Construction method for laying refractory bricks of rotary kiln through bricklaying supporting device

A construction method and technology of refractory bricks, which are applied in the field of masonry of rotary kiln refractory bricks, can solve the problems of large deviation of masonry size and design, long construction period, damage to refractory bricks, etc., so as to reduce the number of repairs in the later period and the investment of construction personnel. , the effect of reducing construction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The content of the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments. The spring steel plate referred to in the 3# kiln masonry is the bridge steel plate (YB168-70) produced by Anshan Iron and Steel Co., Ltd., and other steel plates and iron plates are made of 304. Stainless steel heat-resistant steel plate.

[0041] Our company has four 200-meter rotary kilns producing petroleum proppant. At the end of June 2015, the refractory bricks of 1#, 2# and 3# kilns were all dismantled and rebuilt as a whole.

[0042] The 1# kiln and the 2# kiln are built by traditional kiln support method and bricklaying machine method respectively according to the existing technology.

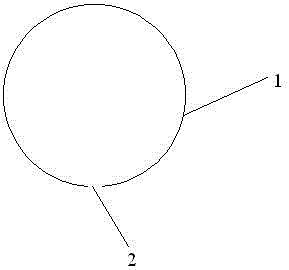

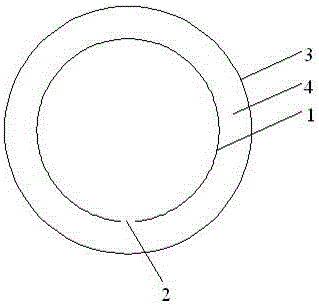

[0043] The 3# kiln is built with brick supporters, such as figure 1 As shown, the brick supporter is a circular ring 1 bent from a spring steel plate. There is an opening 2 in the circular ring 1, and the two ends of the opening ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com