Patents

Literature

3305results about How to "Effective combination" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

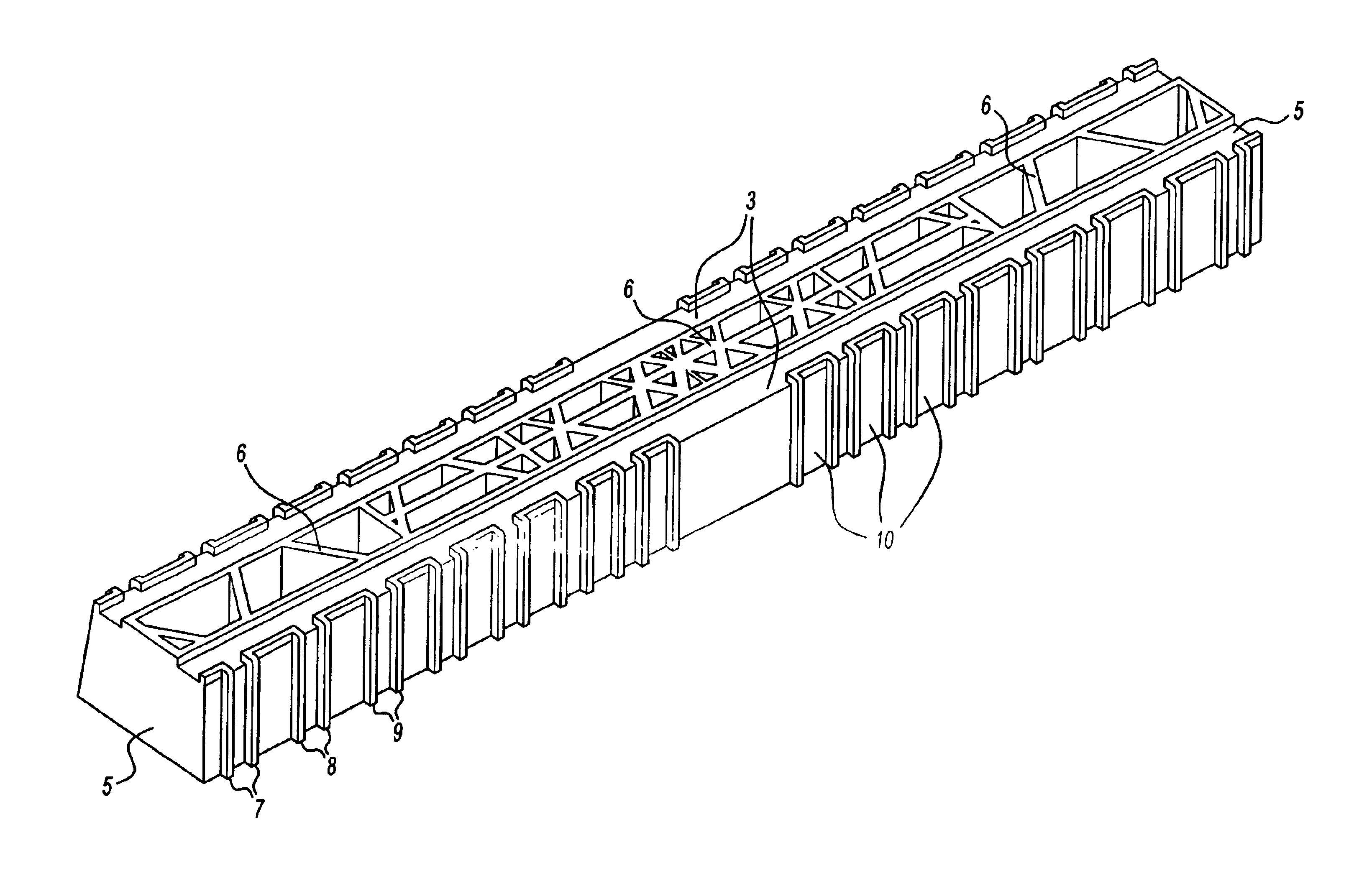

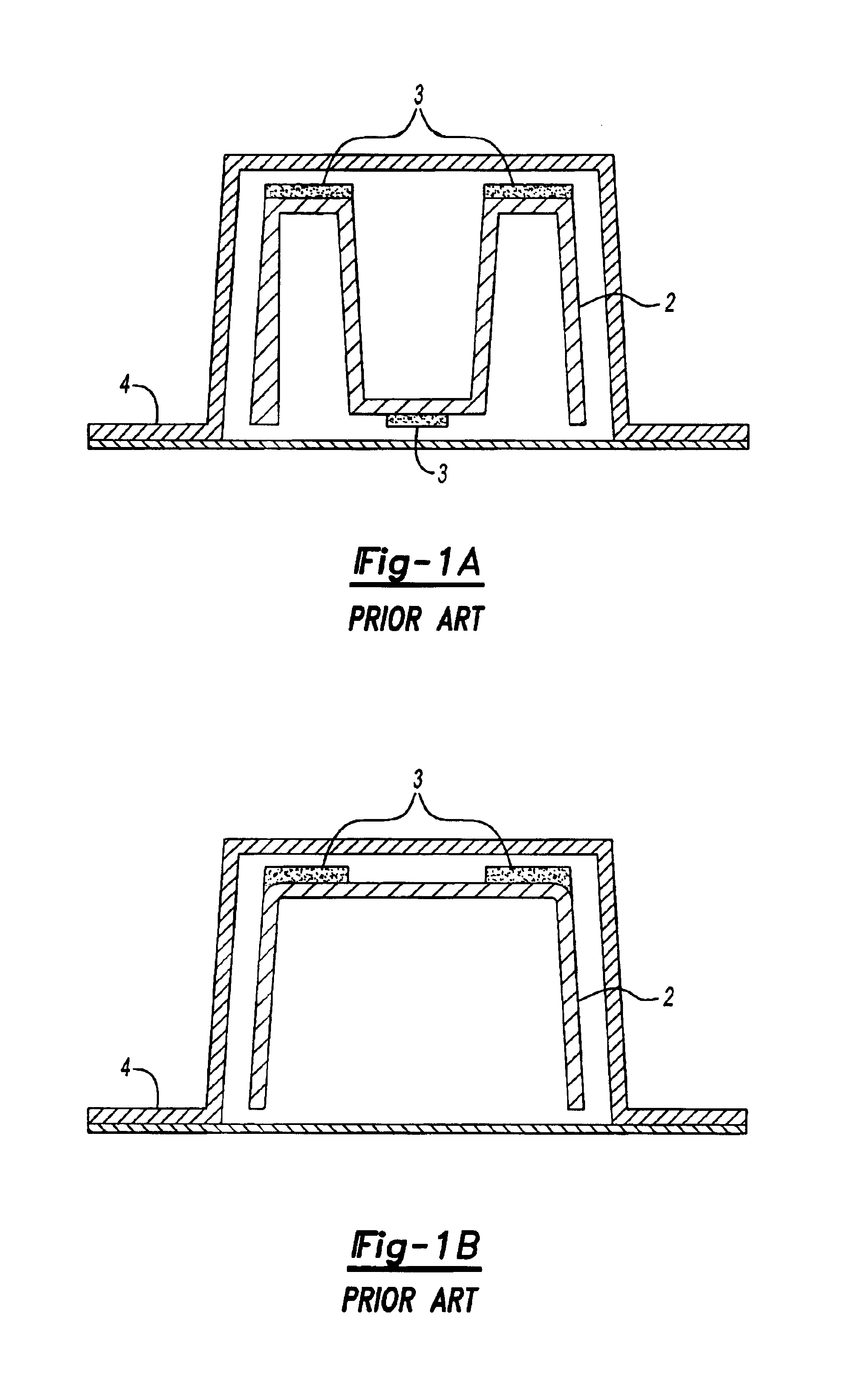

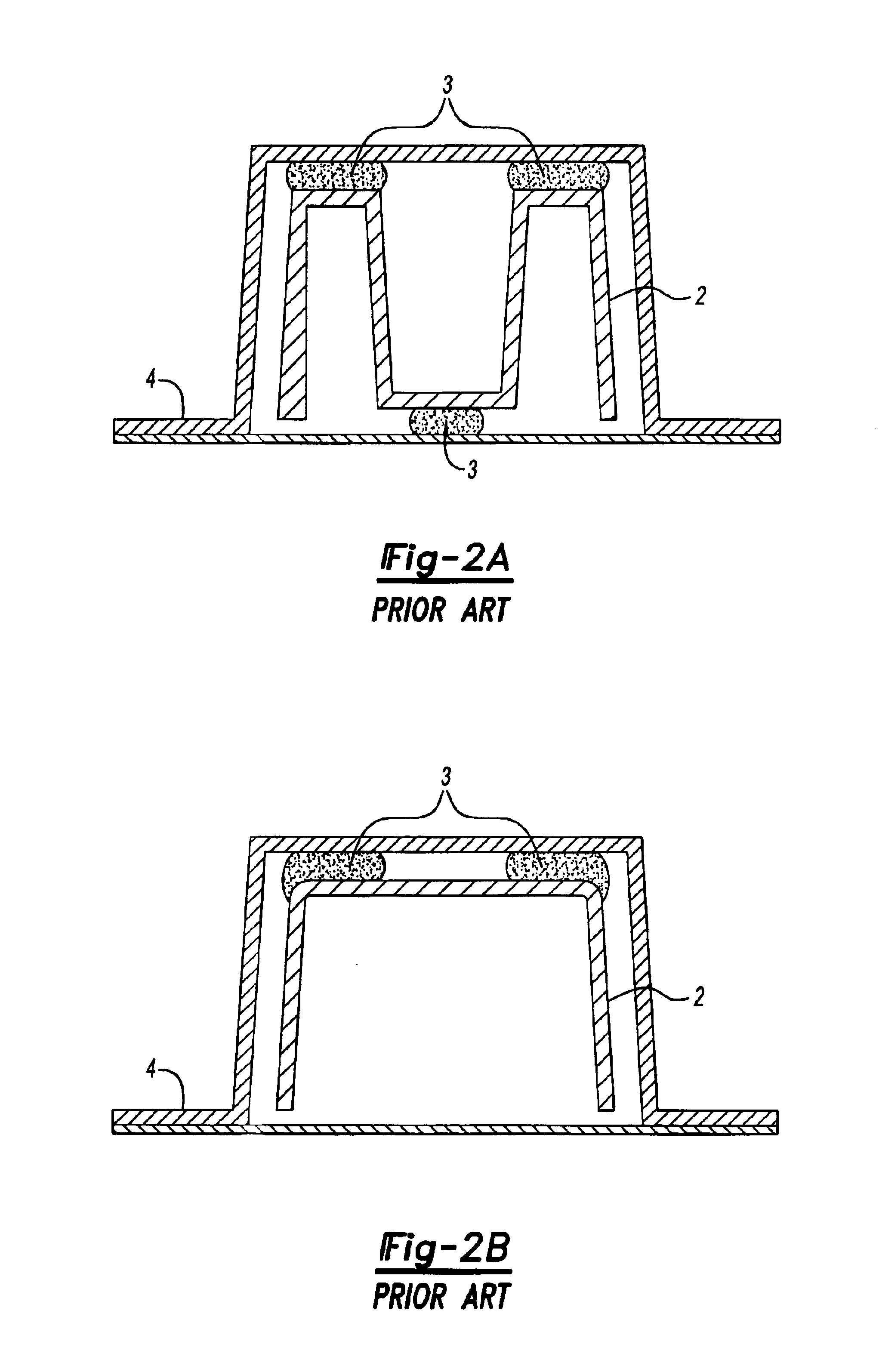

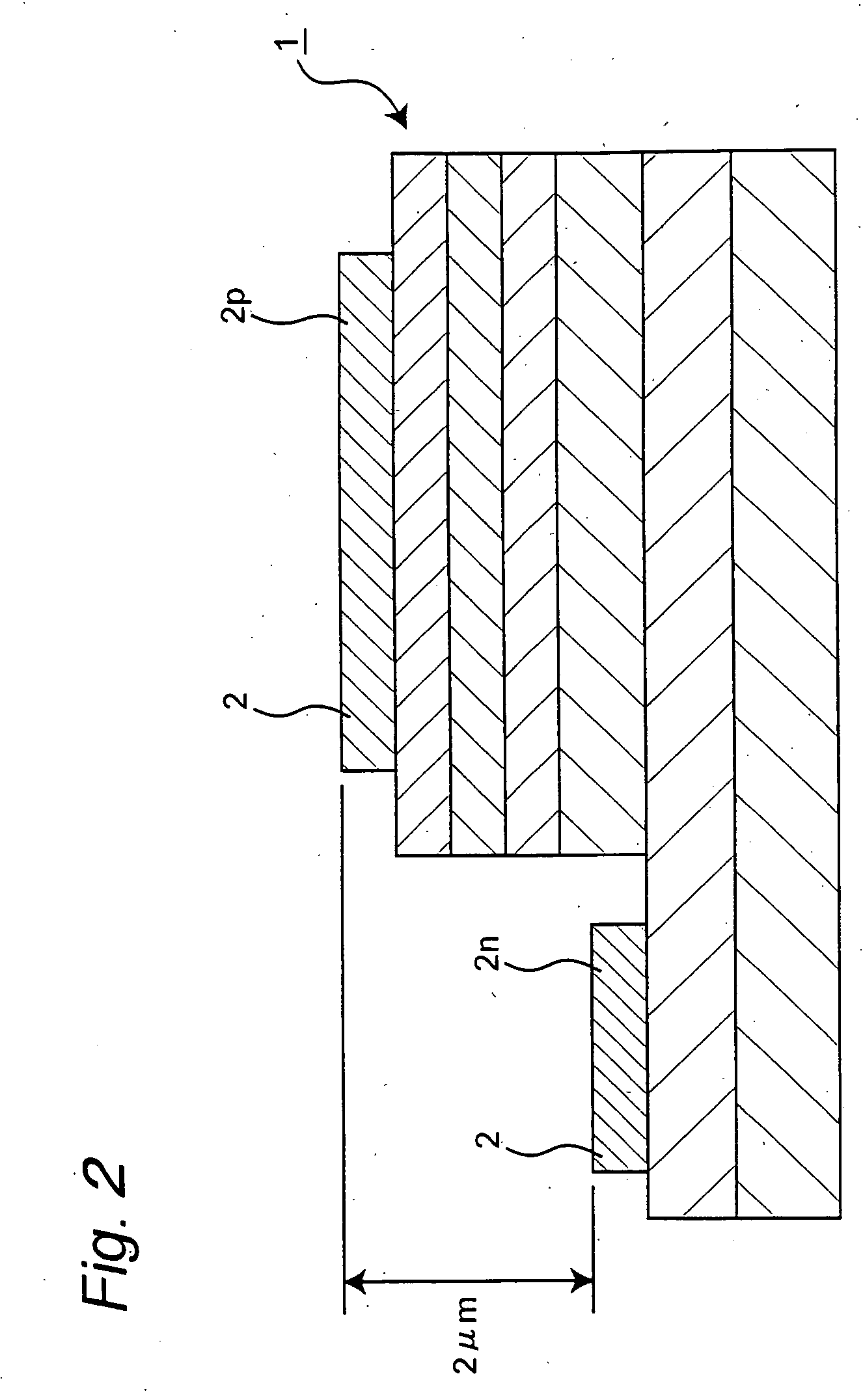

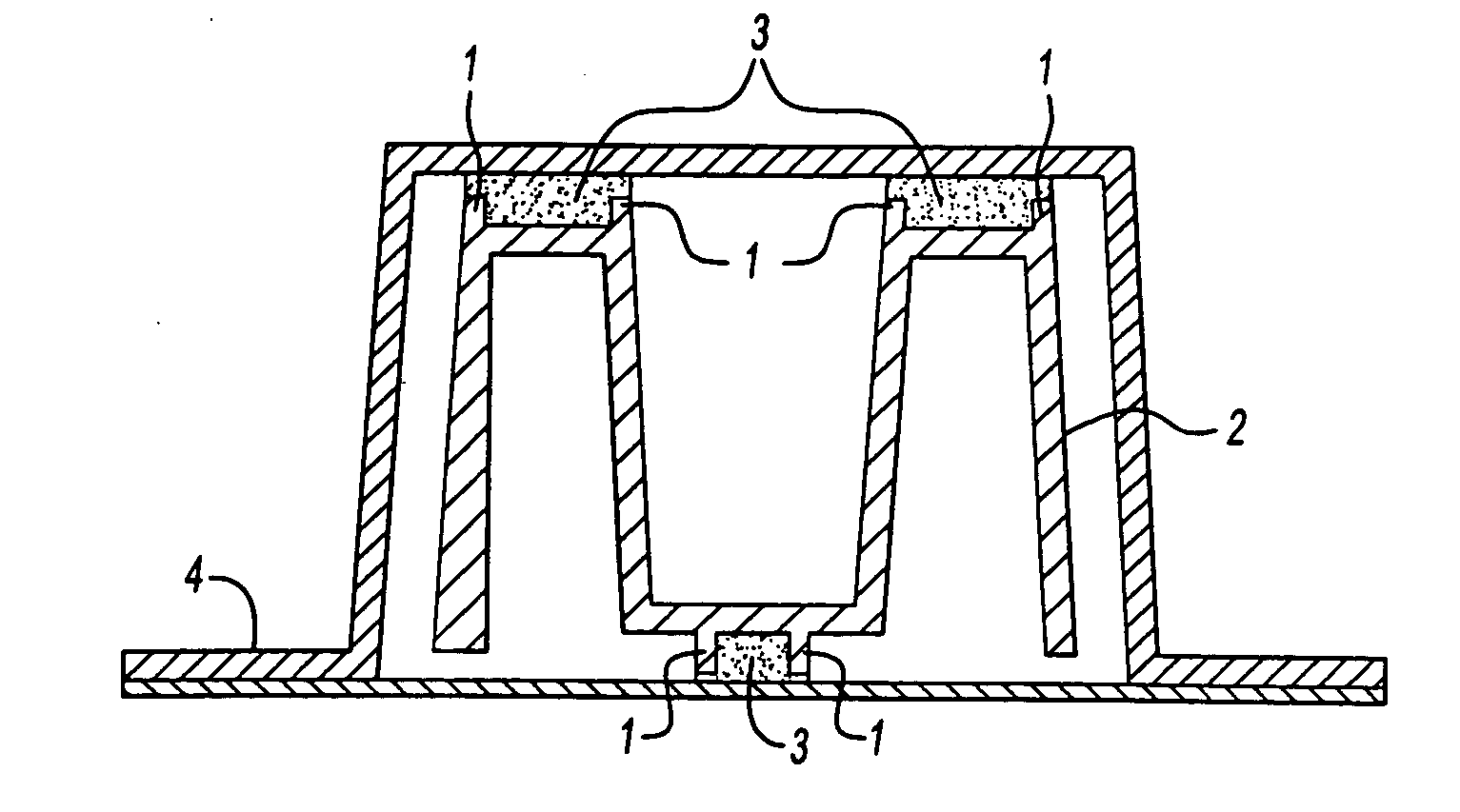

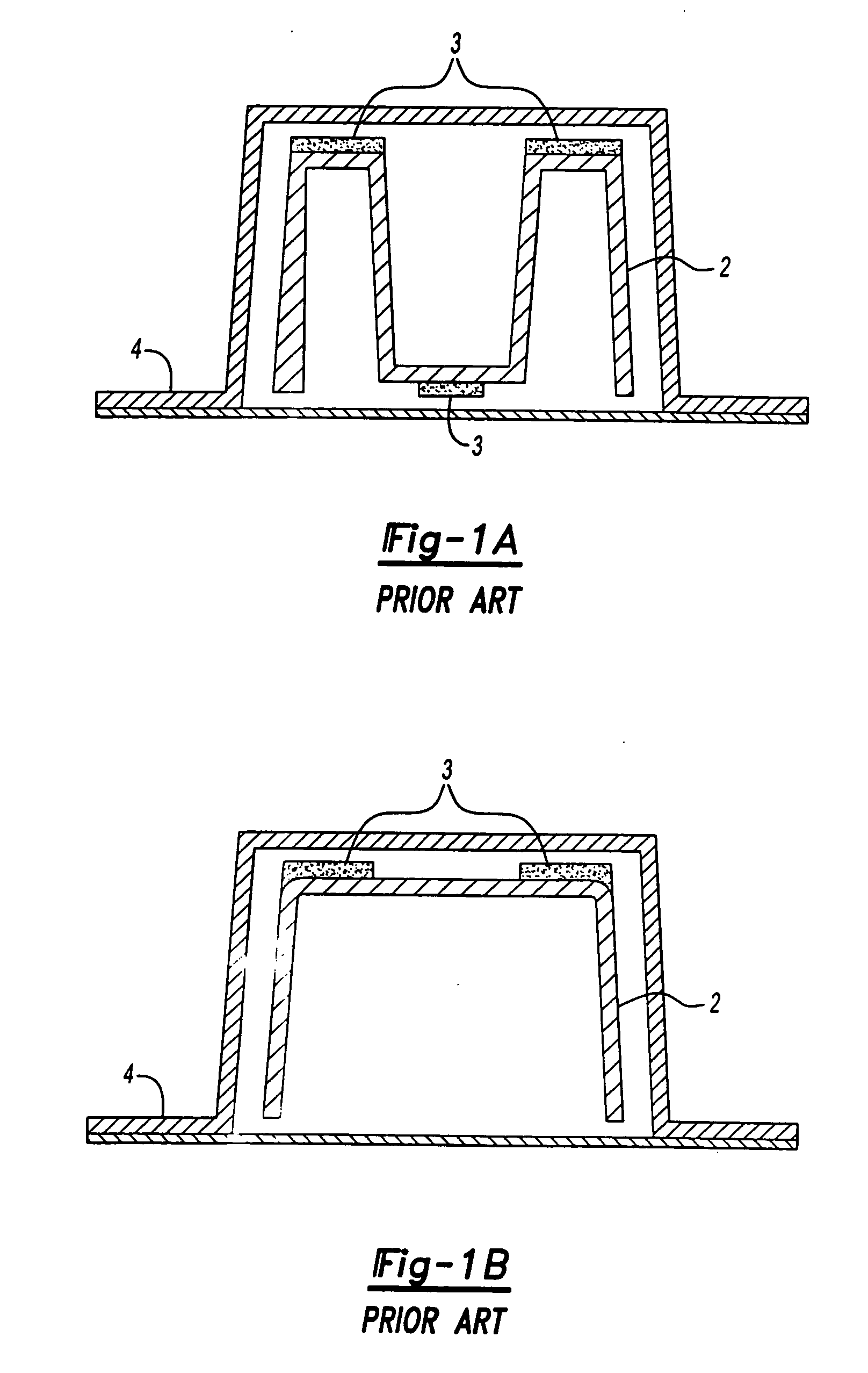

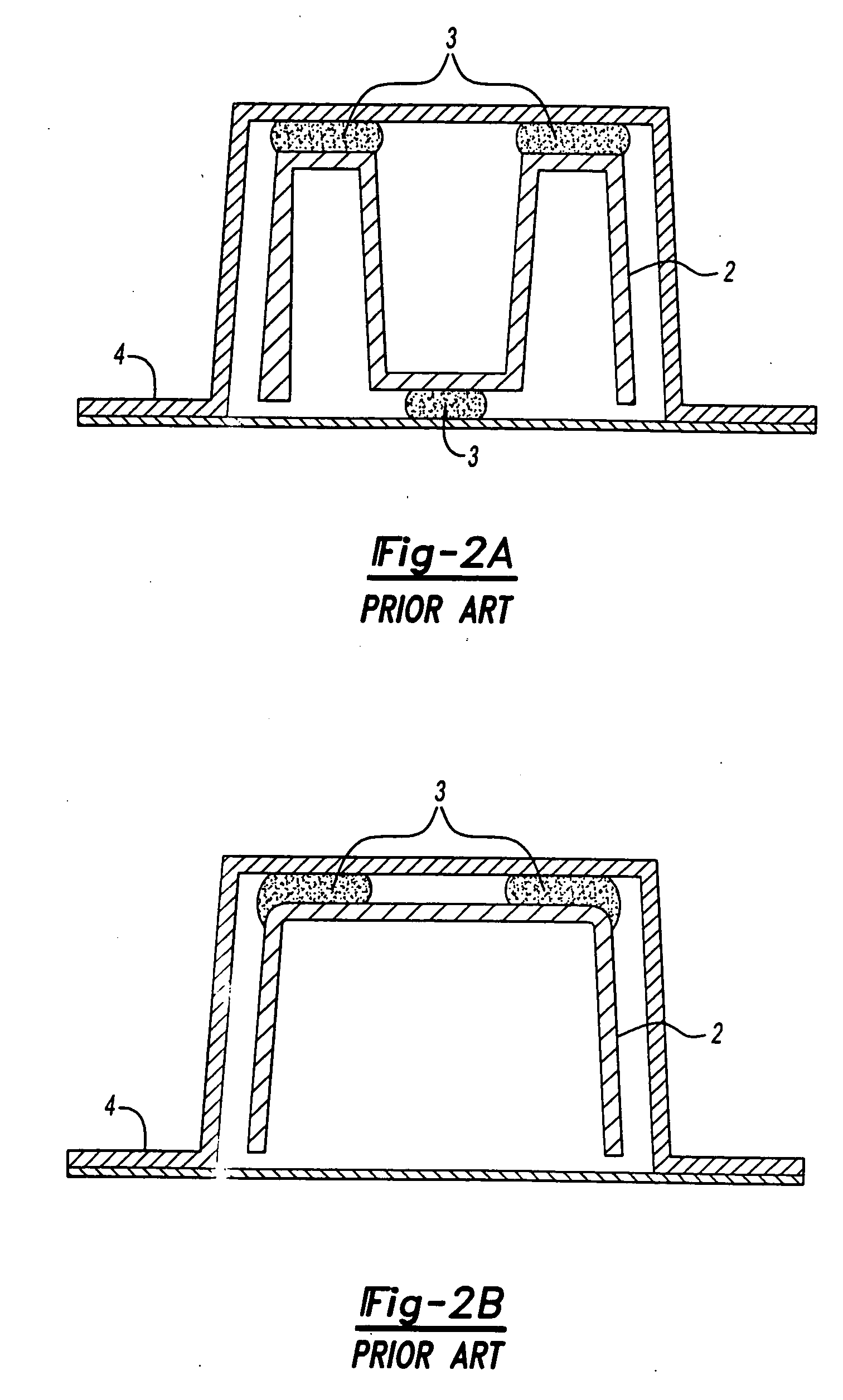

Structural reinforcement

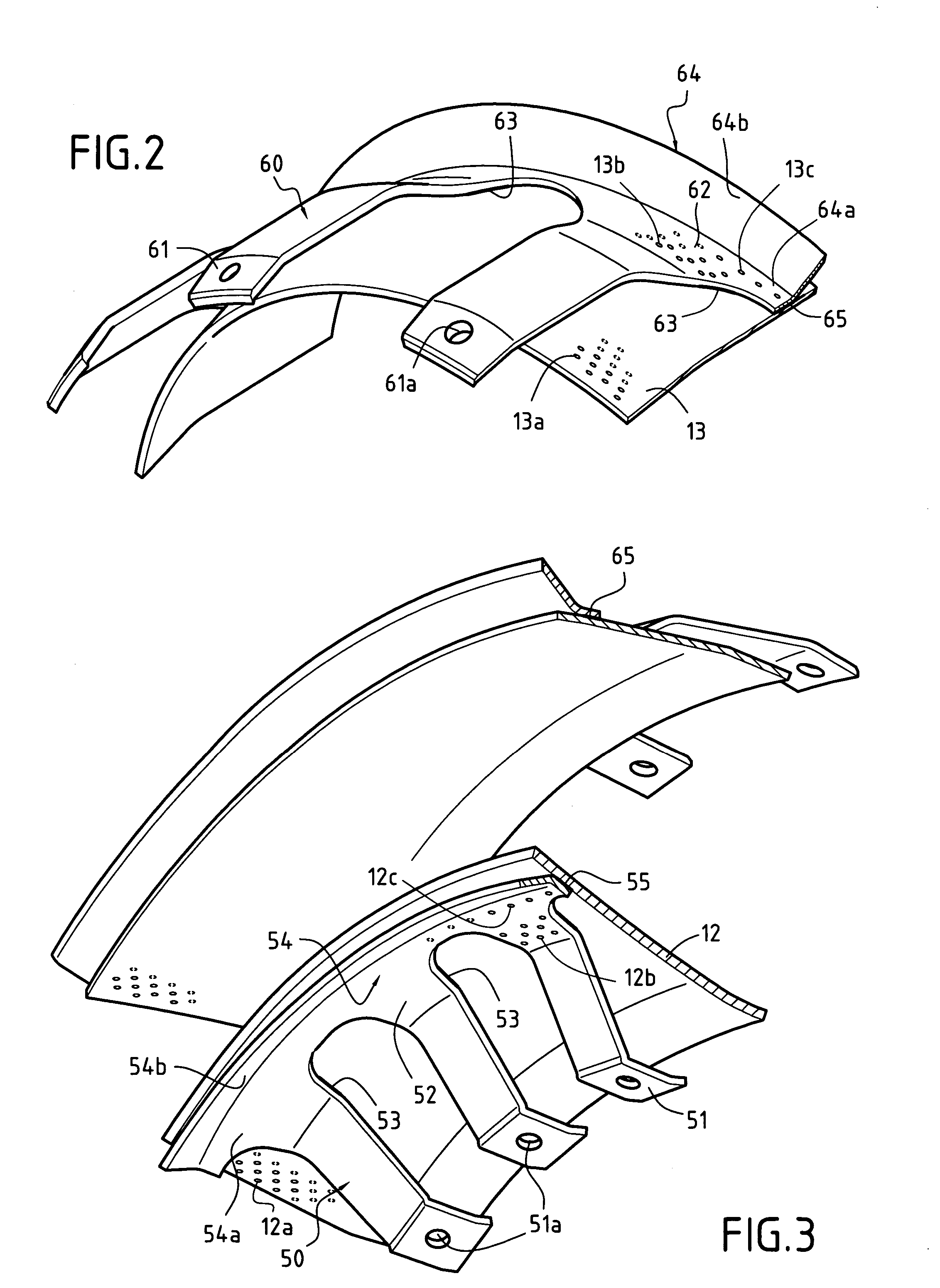

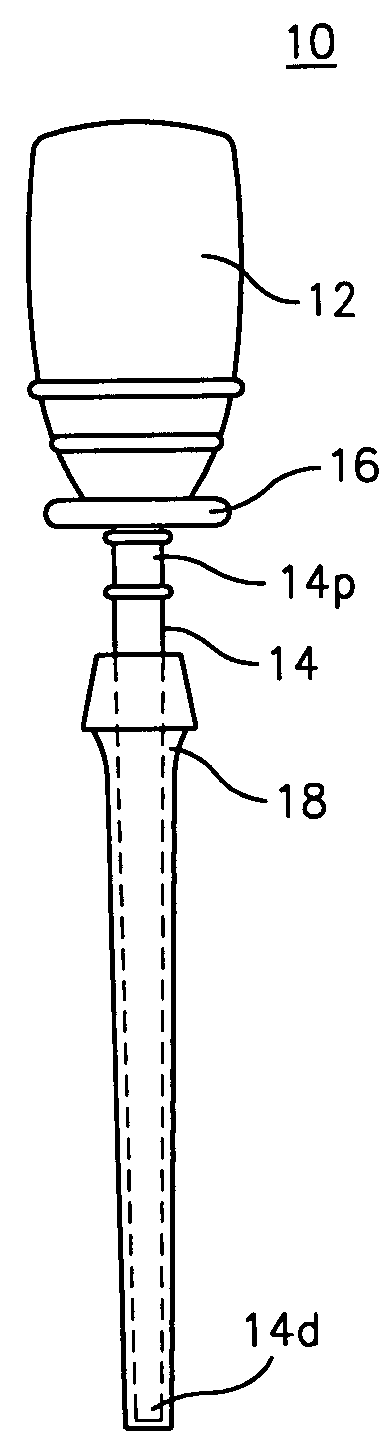

InactiveUS6941719B2Reduced strengthSatisfies requirementVehicle seatsStructural elementsAdhesive materialsBiomedical engineering

A structural reinforcement for a hollow member comprising a rigid reinforcing member having a shape that substantially conforms to the cross section of the hollow member to be reinforced with an expandable adhesive material over at least a portion of the surface of the structural reinforcement having one or more extensions on its external surface which control and direct the direction in which the adhesive material expands to bond the reinforcing member to the internal surface of the hollow member, some of the extensions also provide improved reinforcement.

