Patents

Literature

214 results about "Gap detection" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The Random Gap Detection Test-Standard (RGDT) is an auditory processing disorder test for ages 5 and up using non-verbal stimuli. It is considered a temporal test using temporal resolution and is sensitive to cortical particularly left temporal lobe lesions.

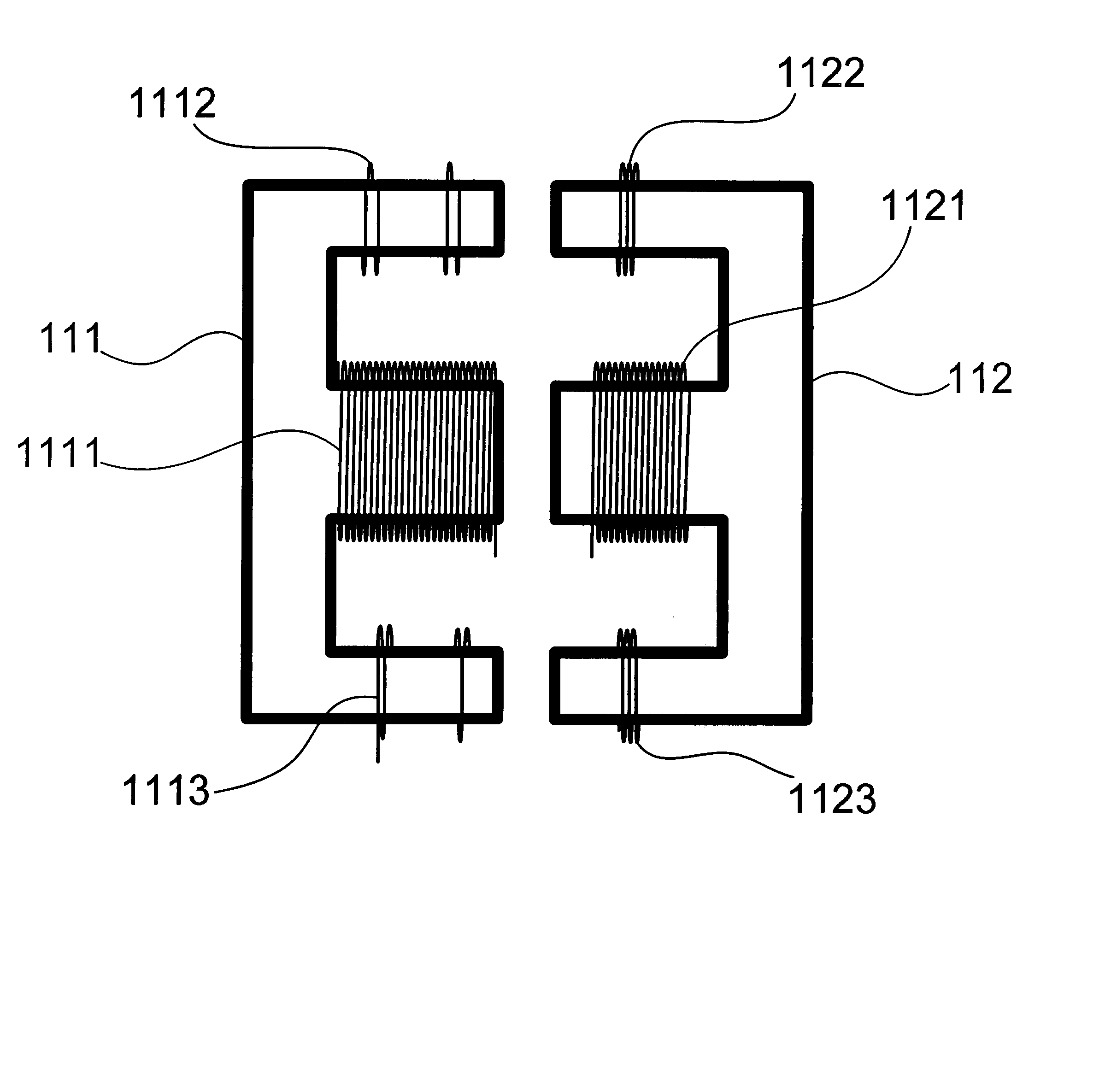

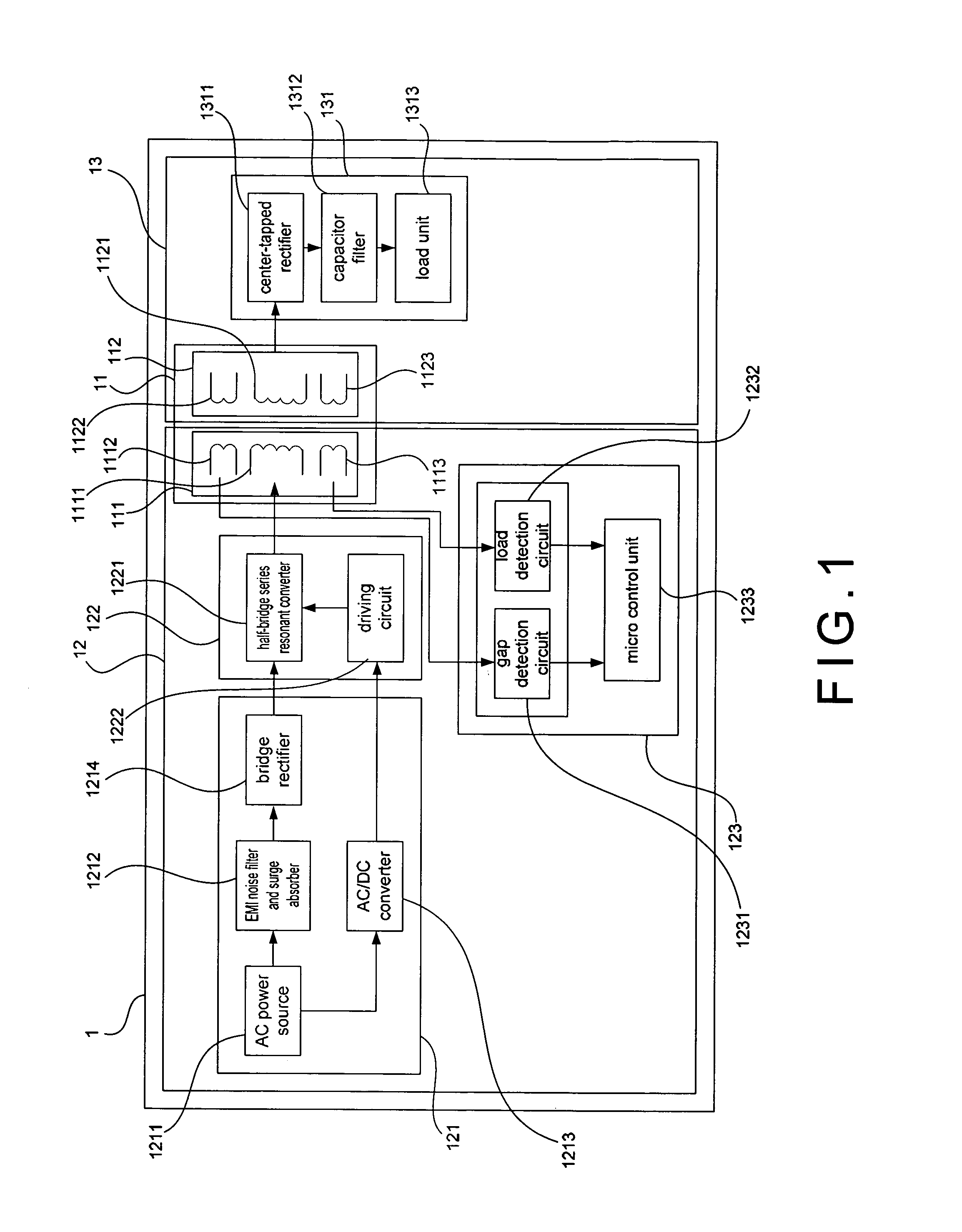

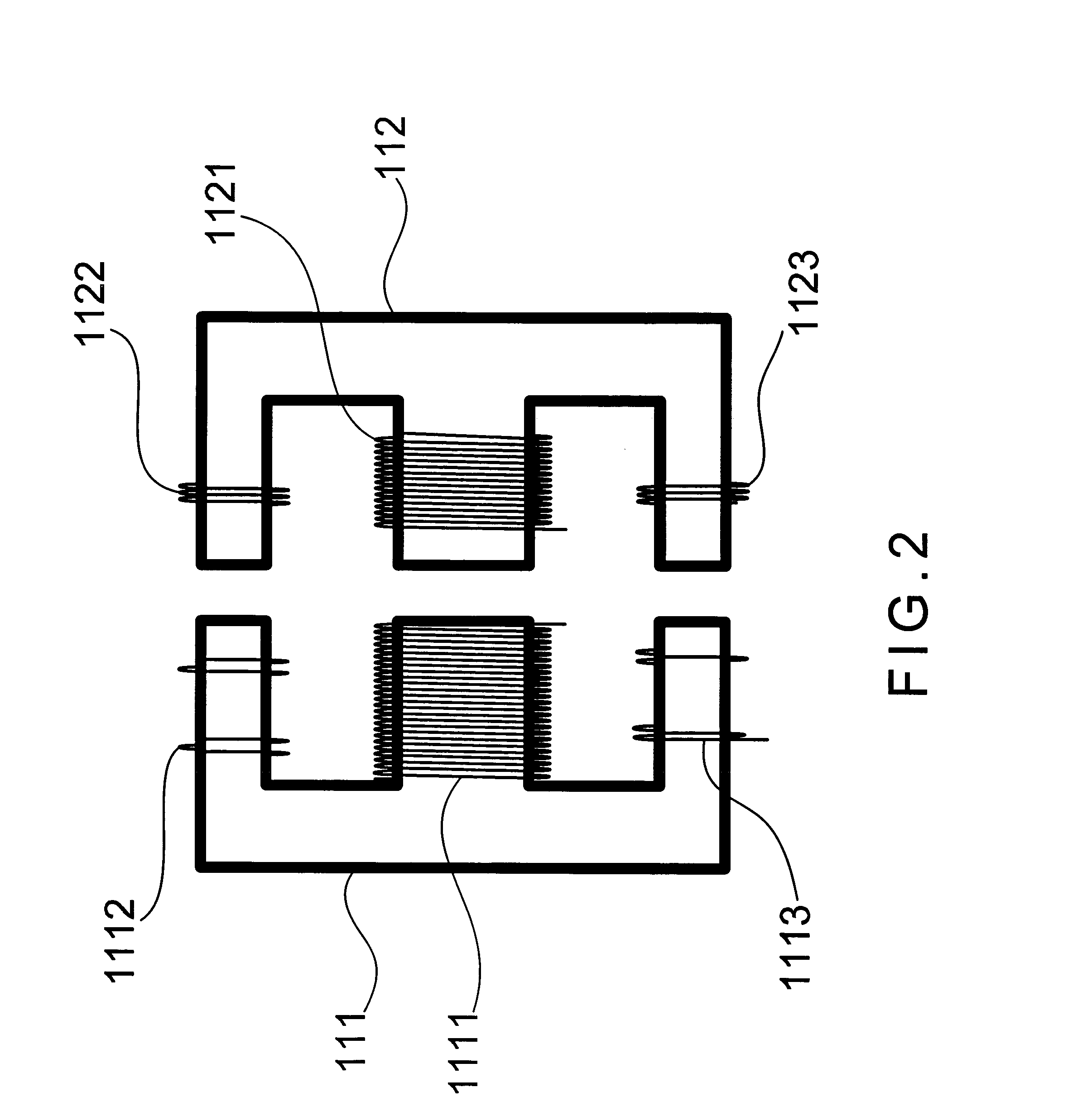

Non-contact power system with load and gap detection

A non-contact power system transfers power and signals simultaneously. The signals control the non-contact power system. And an operational frequency is operated on a resonant frequency so that there is no voltage alternating on power switch and power loss is reduced.

Owner:NAT CENT UNIV

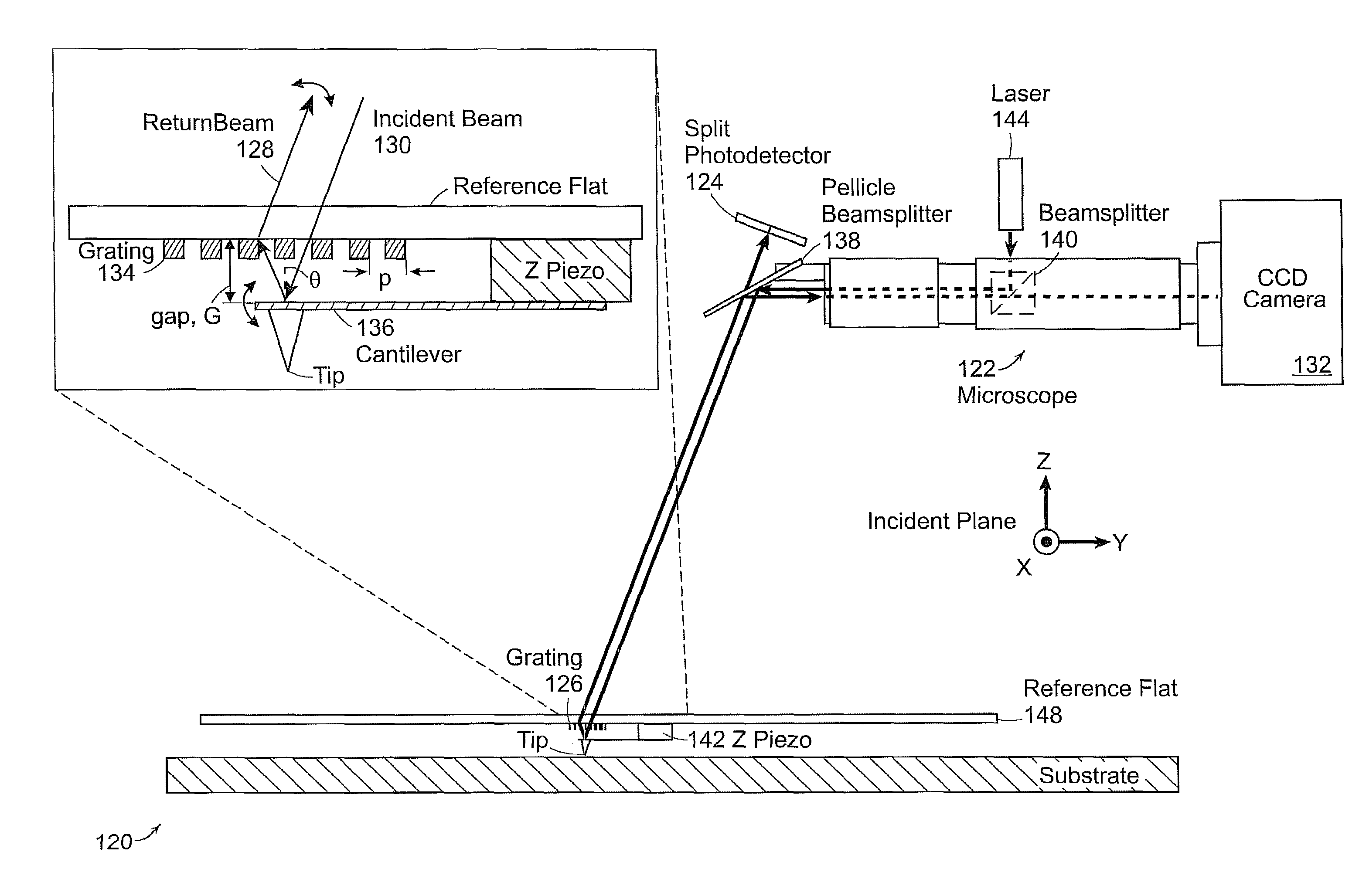

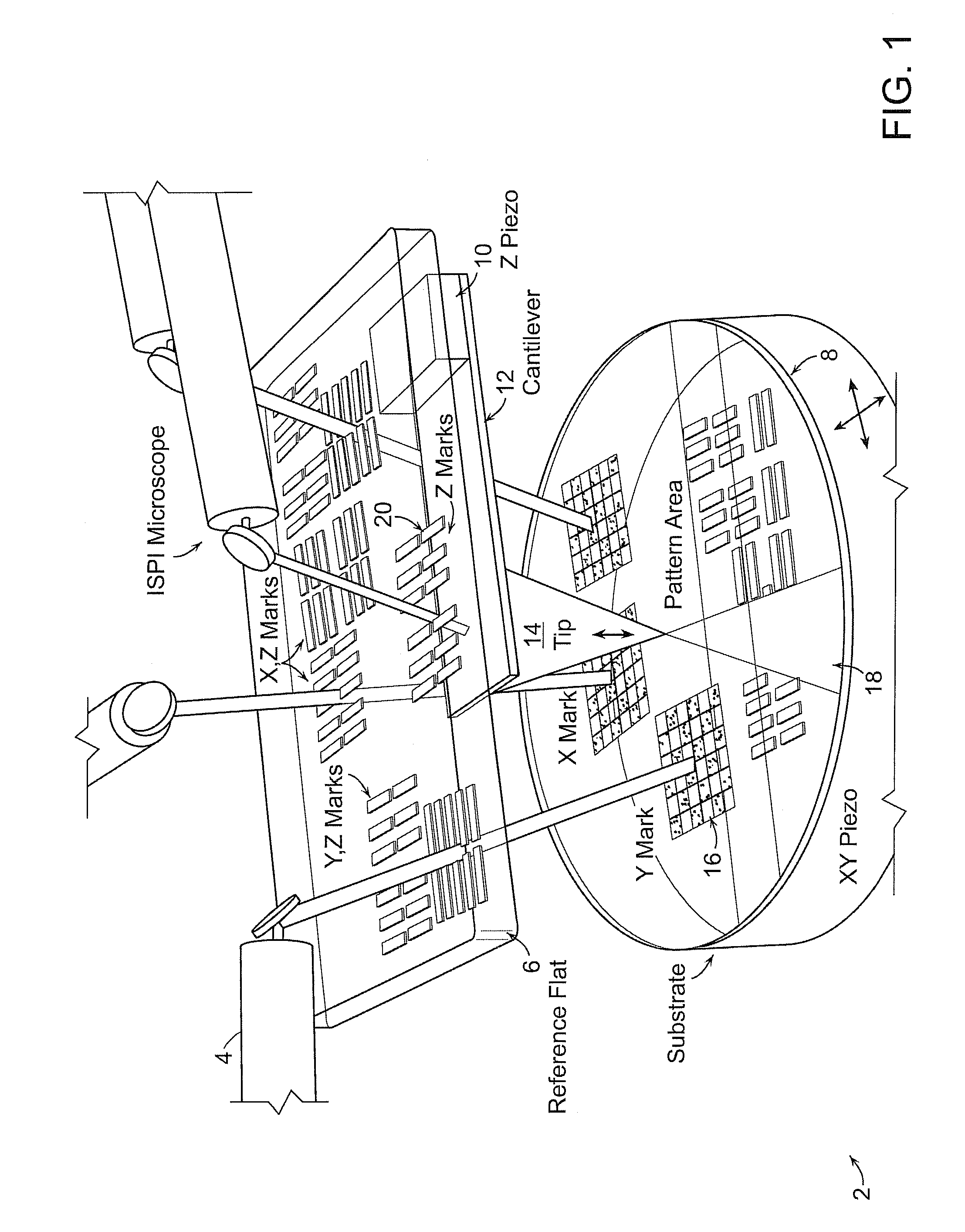

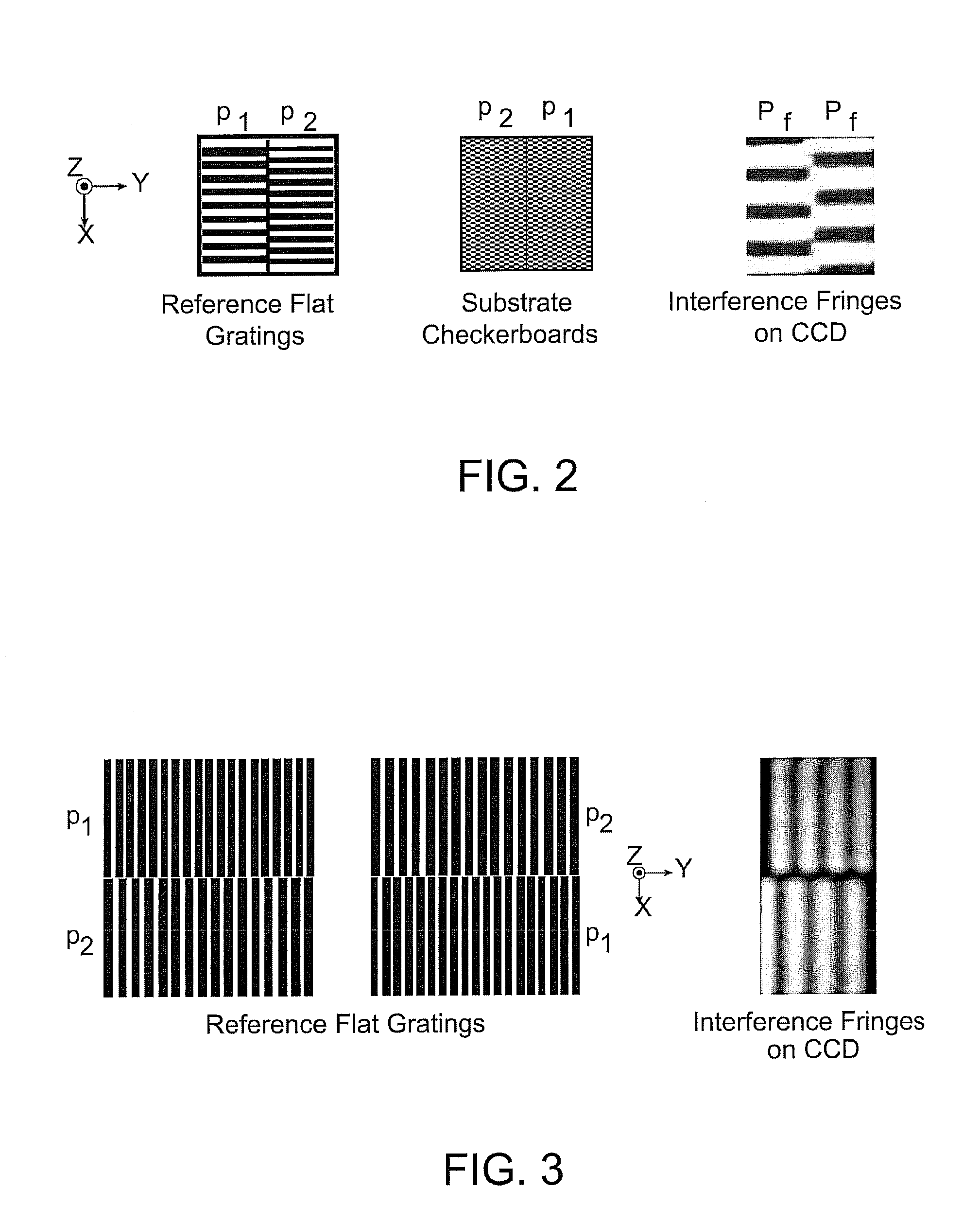

Nanometer-precision tip-to-substrate control and pattern registration for scanning-probe lithography

An interferometric-spatial-phase imaging (ISPI) system includes an alignment mechanism for obtaining continuous six-axis control of a scanning probe tip with respect to a coordinate system attached to a substrate. A gap detection mechanism measures tip height above a substrate and controls tip approach toward the substrate of one or more tips, as well as measures tip deflection during surface contact of the one or more tips. A plurality of complementary marks is provided for attachment to the one or more tips. A plurality of grating marks is provided to backdiffract a reflected beam from a flexible cantilever to detect high-frequency tip deflection in a compact configuration of a light source and a light detector.

