Patents

Literature

875results about "Transfer printing process" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Process for printing images on dark surfaces

InactiveUS20070104899A1Quality improvementImprove adhesionDuplicating/marking methodsTransfer printing processColor imageFiber

Novel processes for printing high quality, high resolution, multi-color images on darkly colored fibrous or porous materials or other ink absorbing materials, is disclosed. The processes are effected by digitally printing a layer of an opaque, lightly colored ink composition, followed by digitally printing the colored image thereon, and optionally further involve applying a wetting composition prior to and / or subsequent to these printings. Processes utilizing wetting compositions and / or liquid ink compositions which can interact therebetween so as to effect a chemical and / or physical change in one or more of these compositions are further disclosed.

Owner:KORNIT DIGITAL LTD

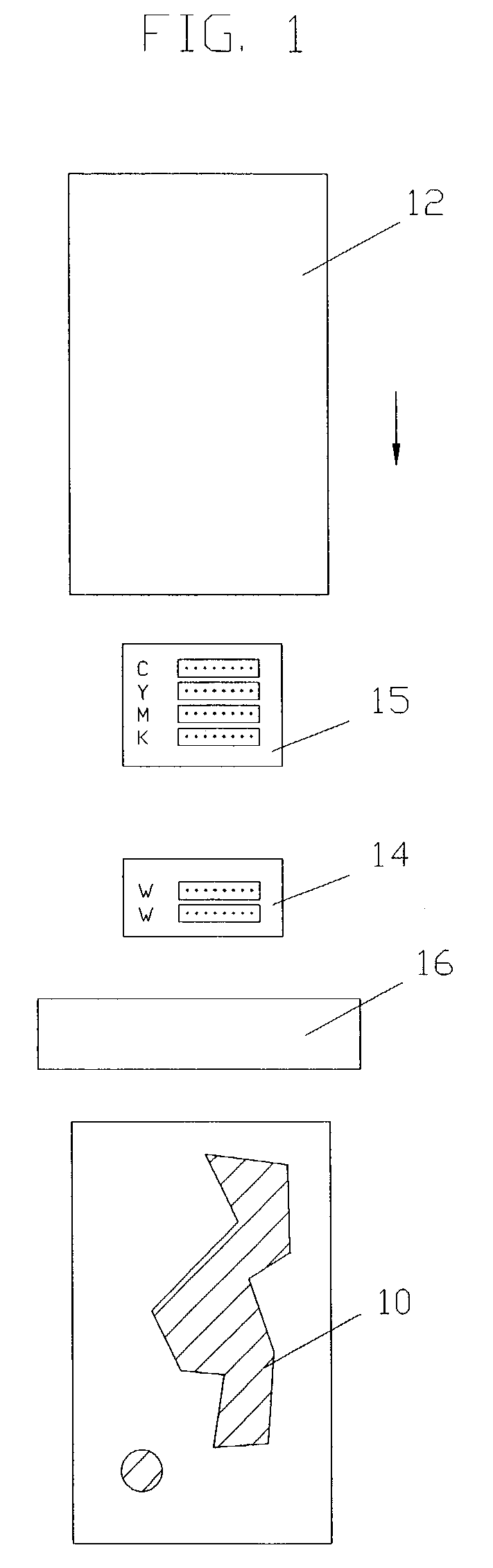

Method for image printing on a dark textile piece

InactiveUS7134749B2Measurement apparatus componentsTransfer printing processColored whiteColor printing

A method and apparatus for color printing on a dark textile piece, the method including the steps of digitally applying a white ink layer directly onto a textile piece, optionally curing the white ink layer, and digitally printing a colored image on said ink layer.

Owner:KORNIT DIGITAL LTD

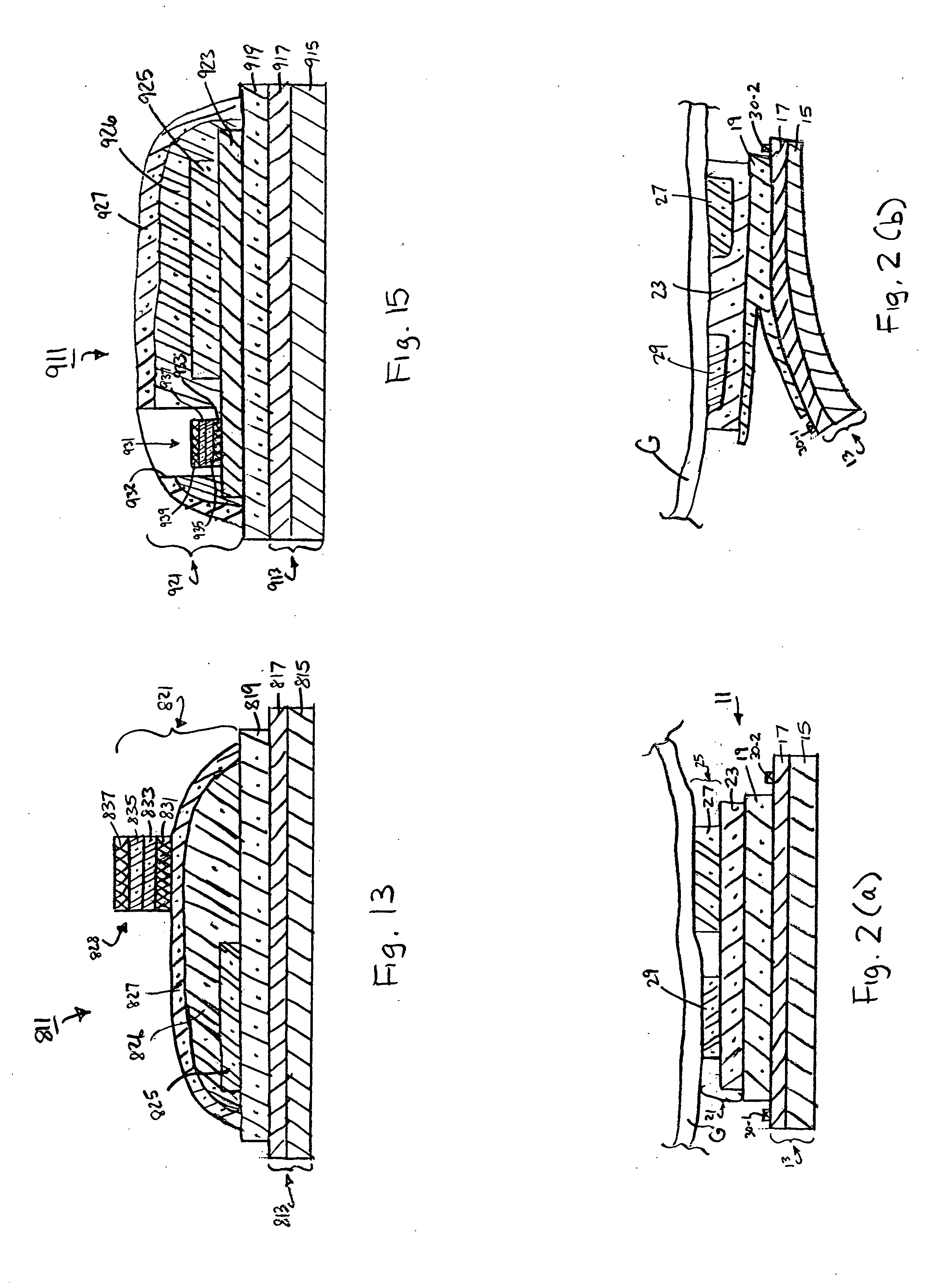

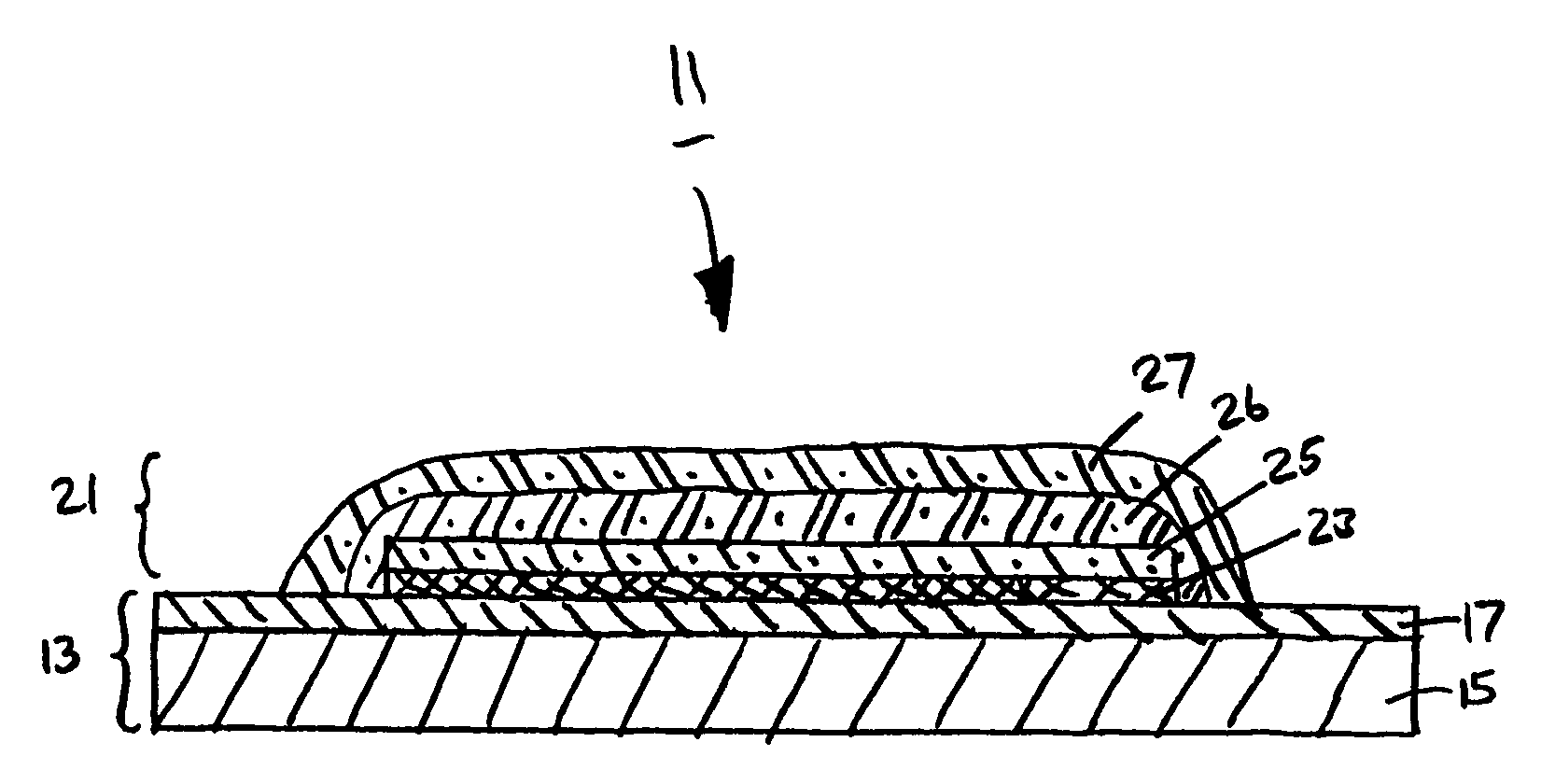

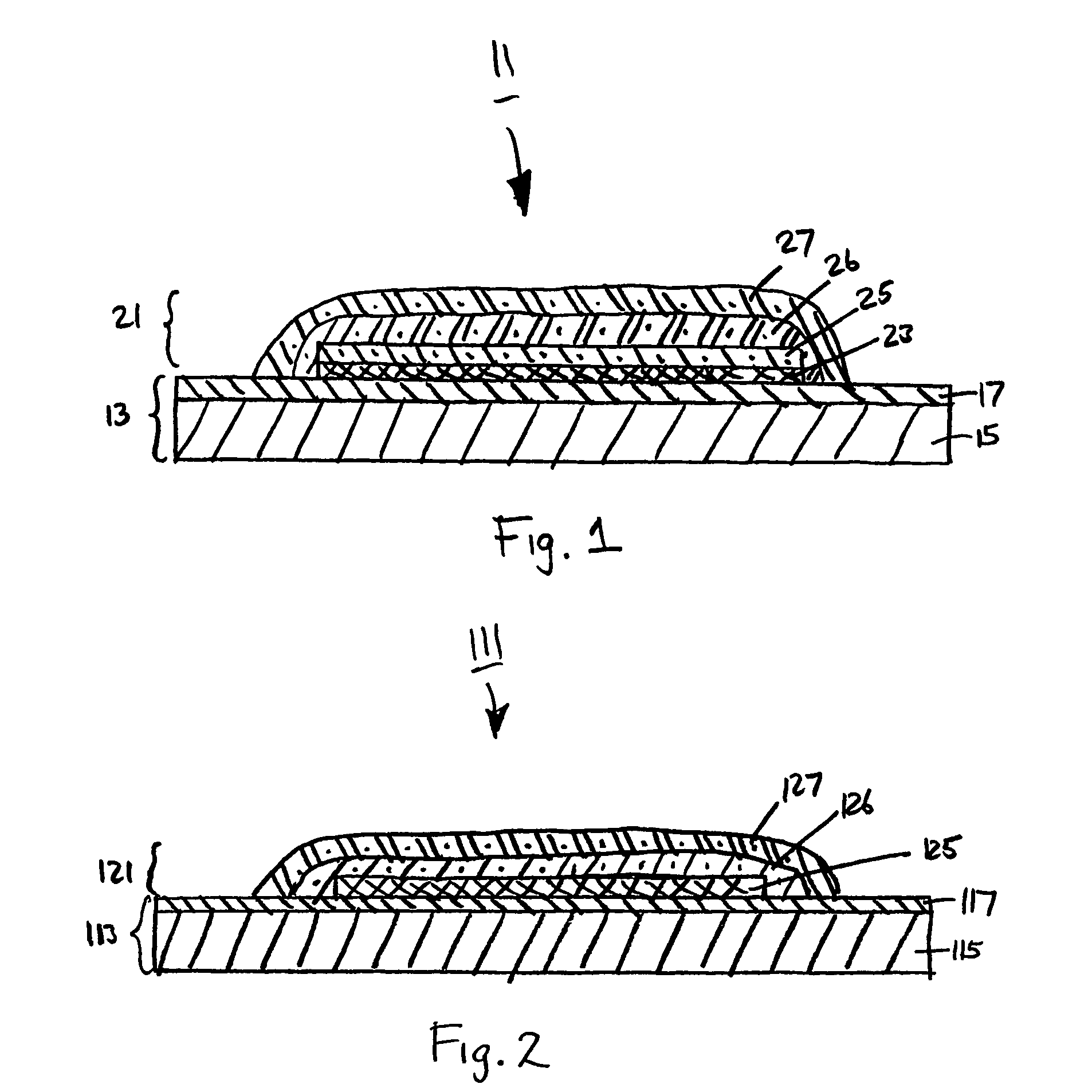

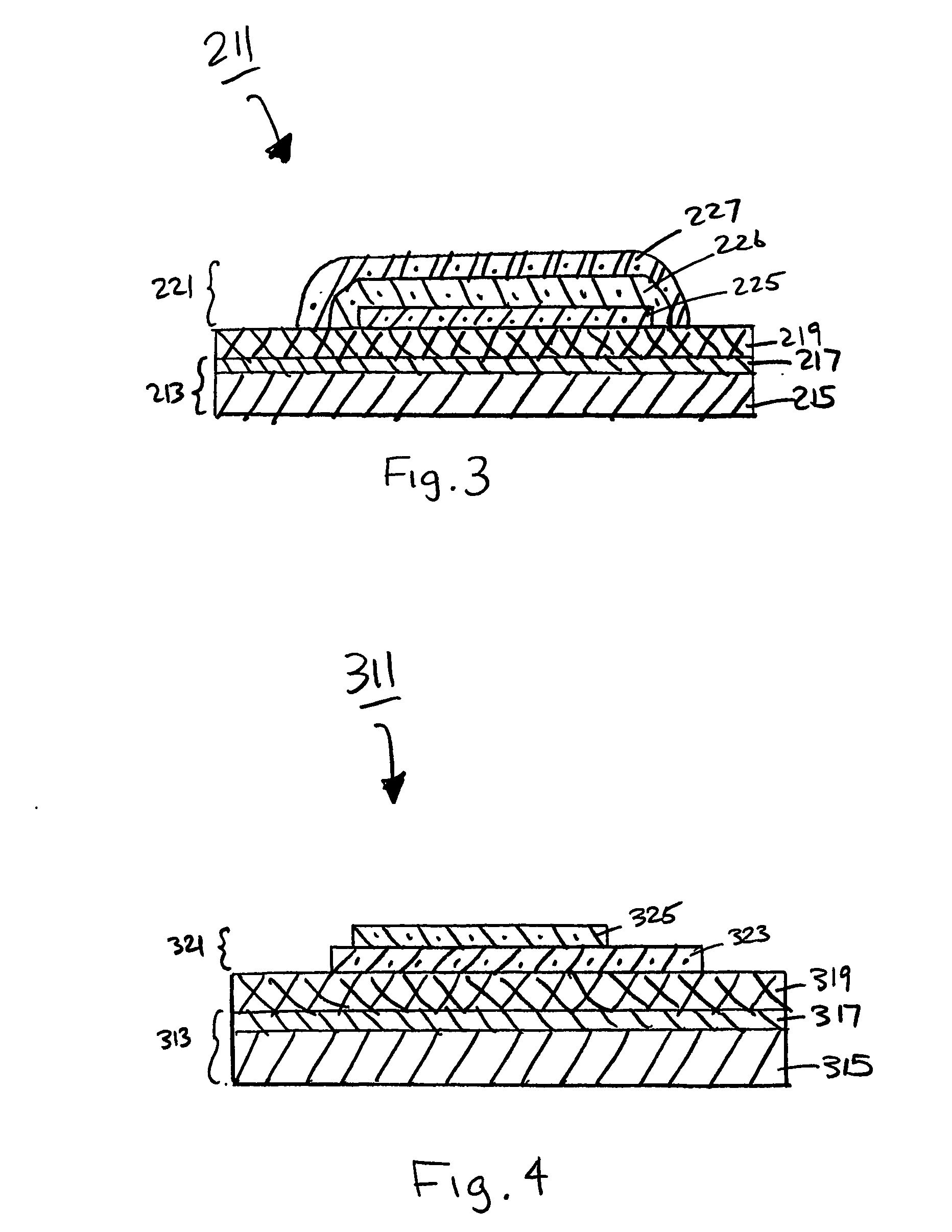

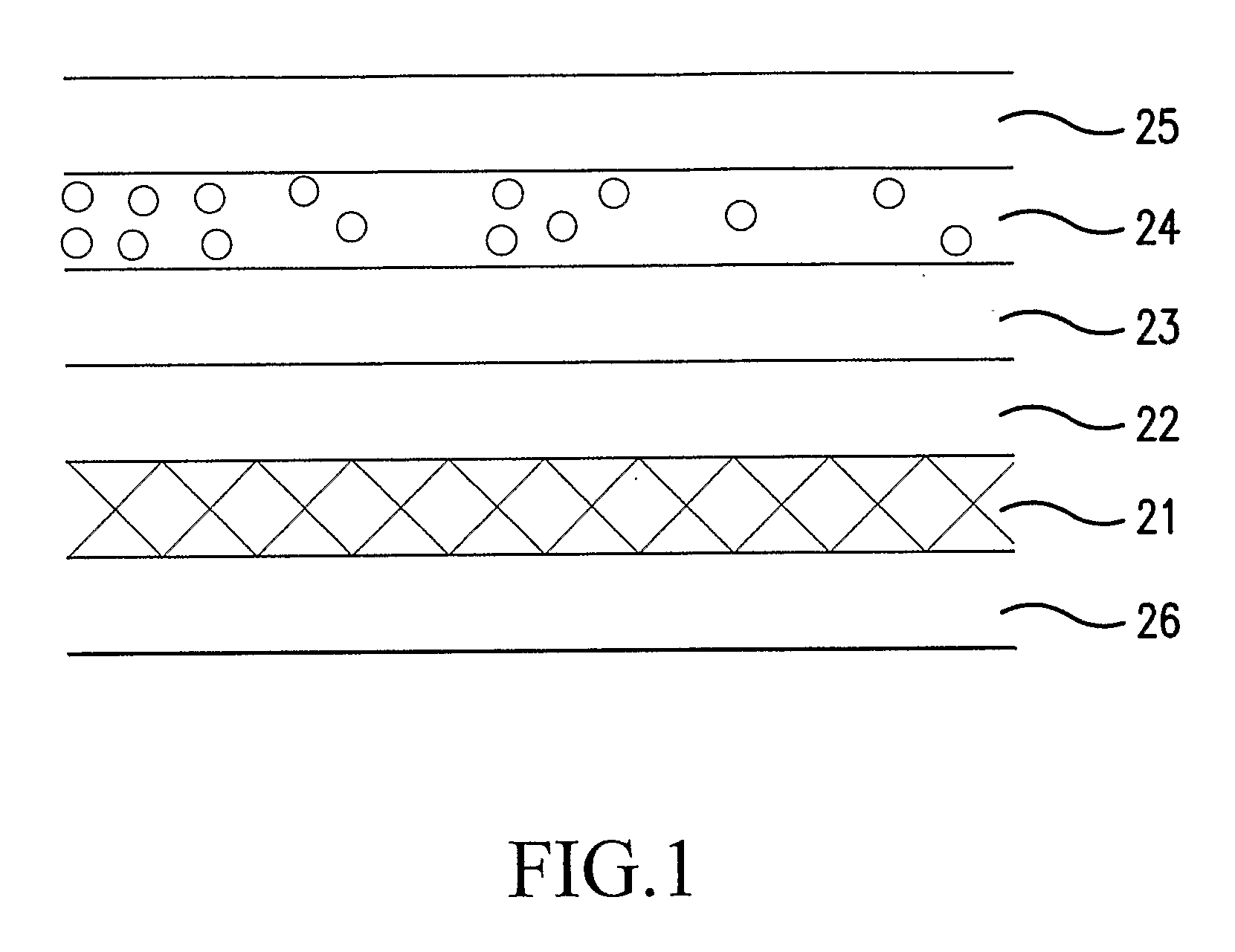

Heat-transfer label well-suited for labeling fabrics and methods of making and using the same

A method for labeling fabrics, such as fabric garments, and a heat-transfer label well-suited for use in said method. In one embodiment, the heat-transfer label comprises (i) a support portion, the support portion comprising a carrier and a release layer; (ii) a wax layer, the wax layer overcoating the release layer; and (iii) a transfer portion, the transfer portion comprising an adhesive layer printed onto the wax layer and an ink design layer printed onto the adhesive layer. Preferably, at least a portion of the ink design layer is printed using a variable printing technique, such as thermal transfer printing.