Owner:ZEPHYROS INC

Organic soil-less culture substrate, orgainc solid fertilizer and soil-less cultivation method

InactiveCN1336104ALow costSave on fertilizer costsSolid waste disposalAgriculture gas emission reductionInorganic fertilizerChemistry

The present invention discloses a solid soiless cultivation organic substrate and organic solid fertilizer for use by this substrate. Said substrate mainly is composed of organic substrate material and inert substrate material, the solid fertilizer mainly is composed of dung fertilizer and cake fertilizer and inorganic fertilizer. The present invention also discloses soilless cultivation method using said solid substrate. The present invention can be used in commercial production of vegetables. It is simple in raw material compoistion which is broad in source. It is also simple in technology, low in cost, no pollution to environment etc.

Owner:INST OF VEGETABLE & FLOWERS CHINESE ACAD OF AGRI SCI

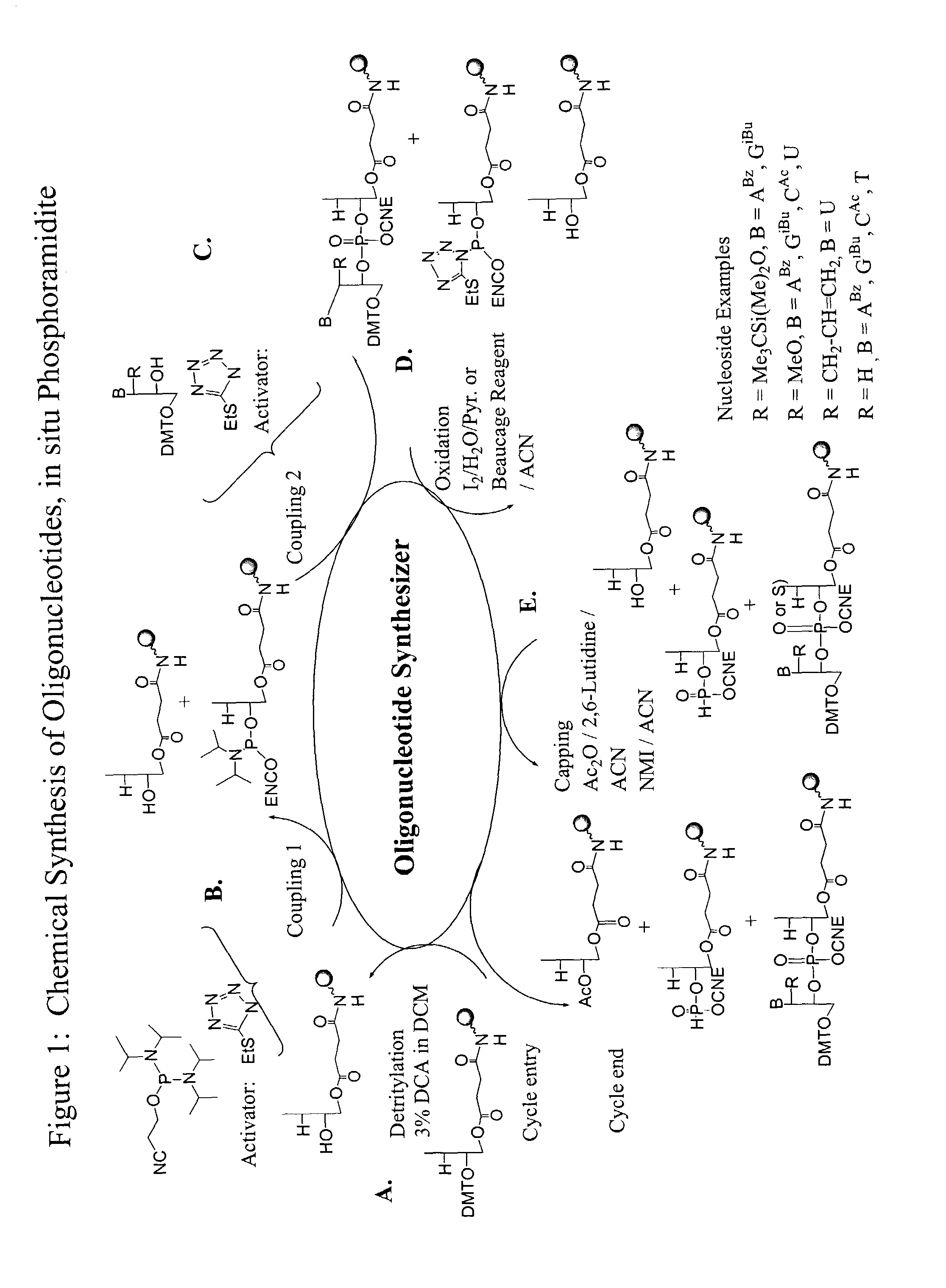

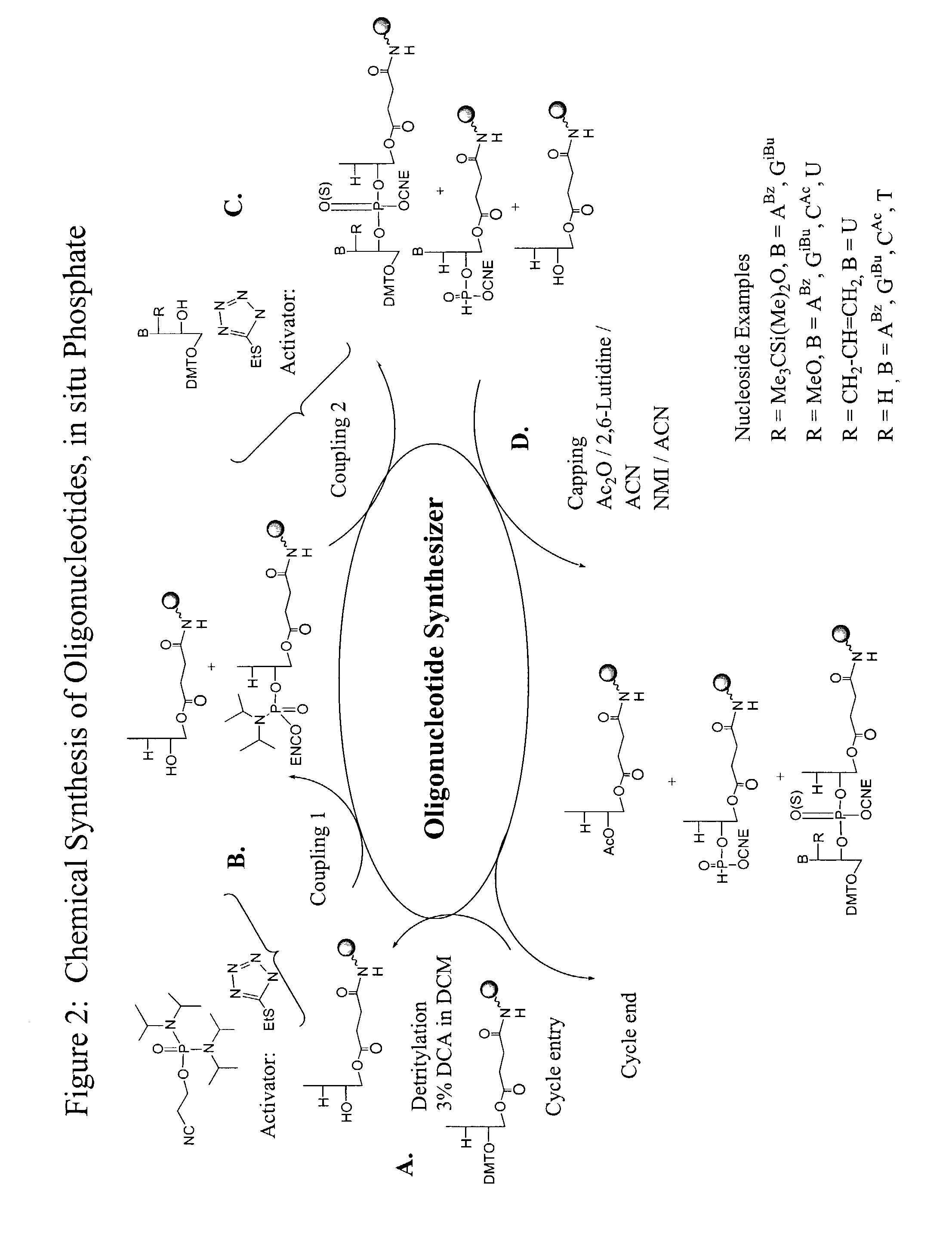

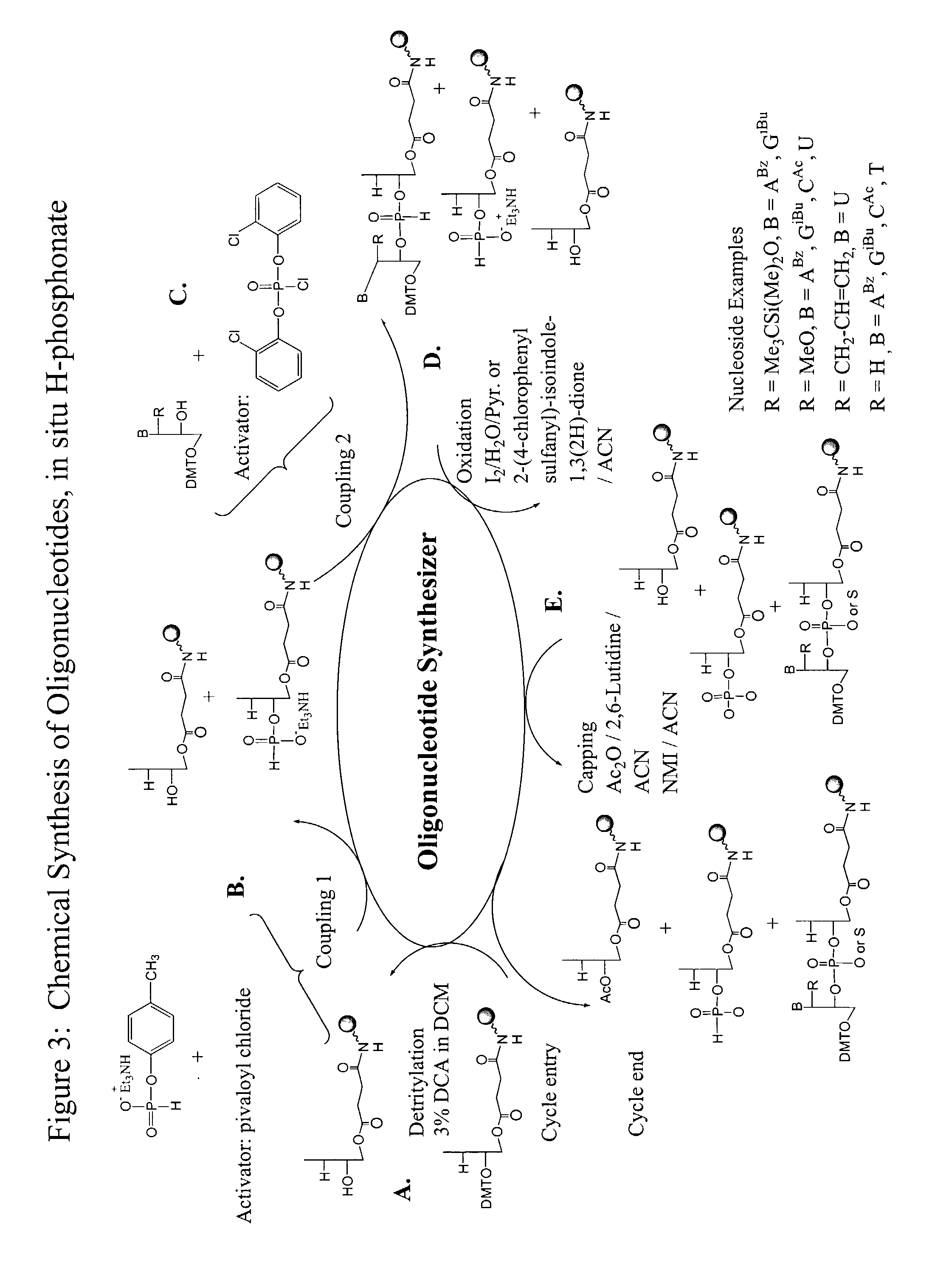

Method for the chemical synthesis of oligonucleotides

InactiveUS6995259B1High yieldHigh purityGroup 4/14 element organic compoundsSugar derivativesChemical synthesisCombinatorial chemistry

Owner:SIRNA THERAPEUTICS INC

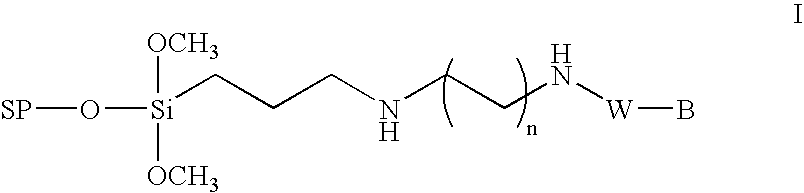

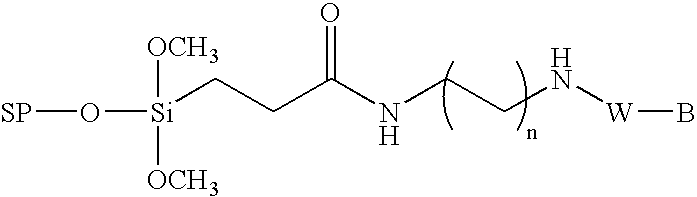

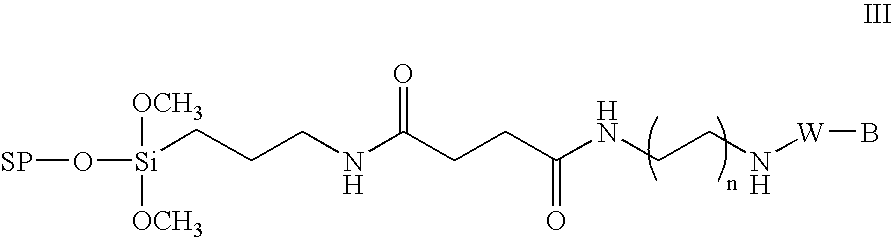

Coupling agents for orthopedic biomaterials

ActiveUS7270813B2Improve lubrication and flow propertyEasy injectionBiocideTissue regenerationPolymer compositesBiocompatible polymers

The invention provides a method for the preparation of bone-polymer composites wherein the mineral portion of the bone is treated with a coupling agent before being incorporated into a biocompatible polymeric matrix. The resulting composites may be used as such or be further processed to form an osteoimplant.

Owner:WARSAW ORTHOPEDIC INC

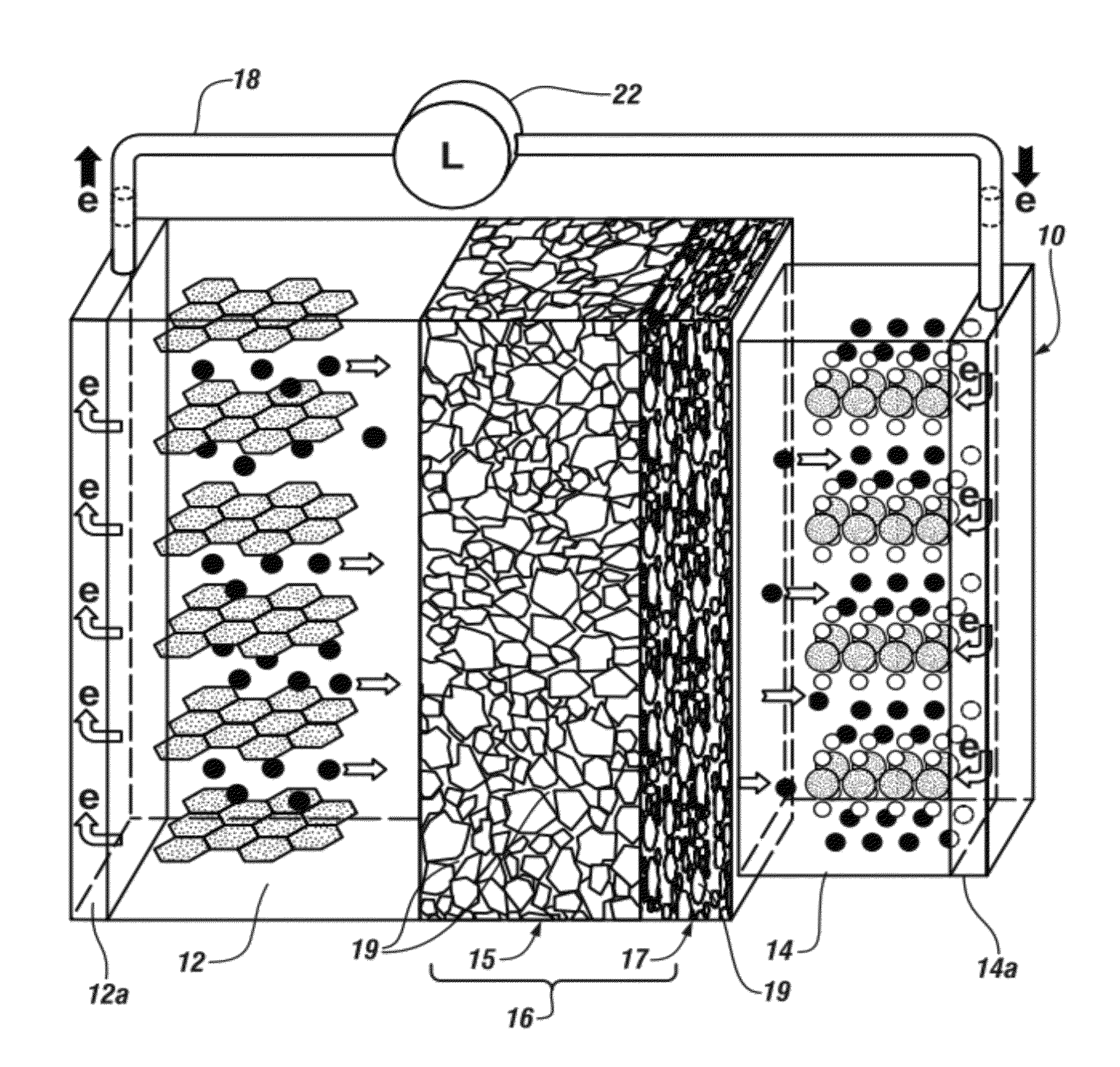

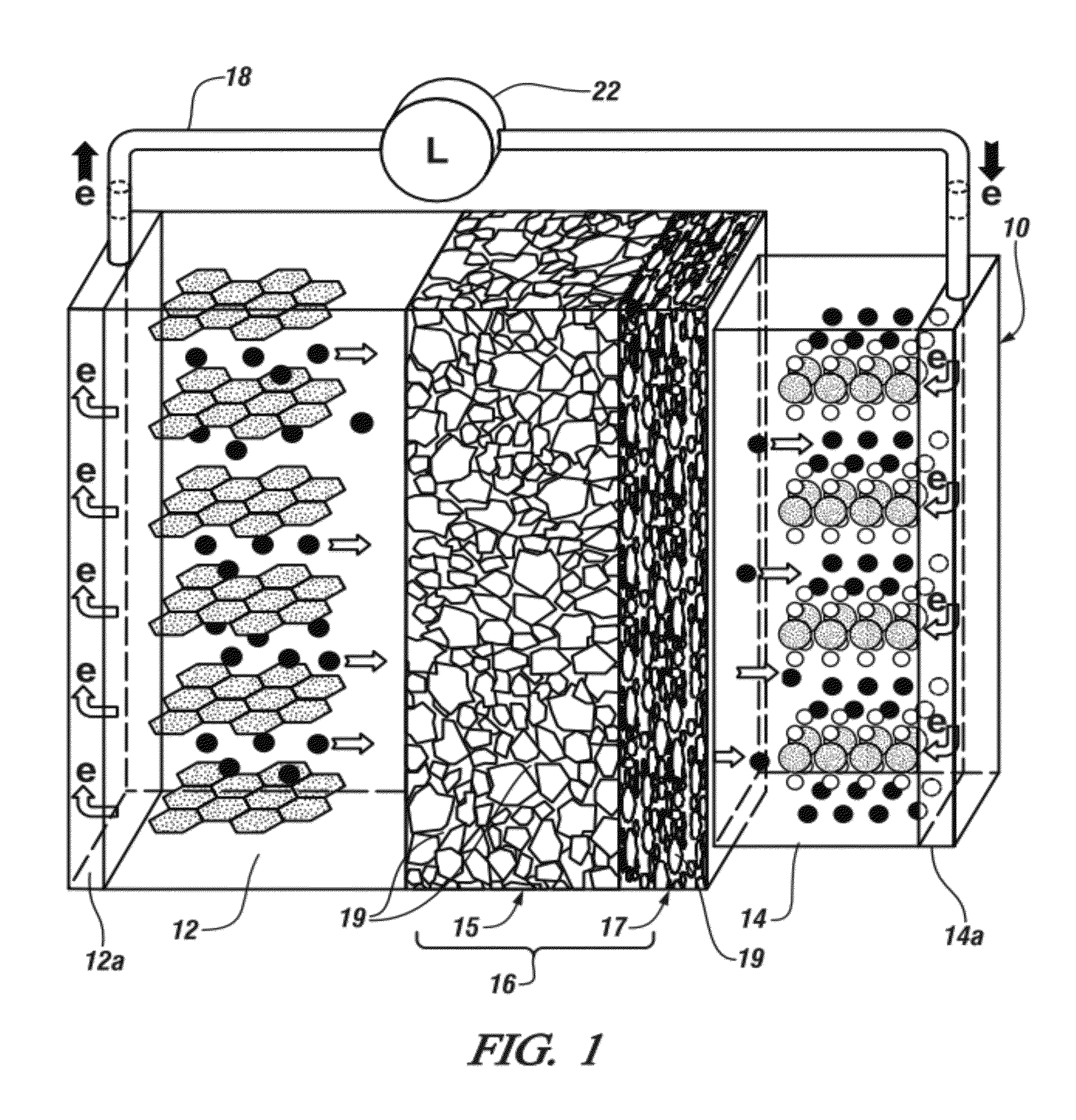

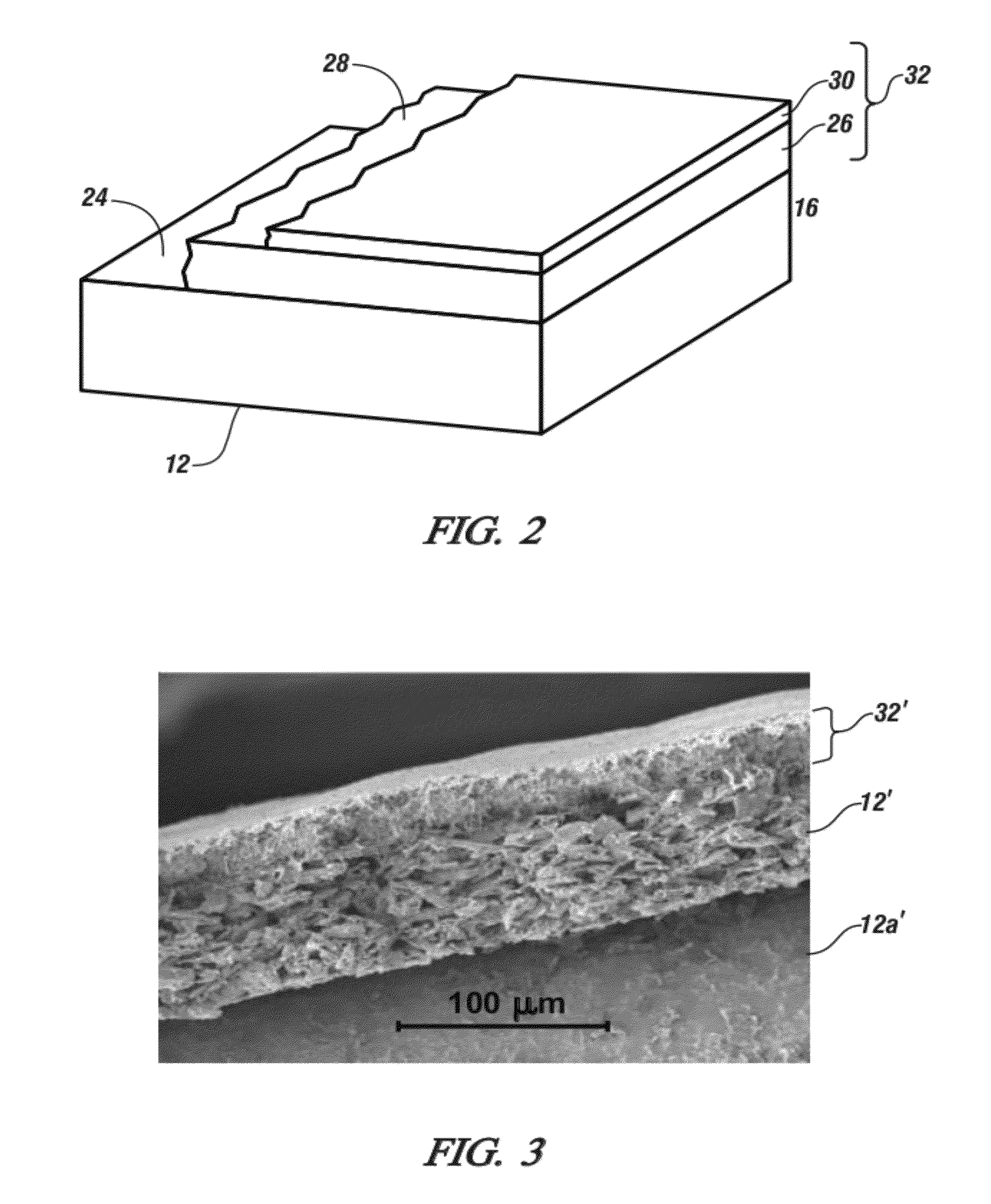

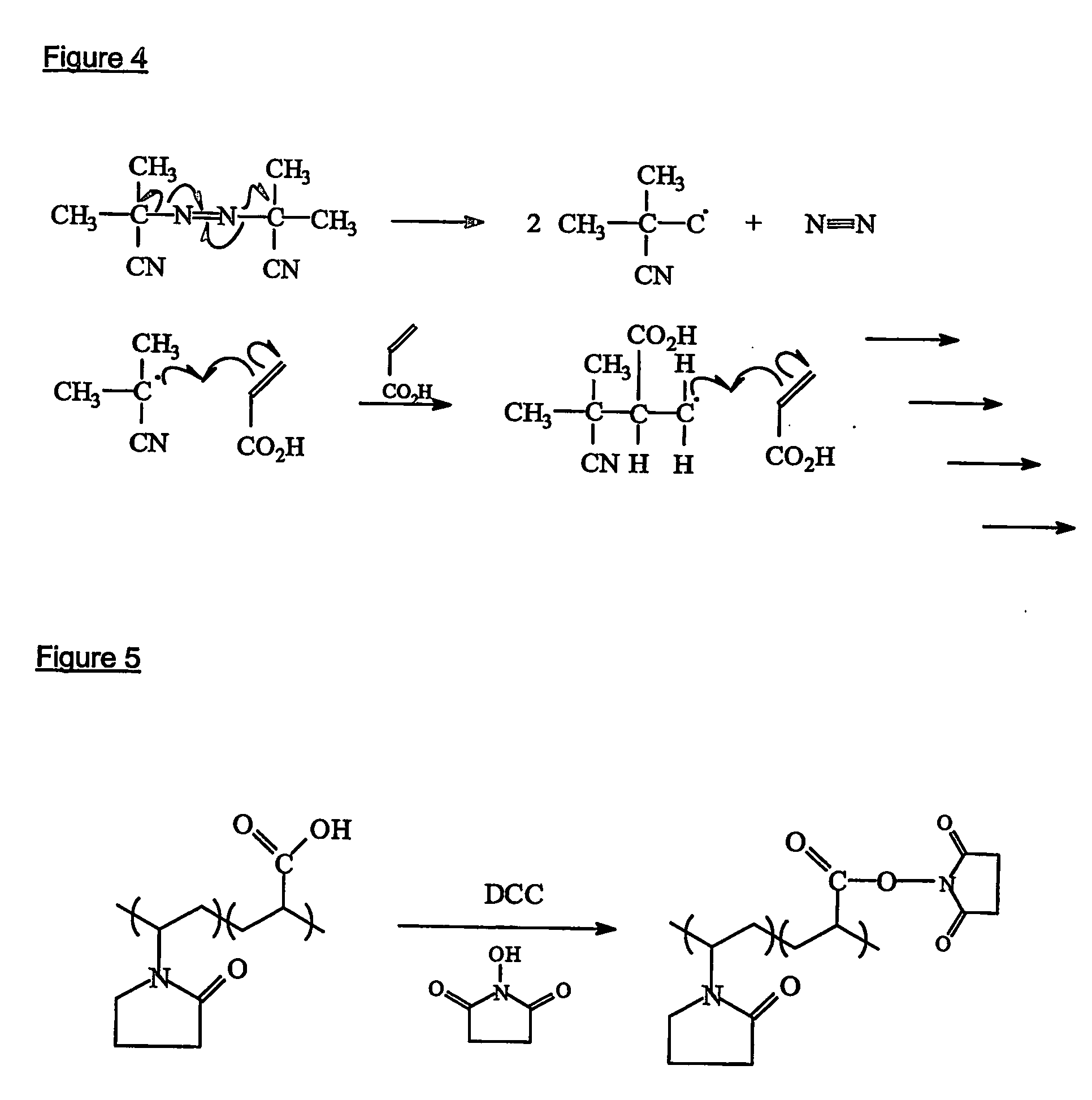

Integral bi-layer separator-electrode construction for lithium-ion batteries

InactiveUS20120231321A1Improve temperature resistanceImprove the immunityFinal product manufacturePrimary cellsEvaporationSlurry

A porous bi-layer separator composed of a first layer with a contacting array of non-conducting particles overlaid with a second layer of a microporous polymer layer, may be fabricated on the electrode surface of the anode of a lithium-ion battery to form an integral electrode-separator construction. The bi-layer separator may prevent development of a direct electronic path between the anode and cathode of the battery while accommodating electrolyte solution and enabling passage of lithium ions. Such an integral separator should be mechanically robust and tolerant of elevated temperatures. Exemplary bi-layer separators may be fabricated by sequential deposition of solvent-containing slurries and polymer solutions with subsequent controlled evaporation of solvent. The elevated temperature performance of lithium-ion battery cells incorporating such integral electrode-bi-layer separators was demonstrated to exceed the performance of similar cells using commercial and experimental single layer polymer separators.

