Patents

Literature

4530 results about "Adhesive materials" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Cement - something that hardens to act as adhesive material. library paste, paste - an adhesive made from water and flour or starch; used on paper and paperboard. rubber cement - an adhesive made by dissolving unvulcanized rubber in a solvent like benzene or naphtha.

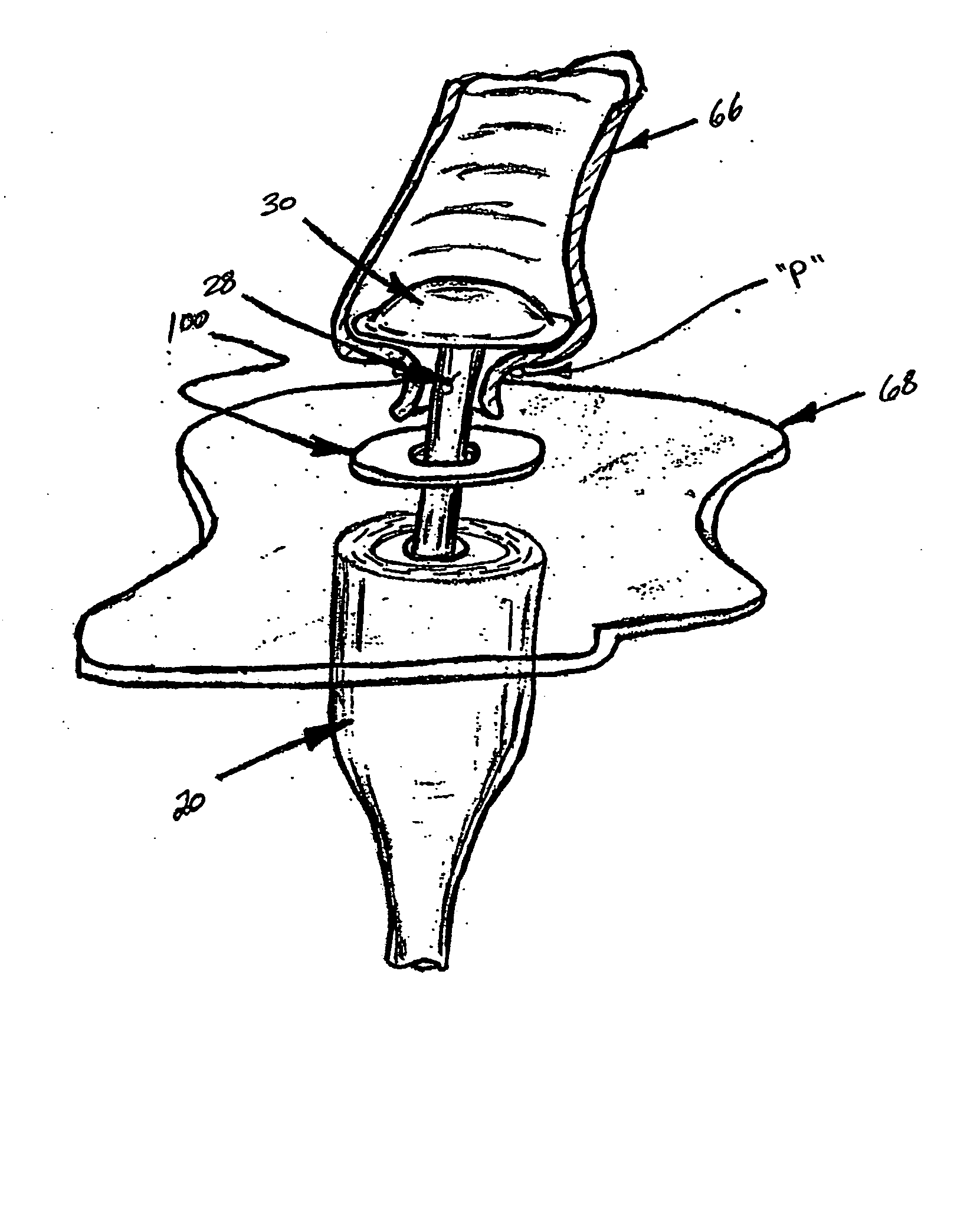

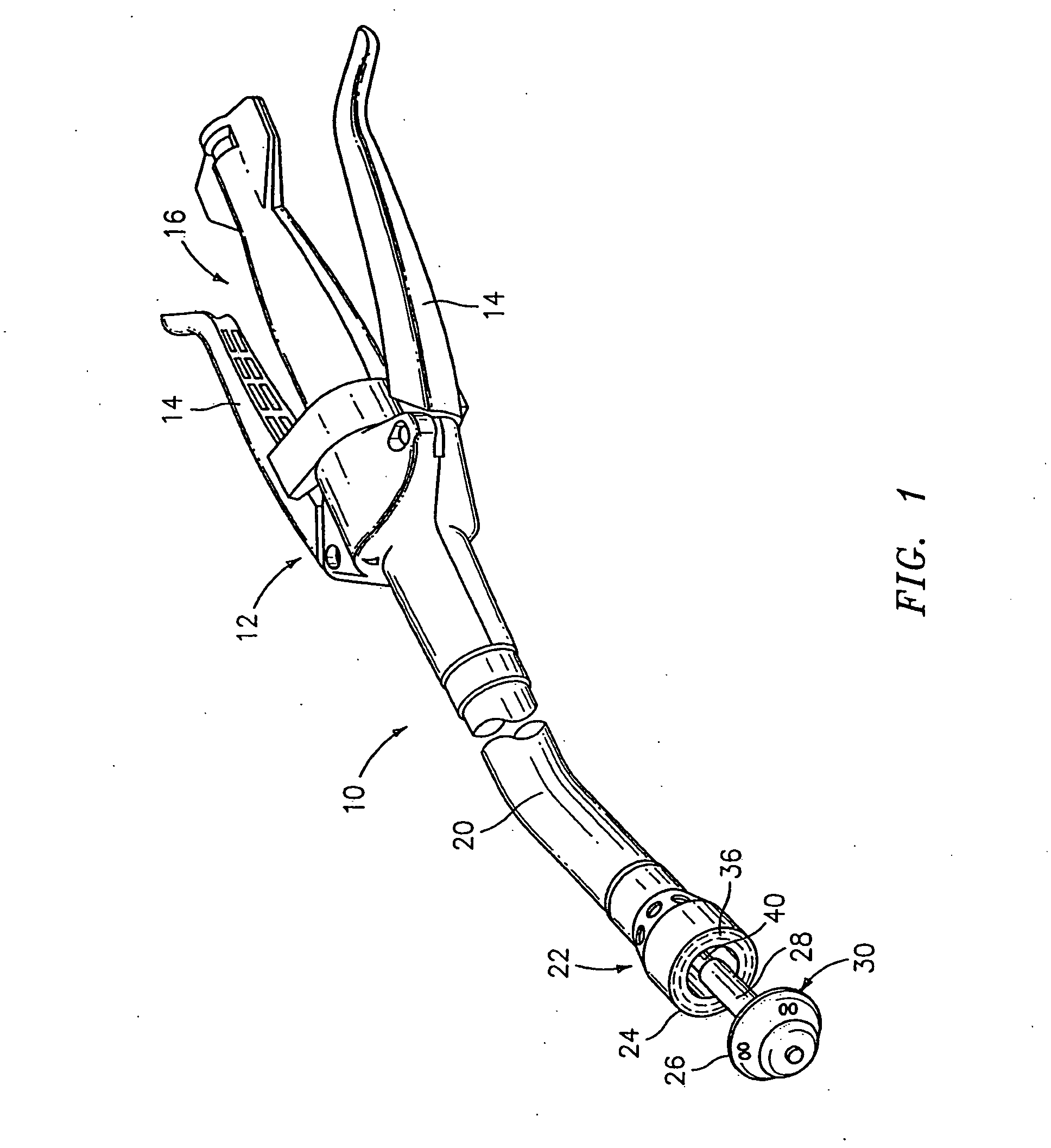

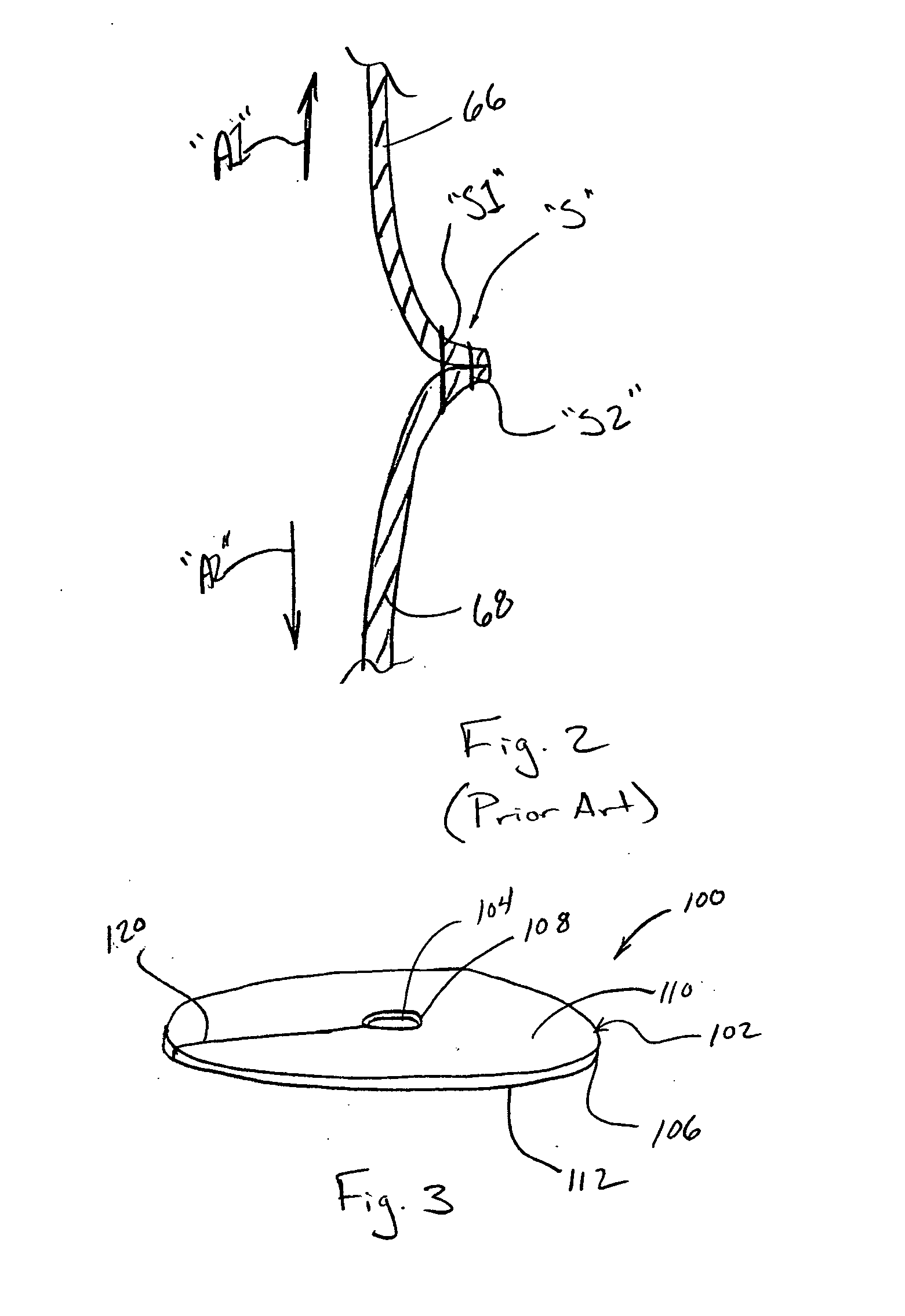

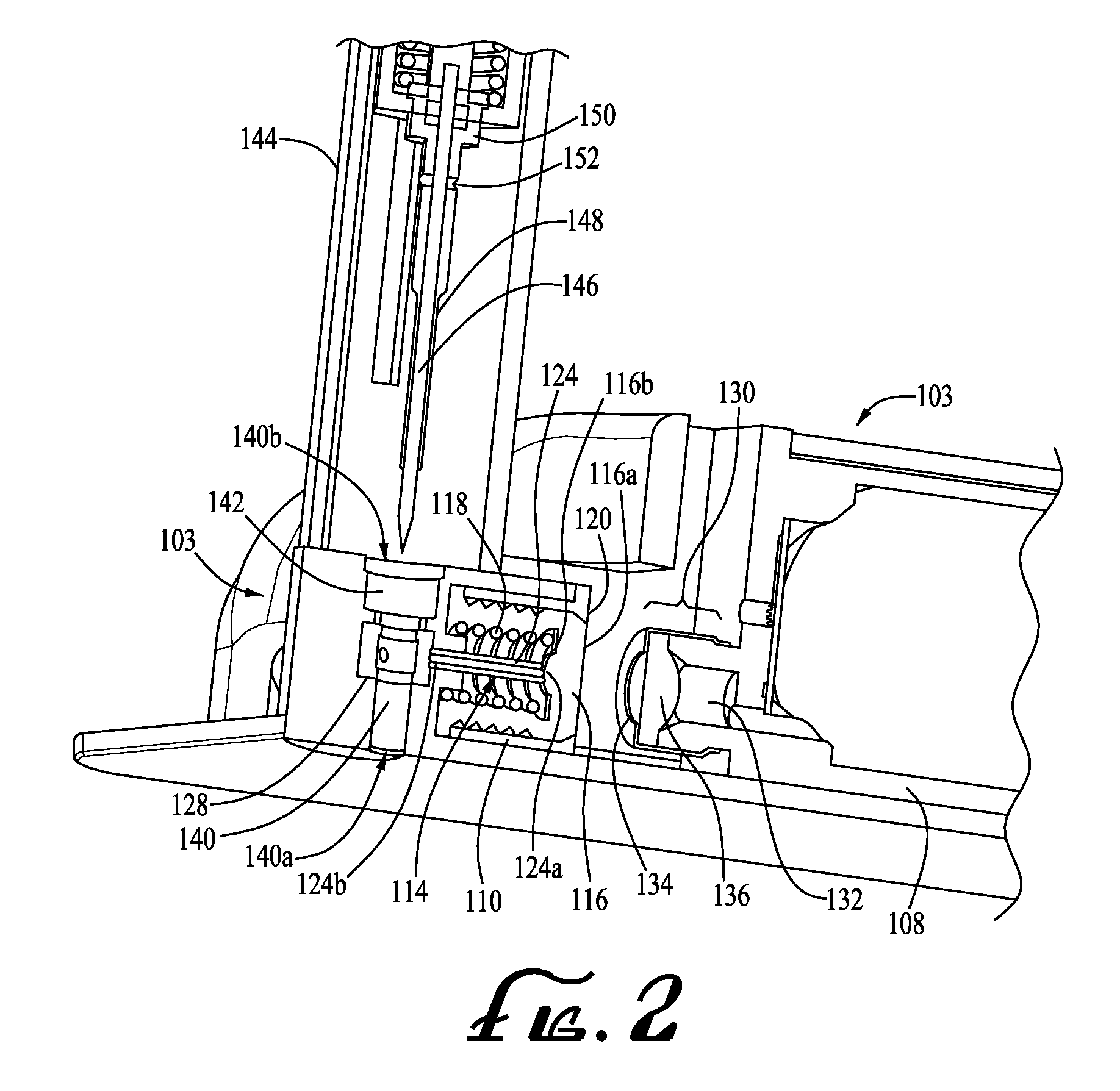

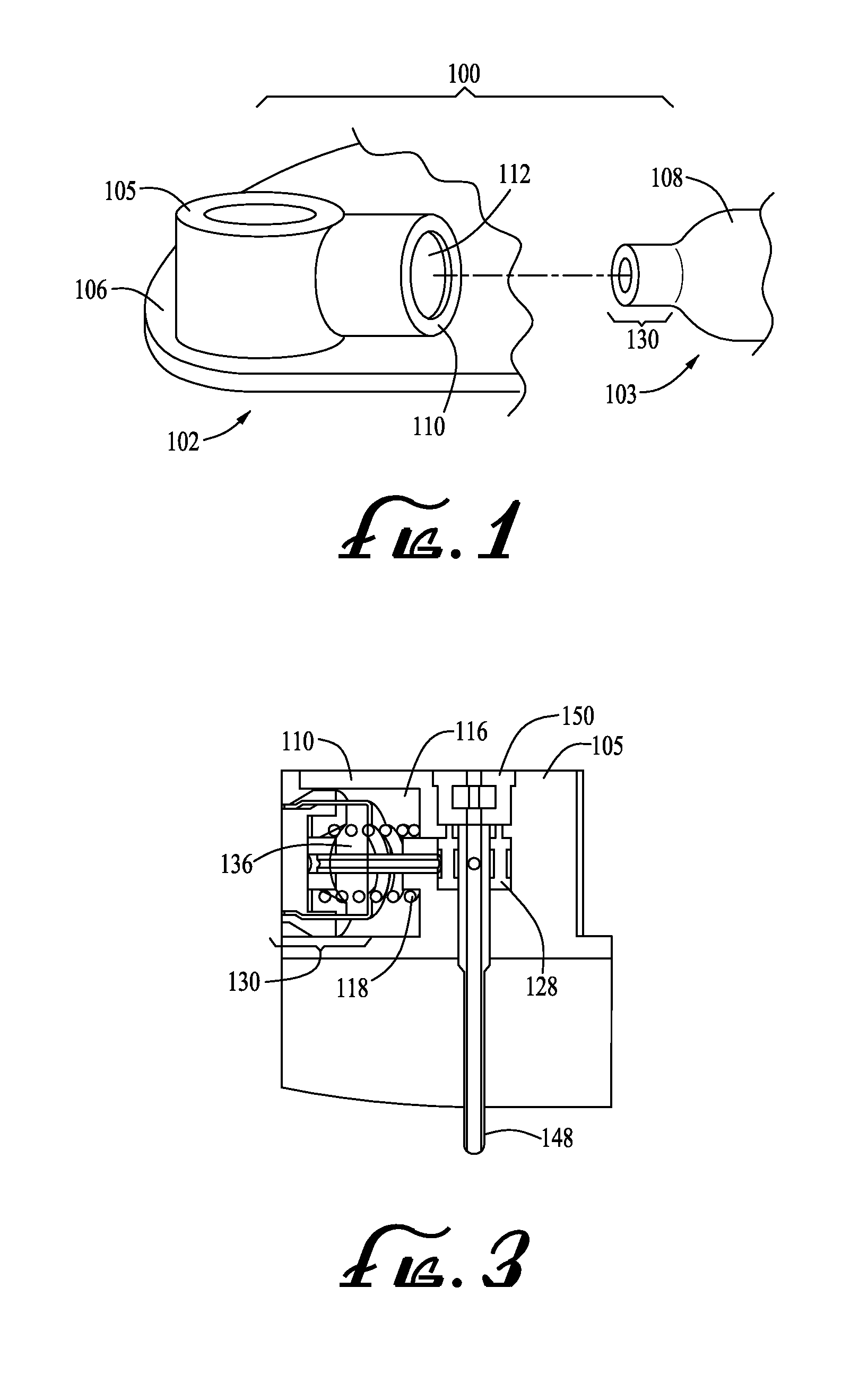

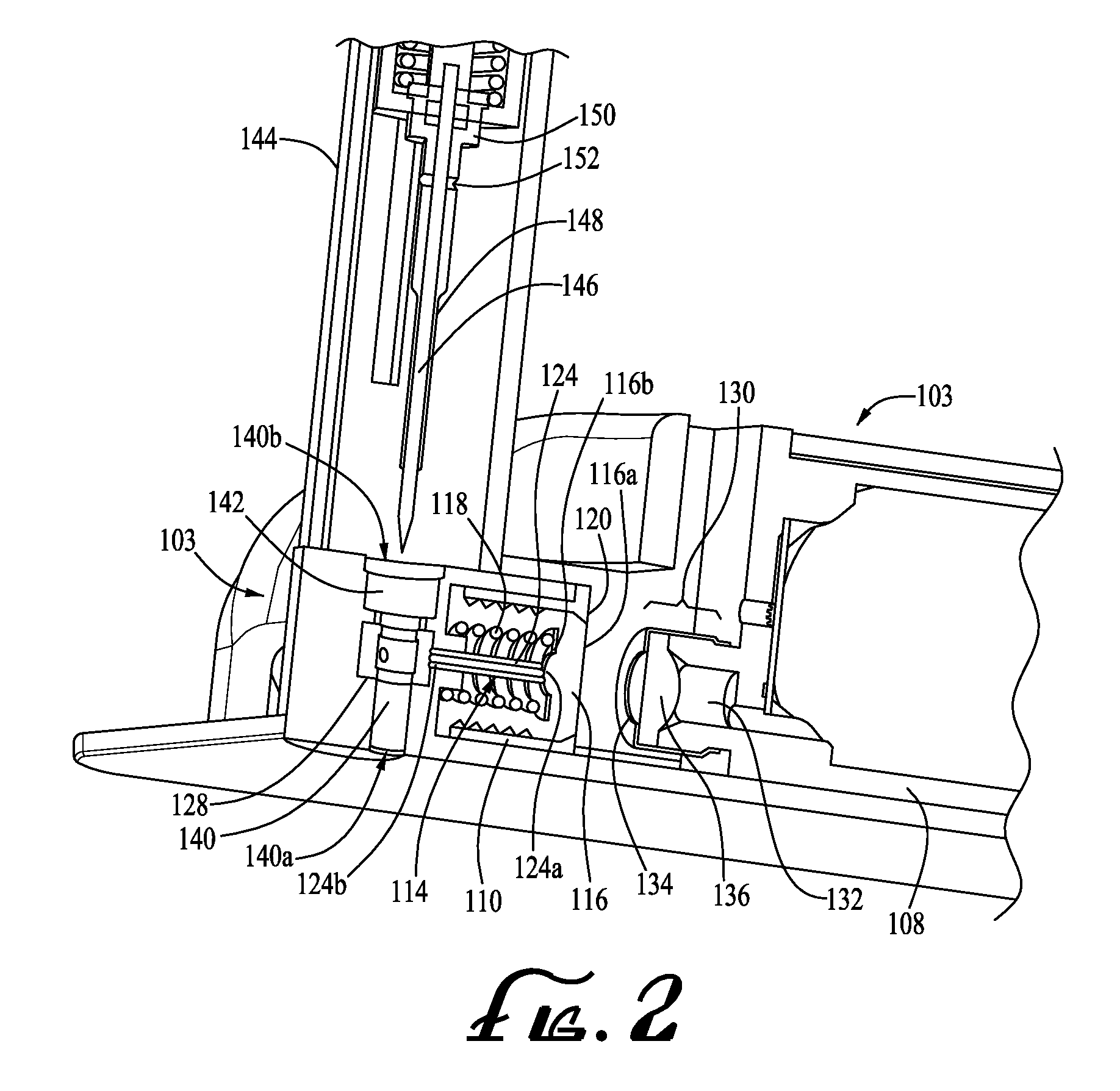

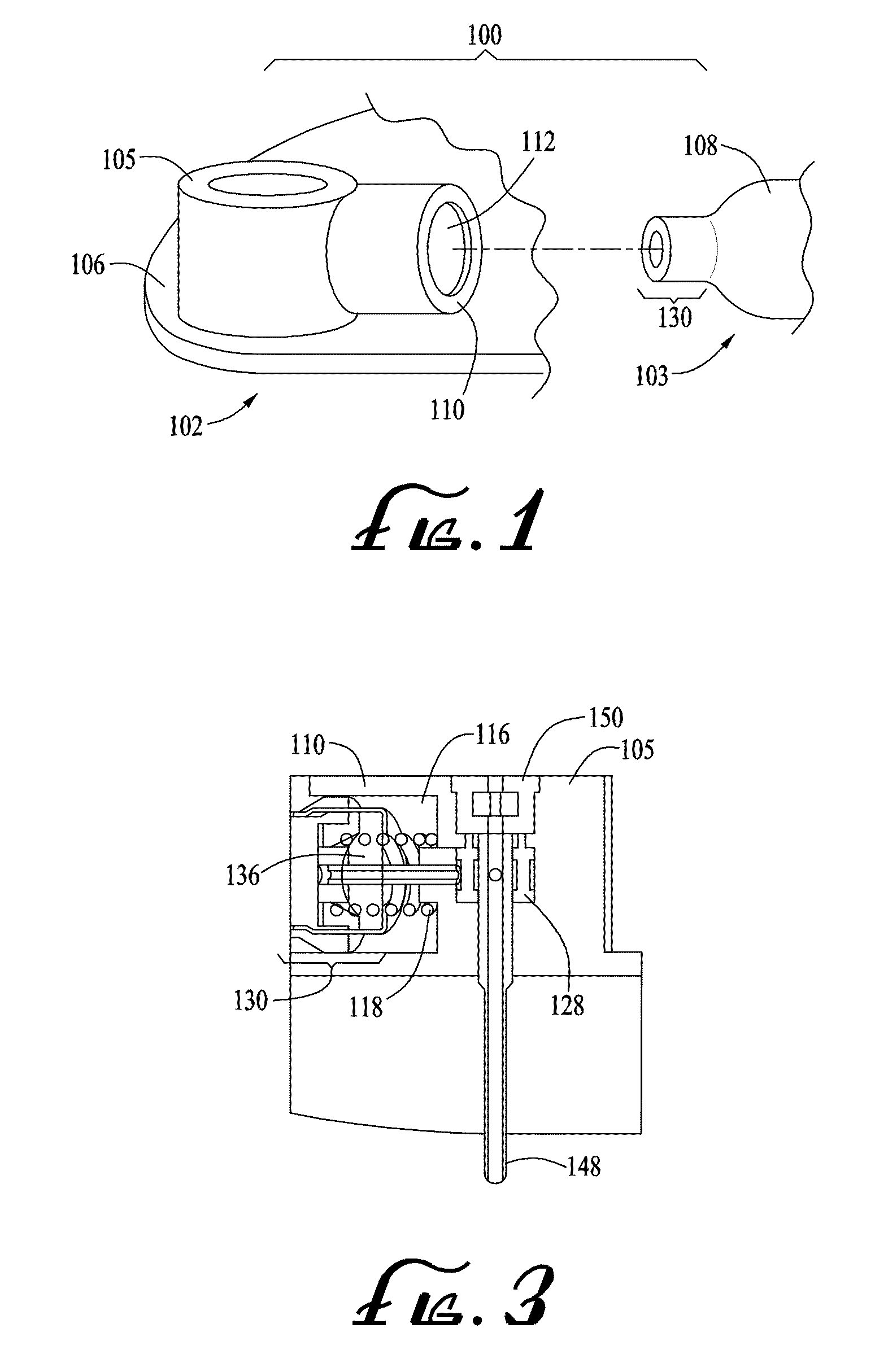

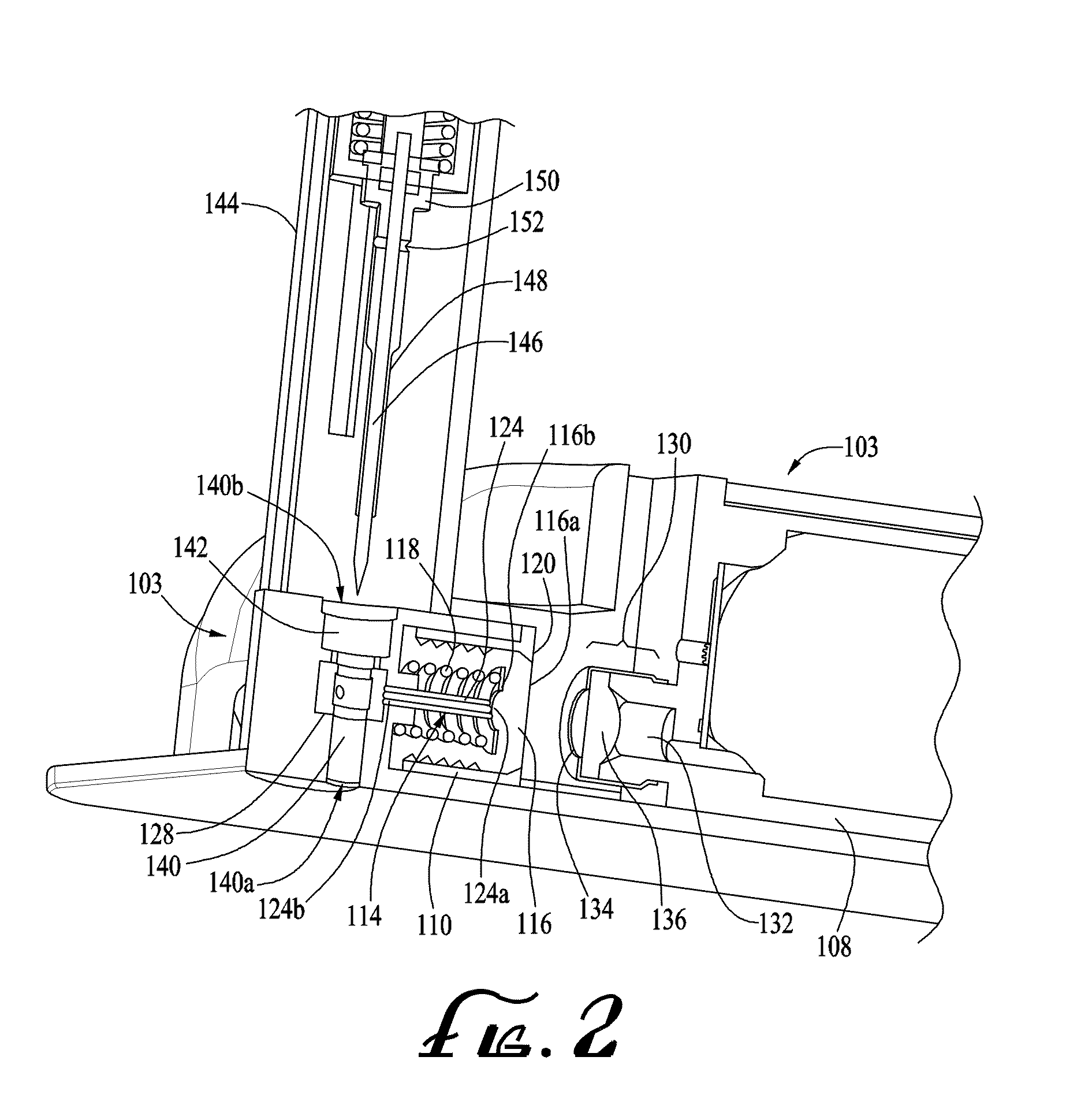

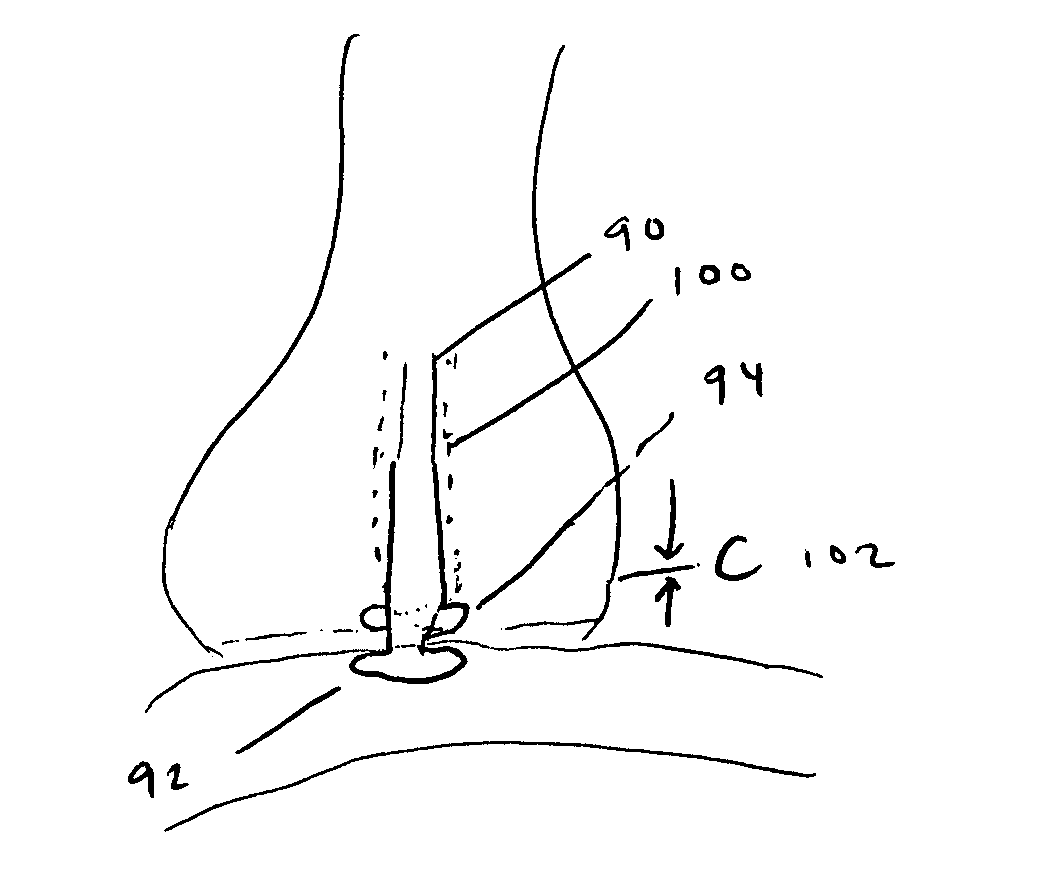

Annular disk for reduction of anastomotic tension and methods of using the same

InactiveUS20070203510A1Reduce generationReduce tensionSurgical staplesWound clampsEngineeringMechanical engineering

An apparatus for forming an anastomosis between adjacent tissue sections is provided. The apparatus includes an anastomosis device including an anvil assembly having a shaft which is selectively attachable to a tubular body portion, wherein the tubular body portion includes at least one annular row of staples operatively disposed therein. The apparatus further includes a disk having an outer terminal portion and a substantially centrally located aperture. The disk includes an adhesive material at the outer terminal portion. Wherein the outer terminal portion of the disk extends radially outward beyond the outer-most row of the at least one annular row of staples to adhesively attach the tissue sections together radially outward of the at least one annular row of staples.

