Patents

Literature

1433results about How to "Reduce replacement time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

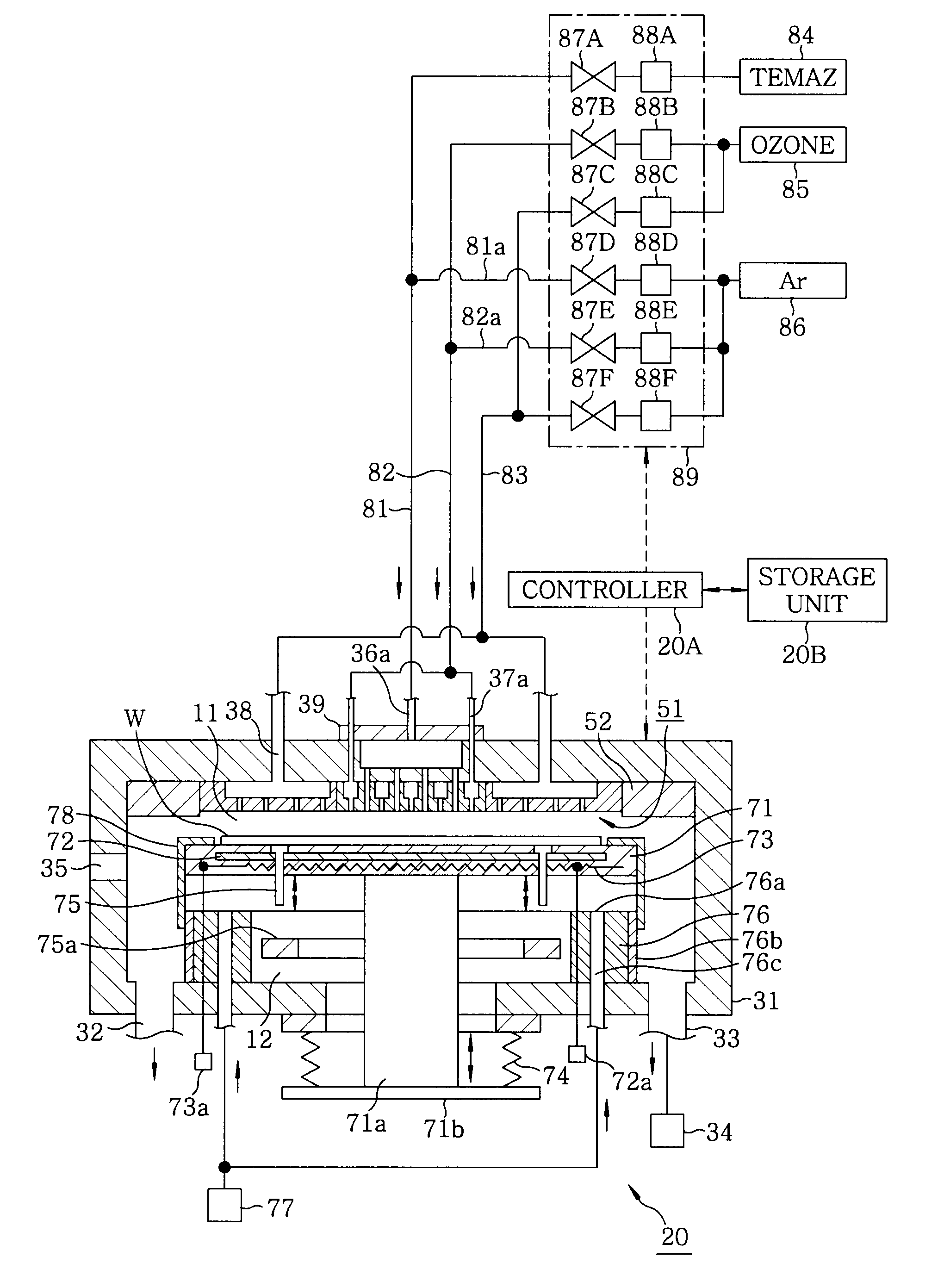

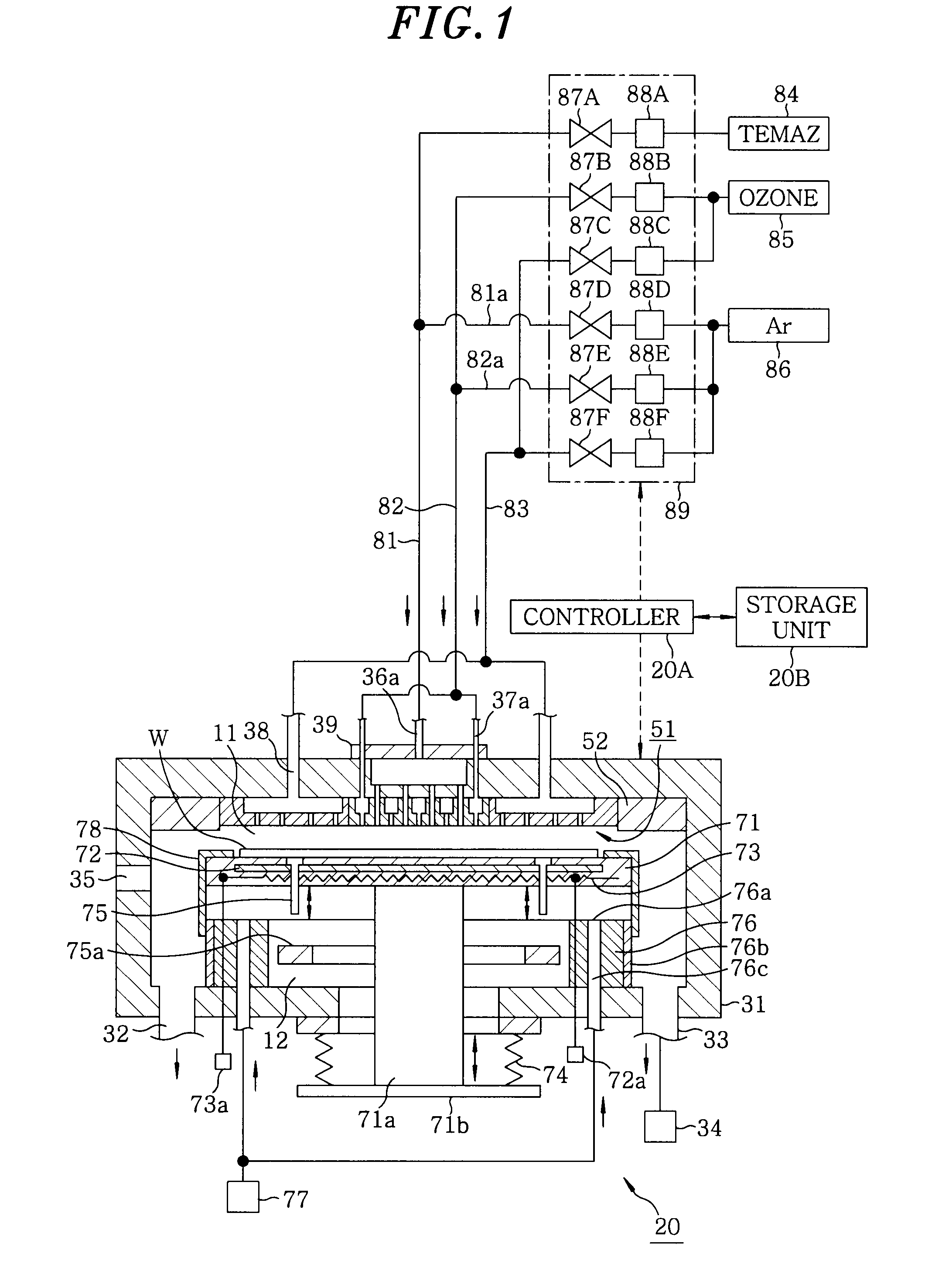

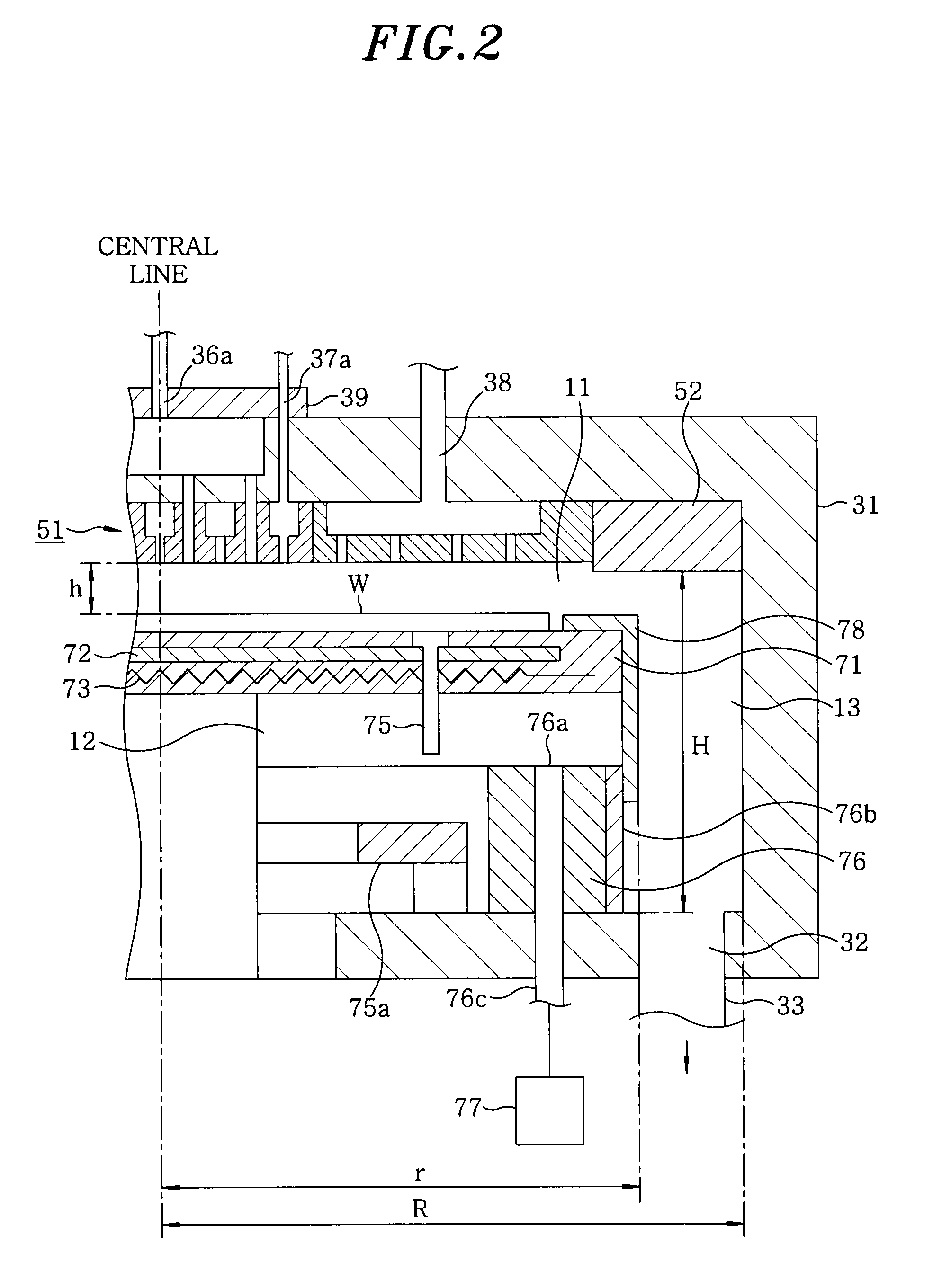

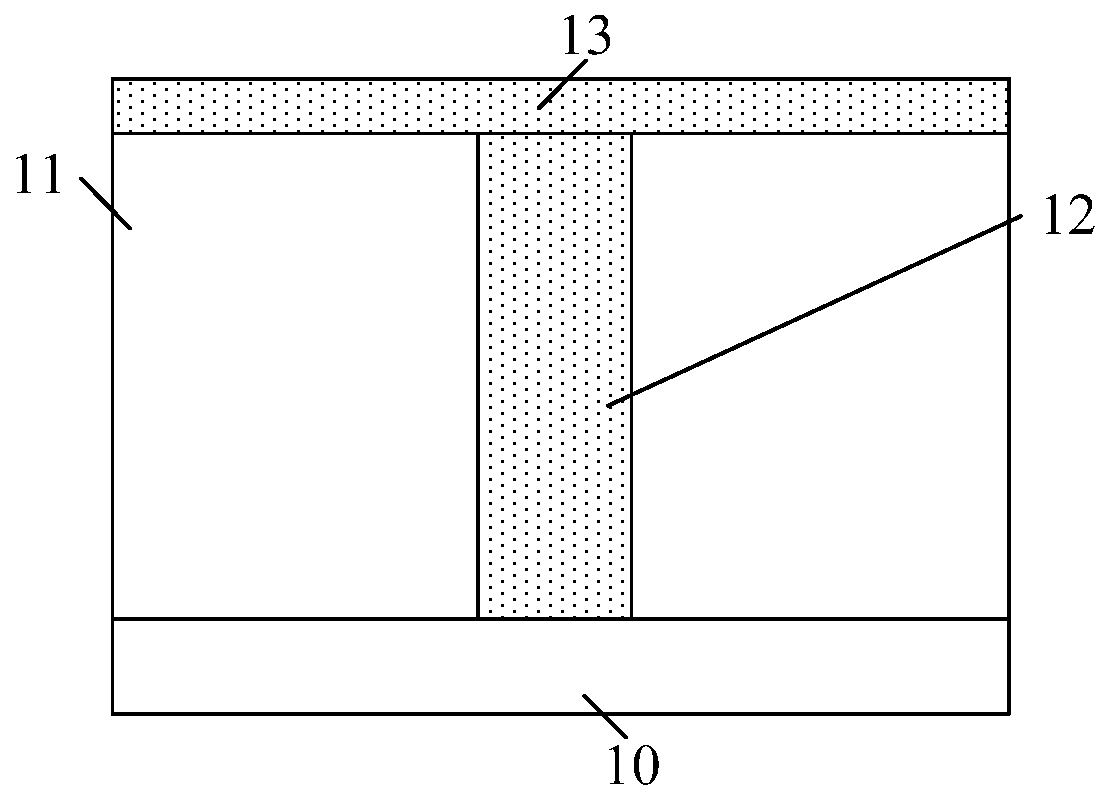

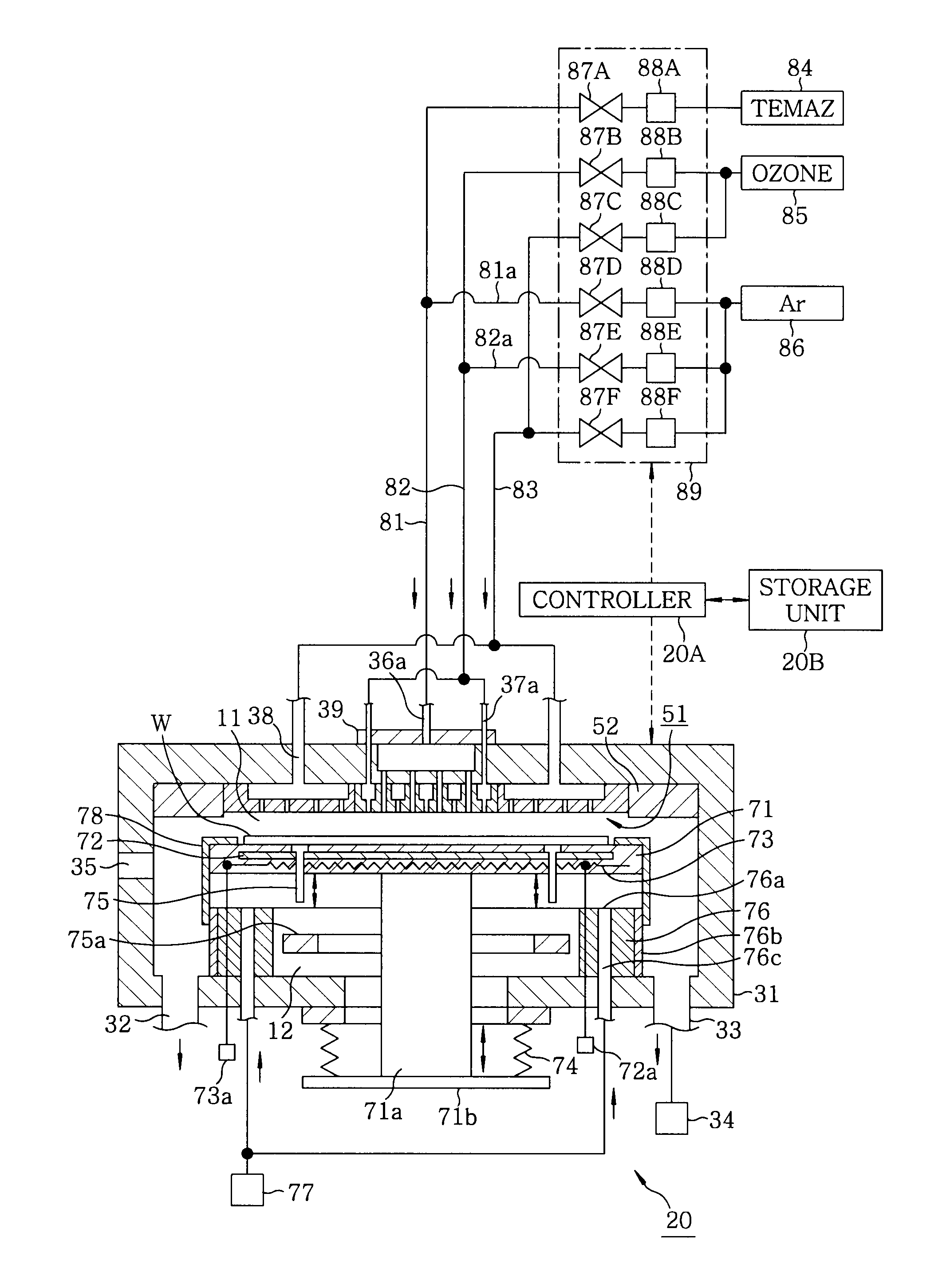

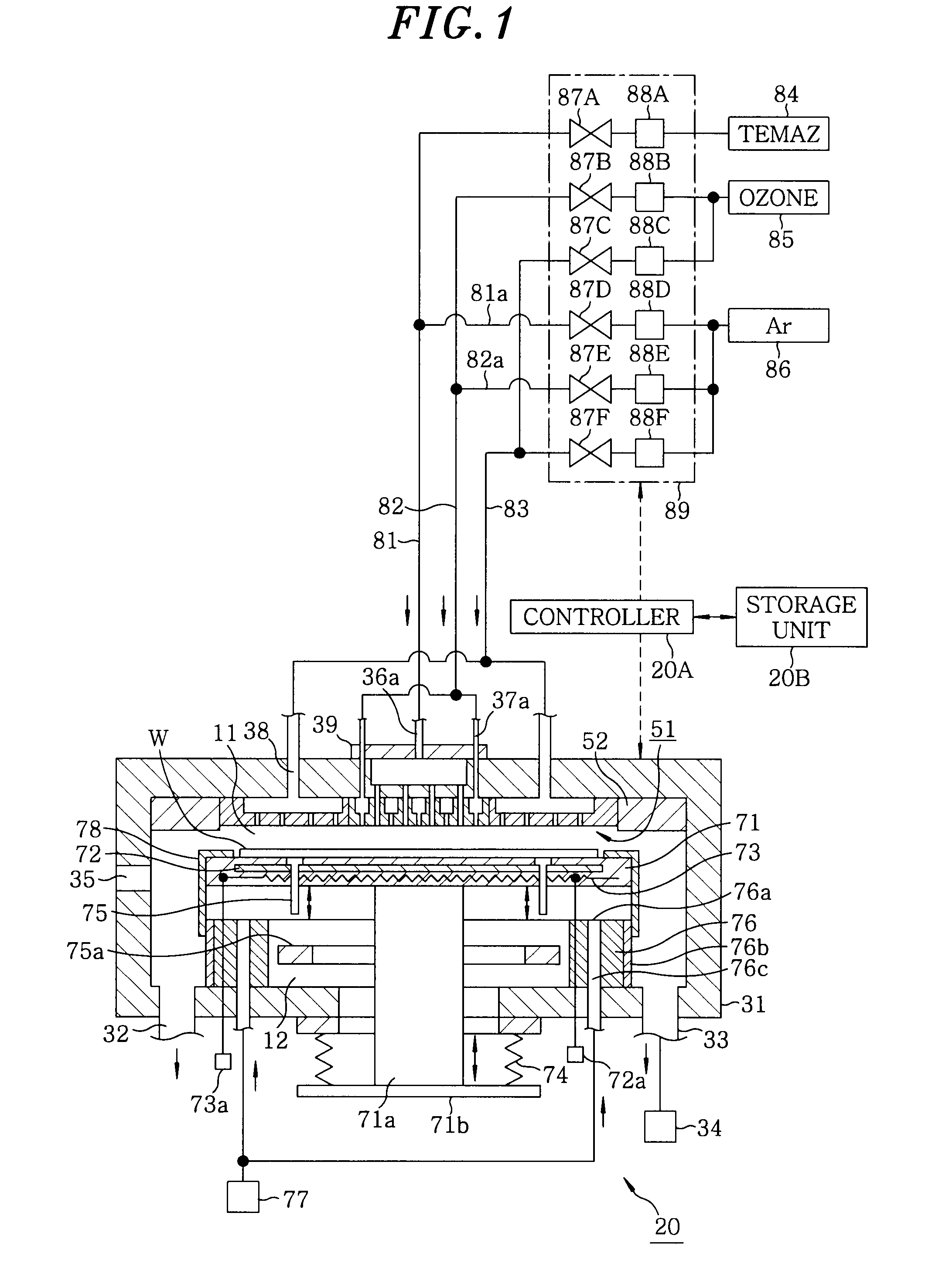

Film forming apparatus, film forming method and storage medium

ActiveUS20100119727A1Reduce gas volumeShorten the timeComputer controlPretreated surfacesEnergy supplyProduct gas

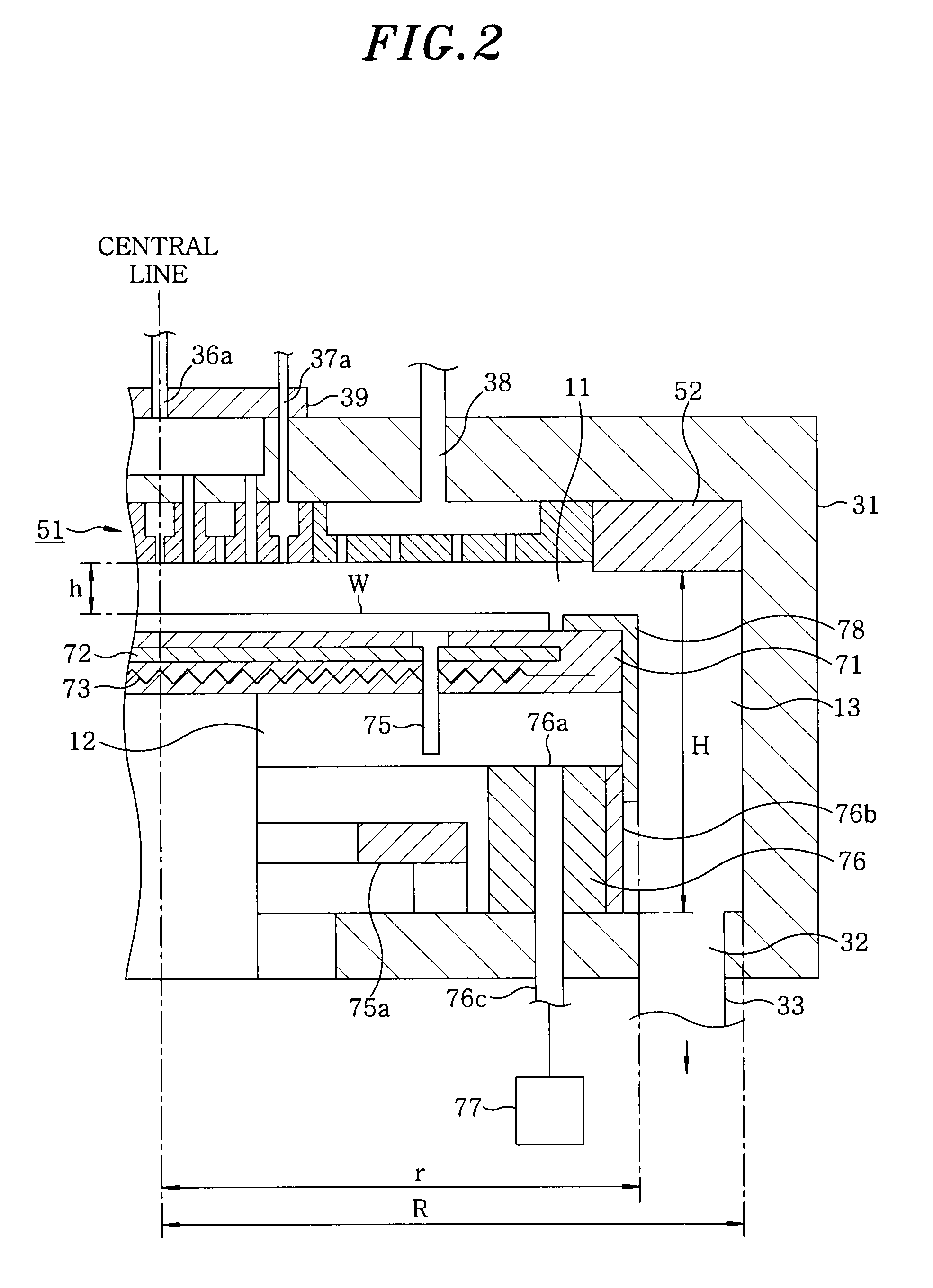

A film forming apparatus includes a processing chamber, and a mounting table disposed in the processing chamber to mount a substrate thereon. The film forming apparatus further includes a gas shower head having gas supply holes and including a central region facing a central portion of the substrate and a peripheral region facing a peripheral portion of the substrate, a first processing gas supply unit for supplying a first processing gas to the central region, a second processing gas supply unit for supplying a second processing gas to the central region, an energy supply unit for supplying energy to react the first processing gas with the second processing gas on the substrate, and a purge gas supply unit for supplying a purge gas to the central region and the peripheral region when one of the first and the second processing gas is switched by the other.

Owner:TOKYO ELECTRON LTD

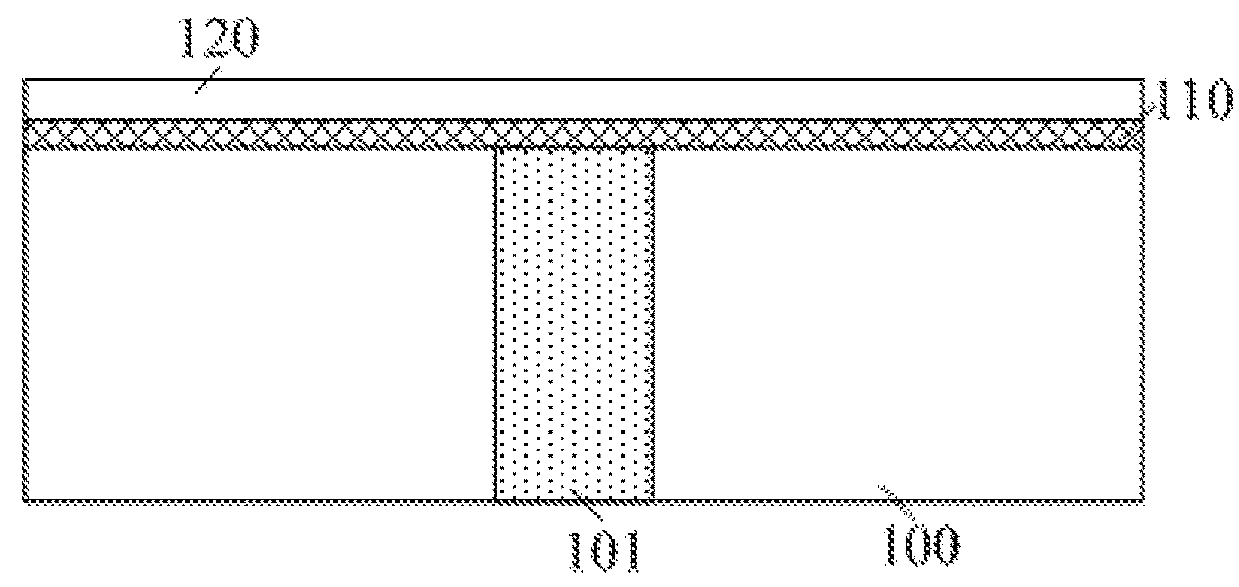

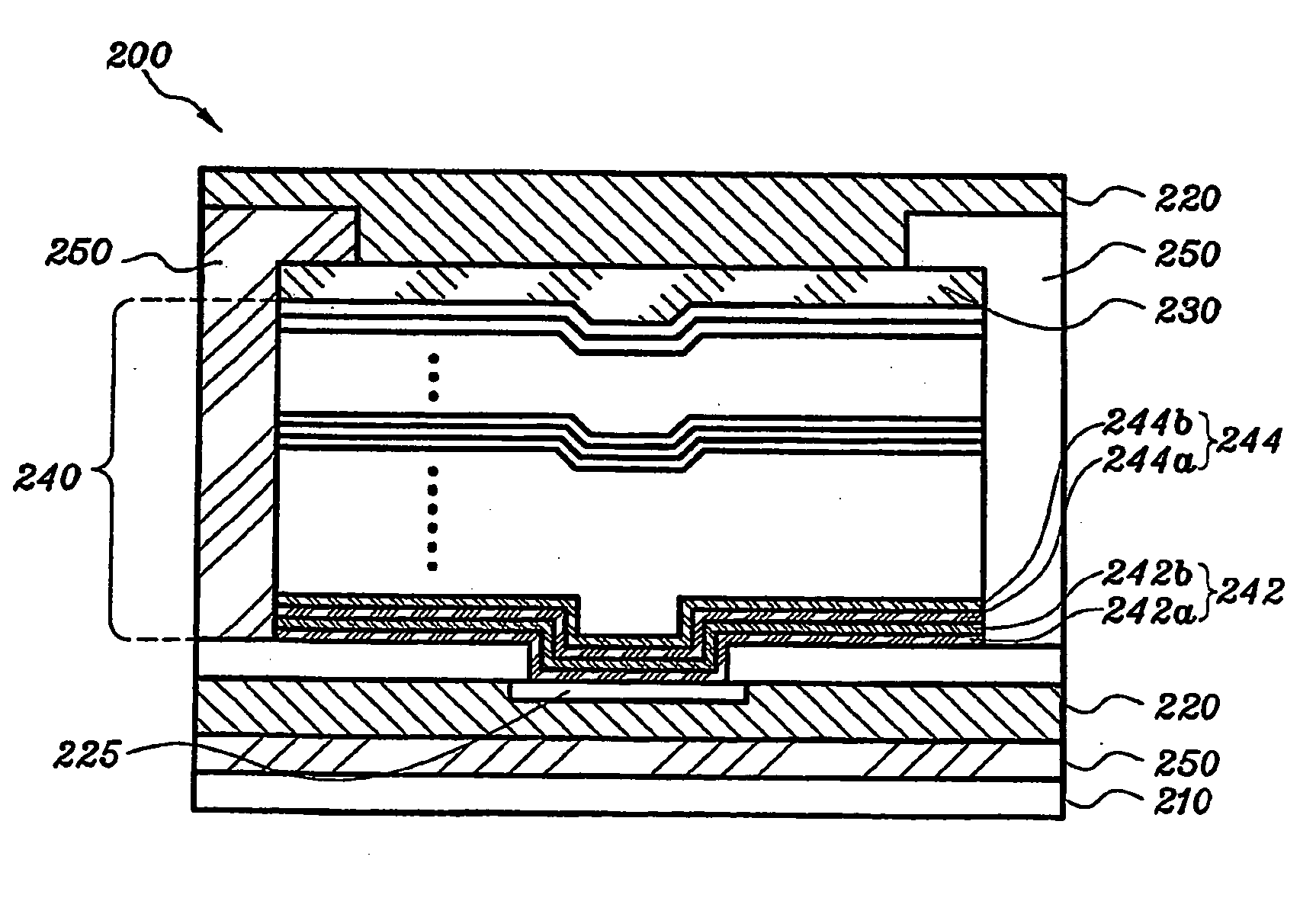

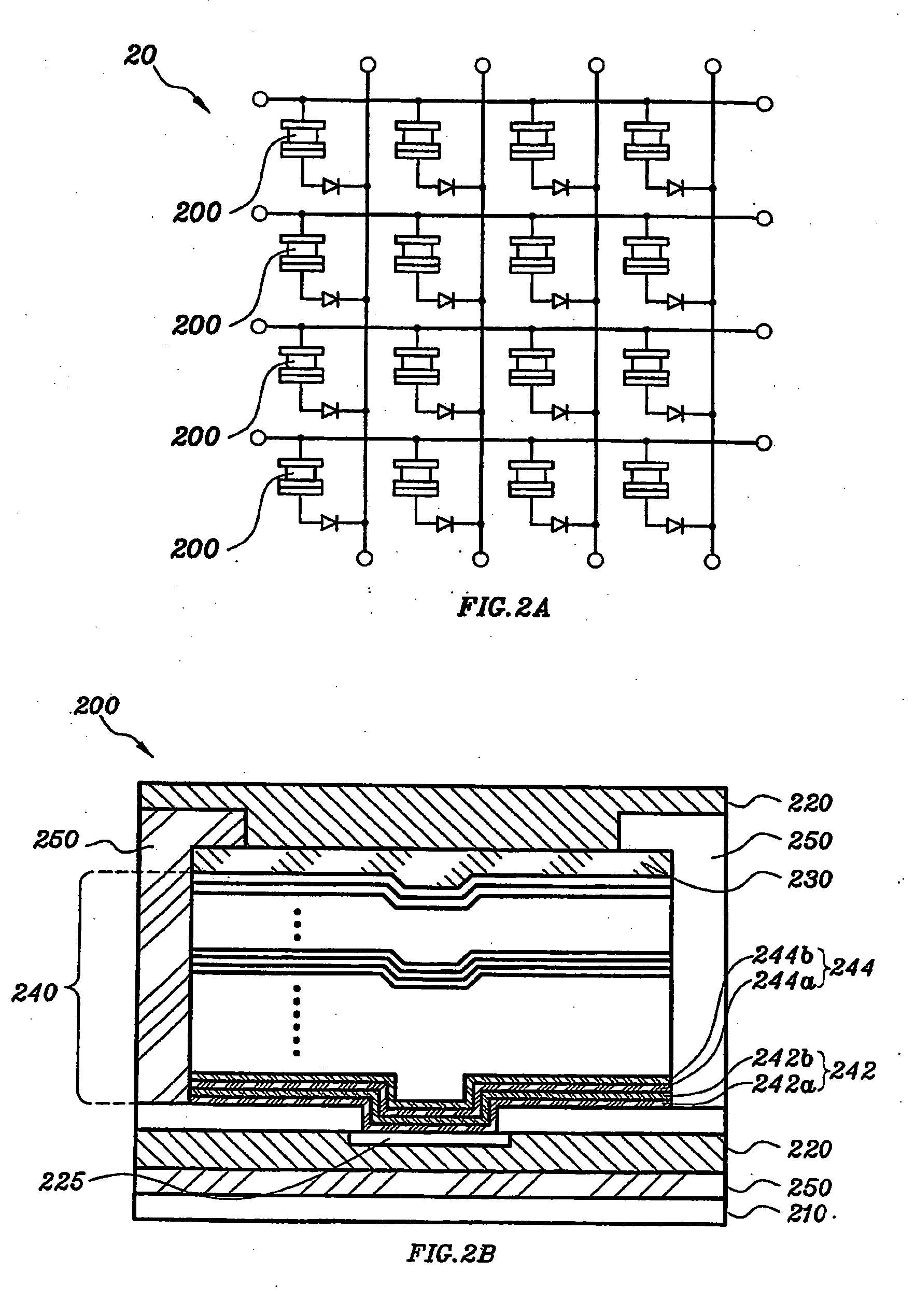

Phase change memory and fabrication method thereof

ActiveUS20180269393A1Change speedReduce replacement timeElectrical apparatusDigital storagePhase-change memoryPhase-change material

A phase change memory and a fabrication method are provided. The fabrication method includes: providing a substrate; forming a heating layer on the substrate; forming a phase change layer on and in contact with one sidewall surface of the heating layer. The phase change memory includes: a substrate; a heating layer on the substrate; and a phase change layer on and in contact with one sidewall surface of the heating layer.