Owner:GM GLOBAL TECH OPERATIONS LLC

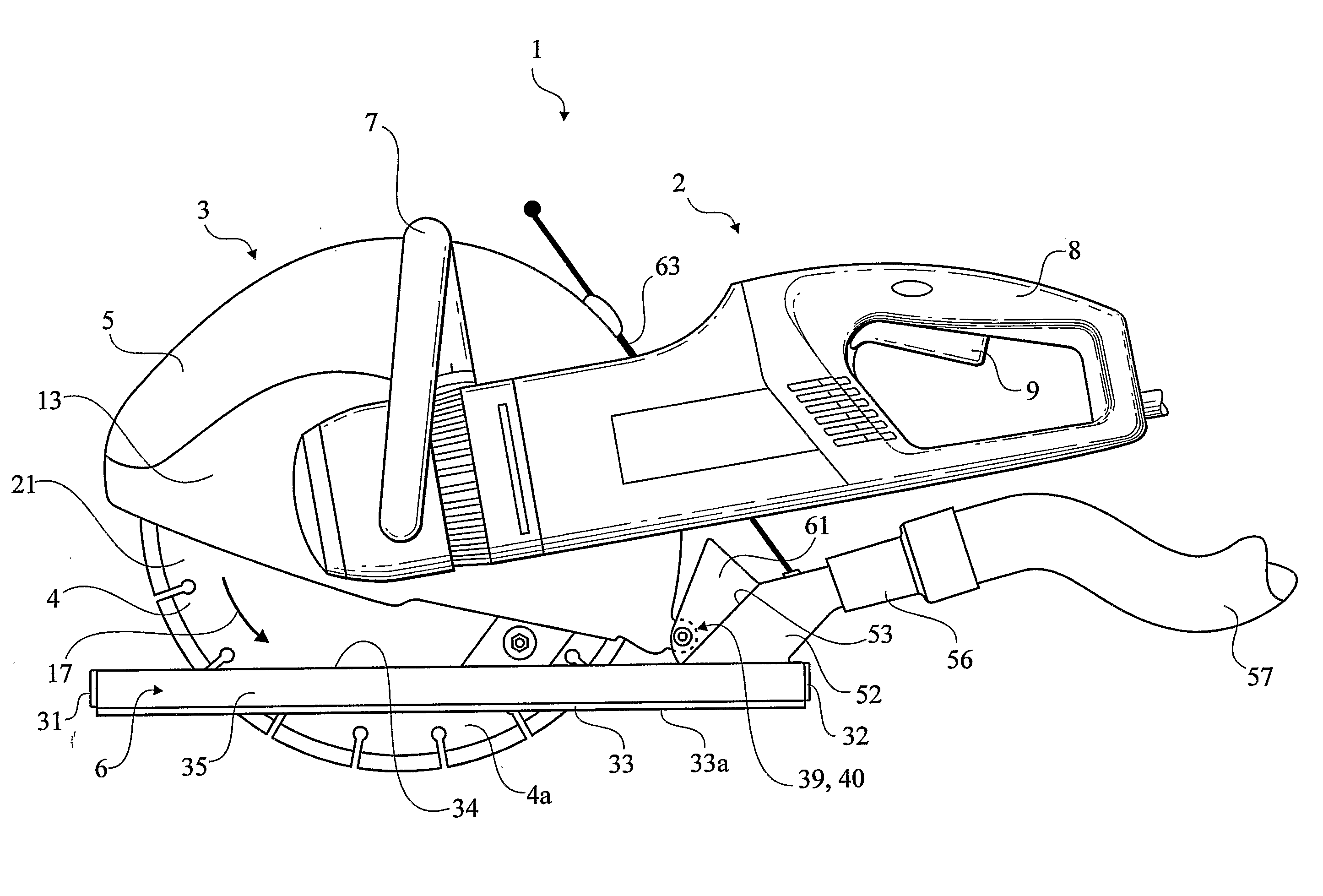

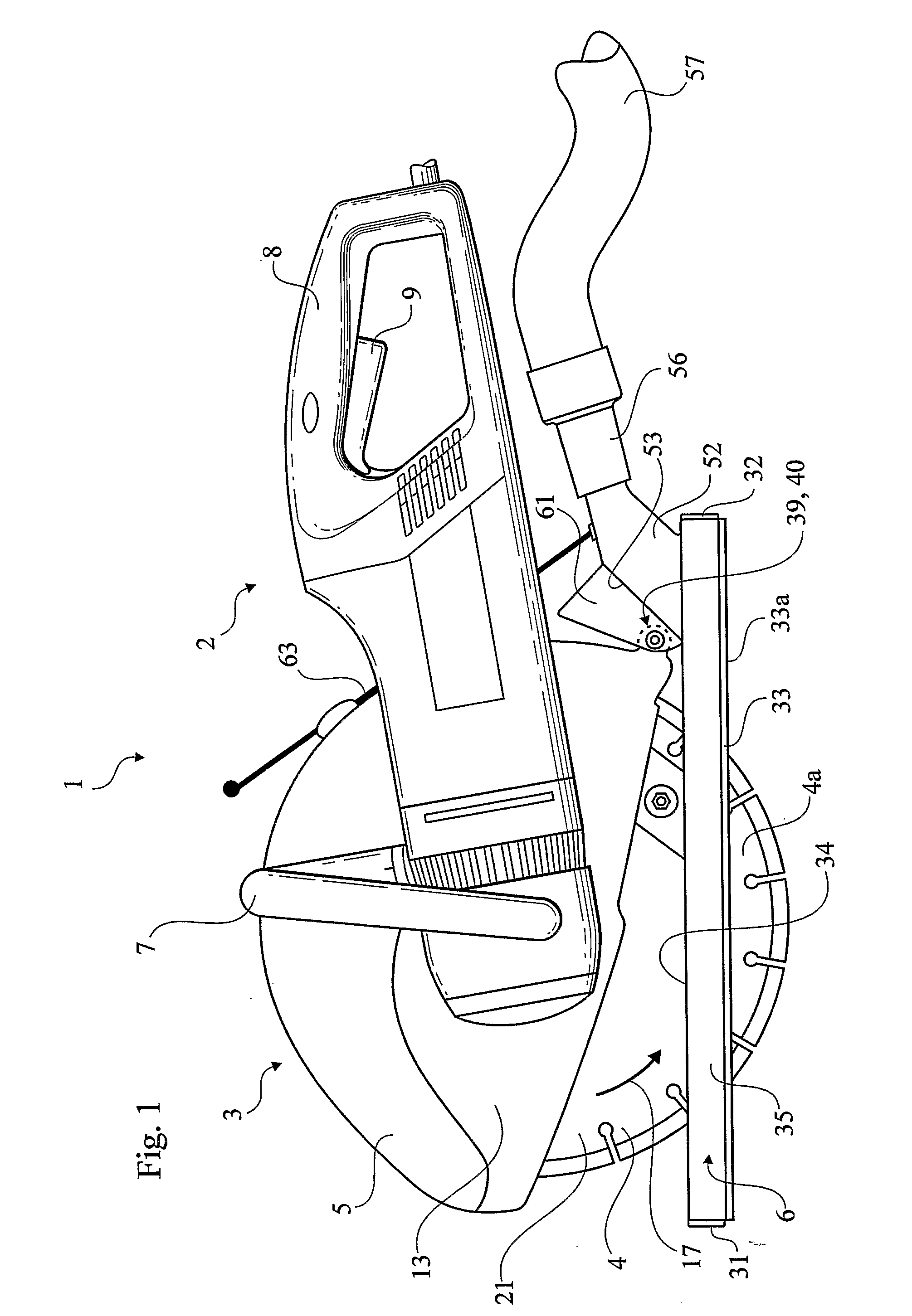

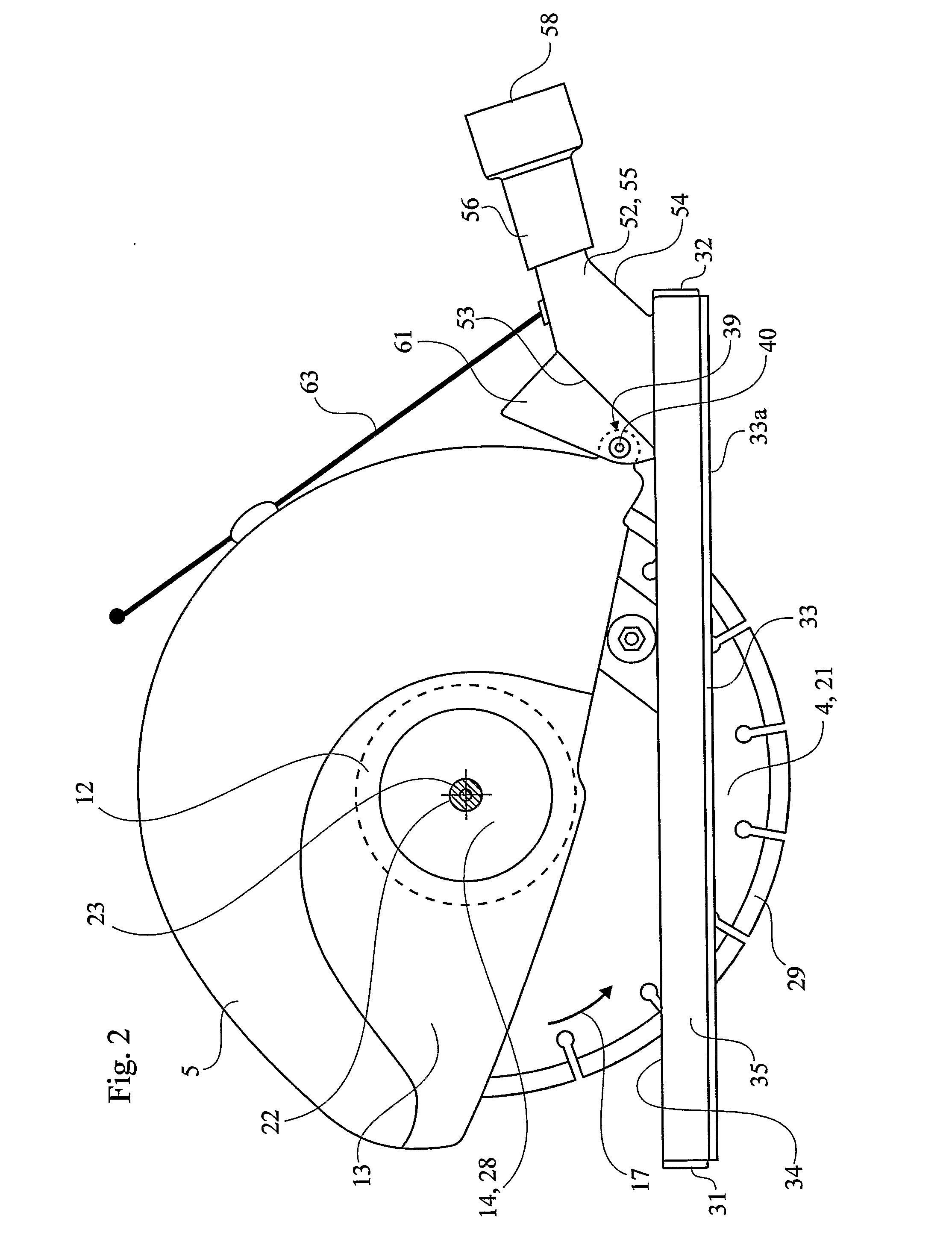

Cutting and Dust Collecting Assembly and Working Machine with Such Assembly

ActiveUS20080163492A1Avoid flyingEfficient collectionMetal sawing devicesMetal sawing accessoriesCircular sawDust control

A cutting and dust collecting assembly comprises a rotatable, circular saw blade (4) having a first side (20), a second side (21), and a cover device (6) with a terminal member (52). The bottom surface (36) of the cover device extends in a plane. A longitudinal passage (45, 46) for the saw blade extends through the cover device from its top surface to its bottom surface. The terminal member comprises a terminal chamber (60) having an inlet (45a), the mouth of which coincides with the plane of said bottom surface. An outlet (58) can be connected to a vacuum source. The direction of rotation of the operating blade is such that the rear part (4a) of the saw blade which has passed beyond the bottom surface of the cover device will move in a direction upwards-rearwards towards the bottom surface. The invention also concerns the cover device, a sealing body belonging to the cover device and a working machine which is provided with the cutting and dust collecting assembly.

Owner:HUSQVARNA AB

Methods and reagents for oligonucleotide synthesis

InactiveUS7205399B1Avoid insufficient lengthSufficient hybridizationSugar derivativesCombinatorial chemistryOligonucleotide synthesis

Owner:SIRNA THERAPEUTICS INC

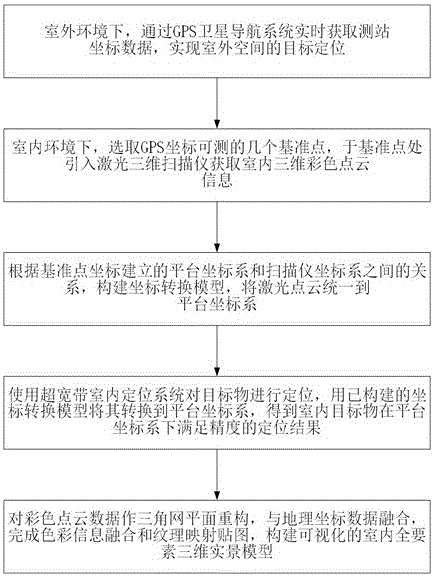

High-precision three-dimensional real scene indoor and outdoor integrated positioning method and device

InactiveCN106646562AHigh precisionEffective combinationNavigational calculation instrumentsSatellite radio beaconingUltra-widebandPoint cloud

The invention discloses a high-precision three-dimensional real scene indoor and outdoor integrated positioning method and device. The method comprises the steps that the GPS positioning result is introduced to the indoor, multiple reference points of which the GPS coordinates are measurable are selected in the indoor, and a platform coordinate system is established with the reference points acting as the origins of coordinates; a laser three-dimensional scanner is introduced to the reference points so that indoor three-dimensional point cloud information is acquired, and high-precision indoor scene reconstruction is completed; an optimized coordinate transformation model is constructed according to the relationship between the platform coordinate system and a scanner coordinate system to unify the point cloud to the platform coordinate system; and coordinate transformation is further performed on an ultra-wideband indoor positioning system coordinate system and the coordinate data so that indoor target positioning is completed. The beneficial effects of the positioning method and device are that the point cloud data are introduced on the basis of the indoor positioning system, the high-precision visual indoor three-dimensional scene with geodetic coordinates is obtained by using the optimized coordinate transformation model, and the indoor positioning precision can be the decimeter level; and integration of indoor and outdoor positioning can be realized, and a browsable spatial information management system is provided.

Owner:EAST CHINA NORMAL UNIV

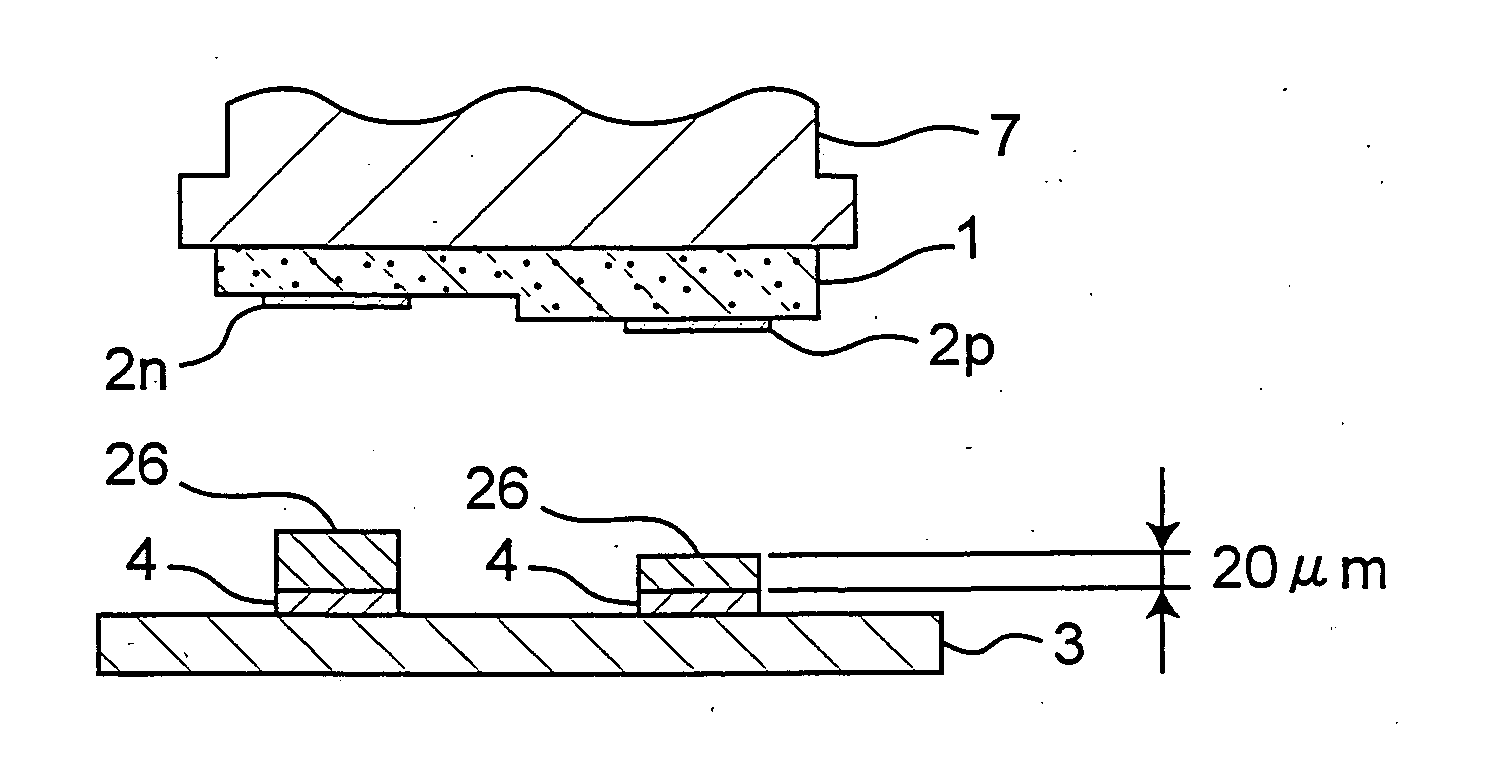

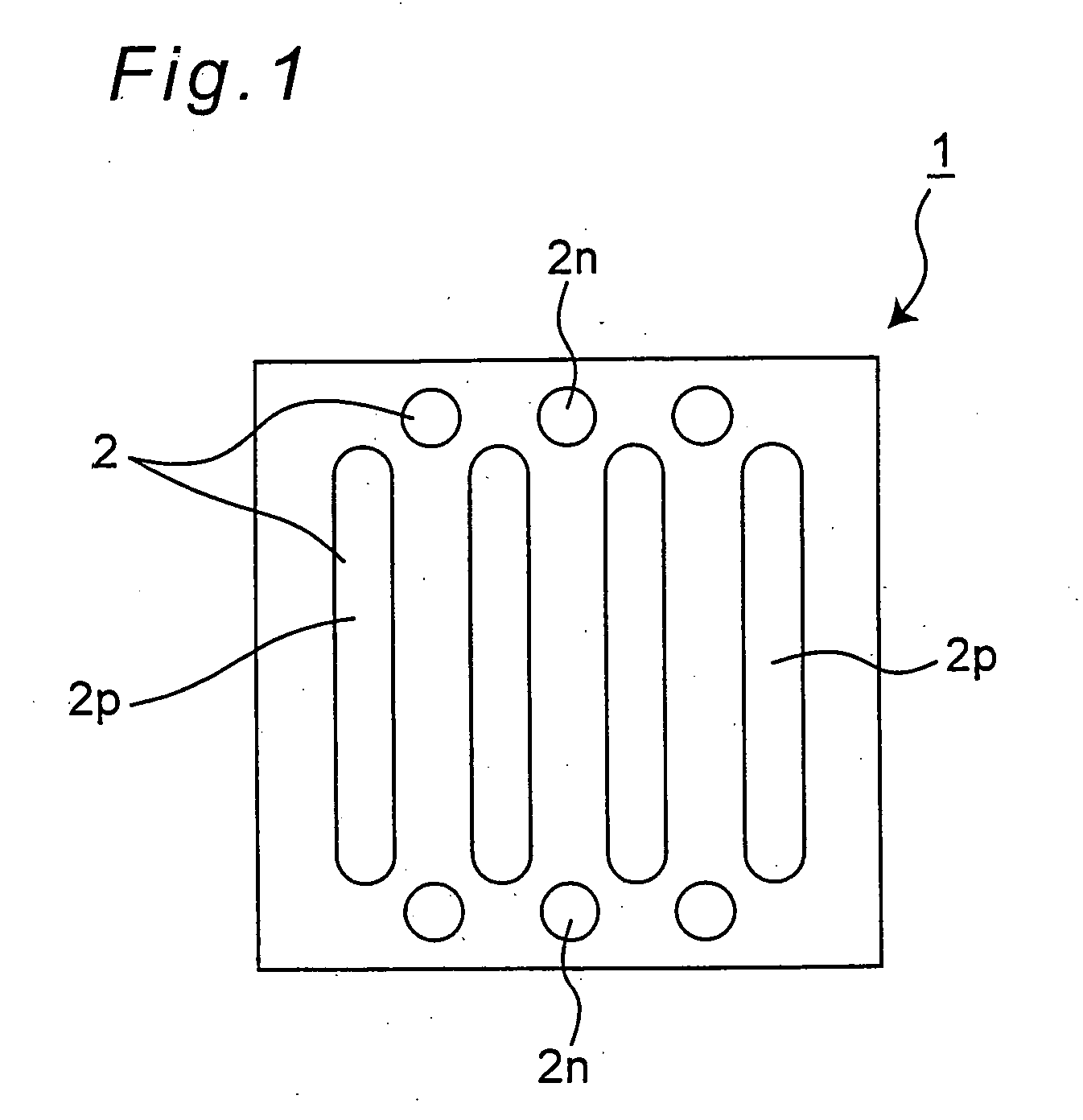

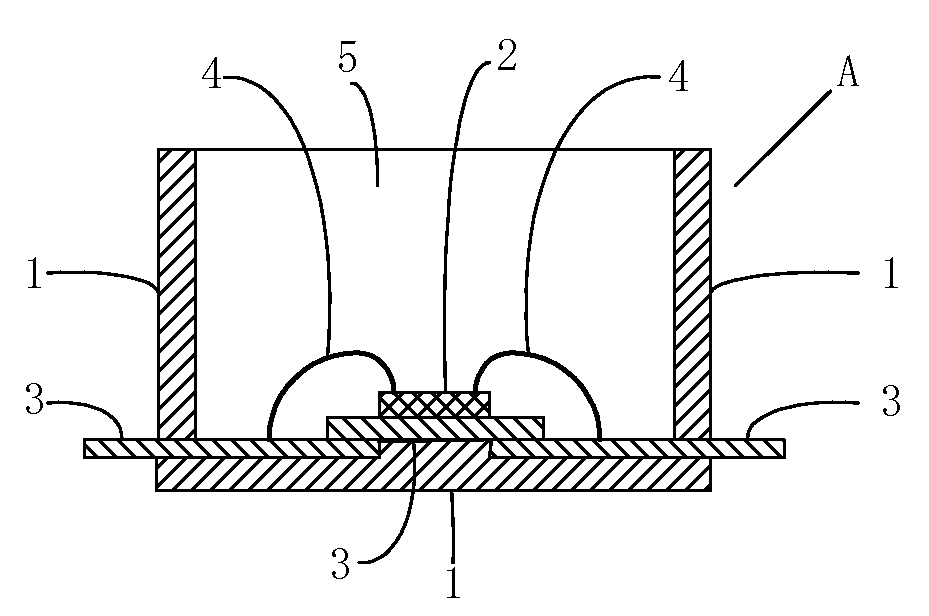

Method for mounting semiconductor chip and semiconductor chip-mounted board

InactiveUS20050110161A1Reduce generationEffective combinationSemiconductor/solid-state device detailsSolid-state devicesSemiconductor chipUltrasonic vibration

By arranging bonding members formed of a gold nanopaste between chip-electrodes and board-electrodes, making the chip-electrodes are brought in contact with the respective board-electrodes via the bonding members and applying ultrasonic vibrations to the bonding members in the contact state, the bonding members are bonded to the board-electrodes and the chip-electrodes.

Owner:PANASONIC CORP

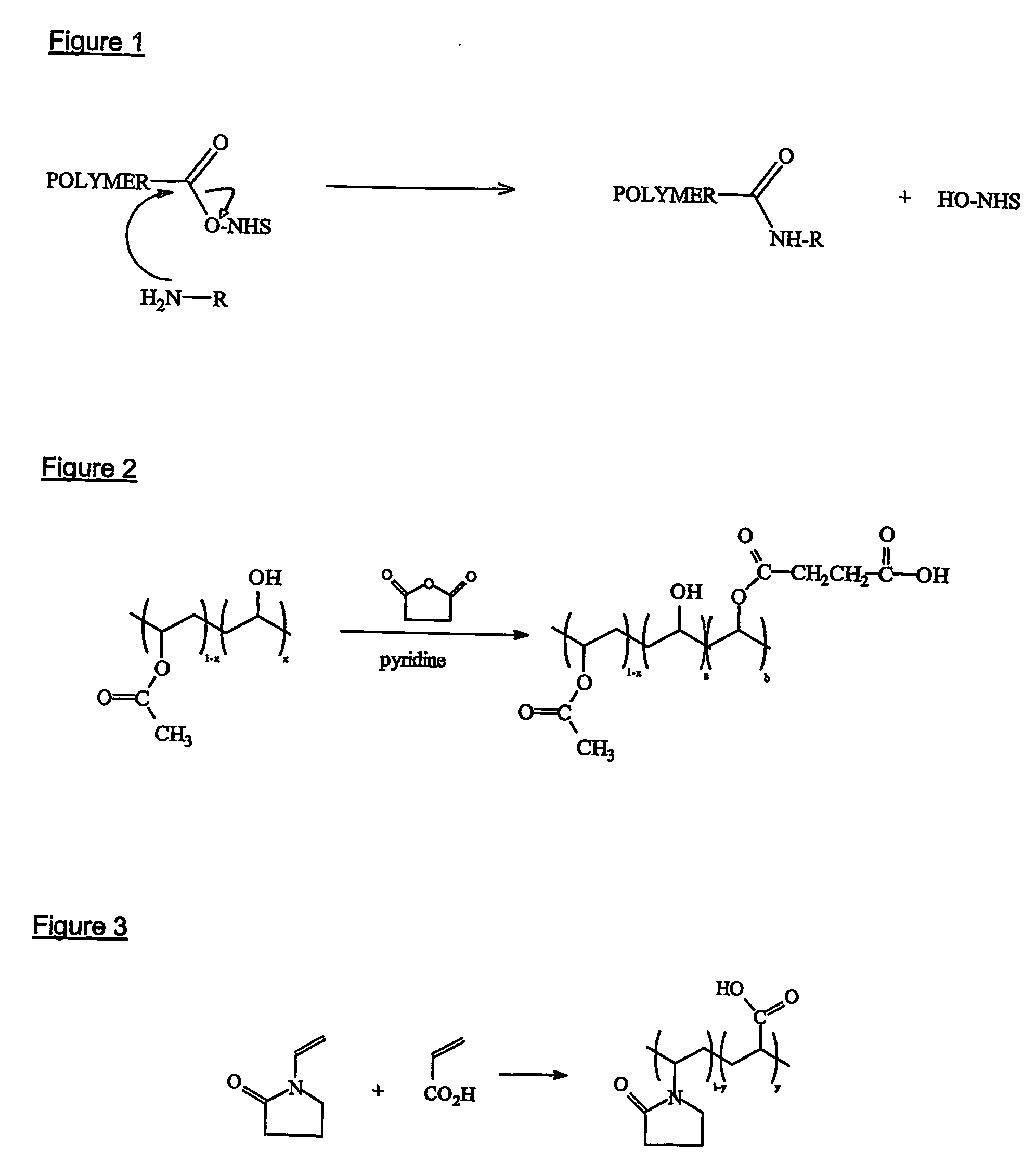

Tissue-adhesive formulations

InactiveUS20060105026A1Efficient use ofGood initial adhesionSurgical adhesivesAbsorbent padsParticulatesMedicine

A tissue-adhesive formulation consists of a naturally occurring or synthetic polymerisable and / or cross-linkable material in particulate form, the polymerisable and / or cross-linkable material being in admixture with particulate material comprising tissue-reactive functional groups. The formulation may be used in the preparation of a tissue-adhesive sheet, by applying the formulation to at least one side of a core of a naturally occurring or synthetic polymeric material.

