Patents

Literature

15931 results about "Polycarbonate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Polycarbonates (PC) are a group of thermoplastic polymers containing carbonate groups in their chemical structures. Polycarbonates used in engineering are strong, tough materials, and some grades are optically transparent. They are easily worked, molded, and thermoformed. Because of these properties, polycarbonates find many applications. Polycarbonates do not have a unique resin identification code (RIC) and are identified as "Other", 7 on the RIC list.

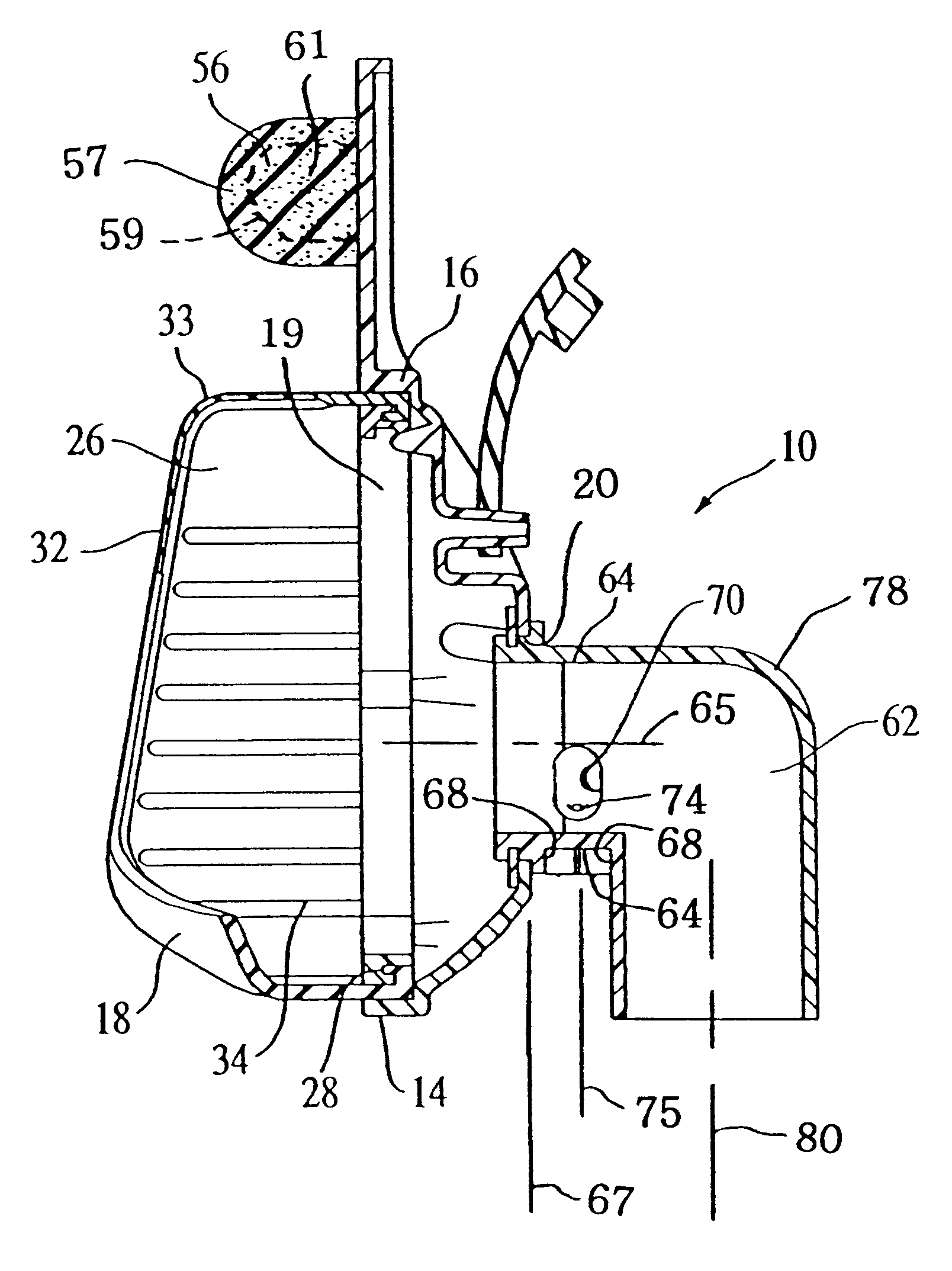

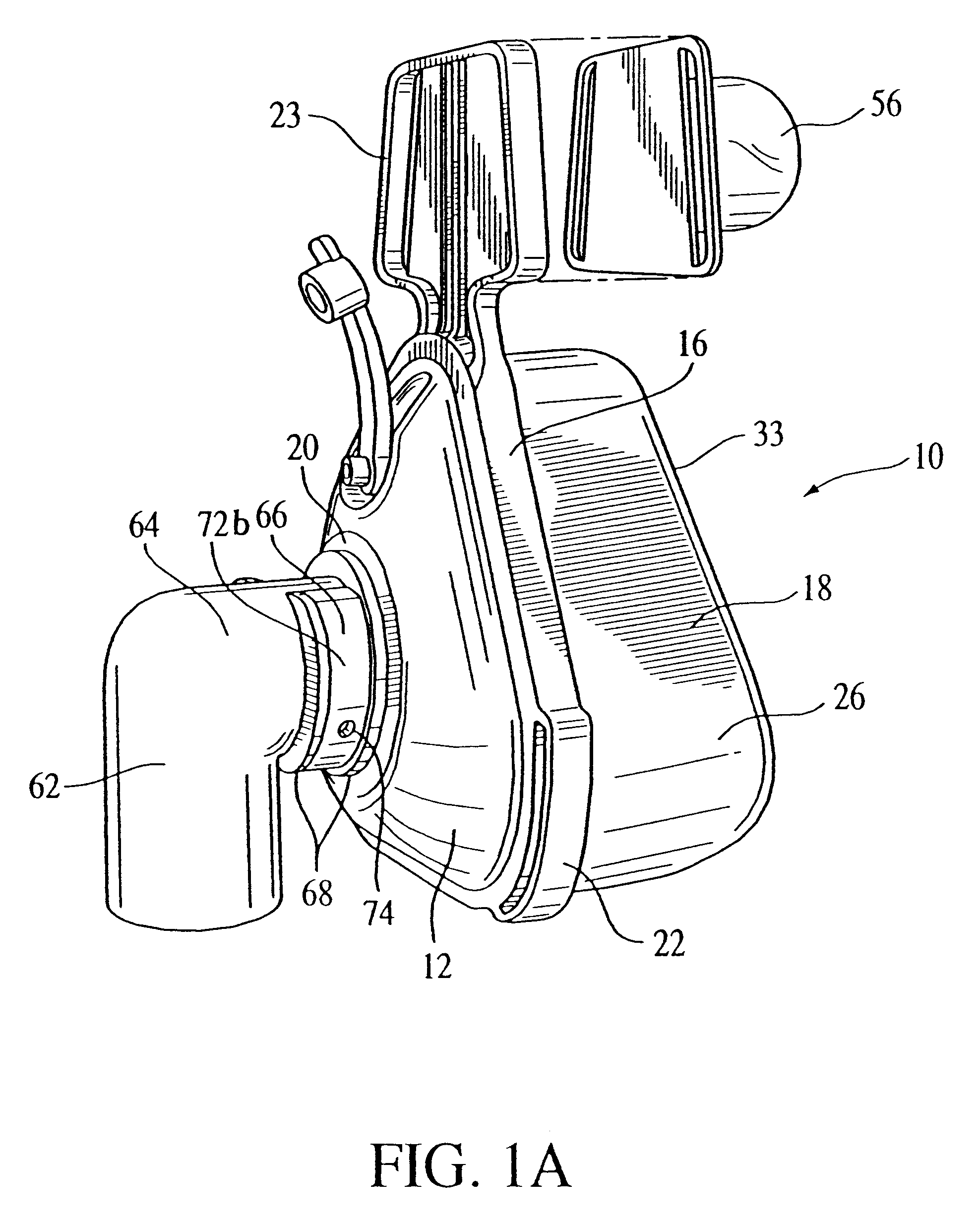

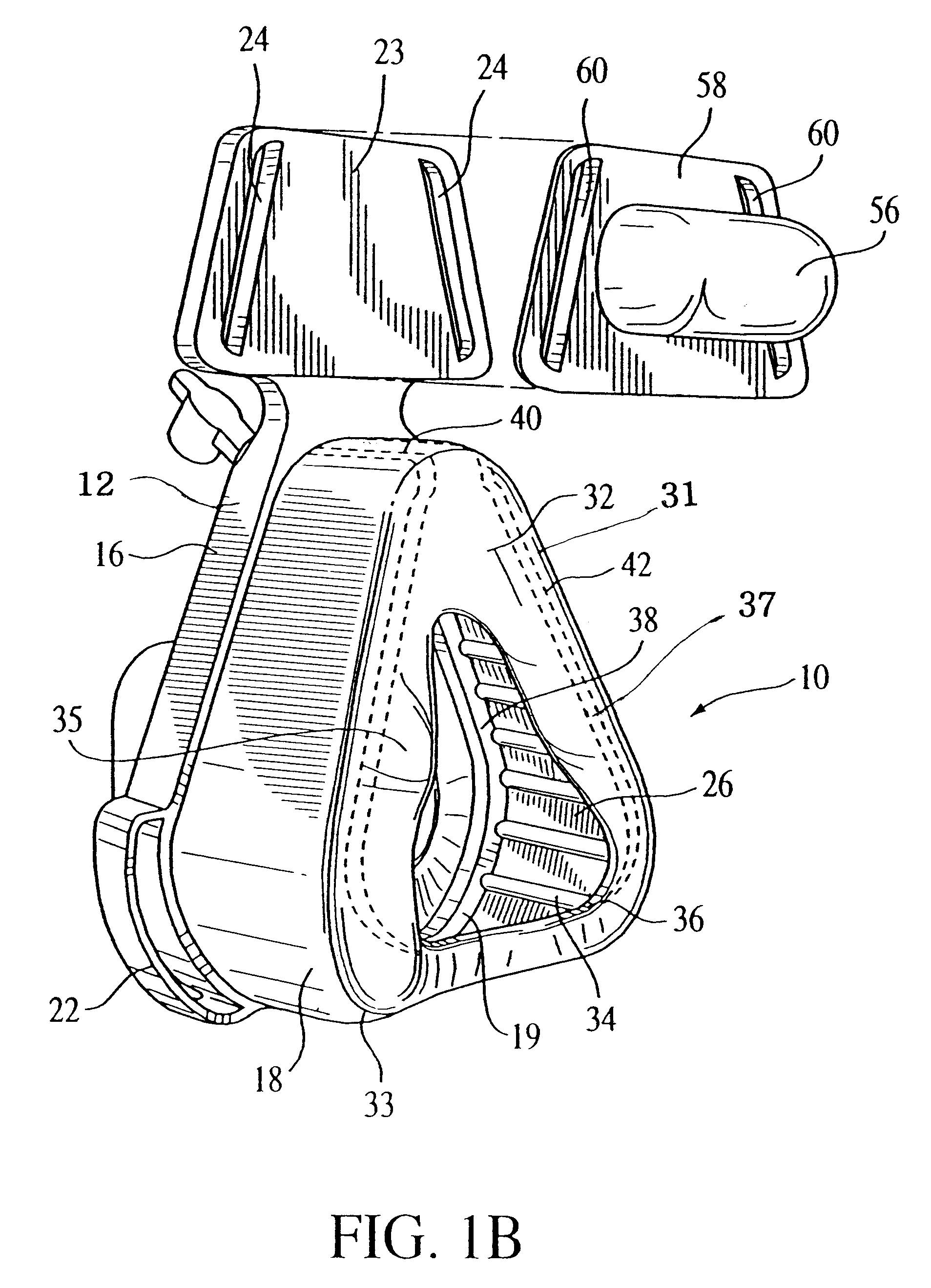

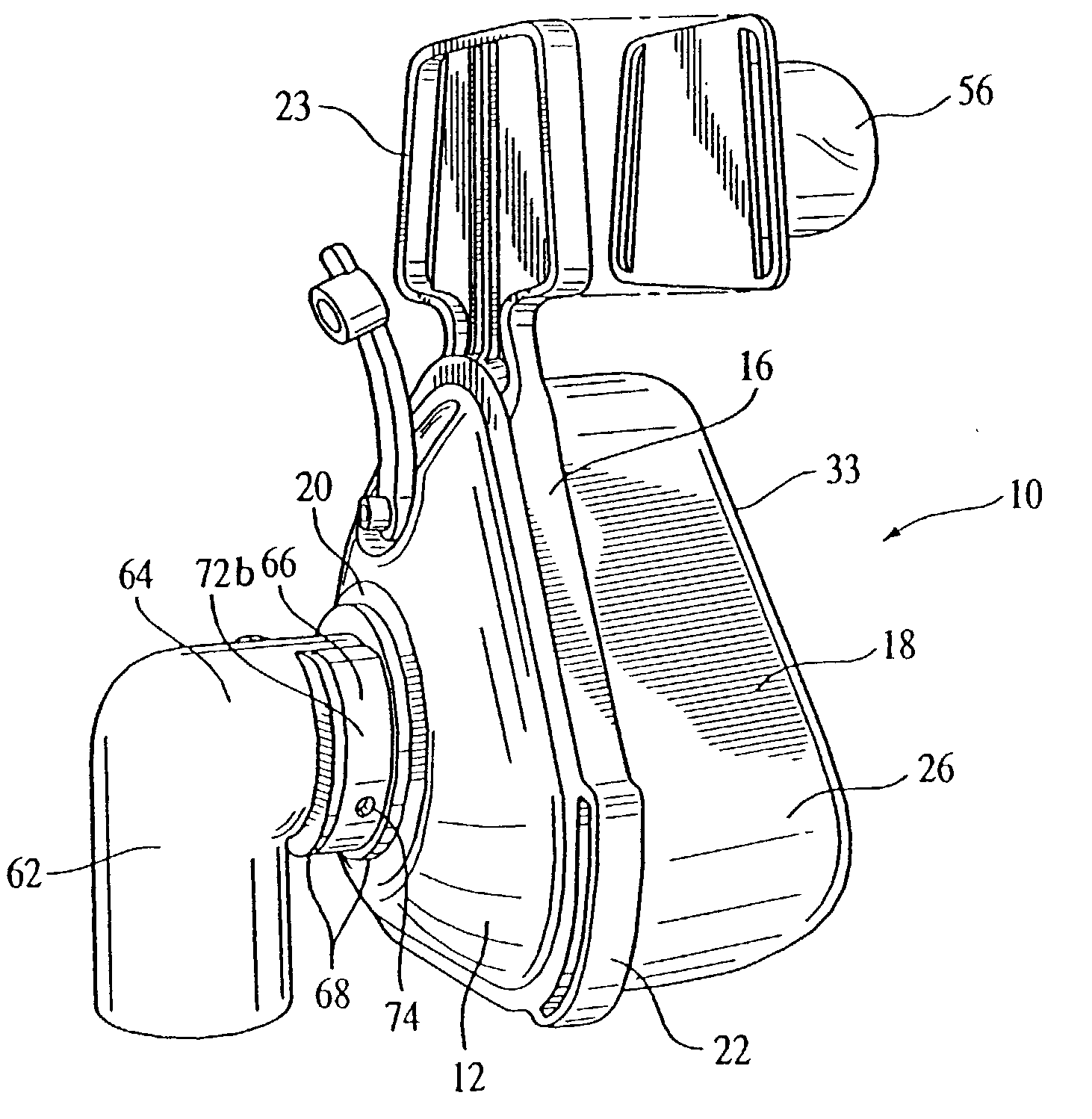

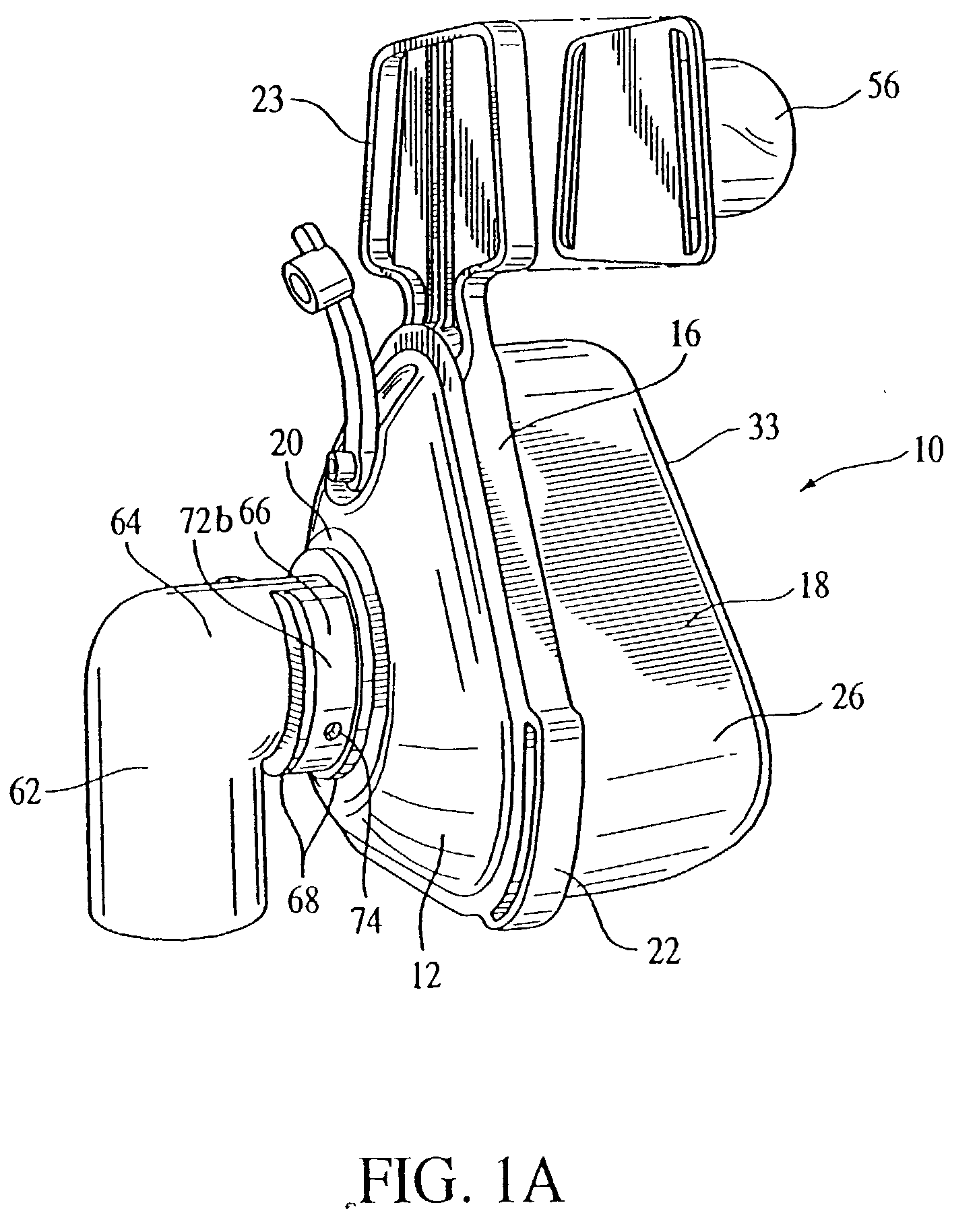

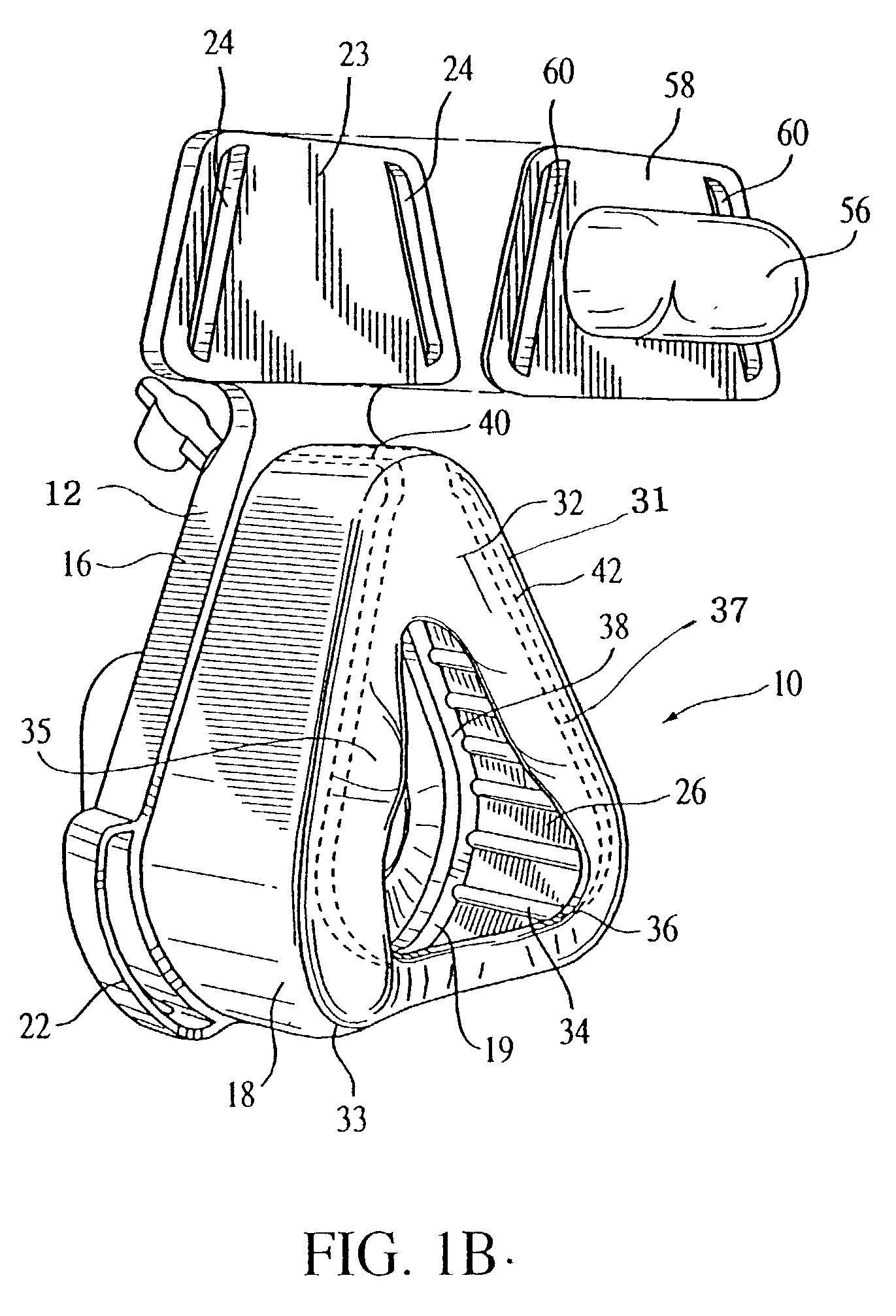

Respiratory mask

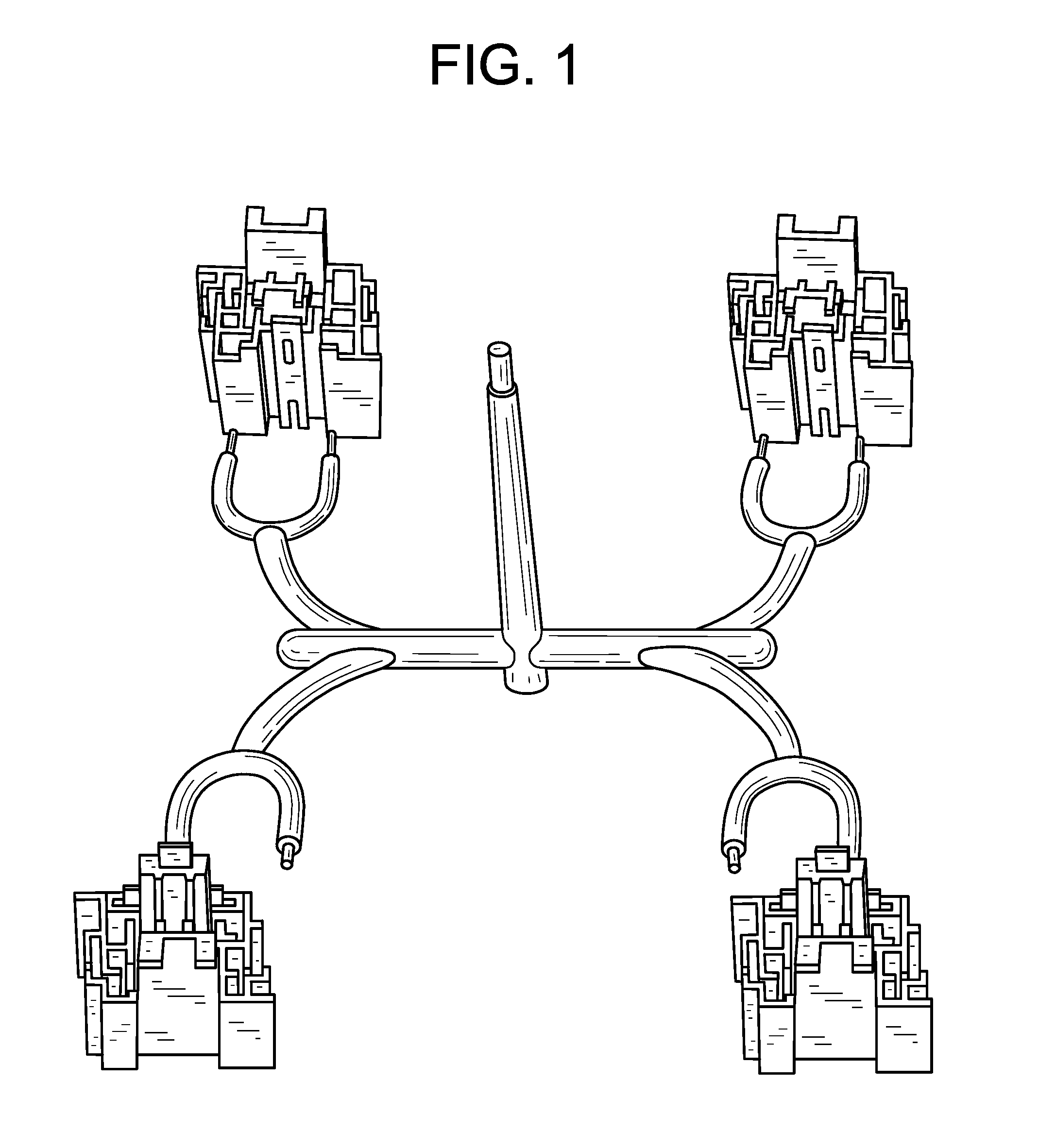

InactiveUS6467483B1Improve comfortReduce noise levelRespiratory masksBreathing masksCushionRespiratory mask

A respiratory mask having a flexible, mask seal portion for engagement with the face of a user, a gel forehead cushion and a rotatable elbow coupling having integral exhaust ports. The mask seal portion has a thin section which permits the mask to more easily adapt to the contour of the face of the user. The gel forehead cushion provides increased compliancy and resiliency to better adapt to multiple user physical profiles. The elbow coupling includes tapered through holes in a polycarbonate arc piece to provide a quiet passage of gas through the holes.

