Patents

Literature

104results about "Structural elements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

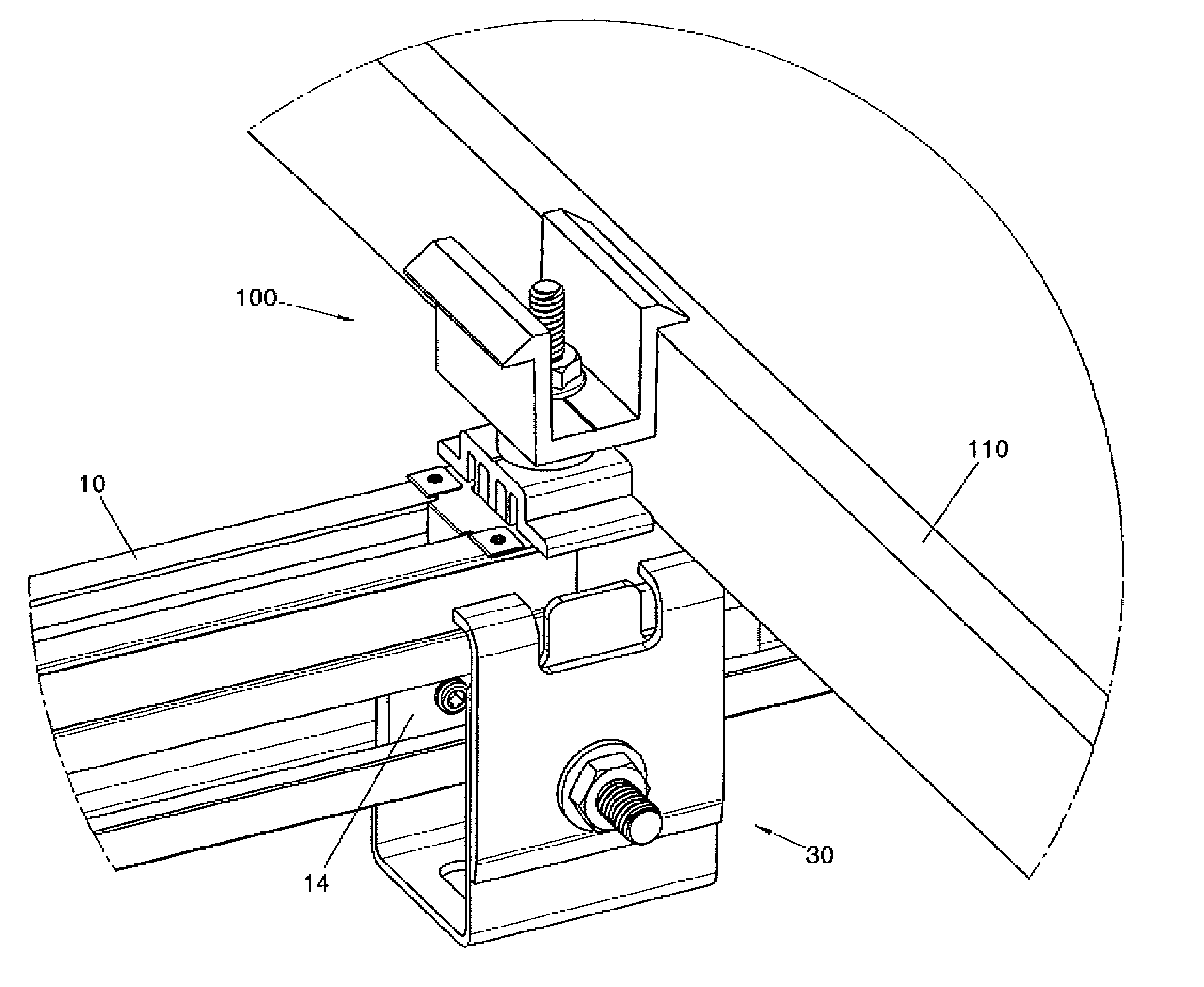

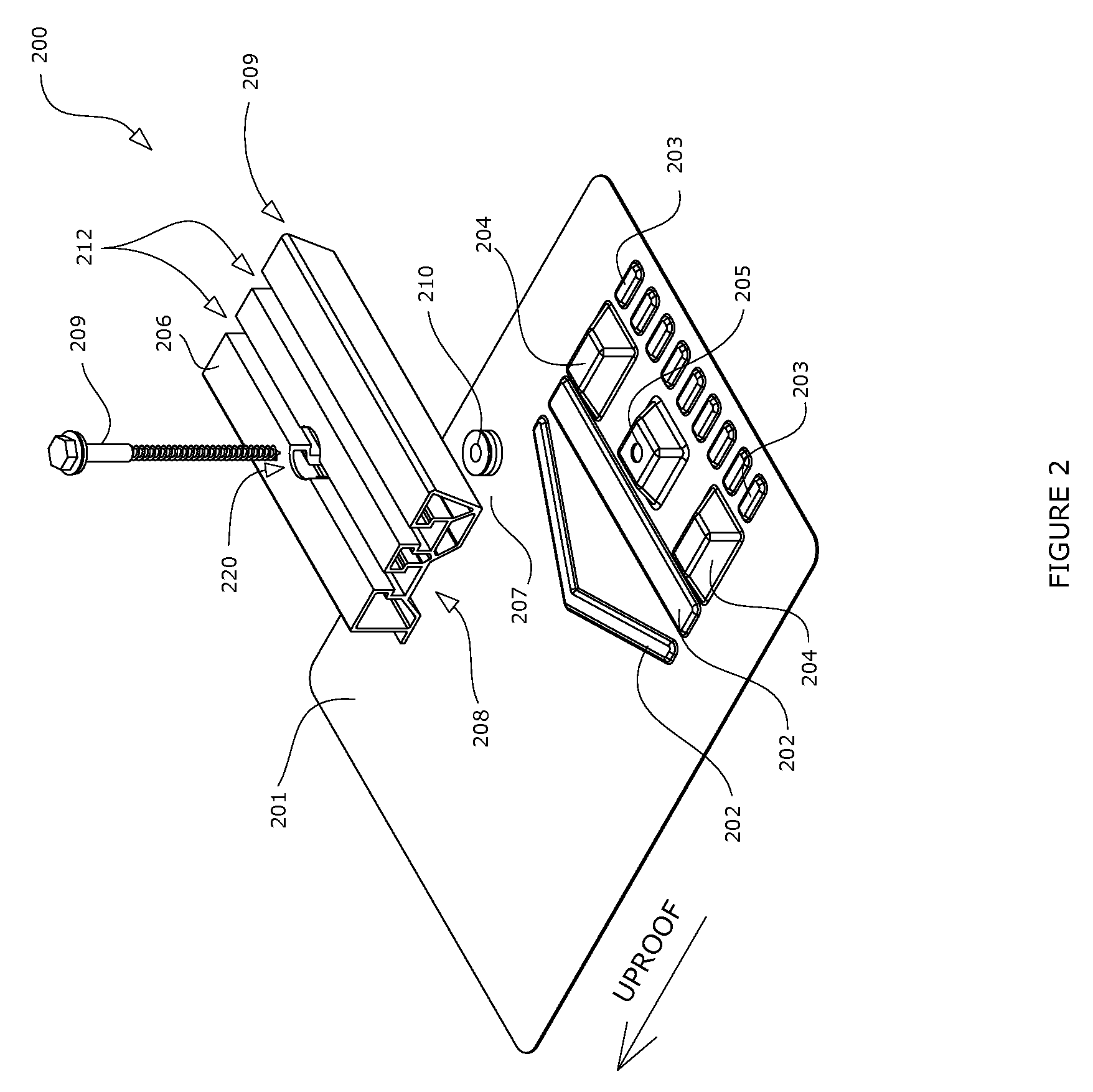

Mounting systems for solar panels

Mounting systems for mounting solar panels to a surface are disclosed and can include panel clamp assemblies and rail clamp assemblies. Panel clamp assemblies can comprise a panel clamp having a base and arms extending from edges of the base, the base having an aperture, a rail clamp having a central portion with an aperture and two flexible tabs extending from the central portion on opposing sides of the aperture and a fastener threaded through the apertures such that that flexible tabs contact a head of the fastener and the arms extend in an opposite direction from the flexible tabs. Rail clamp assemblies can comprise a base member having a bottom and two side walls, the bottom having at least one aperture and each side wall having an elongated aperture, two clamping members and a fastener, wherein the side walls of the base member are positioned such that the opening is of sufficient size to receive the rail.

Owner:APPLIED ENERGY TECH

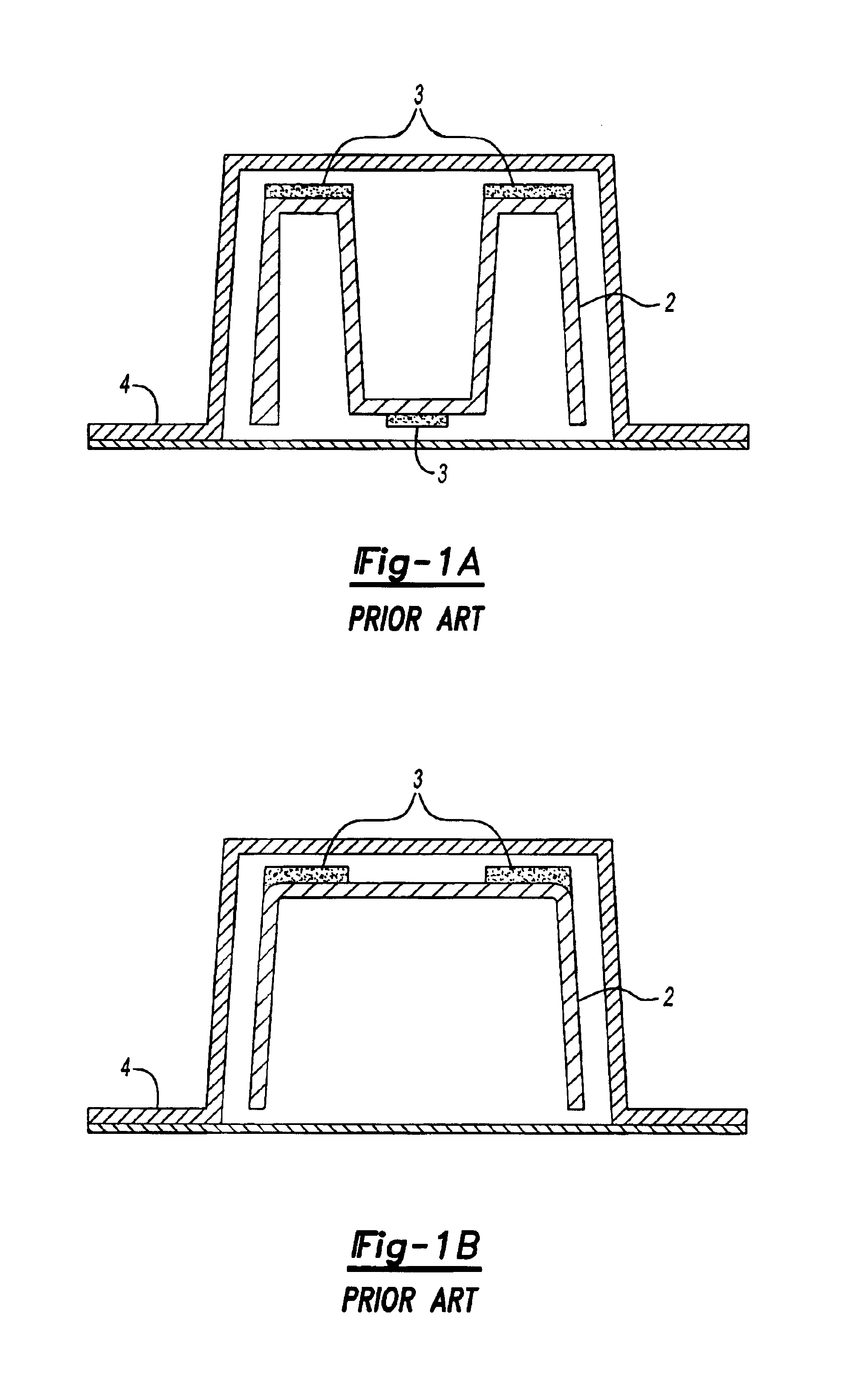

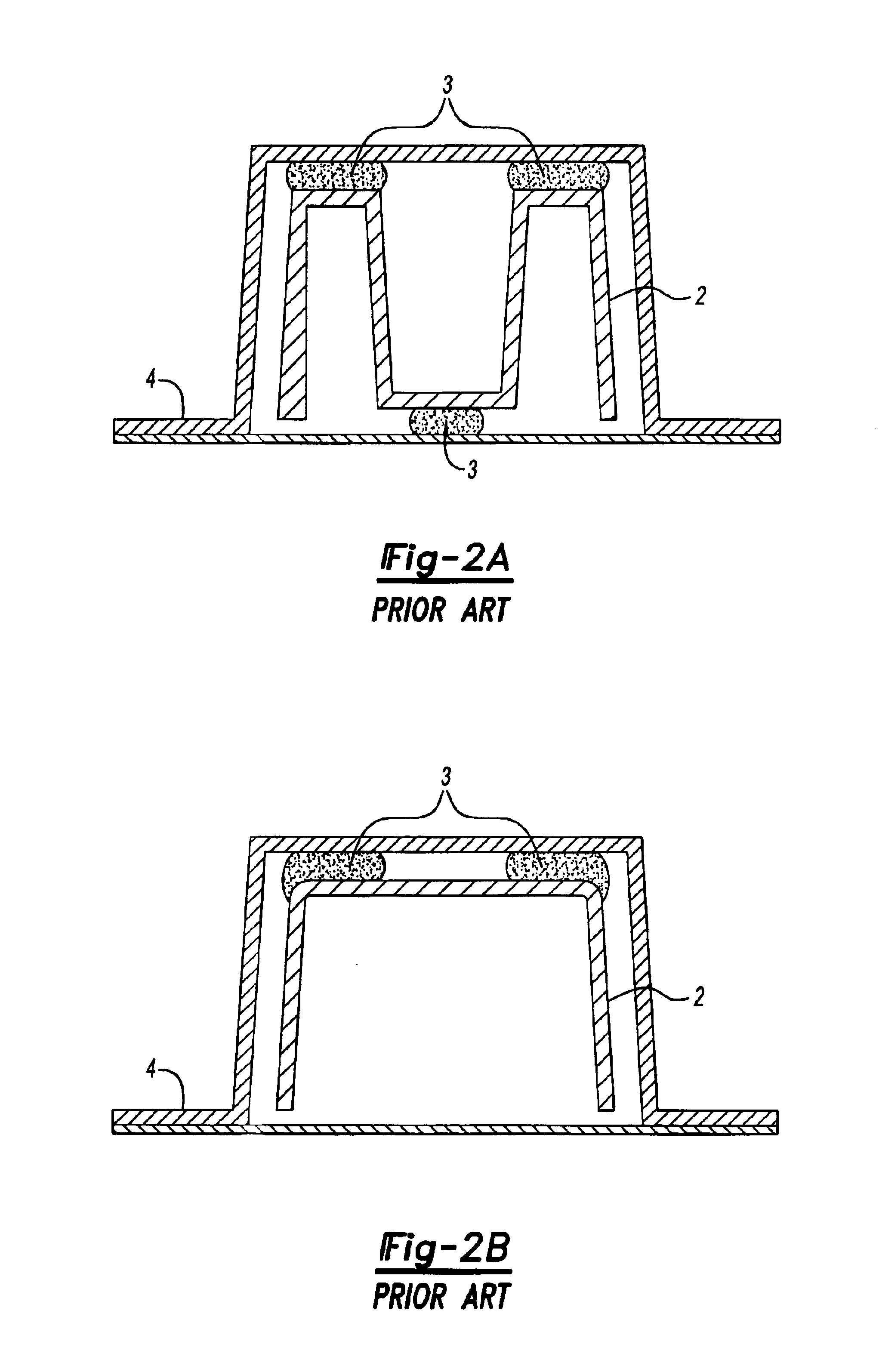

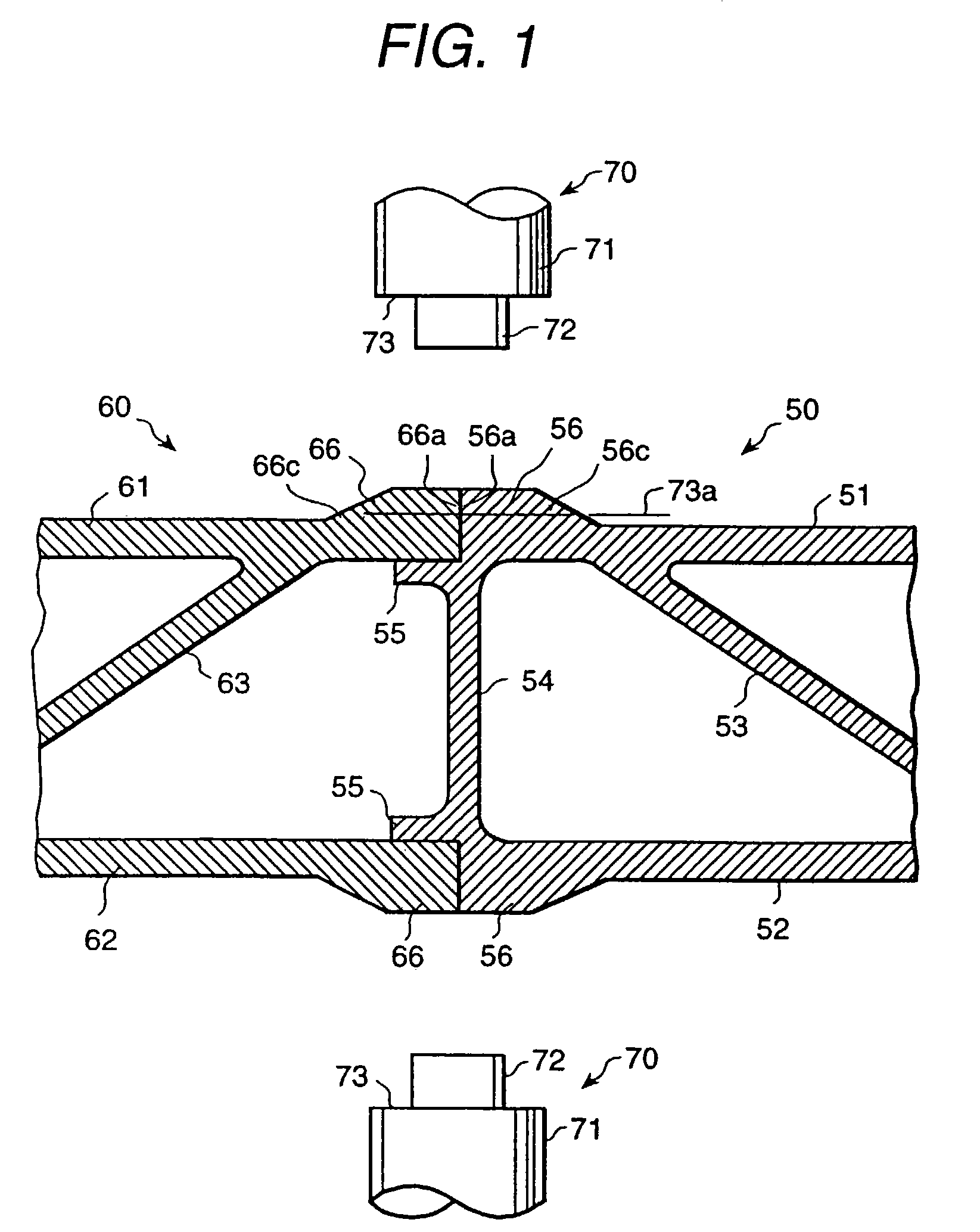

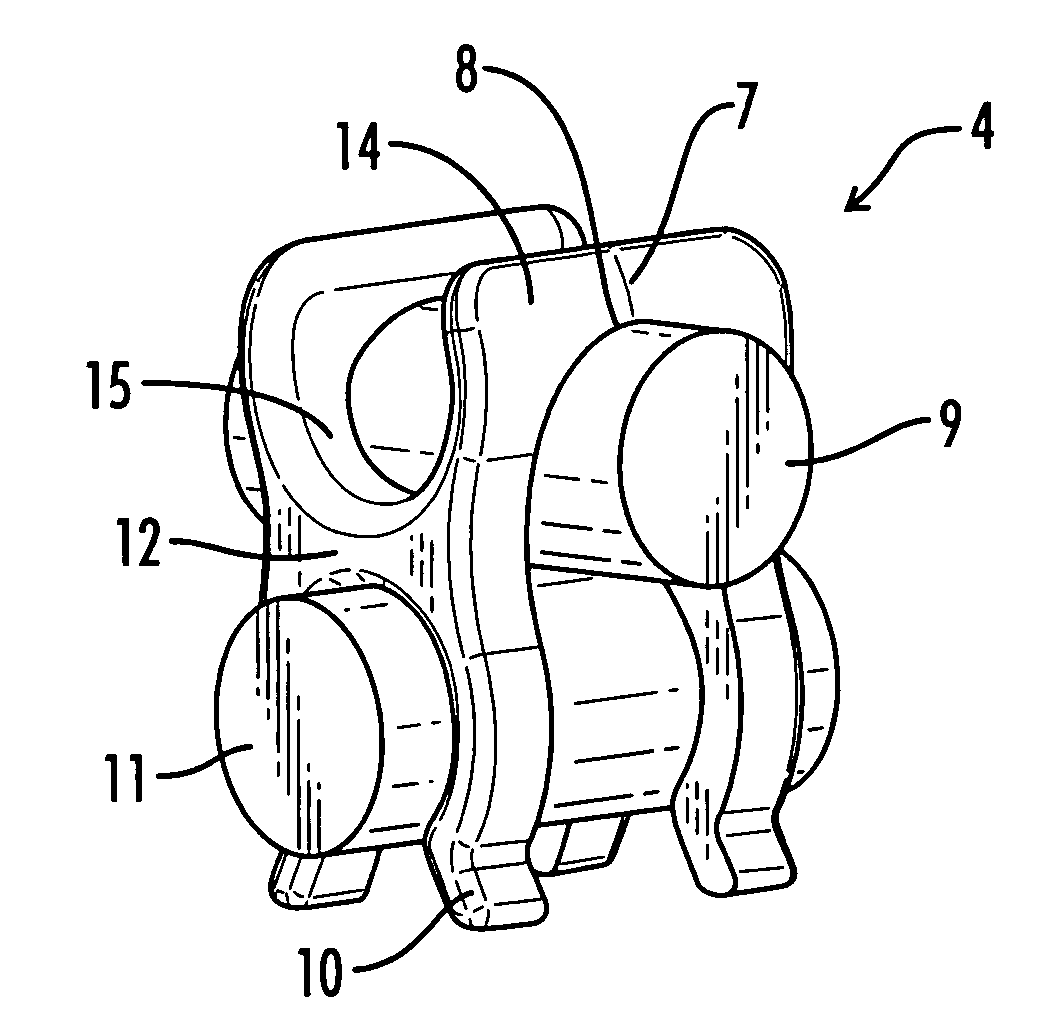

Structural reinforcement

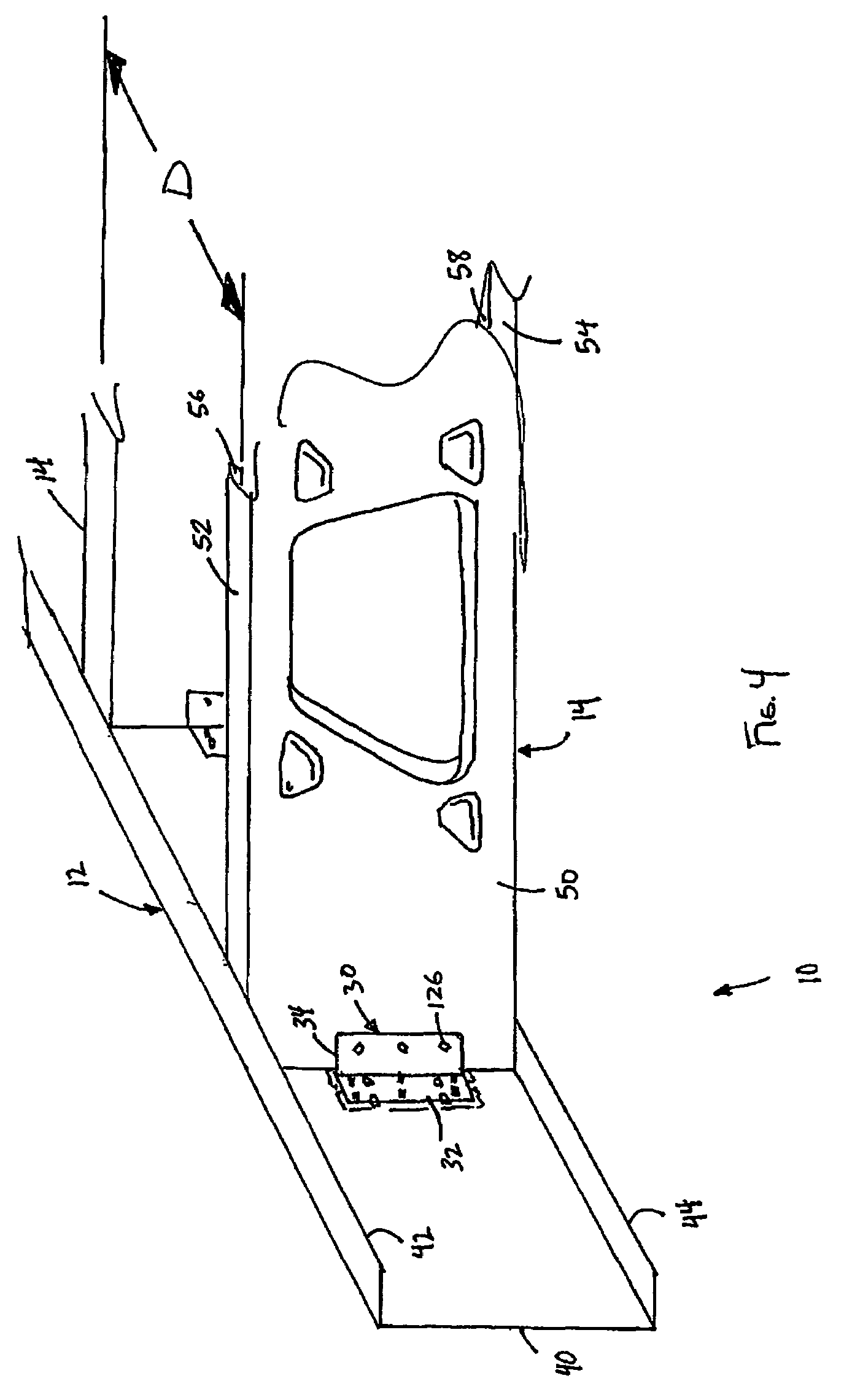

InactiveUS6941719B2Reduced strengthSatisfies requirementVehicle seatsStructural elementsAdhesive materialsBiomedical engineering

A structural reinforcement for a hollow member comprising a rigid reinforcing member having a shape that substantially conforms to the cross section of the hollow member to be reinforced with an expandable adhesive material over at least a portion of the surface of the structural reinforcement having one or more extensions on its external surface which control and direct the direction in which the adhesive material expands to bond the reinforcing member to the internal surface of the hollow member, some of the extensions also provide improved reinforcement.