Owner:TISSUEMED LTD

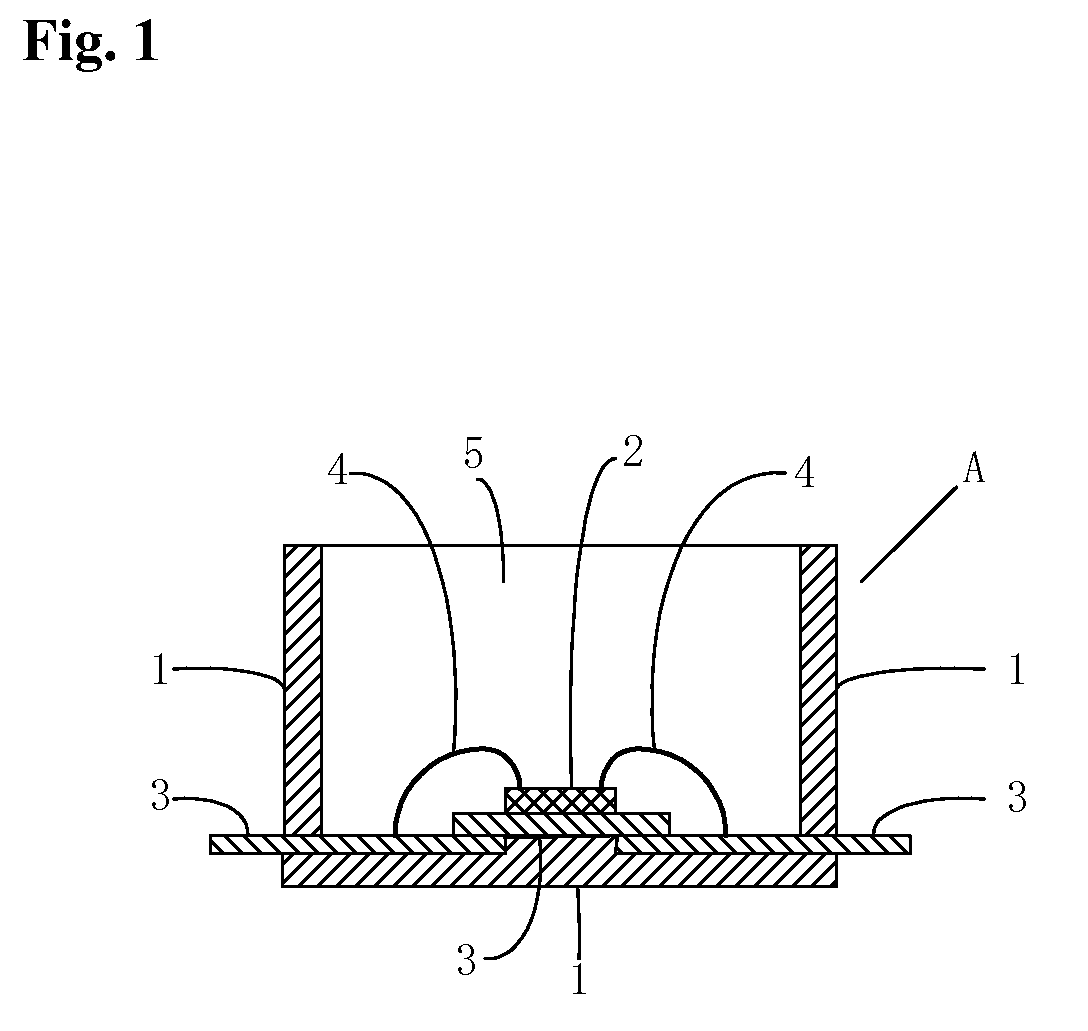

Curable Organopolysiloxane Resin Composition And Optical Part Molded Therefrom

ActiveUS20090118440A1Easy to prepareExtended validity periodSolid-state devicesSemiconductor devicesPolymer scienceOptical transmittance

A curable organopolysiloxane resin composition having a viscosity at 25° C. in the range of 0.001 to 5,000 Pa·s, a total acid number as specified by JIS K 2501 (1992) in the range of 0.0001 to 0.2 mg / g, and light transmittance in a cured state equal to or greater than 80%; an optical part comprised of a cured body of the aforementioned composition. The curable organopolysiloxane resin composition of the invention is characterized by good transparency, low decrease in transmittance when exposed to high temperatures, and excellent adhesion when required.

Owner:DOW CORNING TORAY CO LTD

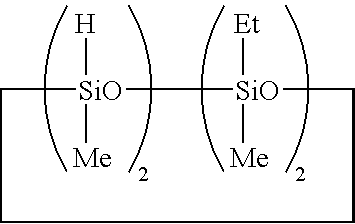

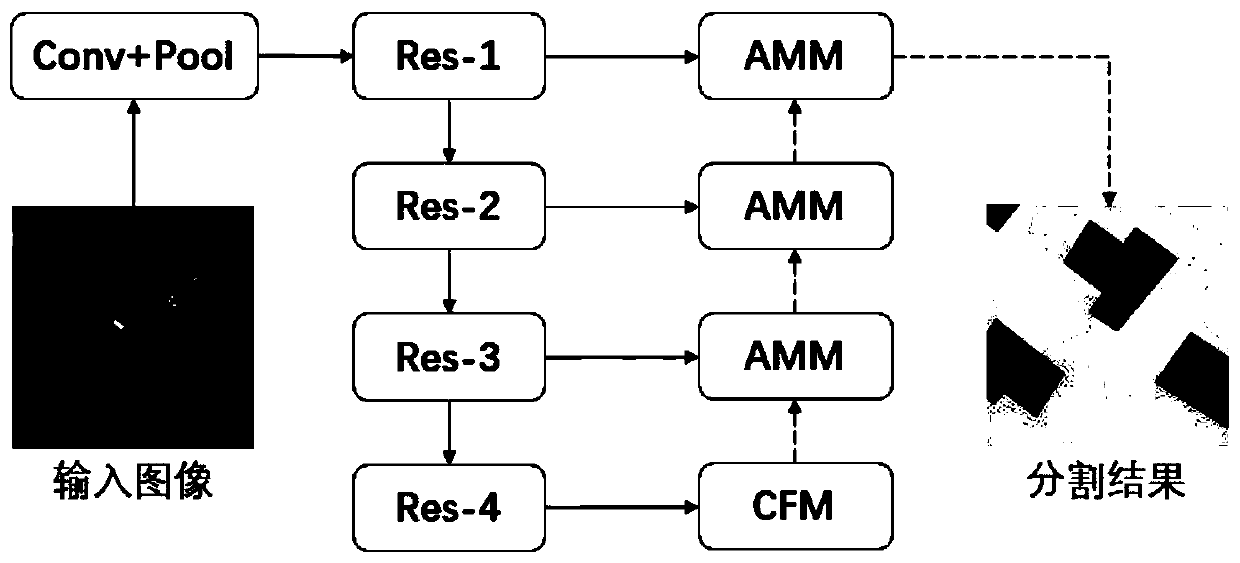

Remote sensing image semantic segmentation method based on context information and attention mechanism

The invention provides a remote sensing image semantic segmentation method based on context information and an attention mechanism. For a to-be-labeled high-resolution remote sensing image, data preprocessing and data amplification are firstly carried out, and then the amplified data is used for training a remote sensing image semantic segmentation model. In the training process, preliminary features are extracted from the image through a backbone network, then multi-scale features are extracted and fused through a multi-scale context information module, then features of different levels are combined with an attention fusion module, and finally bilinear interpolation up-sampling is directly utilized to obtain a final segmentation result. For an unlabeled image, firstly the unlabeled imageis segmented into small image blocks, the small image blocks are input into a semantic segmentation network to obtain a corresponding result, and then the small image blocks are spliced to obtain a final large-size segmentation result graph.

Owner:NO 54 INST OF CHINA ELECTRONICS SCI & TECH GRP

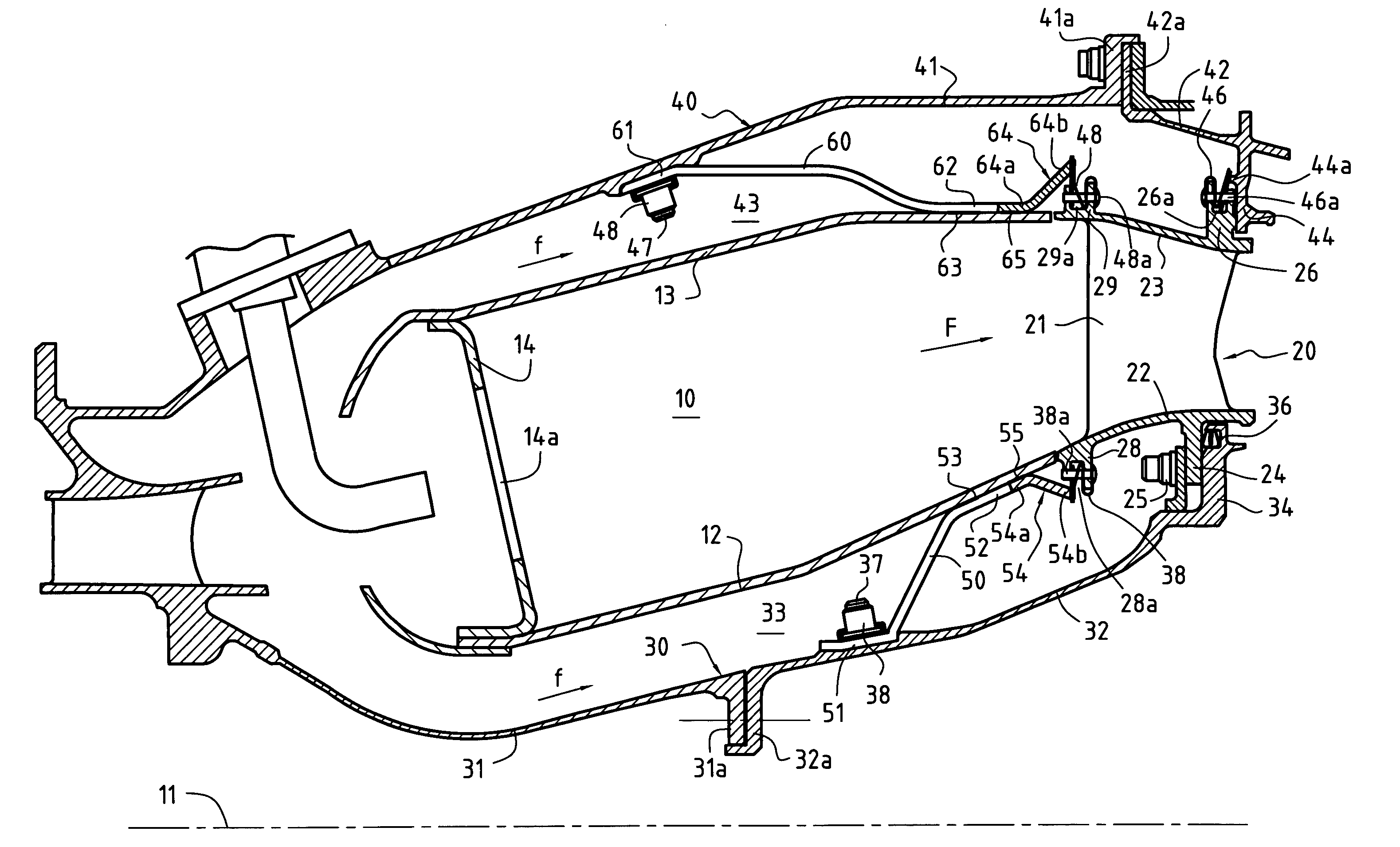

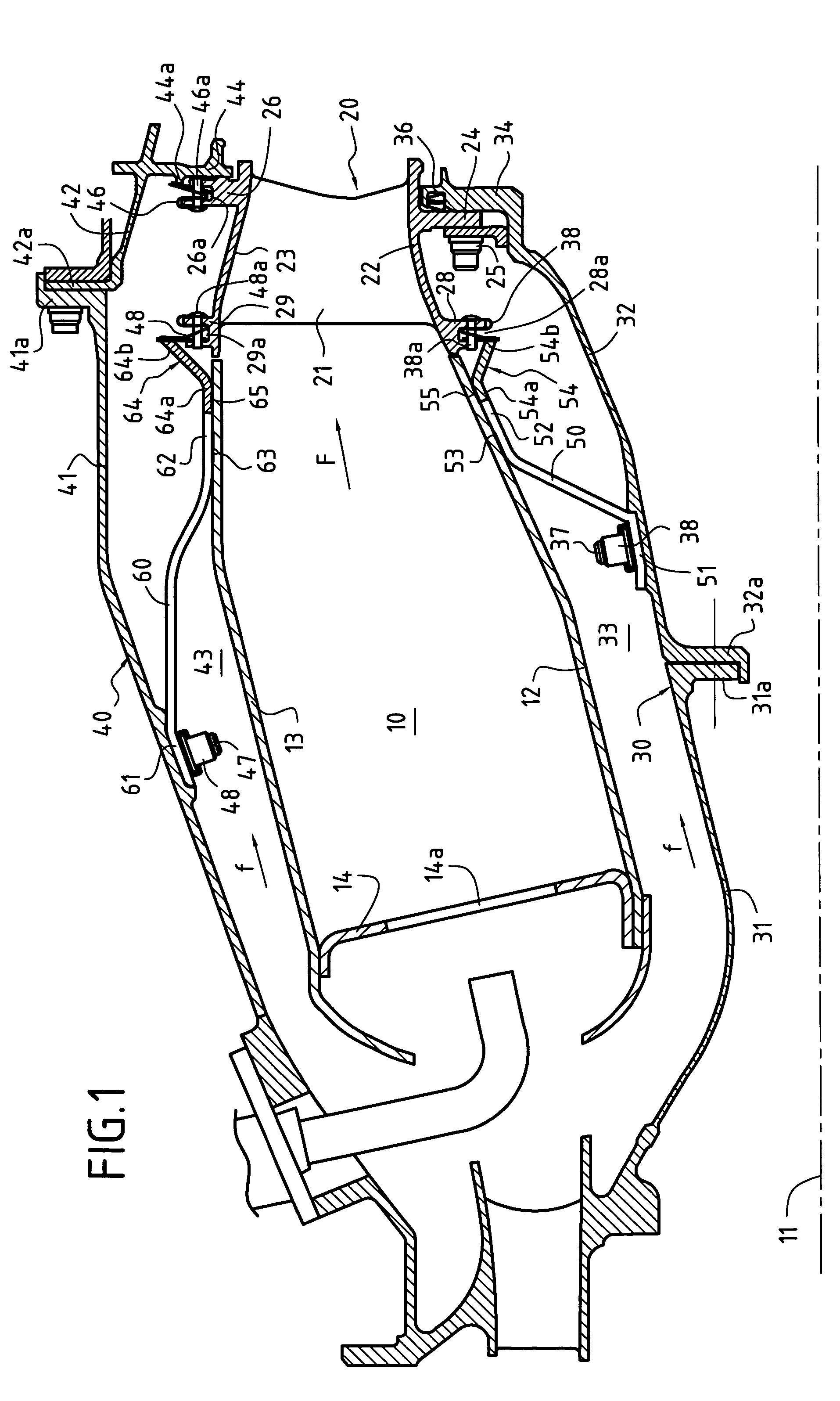

Gas turbine combustion chamber made of CMC and supported in a metal casing by CMC linking members

ActiveUS7234306B2Easy to controlAvoid violationsContinuous combustion chamberGas turbine plantsCombustion chamberCopper

Owner:SN DETUDE & DE CONSTR DE MOTEURS DAVIATION S N E C M A

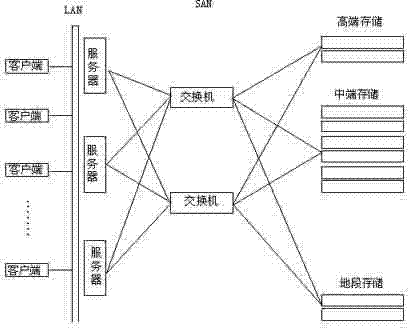

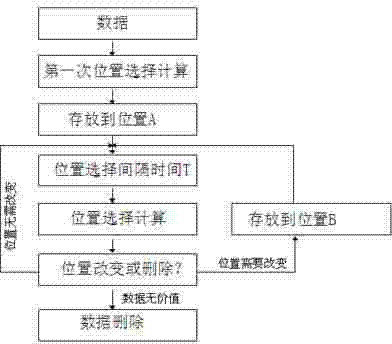

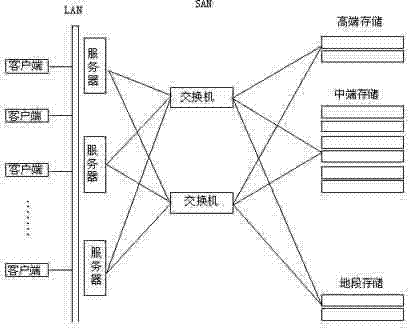

Grading storage method for system

InactiveCN102508789AReduce business costsImprove performanceMemory adressing/allocation/relocationRetention timePerformance index

The invention provides a grading storage method for a system. According to the importance, the visiting frequency, the retention time and the performance index of data, the data is stored in storage devices with different performances by adopting different storage modes, so as to realize automatic migration of data objects among the storage devices; and the data which is not visited frequently is automatically transferred to lower layers in storage layers, so that storage space with higher cost can be released for the data with higher visiting frequency, so that better cost performance is obtained, further, the space occupied by the non-important data in primary local disks can be greatly reduced, and the storage performance of the whole system is quickened.

Owner:LANGCHAO ELECTRONIC INFORMATION IND CO LTD

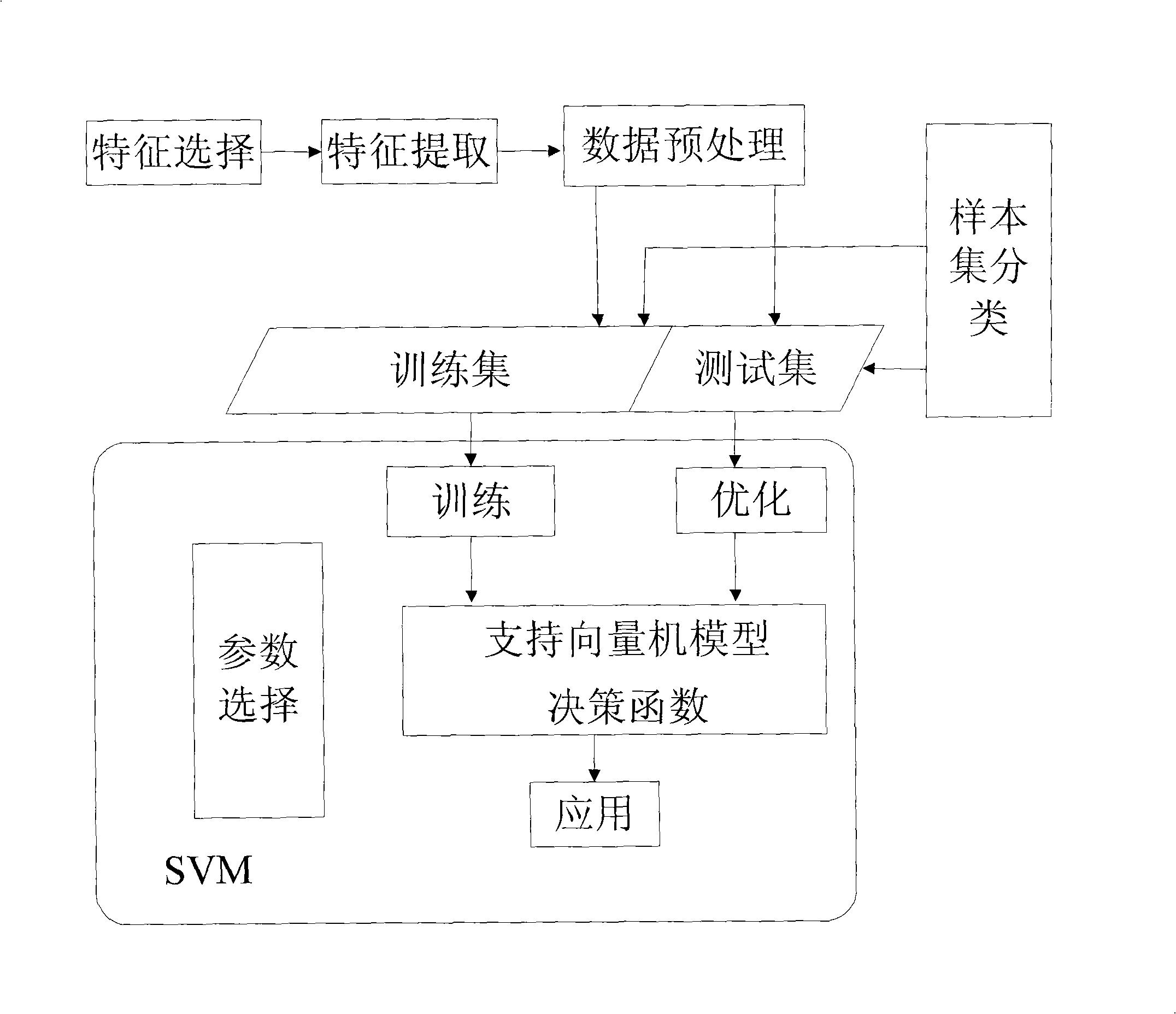

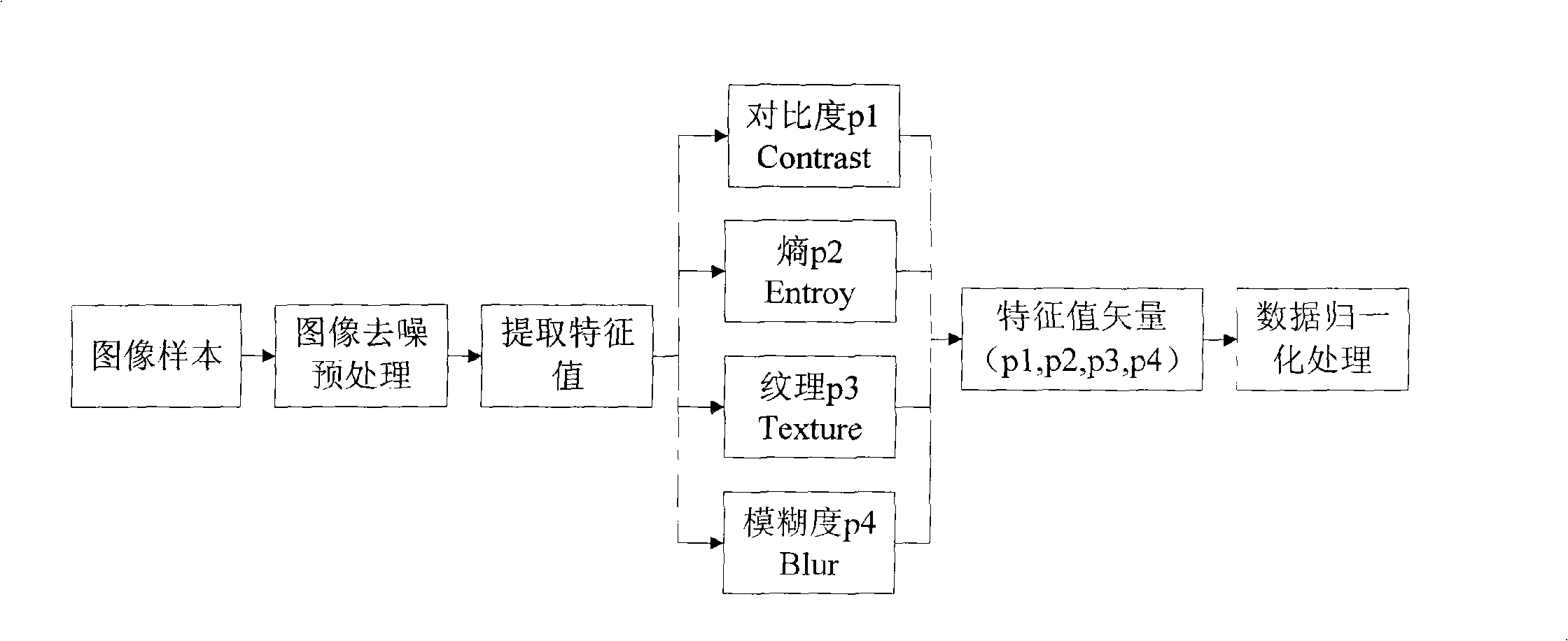

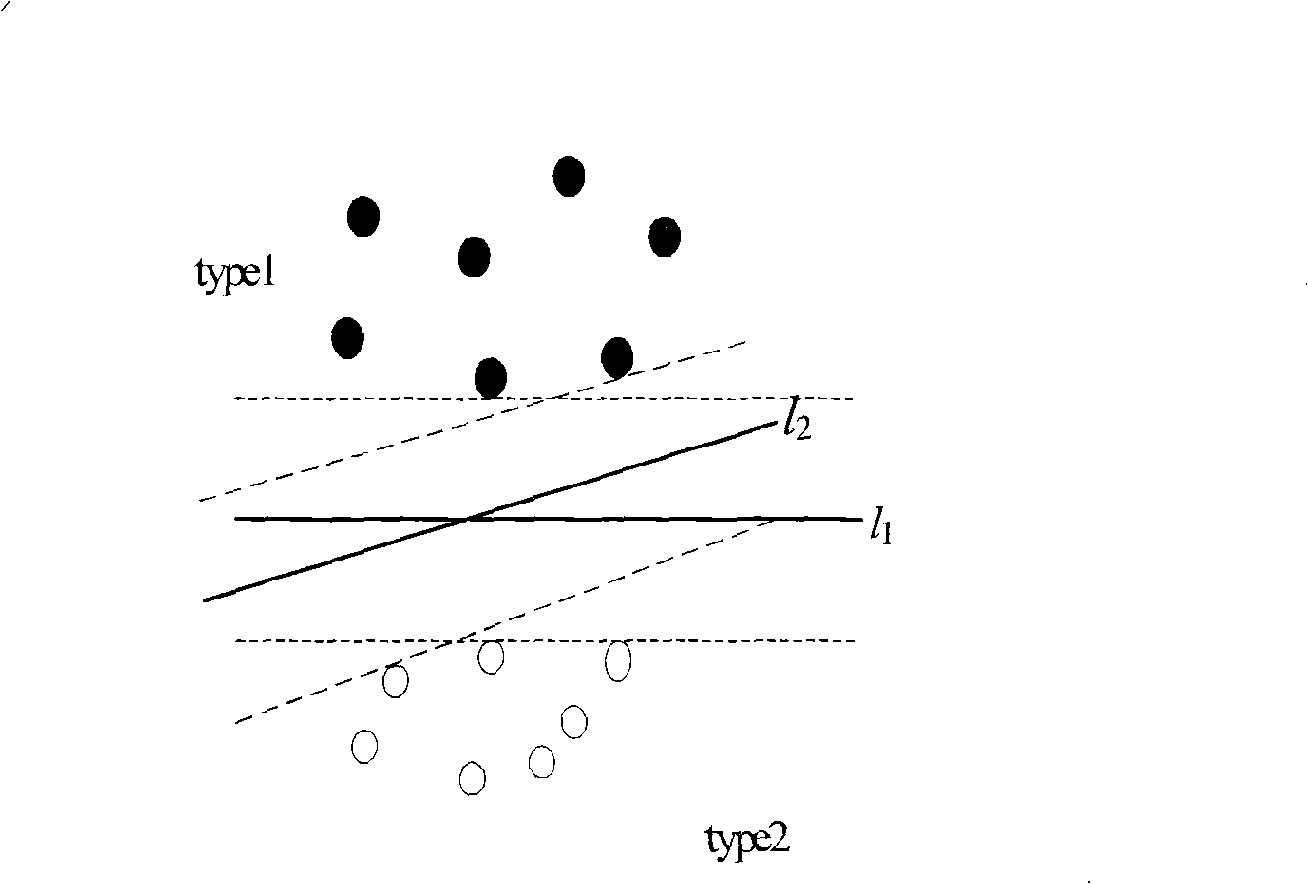

Image quality evaluating method based on support vector machine

InactiveCN101540048AImprove reliabilityEffective combinationImage analysisCharacter and pattern recognitionQuality levelAlgorithm

The invention provides an image quality evaluating method based on a support vector machine. The method comprises the following steps: first, a preprocessed image sample is selected and extracted according to characteristic value, a processed sample set is respectively divided into a training set and a testing set; secondly, the training set is used for training the support vector machine, the number of the support vector machine is ensured according to a certain level which is required by a system, thus ensuring each support vector machine to be trained, wherein, an input sample is the characteristic value of the image and an output sample is the level of the image quality; thirdly, the trained support vector machine is used for adjusting and optimizing correlation parameters with the testing set and determining the parameter of the decision function of the optimal hyperplane of the support vector machine model; and finally, the support vector machine model which is trained and optimized is used for evaluating the quality level of the image sample. The invention has the advantages of little required sample, fast arithmetic speed, high precision, good performance, strong popularization, etc.

