Patents

Literature

138 results about "Radial error" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

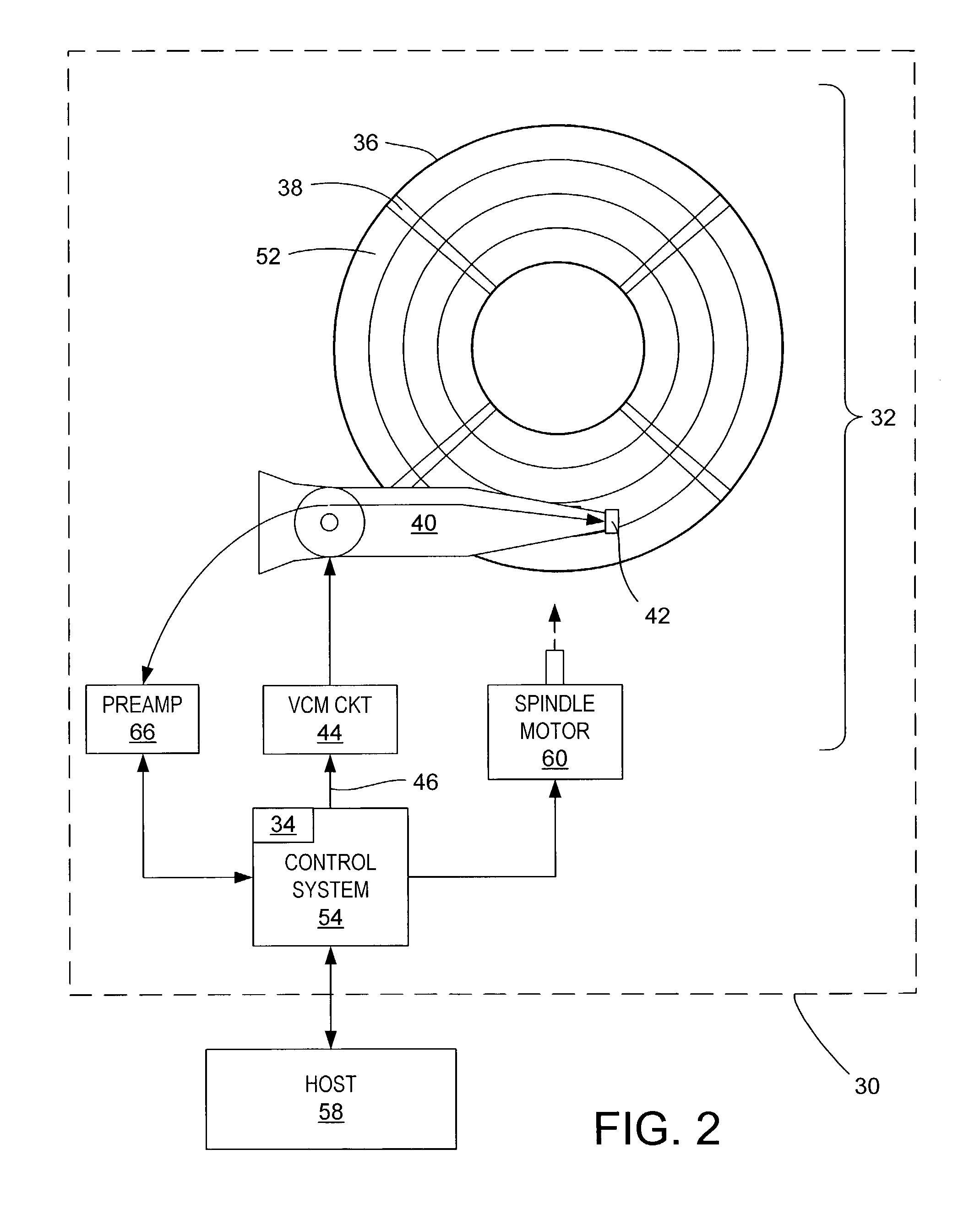

Method for preventing radial error propagation during self-servowriting of tracks in a magnetic disk drive

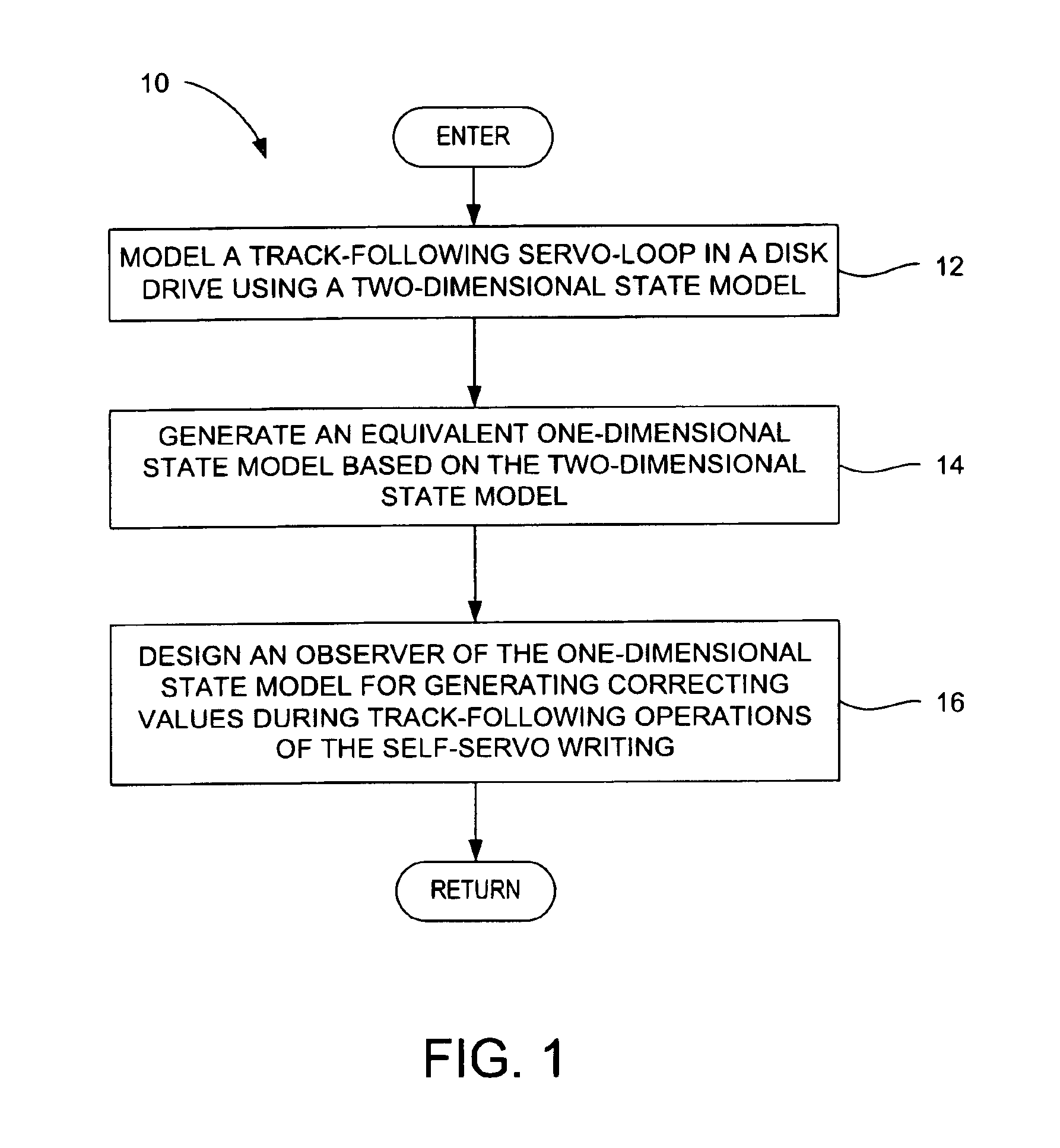

InactiveUS6963465B1Preventing radial error propagationPrevent radial error propagationDriving/moving recording headsRecord information storageRadial errorControl theory

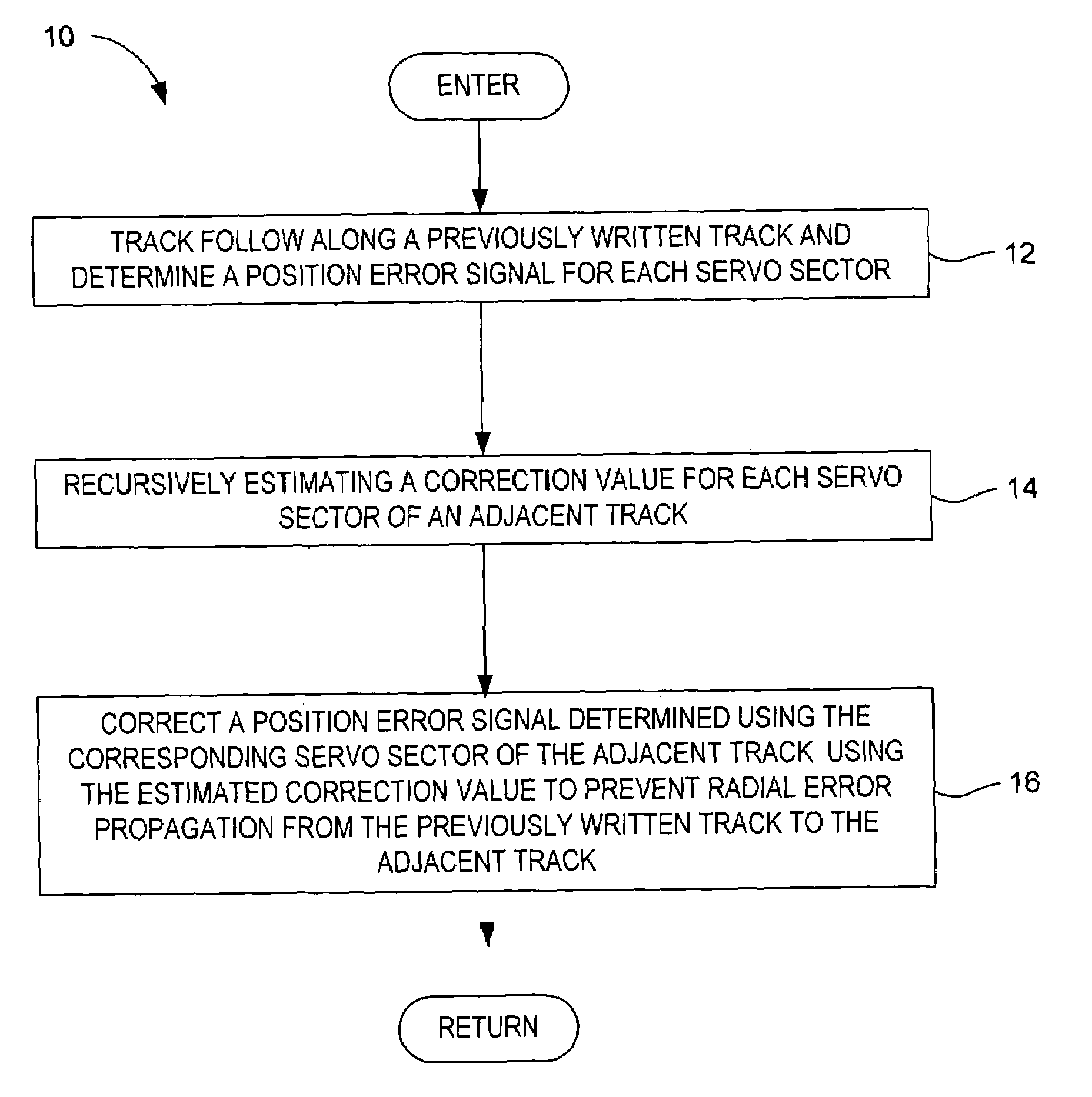

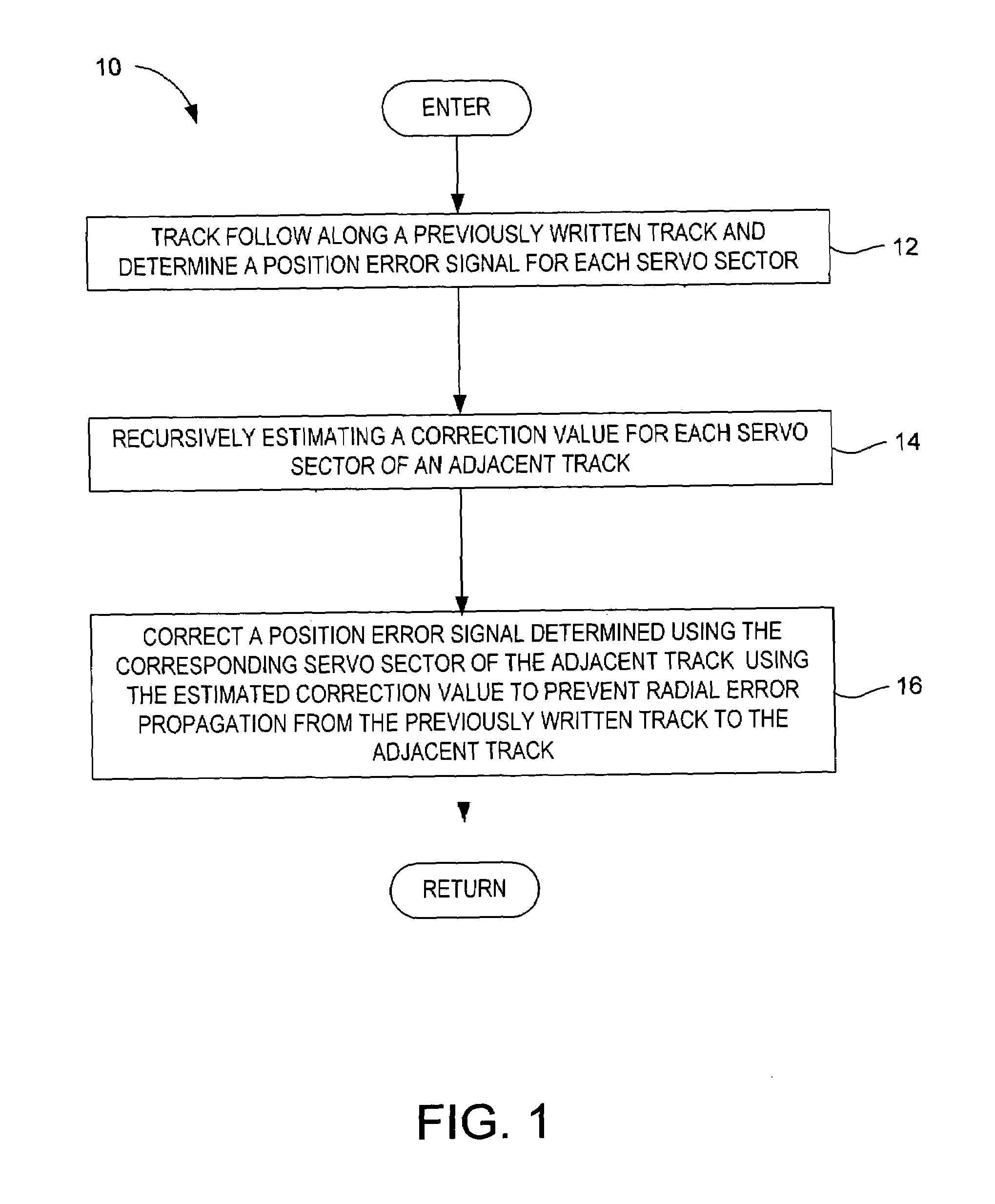

The present invention may be embodied in a method for preventing radial error propagation during self-servowriting of concentric tracks on a magnetic disk in a disk drive. Each written track comprises a plurality of embedded servo sectors that define a circumferential path and that eventually form corresponding servo wedges extending radially across the magnetic disk such that each servo sector t of a track corresponds to a particular servo wedge. In the method comprising, track following is performed along a previously written track and a position error signal is determined for each servo sector. A correction value is recursively estimated for each servo sector of an adjacent track. The correction value is for use in correcting a position error signal determined using the corresponding servo sector of the adjacent track to prevent radial error propagation from previously written track to the adjacent track.

Owner:WESTERN DIGITAL TECH INC

Method and apparatus for self servowriting of tracks of a disk drive using an observer based on an equivalent one-dimensional state model

InactiveUS6924961B1Error propagationRecord information storageAlignment for track following on disksState modelObserver based

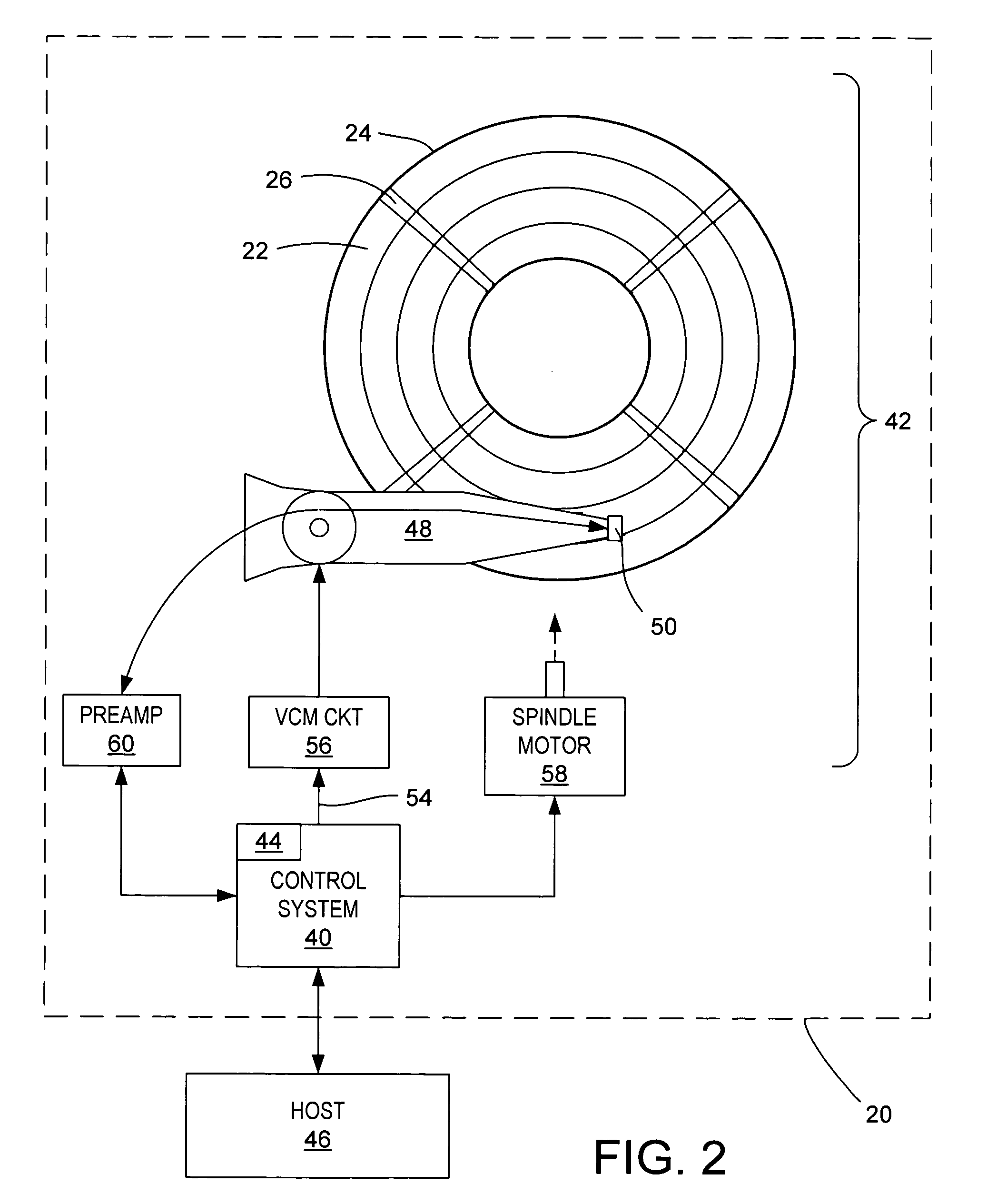

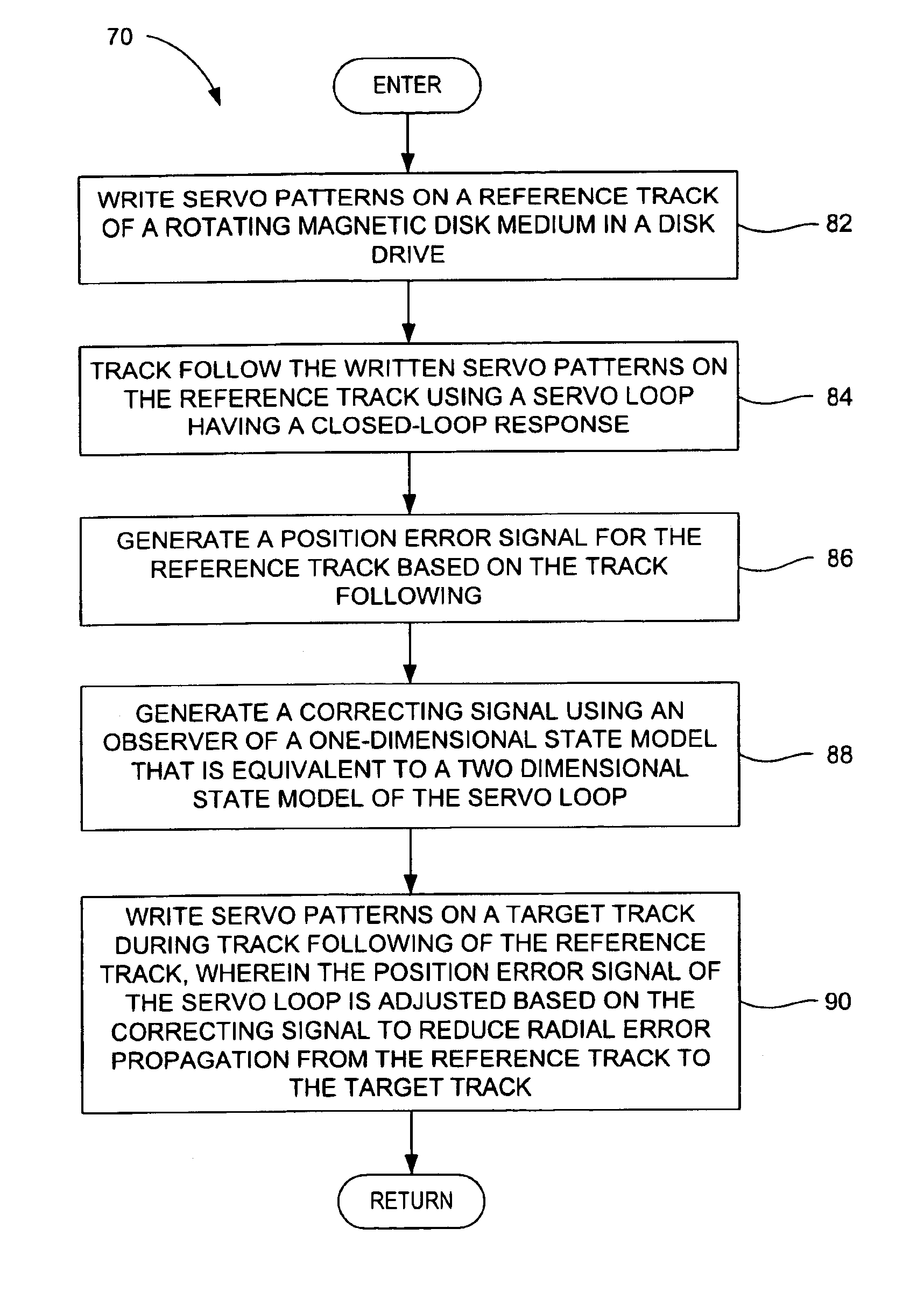

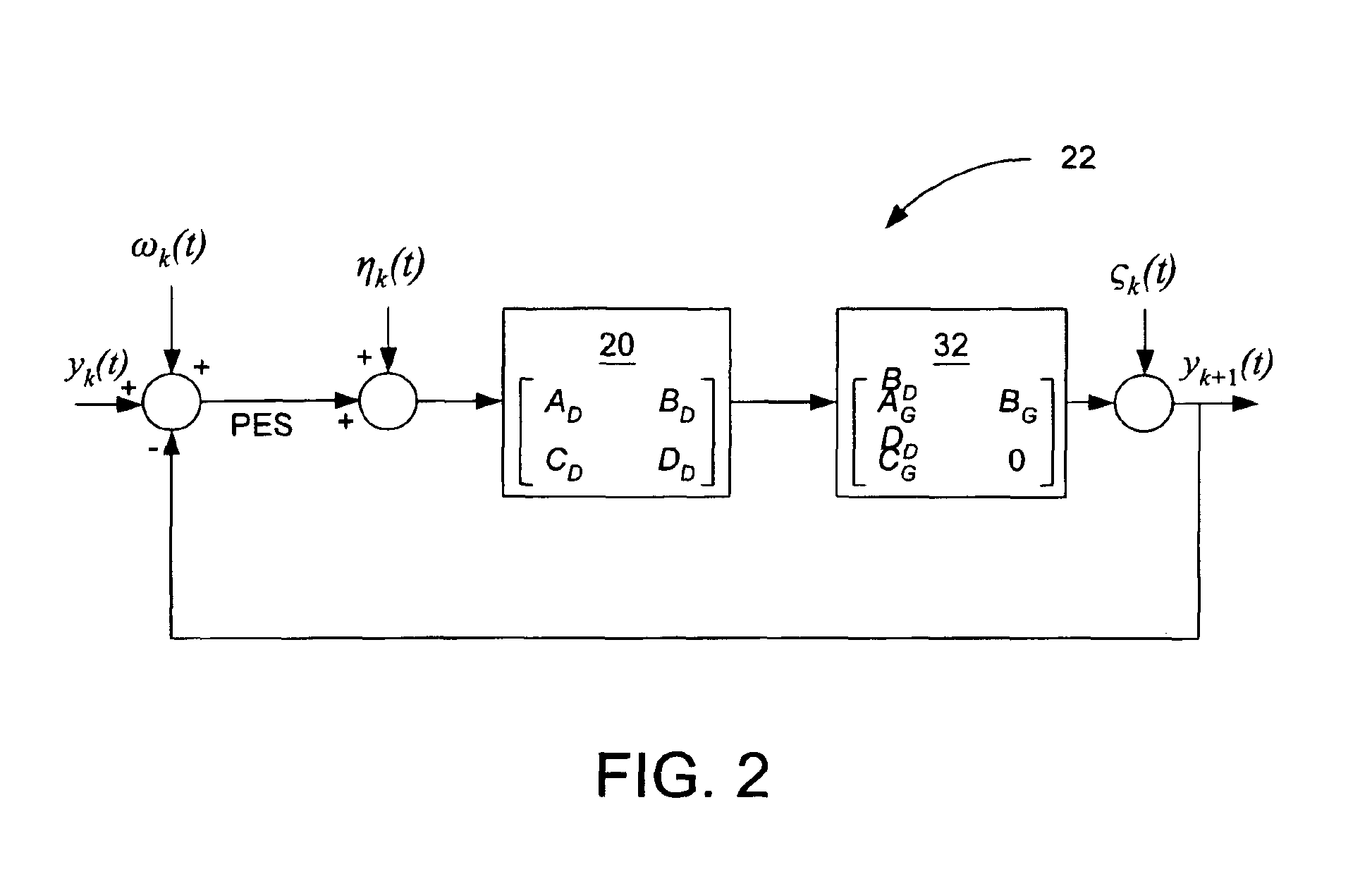

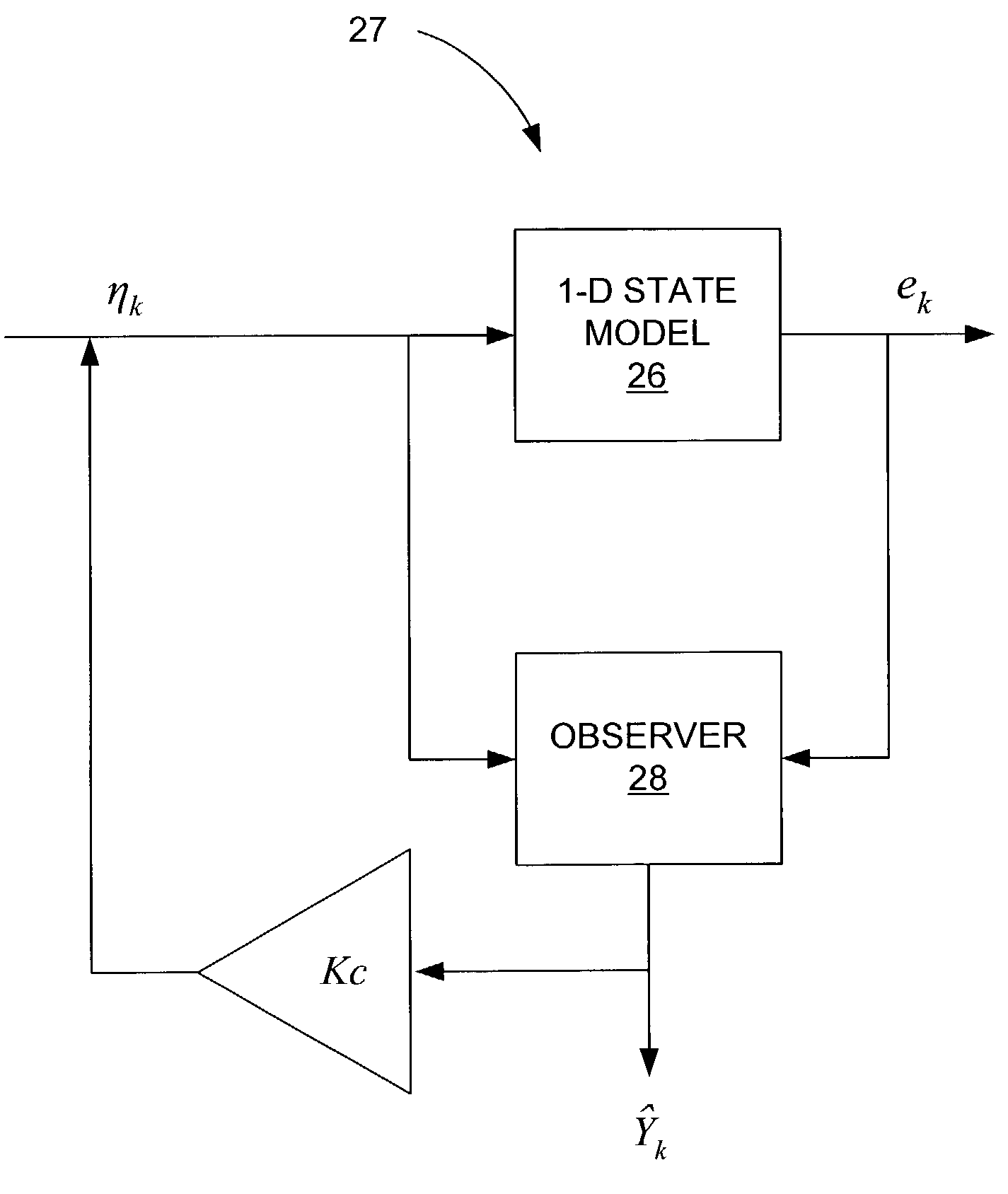

A method is disclosed for writing servo patterns for tracks on a rotating magnetic disk medium of a disk drive. Servo patterns are written on a reference track of the disk medium. Track following of the written servo patterns on the reference track is performed using a servo loop having a closed-loop response. A position error signal is generated for the reference track based on the track following. A correction signal is generated based on the track following using an observer of a one-dimensional state model that is equivalent to a two-dimensional state model of the servo loop. Servo patterns are written on a target track during track following of the reference track. The position error signal of the servo loop is adjusted based on the correction signal to reduce radial error propagation from the reference track to the target track.