Owner:MASSACHUSETTS INST OF TECH

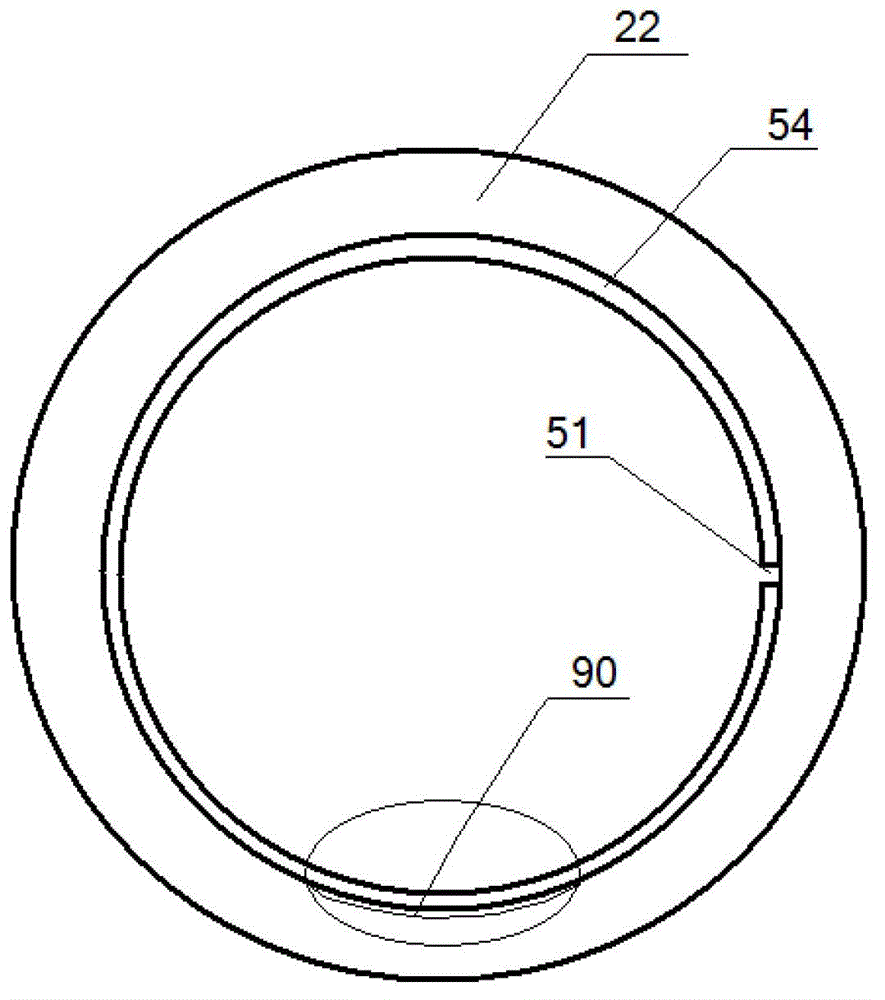

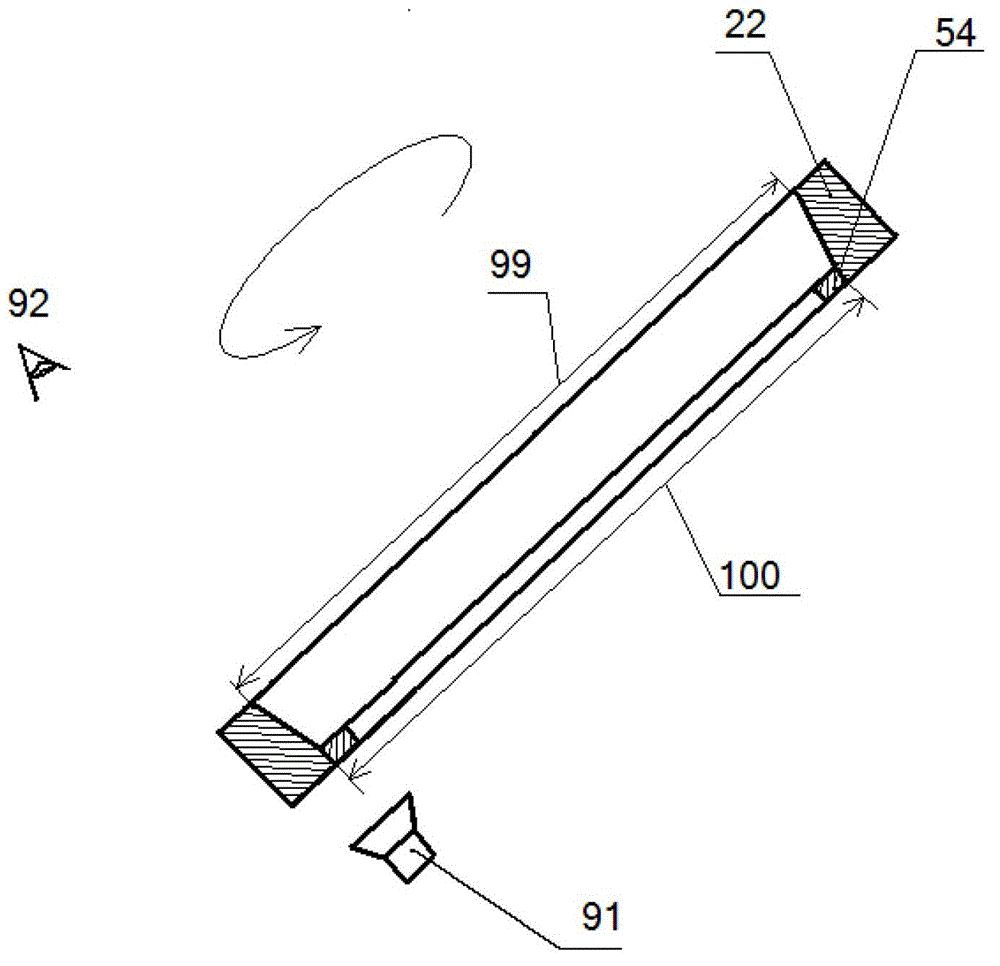

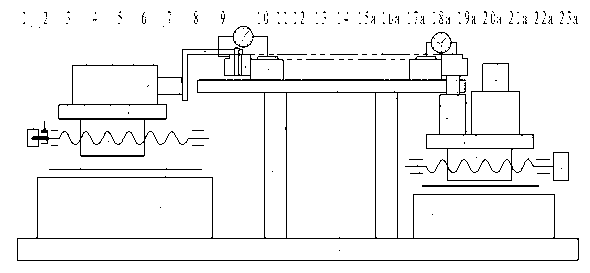

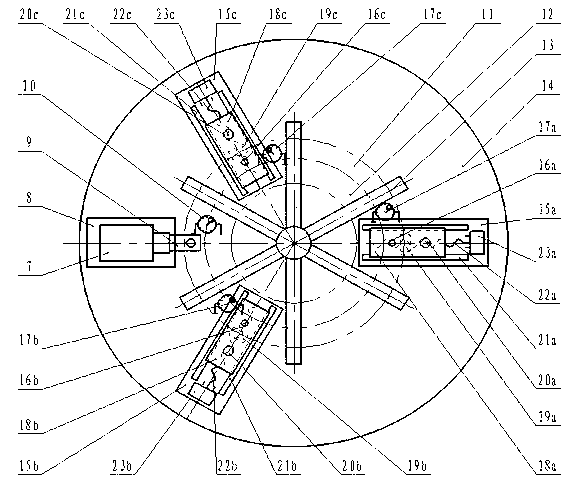

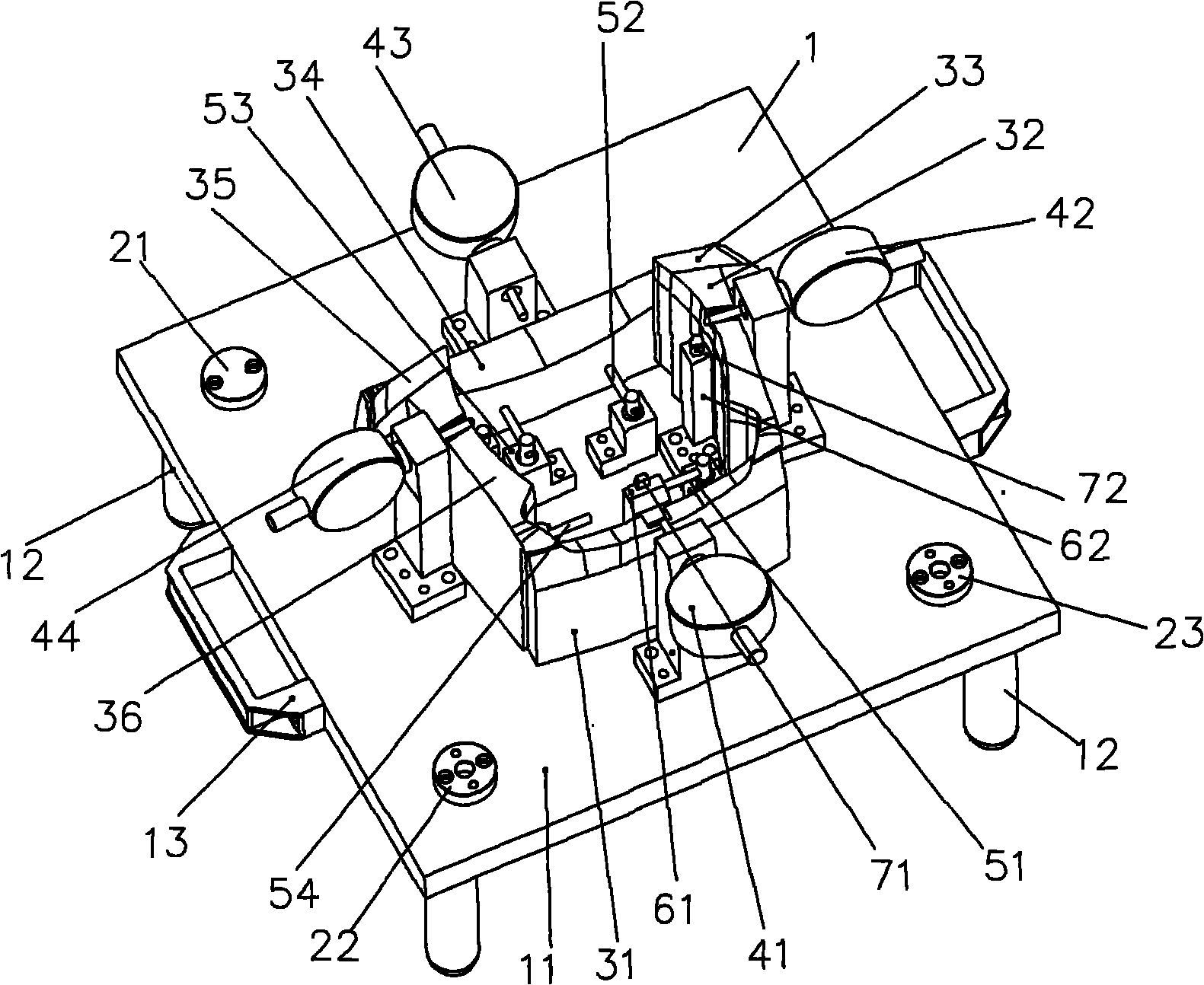

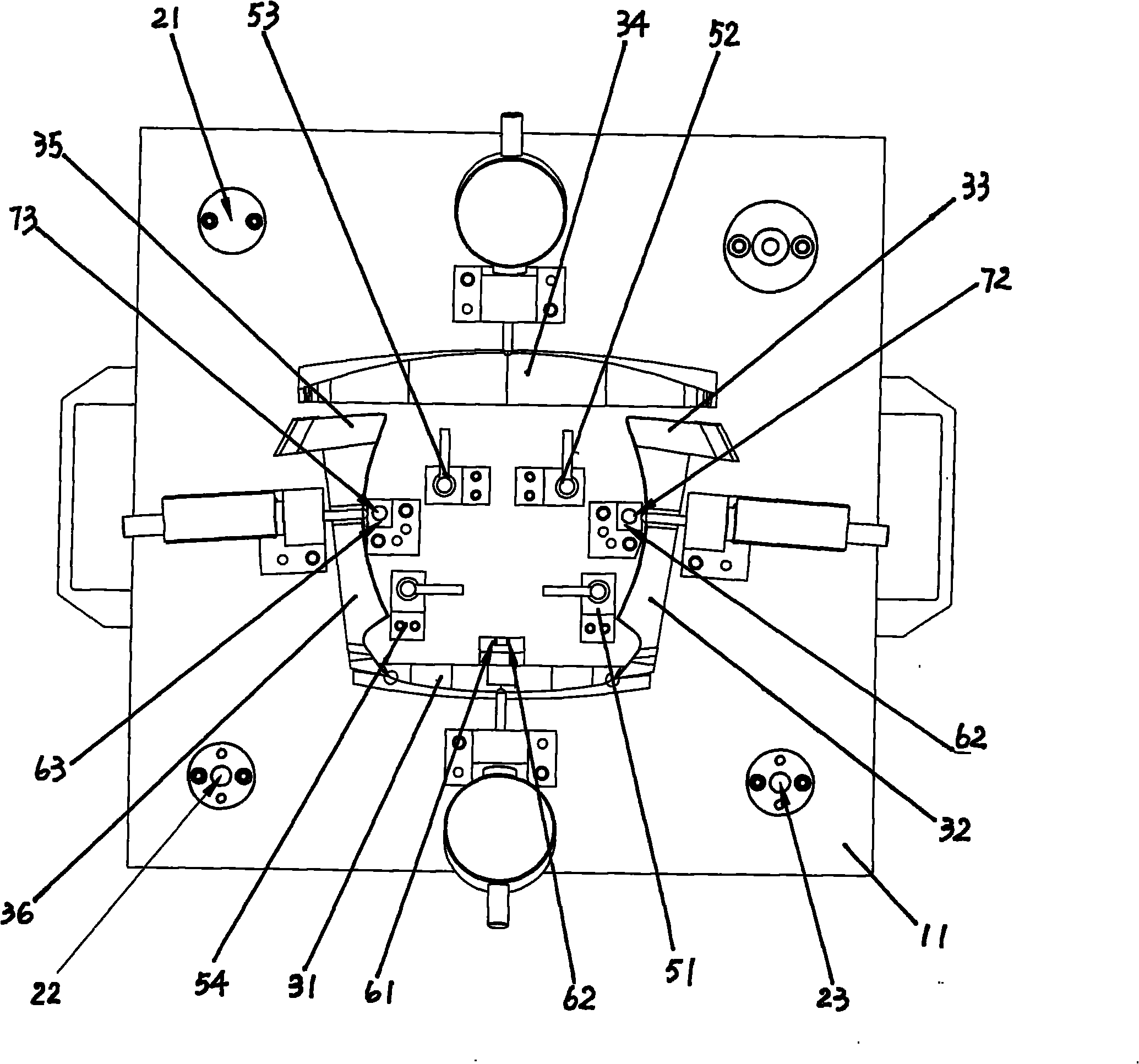

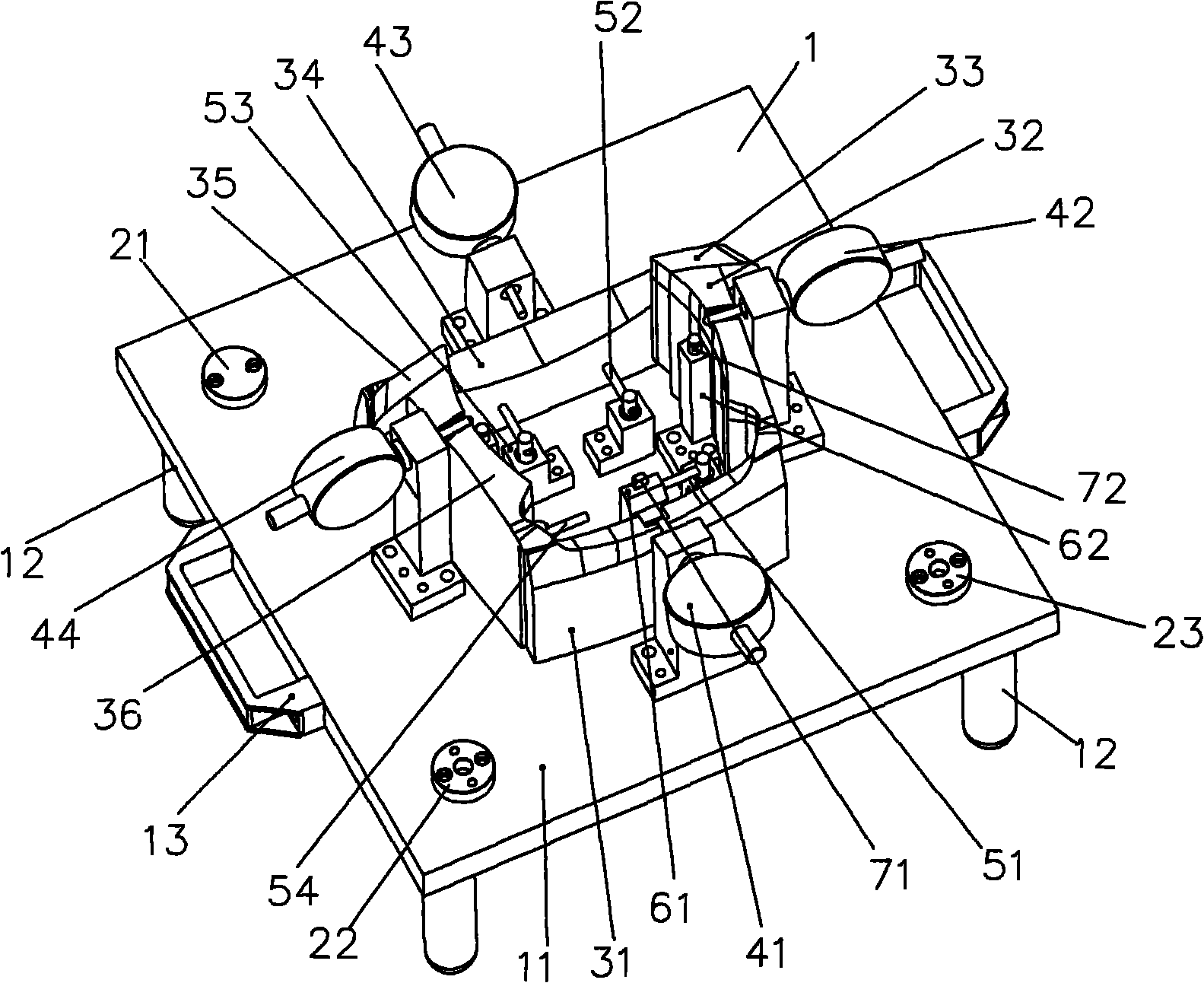

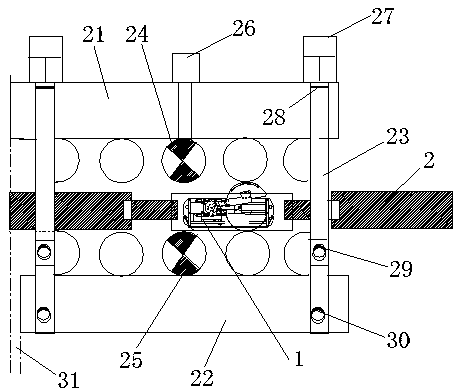

Automatic light leakage degree and closed gap detector of three-station piston ring and calibrating block thereof

InactiveCN102865980AImprove work efficiencyImprove reliabilityUsing optical meansSortingPiston ringLuminosity

The invention relates to an automatic light leakage degree and closed gap detector of a three-station piston ring and a calibrating block thereof. A horizontal workbench is formed at the top of a stand, and is provided with a cantilever beam, a touch screen connected to the cantilever beam, a storage mechanism for storing the piston ring, a push plate positioned below the storage mechanism and a round turntable which is arranged in front of the storage mechanism and the push plate and rotatably inlayed on the horizontal workbench; a separation mechanism is arranged in front of the round turntable; a closed gap detection station, a discharge station and a light leakage degree detection station are formed on the round turntable by three inlayed standard gauges; a first charge coupled device (CCD) sensor corresponding to the closed gap detection station and a second CCD sensor corresponding to the light leakage degree detection station are respectively arranged above the horizontal workbench; and a light leakage degree detection illumination mechanism is arranged at the position below the horizontal workbench, corresponding to the light leakage degree detection station. By adopting the detector and the calibrating block, high efficiency, and the automatic detection and the separation of two indexes of the light leakage degree and the closed gap of small and medium sized piston rings are realized.

