Patents

Literature

675 results about "Heat transfer process" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Heat transfer is the process of moving heat from a location where much heat exists to another location. In physics, it is taught this is mainly accomplished one of three ways: conduction, convection or radiation. In some ways, using this knowledge helps humans manipulate thermal energy in ways that are most beneficial.

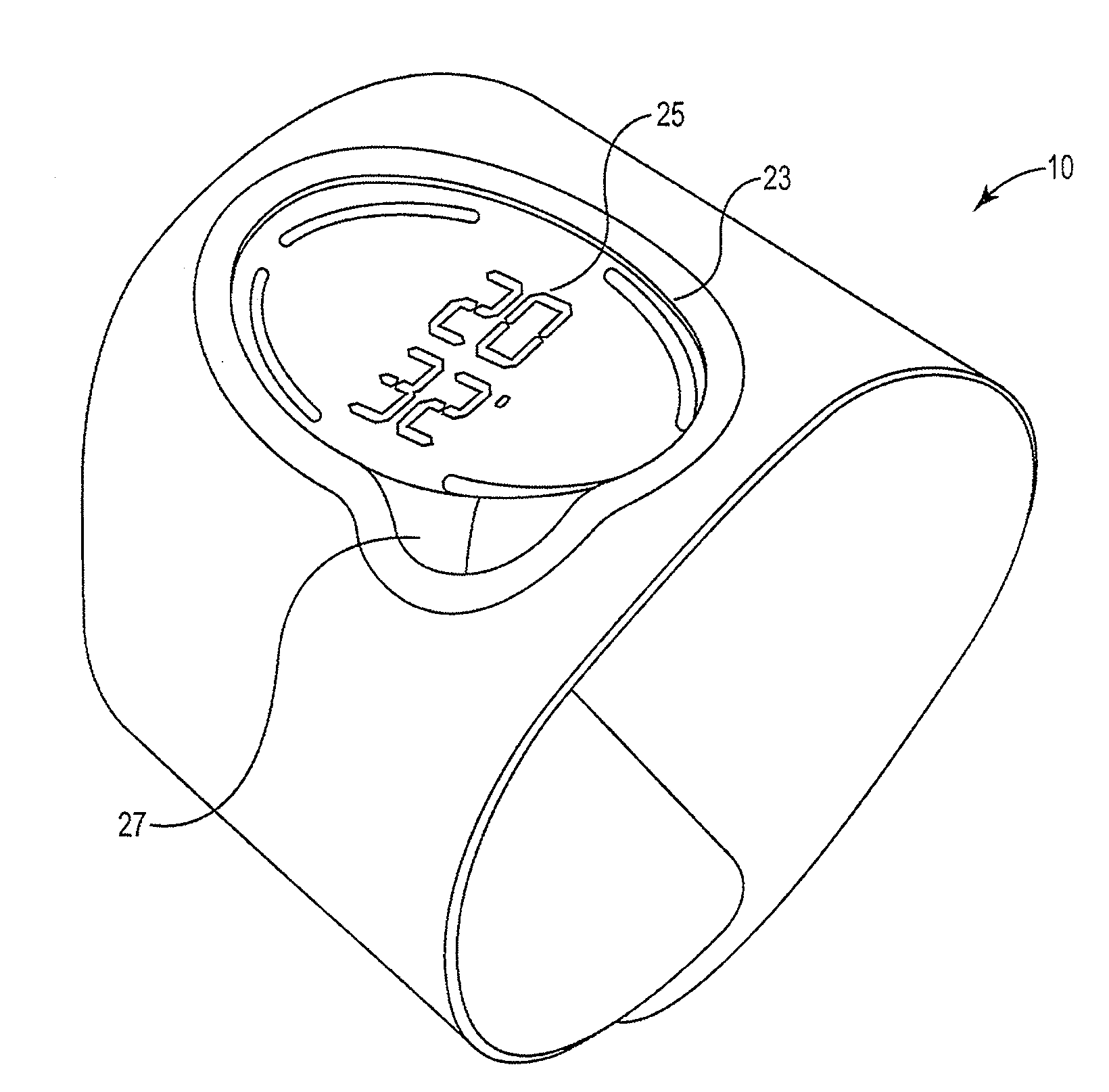

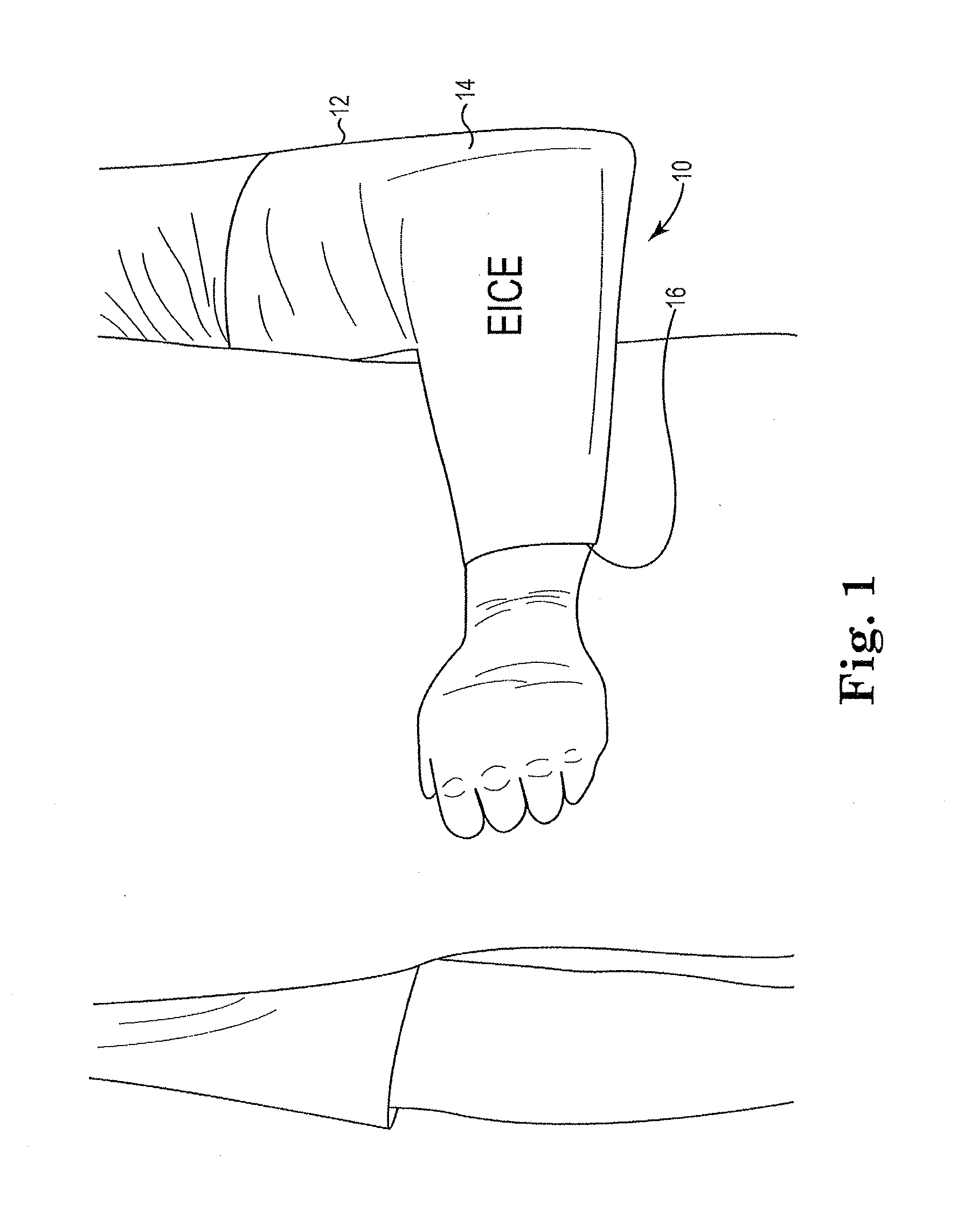

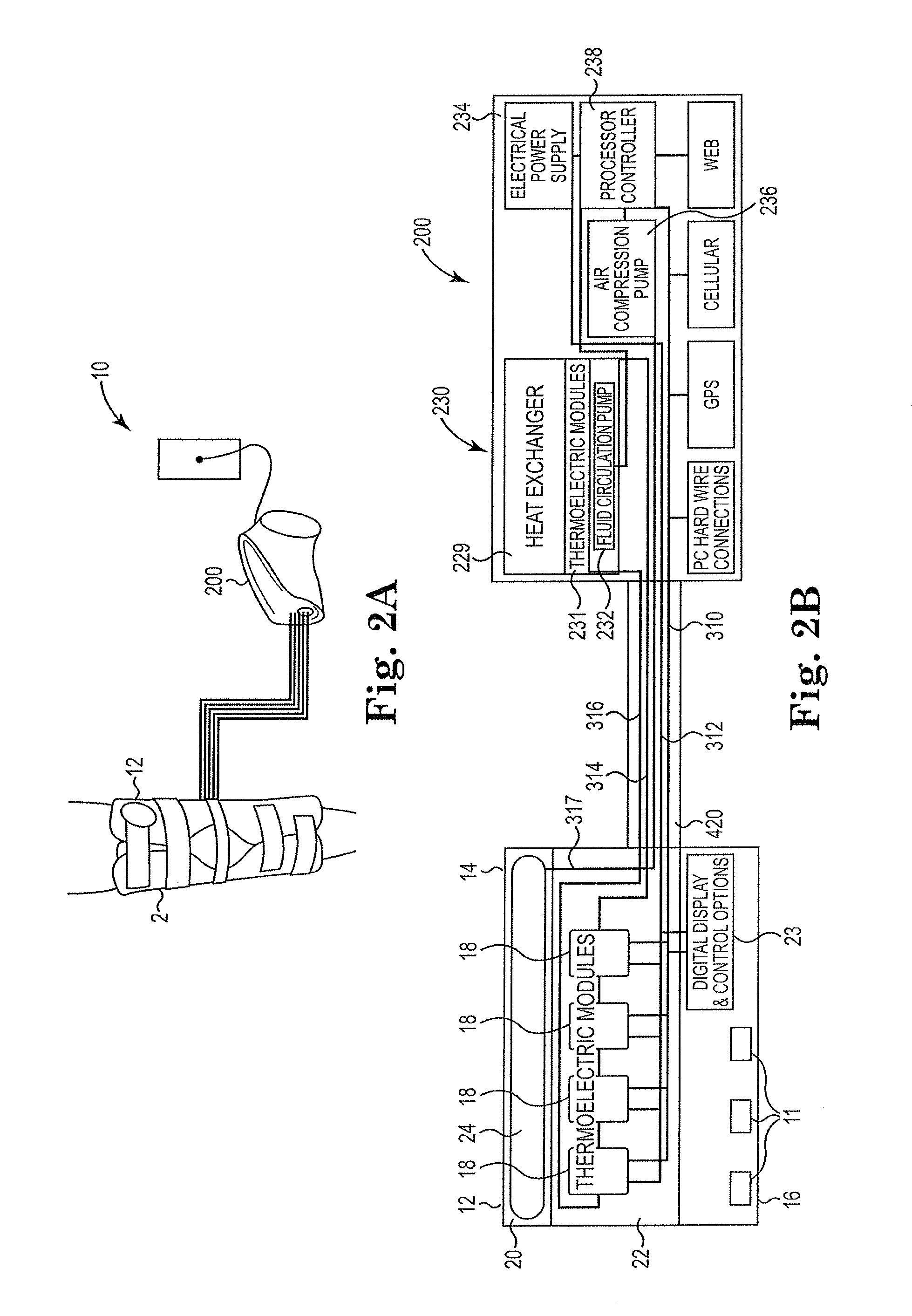

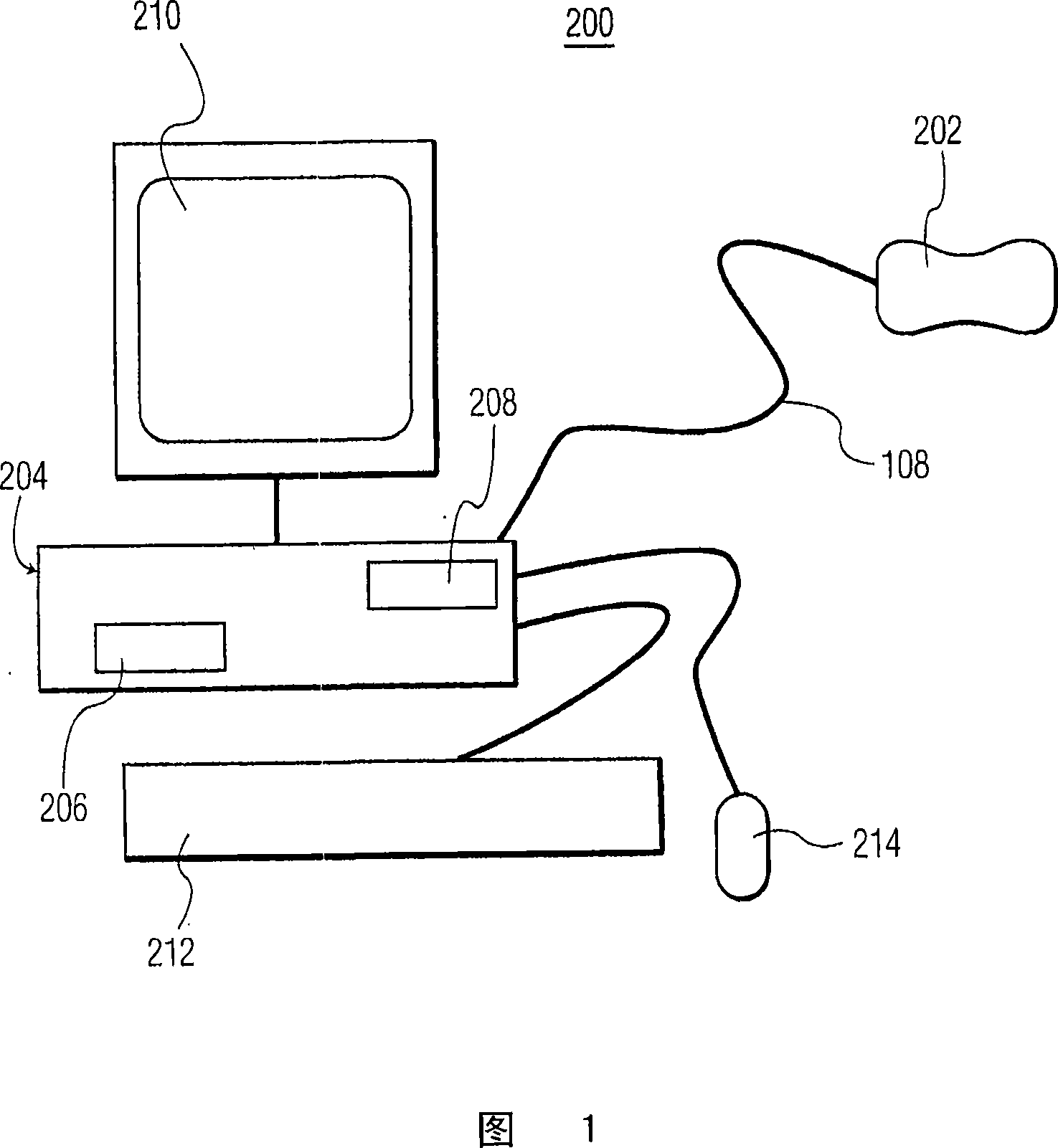

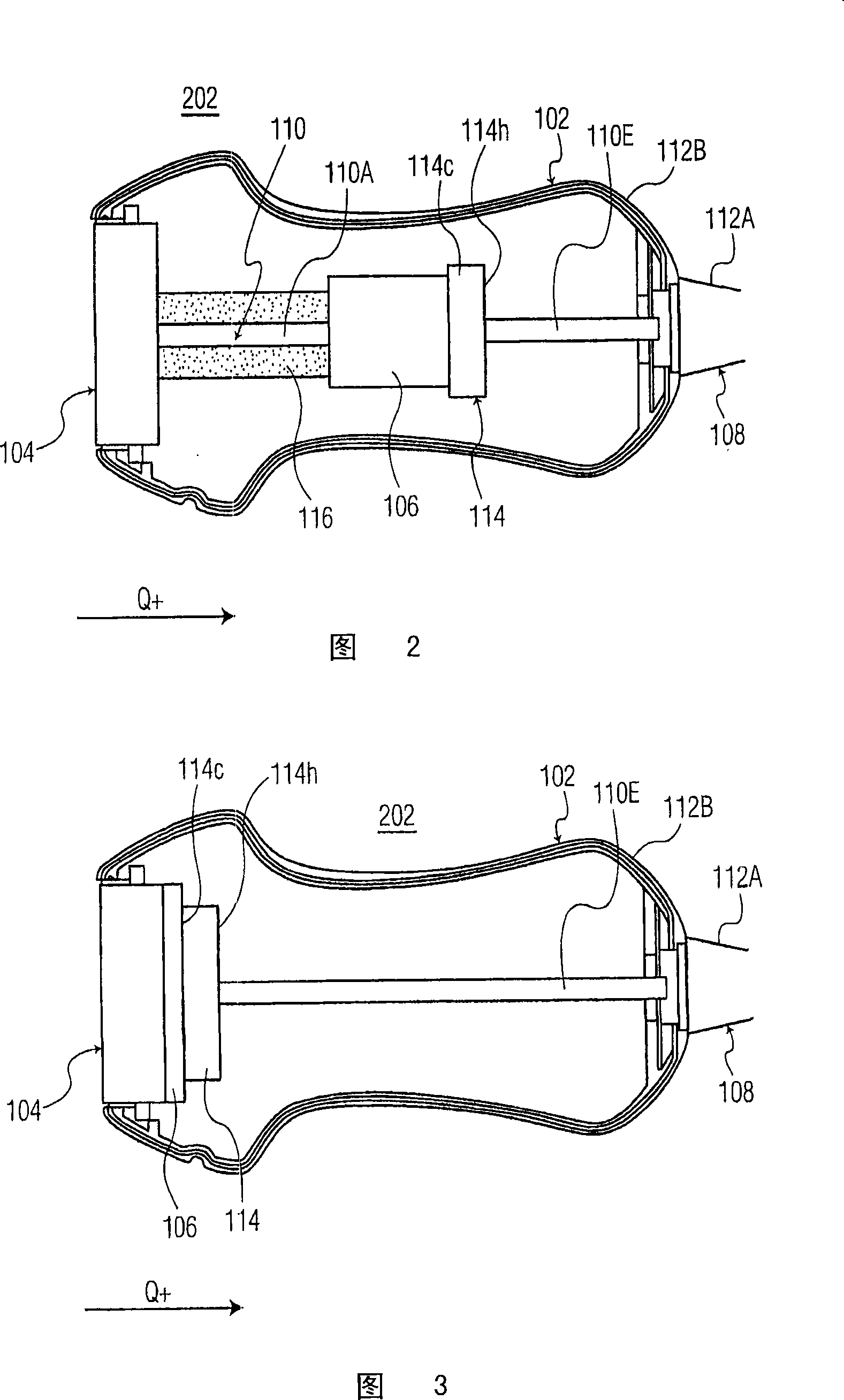

Thermal therapy system and method of use

InactiveUS20130331914A1Remove heatTherapeutic coolingTherapeutic heatingEngineeringHeat transfer process

A system that can be used to provide highly controlled thermal therapy and compression to both cool and heat a skin surface and a joint and surrounding tissue below the skin surface is provided. The system includes a joint conforming wrap; a power supply module for supply power to the joint conforming wrap and a cable operably coupling the wrap and the power supply module. The joint conforming wrap and power supply module include opposing thermoelectric modules. The joint conforming wrap is designed to provide heat transfer processes to the body of a patient to warm or cool the skin and a joint and surrounding tissue disposed under the skin.

