Patents

Literature

57results about How to "Avoid premature reaction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for stabilization of enzymes during exposure to sterilizing radation

InactiveUS20060281165A1Inhibition releaseAvoid premature reactionEnzyme stabilisationOxidoreductasesL lactateZinc

The present invention provides a composition comprising an enzyme, e.g. oxidase enzyme, a source of zinc and / or ammonium ions and a source of lactate ions. The compositions are typically sterilised by exposing the compositions to sterilising radiation, e.g. gamma radiation. The incorporation of a source of zinc and / or ammonium ions and a source of lactate ions, e.g. zinc L-lactate, in the enzyme-containing composition results in an improvement in enzyme activity post-sterilisation. The presence of a source of zinc and / or ammonium ions and a source of lactate ions in the composition therefore has a protective effect on the enzyme during exposure to sterilising radiation so that good recovery of enzyme activity can be obtained.

Owner:INSENSE LIMITED

Aqueous epoxy zinc-rich priming paint and preparation method thereof

InactiveCN108690456AGood dispersionWell mixedAnti-corrosive paintsEpoxy resin coatingsEpoxyGas phase

The invention relates to the technical field of a paint, and concretely discloses an aqueous epoxy zinc-rich priming paint and a preparation method thereof. The priming paint comprises the following raw materials in parts by weight: 10-30 parts of epoxy resin, 0.1-0.5 parts of a wetting dispersant, 0.1-0.5 parts of an antifoaming agent, 1-5 parts of a film-forming auxiliary agent, 40-70 parts of sheet zinc dust, 4-20 parts of spherical zinc dust, 0-25 parts of ferrophosphorous powder, 0.2-2 parts of graphene oxide, 0.2-2 parts of gas-phase silica, 0.1-0.5 parts of a flash rust-prevention agent, 10-30 parts of a curing agent, 0.1-1 part of magnesium lithium silicate, and 5-10 parts of deionized water. The two-component aqueous epoxy zinc-rich priming paint employs a component A and a component B, the construction is simple, the VOC content is low, the hardness is high, adhesive force, impact resistance and sag resistance are excellent, the anti-settling performance is good, the storageperformance of the priming paint is increased, and the anti-salt spray performance is excellent.

Owner:HEBEI CHENYANG INDAL & TRADE GROUP CO LTD

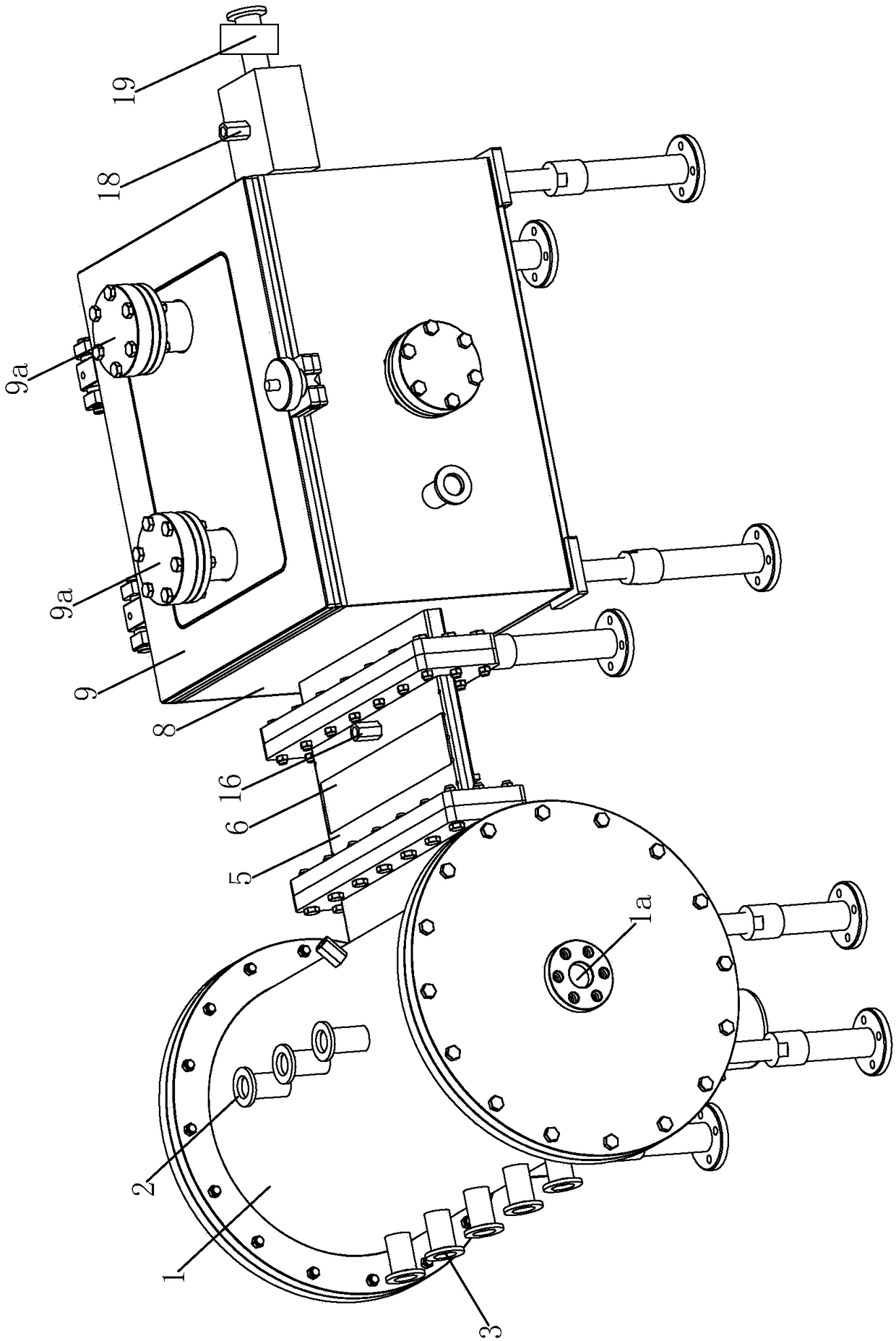

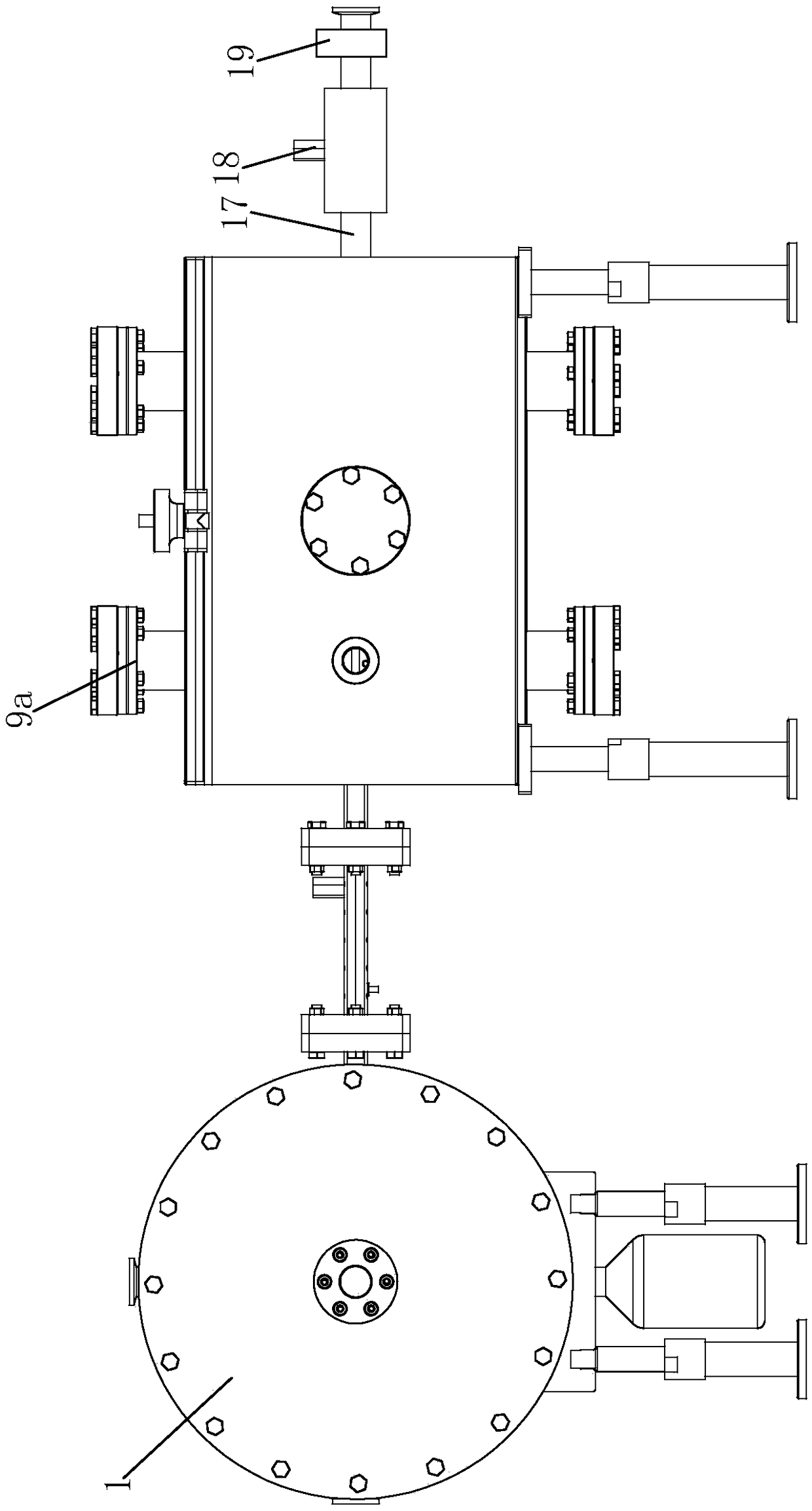

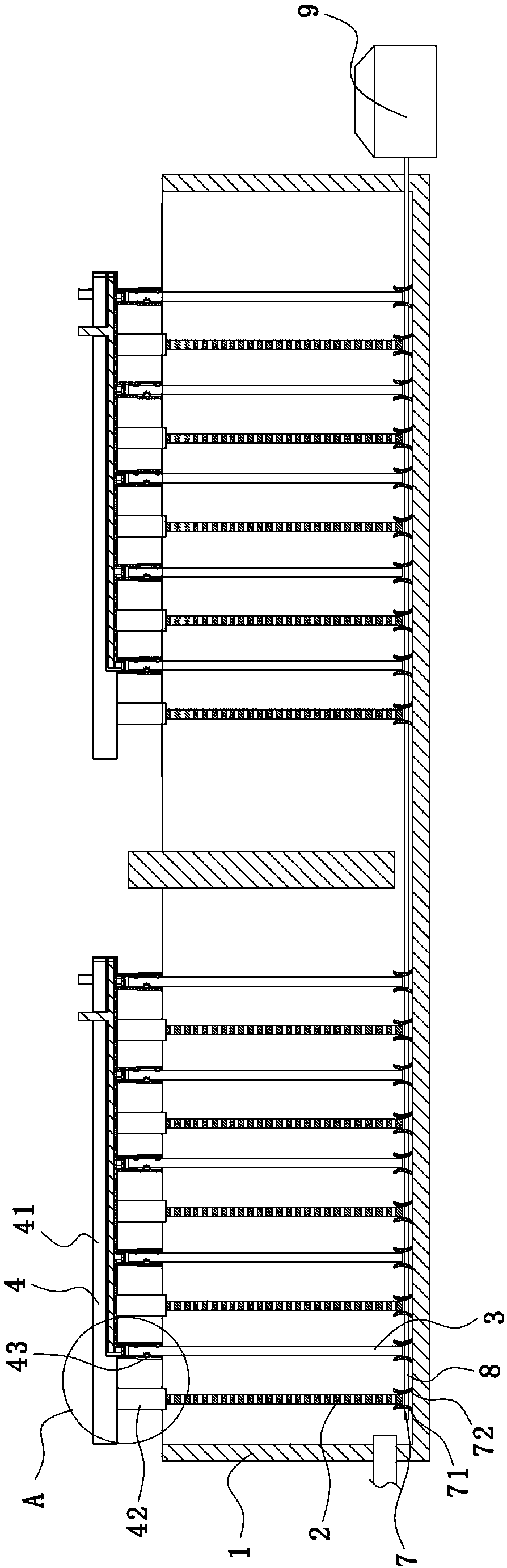

Atomization assisting CVD thin film deposition method

ActiveCN109440083AAdjust gas atmosphereAdjust the atmosphereLiquid/solution decomposition chemical coatingChemical vapor deposition coatingGas phaseRoom temperature

The invention discloses an atomization assisting CVD thin film deposition method. The atomization assisting CVD thin film deposition method is characterized by comprising the following steps that a, an atomization assisting CVD thin film deposition device is designed; b, a plane substrate being about to form a film is placed in an installing hole in a substrate template, then the substrate template is horizontally placed on the upper plate face of a lower lifting plate, and the position of the lower lifting plate is adjusted; d, after a temperature of a reaction area reaches a preset temperature, firstly an atomization source is opened, and is used for atomizing liquid precursors into aerosol precursors, the aerosol precursors are input into a buffering mixing chamber through carrier gas sent out of the atomization source; and e, after the temperature of the reaction area is close to a room temperature or is 45 DEG C or below, the operation that the precursors are input into the buffering mixing chamber through a gas phase matter inflow pipe and an aerosol inflow pipe firstly stops, then a gas sucking pump is closed, finally, a sealing cover is opened, the substrate template is taken out, and finally a substrate is taken down from the substrate template. The thin film deposition method is high in deposition efficiency, reasonable in process arrangement and high in thin film quality.