Owner:ZEPHYROS INC

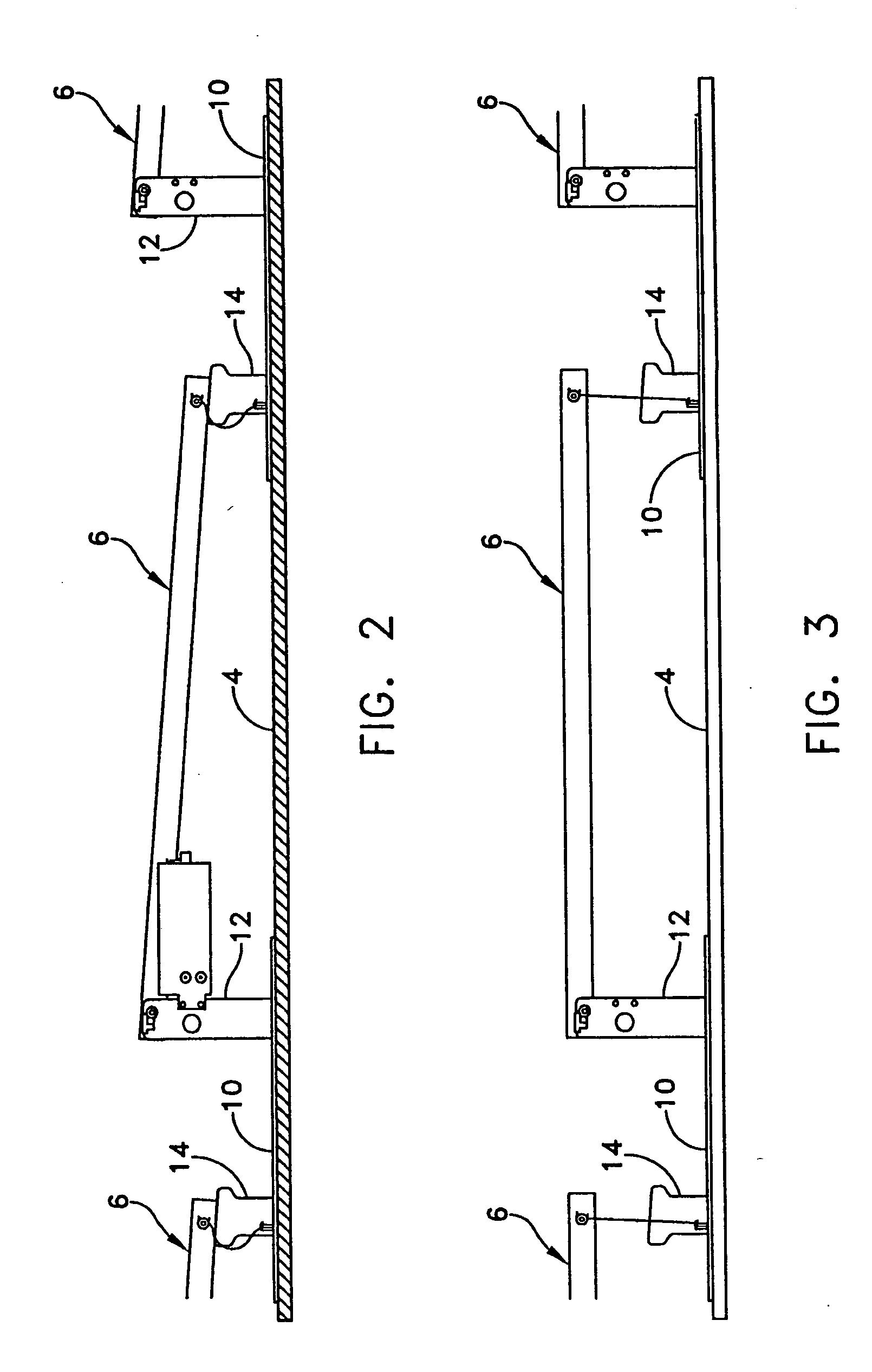

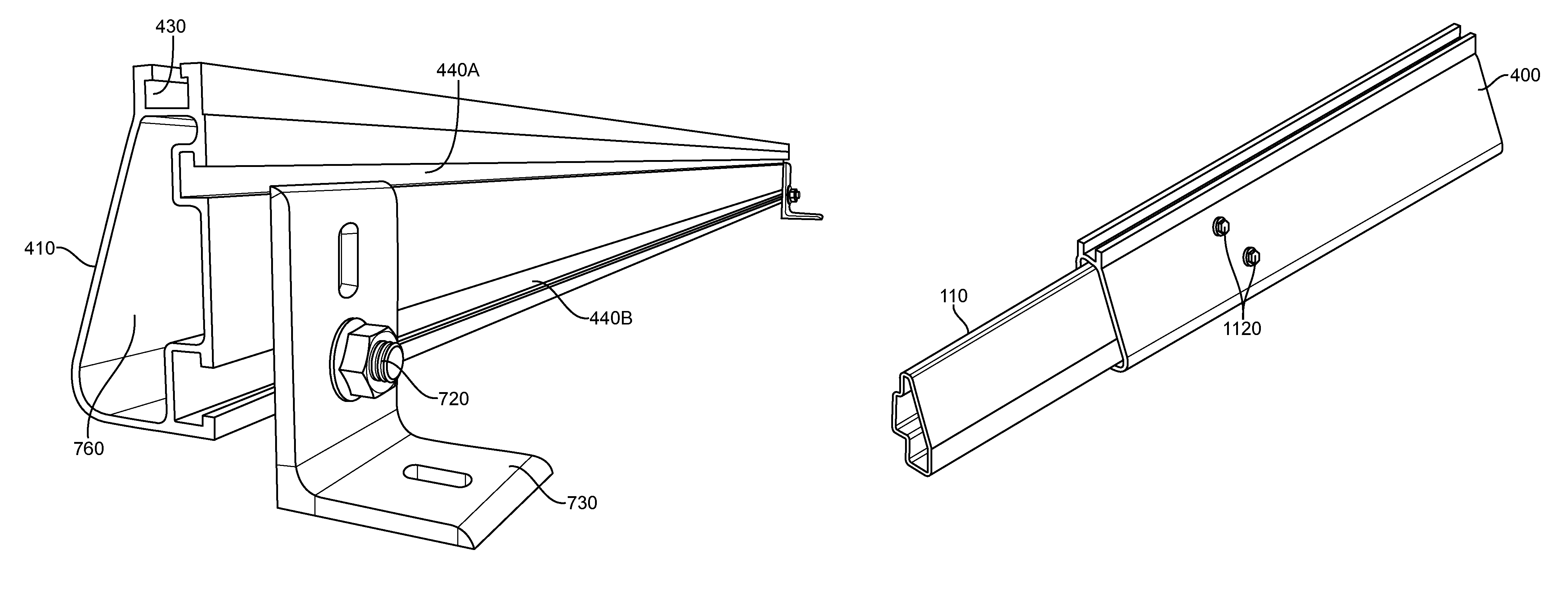

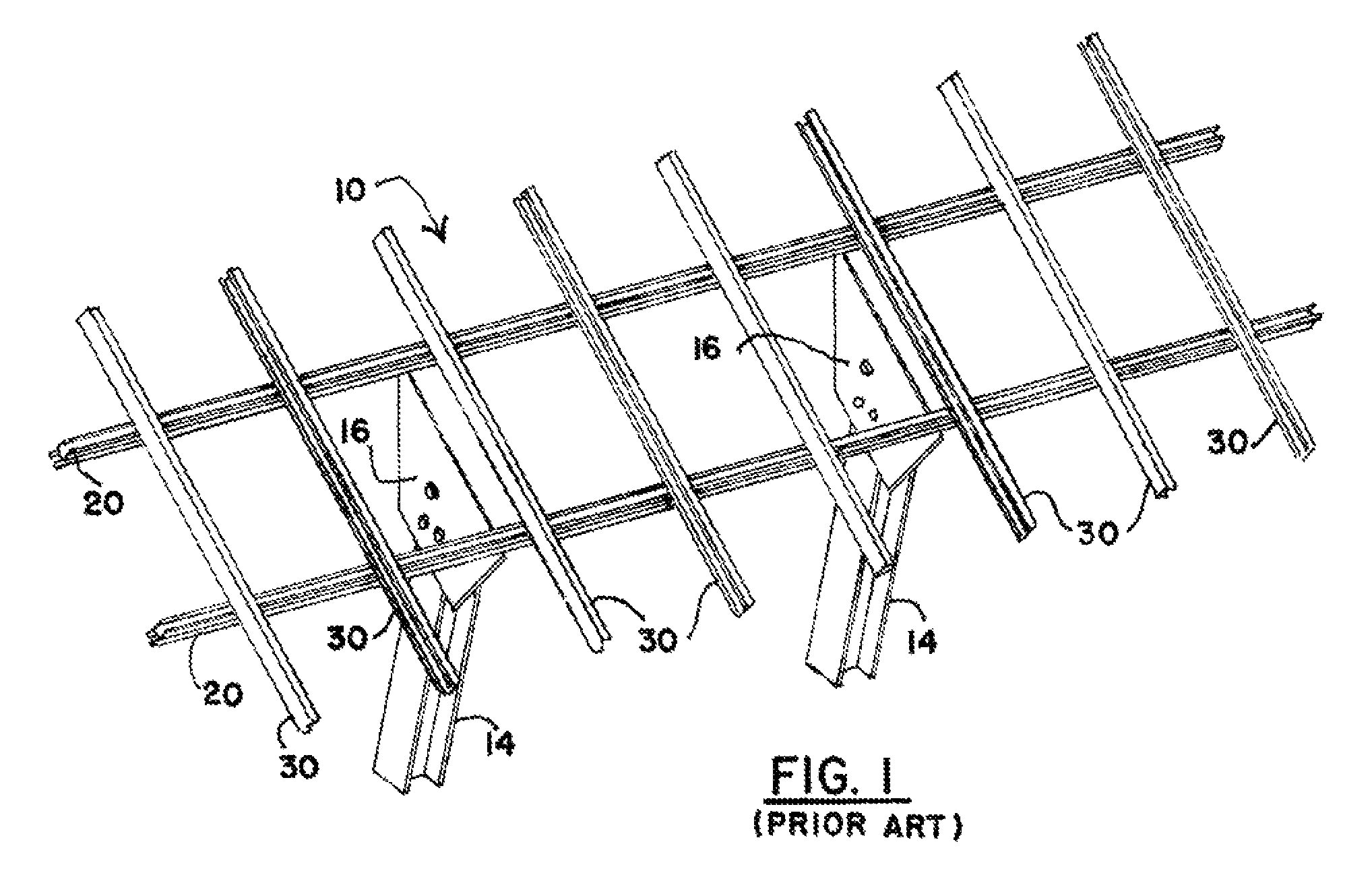

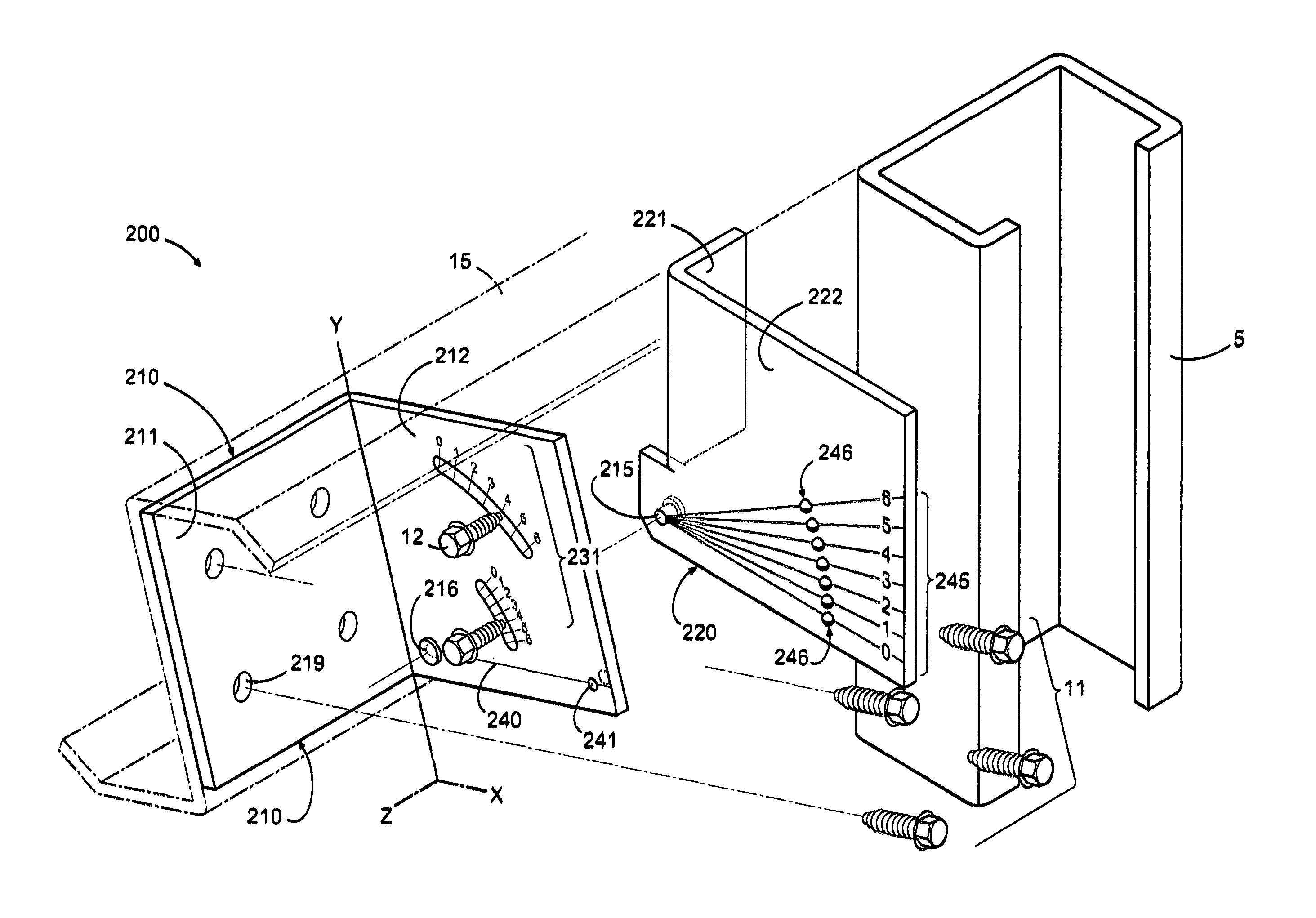

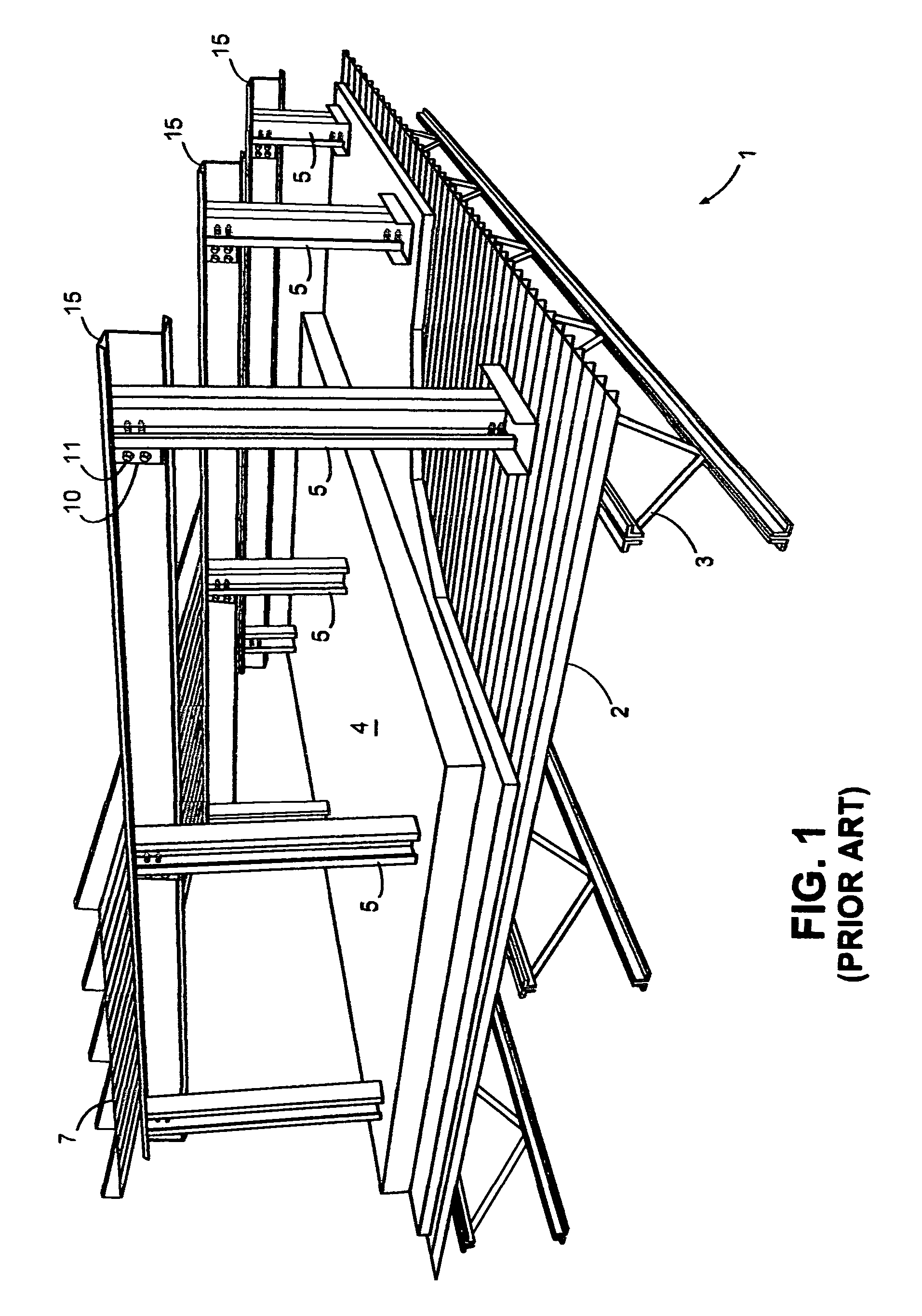

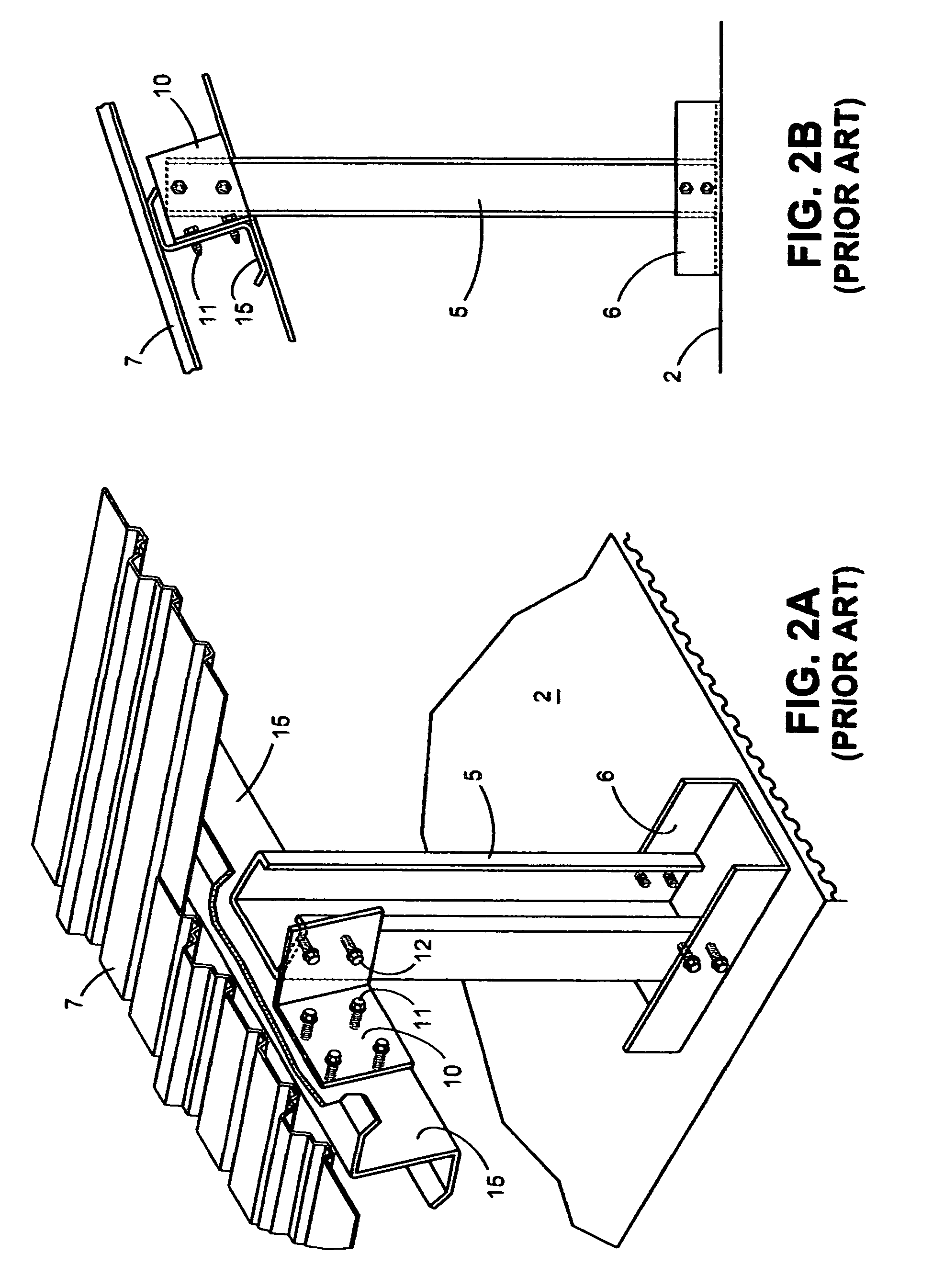

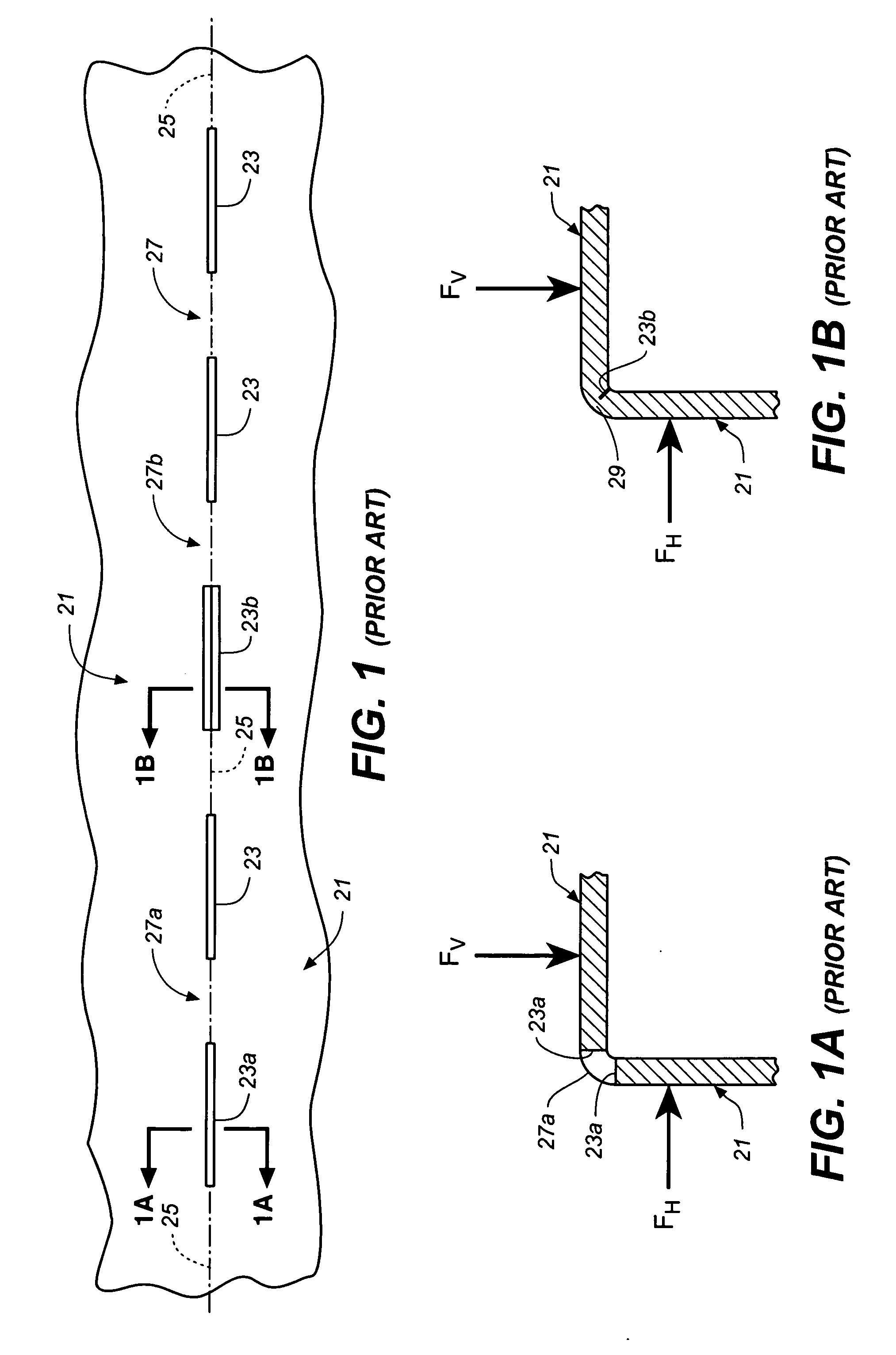

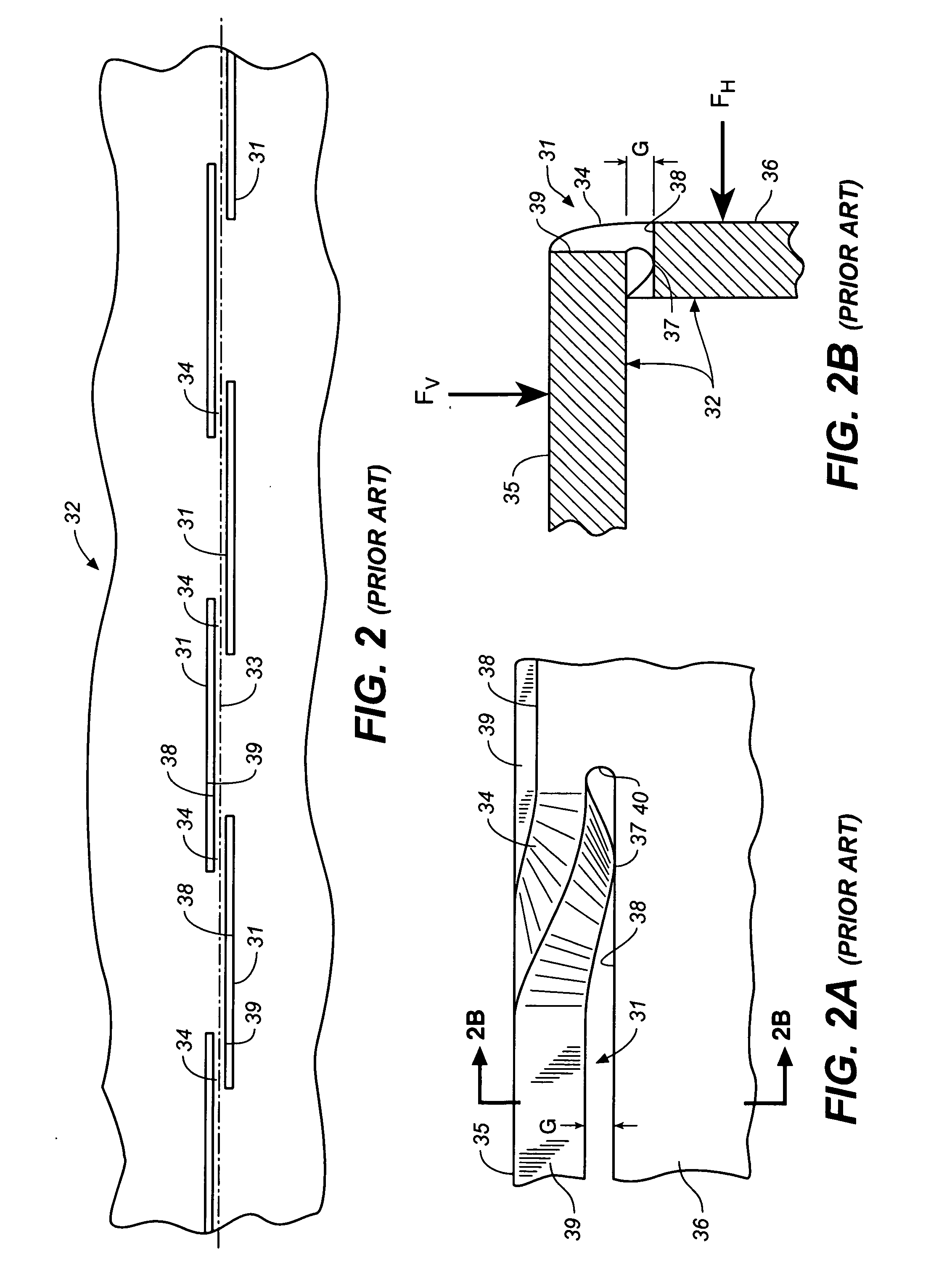

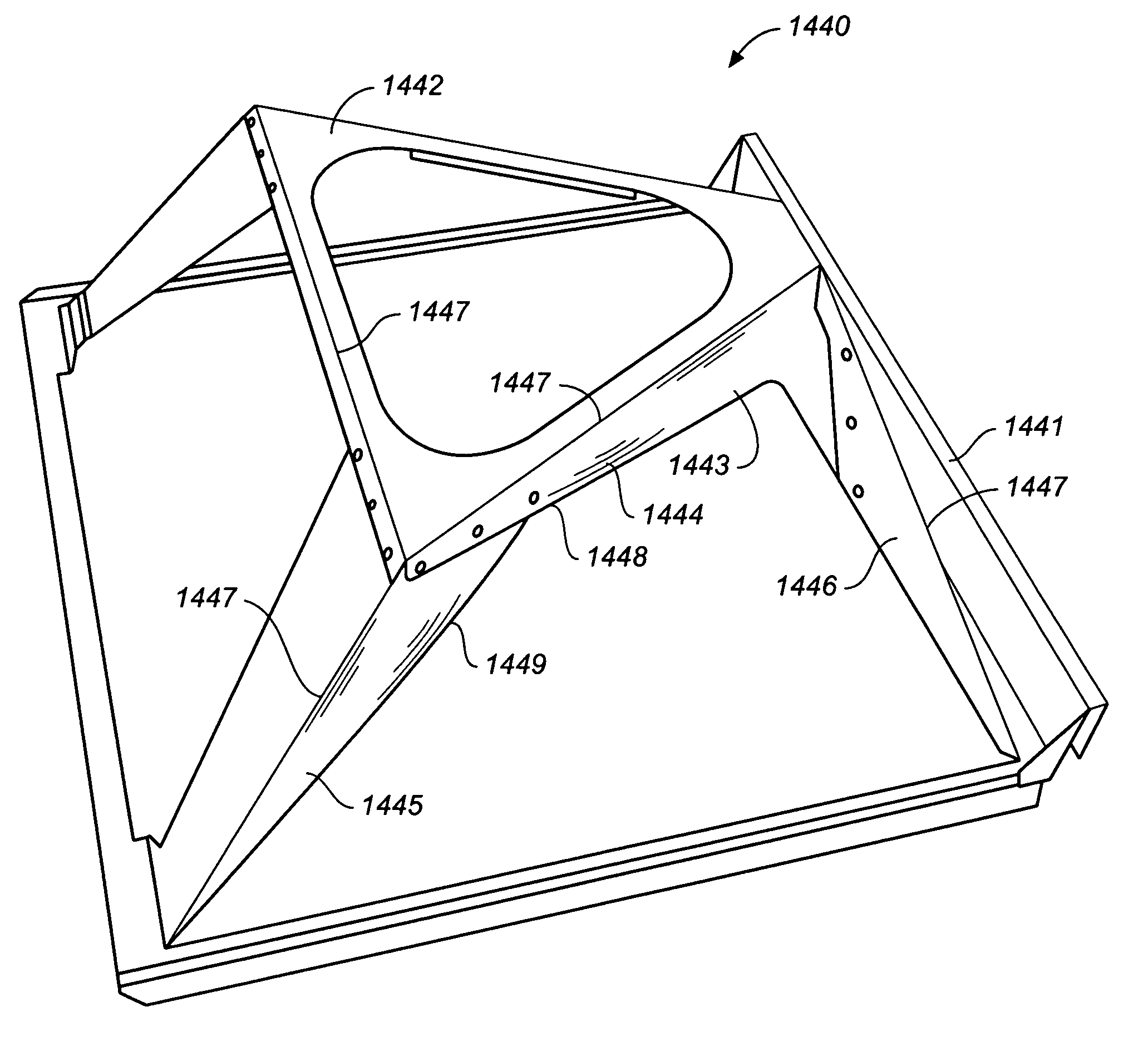

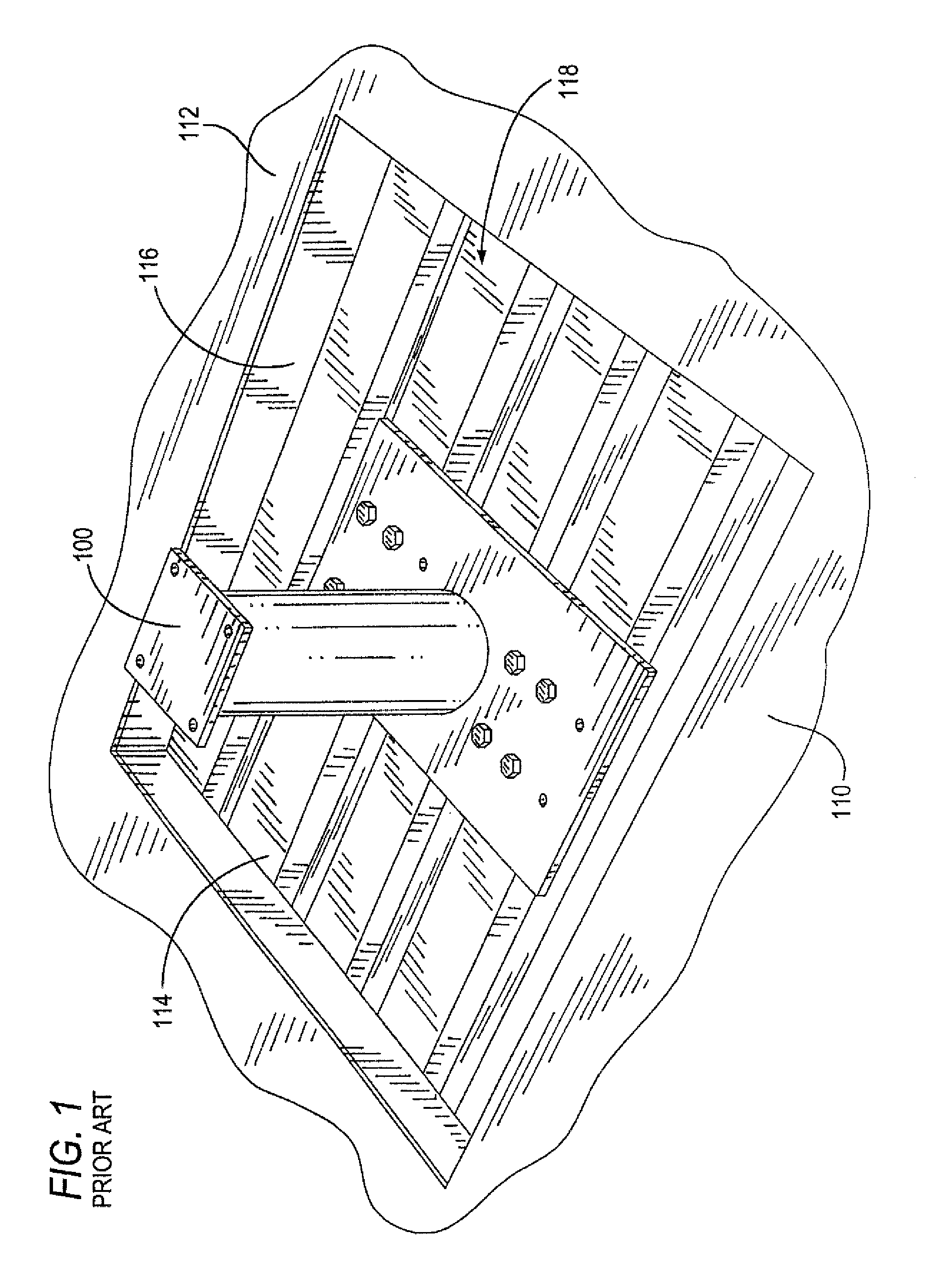

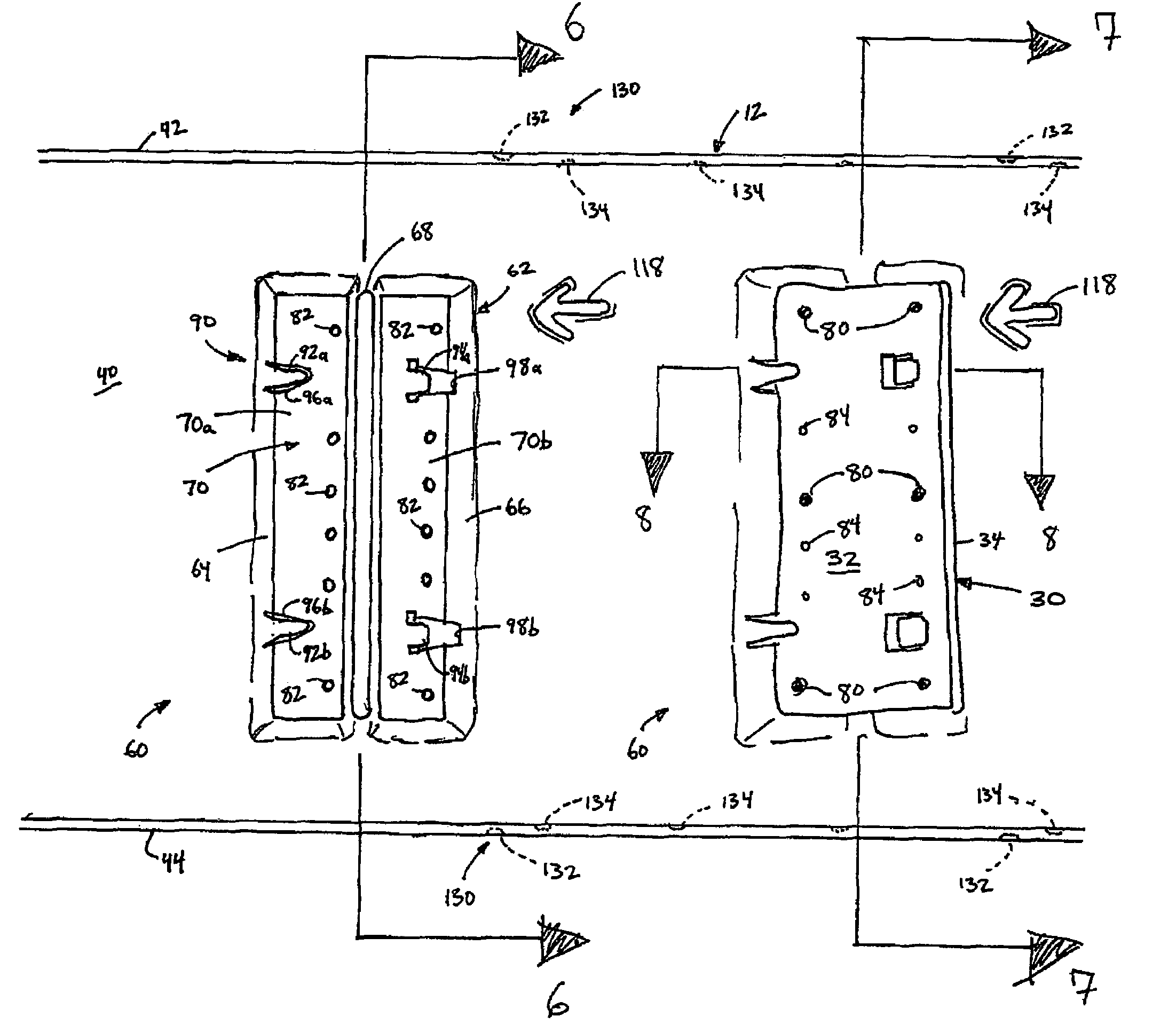

Apparatus for mounting photovoltaic power generating systems on buildings

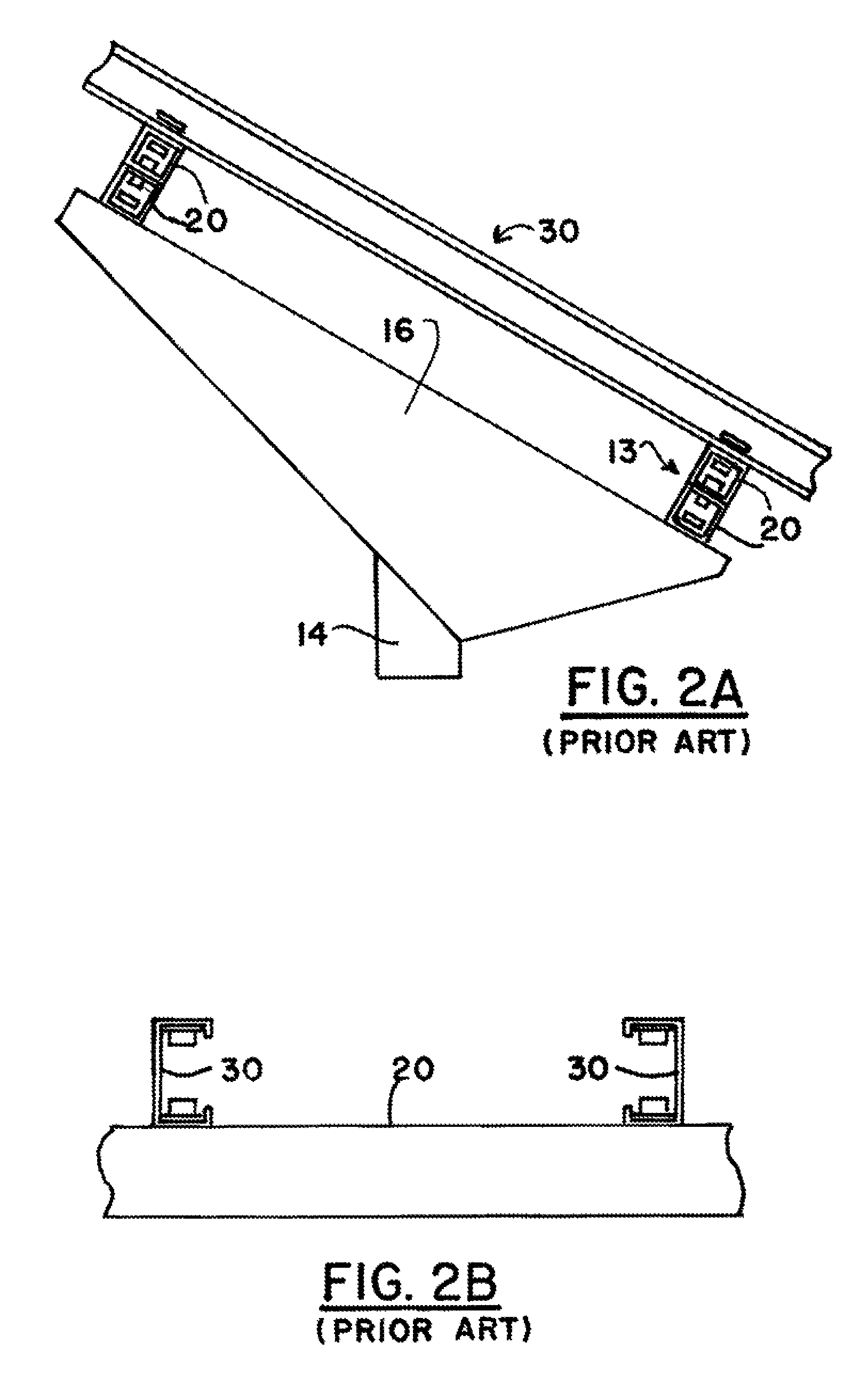

InactiveUS20060053706A1Reduce and eliminate module-distortingReduce and eliminate and module-destructing wind uplift forcePhotovoltaic supportsSolar heating energyStructural engineeringMechanical engineering

Rectangular PV modules are mounted on a building roof by mounting stands that are distributed in rows and columns. Each stand comprises a base plate that rests on the building roof and first and second brackets of different height attached to opposite ends of the base plate. Each bracket comprises dual module-supporting members for supporting two different PV modules, and each PV module has a mounting stud adjacent to each of its four corners. At one end each module is supported by pivotal attachment of two of its mounting studs to module-supporting members of different first brackets. At its other end each module rests on module-supporting members of two different second brackets, whereby the modules assume a predetermined angle of tilt relative to the roof. Two tethers connect the other two mounting studs to the two different second brackets on which the module rests. The tethers allow the modules to pivot up away from the module-supporting members on which they rest to a substantially horizontal position in response to wind uplift forces, thereby enabling the PV modules and their supporting stands to withstand high velocity winds without the base plates being physically attached to the supporting roof structure.