Owner:RIC INVESTMENTS LLC

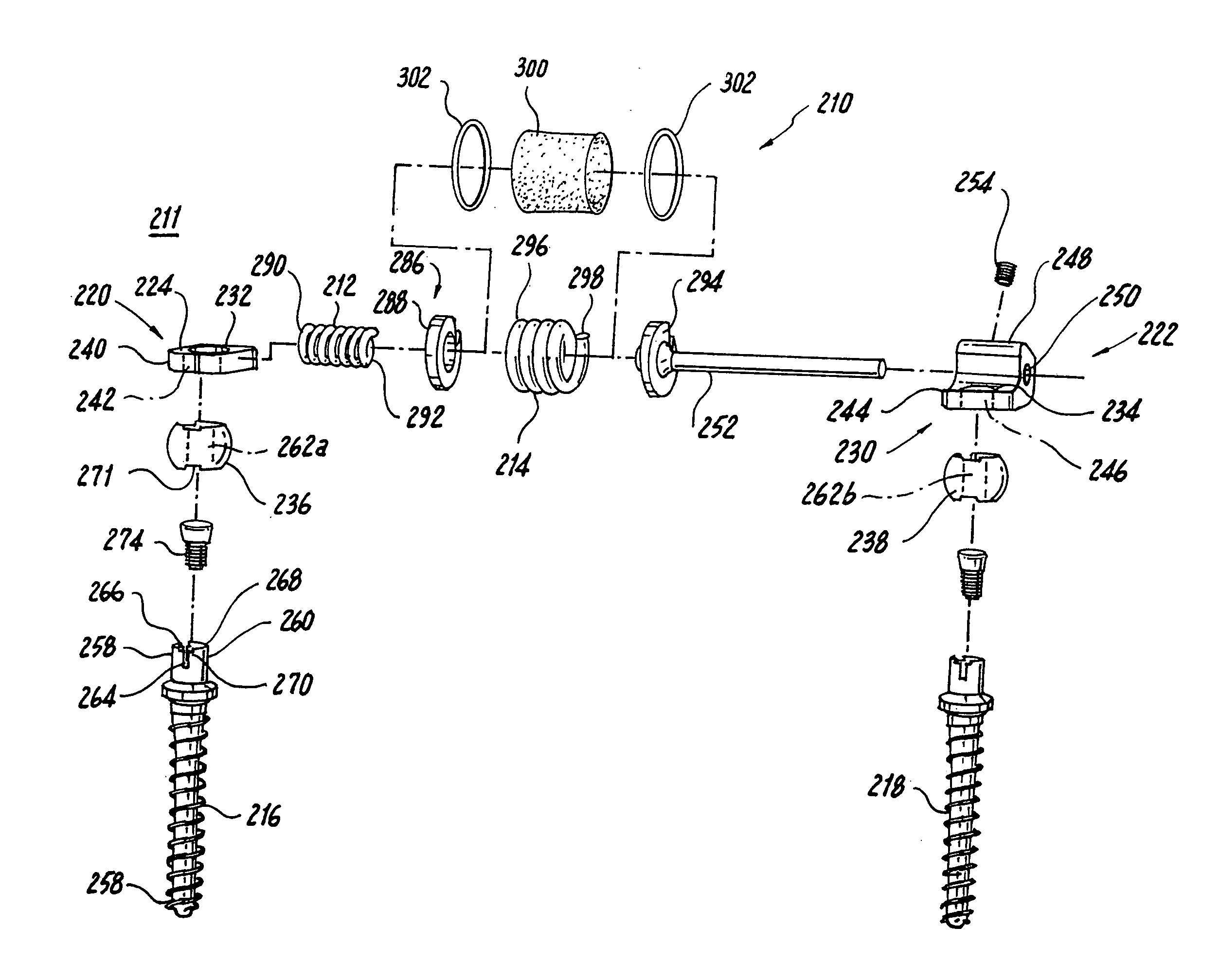

Surgical implant devices and systems including a sheath member

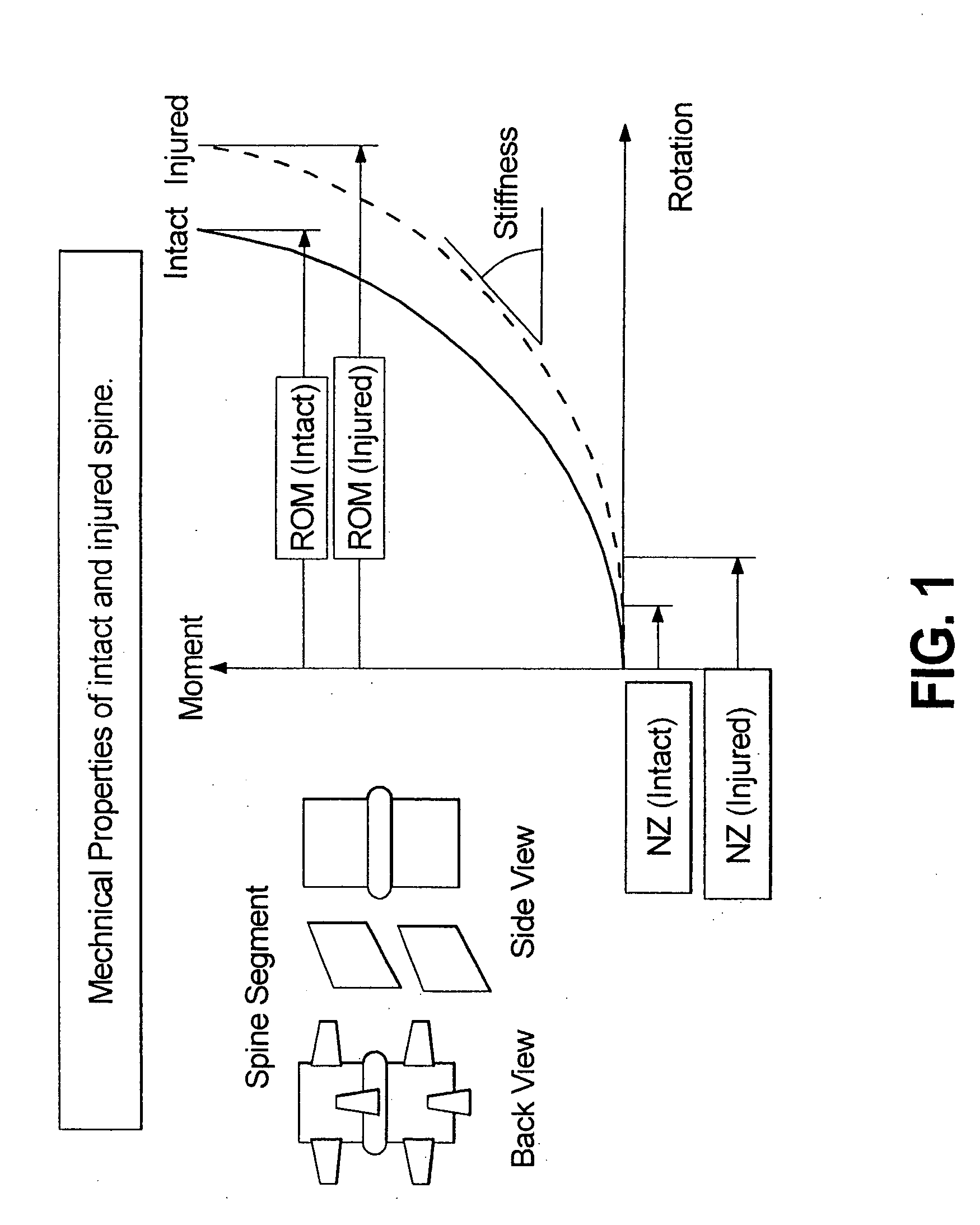

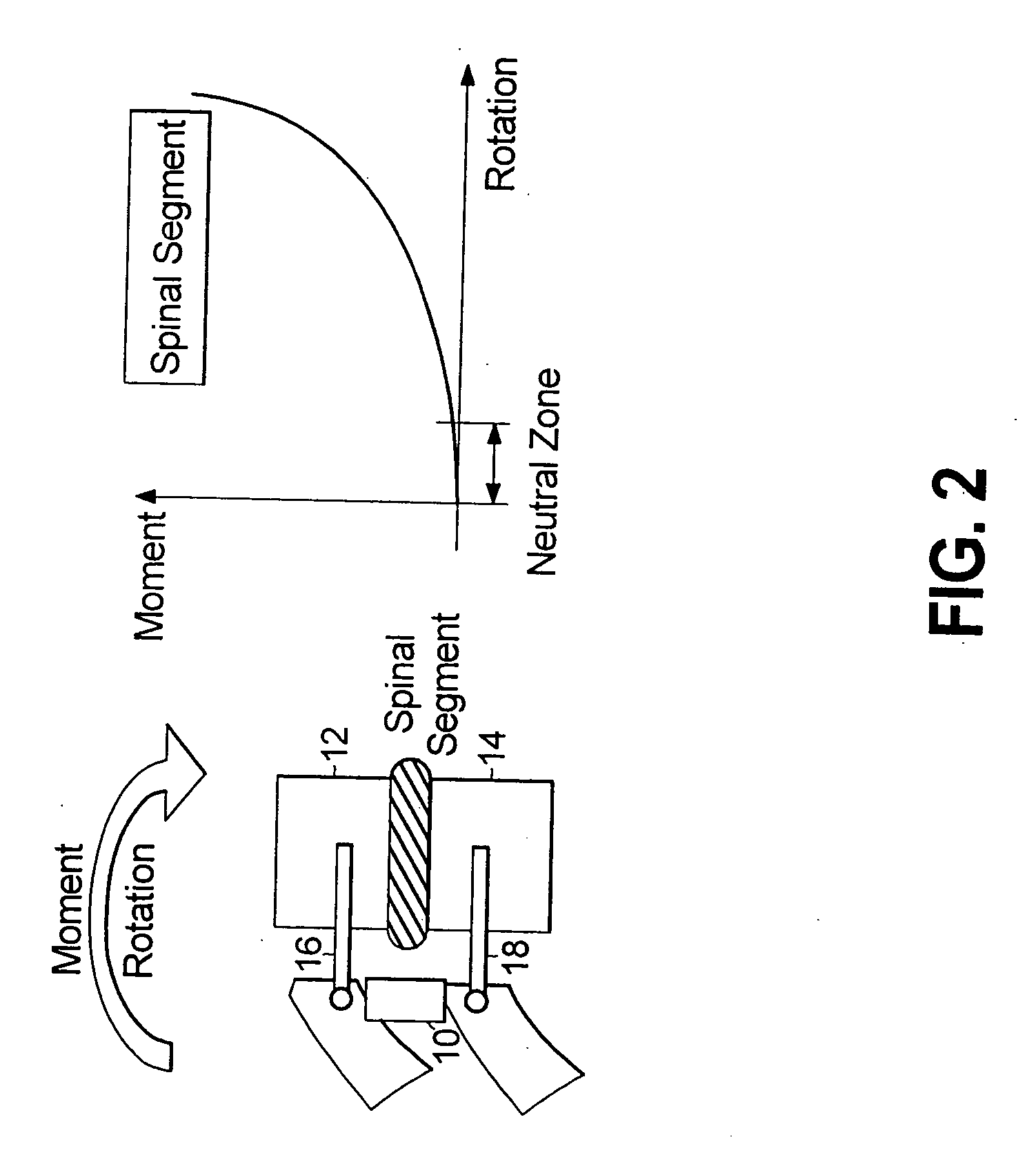

InactiveUS20050177156A1Easy to installImprove clinical outcomesSuture equipmentsInternal osteosythesisAnatomical structuresSpinal column

A surgical implant is provided that includes first and second abutment surfaces between which are positioned a force imparting mechanism. A sheath is positioned between the first and second abutment surfaces, and surrounds the force imparting mechanism. The sheath is fabricated from a material that accommodates relative movement of the abutment members, while exhibiting substantially inert behavior relative to surrounding anatomical structures. The sheath is generally fabricated from expanded polytetrafluoroethylene, ultra-high molecular weight polyethylene, a copolymer of polycarbonate and a urethane, or a blend of a polycarbonate and a urethane. The force imparting member may include one or more springs, e.g., a pair of nested springs. The surgical implant may be a dynamic spine stabilizing member that is advantageously incorporated into a spine stabilization system to offer clinically efficacious results.