Owner:BEIHANG UNIV

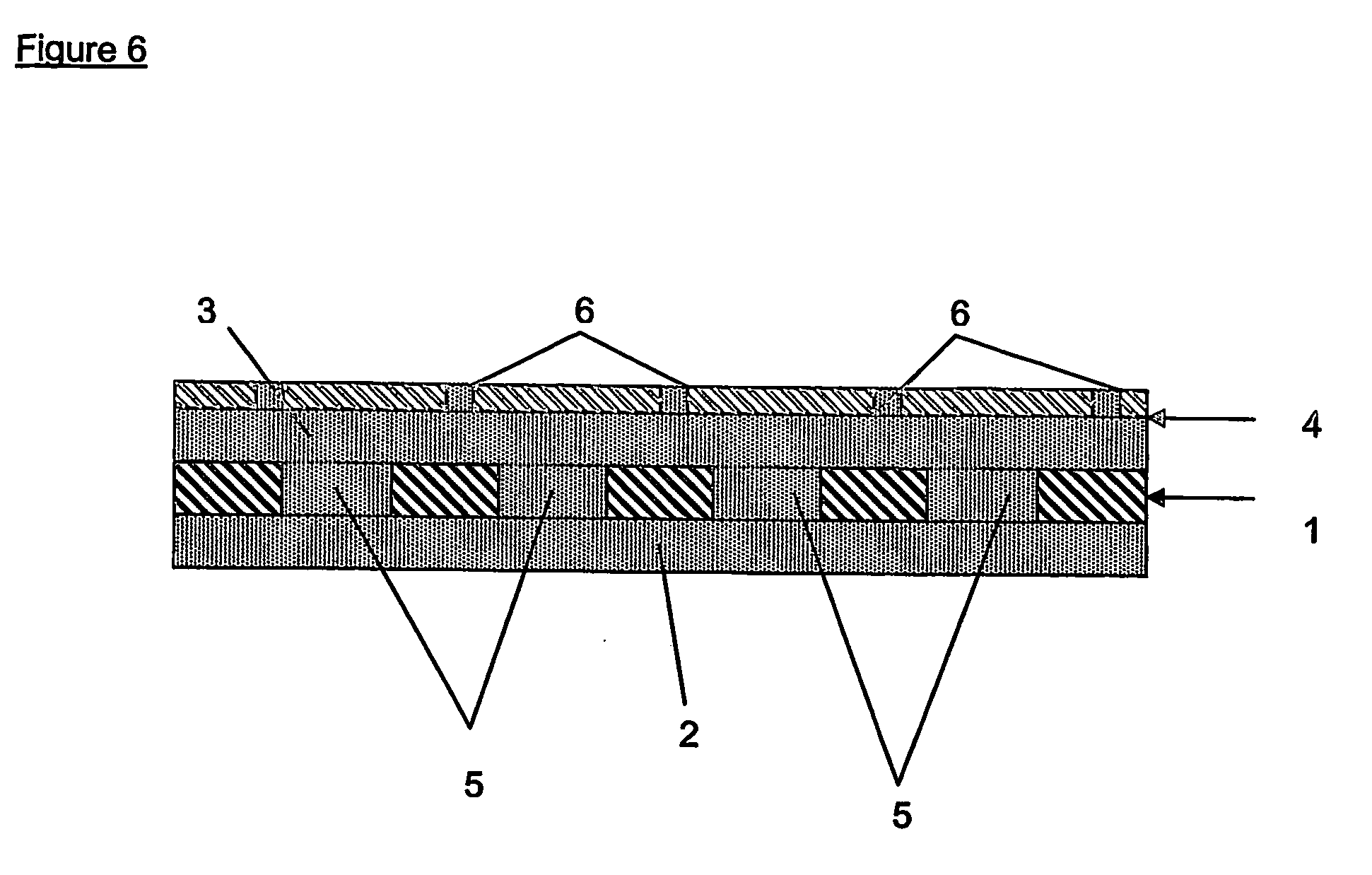

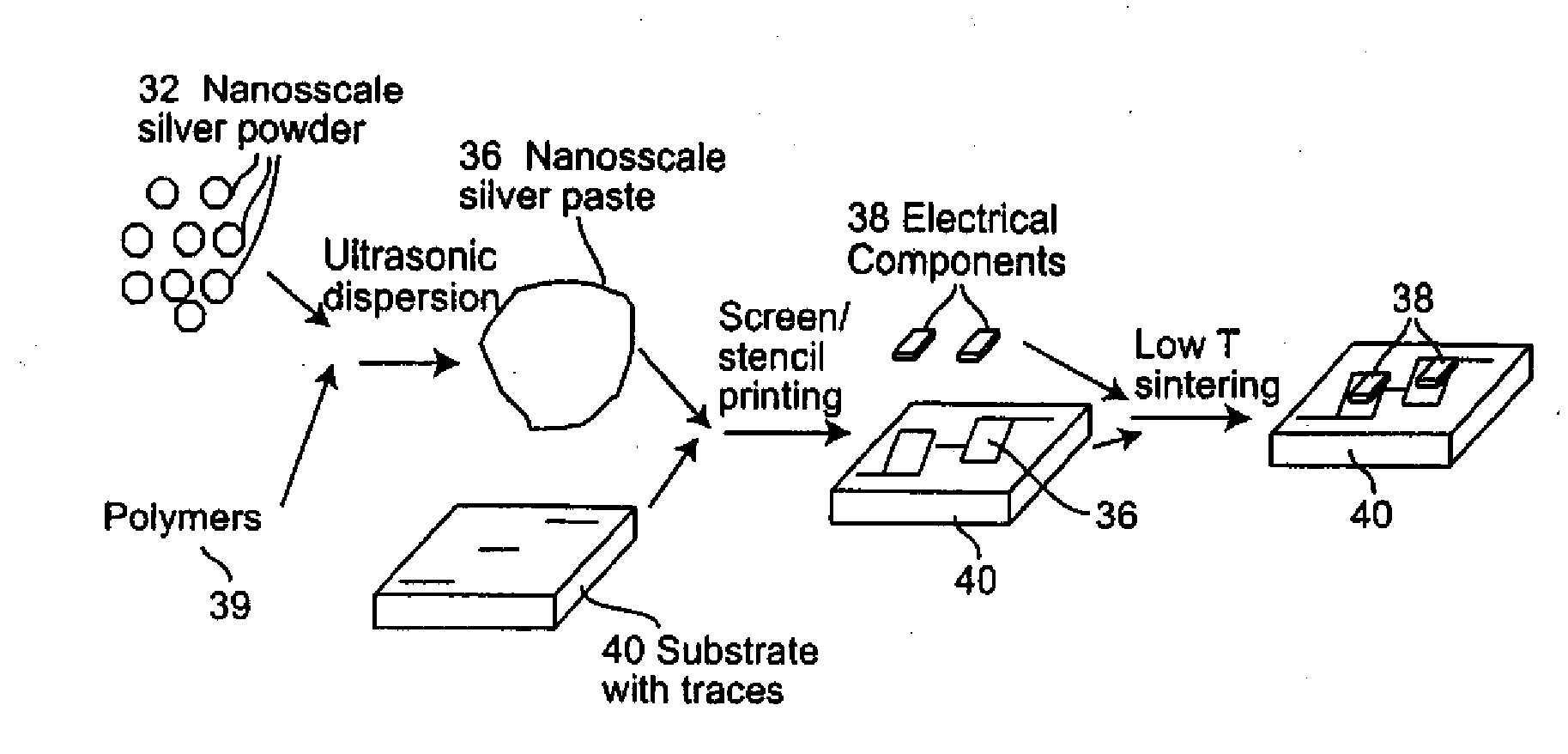

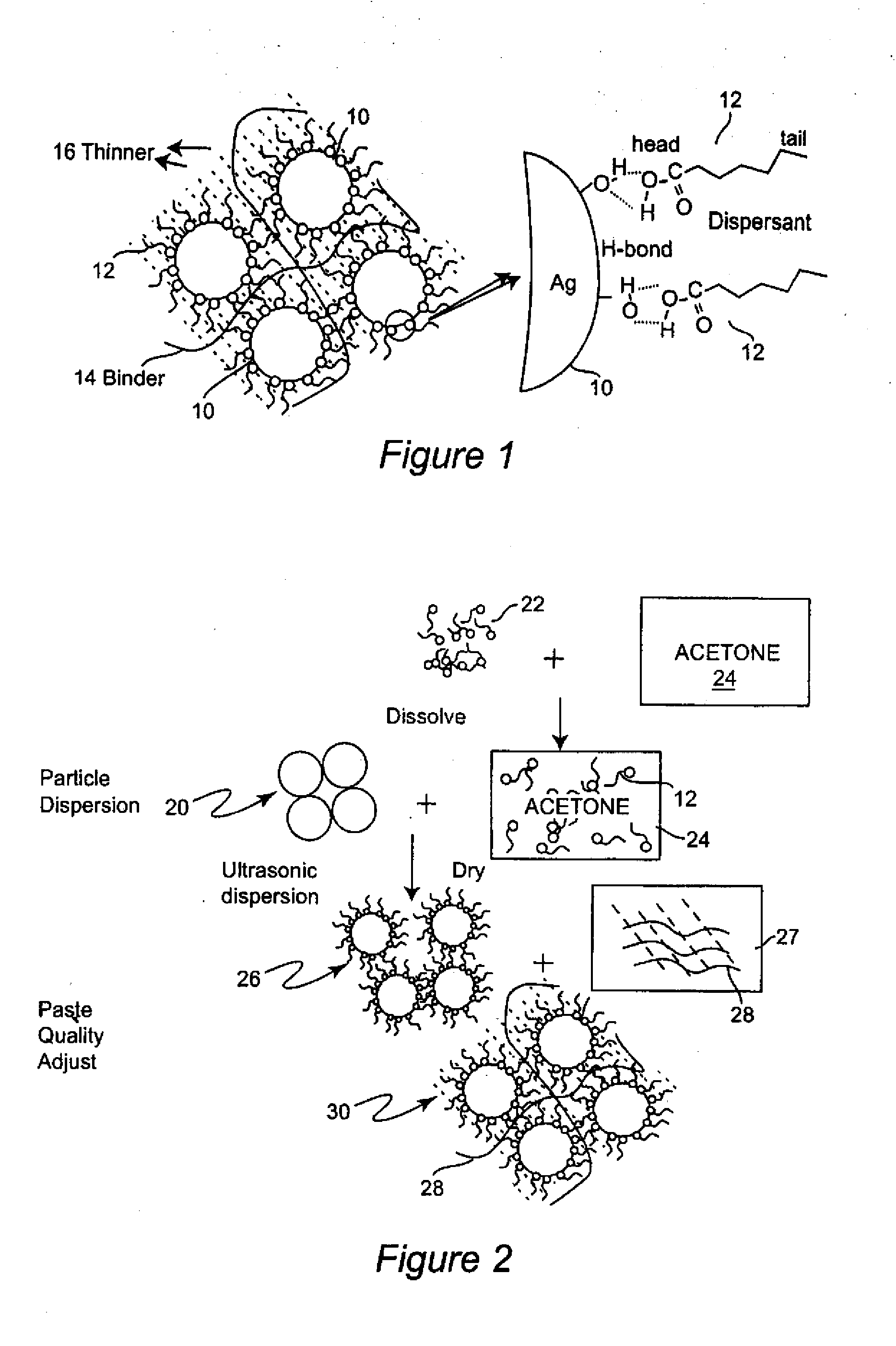

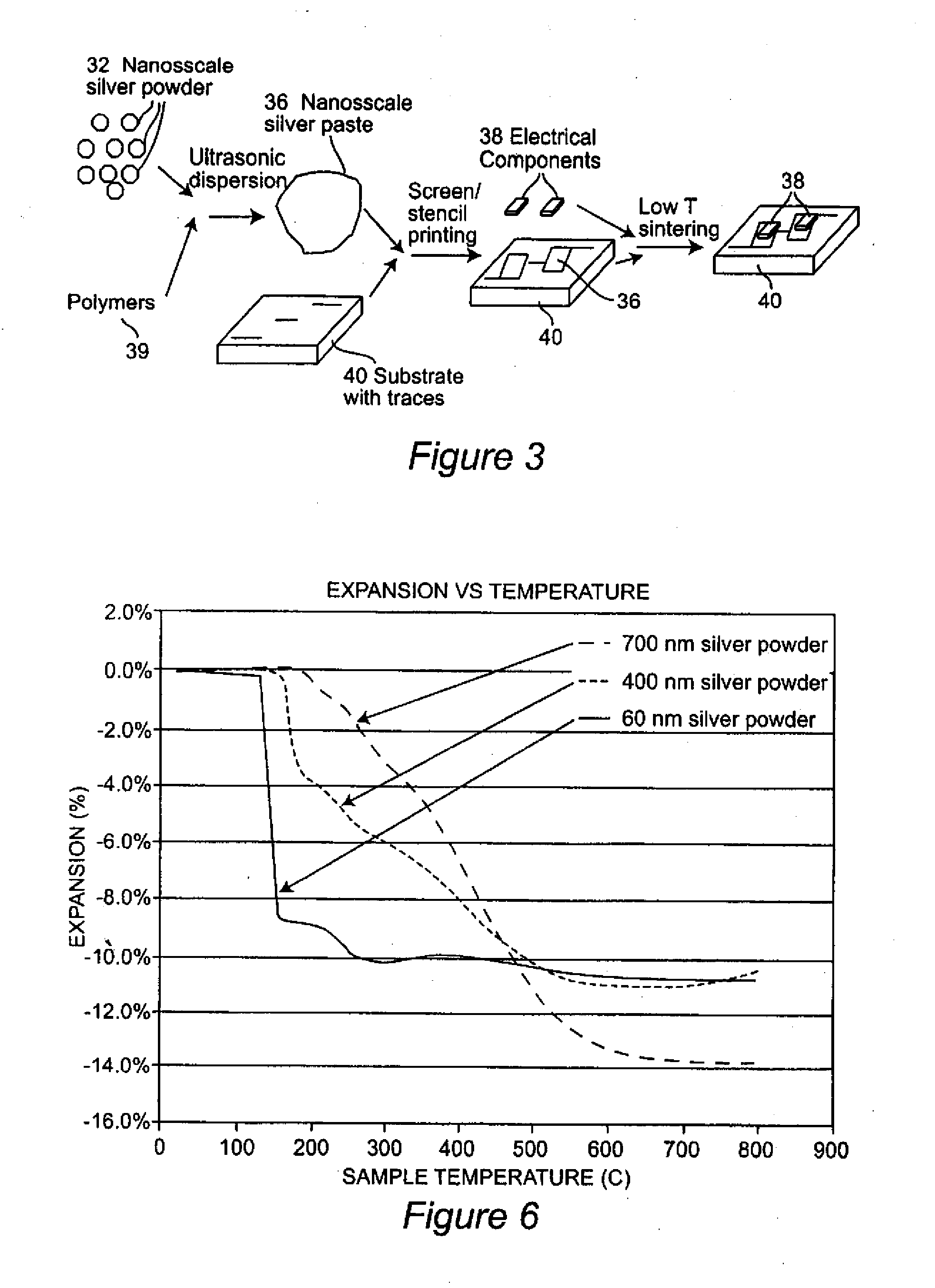

Nanoscale metal paste for interconnect and method of use

ActiveUS20090162557A1Broaden applicationEasy to handleTransportation and packagingPrinted circuit aspectsMicrometerMetal particle

A paste including metal or metal alloy particles (which are preferably silver or silver alloy), a dispersant material, and a binder is used to form an electrical, mechanical or thermal interconnect between a device and a substrate. By using nanoscale particles (i.e., those which are less than 500 nm in size and most preferably less than 100 nm in size), the metal or metal alloy particles can be sintered at a low temperature to form a metal or metal alloy layer which is desired to allow good electrical, thermal and mechanical bonding, yet the metal or metal alloy layer can enable usage at a high temperature such as would be desired for SiC, GaN, or diamond (e.g., wide bandgap devices). Furthermore, significant application of pressure to form the densified layers is not required, as would be the case with micrometer sized particles. In addition, the binder can be varied so as to insulate the metal particles until a desired sintering temperature is reached; thereby permitting fast and complete sintering to be achieved.

Owner:VIRGINIA TECH INTPROP INC

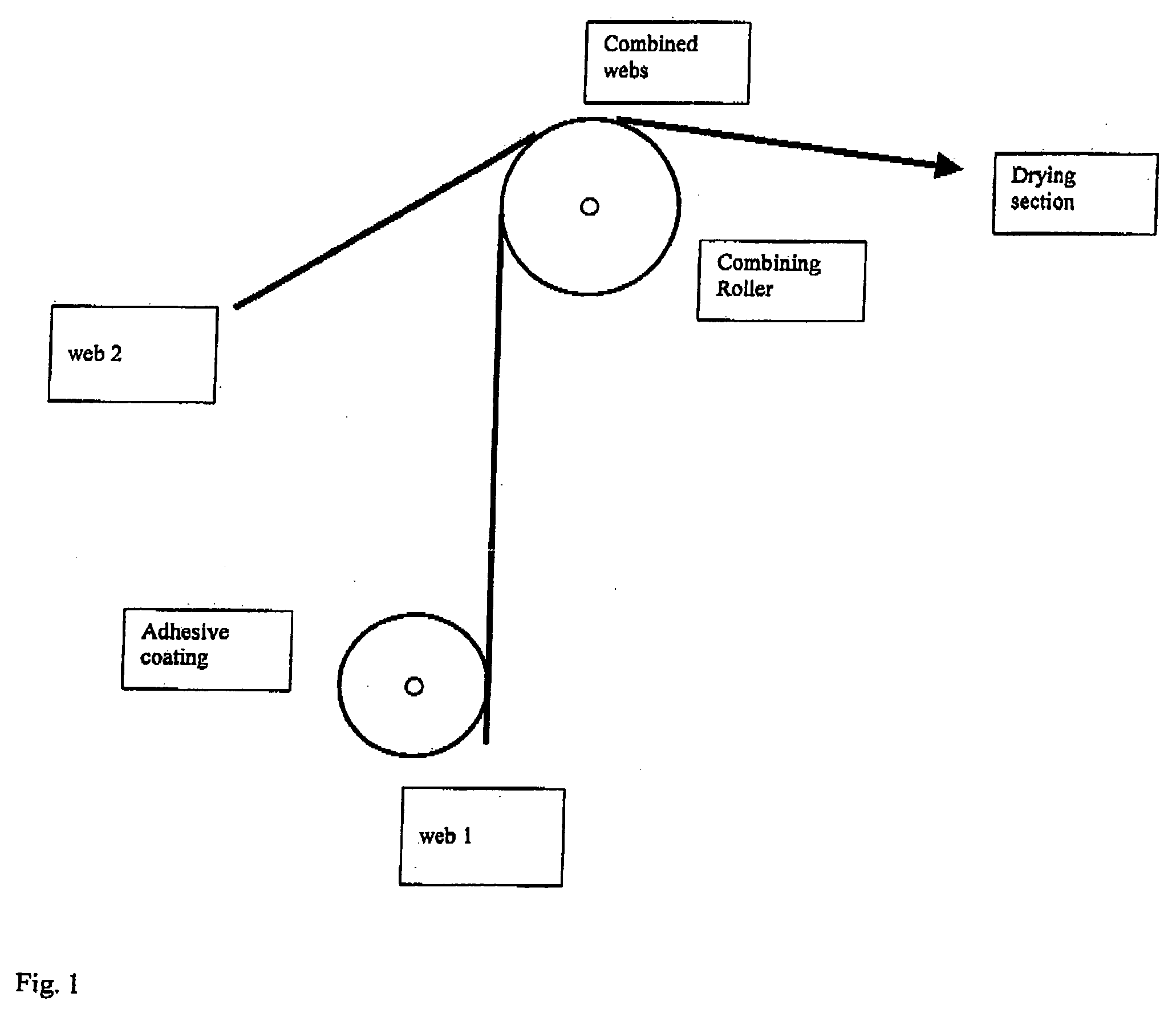

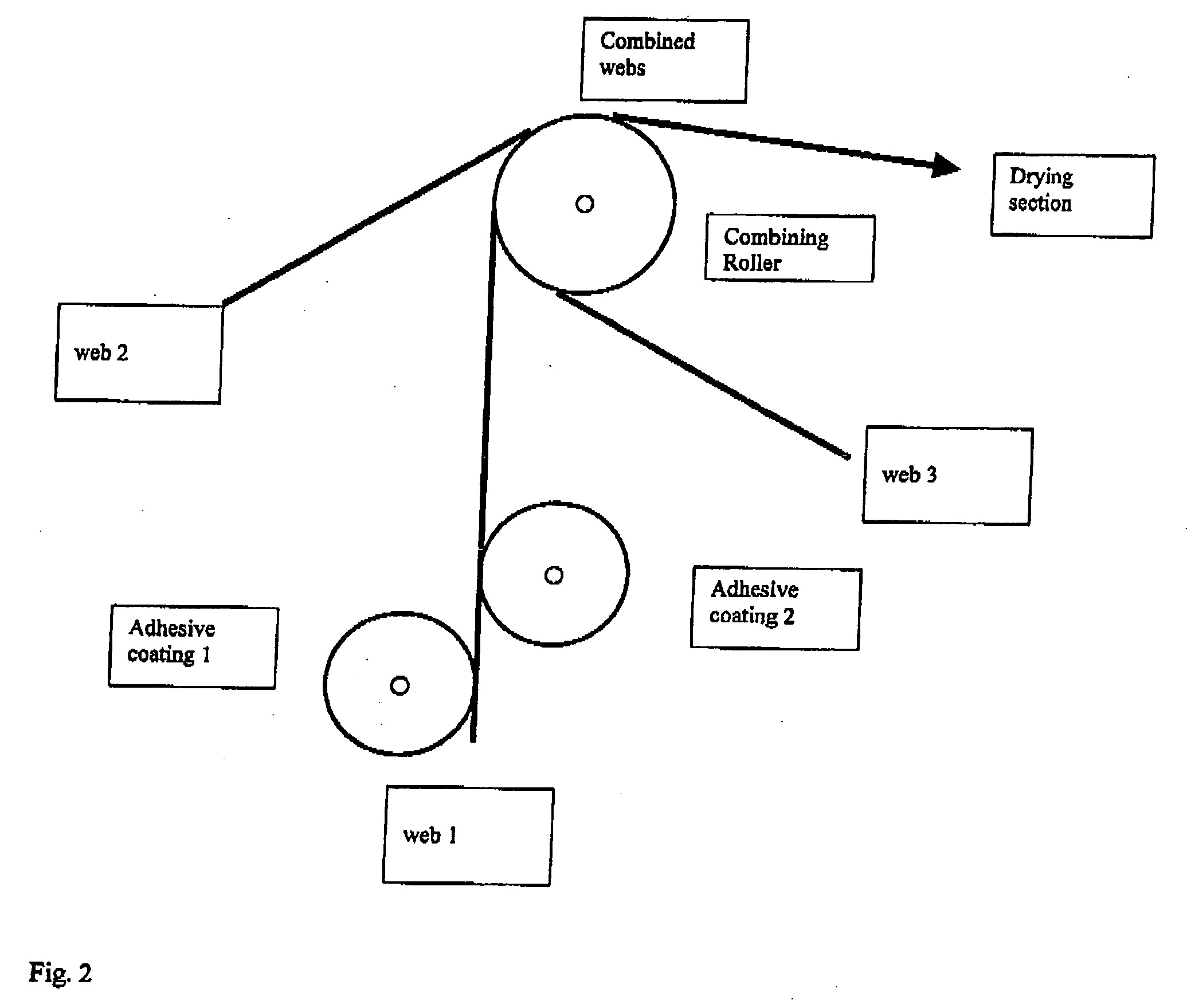

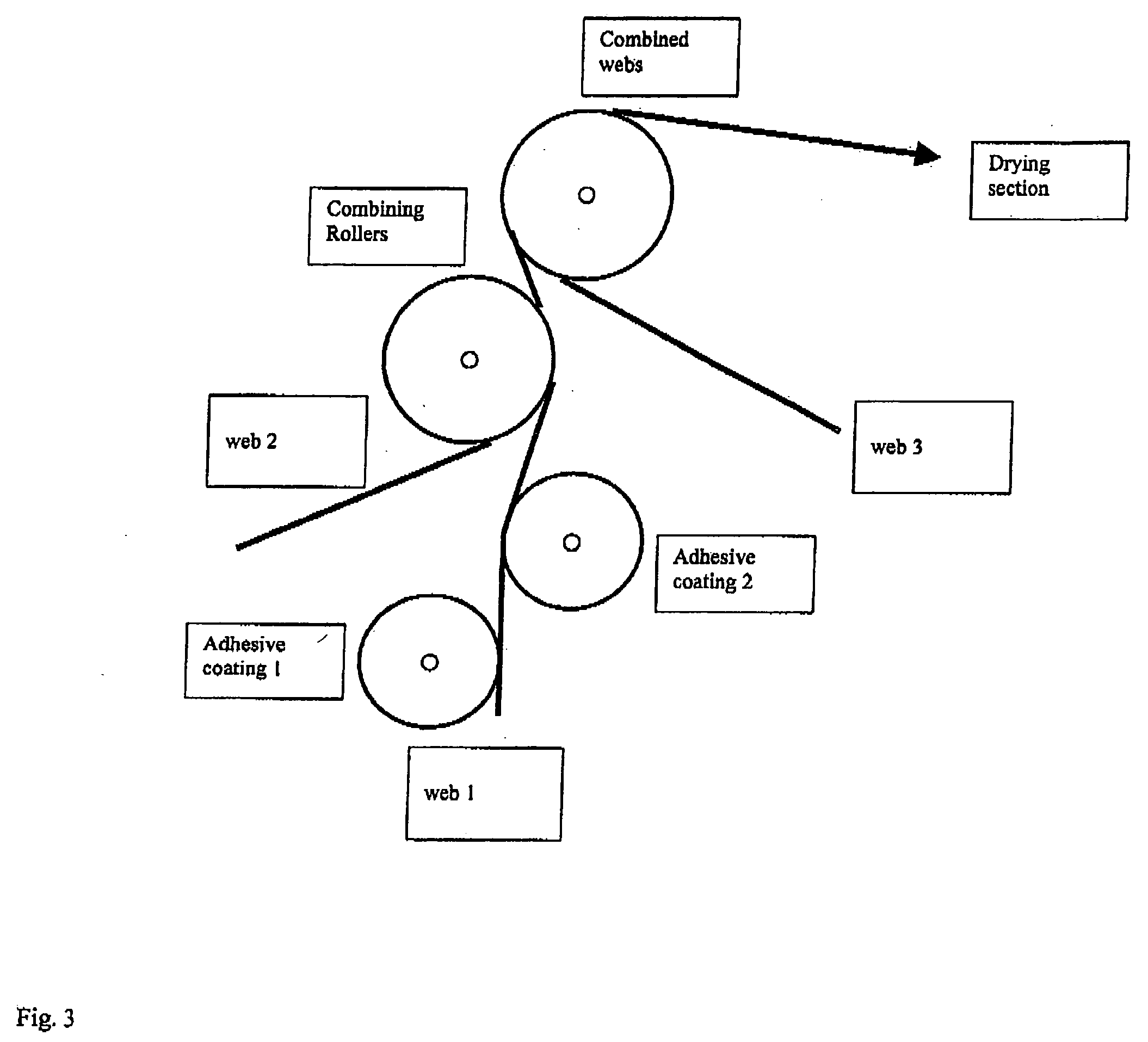

Laminating process and laminates resulting therefrom

InactiveUS20060194004A1Effective combinationIncrease speedAdhesive processesLamination ancillary operationsAdhesiveEngineering

A roll-to-roll lamination process for flexible webs including coating of at least one side of a first flexible web with a film forming adhesive and contacting the adhesive side(s) of the first flexible web to at least one of a second flexible web and a third flexible web on a transport roller while the combined webs are touching the transport roller from one side on a length of more than 5 mm without being further pressurized. Also, a 2 or more ply laminate of flexible webs comprising a first flexible web and a second flexible web, which are permanently attached by a film forming adhesive in a roll-to-roll lamination process, characterised in that the outer surface of the second flexible web has a heat sensitive recording layer and the first flexible web comprises fleece.

Owner:SIHL

Structural reinforcement

InactiveUS20050276970A1Low mobilityReduce pointsSuperstructure subunitsThin material handlingAdhesive materialsBiomedical engineering

A structural reinforcement for a hollow member comprising a rigid reinforcing member having a shape that substantially conforms to the cross section of the hollow member to be reinforced with an expandable adhesive material over at least a portion of the surface of the structural reinforcement having one or more extensions on its external surface which control and direct the direction in which the adhesive material expands to bond the reinforcing member to the internal surface of the hollow member, some of the extensions also provide improved reinforcement.

