Patents

Literature

318results about How to "Reduce temperature loss" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

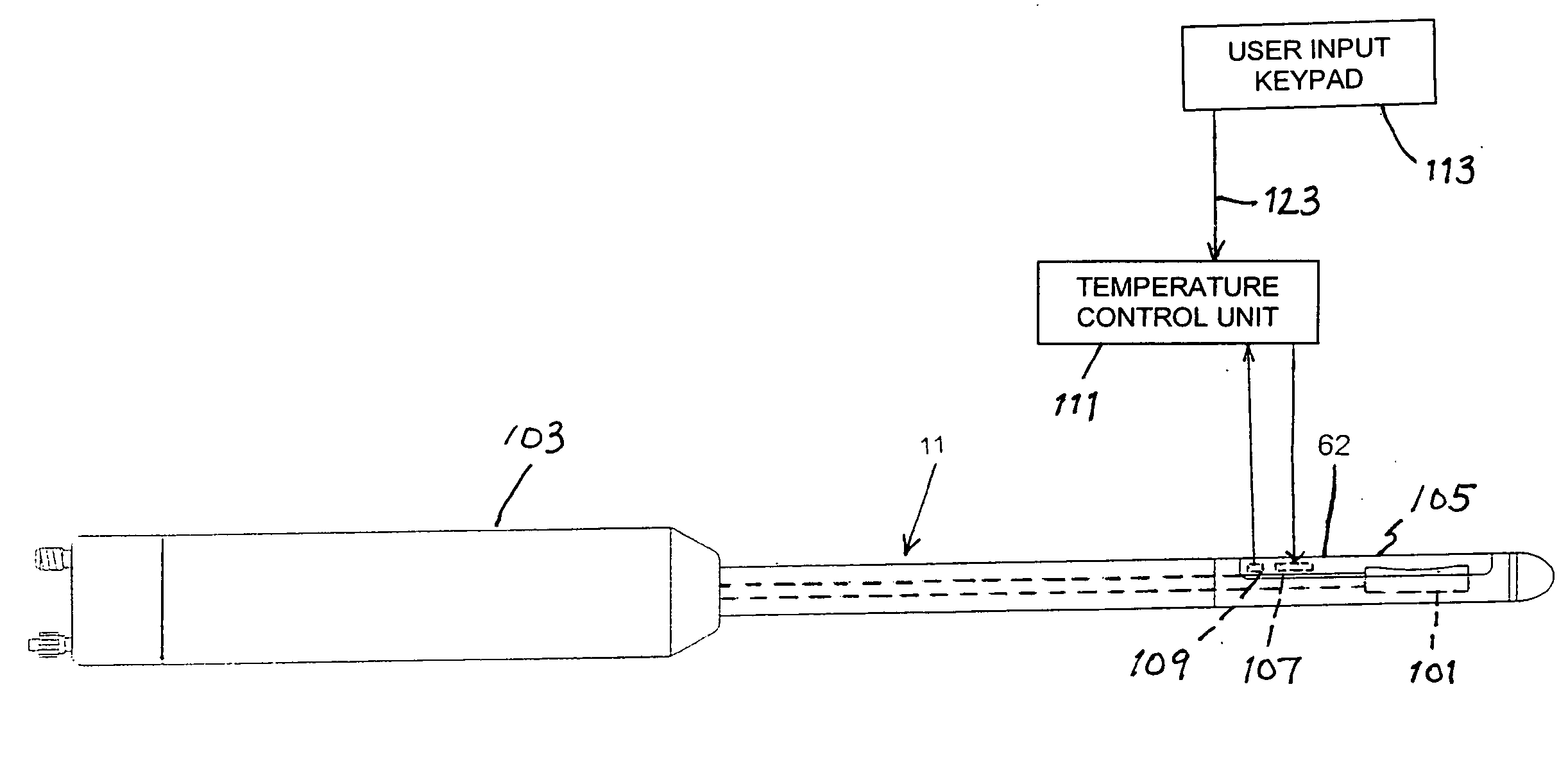

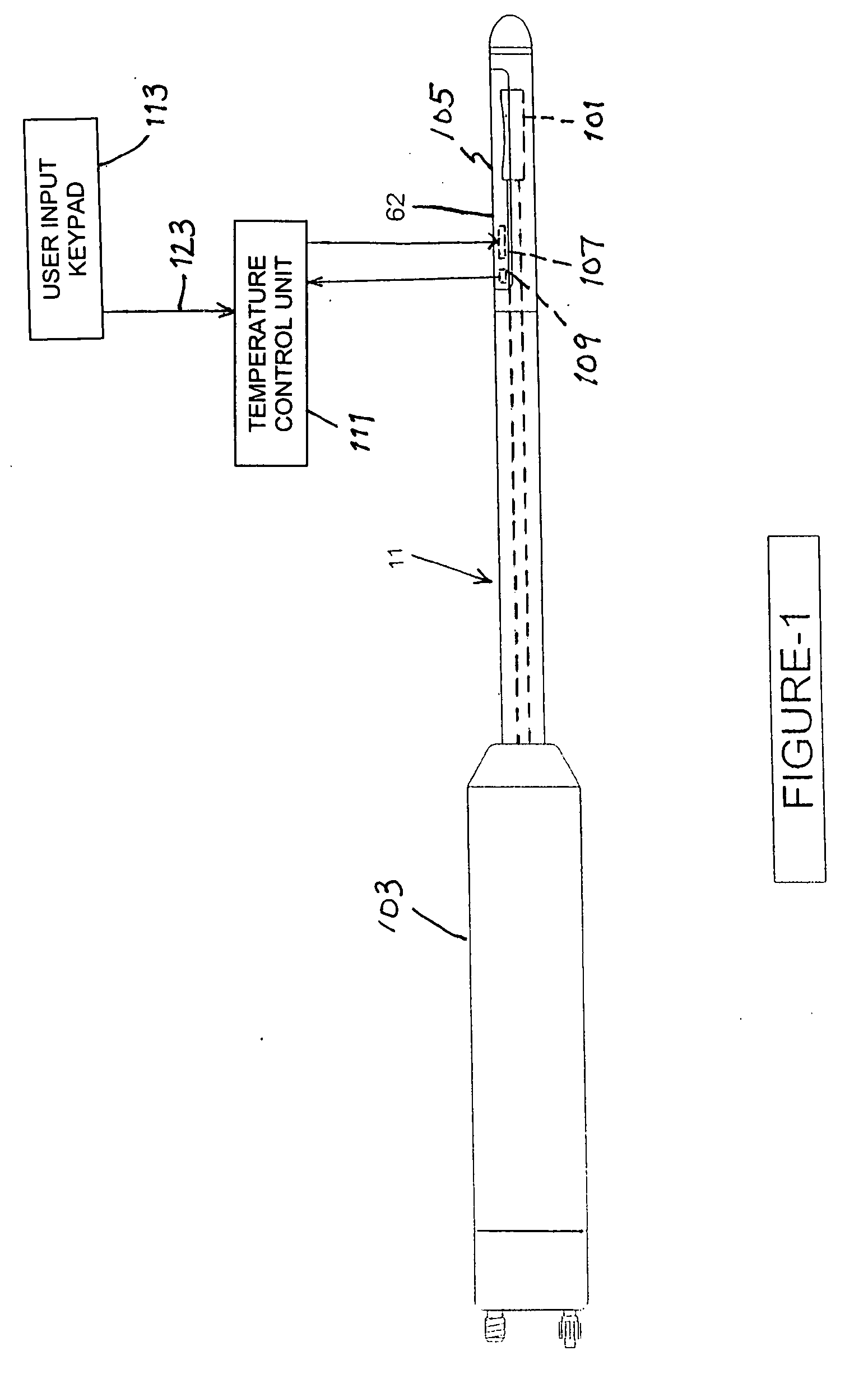

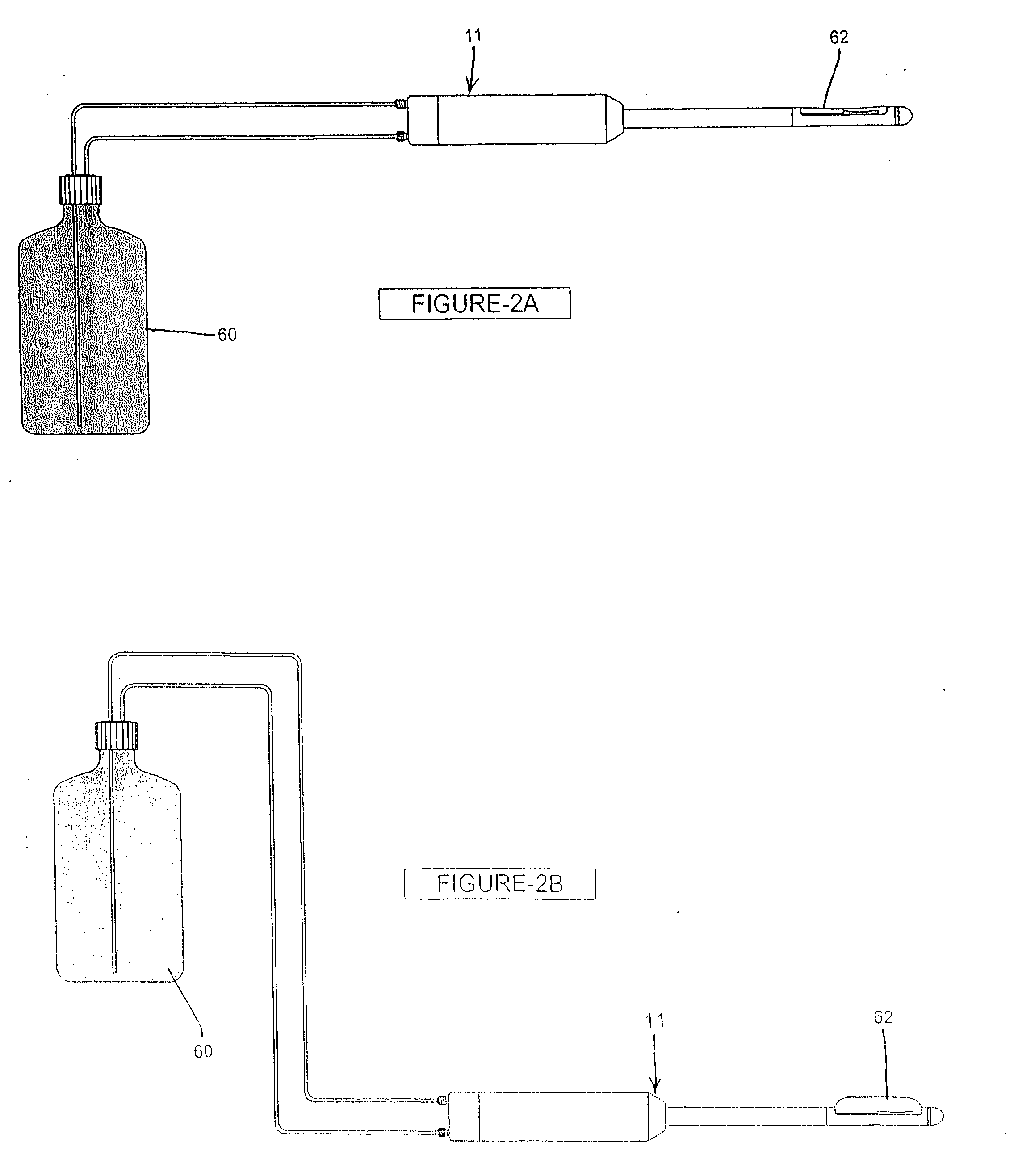

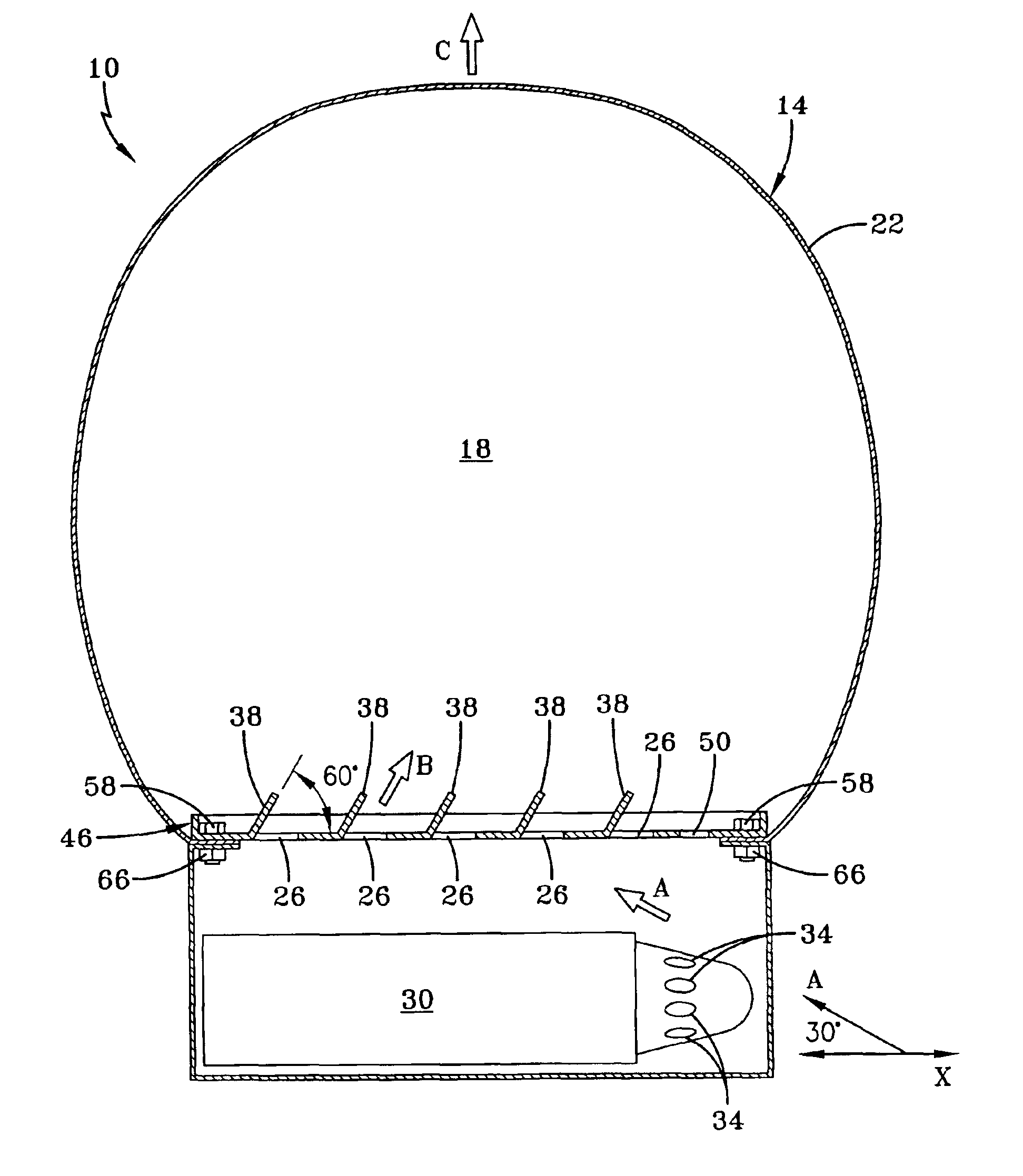

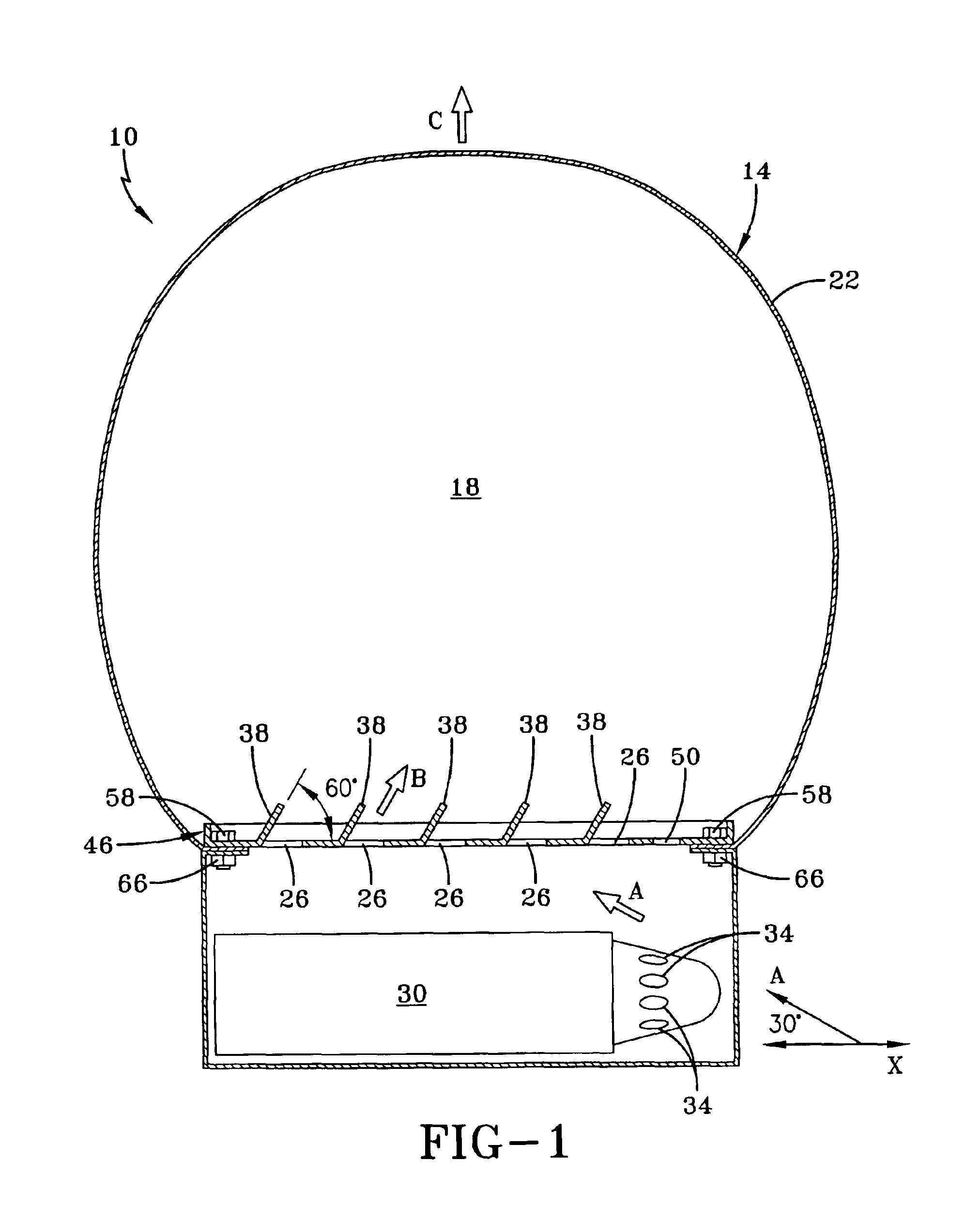

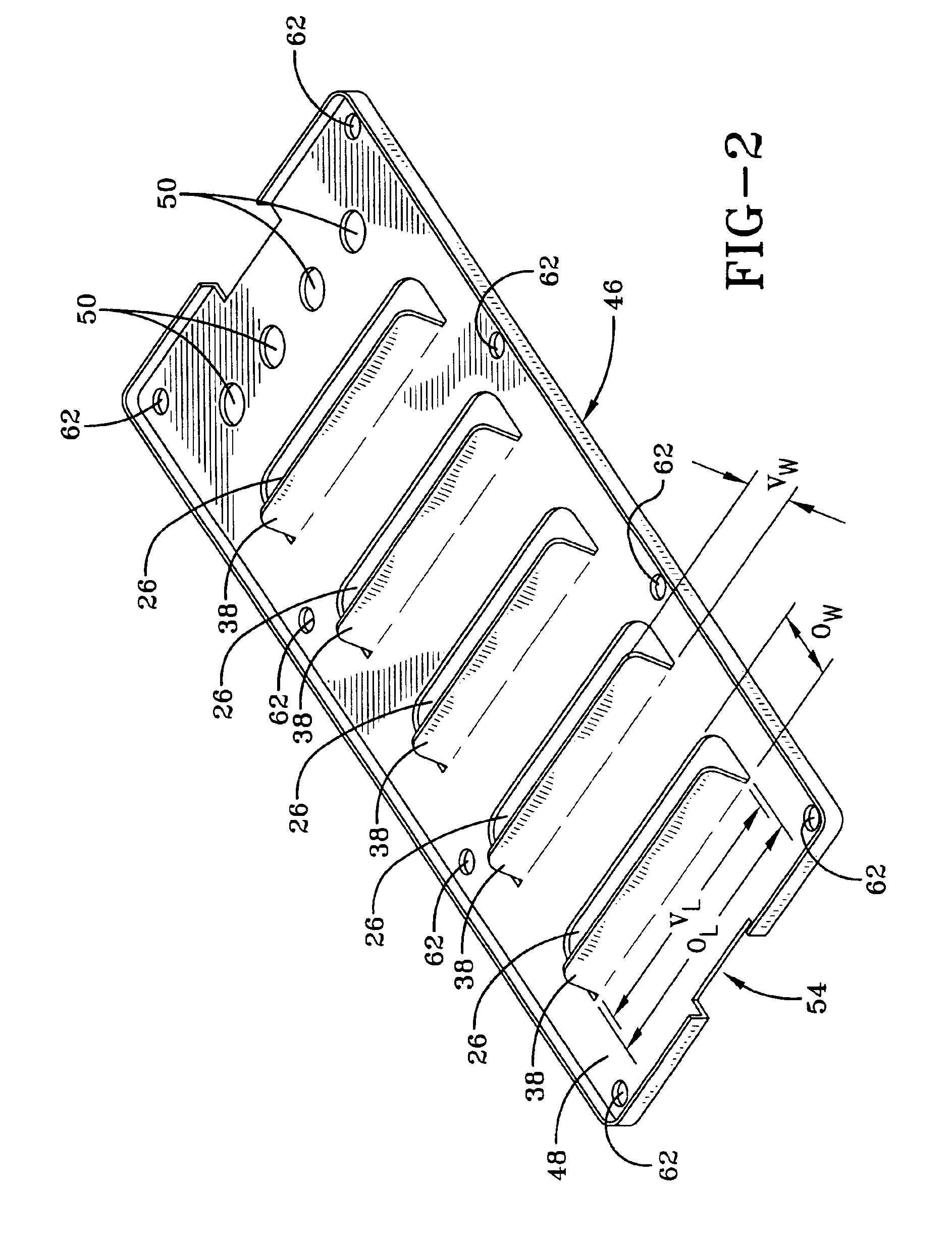

Elevated coupling liquid temperature during HIFU treatment method and hardware

InactiveUS20080281200A1Avoid necrosisEnhanced couplingUltrasonic/sonic/infrasonic diagnosticsUltrasound therapyLiquid temperatureUltrasonic vibration

A medical procedure utilizes a high-intensity focused ultrasound instrument having an applicator surface, a liquid-containing bolus or expandable chamber acting as a heat sink, and a source of ultrasonic vibrations, the applicator surface being a surface of a flexible wall of the bolus, the source of ultrasonic vibrations being in operative contact with the bolus. The applicator surface is placed in contact with an organ surface of a patient, the source is energized to produce ultrasonic vibrations focused at a predetermined focal region inside the organ, and a temperature of liquid in the bolus is controlled while the applicator surface is in contact with the organ surface to control temperature elevation in tissues of the organ between the focal region and the organ surface to necrose the tissues to within a desired distance from the organ surface.