Owner:CHONGQING UNIV OF TECH +1

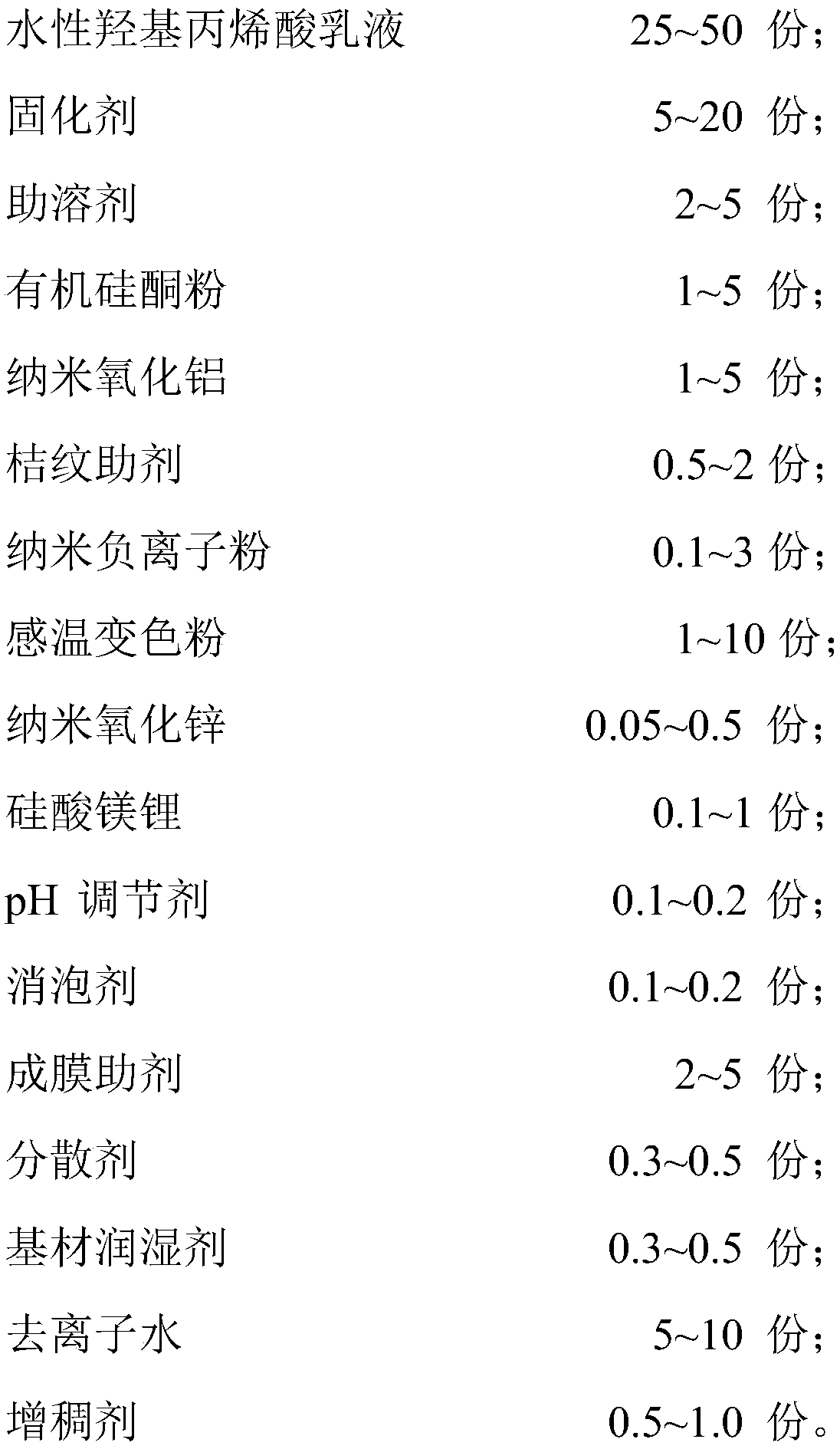

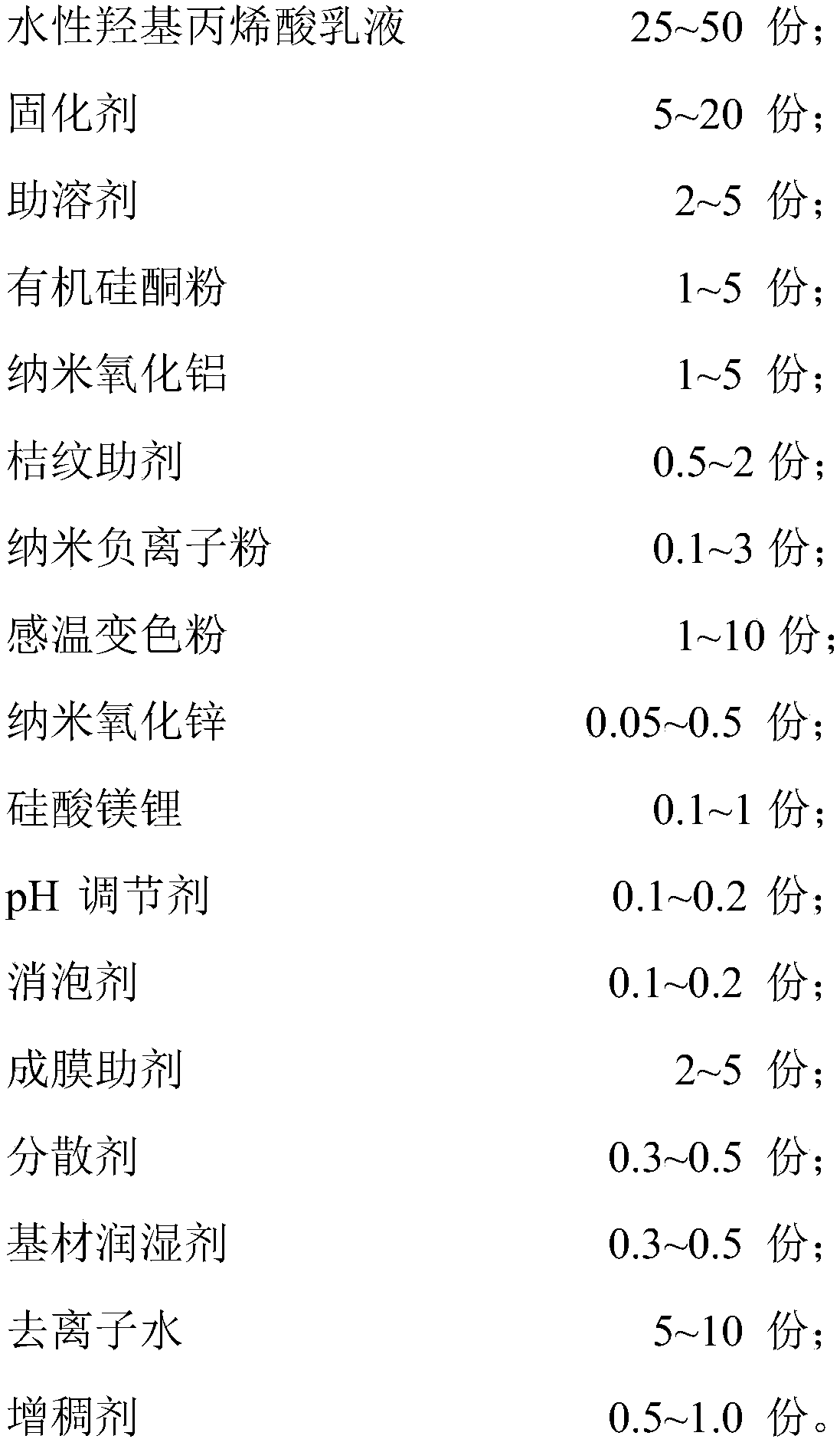

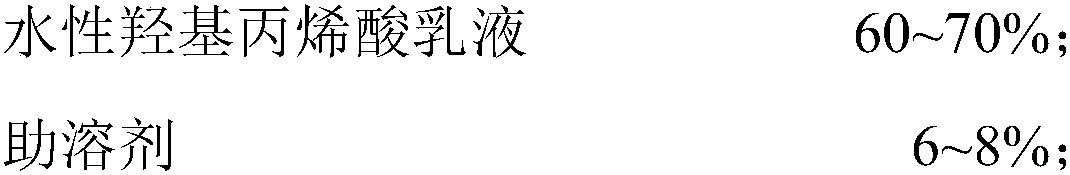

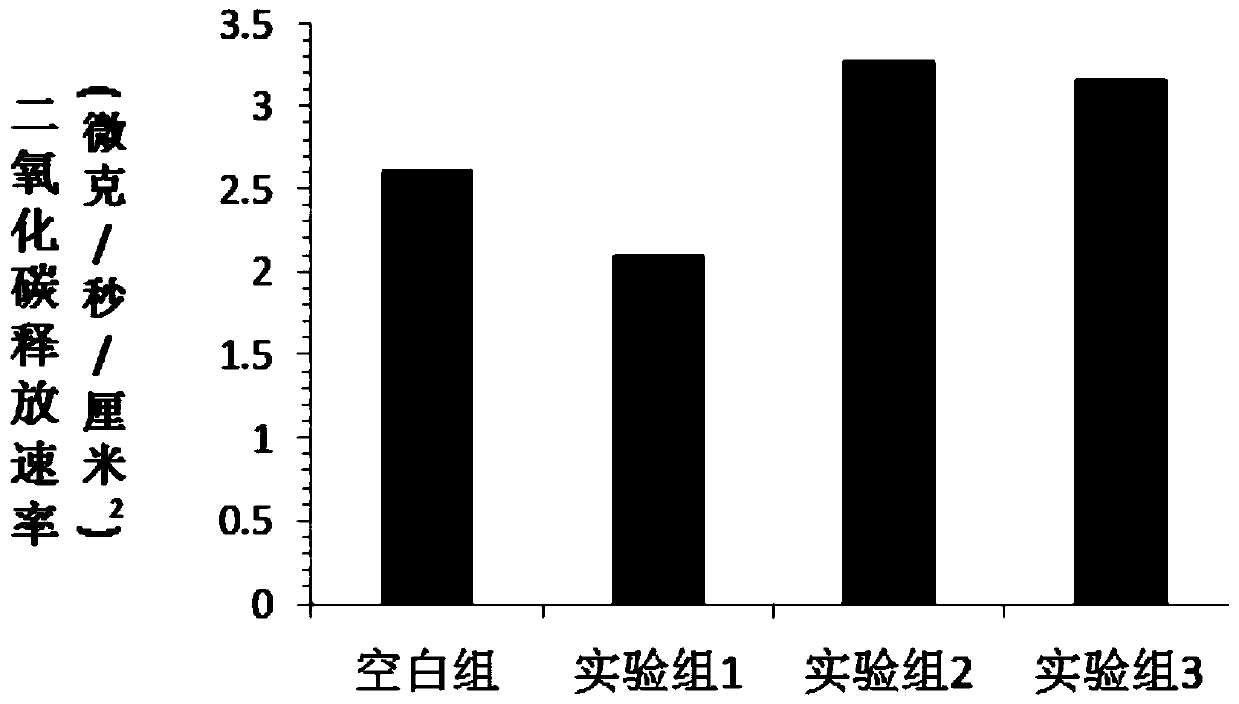

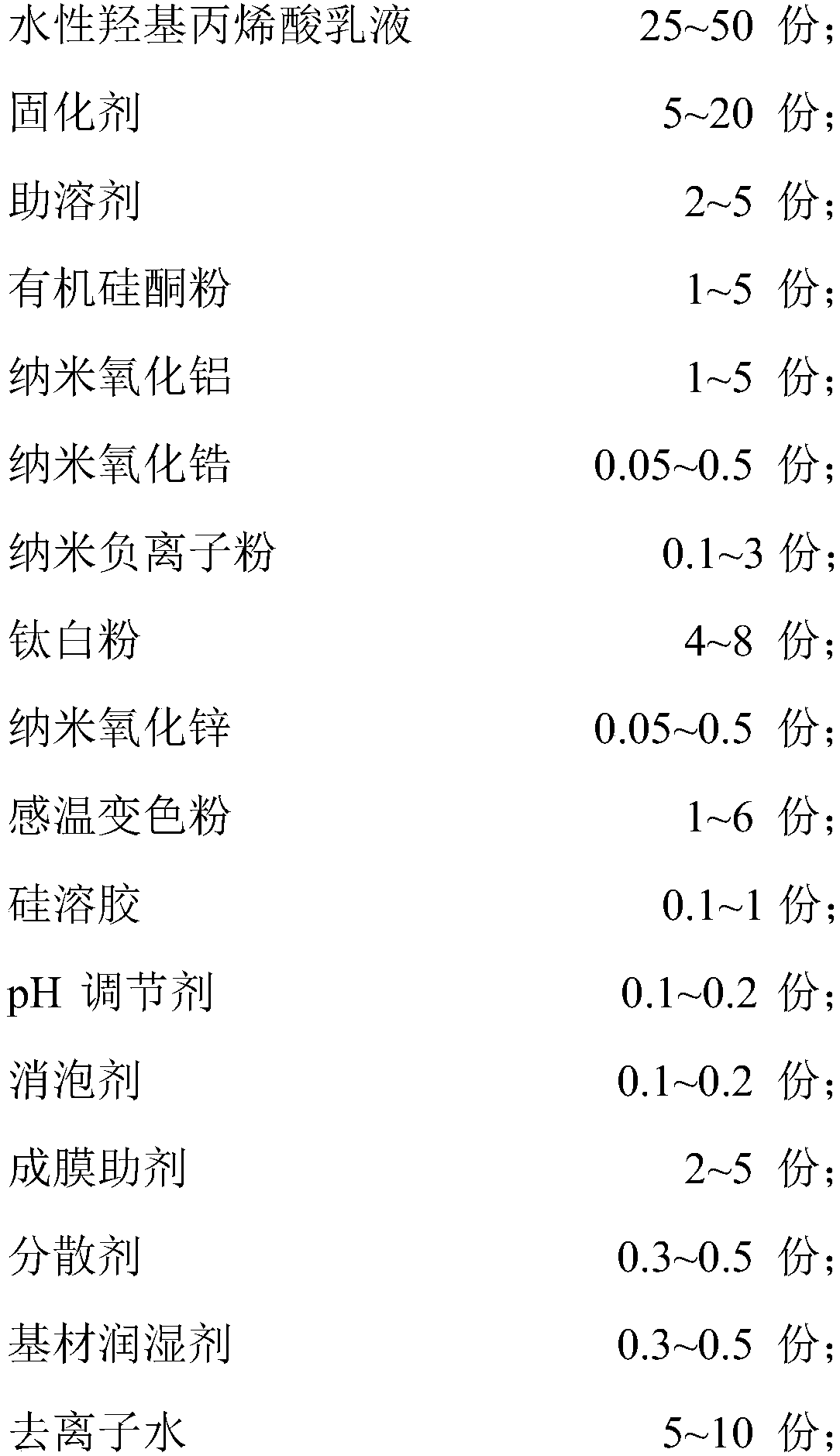

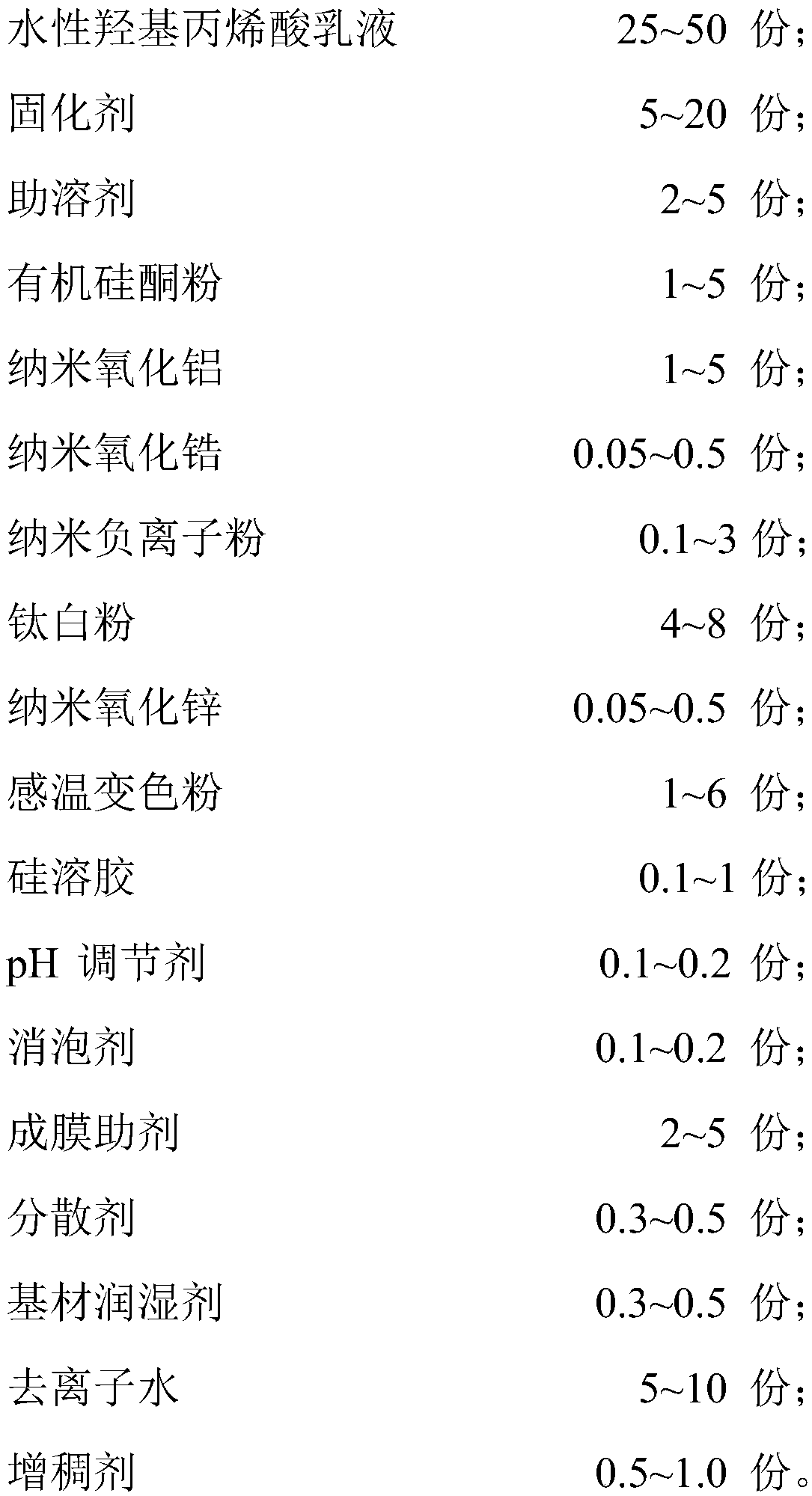

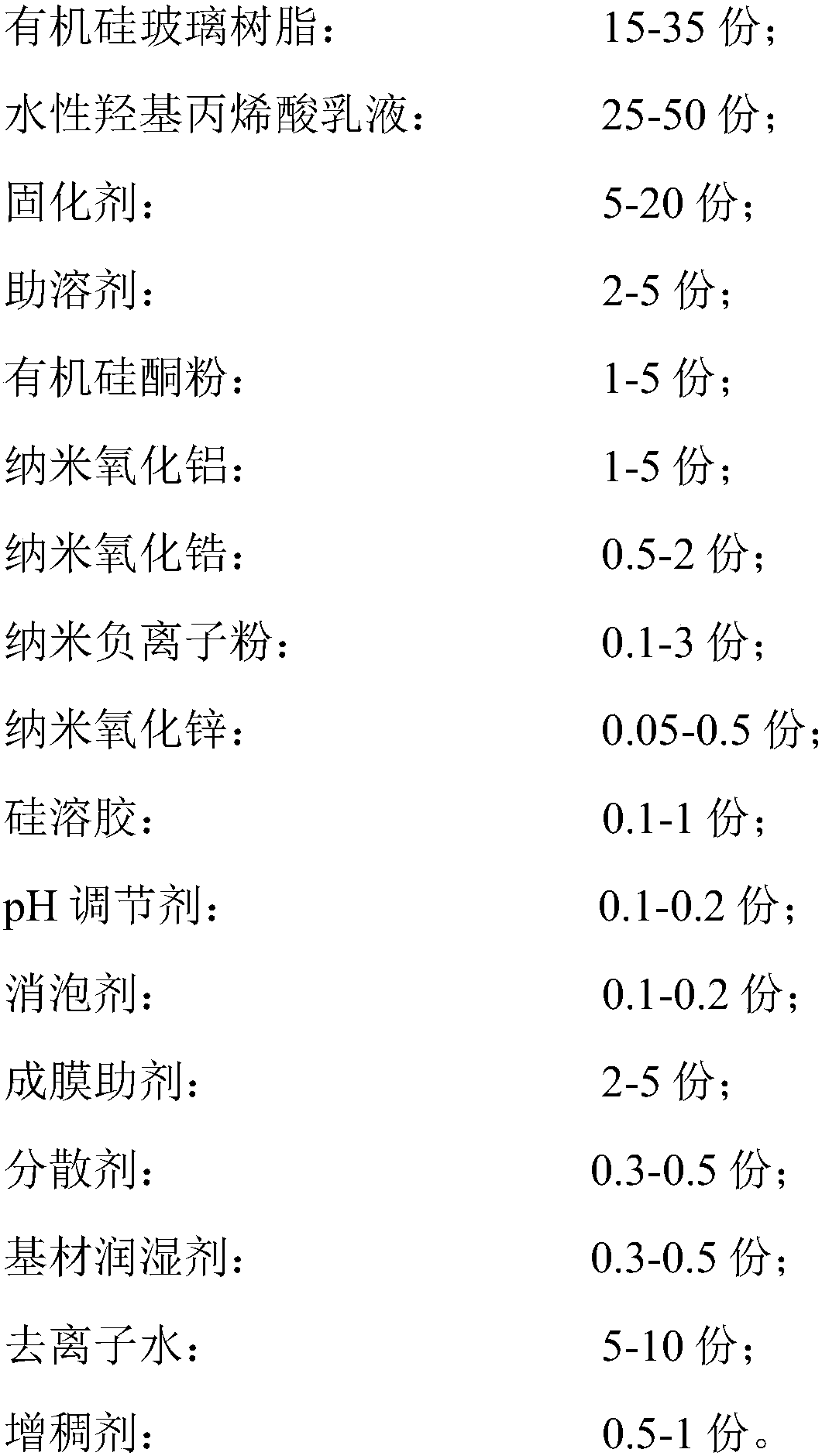

Aqueous three-dimensional effect color changing orange-peel coating material, preparation method and applications thereof

InactiveCN108753076AGood light fastnessGood chemical resistanceAntifouling/underwater paintsPaints with biocidesNano al2o3Color changes

The invention relates to an aqueous three-dimensional effect color changing orange-peel coating material, a preparation method and applications thereof, wherein the aqueous three-dimensional effect color changing orange-peel coating material comprises the following raw materials by weight: 25-50 parts of an aqueous hydroxy acrylic emulsion, 5-20 parts of a curing agent, 2-5 parts of a cosolvent, 1-5 parts of organic silicone powder, 1-5 parts of nanometer alumina, 0.5-2 parts of an orange-peel auxiliary agent, 0.1-3 parts of nanometer negative ion powder, 1-10 parts of thermochromic powder, 0.05-0.5 part of nanometer zinc oxide, 0.1-1 part of lithium magnesium silicate, 0.1-0.2 part of a pH value adjuster, 0.1-0.2 part of an antifoaming agent, 2-5 parts of a film forming aid, 0.3-0.5 partof a dispersant, 0.3-0.5 part of a base material wetting agent, 5-10 parts of deionized water, and 0.5-1.0 part of a thickener. According to the present invention, the obtained coating material has low VOCs content, and the coating has advantages of good light resistance, good chemical resistance, good hardness, good antibacterial property, good air purification performance, good discoloration indication and three-dimensional orange-peel effect.

Owner:HEBEI CHENYANG INDAL & TRADE GROUP CO LTD

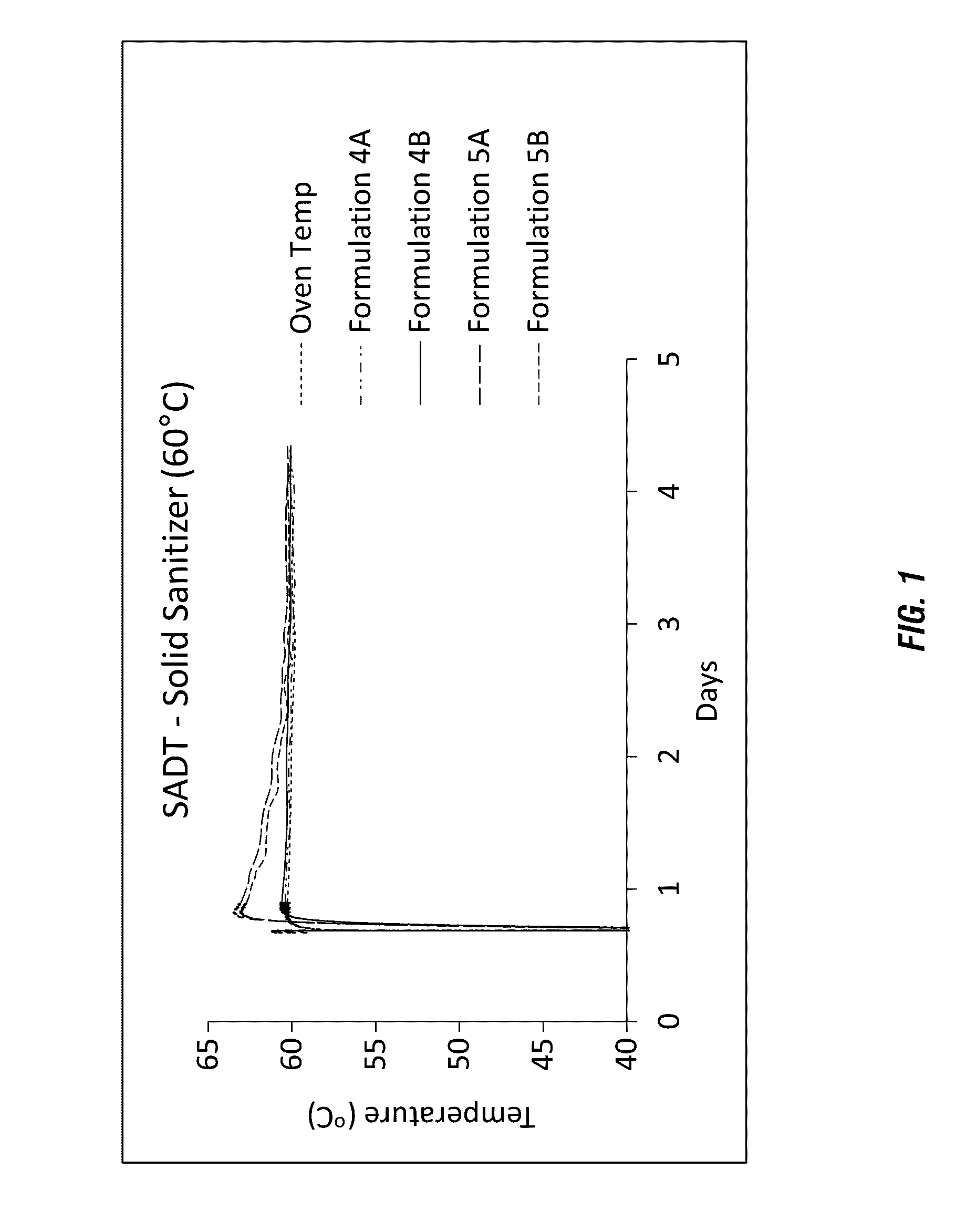

Enhanced peroxygen stability in multi-dispense taed-containing peroxygen solid

ActiveUS20160289606A1Improved shelf stabilityPrevent premature reactionWaste water treatment from quariesInorganic/elemental detergent compounding agentsActive oxygenPhosphenic acid

Stabilized compositions employing a sequestrant system and a binding system for improving shelf stability and dispensing stability of a solid activated bleach composition are disclosed. The compositions contain a peroxygen source and a catalyst activator which require generation of a peroxycarboxylic acid or other active oxygen sanitizing agent at a point of use. Stabilized compositions employ a sequestrant system including a phosphonic acid and / or dipicolinic acid sequestrant and a binding system comprising an anionic surfactant for a solid formulation of a catalyst activator and peroxygen source to provide shelf stability and dispensing stability for a activated bleach composition. Methods of formulating and use are further disclosed.

Owner:ECOLAB USA INC

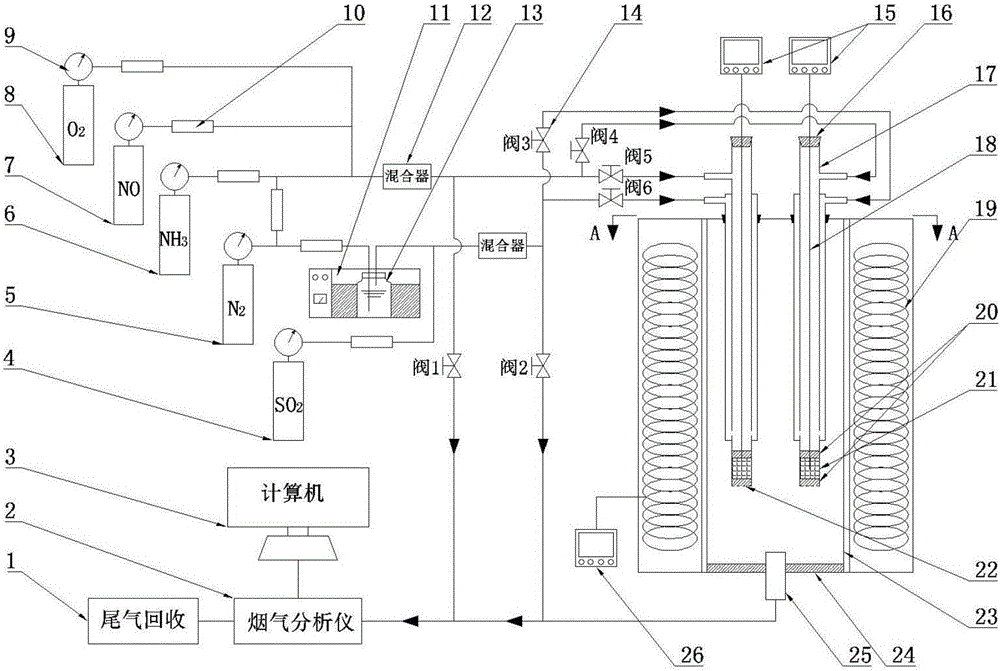

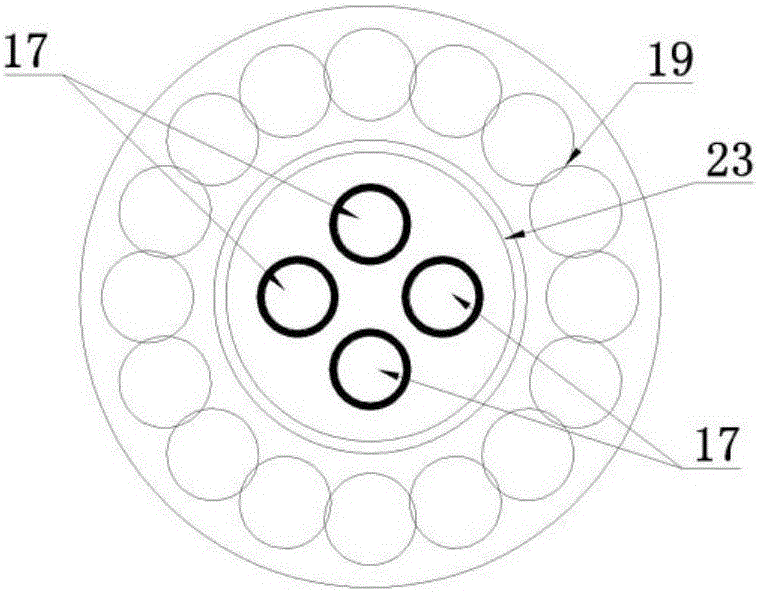

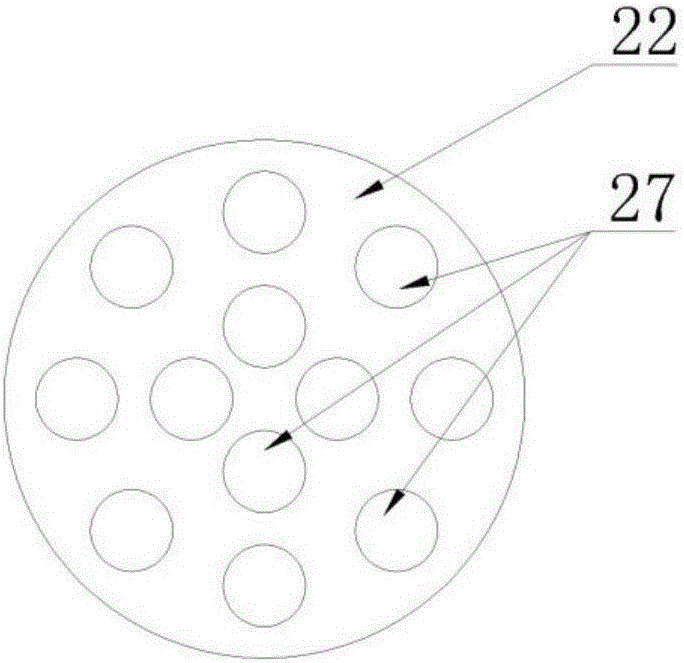

Testing device capable of simultaneously measuring multiple SCR catalysts

ActiveCN105911227AResearch on sulfur and water resistanceEasy to operatePreparing sample for investigationWater vaporGas cylinder

The invention discloses a testing device capable of simultaneously measuring multiple SCR catalysts. The testing device comprises a gas distributing system, a reaction system and a measuring system, wherein the gas distributing system is provided with multiple gas bottles containing N2, O2, NO, NH3 and SO2 respectively; the reaction system comprises multiple reaction tubes, a high temperature tube furnace wrapping the reaction tubes and an outer sleeve; the measuring system comprises a flue gas analyzer, the data output end of the flue gas analyzer is connected with a computer, and the gas outlet end of the flue gas analyzer is connected with a tail gas recovering device. NO removal efficiency of the SCR catalysts at different temperatures can be measured, NO removal efficiency of four SCR catalysts can be simultaneously measured at certain temperature, NO removal efficiency of the four SCR catalysts of the four SCR catalysts can be simultaneously measured under the conditions of different NH3 / NO ratios, different NH3 contents, different NO contents and different O2 contents, NO removal efficiency of the same SCR catalyst at different air speeds can be measured, finally NO removal efficiency of the SCR catalysts in the presence of SO2 and water can be measured, and sulfur and water resistance of the catalysts is researched.

Owner:XI AN JIAOTONG UNIV

Nonwoven plastic pouch separator

A rupturable seal comprising a film of a first polymer, a film of a second polymer and a sealing interlayer. The sealing interlayer has a melting point higher than the melting points of either the first polymer or the second polymer and comprises a plurality of micro-fibers each having an average effective fiber diameter from about 2.5 mum to about 7.0 mum. Fusion bonding of films of the first polymer and the second polymer to either side of a sealing interlayer produces a rupturable seal having a frangible interface including portions thereof wherein the first polymer contacts the second polymer. The rupturable seal parts at the frangible interface by application of force causing a gap and separation of the first film from the second film.

