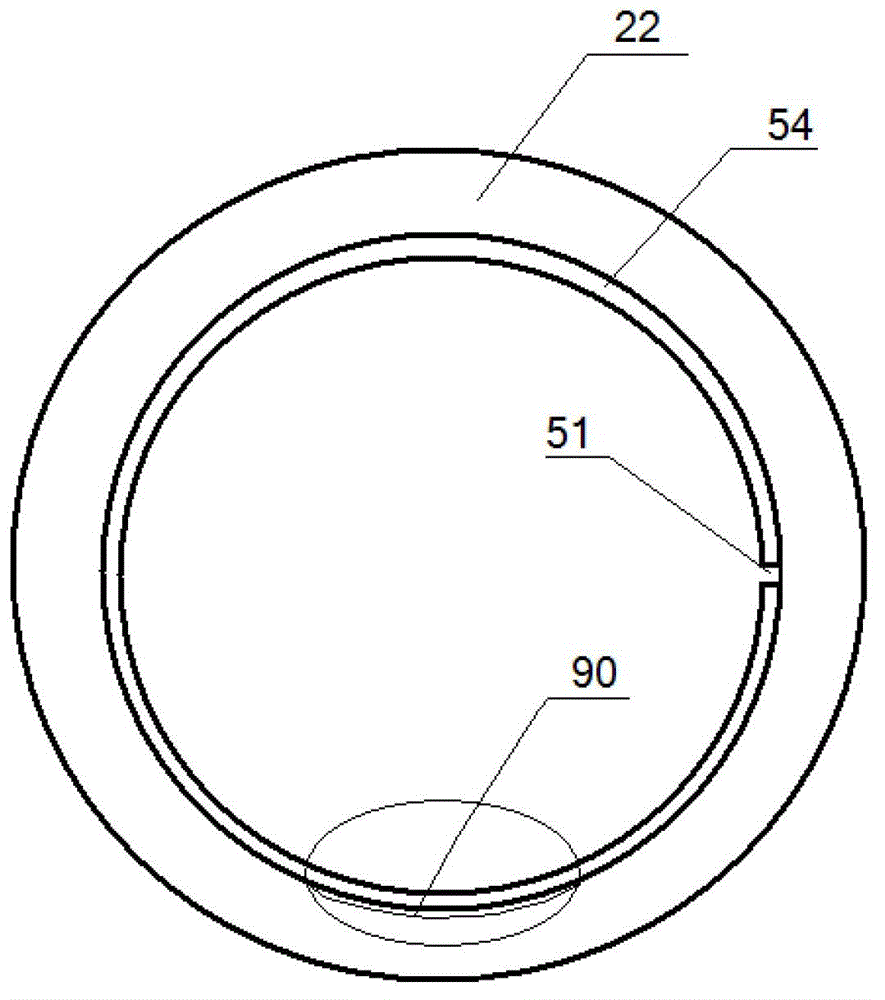

Cylinder

ActiveUS20100288222A1Reciprocation frictionImprove energy efficiencyCylinder headsCylindersTop dead centerPiston ring

A cylinder realizing reduced reciprocation friction between a piston ring and a bore surface of the cylinder in a region where the piston ring slides. The cylinder in which a piston slides on a bore surface of the cylinder. A plurality of recesses is formed in a stroke center region in the bore surface of the cylinder. The stroke center region is a region between an under face position of a ring groove for a bottom piston ring at a top dead center of the piston and a top face position of a ring groove for a top piston ring at a bottom dead center of the piston. The total of areas of all of the recesses is in the range of 1% to 80% when an area of the stroke center region is 100%, and the recesses are not formed in a region other than the stroke center region of the bore surface of the cylinder.