Owner:RACHIOTEK

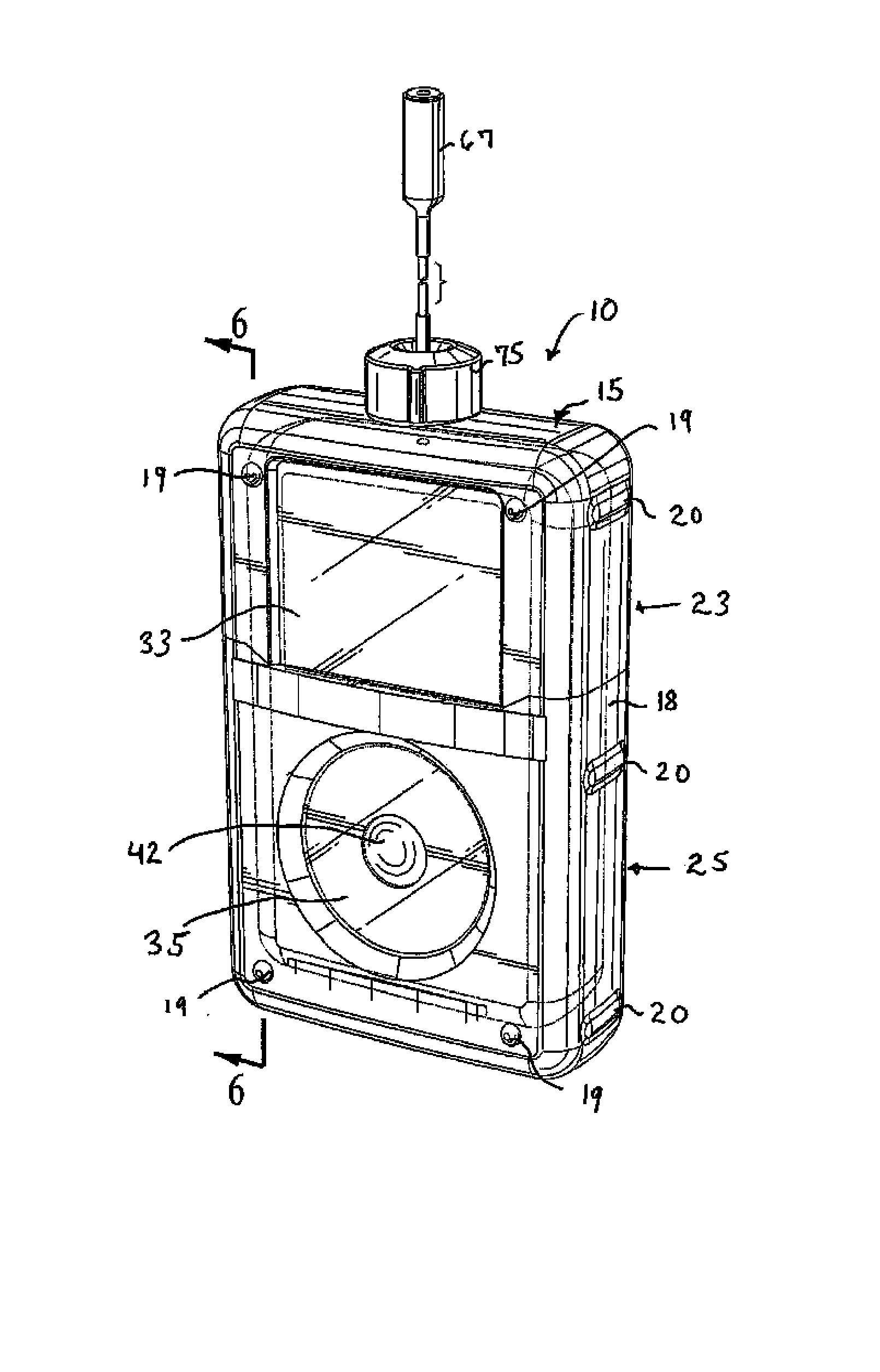

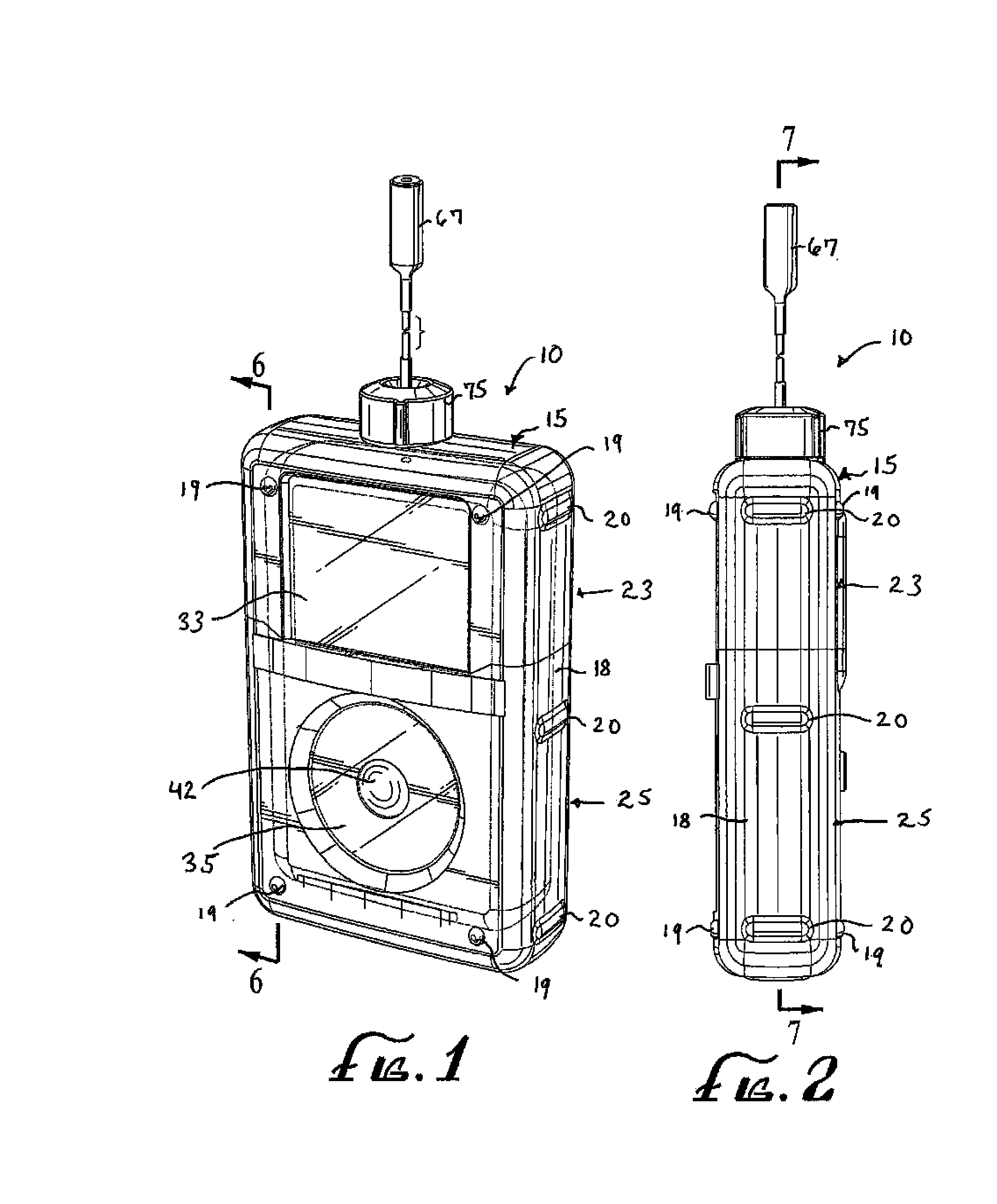

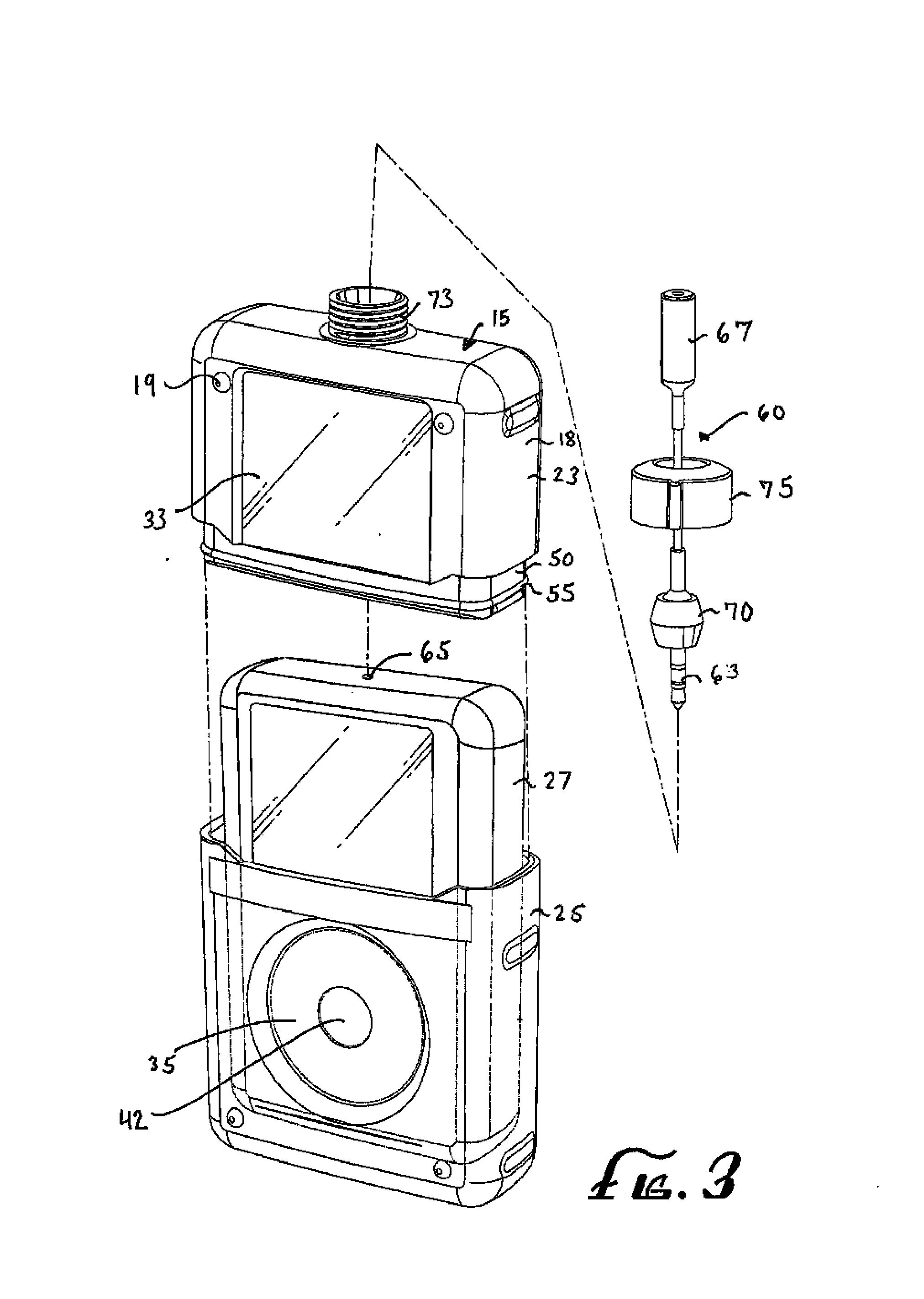

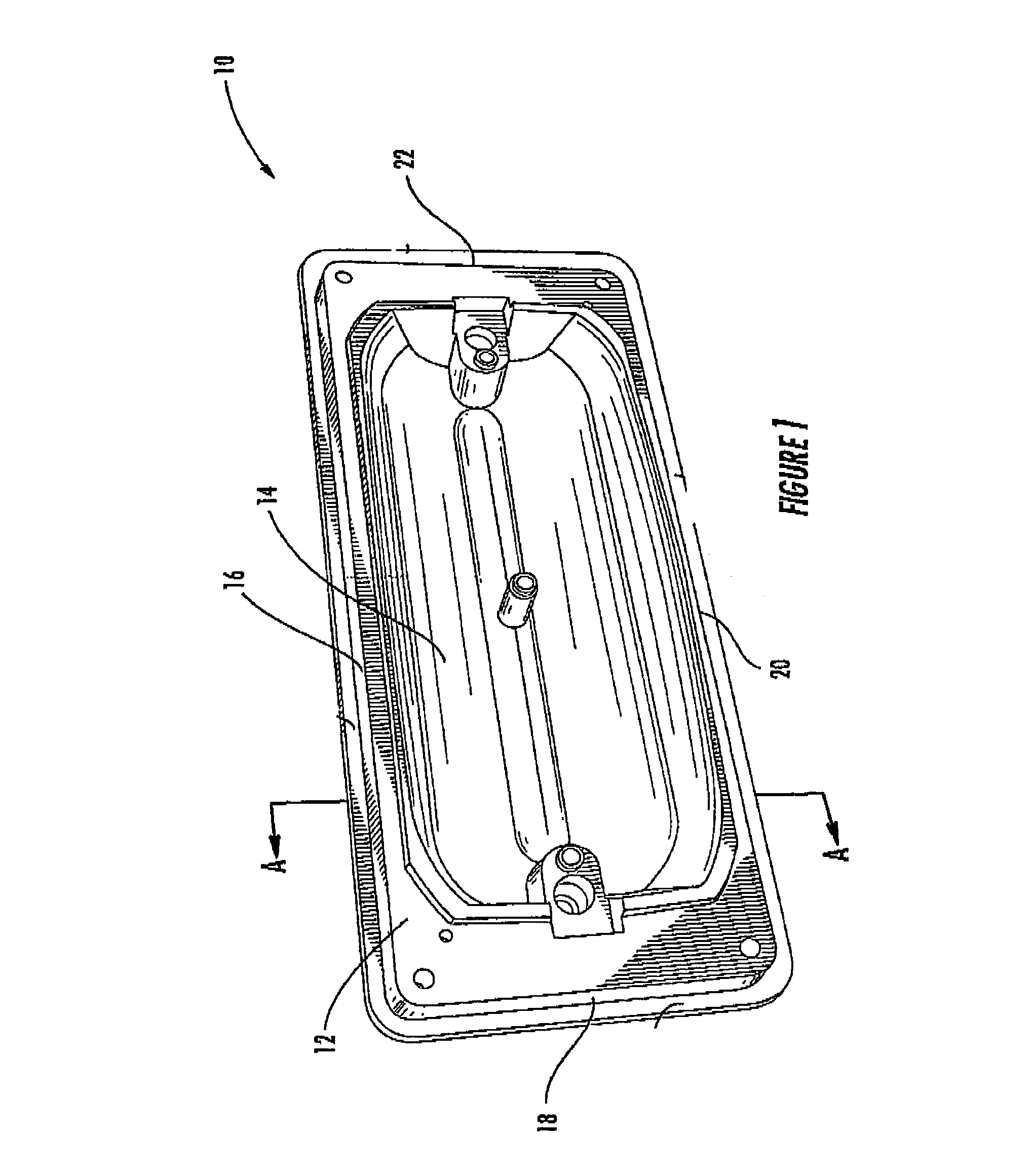

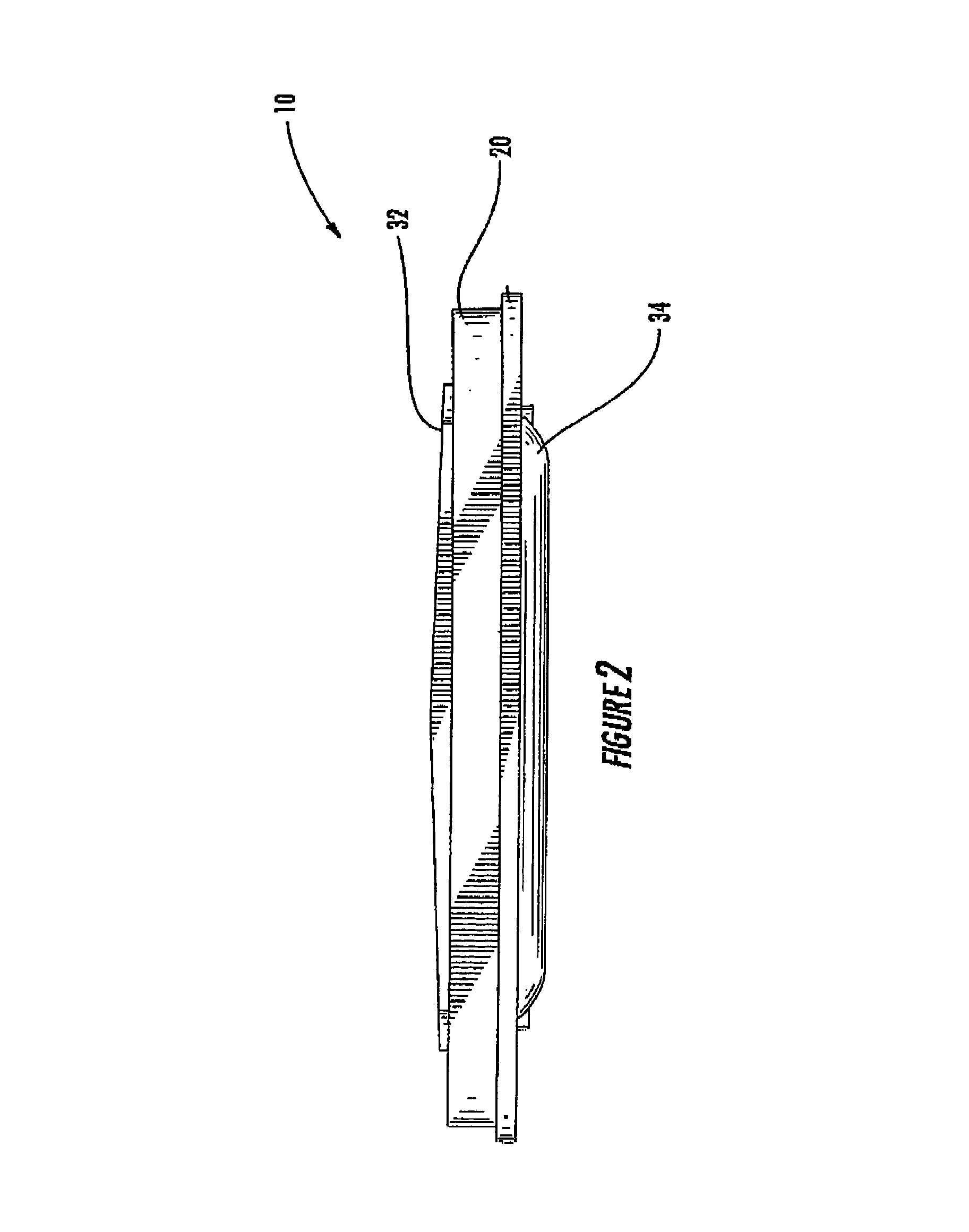

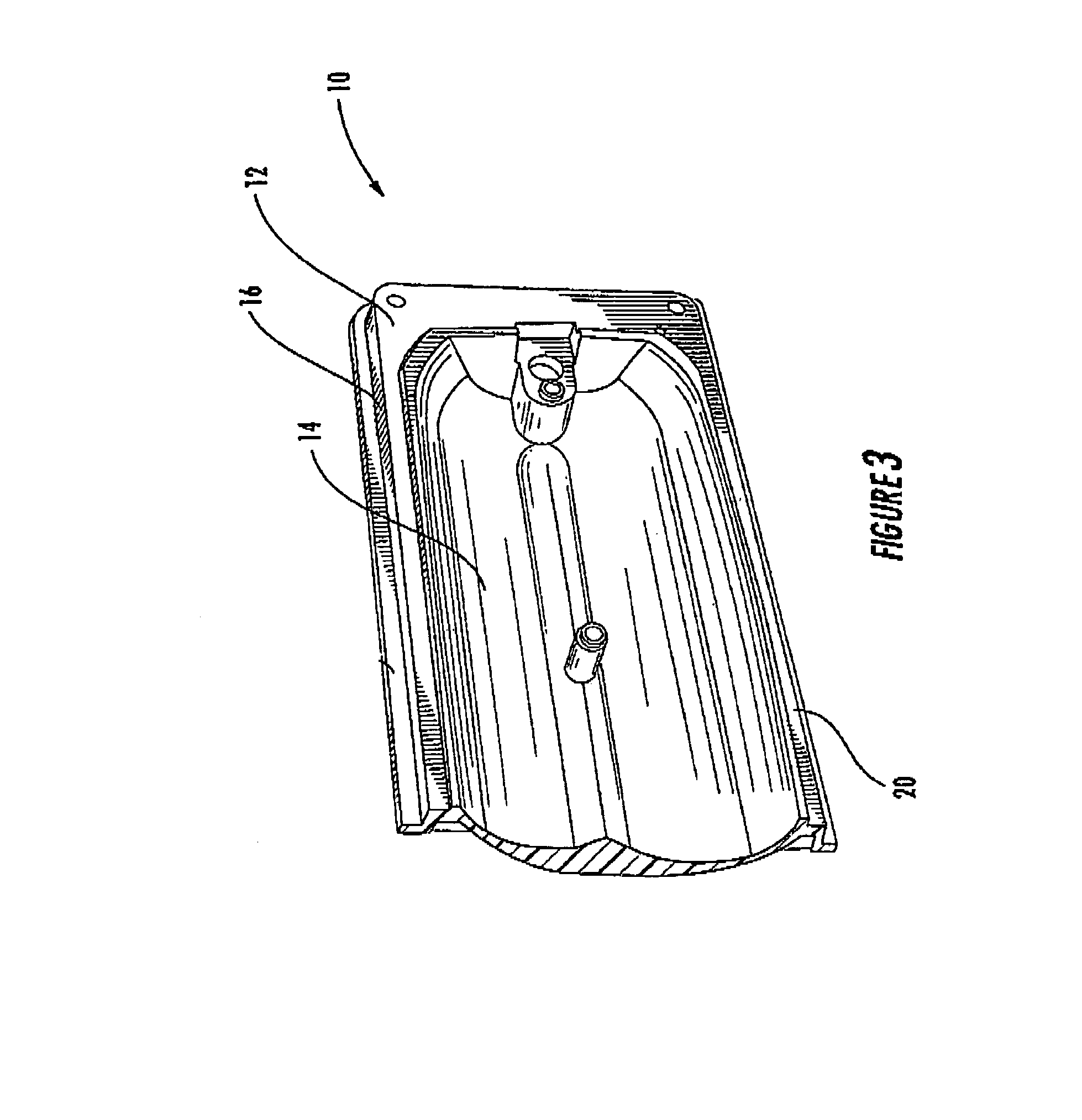

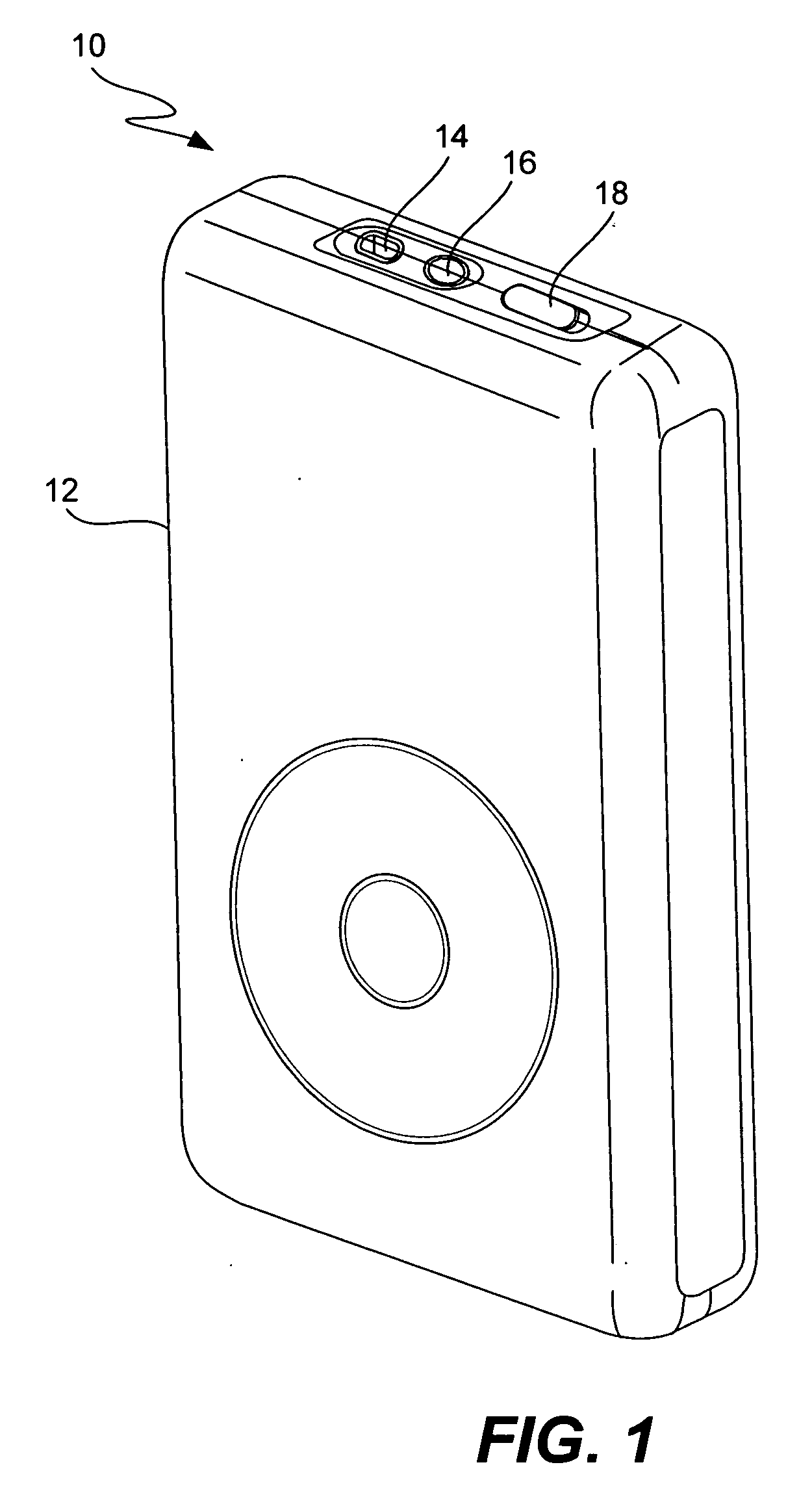

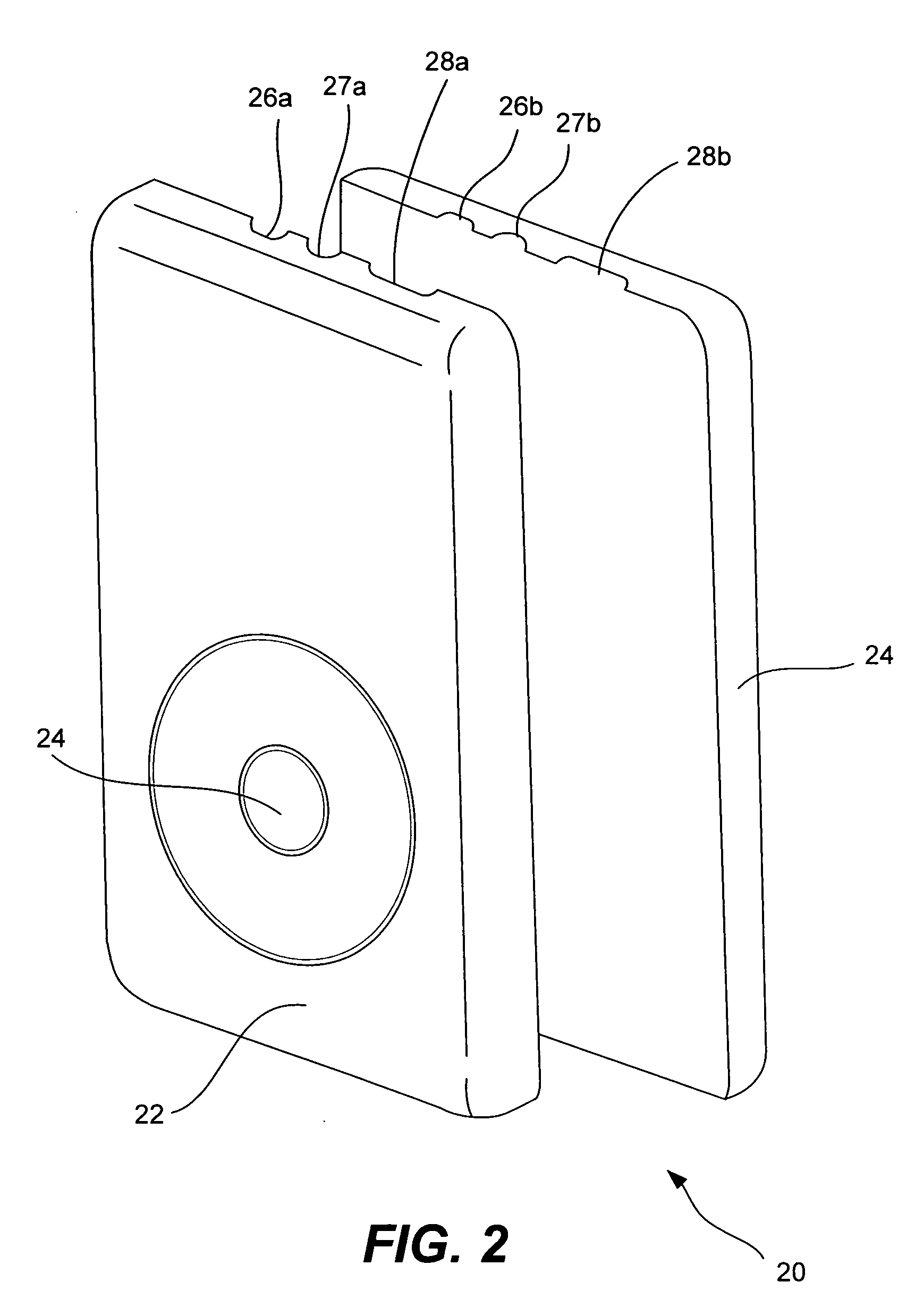

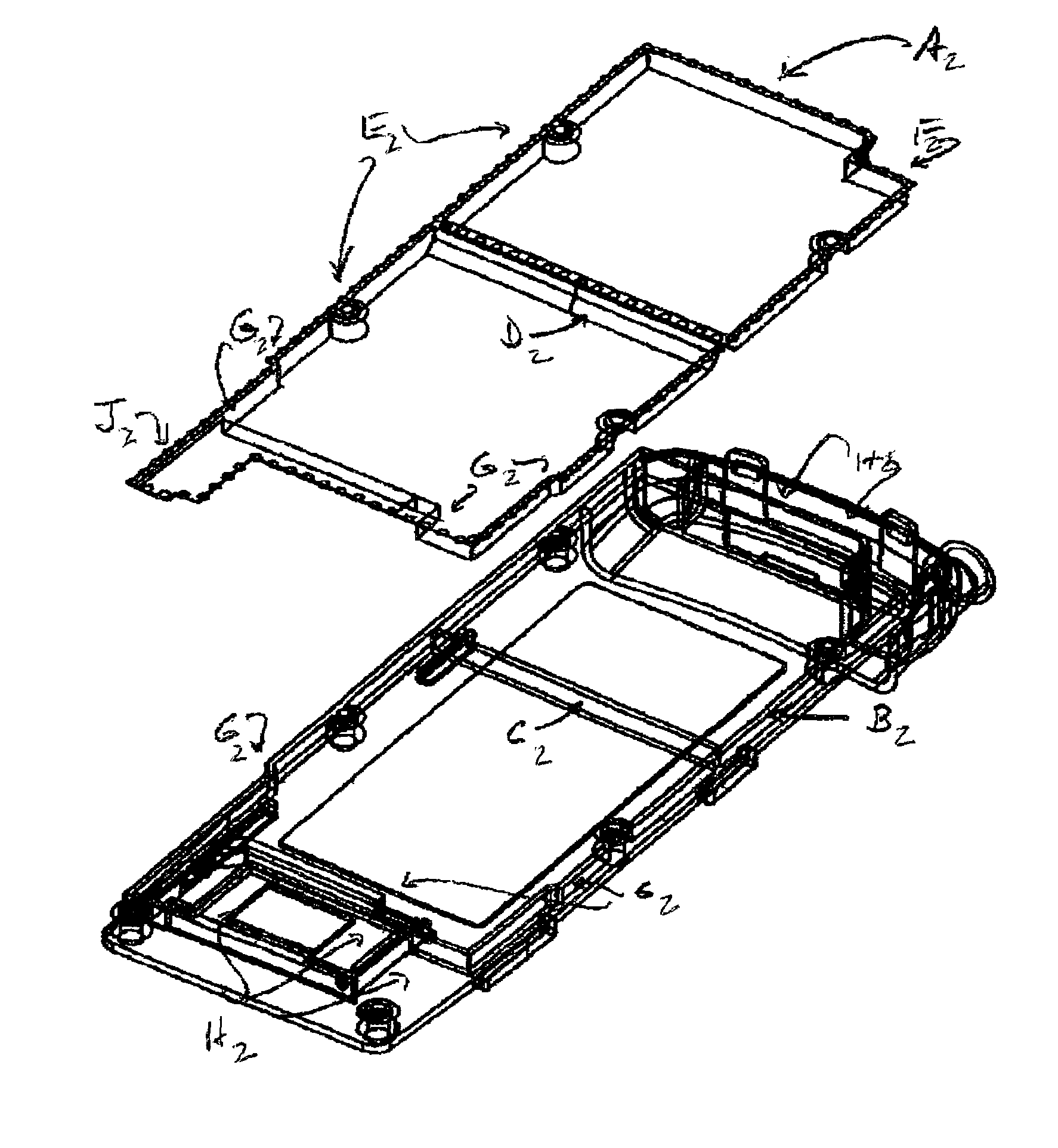

Waterproof case for electronic devices

The present invention provides protective waterproof cases for portable media players such as iPods. In an exemplary embodiment, the waterproof case comprises a transparent polycarbonate shell having an interior compartment formed therein and comprising upper and lower portions that can be detached for placing a portable player in the interior compartment. A polyurethane overmold is molded over selected portions of the shell to form protective layers on the exterior and interior surfaces of the shell. The waterproof case also comprises a window through which the screen of the player can be viewed, and a flexible pad for operating the player while it is in the waterproof case. The waterproof case further comprises a gasket for forming a watertight seal between the upper and lower portions of the shell when they are attached, and a compressible fitting for forming a watertight seal for a headphone connected to the player in the case.

Owner:SKB CORP

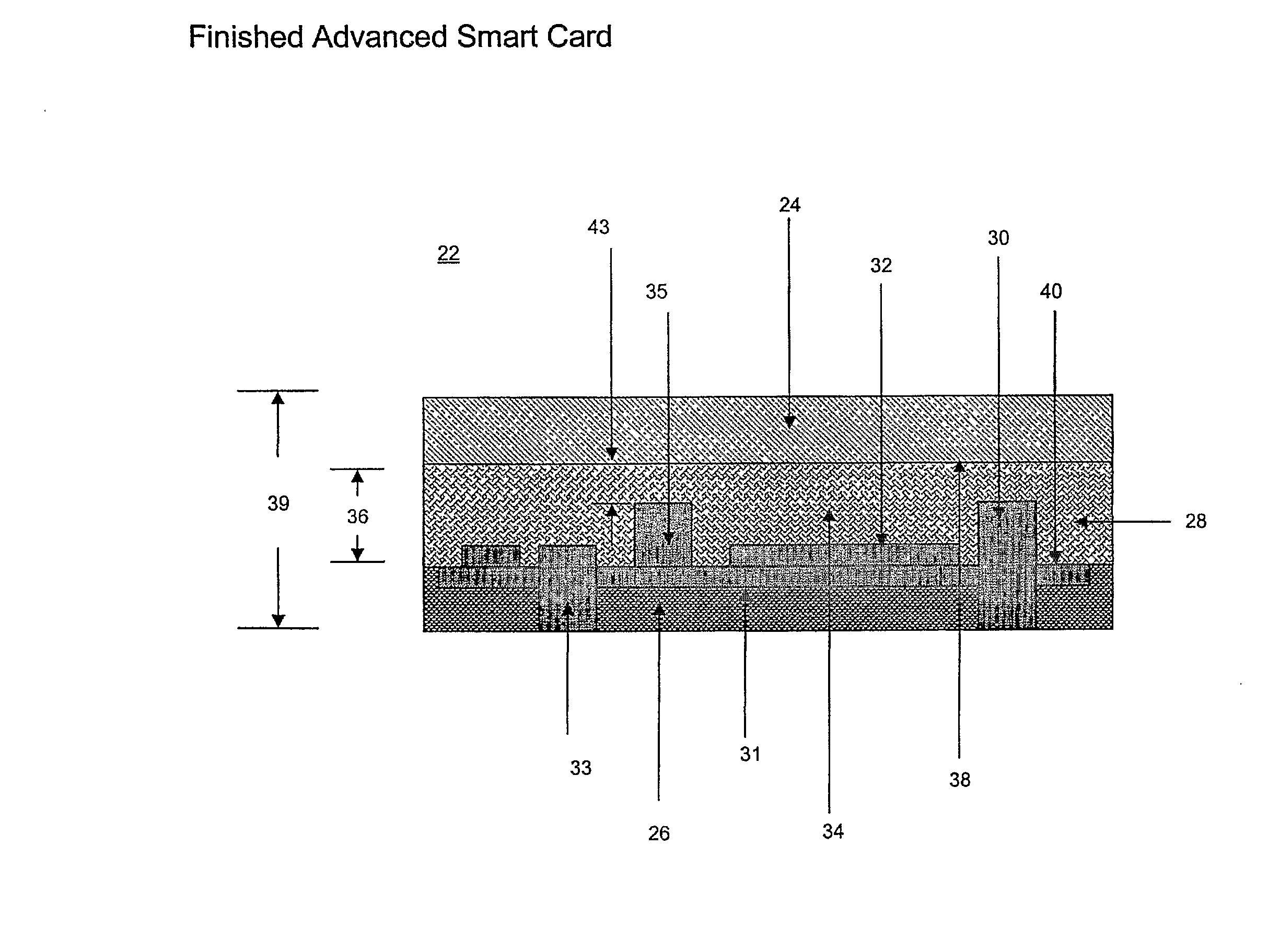

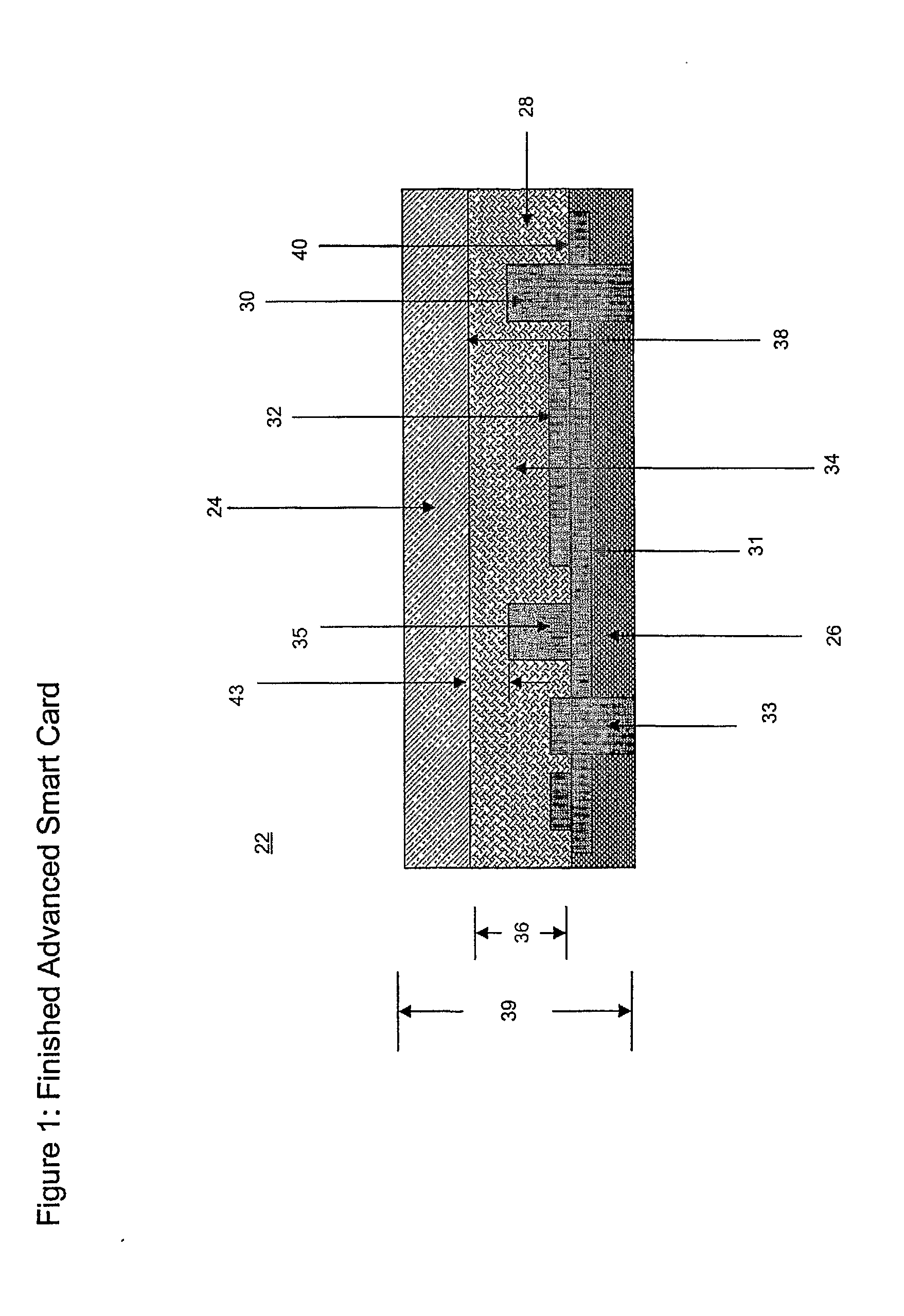

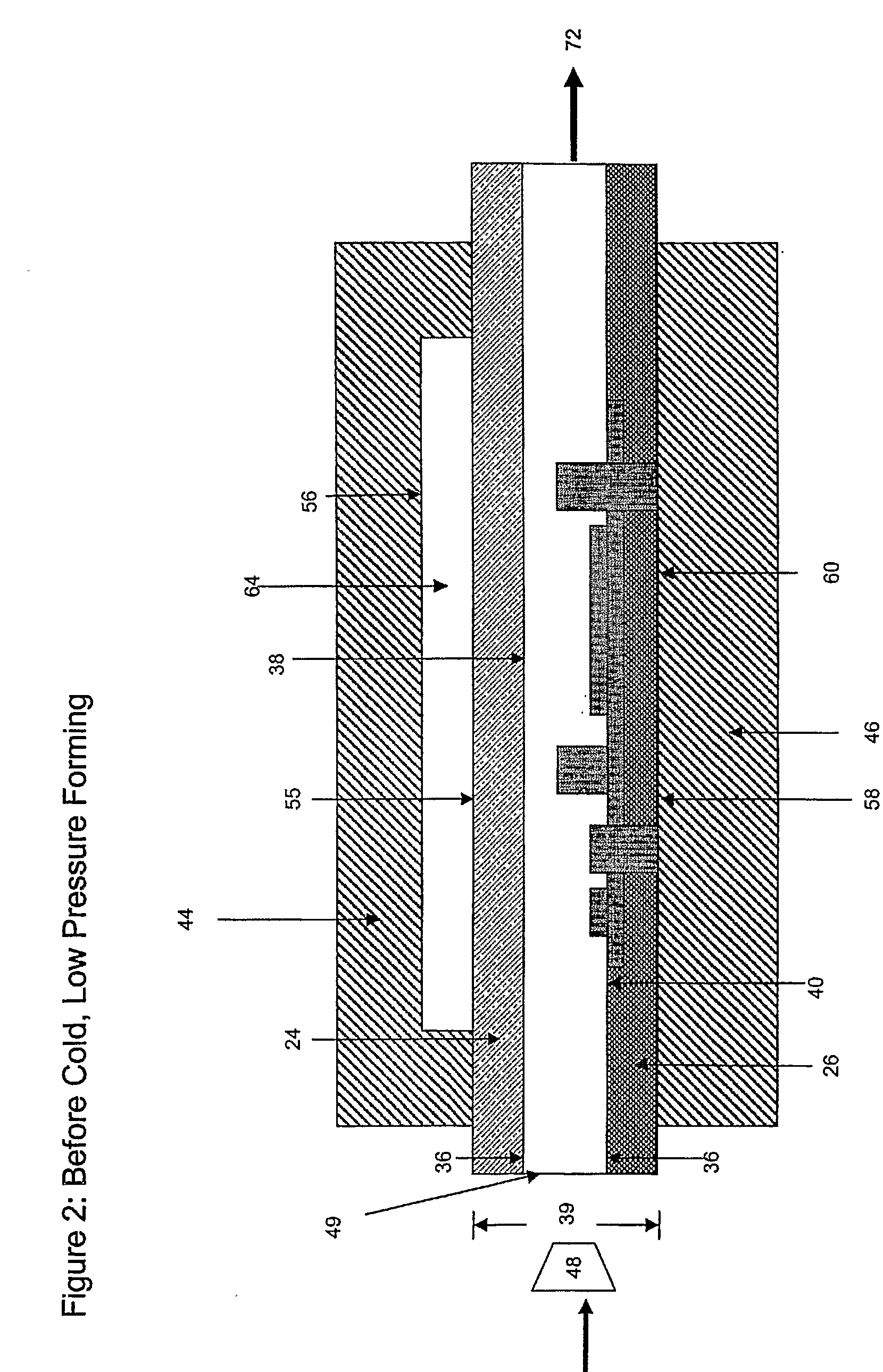

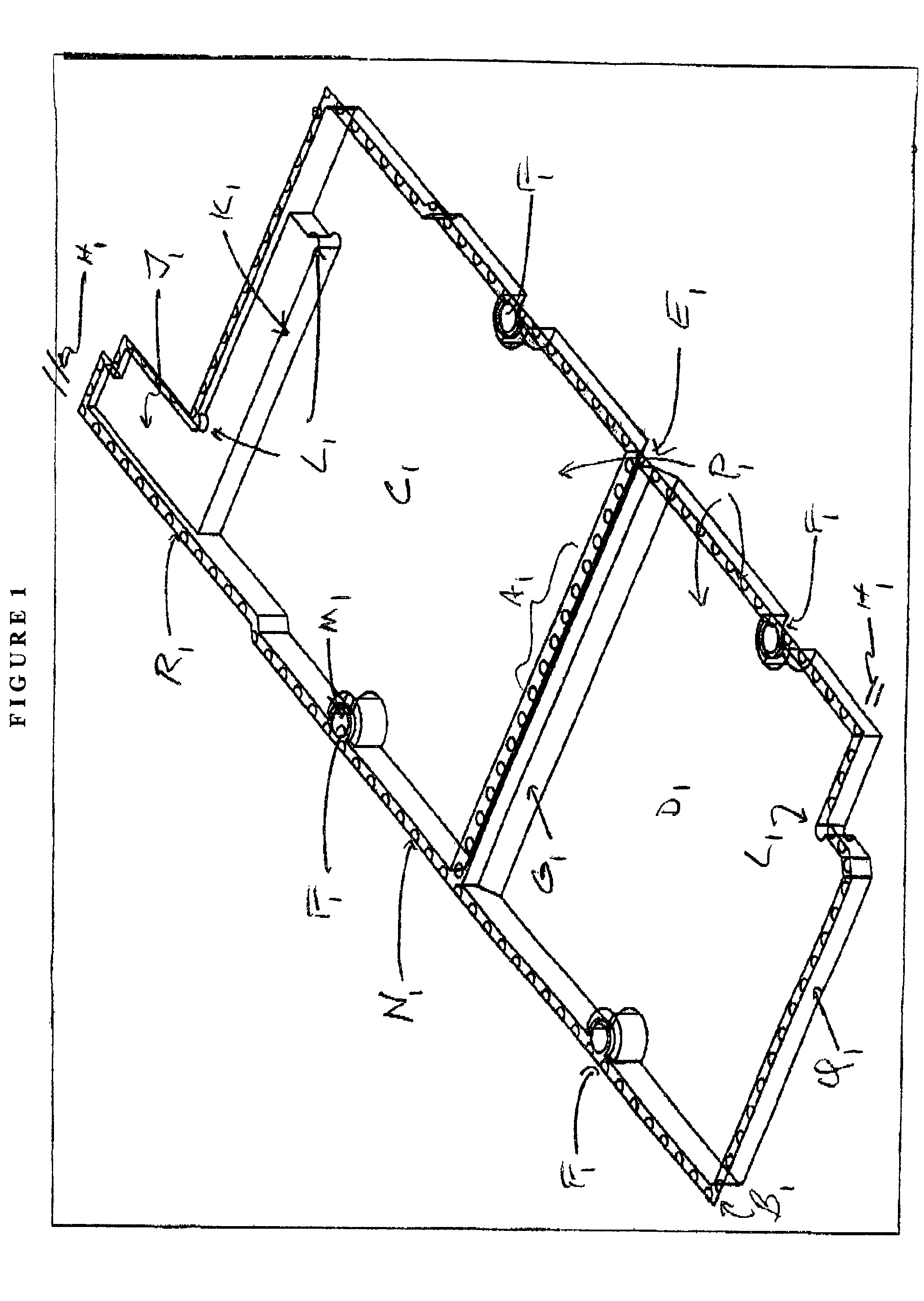

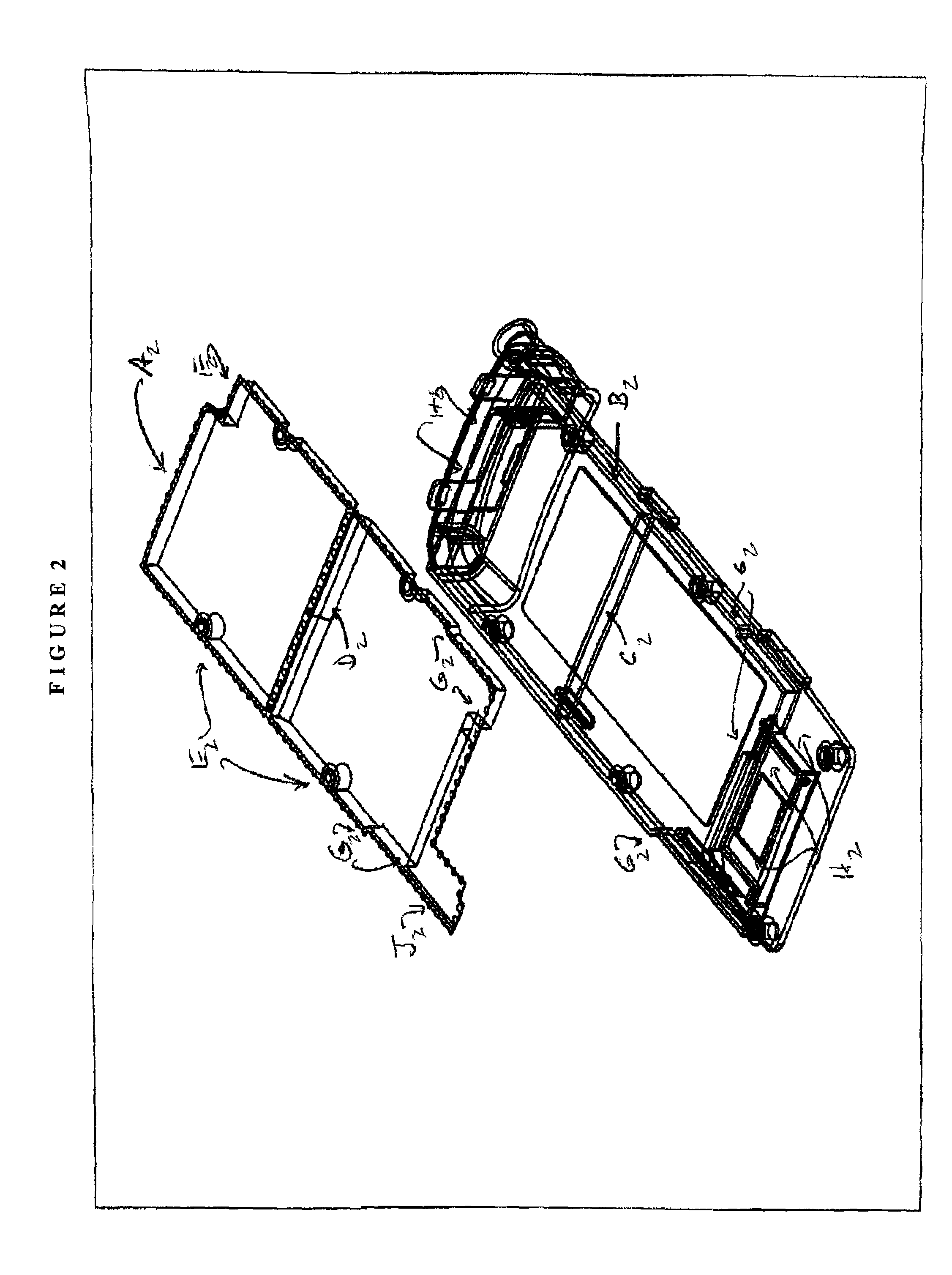

Method for Making Advanced Smart Cards With Integrated Electronics Using Isotropic Thermoset Adhesive Materials With High Quality Exterior Surfaces

