Patents

Literature

554results about How to "Efficient coating" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

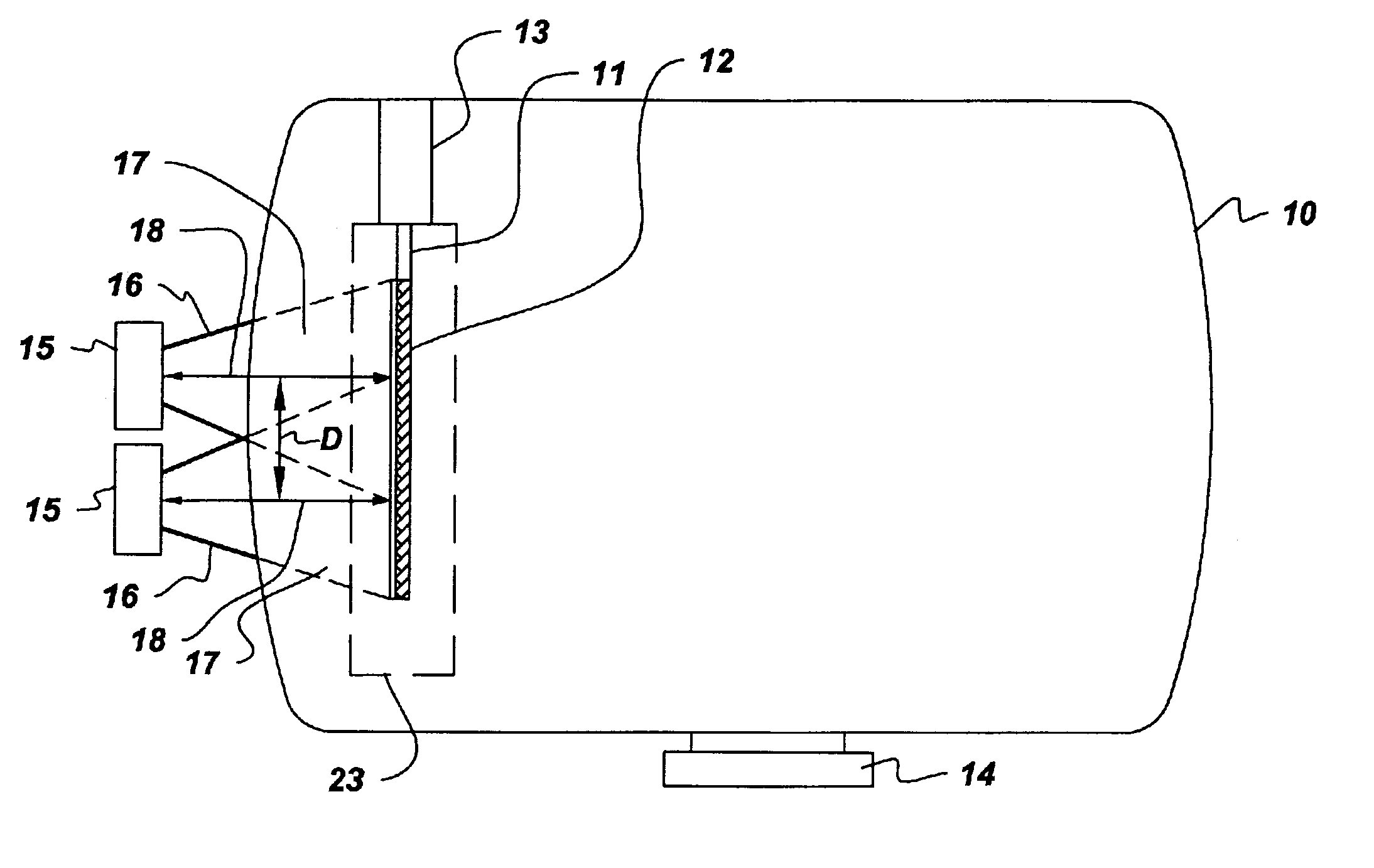

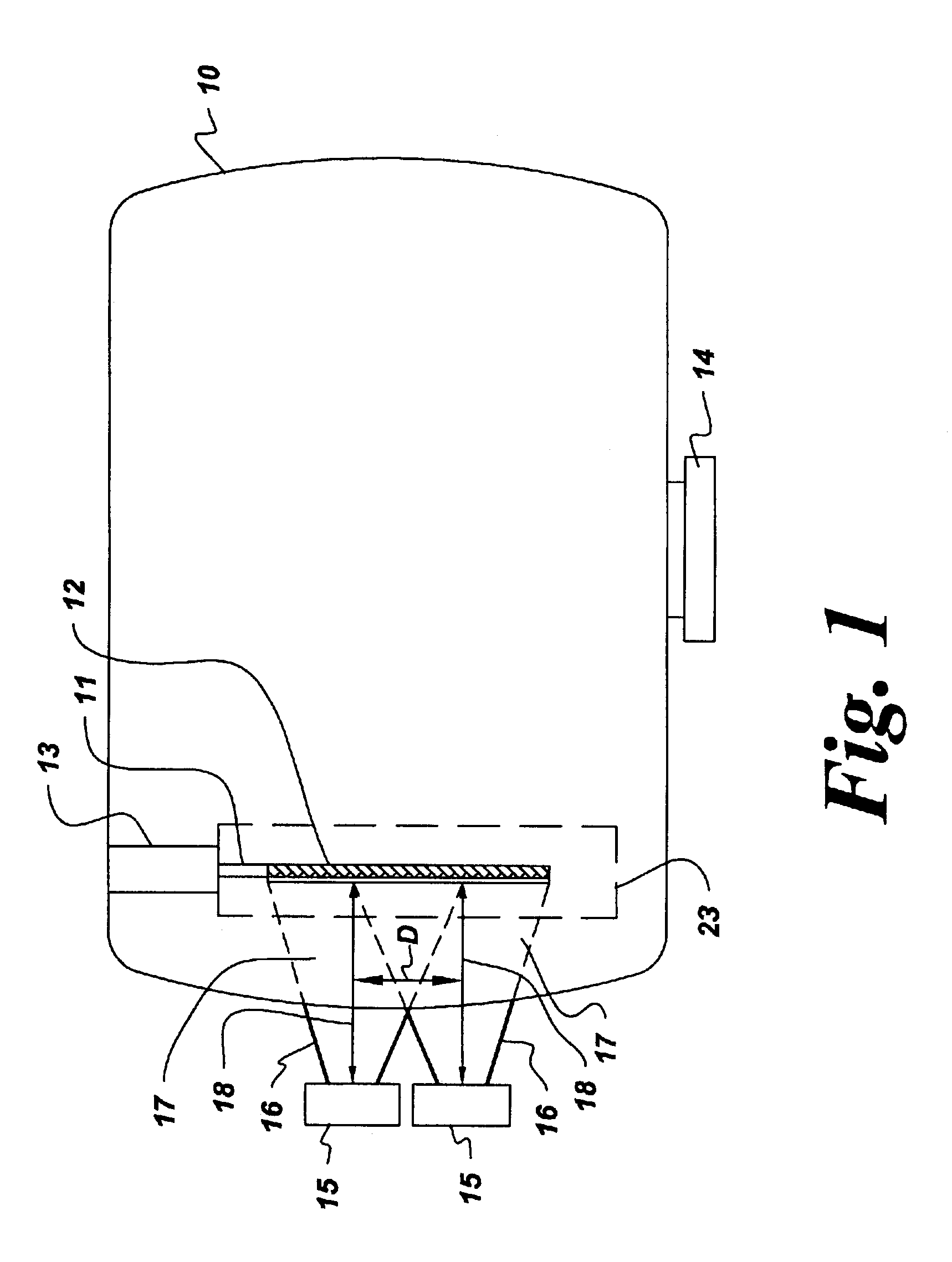

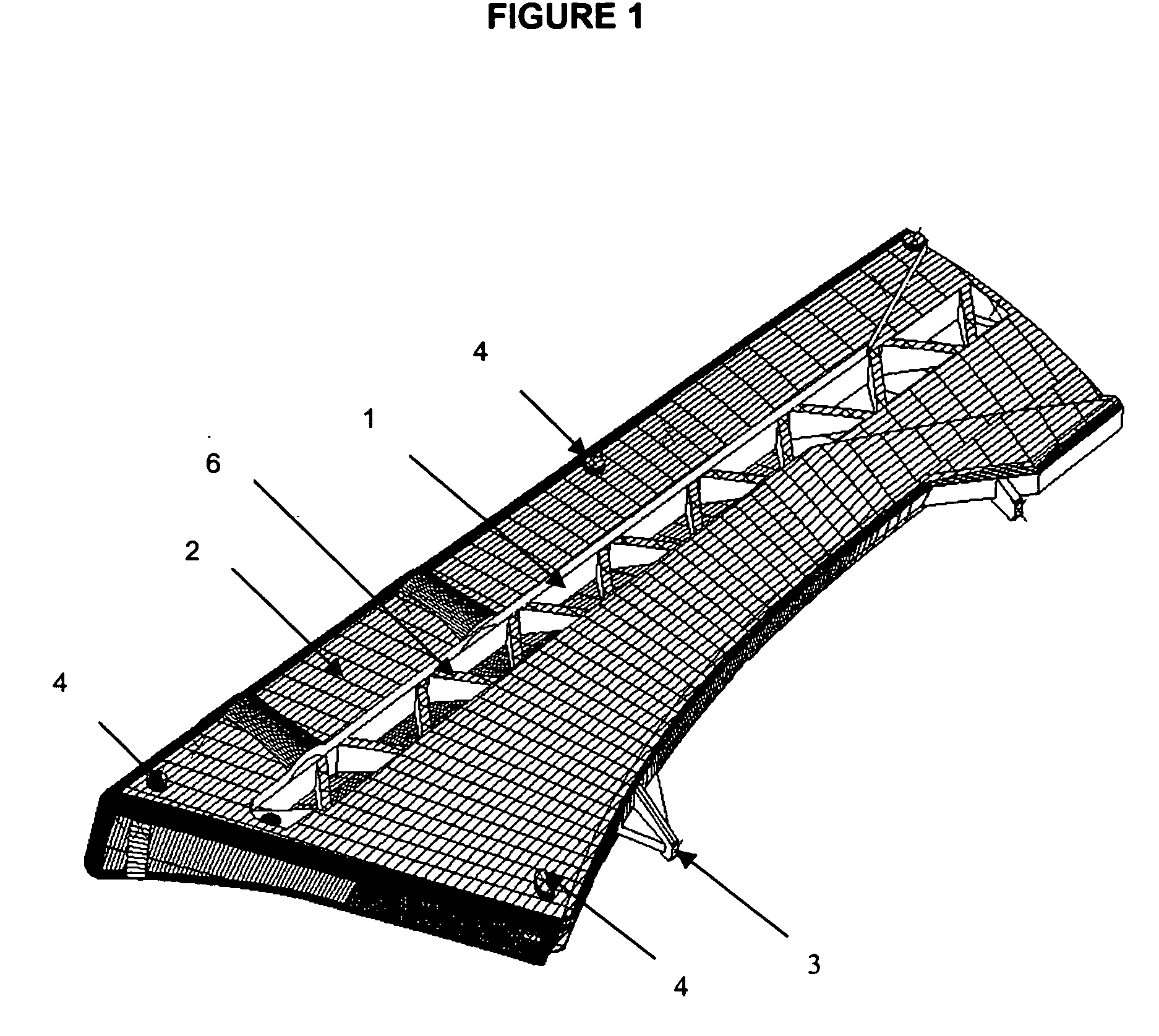

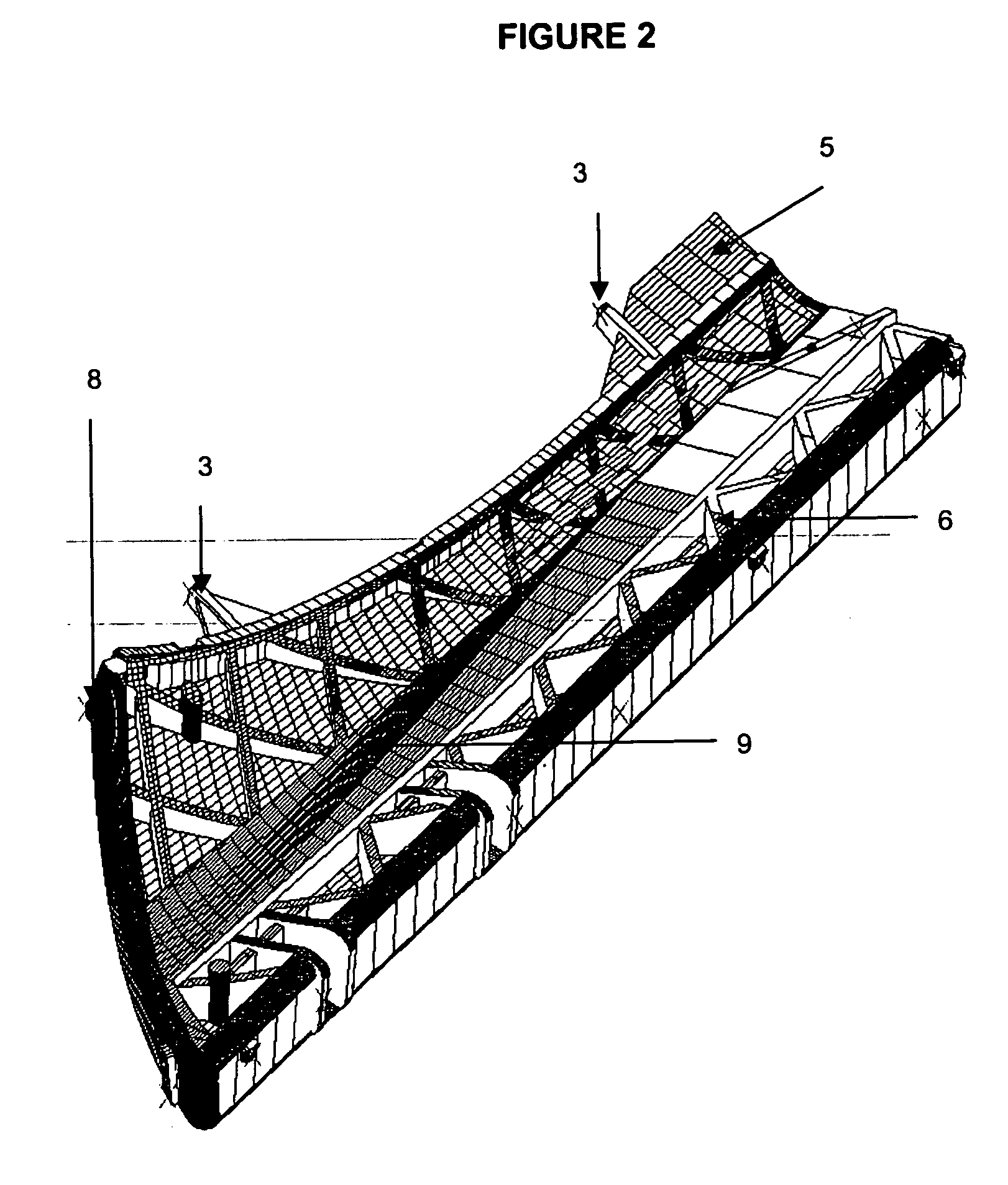

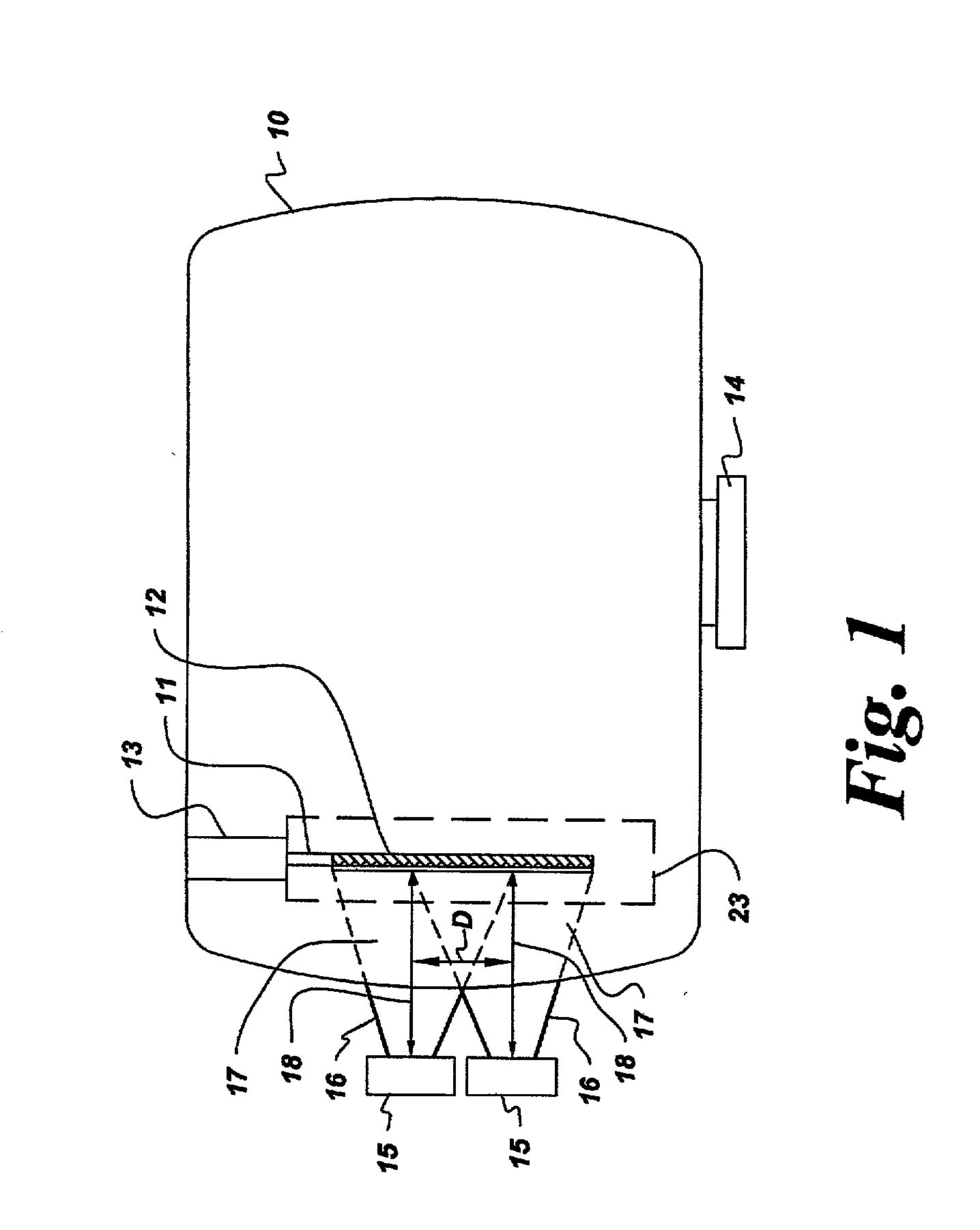

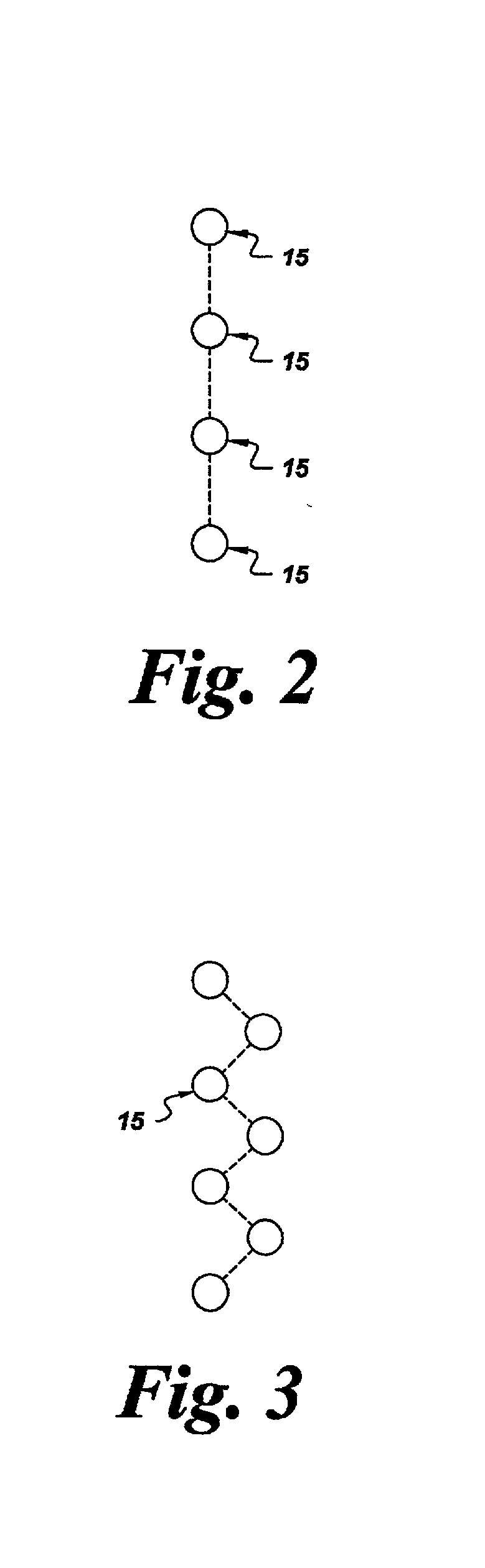

Apparatus for large area chemical vapor deposition using multiple expanding thermal plasma generators

InactiveUS6397776B1Efficient coatingDesirable propertyElectric discharge tubesChemical vapor deposition coatingThermoplasticGas phase

Chemical vapor deposition is performed using a plurality of expanding thermal plasma generating means to produce a coating on a substrate, such as a thermoplastic and especially a polycarbonate substrate. The substrate is preferably moved past the generating means. Included are methods which coat both sides of the substrate or which employ multiple sets of generating means, either in a single deposition chamber or in a plurality of chambers for deposition of successive coatings. The substrate surfaces spaced from the axes of the generating means are preferably heated to promote coating uniformity.

Owner:SABIC INNOVATIVE PLASTICS IP BV

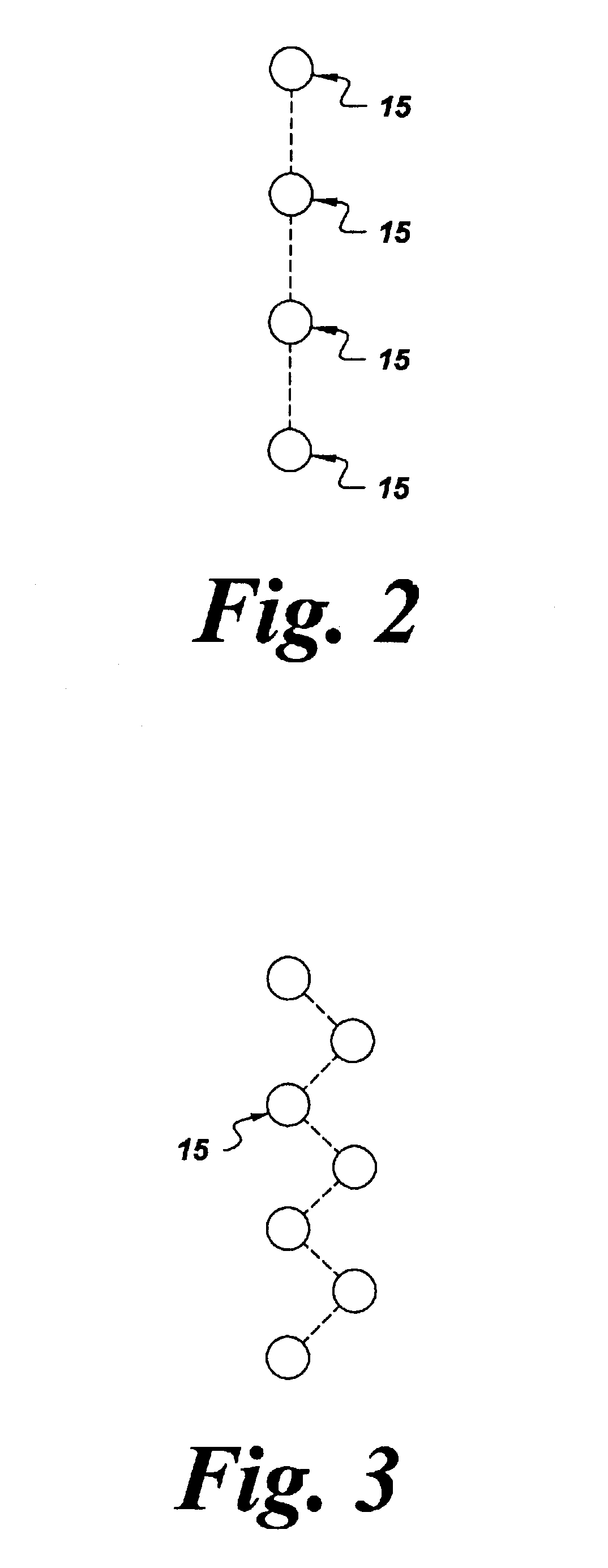

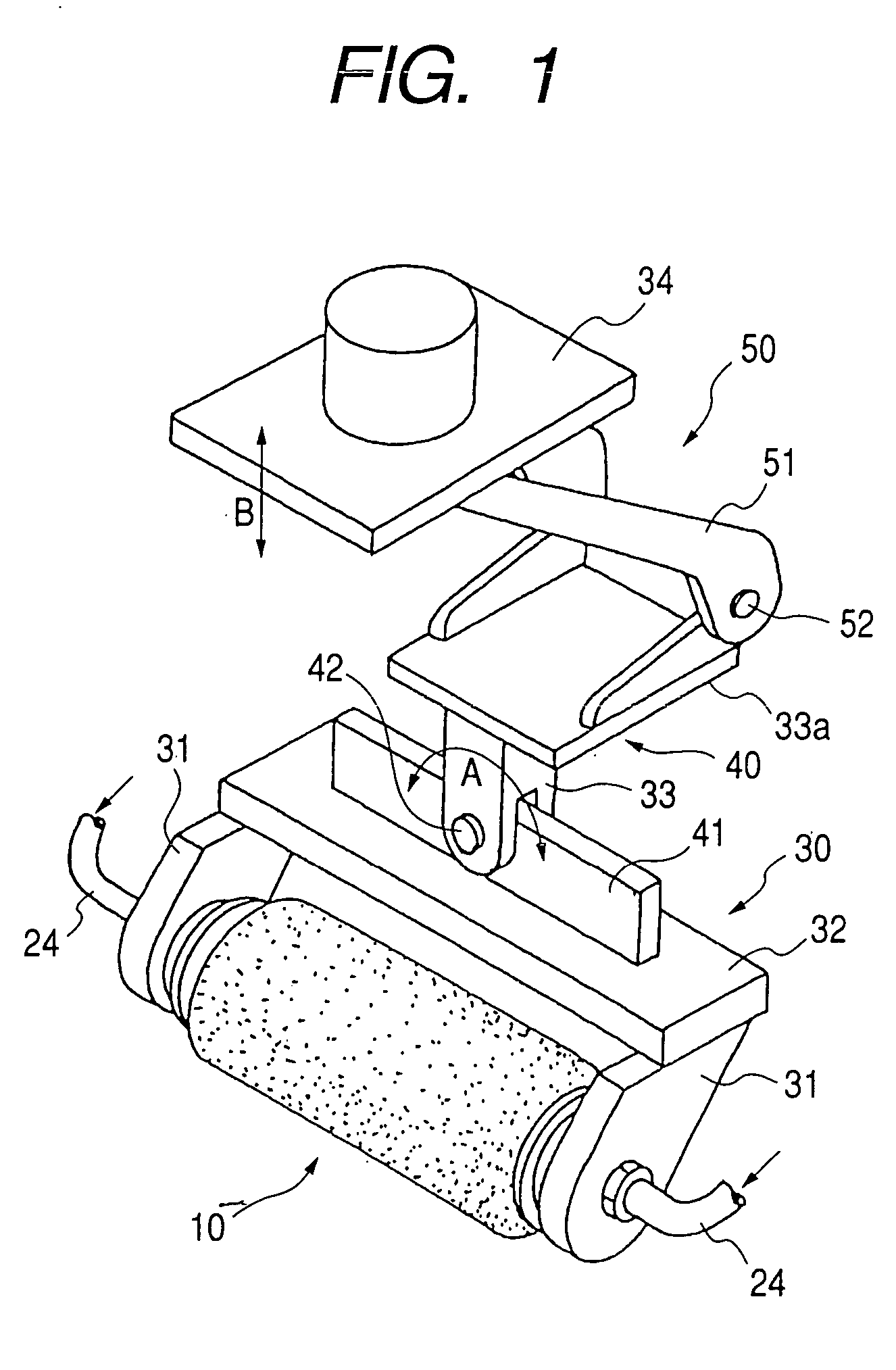

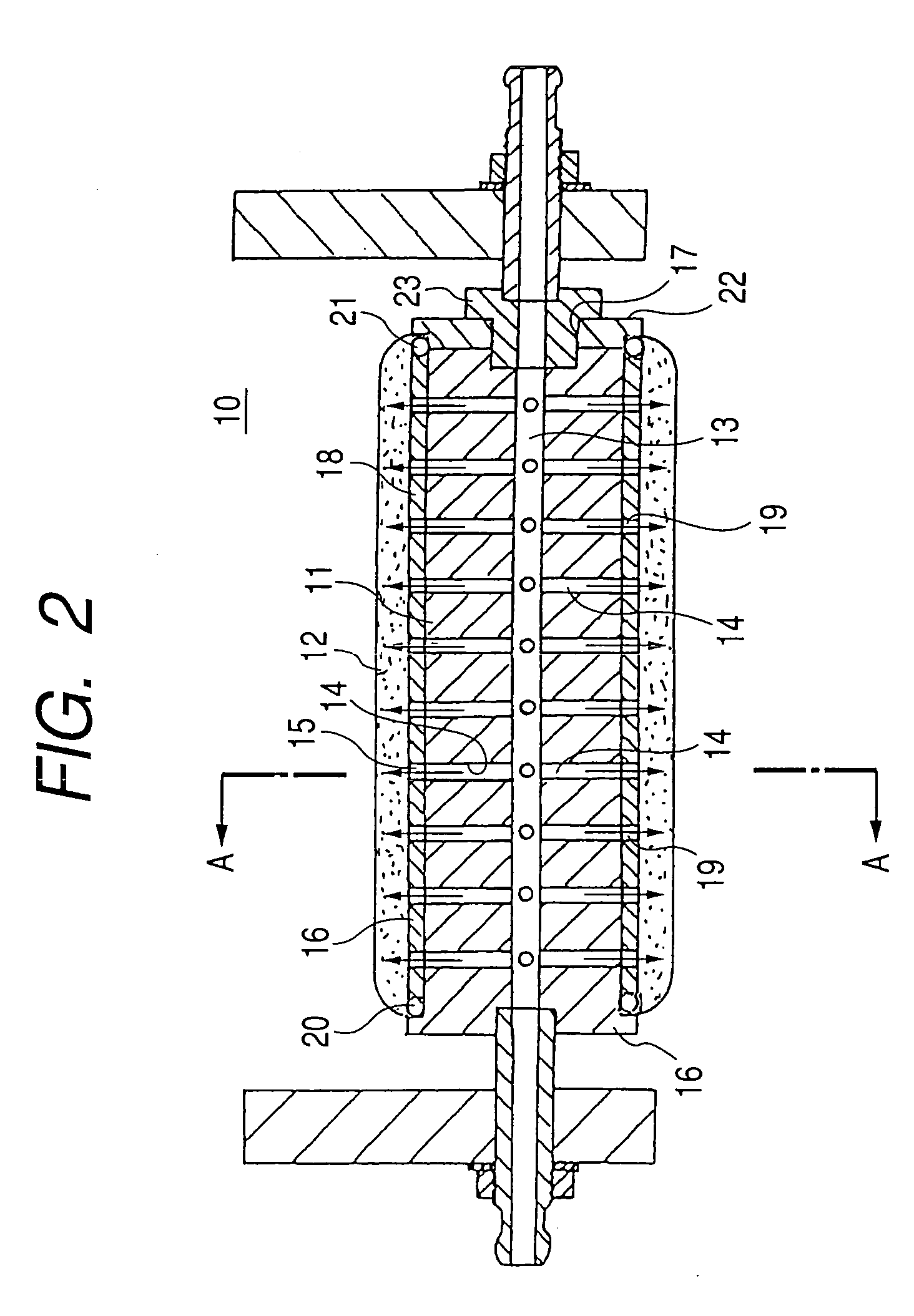

Pressure fed coating roller, roller coating device, automated coating apparatus using this device

InactiveUS20060045981A1Uniform and substantially uniform thicknessEfficient coatingLiquid/solution decomposition chemical coatingSolid/suspension decomposition chemical coatingEngineeringMechanical engineering

An object of the present invention is to provide a coating device of the roller type which reduces a waste of coating material and distributes the coating material uniformly to the roller brush. The coating device includes a sold cylindrical body (11) being solid except an axial center hole (13), and radial holes (14) radially extended from a plurality of positions of the axial center hole (11), a roller brush (12) applied to the outer periphery of the solid cylindrical body (11), coating-material press feeding pipes (24) connected to both ends of the axial center hole (13) of the solid cylindrical body (11), and an arm part (31) for supporting the solid cylindrical body (11) at both ends of the solid cylindrical body (11). Those components are entirely supported by a turnable support mechanism (40) and a vertically movable support mechanism (50).