Owner:WESTERN DIGITAL TECH INC

Method and apparatus for self servowriting of tracks of a disk drive using an observer based on an equivalent one-dimensional state model

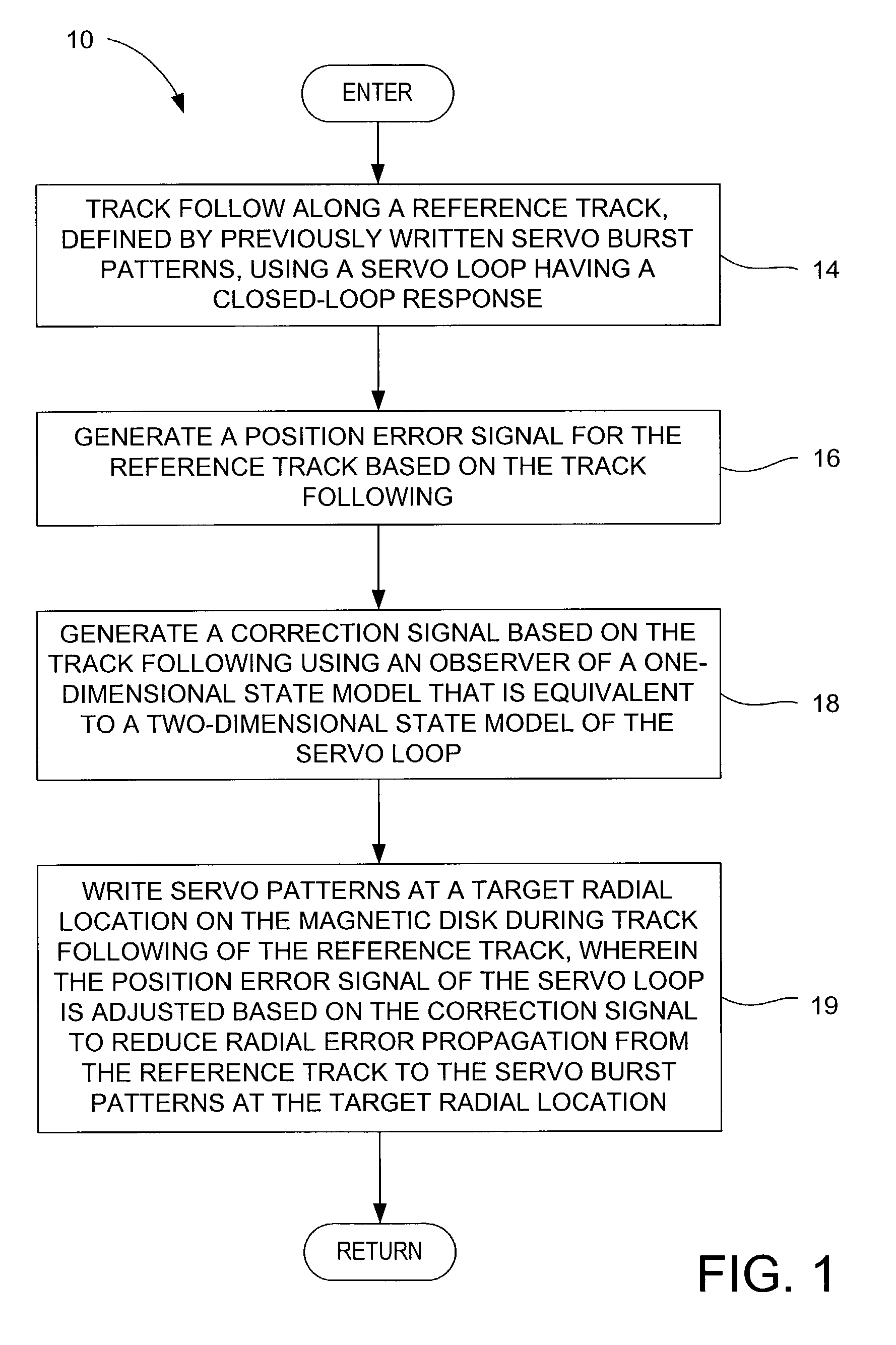

InactiveUS7046472B1Error propagationDriving/moving recording headsRecord information storageState modelObserver based

A method is disclosed for writing servo patterns for tracks on a rotating magnetic disk medium of a magnetic disk drive. In the method, track following is performed along a reference track, defined by previously written servo burst patterns, using a servo loop having a closed-loop response. A position error signal is generated for the reference track based on the track following. A correction signal is generated based on the track following using an observer of a one-dimensional state model that is equivalent to the two-dimensional state model of the servo loop. Servo patterns are written at a target radial location on the magnetic disk medium during track following of the reference track. The position error signal of the servo loop is adjusted based on the correction signal to reduce radial error propagation from the reference track to the servo burst patterns at the target radial location.