Owner:TYCO HEALTHCARE GRP LP

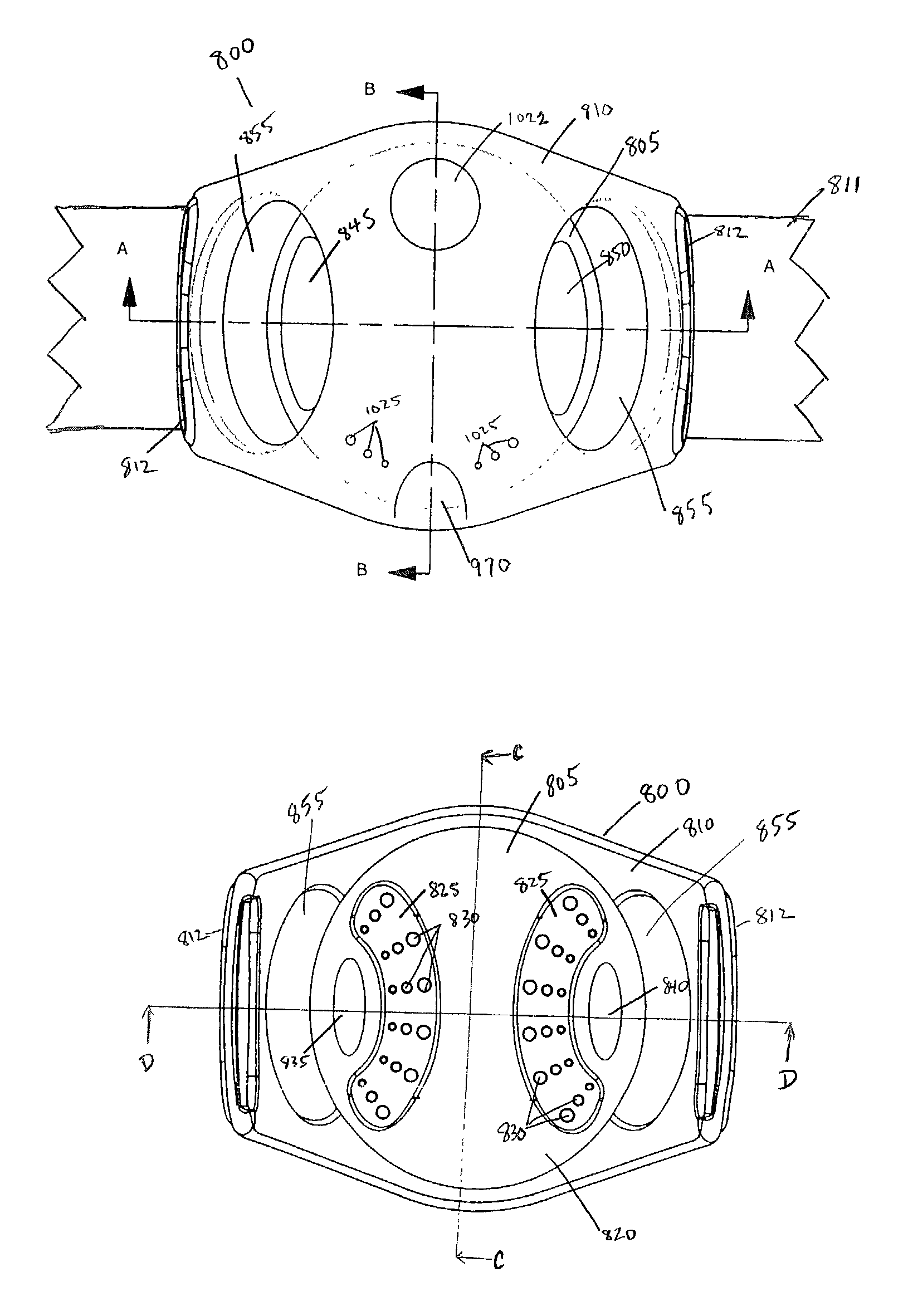

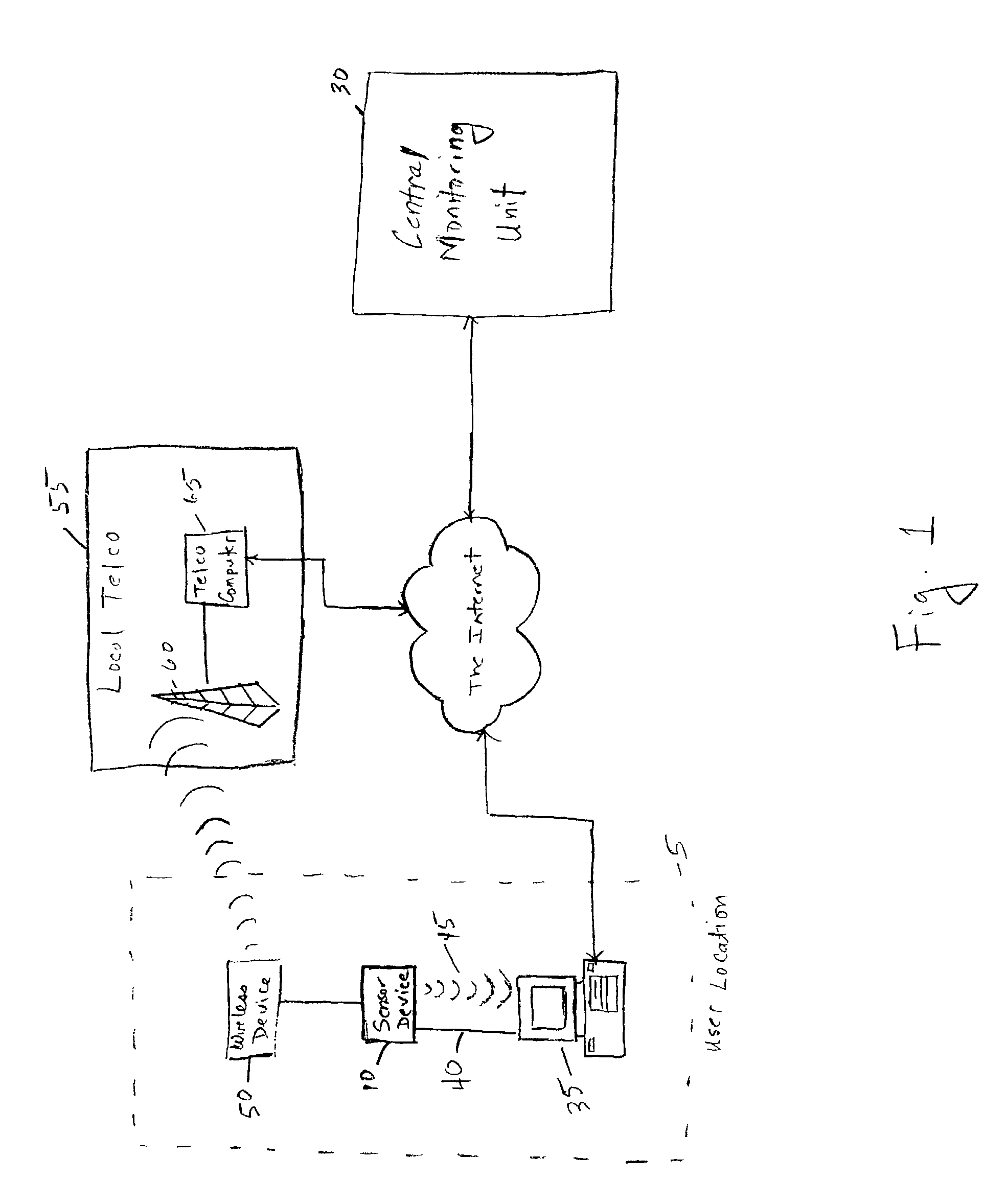

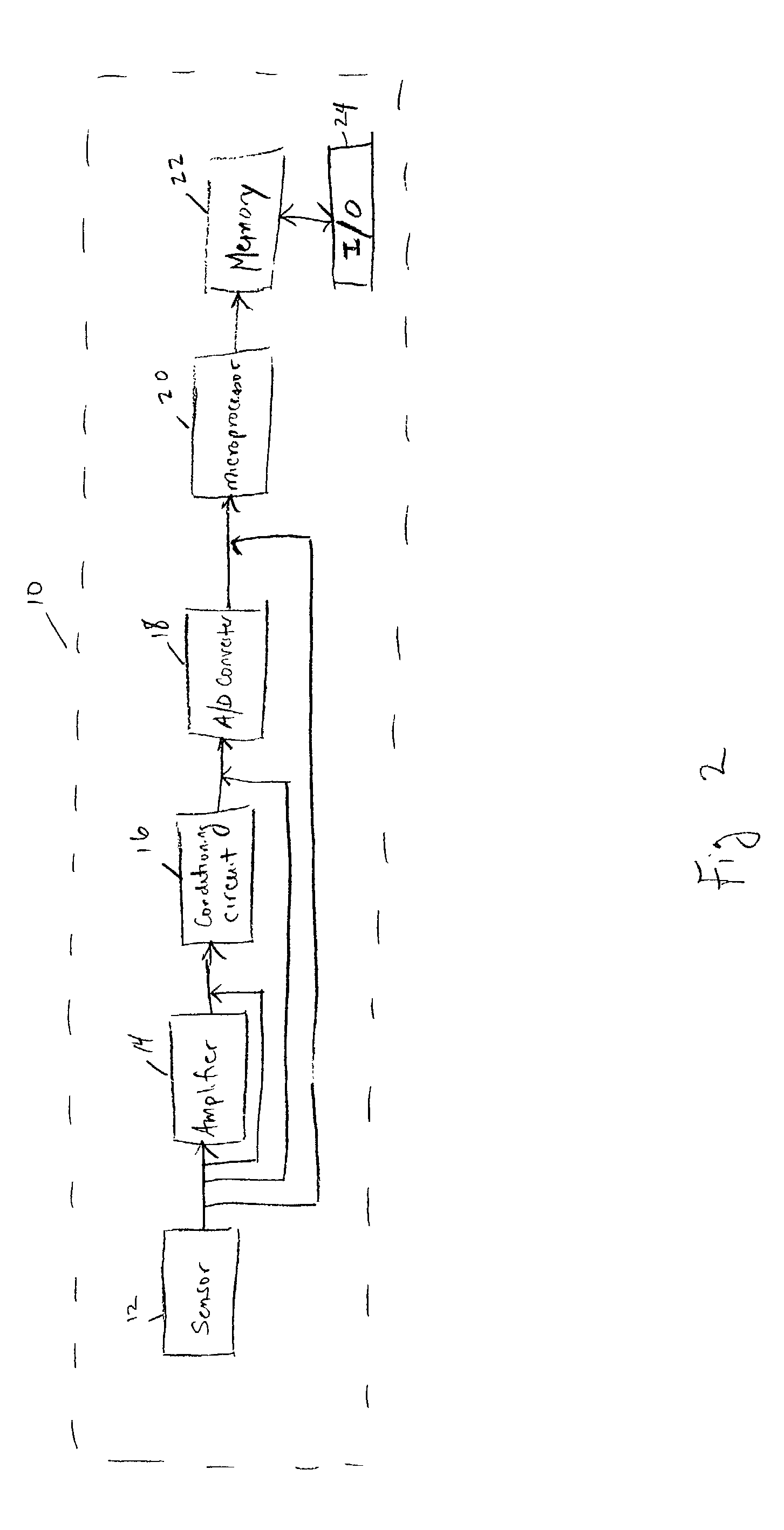

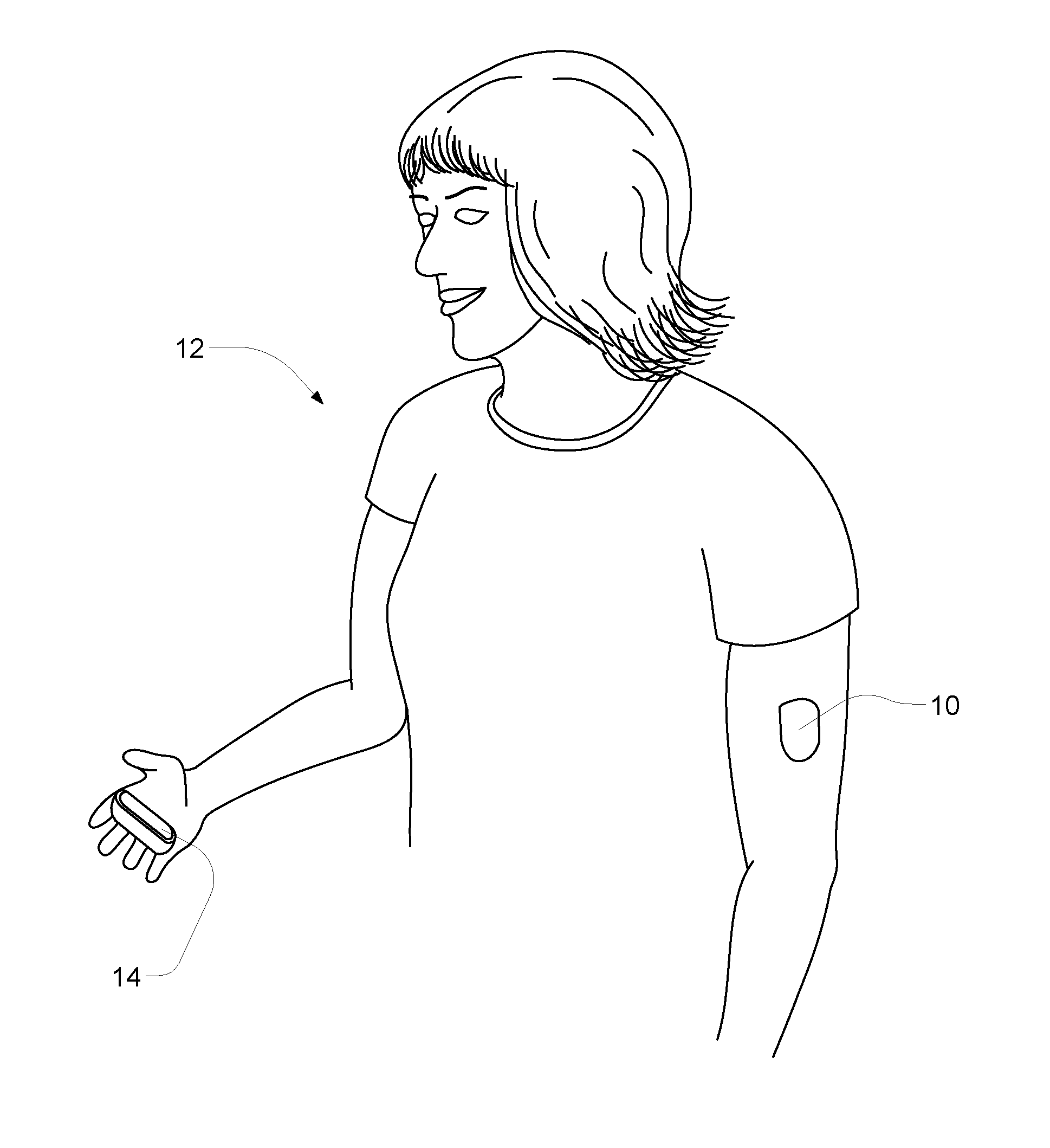

Apparatus for detecting human physiological and contextual information

InactiveUS7020508B2Promote generationWidth dimensionElectrocardiographyDiagnostics using lightThermal energyHeat flux

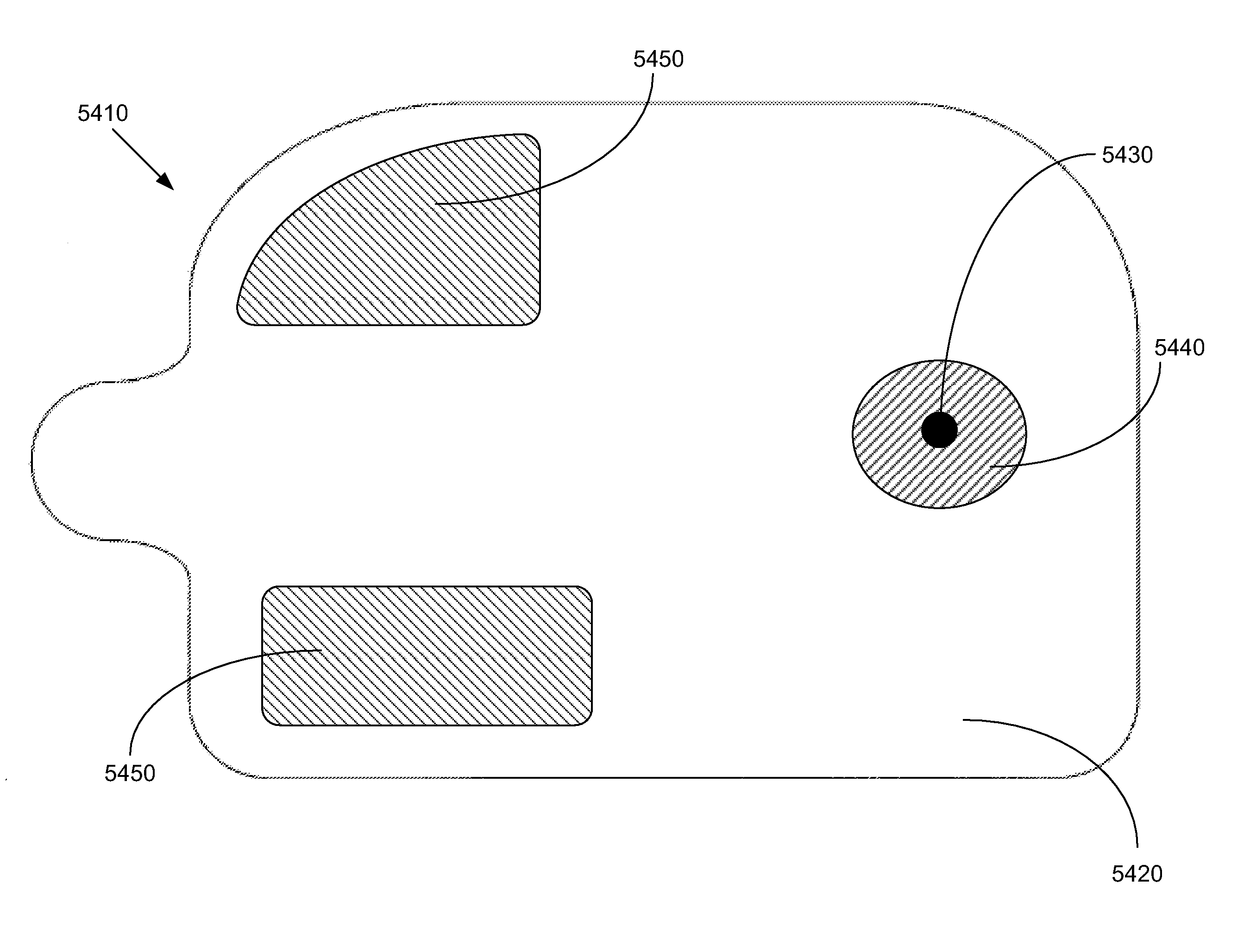

A detecting apparatus includes a housing support section(s), a housing removably attached thereto, one or more sensors and a processor. An alternate apparatus measures heat flux and includes a known resistivity base member, a processing unit and two temperature measuring devices, one in thermal communication with the body through a thermal energy communicator and the other in thermal communication with the ambient environment. A further alternate apparatus includes a housing or flexible section having an adhesive material on a surface thereof for removably attaching the apparatus to the body. A further alternate apparatus includes a housing having an inner surface having a concave shape in a first direction and convex shape in a second direction substantially perpendicular thereto. Also, an apparatus for detecting heart related parameters includes one or more filtering sensors for generating filtering signals related to the non-heart related motion of the body.

Owner:J FITNESS LLC

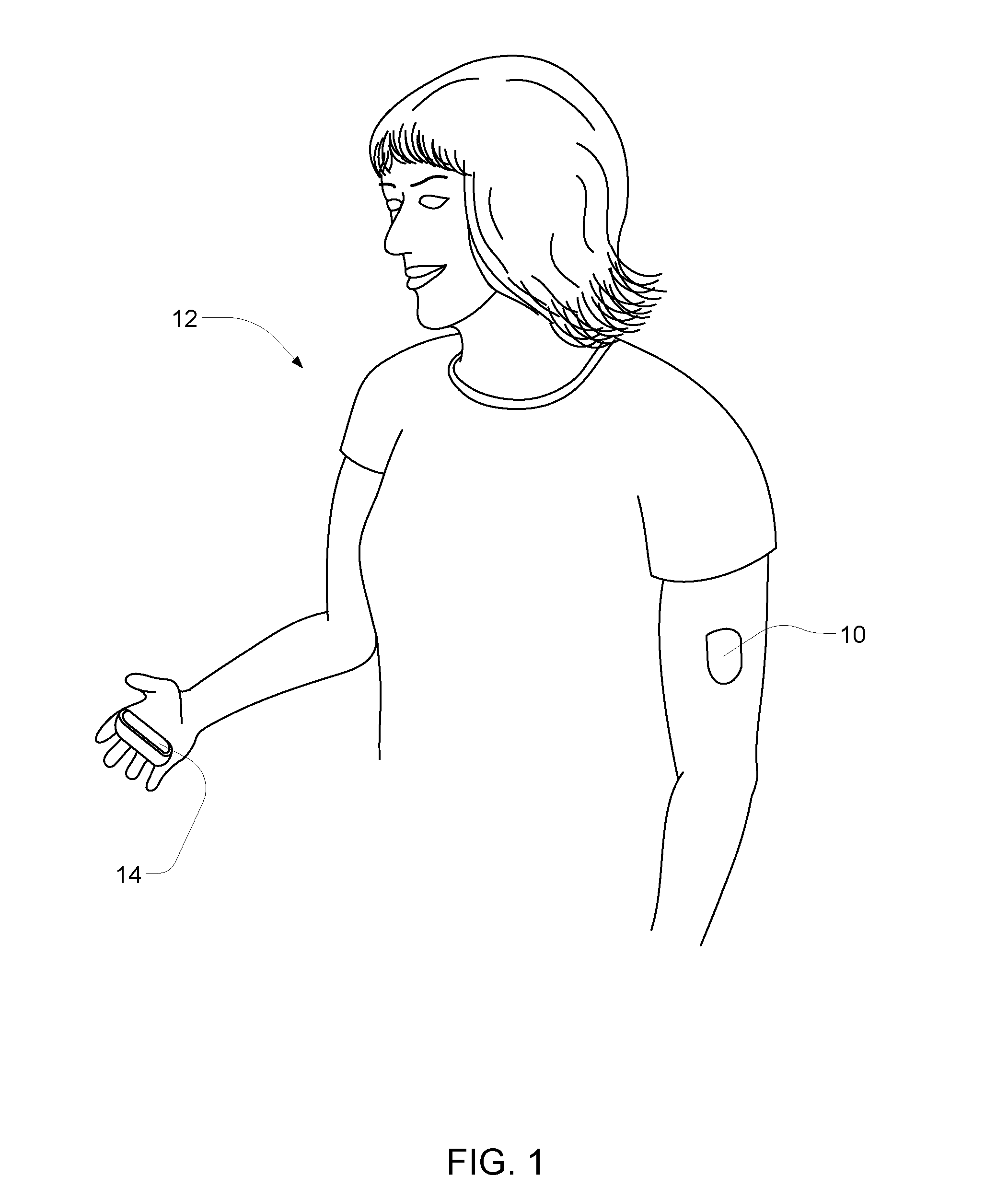

Adhesive Patch Systems and Methods

ActiveUS20080269687A1High bonding strengthReduced adhesion strengthInfusion syringesFiltering accessoriesAdhesion strengthUltimate tensile strength

Various embodiments of the present invention are directed to patches for medical devices. In various embodiments, an adhesive patch of a medical device may have selective areas with adhesive material of varying adhesion strengths. In other embodiments, an adhesive patch of a medical device may include adhesive material that may be activated by a catalyst to increase or decrease the adhesion strength of the adhesive material. In further embodiments, a medical device may include a pierceable membrane containing an agent, the pierceable membrane positioned to be pierced by a needle and to cause some of the agent to be carried to the user-patient.

Owner:MEDTRONIC MIMIMED INC

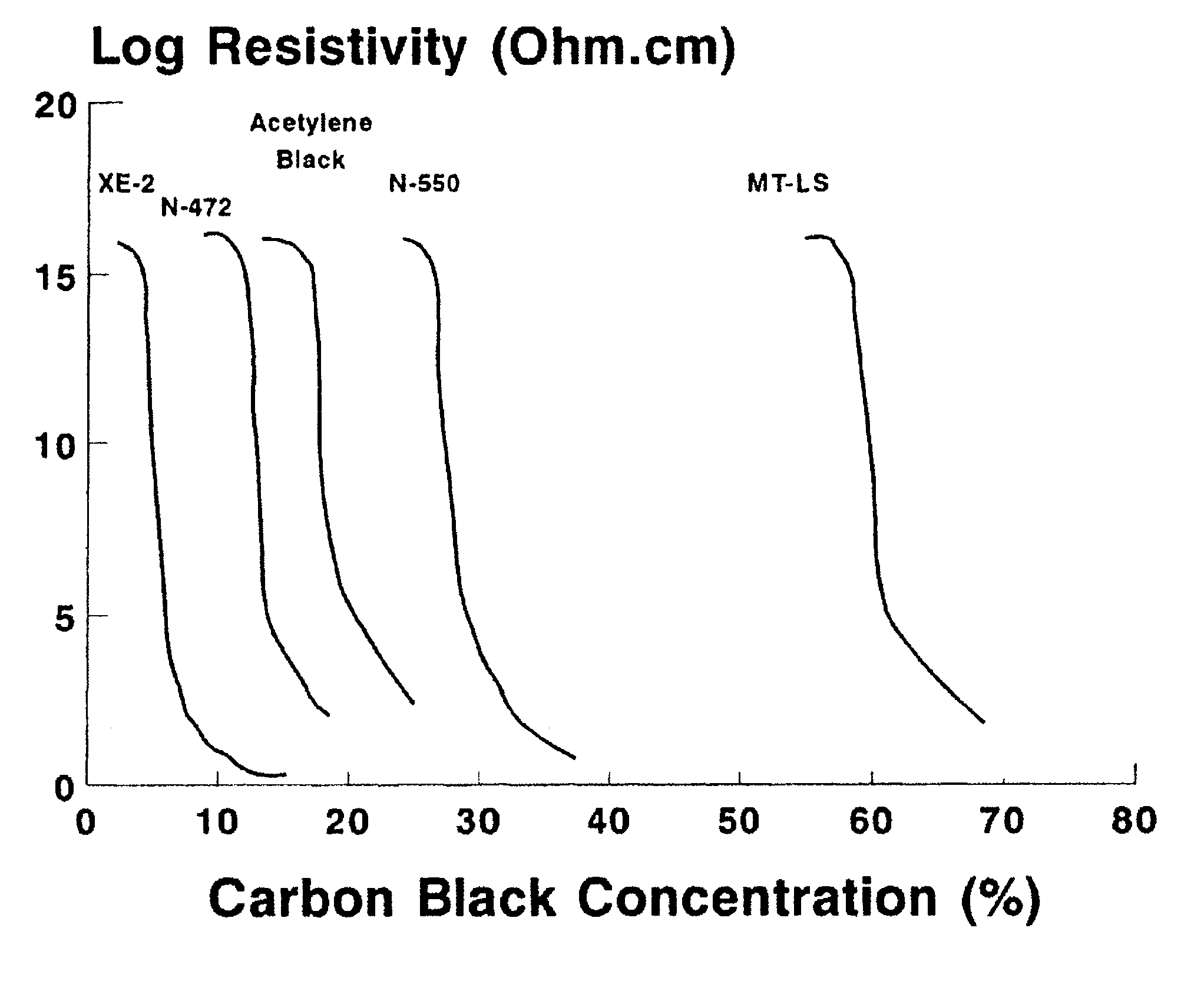

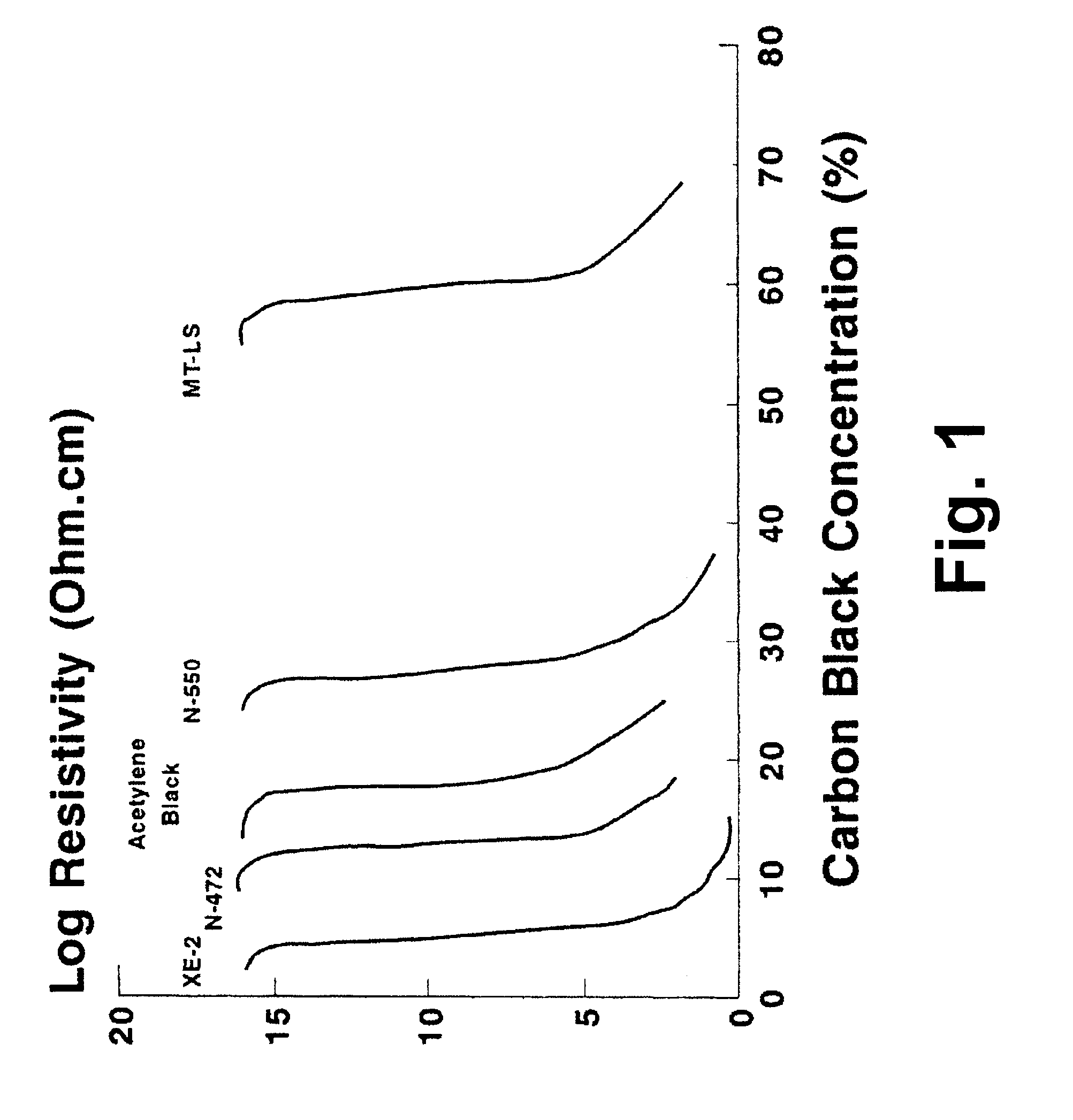

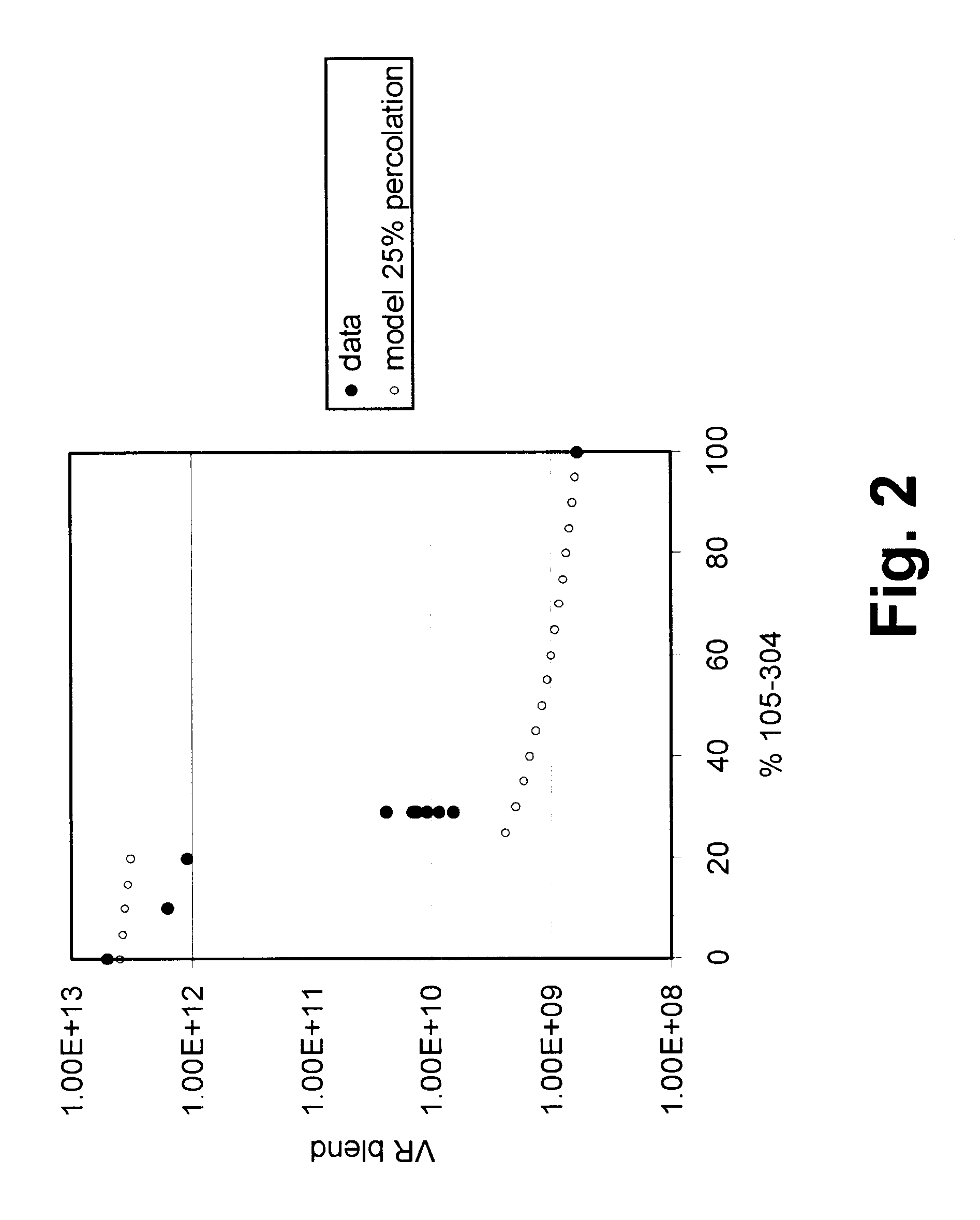

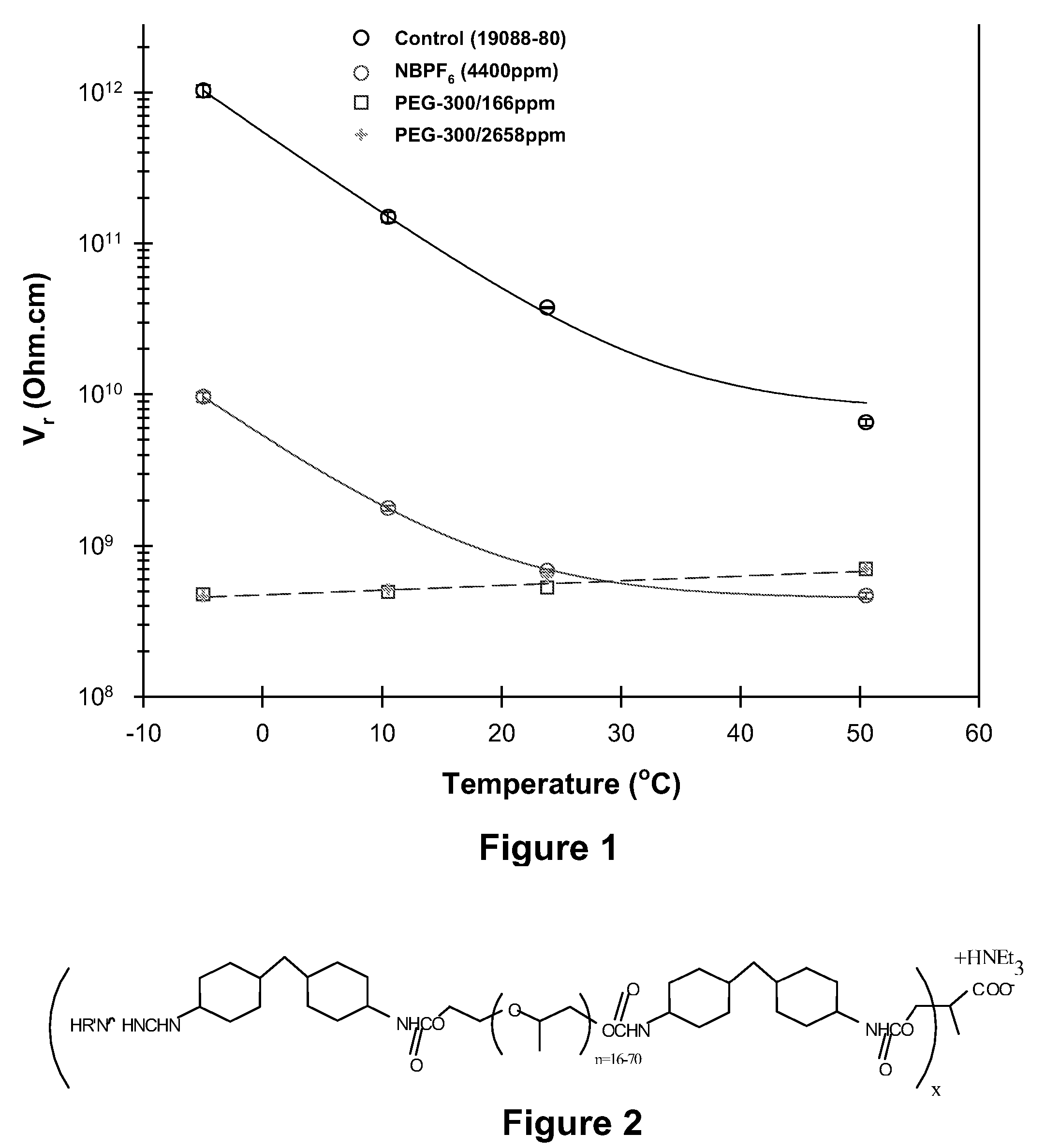

Electro-optic display and adhesive composition for use therein

InactiveUS6657772B2Non-macromolecular adhesive additivesStatic indicating devicesDisplay deviceElectric resistivity

An electro-optic display comprises first and second substrates, and an adhesive layer and a layer of electro-optic material disposed between the first and second substrates. The adhesive layer has a volume resistivity in the range of about 10<9 >to about 10<11 >ohm cm and comprises a mixture of an adhesive material having a volume resistivity of at least about 5x10<11 >ohm cm and a filler having a volume resistivity not less than about 10<7 >ohm cm, the filler being present in the mixture in a proportion above its percolation threshold in the adhesive material.