Owner:KANSAI PAINT CO LTD

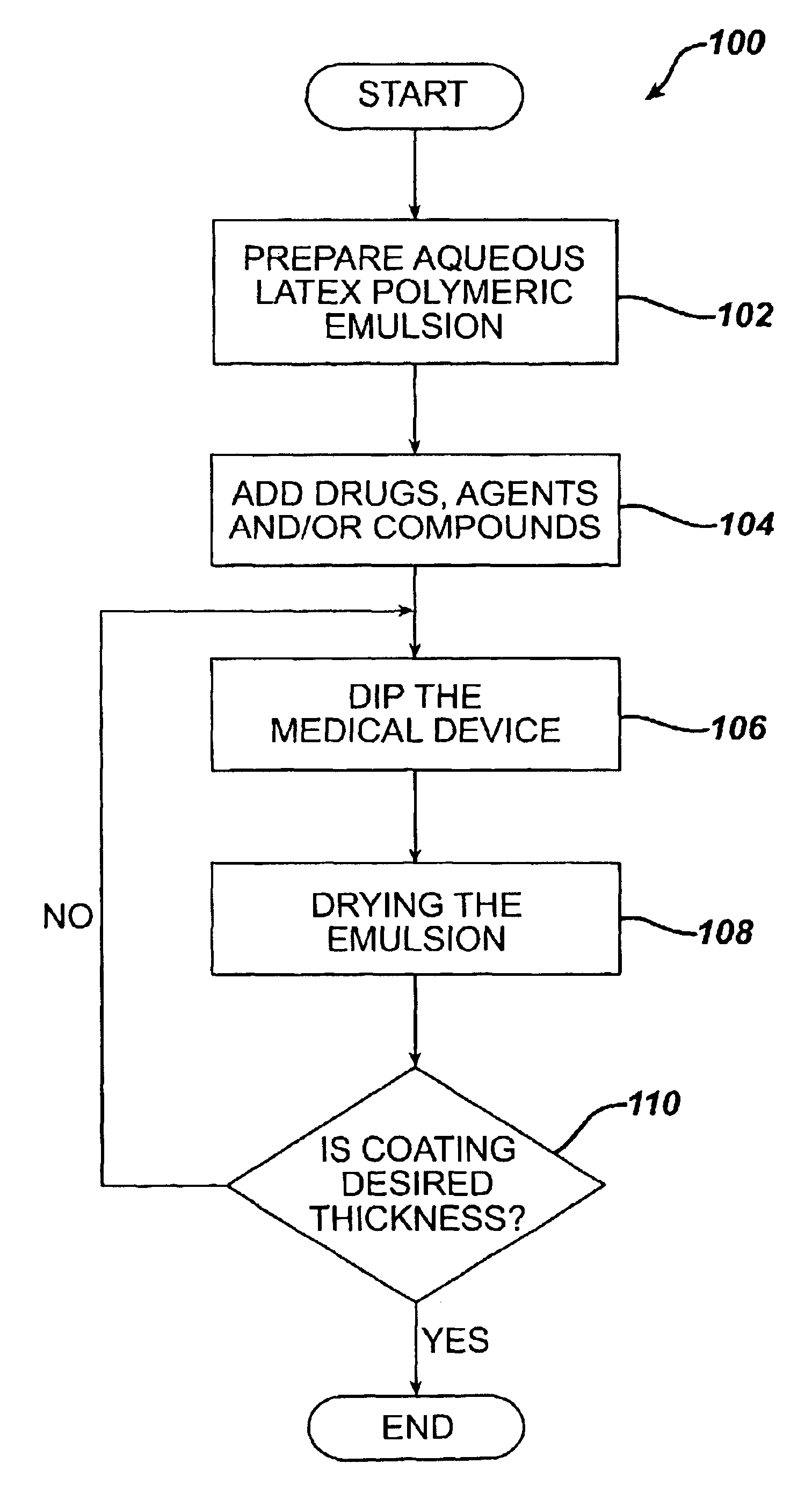

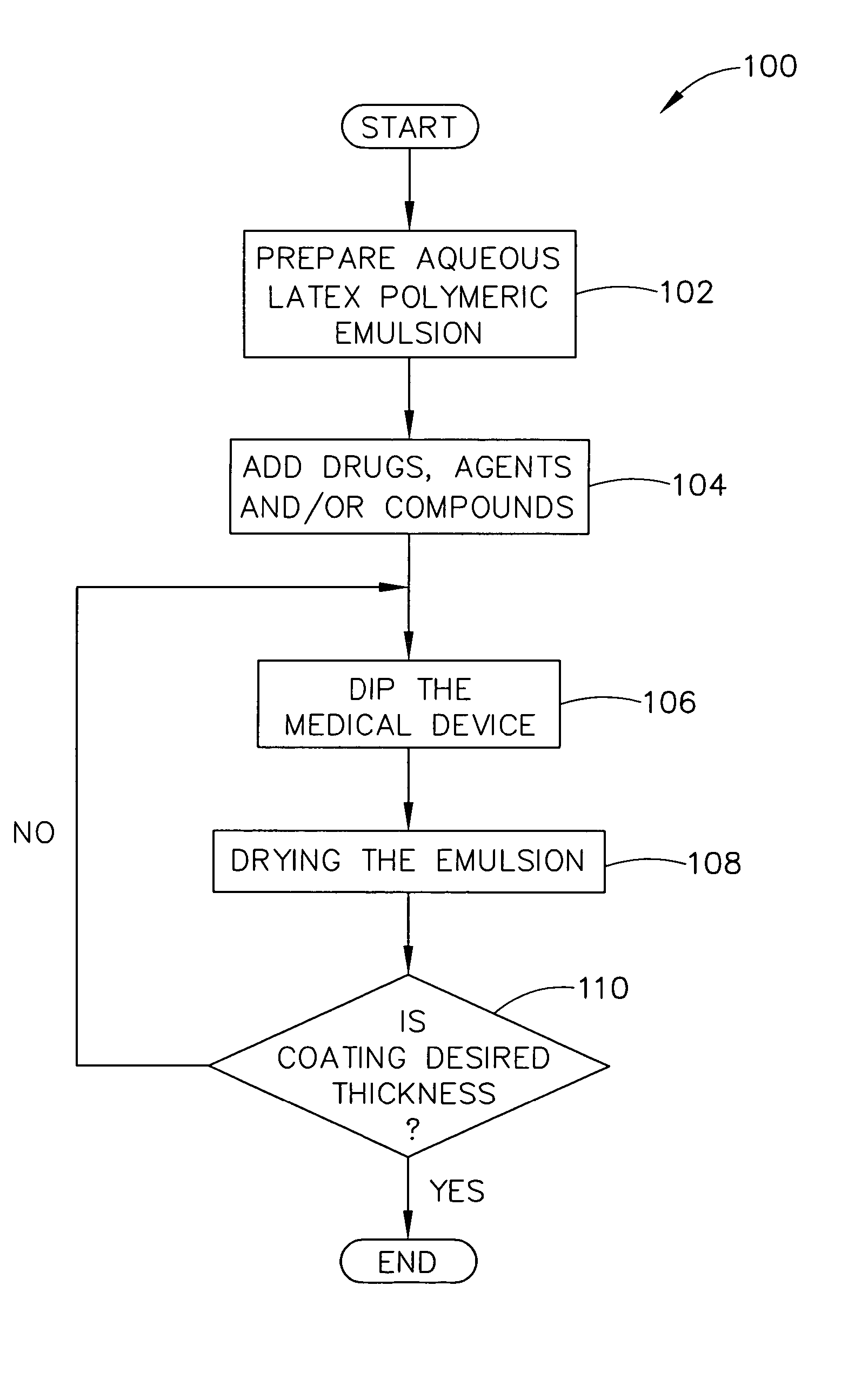

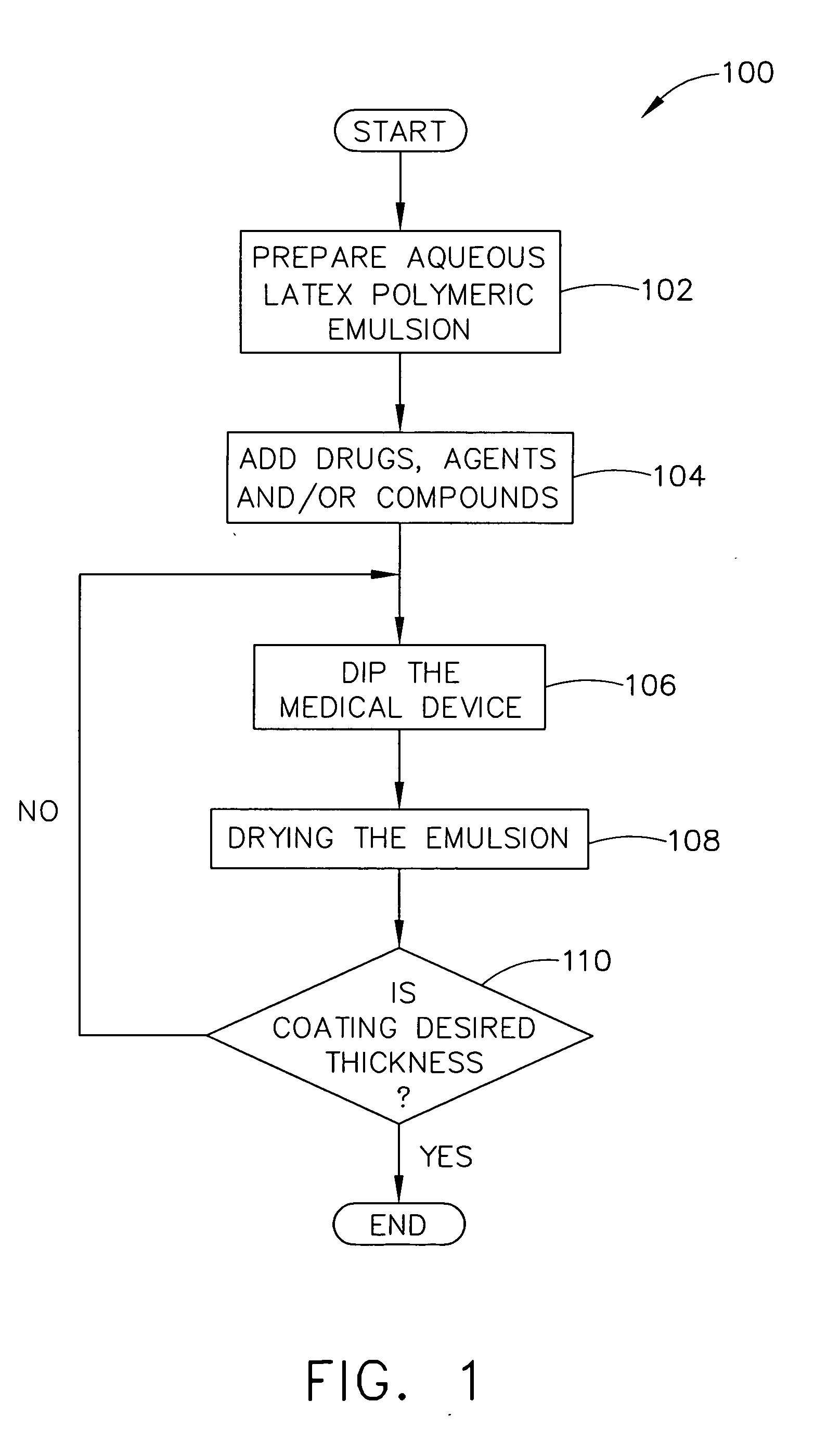

Method for coating medical devices

InactiveUS6919100B2Safe and efficient and effective processSimple and complex configurationOrganic active ingredientsImpression capsBiological bodyOrganic solvent

Medical devices, and in particular implantable medical devices, may be coated to minimize or substantially eliminate a biological organism's reaction to the introduction of the medical device to the organism or to treat a particular condition. A dip coating process is utilized to minimize waste. An aqueous latex polymeric emulsion is utilized to coat any medical device to a desired thickness by allowing for successive dipping and drying cycles. In addition, aqueous latex polymeric emulsions pose less of a chance of the bridging phenomenon associated with organic solvent based polymers.

Owner:WYETH LLC

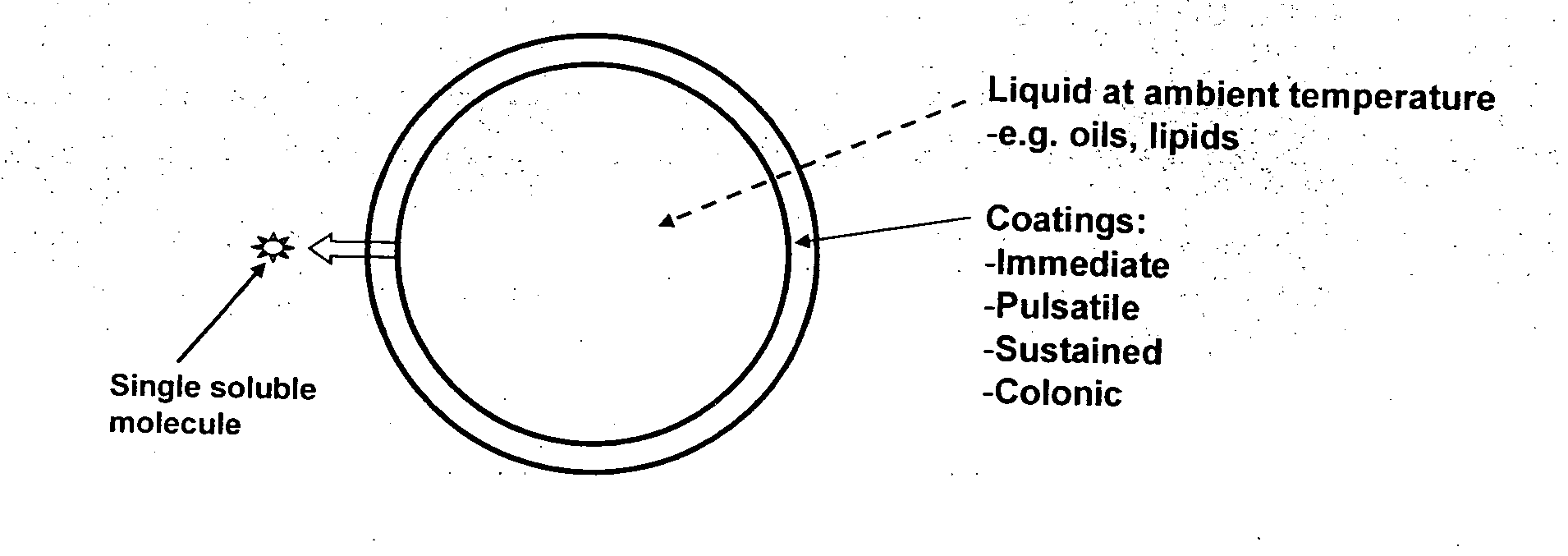

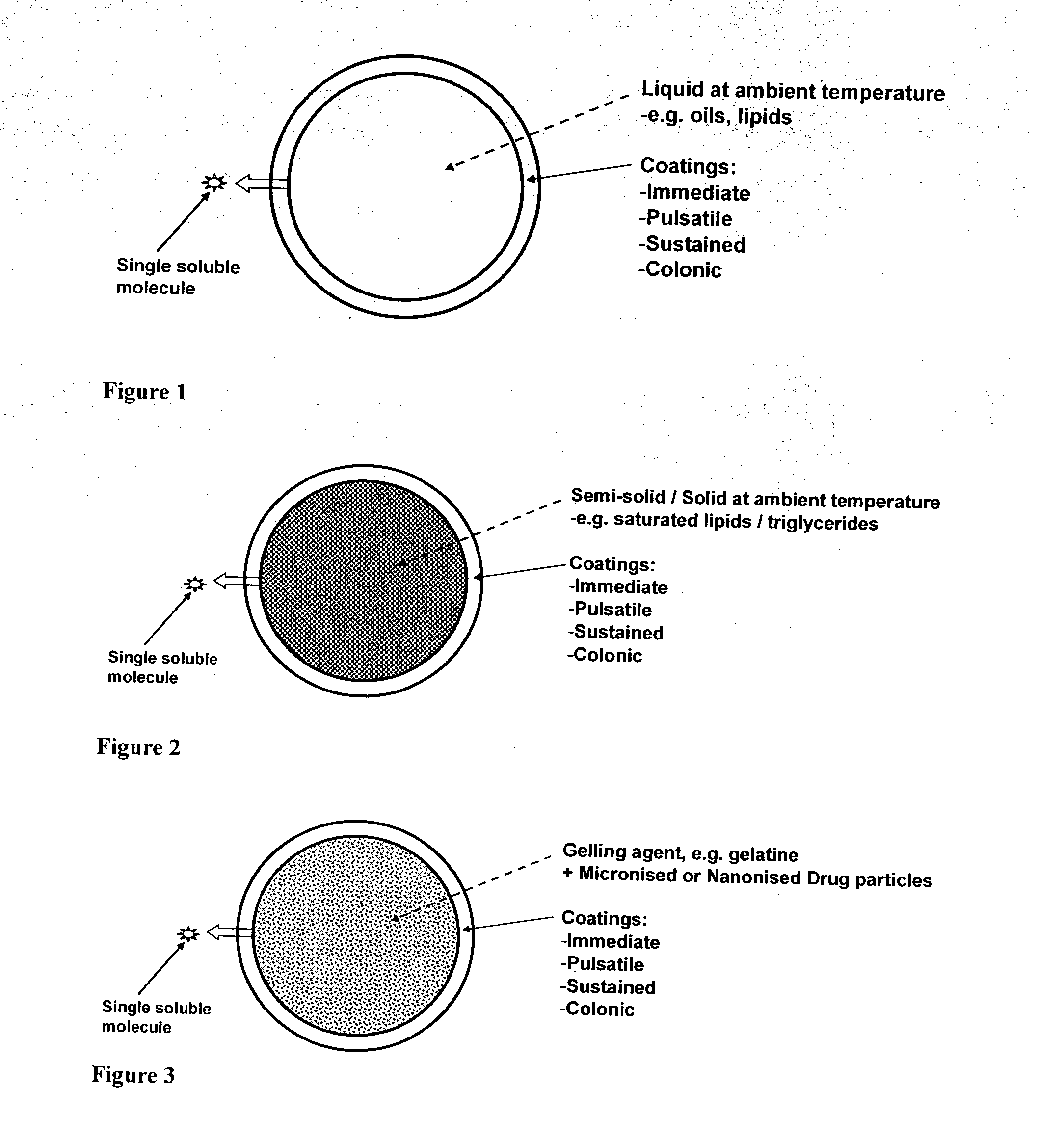

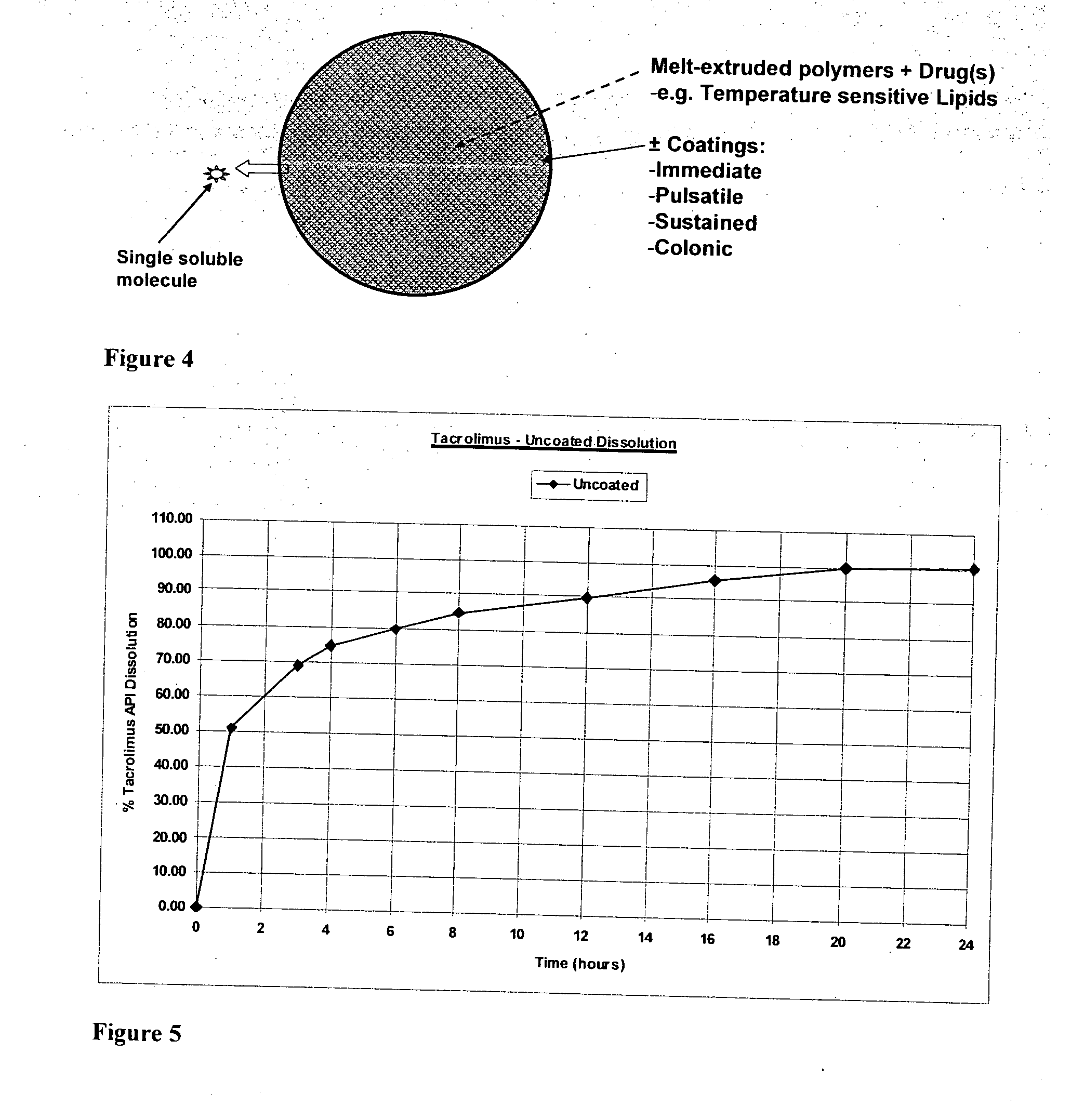

Oral pharmaceutical composition

ActiveUS20100255087A1Improve solubilityImprove breathabilityOrganic active ingredientsNervous disorderSolid coreGastrointestinal tract

Owner:SUBLIMITY THERAPEUTICS LTD

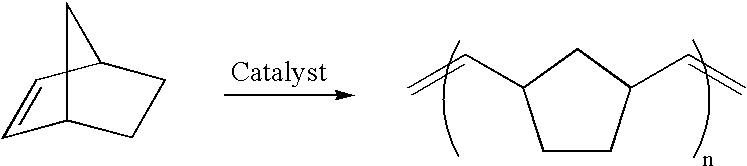

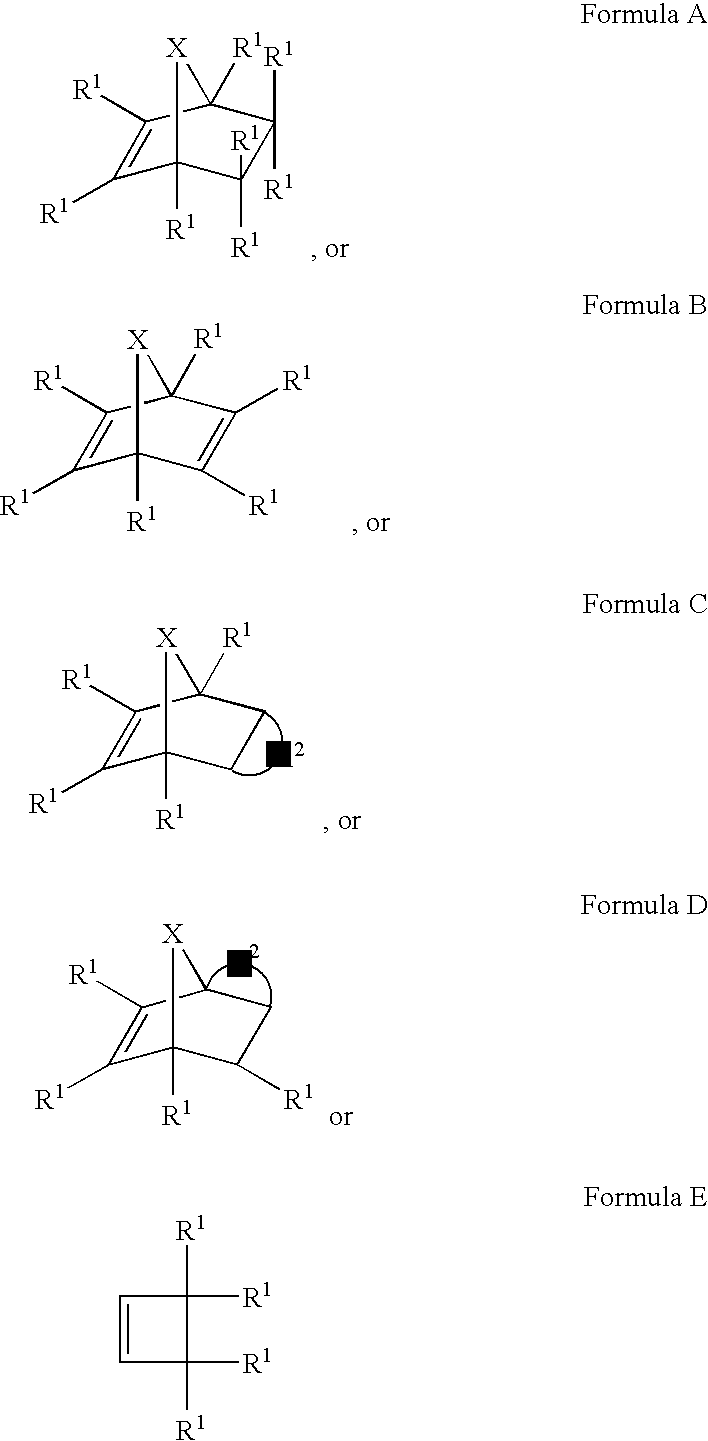

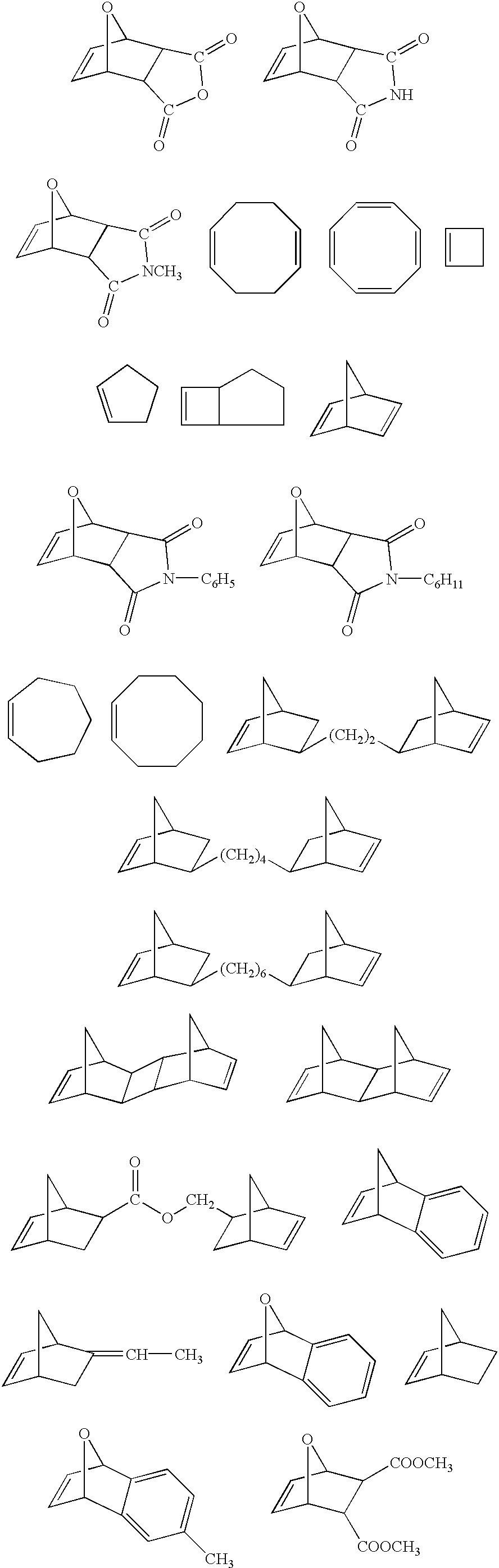

Metathesis polymerization adhesives and coatings

InactiveUS6800170B2Easy to useRemarkable strengthHydrocarbon purification/separationThickenersOligomerCoating system

An adhesive or coating composition prepared by mixing together at least one metathesizable highly-reactive cycloolefin (e.g., a norbornadiene) and a metathesis catalyst. The use of highly-reactive cycloolefins can provide exceptional adherence to a low-surface-tension substrate. Another embodiment is a two-part adhesive or coating system wherein the first part includes at least one first metathesizable material, and the second part includes at least one liquid metathesis oligomer or polymer and a metathesis catalyst.