Owner:US HIFU

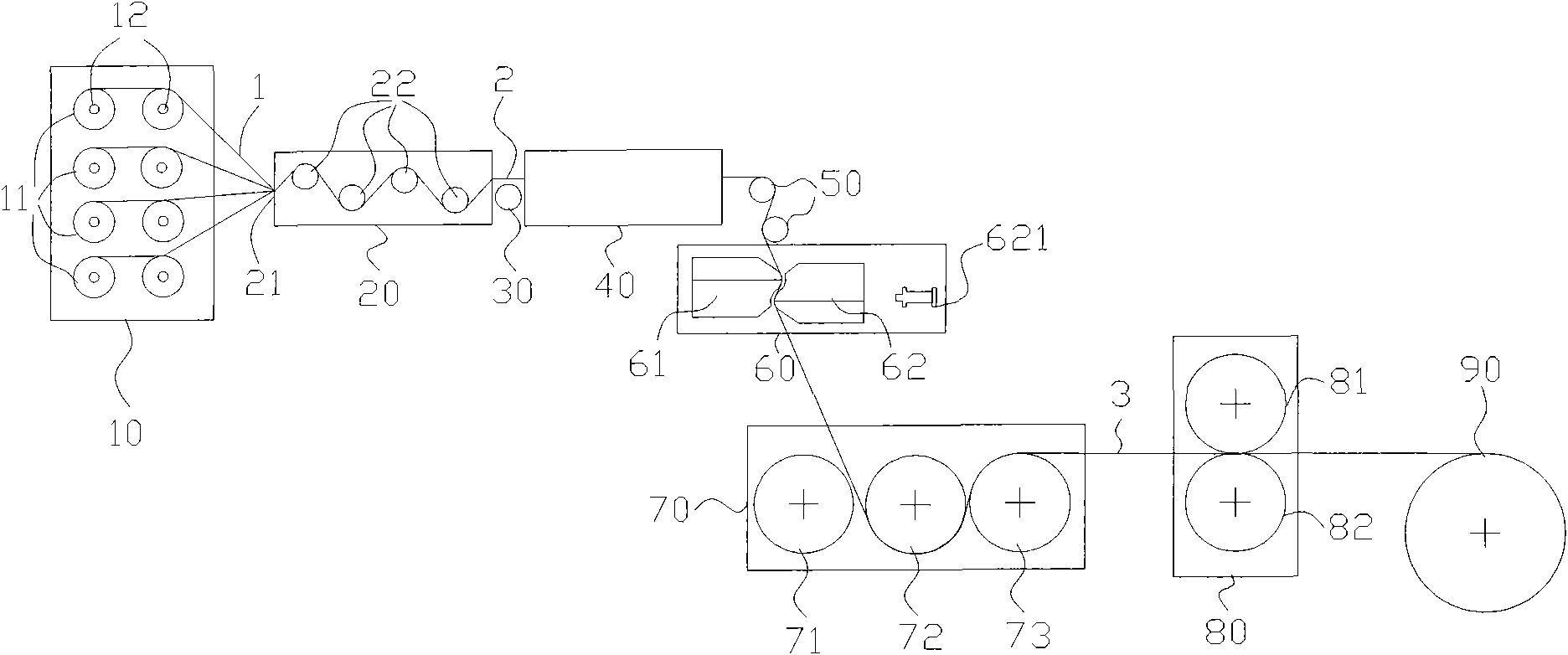

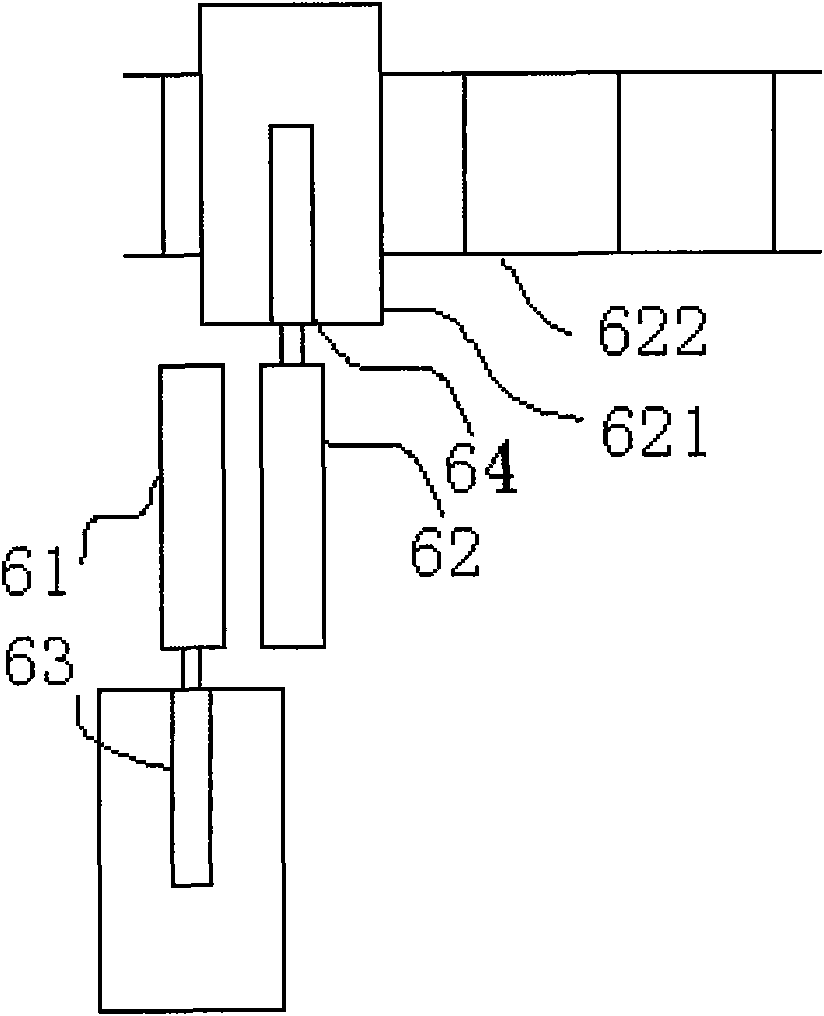

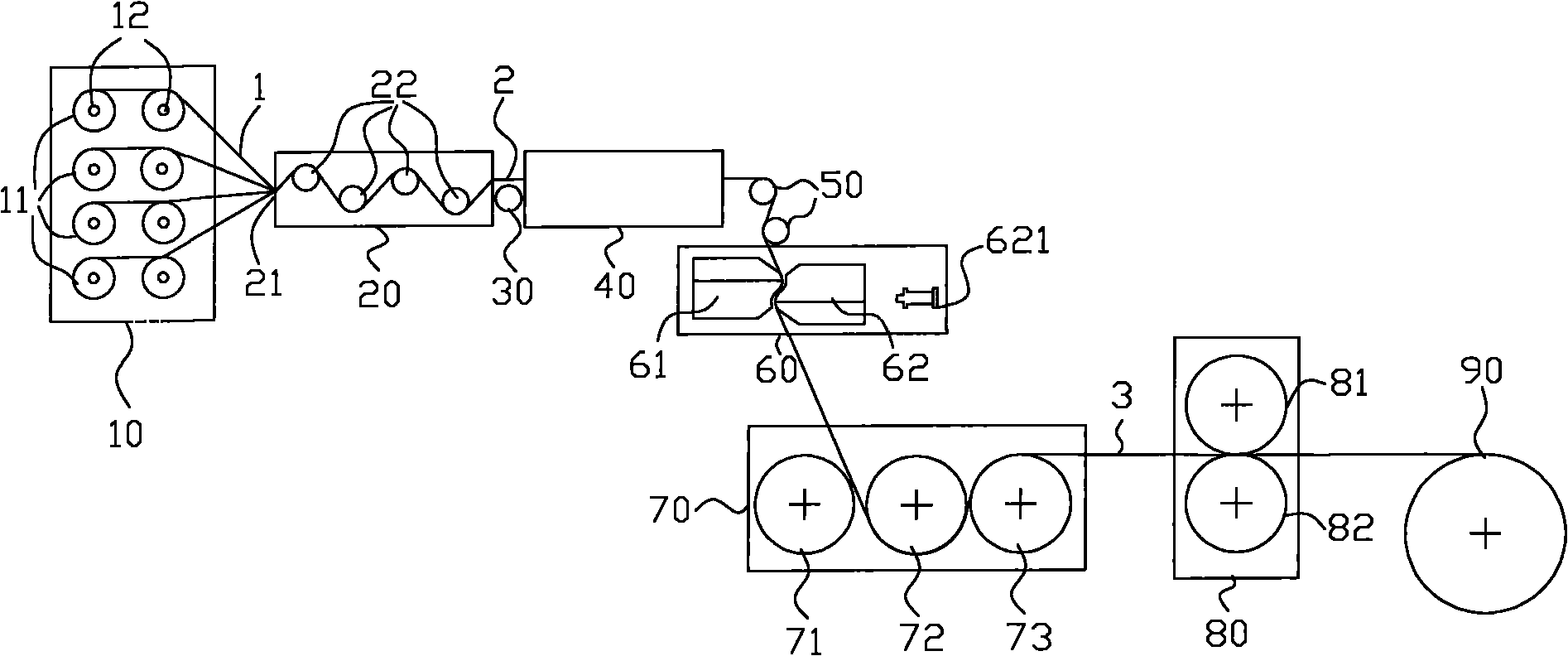

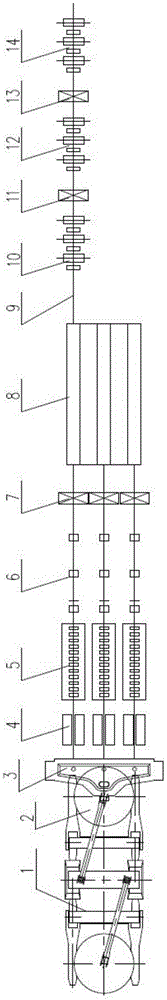

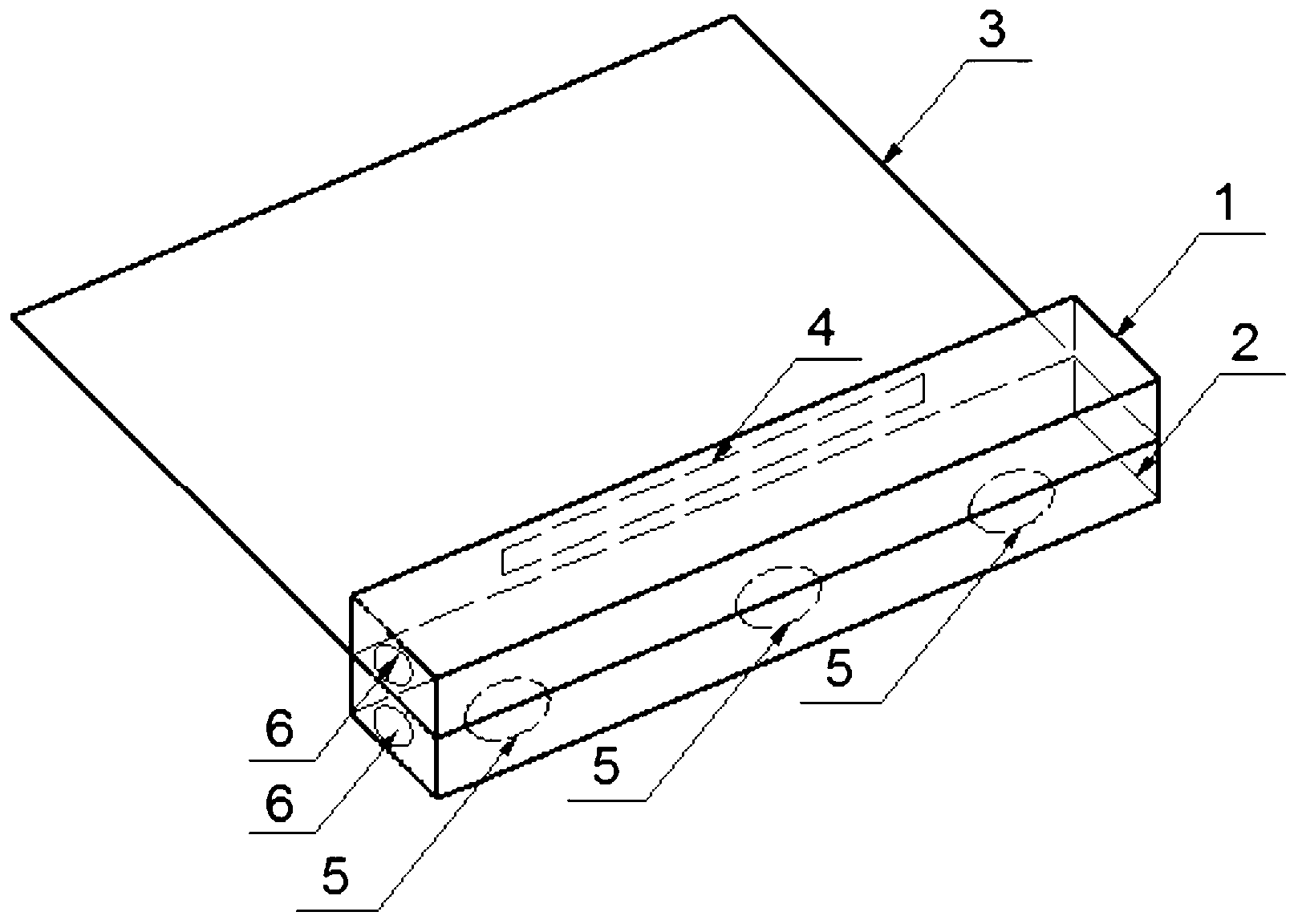

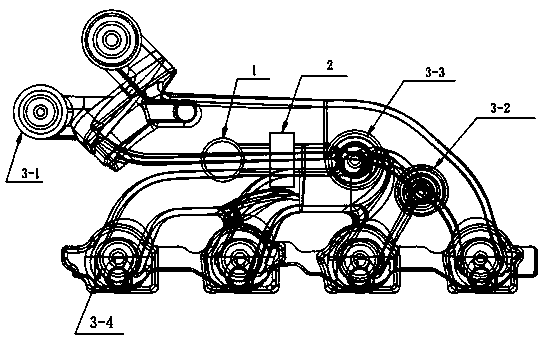

Preparation method of continuous fiber reinforced thermoplastic composite material prepreg and equipment thereof

The invention relates to a preparation method of a continuous fiber reinforced thermoplastic composite material prepreg and equipment thereof. The method comprises the following steps: (a) leading out and unfolding continuous fiber from a creel (10) to pass a tension adjusting device (20) and a static elimination device (30) in sequence, sending the fiber to a preheating oven (40) to preheat, and then passing a tension adjusting device (50); (b) leading a preheated continuous fiber band into a dual-extrusion die head set which can be opened and closed in a staggered manner to presoak; and (c) leading the presoaked continuous fiber band into a soaked rolling roll set (70) to soak, then cooling by a cooling roll-in device (80), and finally leading into a traction rolling device (90) for shaping by winding to obtain the product. Compared with the prior art, the invention significantly improve the dispersion, infiltrating property and operability of the fiber, and obtains the continuous fiber reinforced thermoplastic composite material prepreg which has uniformly dispersed and completely soaked fiber.

Owner:SHANGHAI GENIUS ADVANCED MATERIAL (GRP) CO LTD

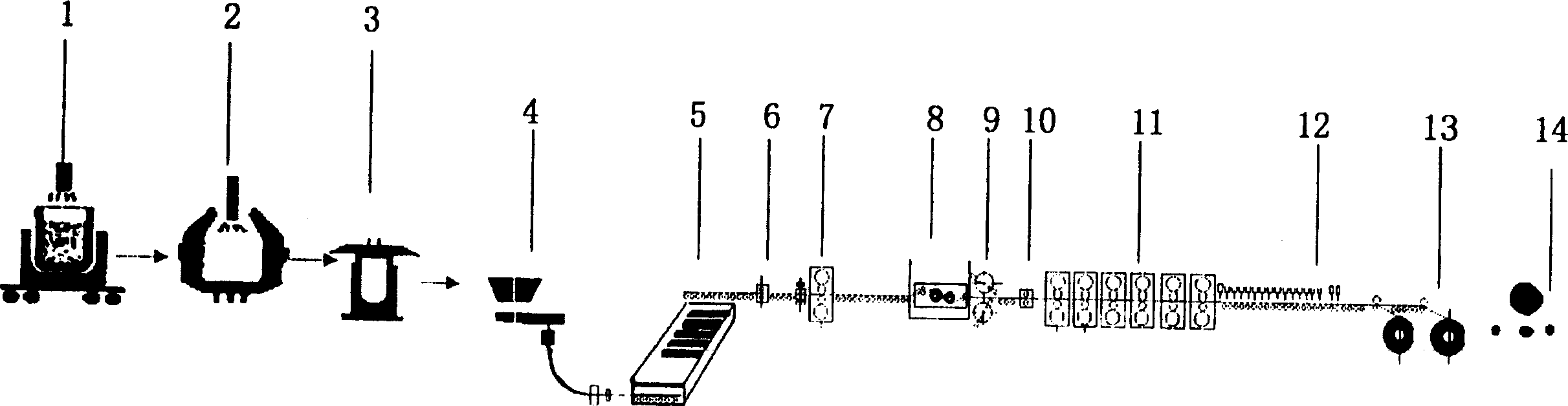

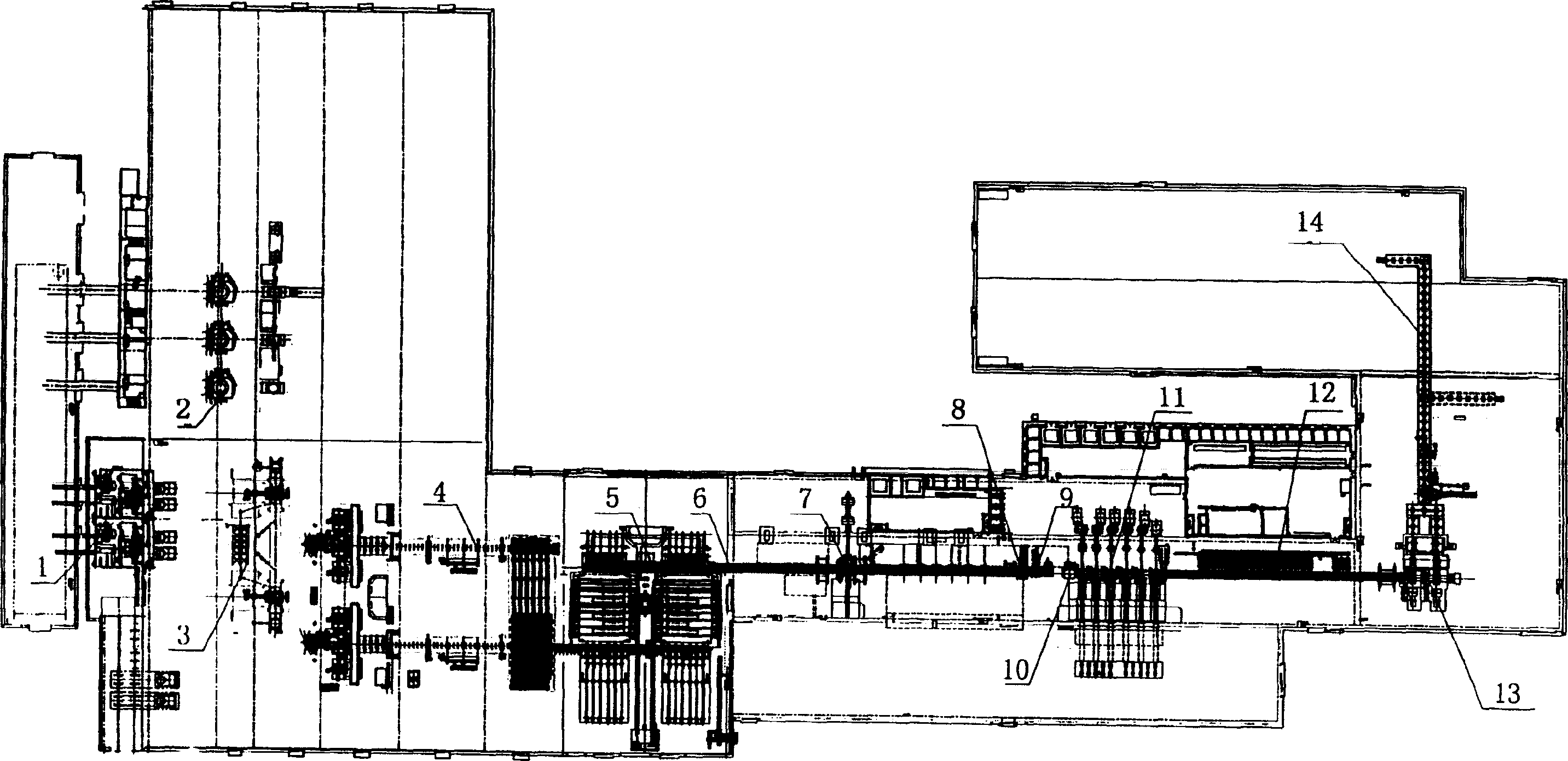

Compact medium-width strip steel production process

ActiveCN1864878AThe process is compact and reasonableSmooth logisticsMetal rolling arrangementsEconomic productionHigh pressure water

The invention relates to a compact method for producing middle-wide strip steel, which comprises: using melt iron to process pretreatment; smelting liquid steel; refining liquid steel; continuously casting the middle-thin plate blank; step beam heater heats uniformly; high-pressure water scale breaker breaks scale; one-frame four-roller reversible roughing mill mills; hot winding box winds; cutting the head and end of middle blank; the high-pressure water scale breaker breaks scale; the finishing roll machine continuously rolls; cooling the interlayer flow; the underground winder winds; and transporting steel coil. Wherein, all processes are inside one workshop or connected workshops. The invention can be used in middle steel factory with 1-2 million ton / year yields to match the metal flow, temperature flow and time flow effectively, to feed the high-temperature non-defect sheet blank at 920Deg. C into step beam heater, to save energy more than 60%, improve 1-2% of metal yield, reduce the producing cost and reduce the transport cost of middle process.