Owner:TIANJIN UNIV

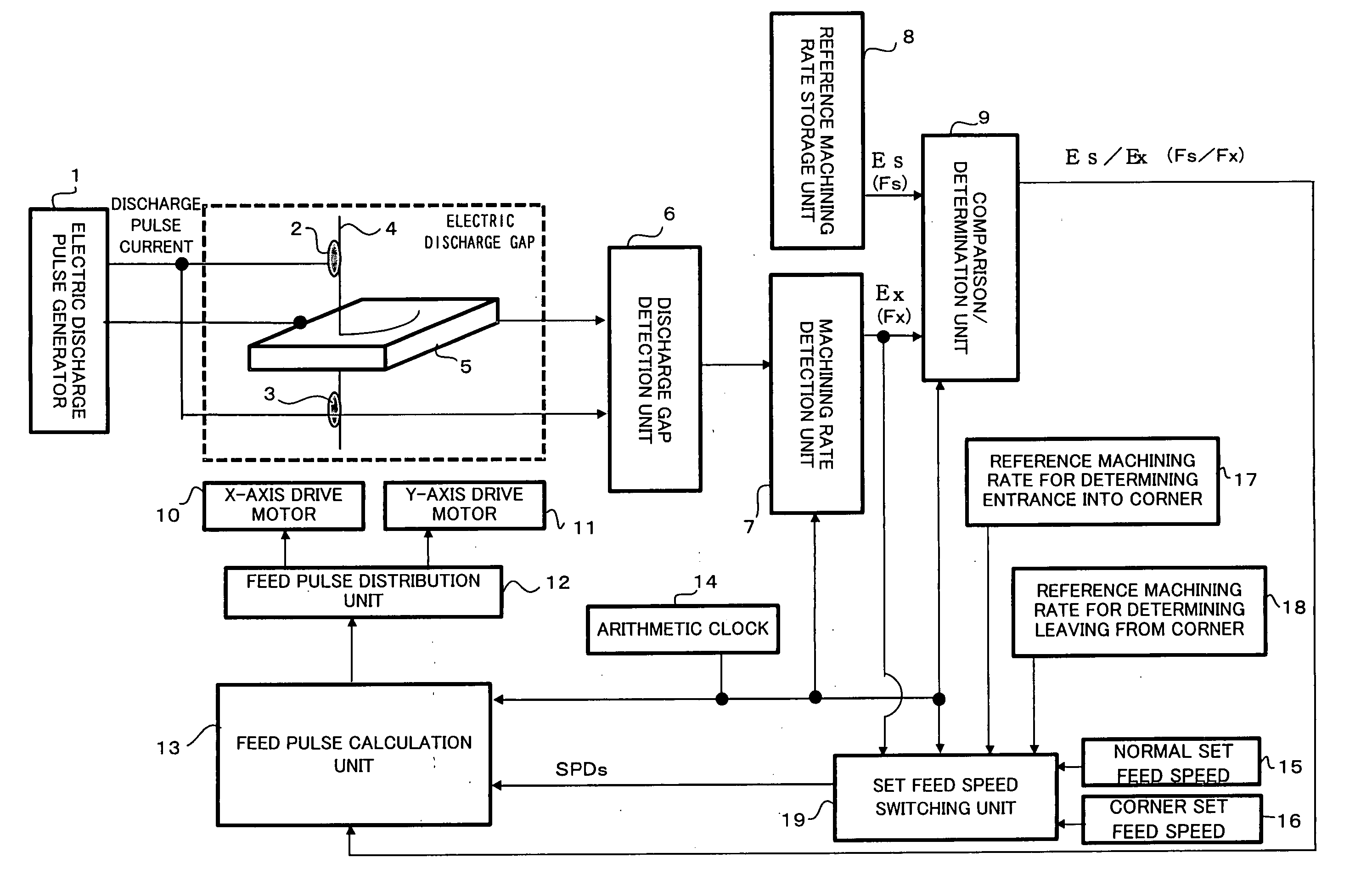

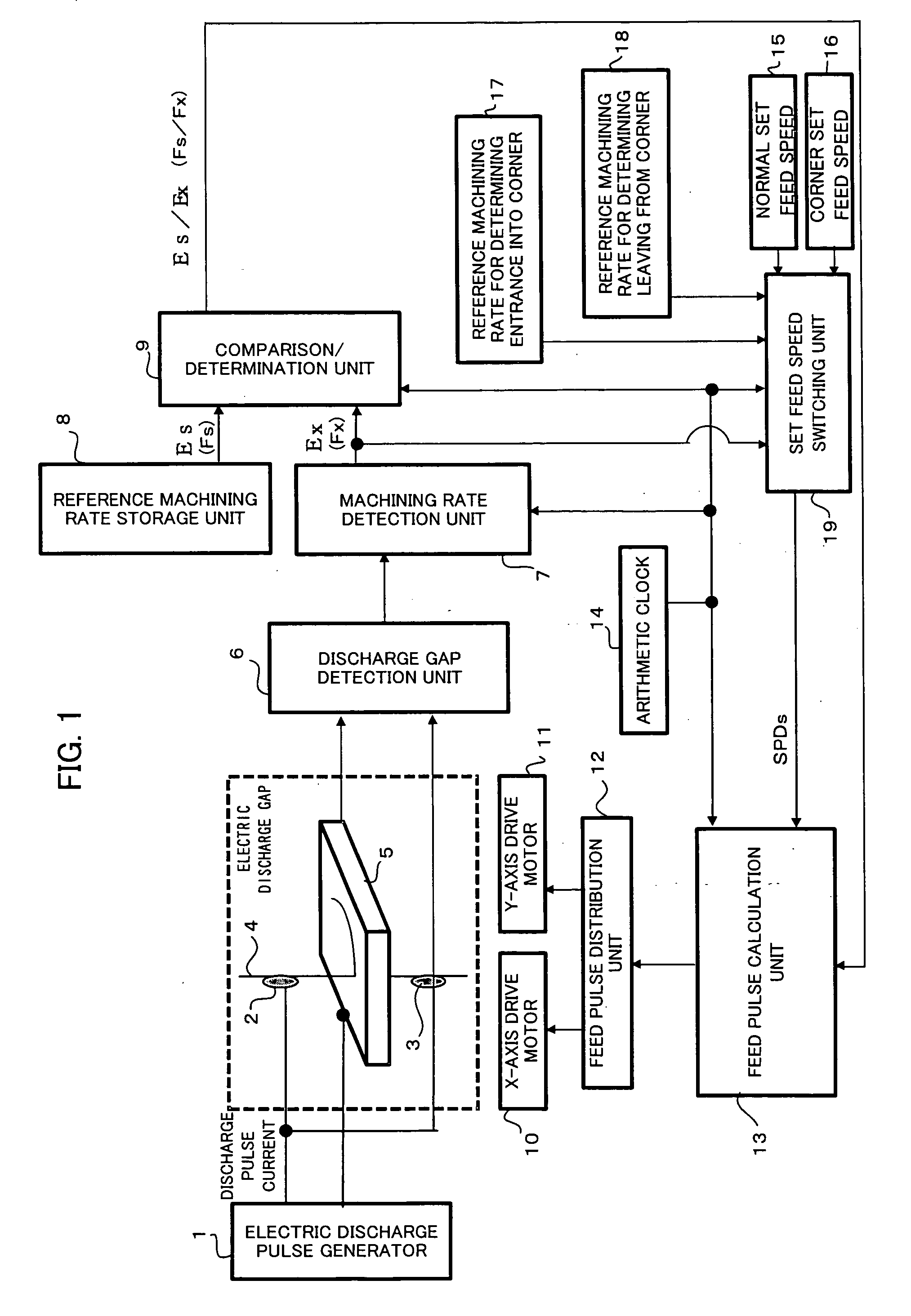

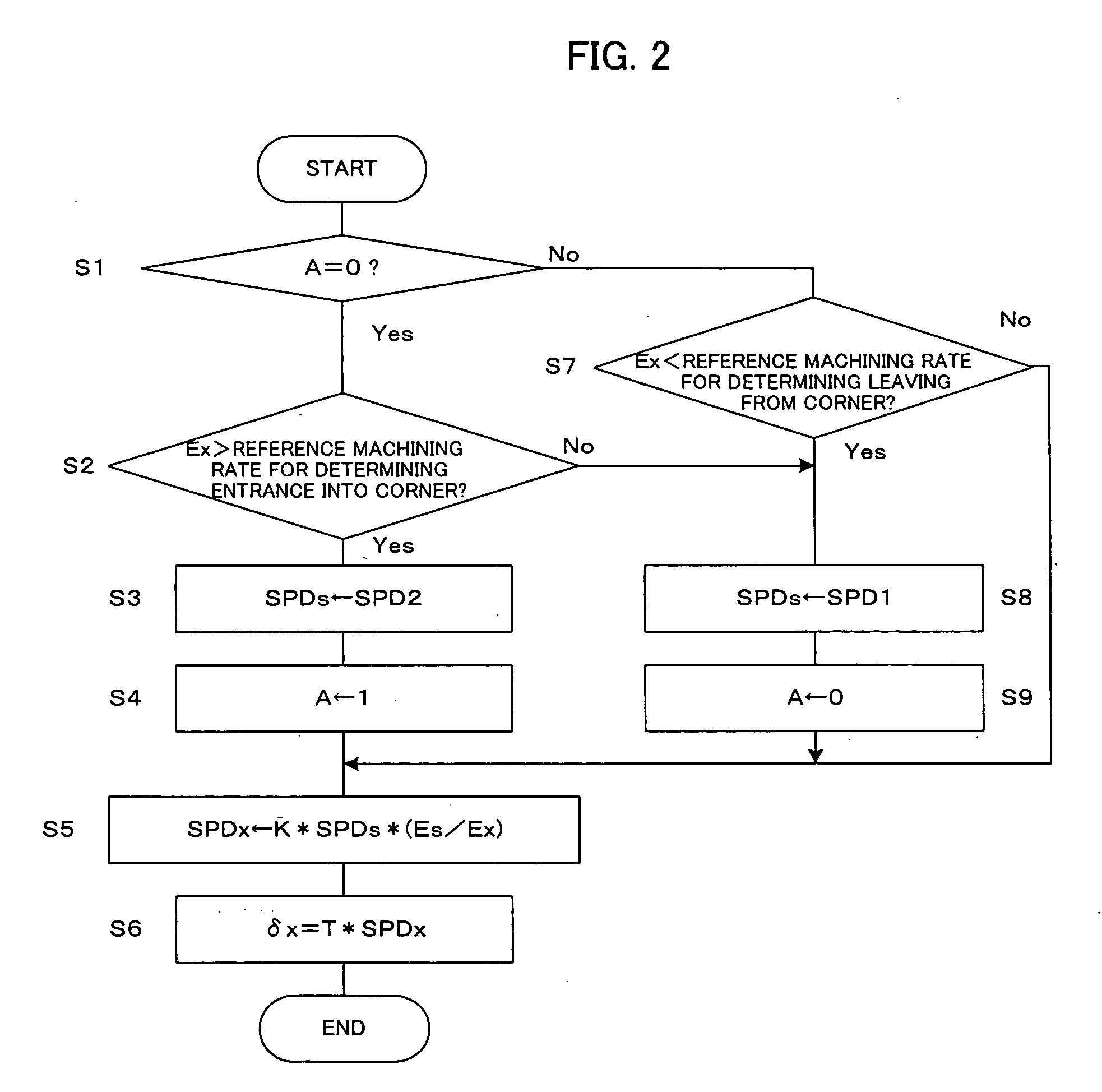

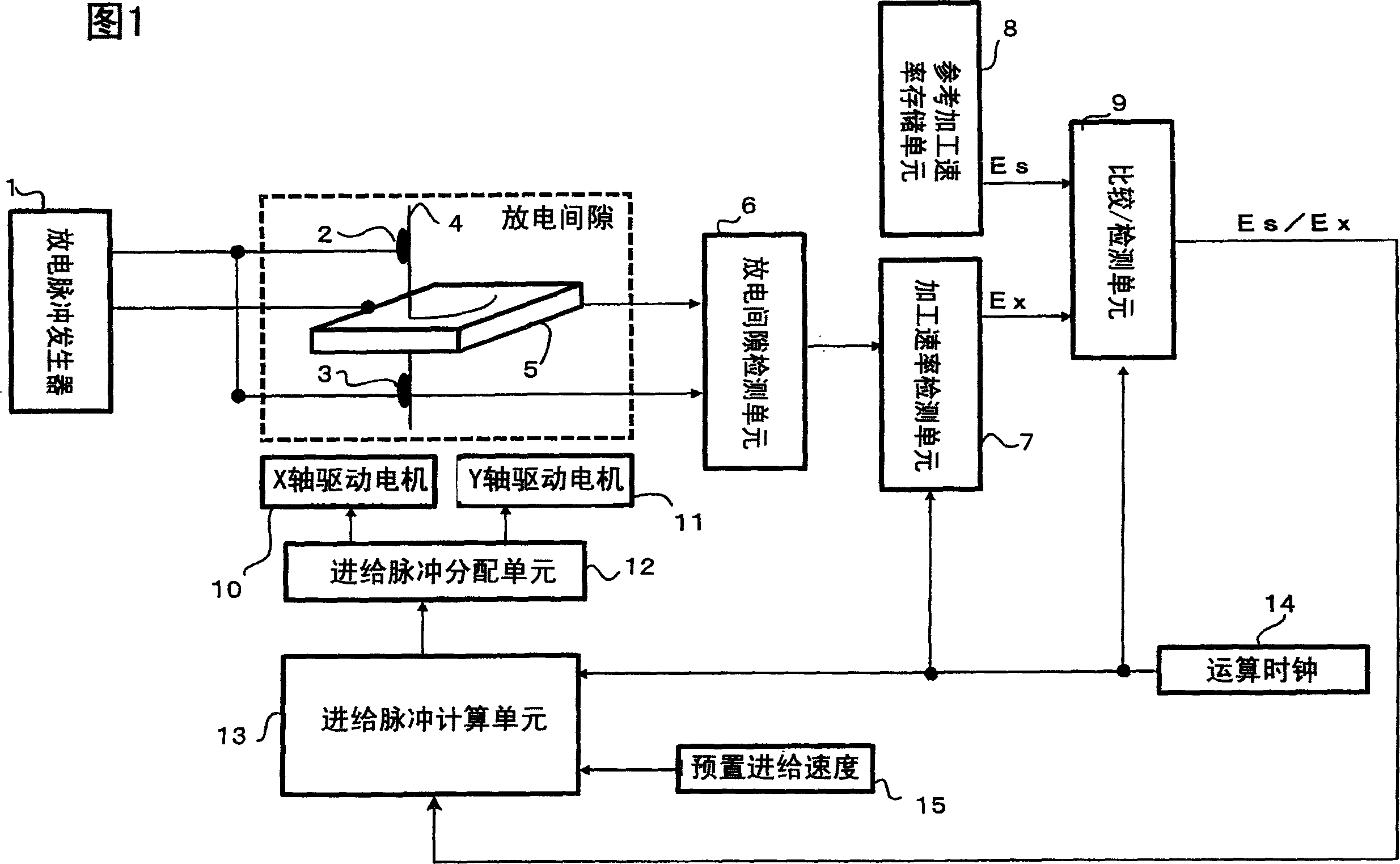

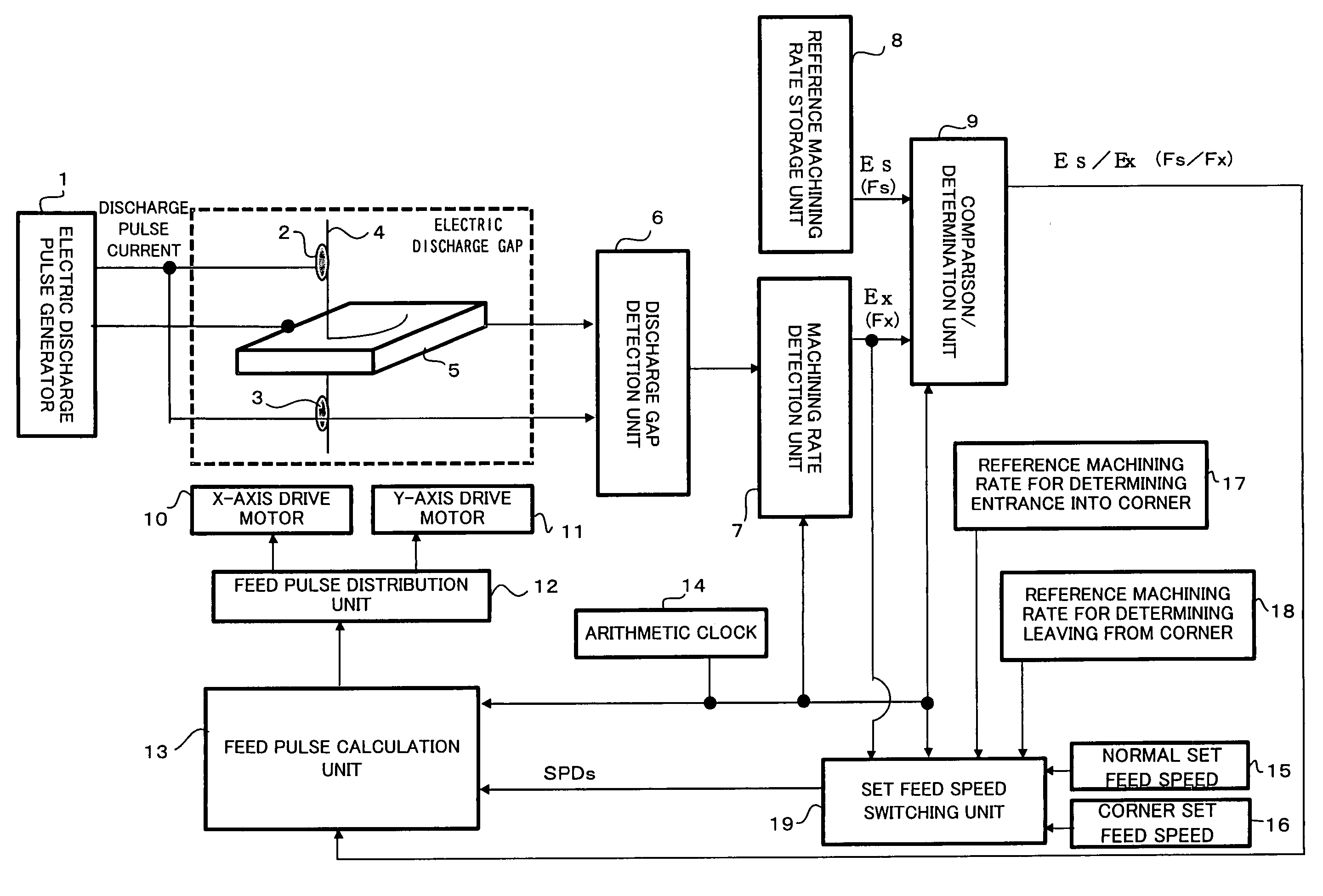

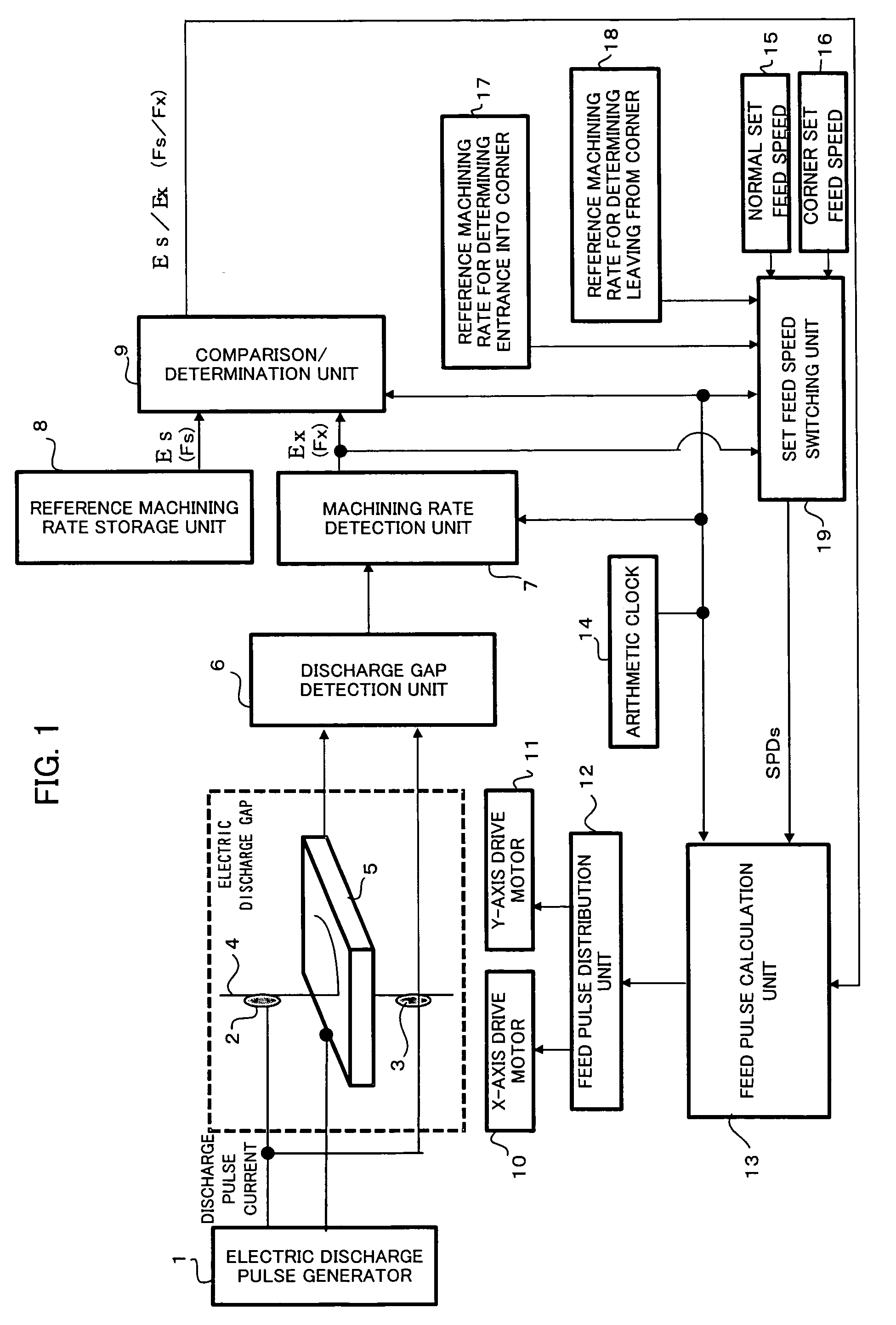

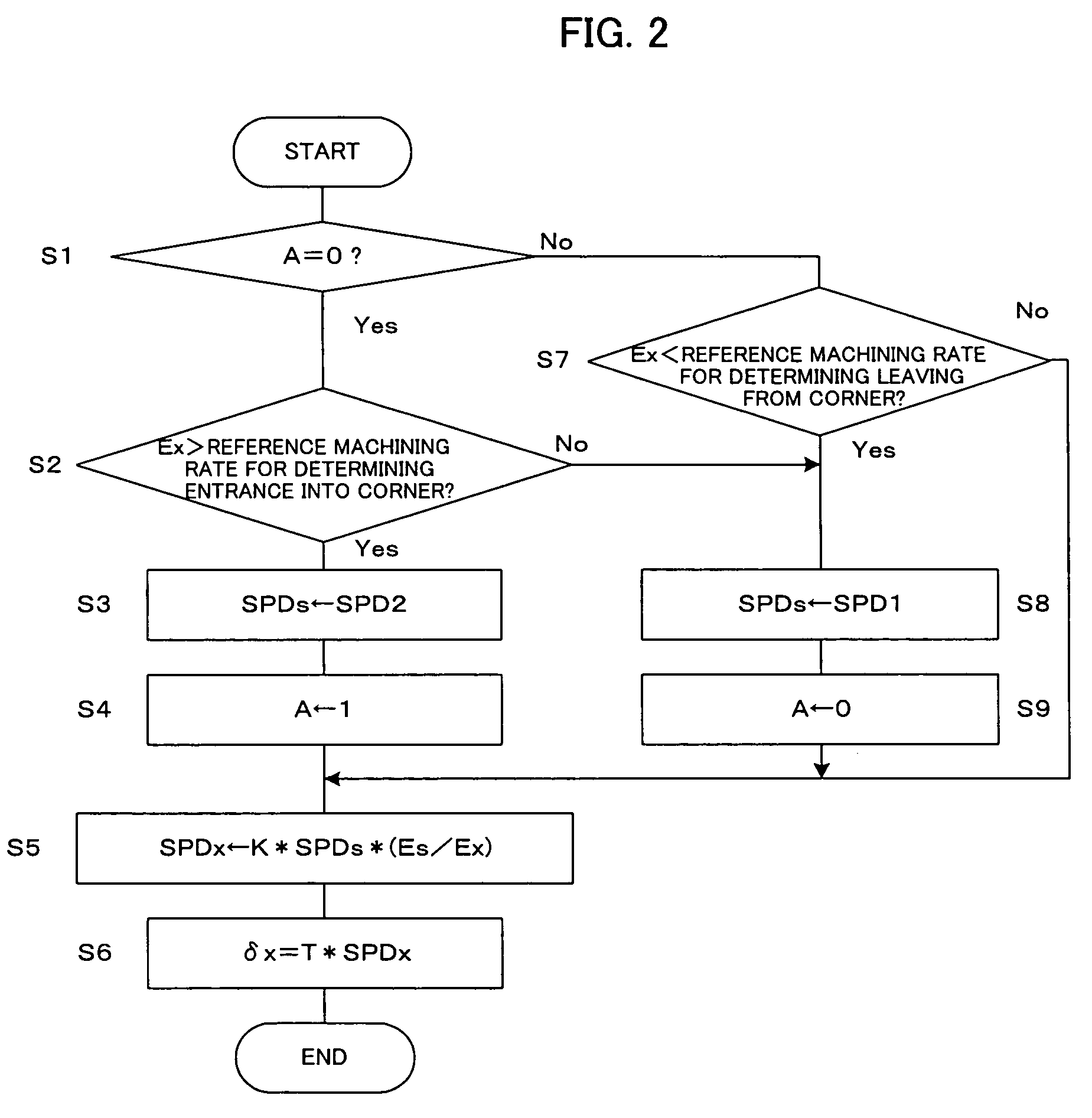

Controller for wire electric discharge machine

ActiveUS20060091113A1Improve accuracyHigh precision machiningElectric circuitsSpecial data processing applicationsElectric dischargeEngineering

A controller for a wire cut electric discharge machine which can provide stable finish machining and corner-region machining with high corner-form accuracy. An electric discharge gap detection device detects a voltage between a wire electrode and a workpiece. A machining rate detection device obtains an average machining voltage and a drop voltage value Ex which is a difference between the obtained average machining voltage and a no-load voltage. A comparison device obtains the ratio Es / Ex between a reference drop voltage value Es stored in a reference machining rate relative value storage device and the obtained drop voltage value Ex. In machining of a corner portion, when the drop voltage value Ex exceeds a entrance-into-corner determination reference machining rate, a set feed speed switch device supplies a corner set feed speed, and when the machining of the corner portion finishes, so that the drop voltage value Ex decreases to a leaving-from-corner determination reference machining rate or lower, the set feed speed switch device supplies a normal set feed speed. A feed pulse calculation device obtains a feed speed which makes the rate of machining constant, on the basis of the ratio Es / Ex and the supplied feed speed, to thereby drive motors. Since the rate of machining is kept constant, the surface accuracy of finish machining is high and stable machining can be performed.

Owner:FANUC LTD

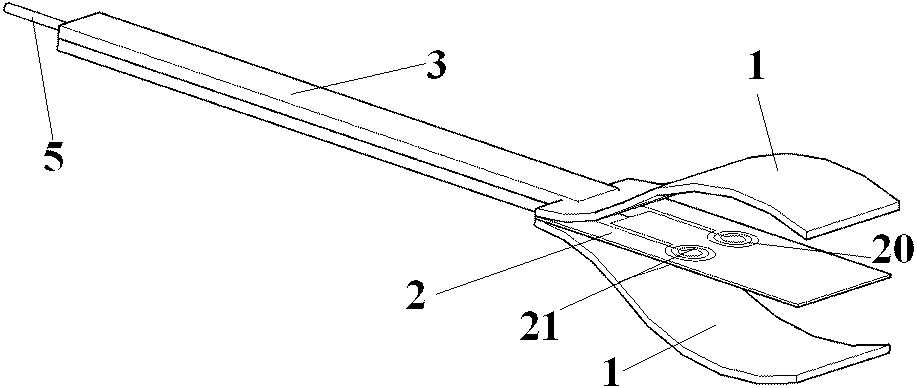

Quick gap electromagnetic measurement method and sensor device

ActiveCN102927895AImprove dynamic rangeImprove linearityUsing electrical meansThin metalSize measurement

The invention discloses a quick gap electromagnetic measurement method and a sensor device. The gap electromagnetic measurement sensor device suitable for any metal or non-metal material and the measurement method of the same are designed based on an electromagnetic induction principle. The sensor device consists of two thin metal sheets, a coil detecting thin plate, a holding rod, a fastener and a lead. The measurement method comprises two steps of calibration and actual measurement. The sensor device and the measurement method adopt an unique ferromagnetic micro-spring piece, namely the sensor device and the measurement method can adapt to gap detection of any material, have the important advantages of being high in measurement speed, precise in quantification and free of leak detection, can effectively replace conventional gap size measurement methods, quickly, precisely and comprehensively measure the gap size of workpieces and are suitable for gap measurement work of various metal or non-metal tubes, plates, bent workpieces and the like, and a detecting signal dynamic range and the linearity degree are improved well.

Owner:EDDYSUN (XIAMEN) ELECTRONICS CO LTD

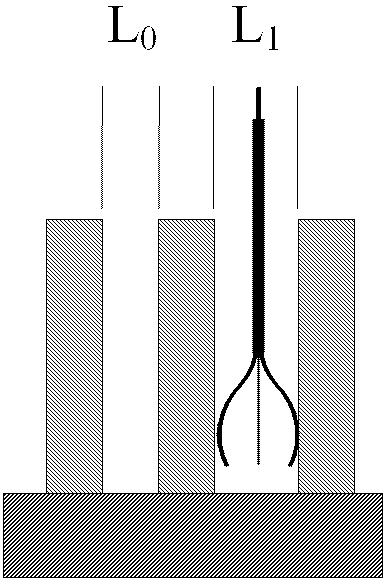

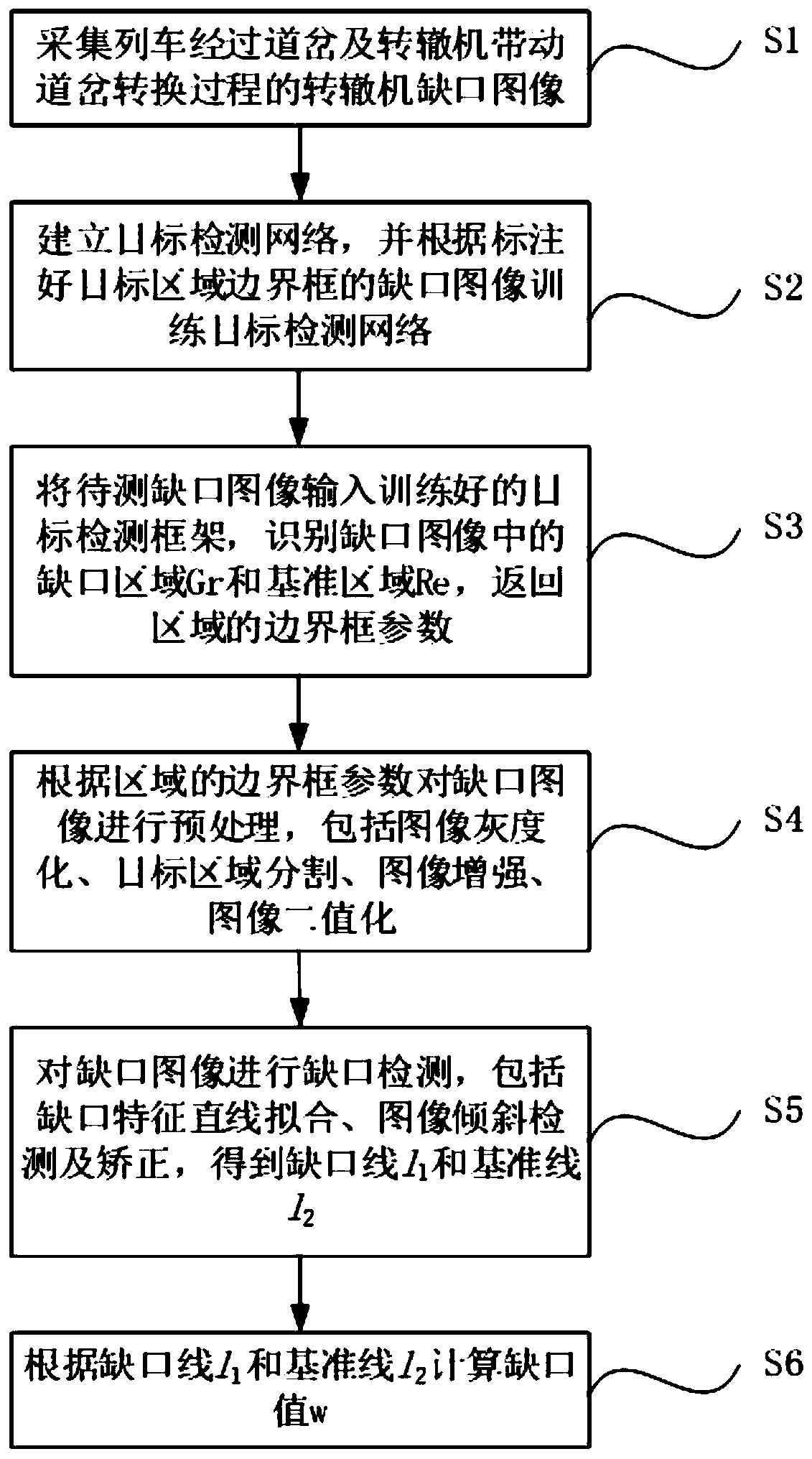

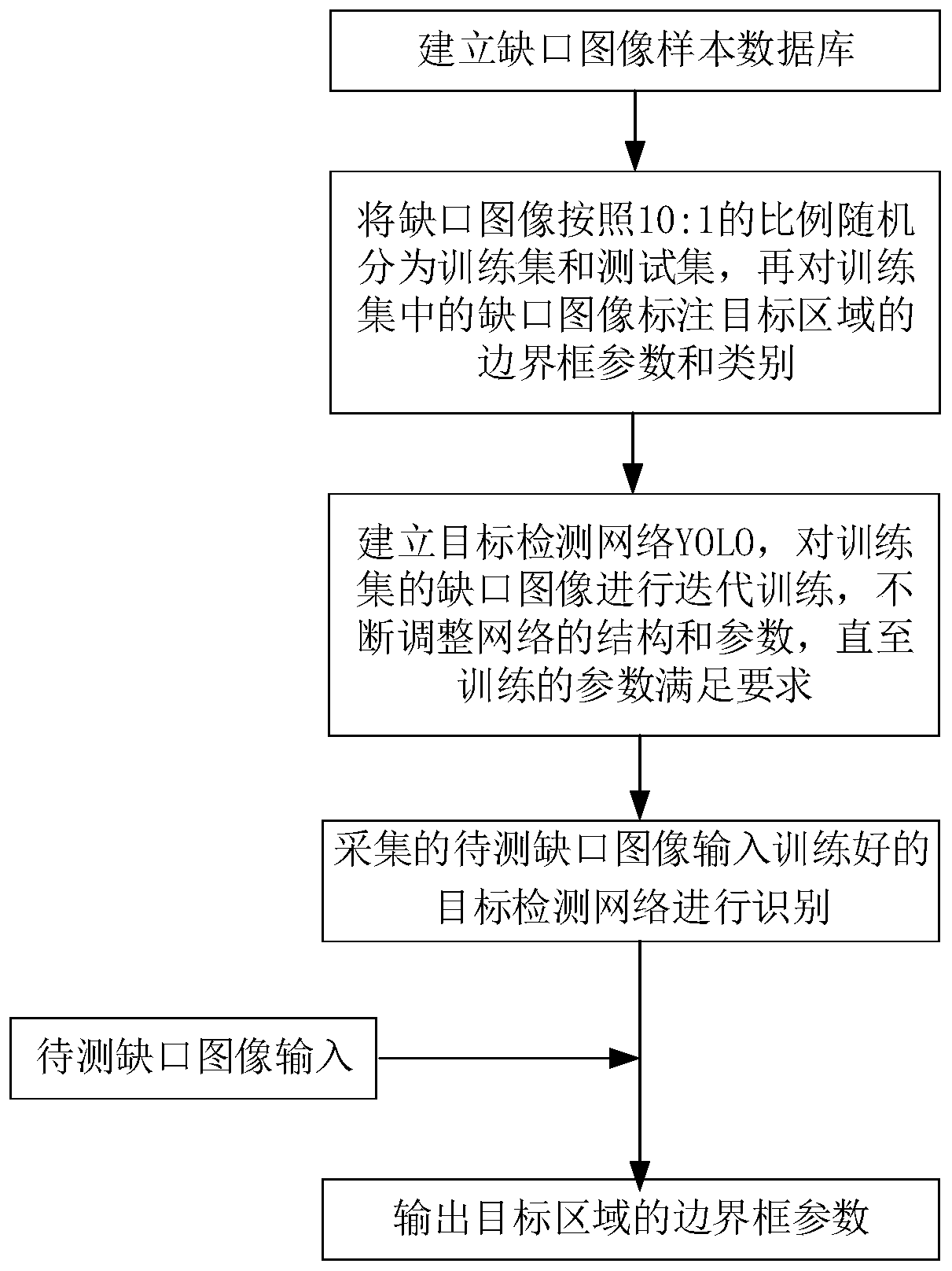

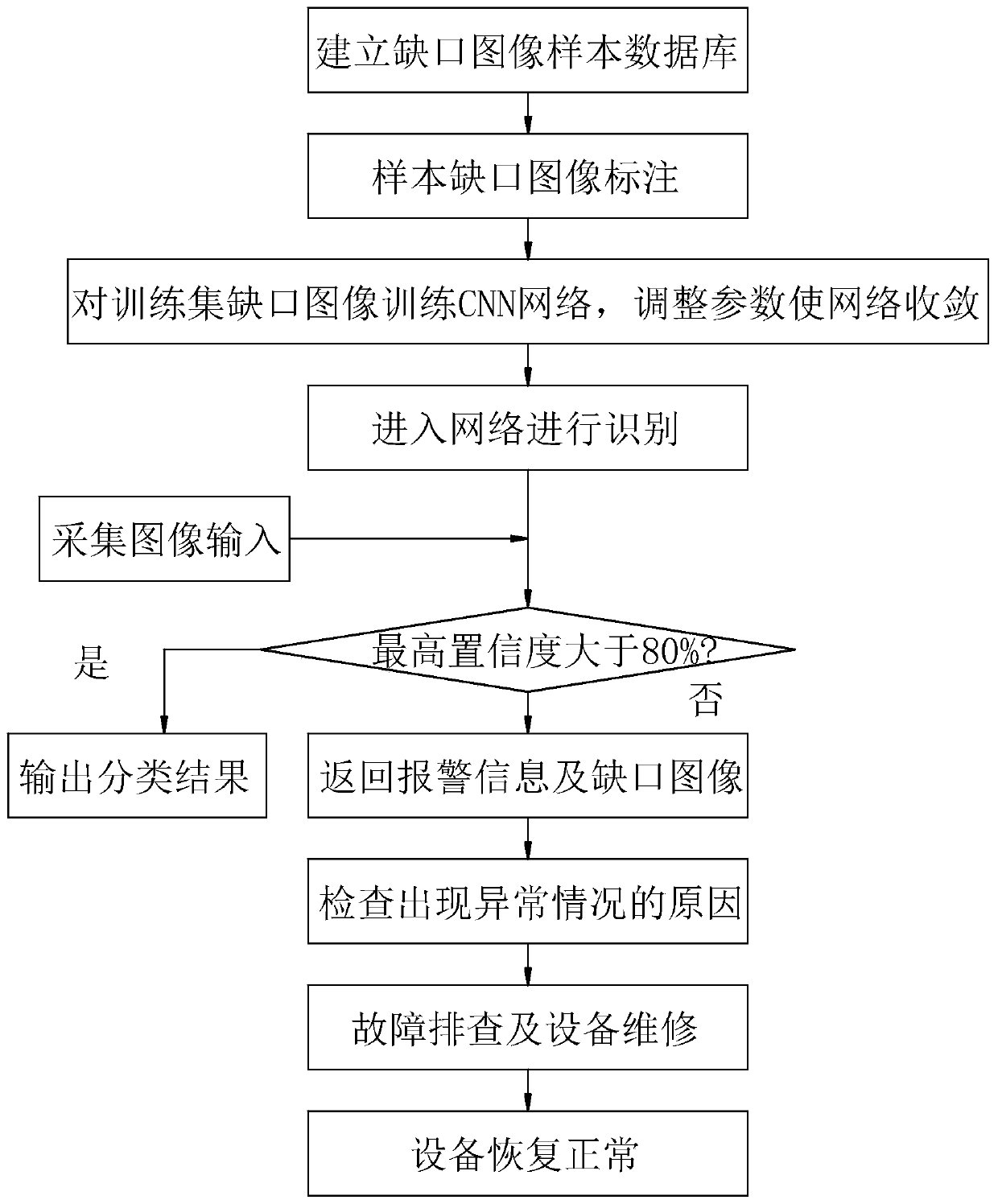

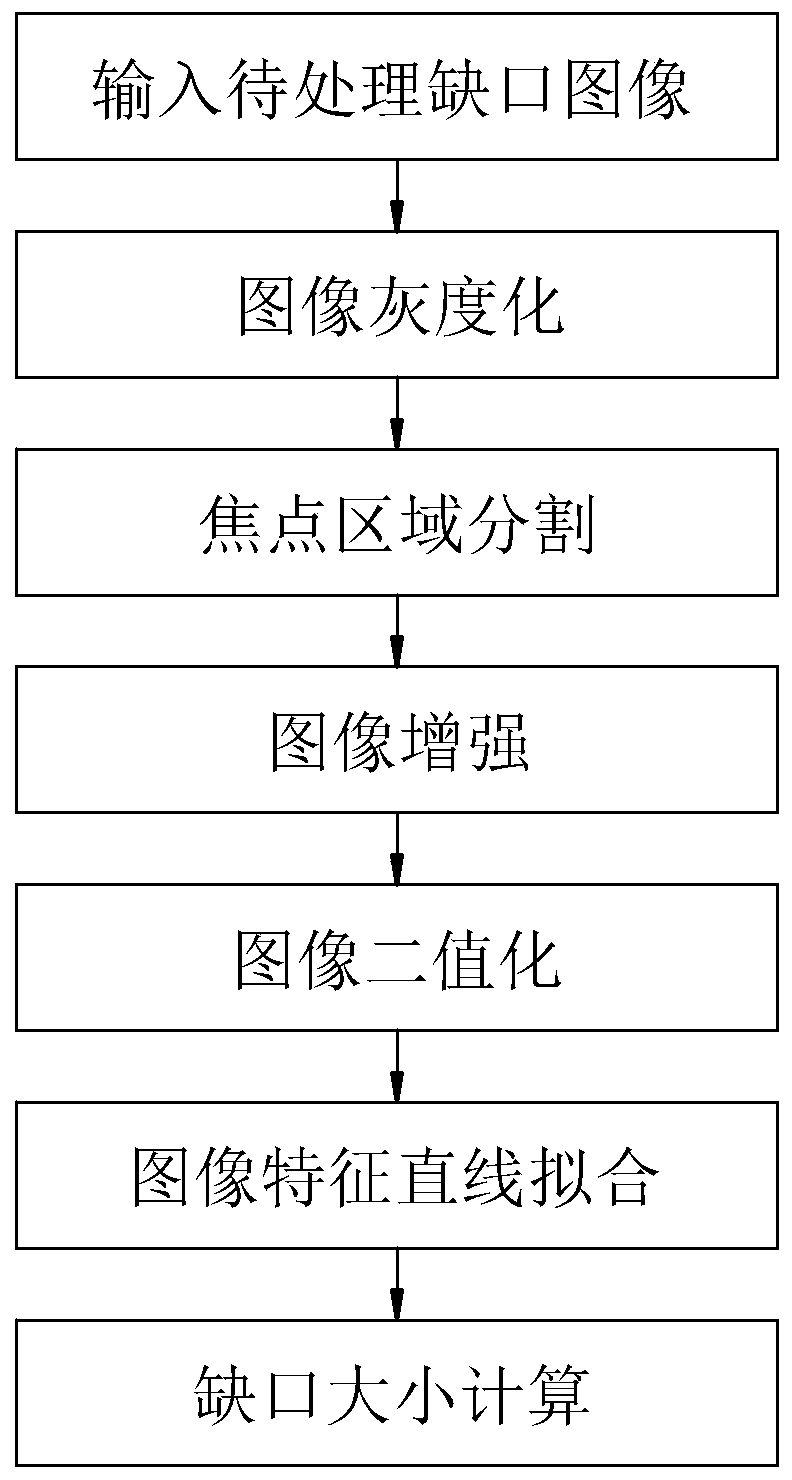

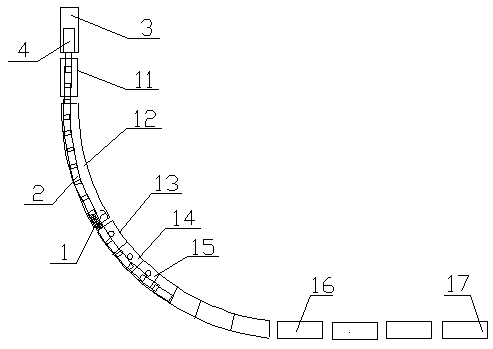

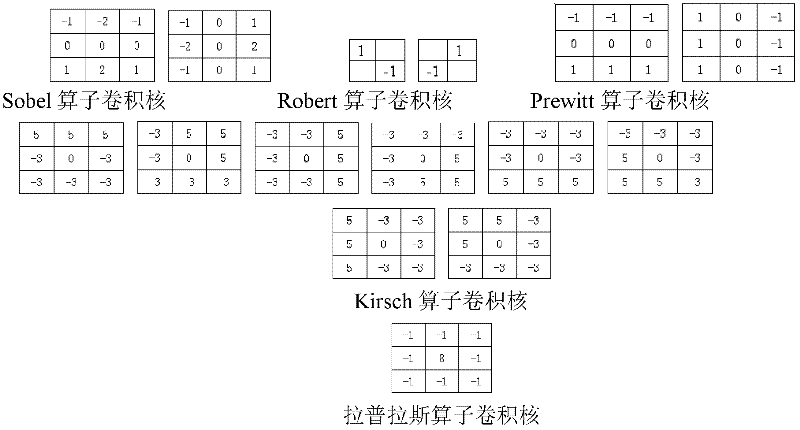

Point switch notch detection method based on target detection and image processing

ActiveCN110310255AReduce complexityGuaranteed uptimeImage enhancementImage analysisPattern recognitionImaging processing

The invention provides a point switch notch detection method based on target detection and image processing. The point switch notch detection method comprises the steps: collecting a point switch notch image in the process that a train passes through a turnout and the turnout is driven by the point switch to be converted; establishing a target detection network and training; inputting the notch image to be detected into the trained target detection network, identifying a target area in the notch image, and obtaining a boundary frame parameter of the area; preprocessing the gap image accordingto the boundary frame parameters of the area; carrying out notch detection on the notch image, including notch feature straight line fitting and image inclination detection and correction; and calculating a gap value w according to the gap characteristic straight line. The point switch notch detection method can be directly applied to various types of switch machines, does not need to set different image preprocessing parameters for the different types of switch machines, is suitable for complex and severe operation conditions such as local overexposure of the notch image and inclination of the notch image, and can further improve the accuracy, robustness and universality of a notch detection system.

Owner:TONGJI UNIV

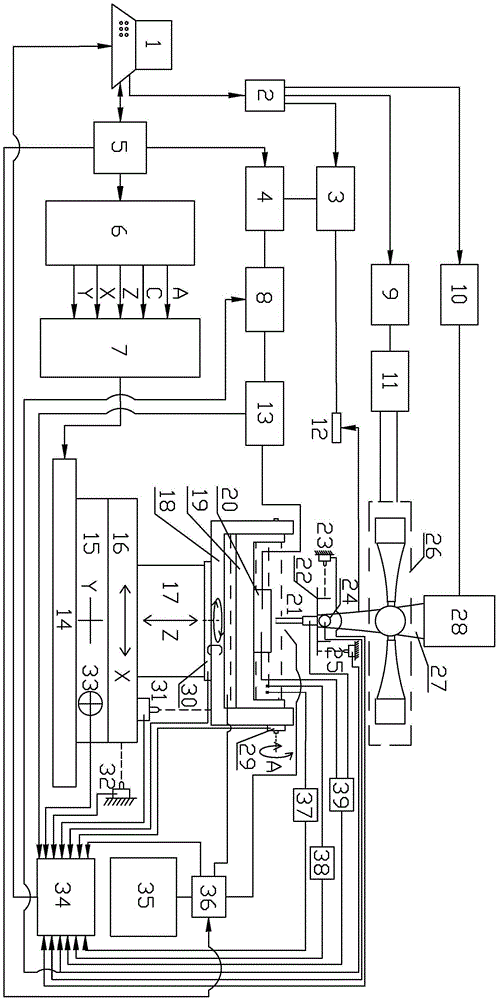

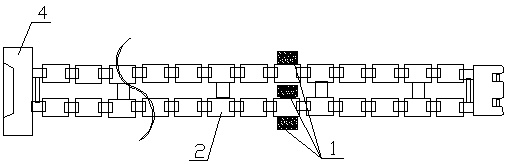

Multi-axis linkage ultrasonic modulation micro-electrochemical machining system

ActiveCN105290548AAchieve protectionEasy to controlElectrical-based machining electrodesElectric circuitsElectrolysisMachine tool control

A multi-axis linkage ultrasonic modulation micro-electrochemical machining system comprises an ultrasonic vibration system, an ultrasonic synchronization system, an electrochemical machining power supply system, a multi-axis machine tool control system, a working liquid circulating system, a machining positioning and gap detection system and an online parameter observation and control system. A transverse and longitudinal excitation device is additionally arranged on the joint of an amplitude-change pole, and a machine tool can machine a complex three-dimensional curve or special-shaped hole groove; a machine tool working table is a multi-axis linkage control feeding mechanism, the micro feeding movement of the multi-dimensional space of the working table is achieved, and it is ensured that the machining process is stable; an encoder and a micro displacement sensor are additionally arranged on a machine tool feeding mechanism, and therefore machining gap control and workpiece precise positioning feeding movement can be facilitated; in the machining process, parameter changes can be online observed in real time, preparing and conveying of needed work liquid can be completed by controlling a working liquid delivery device; and workpiece and tool electrode protection can be achieved during machining area collision or short circuit by controlling a switch of an electromagnetic valve and the multi-axis machine tool control system.

