Patents

Literature

1867results about "Explosive working-up apparatus" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

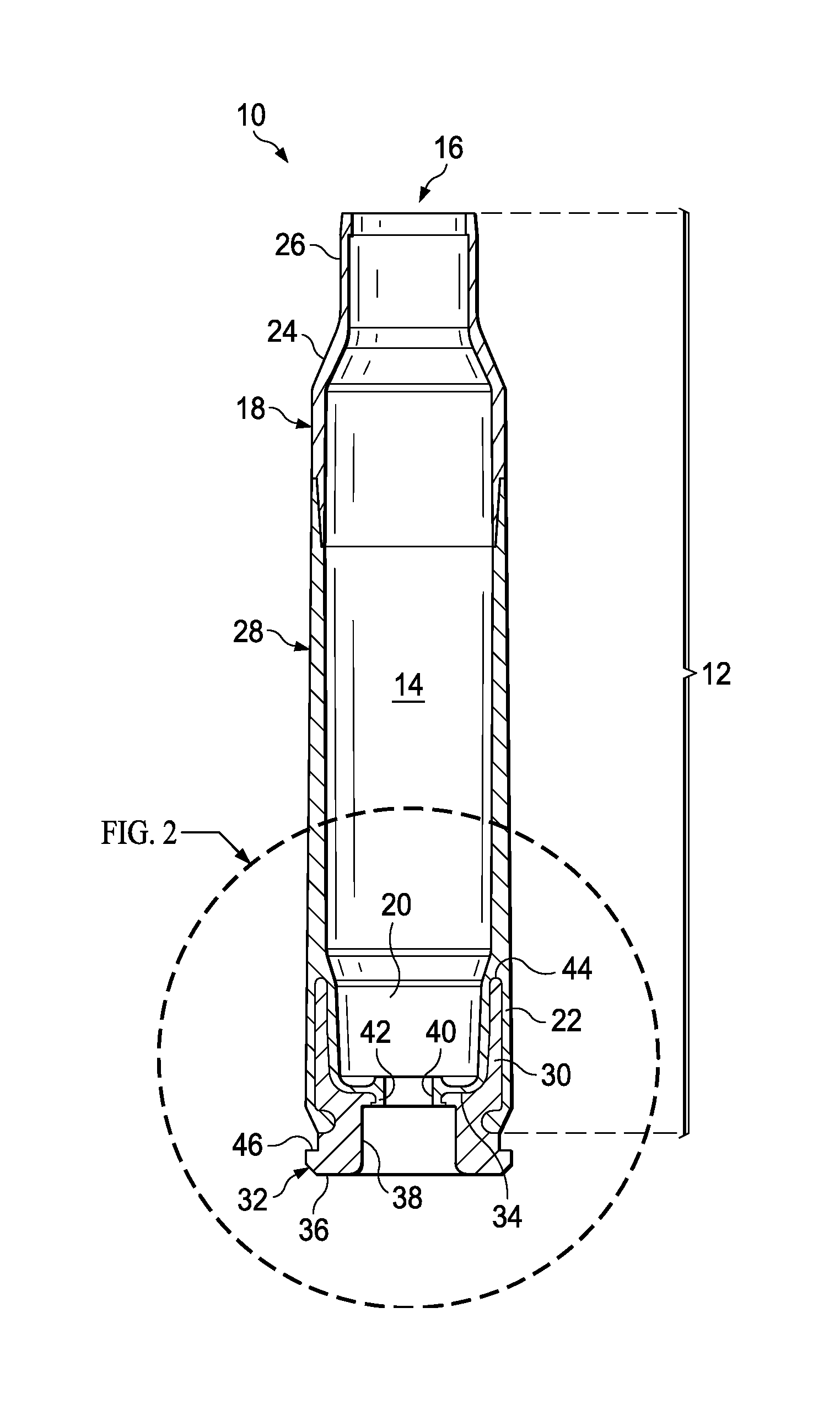

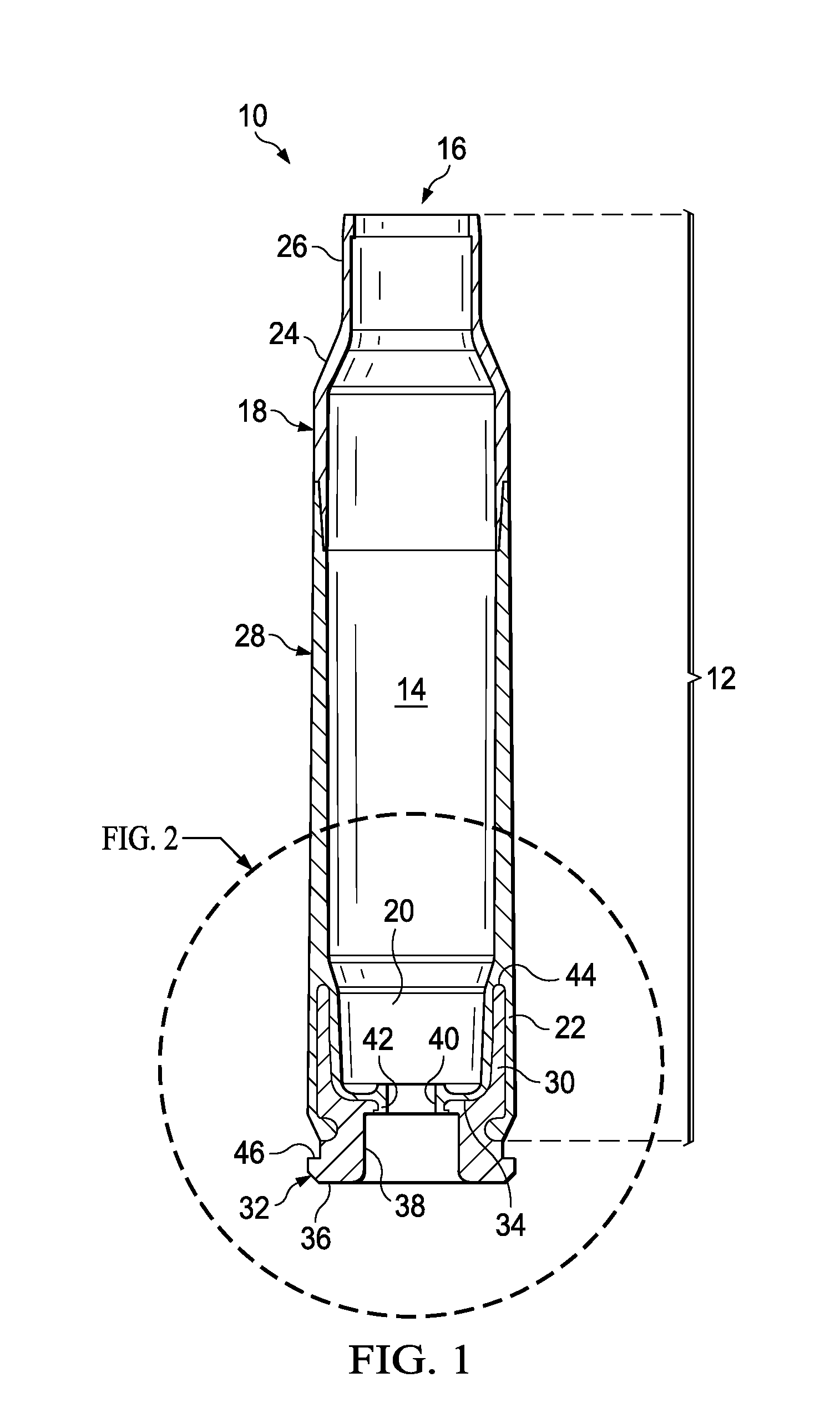

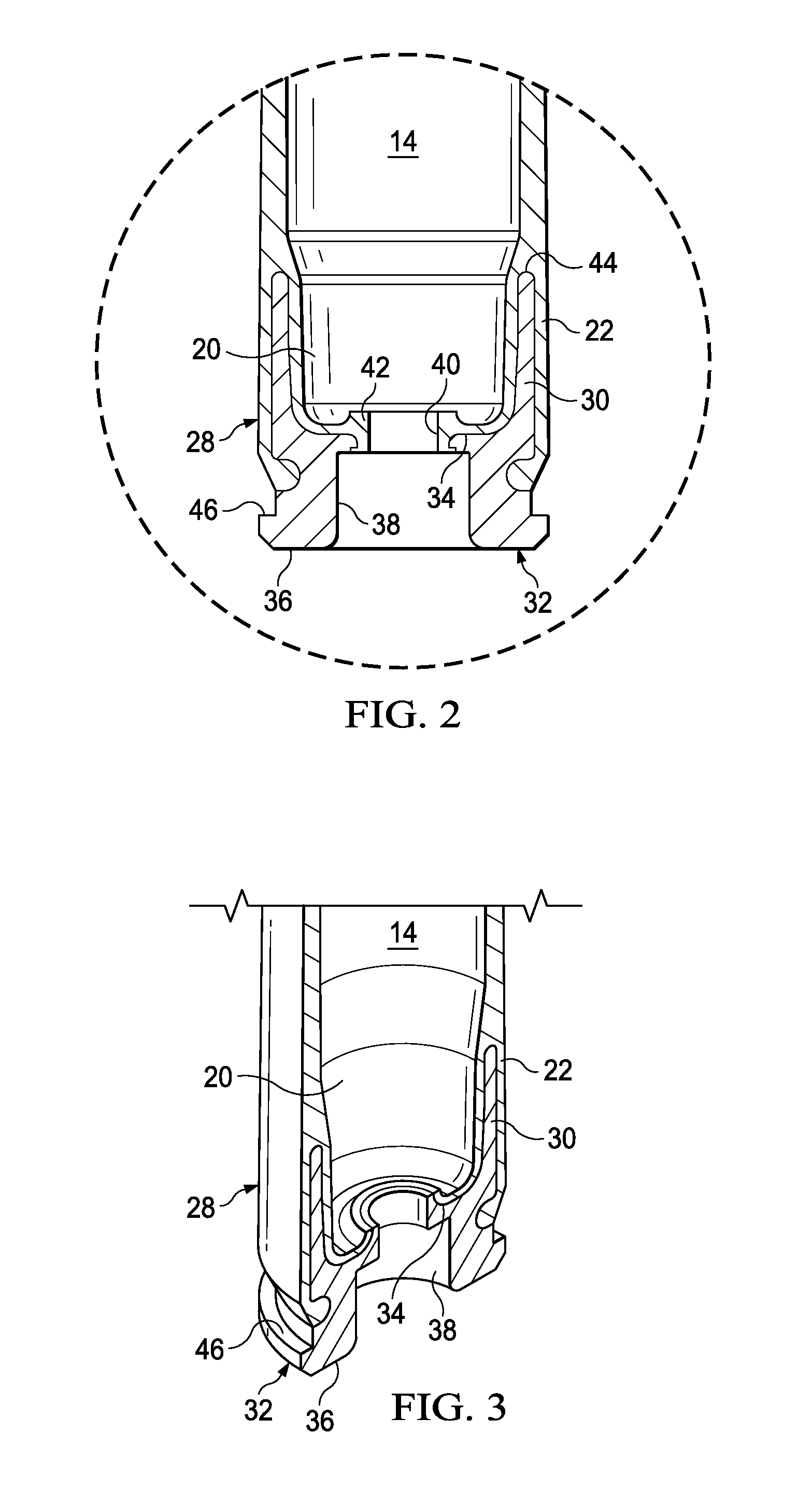

Method of making polymer ammunition having a metal injection molded primer insert

Owner:TRUE VELOCITY IP HLDG LLC

Biopolymer structures and components

InactiveUS20050019545A1Keep shapeIncrease valueVehicle arrangementsAlcoholic beverage preparationBiopolymerEngineering