Owner:LORD CORP

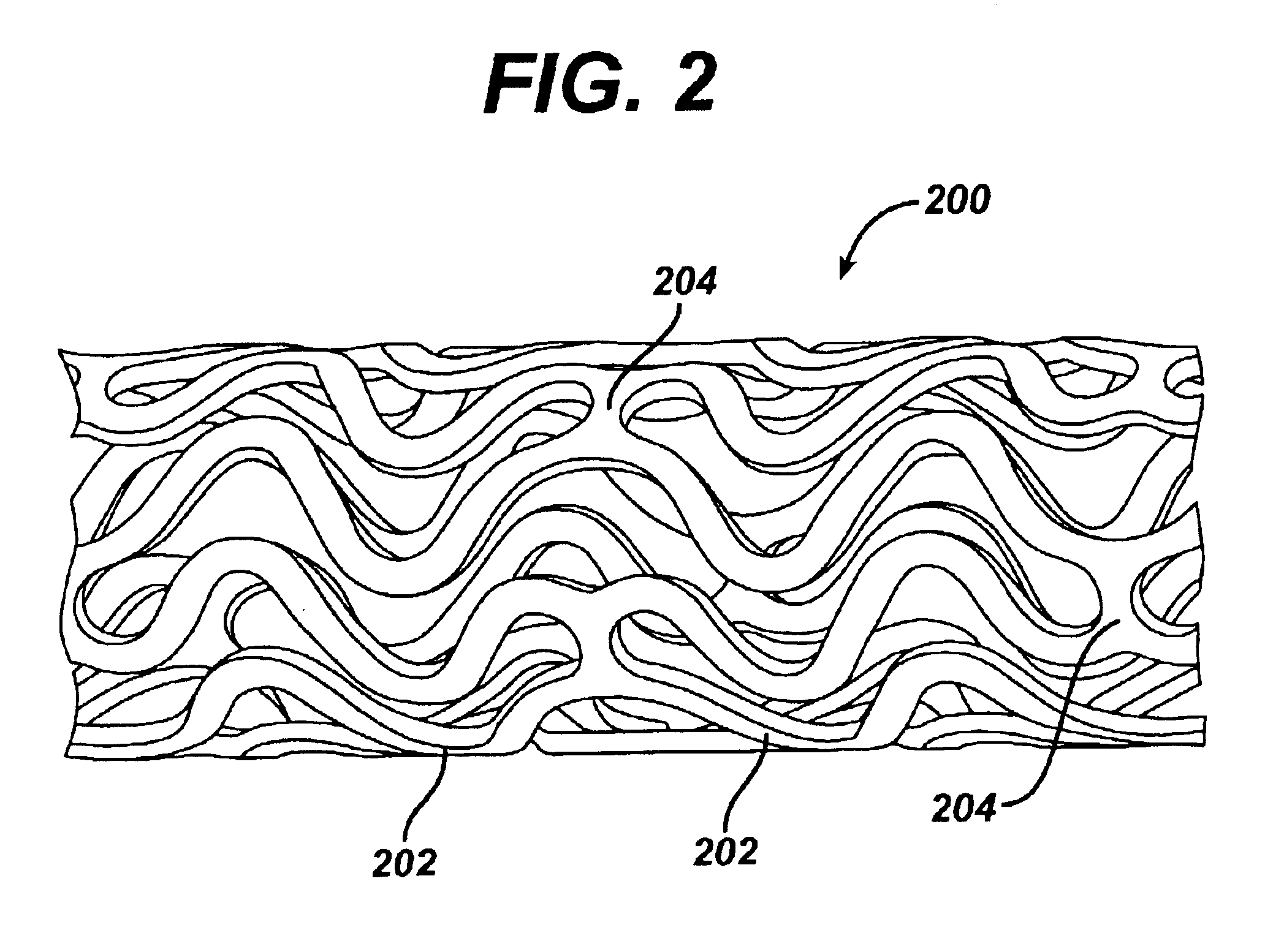

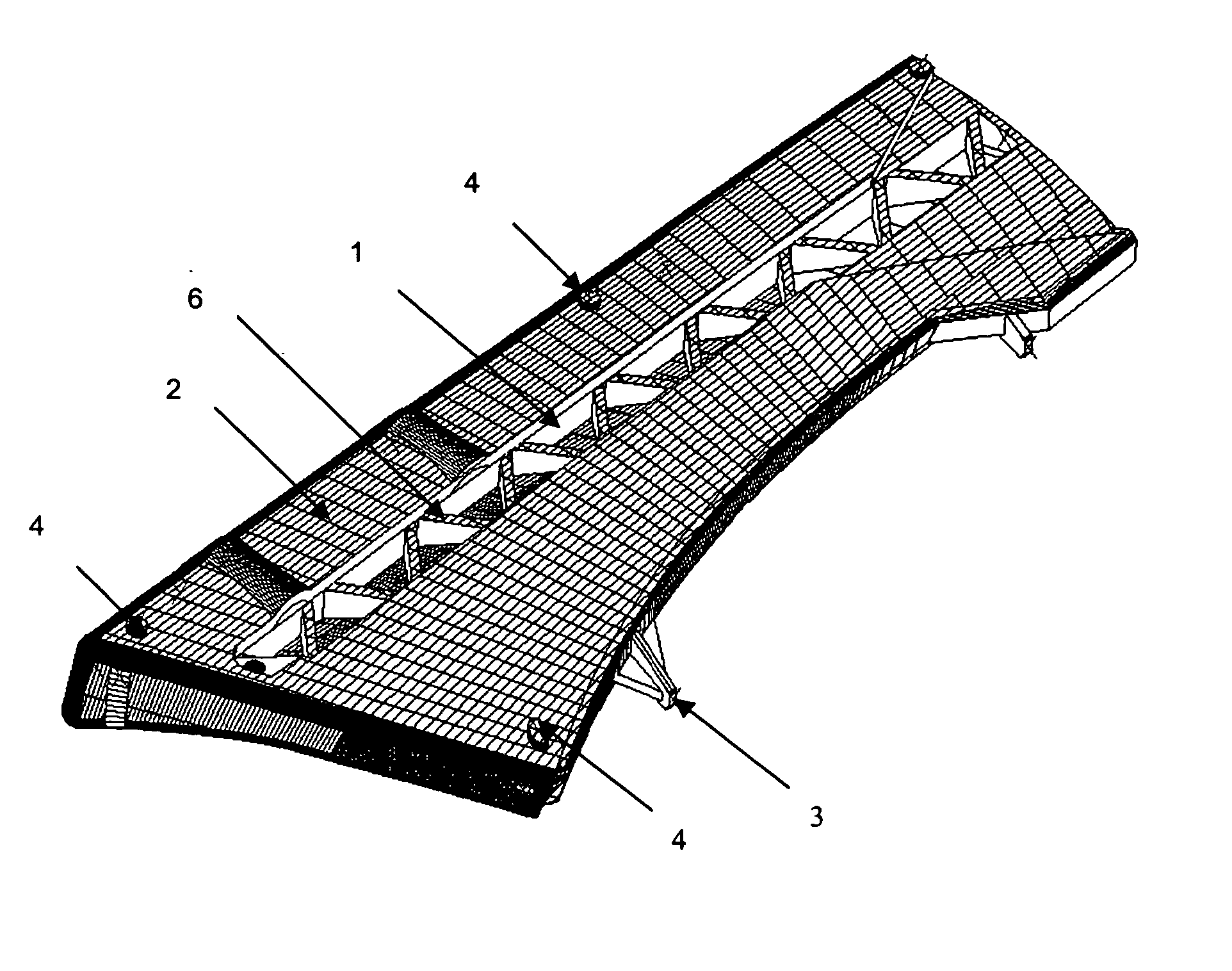

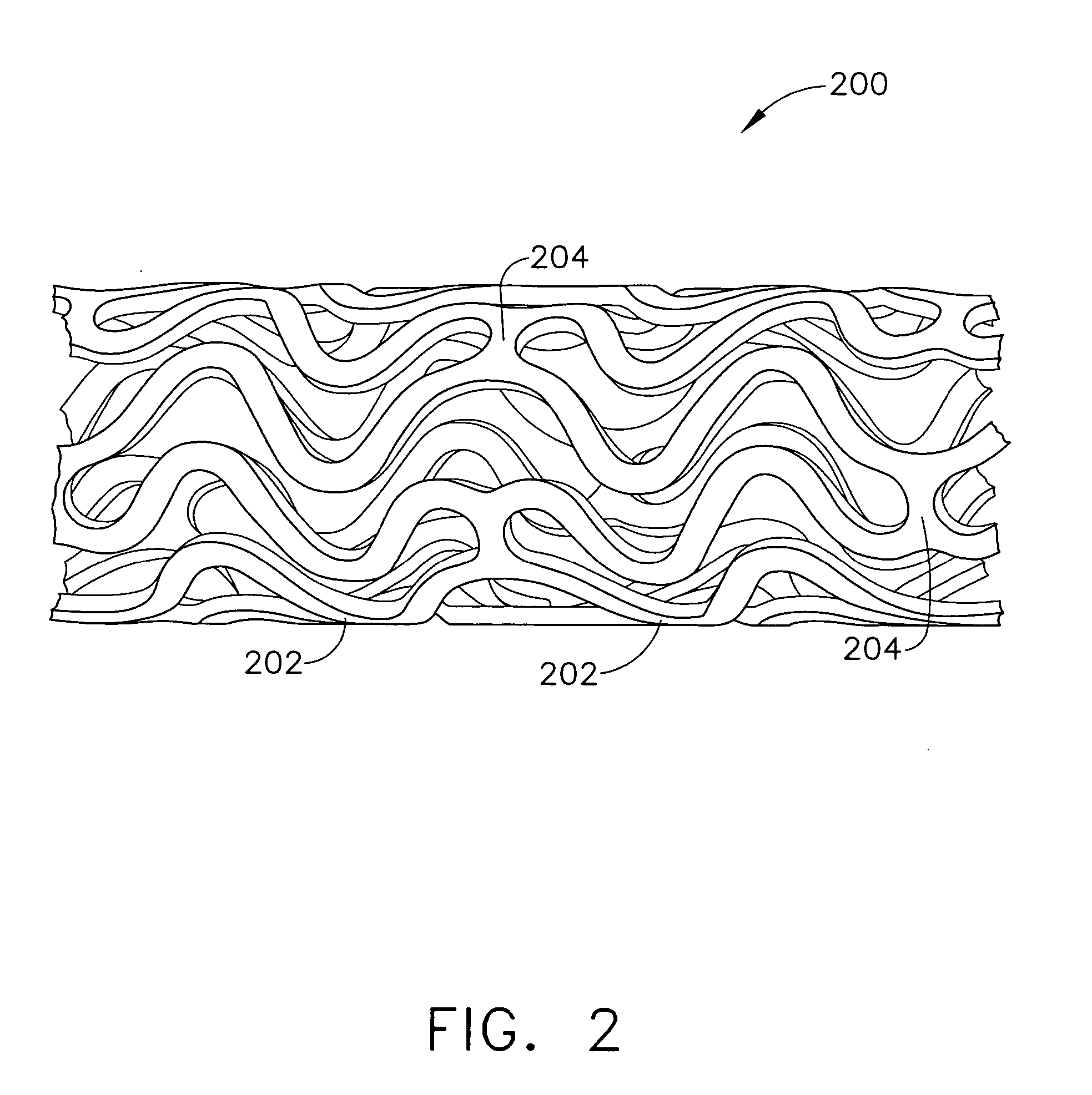

Reinforcing members

ActiveUS20040256888A1Satisfactory performanceEfficient coatingVehicle seatsSuperstructure subunitsEngineeringAdhesive materials

A structural reinforcement for a hollow section at least part of at least one of whose surfaces is the internal surface of an external panel comprising a rigid reinforcing member having a shape that substantially conforms to the cross section to be reinforced. An expandable adhesive material is provided over a portion of the surface of the rigid reinforcing member and the shape of the rigid reinforcing member and the amount and location of the expandable adhesive is such that upon foaming the foam contacts and bonds to the internal surfaces of the hollow section other than the interior surface of the external panel. In this way deformation of the external body panel during the foaming and / or cooling of the foamed expandable material is reduced or prevented.

Owner:ZEPHYROS INC

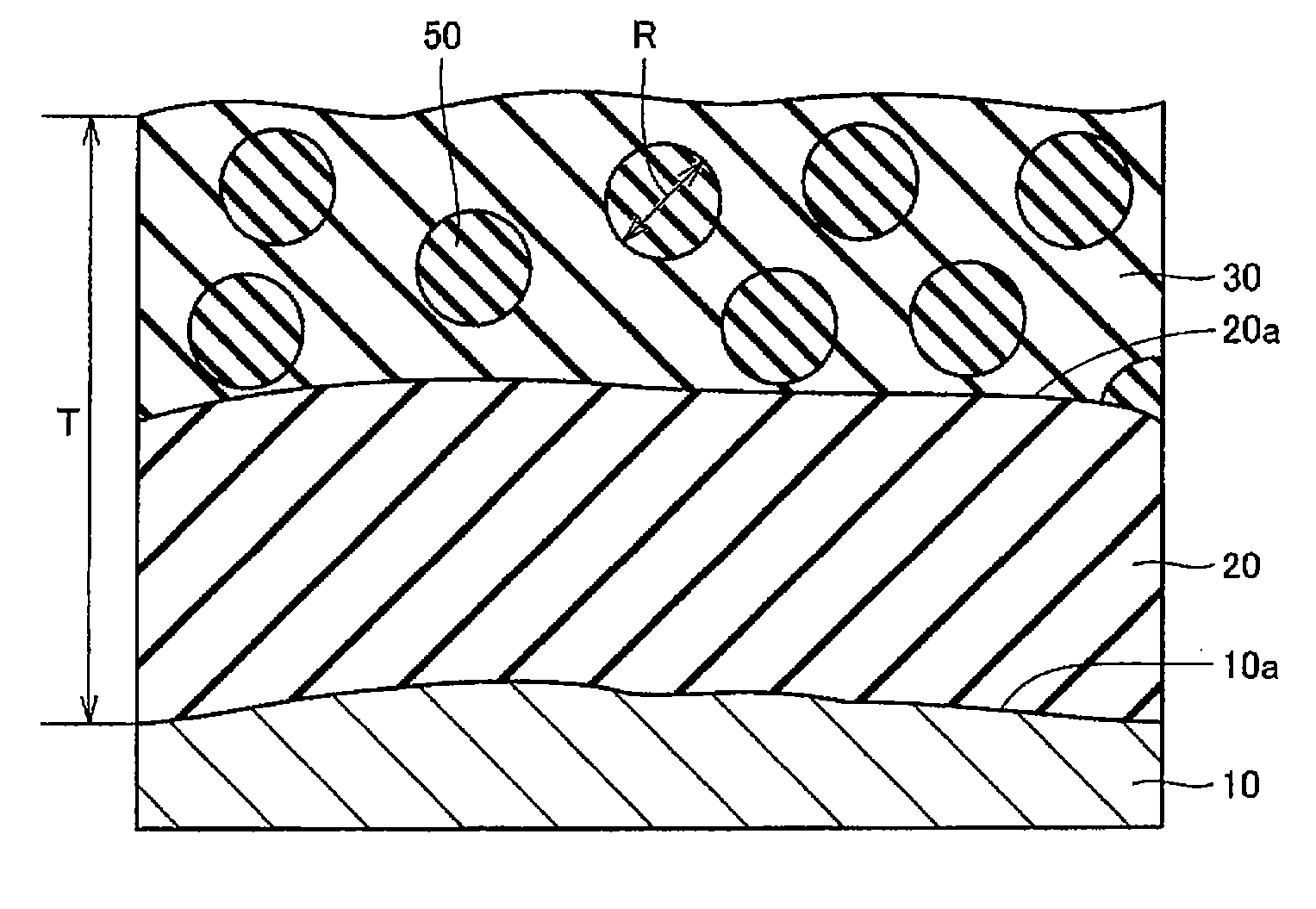

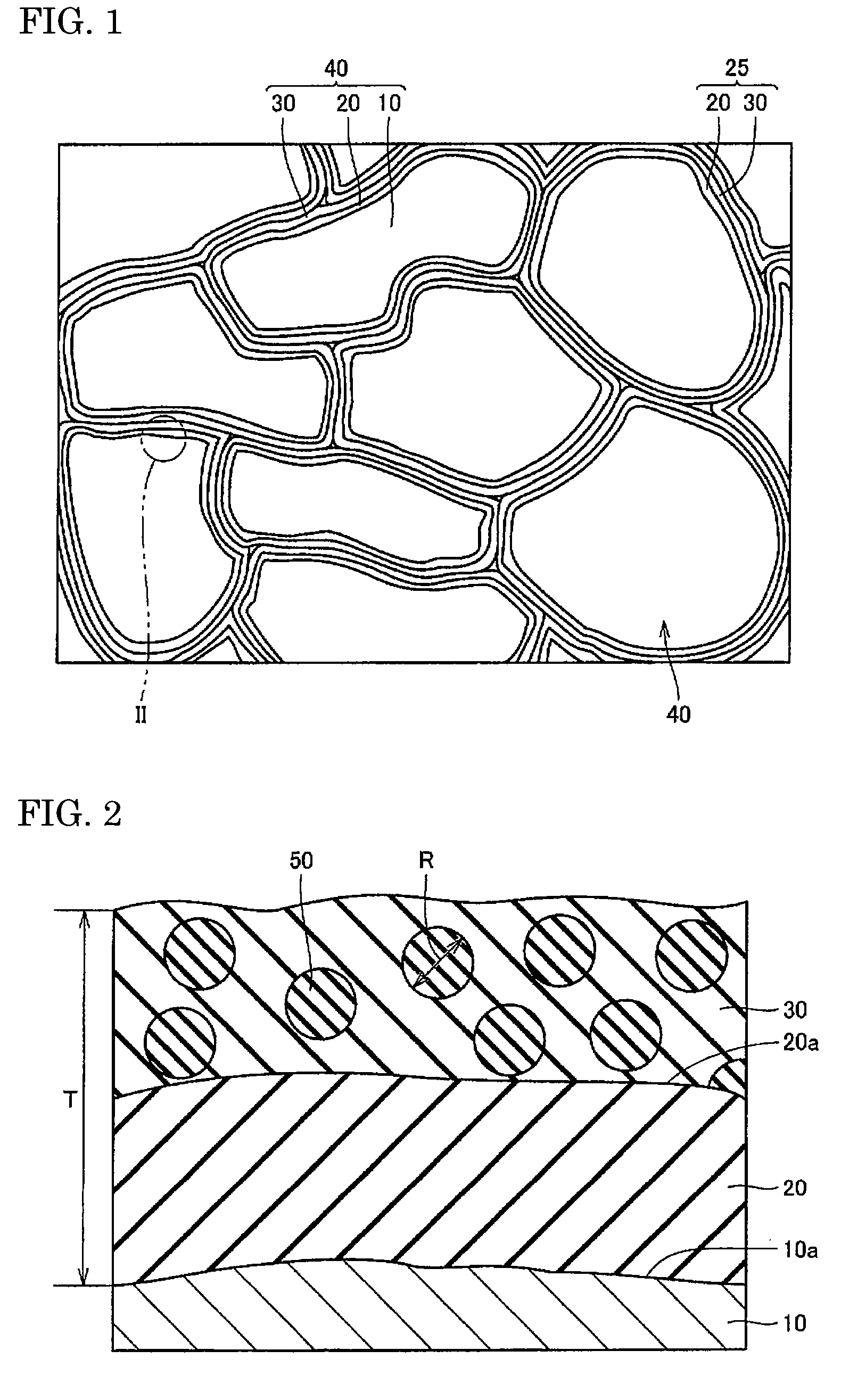

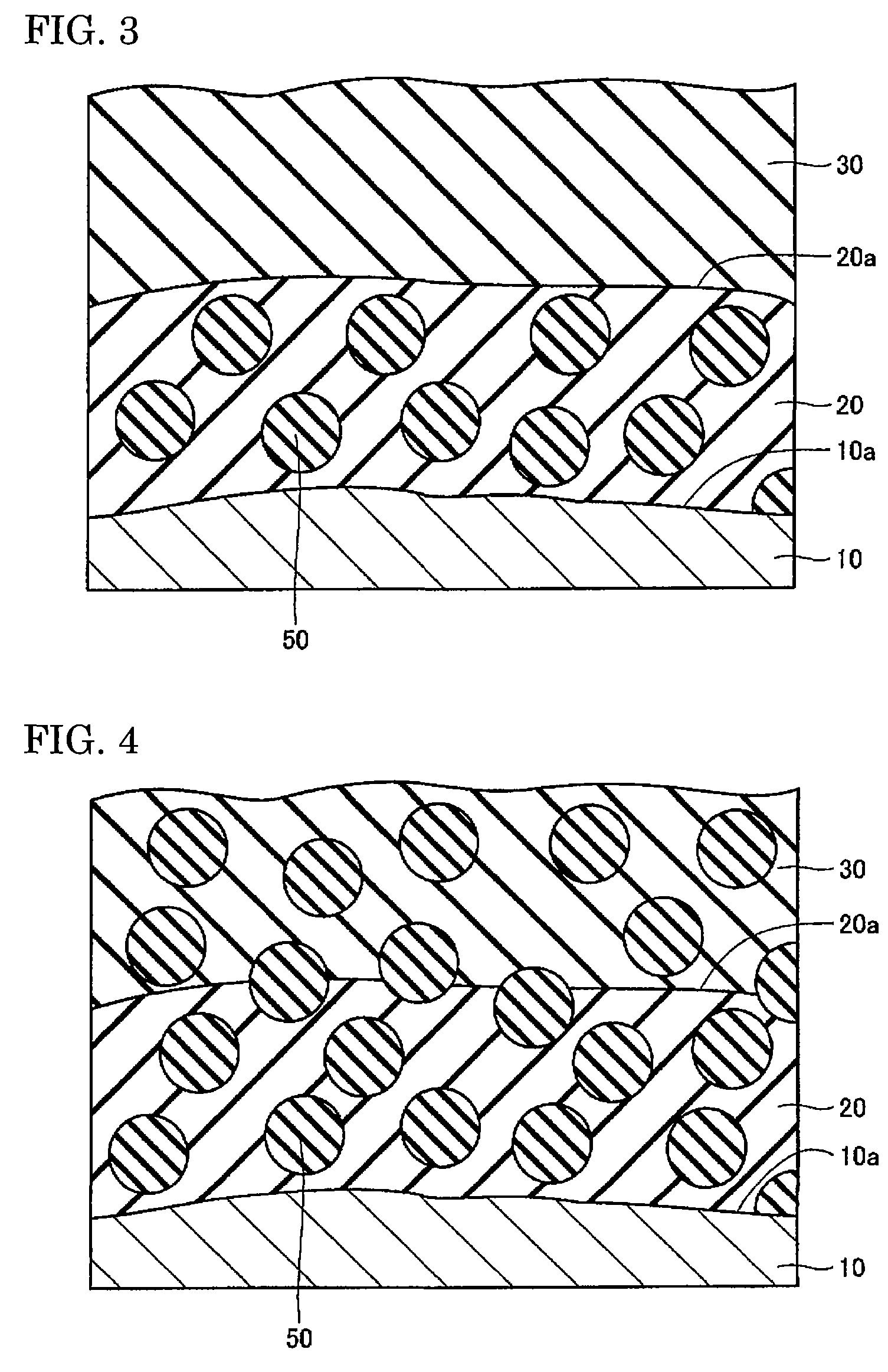

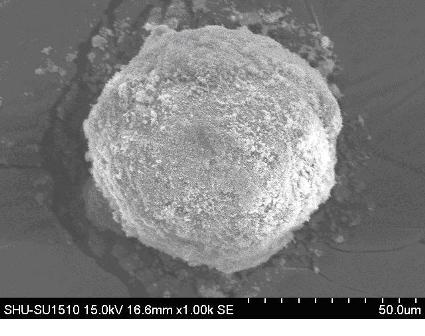

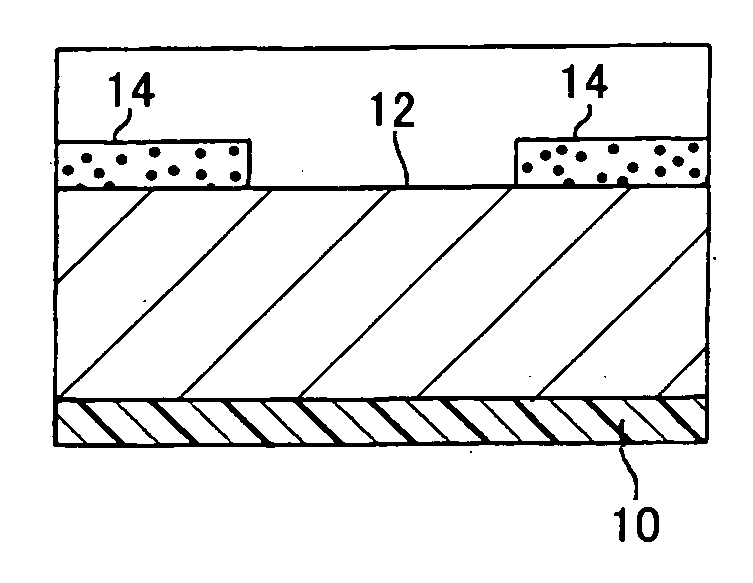

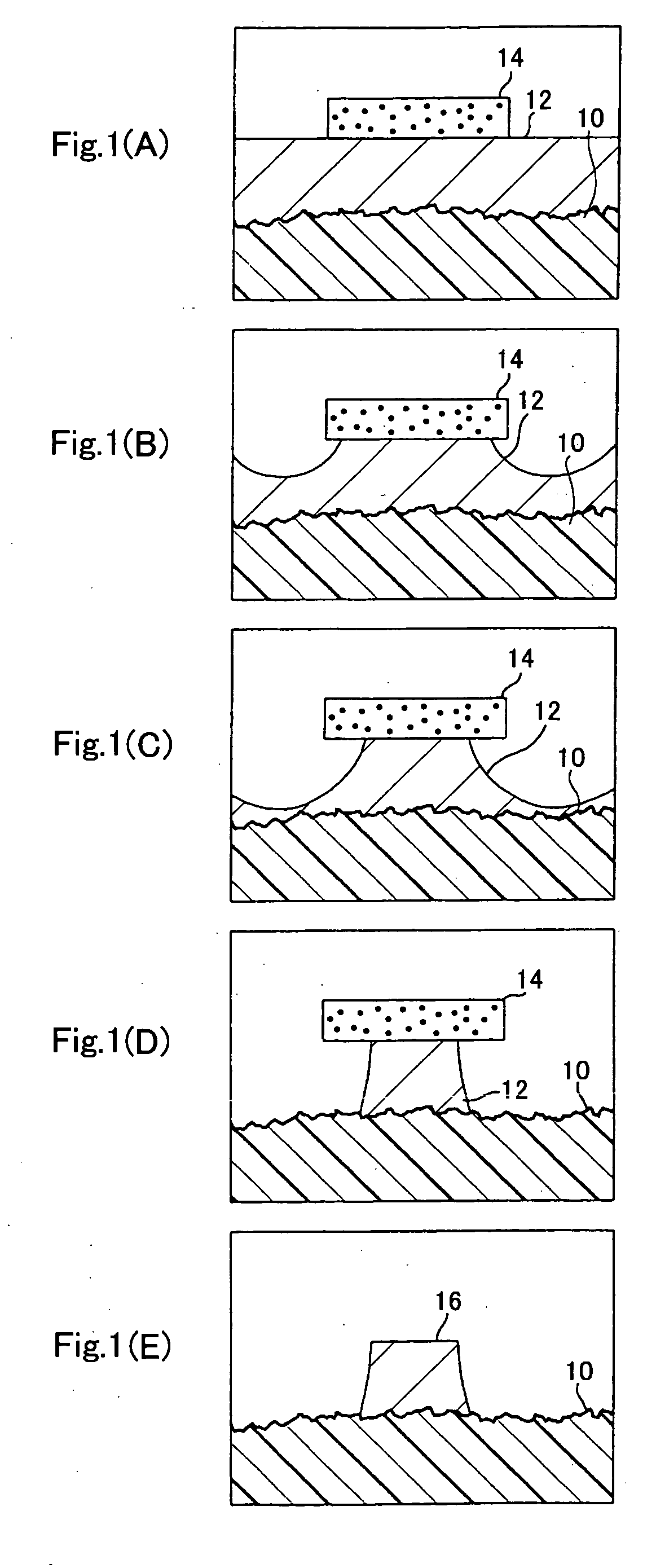

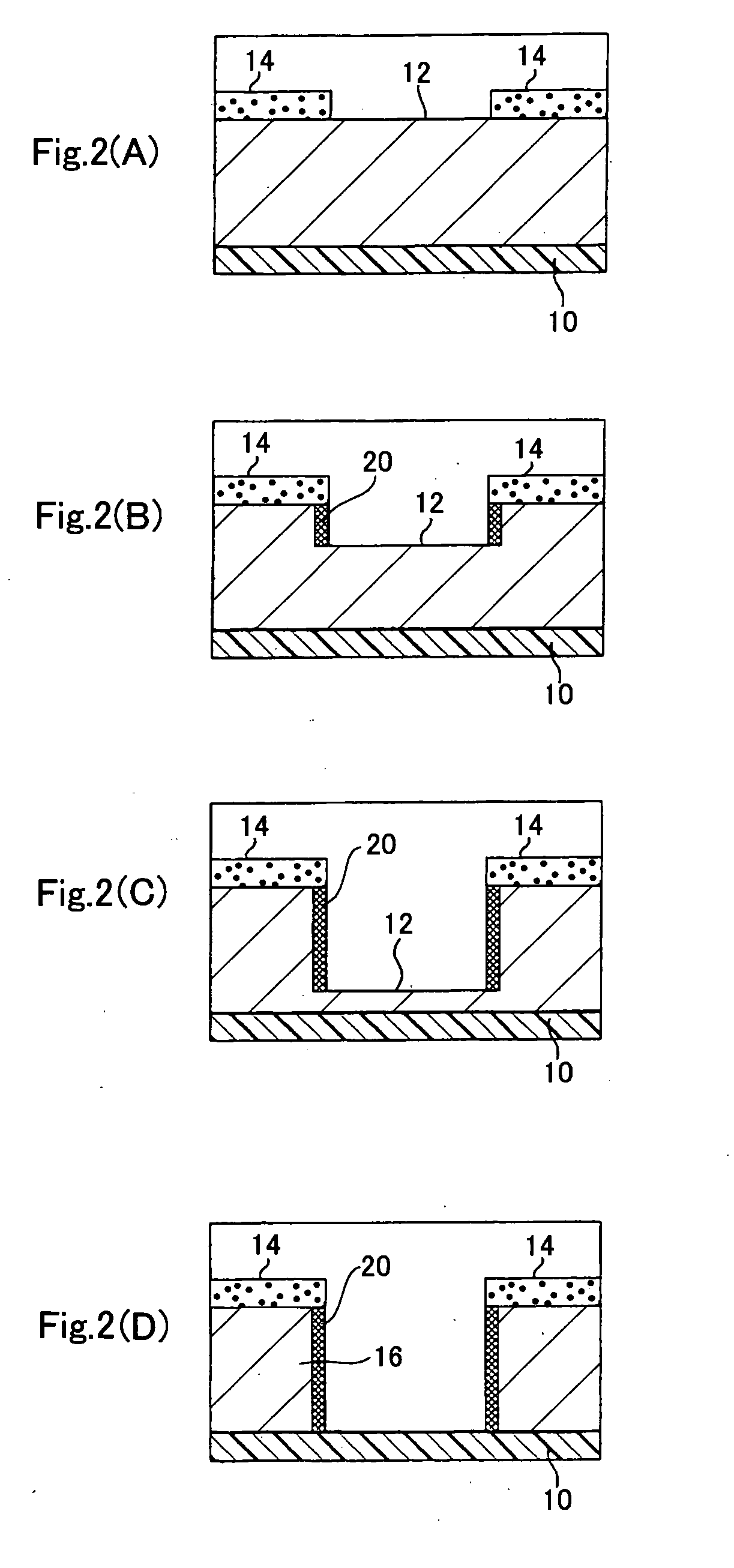

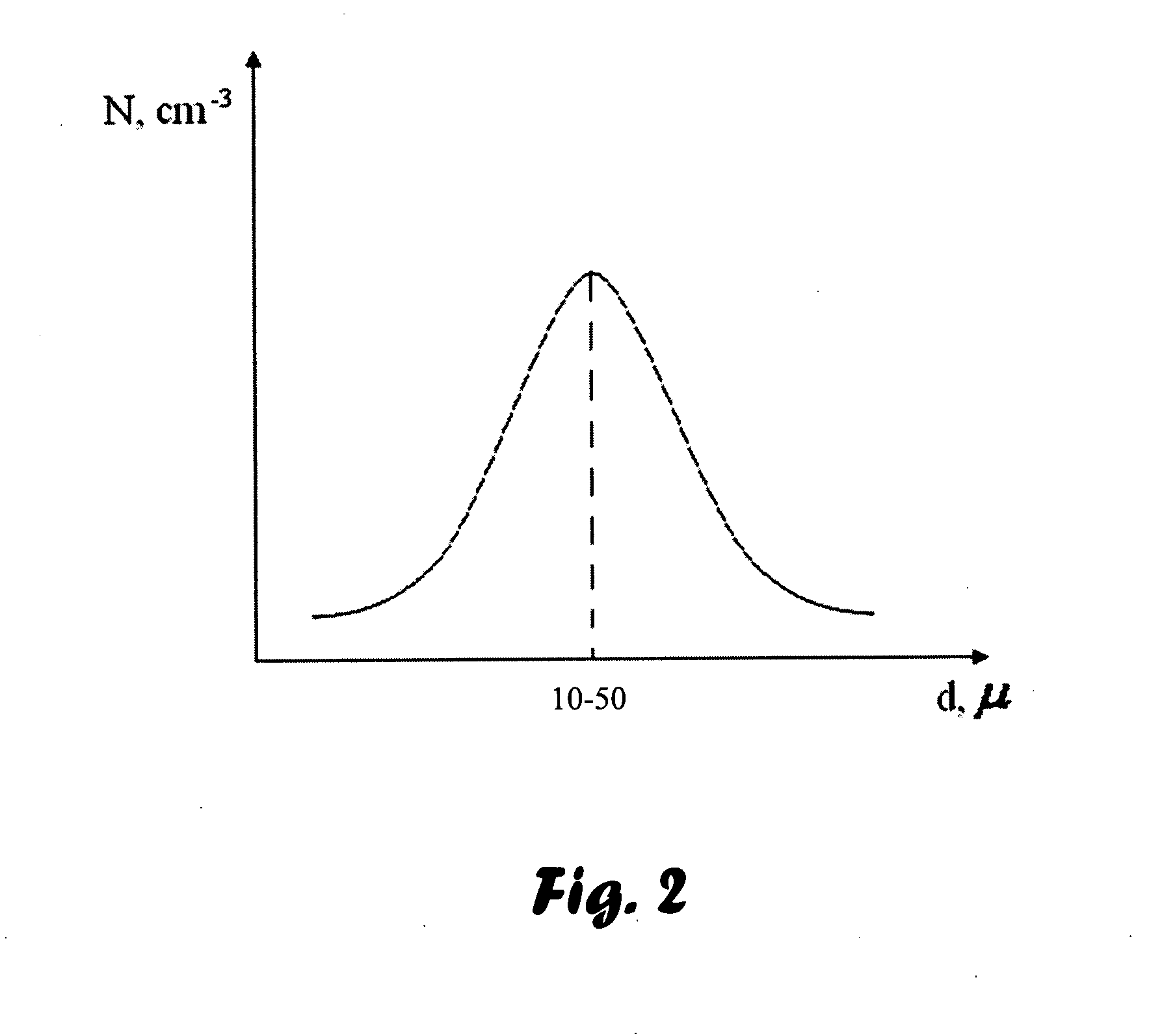

Dust Core and Method for Producing Same

InactiveUS20080231409A1Adequately restrict flowImprove heat resistanceSynthetic resin layered productsCellulosic plastic layered productsHeat resistanceEddy current