Owner:AVERY DENNISON CORP

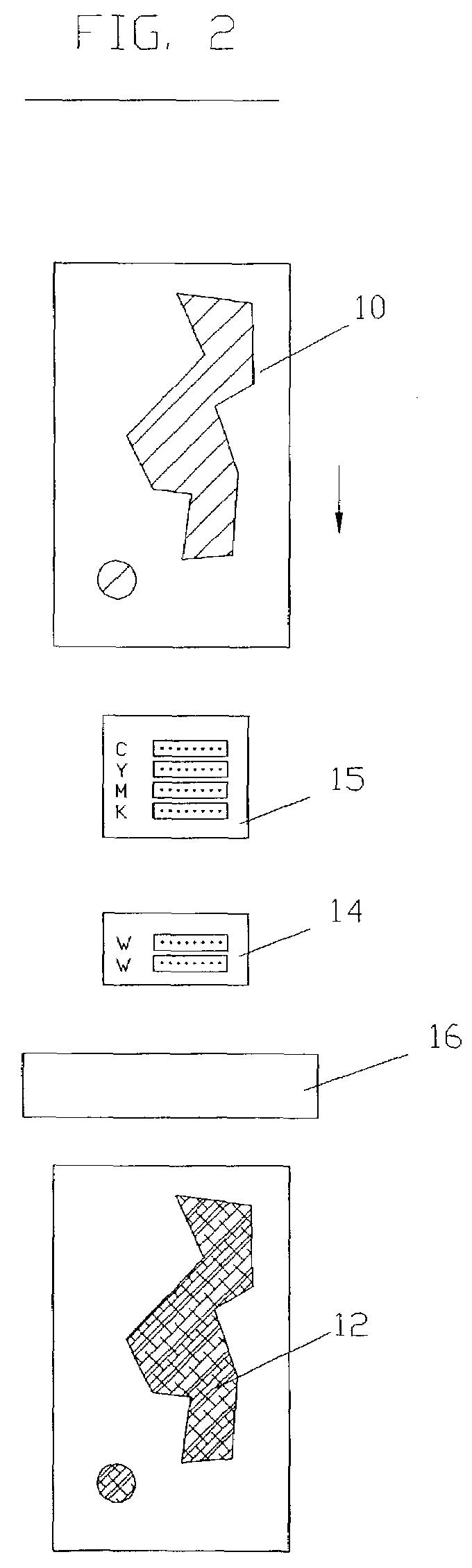

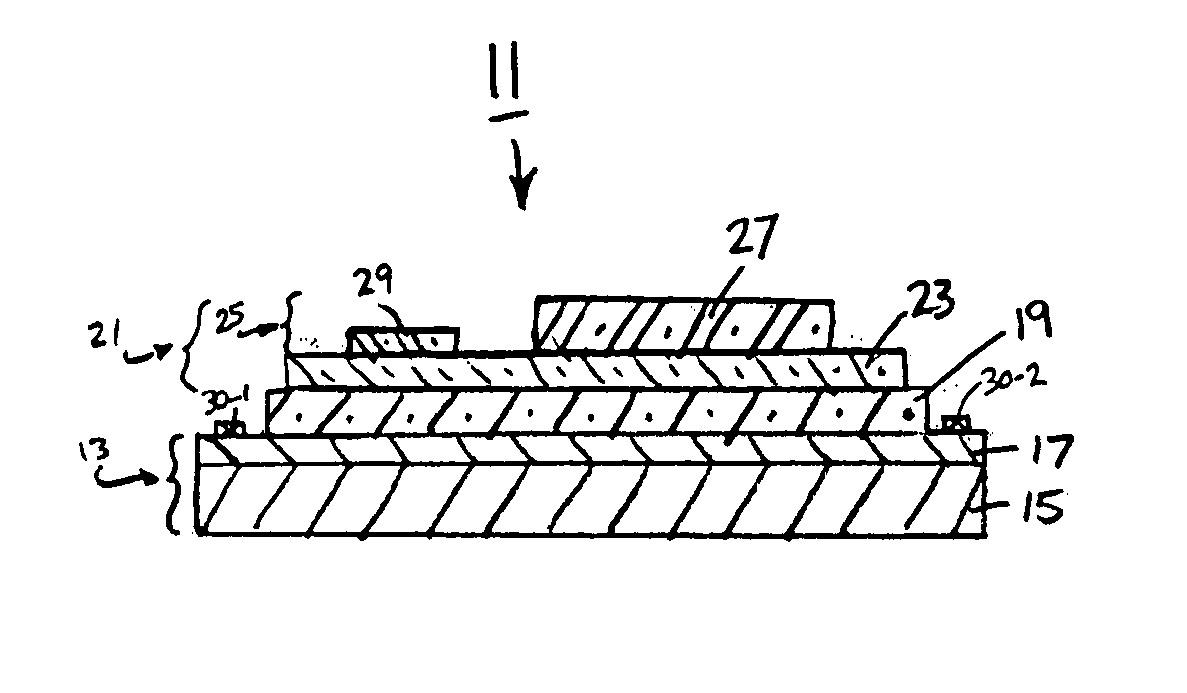

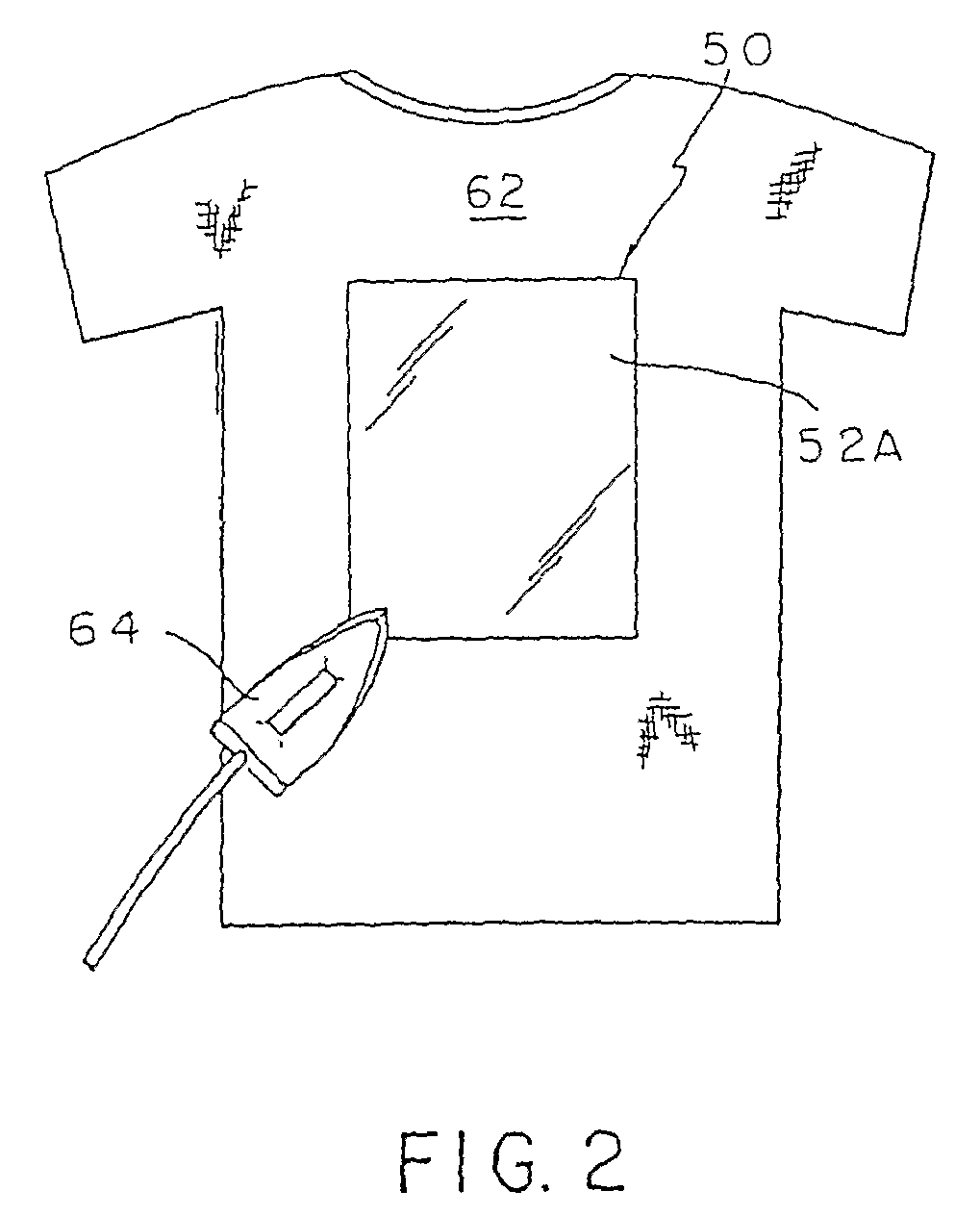

Method for labeling fabrics and heat-transfer label well-suited for use in said method cross-reference to related applications

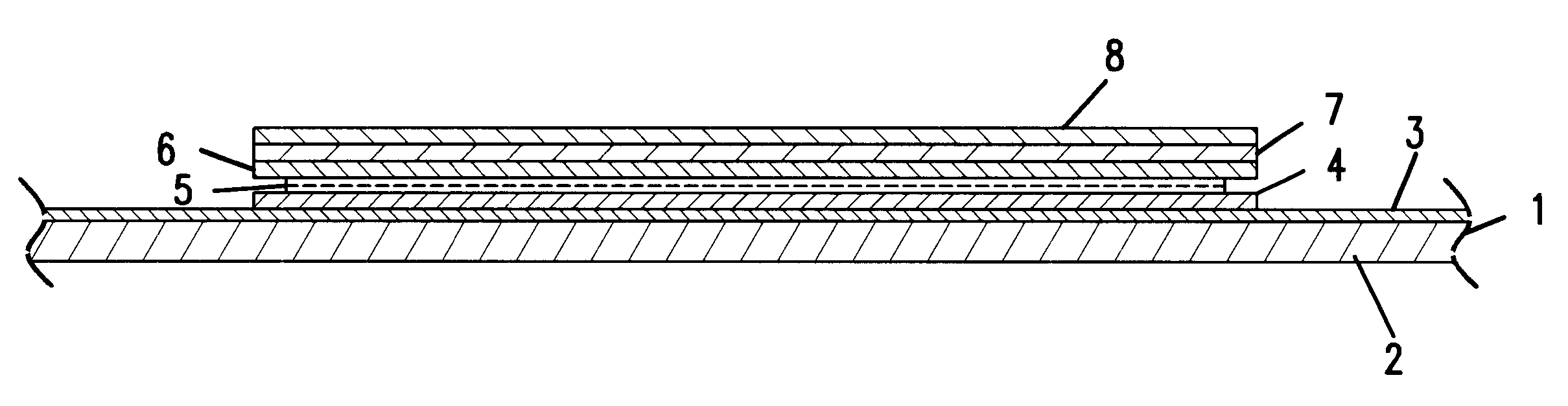

A method for labeling fabrics, such as fabric garments, and a heat-transfer label (311) well-suited for use in said method. In one embodiment, the heat-transfer label (311) comprises (i) a support portion (313), the support portion (313) comprising a carrier (315) and a release layer (317); (ii) a wax layer (319), the wax layer overcoating the release layer (317); and (iii) a transfer portion (321), the transfer portion (321) comprising an adhesive layer (323) printed directly onto the wax layer (319) and an ink design layer (325) printed directly onto the adhesive layer (323). Each of the adhesive layer (323) and the ink design layer includes a non-cross-linked PVC resin. The ink design layer may be screen printed onto the adhesive layer (323) or may be printed onto the adhesive layer (323) using thermal transfer printing, ink jet printing or laser printing.

Owner:AVERY DENNISON CORP

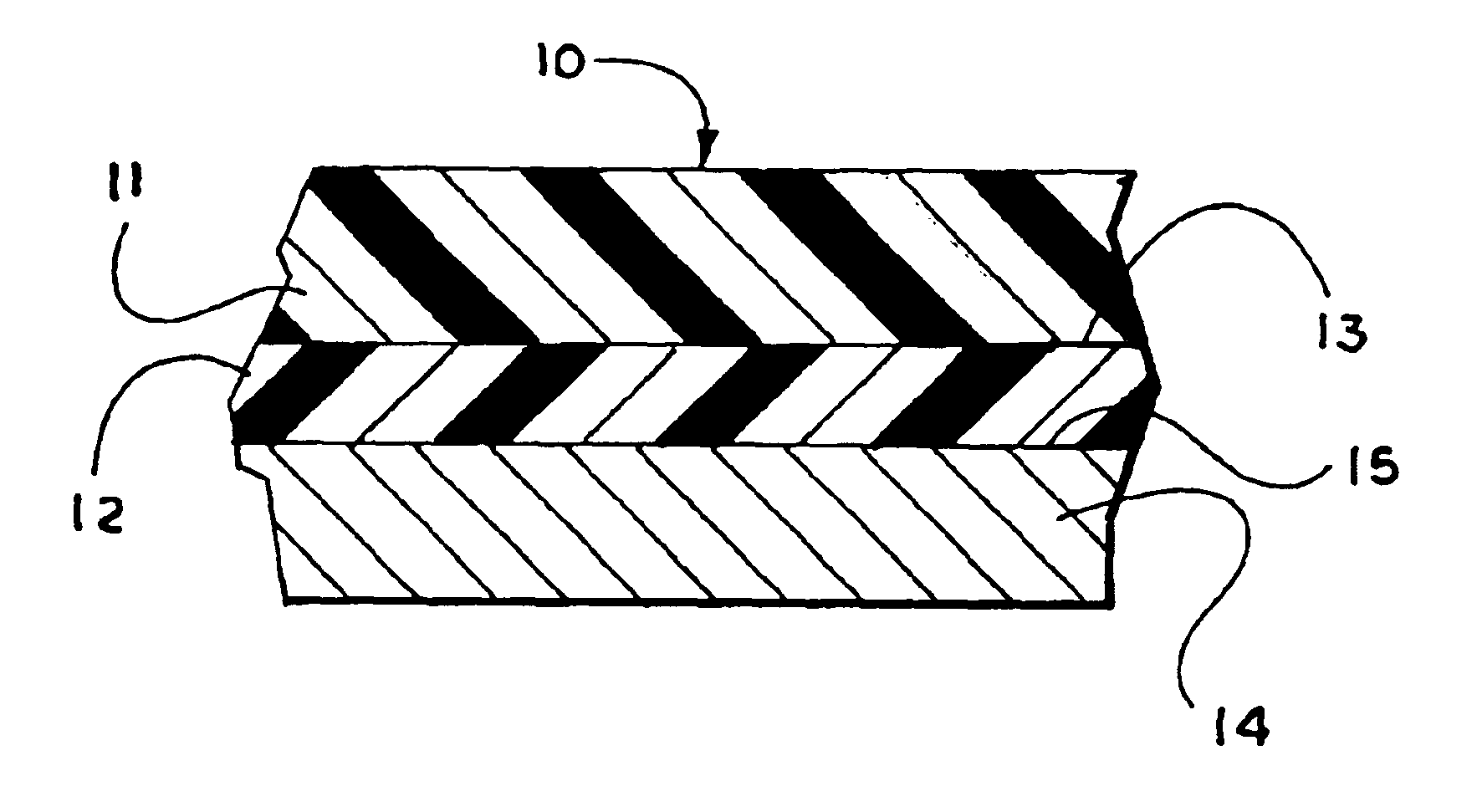

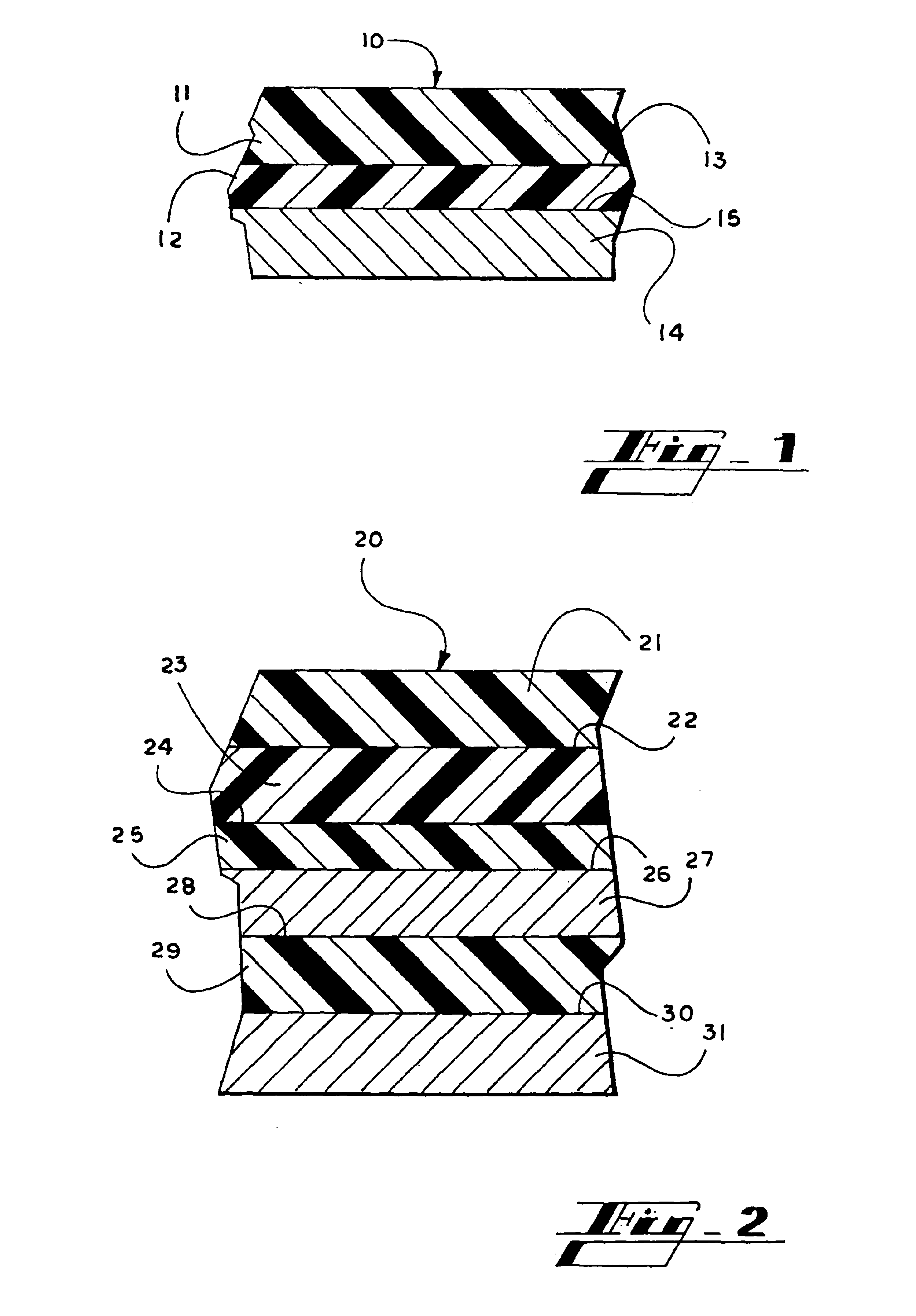

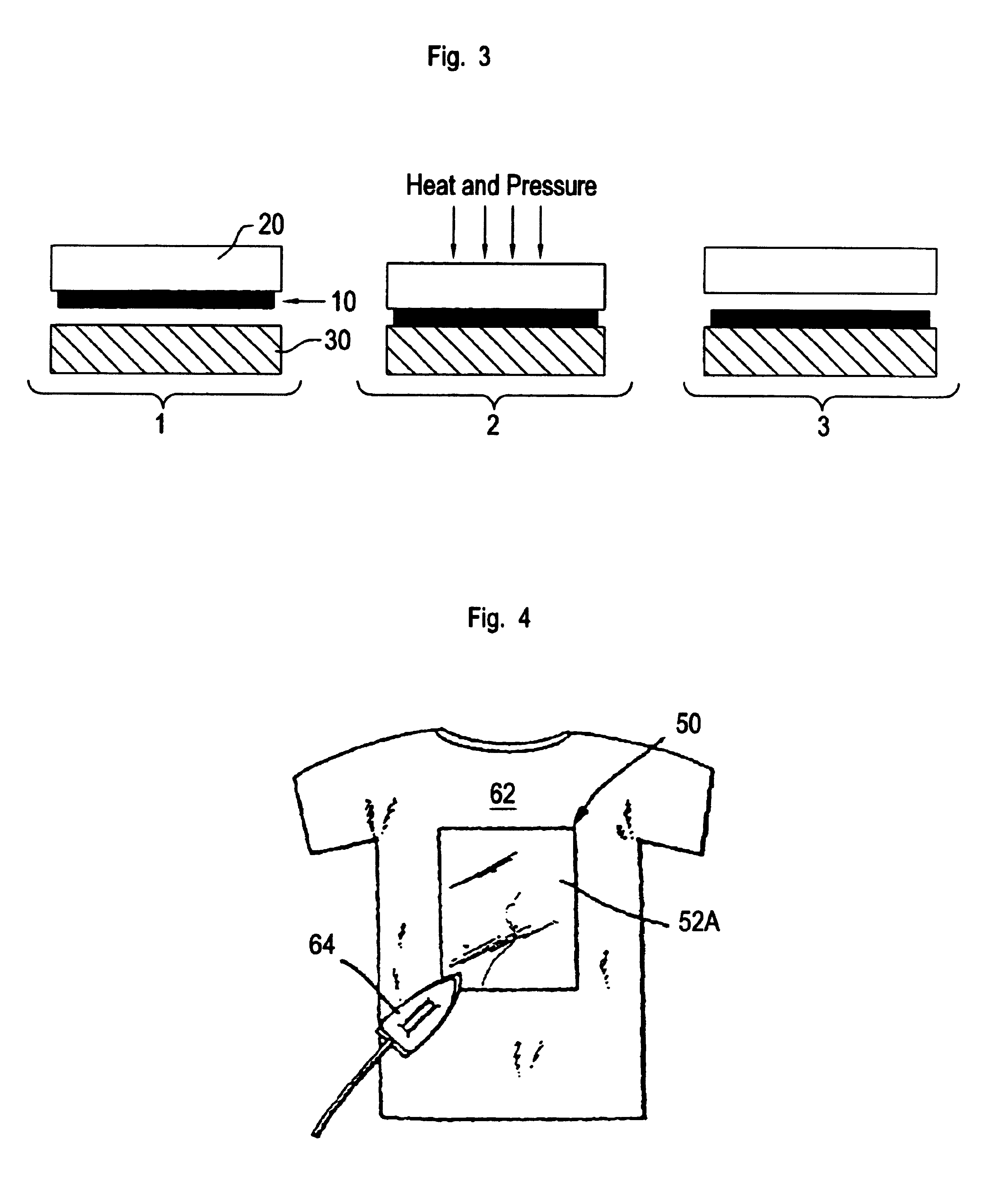

Heat transfer material having meltable layers separated by a release coating layer

InactiveUS6916751B1Improve breathabilityLess coating thicknessDuplicating/marking methodsTransfer printing processYarnMaterials science

Owner:HAWK J RICHARD AGENT FOR CERTAIN LENDERS

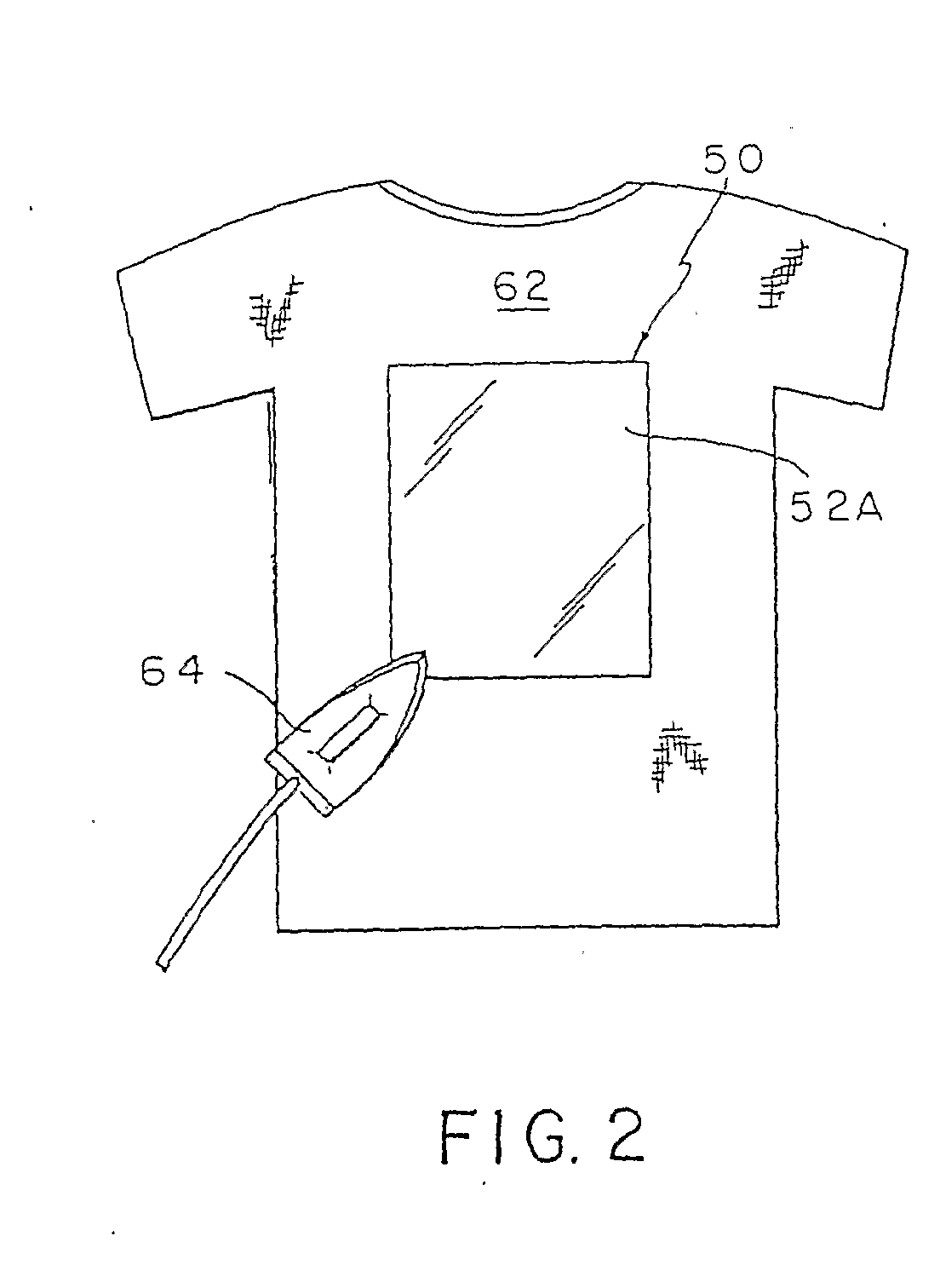

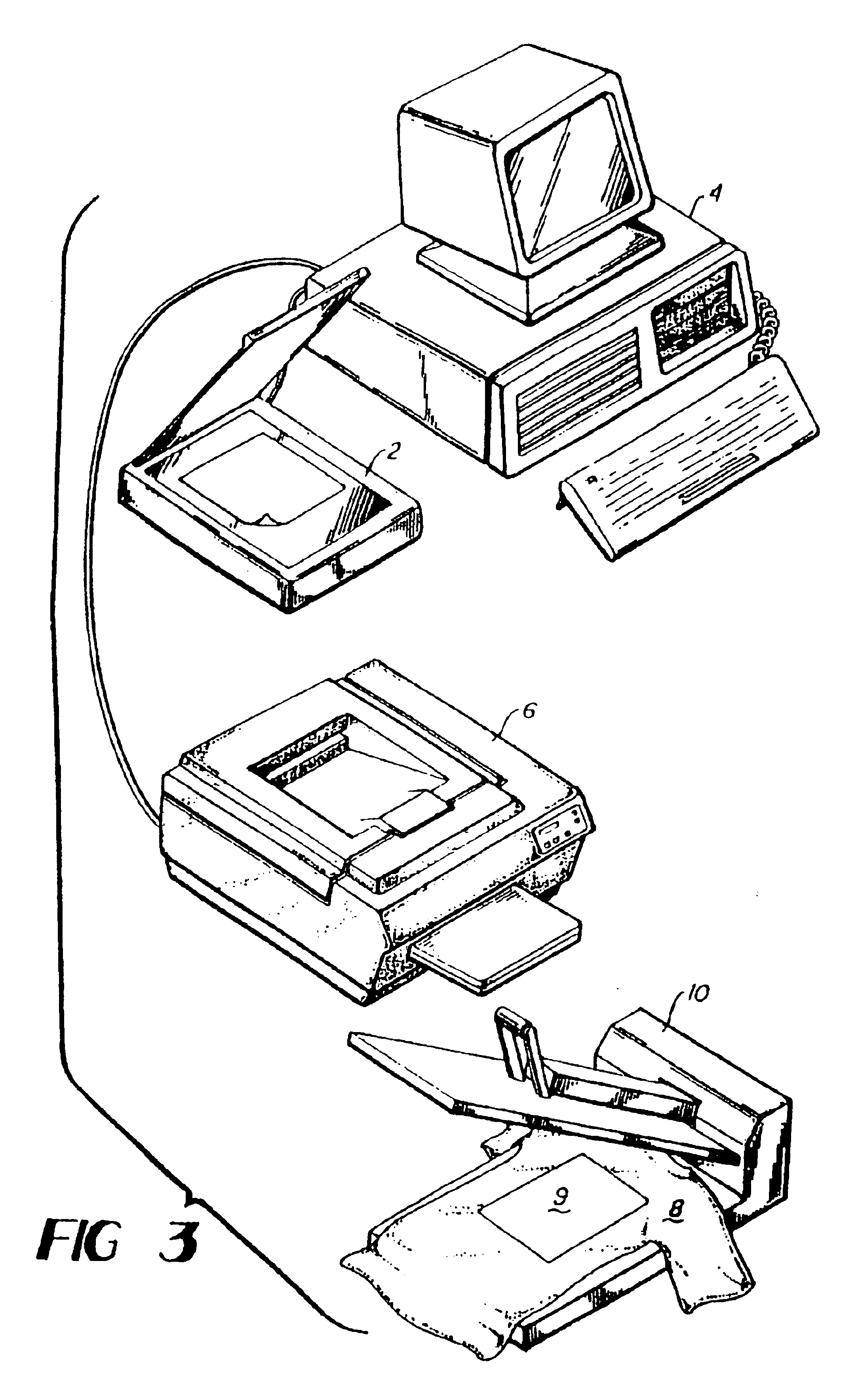

Sublimination dye thermal transfer paper and transfer method

InactiveUS7220705B2Simple technologyAccurate imagingTransfer printing processAblative recordingPolyesterReverse order

An image transfer sheet is provided which comprises a support, a barrier layer, a polyester layer and an optional a sublimation dye receiving layer; wherein the polyester is capable of being physically separated by the user without water, chemicals or heat. The peeled and imaged polyester is placed onto a receptor element and a non-stick sheet is optionally placed thereon. An iron is placed onto the optional non-stick sheet to drive the polyester and image into the receptor. The invention allows for both correct order image-wise printing and reverse order image-wise printing. This invention allows sublimation dye printing onto a cotton receptor.