Owner:E INK CORPORATION

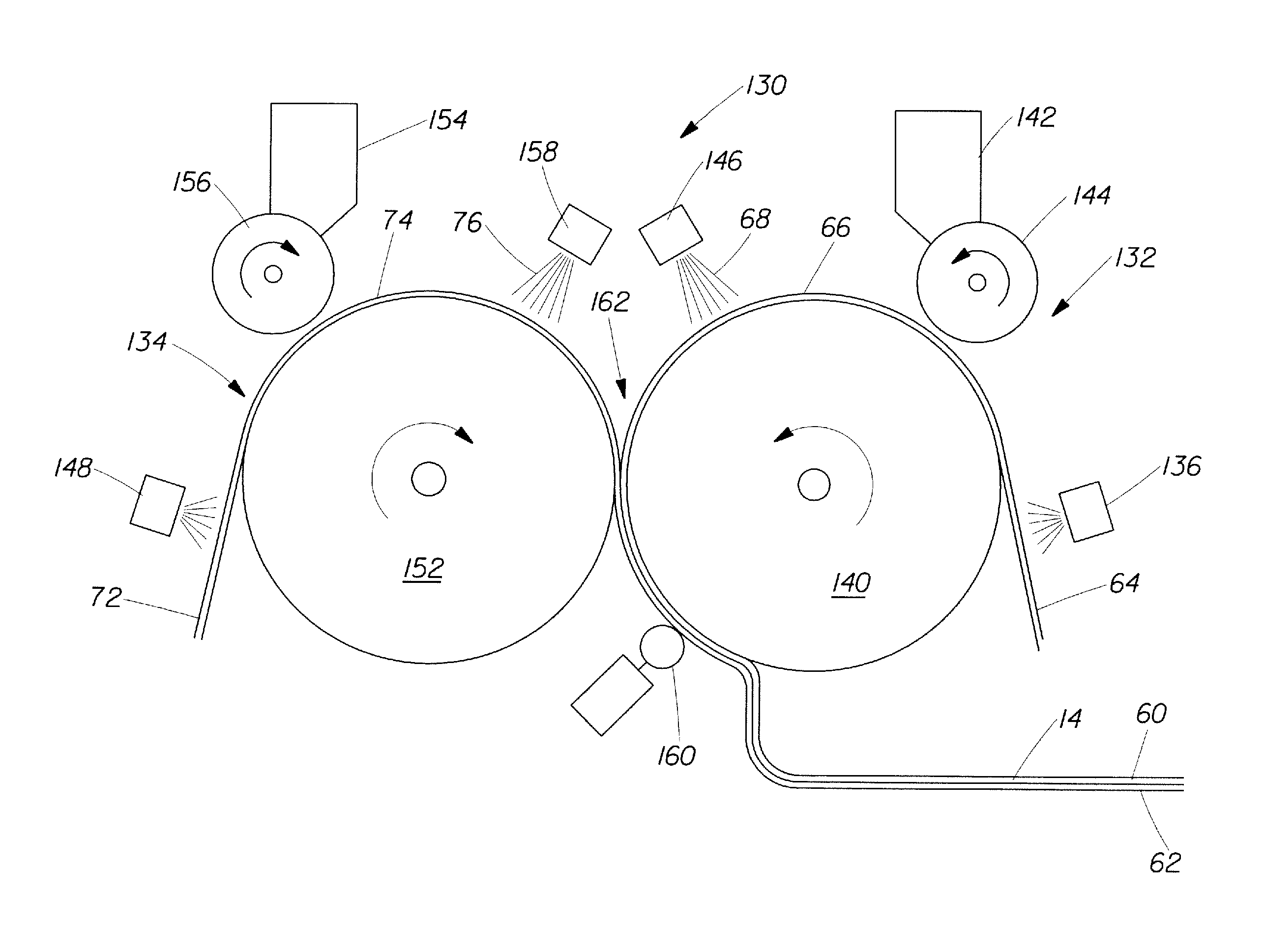

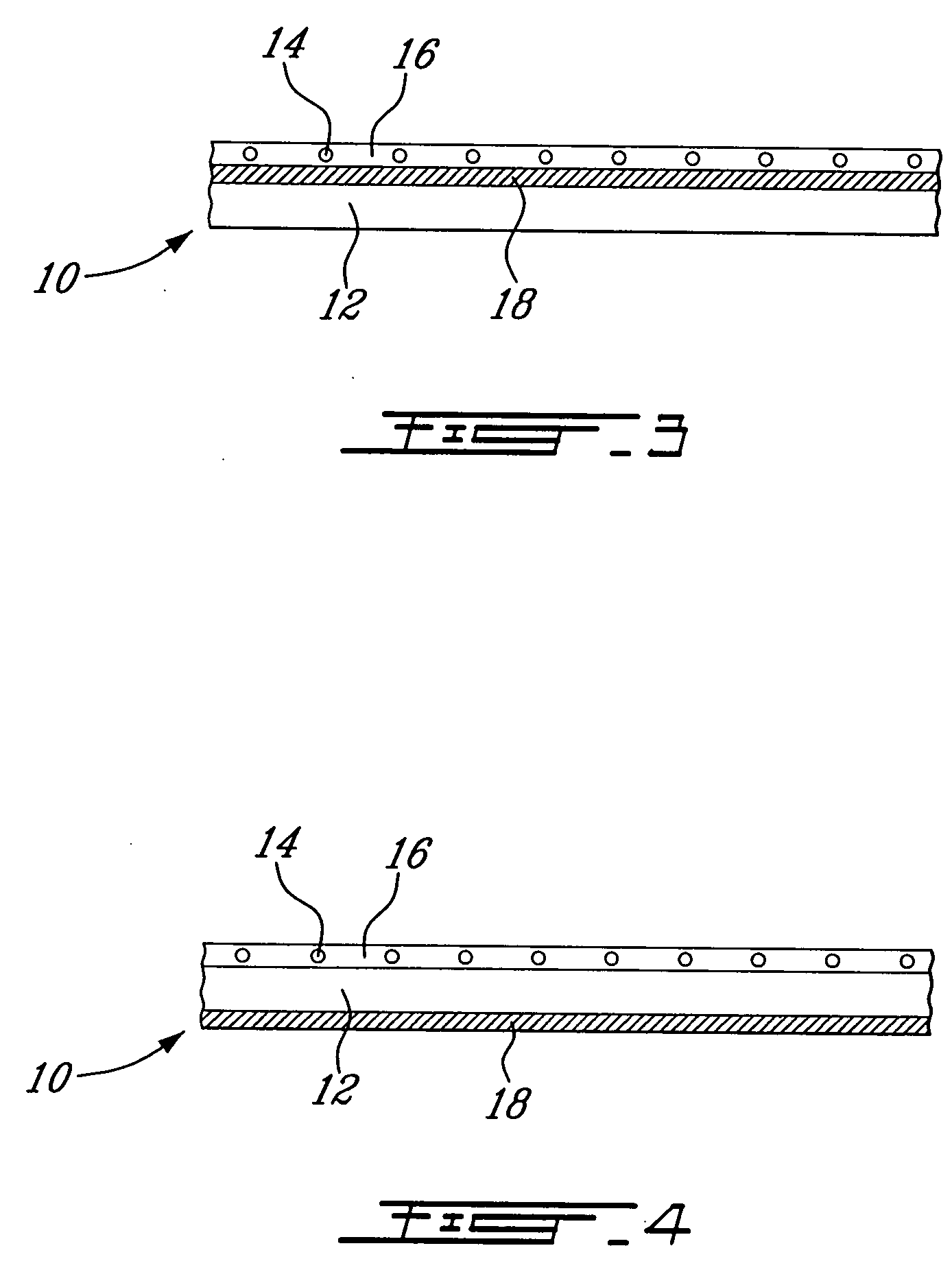

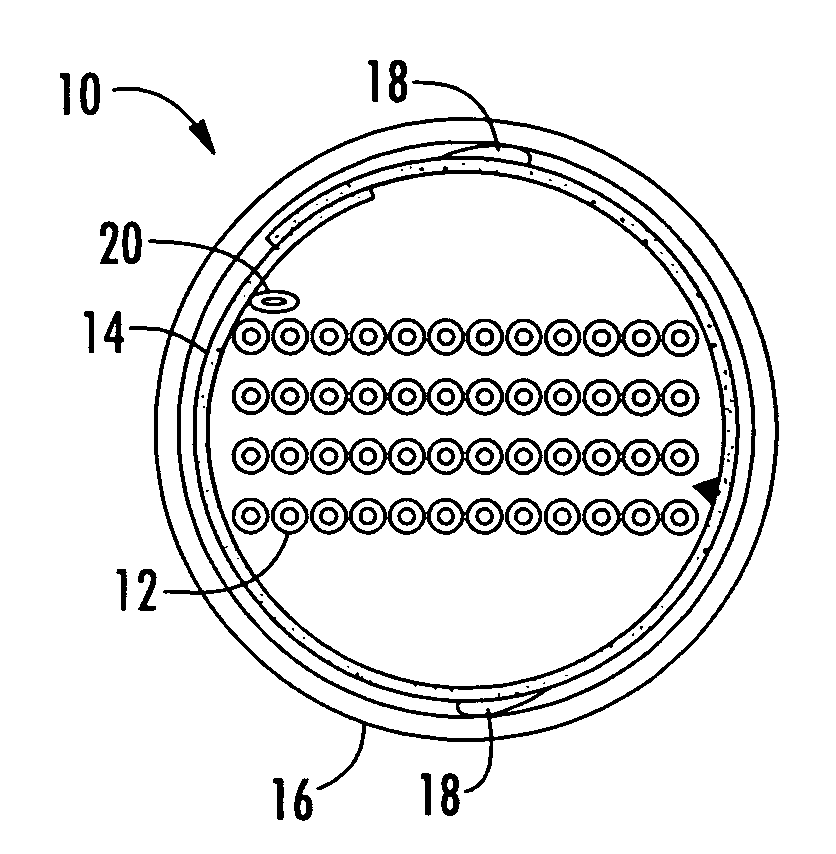

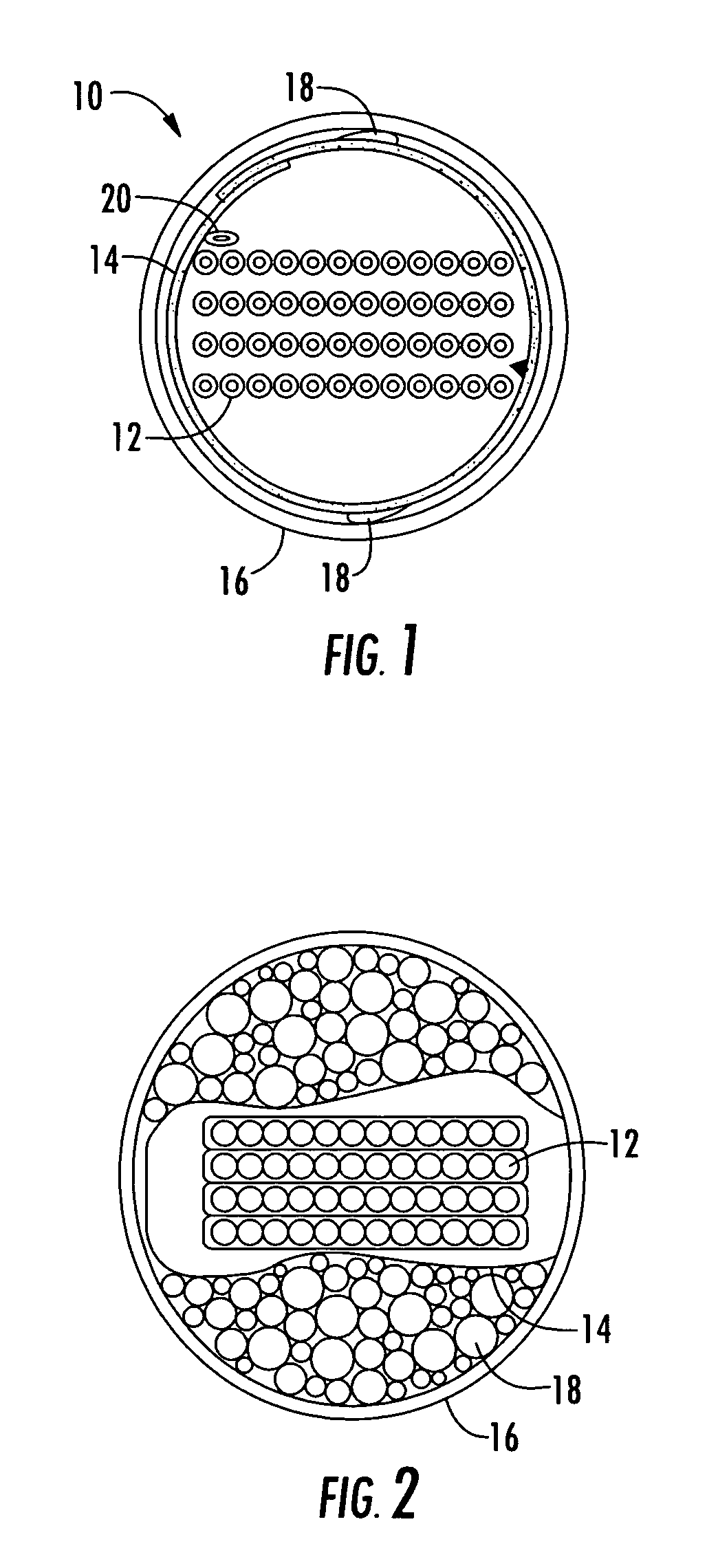

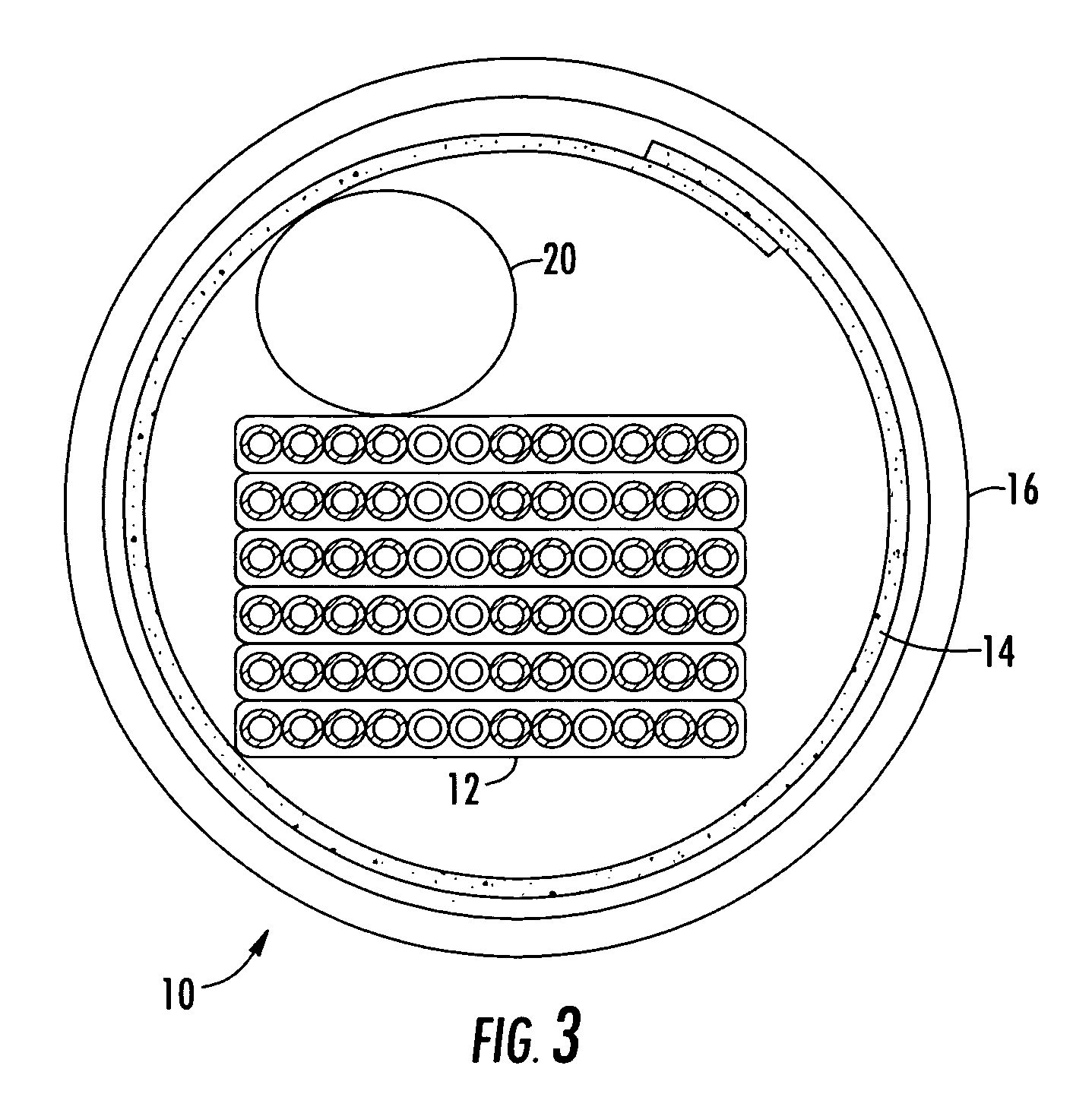

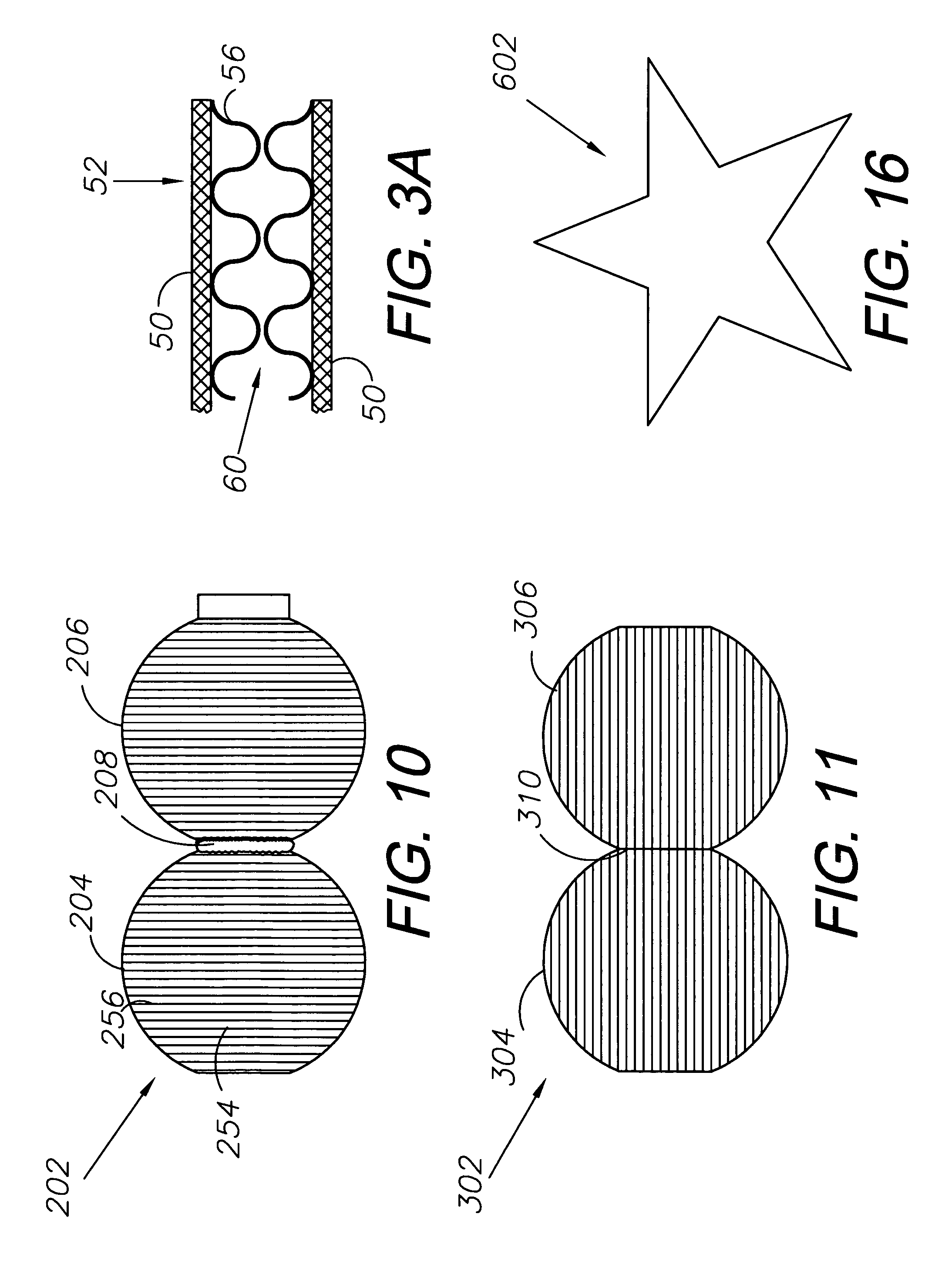

Method And Apparatus For Making Disposable Absorbent Article With Absorbent Particulate Polymer Material And Article Made Therewith

A method for making a disposable absorbent core comprises depositing absorbent particulate polymer material from a plurality of reservoirs in a printing roll onto a substrate disposed on a grid of a support which includes a plurality of cross bars extending substantially parallel to and spaced from one another so as to form channels extending between the plurality of cross bars. The plurality of reservoirs in the first peripheral surface are arranged in an array comprising rows extending substantially parallel to and spaced from one another. The support and printing roll are arranged such that the plurality of cross bars are substantially parallel to the rows of the plurality of reservoirs and the absorbent particulate polymer material is deposited on the substrate in a pattern such that the absorbent particulate polymer material collects in rows on the first substrate formed between the first plurality of cross bars. A thermoplastic adhesive material is deposited on the absorbent particulate polymer material and the substrate to cover the absorbent particulate polymer material on the substrate and form an absorbent layer. A disposable absorbent article and apparatus for making an absorbent article are also disclosed.

Owner:THE PROCTER & GAMBLE COMPANY

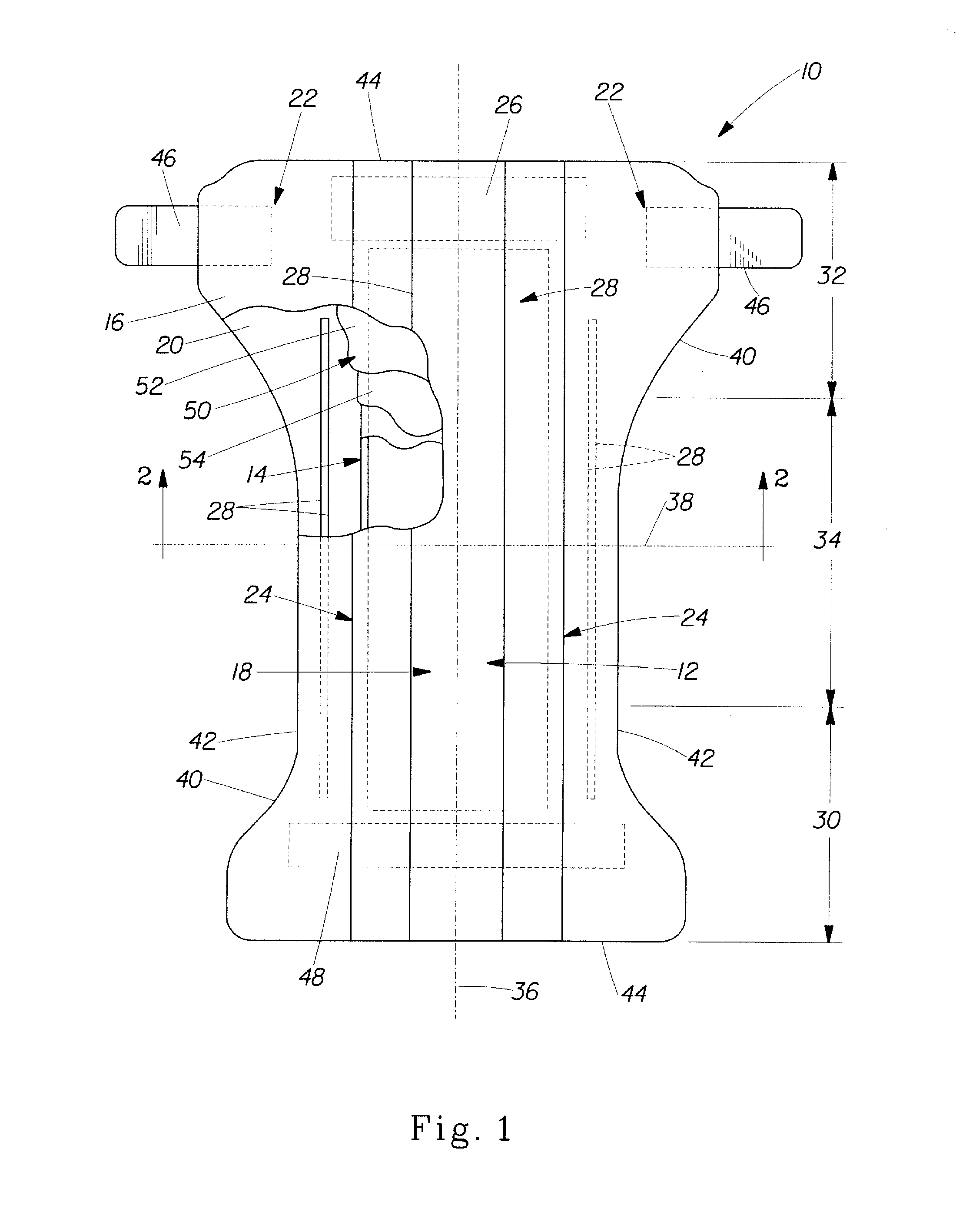

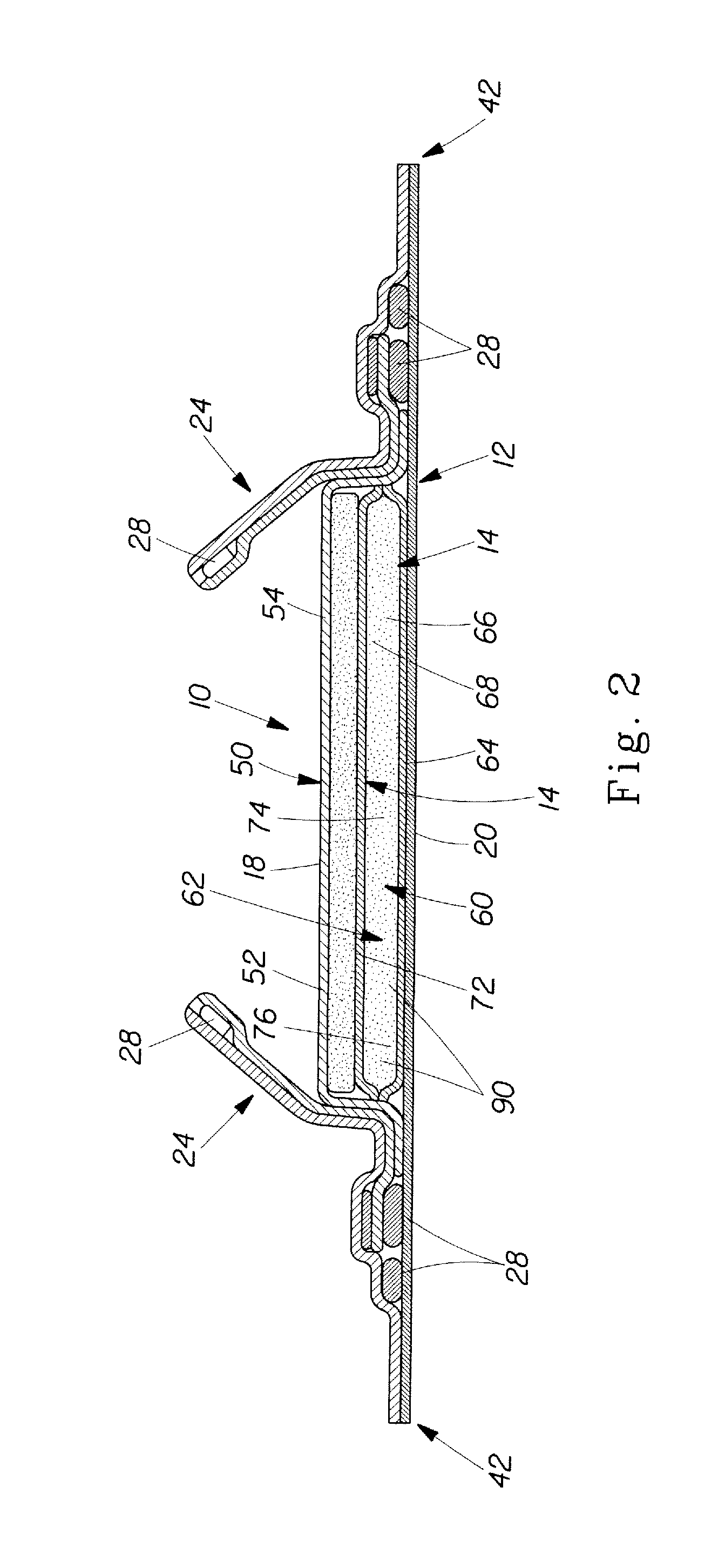

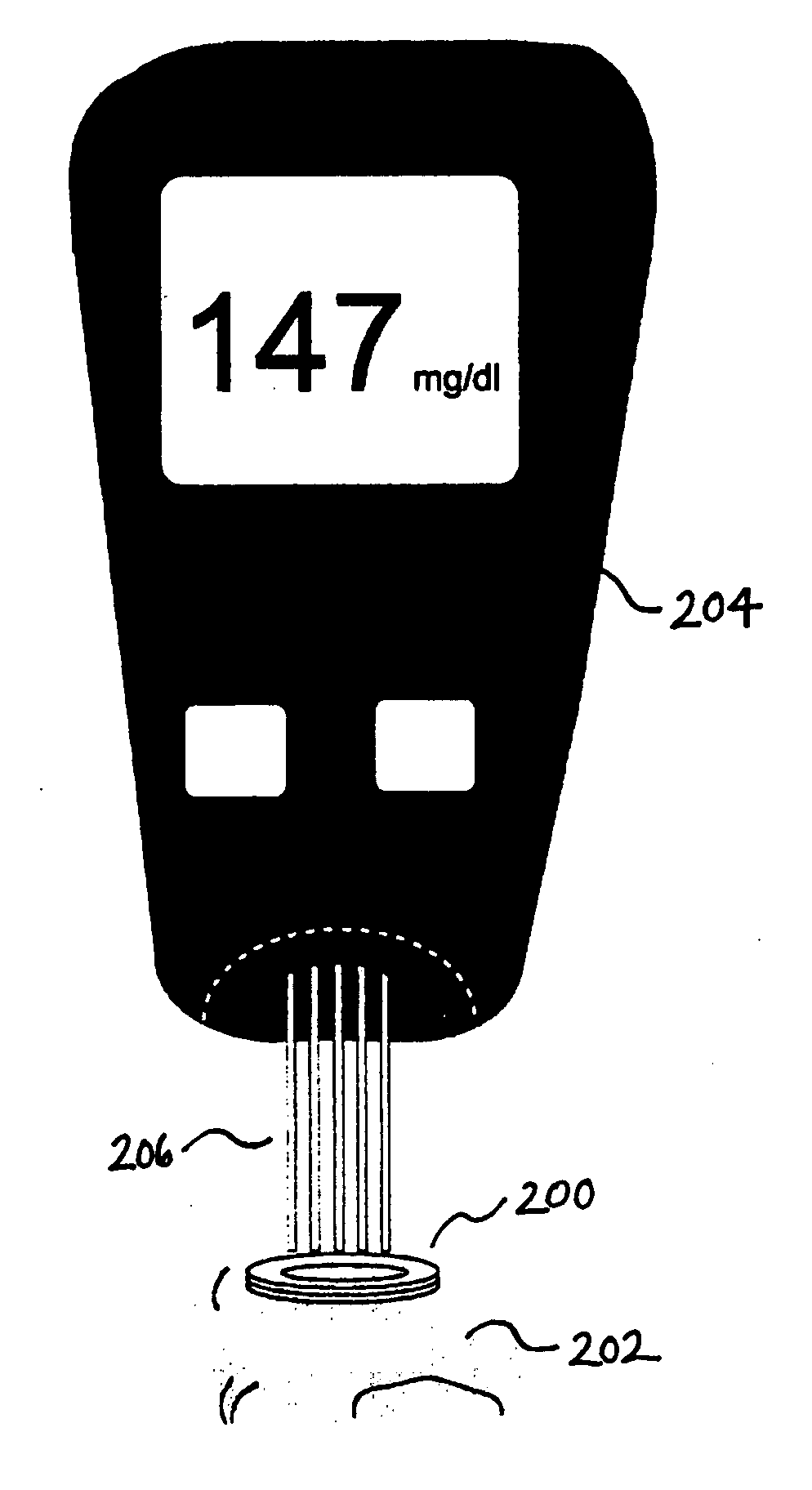

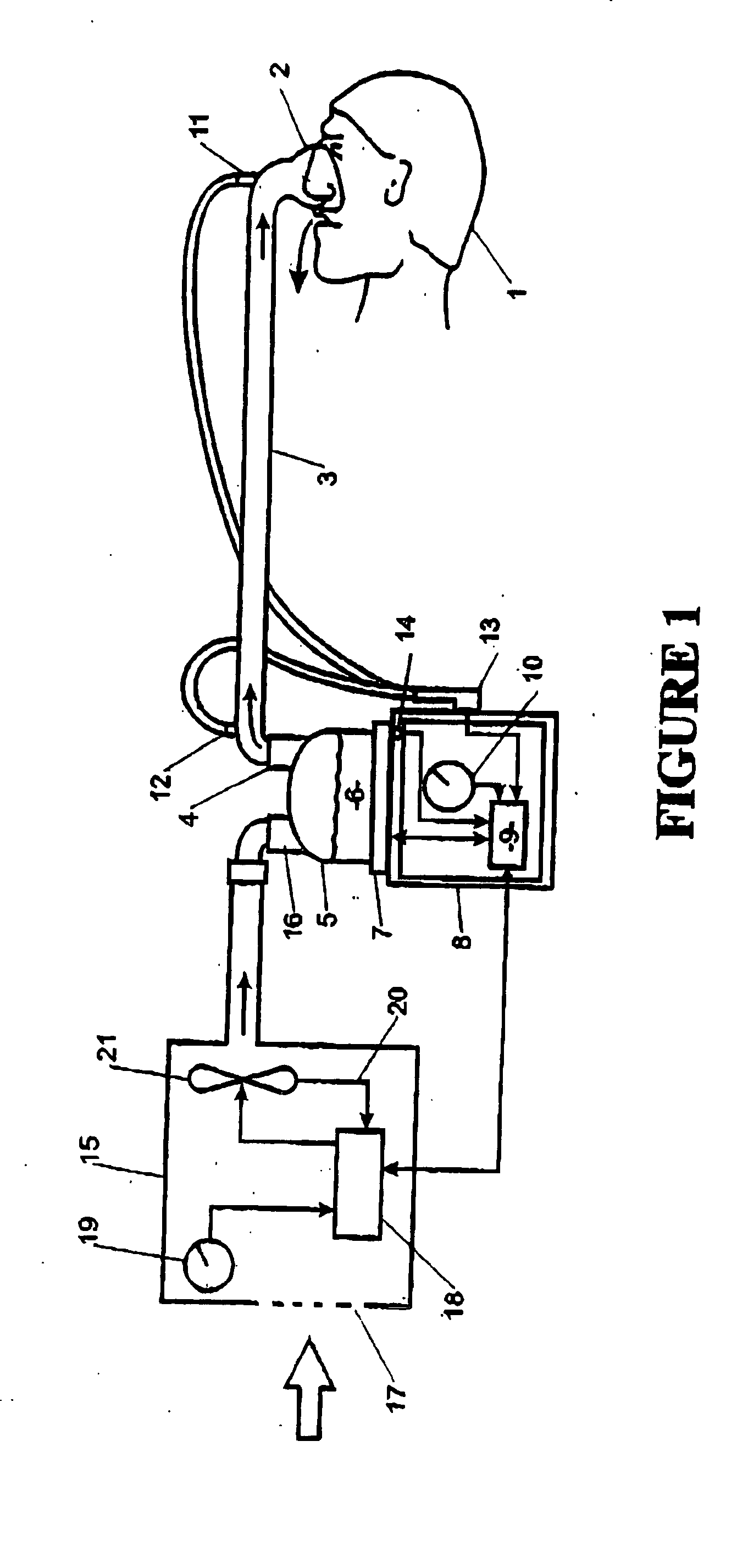

Devices, methods, and kits for non-invasive glucose measurement

InactiveUS20060004271A1Minimize impactMicrobiological testing/measurementSurgeryMeasurement deviceDisplay device

Described are devices, methods, and kits for non-invasively measuring glucose. In general, the devices comprise skin patches for placement on a skin surface and measurement devices for measuring glucose collected in the patches. The patches may include an adhesive material, a collection layer, an interface layer, and a sweat-permeable membrane. The sweat-permeable membrane is configured to act as a barrier to epidermal contaminants and glucose brought to the skin surface via diffusion. In this way, non-correlatable skin surface glucose will not be measured. The patches may further include components to induce a local sweat response. The measurement device typically includes a display, a processor, and a measurement mechanism. The methods typically include the steps of wiping the skin surface with a wipe containing at least one solvent for removing glucose, placing a patch on a skin surface, and measuring glucose collected in the patch. Kits comprising the patch and measurement device are also described.

Owner:VIVOMEDICAL INC

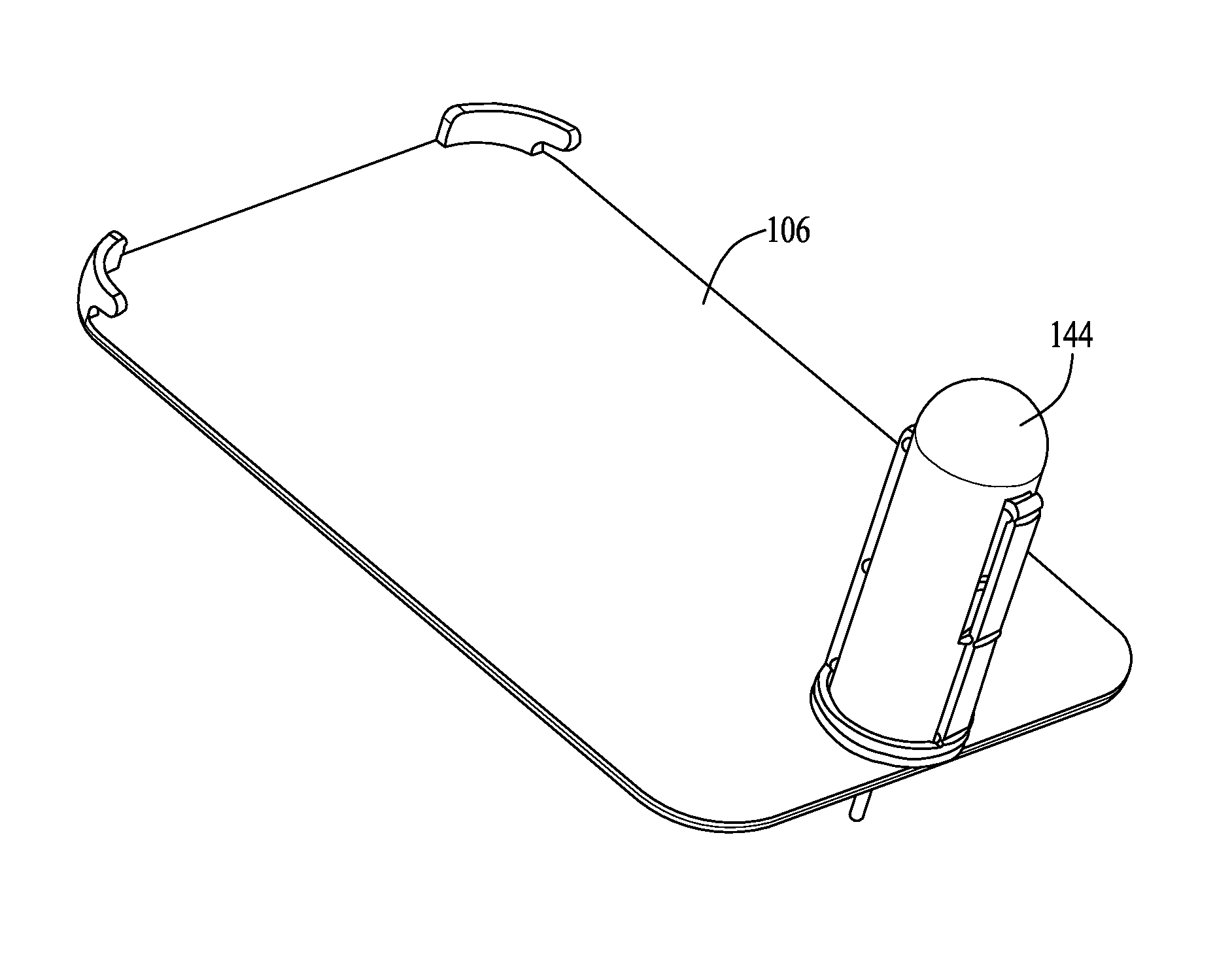

Adhesive patch systems and methods

Owner:MEDTRONIC MIMIMED INC

Adhesive patch systems and methods

ActiveUS20090198215A1High bonding strengthReduced adhesion strengthInfusion syringesFiltering accessoriesUltimate tensile strengthAdhesion strength

Various embodiments of the present invention are directed to patches for medical devices. In various embodiments, an adhesive patch of a medical device may have selective areas with adhesive material of varying adhesion strengths. In other embodiments, an adhesive patch of a medical device may include adhesive material that may be activated by a catalyst to increase or decrease the adhesion strength of the adhesive material. In further embodiments, a medical device may include a pierceable membrane containing an agent, the pierceable membrane positioned to be pierced by a needle and to cause some of the agent to be carried to the user-patient.

Owner:MEDTRONIC MIMIMED INC

Electro-optic displays, and materials for use therein

A first electro-optic display comprises first and second substrates, and an adhesive layer and a layer of electro-optic material disposed between the first and second substrates, the adhesive layer comprising a mixture of a polymeric adhesive material and a hydroxyl containing polymer having a number average molecular weight not greater than about 5000. A second electro-optic display is similar to the first but has an adhesive layer comprising a thermally-activated cross-linking agent to reduce void growth when the display is subjected to temperature changes.