InactiveUS20080096326A1Speed up the flowPrinted circuit assemblingLine/current collector detailsIntegrated electronicsSmart card

Advanced Smart Cards and similar form factors (e.g. documents, tags) having high quality external surfaces of Polyvinylchloride (PVC), Polycarbonate (PC), synthetic paper or other suitable material can be made with highly sophisticated electronic components (e.g. Integrated Circuit chips, batteries, microprocessors, Light Emitting Diodes, Liquid Crystal Displays, polymer dome switches, and antennae), integrated in the bottom layer of the card structure, through use of injection molded thermosetting or thermoplastic material that becomes the core layer of said Advanced Smart Cards. A lamination finishing process can provide a high quality lower surface, and the encapsulation of the electronic components in the thermosetting or thermoplastic material provides protection from the lamination heat and pressure.

Owner:CARDXX

Jettable compositions

ActiveUS20050171237A1Prevent long-term corrosionReaction is slowAdditive manufacturing apparatusLiquid surface applicatorsMeth-Oligomer

A fully curable jettable composition having a viscosity less than 30 cps at a temperature within the range of 15-180° C., more preferably at a temperature of 15-100° C., e.g. 60-80° C. the composition comprising: (A) at least one low viscosity reactive resin selected from the group consisting of compounds containing an oxetane ring, cycloaliphatic epoxy resins, tetrahydrofurans, hexahydropyrans and mono-functional (meth)acrylates, said resin having a molecular weight of not greater than 300 Daltons, e.g. 250 Daltons or less, and a viscosity at a temperature in the said range of less than 30 cps, e.g. 5 to 15 cps; (B) at least one higher viscosity resin selected from the group consisting of epoxy resins, compounds containing an oxetane ring and acrylates, which resin acts to thicken the low viscosity resin and strengthen a jetted deposit of the composition, the higher viscosity resin having: a viscosity greater than twice that of the low viscosity resin at the said temperature in the range stated above, and a functionality of greater than or equal to 2; (C) at least one curable toughener, preferably having a functionality of at least 2, such as hydroxy, epoxy, acrylic or other reactive functionalised polymer / oligomer (e.g. derived by functionalising poly(tetrahydrofuran), polycaprolactone, polycarbonate diol, or a dendrimeric polyol; (D) at least one initiator for the polymerisation of the resins, and (E) at least one stabiliser for delaying the curing of the resins of the composition; wherein the low viscosity resin is slower to react than the higher viscosity resin and acts to solvate the higher viscosity resin prior to curing and at least partly during curing and wherein at least 30% of the components A and B are cationically curable resins. The composition can be jetted from piezo electric printing heads under the control of a computer program to form a multi-layered article, e.g. a three dimensional article, in which the adjacent droplets merge and are cured homogeneously together.

Owner:3D SYST INC +1

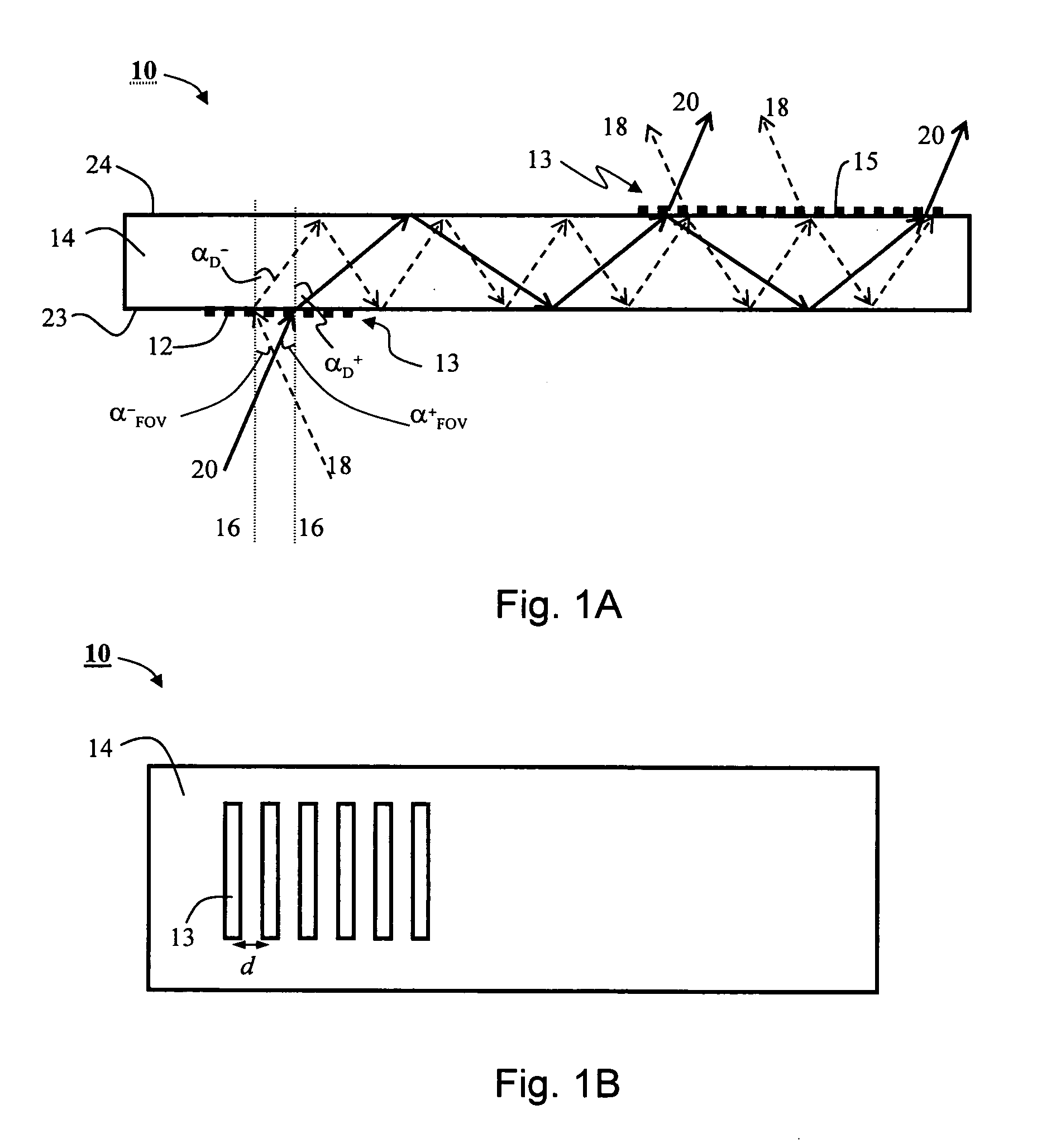

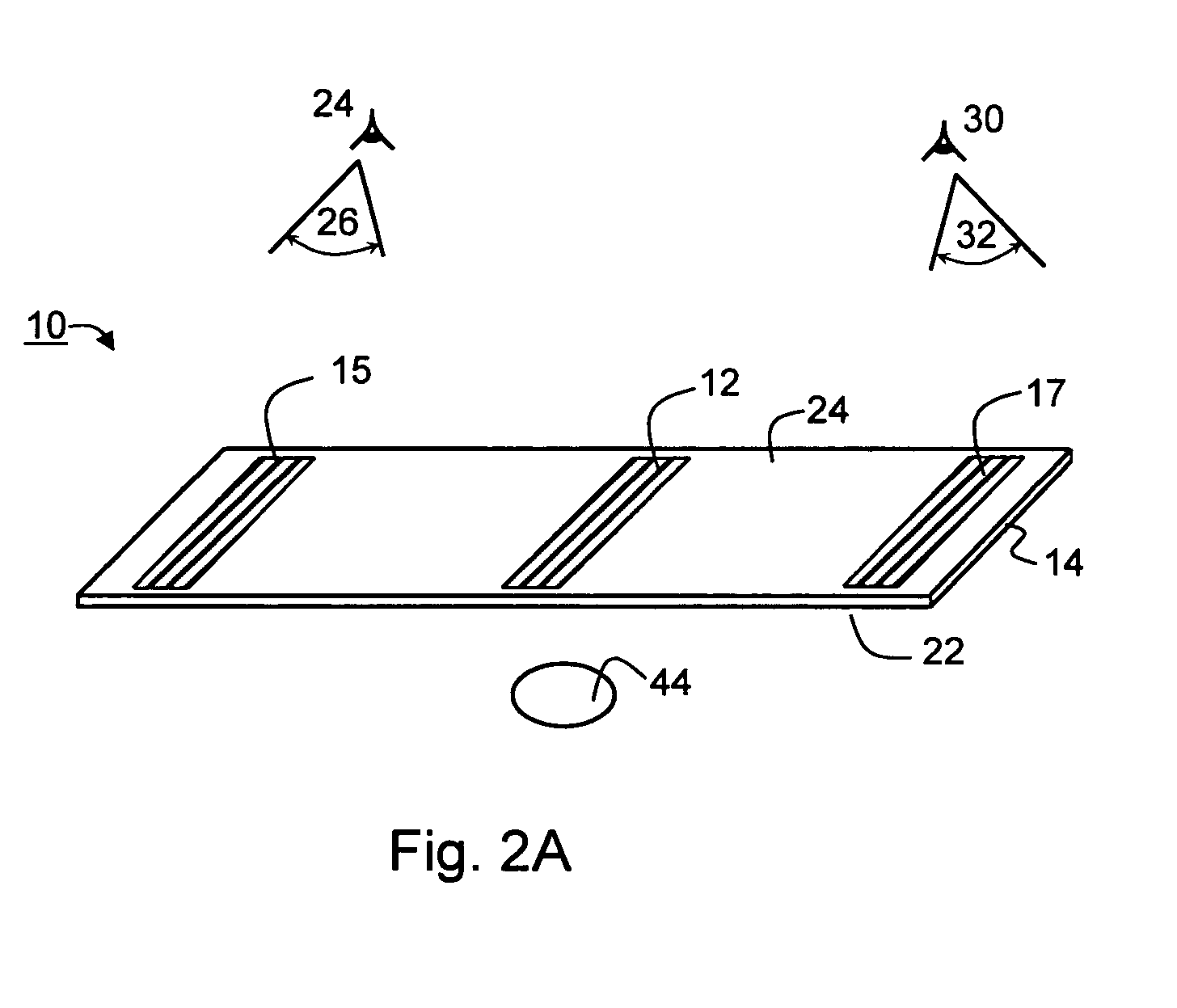

Diffractive optical relay and method for manufacturing the same

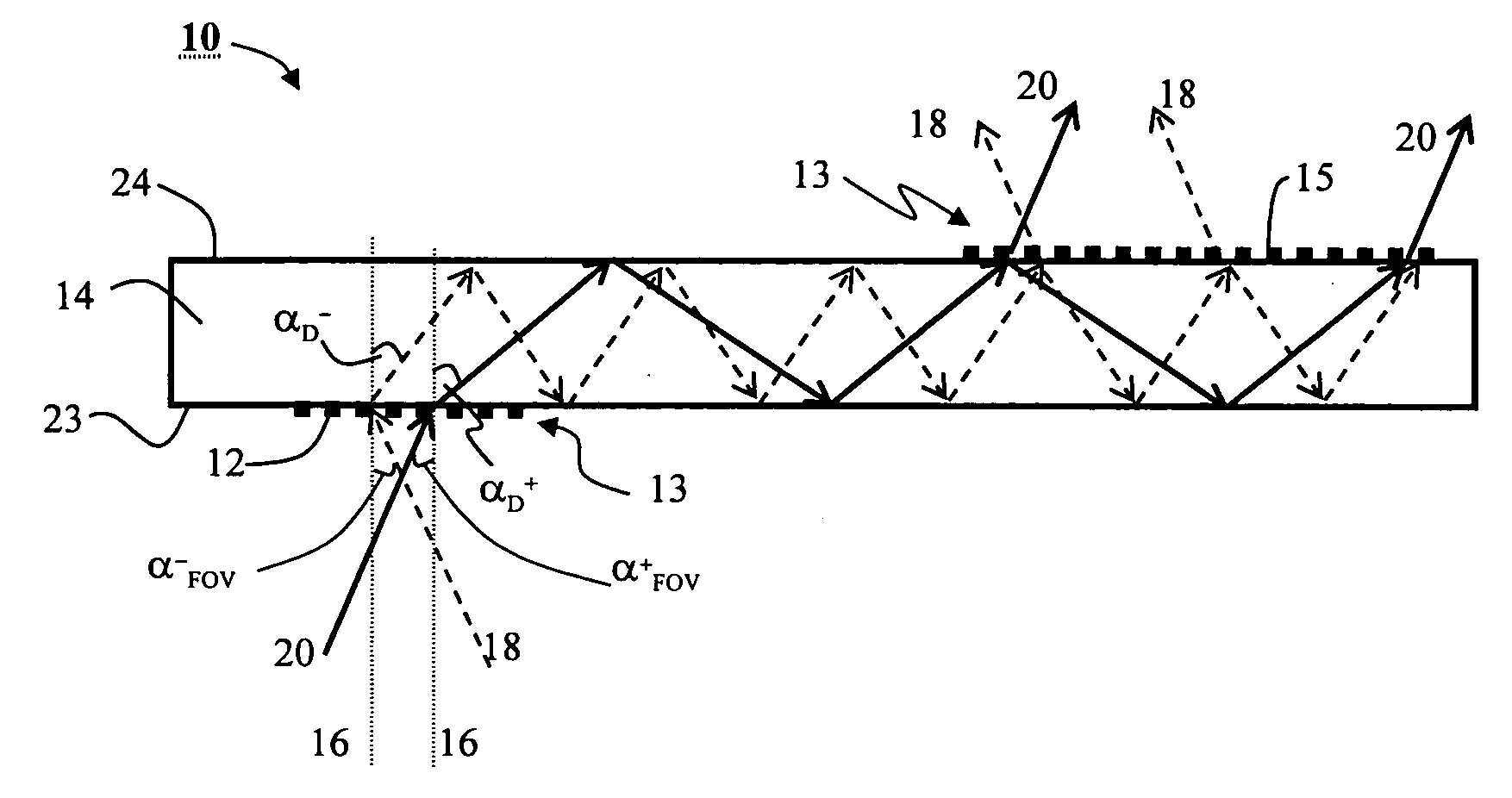

InactiveUS20080043334A1Diffraction gratingsPlanar/plate-like light guidesRefractive indexCyclo olefin polymer

An optical relay device, comprising a substrate, and at least one diffractive optical element is disclosed. The substrate is made, at least in part, of a light transmissive polymeric material characterized by a birefringence, Δn, satisfying the inequality |Δn|<ε, where ε is lower than the birefringence of polycarbonate. In a preferred embodiment, the light transmissive polymeric material comprises a cycloolefin polymer or a cycloolefin copolymer.

Owner:MIRAGE INNOVATIONS

Respiratory mask

InactiveUS20030019496A1Improve comfortReduce noise levelBreathing filtersRespiratory masksPhysical medicine and rehabilitationEngineering

A respiratory mask having a flexible, mask seal portion for engagement with the face of a user, a gel forehead cushion and a rotatable elbow coupling having integral exhaust ports. The mask seal portion has a thin section which permits the mask to more easily adapt to the contour of the face of the user. The gel forehead cushion provides increased compliancy and resiliency to better adapt to multiple user physical profiles. The elbow coupling includes tapered through holes in a polycarbonate arc piece to provide a quiet passage of gas through the holes.

Owner:RIC INVESTMENTS LLC

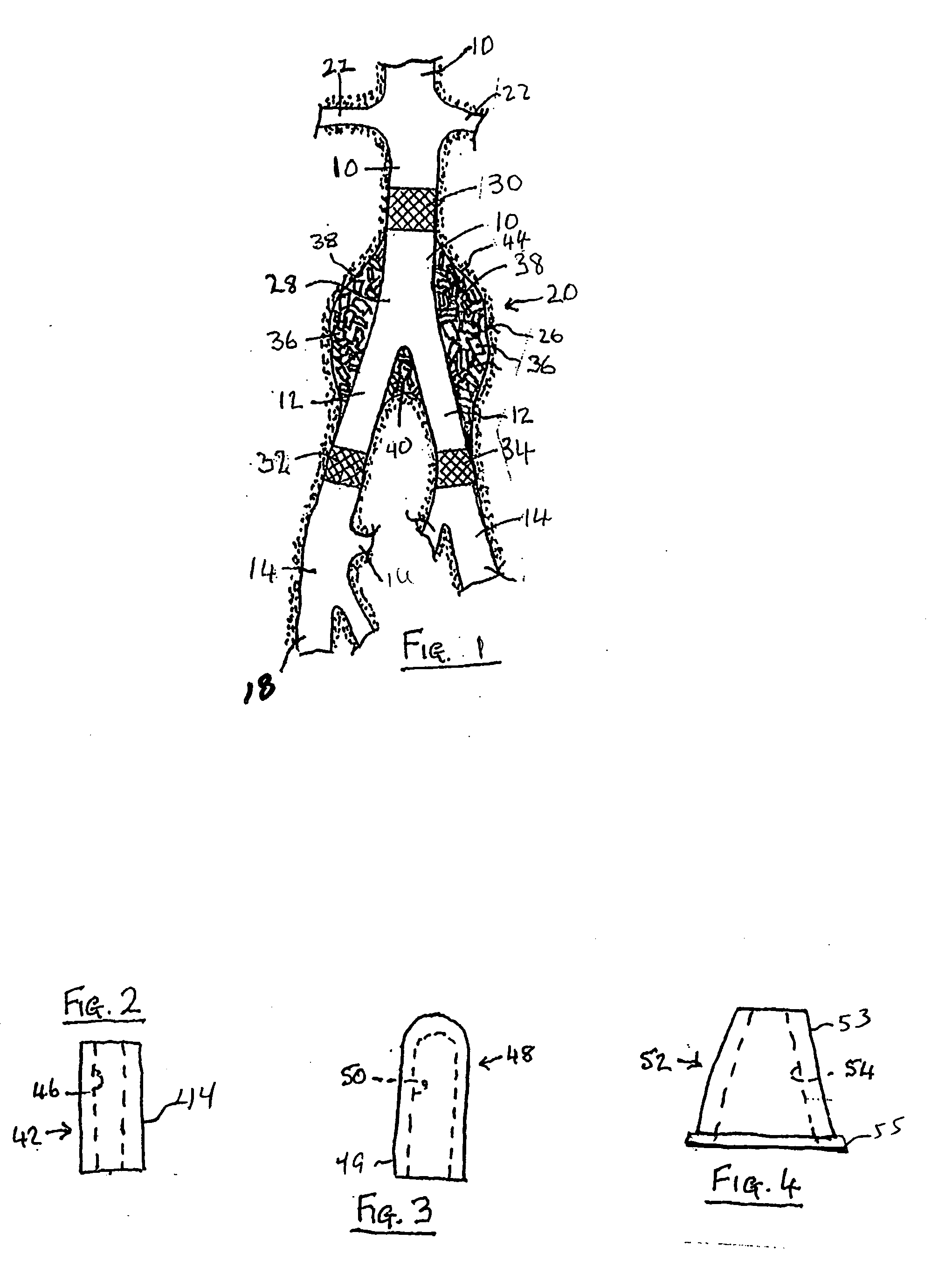

Bioabsorbable polymeric implants and a method of using the same to create occlusions

A new embolic agent, bioabsorbable polymeric material (BPM) is incorporated to a Guglielmi detachable coil (GDC) to improve long-term anatomic results in the endovascular treatment of intracranial aneurysms. The embolic agent, comprised at least in part of at least one biocompatible and bioabsorbable polymer and growth factors, is carried by hybrid bioactive coils and is used to accelerate histopathologic transformation of unorganized clot into fibrous connective tissue in experimental aneurysms. An endovascular cellular manipulation and inflammatory response are elicited from implantation in a vascular compartment or any intraluminal location. Thrombogenicity of the biocompatible and bioabsorbable polymer is controlled by the composition of the polymer. The coil further is comprised at least in part of a growth factor or more particularly a vascular endothelial growth factor, a basic fibroblast growth factor or other growth factors. The biocompatible and bioabsorbable polymer is in the illustrated embodiment at least one polymer selected from the group consisting of polyglycolic acid, poly˜glycolic acid / poly-L-lactic acid copolymers, polycaprolactive, polyhydroxybutyrate / hydroxyvalerate copolymers, poly-L-lactide. Polydioxanone, polycarbonates, and polyanhydrides.

