Radial positioning method for joint part of round pipe component

A technology of radial positioning and round tubes, which is applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of error corbels and rigid beams that cannot be installed, achieve convenient and accurate measurement, and avoid quality accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with accompanying drawing:

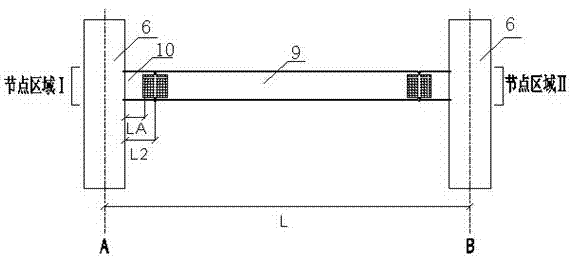

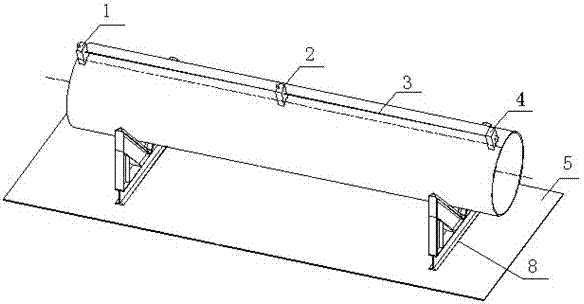

[0033] Such as Figure 1-Figure 6 The radial positioning method of the node part of a circular tube member is shown, and the method includes the following steps:

[0034] (1) Determine the datum plane and measure the out-of-roundness of the two ports of the round tube according to the datum plane, and perform circle calibration of the round pipe port. The specific process is:

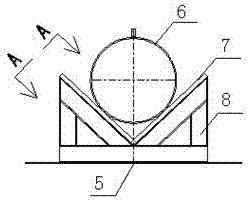

[0035] a. adopt the steel plate leveled by the spirit level as the datum plane 5, place the V-shaped frame 8 on the datum plane 1 and fix it, and place the round pipe 6 on the V-shaped frame 8; the thickness of the steel plate is at least 20 mm, and the The absolute value of the height error on both sides of the V-shaped frame 8 is less than or equal to 1 mm, the included angle of the V-shaped frame 8 is 90 degrees and the absolute value of the angle error is less than or equal to 0.5 degrees, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com