Owner:E INK CORPORATION

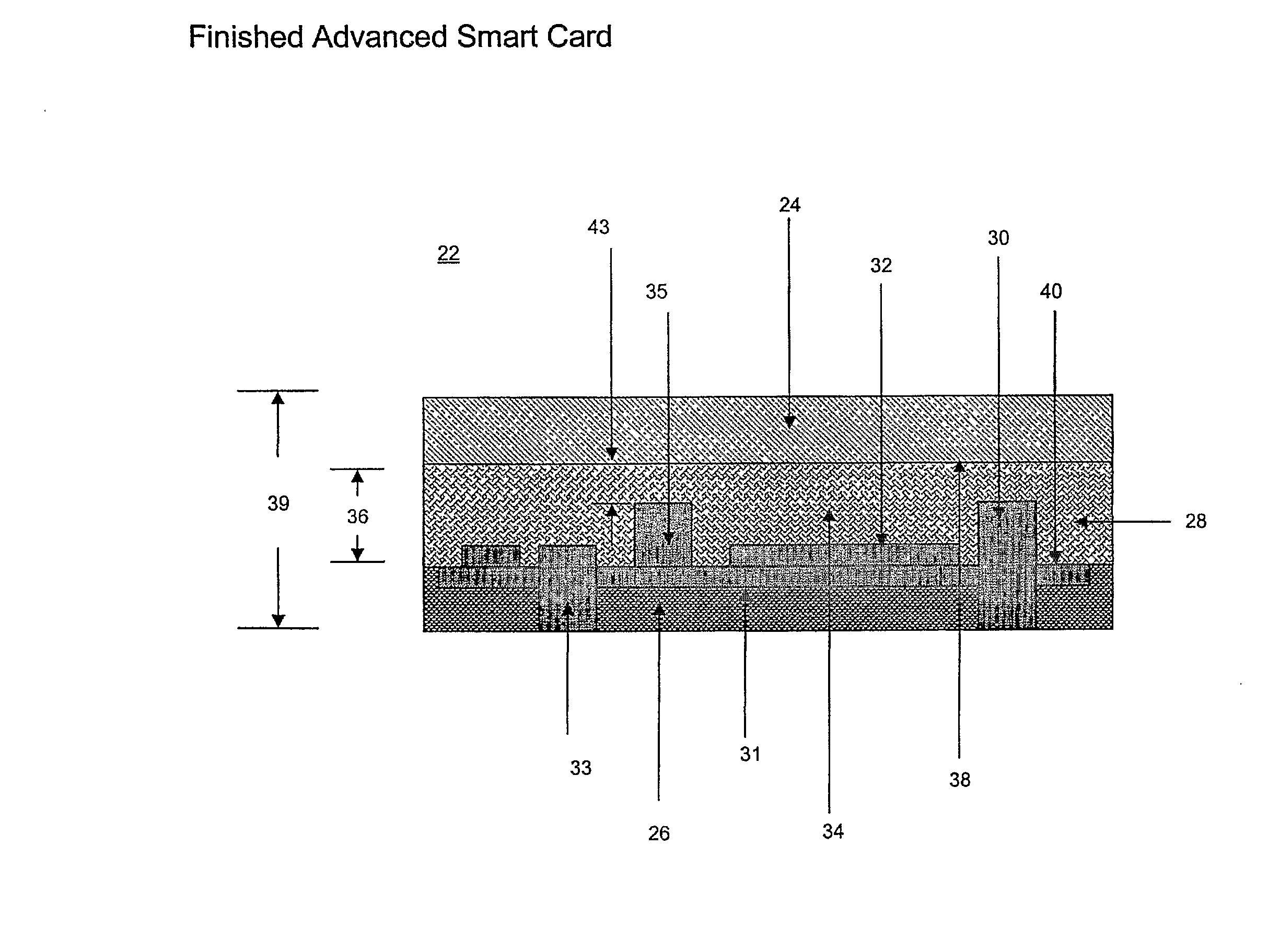

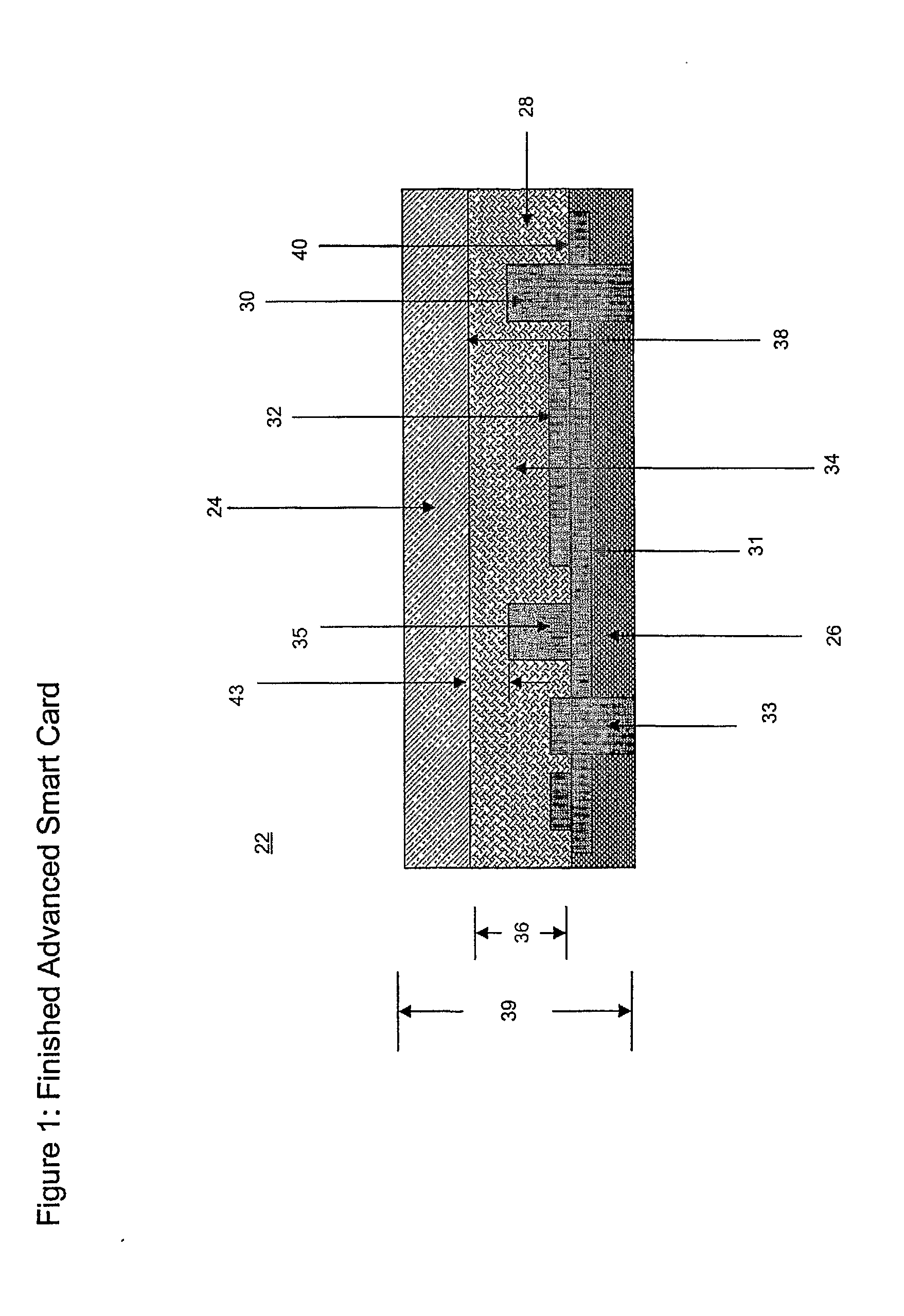

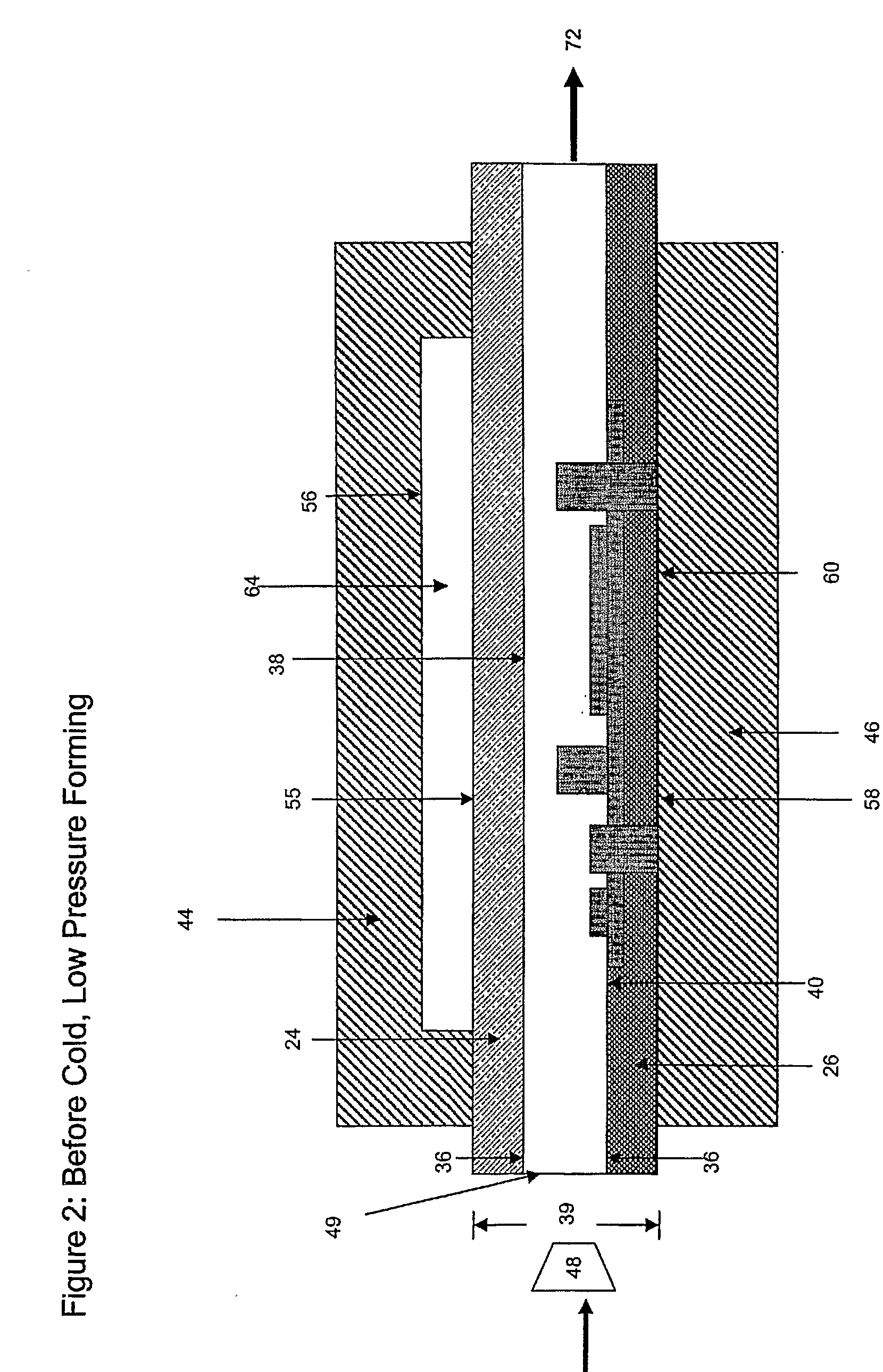

Method for Making Advanced Smart Cards With Integrated Electronics Using Isotropic Thermoset Adhesive Materials With High Quality Exterior Surfaces

InactiveUS20080096326A1Speed up the flowPrinted circuit assemblingLine/current collector detailsIntegrated electronicsSmart card

Advanced Smart Cards and similar form factors (e.g. documents, tags) having high quality external surfaces of Polyvinylchloride (PVC), Polycarbonate (PC), synthetic paper or other suitable material can be made with highly sophisticated electronic components (e.g. Integrated Circuit chips, batteries, microprocessors, Light Emitting Diodes, Liquid Crystal Displays, polymer dome switches, and antennae), integrated in the bottom layer of the card structure, through use of injection molded thermosetting or thermoplastic material that becomes the core layer of said Advanced Smart Cards. A lamination finishing process can provide a high quality lower surface, and the encapsulation of the electronic components in the thermosetting or thermoplastic material provides protection from the lamination heat and pressure.

Owner:CARDXX

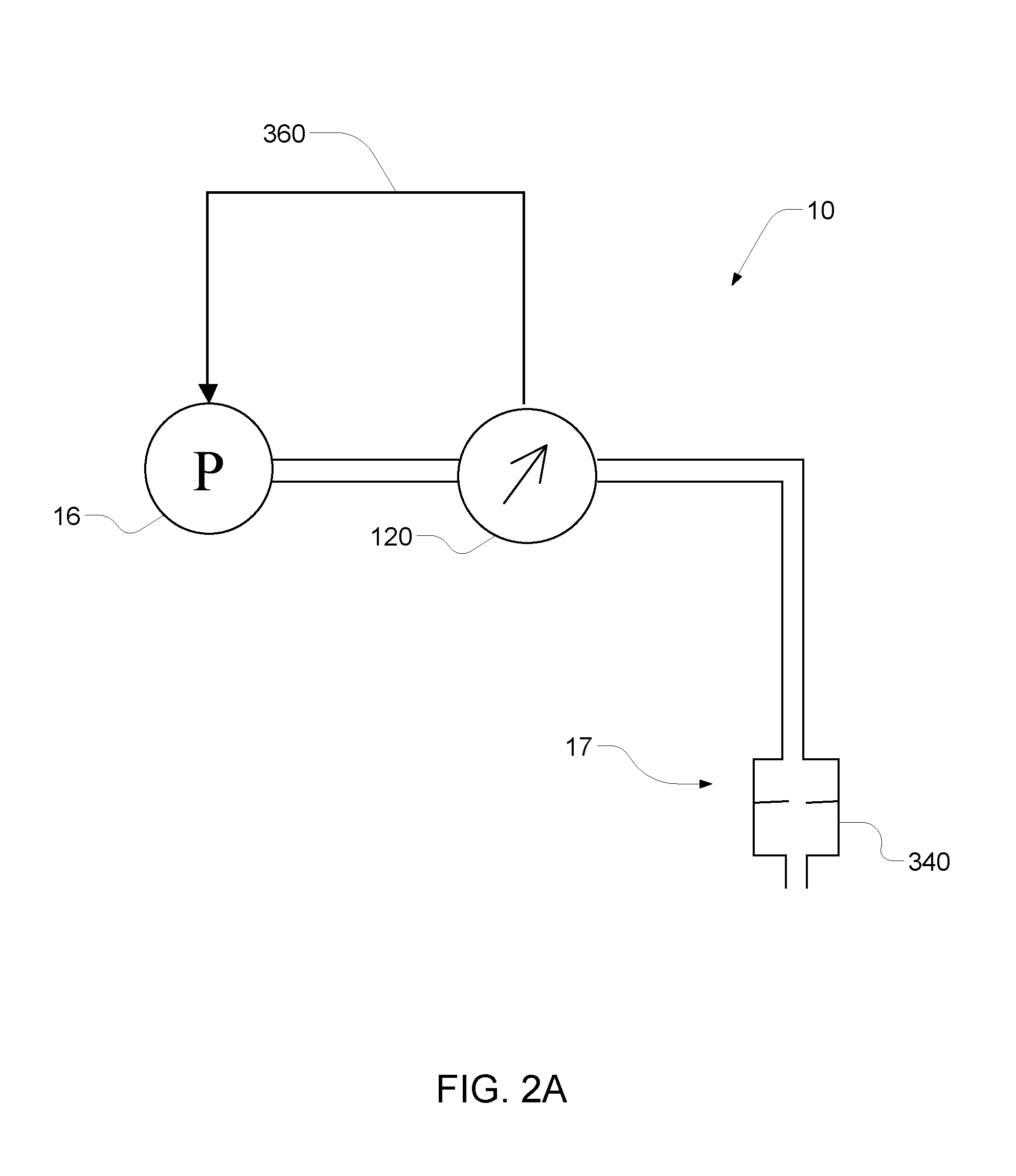

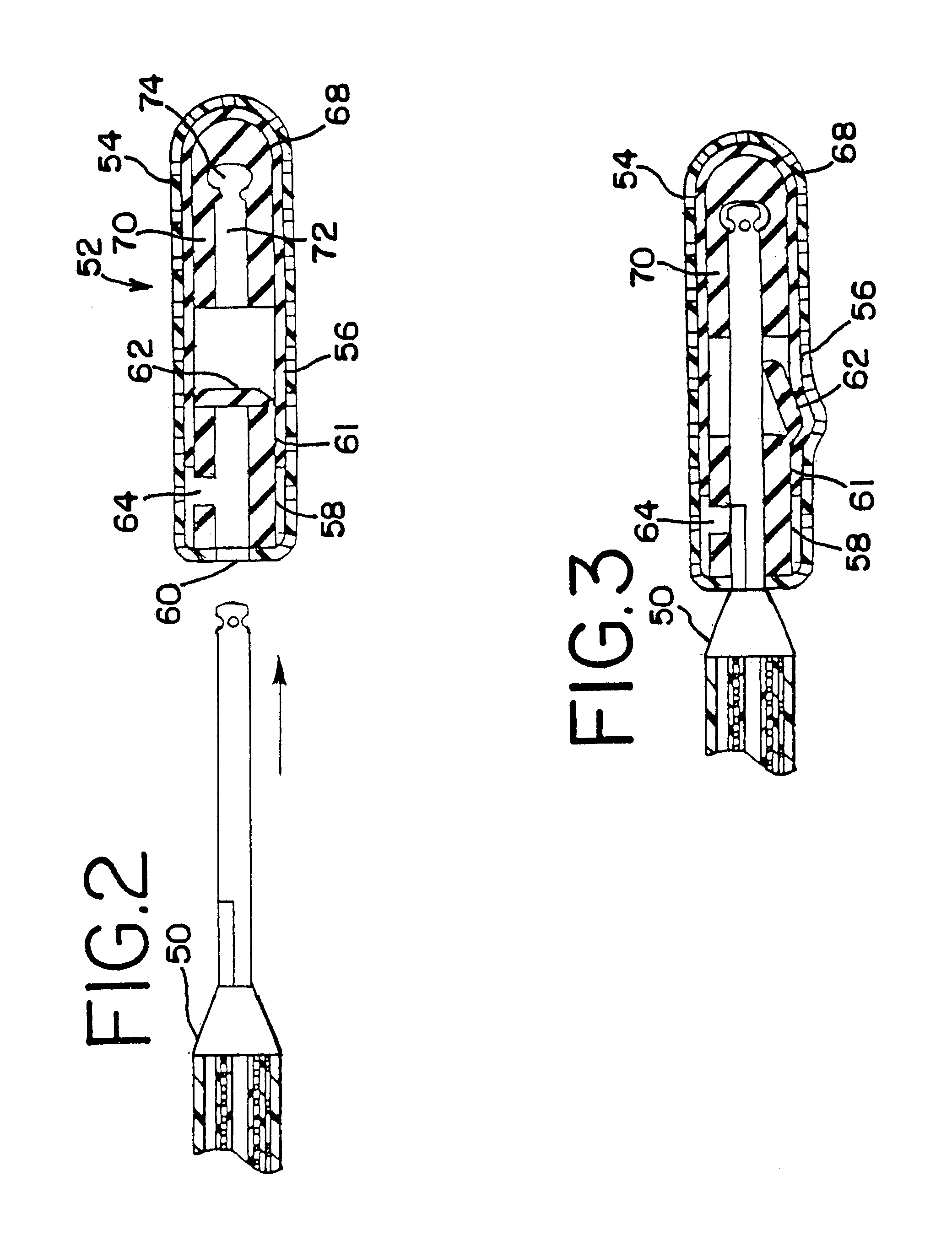

Adhesive and peripheral systems and methods for medical devices

A repeater system may control a pump by using a repeater and a user interface. An adhesive patch system may be used for affixing a pump or other object to a human body. Such an adhesive patch system may include two sets of adhesive members, each member including an adhesive material on at least one side so as to attach to the body. The members of the first set are spaced to allow the members of the second set to attach to the body in spaces provided between the members of the first set, and the members of the second set are spaced to allow members of the first set to detach from the body without detaching the members of the second set. Also, fill stations and base stations are provided for personal pump systems.

