Patents

Literature

281 results about "Brick masonry" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Composite combining silica thermal repairing material and preparation method thereof

The invention discloses a composite bonded silicious hot repair material, which belongs to the technical field of refractory materials. The repair material comprises the following compositions in percentage by weight: 45 to 55 percent of silicious clinker aggregate, 8 to 12 percent of silicious clinker powder, 20 to 30 percent of natural silica powder, 8 to 12 percent of complex binder, 3 to 5 percent of plasticizer, and 1 to 1.5 percent of dispersant. The silicious clinker aggregate and the silicious clinker powder are waste main crown silica bricks (SiO2 is more than or equal to 95 percent) and fused quartz tubes or fused quartz wedges (SiO2 is more than or equal to 98 percent), SiO2 is more than or equal to 96 percent in natural silica, the complex binder is formed by compounding an SiO2 ceramic bond and a phosphorous acid (phosphate) chemical bond, the plasticizer is white clay or bentonite, and the dispersant is silica fume. The repair material is processed according to the particle size. The invention can satisfy various conditions proposed by hot repair of a kiln to the repair material, can also realize the aims of saving energy sources and increasing the service life of the kiln, and can also be used for filling or building positions which are not suitable for silica brick masonry during the cold repair at the same time.

Owner:山西高科耐火材料股份有限公司

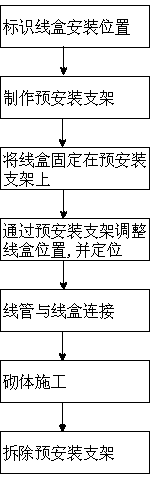

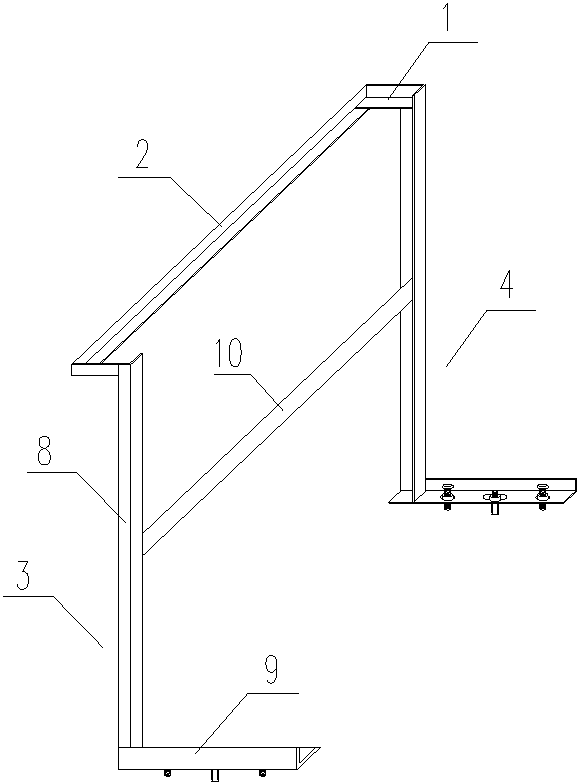

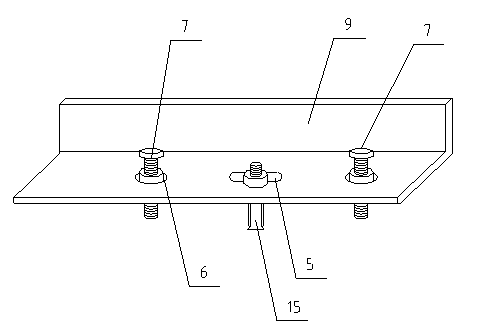

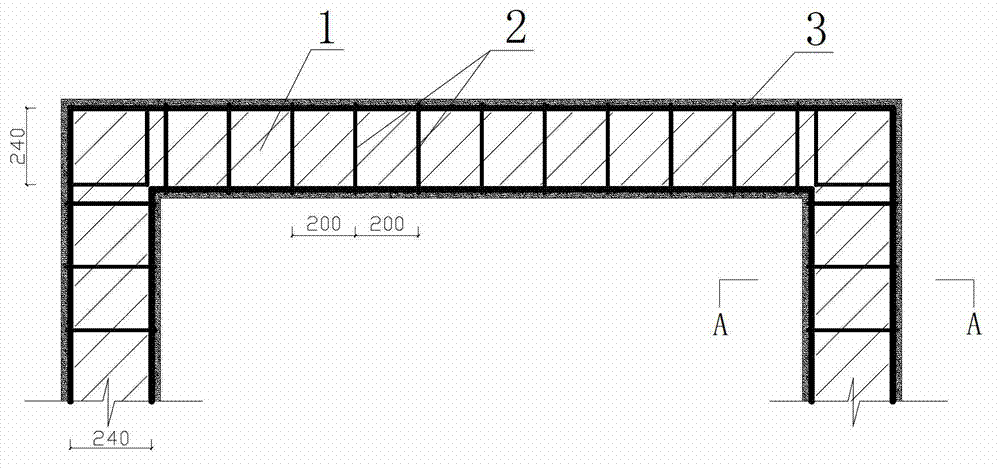

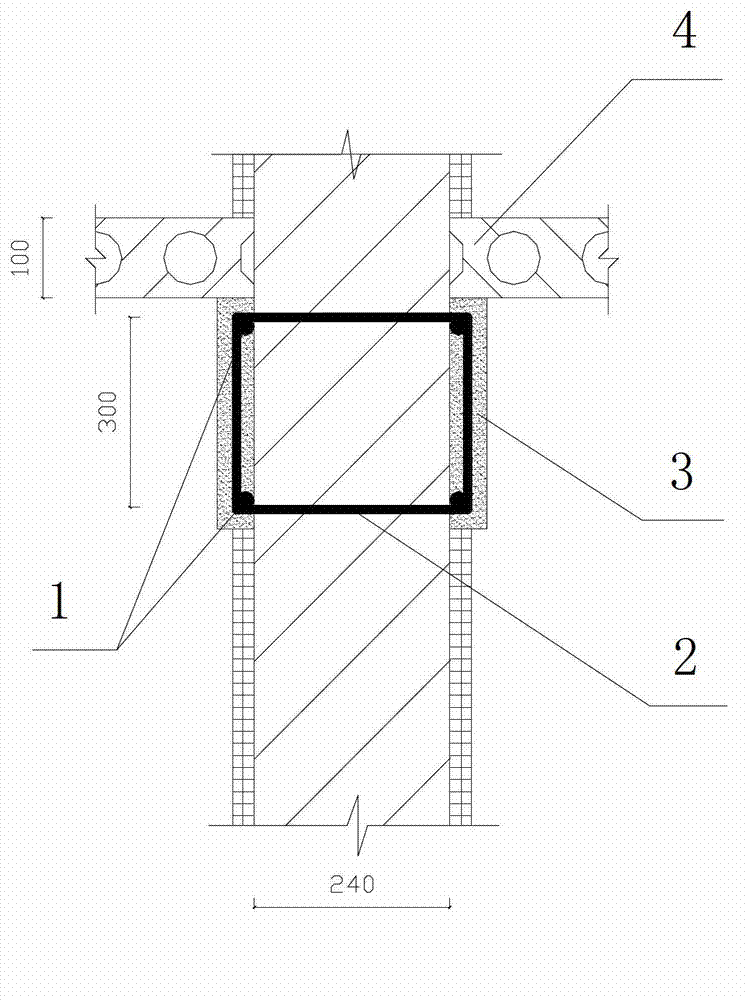

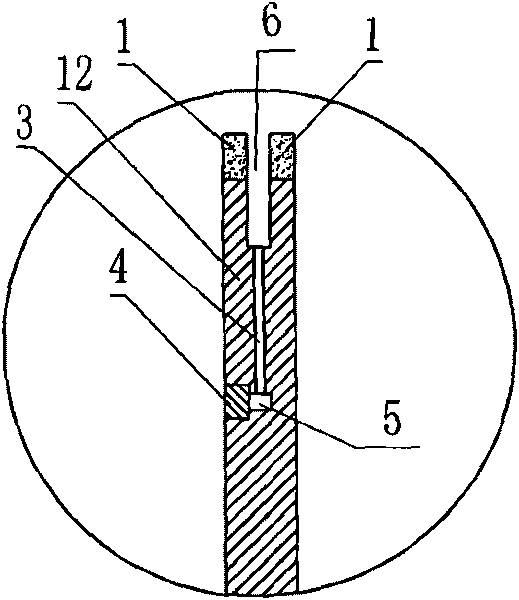

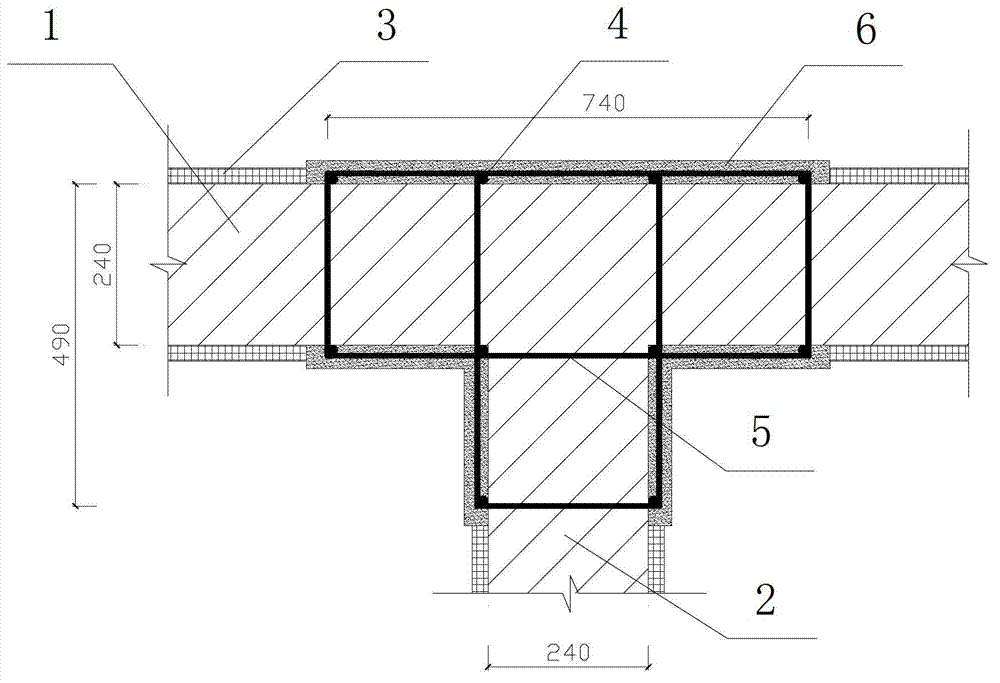

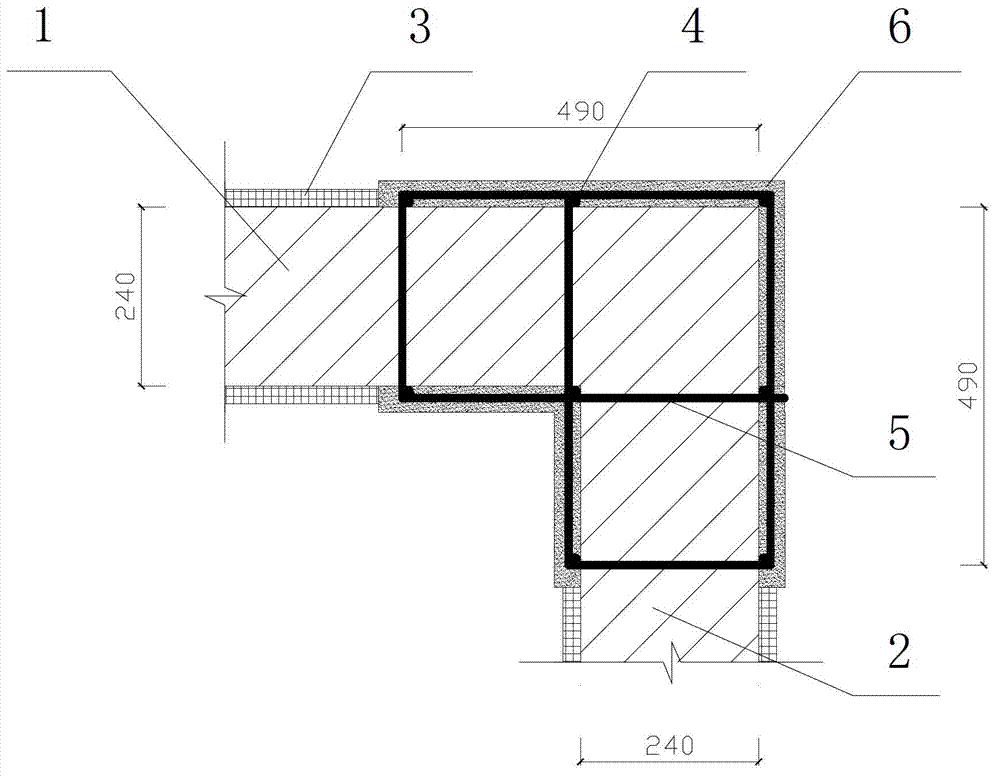

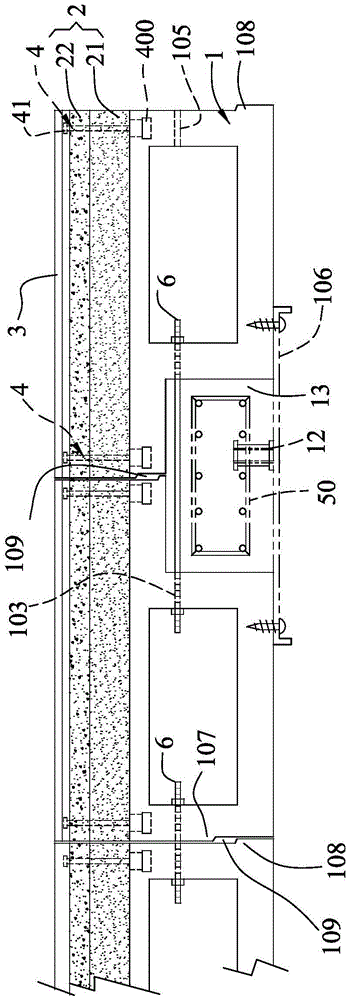

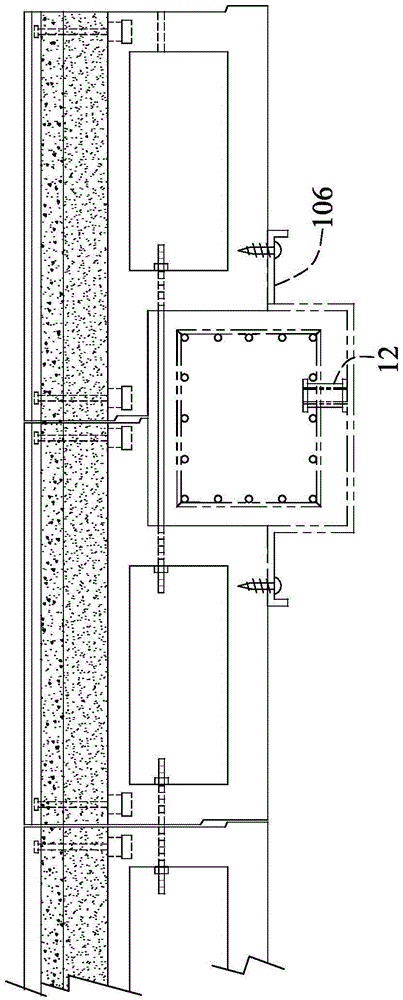

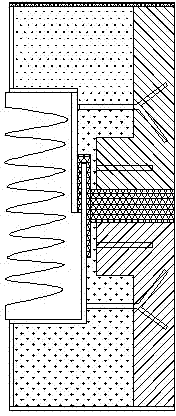

Pre-installation construction method for wire box on building bricked body and pre-installation supporting frame thereof

The invention discloses a pre-installation construction method for a wire box on a building bricked body. The pre-installation construction method comprises the following steps that the installation position of the wire box is marked, a pre-installation supporting frame is manufactured, the wire box is fixed on the pre-installation supporting frame, the wire box is adjusted through the pre-installation supporting frame to be located in the marked installation position and is positioned, a reserved wire pipe is connected with the wire box, strip-shaped bricks and V-shaped groove bricks are prepared and are bricked in the positions of the wire box and the wire pipe in a sleeved mode, and the gaps among the wire box, the wire pipe and the bricks are filled with bricking mortar to be compacted and flat. After a wall is bricked, the pre-installation supporting frame is detached, and the installation of the wire box is finished. The pre-installation supporting frame is used for finishing the pre-installation of the wire box, the construction procedures such as grooving, punching and wall surface repairing are eliminated, the construction period is shortened, and the pre-installation supporting frame can be used repeatedly, so that cost is saved. In addition, the pre-installation supporting frame can carry out position adjustment, construction is more accurate, and the construction quality is better. A certain distance is kept between the supporting frame and the wall to be bricked in the construction process, a construction space is reserved, and construction is more convenient.

Owner:CHENGDU NO 8 CONSTR ENG

Historical building clean water red brick wall renovation technique

The invention provides a repair technology for a plain red brick wall of a historical building, which aims to realize the authentic repair of the plain red brick wall of the historical building. The technology comprises the following steps: 1. the plain red brick wall is cleaned, and a weathered cement mortar covering layer is peeled to expose plain red bricks; 2. high-strength epoxy mortar is adopted to repair cracks of a plain red brick masonry; and 3. damaged pointing joints are treated and filled. The repair technology for the plain red brick wall of the historical building satisfies the international repair standard of the historical building, and adopts the prior materials and technologies to perform large area restored repair on the plain red brick wall; and the restored plain red brick wall of the historical building has historical features of the prior building and maintains the style of the prior historical building when seen from far, and can clearly distinguish which part is left in history when seen at a near distance, so the repair technology prevents the plain red brick wall from being destroyed.

Owner:SHANGHAI BUILDING DECORATION ENG GRP

High-toughness cement based composite material

The invention discloses a high-toughness cement based composite material. The high-toughness cement based composite material is prepared from the following components: cement, coal ash, sand, water, a water reducer and PVA fibers, wherein a mass ratio of the cement to the coal ash to the sand to the water to the water reducer is 1 to (1.0 to 1.2) to (0.6 to 0.8) to (0.42 to 0.57) to (0.001 to 0.003); based on the total volume of a mixture obtained by uniformly mixing the cement, coal ash, sand and water reducer, mixing amount of the PVA fibers is 13-20kg / m<3>. The high-toughness cement based composite material has the characteristics of strain-hardening and multi-seam cracking under stretching, bending and shearing load, and a component prepared by the materials shows a high-ductility characteristic. The high-toughness cement based composite material has a good adhesive property with brick masonry and a steel structure, and is an ecological type building material with high toughness, high durability, high energy consumption, high shock resistance and high deformation resistance.

Owner:KUNMING UNIV OF SCI & TECH

Inorganic heat-insulating mortar for light insulating brick masonry and preparation thereof

InactiveCN101407392AIncrease profitAvoid quality problems such as cracking and water seepageSolid waste managementInorganic ChemicalBrick masonry

The invention relates to inorganic heat insulating mortar used by light-weight heat insulating brick masonry and a preparation method thereof, wherein, the inorganic heat insulating mortar has the raw material compositions and weight contents of 10-30 parts of fly ash, 15-35 parts of vitreous microballon, 1-8 parts of swell soil, 1-10 parts of lime, 250-400 parts of sand and 100 parts of cement. The preparation method comprises the following steps of: uniformly mixing the fly ash, the sand, the swell soil, the hydrated lime and the cement through a machine, adding the vitreous microballon, uniformly mixing through the machine once again and packing by fixed amount. The inorganic heat insulating mortar has the advantages of high strength, low thermal conductivity and good workability, which can avoid the problems of cracking and 'heat bridge' of the masonry body caused by the use of common masonry mortar when being matched with light-weight heat insulating bricks.