Owner:SCHWENDIMANN JODI

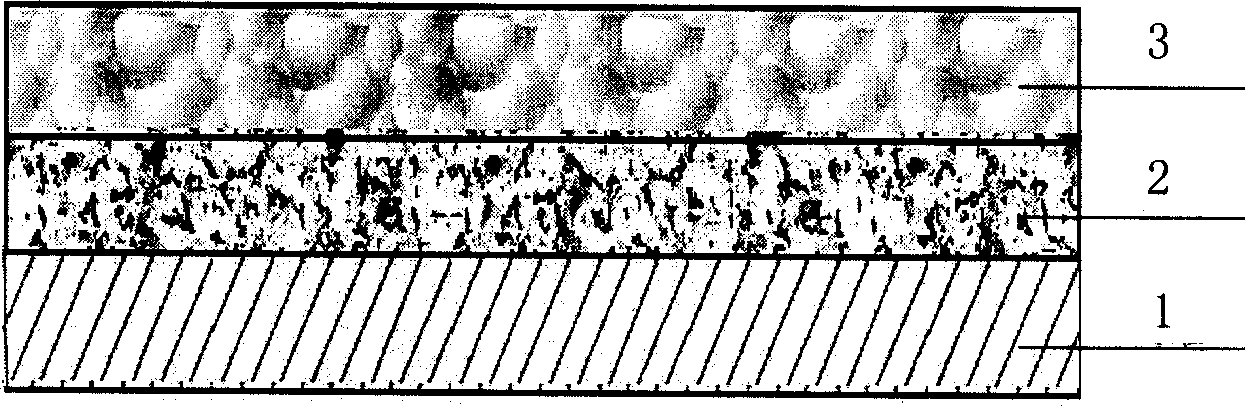

Wet method transfer printing method for natural fiber and polyamide fibre

InactiveCN101105006AHigh color yieldReduce consumptionTransfer printing processDyeing processPolyamidePrinting ink

The invention provides a wet-method transfer printing process of natural fiber and nylon, which mainly comprises the following steps: (1) selecting acidic printing ink or active printing ink; (2) printing: printing the surface of PET or BOPP film with the selected printing ink to obtain a transfer printed film; (3) transfer printing: treating natural fiber and nylon with a soaking liquid, subjecting the transfer printed film and printed fabric simultaneously to the compression by a rolling machine; and (4) oven-drying: oven-drying the fabric after the transfer printing is completed and baking to allow color fixation. The invention has the advantages of high transfer printing rate, high color yield of fabric, bright color, good color fastness, less pollution, reduced water consumption, simple process, high production efficiency, low cost, and success in non-paper transfer printing.

Owner:常州涵源新印花有限公司

Method and apparatus for forming dye sublimation images in solid plastic

InactiveUS6998005B2Avoid stickingEnhance the imageLamination ancillary operationsDecorative surface effectsEngineeringPlastic film

Owner:SEKISUI KYDEX LLC

Heat transfer paper with peelable film and crosslinked coatings

InactiveUS7364636B2Contributes significantly to the durability of the transferred imagePrevent penetrationDecorative surface effectsLayered productsEngineeringCoating

The present invention was directed to a unique heat transfer material for use in transferring an image-bearing coating onto a substrate, such as an article of clothing. The heat transfer material of the present invention may be used in cold peel transfer processes, resulting in an image-bearing coating having superior washability, compared to conventional image-bearing coatings. Additionally, the materials may be used on dark colored fabrics without graying of the opaque background or dulling of colored images typically associated with printing on darker fabrics. The heat transfer material of the present invention produces superior results due to the addition of crosslinking agents to the coatings.

Owner:HAWK J RICHARD AGENT FOR CERTAIN LENDERS

Sublimation Printing Processes and Fabric Pretreatment Compositions for Ink Jet Printing onto Arbitrary Fabrics

InactiveUS20110169901A1Outstanding washfastness to repeated launderingImprove washing fastnessTransfer printing processDyeing processTextile fiberEngineering

An ink jet printing process for sublimation printing of arbitrary textile fiber substrates, wherein the fiber materials are pretreated with an aqueous coating composition, enabling ink jet printing of natural and regenerated cellulosic fibers and blends thereof with synthetic fibers, by direct sublimation or sublimation transfer printing, applying to said fibers a novel textile coating or fabric pretreatment composition, wherein said textile coating or fabric pretreatment comprises: an aqueous dispersion of fluoropolymer particles and a non-fluoropolymer binder.

Owner:ADVANCED COMM SOLUTIONS

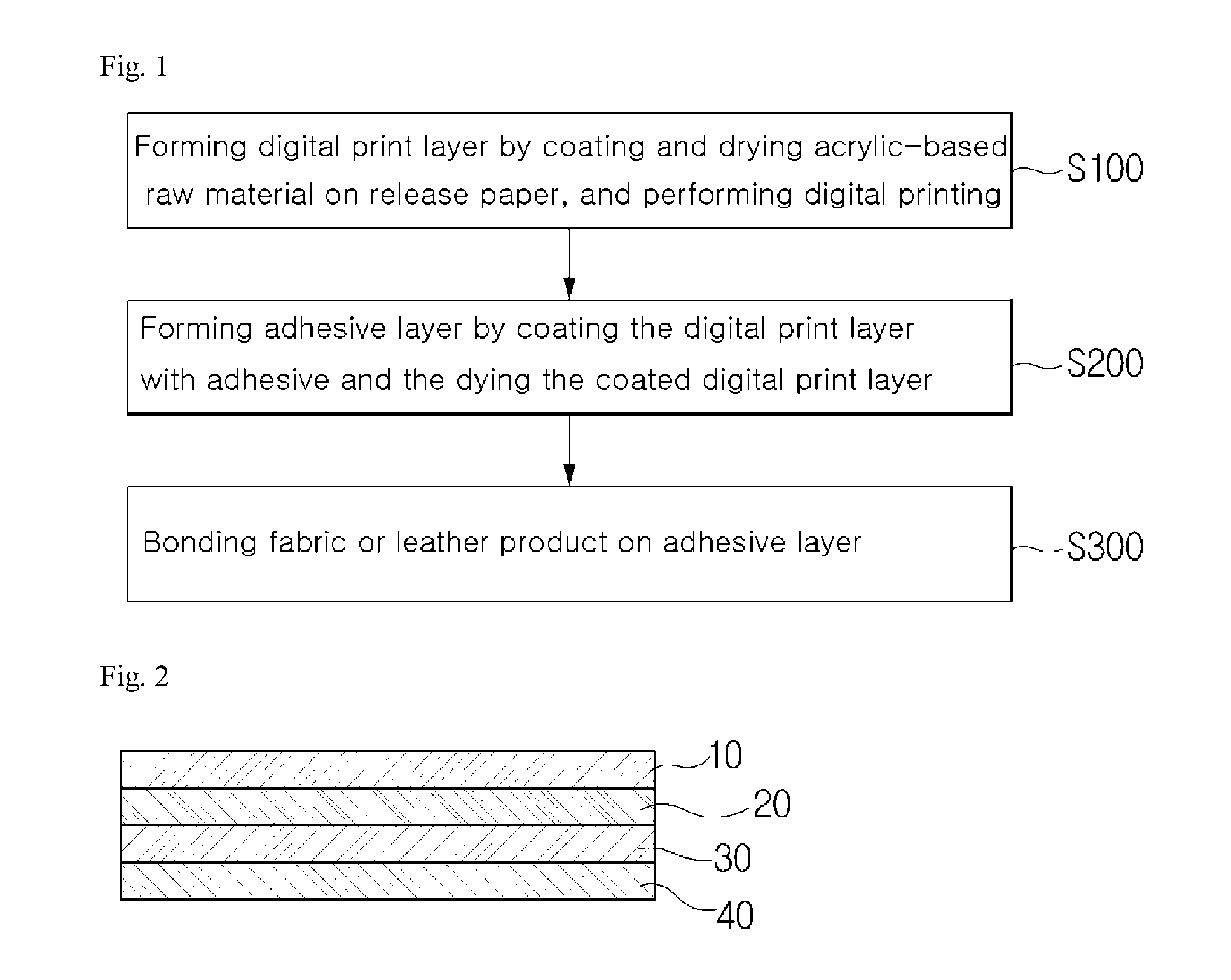

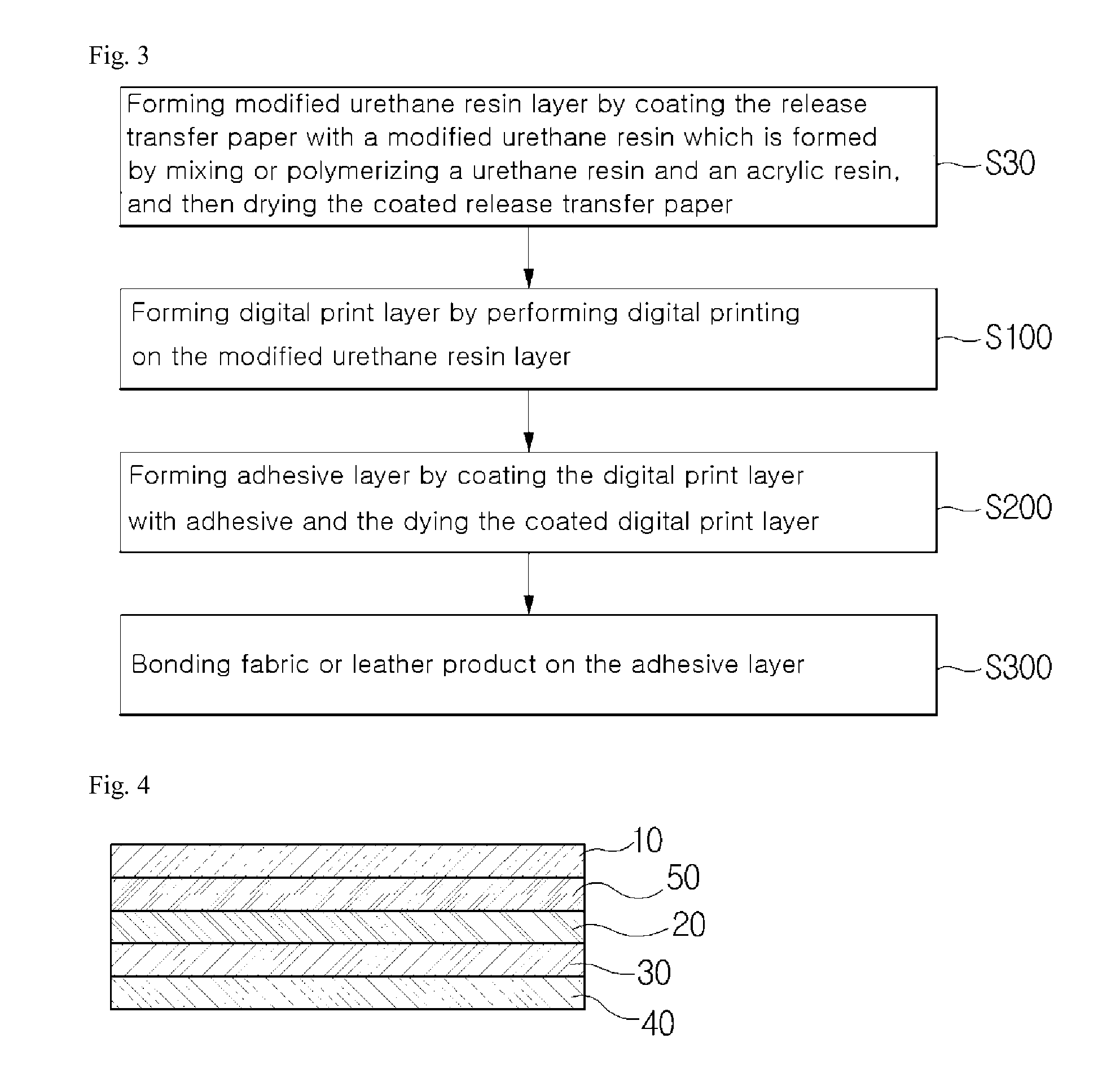

Method for printing fabric or leather product, and printed matter printed by using the same

ActiveUS20160067984A1Simple processReduce manufacturing costDecorative surface effectsDuplicating/marking methodsAdhesiveComputer printing

The present invention relates to a method for printing fabric or leather product, and printed matter printed by using the same, the method comprising the steps of: a) forming a digital print layer by performing digital printing on a release transfer paper by using an inkjet printer; b) forming adhesive layer by coating the digital print layer with an adhesive, and drying for a predetermined time; and c) bonding fabric or leather product to the adhesive layer. Thus, the present invention can precisely print fabric or leather product with high resolution and can enable customized printing so as to allow small quantity batch production.