Owner:YANGZHOU UNIV

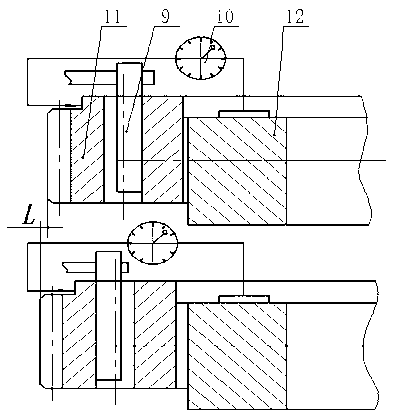

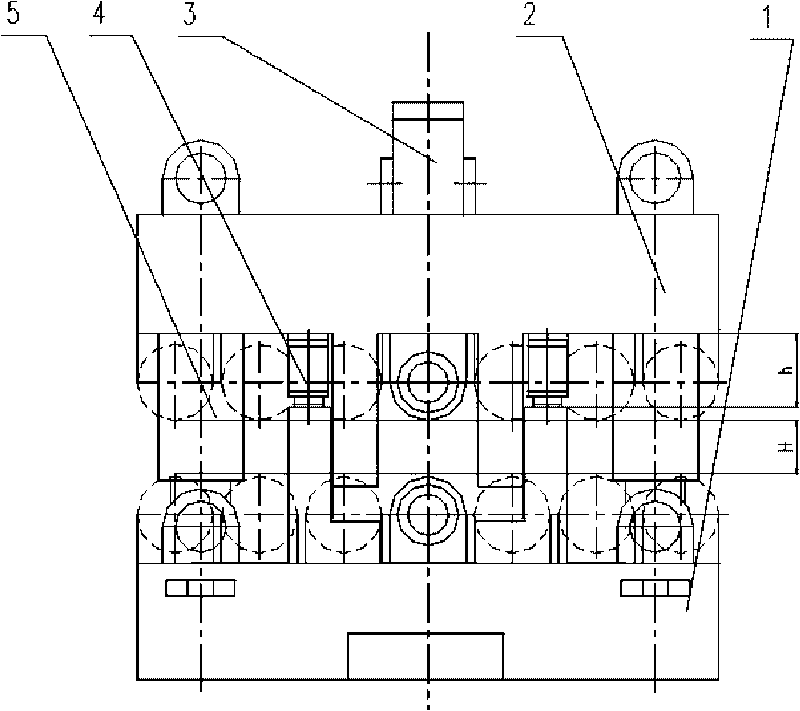

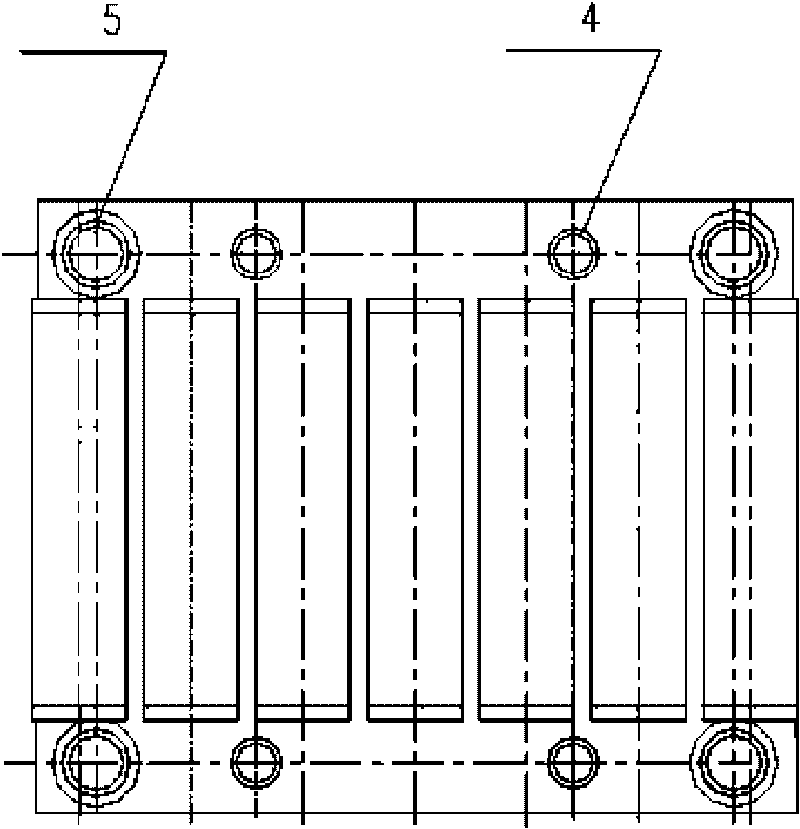

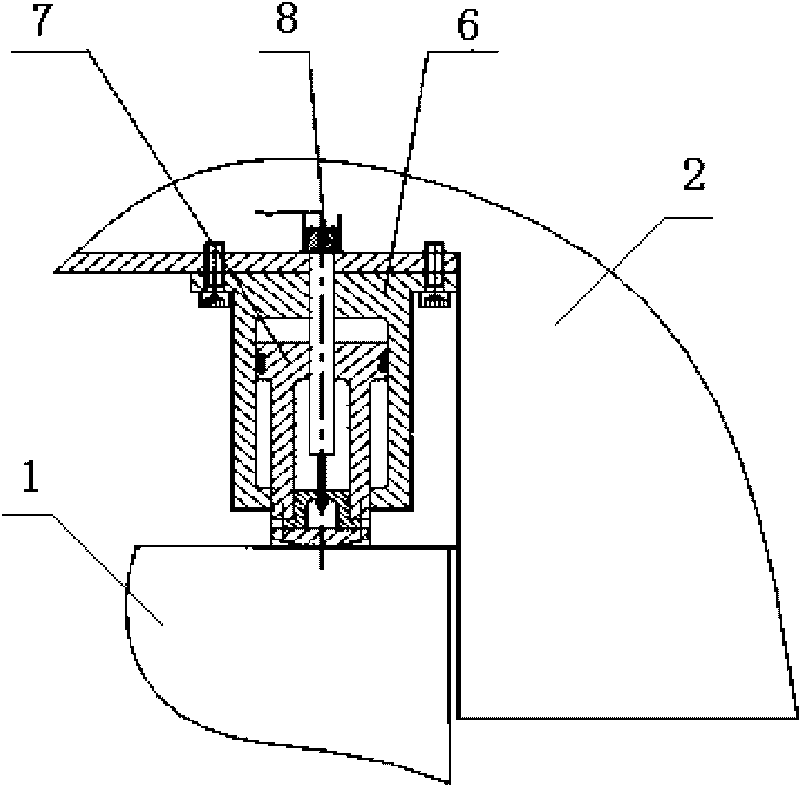

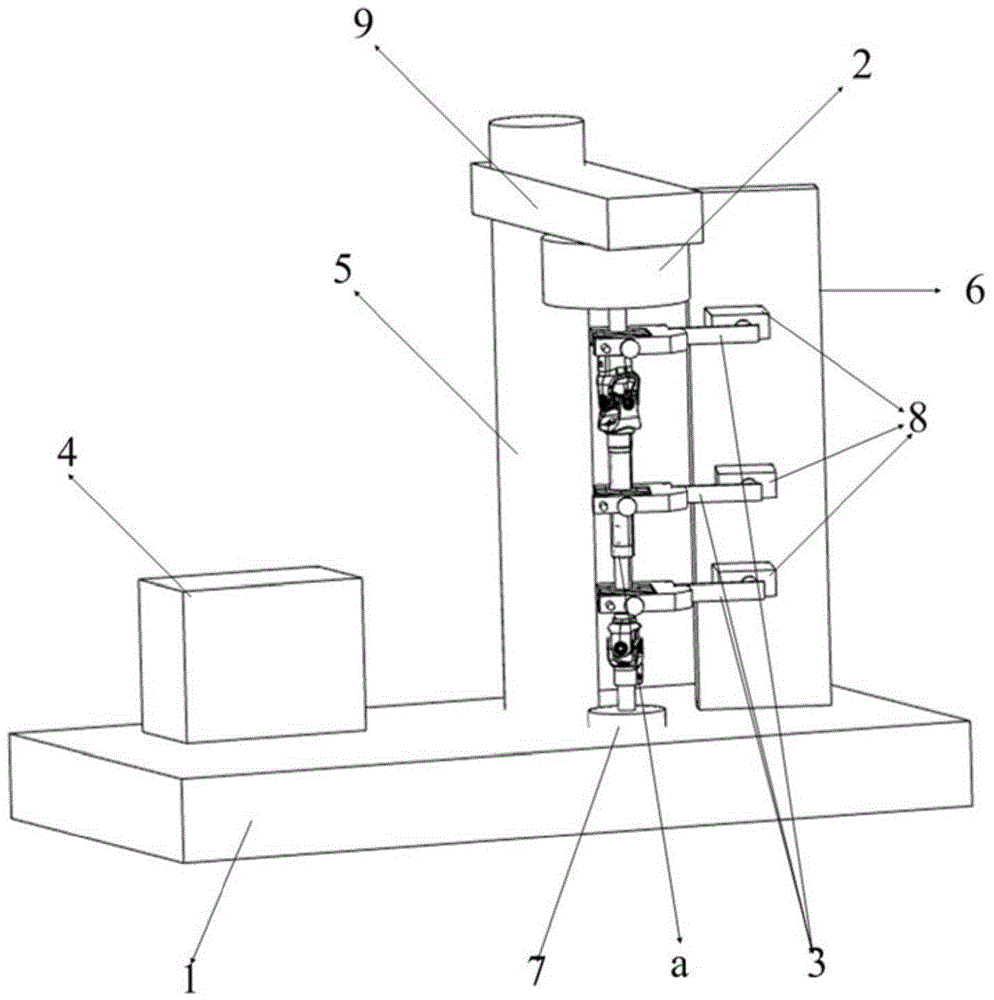

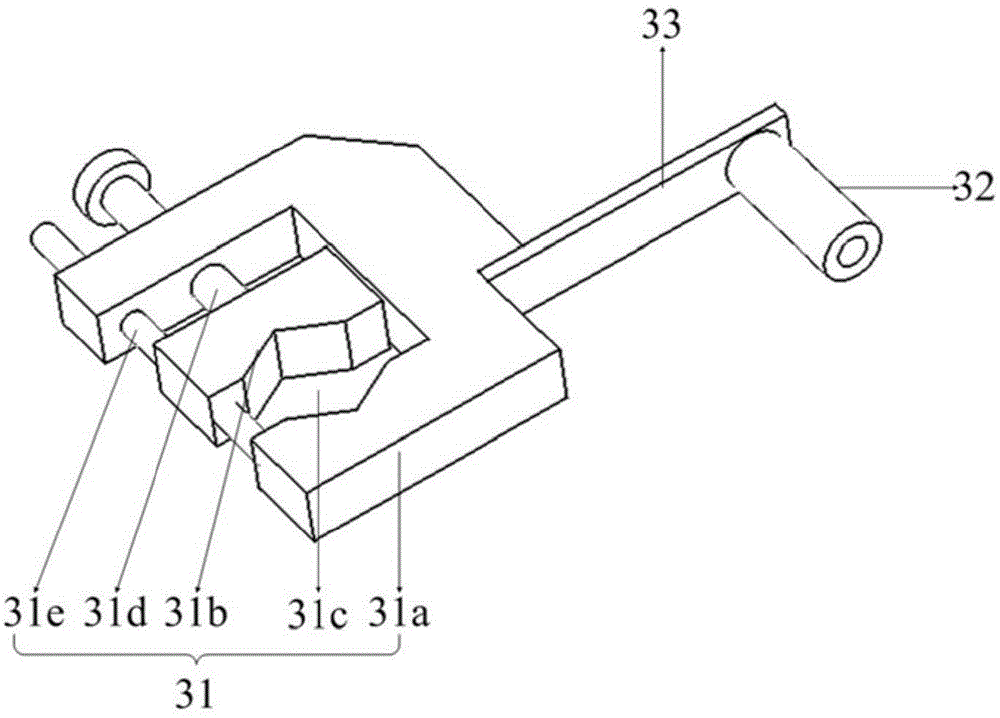

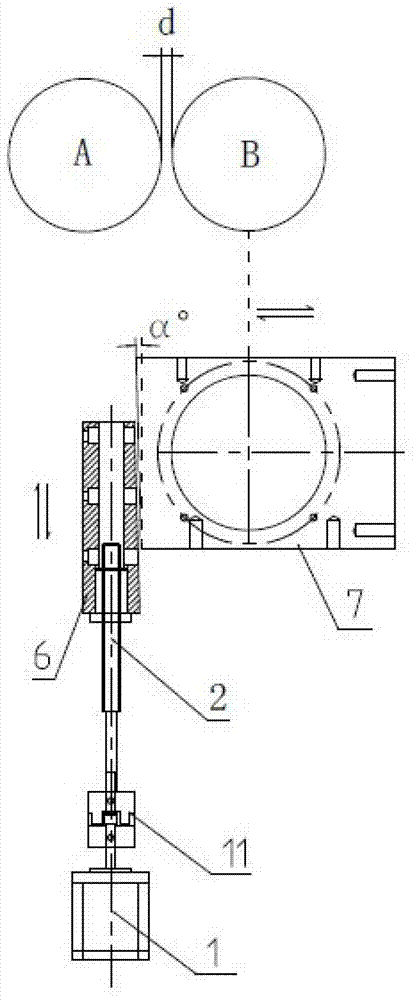

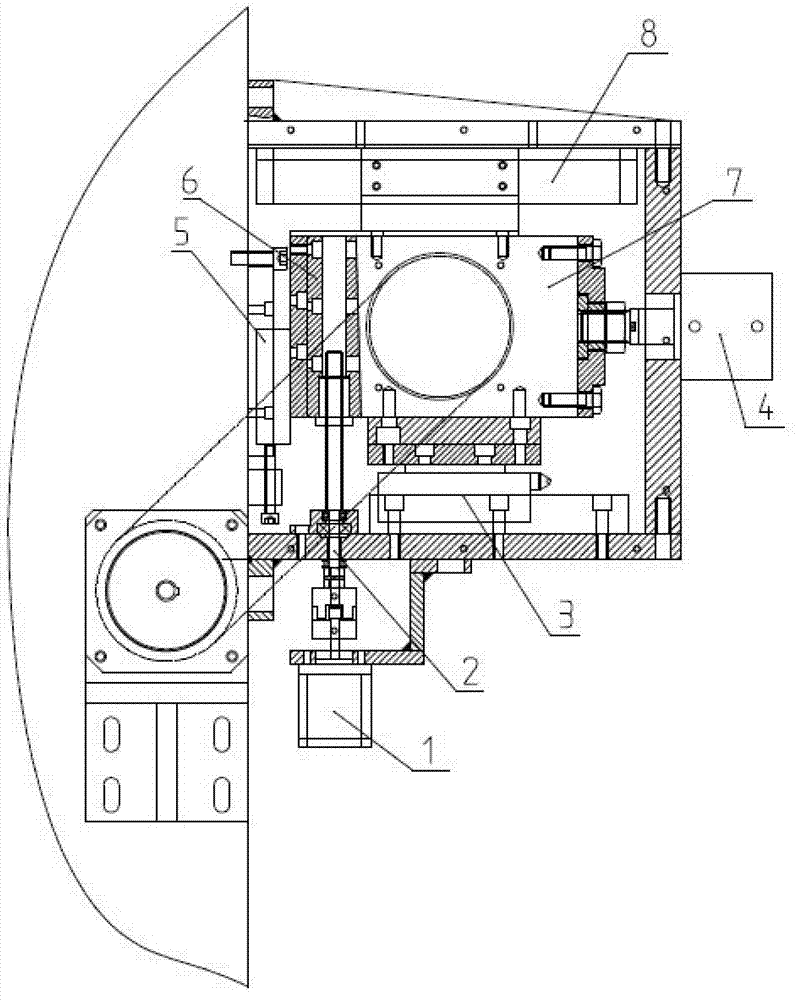

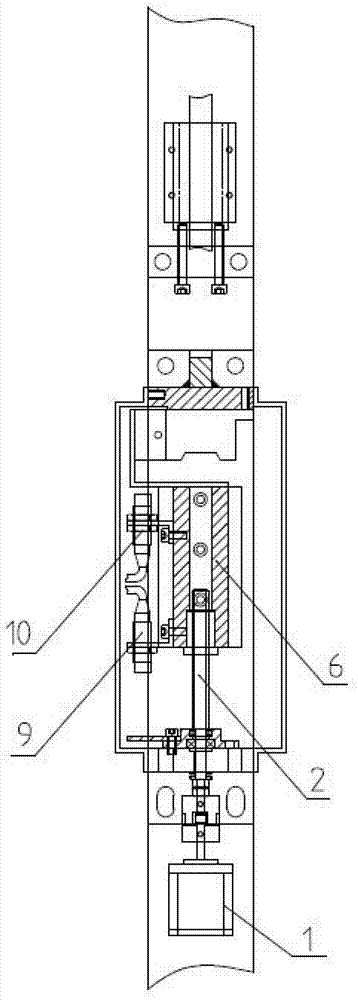

Gap detection device of large slewing bearing

ActiveCN102997885AAvoid damageImprove detection efficiencyMeasurement devicesAxial displacementBall screw

The invention provides a gap detection device of a large slewing bearing and belongs to the technical field of industrial measurement. The gap detection device comprises a radial error detection table, three groups of symmetrically-distributed axial error detection tables, a detection working table frame with a spiral pressing plate clamping mechanism, a slewing bearing to be detected, a controller and a displayer. Each axial error detection table comprises an axial servo motor, an axial rolling guide rail, an axial ball screw, a centering mechanism, an axial screw nut, an axial servo electric pushing rod, an axial working table plate, an axial base and an axial displacement sensor. The radial error detection table comprises a radial servo motor, a locking mechanism, a radial ball screw, a radial rolling guide rail, a radial screw nut, a radial working table plate, a radial servo electric pushing rod, a fork head, a radial base and a radial displacement sensor. The gap detection device of the large slewing bearing has the advantages of being high in detection accuracy, convenient to operate and high in detection efficiency.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY +1

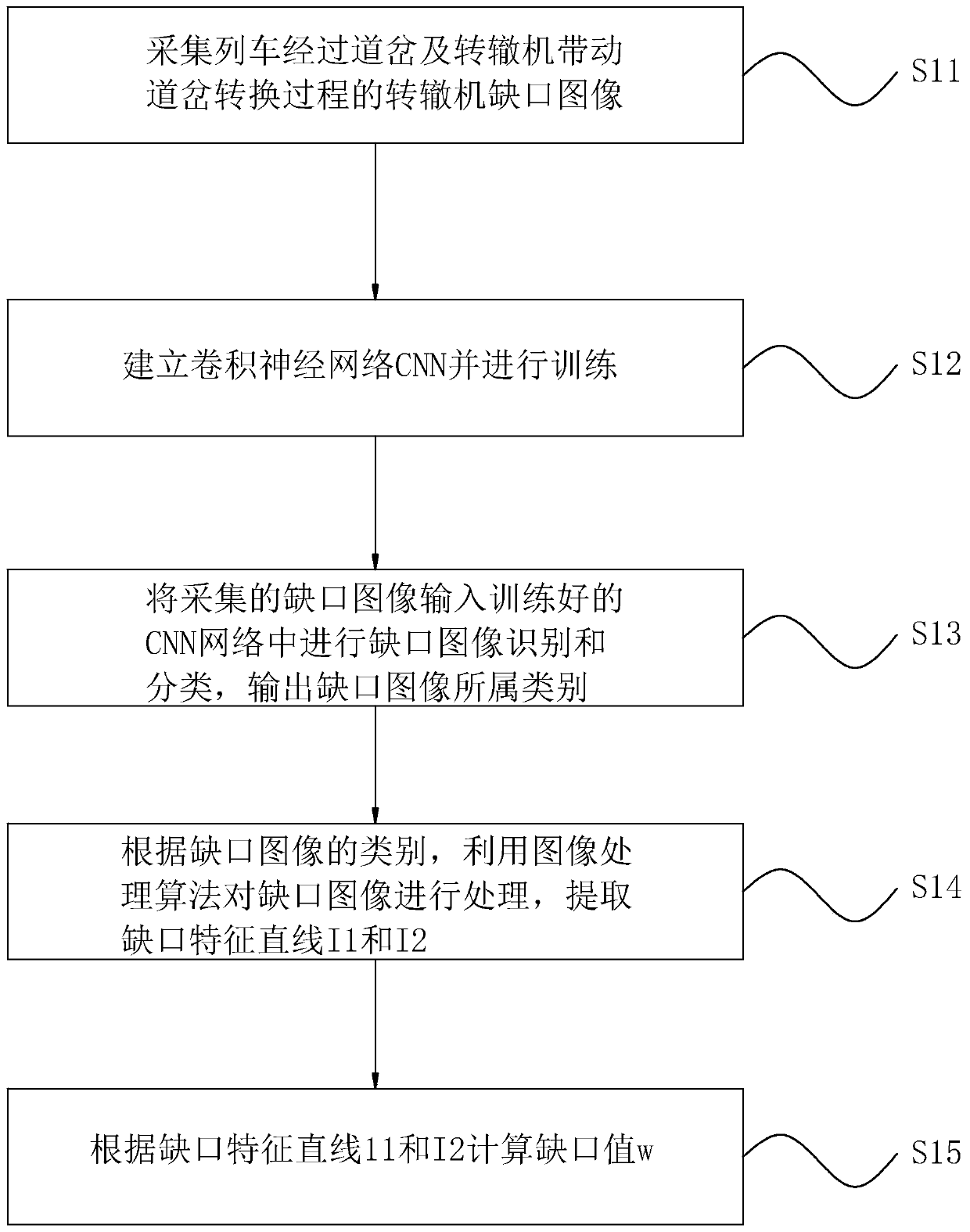

Point switch notch detection method based on CNN and image processing

ActiveCN110363742AReduce complexityReduce development costsImage enhancementImage analysisImaging processingLine fitting

The invention provides a point switch notch detection method based on CNN and image processing, and belongs to the technical field of detection. The method comprises the following steps: acquiring a switch machine gap image of a train passing through a turnout and a switch machine driving turnout conversion process; establishingd and training a convolutional neural network CNN ; inputting the acquired notch images into a trained CNN network for notch image recognition and classification, and outputting categories of the notch images, the categories of the images including six categories: positioning and reverse notch images of ZD6, S700k and ZYJ7 point switches; according to the category of the notch image, processing the notch image through an image processing algorithm, extracting notchfeature straight lines l_1 and l_2, wherein the image processing algorithm comprises image graying, focus area segmentation, image enhancement, image binarization and image notch feature straight linefitting; and calculating a notch value w according to a linear equation of the notch characteristic straight line. Notch detection systems of various types of point switches can be integrated into one system, and the universality and transportability of the system are improved.

Owner:SHANGHAI TIEDA ELECTRONICS & INFORMATION TECH CO LTD

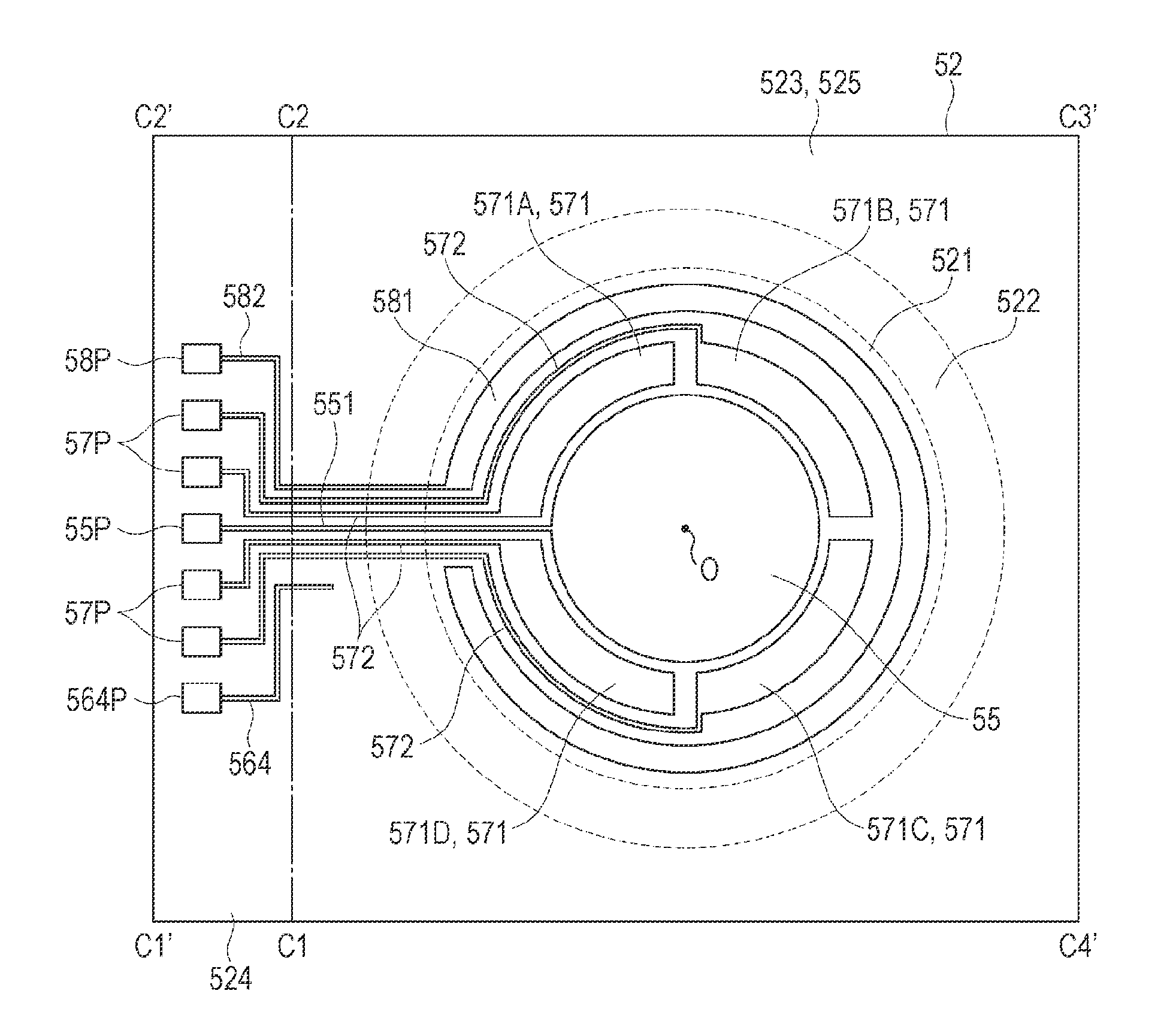

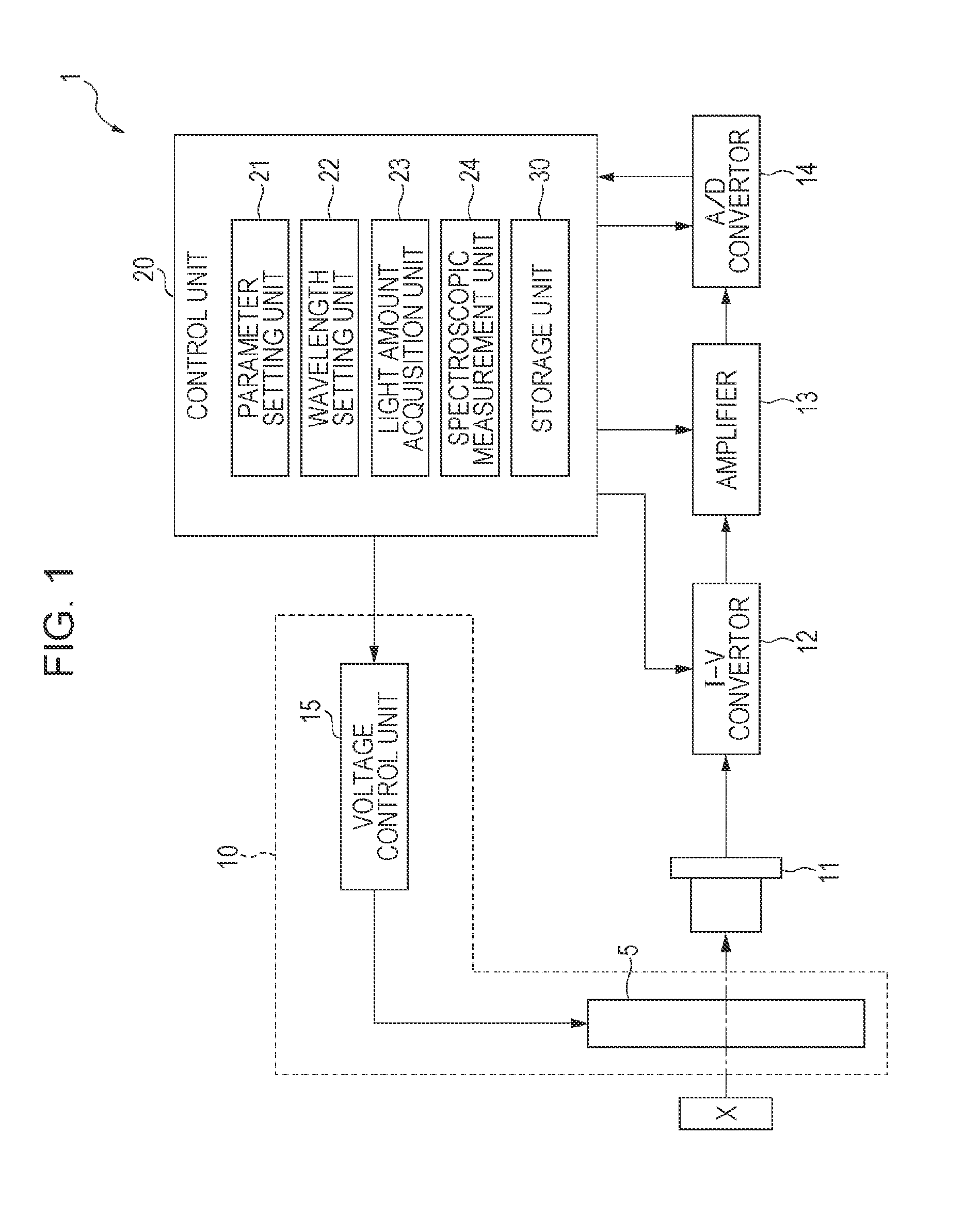

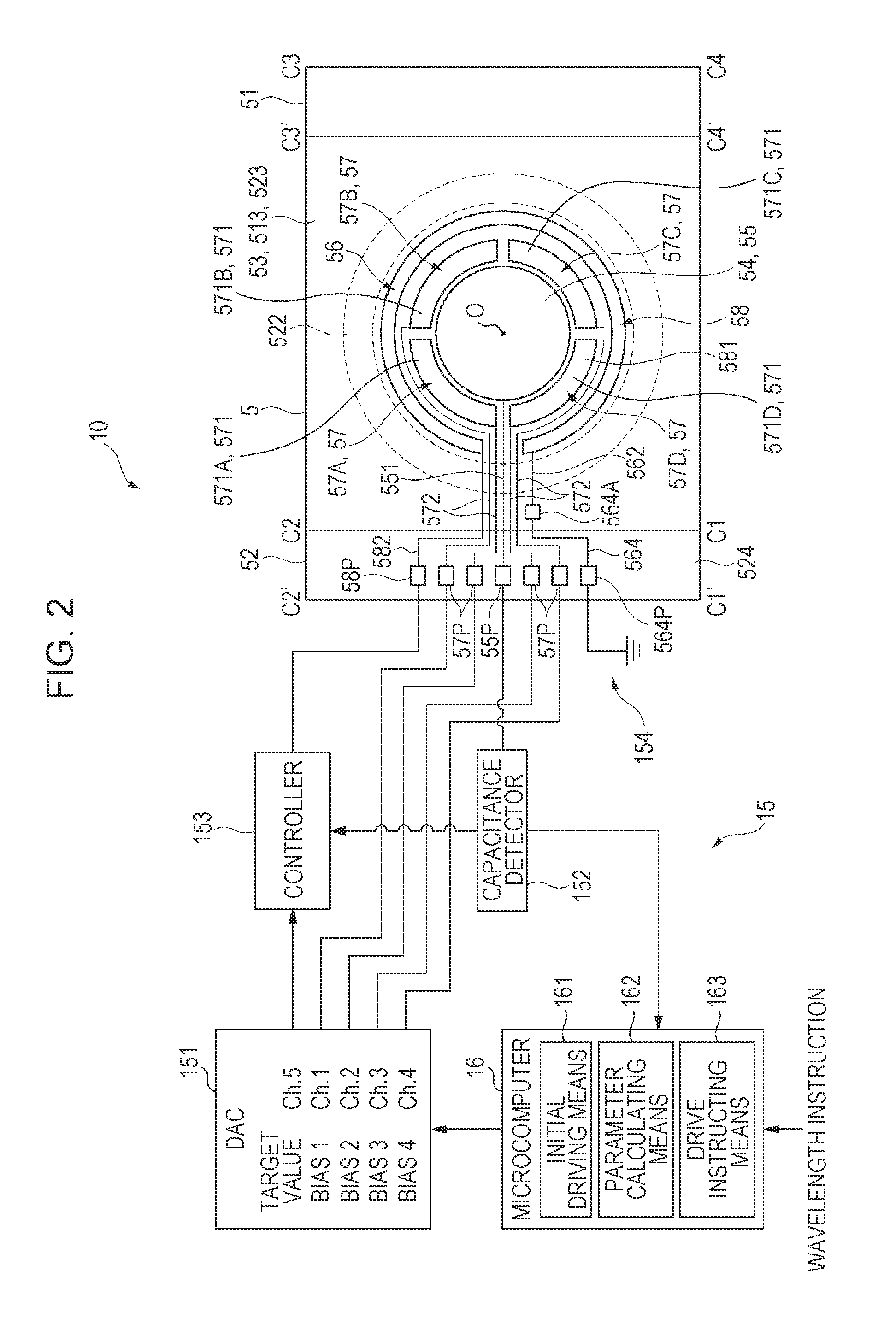

Actuator apparatus, electronic device, and control method

InactiveUS20150318799A1Simple configurationImprove accuracySpectrum generation using multiple reflectionControllers with discontinuous output signalActuatorControl theory