Owner:BERIS ENG & RES CORP +2

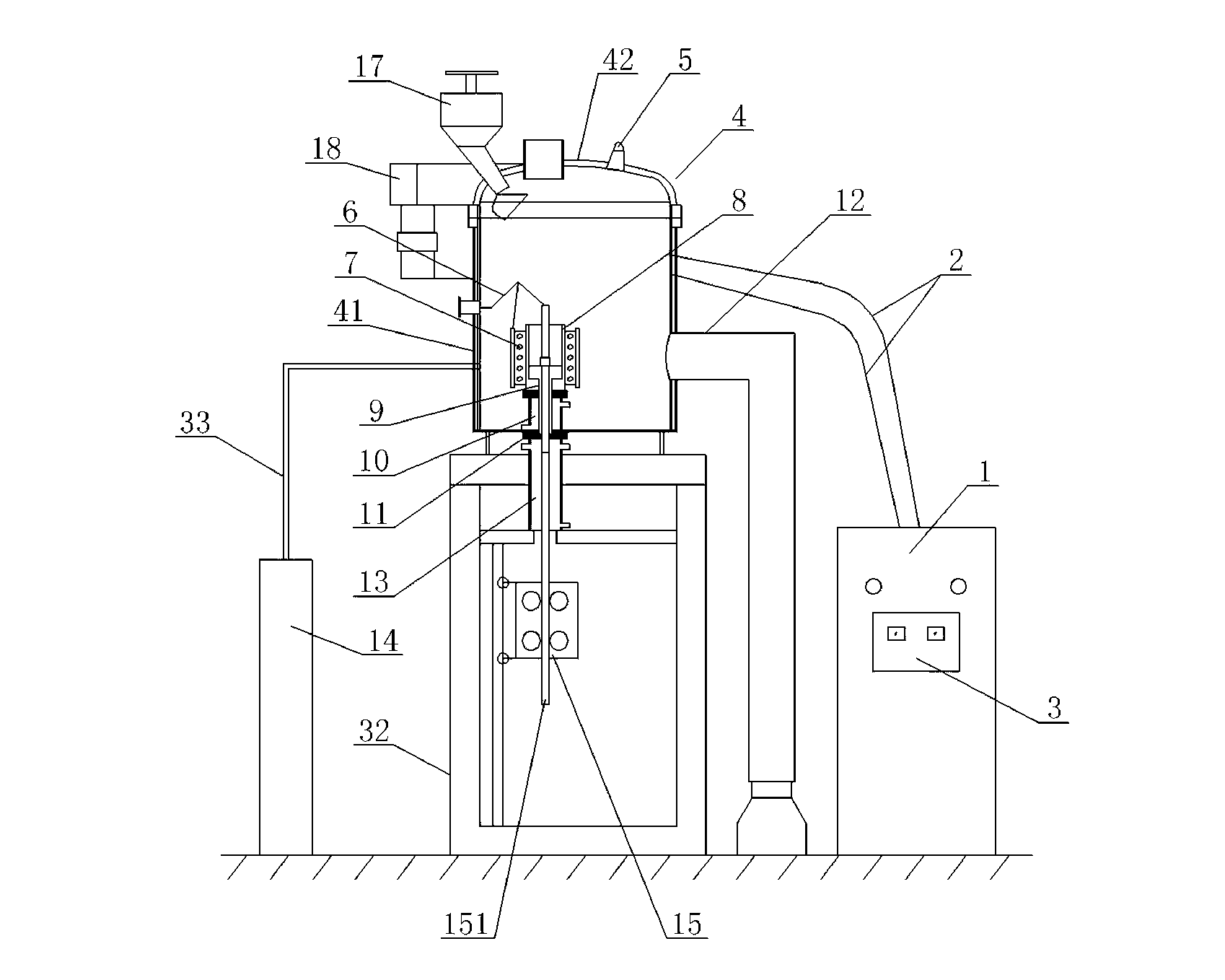

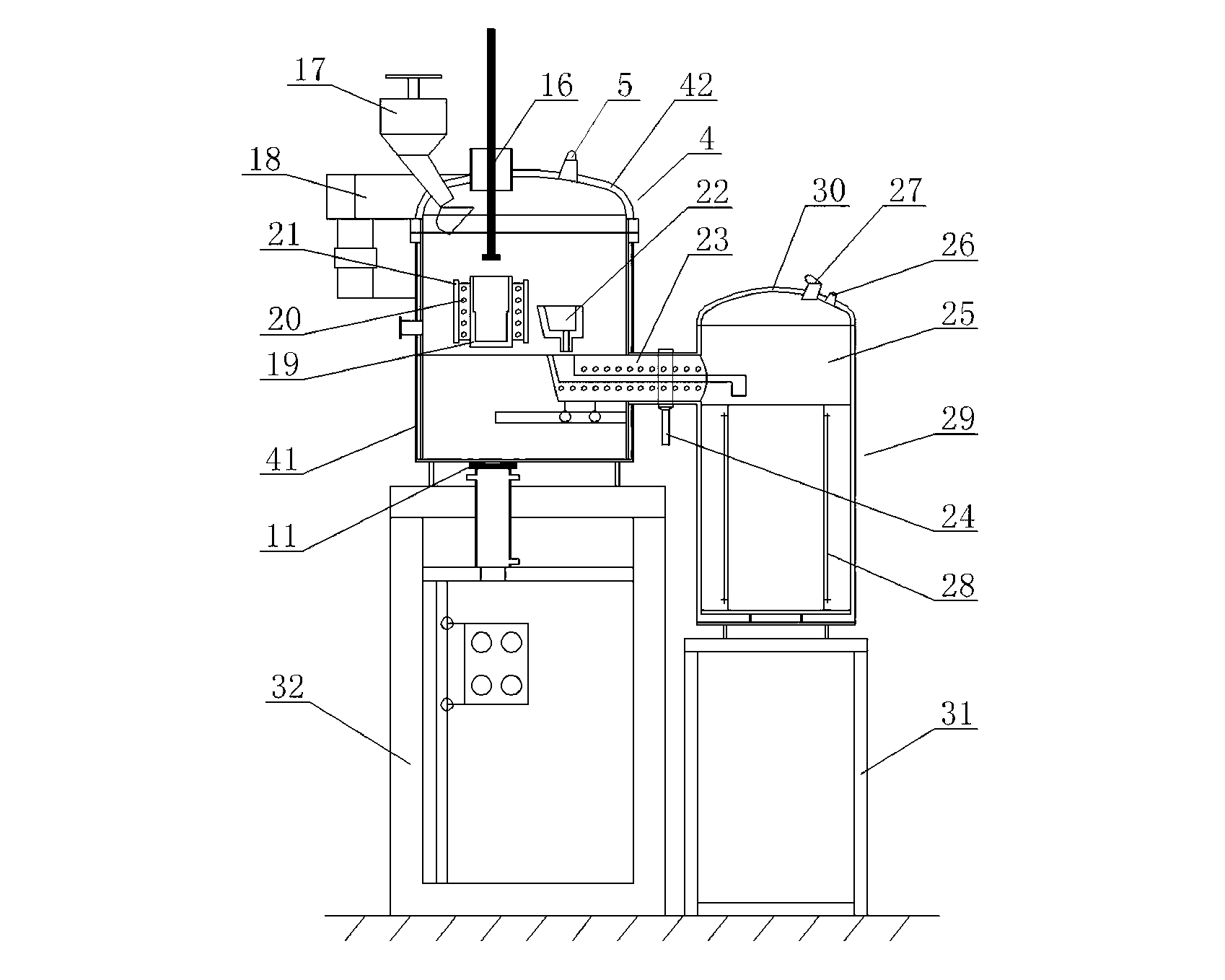

Multipurpose vacuum casting device

ActiveCN103170596AImprove liquidityAchieve oxidation inclusionsIncreasing energy efficiencyFailure rateVacuum pumping

A multipurpose vacuum casting device comprises a smelting furnace and a set of vacuum pumping system communicated with an inner cavity of the smelting furnace. The smelting furnace is provided with a casting pull-down continuous casting molding system which is formed together with the smelting furnace, a vacuum smelting system used for melting metal and a vacuum casting system used for ingot casting molding. Due to adoption of only one set of vacuum pumping system and one smelting furnace, a plurality of purposes such as vacuum induction heating smelting, vacuum casting, vacuum smelting and continuous casting under protection of inert gas can be achieved, the number of device components is greatly reduced, structure of a device is simplified, manufacture cost of the device is decreased to a large extent, production efficiency and casted blank quality are improved, operation is convenient and failure rate of the device is reduced.

Owner:GUANGDONG INST OF NEW MATERIALS

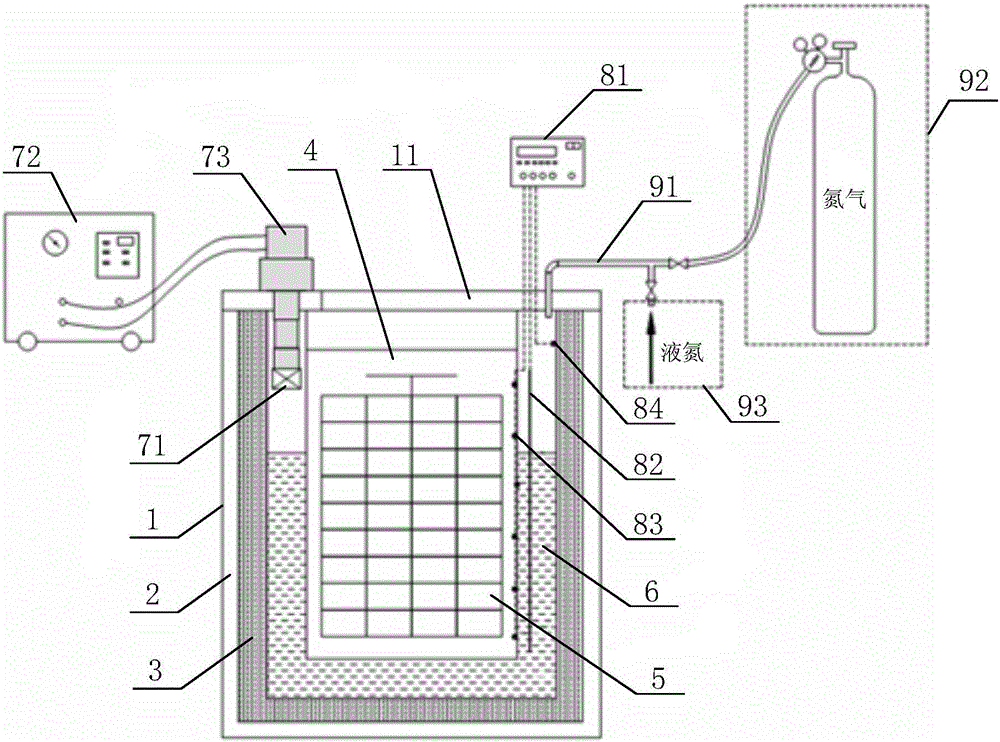

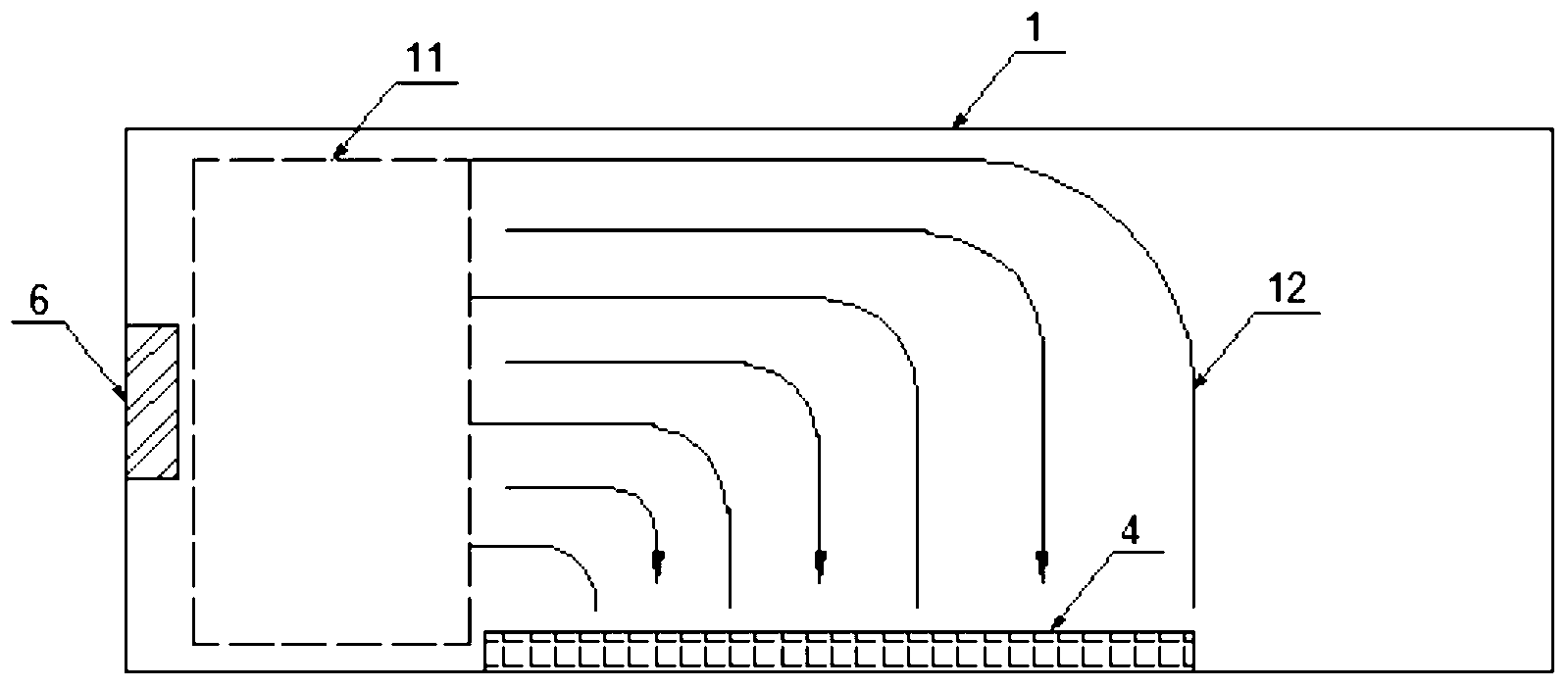

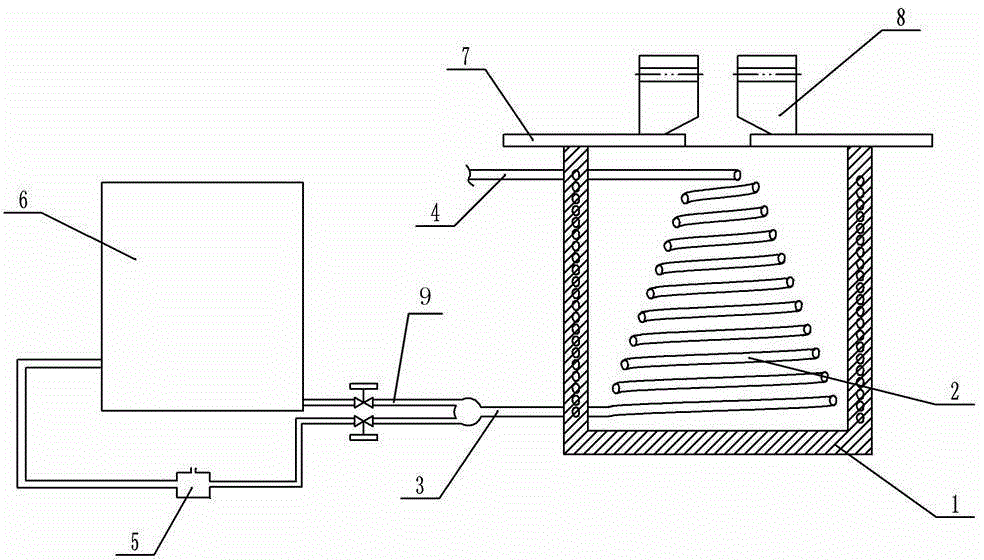

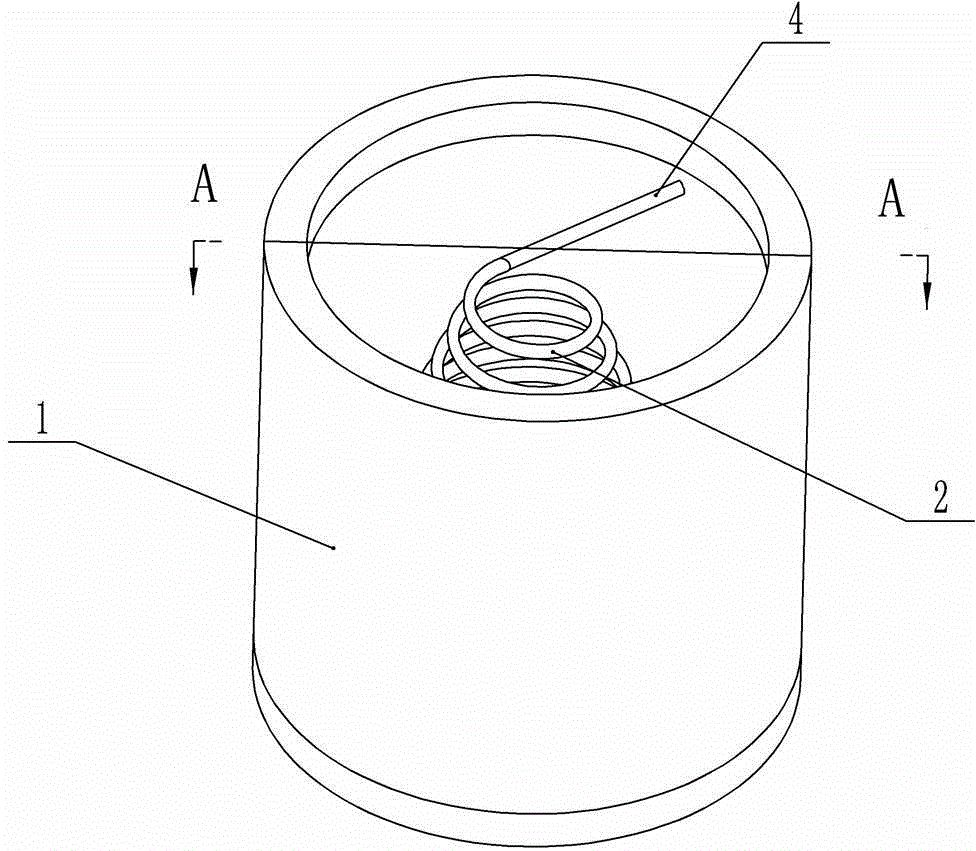

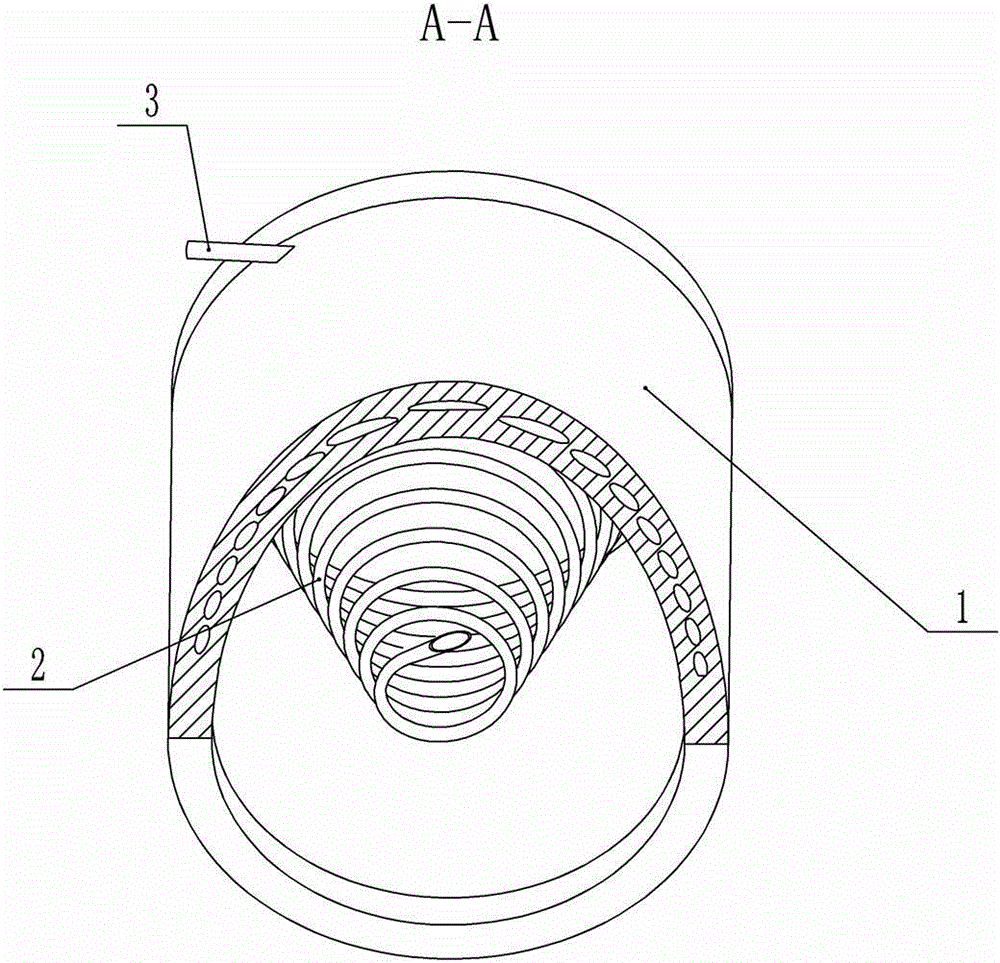

Liquid nitrogen zero-loss biology sample low-temperature storage device

ActiveCN106081363AAchieve zero lossRealized lossLiving organism packagingDomestic cooling apparatusHeat conductingProcess engineering

The invention discloses a liquid nitrogen zero-loss biology sample low-temperature storage device which comprises a storage cylinder provided with a top cover (11), a heat-conducting inner container (4) and liquid nitrogen refrigerating equipment. The wall of the storage cylinder comprises an outer cylinder (1), a vacuum layer (2) and a heat-insulating layer (3). The heat-insulating layer (3) is arranged in the outer cylinder (1). The vacuum layer (2) is arranged between the outer cylinder (1) and the heat-insulating layer (3). Liquid nitrogen (6) is contained in the storage cylinder. The heat-conducting inner container (4) is soaked in the liquid nitrogen (6). A biology sample (5) is arranged in the heat-conducting inner container (4). The liquid nitrogen refrigerating equipment comprises a condensing heat exchanger (71) and a refrigerator (72). The condensing heat exchanger (71) is arranged between the heat-insulating layer (3) and the heat-conducting inner container (4). A refrigerating head (73) of the refrigerating machine (72) is connected with the condensing heat exchanger (71). The situation that in the running process, a large amount of cool air flows out is avoided, the liquid nitrogen zero loss is achieved, liquid nitrogen does not need to be supplemented, and the device is easy to maintain and suitable for places where no liquid nitrogen is supplied.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