Owner:RGT UNIV OF CALIFORNIA

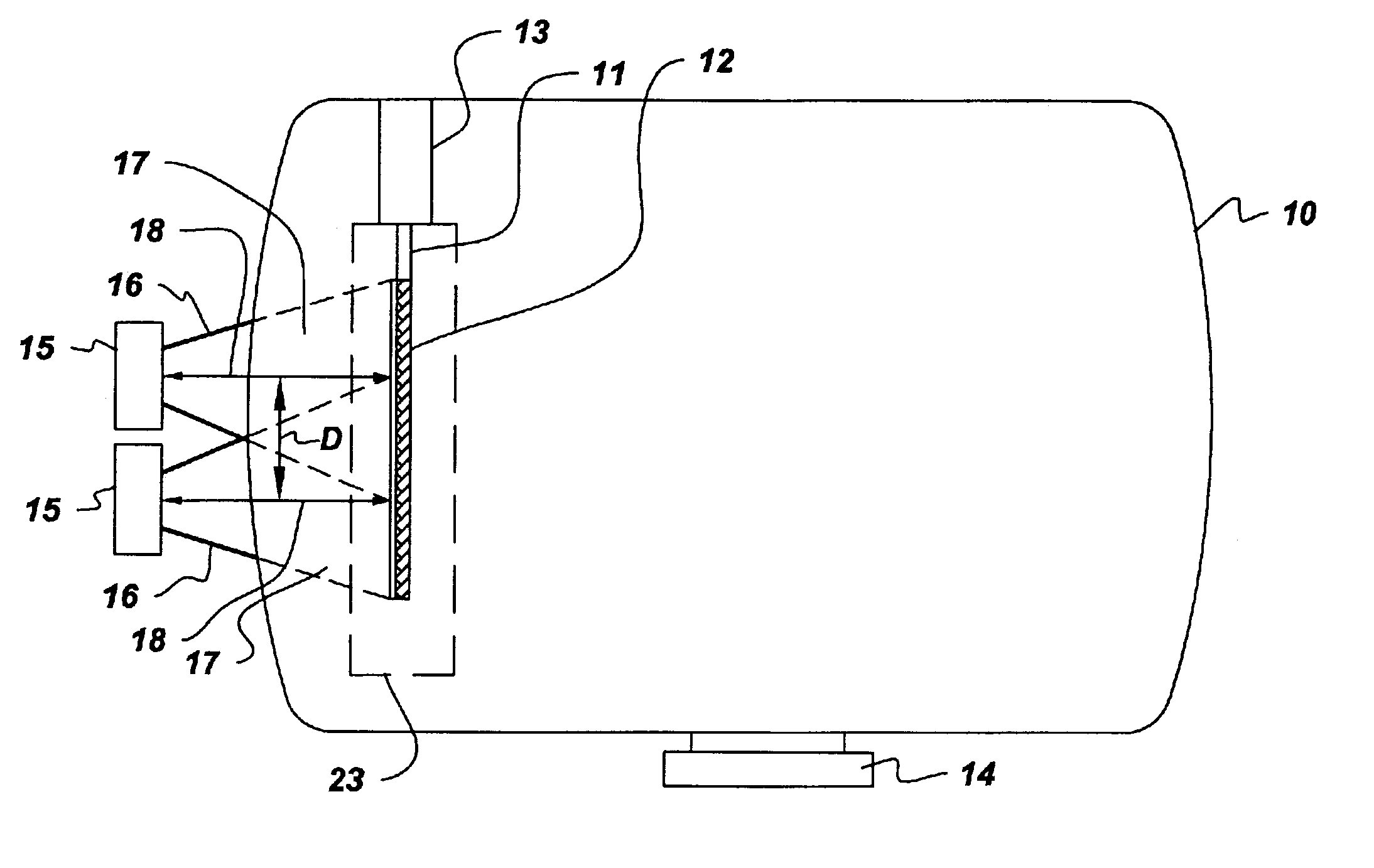

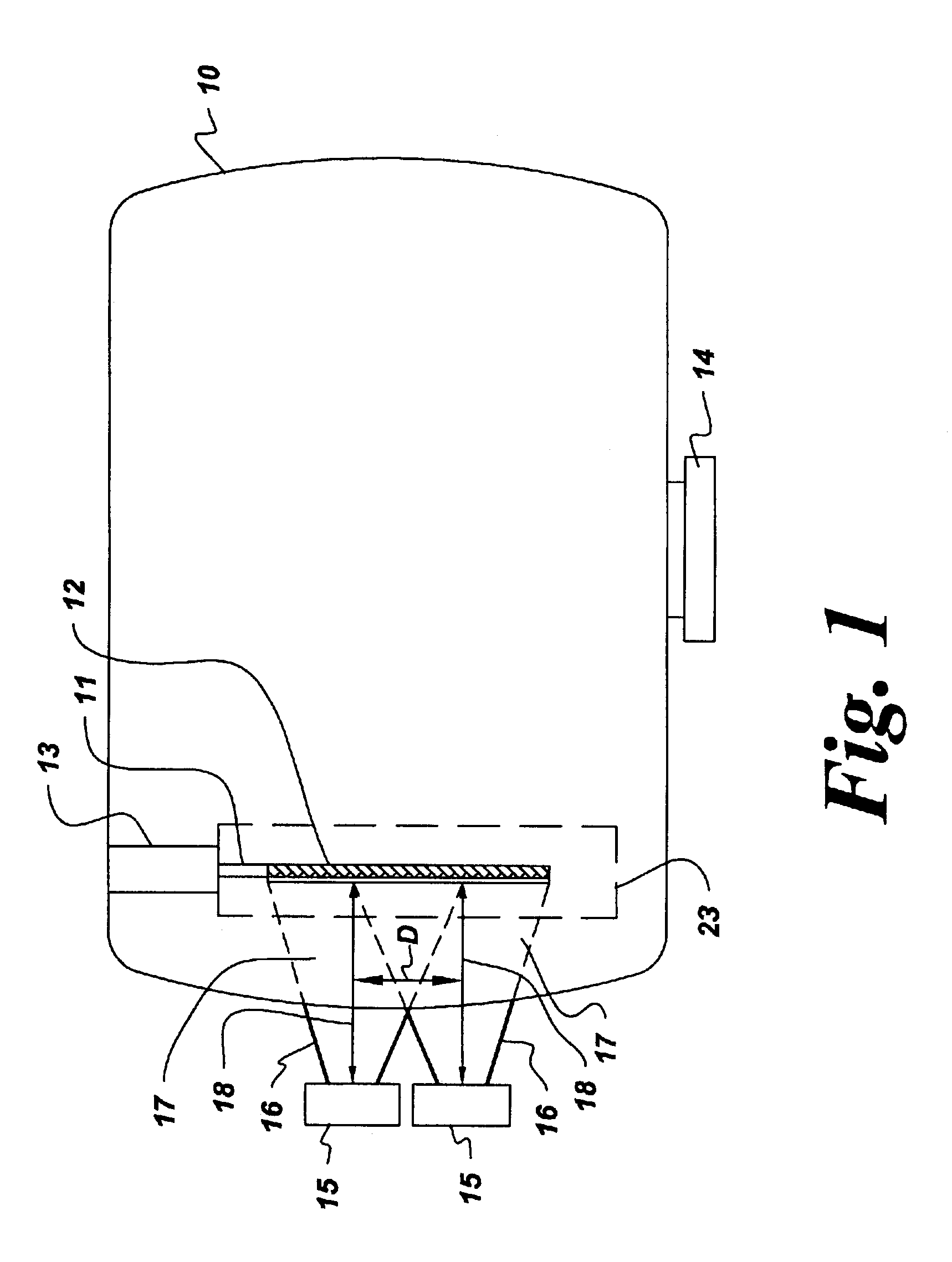

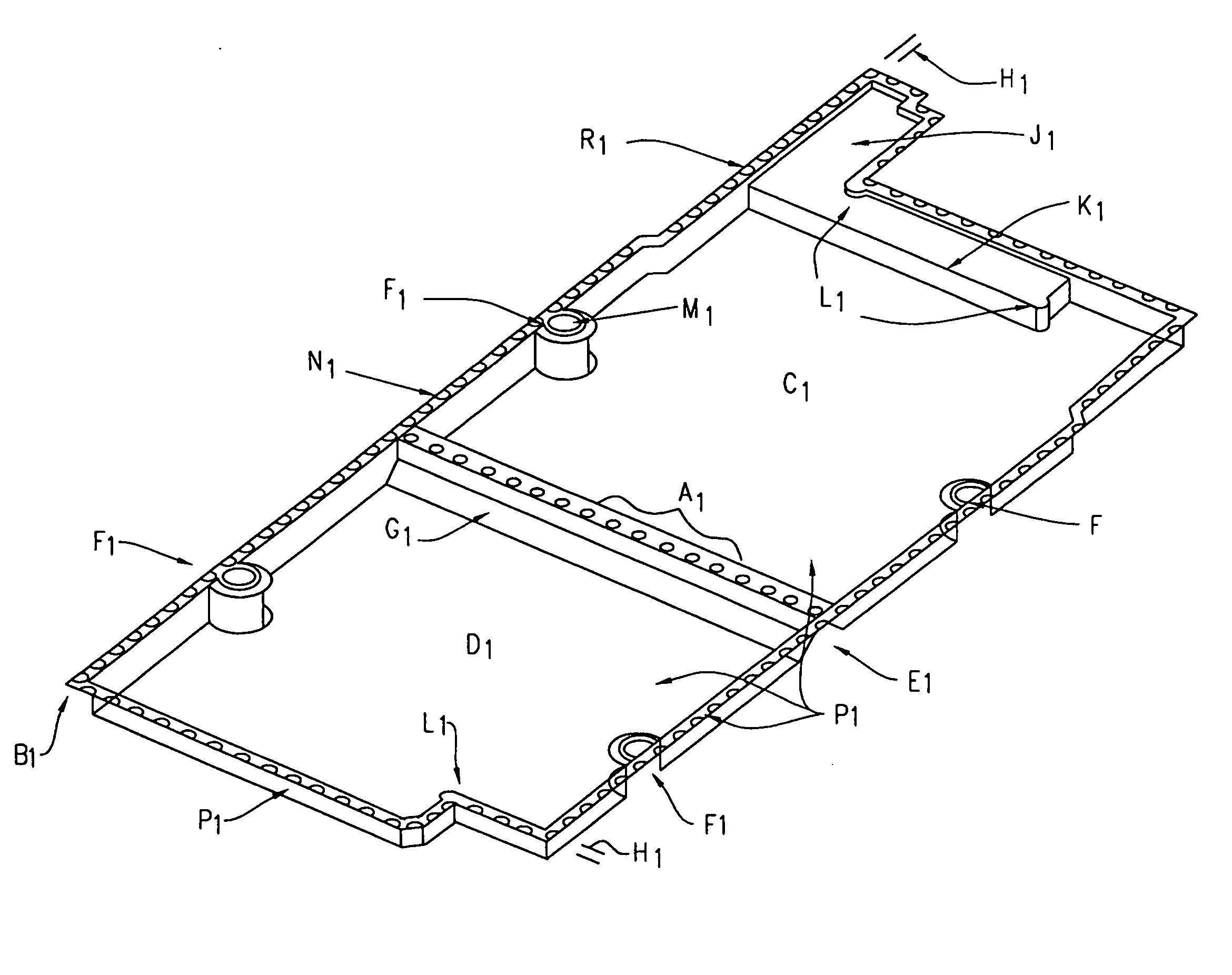

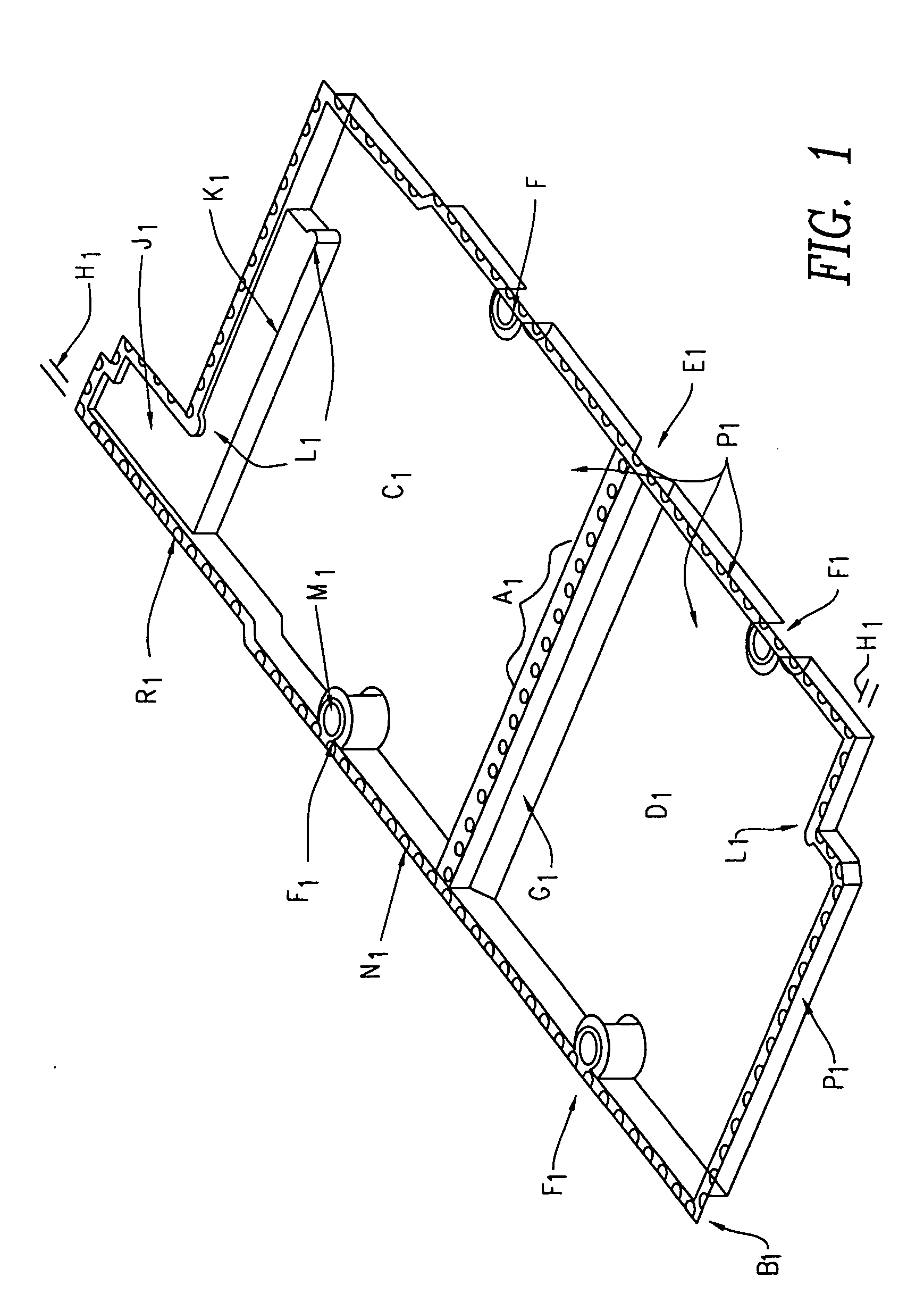

Apparatus for large area chemical vapor deposition using multiple expanding thermal plasma generators

InactiveUS6397776B1Efficient coatingDesirable propertyElectric discharge tubesChemical vapor deposition coatingThermoplasticGas phase

Chemical vapor deposition is performed using a plurality of expanding thermal plasma generating means to produce a coating on a substrate, such as a thermoplastic and especially a polycarbonate substrate. The substrate is preferably moved past the generating means. Included are methods which coat both sides of the substrate or which employ multiple sets of generating means, either in a single deposition chamber or in a plurality of chambers for deposition of successive coatings. The substrate surfaces spaced from the axes of the generating means are preferably heated to promote coating uniformity.

Owner:SABIC INNOVATIVE PLASTICS IP BV

Three-dimensional fabricating systems for rapidly producing objects

InactiveUS20160288376A1High strengthAdditive manufacturing apparatus3D object support structuresFree Radical SuppressionPolypropylene

This invention relates to rapid prototyping systems, specifically, a composition for a release film comprising one or more base materials selected from the group consisting of silicone, polycarbonate, polyethylene, and polypropylene; and one or more free-radical inhibitors.

Owner:DENTSPLY SIRONA INC

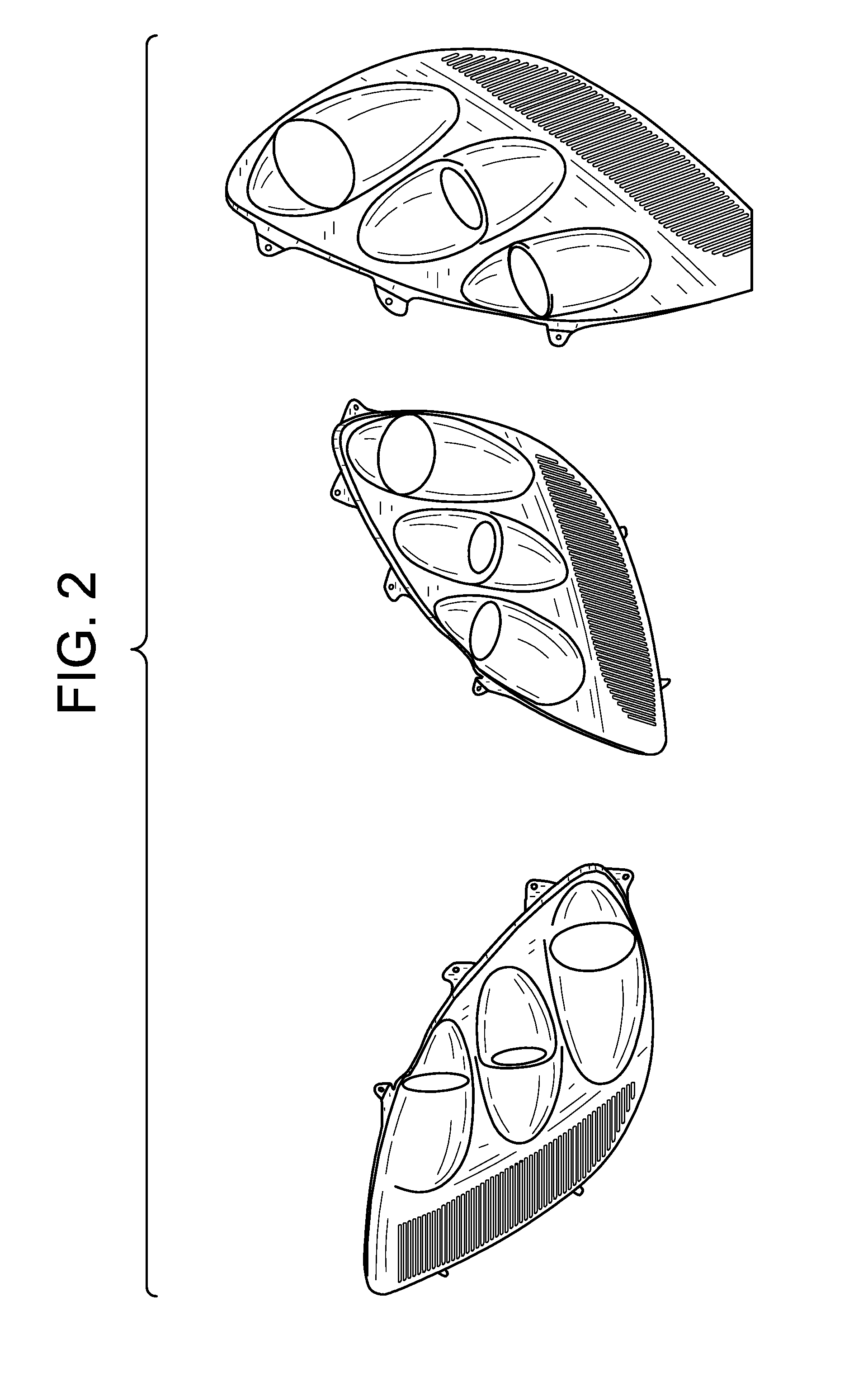

Thermally-conductive plastic articles having light reflecting surfaces

A thermally-conductive polymer composition suitable for making molded reflector articles having light-reflecting surfaces is provided. The composition comprises: a) about 20% to about 80% by weight of a base polymer matrix such as polycarbonate; and b) about 20% to about 80% by weight of a thermally-conductive carbon material such as graphite. The composition can be used to make reflector articles such as housings for automotive tail lamps, head lamps, and other lighting fixtures. A method for manufacturing reflector articles is also provided.

Owner:TICONA POLYMERS INC

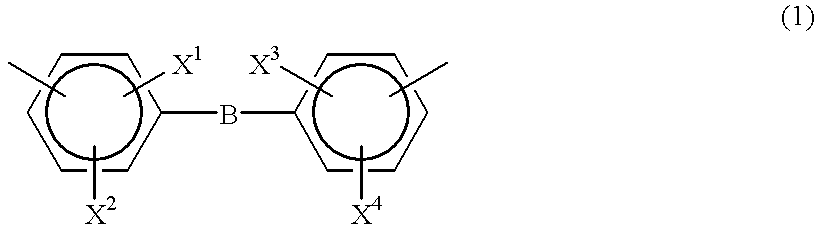

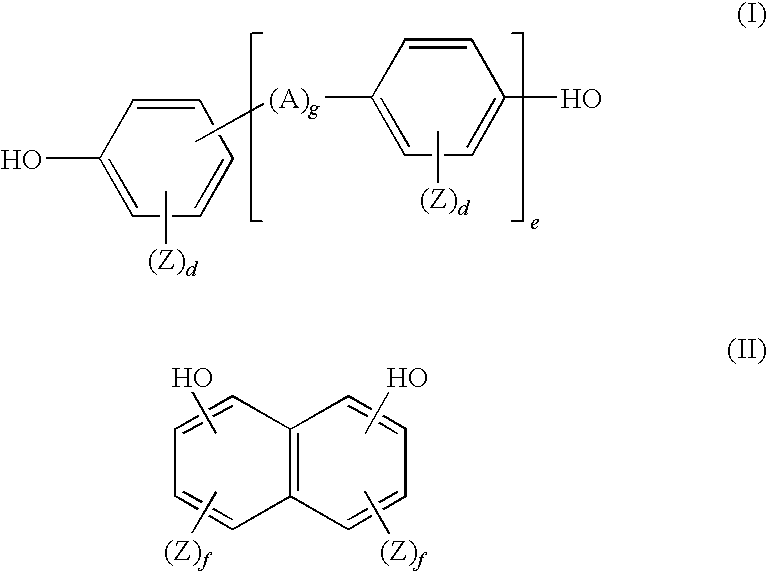

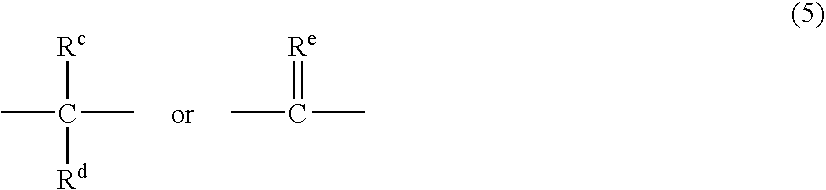

Process for preparing branched aromatic polycarbonates

A process for the production of a branched aromatic polycarbonate that includes adding a branching agent to a polycarbonate oligomer, and producing a branched aromatic polycarbonate having a melt index ratio greater than an aromatic polycarbonate produced from the polycarbonate oligomer without the addition of the branching agent. The branching agent has the formula (I):wherein A is a C1-20 polymethylene, C2-20 alkylene or alkylidene, C5-36 cycloalkylene or cycloalkylidene, C6-36 arylene or alkylarylene, or C3-36 arylalkylene, wherein G is a monovalent C6-C30 hydrocarbon having at least one hydroxyl group bonded directly to an aromatic or cycloaliphatic ring and y is an integer greater than 2, and wherein each G may be the same or different.

Owner:SABIC GLOBAL TECH BV

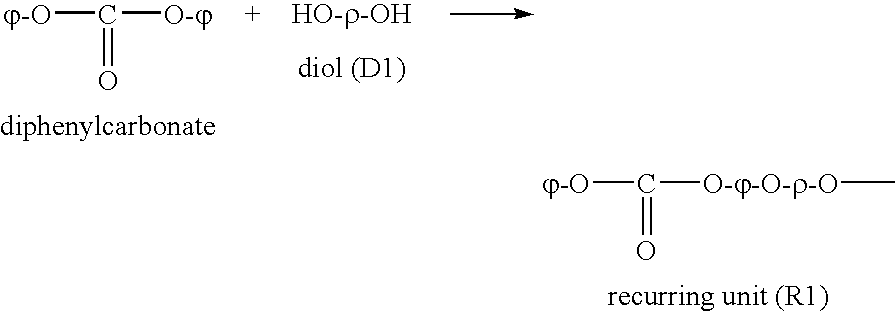

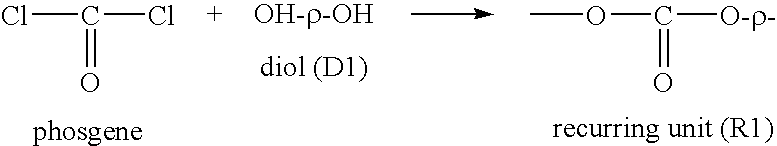

Polycarbonate preparation process

Disclosed is a polycarbonate composition and process from making same, wherein introduction of a chain terminator and an acyl halide other than phosgene is after at least 25 percent of the hydroxyl groups in the dihydric phenol have been converted to chloroformate groups.

Owner:TRINSEO EURO GMBH

Process for the production of branched melt polycarbonate by late addition of fries-inducing catalyst

The invention relates to a method for the production of a branched polycarbonate composition, having increased melt strength, by late addition of branch-inducing catalysts to the polycarbonate oligomer in a melt polycondensation process. Surprisingly, it has been found that by adding branch-inducing catalysts, such as alkali metal compounds and / or alkaline earth metal compounds, to the melt polycarbonate oligomer at a later stage of the melt polycondensation process, preferably after the oligomer has reached an average molecular weight of between about 3,000 and 30,000 g / mole, a unique branched polycarbonate composition is formed that has improved properties. It is believed that the addition of the branch-inducing catalysts at the later stages of the process produces a branched polycarbonate composition having longer chains between the branching points, and thus a new composition is produced. The invention also relates to various applications of the branched polycarbonate composition.

Owner:SABIC GLOBAL TECH BV

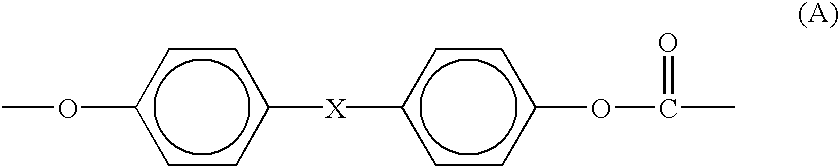

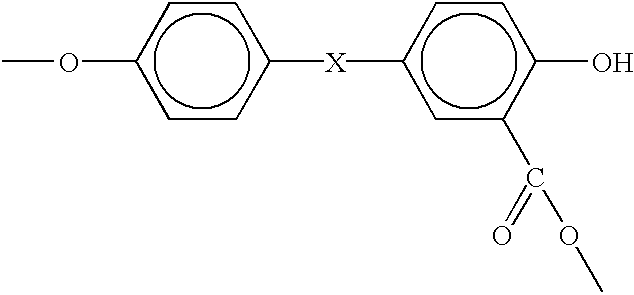

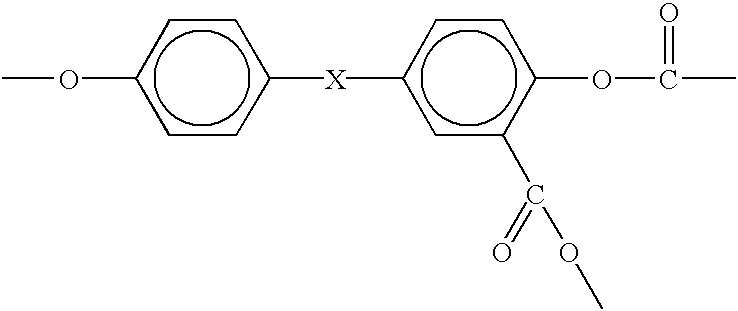

Aromatic polycarbonate composition

Blend (B) comprising:at least one aromatic polycarbonate (P1), andat least one polyarylene (P2), more than 50 wt. % of the recurring units thereof are optionally substituted arylene groups [recurring units (R2)], each of said recurring units (R2) being linked by each of its two ends to two other optionally substituted arylene groups via a direct C—C linkage, and said recurring units (R2) being a mix (M) consisting of:between 0 and 75 mole %, based on the total number of moles of recurring units (R2), of rigid rod-forming arylene units (R2a), optionally substituted by at least one monovalent substituting group, withbetween 25 and 100 mole %, based on the total number of moles of recurring units (R2), of kink-forming arylene units (R2b), optionally substituted by at least one monovalent substituting group.Article or part of an article comprising the blend (B).