The object of the present invention is to provide a powder core and method for making the same that is equipped with insulative coating having superior heat resistance, with the coating making it possible to adequately restrict the flow of eddy currents between particles.The powder core is equipped with a plurality of compound magnetic particles bonded to each other. Each of said plurality of composite magnetic particles includes: a metal magnetic particle 10; an insulative lower layer coating 20 surrounding a surface 10a of said metal magnetic particle 10; an upper layer coating 30 surrounding said lower layer coating 20 and containing silicon; and dispersed particles 50 containing a metal oxide compound and disposed in said lower layer coating 20 and / or said upper layer coating 30. A mean particle diameter R of the dispersed particles 50 meets the condition 10 nm<R≦2 T, where the average thickness of the coating combining the lower layer coating 20 and the upper layer coating 30 is T.

Owner:SUMITOMO ELECTRIC IND LTD

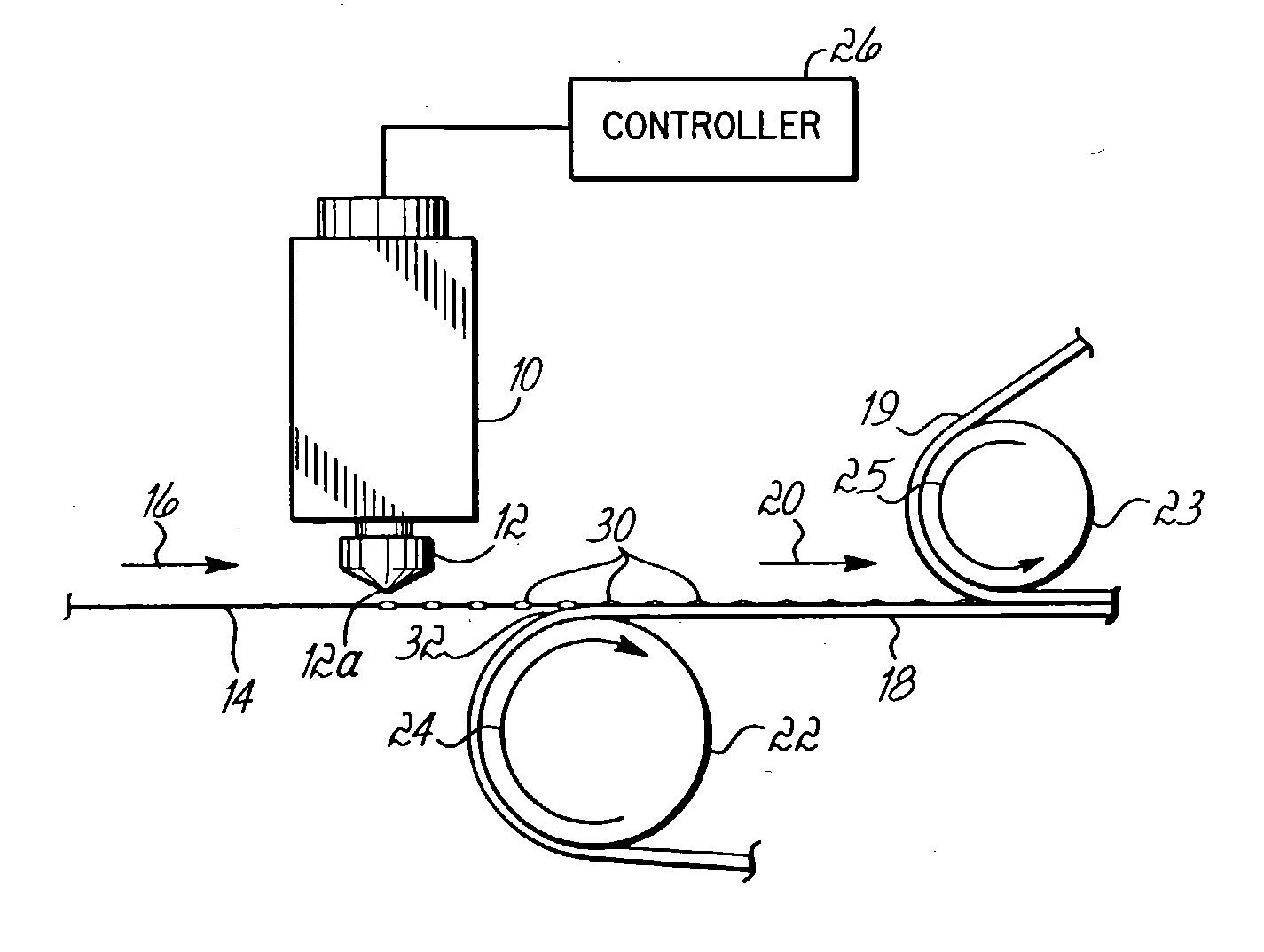

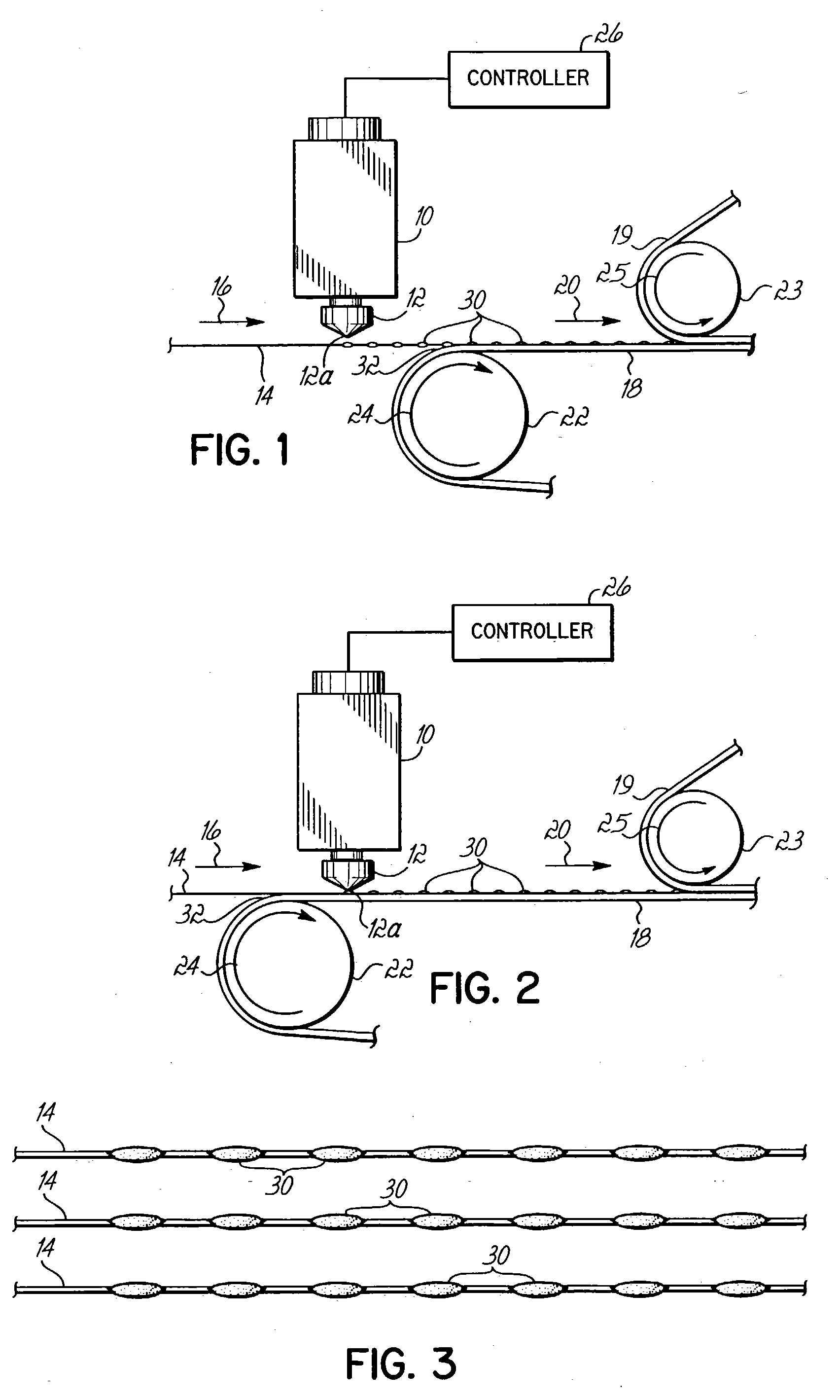

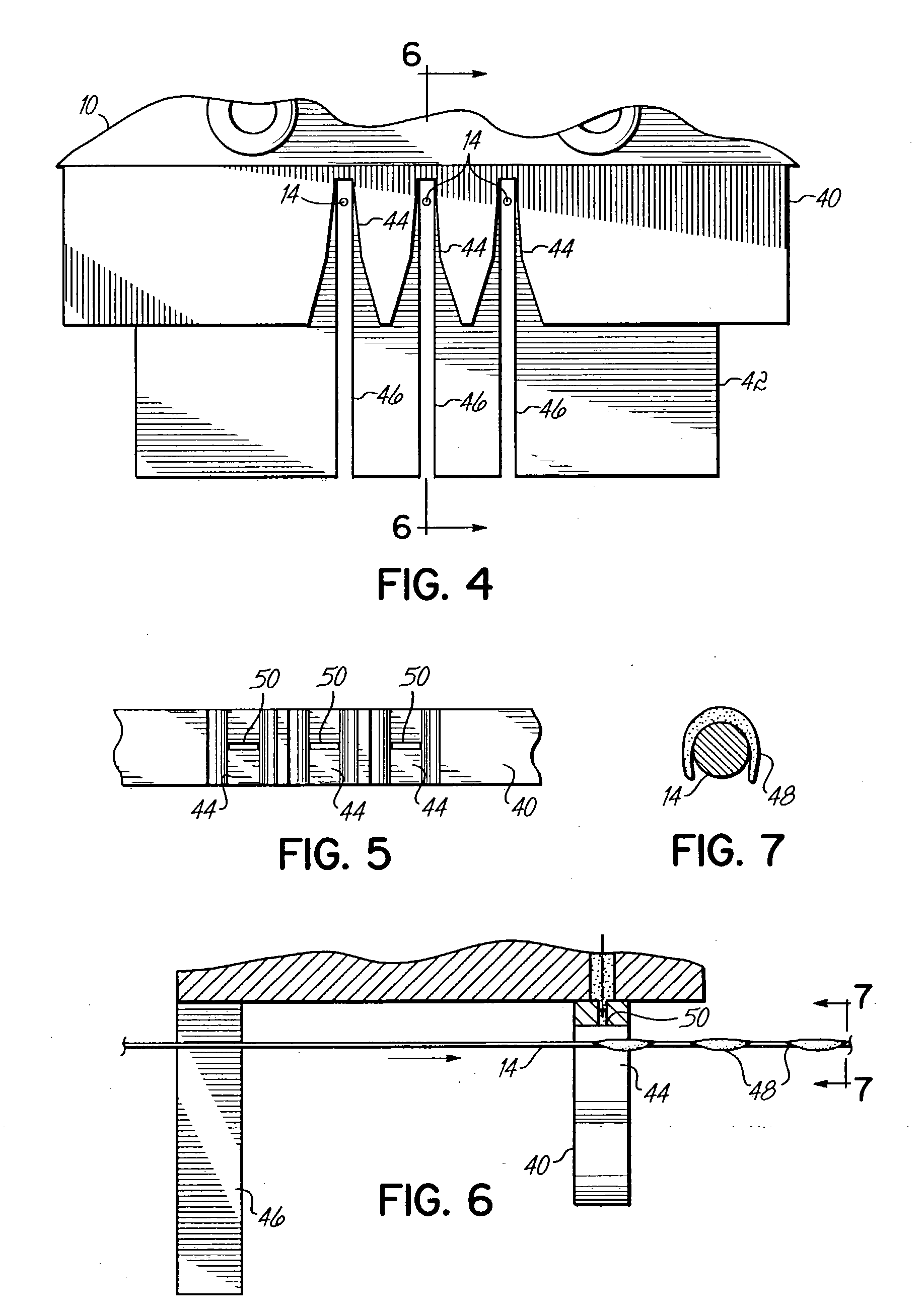

Method of securing elastic strands to flat substrates and products produced by the method

PendingUS20050013975A1Cost reductionIncrease creep resistanceLiquid surface applicatorsPersonal careEngineeringAdhesive

A method of securing an elastic strand to a sheet of material includes moving the elastic strand and the sheet in a converging manner from a position in which the elastic strand is spaced from the sheet to another position in which the elastic strand contacts one surface of the sheet. Discrete elongate segments of adhesive are intermittently applied to the strand. The elongate segments of adhesive secure the strand to the sheet. Various articles of manufacture may be formed using the method, including hygienic articles such as diapers.

Owner:NORDSON CORP

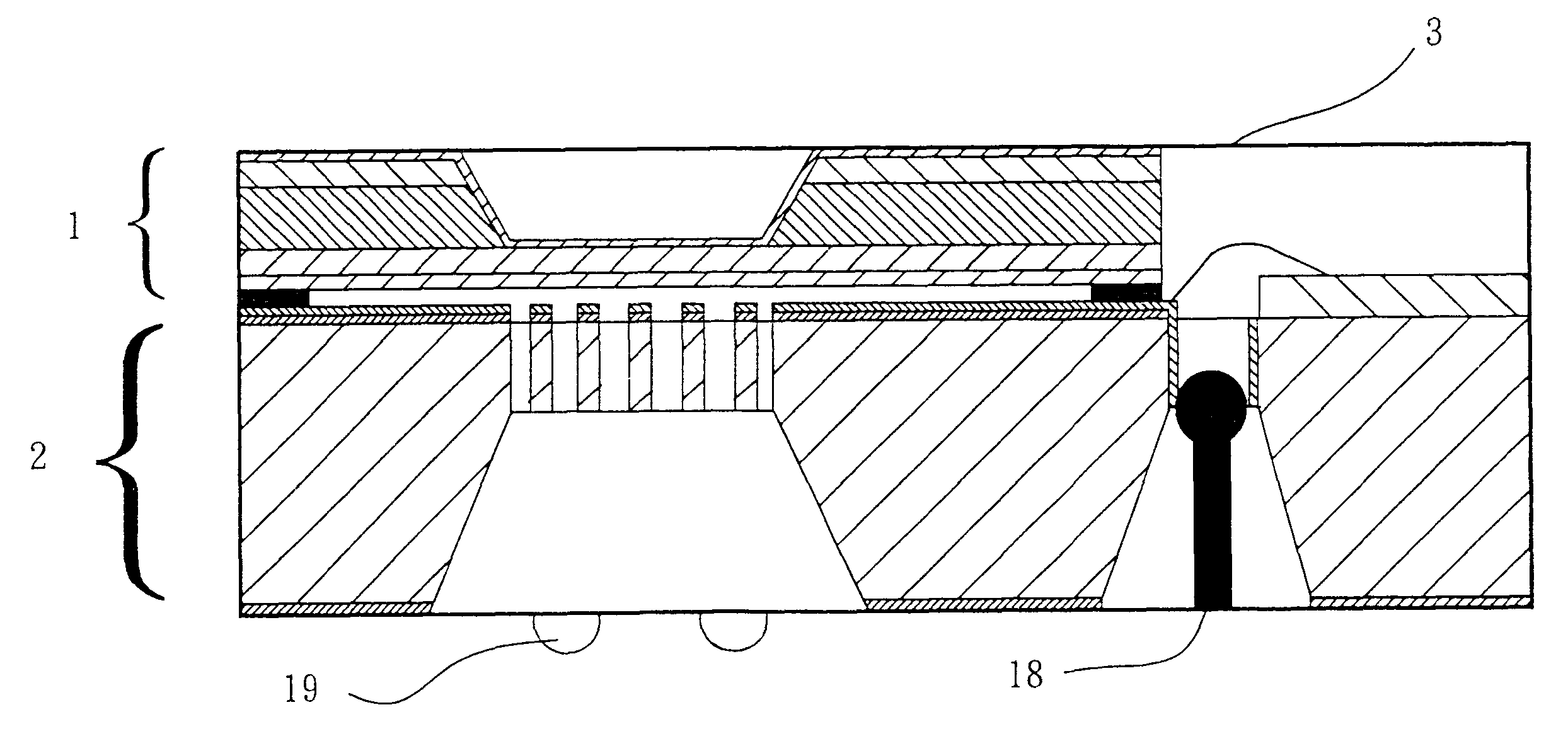

SMT-type structure of the silicon-based electret condenser microphone

InactiveUS6870939B2Reduce Harmonic DistortionStructure miniaturizationPiezoelectric/electrostrictive microphonesElectrets selectrostatic transducerCapacitanceDielectric

This invention mainly provides a SMT-type structure of the minimized and low-power silicon-based electret condenser microphone. Primarily integrates with the electret, silicon-based, MEMS and microphone techniques to implement the minimized and low-power silicon-based electret condenser microphone. The Silicon-based bi-diaphragm of the composite diaphragm-chip was coated with the low-dielectric macromolecule material to allow the microphone acquires the sufficient electrical charges. Moreover, the impedance matching element of the microphone that MOSFET was implemented by the MEMS technology. Conclusively, this silicon-based electret condenser microphone gains several achievements as the smallest volume, a lower bias voltage, a SMT-type structure, a lower residue stress and a lower assembly cost.