Owner:CORNING RES & DEV CORP

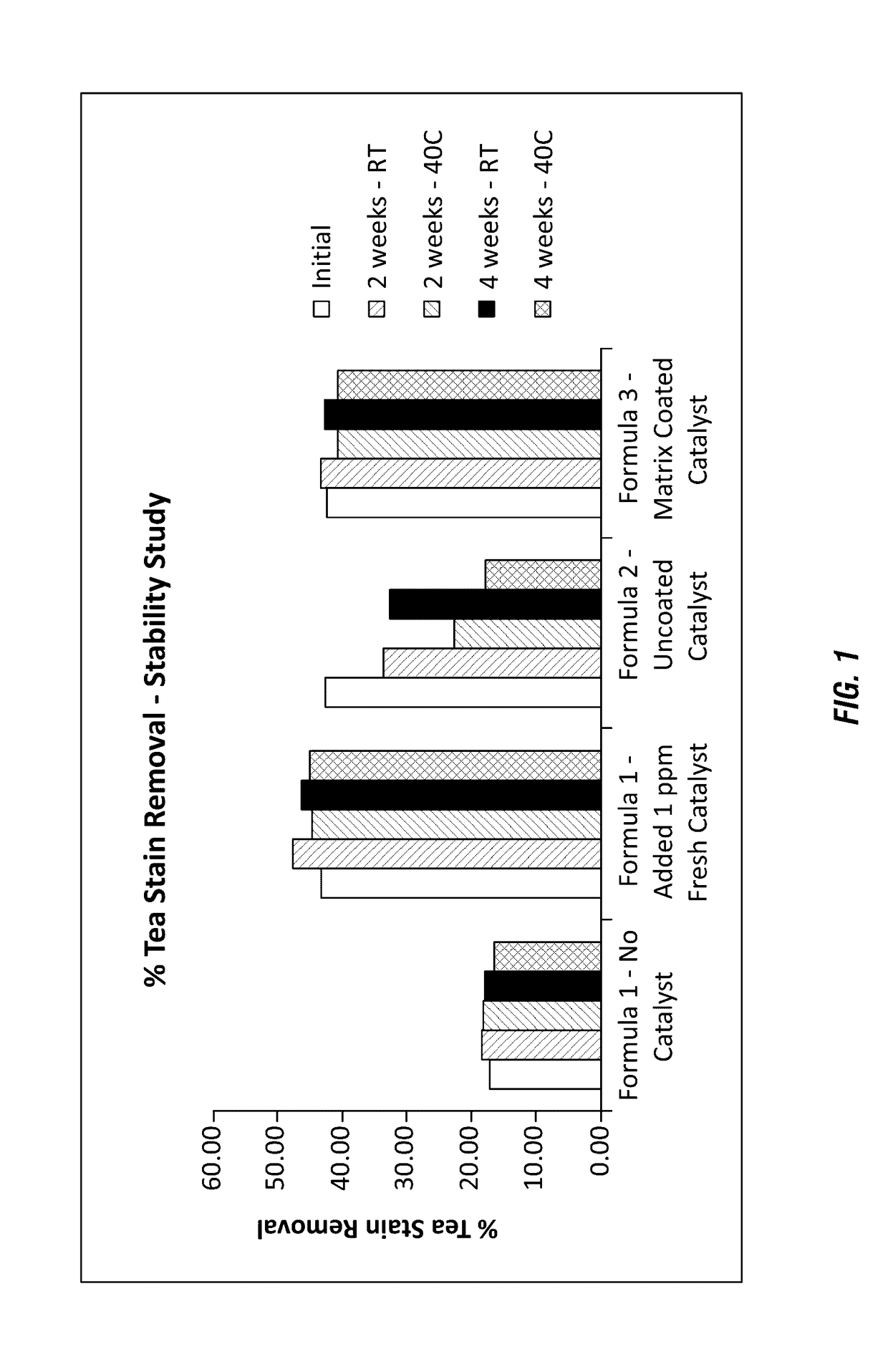

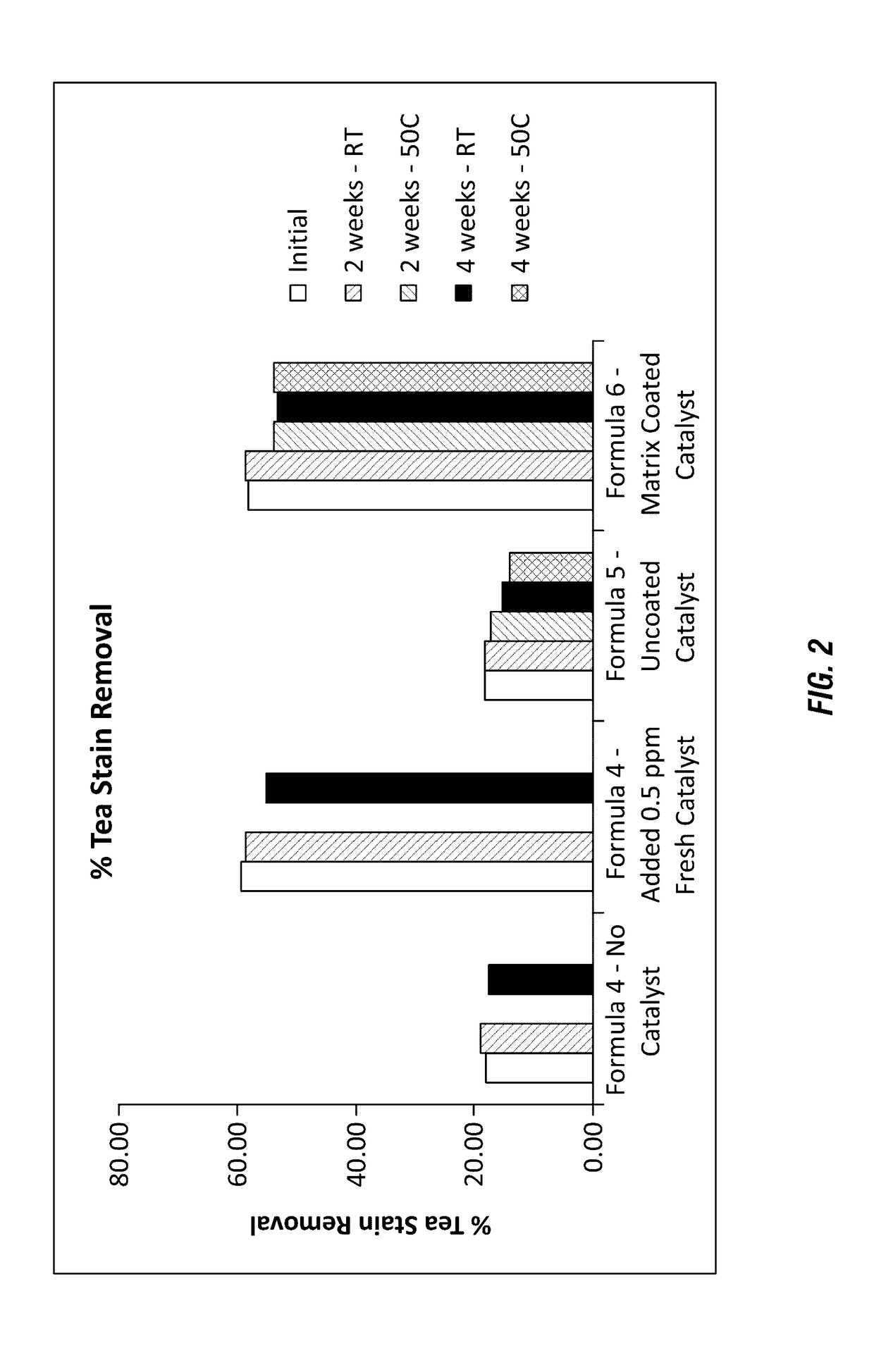

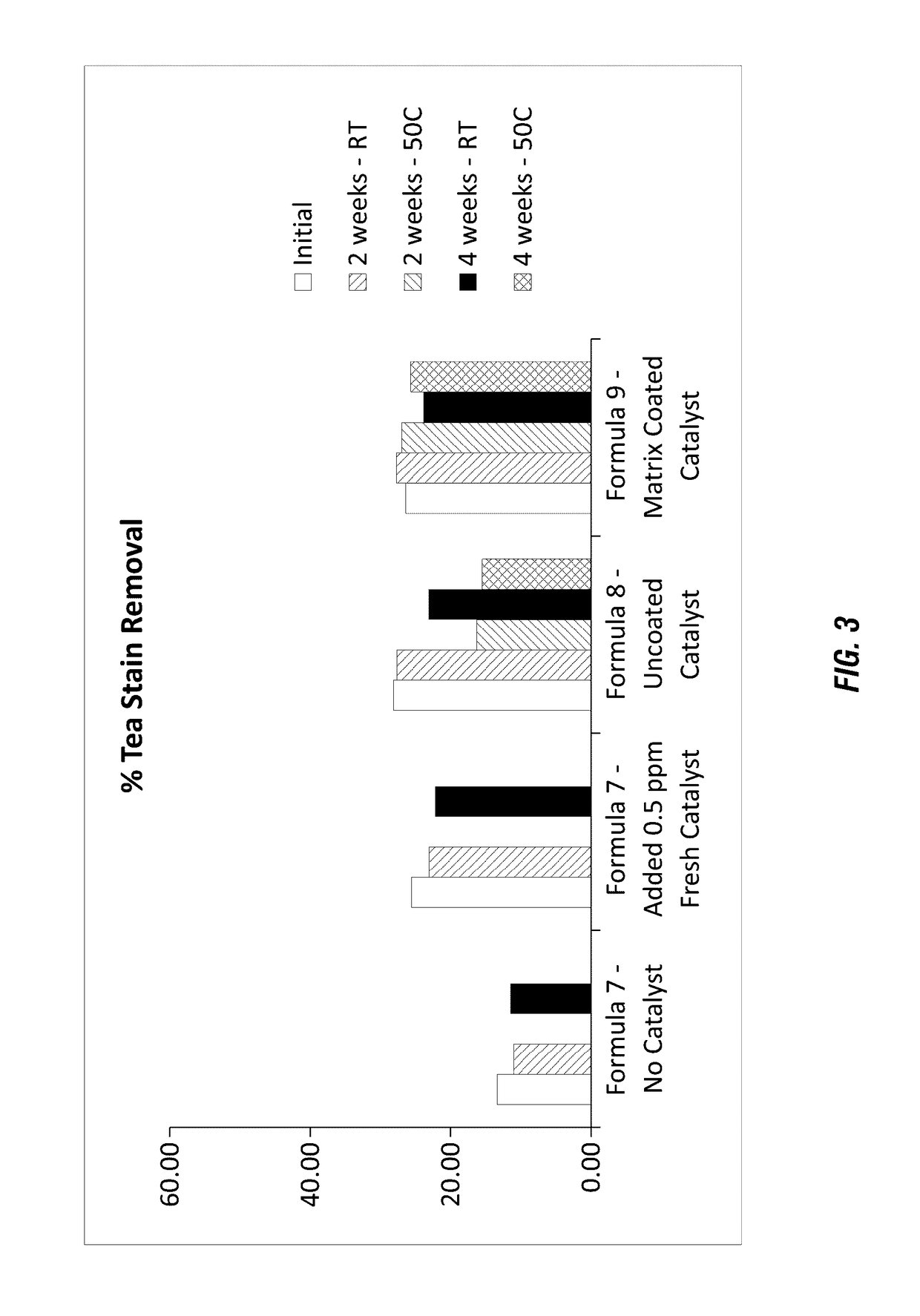

Enhanced catalyst stability in activated peroxygen and/or alkaline detergent formulations

ActiveUS9624119B2Improve stabilityAvoid premature reactionInorganic/elemental detergent compounding agentsOrganic detergent compounding agentsPeroxideActive oxygen

Stabilized catalyst detergent compositions are provided in solid formulations of detergents including an active oxygen source and / or a highly alkaline detergent composition. The compositions are suitable for use with additional detergent and / or bleaching compositions while providing stabilized catalysts within a polymeric matrix. Methods or process for manufacturing the compositions, and methods of use for cleaning are disclosed.

Owner:ECOLAB USA INC

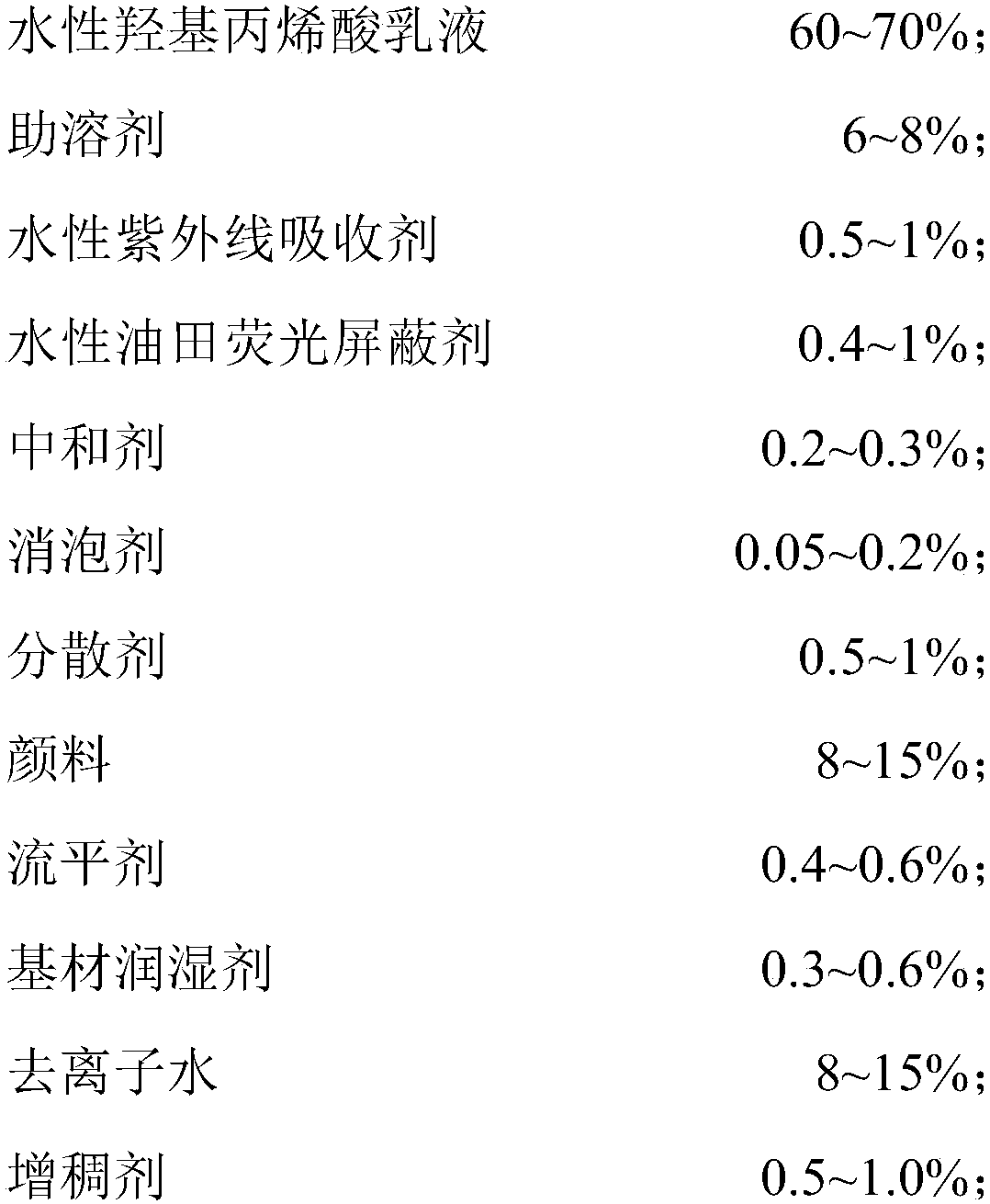

Water-based strong-weather-resistant self-repairing two-component polyurethane topcoat and preparation method thereof

PendingCN108395826AEasy to operateSuitable for mass production operationsPolyurea/polyurethane coatingsWater basedMass ratio

The invention relates to a water-based strong-weather-resistant self-repairing two-component polyurethane topcoat and a preparation method thereof. The topcoat is prepared by mixing a mixture of a group A and a mixture of a group B, wherein the mixture of the group A comprises a water-based hydroxyl acrylic emulsion, a co-solvent, a water-based ultraviolet light absorber, a water-based oilfield fluorescent shielding agent, a neutralizer, a defoaming agent, a dispersant, a pigment, a levelling agent, a substrate wetting agent, deionized water and a thickening agent; and the mixture of the groupB comprises aliphatic isocyanate and an ester organic solvent, and a mass ratio of the mixture of the group A to the mixture of the group B is (4.5-5.5):1. The preparation method comprises the following steps: mixing 50-70% of the deionized water, 40-60% of the neutralizer, the defoaming agent, the dispersant, 15-25% of the co-solvent and the pigment, performing grinding to obtain pre-stage slurry, mixing the water-based hydroxyl acrylic emulsion, and the remaining deionized water, neutralizer and co-solvent, adding the pre-stage slurry into the mixed material, performing mixing, adding the water-based ultraviolet light absorber, the water-based oilfield fluorescent shielding agent, the substrate wetting agent and the levelling agent, adjusting viscosity by using the thickening agent to obtain the mixture of the group A, preparing the mixture of the group B, and mixing the mixtures of the group A and the group B before the topcoat is used.