Owner:WESTERN DIGITAL TECH INC

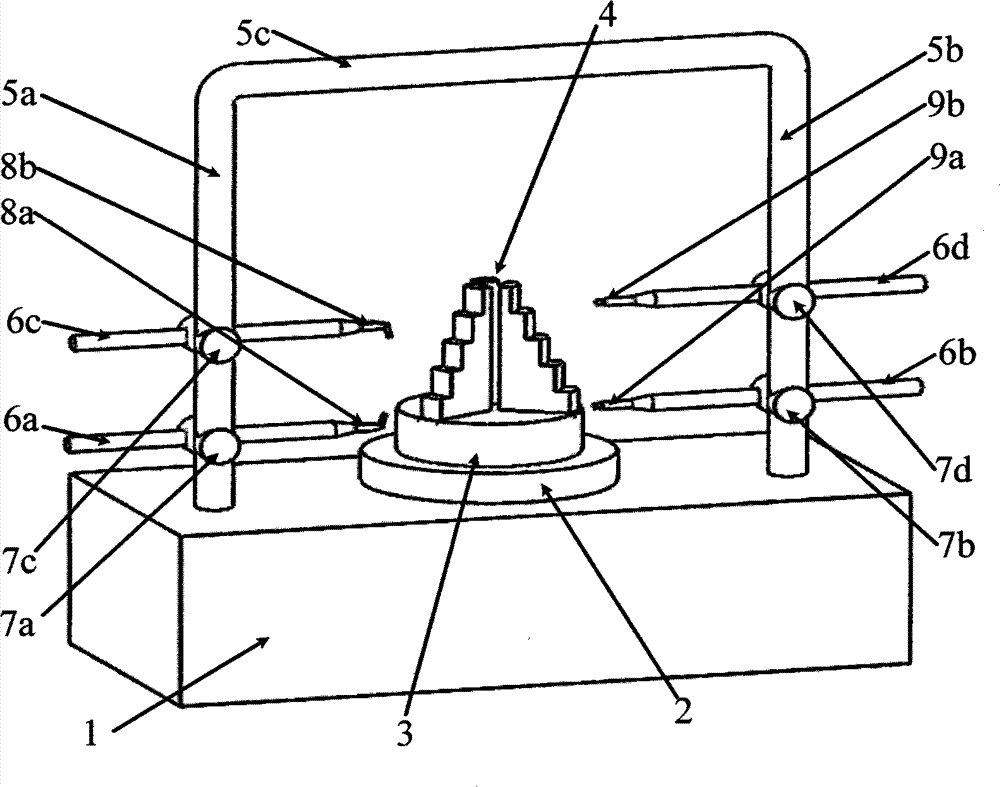

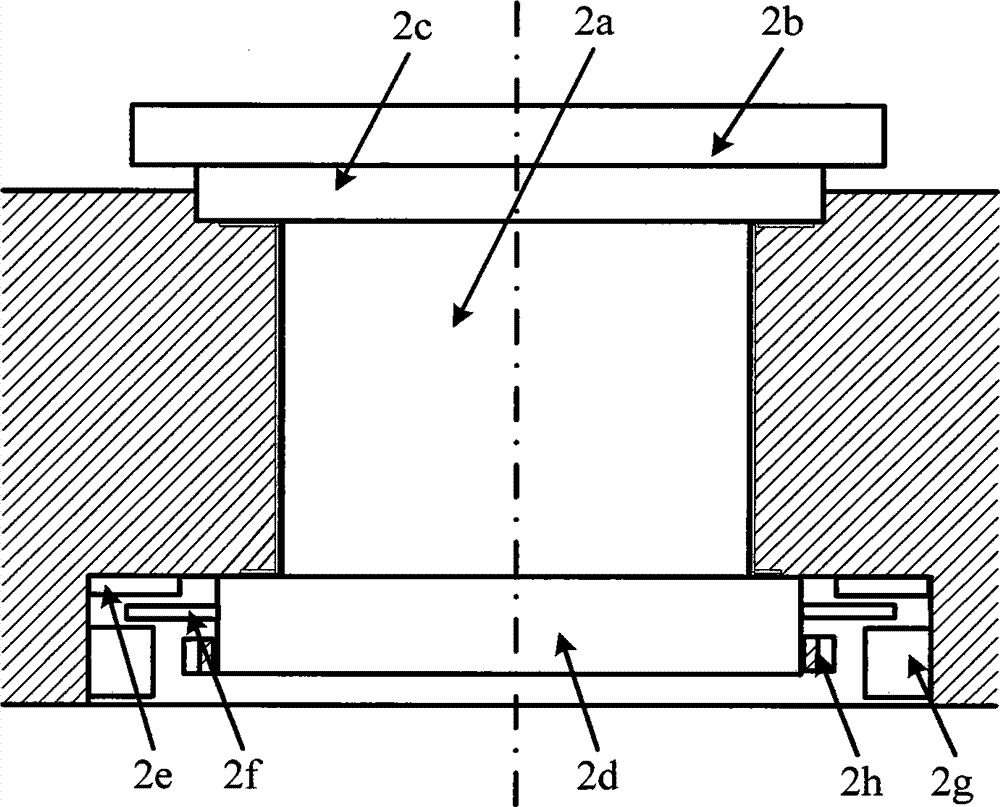

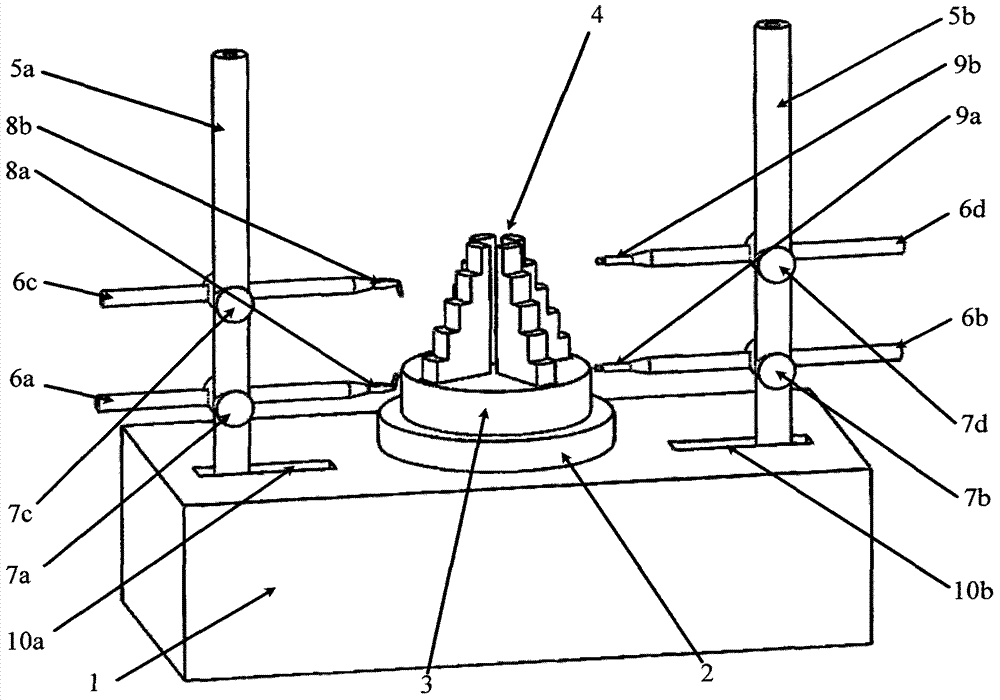

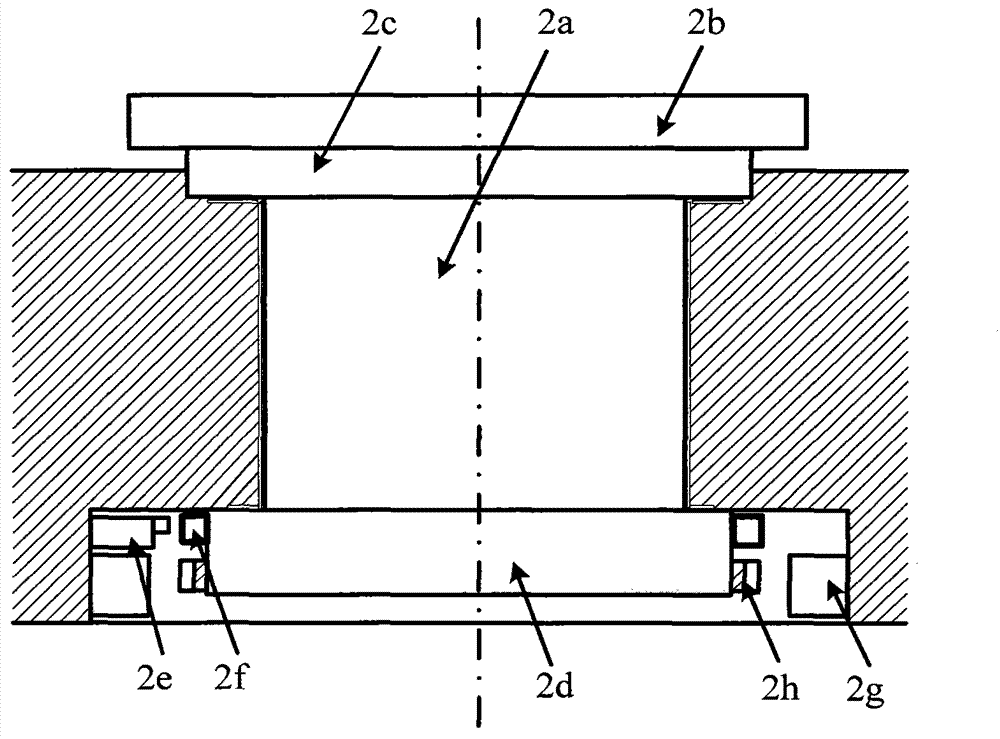

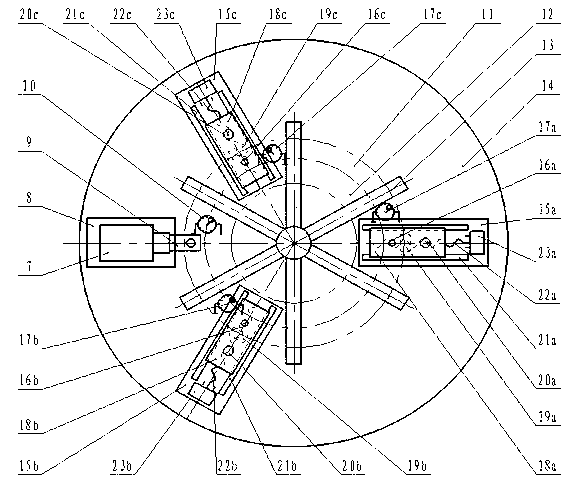

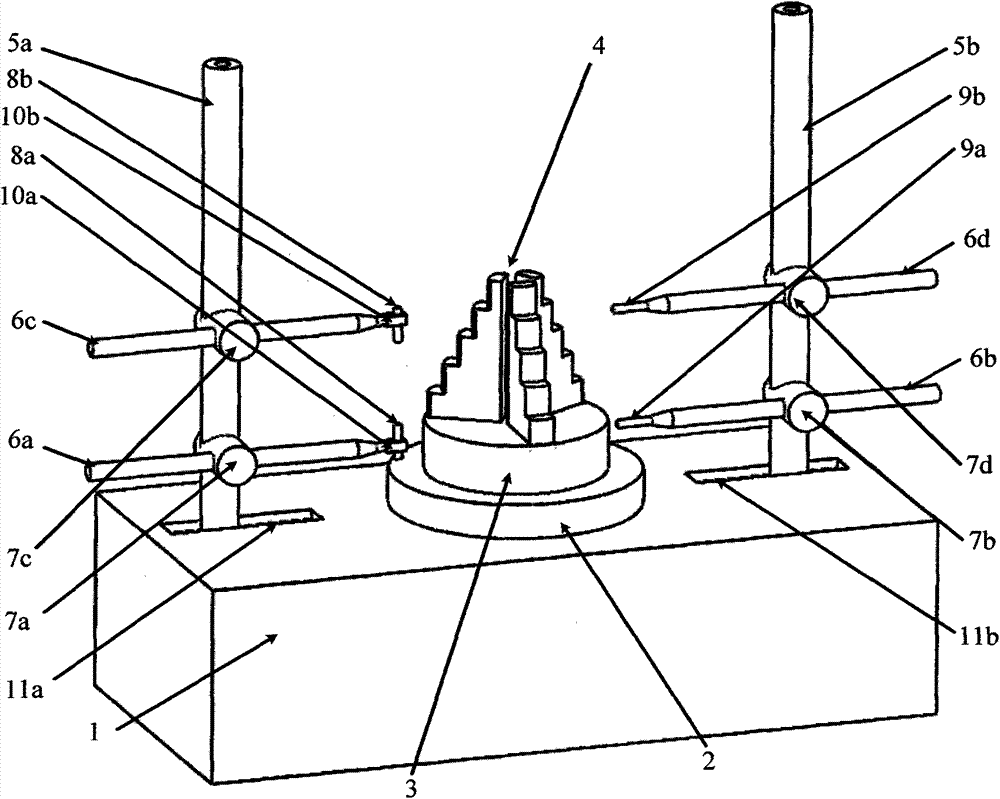

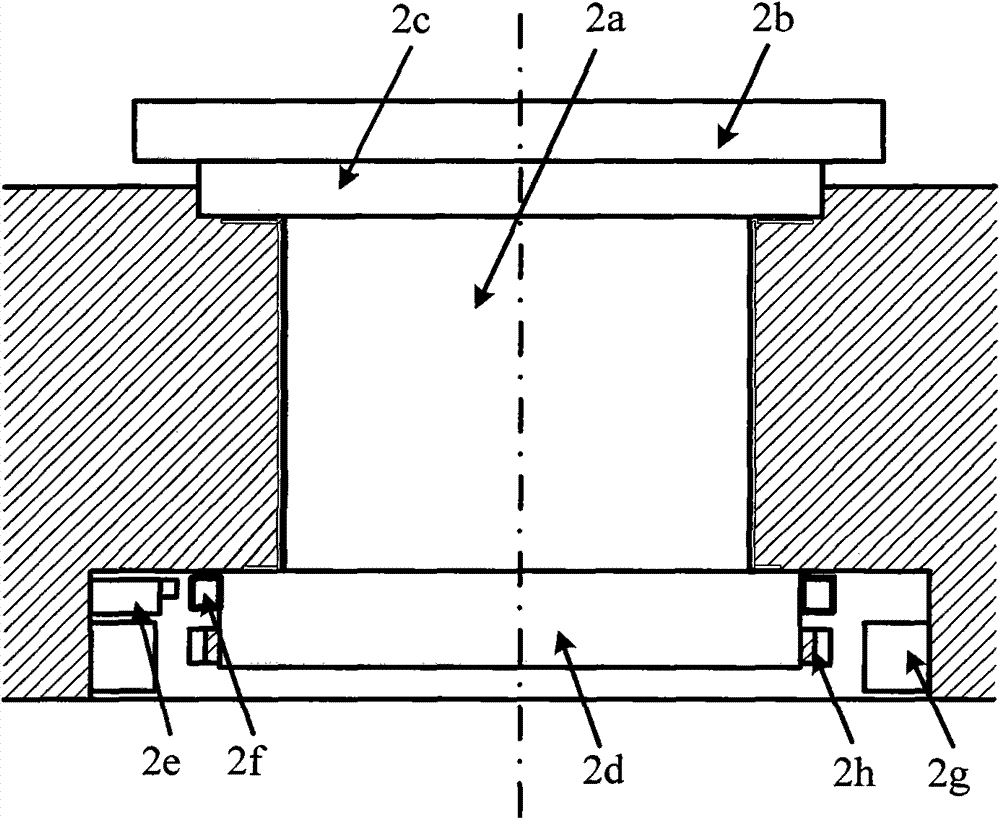

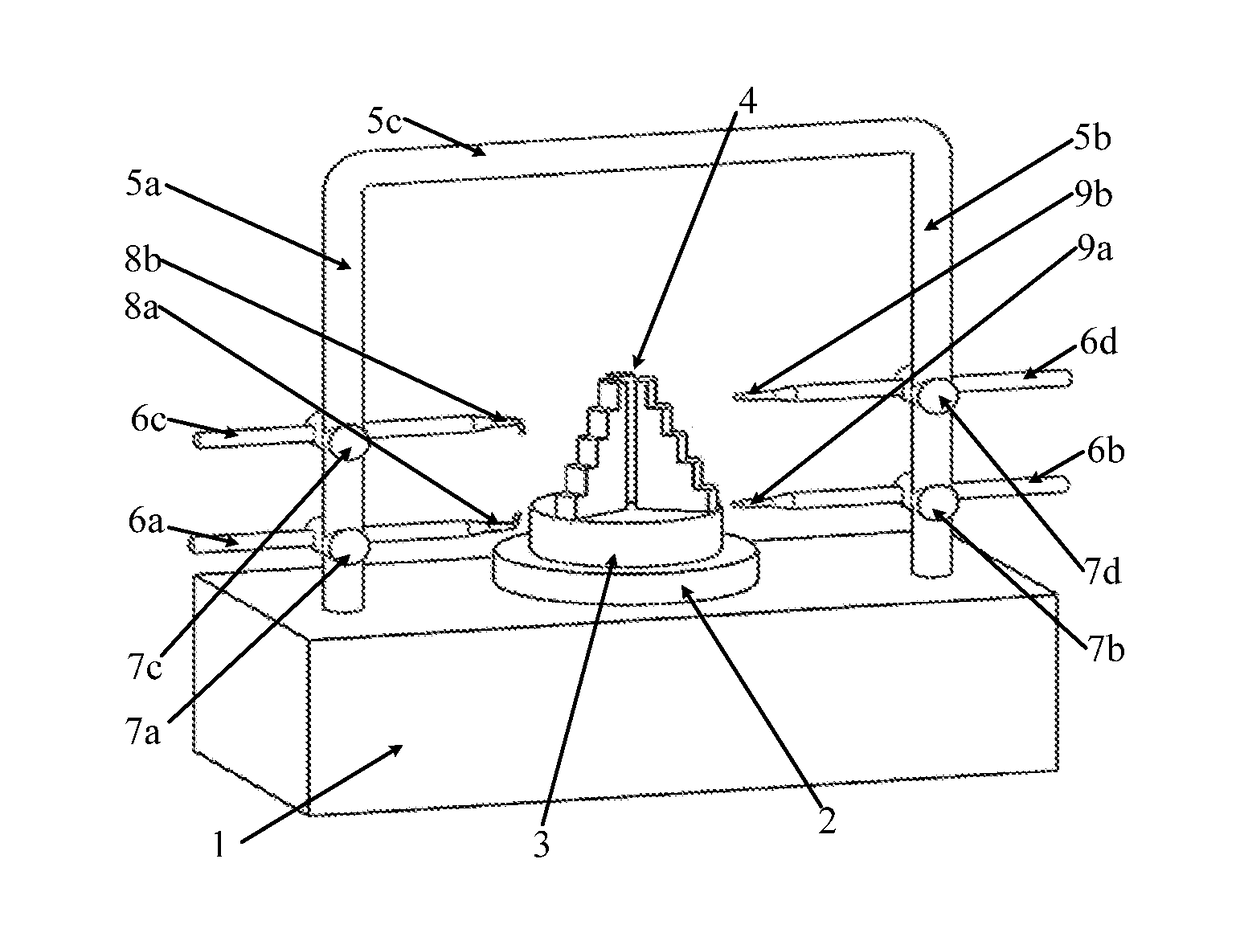

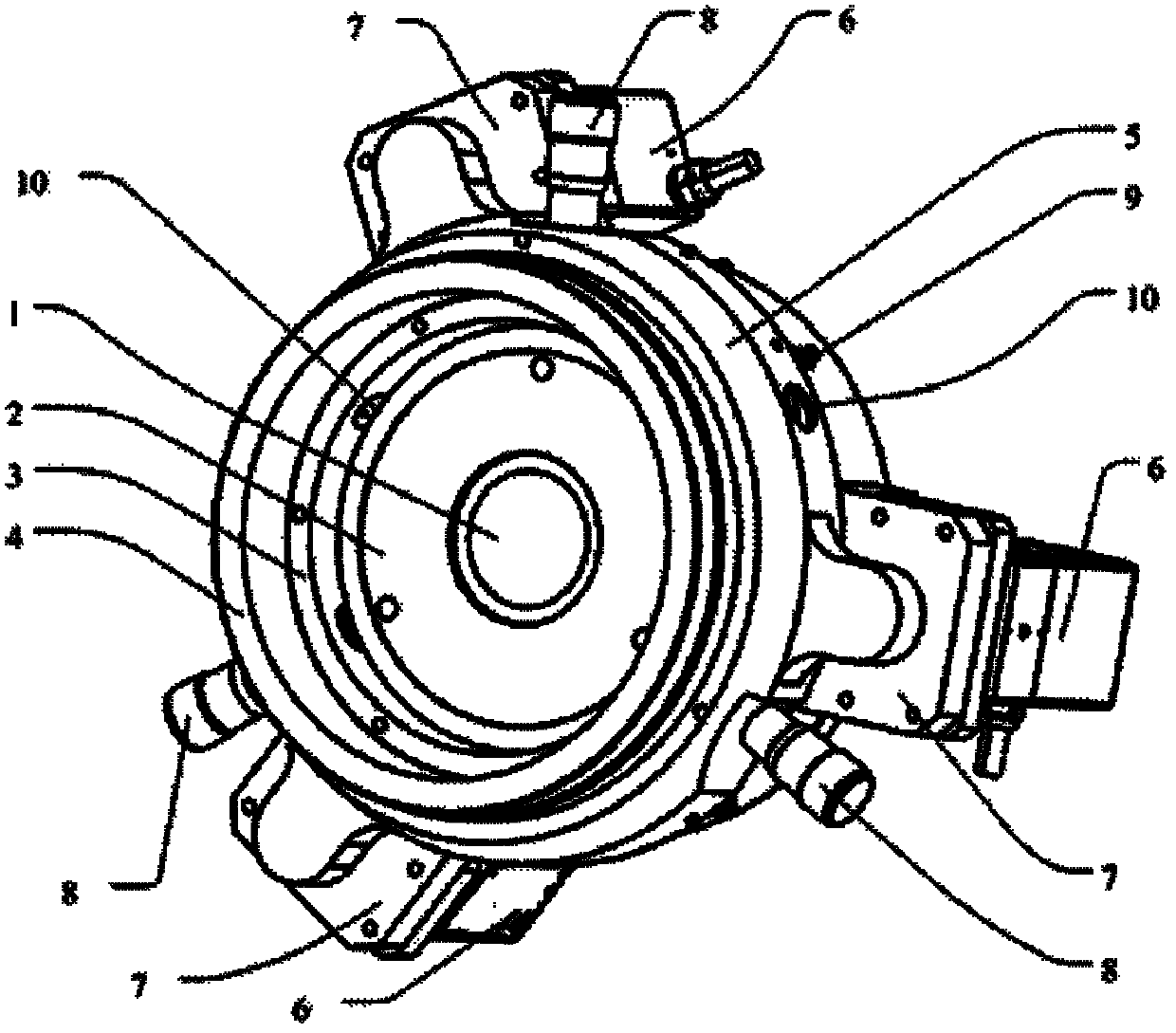

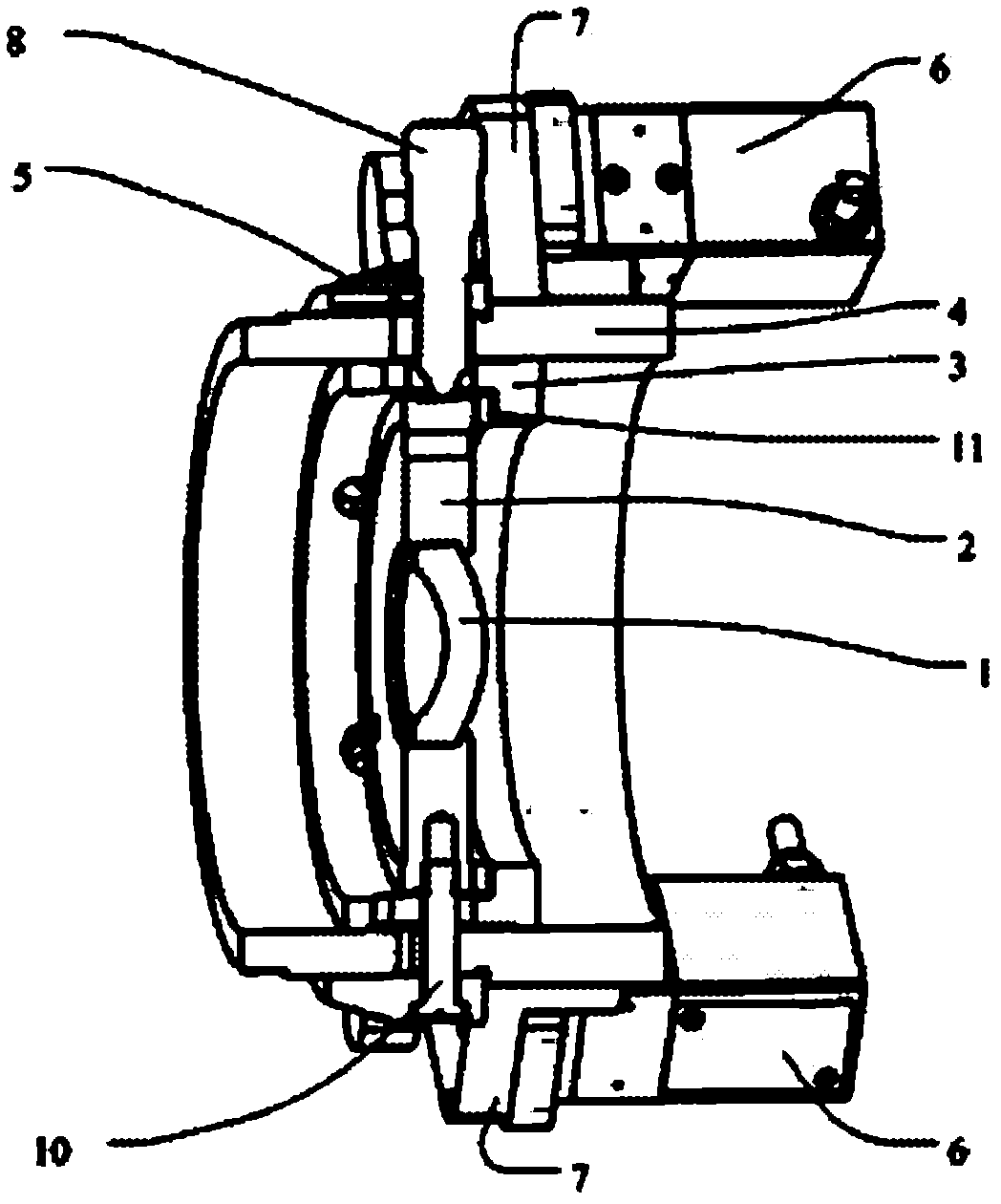

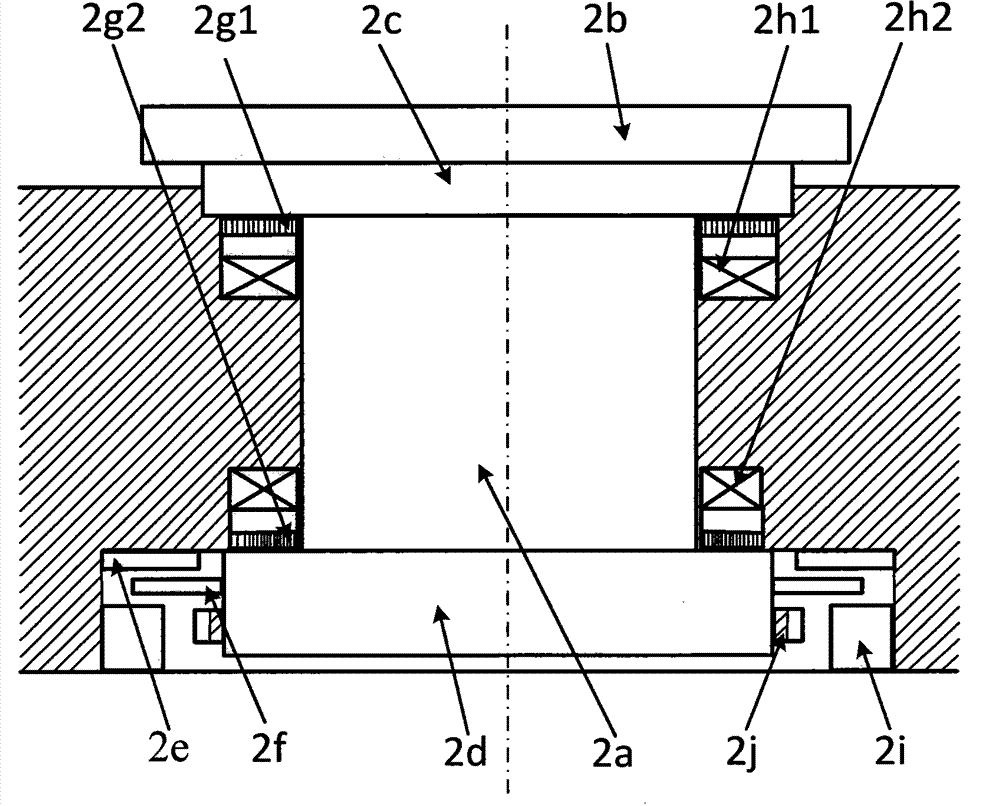

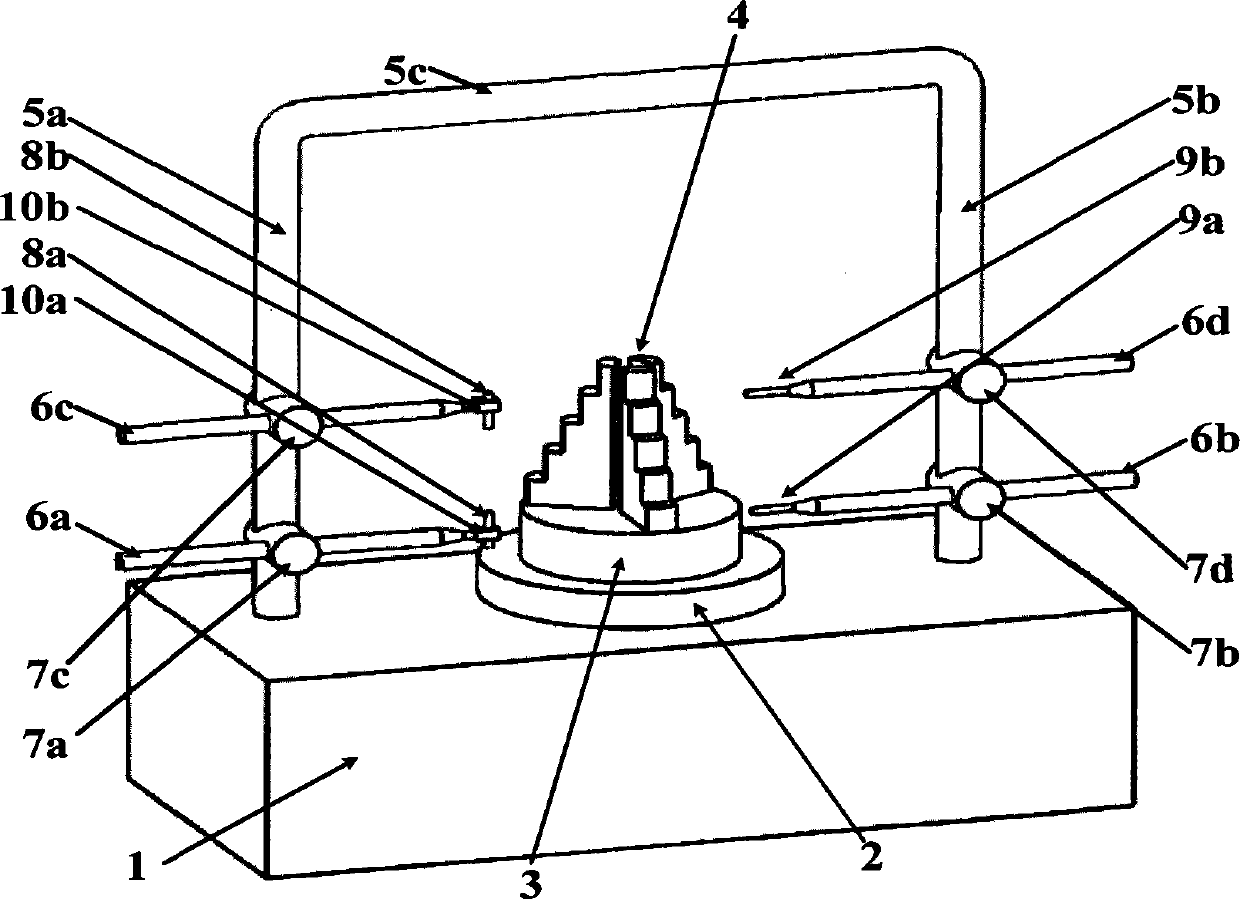

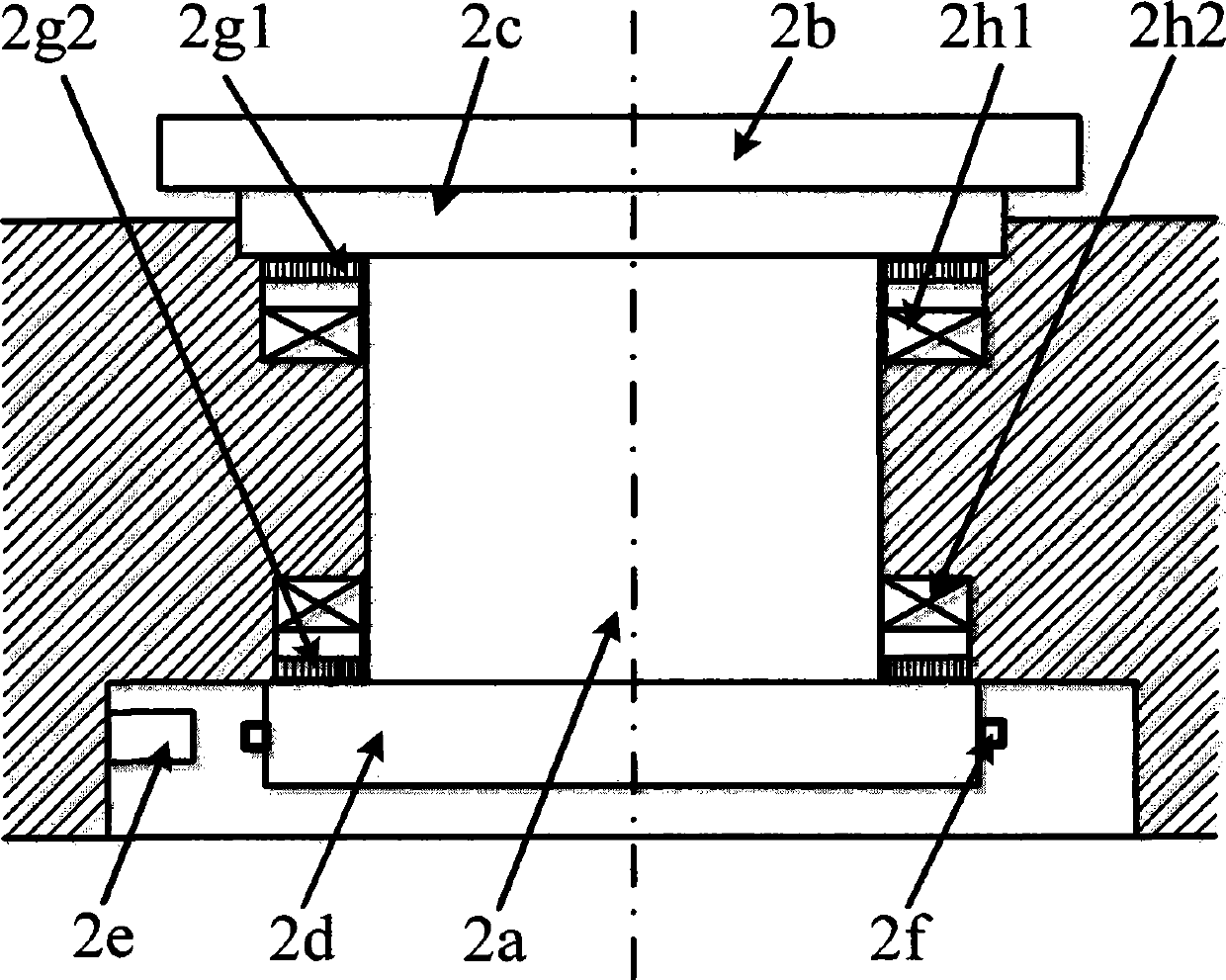

Hydraulic capturing and clamping type aircraft engine rotor assembling method and device based on inductance sensing

InactiveCN103790647AReduce consumptionImprove stabilityMachines/enginesSafety/regulatory devicesAviationRadial error

The invention relates to a hydraulic capturing and clamping type aircraft engine rotor assembling method and device based on inductance sensing, and belongs to the machine assembling technology. According to the hydraulic capturing and clamping type aircraft engine rotor assembling method and device, a rotation standard is determined based on an air floating rotation shaft system; angle location of a rotary table is determined according to an inductive synchronizer; based on a four-measuring-head measuring device, radial errors of a rotor radial assembly face and slant errors of an axial assembly face are extracted, and the influence weights of rotors on the rotor coaxiality after the rotors are assembled are obtained; all the rotors required to be assembled are respectively measured, and the influence weights of the rotors on the rotor coaxiality after the rotors are assembled are obtained; vector optimizing is carried out on the weights of the rotors, and the assembling angles of the rotors are obtained. According to the hydraulic capturing and clamping type aircraft engine rotor assembling method and device, the problem that the coaxiality is low after the aircraft engine rotors are assembled is solved, and after the rotors are assembled, the hydraulic capturing and clamping type aircraft engine rotor assembling method and device have the advantages of being high in coaxiality, reducing vibration, being easy to install and high in flexibility, and improving the engine performance.

Owner:HARBIN INST OF TECH

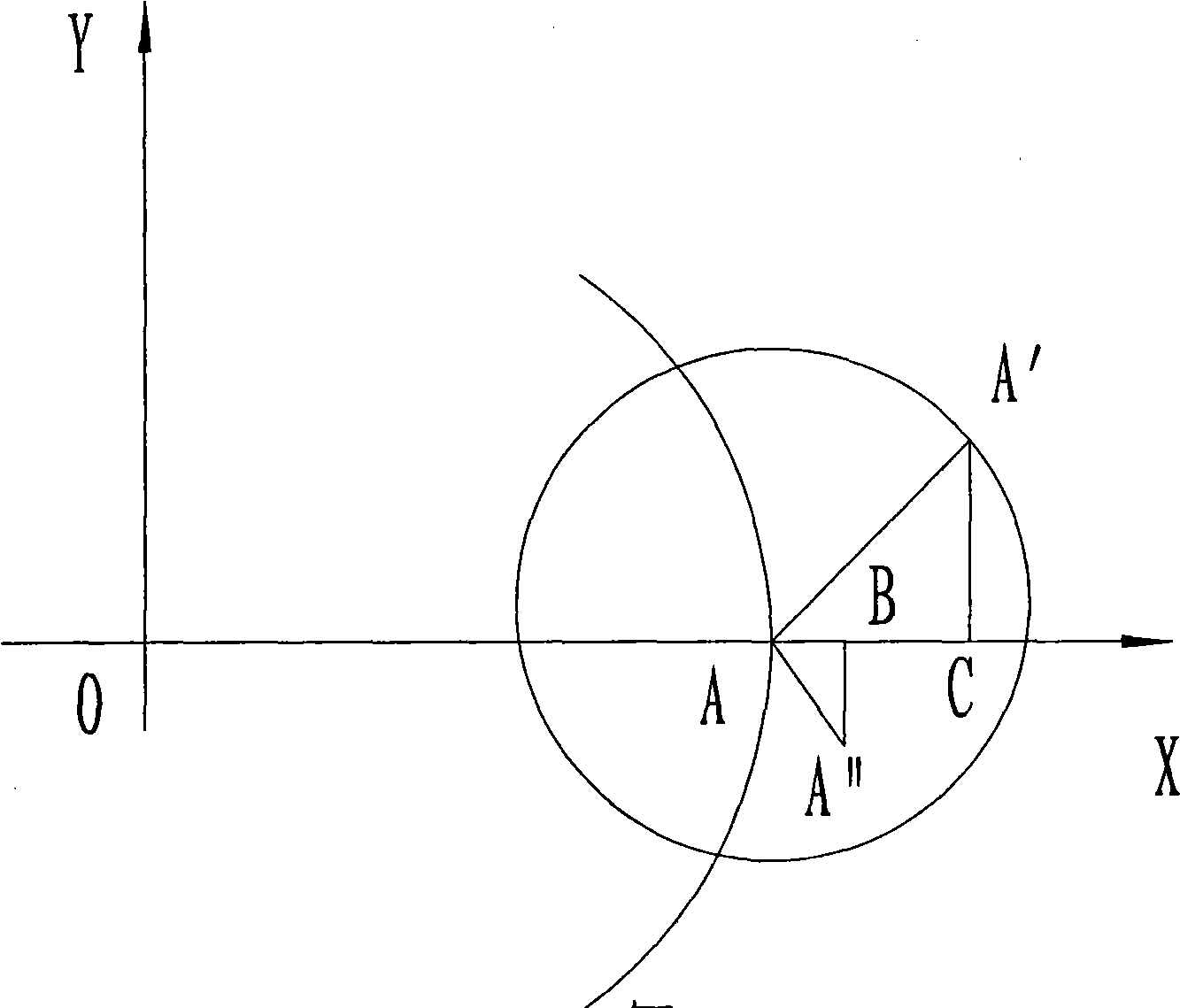

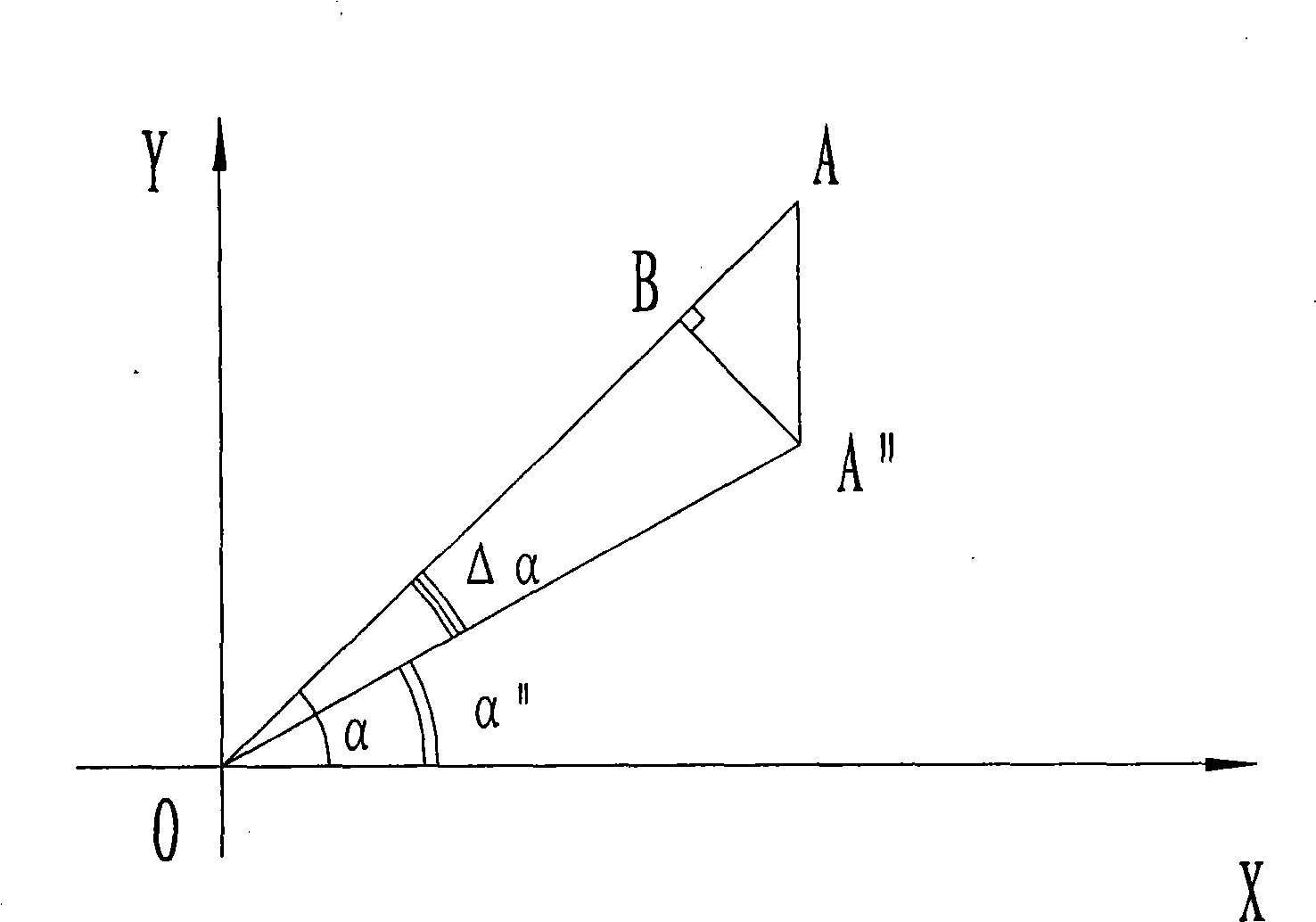

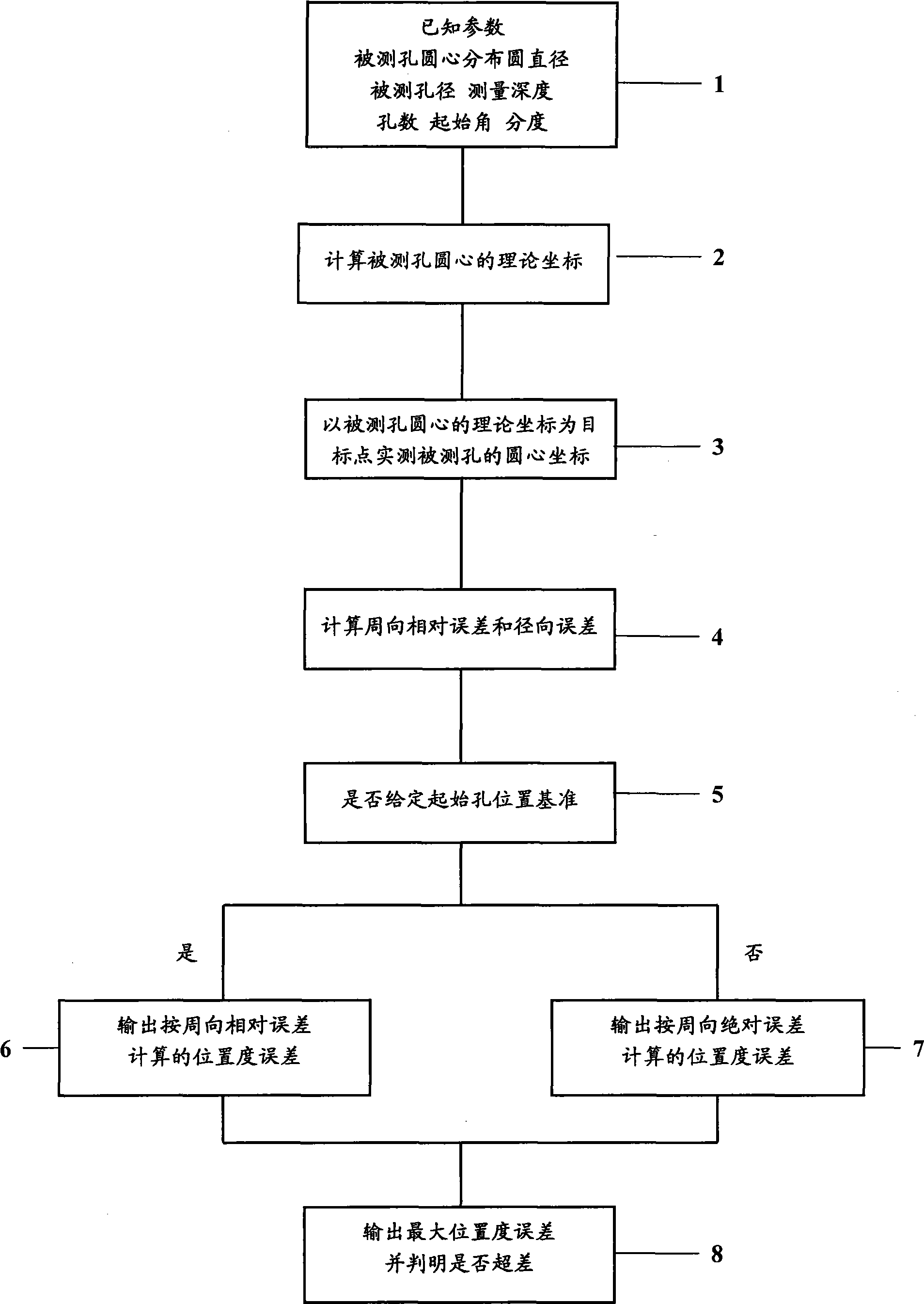

Three-coordinate measuring method for circumferential uniformly-distributed hole true position error

InactiveCN101520296ASolve measurement problemsIncrease productivityMechanical measuring arrangementsRadial errorCoordinate-measuring machine

The invention discloses a three-coordinate measuring method for circumferential uniformly-distributed hole true position error, which comprises the following steps: (1) determining a theoretical coordinate in the center of a circle of a measured hole by calculation; (2) taking the theoretical coordinate in the center of the circle of the measured hole as a target point, and measuring the actual coordinate of the center of the circle of the measured hole; (3) calculating the circumferential relative error and the radial error of the center of the circle of the measured hole; and (4) calculating the true position error according to the circumferential relative error and the radial error or the circumferential absolute error and the radial error, finding out the maximum true position error, and judging whether the maximum true position error exceeds the set error. The three-coordinate measuring method can ensure that a three-coordinate measuring machine realizes automatic measurement and automatic calculation, can accurately measure the benchmark of a given initial datum hole and the benchmark of a non-given initial datum hole, has high universality and simple calculation, and avoids the occurrence that the error caused by the measurement and the calculation makes qualified products in the actual assembly detected as unqualified products so as to bring huge loss to manufactures.

Owner:AVIC HUIYANG AVIATION PROPELLER

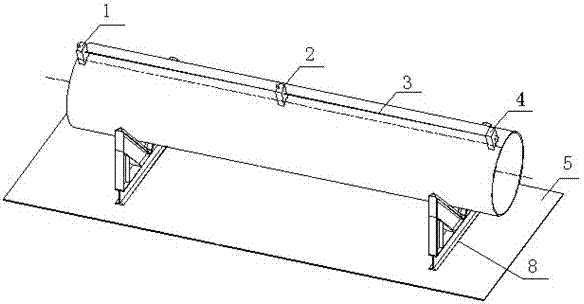

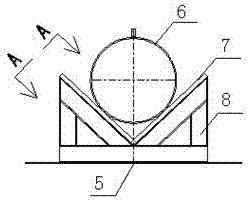

Aero-engine rotor stack-assembling method and device

InactiveCN103899367AReduce consumptionImprove stabilityMachines/enginesSafety/regulatory devicesElectricityAviation

The invention discloses an aero-engine rotor stack-assembling method and device and belongs to the technical field of mechanical assembly. The method comprises the steps of determining a rotary standard based on an air floatation rotary shaft system, determining angle location of a rotary table through an optical-electricity encoder, extracting the radial error of a rotor radial assembly surface and the oblique error of a rotor axial assembly surface through a four-measuring-head measurement device to obtain the influence weight of a rotor on the coaxiality of assembled rotors, measuring all the rotors needed by assembly to obtain the influence weight of each rotor on the coaxiality of the assembled rotors, and conducting vector optimization on the weight of each rotor to obtain the assembly angle of each rotor. The method and device can effectively solve the problem that coaxiality of aero-engine rotors is low after assembly and has the advantages that coaxiality of the rotors is high after assembly, vibration is reduced, installation is easy to achieve, flexibility is high, and the performance of an engine is improved.

Owner:HARBIN INST OF TECH

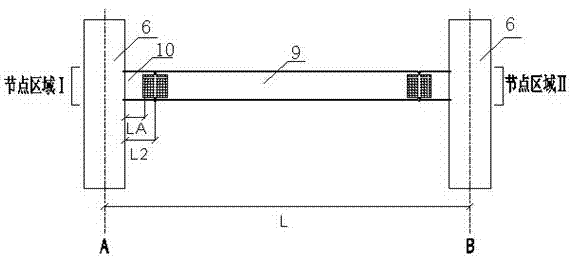

Radial positioning method for joint part of round pipe component

The invention relates to a radial positioning method for a joint part of a round pipe component. The method includes the following steps: determining a reference surface, acquiring out-of-roundness of two ports of a round pipe according to the reference surface, and performing roundness correction on the ports of the round pipe; measuring two ends of the round pipe after being subjected to port roundness correction according to the reference surface to acquire an upper end point of each port, and performing joint punching on the upper end point to acquire a punching point identity; according to the punching point identity, adopting a laser alignment method for measuring to acquire bending error of the round pipe; according to the bending error of the round pipe, adopting a fire correction method and the laser alignment method to align the round pipe, and determining an axial position of a joint according to size specified by a drawing; adopting the laser alignment method to determine out-of-roundness of the axial position of the joint of the round pipe, and acquiring radial error. By the radial positioning method, the problem of radial positioning of the joint part on a finished pipe with deviation in outer diameter and tortuosity is solved, and connecting accuracy of the component and integral safety of structure are guaranteed.