Owner:DEKA PROD LLP

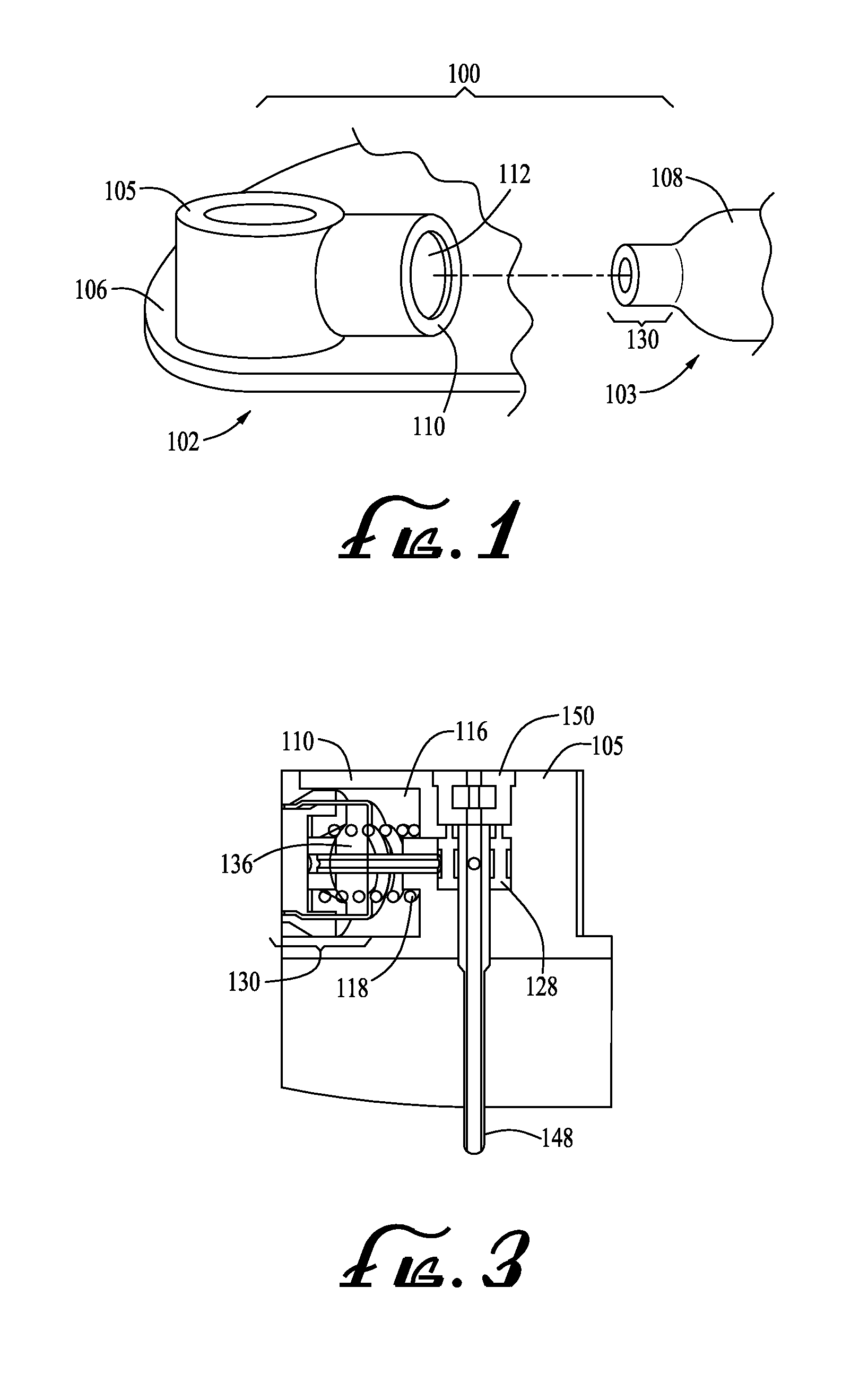

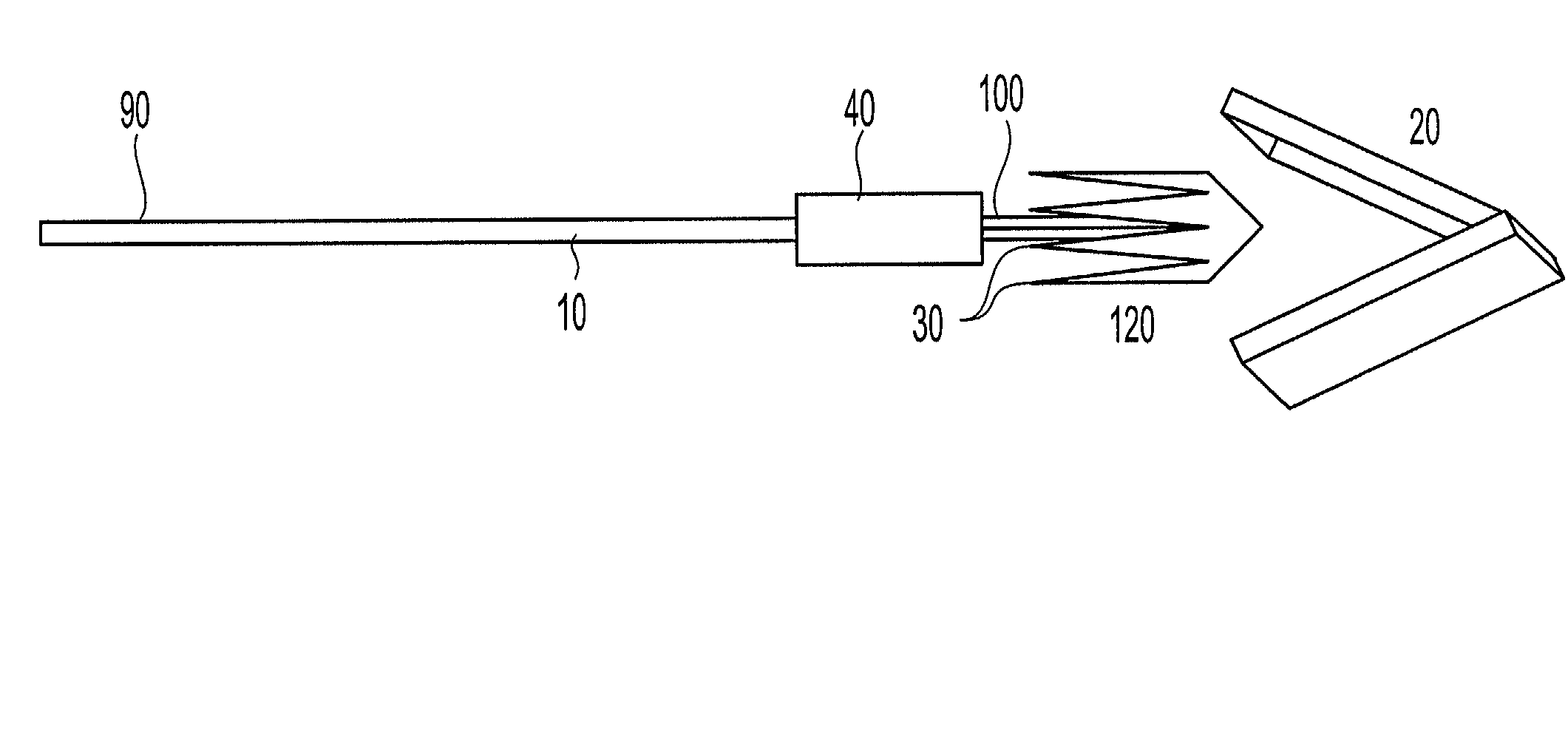

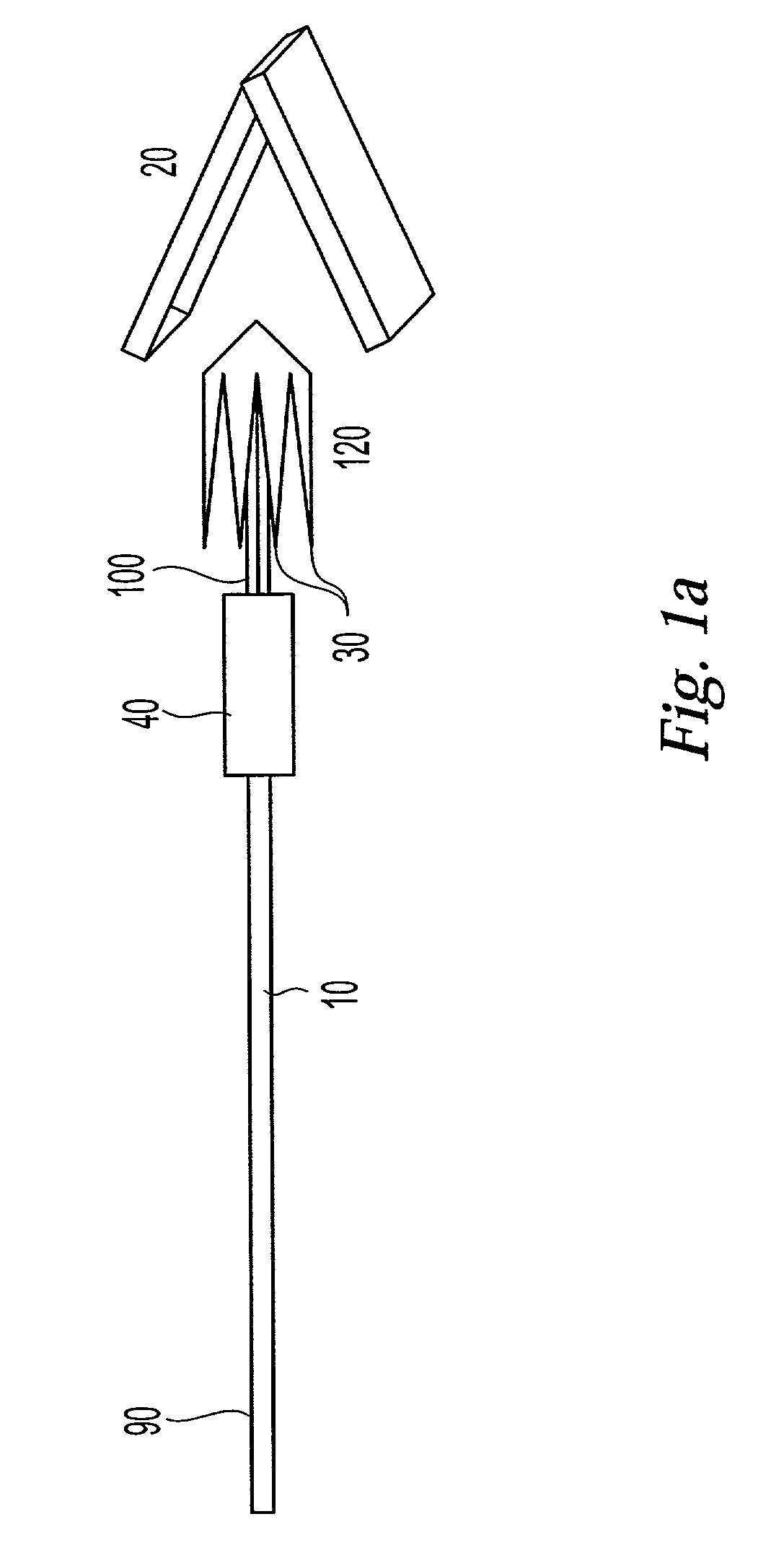

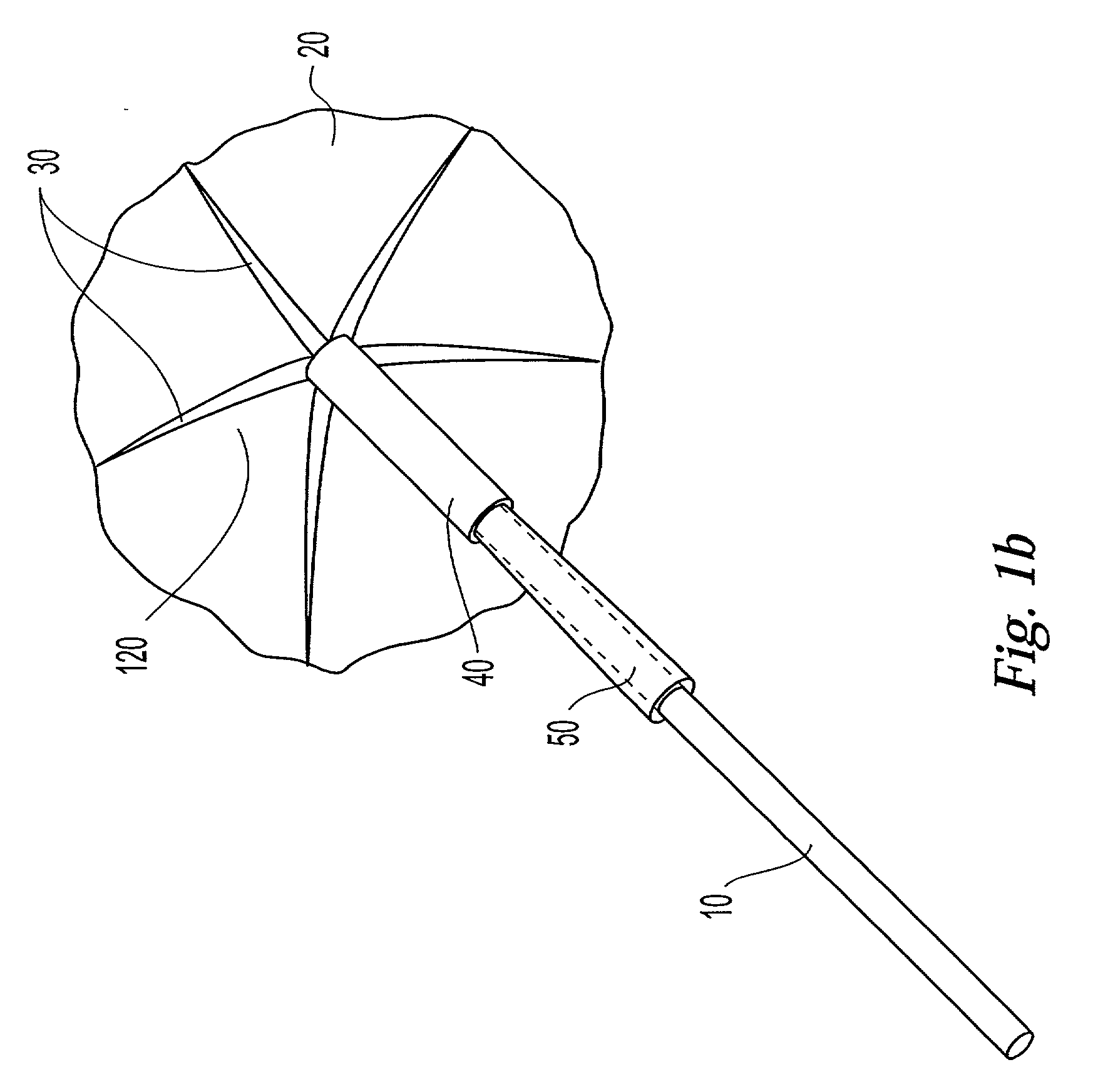

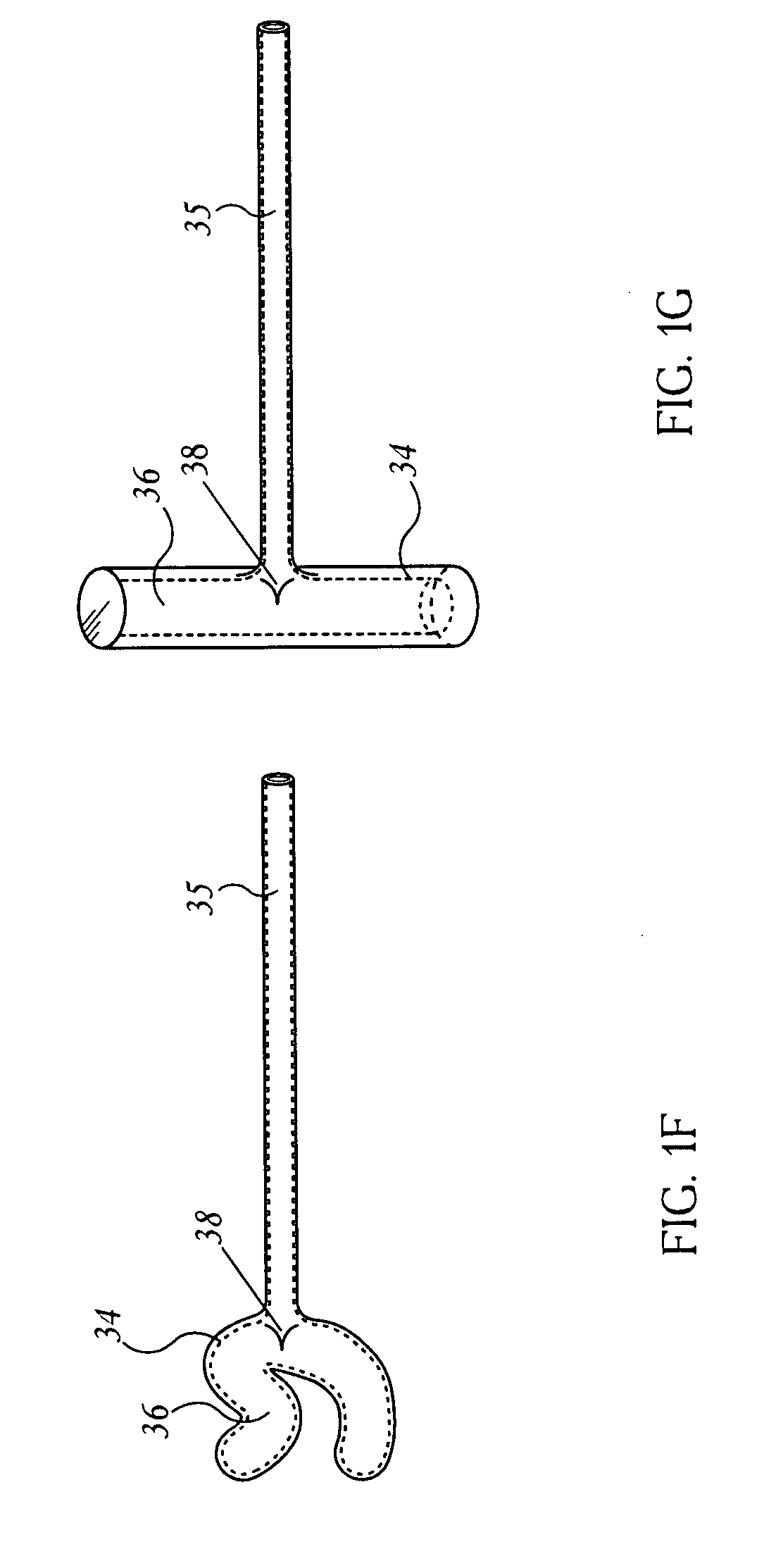

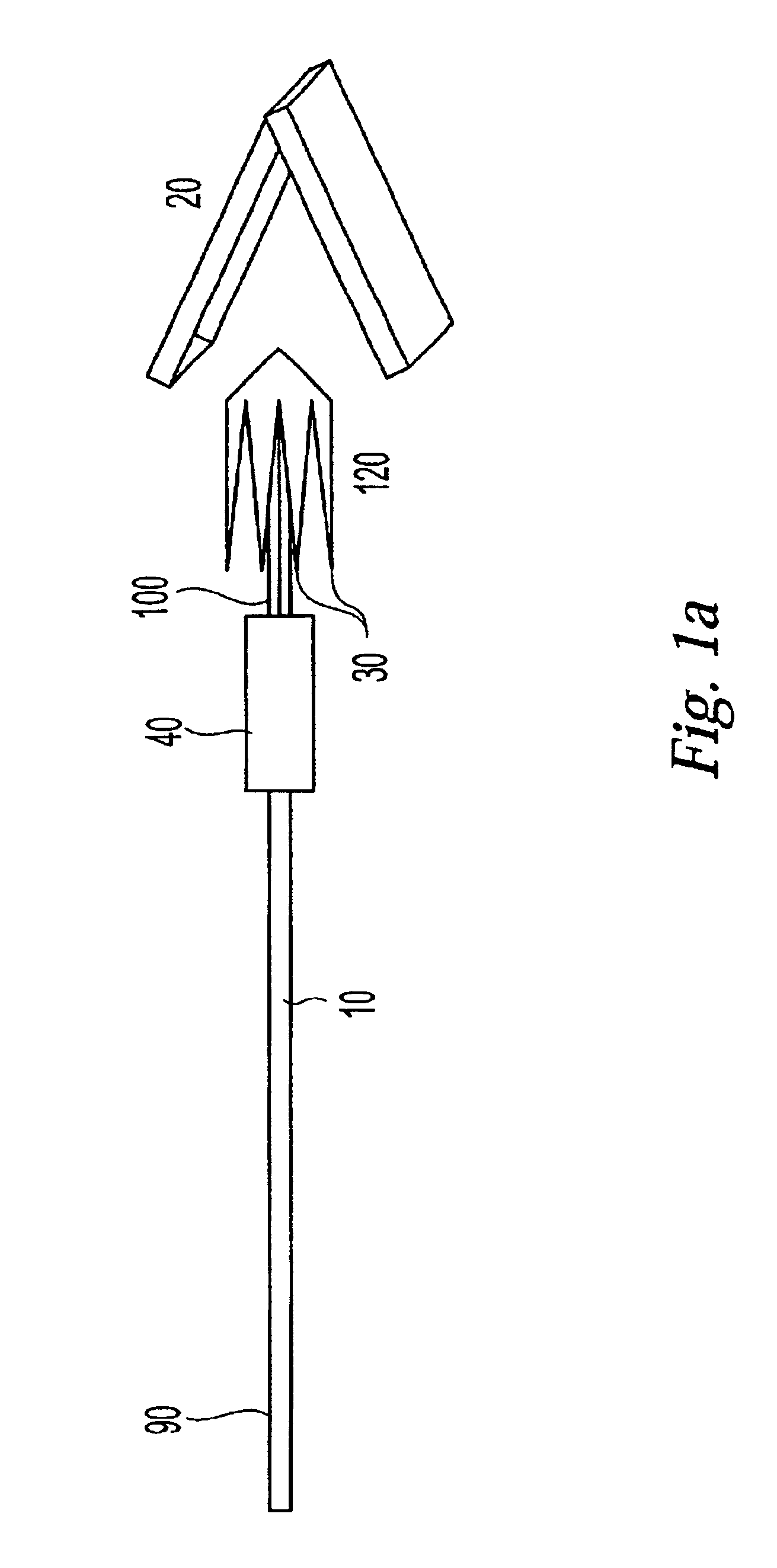

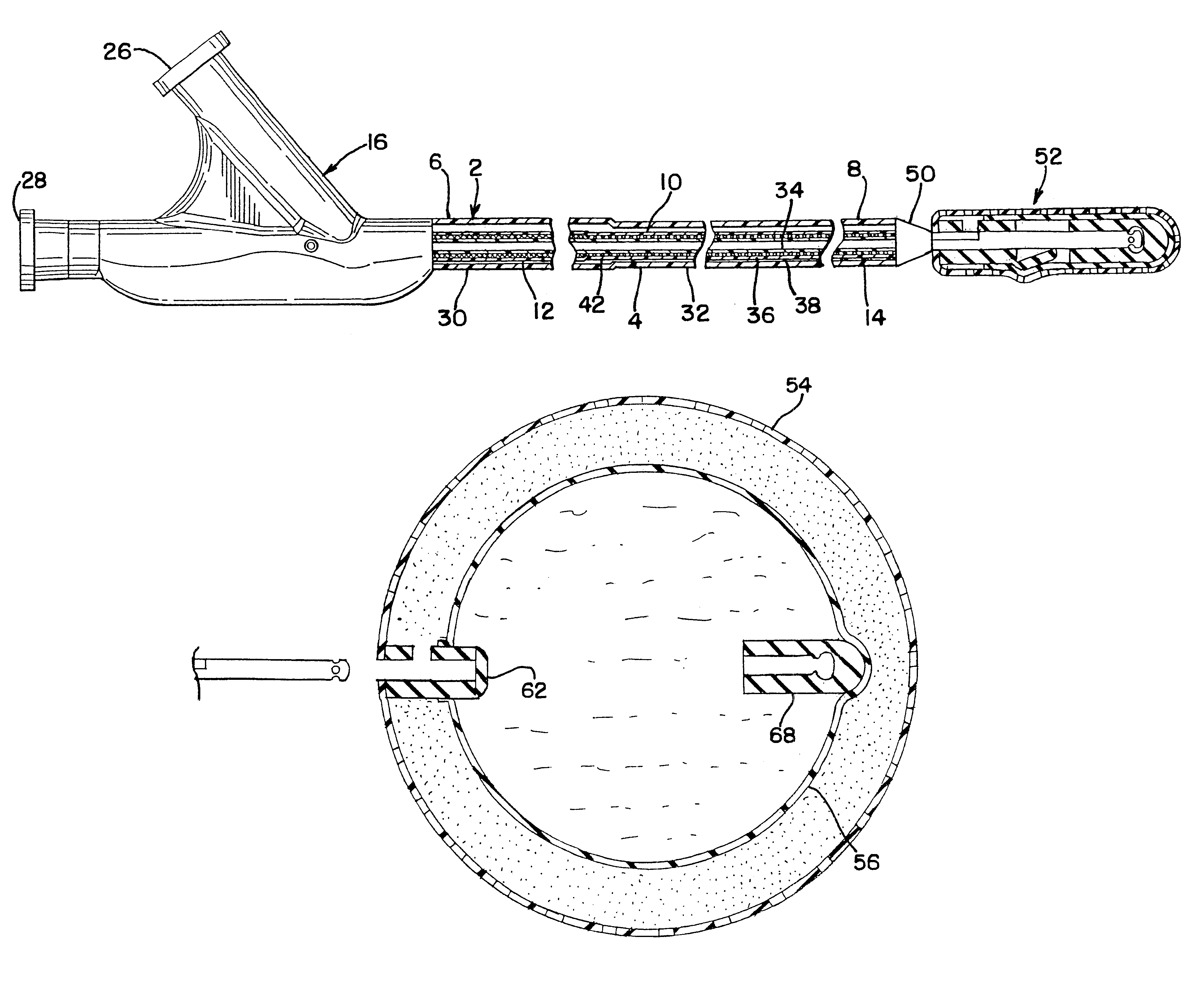

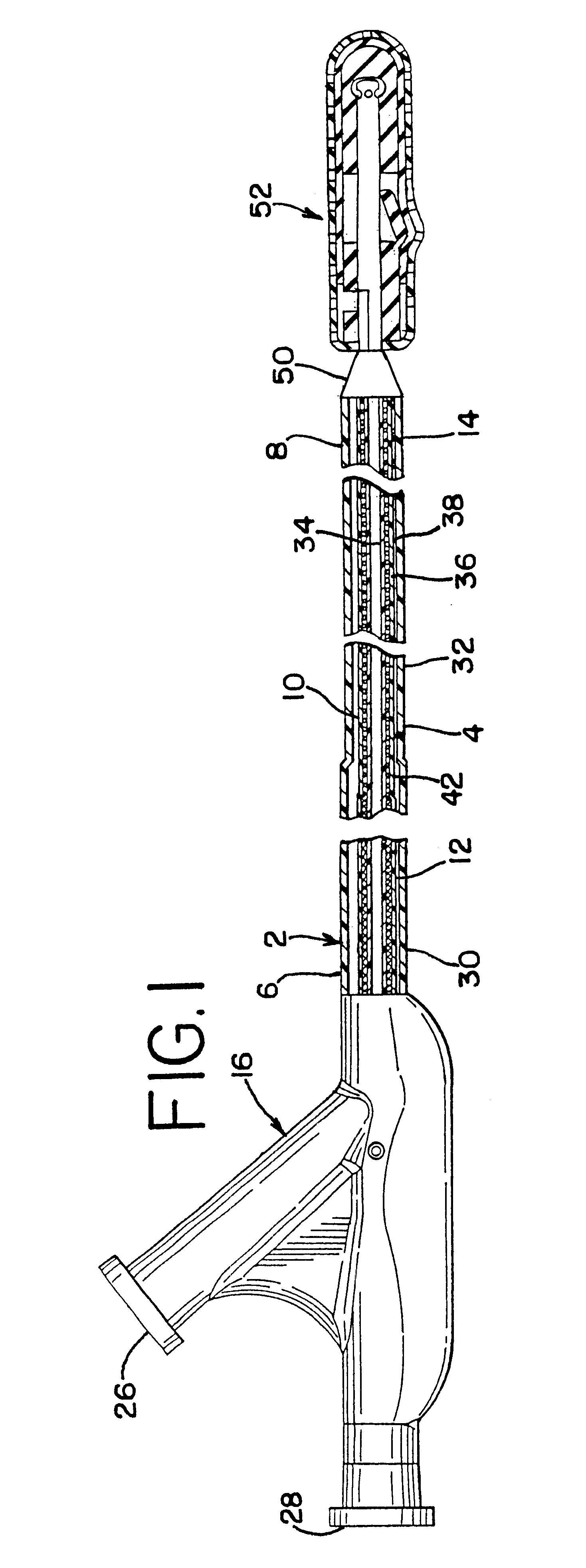

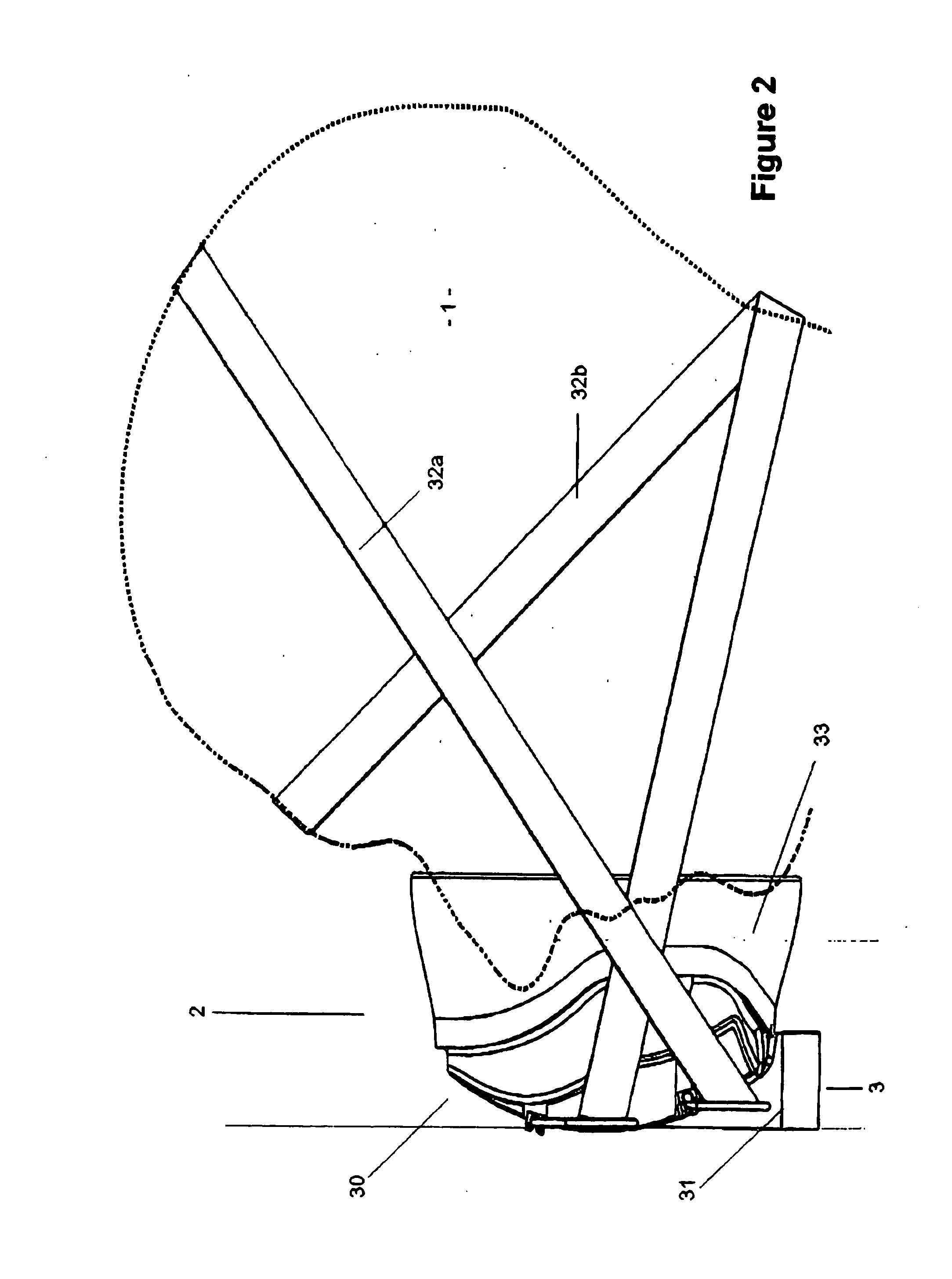

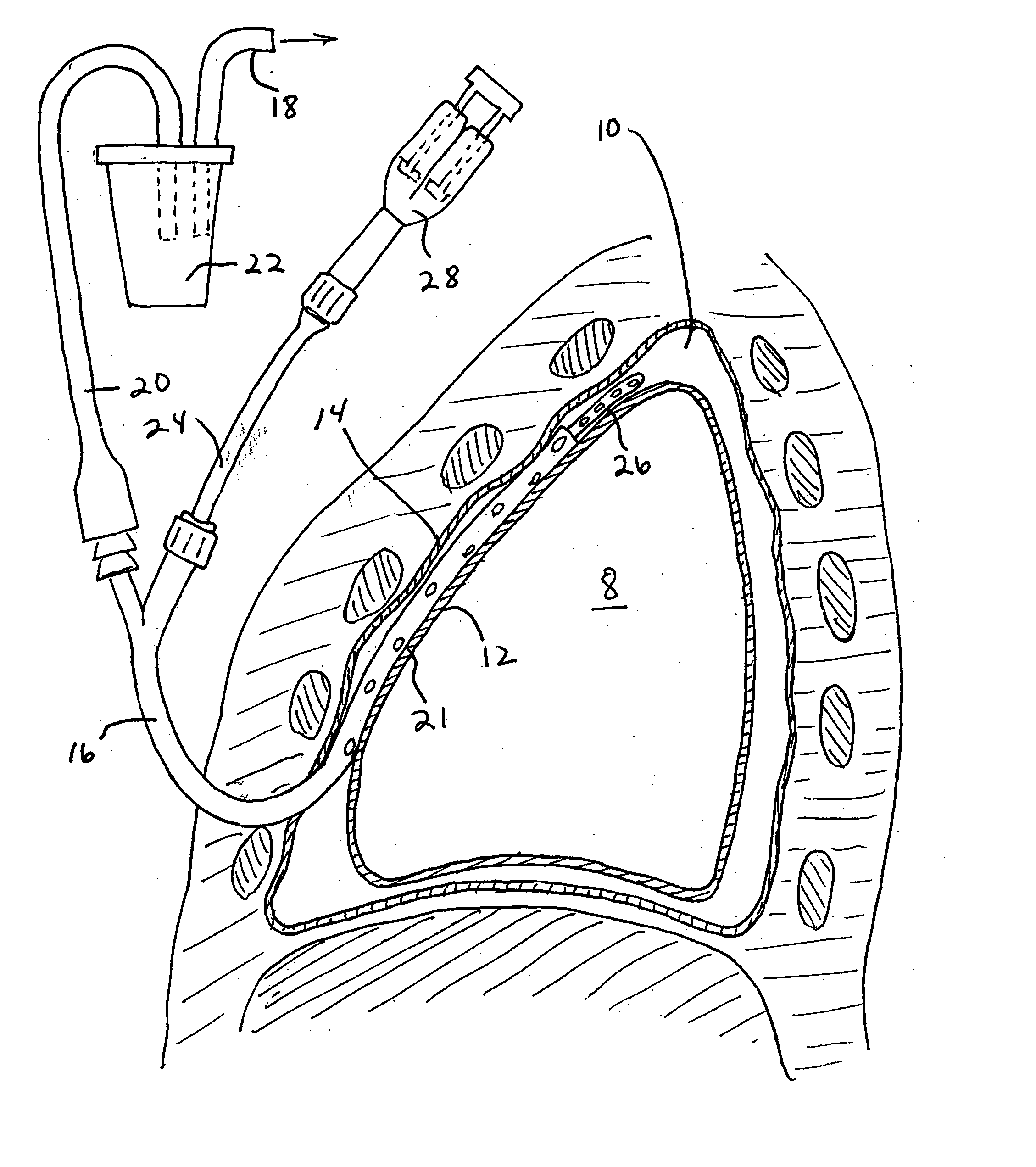

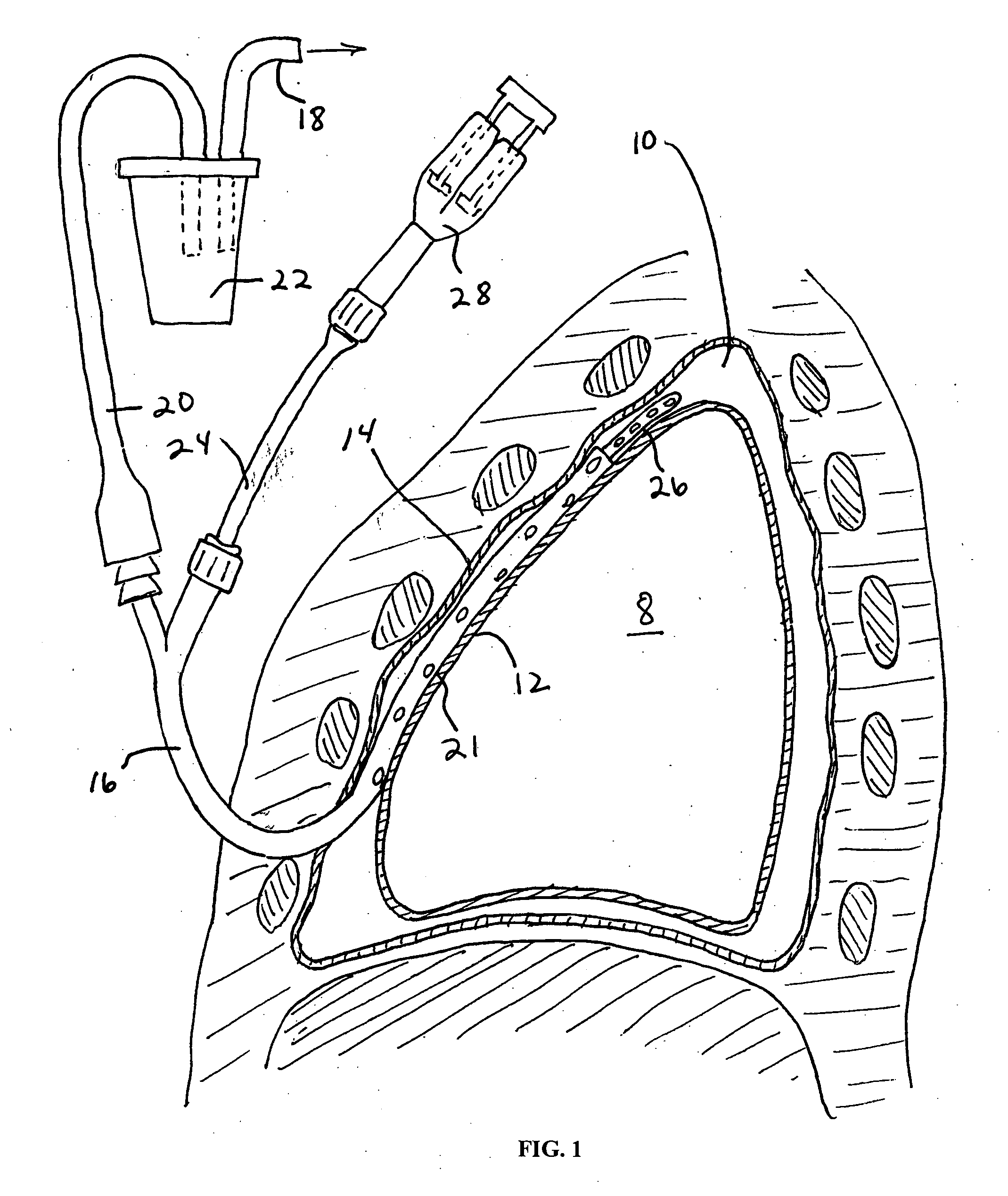

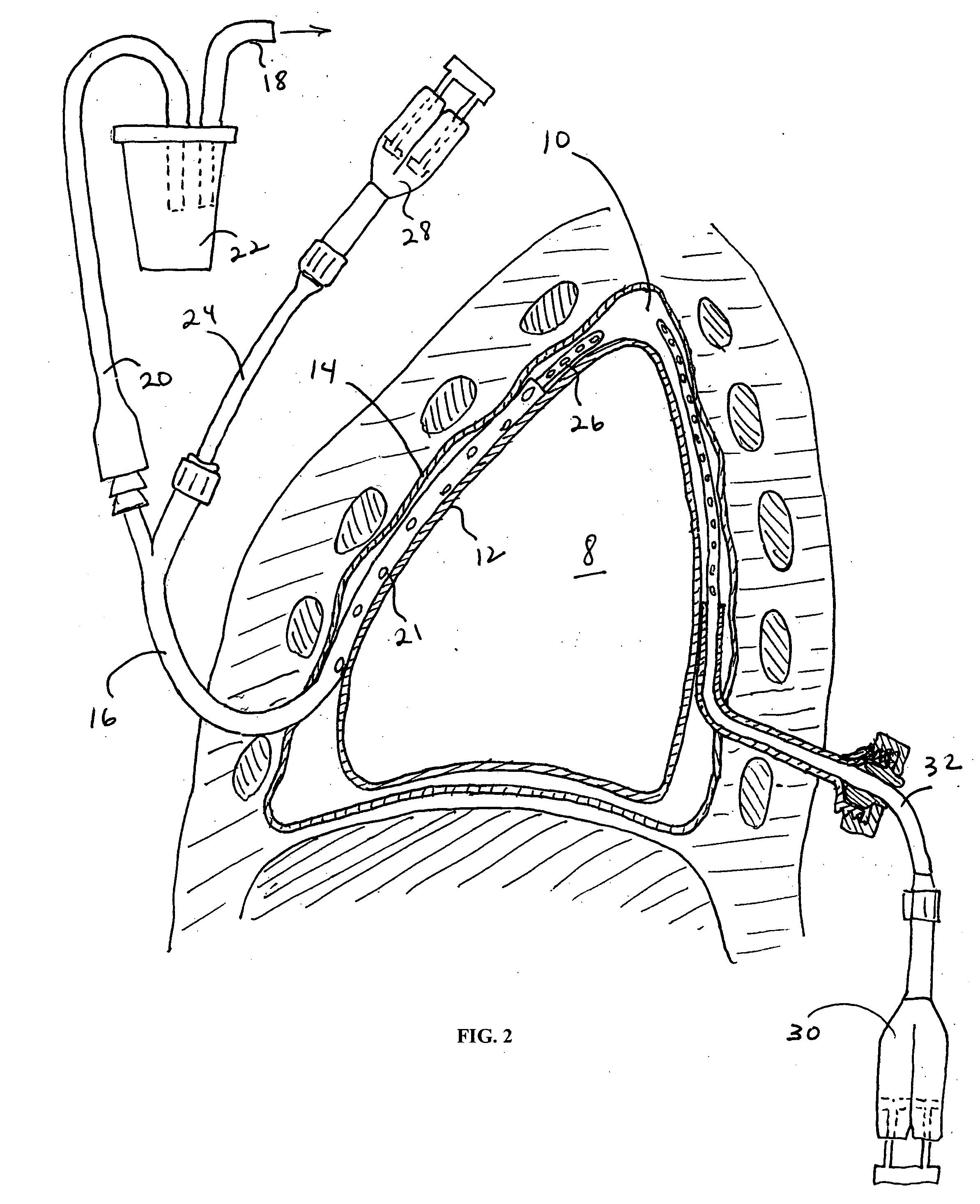

Medical device for delivering patches

InactiveUS20030073979A1Eliminates systemic leakageEliminate leaksAdditive manufacturing apparatusHeart valvesMedical deviceAdhesive materials

The present invention relates to a medical device and method for treating the body tissue of a patient. The present invention is also directed to a method of making the medical device and a method of using the medical device. More particularly, the invention relates to a medical device which is inserted into the body for delivery of therapeutic patches to the surface of a body lumen, organ or cavity. Specifically, the medical device has an umbrella-like or a basket-like expandable assembly; and a therapeutic patch. The expandable assembly is capable of changing from a retracted position to an expanded position. The expandable assembly can be self-expanding or non-self-expanding. In one embodiment, the medical device comprises an elongated member; an umbrella-like expandable assembly which has a plurality of wire elements; and a therapeutic patch. The therapeutic patch comprises a sheet having two opposing surfaces wherein one of the surface comprises an adhesive material and at least one biologically active material. The other opposing surface is disposed onto the plurality of wire elements of the umbrella-like expandable assembly. In another embodiment, the medical device comprises an elongated member, a basket-like expandable assembly having a plurality of wire elements; and a therapeutic patch. The therapeutic patch is disposed onto the plurality of wire elements of the basket-like expandable assembly.

Owner:BOSTON SCI SCIMED INC

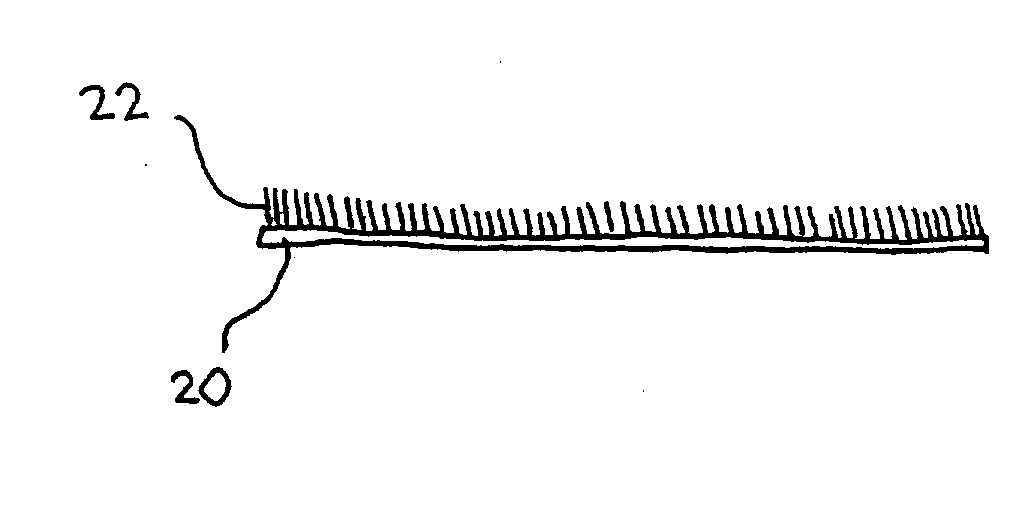

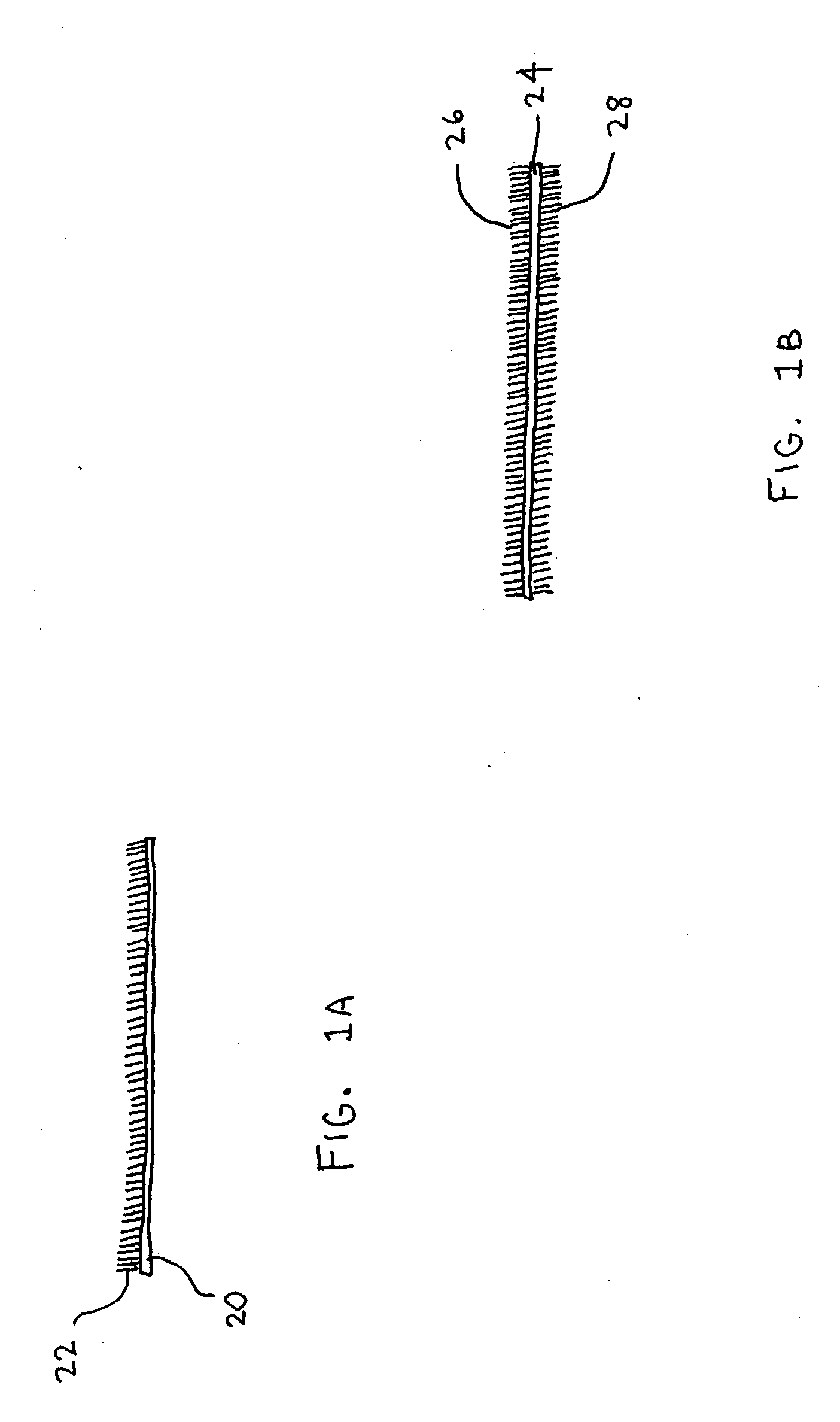

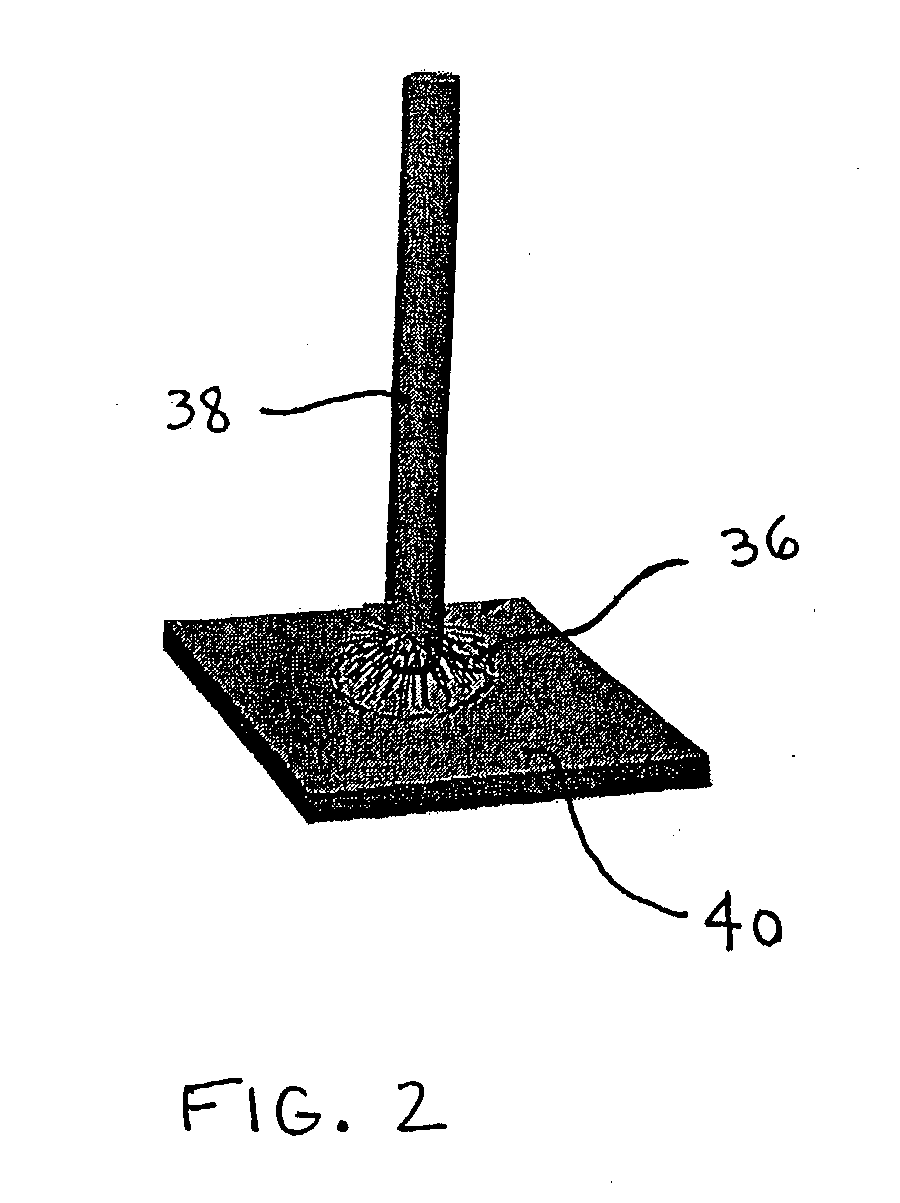

Fiber adhesive material

InactiveUS20040071870A1Improve adhesion performanceMaterial nanotechnologySemiconductor/solid-state device detailsDielectricFiber

A fiber velvet comprising nano-size fibers or nanofibrils attached to micro-size fibers is disclosed. Methods of manufacturing the velvet as well as various uses of the velvet are also described. For example, the fiber velvet can be used as a thermal interface or as an adhesive material. The nanofibrils may be attached to a flat base or membrane, or may be attached to the tip portions of the micro-size or larger diameter fibers. Various attributes of the micro-size fibers and of the nano-size fibers, for example, geometry (e.g. size, length, packing density) material type (e.g. carbon, metal, polymer, or ceramic) and properties (e.g. conductivity, modulus, surface energy, dielectric constant, surface roughness) can be selected depending on the desired attributes of the fiber velvet. The nanofibrils have a diameter of less than about 1 micron, and may advantageously be formed from single walled and / or multi-walled carbon nanotubes.