Owner:IND TECH RES INST

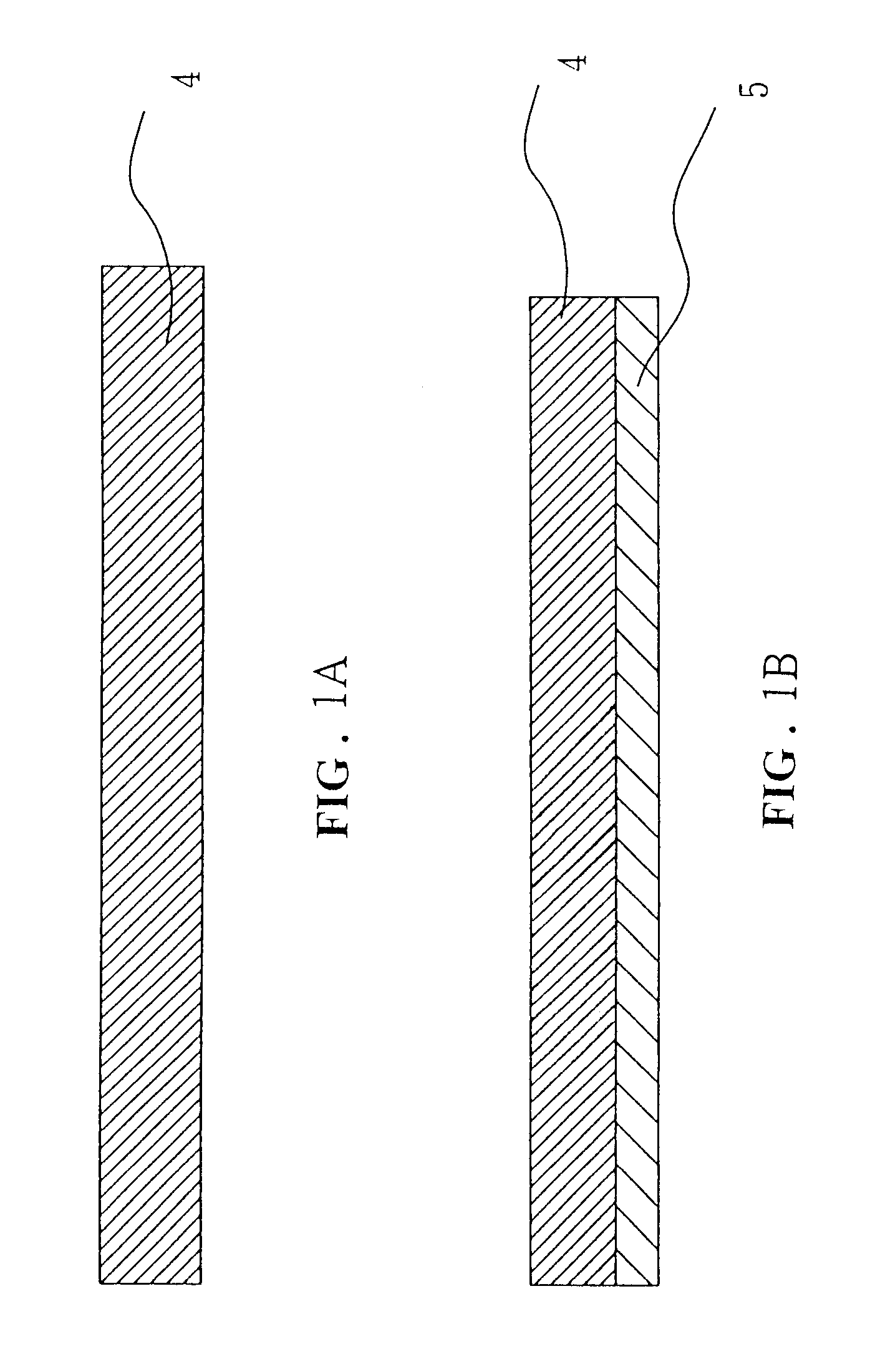

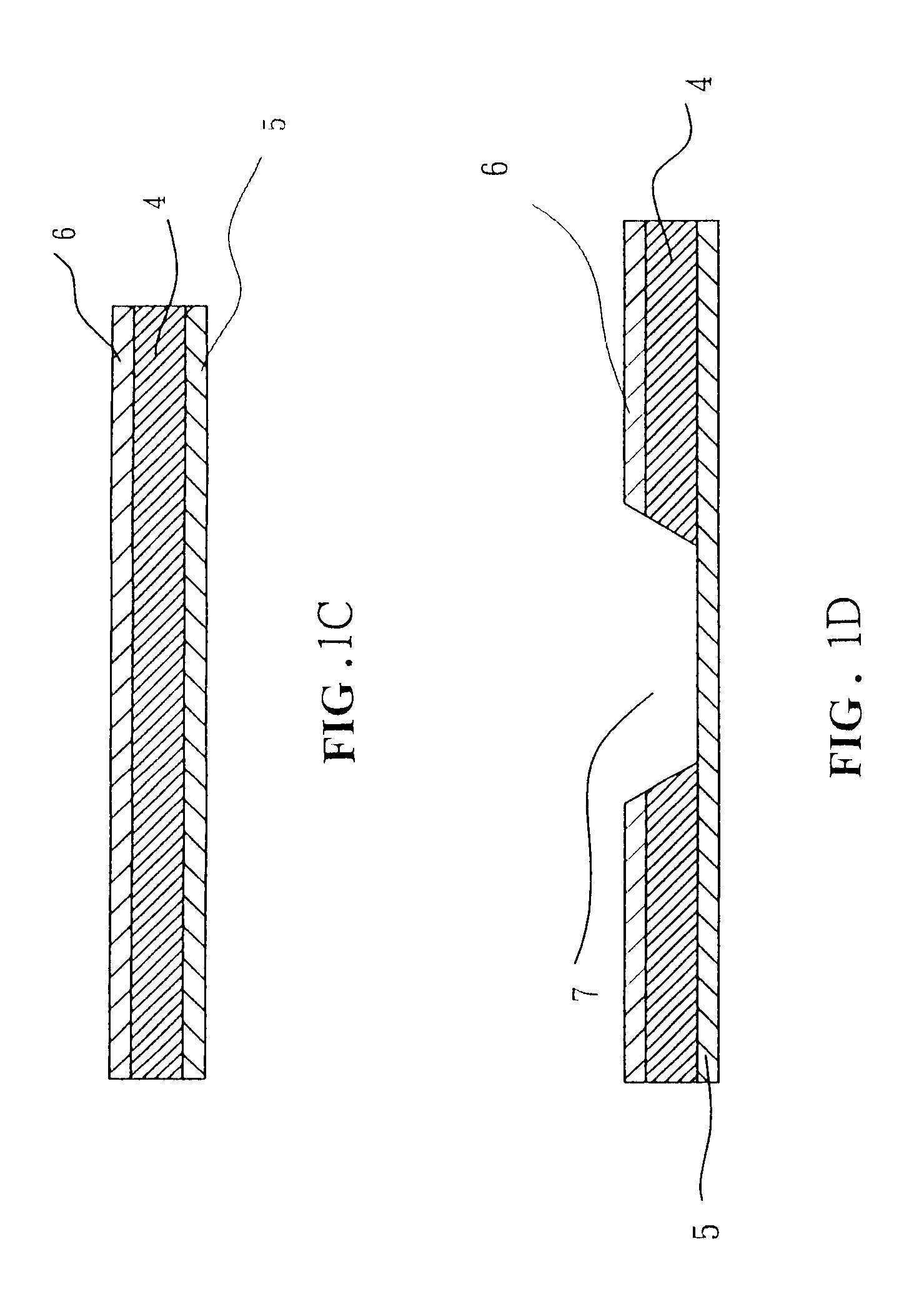

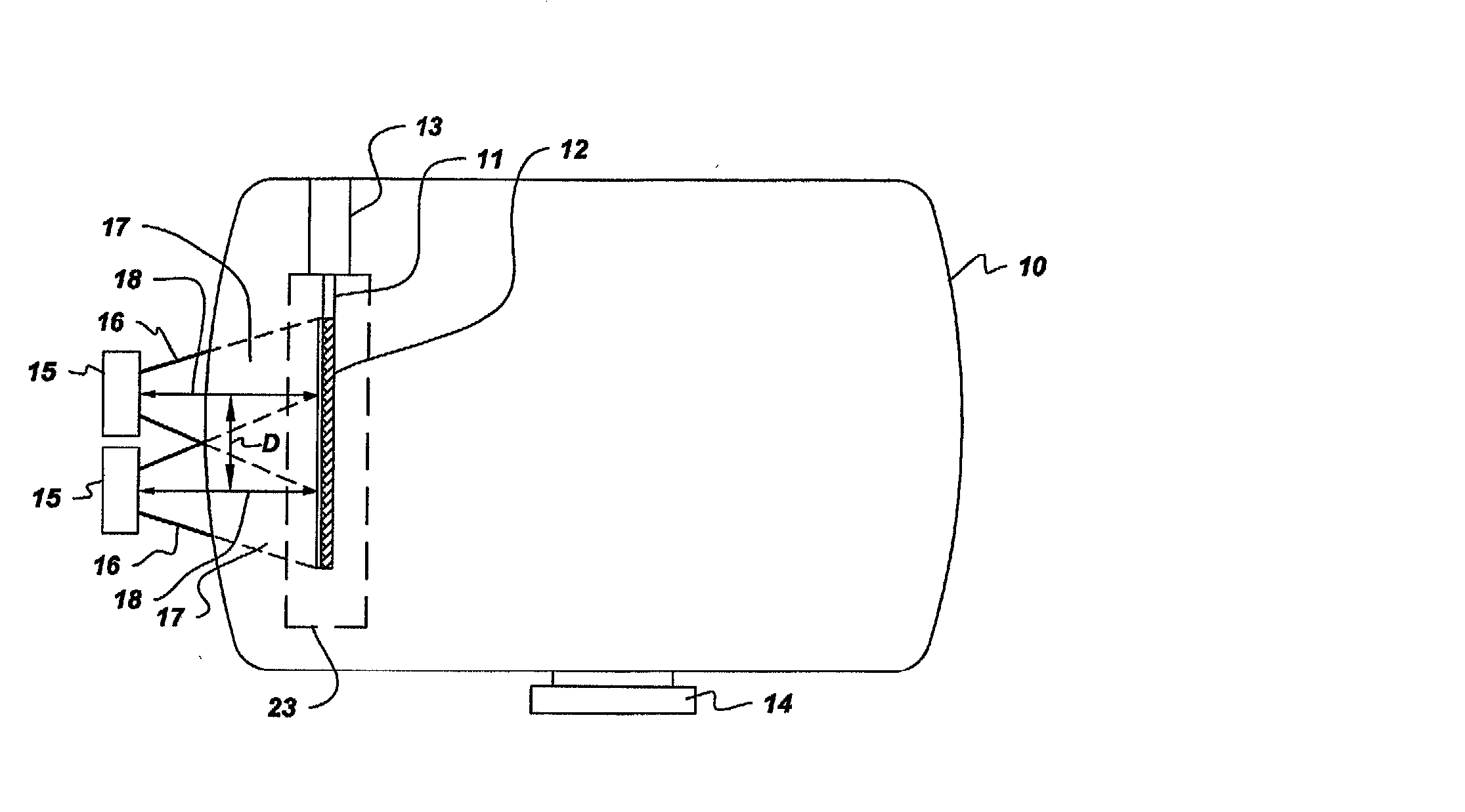

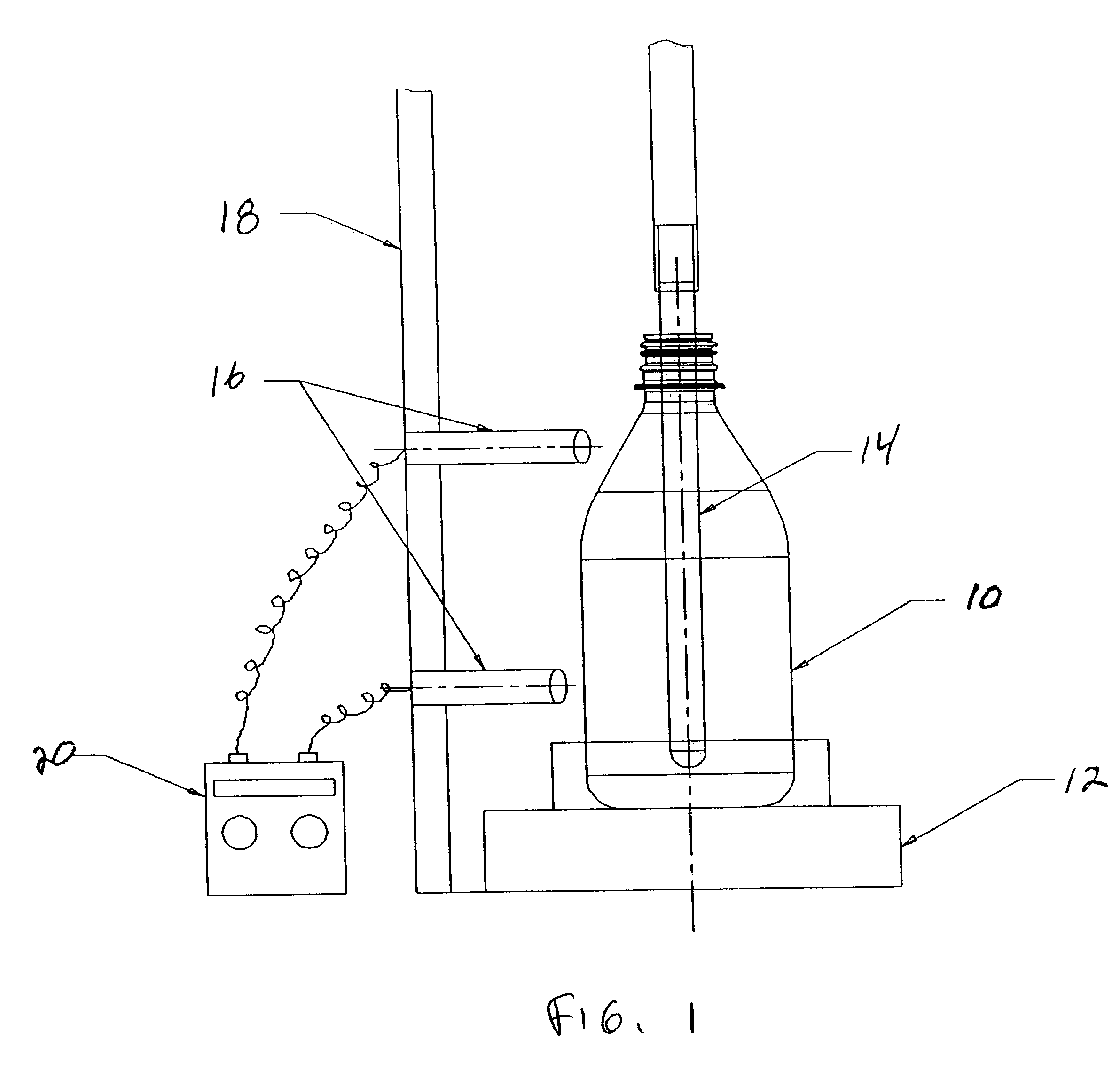

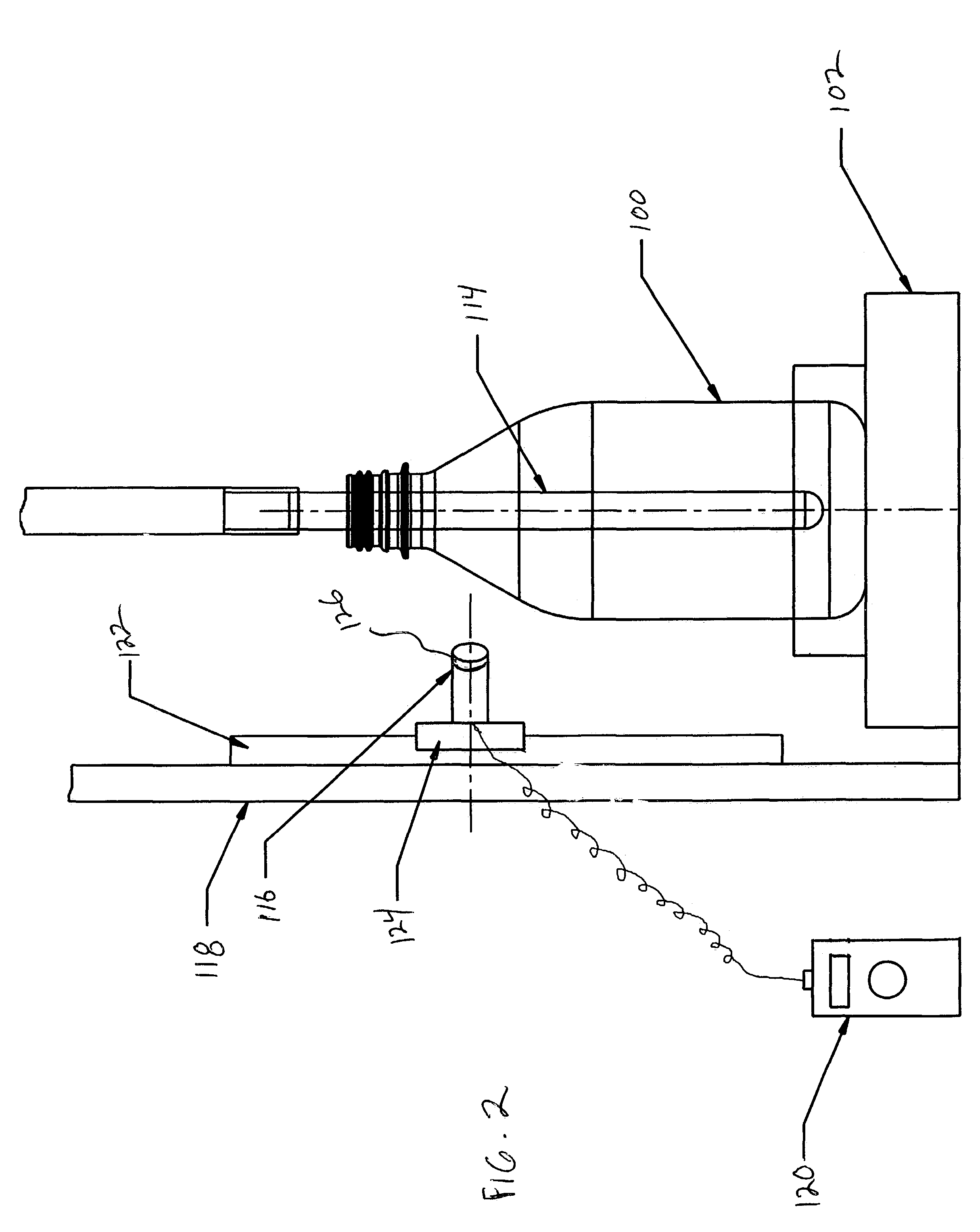

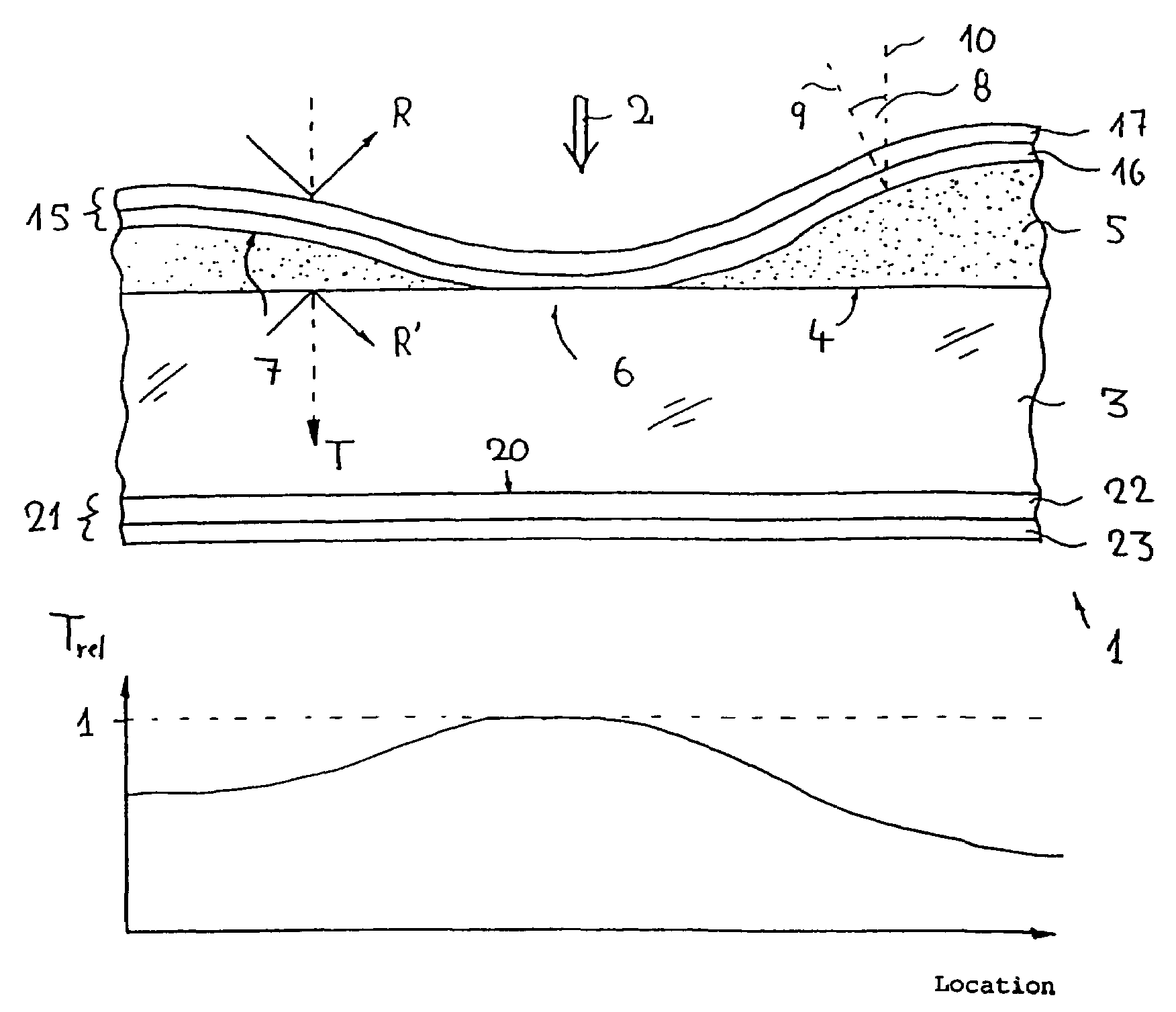

Apparatus and method for large area chemical vapor deposition using multiple expanding thermal plasma generators

InactiveUS20030072881A1Efficient coatingDesirable propertySpark gapsElectric discharge tubesThermoplasticGas phase

Chemical vapor deposition is performed using a plurality of expanding thermal plasma generating means to produce a coating on a substrate, such as a thermoplastic and especially a polycarbonate substrate. The substrate is preferably moved past the generating means. Included are methods which coat both sides of the substrate or which employ multiple sets of generating means, either in a single deposition chamber or in a plurality of chambers for deposition of successive coatings. The substrate surfaces spaced from the axes of the generating means are preferably heated to promote coating uniformity.

Owner:SABIC INNOVATIVE PLASTICS IP BV

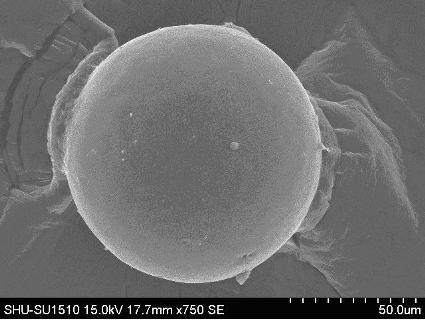

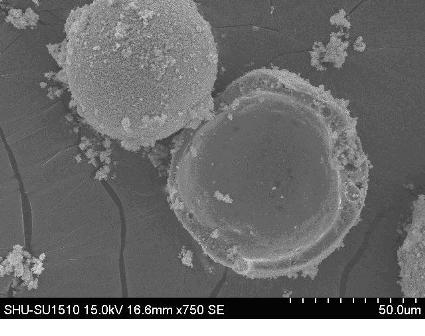

Method for preparing hollow glass microsphere coating titanium dioxide

InactiveCN102002263AEasy to depositExtended service lifePigment treatment with organosilicon compoundsReflecting/signal paintsFiltrationDistilled water

The invention discloses a method for preparing titanium dioxide for coating surfaces of hollow glass microspheres. The method comprises: washing the hollow glass microspheres with alkali liquor to remove impurities and etching to improve activity; performing surface activation and modification by using a silane coupling agent; mixing the activated hollow glass microspheres and distilled water in a mass ratio of 1:10; fully stirring at 40 to 90 DEG C; in the stirring process, dripping solution of titanium sulfate at a constant speed with in 2 to 6 hours according to a mass ratio of the hollow glass microspheres to the titanium sulfate of 1:0.8-1:1.6; slowly adding alkali liquor, keeping the pH value of the reaction system between 5 and 7, and stirring first at a speed of 400r / min for the first 1 / 5 of reaction time and then at a speed of 100 to 300r / min for the rest 4 / 5 of reaction time; and after the reaction is finished, standing, performing suction filtration, washing with distilled water, drying and calcining. The hollow glass microspheres coated with the titanium dioxide can serve as filler for reflective and thermal-insulation coating. Compared with common hollow glass microspheres, the hollow glass microspheres can be used for preparing and synthesizing high-performance coating combining various thermal-insulation mechanisms.