Owner:ANHUI WEIHONG STEEL STRUCTURE GRP

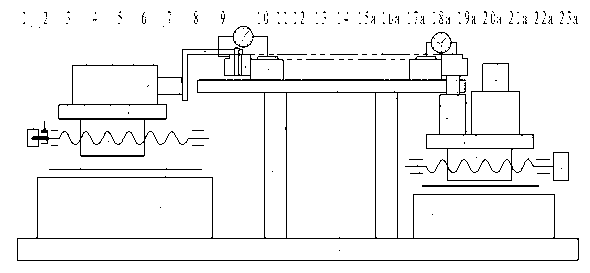

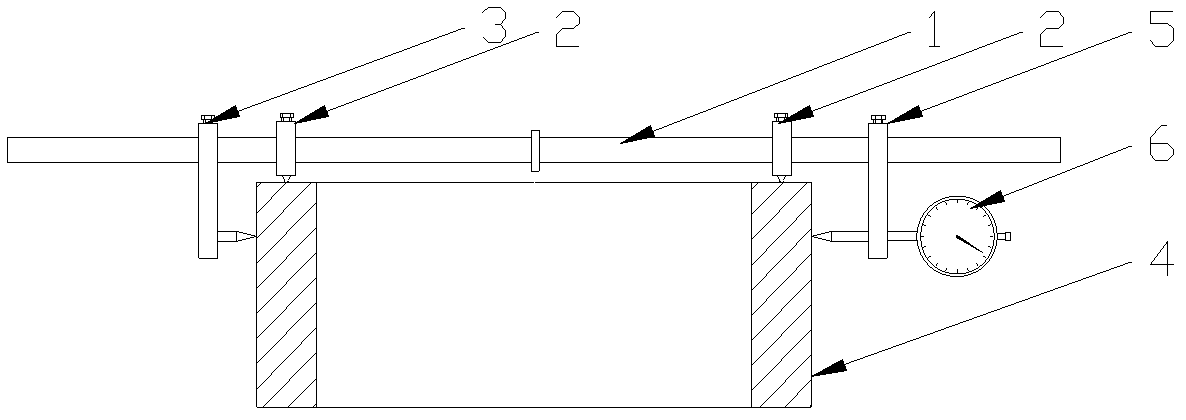

Double-side gear rolling tester for bevel gear

ActiveCN101566456AEasy and accurate detectionHigh-precision detectionAngles/taper measurementsMachine gearing/transmission testingDrive shaftGear wheel

The invention provides a double-side gear rolling tester for a bevel gear, comprising a base on which a driving shaft, a driving shaft seat, a driven shaft and a driven shaft seat are arranged; and the relative positions of the driving shaft, the driving shaft seat and the driven shaft, the driven shaft seat are adjustable; and a precision linear rolling guide is arranged between the driven shaft and the driven shaft seat, the driven shaft can do finite linear movement along the linear rolling guide. The invention further comprises a positioning regulating device for the driven shaft. The driven shaft is provided with a dial gauge or a recoding device. The invention can correctly and conveniently detect radial error conditions of the bevel gear when performing quality testing on the bevel gear.

Owner:ZHEJIANG FENGLI INTELLIGENT TECH CO LTD

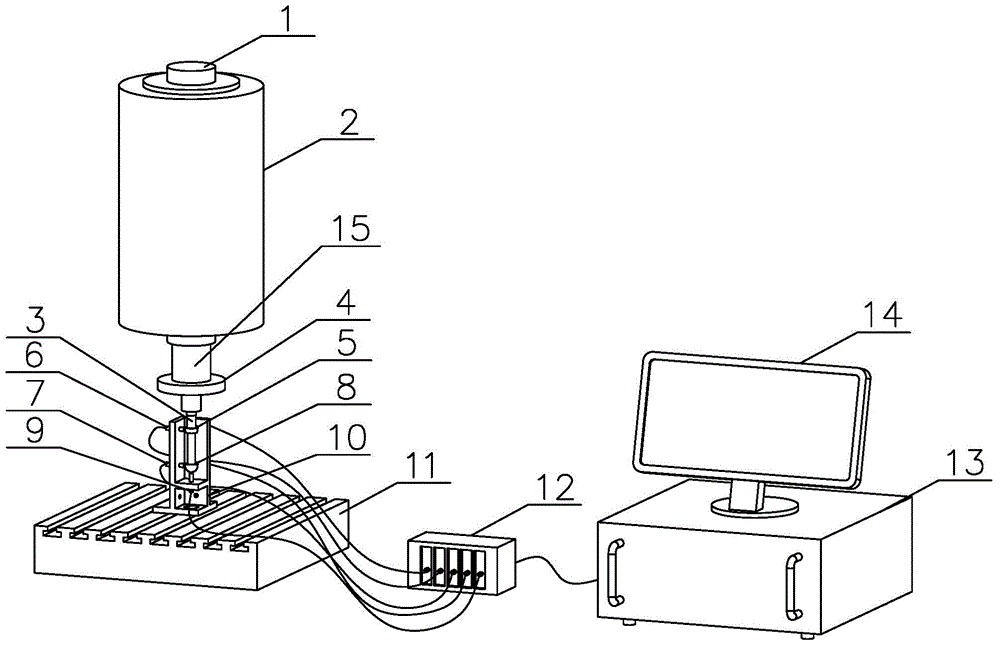

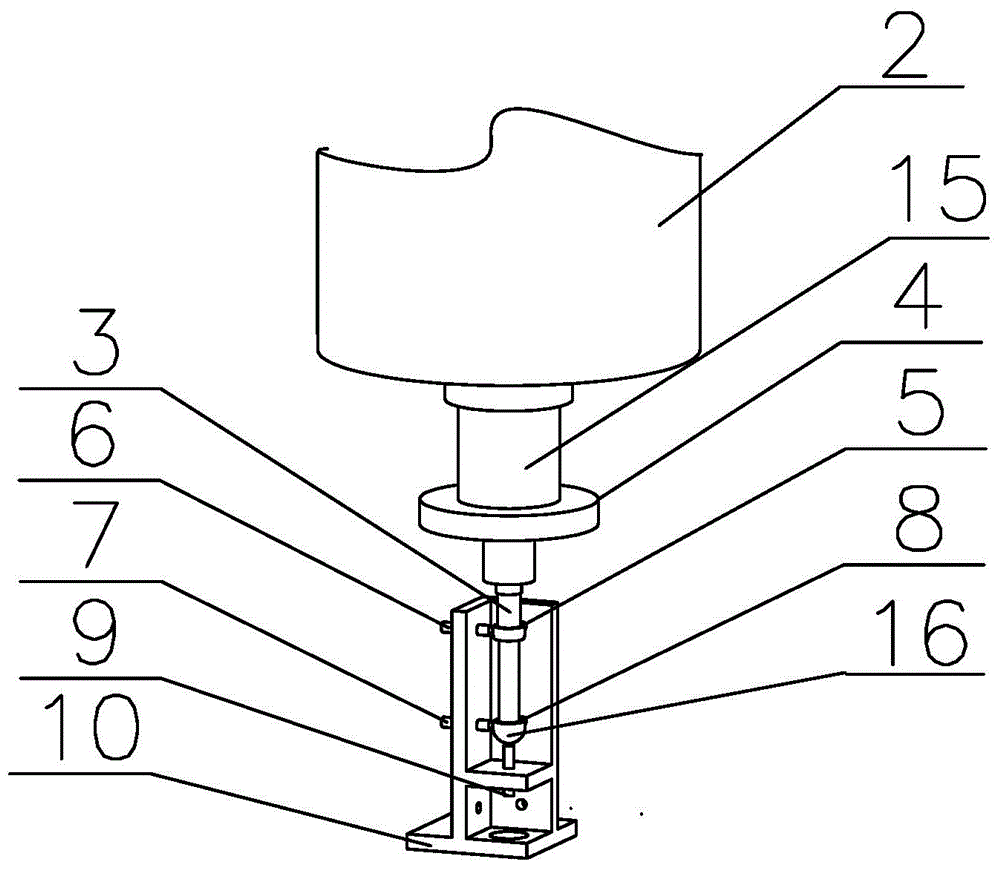

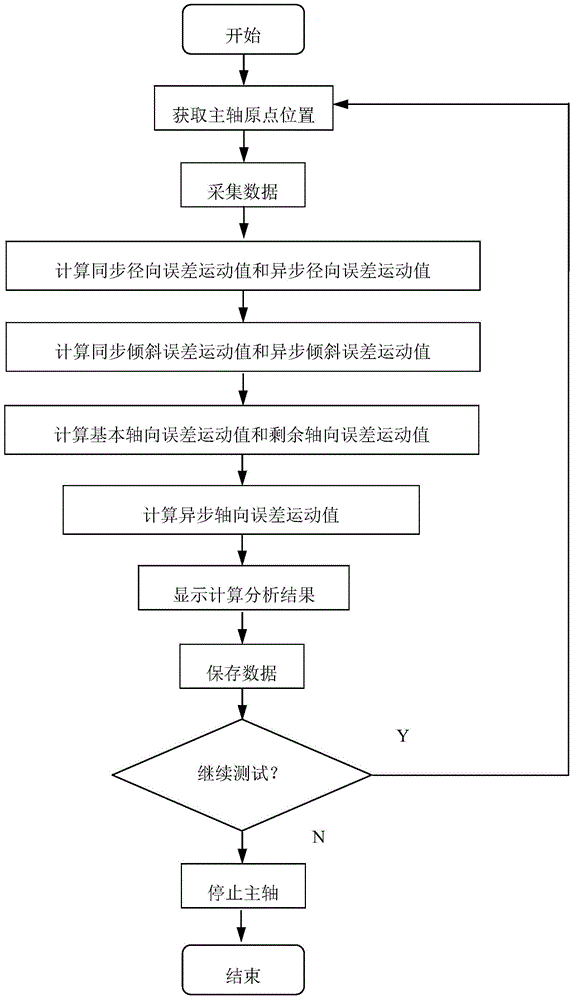

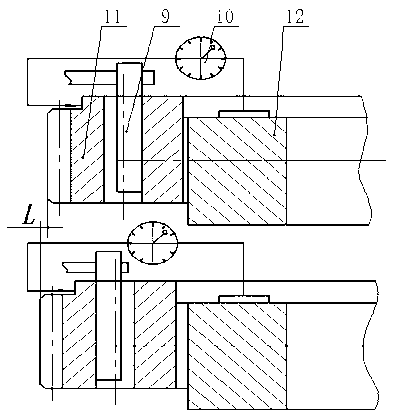

Testing system and testing method for dynamic rotation precision of main shaft

InactiveCN104482849AFlexible and simple system buildingRealize acquisitionUsing electrical meansSystem integrationData acquisition

The invention relates to a testing system and a testing method for dynamic rotation precision of a main shaft. The system adopts the scheme that a worktable is provided with a data acquisition mechanism which is connected with a rotary output shaft of the main shaft through a clamp, the data output end of the data acquisition mechanism is connected with an industrial personal computer through a sensor driving unit, and the main shaft is provided with a coder which is connected with the upper end of the rotary output shaft. The method comprises the following steps: preheating a to-be-tested shaft; acquiring and recording the initial position where data treatment is carried out on the to-be-tested shaft; collecting displacement data of a relative radial capacitive displacement sensor in the rotation process of the to-be-tested shaft and displacement data measured by an axial capacitive displacement sensor and storing the data; calculating a synchronous radial error motion value and an asynchronous radial error motion value; calculating a synchronous heeling error motion value and an asynchronous heeling error motion value; calculating a basic axial error motion value, a residual axial error motion value and an asynchronous radial error motion value; storing the data. All-around system integration is realized by using high-performance modular hardware, so that the dynamic rotation precision of the main shaft is tested.

Owner:TIANJIN UNIV

Gap detection device of large slewing bearing

ActiveCN102997885AAvoid damageImprove detection efficiencyMeasurement devicesAxial displacementBall screw

The invention provides a gap detection device of a large slewing bearing and belongs to the technical field of industrial measurement. The gap detection device comprises a radial error detection table, three groups of symmetrically-distributed axial error detection tables, a detection working table frame with a spiral pressing plate clamping mechanism, a slewing bearing to be detected, a controller and a displayer. Each axial error detection table comprises an axial servo motor, an axial rolling guide rail, an axial ball screw, a centering mechanism, an axial screw nut, an axial servo electric pushing rod, an axial working table plate, an axial base and an axial displacement sensor. The radial error detection table comprises a radial servo motor, a locking mechanism, a radial ball screw, a radial rolling guide rail, a radial screw nut, a radial working table plate, a radial servo electric pushing rod, a fork head, a radial base and a radial displacement sensor. The gap detection device of the large slewing bearing has the advantages of being high in detection accuracy, convenient to operate and high in detection efficiency.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY +1

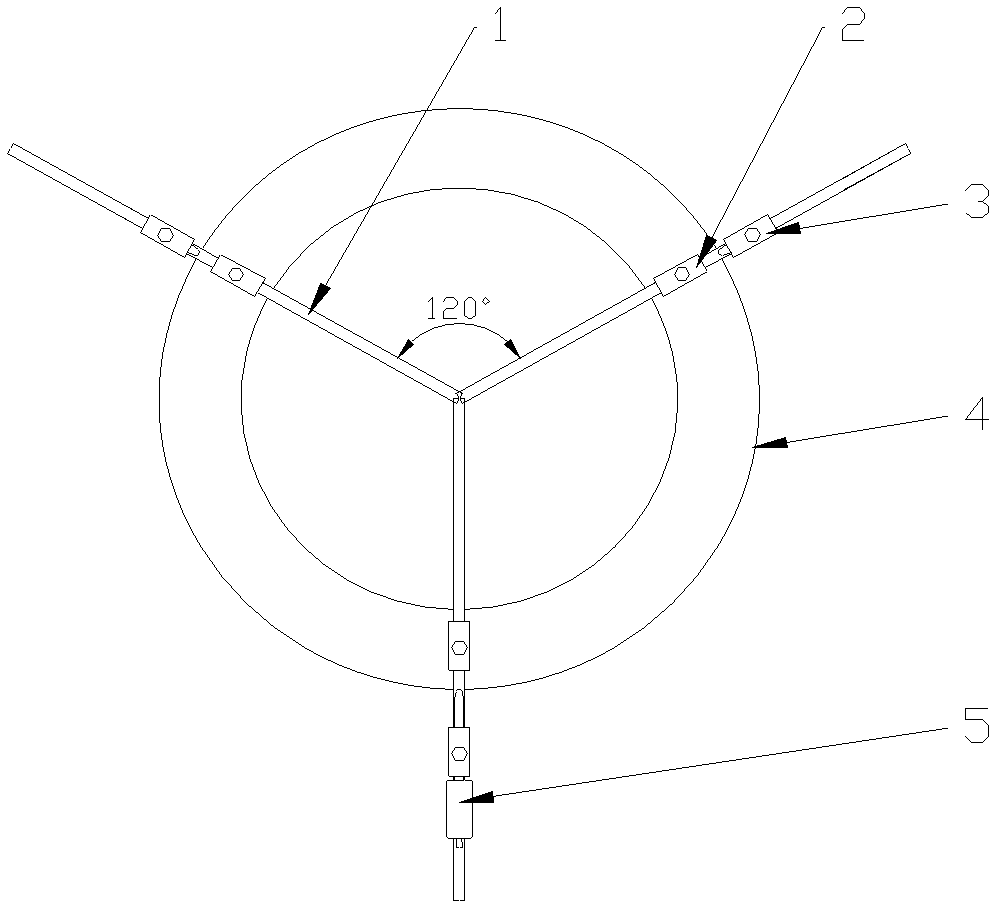

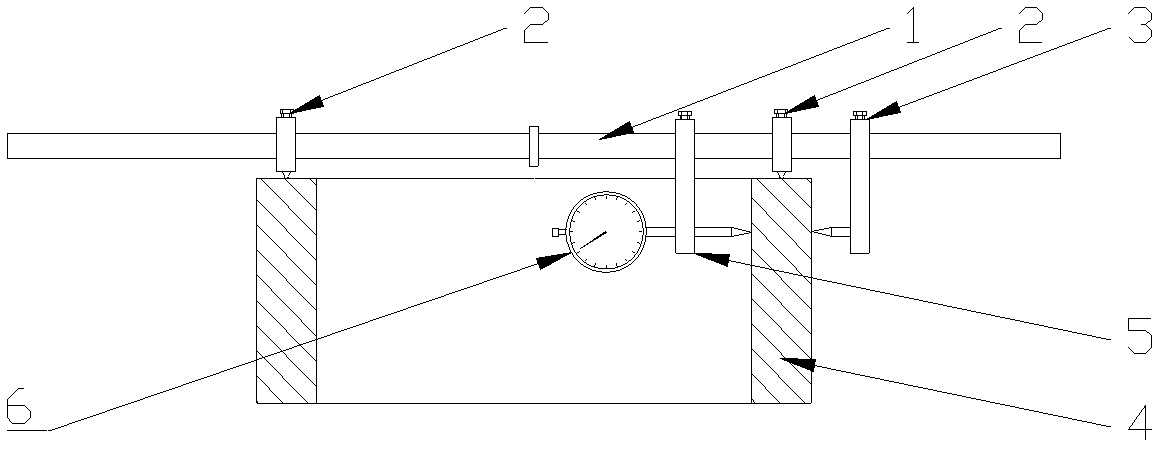

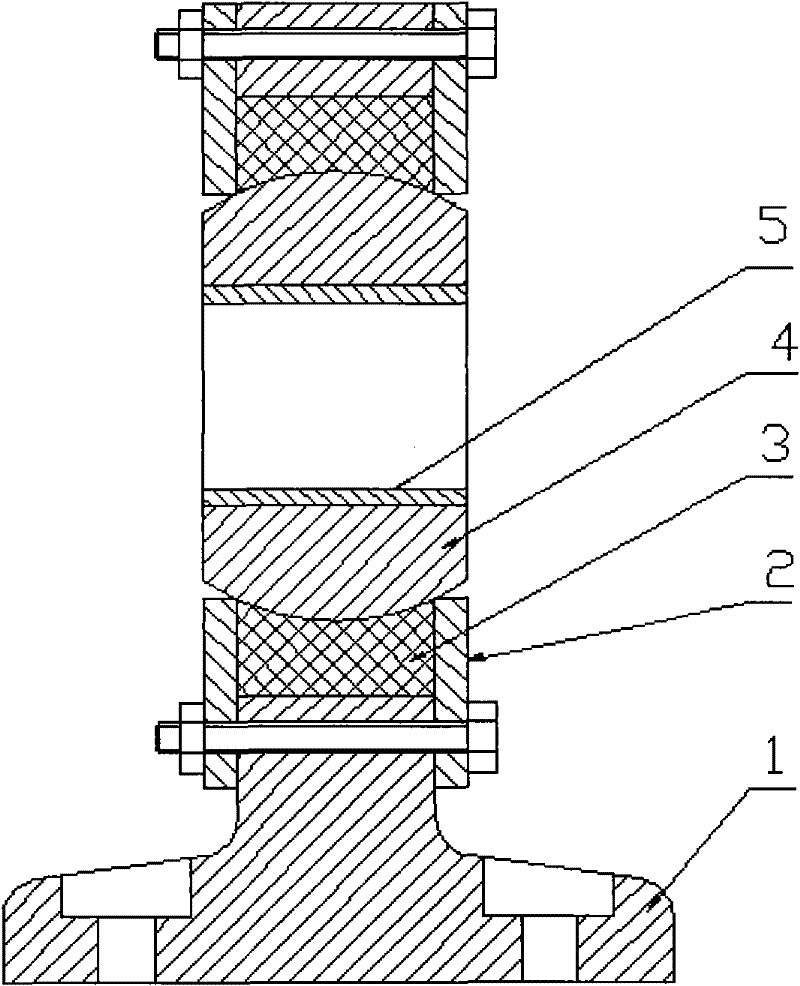

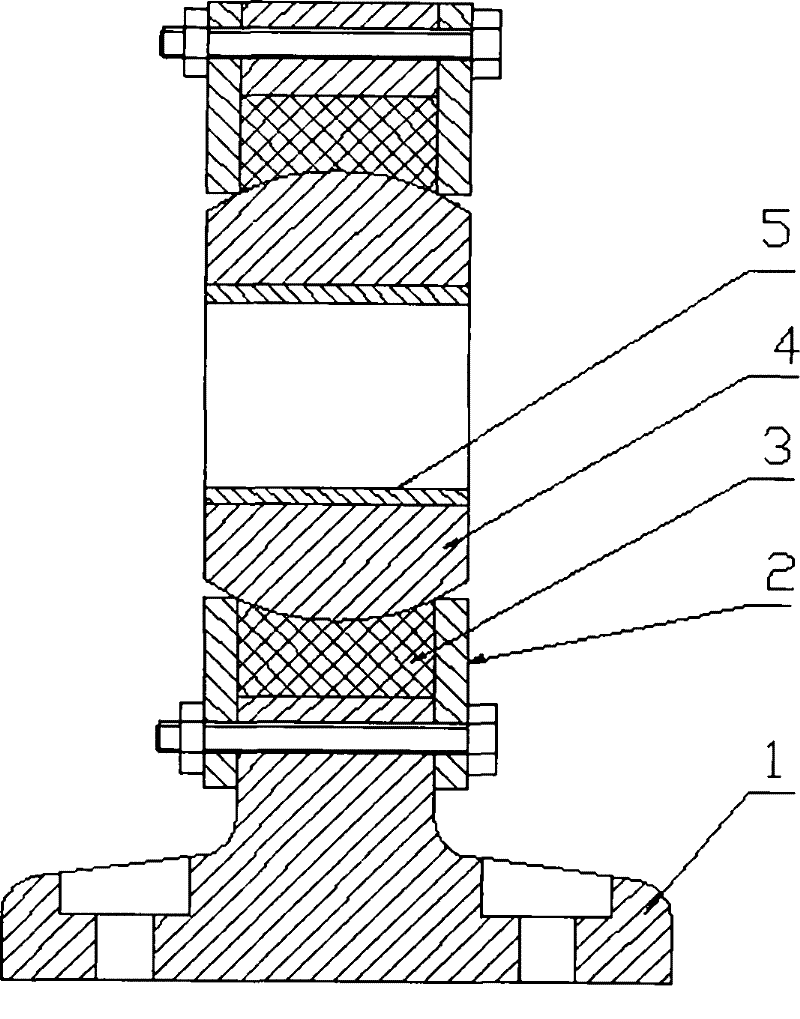

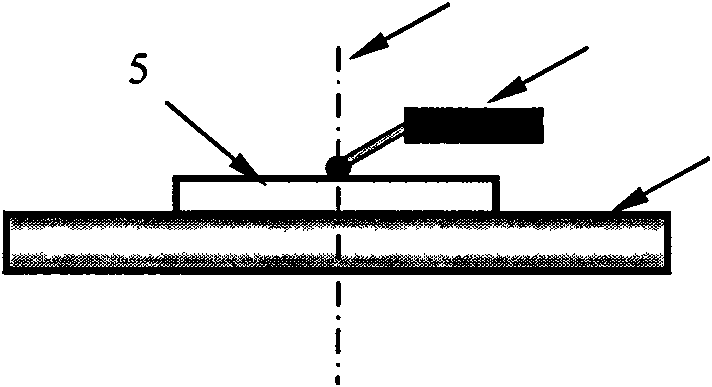

Detection apparatus for heavy and large bearings

InactiveCN102425984AImprove detection accuracyReduce the intensity of manual operationMechanical clearance measurementsRadial errorEngineering

The invention discloses a detection apparatus for heavy and large bearings, wherein the apparatus is portable and has multiple functions; therefore, a problem that it is needed to rotate bearing parts manually to carry out measurement during current measurement process of heavy and large bearing parts can be solved. A technical scheme employed in the invention is as follows: the detection apparatus comprises three rectangular or I-shaped main body supports (1), end face supports (2) and side supports (3) and a measurement support (5); besides, the main body supports (1) are uniformly distributed in a radial shape and included angles between the supports are 120 degrees; and the end face supports (2) and side supports (3) and a measurement support (5) are attachedly assembled along the main body supports (1). The detection apparatus for heavy and large bearings can be used to measure a radial error and an axial error. The method comprises: the detection apparatus is arranged on a measured bearing; and the measured bearing is measured by rotating and moving the detection apparatus. According to the invention, the detection apparatus has the following advantages that: detection precision of heavy and large bearings is improved; and manual operation intensity is reduced.

Owner:瓦房店工业冶金轴承制造有限公司

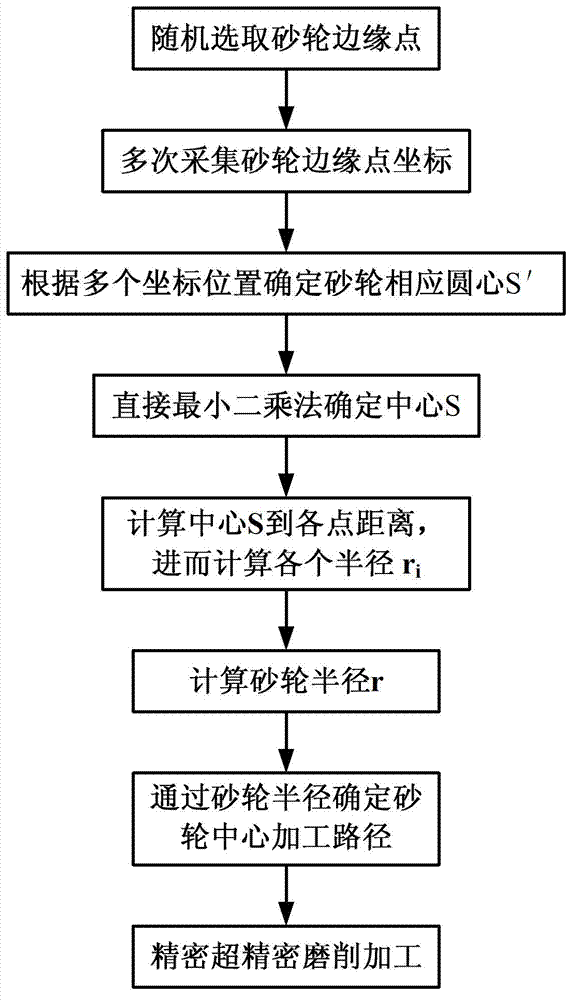

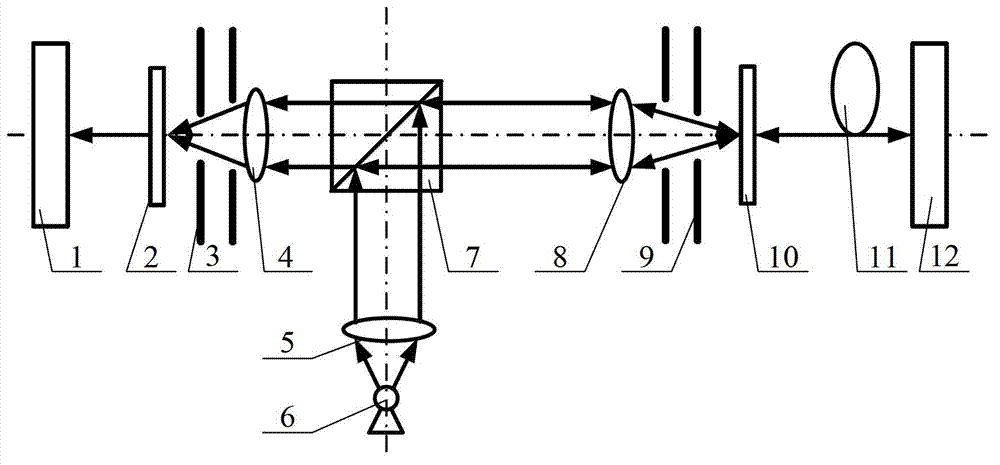

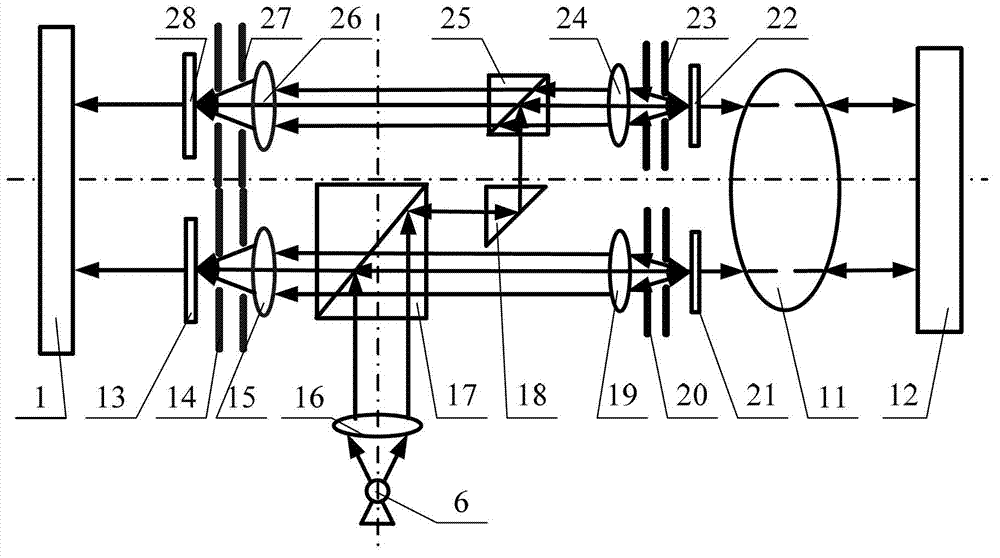

Method for compensating radial error of precise and ultraprecise grinding abrasion wheels and application of method for compensating radial error of precise and ultraprecise grinding abrasion wheel

ActiveCN103029041ARealize online measurementRealize online measurement and determine the wear amount of the grinding wheel at the same timeGrinding feed controlEngineeringRadial error

A method for compensating the radial error of precise and ultraprecise grinding abrasion wheels and an application of the method for compensating the radial error of the precise and ultraprecise grinding abrasion wheels belong to the technical field of precise and ultraprecise processing and aim to solve the problem which is caused by radial error and radial run-out in the prior art. The method comprises the following steps: the radius of the abrasion wheel is determined through a multi-measurement method; a central path of an abrasion wheel grinding process is determined according to the determined radius of the abrasion wheel; and the abrasion wheel with the determined abrasion wheel radius in the step 1 is ground along the central path of the determined abrasion wheel in the step 2. According to the method, the edge points of the abrasion wheel are randomly selected to determine a plurality of circle centers of the abrasion wheel so as to determine the radium of the abrasion wheel, so that the radius of the abrasion wheel is corrected, the surface precision of a processed element is ensured, and the processing precision is increased; and according to the method for compensating the radial error, edge point coordinates are determined when the abrasion wheel rotates at high speed, the distribution of circle center points is integrated to determine the radial run-out of the abrasion wheel to a certain extent, and the compensating process is further corrected.