Owner:SOLVAY ADVANCED POLYMERS LLC

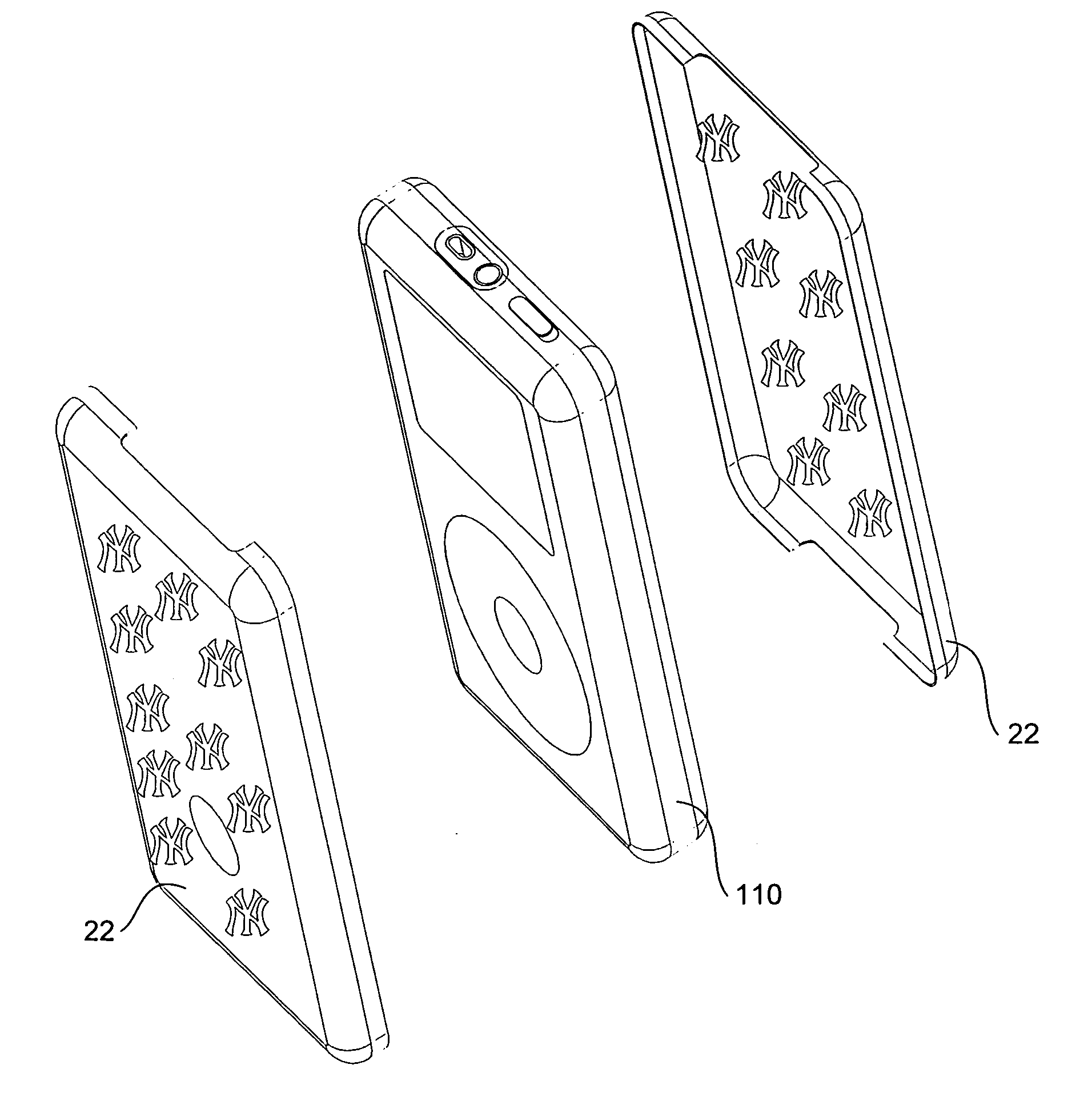

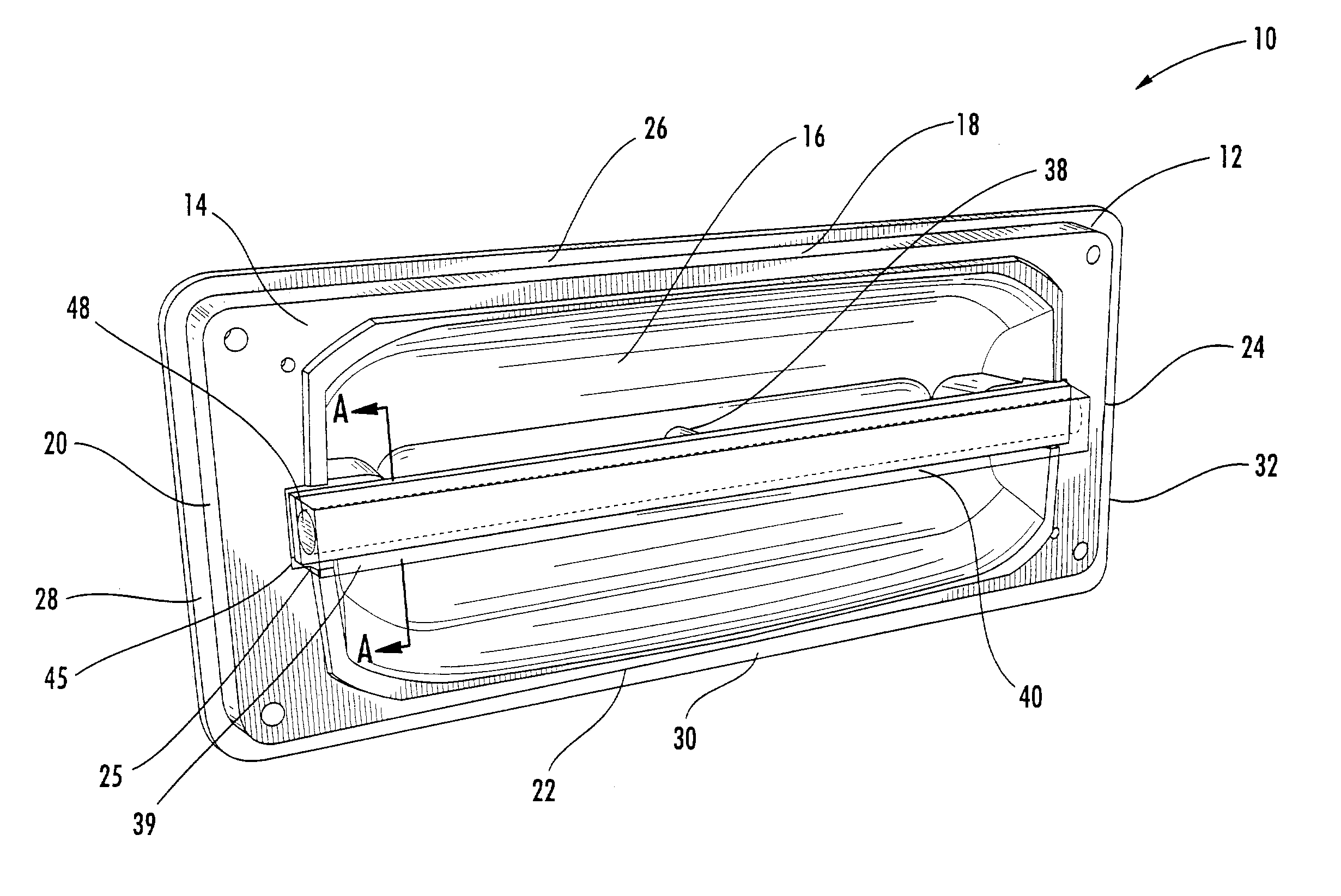

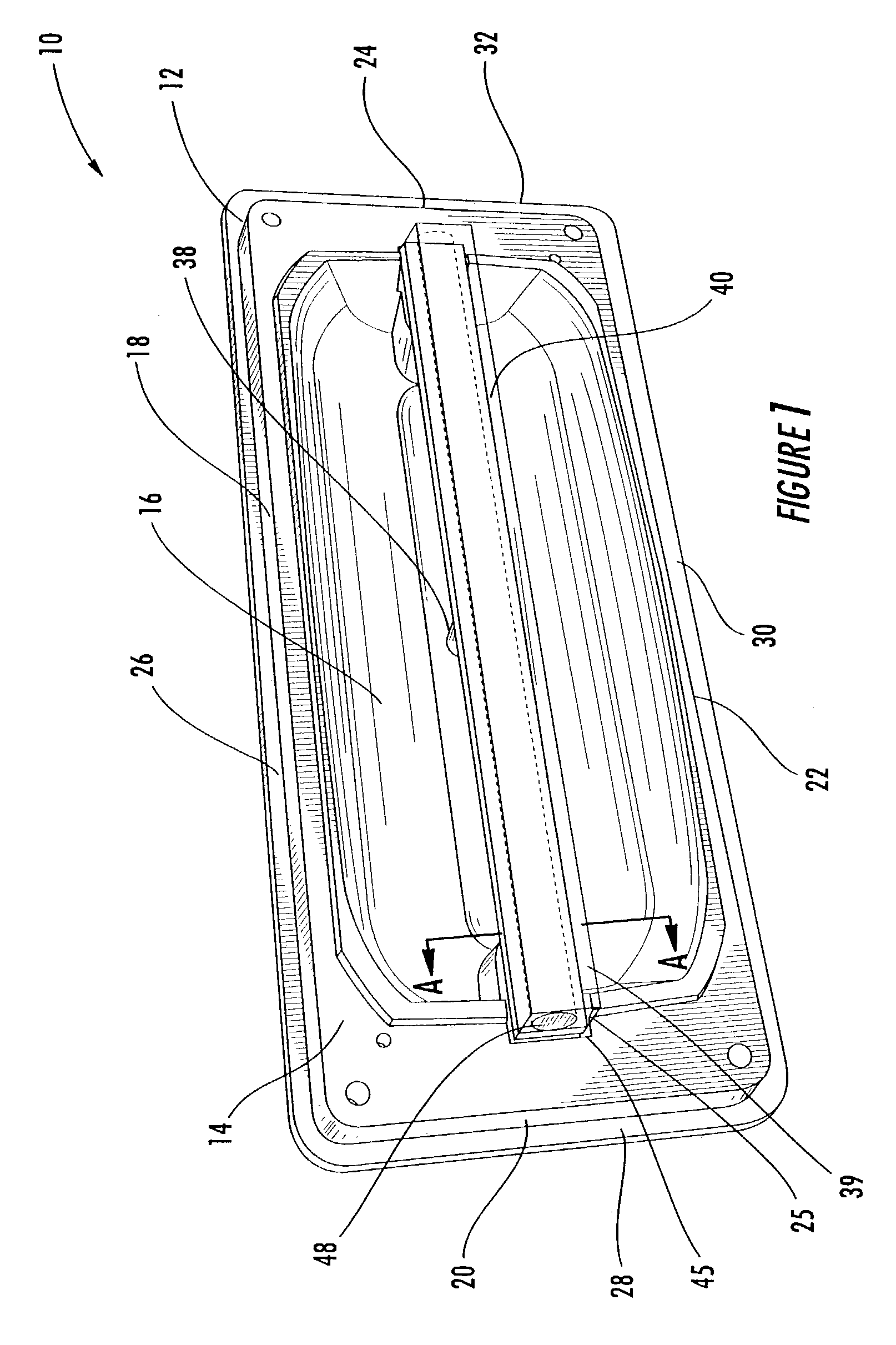

Apparatus and method for making form-fitted molded protective cases for products

A method and apparatus for making inexpensive, form-fitted, protective cases of thermal plastic or polycarbonate material that can be easily printed with decorative imagery and / or electronic circuitry for a variety of products, such as portable music players or radios, cell phones, lap-top computers, and the like. The method involves creating a tool having substantially the same surface dimensions of a product. An element is then molded from bulk film of thermoplastic material using the tool. Once the element is molded, it is trimmed from the bulk film. The resulting apparatus is a protective case intended to form-fit over the surface features and dimensions of the actual product used to define the tool.

Owner:SIK

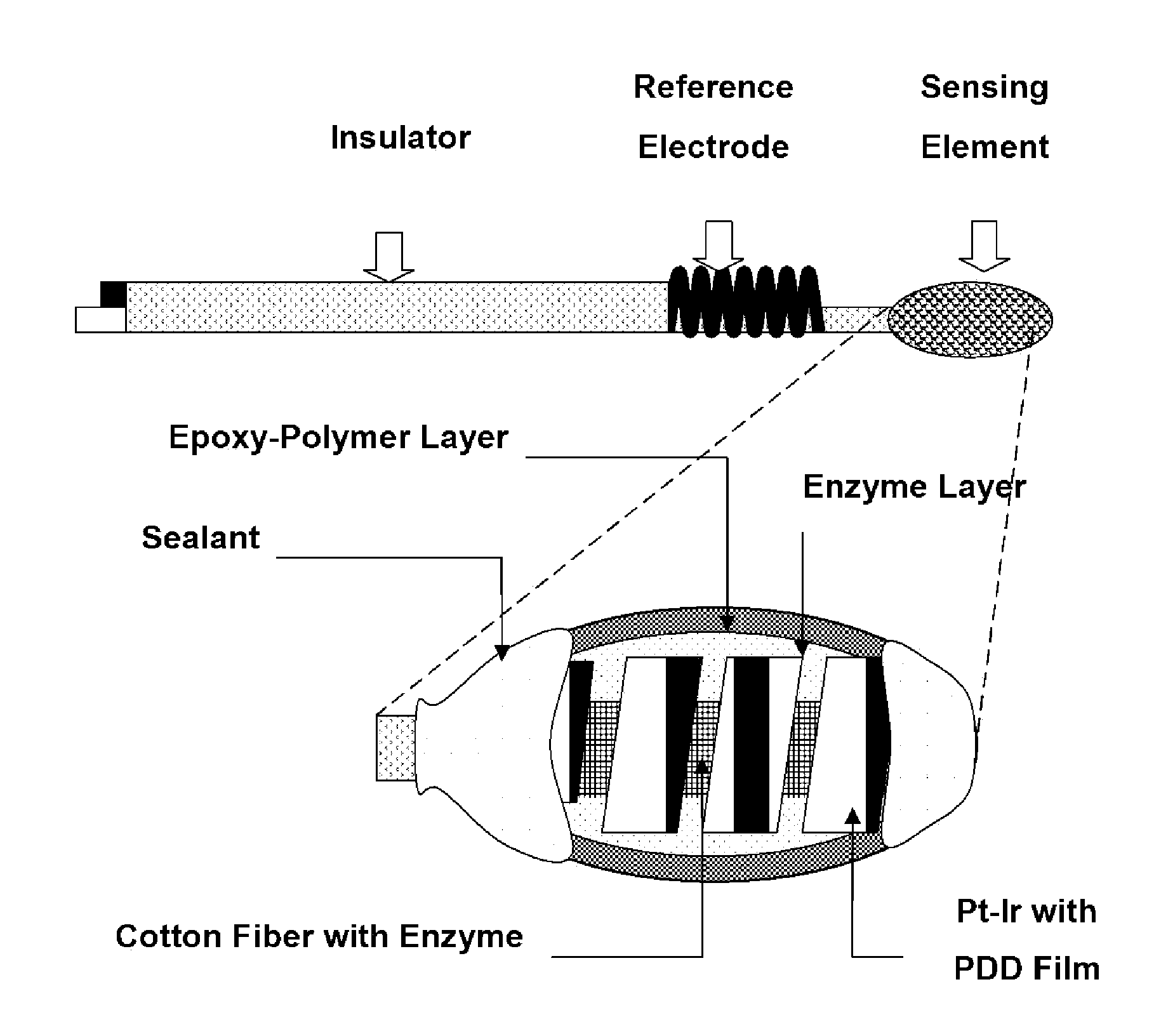

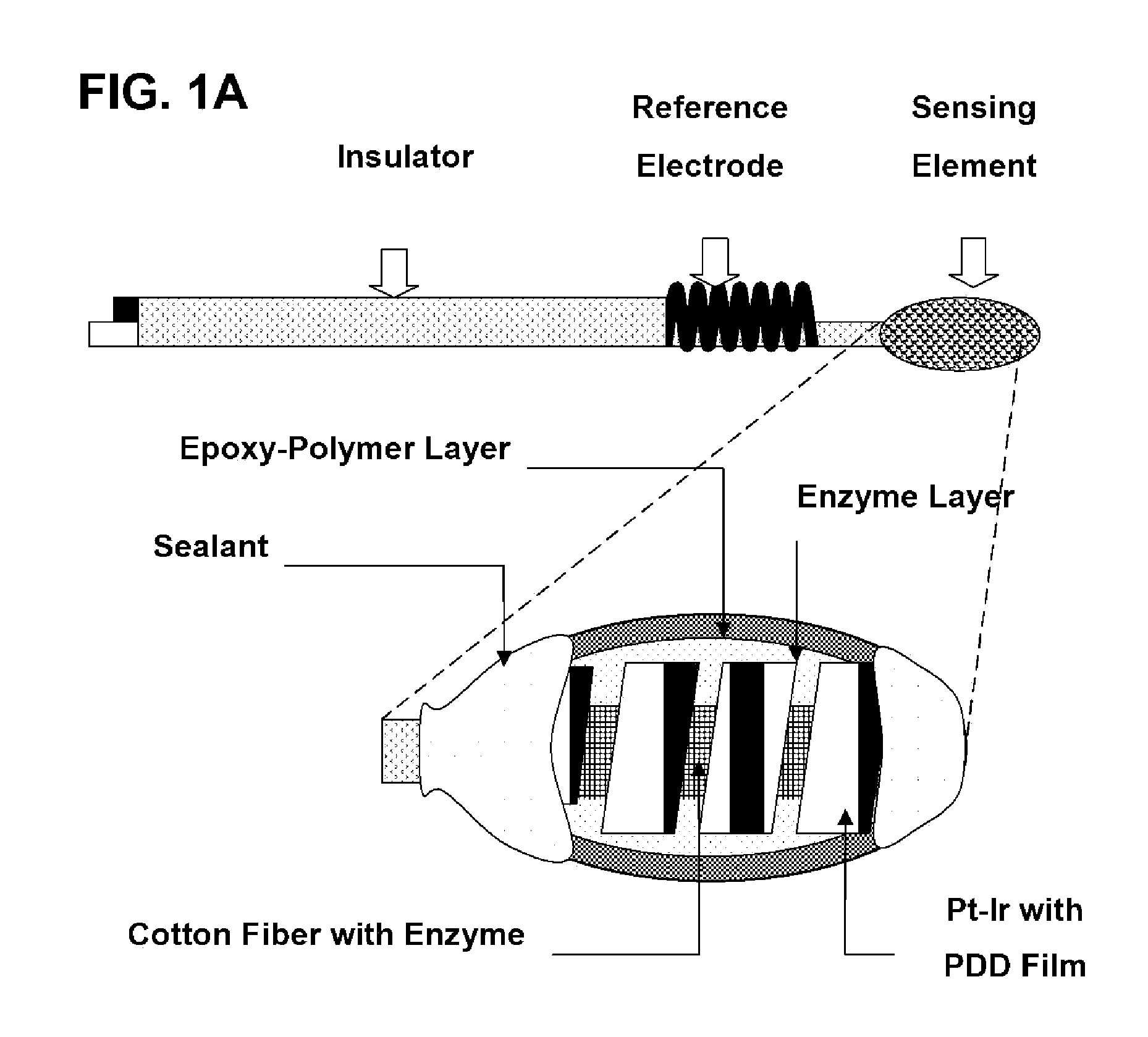

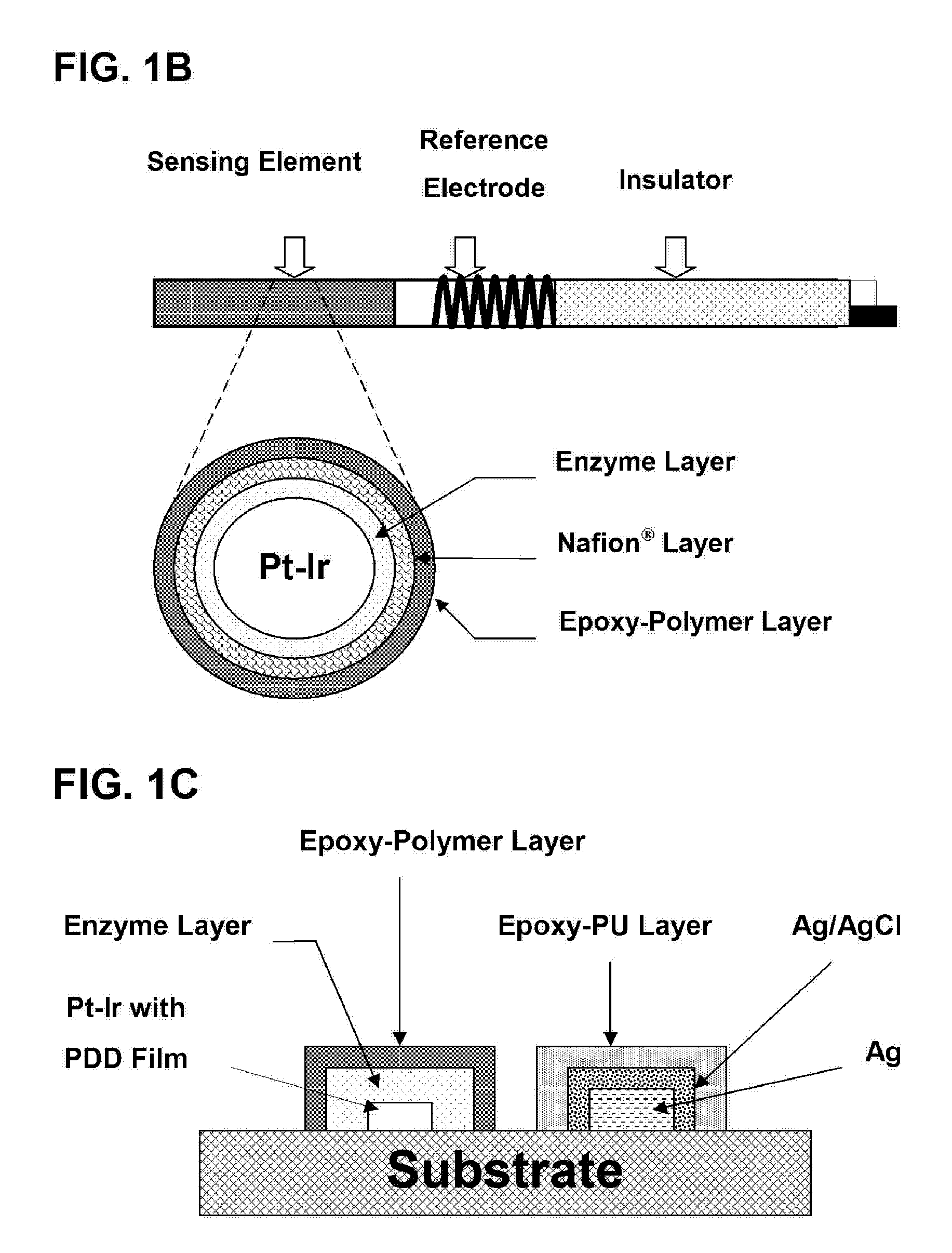

Epoxy Enhanced Polymer Membrane to Increase Durability of Biosensors

ActiveUS20060289307A1Increasing in vivo durabilityImprove long-term stabilityImmobilised enzymesBioreactor/fermenter combinationsEpoxyPolyethylene oxide

The present invention provides a polymer membrane enhanced with cured epoxy resin for use as the outer membrane of biosensors. The membrane includes approximately 30-80% epoxy resin adhesives, 10-60% polymer such as poly(vinyl chloride), polycarbonate and polyurethane and 0-30% plasticizers and 5-15% surface modifier reagent such as polyethylene oxide-containing block copolymers. Utilizing the polymer membrane of the present invention, a three-layered sensing element has been developed. This sensing element will be particularly useful for miniaturized biosensors used for in vitro blood measurements or for continuous in vivo monitoring such as implantable biosensors. This element includes an enzyme layer, an interference-eliminating layer and the novel polymer member of the present invention as the outer polymer layer. This novel sensing element shows excellent response characteristics in solutions and has an extremely long lifetime. This technology is particularly useful for improving the lifetime of implantable biosensors.

Owner:UNIV OF SOUTH FLORIDA

Composite materials comprising polar polymers and single-wall carbon nanotubes

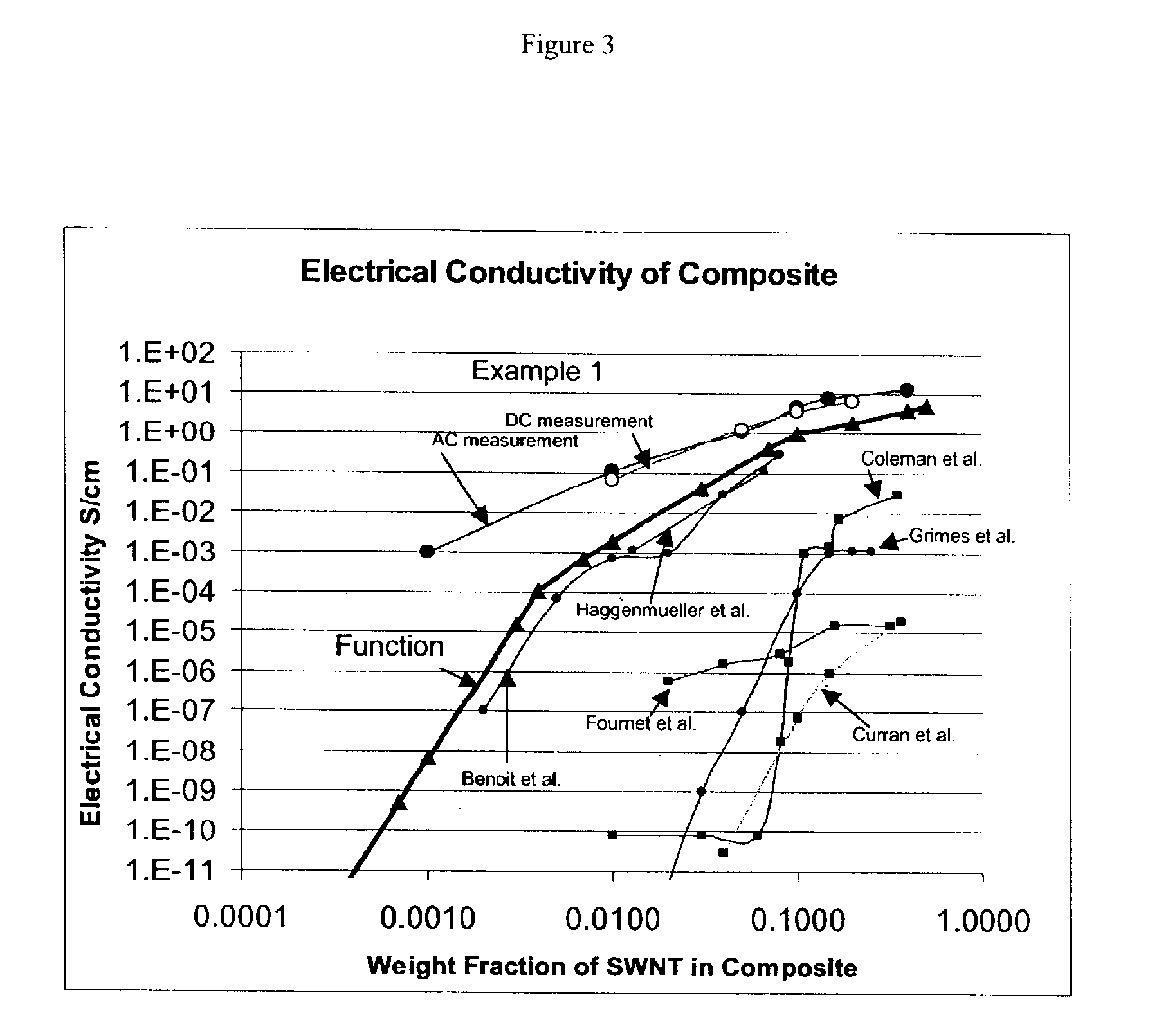

InactiveUS6936653B2Improve conductivityMaterial nanotechnologyIndividual molecule manipulationPolyesterPolymer science

The invention relates to a composite comprising a weight fraction of single-wall carbon nanotubes and at least one polar polymer wherein the composite has an electrical and / or thermal conductivity enhanced over that of the polymer alone. The invention also comprises a method for making this polymer composition. The present application provides composite compositions that, over a wide range of single-wall carbon nanotube loading, have electrical conductivities exceeding those known in the art by more than one order of magnitude. The electrical conductivity enhancement depends on the weight fraction (F) of the single-wall carbon nanotubes in the composite. The electrical conductivity of the composite of this invention is at least 5 Siemens per centimeter (S / cm) at (F) of 0.5 (i.e. where single-wall carbon nanotube loading weight represents half of the total composite weight), at least 1 S / cm at a F of 0.1, at least 1×10−4 S / cm at (F) of 0.004, at least 6×10−9 S / cm at (F) of 0.001 and at least 3×10−16 S / cm (F) plus the intrinsic conductivity of the polymer matrix material at of 0.0001. The thermal conductivity enhancement is in excess of 1 Watt / m-° K. The polar polymer can be polycarbonate, poly(acrylic acid), poly(acrylic acid), poly(methacrylic acid), polyoxide, polysulfide, polysulfone, polyamides, polyester, polyurethane, polyimide, poly(vinyl acetate), poly(vinyl alcohol), poly(vinyl chloride), poly(vinyl pyridine), poly(vinyl pyrrolidone), copolymers thereof and combinations thereof. The composite can further comprise a nonpolar polymer, such as, a polyolefin polymer, polyethylene, polypropylene, polybutene, polyisobutene, polyisoprene, polystyrene, copolymers thereof and combinations thereof.

Owner:SAMSUNG ELECTRONICS CO LTD

Method for shielding an electronic component

Owner:PPG IND OHIO INC

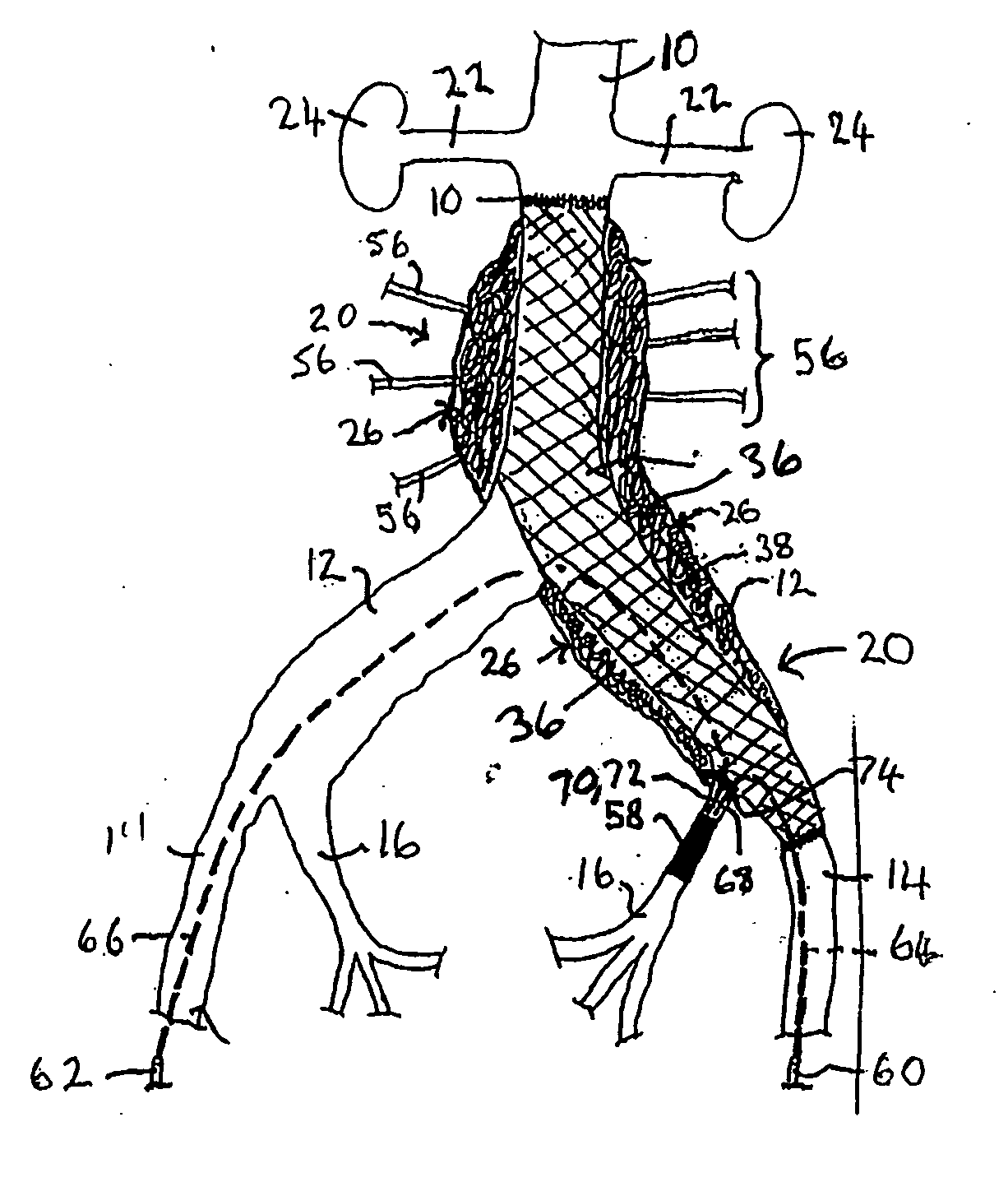

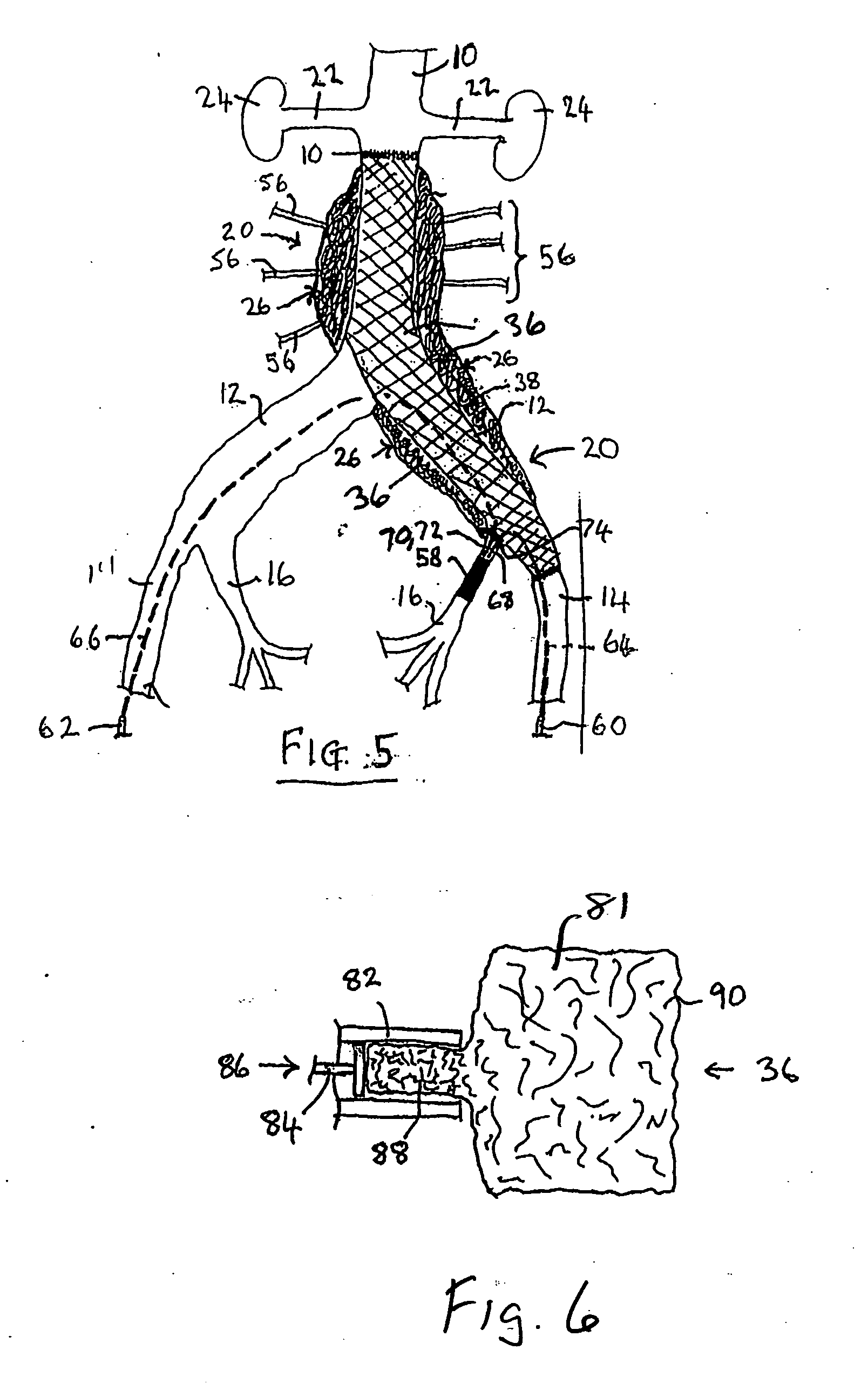

Endovascular treatment devices and methods

InactiveUS20050165480A1Simple and potentially effective treatmentTreating and preventing endoleakageTracheaeOcculdersEndovascular treatmentElastomer

A device for treating or preventing a vascular condition at a mammalian vascular site, comprises an implant formed from a compressible, reticulated elastomeric matrix in a shape conducive to delivery through a delivery instrument. One or more implants are delivered in a compressed state to the mammmalian vascular site where each implant recovers substantially to its uncompressed state following deployment from a delivery instrument. In a preferred embodiment the matrix comprises cross-linked polycarbonate polyurethane-urea or cross-linked polycarbonate polyurea-urethane. In another preferred embodiment the matrix comprises a cross-linked polycarbonate polyurethane. In a yet further embodiment, the matrix comprises thermoplastic polycarbonate polyurethane or thermoplastic polycarbonate polyurethane-urea.