Owner:THE UNITED STATES AS REPRESENTED BY THE DEPARTMENT OF ENERGY

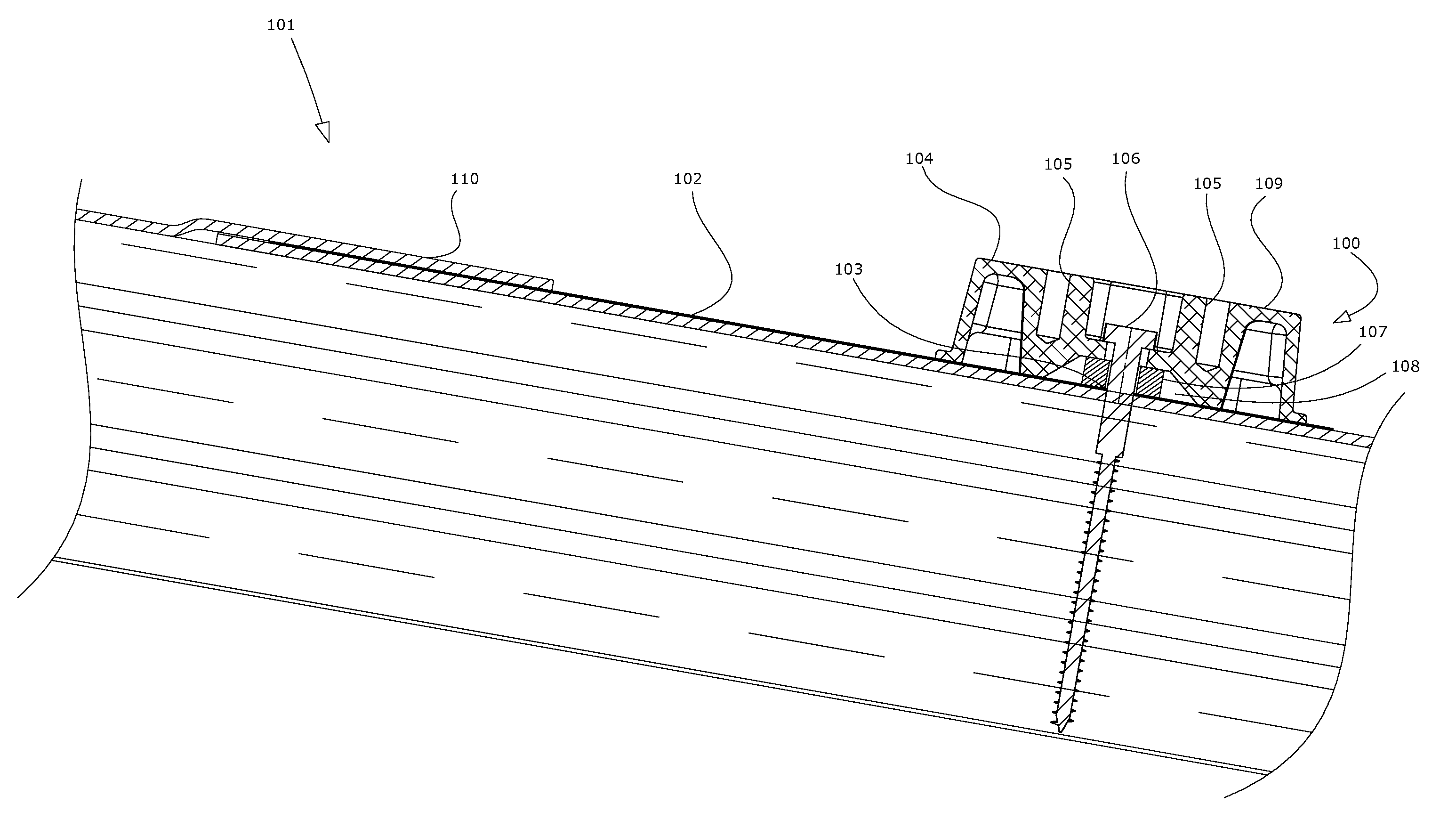

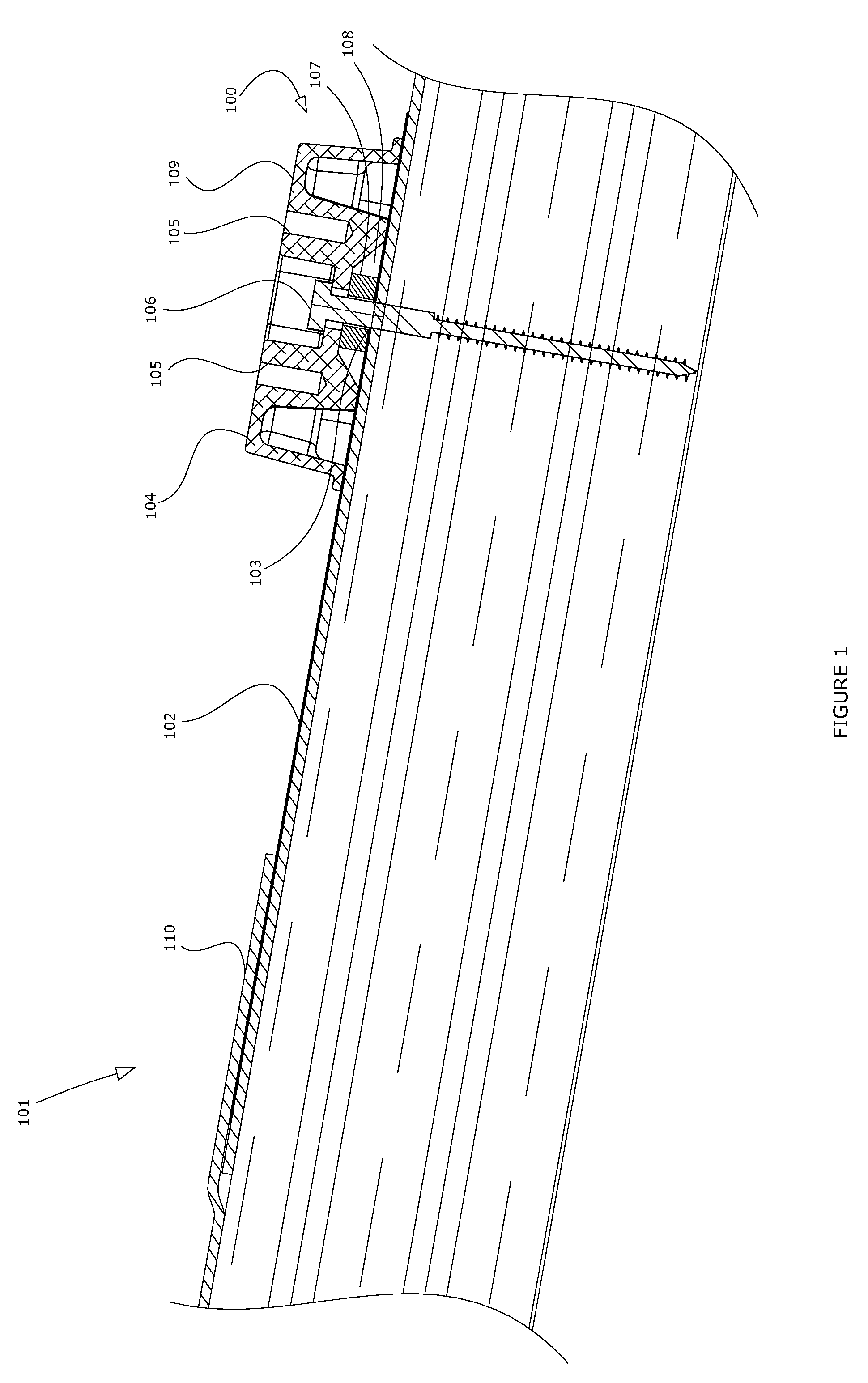

Solar panel attachment system

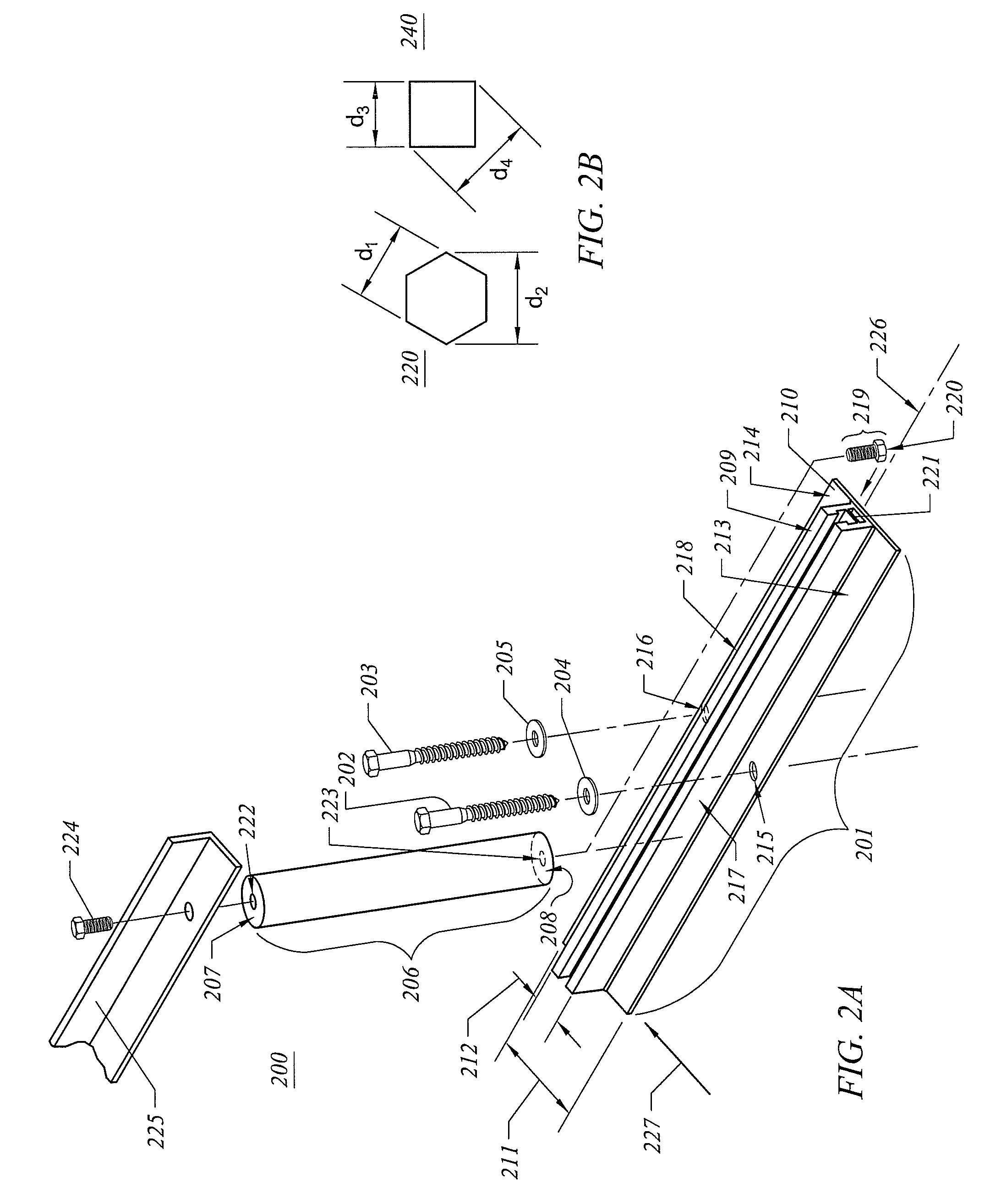

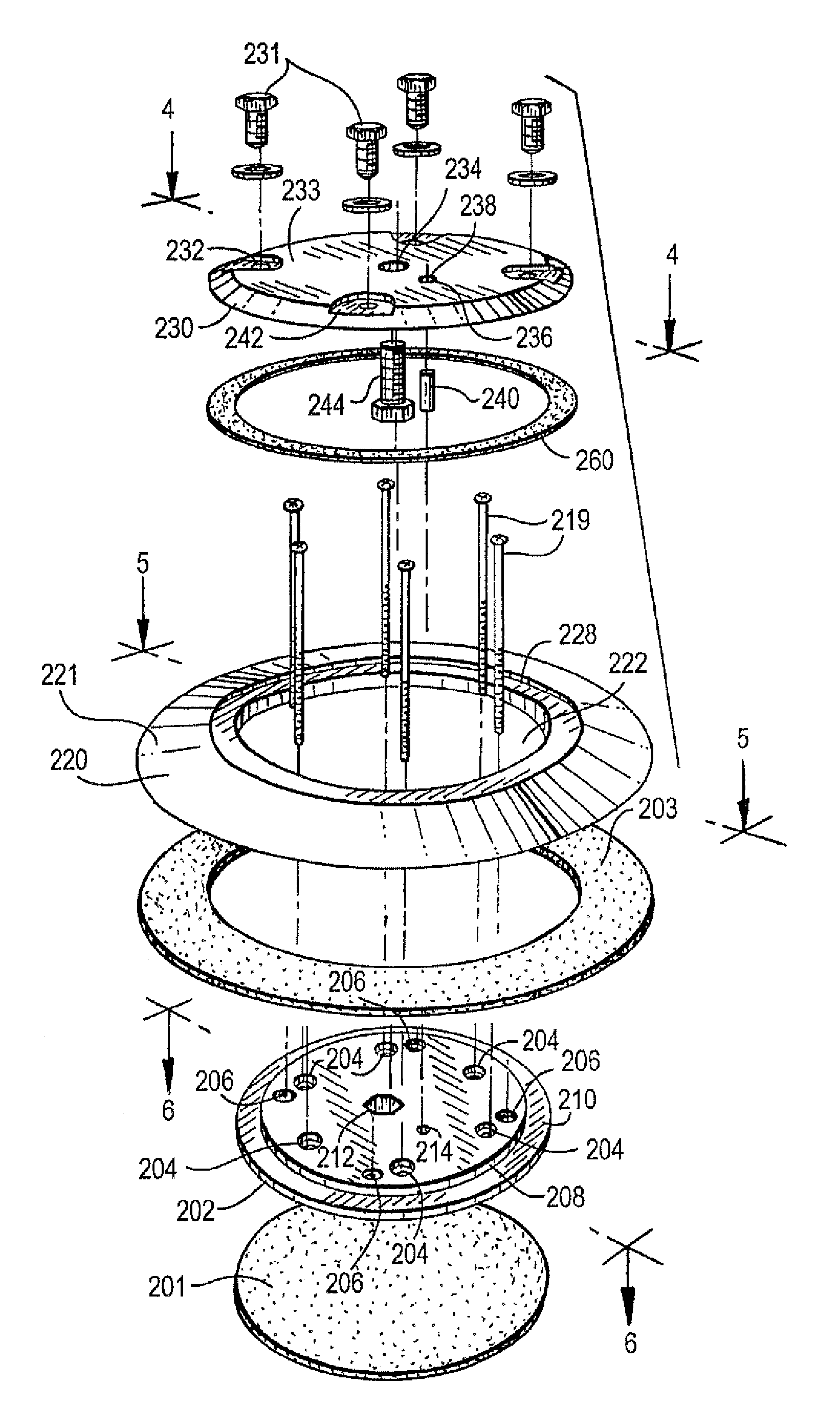

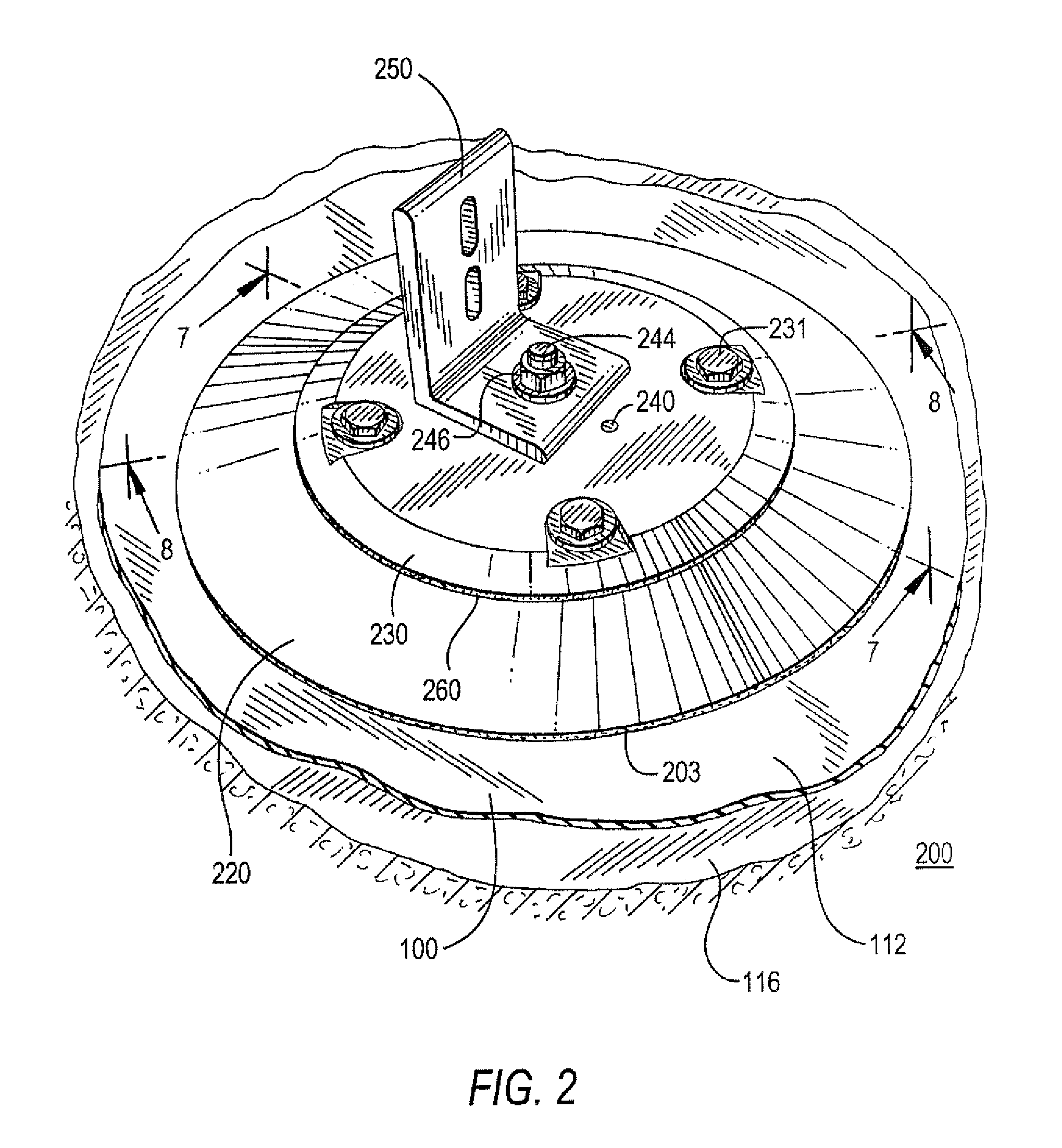

A method, system and apparatus are disclosed regarding an attachment system for solar equipment, sometimes referred to as a flashing device allowing quick and easy assembling of the solar equipment into an array or other combination in a sturdy and durable manner. In examples of the present technology, a flashing device may include a flashing plate which may contain one or more raised features to further direct and control the flow of liquid over the flashing plate. The flashing device may also contain a fluid restrictor such as a seal or part of a seal usually held within an aperture of a block having a skyward facing essentially or substantially flat surface. One or more various items of solar equipment may be attached to the essentially flat surface of the block. Also disclosed are adjustable mounting feet which may be installed in connection with other solar equipment.