Owner:HEBEI CHENYANG INDAL & TRADE GROUP CO LTD

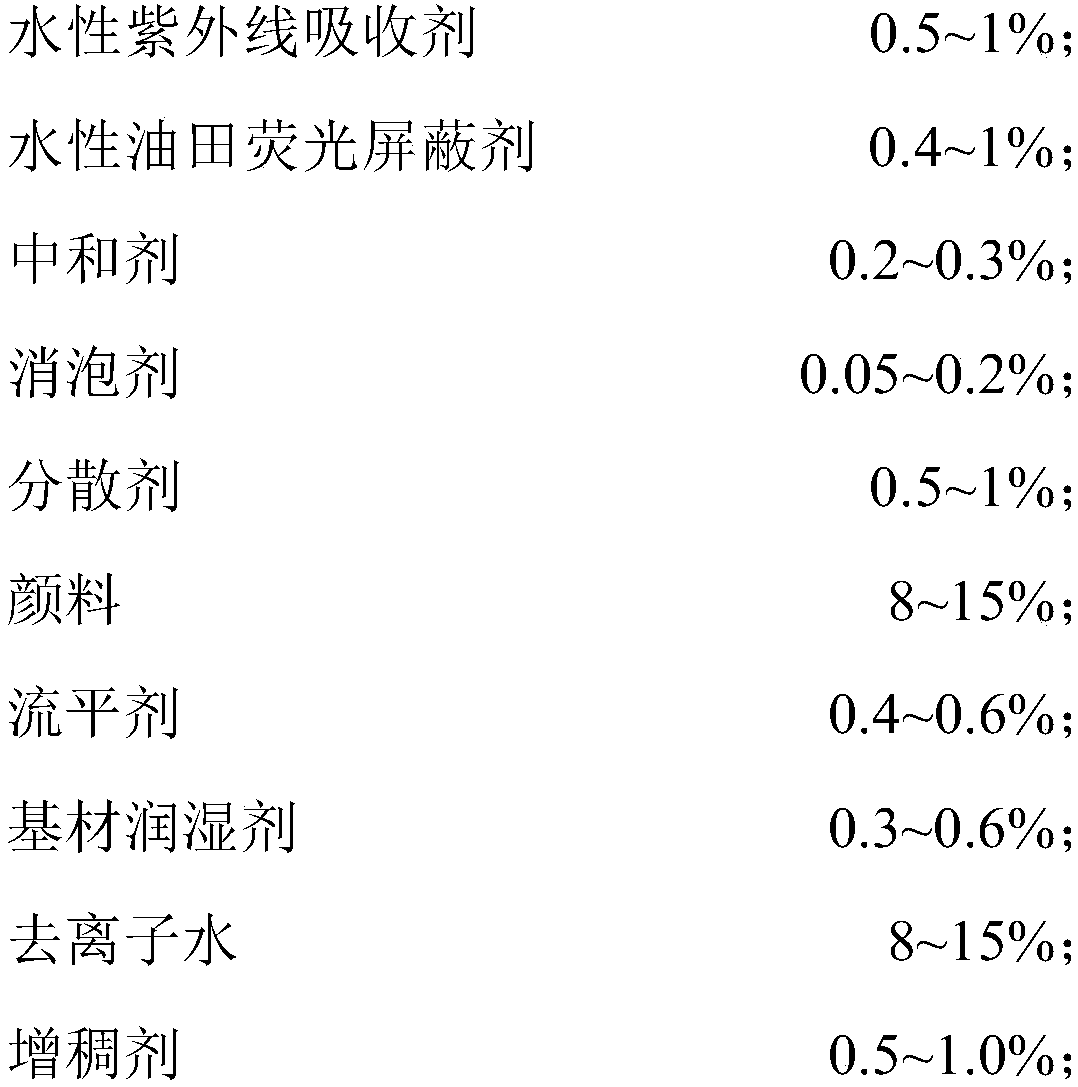

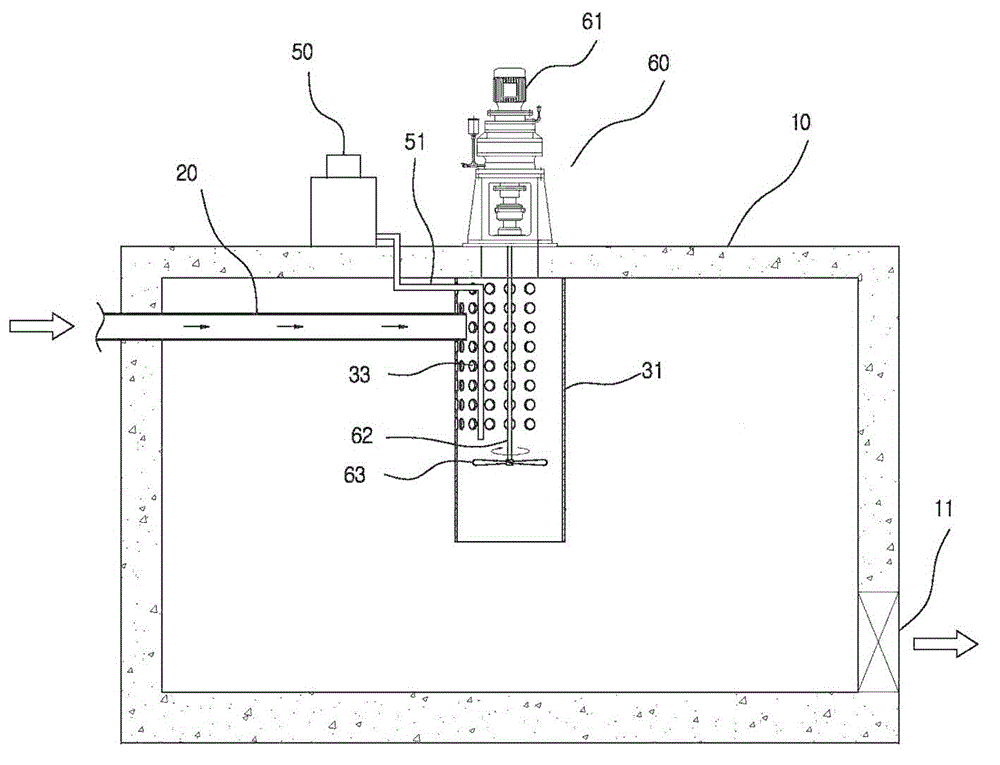

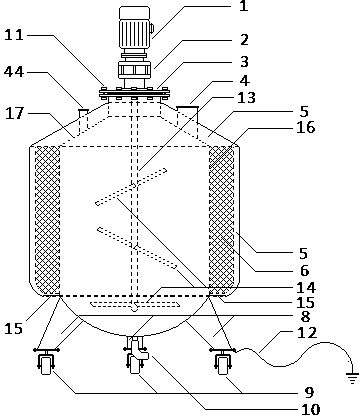

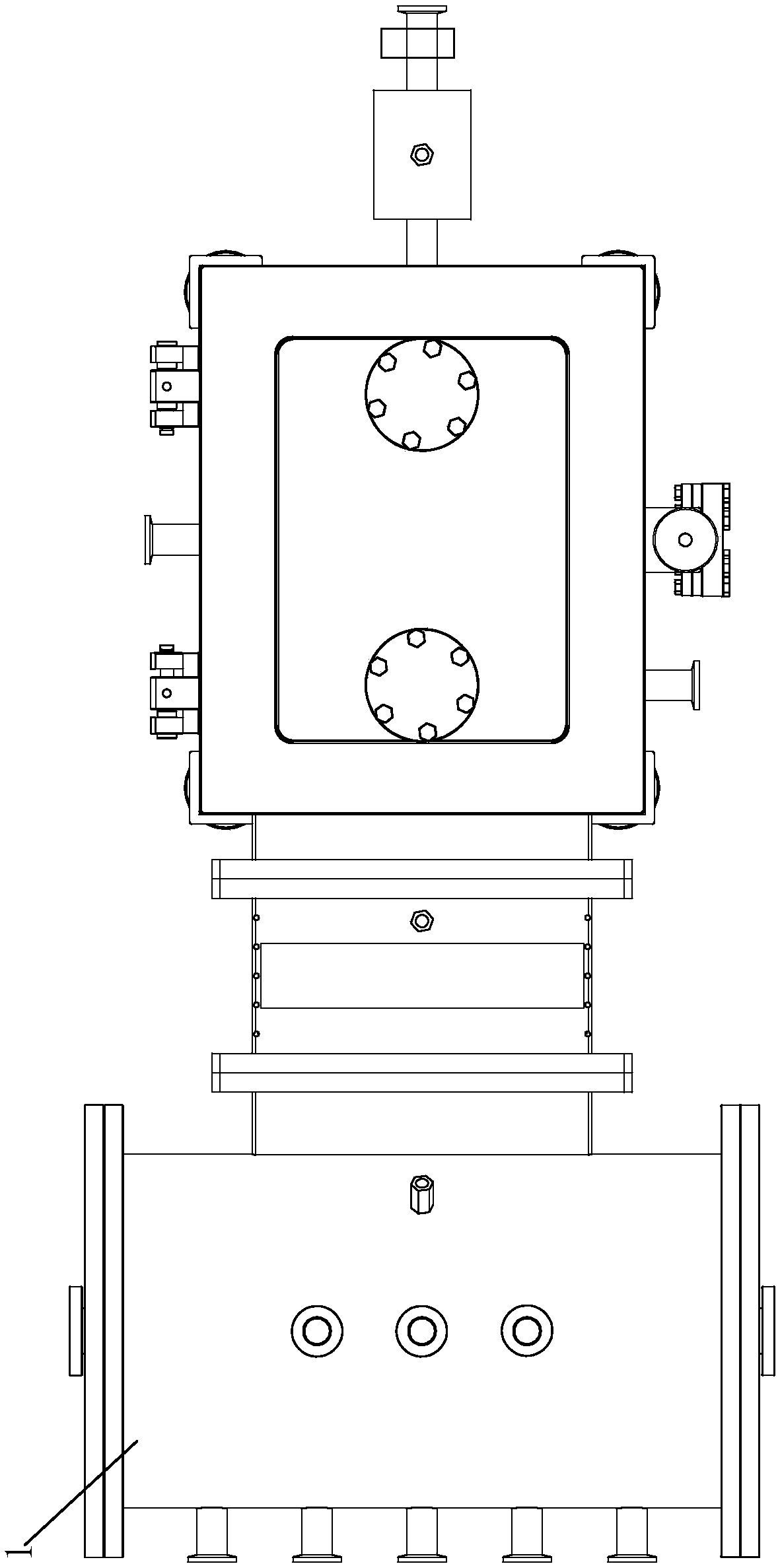

Stirred tank reactor for cutting fluid

ActiveCN104437332AWell mixedAvoid horizontal flowChemical/physical/physico-chemical stationary reactorsEngineeringFan blade

The invention relates to chemical machinery equipment and in particular relates to a stirred tank reactor for cutting fluid. The stirred tank reactor for cutting fluid comprises a reactor body, a feeding pipe, and a stirring paddle arranged in the reactor body, and also comprises a drainage cylinder, wherein the stirring paddle is connected with an output shaft of a motor; the upper cylindrical opening of the drainage cylinder is connected to the inner wall of the reactor body below an upper cover; the stirring paddle is arranged in the drainage cylinder; a drainage hole is formed in the cylindrical bottom of the drainage cylinder; the stirring paddle comprises a spiral fan blade and a connecting shaft which is fixedly connected with the output shaft of the motor; the spiral fan blade is fixedly arranged on the connecting shaft; and the drainage hole is formed in the cylindrical wall of the drainage cylinder positioned above the spiral fan blade at a height position. According to the stirred tank reactor disclosed by the invention, the defect of mixing non-uniformity existing in the prior art is overcome, and due to the stirred tank reactor provided by the invention, reactants are uniformly mixed by virtue of flow of the fluid in the height direction.

Owner:CHONGQING THRIVE CHEM

Flame-retardant adhesive and sealant with improved mechanical properties

ActiveUS20190169476A1Improve flame retardant performanceImprove mechanical propertiesNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesPolymer scienceCarbon Additive

A moisture-curable composition having flame retardant properties and to the use thereof as an adhesive, sealant or coating. The composition according to the invention contains at least one moisture-reactive polymer in a proportion of 10% to 50% by weight, at least one precipitated, surface-coated aluminum trihydrate in a proportion of 30% to 60% by weight and in preferred embodiments up to 25% by weight of at least one phosphorus-containing compound and up to 20% by weight of at least one carbon additive. The inventive moisture-curable composition has excellent flame retardant properties and after curing remains resistant for a long time at high heat levels.

Owner:SIKA TECH AG

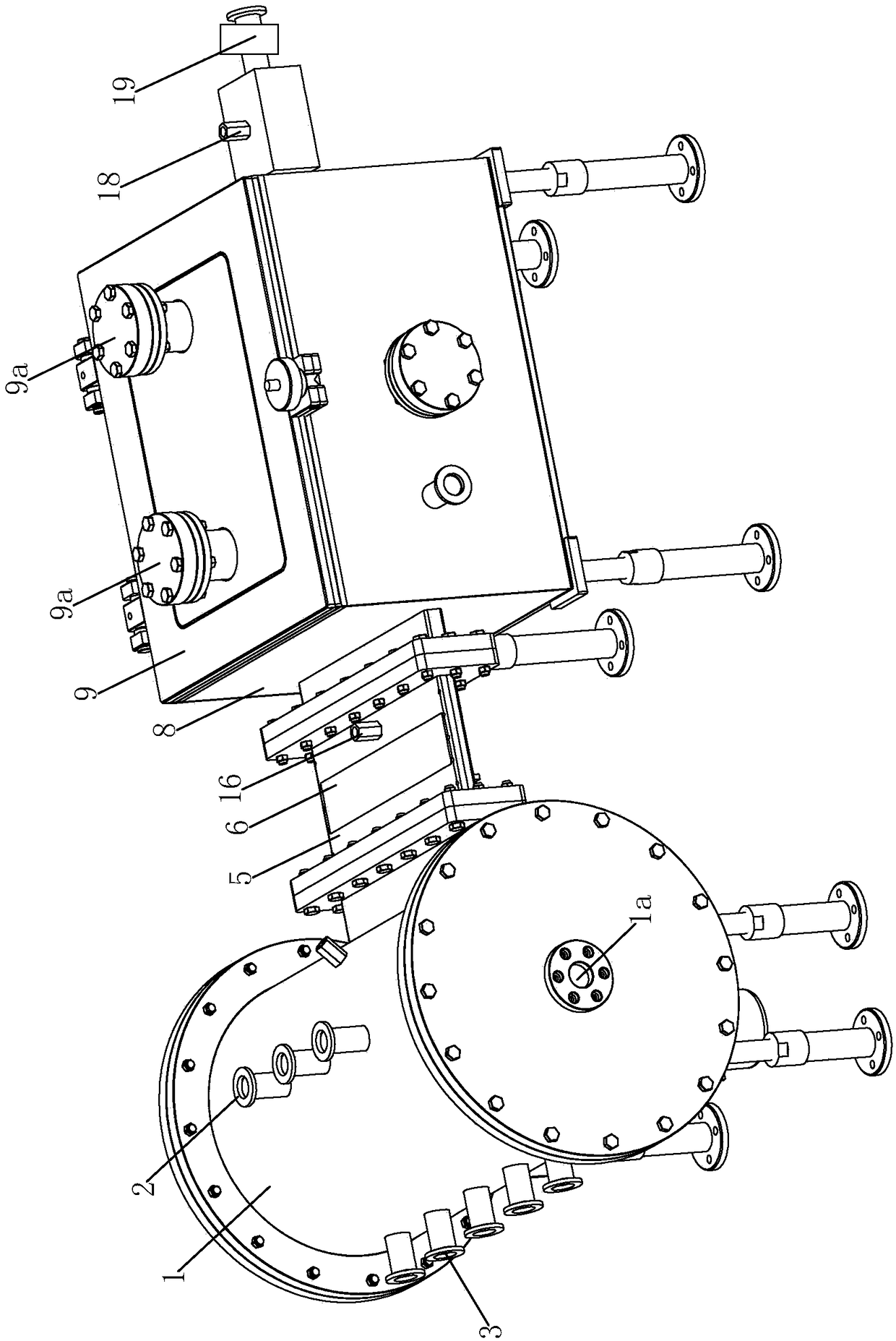

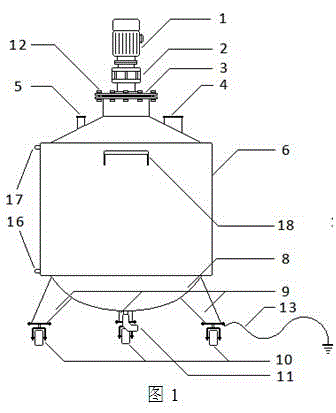

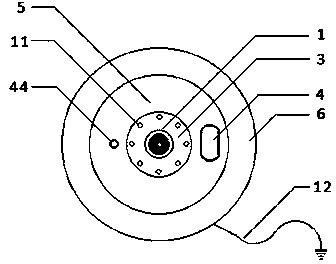

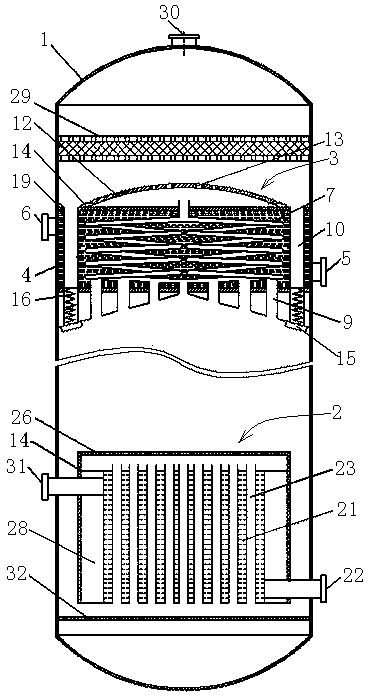

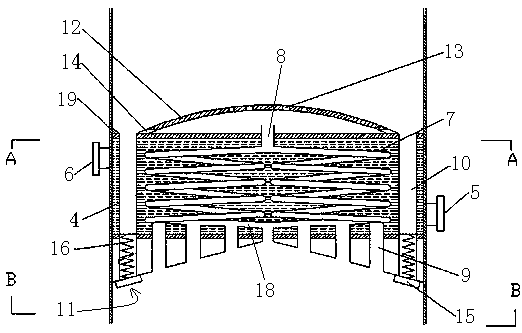

Phase-change constant-temperature glue preparing container

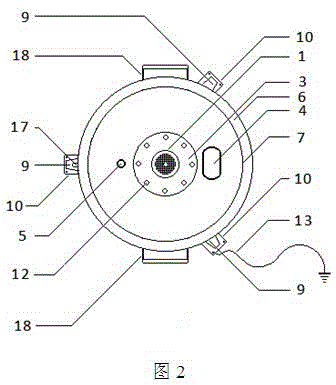

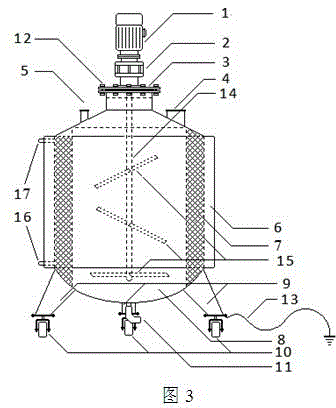

InactiveCN103908912AAvoid premature reactionReduce pollution on the job siteRotary stirring mixersMixer accessoriesSolventElectric machinery

The invention provides a phase-change constant-temperature glue preparing container. The container comprises a variable frequency motor (1) used for stirring, a speed reducer (2), a sealing cover (3), a main feeding port (4), a small feeding port (5), a glue preparing tank temperature-maintaining layer (6), a phase-change constant-temperature inner jacket (7), a cylinder bottom (8) of the glue preparing container, supporting legs (9), universal wheels (10) with braking and locking, a discharging port (11), connecting bolts (12), a ground lead (13), a stirrer shaft (14), stirring blades (15), a feeding port (16) of the inner jacket, a discharging port (17) of the inner jacket, and handles (18). The container is characterized in that: the phase-change constant-temperature inner jacket (7) is filled with a low-temperature phase-change constant-temperature material. In winter, the container can avoid use of excess diluting solvent due to sticky materials. In summer, the container can avoid reaction in advance of the materials due to overhigh temperature, and can avoid contamination of working sites by organic solvents volatilized due to the overhigh temperature.

Owner:ANHUI MINGXUN NEW MATERIAL TECH

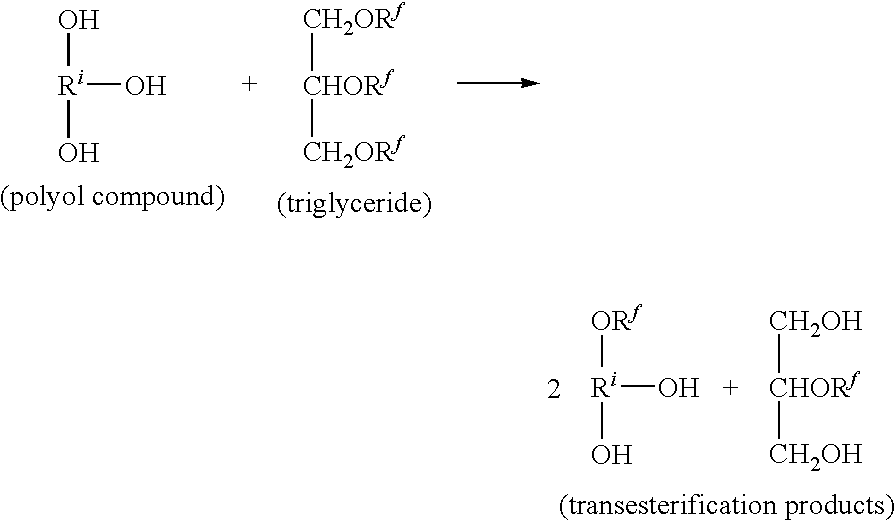

Process for producing wood particleboard

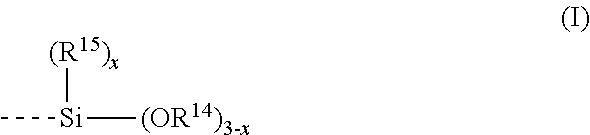

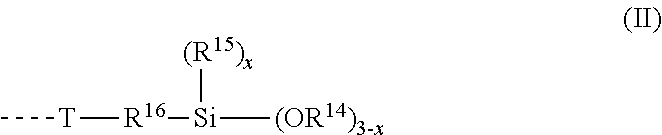

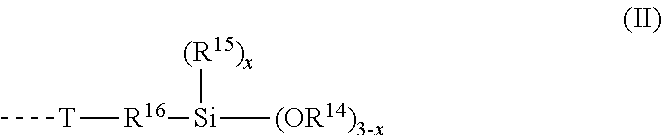

InactiveUS6998078B2Avoid premature reactionHigh-quality bondingNon-fibrous pulp additionNatural cellulose pulp/paperWood fibreMechanical engineering

The invention relates to a process for producing wood fiberboard by pressing wood fibers which have been treated with binder, in which the wood fibers are boiled and milled at elevated temperature under steam pressure in a refiner unit, subsequently are transferred to a blow-line, then dried and finally pressed under pressure and, if desired, at elevated temperature to produce boards, wherein the treatment with binder is carried out using a multi-component binder, preferably with one component A) containing functional groups which are nonreactive at elevated temperature and a second component B) containing functional groups which are reactive at elevated temperature the component A) being added in the refiner unit at a temperature of from 120° C. to 200° C. prior to the milling step, during the milling step, or shortly after the milling step in the front section of the blow-line and component B) being added at a lower temperature of not more than 150° C. at the end of the blow-line or during or after the drying of the wood fibers.