Owner:SHANGHAI UNIV

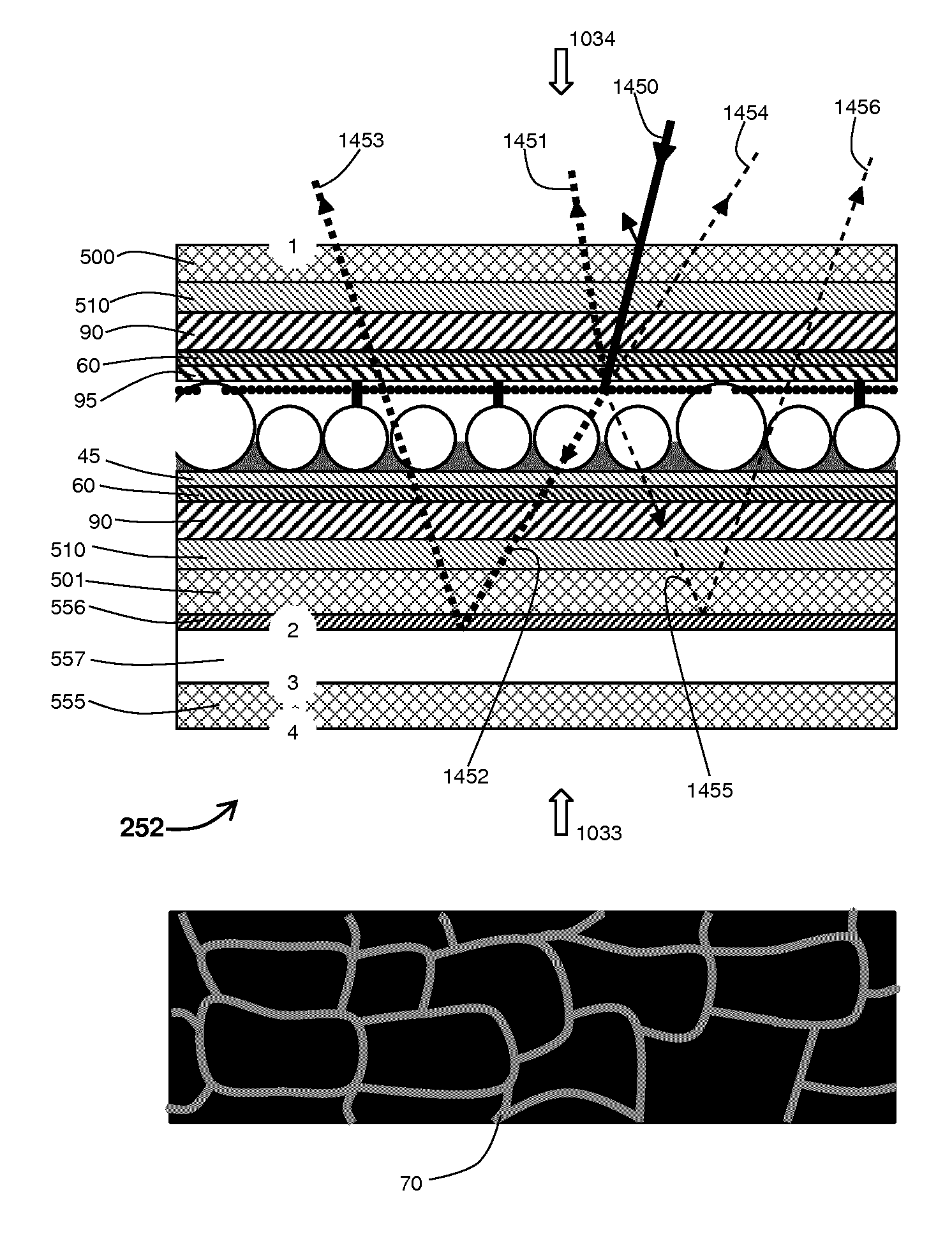

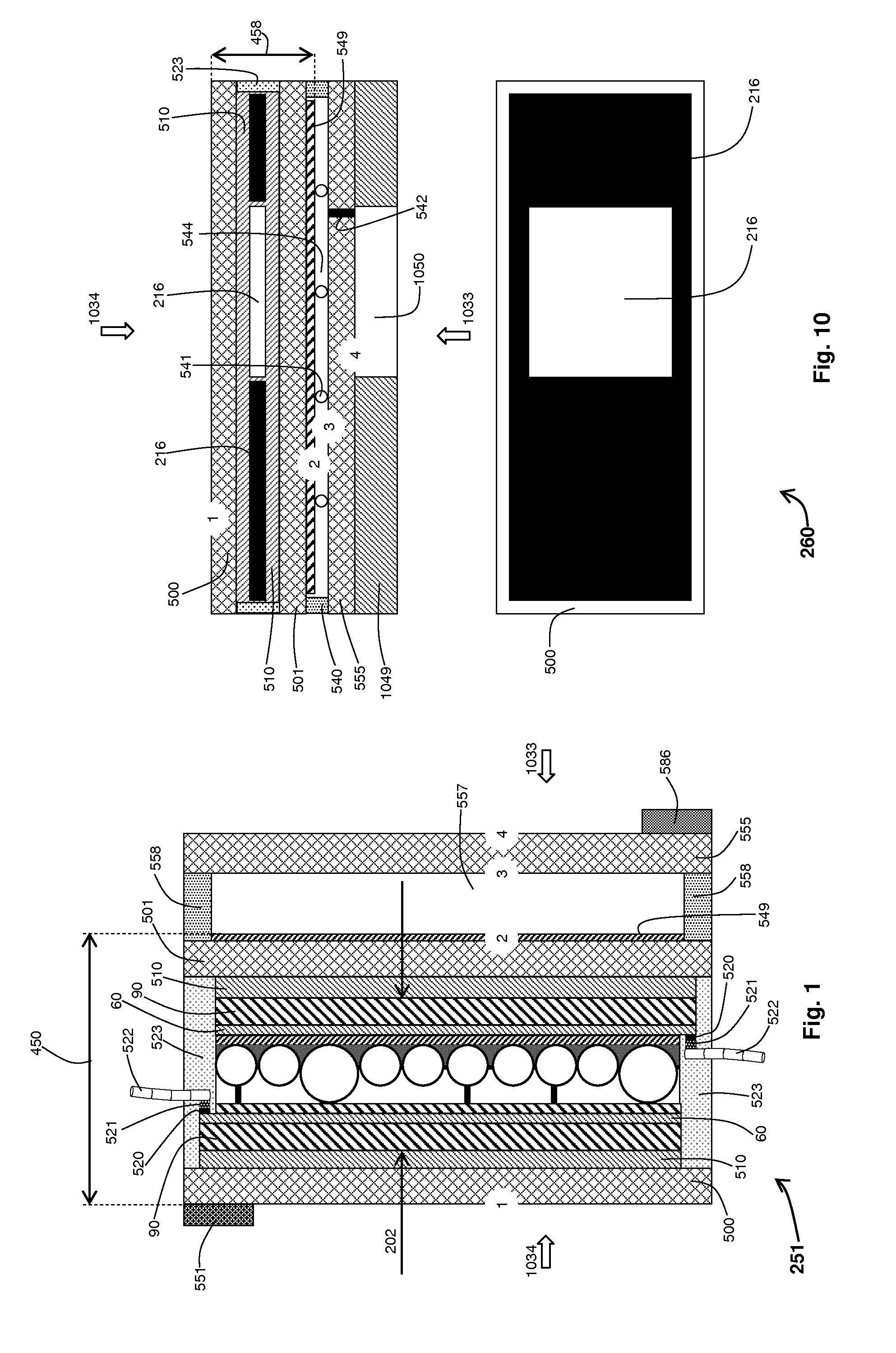

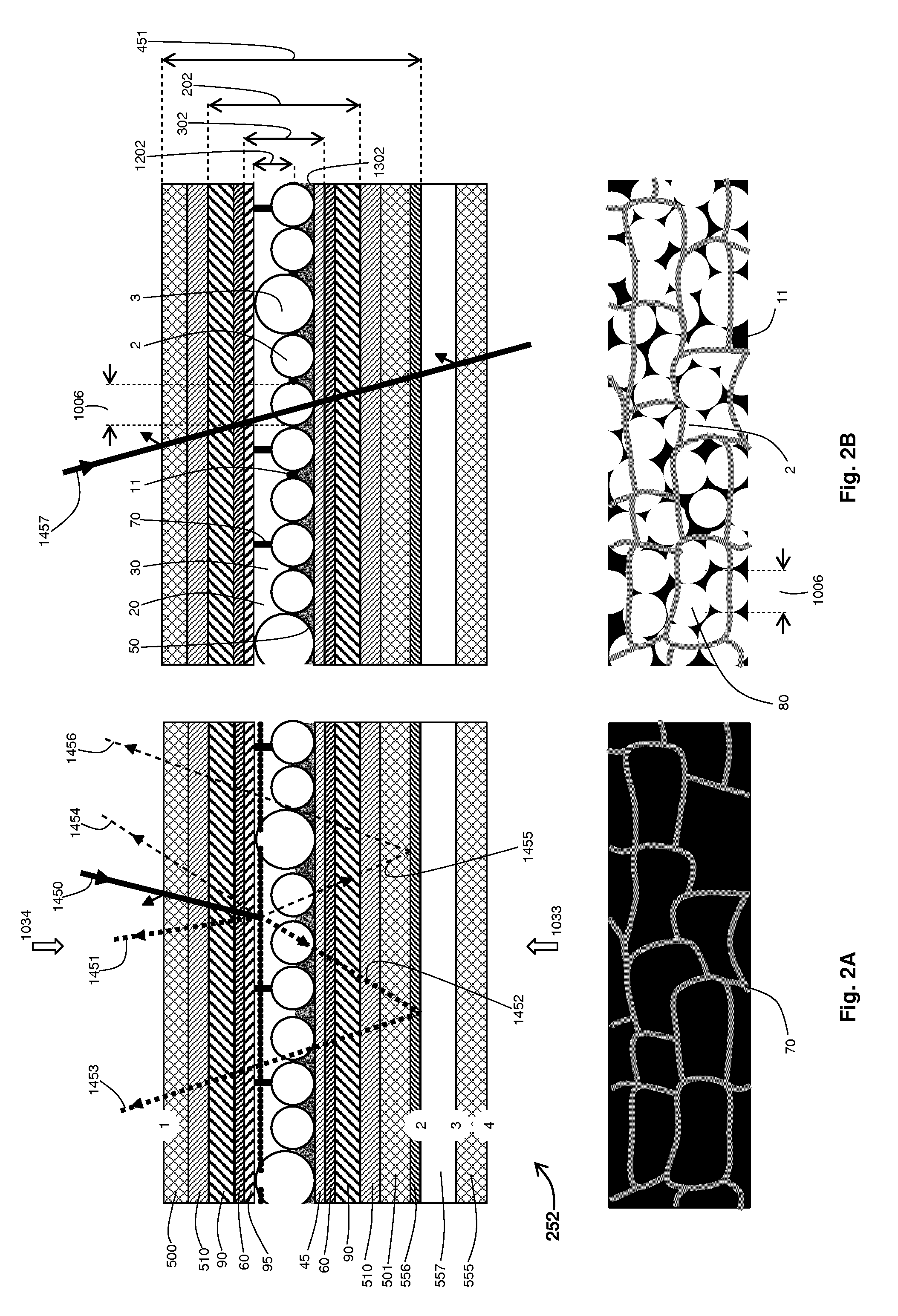

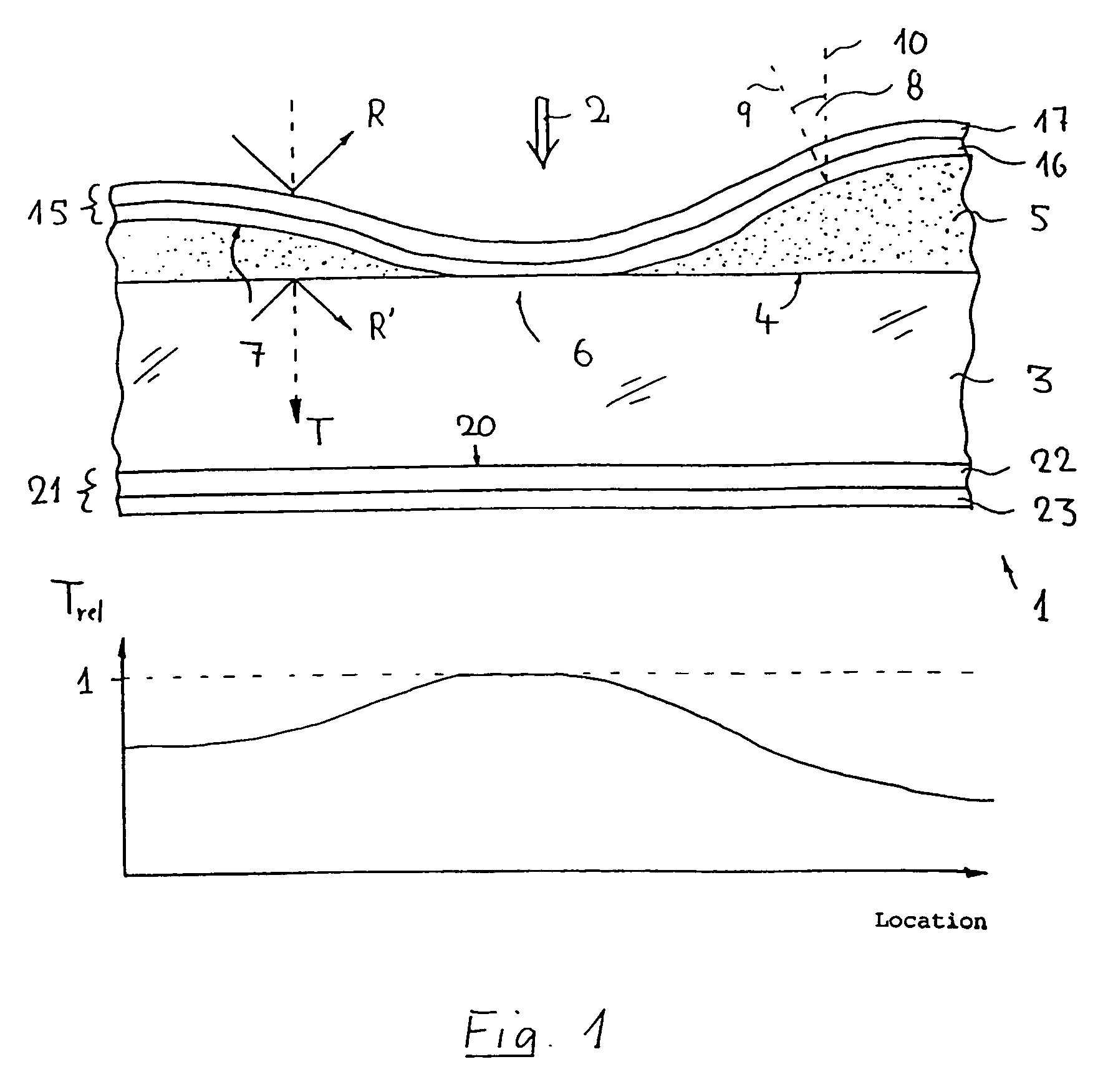

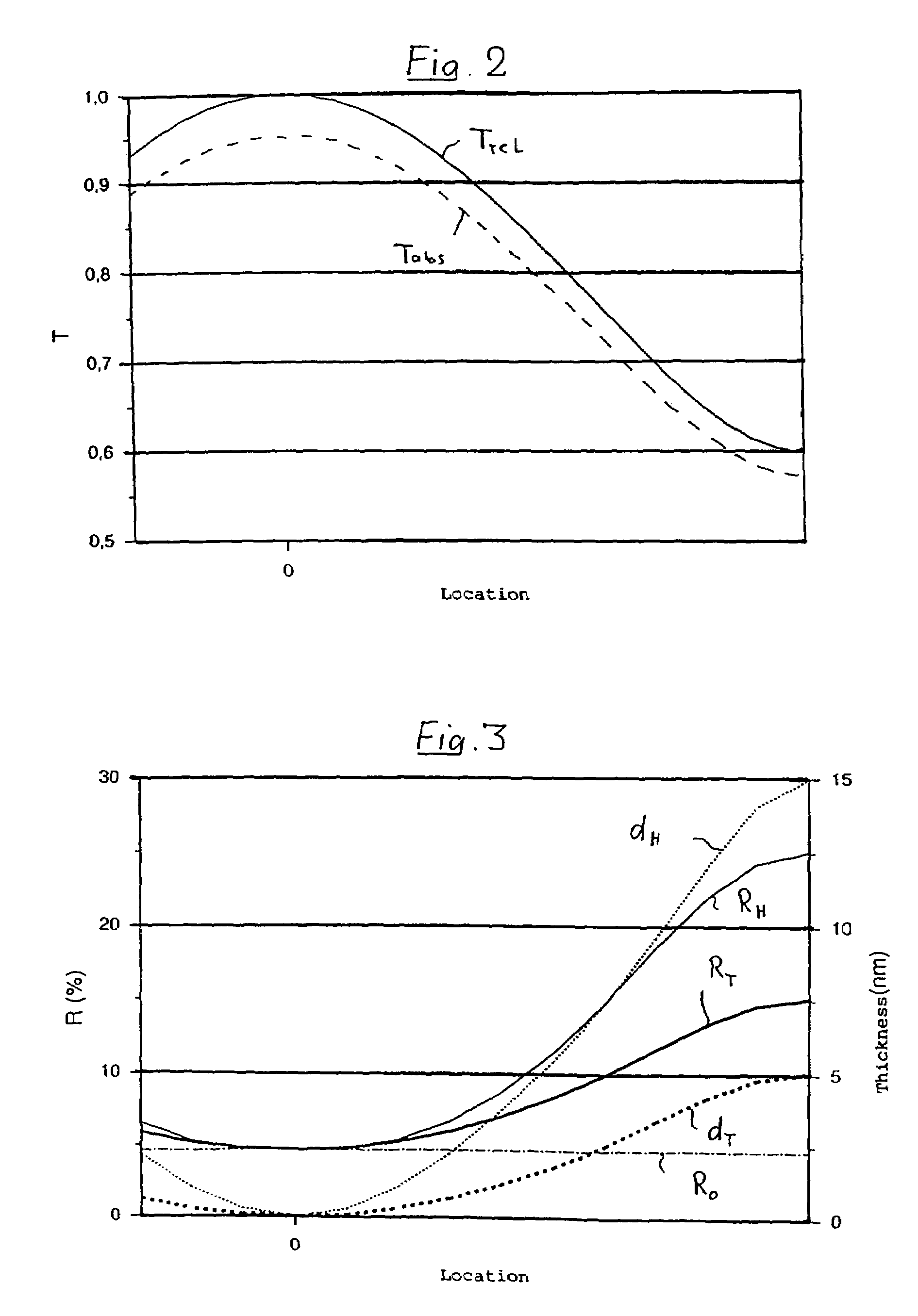

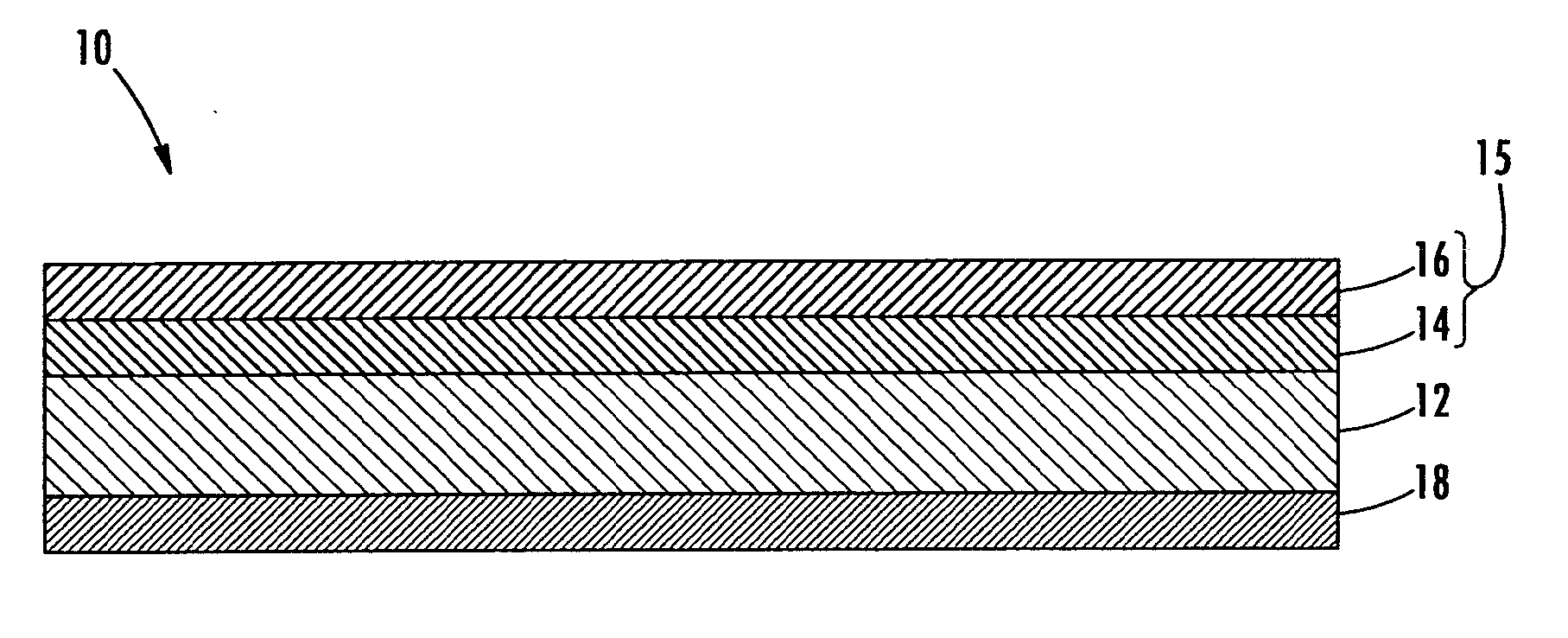

Electrophoretic insulated glass unit

ActiveUS20160124284A1Minimizing temperatureThickness minimizationLight protection screensNon-linear opticsElectrophoresisLength wave

An electrophoretic insulated glass unit (IGU) comprises an electrophoretic laminate and a pane spaced apart from the electrophoretic laminate, the respective inner faces of the laminate and the pane defining a sealed cavity there between. An outer face of the electrophoretic laminate is in contact with an environment. One inner face of the cavity has a coating that is transparent to visible light and which rejects infrared light greater than a cut-off wavelength. The electrophoretic laminate includes an electrophoretic device including charged particles of at least one type in an electrophoretic cell, the particles being responsive to an electric field applied to the electrophoretic device to move between: a first extreme light state in which particles are maximally spread within the cell to lie in the path of sunlight through the cell and to strongly absorb visible sunlight transmitted through the cell and a second extreme light state in which the particles are maximally concentrated within the cell to remove them from the path of sunlight through the cell and to substantially transmit visible sunlight through the cell. The coating is arranged to direct thermal radiation emitted by the charged particles to the environment in contact with the outer face, and the sealed cavity is arranged to direct thermal conduction diffusing from the charged particles to the environment in contact with the outer face.

Owner:E INK CORPORATION

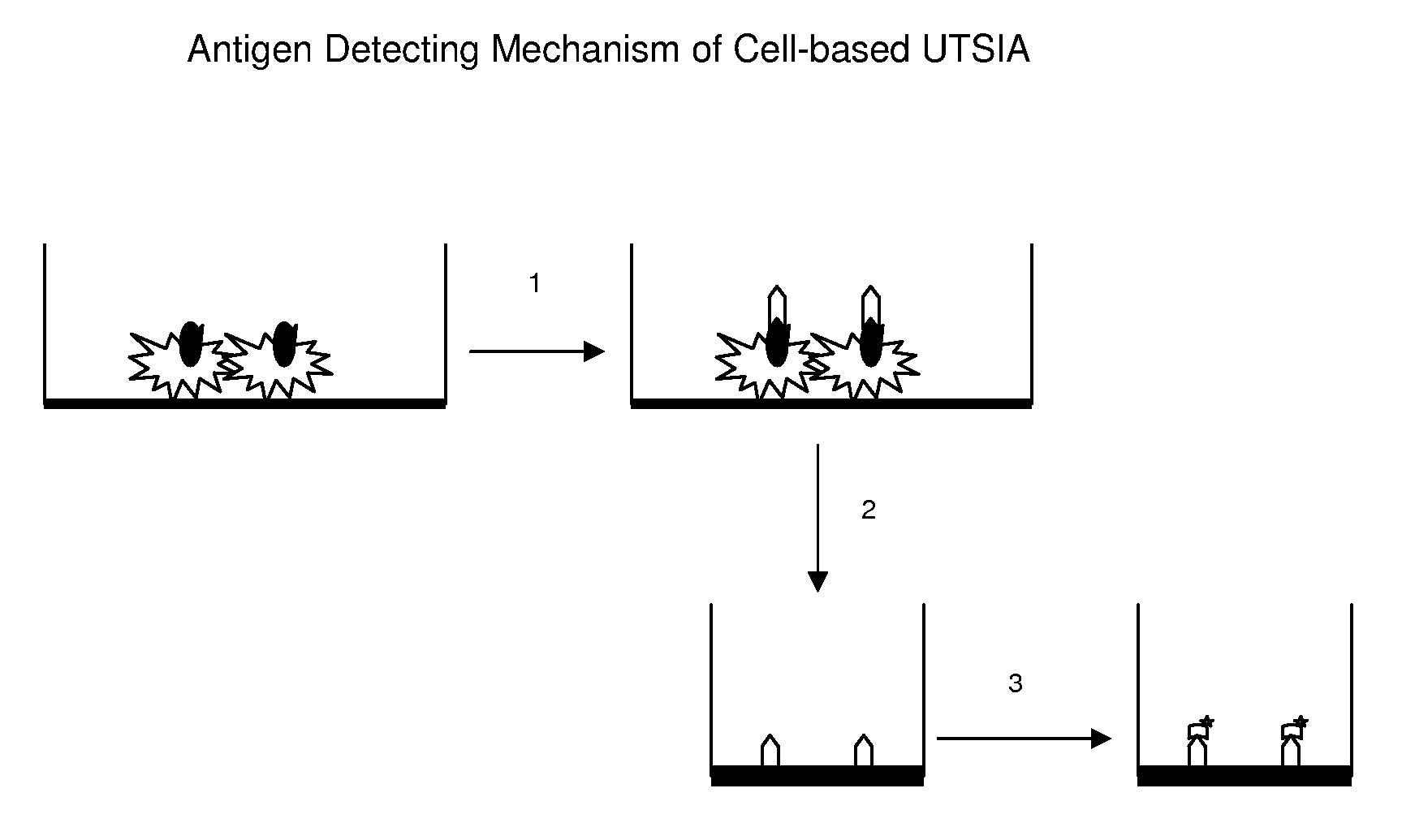

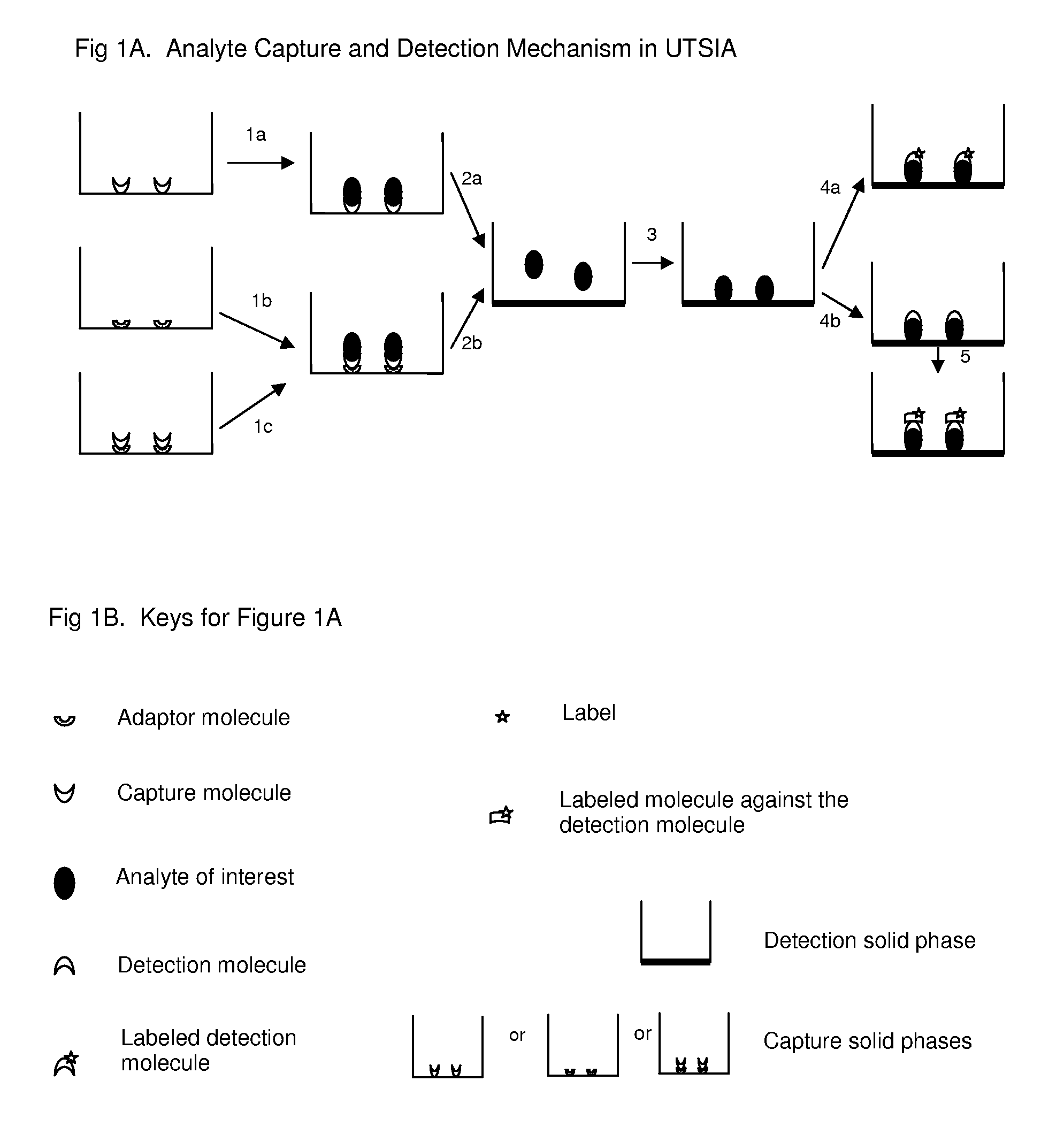

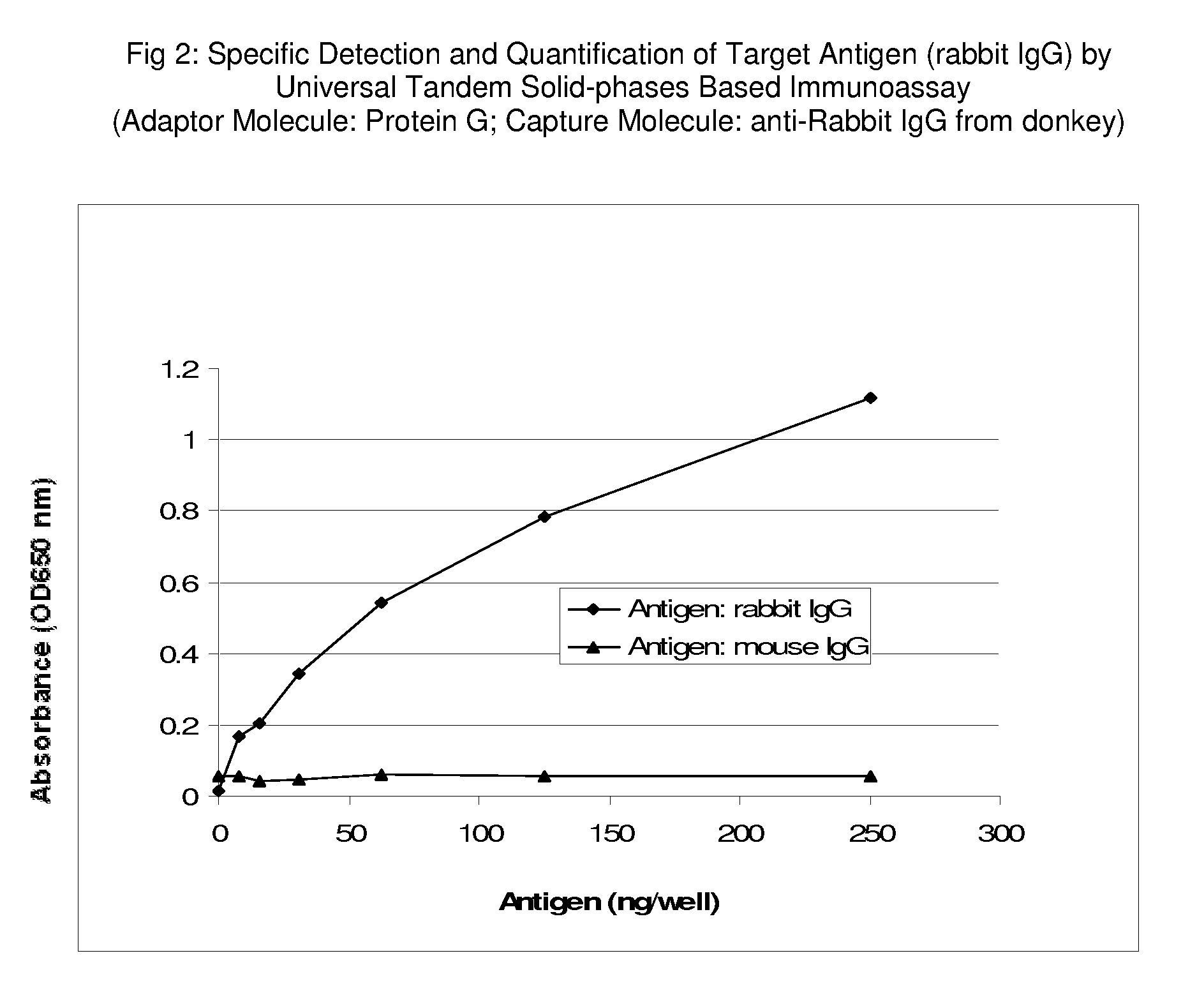

Universal tandem solid-phases based immunoassay

InactiveUS20100009394A1Efficient coatingIncrease concentrationBiological testingSolid phasesCell based

Universal tandem solid-phases based immunoassay (UTSIA) is a sandwich-ELISA equivalent assay for low abundance antigen determination that overcomes limitations of sandwich-ELISA (antibody inactivation by solid phase and strict requirement of a pair of primary and secondary antibodies) by using an affinity binding solid phase to capture antigen specifically from a fluid sample, sequentially dissociating the antigen, transferring, and coating the antigen to a non-affinity binding solid phase for specific antigen determination. Cell-based UTSIA is a cell-based ELISA equivalent assay that overcomes limitations of image method for determining an antigen in the cells or tissue immobilized on a solid phase by dissociating and transferring the detection antibody bound on the antigen of the cells or tissue immobilized on the solid phase to a second solid phase and immobilizing the detection antibody there for specific detection of the antigen via the detection of the detection antibody.

Owner:GUO RIBO

Process and apparatus for testing bottles

ActiveUS6995377B2Efficient coatingEffective barrierTransmissivity measurementsOptically investigating flaws/contaminationUltraviolet lightsEngineering

Process and apparatus for testing the coating thickness on a container by shining ultraviolet light through the container to at least one sensor.

Owner:PLASTIPAK PACKAGING

Etching solution, method of etching and printed wiring board

ActiveUS20060199394A1Efficient processEfficient coatingInsulating substrate metal adhesion improvementDecorative surface effectsTriazole antifungalsHigh concentration

There is provided an etching solution comprised of a cupric chloride solution and a high-concentration triazole type compound added to the cupric chloride solution and capable of forming an etching-inhibiting coating. In a process of forming a circuit pattern by etching with the etching solution, an etching-inhibiting coating is selected formed on parts of a copper foil laid under the edge of an etching resist to effectively inhibit horizontal side-etching of the copper foil from the edge of the etching resist. Also, nonuniform irregularities formed on the side wall of the circuit pattern by the etching improves the adhesion between the circuit pattern and an insulating resin layer covering the circuit pattern.

Owner:IBIDEN CO LTD

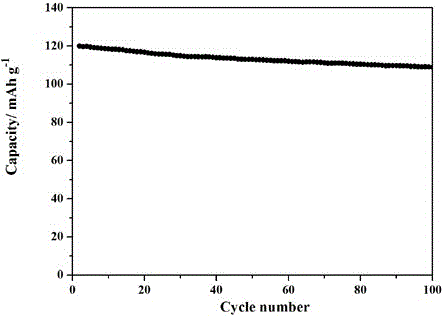

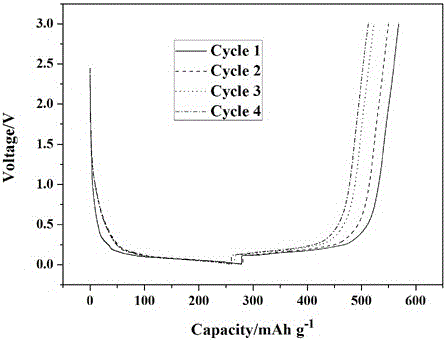

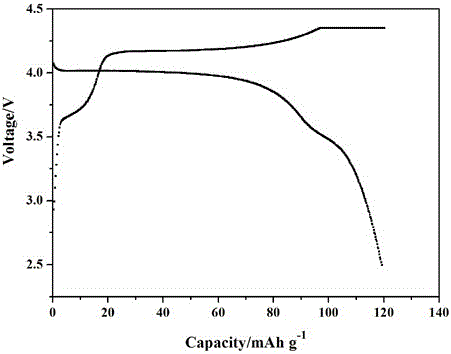

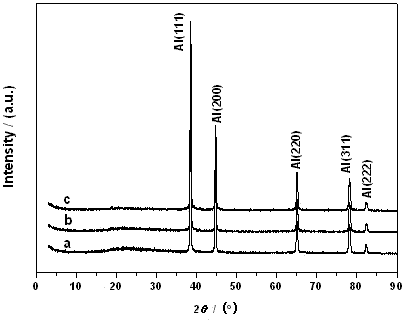

Lithium battery electrode preparation method including polymer material with stable interface and application of lithium battery electrode in solid lithium battery

ActiveCN105702919AImprove discharge capacityReduce discharge capacityCell electrodesLi-accumulatorsSolid state electrolyteDecomposition

The invention discloses a lithium battery electrode preparation method including polymer material with a stable interface and the application of a lithium battery electrode in a solid lithium battery. The preparation method is characterized in that the polymer material with the stable interface is poly-vinylene carbonate (PVCA) or copolymers thereof. The free radical triggers the monomer to perform mass polymerization to obtain a polymer, the polymer material with the stable interface can form a cover film on the surface of the electrode, thus destruction on the electrode material and decomposition of the solid electrolyte on the surfaces of the positive and negative electrodes can be effectively restrained. Meanwhile, the polymer material can form a stable protection layer on the surface of lithium metal to inhibit the growth of the lithium dendrites, thus the cycle performance of the solid lithium battery is improved. The invention also provides a preparation method of the electrochemical stable polymer material, and the solid lithium battery assembled by using the polymer material.