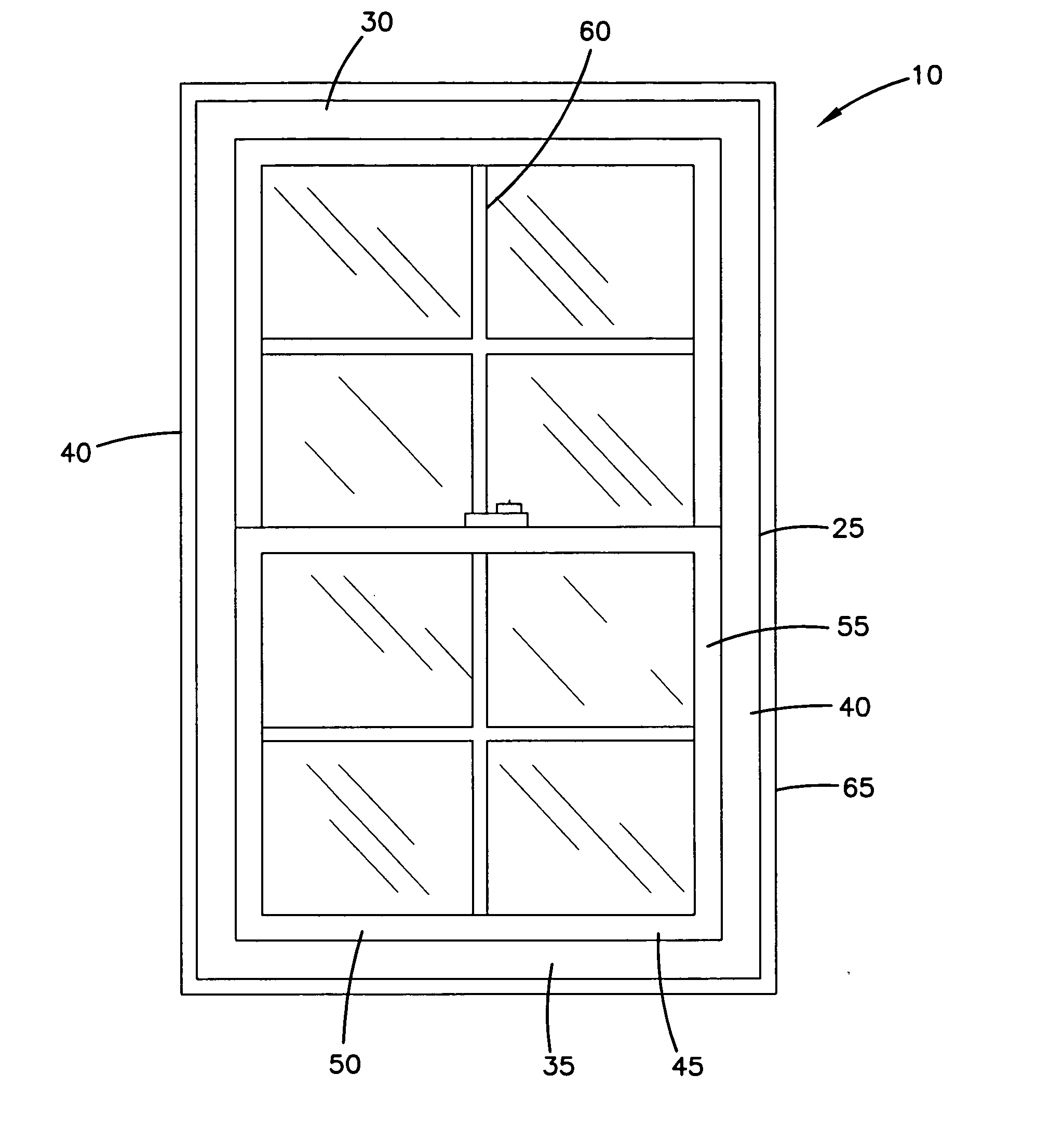

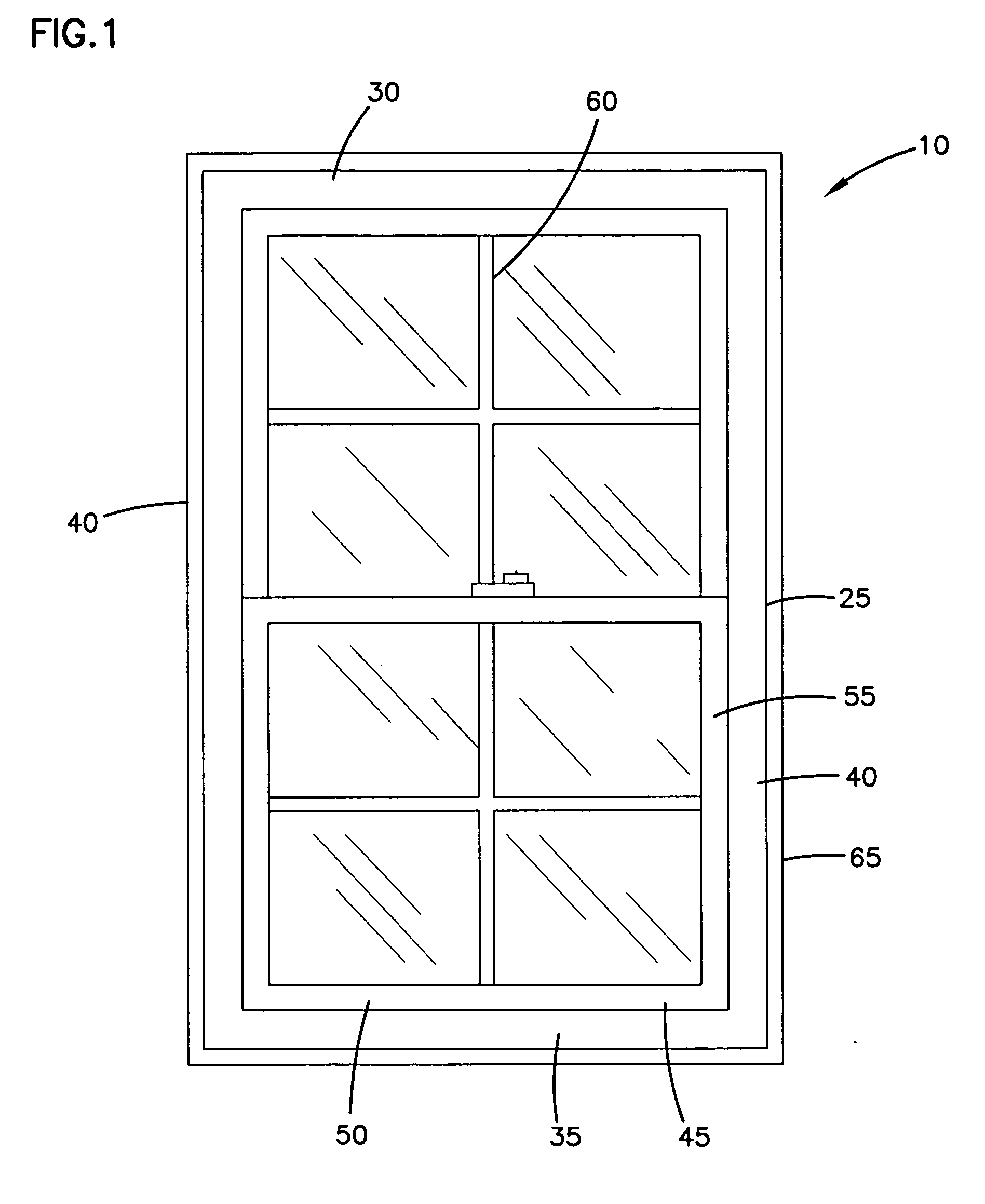

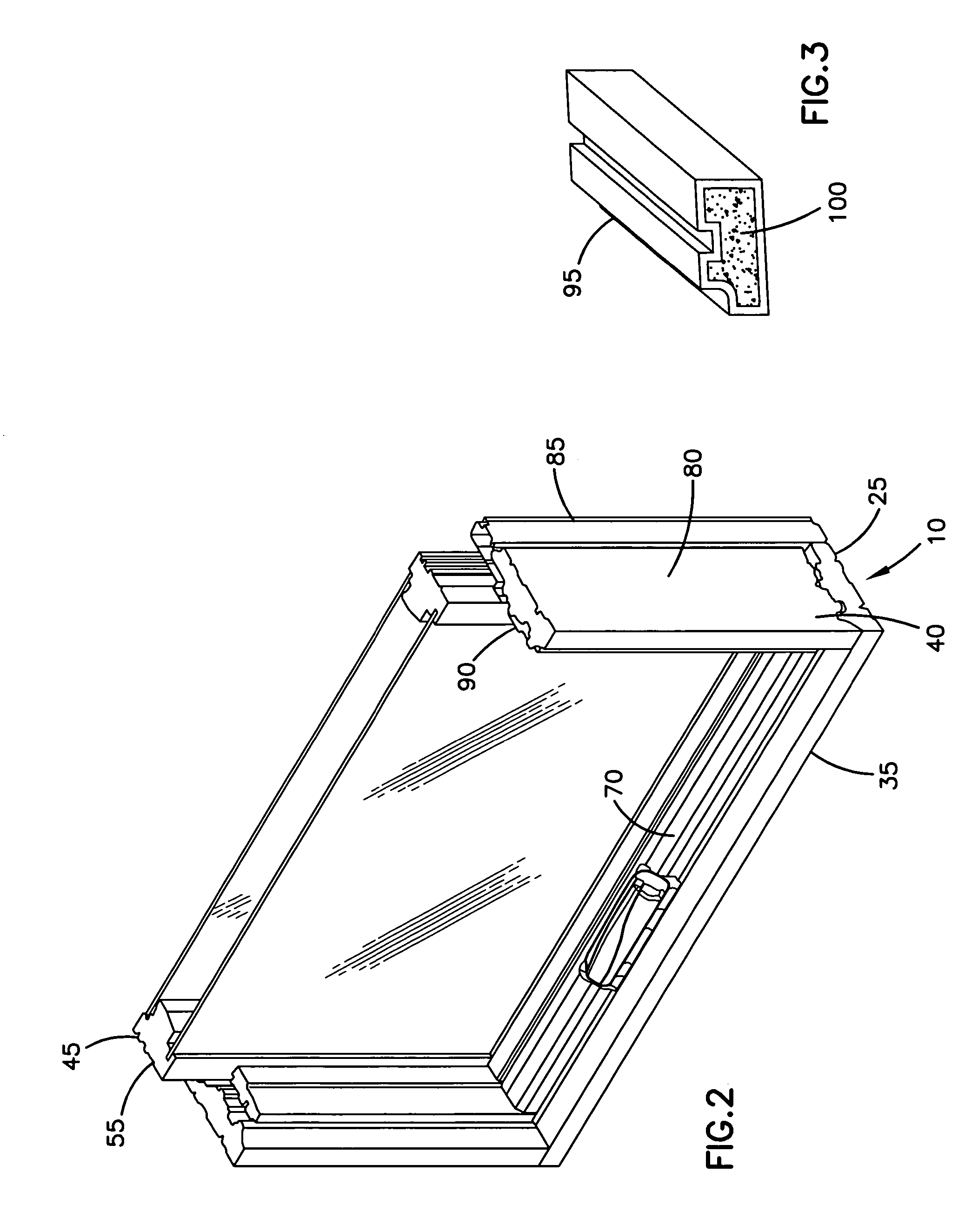

Structures can be formed from a composition, which can be referred to as a biopolymer, that includes fermentation solids and thermoactive material. Methods of making biopolymer products include for example extruding, injection molding, or compounding fermentation solid and thermoactive material. Structures formed from biopolymer can include lumber replacements, window components, door components, siding assemblies, and other structures.