Owner:TESLA INC

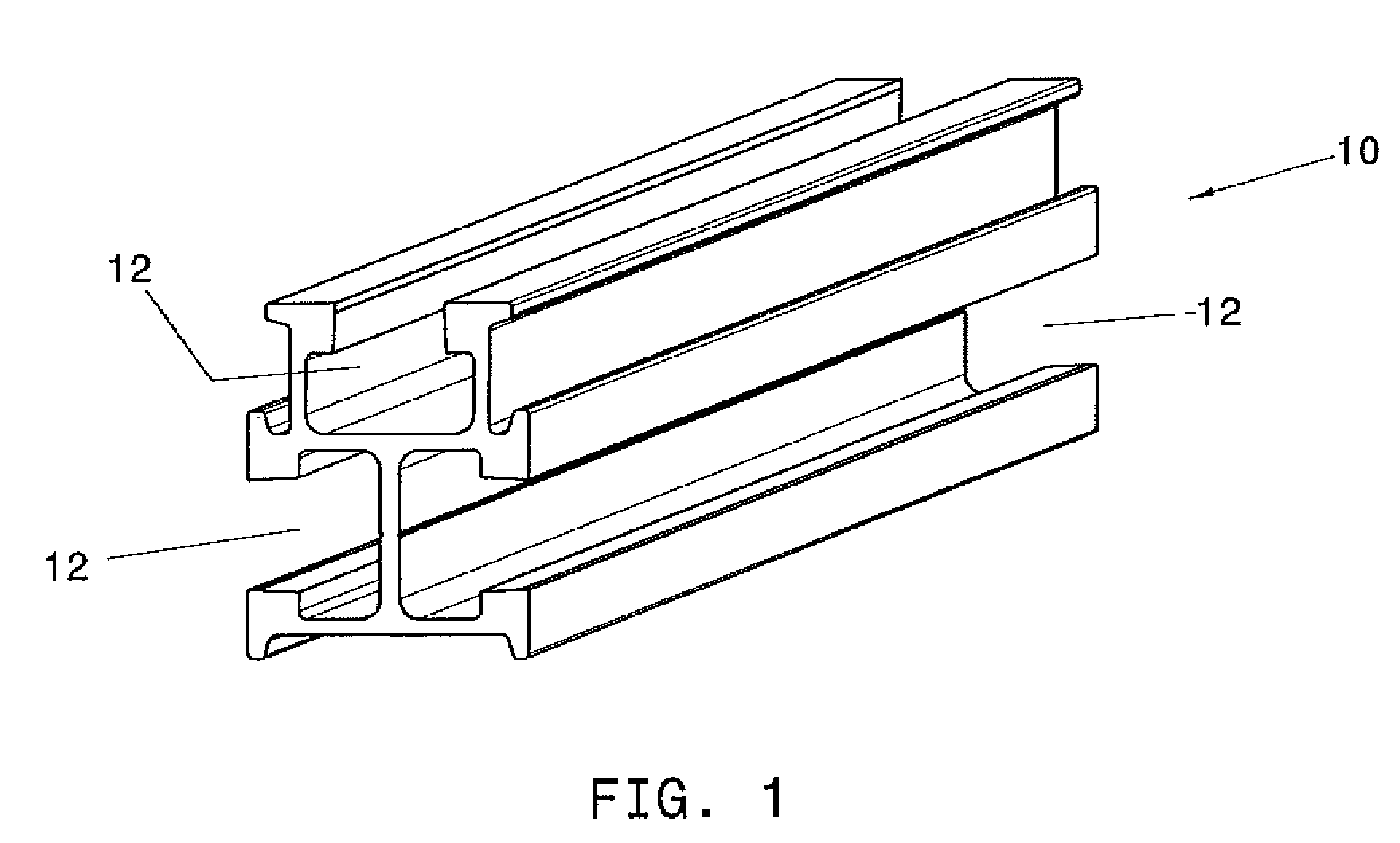

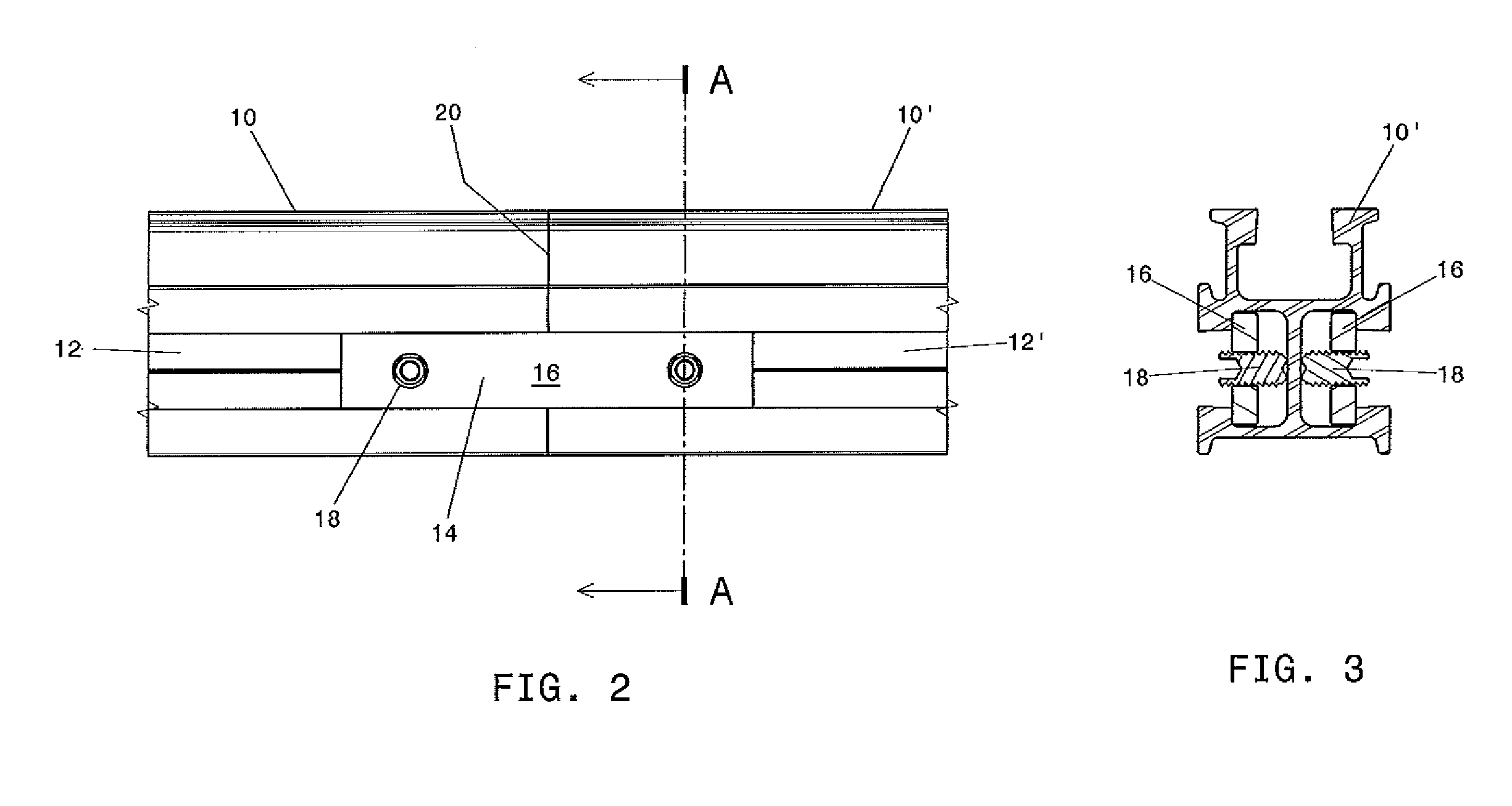

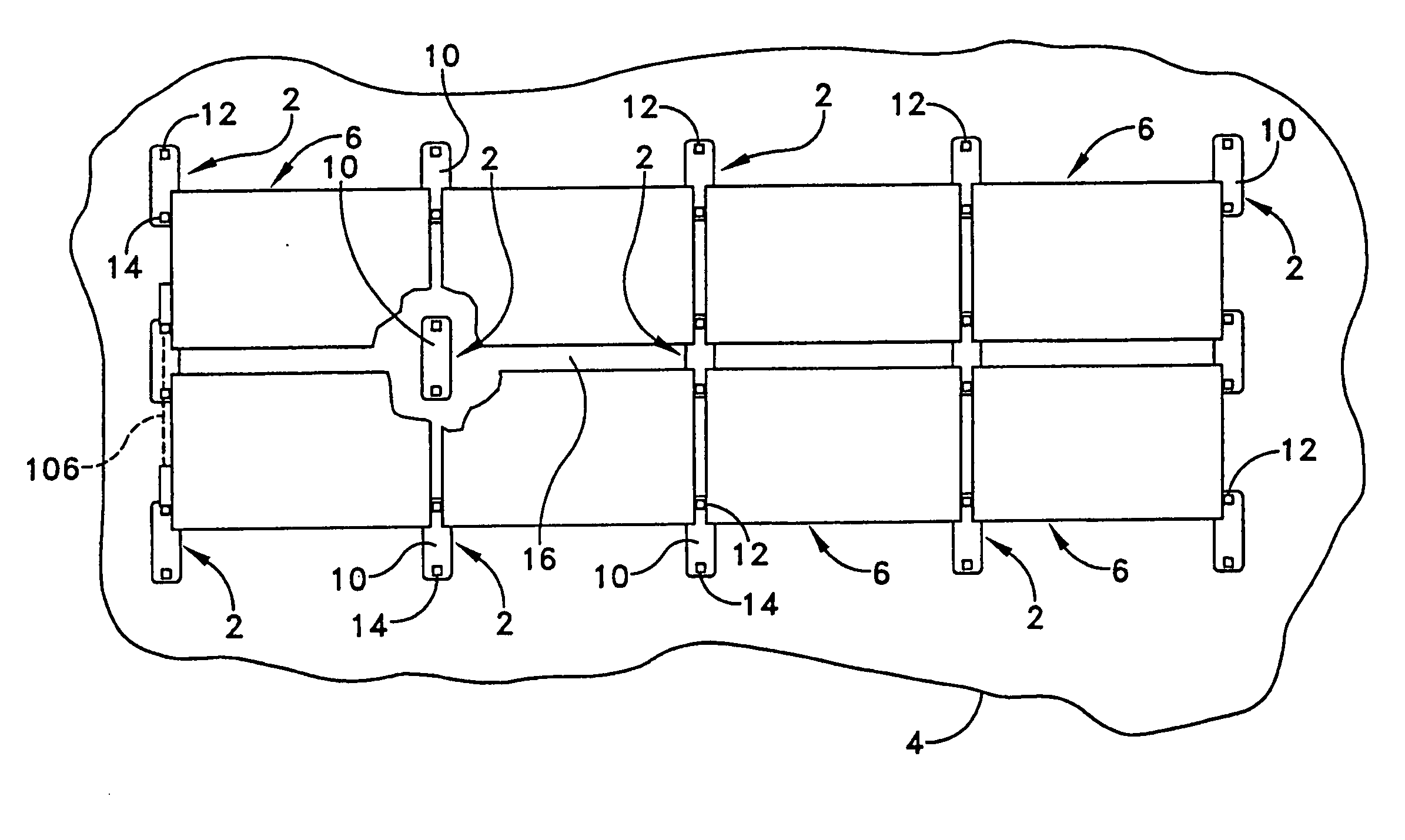

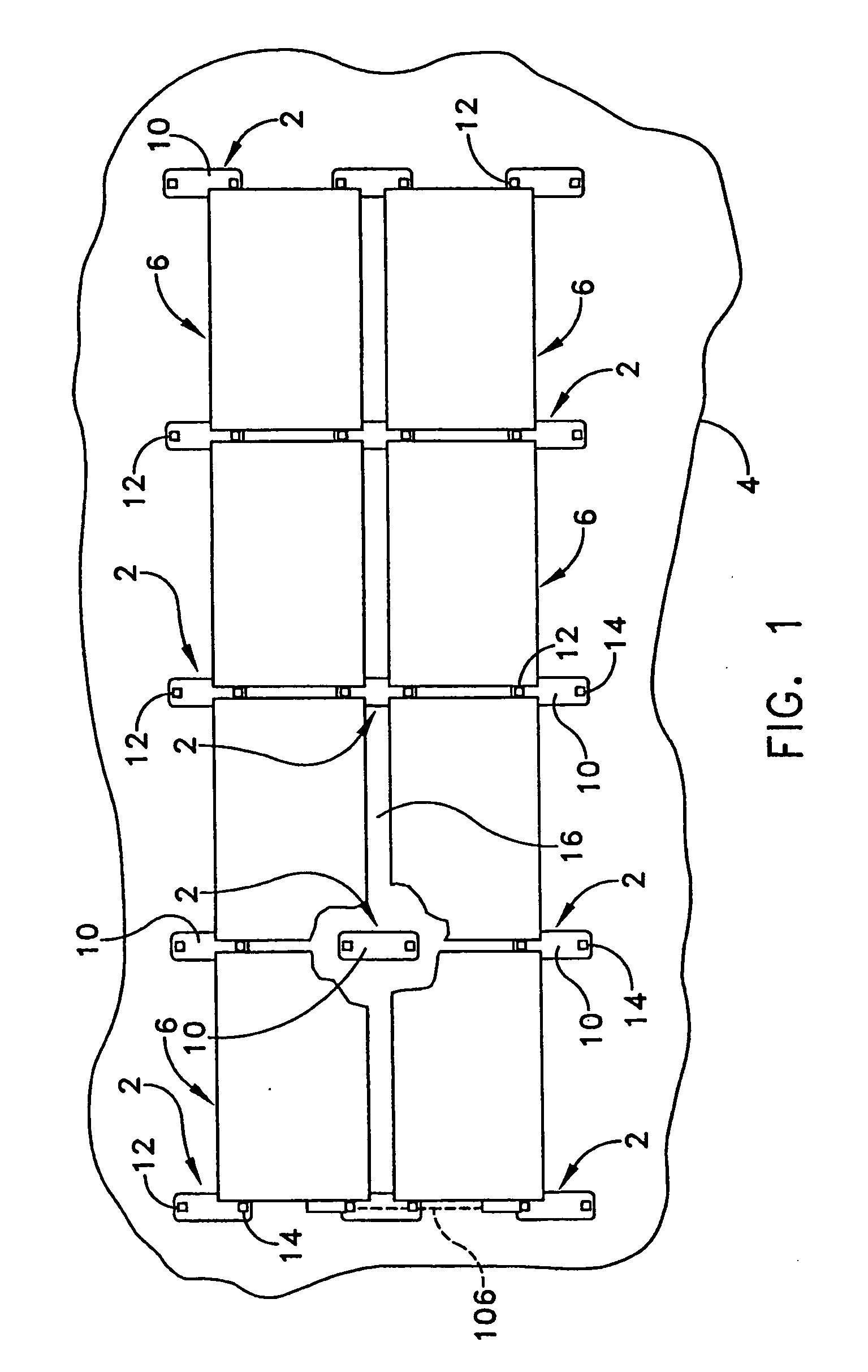

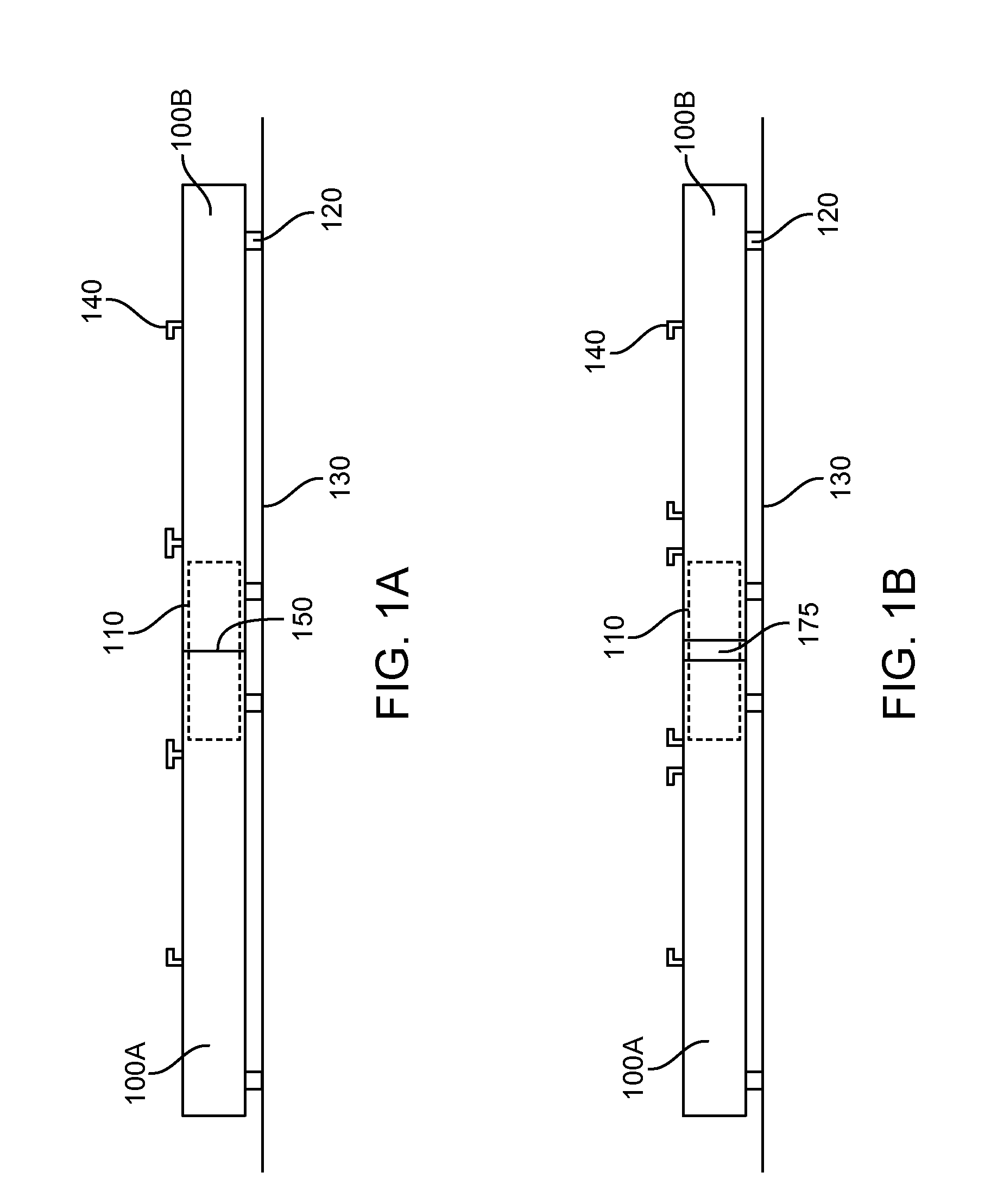

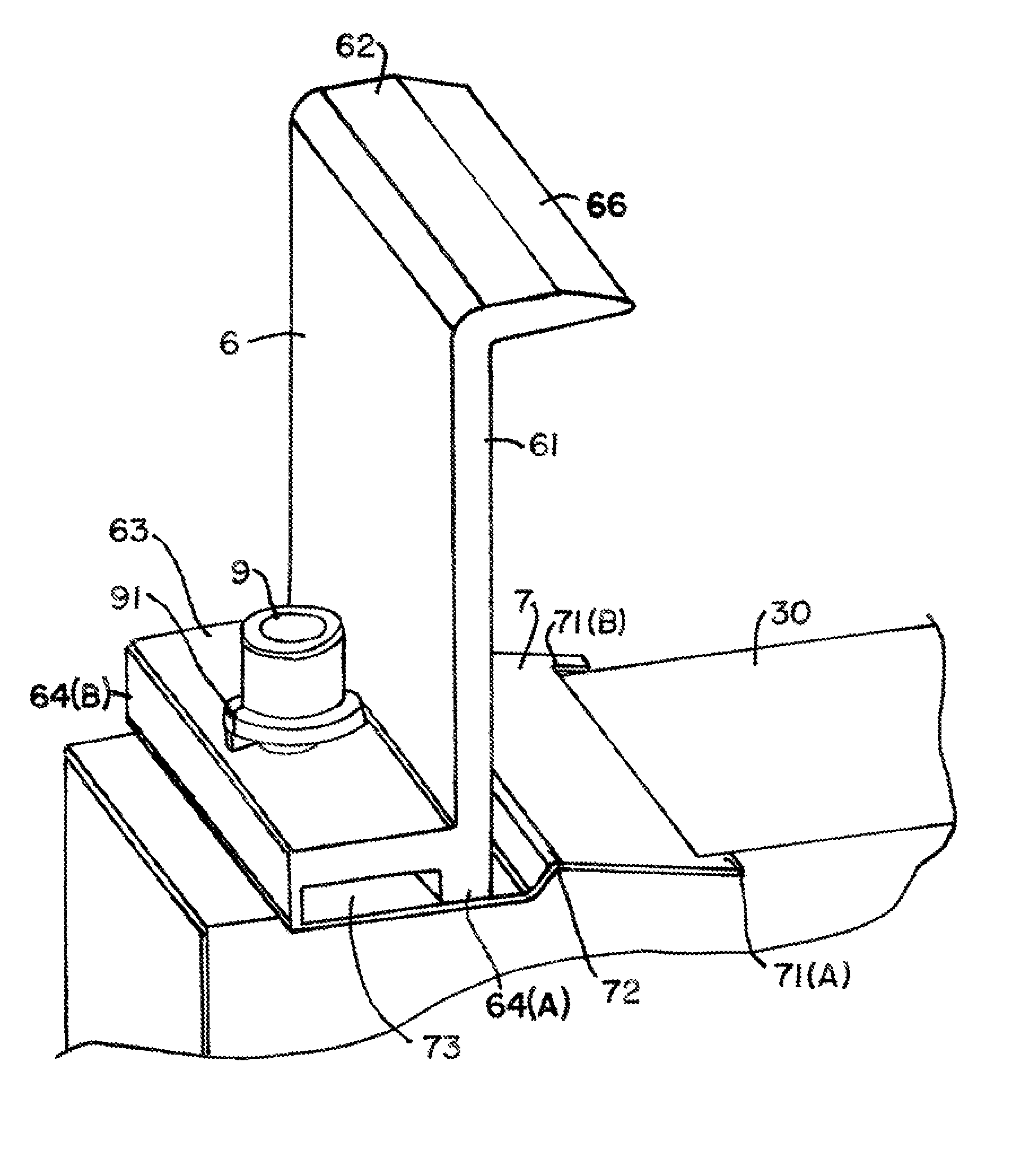

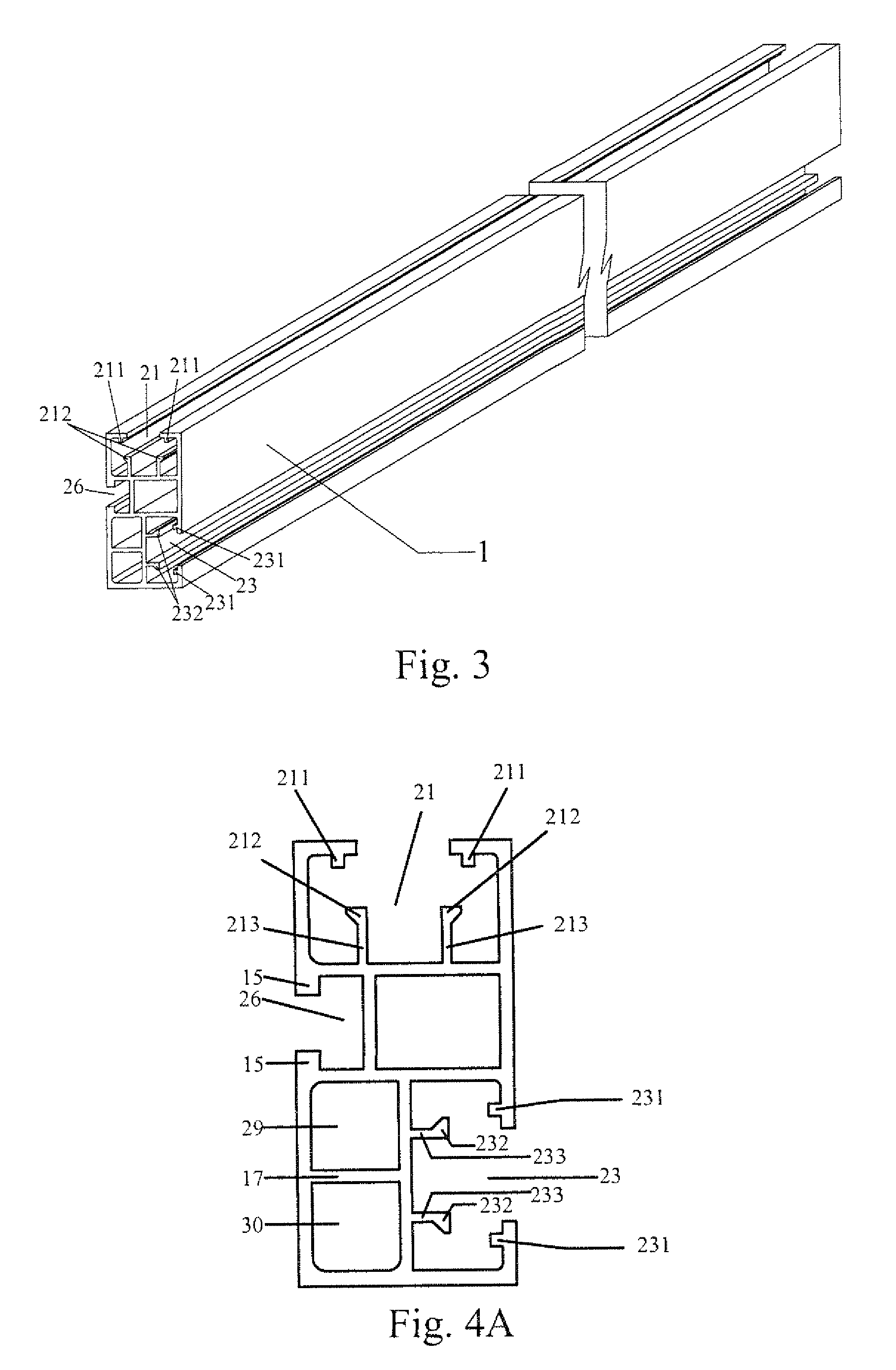

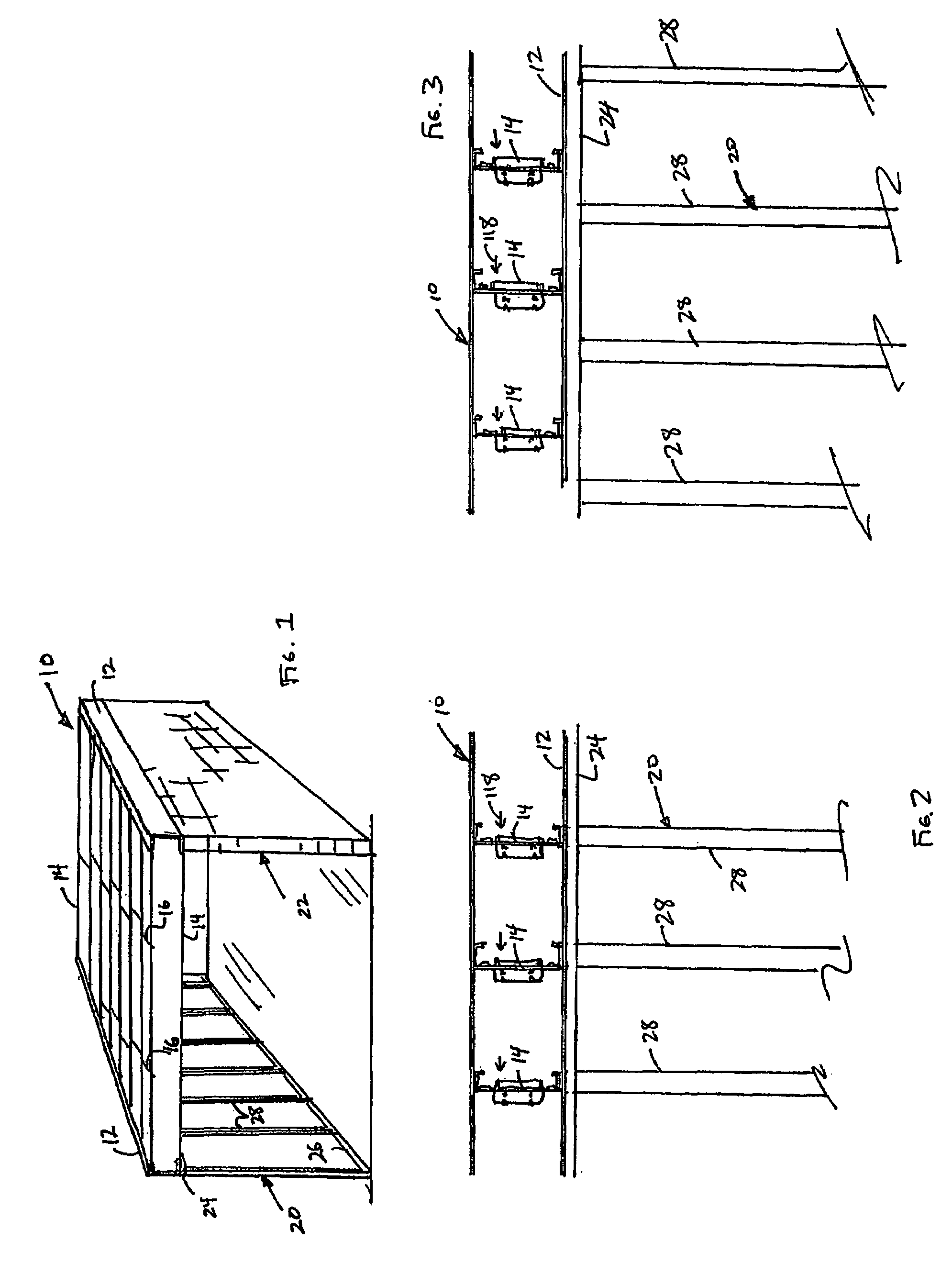

Systems and methods for splicing solar panel racks

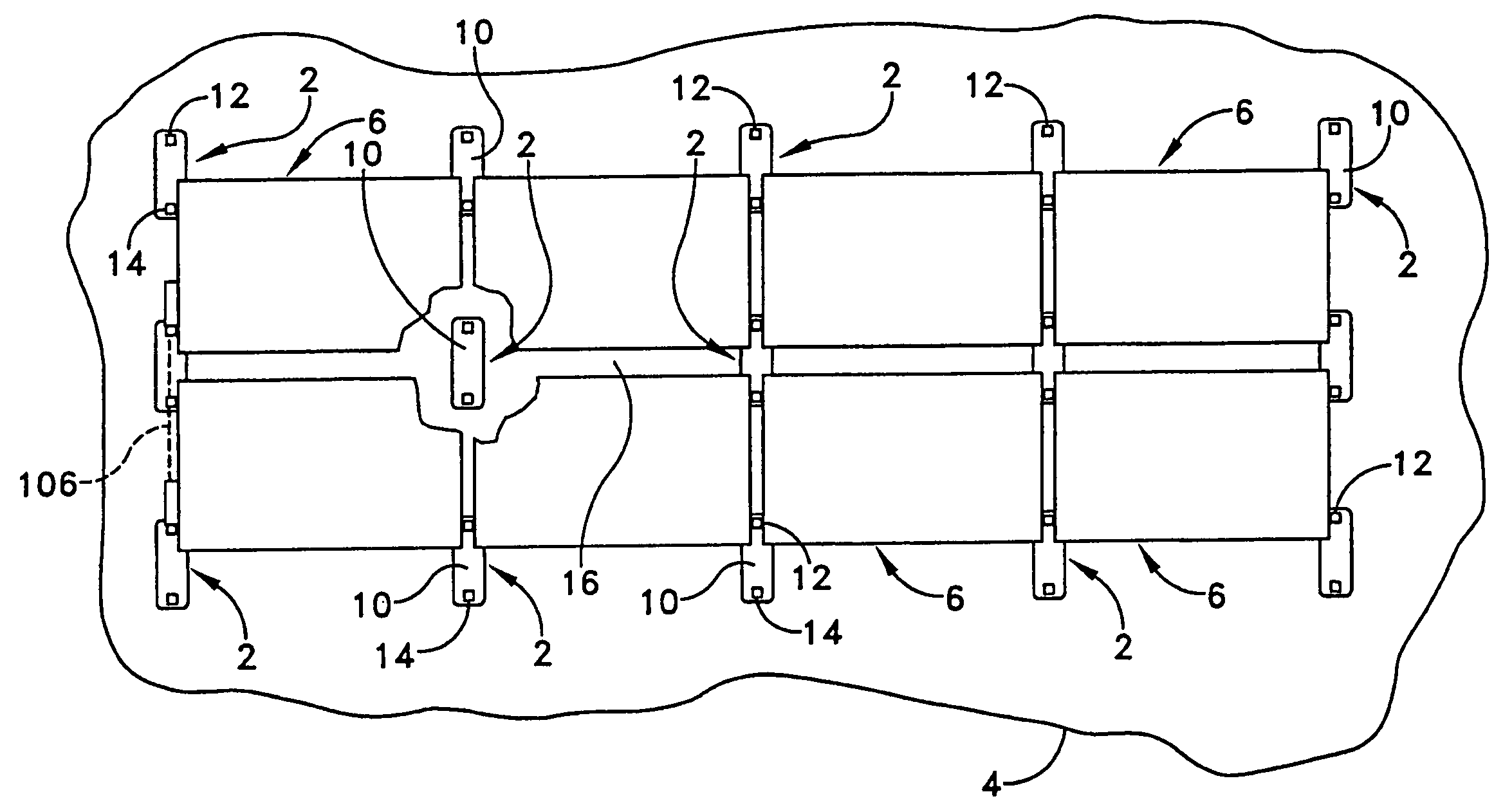

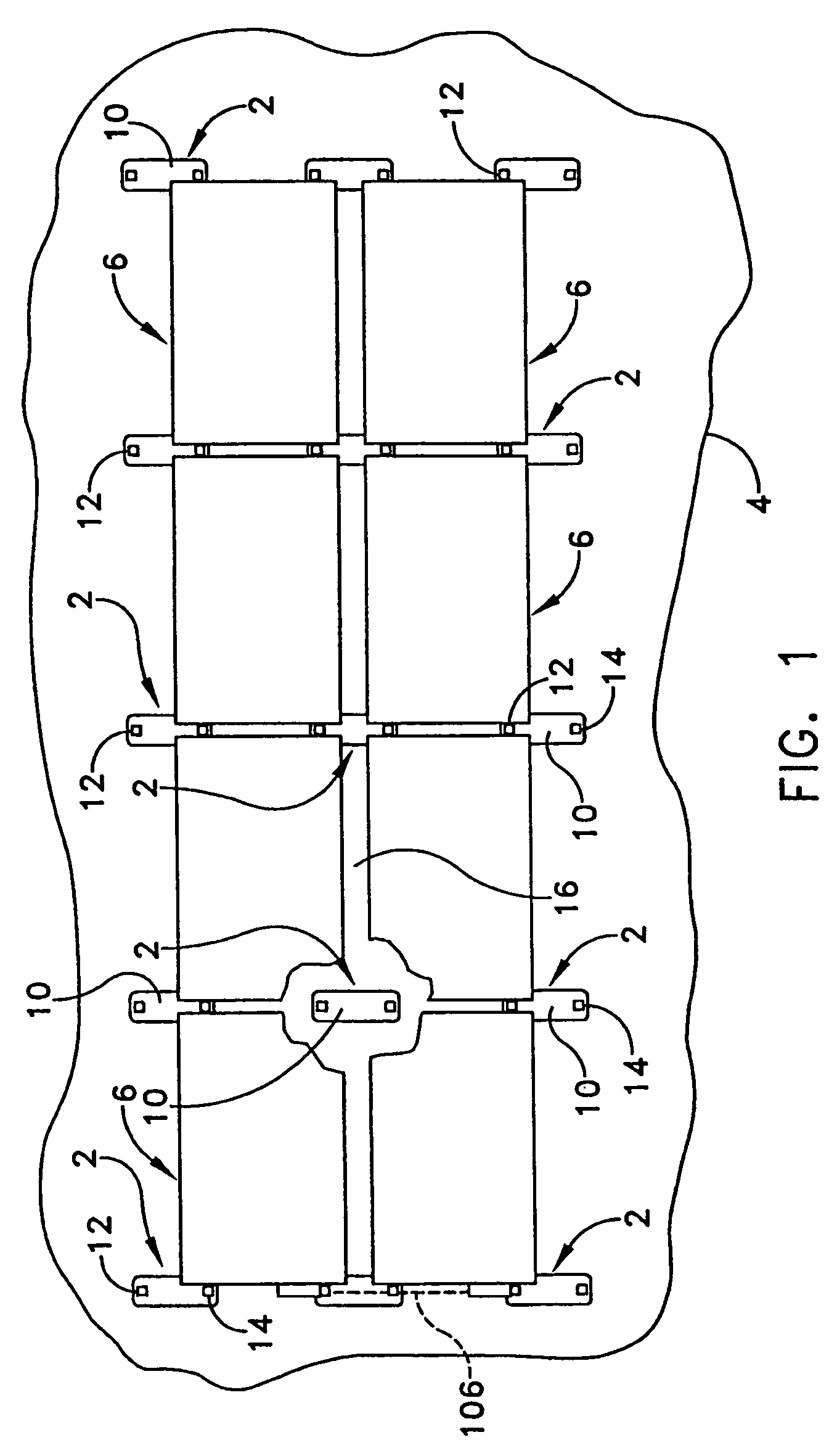

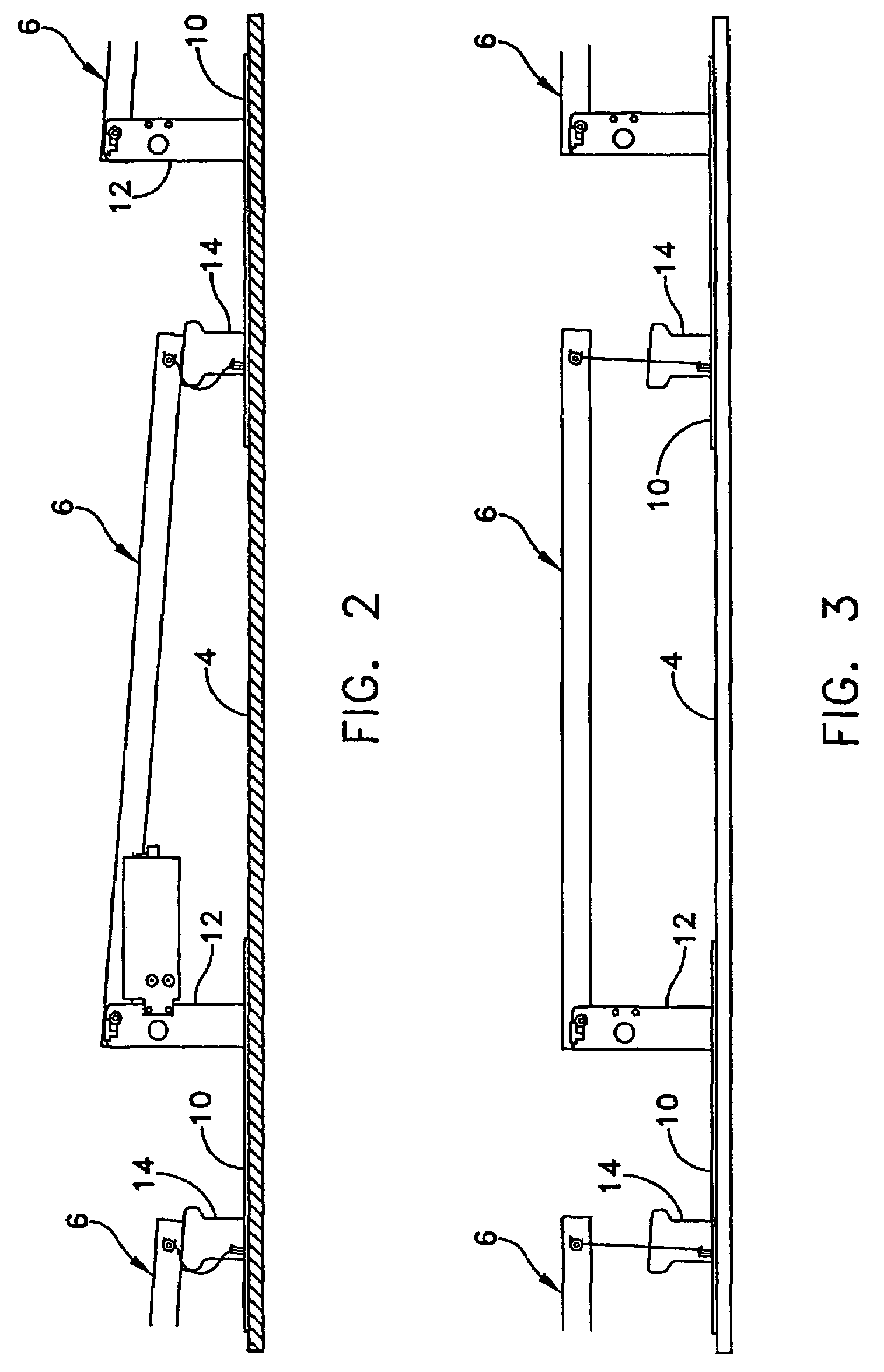

ActiveUS8695290B1Avoid less flexibilityReduce needPhotovoltaic supportsSolar heating energyEngineeringSupport surface

The invention provides systems and methods for splicing solar panel racks. Solar panel racks may include one, two, or more solar rack sections that may be connected to one another with an internal splice. The internal splice may internally support the adjoining solar racks. The solar rack may be secured to a support surface using one or more feet. The solar panel racks may be configured to support the weight of one or more solar modules. One or more solar module securing component may be used to secure the solar modules to a solar rack surface.

Owner:IRONRIDGE

Mounting systems for solar panels

Mounting systems for mounting solar panels to a surface are disclosed and can include panel clamp assemblies and rail clamp assemblies. Panel clamp assemblies can comprise a panel clamp having a base and arms extending from edges of the base, the base having an aperture, a rail clamp having a central portion with an aperture and two flexible tabs extending from the central portion on opposing sides of the aperture and a fastener threaded through the apertures such that that flexible tabs contact a head of the fastener and the arms extend in an opposite direction from the flexible tabs. Rail clamp assemblies can comprise a base member having a bottom and two side walls, the bottom having at least one aperture and each side wall having an elongated aperture, two clamping members and a fastener, wherein the side walls of the base member are positioned such that the opening is of sufficient size to receive the rail.

Owner:APPLIED ENERGY TECH

Spring clip

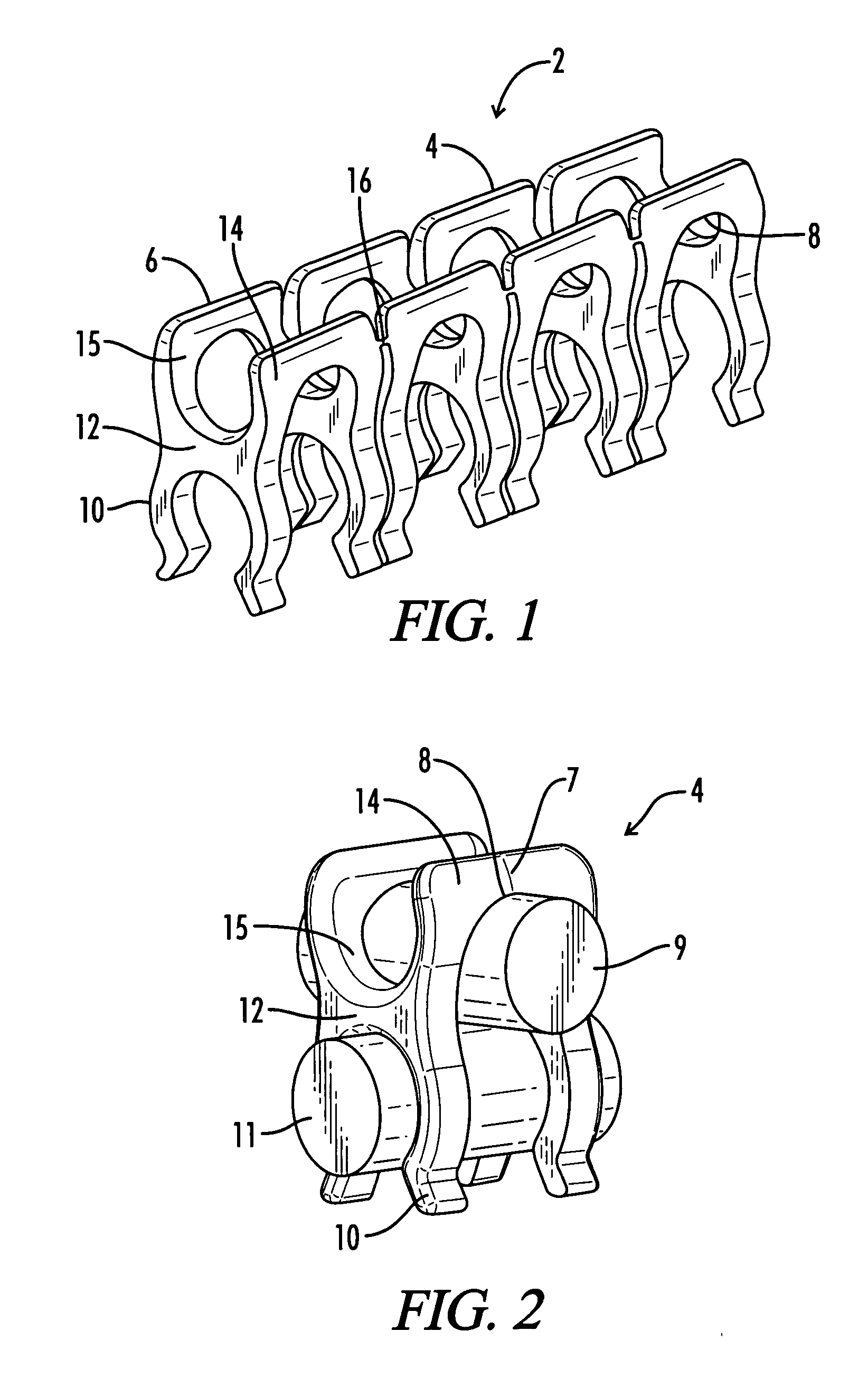

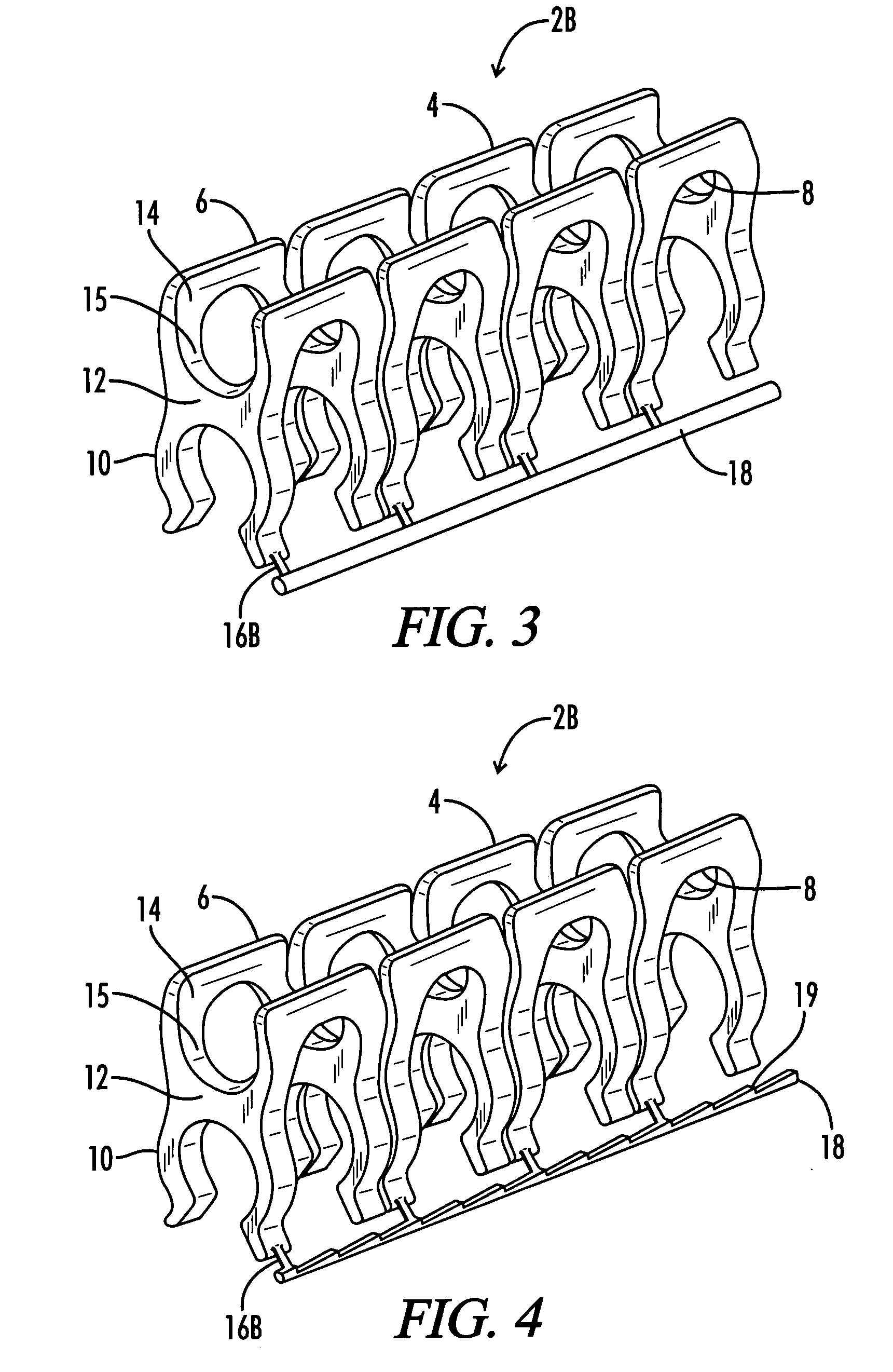

ActiveUS8839573B2Quick and safe installationPhotovoltaic supportsSolar heating energyJoistEngineering

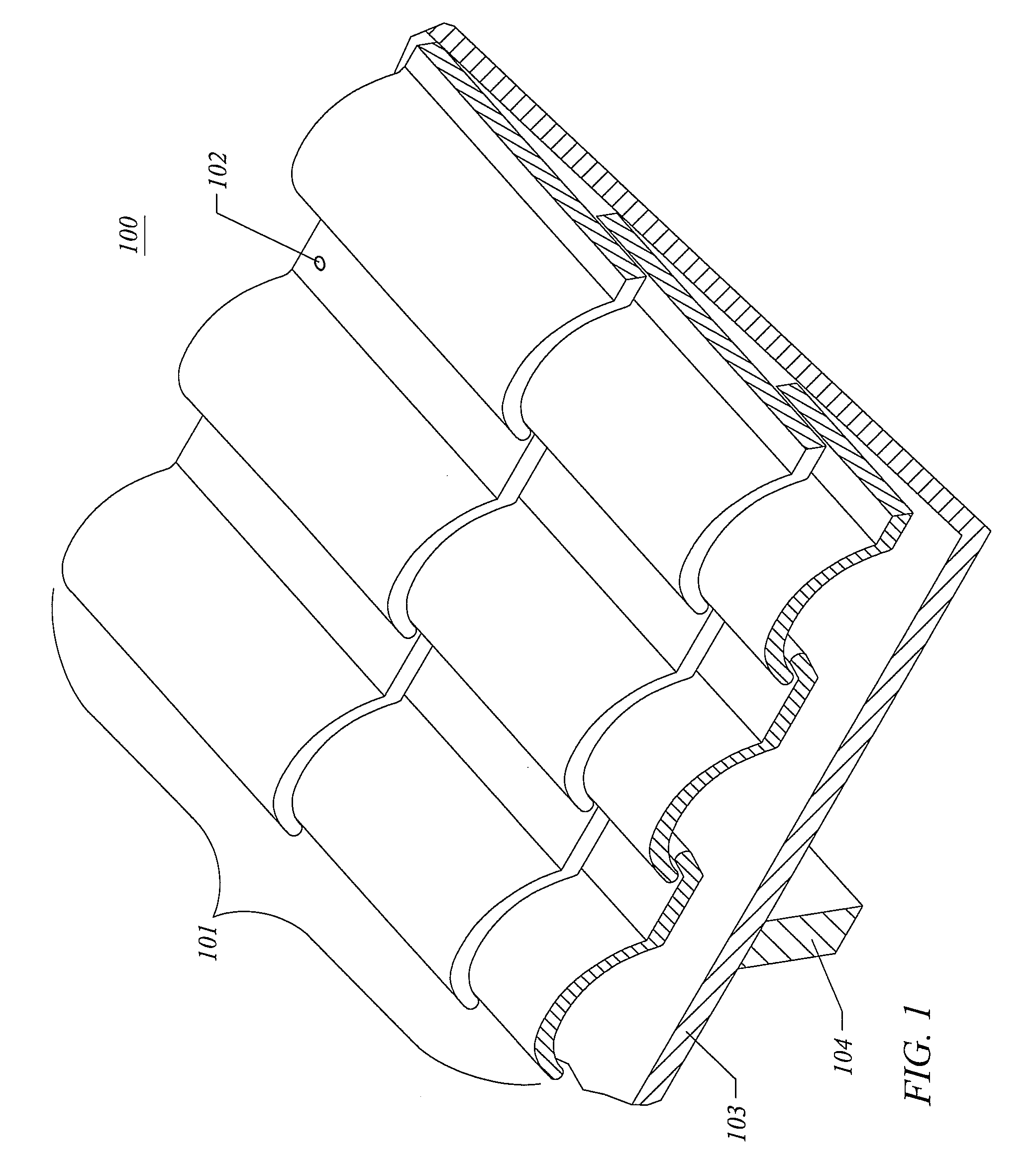

A panel array support assembly has lower support joists supporting varied panel rails, to which are connected panel holding device or clips. The panel clips are spring-based and configured so that the length of each clip extends in a direction along the length of the panel rails. The panels are supported well inside of the edges extending in the same direction as the panel rails.

Owner:NORTHERN STATES METALS

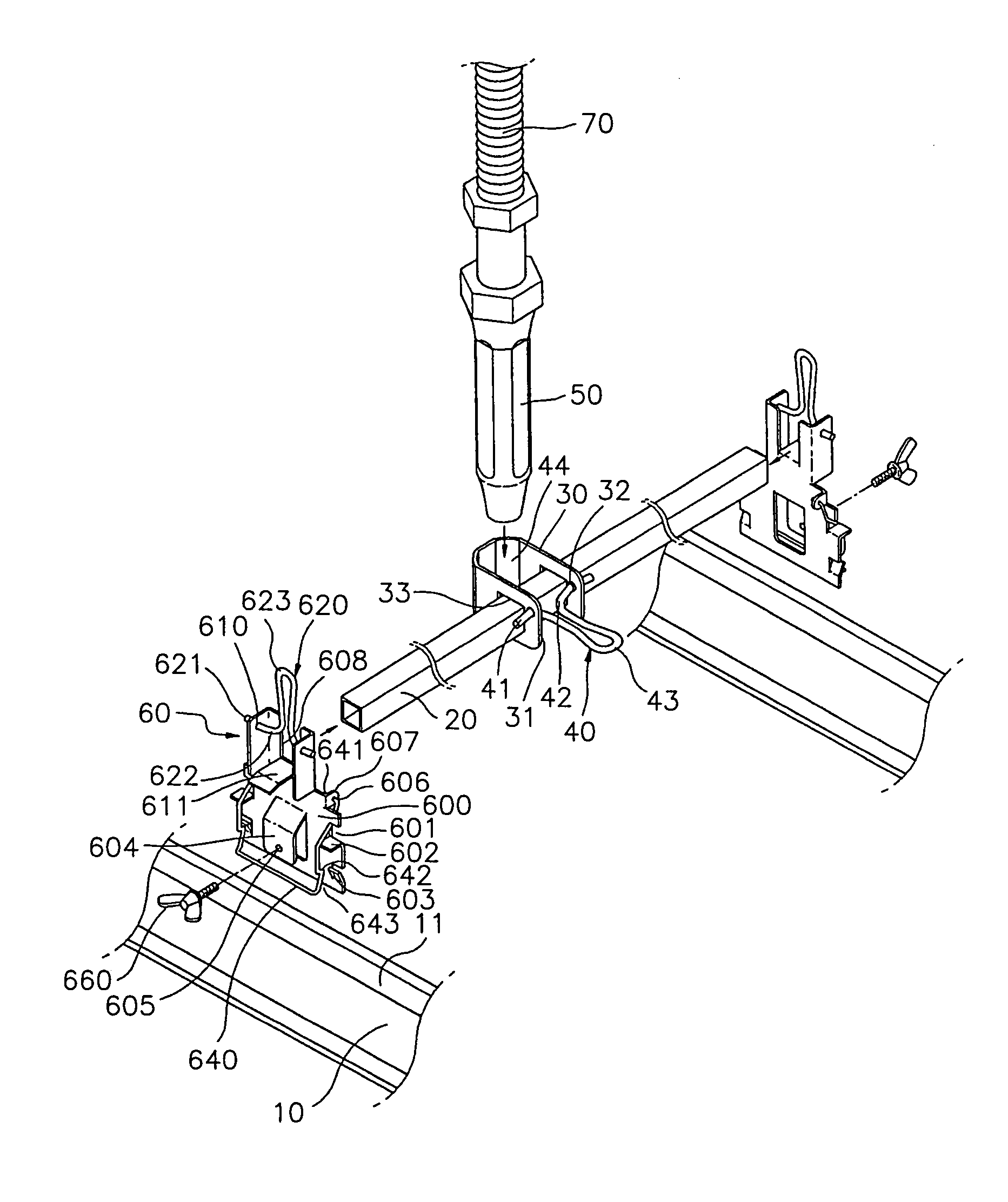

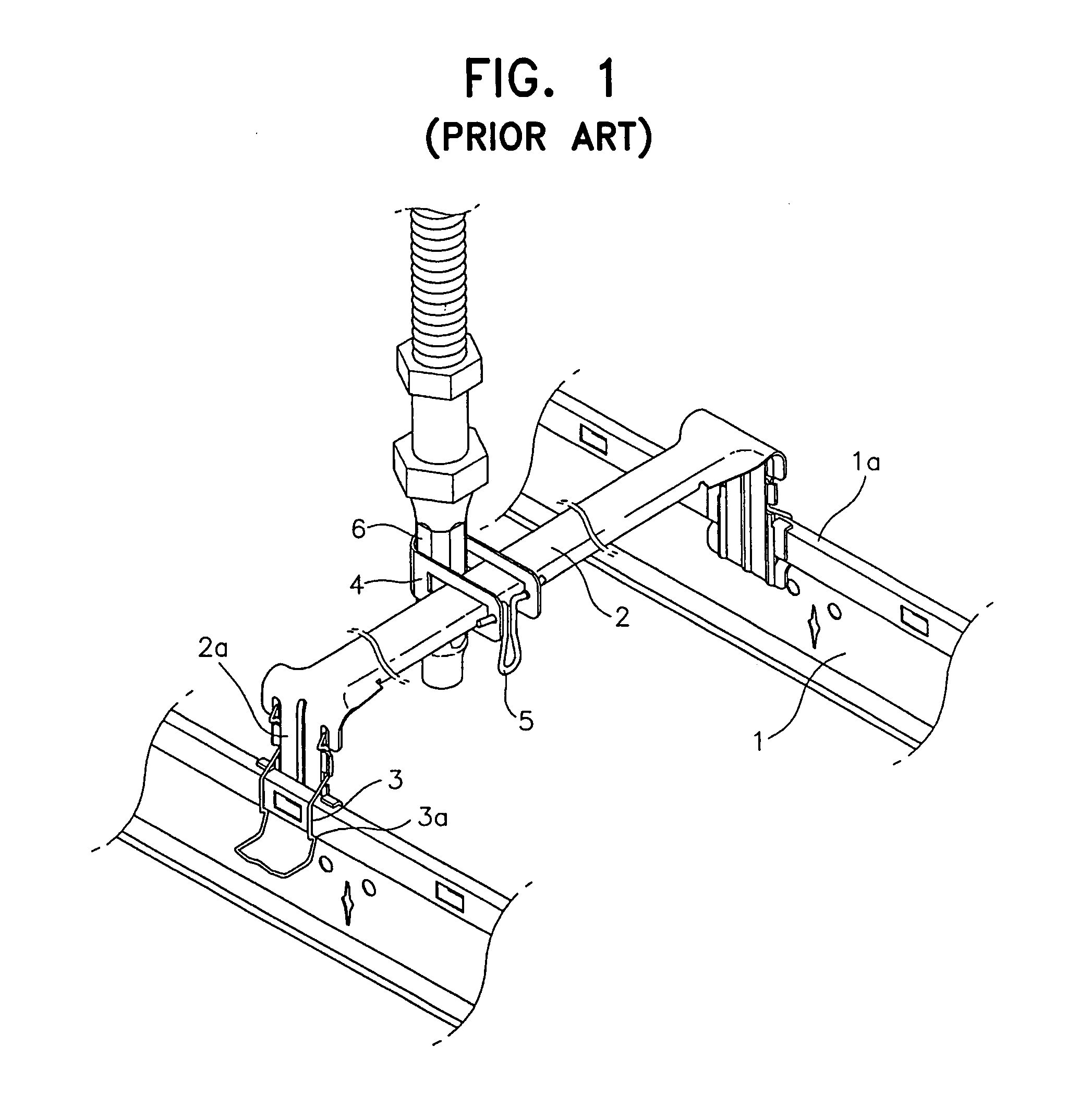

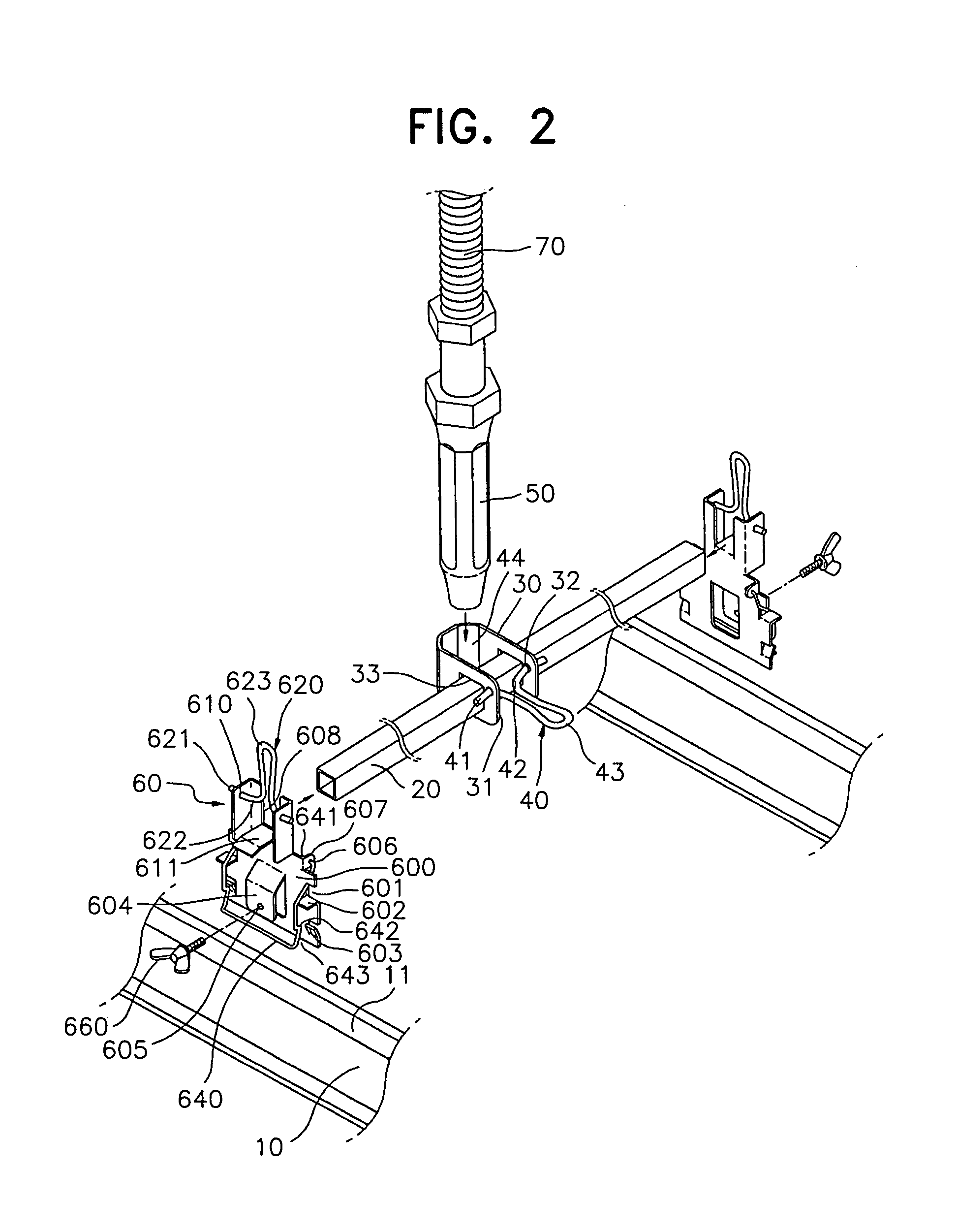

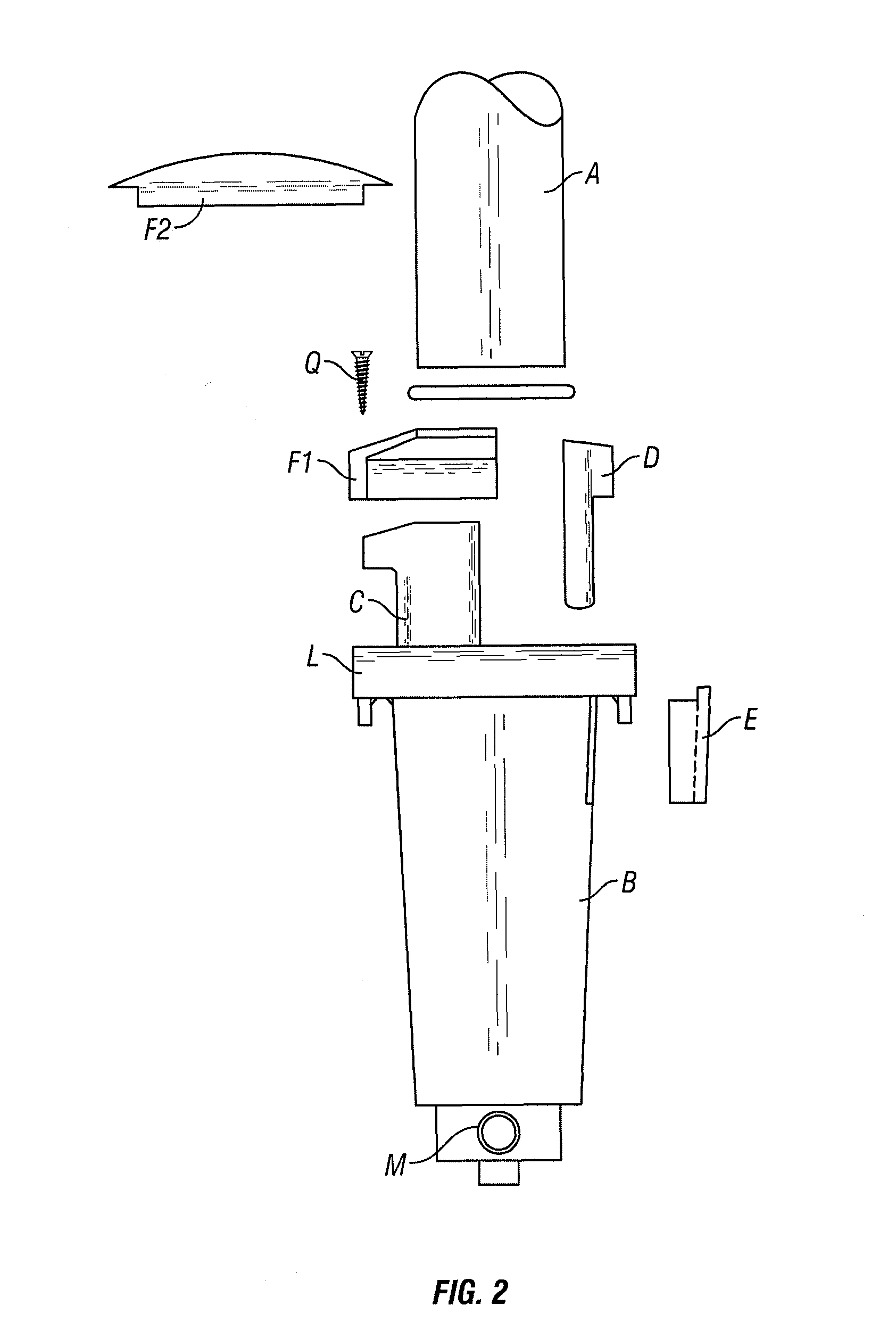

Stock bar and T-bar coupling structure for mounting sprinkler

Disclosed herein is a stock bar and T-bar coupling structure for mounting a sprinkler. In the present invention, a locking bracket is easily securely coupled to a T-bar using an elastic locking unit and a wing bolt. Furthermore, a stock bar made of standard rectangular pipe is coupled to the locking bracket by a first locking unit such that the stock bar crosses over the T-bar. Because this locking bracket is manufactured as a separate component from the stock bar, the present invention can be used without limiting the distance between the T-bars. Furthermore, the present invention has an advantage in that a standard rectangular pipe can be easily used as a stock bar merely by cutting the pipe to a desired length.

Owner:KOFULSO

Roofing bracket and system

Various novel roofing brackets and roofing systems are disclosed. A first embodiment can be considered a roofing bracket to be coupled to a vertical post and a horizontal purlin of a roofing system whereby the horizontal purlin is positioned to support roof panels at a requisite pitch. The roofing bracket includes a reference brace and a clip. The reference brace includes a first brace face positioned planarly parallel with the vertical post and a second brace face extending at an angle angle from the first brace face and positioned planarly parallel with the vertical post. The clip includes a first clip face positioned to be fastened generally flush with the horizontal purlin and a second clip face extending at an angle from the first clip face and positioned to be fastened planarly parallel with the vertical post. The second clip face is coupled to the first brace face at a pivot point such that the clip can be rotated a particular angle relative to the reference brace. The angle of rotation is consistent with the requisite pitch of the roofing system.