Owner:WACKER CHEM GMBH

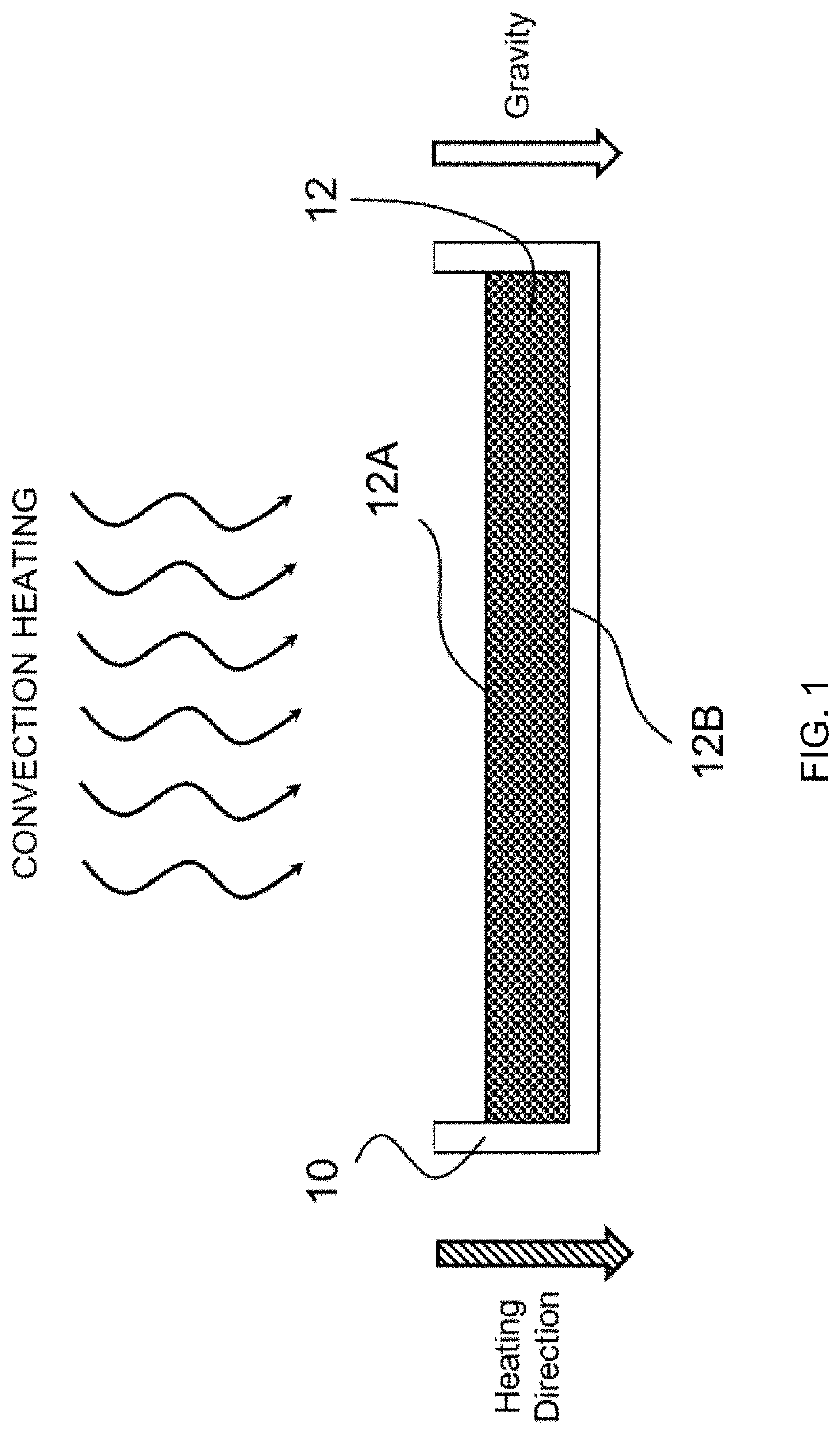

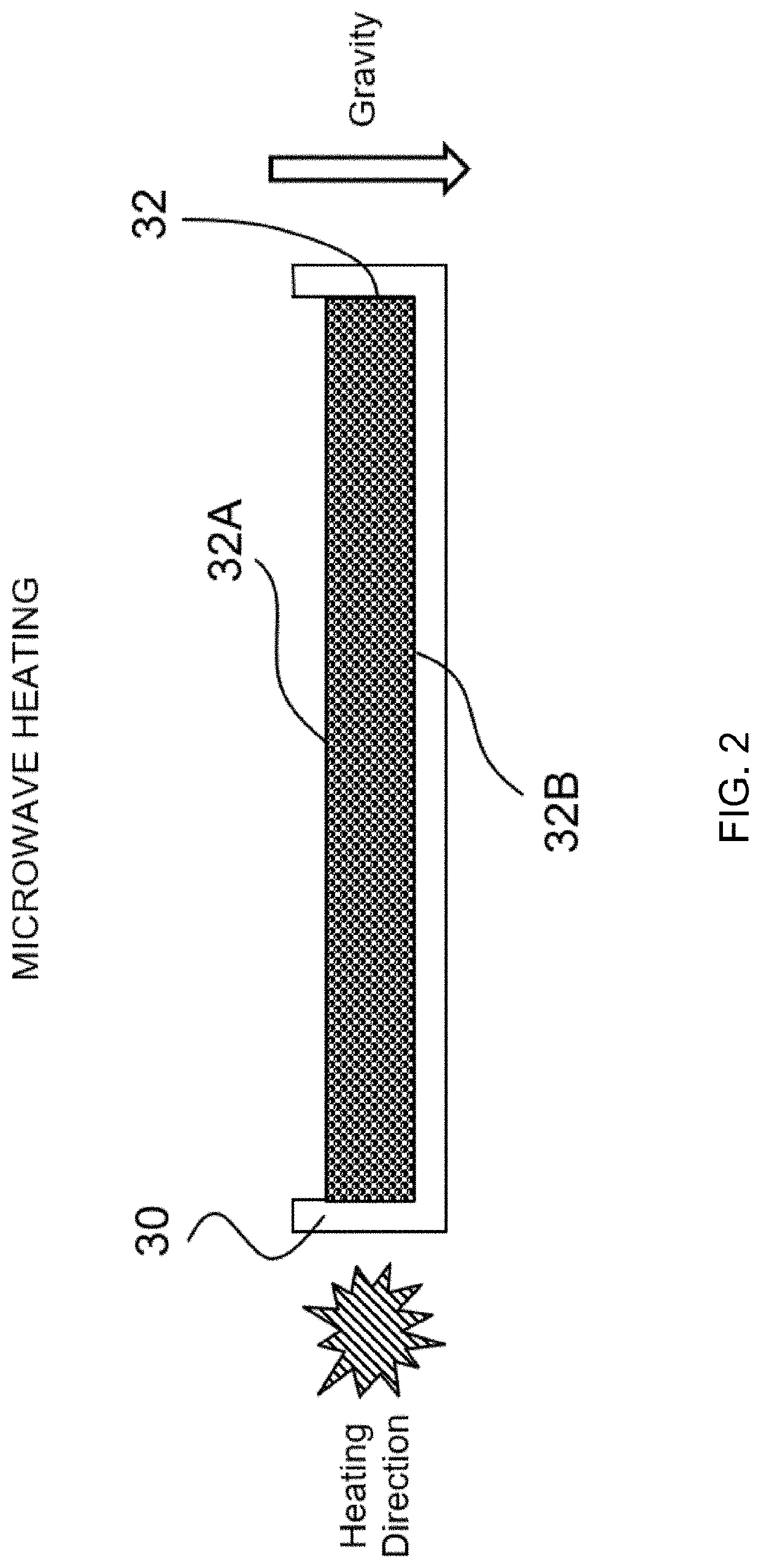

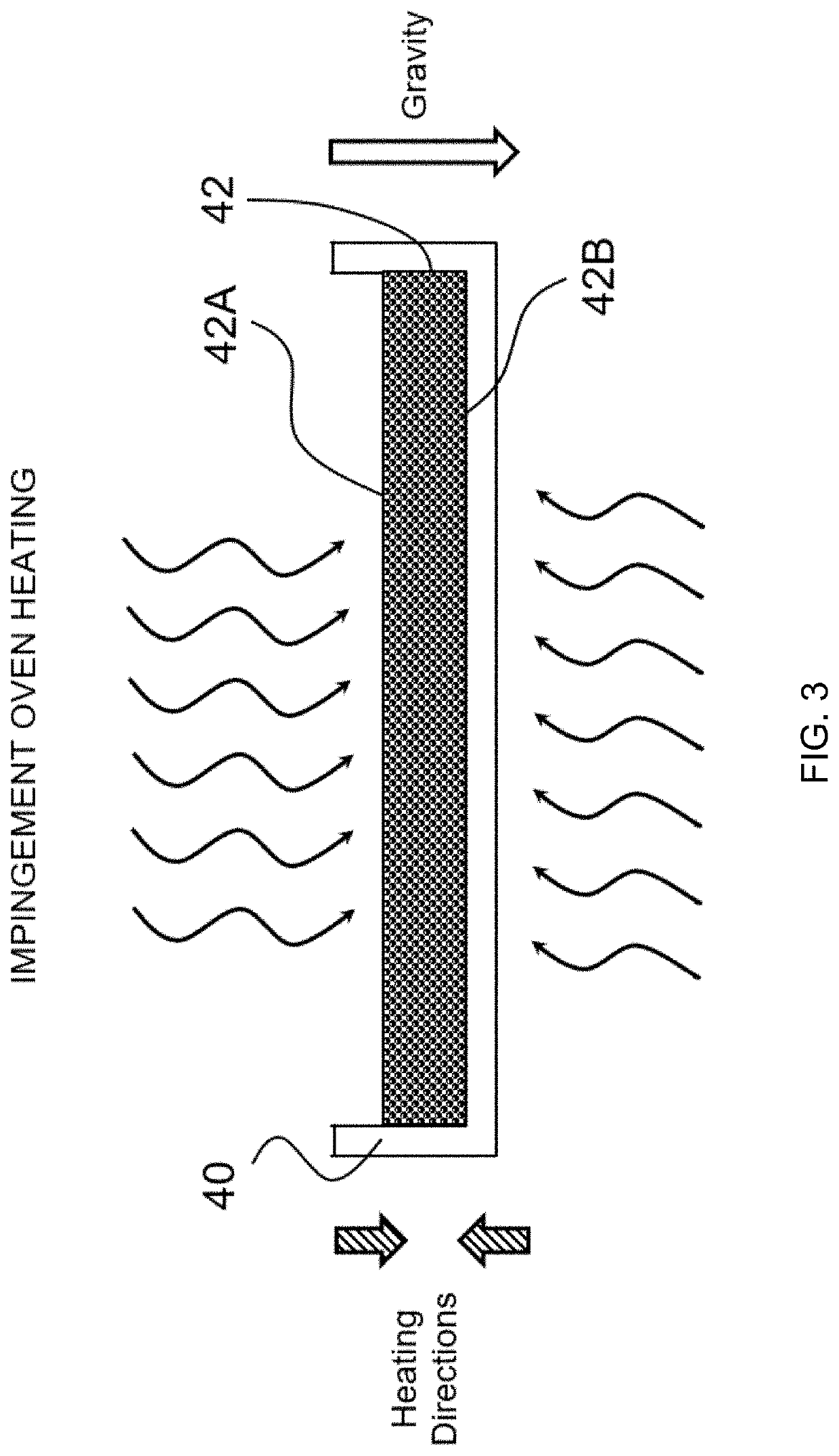

Heated cleaning articles using a reactive metal and saline heat generator

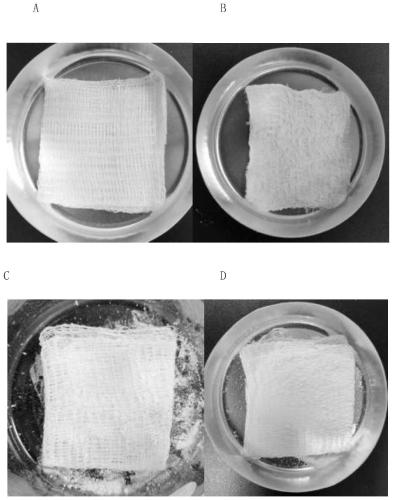

ActiveUS20160270622A1Good curative effectConvenient and safe and self-heatingExothermal chemical reaction heat productionCarpet cleanersWater vaporSalt water

Cleaning articles including a heat engine incorporated therein. The cleaning article may include a substrate (e.g., a non-woven wipe) including one or more layers. The heat engine may be in the wipe or pad, and includes a reactive metal composition which upon contact with a salt water (e.g., saline) composition, reacts to produce heat. The cleaning article may thus produce water vapor and / or steam upon activation of the heat engine. A venting structure may be provided adjacent to or surrounding the heat engine that includes an impermeable material (e.g., impermeable to water and / or air or other gas), which includes one or more vents through the impermeable material. The venting structure directs water vapor and / or steam to a desired face of the cleaning article, away from the user. A heat barrier layer may insulate a user's hand from the generated heat, and / or a handle may be attachable to the pad.