An actuator apparatus includes a pair of substrates facing each other; a plurality of bias actuators that each vary a gap dimension of a gap between the pair of substrates; a gap detection portion that detects the gap dimension; and a voltage control unit that controls driving of each of the bias actuators on the basis of the detected gap dimension. The bias actuators are located asymmetric relative to a driving central axis and are mutually independently driven; and the voltage control unit derives driving parameters for use in driving the bias actuators, on the basis of voltages and gap dimensions obtained by sequentially switching and driving the bias actuators on by one.

Owner:SEIKO EPSON CORP

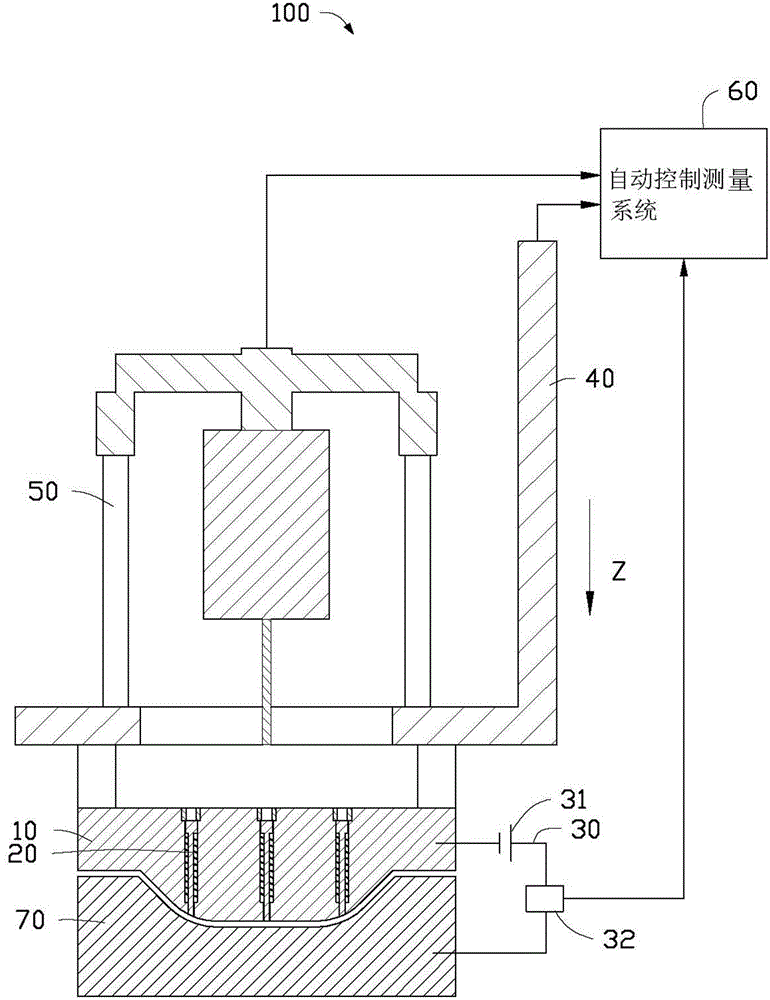

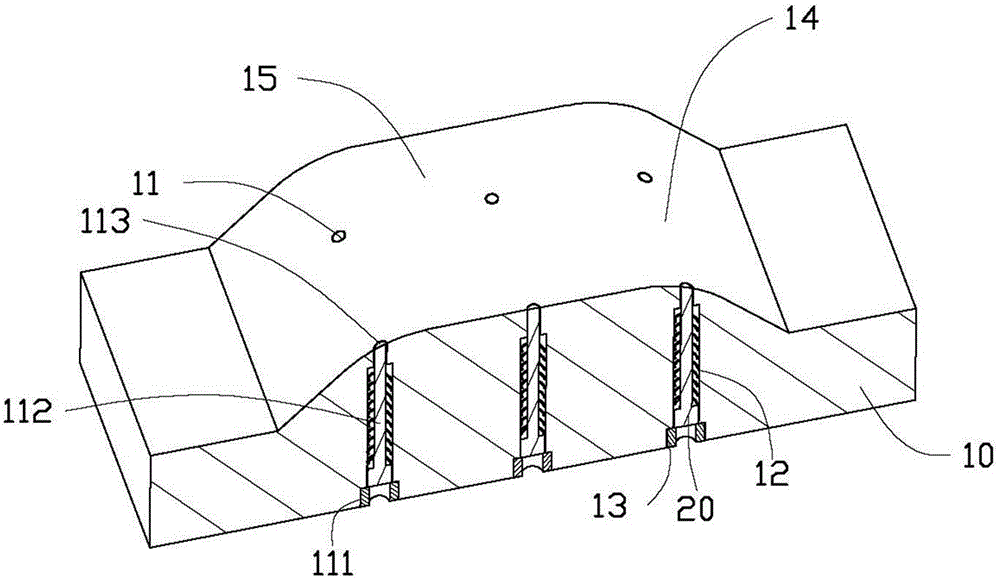

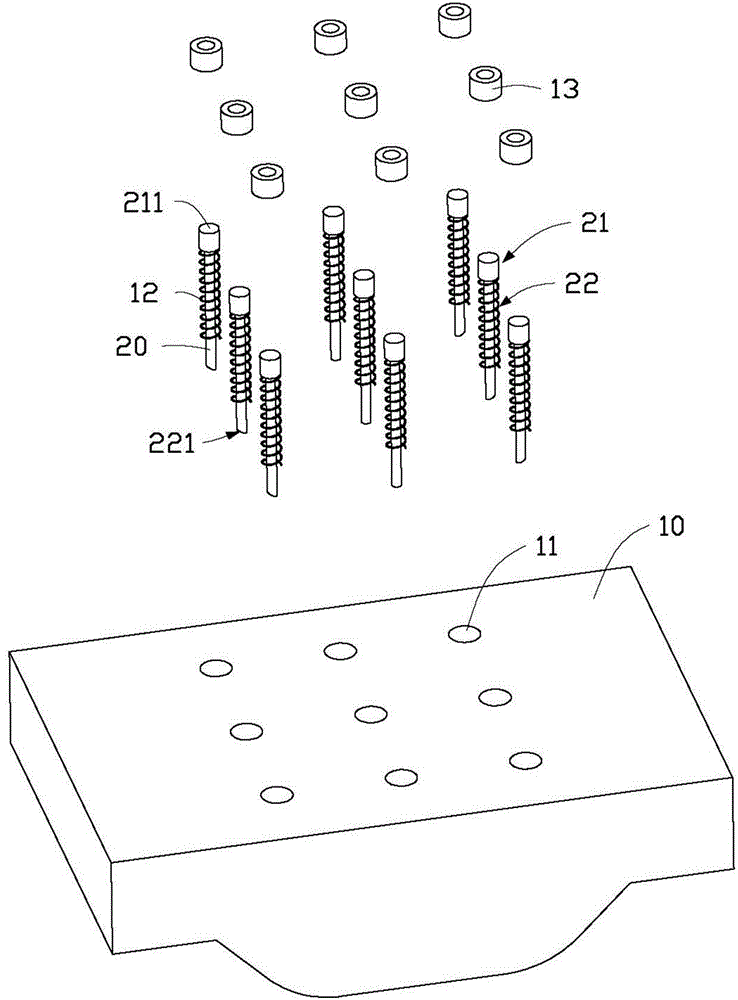

Detecting device and detecting method for electrolytic machining gap

ActiveCN104625272AImprove alignment accuracyMachining electric circuitsElectrical-based machining electrodesElectrolysisAutomatic control

A gap detection apparatus for determining in real time the gap required for electrochemical machining gap includes a tooling electrode, a plurality of tool adjusting electrodes, a feedback circuit, a processing feed mechanism for controlling the tooling electrode, a three-dimensional driving mechanism, and an automatic control and measurement system. The tooling electrode includes a plurality of through-holes for receiving tool adjusting electrodes. The three-dimensional driving mechanism is mounted upon the processing feed mechanism, which includes a Z-coordinate feeding portion having a thimble for the feeding of the tool adjusting electrodes. The automatic control and measurement system controls the feed of the processing feed mechanism and the three-dimensional driving mechanism, and establishes the required gap for electrochemical machining.

Owner:FUTAIHUA PRECISION ELECTRONICS ZHENGZHOU

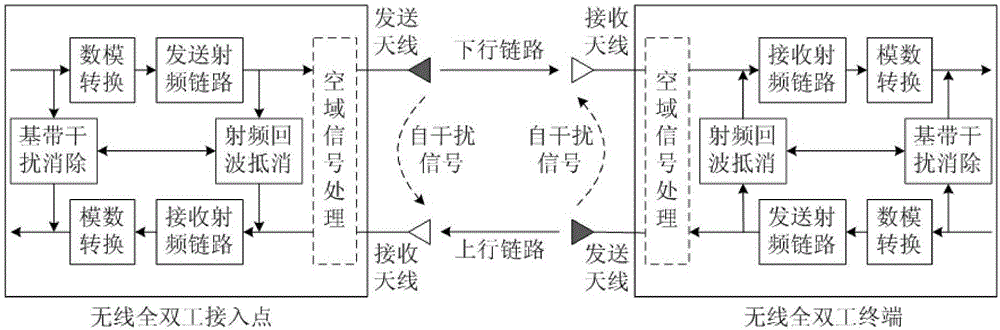

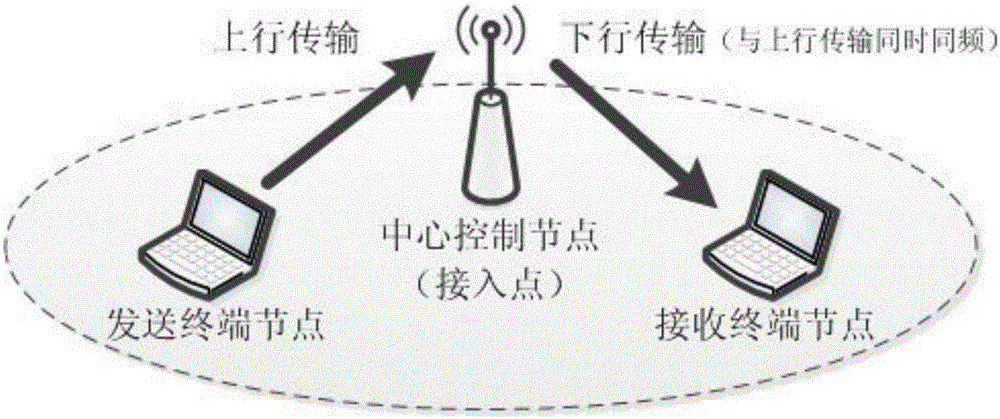

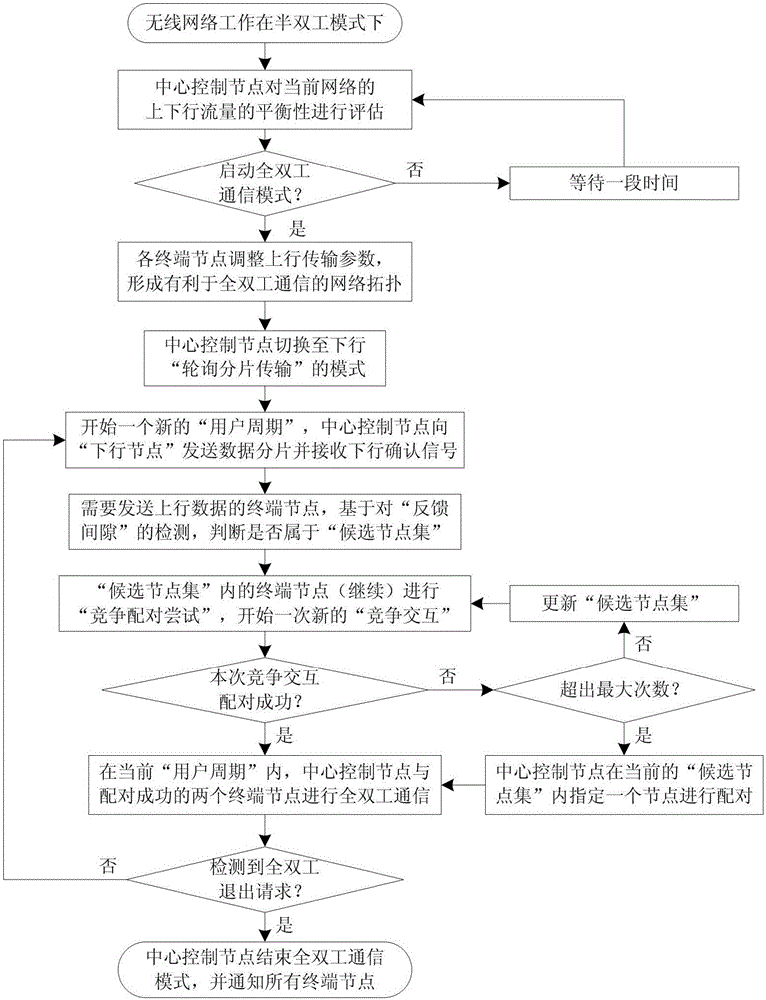

Method for node matching and resource competition in full-duplex wireless network

ActiveCN105162568AOptimize topologySolve resource problemsDuplex signal operationComputer networkMulti user environment

The invention relates to a method for node matching and resource competition in a full-duplex wireless network. According to the invention, key problems such as resource competition, flow matching, co-channel interference, node matching, uplink multi-terminal competition access and the like in an existing full-duplex network are effectively solved through comprehensively applying technical means of flow balance evaluation, uplink parameter adaption, polling fragment transmission, feedback gap detection, competition matching attempt and the like, and reliable and efficient co-channel two-way transmission is realized under a multi-user environment.

Owner:SHANGHAI INST OF MICROSYSTEM & INFORMATION TECH CHINESE ACAD OF SCI

Gap detection device of safety airbag

InactiveCN101922905AImprove detection efficiencyImprove work efficiencyMechanical clearance measurementsEngineeringAirbag deployment

The invention provides a gap detection device of a safety airbag, which comprises a base, three reference blocks, six simulation blocks, four dial indicators, four clamping devices and three positioning columns. Compared with the prior art, the gap detection device of the safety airbag has the advantages of high detection efficiency and simple operation. Only ten minutes are needed for detecting one airbag, therefore, the working efficiency is greatly improved.

Owner:SHANGHAI TRW AUTOMOTIVE SAFETY SYST

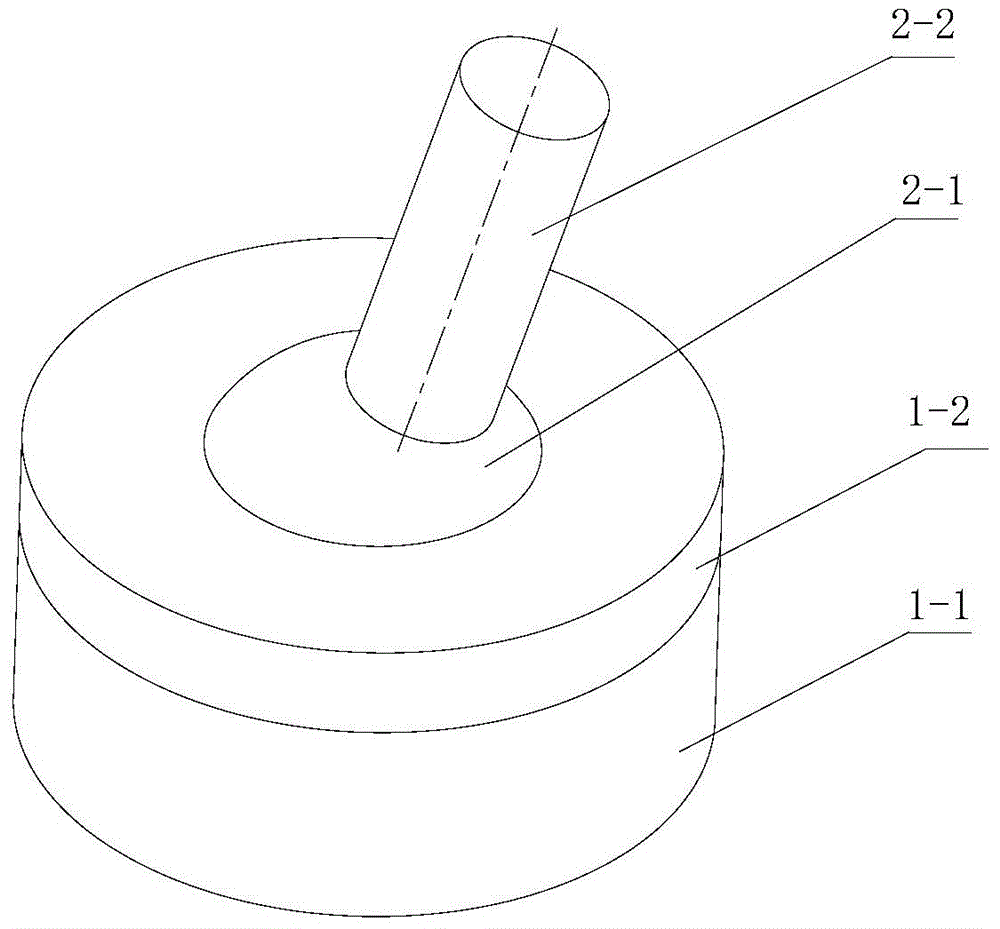

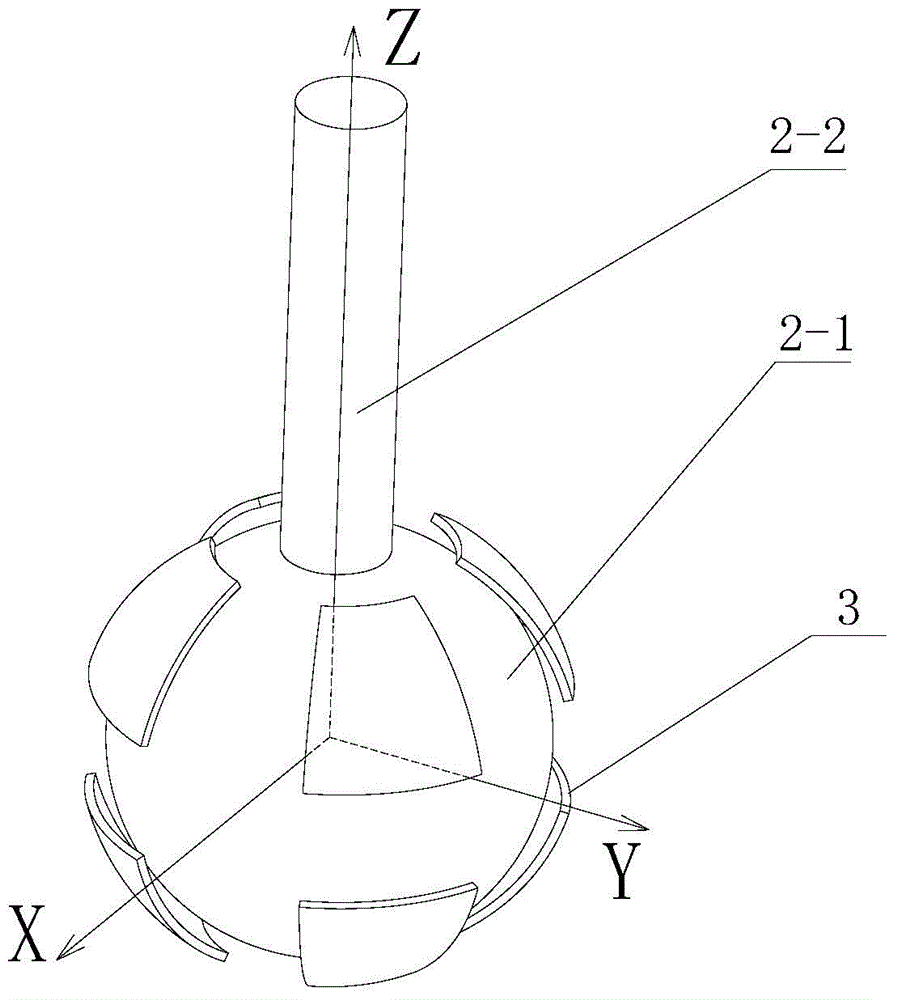

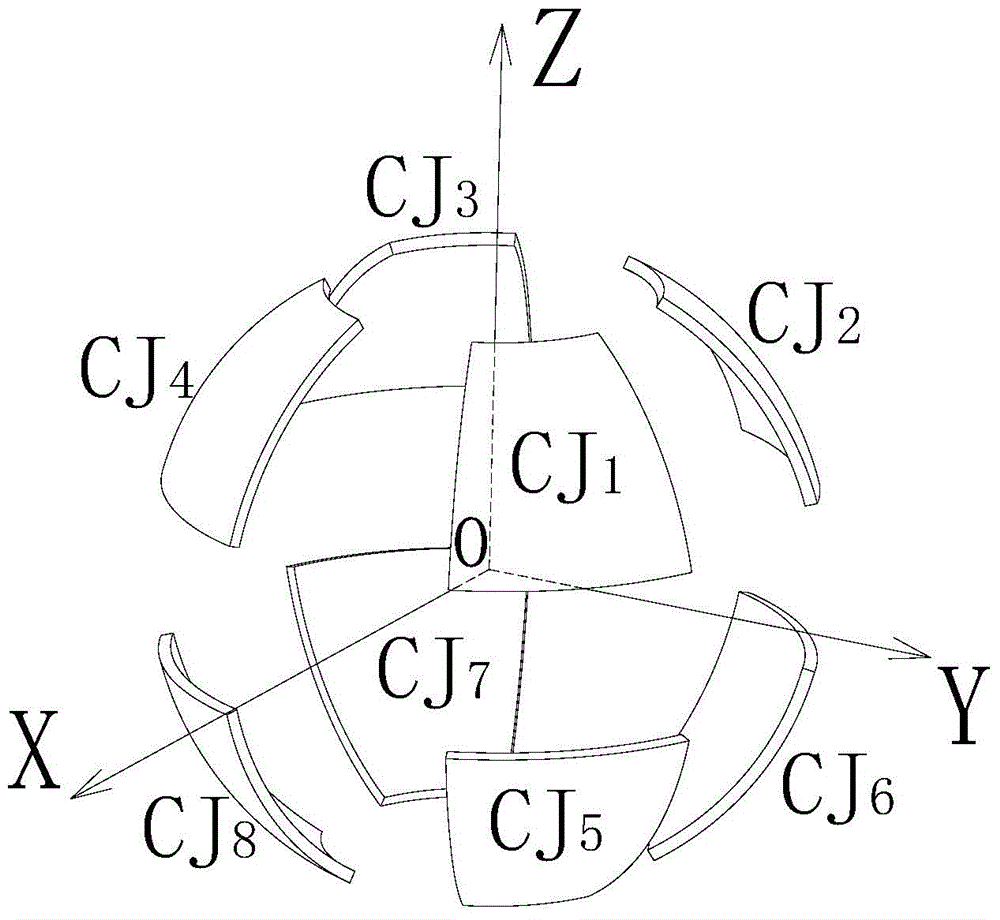

Precision spherical hinge joint gap detection method based on spherical capacitance principle

ActiveCN104677257ARealize real-time online non-contact detectionHigh detection sensitivityUsing electrical meansCapacitanceGyroscope

The invention discloses a precision spherical hinge joint gap detection method based on a spherical capacitance principle. The detection technology for spherical hinge joint gaps is still immature; a method for detecting the eccentric displacement of a rotor in an electrostatic gyroscope technology is difficult to be directly used for precision spherical hinge joint gap detection. The precision spherical hinge joint gap detection method comprises the following steps of fixing static pole plates CJi in a ball socket, wherein i is equal to 1, 2, ..., 8, and distributing the static pole plates CJi in eight quadrants of a three-dimensional coordinate system to form a spherical surface in an encircling mode; taking a spherical head as a dynamic pole plate, and forming eight spherical surface capacitors with the static pole plates CJi; establishing a calculation model between a detected differential capacitance value and the eccentric displacement of the spherical head, and thus obtaining the gap error of precision spherical hinge joints. The method realizes real-time non-contact detection of three degree of freedom eccentric displacement of the spherical hinge joints according to the principle that the change of the gap between the capacitance plates of a spherical surface causes the change of output capacitance.

Owner:HANGZHOU DIANZI UNIV

Method for improving detecting precision of continuous casting hydraulic fanshaped section roll gap through online roll gap apparatus

ActiveCN108687321AHigh precisionSolve the problem of online roll gap managementCasting parameters measurement/indication devicesEngineeringQuality management

The invention discloses a method for improving the detecting precision of a continuous casting hydraulic fanshaped section roll gap through an online roll gap apparatus. According to the method, a tong-type online roll gap apparatus is mounted in the middle of a casting machine dummy bar to carry out roll gap detection; before a casting machine starts casting, the roll gap apparatus stops betweenthe bending section and the first fanshaped section of the casting machine, when the hydraulic fanshaped section is detected, upper driving rollers are in depressed state, according to the basic character of the hydraulic fanshaped section roll gap, the roll gap state during the casting process of the hydraulic fanshaped section is simulated to eliminate the gap of the connecting ends of a controlair cylinder of the hydraulic fanshaped section roll gap, the gaps among all hinge joint points on a roll gap control stand column and the centring gap between an upper frame and a lower frame, so that continuous casting machine roll gap measurement values with higher precision are obtained; in addition, through analysis of data contact ratio, direct adjustment of the casting machine roll gap orabnormal roll replacement is realized, so that the online roll gap management problem of the casting machine hydraulic fanshaped section is solved, and convenient and reliable safeguard is provided for quality management and prolonging of the service life of the fanshaped section.