Owner:RHMD

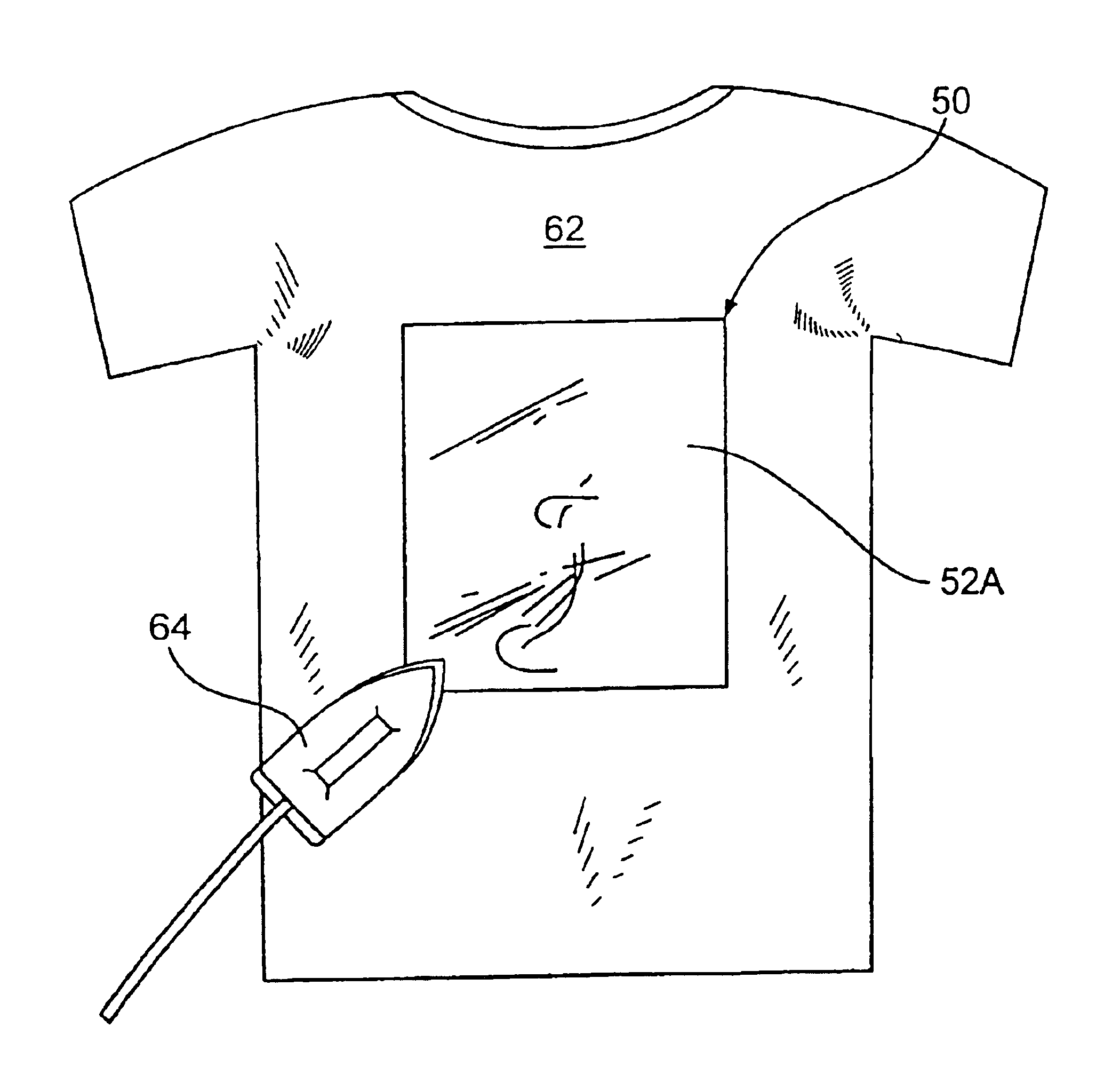

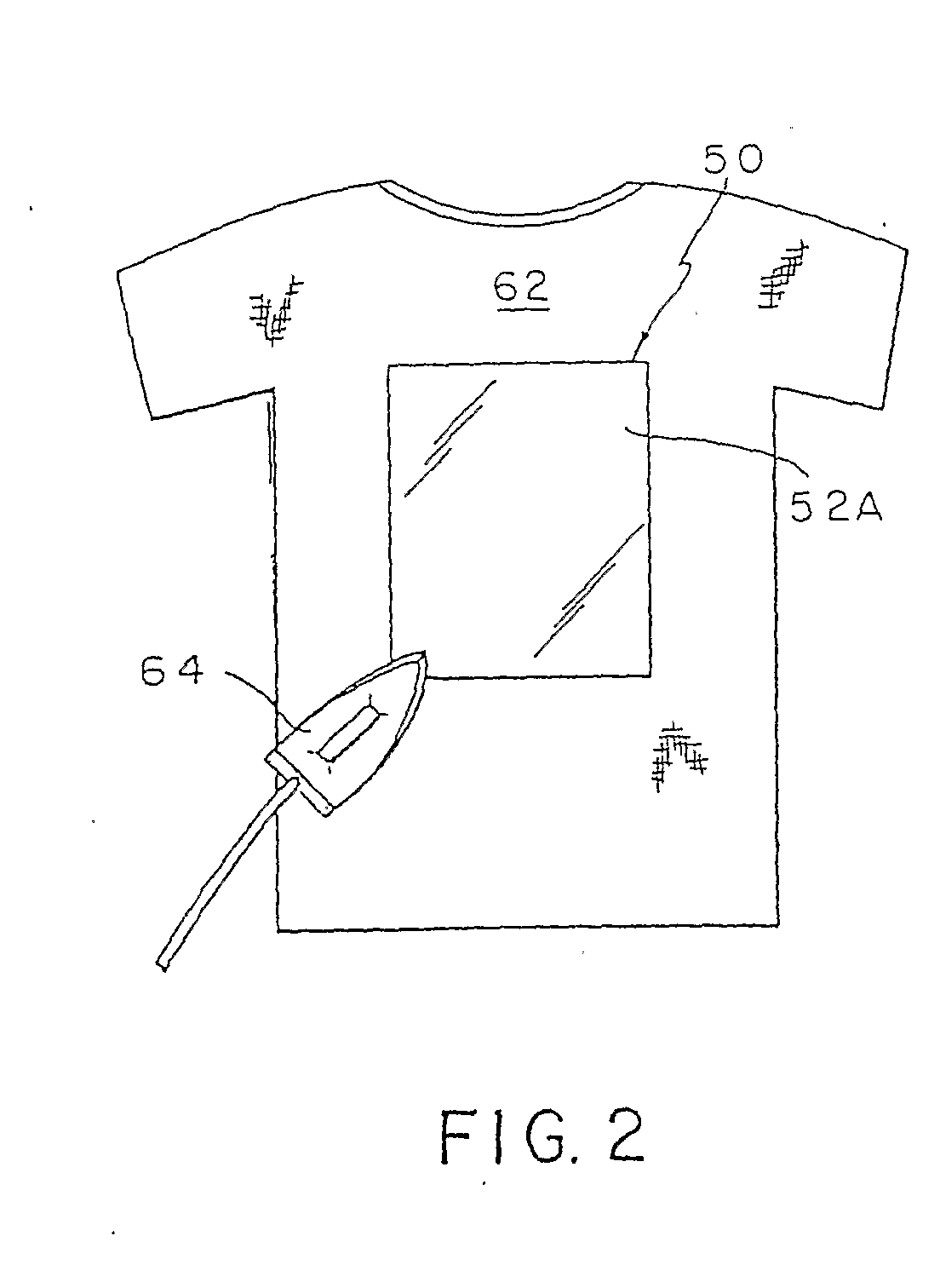

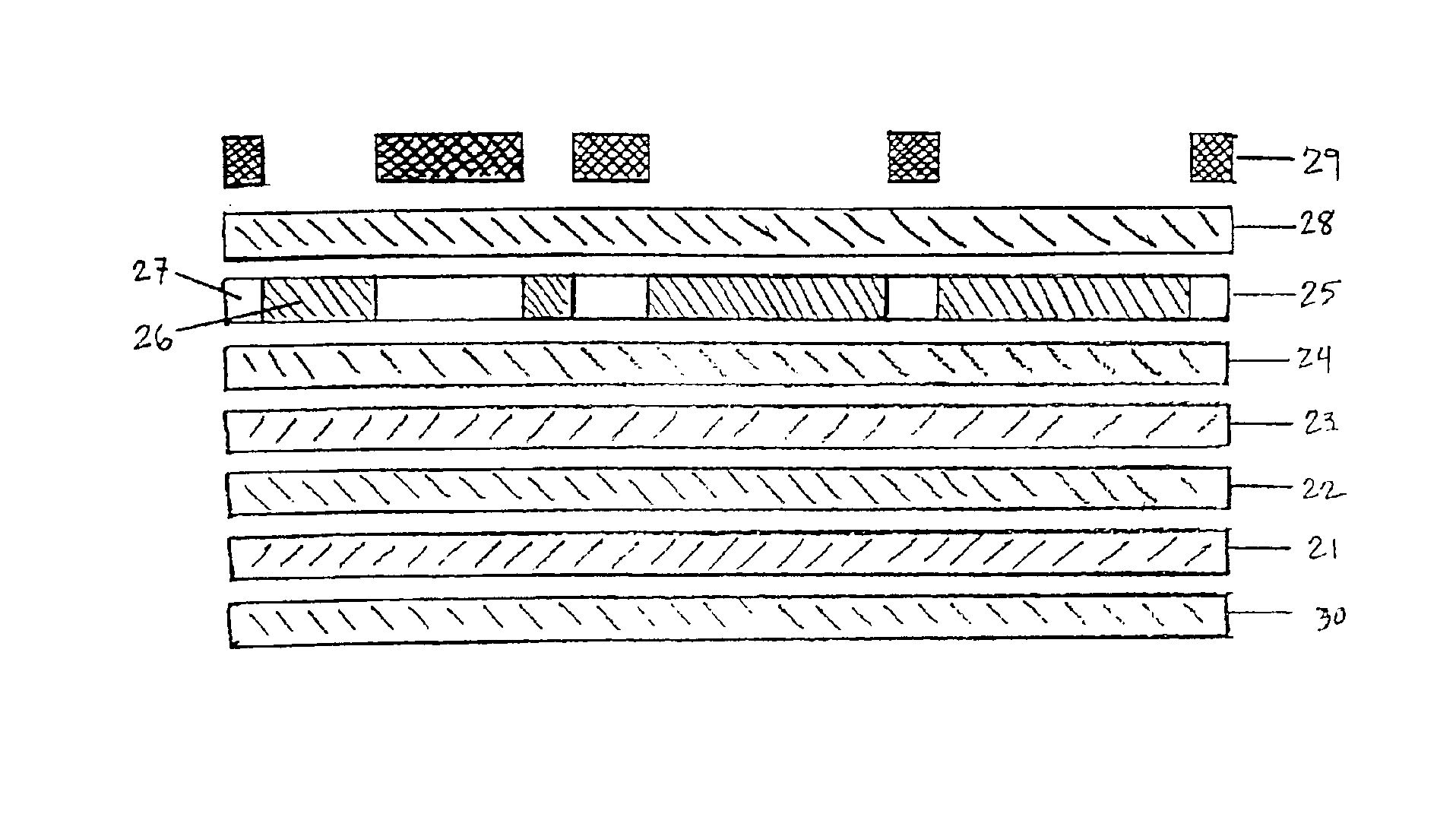

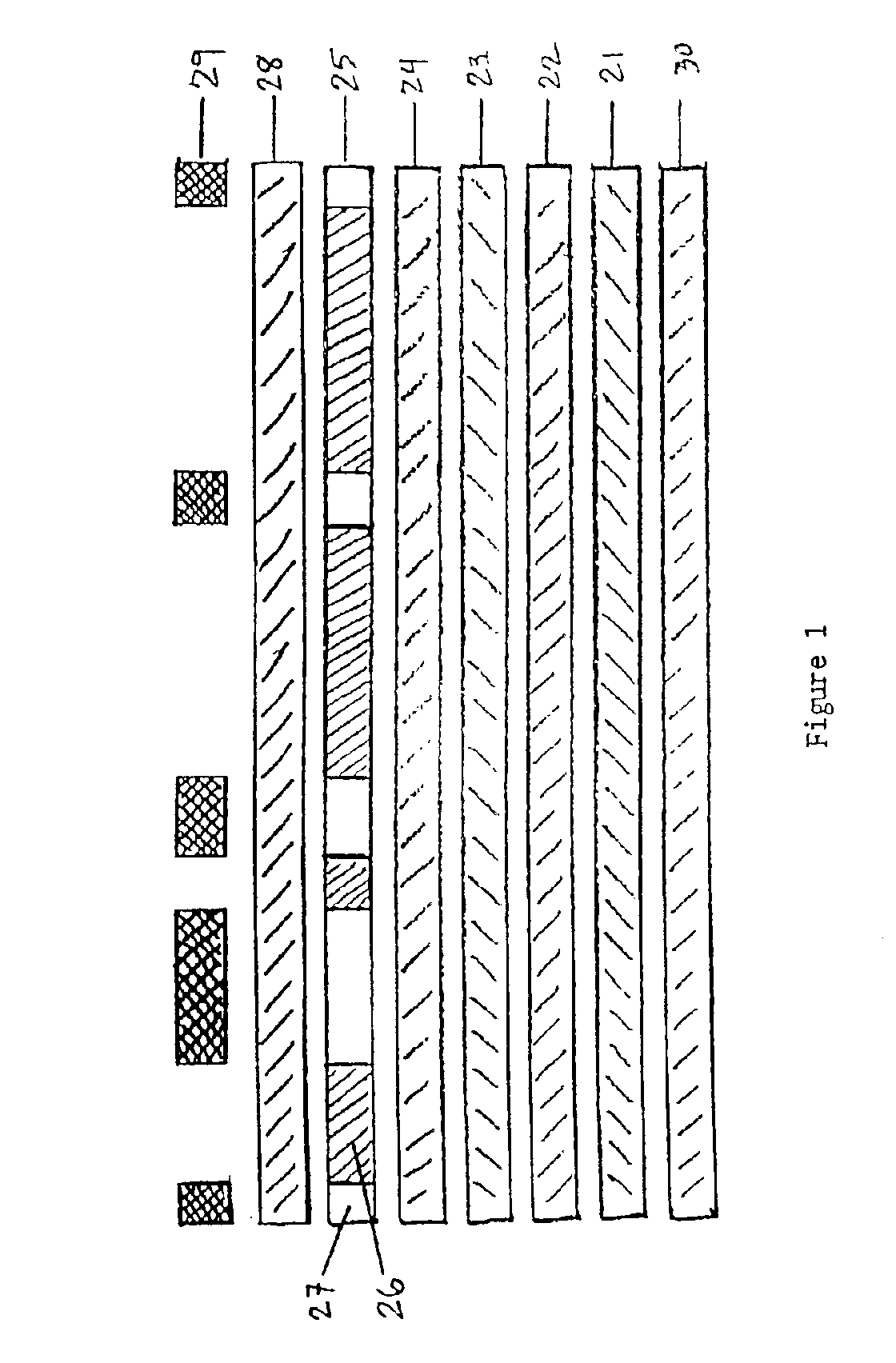

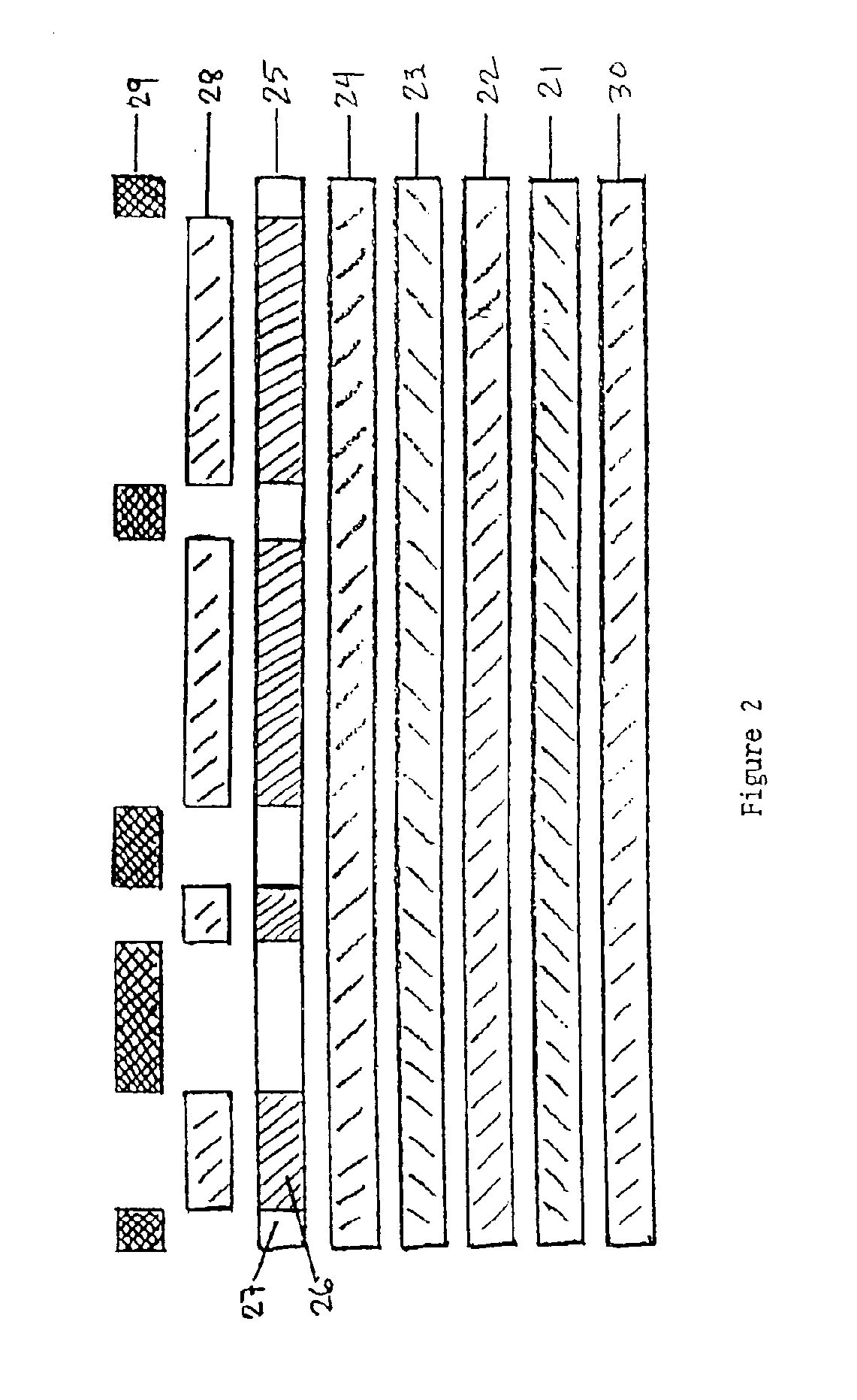

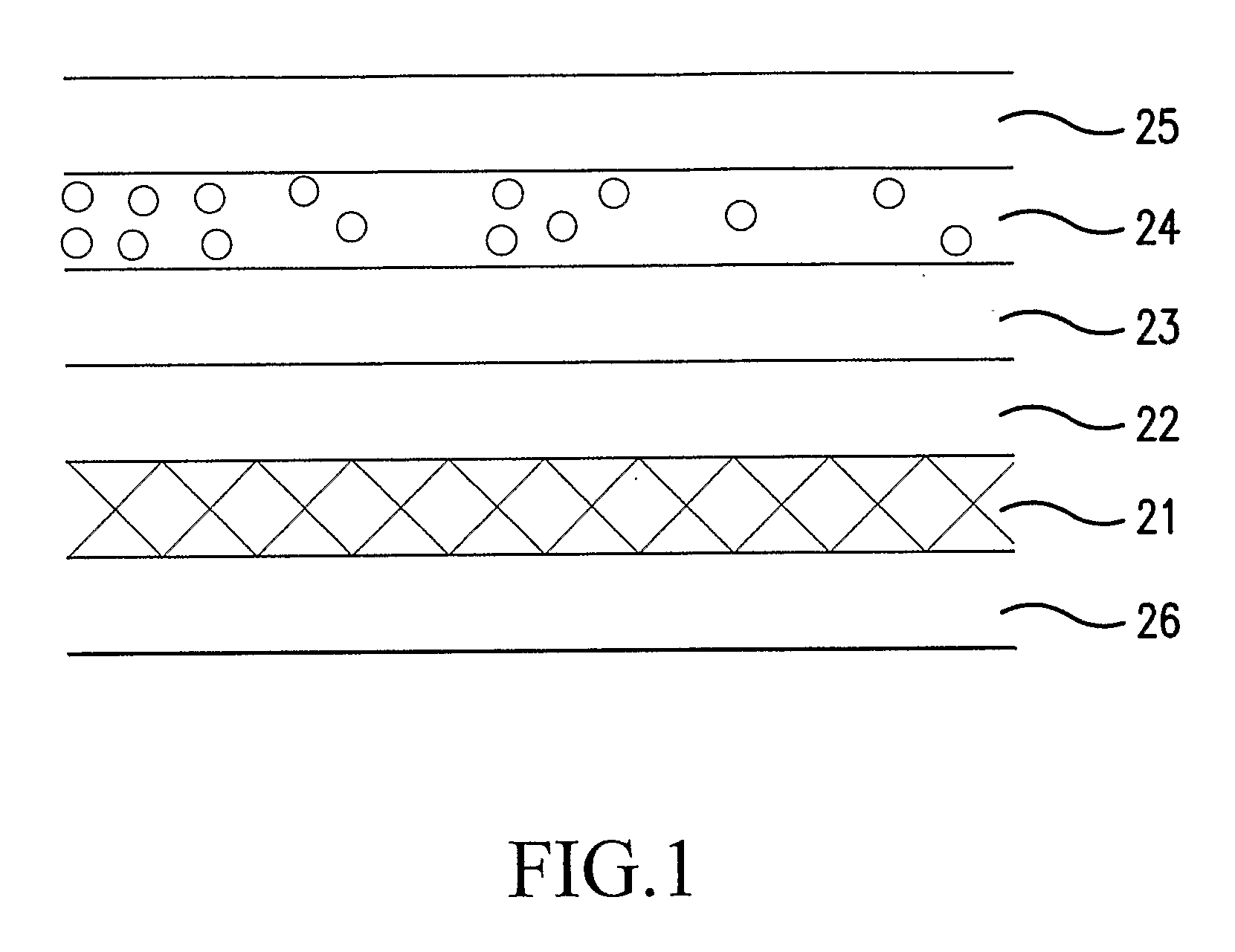

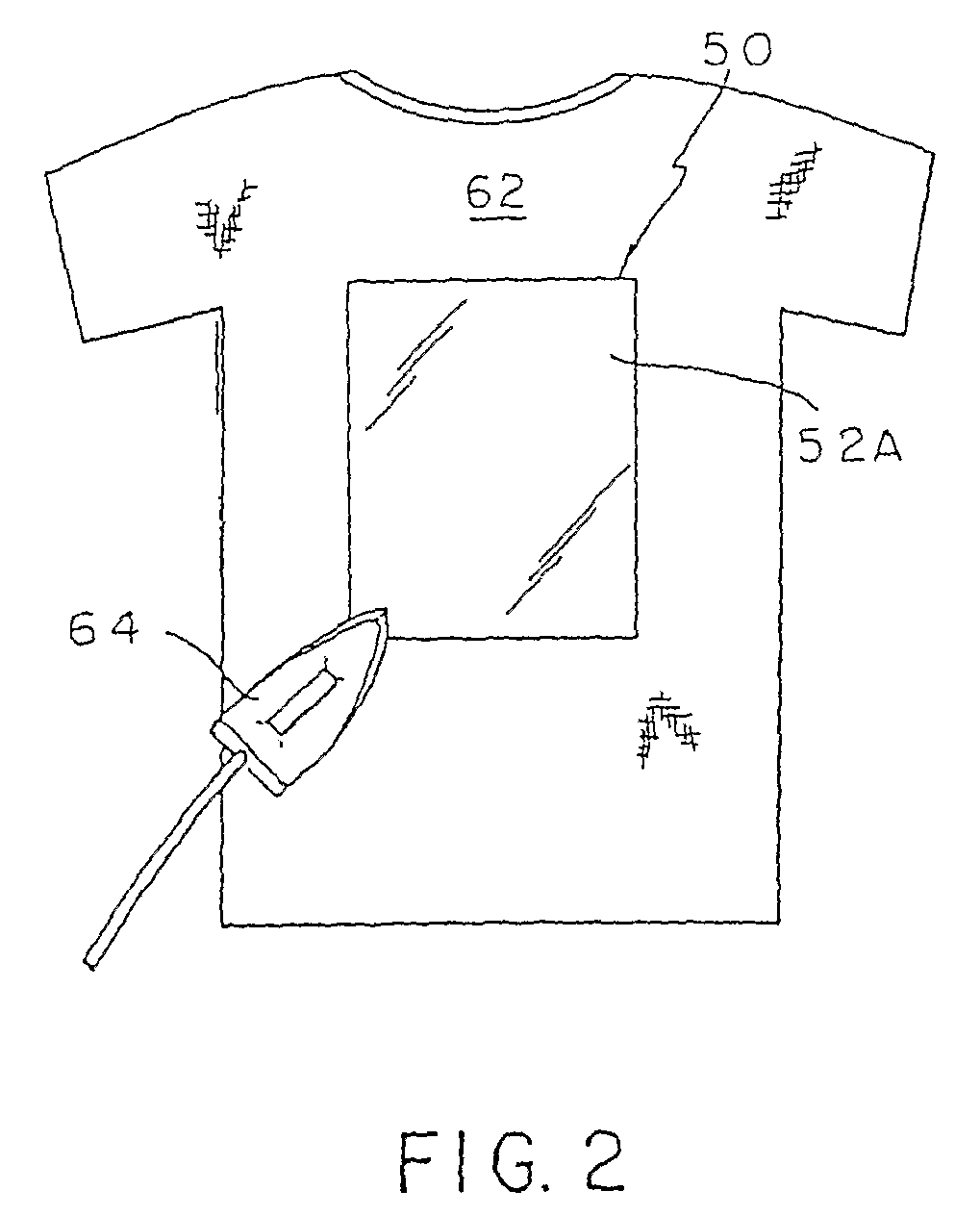

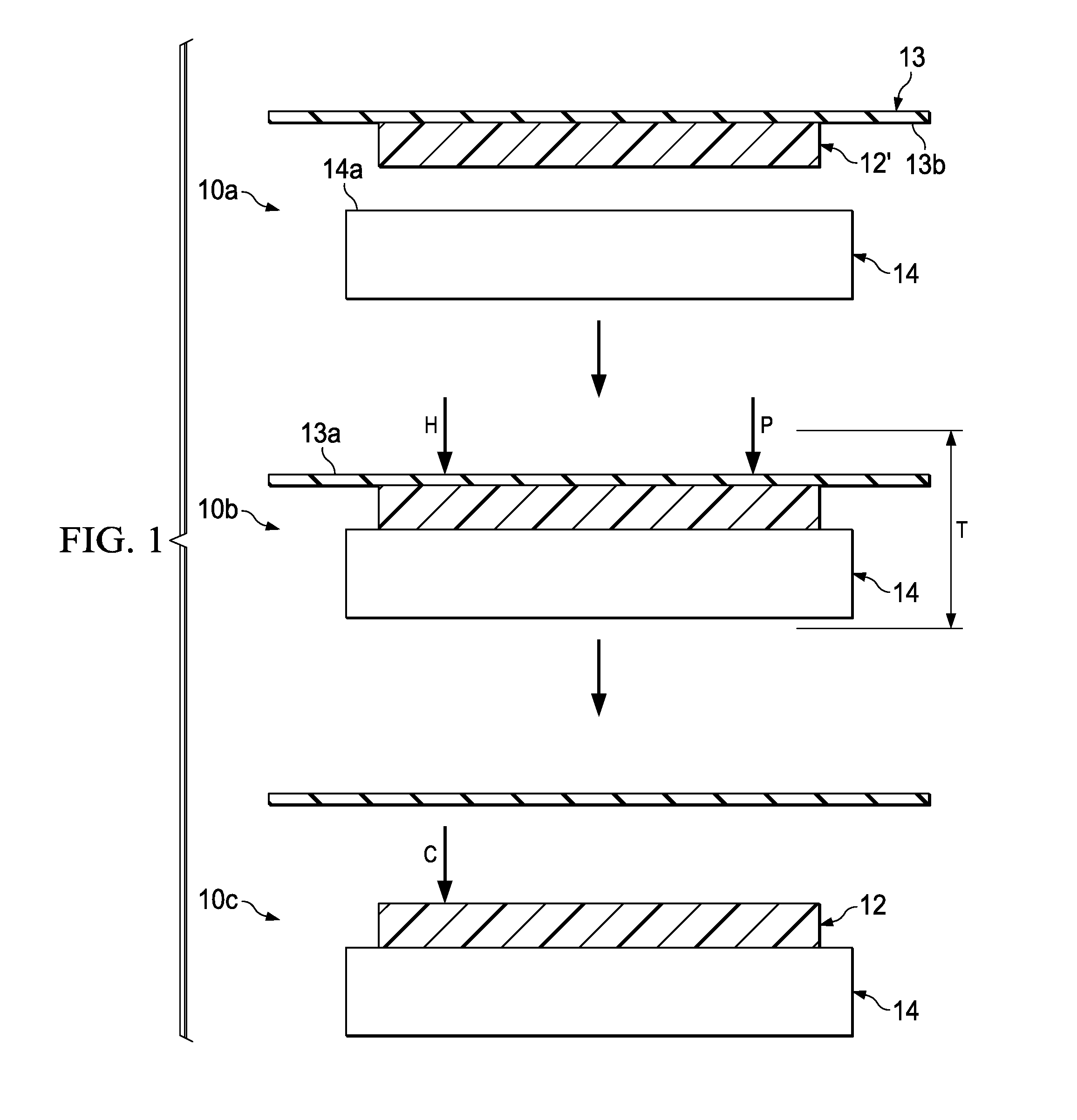

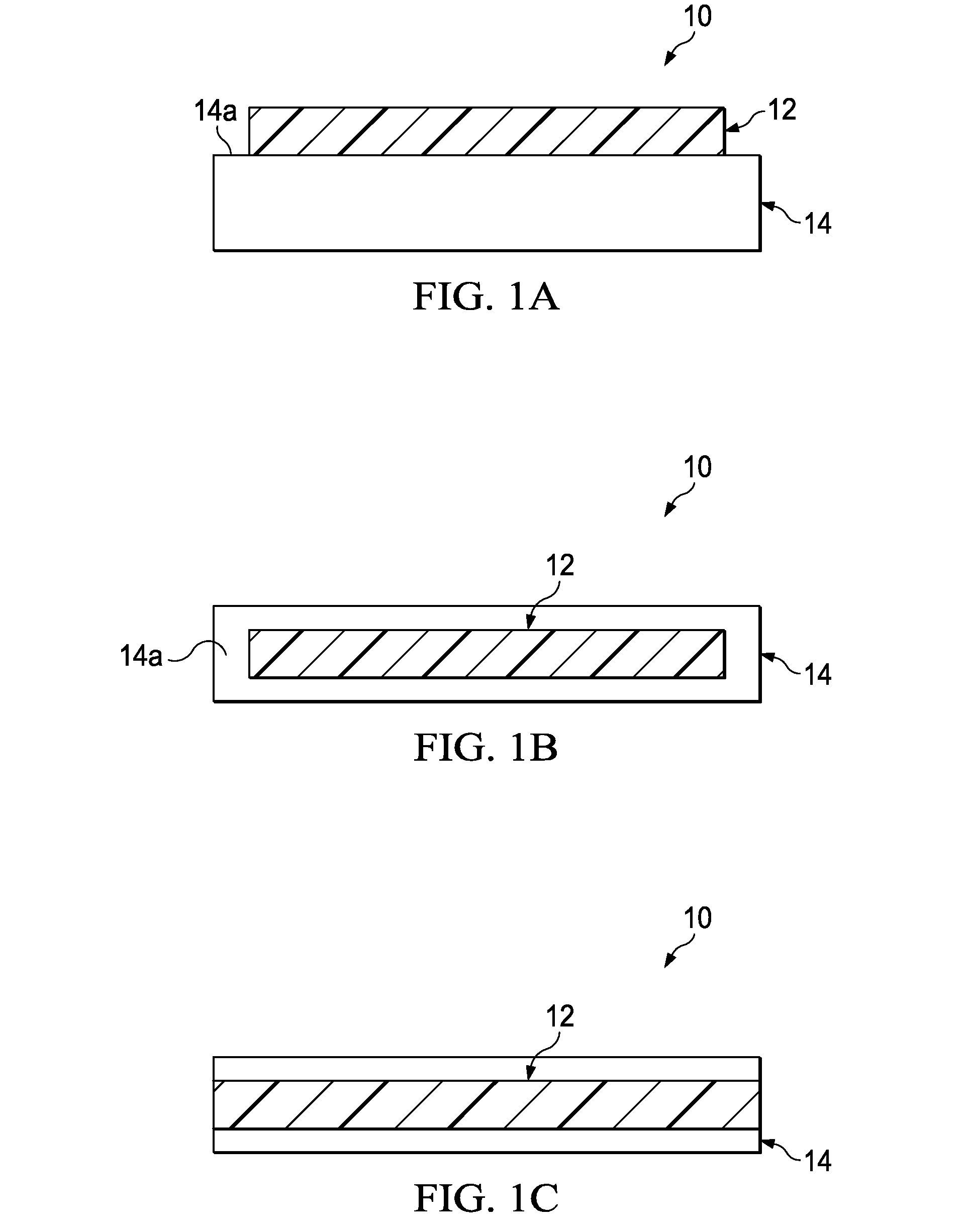

Image transfer sheet with transfer blocking overcoat and heat transfer process using the same

InactiveUS6849312B1Cost efficientReduction of the polymer haloDecorative surface effectsSynthetic resin layered productsImage transferBiochemical engineering