Owner:THE CLOROX CO

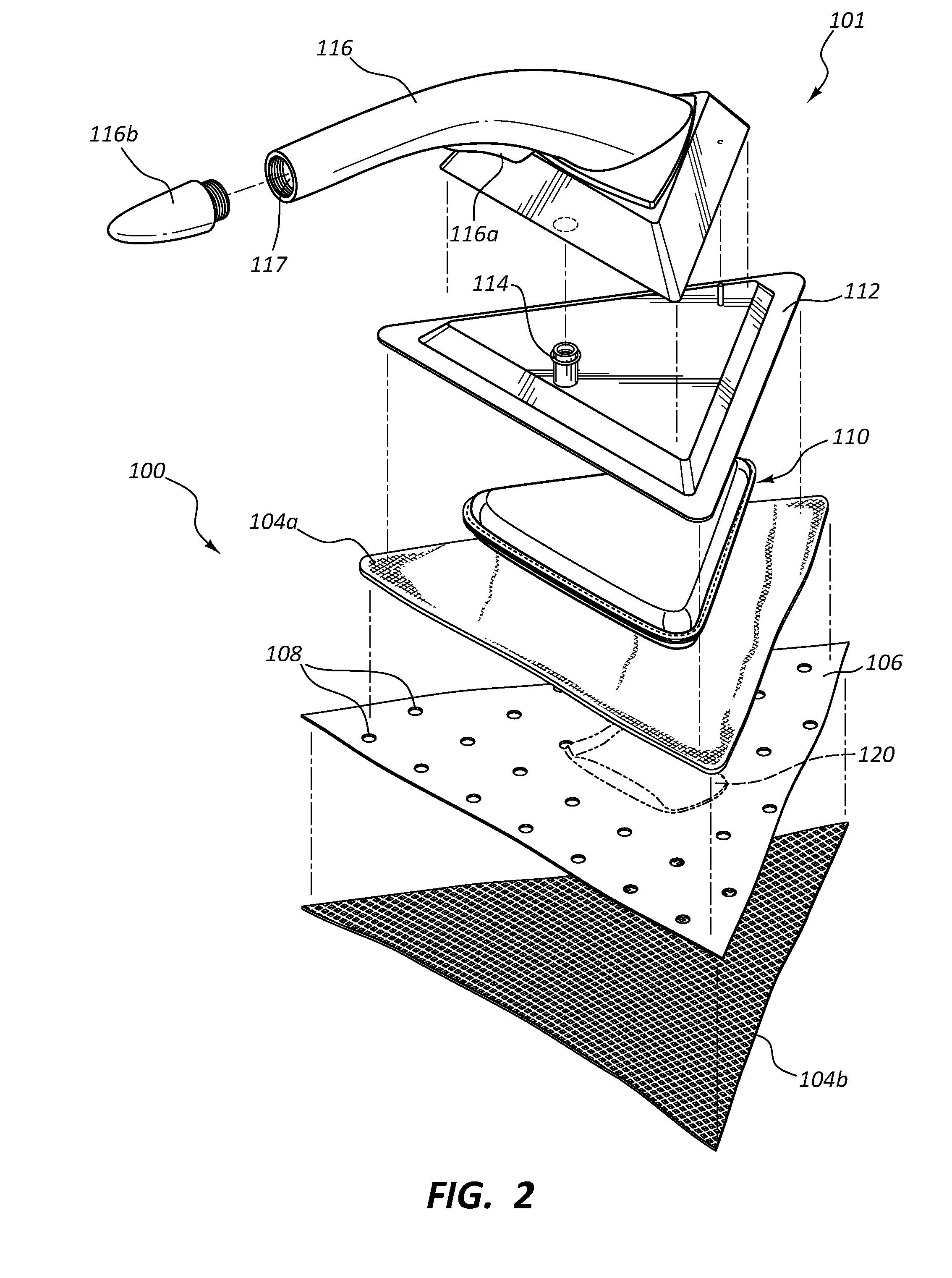

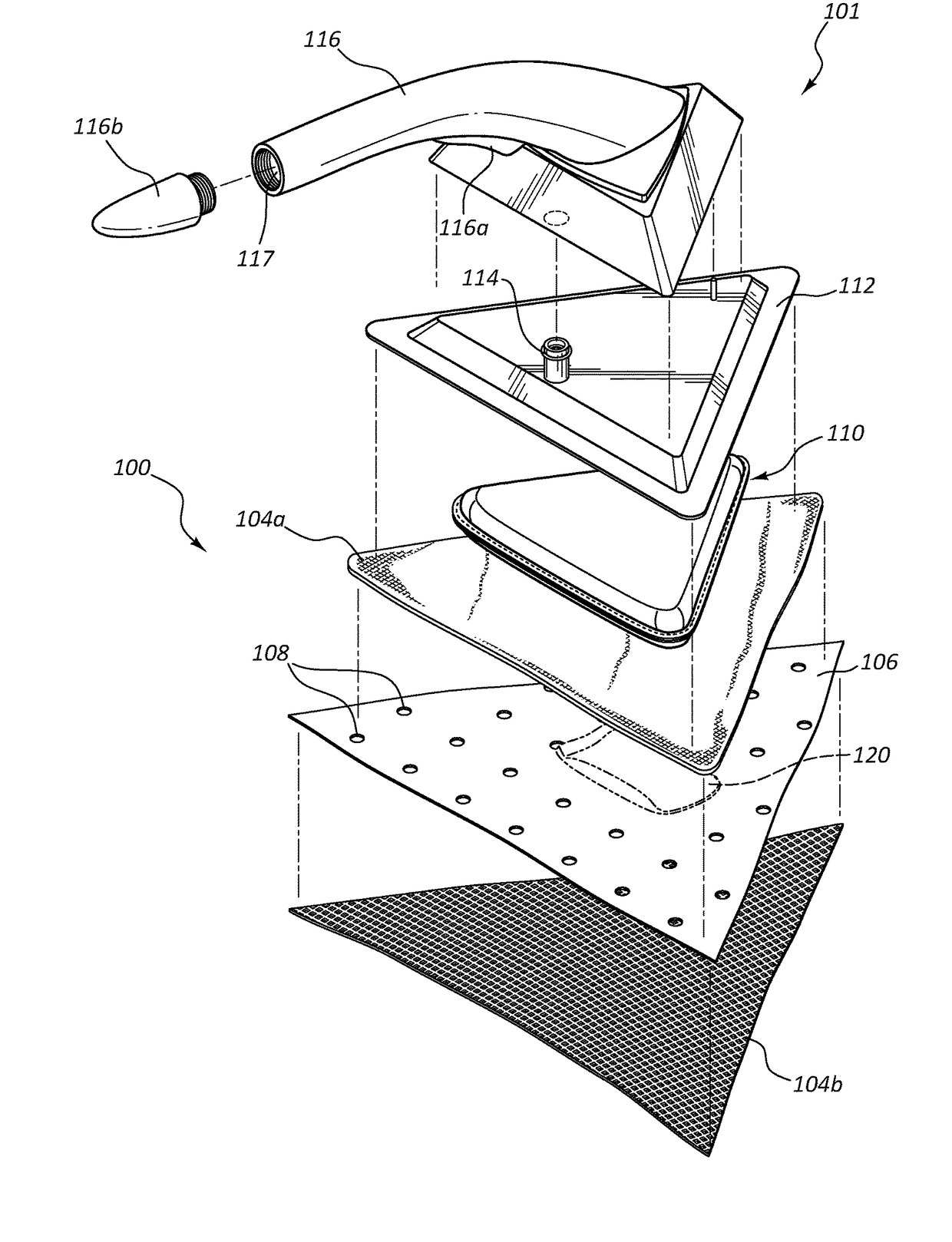

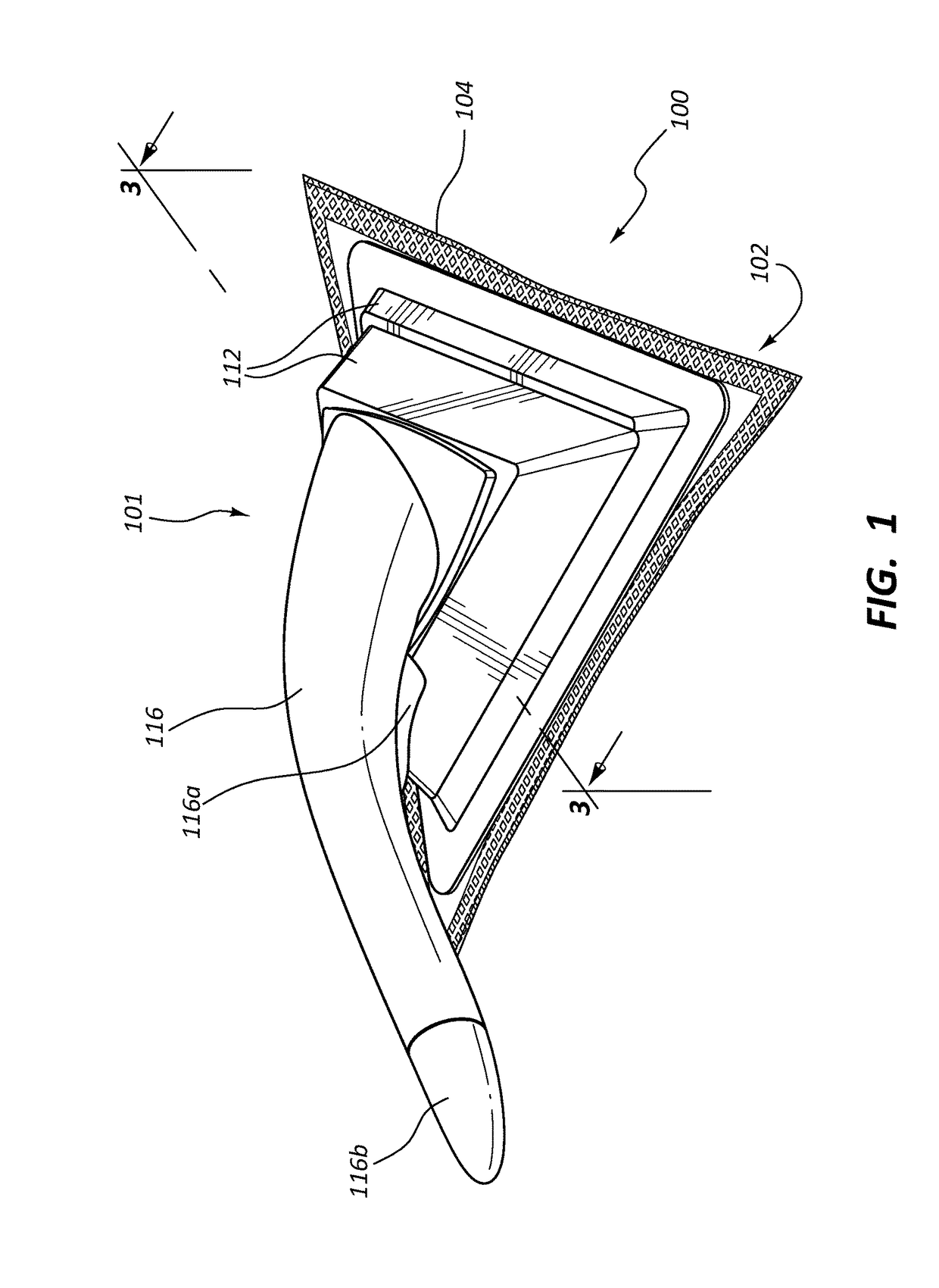

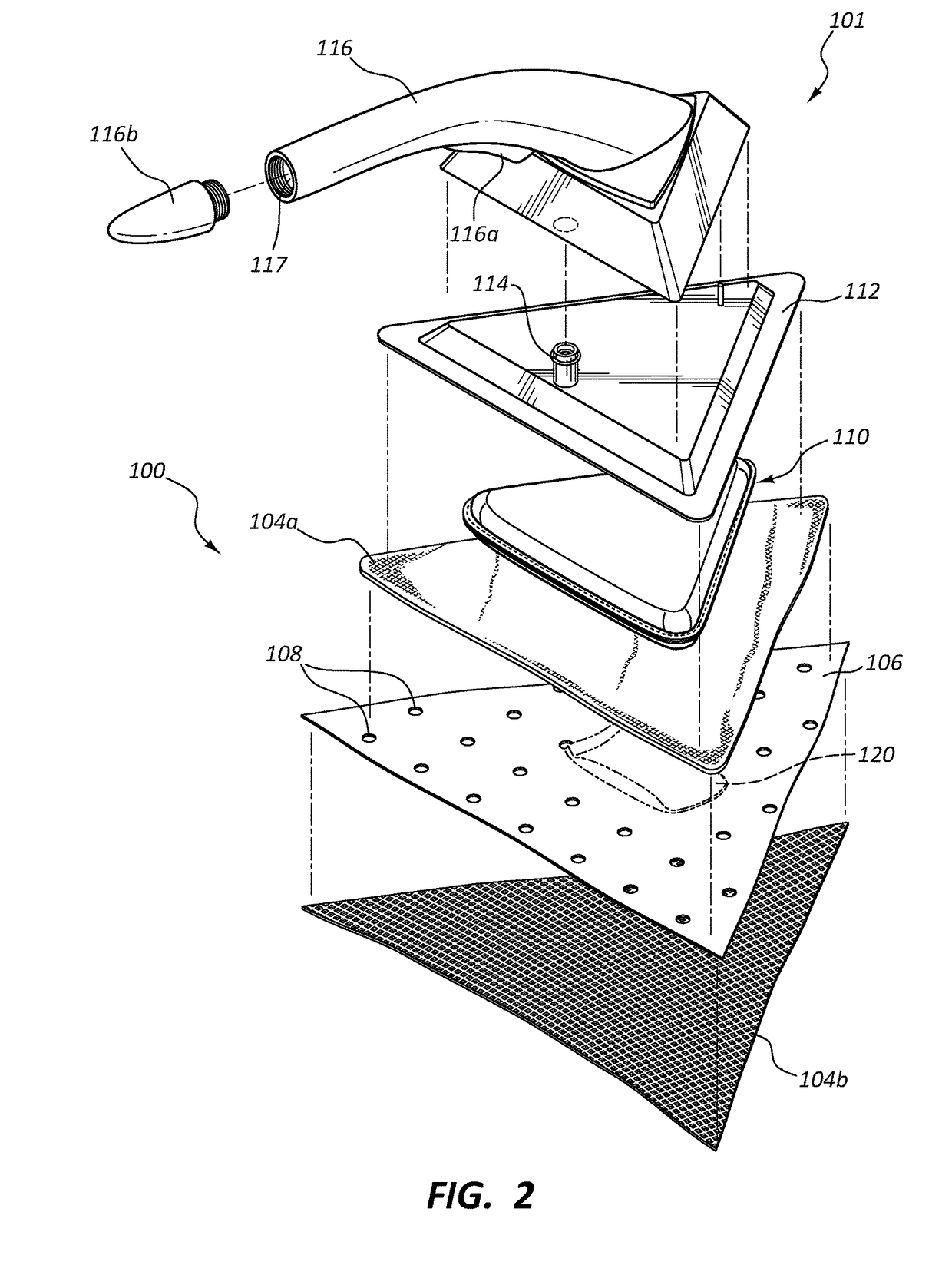

Heated cleaning articles using a reactive metal and saline heat generator

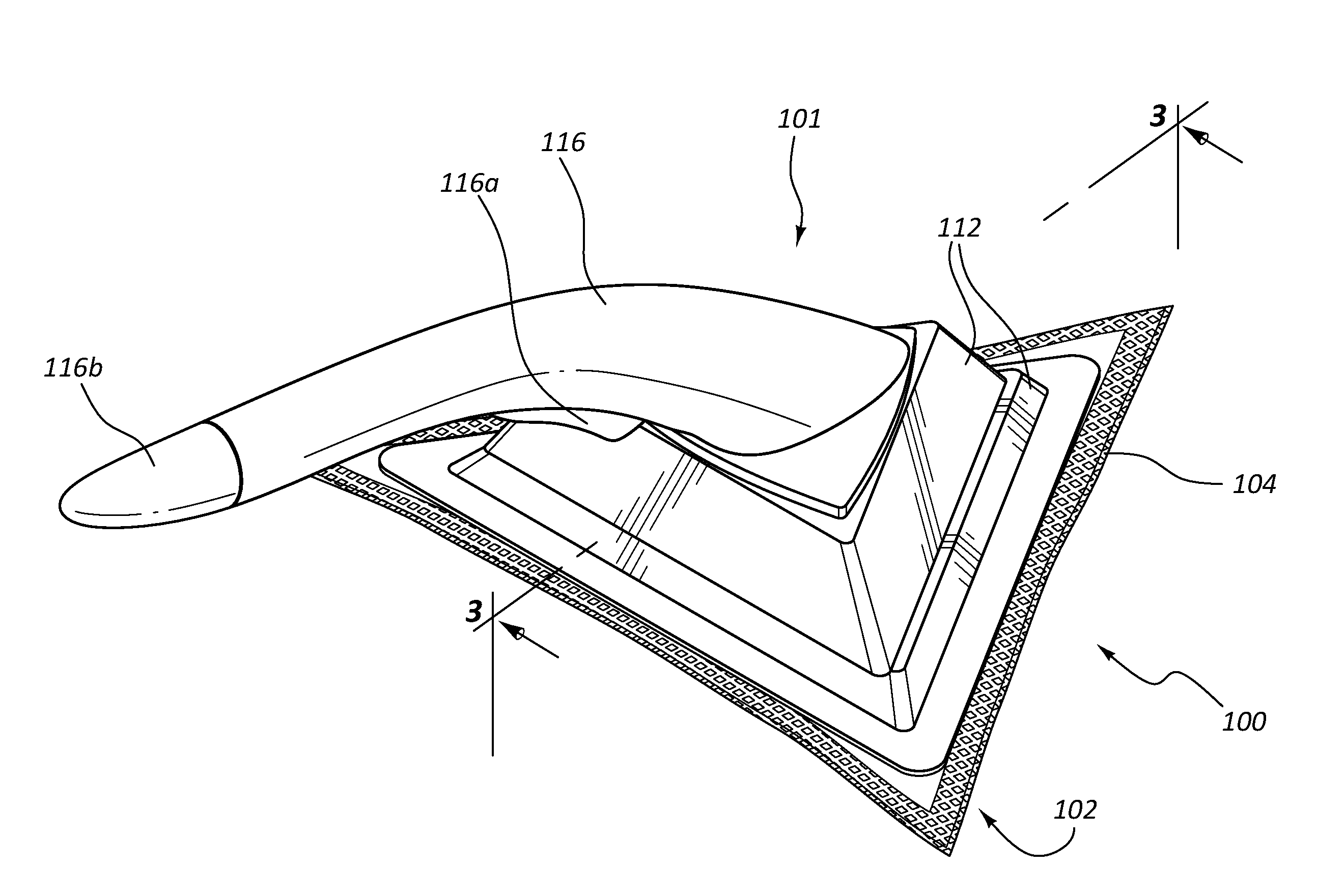

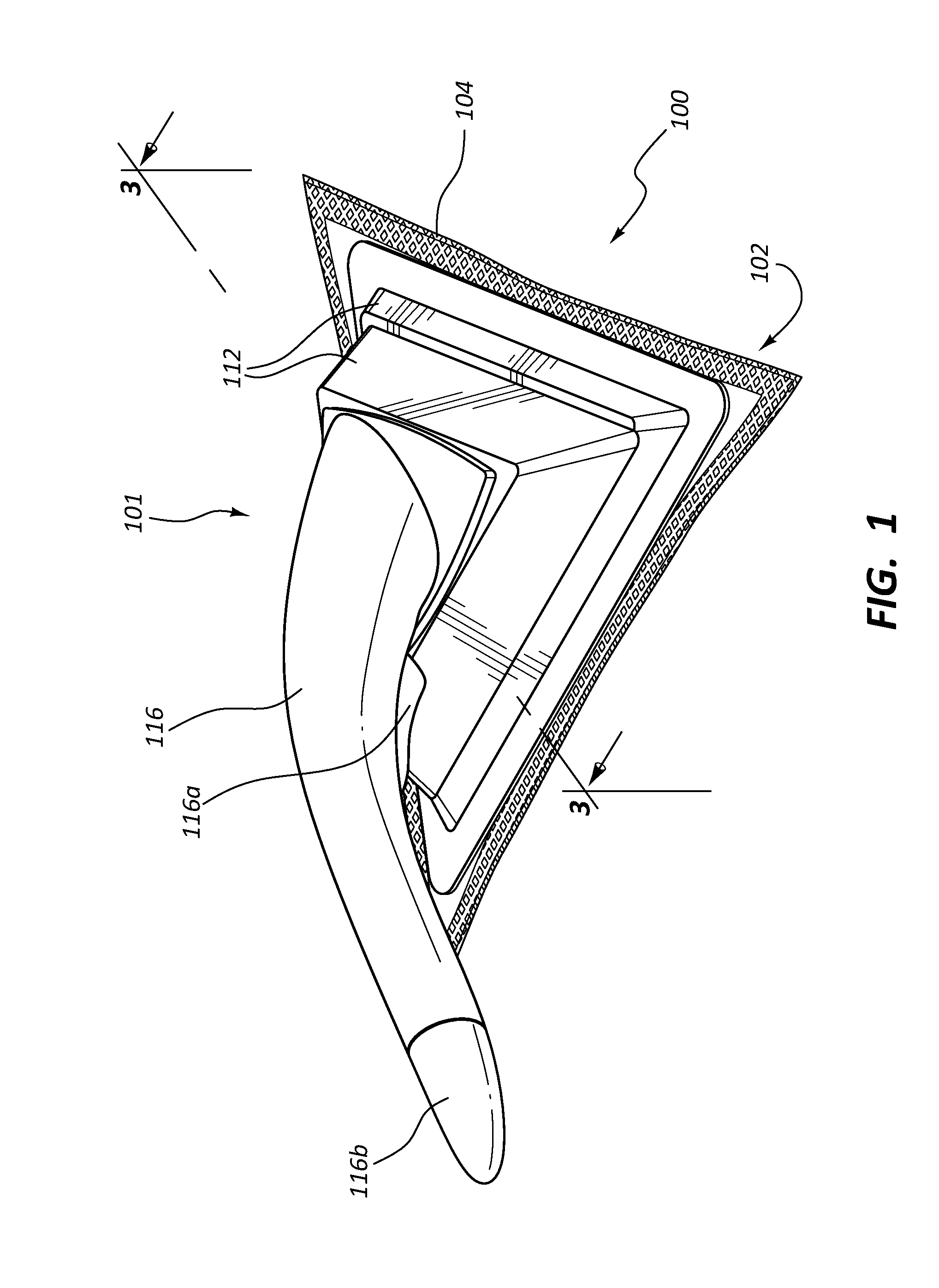

ActiveUS9826878B2Good curative effectSafe and convenient cleaningExothermal chemical reaction heat productionCarpet cleanersWater vaporSalt water

Cleaning articles including a heat engine incorporated therein. The cleaning article may include a substrate (e.g., a non-woven wipe) including one or more layers. The heat engine may be in the wipe or pad, and includes a reactive metal composition which upon contact with a salt water (e.g., saline) composition, reacts to produce heat. The cleaning article may thus produce water vapor and / or steam upon activation of the heat engine. A venting structure may be provided adjacent to or surrounding the heat engine that includes an impermeable material (e.g., impermeable to water and / or air or other gas), which includes one or more vents through the impermeable material. The venting structure directs water vapor and / or steam to a desired face of the cleaning article, away from the user. A heat barrier layer may insulate a user's hand from the generated heat, and / or a handle may be attachable to the pad.

Owner:THE CLOROX CO

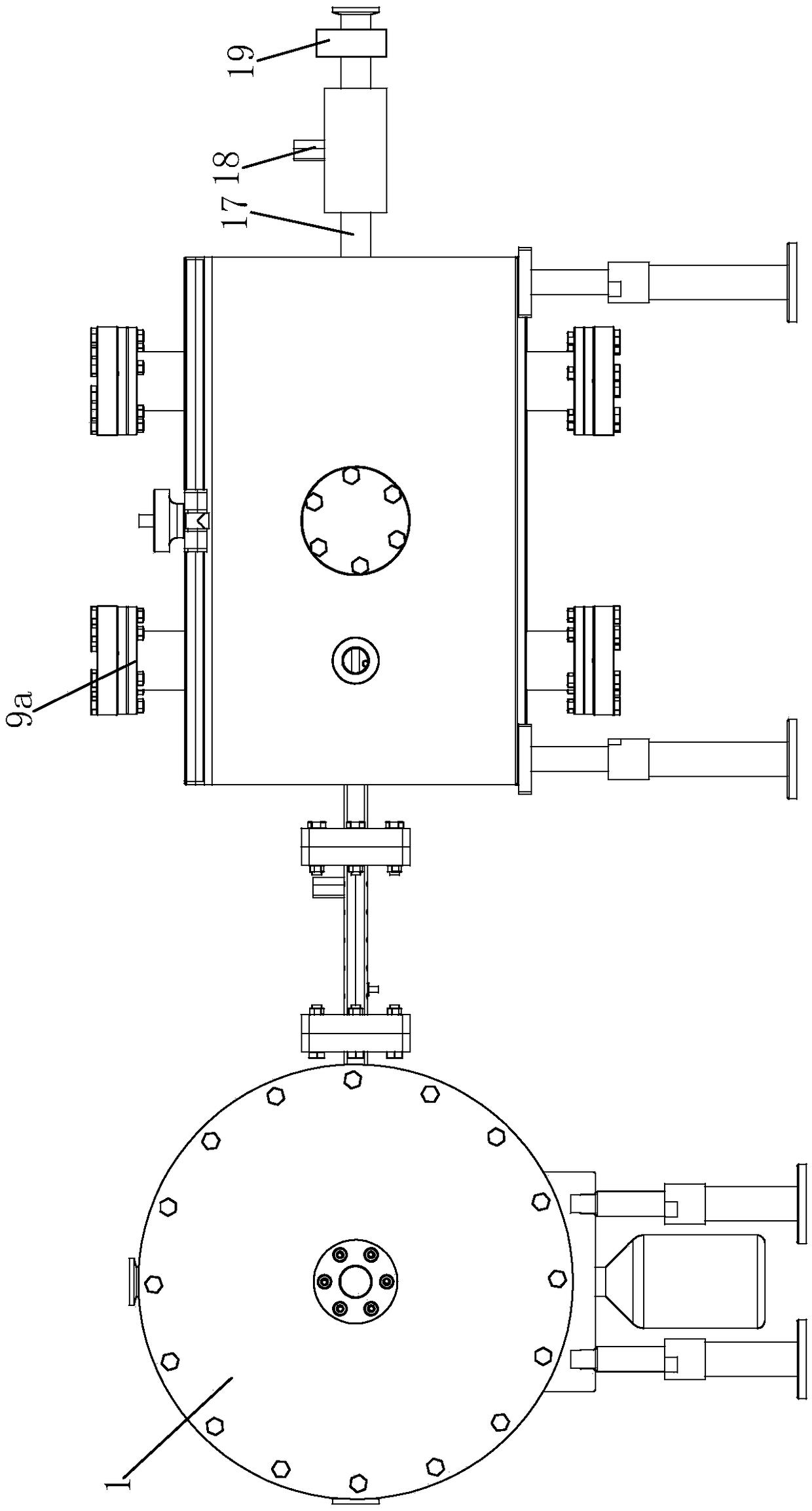

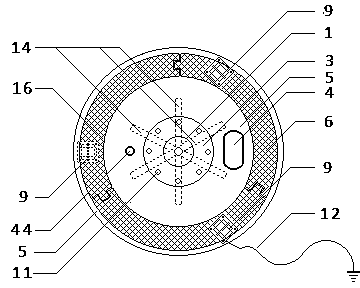

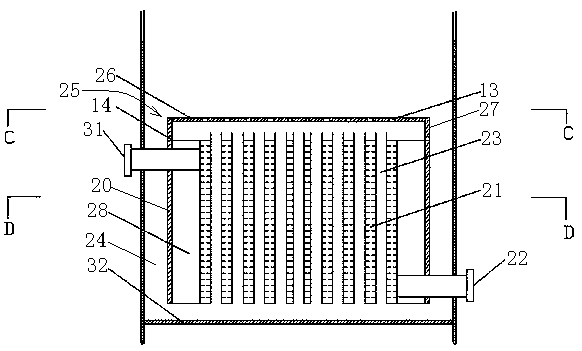

Phase change constant-temperature batching device

InactiveCN103861505AAvoid scrappingProduction quality and stable performanceRotary stirring mixersMixer accessoriesSolventSolvent evaporation

The invention discloses a phase change constant-temperature batching device. The phase change constant-temperature batching device comprises a batching barrel body, a driving motor, a speed reducer, a stirring shaft, a stirring paddle, a main material feeding inlet, an auxiliary material feeding inlet, a discharge port, support legs, brake universal wheels, a phase change constant-temperature assembly, a shoulder part temperature preservation layer, a temperature preservation layer, a grounding wire and a phase change constant-temperature assembly. The phase change constant-temperature batching device is characterized in that the phase change constant-temperature assembly surrounds the outer ring of a batching barrel and is folded by a convex-concave embedded mortise and tenon joint. According to the invention, the usage of excessive diluting solvents caused by sticky materials can be prevented in winter; the reaction of materials in advance because of too high temperature can be prevented in summer; the pollution to the operation field caused by volatile organic solvents because of too high temperature is reduced; scrappage caused by gel of adhesives because of solvent evaporation also can be prevented; conditions are created for production quality and performance stability.

Owner:ANHUI MINGXUN NEW MATERIAL TECH

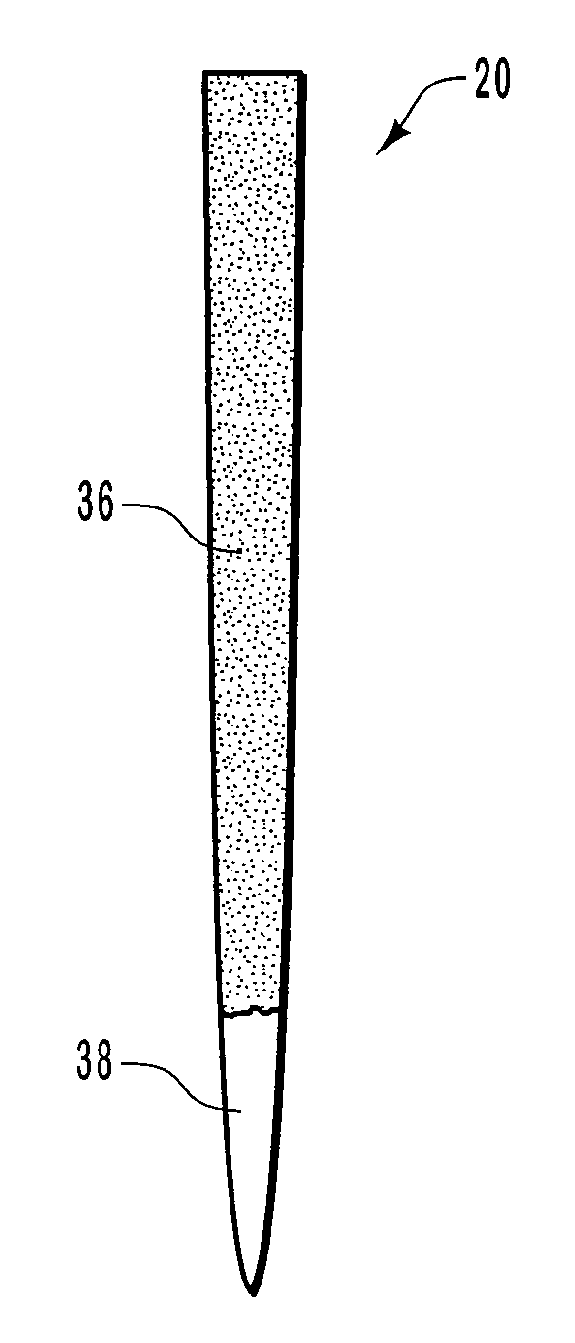

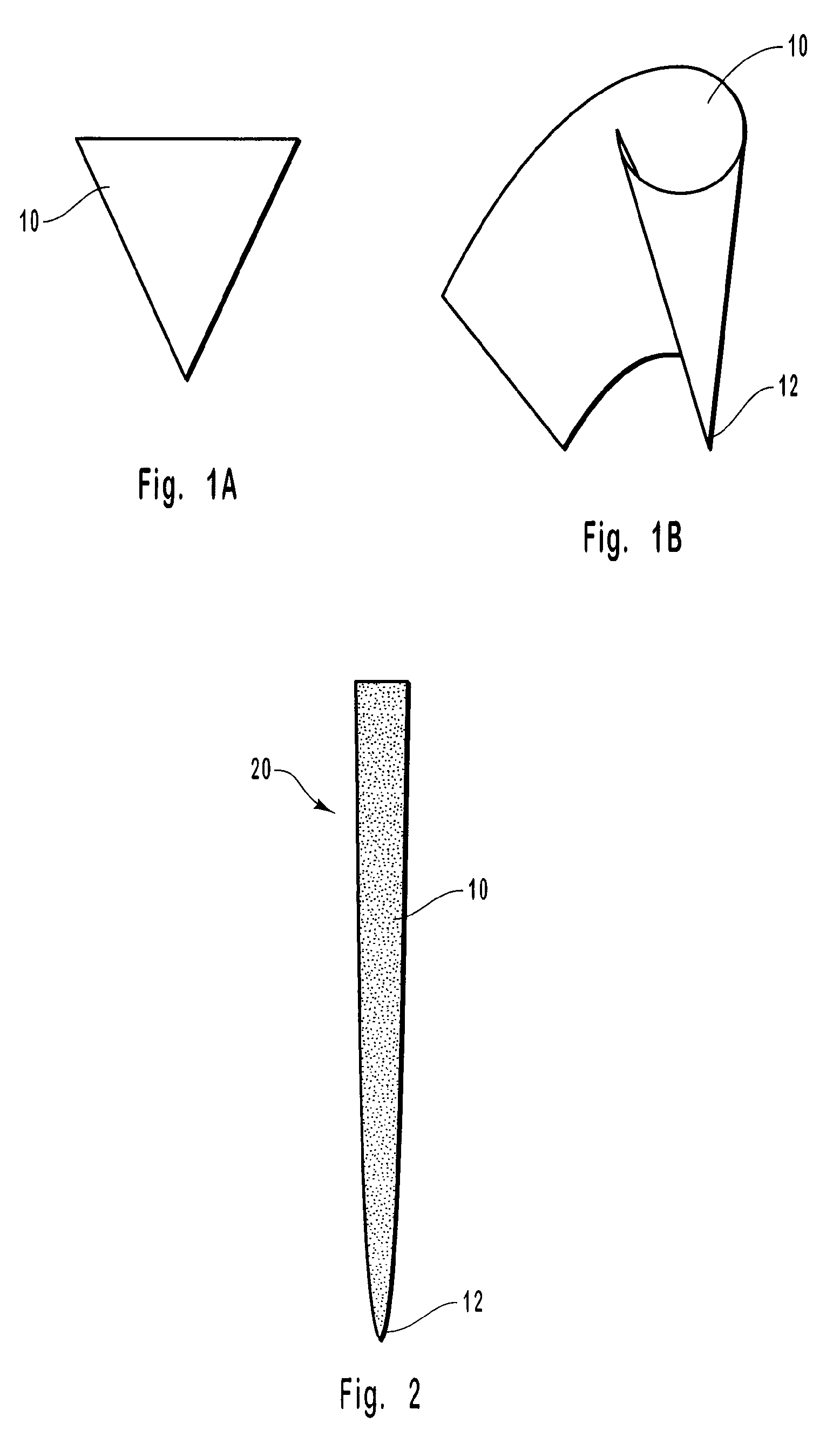

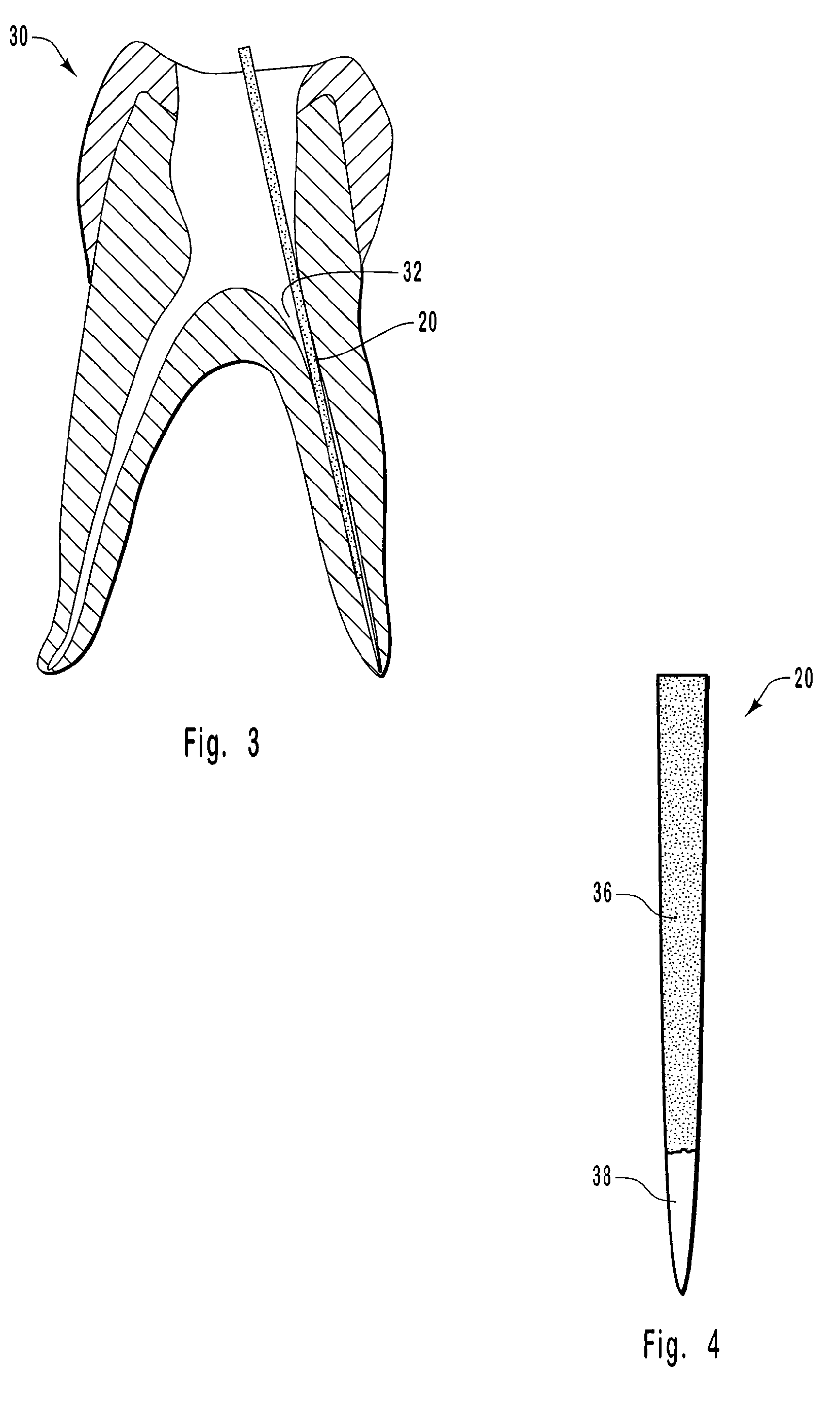

Water and sodium hypochlorite indicating endodontic monitoring devices

InactiveUS8215960B2Accurate distinctionAvoid premature reactionNerve needlesTeeth cappingColor changesAqueous solution

Water and aqueous sodium hypochlorite indicating endodontic monitoring devices include a cone-shaped water absorptive material and color changing system applied thereto that selectively changes to different colors when exposed to either water or aqueous sodium hypochlorite within a root canal chamber. The devices include a pH changing material, pH indicator, and pH insensitive dye. The dye imparts an initial color when the device is dry. The pH changing material and pH indicator react with water to yield a second color. In the presence of aqueous sodium hypochlorite, the device changes to a third color different from the initial color and second color as a result of bleaching the dye and / or pH indicator. Color changing devices are manufactured by applying an aqueous solution that includes a pH changing material and dye to a water absorptive cone, drying the cone, applying an anhydrous pH indicator solution, and then drying the cone again.

Owner:ULTRADENT PROD INC

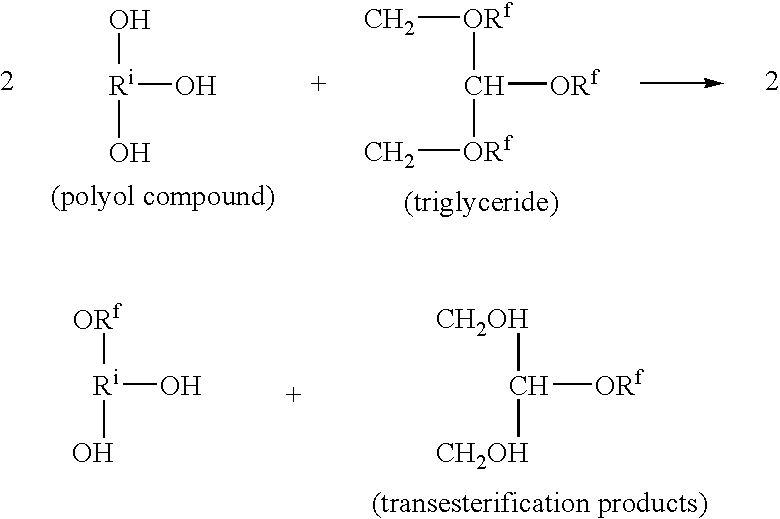

Compositions containing functionalized oils and polyolefins

InactiveUS20070191539A1Avoid premature reactionPolyurea/polyurethane coatingsPolymer sciencePolyolefin

A composition comprises a polyolefin having electronegative substituents and a material comprising a plurality of hydrocarbyl groups, each hydrocarbyl group having at least seven carbon atoms.

Owner:A LINE PRODS

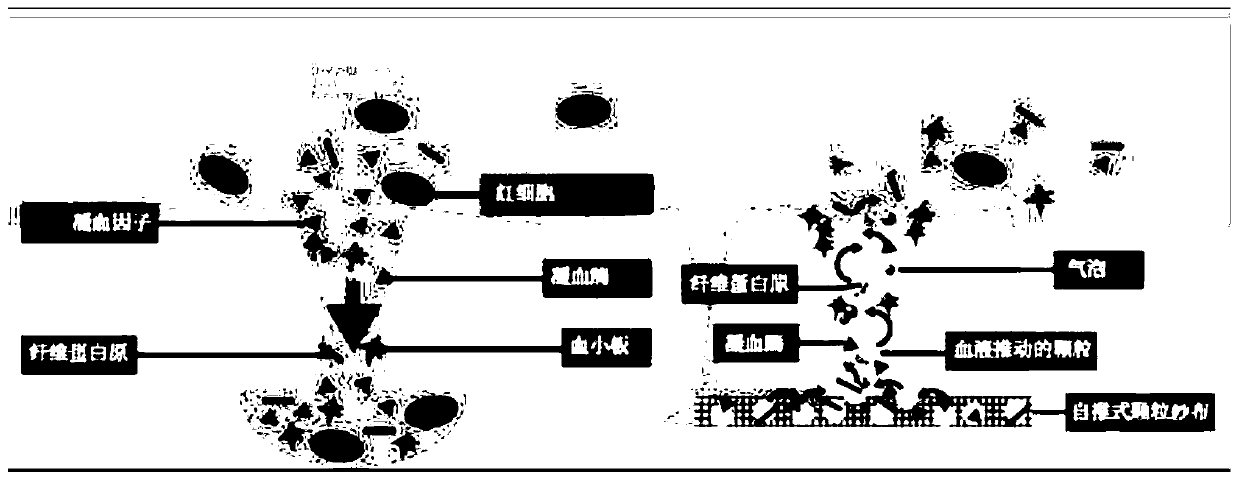

Self-pushing hemostatic gauze/dressing

InactiveCN111420114AHemostasis achievedAvoid intracavitary trauma bleedingPharmaceutical delivery mechanismAbsorbent padsHemolysisTissue sealant

The invention discloses a self-pushing hemostatic gauze / dressing. The self-pushing hemostatic gauze / dressing comprises a component A and a component B which have good biocompatibility; the component Aand the component B generate gas when meeting liquid, and the gas generates conveying capacity opposite to the moving direction of the flowing liquid. The component A is a weak acid strong base saltcontaining a bioactive substance, and the component B is a protonated solid acid, wherein the bioactive substance has functions of accelerating coagulation and reducing hemolysis. The invention changes the defects that existing tissue sealants and hemostatic gauze are only limited to accessible bleeding parts and the like, so that the self-pushing hemostatic gauze / dressing has a wider applicationrange and a better hemostatic effect.