Owner:SHANGHAI BAOSTEEL IND TECHNOLOGICAL SERVICE +1

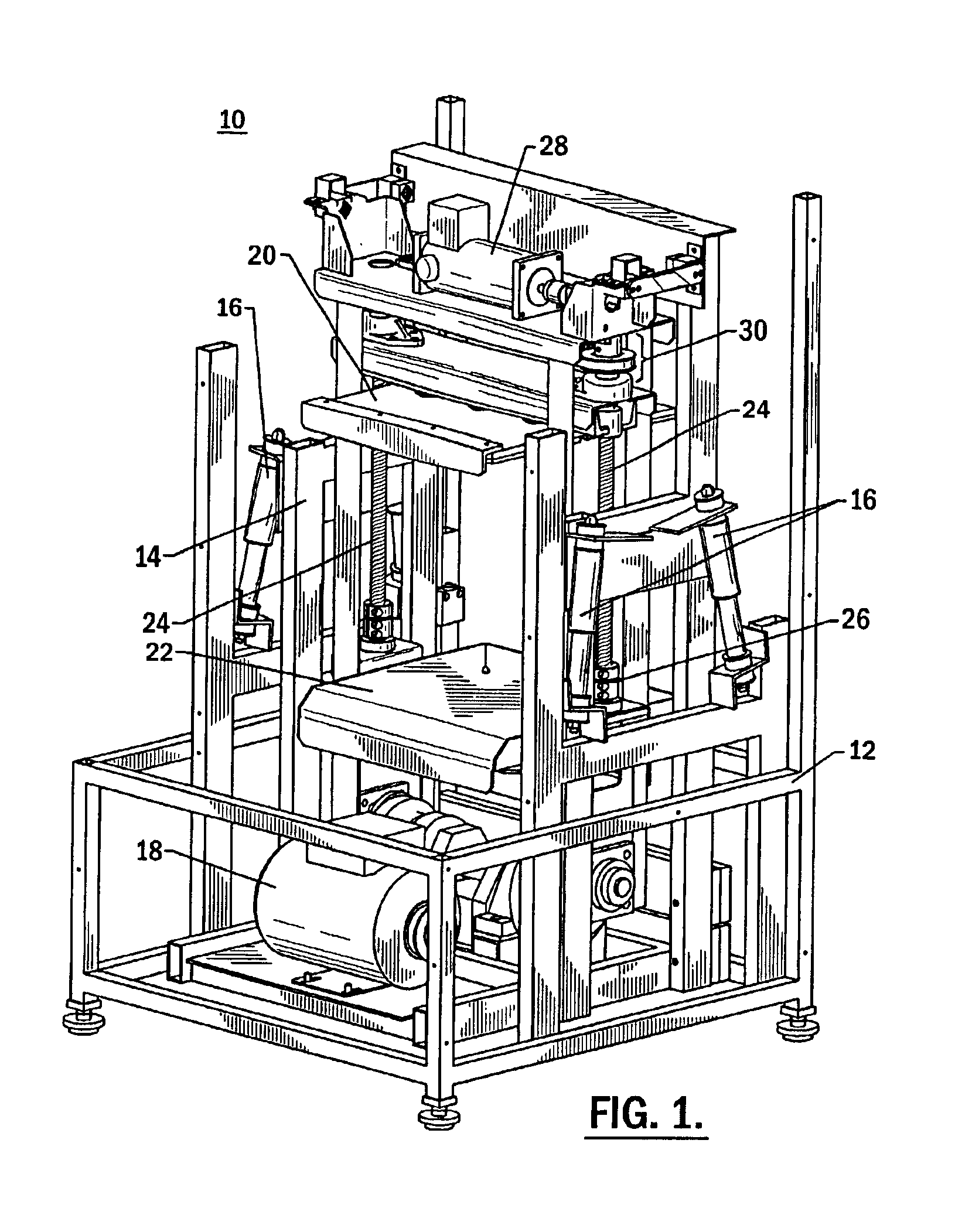

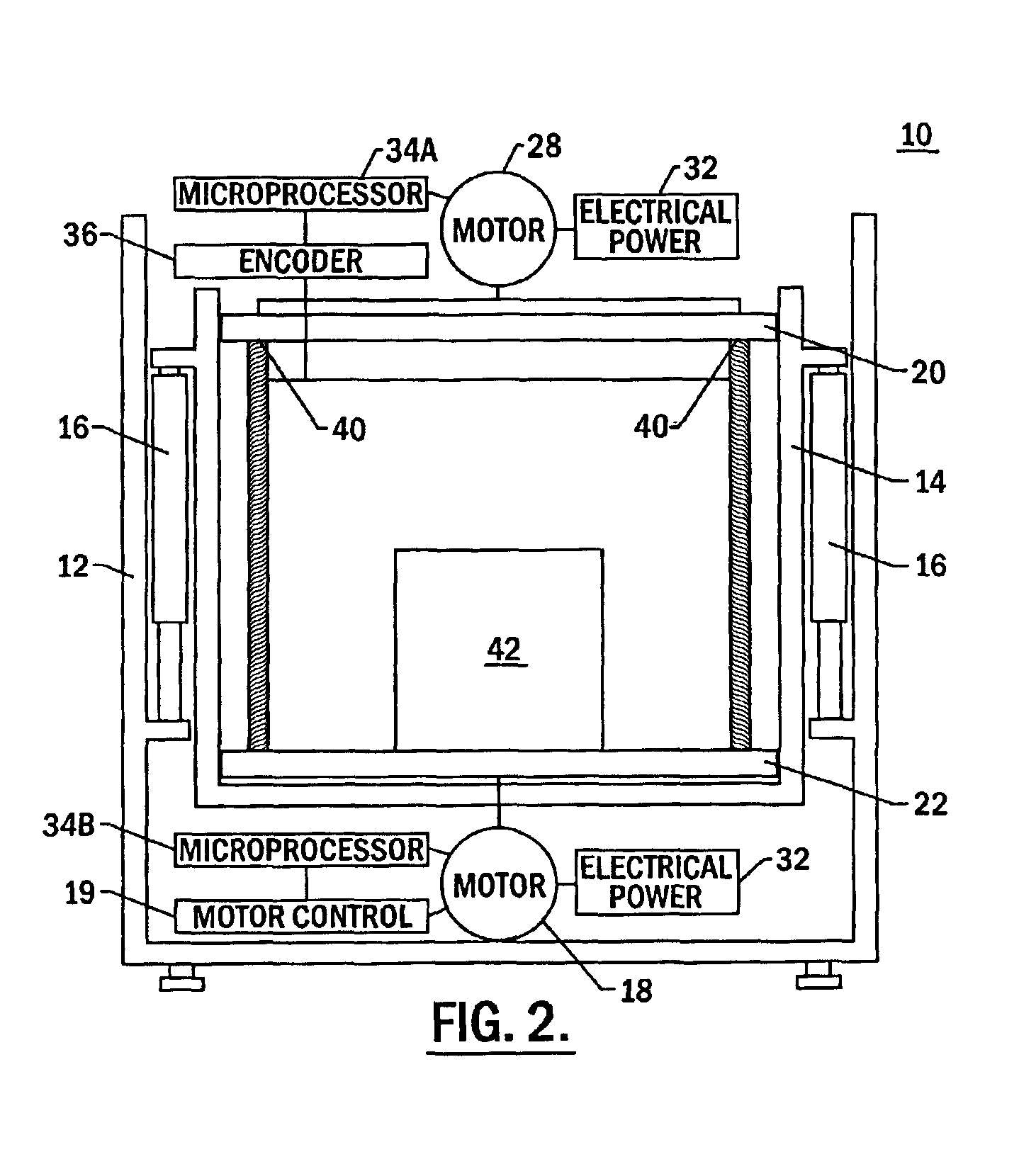

Vibrational paint shaker with managed can detection and clamping features

InactiveUS6883955B2Securely holdMaximum usefulnessShaking/oscillating/vibrating mixersOther chemical processesPower flowReference current

An improved method of detecting the height of, and clamping, a paint or other liquid-containing can relies upon a subtractive comparison of a current draw of a clamping motor to a baseline reference current draw in order to detect the can height. Because the baseline reference current draw accounts for anomalous current draw readings, periodic manual adjustment of the current draw level considered to indicate a can height is unnecessary. The method further includes advanced detection and elimination of gaps developing between the can and the clamping apparatus. A system for agitating a liquid-containing can includes apparatus to carry out can-height detection, clamping, and gap detection and correction using current draw, can height, and clamping plate position data.

Owner:I C T C HLDG

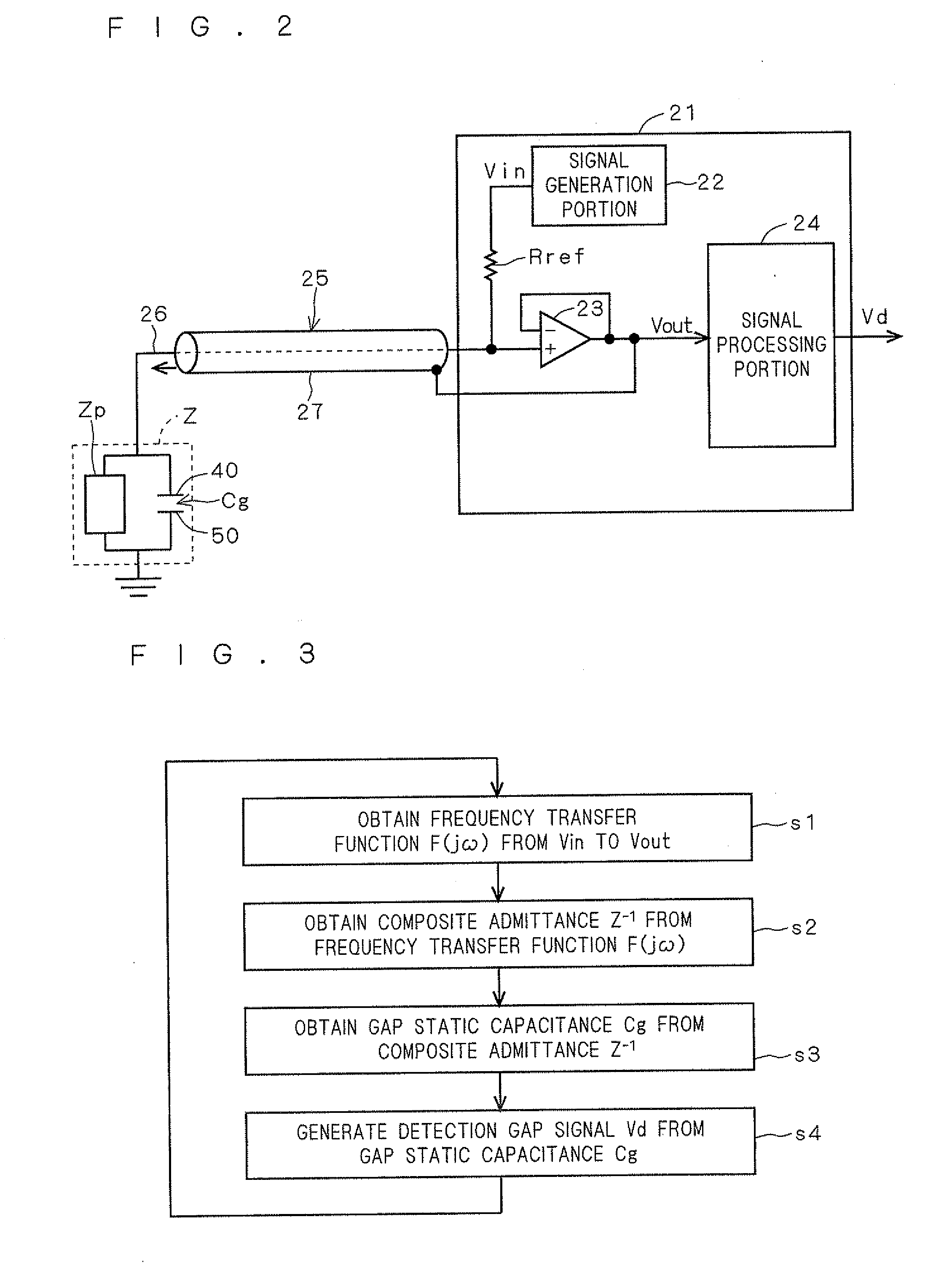

Gap detection device for laser beam machine, laser beam machining system and gap detection method for laser beam machine

InactiveUS20070284348A1Improve accuracyHigh precision machiningResistance/reactance/impedenceArc welding apparatusCapacitanceElectrical resistance and conductance

A signal processing portion obtains the reciprocal of a composite impedance of gap static capacitance and a plasma impedance, obtains composite static capacitance which is the sum of the gap static capacitance and a static capacitance component included in the plasma impedance from an imaginary part of the reciprocal, and obtains a resistance component included in the plasma impedance from a real part of the reciprocal. A gap detection device obtains the static capacitance component by using a model representing the characteristics of the reciprocal of the plasma impedance and the resistance component and obtains the gap static capacitance by subtracting the static capacitance component from the composite static capacitance. The gap detection device obtains a gap from the obtained gap static capacitance. Thus provided is a technique to detect a gap between a nozzle of a laser beam machine for outputting a laser beam and an object to be machined with high accuracy.

Owner:MITSUBISHI ELECTRIC CORP

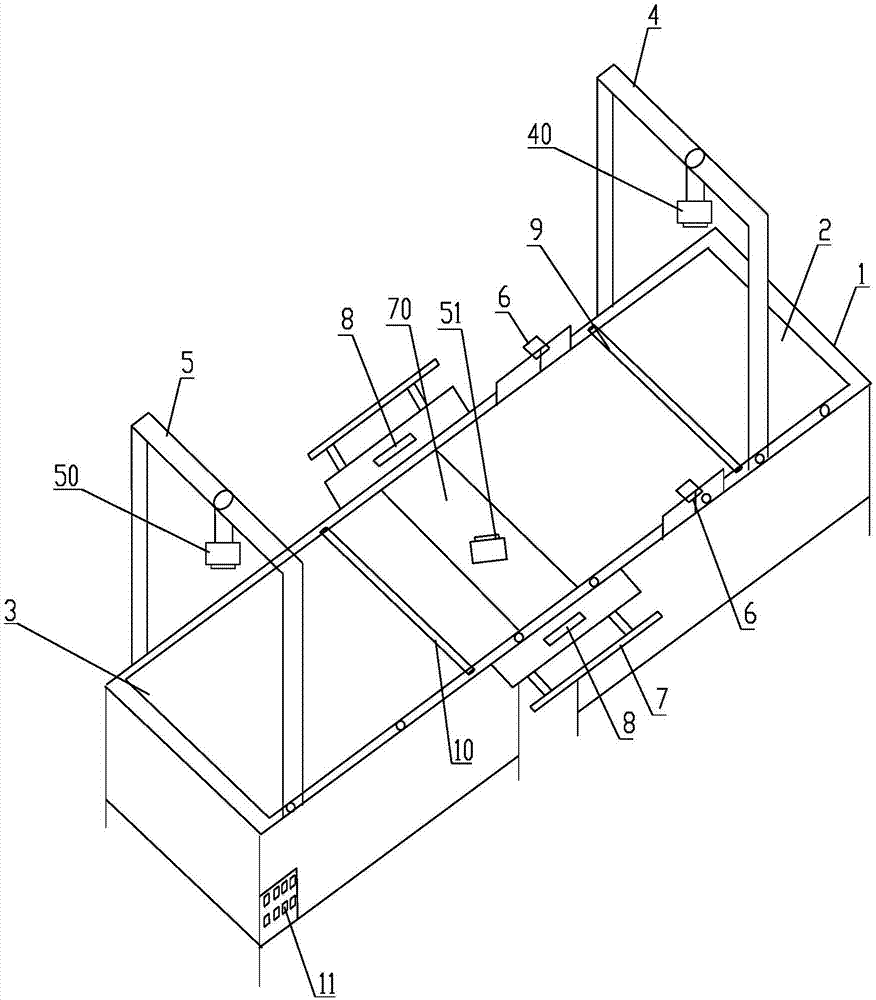

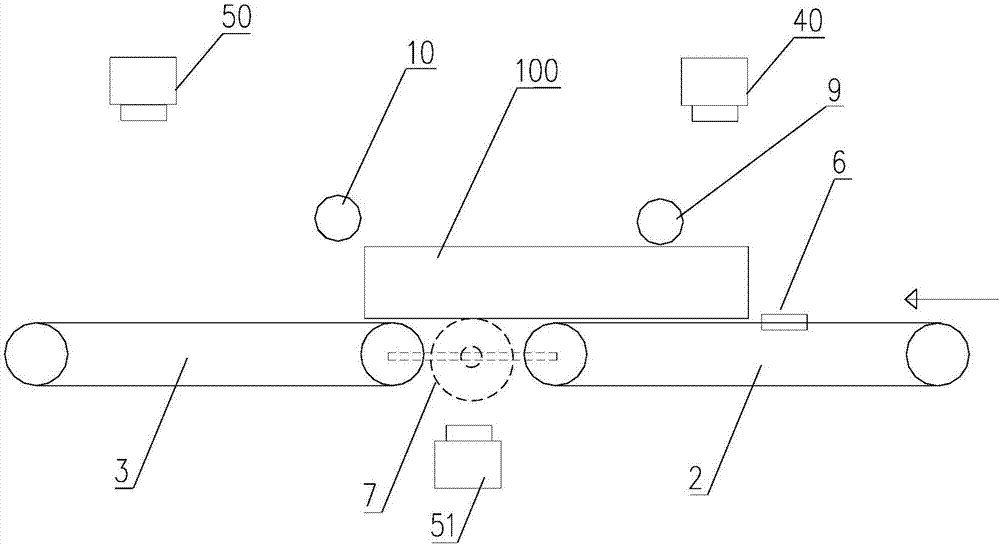

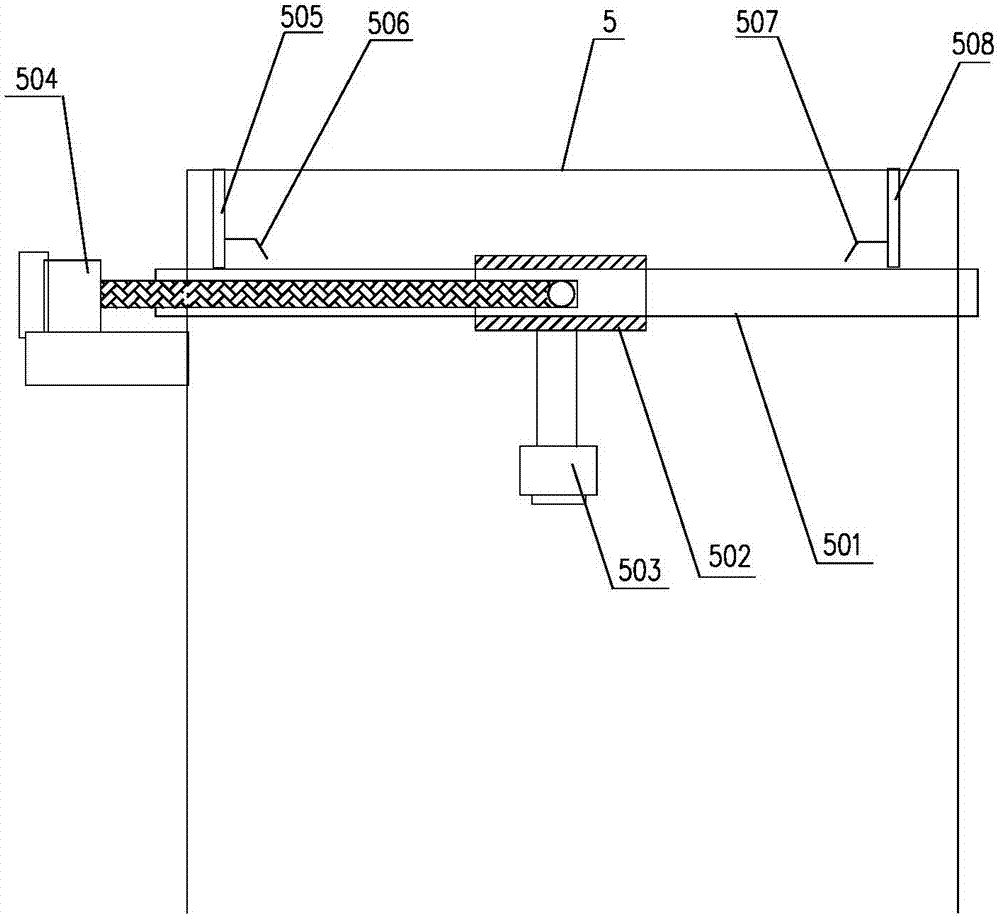

Plate defect detection device and detection method thereof

PendingCN108007938AQuick detection and processingSimple structureOptically investigating flaws/contaminationMeasurement deviceEngineering

The invention discloses a plate defect detection device. The device comprises a machine frame, a first conveying mechanism horizontally laid on the upper surface of the machine frame, a second conveying mechanism, a first support cross beam which is transversely connected with the first conveying mechanism in a bridge joint mode and a second support cross beam which is transversely connected withthe second conveying mechanism in a bridge joint mode, a width measurement device vertically extending toward the surface of the first conveying mechanism is installed on the first support cross beam,thickness measurement devices are installed on both sides of the first conveying mechanism, a first gap measurement device vertically extending toward the surface of the second conveying mechanism isinstalled on the second support cross beam, and a second gap measurement device is arranged in the scanning gap between the first conveying mechanism and the second conveying mechanism. The inventionalso discloses a detection method, and the method includes load adjustment, width and thickness detection, plate gap detection and detection data value processing. According to the device and the method, real-time and rapid detection of defects of plates is achieved, thereby achieving the purpose of high-speed and high-quality production.

Owner:湖北我的科技有限公司

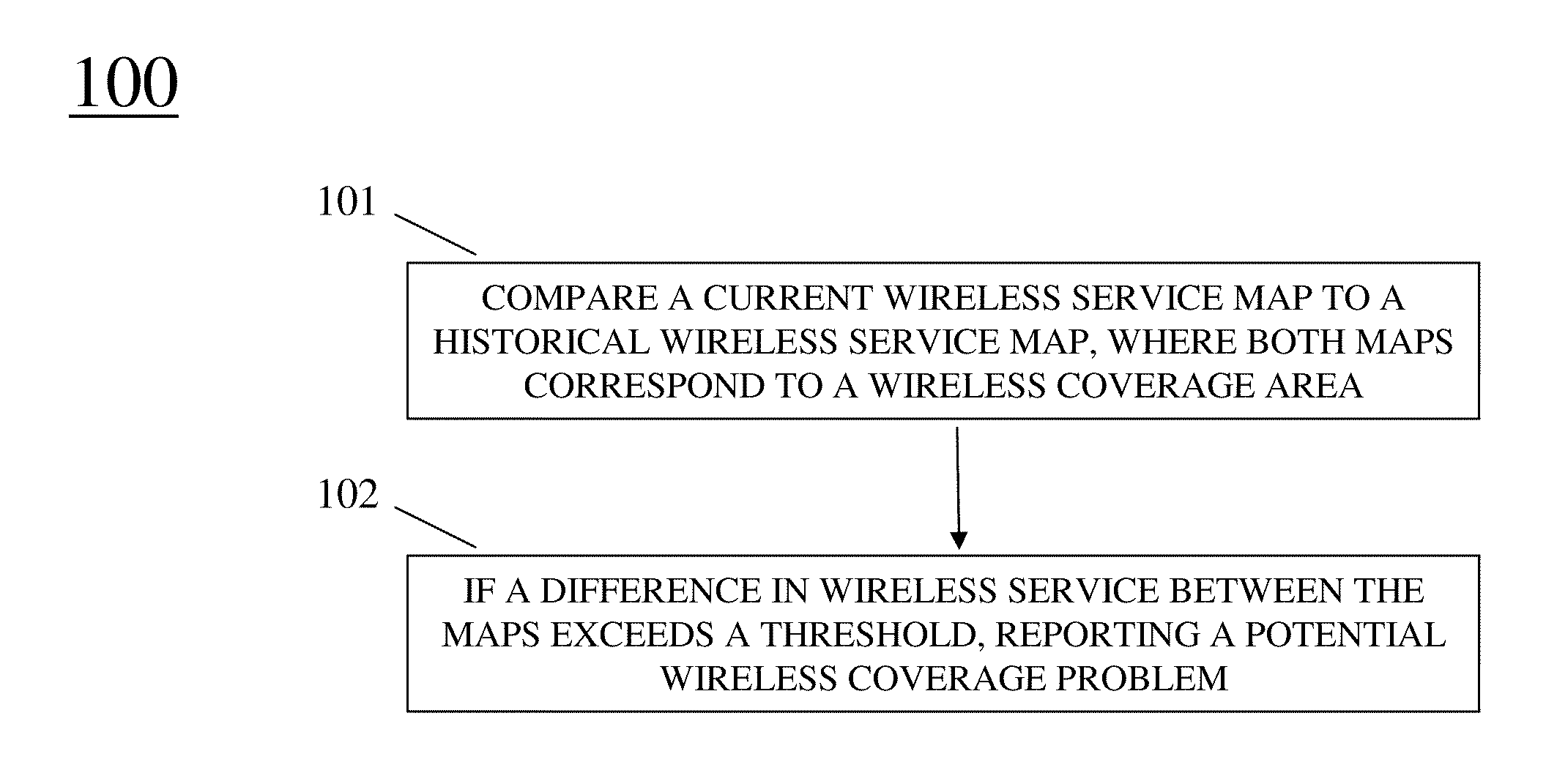

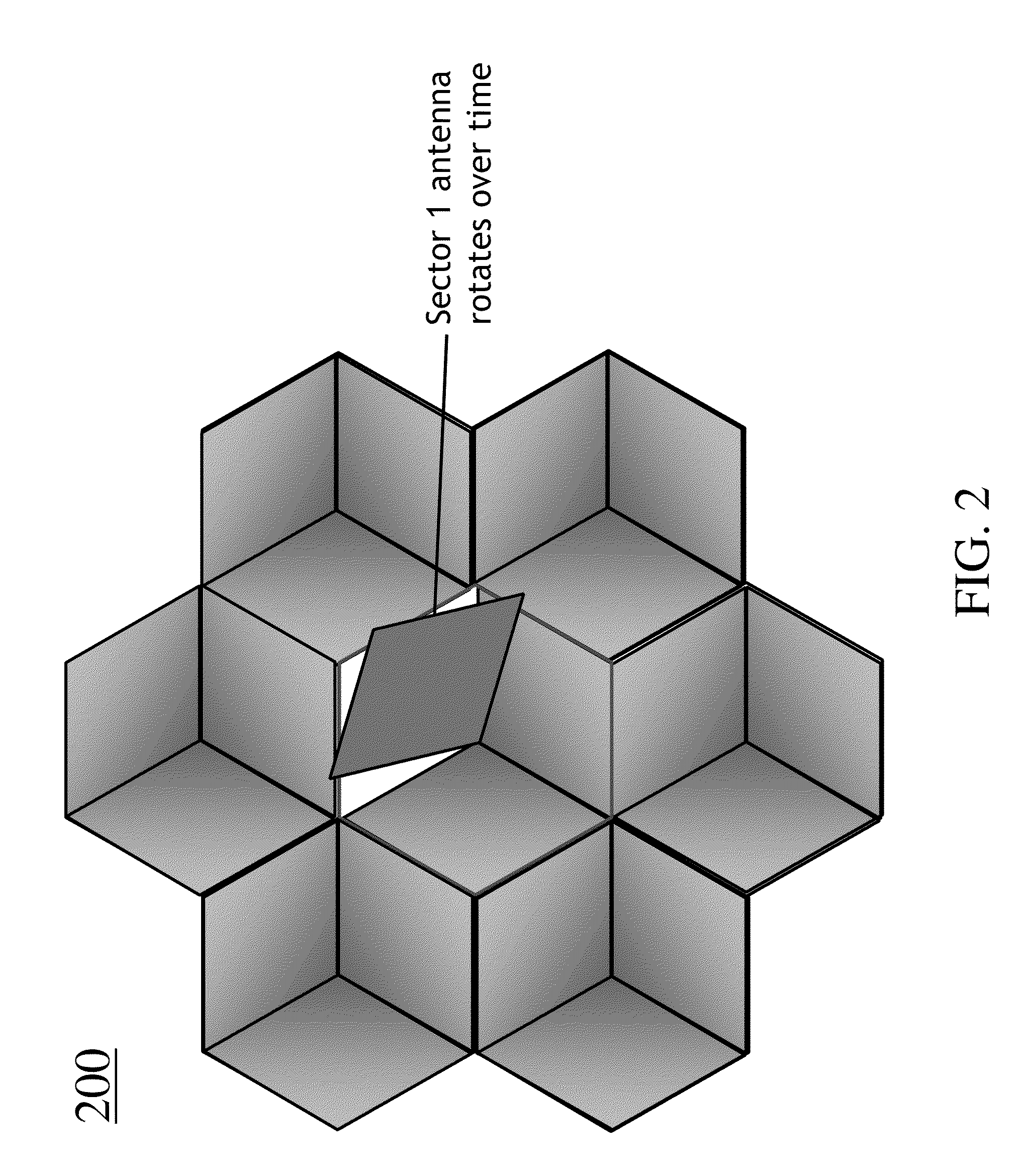

Coverage Gap Detection In Wireless Networks

InactiveUS20110131317A1Network traffic/resource managementDigital data processing detailsWireless mesh networkCommon method

Embodiments are described herein to provide a general approach to wireless coverage gap detection. One general approach involves network equipment comparing (101) a current wireless service map to a historical wireless service map, where the current wireless service map and the historical wireless service map correspond to the same wireless coverage area. If a difference in wireless service between the current wireless service map and the historical wireless service map exceeds a threshold, a potential wireless coverage problem is reported (102). Such an approach may be able to detect network performance problems related to antenna misalignment / malfunction in an effort to minimize the service interruption to subscribers.