Owner:ZEPHYROS INC

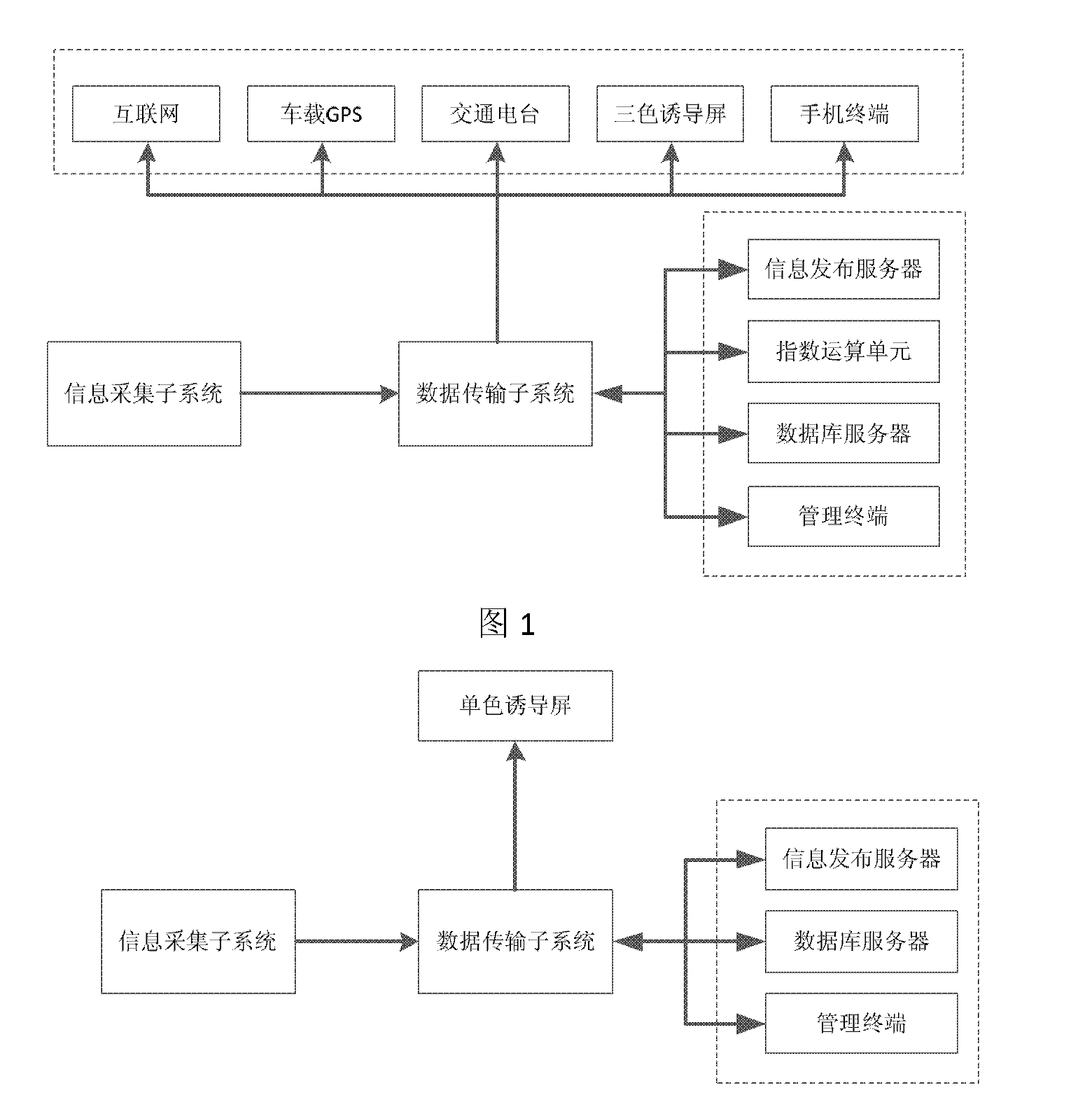

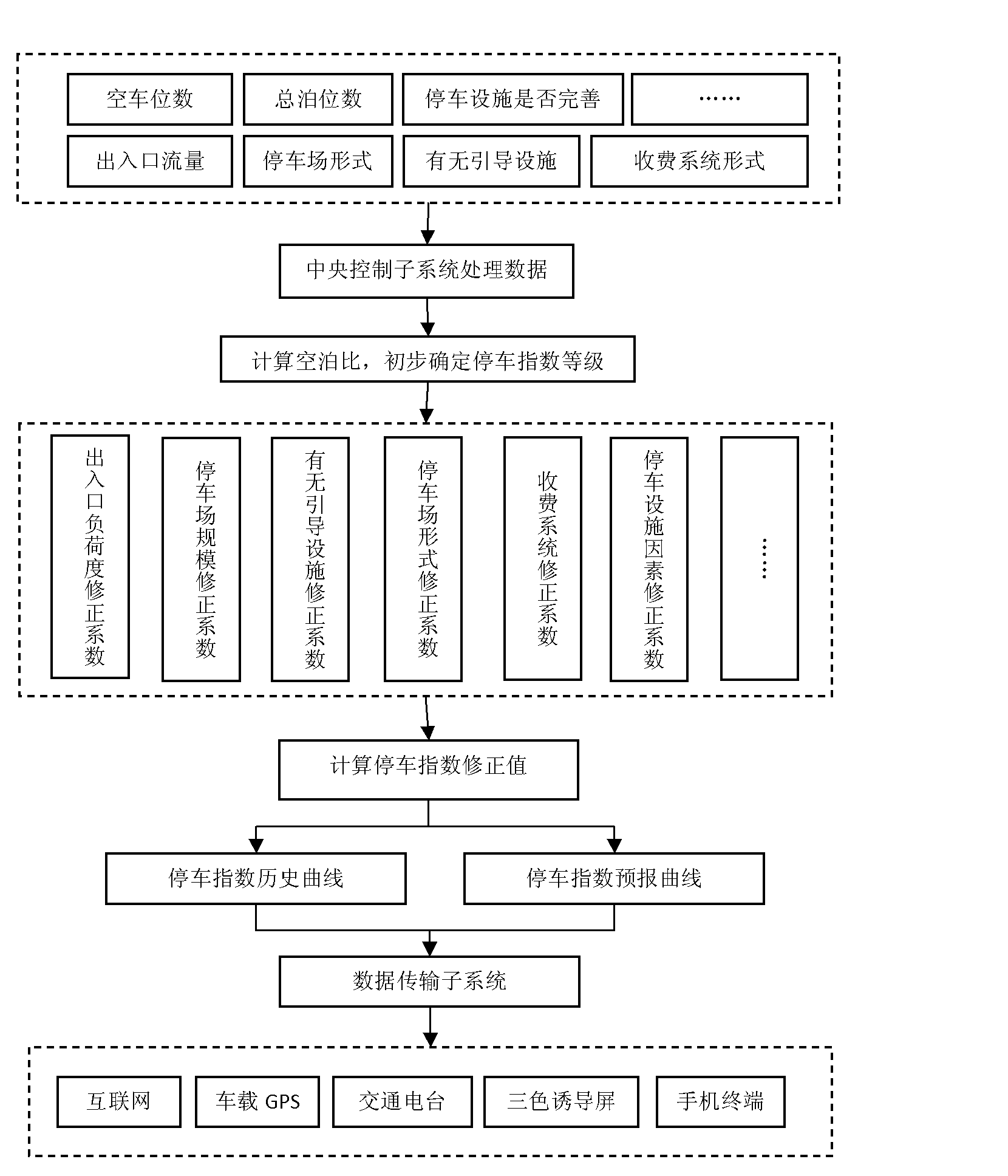

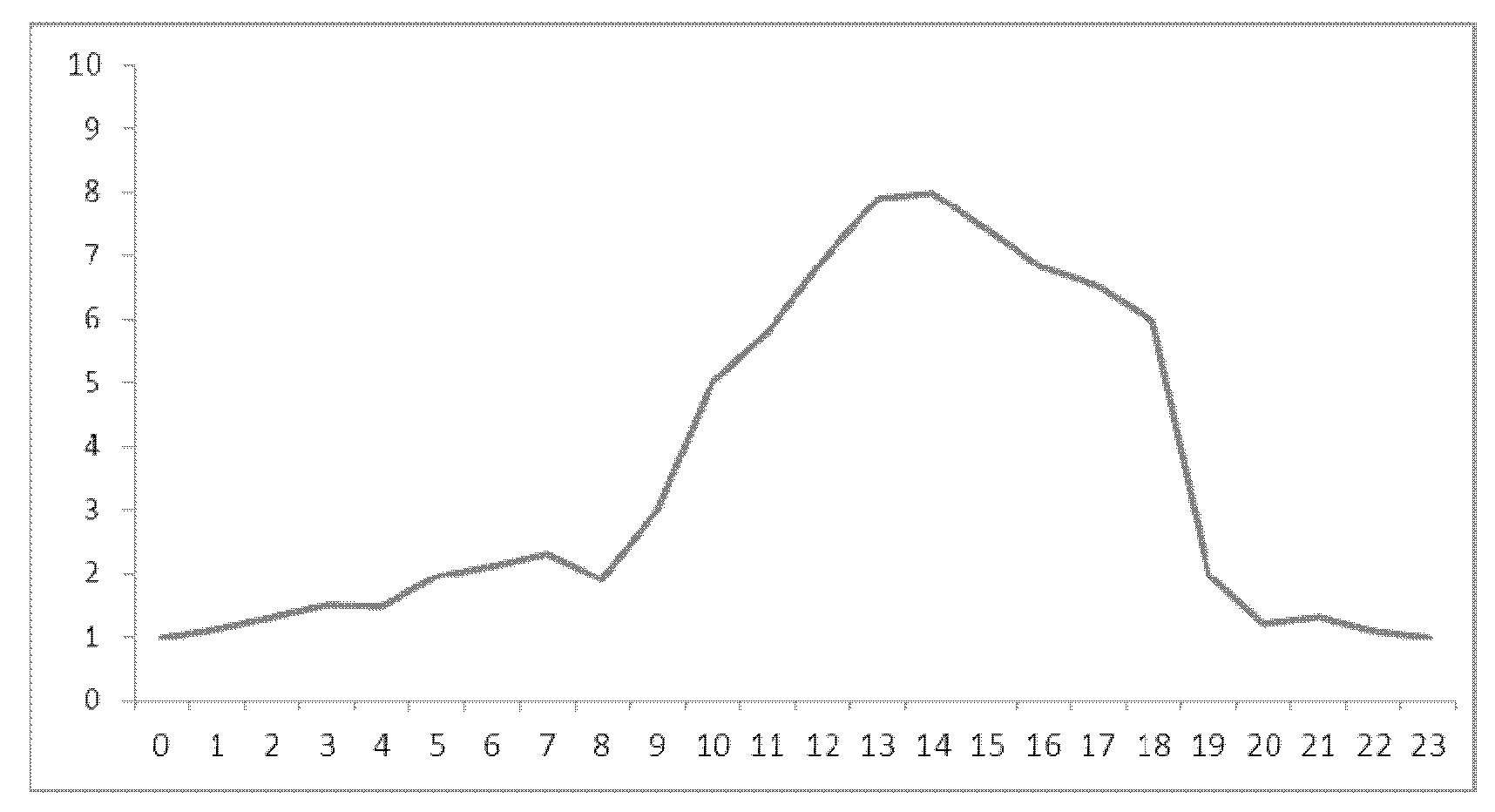

Parking guidance system and method thereof based on release and forecast of parking index

InactiveCN102542841APublishing communicates intuitivelyAdd exponent operation unitIndication of parksing free spacesData transmissionGuidance system

The invention discloses a parking guidance system and a method thereof based on release and forecast of a parking index, and belongs to the technical field of parking management and vehicle detection of the internet of things. The parking guidance system comprises an information acquisition subsystem, a data transmission subsystem, a central control subsystem and an information release subsystem,wherein the central control subsystem comprises an information release server, an index operation unit, a database server and a management terminal; in addition, the information release subsystem comprises terminals such as an internet, a vehicle-mounted GPS (Global Positioning System), a traffic transceiver, a three-color guiding panel, a mobile phone. The method of the parking guidance system acquires the flow information of an outlet and an inlet of a parking lot, uploads the data, and computes the parking index. Finally, the computed result of the parking index is transmitted to the terminals of the information release subsystem. The parking guidance system and the method thereof can release the parking index and forecast the travel information visually and roundly, and can effectively integrate the conventional parking guiding information and other dynamic information such as real time traffic status.

Owner:北京百会科技有限公司 +2

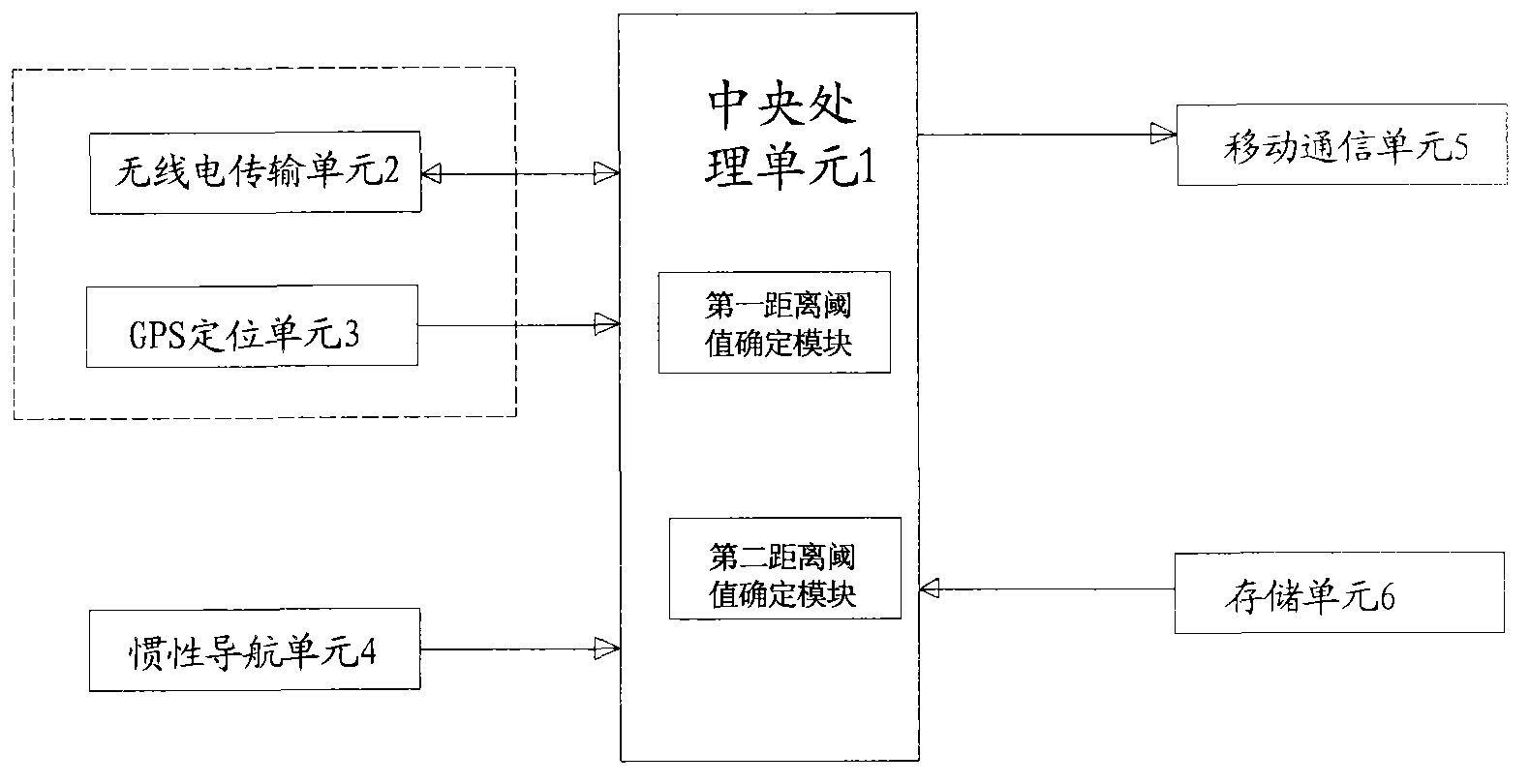

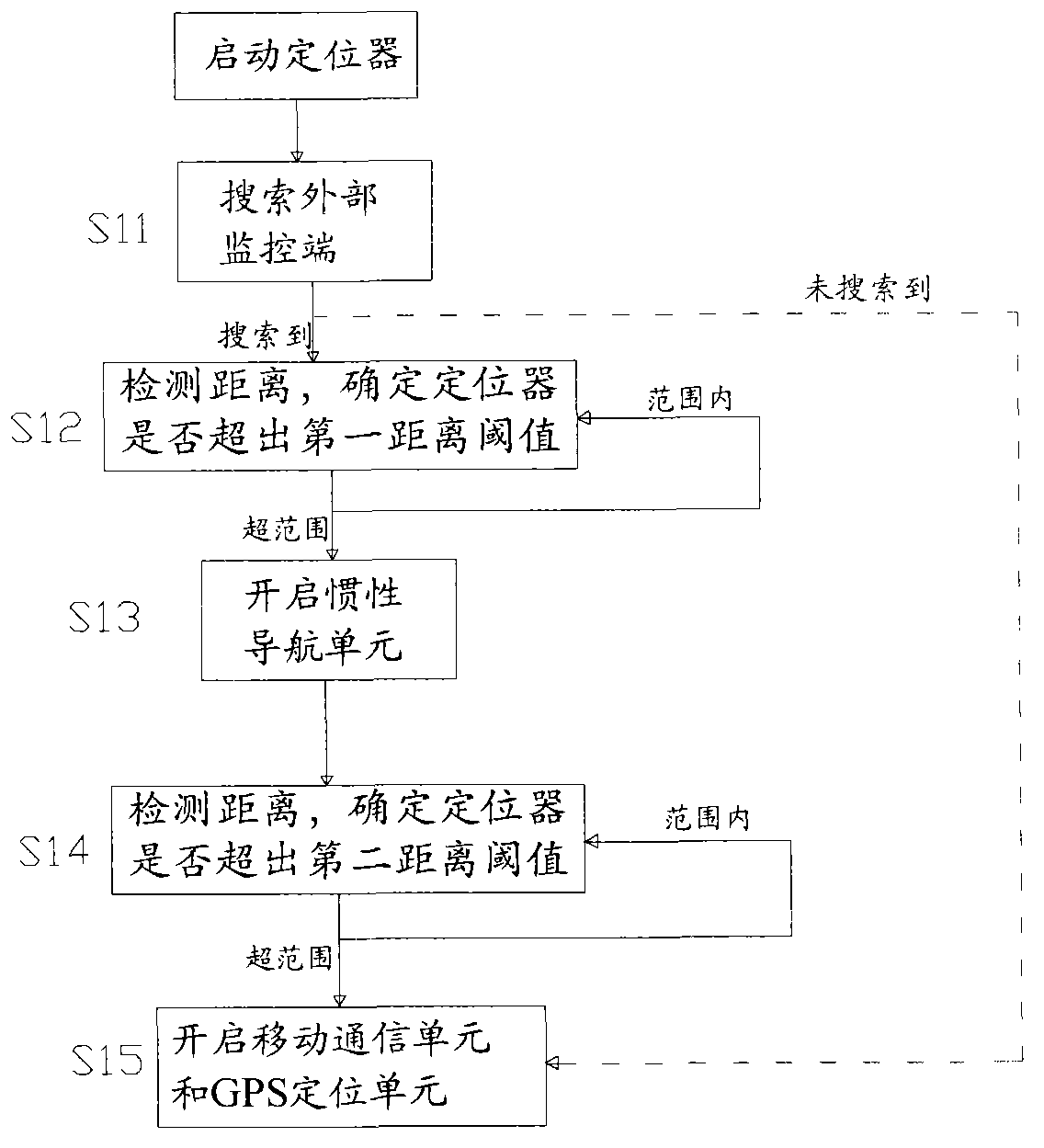

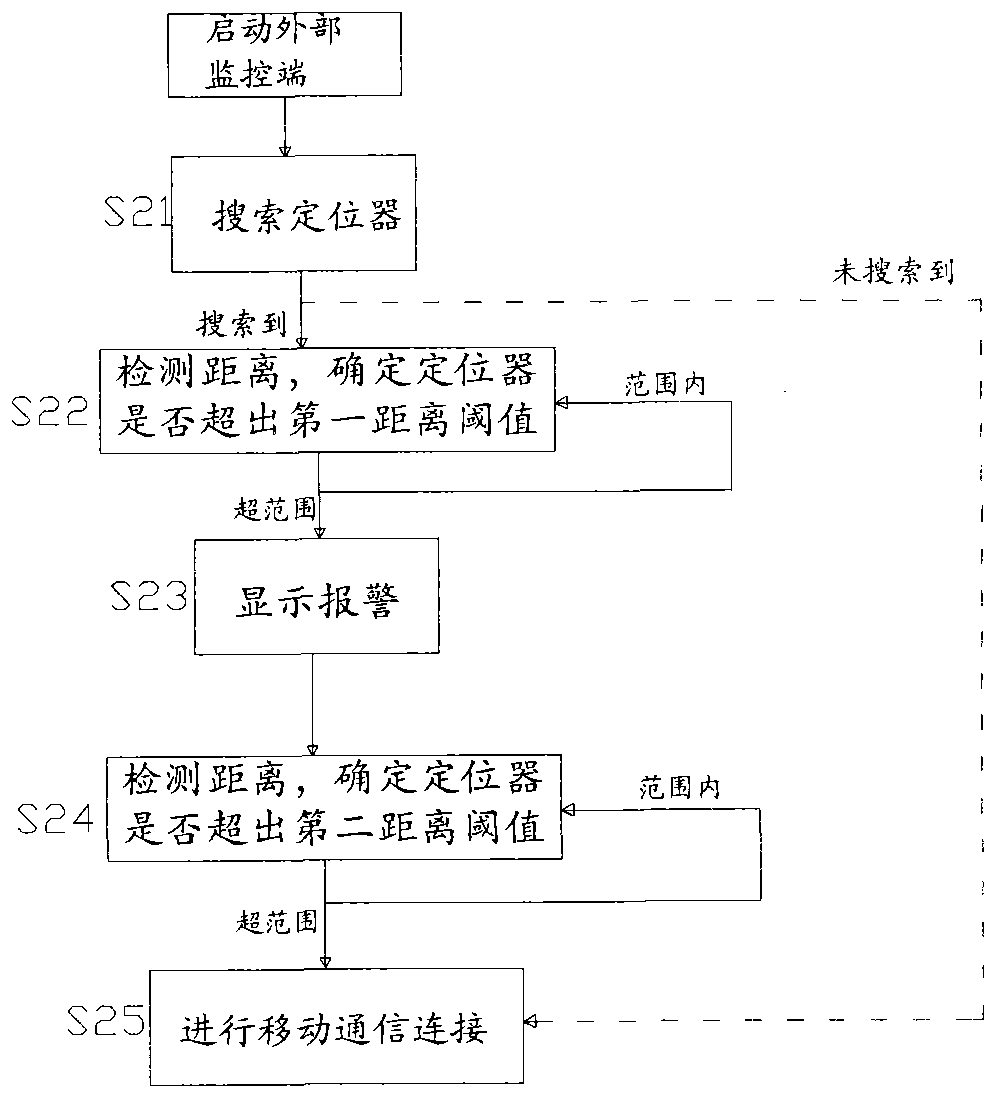

Locator-based locating method

ActiveCN103237292ASolve power consumptionSolve the problem of indoor positioning trackingEnergy efficient ICTNear-field systems using receiversGyroscopeAccelerometer

The invention provides a locator-based locating method. A locator comprises a central processing unit, a wireless unit, a global positioning system (GPS) locating unit, an inertial navigation unit, a mobile communication unit and a storage unit. The method comprises the following steps that a corresponding external monitoring end is searched based on a wireless detection signal; whether the current distance between the locator and the external monitoring end exceeds a first distance threshold value is determined based on the current wireless signal intensity and a mapping table stored in the storage unit; the inertial navigation unit is started when the current distance exceeds the first distance threshold value; whether the current distance exceeds a second distance threshold value is determined by detecting whether wireless connection can be established between the locator and the external monitoring end; and the mobile communication unit and the GPS locating unit are started when the current distance exceeds the second distance threshold value. By combining low power consumption Bluetooth, wireless fidelity (WIFI), a gyroscope and an accelerometer, the problem of power consumption due to the sustained use of a mobile network and GPS locating is solved.

Owner:钟国峰

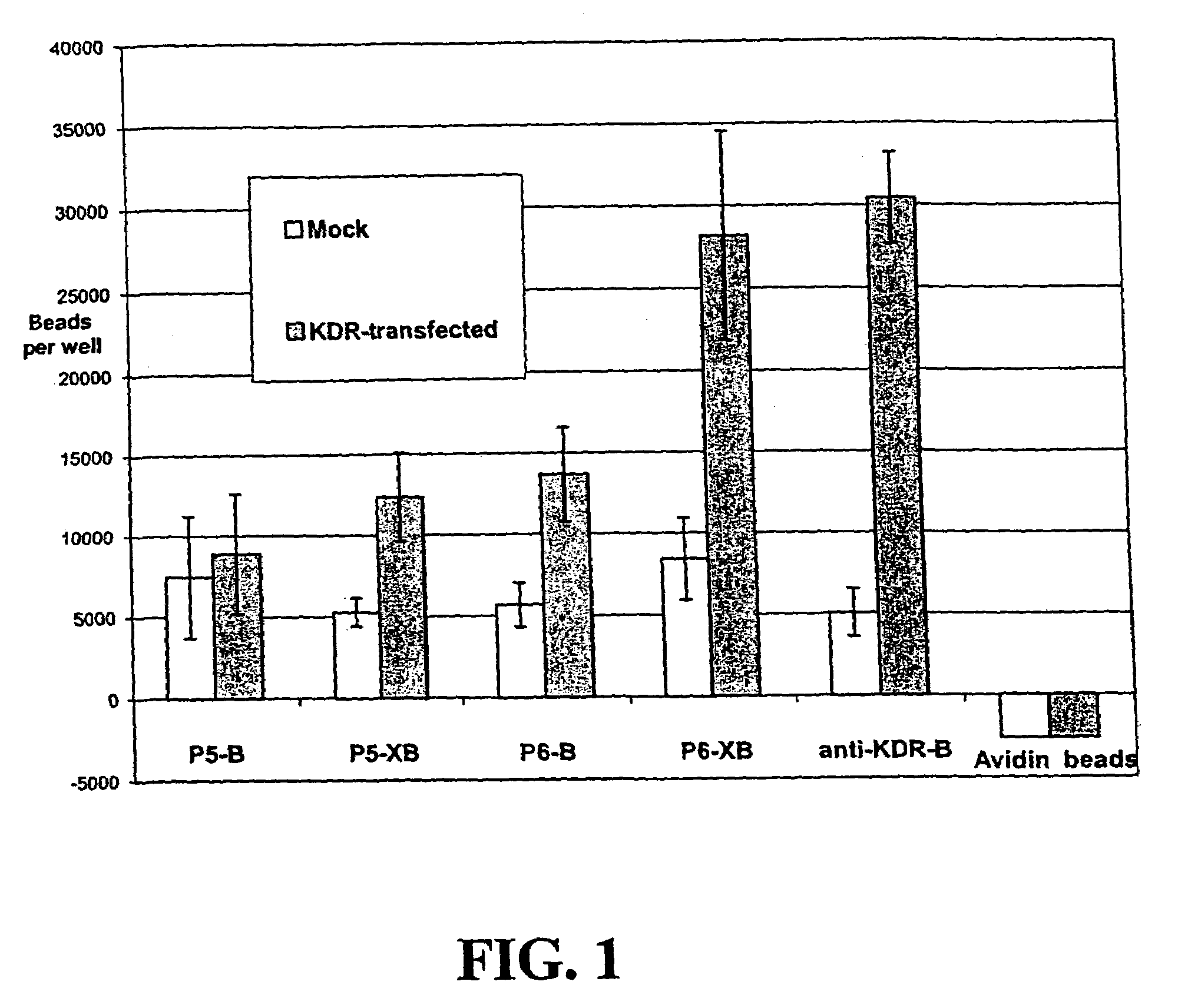

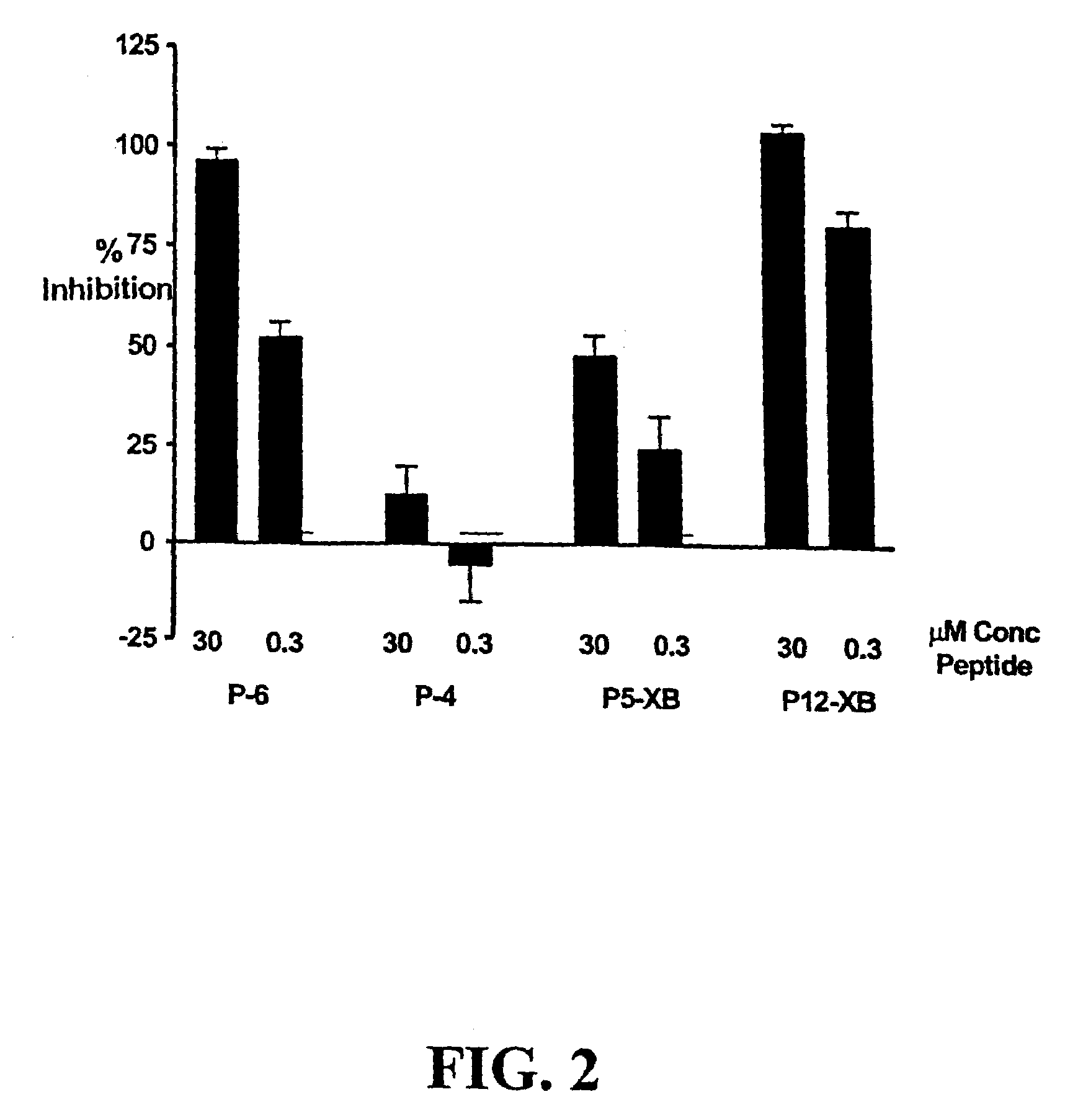

Multivalent constructs for therapeutic and diagnostic applications

InactiveUS7211240B2Improve propertiesImprove abilitiesSenses disorderPeptide/protein ingredientsPathology