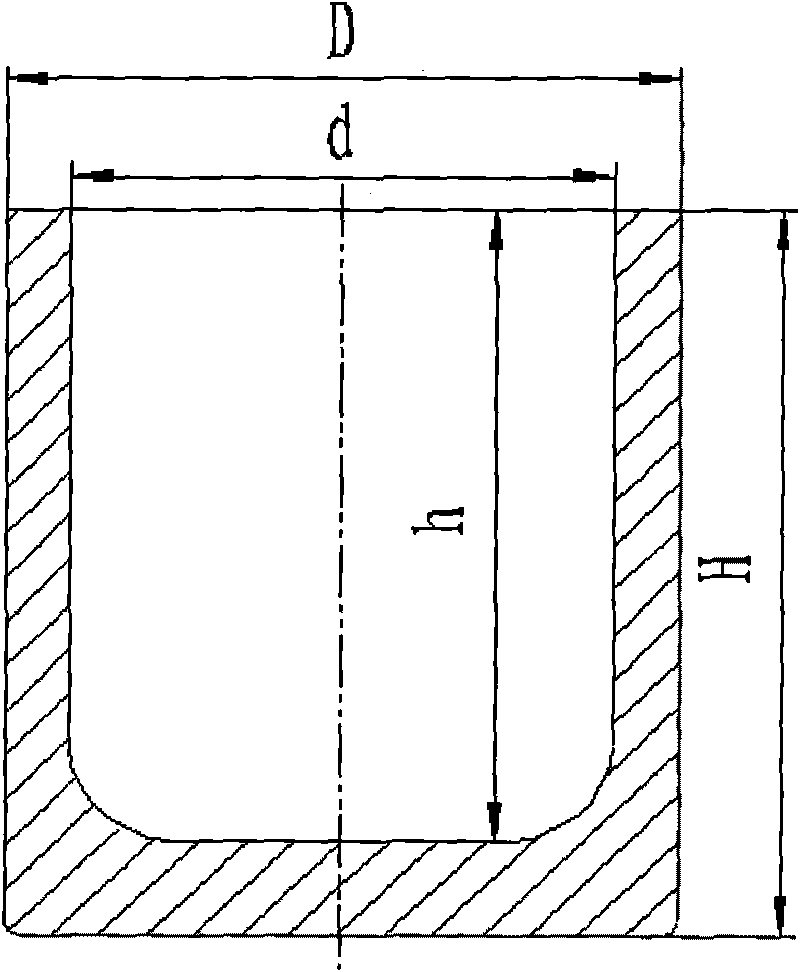

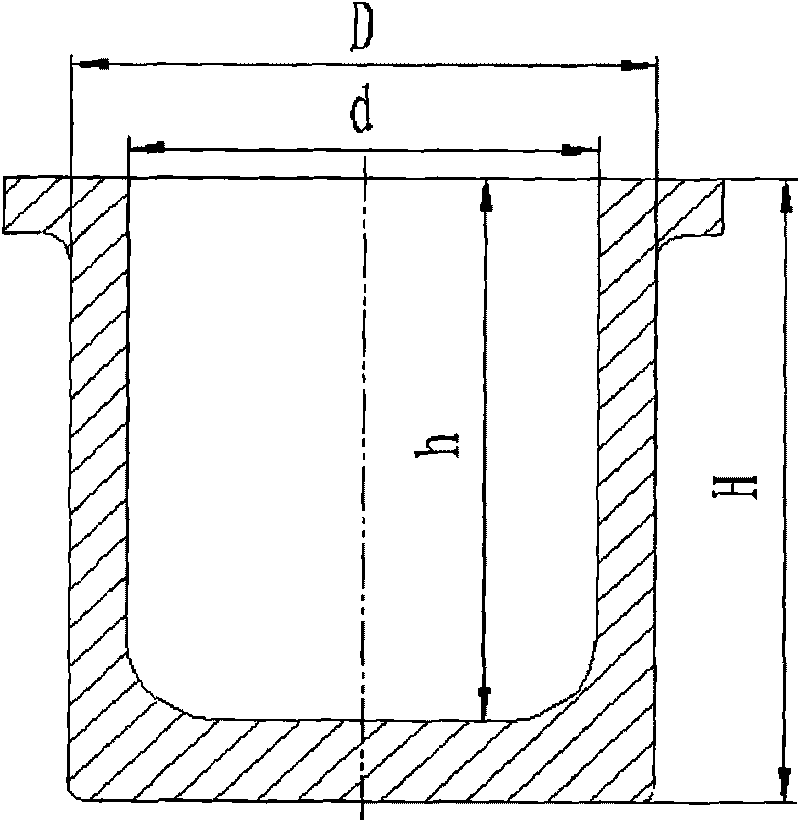

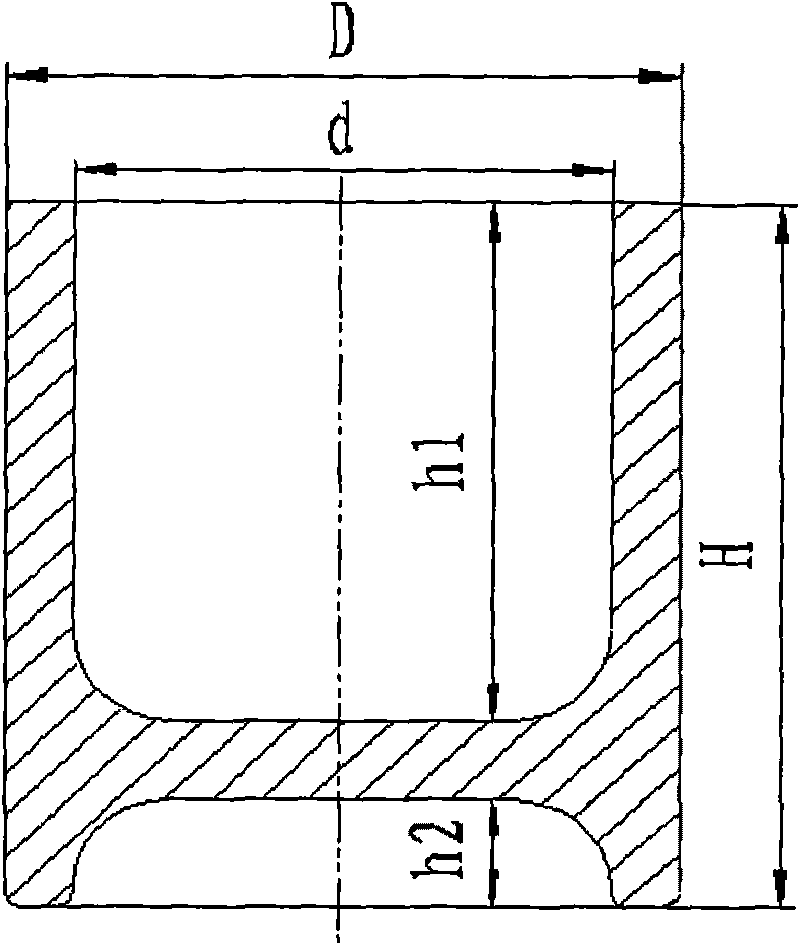

Upsetting and extruding precision die-forging forming method for large titanium alloy deep tube parts

ActiveCN101693279ALower supply standardsLower purchase priceMetal-working apparatusMetallurgyTitanium alloy

The invention discloses an upsetting and extruding precision die-forging forming method for large titanium alloy deep tube parts. The method includes that: firstly, enabling draft of a tube body die to range from 1 degree to 3 degrees, enabling the outer diameter of a blank to be 50% to 98% of that of a die tube body, enabling the height of the blank to be 60% to 150% of that of the tube body; spraying a protective lubricating layer with thickness ranging from 0.2mm to 3mm on the blank; heating the blank in an electric furnace under 5 DEG C to 50 DEG C of the temperature phase-transition point (alpha +beta / beta), enabling the heating coefficient to be larger than or equal to 0.6 min / mm, simultaneously preheating the die for 6h to 24h at a temperature ranging from 200 DEG C to 450 DEG C; finally, installing the die on a pressure machine, a die forging hammer or a counter-blow hammer, and forging the diathermal blank inside a die cavity. The upsetting and extruding precision die-forging forming method for producing the large titanium alloy deep tube parts is simple in procedure operation, stable and reliable in performance, and is easy to control quantity and to realize large-batch industrialized production of products.

Owner:XIAN SUPERCRYSYAL SCI TECH DEV CO LTD

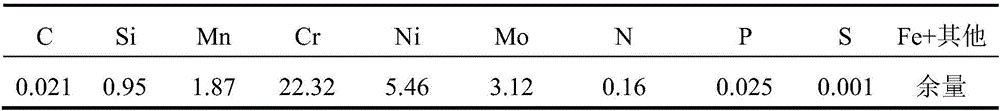

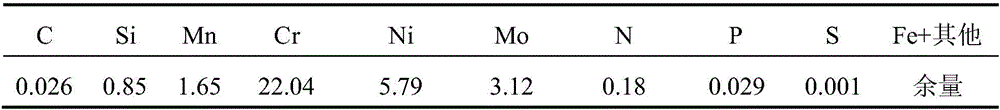

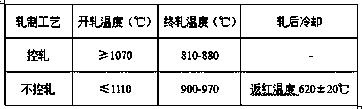

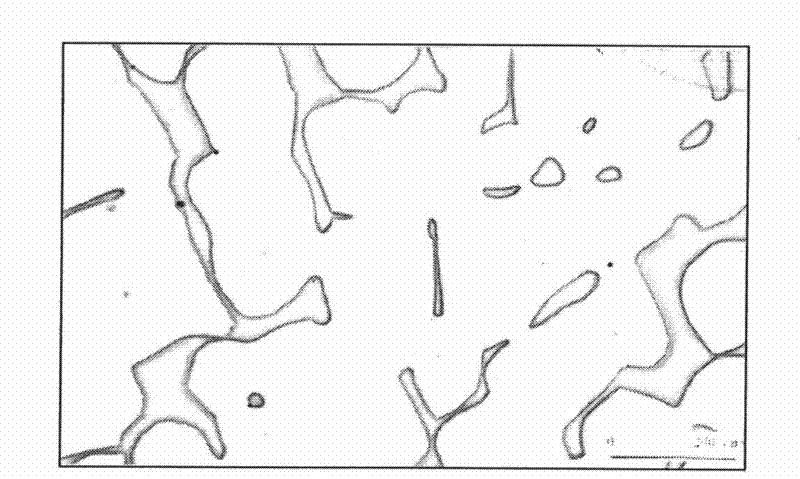

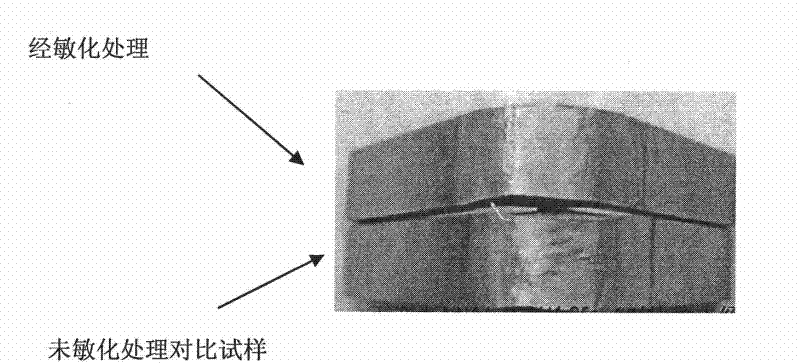

Method for eliminating cracks of hot processed surface of 2205 dual-phase stainless steel middle plate

InactiveCN106391704AQuality improvementNo crackWork treatment devicesMetal rolling arrangementsReduction rateMetallurgy

The invention belongs to the technical field of stainless steel rolling, and particularly discloses a method for eliminating cracks of a hot processed surface of a 2205 dual-phase stainless steel middle plate. The method is characterized by comprising the steps that blank selection and grinding are carried out; a cast blank is heated, specifically, the temperature of a preheating section is 1100-1150 DEG C, the temperature of a heating section is 1150-1240 DEG C, the temperature of a soaking section is 1220-1240 DEG C, and for every 10 mm of the cast blank thickness, the furnace standing time is 9-10 min; scale removal is carried out with water of high pressure of 20-25 MPa; the initial rough rolling temperature is higher than 1150 DEG C, the reduction rate is smaller than 25%, rolling is carried out for 8-11 passes, and the thickness of an intermediate blank is 35-45 mm; and the initial finish rolling temperature is larger than 1050 DEG C, the final rolling temperature is larger than 950 DEG C, the reduction rate is smaller than 18%, and rolling is carried out for 8-12 passes. The method has the advantages that the blank specifications are selected reasonably, parameters such as rolling temperature and reduction rate are matched reasonably after grinding and optimal heating, and the surface crack defect of the 2205 dual-phase stainless steel middle plate is effectively avoided.

Owner:NORTHEASTERN UNIV

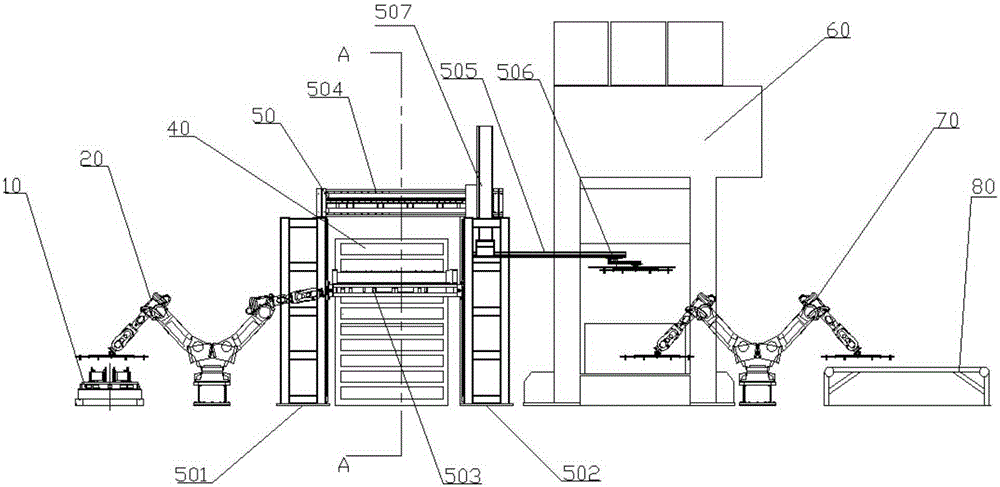

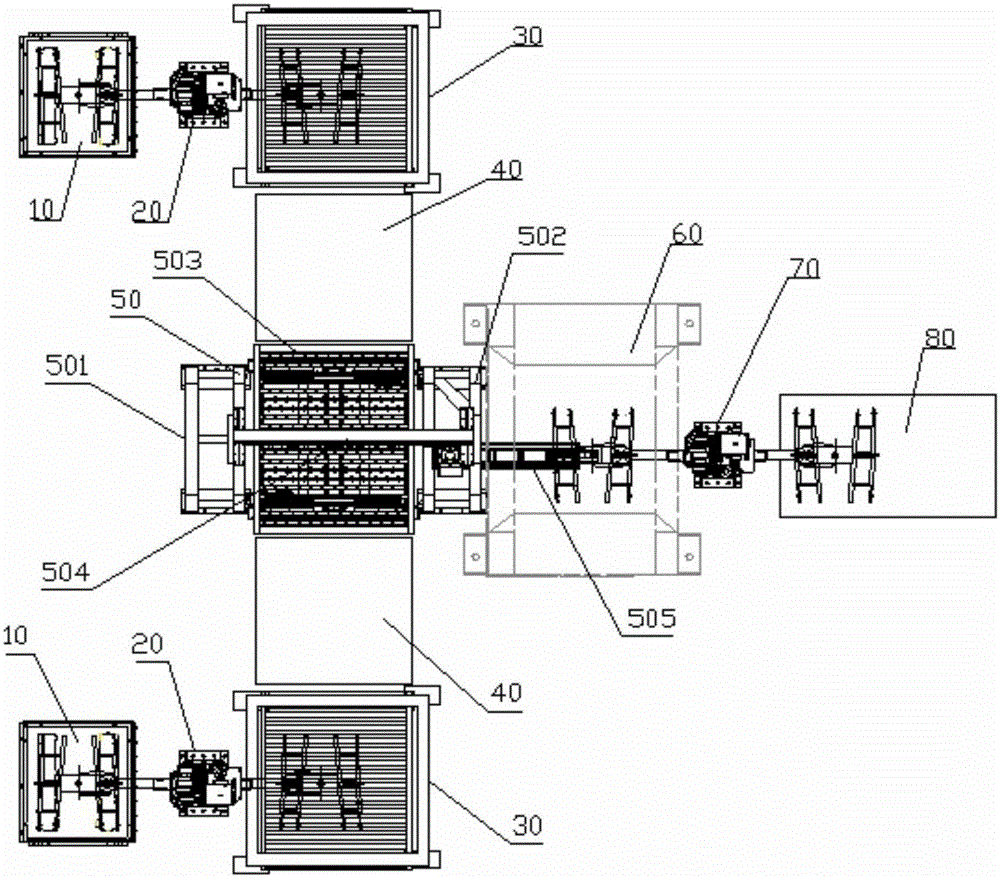

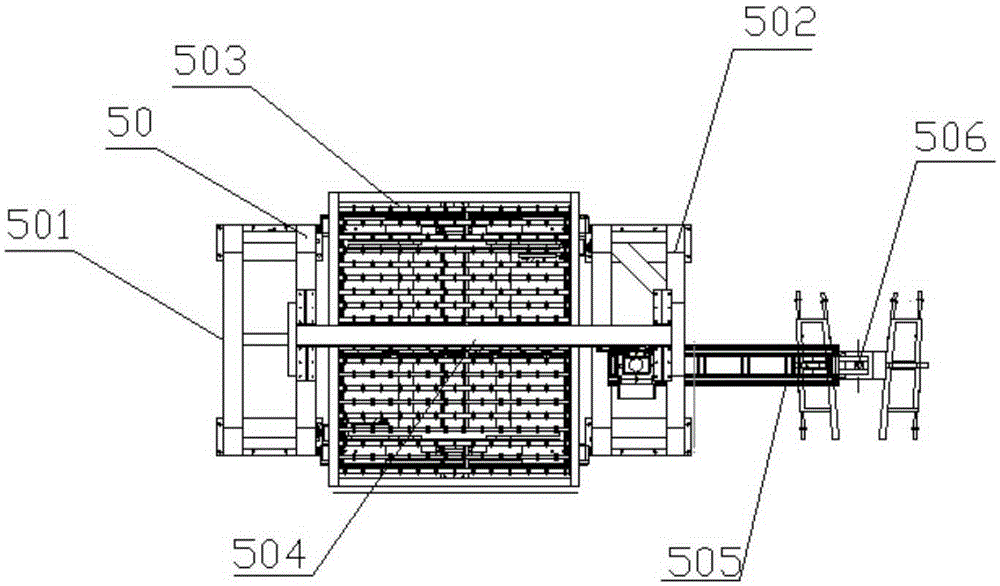

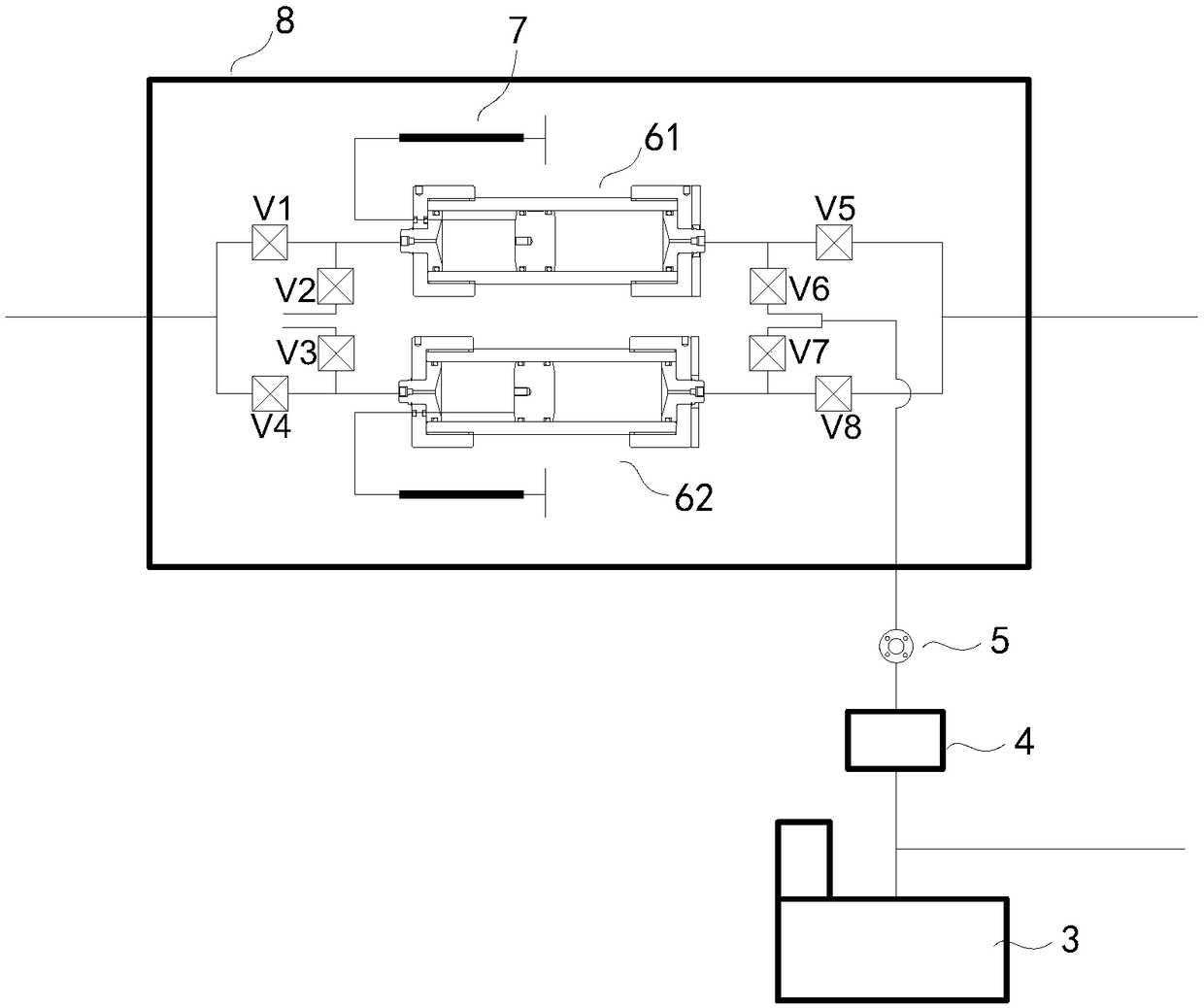

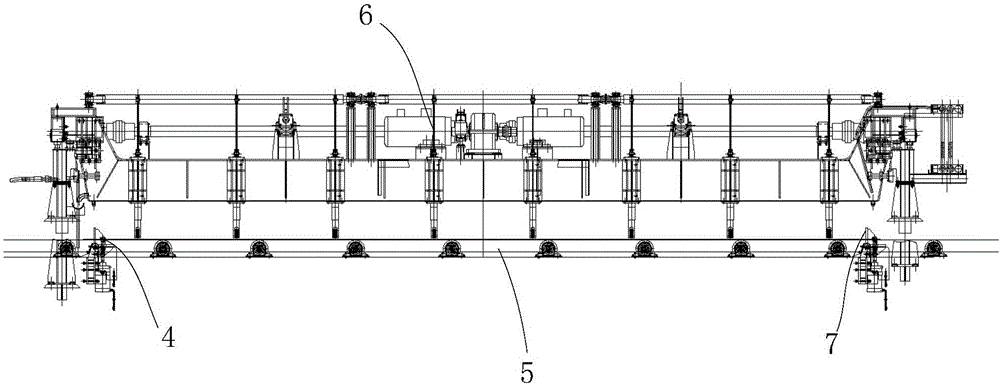

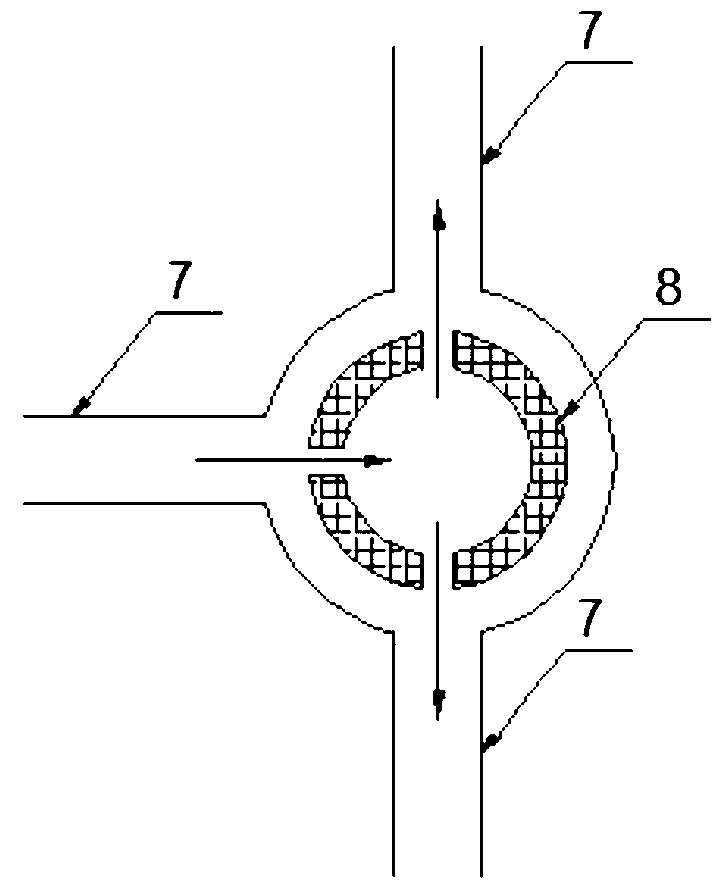

Hot stamping forming production line

ActiveCN105195585AShorten the delivery pathReduce temperature lossShaping toolsMetal-working feeding devicesHot stampingHeating furnace

The invention discloses a hot stamping forming production line. The hot stamping forming production line comprises a press, a combined feeding system arranged on a medial axis on one side of the press, a conveyor belt arranged on the other side of the press, multi-layer heating furnaces arranged on two sides of the combined feeding system and a supply system corresponding to the multi-layer heating furnaces. The combined feeding system is added and mounted on the medial axis of the press, so that simple straight feeding can be realized, and a blank conveying route is shortened; the multi-layer heating furnaces are arranged on two sides of the combined feeding system in opposite directions, accordingly, the combined feeding system can be shared, the product quality is guaranteed, and the production efficiency is improved.