Owner:ALCATEL-LUCENT USA INC

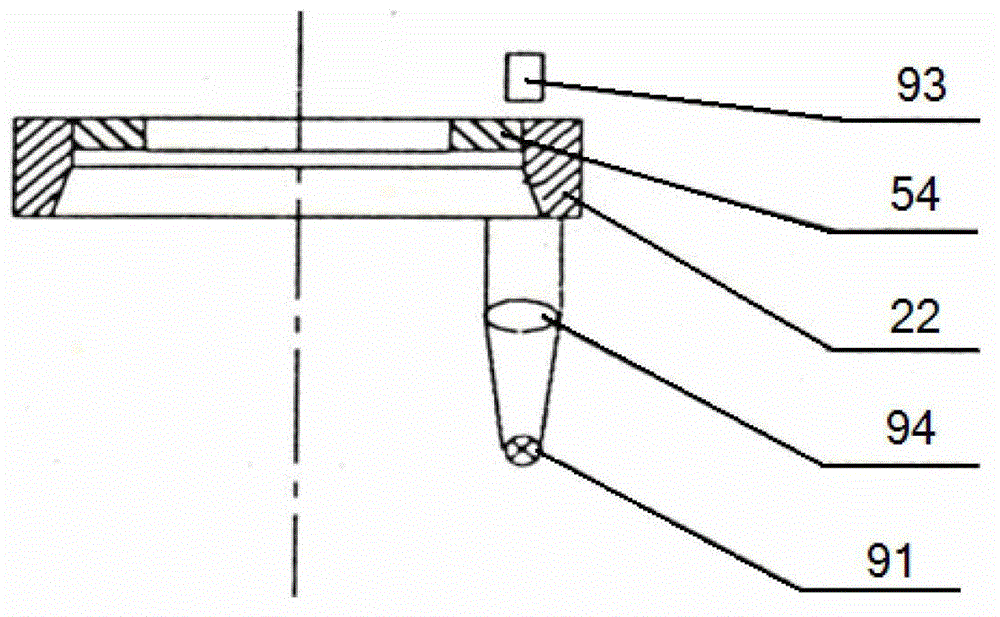

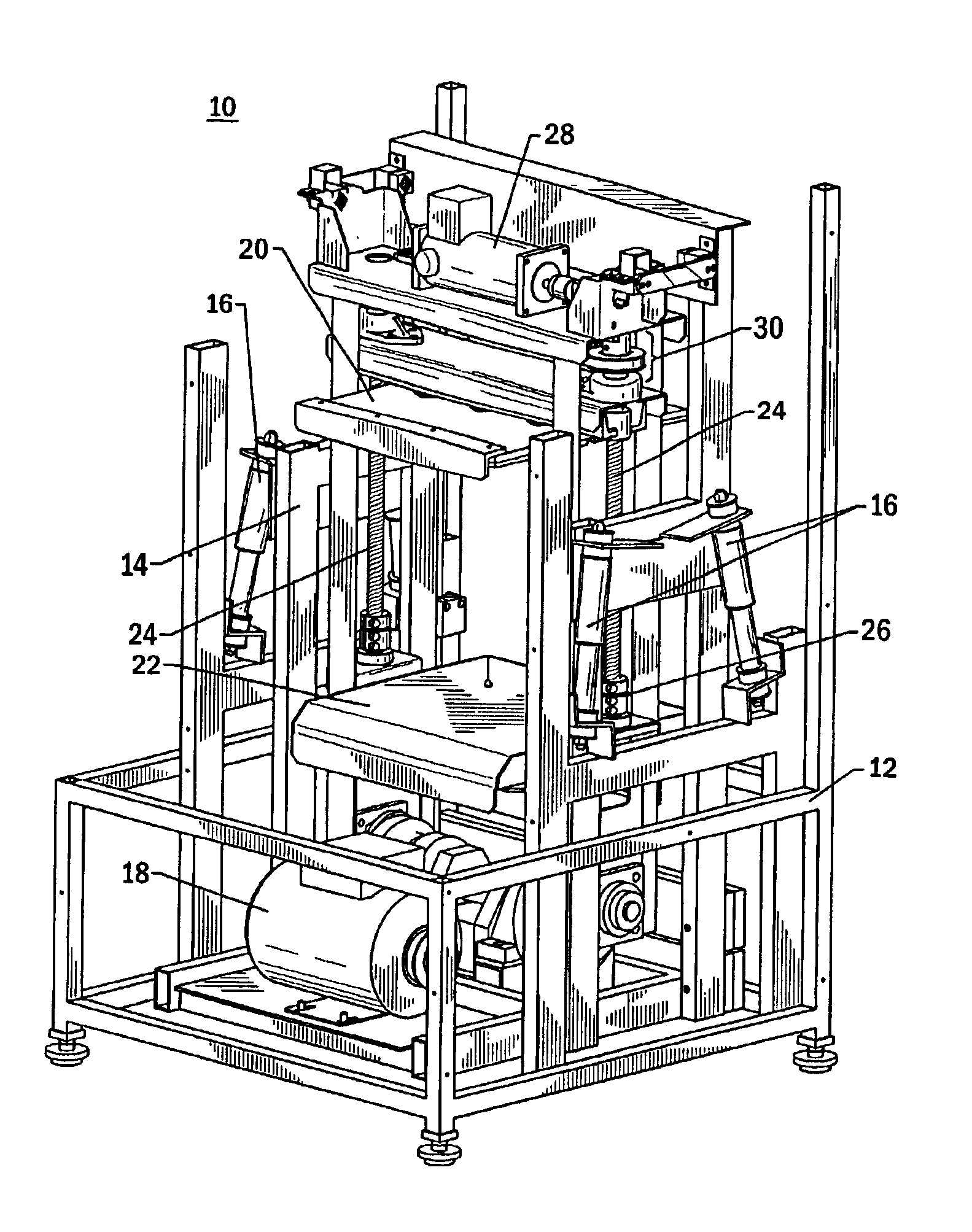

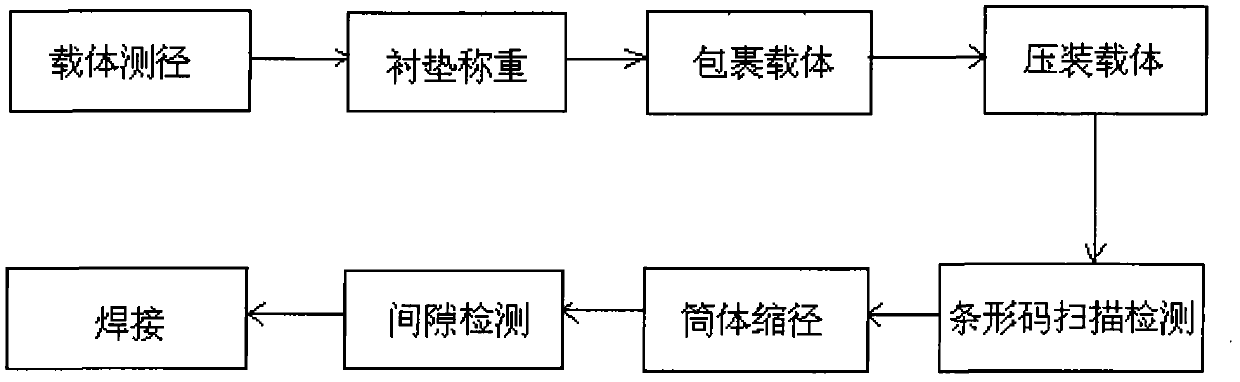

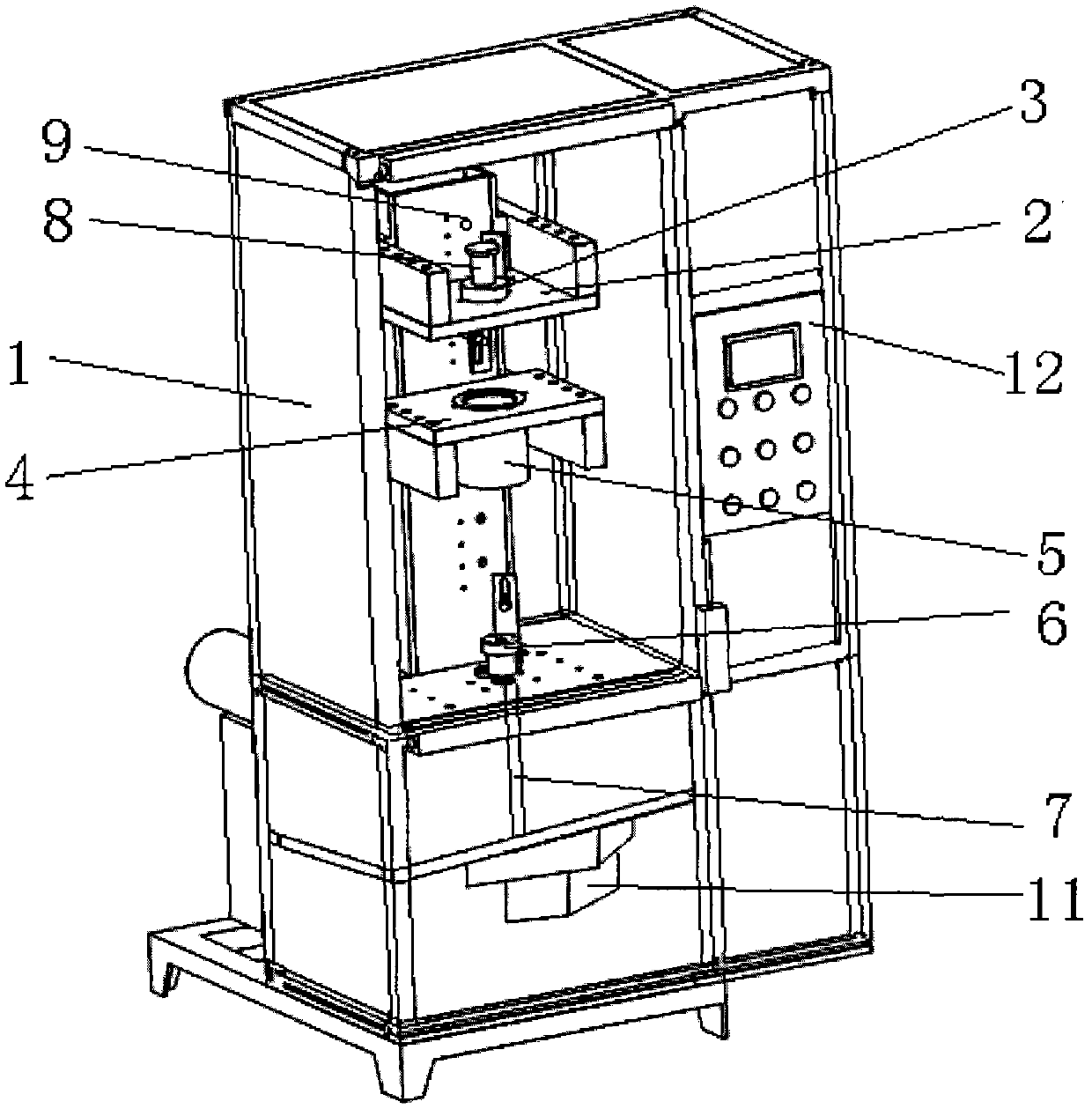

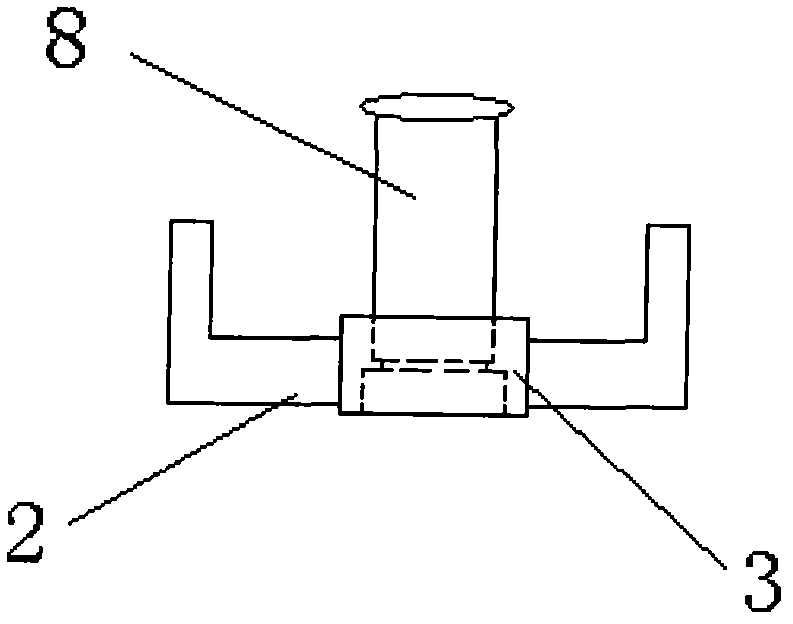

Carrier packaging process of three-way catalytic converter and carrier pressing machine

InactiveCN102000961AUniform compressionUniform deformationMetal working apparatusWhole bodyEngineering

The invention discloses a carrier packaging process of a three-way catalytic converter and a carrier pressing machine. The process comprises the following steps of: carrier calibration, pad weighing, carrier packaging, carrier pressing, bar code scanning and detecting, cylinder reducing, gap detection and welding. The carrier pressing machine comprises a cabinet body, a fixed table, an upper centering mode and a mounting table, wherein the fixed table is arranged in the cabinet body; the upper centering mode is arranged on the fixed table; the mounting table is arranged under the fixed table and controlled by an air cylinder to lift; the mounting table is provided with a through hole; a cylindrical guide compressing mould extends downwards from the periphery of the through hole; a carriertray is arranged under the guiding compressing mould; and the carrier tray is fixed on a lead screw which is controlled by a servo motor to lift. By using the process and the structure, the inventionhas the following advantages that: the production is convenient and the produced carrier is difficult to crack; and the fixed-quantity reducing of the cylinder in the catalytic converter packaging process is solved so that the outside diameter of the catalytic converter can uniformly shrink for many times without indentation, the whole body is thin and tightened, and the pad is uniformly compressed and deformed.

Owner:WUHU EVERSHINE AUTOMOTIVE COMPONENT

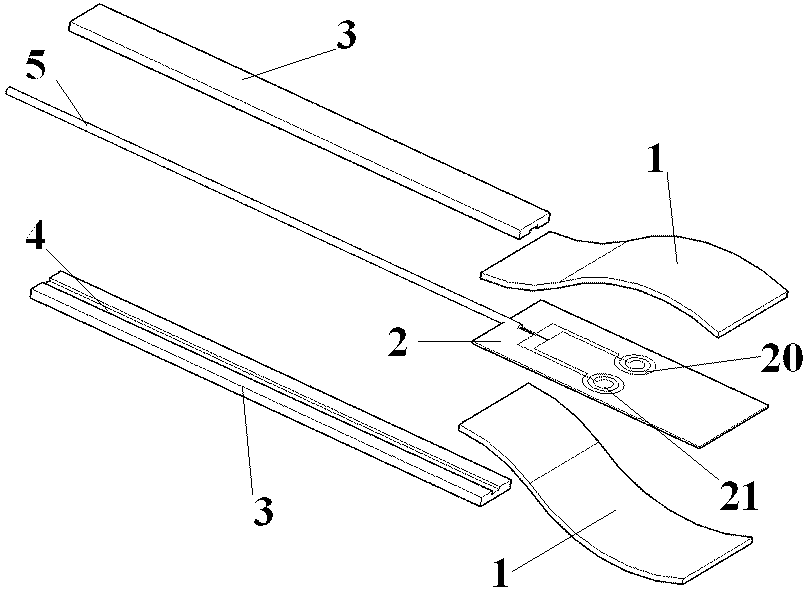

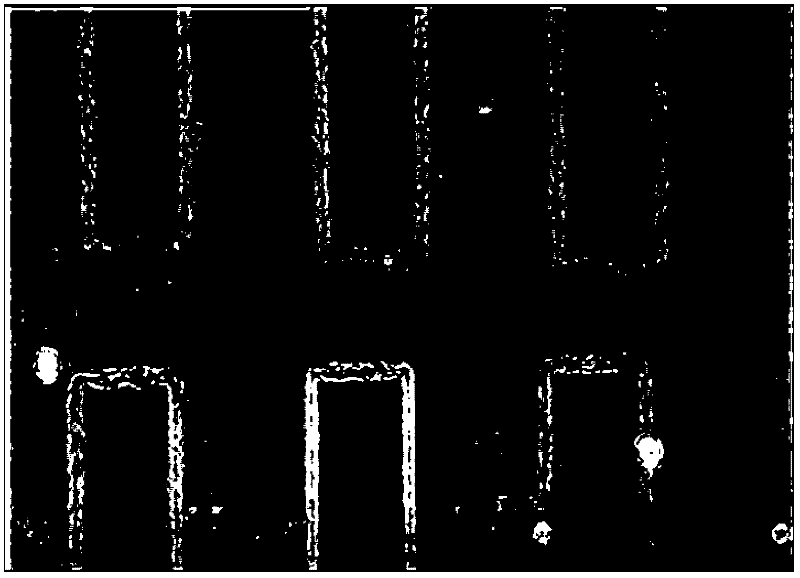

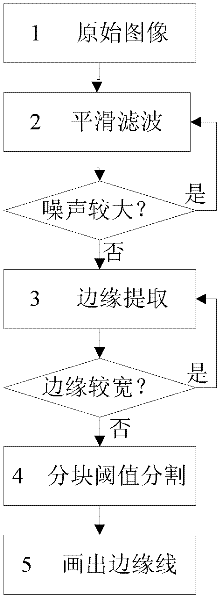

Strip gap detection method

InactiveCN102393964AAvoid interferenceSimple calculationImage analysisDigital signal processingPattern recognition

The invention relates to a strip gap detection method, and belongs to the technical field of digital image processing. The strip gap detection method comprises the following steps of: carrying out smoothing filtering on an original image, and if the noise is higher, carrying out smoothing filtering for multiple times; carrying out edge extraction on the filtered image; judging whether the edge ofthe image subjected to the edge extraction is too wide, if so, repeating the previous process, or carrying out block threshold division on the image subjected to the edge extraction; and drawing edgelines by utilizing the image subjected to block threshold division, and thus figuring out the strip gap. According to the strip gap detection method, the influence of noise, illumination condition and other external factors is overcome, the edge lines of a single-pixel strip can be rapidly and accurately drawn, and the strip width is figured out.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

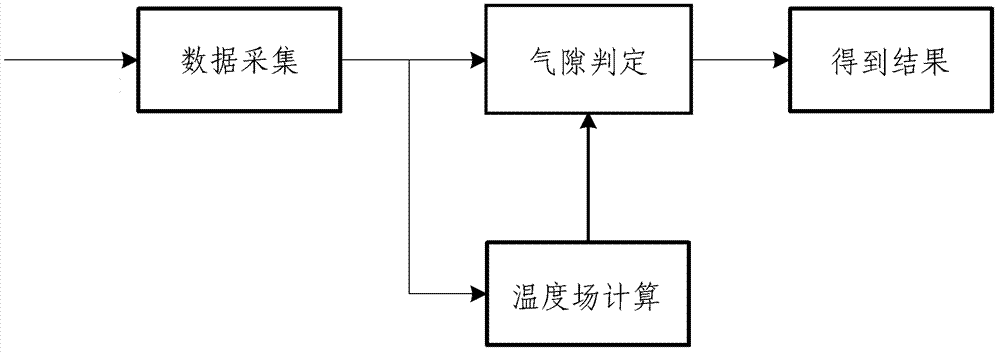

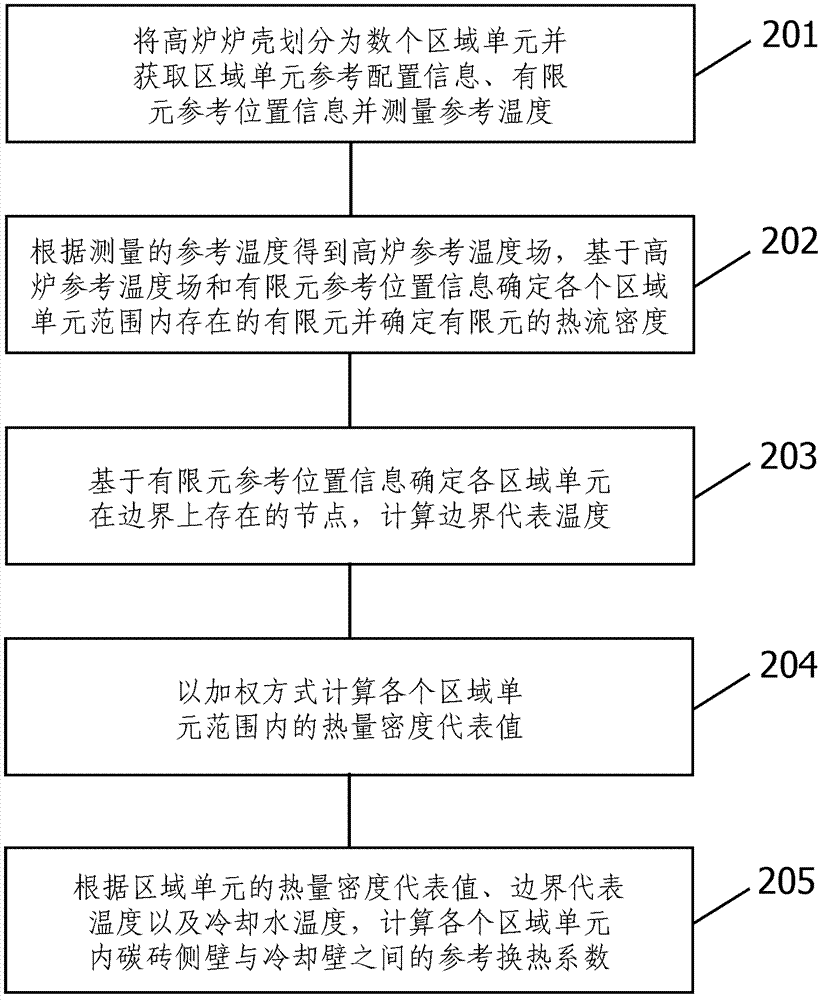

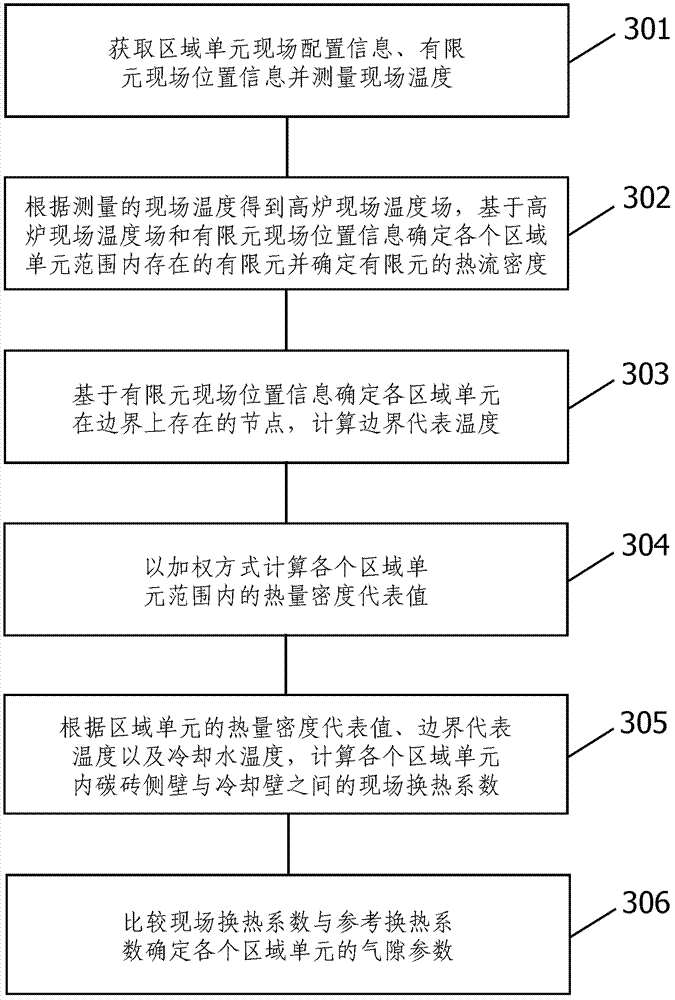

Method for detecting air gap on a blast furnace shell

ActiveCN103088176ATimely reflection of air gap parametersAccurate detectionChecking devicesReference configurationSHELL model

The invention discloses a method for detecting air gap on a blast furnace shell. The method comprises steps of: establishing a blast furnace shell model; dividing the blast furnace shell into a plurality of regional units; collecting reference configuration information and finite element reference position information in the regional units, and measuring reference temperature; calculating to obtain a reference heat transfer coefficient of the blast furnace shell model based on the above reference configuration information, the finite element reference position information and measured reference temperature; determining an air gap parameter of the blast furnace shell based on the blast furnace shell model; collecting on-site configuration information, finite on-site element position information in the regional units, and measuring an on-site temperature; calculating to obtain an on-site heat transfer coefficient based on the on-site configuration information, finite on-site element position information and measured on-site temperature; and comparing the on-site heat transfer coefficient with the reference heat transfer coefficient to obtain air gap parameter of the blast furnace shell. The method provided by the invention can effectively and timely reflect the air gap parameter of the blast furnace shell, show the change of the heat transfer coefficient of the blast furnace shell, and provide direct evidence for gap detection.

Owner:SHANGHAI BAOSIGHT SOFTWARE CO LTD

Controller for electric spark line processing machine tool

Owner:FANUC LTD

Method for automatically detecting and controlling segment roll gap by adopting balancing oil cylinder

InactiveCN101704082AAchieving automatic adjustment and maintaining the requirementsDefy gravitySlab casterEngineering

The invention relates to manufacture of large panels, strips, sectional bars and the like in ferrous metallurgy industry, in particular to a method for automatically detecting and controlling a segment roll gap by adopting a balancing oil cylinder, which is characterized by at least comprising a lower frame with a guide roll, an upper frame with a guide roll, a hold down roll device for driving a dummy bar and a casting blank, balancing oil cylinders used for roll gap detection and control, and a clamp oil cylinder for connecting the upper frame and the lower frame and keeping the roll gap, wherein the hold down roll device is fixed in the upper central position of the upper frame, and the balancing oil cylinders are evenly distributed between the upper frame and the lower frame, so that a plate blank continuous casting machine dynamically and lightly presses the solidified end of the casting blank in the production process of pouring steel, the quality defects of center segregation, rarefaction and the like of the casting blank can be effectively avoided, and the steel quality and the metal yield are improved.

Owner:陕西多伦科技发展有限公司 +1

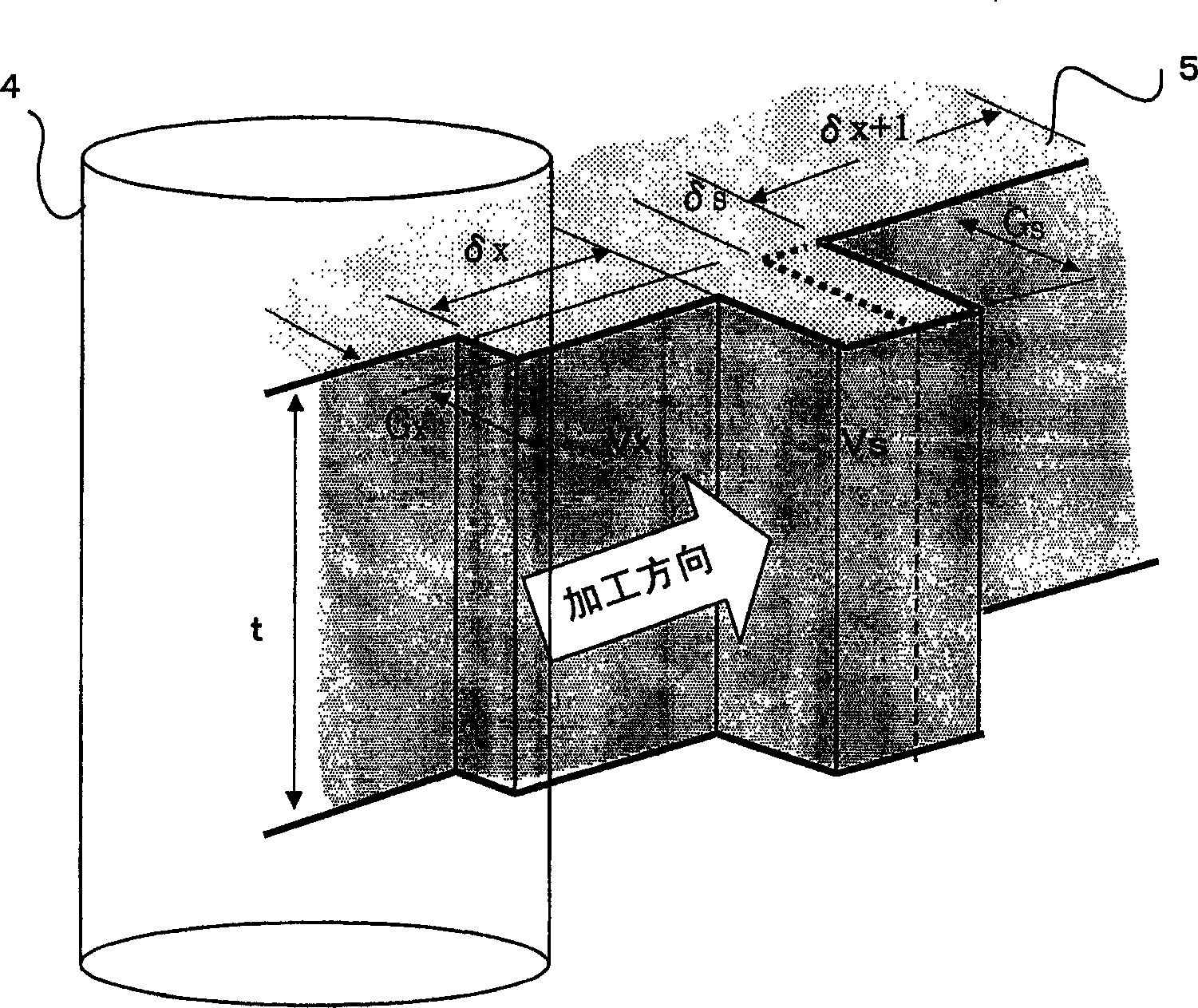

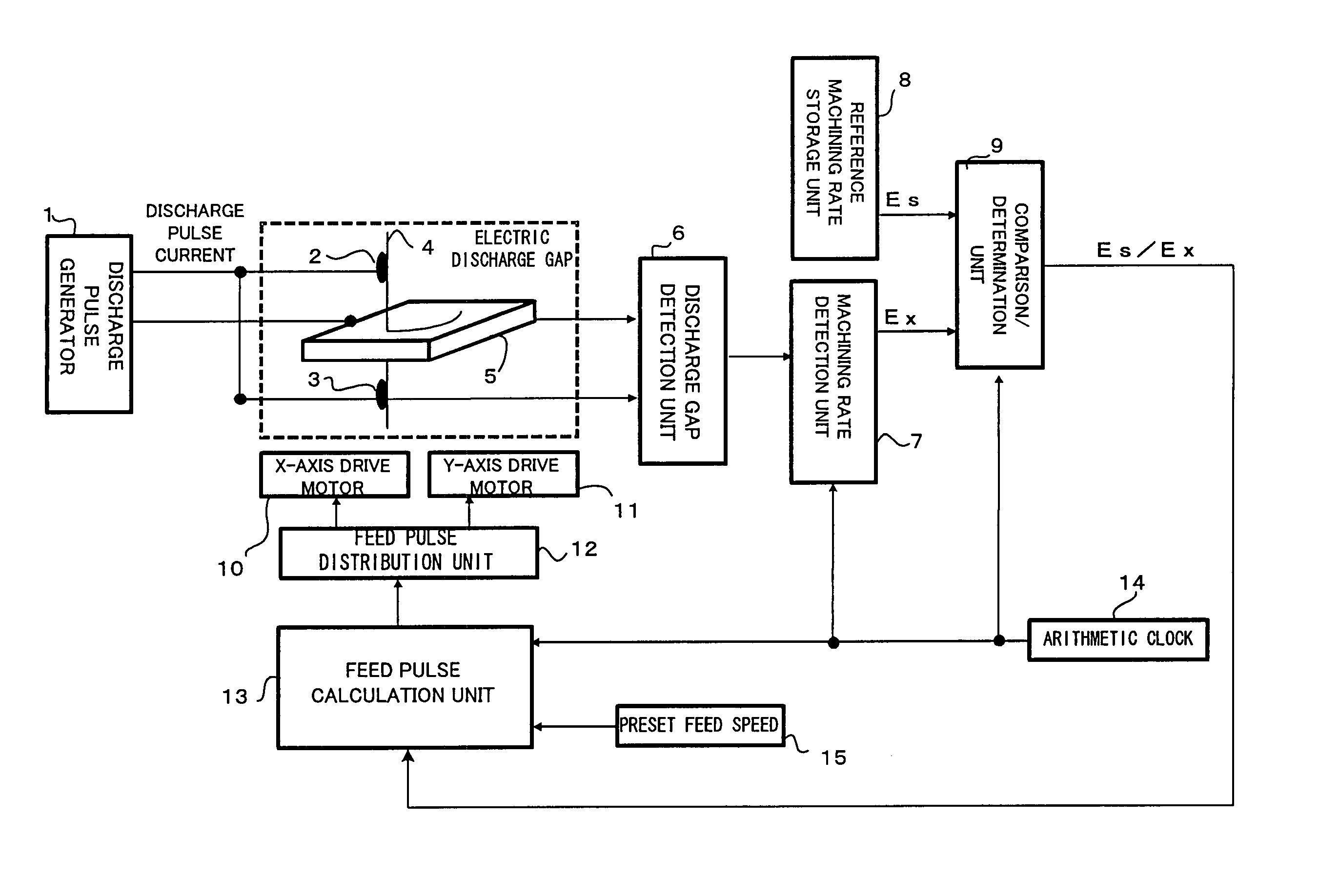

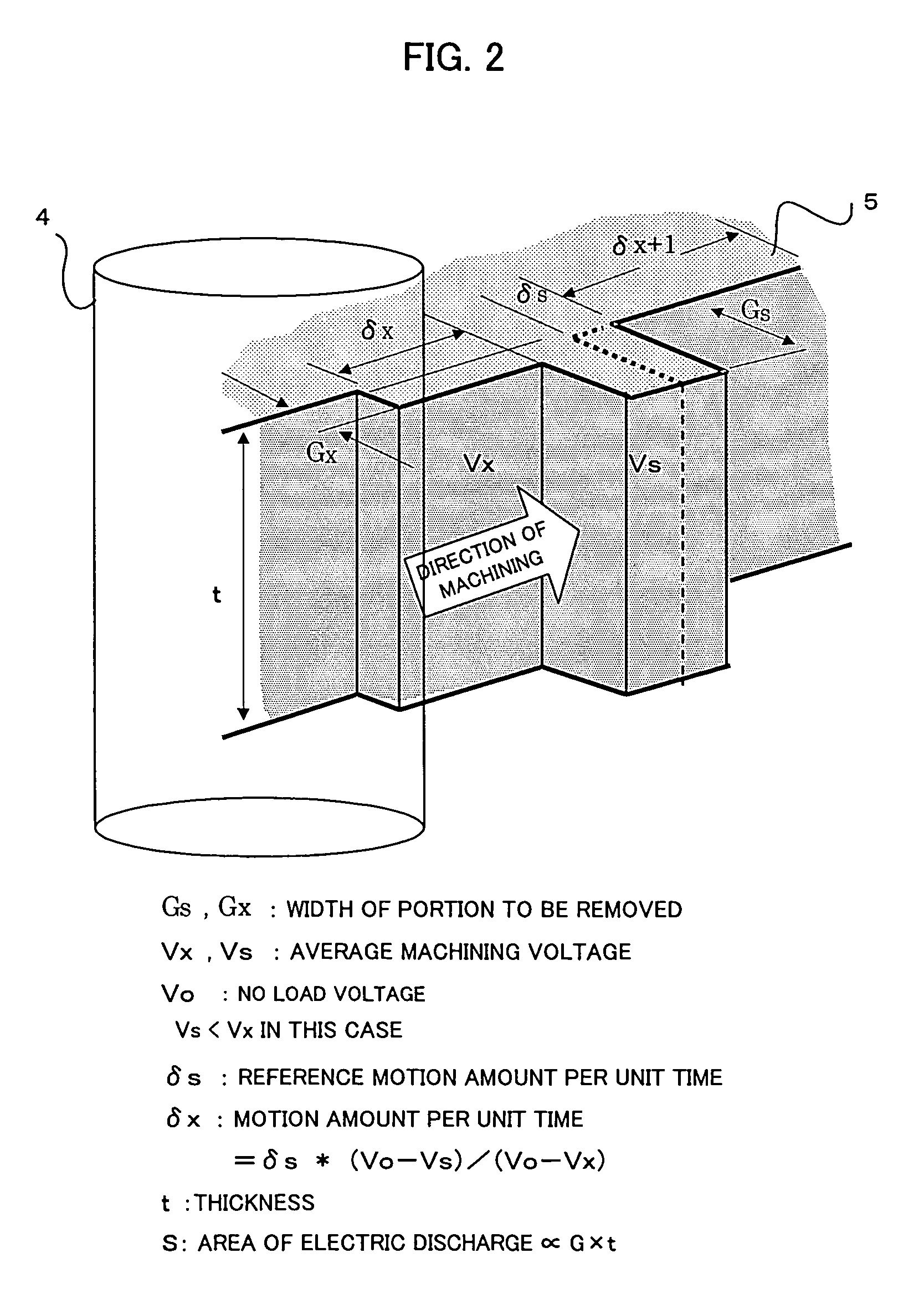

Controller for wire electric discharge machine

ActiveUS7039490B2Stable processingImprove surface accuracyElectric circuitsSpecial data processing applicationsElectric dischargePartition of unity