Owner:浙江西安交通大学研究院

Chromotropic paint used for medical instrument and preparation method and application thereof

PendingCN108690448AGood environmental characteristicsGood light fastnessAntifouling/underwater paintsPaints with biocidesAir cleaningNano al2o3

The invention relates to a chromotropic paint used for a medical instrument and a preparation method and an application thereof. The chromotropic paint comprises the following raw materials in parts by weight: 25-50 parts of an aqueous hydroxyl acrylic emulsion, 5-20 parts of a curing agent, 2-5 parts of a cosolvent, 1-5 parts of organic silicone powder, 1-5 parts of nano alumina, 0.05-0.5 parts of nano zirconia, 0.1-3 parts of nano negative ion powder, 4-8 parts of titanium dioxide, 0.05-0.5 parts of nano zinc oxide, 1-6 parts of temperature-sensitive color-changing powder, 0.1-1 part of silica sol, 0.1-0.2 parts of a pH conditioning agent, 0.1-0.2 parts of an antifoaming agent, 2-5 parts of a film-forming auxiliary agent, 0.3-0.5 parts of a dispersant, 0.3-0.5 parts of a base material wetting agent, 5-10 parts of deionized water, and 0.5-1.0 parts of a thickening agent. The VOCs content of the paint is low, and a coating has good light resistance, chemically-resistant performance, hardness, bacterinertness, air cleaning performance, and color-changing indication effect.

Owner:HEBEI CHENYANG INDAL & TRADE GROUP CO LTD

Acetic acid rectifying tower with built-in condenser and built-in reboiler

ActiveCN108815873ASave spaceReduce reaction cycle timeCarboxylic compound separation/purificationFractional distillationAcetic acidReboiler

The invention discloses an acetic acid rectifying tower with a built-in condenser and a built-in reboiler. The acetic acid rectifying tower comprises a tower body, wherein the tower body is internallyprovided with the reboiler and the condenser in sequence from bottom to top; a condenser main body is a cylindrical tank body of which the inner part is fully filled with cooling water; a steam pipeline is spirally distributed in the cylindrical tank body from bottom to top; the steam pipeline is provided with a gas-phase outlet which is located at the middle part of an upper end plate of the cylindrical tank body; the steam pipeline is provided with a plurality of gas-phase inlets; multiple liquid-phase return pipes are arranged at the periphery of the cylindrical tank body; the upper end plate of the cylindrical tank body is provided with upper end openings of the liquid-phase return pipes, and low end openings of the liquid-phase return pipes are communicated with the tower body underthe condenser; automatic opening and closing sealing blocks are arranged on the lower end openings of the liquid-phase return pipes. According to the acetic acid rectifying tower disclosed by the invention, the whole space is saved, and the reaction cycling time is reduced.

Owner:HUAIYIN INSTITUTE OF TECHNOLOGY +1

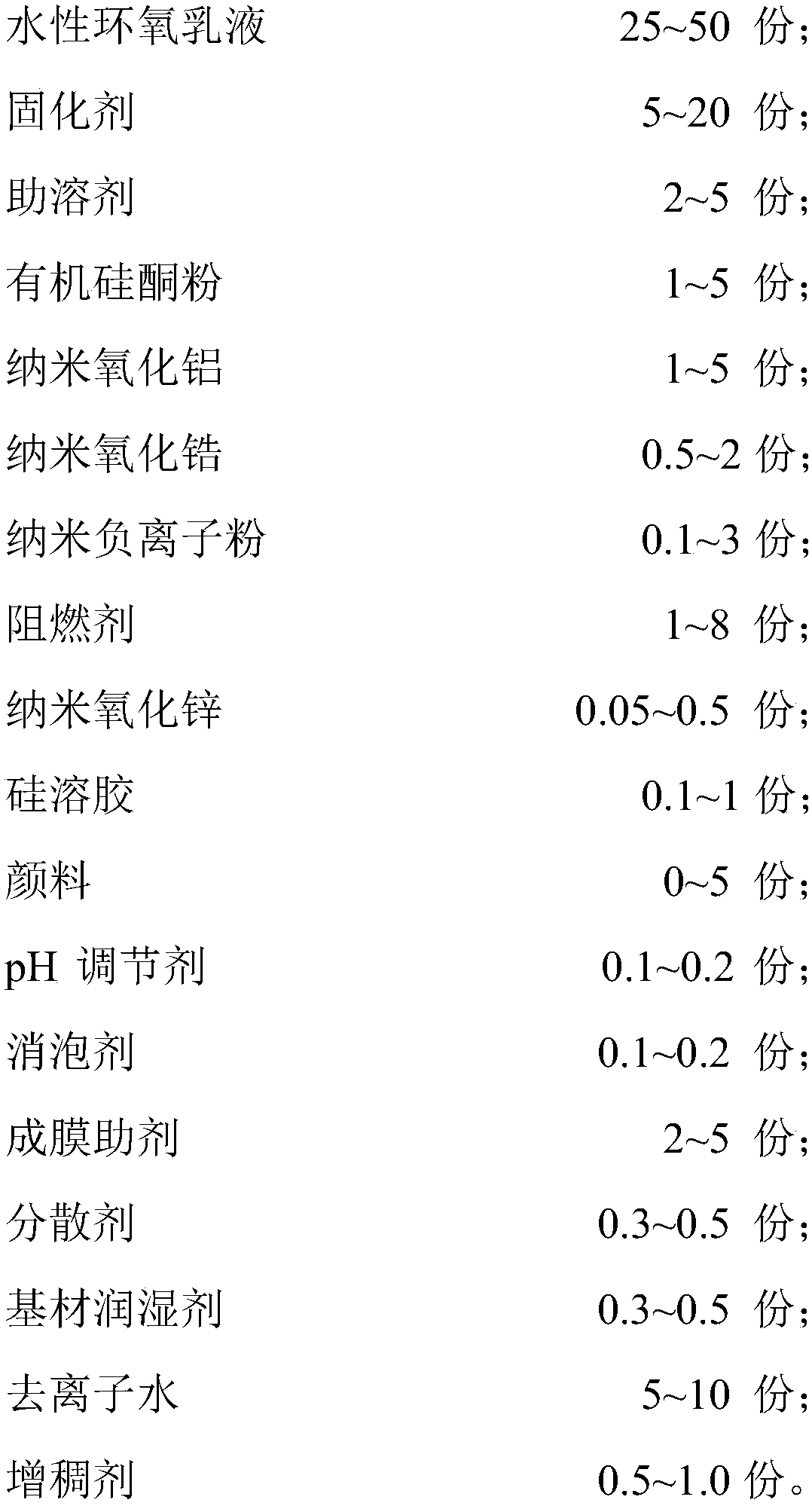

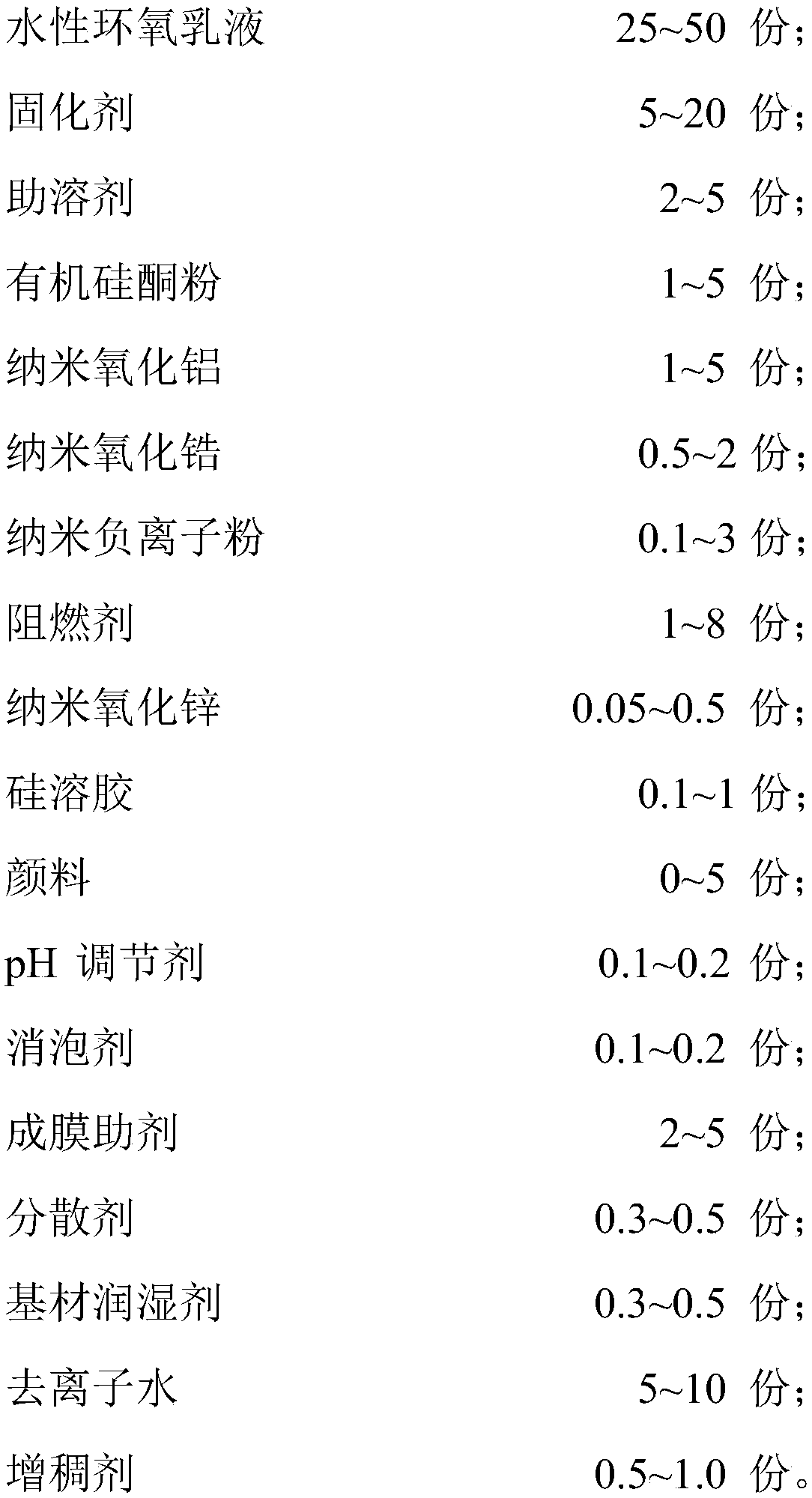

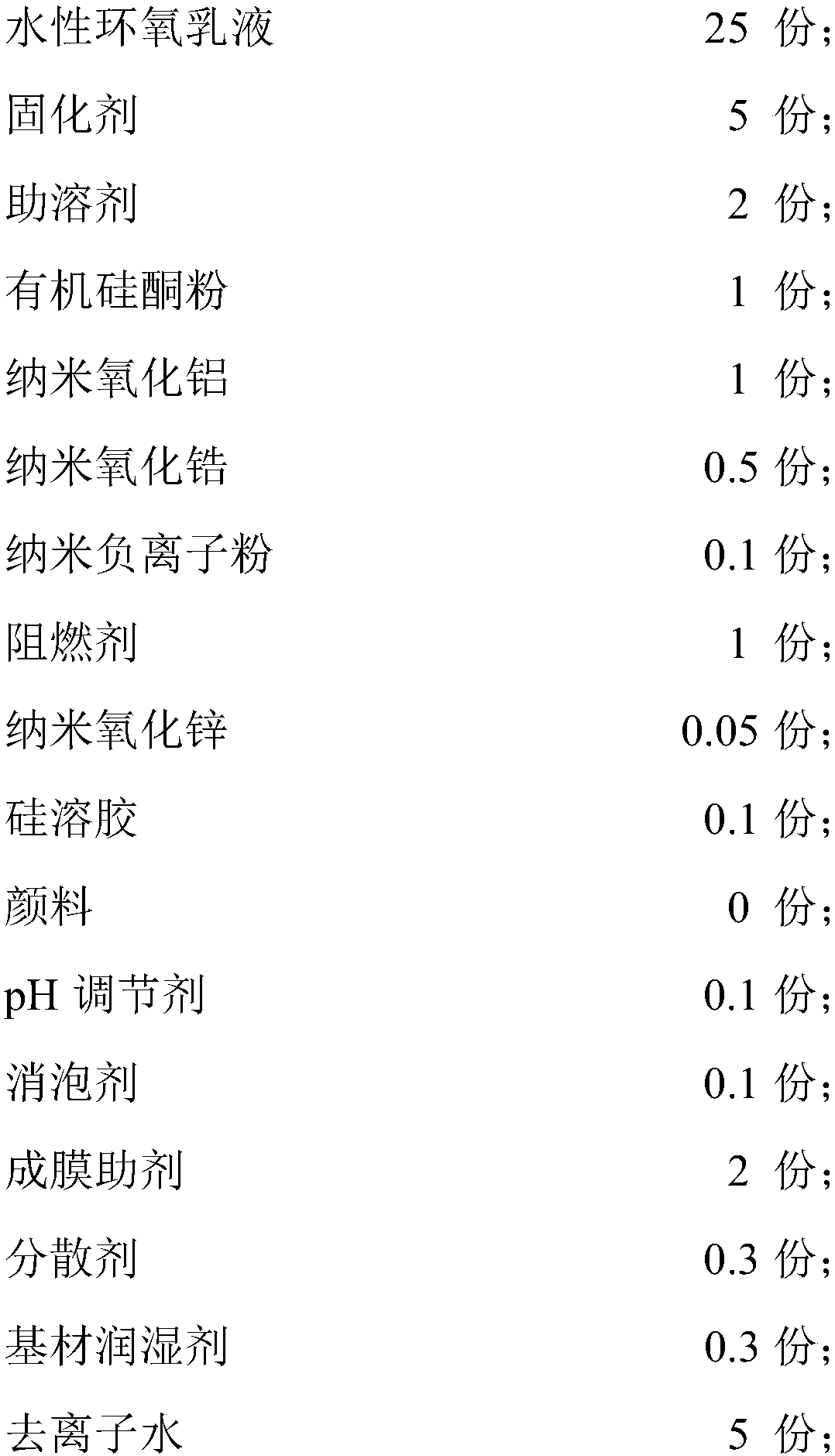

Fireproof bacteriostatic aqueous terrace paint used for bus and preparation method and application thereof

InactiveCN108690455ALow VOCs contentGood environmental protectionFireproof paintsAntifouling/underwater paintsAir cleaningIon

The invention relates to a fireproof bacteriostatic aqueous terrace paint used for bus and a preparation method and an application thereof. The paint comprises the following raw materials: an aqueousepoxy emulsion, a curing agent, a cosolvent, organic silicone powder, nano alumina, nano zirconia, nano negative ion powder, a fire retardant, nano zinc oxide, silica sol, a pigment, a pH conditioningagent, an antifoaming agent, a film-forming auxiliary agent, a dispersant, a base material wetting agent, deionized water, and a thickening agent. The preparation method is characterized in that theraw materials excepting the curing agent, the cosolvent and 1 / 3-1 / 2 formula amount of the deionized water are prepared to obtain a component A, the curing agent, the cosolvent and 1 / 3-1 / 2 formula amount of the deionized water are prepared to obtain a component B, before use, the component A and the component B are mixed to obtain the product. The VOCs content of the paint is low, and a coating hasgood light resistance, chemically-resistant performance, flame resistance and hardness, and the paint has bacterinertness and air cleaning performance, and is suitable for the bus.

Owner:HEBEI CHENYANG INDAL & TRADE GROUP CO LTD

Multilayer dissolvable solid article containing solid particles for making the same

PendingUS20220112449A1Improve stabilityImprove abilitiesCosmetic preparationsBiocidePolymer sciencePorous sheet