Owner:奥捷科技股份有限公司

High-ductility mortar

The invention discloses a high-ductility mortar. The invention solves the problems of fragility, poor crack resistance and poor earthquake resistance existing in the traditional mortar. The high-ductility mortar comprises the components of cement, fly ash, silica fume, sand, PVA (Polyvinyl Acetate) fiber and water, wherein according to the mass percentages, cement: fly ash: silica fume: sand: water =1:0.9:0.1:0.76:0.58; and when the total volume of uniformly mixed cement, fly ash, silica fume, sand and water is used as a base number, the volume mixing amount of PVA fiber is 1.5%. The high-ductility mortar has plastic deformability similar to steel, has good adhesive property to brick masonry and is an ecological building material with high strength, high ductility, high durability and high damage resistance, and the strength and the deformability of the mortar can be effectively increased.

Owner:西安五和新材料科技集团股份有限公司

Method for producing cement products by recycling construction waste

The invention relates to a method for producing cement products by recycling construction waste. Firstly, the construction waste is classified, metal, wood and plastic waste are removed, and then crushed into granules, and Portland cement and water are added according to the proportion of concrete. , Stir evenly, and use the molding machine to produce cement products of various shapes. The present invention makes full use of the concept of turning construction waste into treasure to protect the environment, because the method of the present invention can produce a variety of cement products from construction waste, such as block bricks, etc., which can replace some existing cement products and ordinary cement products. Uses of clay fired bricks. The invention also reduces the traditional method of obtaining stone materials from mountain development to make cement products, reduces water and soil loss, has relatively low cost, is energy-saving and environment-friendly, and realizes recycling of waste.

Owner:黄传文

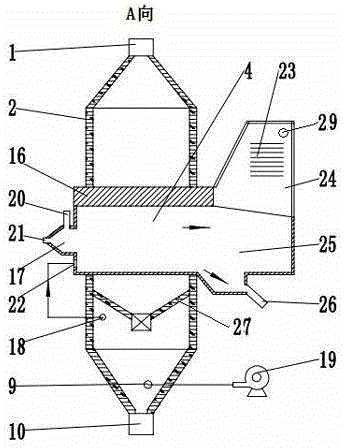

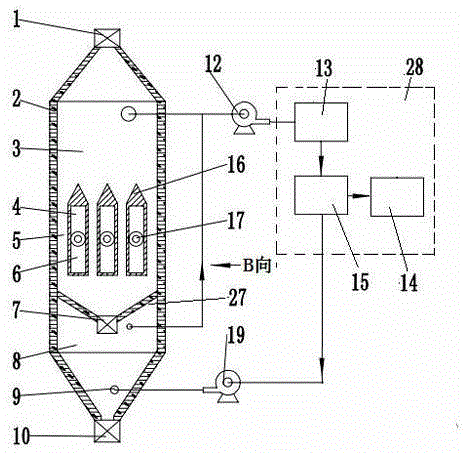

Shaft kiln capable of heating material through dividing wall

The invention relates to a shaft kiln capable of heating a material through a dividing wall. The shaft kiln comprises a waste heat boiler, a generating set, a kiln body, a draught fan, a cooling fan, feeding equipment, an air supply system and a fuel supply system, wherein the kiln body is provided with a feeding hole, a discharging hole, a decomposed air outlet, a cooling air inlet and a cooling air outlet; a combustion chamber is arranged in a heating zone; a combustor is arranged at one end of the combustion chamber and the other end of the combustion chamber is communicated with the waste heat boiler; a baffle is arranged between the heating zone and a cooling zone; the baffle is of a conical platform structure; a material lock is arranged at the lower part of the conical platform; a steam pipe coil is arranged on the waste heat boiler and connected to the generating set; the decomposed air outlet is connected with a carbon dioxide treatment unit through the draught fan; the cooling air outlet is connected to a secondary air inlet or the inlet of the draught fan; and the inlet of the cooling fan is connected with the carbon dioxide treatment unit or communicated with the air. By heating the material inside the kiln body in a flame isolation manner through use of heat conducting brick masonries, improvement of the quality of a roasted material can be facilitated, high-purity carbon dioxide can be recycled and energy consumption of a lime kiln can be reduced.

Owner:SHIJIAZHUANG XINHUA IND FURNACE CO LTD

Novel porous brick and preparation method thereof

InactiveCN105732088AHigh tensile strengthImprove plastic deformation abilitySolid waste managementCeramicwareFoaming agentExpanded clay aggregate

The invention discloses a novel porous brick and a preparation method thereof. Raw materials (in parts by weight) comprise 20 parts of ceramsite, 10 parts of Tauscha, 40 parts of recycled fine aggregates, 20 parts of fly ash, 5 parts of montmorillonite, 8 parts of plant straw powder, 2 parts of lignocellulose, 1 part of coal gangue, 0.1 part of a water reducer and 0.2 part of a foaming agent, wherein the recycled fine aggregates are obtained by directly crushing and filtering abandoned concrete, and the particle sizes of the recycled fine aggregates are less than 5 mm. The porous brick prepared by the invention adopts the abandoned concrete to save resources and solve the problem of secondary pollution on the environment caused by the abandoned concrete; the strength and ductility of a porous brick masonry formed by pressing are improved, and the seismic capacity of the porous brick formed by pressing is enhanced.

Owner:欧士玺

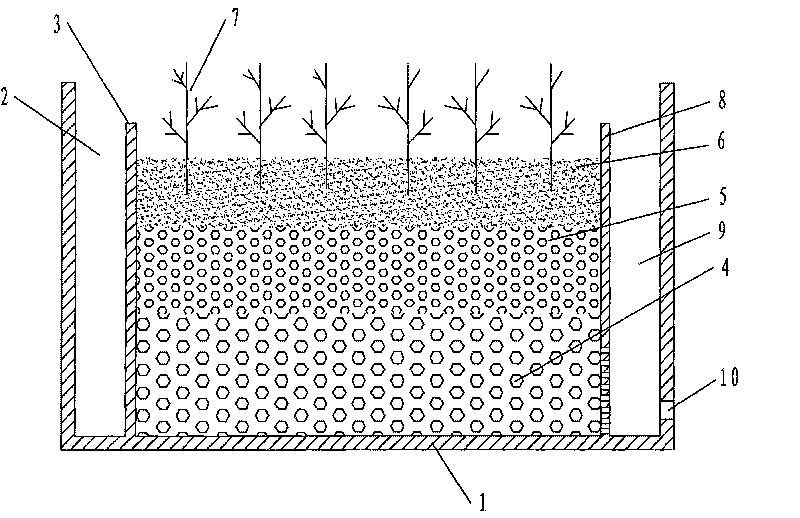

Anti-clogging clay pipe packing subsurface flow constructed wetland

ActiveCN101708899AImprove processing efficiencyIncrease diameterSustainable biological treatmentBiological water/sewage treatmentConstructed wetlandWater storage tank

The invention provides an anti-clogging clay pipe packing subsurface flow constructed wetland comprising a wetland main body, a water distribution plate, a water storage tank, a multi-dimension packing layer, a water baffle and an impounding reservoir; the outer layer of the wetland main body is of a brick masonry structure, and the inner wall and the bottom are of impermeable layer structures; the water distribution plate is arranged at one side in the wetland main body, and the water storage tank is formed in a space between the wall surface at the side and the water distribution plate; the water baffle is arranged at the other side in the wetland main body, and the impounding reservoir is formed in a space between the wall surface at the side and the water baffle, and the bottom of the impounding reservoir is provided with a water outlet; the multi-dimension packing layer is arranged in a space between the water distribution plate and the water baffle and is divided into an upper layer, a middle layer and a lower layer, the packing at the lower layer is a clay pipe with larger external diameter, the packing at the middle layer is a clay pipe, a gravel or a roseite with small external diameter, the packing at the upper layer is natural soil or the combination of upper natural soil and lower turf, and plants growing in wetlands are planted in the packing at the upper layer. The invention improves the processing efficiency to the greater extent, prevents clogging and can provide larger special surface area and increase the biomass.