Owner:GP INNOVATIVE CONCEPTS

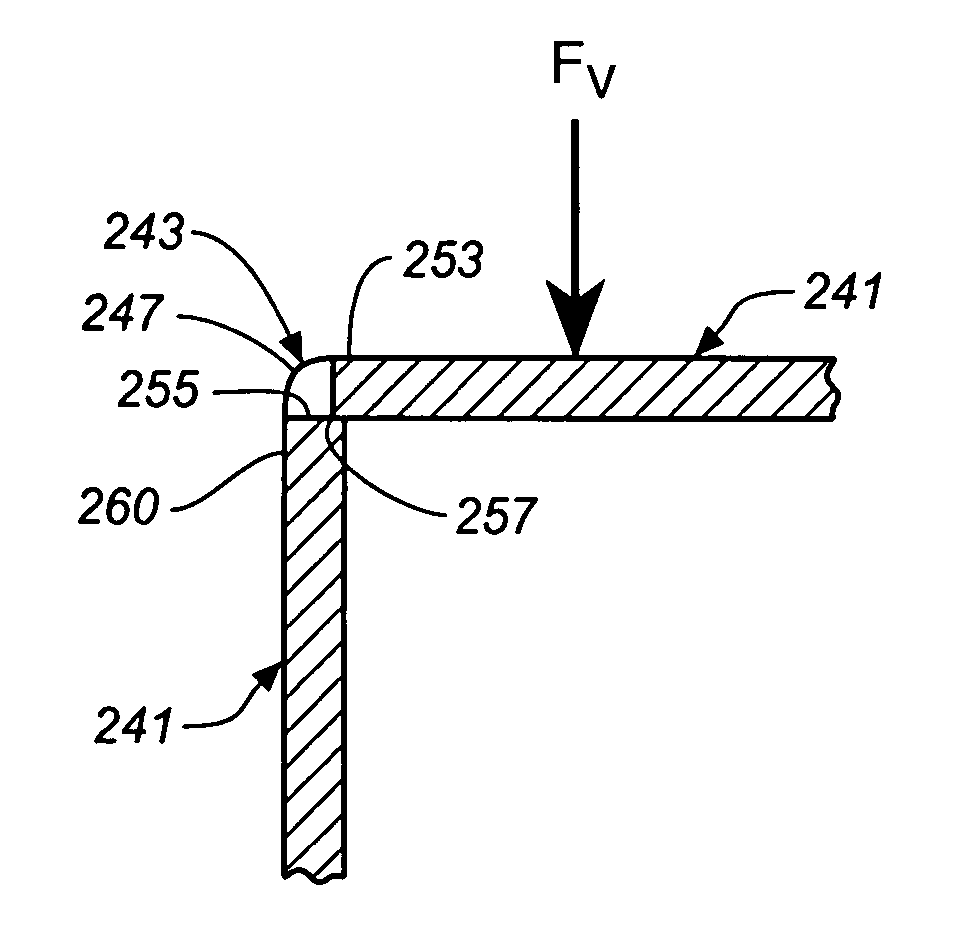

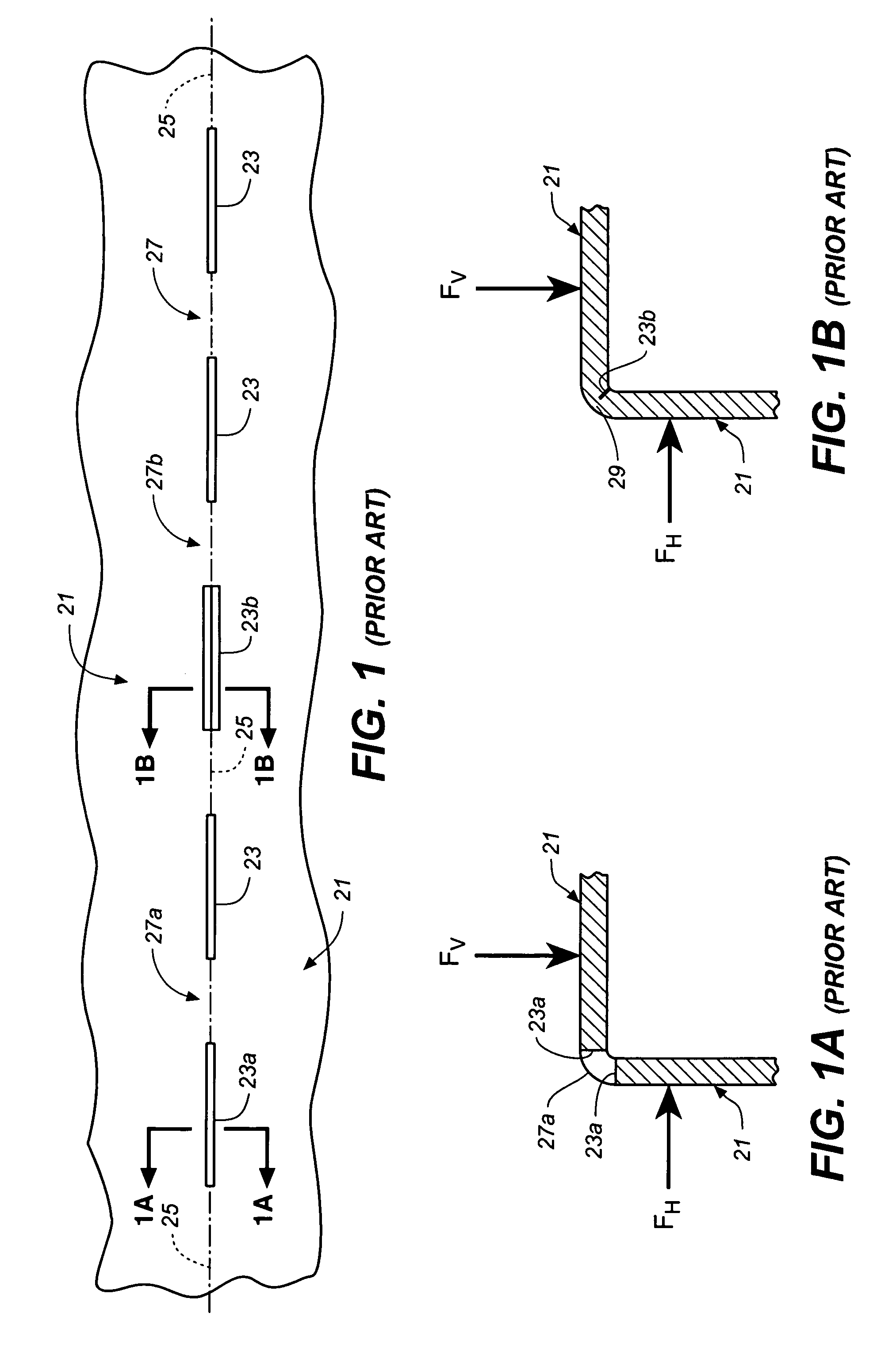

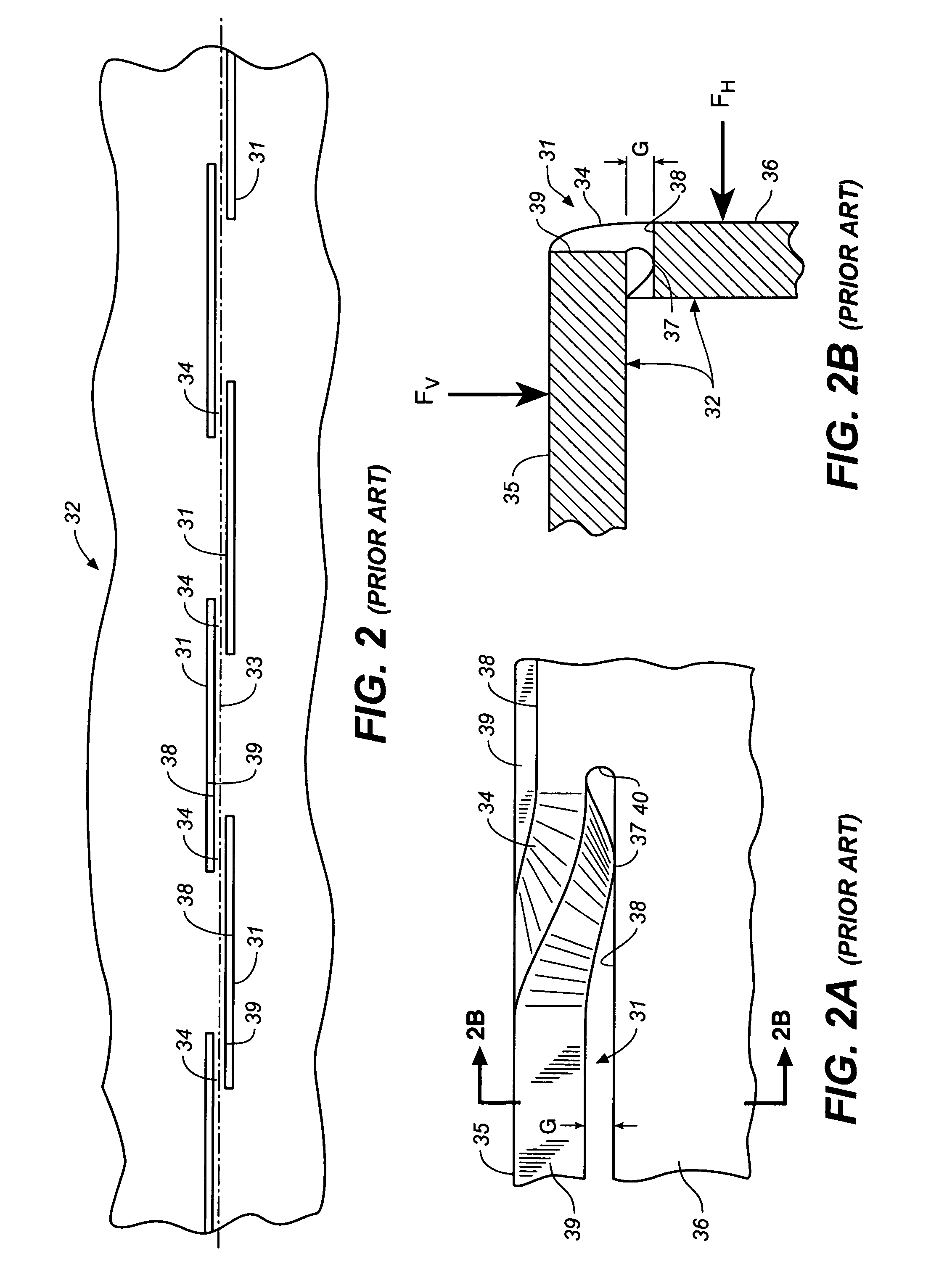

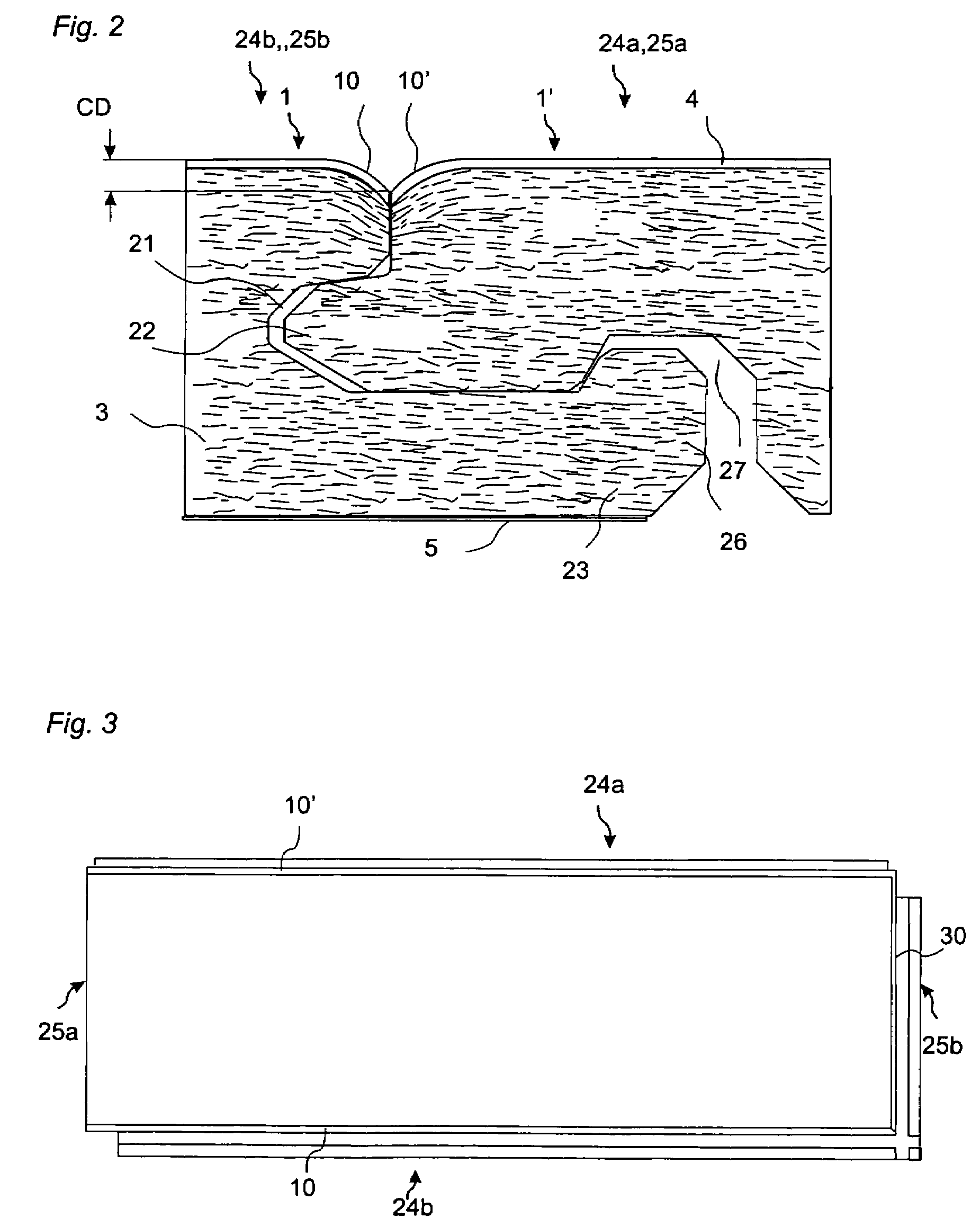

Precision-folded, high strength, fatigue-resistant structures and sheet therefor

Precision-folded, high strength, fatigue-resistant structures and a sheet therefore are disclosed. To form the structures, methods for precision bending of a sheet of material along a bend line and a sheet of material formed with bending strap-defining structures, such as slits or grooves, are disclosed. Methods include steps of designing and then separately forming longitudinally extending slits or grooves through the sheet of material in axially spaced relation to produce precise bending of the sheet when bent along the bend line. The bending straps have a configuration and orientation which increases their strength and fatigue resistance, and most preferably slits or arcs are used which causes edges to be engaged and supported on faces of the sheet material on opposite sides of the slits or arcs. The edge-to-face contact produces bending along a virtual fulcrum position in superimposed relation to the bend line. Several slit embodiments suitable for producing edge-to-face engagement support and precise bending are disclosed. With these teachings, forming numerous three-dimensional load-bearing structures from a two dimensional sheet are enabled. Examples of straight and curved beams, chassis, and exoskeletons are disclosed.

Owner:IND ORIGAMI INC CA US

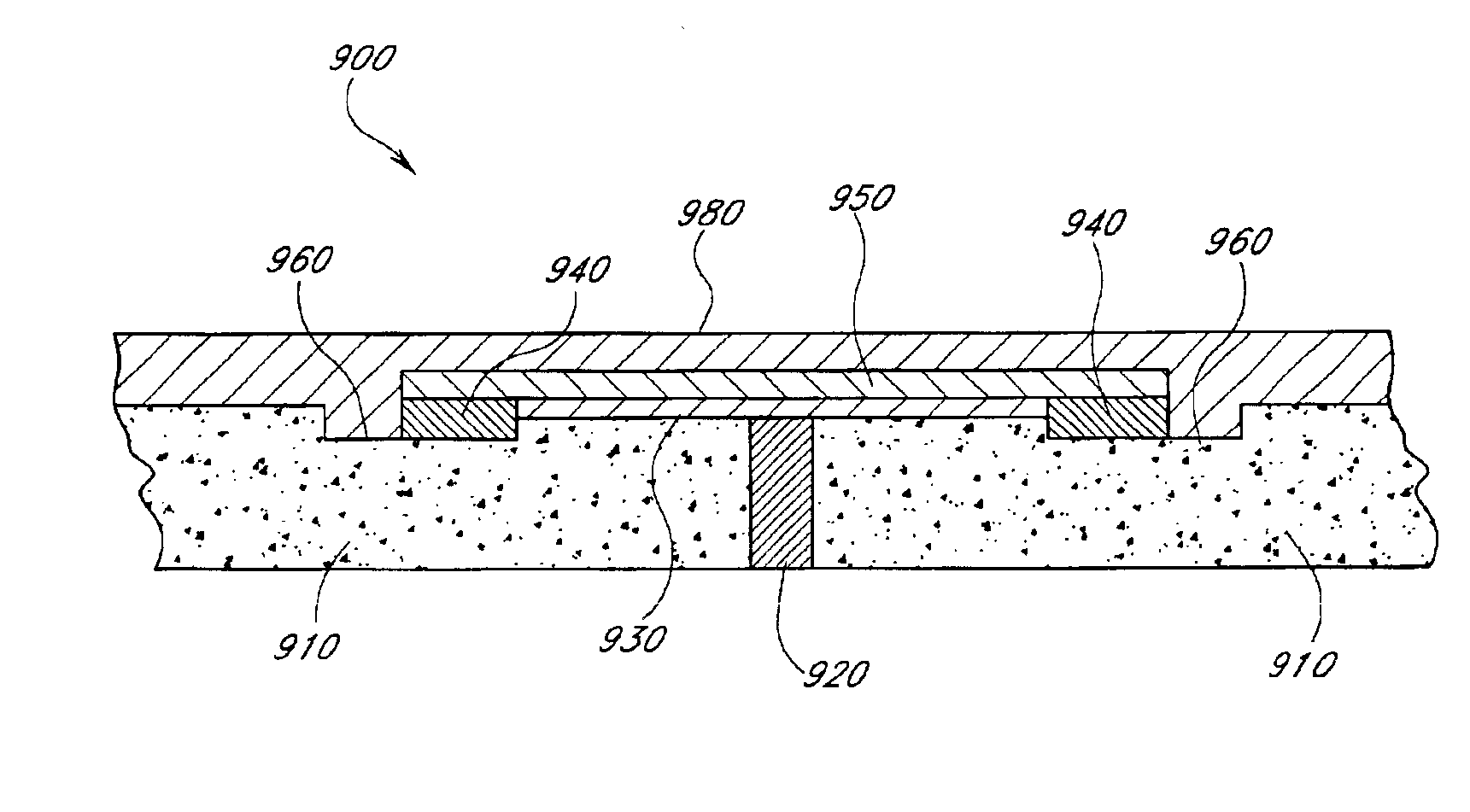

Panelized wall system utilizing trough-edge building panels

Disclosed herein are panelized wall systems and methods for their construction, wherein the wall systems have elastomeric joints that are resistant to cracking. The walls are constructed with trough-edge building panels. The trough-edge building panels are preferably fiber cement. The front surface of each panel has a trough adjacent to an edge of the panel. Panels are fastened to a frame with the trough-edges adjacent to each other. A joint tape is applied to the seam between the panels such that the edges of the joint tape fall within the troughs of the adjacent panels. The wall is then finished with an elastomeric finish.

Owner:JAMES HARDIE TECH LTD

Strut runner member and assembly using same for mounting arrays on rooftops and other structures

Owner:FTC SOLAR INC

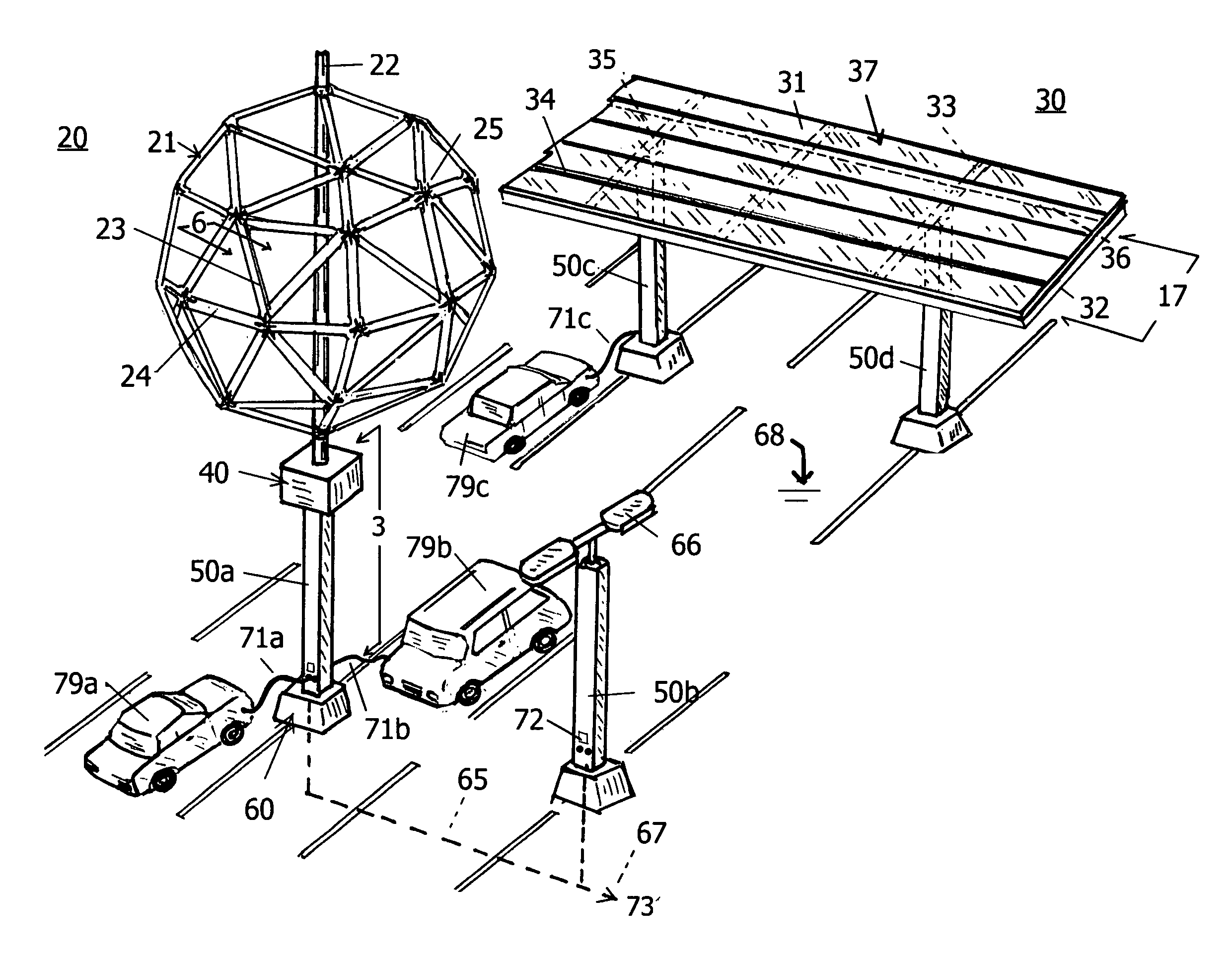

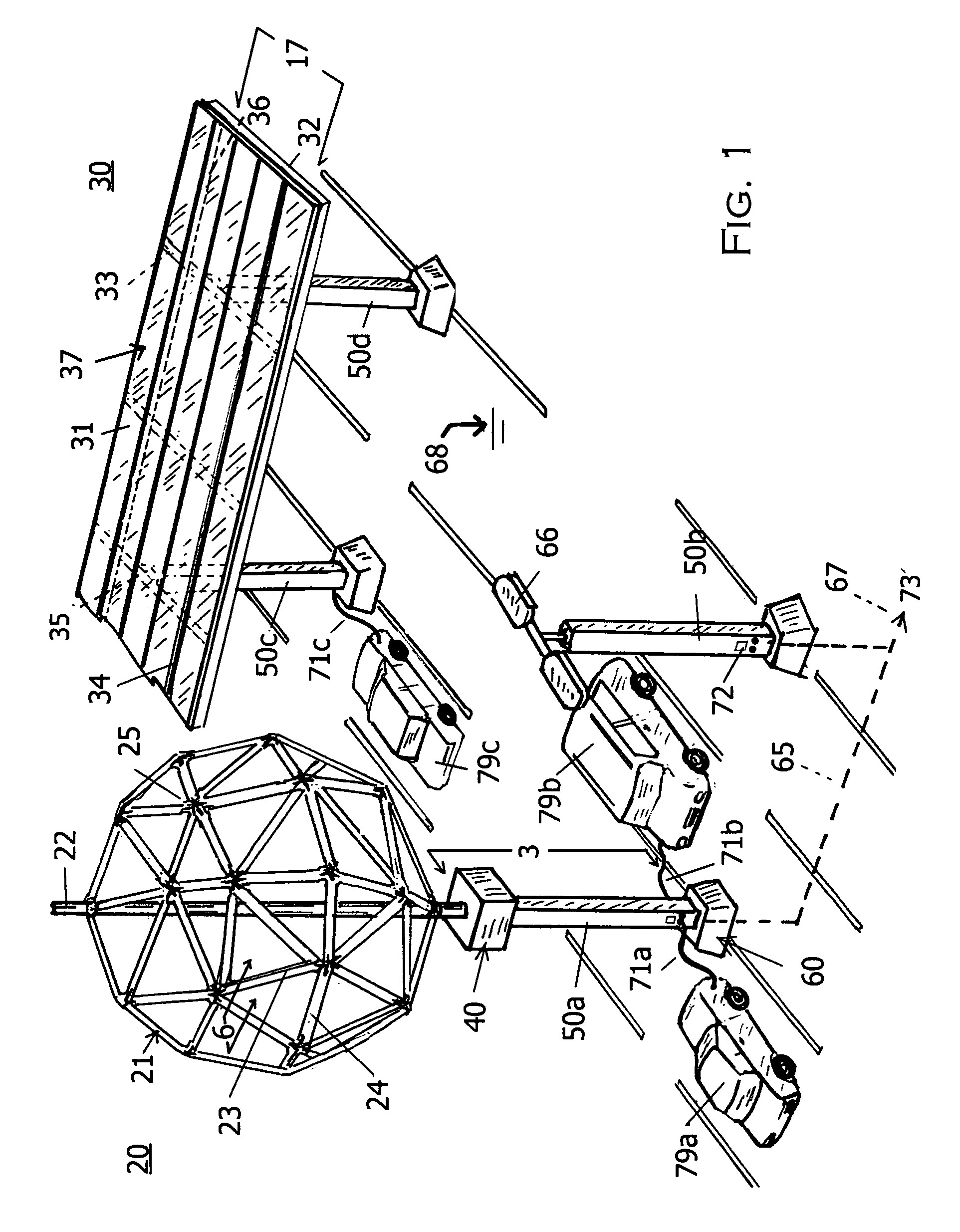

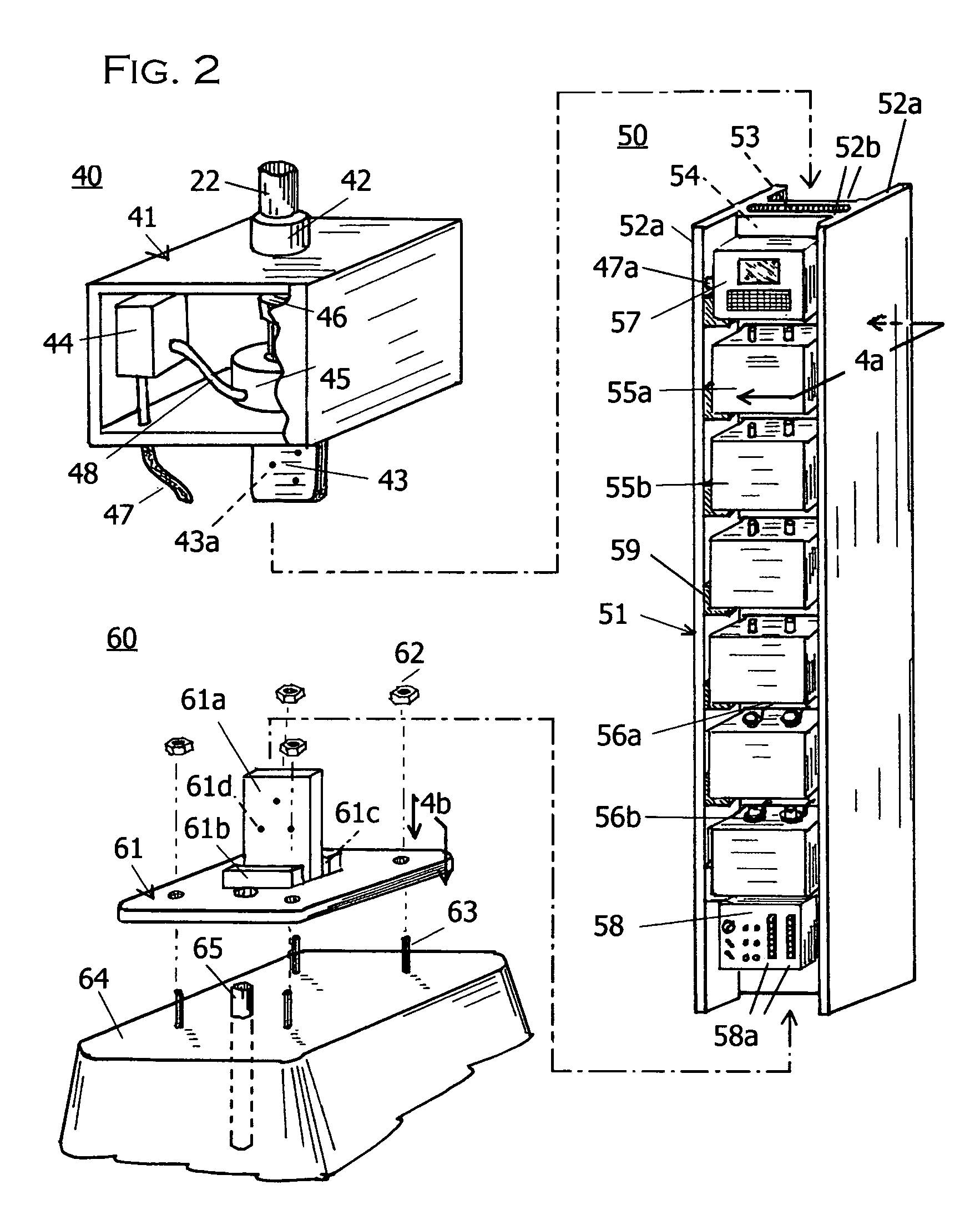

Renewable energy vehicle charging station

Owner:SUSTAINABLE STRUCTURES

Roof support apparatus for solar panels

Owner:TESLA INC

Panelized wall system utilizing adhesive-edge building panels

Disclosed herein are panelized wall systems and methods for their construction, wherein the wall systems have elastomeric joints that are resistant to cracking. The walls are constructed with adhesive-edge building panels. The adhesive-edge building panels are preferably fiber cement. The front surface of each panel has an adhesive preapplied to an edge of the panel. Panels are fastened to a frame with the adhesive-edges adjacent to each other. A joint tape is applied to the seam between the panels such that the edges of the joint tape adhere to the adhesive-edges of the adjacent panels. The wall is then finished with an elastomeric finish.