Owner:BRACCO SUISSE SA +1

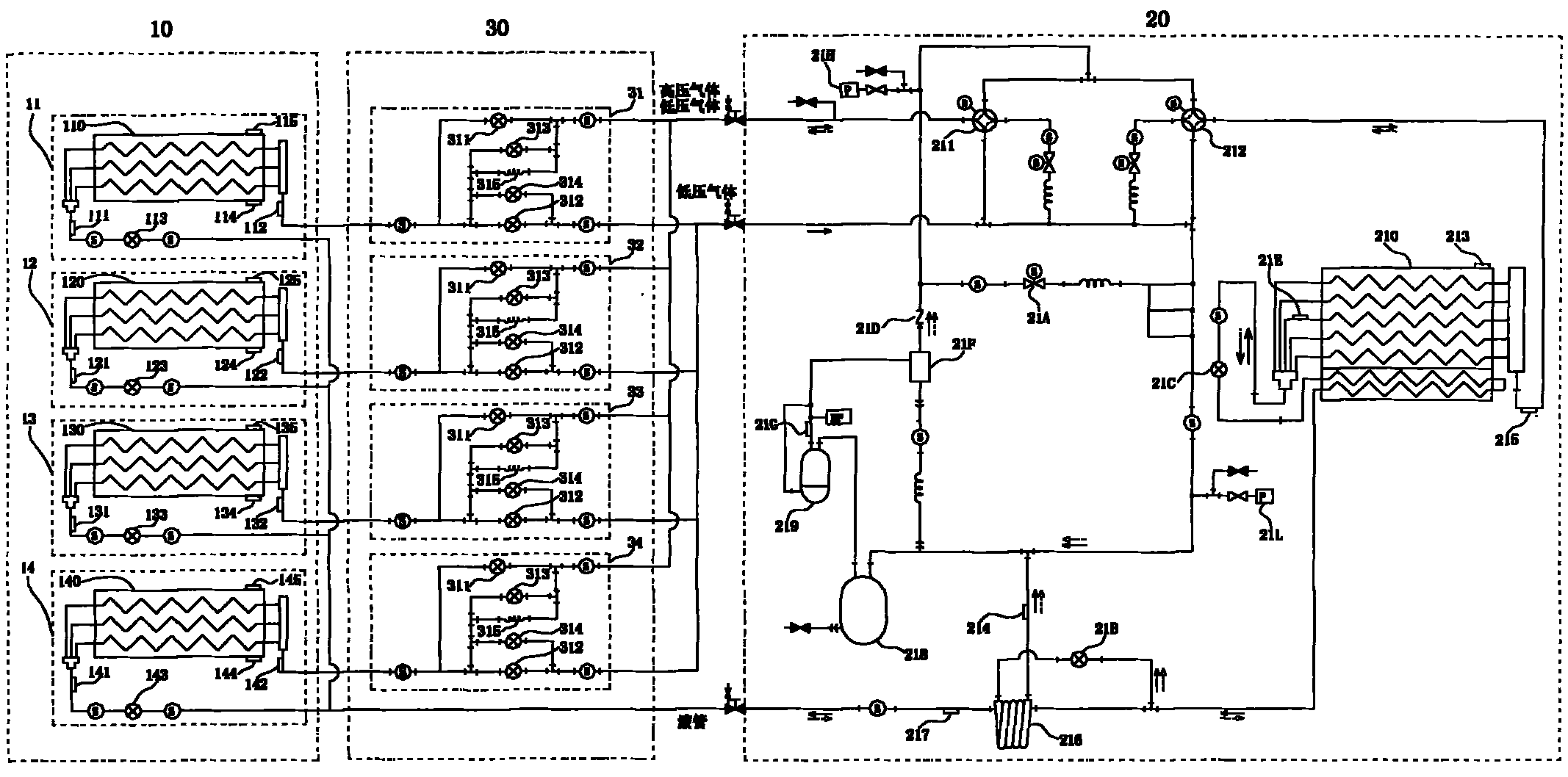

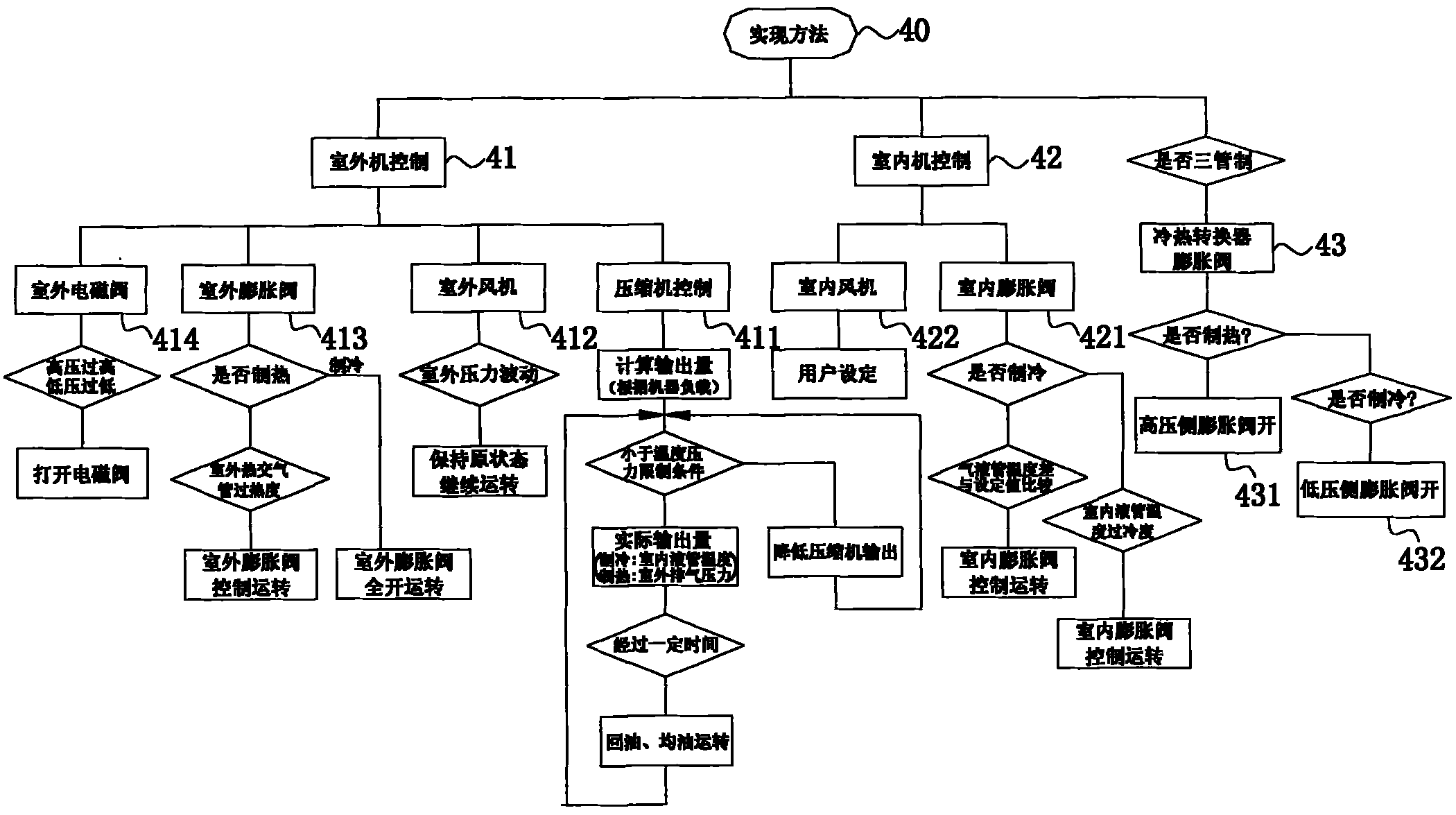

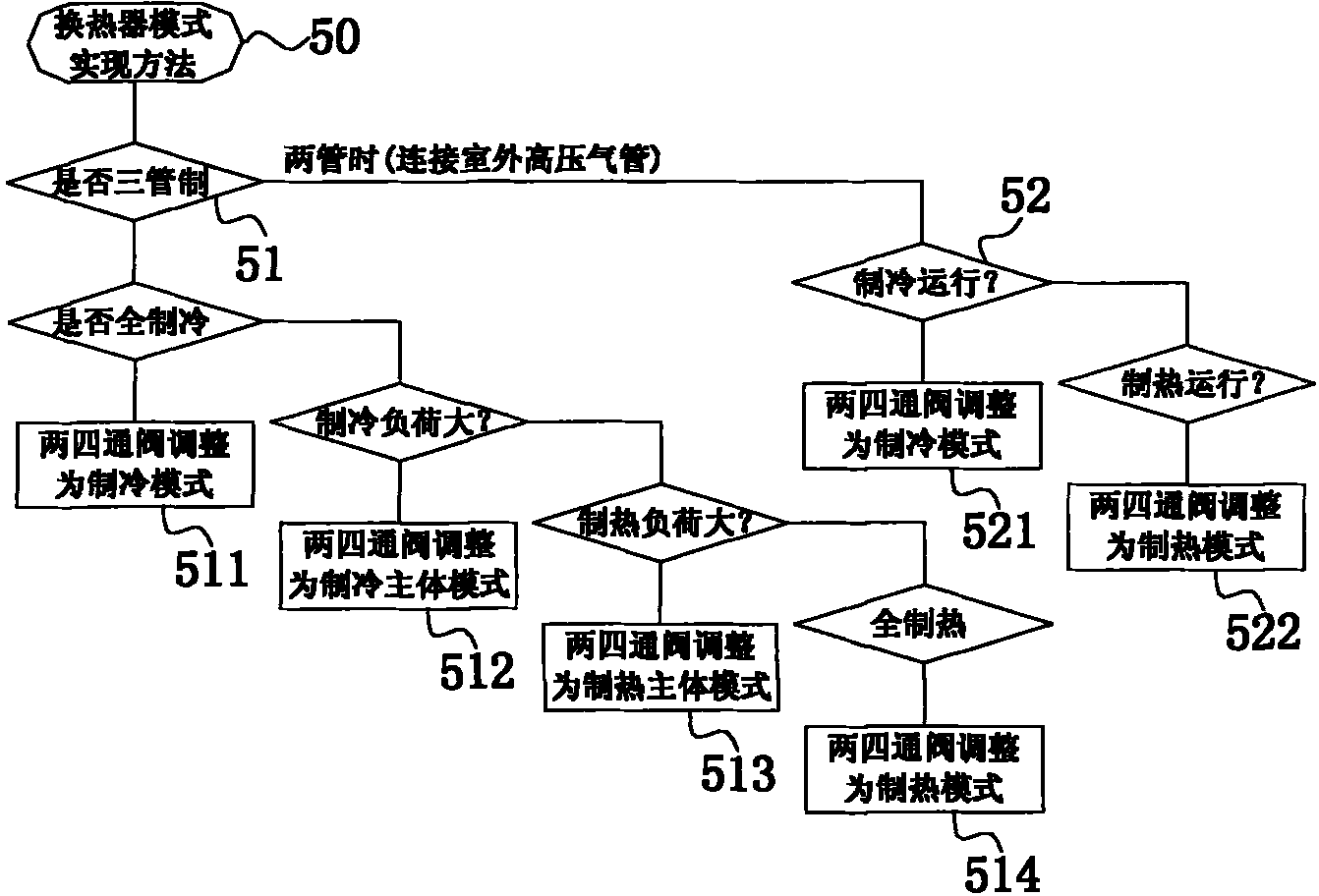

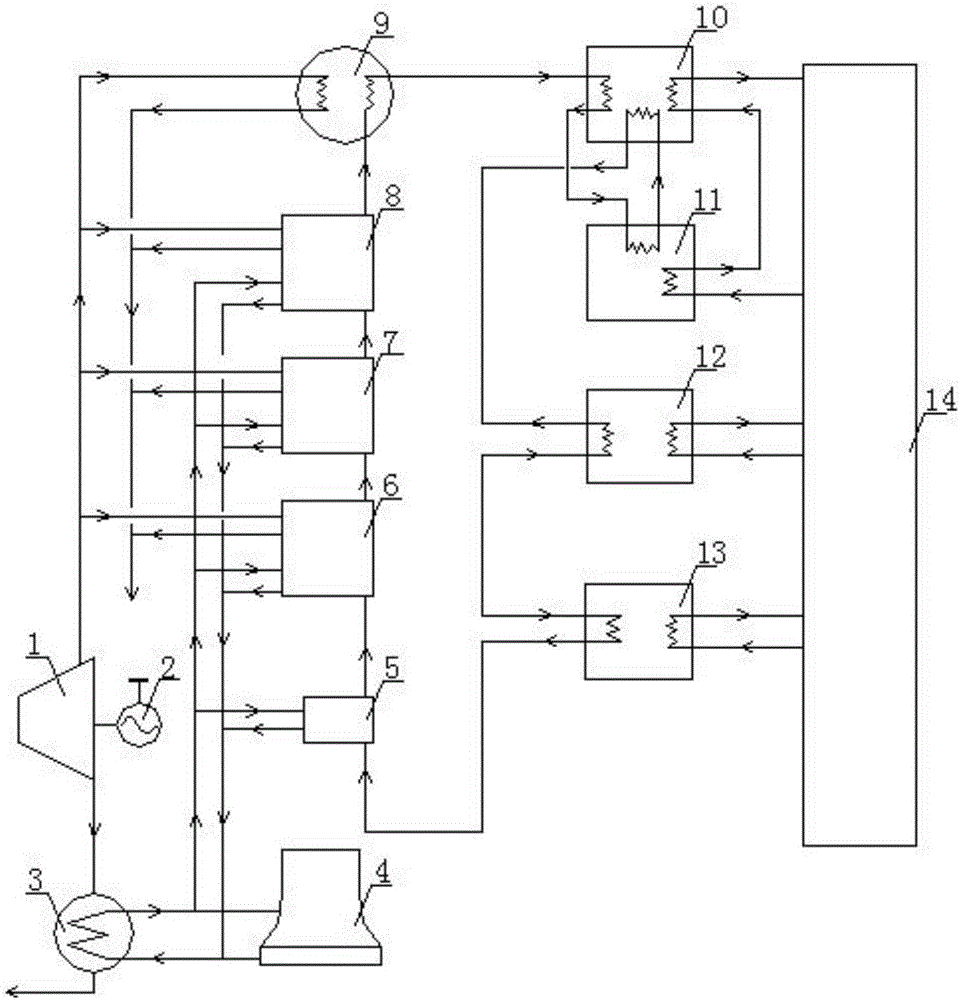

Heat recovery type multi-connection air condition unit

ActiveCN102042648AEffective combinationIncrease the heat exchange areaEnergy recovery in ventilation and heatingSpace heating and ventilation safety systemsEngineeringHigh pressure

The invention discloses a heat recovery type multi-connection air condition unit, comprising at least one outdoor unit, a plurality of indoor units and at least one hot and cold converter. The outdoor unit comprises a compressor, an outdoor heat exchanger, a subcooler, two four-way reversing valves and three refrigerant pipelines; each indoor unit comprises an indoor heat exchanger; and the hot and cold converter comprises expansion valves and a bypass capillary, wherein the expansion valves control the on-off of a high pressure air pipe and a low pressure air pipe, and the bypass capillary is arranged between the high pressure air pipe and the low pressure air pipe. When the indoor unit connected with the hot and cold converter is used for heating, the expansion valve at the high pressure air pipe side is turned on and the expansion valve at the low pressure air pipe side is turned off to realize the connection of the air pipe of the indoor unit and the high pressure air pipe. When the indoor unit connected with the hot and cold converter is used for cooling, the expansion valve at the low pressure air pipe side is turned on and the expansion valve of the high pressure air pipe is turned off to realize the connection of the air pipe of the indoor unit and the low pressure air pipe. By the air condition unit, the combination of the units as well as the function of two-pipe heat pump air condition can be realized, and the common two-pipe heat pump air conditioner and the heat recovery type air conditioner capable of cooling and heating simultaneously are effectively combined.

Owner:QINGDAO HISENSE HITACHI AIR CONDITIONING SYST

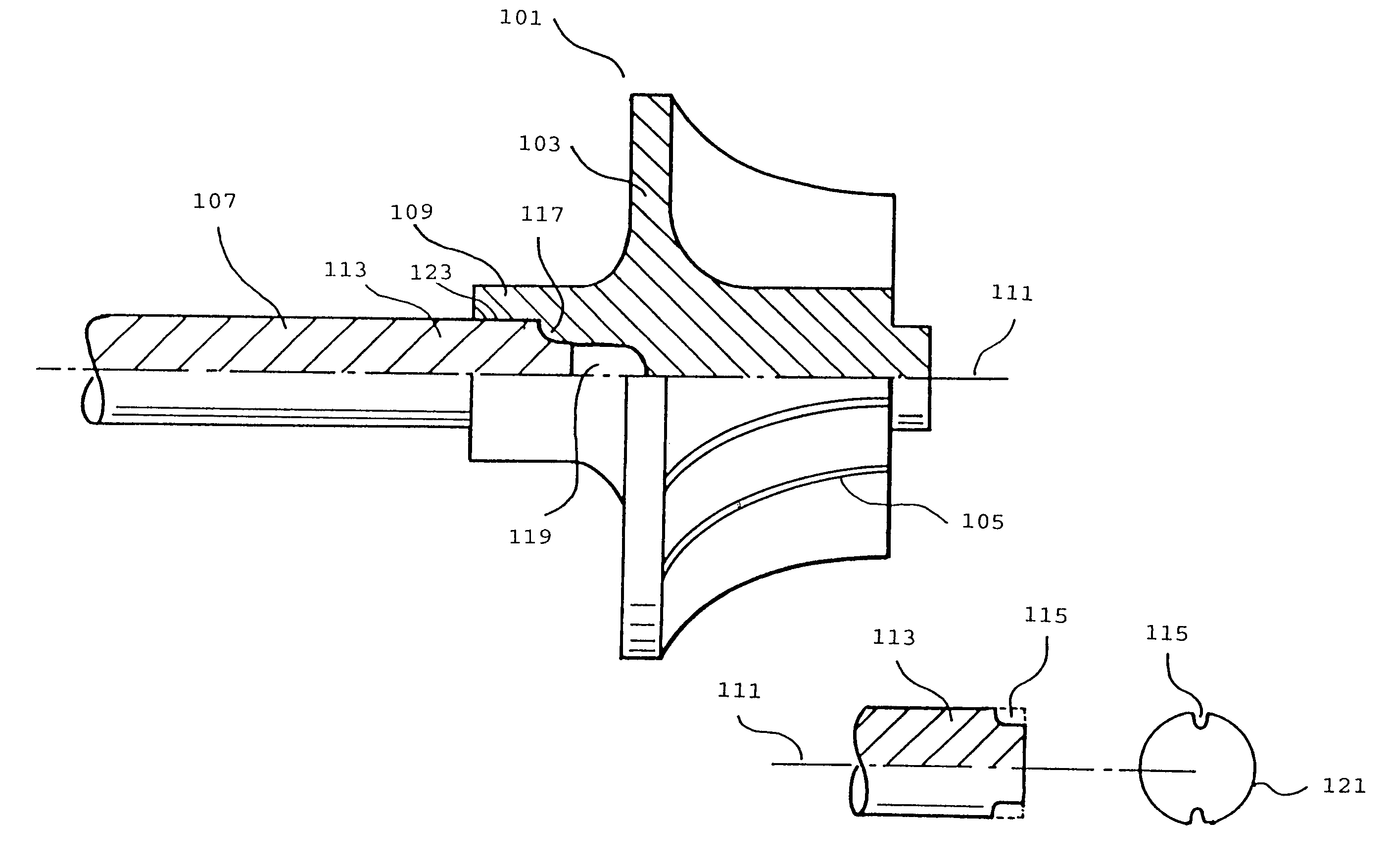

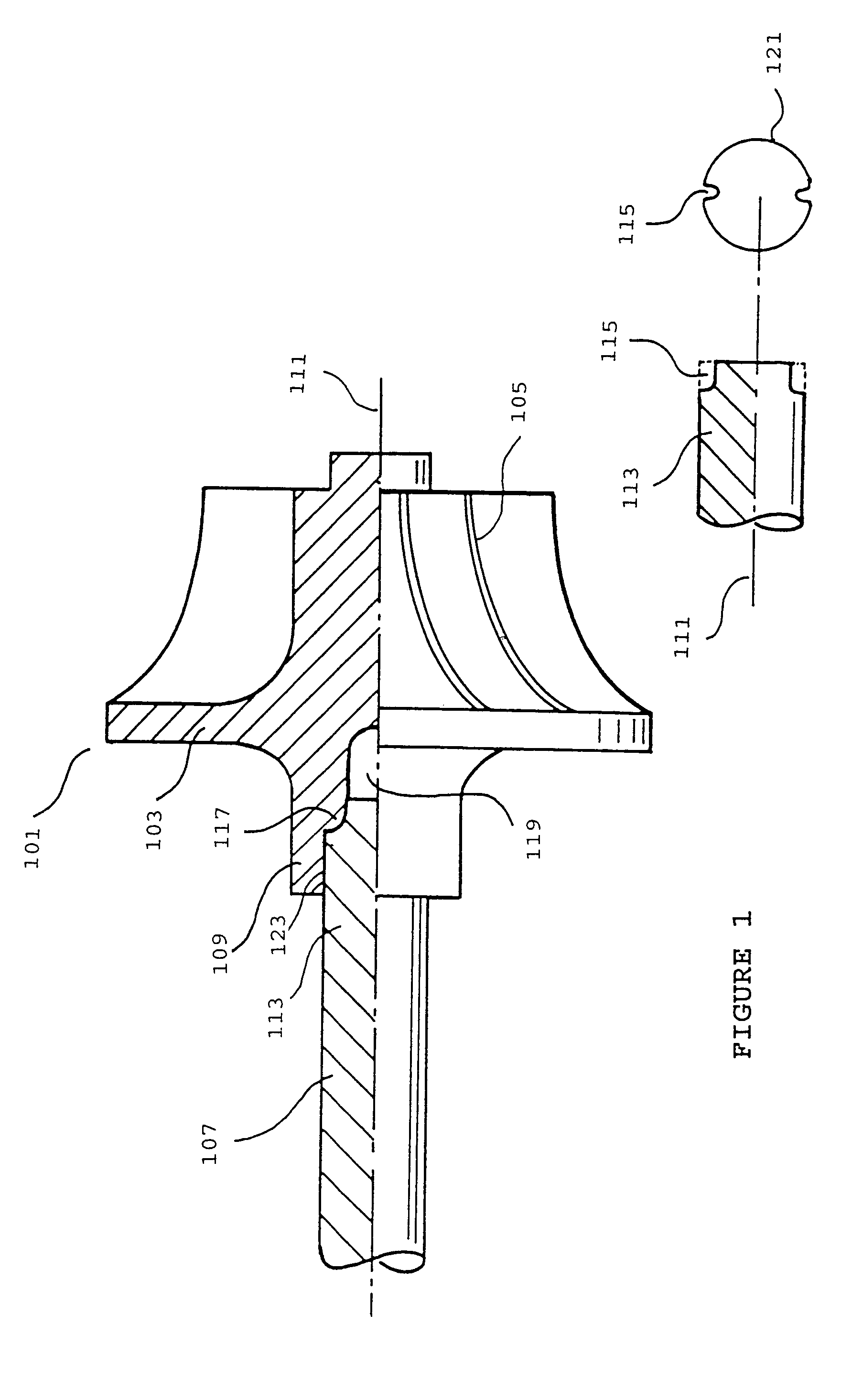

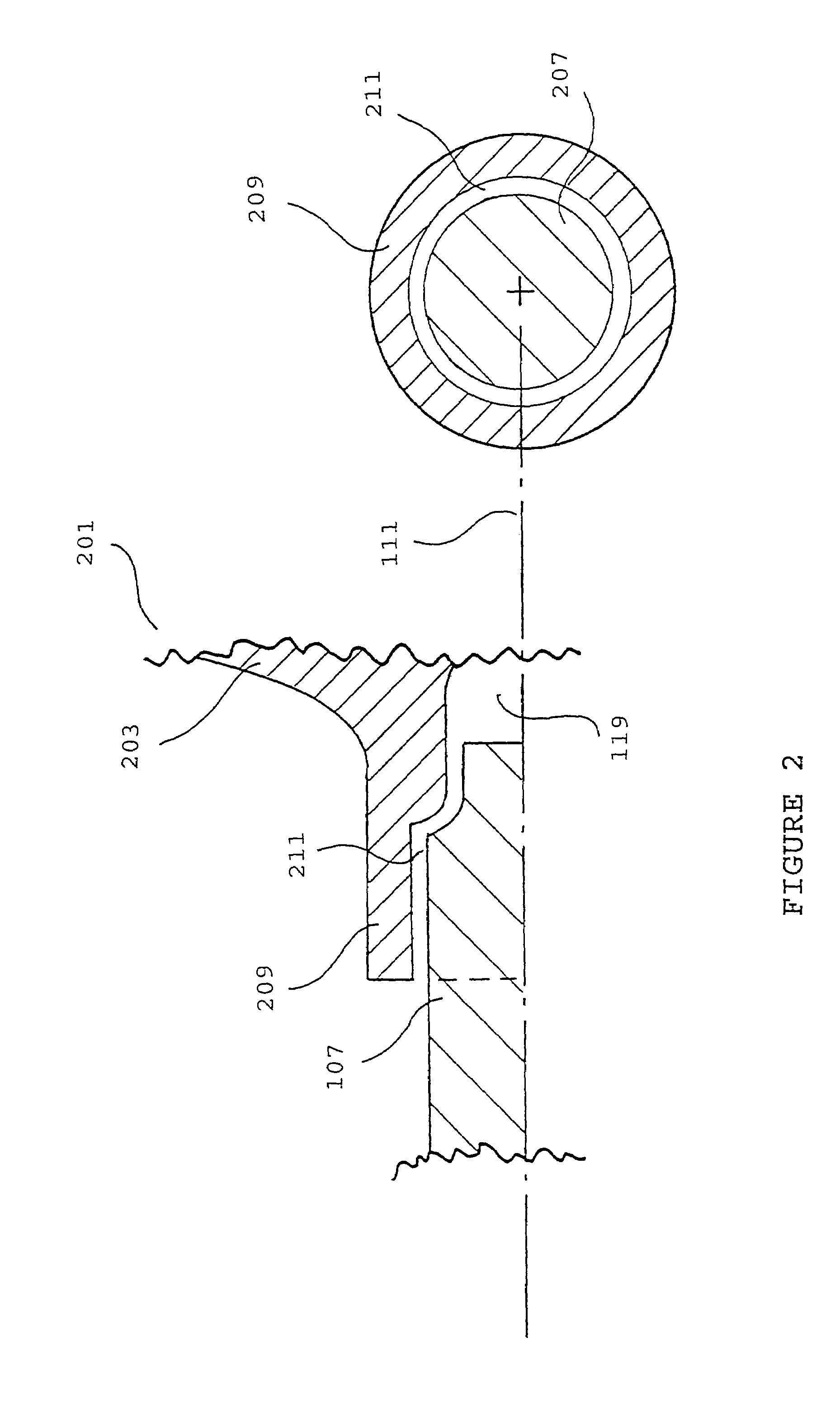

Metal injection molded turbine rotor and metal shaft connection attachment thereto

ActiveUS7052241B2Effective combinationMinimize heat transferTurbinesPropellersTurbochargerMaterials science

A rotor shaft assembly (101) of a type used in a turbocharger, manufactured by mounting a powder compact (203) of a titanium aluminide rotor (103) to a pre-formed steel shaft (107), and sintering the combination, which provides a strong metallurgical bond between the shaft (107) and rotor (103). There is provided a rotor shaft assembly (101) and an inexpensive and efficient method of its manufacture, for an assembly capable of withstanding the high forces and fluctuating temperatures within a turbocharger.