Owner:SEMICON MFG INT (SHANGHAI) CORP +1

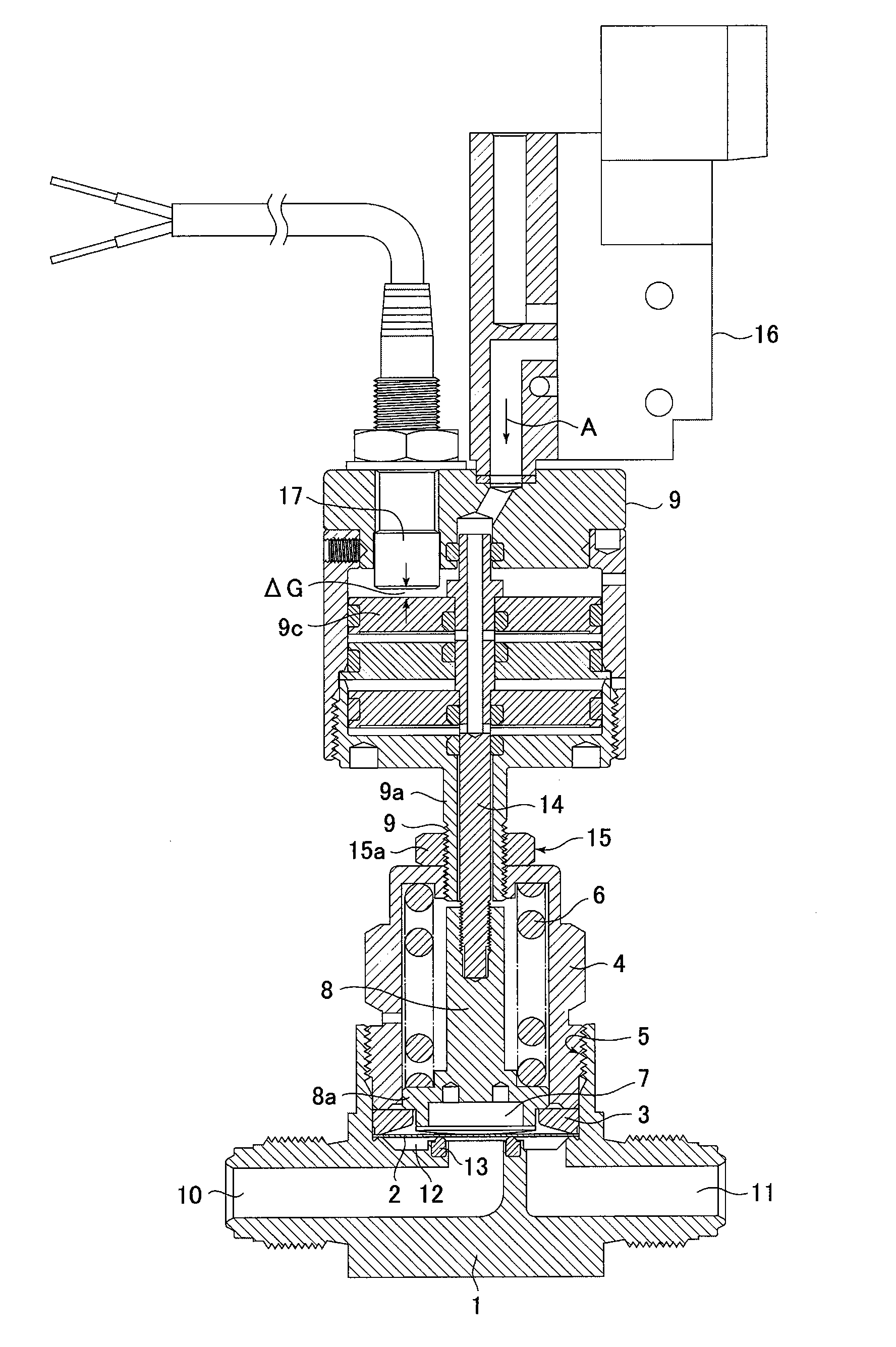

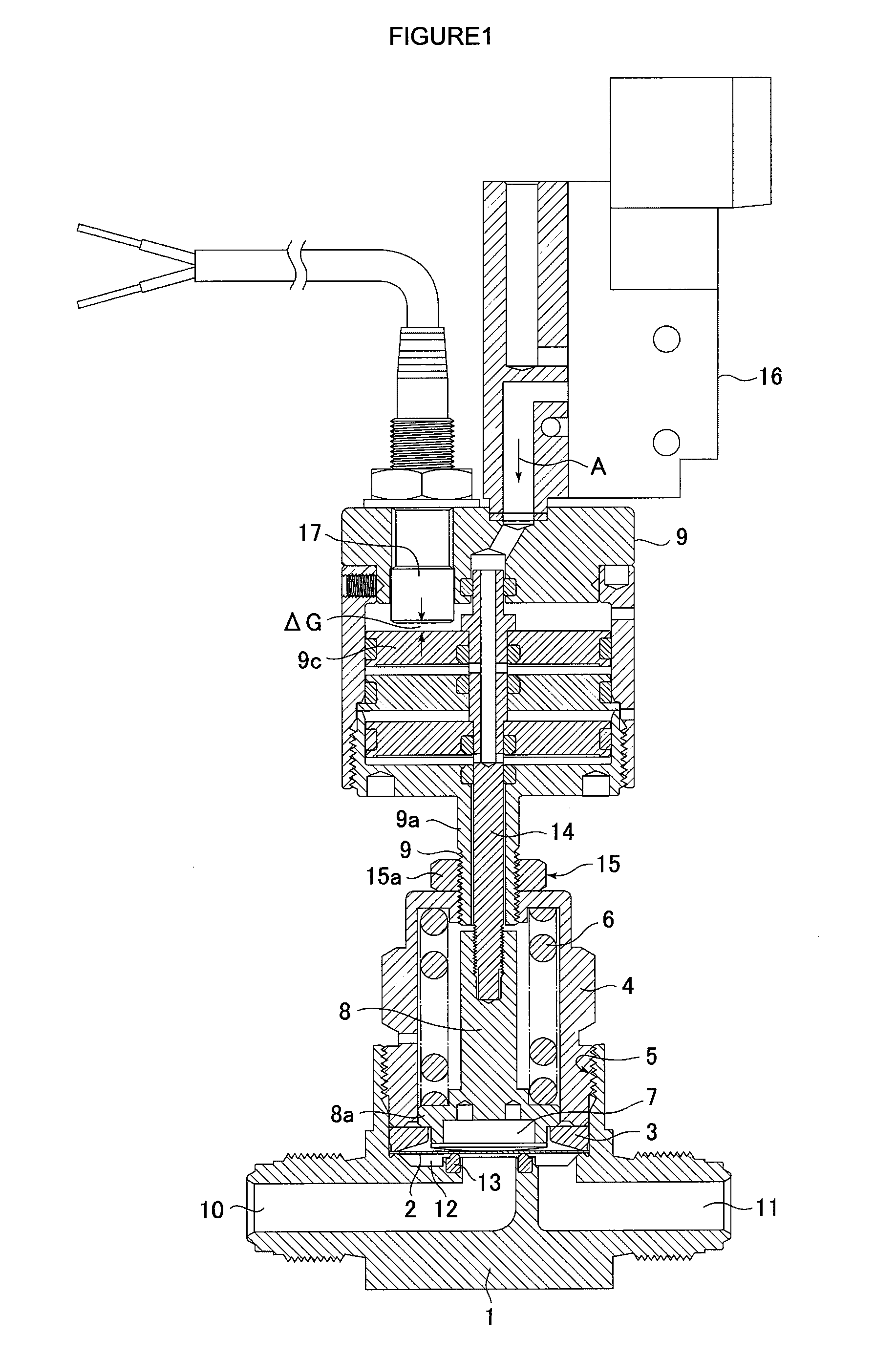

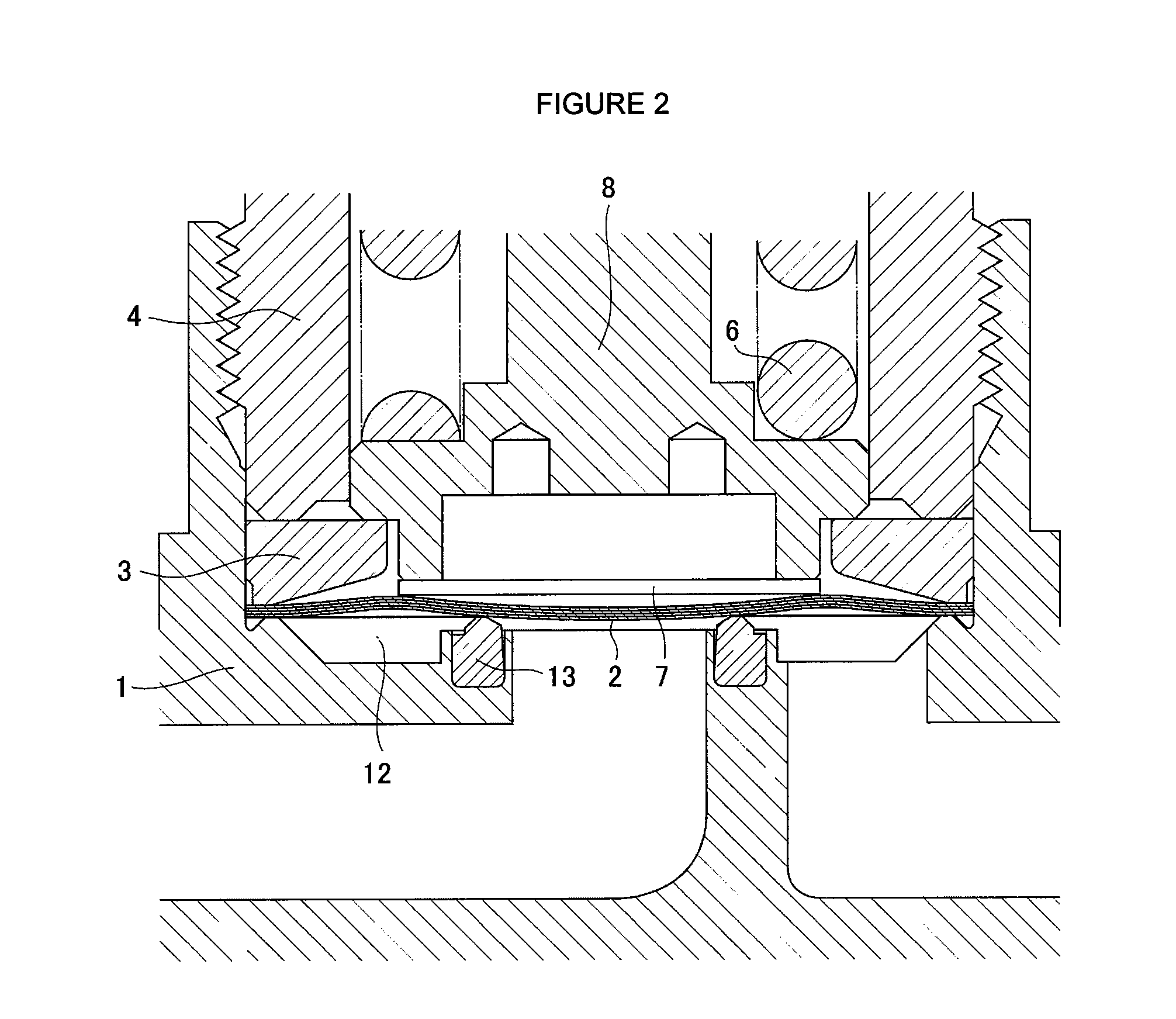

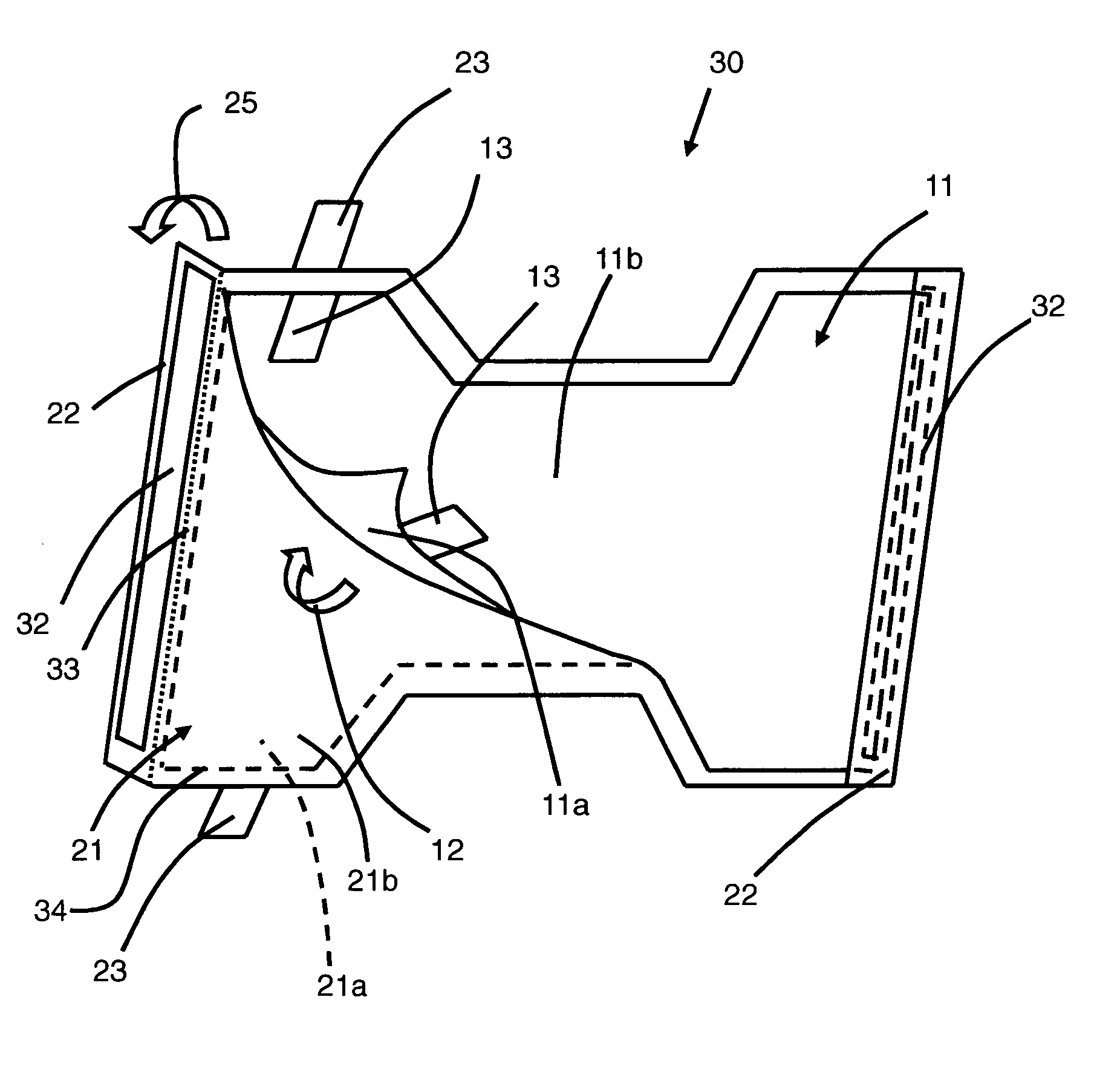

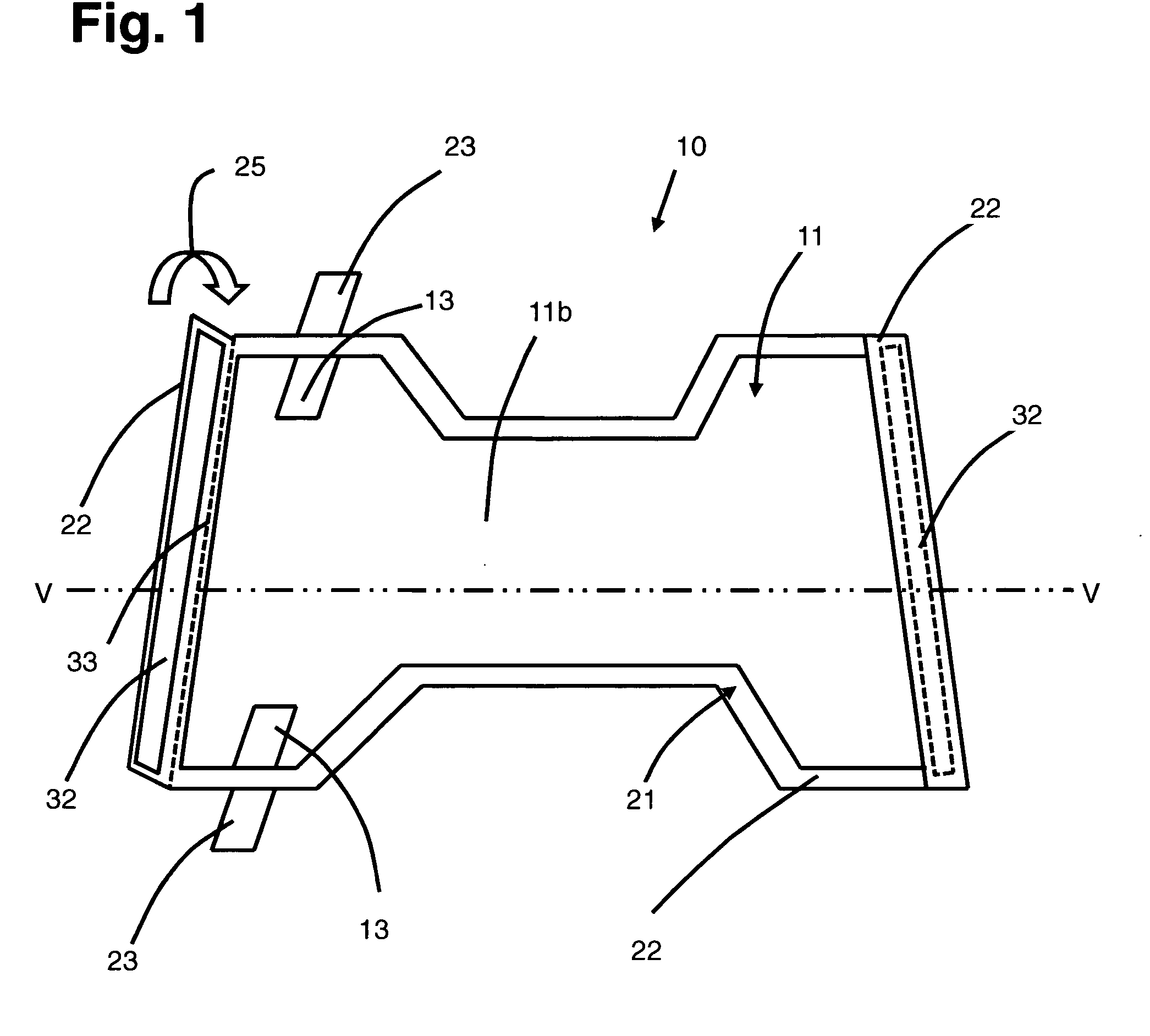

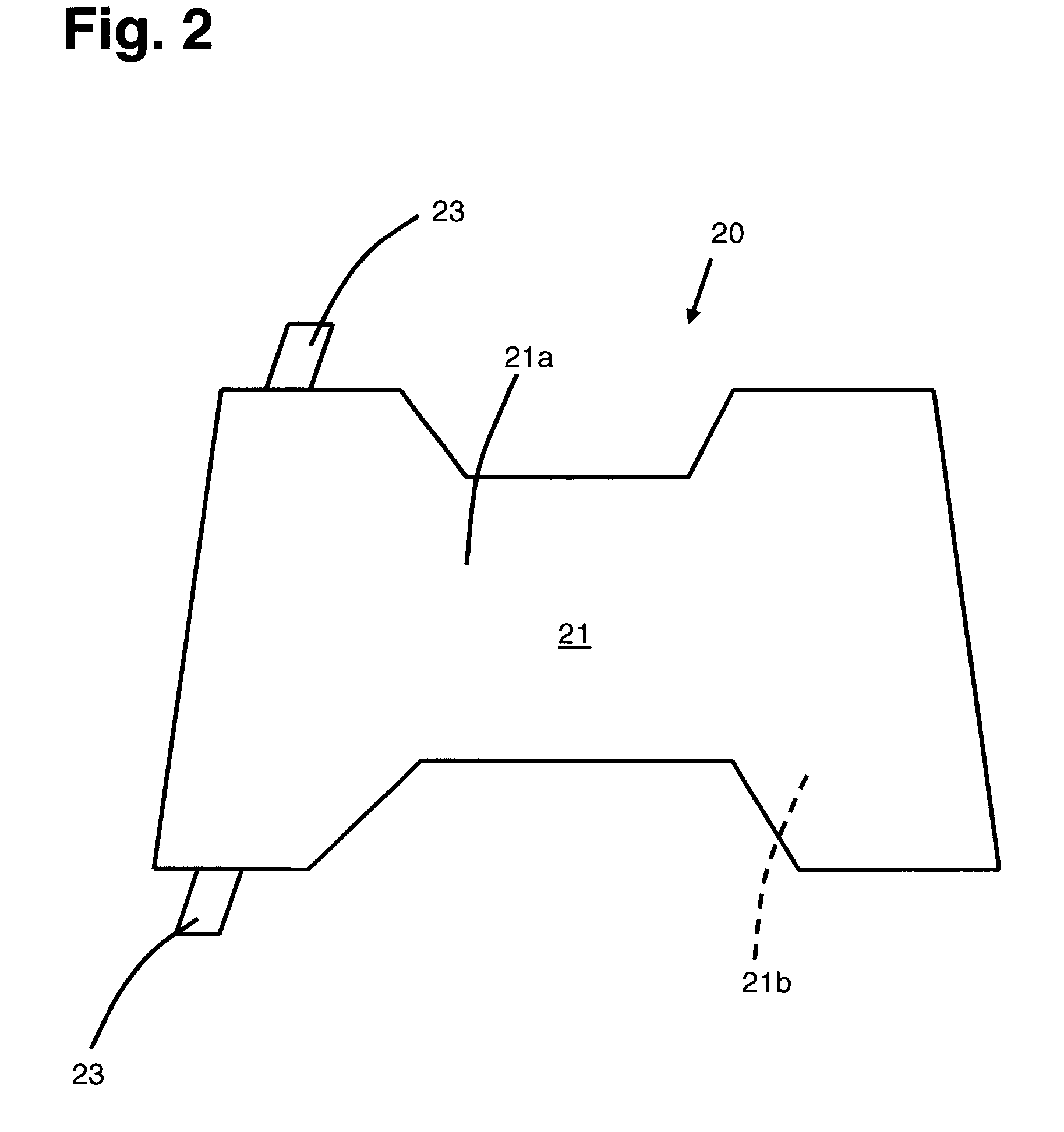

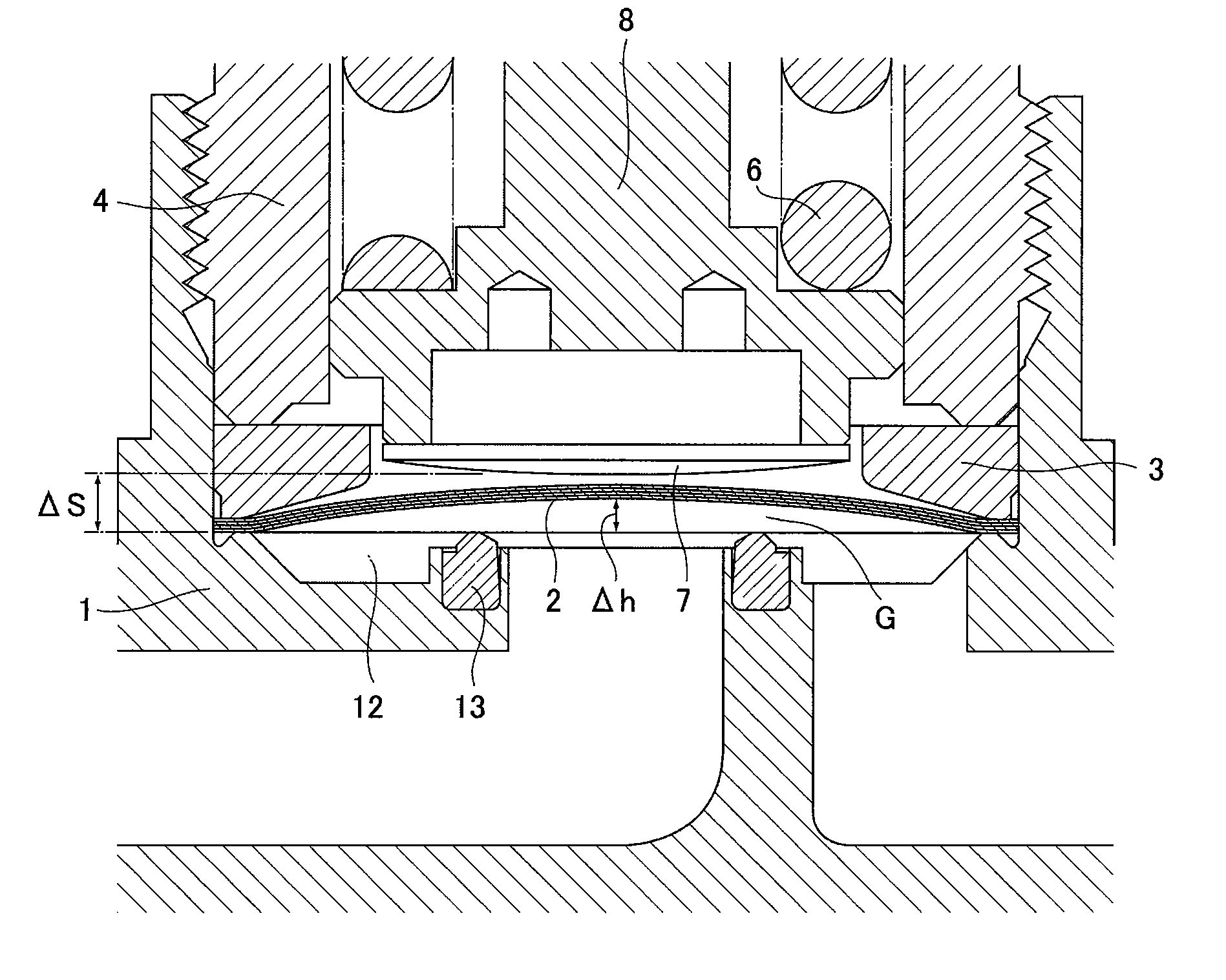

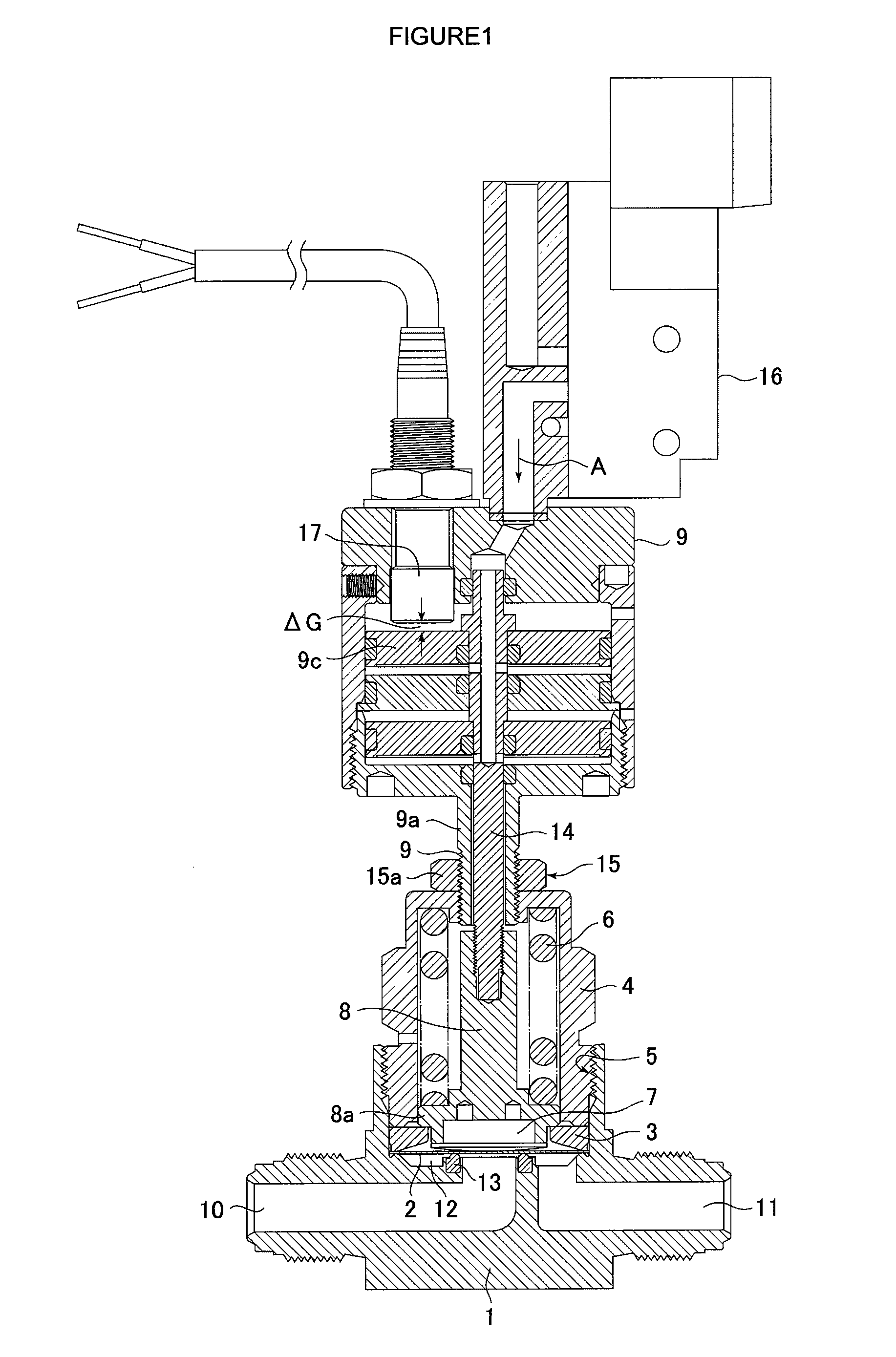

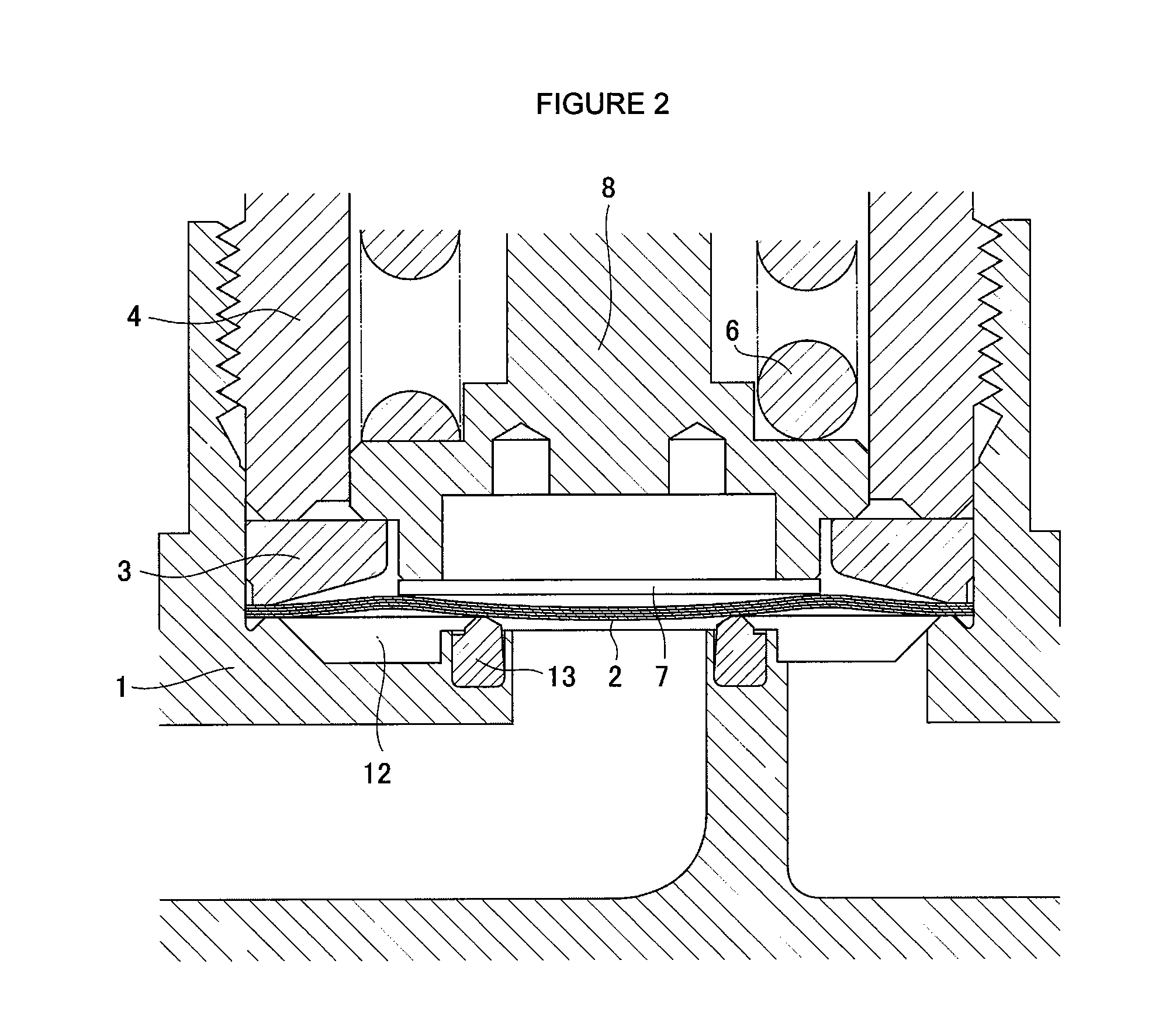

Direct touch type metal diaphragm valve

ActiveUS20100090151A1Reduce replacement timeAchieve stabilityDiaphragm valvesOperating means/releasing devices for valvesDirect touchEngineering

A direct touch type metal diaphragm valve, wherein durability of the valve, that is to say, the ensured number of continuous open / close operations of the valve, is substantially increased under conditions that an appropriate flow rate coefficient Cv is maintained, and changes of the afore-mentioned Cv value over time are mitigated by means of restricting the deformation of the valve seat over time. The afore-mentioned metal diaphragm is formed in a round, reverse-dish shape by laminating a plural number of thin stainless steel plates and a thin Nickel.Cobalt alloy plate, and its center part is bulged upward, and the maximum valve stroke of the valve is regulated to be 55% to 70% of the distance of the maximum bulge height Δh of the afore-mentioned metal diaphragm.