Owner:CHANGCHUN UNIV OF SCI & TECH

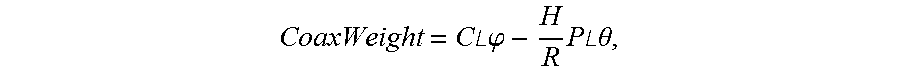

Aircraft engine rotor assembling method and device based on multi-component concentricity optimizing

InactiveCN103790648AReduce consumptionImprove stabilityMachines/enginesSafety/regulatory devicesAviationElectricity

The invention relates to an aircraft engine rotor assembling method and device based on multi-component concentricity optimizing, and belongs to the machine assembling technology. According to the aircraft engine rotor assembling method and device, a rotation standard is determined based on an air floating rotation shaft system; angle location of a rotary table is determined according to an optical-electricity encoder; based on a four-measuring-head measuring device, radial errors of a rotor radial assembly face and slant errors of an axial assembly face are extracted, and the influence weights of rotors on the rotor coaxiality after the rotors are assembled are obtained; all the rotors required to be assembled are respectively measured, and the influence weights of the rotors on the rotor coaxiality after the rotors are assembled are obtained; vector optimizing is carried out on the weights of the rotors, and the assembling angles of the rotors are obtained. According to the aircraft engine rotor assembling method and device, the problem that the coaxiality is low after the aircraft engine rotors are assembled is solved, and after the rotors are assembled, the aircraft engine rotor assembling method and device have the advantages of being high in coaxiality, reducing vibration, being easy to install and high in flexibility, and improving the engine performance.

Owner:HARBIN INST OF TECH

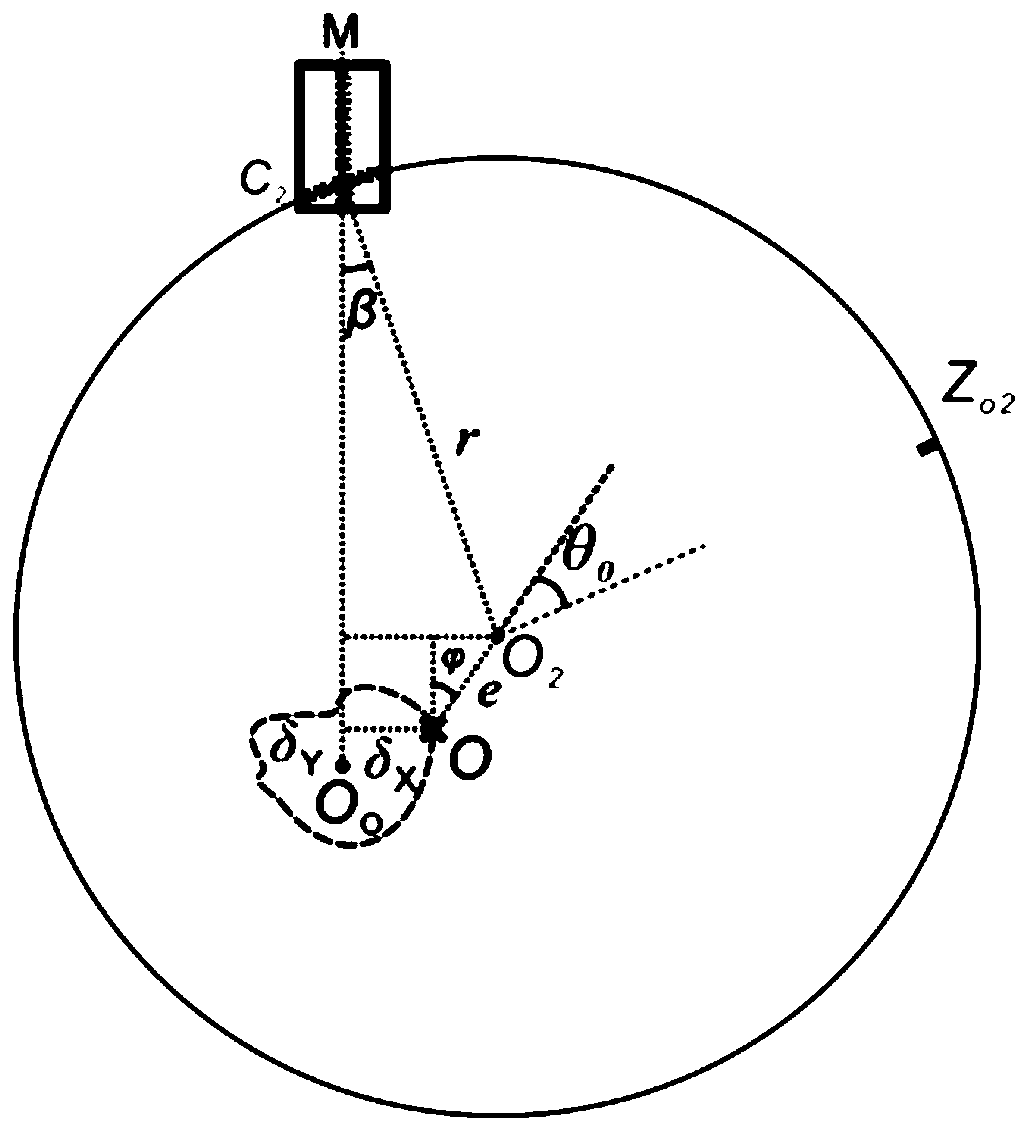

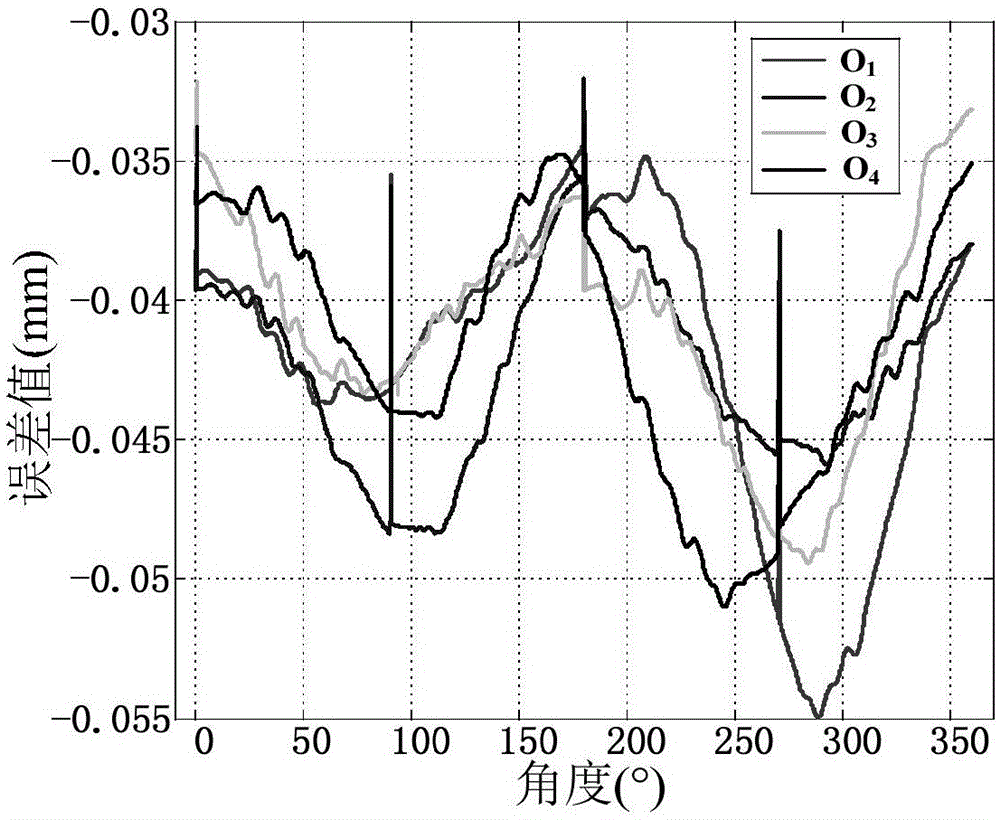

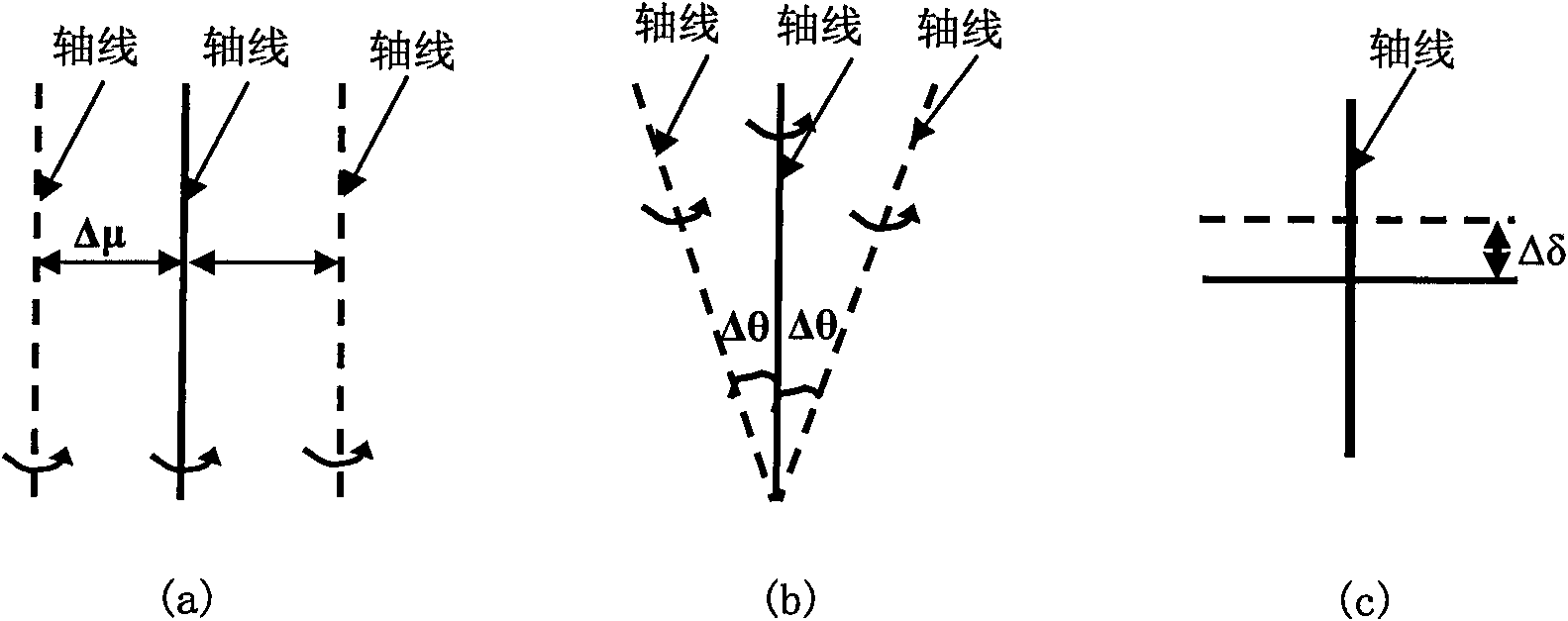

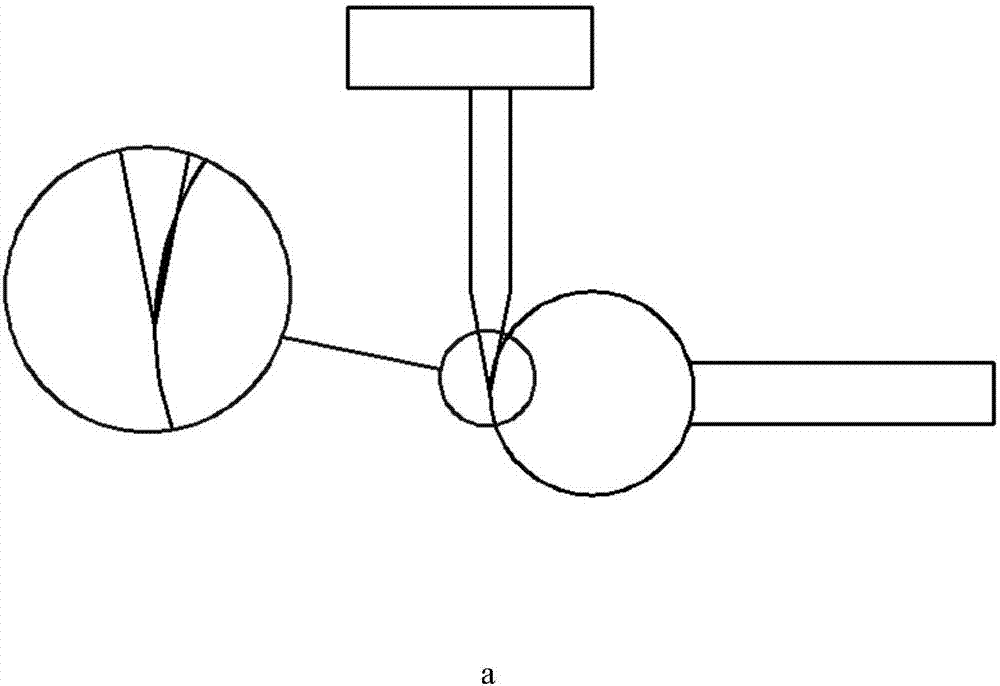

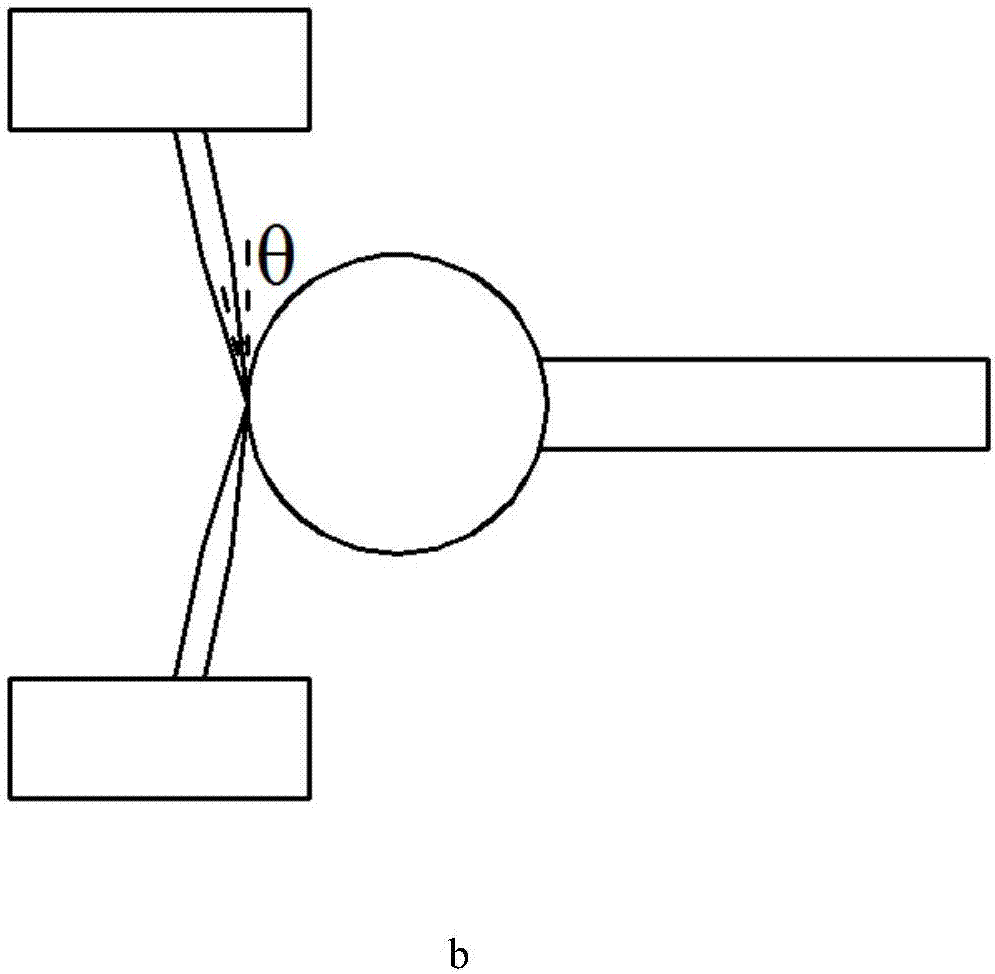

Circular grating sensor angle measurement error correcting method based on error source analysis

The invention belongs to the field of measuring instruments, and discloses a circular grating sensor angle measurement error correcting method based on error source analysis. The circular grating sensor angle measurement error correcting method comprises the steps of: establishing an angle measurement error model of a circular grating sensor; taking an image picture of surface grooves of a gratingdisc of the circular grating sensor by means of a CCD camera and a microscope of an eccentricity detecting device; adopting an image processing method on right side end point coordinates of each grooves of each image to obtain an installation grating disc eccentric magnitude e and an installation eccentric angle theta 0; detecting a radial error delta Y(theta) of a rotating shaft at the end surface of the grating disc; substituting the measured e, theta 0 and the delta Y(theta) into the angle measurement error model to obtain an angle measurement error Delta theta of the circular grating sensor, wherein a correction function is -Delta theta. The circular grating sensor angle measurement error correcting method can perform online adjustment on the rotating shaft and the grating disc conveniently, improve the angle measurement precision of the circular grating sensor and reduce errors.

Owner:HEFEI UNIV OF TECH

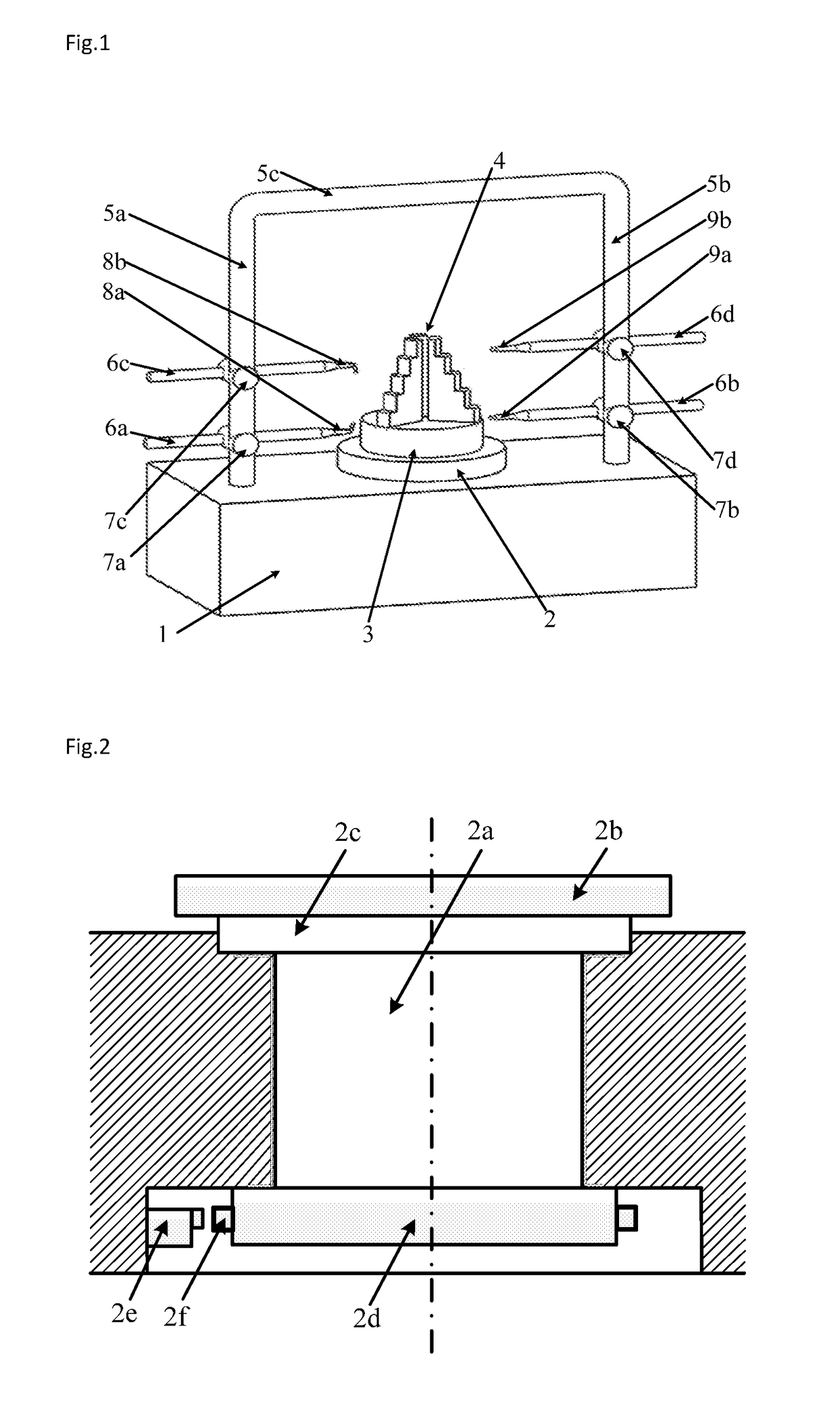

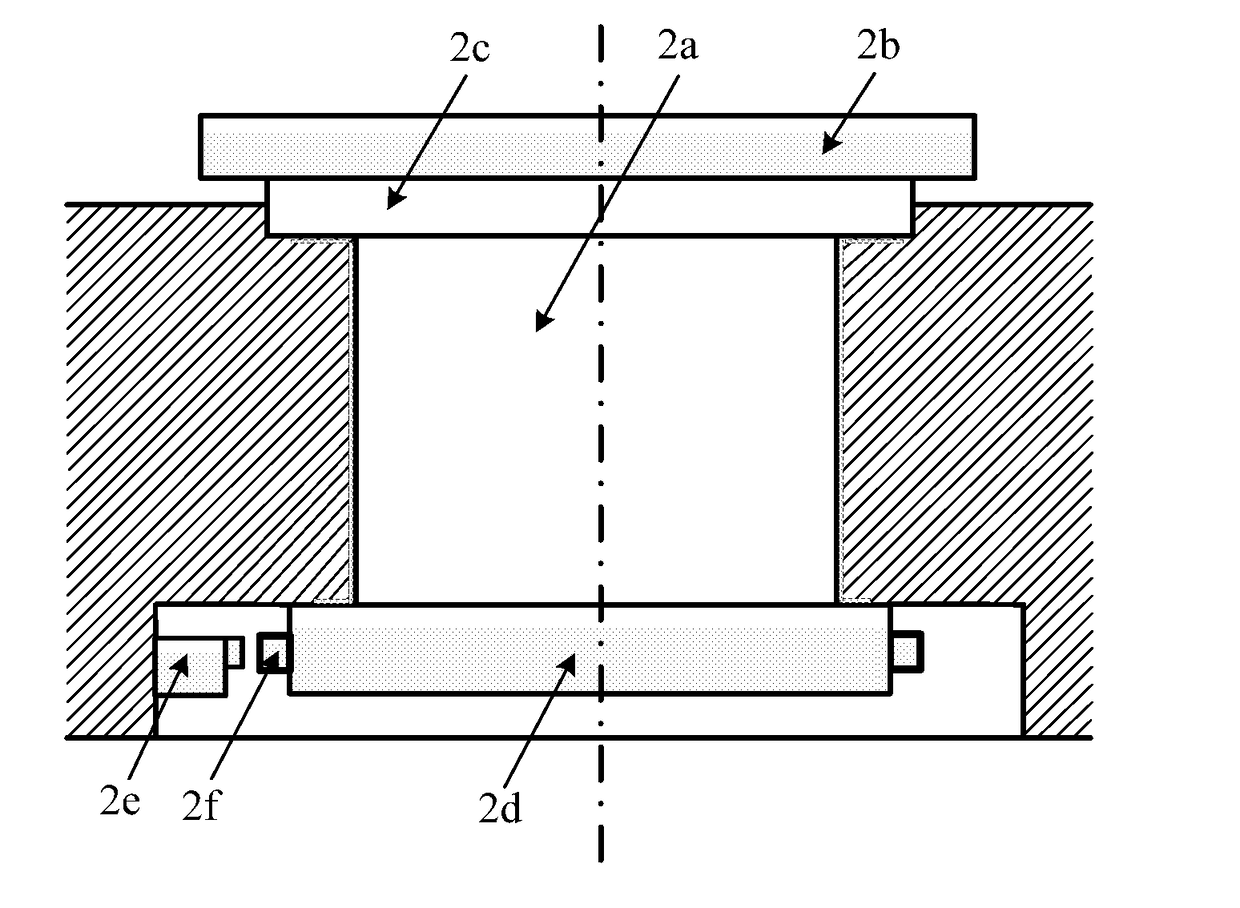

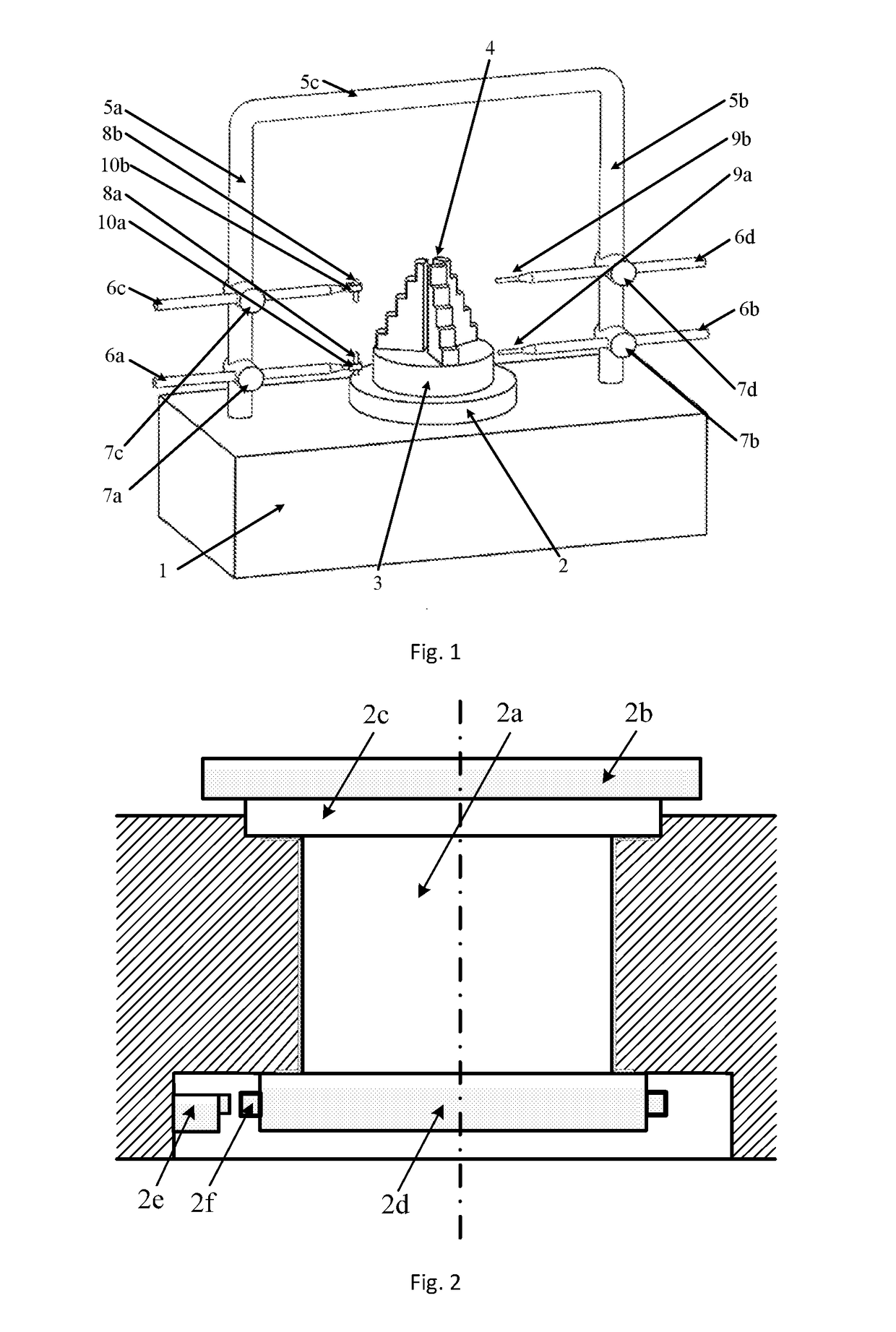

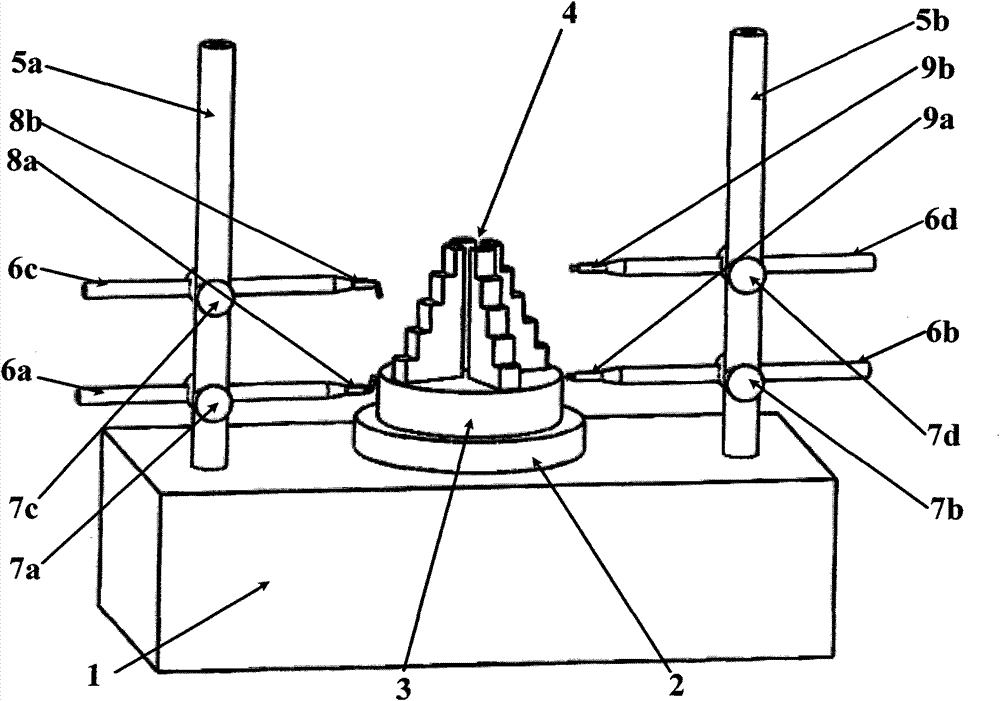

Aero engine rotor assembling method and device based on concentricity and verticality measurement

ActiveUS20170167866A1Low costShorten the timeEngine testingBlade accessoriesAir bearingAngular degrees

An aero engine rotor assembling method and device based on concentricity and verticality measurement belongs to mechanical assembly technology. The present invention effectively solves the problem of poor coaxality after the aero engine rotor is assembled and has the characteristics of high coaxality after the rotor is assembled, reduced vibration, mounting easiness, high flexibility and improved engine performance. The measurement and device is: determining rotary reference based on an air bearing rotary; determining the angular positioning of a rotary table according to a photoelectric encoder; extracting the radial error of the radial mounting plane and the inclination error of the axial mounting plane of the rotor based on the four-probe measuring device to obtain the influencing weight of this rotor to the assembled rotor on coaxality; measuring respectively all the rotors required for assembling to obtain the influencing weight of each rotor to the assembled rotor on coaxality; vector optimizing the weight of each rotor to obtain the assembling angle of each rotor.