Owner:CHUNG DOO HO

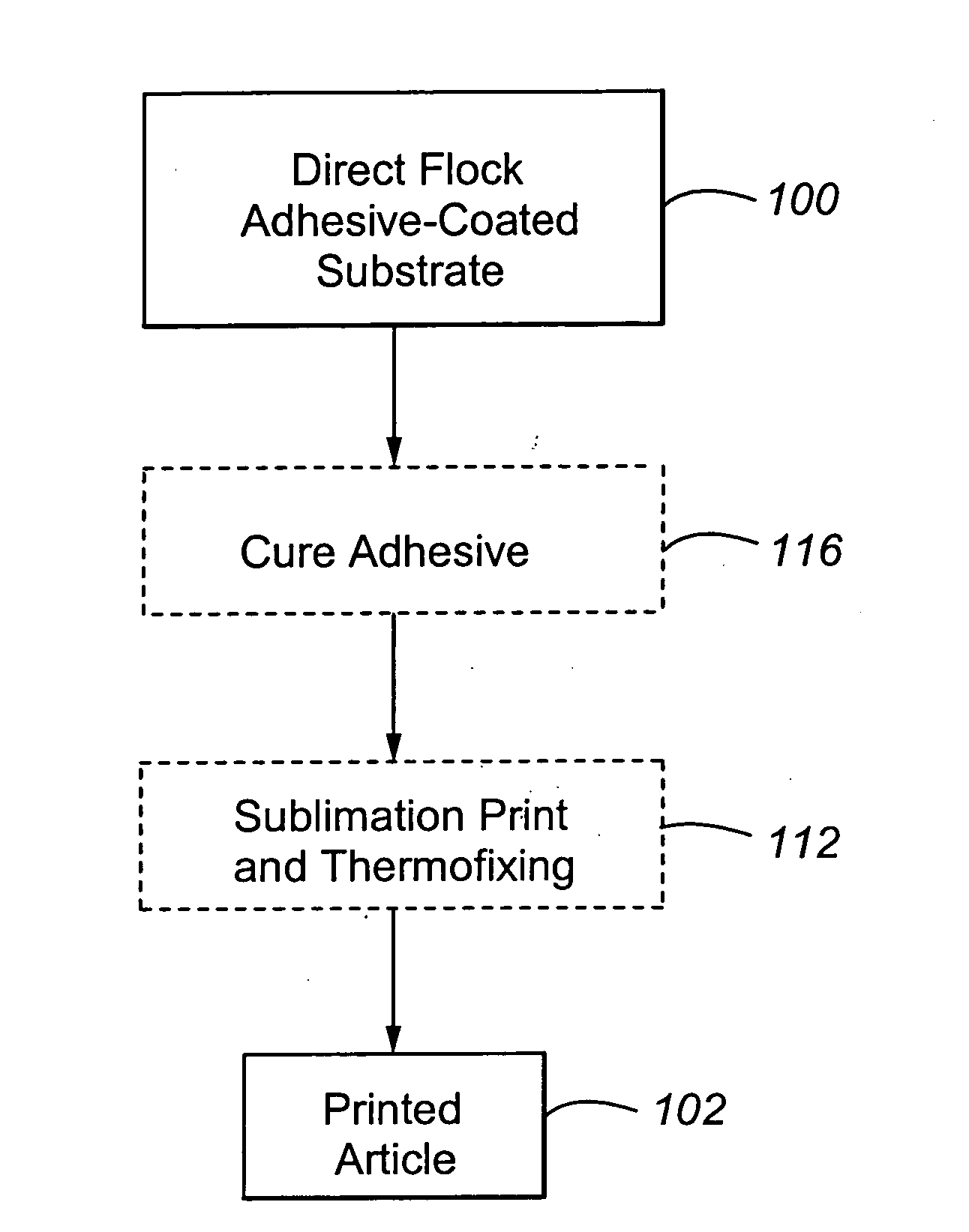

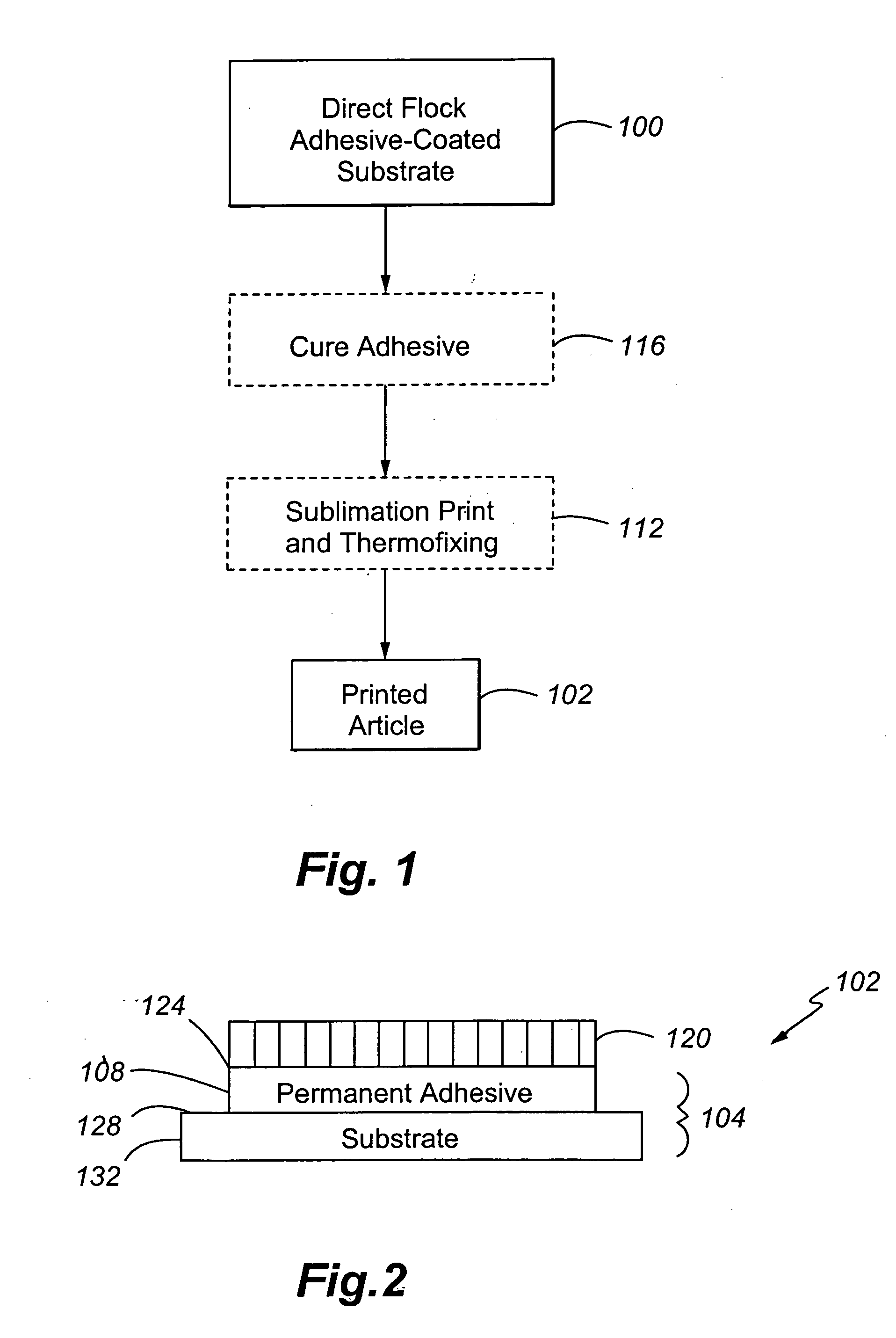

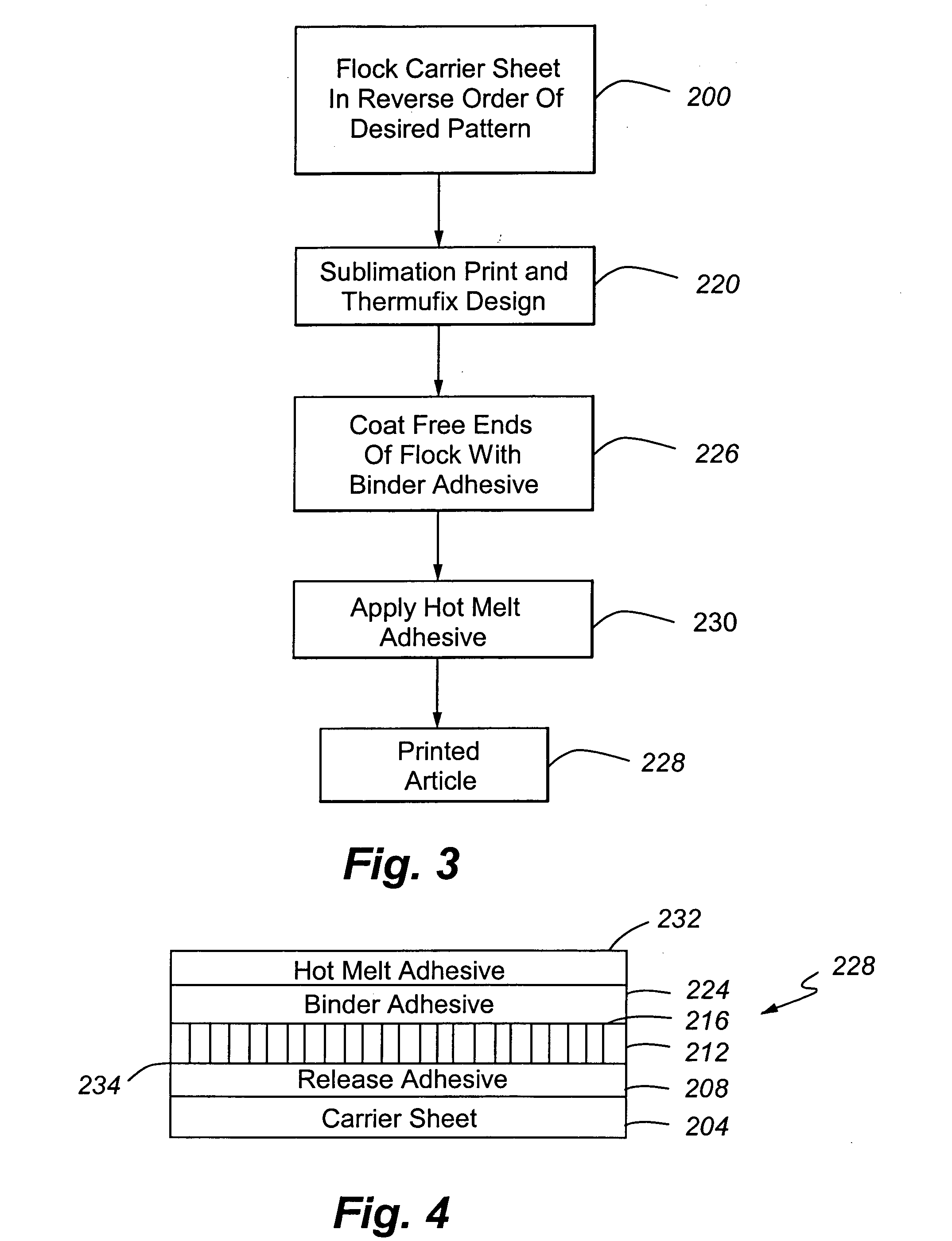

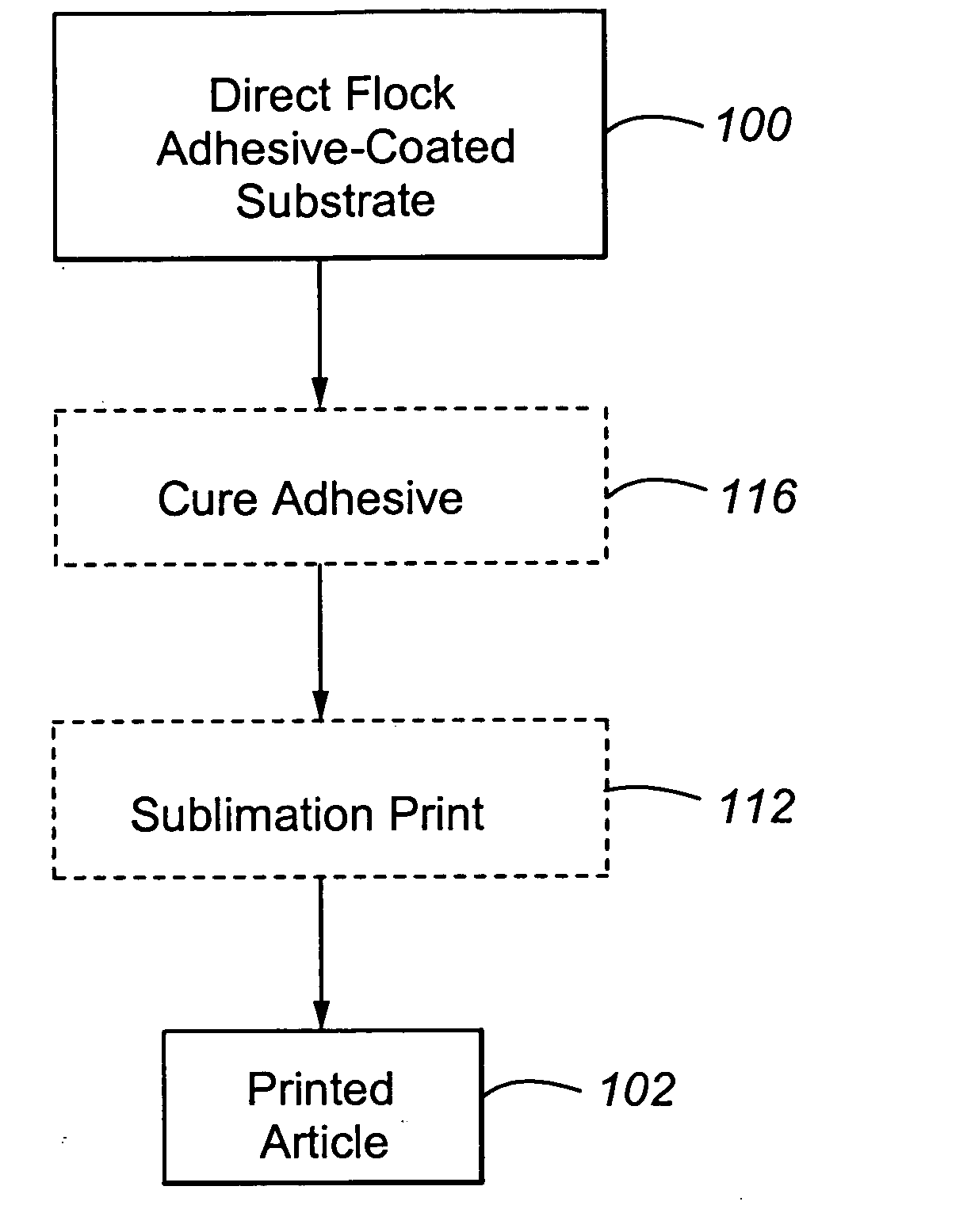

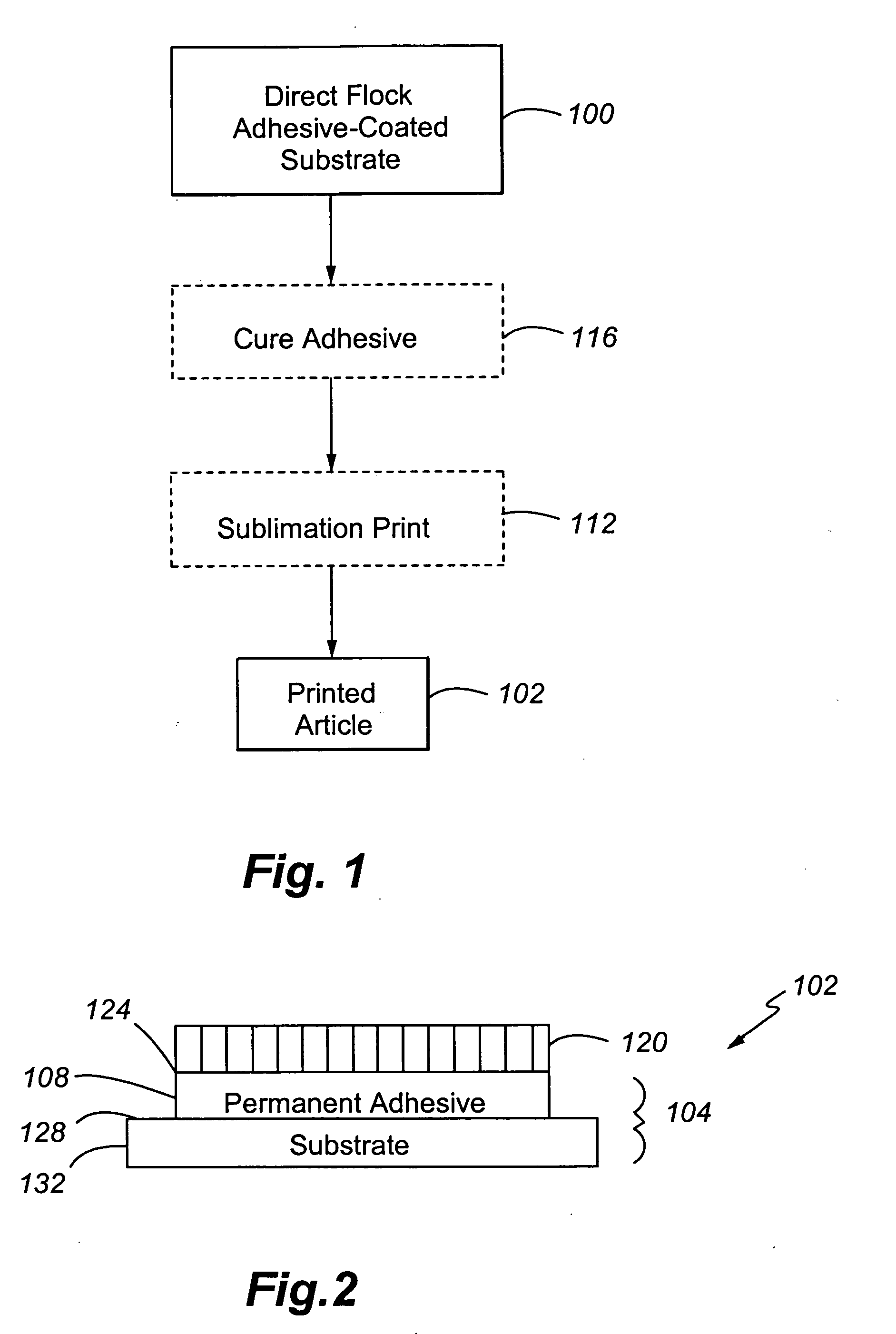

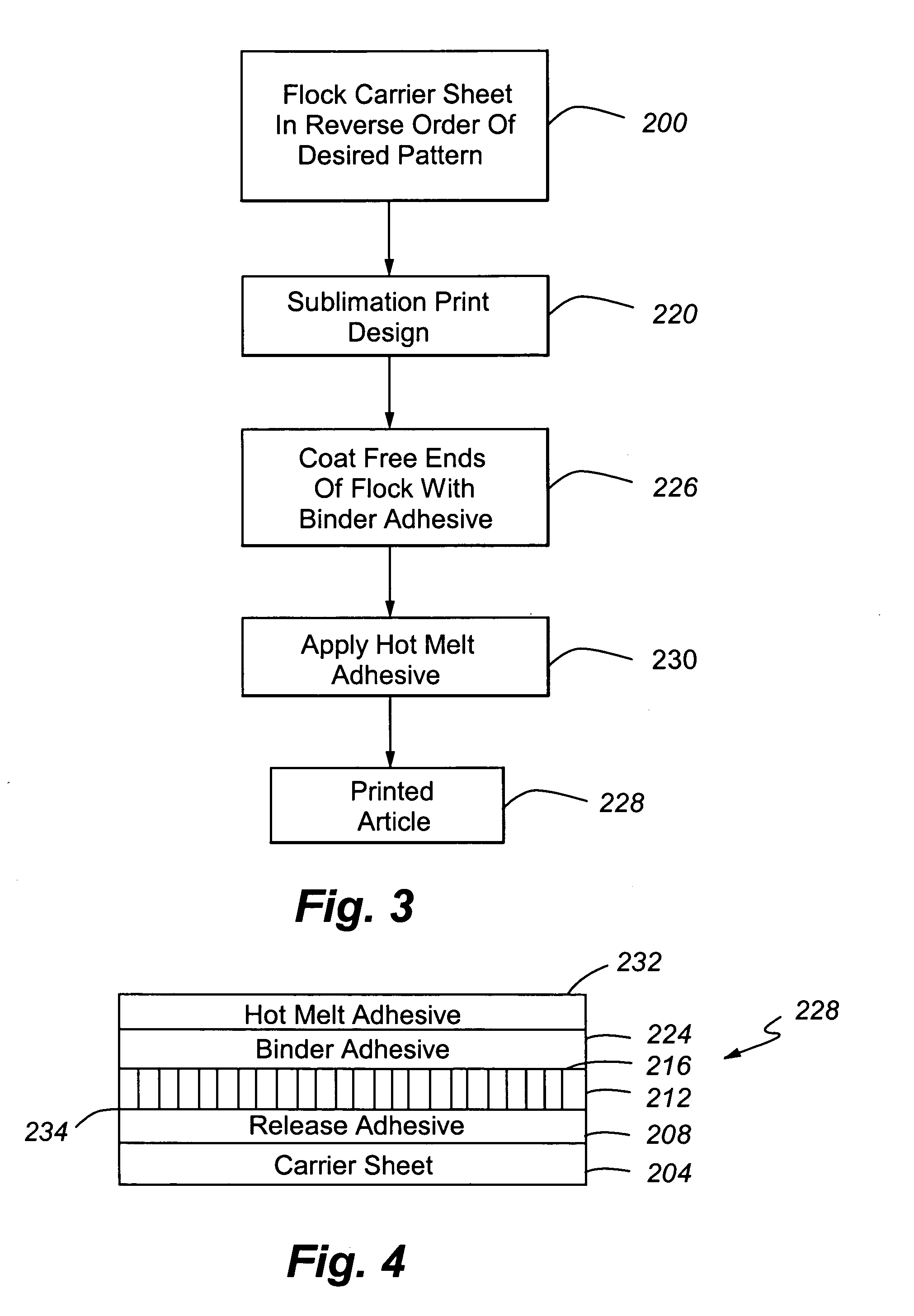

Process for high and medium energy dye printing a flocked article

InactiveUS20050268407A1Maintain loftStay flexibleTransfer printing processDyeing processDimethyl terephthalateFiber

The processes and articles of the present invention use thermally stable and loft retentive polymers in sublimation printed flock fibers, which are particularly attractive for forming molded and heat laminated articles. The process and articles use high, medium and low energy dyes on the fibers. A preferred polymer for use in the fibers is poly(cyclohexylene-dimethylene terephthalate).

Owner:ABRAMS LOUIS BROWN

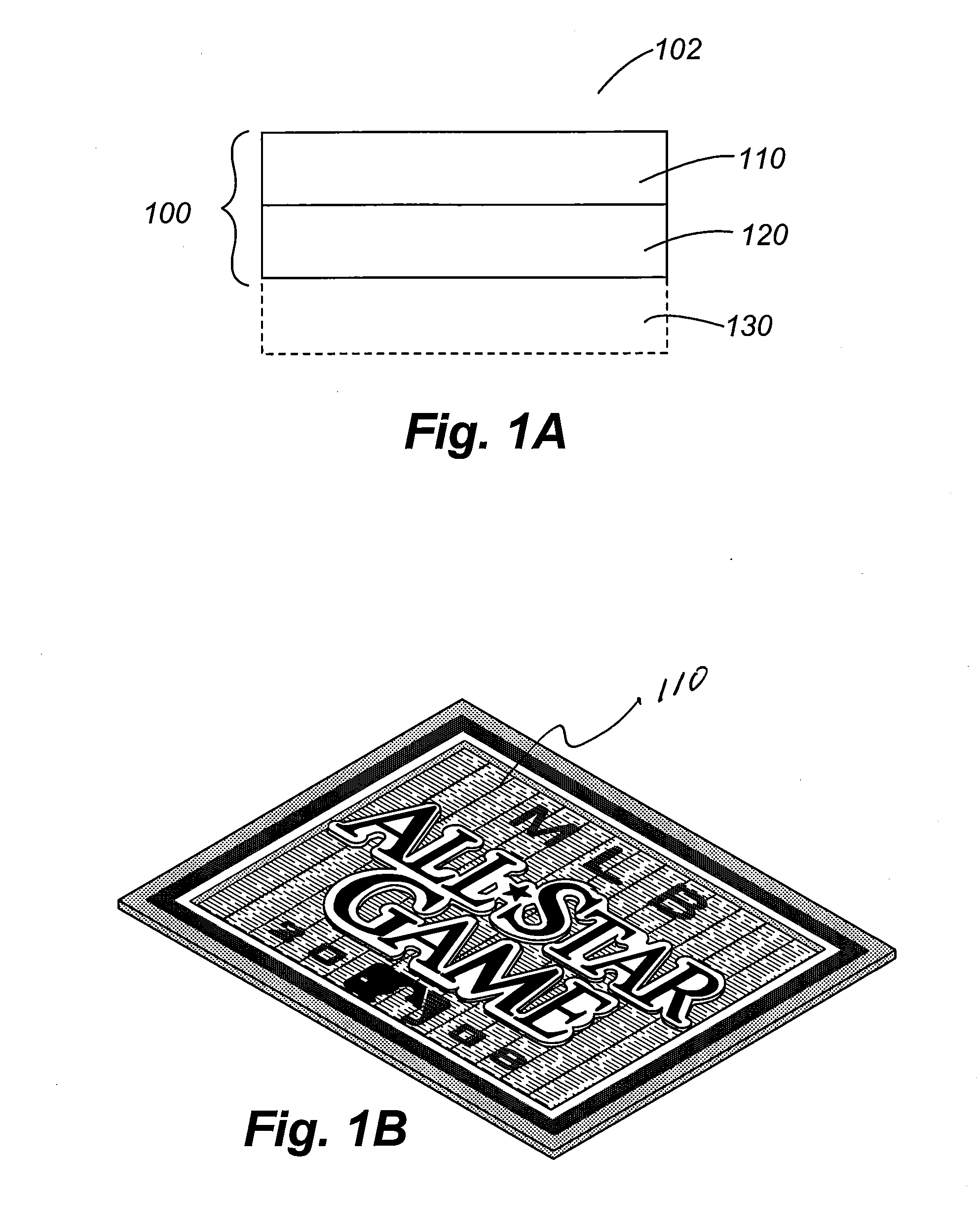

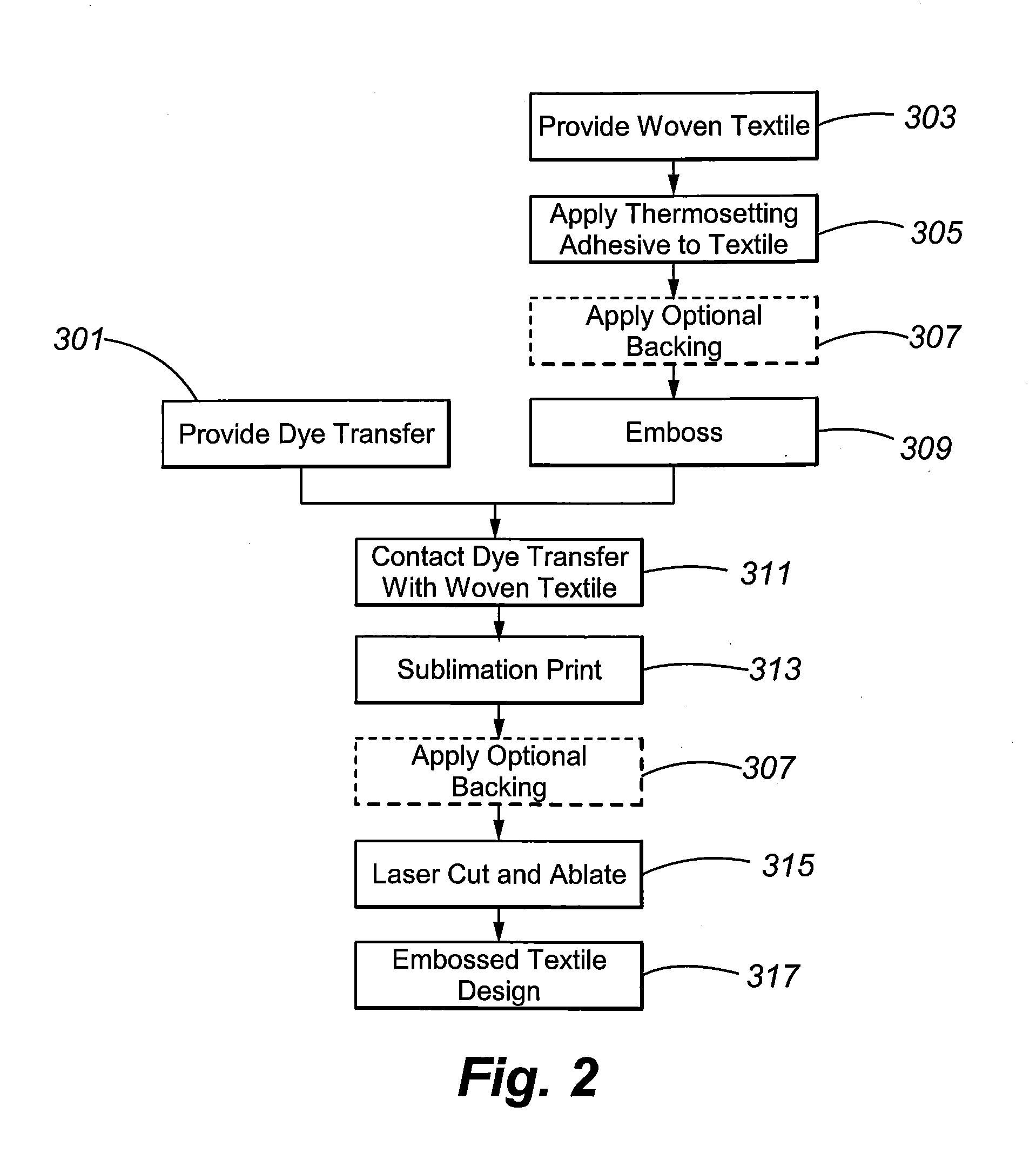

Sublimation dye printed textile

ActiveUS20090075075A1Quality improvementIncreased surface dimensionality and characterLiquid surface applicatorsDecorative surface effectsTextile printerDigital imaging

The present invention is directed to an unstitched design having the appearance of being stitched or embroidered. A stitched design is digitally imaged, and the digital image used to control dye sublimation printing of a representation of the image onto a desired surface. In one configuration, the surface is a woven textile.

Owner:HIGH VOLTAGE GRAPHICS

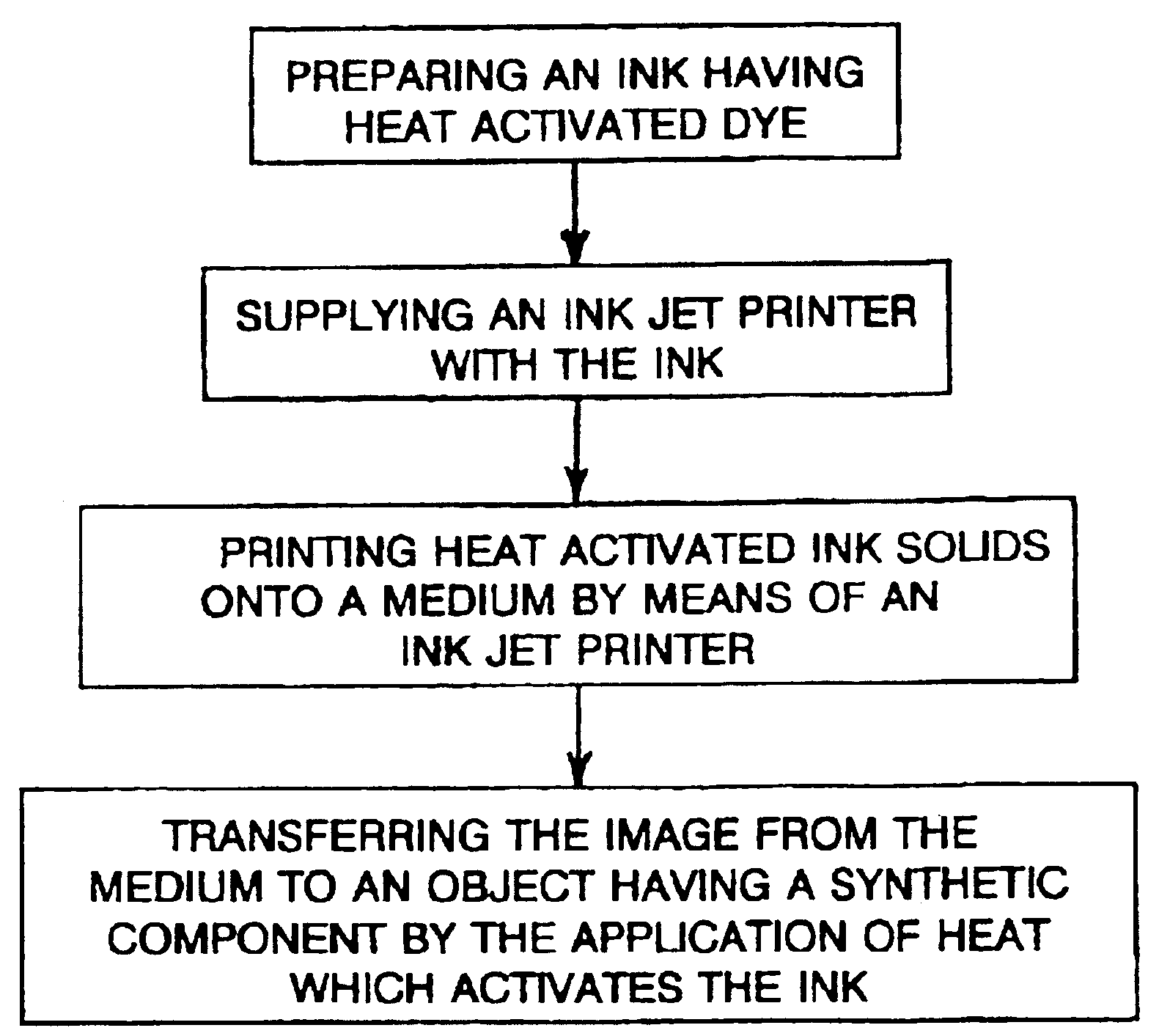

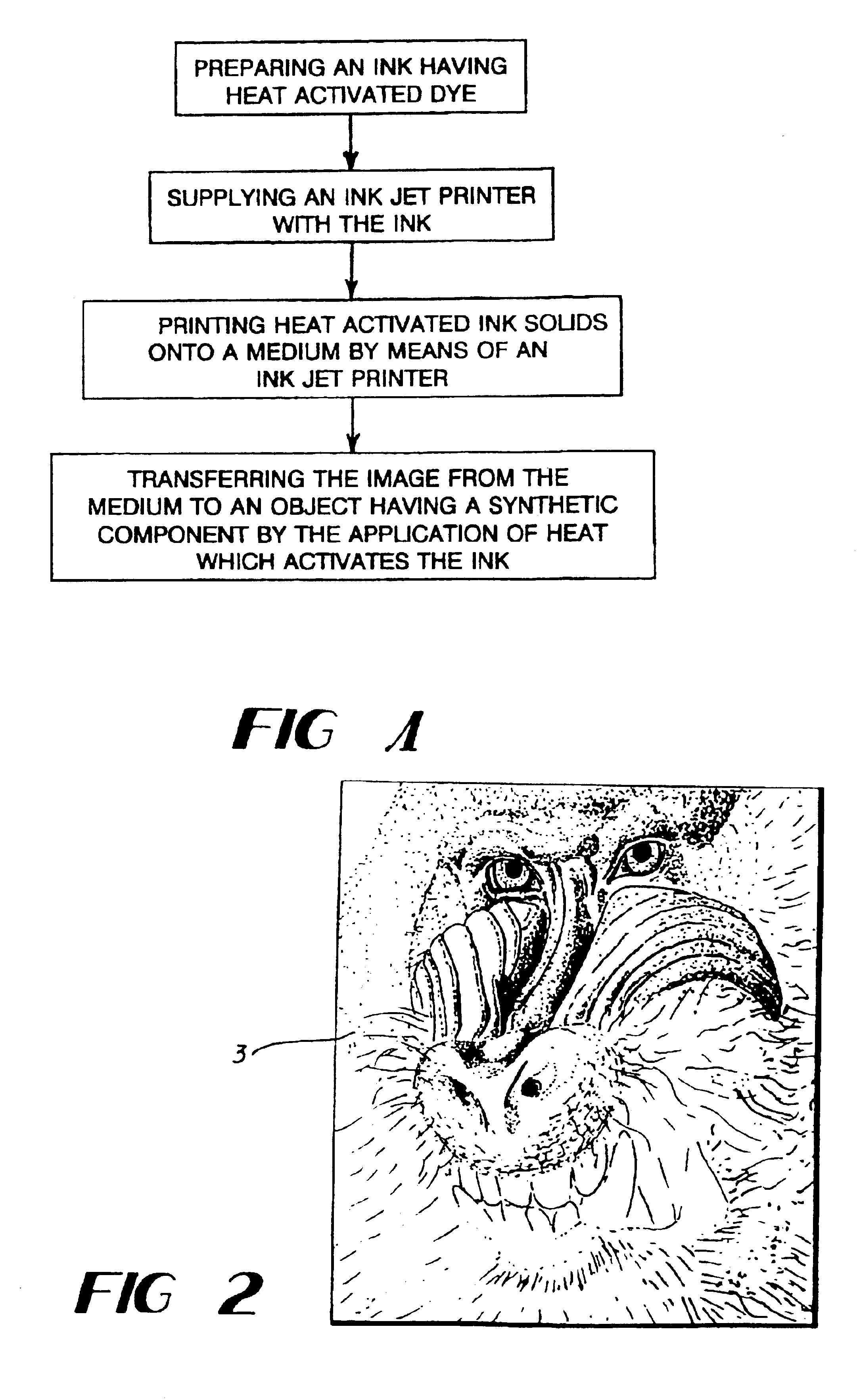

Permanent heat activated ink jet printing process

InactiveUS6450098B1Improve bindingFacilitate and withstand temperatureTransfer printingMeasurement apparatus componentsEngineeringComputer drive

Owner:SAWGRASS SYST INC

Treated textile fabric

The present invention provides a water repellant, water resistant, stain resistant fabric that feels like fabric rather than plastic. The fabric of the present invention is prepared by treating a fabric with at least one treatment composition comprising from about 5 weight percent to about 20 weight percent of fluorochemical(s), which is then backed with at least one polymeric film to provide a water repellant, water resistant, stain resistant fabric.