Owner:FUJIKIN INC

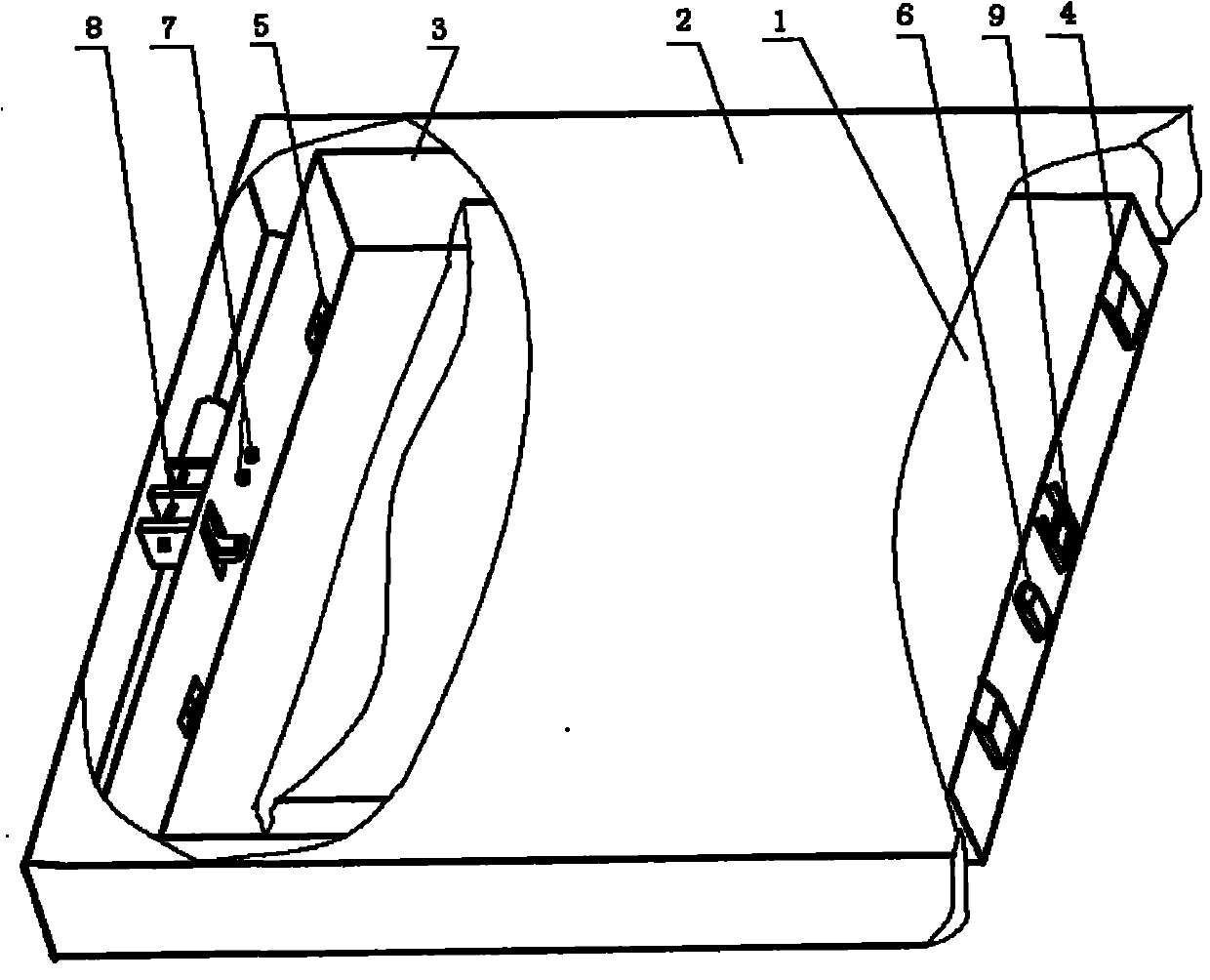

Battery container locking system and installation method of electric vehicle

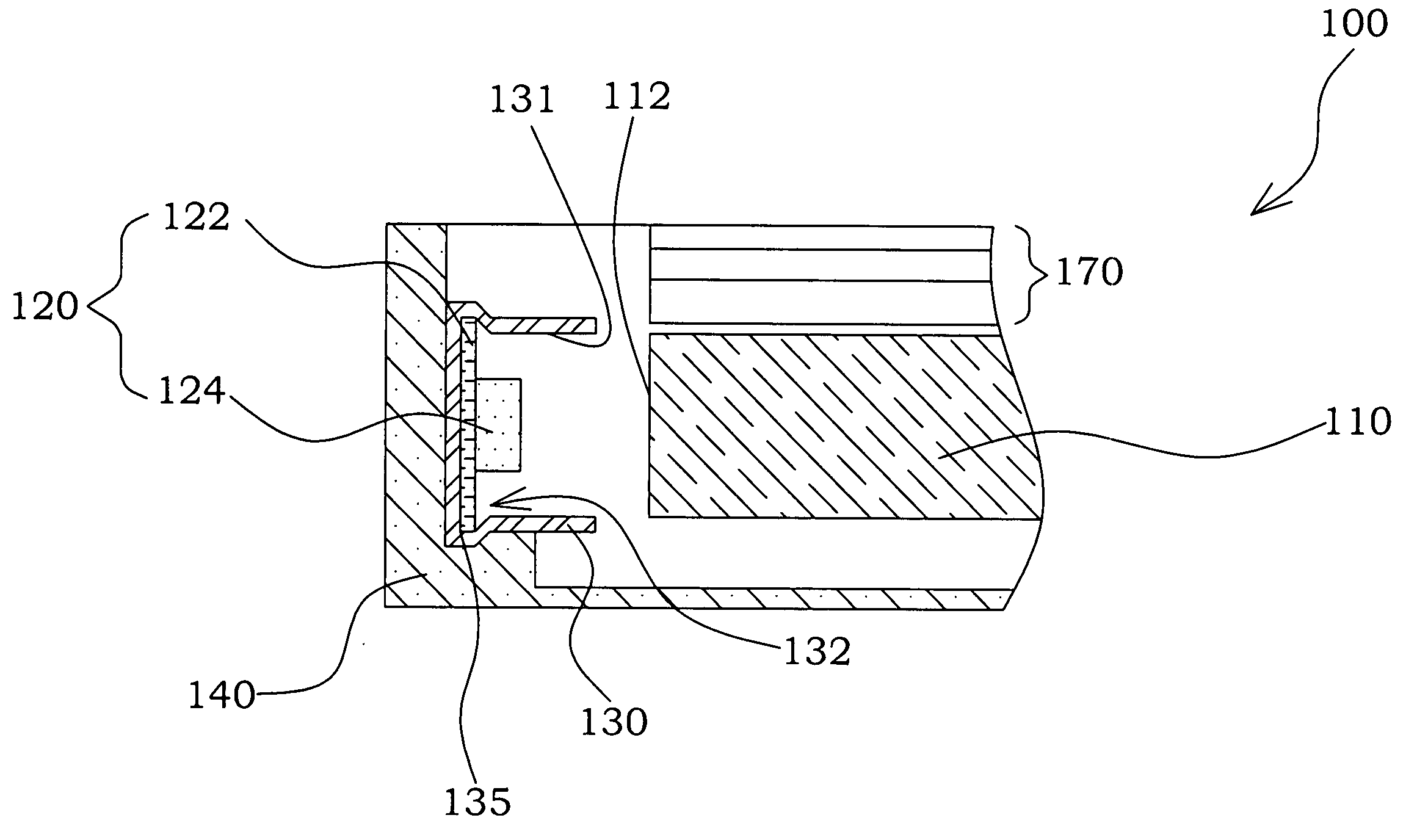

ActiveCN101973201AStable jobReduce replacement timeCharging stationsRailway vehiclesAutomotive batteryEngineering

The invention relates to battery container locking system and installation method of an electric vehicle. The battery container locking system comprises a battery container guiding and positioning device, a battery container pre-tightening device and a battery container locking device, wherein the battery container guiding and positioning device is used for guiding and positioning a battery container during the process of installing the battery container; the battery container pre-tightening device is used for tightly compressing the battery container so as to improve installation rigidity of the battery container; and the battery container locking device is used for locking and fixing the battery container in a battery box. In the invention, the battery container can be installed and locked quickly and efficiently, and the stable work of the battery container is ensured.

Owner:BEIJING KEY POWER TECH

Film forming apparatus, film forming method and storage medium

ActiveUS8539908B2Reduce gas volumeShorten the timeComputer controlSemiconductor/solid-state device manufacturingEnergy supplyProcess engineering

A film forming apparatus includes a processing chamber, and a mounting table disposed in the processing chamber to mount a substrate thereon. The film forming apparatus further includes a gas shower head having gas supply holes and including a central region facing a central portion of the substrate and a peripheral region facing a peripheral portion of the substrate, a first processing gas supply unit for supplying a first processing gas to the central region, a second processing gas supply unit for supplying a second processing gas to the central region, an energy supply unit for supplying energy to react the first processing gas with the second processing gas on the substrate, and a purge gas supply unit for supplying a purge gas to the central region and the peripheral region when one of the first and the second processing gas is switched by the other.

Owner:TOKYO ELECTRON LTD

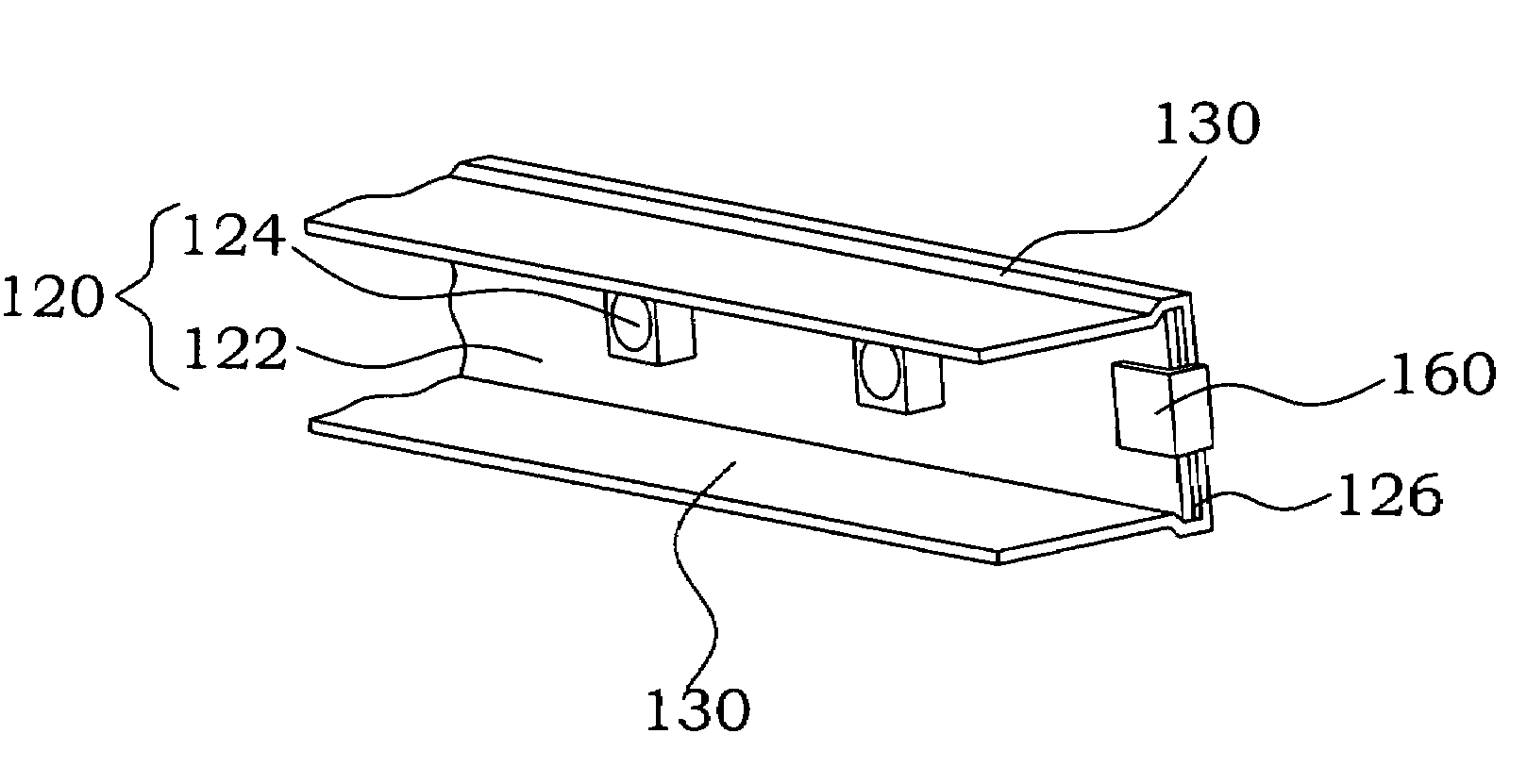

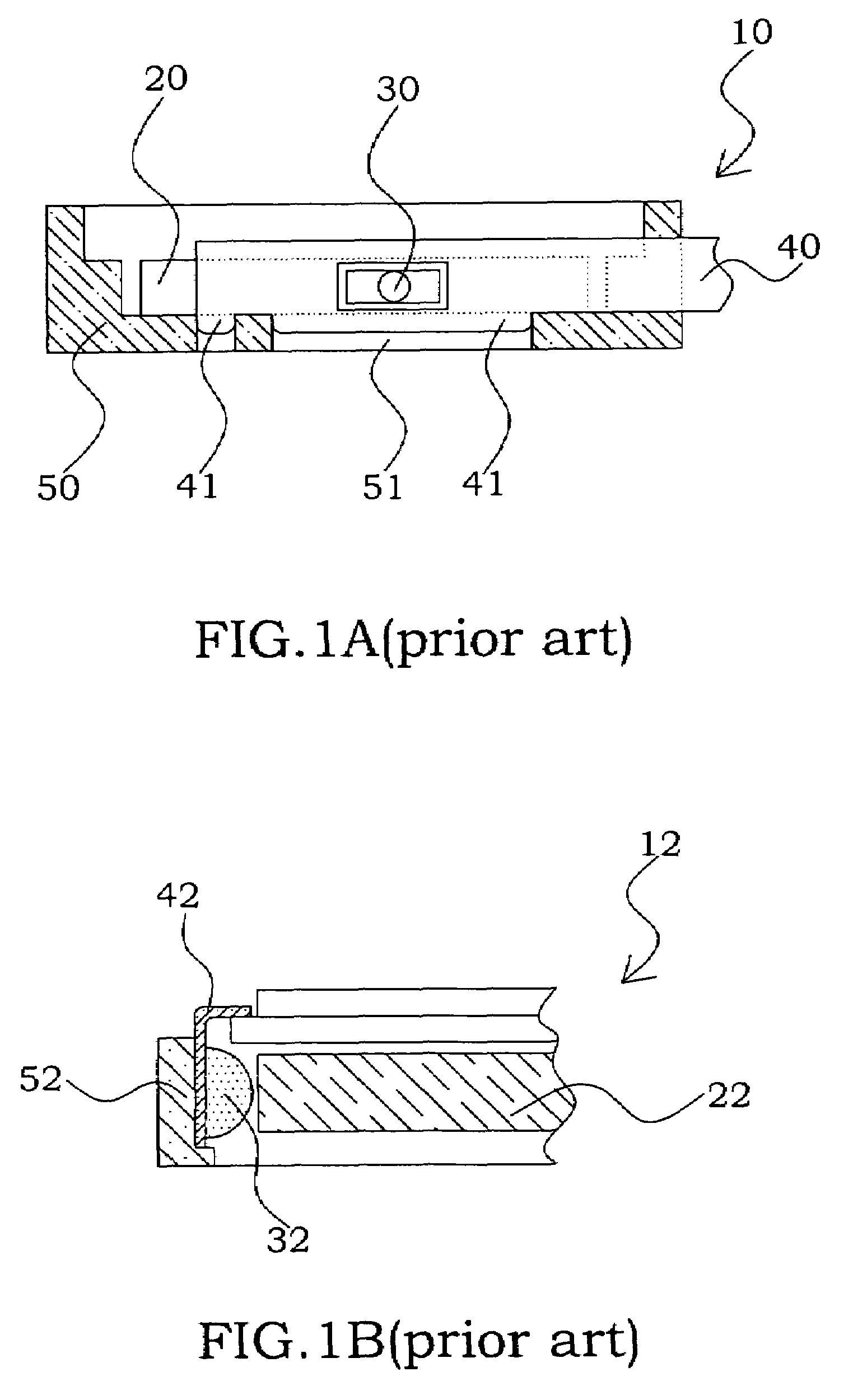

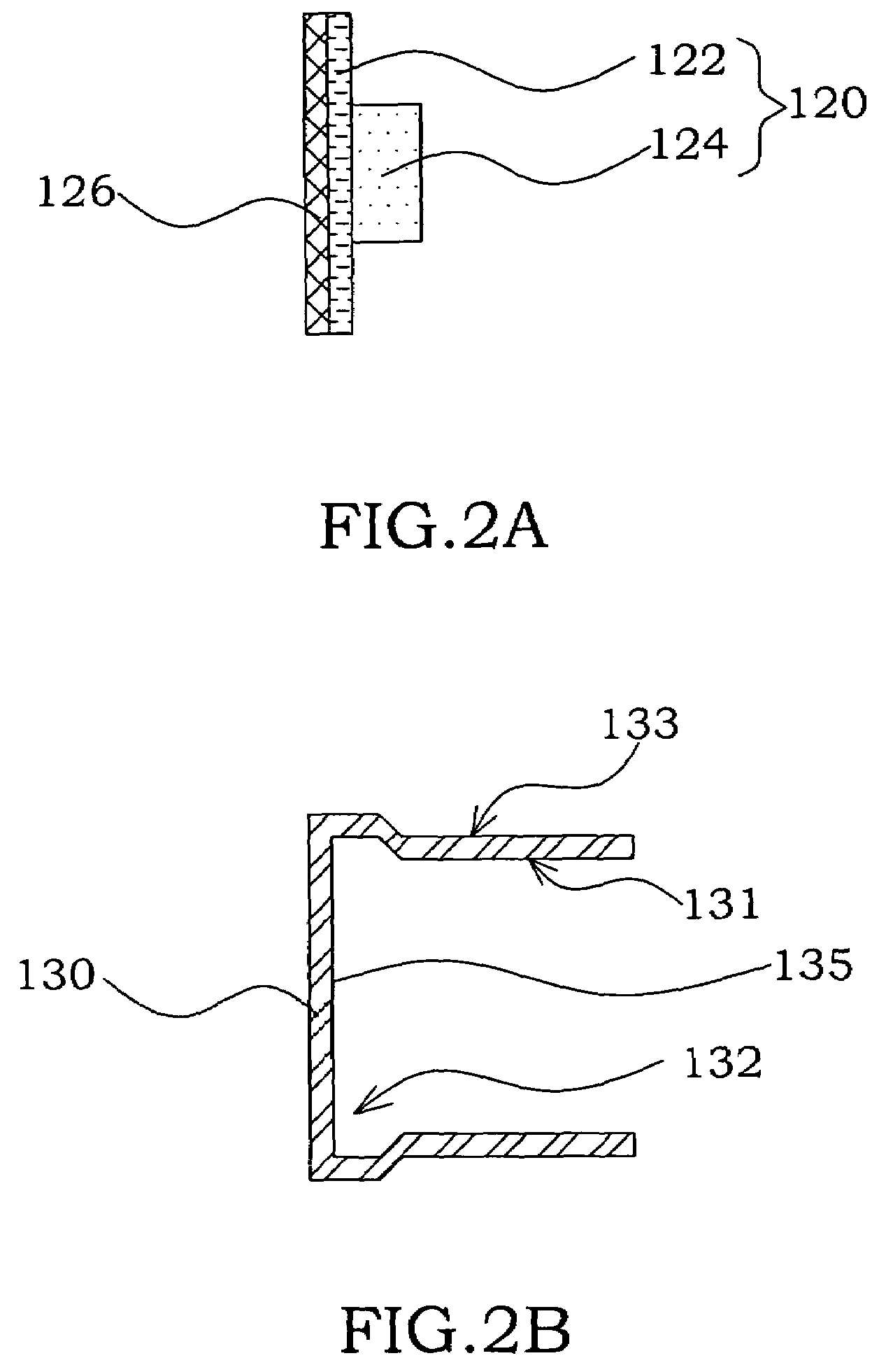

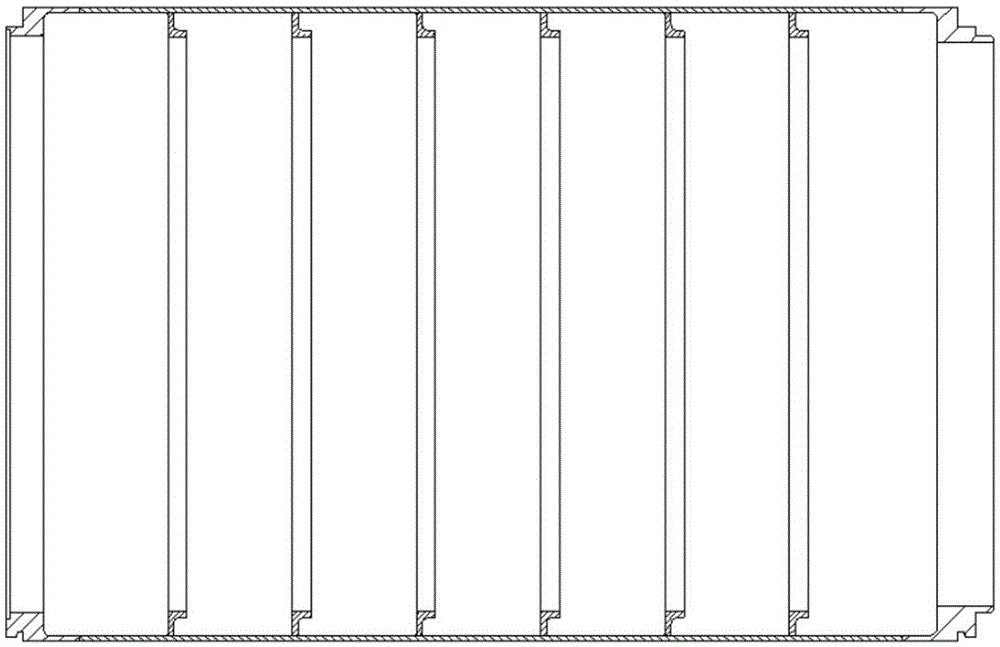

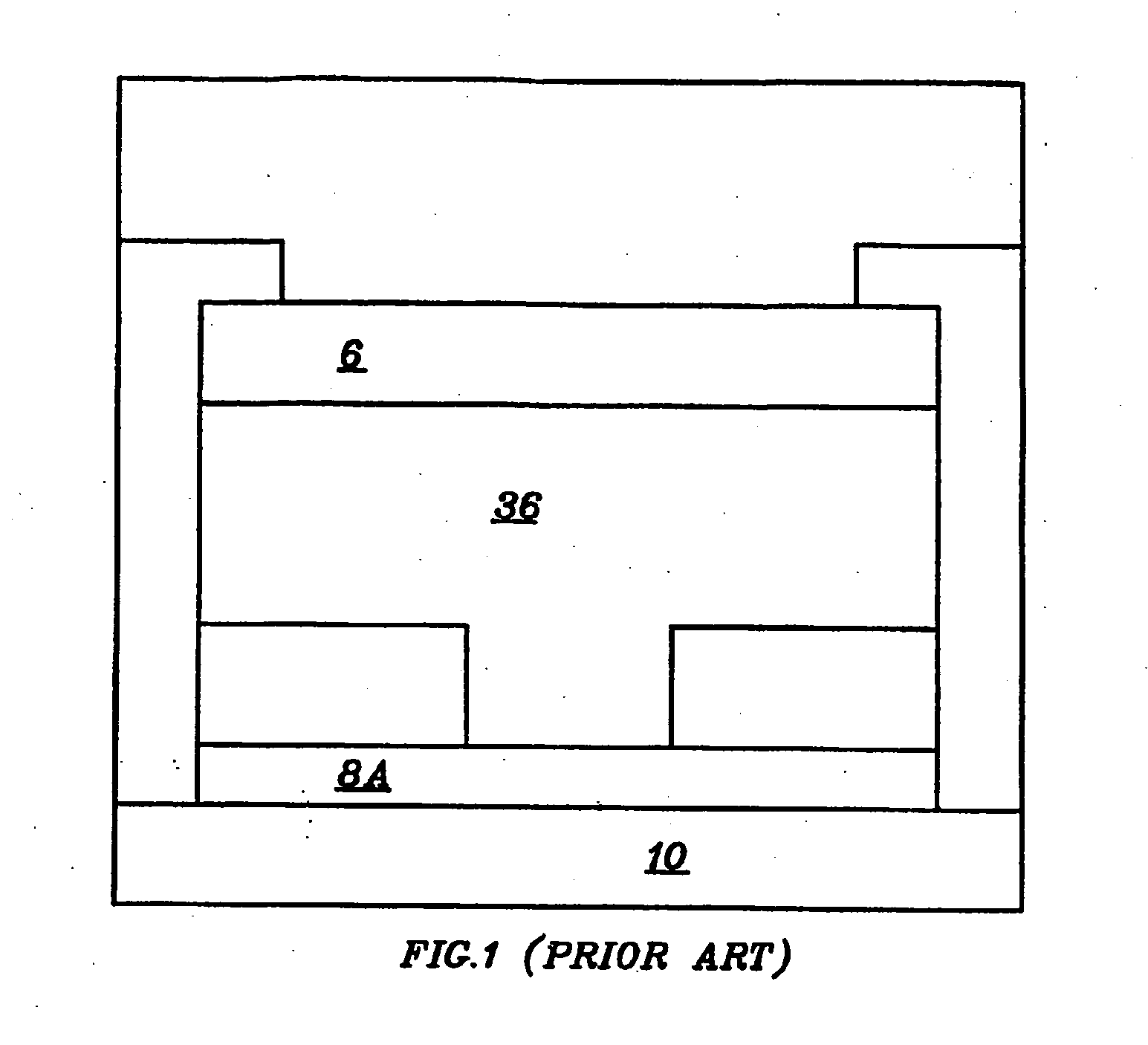

Light-source fixing structure for backlight module

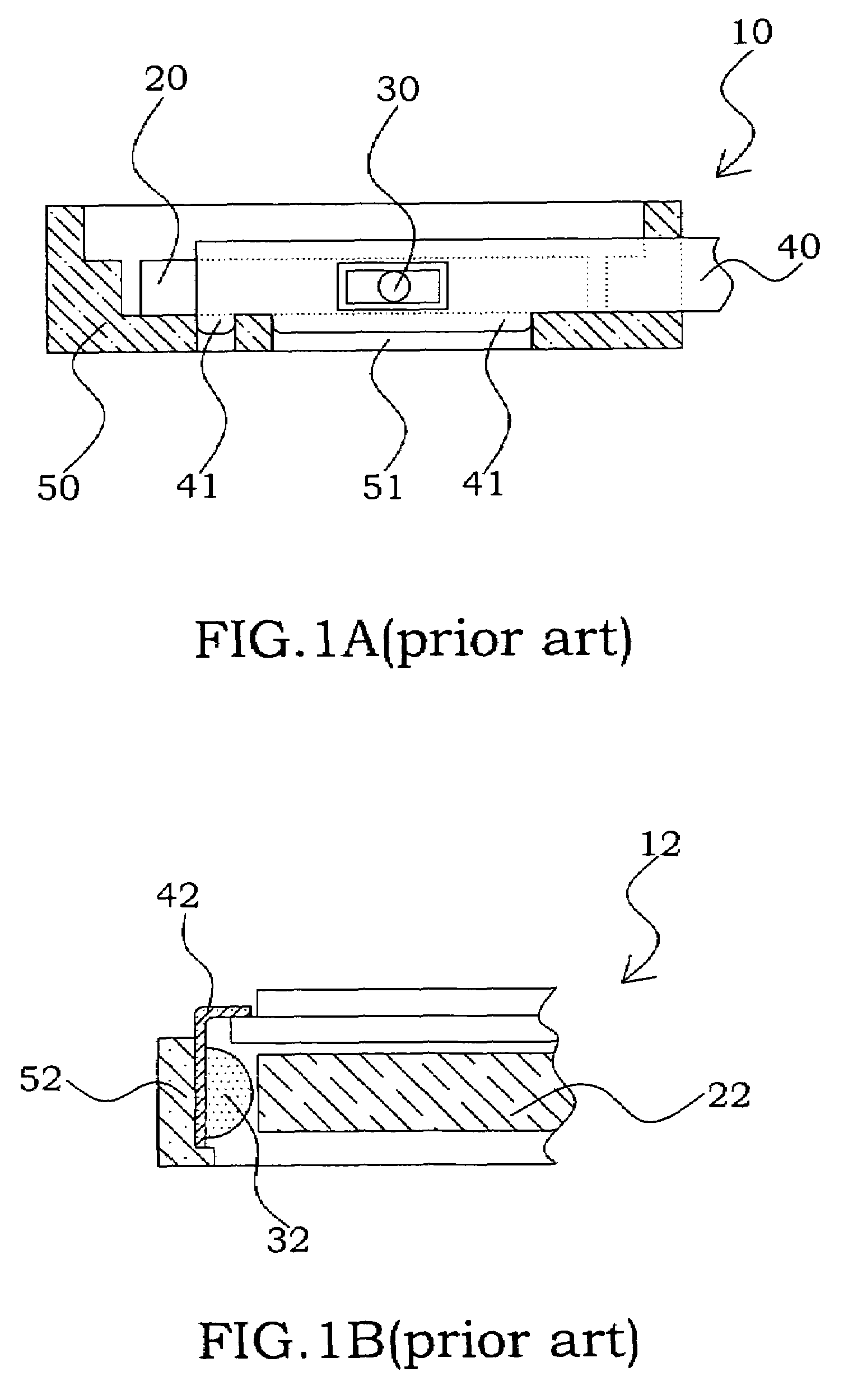

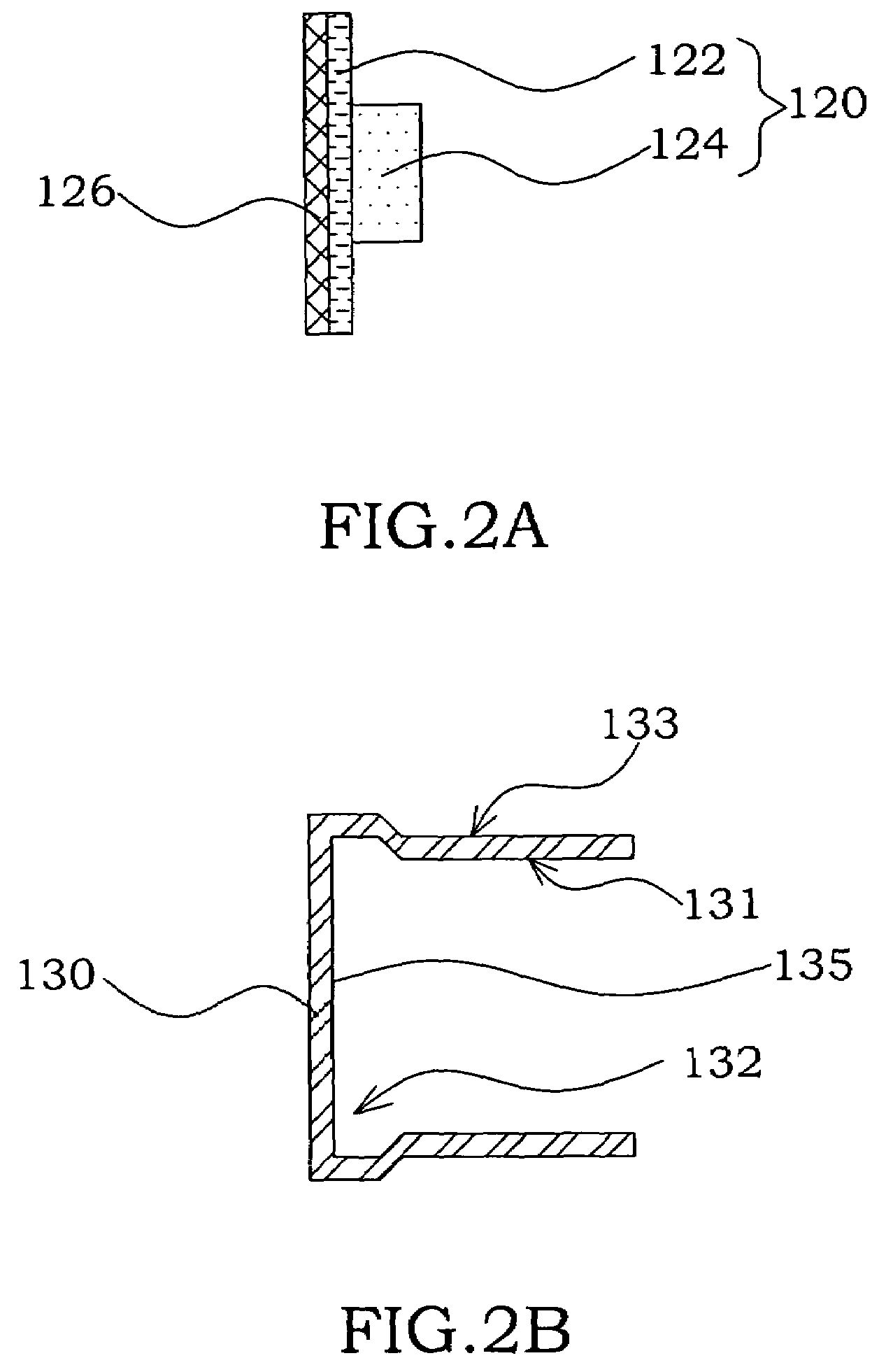

InactiveUS20080049444A1Low production costUnnecessary reflectionOptical light guidesReflectorsLight guideEngineering

A light-source fixing structure for the backlight module is disclosed. The light-source fixing structure includes: a light guide plate provided with a light-incident surface; a cover having a groove, wherein the groove has a surface facing toward to the light-incident surface of the light guide plate; a light bar arranged upon the surface of the groove. The light bar may be replaced easily by sliding out from the groove when the light bar is damaged. The cover not only may enhance the strength of the backlight module but also may prevent the backlight module over temperature.