Owner:KULR TECH

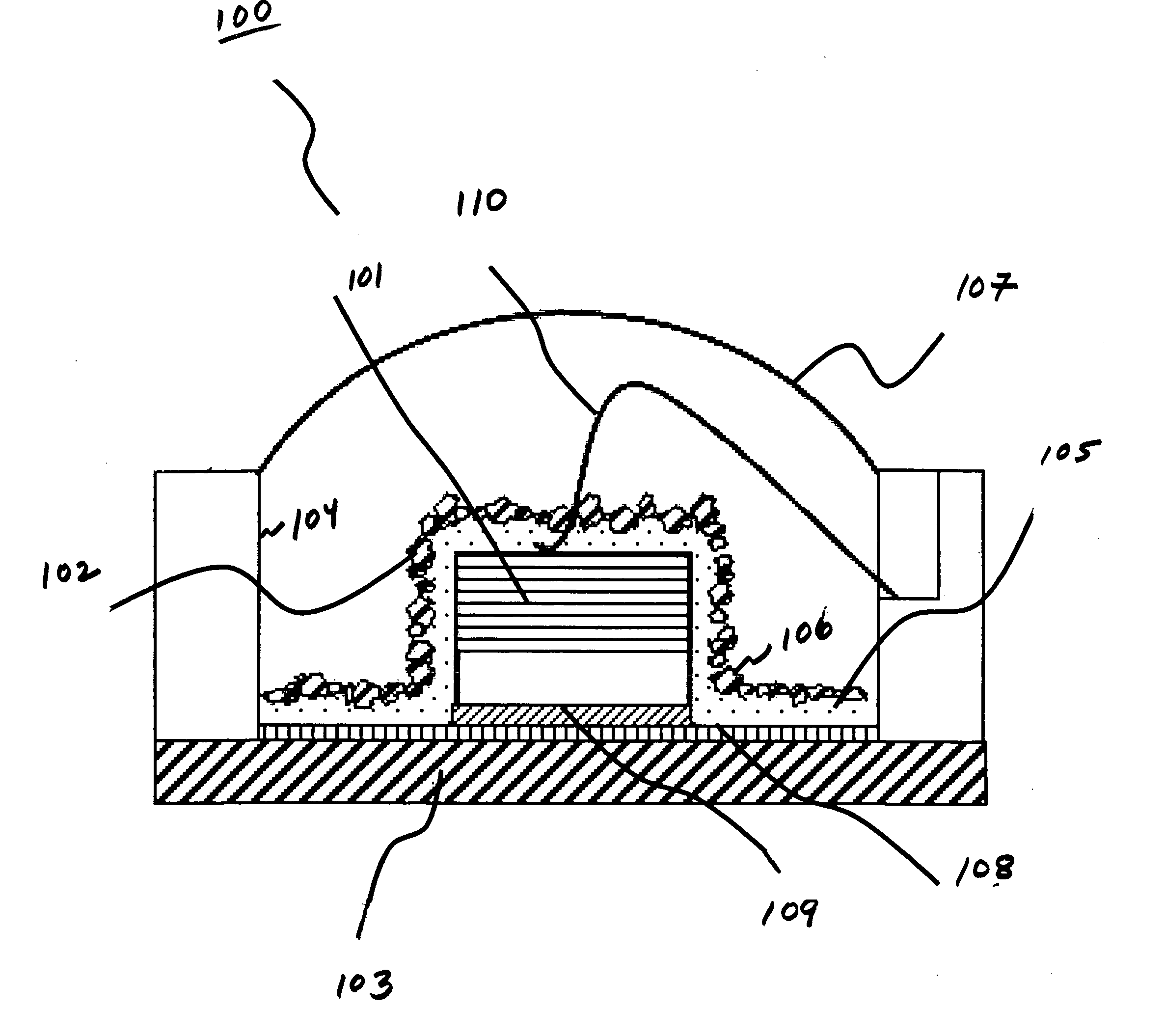

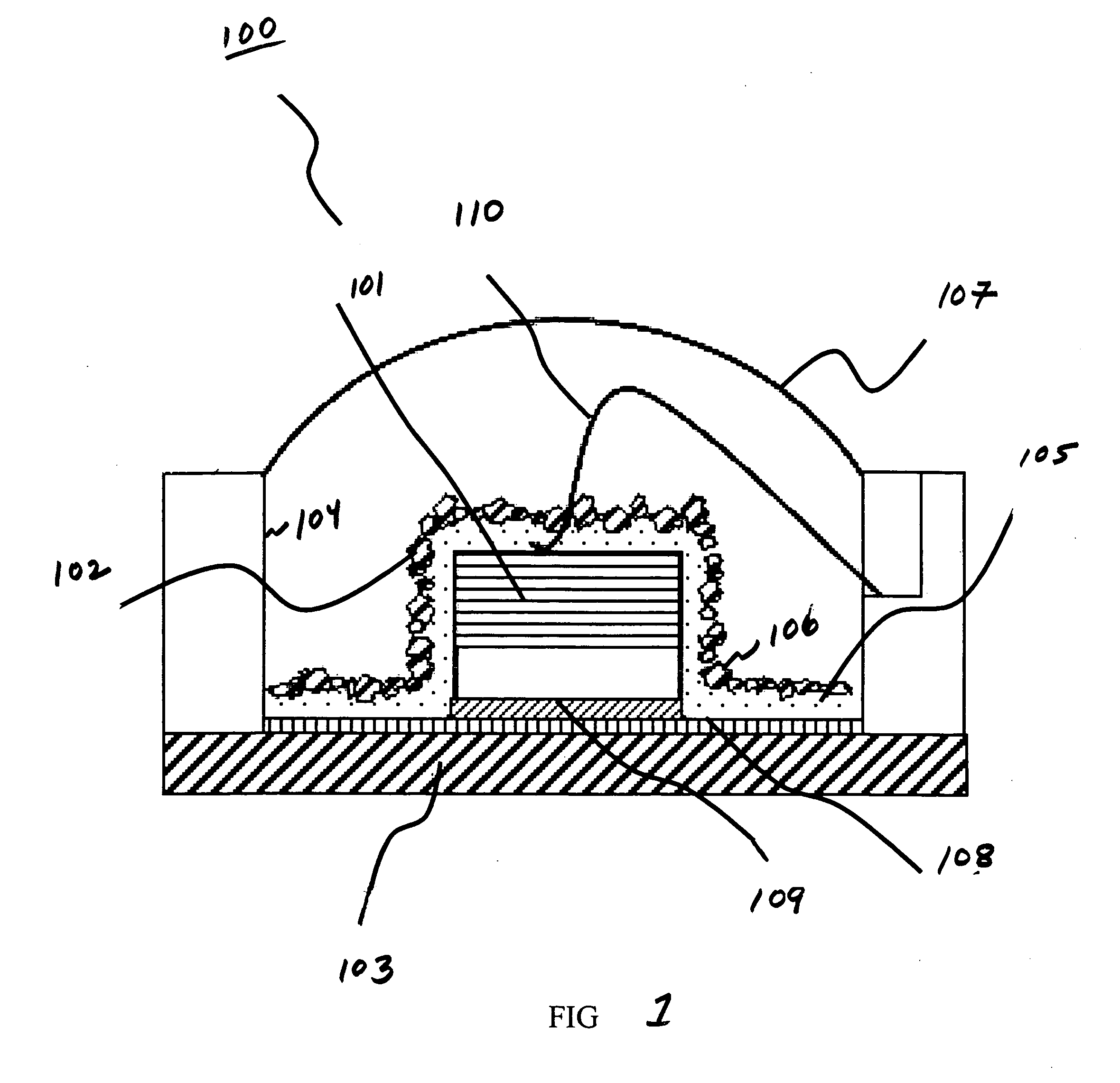

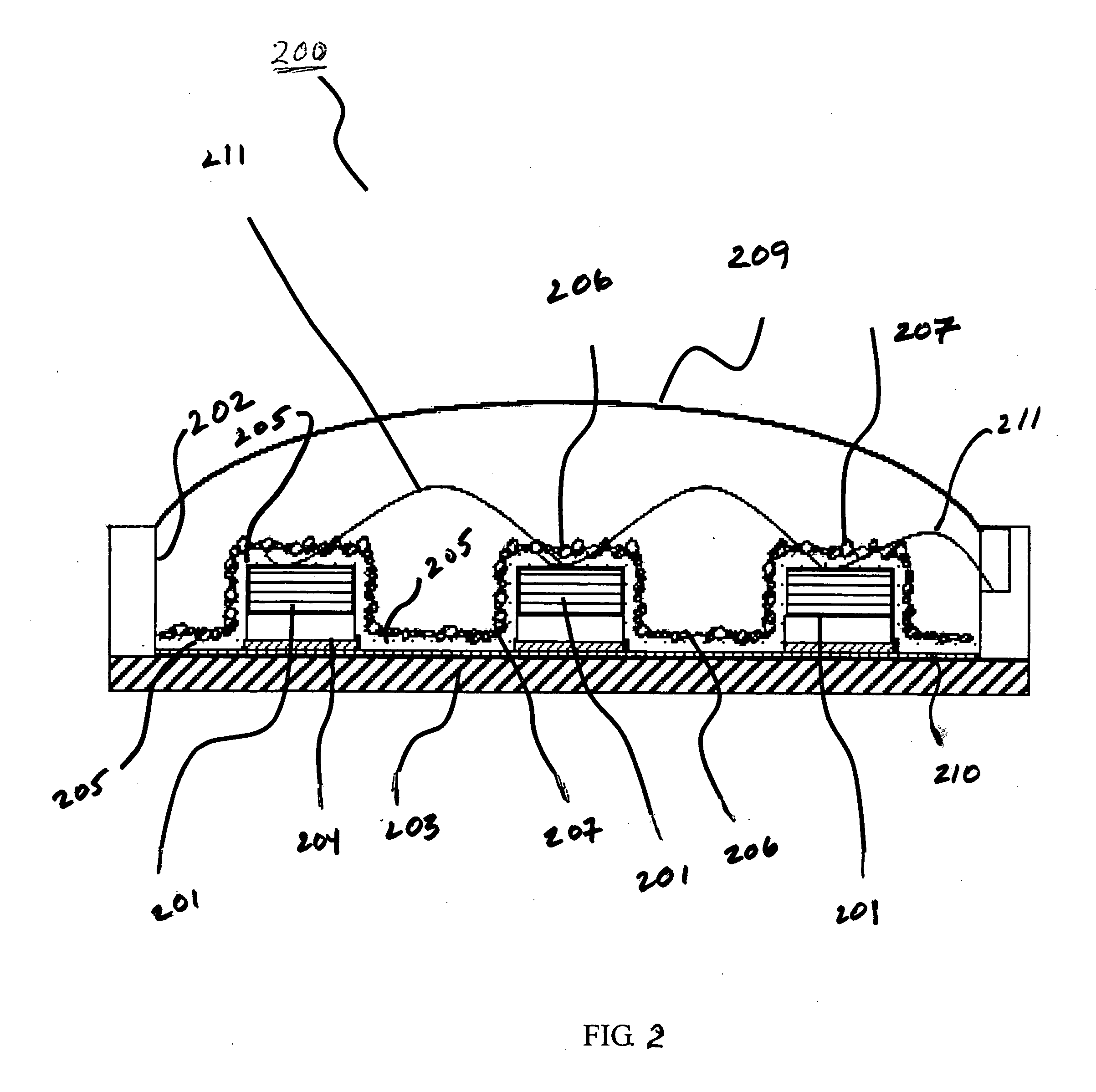

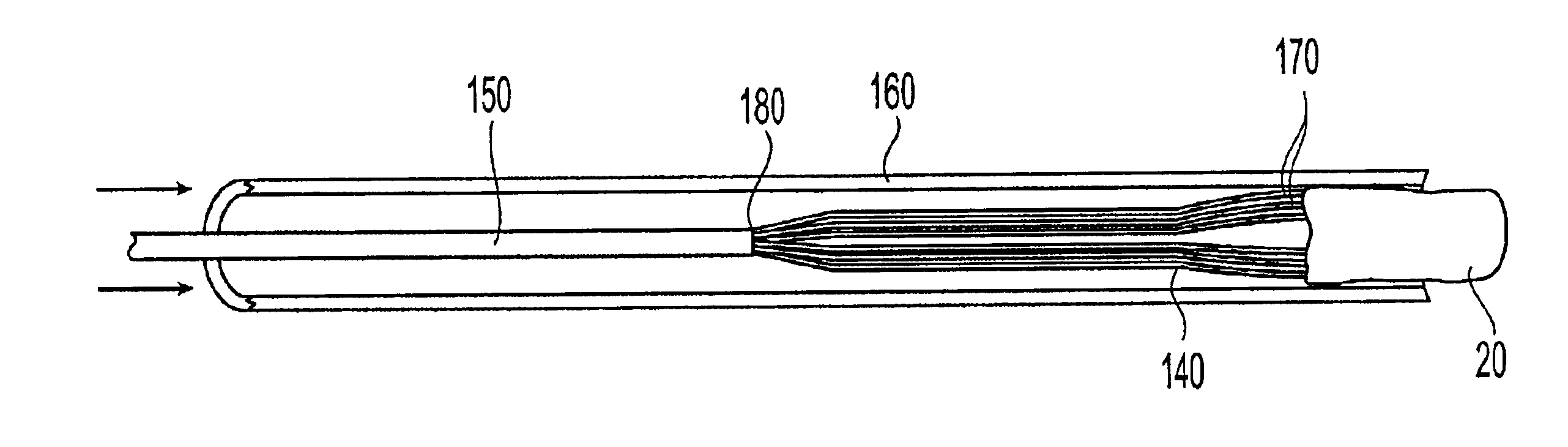

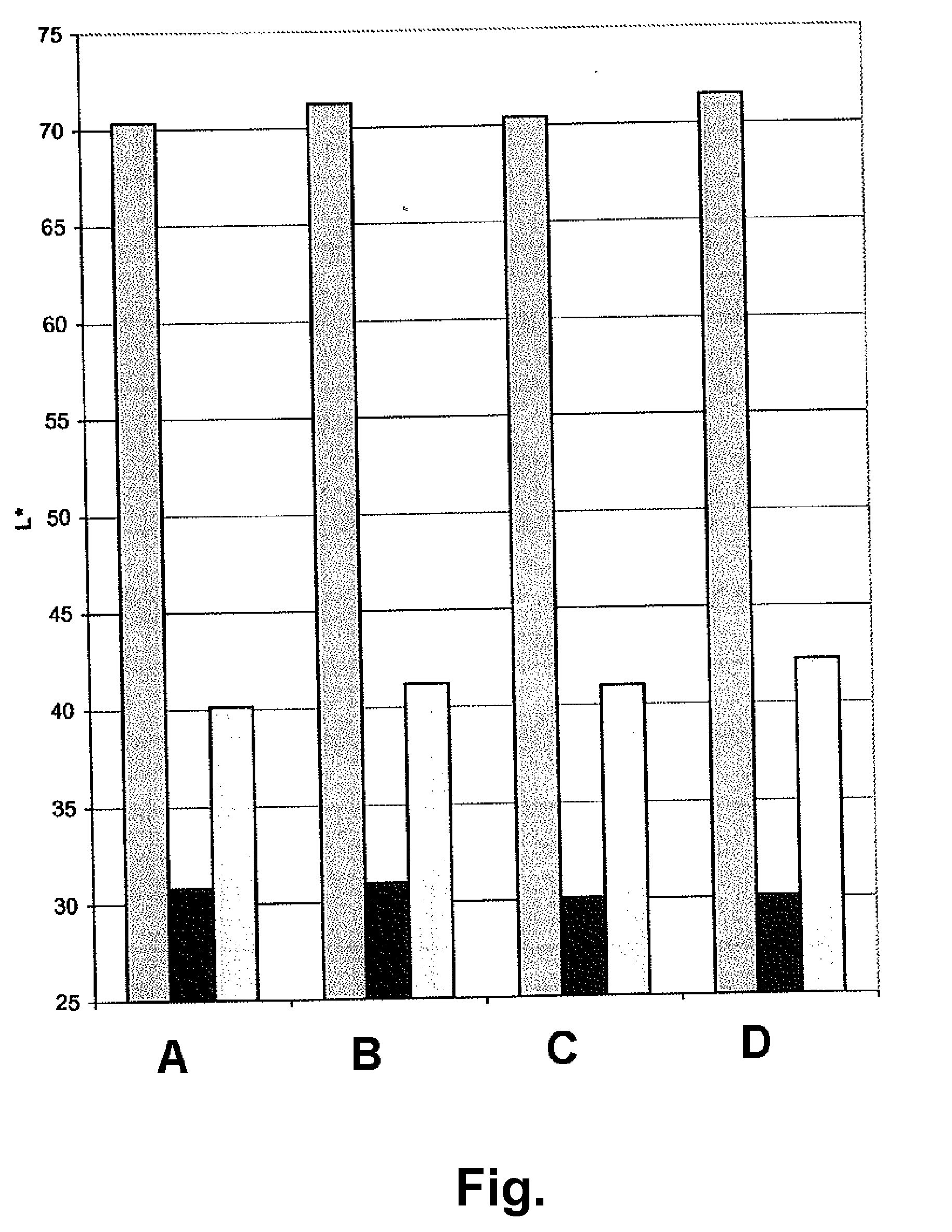

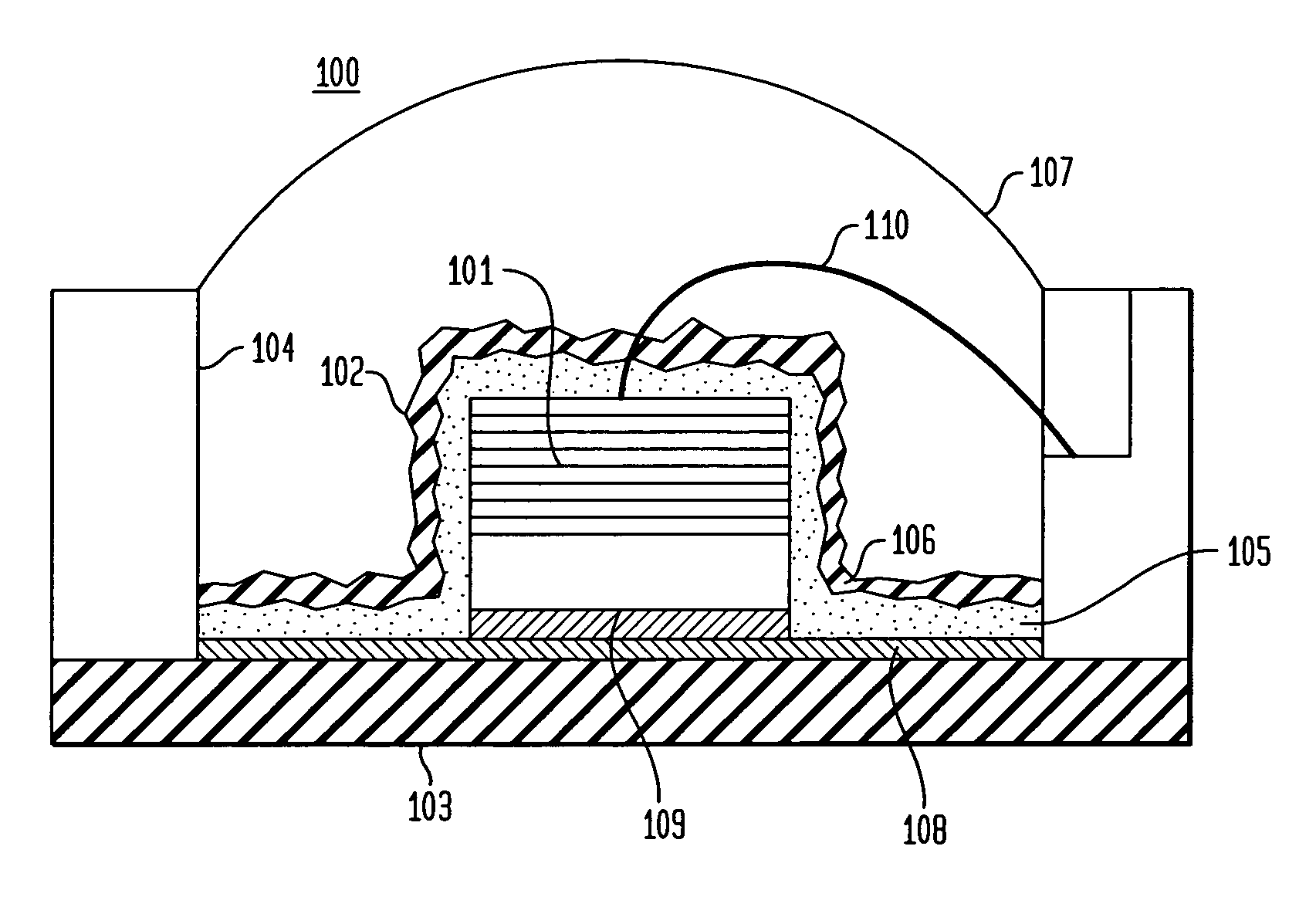

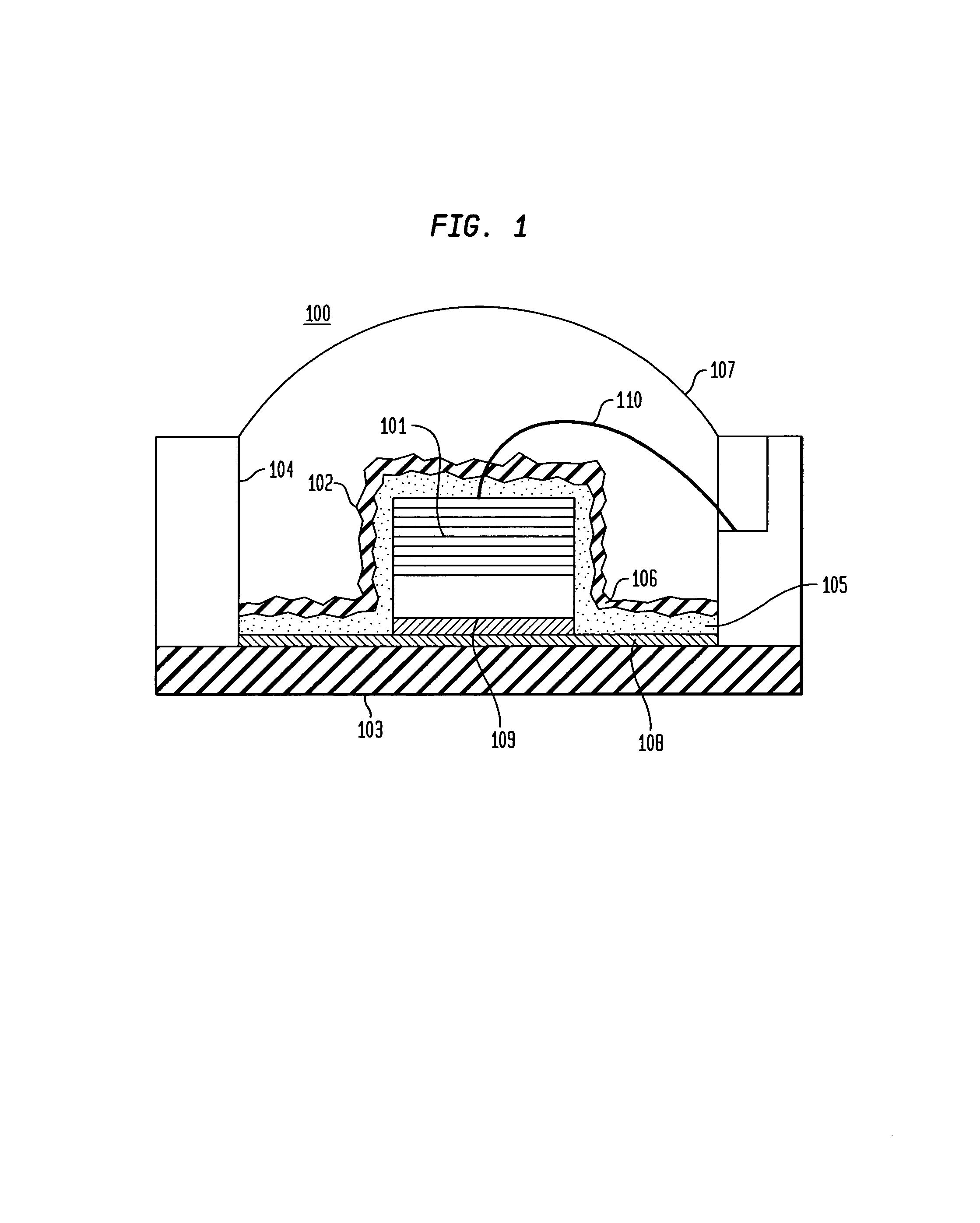

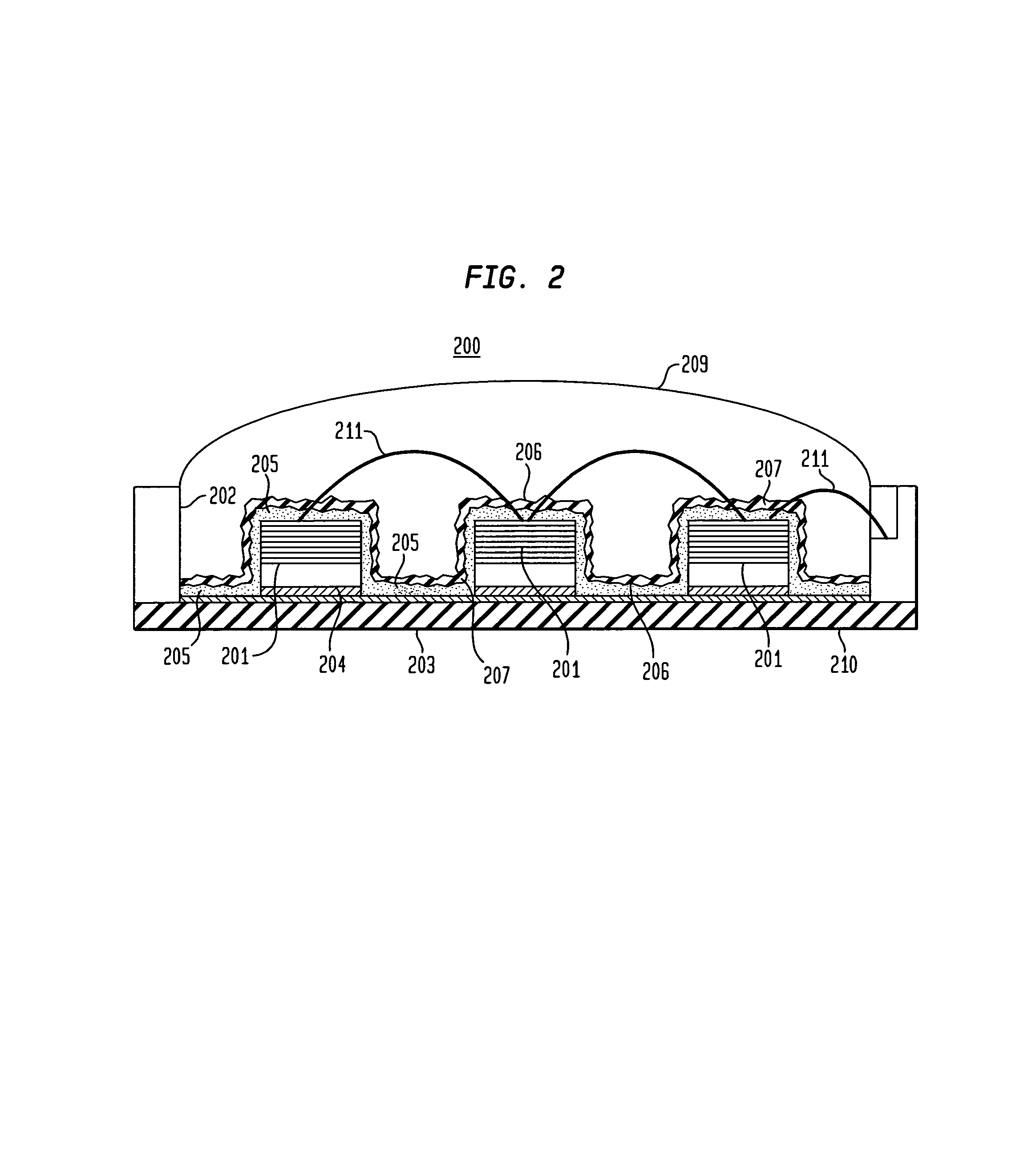

Illumination devices comprising white light emitting diodes and diode arrays and method and apparatus for making them

In accordance with the invention, an illumination device comprises a substrate having a surface and a cavity in the surface. At least one light emitting diode (“LED”) is mounted within the cavity, and a monolayer comprising phosphor particles overlies the LED. The phosphor monolayer is adhered to the LED by a monolayer of transparent adhesive material. An optional optical thick layer of transparent material overlies the phosphor monolayer to encapsulate the LED and optionally to form a lens. Methods and apparatus for efficiently making the devices are disclosed.

Owner:LIGHTING SCI GROUP

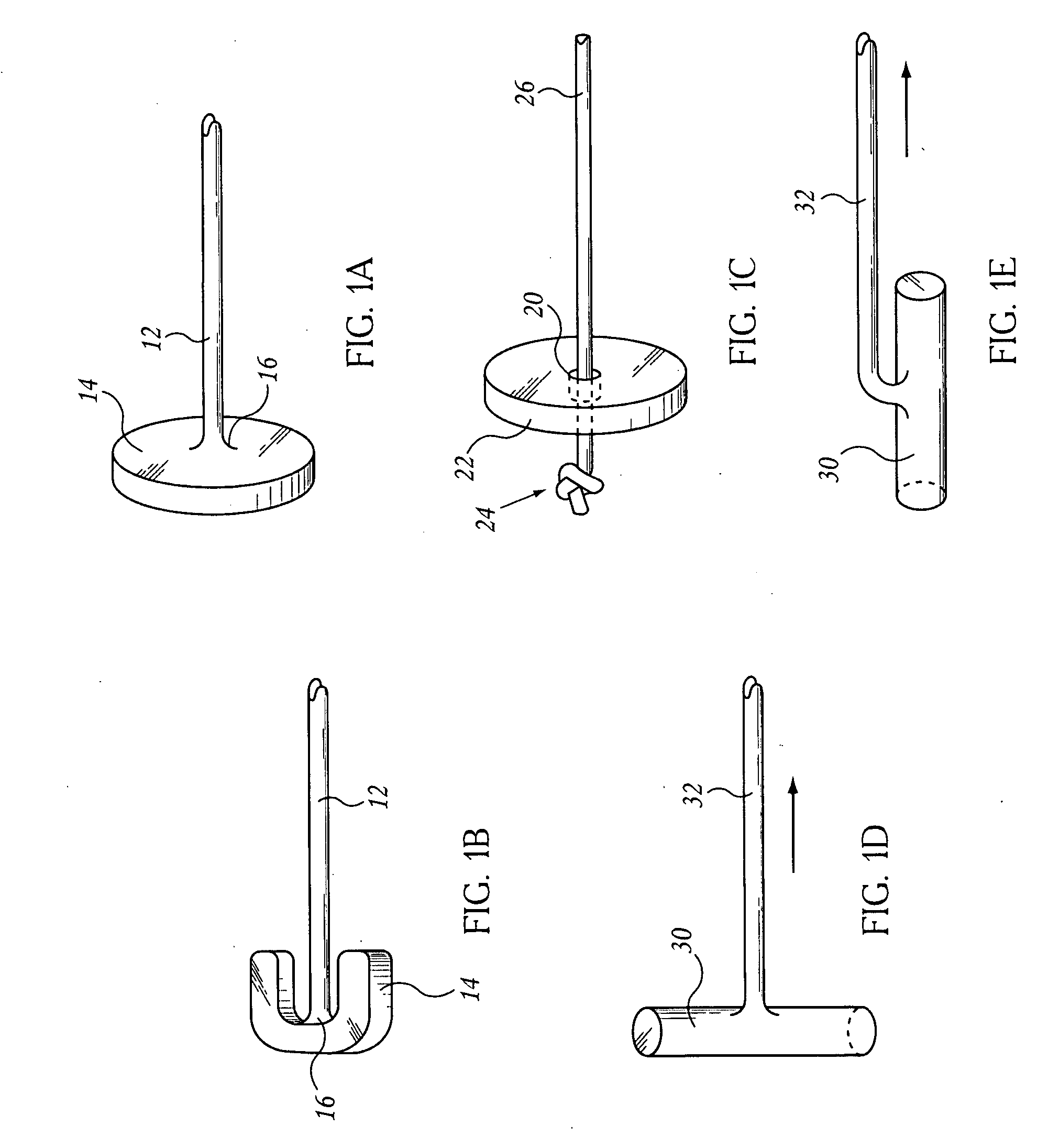

Methods and devices to facilitate connections between body lumens

InactiveUS20060142790A1Increase heightLonger-term implantationSuture equipmentsElectrotherapyAdhesive materialsBody cavity

Methods and devices to urge two gastrointestinal organs toward one another by penetrating through a first wall of a first gastrointestinal organ with an elongate structure comprising at least two expandable elements slideable along the elongate structure, penetrating through a second gastrointestinal organ with the elongate structure, expanding a first expandable element of the elongate structure adjacent a first wall of the first gastrointestinal organ, expanding a second expandable element adjacent a second wall of the second gastrointestinal organ, urging the first and second gastrointestinal organs together, optionally applying an adhesive material to the region between the two gastrointestinal organs.

Owner:GERTNER MICHAEL

Medical device for delivering patches

InactiveUS6893431B2Eliminate leaksMinimally inflammatoryAdditive manufacturing apparatusHeart valvesMedicineAdhesive materials

The present invention relates to a medical device and method for treating the body tissue of a patient. The present invention is also directed to a method of making the medical device and a method of using the medical device. More particularly, the invention relates to a medical device which is inserted into the body for delivery of therapeutic patches to the surface of a body lumen, organ or cavity. Specifically, the medical device has an umbrella-like or a basket-like expandable assembly; and a therapeutic patch. The expandable assembly is capable of changing from a retracted position to an expanded position. The expandable assembly can be self-expanding or non-self-expanding. In one embodiment, the medical device comprises an elongated member; an umbrella-like expandable assembly which has a plurality of wire elements; and a therapeutic patch. The therapeutic patch comprises a sheet having two opposing surfaces wherein one of the surface comprises an adhesive material and at least one biologically active material.

Owner:BOSTON SCI SCIMED INC

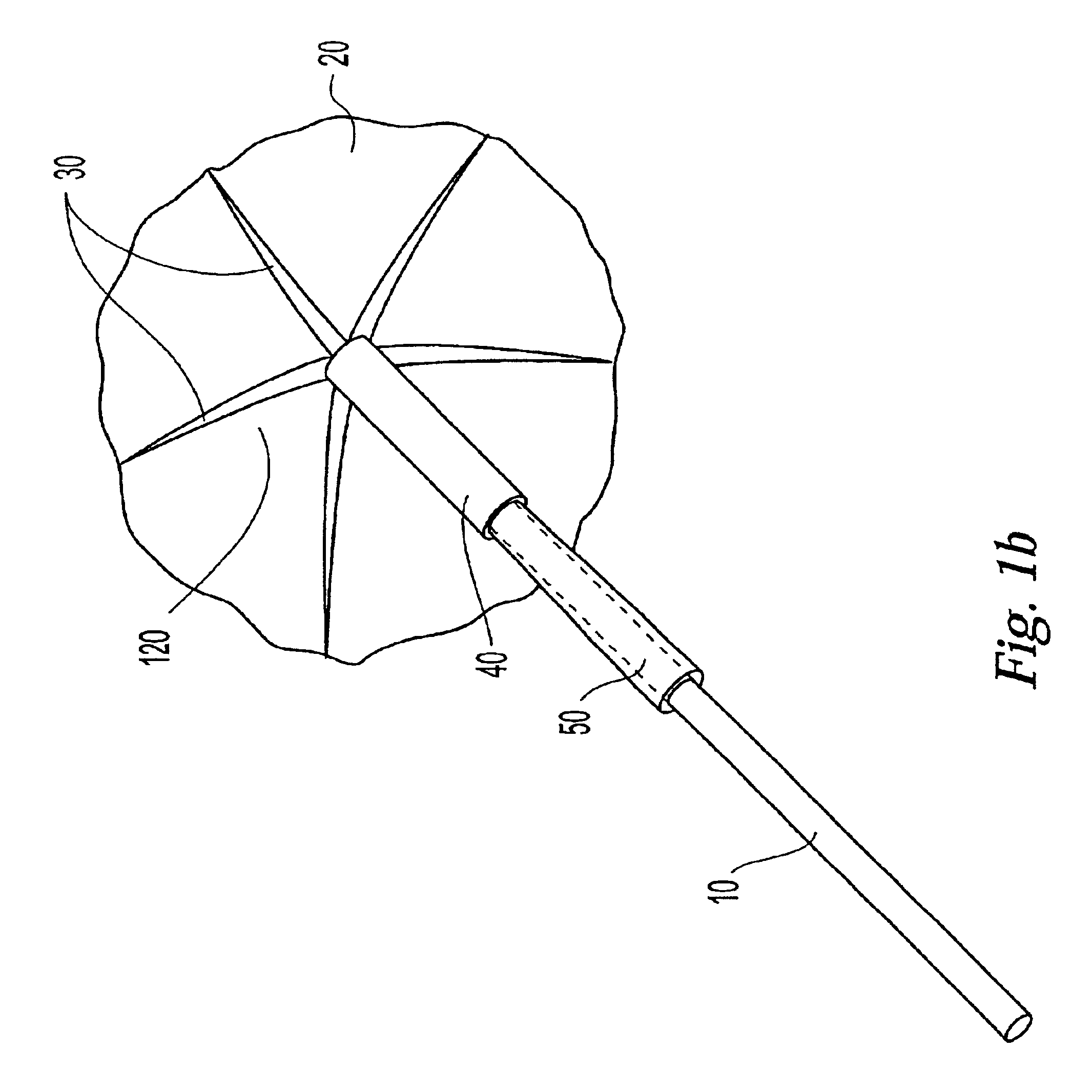

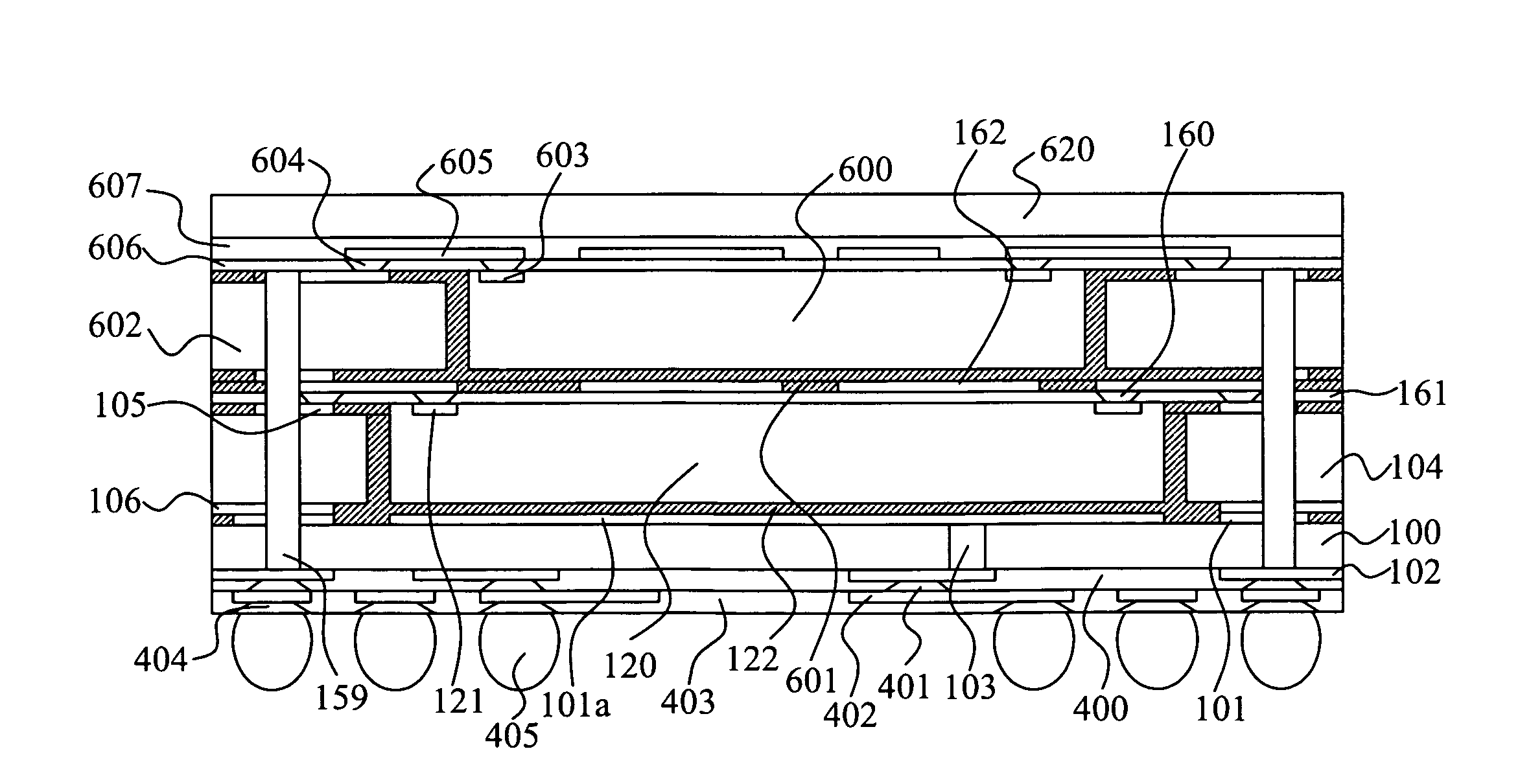

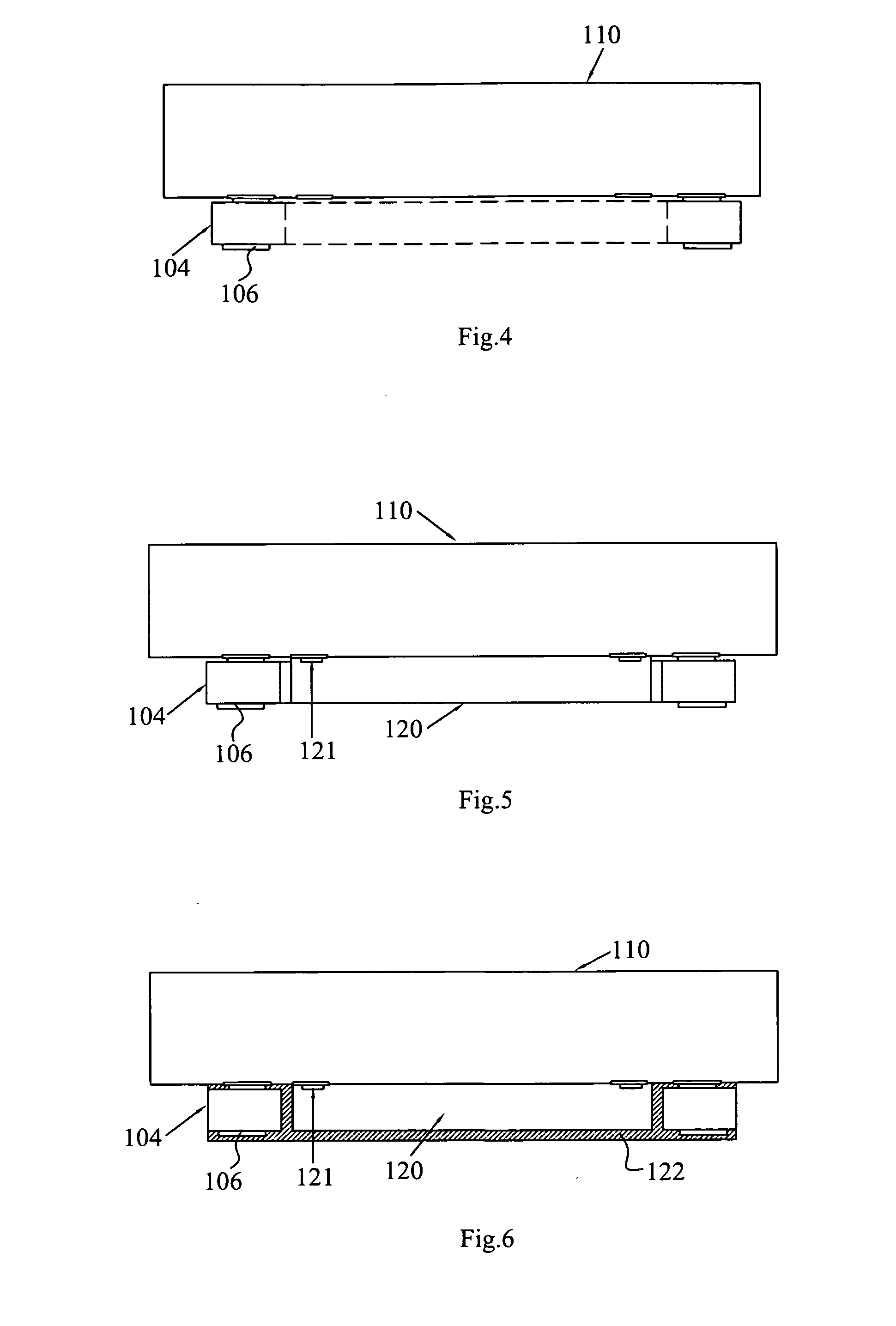

Substrate structure with die embedded inside and dual build-up layers over both side surfaces and method of the same

ActiveUS20100072588A1Overcome problemsExcellent CTE matching performanceSemiconductor/solid-state device detailsSolid-state devicesEngineeringAdhesive materials

The present invention discloses a structure of device package comprising a first substrate with a die metal pad, a first wiring circuit on top surface of said first substrate and a second wiring circuit on bottom surface of said first substrate. A die is disposed on the die metal pad. A second substrate has a die opening window for receiving the die, a third wiring circuit on top surface of the second substrate and a fourth wiring circuit on bottom surface of the second substrate. An adhesive material is filled into the gap between back side of the die and top surface of the first substrate and between the side wall of the die and the side wall of the die receiving through hole and the bottom side of the second substrate.

Owner:YANG CHING LUNG

Detachable balloon embolization device and method

An endovascular aneurysm occlusion device comprising a detachable balloon assembly. The balloon assembly is comprised of an outer balloon and an inner balloon. The outer balloon is formed from a porous material. The occlusion device is expanded within an aneurysm and adhesive material is injected into and perfused through the outer balloon. The adhesive material forms a bond between the aneurysm, the outer balloon, and the inner balloon. The inner balloon is then deflated, which acts to reduce the size of the aneurysm.