Owner:SUZHOU PRESSLER ADVANCED FORMING TECHNOLOGIES CO LTD

Air bag module diffuser

InactiveUS6871872B2Increase temperatureReduce heat lossPedestrian/occupant safety arrangementAerospace engineering

Owner:KEY SAFETY SYST

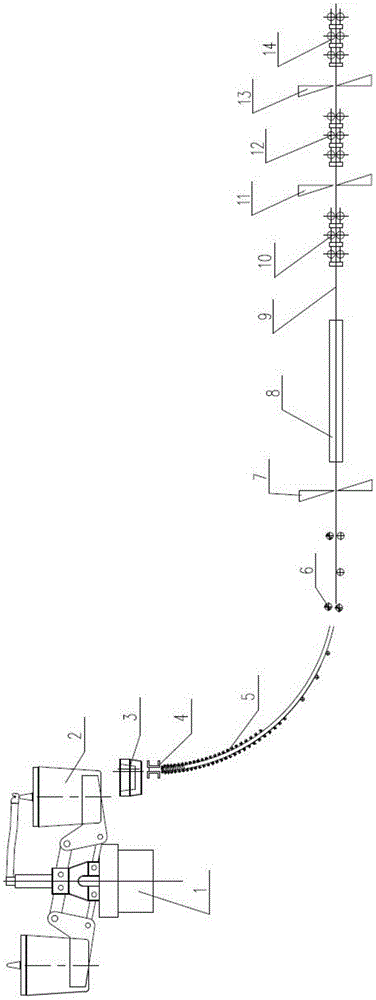

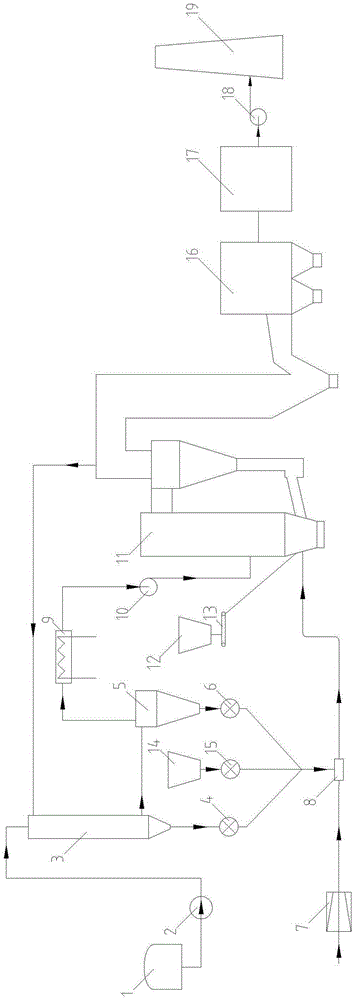

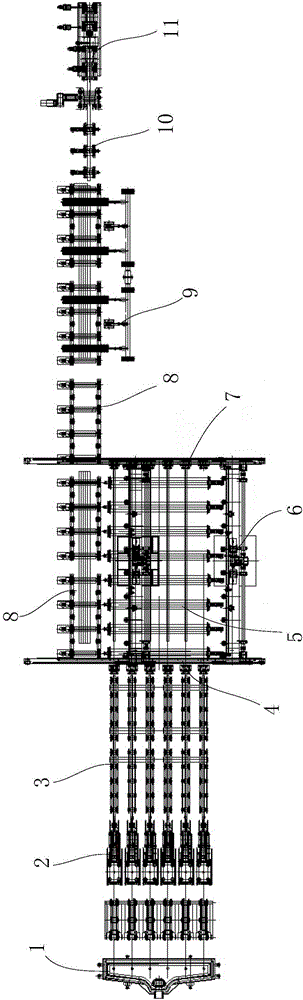

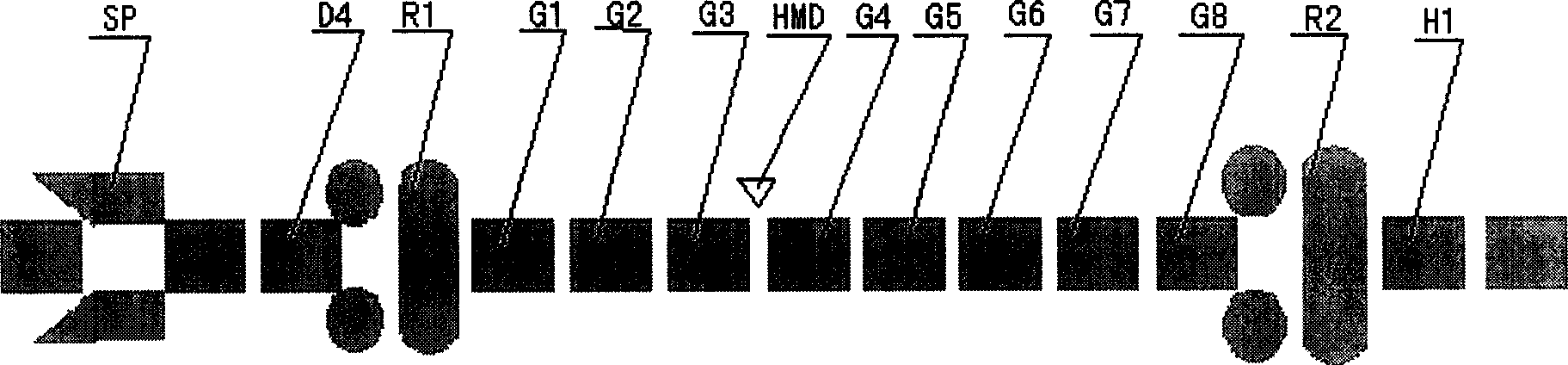

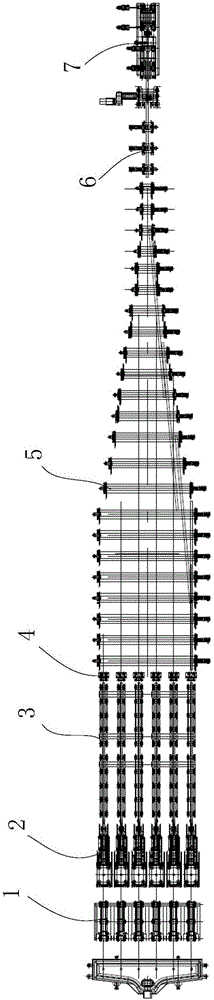

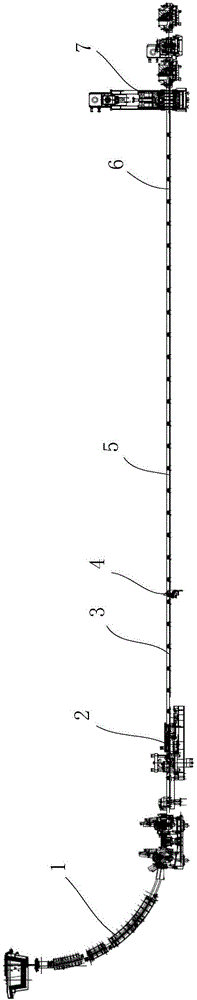

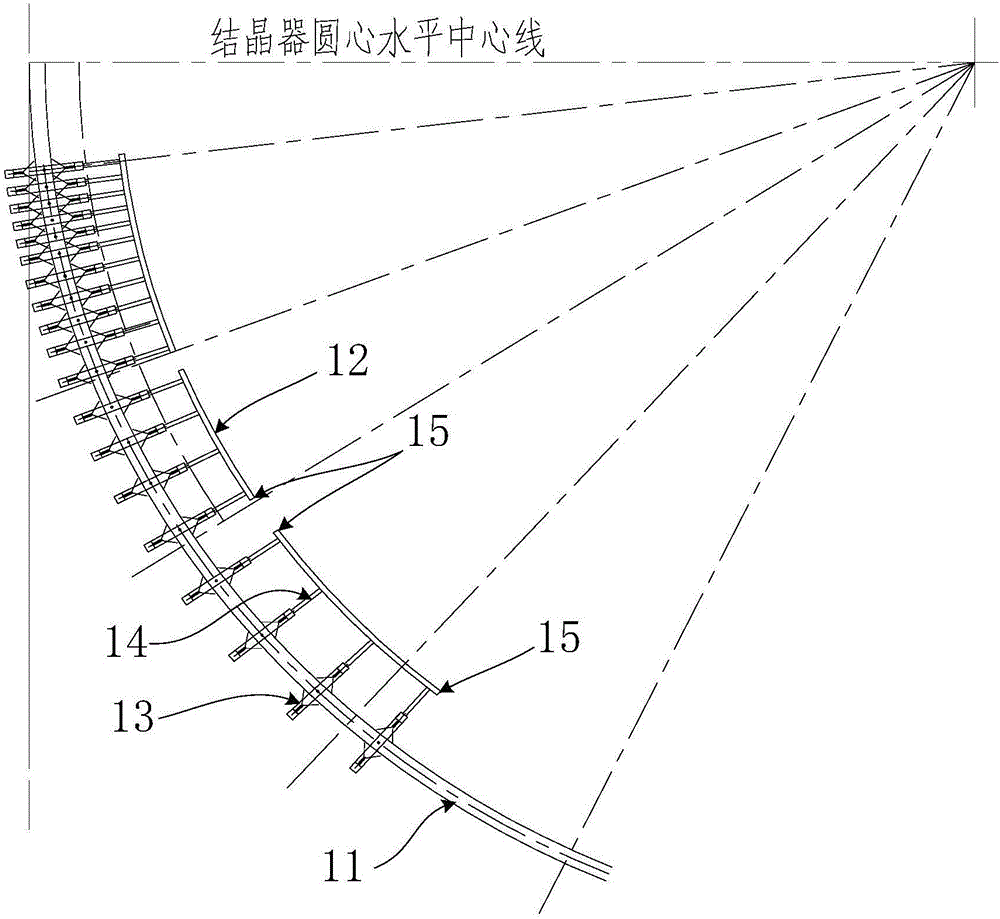

Continuous casting and rolling production line of wire rods and production method of production line

InactiveCN105414185AAchieve seamless connectionRealize construction costMetal rolling arrangementsWire rodProduction line

The invention discloses a continuous casting and rolling production line of wire rods and a production method of the production line. The continuous casting and rolling production line of the wire rods comprises a continuous casting machine, a parallel-flow device and a rolling mill unit. The method comprises the steps that a square casting blank or a circular casting blank is produced by means of the continuous casting machine firstly, the produced square casting blank or circular blank is cut through a cutting machine, parallel flowing is conducted through the parallel-flow device, the parallel flowed square casting blank bodies or circular casting blank bodies are conveyed to an inlet of the rolling mill unit through a conveyor roller way finally, and the rods are prepared by rolling through a rough mill, an intermediate mill and a finishing mill in sequence. According to the continuous casting and rolling production line of the wire rods and the production method of the production line, seamless connection of the continuous casting machine and rolling mills is achieved, the casting blank can be directly hot-delivered into the rolling mill unit to be rolled into the rods, secondary heating through a heating furnace is not needed, and the continuous casting and rolling production line of the wire rods and the production method of the production line have the advantages of being high in pouring speed, small in casting machine flow number, compact in production rhythm, high in efficiency, less in energy consumption and low in construction investment and operation maintenance cost.

Owner:CISDI ENG CO LTD

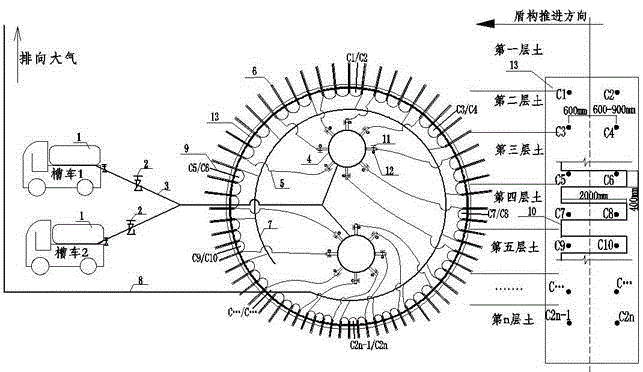

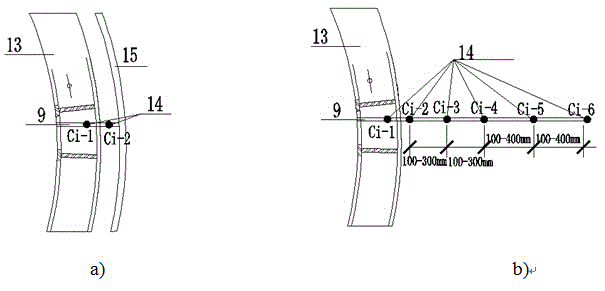

Liquid nitrogen freezing system of high water pressure super-long-distance large-sectional tunnel and method of quickly changing shield tail brushes

Disclosed are a liquid nitrogen freezing system of a high water pressure super-long-distance large-sectional tunnel and a method of quickly changing shield tail brushes. The system comprises a liquid nitrogen storage tank, a main gate valve, a liquid supply pipe, distributors, liquid distributing pipes, freezing pipes, gas colleting pipes, exhaust pipes, a temperature measuring hole and cold discharge pipes. The liquid nitrogen storage tank is connected with the liquid supply pipe provided with the main gate valve. Two branches of the liquid supply pipe are connected with the distributors respectively; each distributor includes 8 to 10 branches, each branch is connected with a group of series freezing pipes through one liquid distributing pipe, each group of last freezing pipes is connected with one gas collecting pipe and is connected with one exhaust pipe through the gas collecting pipe; the exhaust pipes discharge vaporized nitrogen into air; the front ends of the cold discharge pipes are connected with the liquid distributing pipes, and the their tail ends are connected with the gas collecting pipes. The method of quickly changing the shield tail brushes is further provided. The system and the method are suitable for the projects of quickly changing the shield tail brushes for the high water pressure super-long-distance large-sectional tunnels; the system and the method have the advantages such as high forming speed of a frozen wall, high strength, no toxicity or pollution, safety and reliability in use, and convenience in construction.

Owner:NANJING FORESTRY UNIV +1

Continuous casting tundish hollow particle carbon-free covering agent and preparation method thereof

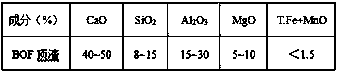

The invention relates to a continuous casting tundish hollow particle carbon-free covering agent, belonging to the iron and steel smelting field. The carbon-free covering agent comprises the followingcomponents by weight percent: 25-35% of SiO2, 8-20% of Al2O3, less than 1.5% of Fe2O3, 25-35% of CaO, 8-16% of MgO and less than 0.5% of H2O, wherein 0.15-1.0mm of particles account for 90-100% and the bulk specific weight is 0.6-0.9g / cm<3>. The continuous casting tundish hollow particle carbon-free covering agent has good spreadability, when added the covering agent can be molten fast and can cover the whole surface of molten steel, thus avoiding the secondary oxidation of molten steel; the covering agent has function of absorbing inclusion, can purify molten steel and increase the casting blank quality; the covering agent has good thermal insulation property, thus significantly reducing the temperature loss of molten steel; the slag of the covering agent can not incrust and stick to thestopper rod; and the content of carbon in molten steel is not increased.

Owner:SHANDONG IRON & STEEL CO LTD

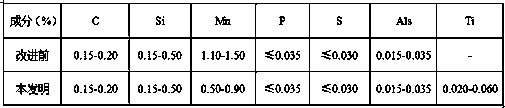

Low-cost manufacturing method of flaw-detection-ensured Q345B stage steel plate

The invention discloses a low-cost manufacturing method of a flaw-detection-ensured Q345B stage steel plate. The steel plate comprises, by mass percent, 0.15 to 0.20% of C, 0.15 to 0.50% of Si, 0.50 to 0.90% of Mn, not larger than 0.035% of P, not larger than 0.025% of S, 0.020 to 0.060% of Ti, 0.015 to 0.035% of Als, and the balance Fe and inevitable impurities. During preparing, molten iron is subject to KR desulfurization treatment firstly, the molten iron obtained after desulfurization treatment is subject to slag removal, the molten iron is converted into a converter to be smelted, outputmolten steel is subject to continuous casting and rolling, finally, the rolled steel plate is subject to stacking for slow-cooling for 24 to 72 hours, and then sampling inspection is carried out; thechemical components and the production process of the prepared Q345B stage steel plate are simple, the production cost is low, the flaw detection property is good, and the method has the good application and popularization prospects.

Owner:WUHAN IRON & STEEL GRP ECHENG IRON & STEEL CO LTD

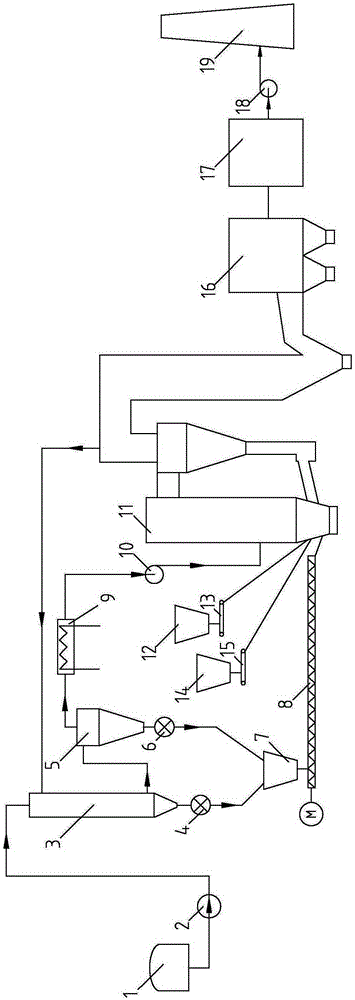

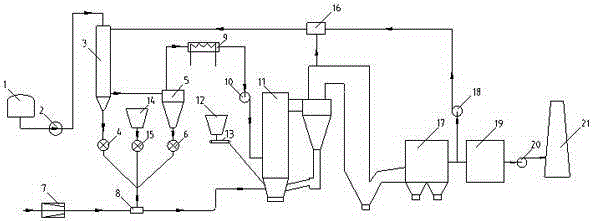

Coal-sludge co-combustion system based on high-temperature smoke drying and pneumatic conveying

ActiveCN105276603AIncrease speedEasy to handleSludge treatment by de-watering/drying/thickeningDispersed particle separationSludgeRotary feeder

The invention relates to a coal-sludge co-combustion system based on high-temperature smoke drying and pneumatic conveying. A sludge storage bin is connected with a spray drying pipe through a screw pump. An air inlet of the spray drying pipe is connected with a cyclone separator outlet flue of a circulating fluidized bed boiler. A first outlet of the spray drying pipe is connected with a first rotary feeder, and a second outlet of the spray drying pipe is connected with a cyclone separator. An exhaust opening of the cyclone separator is connected with the circulating fluidized bed boiler through a cooling condenser and an exhaust gas fan, and a discharging opening of the cyclone separator is connected with a second rotary feeder. A limestone bin is connected with a third rotary feeder. An outlet of the first rotary feeder, an outlet of the second rotary feeder and an outlet of the third rotary feeder are connected with a feeding opening of a jet feeding device, an air inlet of the jet feeding device is connected with a Roots fan, and an outlet of the jet feeding device is connected with the circulating fluidized bed boiler. The functions of sludge drying and conveying, dry tail gas waste heat utilization, sludge and coal co-combustion, pollutant control and the like can be achieved, bad smell and dust diffusion can be avoided, and the coal-sludge co-combustion system has the beneficial effects of being simple, environment-friendly and efficient.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