Owner:CHUNGHWA PICTURE TUBES LTD

Hydrophobic silica aerogel heat-insulation composite material

The invention relates to a hydrophobic silica aerogel heat-insulation composite material. The composite material consists of silica aerogel and an inorganic fiber product, wherein the silica aerogel is doped with a flame retardant and an infrared blocking agent; the inorganic fiber product comprises one or more of glass fibers, quartz glass fibers, aluminium silicate fibers, ceramic fibers, alumina fibers, zirconia fibers, rock wool fibers and basalt fibers, and the porosity of the inorganic fiber product is higher than 50%. The composite material has the overall waterproof performance, the extremely low heat conductivity coefficient and the excellent high-temperature heat-insulation performance, can pass an incombustibility test under the condition that the material is ensured to be hydrophobic as a whole, and reaches level A1 according to the incombustibility test; the preparation process is simple, the production cycle is short, the cost is lower, the equipment requirement is low, and reaction conditions are controllable.

Owner:纳诺科技有限公司

Double diaper system

InactiveUS20080119812A1Preventing soilInhibit migrationBaby linensTamponsMechanical engineeringSkin contact

A double diaper package includes adhesively attached, similarly sized inner and outer diapers. Each of the diapers has a liquid permeable skin contacting net and a liquid impermeable polymeric back sheet edge bonded to each other so as to surround and encase a super-absorber in a fibrous matrix. The inner diaper has an adhesive coated edge flap of the liquid impermeable sheet extending from the edge bond. This edge flap secures the outer diaper to the inner diaper, forming a double diaper package that is attached to the baby using waist-securing tabs connected to the inner diaper. When soiled, the inner diaper is pulled away by releasing the waist-securing tabs and the adhesive edge flap attachment. The fresh, clean, outer diaper is attached using the waist-securing tabs of the outer diaper. The inner soiled diaper is then discarded.

Owner:I DID IT

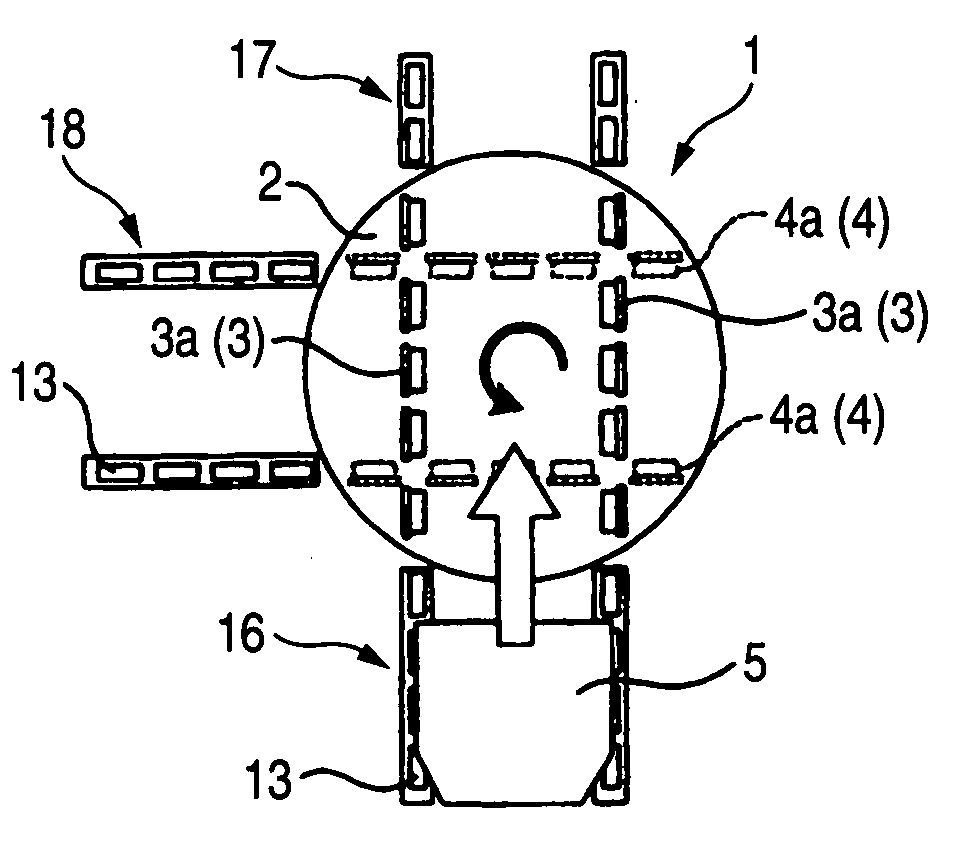

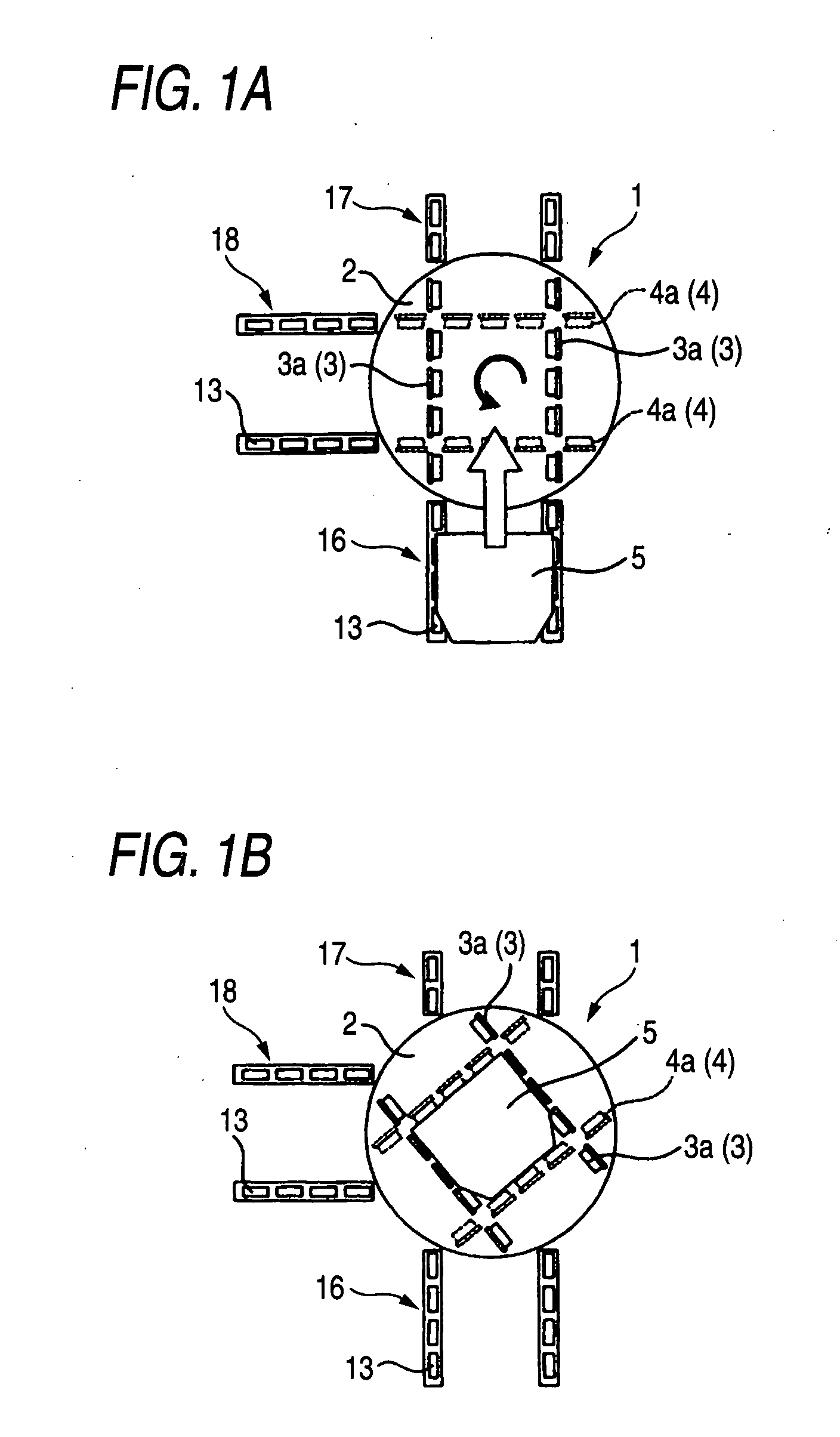

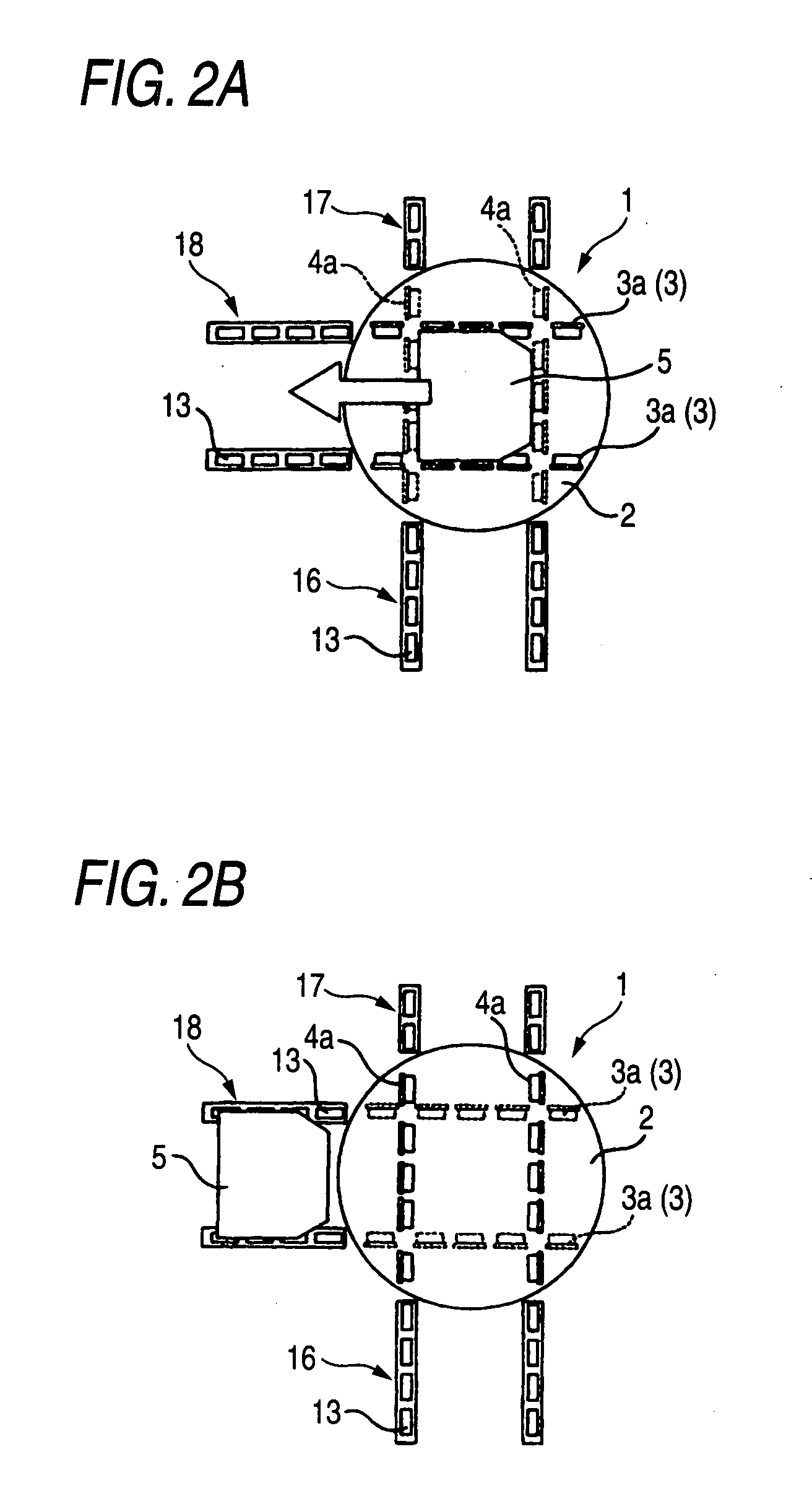

Direction change device

InactiveUS20070186799A1Reduce replacement timeSemiconductor/solid-state device manufacturingControl devices for conveyorsTransport engineeringFOUP

A direction change device includes first and second transport passage 3, 4, in which one of the transport passages is disposed at the same vertical position as that of the first transport rail 16, the other is disposed below the one, a rotating unit 22 rotating the transport passages 3, 4 about their central points, a lift unit 23 lifting the transport passages 3, 4 in a vertical direction and a control unit 21. The control unit 21 controls such that when the FOUP 5 is carried out from the transport rail 16 to the transport passage disposed at the same vertical position as that of the transport rail 16, rotating the transport passages 3, 4 by about 90°, carrying out the FOUP 5 from one of the transport passages, and exchanging the respective vertical positions of the first and second transport passages 3, 4.

Owner:ASYST SHINKO INC

Direct touch type metal diaphragm valve

ActiveUS8256744B2Reduce replacement timeFlow rate coefficient Cv (Cv value) is more stableDiaphragm valvesOperating means/releasing devices for valvesDirect touchDiaphragm valve

A direct touch type metal diaphragm valve, wherein durability of the valve, that is to say, the ensured number of continuous open / close operations of the valve, is substantially increased under conditions that an appropriate flow rate coefficient Cv is maintained, and changes of the afore-mentioned Cv value over time are mitigated by means of restricting the deformation of the valve seat over time. The afore-mentioned metal diaphragm is formed in a round, reverse-dish shape by laminating a plural number of thin stainless steel plates and a thin Nickel.Cobalt alloy plate, and its center part is bulged upward, and the maximum valve stroke of the valve is regulated to be 55% to 70% of the distance of the maximum bulge height Δh of the afore-mentioned metal diaphragm.

Owner:FUJIKIN INC

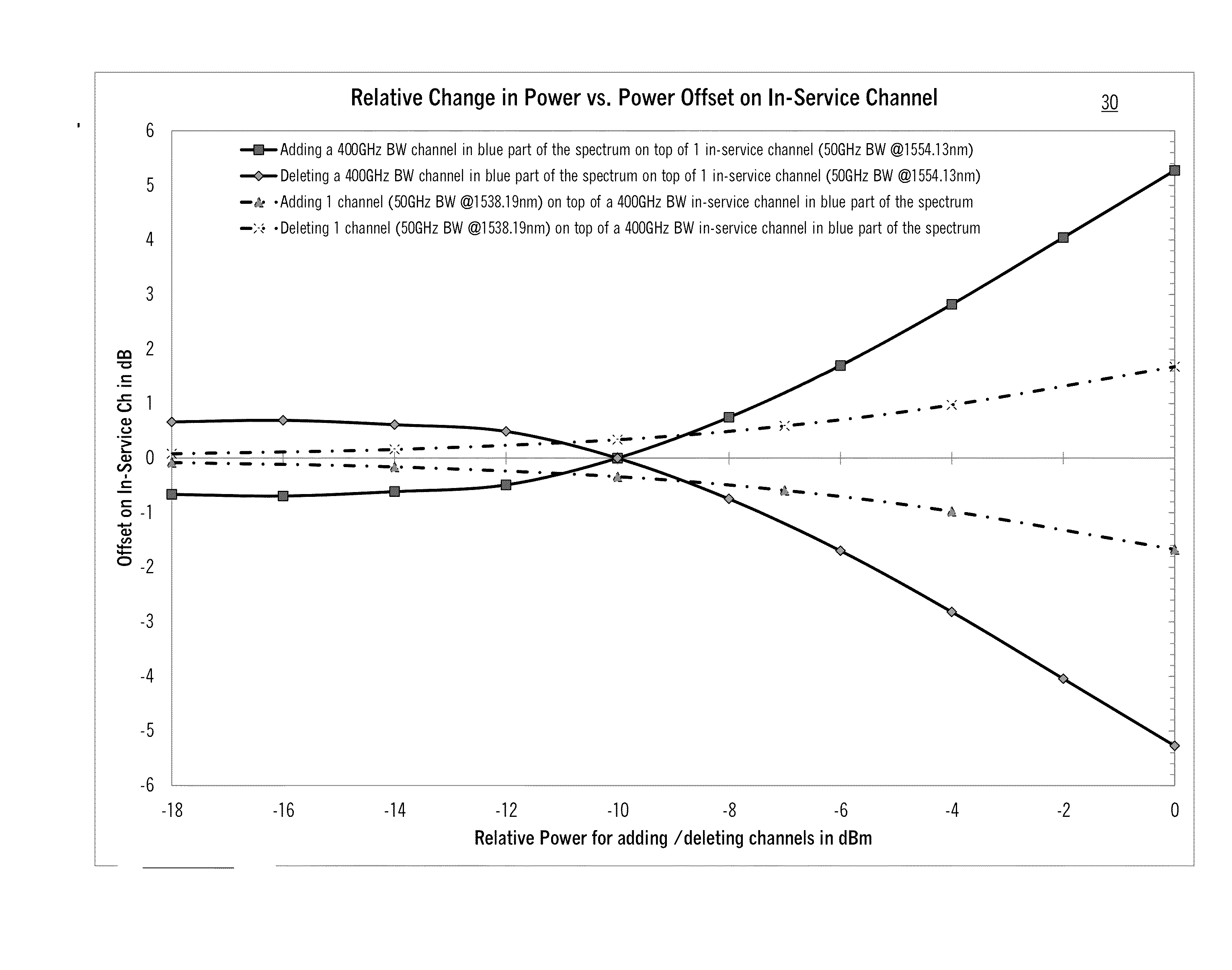

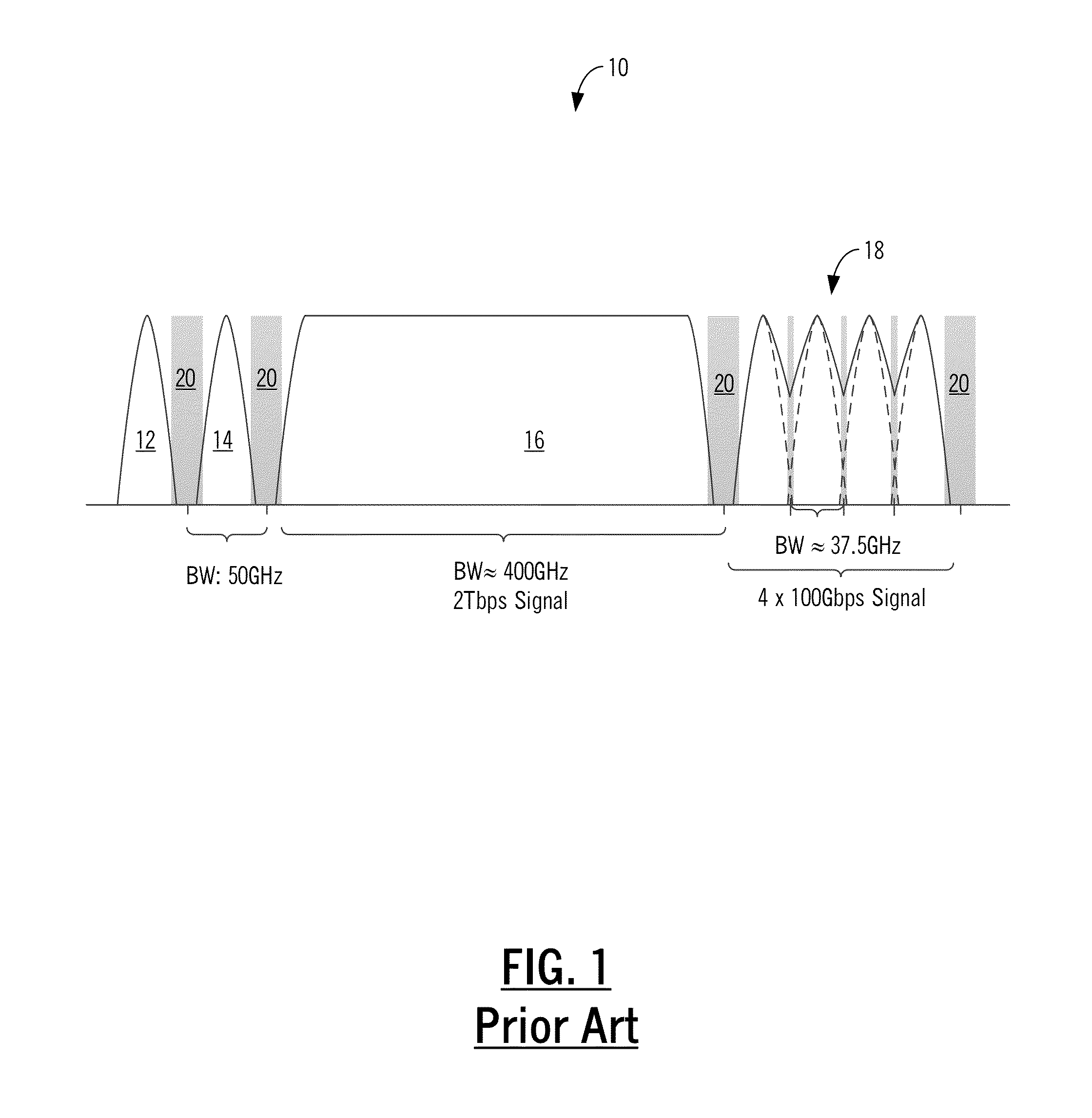

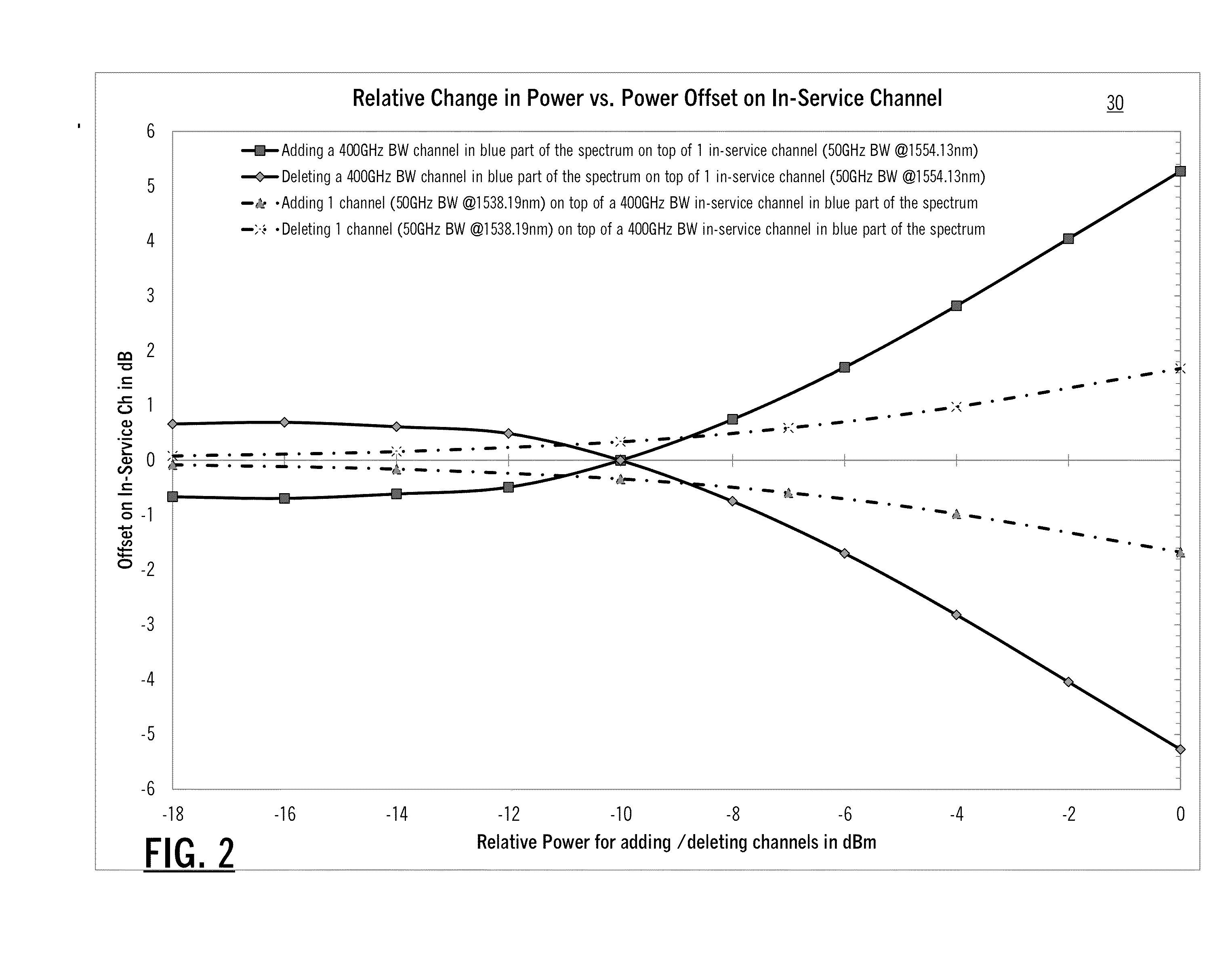

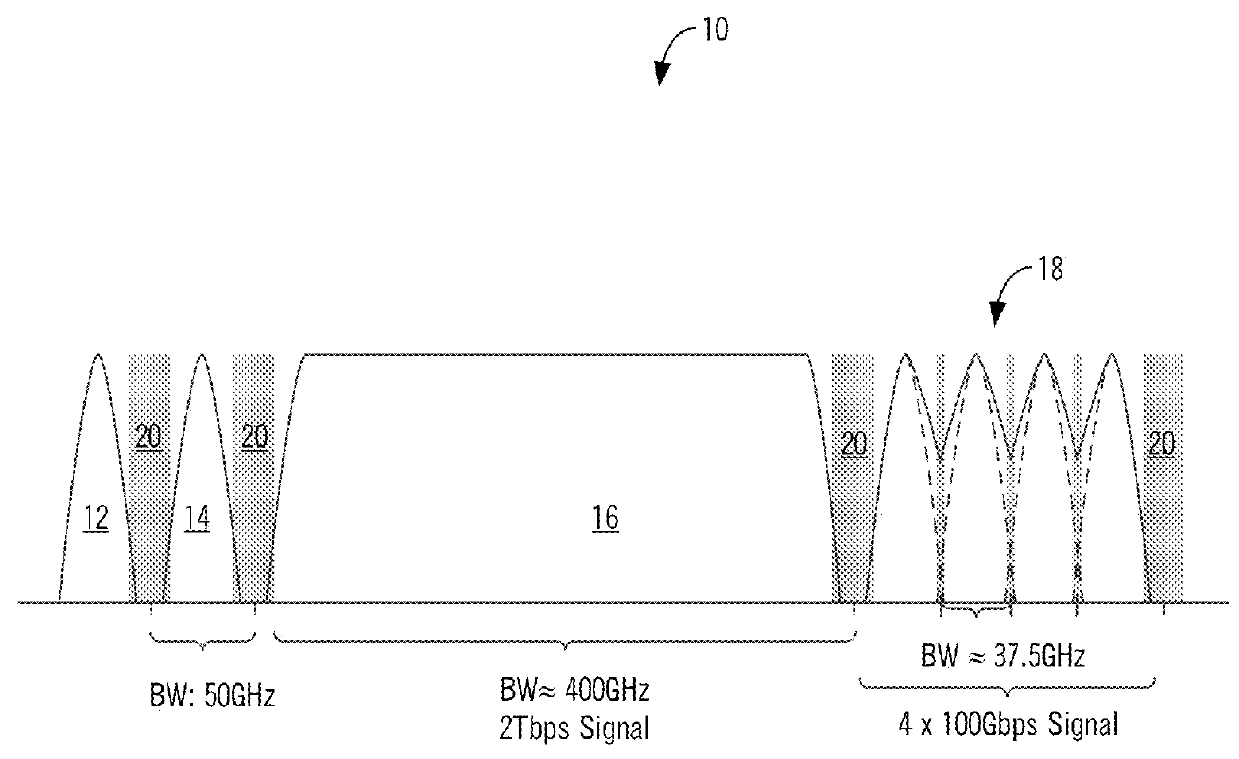

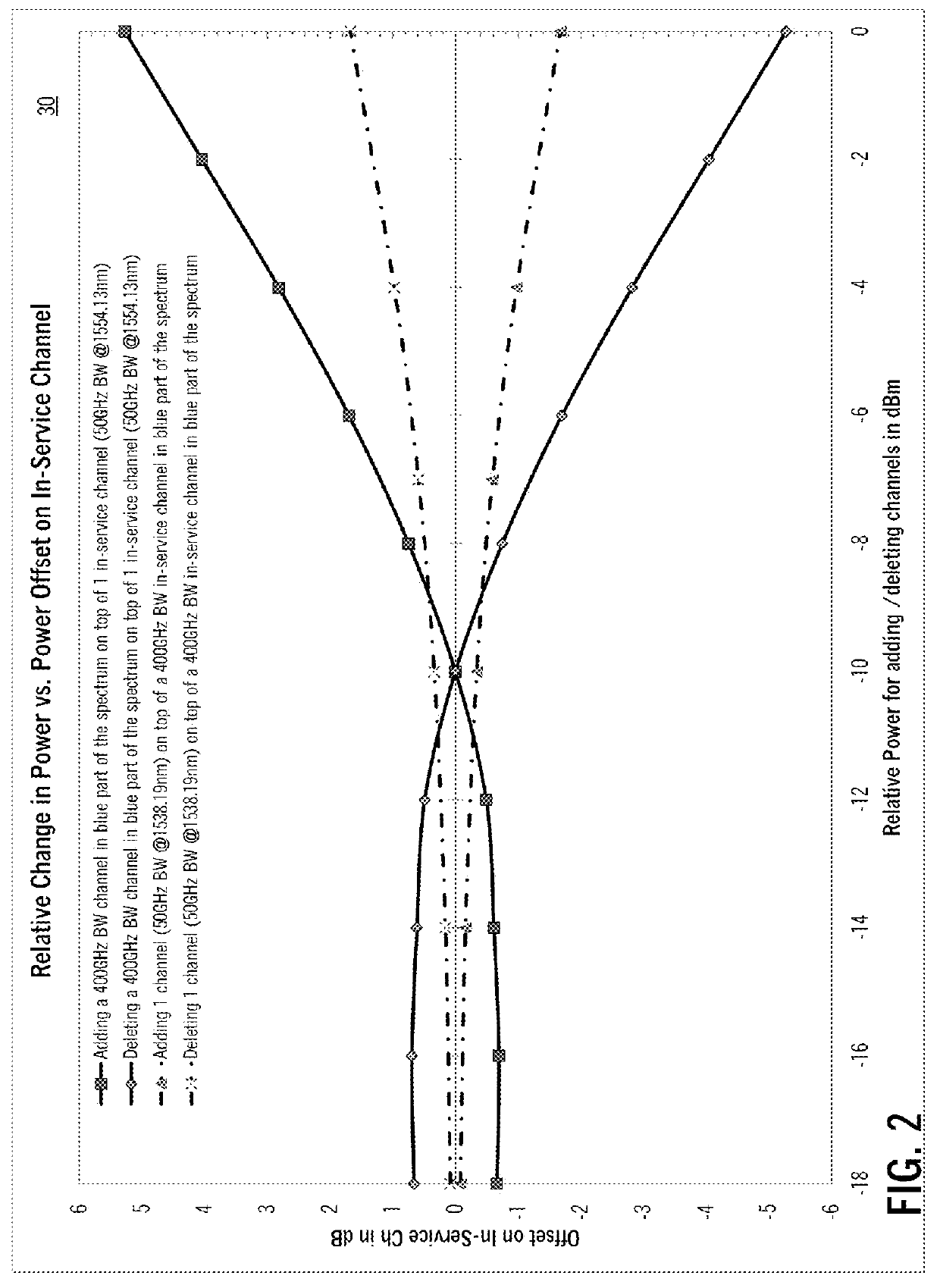

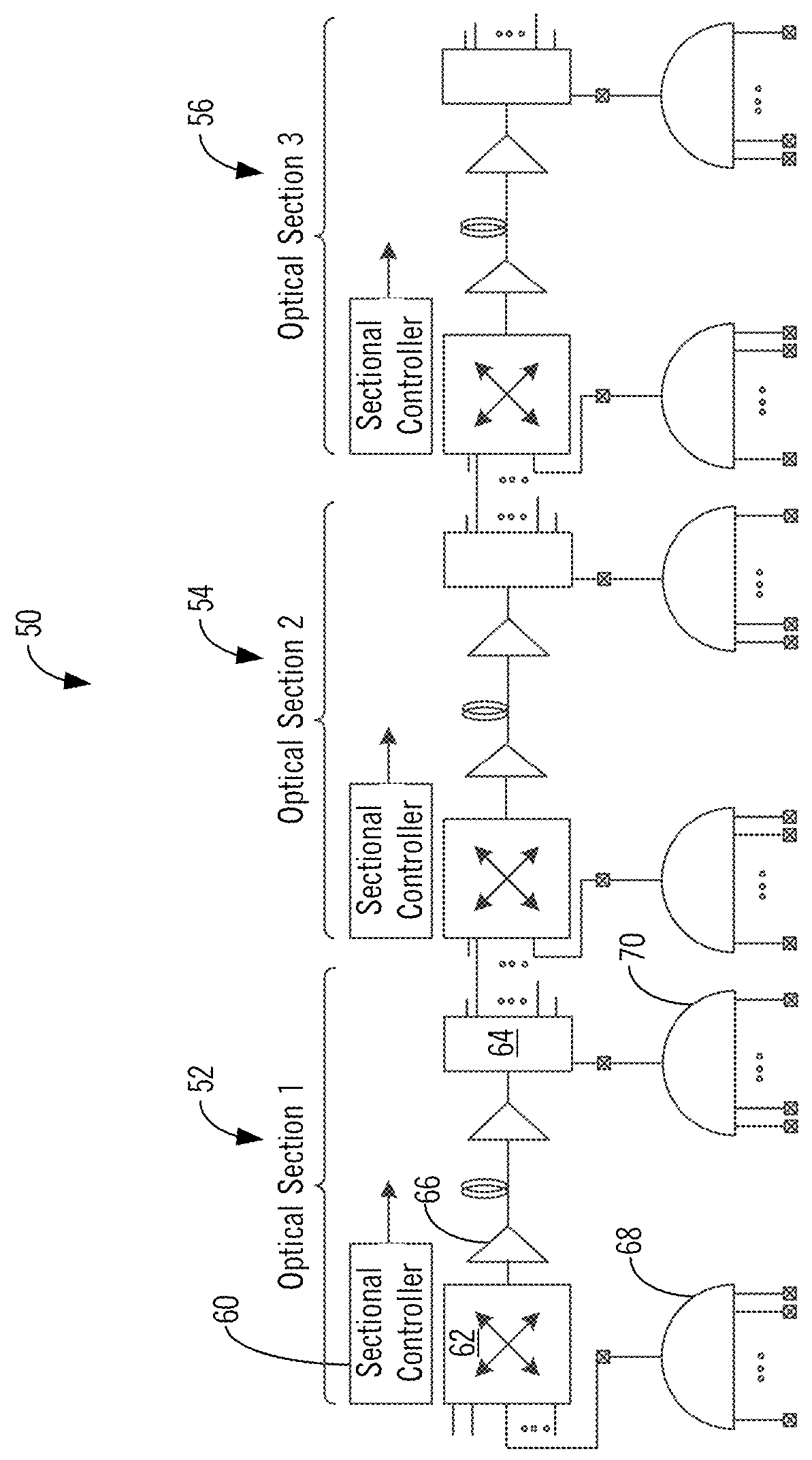

Systems and methods for capacity changes in DWDM networks including flexible spectrum systems

ActiveUS20150117858A1Reduce overall capacity change timingReduce replacement timeTransmission monitoringOptical multiplexAudio power amplifierFrequency spectrum

A method, a controller, and an optical section include performing an analysis to determine an amount of power offset on any in-service channels in an optical section due to a capacity change with a channel; defining a step size to ensure the capacity change does not exceed an offset limit based on the analysis; performing the capacity change in one or more iterations using the step size to limit the capacity change; and performing an optimization between each of the one or more iterations to adjust amplifier gains in the optical section to compensate for offsets on the in-service channels caused by a previous iteration.