Owner:HINO MOTORS LTD +1

Automatic light leakage degree and closed gap detector of three-station piston ring and calibrating block thereof

InactiveCN102865980AImprove work efficiencyImprove reliabilityUsing optical meansSortingPiston ringLuminosity

The invention relates to an automatic light leakage degree and closed gap detector of a three-station piston ring and a calibrating block thereof. A horizontal workbench is formed at the top of a stand, and is provided with a cantilever beam, a touch screen connected to the cantilever beam, a storage mechanism for storing the piston ring, a push plate positioned below the storage mechanism and a round turntable which is arranged in front of the storage mechanism and the push plate and rotatably inlayed on the horizontal workbench; a separation mechanism is arranged in front of the round turntable; a closed gap detection station, a discharge station and a light leakage degree detection station are formed on the round turntable by three inlayed standard gauges; a first charge coupled device (CCD) sensor corresponding to the closed gap detection station and a second CCD sensor corresponding to the light leakage degree detection station are respectively arranged above the horizontal workbench; and a light leakage degree detection illumination mechanism is arranged at the position below the horizontal workbench, corresponding to the light leakage degree detection station. By adopting the detector and the calibrating block, high efficiency, and the automatic detection and the separation of two indexes of the light leakage degree and the closed gap of small and medium sized piston rings are realized.

Owner:TIANJIN UNIV

Combination structure of piston ring and cylinder liner for internal combustion engine

InactiveUS20100319647A1Wear minimizationReduce harmPiston ringsCylinder headsContact pressurePiston ring

An object of the present invention is to provide a cylinder structure reduced in mutual damage caused by a sliding operation of a piston ring and a cylinder liner when the piston ring having a linear expansion property which follows linear expansion of the cylinder liner made of an aluminum alloy is used. In order to achieve the object, a combination structure of the piston ring and the cylinder liner for an internal combustion engine described below is employed. In the cylinder liner for an internal combustion engine, the inner circumferential surface satisfies the conditions, a ten-point height of roughness profile (RzJIS94) of 0.5 μm to 1.0 μm, a core roughness depth (Rk) of 0.2 μm to 0.4 μm, a reduced peak height (Rpk) of 0.05 μm to 0.1 μm and a reduced valley depths (Rvk) of 0.08 μm to 0.2 μm. In the piston ring, the sliding surface against to an inner circumferential surface in the cylinder liner satisfies the conditions, a ten-point height of roughness profile (RzJIS94) of not more than 1.6 μm and a reduced peak height (Rpk) of not more than 0.3 μm. The piston ring is used at a contact pressure of 0.03 MPa to 0.2 MPa against to the inner circumferential surface of the cylinder liner.

Owner:NIPPON PISTONRING CO LTD

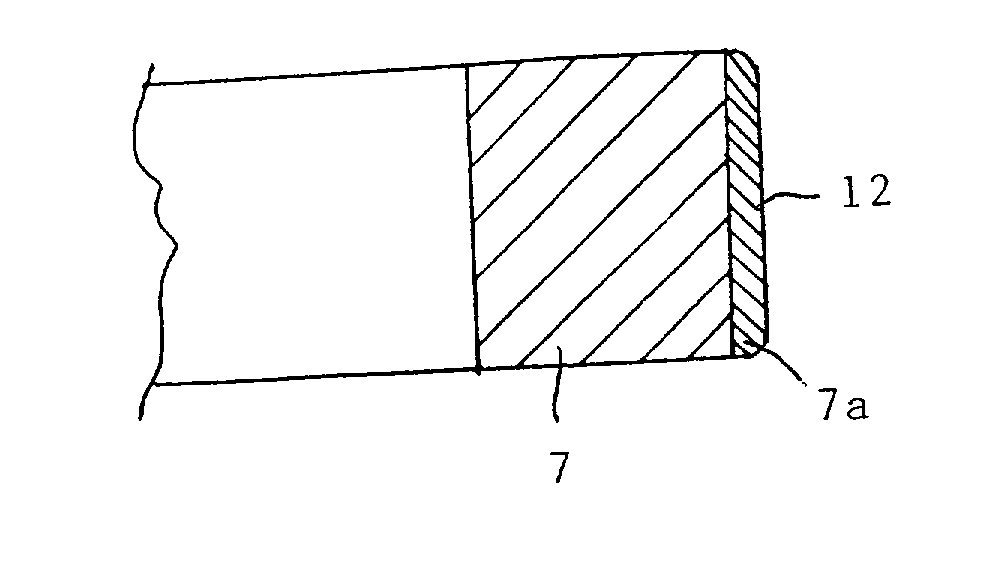

Piston ring

InactiveUS20120205876A1Prevent scratch and scuffRelieve stressPiston ringsBraking action transmissionPiston ringEngineering

A piston ring is provided at its outer periphery with a sliding surface, wherein in a cross section thereof which is perpendicular to a radial direction of the piston ring, the sliding surface includes a first sliding surface which occupies a predetermined region from one end thereof, and a second sliding surface which occupies a region extending from one end to the other end of the first sliding surface, the first sliding surface is formed of hard film, the second sliding surface is not formed of hard film, and the second sliding surface exists at a position deviated inward from a phantom line extending from the first sliding surface toward the other end.