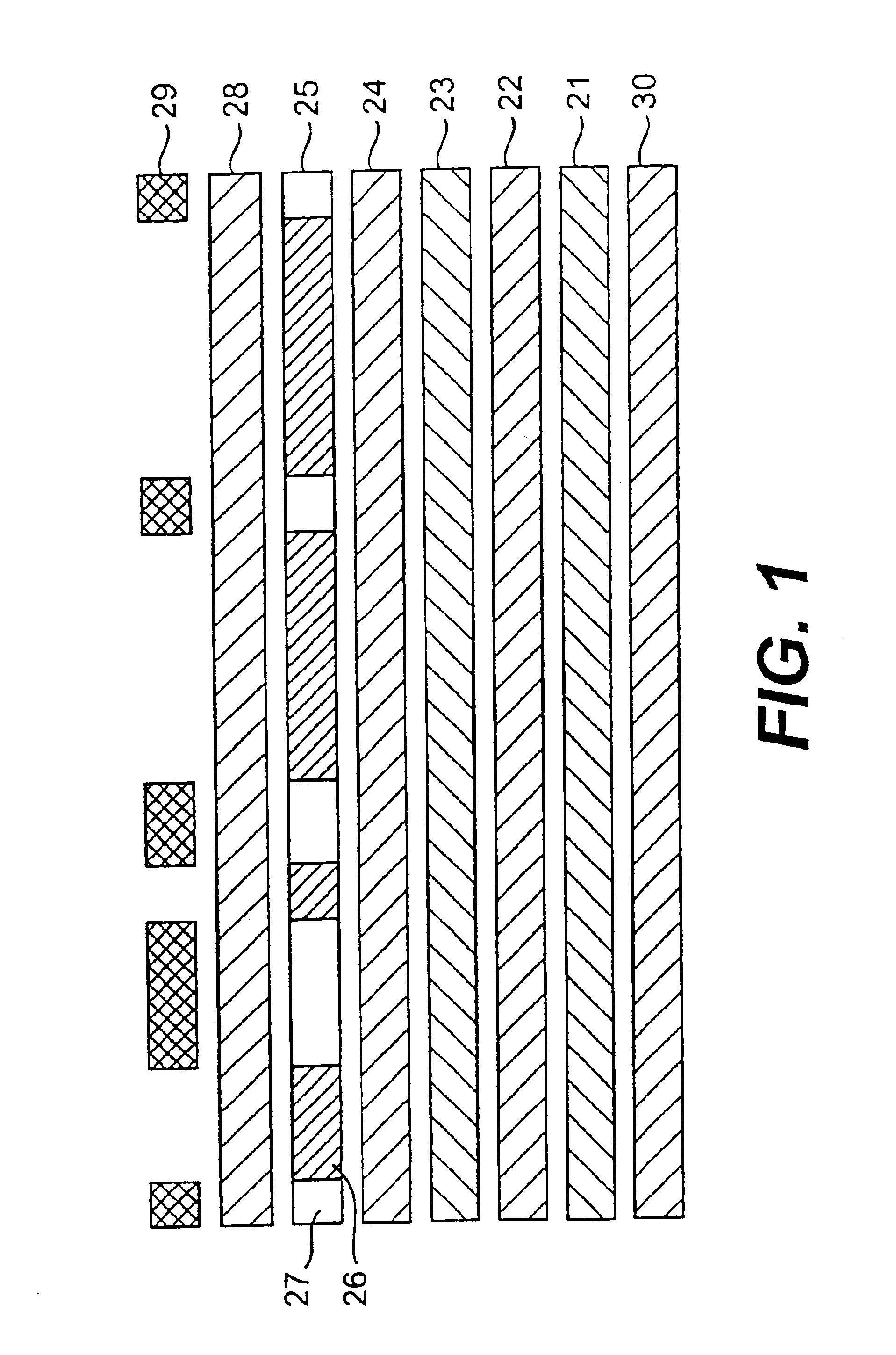

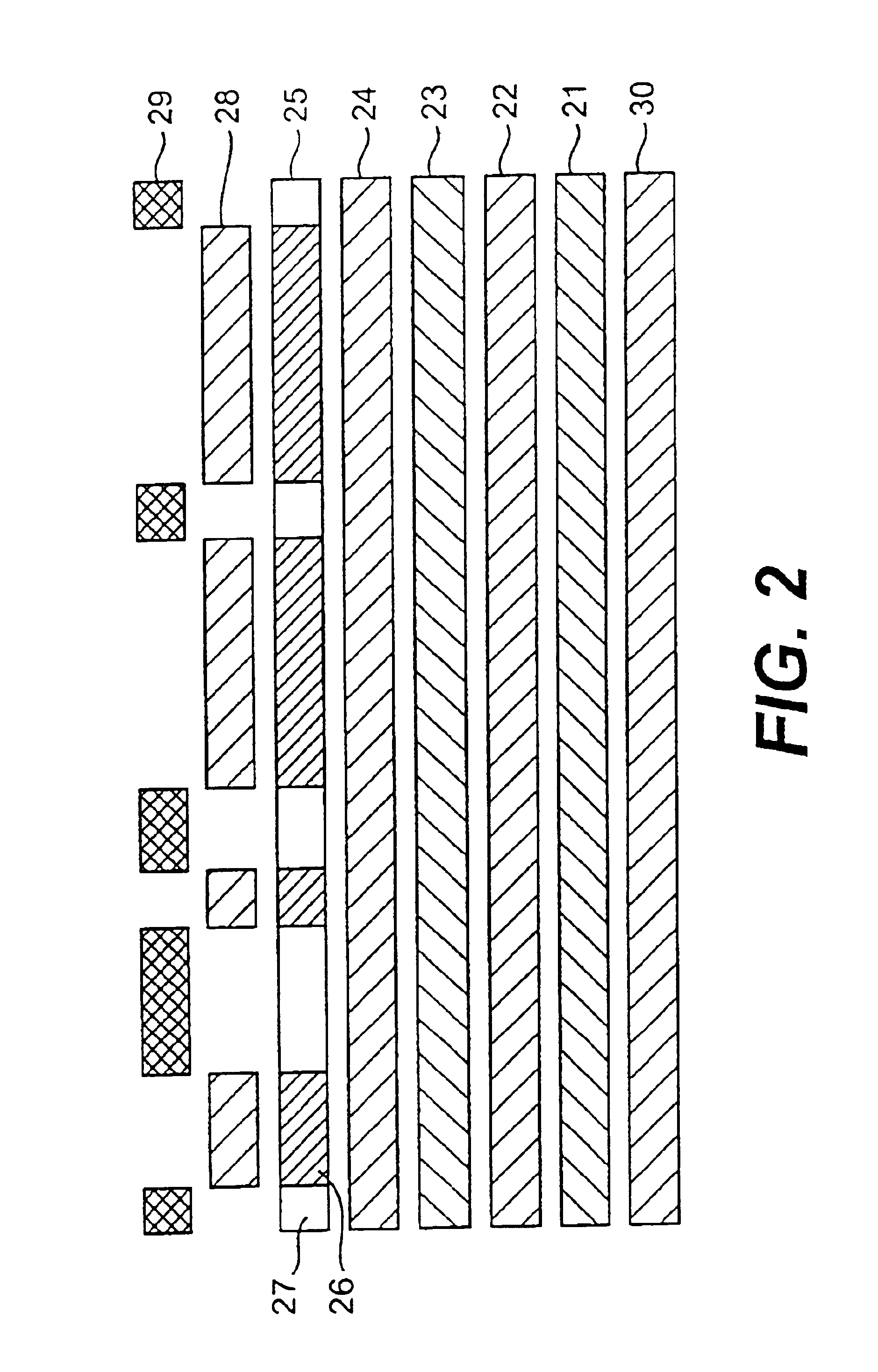

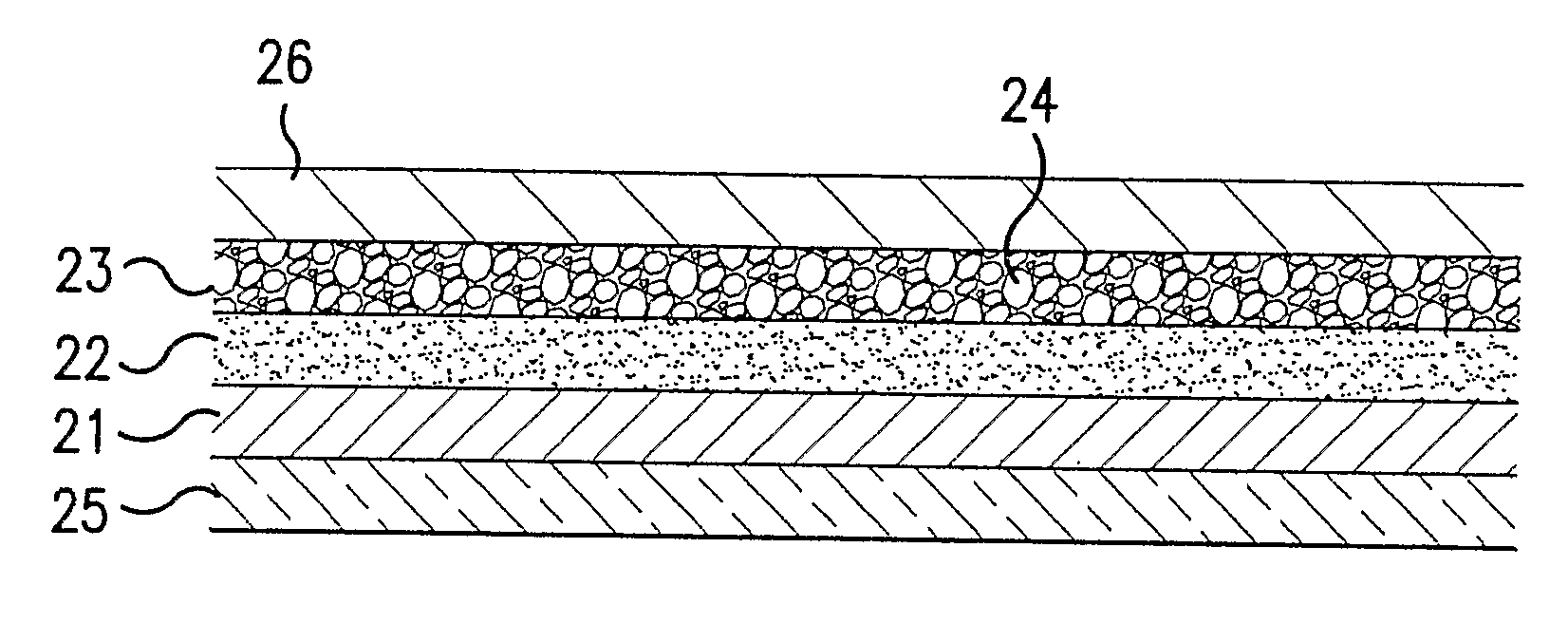

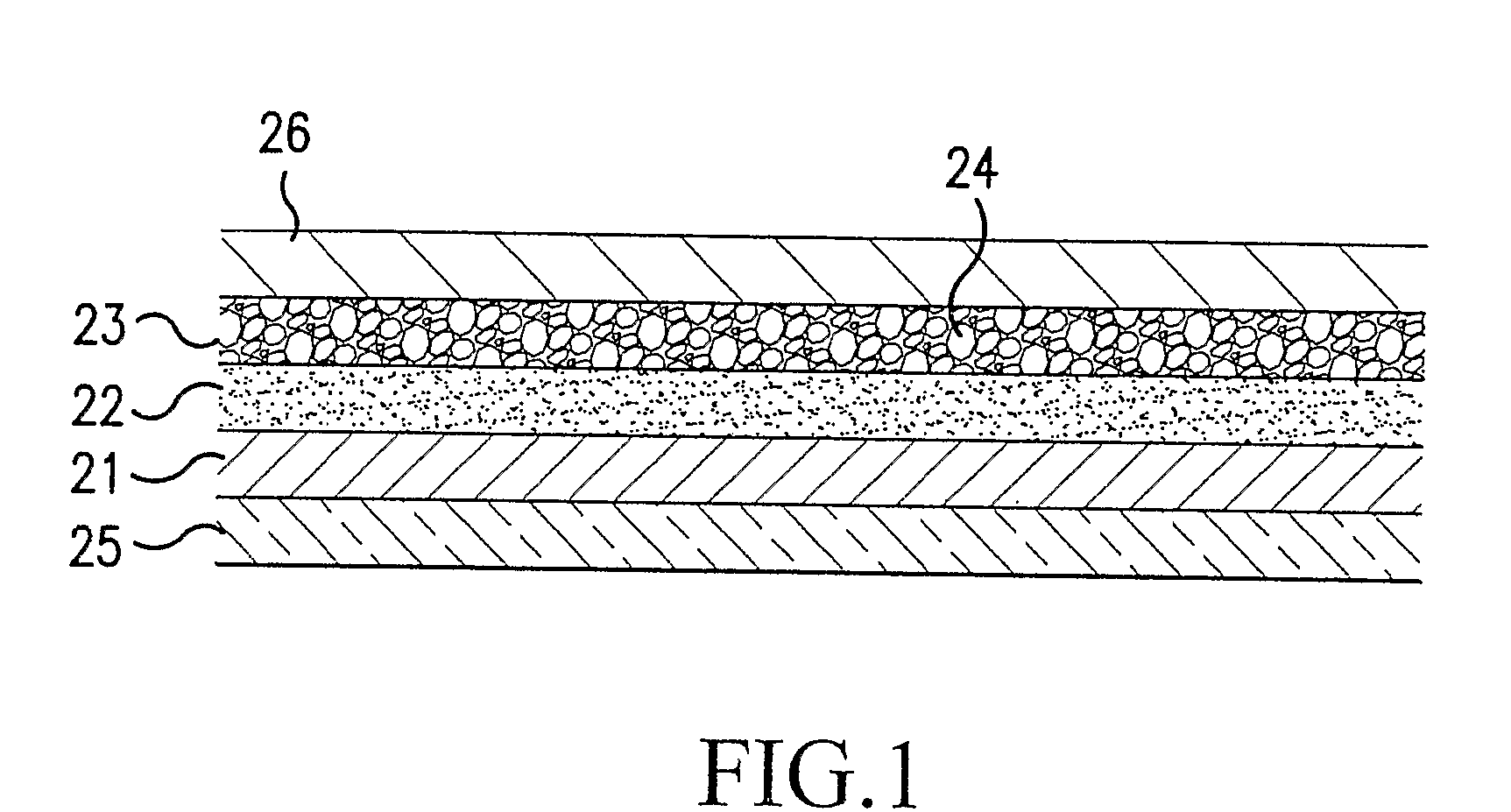

An image transfer sheet, having a support sheet, an optional barrier layer on the support sheet, a heat release layer on the optional barrier layer or on the support sheet, an optional image-receiving layer on the heat release layer, a design layer having image and non-image areas on the optional image-receiving layer on the heat release layer, an optional non-water-dispersible polymer layer on the design layer, and a transfer blocking overcoat layer on the optional polymer layer or the design layer, is used in a dry heat transfer process to transfer an image area to a receptor.

Owner:SCHWENDIMANN JODI

Image transfer material and heat transfer process using the same

Provided is an image transfer material, comprising an optional support material, and a non-woven or woven fiber web layer, wherein the fiber web is impregnated or coated with a image receiving formulation. The fiber web layer is optionally attached to the support with an adhesion layer. Also provided is a heat transfer process wherein after imaging, the fiber web and adhesion layer are peeled from the optional support material and placed, preferably image side up (when imaged), on top of a receptor element. Alternatively, the fiber web and adhesion layer are peeled and then optionally imaged prior to being placed on the receptor element. Then, an optional non-stick sheet is placed over the imaged fiber web (if placed imaged side up) and heat is applied to the fiber web or the non-stick sheet, if present. The adhesion layer then melts and adheres the imaged web layer to the receptor element.

Owner:SCHWENDIMANN JODI

Image transfer material with image receiving layer and heat transfer process using the same

InactiveUS6869910B2Cost efficientDecorative surface effectsAblative recordingWater dispersiblePrecipitated calcium carbonate

An image transfer sheet, having a support sheet, an optional barrier layer on the support sheet, at least one heat release layer on the optional barrier layer or on the support sheet, an image receiving layer on the heat release layer, an optional image layer on the image receiving layer, an optional non-water-dispersible polymer layer on the image layer, and an optional transfer blocking overcoat layer on the optional polymer layer or the image layer, is used in a dry heat transfer process to transfer an image to a receptor element. The image receiving layer of the present invention is a precipitated calcium carbonate (PCC)-containing image receiving layer, a polyvinylpyrrolidone (PVP)-containing image receiving layer, or an image receiving layer containing both PCC and PVP (PCC / PVP).

Owner:SCHWENDIMANN JODI

Thermally coupled monolith reactor

InactiveUS20070009426A1Easy to useMaximize heat transferCatalytic gas-gas reactionPhysical/chemical process catalystsChemical treatmentGas phase

The invention comprises, in one form thereof, a chemical processing method to thermally contact an endothermic and an exothermic reaction without mixing the two streams, utilizing a thermally coupled monolith reactor (TCMR). A ceramic or metal monolith is modified to produce a structure containing at least two sets of discrete flow paths and which are separated by a number of common walls. Manifolds are arranged such that one reaction mixture flows through one set of channels and a different reaction mixture flows through the second. Catalytic material, which is active for the relevant reaction, is coated onto the inner walls of each of the sets of channels. The two reactions are chosen such that one is exothermic and one is endothermic, such that the energy required by the endothermic process is supplied directly through the dividing wall from the exothermic process occurring on the opposing side. This method of heat transfer completely decouples the gas phase hydrodynamics from the heat transfer process.

Owner:ZEROPOINT CLEAN TECH

Image transfer material and polymer composition

InactiveUS20070172609A1Raise transfer toDecorative surface effectsTransfer printing processImage transferCrosslinked polymers

Provided is an image transfer material, comprising a support, optionally at least one barrier layer, a melt transfer layer, and an image receiving layer. Also provided is a process for preparing the image transfer material. Further provided is a heat transfer process using the disclosed material. In the heat transfer process, after imaging, the image receiving layer and melt transfer layer are peeled away from the optionally barrier-coated support material and placed, preferably image side up, on top of a receptor element. A non-stick sheet is then optionally placed over the imaged peeled material and heat is applied to the top of the optional non stick sheet. The melt transfer layer then melts and adheres the image to the receptor element. A composition comprising: at least one self-crosslinking polymer; and at least one dye retention aid.

Owner:SCHWENDIMANN JODI

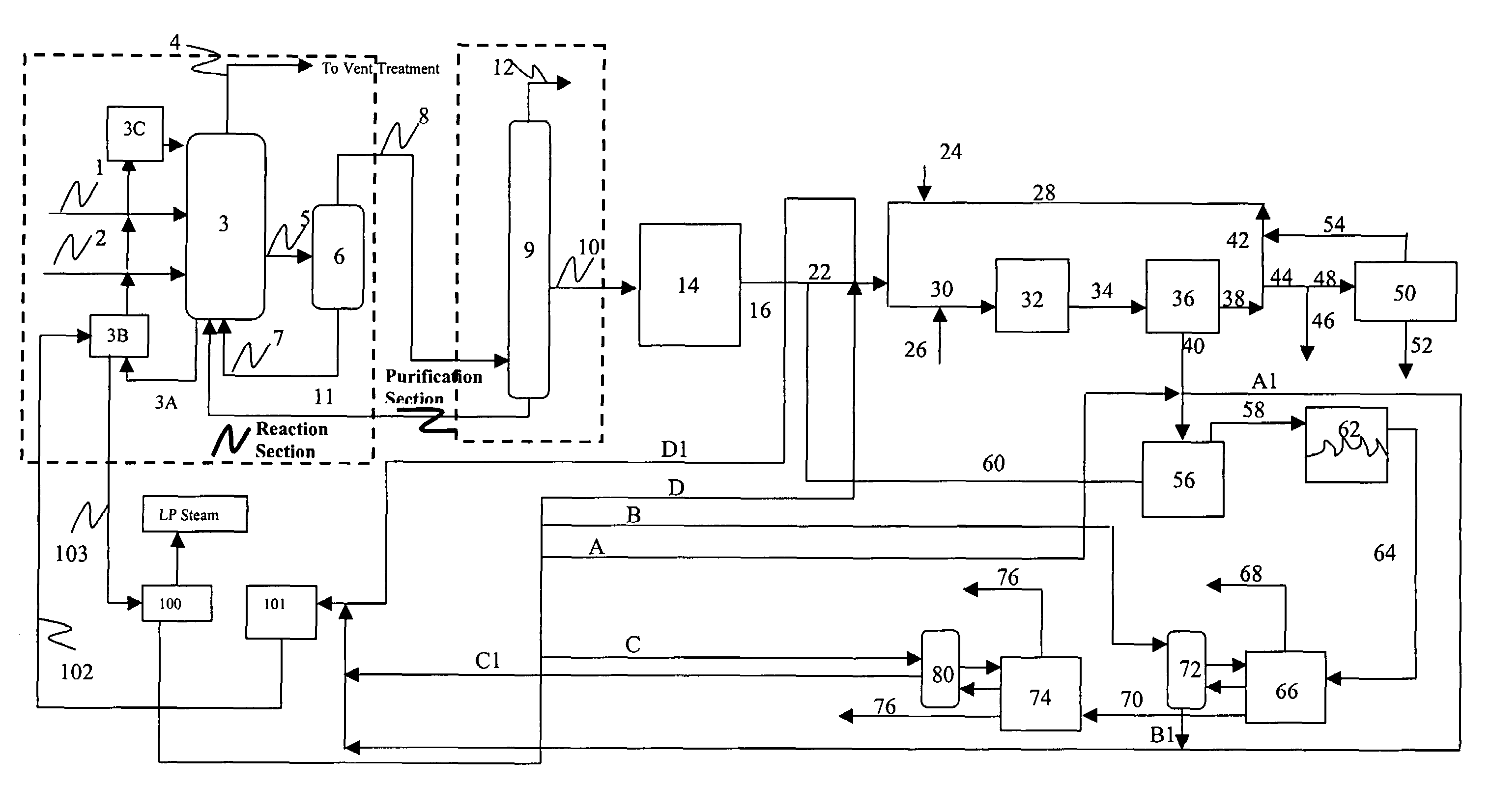

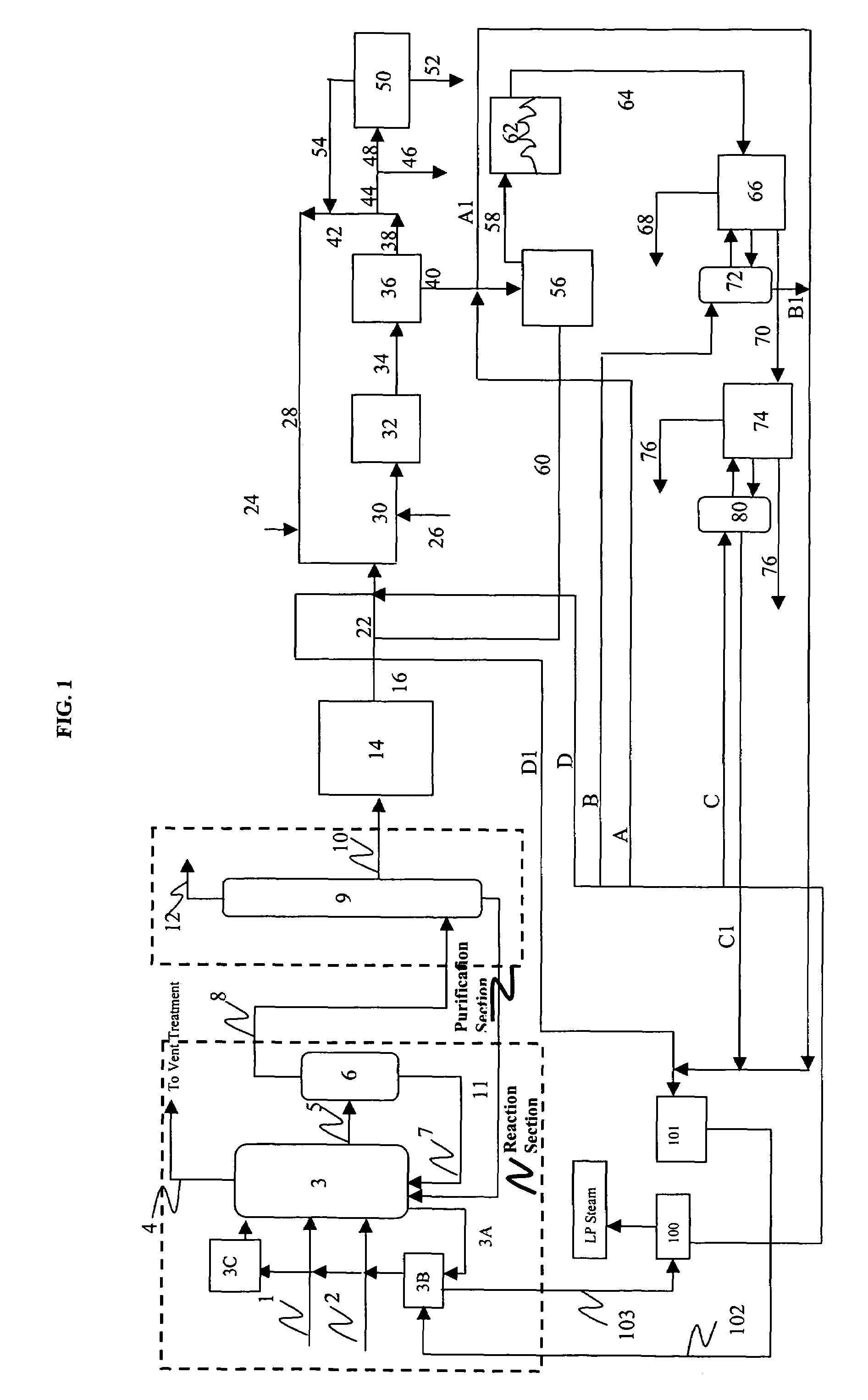

Utilization of acetic acid reaction heat in other process plants

InactiveUS7465823B2Save energy and costOrganic compound preparationChemical industryAcetic acidProcess plant

Owner:CELANESE INT CORP

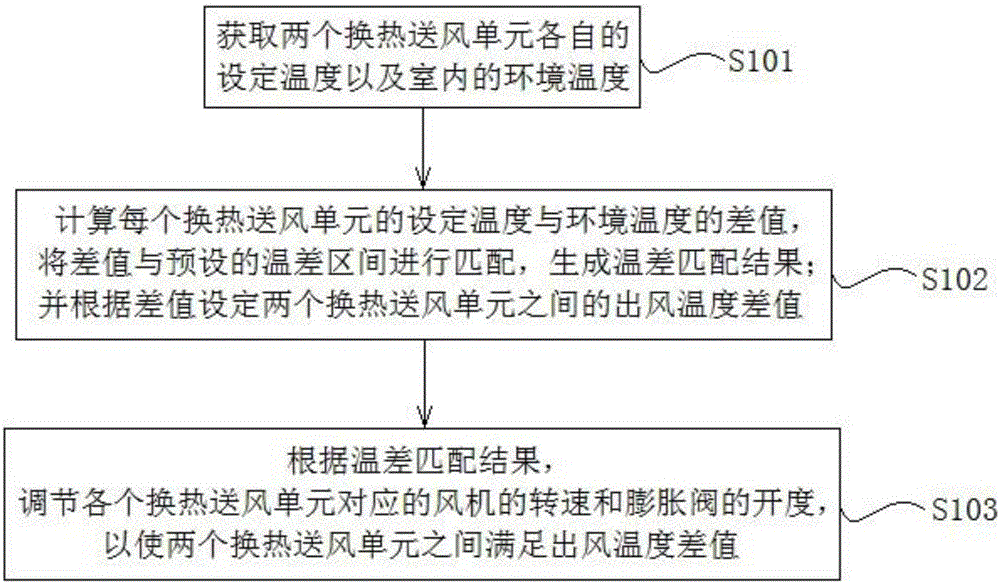

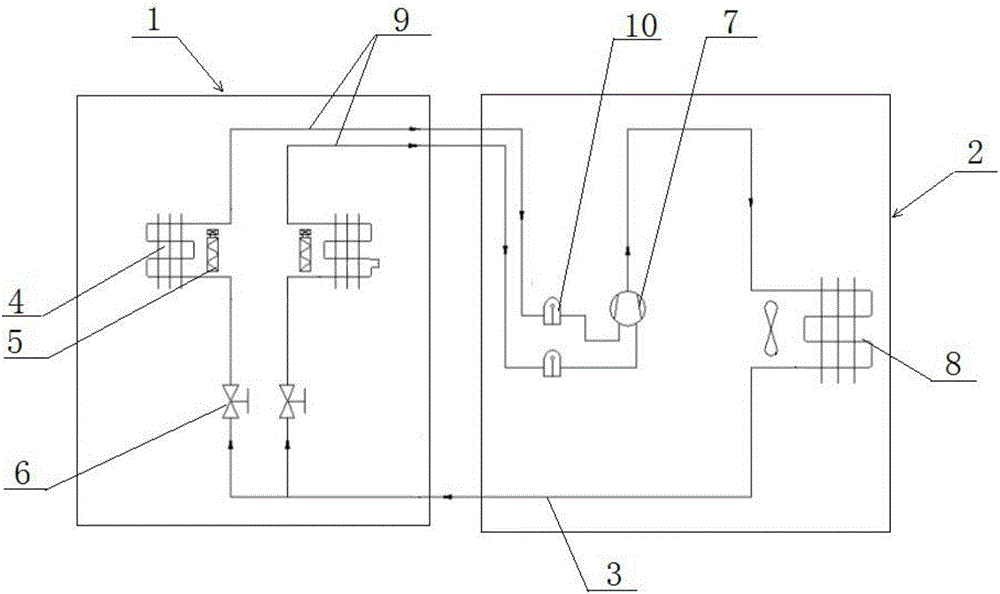

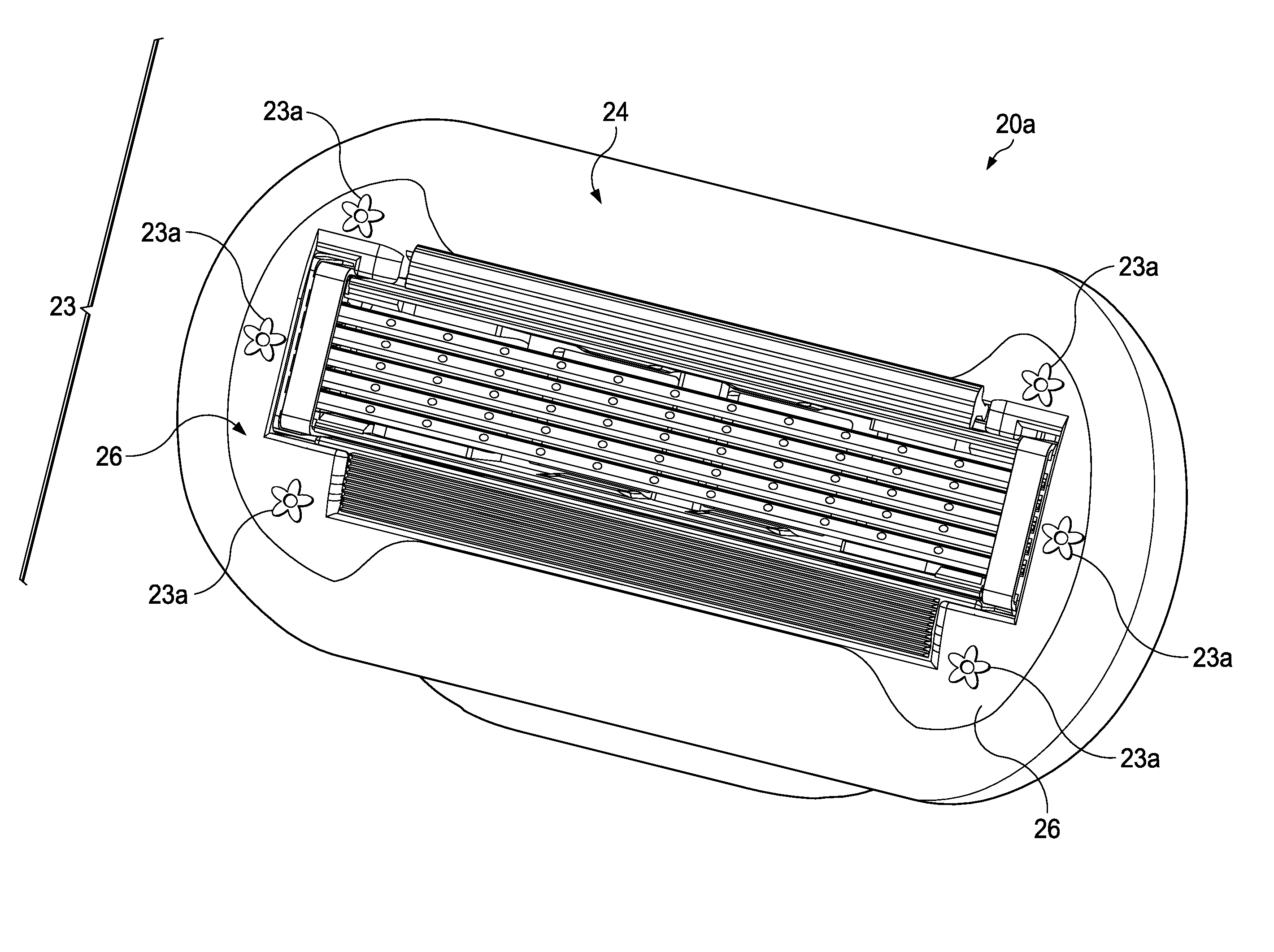

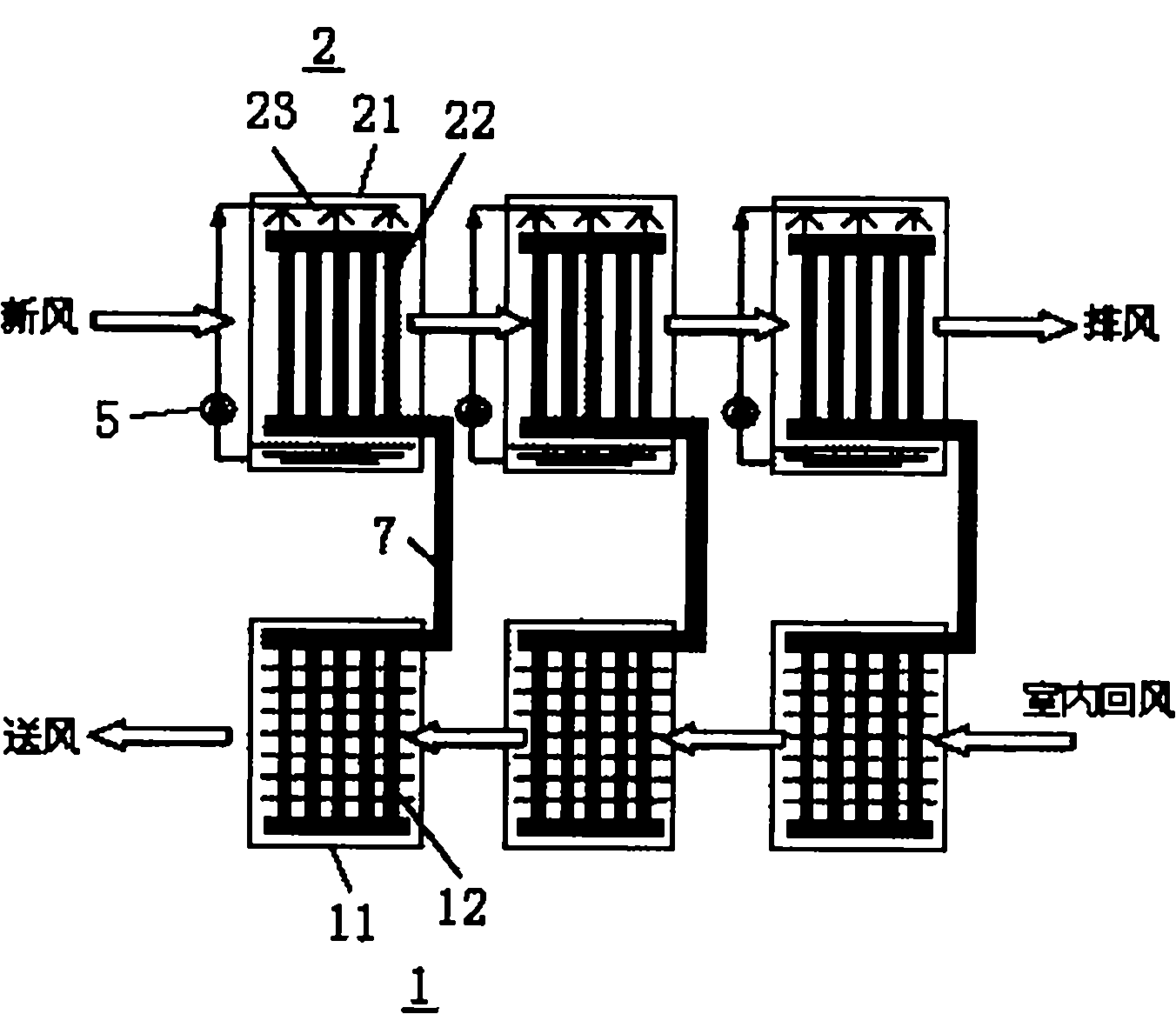

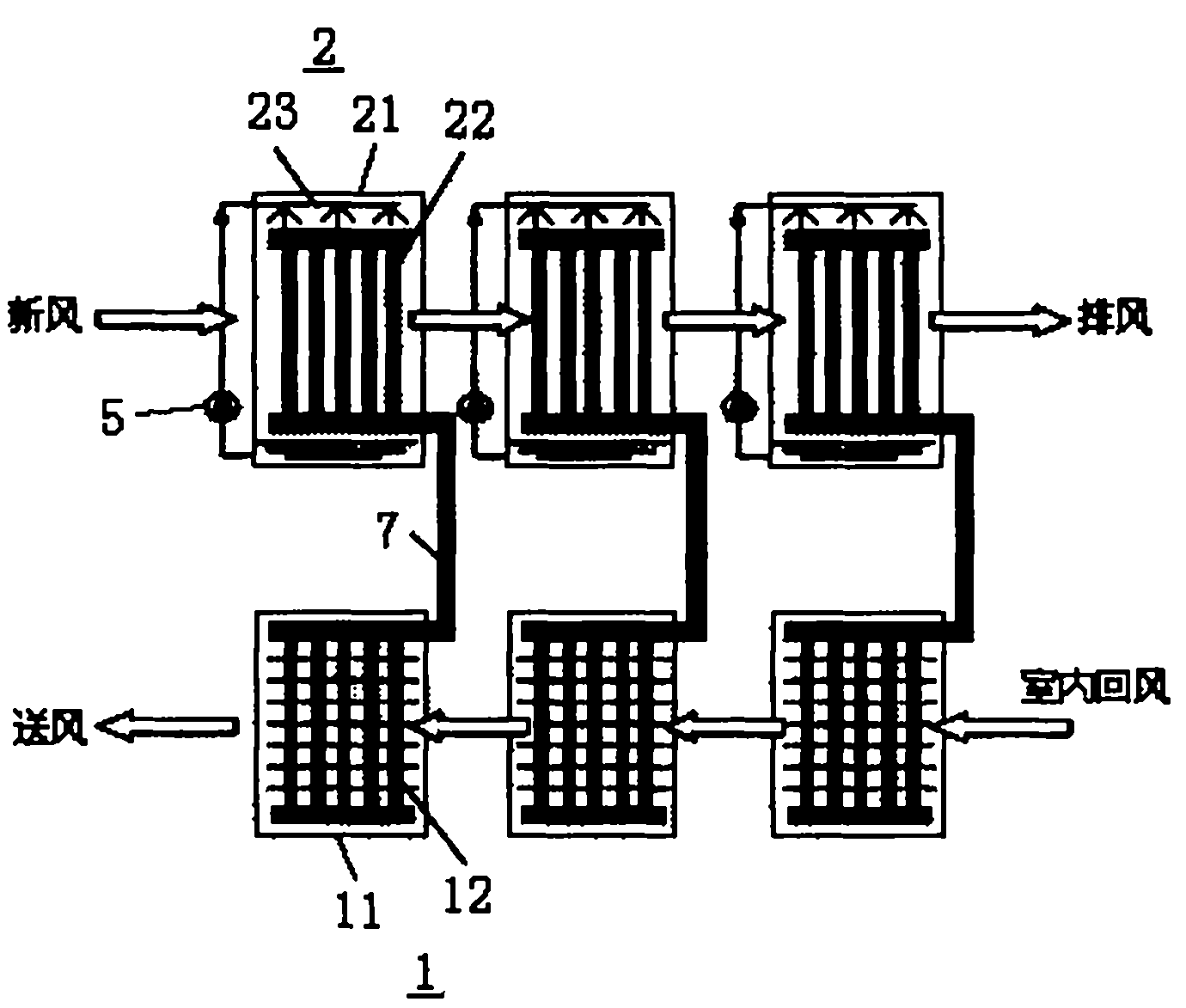

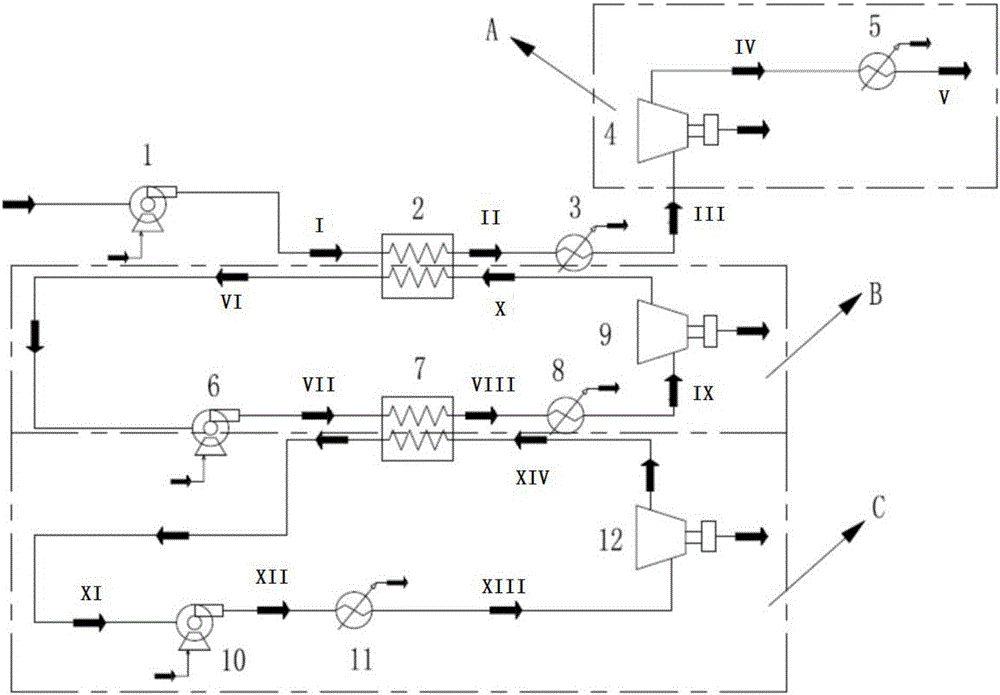

Controlling method and device used for air-conditioners and air-conditioners

ActiveCN106352470AEasy to useAvoid large air temperature differenceMechanical apparatusSpace heating and ventilation safety systemsTemperature differenceProcess engineering