Owner:SHANDONG UNIV

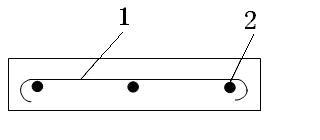

Mechanical property detecting method for shale porous brick masonry

InactiveCN101458183AAccurate measurementGuaranteed Build QualityMaterial testing goodsStrength propertiesBrick masonryVertical load

The invention relates to a method for detecting the mechanical performance of shale perforated brick masonry, and the steps are as follows: (1) difference grouping is carried out according to different brick types, brick body strengths and masonry mortar strengths; (2) the loading surfaces of all test pieces are leveled by 1:3 cement mortar before test, and the leveling layer is 10mm; the flatness is checked, and the maintenance lasts three days; (3) axle center compression test is carried out in a 2,000KN pressure test machine; (4) steel plates with the thickness being 50mm are cushioned at the upper end and the lower end of a center compression test piece, and hydraulic loading speed is controlled around 0.3-0.5Mpa / s; (5) a cleavage test and a bending tension test are finished on a 250KN vertical load frame by adopting an oil jack, a pressure sensor and a load indicator; (6) a right-angle load framework welded by steel plates is applied in a principal tensile stress cleavage test. The detection method can precisely detect the mechanical performance of the shale perforated brick masonry, thus providing mechanical parameters for shale perforated brick masonries used in building, and ensuring the building quality.

Owner:郝亮

Anti-skid intensifier for smooth brick masonry surface and method for preparing same

InactiveCN1699289AImprove skid resistanceReduce freeze-thaw intensityCationic polyelectrolytesBrick masonry

The invention provides an anti-skid intensifier for smooth brick masonry surface and method for preparation, which comprises (by weight ratio) organic silicon 10-20, penetrating agent 0.2-0.6, surface active agent 0.1-0.4, PF cationic polyelectrolyte 0.4-0.8, water 79-89. The preparation process comprises charging organic silicon, penetrating agent, surface active agent into synthesizing still and stirring, then charging pure water, continuously stirring to colorless and transparency, and charging PF cationic polyelectrolyte, mixing and stewing.

Owner:SHANDONG NORMAL UNIV

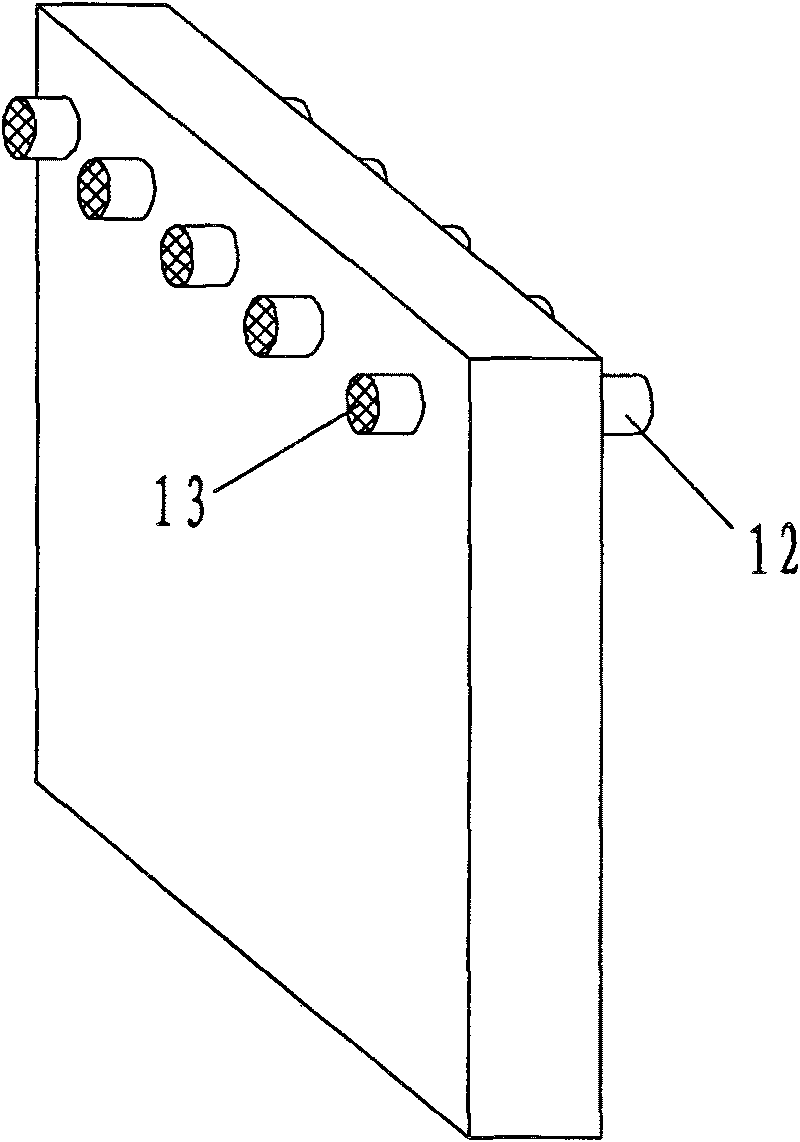

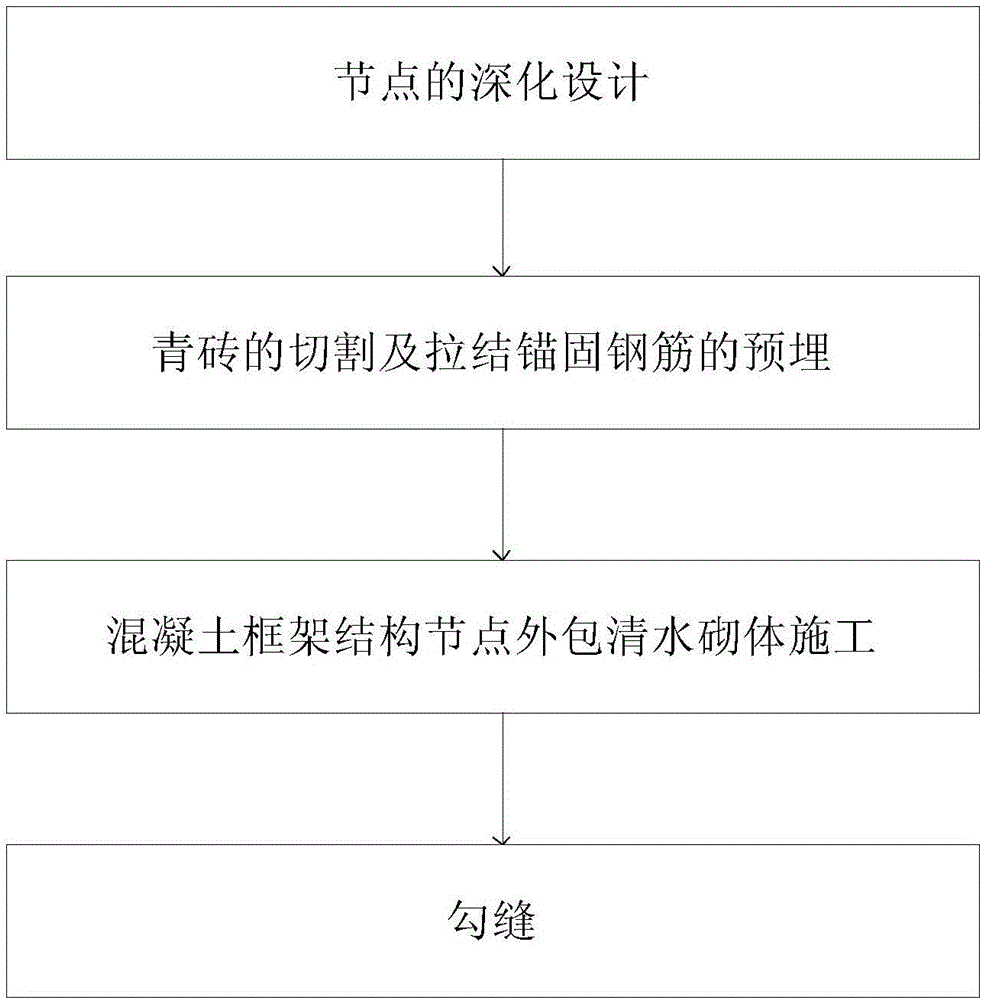

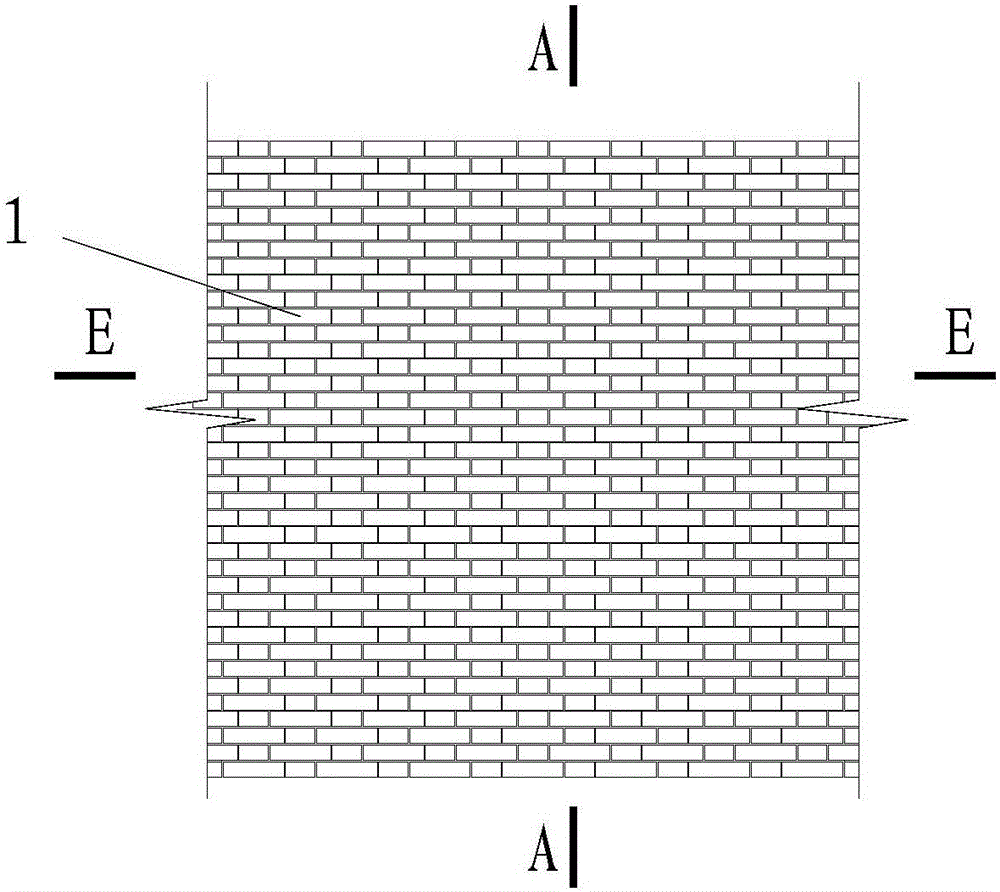

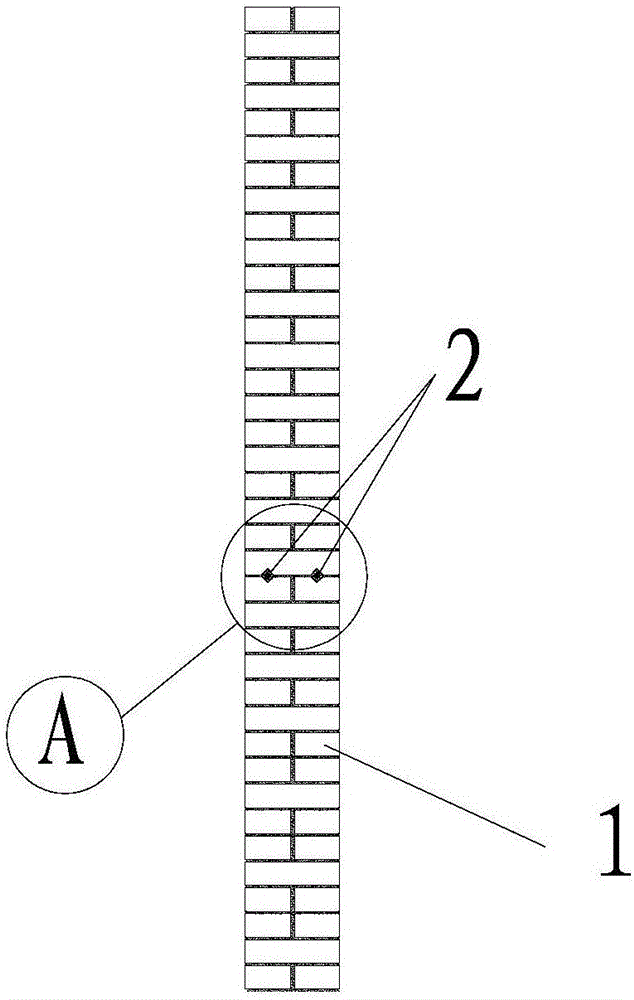

Construction method of wrapping fair brick masonry for concrete structure of historic building

The invention discloses a construction method of wrapping fair brick masonry for a concrete structure of a historic building. The method comprises following steps: step 1, deepening design of joints, wherein joints composed of the fair brick masonry and a concrete framework structure comprise framework columns, framework beams, door and window opening beams, structure columns, wall surface ornaments and special-shaped windows; step 2, cutting of black bricks and pre-burying of lacing and anchoring steel bars; step 3, construction of the fair brick masonry with joints wrapped for the concrete framework structure; step 4, pointing: pointing from the top to the bottom after the wrapped fair brick masonry of the concrete framework structure is finished after the bricklaying of the wrapped fair brick masonry of the concrete framework structure is finished, wherein the pointing form is flush joint at the depth of 6mm. The construction method of wrapping the fair brick masonry for the concrete structure of the historic building has the following beneficial effects: the construction method is simple in step, reasonable in design, easy and convenient in construction and good in application effect; the fair brick masonry is wrapped by utilizing black bricks processed after deepening design of all joints according to the concrete framework structure such that the wall surface of the historic building looks more exquisite.