Owner:NIPPON PISTONRING CO LTD

Amorphous hard carbon film, mechanical parts and method for producing amorphous hard carbon film

InactiveUS20020022129A1Reduce coefficient of frictionHigh hardnessLayered productsVacuum evaporation coatingCarbon filmPiston ring

An amorphous hard carbon film has low friction coefficient from the beginning of sliding, when the metal oxide is contained in the film. The adhesion of the film to the substrate is also improved due to the low temperature treatment of RF plasma enhanced CVD method. This film can be applied to many sliding members, e.g., a piston ring, a vane of compressor and a plunger of fuel injection pump, used under severe condition.

Owner:RIKEN CO LTD

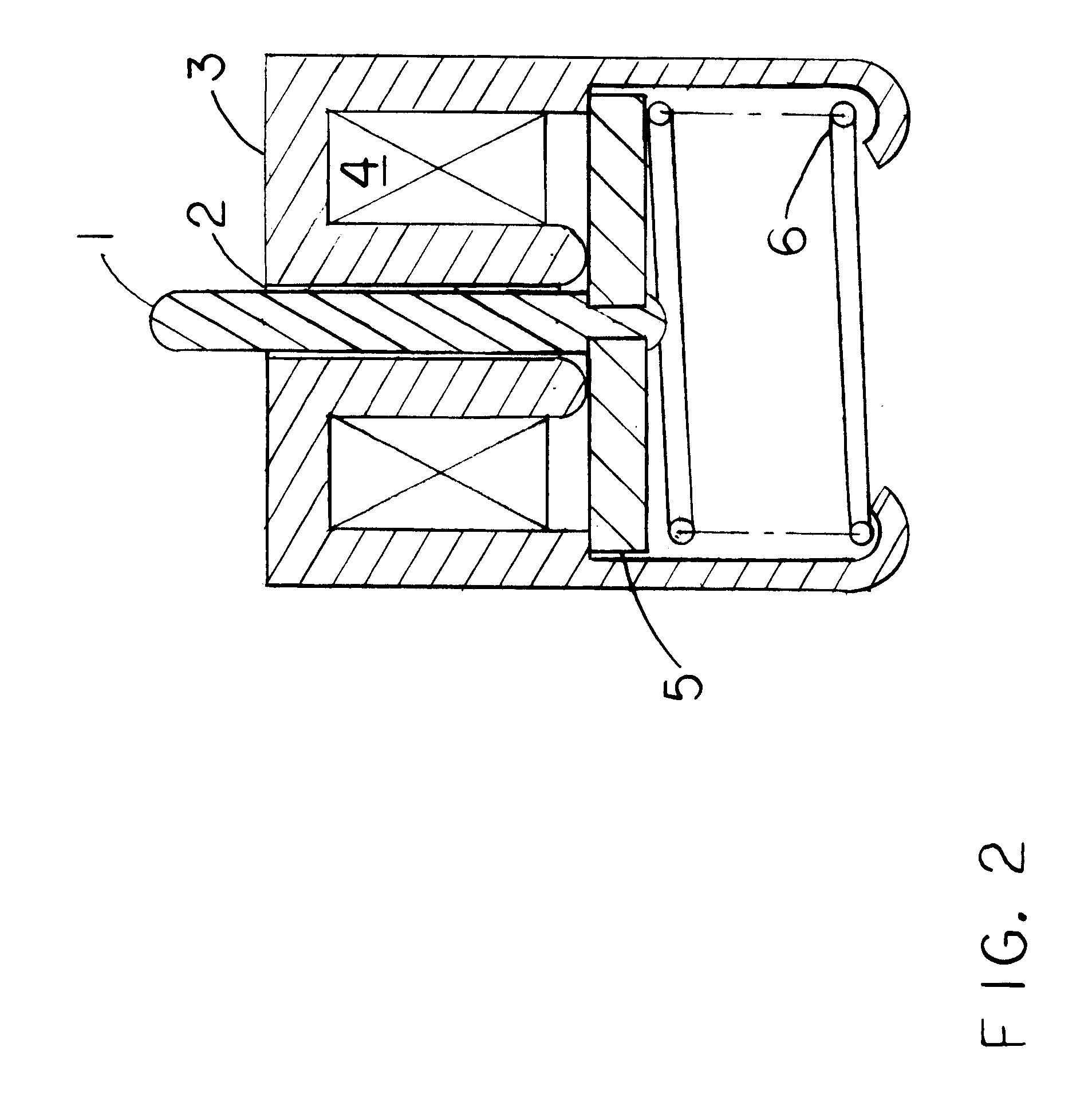

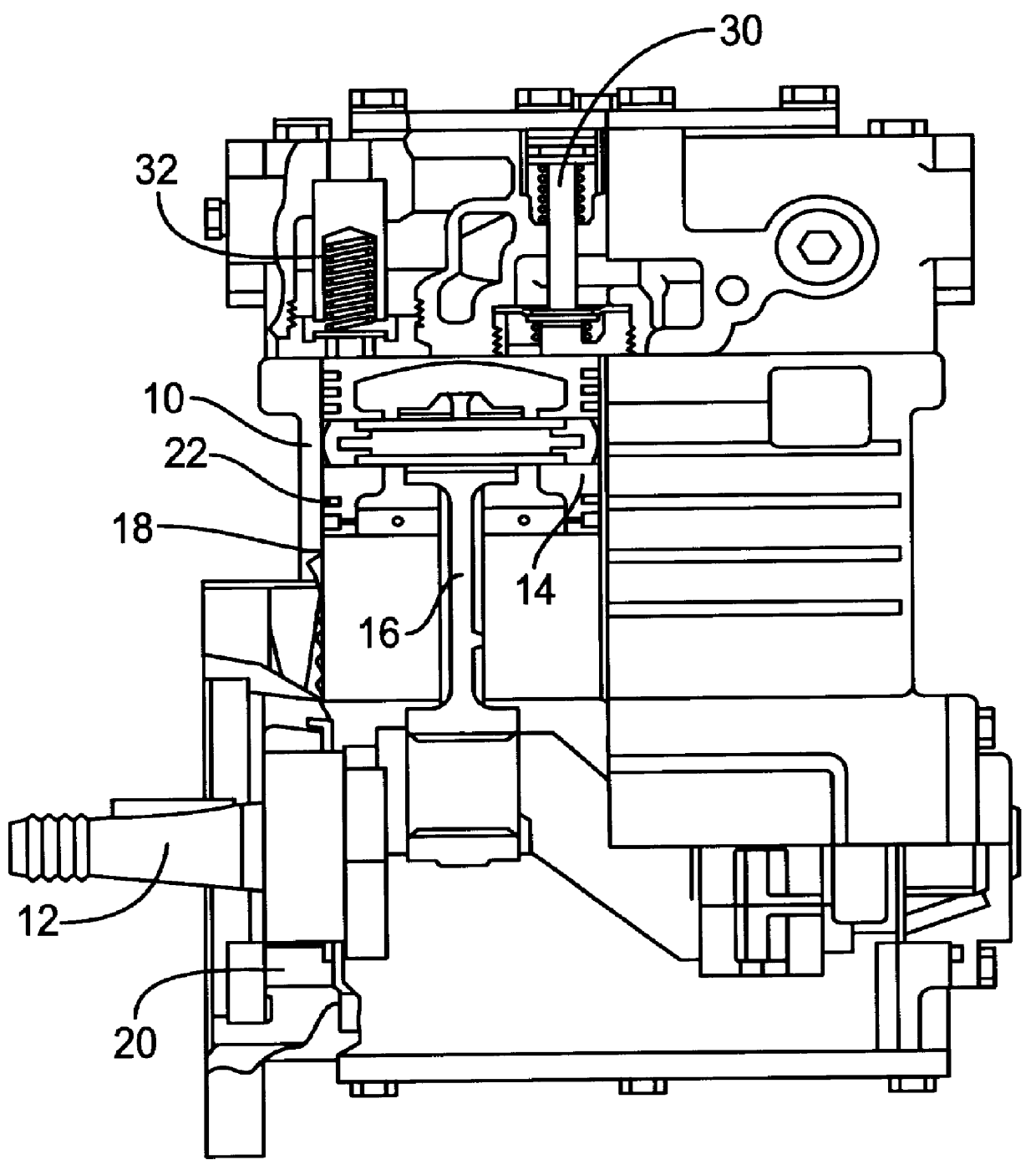

Oil-less/oil-free air brake compressor with a dual piston arrangement

A cylinder is divided into two chambers by a wall to receive a pair of pistons. This reduces the stroke length and correspondingly reduces the linear speed of the piston. This leads to a reduced PV factor associated with degradation and wear of the piston rings. Moreover, the multi-cylinder arrangement provides the same performance in an oil-free compressor assembly without appreciably expanding dimensional constraints relative to known systems.