Owner:HARBIN INST OF TECH

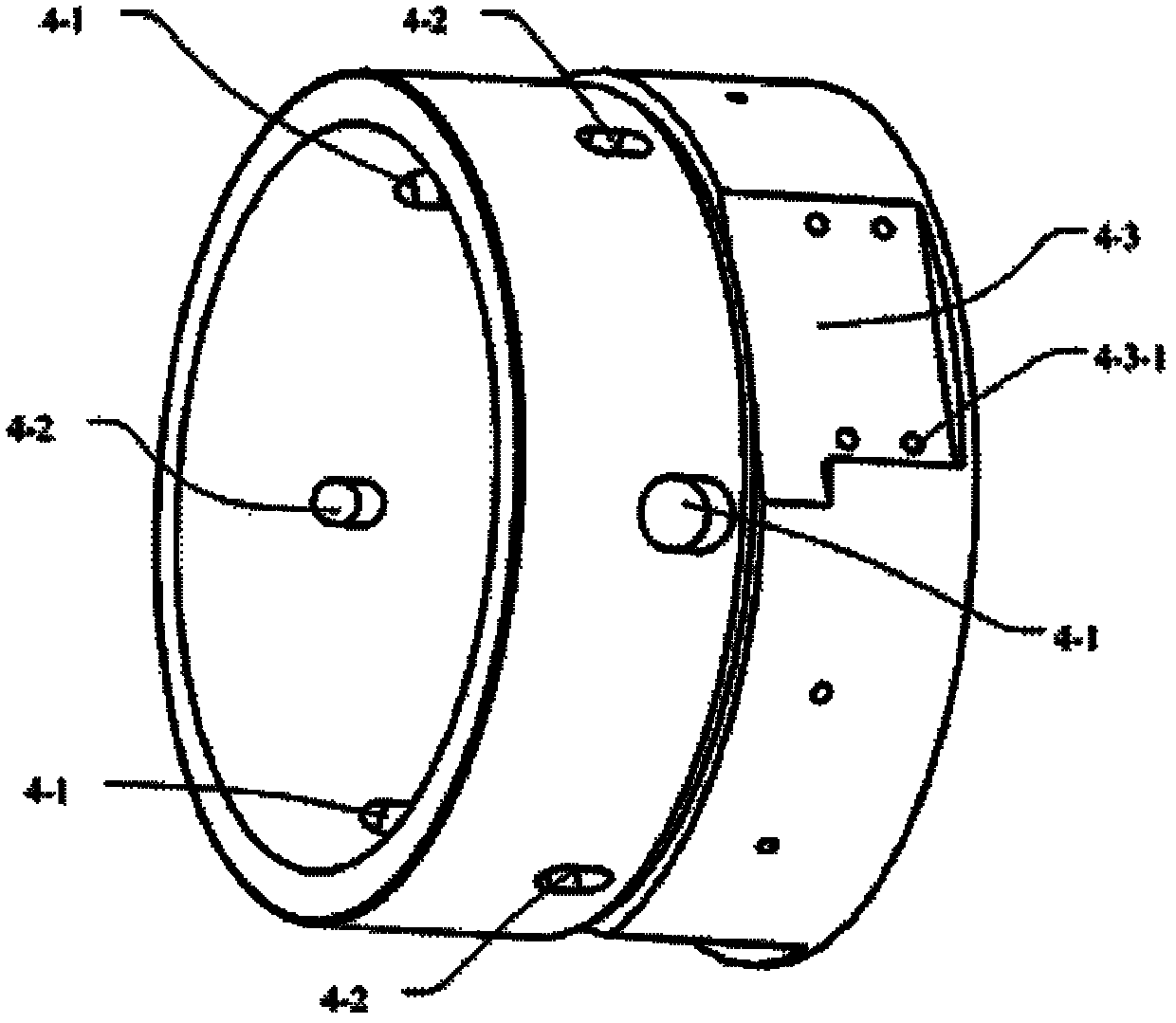

Optical element axial adjusting device with aligning function

InactiveCN102169218AWith centering functionOvercome the shortcomings that inevitably bring radial motion errorsPhotomechanical exposure apparatusMicrolithography exposure apparatusLithographic artistEngineering

The invention provides an optical element axial adjusting device with an aligning function and relates to the technical field of deep ultraviolet lithography objective lens design and debugging. By using the device, the problem that the radial error is caused in the axial adjustment of the traditional optical element axial adjusting device is solved. The axial adjusting device can be regarded as a lens cone unit of an objective lens integrally, wherein a lens base is placed into the lens cone through the precise matching of an axle hole; a sliding frame is arranged on an external cylindrical surface of the lens cone; the lens base is used for aligning a lens frame component; the sliding frame is connected with an internal lens frame component through guide nails; the sliding frame is pushed by three piezoelectric drivers at the same time, so as to drive the lens frame and an optical element to axially move forwards; a recovering force supporting the sliding frame to retreat is supplied by a spring; and when any position of stroke is adjusted axially, the optical element can be aligned by precisely adjusting a spiral dial gauge and the guide nails. The axial adjusting device provided by the invention has the advantages of large adjustment stroke, high adjustment precision and the like and is convenient to operate.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

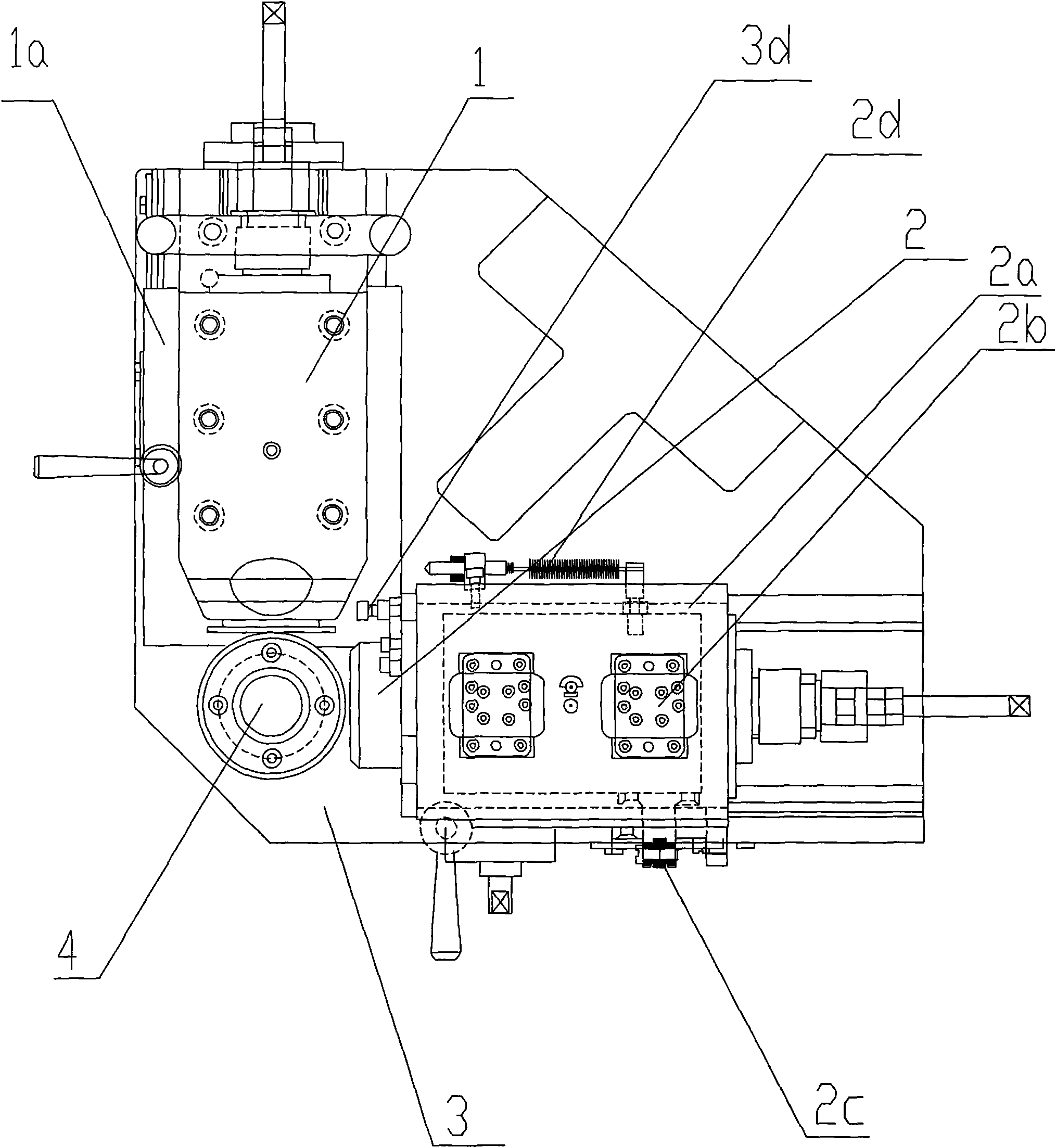

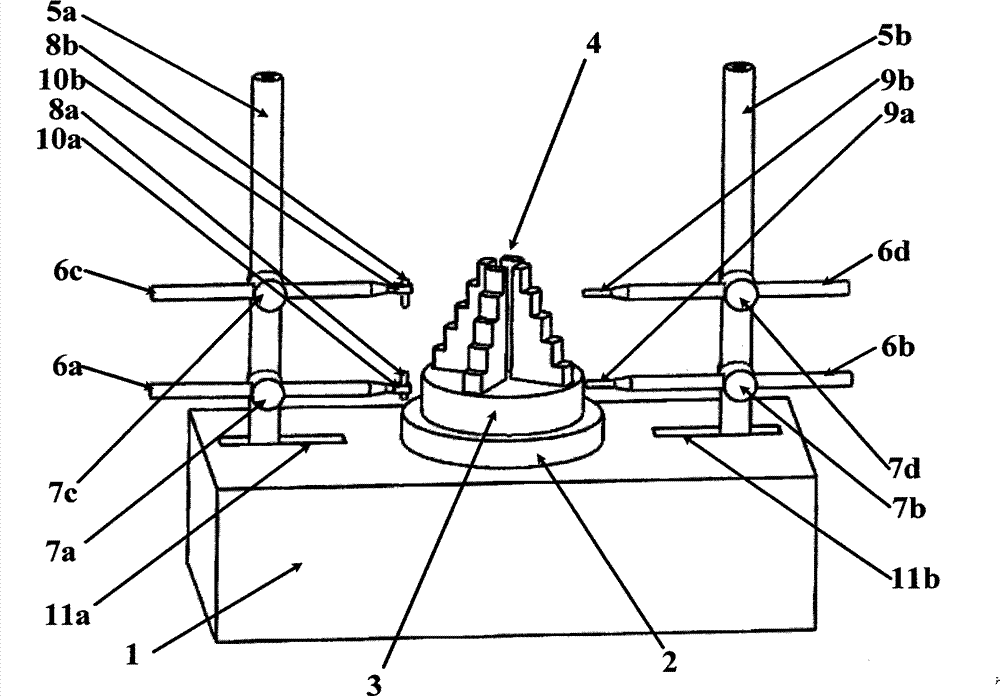

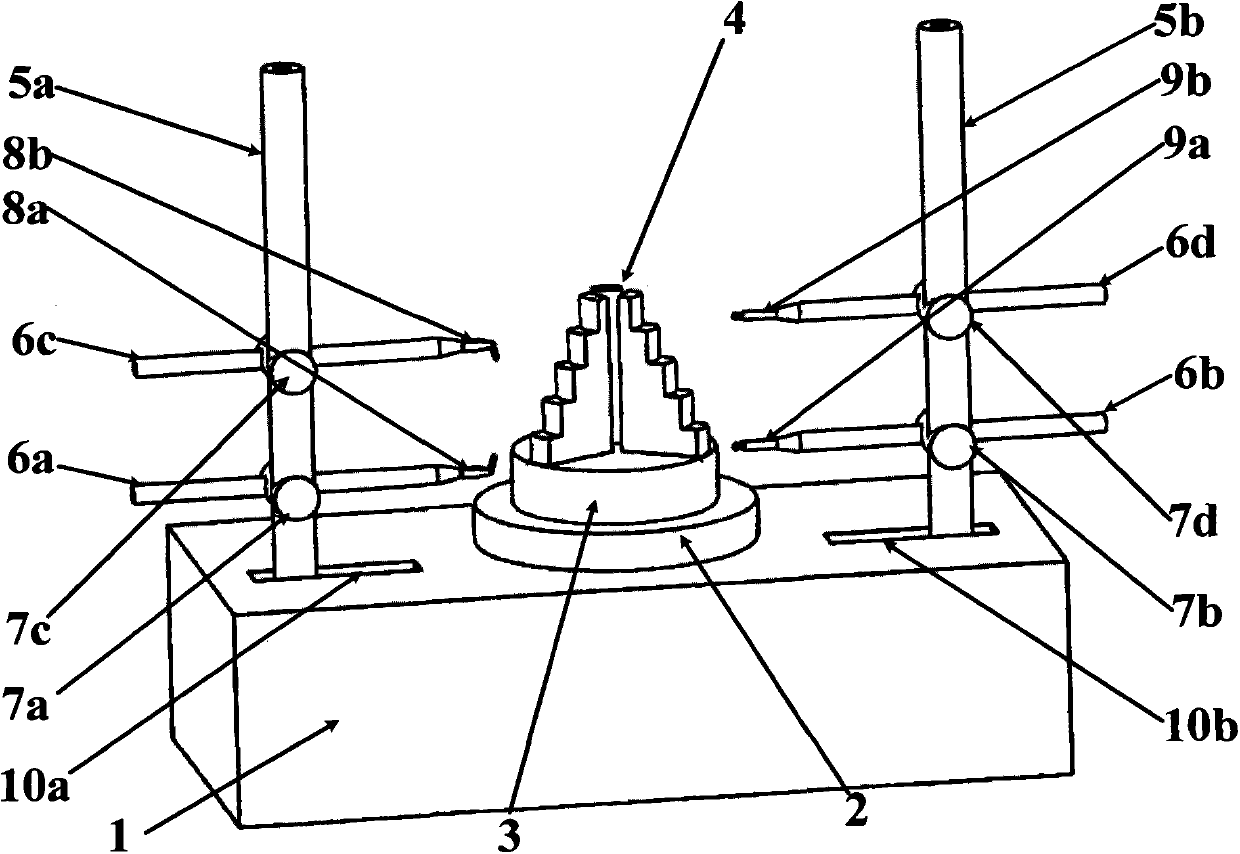

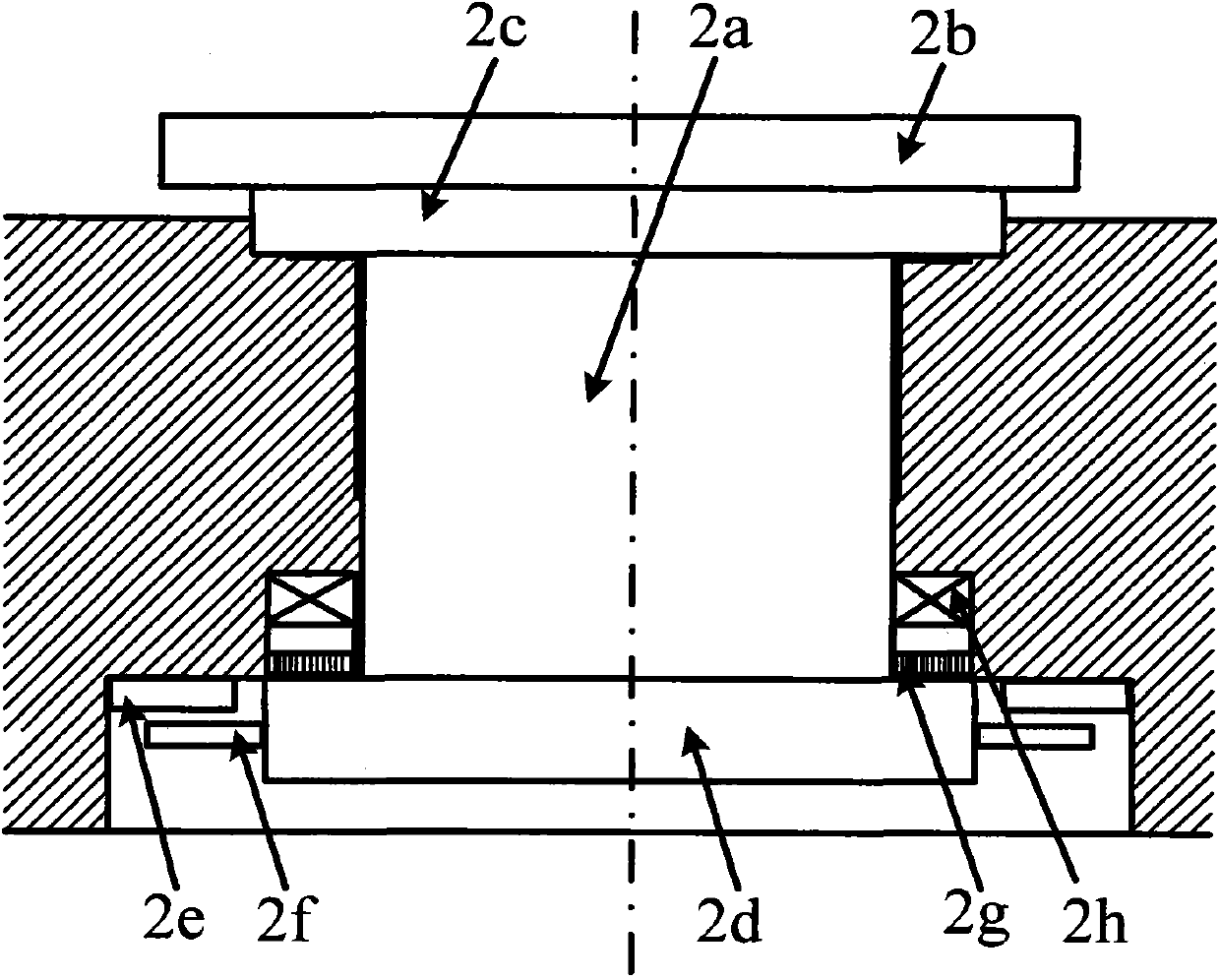

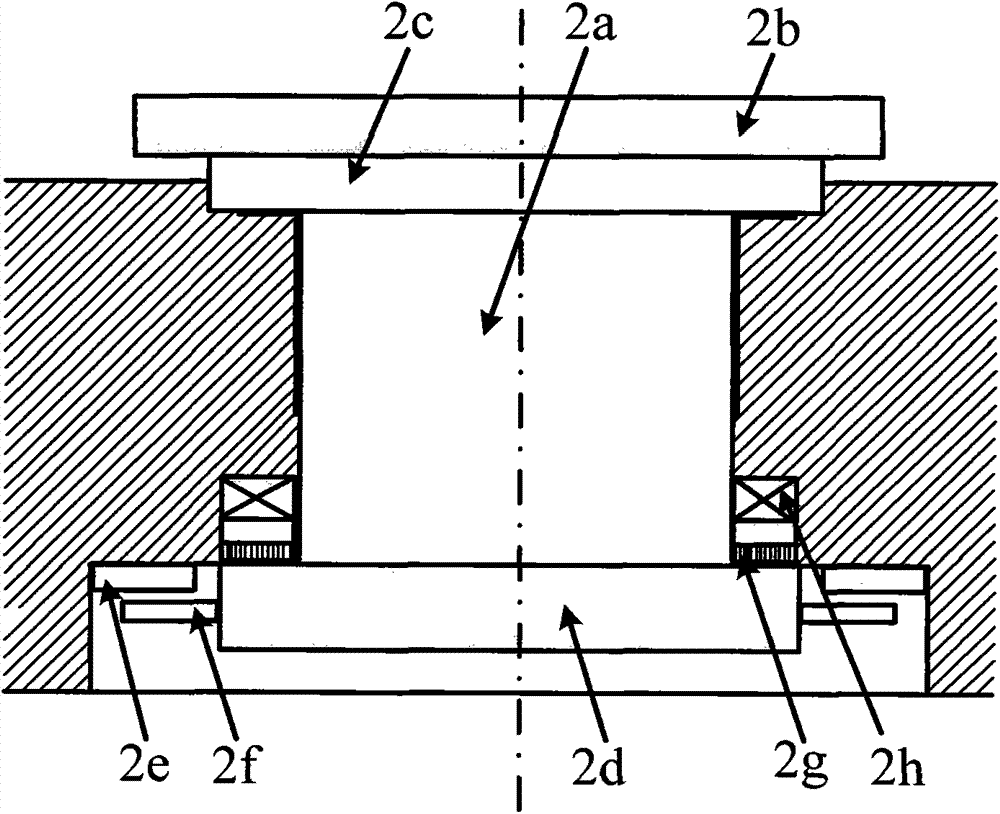

Double-stand-column aero-engine rotor electric drive assembly method and device based on eddy current sensing

Disclosed are a double-stand-column aero-engine rotor electric drive assembly method and device based on eddy current sensing. According to the assembly method and device, rotation reference is determined based on a magnetic levitation rotation shaft system, angle location of a rotary platform is determined through an inductosyn, the radial error of the radial assembly face and the inclination error of the axial assembly face of each rotor are extracted through a four-measuring-head measurement device, and the weight of influence on the coaxiality of the assembled rotors from the rotors is obtained; all the rotors needed by assembly are measured, and the weight of influence on the coaxiality of the assembled rotors from the rotors is obtained; vector optimization is carried out on the weight of each rotor, and then the assembly angle of each rotor is obtained. The double-stand-column aero-engine rotor electric drive assembly method and device based on eddy current sensing can effectively solve the problem of the low coaxiality after the aero-engine rotors are assembled, and have the advantages that the coaxiality achieved after the rotors are assembled is high, vibration is reduced, installation is easy, the flexibility is high, and performance of an engine is improved.

Owner:HARBIN INST OF TECH

Aero-engine multiaxis rotor assembling method and device based on radial and axial datum

The invention relates to an aero-engine multiaxis rotor assembling method and device based on a radial and axial datum and belongs to the mechanical assembling technology. A measuring method and a measuring device of the aero-engine multiaxis rotor assembling method and device determine the rotation datum based on a magnetic levitation rotation shaft system; an optical-electricity encoder is used for determining angle positioning of a rotation platform; based on a four-measuring-head measuring device, the radial errors of a rotor radial assembling face and the inclination errors of a rotor axial assembling face are extracted to obtain the influence weight of a rotor on the coaxial degree of the assembled rotor is obtained; all rotors needed by assembly are measured respectively to obtain the influence weights on the coaxial degrees of the assembled rotors by all the rotors are obtained; the weights of all the rotors receive vector optimization to obtain the assembly angles of all the rotors. According to the aero-engine multiaxis rotor assembling method and device based on the radial and axial datum, the problem that the coaxial degrees of rotors are low after the rotors of an aero-engine are assembled is solved. The aero-engine multiaxis rotor assembling method and device based on the radial and axial datum have the advantages of being capable of relieving vibration, high in flexibility and capable of improving the performance of the engine and the coaxial degrees of the rotors after being assembled are high. The aero-engine multiaxis rotor assembling device is easy to install.