Owner:THE BIOMERIX CORP

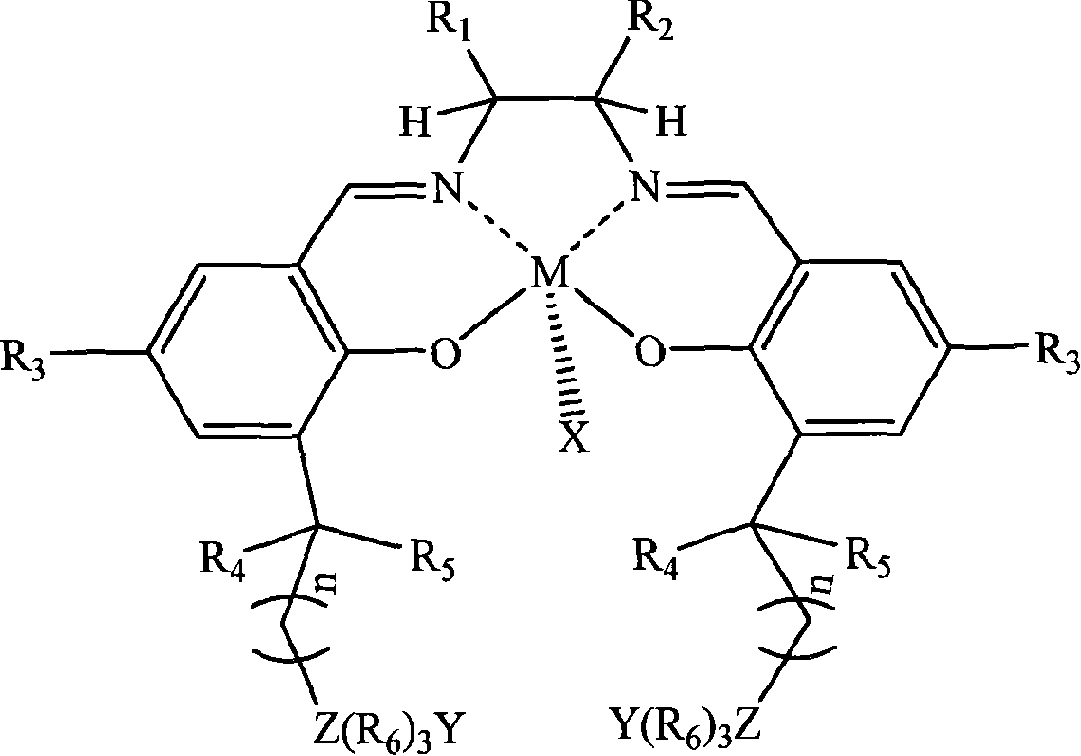

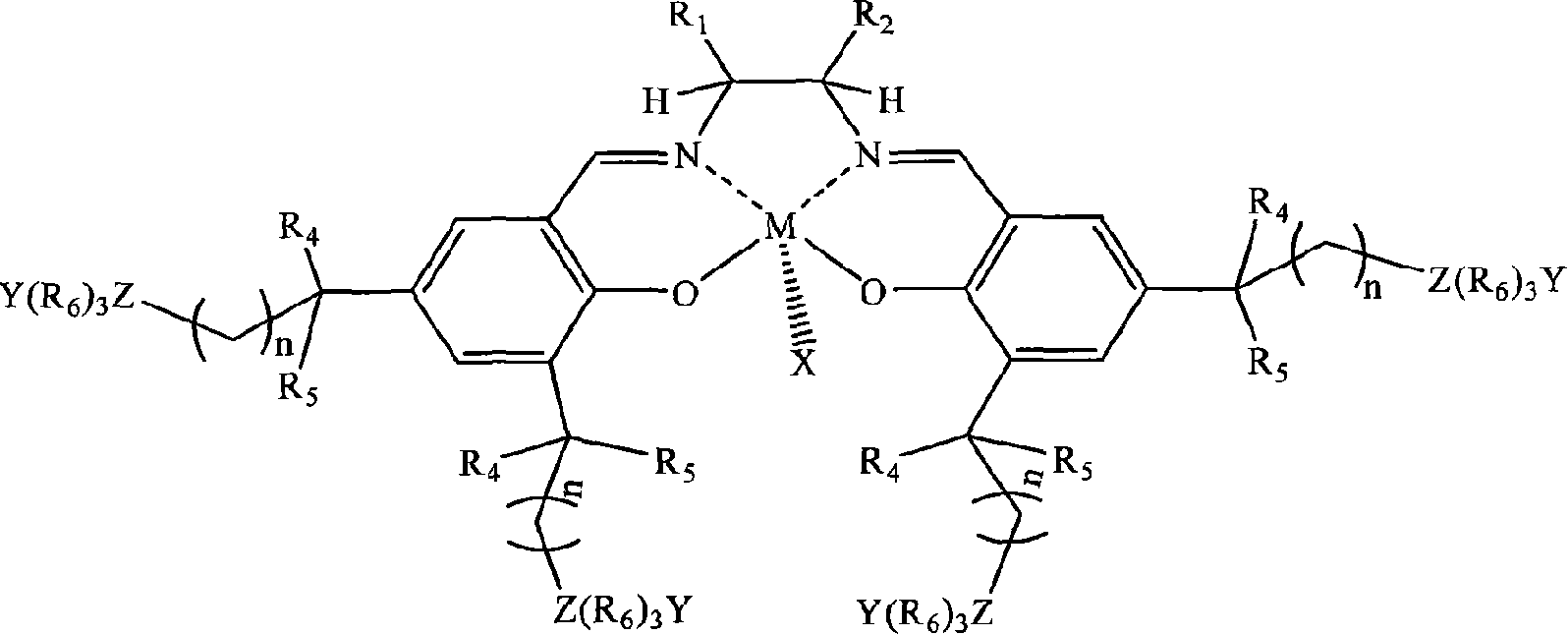

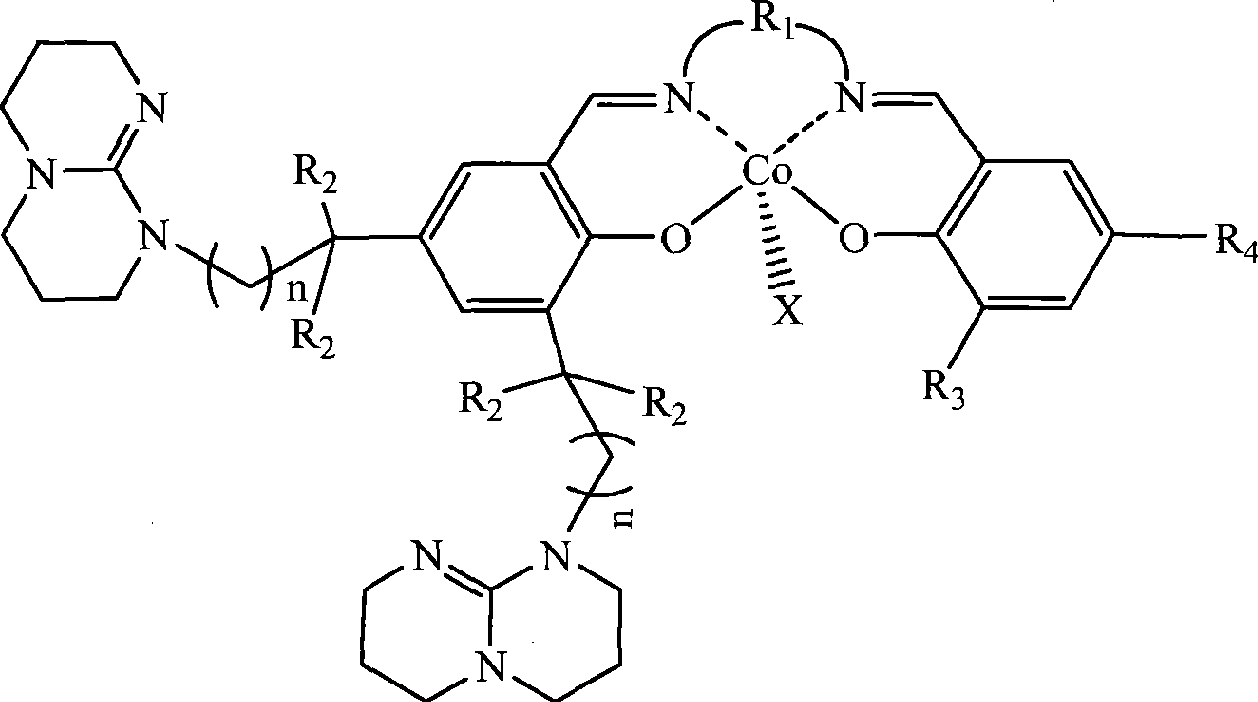

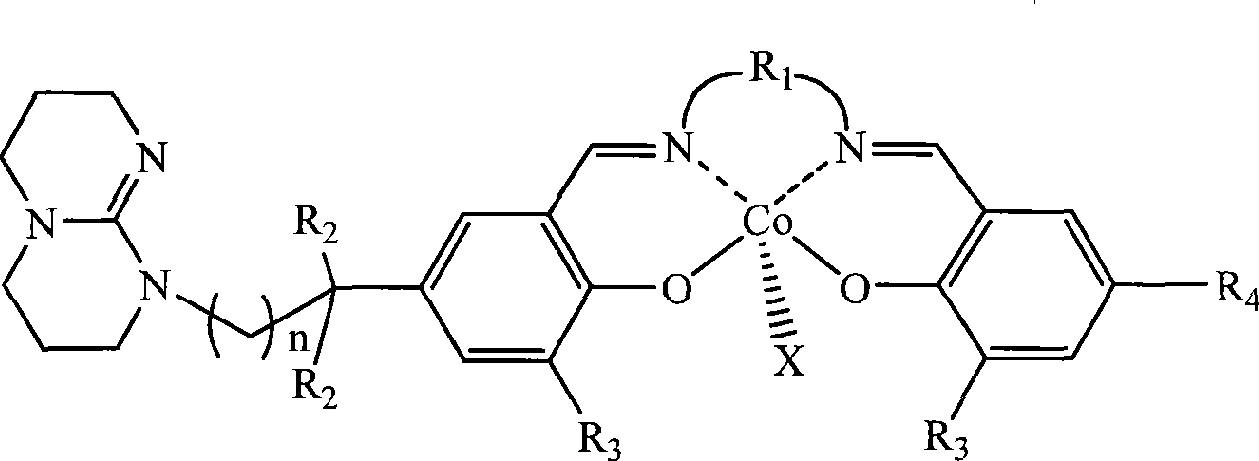

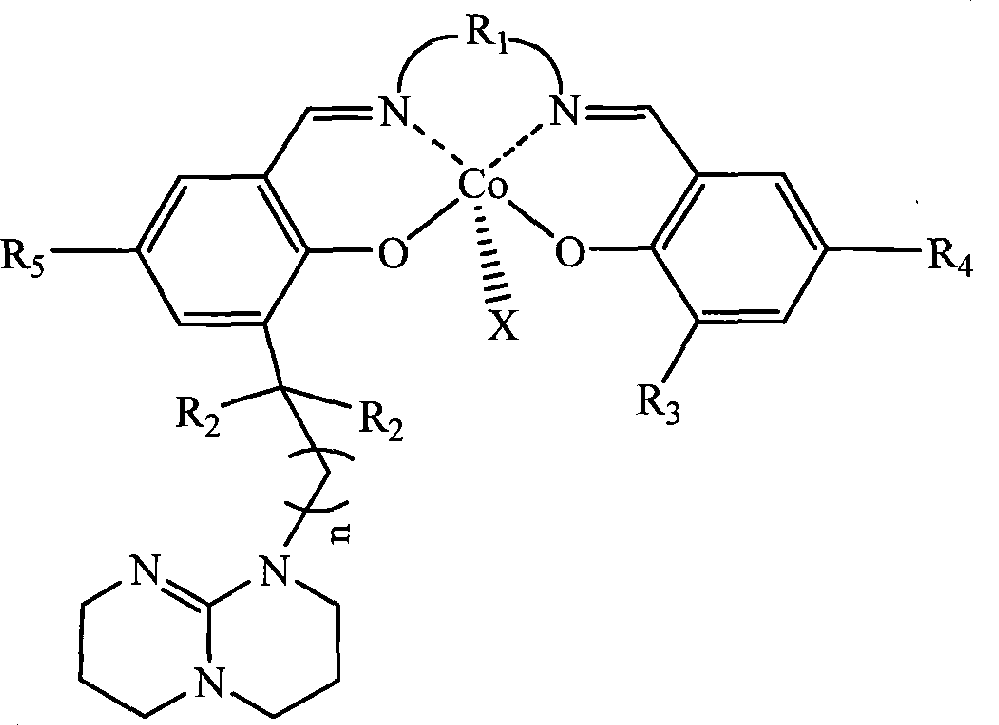

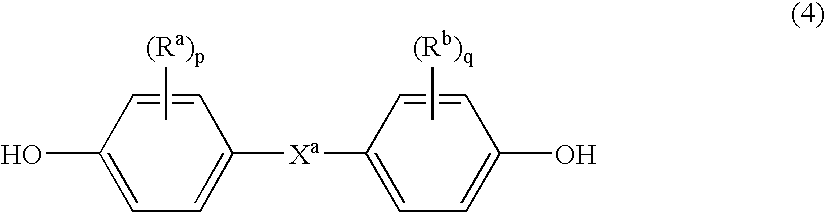

Double function catalyst for synthesizing polycarbonate

ActiveCN101020747AMild reaction conditionsThe process is simple and convenientAlkaneQuaternary ammonium cation

The present invention relates to one kind of high activity catalyst for catalyzing and activating CO2 to react with alkane epoxide to synthesize polycarbonate. The high activity catalyst is tetradentate Schiff base metal complex with double function, i. e., it has both electrophlic center originated from the metal ion in the complex and nucleophilic center originated from the quaternary ammonium salt or quaternary phosphonium salt connected to the benzene ring in the complex. The catalyst can catalyze the reaction of CO2 and alkane epoxide effectively to prepare polycarbonate.

Owner:DALIAN UNIV OF TECH

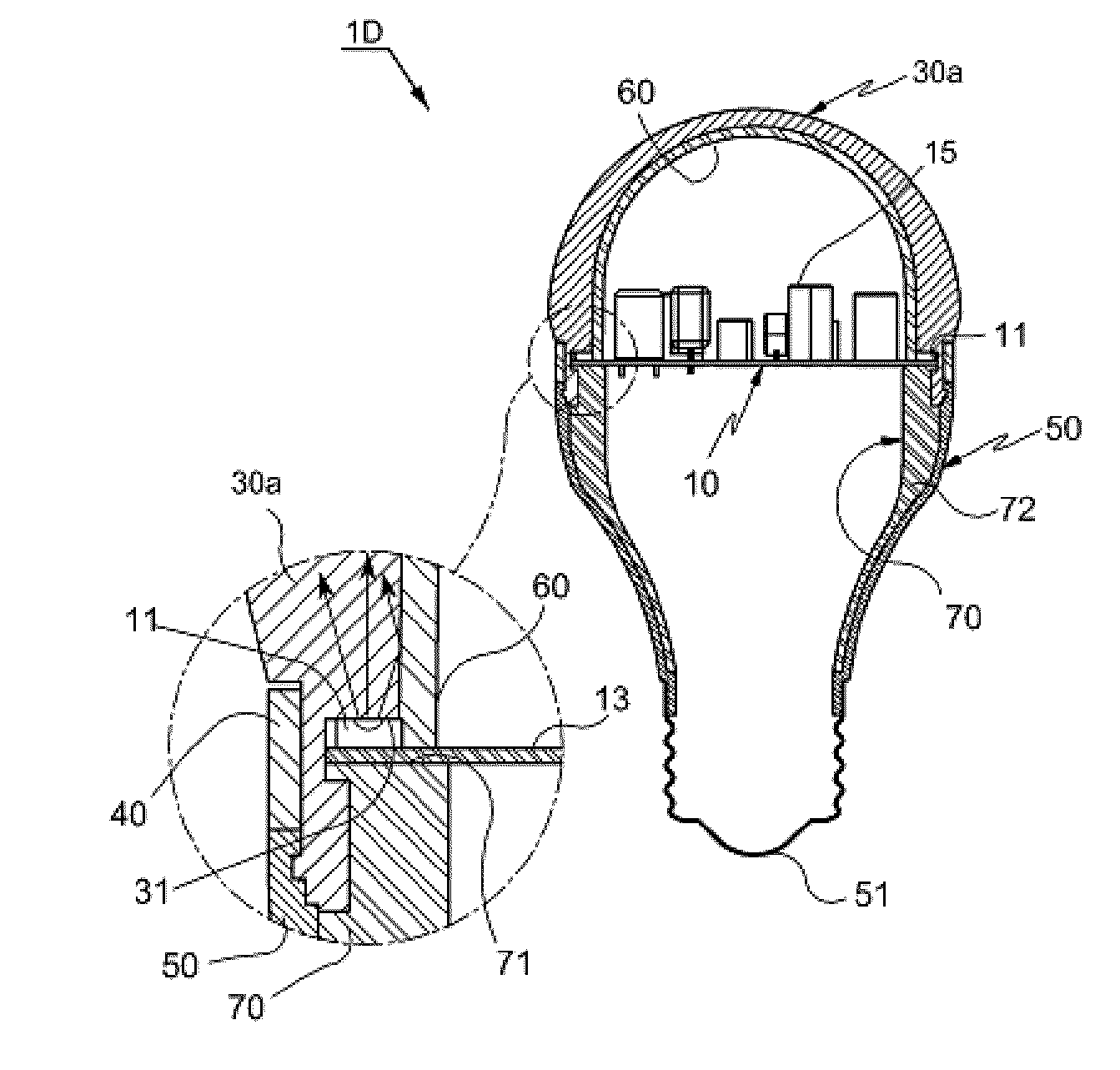

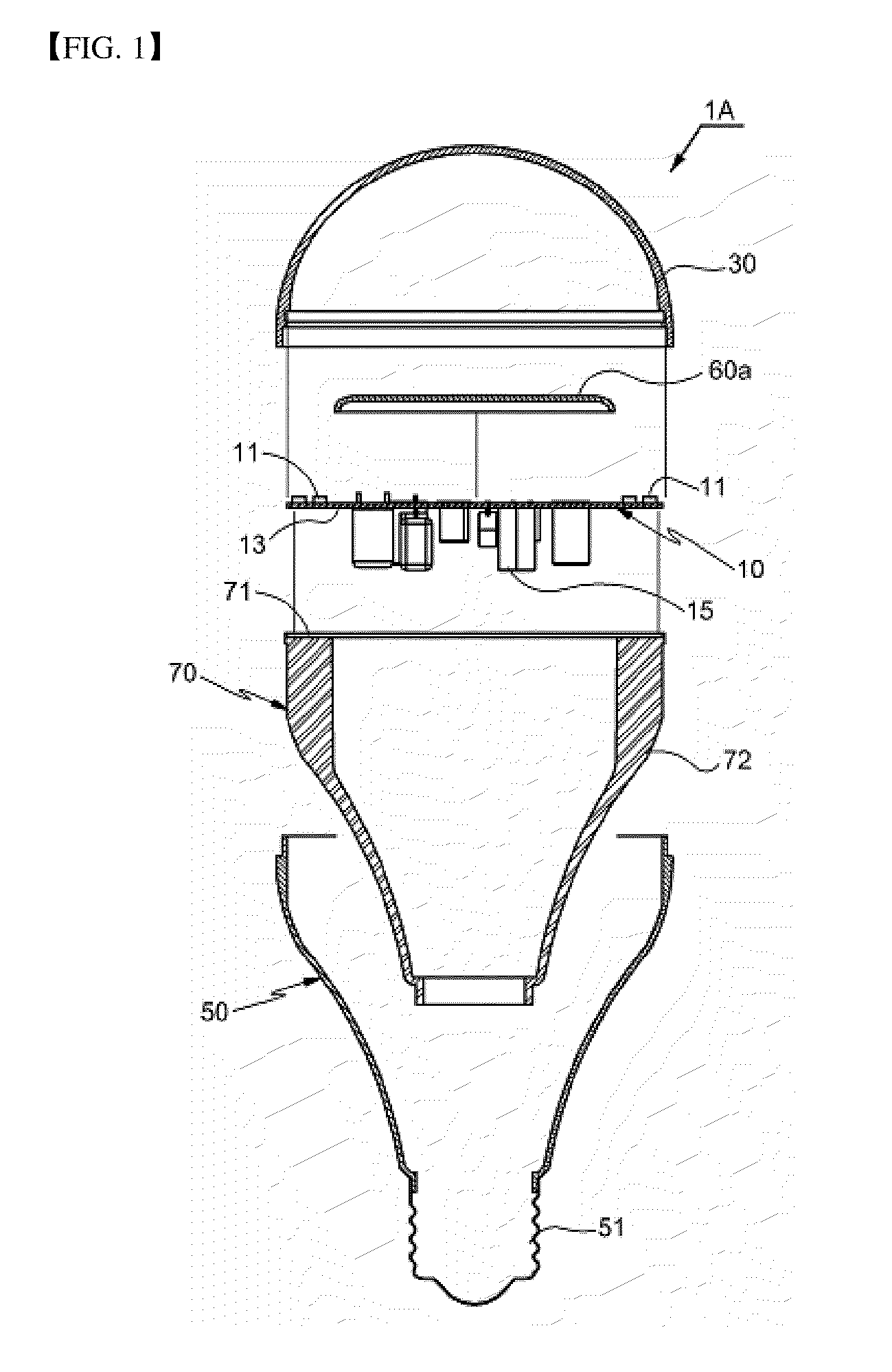

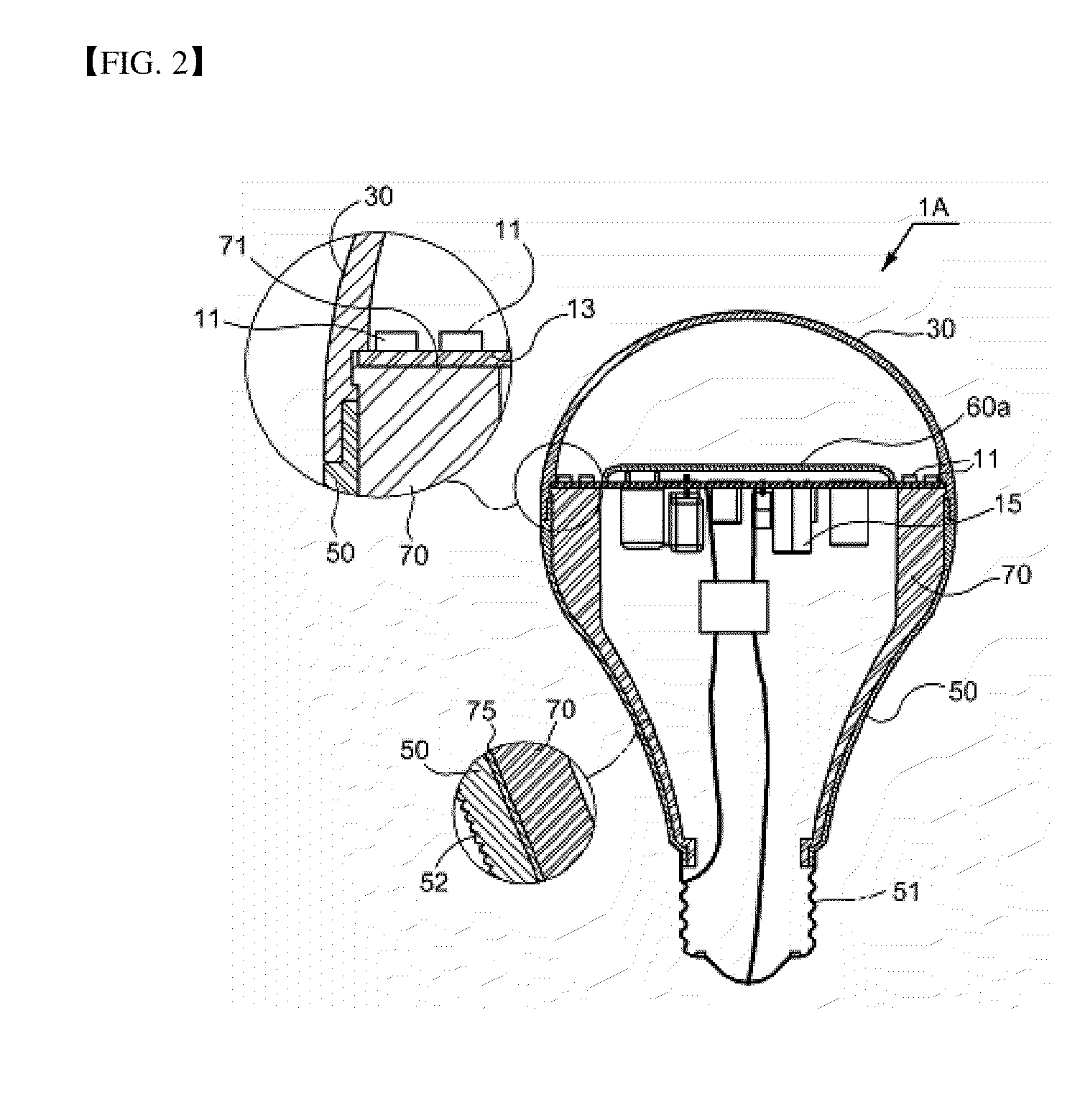

LED lamp

InactiveUS20110101861A1Increase emission rateConstant gainPoint-like light sourceElongate light sourcesEngineeringPolycarbonate

The present invention relates to an LED lamp in which, because the lamp has therein a heat dissipation transfer member and the power source base thereof is made of materials including polycarbonate, etc. with a high emission rate of radiation so as to enhance its surface heat dissipation constant, the power source base has sufficient heat dissipation performance and, thus, a separate insulation circuit is not necessary, thereby improving reliability and productivity of the lamp as well as reducing the cost of manufacturing.To this end, the present invention provides an LED lamp comprising one or more LEDs mounted on a PCB, a floodlight cover that transmits light from the LEDs, and a power source base coupled to the floodlight cover and having a terminal at one end thereof, wherein the power source base is made of an insulation material; and the LED lamp also comprises a heat dissipation transfer member that has a heat sink in contact with the PCB on which the LEDs are mounted, and is formed and installed so as to overlap with and be in tight contact with the inner face of either the power source base or the floodlight cover or both.

Owner:YOO YOUNG HO +1

Light-emitting diode reflector assembly having a heat pipe

InactiveUS6976769B2Point-like light sourcePortable electric lightingConductive polymerCarbon graphite

A light-emitting diode reflector assembly having a heat pipe and a reflector body is provided. The assembly further includes a mounting member for mounting a circuit board having an array of light-emitting diodes. The mounting member and reflector body are made from a thermally-conductive polymer composition comprising: i) about 20% to about 80% by weight of a base polymer matrix such as polycarbonate; and ii) about 20% to about 80% by weight of a thermally-conductive material such as carbon graphite.