Owner:SHAANXI CONSTR ENG GRP NO 7 BUILDING ENG

Method for increasing ring beam for brick masonry wall

ActiveCN102889004AImprove performanceImprove deformation abilityBuilding repairsShock proofingFiberBrick masonry

The invention discloses a method for increasing a ring beam for a brick masonry wall for solving the problems that the reinforcement effect is bad, the construction process is complex and the appearance of a building is influenced after the ring beam is increased in the conventional method for increasing the ring beam for the brick masonry wall. The method comprises the following steps of: horizontally arranging longitudinal reinforcements at four corners on which the constructional column is pre-increased under the floor of the brick masonry structure; longitudinally holing along horizontal mortar joints every 150 to 300mm at intervals along with ring beam and allowing a stirrup to penetrate through the hole; and finally, daubing high-elongation fiber concrete on the surface of the wall on which the ring beam is pre-increased. The ring beam is increased by utilizing the mechanical property characteristics of the high-elongation fiber concrete and high adhesion performance between the high-elongation fiber concrete and the brick masonry, so that the integrity of the wall can be greatly improved, brittle failure is avoided, and the seismic resistance of the brick masonry wall is obviously improved. The method has the characteristics of good reinforcement effect, simple construction process and low influence on the appearance of the original building.

Owner:西安五和新材料科技集团股份有限公司

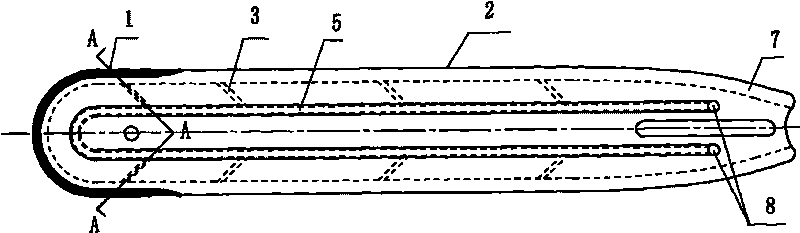

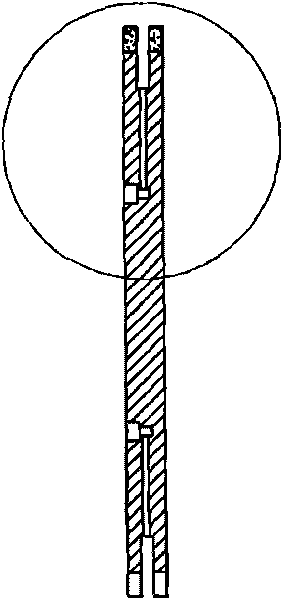

Chain saw guide plate

InactiveCN101708564AExtend your lifeImprove work efficiencyMetal sawing devicesMetal sawing accessoriesThin metalBrick masonry

The invention discloses a chain saw guide plate for special chain saws used for cutting brick masonry walls, stones, thin metal plates and the like. The chain saw guide plate comprises a guide plate body, a guide chain device, a chain guide groove and a cooled water conveying channel. Because the cooled water conveying channel is arranged on the guide plate body, heat as well as accumulated dusts and impurities of the cut objects and a saw chain can be reduced, the abrasion of the guide plate and the chain is reduced, and the service life of the chain saw is improved. The invention is especially suitable for rescuing requirements under severe environment of earthquake relief work, fire fighting and the like.

Owner:杭州精锋园林工具有限公司

Method for increasing constructional column for brick masonry wall

ActiveCN102889003AImprove performanceImprove deformation abilityBuilding repairsShock proofingFiberBrick masonry

The invention discloses a method for increasing a constructional column for a brick masonry wall for solving the problems that the construction process is complex and the appearance of a building is influenced by the increased constructional column in the conventional method for increasing the constructional column. The method comprises the following steps of: arranging longitudinal reinforcements at the periphery of the brick masonry wall on which the constructional column is required to be increased; holing along vertical mortar joints every 150 to 300mm at intervals along with the height of the constructional column, and allowing a stirrup to penetrate through the hole; and finally, daubing high-elongation fiber concrete on the surface of the wall. The constructional column is increased by utilizing the mechanical property advantages of the high-elongation fiber concrete and high adhesion performance between the high-elongation fiber concrete and the brick masonry, so that the shear capacity of the wall can be greatly improved, brittle failure is avoided, and the seismic resistance of the brick masonry wall is obviously improved. The method has the characteristics of good reinforcement effect, simple construction process and low influence on the appearance of the original building.

Owner:西安五和新材料科技集团股份有限公司

Building method for controlling temperature cracks of masonry

InactiveCN102182316AEasy to useHigh recovery rateBuilding material handlingSocial benefitsTransformer

The invention relates to a building method for controlling temperature cracks of a masonry, which comprises the following steps of: A. pouring water over bricks and fully soaking the bricks before brick laying, ensuring that the water content ratio of fly ash bricks is 8 to 12% and the water absorbing depth around the cross section of each fly ash brick is 15 to 20mm; B. locating, paying-off and laying bricks; C. building a brick masonry, wherein a control joint and a concrete slab strip of a steel bar are arranged on the brick masonry so as to control masonry damage caused by temperature fluctuation and drying shrinkage and deformation of materials: and D. carrying out sedimentation and maintenance after the brick laying of a wall is completed. The invention has the advantages that: in the process of the brick masonry construction of a transformer substation building, the cracks caused by temperature and material shrinkage are greatly reduced; from the application condition of the transformer substation construction, the building method has obvious effects, and the temperature cracks of the masonry are better controlled; from the aspect of economic benefit, the recovery rate of guarantee deposit is increased; meanwhile, the improvement for construction quality ensures the safe operational performance of the building, and favorable social benefit is obtained.

Owner:SHANDONG ELECTRIC POWER TRANSMISSION & SUBSTATION ENG CO

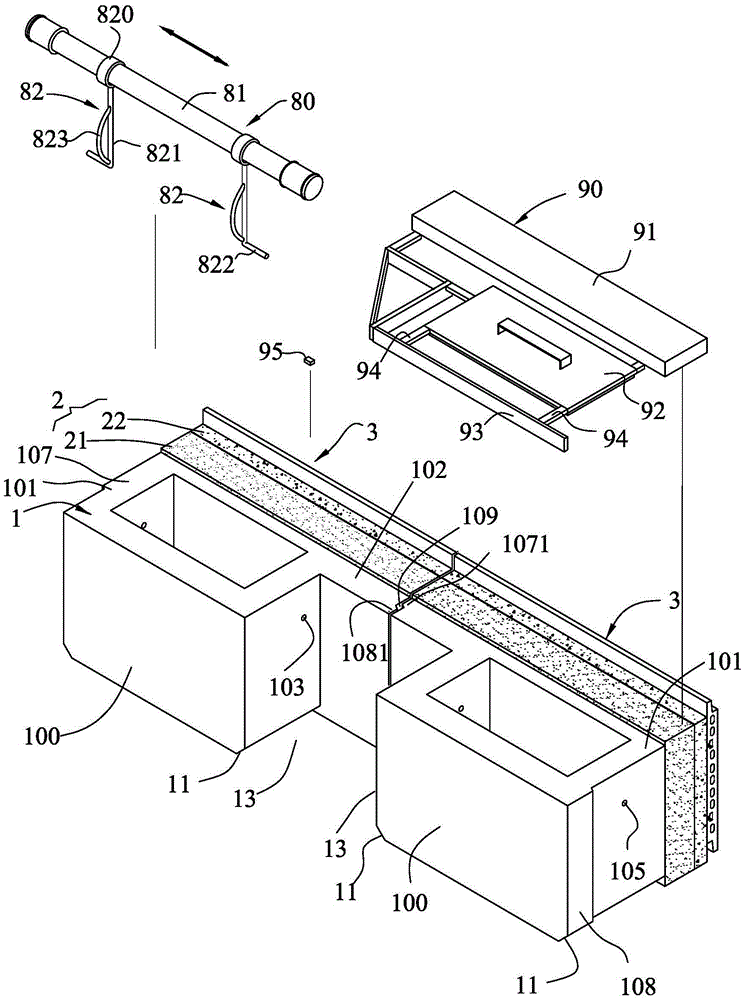

Base module, assembly, preparation die, and construction method for ceramic brick masonry wall

InactiveCN105484386AEasy to transportEasy to stackConstruction materialWallsStone wallThermal insulation

The invention relates to a base module, an assembly, a preparation die, and a construction method for a ceramic brick masonry wall in the building field. The base module includes an external decorative plate forming an outer wall of a building, a thermal insulation unit, and a plurality of bridge-cut joint devices which pre-assemble the thermal insulation unit and the external decorative plate. A ceramic brick used for forming an internal wall of the building can be integrally formed at one side of the thermal insulation unit by putting the base module in the die. The base module and the ceramic brick are integrated into an impartible state. The other side of the ceramic brick opposit the thermal insulation unit is arranged as an internal wall side. A grouting groove which runs through the ceramic brick up and down and forms an opening towards the building interior side is recessed in the internal wall side. During the construction and pile-up, steel bars are wrapped in the grouting groove. A steel bar cement column formed after the grouting is located on the surface of the internal wall of the building. The inspection is convenient and the construction quality is ensured. In addition, reinforcing steel bars transversely pass through up and down piled ceramic bricks and also pass through the grouting groove so as to greatly improve the wall strength.