The invention discloses a controlling method and device used for air-conditioners and air-conditioners. The controlling method comprises the steps of obtaining the set temperatures of the two heat-transferring and air supplying units respectively and an indoor environment temperature, calculating the temperature difference value between every heat-transferring and air supplying unit and the environment temperature, matching the difference value with the preset temperature difference interval and generating results of temperature difference matching; according to the temperature difference value, setting an air-out temperature difference between the two heat-transferring and air supplying units; according to the results of temperature difference matching, adjusting the rotate speed of the draught fan and the opening of the expansion valve which are corresponding to the two heat-transferring and air supplying units, so that an air-out temperature difference between the two heat-transferring and air supplying units can be satisfied. The controlling method used for air-conditioner can adjust the expansion valve and the air speed of the heat-transferring and air supplying units which supply air to various zones, satisfy the different setting temperatures of the heat-transferring and air supplying units, and in the meanwhile, the controlling method avoids excessive air-out difference values during the heat-transferring process, enables the air-supplying process to be more stable, and improves the user experience.

Owner:QINGDAO HAIER AIR CONDITIONER GENERAL CORP LTD

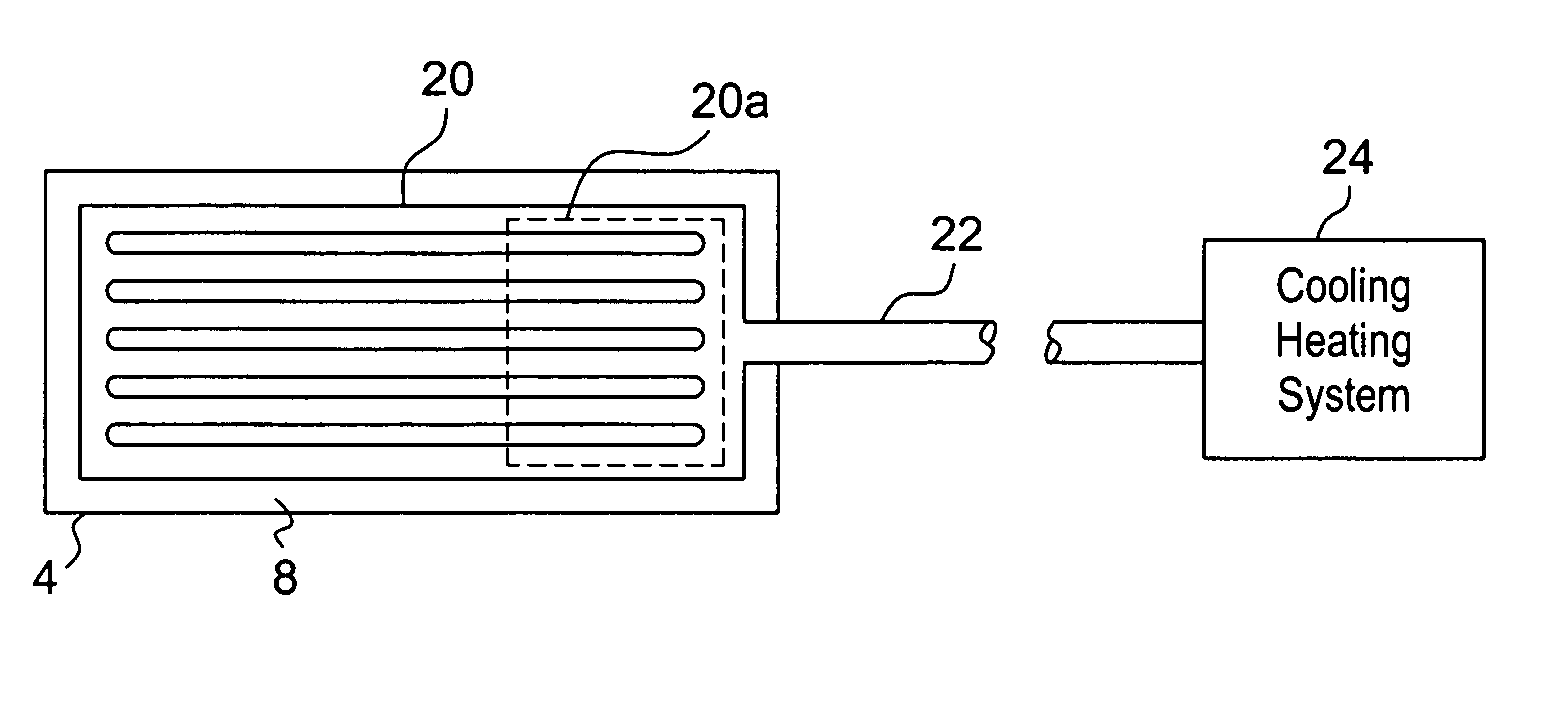

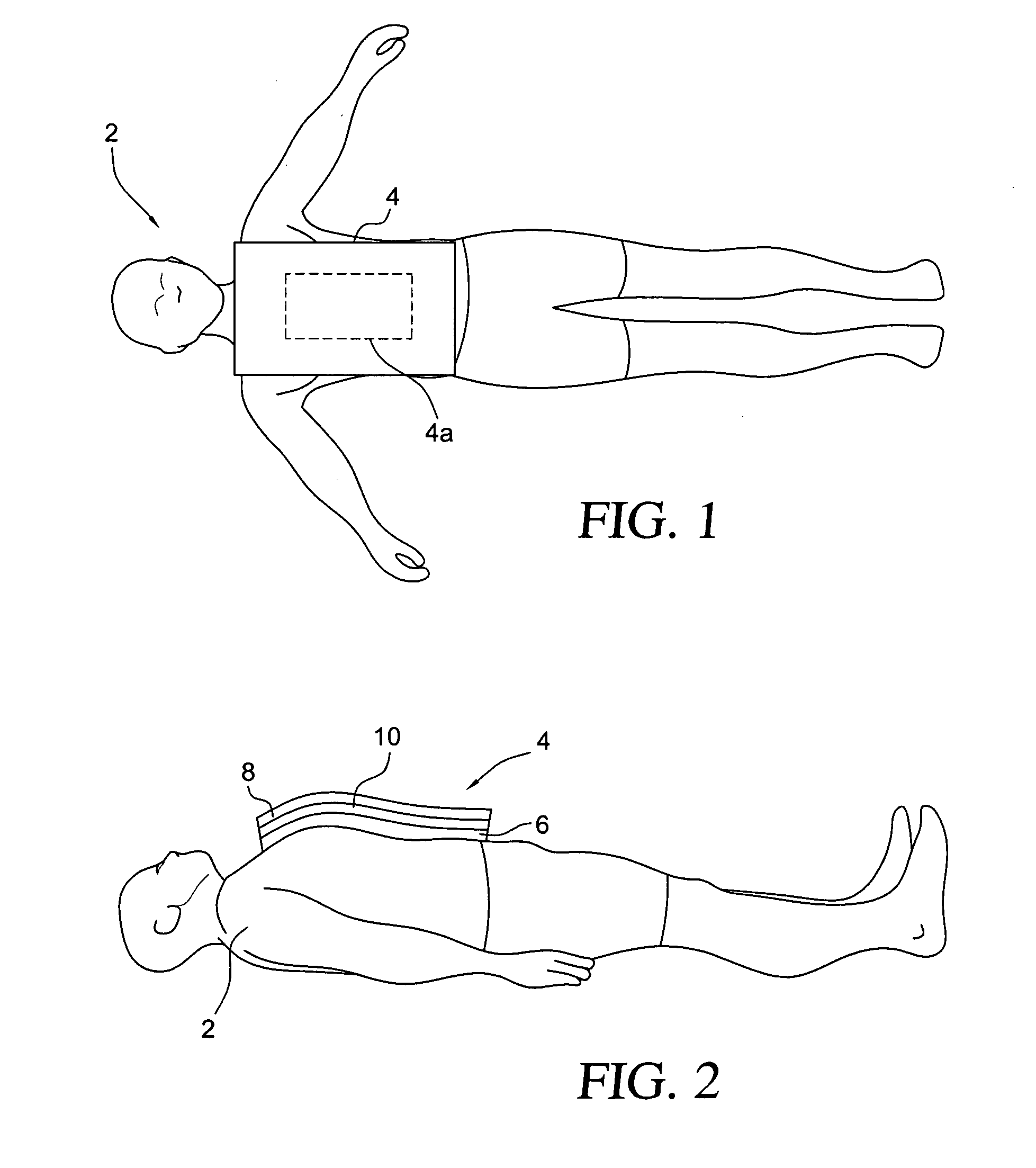

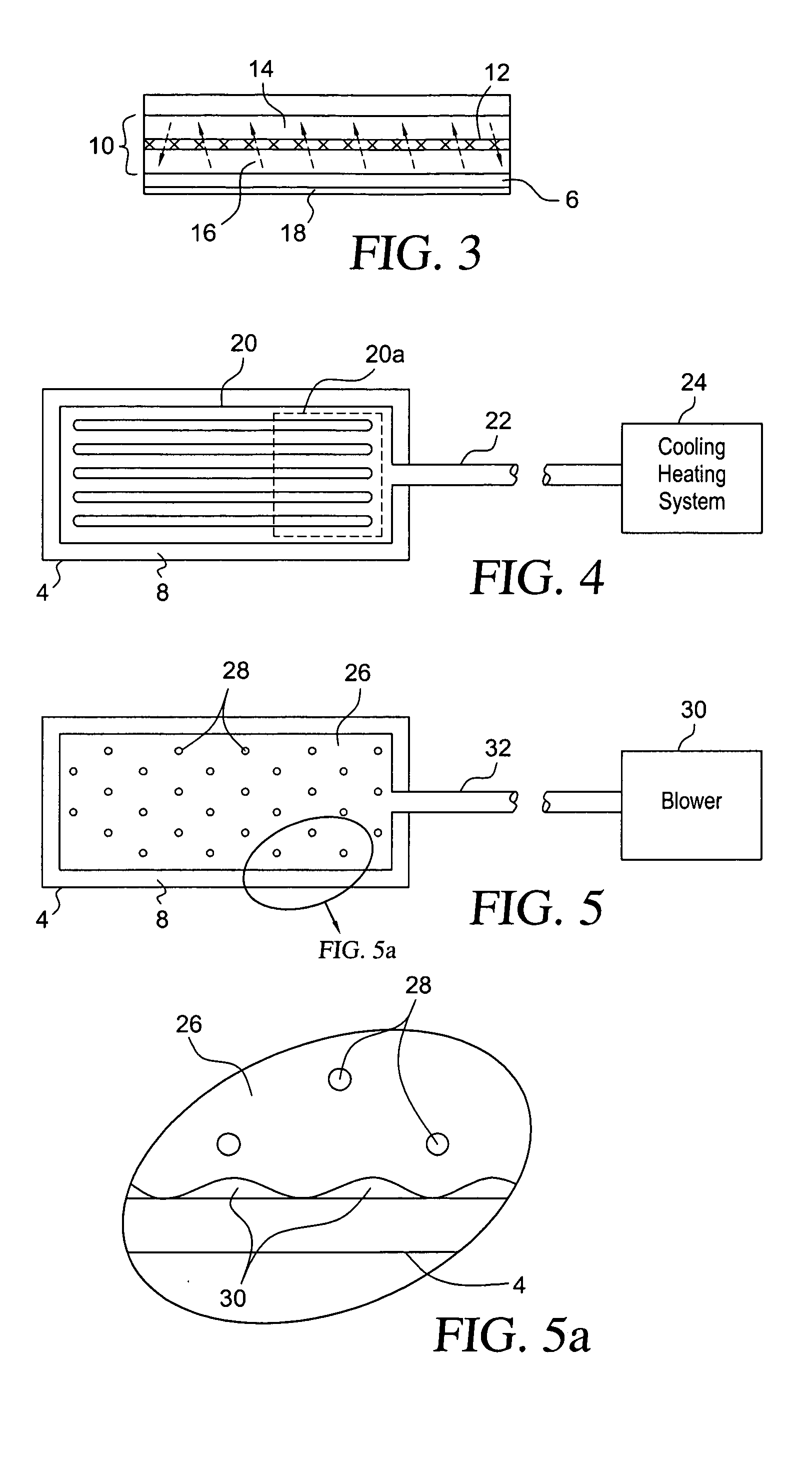

Patient heat transfer device

InactiveUS20090228082A1Controlled and rapid induced hypothermiaQuick controlIndirect heat exchangersTherapeutic coolingLiquid stateMedicine

To rapidly induce hypothermia to a patient, in the event the patient has a stroke, hyperthermia or some other temperature related heath problems which requires prompt action to regulate the temperature of the patient, a flat flexible structure conformable to the body of the patient is placed into contact with the patient. The structure has at least two heat transfer portions. One of heat transfer portions is positioned in contact with the body of the patient. The structure is hermetically sealed and a fluidized medium responsive to temperature change is provided in the structure between the heat transfer portions. The fluid is changeable between a liquid state and a gaseous state, when it is exposed to heat and cold. The heat absorbed by the heat transfer portion in contact with the patient is carried by the fluidized medium, as latent heat in the gas that results when the liquid is vaporized to its gaseous state, to the heat transfer portion layer not in contact with the patient, so that the latent heat in the gaseous vapor is dissipated. Upon dissipation, the gaseous vapor is condensed and the fluidized medium returns to its liquid state. The structure may be formed from a flat flexible heat pipe and may also be configured as a rib cage shaped jacket to embrace the torso of the patient. A cooling circuit or mechanism may be added to the structure to facilitate the removal of heat therefrom. The structure may also be used to raise the core temperature of a patient.

Owner:SMITHS MEDICAL ASD INC

Erodible Label For Razor Cartridge

A novel razor cartridge is disclosed including at least one erodible label disposed onto at least one exterior surface of at least one razor cartridge component via label transfer technologies (e.g., heat transfer process). The erodible label is comprised substantially of a water soluble polymer (from about 10% to about 100% water soluble polymer by weight of composition), may wear off completely after about 2 to 10 shaves, and may include a plurality of erodible labels each with a different composition. An adhesive layer may be disposed above or below the erodible label. Further, the label may provide functional and / or aesthetic benefits, serve as cues or indicia communicated or obtained to the user before, during or after use of the razor product. In one embodiment, a water droplet label on the lube ring provides moisturization benefits during use and also conveys these benefits to the consumer before use (e.g., lubriciousness).

Owner:THE GILLETTE CO

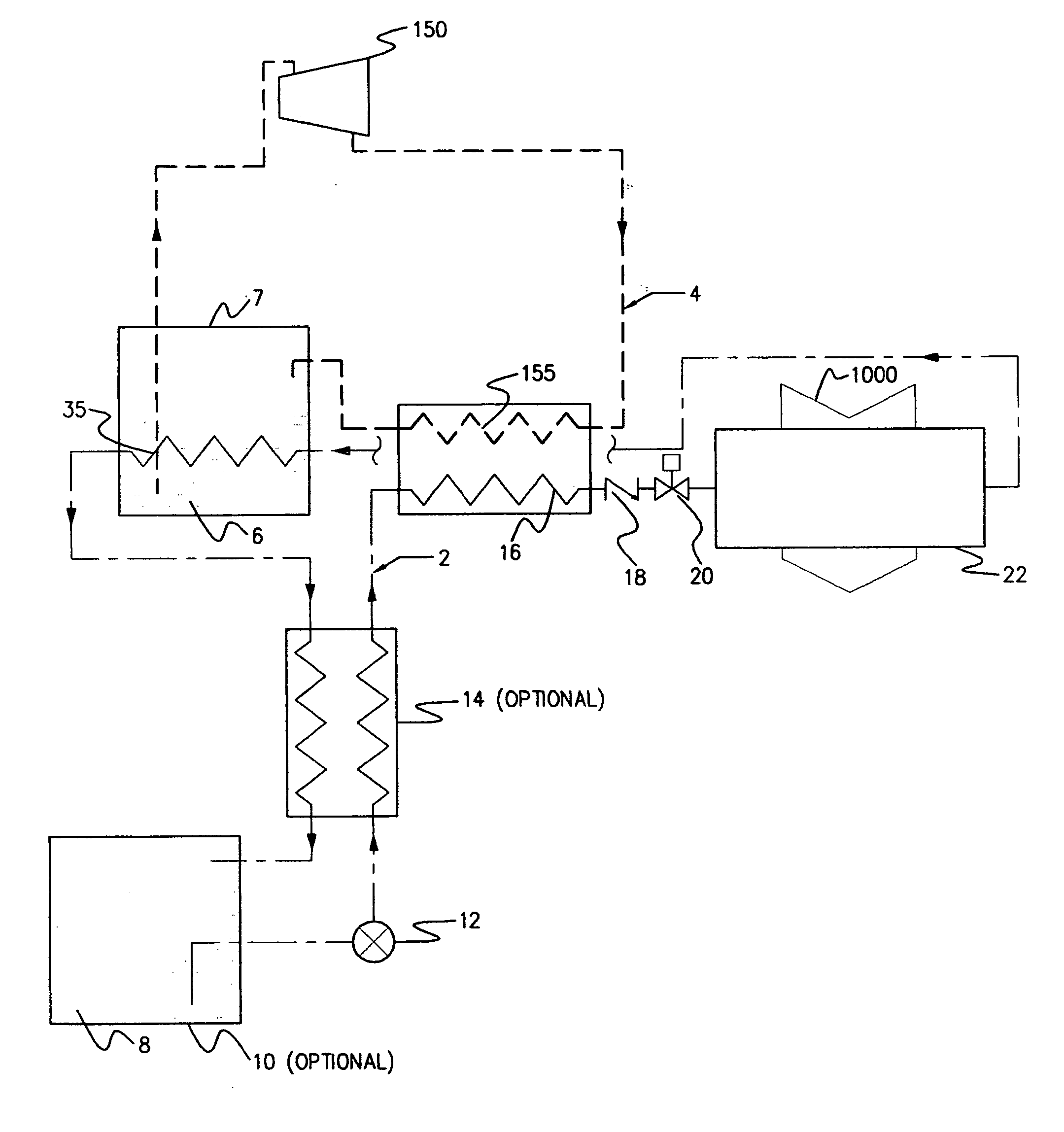

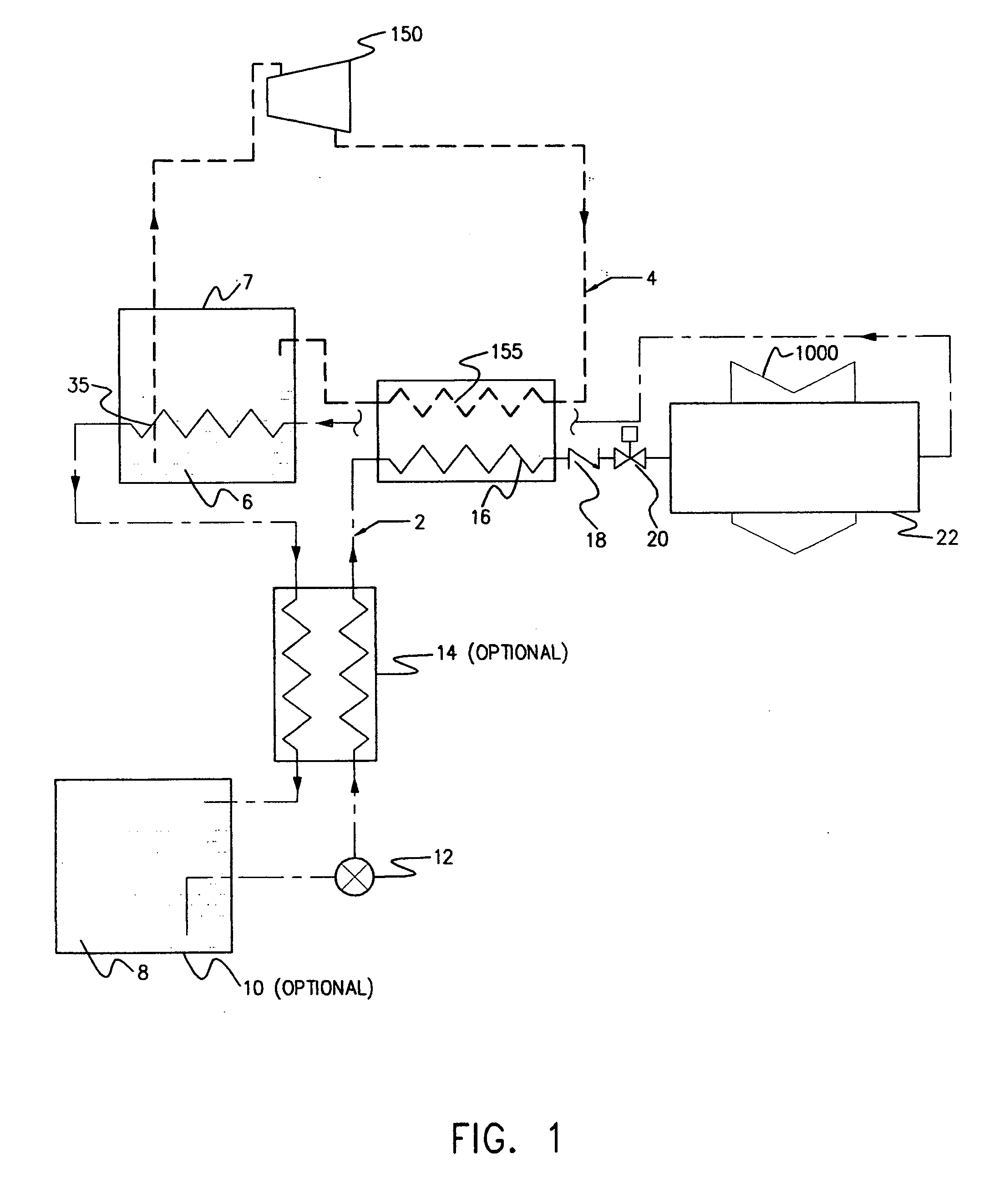

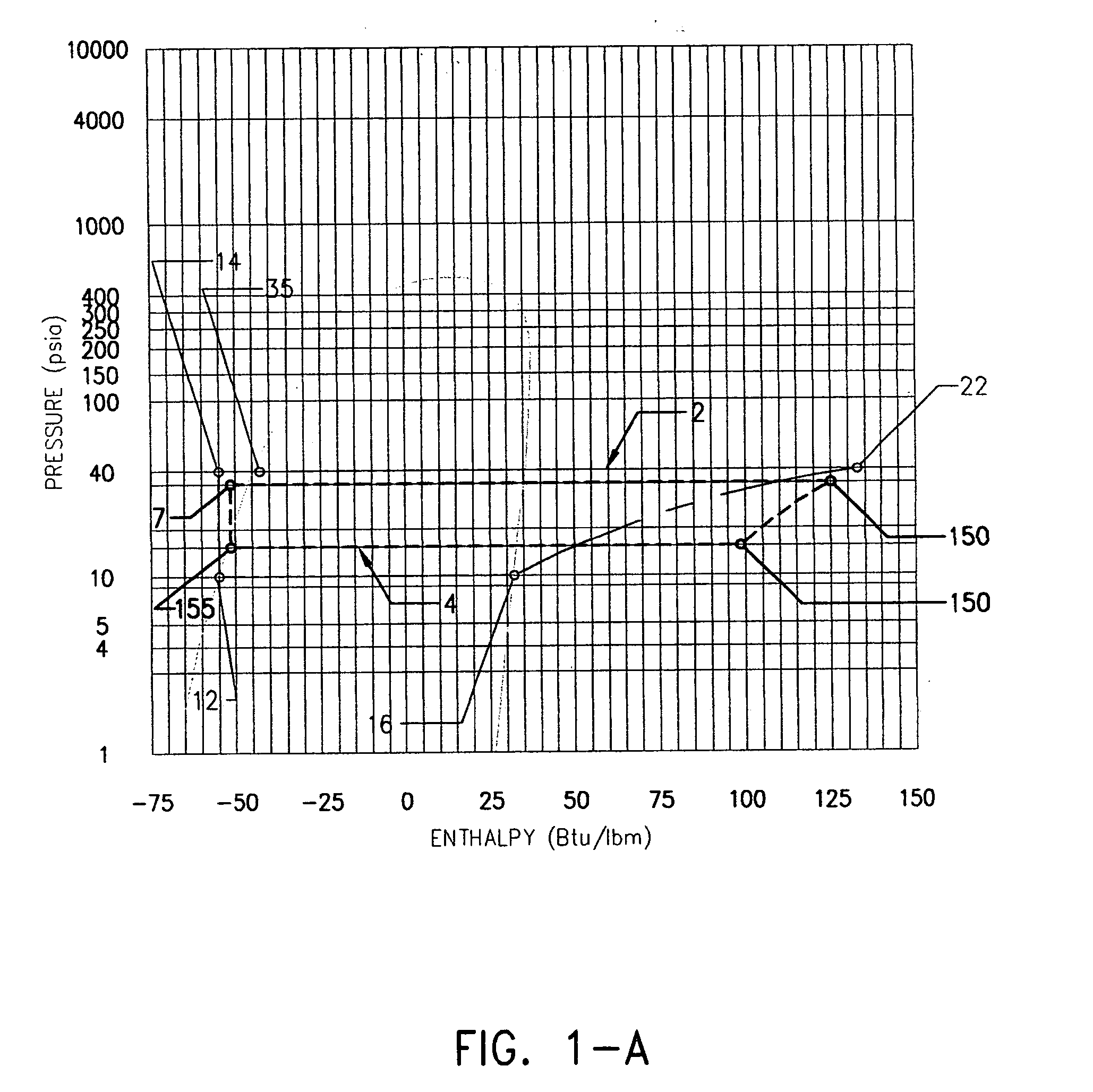

Cryogenic cogeneration system

A cryogenic and thermal source cogeneration method for converting energy from a heat source, through a cryogenic heat transfer process, into mechanical and / or electrical energy, comprising, utilizing a vapor compression cycle (2) to absorb heat from the heat source and, utilizing a Rankine cycle (4) for energy transfer, for converting thermal energy to mechanical and / or electrical energy.