Owner:POET RES INC

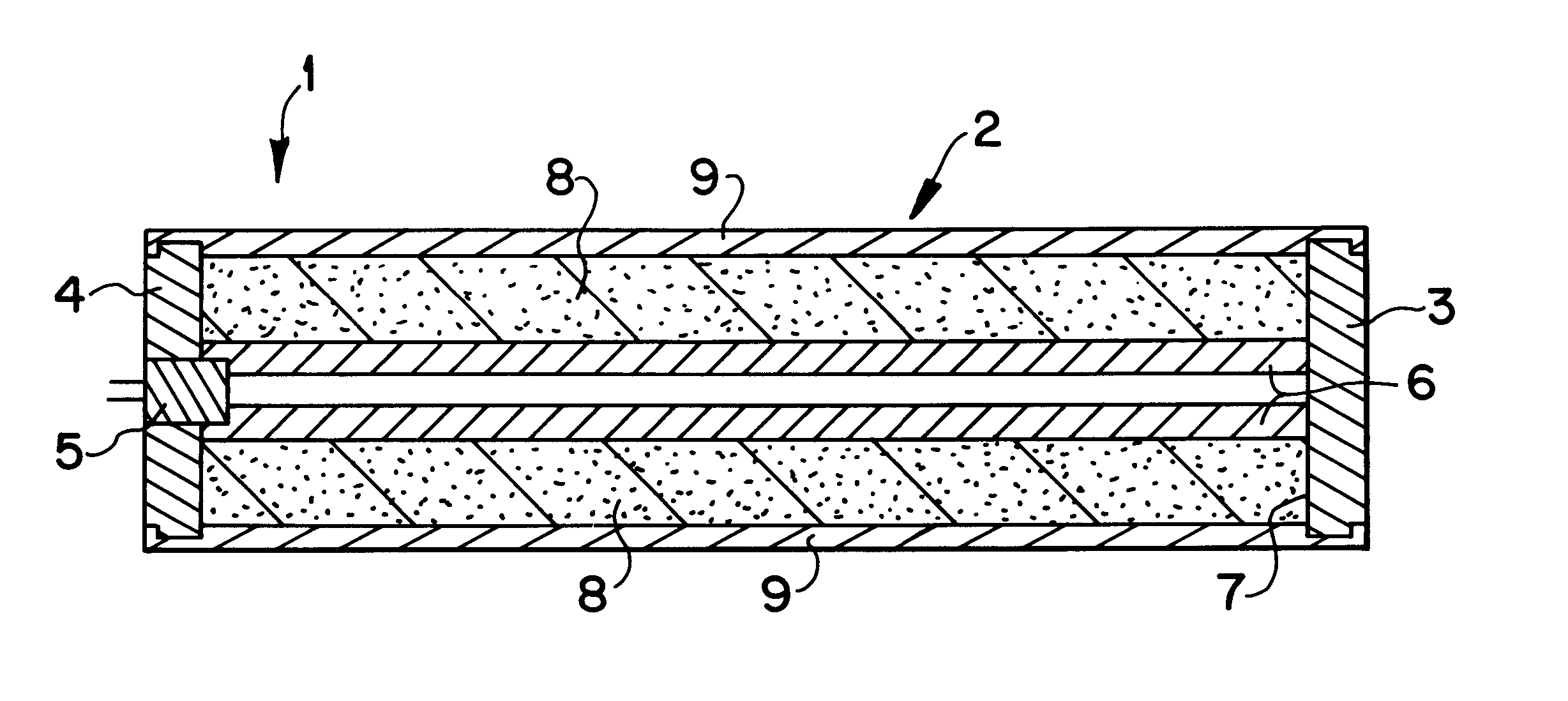

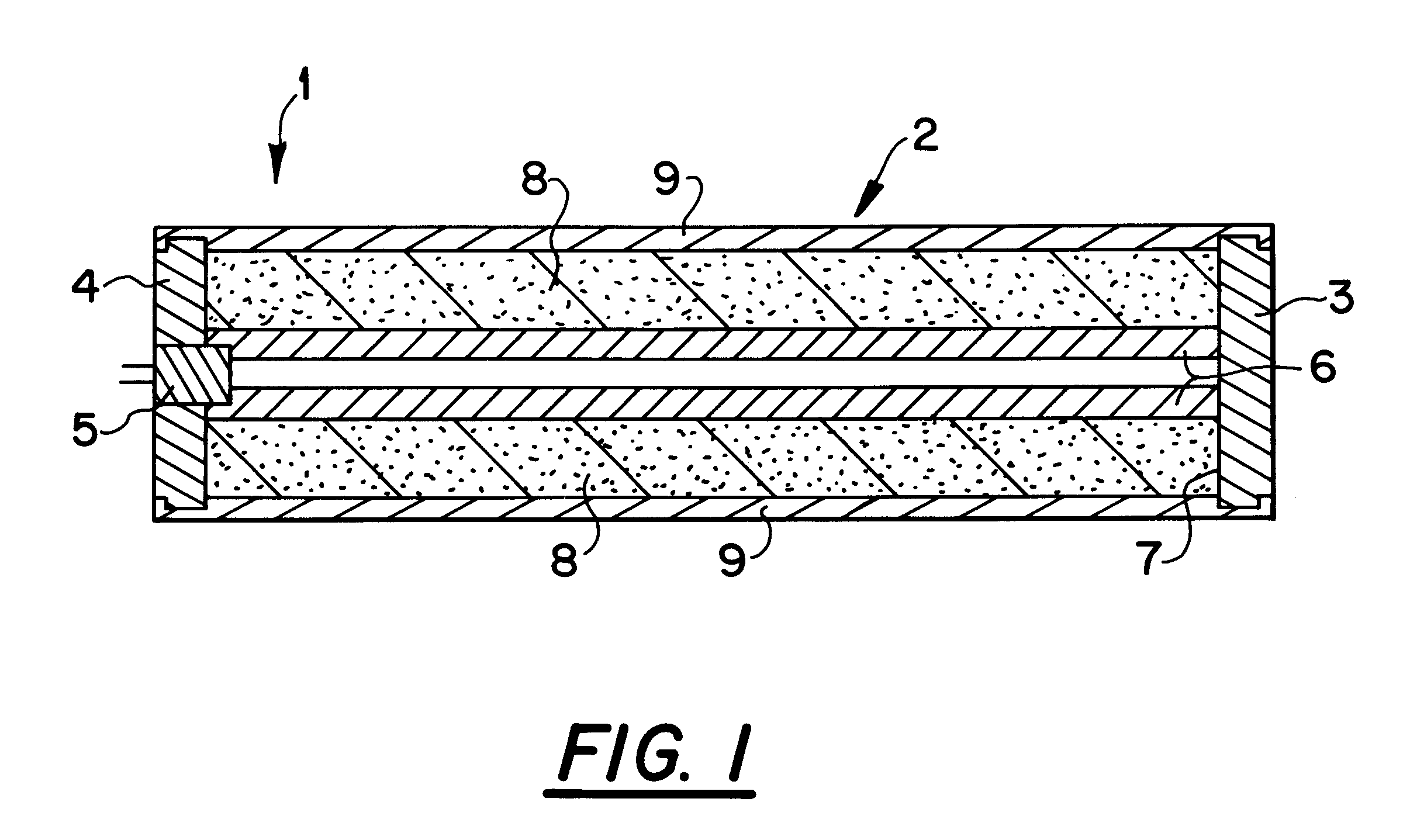

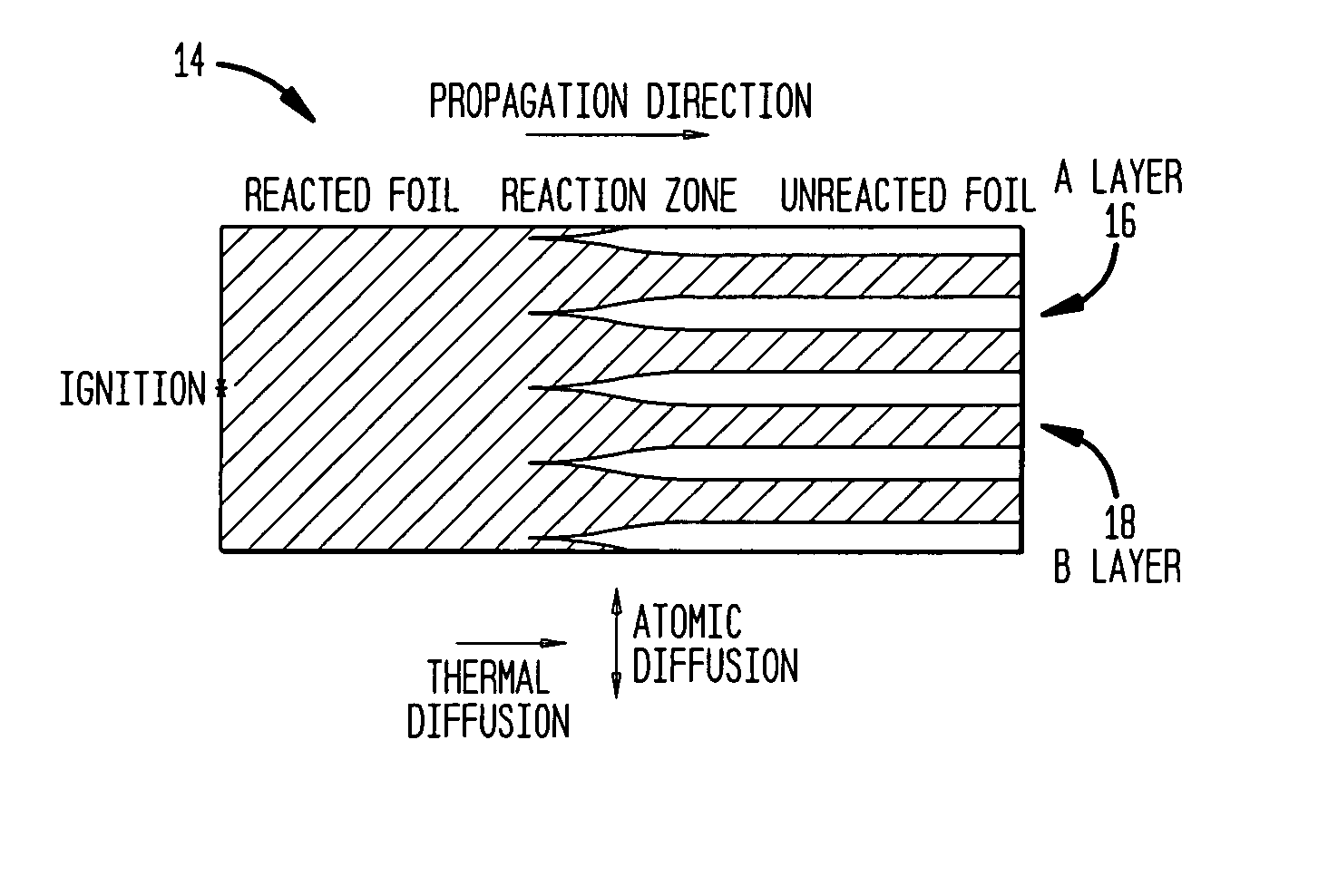

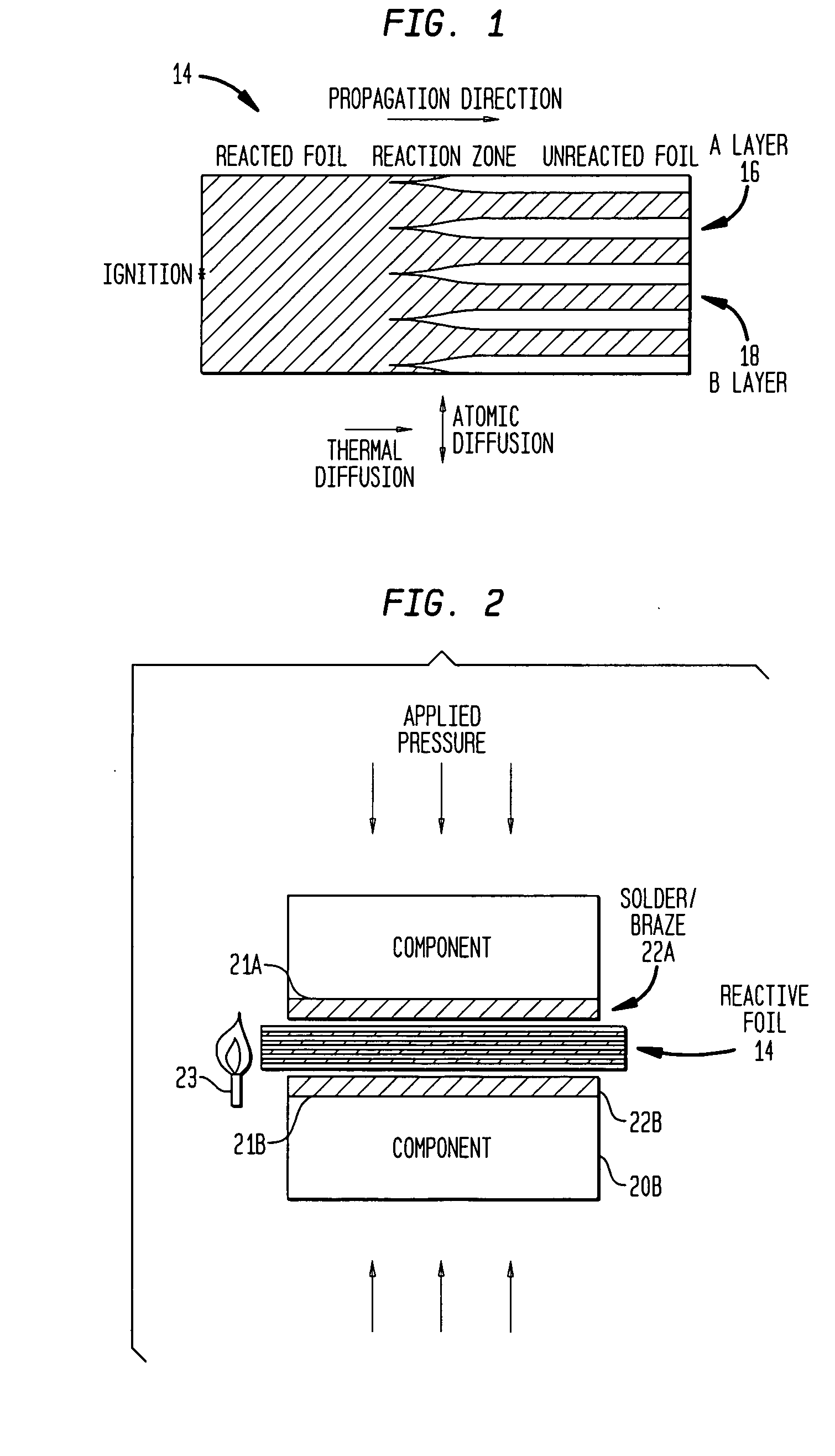

Composite reactive multilayer foil

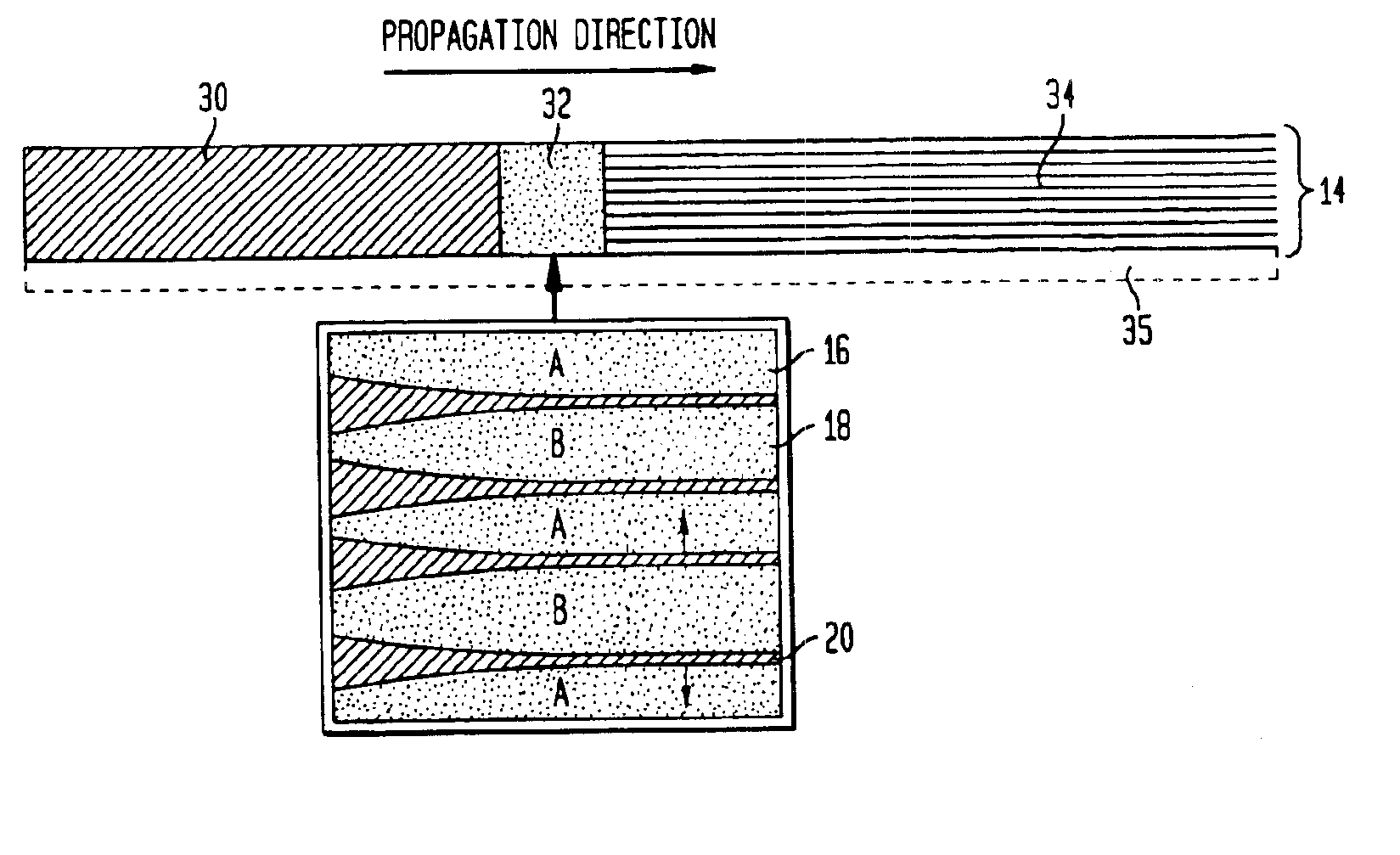

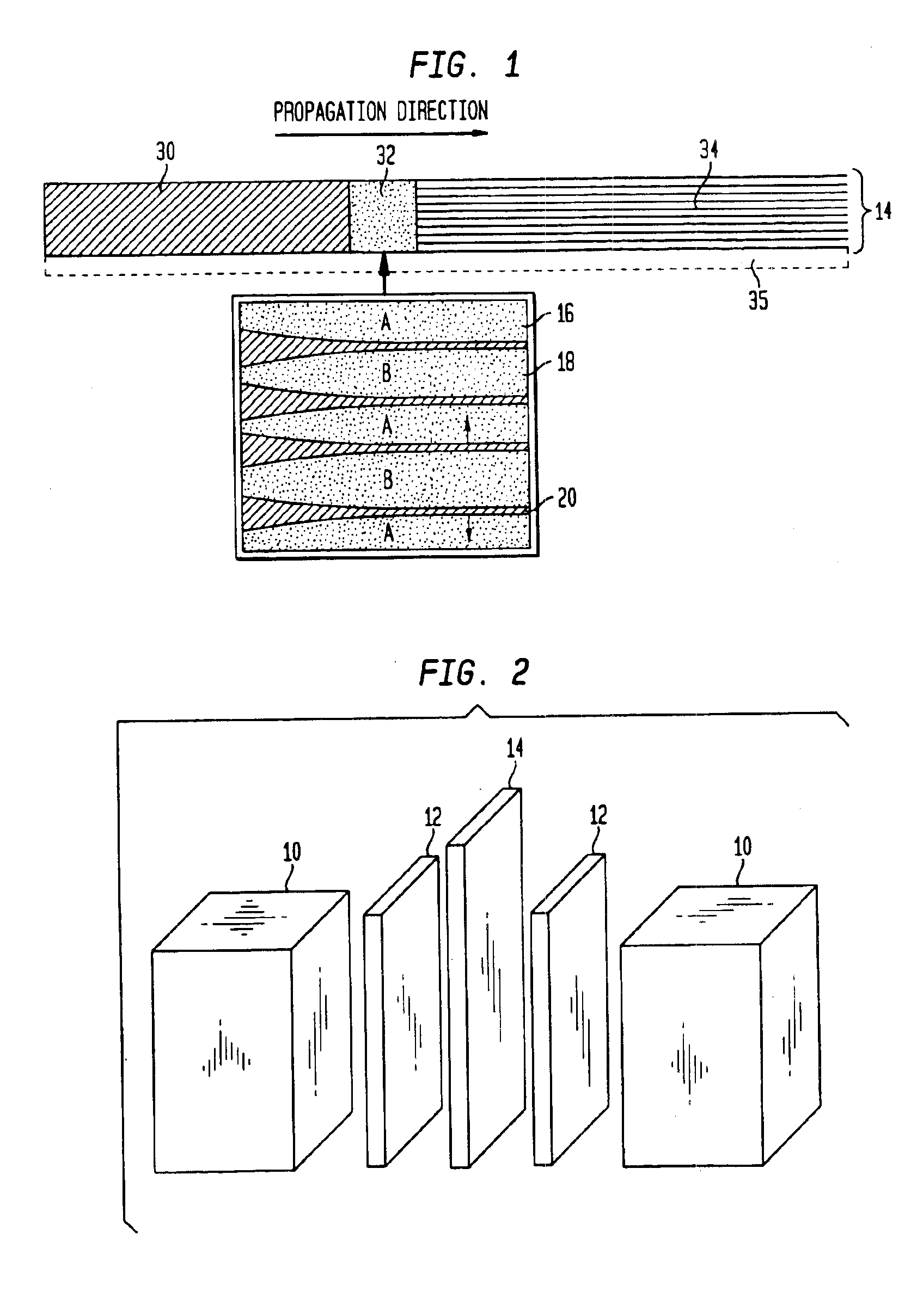

InactiveUS6863992B2Increase heatFast bondingExothermal chemical reaction heat productionVacuum evaporation coatingThermal energyRoom temperature

Reactive foils and their uses are provided as localized heat sources useful, for example, in ignition, joining and propulsion. An improved reactive foil is preferably a freestanding multilayered foil structure made up of alternating layers selected from materials that will react with one another in an exothermic and self-propagating reaction. Upon reacting, this foil supplies highly localized heat energy that may be applied, for example, to joining layers, or directly to bulk materials that are to be joined. This foil heat-source allows rapid bonding to occur at room temperature in virtually any environment (e.g., air, vacuum, water, etc.). If a joining material is used, the foil reaction will supply enough heat to melt the joining materials, which upon cooling will form a strong bond, joining two or more bulk materials.

Owner:THE JOHN HOPKINS UNIV SCHOOL OF MEDICINE

Supplemental-restraint-system gas generating device with water-soluble polymeric binder

InactiveUS6224099B1Easy to manufactureSelectable characteristicLoomsPedestrian/occupant safety arrangementSystems designIn vehicle