Owner:JAMES HARDIE INT FINANCE BV

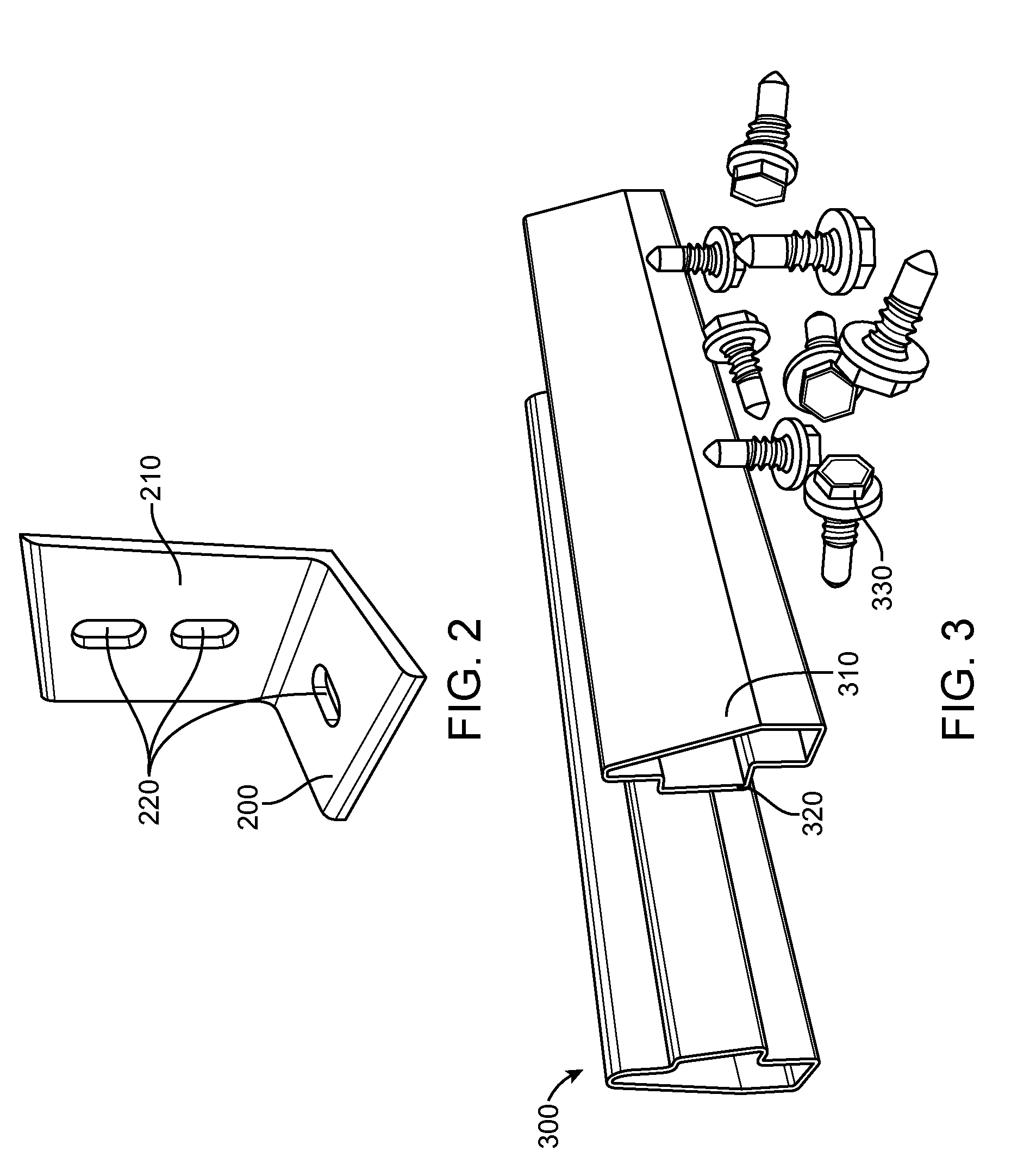

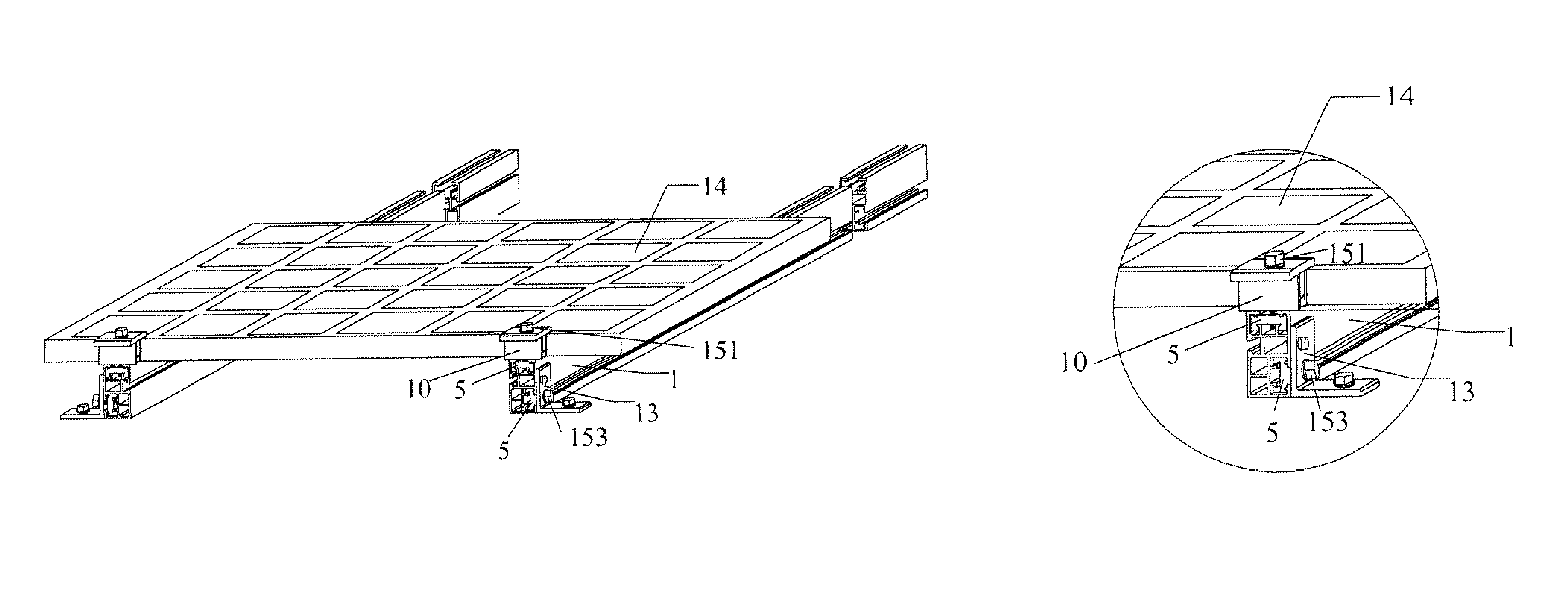

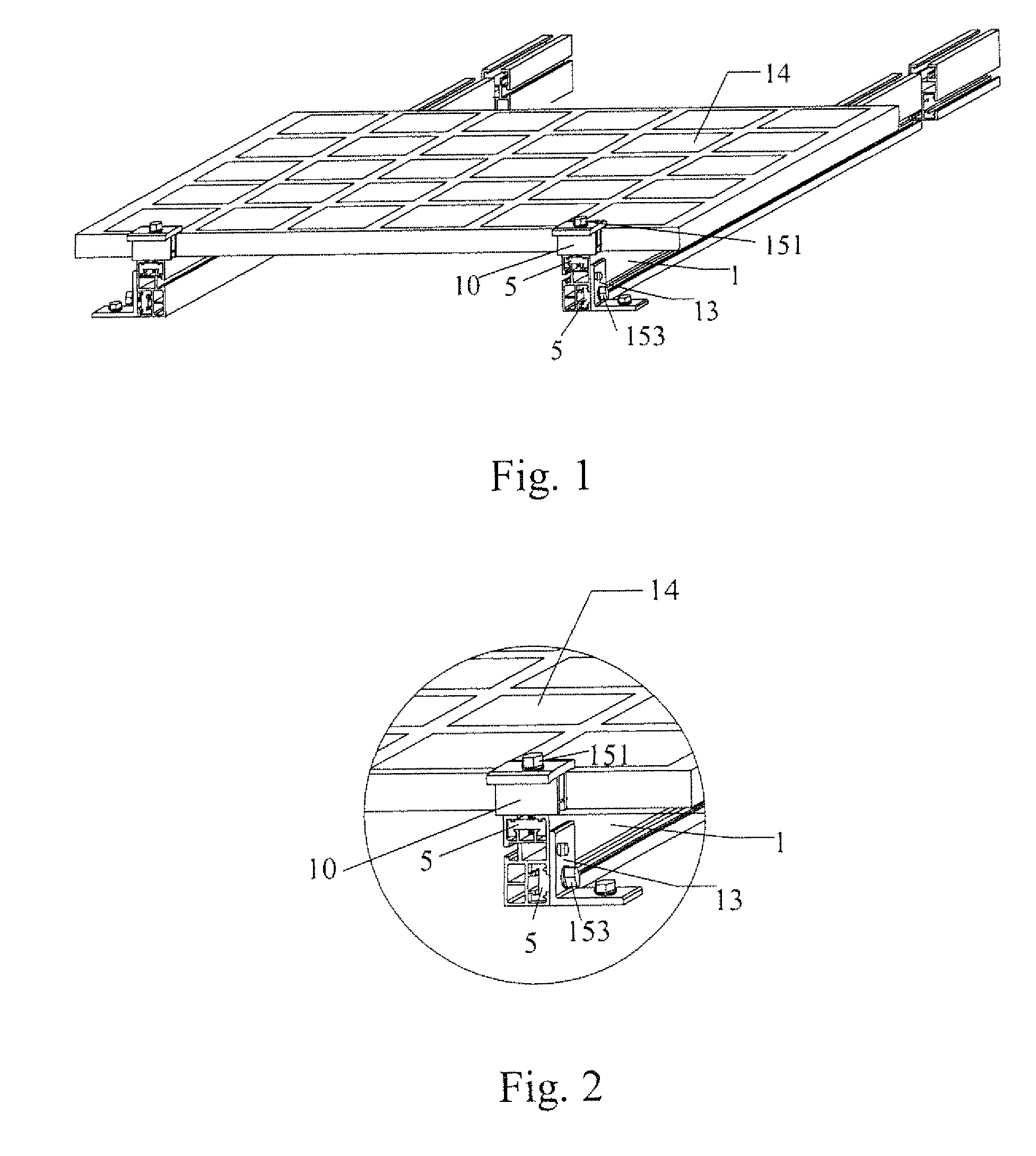

Panel fastening system

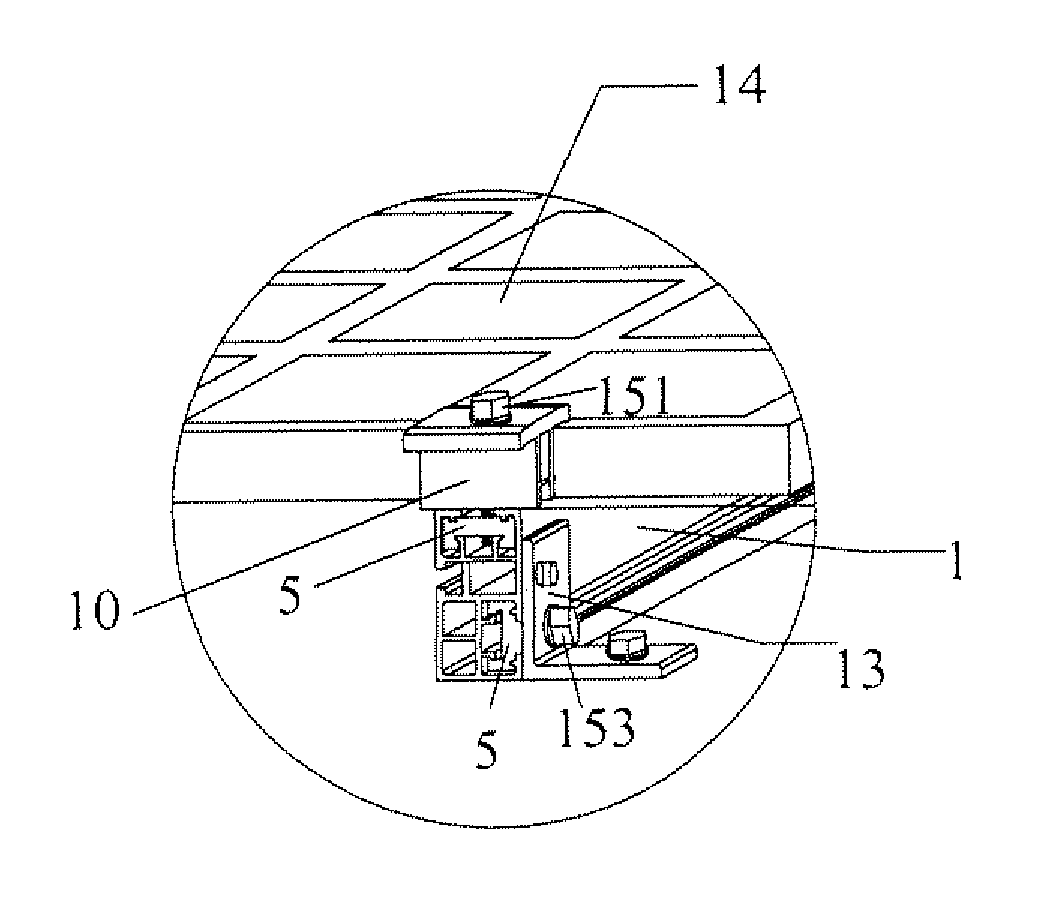

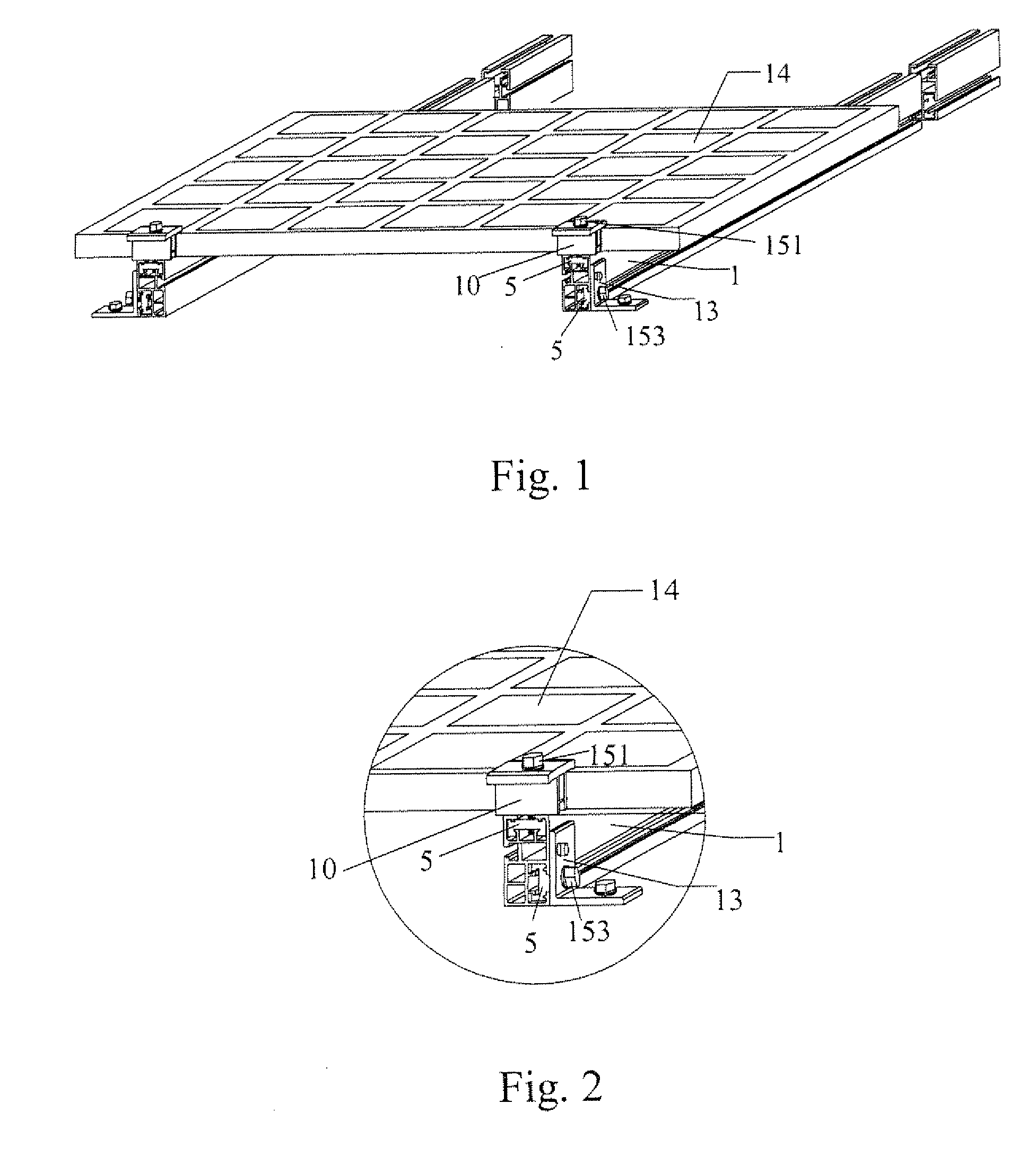

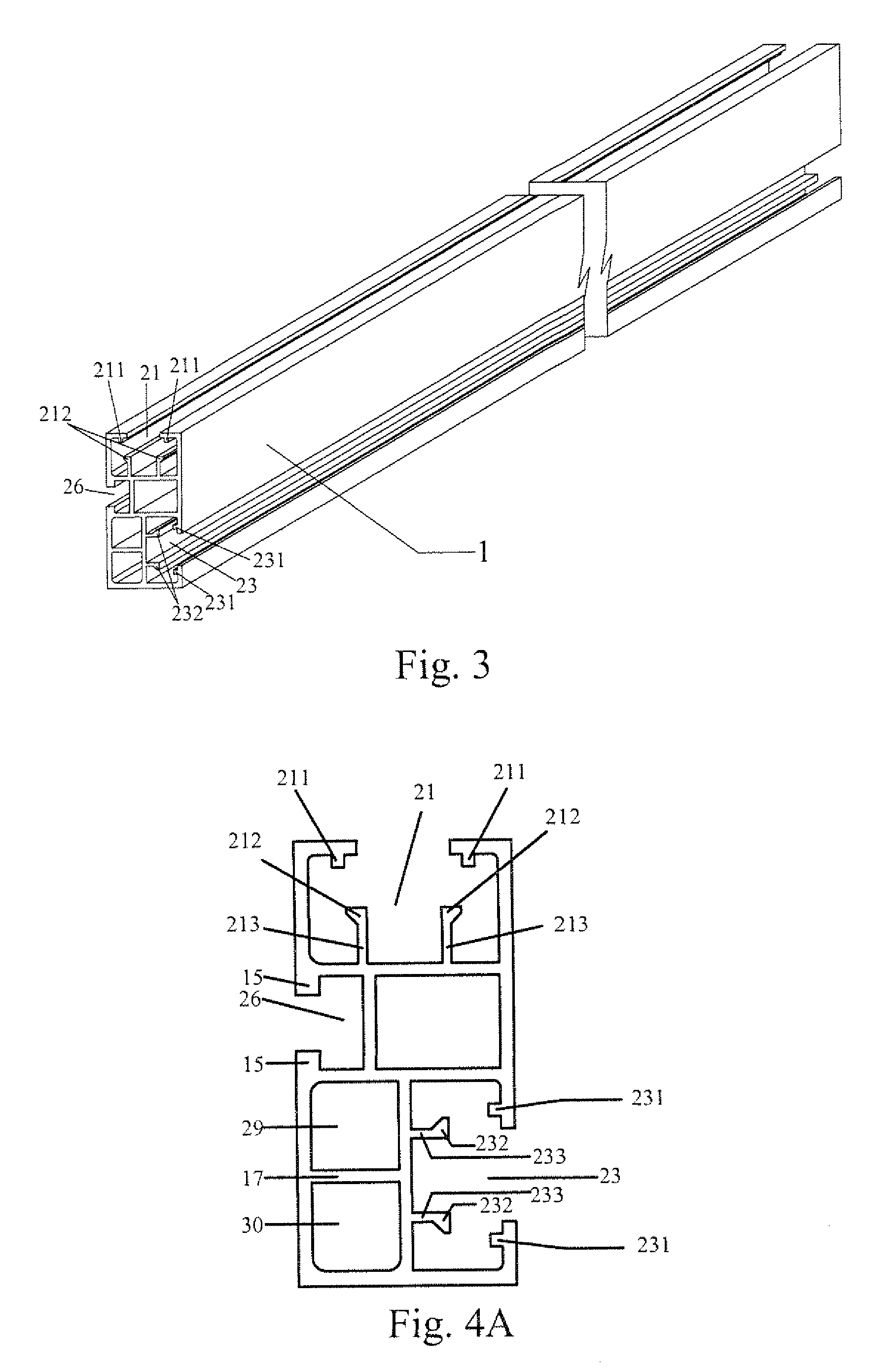

InactiveUS20110174947A1High tensile strengthLight weightPhotovoltaic supportsSolar heating energyUltimate tensile strengthOpen cavity

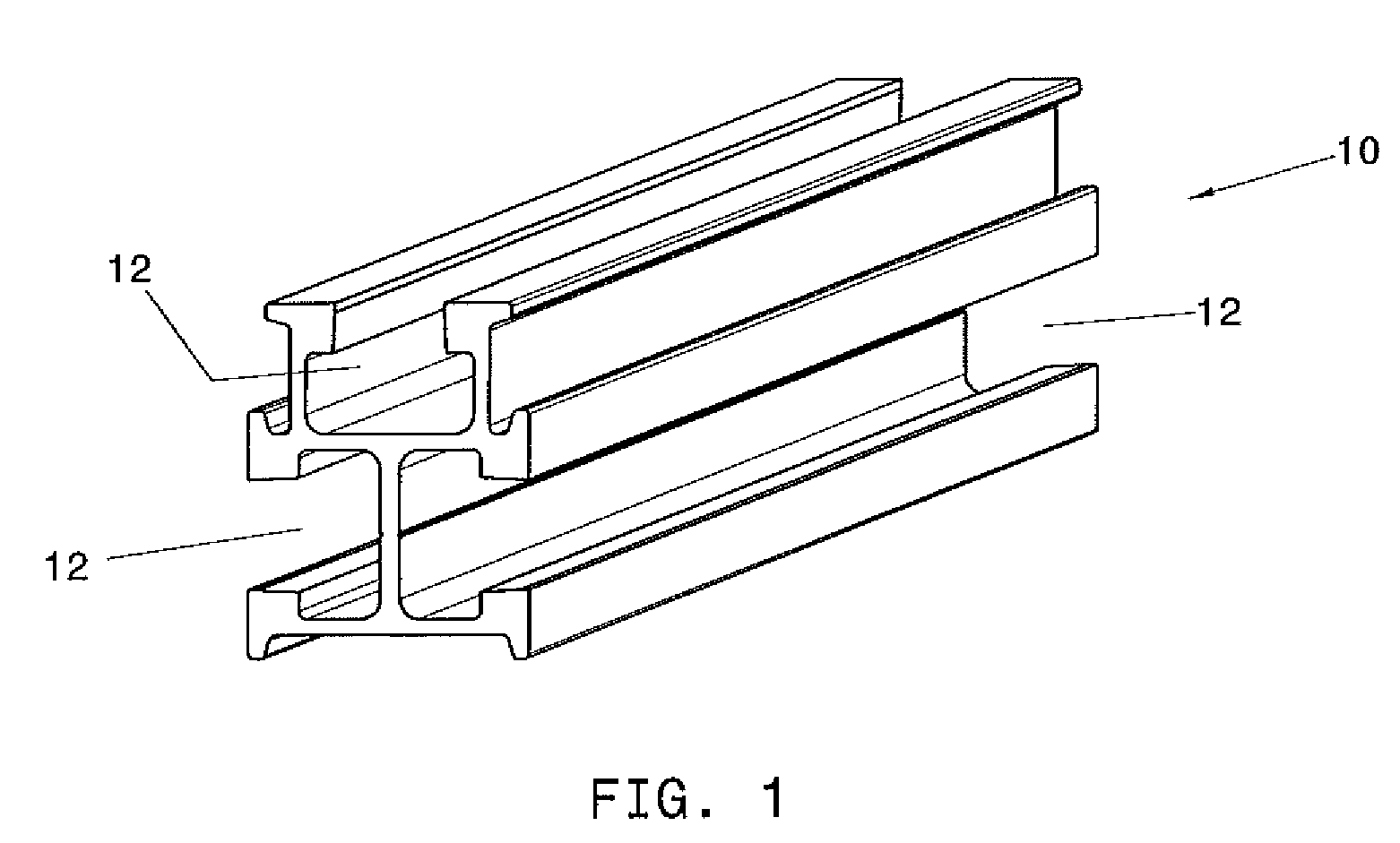

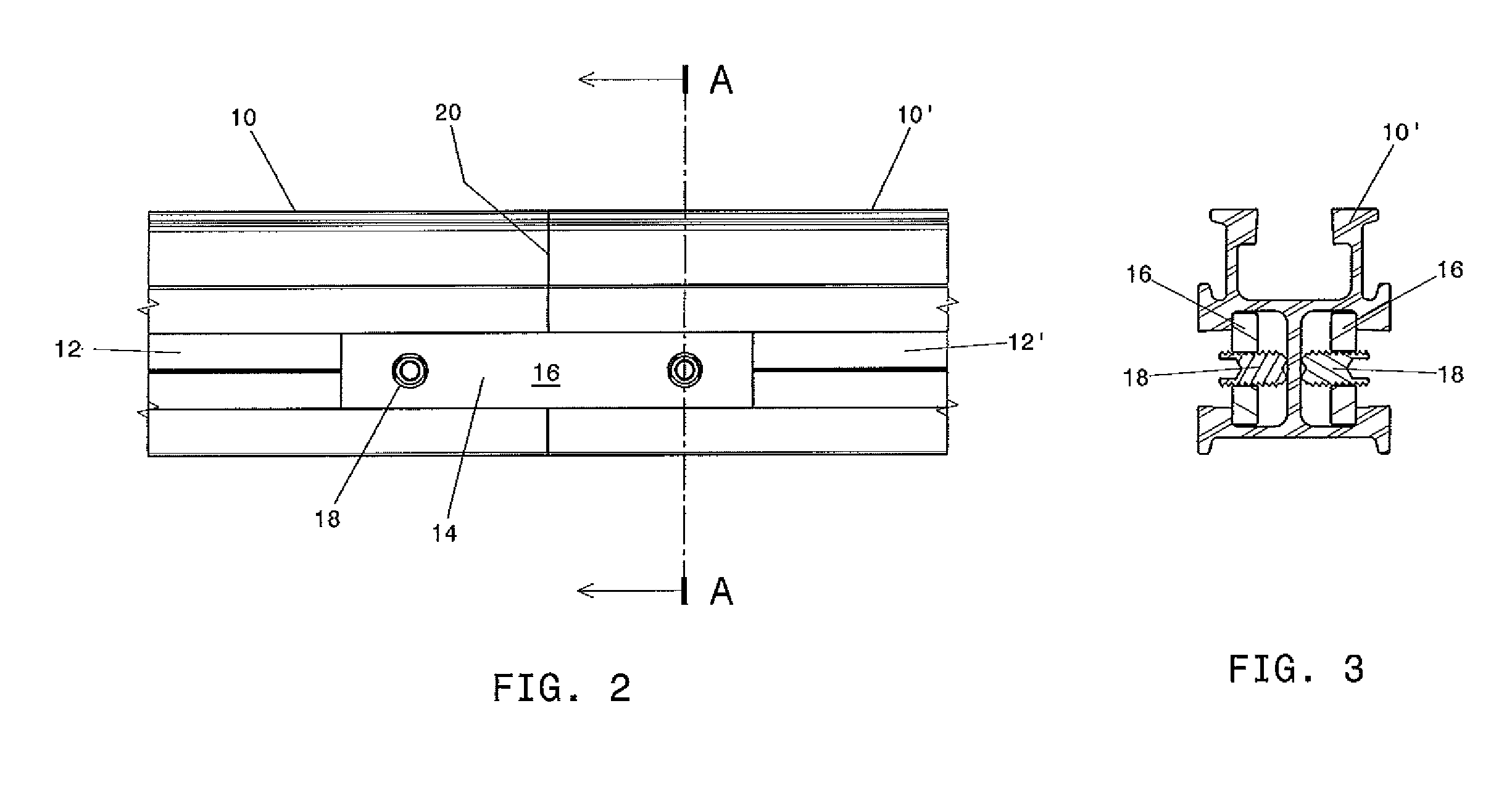

The present invention discloses a fastening system for a panel. The fastening system includes: at least two mounting rails which each has a plurality of engaging open cavities formed therein; and a plurality of engaging slide blocks respectively engaging with the engaging open cavities; wherein the panel is disposed on the mounting rails and fixedly connected with the engaging slide blocks respectively. Basing on the engagement structure, the present invention can be fastened on a surface of a mounted object via two rails and provide high tensile strength and simple installation. The present invention can fix different shapes of panel assemblies on a roof, the ground, a wall or a surface of a framework safely, quickly and stably, and the present invention has a simple structure, light weight and low total costs.

Owner:RACWORTH

Apparatus for mounting photovoltaic power generating systems on buildings

InactiveUS7574842B2Eliminate forcePhotovoltaic supportsSolar heating energyEngineeringMechanical engineering

Owner:THE UNITED STATES AS REPRESENTED BY THE DEPARTMENT OF ENERGY

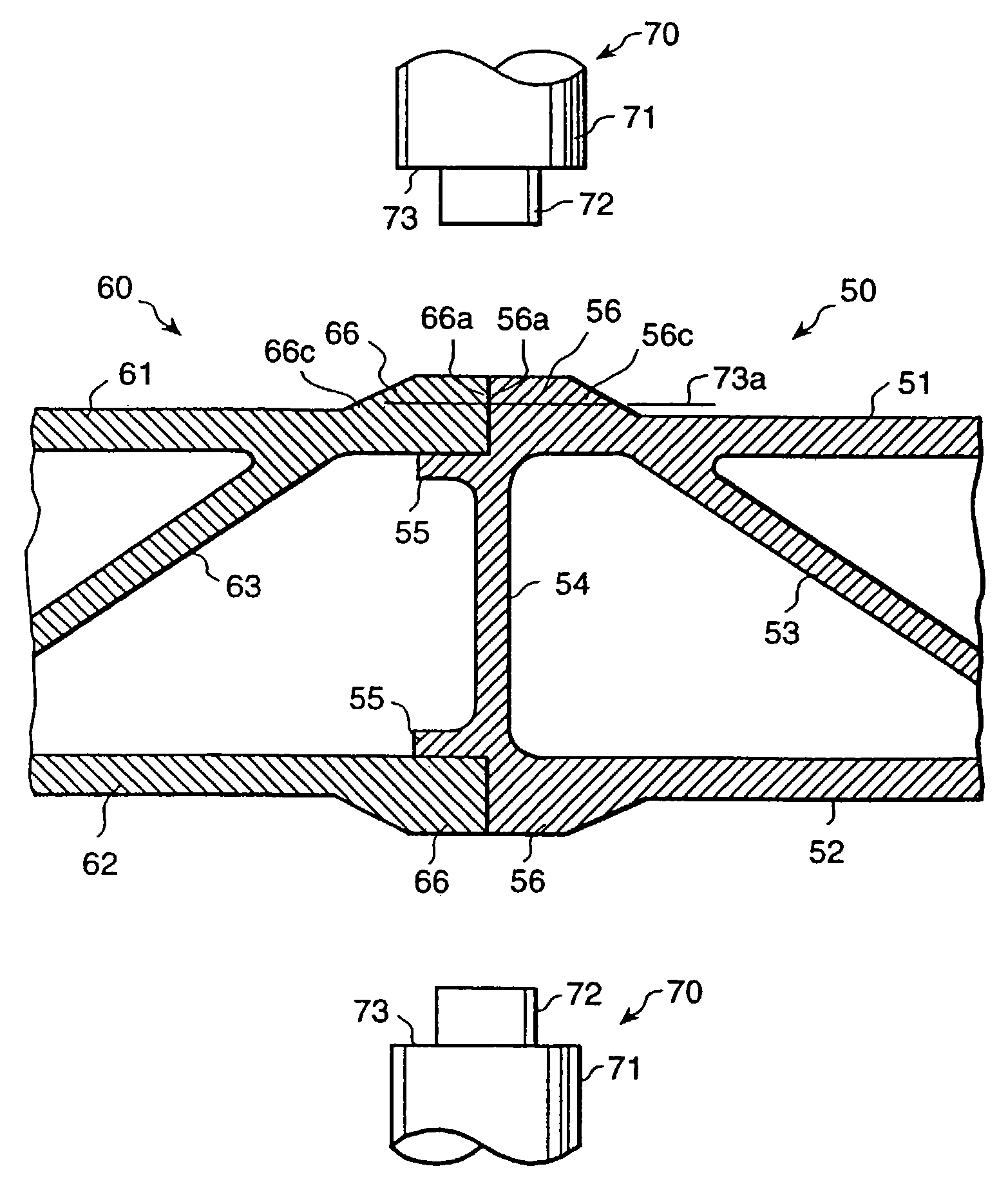

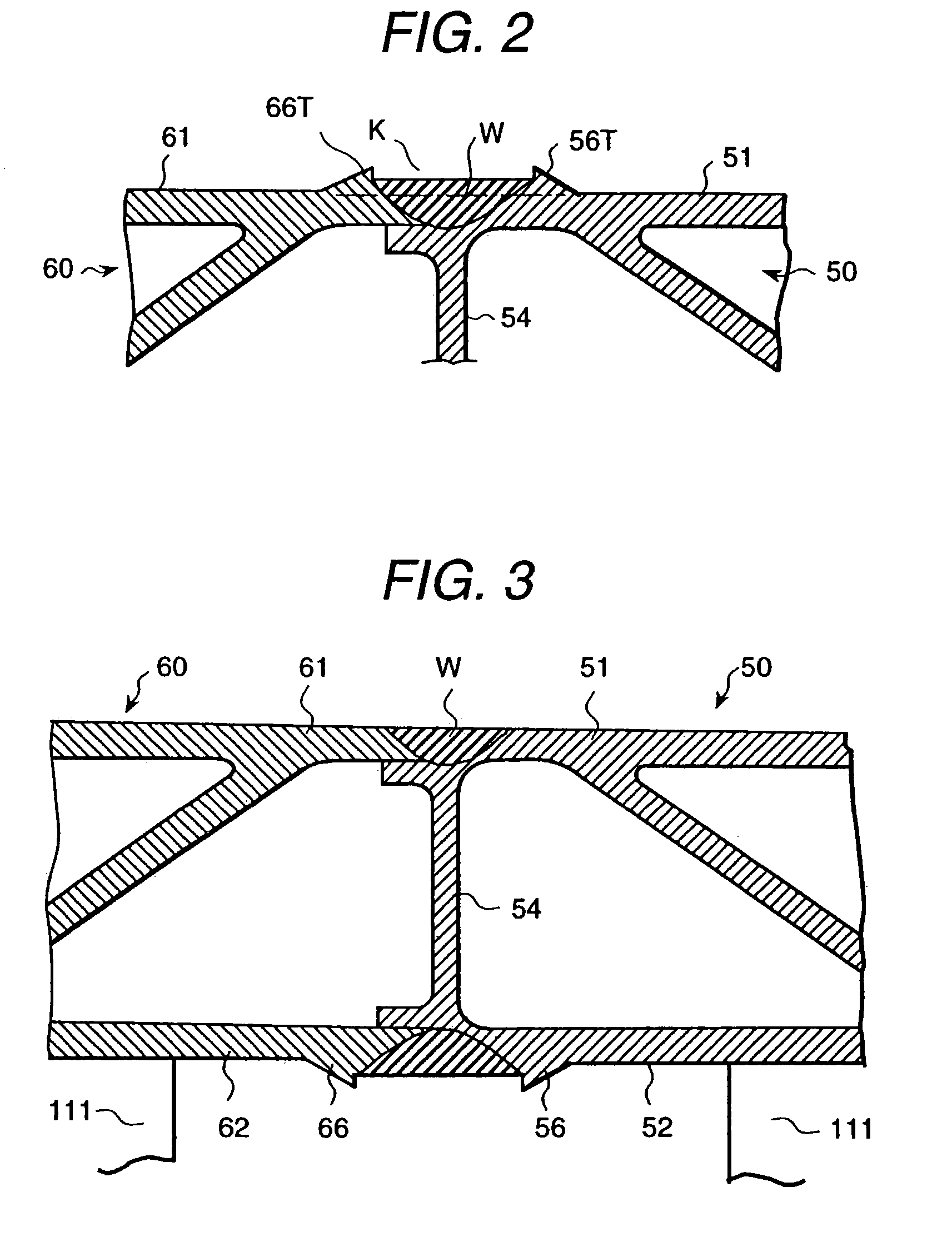

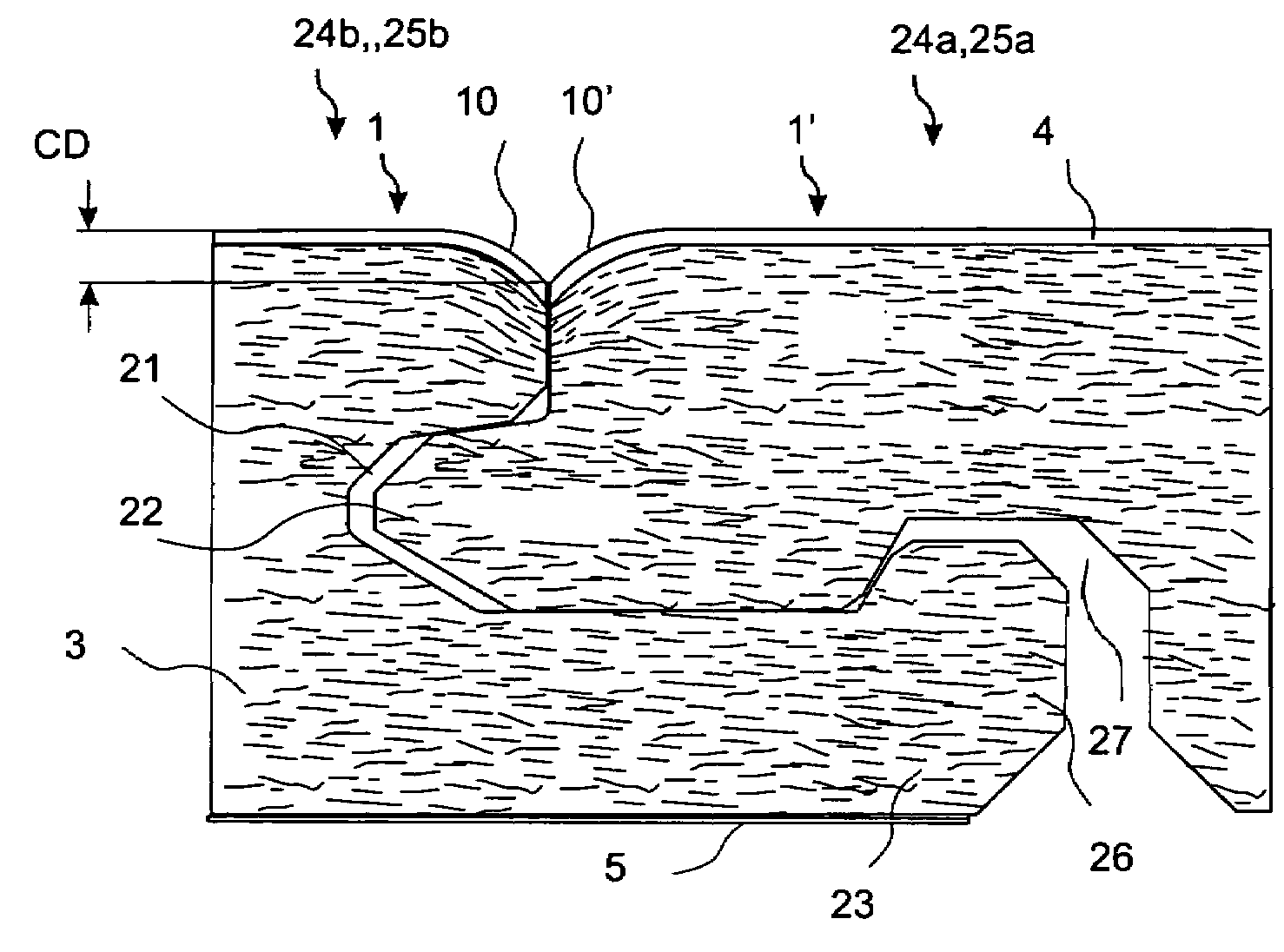

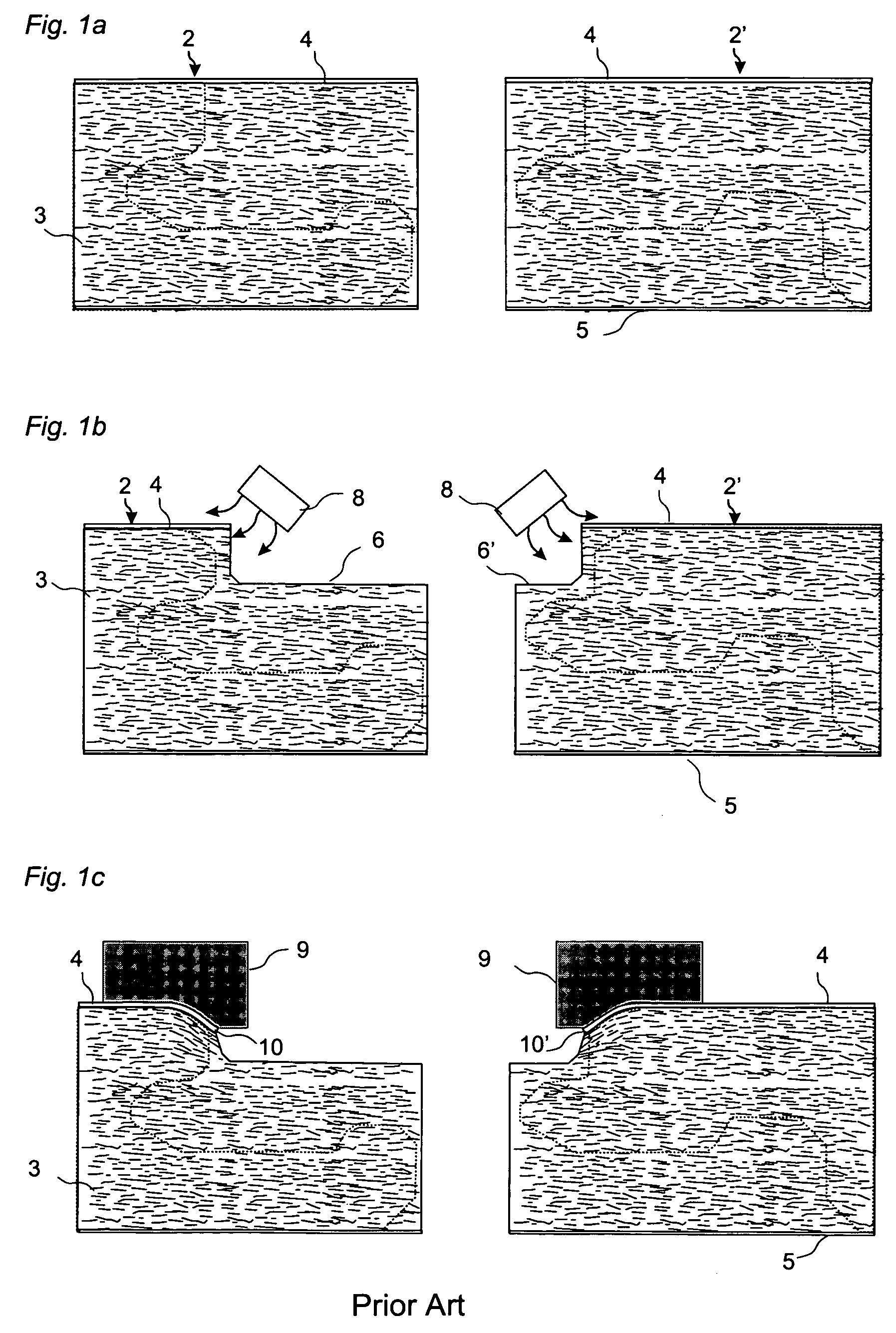

Friction stir welding method, frame members used therein, and product formed thereby

InactiveUS7036707B2High resultEasy to deleteWelding/cutting auxillary devicesStructural elementsEngineeringFriction stir welding

Disclosed is a friction stir welding technique which avoids occurrence of a dent, in a joining region, extending to a level beneath the joined surfaces. At end portions of the frame members to be joined, at the joining region, thickened parts which project toward the rotary body joining tool are provided. Two adjoining thickened parts, of adjacent members to be joined, can form a trapezoid shape. The rotary body joining tool has a small-diameter tip portion and a larger diameter portion. The rotary body joining tool is inserted in the thickened parts. In a state where the rotary body joining tool has been inserted small-diameter tip end first, to a level where the larger diameter portion of the rotary body joining tool overlaps the thickened part but does not extend below the upper surface of the non-thickened surfaces of the members joined, the rotary body is rotated and moved along the joining region. Even when a gap exists between two thickened parts, a desirable joining can be carried out. After the joining, the remaining parts of the thickened parts can be machined so as to form a smooth surface.