Owner:CIENA

Light-source fixing structure for backlight module

InactiveUS7611274B2Low production costUnnecessary reflectionLighting support devicesOptical light guidesLight guideEngineering

Owner:CHUNGHWA PICTURE TUBES LTD

Systems and methods for capacity changes in DWDM networks including flexible spectrum systems

ActiveUS9344191B2Reduce replacement timeWavelength-division multiplex systemsElectromagnetic transmissionAudio power amplifierFrequency spectrum

A method, a controller, and an optical section include performing an analysis to determine an amount of power offset on any in-service channels in an optical section due to a capacity change with a channel; defining a step size to ensure the capacity change does not exceed an offset limit based on the analysis; performing the capacity change in one or more iterations using the step size to limit the capacity change; and performing an optimization between each of the one or more iterations to adjust amplifier gains in the optical section to compensate for offsets on the in-service channels caused by a previous iteration.

Owner:CIENA

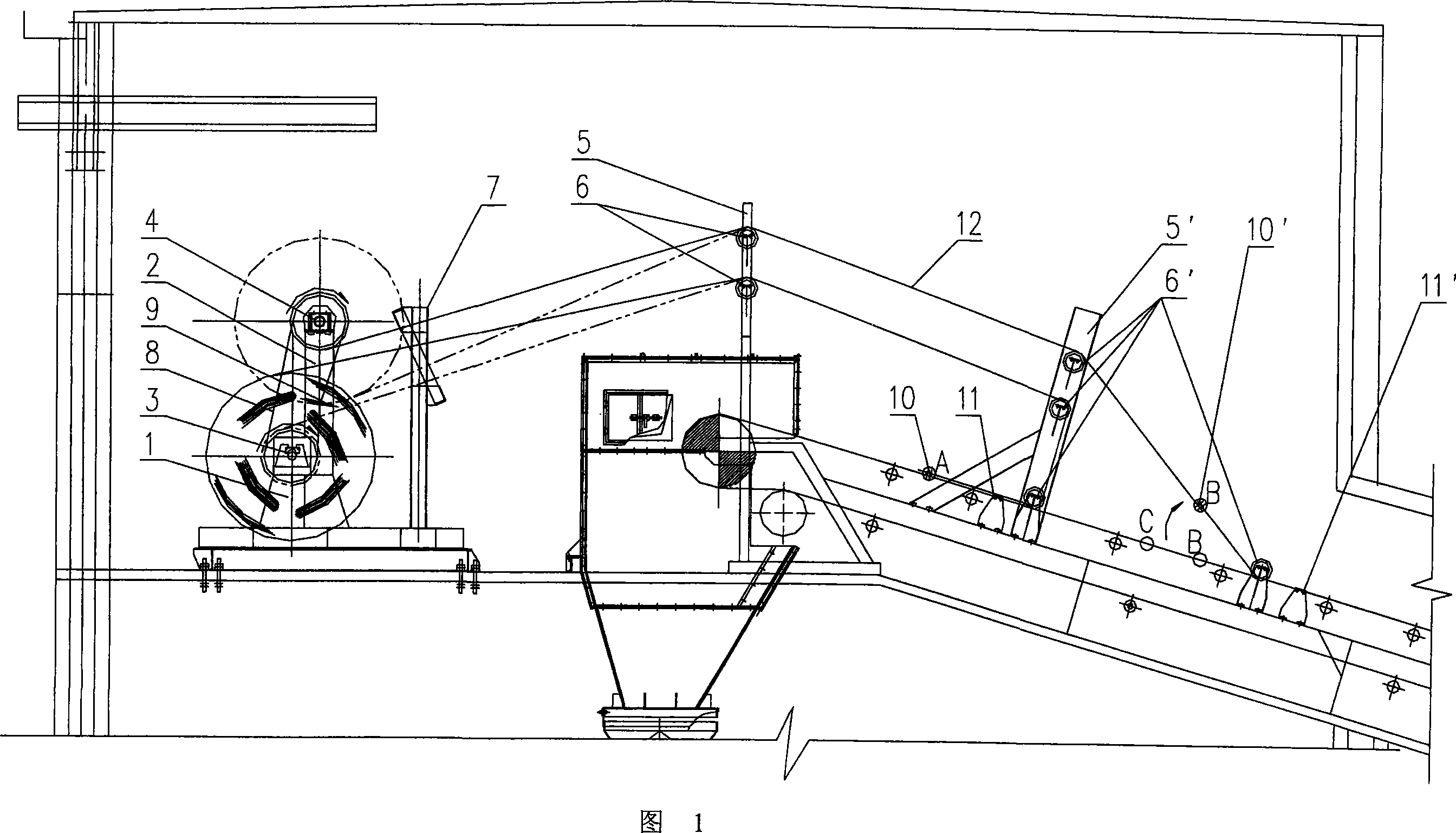

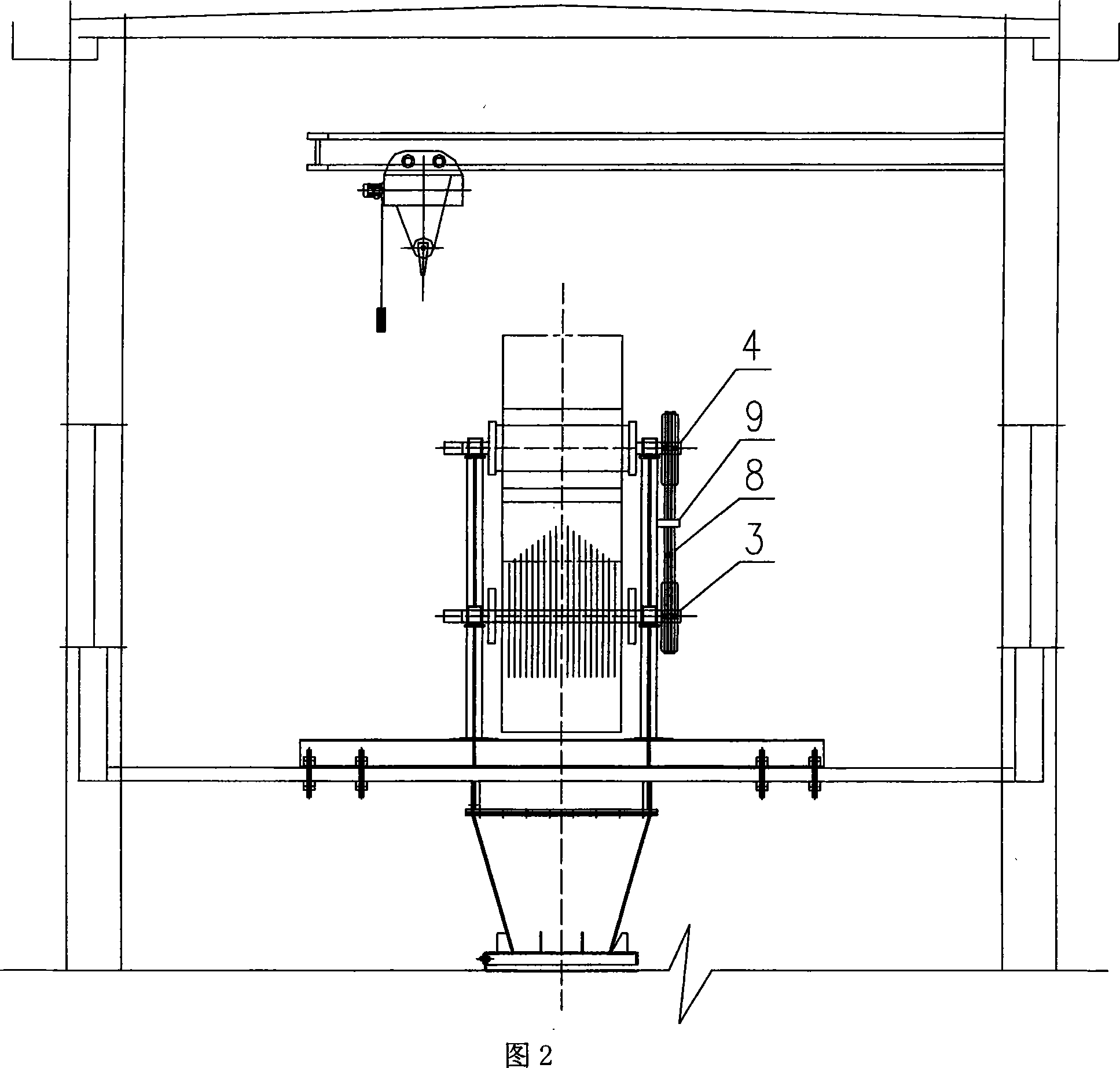

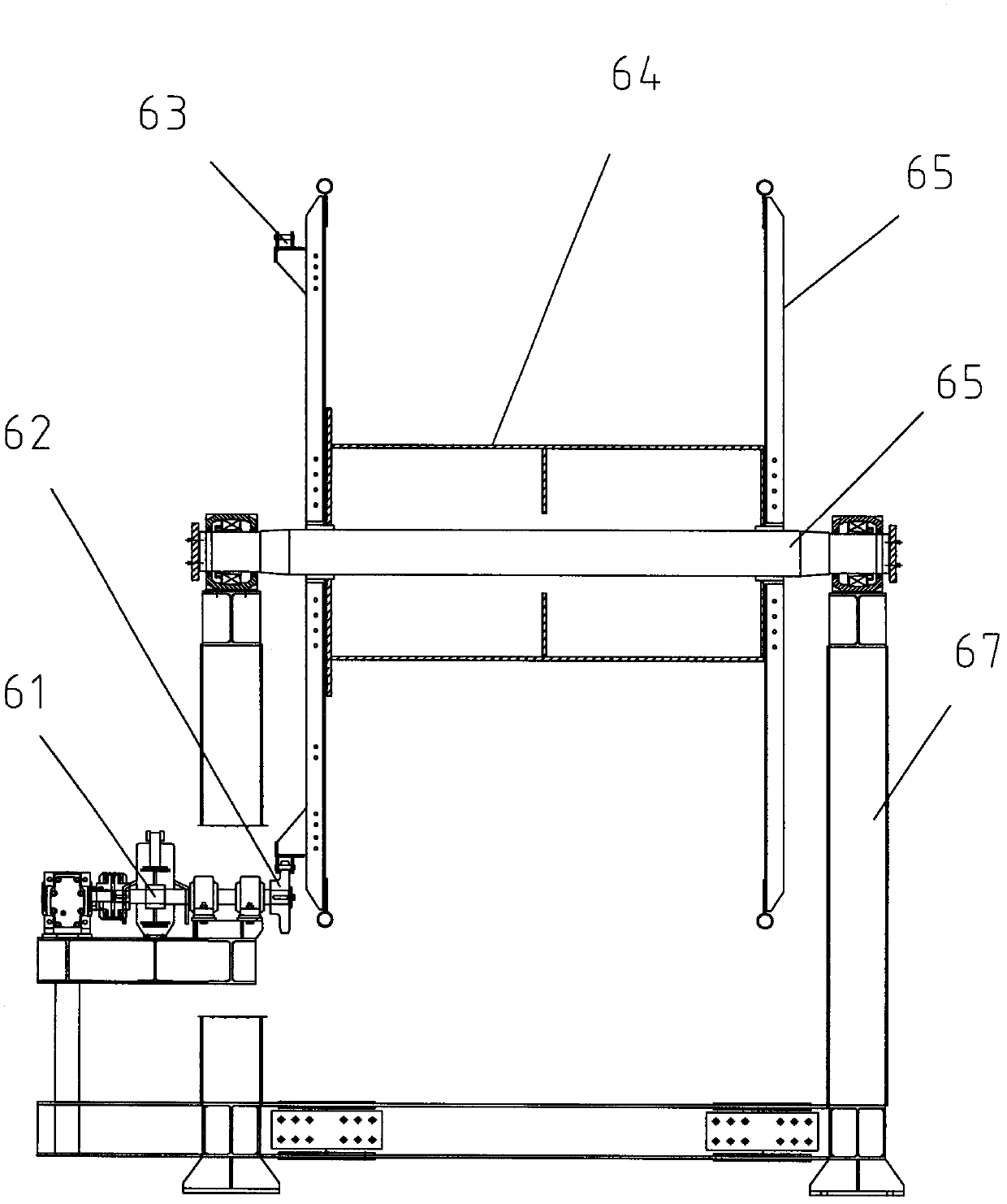

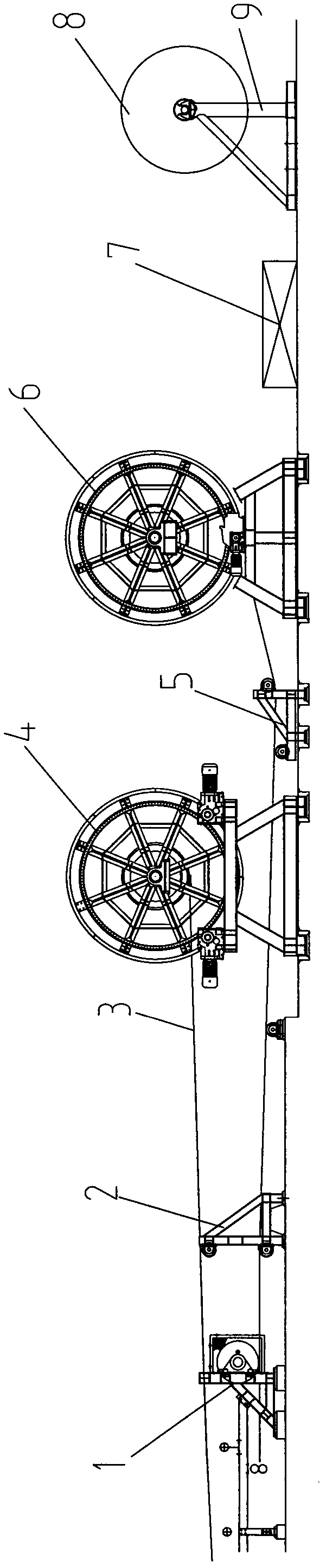

Wound steel rope replacing method

InactiveCN101700858AEasy replacementReduce replacement timeWinding mechanismsAgricultural engineeringPull force

The invention discloses a wound steel rope replacing method with simple operation, which comprises the steps of preparing, cutting an old steel rope, connecting ends of the old steel rope and a new steel rope, fixing two ends of the new steel rope, and the like. By adopting a mode that the old steel rope is divided into two parts, one of parts of the old steel rope is connected with the new steel rope, the new steel rope is led under the pull force of a winding drum to be wound on a movable pulley block and a fixed pulley block and then two ends of the new steel rope are fixed. The invention realizes the semi-automation of replacing the steel rope, simplifies the replacement operation, saves the replacement time, reduces the operating personnel, improves the safety, and is suitable for replacement operations of the steel ropes wound on various winding drums.

Owner:RUI STEEL INDAL OF PANZHIHUA GANGCHENG GROUP

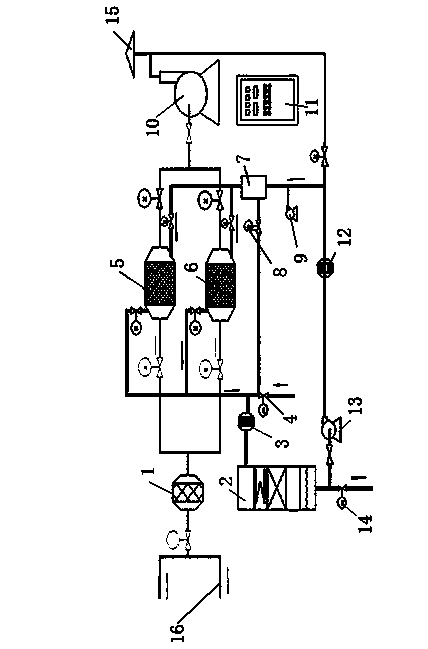

Organic waste gas adsorption and desorption concentration catalytic combustion equipment system

ActiveCN103438467AExtended replacement timeReduce replacement timeCombination devicesIncinerator apparatusActivated carbonFlame arrester

The invention discloses an organic waste gas adsorption and desorption concentration catalytic combustion equipment system which comprises a dry-type filtering device. The organic waste gas adsorption and desorption concentration catalytic combustion equipment system is characterized in that a catalytic combustion bed is connected to the lower end of the dry-type filtering device, a flame arrester a is connected to the right end of the catalytic combustion bed, a cold air supplement valve is connected to the lower right end of the flame arrester a, and a temperature adjusting valve is further connected to the lower end of the catalytic combustion bed. According to the organic waste gas adsorption and desorption concentration catalytic combustion equipment system, the replacement interval of activated carbon is greatly prolonged, the replacement time of the activated carbon is shortened, the activated carbon can be effectively used for desorption, regeneration and recycling, organic waste gas after desorption is thoroughly decomposed into CO2 and H2O after catalytic combustion is carried out, no secondary pollution exists, a PLC and a human-computer interface are adopted in the system to control an operation system, the operation is easy to achieve, and the possibility of misoperation is reduced.

Owner:KUNSHAN GONGTONG ENVIRONMENTAL PROTECTION MACHINECO

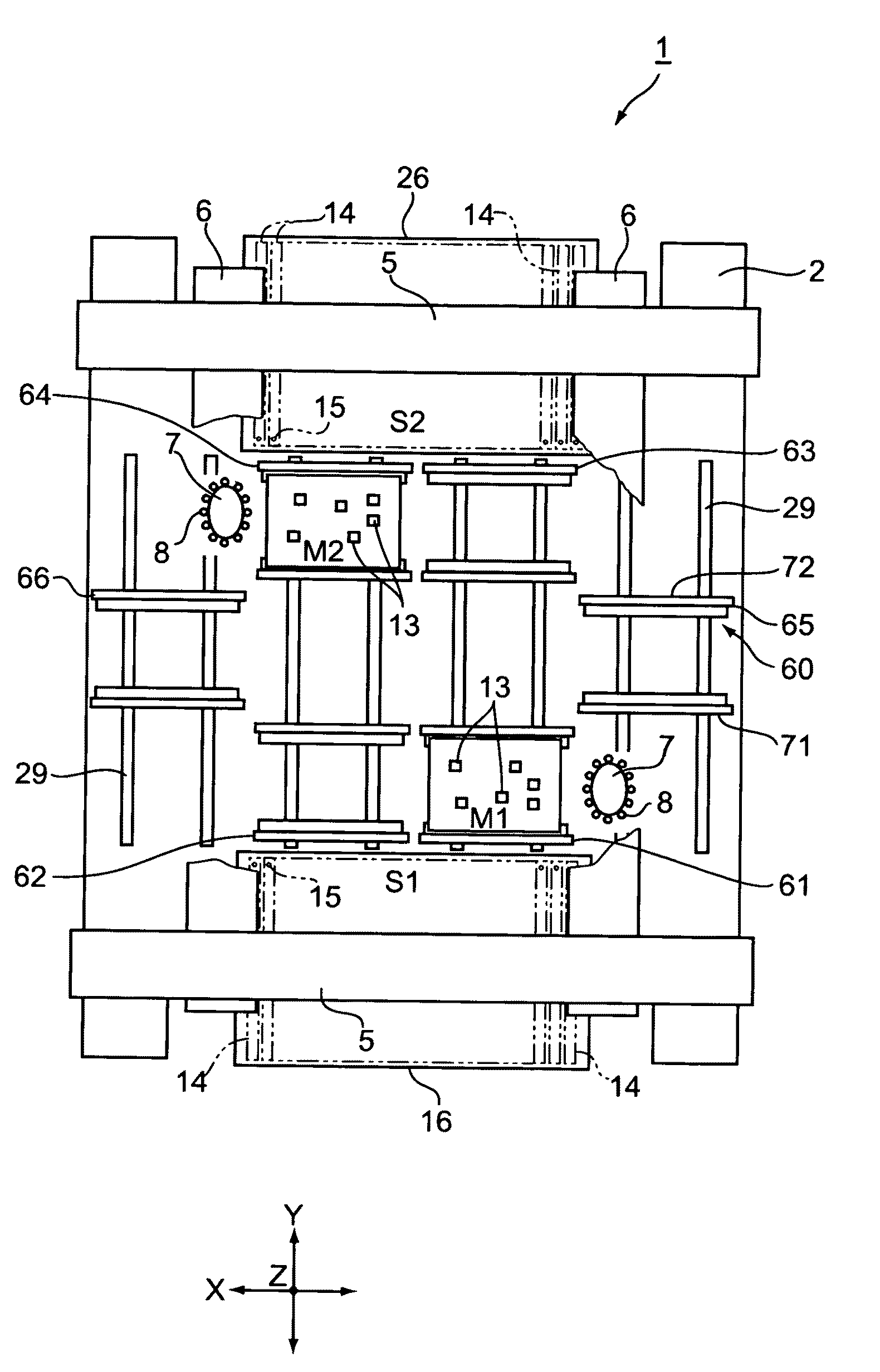

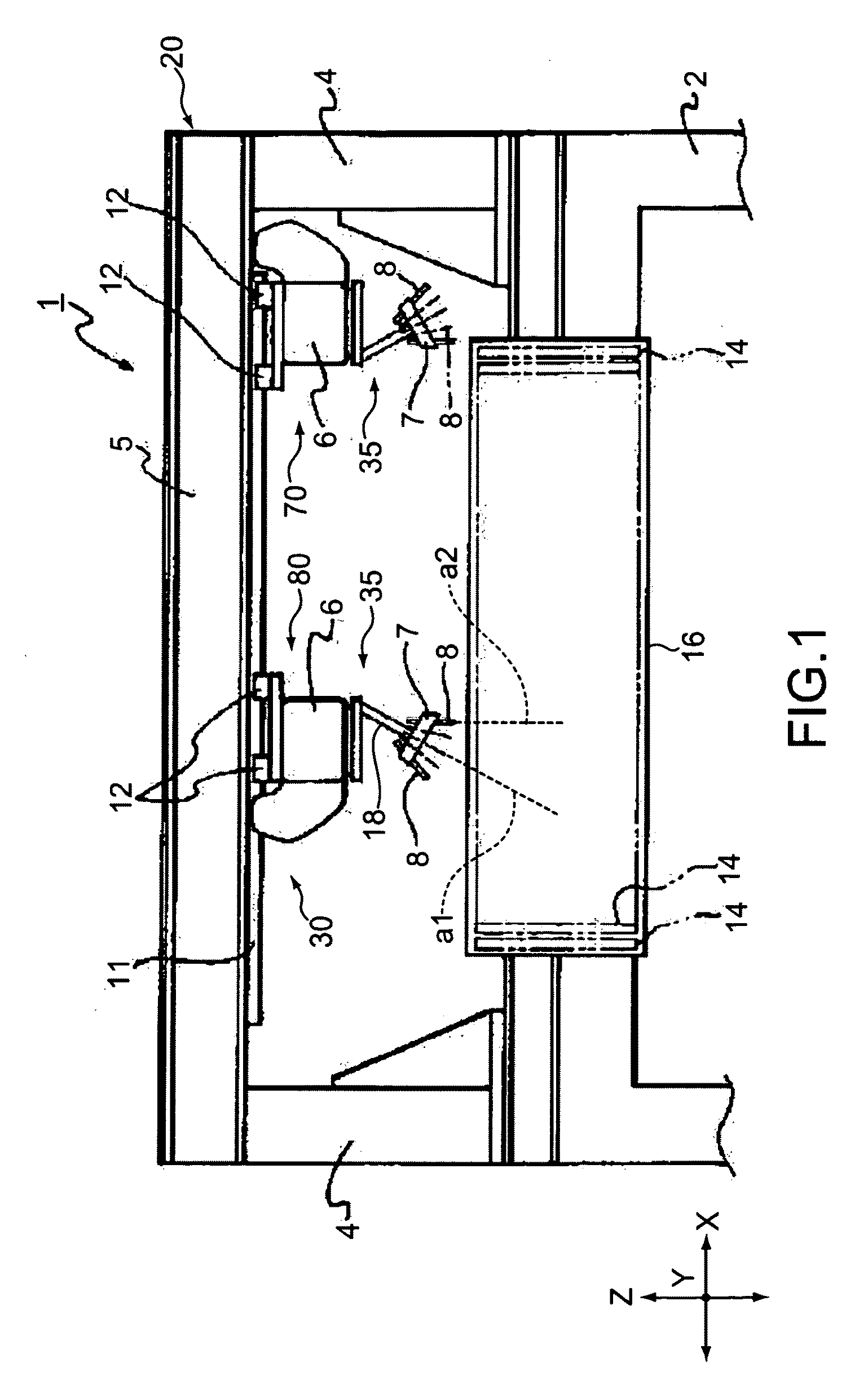

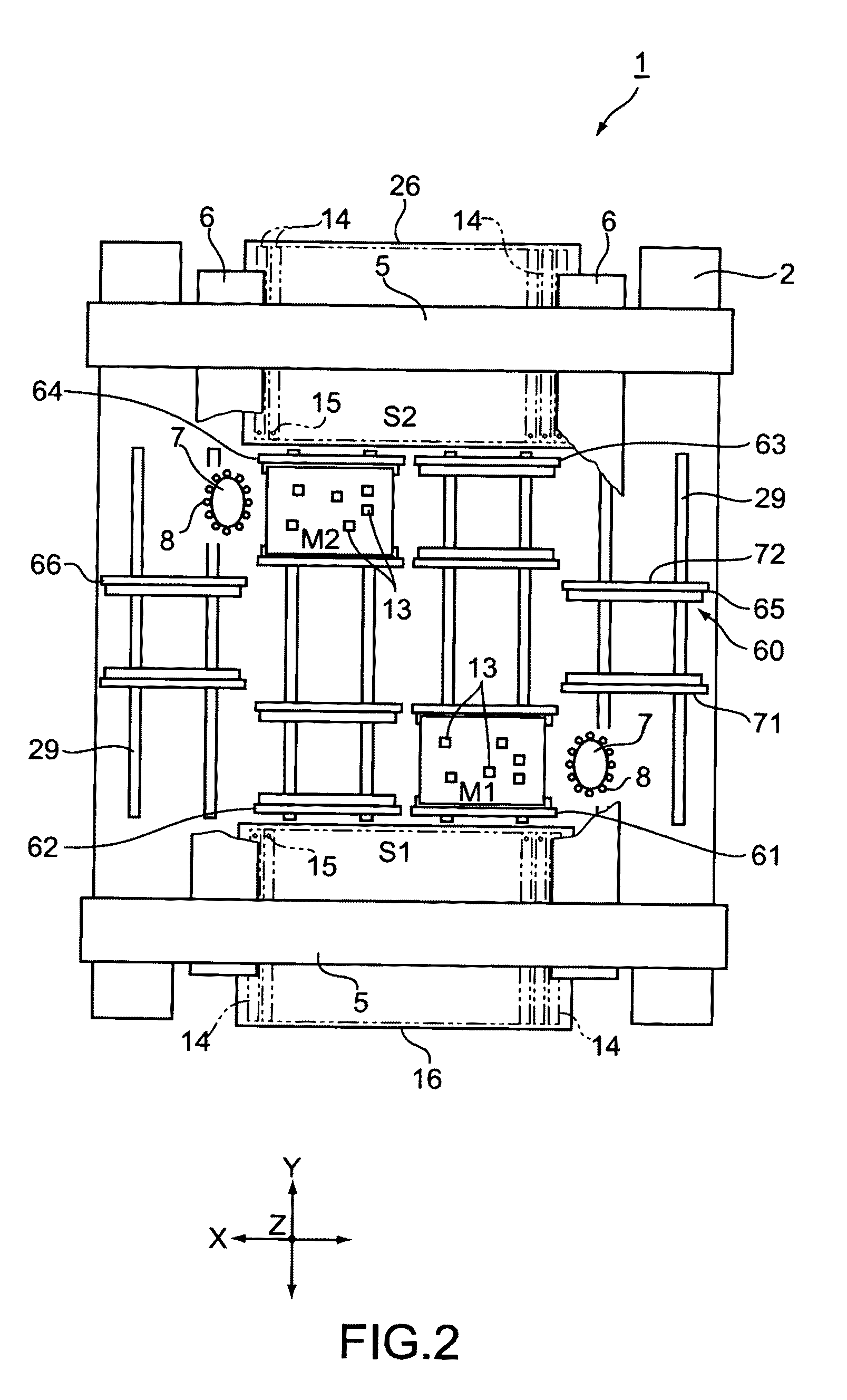

Component mounting apparatus, mounting-component producing method, and conveyor apparatus

InactiveUS20090250313A1Replacement time of be shortenShortening substrate replacement timeCharge manipulationPackagingEngineeringElectrical and Electronics engineering

A component mounting apparatus includes: a load area to load a substrate; an unload area to unload the substrate; a main area interposed between the load and unload areas, including a first area including a first mounting area, a second area including a second mounting area, and a third area interposed therebetween; two mounting units to mount, on the substrate, first and second components in the first and second mounting areas, respectively; a conveyor group to convey the substrate, including first to fourth conveyors, the second and fourth conveyors being capable of receiving the substrate from the first and third conveyors in the first and second areas, respectively; and a driving mechanism capable of moving at least one of the first and second conveyors between the first and third areas and moving at least one of the third and fourth conveyors between the second and third areas.