Owner:CODMAN & SHURTLEFF INC

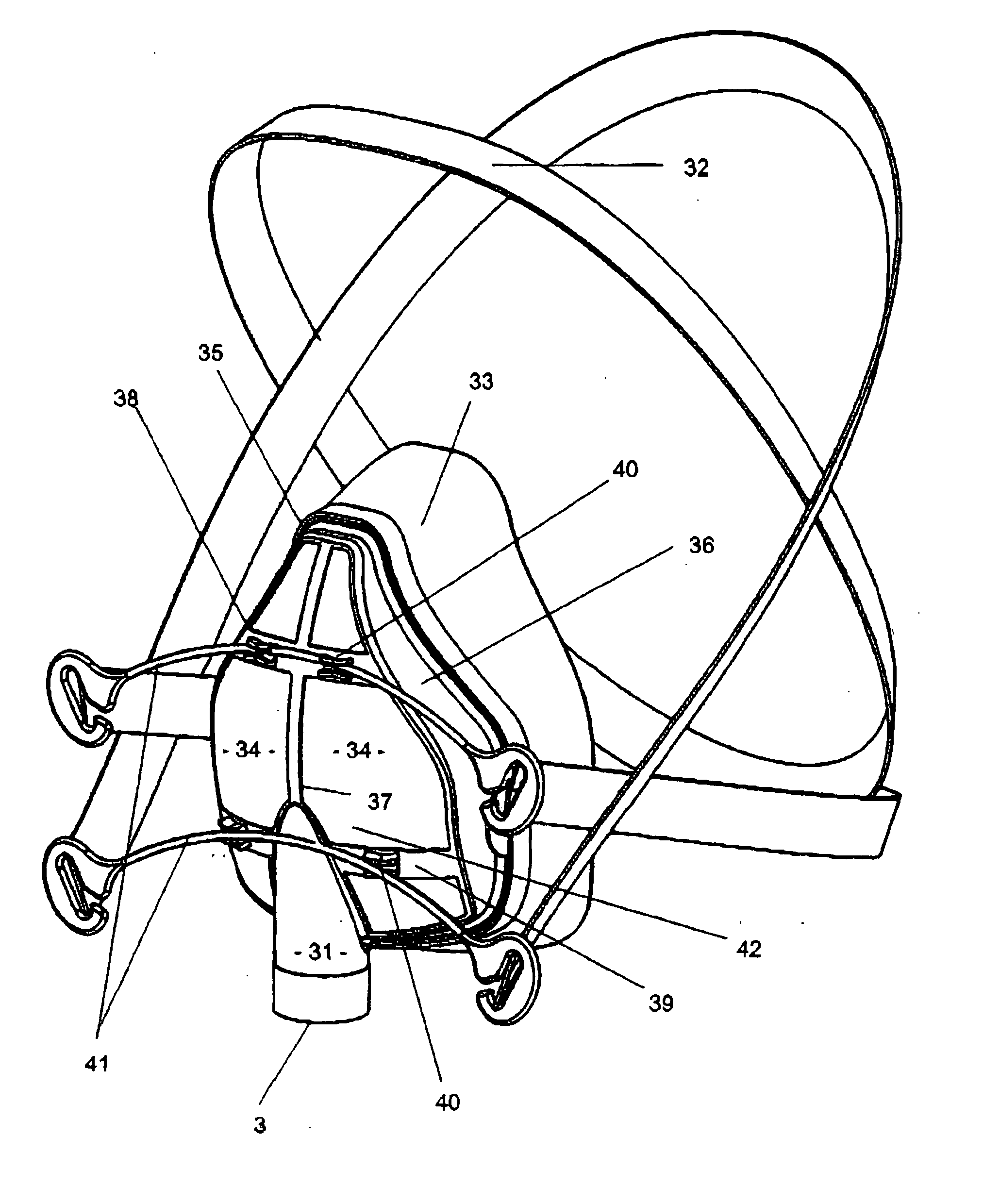

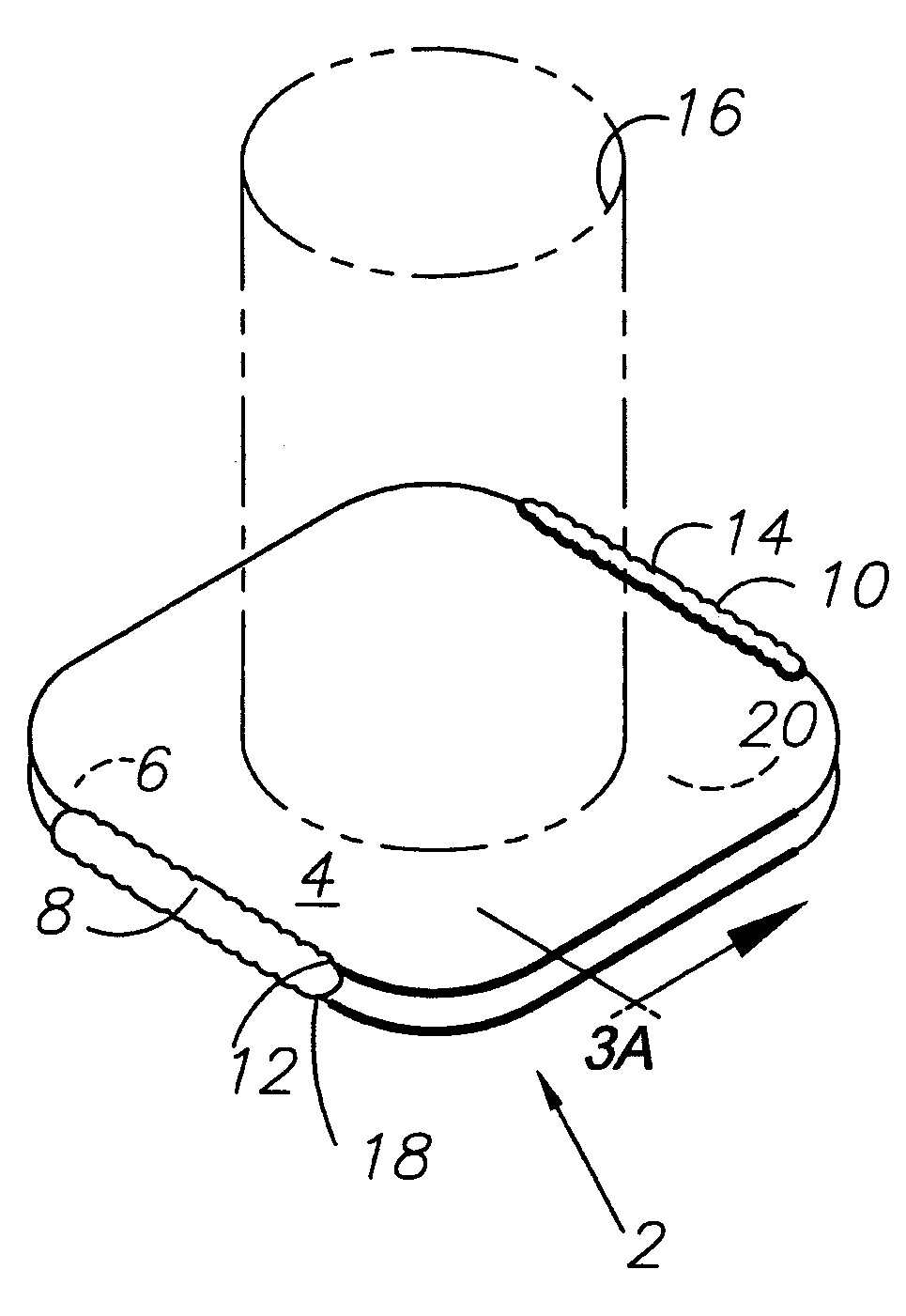

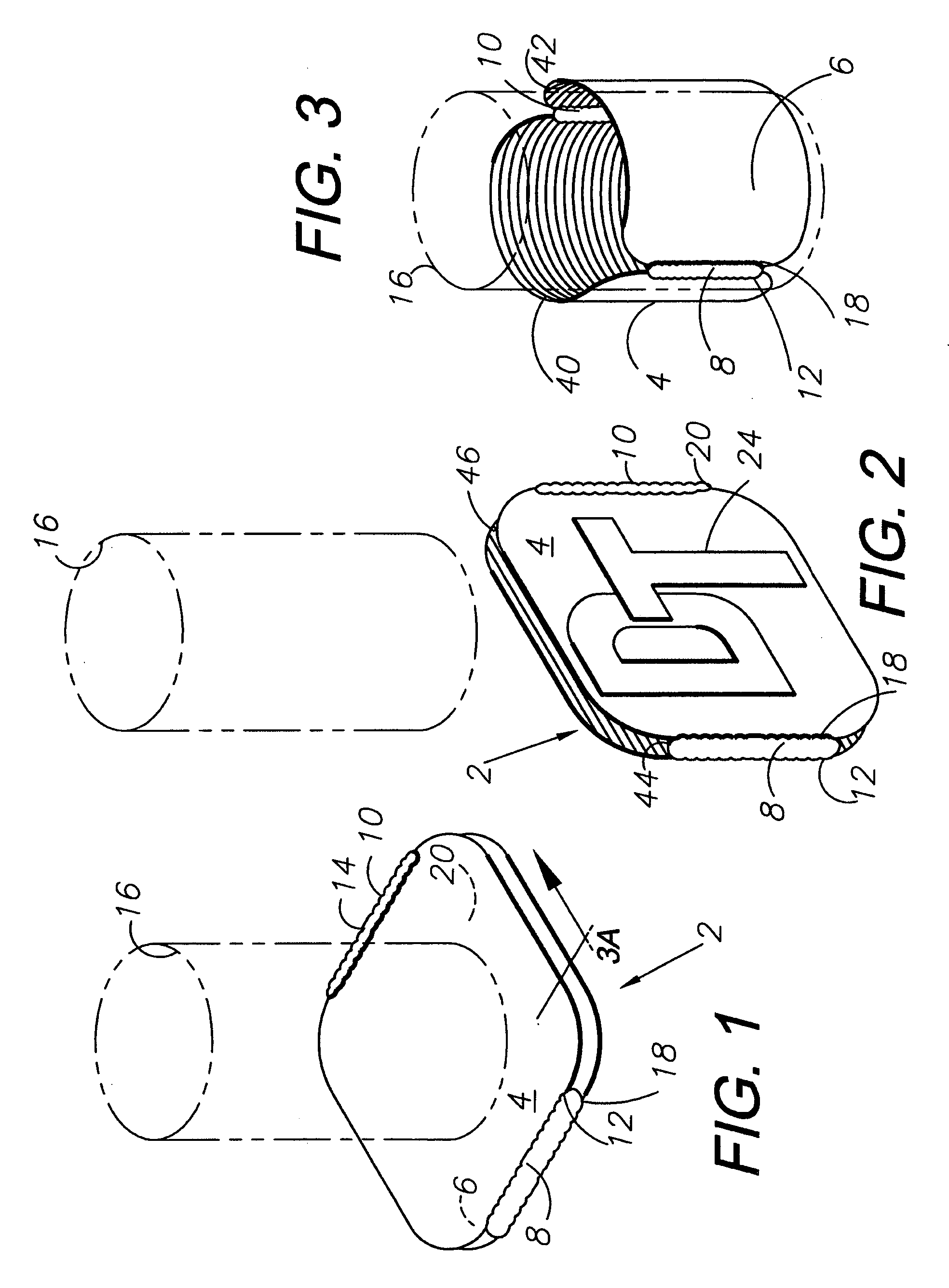

Breathable respiratory mask

A patient interface is disclosed which is comfortable for the user to wear and includes at least in part a moisture permeable or breathable area in the body of the patient interface. In another embodiment the patient interface is a strapless mask that is moulded to fit the contours of a user's face and maximise the mask-to-skin seal. An adhesive material is bonded to the mask cushion and is stamped in place to form substantially the same shape as the cushion such that it fits the facial contours of the user.

Owner:FISHER & PAYKEL HEALTHCARE LTD

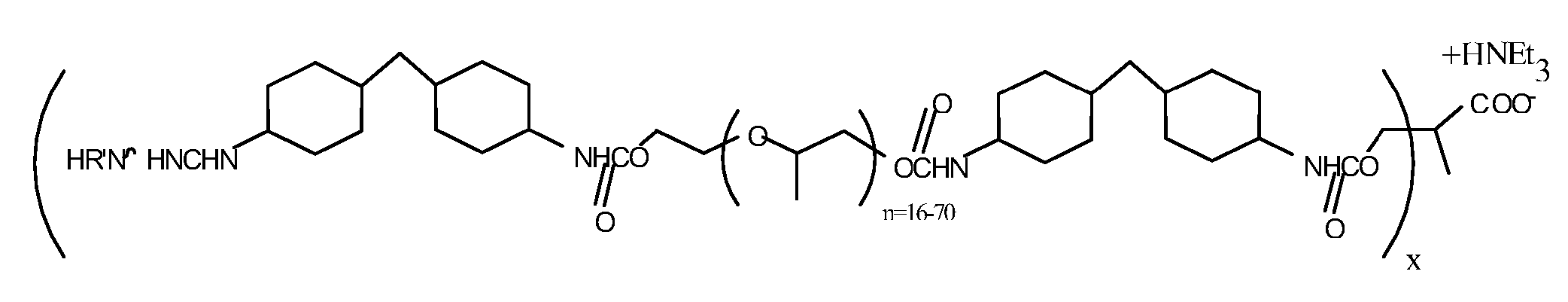

Electro-optic assemblies, and adhesives and binders for use therein

InactiveUS20090122389A1Lower volume resistivityLayered productsPolyureas/polyurethane adhesivesOrganic matterAdhesive materials

An electro-optic assembly comprises an adhesive layer and a layer of electro-optic material. The adhesive layer comprises a polymeric adhesive material and an ionic material having either its cation or its anion fixed to the polymeric adhesive material. The ionic material reduces the volume resistivity of the polymeric adhesive material and is not removed upon heating to 50° C. In a similar electro-optic assembly comprising an adhesive layer and a layer of electro-optic material, the adhesive layer comprises a polymeric adhesive material which has been subjected to dialysis or diafiltration to remove organic species having a molecular weight less than about 3,500, so that the adhesive material has a content of N-methylpyrrolidone not exceeding 500 ppm based upon the total weight of the adhesive layer and layer of electro-optic material.

Owner:E INK CORPORATION

Pleural effusion treatment device, method and material

The invention discloses a method of treating a patient for pleural effusion comprising percutaneously delivering an adhesive material to a pleural space of the patient. Suitable adhesive materials for performing any of the embodiments of the methods of the invention can be selected from the group consisting of hydrogels, collagen, poly(lactic acid), poly(glycolide), cyanoacrylates, glutaraldehyde, PEG, protein, and polysaccharide and derivatives thereof. The invention also discloses a pleural effusion treatment apparatus comprising an adhesive material adapted to adhere pleural membranes defining a pleural space and a pleural space access member adapted to deliver the adhesive material to the pleural space.

Owner:EKOS CORP

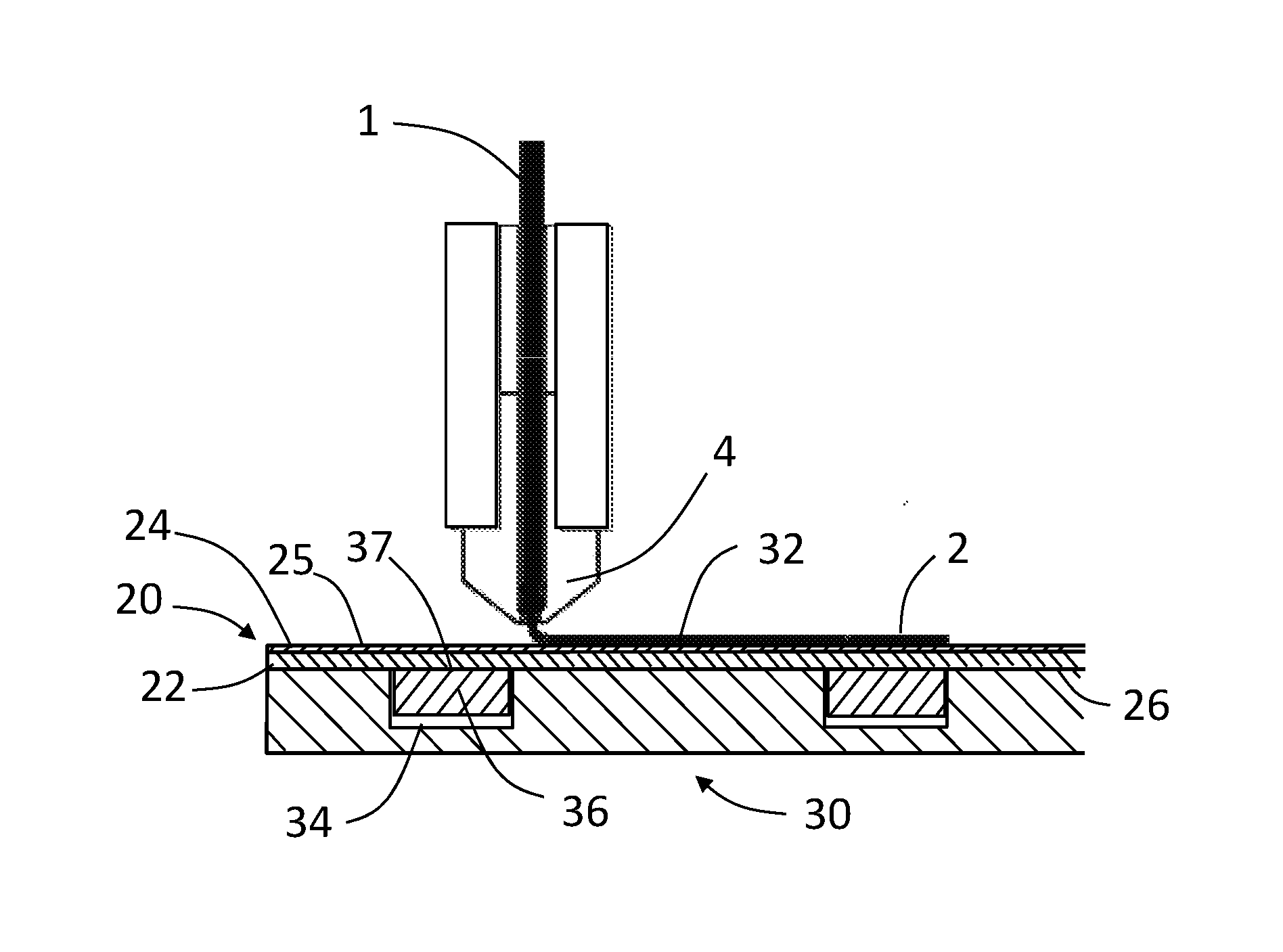

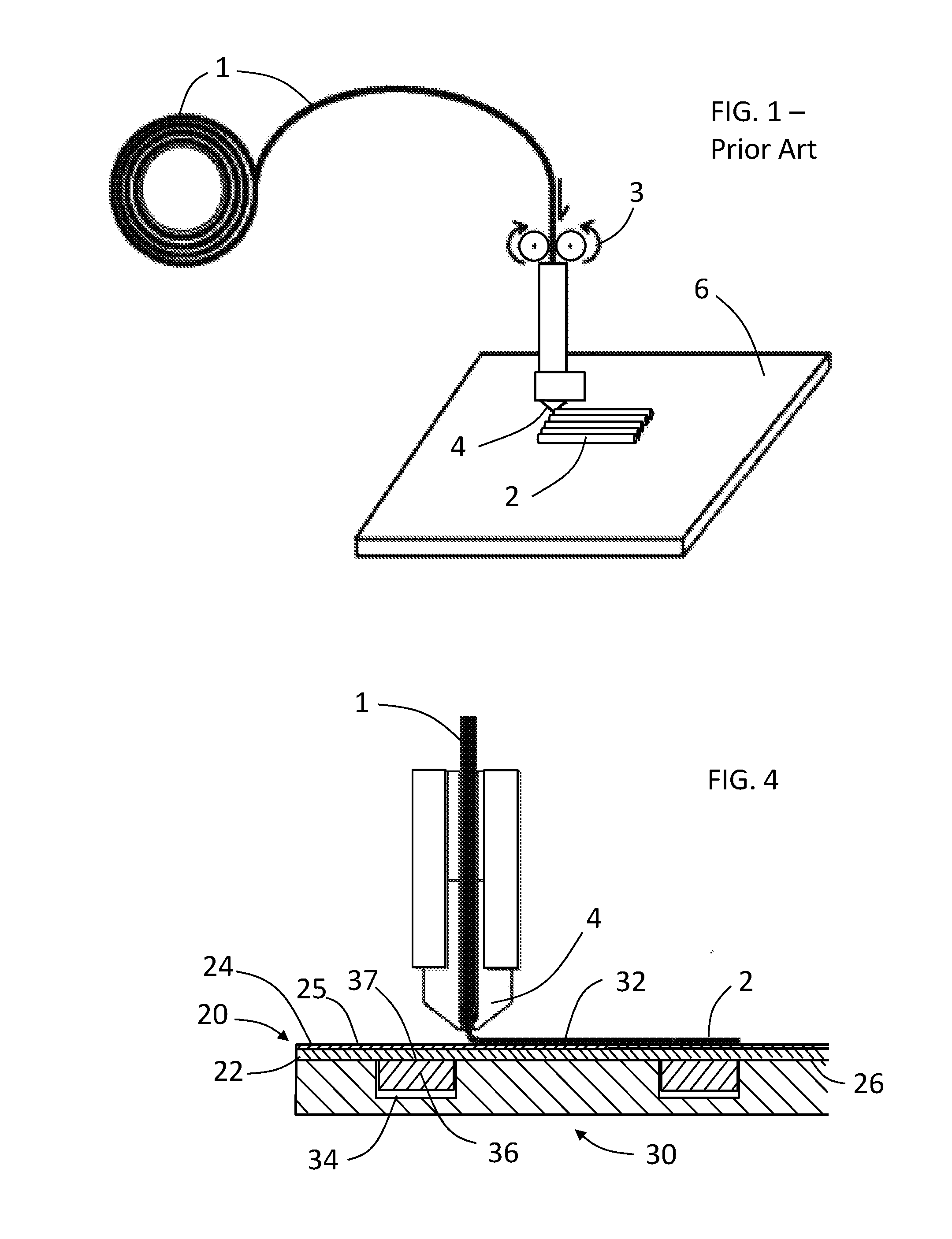

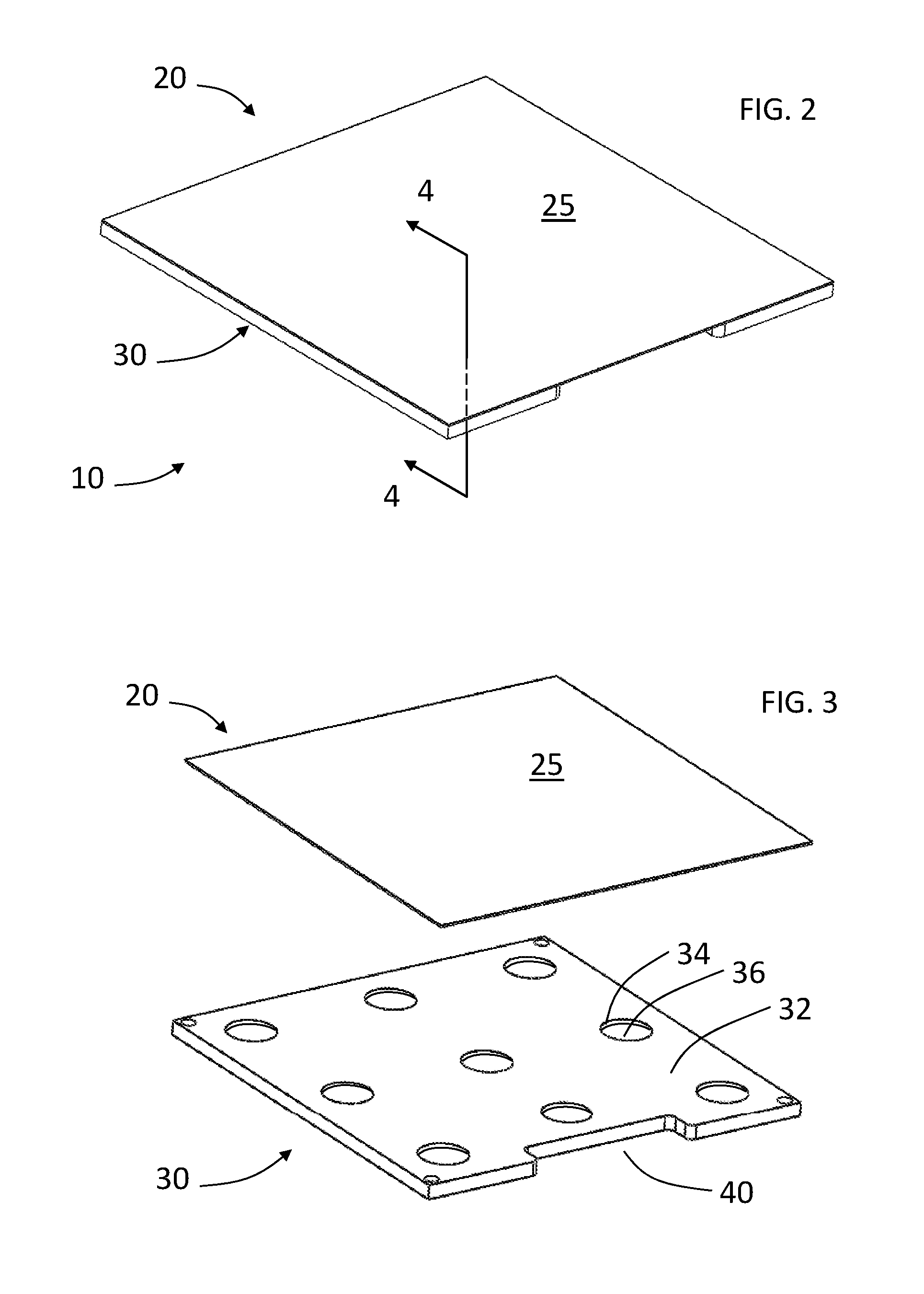

3D Print Bed Having Permanent Coating

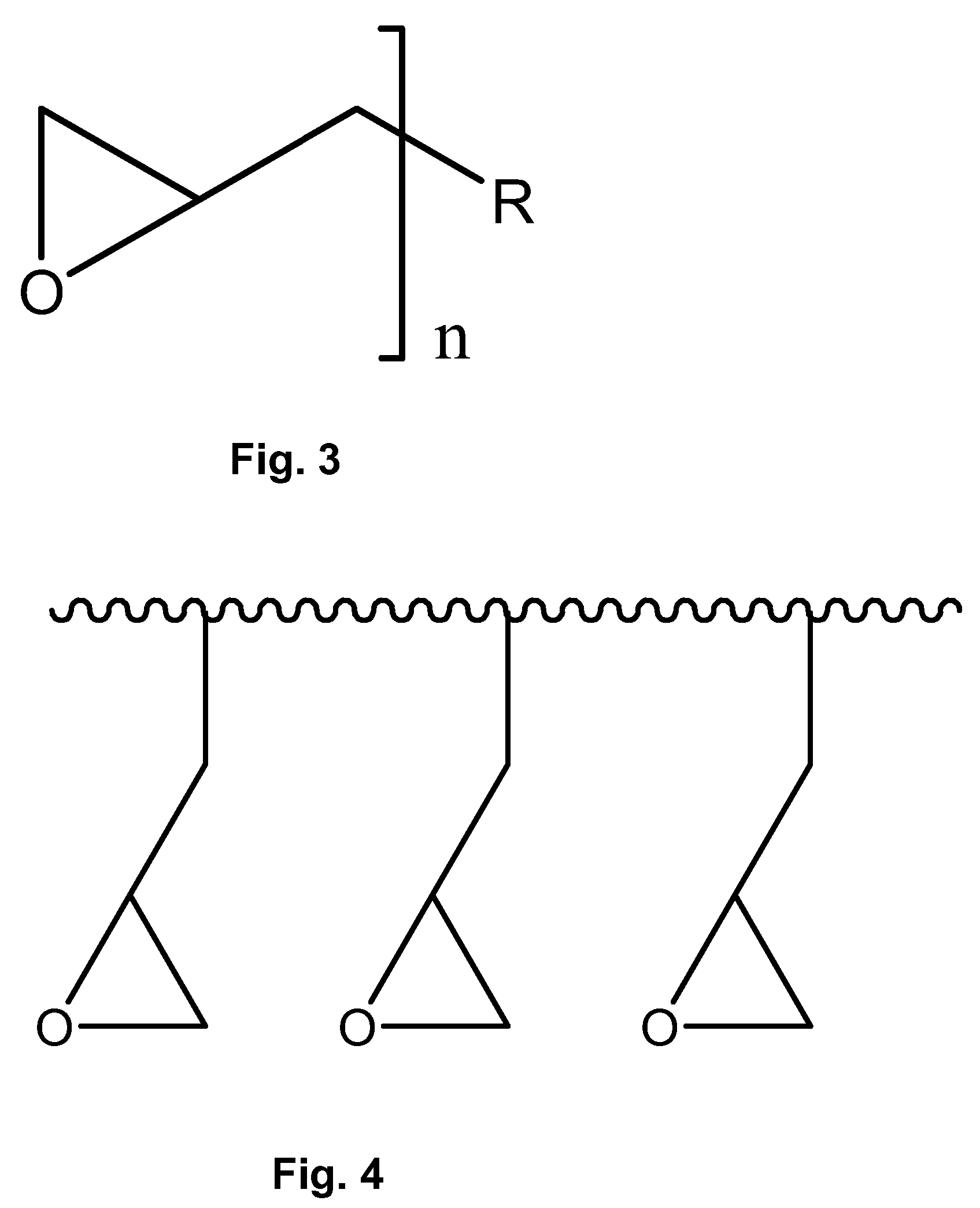

PendingUS20170036403A1Improve adhesionSufficient level of adhesionManufacturing platforms/substratesPretreated surfacesEpoxyWater based

A coated print bed for a 3D printer having a permanent print-surface coating permanently secured to a print bed substrate plate, having a smooth, planar surface that provides an adhesive interface layer between a first layer of an applied plastic print material and the coated print bed. The coating contains a matrix-forming compound, such as a solvent- or water-based epoxy resin, an adhesive material, and optionally a filler. The user can print a series of print object directly onto the permanent print surface coating of the coated print bed, without having to refresh or refurbish the print surface, such as by applying to the print bed surface a temporary coating such as painter's tape, or a liquid adhesive.

Owner:EZ PRINT

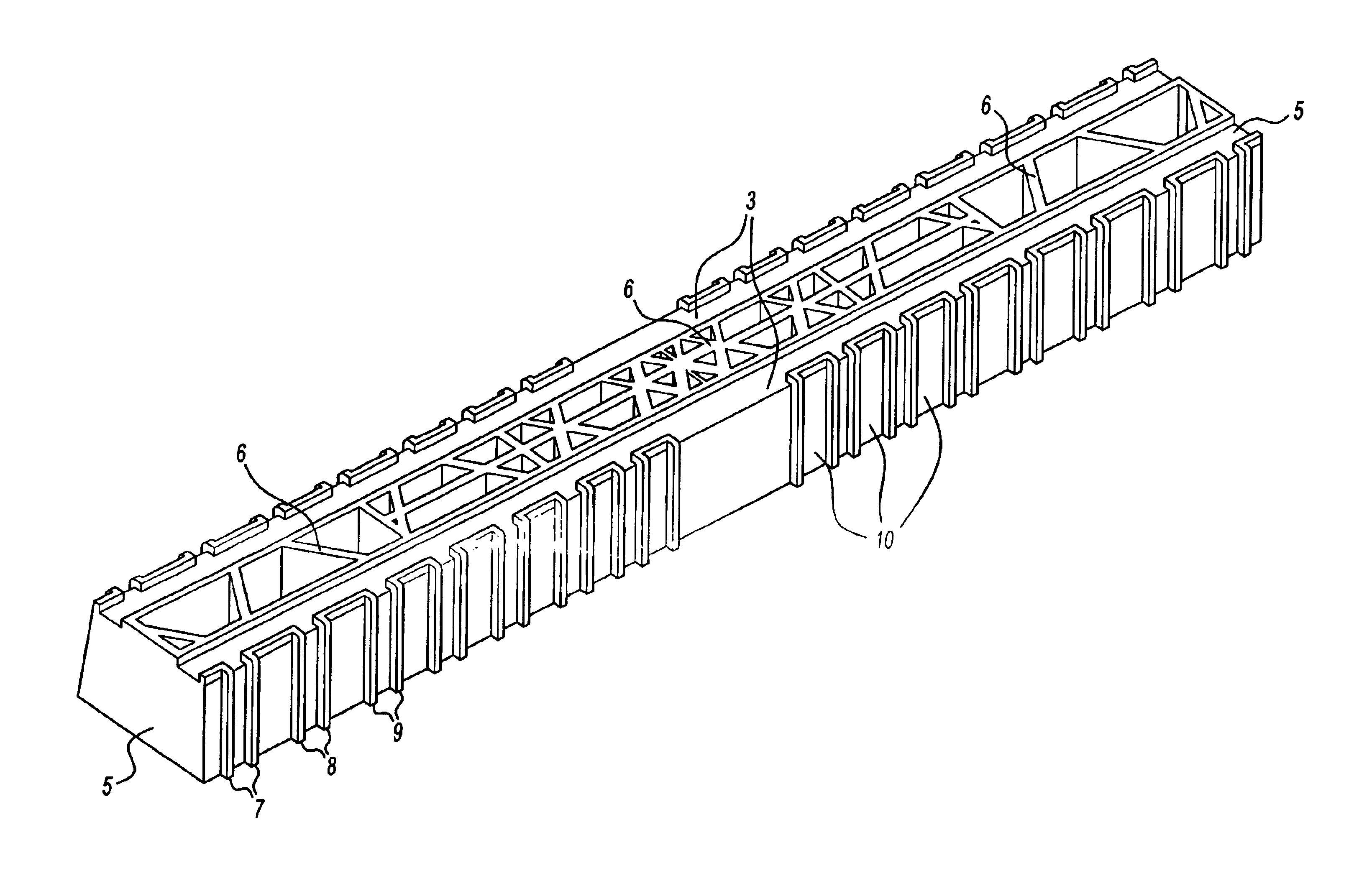

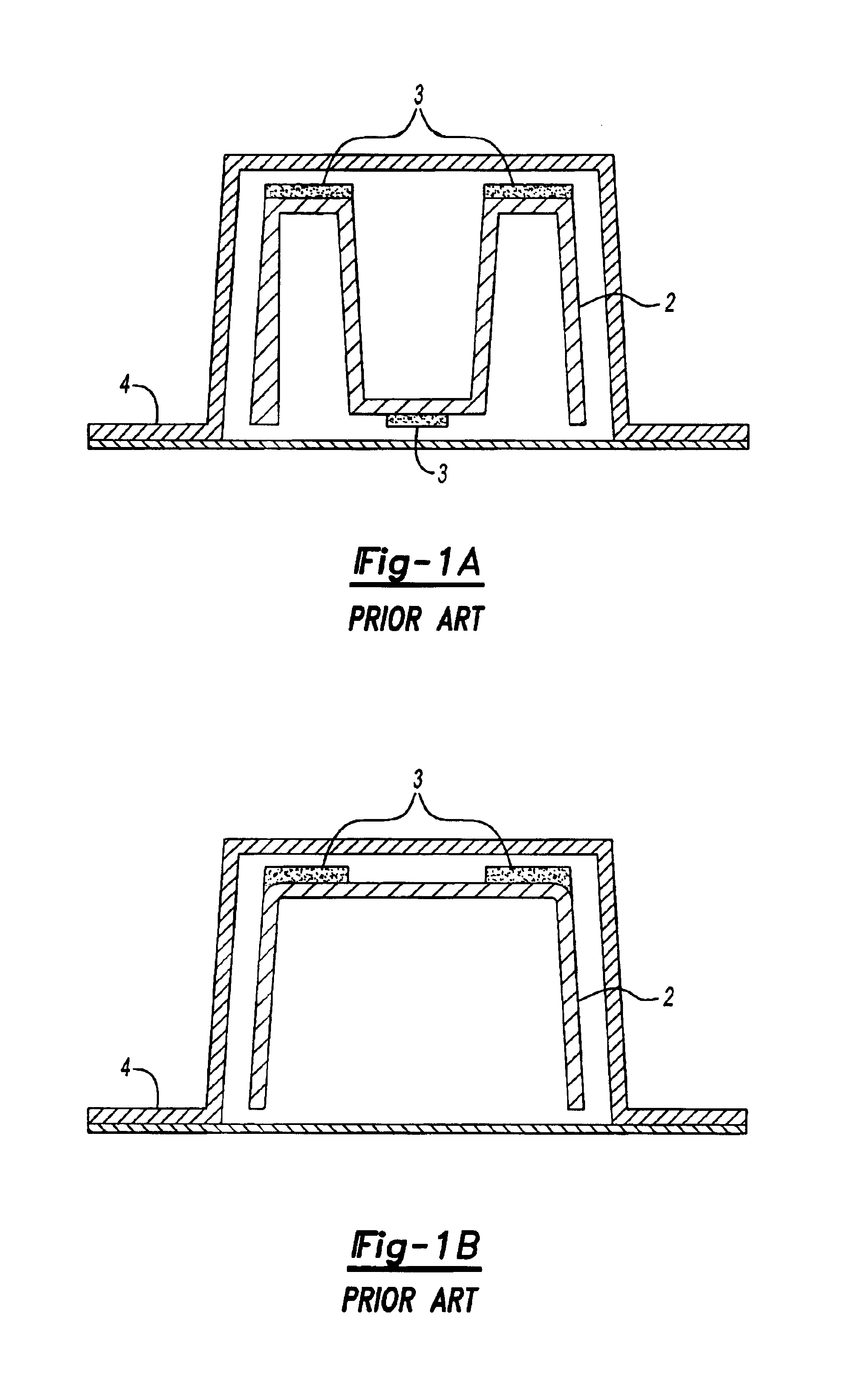

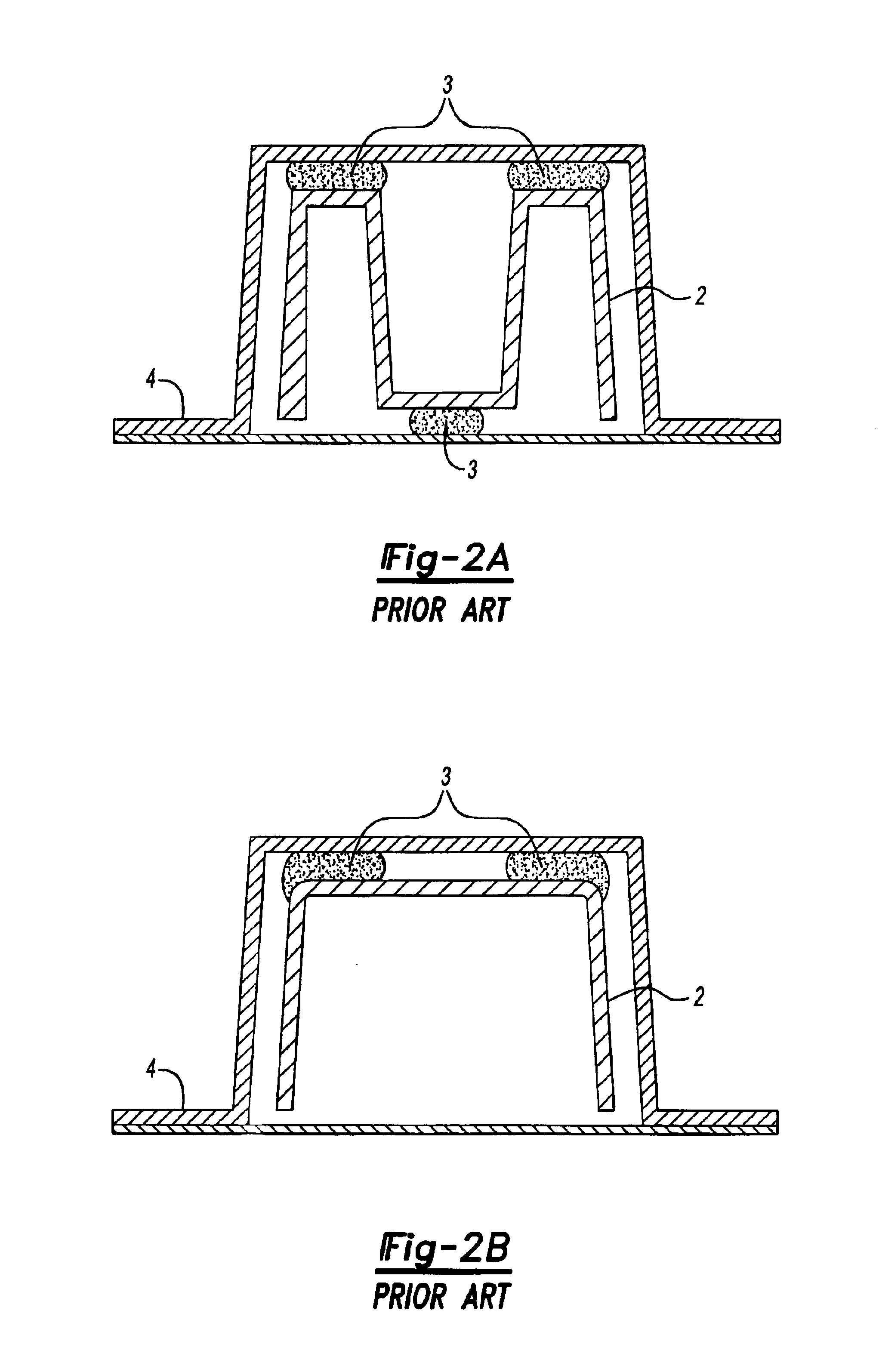

Structural reinforcement

InactiveUS6941719B2Reduced strengthSatisfies requirementVehicle seatsStructural elementsAdhesive materialsBiomedical engineering

A structural reinforcement for a hollow member comprising a rigid reinforcing member having a shape that substantially conforms to the cross section of the hollow member to be reinforced with an expandable adhesive material over at least a portion of the surface of the structural reinforcement having one or more extensions on its external surface which control and direct the direction in which the adhesive material expands to bond the reinforcing member to the internal surface of the hollow member, some of the extensions also provide improved reinforcement.