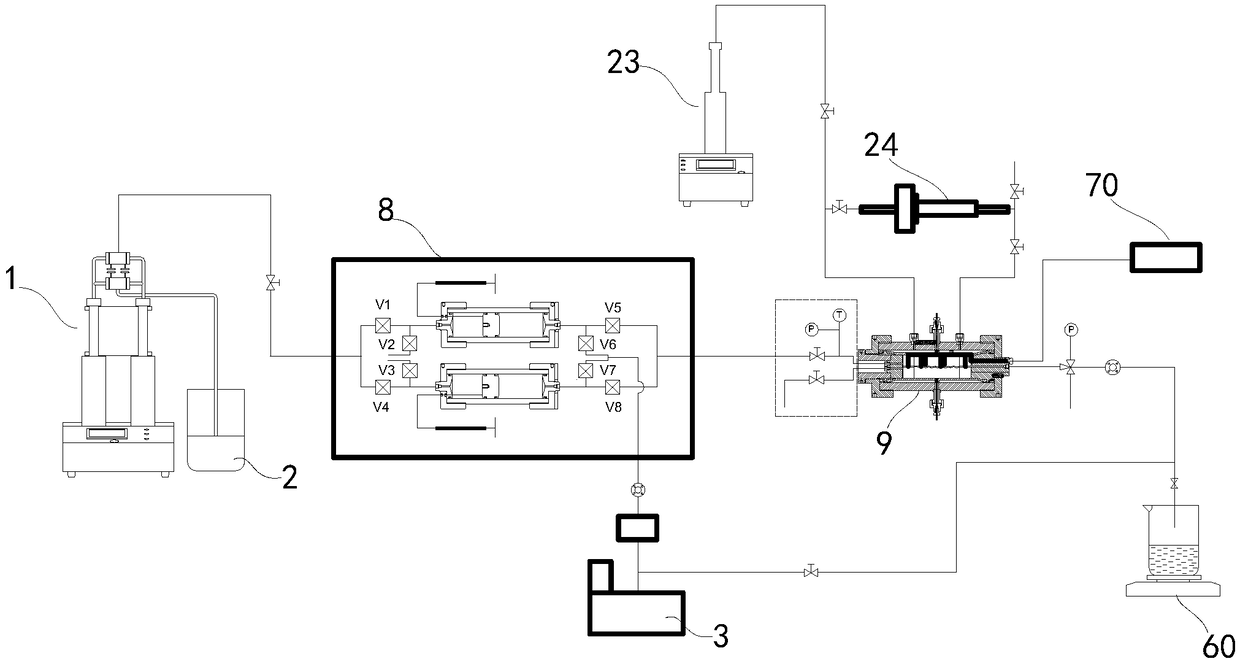

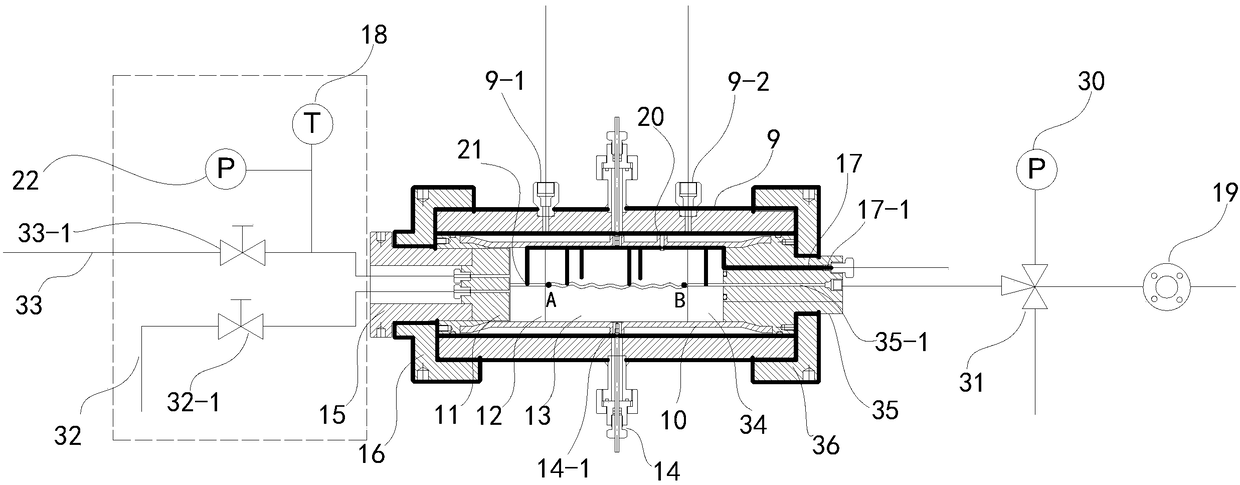

Method for measuring convective heat transfer coefficient of water-rock interface during seepage heat transfer process of crack sample

The invention discloses a method for measuring convective heat transfer coefficient of a water-rock interface during a seepage heat transfer process of a crack sample. Constant-temperature and constant-current water flow is injected to a convective heat transfer coefficient test system through a liquid constant-voltage constant-current high-precision injection system and a cold drive hot water flow constant temperature control system; a convective heat transfer coefficient h of the water-rock interface is measured through the convective heat transfer coefficient test system; during measurement, variables related to the convective heat transfer coefficient, such as flow rate, inlet water temperature, crack initial gap length b0 and crack gap length deformation delta b, all can be set according to requirements of an experimenter; the test measurement variables such as outlet water flow rate Q, crack outlet water temperature Tout, crack inner edge water temperature Ff and crack inner surface temperature Ti all can be accurately measured; finally, the convective heat transfer coefficient h is obtained by calculating. According to the method for measuring convective heat transfer coefficient of a water-rock interface during a seepage heat transfer process of a crack sample in the invention, the variables are controlled more accurately; the numerical value of the convective heat transfer coefficient h in a certain state can be obtained through an improved calculation method; and the quantitative relationship between h and different variables can be researched.

Owner:CHINA UNIV OF MINING & TECH

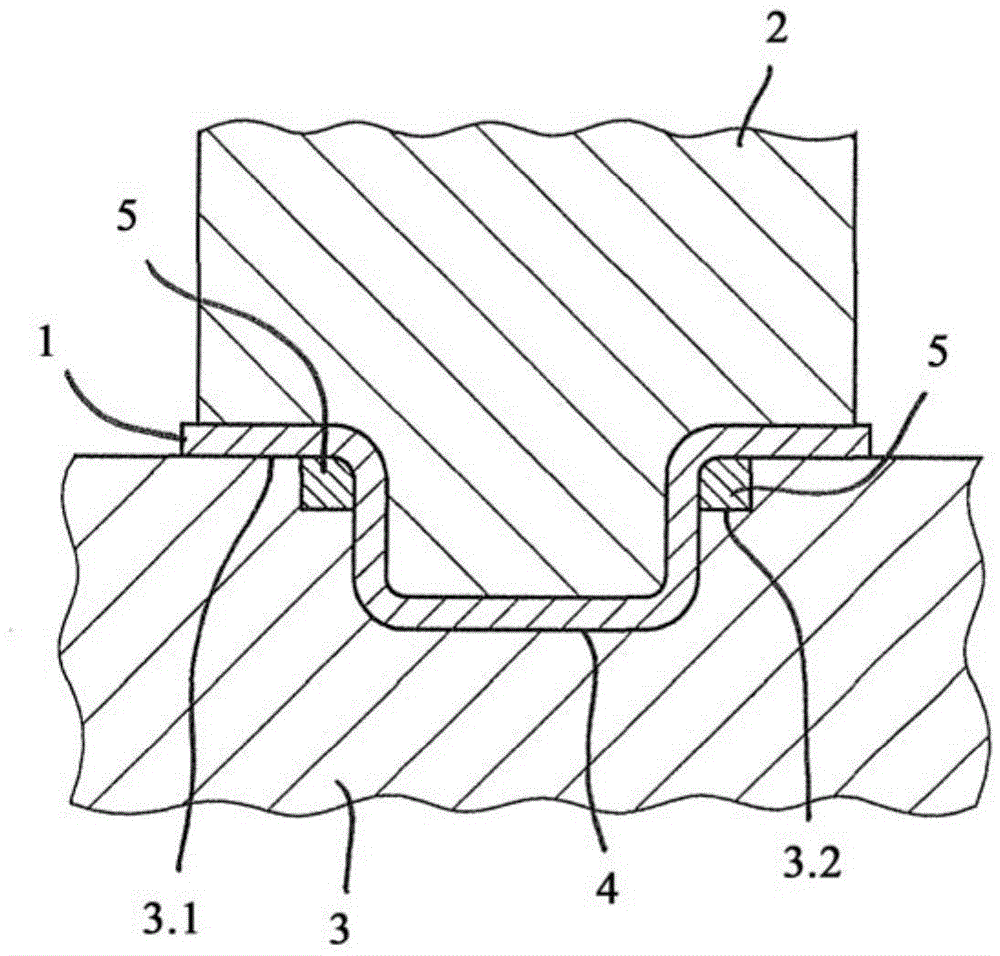

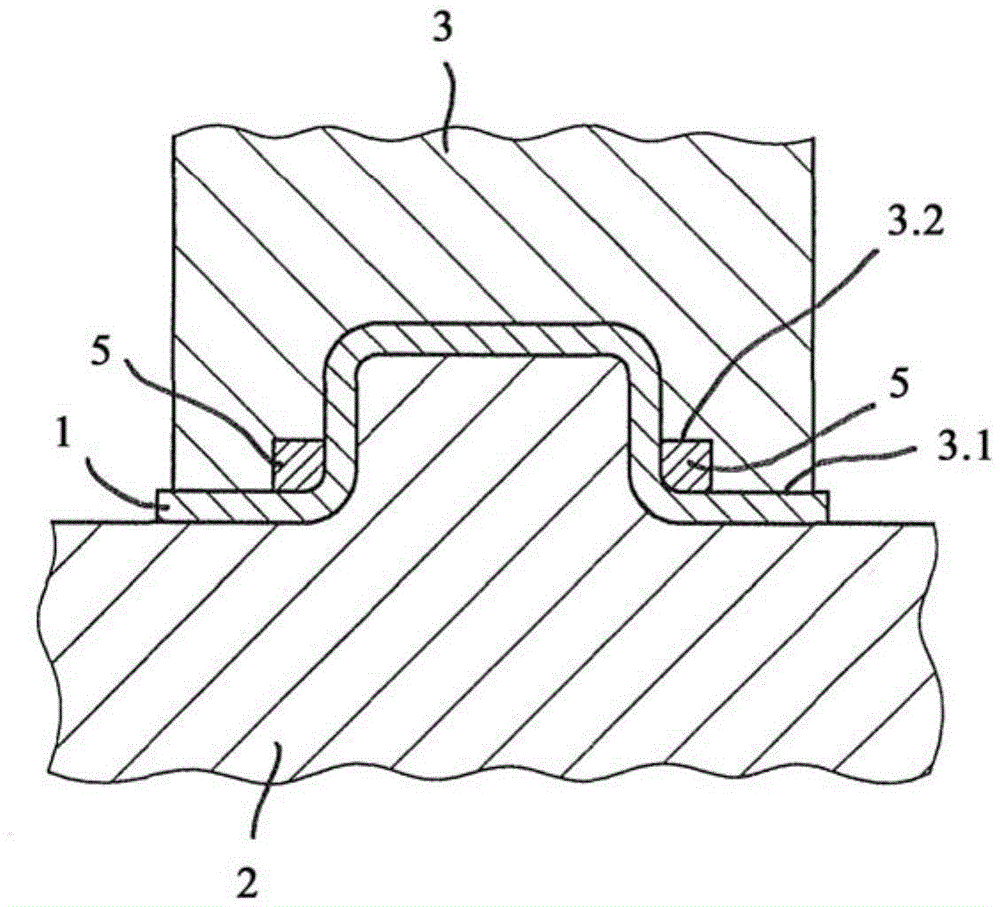

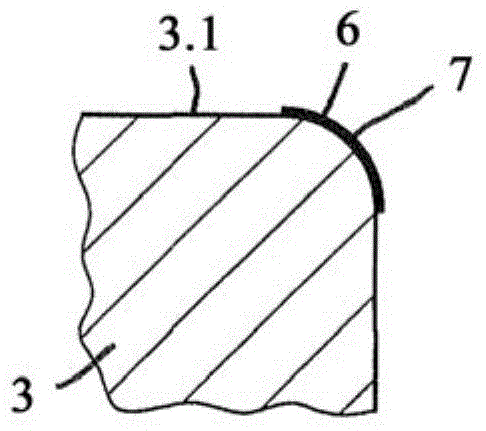

Method and forming tool for hot forming and press hardening work pieces made of sheet steel, in particular galvanized sheet steel

InactiveCN103958087AReduce or prevent damageReduce heat lossShaping toolsQuenching devicesSheet steelBond coating

The invention relates to a method for hot forming and press hardening plate-shaped or preformed workpieces made of sheet steel, in particular galvanized workpieces (1) made of sheet steel, in which the workpiece (1) is heated to a temperature exceeding the austenitizing temperature and subsequently formed and quenched in a cooled forming tool comprising a stamp (2) and a die (3), characterized in that the drawing edge region, which is defined by a positive die radius, of the die (3) used for hot forming and press hardening is provided with a materially bonded coating of a material (6, 6') and / or is provided with an insert (5) having a thermal conductivity that is lower than the thermal conductivity of section (3.1) of the die (3), which is adjacent to the drawing edge region, by at least 10 W / (m*K), which section comes into contact with the workpiece (1) during hot forming and press hardening of the same. The surface of the material (6, 6') applied to the drawing edge region and facing the workpiece (1) or the surface of the provided insert (5) has a lateral dimension extending across the drawing edge (7), which is in the range of 1.6 times to 10 times the positive die radius of the die (3). The invention also relates to a corresponding forming tool.

Owner:THYSSENKRUPP STEEL EURO AG

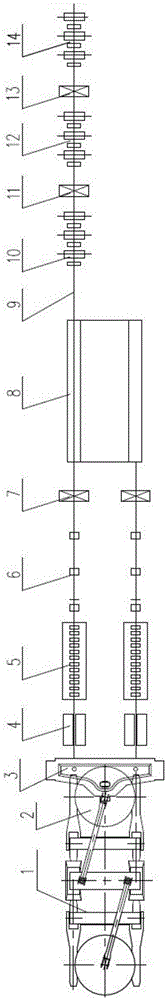

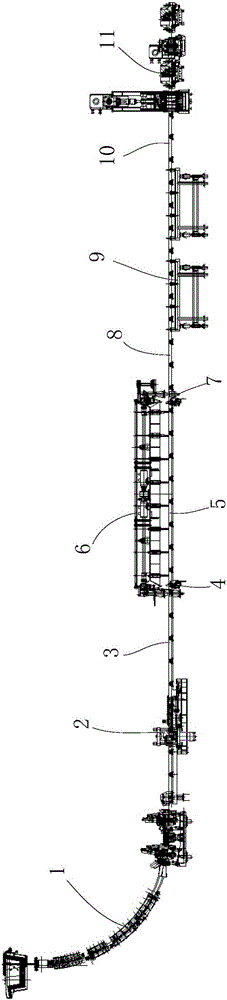

High-speed direct-delivery direct-rolling system and method for wire bar continuously-cast slabs

ActiveCN106180192AReduce temperature lossAvoid damageWork cooling devicesMetal rolling arrangementsEngineeringContinuous casting

The invention provides a high-speed direct-delivery direct-rolling system and method for wire bar continuously-cast slabs. The system comprises a small-radius high-drawing-speed continuous casting machine, a fast hydraulic shear, a cut slab roller table, a slab discharging roller table, a grouped cast slab hot-delivery roller table, a single-cast-slab delivery roller table and a wire bar rolling mill which are sequentially and compactly arranged. A transverse steel transfer machine is arranged between the slab discharging roller table and the grouped cast slab hot-delivery roller table. A steel bar splitting machine is arranged between the grouped cast slab hot-delivery roller table and the single-cast-slab delivery roller table. Cast slabs are gathered into groups on the slab discharging roller table and transferred into the grouped cast slab hot-delivery roller table from the transverse steel transfer machine. The grouped cast slabs are split into single cast slabs through the steel bar splitting machine and delivered to the wire bar rolling mill through the single-cast-slab delivery roller table for rolling. The small-radius high-drawing-speed continuous casting machine is efficient in continuous casting, the drawing-out temperature of the cast slabs is high, the shape of the cast slabs is regular, and the temperature loss is small; and the cutoff speed of the cast slabs is high, and the initial temperature of the cast slabs is high. All streams of the cast slabs are grouped at a high speed through the transverse steel transfer machine and delivered in a grouped manner through the hot-delivery roller table for steel rolling, and by means of the manner, the temperature drop is extremely small in the delivery process of the cast slabs.

Owner:CISDI ENG CO LTD

Coal-sludge co-combustion system based on high-temperature smoke drying and circulating fluidized bed boiler

The invention relates to a coal-sludge co-combustion system based on high-temperature smoke drying and a circulating fluidized bed boiler. A discharging outlet of a sludge storage bin is connected with a feeding inlet of a spray drying pipe through a screw pump. An air inlet of the spray drying pipe is connected with an outlet flue of a cyclone separator of the circulating fluidized bed boiler. An outlet I of the spray drying pipe is connected with a dry sludge bin through a rotary feeder I, and an outlet of the dry sludge bin is connected with the circulating fluidized bed boiler through a spiral conveyer so that dry sludge in the dry sludge bin can be fed into a dense-phase zone of the circulating fluidized bed boiler through the spiral conveyer to be combusted; an outlet II of the spray drying pipe is connected with the cyclone separator, an unloading opening of the cyclone separator is connected with the dry sludge bin through a rotary feeder II, and an exhaust opening of the cyclone separator is connected with the circulating fluidized bed boiler through a cooling condenser and a vent fan. The coal-sludge co-combustion system integrates the functions of sludge drying, combustion and pollutant control, and has the characteristics of being concise, environmentally friendly and efficient.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

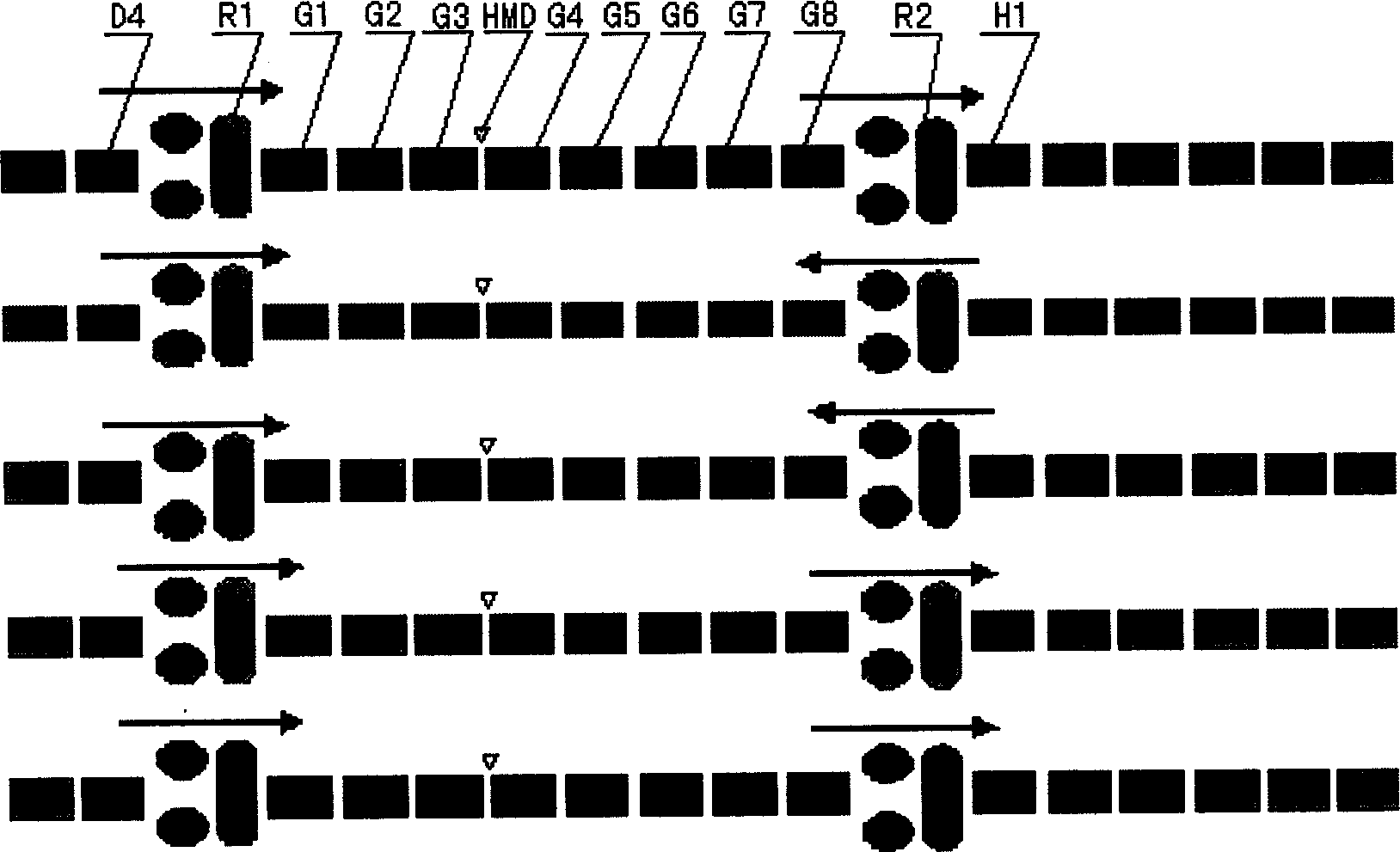

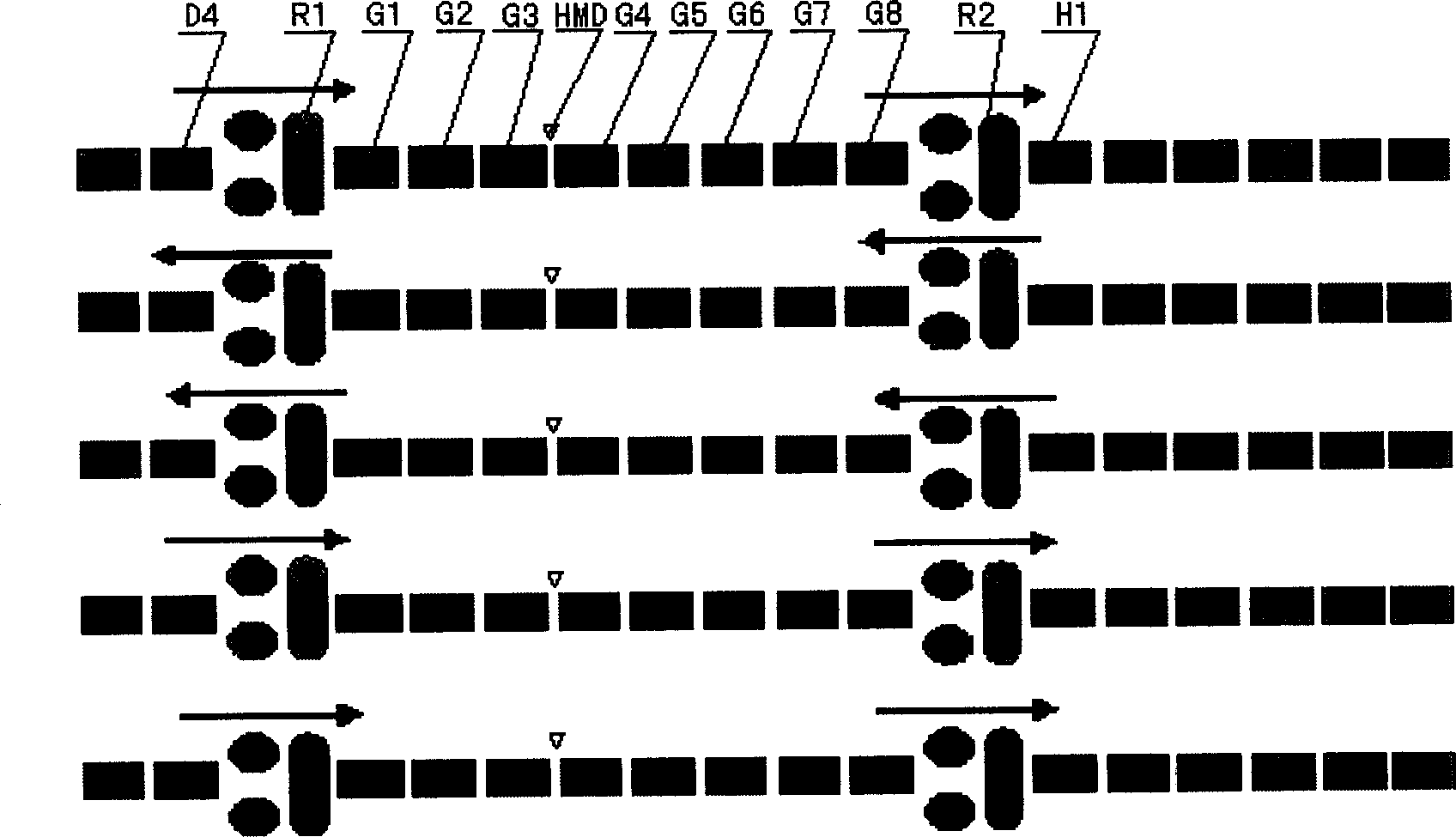

Method of parallel rolling by two roughing mills in the rough roll zone on hot rolling production line

InactiveCN1654137AReduce head-to-tail temperature differenceQuality improvementProgramme controlComputer controlProduction lineStrip steel

The parallel rolling process with two roughing mills in the roughing area of the production line features that the computer program controlled 3 gate + 3 gate rolling mode with the first roughing mills R1 in forward direction rolling and the second roughing mills R1 in reverse direction rolling simultaneously. In the first or the third gates of the R1 and the R2, the R2 is preferential, while in the second gate of the R1 and the R2, the R1 is preferential. The present invention has effectively controlled time sequence, and compared with original rolling process, the present invention has reduced rolling time, saving in power consumption, and raised rolling quality.