Owner:SONY CORP

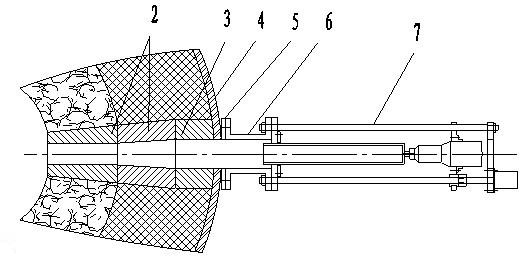

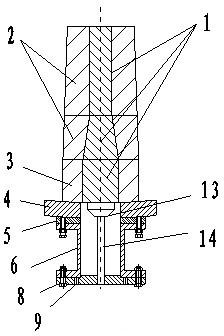

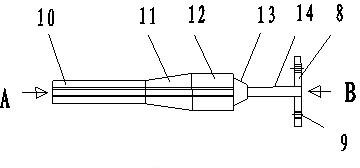

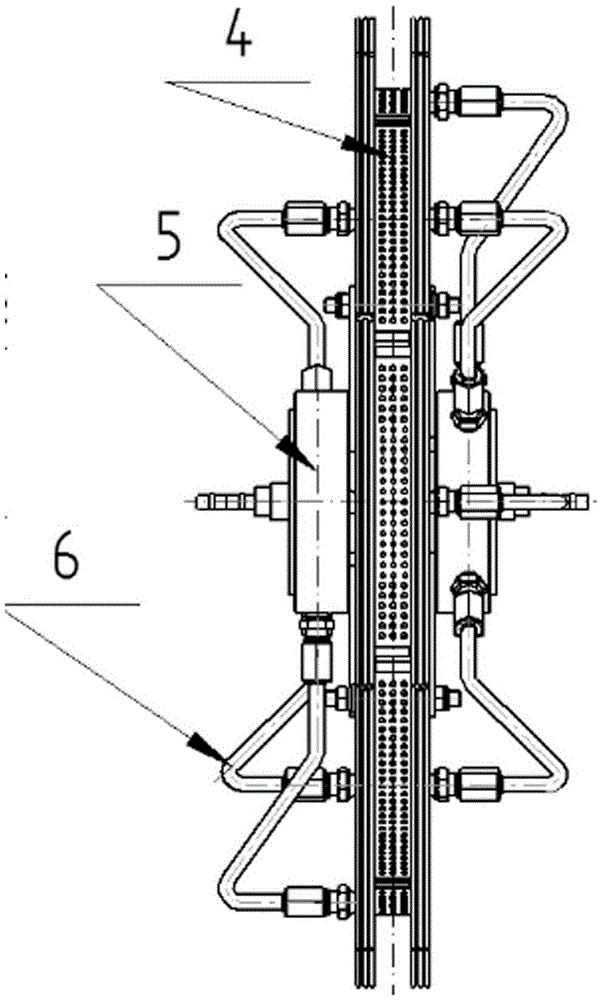

Converter bottom blowing air brick, special drilling machine and quick thermal replacement method of air brick

ActiveCN102676730AReduce replacement timeGood high temperature strength and thermal shock resistanceManufacturing convertersElectrical and Electronics engineeringCorundum

The invention relates to a converter bottom blowing air brick, a special drilling machine and a quick thermal replacement method of the air brick, which belong to the technical field of converter top and bottom composite blowing equipment and a method and are used for performing quick thermal replacement on the converter bottom blowing air brick. The technical scheme is as follows: the adopted air brick consists of an upper section, a middle section and a lower section. A protecting sleeve brick consists of an upper sleeve brick and a lower sleeve brick. The upper sleeve brick is a magnesia carbon brick, and the lower sleeve brick is made of a corundum-cast material. The protecting sleeve brick is sleeved outside the air brick. A converter bottom flange is welded at a converter bottom opening and is connected with the special drilling machine. The method comprises the following steps of: preparing the air brick, the protecting sleeve brick, the converter flange, a cylinder flange and the drilling machine; disassembling an old air brick; cleaning the cone frustum part of the lower sleeve brick of the protecting sleeve brick; drilling by using the drilling machine; installing the air brick; and connecting a tail pipe. According to the invention, a damaged bottom blowing air brick is replaced in short time under a hot state and the protecting sleeve brick can be replaced for several times without being damaged, so that the combined blowing of a converter in the whole service life can be realized.

Owner:宣化钢铁集团有限责任公司 +2

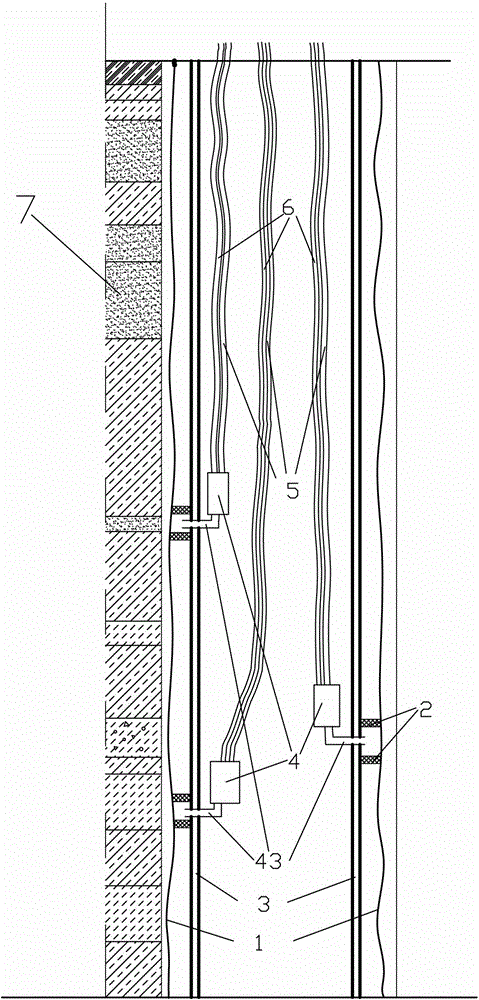

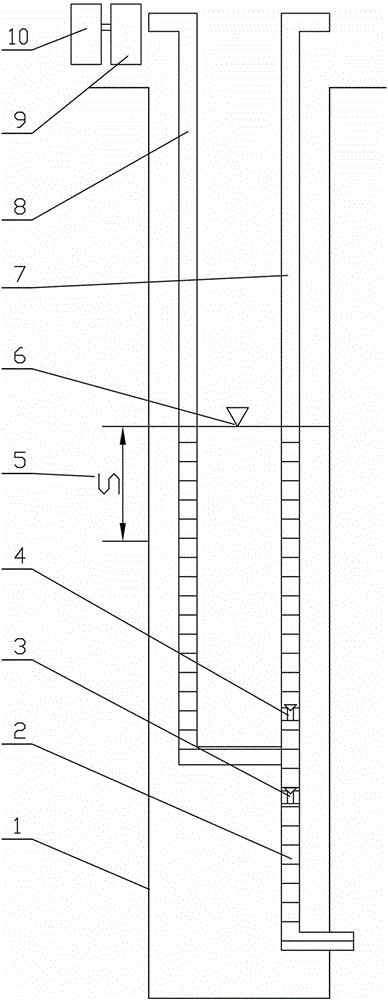

Pneumatic pump sampling system device of multi-stage monitoring well and method thereof

The invention discloses a pneumatic pump sampling system device of a multi-stage monitoring well. The device is arranged inside a drilled multi-stage underground water monitoring well, wherein the well passes through a plurality of aquifers in depth; every two adjacent aquifers are mutually sealed and isolated; a water inlet window pup joint assembly is arranged on a local section of a well casing at the position of each monitoring layer after the well is formed; the water inlet window pup joint assembly comprises water inlet windows; a water inlet of each water inlet window is communicated with a water inlet pipe joint of a pneumatic pump; air supply outlets and water outlets of the pneumatic pumps are communicated with the earth surface respectively via an air supply pipe and a water outlet pipe; check valves are respectively arranged in water inlet and outlet pipelines of all the pneumatic pumps; at least one group of air supply units is arranged on the earth surface; each air supply unit is composed of an air source and an air adjuster in connection combination, and the outlet of each air adjuster at a working period is instantly connected with an air supply port requiring sampling. Water samples with component representativeness can be conveniently and fast extracted, and the pneumatic pump sampling system device is simple, practical and low in cost.

Owner:CENT FOR HYDROGEOLOGY & ENVIRONMENTAL GEOLOGY CGS

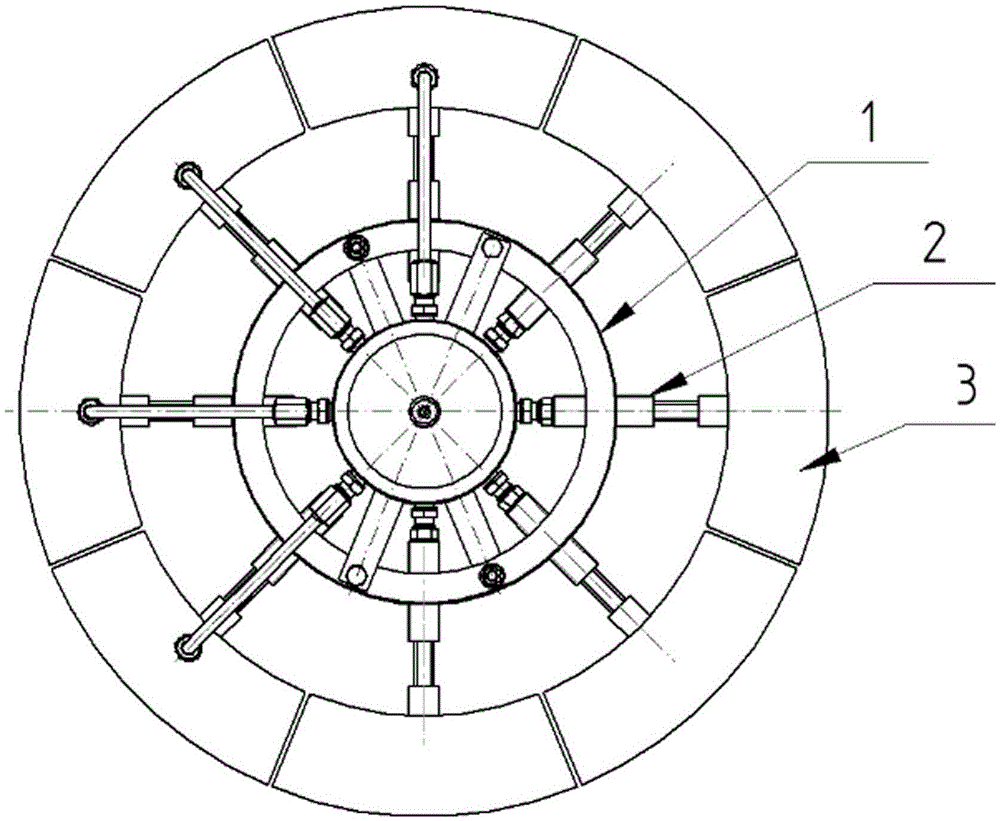

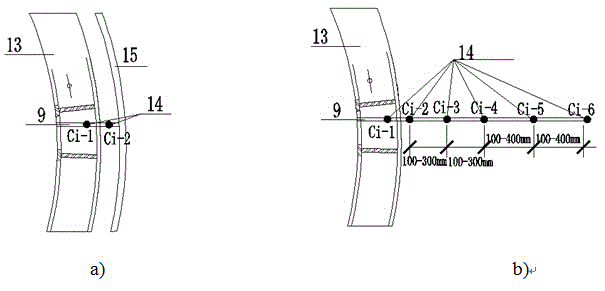

Butt joint circular seam reverse side gas shielding device for barrel fusion welding

InactiveCN105522266AImprove protectionReduce Ellipse DistortionShielding gas supply/evacuation devicesWelding/cutting auxillary devicesMelting tankButt joint

Disclosed is a butt joint circular seam reverse side gas shielding device for barrel fusion welding. The butt joint circular seam reverse side gas shielding device for barrel fusion welding is characterized by comprising a welding jig and a gas shielding channel. The welding jig comprises a supporting ring (1), eight adjusting screw rods (2) and eight arc-shaped gas shielding grooves (3), wherein the radian of each arc-shaped gas shielding groove is equal to the inner diameter of a barrel. Air inflation holes (7) are formed in the sides of the gas shielding grooves (3), perforated plates (4) which assist in uniform diffusion of gas are added to the interior of the gas shielding grooves, and sealing grooves (8) are formed in the arc-shaped surfaces, making contact with the inner wall of the barrel, of the two sides of each gas shielding groove (3). The butt joint circular seam reverse side gas shielding device for barrel fusion welding has the advantages that the whole device is flexible in structure, adjustable, and easy and convenient to operate, and adapts to barrel circular seams with different diameters, the effect of gas shielding of a welding seam molten pool and a near weld zone is good, oval deformation of barrel welding can be reduced, the shielding gas is saved, and the time needed by gas replacement in the process of gas ventilation in advance is shortened.

Owner:云南昆船机械制造有限公司

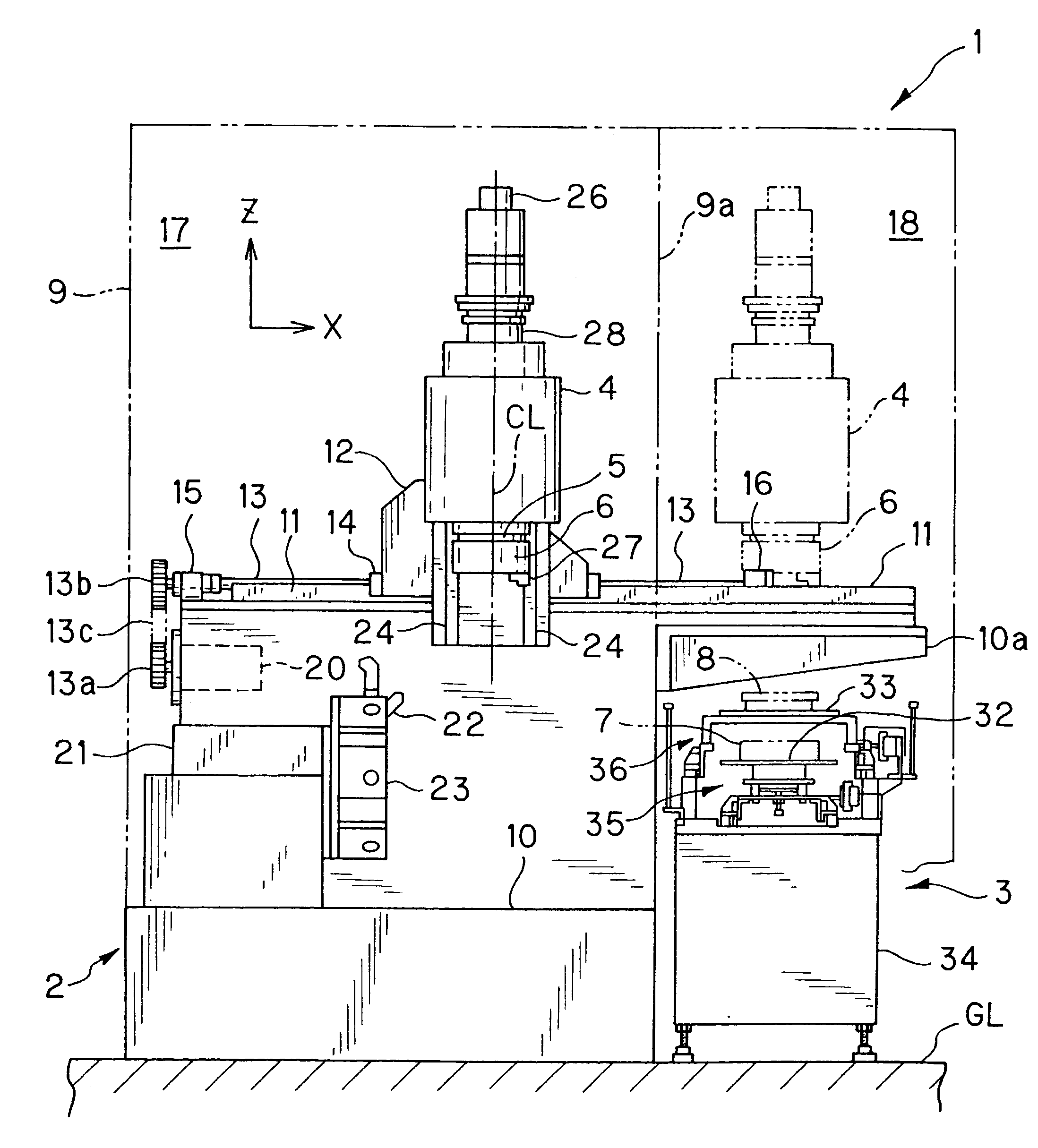

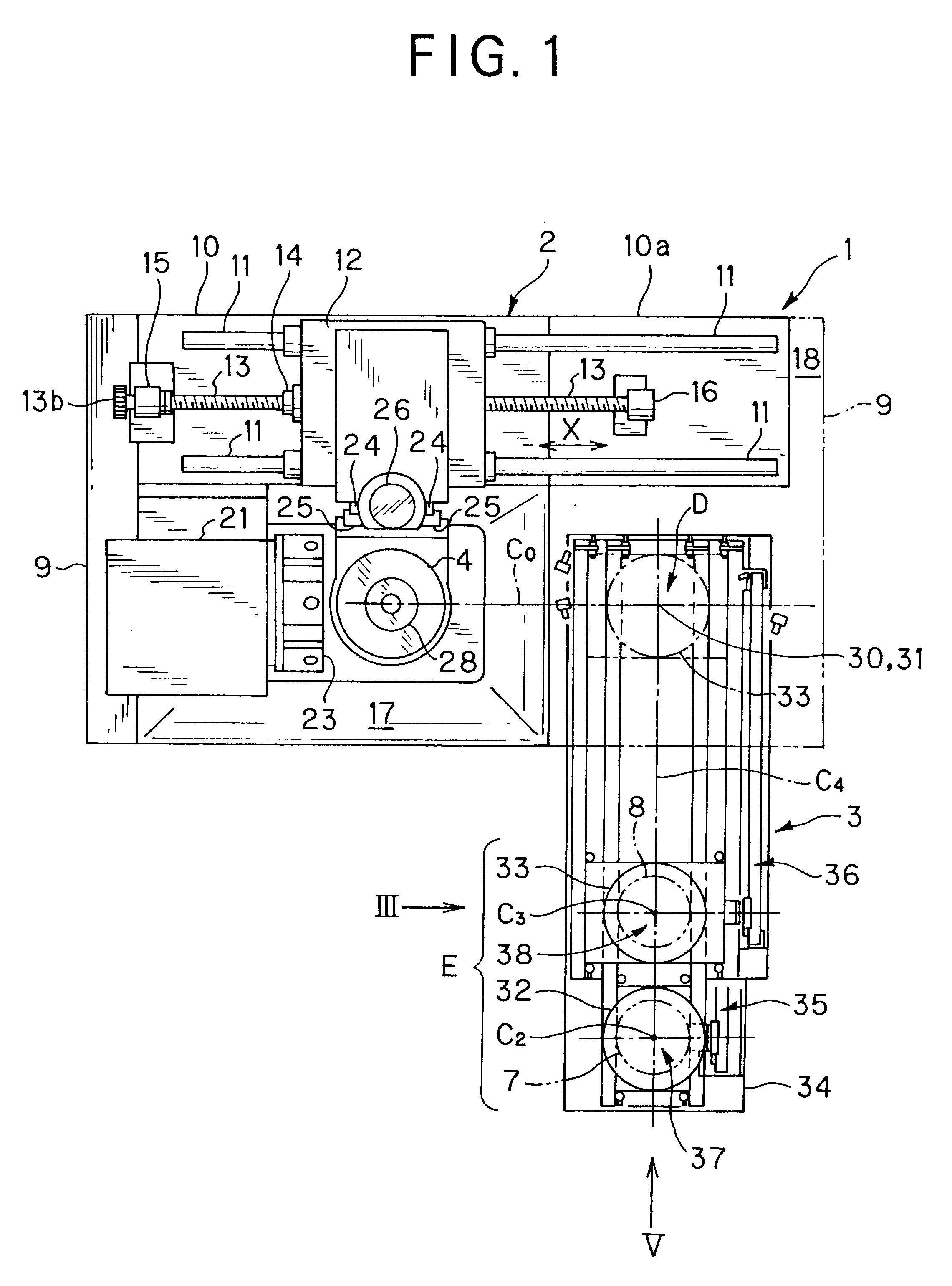

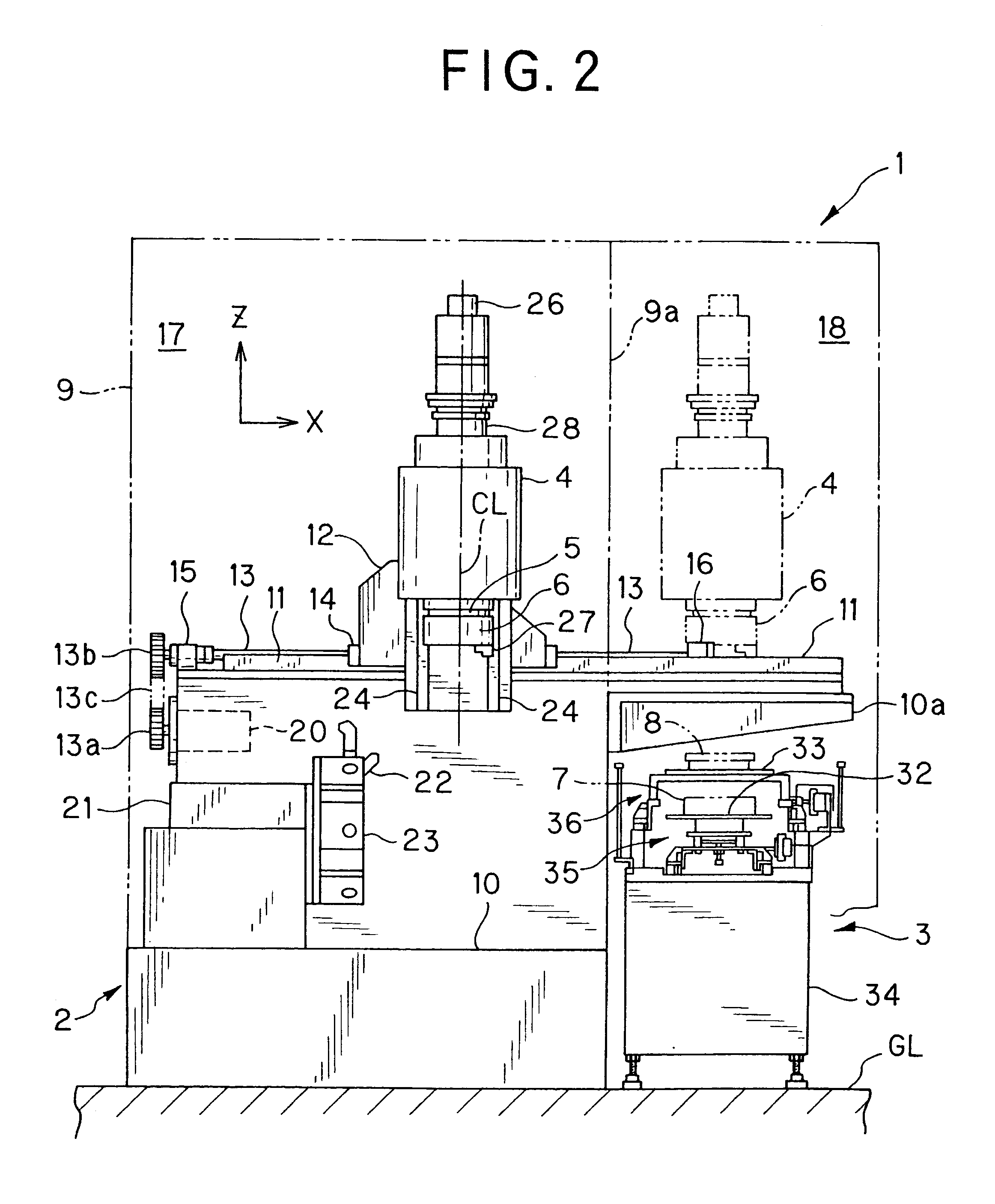

Work transfer method and apparatus in machine tool with movable spindle and machining system

InactiveUS6257108B1Possible changeMake the work transfer apparatus compactLathesAutomatic/semiautomatic turning machinesEngineeringMachining system

In a work transfer method in a machine tool with a movable spindle, a machined work transfer portion for laying a machined work on a first pallet and for transferring the work is disposed in an upper stage or a lower stage of a non-machined work transfer portion for laying a non-machined work on a second pallet and for transferring the work. Then, the non-machined work pallet is moved between a non-machined work receiving position and a work loading position. The machined work pallet is moved between a machined work sending position and a work unloading position. Thus, the work is received or sent between a chuck and a work transfer apparatus.

Owner:MORI SEIKI HITECH

Method for rapidly replacing belt type conveyor rubber belt

The invention relates to a method for rapidly exchanging the rubber belt of a belt-typed transporter. The invention employs the power of an original belt-typed transporter and simultaneously accomplishes the arrangement of a new rubber belt and the reeling of a used rubber belt. The reel supports of the new rubber belt and the used rubber belt are disposed on the same base foundation, any one cutting point is disposed on the used rubber belt of the belt-typed transporter, and then the used rubber belt is connected with a connecting rubber belt and the new rubber belt. Guide supports and guide wheels are arranged among the connecting points of a new rubber belt reel, the new rubber belt and the used rubber belt and also disposed among the connecting points of a used rubber belt reel, the connecting rubber belt and the used rubber belt. Compared with the prior art, the invention has the advantages that reel shafts of the new rubber belt and the used rubber belt are provided with driving pulleys, the new rubber belt is connected with the used rubber belt by driving belts, and then an enclosed transferring system is formed by the new rubber belt and the used rubber belt. No external power is needed to be added, and the rapid and simultaneous arrangement of the new rubber belt and the reeling of the used rubber belt can be realized, thereby the invention can greatly reduce the exchanging period, lower the labor intensity of maintenance personnel and reduce the exchanging cost.

Owner:ACRE COKING & REFRACTORY ENG CONSULTING CORP DALIAN MCC

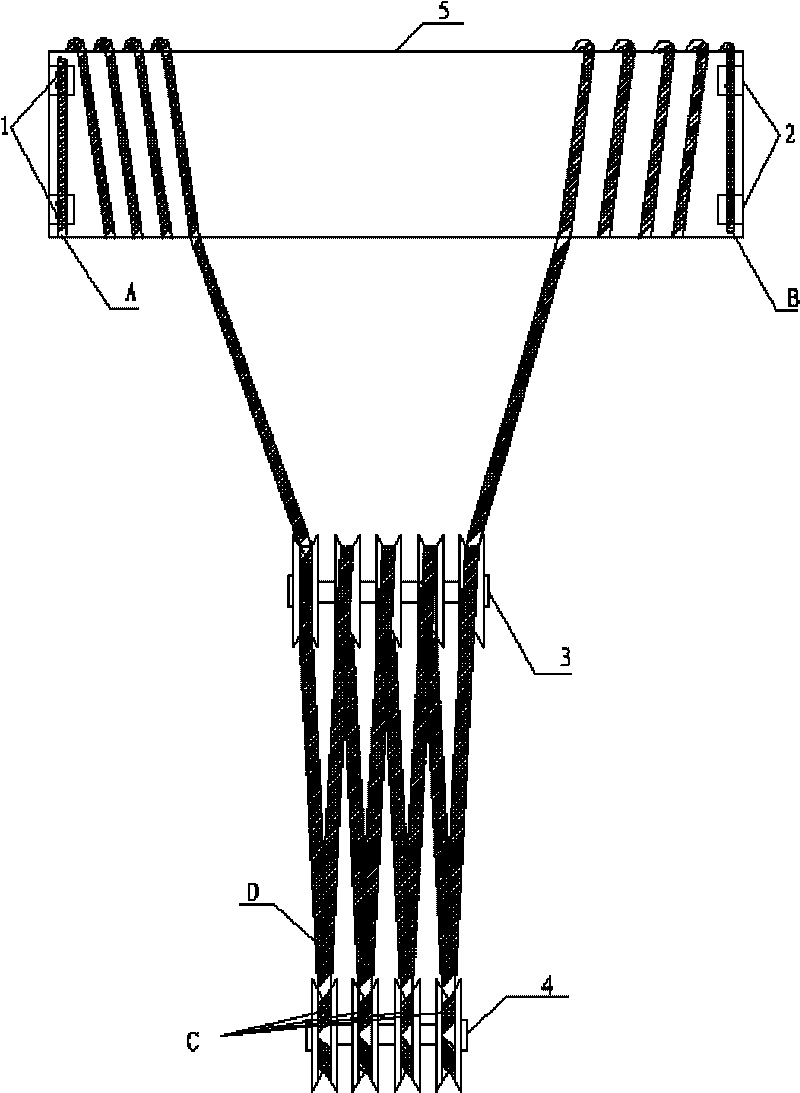

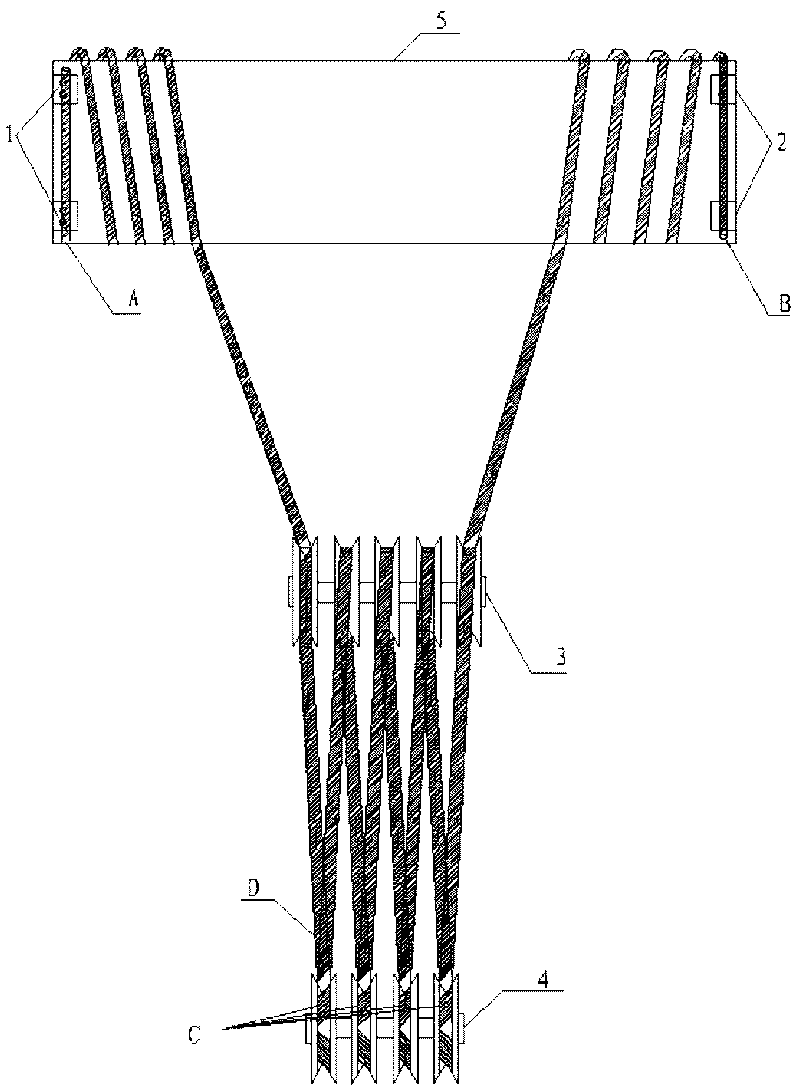

Method for changing long rubber belt of large wide belt of belt conveyer

InactiveCN101948054AReduce vulcanization joint timeReduce replacement timeConveyorsArticle deliveryEngineeringUltimate tensile strength

The invention relates to a method for changing a long rubber belt of a large wide belt of a belt conveyer. The method comprises the following steps of: winding a finished new rubber belt on a first winding drum until a required rubber belt length; cutting off an old rubber belt, fixing one end of the old rubber belt on a second winding drum and connecting the other end of the old rubber belt with the new rubber belt on the first winding drum; winding the old rubber belt onto the second winding drum to drive the new rubber belt to be conveyed onto the belt conveyer; separating the new rubber belt from the old rubber belt; and vulcanizing and connecting two ends of the new rubber belt by a conventional method. The invention has the advantages that the operations of laying the new rubber belt and winding the old rubber belt can be synchronously carried out, thus the method shortens the changing time, reduces the labor intensity of maintenance personnel and greatly improves the belt changing efficiency.