Owner:THE PROCTER & GAMBLE COMPANY

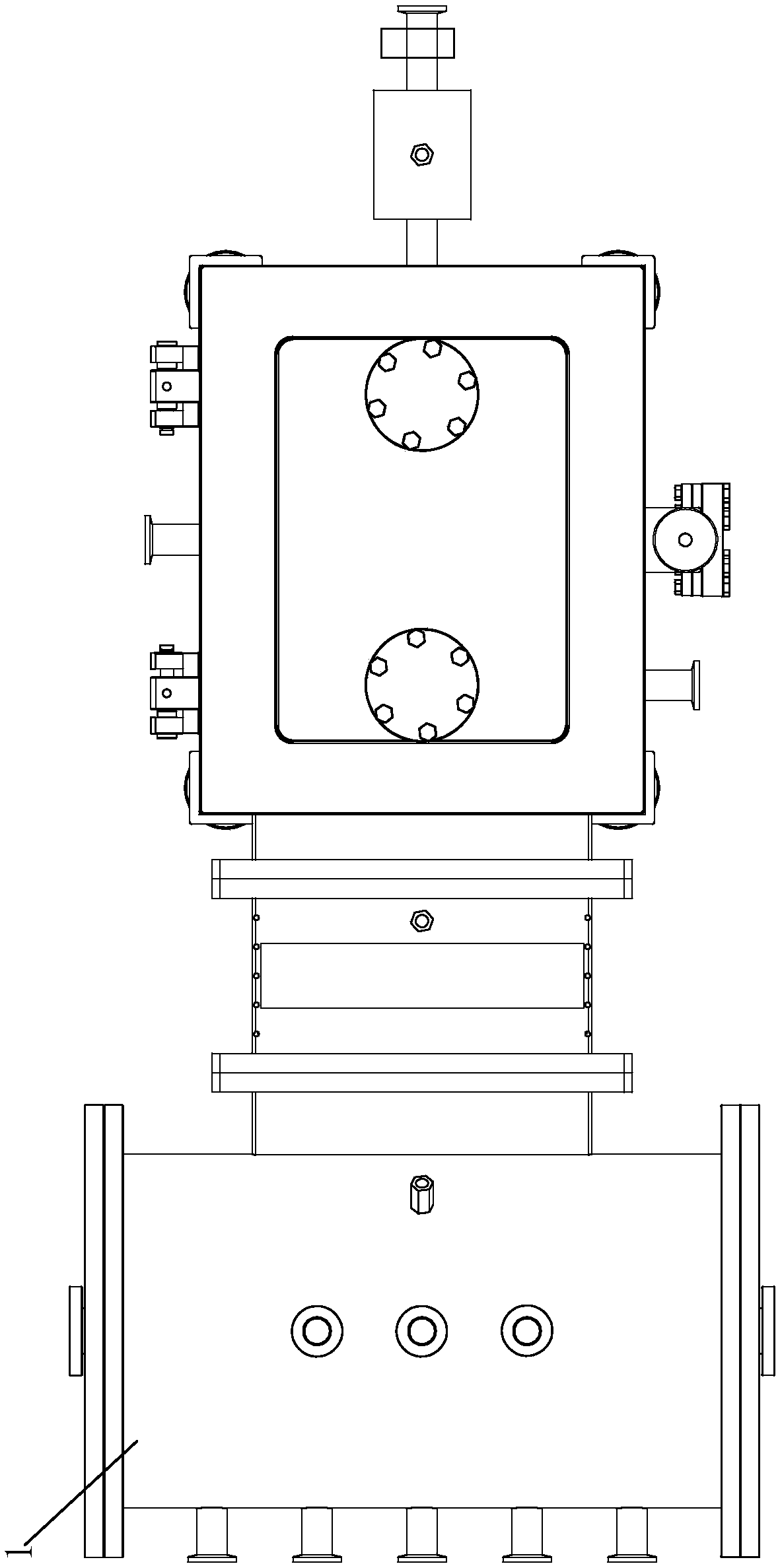

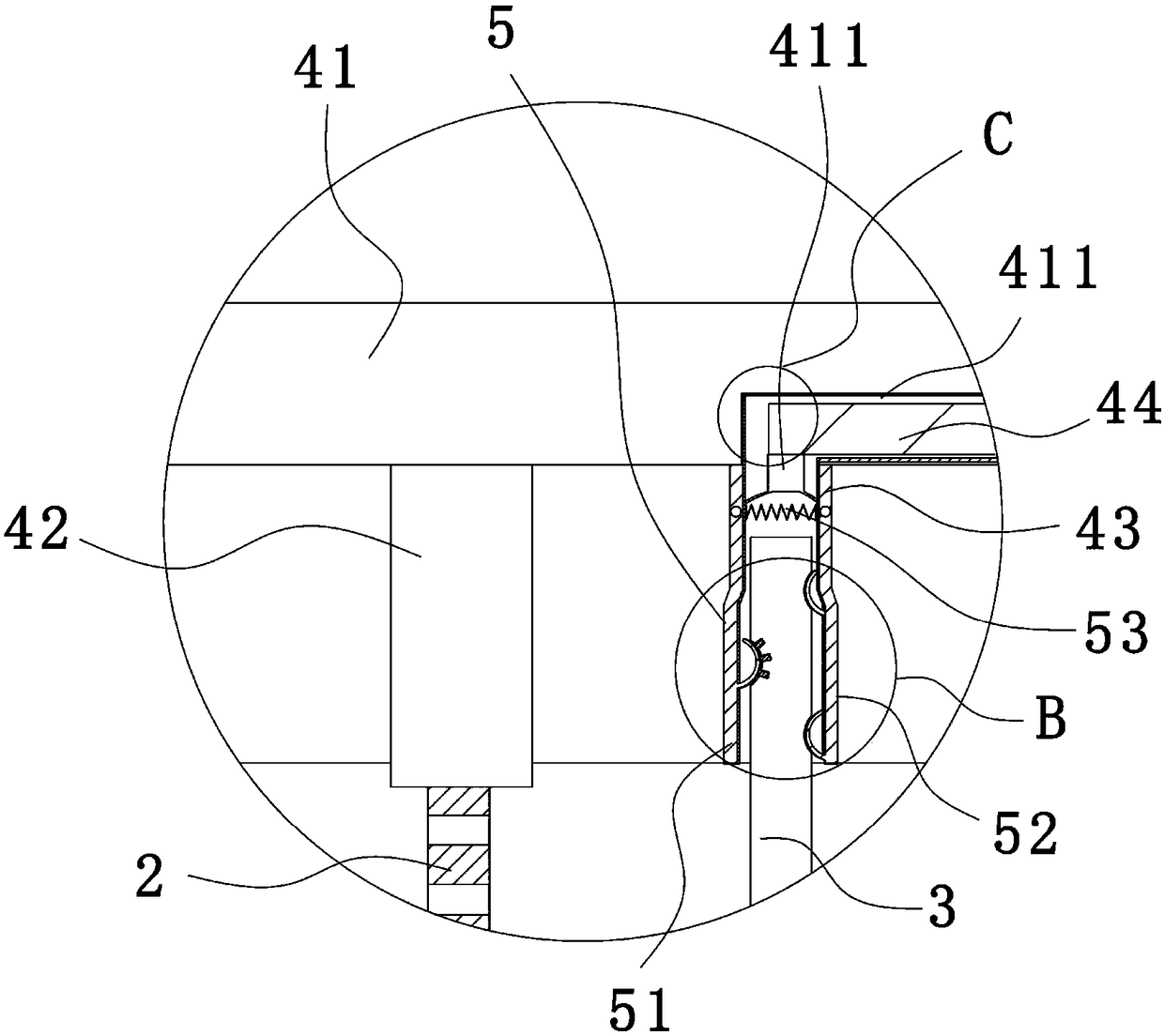

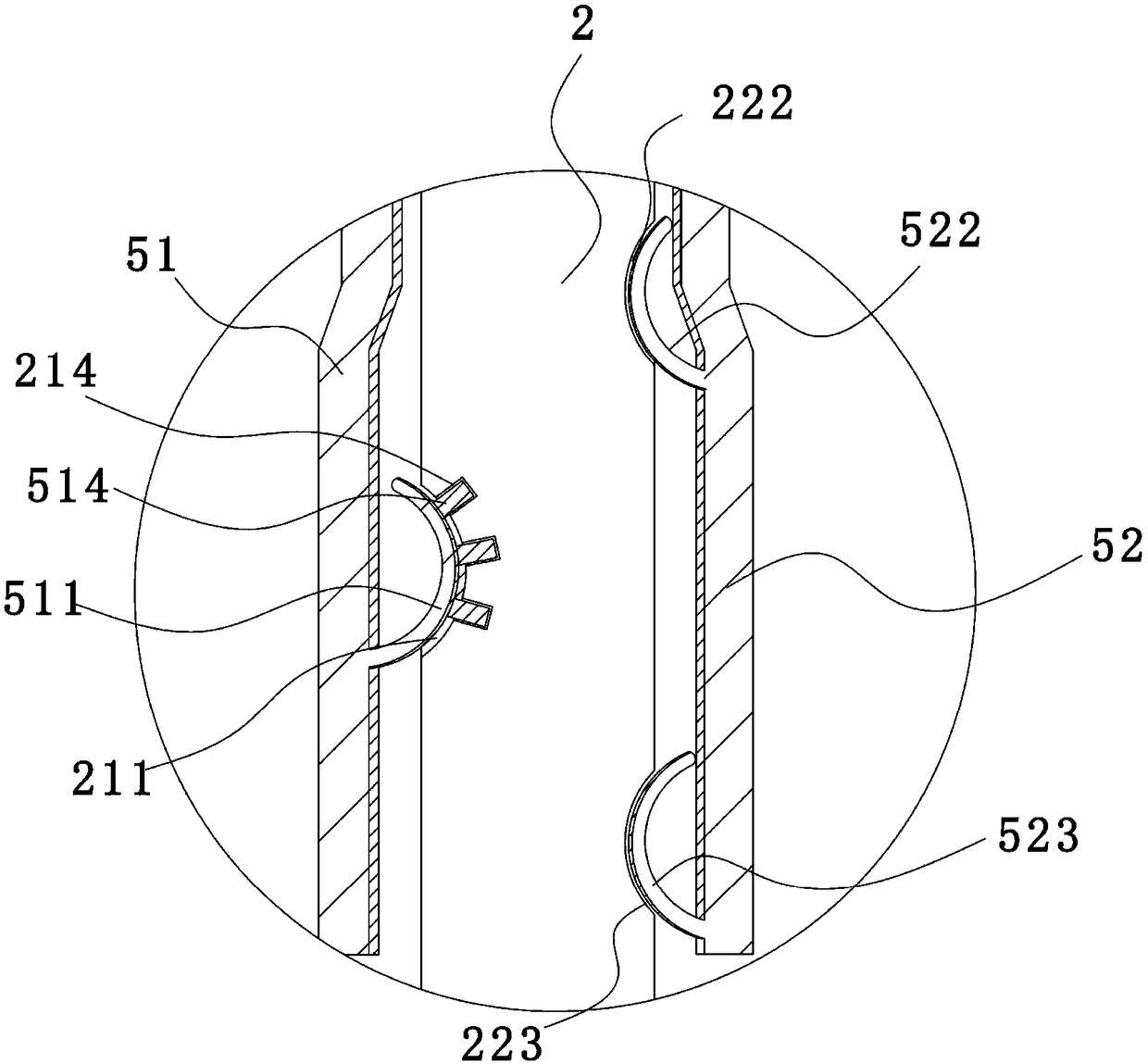

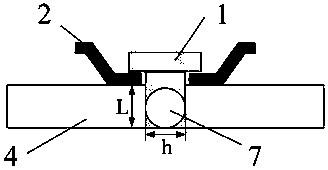

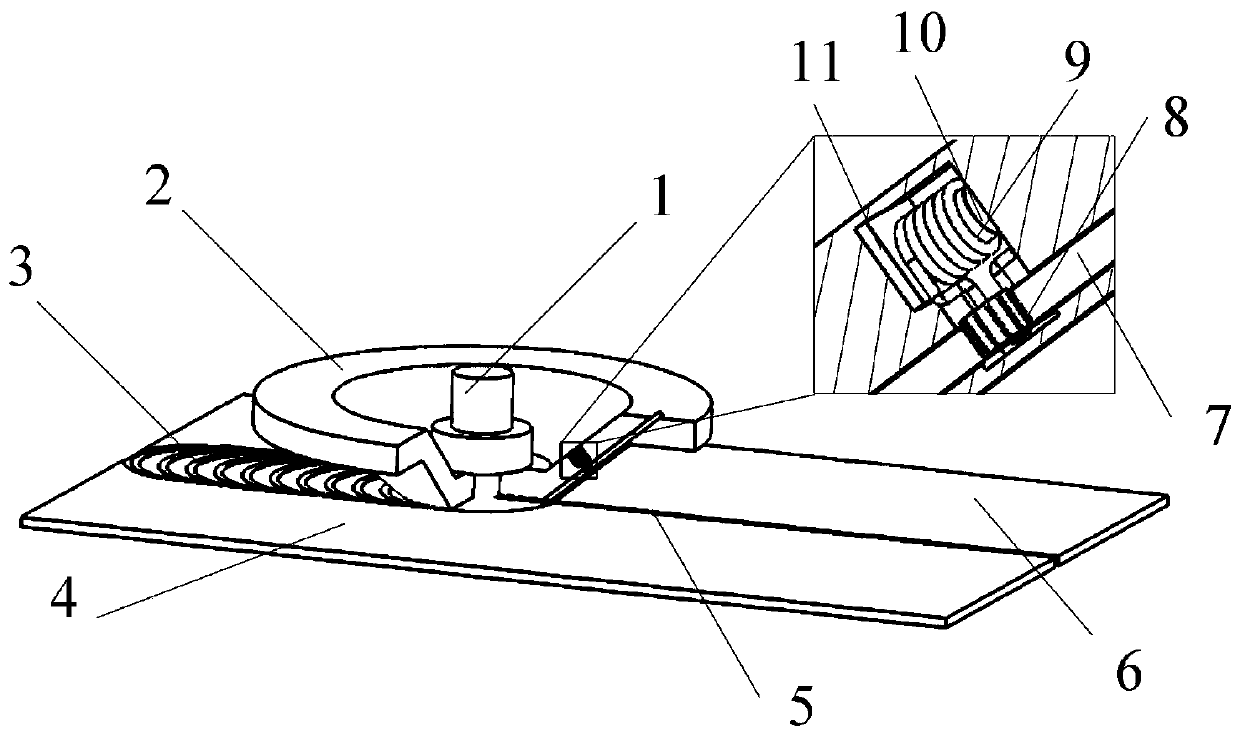

Atomization assisted CVD film deposition device

ActiveCN109338338ASignificant technological progressEffective combinationFinal product manufactureLiquid/solution decomposition chemical coatingGas phaseIodine

The invention discloses an atomization assisted CVD film deposition device. The atomization assisted CVD film deposition device comprises a buffering mixing chamber, a transition cavity and a reactionchamber; the top of the buffering mixing chamber is vertically provided with a plurality of gas phase object inlet pipes; the left side of the outer wall of the buffering mixing chamber is provided with a plurality of aerosol inlet pipes; a set of upper iodine-tungsten filament lamps are fixed to the upper board face of an upper lifting board in the length direction of a reaction cavity side by side; and the left ends and the right ends of the upper lifting board and a lower lifting board are connected with the outer surface of the reaction cavity through two height adjusting assemblies separately, and the heights of the upper lifting board and the lower lifting board can be adjusted under the function of the height adjusting assemblies. According to the scheme, the components and contentof a precursor are ensured mainly from the aspects of a precursor mixing mode and liquid collection, the reaction environment of a reaction area is controlled through the two aspects of ensuring thestability of an airflow field and controlling a temperature field, the technical means of the above four aspects are mutually matched to jointly achieve high-quality film preparation, and the device is especially suitable for manufacturing oxide films.

Owner:XIDIAN UNIV +1

Treatment method of domestic sewage

ActiveCN108218053AReduce CODPromote oxidationWater contaminantsTreatment involving filtrationHypochloriteHydrogen

The invention discloses a treatment method of domestic sewage. The treatment method comprises the following steps of a), removing a solid substance in source water, detecting the potential of hydrogen(PH) of a water body, and then adding a PH regulator to regulate the PH to 6.5 to 7.5, so as to obtain a water body A; adding a flocculating agent into the water body A, filtering, then introducing chlorine, and afterwards, adding alkali liquor. According to the treatment method, the water body is regulated to be neutral; a hydroxide ion in the water body is prevented from prematurely reacting with the chlorine; the chlorine can be dissolved in the water body; a generated hypochlorite reacts with an ammonium ion in the water; the ammonium ion in the water body is removed; quick lime is addedinto the water; a microorganism and a germ in the water can be killed; the quick lime generates slaked lime in the water, and the slaked lime reacts with a phosphorus ion in the water, so that a phosphorus element in the water can be removed.

Owner:江西挺进环保科技股份有限公司

Compositions containing functionalized oils and polyolefins

InactiveUS7858698B2Avoid premature reactionPolyurea/polyurethane coatingsPolyolefinPolymer chemistry

A composition comprises a polyolefin having electronegative substituents and a material comprising a plurality of hydrocarbyl groups, each hydrocarbyl group having at least seven carbon atoms.

Owner:A LINE PRODS

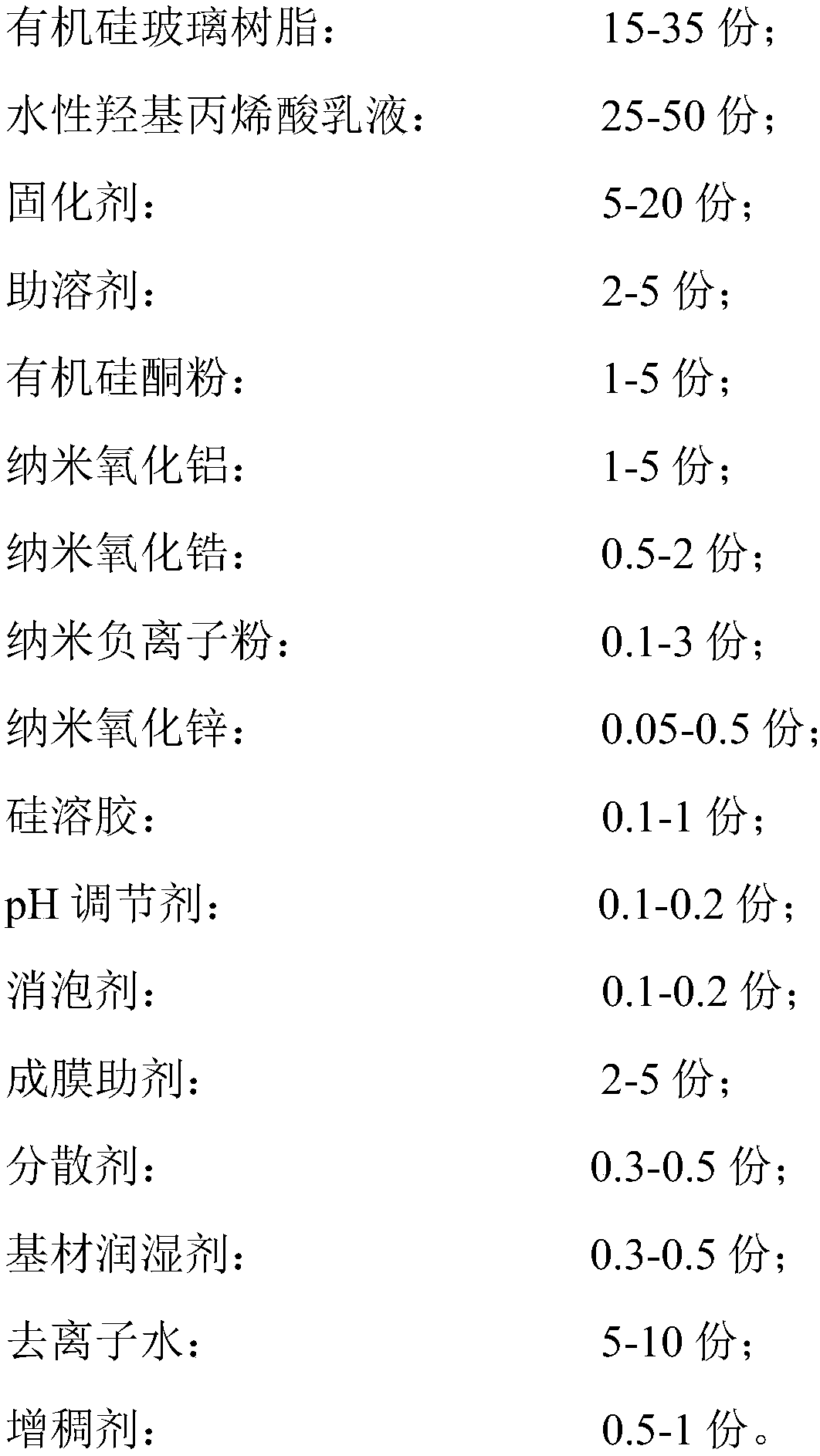

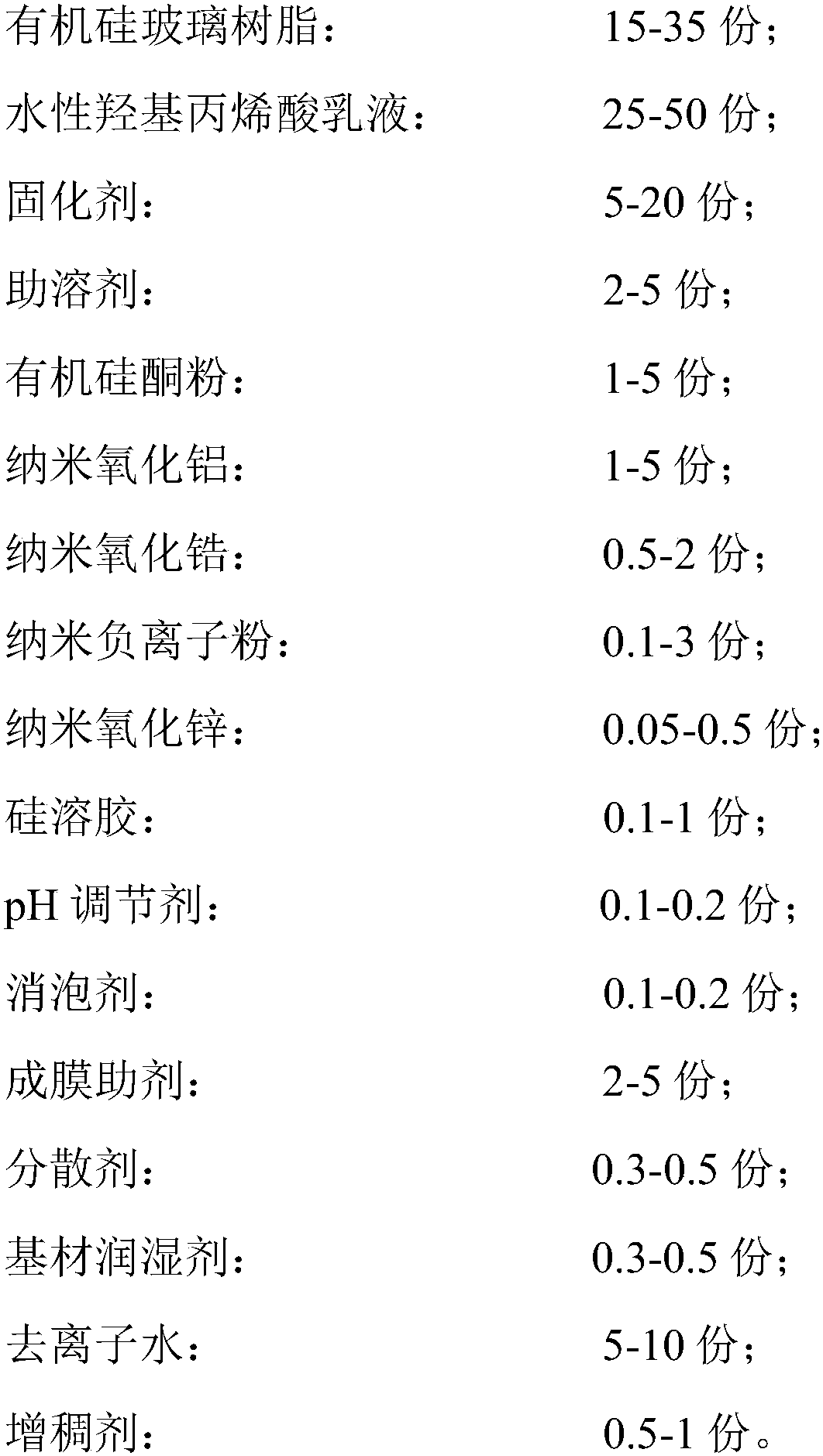

Aqueous polyurethane paint and preparation method and application thereof

InactiveCN108690438AEasy to prepareExtended shelf lifeAntifouling/underwater paintsPaints with biocidesNano zinc oxideChemistry

The invention relates to the technical field of a paint, and concretely discloses an aqueous polyurethane paint and a preparation method and an application thereof. The aqueous polyurethane paint comprises the following components in parts by weight: 15-35 parts of organic silica glass resin, 25-50 parts of an aqueous hydroxy-acrylic resin emulsion, 5-20 parts of a curing agent, 2-5 parts of a cosolvent, 1-5 parts of organic silicone powder, 1-5 parts of nano alumina, 0.5-2 parts of nano zirconia, 0.1-3 parts of nano negative ion powder, 0.05-0.5 parts of nano zinc oxide, 0.1-1 part of silicasol, 0.1-0.2 parts of a pH conditioning agent, 0.1-0.2 parts of an antifoaming agent, 2-5 parts of a film-forming auxiliary agent, 0.3-0.5 parts of a dispersant, 0.3-0.5 parts of a base material wetting agent, 5-10 parts of deionized water, and 0.5-1 part of a thickening agent. The aqueous polyurethane paint has the advantages of excellent hardness, water resistance, wear resistance and antibacterial activity.

Owner:HEBEI CHENYANG INDAL & TRADE GROUP CO LTD

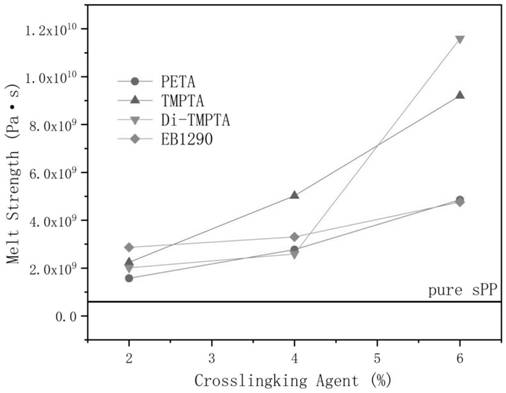

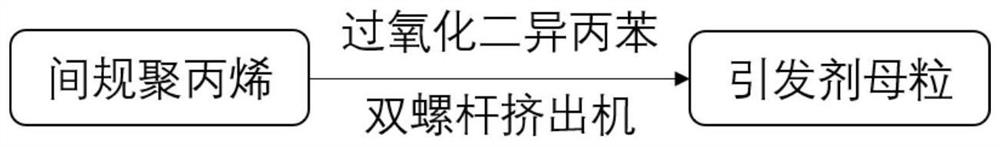

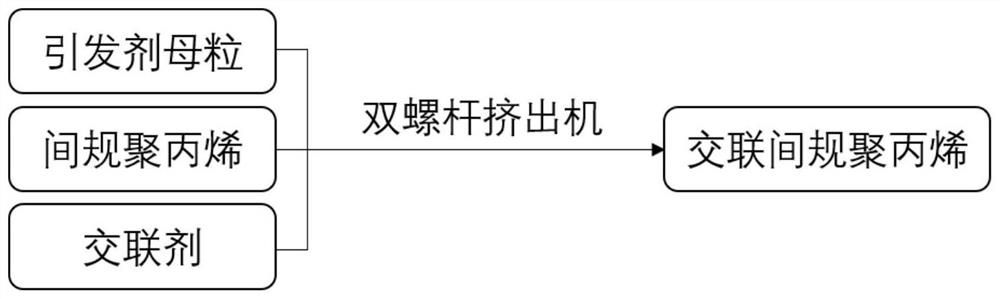

Cross-linked syndiotactic polypropylene foam and preparation method and application thereof

ActiveCN113292760AAvoid premature reactionReduced mixing capacity requirementsPolymer scienceFoaming agent

The invention provides cross-linked syndiotactic polypropylene foam and a preparation method and application thereof. The preparation method comprises the following steps: (1) preparing initiator master batches for crosslinking: extruding syndiotactic polypropylene and an initiator in a double-screw extruder to obtain the initiator master batches; (2) preparing cross-linked syndiotactic polypropylene: extruding the syndiotactic polypropylene, the initiator master batch and the cross-linking agent in a double-screw extruder to obtain the cross-linked syndiotactic polypropylene; and (3) preparing the cross-linked syndiotactic polypropylene foam: extruding and foaming the cross-linked syndiotactic polypropylene and the foaming agent master batch in a single-screw extruder to obtain the cross-linked syndiotactic polypropylene foam. The method can be used for preparing the low-rate cross-linked syndiotactic polypropylene foam with better mechanical properties, and can be applied to the fields of automotive trim, building material decoration, buffer interlayers and the like.

Owner:BEIJING UNIV OF CHEM TECH

Method and device for dissimilar metal friction-stir welding

InactiveCN111331246AAvoid direct contactAvoid it happening againWelding/soldering/cutting articlesNon-electric welding apparatusFriction weldingWeld seam

The invention relates to a method for dissimilar metal friction-stir welding. The method specifically comprises the following steps: step I of clamping to-be-welded boards onto a clamp of a friction-stir welding machine, and reserving a wire filling gap between the two to-be-welded boards; step II, mounting a stirring tool and a static shaft shoulder, selecting a proper welding wire according to the material of the to-be-welded boards, and feeding the welding wire into the reserved seam through a wire feeding wheel in the static shaft shoulder; step III, setting welding parameters, and starting the welding machine and the wire feeding mechanism to weld; and step IV, withdrawing the wire feeding mechanism to pull off the welding wire after welding is accomplished, stopping the wire feedingmechanism, and stopping the welding machine. The method adopts a static shaft shoulder way to weld. The static shaft shoulder can provide relatively great upsetting force to a welding seam region, andexcessive welding heat is absorbed to refine crystal grains; and structural binding strength is improved through extra upsetting force provided by the static shaft shoulder, so that quality of a welding joint is improved.

Owner:HARBIN WANZHOU WELDING TECH CO LTD

Multi-flavor bubble potato chips and preparation method thereof

PendingCN112753972AGuaranteed to stayExtended shelf lifeYeast food ingredientsBiotechnologyChipped potatoes

The invention discloses multi-flavor bubble potato chips and a preparation method thereof. The multi-flavor bubble potato chips comprise potatoes, modified citric acid, copper hydroxide, ammonia water and ethyl alcohol. When the multi-flavor bubble potato chips are prepared, a frying technology is used for twice, first-time frying is carried out on the surface of oil, acrylamide inhibitor powder is sprayed on the potato chips after frying, then second-time frying is carried out in an oil middle layer, the potato chips are fried in an oil phase, and the fried potato chips are deoiled in a nitrogen atmosphere, wherein the added acrylamide inhibitor is the modified citric acid; the citric acid and copper ammonia are complexed, so that the potato chips are salty when being tasted initially, the taste is changed into soda taste after the potato chips are chewed, and accompanied generated ammonium chloride enters the body and can further reduce phlegm and stop coughing; the potatoes are prepared into mashed potato, the mashed potato is subjected to 3D printing to form a thin film, potato slices are transferred into ethanol solution, anaerobic fermentation is performed by using saccharomycetes, and glucose can be converted into carbon dioxide and alcohol through fermentation, so that the bubble and ethanol taste of the potato chips is increased.

Owner:黄天明

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com