Owner:NORTHROP GRUMMAN INNOVATION SYST INC

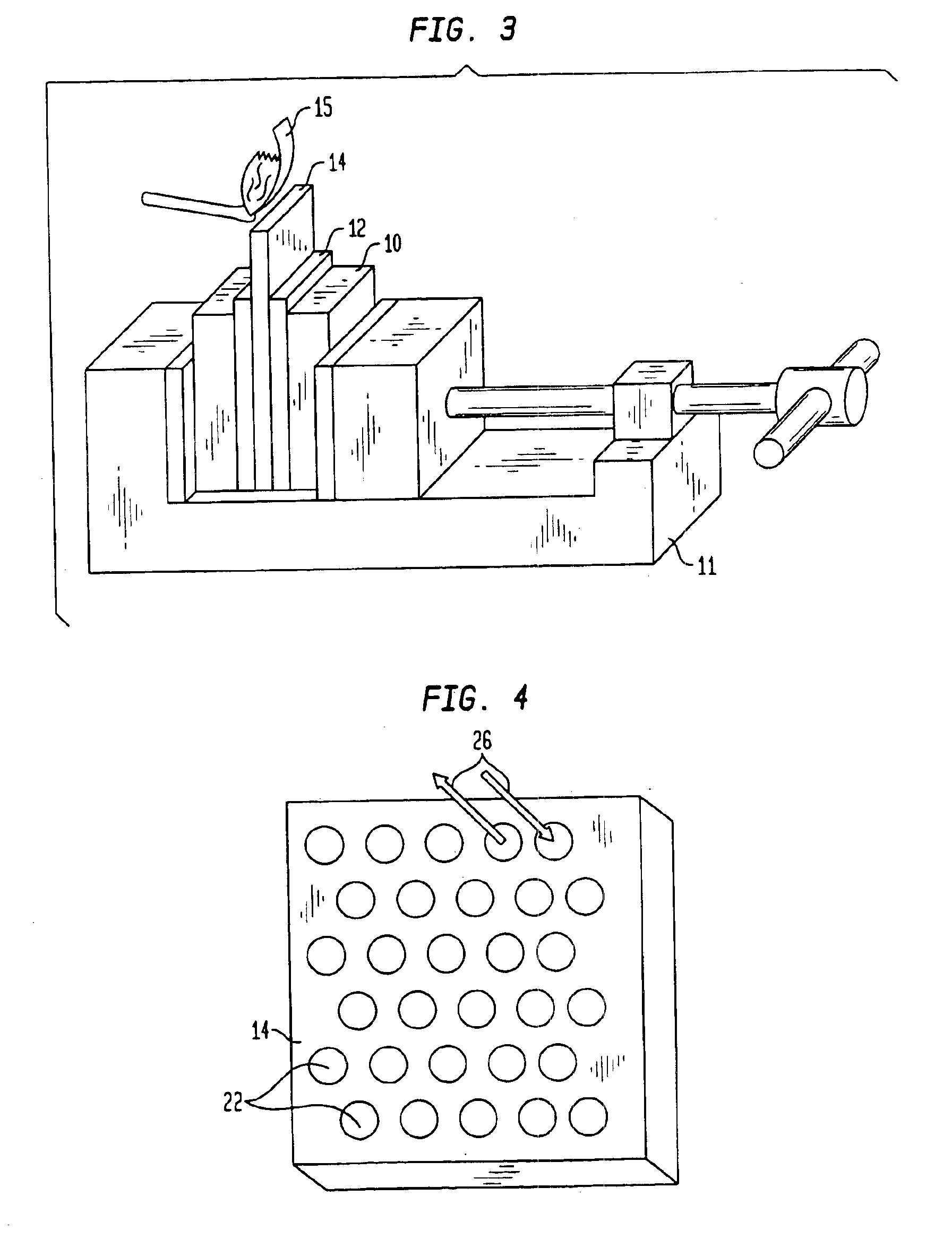

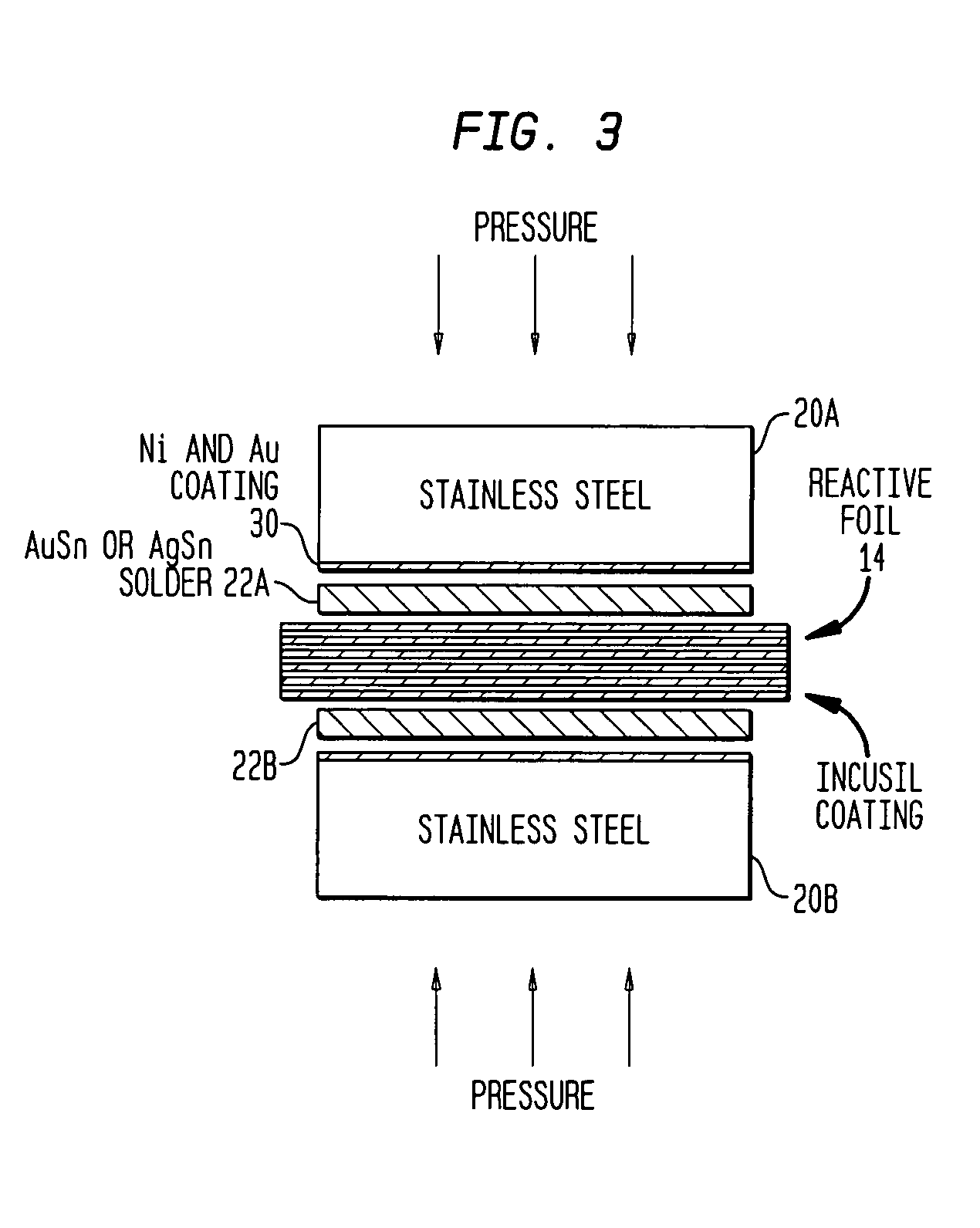

Method of joining using reactive multilayer foils with enhanced control of molten joining materials

InactiveUS20050082343A1Reducing applied pressureExtended durationExothermal chemical reaction heat productionVacuum evaporation coatingCopperMaximum pressure

In accordance with the invention, bodies of materials are joined by disposing between them a reactive multilayer foil and one or more layers of meltable joining material such as braze or solder. The bodies are pressed together against the foil and joining material, and the foil is ignited to melt the joining material. The pressing is near the critical pressure and typically produces a joint having a strength of at least 70-85% the maximum strength producible at practical maximum pressures. Thus for example, reactively formed stainless steel soldered joints that were heretofore made at an applied pressure of about 100 MPa can be made with substantially the same strength at a critical applied pressure of about 10 kPa. Advantages of the process include minimization of braze or solder extrusion and reduced equipment and processing costs, especially in the joining of large bodies.