Owner:HI TEX INC

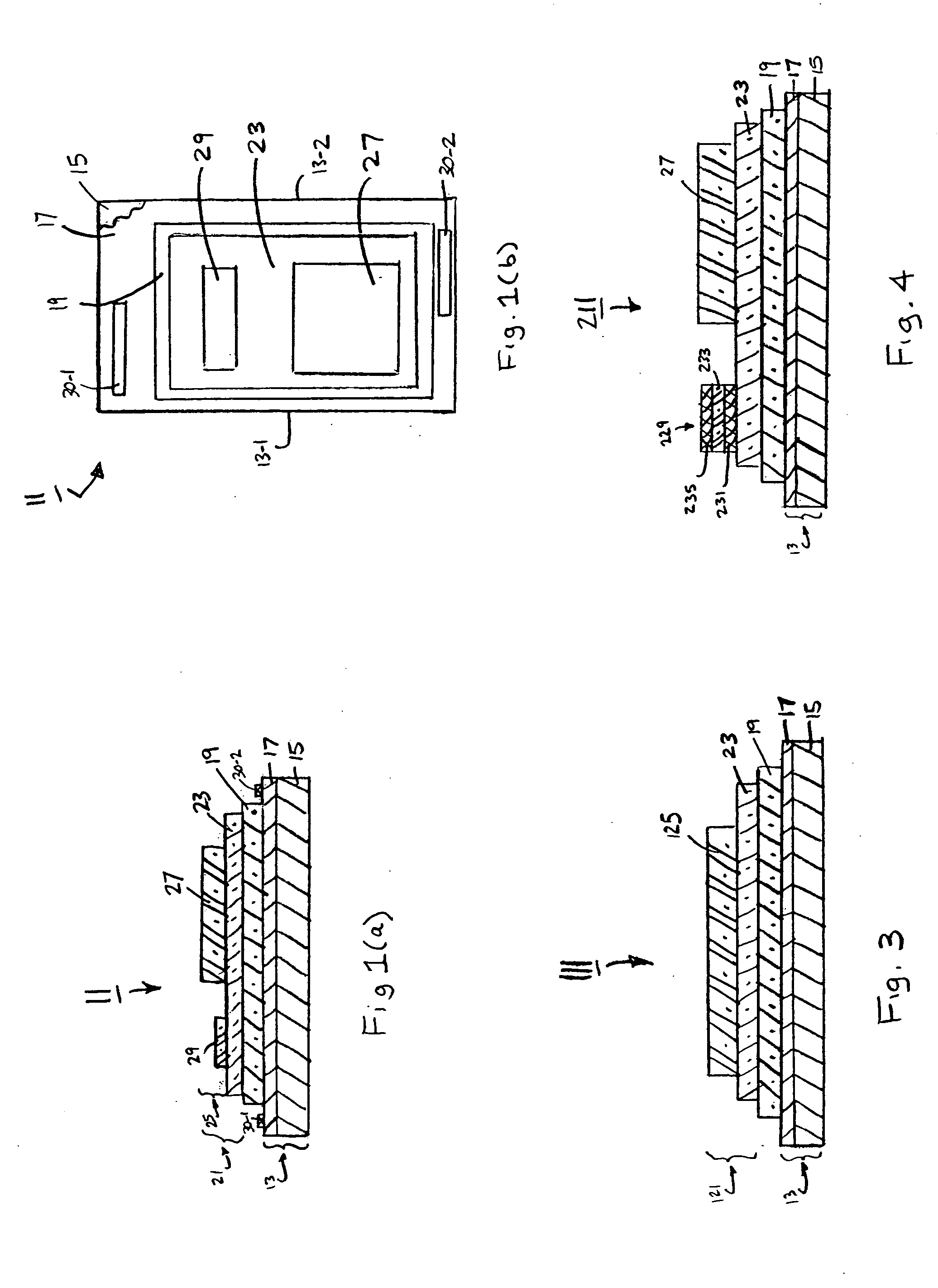

Transfer for decorating textiles with colored patterns

InactiveUS6521327B1High fastnessPoint becomes highLamination ancillary operationsDecorative surface effectsElastomerHot melt

A transfer capable of applying one- or multi-coloured patterns to textiles under heat and pressure comprises a carrier sheet (1) having a non-binding surface which carries (a) a one- or multi-coloured pattern (5) printed on the carrier sheet using a digitally controlled colour printer; (b) a transparent (6) or white-pigmented (7) elastomer layer of a polymer having a high plasticizing point printed configuratively on the pattern (5); and (c) a heat-activatable thermoplastic polymeric glue layer (8) printed configuratively on the transparent (6) or white-pigmented (7) elastomer layer or a heat-activatable hot melt granulate sprinkled on the elastomer layer while said layer was still wet. An even better encapsulation of the coloured pattern is obtained when the carrier sheet has printed thereon a first transparent elastomer layer of a polymer having a high plasticizing point, and the pattern is printed on this elastomer layer using a digitally controlled colour printer. Additional strength is obtained when both a transparent elastomer layer and a white-pigmented elastomer layer are printed on top of the coloured pattern.

Owner:REFLEX HLDG +1

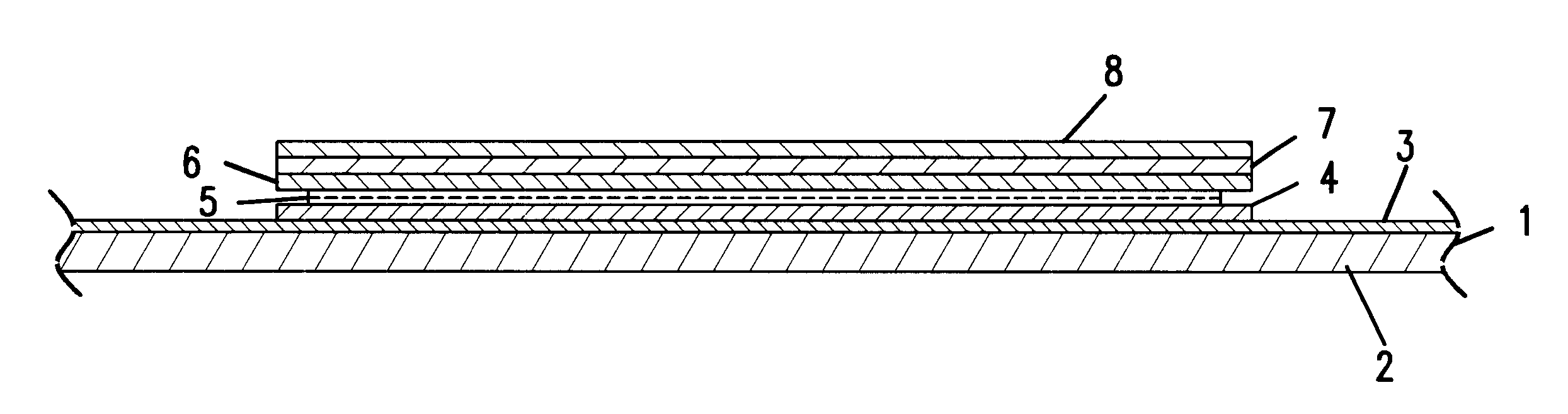

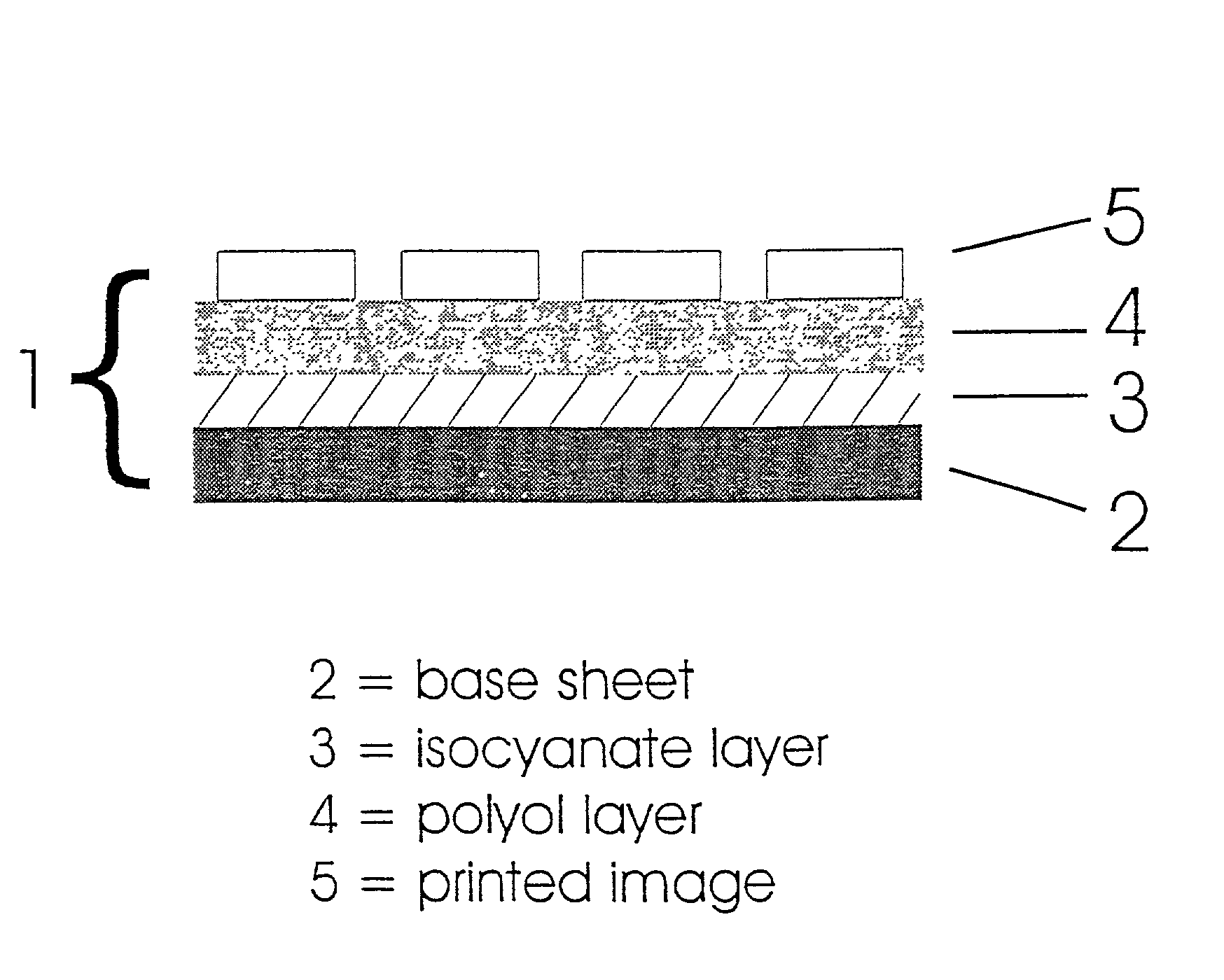

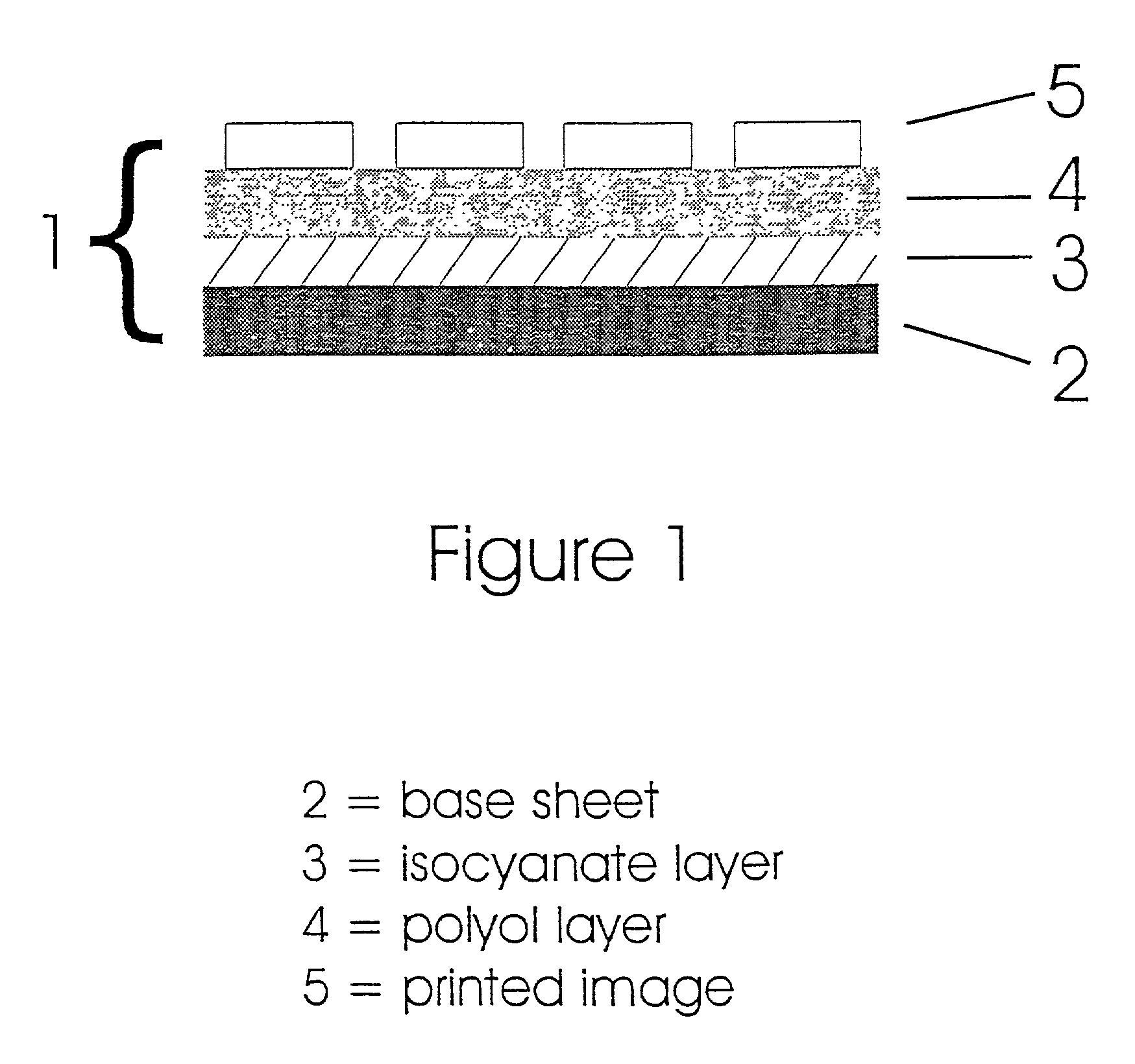

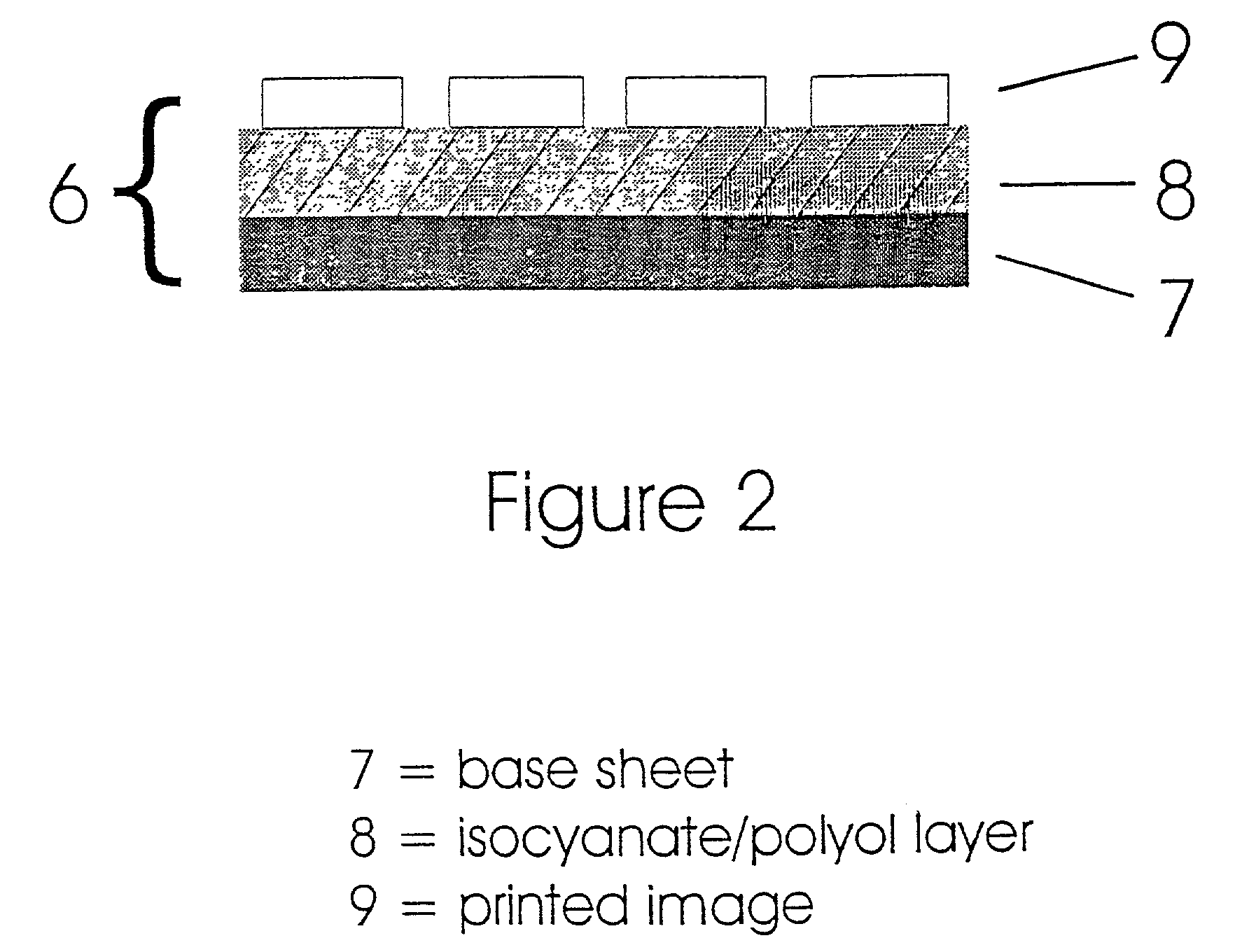

Intermediate transfer recording medium

InactiveUS7001649B2Avoid premature reactionExcellent abrasion resistanceDecorative surface effectsTransfer printing processColor imageHydrogen

A color image is digitally printed onto an intermediate transfer medium. The image is subsequently transferred from the intermediate transfer medium to a final substrate, which may be a cellulosic textile, such as cotton. Bonding of the color images is provided by the reaction between compounds selected from each of two chemical groups contained in the intermediate transfer medium. The first groups comprises compounds with functional groups capable of reacting with active hydrogen, such as isocyanate or epoxy groups. The second group comprises compounds with functional groups containing active hydrogen, or compounds with functional groups containing active hydrogen after a conversion process. The functional groups of one or both reactive chemical groups may be protected either by blocking with internal or external blocking agents or by a physical barrier such as encapsulating agents. The blocking agents are removed by the application of energy, such as heat, during the transfer of the image from the intermediate transfer medium to the final substrate. The intermediate transfer medium may be comprised of additional components which may be combined with either or both of the above two chemical groups, or applied as separate layers. Examples of such components are a thermally expandable material, an exothermic chemical, a release agent, and / or absorbent material. Transferred images so produced have a soft hand, particularly when applied to a textile, and excellent fade and abrasion resistance.

Owner:SAWGRASS TECH INC

Method for wet transfer printing digital color image onto fiber fabric of cellulose, and dedicated transfer paper

InactiveCN1727571AImprove breathabilityGood colorDuplicating/marking methodsTransfer printing processColor imageImage resolution

A method for transferring the digital color pattern onto cellulose fibre fabric includes such steps as printing said pattern on a transfer paper by ink-jet printer, wetting the position on said fabric, where the pattern is transferred, by the aqueous solution of sodium dicarbonate, coating a layer of transfer slurry, sticking the transfer paper to it, pressing until the transfer paper is wet, ironing by iron or plate-type thermotransfer machine, high-pressure steaming for 8-12 min, washing, and drying. Said transfer paper is composed of substrate paper, adhesive film and water-soluble resin layer.