Owner:应家荣

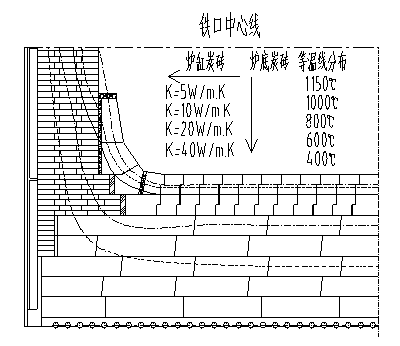

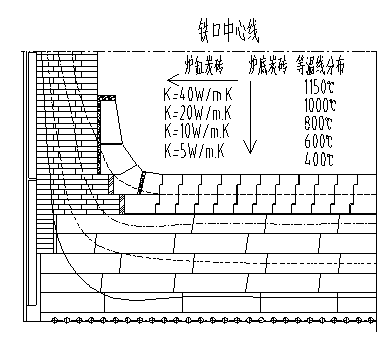

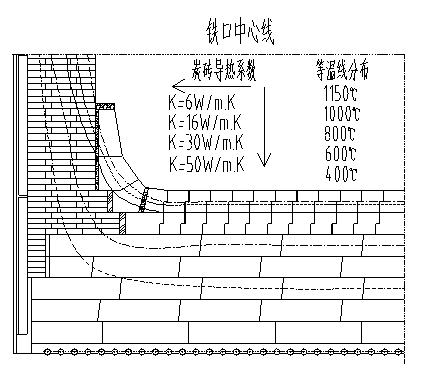

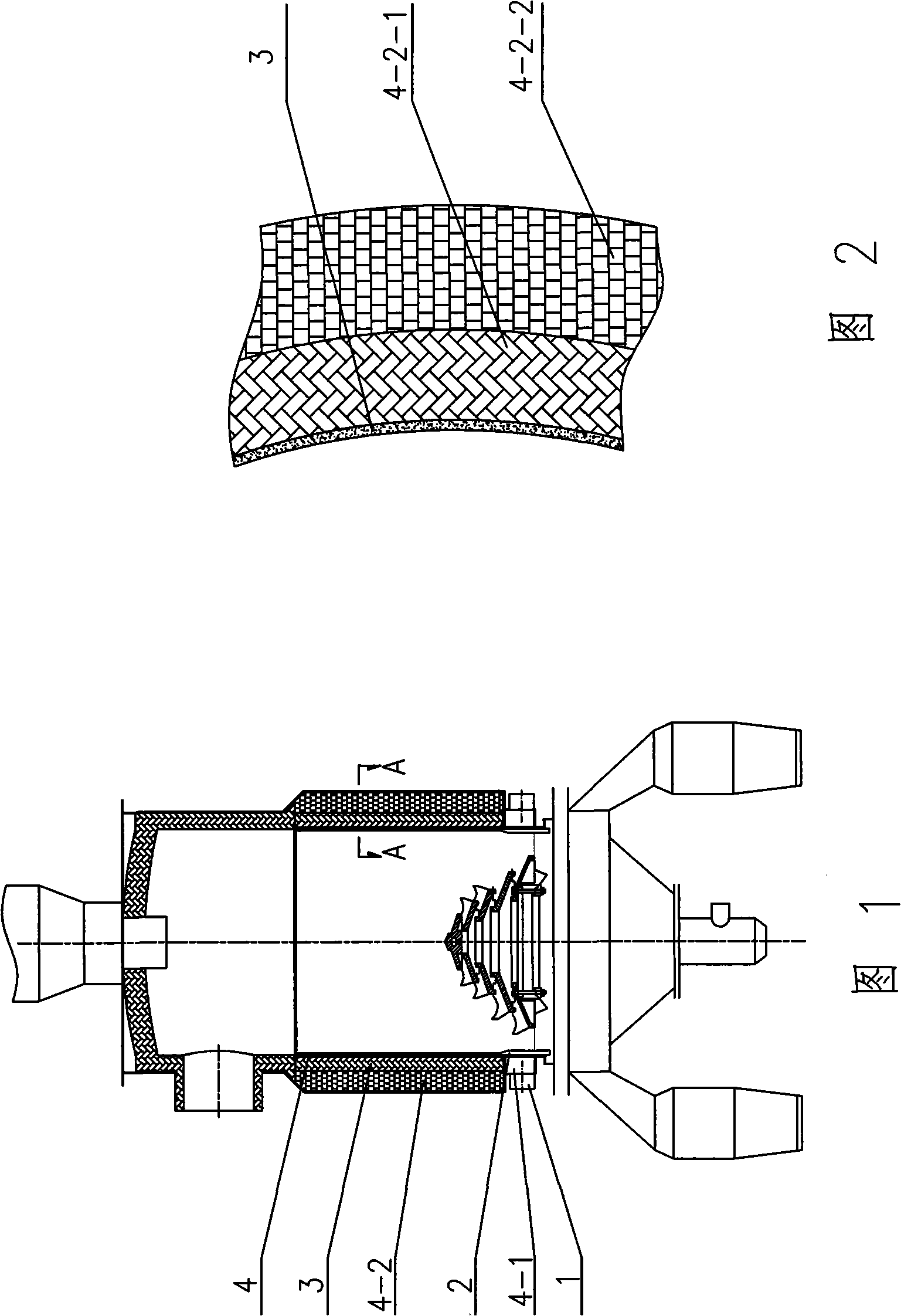

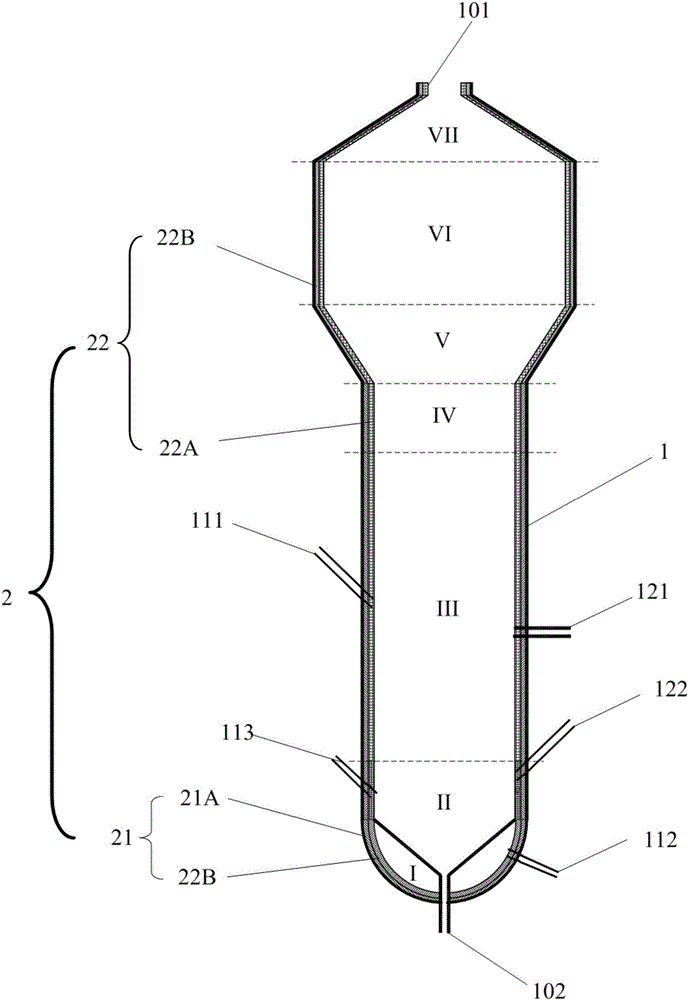

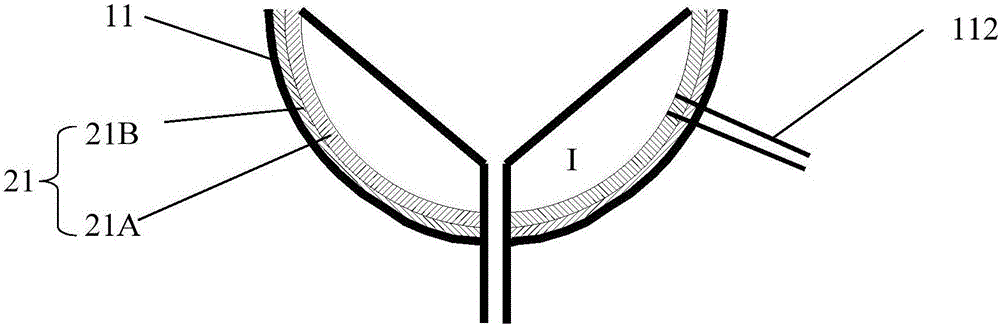

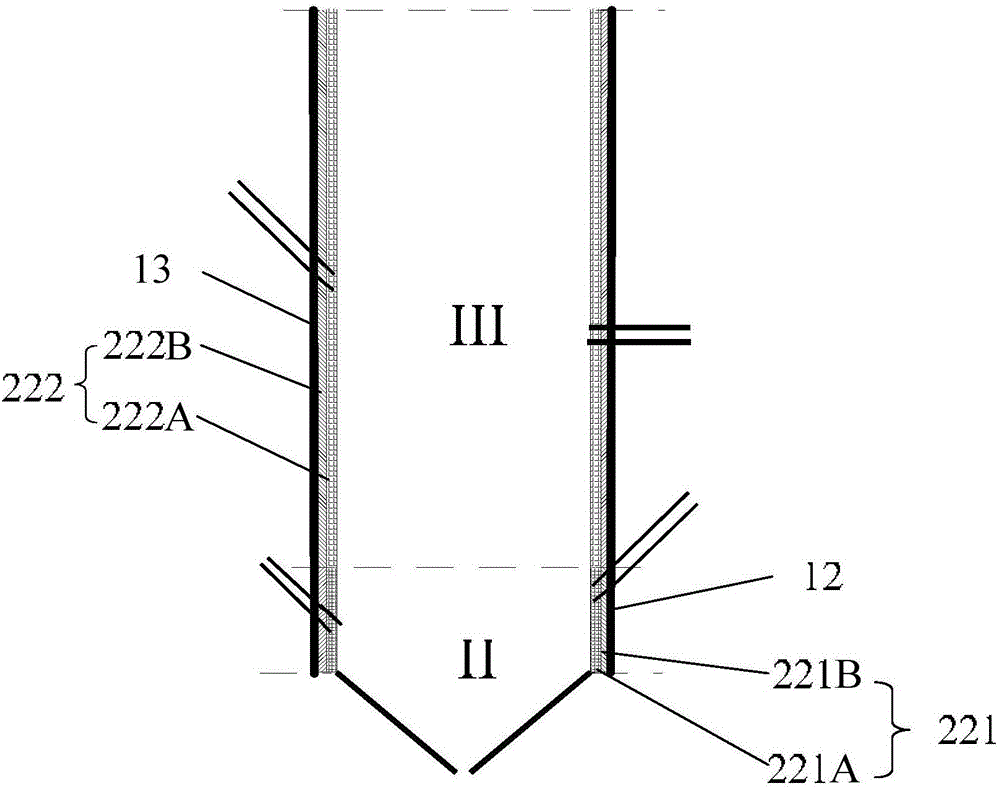

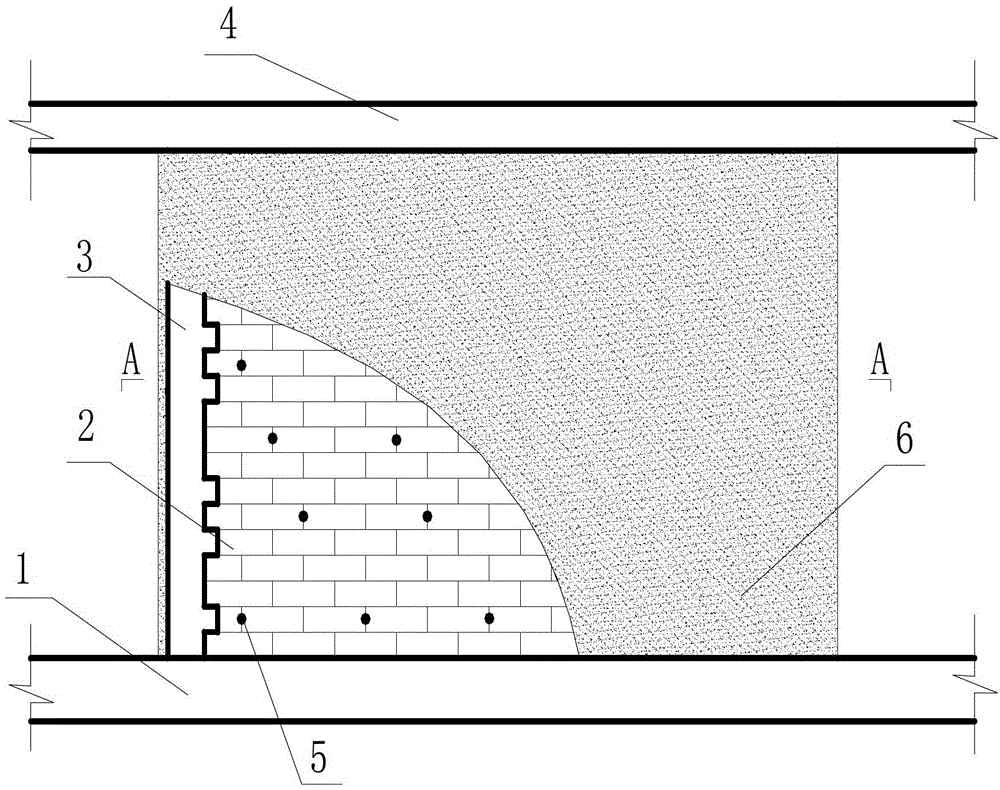

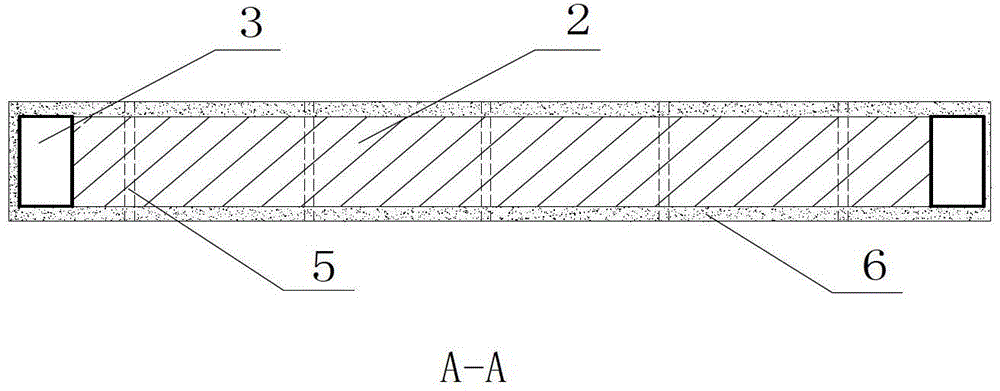

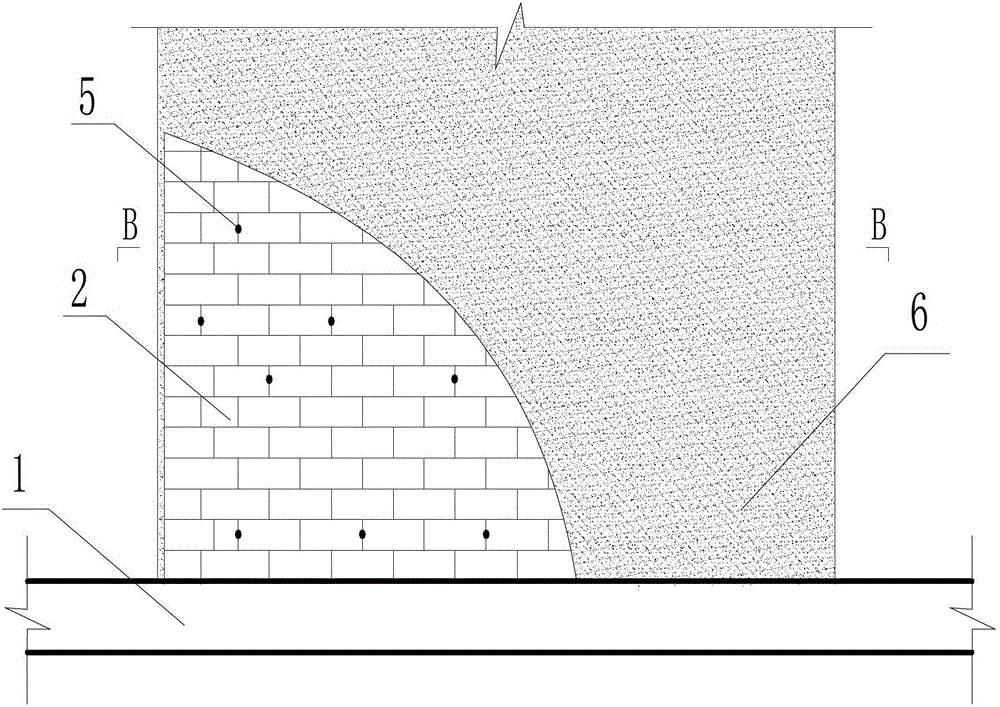

Blast furnace cold-intensifying and heat-avoiding type gradient brick distribution method

InactiveCN103305642AChange thermal conductivityChange layoutBlast furnace detailsInternal formsDistribution methodBrick masonry

The invention relates to a blast furnace cold-intensifying and heat-avoiding type gradient brick distribution method and belongs to the technical field of long life of iron-making blast furnaces. According to the technical scheme, the method comprises the following process steps of: (1) performing flat steel mesh installation and leveling layer construction on the blast furnace hearth and furnace bottom, and sequentially performing layered construction; (2) performing wall-to-wall furnace bottom graphite brick masonry construction on the layer I; (3) performing wall-to-wall furnace bottom carbon brick masonry construction on the layers II, III, IV and V; (4) performing furnace bottom ceramic cup pack-up block masonry construction; (5) performing furnace bottom and hearth side wall carbon brick masonry construction; and (6) performing hearth ceramic cup wall masonry construction. Because the brick layers of different heat conductivity coefficients are arranged at the hearth and the furnace bottom, the heat conductivity coefficient of each refractory material layer is gradually increased from the surface close to a molten iron heat surface to a cooling surface so as to form gradient. The method has the advantages and effects that the heat conductivity coefficient and an arrangement mode of the refractory material used by the hearth and the furnace bottom are changed, so that an optimal cooling or thermal insulating effect is achieved, and the service life of the hearth and the furnace bottom is prolonged.