Owner:HITACHI LTD

Anchoring system for posts

Owner:NOK LOK LICENSING

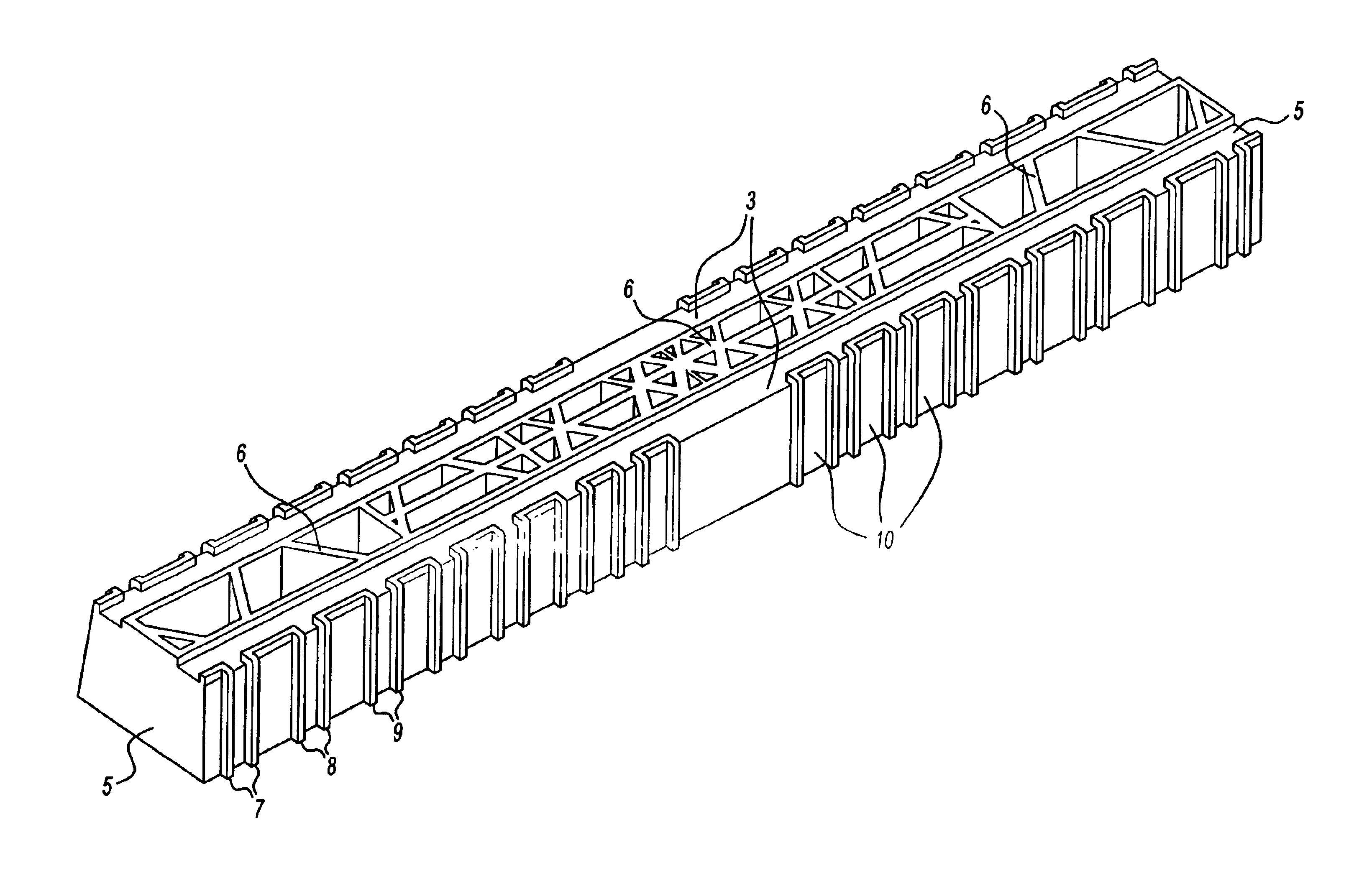

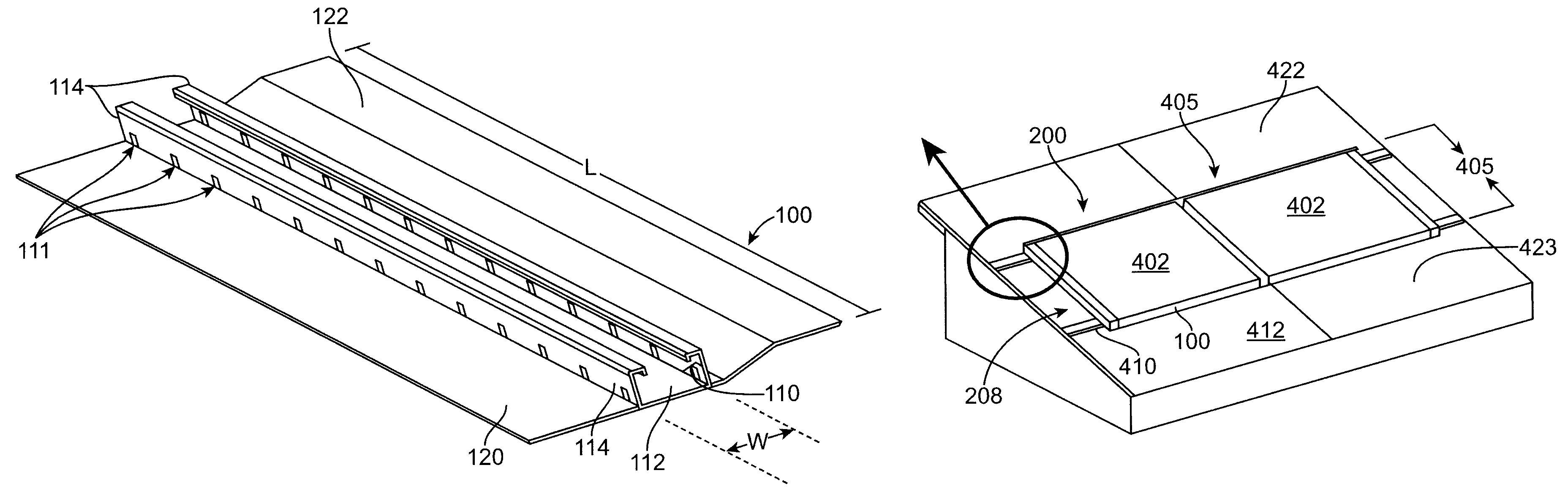

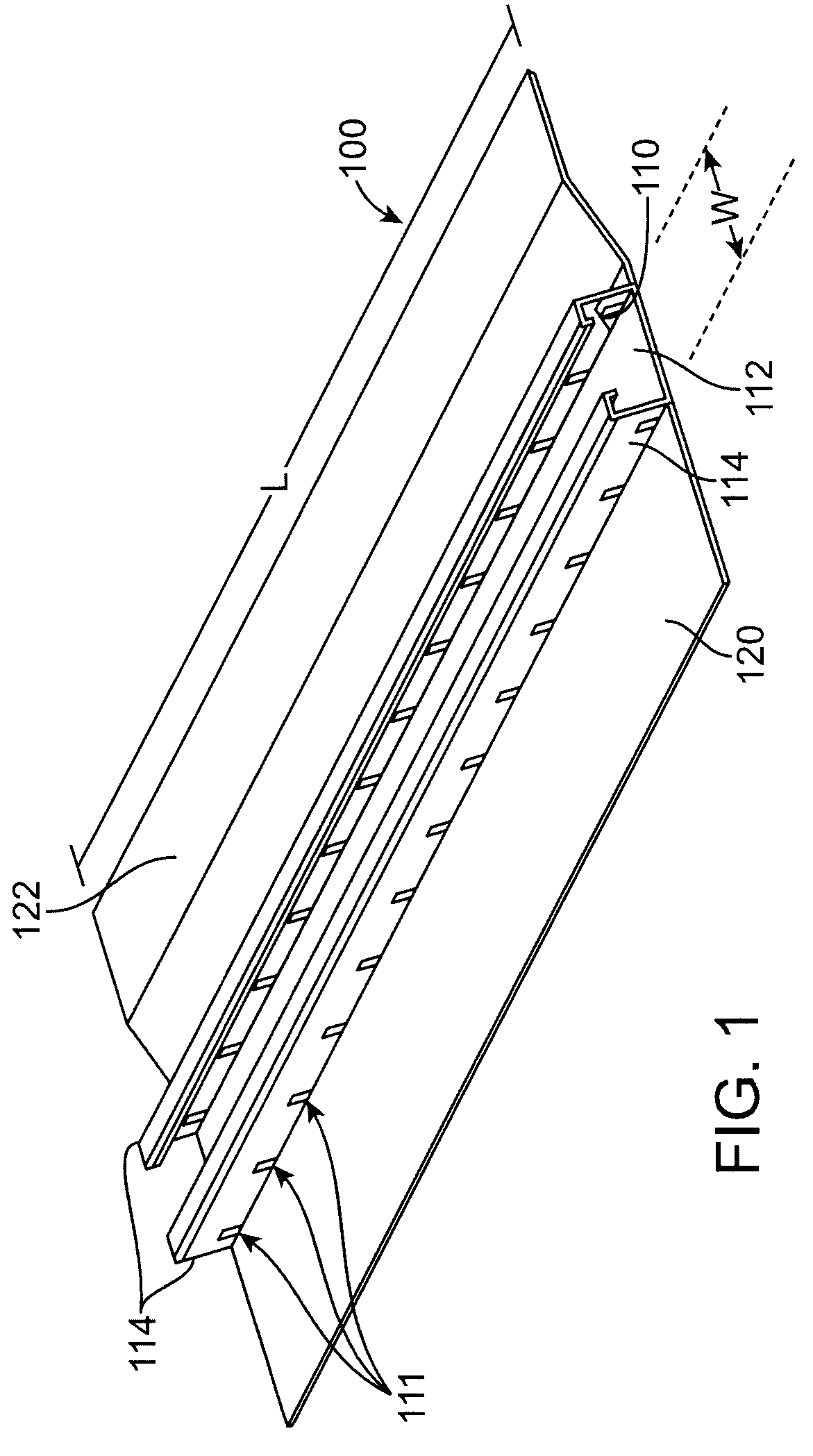

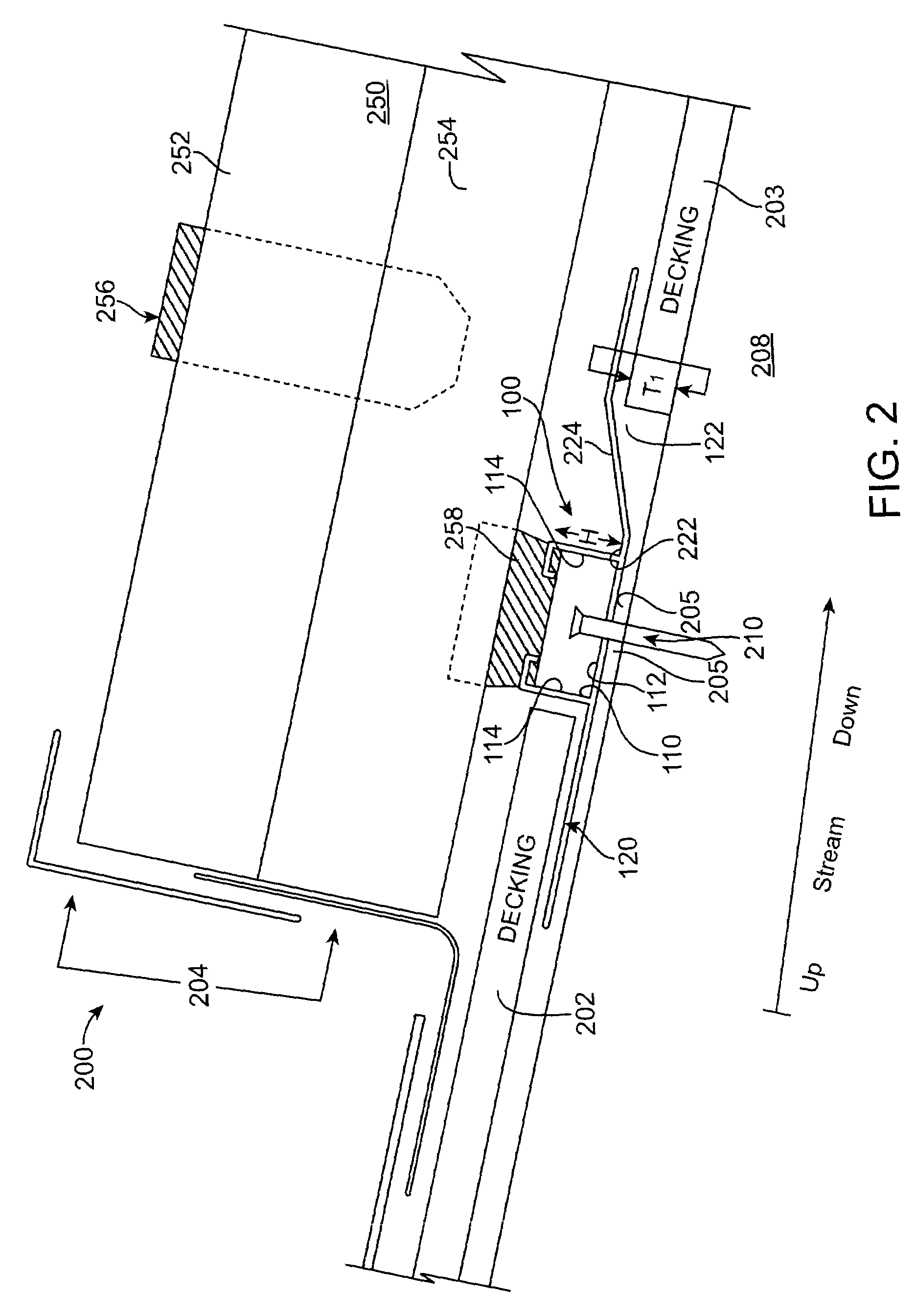

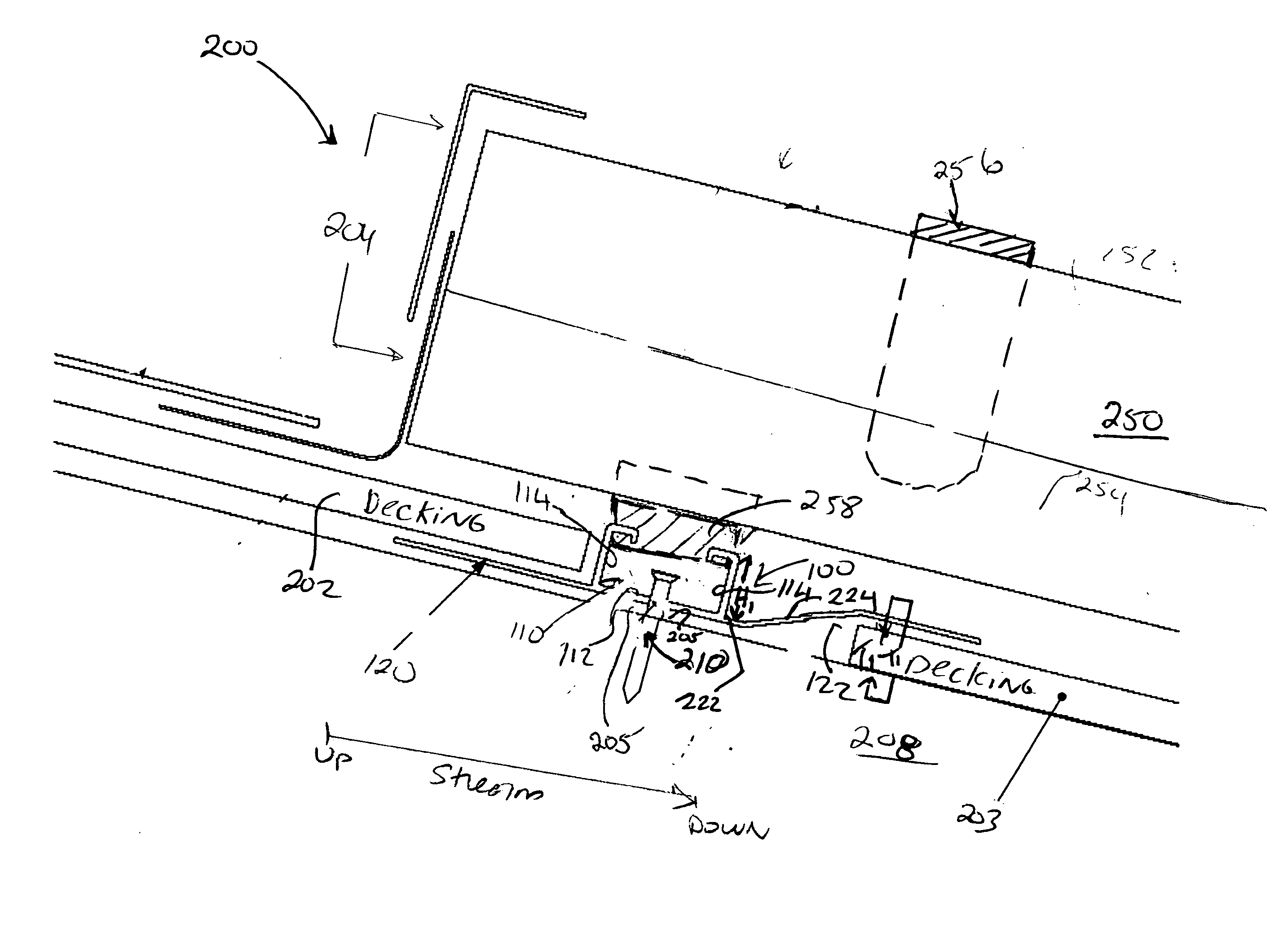

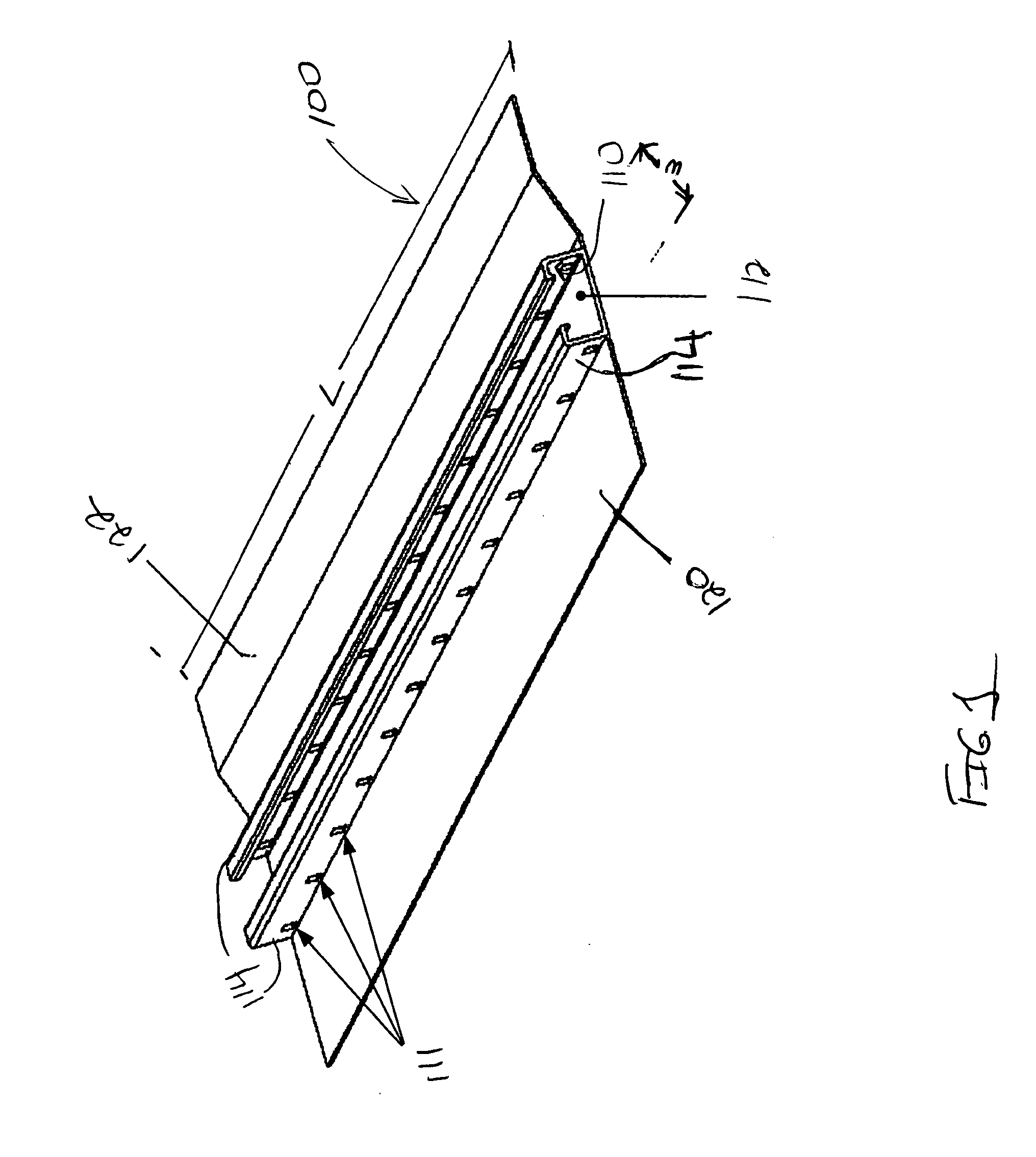

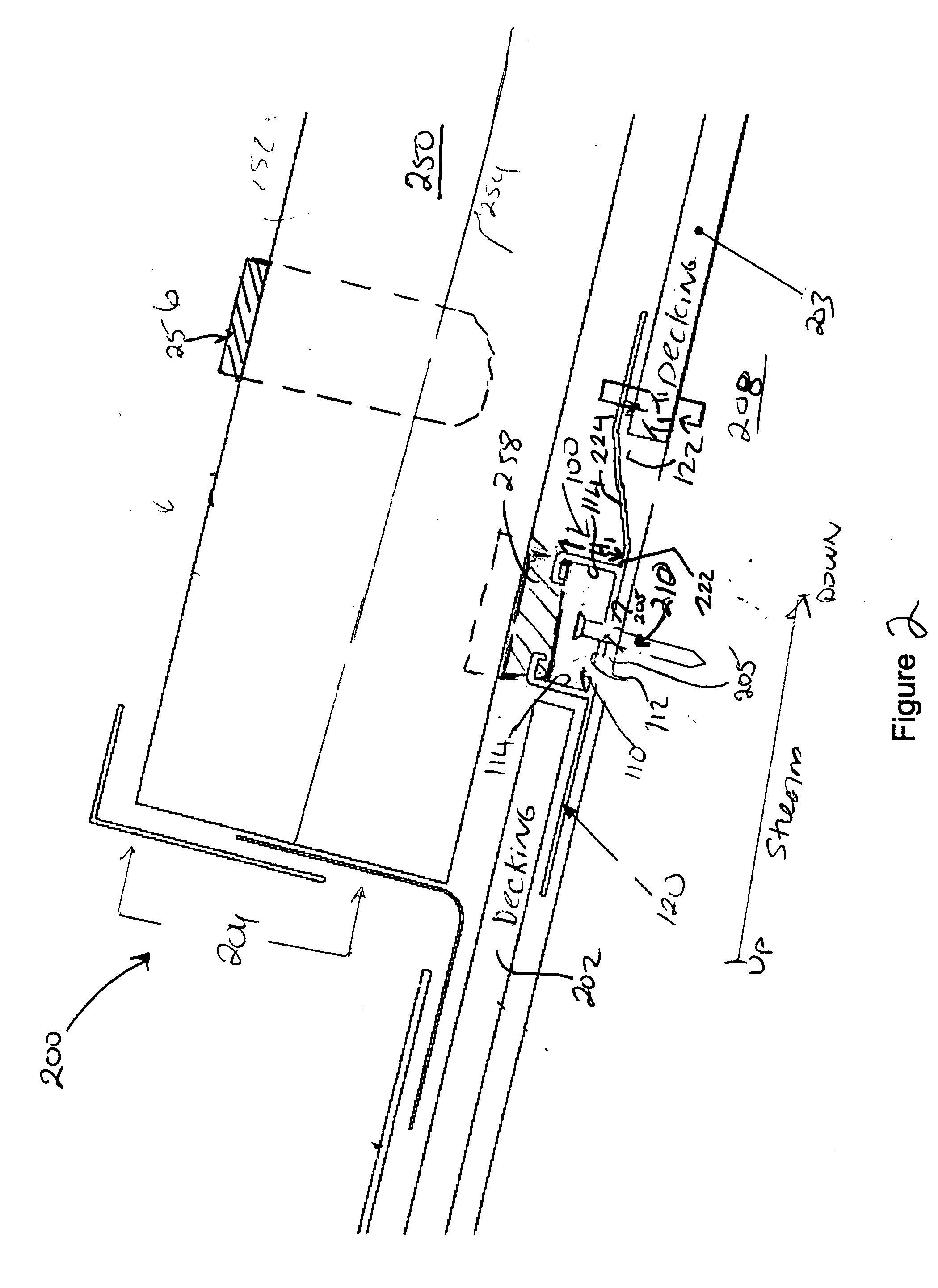

Strut runner member and assembly using same for mounting arrays on rooftops and other structures

A strut runner includes a member extending lengthwise in a first direction, where the member includes an underlying panel and one or more walls that extend from the panel. The member may be configured to at least partially support the panel array while being integrated or directly connected to the underlying structure. Additionally, the strut runner may include one or more peripheral extensions that extend a distance outward from the body.

Owner:FTC SOLAR INC

Precision-folded, high strength, fatigue-resistant structures and sheet therefor

Precision-folded, high strength, fatigue-resistant structures and a sheet therefore are disclosed. To form the structures, methods for precision bending of a sheet of material along a bend line and a sheet of material formed with bending strap-defining structures, such as slits or grooves, are disclosed. Methods include steps of designing and then separately forming longitudinally extending slits or grooves through the sheet of material in axially spaced relation to produce precise bending of the sheet when bent along the bend line. The bending straps have a configuration and orientation which increases their strength and fatigue resistance, and most preferably slits or arcs are used which causes edges to be engaged and supported on faces of the sheet material on opposite sides of the slits or arcs. The edge-to-face contact produces bending along a virtual fulcrum position in superimposed relation to the bend line. Several slit embodiments suitable for producing edge-to-face engagement support and precise bending are disclosed. With these teachings, forming numerous three-dimensional load-bearing structures from a two dimensional sheet are enabled. Examples of straight and curved beams, chassis, and exoskeletons are disclosed.

Owner:IND ORIGAMI INC CA US

Bar Connecting Apparatus

A bar connecting apparatus applies clips to connect transverse bars used in reinforced concrete. A clip string is fed into the bar connecting apparatus by a clip feed assembly, so several pairs of transverse bars can be connected in rapid succession. A hammer reciprocates in the barrel of the bar connecting apparatus, and drives a clip from the barrel into engagement with the bars. An alignment head aligns the bar connecting apparatus with the transverse bars so the clips properly engage the bars.

Owner:DAYTON SUPERIOR CORP

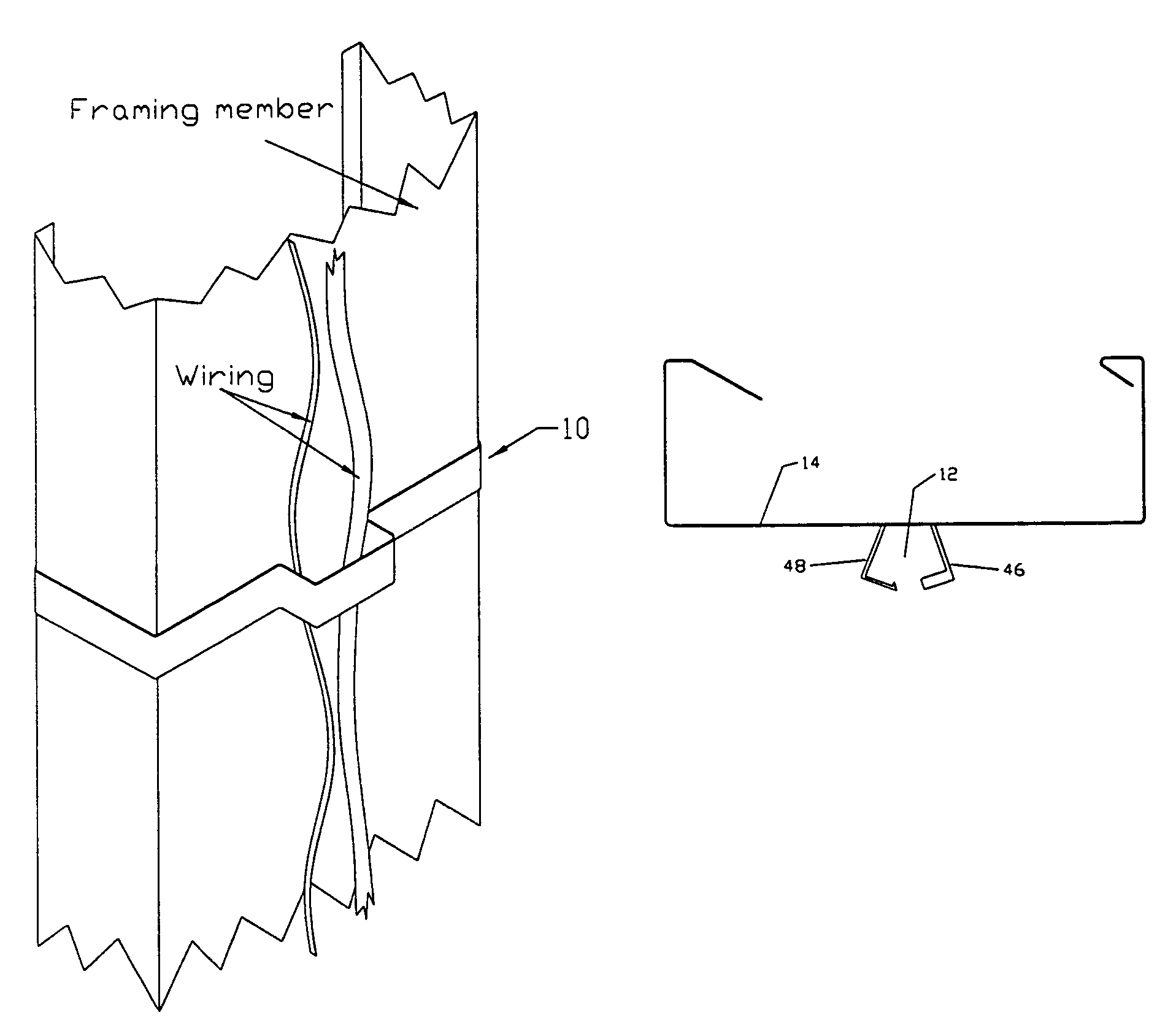

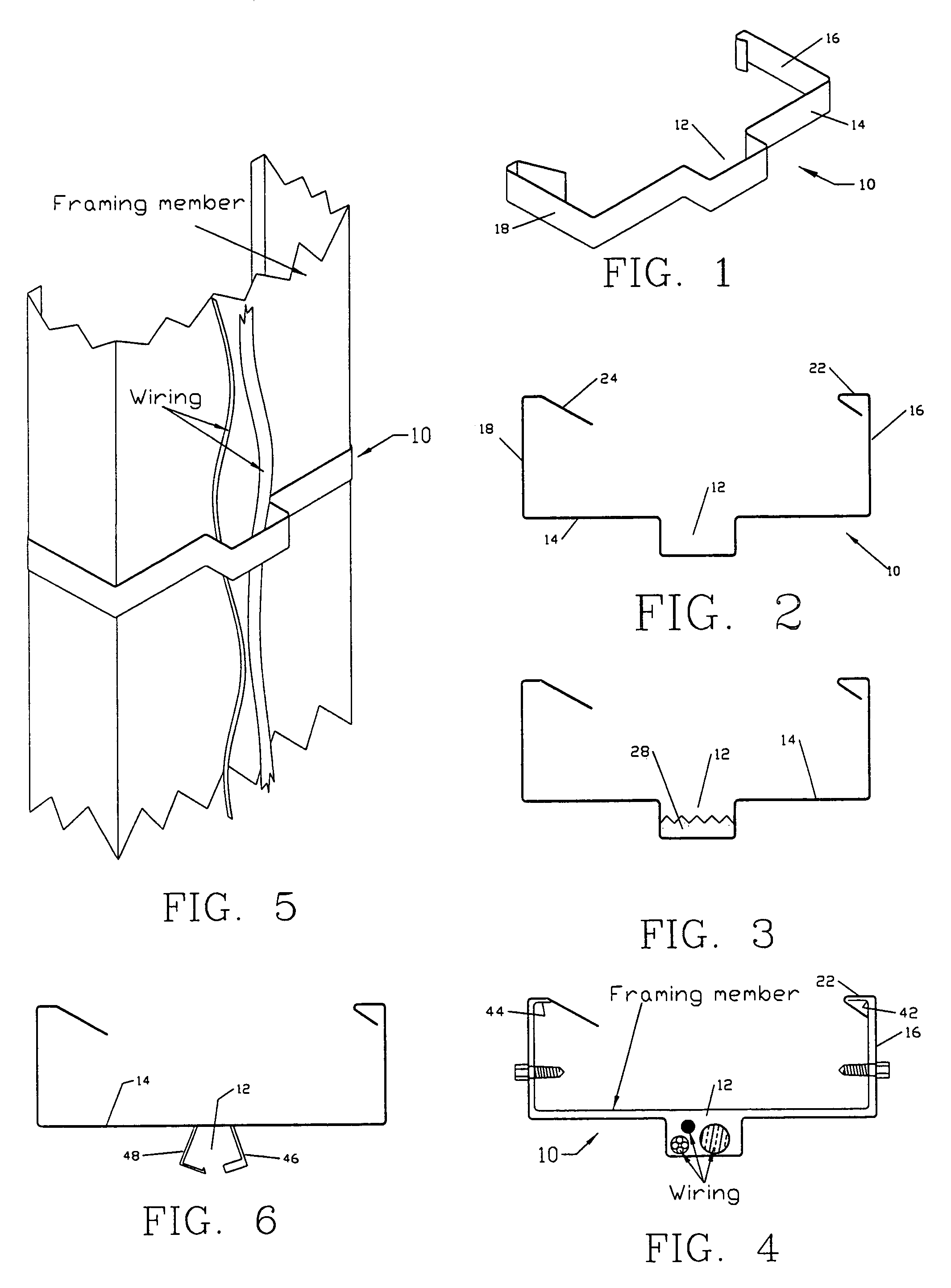

Wiring clip securing electrical wiring to a framing member

A wiring clip for securing electrical wiring to metal framing members. In a specific embodiment, the subject clip can secure the wiring a required distance from the nearest edge or face of the metal framing member to which a wall board is to be secured. The wire clip generally resembles an open frame having a wire receiving area formed in the main body, where the wire receiving area is centrally located within the main body. The wire clip is generally of U-shaped configuration, with two arms being joined to the main body. The end of the first arm is bent to form a J-hook, such that the J-hook can be hooked about a first inner edge of a metal stud. The end of the second arm comprises a clip, such that the clip can be removable, secured about the second inner edge of the metal stud. The arms, as well as the main body, are resilient, such that the arms and the main body will embrace the metal stud.

Owner:COLLETT DENISE MARIE

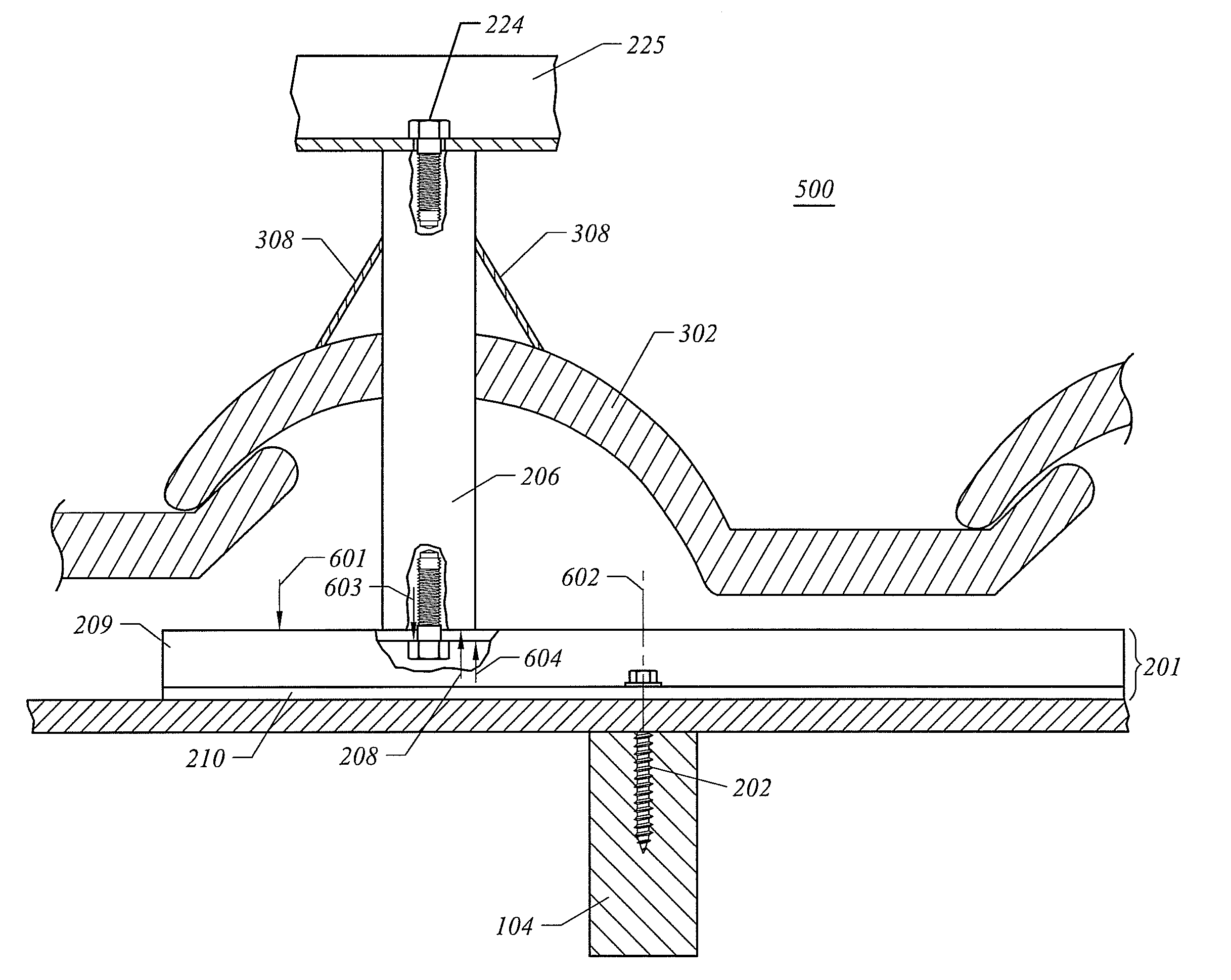

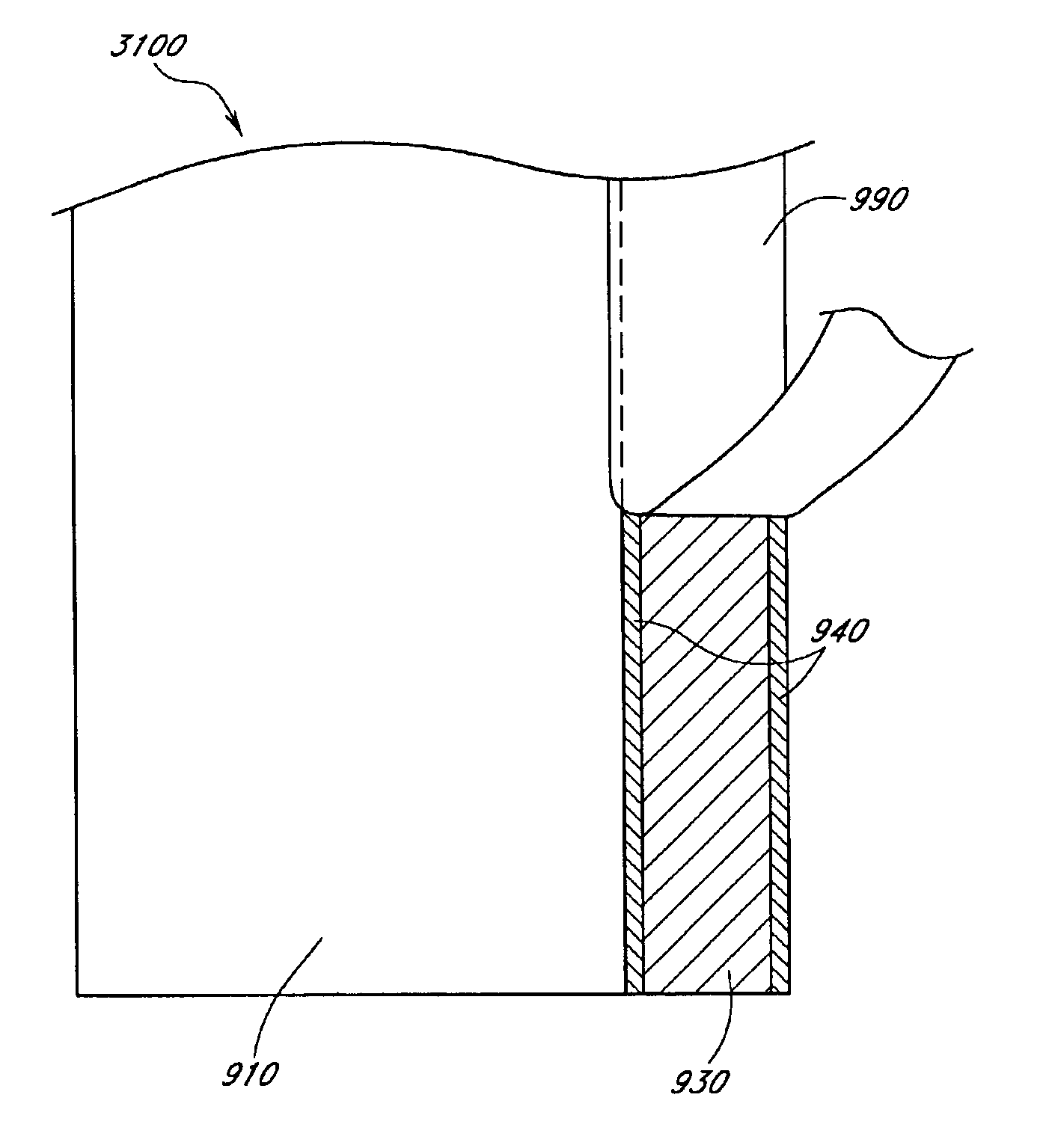

Non-invasive roof mounting adaptor and method for installing same

ActiveUS8733718B2Minimize damagePhotovoltaic supportsSolar heating energyNon invasiveThreaded fastener