Owner:熊平清

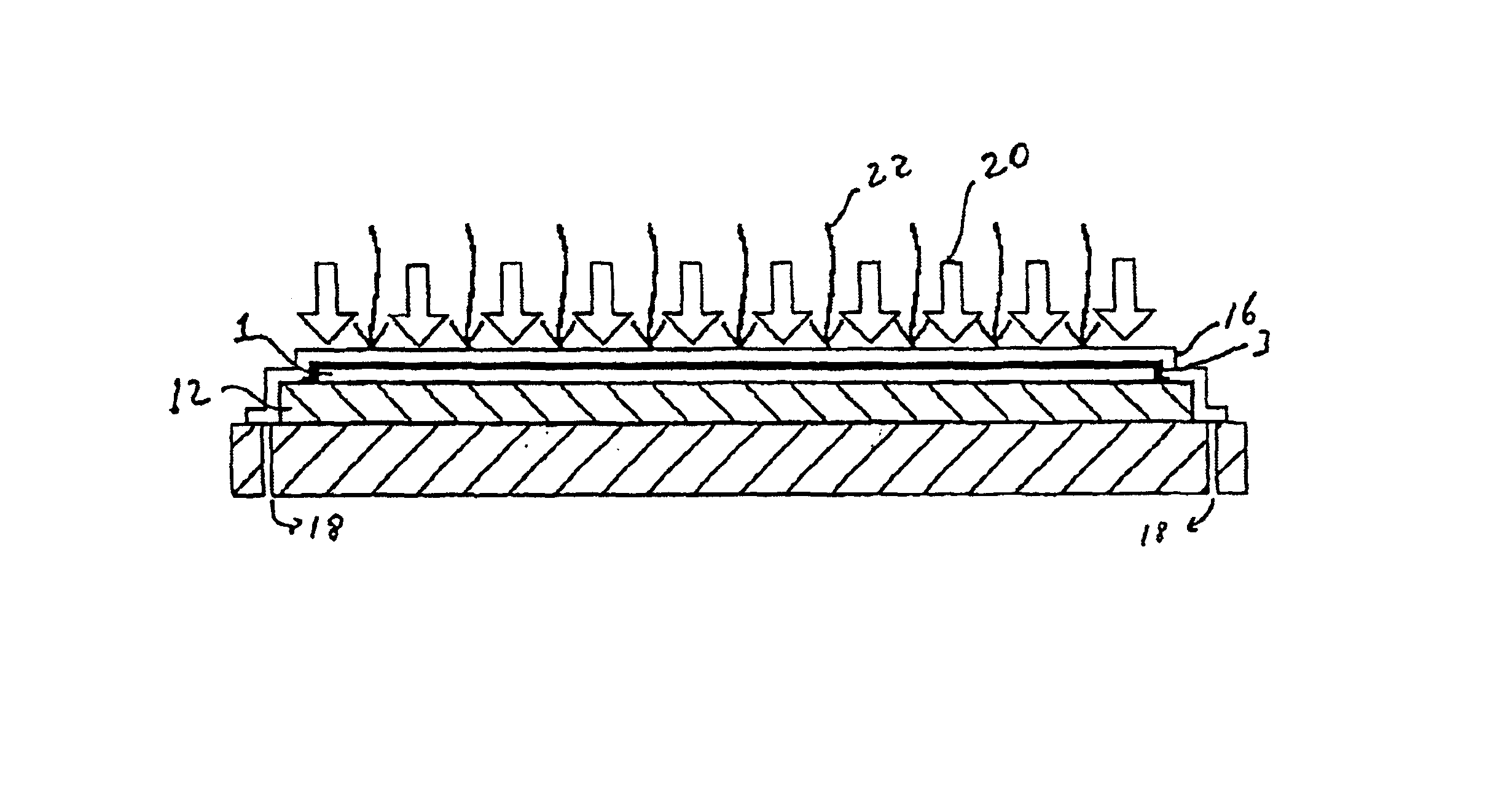

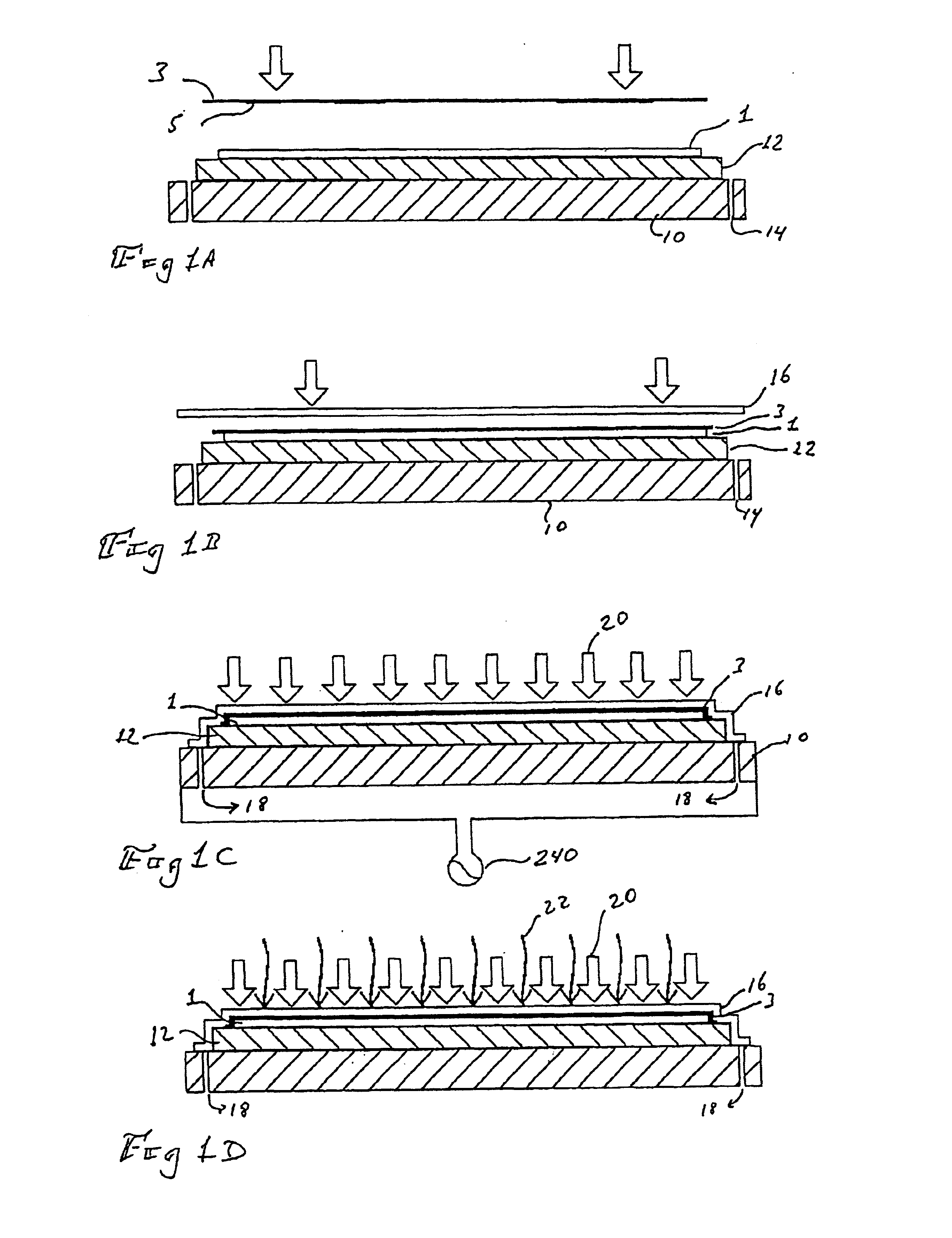

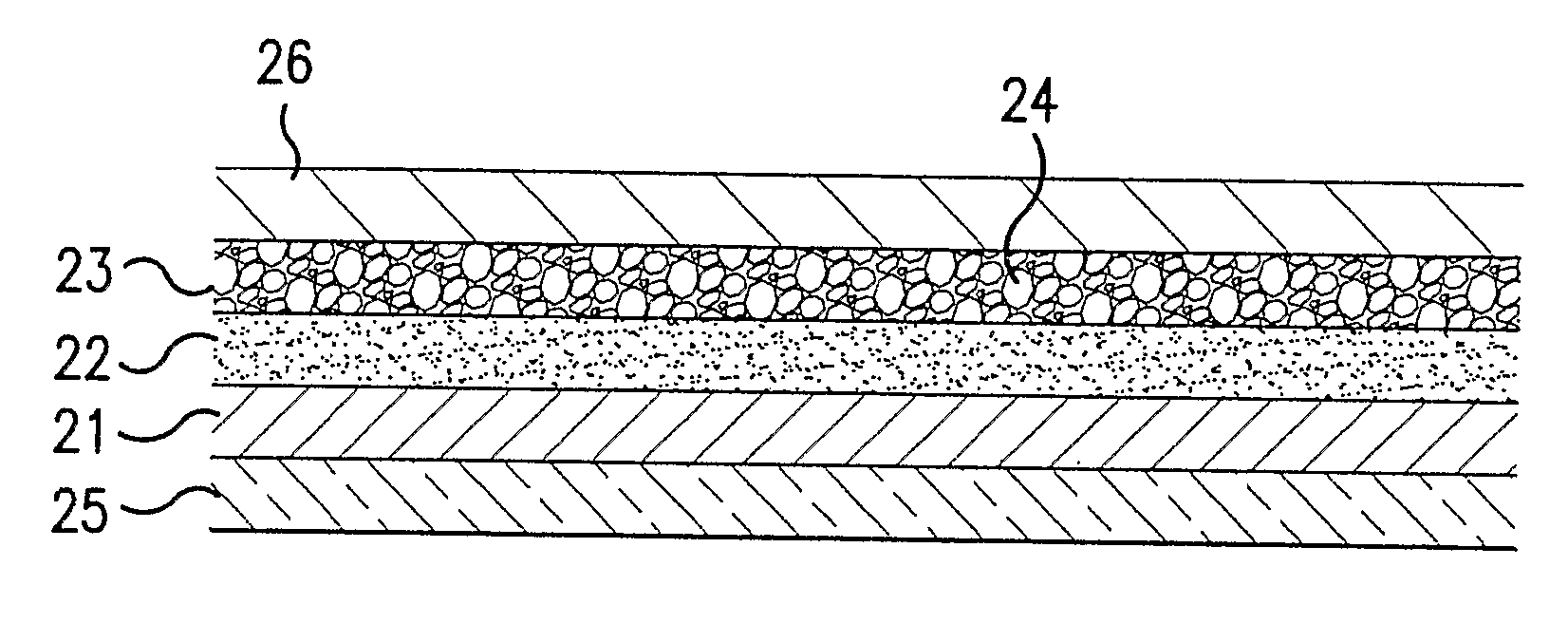

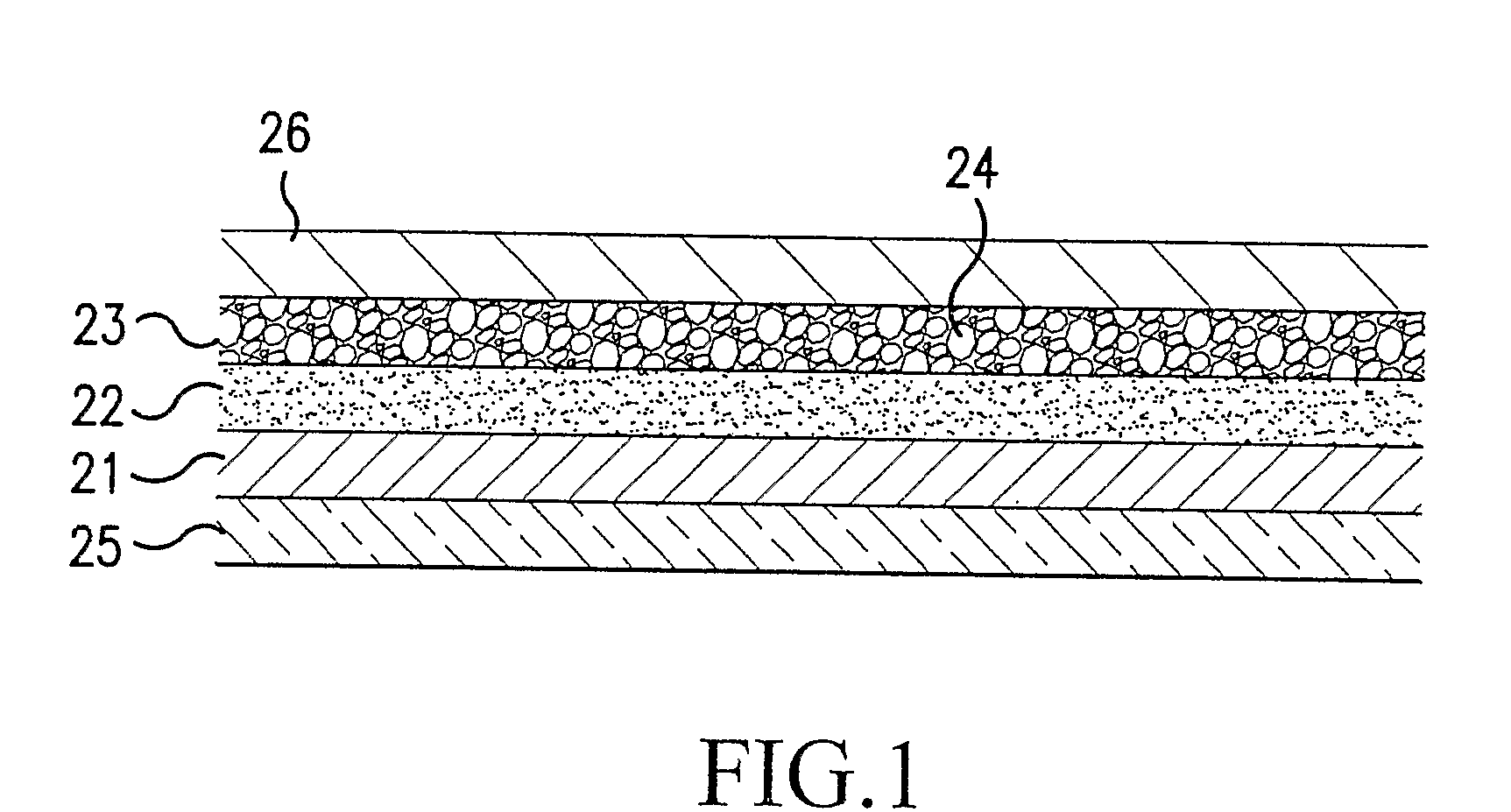

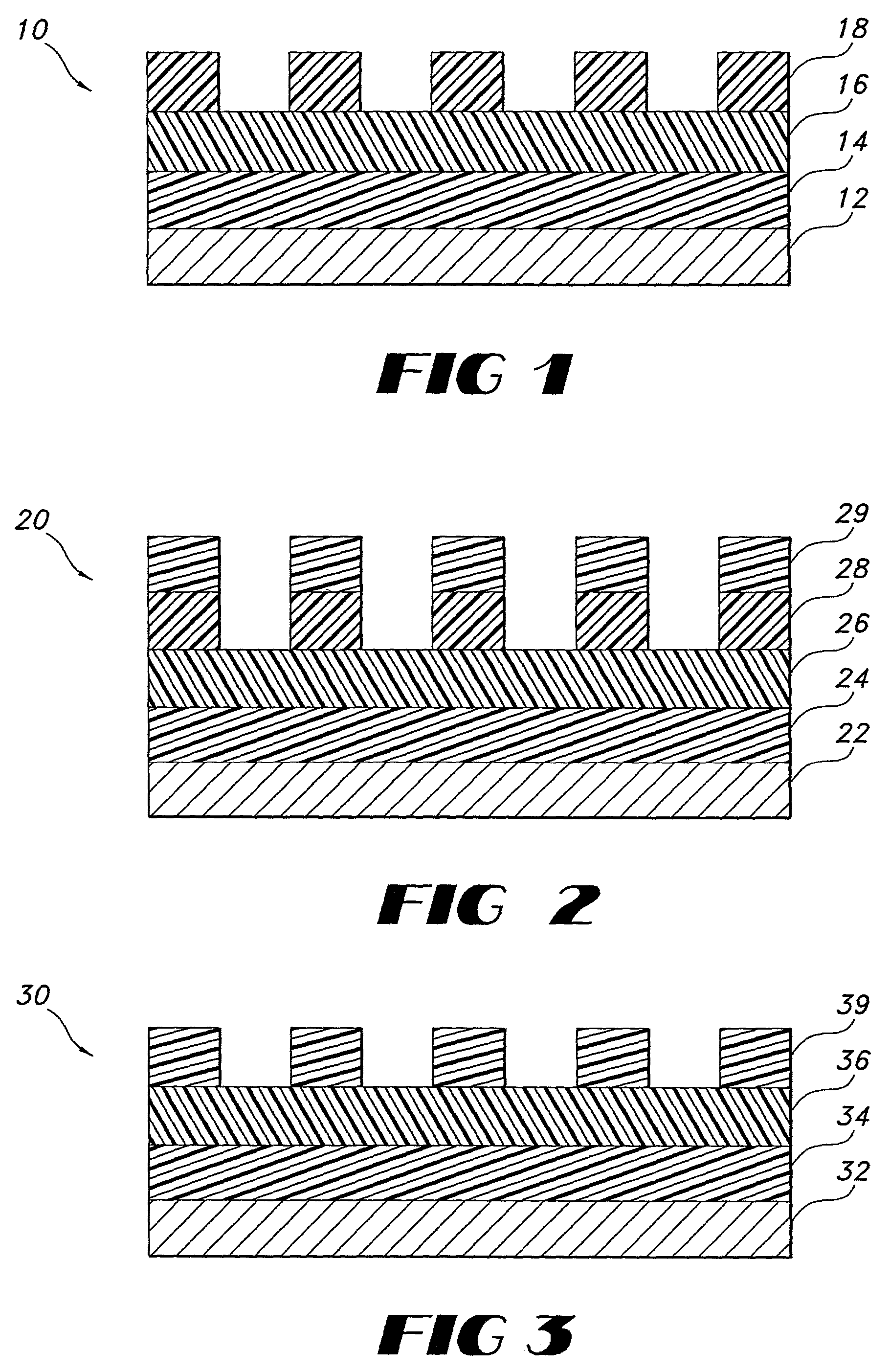

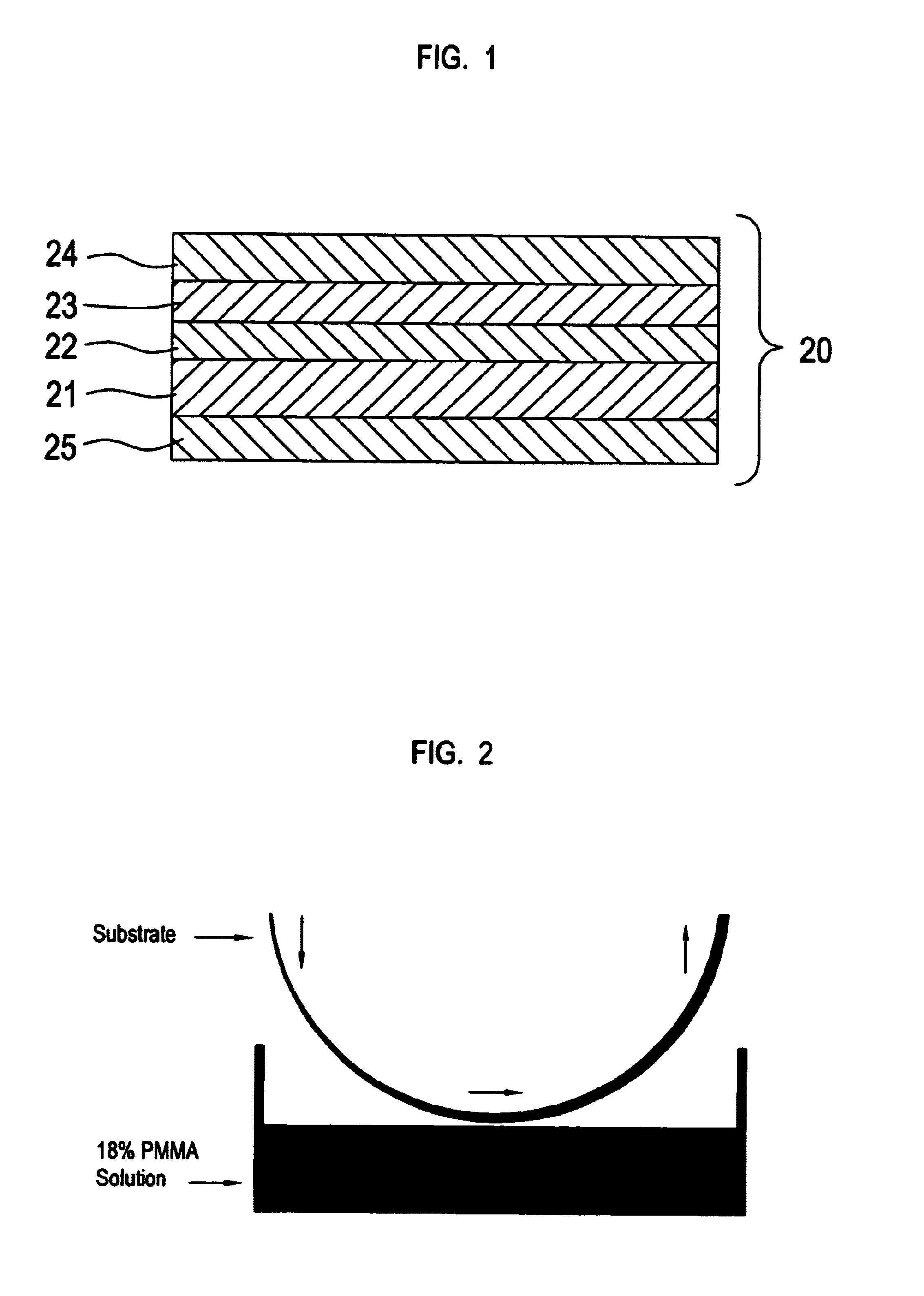

Image transfer material and heat transfer process using the same

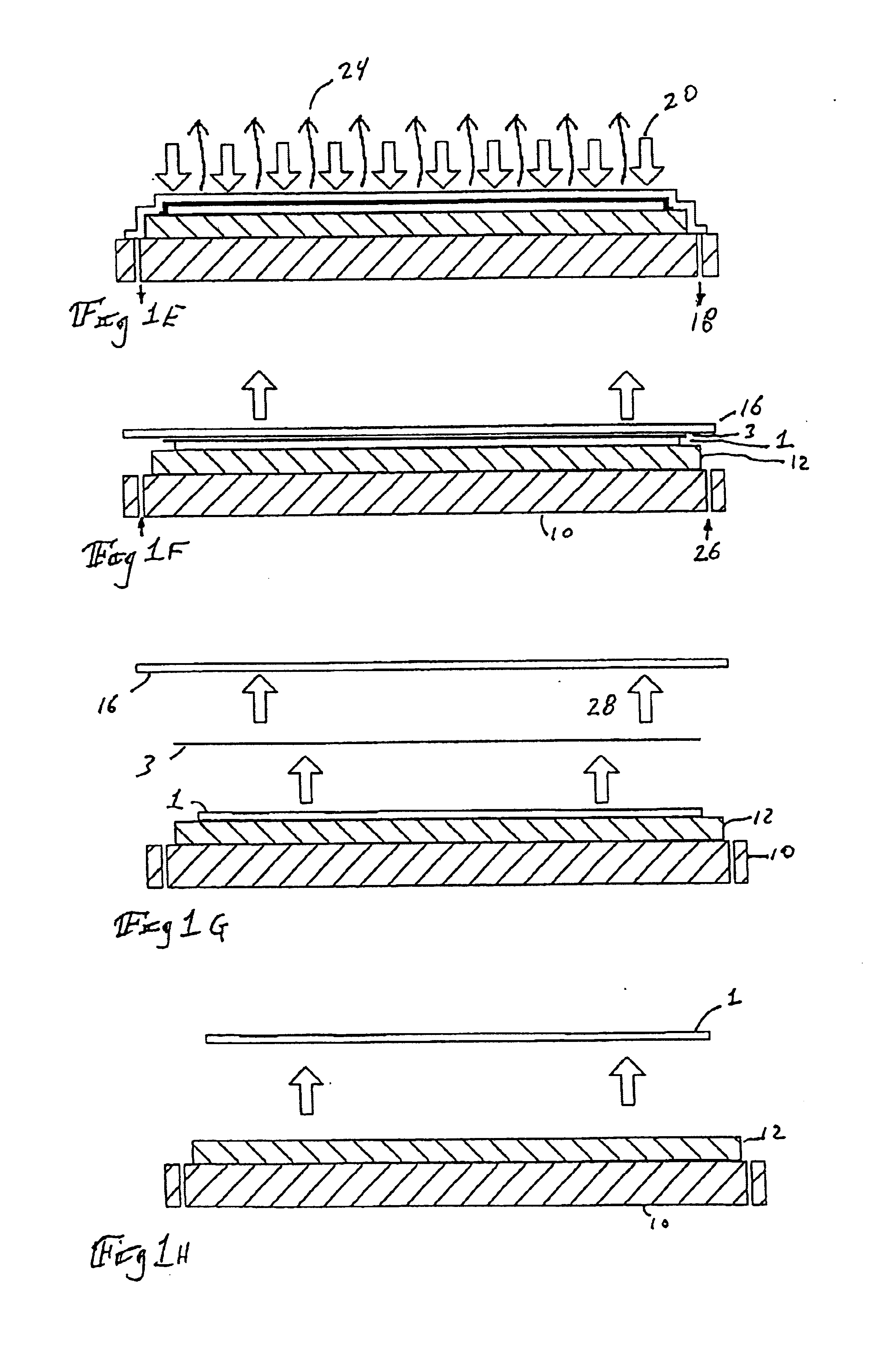

Provided is an image transfer material, comprising an optional support material, and a non-woven or woven fiber web layer, wherein the fiber web is impregnated or coated with a image receiving formulation. The fiber web layer is optionally attached to the support with an adhesion layer. Also provided is a heat transfer process wherein after imaging, the fiber web and adhesion layer are peeled from the optional support material and placed, preferably image side up (when imaged), on top of a receptor element. Alternatively, the fiber web and adhesion layer are peeled and then optionally imaged prior to being placed on the receptor element. Then, an optional non-stick sheet is placed over the imaged fiber web (if placed imaged side up) and heat is applied to the fiber web or the non-stick sheet, if present. The adhesion layer then melts and adheres the imaged web layer to the receptor element.