Owner:BLOCK ZINA +1

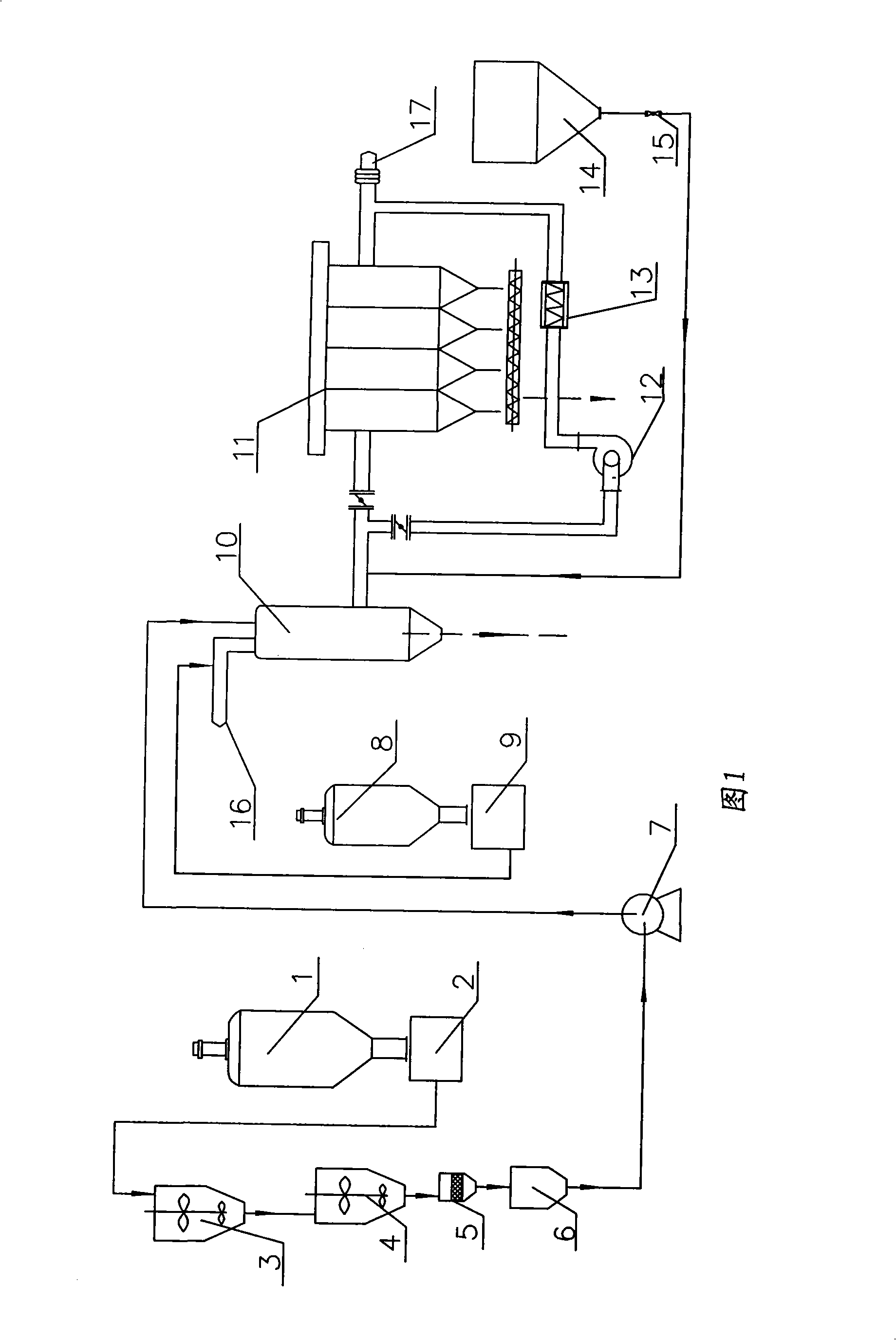

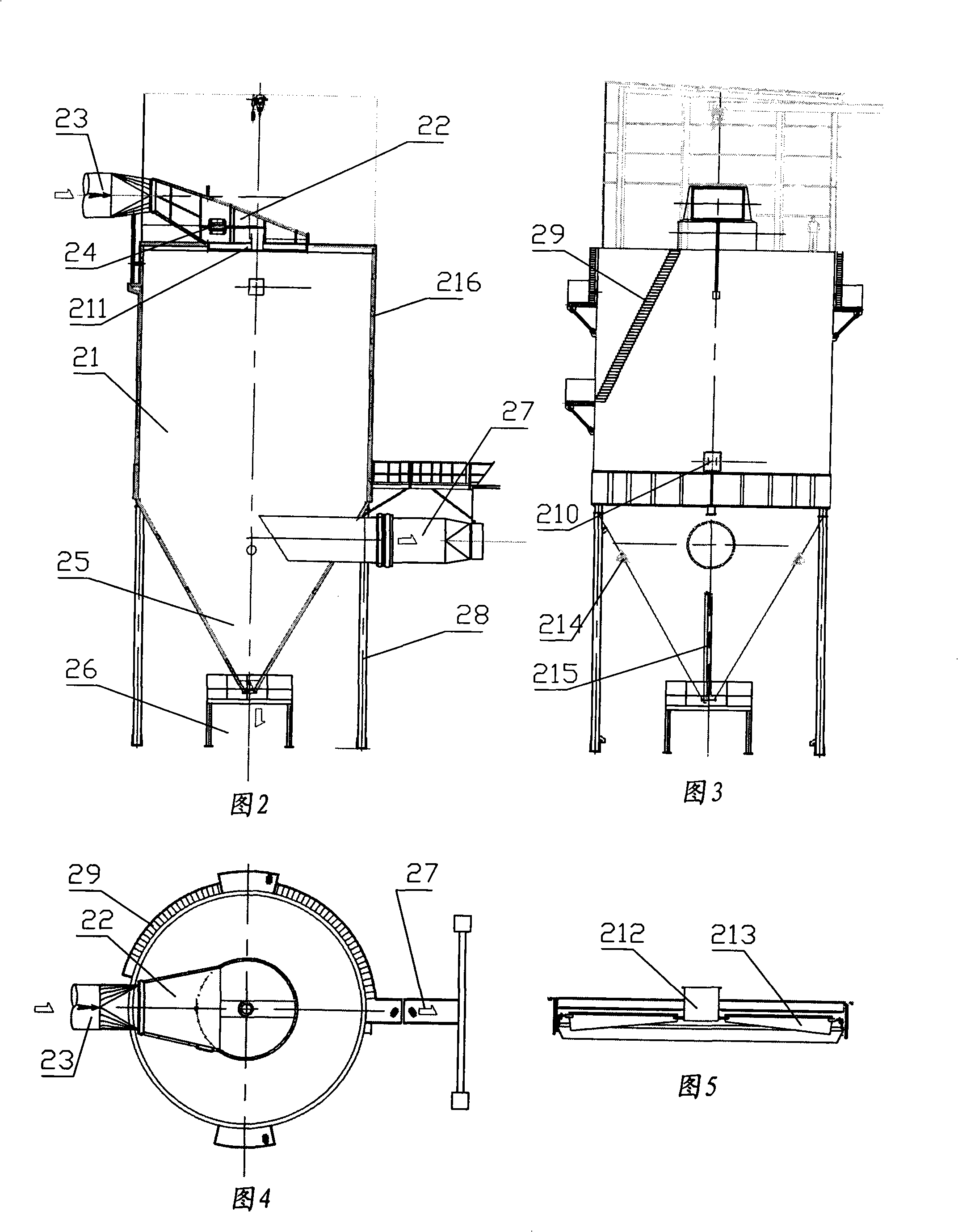

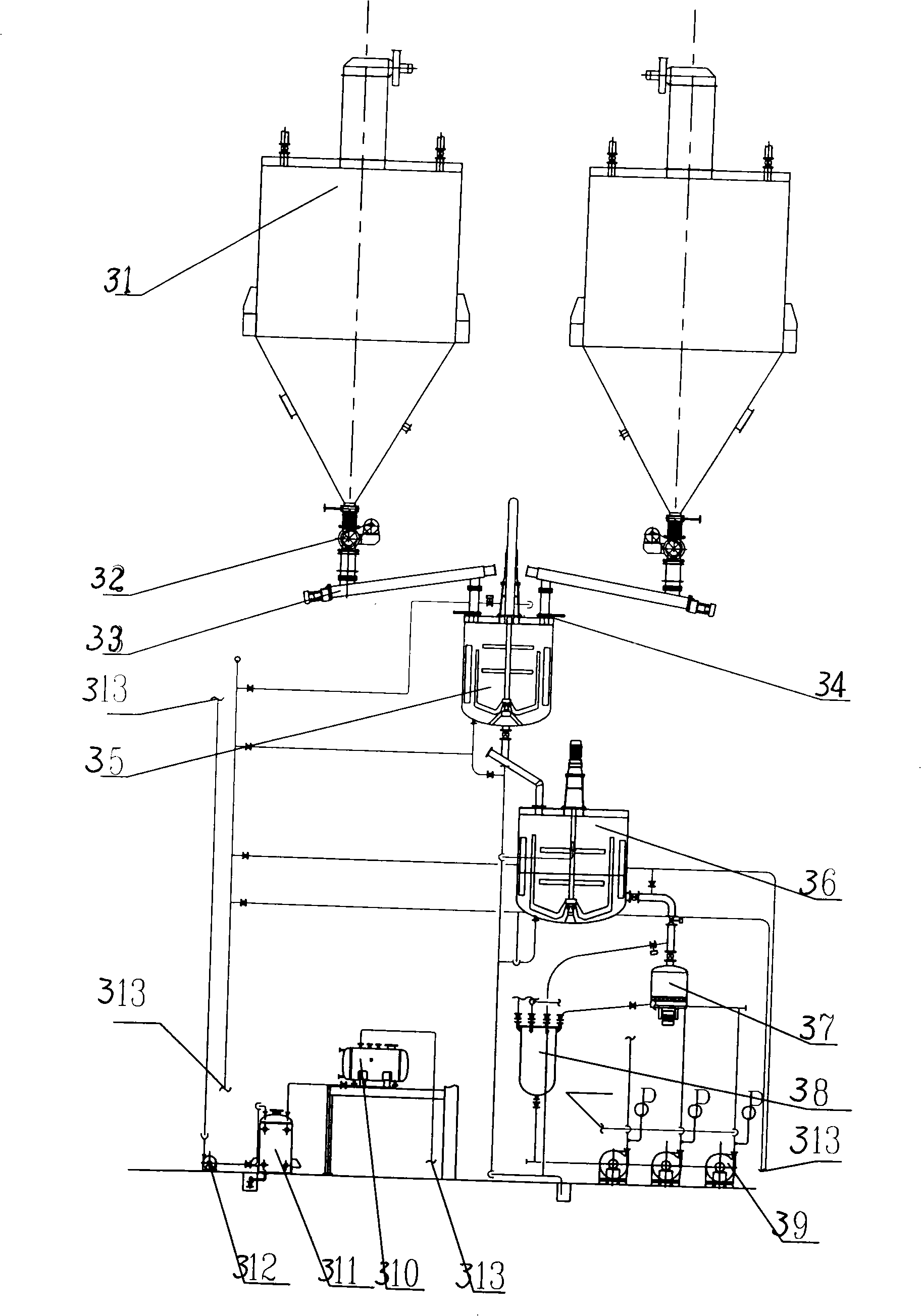

Semi-dry method refuse burning fume cleaning treatment method and system thereof

ActiveCN101310835AEvenly distributedImprove absorption efficiencyDispersed particle separationAutomatic controlWater discharge

The invention provides a semi-dry garbage incineration flue gas purifying treatment method and a system device thereof, flue gas enters a spray tower from a waste heat boiler, activated carbon is injected into a horizontal inlet flue to remove dioxin and heavy metals in the flue gas; the flue gas is simultaneously carried out the reaction with a high specific surface area alkaline neutralizer, most of the harmful substances in the flue gas are purified by generating chemical reactions with the alkaline neutralizer; when the flue gas passes through a filter layer which is formed by granule materials in a bag dust collector, gaseous pollutants can still be reacted with non-reacted lime and activated carbon in the filter layer to be further purified. The system device can lead the flue gas and the high specific surface area lime emulsion to achieve the best contact area, thus ensuring the best flue gas retention time, achieving the full heat transfer and the chemical and heat transfer process; furthermore, the spray is even, the anti-blockage and the anti-corrosion performances are better; a lime emulsion preparation device can automatically control and prepare the concentration and the using amount of the emulsion to be participated in the reaction according the content of wastes in the ingredients of the flue gas and the temperature of the flue gas; the usage and the regulation of the neutralizer are flexible. The system device further has the advantages of low investment cost, strong load adaptability and no waste water discharge, etc.

Owner:DESIGN INST OF CHONGQING IRON & STEEL GRP

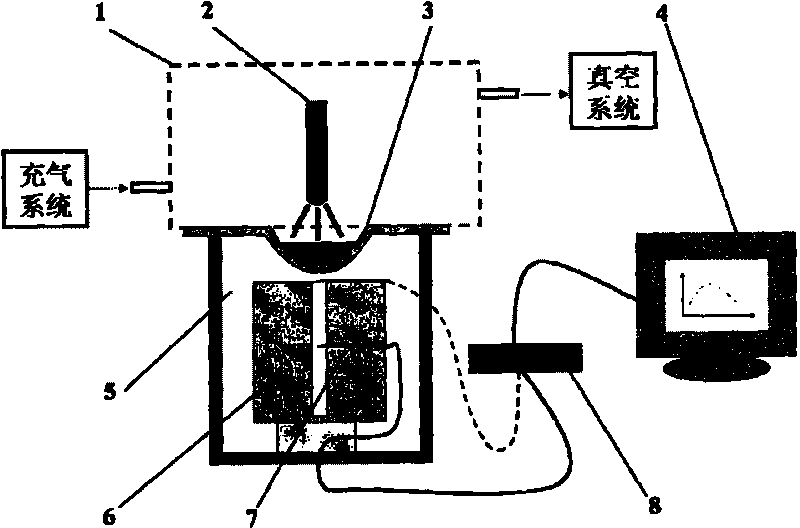

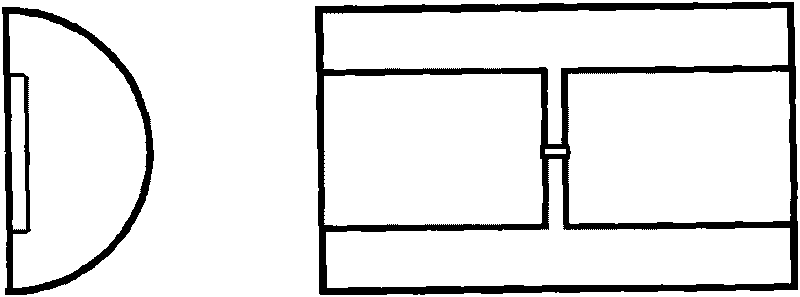

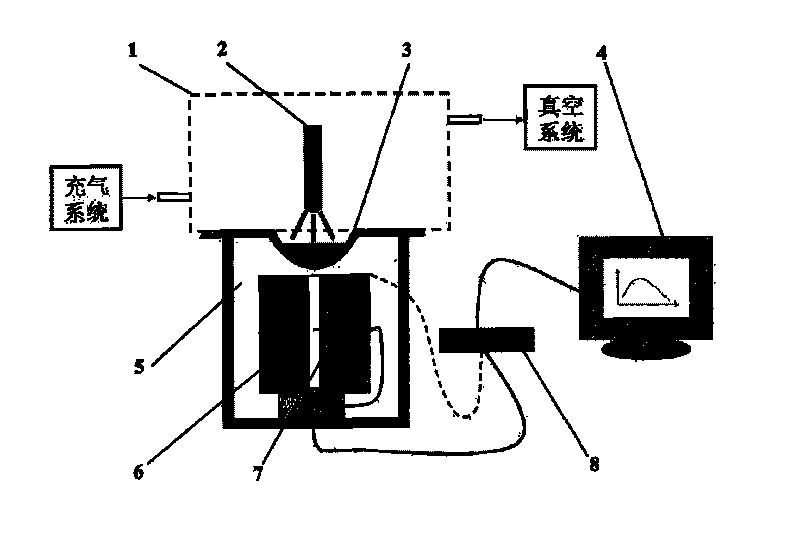

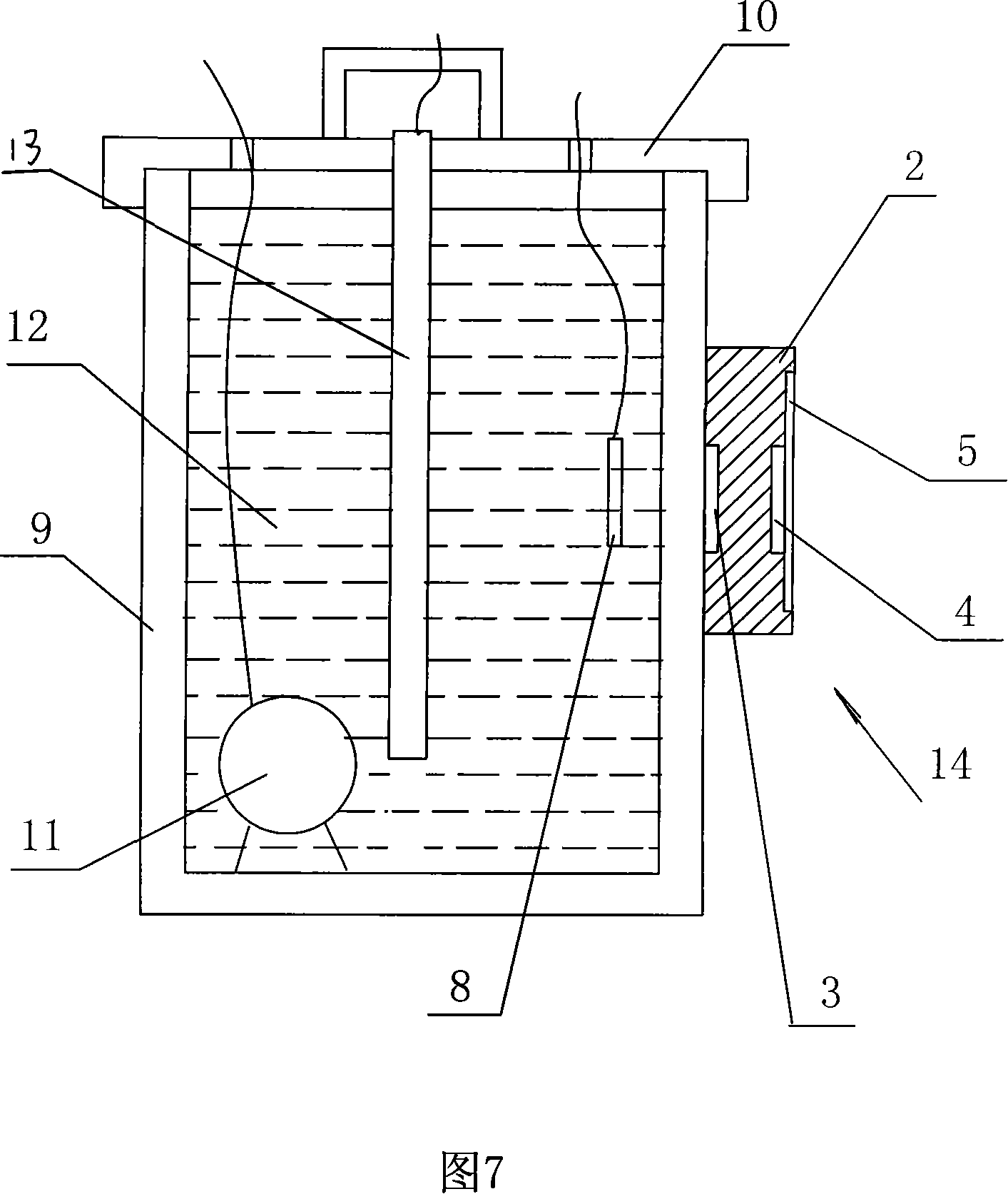

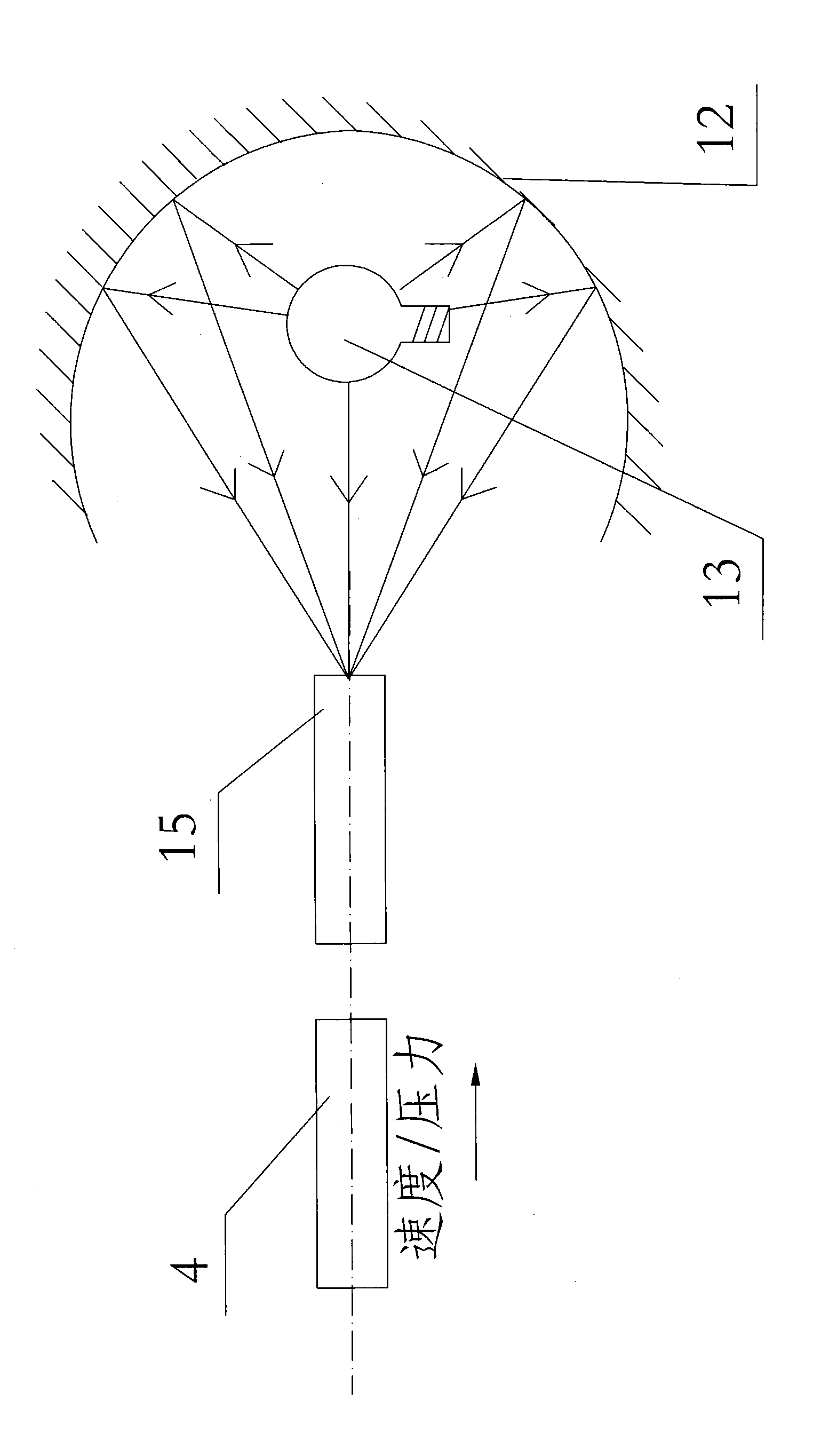

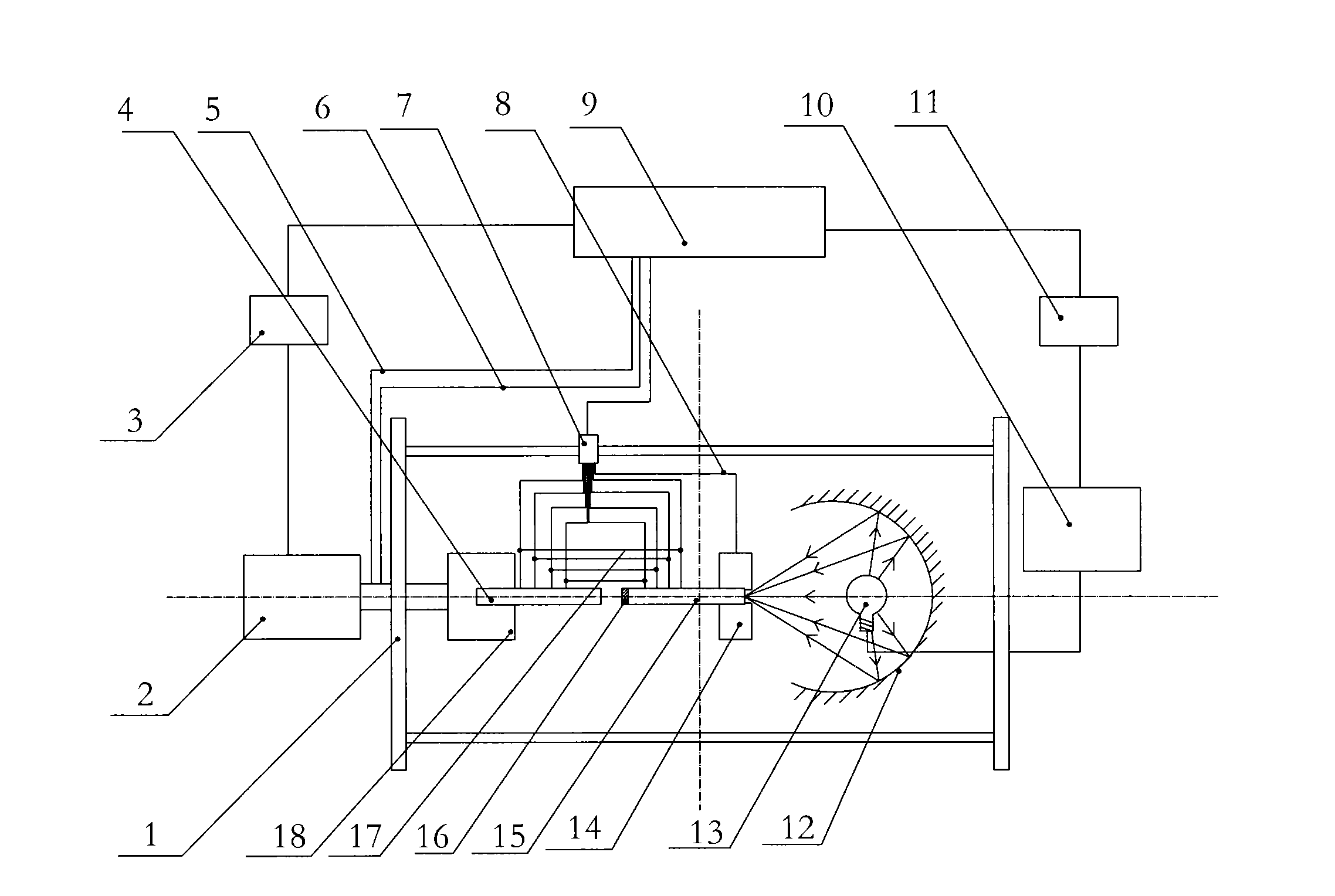

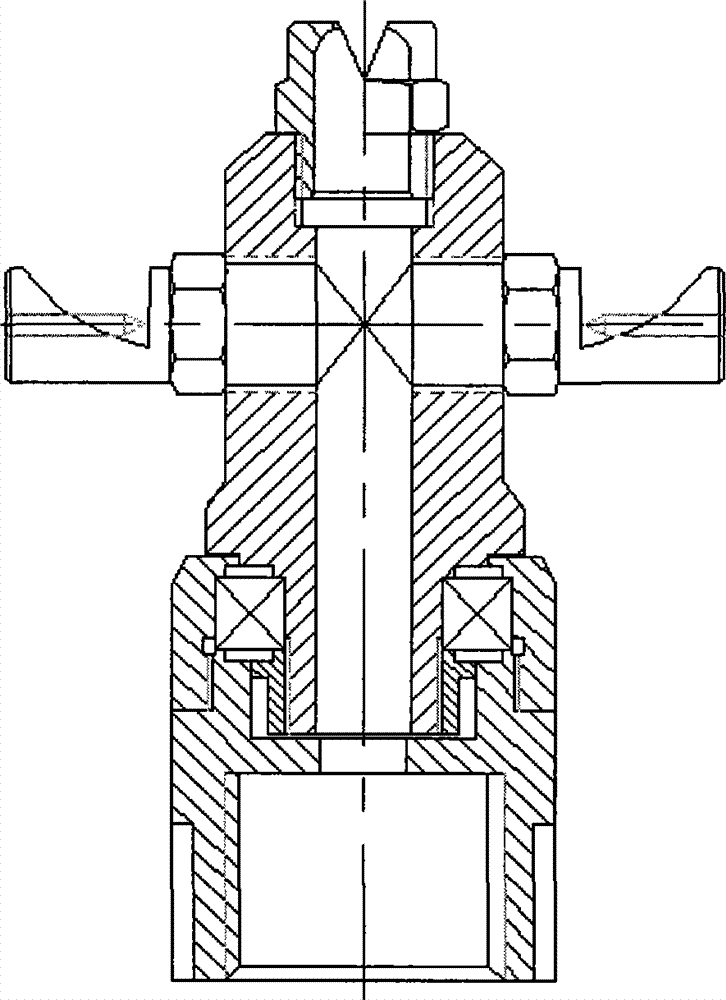

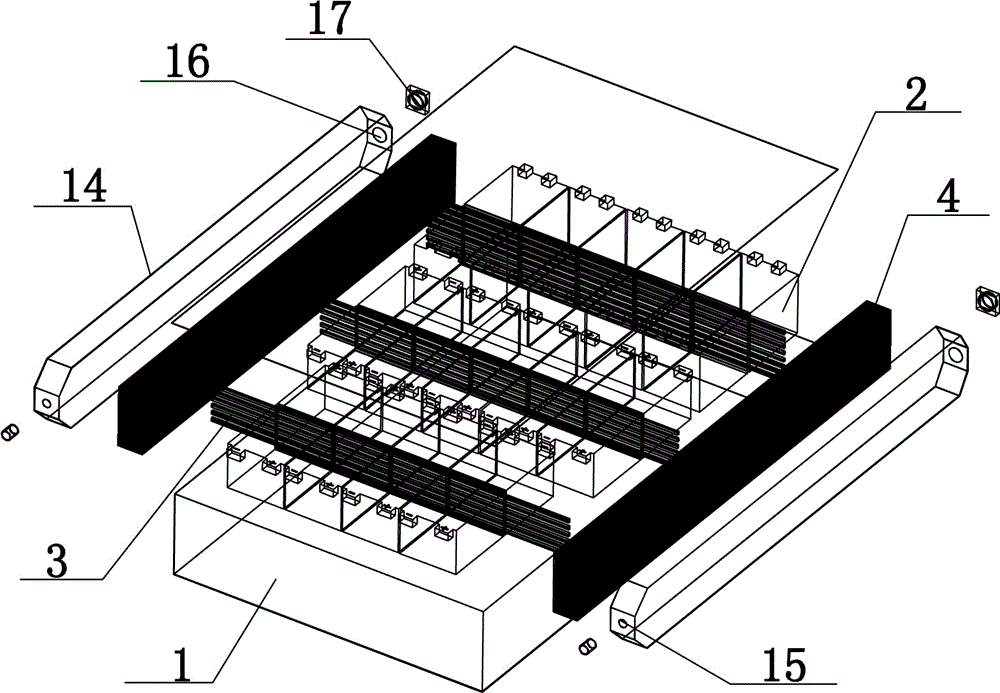

Physical simulation method and physical simulation device utilizing suction casting to research solidification of strip continuous casting

The invention relates to a physical simulation method of the solidification process of strip continuous casting and a realization device thereof, which belong to the field of physical simulation and control of growth process of metal solidification structures. The invention provides a physical simulation method of the solidification process of the strip continuous casting process, so that a physical simulation test can reach the cooling rate of actual strip continuous casting to simulate the heat transfer process of the strip continuous casting; and the method researches an evolution law of solidification structures of the strip continuous casting and a basic law of the solidification by adjusting alloy element components and strip thickness, and can contrastively research an influence law of a rolling force on the solidification during the strip continuous casting. The invention provides a set of equipment which can realize physical simulation on the solidification process of the strip continuous casting. The invention designs a physical simulation device which has a concise structure and small scale and is flexible and smart, wherein main parameters of the device comprise that: the final vacuum is 6.6*10-4Pa, the radius of four water-cooled copper crucibles is 25mm, the working current is between 800 and 1,000A, and the rotating speed of electromagnetic stirring is between 0 and 200rpm.