Owner:TICONA POLYMERS INC

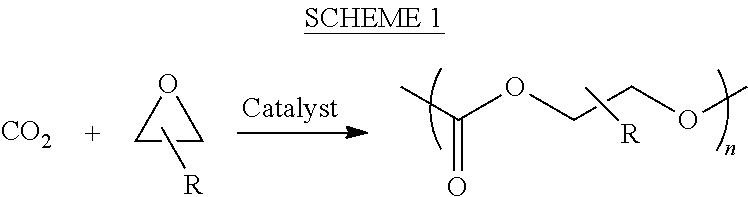

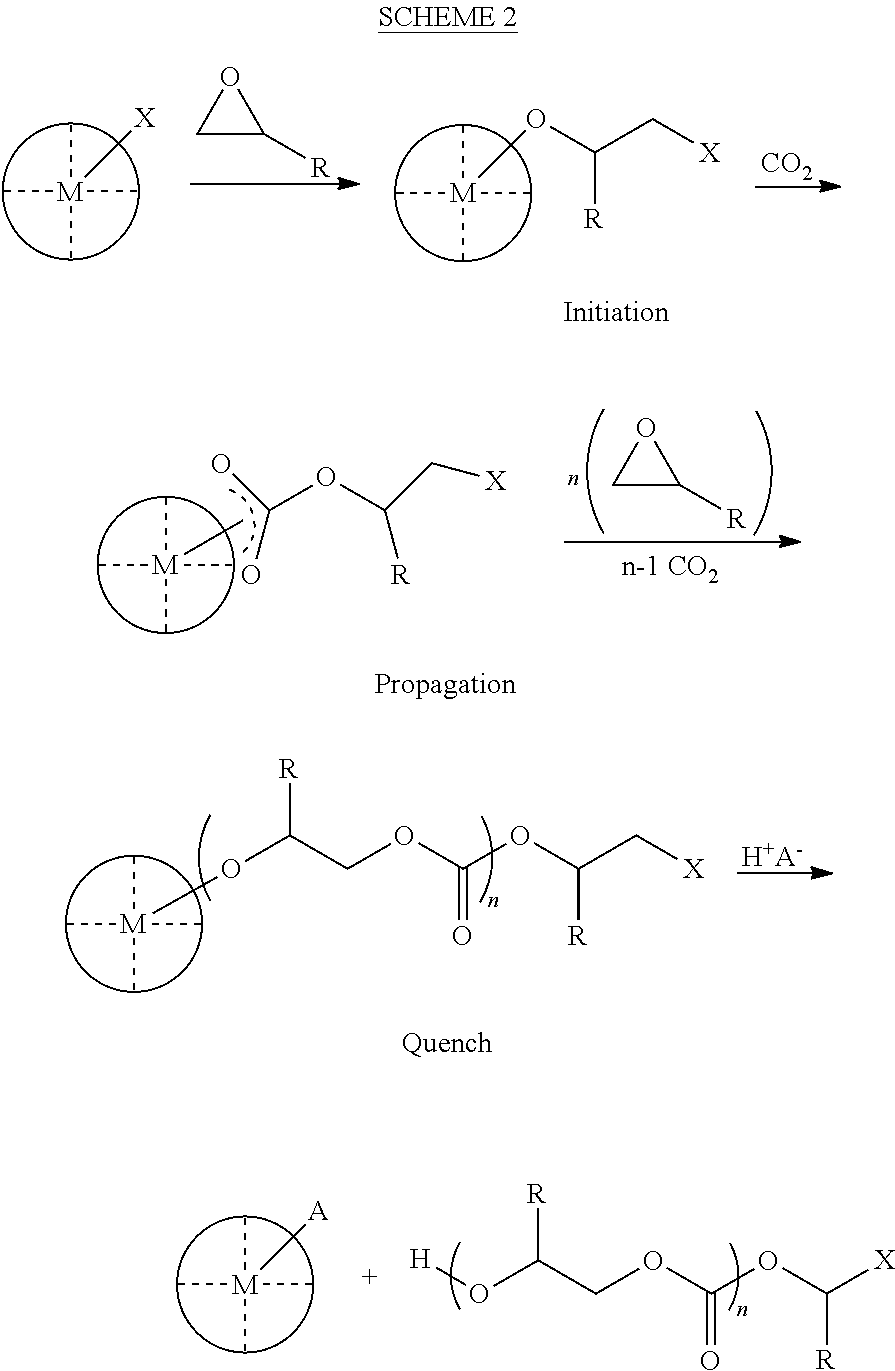

Polycarbonate polyol compositions and methods

ActiveUS8247520B2Increase ratingsIncreases extentOrganic chemistryOrganic-compounds/hydrides/coordination-complexes catalystsEnd-groupPolycarbonate

In one aspect, the present disclosure encompasses polymerization systems for the copolymerization of CO2 and epoxides comprising 1) a catalyst including a metal coordination compound having a permanent ligand set and at least one ligand that is a polymerization initiator, and 2) a chain transfer agent having two or more sites that can initiate polymerization. In a second aspect, the present disclosure encompasses methods for the synthesis of polycarbonate polyols using the inventive polymerization systems. In a third aspect, the present disclosure encompasses polycarbonate polyol compositions characterized in that the polymer chains have a high percentage of —OH end groups and a high percentage of carbonate linkages. The compositions are further characterized in that they contain polymer chains having an embedded polyfunctional moiety linked to a plurality of individual polycarbonate chains.

Owner:SAUDI ARAMCO TECH CO

Articles derived from compositions containing modified polybutylene terephthalate (PBT) random copolymers derived from polyethylene terephthalate (PET)

ActiveUS20070275242A1Useful performance propertyPlastic recyclingSpecial tyresPolytetramethylene terephthalatePolyethylene terephthalate glycol

Compositions of matter including articles derived from (a) from 5 to 99.99 wt % of a modified polybutylene terephthalate random copolymer that (1) is derived from polyethylene terephthalate and (2) contains a at least one residue derived from polyethylene terephthalate selected from the group consisting of antimony, germanium, diethylene glycol groups, isophthalic acid groups, cis isomer of cyclohexane dimethanol, trans isomer of cyclohexane dimethanol, sodium benzoate, alkali salts, napthalane dicarboxylic acids, 1,3-propane diols, cobalt, cobalt-containing compounds, and combinations thereof, and (b) from 0.01 to 95 wt. % of a member selected from the group consisting of (1) fillers, (2) a carboxy reactive component, (3) polyethyelene terephthalate, (4) a component including a polycarbonate and an impact modifier. The articles may be derived from various conversion processes, e.g., injection molding processes, extrusion processes, thermoforming processes, melt-blown process.

Owner:SHPP GLOBAL TECH BV

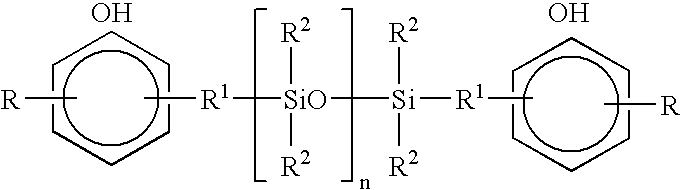

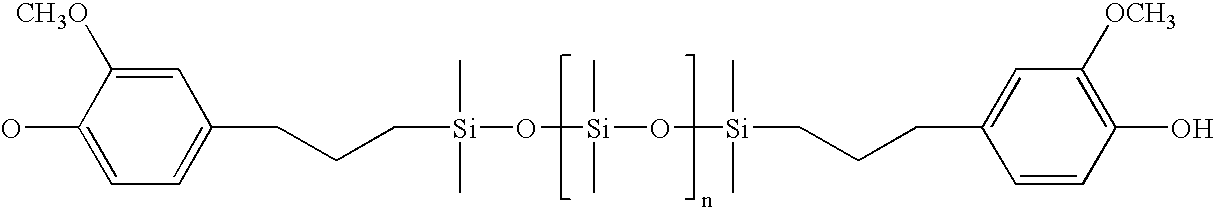

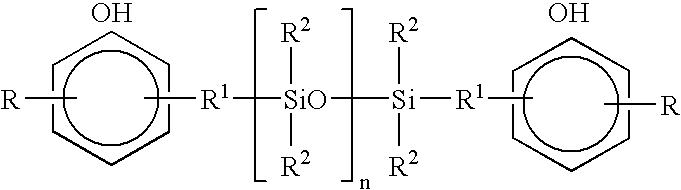

Transparent and high-heat polycarbonate-polysiloxane copolymers and transparent blends with polycarbonate and a process for preparing same

Owner:SHPP GLOBAL TECH BV

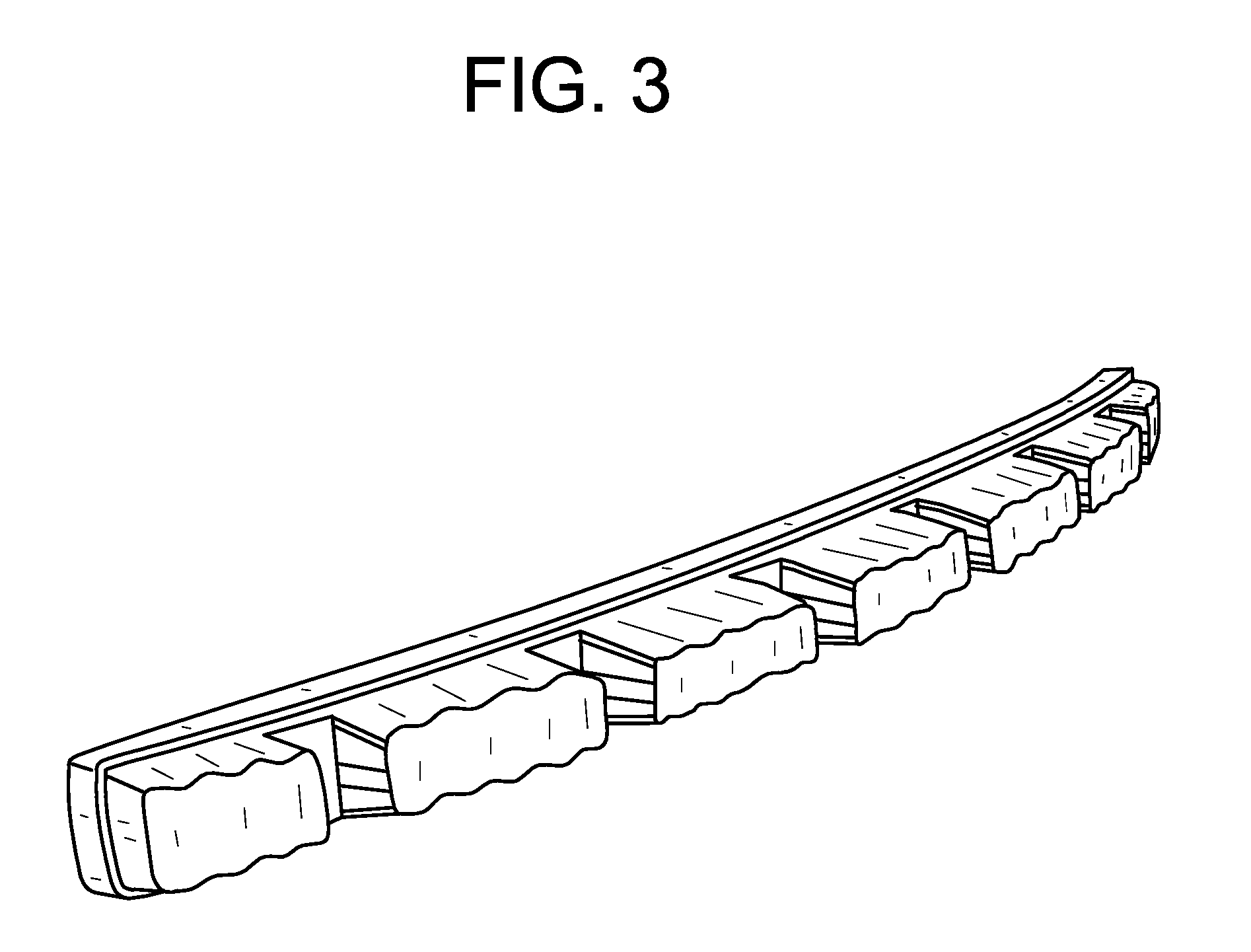

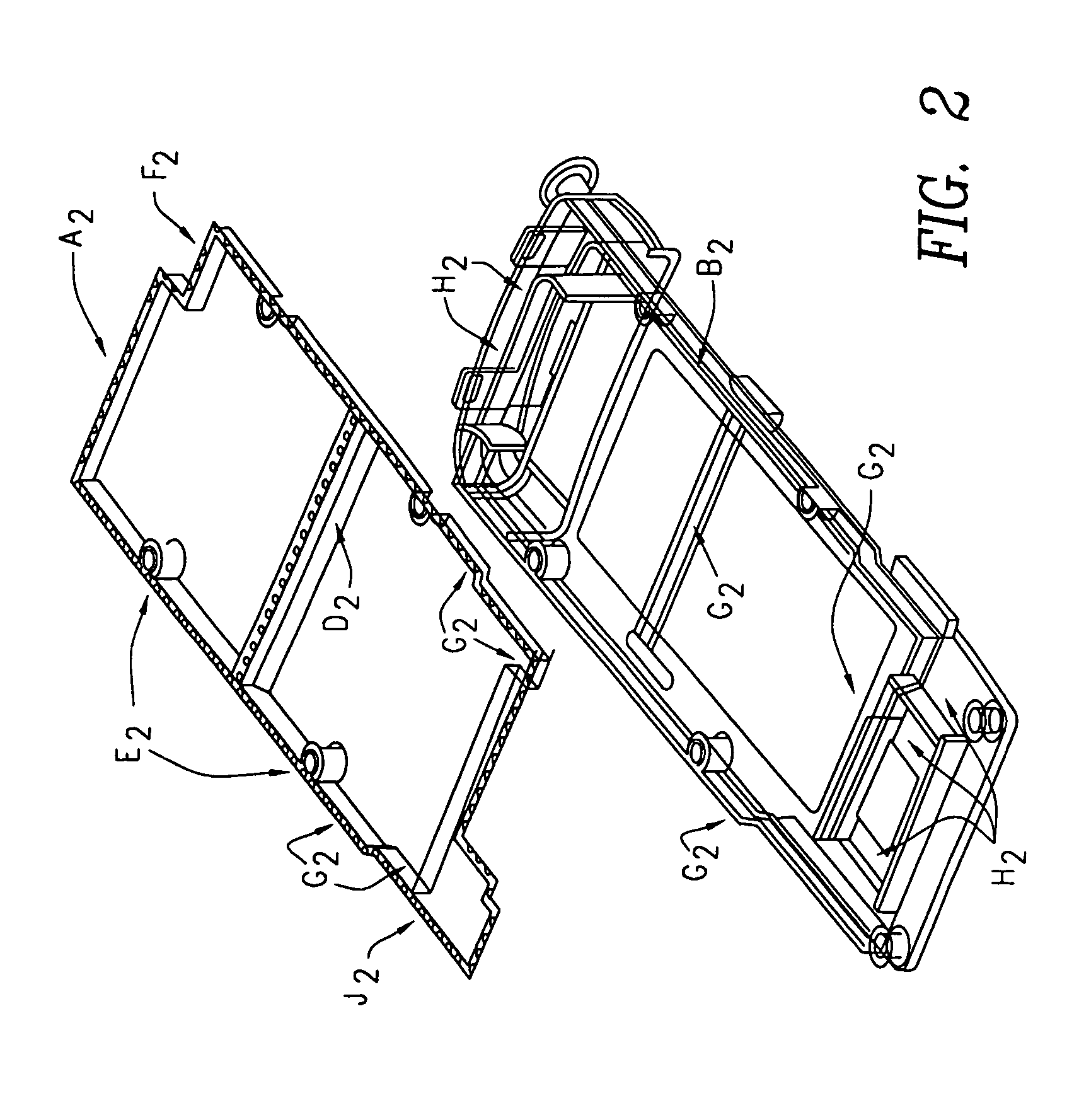

Conforming shielded form for electronic component assemblies and methods for making and using same

The present invention is directed to electronic components shielded from electromagnetic interference through the use of conforming shield enclosures. Conforming shield enclosures are flexible metalized thermoformed thin-wall polycarbonate polymer film substrates used to shield a radiation source. The present invention relates to conforming shielded forms for electronic component assemblies and specifically to electronic component assemblies which are shielded to protect against electromagnetic and radiofrequency interference. Specifically, the shielded electronic component assembly comprises (a) a semiconductor device to be shielded from electromagnetic frequencies; (b) a reference potential source; (c) a housing enclosing the semiconductor device within the assembly; and (d) a conforming shield enclosure electrically connected to the reference potential source. The conforming shield enclosure comprises a flexible, metalized thermoformable polymer having dimensions conforming to the inside of the housing and enclosing and thereby shielding the semiconductor device from electromagnetic frequencies. The conforming shield enclosure is prepared by paint metalization.

Owner:PPG IND OHIO INC

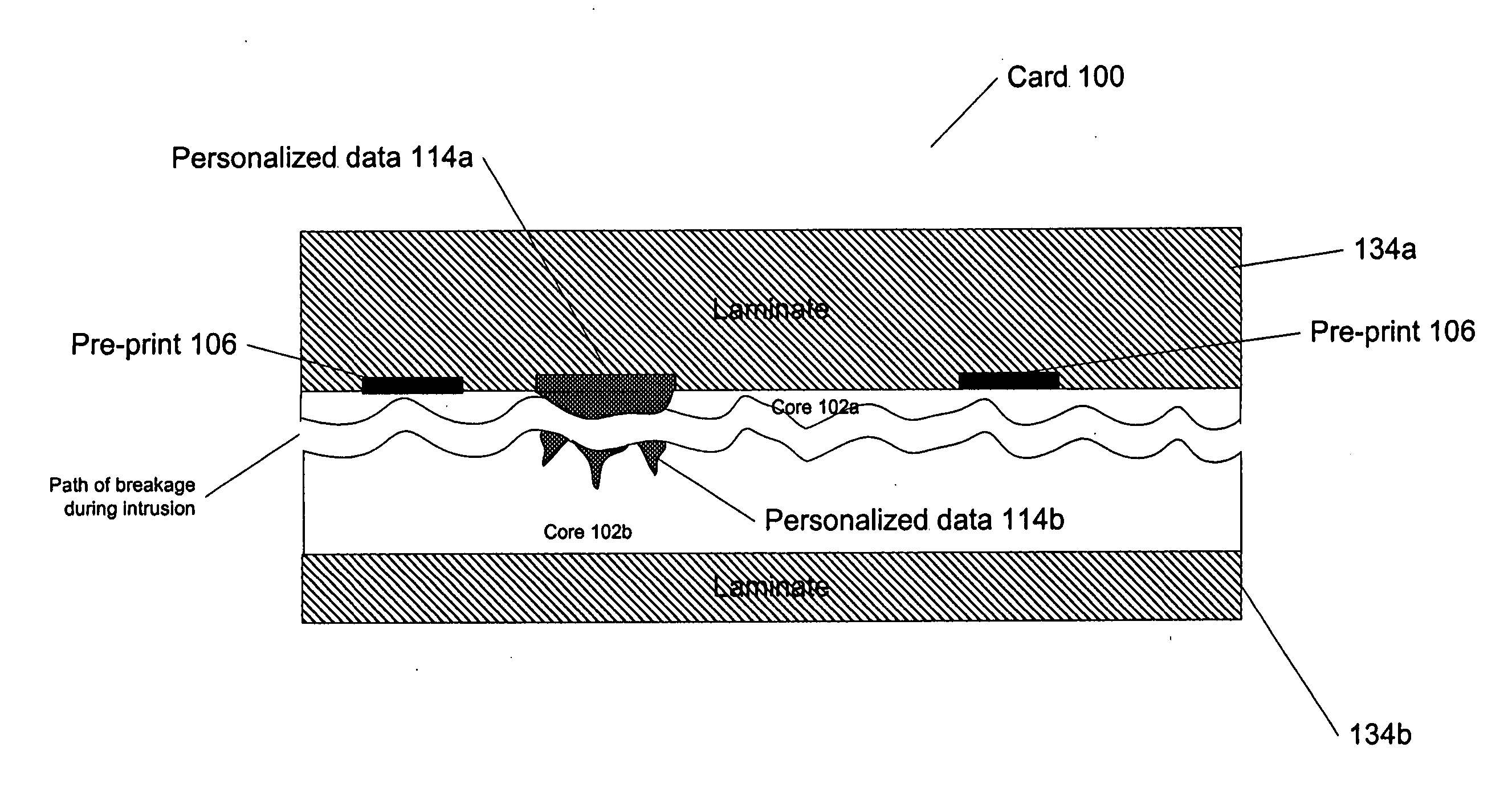

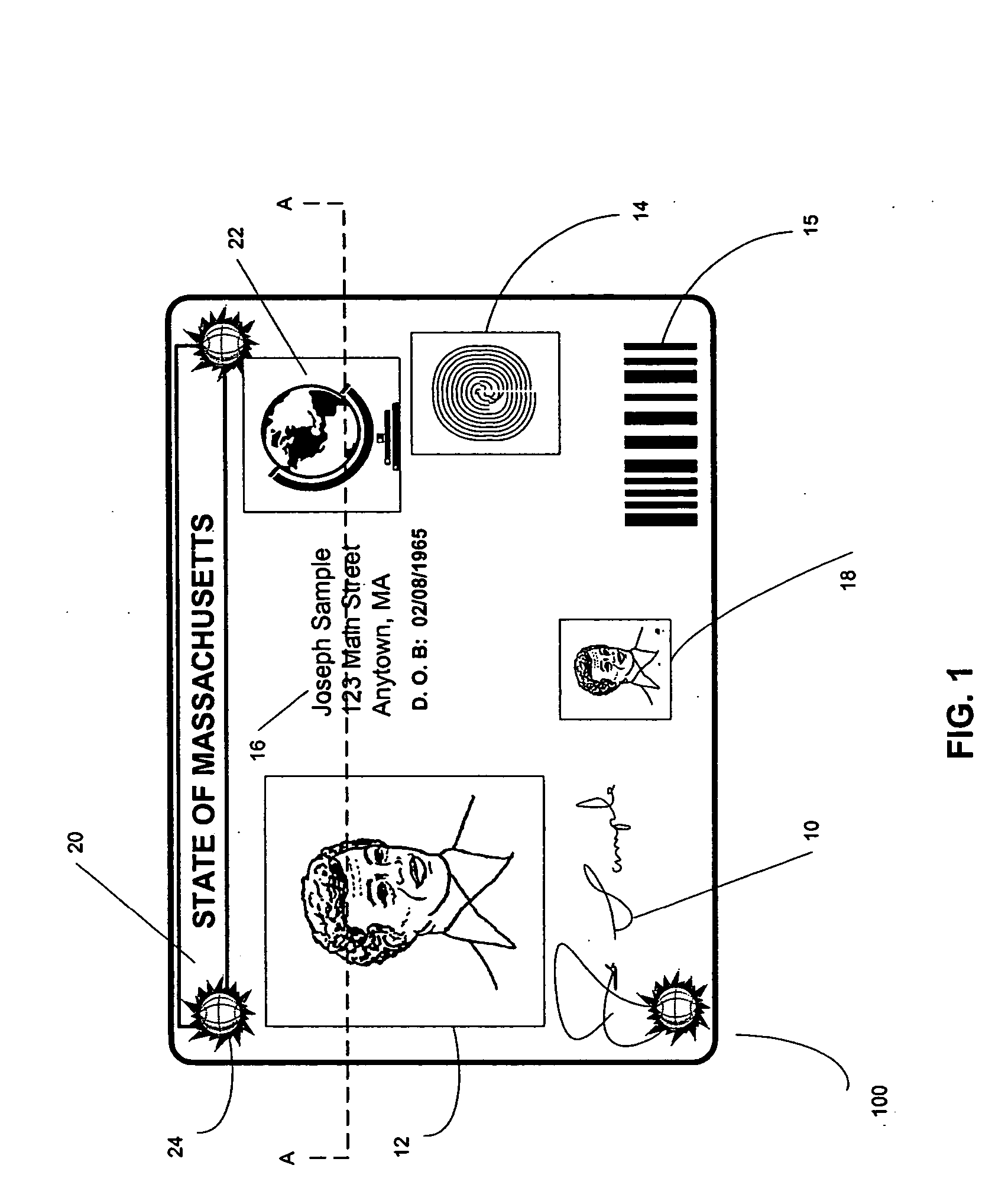

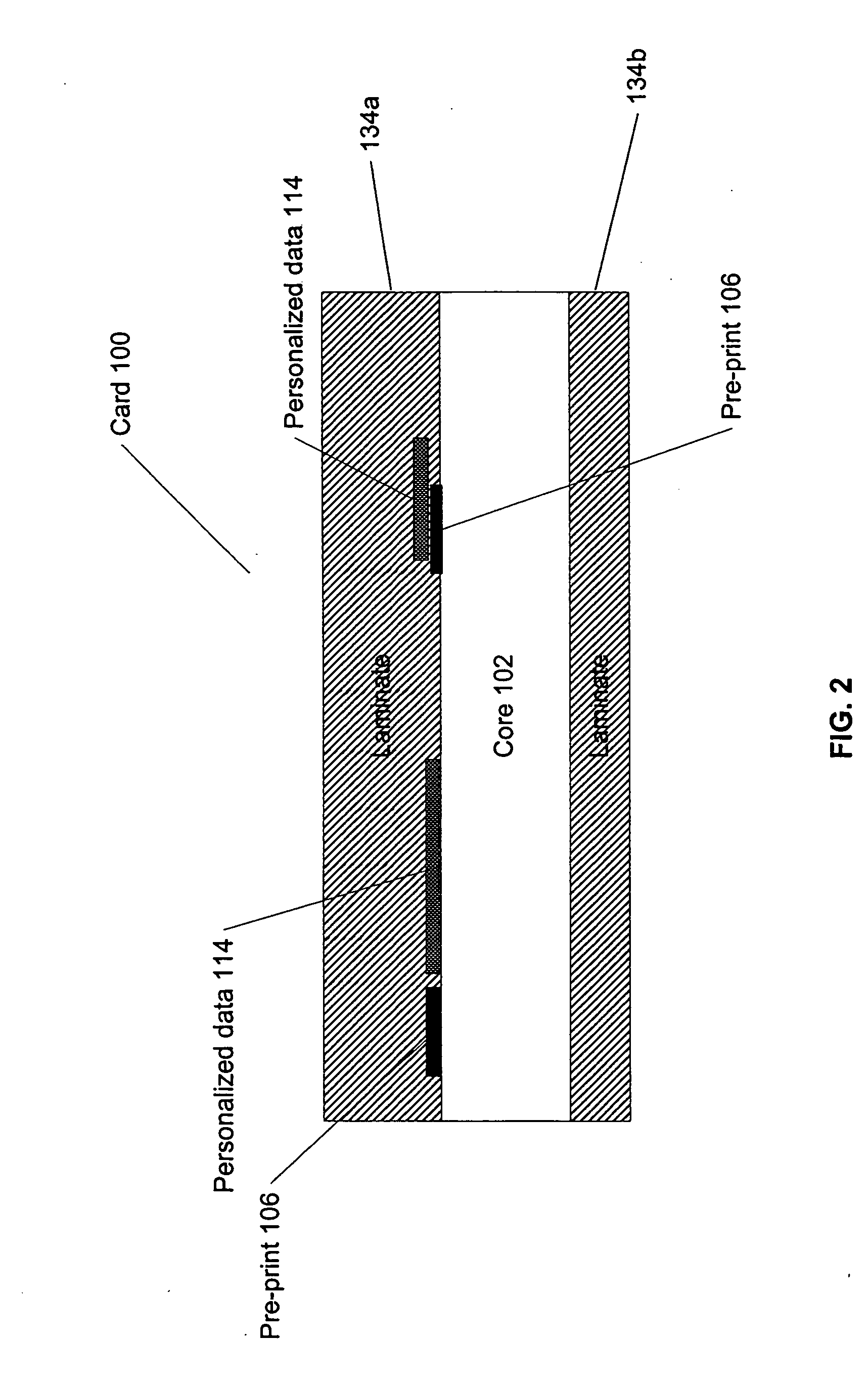

Identification document having intrusion resistance

InactiveUS20050247794A1Improve security levelUltimate in durabilityOther printing matterRecord carriers used with machinesAdhesiveEngineering

An identification document is provided, comprising a core layer, such as TESLIN, laminated directly to a laminate layer, such as polycarbonate, without the use of an adhesive. The core layer has at least one indicium formed thereon and has a first surface. The first layer of laminate is affixed to the core layer by a press lamination process where the press lamination process is sufficient to couple the core layer to the first layer such that an attempt to separate the first layer from the core layer causes at least a partial destruction of the core layer.

Owner:DIGIMARC CORP

Single site catalyst for synthesizing polycarbonate

The invention discloses a high-activity catalyst which catalyzing and activating carbon dioxide to perform the copolymerization reaction with alkylene oxide to synthesize polycarbonate. The catalyst is characterized in that the catalyst is a tetradentate schiff base complex contains one or two organic base groups and has single active site initiation and controllable polymerization. The catalyst has the advantages that under milder conditions and at lower concentration of the catalyst, the catalyst can highly and efficiently catalyze the carbon dioxide to make the copolymerization reaction with the alkylene oxide to prepare the polycarbonate, the catalytic efficiency is 10<6>g polymer / mol catalyst, the polymer molecular weight is adjusted in the range of between 5,000 and 500,000, the molecular weight distribution is less than 2, the alternating structure is over 97 percent, and the catalyst can be degraded into small molecule compounds under certain condition. By utilizing the catalyst, the telomerization reaction between the carbon dioxide and two or more than two types of alkylene oxide can be catalyzed to synthesize a polycarbonate telomer with adjusting glass transition temperature.

Owner:DALIAN UNIV OF TECH

Flame retardant thermoplastic polycarbonate compositions, use, and method of manufacture thereof

Owner:SABIC INNOVATIVE PLASTICS IP BV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com