A controller for a wire electric discharge machine which can achieve stable machining with high surface accuracy without requiring adjustment of a gain or the like in wire-electrode feed control. A discharge gap detection unit detects a voltage between a wire electrode and a workpiece. An amount-of-machining-per-unit-distance change detection unit obtains an average machining voltage, and a voltage drop EX that is a difference between the obtained average machining voltage and a no-load voltage. A comparative determination unit obtains a ratio ES / EX between a reference voltage drop ES stored in a reference-amount-of-machining-per-unit-distance relative value storage unit and the drop voltage EX. A feed pulse arithmetic unit obtains a feed speed that makes the amount of machining per unit time constant, on the basis of the ratio ES / EX and a predetermined feed speed, and distributes feed pulses to motors to thereby move the wire electrode relatively to the workpiece. Since the amount of machining per unit time is kept constant, the surface accuracy in finishing is high and stable machining can be performed.

Owner:FANUC LTD

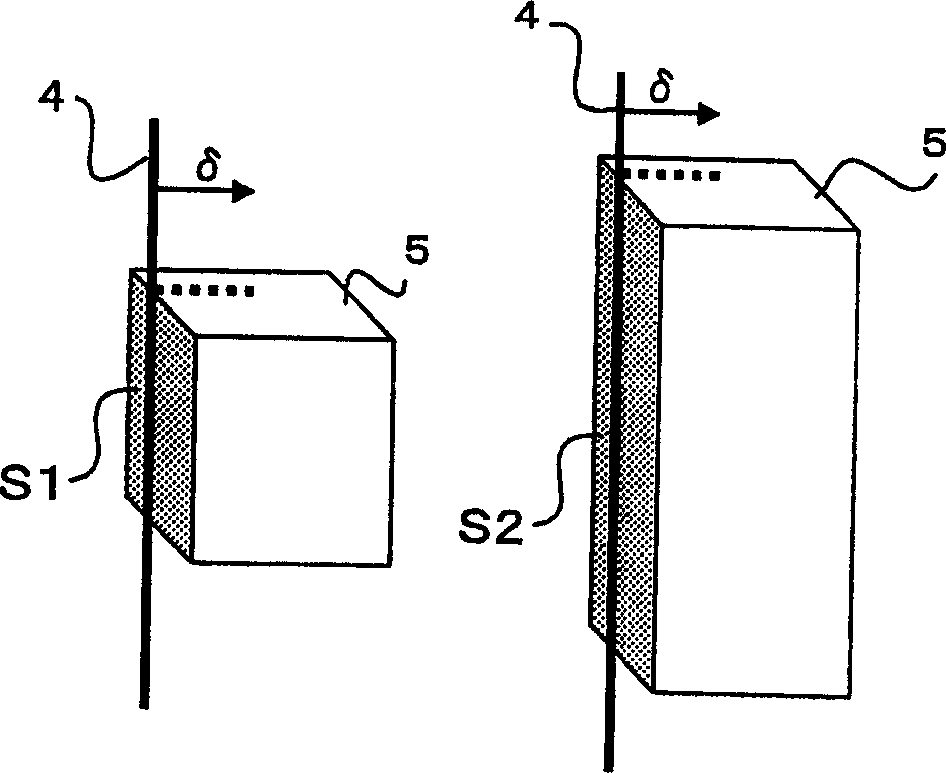

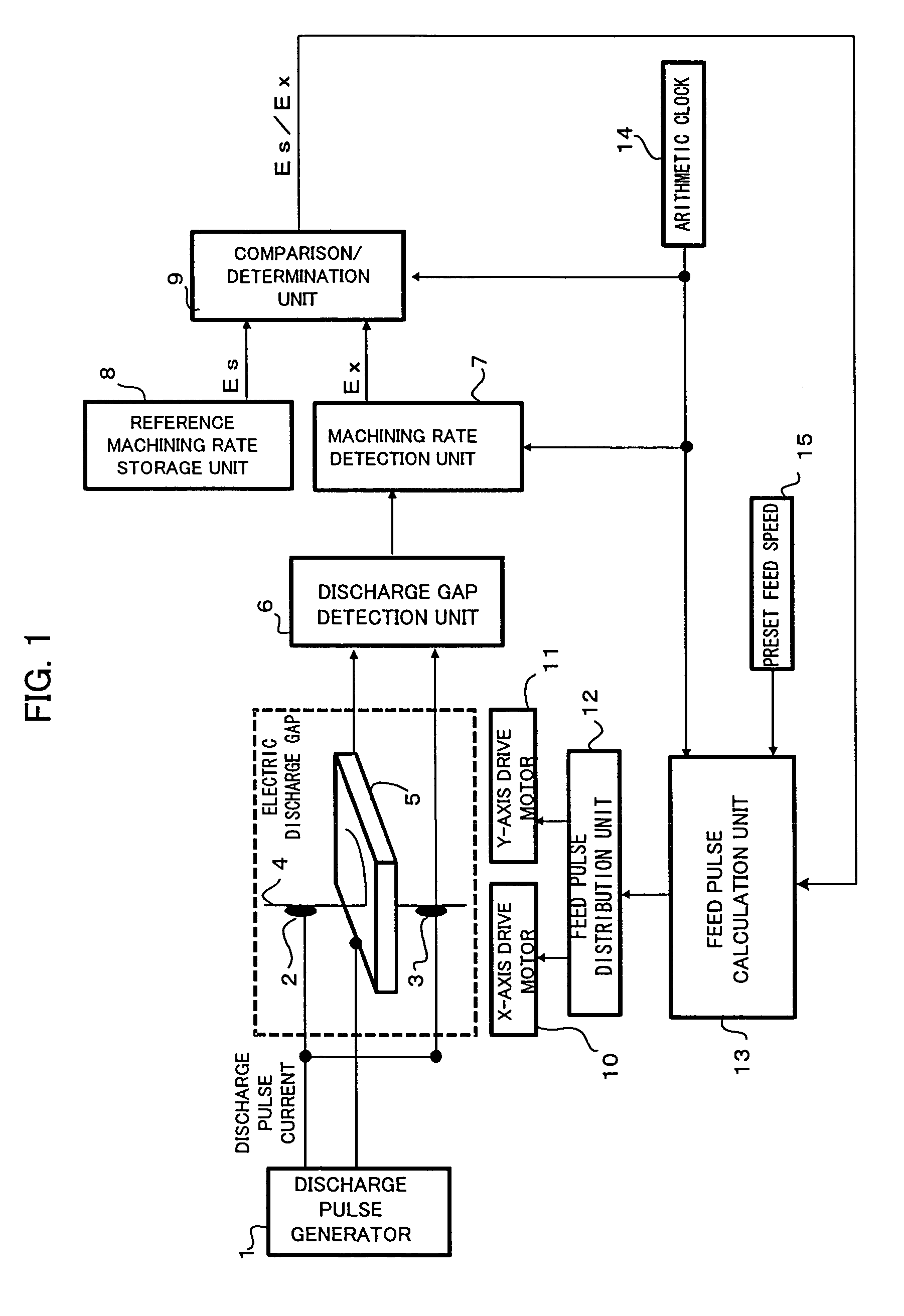

Controller for wire electric discharge machine

ActiveUS7262381B2Stable finish machiningImprove accuracyElectric circuitsSpecial data processing applicationsElectric dischargeEngineering

A controller for a wire cut electric discharge machine which can provide stable finish machining and corner-region machining with high corner-form accuracy. An electric discharge gap detection device detects a voltage between a wire electrode and a workpiece. A machining rate detection device obtains an average machining voltage and a drop voltage value Ex which is a difference between the obtained average machining voltage and a no-load voltage. A comparison device obtains the ratio Es / Ex between a reference drop voltage value Es stored in a reference machining rate relative value storage device and the obtained drop voltage value Ex. In machining of a corner portion, when the drop voltage value Ex exceeds a entrance-into-corner determination reference machining rate, a set feed speed switch device supplies a corner set feed speed, and when the machining of the corner portion finishes, so that the drop voltage value Ex decreases to a leaving-from-corner determination reference machining rate or lower, the set feed speed switch device supplies a normal set feed speed. A feed pulse calculation device obtains a feed speed which makes the rate of machining constant, on the basis of the ratio Es / Ex and the supplied feed speed, to thereby drive motors. Since the rate of machining is kept constant, the surface accuracy of finish machining is high and stable machining can be performed.

Owner:FANUC LTD

Automotive steering intermediate shaft torsion gap detection device

The invention relates to the automobile part detection apparatus technology field and discloses an automotive steering intermediate shaft torsion gap detection device. The device comprises a detection pedestal, a driving connection portion connected to an intermediate shaft driving end and at least one group of clamping portions. A PC, a fixing stand column connected to the driving connection portion, a sensor support and a fixing connection portion connected to an intermediate shaft fixing end are fixed to the detection pedestal. Displacement sensors which form one-to-one correspondence with the clamping portions are fixed to the sensor support. The driving connection portion is provided with a torque sensor and a driving motor. Each clamping portion comprises an intermediate shaft clamping end, a connecting pipe and a connecting rod which is vertically connected between the intermediate shaft clamping end and the connecting pipe. An axis of the connecting pipe is vertical to an axis of the intermediate shaft. A push rod of each displacement sensor is connected into the connecting pipe. The PC is electrically connected to the displacement sensors, the torque sensor and the driving motor respectively. By using the detection apparatus, changing curves of twisting angles of each portion on the intermediate shaft under continuous torque effects can be conveniently and accurately acquired.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

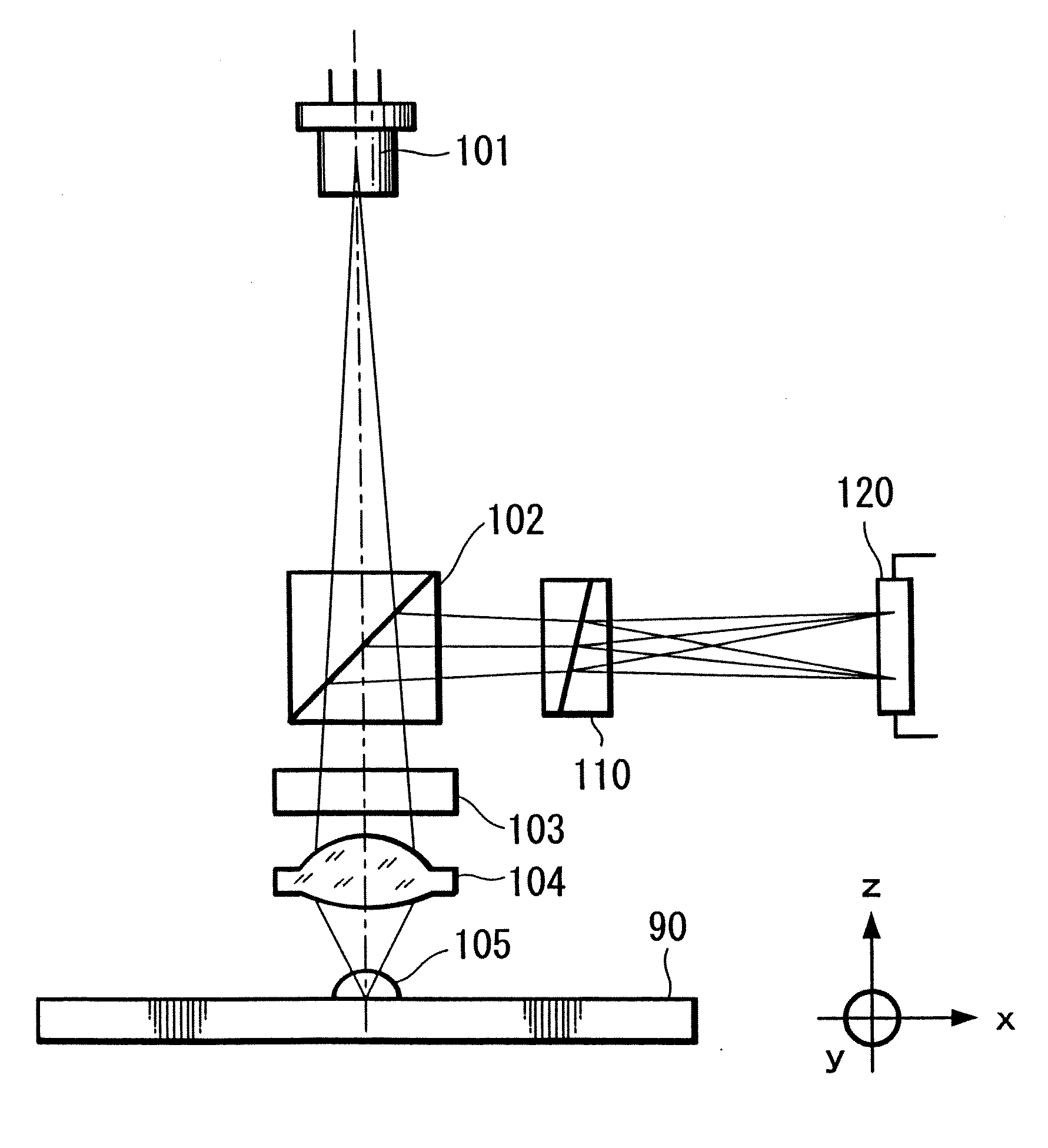

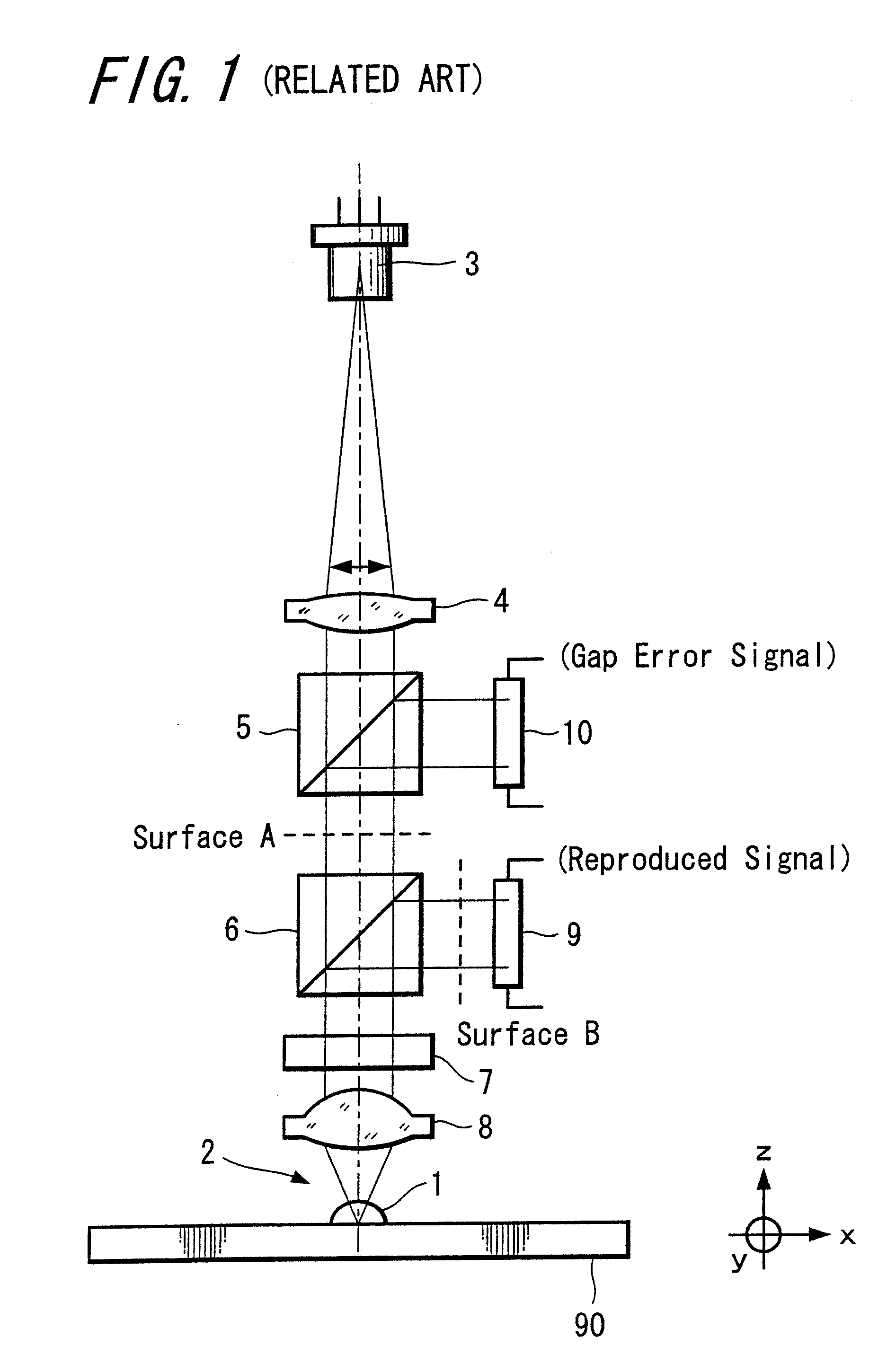

Optical pickup device, recording and reproducing apparatus and gap detection method

InactiveUS20070183298A1Easy to controlDelay detectionCombination recordingRecord information storageOptical pickupBeam splitter

An optical pickup device and an optical recording and reproducing apparatus are suitable for use with a near-field optical recording and reproducing system. An optical pickup device comprises an objective lens composed of a solid immersion lens (SIL) the objective lens having a numerical aperture greater than 1, a beam splitter configured to reflect both of a p-polarized light component and an s-polarized light component of reflected lights from an optical recording medium when the optical pickup device irradiates the optical recording medium with a bundle of rays in a predetermined polarized state from a light source through the objective lens, a divider configured to divide incident light into a p-polarized light component and an s-polarized light component reflected by the beam splitter, and a photo-detector configured to separately detect the p-polarized light component and the s-polarized light component divided by the divider.

Owner:SONY CORP

Leveling method of circular saw web base body

Provided is a leveling method of a circular saw web base body. When manual leveling is carried out on a circular saw web, the circular saw web base body is placed on a leveling platform, a half of the circular saw web base body is suspended and lifted, a leveling ruler is used for checking a gap of the circular saw web base body, the saw web base body is rotated, lifting positions are changed, positions of the leveling ruler are replaced, the leveling ruler respectively conducts gap distribution detection in a diameter scope of 2 / 3 circular saw web base body and a symmetrical scope at the centre hole of the circular saw web base body, which parts or areas need a grinding hammer or a leveling hammer to hammer is judged according to positions and sizes of gaps at detection positions, gap detection and leveling are carried out by using the leveling ruler for multiple saw web lifting, tension value of the whole circular saw web base body is even in distribution, and process specified value is achieved. By means of the leveling method, the tension value (internal stress) of the leveled circular saw web base body on the whole divergence are adjusted to be even in distribution, various performance indexes of the circular saw web base body in actual work are greatly improved, therefore, service life of the circular saw web base body is prolonged.

Owner:HEIXUANFENG SAW IND

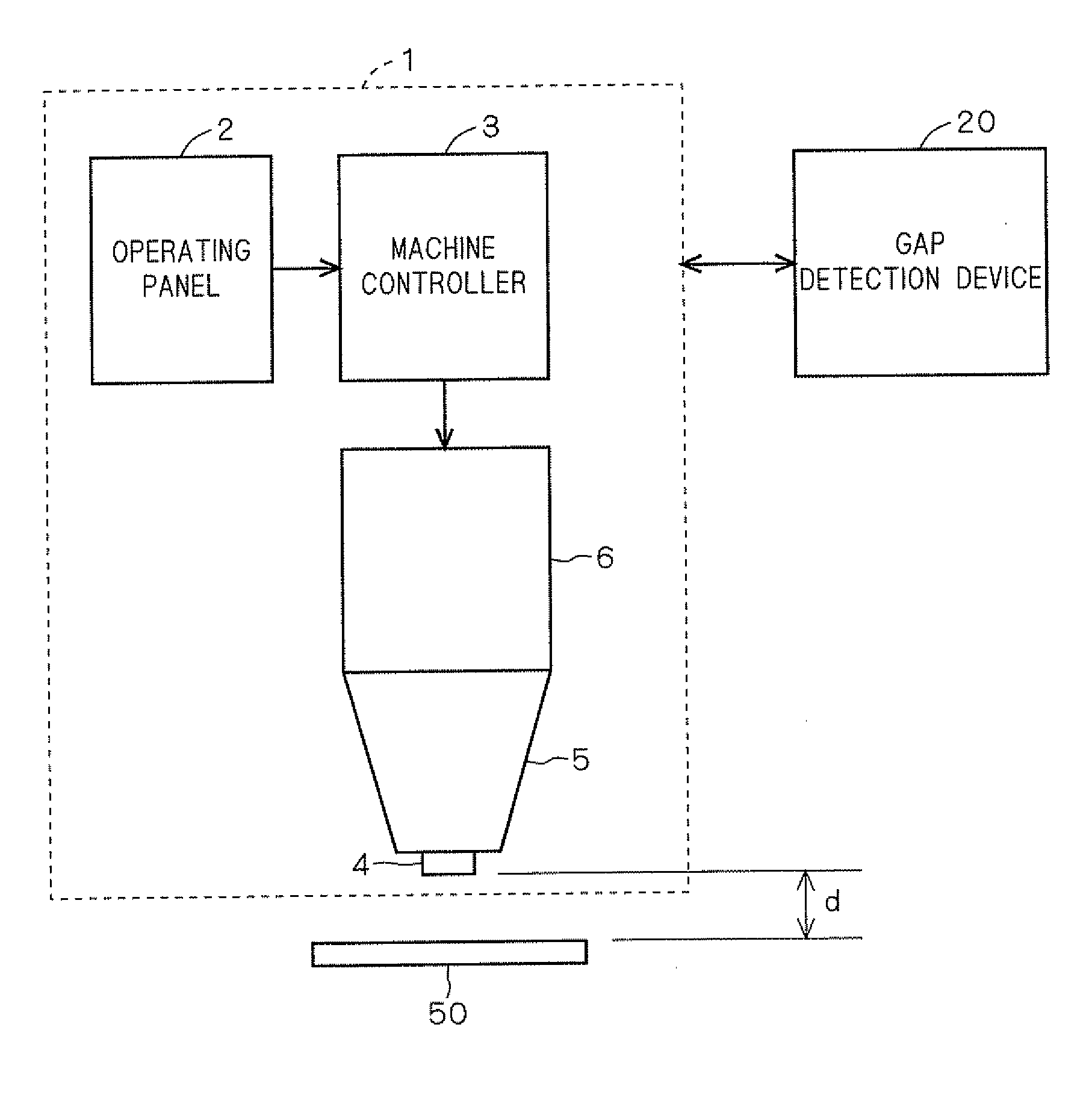

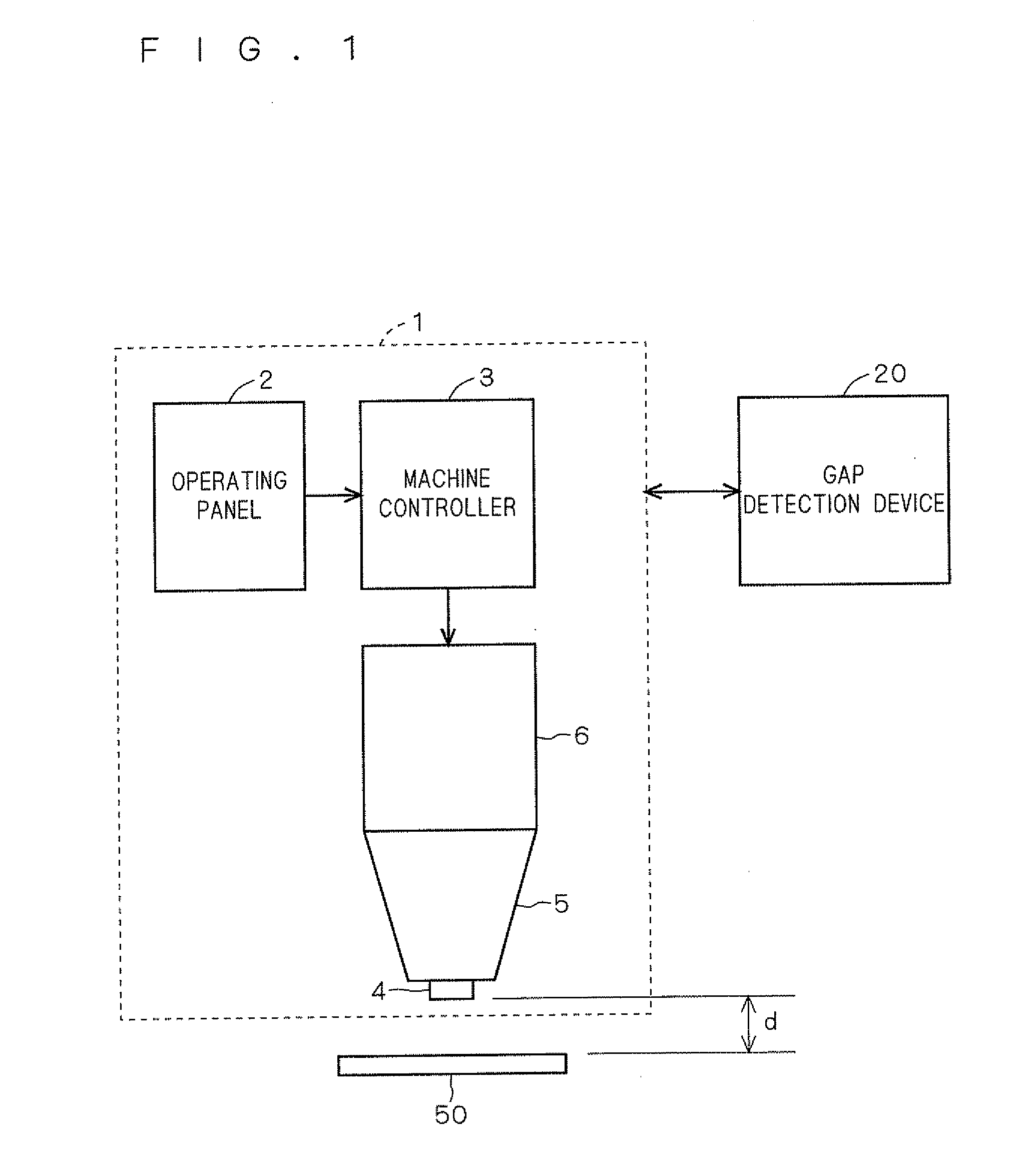

Roll gap regulating system and control flow

The invention relates to the field of a compound coating machine, aiming at providing a roll gap regulating system. The system uses an air cylinder as one of power sources for controlling a transferring roll to move in a linear guide rail, a linear stepping motor is used as another power source for controlling the transferring roll moving in the linear guide rail and applies thrust to the transferring roll through a screw rod and a micro-space sliding block, and the two power sources act together to ensure the reliable controlled sliding of the transferring roll on the linear guide rail. A control system controls the linear stepping motor and the air cylinder to control the movement of the transferring roll according to a gap set value, a gap detection device detects a gap value in real time and feeds the value back to the control system so as to ensure the accuracy of automatic regulation. In view of the accuracy requirement of the roll gap, the linear stepping motor converts a rotational motion into a linear motion through the screw rod, and the component on the linear guide rail direction of the sliding displacement of the micro-space sliding block on the wedge-shaped surface of a mounting base is the moving displacement of the transferring roll relative to a metering roll, so that the high-accuracy micro-gap movement is achieved.

Owner:CHONGQING SINSTAR PACKAGING MACHINERY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com