Owner:SHANGHAI UNIV

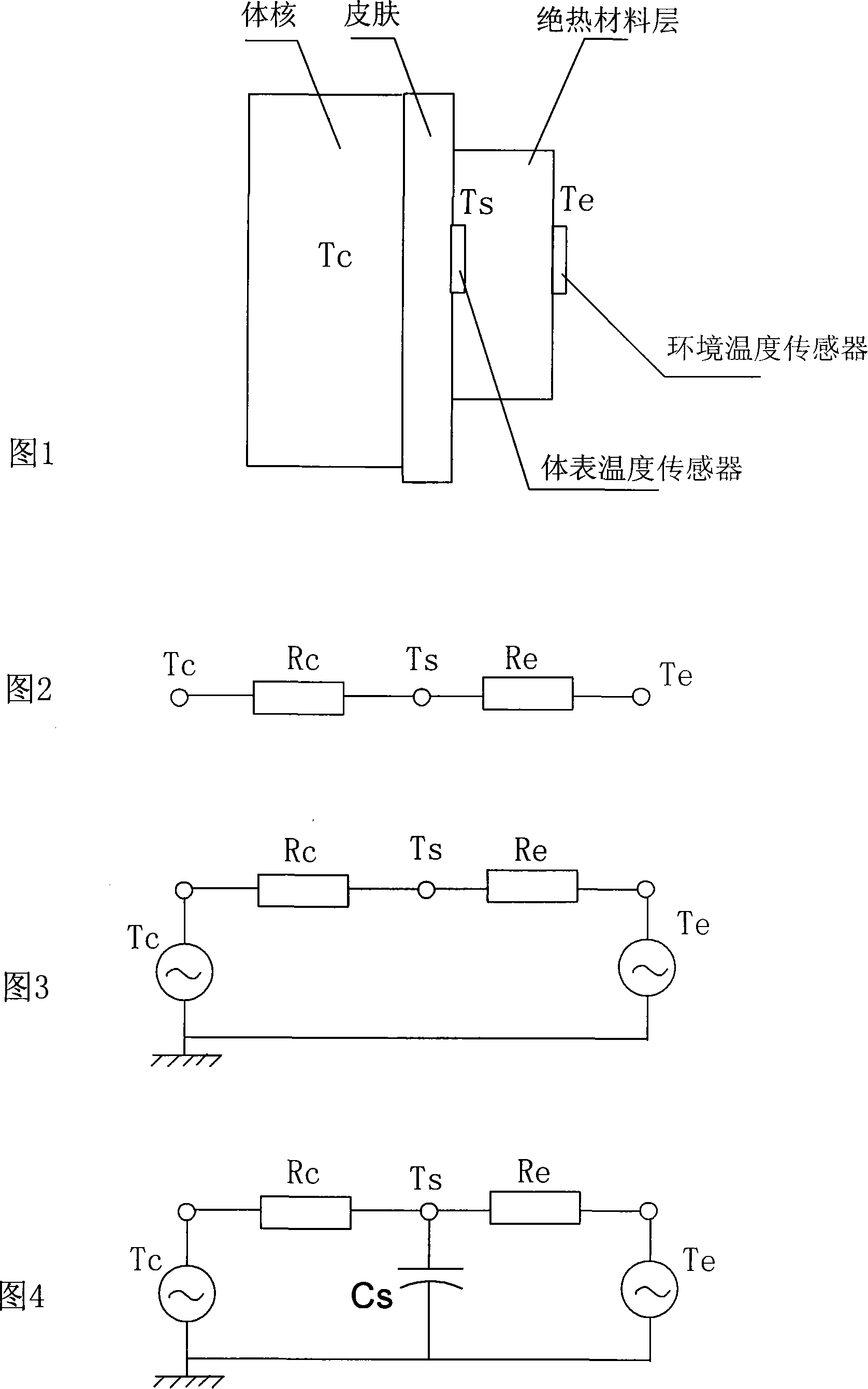

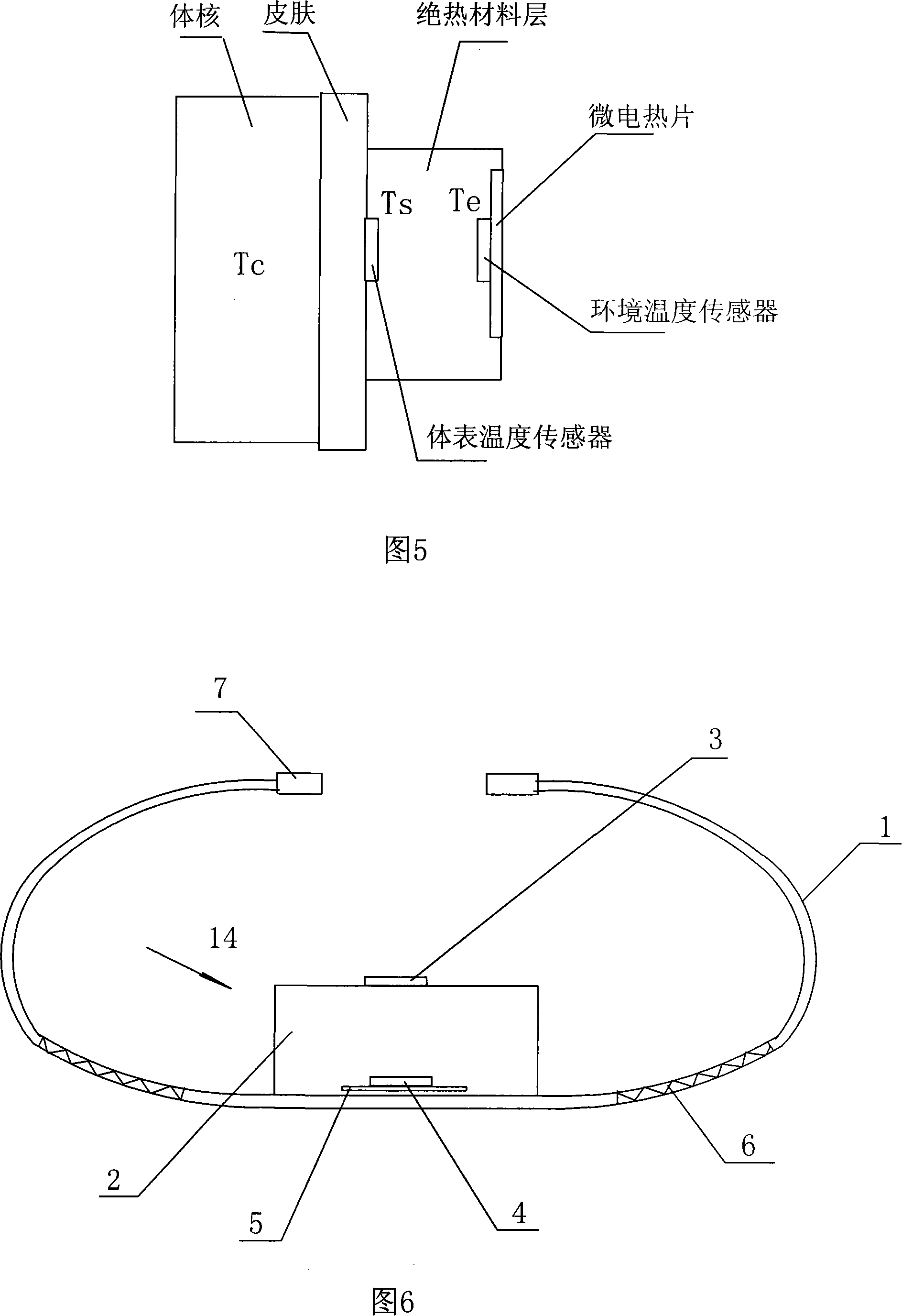

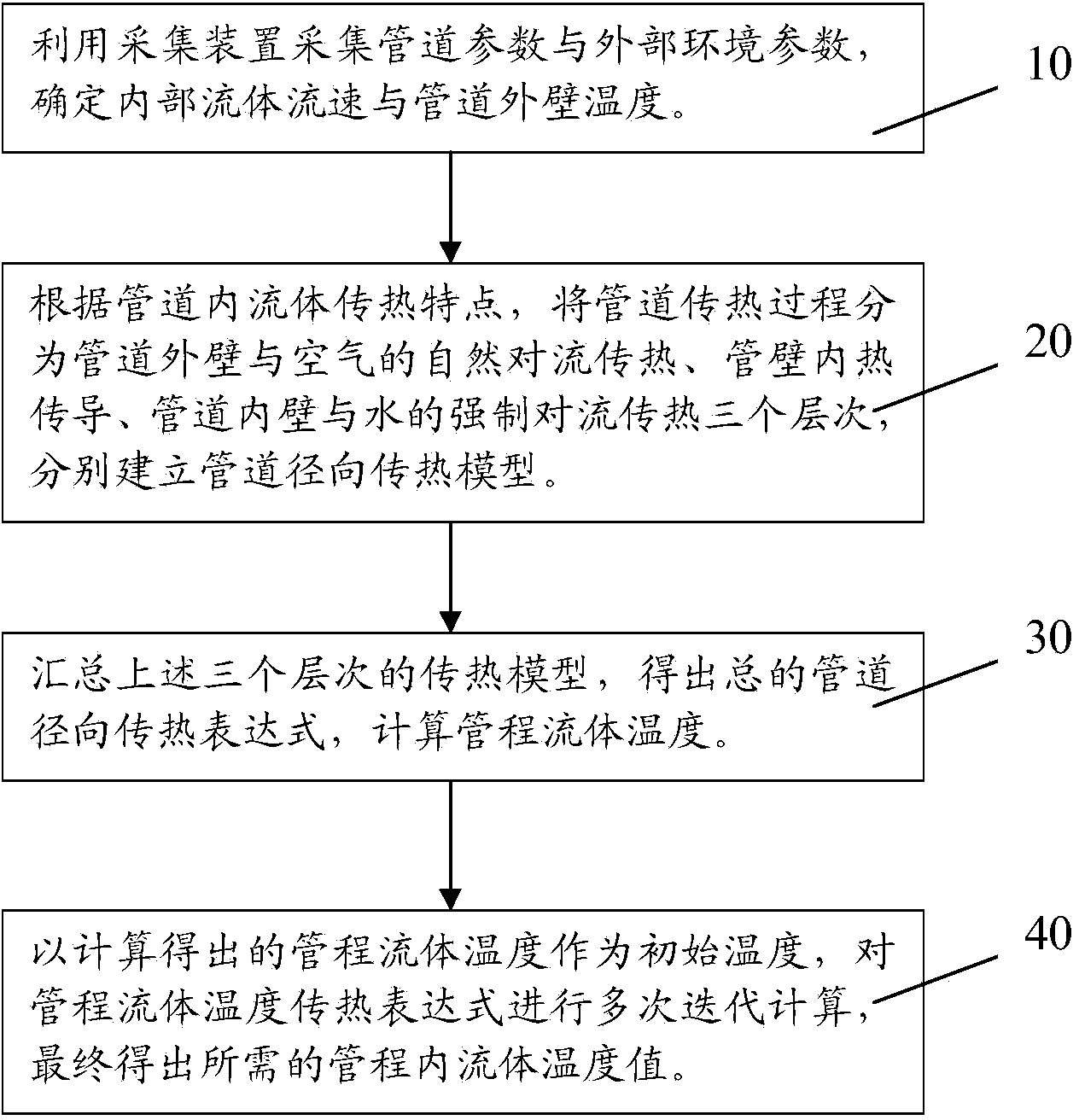

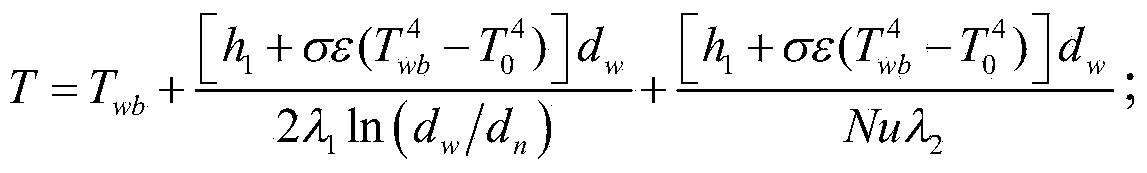

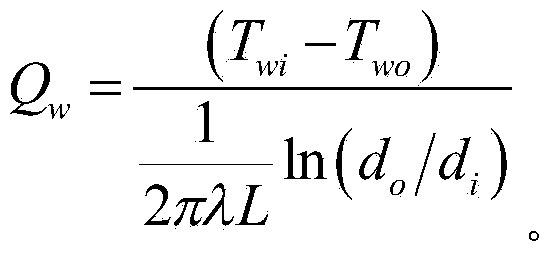

Method and equipment for non-invasive core temperature measuring and the calibration equipment and the calibration method thereof

InactiveCN101112306AEasy to useReduce manufacturing costDiagnostic recording/measuringSensorsHuman bodyEngineering

The invention discloses a method, a device, a marking device and a marking method of the non-invasive karyosome temperature measurement, characterized in that a heat insulating material layer is arranged on the body surface of the human body, a body surface temperature sensor is arranged between the inner side of the heat insulating material layer and the body surface of the human body to detect the temperature of the body surface of the human body (Ts), an environment temperature sensor is arranged at the outer side of the heat insulating material layer to detect the environment temperature (Te), an electric heating component is arranged on the outer side of the heat insulating material layer to generate the simulated temperature of environment. The temperature data of the body surface and the environment is obtained by measuring and is undergone the analysis of the heat transfer process by an analog circuit, then the temperature of the human body karyosome (Tc) is estimated by the analytic method of increasing the transient analog circuit. By adopting the method and the device of the invention, the non-invasive karyosome temperature measurement to the human body can be continuously, dynamically, personably carried out for a long term. The invention is convenient in use, low in manufacture and operation, high in accuracy. The accuracy of measuring the human body karyosome can be improved by adopting the marked device and the using method of the invention.

Owner:杨福生 +2

Method and device for measuring dynamic contact heat exchange coefficient of high-temperature solid interface

InactiveCN101661009ARealize measurementEfficient heatingMaterial thermal conductivityMaterial heat developmentContact pressureMeasurement device

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Gas hydrate generation accelerant and preparation method thereof

ActiveCN103663451AEnhance heat and mass transferShorten the timeCarbon compoundsGeneration processLiquid water

The invention belongs to the field of gas hydrate production and utilization and in particular relates to an accelerant capable of reinforcing gas hydrate generation and a preparation method thereof. The hydrate generation accelerant is a mixed water solution formed by compounding nano dispersed particles with a surfactant and dissolving the compound in water, wherein nano graphite powder is adopted as the nano dispersed particles; SDBS (sodium dodecylbenzenesulfonate) is adopted as the surfactant; based on the total amount of the mixed water solution, the mass fraction of the nano graphite powder is 0.05-1.5%, the mass fraction of SDBS is 0.02-0.08% and the balance is water. The accelerant has the obvious advantages that the mass and heat transfer processes of the hydrate can be greatly reinforced, the overall time of hydrate generation can be shortened and the synthetic efficiency of the hydrate can be improved by adopting the accelerant to reinforce the hydrate generation process; the graphite nano-particles can flow out along with liquid water and can be reused, thus saving the cost.

Owner:溧阳常大技术转移中心有限公司

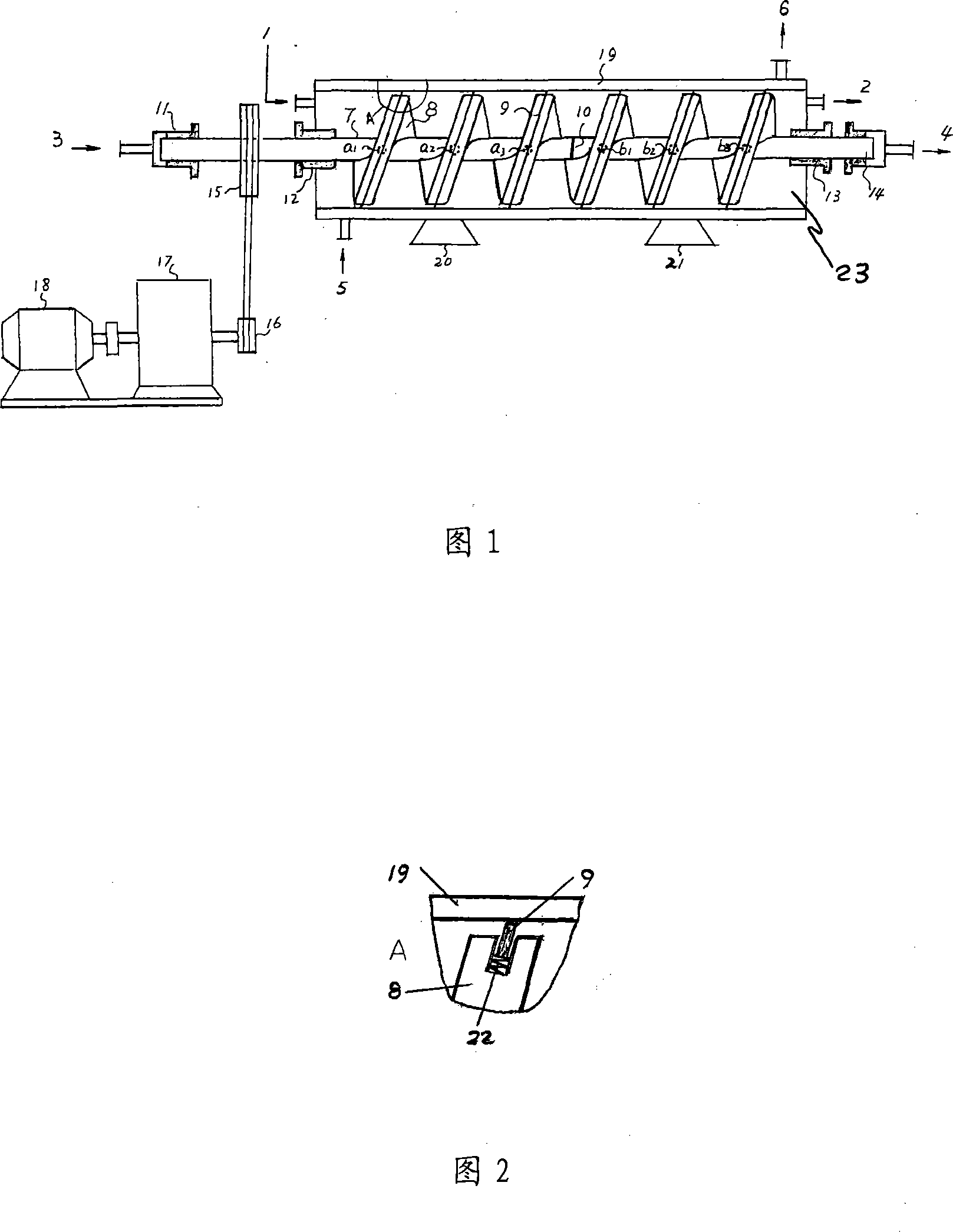

Helix stirred reactor with cryogen gong through inside, application, and technical method of polyreaction

ActiveCN101091901AReasonable workmanshipReduce manufacturing costRotating receptacle mixersTransportation and packagingTextile fiberPolymer science

The invention relates to a screw agitation reactor of the freezing mixture and the use and the polyreaction technique. The reactor includes the support, the tubular material trough which has the material entrance and the export circle, the bearing, the spiral stirrer, the gland seal and the power dragging turning gear. It is suitable for producing polymer by the solution polymerization method technological process like synthetic rubber, the plastic and the textile fiber, especially suitable for synthesizing isoprene rubber and cis-butadiene rubber in the rare earths catalysis system. It replaces the complete mixing flow type of the completely backmixing by the plug flow type of no backmixing, strengthened the polyreaction process and the heat transfer process, the reactor volume is reduced obviously, the energy consumption is reduced largely, the polymer performance is enhanced.

Owner:FUSHUN YIKESI NEW MATERIAL

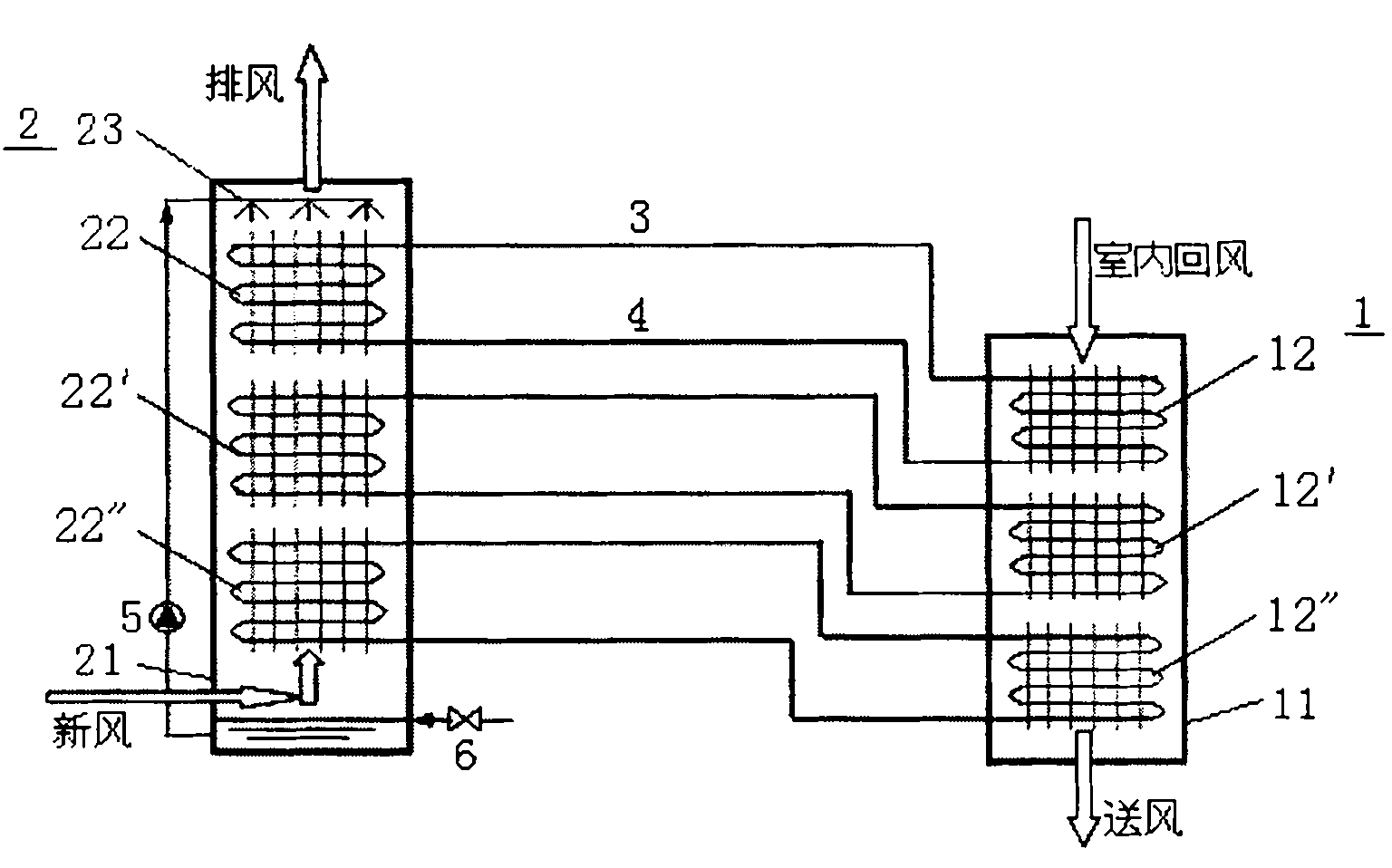

Machine room heat removal device for evaporation cooling type heat-pipe heat exchange

ActiveCN101886836AUniform temperature differenceExtended use timeLighting and heating apparatusSpace heating and ventilation detailsWater cyclingEvaporation

The invention relates to a machine room heat removal device for evaporation cooling type heat-pipe heat exchange. The device is characterized by comprising more than one group of evaporators arranged in a machine room, more than one group of water-cooled condensers arranged outside the machine room and more than one gas-liquid main pipe, wherein each group of evaporators comprises an evaporation tank body and an evaporation side heat pipe arranged in the evaporation tank body; each group of water-cooled condensers comprises a condensation tank body, a condensation side heat pipe arranged in the condensation tank body and a spray device arranged on the top of the condensation tank body; a cooling water circulating loop is formed by communicating the spray device and the bottom of the condensation tank body through a water pump; the top of each group of evaporation side heat pipe is communicated with the bottom of the corresponding condensation side heat pipe through one gas-liquid main pipe; and the evaporation side heat pipe and the condensation side heat pipe are filled with a refrigerating medium. The device ensures more uniform temperature difference between the groups of heat pipes during the heat transfer, has an overall heat exchange efficiency close to one and air supply temperature close to the wet bulb temperature of outdoor air, can reduce the starting temperature difference between indoor temperature and outdoor temperature and further increase the service time of the heat pipe to achieve better energy saving effect.

Owner:TSINGHUA UNIV

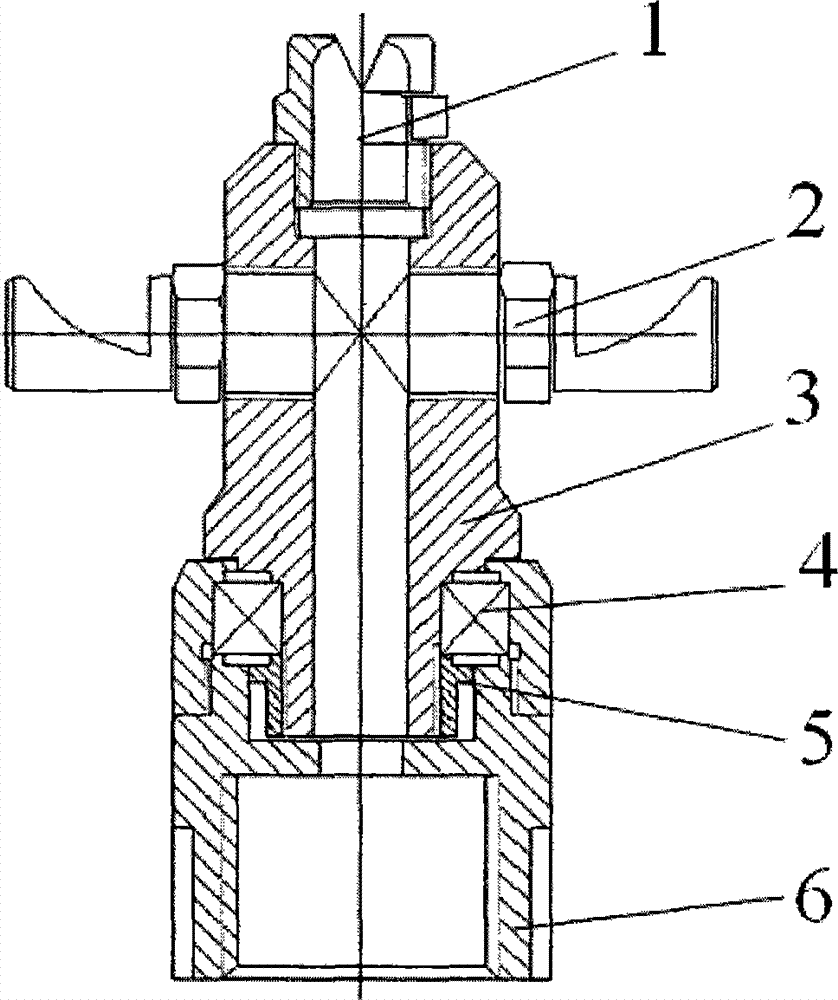

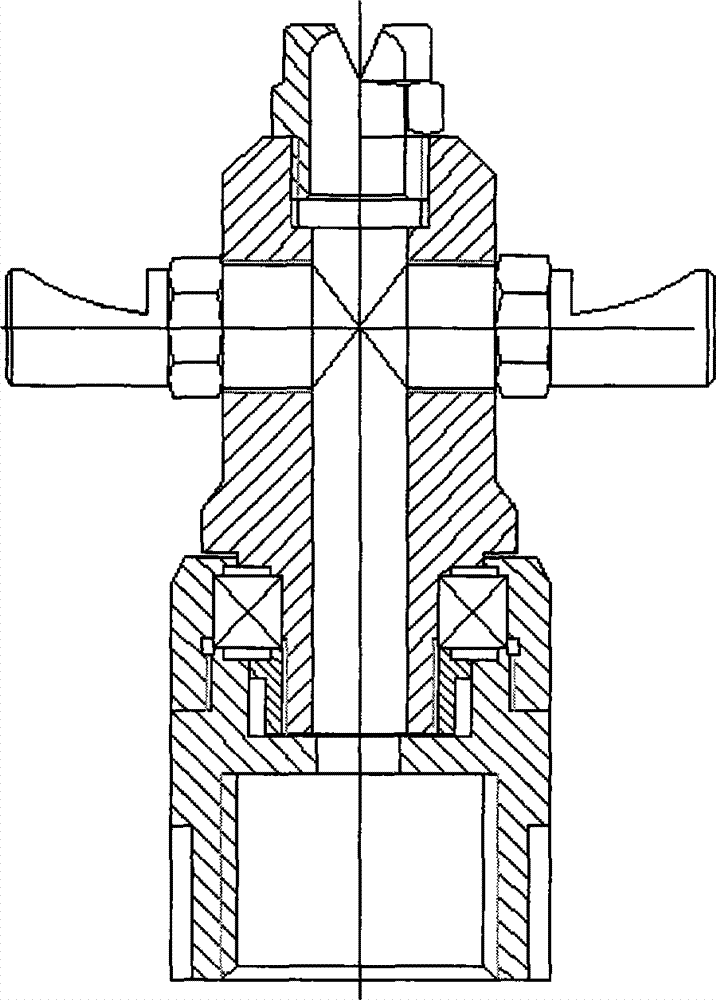

Novel rotational flow atomization apparatus and application technology

InactiveCN104741258APromote aggregationLow costUsing liquid separation agentMovable spraying apparatusSprayerEngineering

The invention relates to a novel rotational flow atomization apparatus and an application technology. The structure characteristics of a core unit, namely a novel rotary sprayer is that the upper part, connected with fluid, of the rotary sprayer is fixed, the lower part of the rotary sprayer is connected with the upper part through one or a plurality of nozzles by virtue of bearings, the lower part of the sprayer is pushed to rotate at high speed by reactive force formed when a part of kinetic energy of the fluid under pressure is ejected from the nozzles, and meanwhile, most of kinetic energy can be effectively converted into surface energy which can facilitate water flow atomization when impacting the bevel or oblique seam of the sprayer or passing through a hole. The novel sprayer has the advantages that the use pressure is low, the rotating speed is rapid, fogdrops are small and uniform, and the fog spraying coverage area is large. The novel rotational flow atomization apparatus can be applied to extinguishment, black smoke can be instantaneously eliminated, fire head is suppressed in seconds, and big fire can be extinguished within ten seconds; when the novel rotational flow atomization apparatus is applied to flue gas purification, rotational flow like tornado can be produced in a tower, and high-efficient desulfurization dust removal is realized; the novel rotational flow atomization apparatus can be widely applied to city purification, park green space watering, landscape decoration, and crop watering, fertilization, pesticide application and industrial mixing, separating, mass transfer and heat transfer processes, and the circumjacent PM 2.5 and other gaseous pollutant can be effectively removed.