Owner:CORSI PETER A

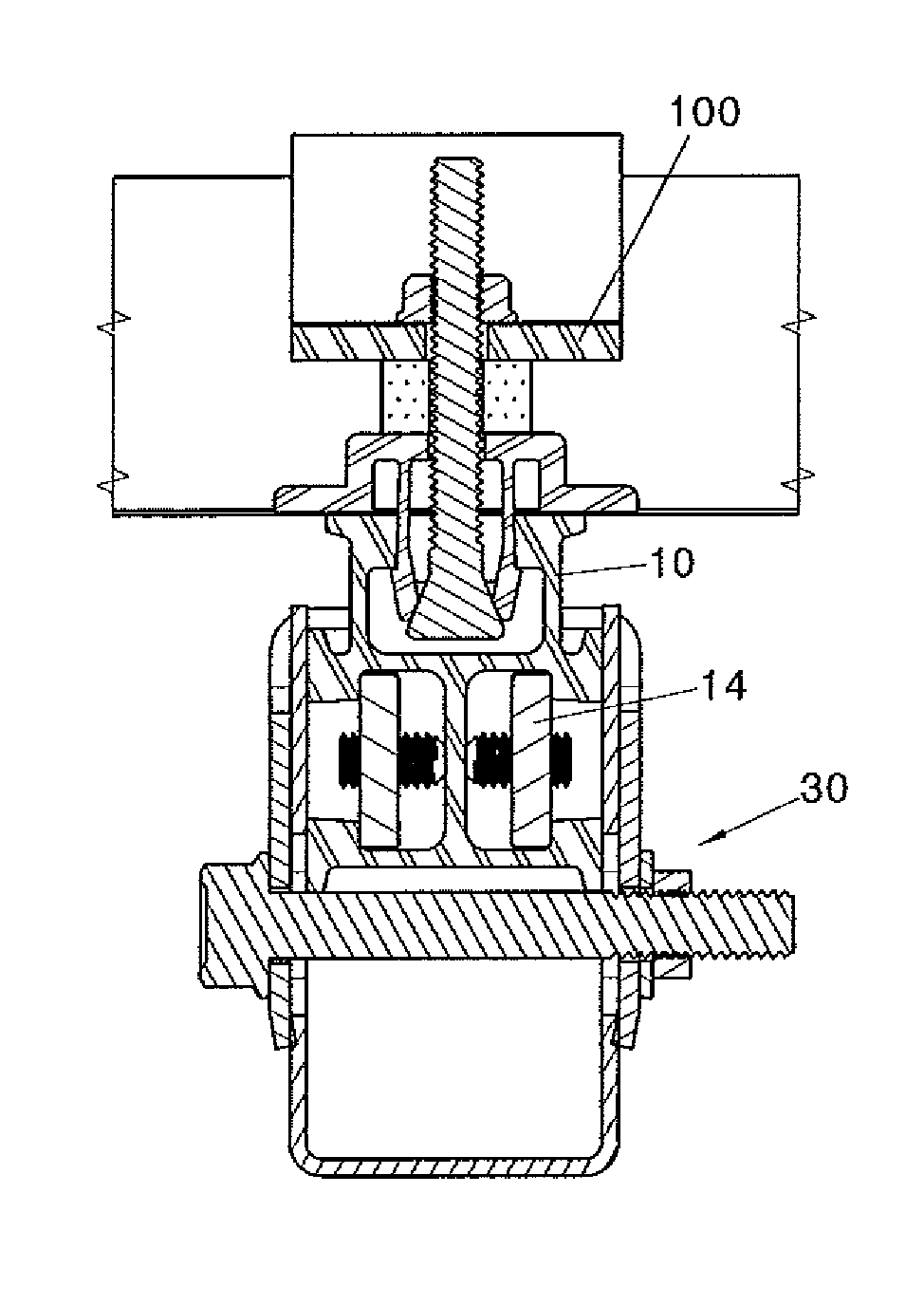

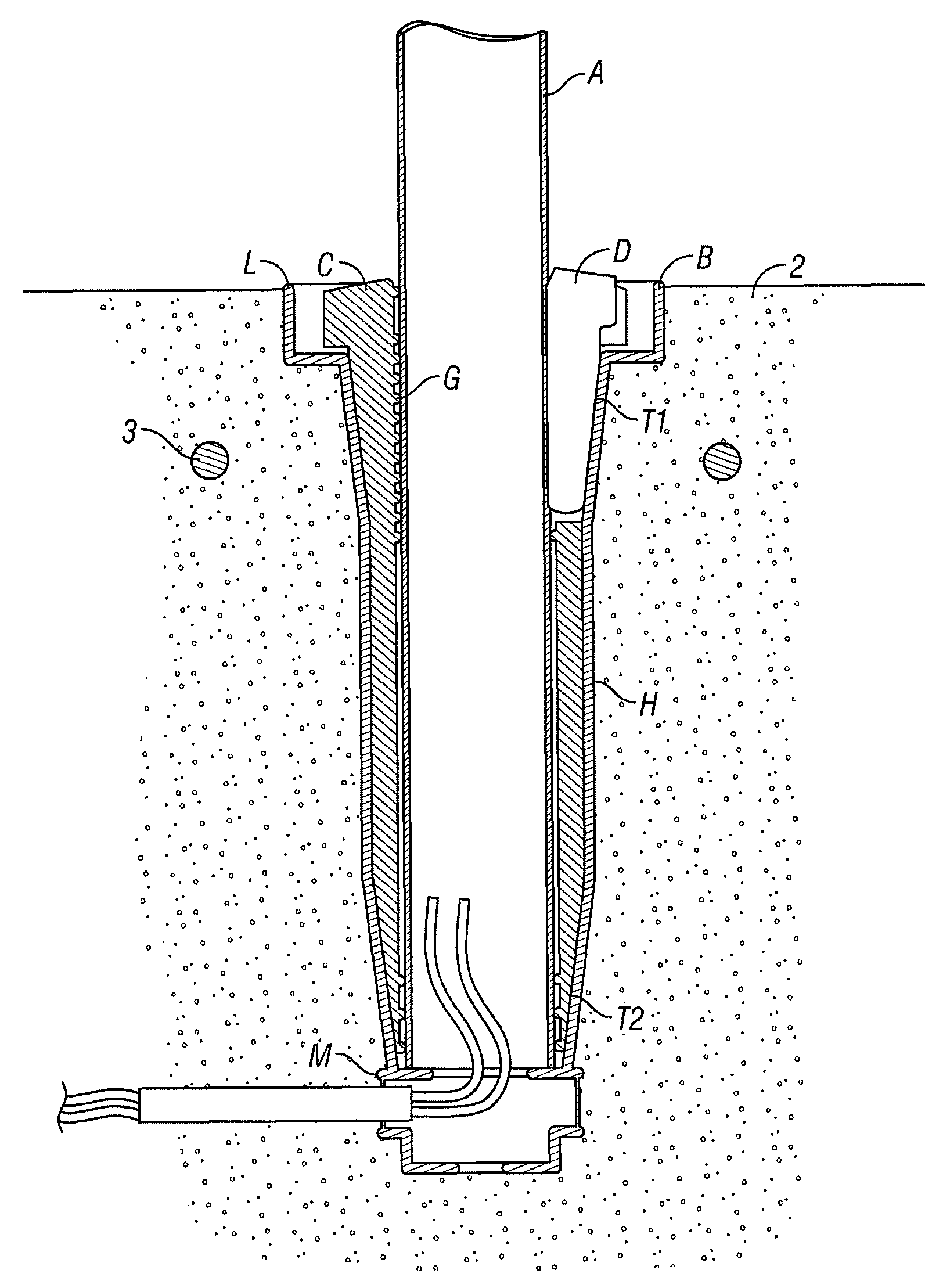

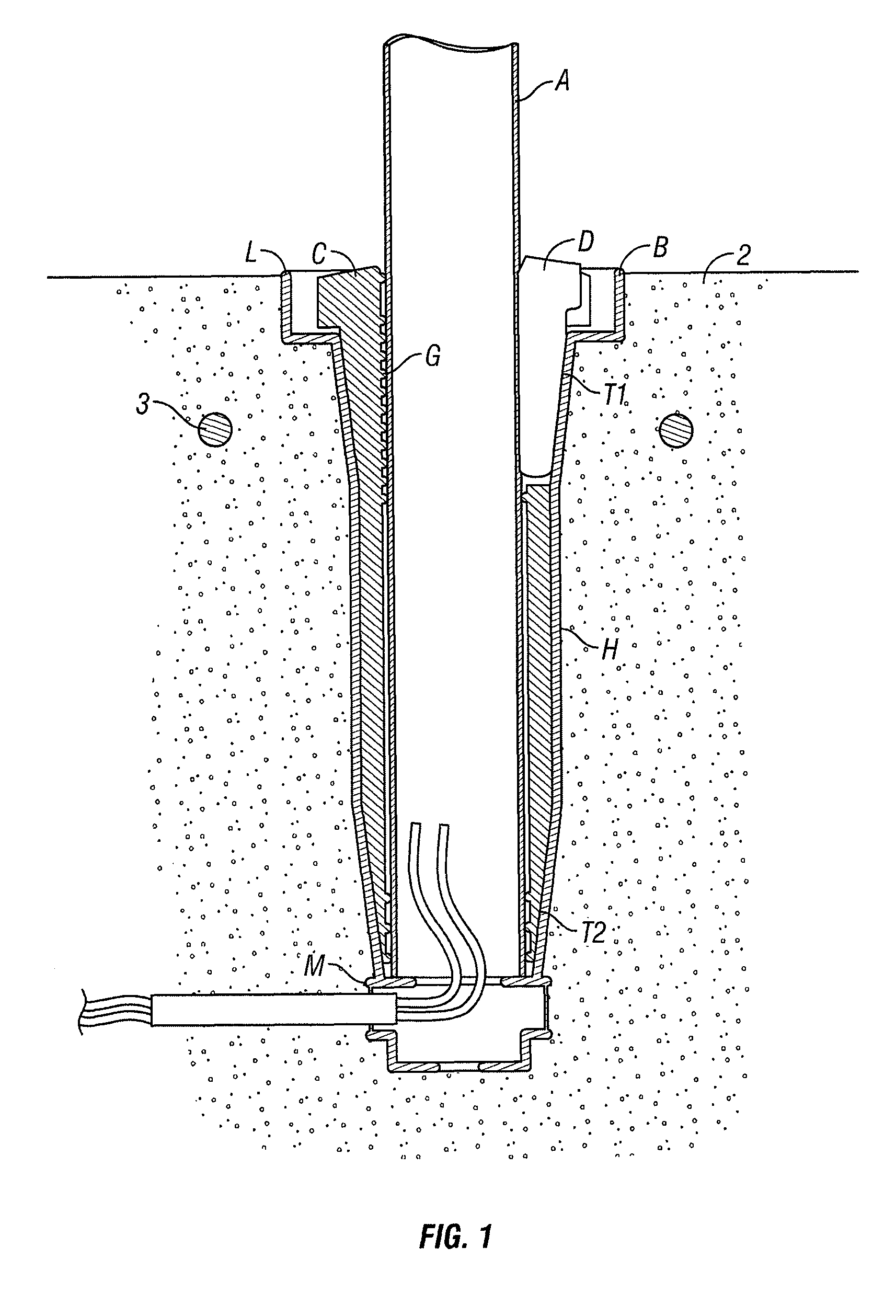

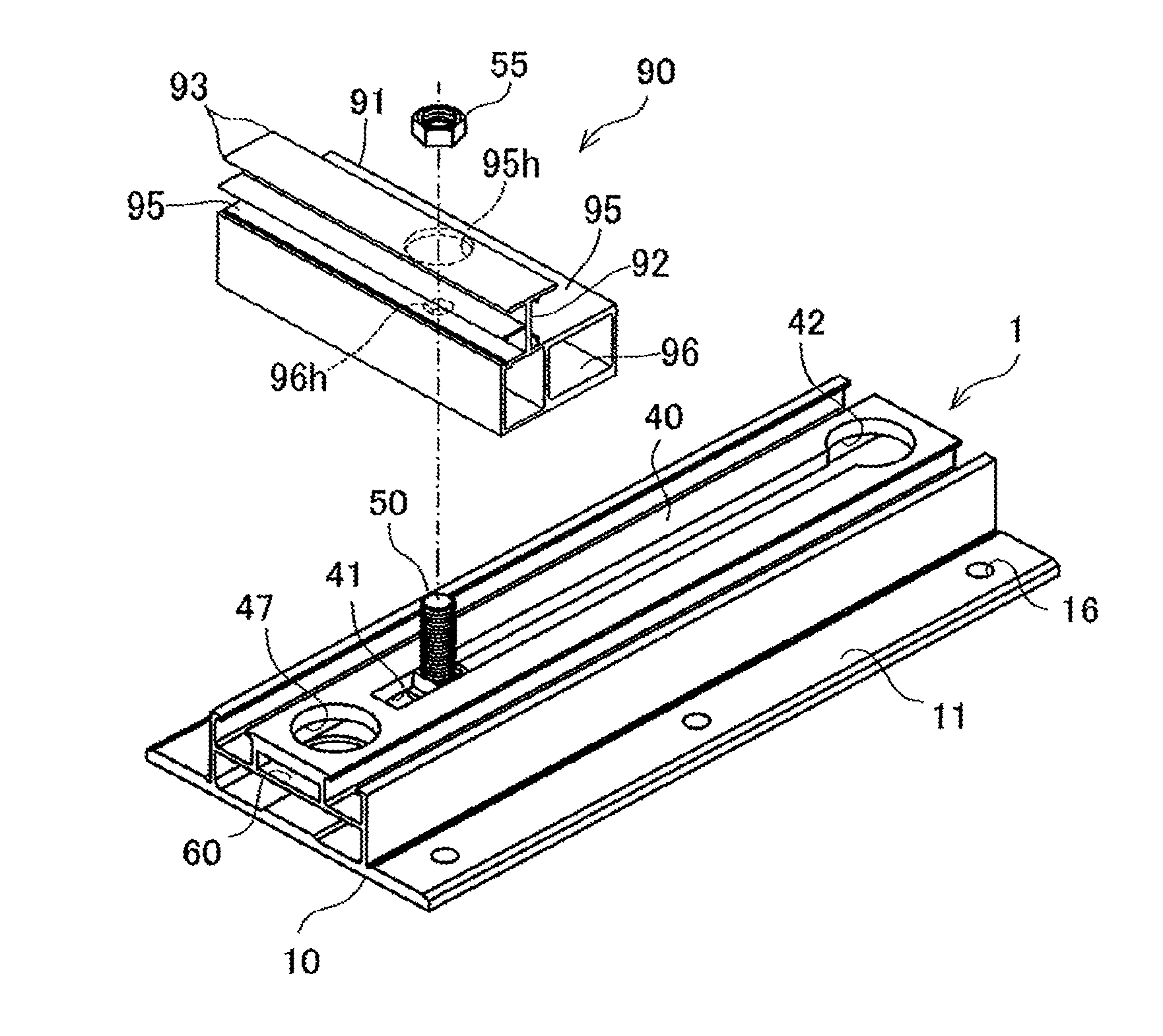

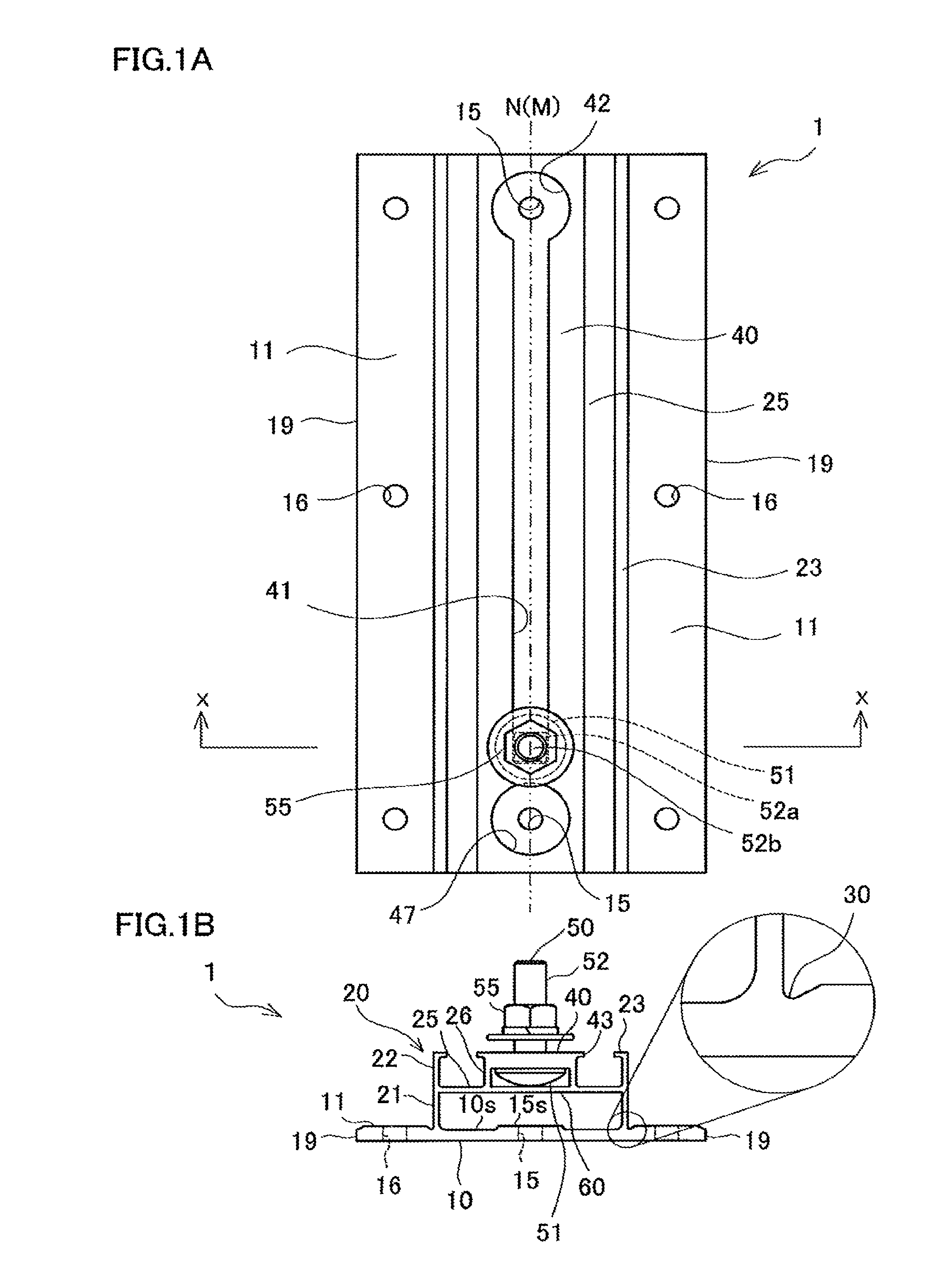

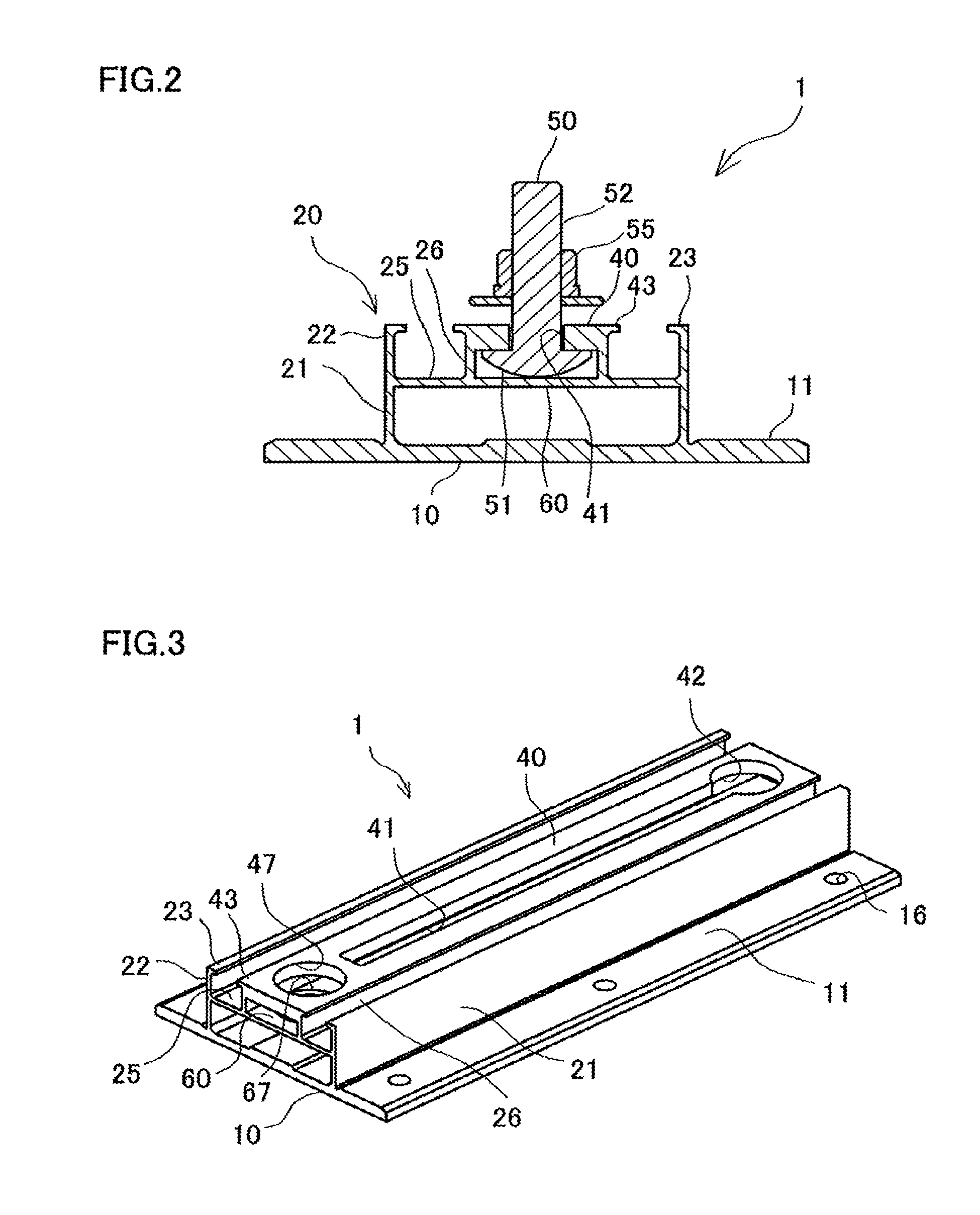

Securing member

ActiveUS8647009B2Improve installation strengthPhotovoltaic supportsSolar heating energyEngineeringMechanical engineering

A securing member includes a flat base portion, a flat top board portion which is supported by a pair of top board supporting portions erected on the base portion, a long hole which penetrates through the top board portion and of which both ends are closed, a bolt having a head which does not pass through the long hole, and of which shaft is inserted through the long hole in a state where the head is located lower than the top board portion and is to be inserted through a supporting hole provided on a supporting member of a solar battery module, a head insertion hole through which the head of the bolt passes, penetrates through the top board portion, and communicates with the long hole, securing holes which are located on a line obtained by projecting a center line of the long hole, and penetrate through the base portion.

Owner:YANEGIJUTSUKENKYUJO CO LTD

Device and method for compressing an edge of a building panel and a building panel with compressed edges

ActiveUS20080120938A1Increase speedDeeper curved edge portionPlywood pressesCovering/liningsArchitectural engineeringStructural engineering

Owner:VÄLINGE INNOVATION AB

Panel fastening system

InactiveUS8595997B2High tensile strengthEasy to installPhotovoltaic supportsSolar heating energyEngineeringUltimate tensile strength

The present invention discloses a fastening system for a panel. The fastening system includes: at least two mounting rails which each has a plurality of engaging open cavities formed therein; and a plurality of engaging slide blocks respectively engaging with the engaging open cavities; wherein the panel is disposed on the mounting rails and fixedly connected with the engaging slide blocks respectively. Basing on the engagement structure, the present invention can be fastened on a surface of a mounted object via two rails and provide high tensile strength and simple installation. The present invention can fix different shapes of panel assemblies on a roof, the ground, a wall or a surface of a framework safely, quickly and stably, and the present invention has a simple structure, light weight and low total costs.

Owner:RACWORTH

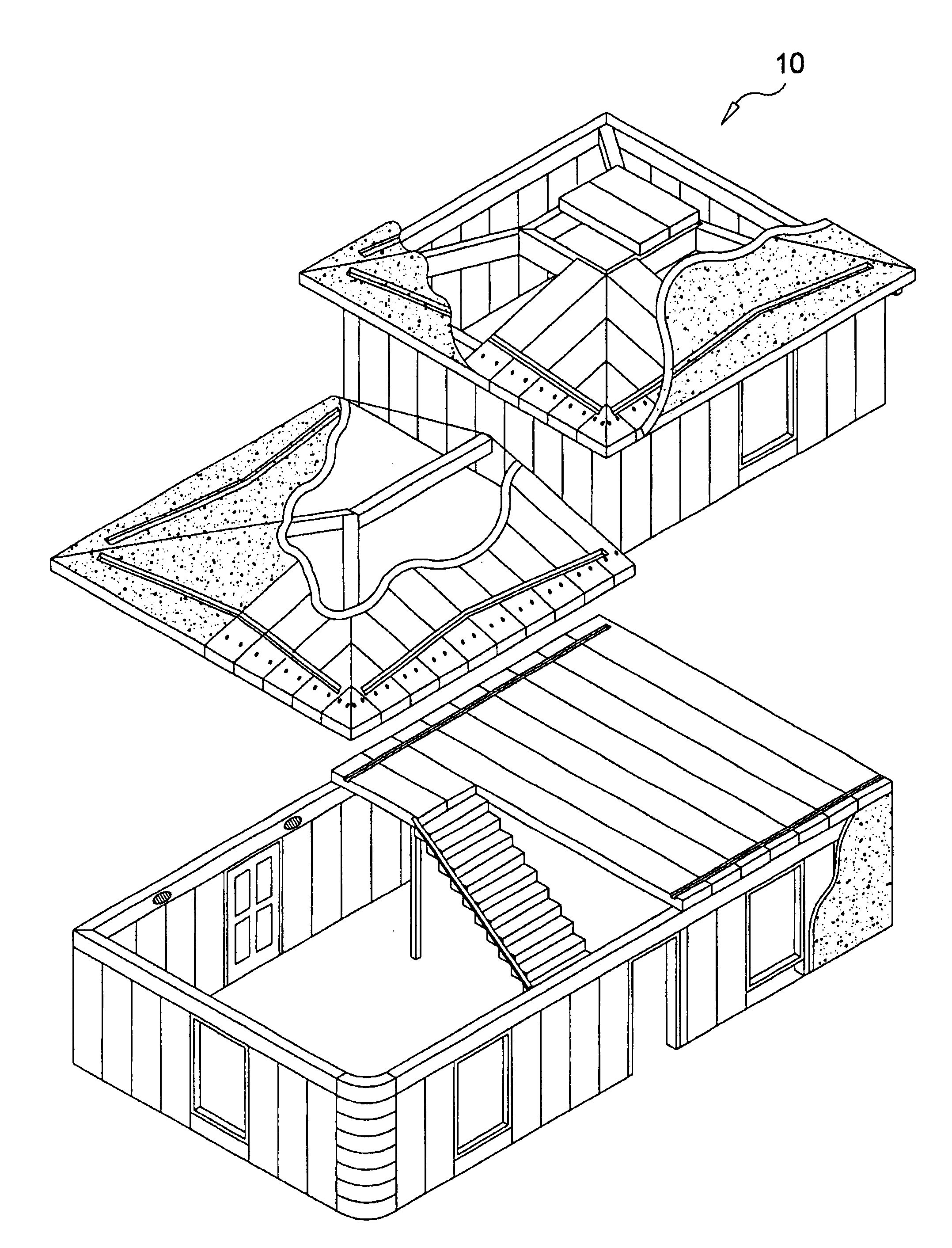

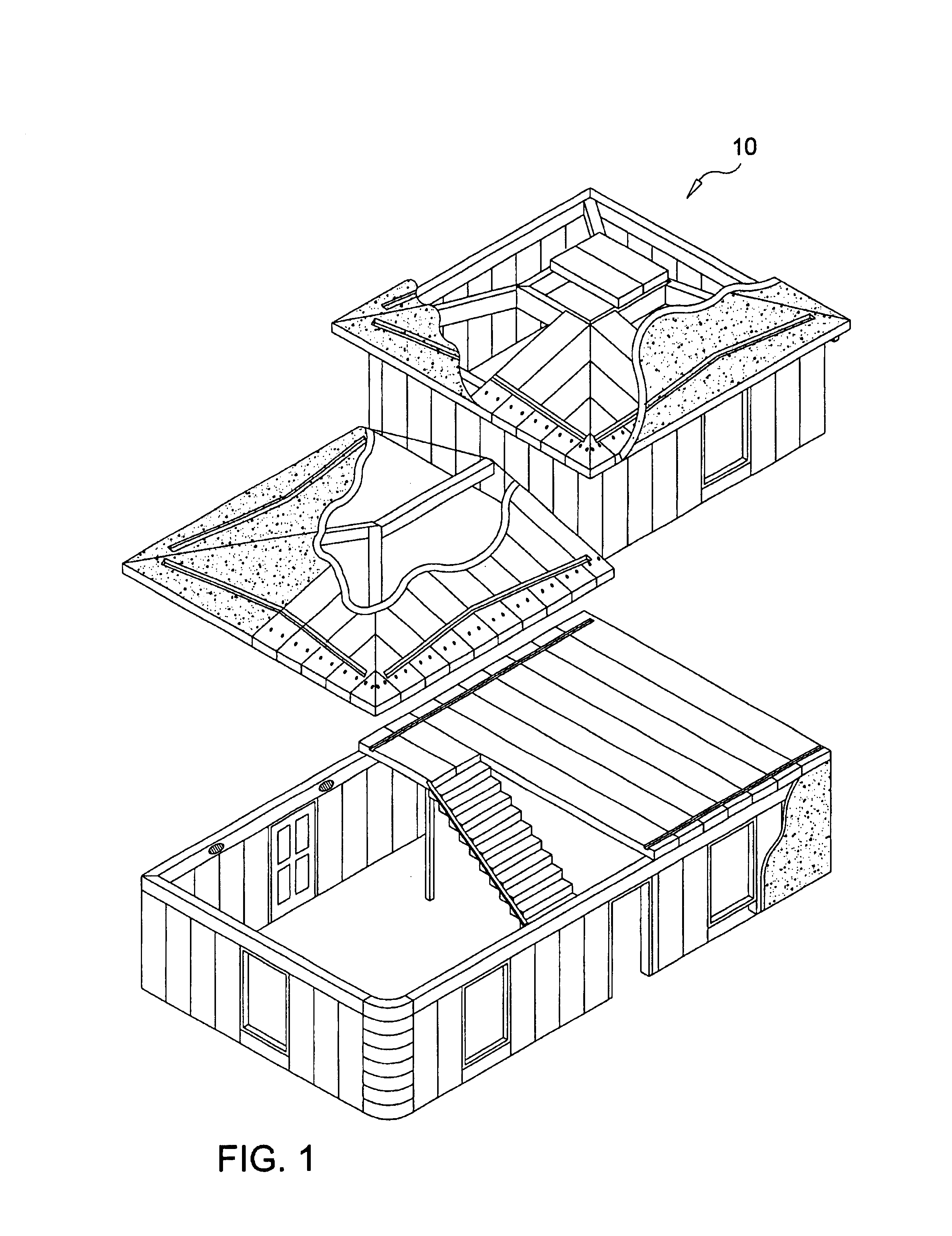

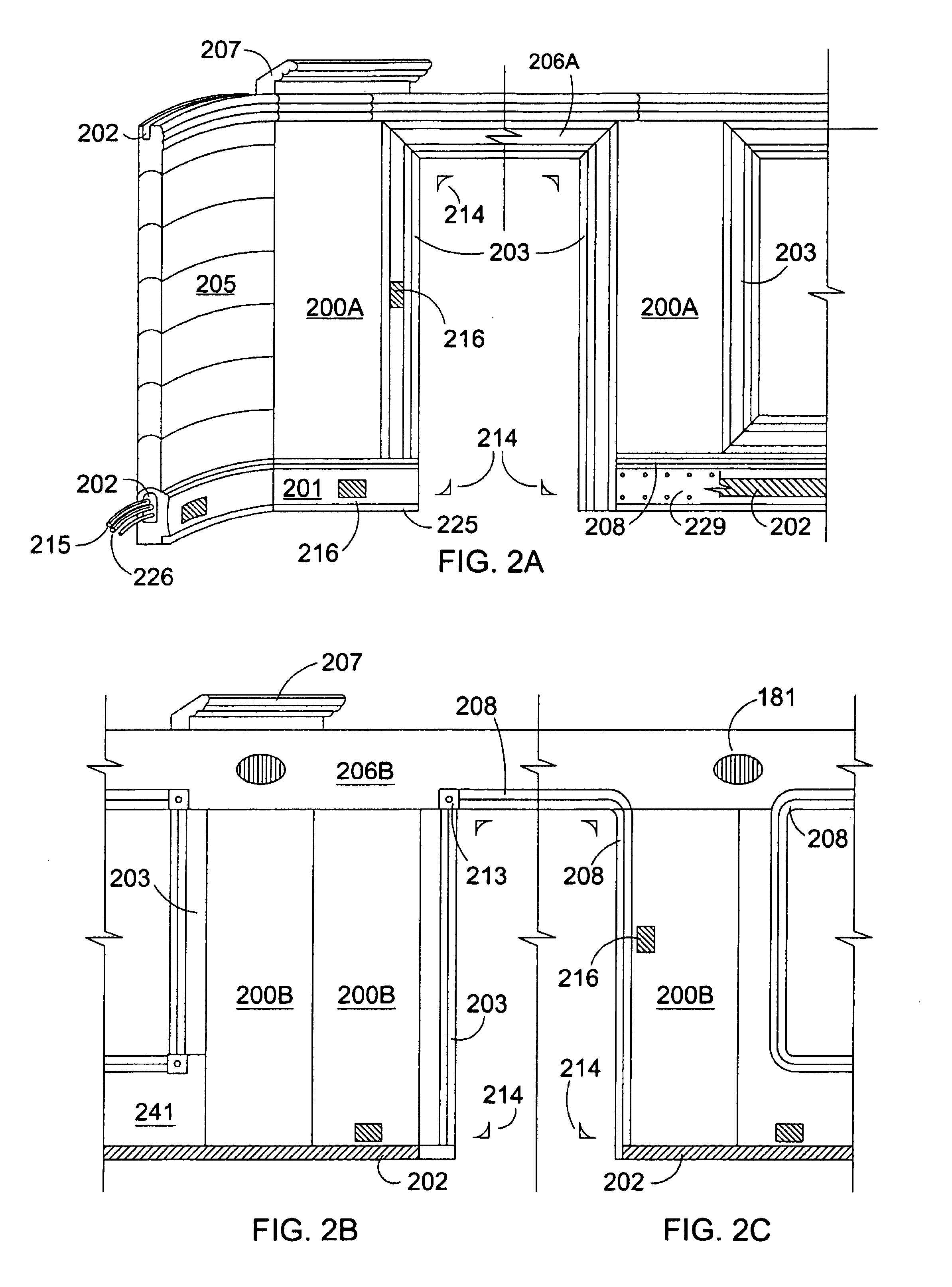

System for manufacturing structures of cementitious materials

InactiveUS7204060B2Overcome problemsBuilding roofsSolar heating energyHigh pressureAutoclaved aerated concrete

Owner:HUNT CHRISTOPHER M

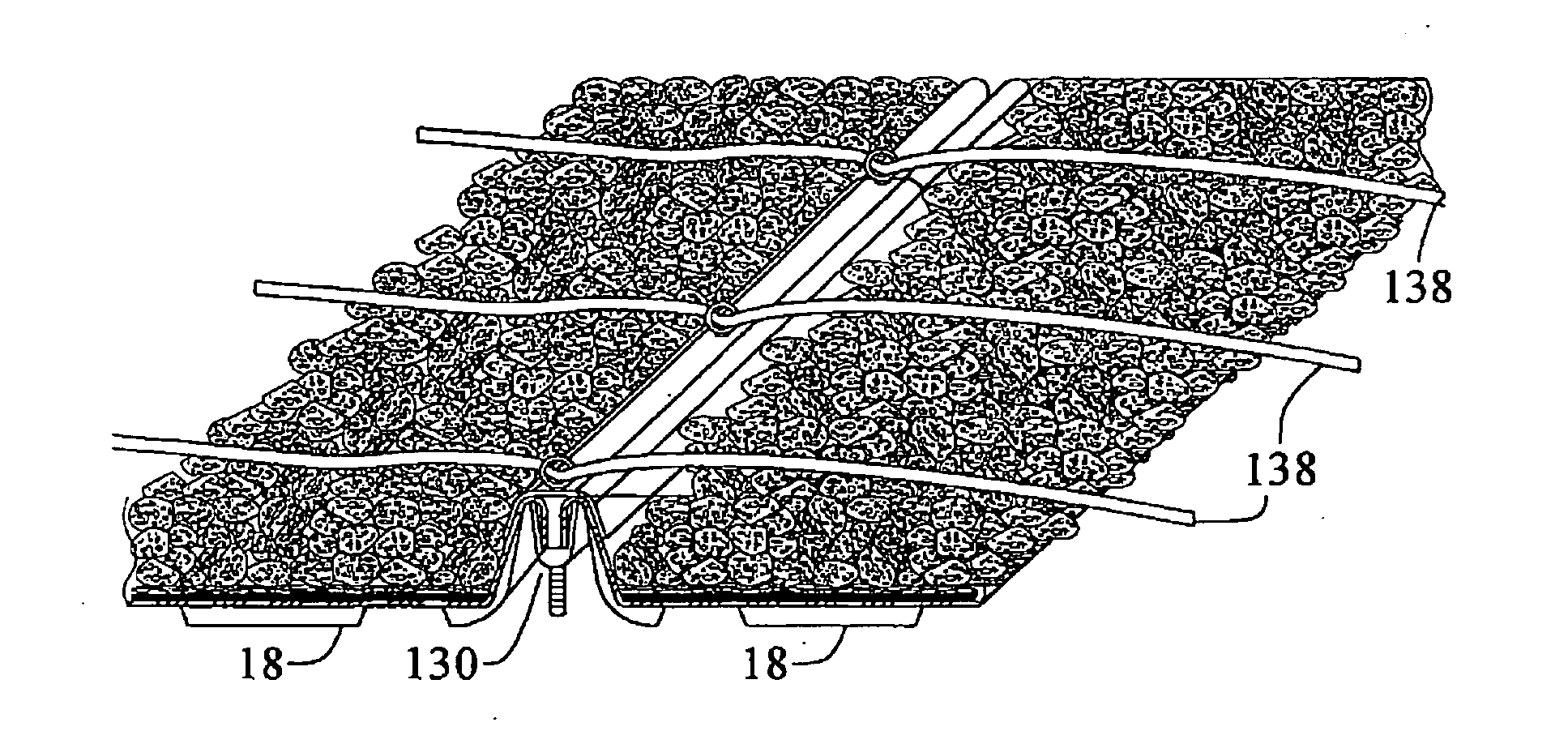

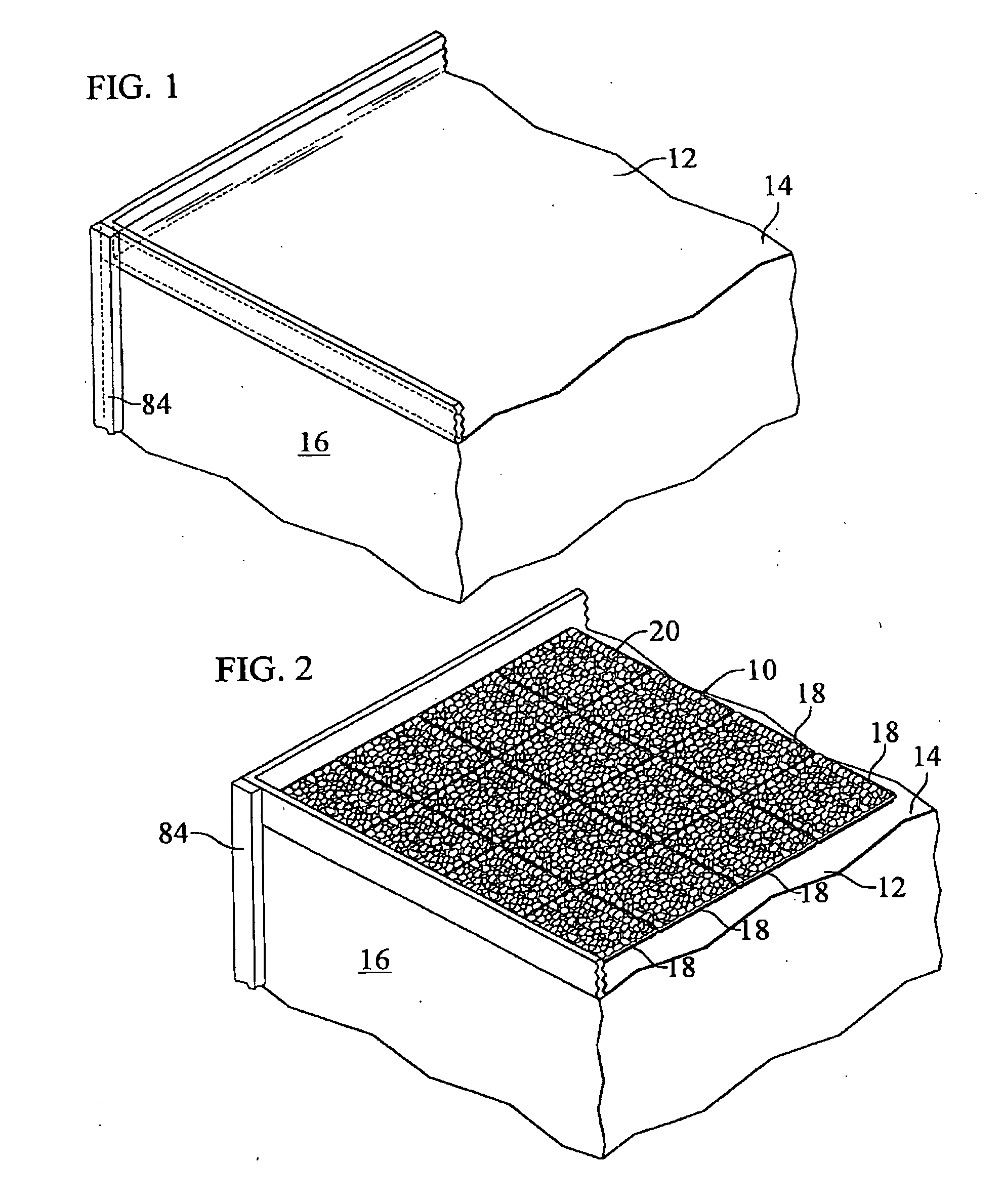

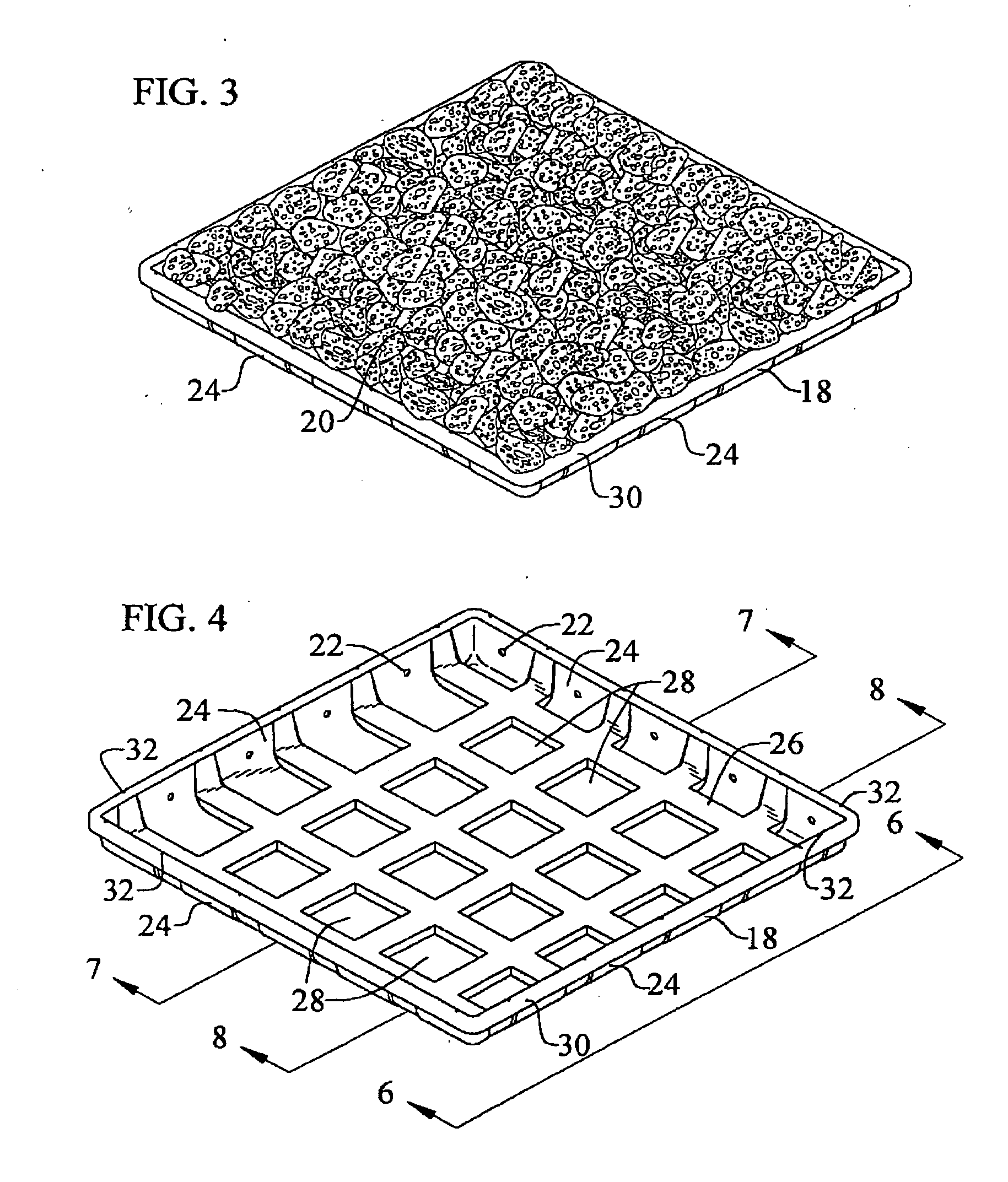

Modular ballast system for membrane roofs

ActiveUS20100325975A1Reduce evaporationPredictable and relatively large volumePhotovoltaic supportsSolar heating energyTime segmentEnvironmental engineering

Owner:WESTON SOLUTIONS

Floor system

A floor system includes a pair of joist rim assemblies each having a web defining a first surface. The web also includes a mounting portion defining a second surface offset from the first surface. The joist rim may also include a prong defining a slot along with the web. A joist connector bracket is received within the slot and is connectable to the mounting portion of the web. A joist extends between the pair of joist rim assemblies and is connected to the joist connector bracket of each joist rim assembly.

Owner:CEMCO LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com