Owner:ALLIEDSIGNAL TRUCK BRAKE SYST

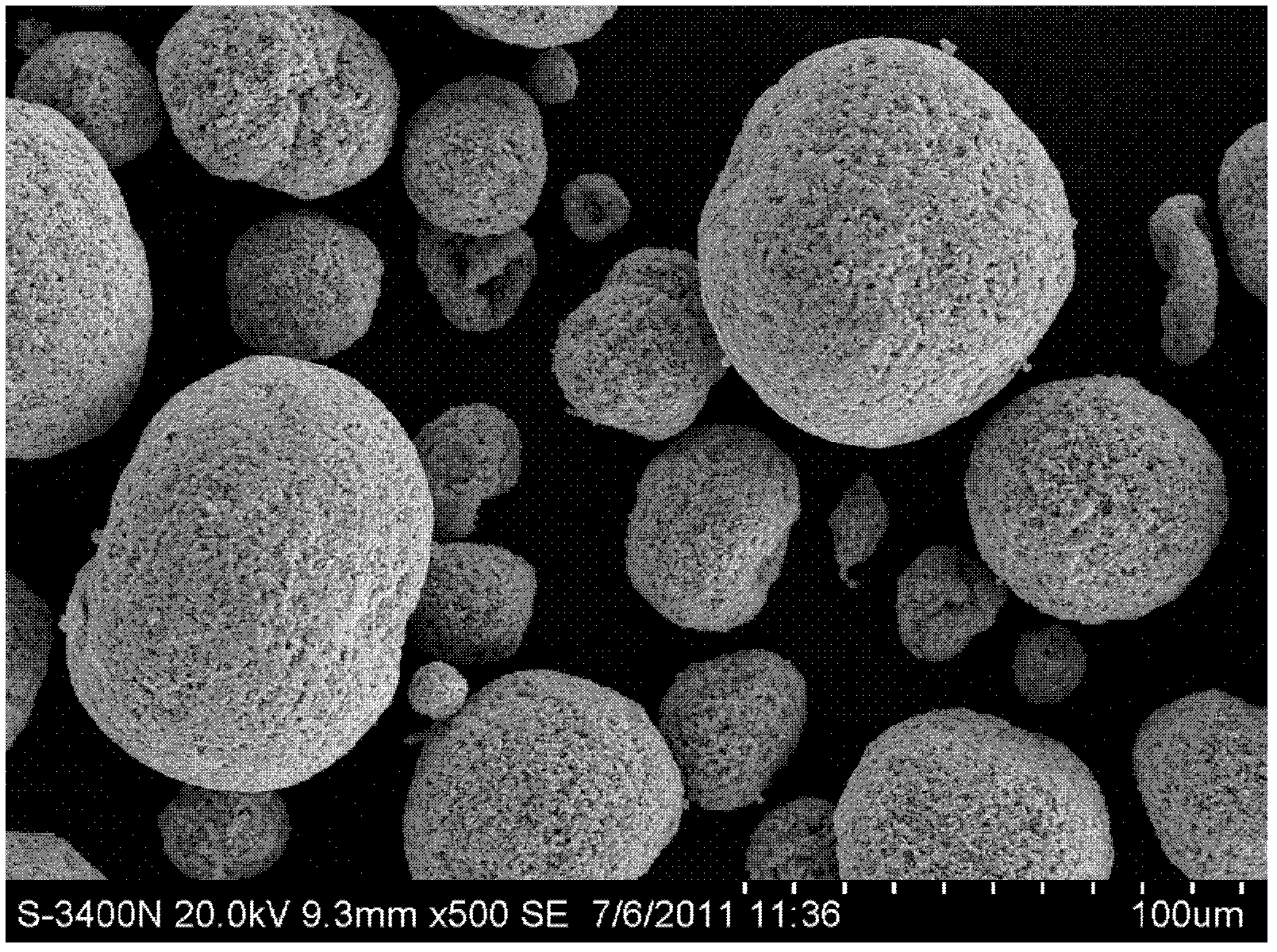

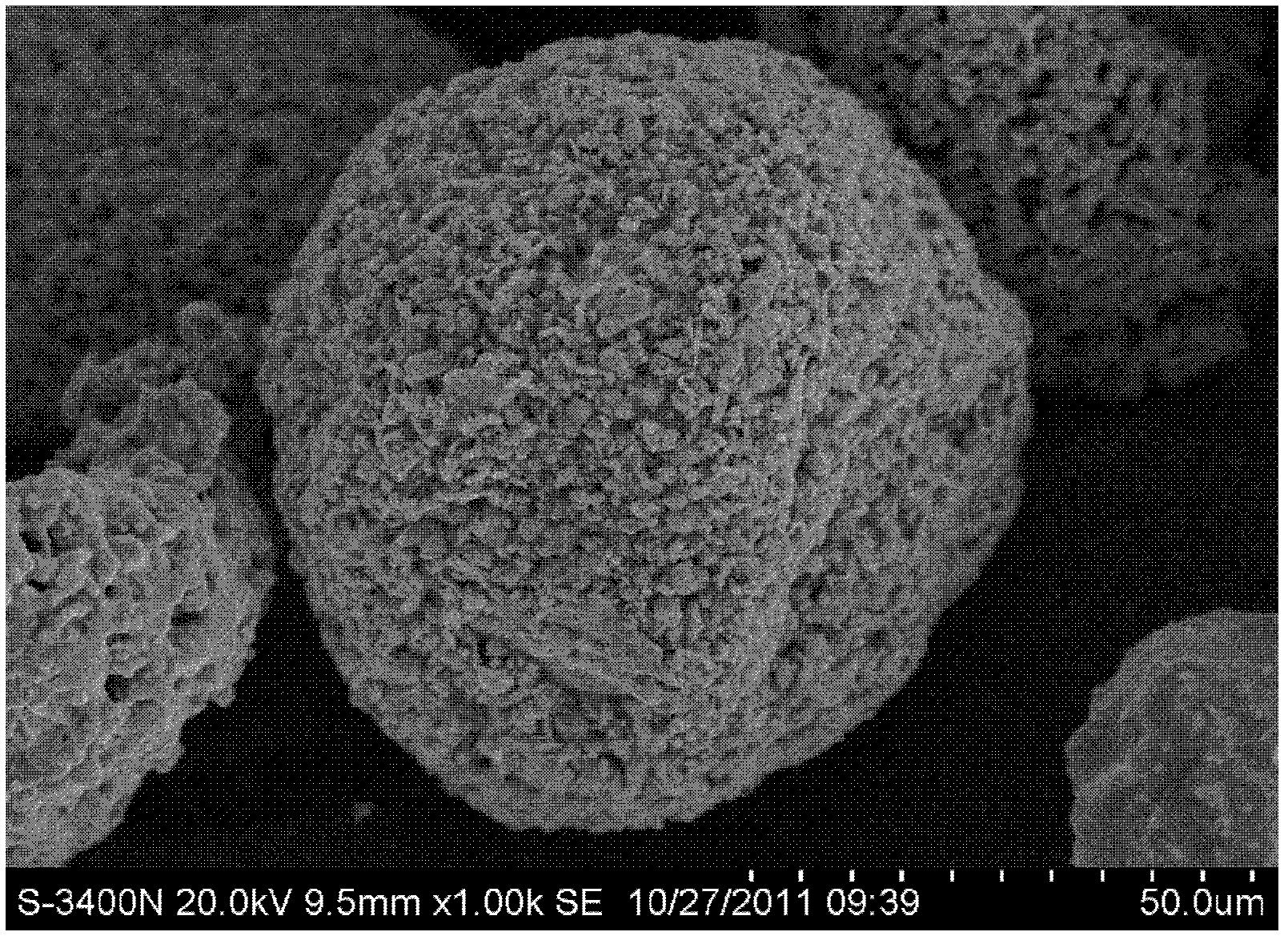

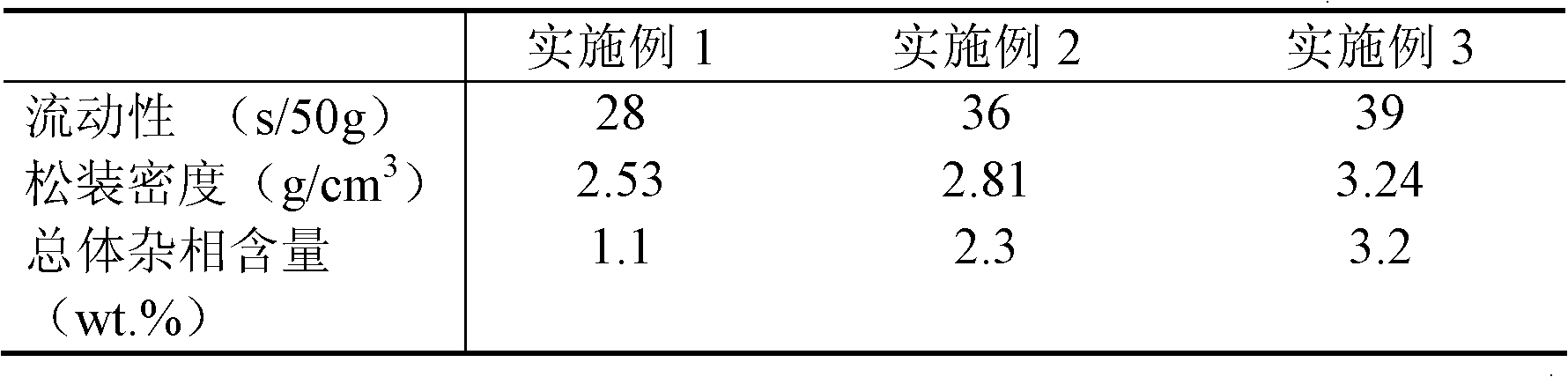

Preparation method of coating containing TiB2 metal ceramic composite powder for thermal spraying piston ring

InactiveCN102581292AImprove deposition efficiencyGuaranteed contentMolten spray coatingThermal sprayingPolyvinyl alcohol

The invention relates to a preparation method of a coating containing TiB2 metal ceramic composite powder for a thermal spraying piston ring, belonging to the field of composite power body technology. The preparation method provided by the invention comprises the following steps: firstly, adopting a ball-milling method to perform mixing and wet grinding on 25-75wt.% TiB2 powder, 25-10wt.% NiCr alloy powder and 50-15wt.