Owner:BEIJING CHINA SCI PURIFICATION ECO TECH

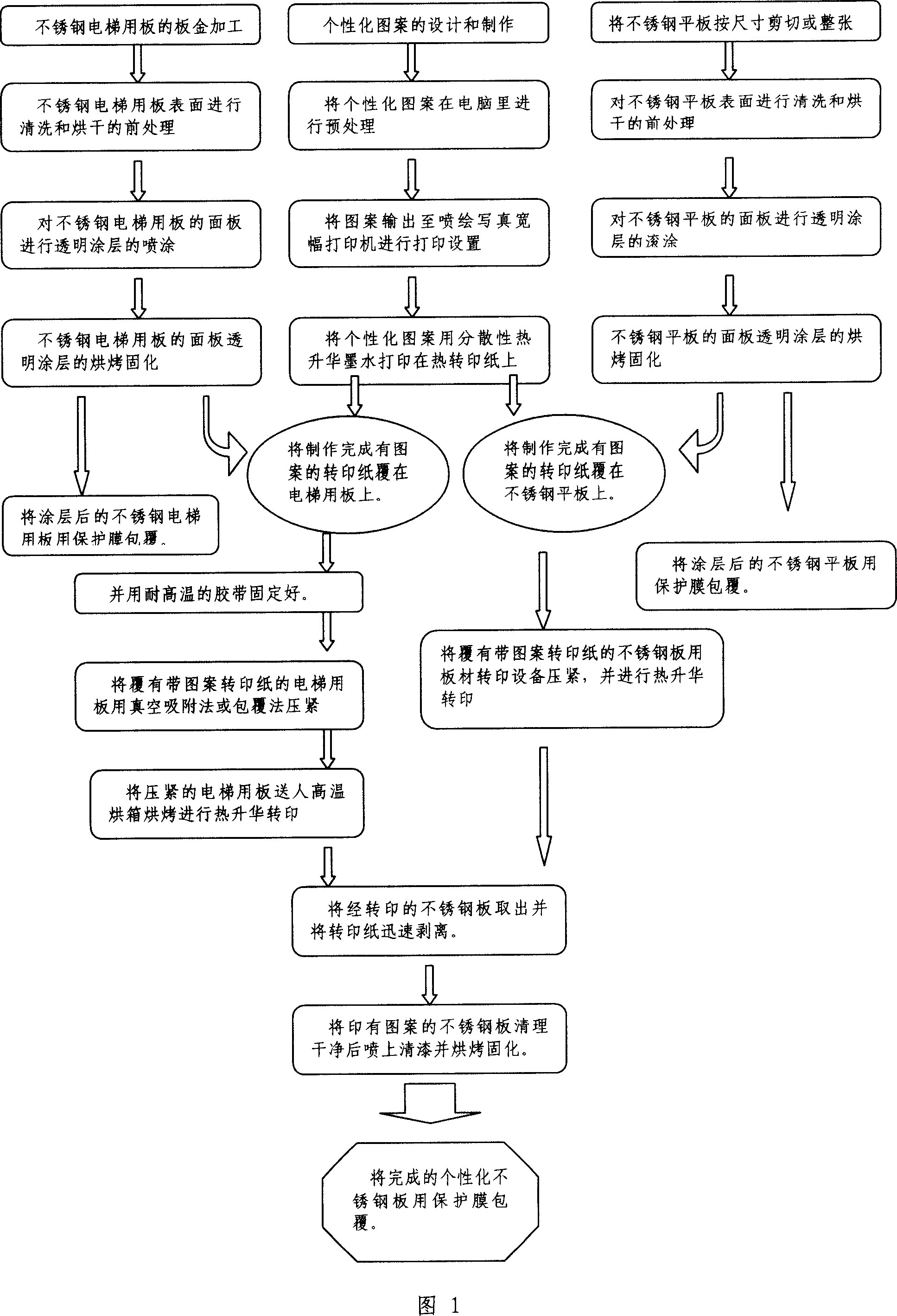

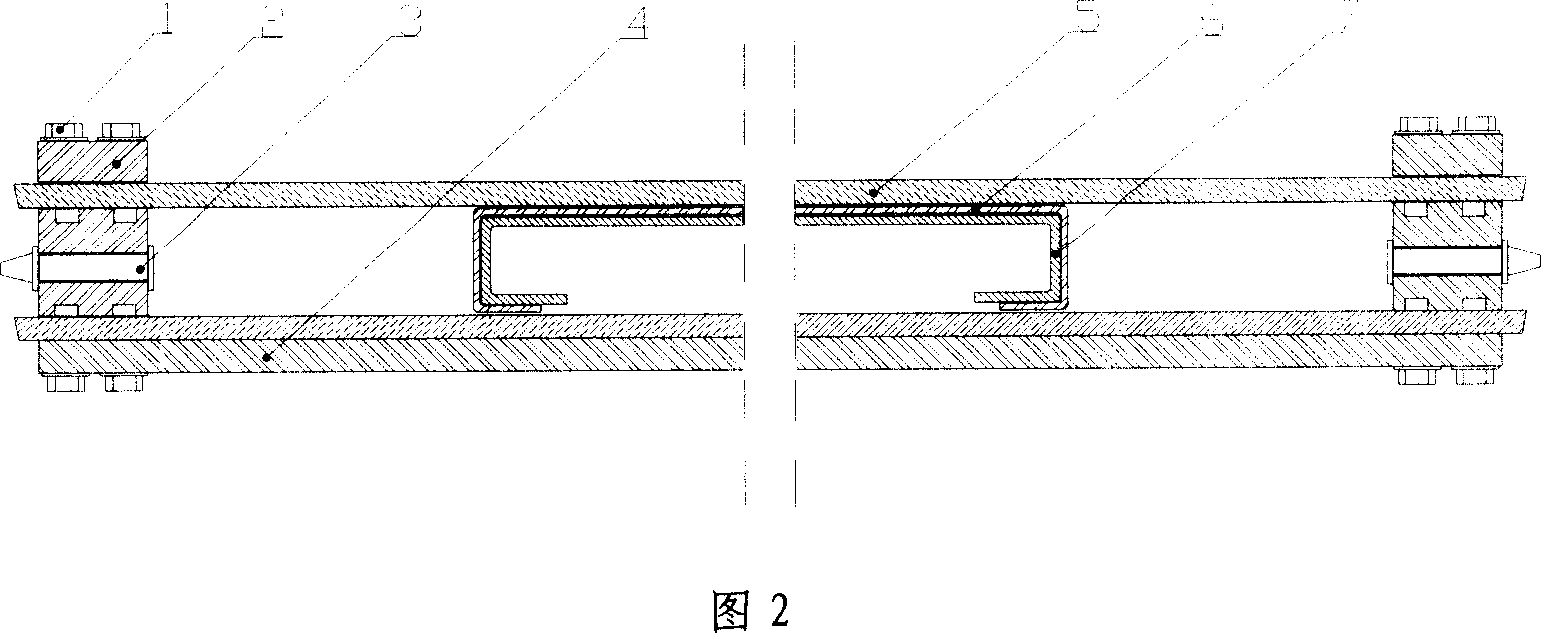

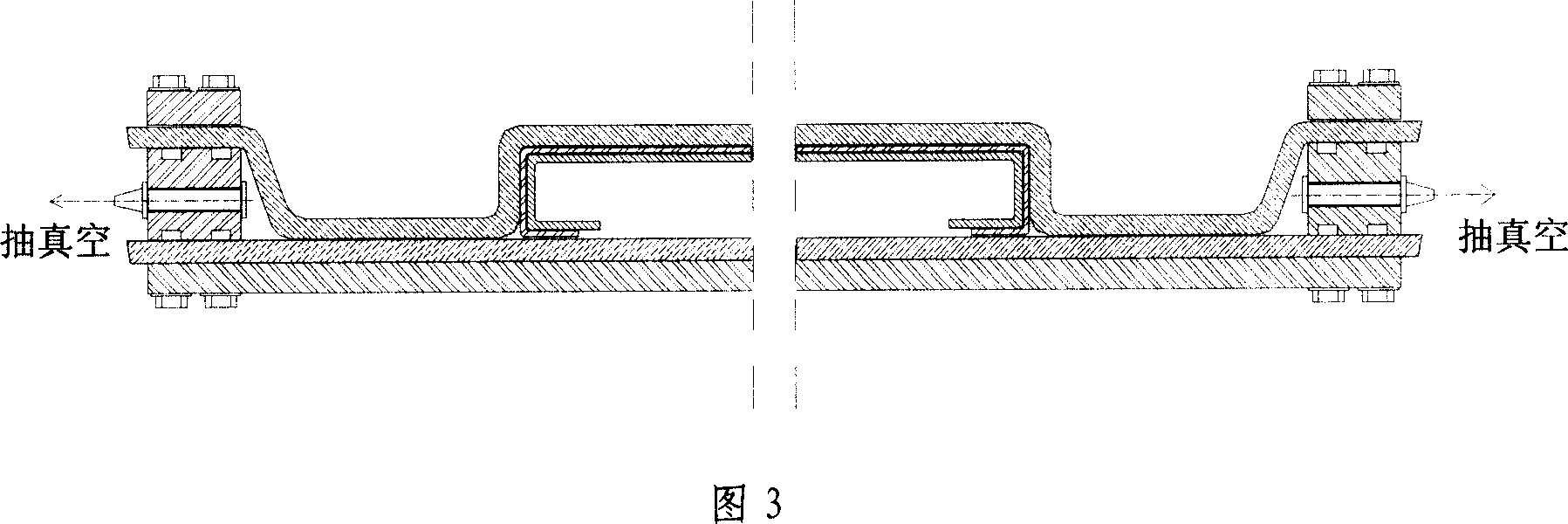

Stainless steel plate surface treatment, pattern heat transfer process and plate made thereby

The invention discloses stainless steel surface treatment and drawing thermal transfer method and the corresponding system in stainless steel plate and stainless steel that surface decorative motifs plate. The said surface treatment including cleaning and drying, Smooth or spray coating layer transparent, baking and curing and so on, the process of cleaning and drying including detergent spray degreasing, spray rinse, compressed air dehydration, hot air drying, the film material of transparent coating is polyester resin, butanol etherified melamine resin. The said thermal transfer method use of Plate Transfer equipment when used in flat-panel; when applied to three-dimensional workpieces, using vacuum adsorption method or cladding method for packing trans-print paper and workpiece. The invention is character of the coating surface with strong metal texture, the Transfer Printing pictorial clear.

Owner:海宁市红狮电梯装饰有限公司

Power generation system and generating method based on same

ActiveCN104989473AImprove power generation efficiencyReduce lossesSteam engine plantsCombined combustion mitigationPropaneHeat transfer process

The invention provides a power generation system and a generating method based on the same. The power generation system comprises a mixed working medium Rankine circulation expansion acting portion, a propane working medium Rankine circulation expansion acting portion and a natural gas direct expansion generating portion. The generating method comprises steps of natural gas medium one-grade direct expansion, first grade Rankine circulation and second grade Rankine circulation. The generating method is advantageous in that based on the principle of energy temperature orientation and step utilization and on the premise that the complexity of the system is not greatly increased, the cold energy of LNG is utilized step by step through two Rankine circulation in series, the loss of available energy can be reduced when the LNG exchanges heat with the Rankine circulation, the generating efficiency using the cold energy is higher. The pressure energy of the LNG can be fully utilized through the disposed natural gas one-grade direct expansion, on the premise that needed pressure can be supplied to a pipe network and users.

Owner:SHANGHAI JIAO TONG UNIV

Non-contact tube pass fluid temperature measuring method based on temperature measurement of pipeline outer wall

ActiveCN104062034ARealize non-contact measurementEnables non-destructive measurementsTemperature measurement of flowing materialsThree levelNatural convection

Owner:SHENZHEN TAIKE TEST

Method for synthesizing phenolic resin

ActiveCN104327227ASynthetic Method AdvantagesReduce volumeChemical/physical/physico-chemical processesCompound (substance)Treatment costs

The invention relates to a method for synthesizing phenolic resin. The method comprises the following steps: mixing raw materials, preparing a catalyst, synthesizing, extracting and distilling. By using a micro-channel reactor, the heat conduction process is intensified, the mass transfer problem is well solved, the material waste is greatly reduced, and the later treatment cost is also reduced. As a parallel 'quantity enlargement' mode is adopted during the industrial enlargement of the micro-channel reactor, direct enlargement from a laboratory to the industrial production process is achieved, and the practical production is relatively flexible. Modern high-efficiency chemical development and production windows are opened, and the modern chemical engineering develops towards environment protection, safety and high efficiency.

Owner:XIAN ORIGIN CHEM TECH

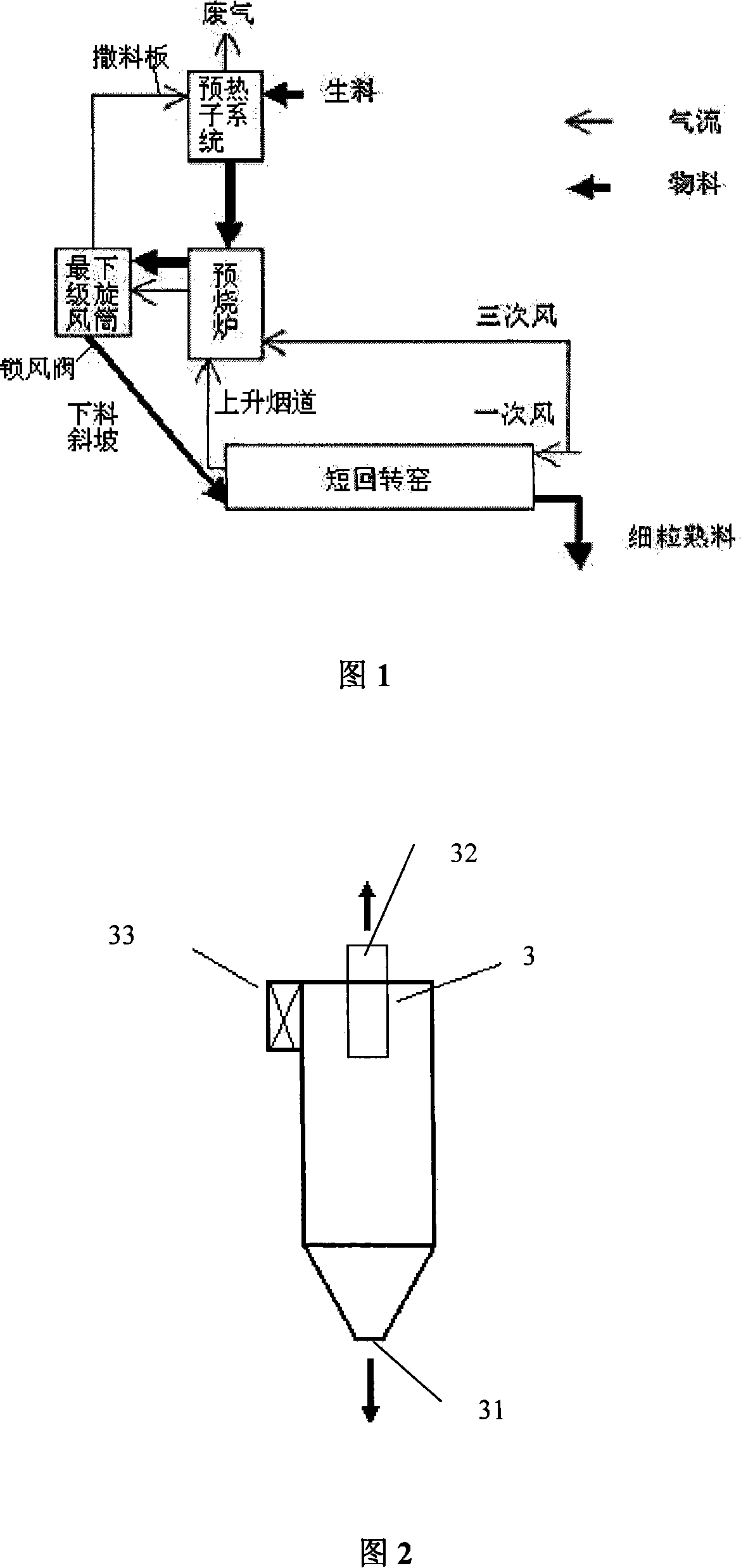

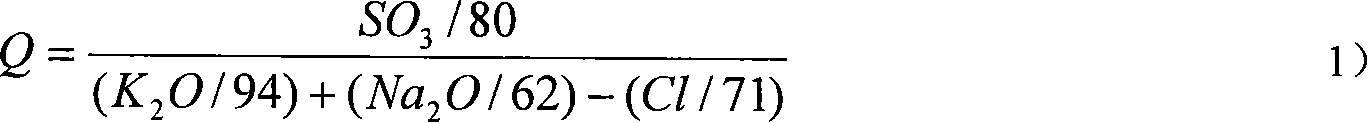

Cement presintering production method and system

ActiveCN101139175AIncrease productionQuality improvementRotary drum furnacesCharge manipulationElectricityBottle neck

The present invention relates to a new cement manufacturing technology. By enhancing the temperature of the kiln feed of a rotary kiln, the inefficient heat transfer process remaining in the cement rotary kiln is greatly reduced or eliminated and the thermal bottle-neck problem in the cement calcinations is solved so as to realize the fast firing of the fine particles and highly efficient cooling of the clinkers, and the anti-skinning materials, high temperature resistant materials and insulating materials are adopted and the aspect ratio, rotation speed and slope of the rotary kiln are changed so as to realize the present invention, thus generating the very obvious comprehensive effects of enhancing the output of the cements, lowering the burning heat consumption and the grinding pow consumption and enhancing the clinker quality.

Owner:CHINA BUILDING MATERIALS ACAD

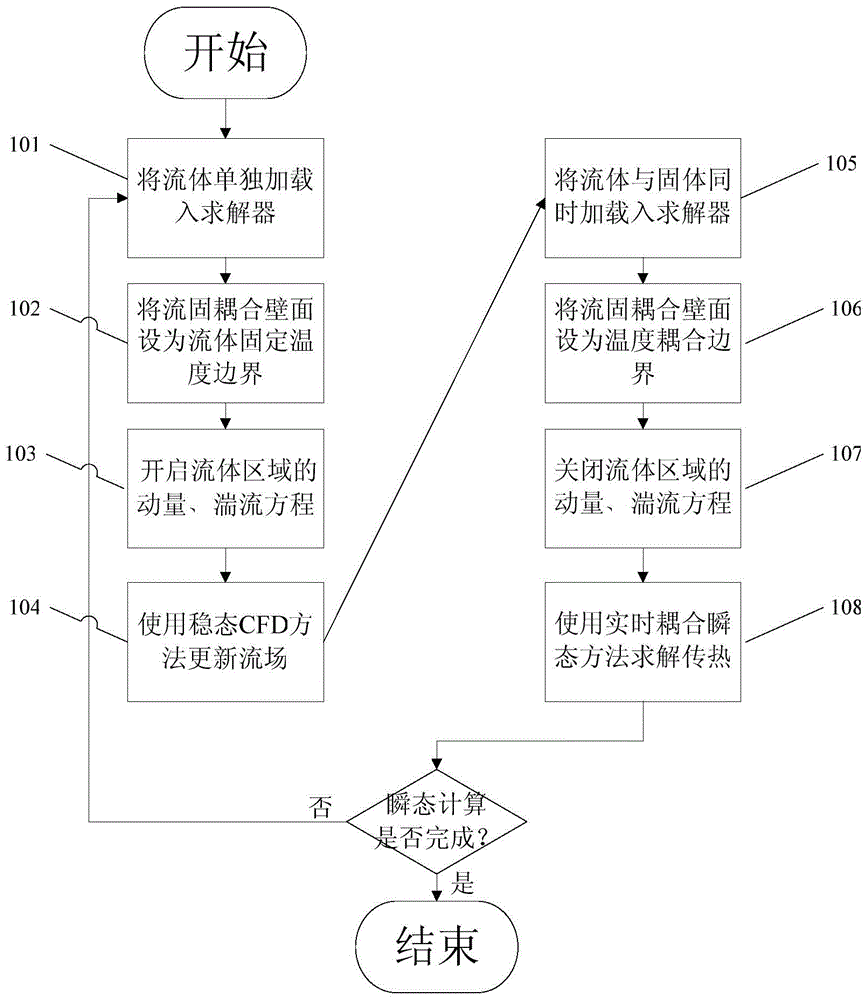

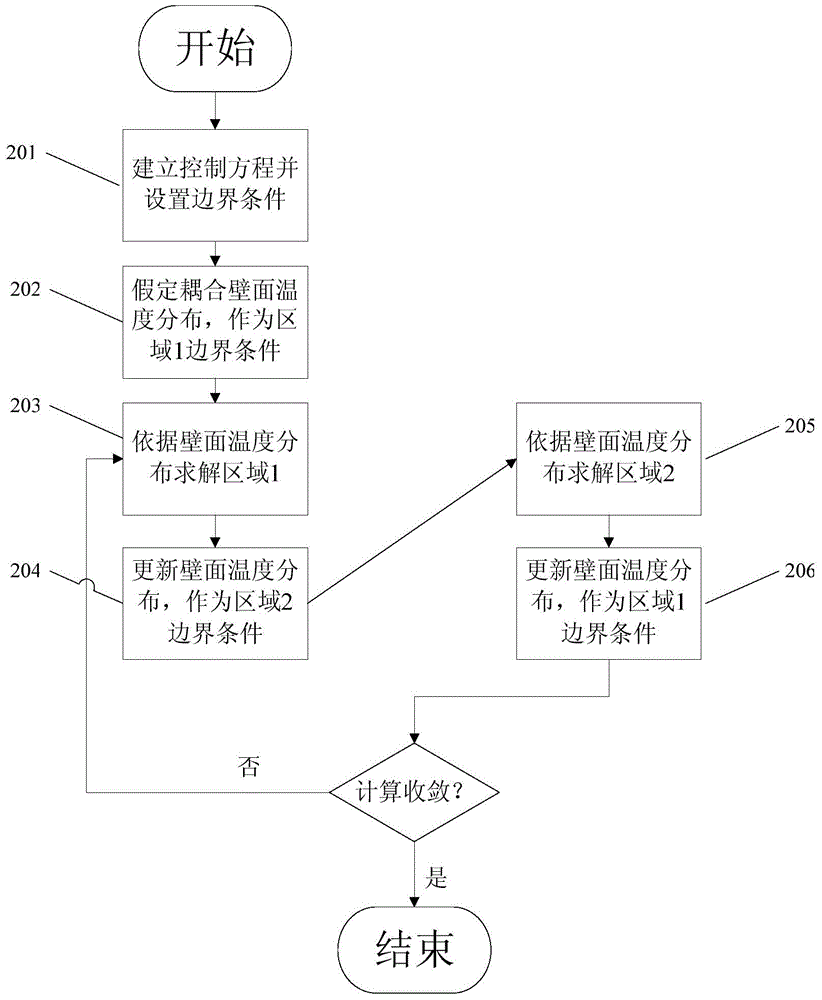

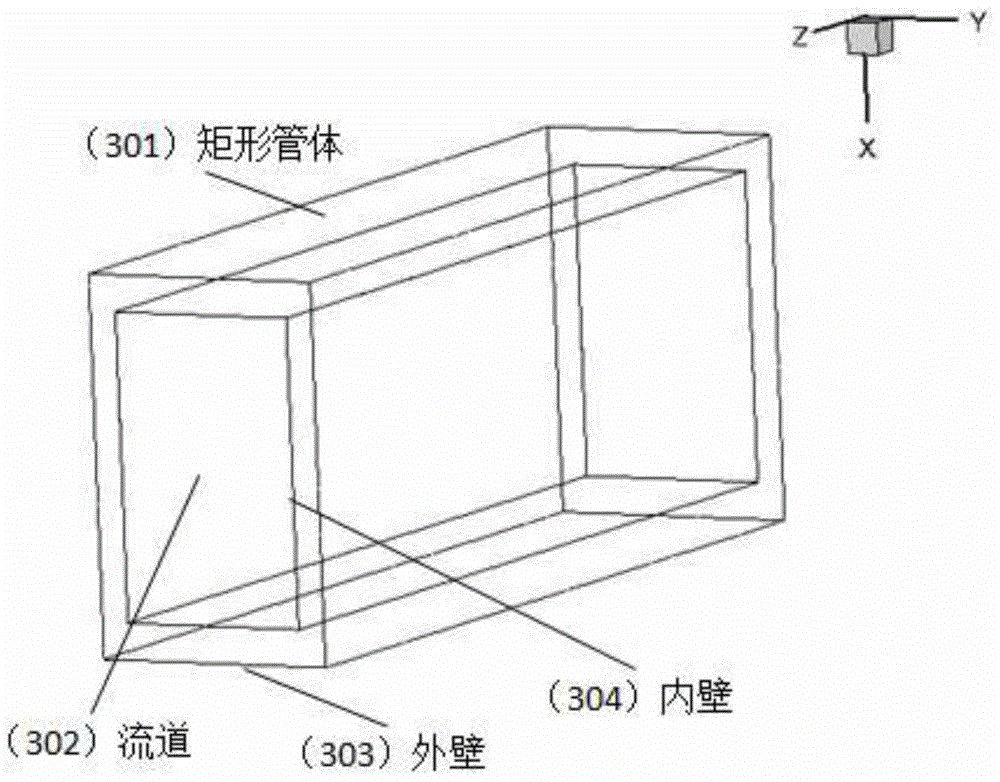

Loose coupling modeling method for fluid-solid coupling heat transfer

The invention provides a loose coupling modeling method for fluid-solid coupling heat transfer. The loose coupling modeling method is characterized in that the transient change process of a flow filed is ignored, and the global transient heat transfer process is assumed to be performed in a quasi-stable-state flow field. The method comprises the specific calculation procedures that 1, the flow field is updated, wherein only fluid is taken as a solving object, the fluid-solid coupling wall surface is set as a fixed temperature boundary of the fluid, and the flow field is solved through a stable-state CFD algorithm; 2, transient heat transfer is calculated, wherein the fluid and solid are both taken as the solving object, the fluid-solid coupling wall surface is set as a heat transfer coupling boundary, a momentum equation and a turbulent flow equation of the fluid are closed, and transient heat transfer is calculated until the flow field is updated for the next time and / or calculation stops; 3, the first step and the second step are repeated, wherein flow field updating and transient heat transfer calculating are alternately performed until the time arrives at the transient heat transfer termination moment. For the forced-convection heat transfer process of air in a pipe, by comparing the modeling method with a tight coupling calculation result of Fluent commercial software, the absolute error is 1 K or below, the calculation efficiency is improved by one order of magnitude, and the engineering calculation requirement is met.