Owner:宣化钢铁集团有限责任公司 +1

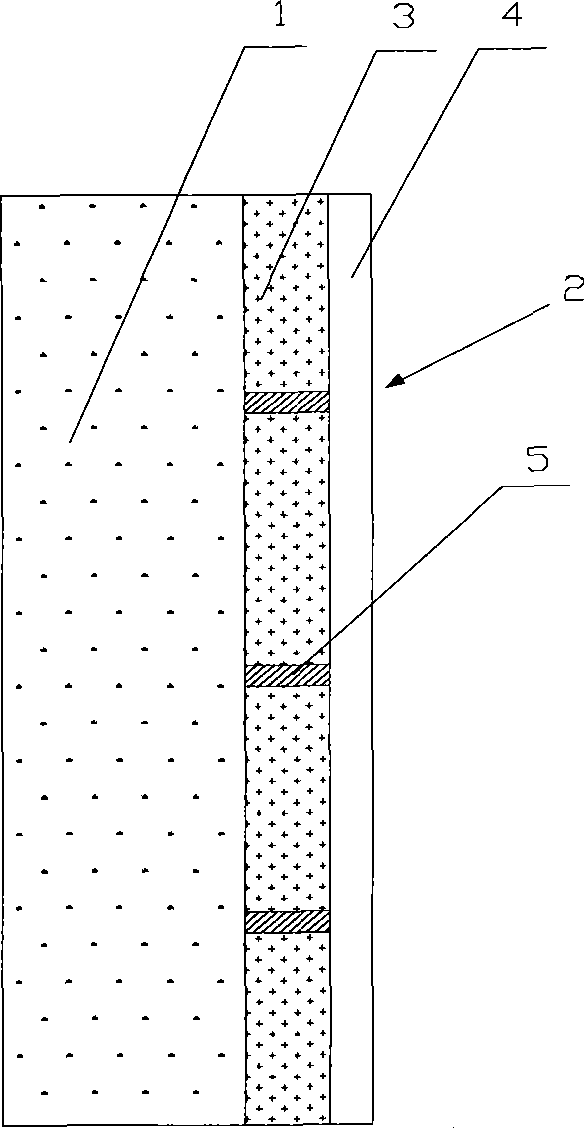

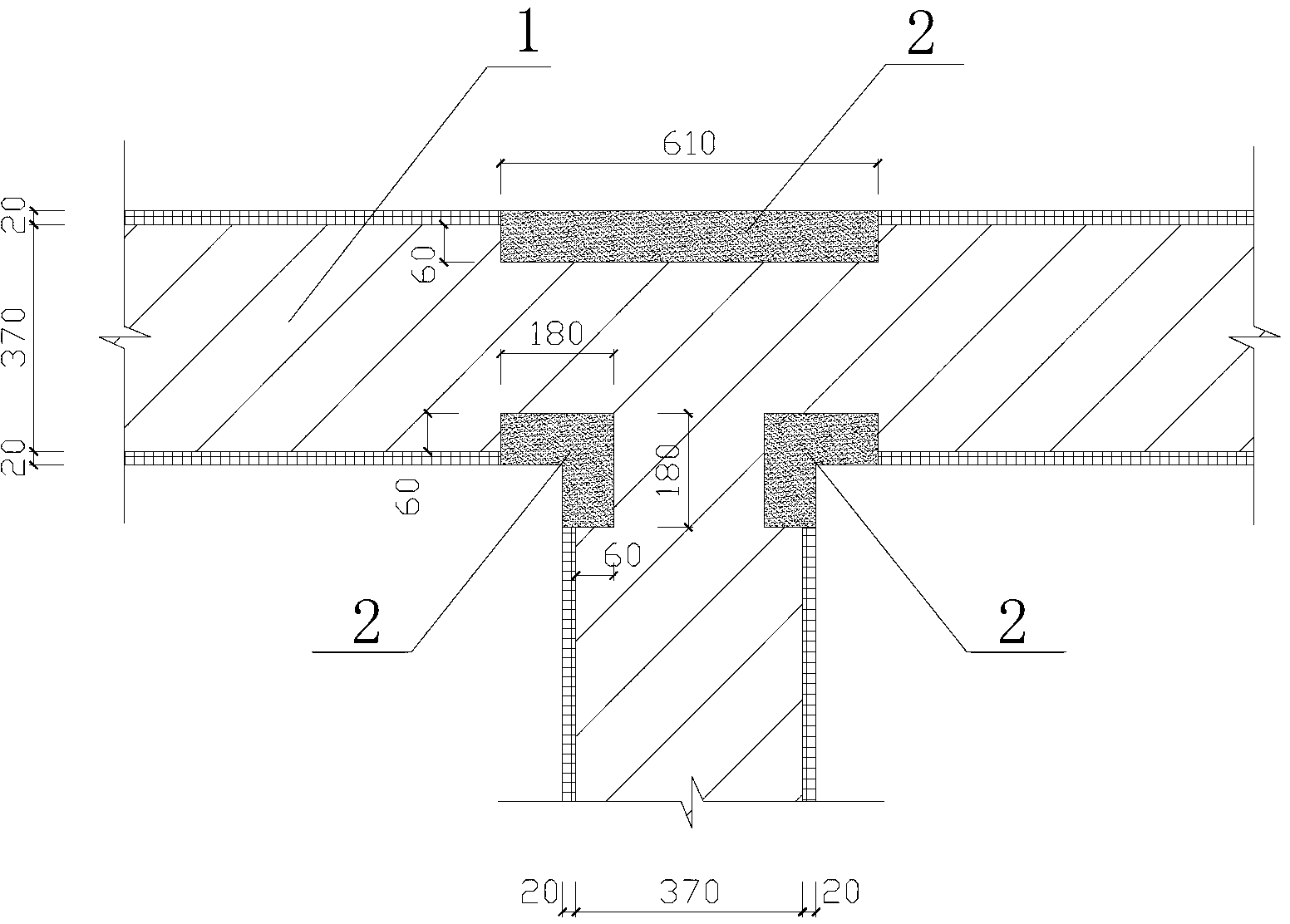

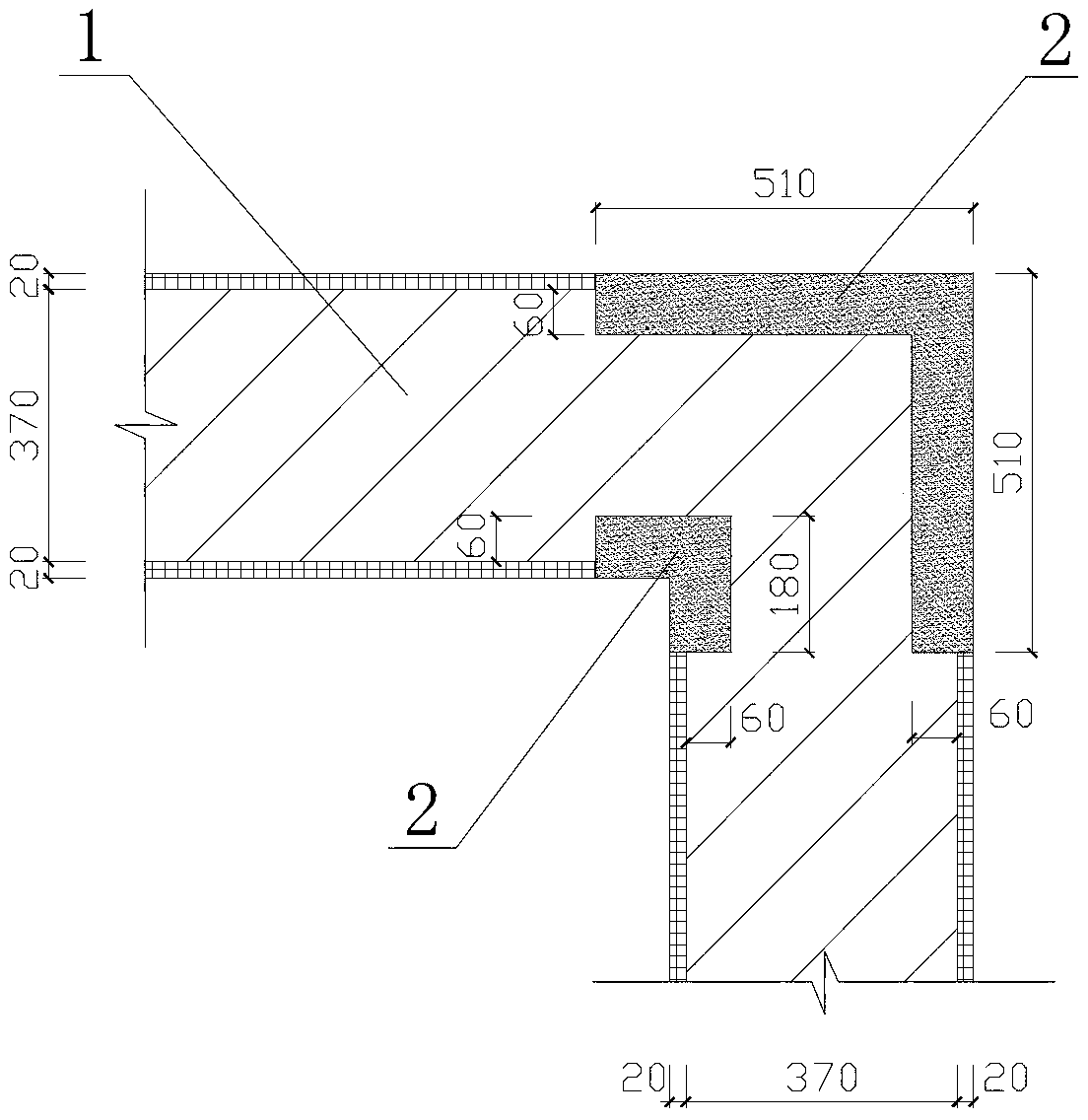

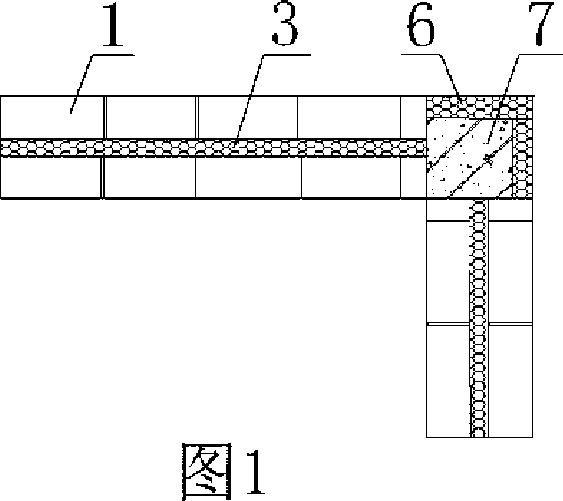

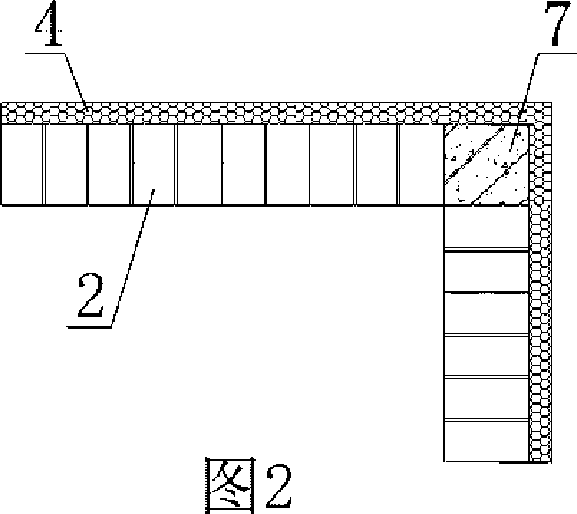

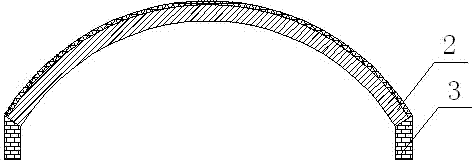

Heat-preserving energy-saving wall structure

The invention relates to a wall body structure with heat-insulating and energy-saving effects, which mainly solves the problem that a wall body of the prior heat-insulating structure has insufficient strength and is easy to damage. The wall body structure consists of a brick masonry layer (1) and a heat-insulating layer (2), wherein the heat-insulating layer (2) is formed by combining a heat-insulating material layer (3) and an OSB board (4); and the heat-insulating material layer (3) is close to the brick masonry layer (1). After adoption of the structure, the wall body structure has the advantages of compactness, high strength, strong deformation resistance, corrosion resistance, mothproof property, deformation resistance, fire retardation, water resistance, heat insulation and sound insulation, and has good heat-insulating and energy-saving effects, and the surface of the wall body structure is easy to process and finish.