Owner:SCHWENDIMANN JODI

Process for printing and molding a flocked article

InactiveUS20050266204A1Feel goodSoft touchLiquid surface applicatorsTransfer printing processFiberTextile printer

Owner:HIGH VOLTAGE GRAPHICS

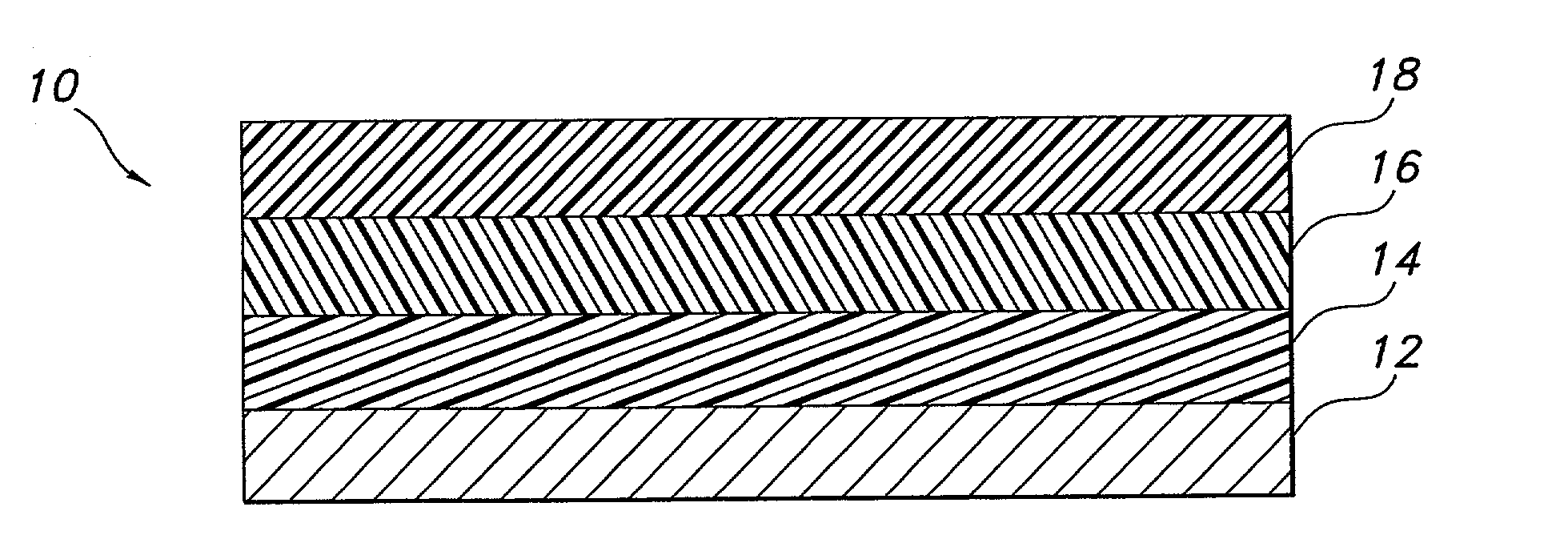

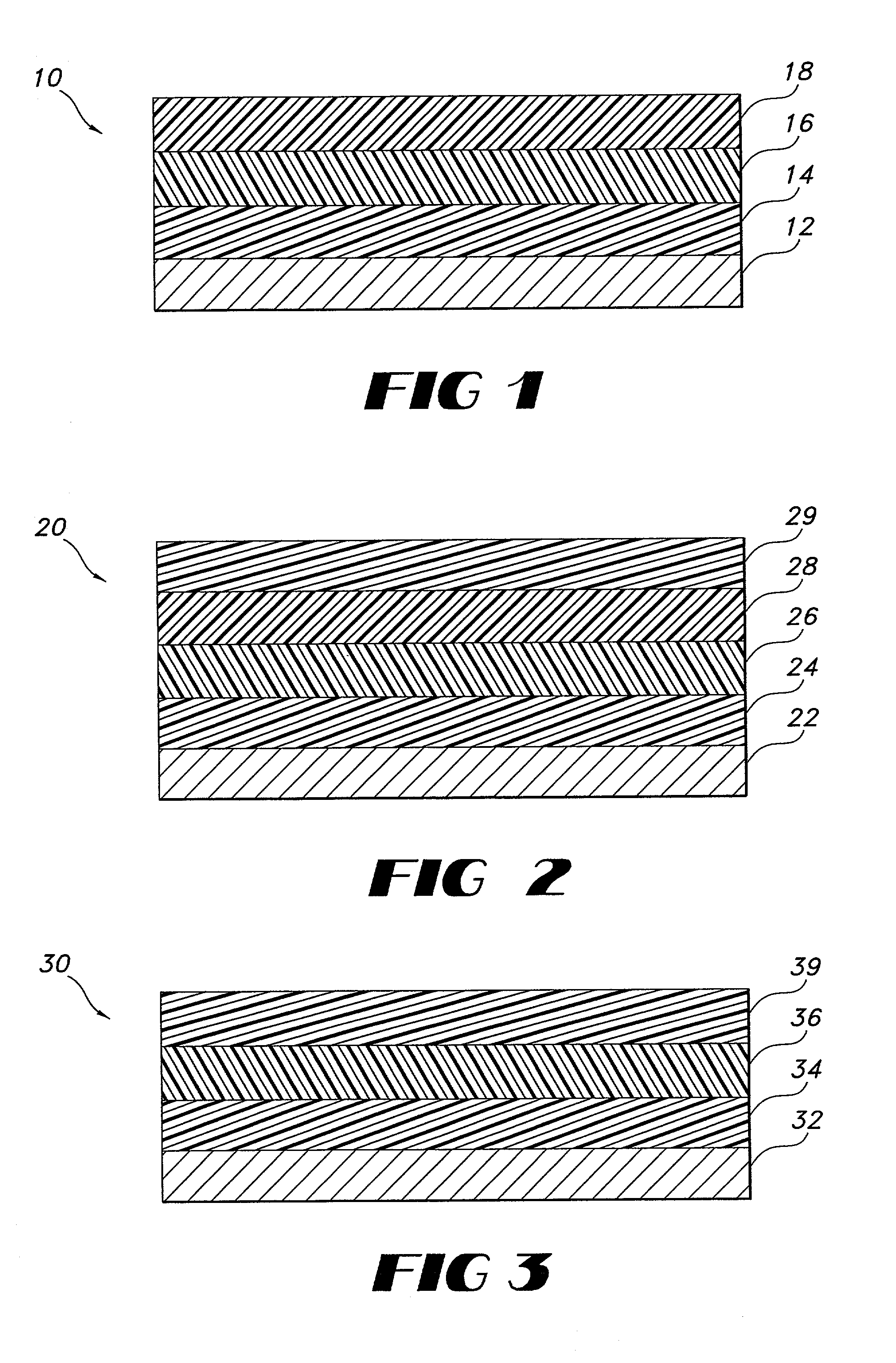

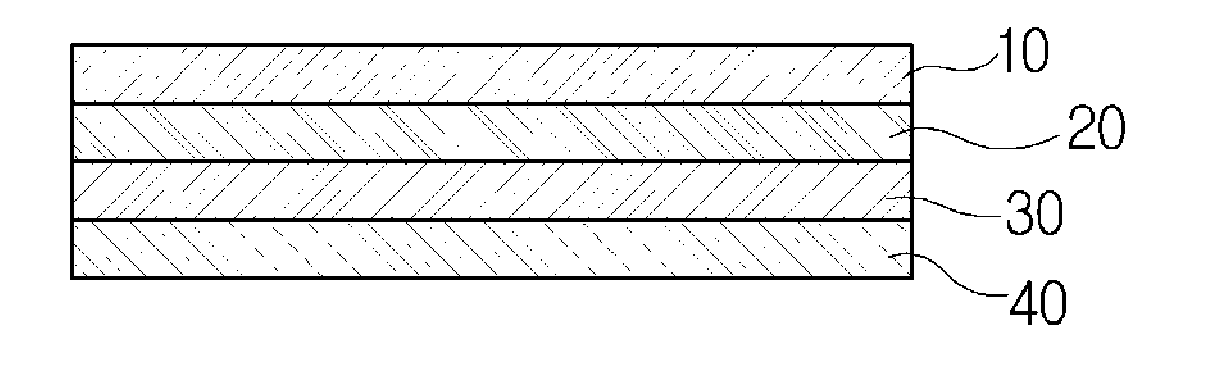

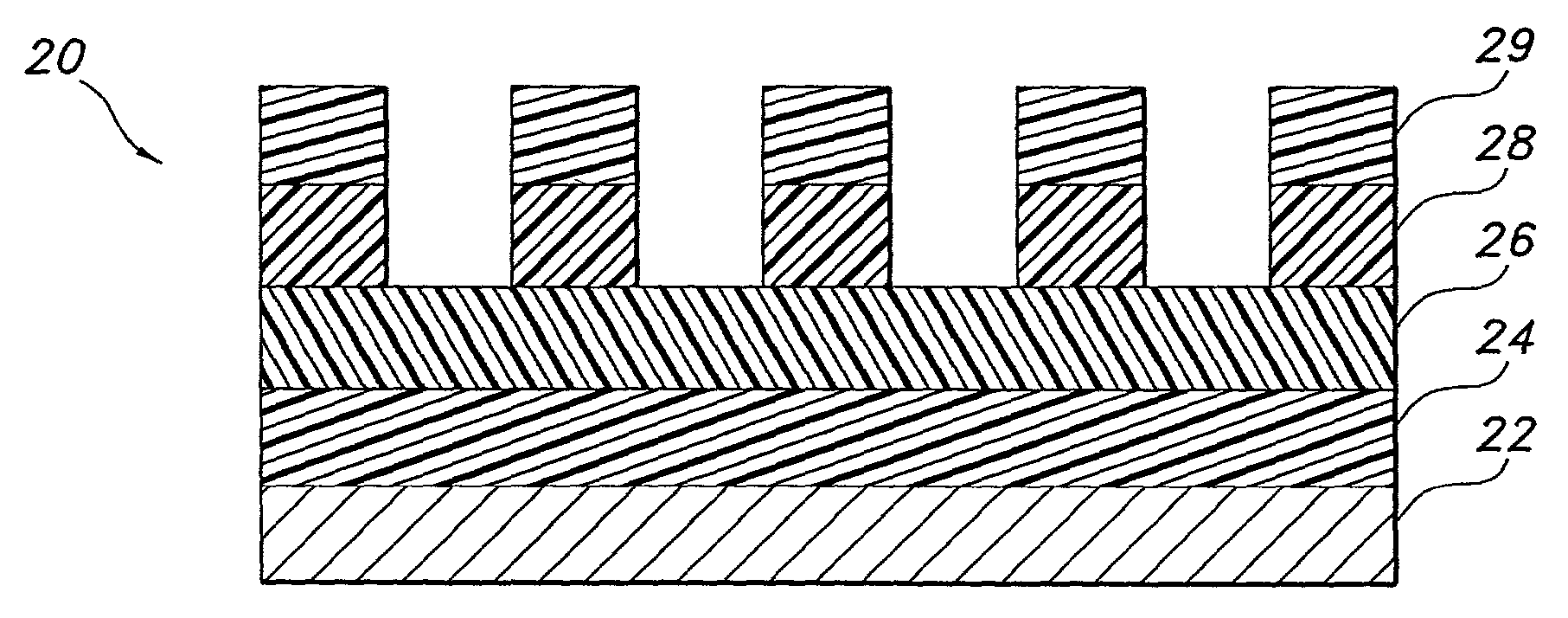

Image transfer material and polymer composition

InactiveUS20070172609A1Raise transfer toDecorative surface effectsTransfer printing processImage transferCrosslinked polymers

Provided is an image transfer material, comprising a support, optionally at least one barrier layer, a melt transfer layer, and an image receiving layer. Also provided is a process for preparing the image transfer material. Further provided is a heat transfer process using the disclosed material. In the heat transfer process, after imaging, the image receiving layer and melt transfer layer are peeled away from the optionally barrier-coated support material and placed, preferably image side up, on top of a receptor element. A non-stick sheet is then optionally placed over the imaged peeled material and heat is applied to the top of the optional non stick sheet. The melt transfer layer then melts and adheres the image to the receptor element. A composition comprising: at least one self-crosslinking polymer; and at least one dye retention aid.

Owner:SCHWENDIMANN JODI

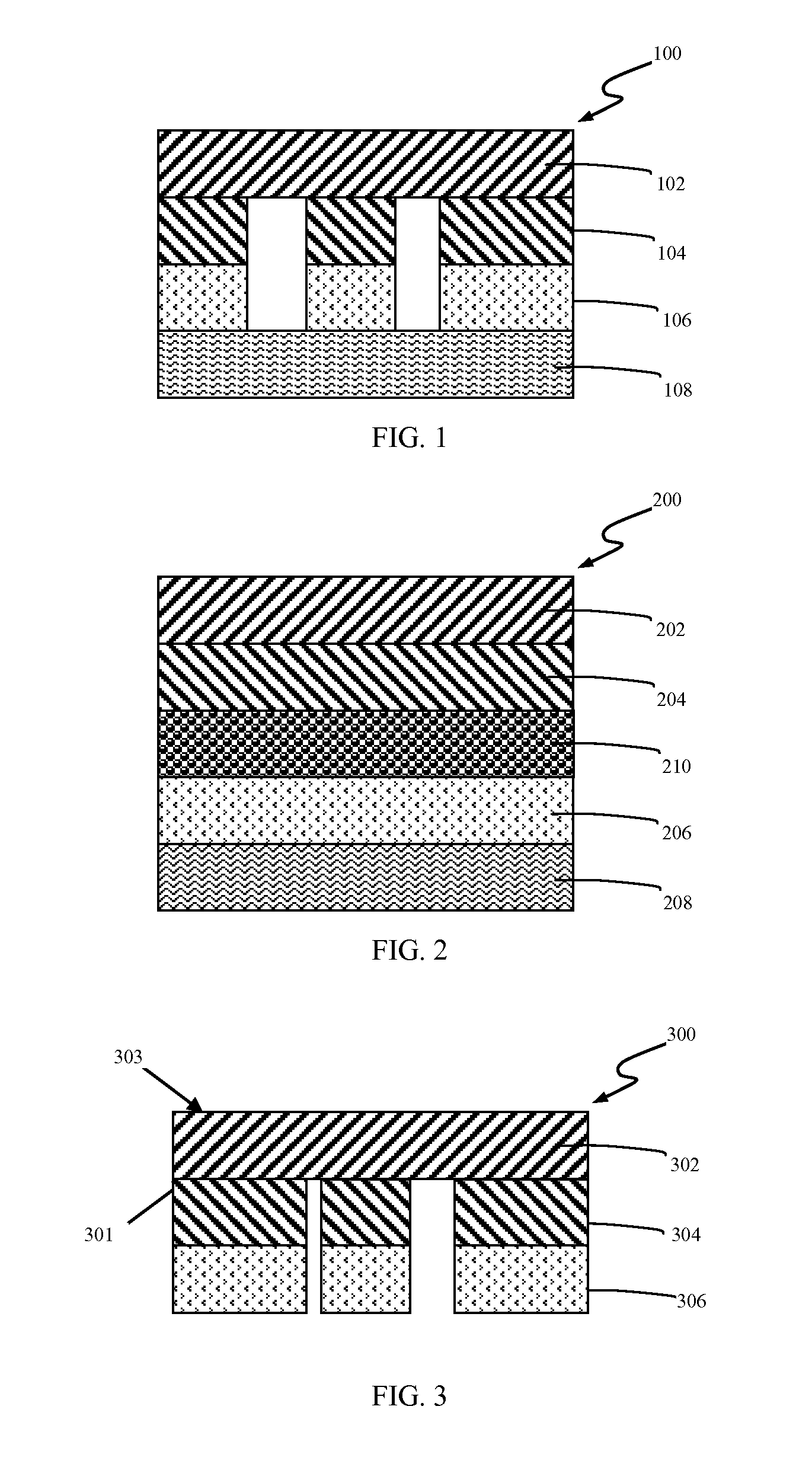

Heat transfer paper with peelable film and discontinuous coatings

InactiveUS7238410B2Preserving porosityPreserving stretchabilityLayered productsDecorative surface effectsCrack resistanceEngineering

The present invention is directed to a unique heat transfer material for use in transferring a discontinuous coating onto a substrate, such as an article of clothing. The heat transfer material of the present invention may be used cold peel transfer processes, resulting in an image-bearing coating having superior crack resistance, washability, and breathability compared to conventional image-bearing coatings. Additionally, the materials may be used on dark colored fabrics without washed-out appearance typically associated with printing on darker fabrics. The heat transfer material of the present invention produces superior results due to the use of discontinuous coatings.

Owner:NEENAH PAPER INC +1

Polymeric composition and printer/copier transfer sheet containing the composition

InactiveUS7008746B2Enhance the imageEfficient releaseDiffusion transfer processesPhotography auxillary processesWaxEmulsion

Owner:JODI A SCHWENDIMANN

Permanent heat activated ink jet printing process

InactiveUS6966643B2Prevent undesired activationAvoid cakingTransfer printingMeasurement apparatus componentsComputer printingEngineering

Owner:HALE NATHAN +1

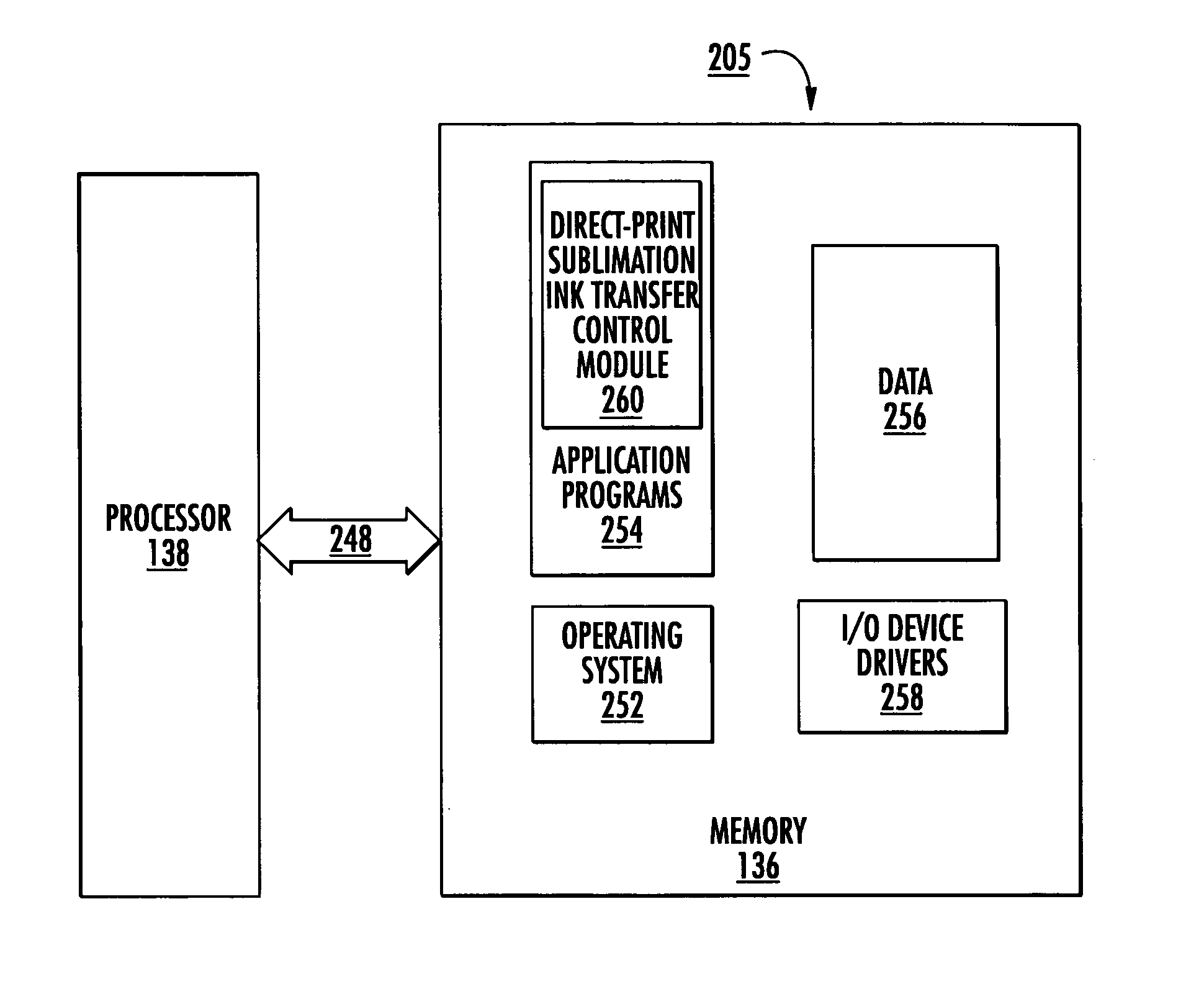

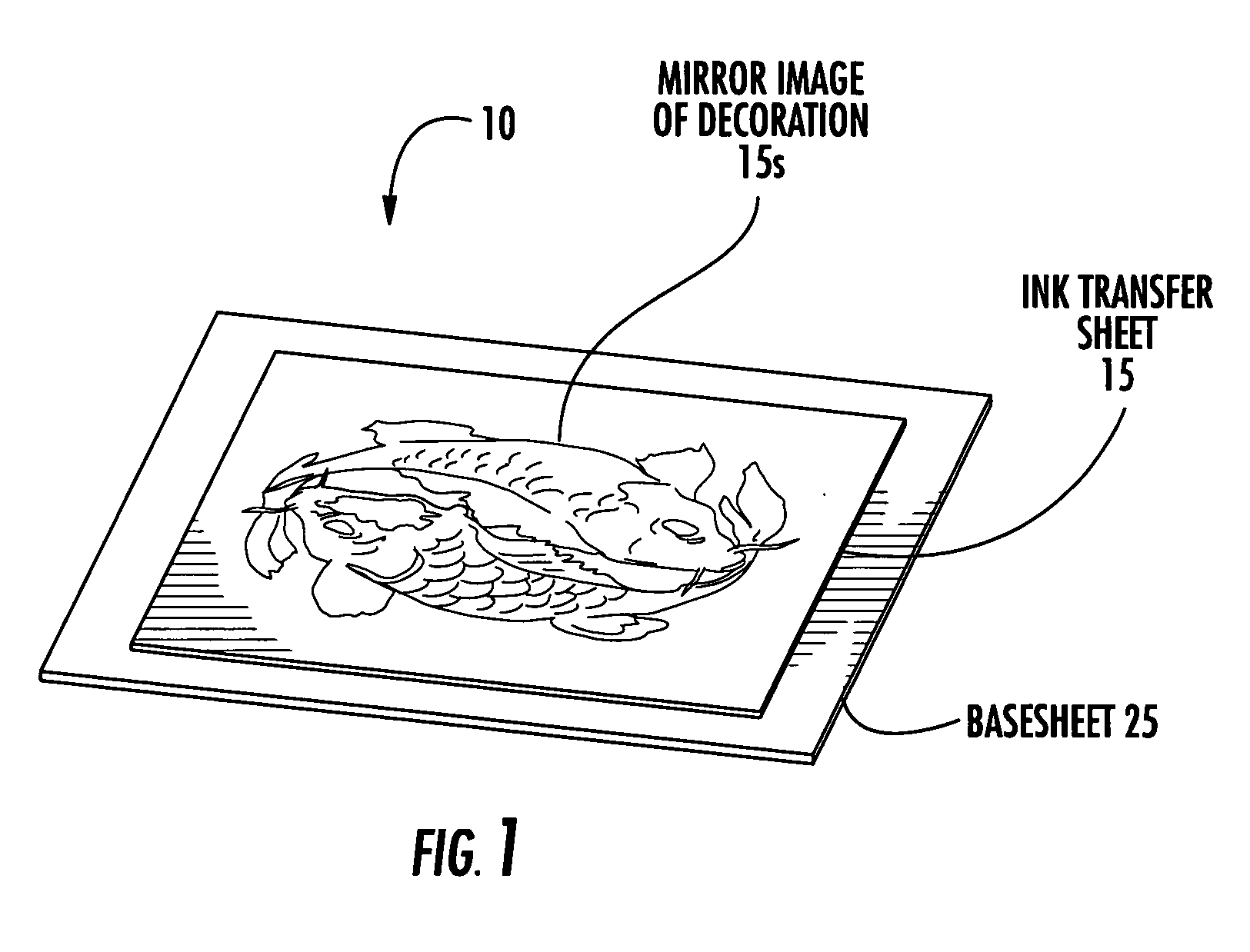

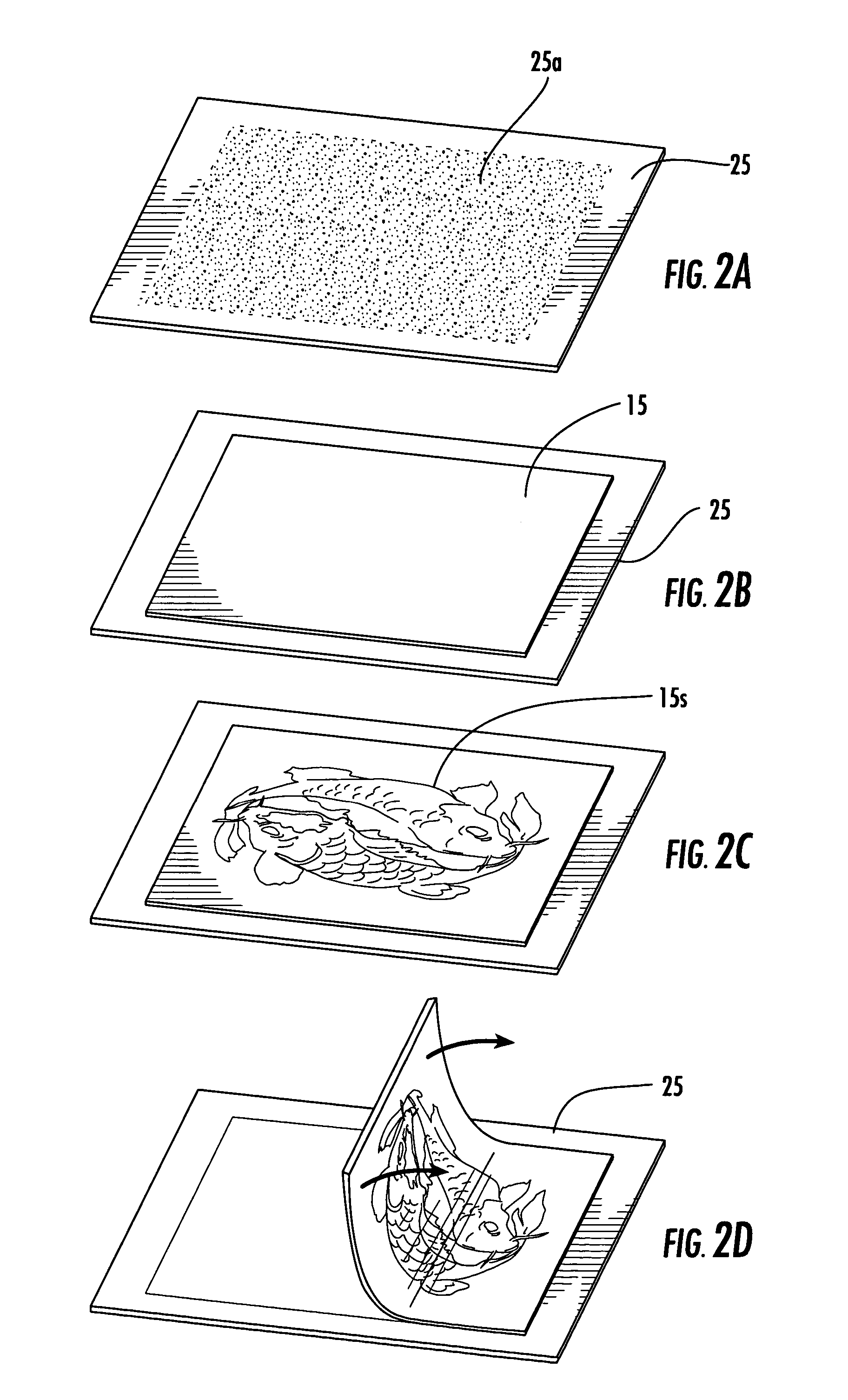

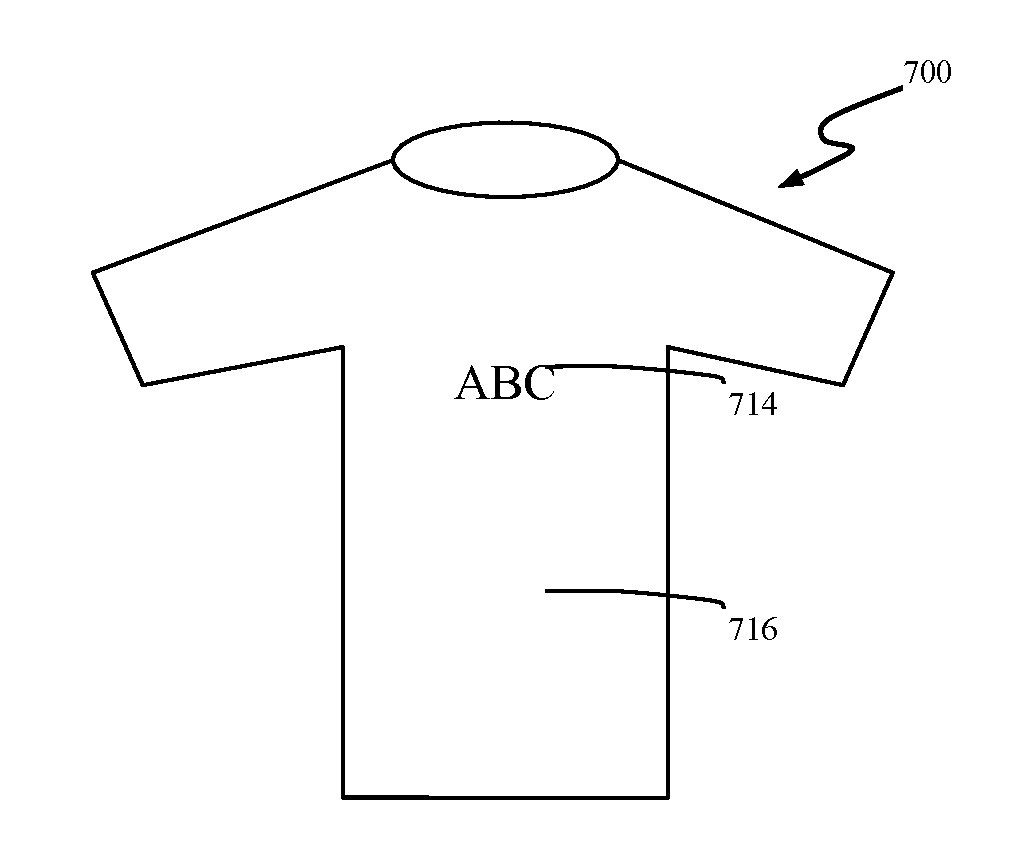

Direct-print sublimation ink support substrates and related methods of producing printed sublimation fabrics and/or sublimating a decoration onto target products