Owner:ANGANG STEEL CO LTD

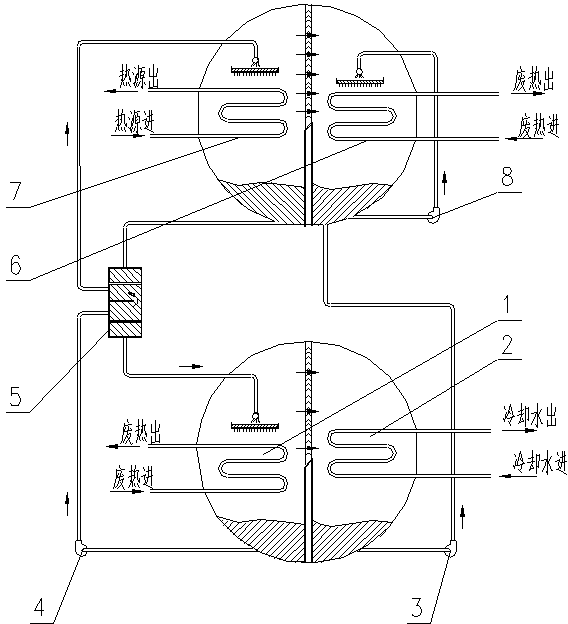

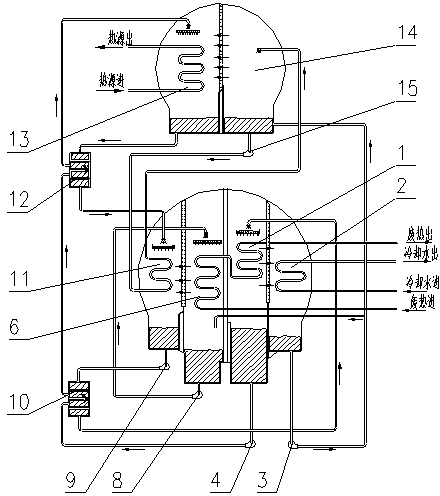

Two-stage absorption second-kind lithium bromide absorption heat pump unit with flash evaporator

ActiveCN103808060AIncrease absorption pressureIncrease concentration differenceClimate change adaptationEnergy efficient heating/coolingLithium bromideAbsorption heat pump

The invention relates to a two-stage absorption second-kind lithium bromide absorption heat pump unit with a flash evaporator. The two-stage absorption second-kind lithium bromide absorption heat pump unit comprises a generator (1), a condenser (2), an evaporator (6), an absorber and a solution heat exchanger. The flash evaporator (14) is additionally arranged in the unit, meanwhile, the absorber is divided into a first-stage absorber body (11) and a second-stage absorber body (13), the solution heat exchanger is divided into a high-temperature solution heat exchanger body (12) and a low-temperature solution heat exchanger body (10), the second-stage absorber body (13) and the flash evaporator (14) are located in a same cavity, the first-stage absorber body (11) and the evaporator (6) are located in a same cavity, the generator (1) and the condenser (2) are located in a same cavity, waste heat sources enter the evaporator (6) and the generator (1), solutions circulate in a series connection mode, the concentrated solutions firstly enter the second-stage absorber body (13) to become the middle solutions and then enter the first-stage absorber body (11) to become the dilute solutions, and the dilute solutions enter the generator (1) to be concentrated into the concentrated solutions. According to the two-stage absorption second-kind lithium bromide absorption heat pump unit, middle (low)-temperature waste heat sources are used for driving, and the heat source temperature rise amplitude can be improved under the condition that cooling water is used.

Owner:SHUANGLIANG ECO ENERGY SYST CO LTD

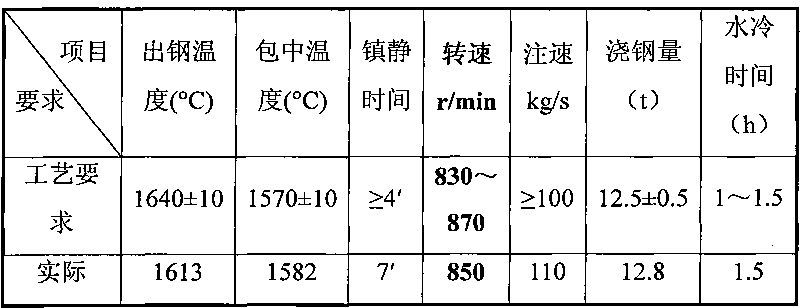

Centrifugal casting process for main pipeline of million kilowatt-grade nuclear power plant

ActiveCN102233417ATo achieve the effect of heat insulationAdjust the setting characteristicsFoundry mouldsFurnace typesMolten steelSubmarine pipeline

The invention relates to a centrifugal casting process for a main pipeline of a million kilowatt-grade nuclear power plant. The centrifugal casting process comprises the main steps of smelting, cylinder coating, centrifugal casting, heat treatment and the like, wherein the tapping temperature of pressure molten steel is 1,640+ / -10 DEG C; after a cylinder is coated, the cylinder is roasted to the temperature of more than or equal to 280 DEG C and heat is preserved for 1 to 2 hours; the temperature of pouring steel is 1,570+ / -10 DEG C; the calming time is not less than 4 minutes; the rotating speed of the cylinder is controlled to be 800 to 870 r / min; and the casting speed is more than or equal to 100 kg / s. In the centrifugal casting process, process parameters and the process are controlled strictly, so the main pipeline capable of meeting the requirements of the million kilowatt-grade nuclear power plant can be manufactured.

Owner:烟台台海玛努尔核电设备有限公司

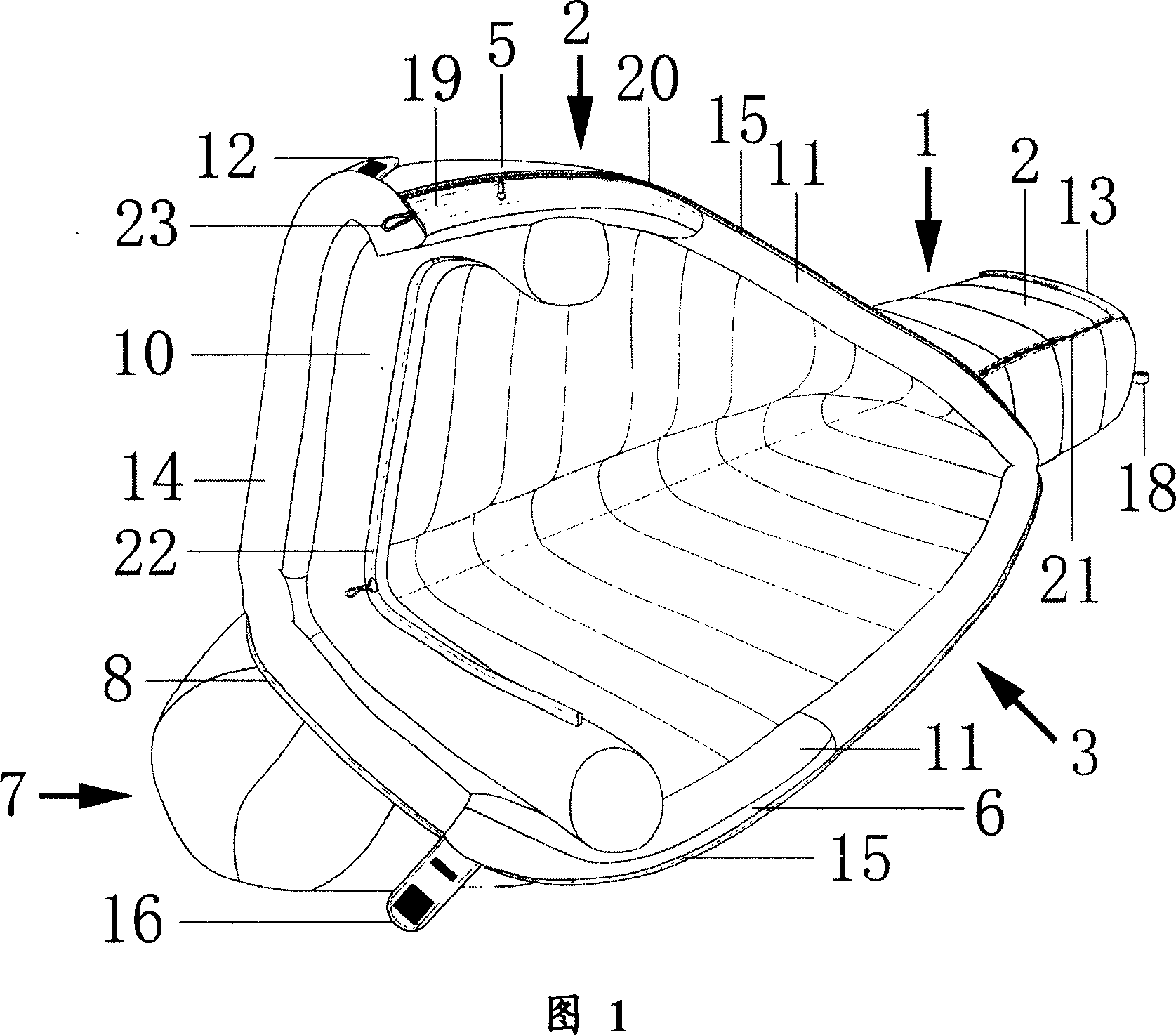

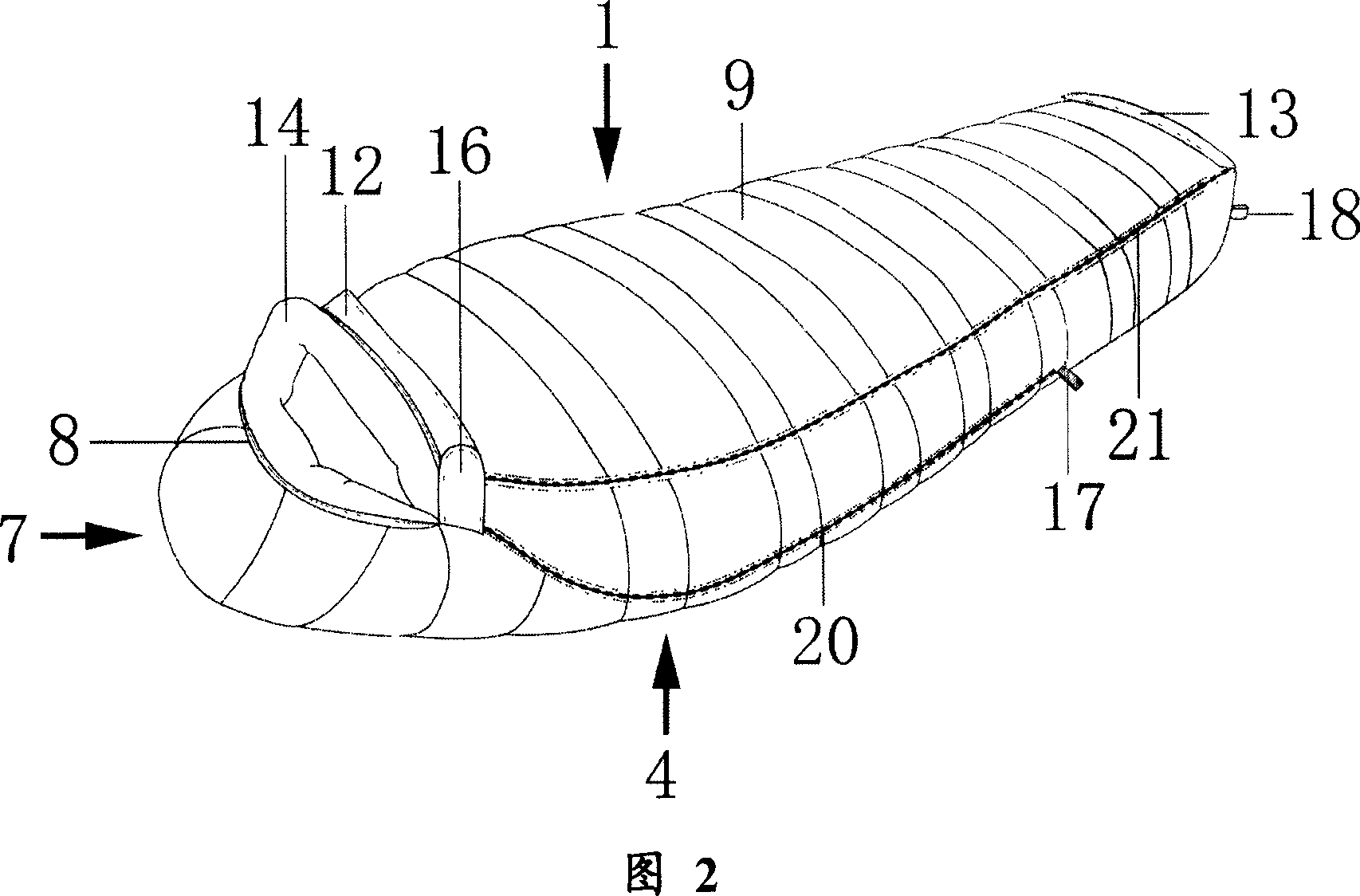

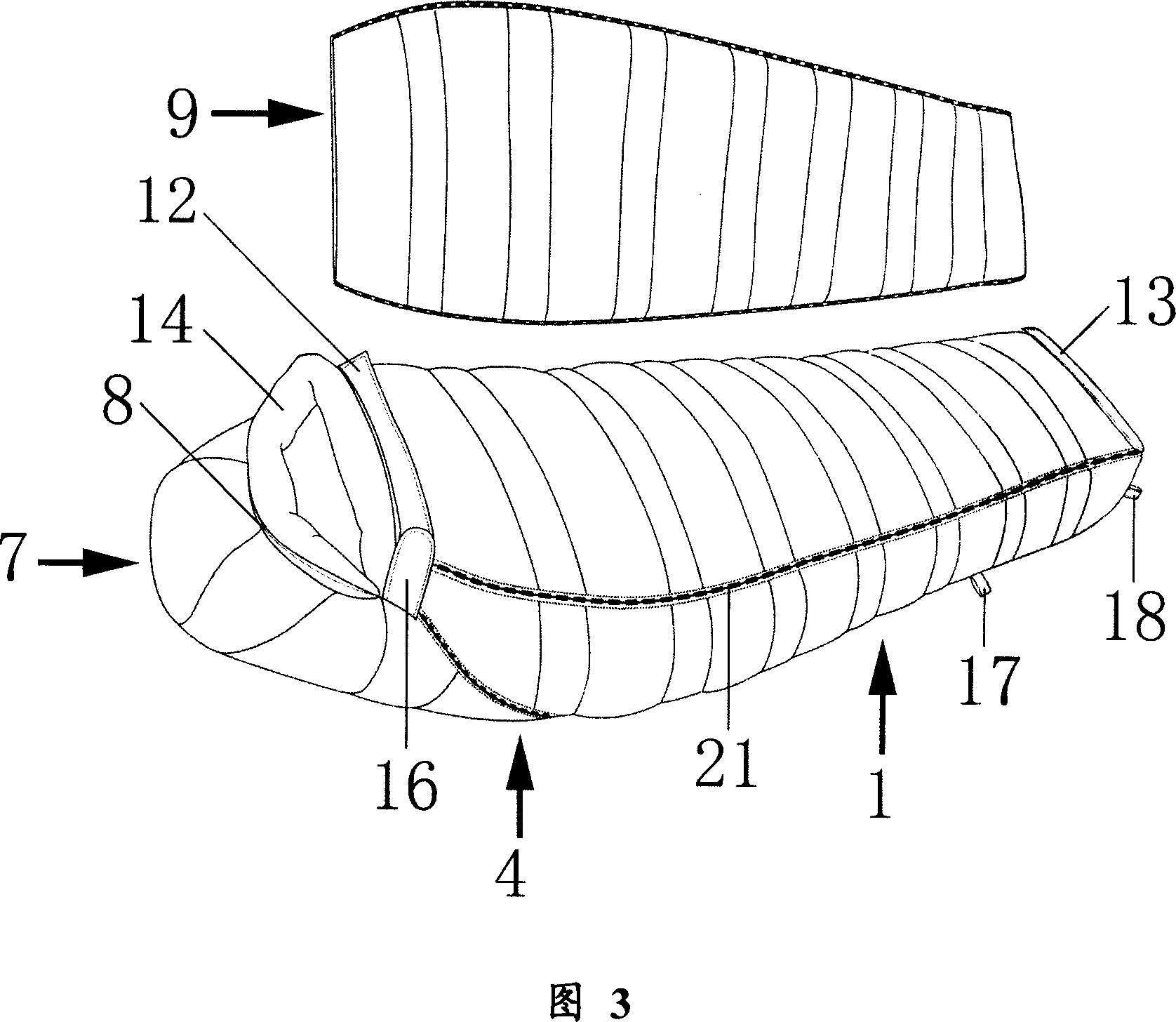

Compound sleeping bag and making method thereof

Owner:HIGH ROCK RECREATION PROD CO LTD

Local air supply system based on bed

InactiveCN103968513AEnergy efficient operationAvoid wastingSpace heating and ventilation safety systemsLighting and heating apparatusThermal comfortEngineering

The invention relates to the field of air conditioners and discloses a local air supply system based on a bed. The local air supply system based on the bed comprises an upper air supply bellows, a lower air supply bellows, the bed, an upper air supply outlet, a lower air supply outlet, an air pipe connector, an air pipe and a three-way valve. The bed has the certain height and divides a room to be an upper local space and a lower local space which are different in use function, wherein the upper local space is an upper sleeping area and the lower local space is a lower working area. By selecting different air conditioner air supply branches or supplying air to the upper air supply bellows, the temperature of air of the upper sleeping area of the bed is controlled; or by supplying air to the lower air supply bellows, the temperature of air of the working area is controlled. The upper air supply outlet and the lower air supply outlet are respectively provided with a guide device, so that the air conditioner wind airflow direction is adjusted within the large range. According to the local air supply system based on the bed, hot wind of an air conditioner under the heating operating condition in winter can be conveyed to the lower layer indoors, so that not only is the thermal comfort of the air conditioner improved, but also heat energy gathered at the upper layer indoors in winter can be utilized, and the energy-saving type local air conditioner air supply system is flexible to adjust, remarkable in effect and large in air conditioner control area.

Owner:CHONGQING UNIV

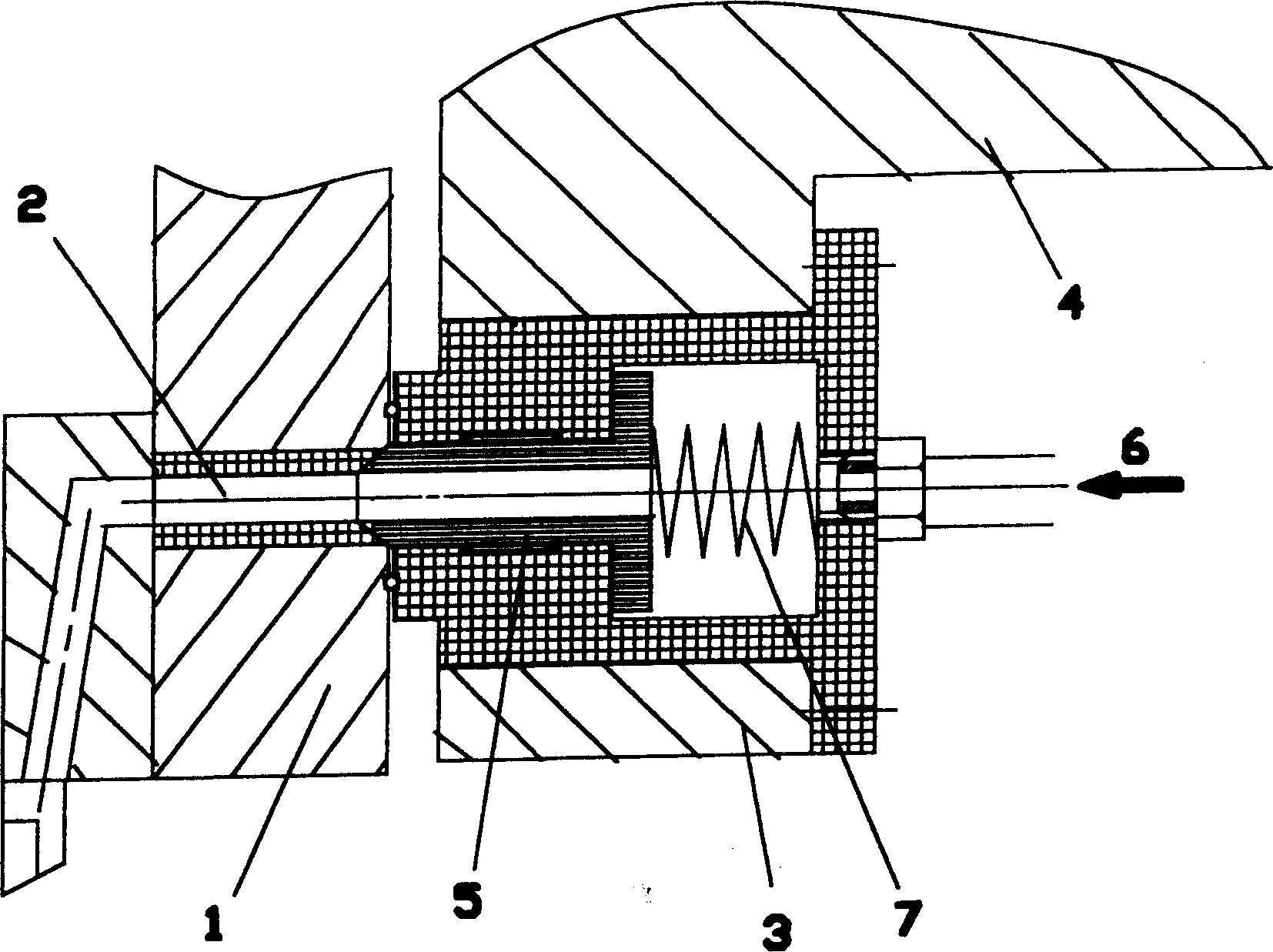

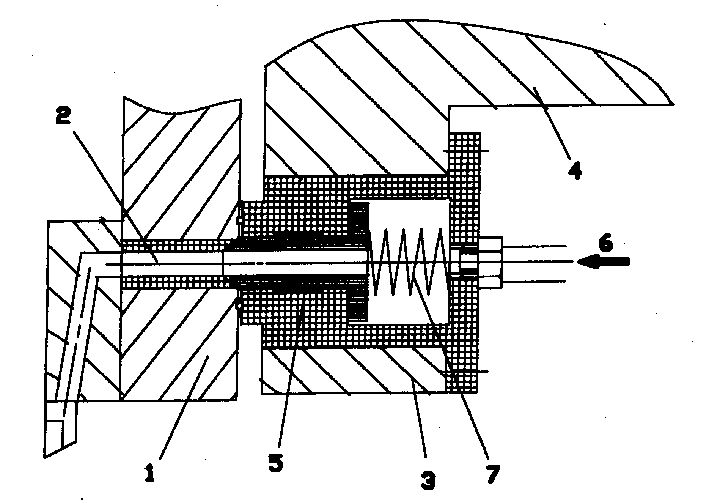

Automatic butter connection mechanism for capstan and low-temp. fluid delivery unit

InactiveCN1537700AReduce temperature lossReduce lossMaintainance and safety accessoriesEngineeringCooling medium

An automatic butt connection mechanism for capstan and low-temp fluid delivering unit features that an insulating elastic sleeve tube is used between the cooling medium supplying system and the one of the fluid inlets on polygonal capstan. When said polygonal capstan ais turned by an angle, said elastic sleeve tube can be automatically withdrawn and then connected with another fluid inlet in working state.