Owner:ZEPHYROS INC

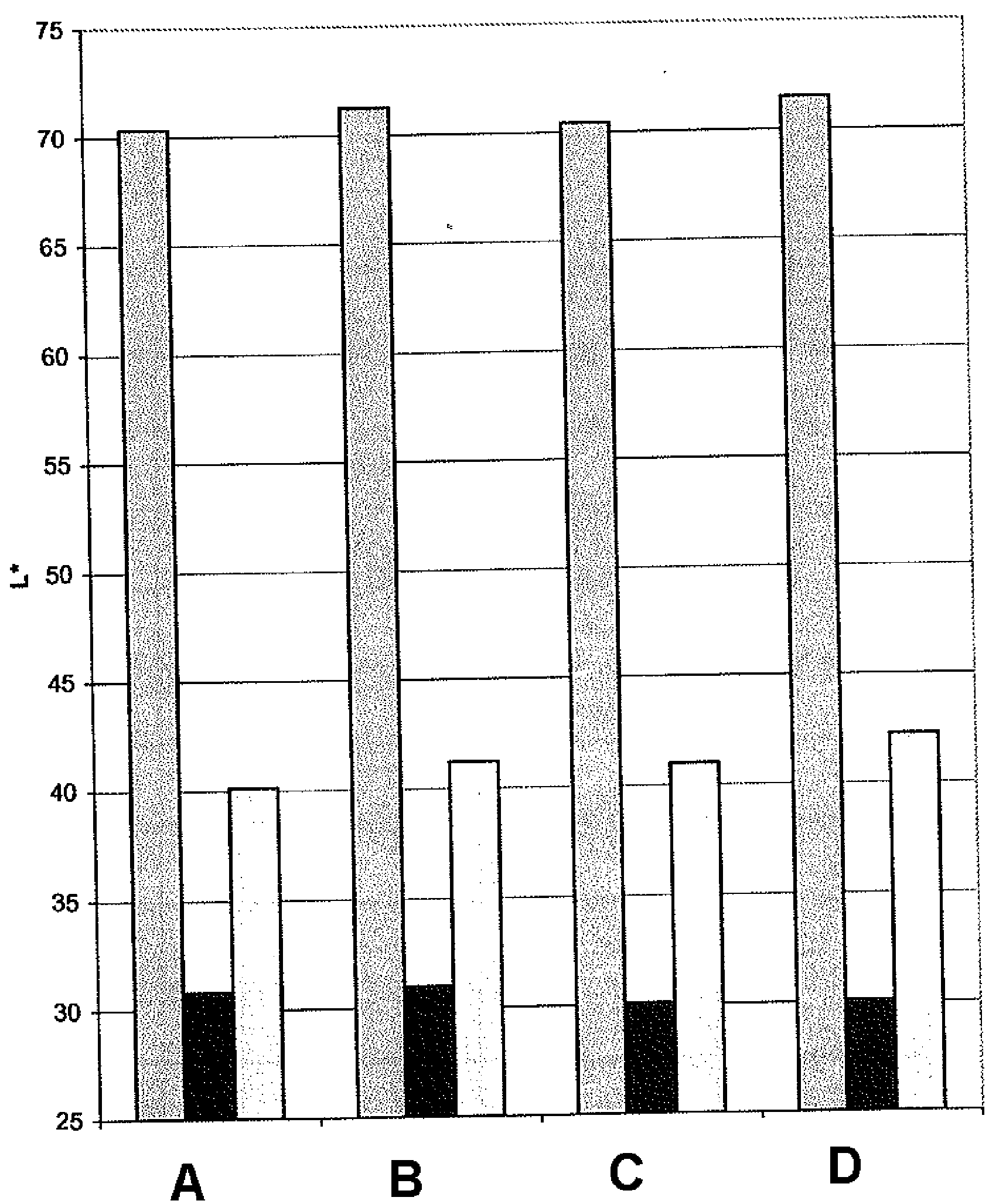

Illumination devices comprising white light emitting diodes and diode arrays and method and apparatus for making them

ActiveUS7157745B2Solid-state devicesSemiconductor/solid-state device manufacturingPhosphorAdhesive materials

In accordance with the invention, an illumination device comprises a substrate having a surface and a cavity in the surface. At least one light emitting diode (“LED”) is mounted within the cavity, and a monolayer comprising phosphor particles overlies the LED. The phosphor monolayer is adhered to the LED by a monolayer of transparent adhesive material. An optional optical thick layer of transparent material overlies the phosphor monolayer to encapsulate the LED and optionally to form a lens. Methods and apparatus for efficiently making the devices are disclosed.

Owner:LIGHTING SCI GROUP

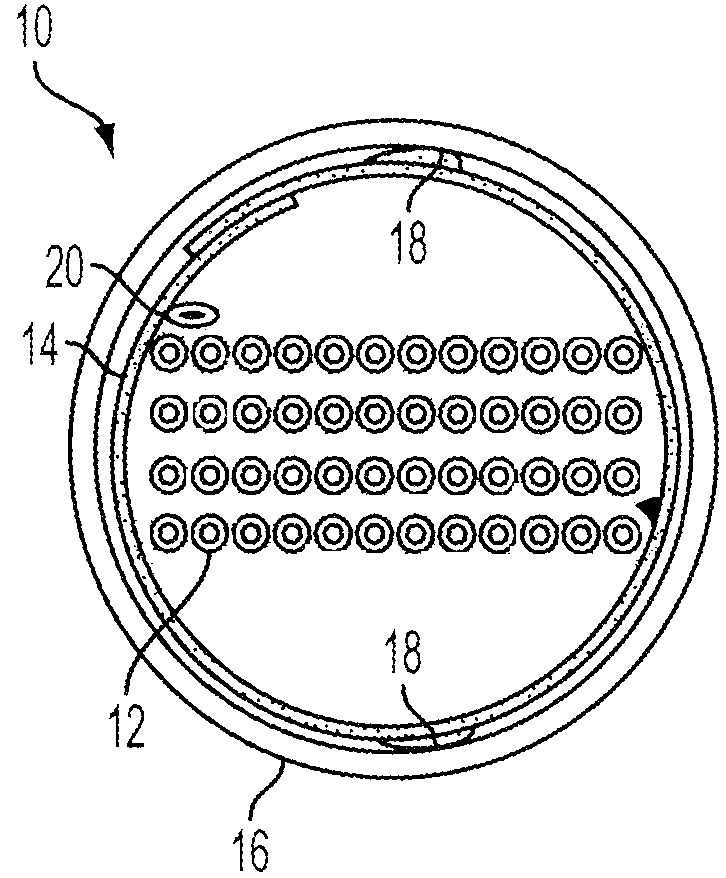

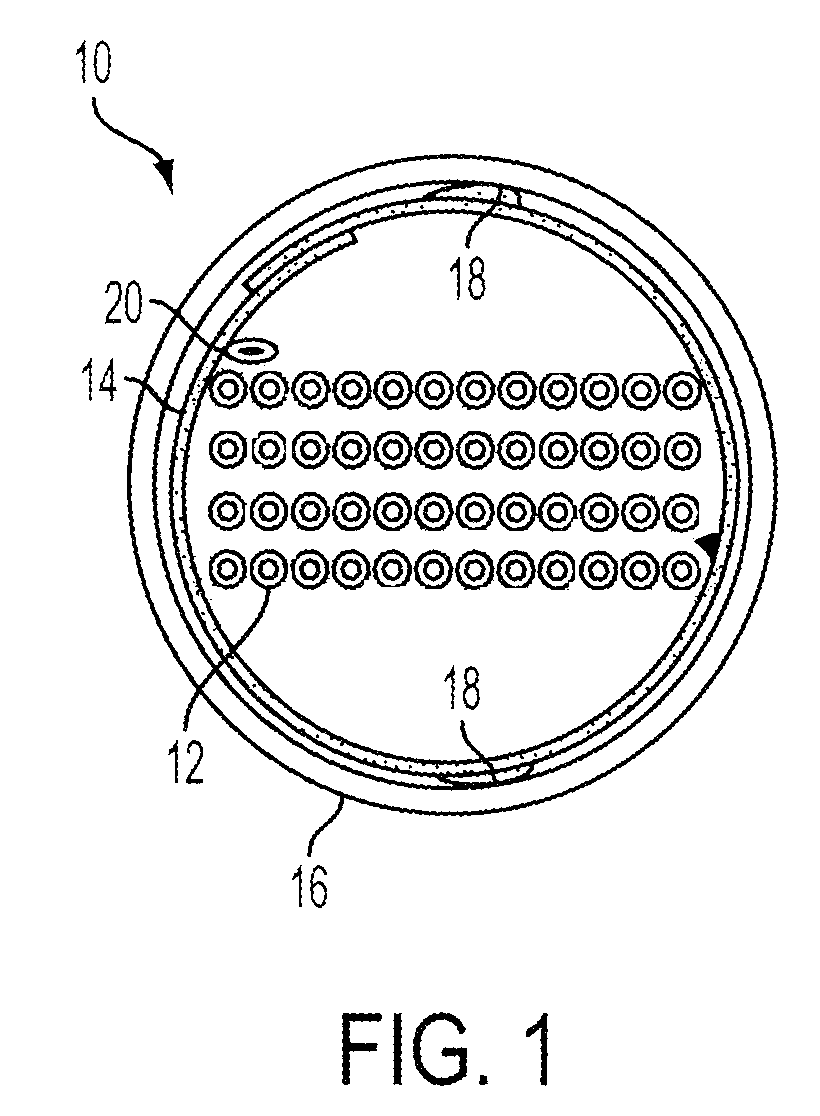

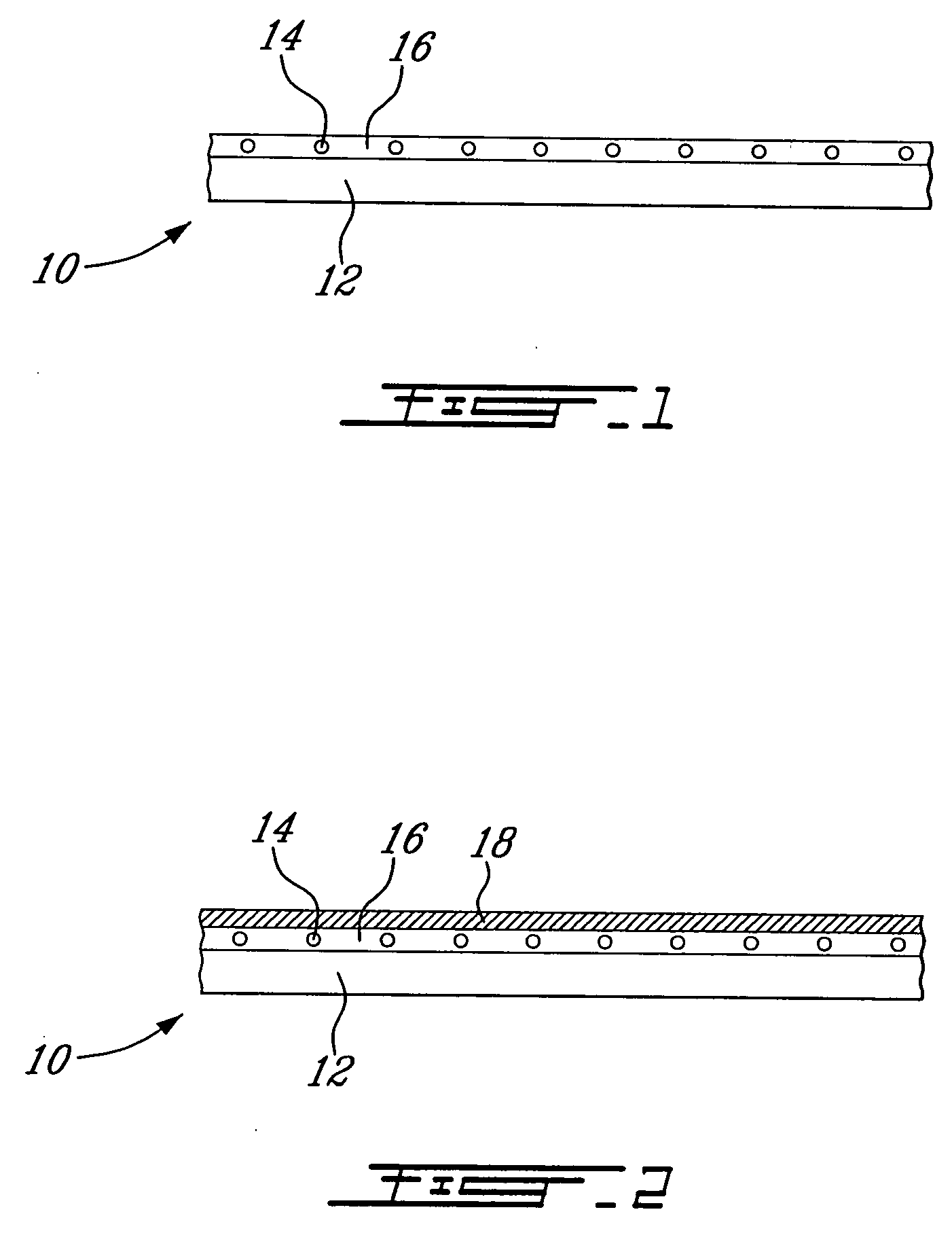

Fiber optic cable having a water-swellable element

ActiveUS7567739B2Reduces microbending and other optical attenuation of opticalImprove surface smoothnessFibre mechanical structuresFiberCoupling

Disclosed is a fiber optic cable that includes optical fibers and a water-swellable element, such as a powder-free fabric tape, that are enclosed within a buffer tube. Adhesive material, such as discrete domains of adhesive foam, may be optionally employed to provide adhesive coupling of the optical fibers and the water-swellable element.

Owner:DRAKA COMTEQ BV

Antimicrobial material

InactiveUS20060141015A1Lower surface energyImproved surface distributionBiocideSynthetic resin layered productsPolymer scienceAdhesive materials

The present invention relates to an antimicrobial material comprising sheet of fabric and- metallic salt crystals embedded in an adhesive material covering the sheet of fabric.

Owner:GROUPE CTT

Gel-free buffer tube with adhesively coupled optical element

Owner:DRAKA COMTEQ BV

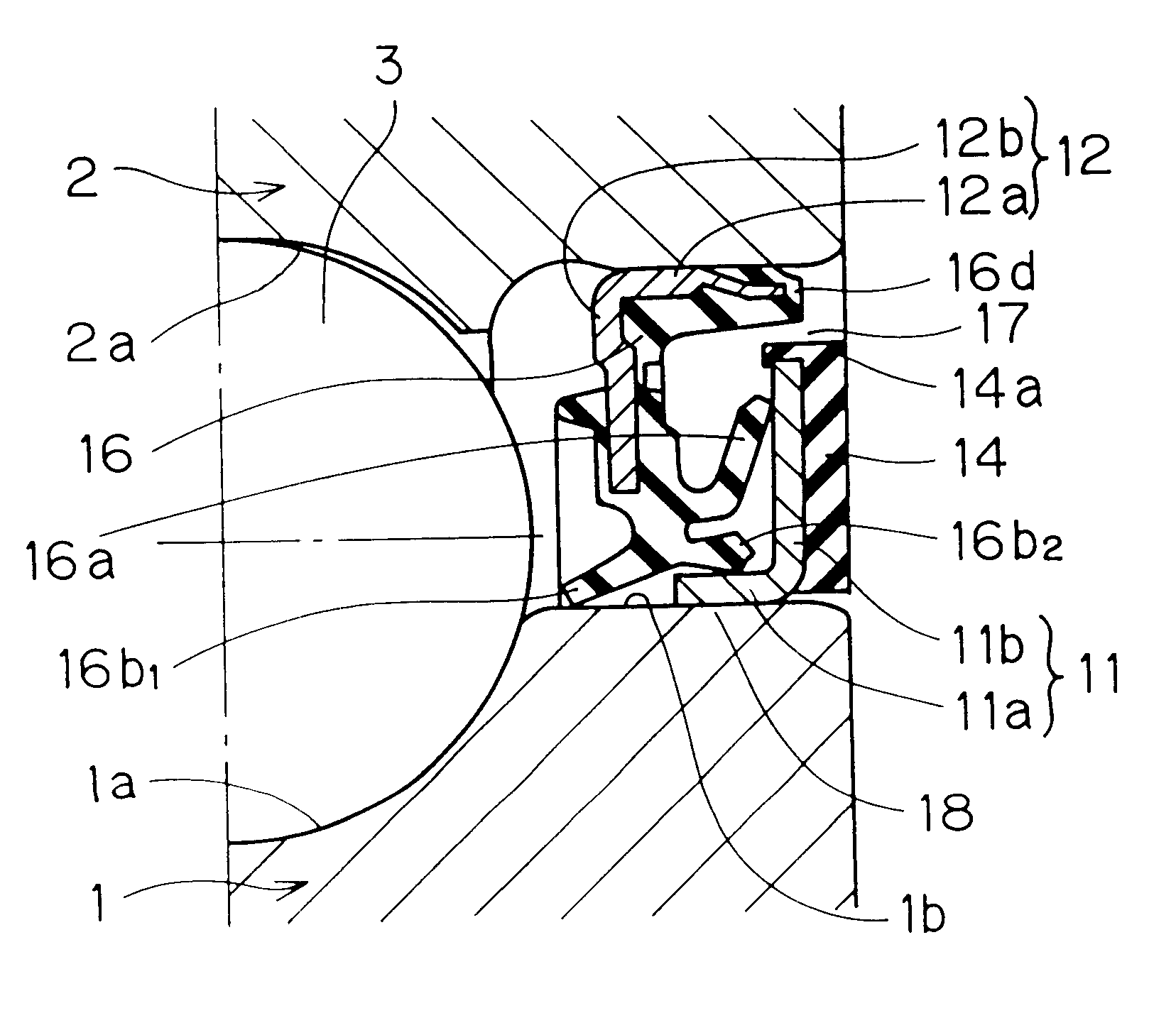

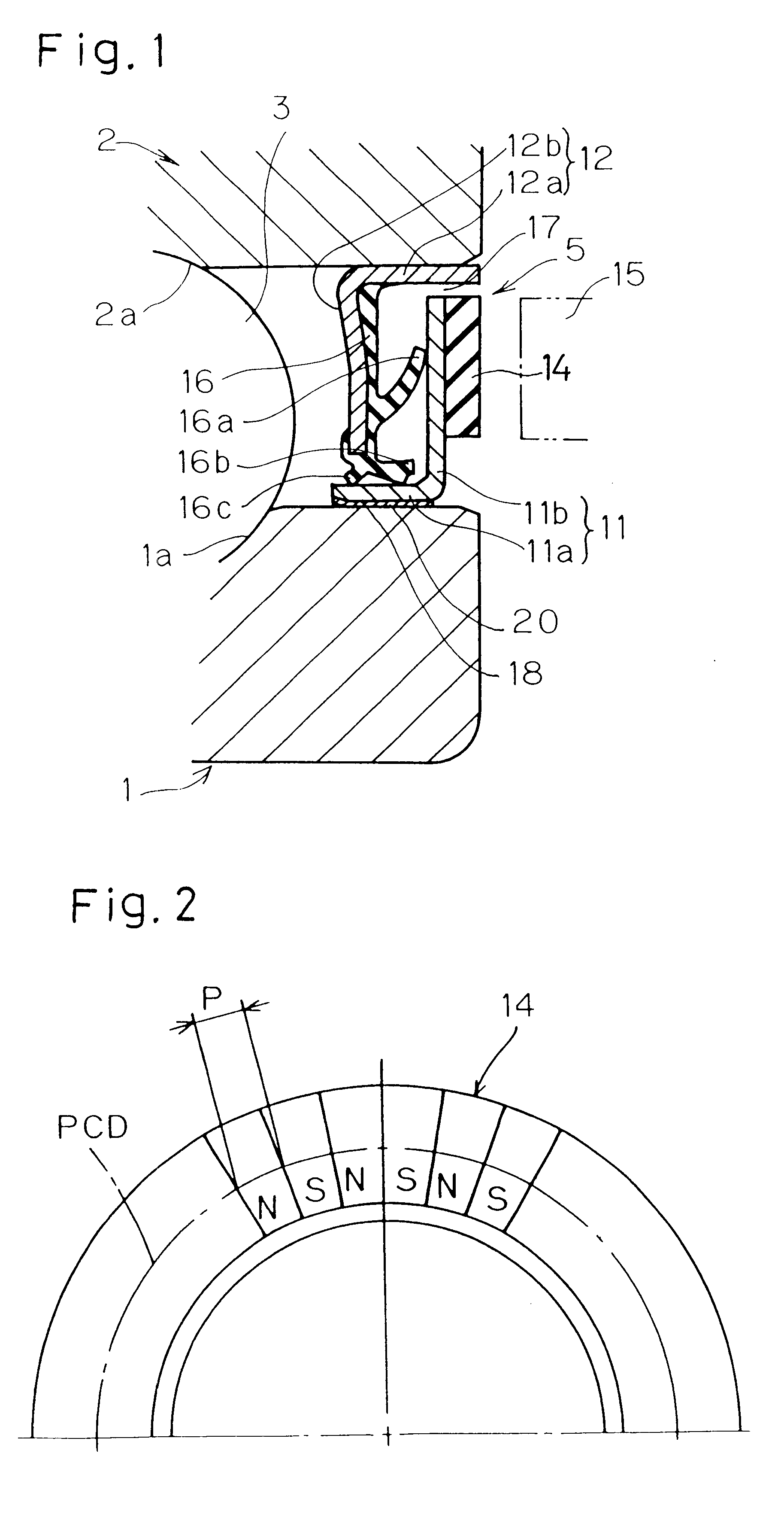

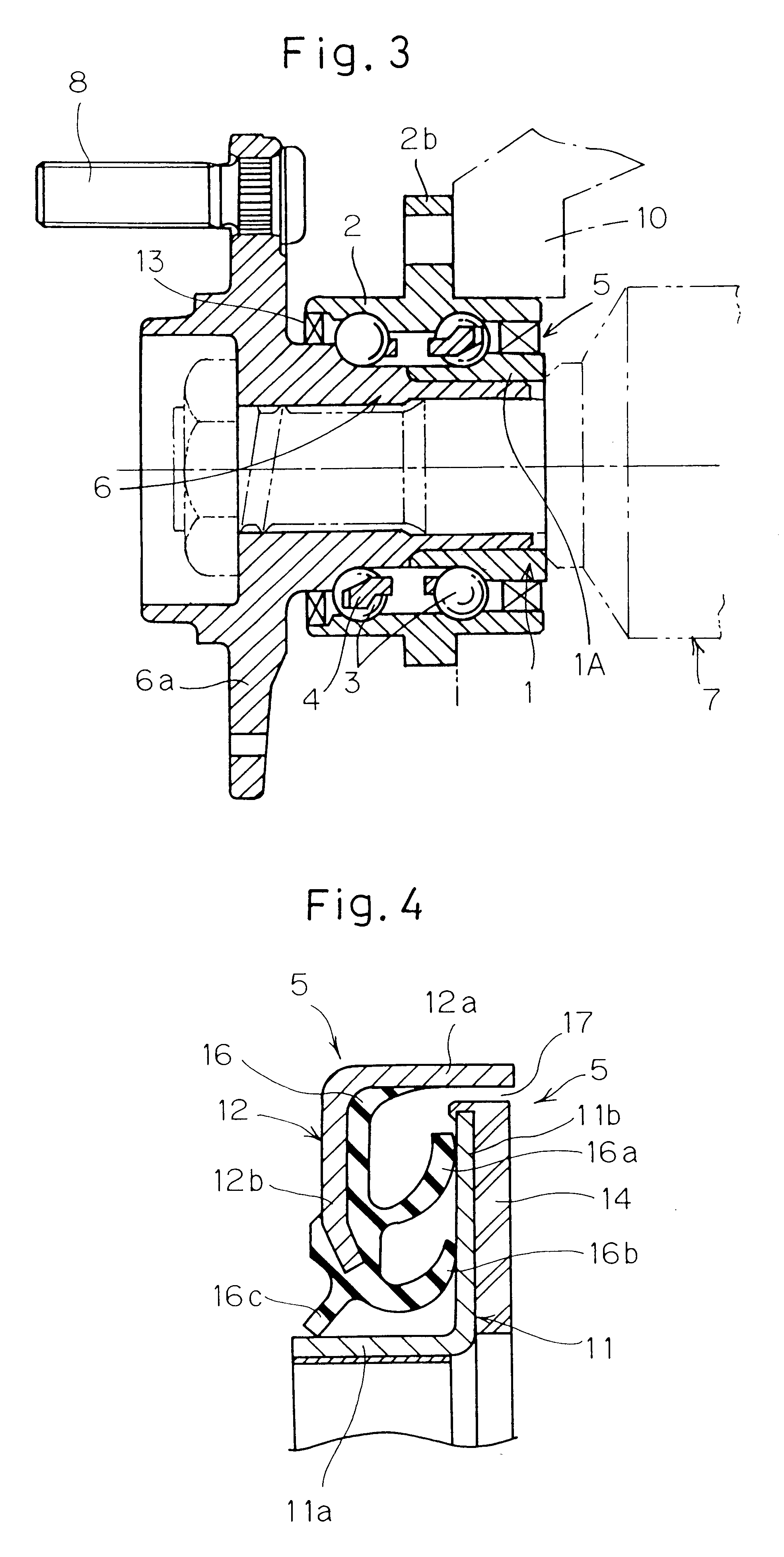

Wheel bearing and sealing device therefor

A wheel bearing includes a sealing device 5 positioned between inner and outer members 1 and 2. This sealing device 5 includes an elastic member 14, which eventually forms an encoder grid and is provided on a first annular sealing plate 11. A second annular sealing plate 12 is provided with sealing lips 16a to 16c. An engagement 18 between a cylindrical wall 11a of the first annular sealing plate 11 and the inner member 1 is provided with an elastic member 20 made of a material dissimilar to that for the elastic material 14. This elastic member 20 may be a rubber coated layer, resin paint layer, a thin film of adhesive material or a ring-shaped rubber member. Thereby, any possible ingress of water across an engagement surface of the annular sealing plate is prevented, accompanied by increase of the lifetime of the bearing, with no problem associated with separation and displacement of the annular sealing plates. The magnetic flux density can also be easily secured.

Owner:NTN CORP

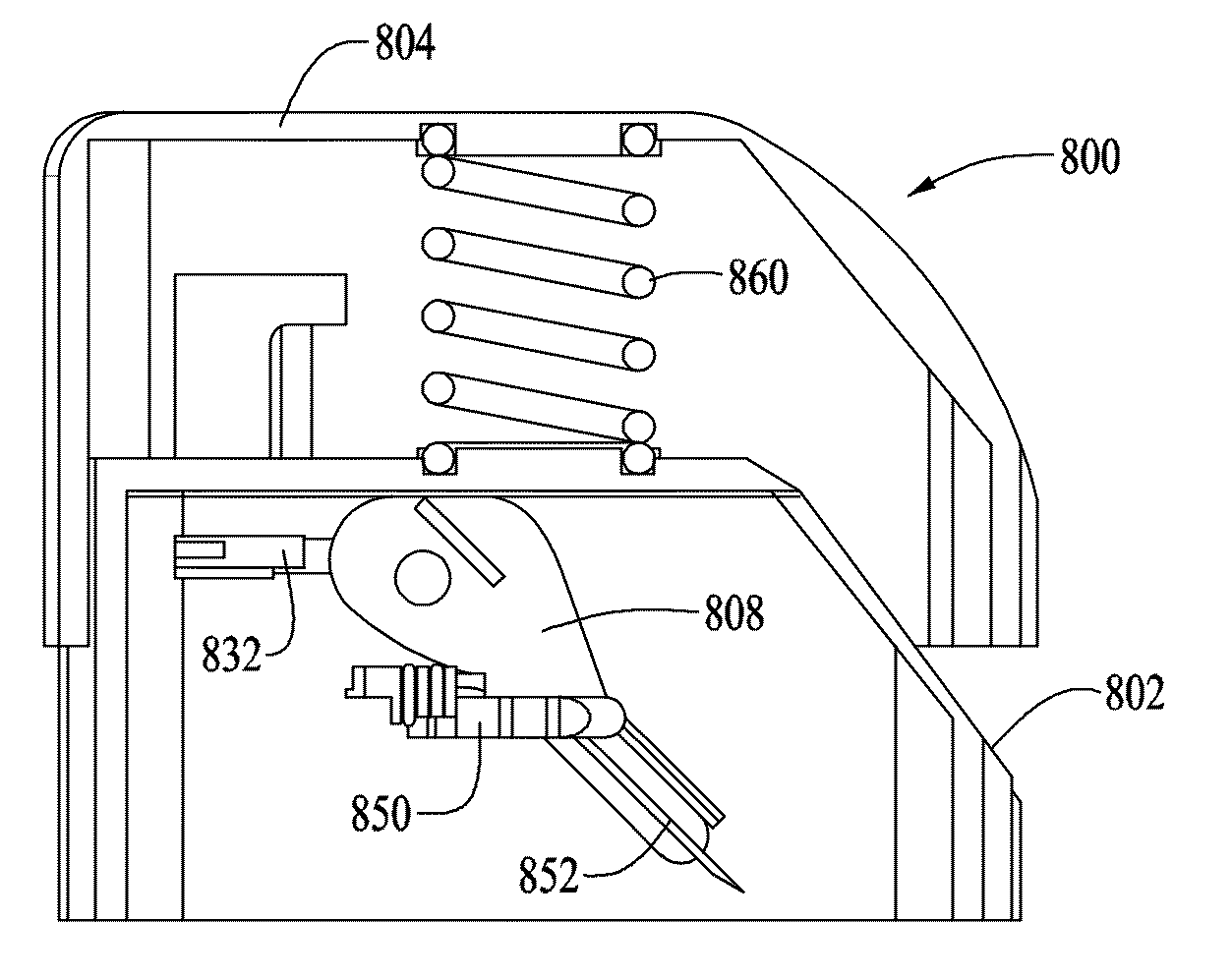

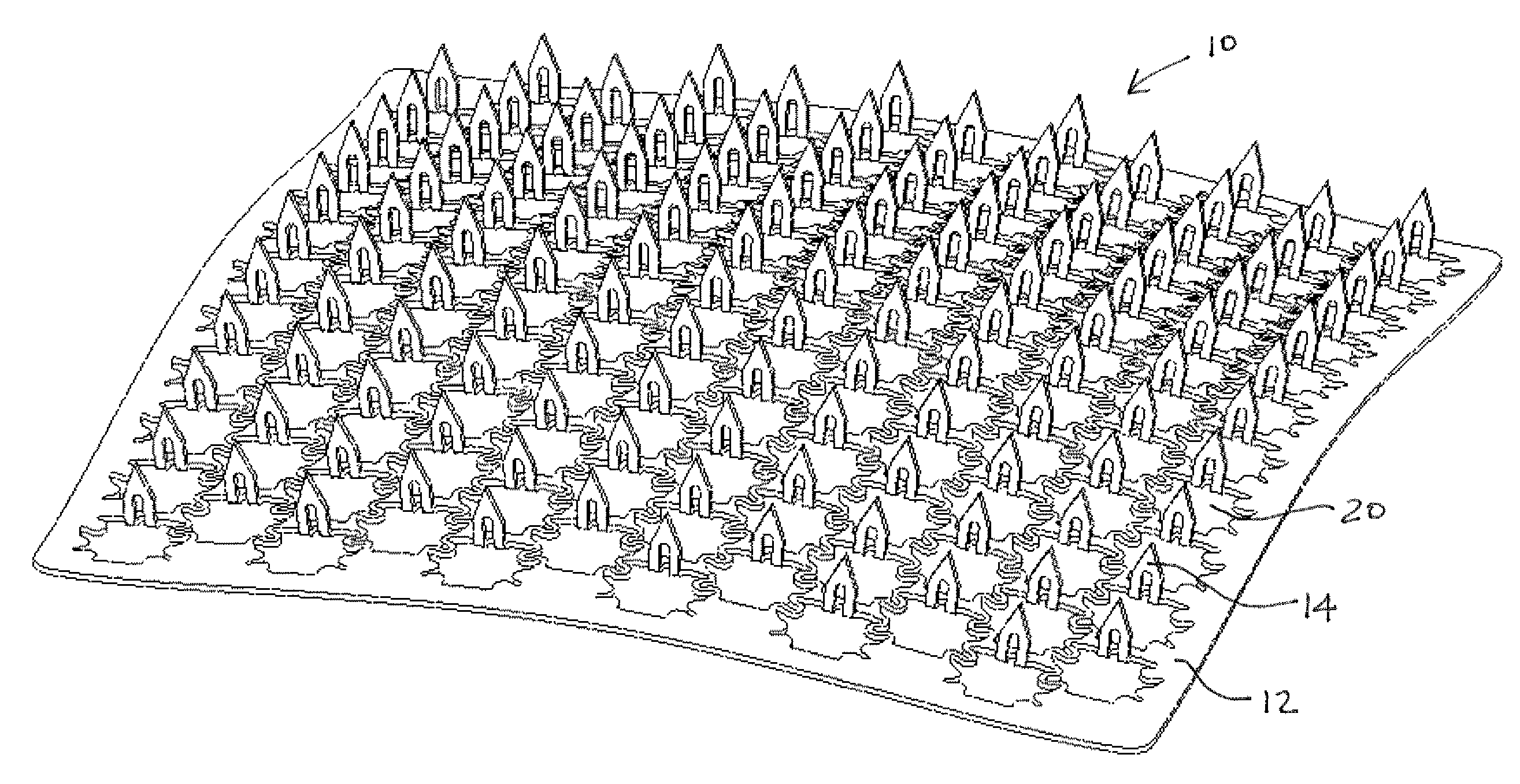

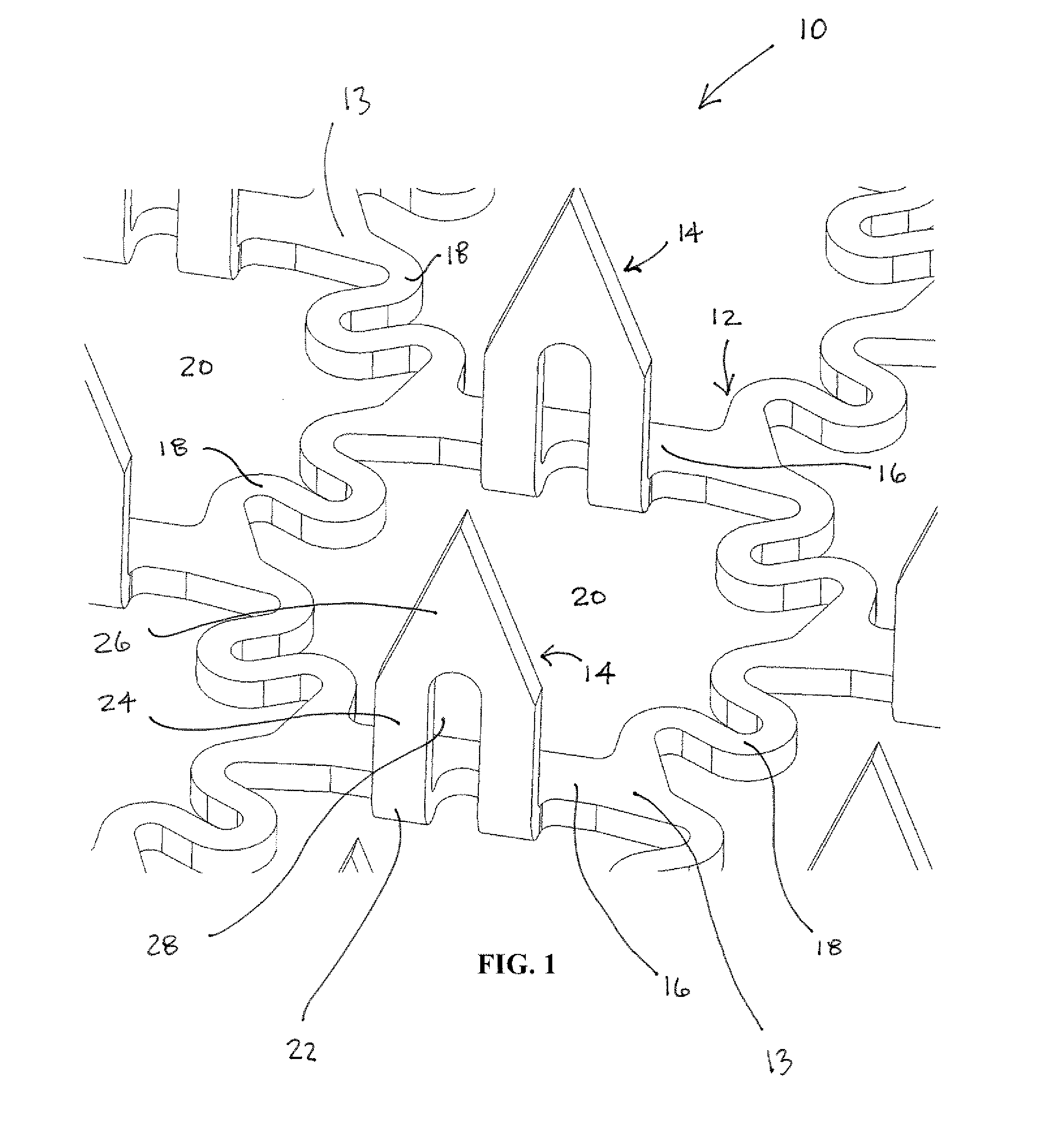

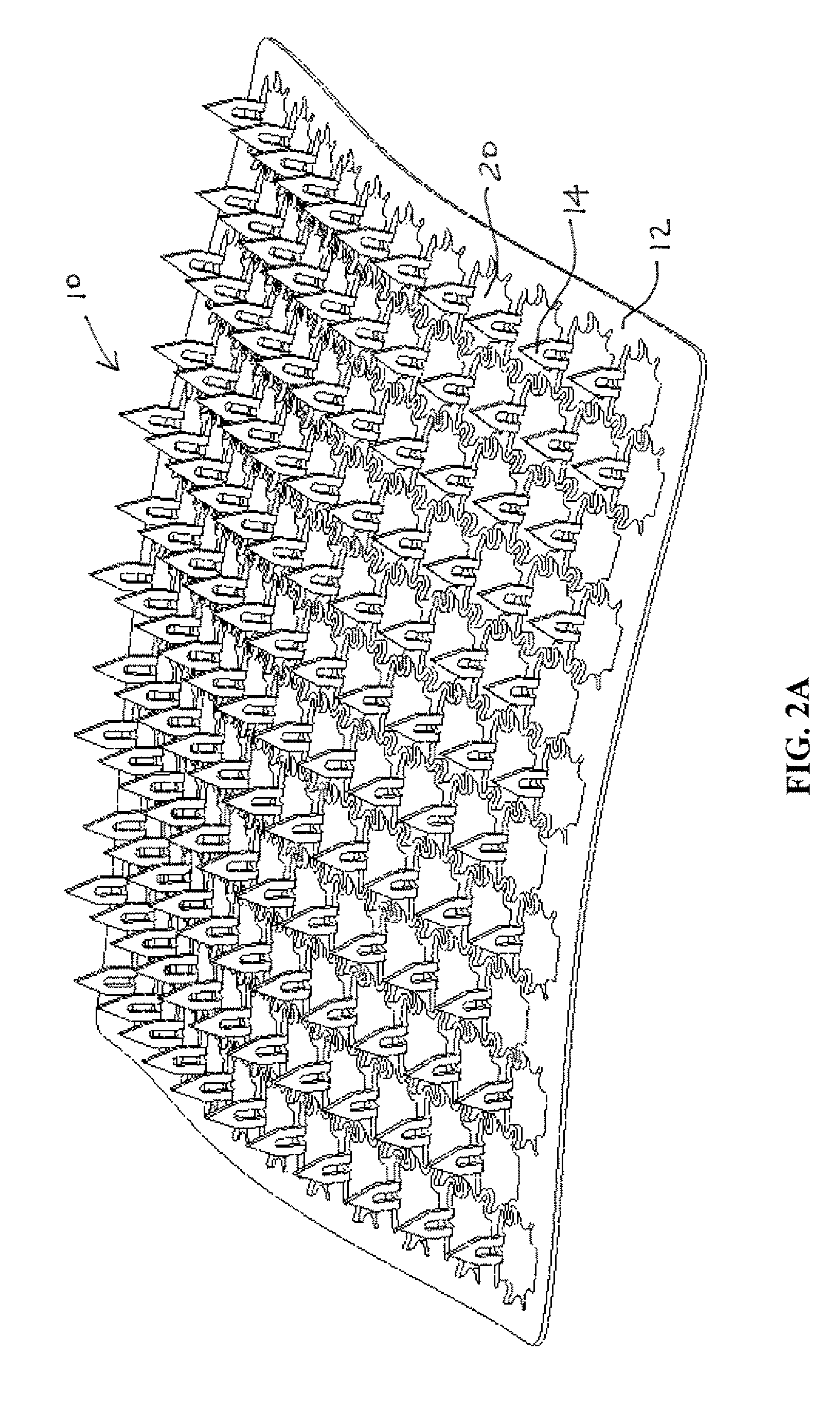

Tissue Conforming Microneedle Array and Patch For Transdermal Drug Delivery or Biological Fluid Collection

Microneedle arrays are provided for use on a contoured or flexible tissue surface. In one embodiment, the microneedle array includes a plurality of microneedles, each having a base portion, a tip end portion distal to the base portion, and body portion therebetween; and a flexible substrate which comprises a plurality of apertures, each of which are defined by (i) a plurality of substrate elements which are integral with the base portions of the microneedles, and (ii) at least one spring element connecting at least two of the substrate elements. The spring element may include a curved element, such as a C-shaped, U-shaped, or S-shaped element. Apertures may be defined, for example, by two substrate elements, which connected to three or four spring elements. A skin patch is provided for therapeutic or diagnostic applications, which includes the microneedle array and an adhesive material.

Owner:YUZHAKOV VADIM V

Combination coaster and sleeve apparatus

An improved combination holder and coaster apparatus for receiving a container or vessel which includes first and second thermally insulative, flexible panels joined together by a joint comprised of a stretchable, flexible, adhesive material adapted to return the device to a collapsed coaster configuration. While in receipt of the vessel or container, the device is adapted to an elliptical holder configuration in which the panels are separated by a projected dihedral angle generally between approximately 0 degrees through approximately 180 degrees allowing the elliptical holder to receive the vessel or container.

Owner:TULP DAVID W

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com