InactiveUS20050248649A1Reduce Shrinkage ProblemsAccumulates inkRecording apparatusPrinting mechanismsEngineeringPrinting ink

Owner:HOLT SUBLIMATION PRINTING & PROD

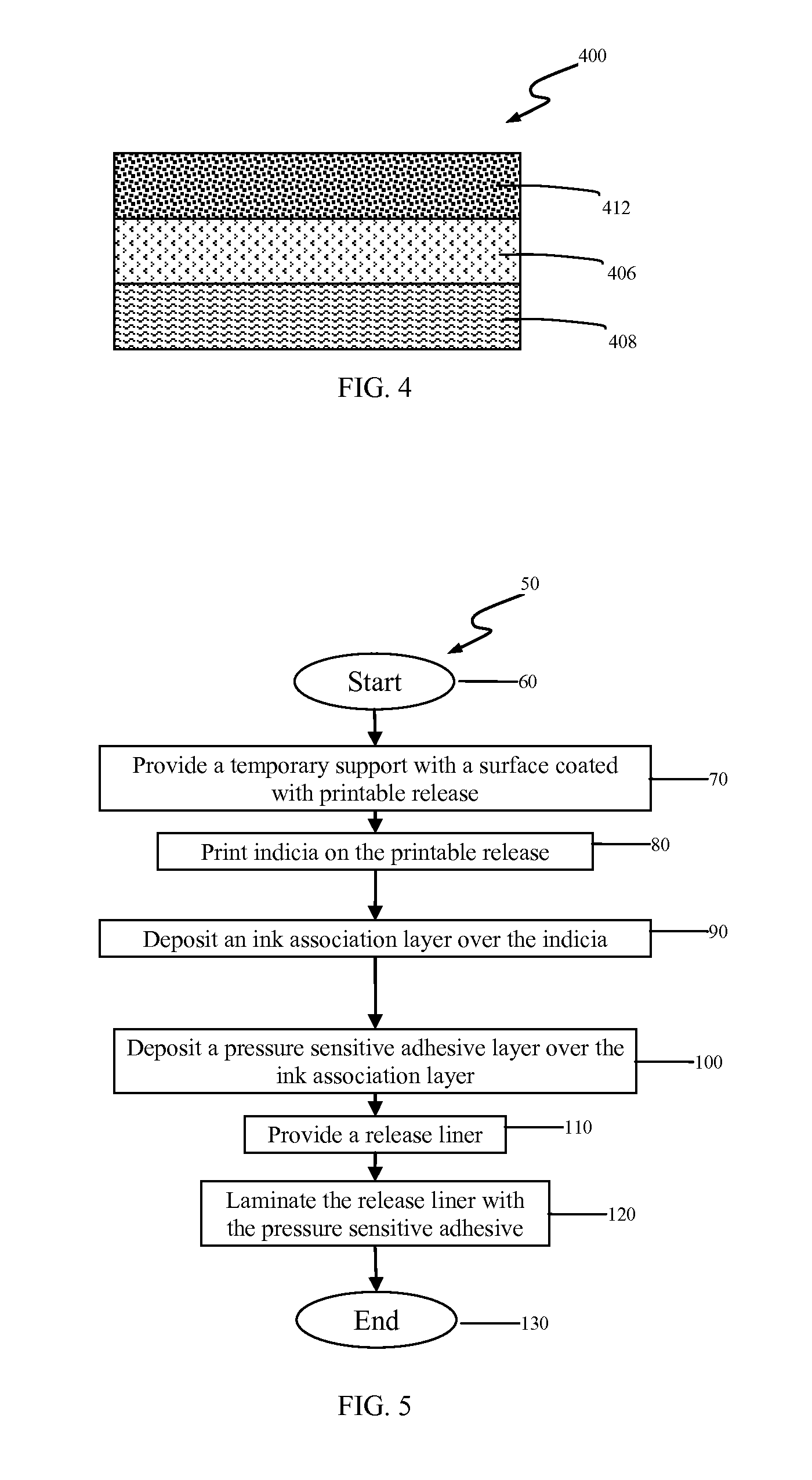

Pressure sensitive labels for use in a cold transfer method and process for making

The present invention relates to a pressure sensitive label for use in a cold transfer process that can be used for garment identification and labeling. The pressure sensitive label can be applied on textile surface or any other surfaces for which heat transfer is unfavorable or unavailable. The pressure sensitive label can remain on the substrate to which it is attached through repeated washing and drying cycles.

Owner:AVERY DENNISON CORP

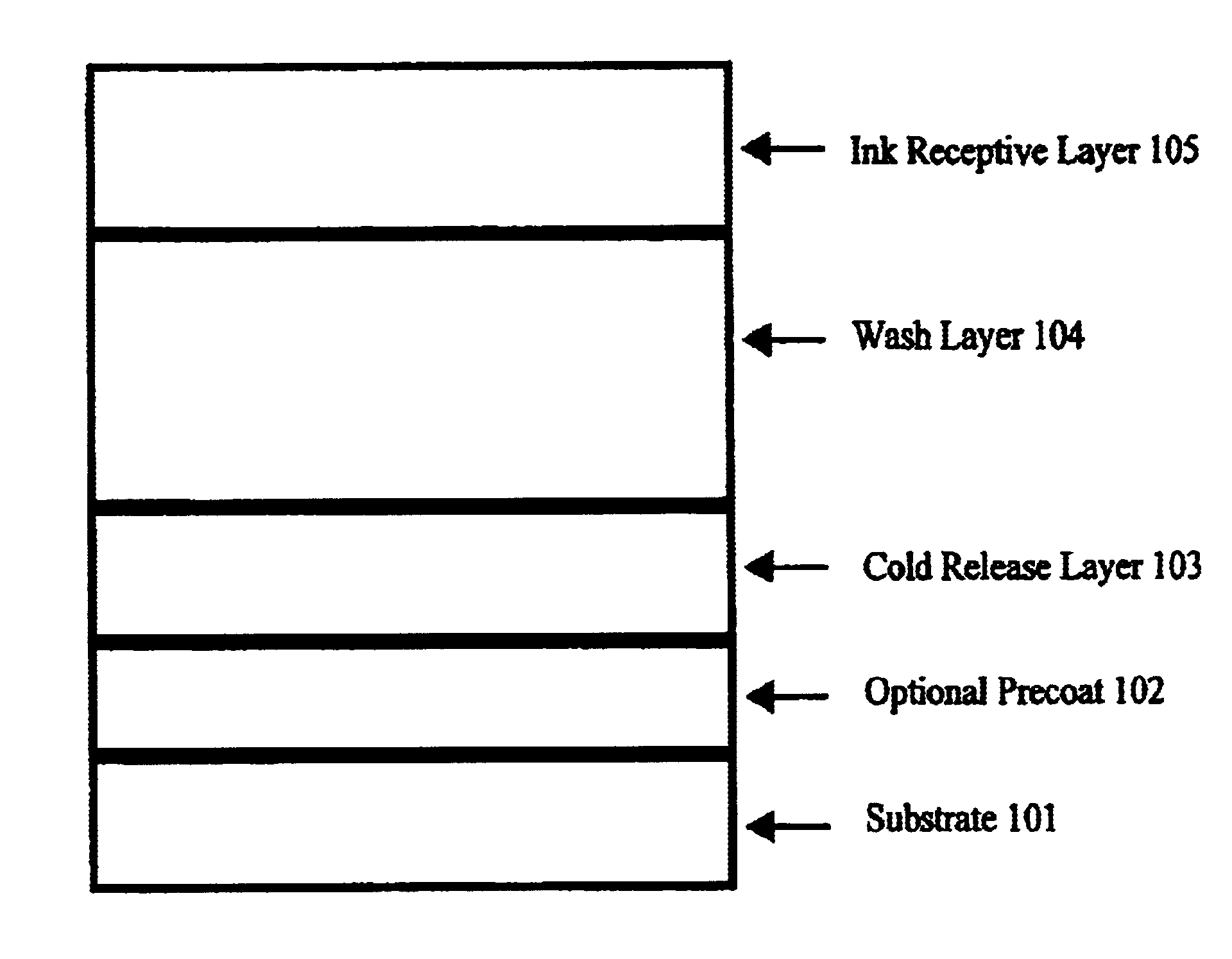

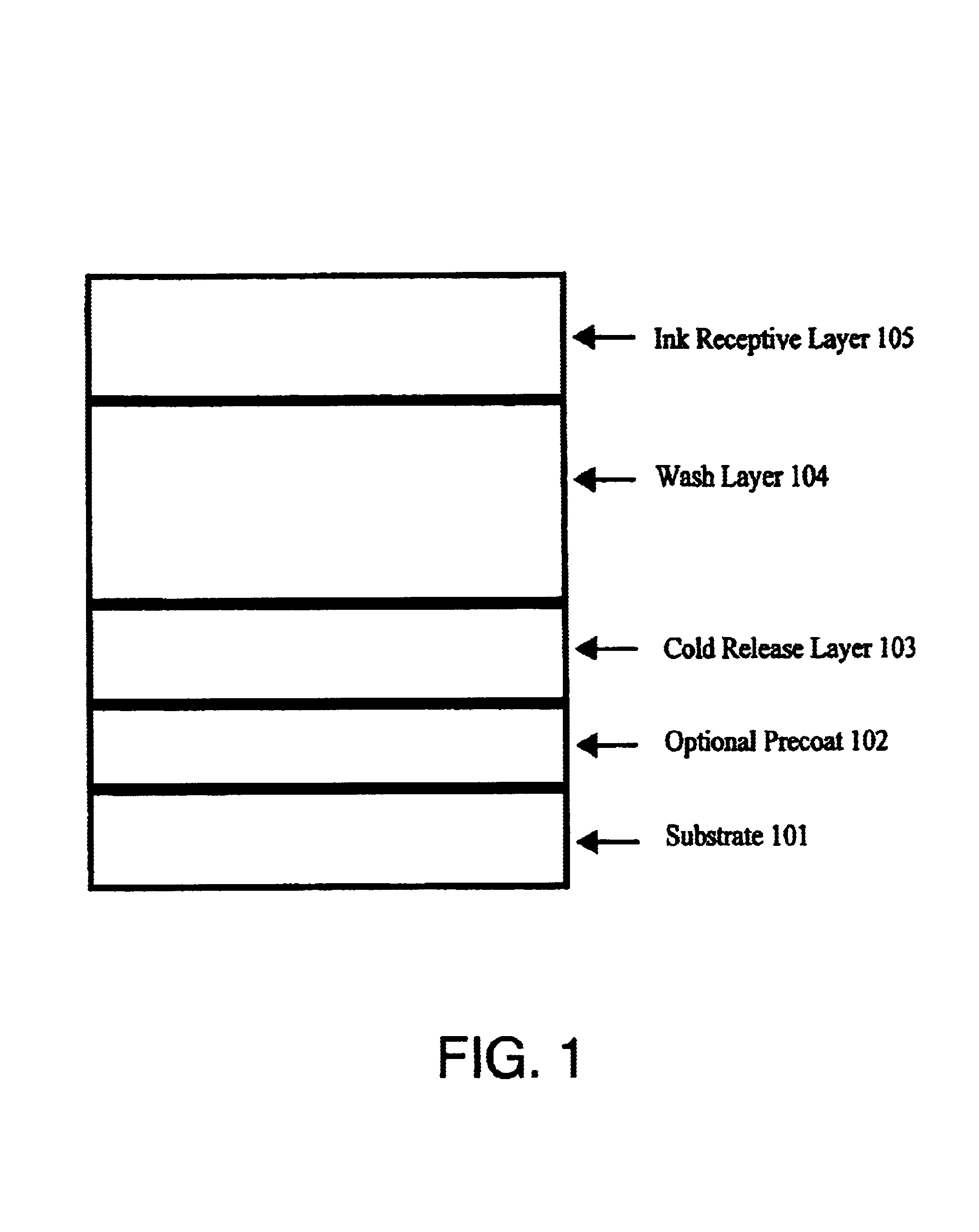

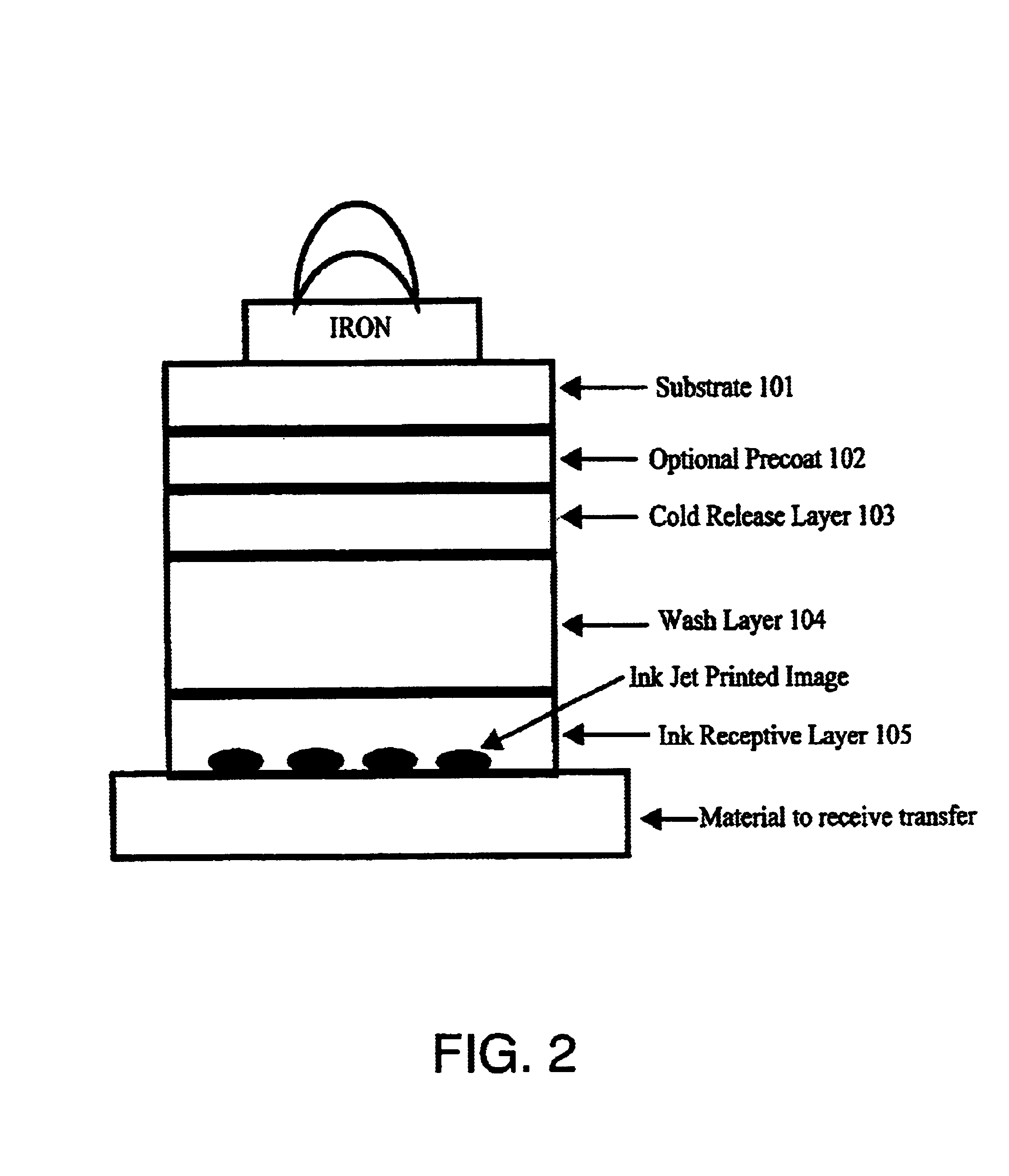

Ink jet printable heat transfer paper

InactiveUS6951671B2Quality improvementAbrasion excellentDecorative surface effectsTransfer printing processThermoplasticAntioxidant

This patent describes an ink jet printable heat transfer material with cold release properties. The invention consists of multiple layers of coatings applied to a suitable substrate, typically paper. The first optional layer coating consists typically of a pigmented coating bound together with a synthetic or natural binder and is applied in sufficient quantity to level and densify the surface of a given substrate. The second coating is applied over the first and consists of a silicone coating with a controlled surface energy. The surface energy must be such that the subsequent aqueous coatings can be applied over top with good wetting and adhesion, but low enough for an easy removal from the heat transfer after cooling. A third or wash layer is applied over the silicone release layer. This layer must easily wet and adhere to the silicone release layer so the coating does not come off during subsequent coating passes and during handling by the user. The wash layer consists of one or more thermoplastic polymers including ethylene acrylic acid, waxes, and other polymers along with dispersions of non-water soluble plasticizers and antioxidants. An ink receptive layer consists of a low binder thermoplastic organic pigmented coating containing non-water soluble plasticizers and antioxidants along with water soluble and insoluble cationic polymers and / or cationic inorganic pigments. The non-water soluble cationic materials, either organic or inorganic, aid in the retention of the dyes and reduce the wet bleed and wash out of the dyes when the transfers get wet.

Owner:P H GLATFEITER +1

Pad transfer printing method for making colored contact lenses

A method comprises the steps of (a) providing a water based ink in at least one cliché with a contact lens pattern; (b) transferring the water based ink from the cliché to at least a surface of at least a contact lens forming mold by means of at least a transfer pad; (c) at least partially curing the ink transferred on the mold to form a colored film; (d) dispensing a hydrogel lens-forming material into a lens-forming cavity of the mold; and (e) curing the lens-forming material within the lens-forming cavity to form the contact lens, whereby the colored film detaches from the molding surface and becomes integral with the body of the contact lens; characterized in that the relative air humidity in the immediate vicinities of the transfer pad / s is kept higher than 50% at standard temperature and pressure conditions during ink transfer.

Owner:ALCON INC

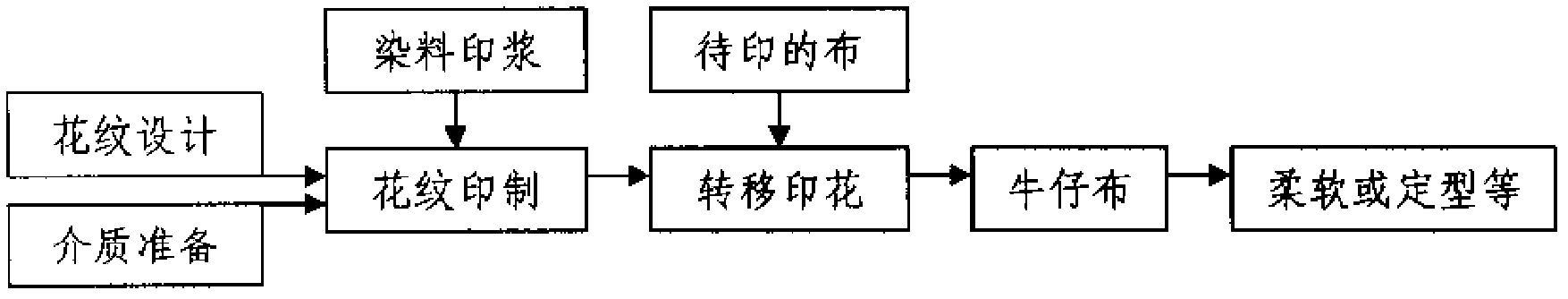

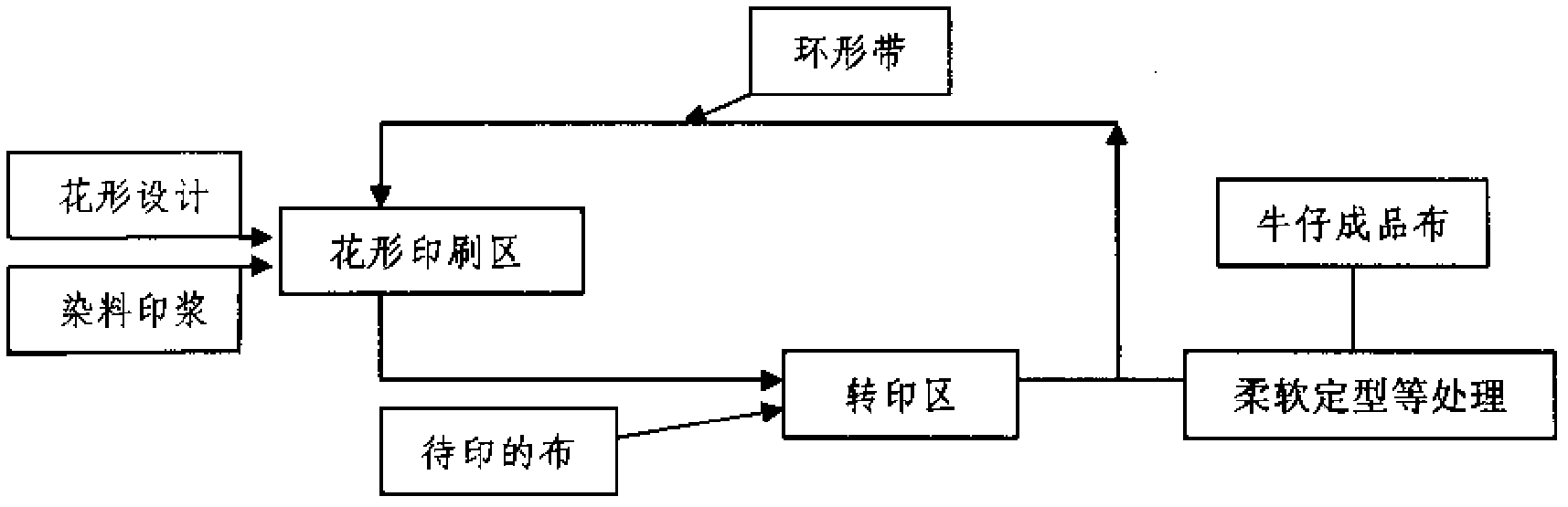

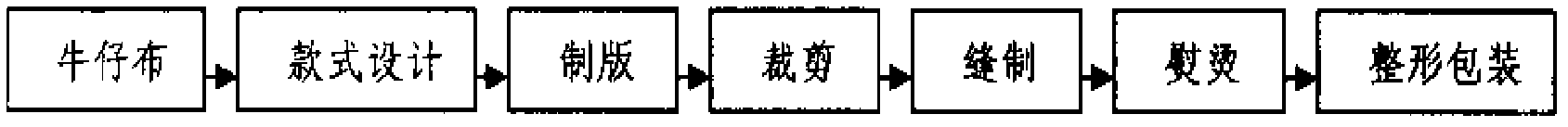

Printing technology for pure cotton or polyester-cotton jean

InactiveCN102304862APrinting process does not consume waterNo sewageTransfer printing processDyeing processWater basedFiber

The invention discloses a printing technology for pure cotton or polyester-cotton jean, belonging to the technical field of textile printing and dyeing. The printing technology comprises the following steps: firstly, preparing a dye into water-based ink suitable for intaglio printing; pretreating fiber fabrics to be served as cloth to be printed; preparing a medium capable of undertaking the printing of figures; designing figure patterns; printing the designed figure patterns on the medium in a common printing mode to obtain a transfer printing medium; carrying out transfer printing of the figures on the transfer printing medium to the cloth by a transfer machine to finish the printing of the jean; and carrying out the processes of softening, shaping and the like with the traditional padding-shaping machine as required. The printing technology has the beneficial effects that the jean with the traditional jean style can be printed, no water is consumed for printing, no sewage is generated, and the printing technology belongs to the clean production technology.

Owner:北京三丽科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com