Owner:张昌义 +1

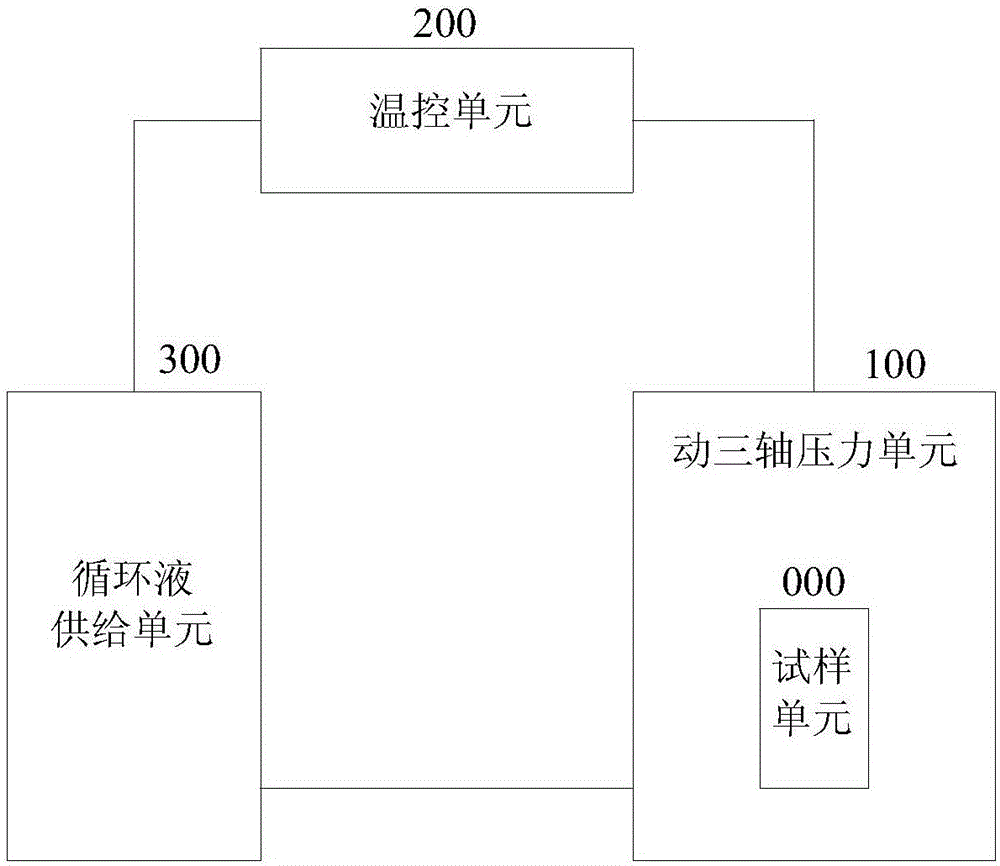

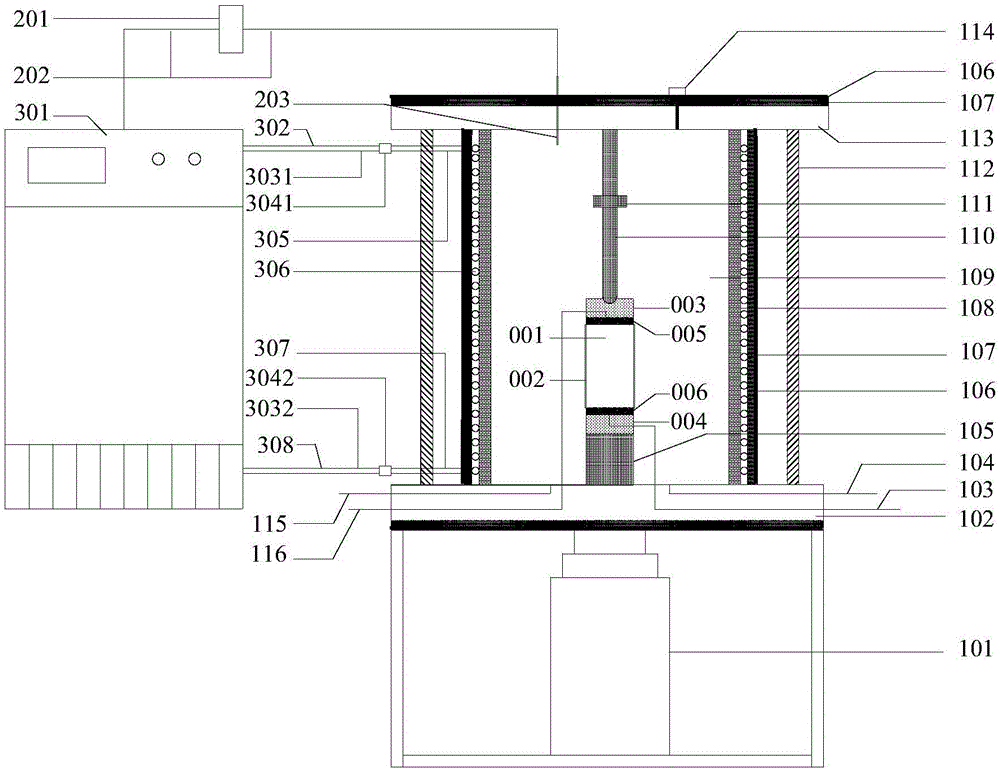

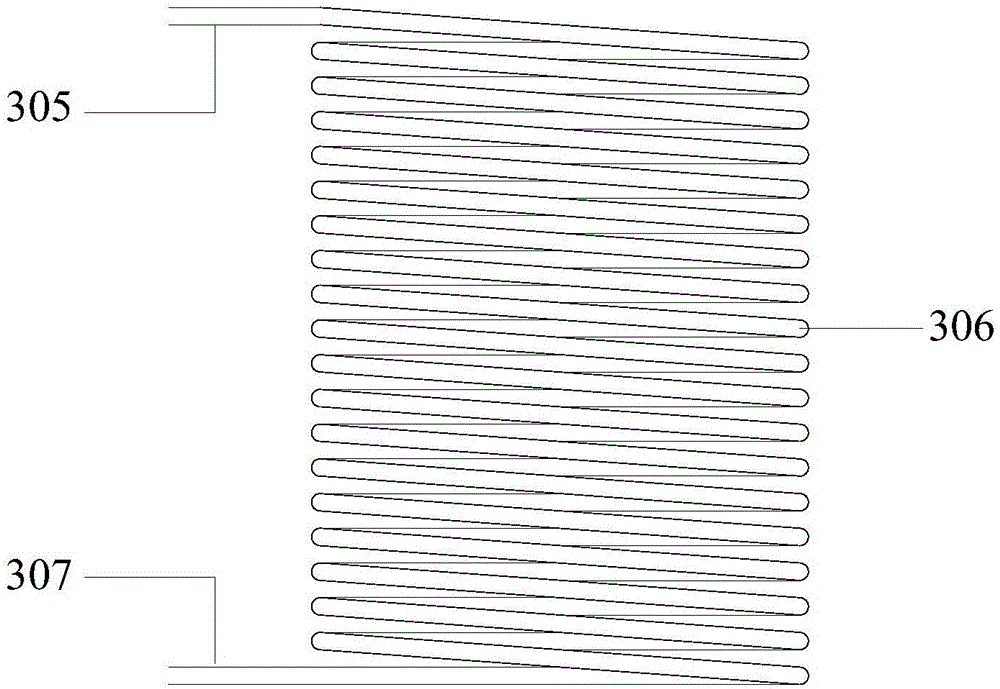

Triaxial test device of soil freeze-thaw circulation and dynamic load coupling and method thereof

PendingCN106769563ARealize automatic controlRealize dynamic triaxial testMaterial strength using repeated/pulsating forcesTemperature controlLiquid temperature

The invention discloses a triaxial test device of soil with coupling of freeze-thaw circulation and dynamic load and a method thereof and relates to the test technology of strength of positive dynamic frozen-thawed soil. The device comprises a sample unit (000), a dynamic triaxial pressure unit (100), a temperature control unit (200) and a circulation liquid supply unit (300), wherein the sample unit (000) is arranged inside the dynamic triaxial pressure unit (100); the temperature control unit (200) is connected with the dynamic triaxial pressure unit (100) and is used for monitoring temperature of confining pressure liquid of the dynamic triaxial pressure unit (100; the temperature control unit (200) is also connected with the circulation liquid supply unit (300) and is used for controlling temperature of circulation liquid; the circulation liquid supply unit (300) is connected with the dynamic triaxial pressure unit (100) and is used for supplying circulation liquid to the dynamic triaxial pressure unit (100). The triaxial test device is capable of achieving freeze-thaw circulation and application of dynamic load of soil samples in the presence of load; the temperature control accuracy is high; the triaxial test device is convenient to mount and dismount.

Owner:INST OF ROCK AND SOIL MECHANICS - CHINESE ACAD OF SCI

Wire rod continuous casting billet heating-free direct rolling system and method

ActiveCN106180191AReduce temperature lossReduce temperature dropMetal rolling arrangementsWire rodRolling mill

The invention provides a wire rod continuous casting billet heating-free direct rolling system and method. The wire rod continuous casting billet heating-free direct rolling system comprises a continuous casting machine, a rapid hydraulic shear, a cut roller bed, a casting billet stream gathering roller bed, a transportation hot delivery roller bed and a wire rod rolling mill which are closely arranged in sequence. The casting billet stream gathering roller bed gathers casting billets on each stream onto the transportation hot delivery roller bed. A gate mechanism used for blocking the casting billets from entering and releasing the casting billets is arranged between the cut roller bed and the casting billet stream gathering roller bed. According to the wire rod continuous casting billet heating-free direct rolling system and method, efficient continuous casting of the continuous casting machine is conducted, and the casting billets are high in pull-out temperature, regular in shape, low in temperature loss, rapid in shearing and high in initial temperature; by means of the gate mechanism, the sheared casting billets sequentially enter the high-speed casting billet stream gathering roller bed in order, operation is easy and convenient, and production is easy to organize; and when the casting billets reach an inlet of the rolling mill, the temperature of the casting billets is high, and the casting billets can be directly rolled in a heating-free mode, so that the damage to the rolling mill is small.

Owner:CISDI ENG CO LTD

Coal-sludge multi-fuel combustion system based on two-medium flue gas drying and pneumatic transportation

The invention relates to a coal-sludge multi-fuel combustion system based on two-medium flue gas drying and pneumatic transportation. A sludge storage cabin is connected with a spraying drying pipe; the spraying drying pipe is connected with a mixing chamber; one path of an inlet of the mixing chamber is connected with an outlet flue of a cyclone separator, and the other path is connected with an outlet of a dust remover through a cold smoke draught fan; a spraying drying pipe outlet I is connected with a rotary feeder I; a spraying drying pipe outlet II is connected with the cyclone separator; an exhausting hole of the cyclone separator is connected with a circulating fluidized bed boiler through a cooling condenser and an exhausting steam draught fan; an unloading hole of the cyclone separator is connected with a rotary feeder II; a limestone cabin is connected with a rotary feeder III; the rotary feeder I, the rotary feeder II and the rotary feeder III are connected with the circulating fluidized bed boiler through a spraying feeder; and a gas inlet of the spraying feeder is connected with a Roots draught fan. With the adoption of the coal-sludge multi-fuel combustion system, functions of sludge desiccation and transportation, residual heat utilization of dry tail gas, multi-fuel combustion of sludge and coal, control of pollutants and the like can be realized, and the diffusion of stench and dust is facilitated; and the system has the characteristics of simplicity, environmental friendliness and high efficiency.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

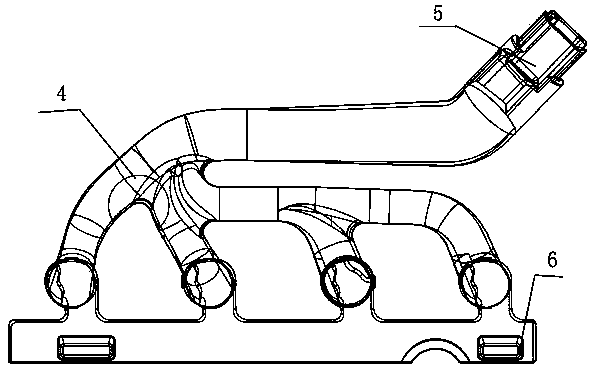

Thick-wall cast steel exhaust manifold casting process

ActiveCN108655348AReality GuaranteeComplex structureFoundry mouldsFoundry coresPass rateCasting mold

The invention discloses a thick-wall cast steel exhaust manifold casting process and belongs to the technical field of exhaust manifold casting. According to the thick-wall cast steel exhaust manifoldcasting process, a thick-wall cast steel exhaust manifold casting mold and method are included. The casting mold comprises a sand mold, feeder heads, a sand core and a pouring system. The sand core is provided with multiple sand jetting openings. The pouring system comprises a sprue bar, a cross gate and an ingate. The sprue bar communicates with the cross gate in a perpendicular manner. A filteris arranged in the middle of the cross gate. The feeder heads comprise the large-face feeder heads, the triangular flange feeder heads, the fire inlet feeder head and the heat preservation feeder head. The fire inlet feeder head is arranged at the tail end of the cross gate. The thick-wall cast steel exhaust manifold casting process is good in mechanical performance, uniform in wall thickness andresistant to high temperature. The thick-wall cast steel exhaust manifold casting mold and method are included. The wall thickness of a casting ranges from 5.5 mm to 6.5 mm, and the weight ranges from 8 Kg to 12 Kg. Technical requirements are met; performance is stable; the problem that molding is difficult to achieve when common casting processes are adopted is solved; and the qualification rateof products is high.

Owner:NANYANG FEILONG AUTOMOBILE PARTS CO LTD

Machine tool fixture for thin-wall workpiece

PendingCN104990322AEasy to passSpeed up meltingLighting and heating apparatusIce productionCold airEngineering

The invention discloses a machine tool fixture for a thin-wall workpiece. The machine tool fixture comprises a material cylinder, a cooling pipe, an air inlet pipe, an air outlet pipe, a vortex pipe and a heat preservation tank, wherein the material cylinder adopts a hollow cylinder body; the cylinder body is filled with a water solution; a passage for air flow is arranged on the cylinder wall of the cylinder body; two ends of the passage are respectively communicated with the air inlet pipe and the air outlet pipe; the cooling pipe is arranged in the material cylinder; the cooling pipe is in the shape of a coned screw; the conicity of the coned screw is 20-50 degrees; the cooling pipe opening positioned in the tip end of the coned screw is communicated with the air outlet pipe; the cooling pipe opening positioned in the thick end of the coned screw is communicated with the air inlet pipe; a cold air pipe of the vortex pipe is communicated with the air inlet pipe; a hot air pipe of the vortex pipe is communicated with the heat preservation tank; an unfreezing pipe communicated with the air inlet pipe is also arranged on the heat preservation tank; a pipe valve is arranged on each of the hot air pipe and the unfreezing pipe. Compared with the conventional thin-wall fixture, the temperature deformation and stress deformation of the workpiece are effectively reduced.

Owner:CHONGQING ZHUOSHAN MACHINERY MFG

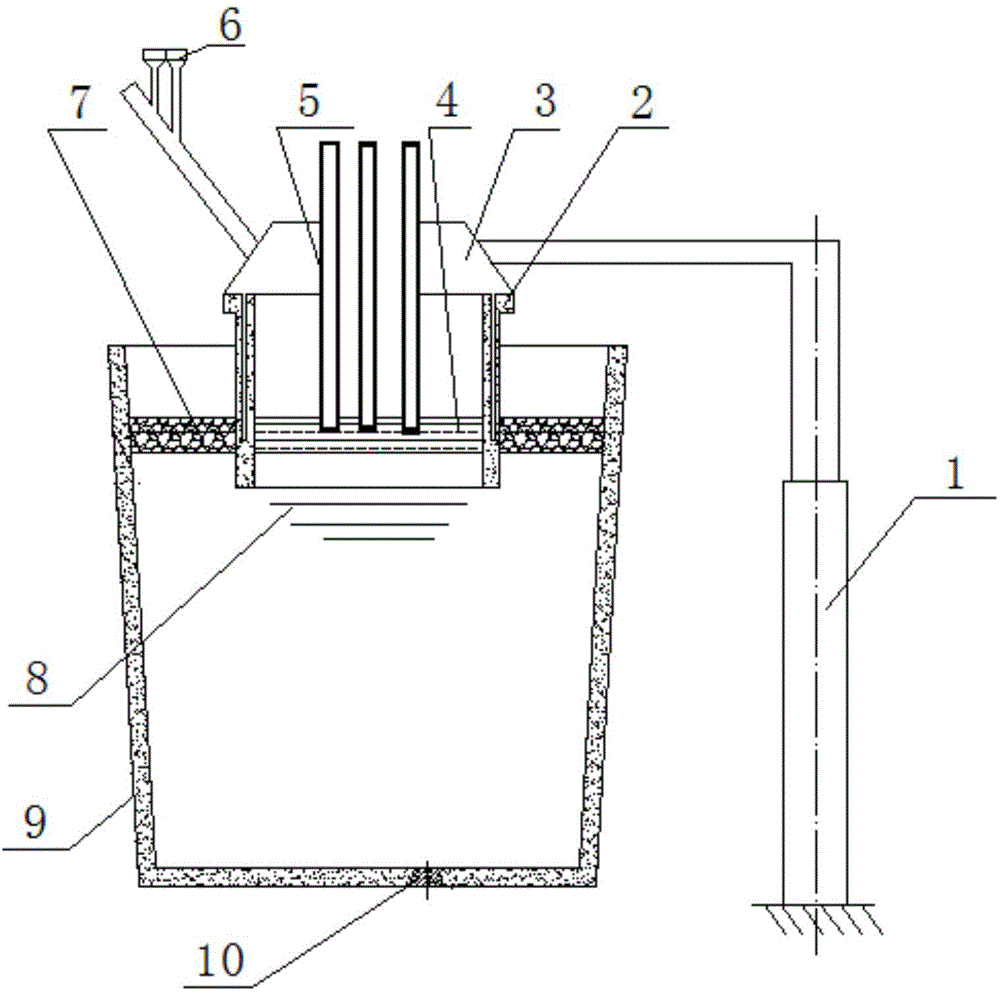

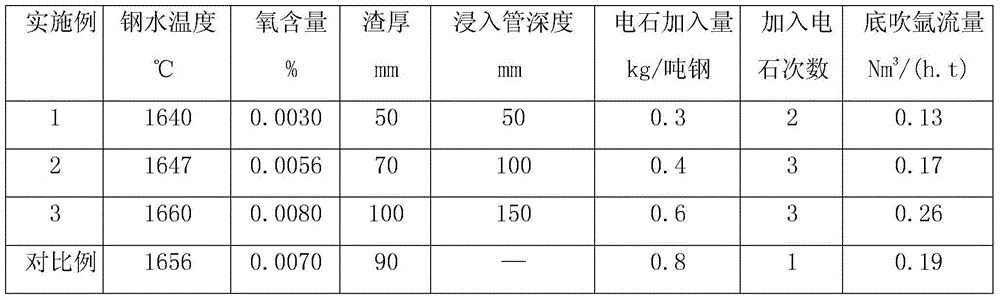

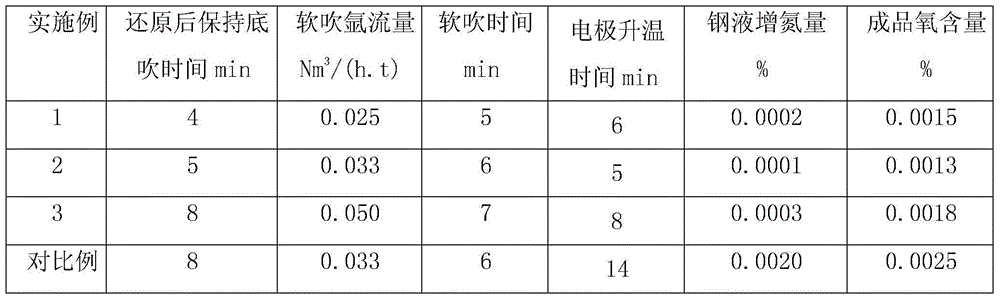

Refining device and method for controlling nitrogen content of molten steel

ActiveCN105624367AThe purpose of controlling nitrogen increaseReduce exposureProcess efficiency improvementSlagMolten steel

The invention provides a refining device for controlling the nitrogen content of molten steel. The refining device comprises a lifting hydraulic cylinder, immersing pipes, a furnace cover, electrodes, a bin and a steel ladle. The front end of a connecting rod at the front end of a piston rod of the lifting hydraulic cylinder is welded to the furnace cover. The electrodes are arranged in the middle of the furnace cover. The bin is arranged above a feeding port in one side. The immersing pipes are fixed below the furnace cover. The furnace cover is lifted and hung above the steel ladle through the lifting hydraulic cylinder. Compared with a conventional method, the contact opportunity between the molten steel and air can be reduced, and the nitrogen increasing amount of the molten steel is not larger than 0.0003%; the temperature drop of the molten steel in the treatment process is reduced, and the temperature loss is reduced by 50%; and inclusions in the molten steel are effectively removed, the cleanliness of the molten steel is improved, the use amount of pre-melted slag is reduced by 40%, and cost is reduced. The refining device is simple in structure, easy to operate, low in investment and free of influences on normal operation of other equipment, and the immersing pipes can be repeatedly used.

Owner:ANGANG STEEL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com