Owner:TONGLING MIRACLE MECHANICAL EQUIP

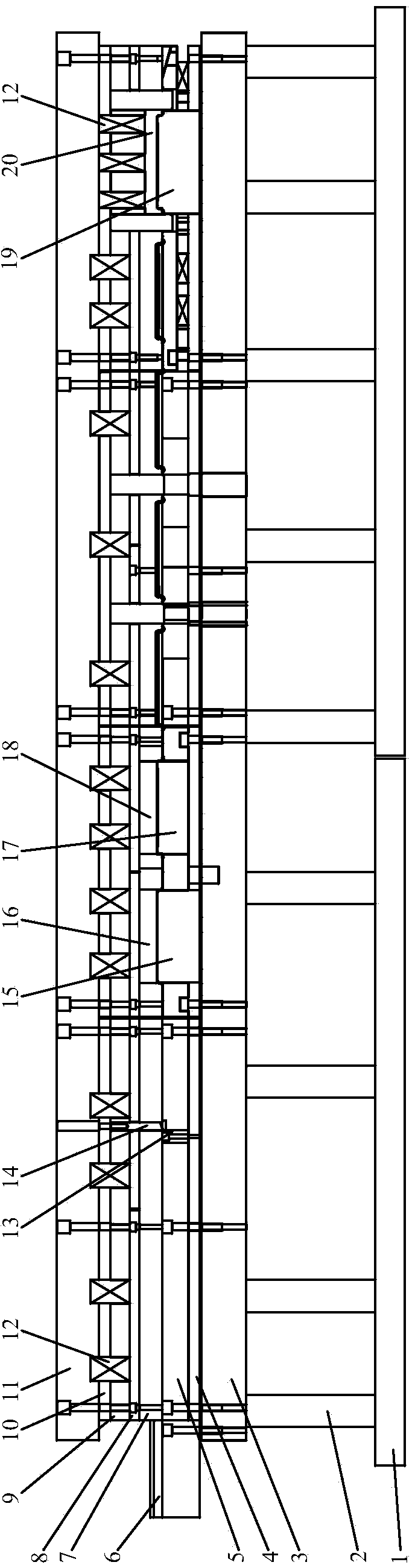

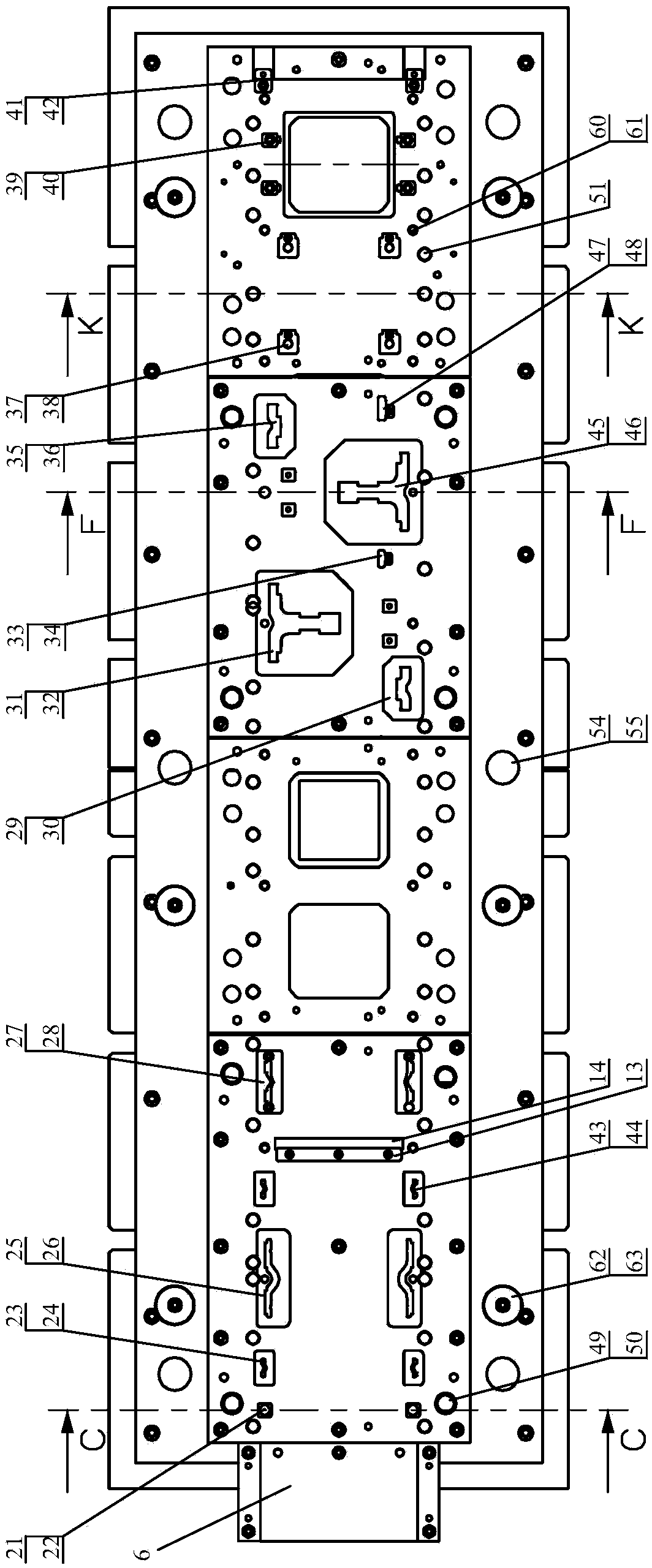

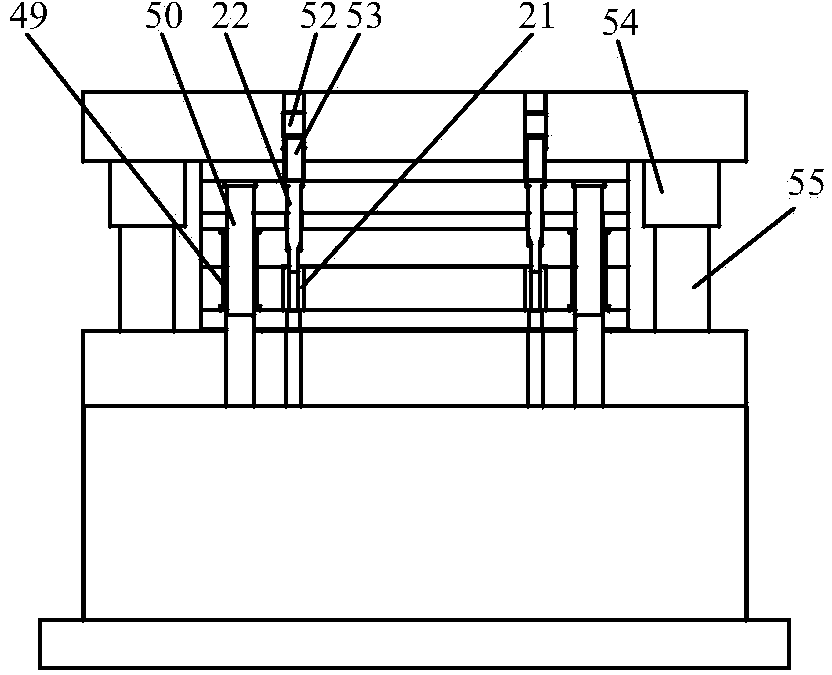

Suspension supporting base multi-station progressive die

ActiveCN103962452ACompact structureHigh guiding precisionShaping toolsPerforating toolsPunchingEngineering

The invention relates to a suspension supporting base multi-station progressive die which comprises an upper die assembly, a lower die assembly, an unloading plate, an unloading plate base plate and a mis-feeding detection device. The upper die assembly is sequentially provided with a corresponding male die in the feeding direction, the lower die assembly is sequentially provided with a female die embedding sleeve matched with the male die of the upper die assembly, corresponding positions on the unloading plate and on the unloading plate base plate are provided with a through hole capable of penetrating through the male die of the upper die assembly, the unloading plate is disposed on the unloading plate base plate, and the unloading plate base plate is arranged on the upper die assembly through an unloading spring. By means of the progressive die, suspension supporting bases are produced in a continuous drawing progressive die mode. The mechanism is compact in structure, high in guide precision, stable in unloading and precise in pitch fixing, and feeding and discharging are convenient to achieve. A quick replacement structure is adopted to a punching male die, and maintenance and replacement time of the die is effectively shortened. After being tried, the mechanism is good in use effect and can meet requirements for high efficiency and high precision of stamping production.

Owner:LIUZHOU VOCATIONAL & TECHN COLLEGE

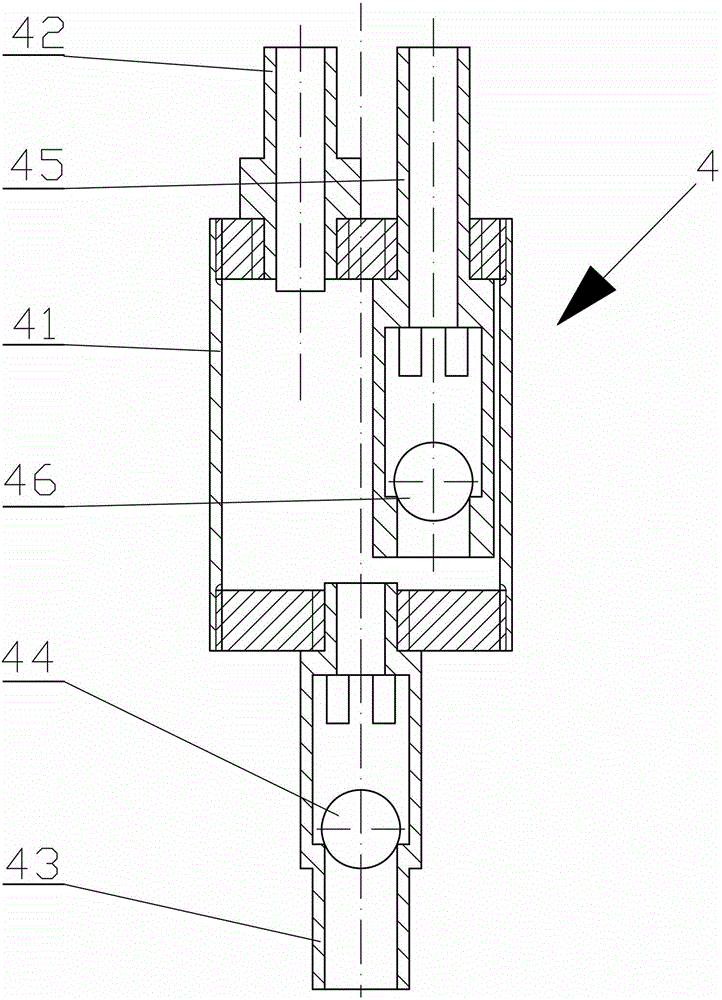

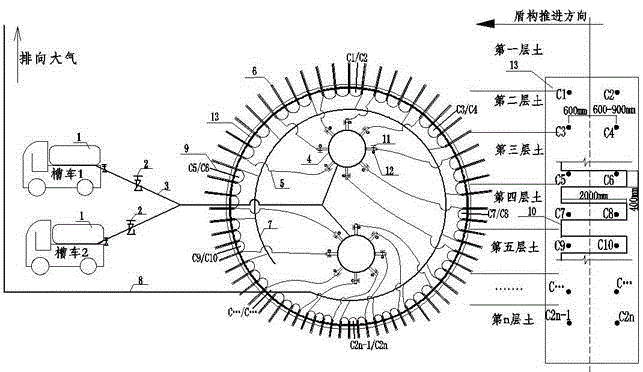

Liquid nitrogen freezing system of high water pressure super-long-distance large-sectional tunnel and method of quickly changing shield tail brushes

Disclosed are a liquid nitrogen freezing system of a high water pressure super-long-distance large-sectional tunnel and a method of quickly changing shield tail brushes. The system comprises a liquid nitrogen storage tank, a main gate valve, a liquid supply pipe, distributors, liquid distributing pipes, freezing pipes, gas colleting pipes, exhaust pipes, a temperature measuring hole and cold discharge pipes. The liquid nitrogen storage tank is connected with the liquid supply pipe provided with the main gate valve. Two branches of the liquid supply pipe are connected with the distributors respectively; each distributor includes 8 to 10 branches, each branch is connected with a group of series freezing pipes through one liquid distributing pipe, each group of last freezing pipes is connected with one gas collecting pipe and is connected with one exhaust pipe through the gas collecting pipe; the exhaust pipes discharge vaporized nitrogen into air; the front ends of the cold discharge pipes are connected with the liquid distributing pipes, and the their tail ends are connected with the gas collecting pipes. The method of quickly changing the shield tail brushes is further provided. The system and the method are suitable for the projects of quickly changing the shield tail brushes for the high water pressure super-long-distance large-sectional tunnels; the system and the method have the advantages such as high forming speed of a frozen wall, high strength, no toxicity or pollution, safety and reliability in use, and convenience in construction.

Owner:NANJING FORESTRY UNIV +1

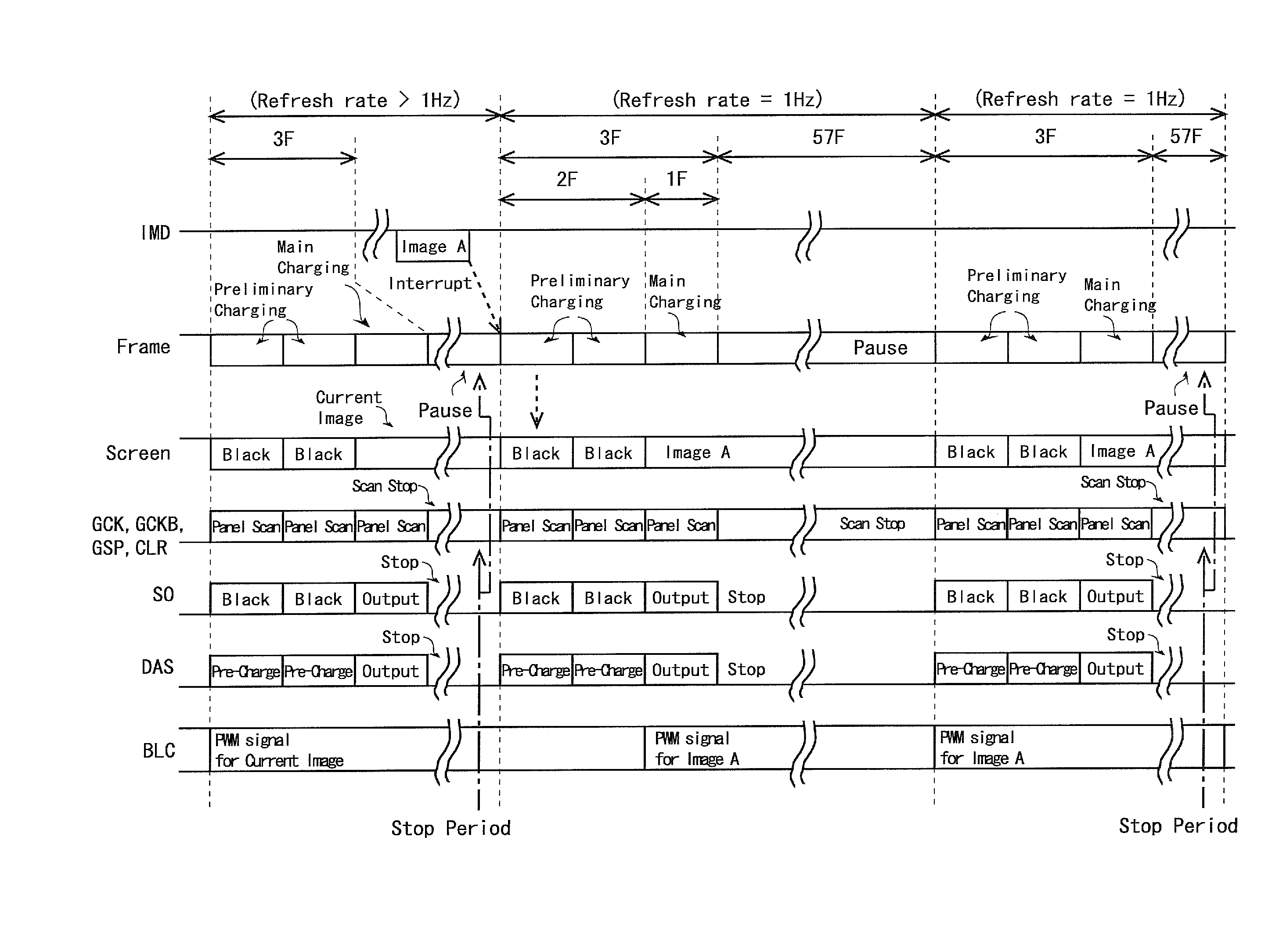

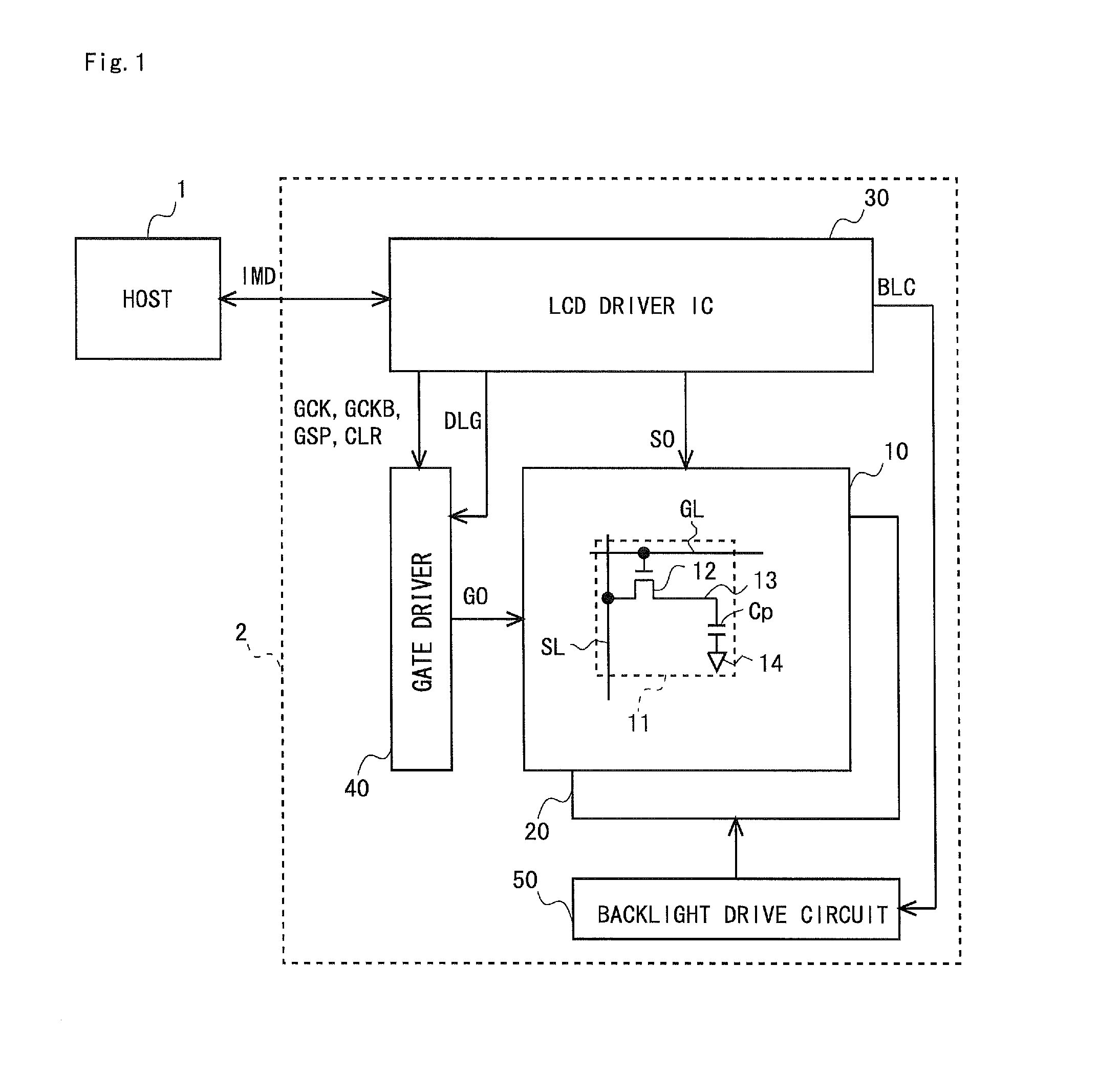

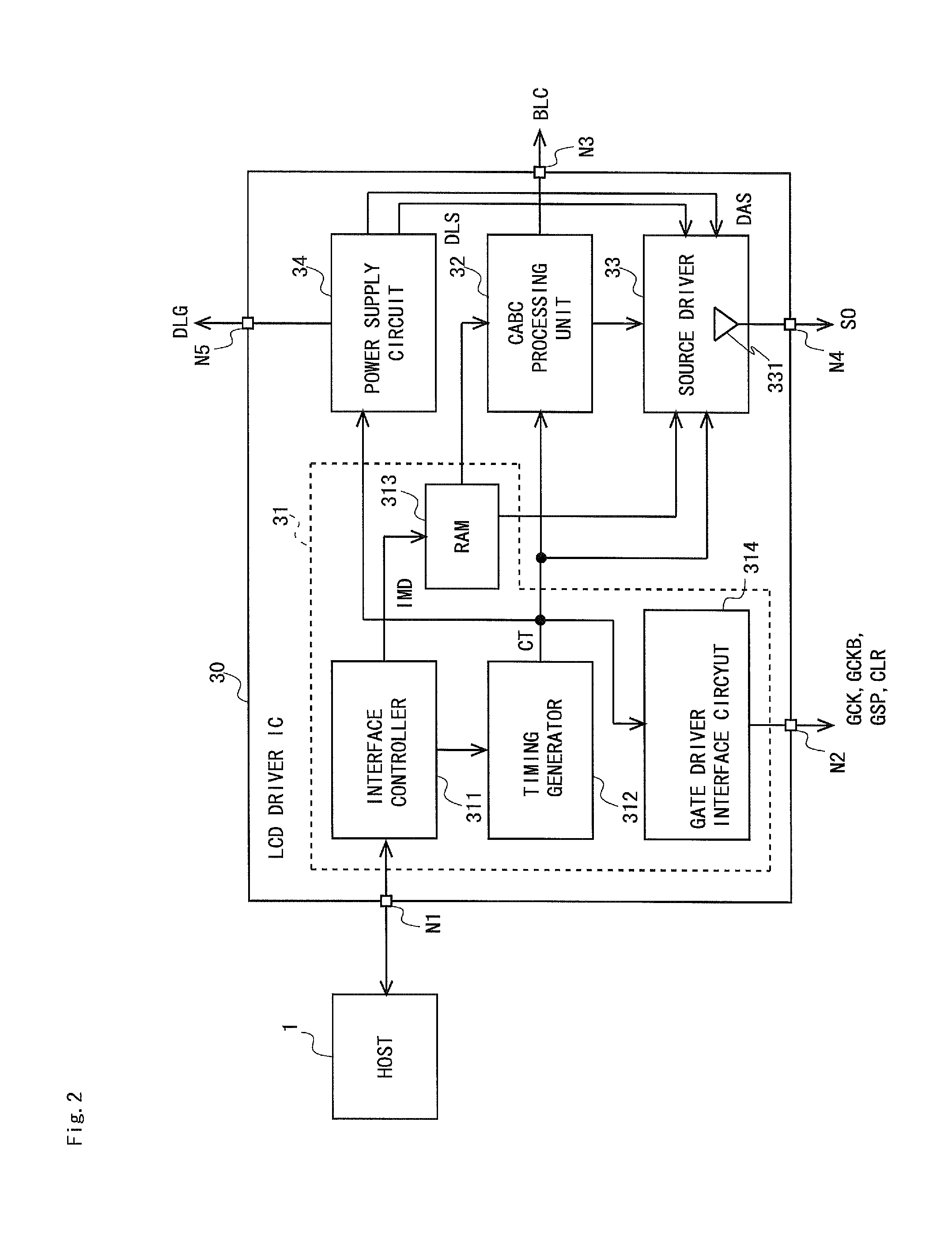

Drive control device, display device including the same, and drive control method

InactiveUS20140368490A1Reduce power consumptionPerform quicklyCathode-ray tube indicatorsPower supply for data processingEngineeringReal-time computing

Low frequency drive is performed that provides, after a charging period for refreshing a screen, a pause period for pausing the refresh. The length of the charging period is, for example, one frame and the length of the pause period is, for example, 59 frames. When new image data IMD is transmitted from a host to an LCD driver IC during the pause period, an interrupt process where the pause period is allowed to transition to the charging period is performed immediately thereafter. By performing the interrupt process, without waiting for the pause period with the predetermined length to end, the next charging period where refresh based on the new image data IMD is to be performed starts.

Owner:SHARP KK

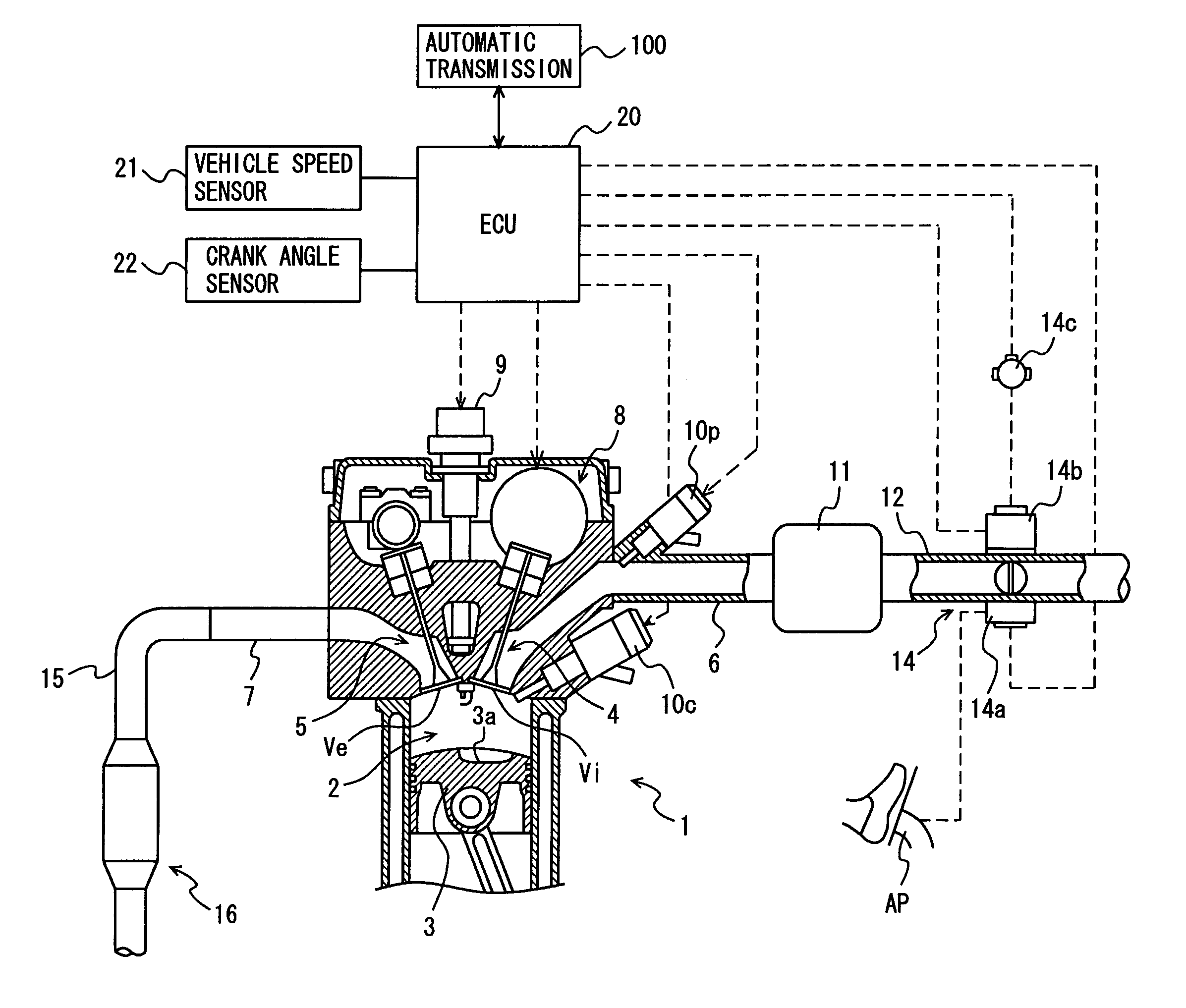

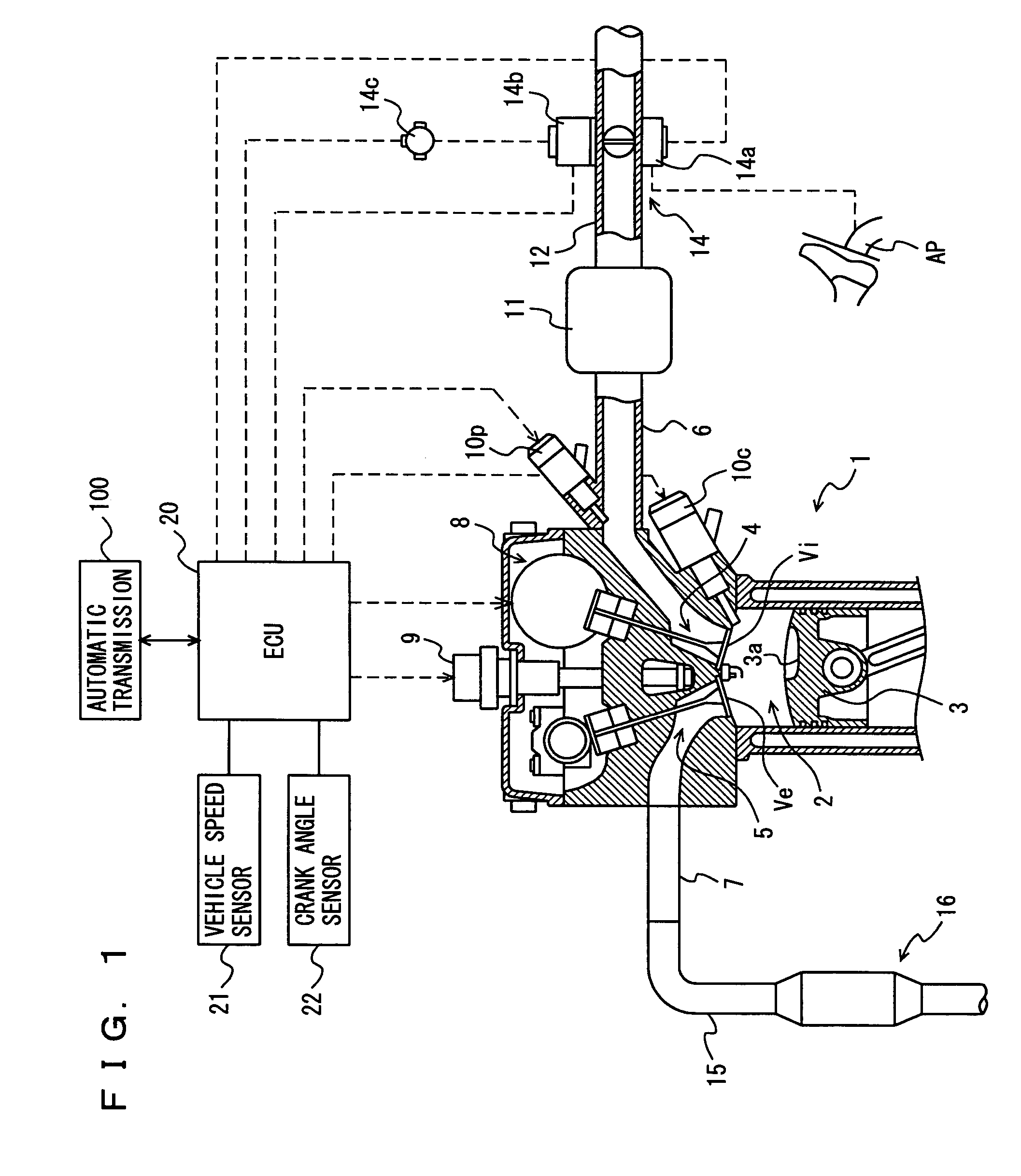

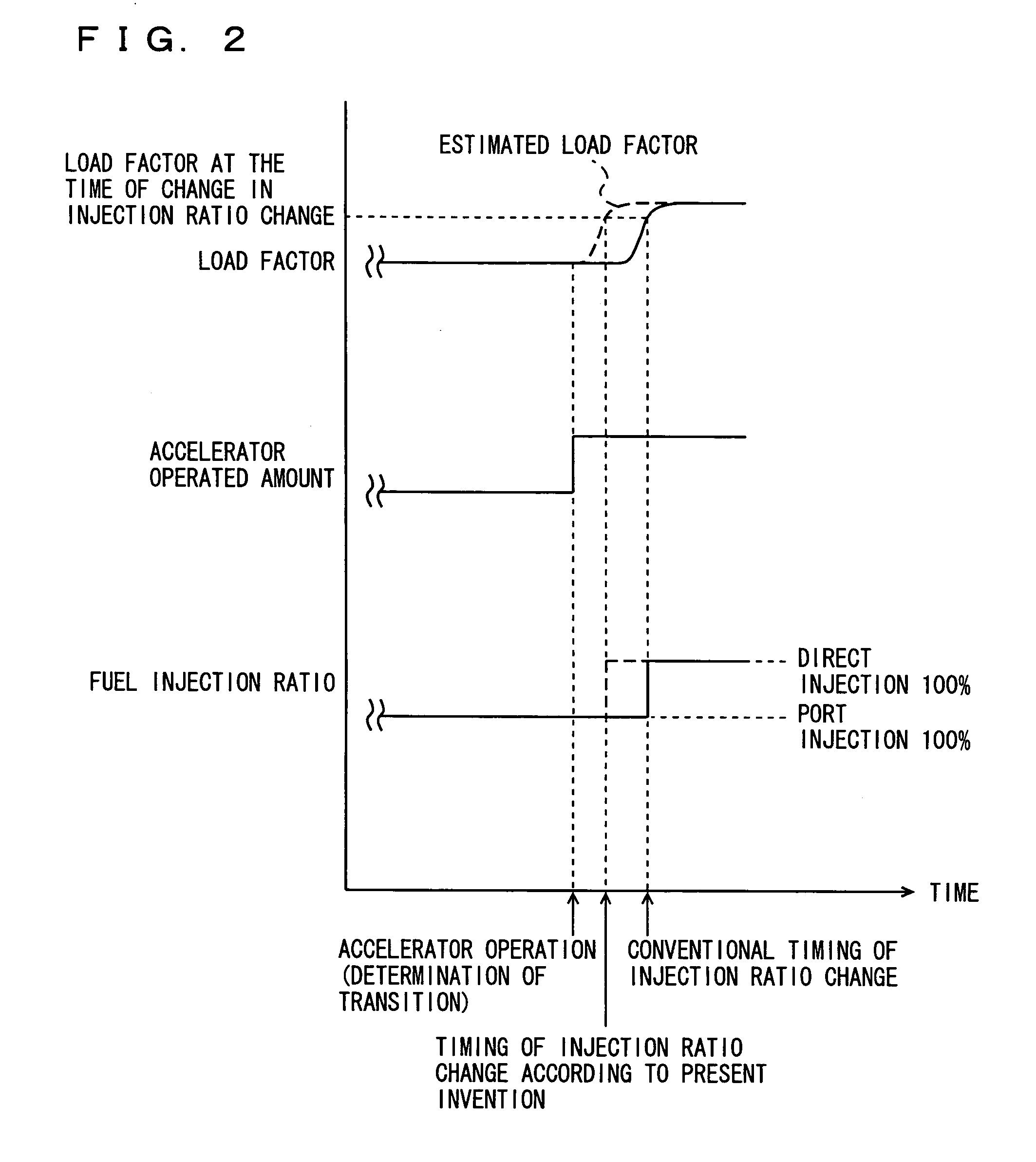

Device and method for controlling internal combustion engine

ActiveUS7207315B2Satisfactory suppressionReduce replacement timeElectrical controlVehicle fittingsExternal combustion engineInternal combustion engine

An internal combustion engine includes a port injector injecting a fuel into an intake port, an in-cylinder injector directly injecting a fuel into a combustion chamber, and an ECU. When the ECU determines that an operation state of the internal combustion engine exhibits a transition state, the ECU obtains an estimated load factor of the internal combustion engine based on the operation state of the internal combustion engine, and calculates a fuel injection ratio between the port injector and the in-cylinder injector based on the estimated load factor.

Owner:TOYOTA JIDOSHA KK

Electrically Writeable and Erasable Memory Medium

InactiveUS20080001136A1Low thermal conductivityReduce diffuseSemiconductor/solid-state device manufacturingDigital storageAtomic elementElectrical impulse

A memory cell for an electrically writeable and erasable memory medium as well as a memory medium thereof is provided. The memory cell comprises a data recording element, the data recording element has a plurality of multiple-layer structure disposed one on top of another, each the multiple-layer structure comprising a plurality of sequentially disposed individual layers. At least one of the plurality of individual layers is capable of changing phase between a crystalline state and an amorphous state in response to an electrical pulse, one of the plurality of individual layers having at least one atomic element which is absent from other one of the plurality of individual layers, and the plurality of multiple-layer structure is of a superlattice-like structure to lower a heat diffusion out of the data recording element to shorten a phase change time of the respective individual layers.