Owner:QINGDAO INST OF BIOENERGY & BIOPROCESS TECH CHINESE ACADEMY OF SCI

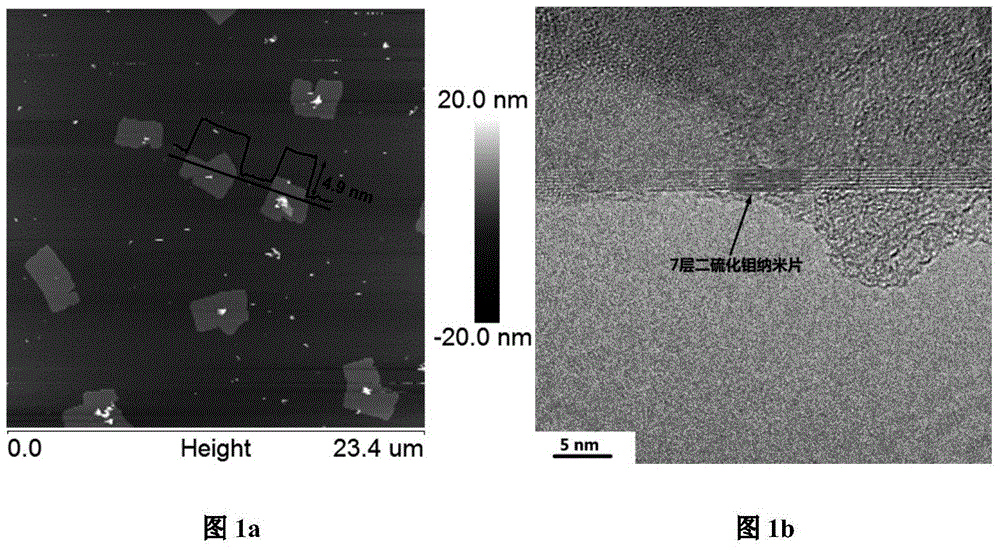

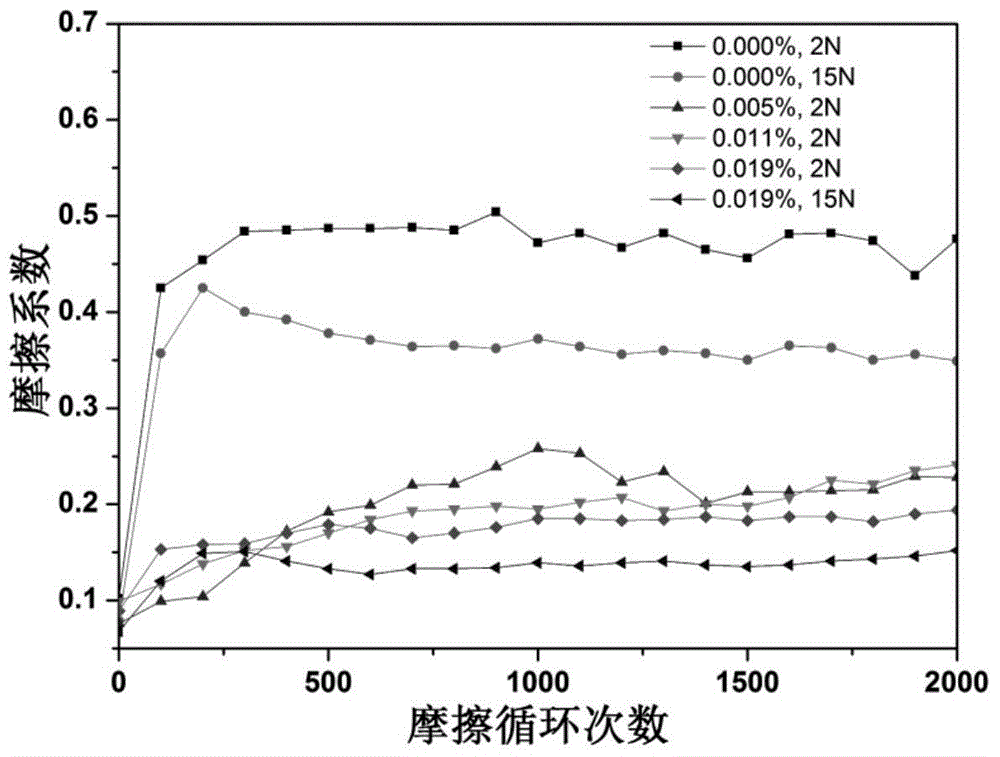

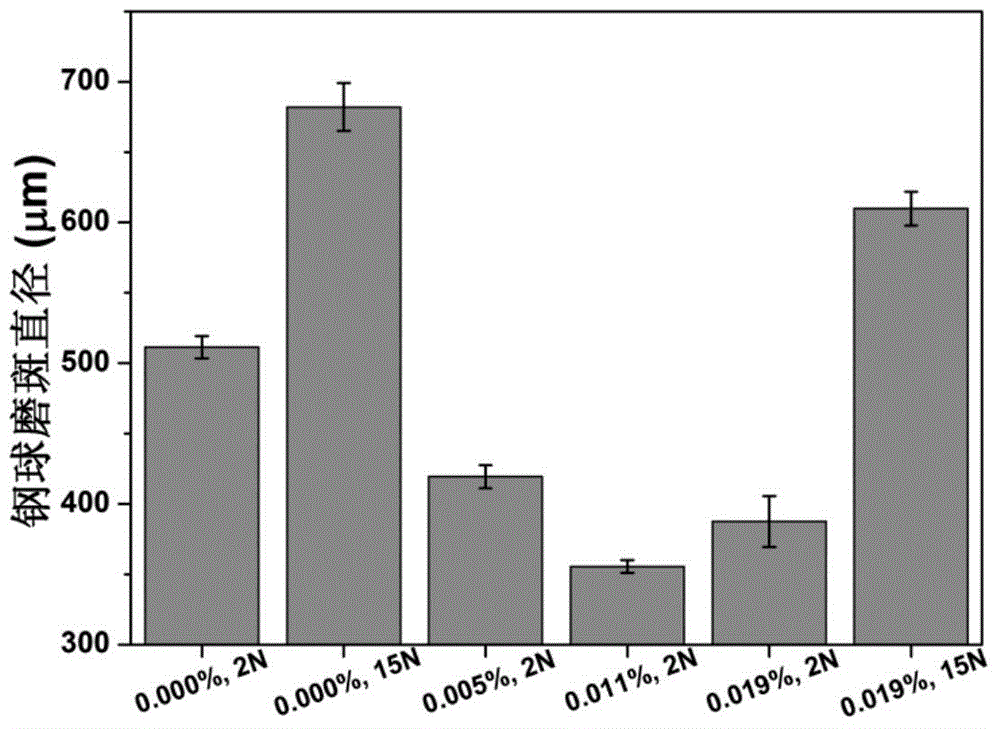

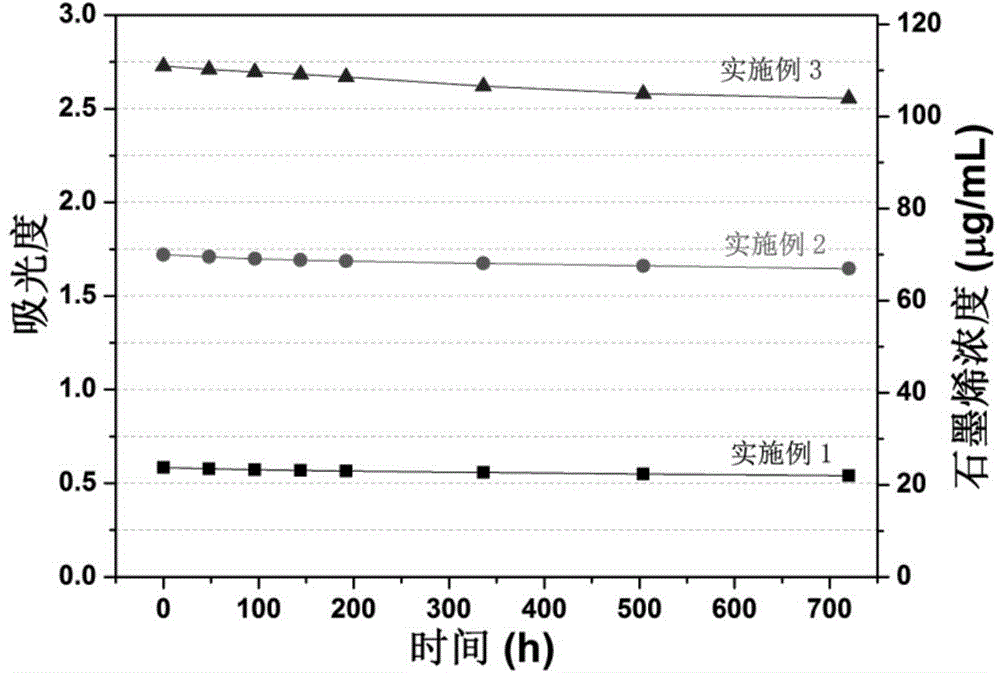

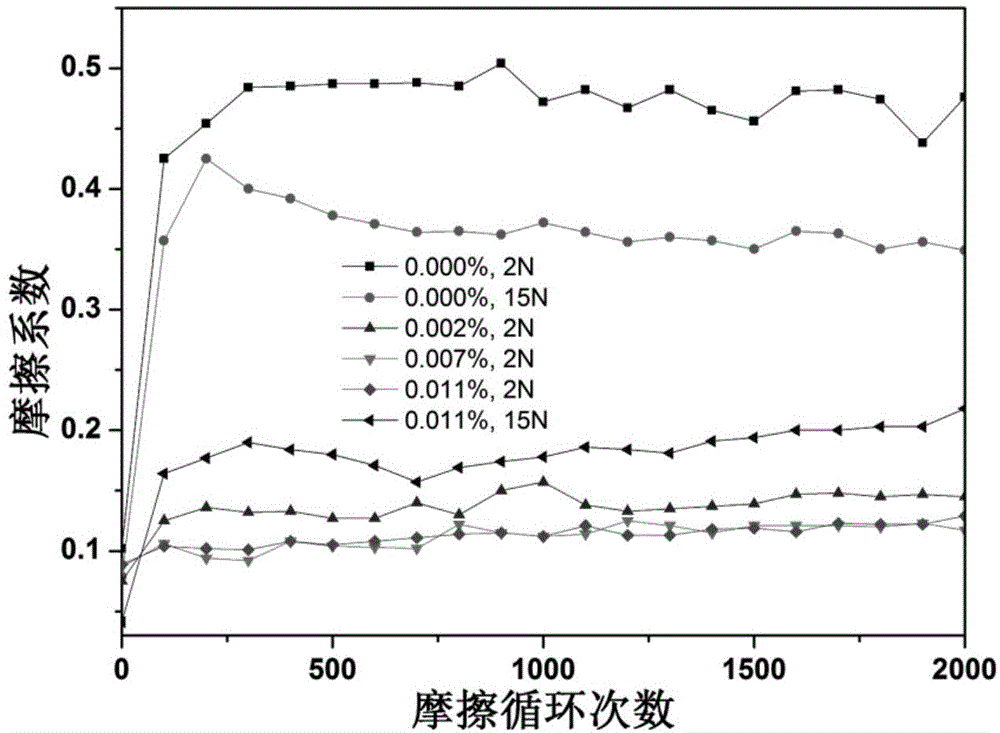

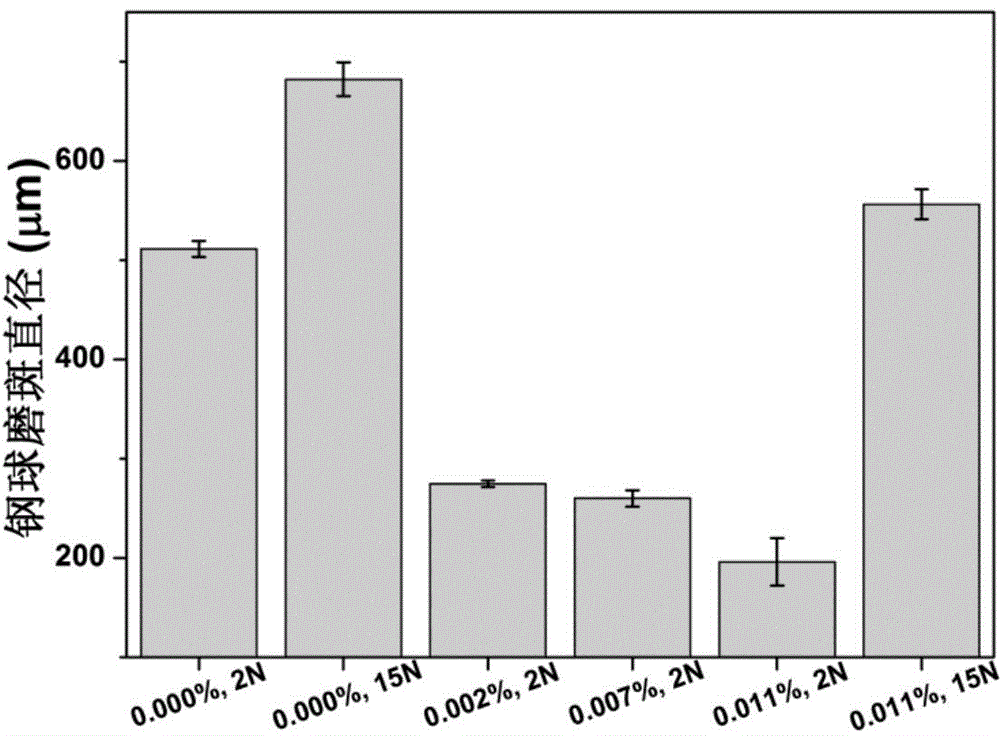

In-situ preparation method of water-based lubricant containing molybdenum disulfide nanosheet

An in-situ preparation method of a water-based lubricant containing a molybdenum disulfide nanosheet comprises six steps as follows: (1), a surface active agent is dissolved in deionized water in a proportion to obtain a solution; (2), molybdenum disulfide powder is uniformly dispersed into the solution; (3), a molybdenum disulfide dispersion liquid is subjected to ultrasonic cavitation processing; (4), the solution is left to stand for a certain period of time, and a supernatant liquid of the solution is taken; (5), the obtained solution is subjected to centrifugal separation processing; (6) the supernatant liquid of the centrifugal solution is collected, and the water-based lubricant containing the in-situ prepared molybdenum disulfide nanosheet is obtained. The method is easy, convenient and feasible, and the dispersion stability of the molybdenum disulfide nanosheet is good. A friction experiment result indicates that the wear-resistant and anti-friction performance of the lubricant can be greatly improved by adding a small quantity of the molybdenum disulfide nanosheet on the premise that the original excellent characteristics of good cooling performance and processability and the like of the water-based lubricant are not influenced, and the addition quantity of the molybdenum disulfide nanosheet ranges from 0.001% to 1%.

Owner:BEIHANG UNIV

Attenuating filter for ultraviolet light

InactiveUS7196842B2Simple and inexpensive to fabricateVariation of the transmittance of the filter coatingMirrorsOptical filtersSpectral transmittanceUltraviolet lights

Owner:CARL ZEISS SMT GMBH

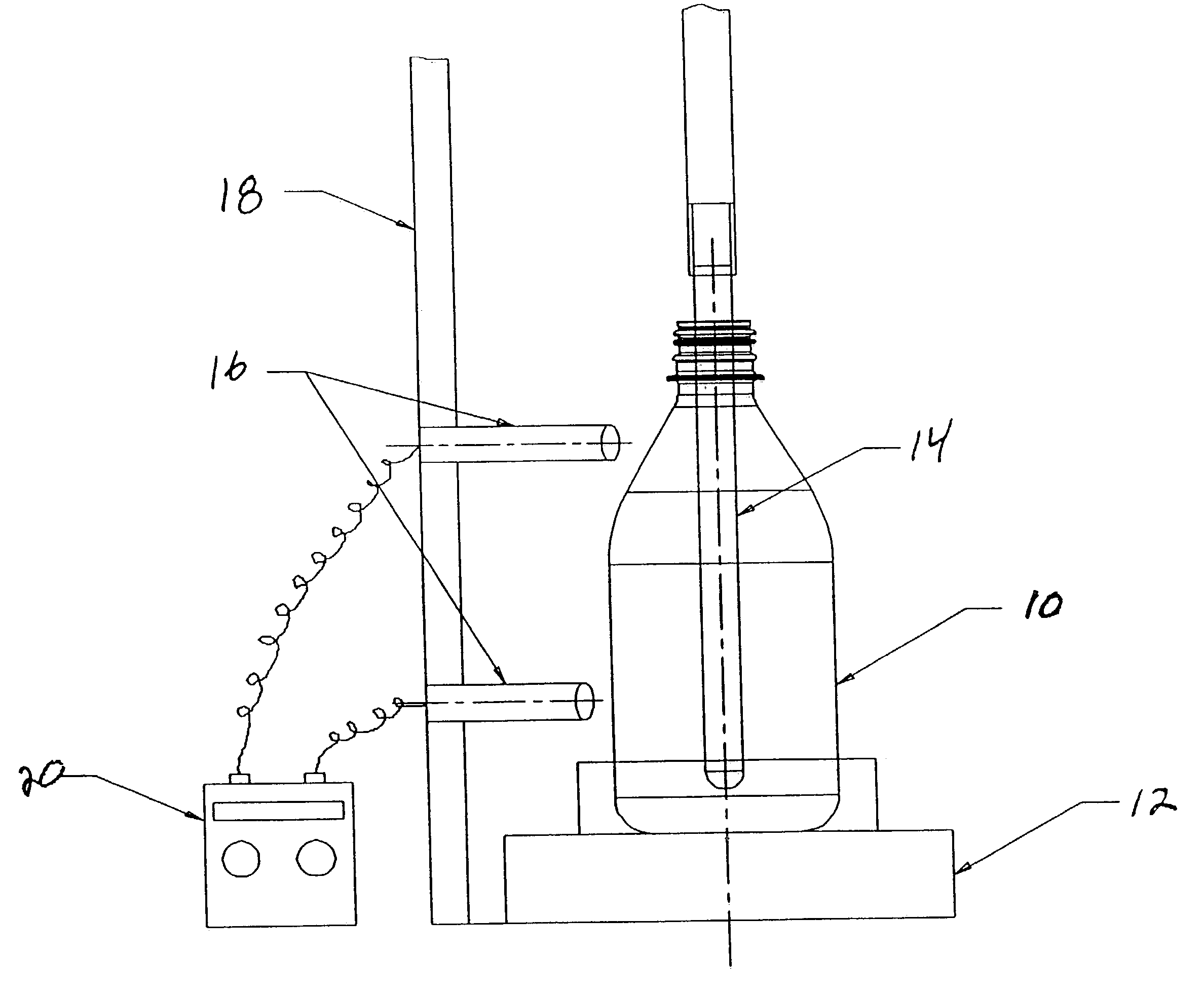

Method for applying drug coating to a medical device in surgeon room

ActiveUS20050037133A1Safe and efficient and effective processSimple and complex configurationOrganic active ingredientsSurgeryDip-coatingDelivery system

Medical devices, and in particular implantable medical devices such as stents and stent delivery systems including catheters, may be coated to minimize or substantially eliminate a biological organism's reaction to the introduction of the medical device to the organism or to treat a particular condition. A dip coating process is utilized to minimize waste and to customize coating thickness and drug loading directly at the clinical site just prior to therapeutic use on a patient. An aqueous latex polymeric emulsion is utilized to coat any medical device to a desired thickness by allowing for successive dipping and drying cycles at the clinical site. In addition, aqueous latex polymeric emulsions pose less of a chance of the bridging phenomenon associated with organic solvent based polymers.

Owner:WYETH LLC

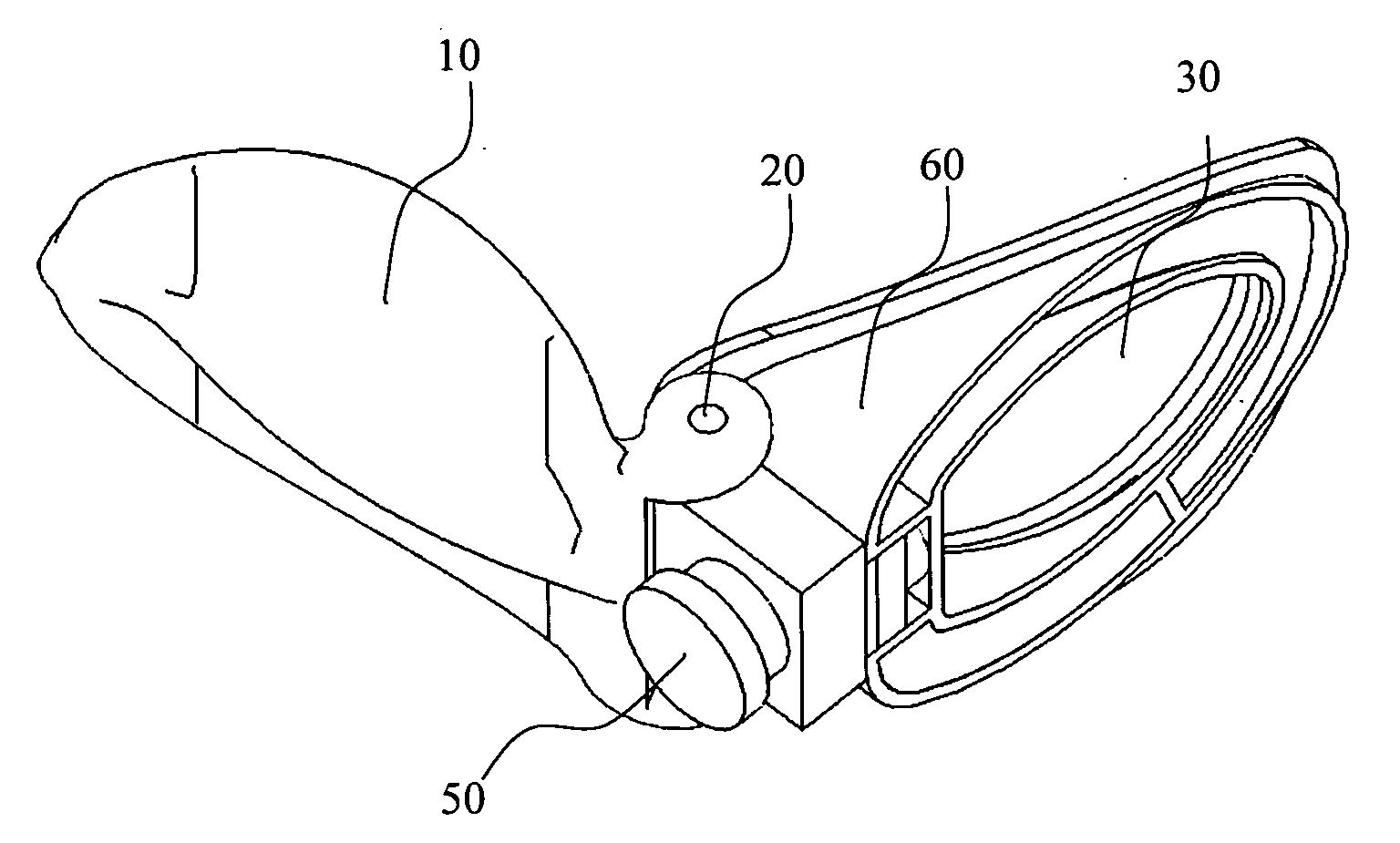

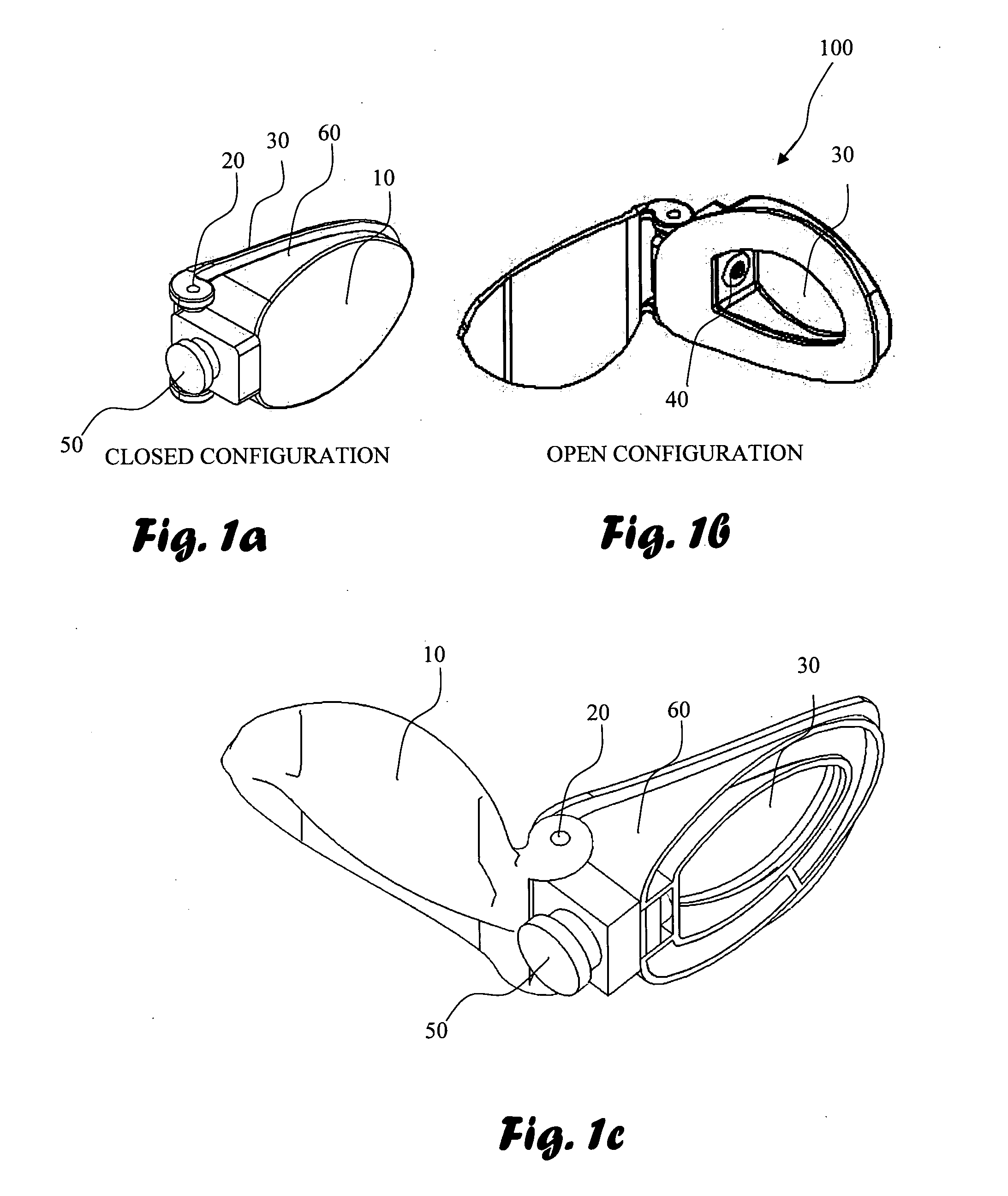

Device for applying an ophthalmic medicament mist

InactiveUS20120179122A1Efficient deliveryPrevent escapeNon-optical adjunctsMedical devicesOphthalmologyInterconnection

A device for applying an ophthalmologic medicament to a patient's eye is disclosed. The device comprises spectacles defined by a frame and at least one lens; at least one container adapted for accommodating the ophthalmologic medicament; the container is incorporated into the frame; dosing mechanism adapted to control doses of the medicament; and at least one nozzle in a fluid interconnection with the medicament container; the nozzle is secured mechanically to the frame; the nozzle is adapted for providing a medicament mist flow. The nozzle is placed in front of a peripheral portion of a patient's eye slot and adapted to provide the mist flow in front of the patient's eye.

Owner:ADVANCED OPHTHALMIC PHARMA

Method for applying a coating to a medical device

InactiveUS6858248B2Minimize formationEfficient coatingPretreated surfacesCeramic shaping apparatusPolyelectrolytePre-condition

This invention provides a method for efficiently applying a coating to each of a plurality of objects selected from the group consisting of ophthalmic lenses, molds for making ophthalmic lenses, and other medical devices, the method comprising dipping the plurality of objects into a coating bath containing a coating solution having a coating material; and creating with a means a convective current flow and thereby forcing a coating solution flowing over and under each of the plurality of ophthalmic lenses. In a preferred embodiment, the plurality of objects are held in baskets which are pre-conditioned to have a first layer of polyelectrolytes and a second layer of aqueous solution or have a mixed layer of polyelectrolytes and aqueous solution on the surfaces of the baskets.

Owner:ALCON INC

Neodymium-iron-boron magnet of aluminum or aluminum alloy composite coating and preparation method thereof

ActiveCN102031522AImprove processing efficiencyLow costVacuum evaporation coatingSputtering coatingHigh humidityAlloy composite

The invention discloses a neodymium-iron-boron magnet of an aluminum or aluminum alloy composite coating and a preparation method thereof. An aluminum or aluminum alloy film is deposited on the neodymium-iron-boron magnet by adopting multi-arc ion plating technology, and then phosphate treatment is performed. The coating is uniform and dense, and is well combined with a matrix. The neodymium-iron-boron magnet applied with the aluminum composite coating with thickness of 10 to 20 microns tolerates high pressure and high humidity (100 to 130 DEG C, 2 to 2.6atm, and 95 to 100 percent RH) for over 200 hours, and tolerates NaCl salt fog corrosion (3.5 to 5 weight percent of NaCl and 25 to 35 DEG C) for over 500 hours. The coating process has high efficiency and low cost; and the prepared composite coating has good corrosion resistance and adhesion performance, and has no influence on the magnetism of the neodymium-iron-boron matrix (mainly small-size magnet).

Owner:北京钐元新材料股份有限公司

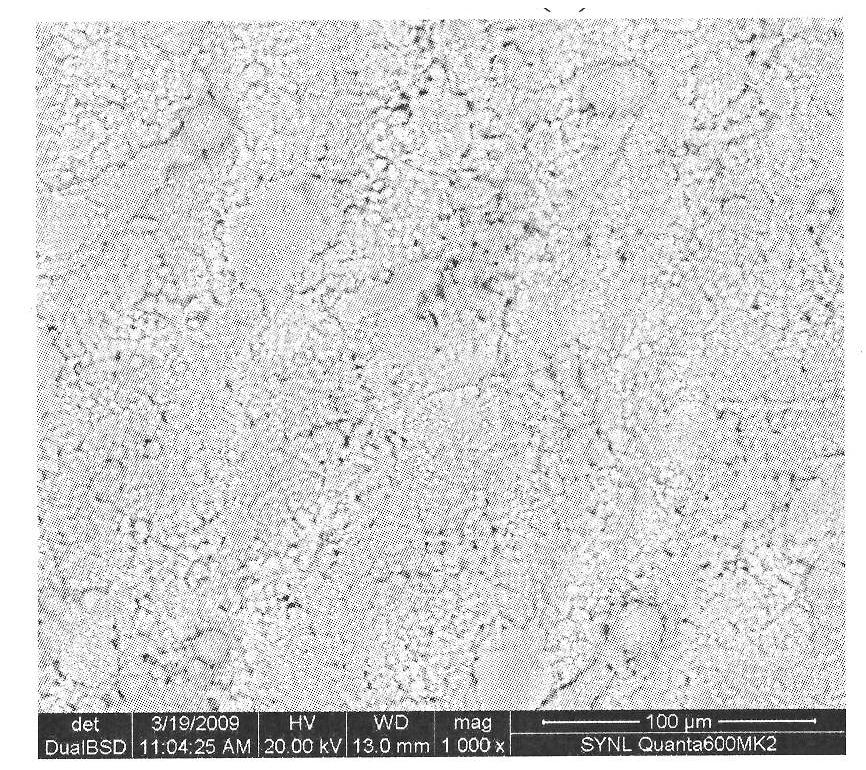

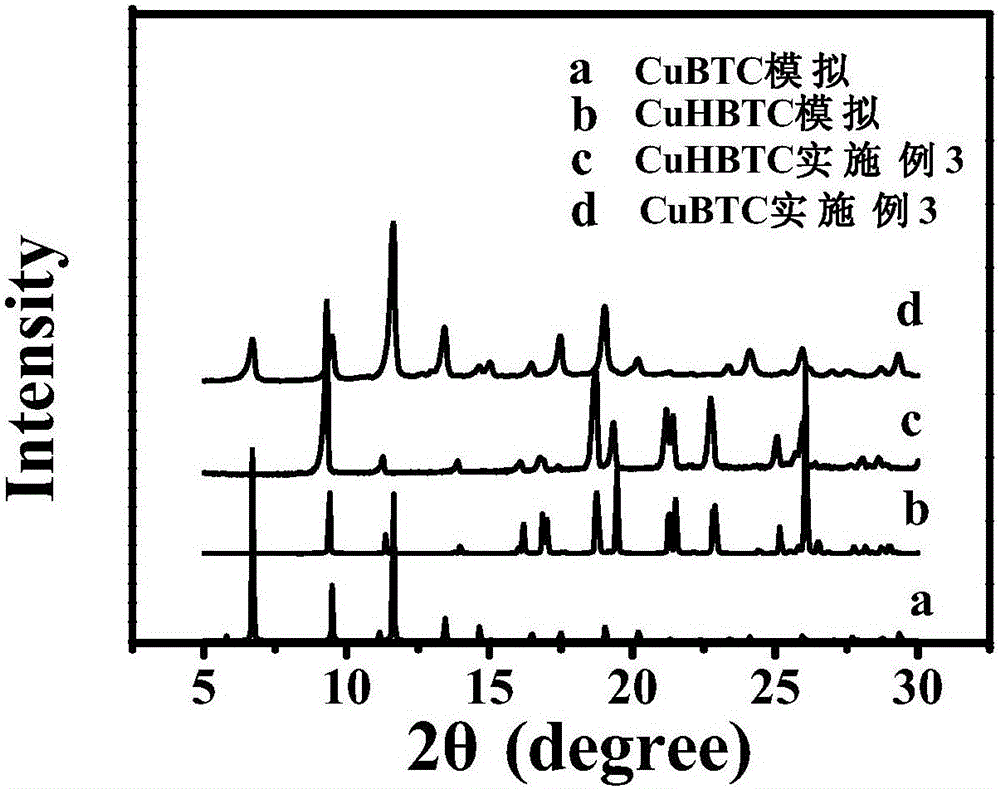

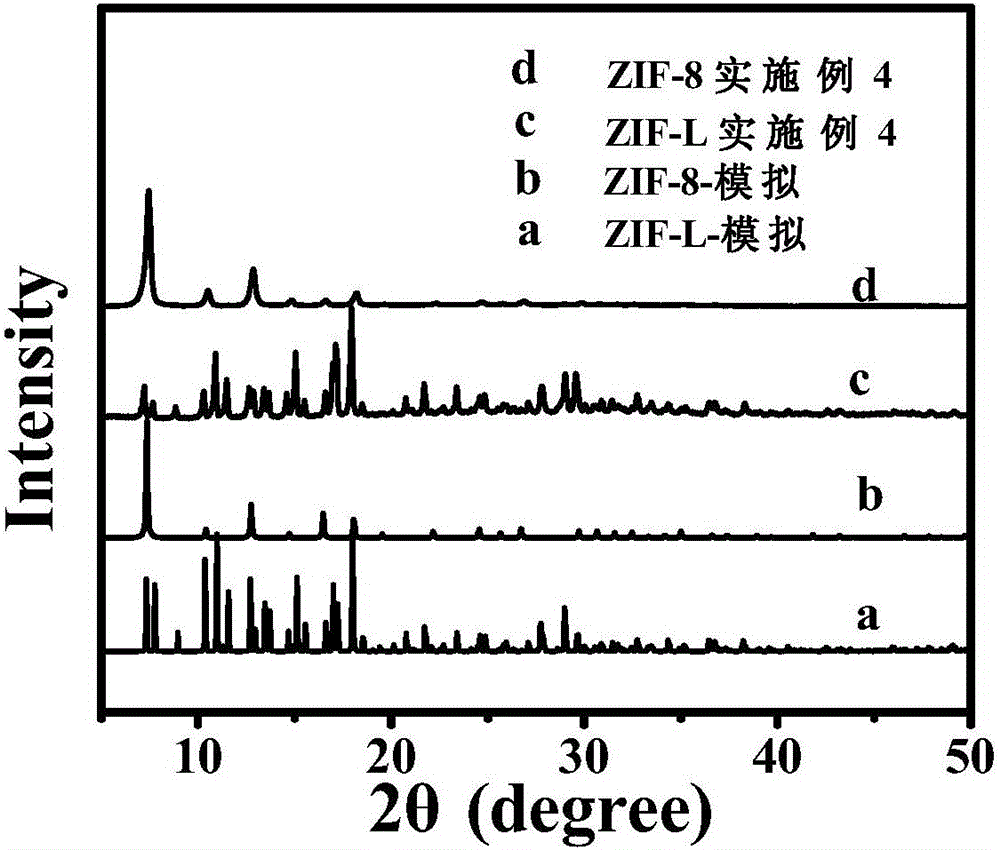

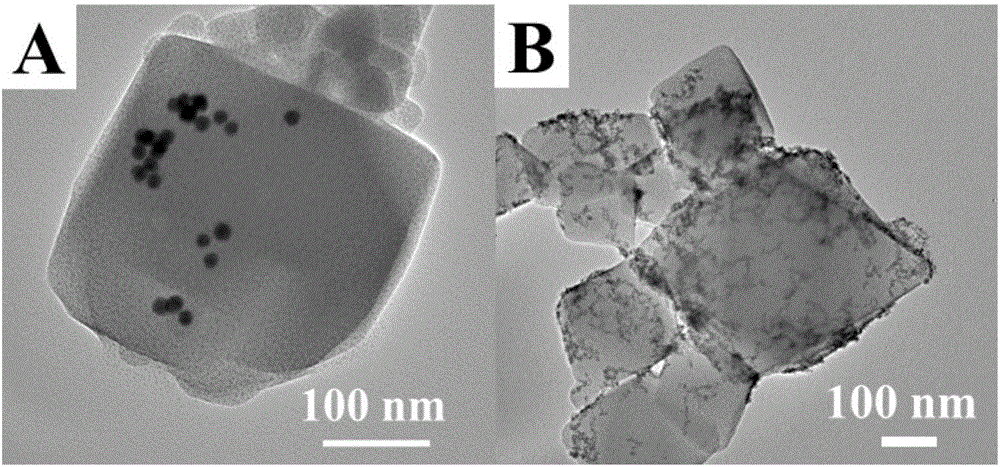

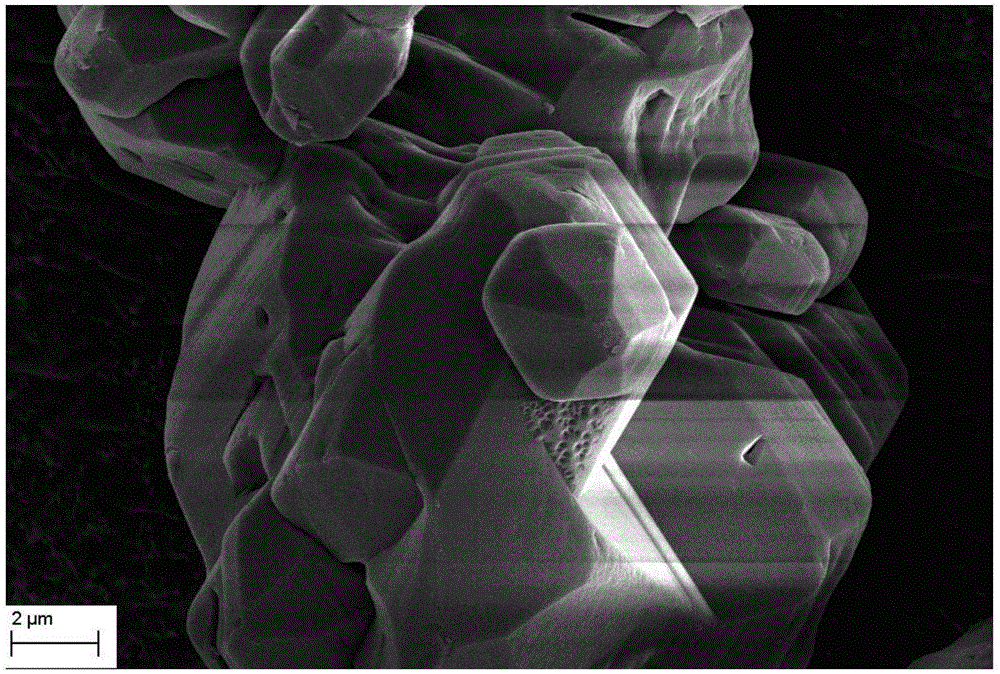

Method for preparing nanometer material@metal organic framework material

The invention discloses a method for preparing a nanometer material@metal organic framework material. The method comprises the following steps: subjecting a nanometer material to pre impregnating and depositing on the surface of a metal organic complex, carrying out centrifugal separation so as to obtain a composite material containing the nanometer material, and subjecting the composite material to a reaction in a mixed solvent of an organic solvent or an organic solvent and water so as to obtain the nanometer material@metal organic framework material. Compared with a permeation method, the method provided by the invention can realize complete coating of the nanometer material, and achieves a better packaging effect. Compared to an in-situ growth method, the method can broaden the application scope of metal organic frameworks (MOFs) in the nanometer material@metal organic framework material, and realizes effective coating of carboxylic acid metal organic frameworks (MOFs) on the nanometer material.