Owner:HARBIN INST OF TECH

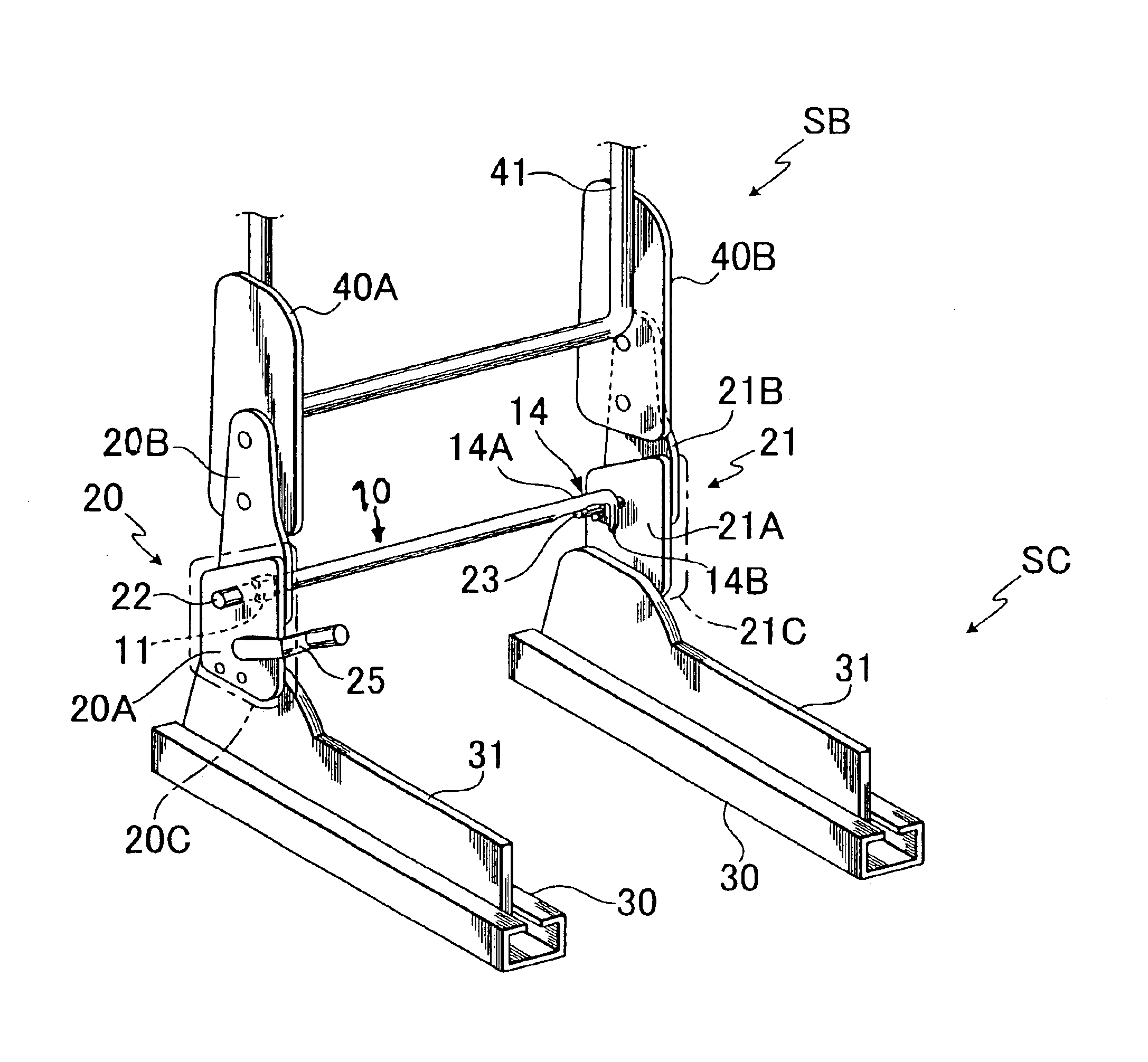

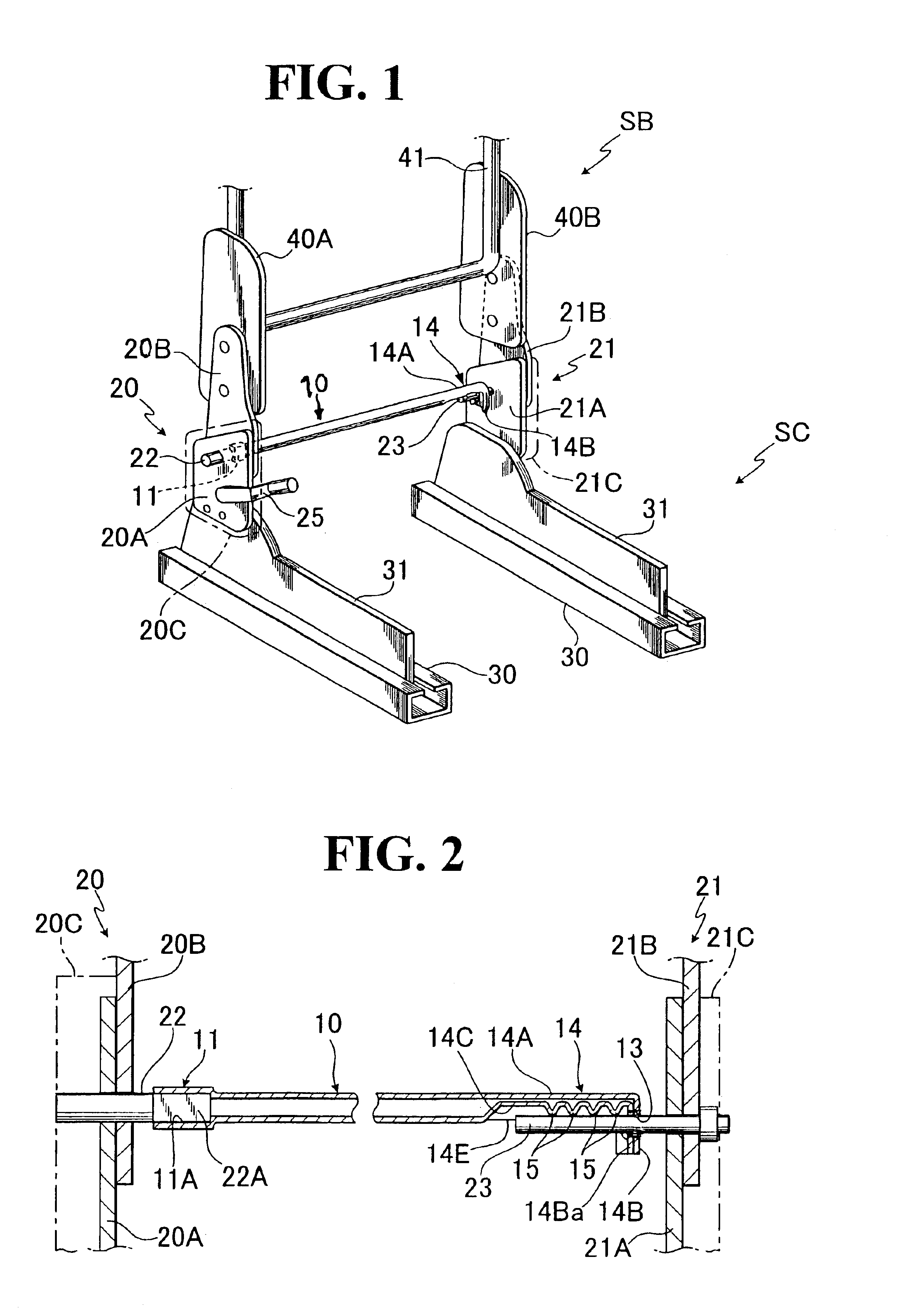

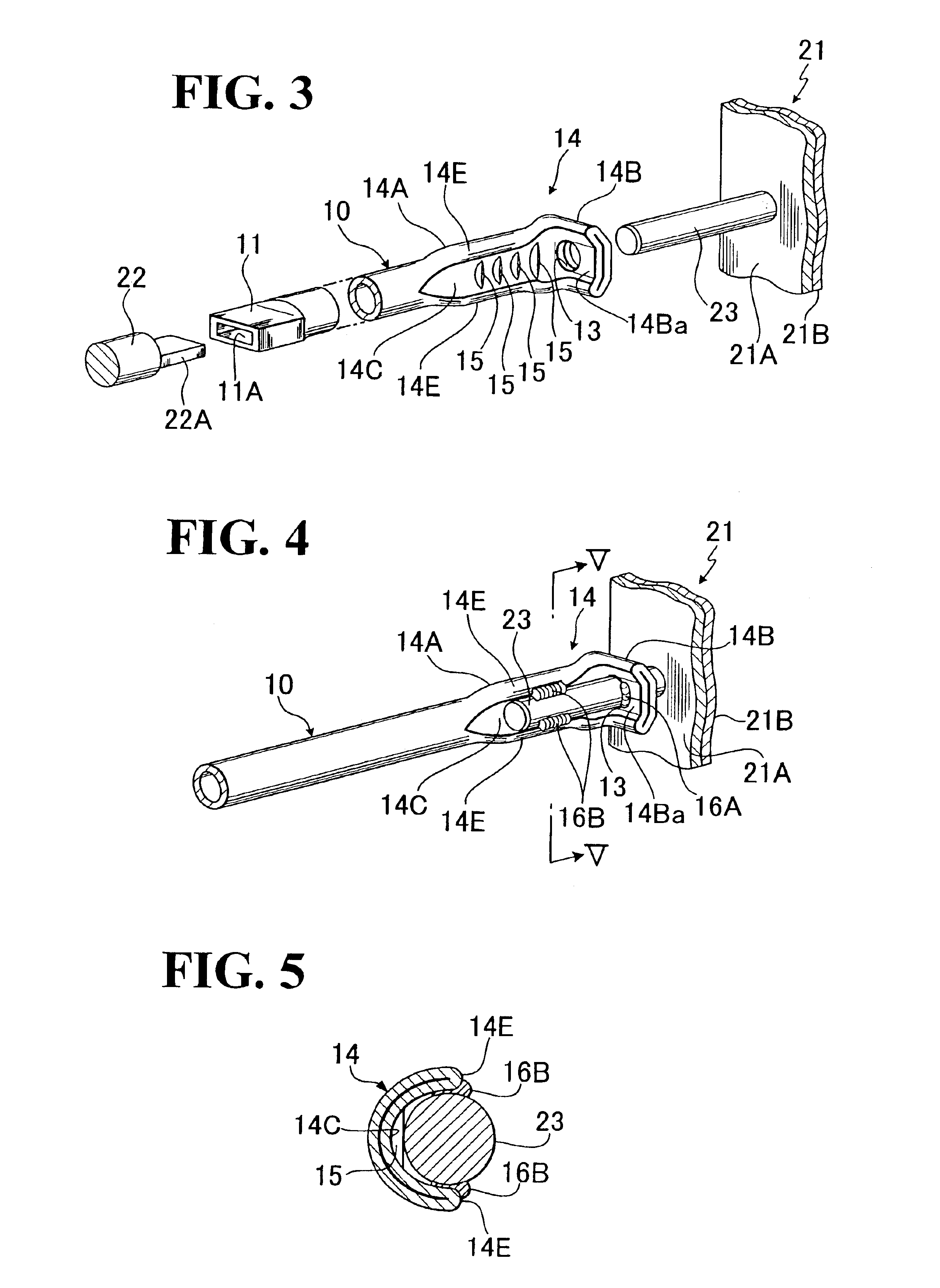

Dual reclining device for vehicle seat

A dual reclining device comprising a pair of reclining elements provided on both lateral sides of an automotive seat, with a tubular connecting rod being connected with two shafts respectively of those two reclining elements. The tubular connecting rod has an L-shaped end portion having a longitudinal pressed region and a transverse flange portion, wherein a hole is formed in the transverse flange portion. One of the two reclining element shafts is inserted through such hole of transverse flange portion and welded thereto, while being also welded to the longitudinal pressed region of transverse flange portion. Such easy welding is effective in absorbing both longitudinal and radial errors or non-alignment between the two shafts.

Owner:TACHI S CO LTD

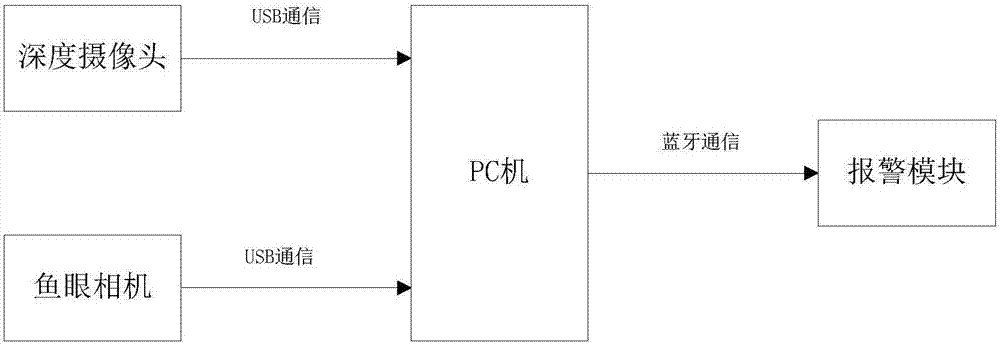

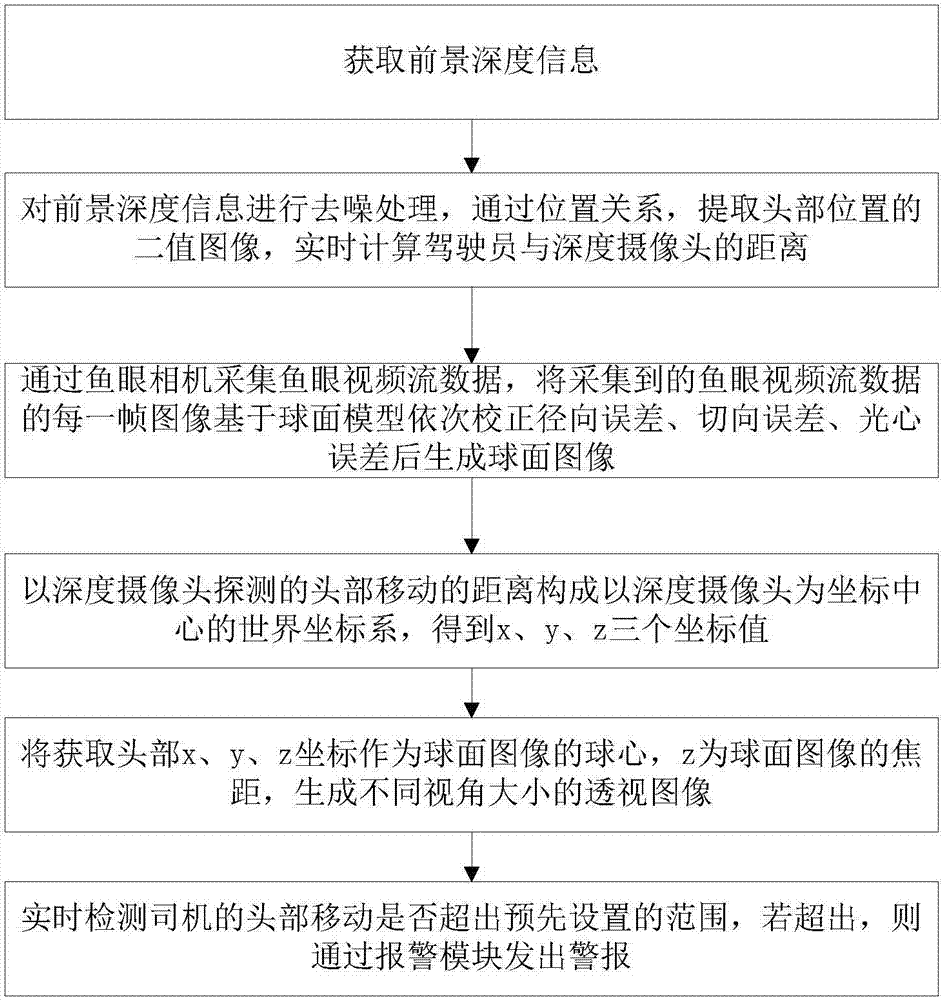

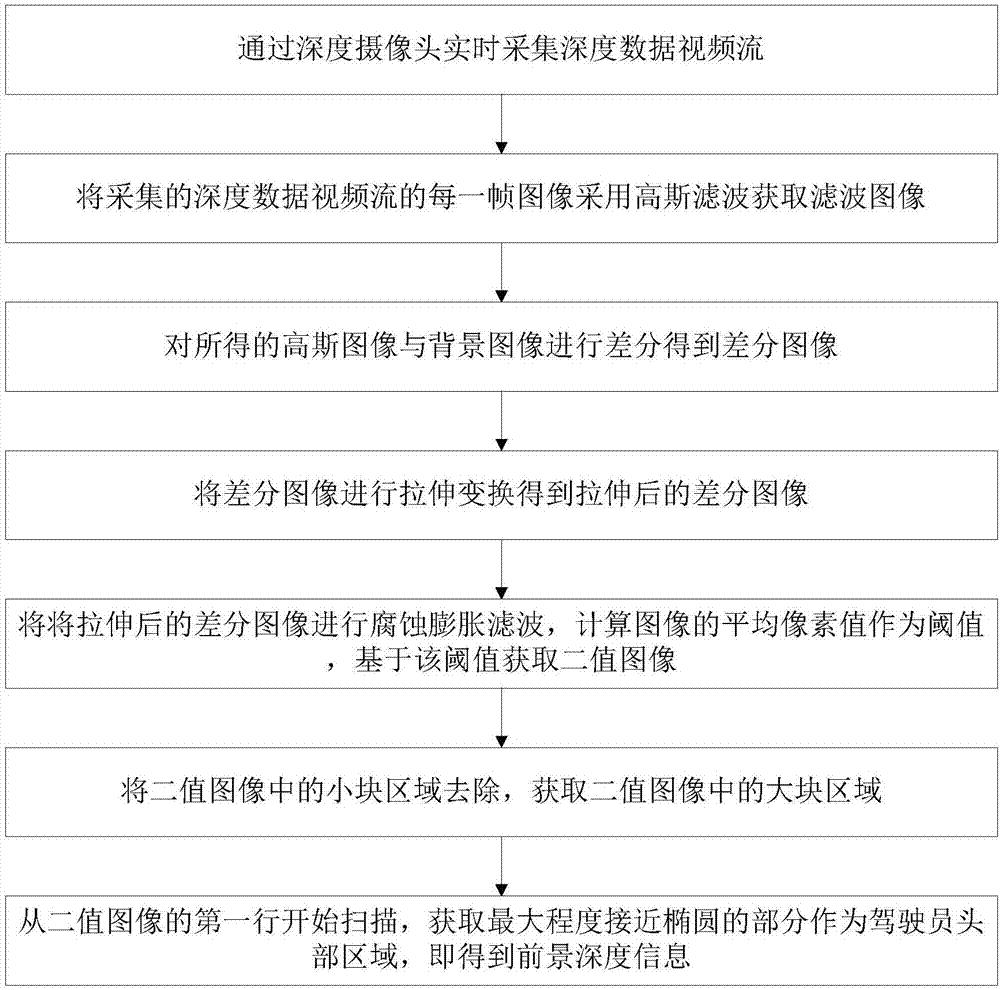

Perspective method for vehicle A-column blind zone based on depth data and fisheye images

ActiveCN106915303AEliminate A-pillar blind spotsCharacter and pattern recognitionSignalling/lighting devicesBlind zoneStream data

The method relates to a perspective method for a vehicle A-column blind zone based on depth data and fisheye images. The perspective method comprises the following steps: (1) acquiring front view depth information; (2) denoising the front view depth information, extracting a binary image of the head position through the position relation, and calculating the distance between a driver and a depth camera in real time; (3) collecting fisheye video stream data, sequentially rectifying the radial error, the tangential error and the optic center error of each frame of images of the collected fisheye video stream data based on a spherical model to generate a spherical image; (4) creating the world coordinate system which takes the depth camera as the coordinate center by utilizing the distance, by which the head moves, detected the depth camera; (5) generating perspective images with different viewing angles by taking the obtained x, y and z coordinates of the head as the spherical center of the spherical image, wherein z refers to the focal distance of the spherical image; and (6) detecting whether the head of the driver exceeds the preset range in real time, and an alarm module giving out an alarm if the head of the driver exceeds the preset range.

Owner:南京小泰信息科技有限公司

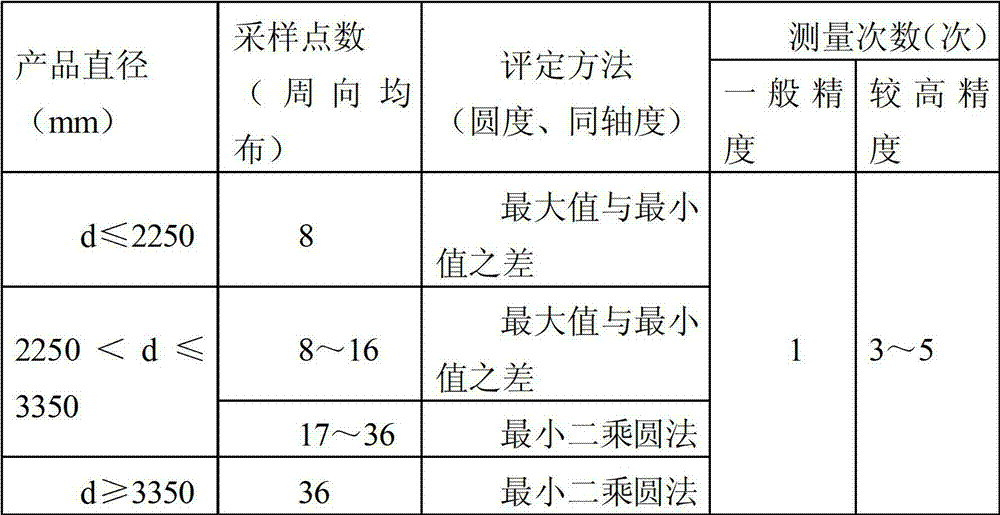

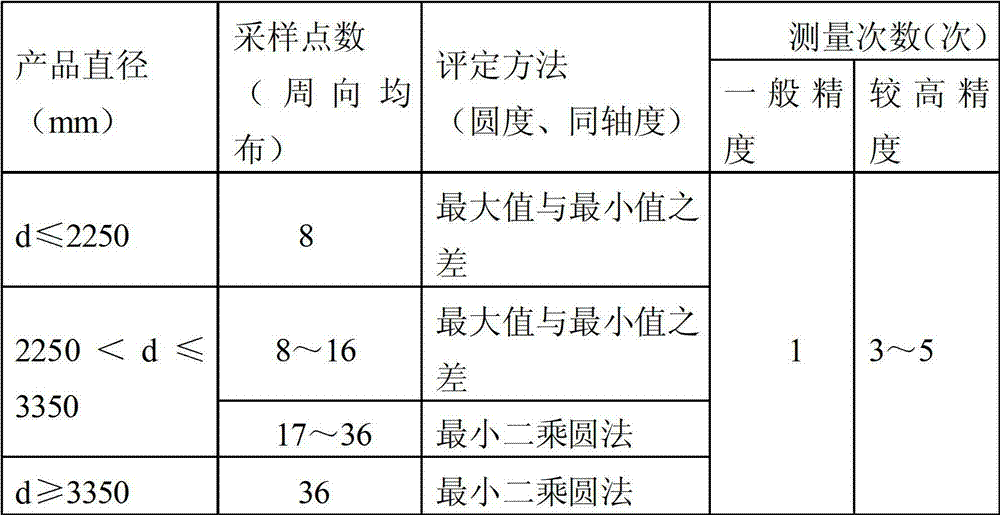

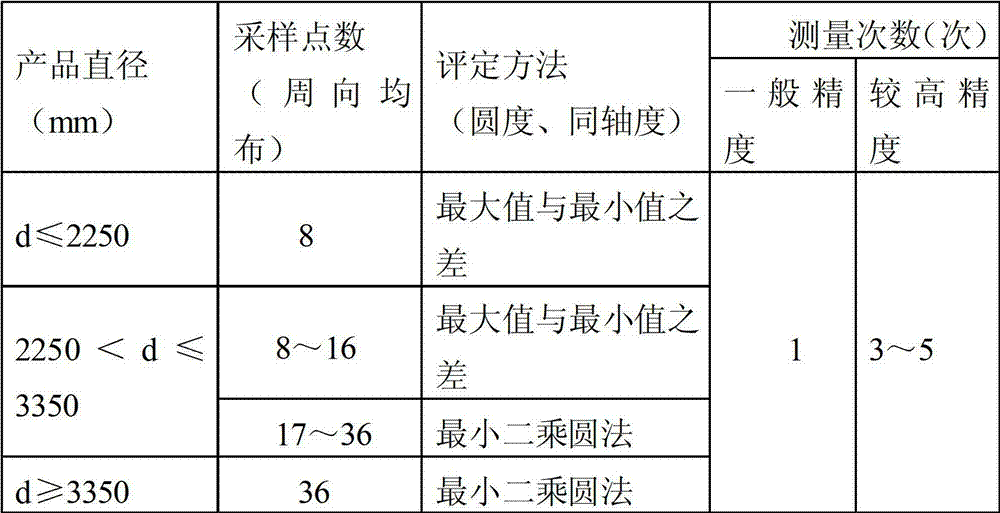

Shape and position error detection and evaluation method for skin frame truss structure housing

InactiveCN103712532AIncrease credibilityAngles/taper measurementsMechanical counters/curvatures measurementsPosition toleranceVernier scale

The invention belongs to a detection evaluation method, and specifically relates to a shape and position error detection and evaluation method for a skin frame truss structure housing. The method comprises the following steps: step one, adjusting a measuring bench, and using a crown block to install a transition ring on the measuring bench; step two, according to positioning signs of the transition ring and a product, lifting the product on the transition ring for positioning and clamping; step three, using tools such as a dial gauge, a vernier caliper, standard gauge block and the like to measure the radial error values of the product and performing recording; and step four, calculating shape and position tolerance values and performing recording, the shape and position tolerance values being final detection results. The verification results demonstrate that the measuring results obtained by use of the technology is of high credibility, thus the method provided by the invention can be used as a method for measuring shape and position tolerance of a skin frame truss structure housing product. The technology can also be polarized and applied to the detection and evaluation of a part with quite large profile dimension.

Owner:CAPITAL AEROSPACE MACHINERY +1

Self-adaptive shock-absorbing bearing pedestal

InactiveCN102242772AReduce wearTo achieve the effect of anti-vibrationBearing unit rigid supportRadial errorEngineering

A self-adaptive shock-absorbing bearing pedestal. The bearing pedestal can guarantee that in a mechanism comprising a slender shaft supported by the bearing pedestal and rotating at high speed, through effects from a centrifugal force, a running state between the slender shaft and a bearing is adjusted automatically into an optimal state and the optimal state is maintained. Therefore, the bearing pedestal can realizes the effects of absorbing shock, guaranteeing a radial error within the smallest technical scope by auto-adaptation, reducing a wear extent of a slender shaft and a bearing, and lengthening a service life of its mechanism. The bearing pedestal is composed of a support, covers, a rubber shock-absorbing sleeve loop, a spherical shaft sleeve and a bearing by connection.

Owner:陈友勤

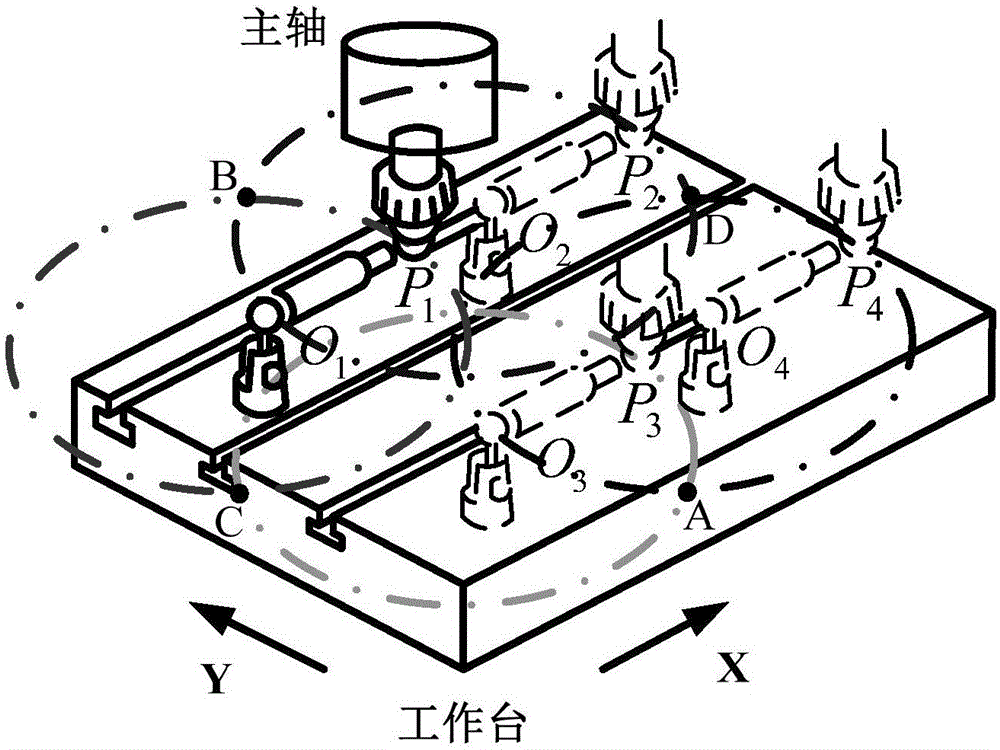

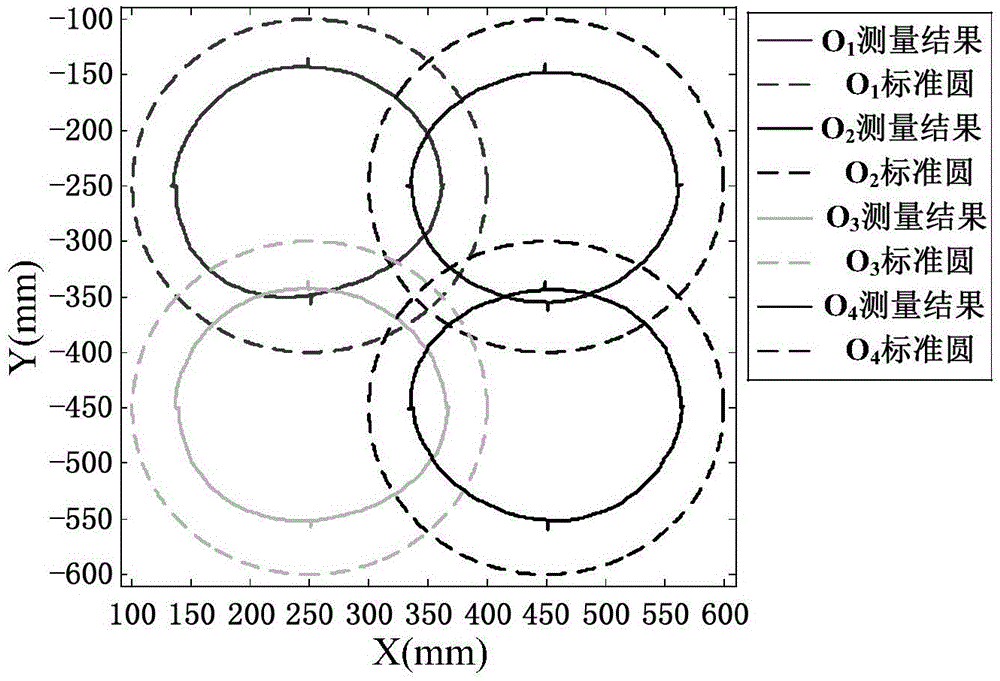

Large-stroke linkage mechanism two-dimensional plane roundness error calibration method

ActiveCN105136076ALinkage error convenient compensationLow costMeasurement devicesCommon baseRadial error

A large-stroke linkage mechanism two-dimensional plane roundness error calibration method relates to work piece processing two-dimensional plane error. The method comprises the following steps: the overall linkage area of a mechanism is divided into multiple local areas, every two adjacent local areas overlap, the bar length of a ball bar is selected, and linkage error detection is carried out in all the local areas to obtain multiple pieces of local linkage error information based on the center of each local area; error separation is carried out on the local linkage error information based on the center of each local area to obtain the local motion error of two linkage linear axes in each detection area and further obtain the actual coordinates of the end of the ball bar at each motion position; an overall linkage trajectory based on all the local areas is spliced according to the fact that adjacent detection areas have the same error separation information in the overlapping portion; and the center of the whole detection area is set as a common base point, the radial error of each point on the overall linkage trajectory to the base point is calculated, and the overall motion error of each linear axis of motion is separated based on the least squares algorithm for mechanism linkage error compensation.