Owner:CHENGDU CANYA WOOD IND

Construction method for decorative ganged brick masonry

ActiveCN103046756AGive full play to the beautyGive full play to textureBuilding material handlingBrick masonryArchitectural engineering

The invention discloses a construction method for decorative ganged brick masonry. The method is optimized and innovated continuously on the basis of a series of construction crafts such as selecting, grinding, cutting, building and hooking. With no influence on design and composition, the method makes improvement on the forming of the ganged bricks and other construction crafts, and accordingly the attractive appearance and comfortable touch of the ganged bricks as decorative materials are enhanced fully. The method is comprehensive and high in construction crafts, capable of reducing the construction cost and greatly improving the construction quality, and has possessing advancement, economical efficiency and practicability. Besides, by the method, great effect on popularization of the decorative ganged bricks on architectures such as pseudo-classic architecture is achieved, and appearance and outside facade overall effect of the ganged bricks are much better than those of conventional decorative bricks.

Owner:陕西建工第三建设集团有限公司

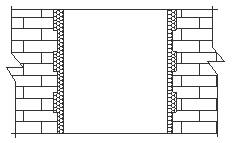

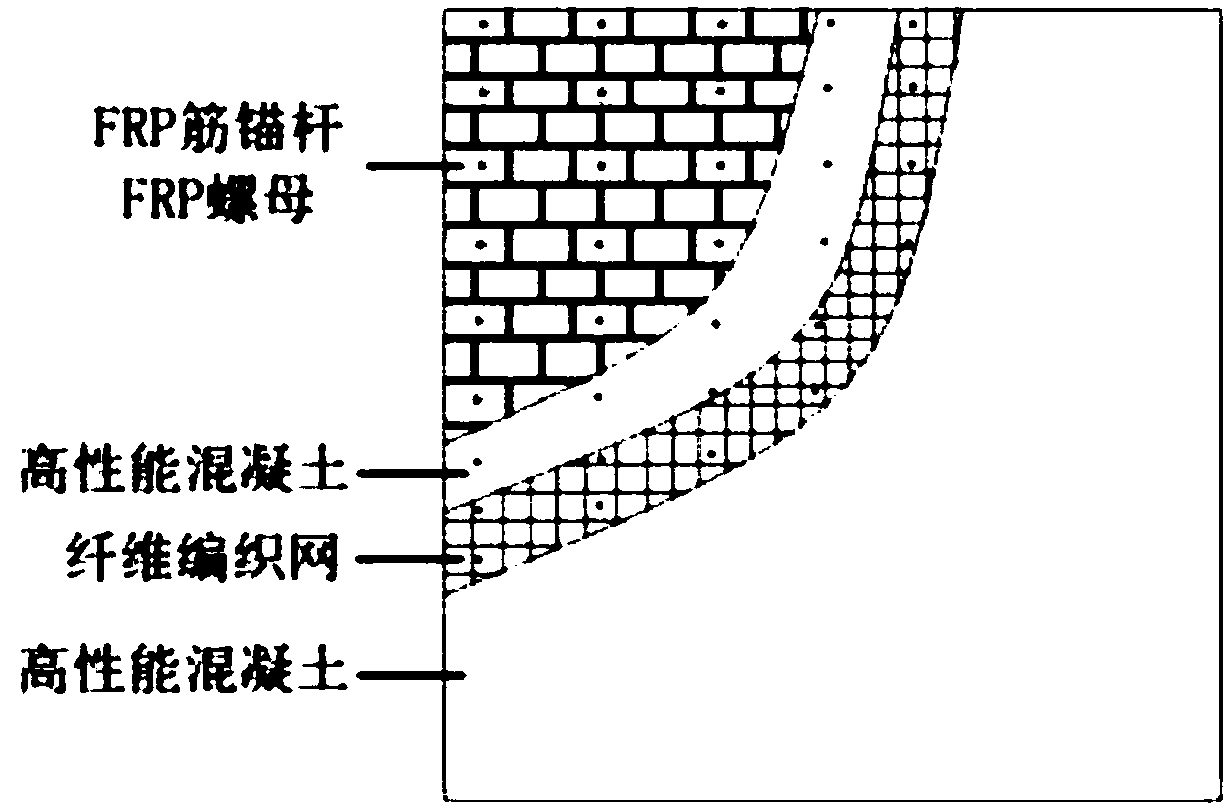

Reinforcement method of TRC for improving anti-seismic performance of multi-piece brick masonry wall

InactiveCN108532981AImprove seismic performanceImprove shear resistanceClimate change adaptationBuilding repairsFiberBrick masonry

The invention discloses a reinforcement method of TRC for improving an anti-seismic performance of multi-piece brick masonry wall, and belongs to the technical field of repair, reinforcement and construction of masonry walls. The reinforcement method comprises the steps that a plurality of penetrating circular holes are drilled in the wall to be reinforced, and fiber reinforced plastic (FRP) rib anchor rods are used for penetrating through the circular holes; the surface of the wall to be reinforced is coated with high-performance concrete, a fiber woven net is impregnated with epoxy resin, and the surface of the fiber woven net is coated with the high-performance concrete again; If one layer of fiber woven net can not meet the requirement of wall anti-seismic performance improvement, twoor more layers of fiber woven nets can be laid; and wet water curing is carried out until the high-performance concrete age is reached. According to the reinforcement method of TRC for improving the anti-seismic performance of the multi-piece brick masonry wall, in-plane shear resistance and out-of-plane bending resistance of the multi-piece brick masonry wall are improved, the risk of serious damage or even collapse of a masonry structure in earthquake is reduced, the inadaptability of a masonry material caused by the use of the epoxy resin in FRP reinforcement is avoided, deficiency of low reinforcement efficiency of engineered cementitious composite (ECC) reinforcement is effectively improved, and the integrity of multi-piece brick masonry wall is improved.

Owner:CHINA UNIV OF MINING & TECH

Construction method of high elongation concrete embedded constructional column

ActiveCN102936964AImprove performanceImprove deformation abilityBuilding repairsShock proofingFiberBrick masonry

The invention discloses a construction method of a high elongation concrete embedded constructional column. The method is applicable to a brick masonry structure with wall thickness larger than 240mm. During construction, firstly the size of a pre-added constructional column at a connection position of a vertical wall and a transverse wall of the brick masonry structure is determined, then surface mortar of an original building at the pre-added constructional column position and a part of brick masonry wall are removed, and finally a formwork is built and high elongation fiber concrete is poured. By means of mechanical performance advantages of the high elongation fiber concrete and good bonding performance between the high elongation fiber concrete and the brick masonry, a constructional column is added to greatly improve shear capacity, avoid brittle failure and greatly improve anti-seismic performance of the brick masonry wall. The method has the advantages that reinforcing effect is good, construction process is simple, and appearance of the original building after reinforcing is not affected.

Owner:西安五和新材料科技集团股份有限公司

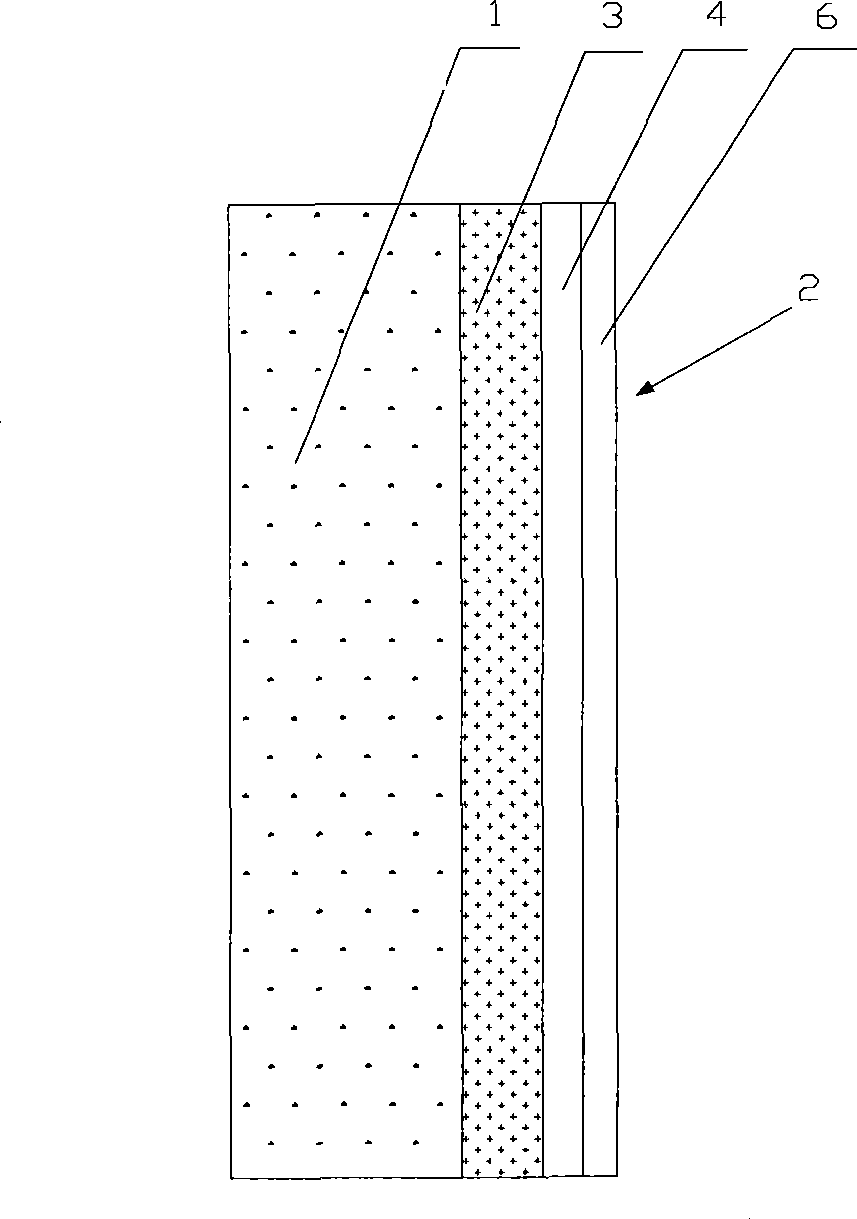

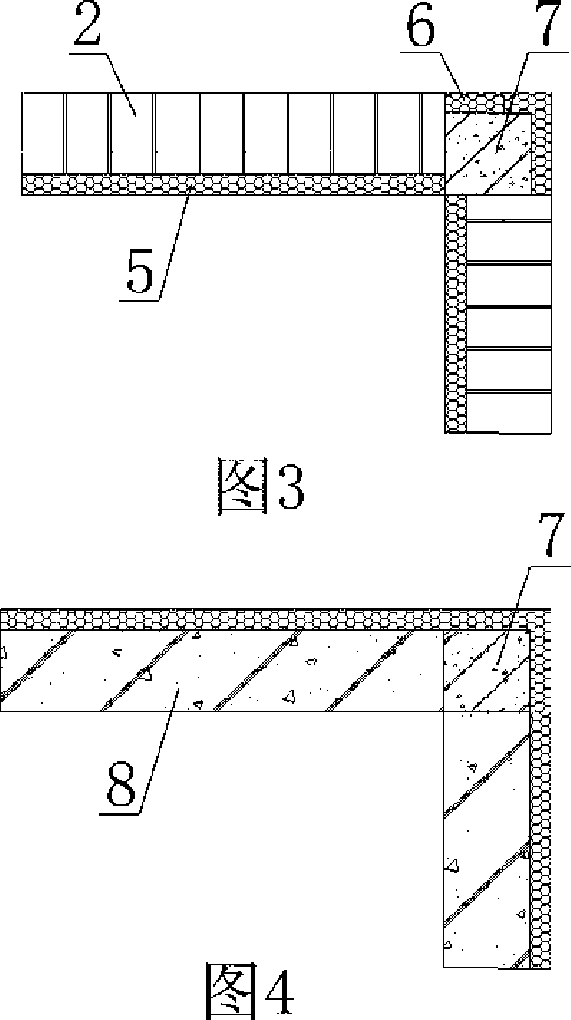

Multilayer brick mixed thermal insulation wall and construction method thereof

The invention relates to a multilayer brick concrete laying insulation wall body and a construction method thereof. The insulation wall body is a brick concrete structure. A brick masonry is circularly laid by the combination of the following three layers. An insulation layer is formed by a middle insulation layer, an external insulation layer and an internal insulation layer which are circularly and alternately arranged in the brick masonry from bottom to top sequentially. A first layer of brick masonry is formed by two stripes of stretcher bricks from a first layer to a fifth layer; a gap for the middle insulation layer is reserved between the two stripes of the stretcher bricks; the gap is filled with an insulation material; and the outside of a reinforced concrete structural column at a corner is coated by the structural column external insulation layer. A second layer of brick masonry is laid by paralleled header bricks from a first layer to a fifth layer, and an external insulation layer is adhered to the outsides of the header bricks. A third layer of brick masonry is laid by paralleled header bricks from a first layer to a fifth layer; the outside of the header bricks fit the outside of the wall body; and the internal insulation layer is adhered to the insides of the header bricks. By changing the laying mode of the bricks, the construction method can meet the requirements of the wall body on insulation effect. The construction method which is simple and saves materials and energy can be widely applied to brick concrete insulation wall bodies.