% Mo metal powder to obtain mixed powder with the particle size less than 3 micrometers; then mixing the mixed powder with adhesion agent PVA (Polyvinyl Alcohol), dispersing agent and deionized water in proportion in to slurry, performing atomization and granulation of the slurry at the drying temperature rang of 150-250 DEG C and under the atomizing disc frequency range of 140-190Hz through a spray drying device; and finally performing densification treatment on the powder through heat treatment technology and plasma balling technology. For the composite powder prepared by the preparation method of the invention, the particle size is uniformly distributed, the spherical degree, the densification degree and the mobility are good, the deposition efficiency of TiB2 can be improved, and the metal ceramic coating with good wear-resisting property can be prepared.

Owner:BEIJING UNIV OF TECH

Piston for internal combustion engine

ActiveUS7406940B2Increase resistanceReduce coefficient of frictionCasingsPlungersHydrogen atomPiston ring

A piston for an internal combustion engine of an automotive vehicle. The piston has a piston ring and a piston skirt section each of which has a sliding section in slidable contact with a cylinder bore section of a cylinder block in presence of a lubricating oil. The cylinder bore section is formed of eutectic or hyper-eutectic aluminum alloy. Additionally, a hard carbon thin film is coated on the sliding section of the piston and contains hydrogen atom in an amount of not more than 1 atomic %. Here, the lubricating oil contains at least one selected from the group consisting of ashless fatty acid ester friction modifier, ashless aliphatic amine friction modifier, polybutenyl succinimide, derivative of polybutenyl succinimide, zinc dithiophosphate, and derivative of zinc dithiophosphate.

Owner:NISSAN MOTOR CO LTD

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com