Owner:BORGWARNER INC

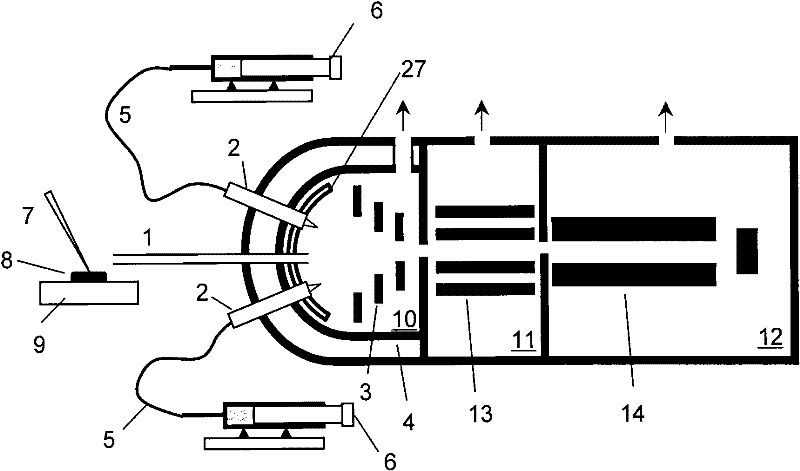

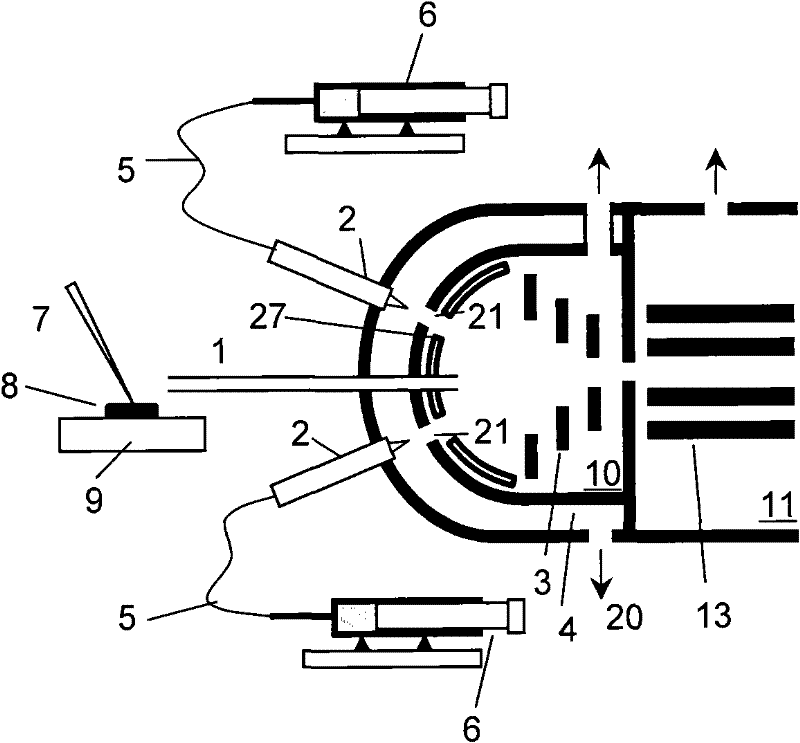

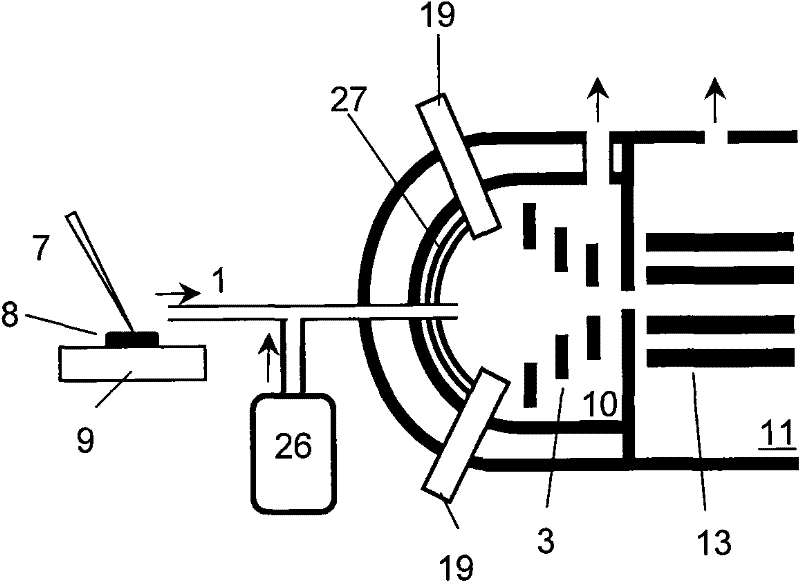

Method and device for generating and analyzing ions

ActiveCN102221576AEffective after ionizationEffective combinationMaterial analysis by electric/magnetic meansIon sources/gunsSpectrographMass analyzer

Owner:SHIMADZU RES LAB SHANGHAI

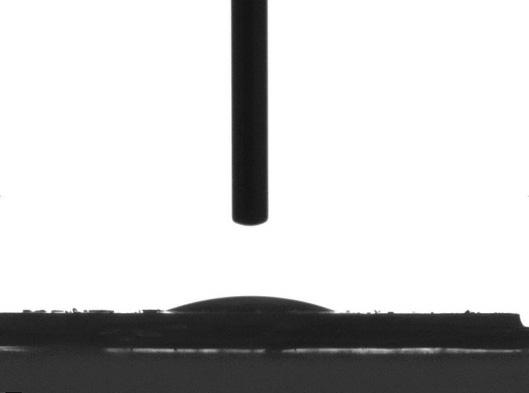

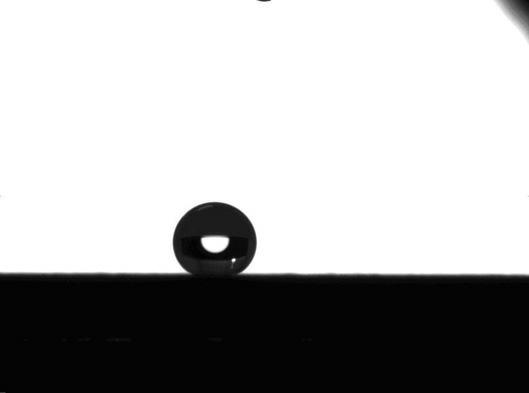

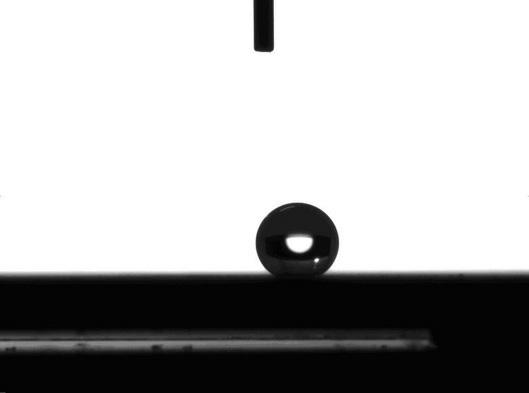

Preparation method for high-wave permeability super-hydrophobic moisture-proofing coating for antenna housing material

InactiveCN102492339AReduce porosityLow dielectricPretreated surfacesSpecial surfacesEpoxySilicon dioxide

The invention discloses a preparation method for high-wave permeability and super-hydrophobic moisture-proofing coating for an antenna housing material. The preparation method is characterized by comprising the following steps of: preparing hole-sealing emulsion; preparing super-hydrophobic moisture-proofing emulsion; coating the hole-sealing emulsion on the antenna housing material, surface-drying the film coating under a room temperature, and then curing the film coating under the temperature of 100 DEG C to 140 DEG C; cooling and immersing the film coating to the super-hydrophobic moisture-proofing emulsion; surface-drying the film coating under the room temperature, and curing the film coating under the temperature of 80 DEG C to 160 DEG C to acquire the high-wave permeability and super-hydrophobic moisture-proofing coating for the antenna housing material. Micron-level silicon dioxide and fluorine-containing polymer are used in the method to perform accumulating and hole-sealing;a micron surface structure with certain roughness is provided, and epoxy resin with good viscosity is added to the hole-sealed coating, so that the mechanical property of the hole-sealed coating is improved; a self-growth method is adopted for depositing micron-level fluorine-containing polymer, which is in-situ packaged by organic silicon resin and attached with hydrophobic nanometre silicon dioxide, to the surface of the hole-sealed coating, so that the high-wave permeability and super-hydrophobic moisture-proofing coating of the antenna housing material is prepared.

Owner:SOUTHWEAT UNIV OF SCI & TECH

Energy-saving heat supply system with function of reducing temperature of heat supply return water

InactiveCN106705185AIncrease profitReduce circulating water flowLighting and heating apparatusSteam useCooling towerTemperature difference

The invention discloses an energy-saving heat supply system with a function of reducing the temperature of heat supply return water, and belongs to the field of improvement of energy utilization efficiency. Heat exchange can be repeatedly carried out on heat sources by multistage heat exchangers, multistage absorption heat exchange units, multistage compression heat pumps and an ice making type refrigerator, accordingly, the heat supply areas can be enlarged, and the energy utilization efficiency can be improved. The energy-saving heat supply system has the advantages that the temperature of the return water of heat supply primary pipe networks can be reduced and reach 0 DEG C, the return water contains 10% of ice particles, accordingly, route heat loss of the return water of the heat supply primary pipe networks can be reduced, the temperature difference of the return water of the heat supply primary pipe networks can be increased and reaches 118 DEG C from the original 60 DEG C, the flow rate of circulating water of the heat supply primary pipe networks can be lowered, energy consumption of circulating pumps can be reduced, heat supply flow rates of a user side can be greatly increased, the delivery efficiency of the pipe networks can be improved, the heat supply scale can be expanded, waste heat of a cooling tower can be recycled, and the like.

Owner:DALIAN BAOGUANG ENERGY SAVING AIR CONDITIONING EQUIP

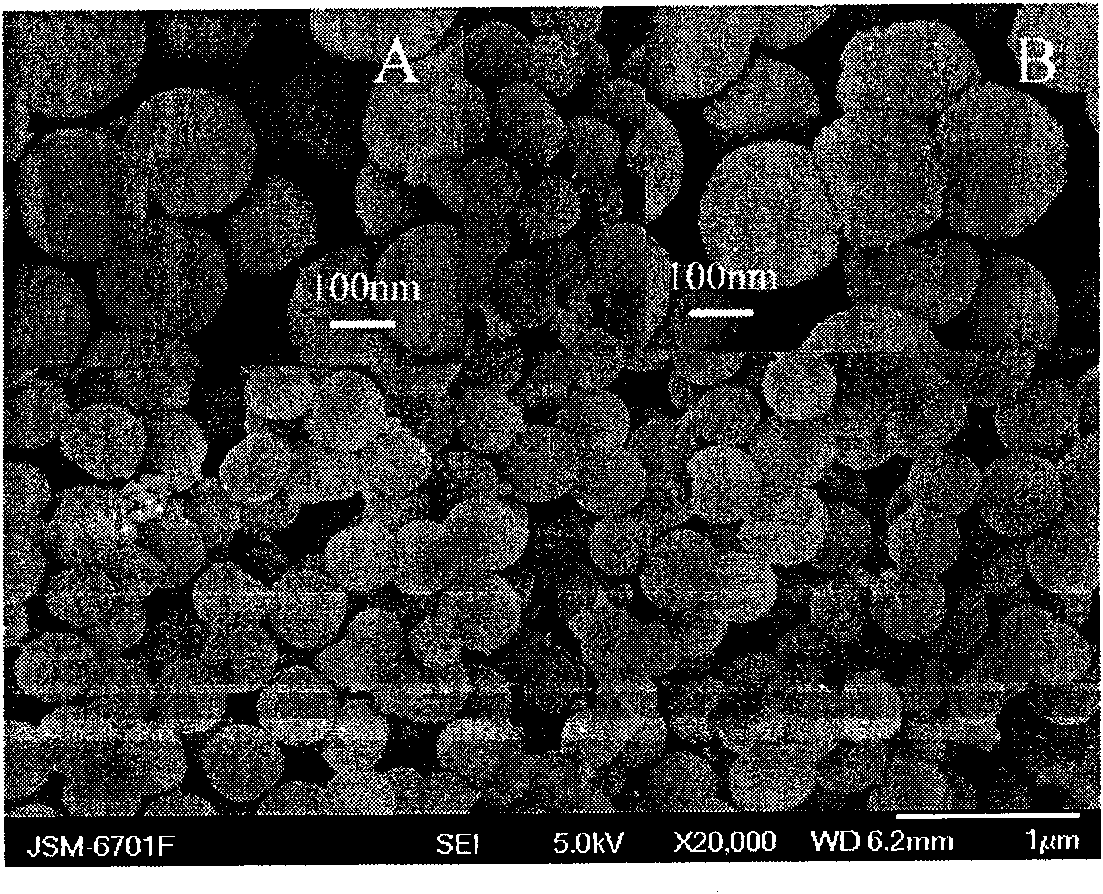

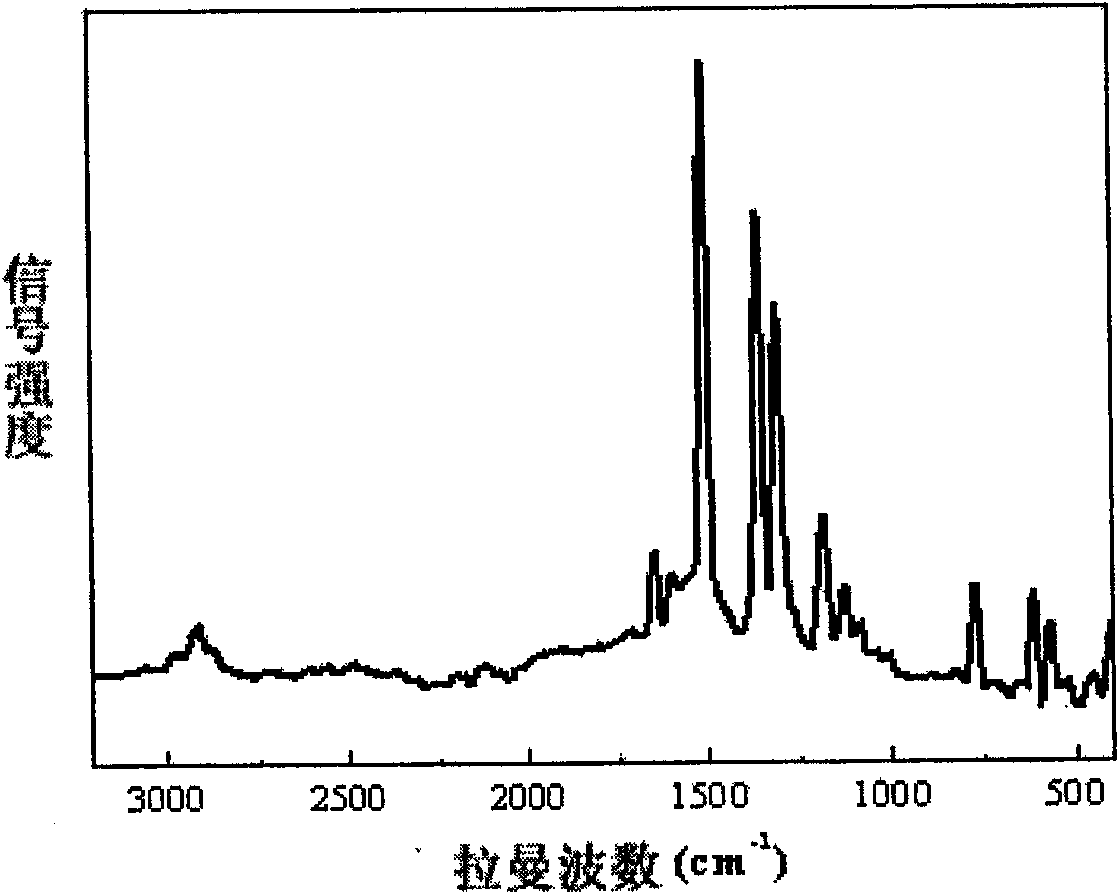

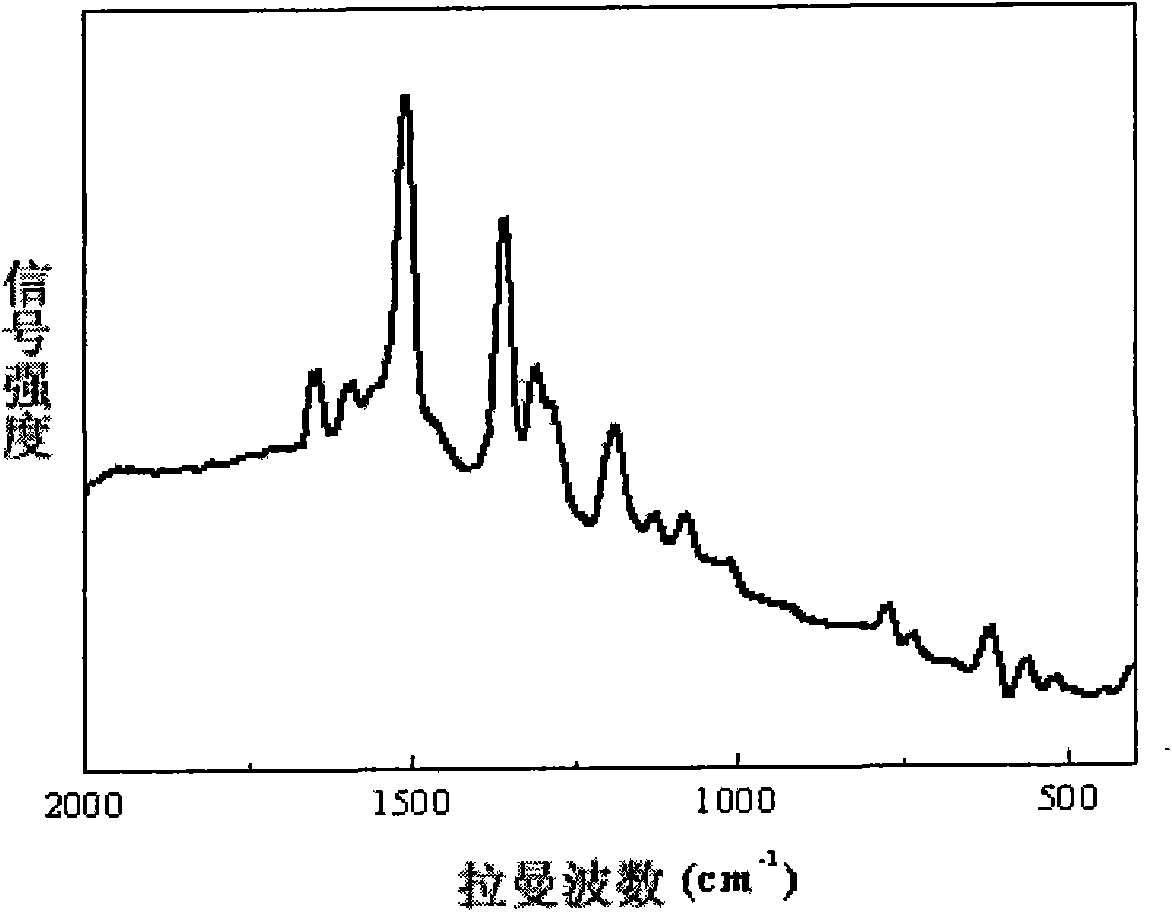

Substrate with surface-enhanced Raman scattering activity and preparation method thereof

The invention provides a substrate with surface-enhanced Raman scattering activity and a preparation method thereof, and the method comprises the following steps: the glass base surface is subjected to hydroxylation and amination treatment; catalytic hydrolysis is carried out on ethyl orthosilicate under the alkali condition by taking alcohol as a solvent; Silica microspheres with even size and smooth surface are prepared by an oscillation method; silane coupling agent of which the tail end is provided with amino is assembled on the surface of the silica microspheres; silver sol obtained by reducing sodium borohydride to silver nitrate through oscillation is assembled on the surface of SiO2-NH2NPs, and is diffused in water again after centrifugal separation and washing by distillated water; self assembly is carried out on the silver sol after being placed in SiO2@Ag NPs dispersion for 6-12h; the SERS active substrate is obtained after taking out from water and drying. In the SERS active substrate of the invention, the active particles and the substrate are combined firmly, thus being applicable to detecting unimolecular Raman signals in aqueous solution; the substrate can be used for SERS detection repeatedly, thus improving repeated utilization ratio of the substrate.

Owner:NORTHWEST NORMAL UNIVERSITY

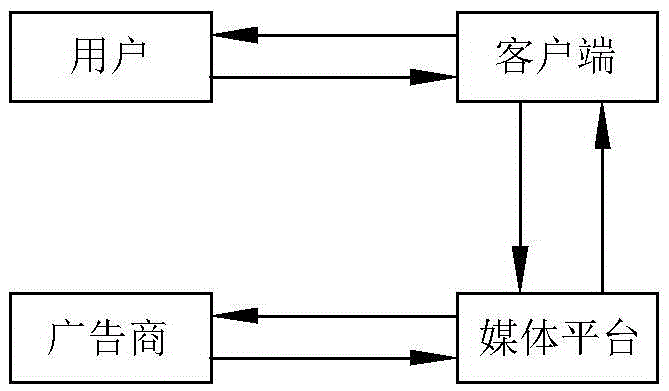

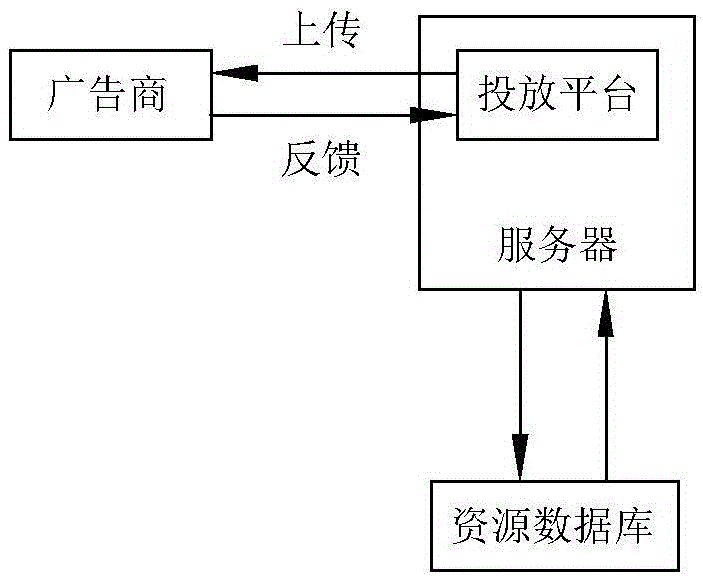

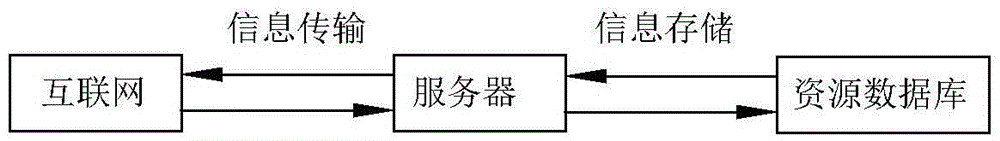

Interactive internet advertisement putting method and system

InactiveCN105427135AIncrease the fun of reading advertisementsActive attentionMarketingThe InternetQuestions and answers

The invention relates to an interactive internet advertisement putting method and system. Interactive activities are loaded to advertisements pushed by a media platform, and users obtain bonuses corresponding to the current interactive activity after accomplishing the interactive activity, wherein the interactive activities include interactive games, interactive questions and answers or real-time lotteries. By adopting the method and the system, users have the opportunity to obtain multiple bonuses provided by advertisers by browsing advertisements and freely participating in interactive activities, such as cash bonus, gifts, vouchers, free tickets, or integrals of the media platform and the like; users participating in interesting interaction can be changed from passive to active and gain benefits, and the interest of browsing advertisements can be aroused. As for advertisers, when interesting interaction is set in advertisements, the attraction is enhanced, users can positively concern advertisement contents, and multiple propagation effects of advertisement putting can be achieved.

Owner:HUAQIAO UNIVERSITY

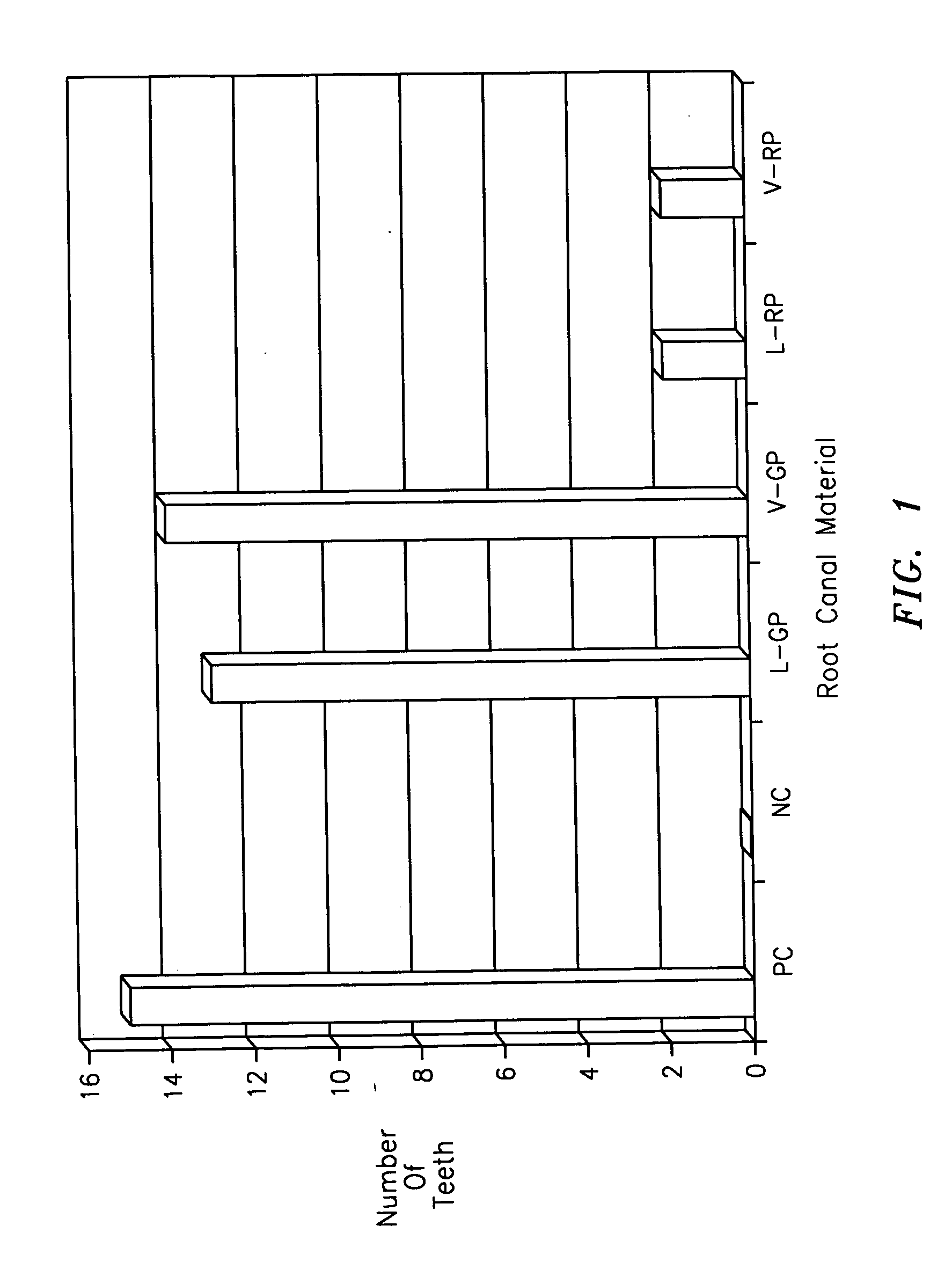

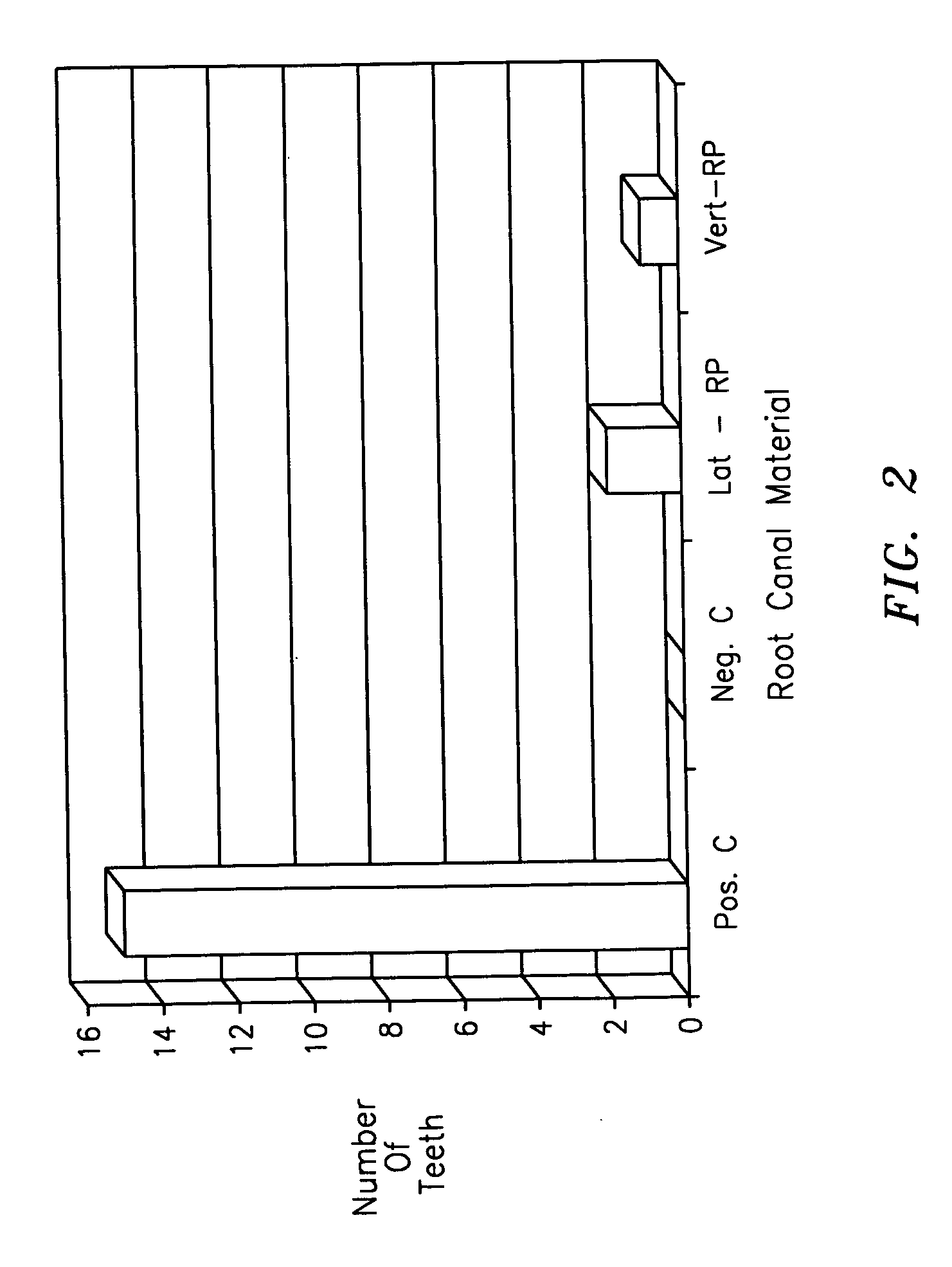

Dental filling material

ActiveUS20050066854A1High strength and rigidityGood fusion characterImpression capsWheelchairs/patient conveyanceFilling materialsPlasticizer

A dental filling material comprising an inner core and outer layer of material disposed and surrounding the inner core, both the inner core and outer layer of material each containing a thermoplastic polymer. The thermoplastic polymer may be biodegradable. A bioactive substance may also be included in the filling material. The thermoplastic polymer acts as a matrix for the bioactive substance. The composition may include other polymeric resins, fillers, plasticizers and other additives typically used in dental materials. The filling material is used for the filing of root canals.

Owner:PENTRON CLINICAL TECH

Constructs binding to phosphatidylserine and their use in disease treatment

ActiveUS20060228299A1Accelerated destructionFunction increaseAntibacterial agentsSenses disorderDiseaseCancers diagnosis

Disclosed are new phosphatidylserine binding constructs with surprising combinations of properties, and a range of diagnostic and therapeutic conjugates thereof. The new constructs effectively bind phosphatidylserine targets in disease and enhance their destruction, and can also specifically deliver attached imaging or therapeutic agents to the disease site. Also disclosed are methods of using the new construct compositions, therapeutic conjugates and combinations thereof in tumor vasculature targeting, cancer diagnosis and treatment, and for treating viral infections and other diseases.

Owner:PEREGRINE PHARMA INC +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com