Owner:AGENCY FOR SCI TECH & RES

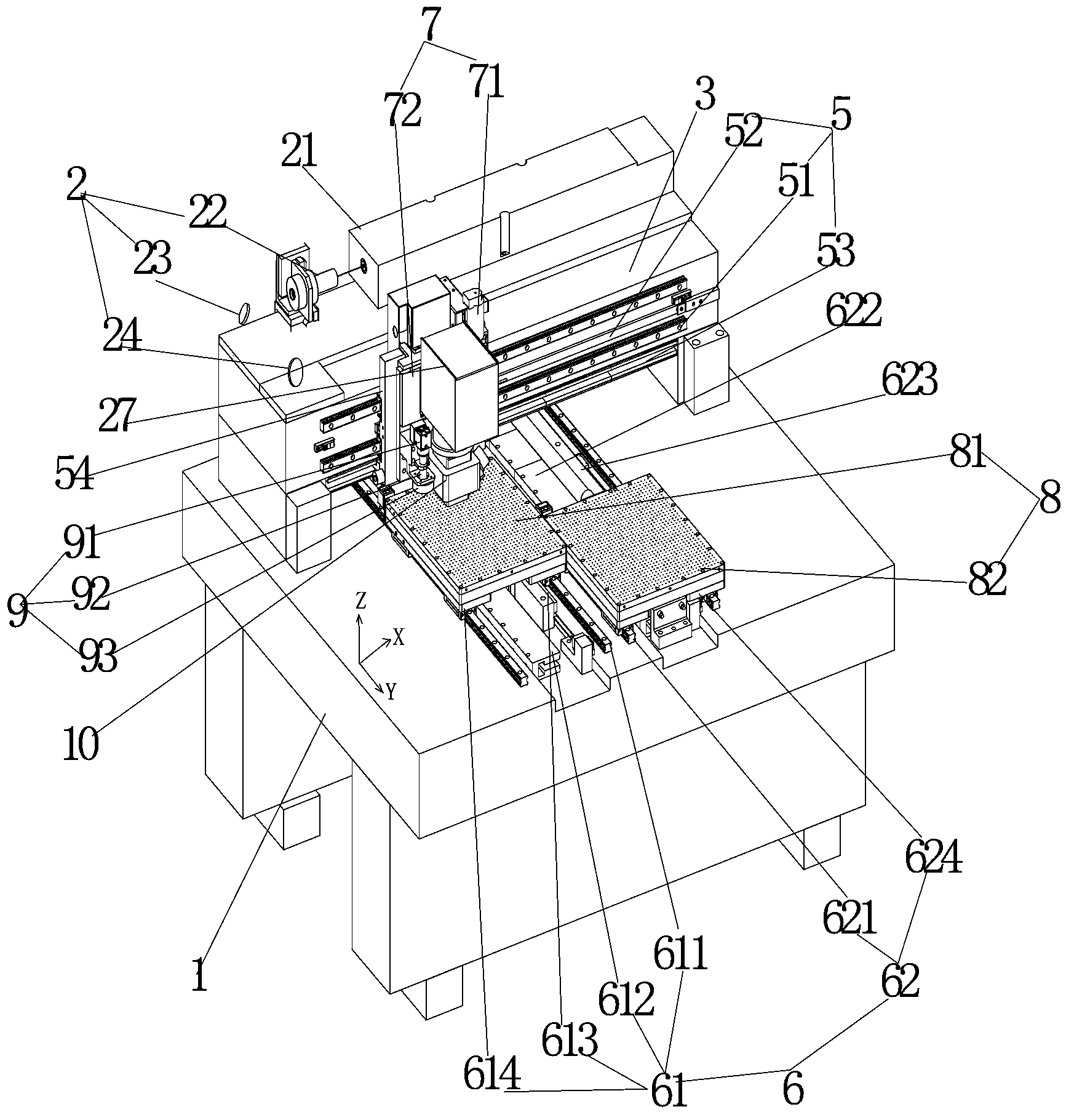

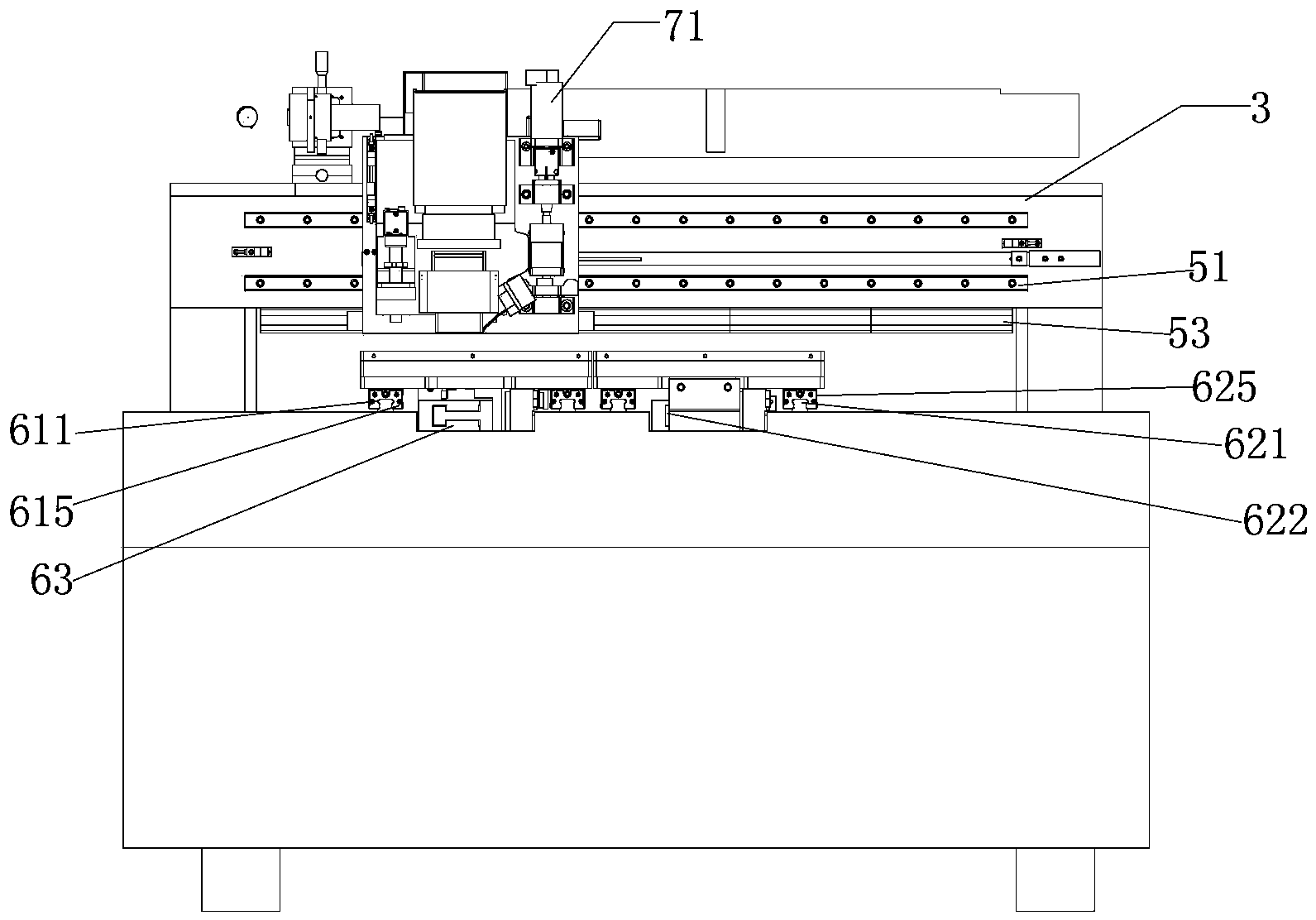

Laser processing device

InactiveCN103406665AReduce replacement timeImprove processing efficiencyLaser beam welding apparatusOptoelectronicsLaser

The invention provides a laser processing device which comprises a lathe bed, a beam and a laser processing system. The laser processing system comprises a laser processing assembly, wherein at least two movable positioning working platforms are arranged on the lathe bed, and the laser processing assembly is movably arranged on the beam and positioned above the positioning working platforms. Workpieces to be processed on the at least two positioning working platforms are continuously processed through the laser processing assembly, replacing time of the workpieces to be processed is saved, the laser processing assembly can work continuously, and therefore processing efficiency is improved substantially.

Owner:HANS LASER TECH IND GRP CO LTD +1

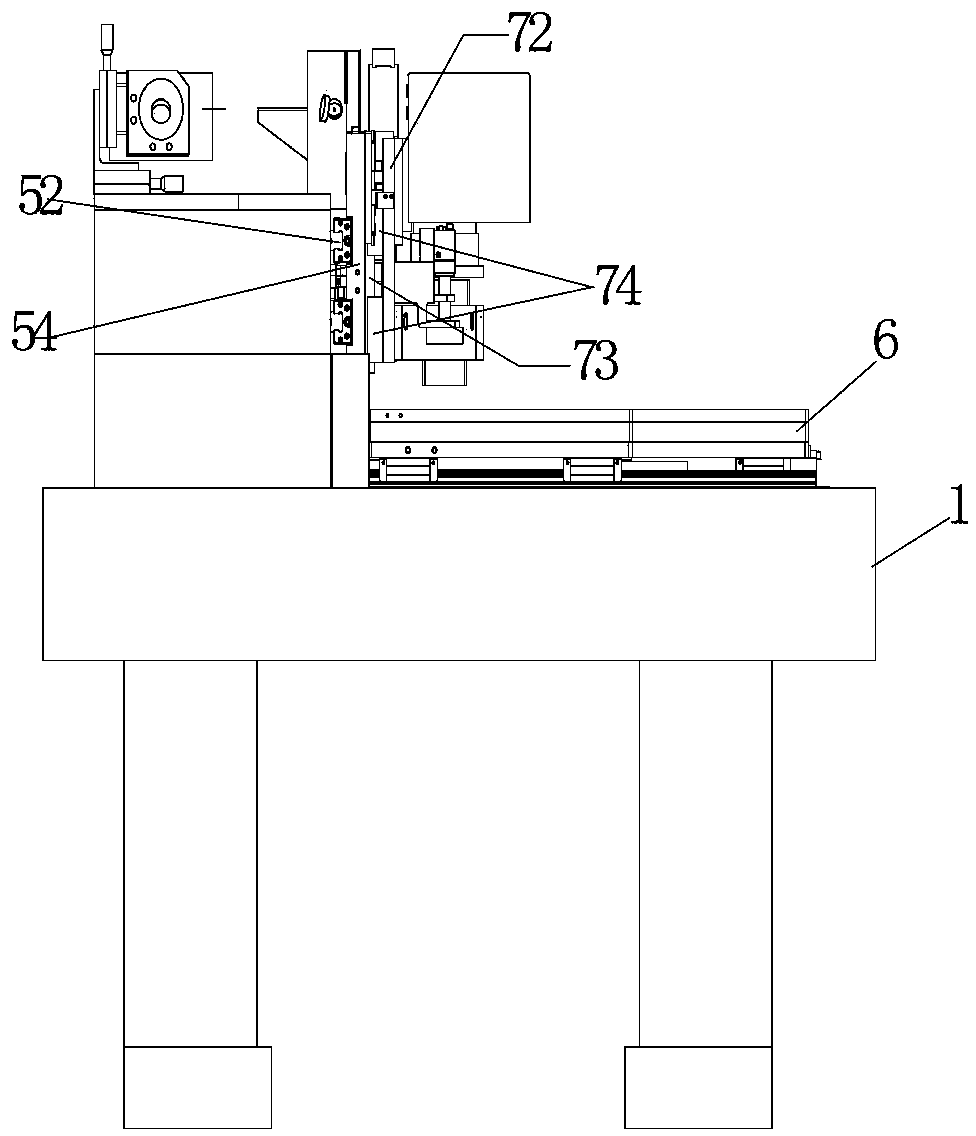

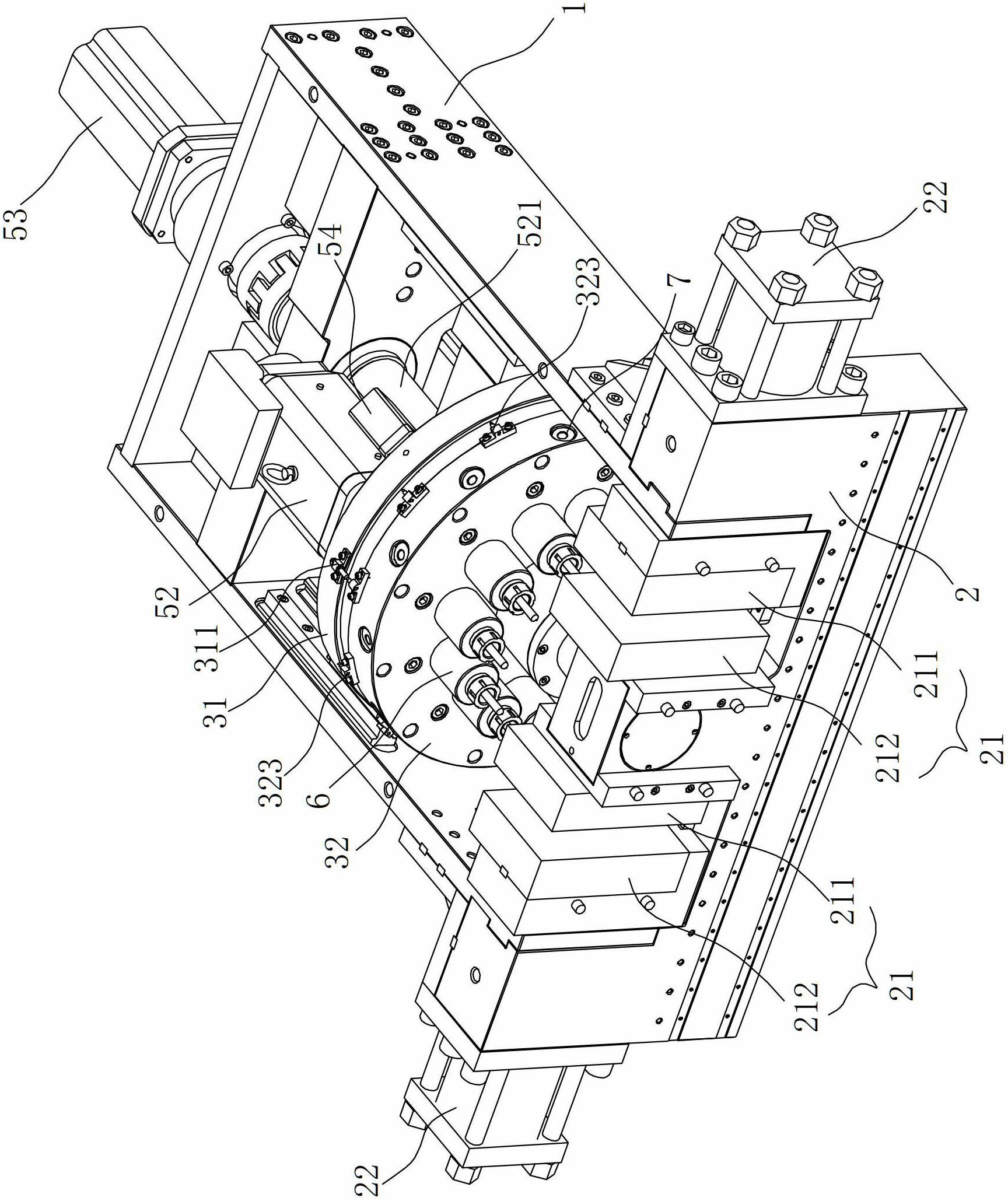

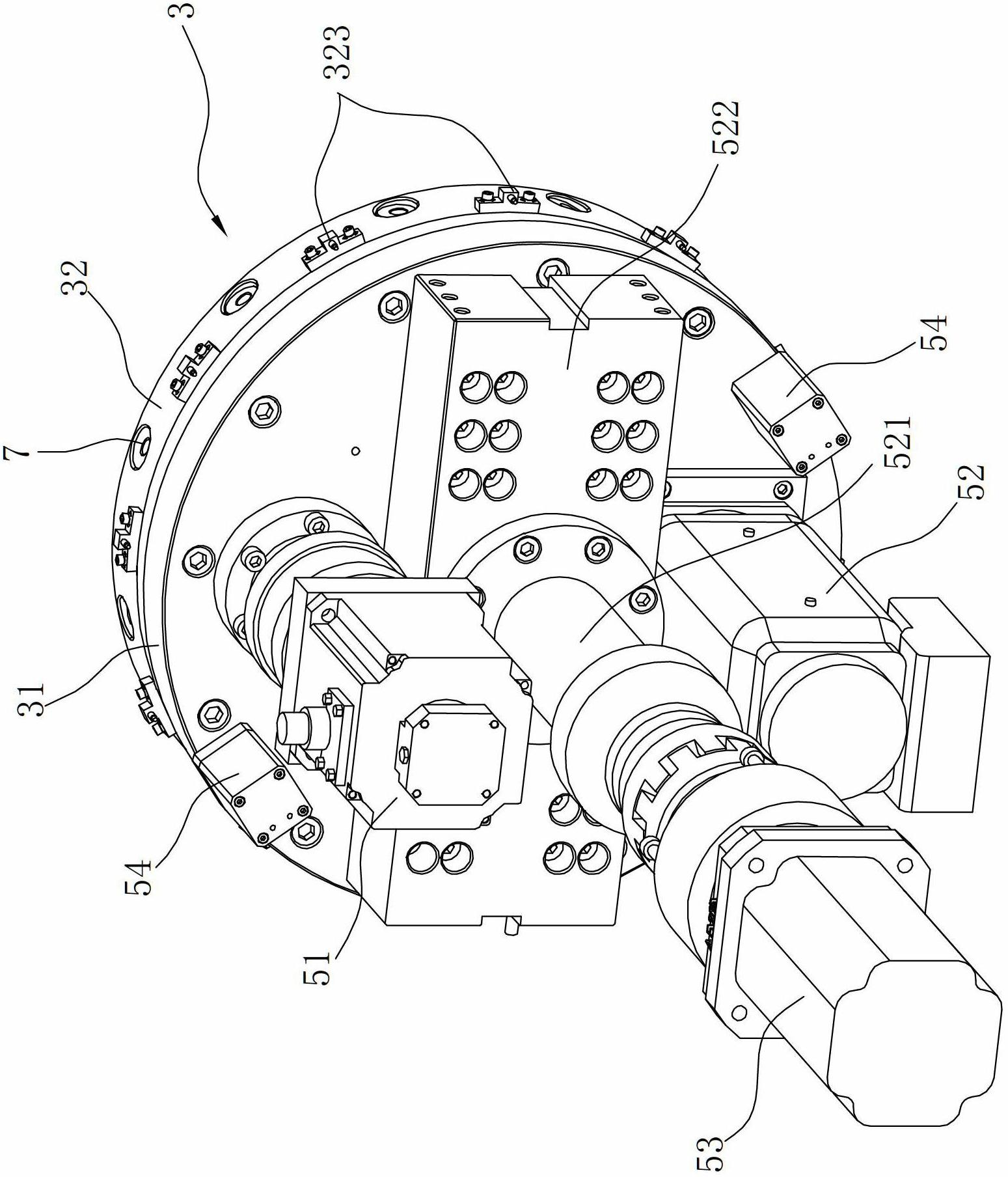

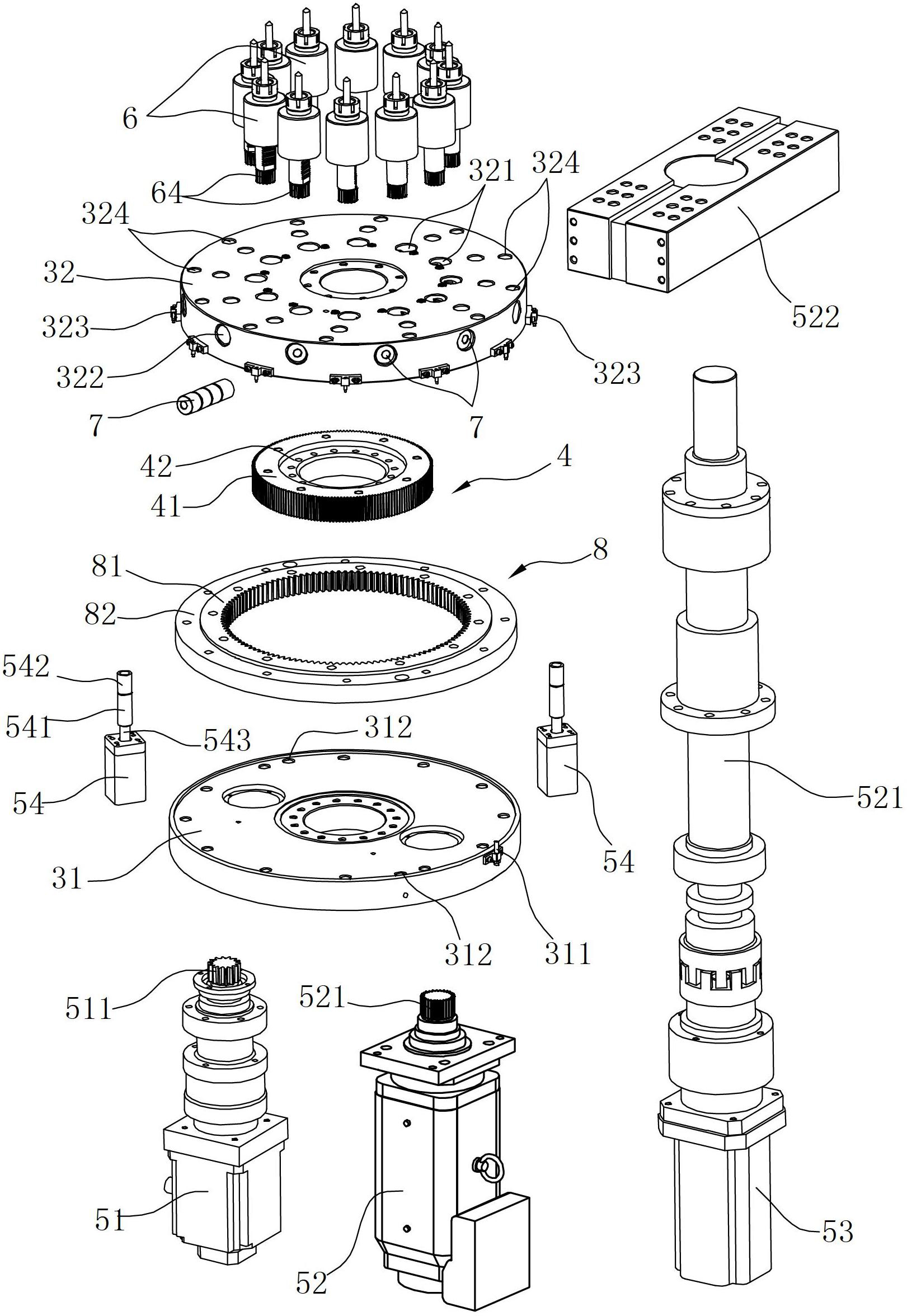

Multi-station pipe end machining equipment

ActiveCN102689235AEasy loading and unloadingReduce replacement timeTool holdersDriving apparatusPipe fittingEngineering

Owner:ZHEJIANG MOTORBACS TECH

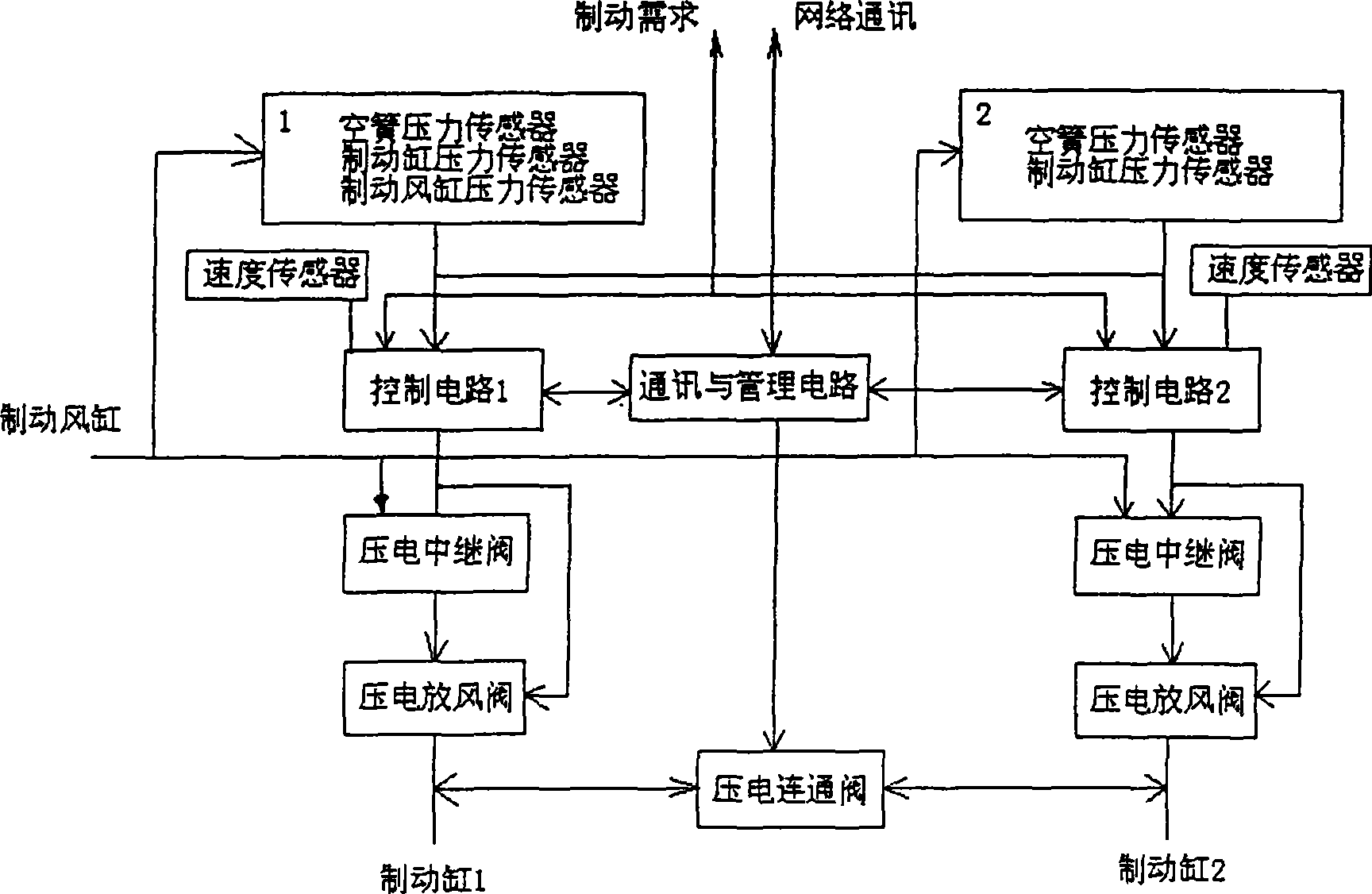

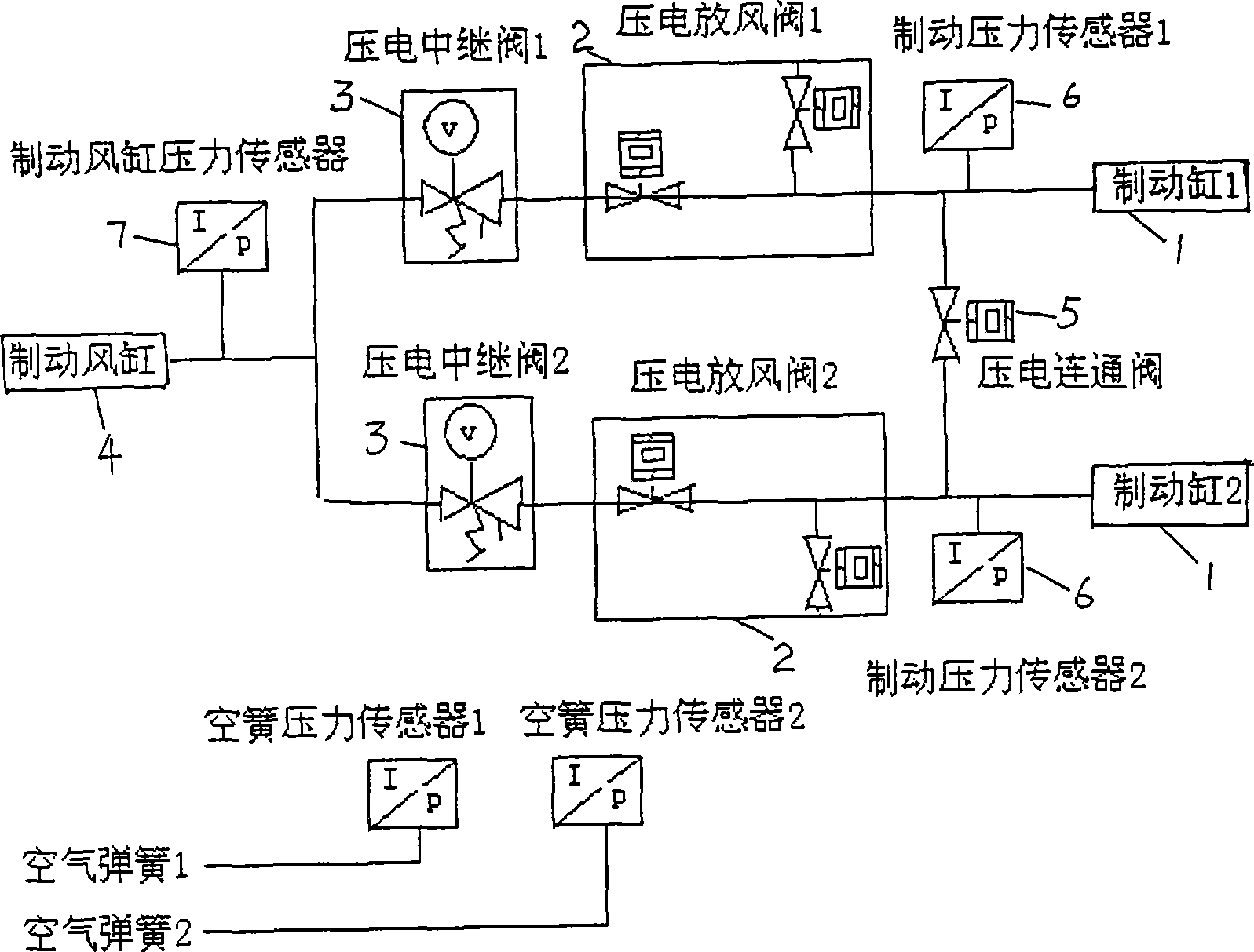

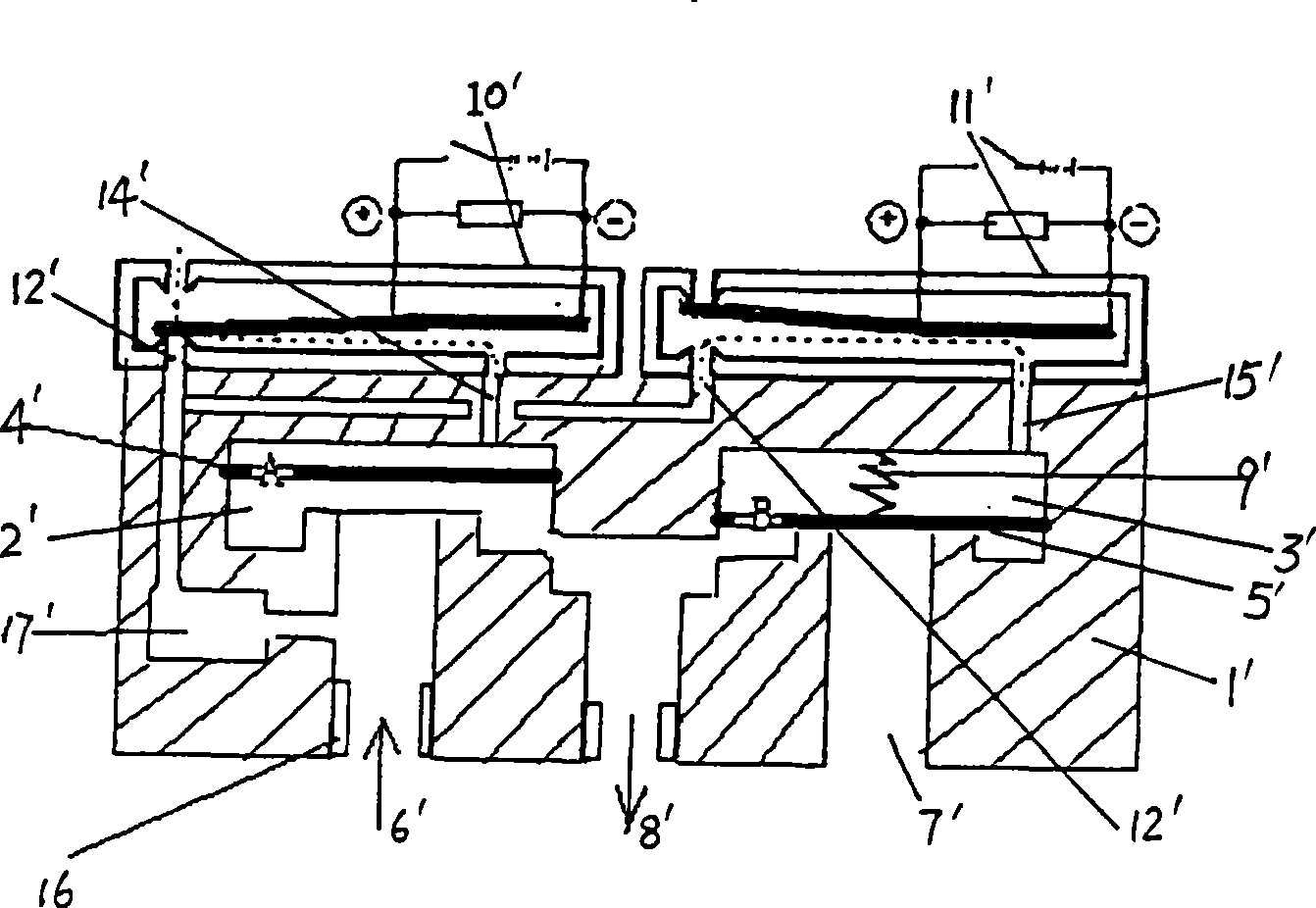

Electropneumatic brake method and system with fault complementation control based on single-axle control

InactiveCN101508287ASmall volumeSmall flow requirementsRailway braking systemsBrake safety systemsElectricityBogie

The invention relates to an electropneumatic braking method and an electropneumatic braking system with fault complementation control on the basis of single-axis control, which is characterized in that two independent embedded type electropneumatic braking units are adopted, and each unit comprises a control circuit, a piezoelectric relay valve, a piezoelectric ventilation valve and a corresponding pressure sensor; the two units are managed by a communication and management circuit and arranged near a steering frame; and two axles on the same steering frame are controlled by the two embedded type electropneumatic braking units respectively. The method and the system can greatly reduce the volume of a cylinder and a pipeline by directly controlling a single braking cylinder, and have the advantages of rapid control response, high precision and good safety.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com