Owner:XIAMEN UNIV

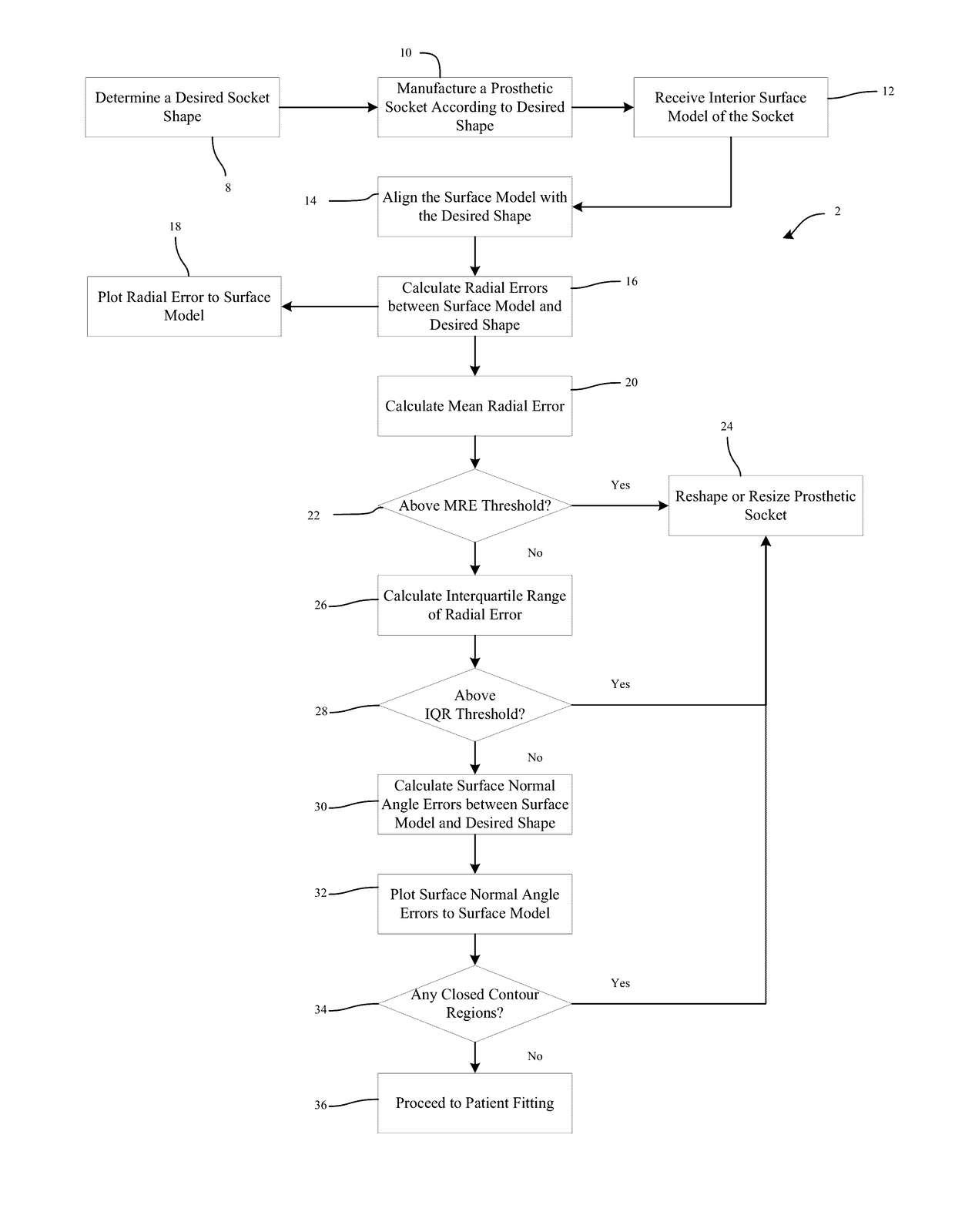

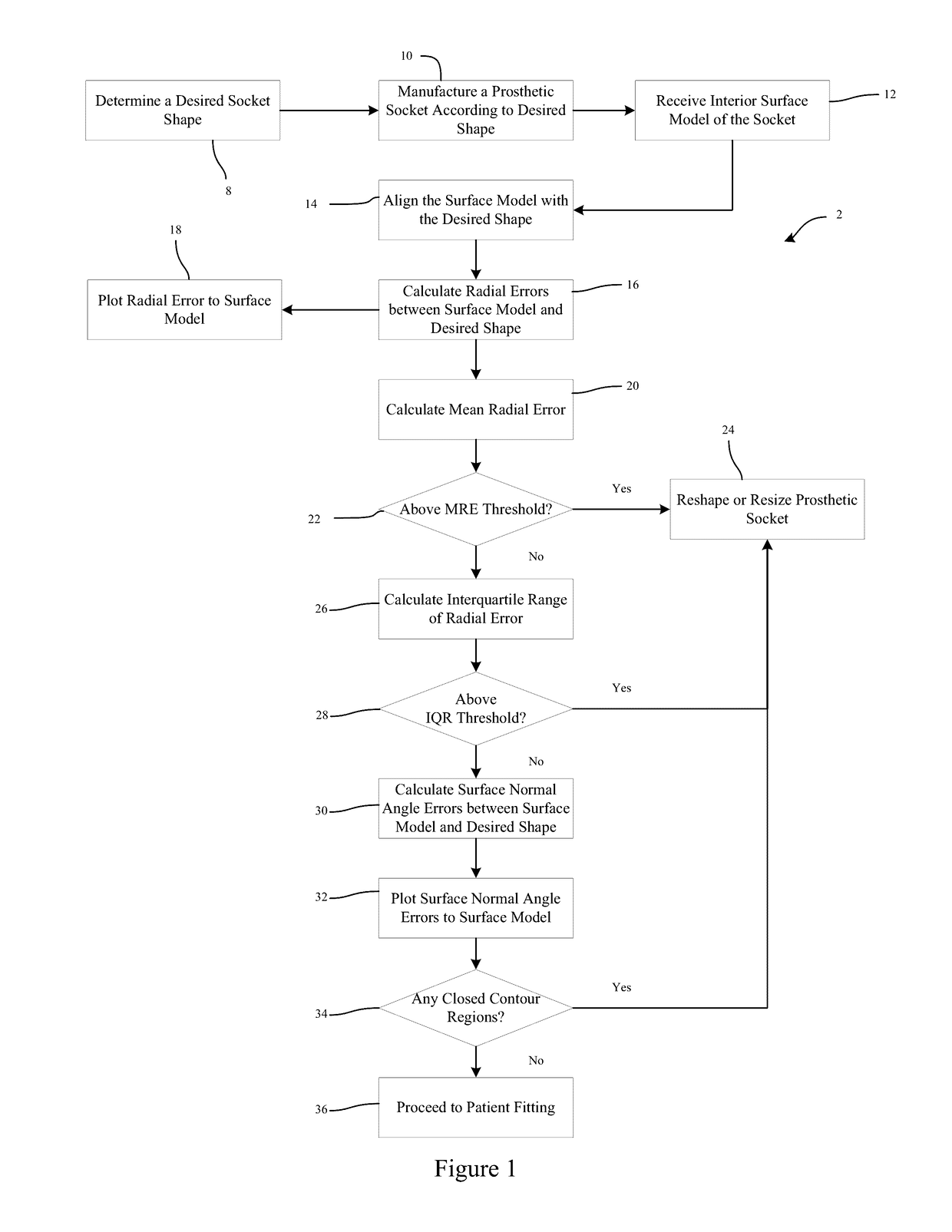

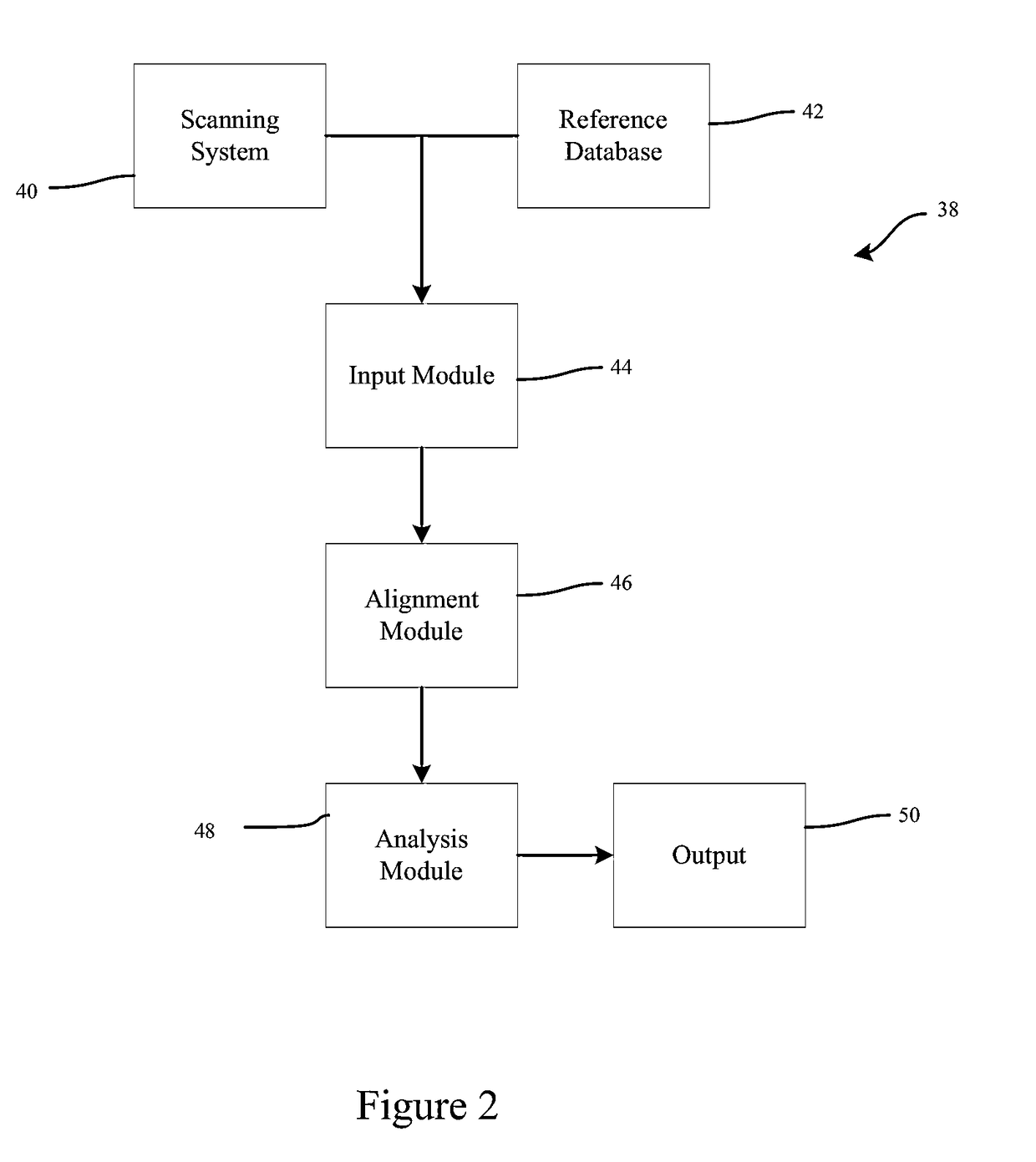

System to evaluate prosthetic sockets

ActiveUS9636238B2Reduce in quantitySpecial data processing applicationsProsthesisSignificant errorMedicine

Systems, methods, and software are provided for assessing manufacturing errors of a prosthetic socket to facilitate a clinical assessment of the socket. The embodiments disclosed herein may align and compare a manufactured socket shape to a desired socket shape to determine whether clinically significant errors are present in the manufactured socket. A mean radial error (MRE) may be calculated and compared to a set threshold. If the MRE falls below the threshold an interquartile range (IQR) may be calculated and compared to an IQR threshold. If the IQR falls below the IQR threshold, surface normal angle errors (SNAE) may be calculated and plotted to the surface model. If the SNAE plot does not include closed contour regions, the socket may proceed to patient fitting. If the MRE or IQR thresholds are exceeded, or if the SNAE plot indicates closed contour regions, the socket may be reshaped accordingly, prior to fitting.

Owner:UNIV OF WASHINGTON CENT FOR COMMERICIALIZATION

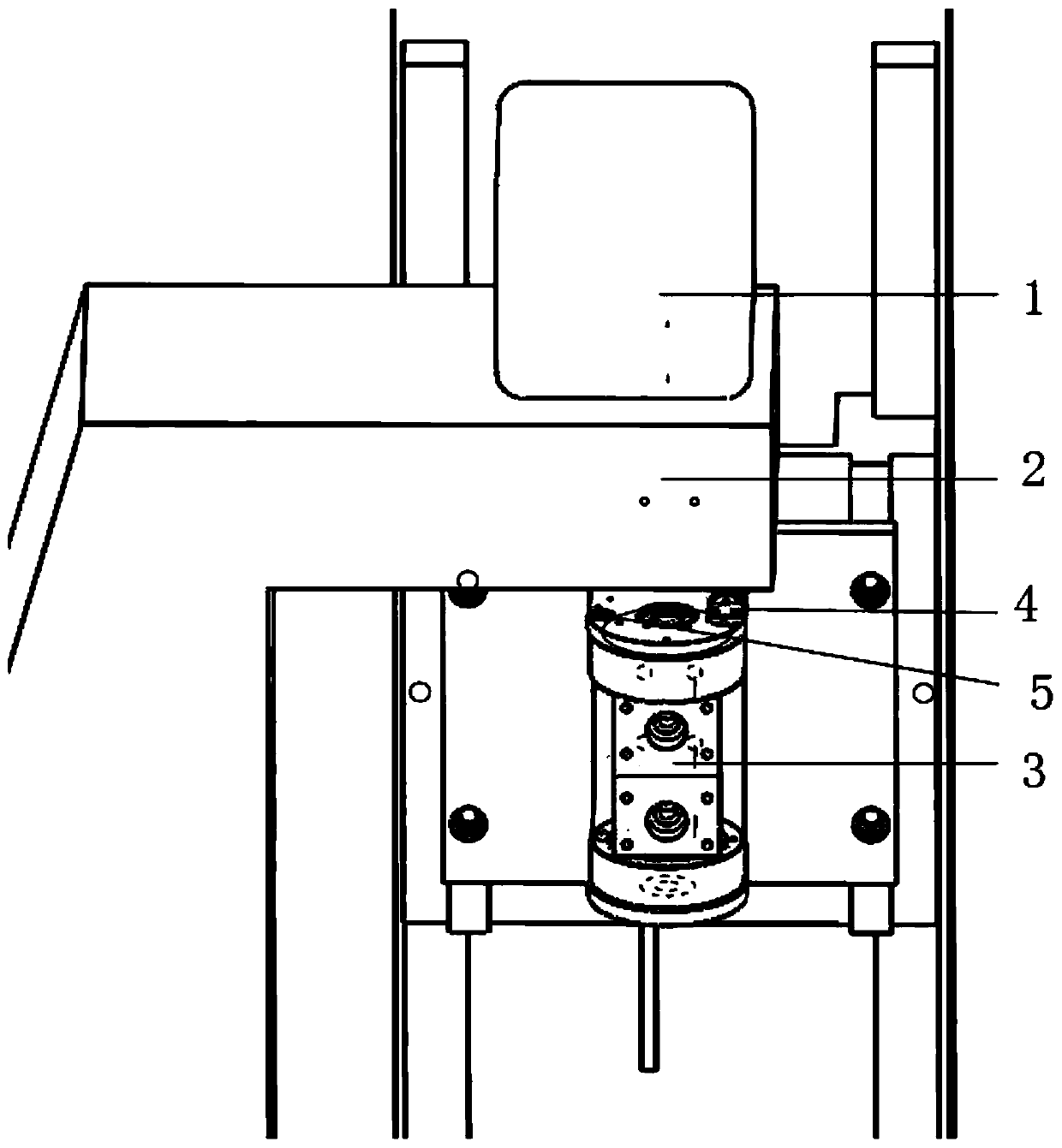

Aero engine rotor air floatation assembling method and device based on gantry structure

An aero engine rotor air floatation assembling method and device based on a gantry structure belong to mechanical assembling technology. The present invention can effectively solve the problem of poor coaxality after the aero engine rotor is assembled and has the characteristics of high coaxality after the rotor is assembled, reduced vibration, mounting easiness, high flexibility and improved engine performance. The measuring method and device are: determining rotary reference based on a rotary air bearing; determining the angular positioning of a rotary table according to a grating ruler; extracting the radial error of the radial mounting plane and the inclination error of the axial mounting plane of the rotor based on the four-probe measuring device to obtain the influencing weight of this rotor to the assembled rotor on coaxality; measuring respectively all the rotors required for assembling to obtain the influencing weight of each rotor to the assembled rotor on coaxality; vector optimizing the weight of each rotor to obtain the assembling angle of each rotor.

Owner:HARBIN INST OF TECH

Measuring method based on two-cross-section radial difference and gradient extraction main shaft gyration accuracy

InactiveCN101614563AHigh measurement accuracyAutomatically eliminate roundness errorsInstrumentsGyrationRadial error

A Measuring method based on two-cross-section radial difference and gradient extraction ultra-precision main shaft gyration accuracy belongs to the technical field of ultra-precision measurement and ultra-precision machining, the method comprises a ultra-precision main shaft or rotary platform axial gyration accuracy method based on gradient extraction and an angle gyration accuracy measurement method based on the radial error of two cross sections ; the method comprises the following steps: carrying out a secondary radial gyration accuracy measurement on a certain cross section of a roundness standard device based on the least square method, obtaining angle gyration accuracy of a shafting to be measured through the secondary radial error and revolution angle geometric relationships; extracting the gradient which the plane optical flat center is relative to the shafting to be measured based on a least-squares circle evaluation method, automatically segregating the tilt error in the axial gyration accuracy measurement; the measuring method of the invention can effectively eliminate the error source existing in the angle gyration accuracy and axial gyration measuring process, thus greatly improving measuring accuracy of the gyration accuracy of the ultra-precision spindle and the rotary platform.

Owner:HARBIN INST OF TECH

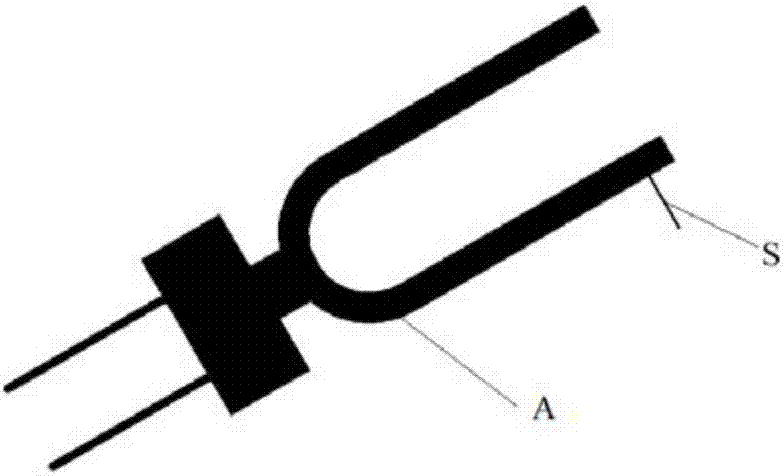

Method for high-precision measurement of sphericity of micro-spherical probe of nanometer three-coordinate measuring machine

InactiveCN107218879AEliminate radial errorsRealize high-precision measurementElectric/magnetic contours/curvatures measurementsPoint coordinate measurementsMicrosphereSpherical probe

The invention discloses a method for high-precision measurement of the sphericity of the micro-spherical probe of a nanometer three-coordinate measuring machine. A tungsten probe with large length-to-diameter ratio and a quartz tuning fork are combined. Scanning probe heads with nanometer-level resolution are constructed based on a precision micro stage. During measurement, the two scanning probe heads are driven by the micro stage to scan the large-section contour of a microsphere in the x-axis direction in a differential manner. Radial error generated in the scanning process can be automatically eliminated in a differential manner, and thus, accurate parameters of the large-section contour of the microsphere can be obtained. After the microsphere is rotated a certain angle, the measurement is repeated to acquire multiple sets of parameters of the large-section contour. A three-dimensional spatial contour of the microsphere is constructed through fitting according to feature points obtained. The geometric parameters of the microsphere are calculated based on the three-dimensional spatial contour. Thus, high-precision measurement of the sphericity of the microsphere is realized. The method has the characteristics of small measuring force, wide measuring range, and high measuring precision.

Owner:HEFEI UNIV OF TECH

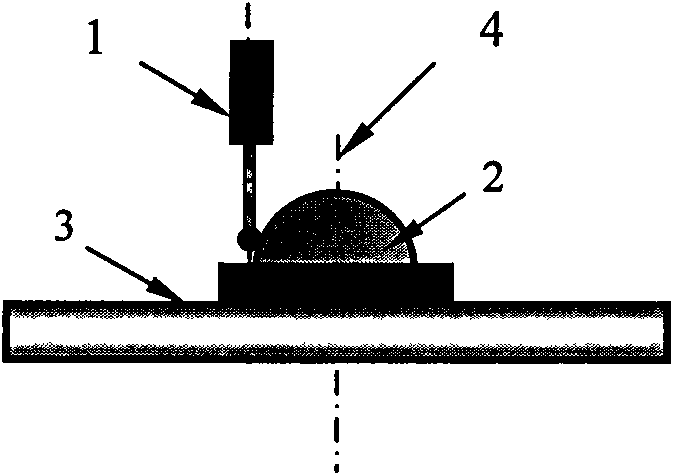

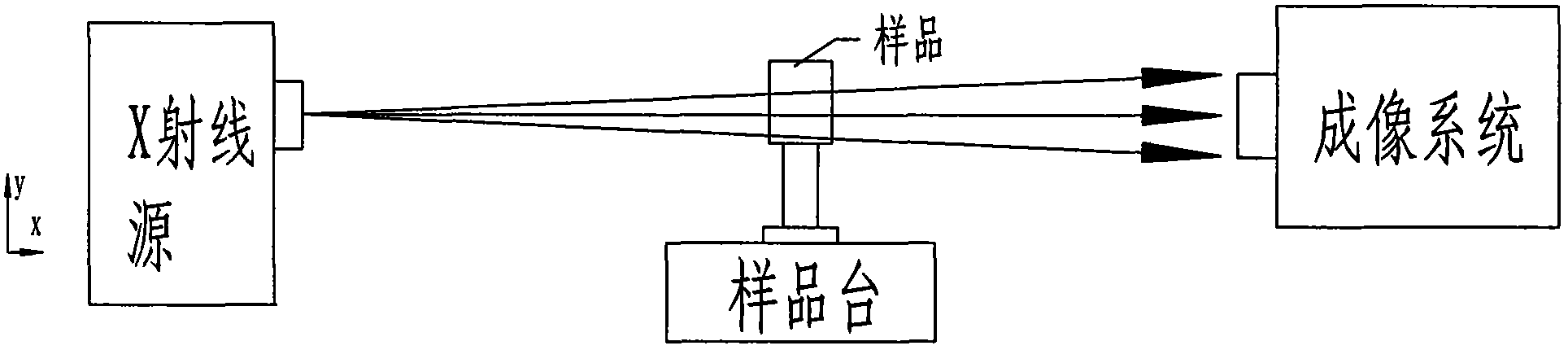

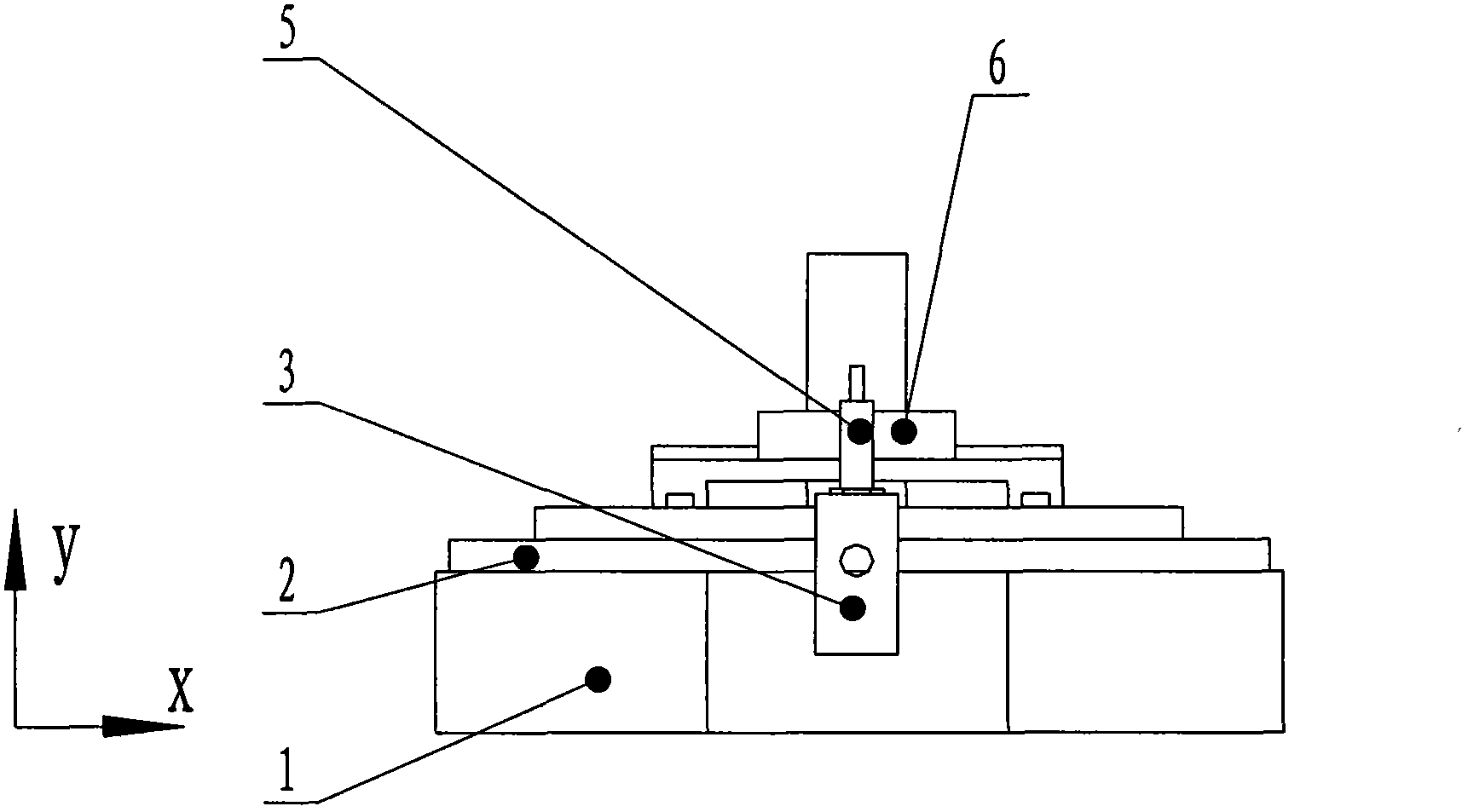

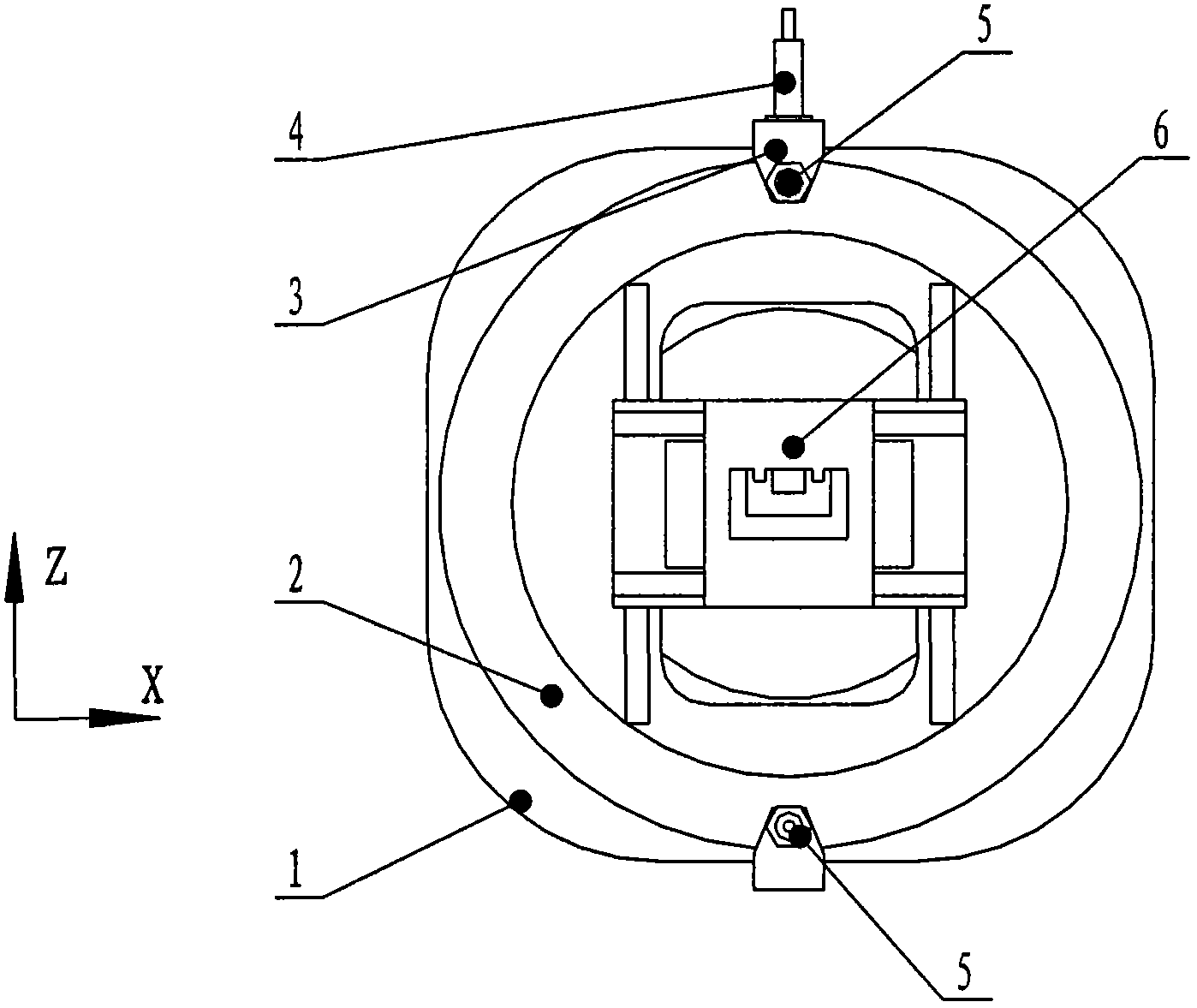

Metering type high-precision x-ray microscope sample scanning table

The invention discloses a metering type high-precision x-ray microscope sample scanning table. A scanning rotary table (2) is arranged on a fixed base (1) and is used for providing rotary scanning motion needed by a scanned sample; a three-dimensional positioning platform (6) is fixedly arranged on the upper part of the scanning rotary table (6); a sensor installation seat (3) is arranged outside the fixed base (1); a radial run-out error measuring sensor (4) and an axial run-out error and swing error measuring sensor group (5) are respectively arranged on the sensor installation seat (3); a sample strand (8) is fixed above a y-direction platform. The metering type high-precision x-ray microscope sample scanning table can achieve real-time measuring of radial errors, axial errors, and swing error of a rotary shaft in a rotary process of the sample scanning table; a measured error result can be used for carrying out error correction on the motion of the sample, so that the difficulty of three-dimensional image reconstructing distortion caused by precision error of the sample scanning table can be solved.

Owner:天津三英精密仪器股份有限公司

Gas and magnetism composite supporting type aero-engine rotor assembling method and device based on concentricity optimization

Owner:HARBIN INST OF TECH

Assembly method and device for aero-engine rotors based on vector stacking principle

The invention discloses an assembly method and device for aero-engine rotors based on a vector stacking principle and belongs to a mechanical assembly technology. A measuring method and device are based on a gas-magnetic combination rotating shaft system to determine rotating datum; based on an induction synchronizer, the angle positioning of a rotary table is determined; based on a four-measuring-head measuring device, the radial error of the radial assembly face of one rotor and the tilt error of the axial assembly face of one rotor are extracted, so that the weight value of influence, on coaxiality of next rotor assembly, of the rotor is obtained; all the rotors needed for assembly are respectively measured, so that the weight value of influence, on coaxiality of the next rotor assembly, of each rotor is obtained; vector optimization is performed on the weight values of all the rotors, so that assembly angles of all the rotors are obtained. The problem that the coaxiality is low after the aero-engine rotors are assembled can be effectively solved. The stacking assembly device has the advantages of being high in coaxiality after rotor assembly, reduces vibration, easy to install and high in flexibility and improving engine performance.

Owner:HARBIN INST OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com