Owner:CHINA CONSTR FIRST GROUP THE FIFTH CONSTR +4

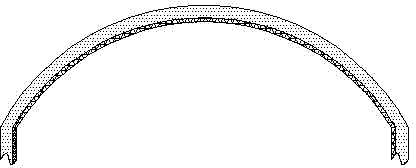

High-temperature resistant expansion joint for dry quenching

InactiveCN103788966AShorten maintenance timeReduce replacement timeCoke quenchingCondensation processBrick masonry

The invention relates to the field of refractory materials, in particular to a high-temperature resistant expansion joint for dry quenching. The original castable structure of the high-temperature resistant expansion joint is changed to be a refractory brick masonry structure; clay bricks and high-alumina light bricks are piled up to form a refractory layer and a heat-preservation layer during piling up, a pouring condensation process is not required, the maintaining and replacement time of the refractory material of the expansion joint is shortened, and the construction period is greatly shortened; a vault is provided with a granule backfilling layer and a vault gap pressing layer, the vault gap pressing layer is filled with clay bricks to ensure the connecting strength, a vault refractory layer and the heat-preservation layer are regulated by backfilling granules when being heated and expanded, and the refractory layer and the heat-preservation layer of a side wall and an arch corner are regulated by a side wall labyrinth layer and an arch corner labyrinth layer when being heated and expanded, the fire resistance is ensured and the service life is prolonged.

Owner:GANSU JIU STEEL GRP HONGXING IRON & STEEL CO LTD

Novel gas generator

InactiveCN101275088AUniform temperatureIncrease gasification strengthCombustible gas productionWear resistantSlag

The present invention provides a new type gas producer, including a furnace body and a disintegrating slag strip, characterized in that the middle wall of the furnace body is poured by a high temperature resistant, heat insulating non-metal material brick masonry or high temperature resistant, heat insulating castable, the inner wall of the furnace wall is covered with a high temperature resistant, wear resistant porcelain plate or coated with high temperature and wear resistant coating layer; the lower of the furnace body is a metal ring cylinder which inner is ring steam channel, the disintegrating slag strip is mounted on the inside of the ring cylinder, the inner wall of the ring cylinder is provided with a steam pylome, the outer wall is provided with an air inlet joint. The invention has no water line jacket, having no water wall effect, the temperature of the furnace inside is evenly, having gasification intensity, adequate coal carbon burn, lower quantity of slag discharge and carbon residue, having high utilization ratio of gasified coal; the invention also has a simple structure, lower investment, convenient operation, lower safety evaluation grade standard, gasified raw material coal having high quality is saved at the same time.

Owner:彭思尧

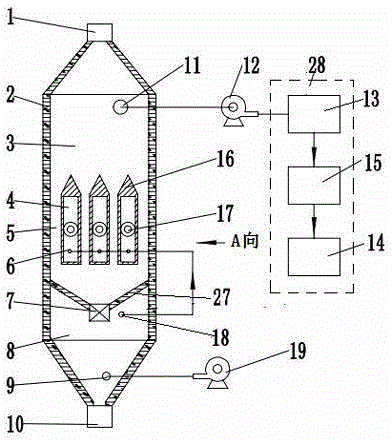

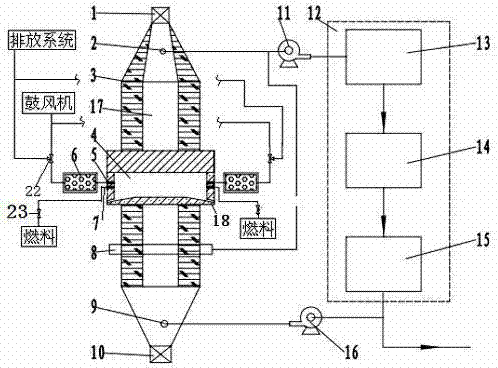

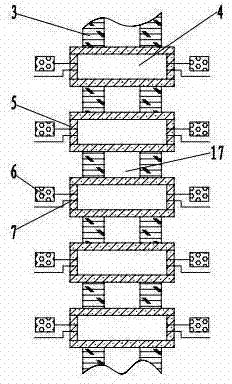

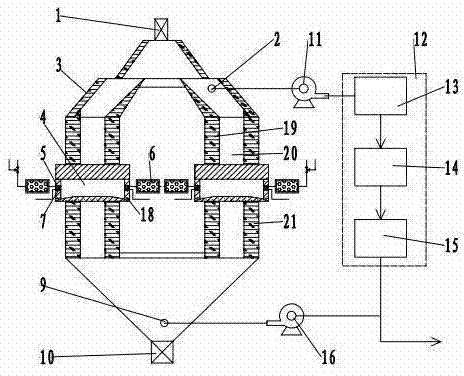

Heat accumulating type dividing-wall heating industrial furnace

ActiveCN104119003AHigh thermal efficiencyQuality improvementCarbon compoundsEnergy inputCombustion chamberDecomposition

The invention relates to a heat accumulating type dividing-wall heating industrial furnace including a lime kiln and a carbon dioxide processing unit; the lime kiln is provided with a feed port, a discharge port, a decomposition gas outlet and a cooling air inlet. The decomposition gas outlet is connected with the carbon dioxide processing unit through a draught fan, and an inlet of a cooling fan is connected with the carbon dioxide processing unit or is communicated with the atmosphere. A calcining zone of the lime kiln is provided with combustion chambers, and the walls of the combustion chambers are formed by constructing heat conduction brick masonry or are made of a metal material. An air port of each combustion chamber is connected with a heat accumulator, and the other end of each heat accumulator is connected with an air blower and a draindown system through a three-way valve. A cooling zone is provided with a lower suction beam, and an outlet of the lower suction beam is connected to the drought fan or a fuel preheater. With additional arrangement of the combustion chambers and the heat accumulators, a material in a kiln body is heated through the heat conduction brick masonry in a flame isolation mode, high-purity carbon dioxide is facilitated to be recycled, combustion-supporting air is preheated by flue gas, the combustion-supporting air temperature is increased, heat energy resources are fully utilized, and the energy consumption of the lime kiln is reduced.

Owner:SHIJIAZHUANG XINHUA IND FURNACE CO LTD

Fluidized bed gasifier and building method thereof

ActiveCN106811236AImprove integrityImprove sealingGasification processes detailsGasification apparatus detailsMaterials scienceIndustrial engineering

The invention discloses a fluidized bed gasifier and a building method thereof and relates to the technical field of catalytic coal gasification and aims to lower construction difficulty and solve the problems that the refractory lining of an existing catalytic gasification fluidized bed gasifier is weak in alkaline corrosion resistance and friction resistance, and the refractory lining falls off easily. The fluidized bed gasifier comprises a gasifier body structure and a gasifier chamber, wherein the gasifier chamber comprises a gas chamber area, a dense-phase bed material area and a dilute-phase area, the gasifier body structure comprises a pressure-resistant shell and the refractory lining, and the refractory lining contains alkali-resistant materials and comprises a first lining part and a second lining part; the second lining part comprises a first refractory pouring layer contacting with the dense-phase bed material area and the dilute-phase area and a refractory brick masonry layer contacting with the inner wall of the pressure-resistant shell, and the first refractory pouring layer is located between the inner wall of the pressure-resistant shell and the refractory brick masonry layer. The fluidized bed gasifier has the advantages that the first lining part and the second lining part are manufactured in a sectioned manner, and the fluidized bed gasifier is applicable to the catalytic coal gasification technology.

Owner:ENN SCI & TECH DEV

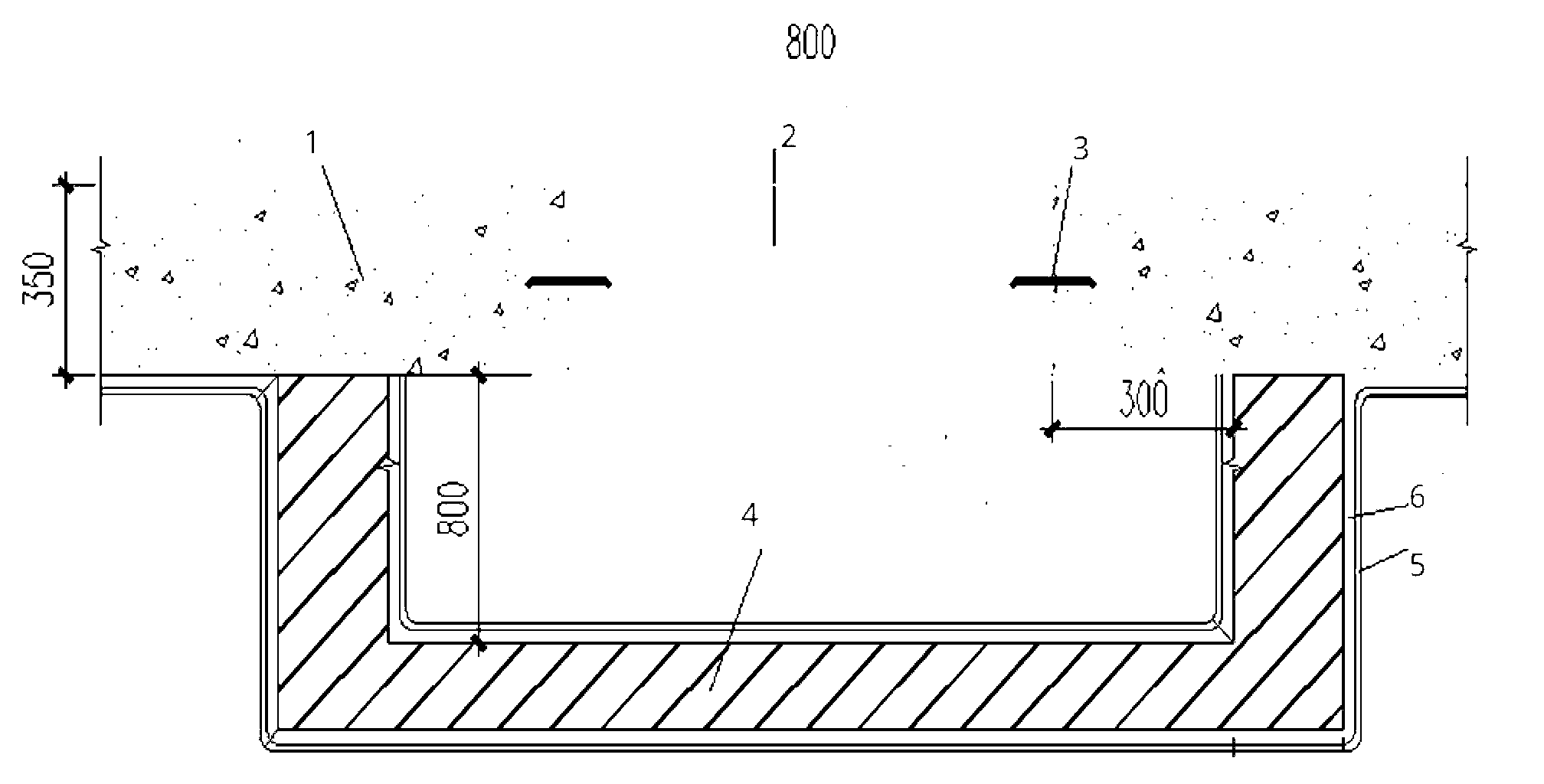

Basement exterior wall post-cast strip construction technology

InactiveCN103266632ASimple processIncrease stiffnessArtificial islandsUnderwater structuresBasementBrick masonry

The invention discloses basement exterior wall post-cast strip construction technology. The basement exterior wall post-cast strip construction technology includes the steps: 1) building a shale and solid brick masonry at the position of a basement exterior wall post-cast strip; 2) performing exterior wall waterproof roll construction; and 3) backfilling. Since construction is performed by using the masonry for protecting the post-cast strip, the basement exterior wall post-cast strip construction technology is convenient, rigidity is increased, and safety is higher.

Owner:ZHEJIANG HONGCHENG CONSTR GRP

High-ductility fiber concrete combined brick masonry wall and method for constructing same

ActiveCN102912892AImprove integrityImprove seismic performanceWallsBuilding material handlingFiberSurface layer

The invention discloses a high-ductility fiber concrete combined brick masonry wall and a method for constructing the same to solve problems of fragility, and poor seismic resistance and wholeness of prior common brick masonry walls. The high-ductility fiber concrete combined brick masonry wall is composed of a brick wall, short rebars and a high-ductility fiber concrete surface layer. During the construction, a masonry wall is constructed, the short rebars are embedded in vertical mortar joints of the brick wall, and the high-ductility fiber concrete is coated on the surface of the brick wall. According to the high-ductility fiber concrete combined brick masonry wall and the method for constructing the same, the compressive capacity, the shearing resistance and the seismic resistance of the brick masonry wall are better than those of a traditional brick wall, and brittle failure is not easy to occur; and simultaneously, the brick masonry wall is simple to construct and low in construction cost.

Owner:西安五和新材料科技集团股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com