Owner:NANJING UNIV OF TECH

Ink-jet media having supporting intermediate coatings and microporous top coatings

InactiveUS20100260939A1Quality improvementLow production costDuplicating/marking methodsPretreated surfacesCoatingChemistry

Owner:ARKWRIGHT ADVANCED COATING

Method for preparing graphene water-based lubricating agent in situ

InactiveCN104593130ASimple preparation processEasy to prepareLubricant compositionWater basedFriction reduction

The invention discloses a method for preparing a graphene water-based lubricating agent in situ, belonging to the field of application of graphene serving as a nanometer lubricating additive. The lubricating agent consists of graphene nanoparticles, a surface modifier and purified water. The method comprises the following preparation steps: 1, dissolving a surfactant in deionized water according to a ratio, thereby obtaining a liquid; 2, uniformly dispersing graphene powder in the liquid; 3, performing ultrasonic cavitation treatment on the graphene dispersion liquid; 4, standing the liquid for a certain time, and taking the upper liquid; 5, performing centrifugal separation treatment on the obtained liquid; and 6, collecting the supernatant of the centrifuged liquid, thereby obtaining the water-based lubricating agent containing graphene prepared in situ. The method disclosed by the invention is simple in feasible, and the dispersion stability of the graphene is high. The friction test result proves that according to the extremely small addition amount (0.001-1 percent) of the graphene, the anti-wear and friction reduction properties of the lubricating agent can be greatly improved, and excellent characteristics such as good inherent cooling property, high machinability and environment friendliness of the water-based lubricating agent are not influenced.

Owner:BEIHANG UNIV

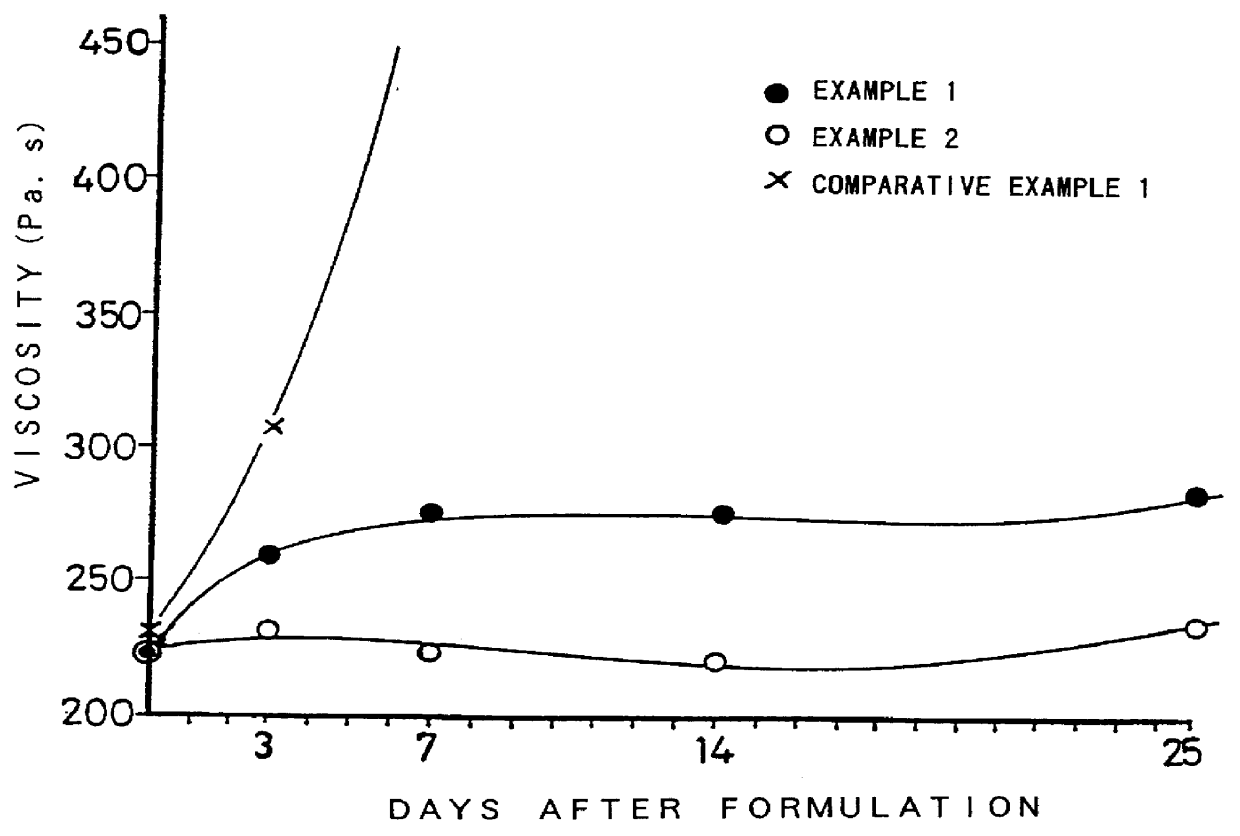

Solder paste

InactiveUS6159304AImprove solderabilityEasy to corrodeWelding/cutting media/materialsSoldering mediaEthylene oxideAlloy

In order to prevent aging of an Sn-Zn system alloy solder paste, 0.5-5% by weight of a compound obtained by adding an ethylene oxide to cyclohexylamine, preferably together with 0.5-5% by weight of a polyoxyethylene alkylamine is added to a flux of said solder paste.

Owner:PANASONIC CORP +1

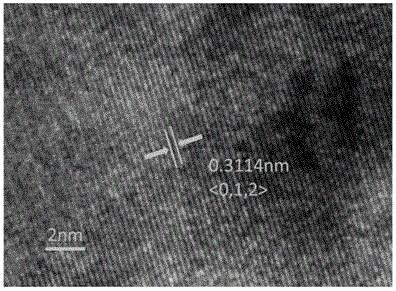

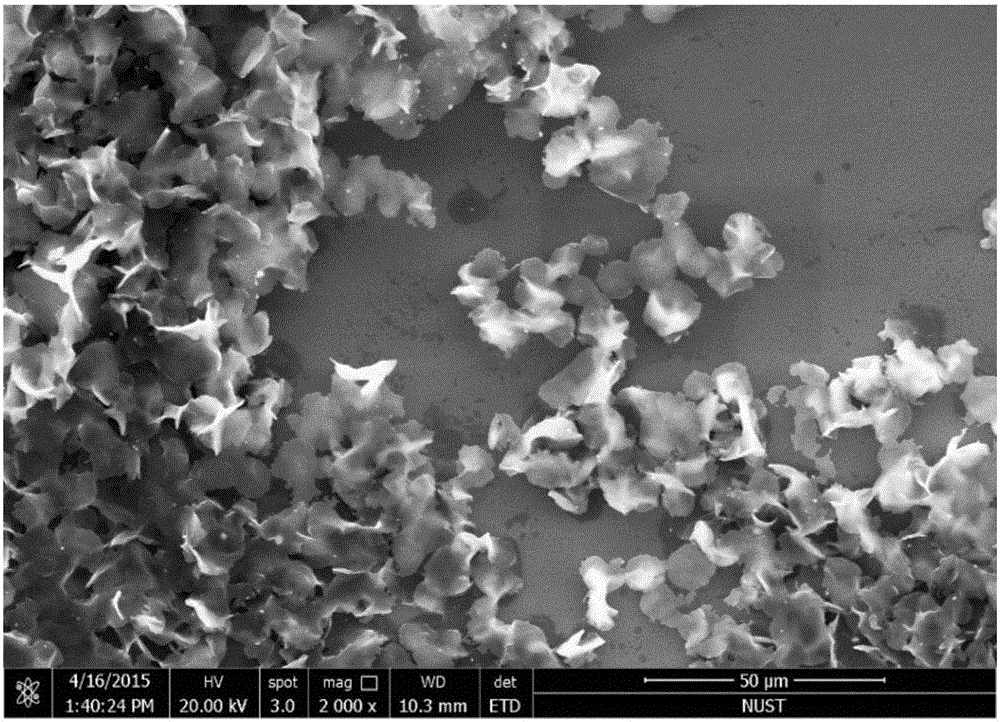

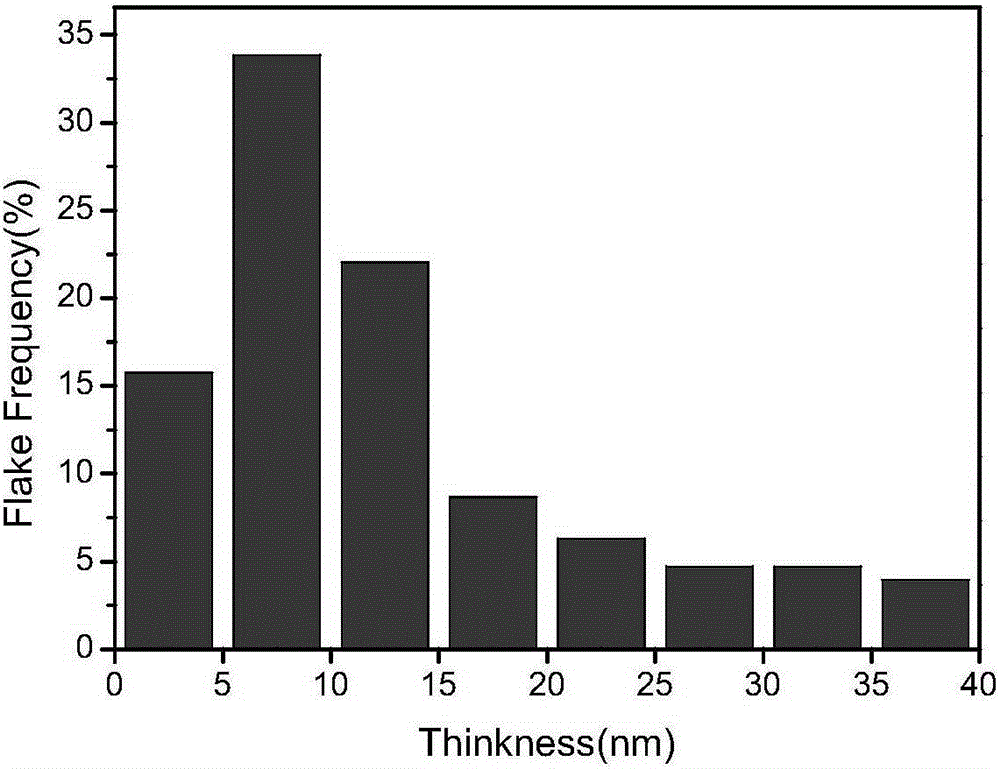

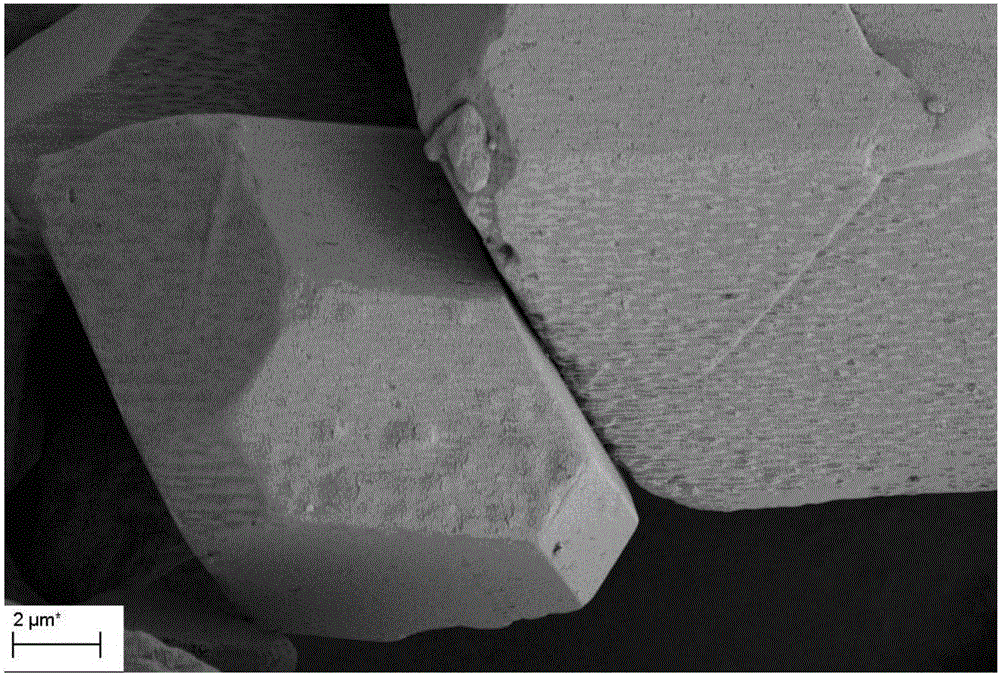

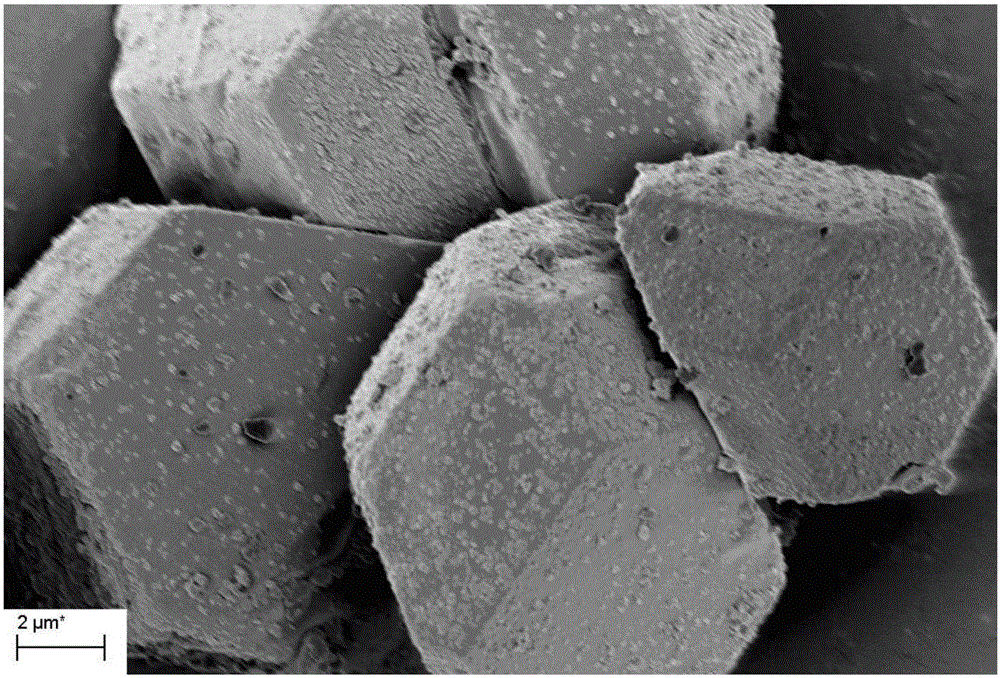

Preparation method of single-crystal less-layer antimonene

InactiveCN105297133APrevent coagulationSimple processPolycrystalline material growthSingle crystal growth detailsAntimonyCrystallinity

The invention discloses a preparation method of high-quality and large-scale novel two-dimensional material, namely, single-crystal less-layer antimonene. The liquid phase ultrasonic stripping technology is adopted, and a fifth main-group antimony nano-sheet is stripped through ultrasonic assisting of antimony powder, ethanol and surfactant. Firstly, the antimony powder and ethanol are mixed at room temperature; secondly, a proper amount of surfactant is added, the mixture is ultrasonically treated for a period of time under certain power, and then antimonene is massively prepared. Preparation process parameters are adjusted, and the size of antimonene can be adjusted. Reaction conditions are mild, the preparation process is simple, and the preparation method can be used for large-scale preparation. The less-layer antimonene prepared through the method is uniform in thickness and size, adjustable in size, high in purity and good in degree of crystallinity.

Owner:NANJING UNIV OF SCI & TECH

Method for coating energetic crystal surfaces

ActiveCN105777457AEfficient coatingExplosive working-up apparatusNitrated acyclic/alicyclic/heterocyclic amine explosive compositionsFiltrationVacuum drying

The invention discloses a method for coating energetic crystal surfaces. Coating of the energetic crystal surfaces is achieved through oxidation-self-polymerization of dopamine under the condition of a weakly alkaline aqueous solution and formation of poly-dopamine coatings powerfully adhering to material surfaces. The method comprises the following steps: dissolving Tris in a mixed solution of water and ethanol in a volume ratio of 9 to 1 and then dropwise adding hydrochloric acid to prepare a buffer solution with the pH value of 8.0-10.0; then dissolving dopamine in the buffer solution to prepare a dopamine solution with the concentration of 1-5g / L; then adding a proper amount of energetic crystal to the dopamine solution and stirring the materials at a stirring rate of 200-900rpm to form uniform suspension; and continuously stirring the suspension for a period of time and then carrying out suction filtration and vacuum drying. The method has the beneficial effects that coating of the energetic crystal surfaces is completed in the aqueous phase, so the method is green and safe; and especially, the method can achieve efficient coating aiming at the energetic crystal surfaces with different characteristics.

Owner:INST OF CHEM MATERIAL CHINA ACADEMY OF ENG PHYSICS

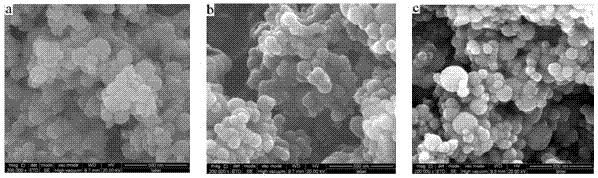

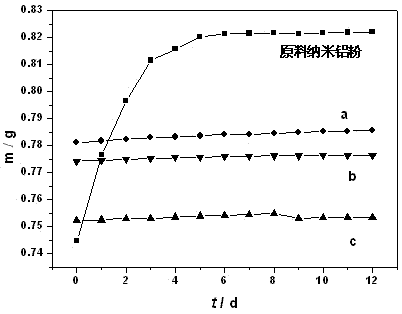

Method for preparing nanometer aluminum composite powder coated with nitro-cotton

InactiveCN102581272AGuaranteed reactivityKeep aliveMaterial nanotechnologyEthyl acetateEthyl fumarate

The invention discloses a method for preparing nanometer aluminum composite powder coated with nitro-cotton. The method includes the steps of: dispersing nanometer aluminum powder into absolute ethyl alcohol; adding silane coupling agent with the weight accounting for 5-10% of that of the nanometer aluminum powder to obtain nanometer aluminum powder treated by the silane coupling agent; dissolving the nitro-cotton and plasticizer into ethyl acetate or acetone; dispersing the nanometer aluminum powder treated by the silane coupling agent into cyclohexane to form cyclohexane dispersing agent; adding nitro-cotton liquor into the cyclohexane dispersing agent and evenly mixing the nitro-cotton liquor; and performing filtering and vacuum drying to obtain the nanometer aluminum composite powder coated with the nitro-cotton, wherein the weight of the nitro-cotton is 0.04-0.15 time that of the aluminum powder, and the weight of the plasticizer accounts for 3-10% of that of the nitro-cotton. The nanometer aluminum powder is firstly treated by the silane coupling agent and then coated with the nitro-cotton, the surface of the nanometer aluminum powder is effectively coated with the nitro-cotton, the activity of the nanometer aluminum powder can be kept, and the oxidation resistance of the nanometer aluminum powder is improved.

Owner:XIAN MODERN CHEM RES INST

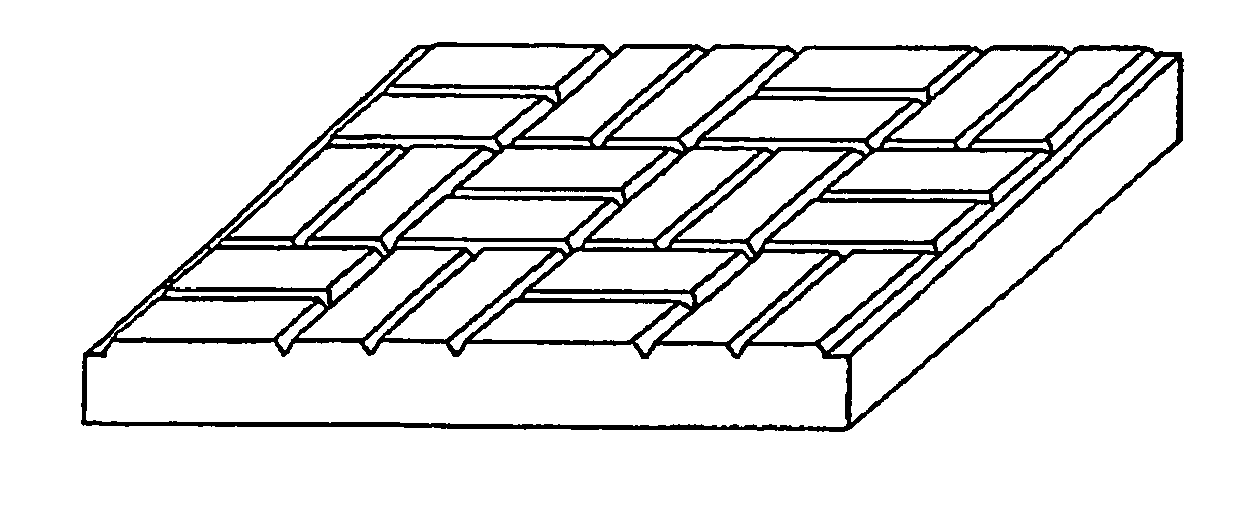

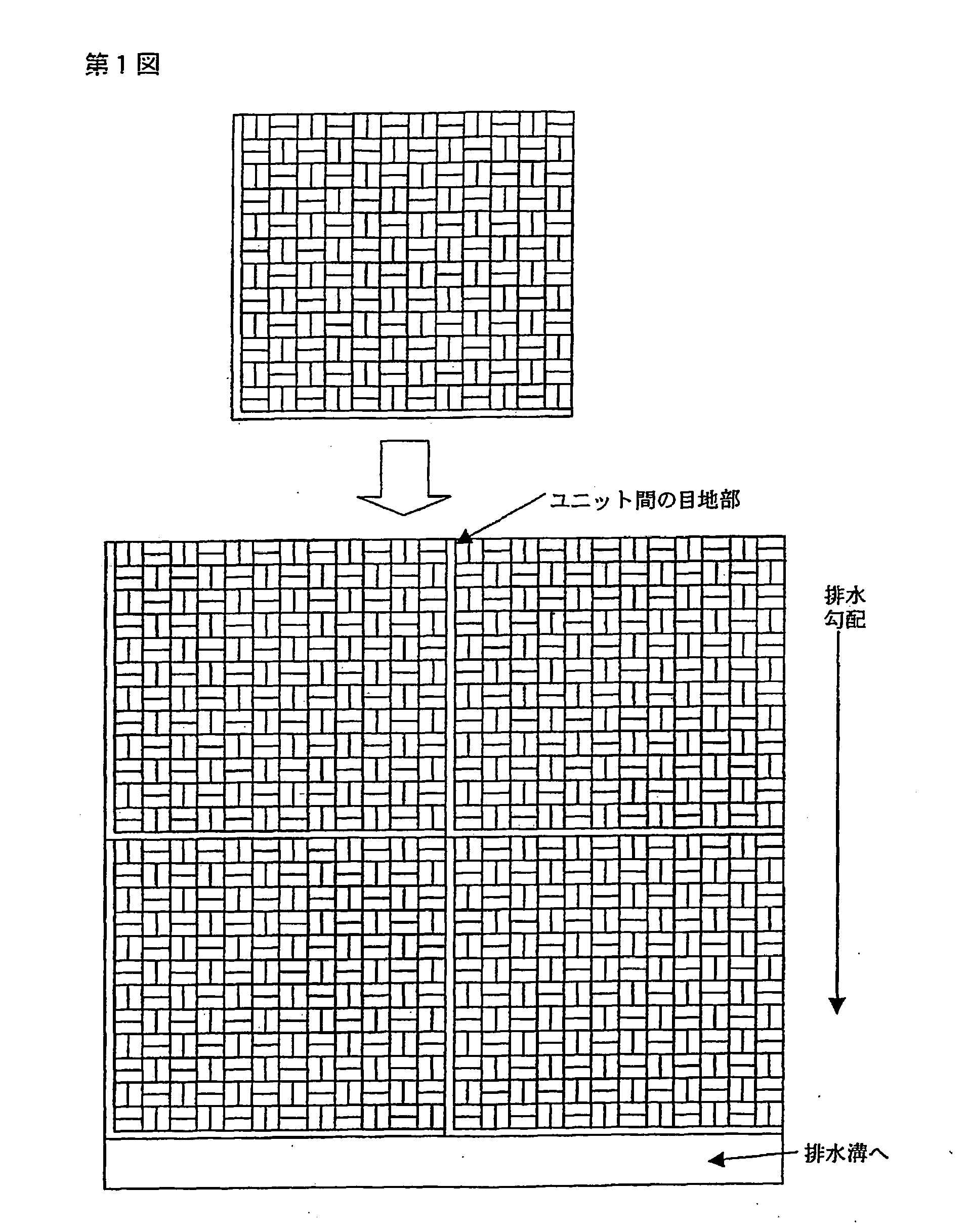

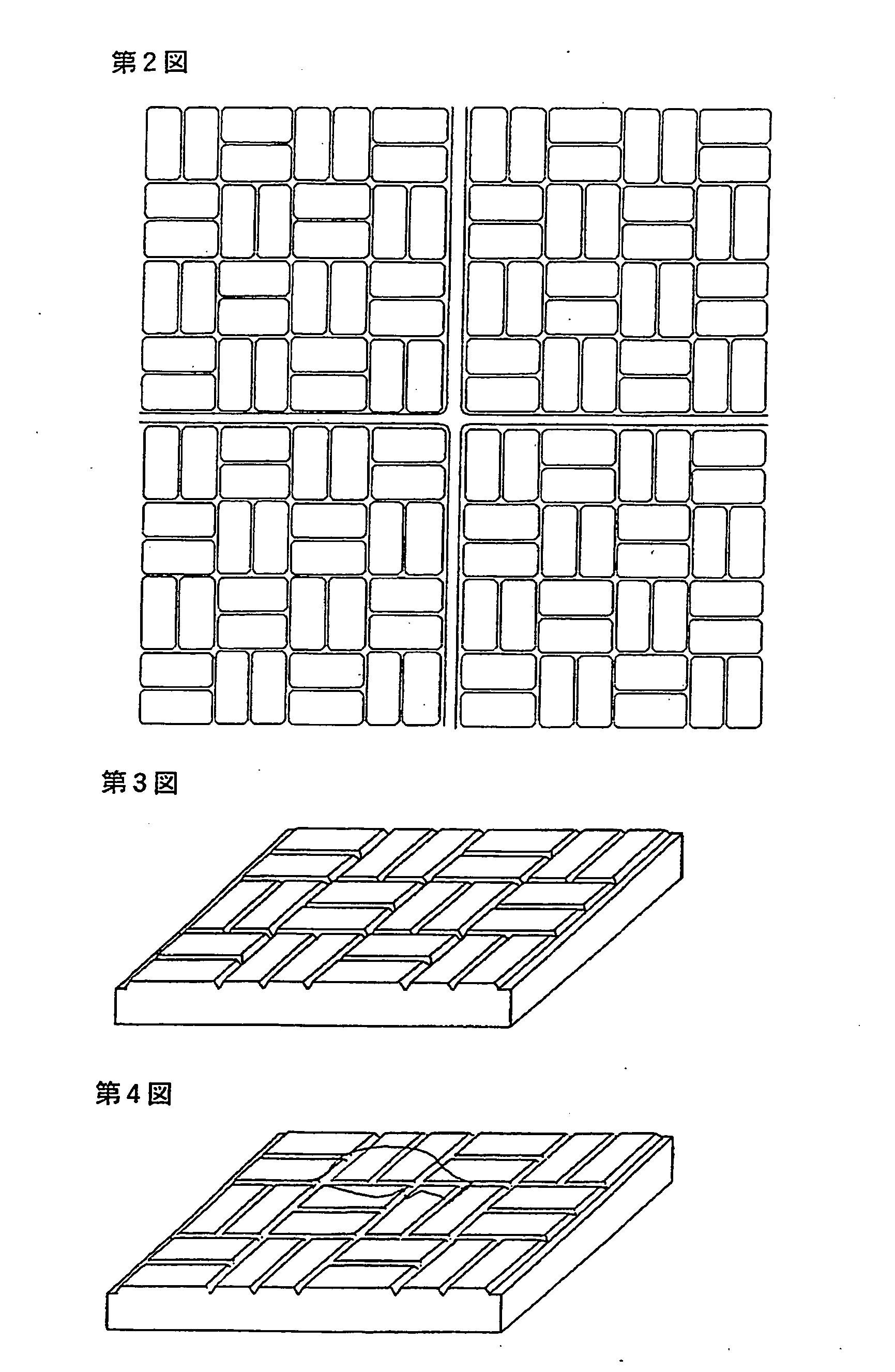

Building material and method of manufacturing the material

InactiveUS20050129913A1Accelerated dryingEasy to useLayered productsRoof covering insulationsCurve shapeMaterials science

The present invention provides a building material in which water remaining on the surface can be dried up quickly and keep a hygienic state for a long period of time. The building material is comprised of grooves having a width of 0.5 mm or more and 3.0 mm or less and a depth of 0.5 mm or more and 2.0 mm or less, the grooves being arranged in multiple directions, and island-shaped projections for preventing slippage constructed of a unit having a size of 5 mm×5 mm or more and 25 mm×25 mm or less, the island-shaped projections being surrounded by the grooves, wherein the surface of the island-shaped projections for preventing slippage has a flat shape or a curved shape.

Owner:TOTO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com