Owner:BEIHANG UNIV

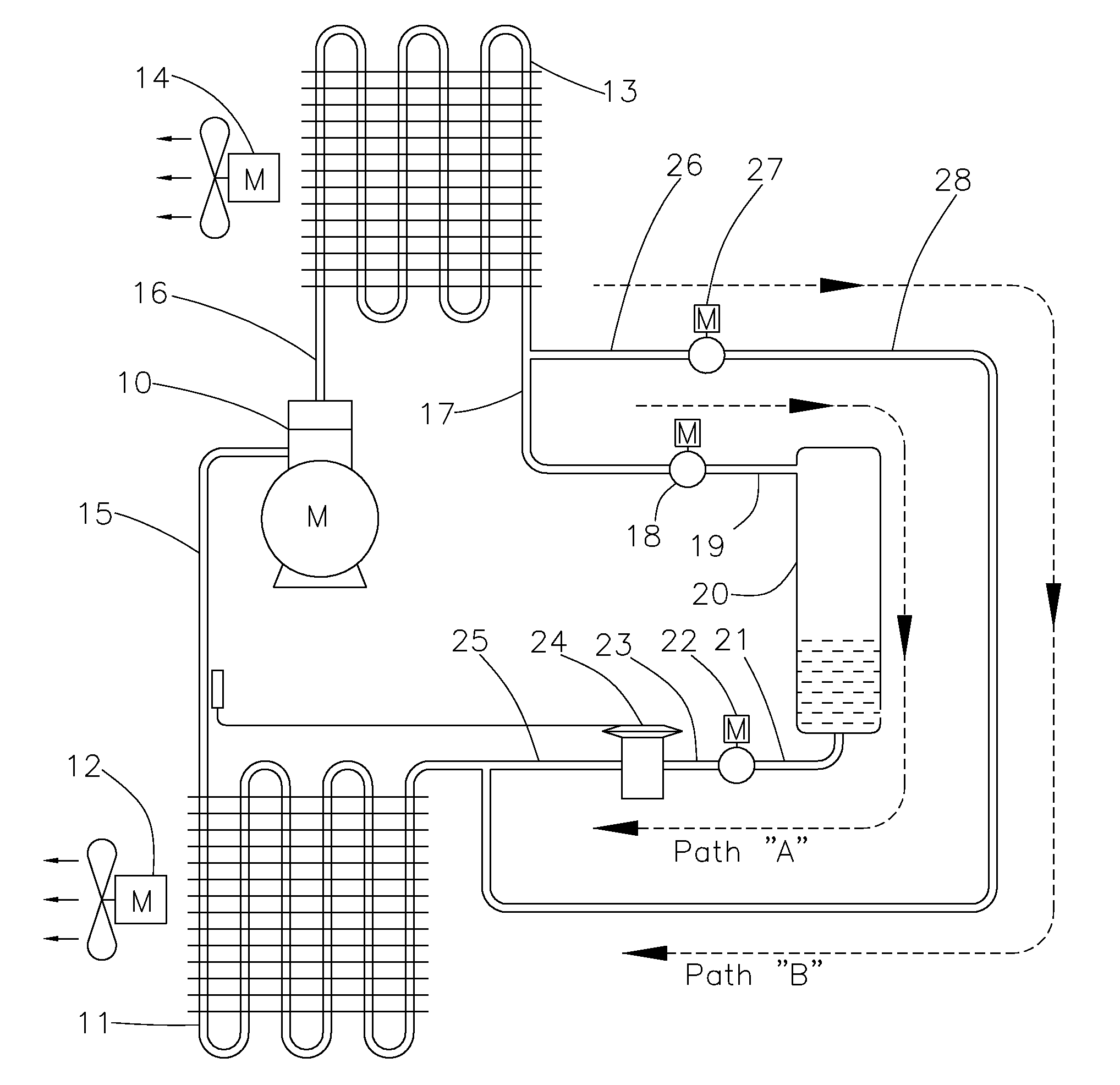

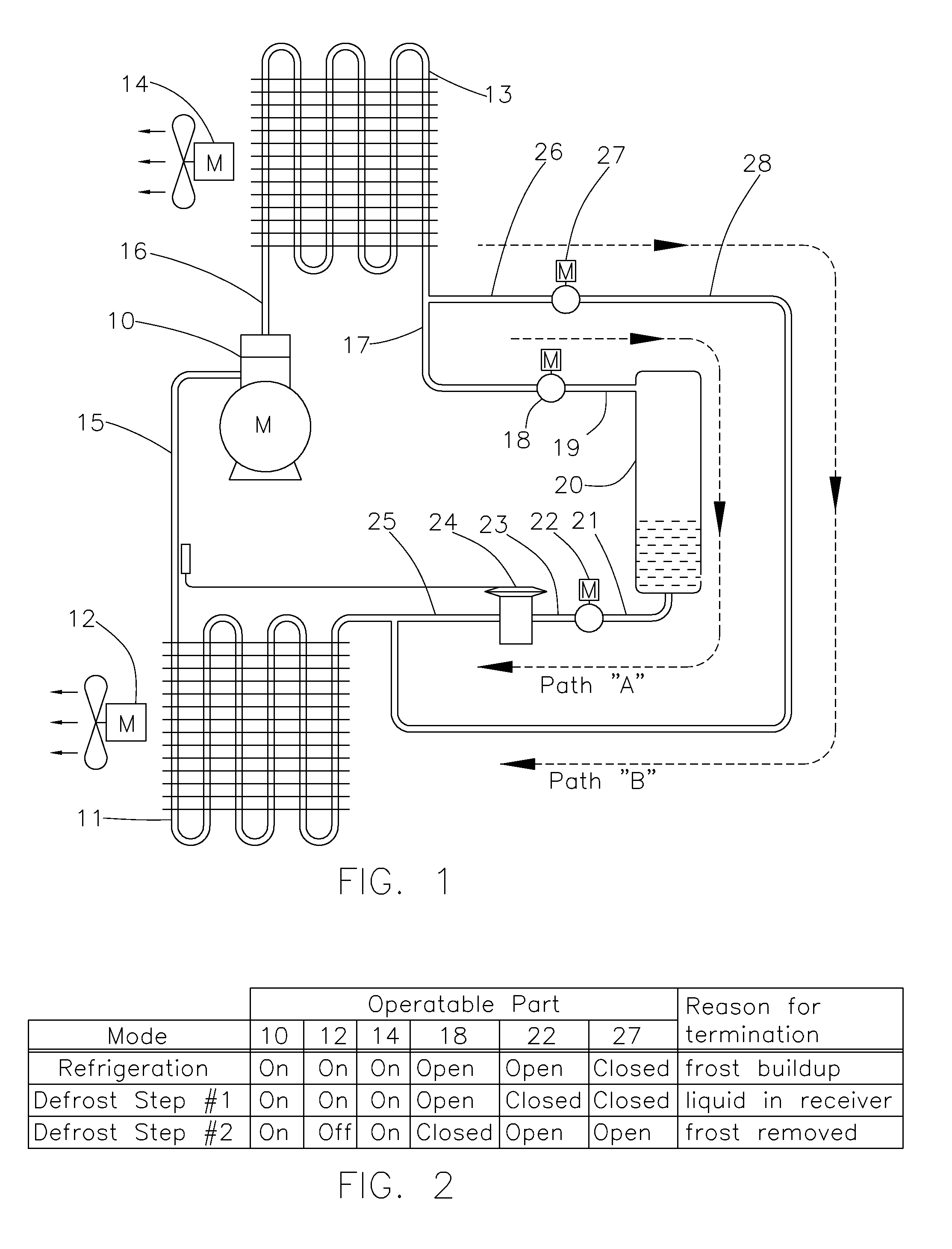

Systems and methods for defrosting an evaporator in a refrigeration system

ActiveUS9410727B1Reliable and easy to implementMinimum amount of timeMechanical apparatusEvaporators/condensersHigh densityEngineering

A gas defrosting method is disclosed which provides a distinct two-step process for defrosting a frosted evaporator. In deliberate fashion, the method assures that only refrigerant vapor returns to the compressor and thereby protects the compressor from damage due to receiving liquid refrigerant. The method optimizes the heat transfer process by maintaining full refrigerant flow through the condenser and by controlling the vapor in a nearly saturated state, high density state. In addition, the method strives to minimize the compressor power expended during the defrosting process.

Owner:HILL PHOENIX

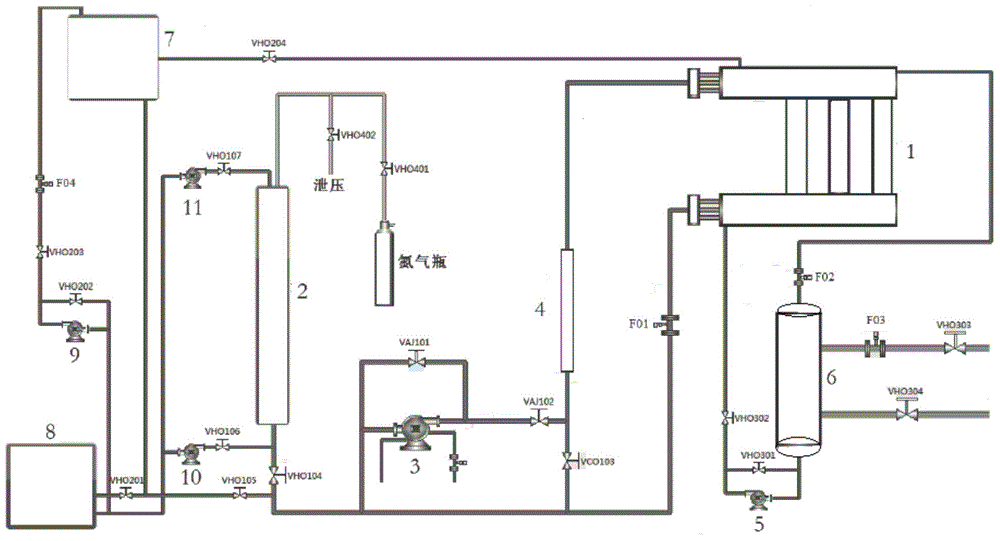

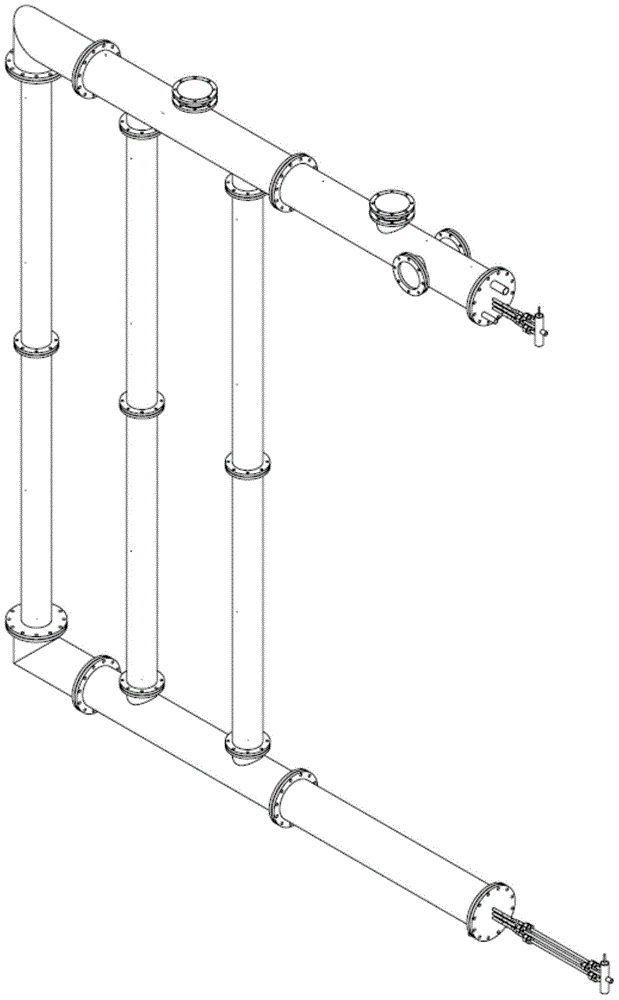

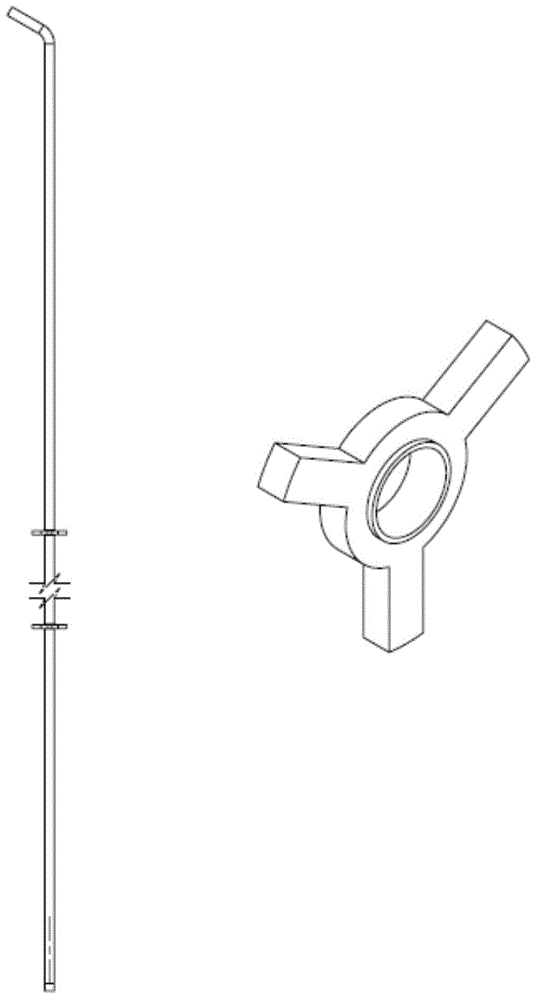

Passive residual heat removal heat exchanger testing device

ActiveCN104952497AReduce water consumptionAvoid stress deformationNuclear energy generationNuclear monitoringWater useEngineering

The invention relates to a passive residual heat removal heat exchanger testing device which comprises a heat transfer testing section, a voltage stabilizer, a shield pump, a heater, a circulation pump, a heat exchanger, a high-level water tank, a low-level water tank, a lifting pump, a water supplying pump and a spraying pump, wherein the heat transfer testing section, the voltage stabilizer, the shield pump, and the heater form a main loop system of the testing device; the heat transfer testing section comprises 3 C-shaped heat transfer pipes and a cooling water tank; the voltage stabilizer is connected with an outlet pipeline of the heat transfer testing section and an inlet pipeline of the shield pump; the shield pump is connected with the outlet pipeline of the heat transfer testing section; the flowing amount of a main loop is adjusted by adjusting a valve and a bypass valve in front of the shield pump; the heater is arranged between the shield pump and the heat transfer testing section. According to the device, the forms, sizes and materials of the heat transfer pipes are designed reasonably, so that the stress deformation problem can be reasonably avoided, the water use amount can also be greatly reduced, the heat transfer process can be simulated relatively accurately, and relatively accurate heat transfer data can be obtained.

Owner:CHINA INSTITUTE OF ATOMIC ENERGY

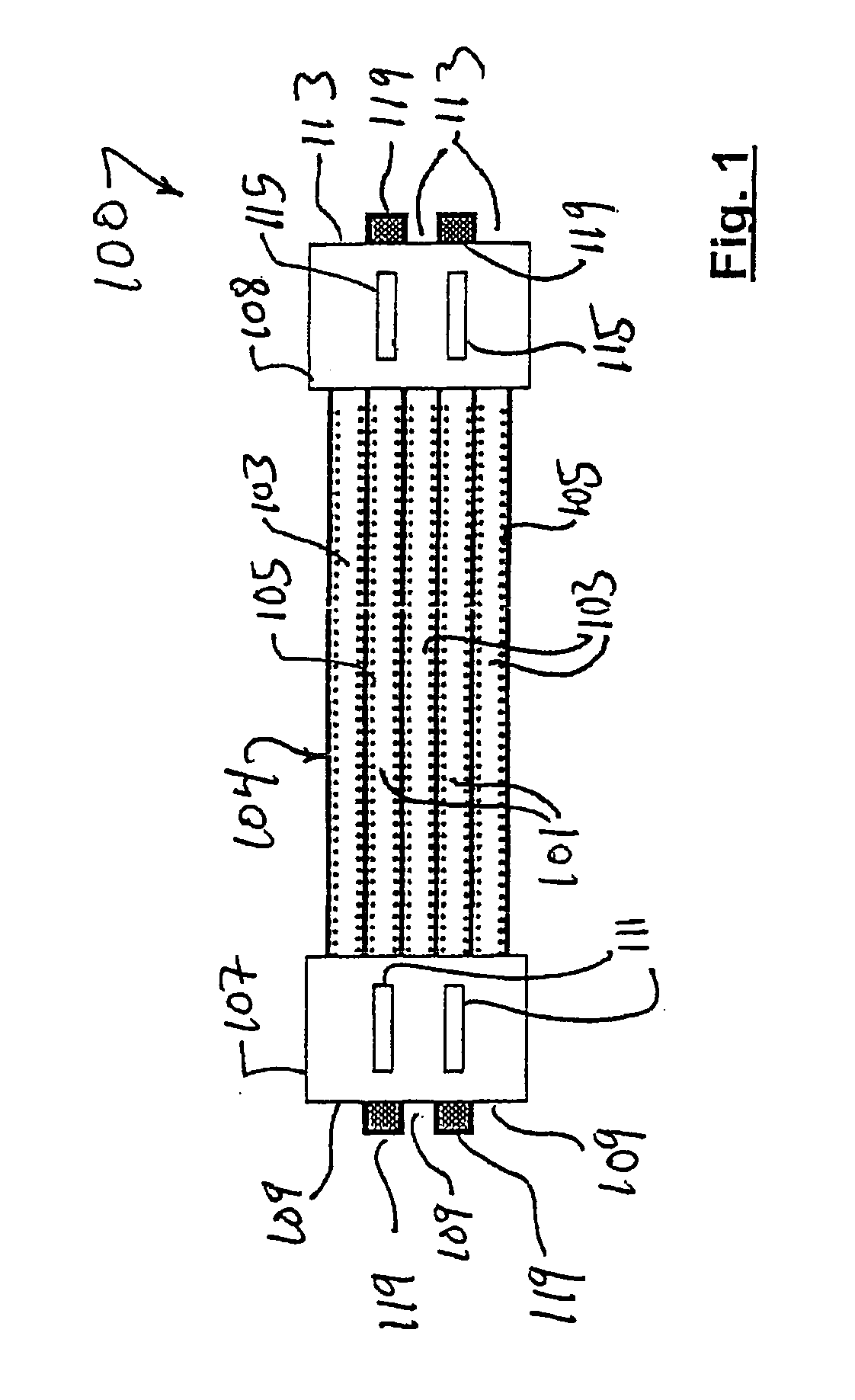

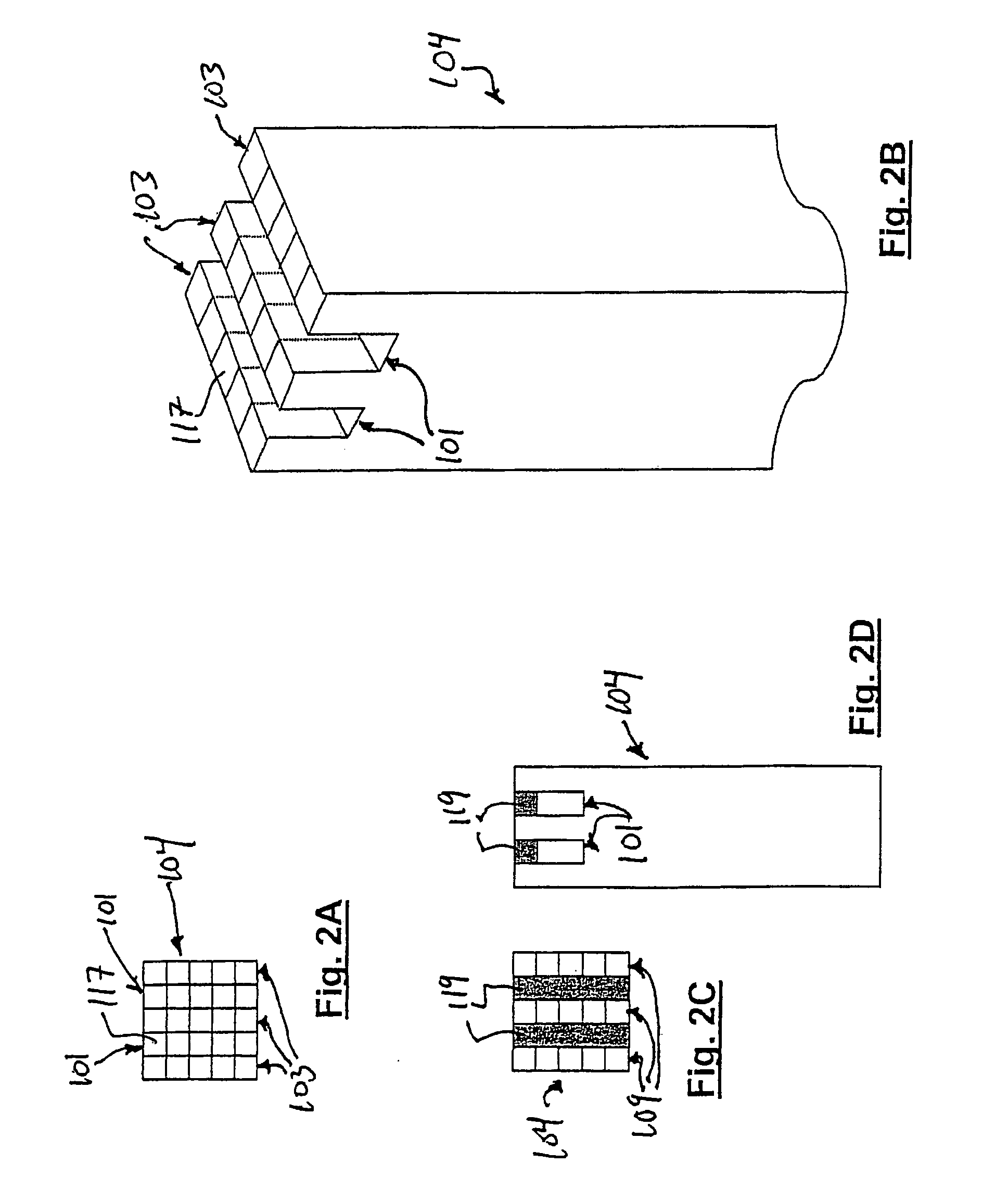

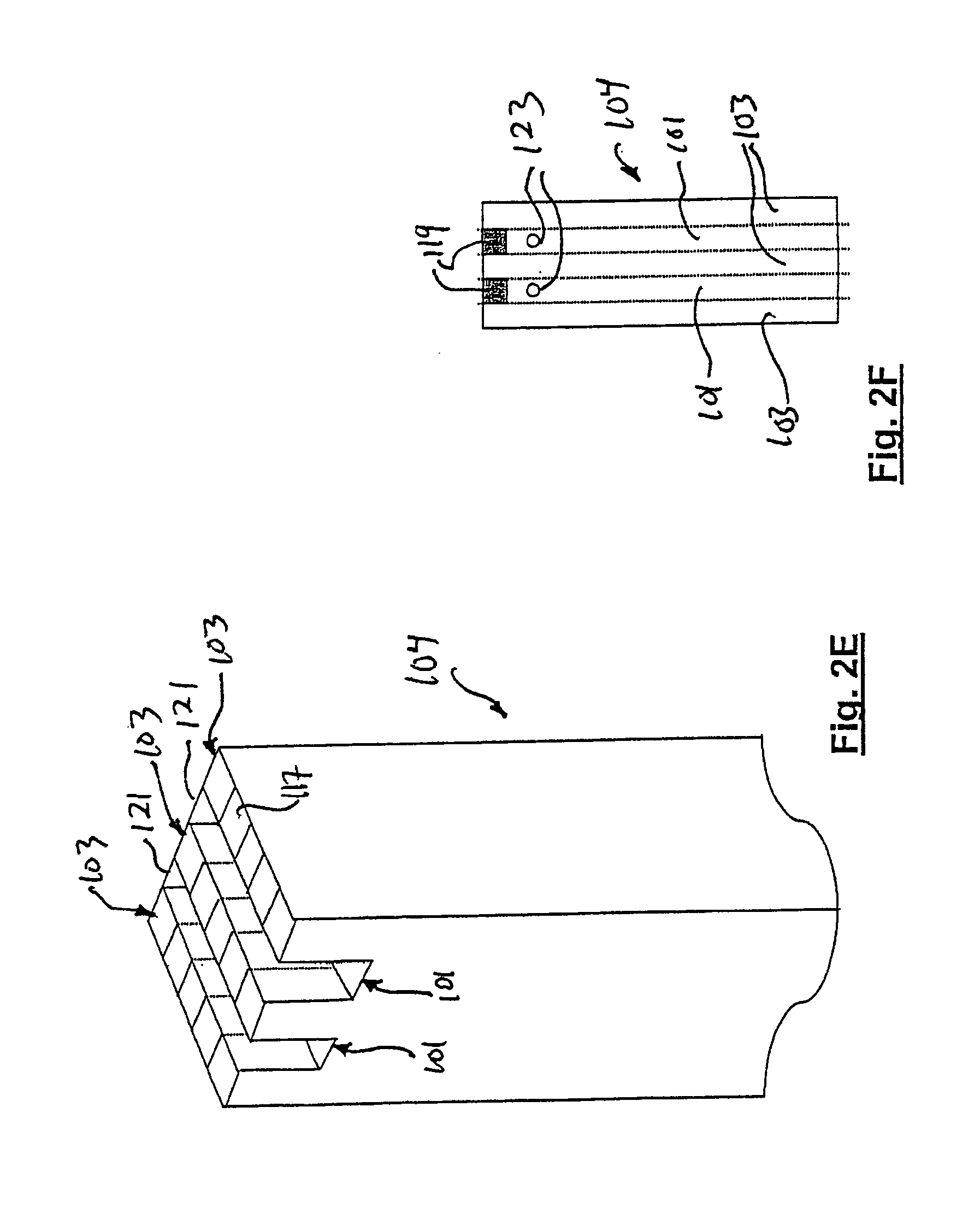

Ultrasound transducer assembly having improved thermal management

InactiveCN101166472AUltrasonic/sonic/infrasonic diagnosticsInfrasonic diagnosticsThermoelectric coolingHeat flow

An improved thermal management of an ultrasound transducer assembly is provided. The ultrasound transducer assembly includes an ultrasound transducer operable to transmit ultrasound energy along a propagation path; and a self-contained cooling system thermally coupling the ultrasound transducer to at least one heat sink. The self- contained cooling system includes at least one heat transfer member. The self-contained cooling system defines a heat flow from the ultrasound transducer assembly to the heat sink via the at least one heat transfer member. The propagation path of the ultrasound energy is opposite in direction to the heat flow path. The heat transfer process is augmented by the addition of a thermoelectric cooler positioned in thermal communication with the ultrasound transducer assembly. The self-contained cooling system provides for minimum thermal resistance, while the thermoelectric cooler maintains the heat flow in a positive direction and maintains positive thermal gradients thus enhancing the heat flow to the heat sink.

Owner:KONINKLIJKE PHILIPS ELECTRONICS NV

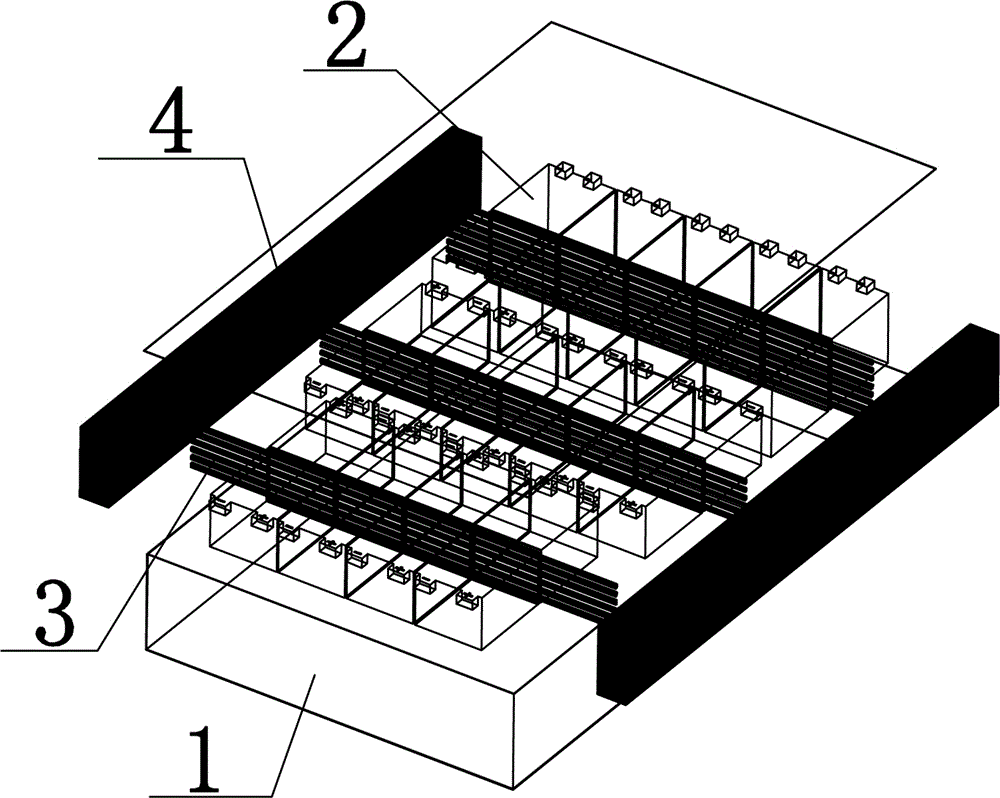

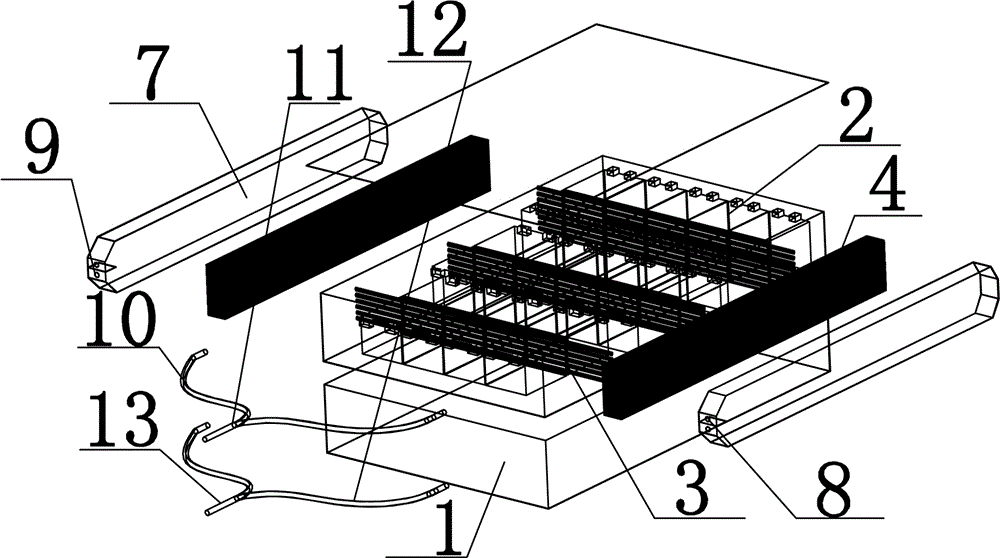

Cooling device of heat pipe fins for power battery system and mode selecting method

The invention relates to a cooling device of heat pipe fins for a power battery system and a mode selecting method. The cooling device of the heat pipe fins for the power battery system comprises a battery box, wherein a plurality of battery module groups are arranged in the battery box in parallel; each battery module group is provided with a heat pipe group in a matched manner; and two ends of each heat pipe group penetrate through the battery box and are connected with cooling fins. The mode selecting method comprises the following steps: establishing equivalent heat resistance models of the heat pipe groups and the cooling fins; establishing a concentrated parameterized ID heat transfer modules for a main heat transfer path after the equivalent heat resistance models are established; establishing a partial differential equation of a heat transfer process of each element; and after determining a convective heat transfer coefficient (h) required for the system, selecting a cooling scheme. The cooling device of the heat pipe fins for the power battery system has the advantages of high cooling efficiency, low complexity of the system and high safety; meanwhile, the expandability is high, the cooling mode can be randomly adjusted according to actual demands of products, and the degree of standardization is high; and IP67 design of the battery box is realized easily, space and cost are saved, and safety of the power battery system is improved.

Owner:杭州捷能科技有限公司

Supercritical fluid fluidized intensified heat diffusion method and its heat diffusion working medium and applications

InactiveCN101285657AReduce thermal resistanceWide operating temperature rangeFluidised bed heat exchangersEnhanced heat transferEngineering

The invention discloses a fluidization enhanced heat transfer method and a fluidization multiphase heat transfer medium. The heat transfer process is enhanced by adding particles inside a supercritical flow body. The technique can be widely applied to an air conditioner, a heat pump, a heat pipe, the heating, the cooling of an internal-combustion engine, an electronic device and the cooling of a power device, raises the energy utilization rate of the whole system, improves the heat control of the system and increases the thermal management ability.

Owner:李建民

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com