Owner:THE JOHN HOPKINS UNIV SCHOOL OF MEDICINE

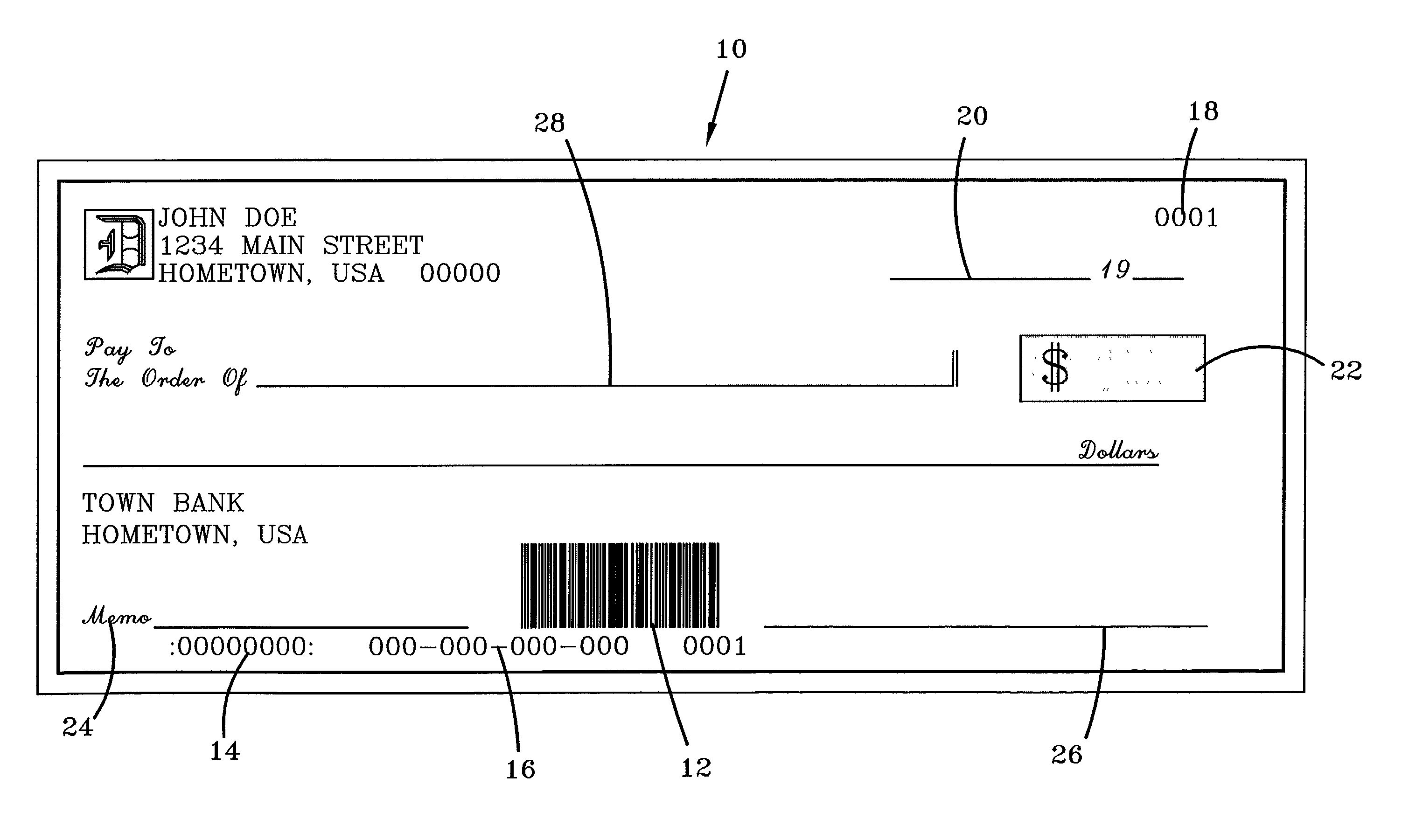

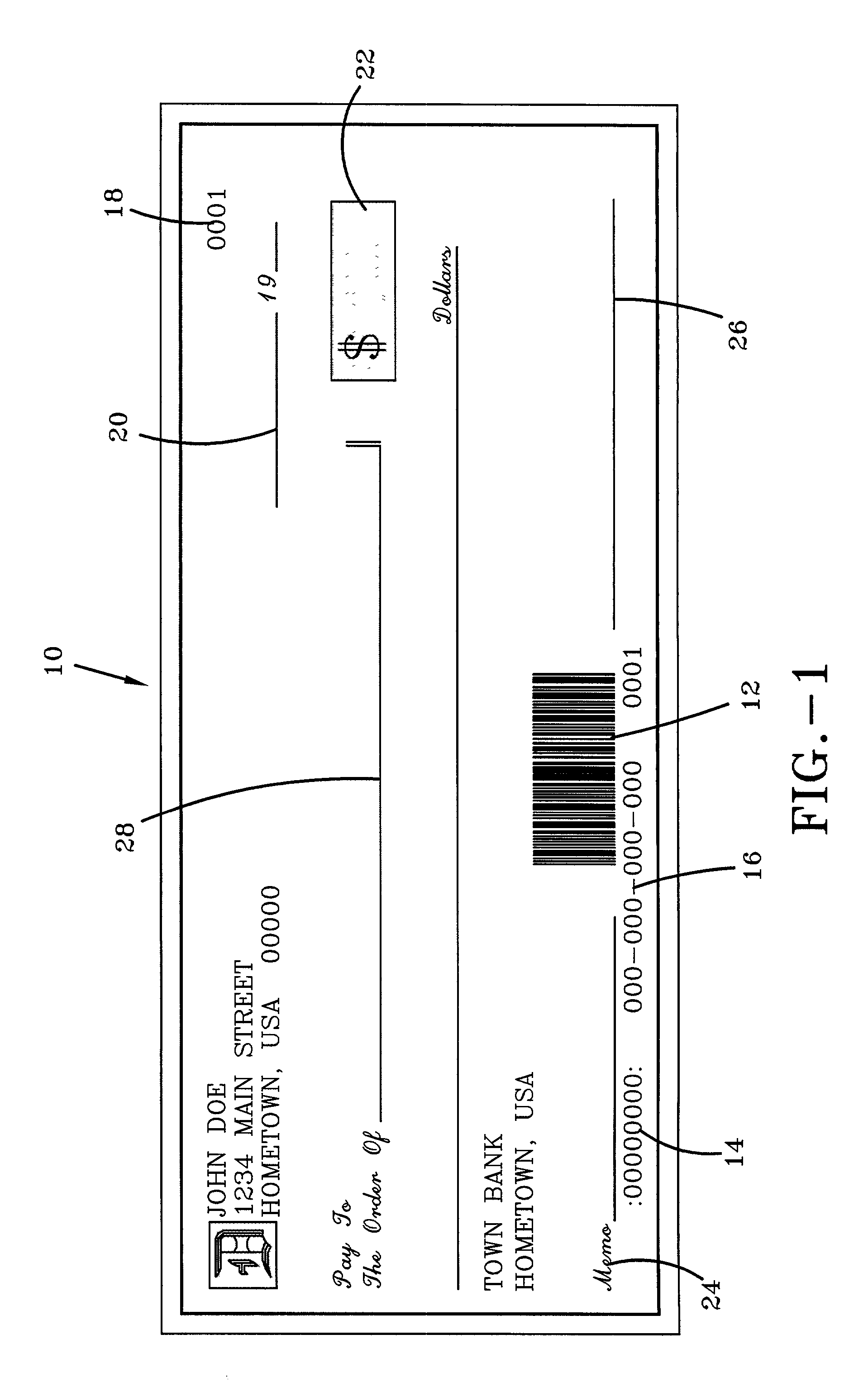

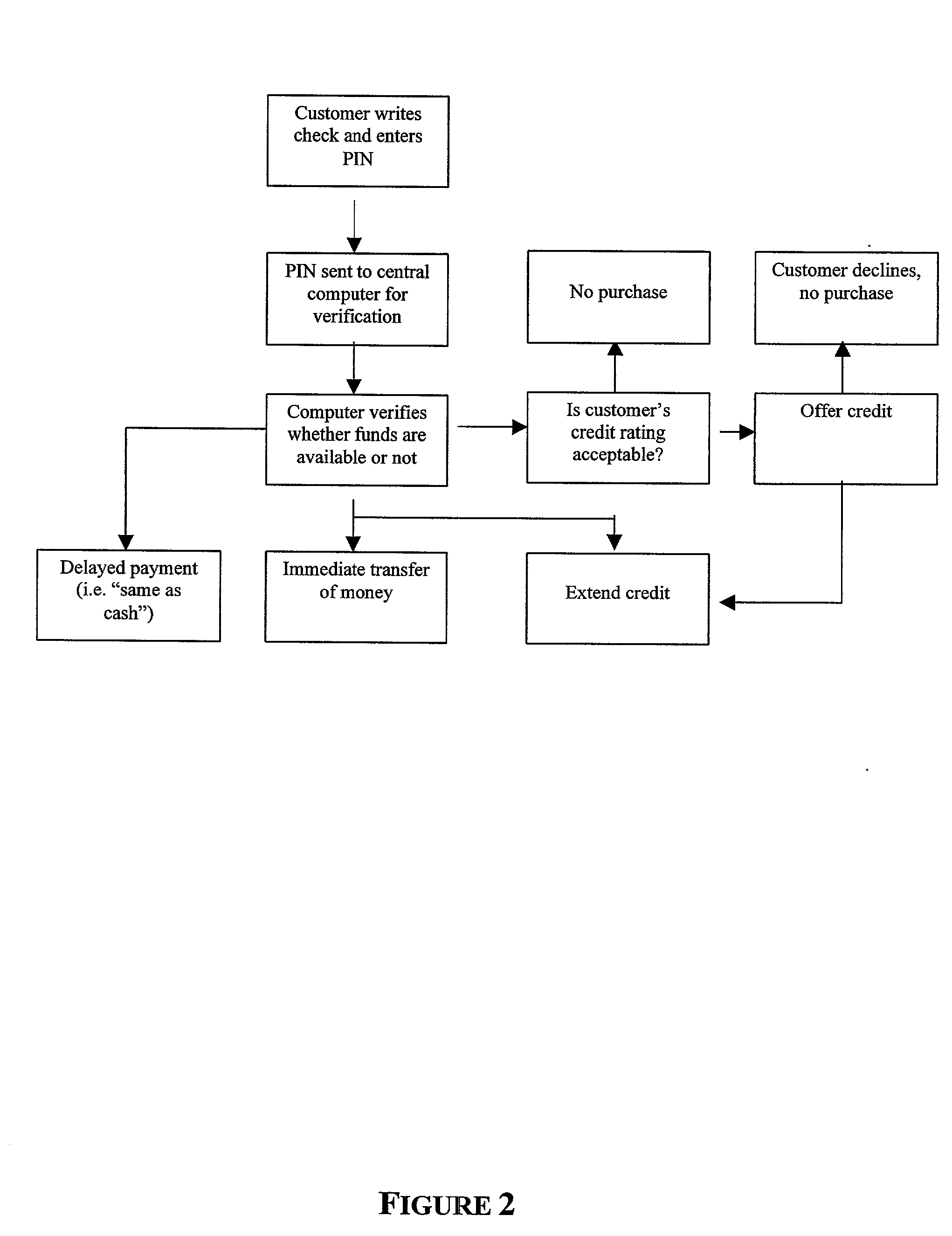

Method and device for preventing check fraud

InactiveUS20020184152A1Great confidenceQuickly and efficiently determineFinancePaper-money testing devicesBarcodeInvoice

An inventive check is disclosed including a barcode, which includes at least one of the following pieces of information: the date the check was paid, the amount of the check, the payee, the drawers account number, the banks routing number, and the identifier number of the check. A method for preventing check fraud is also provided, including the steps of attaching a machine readable code on a negotiable instrument, creating a negotiable instrument, the drawee receiving the negotiable instrument, and the drawee scanning the machine readable code. A method is also included for integrating the entire checking process. The invention also includes methods for including payee information on an invoice, as well as for determining available funds and creditworthiness of customers. Also included is a method for controlling spending.

Owner:MARTIN DAVID A

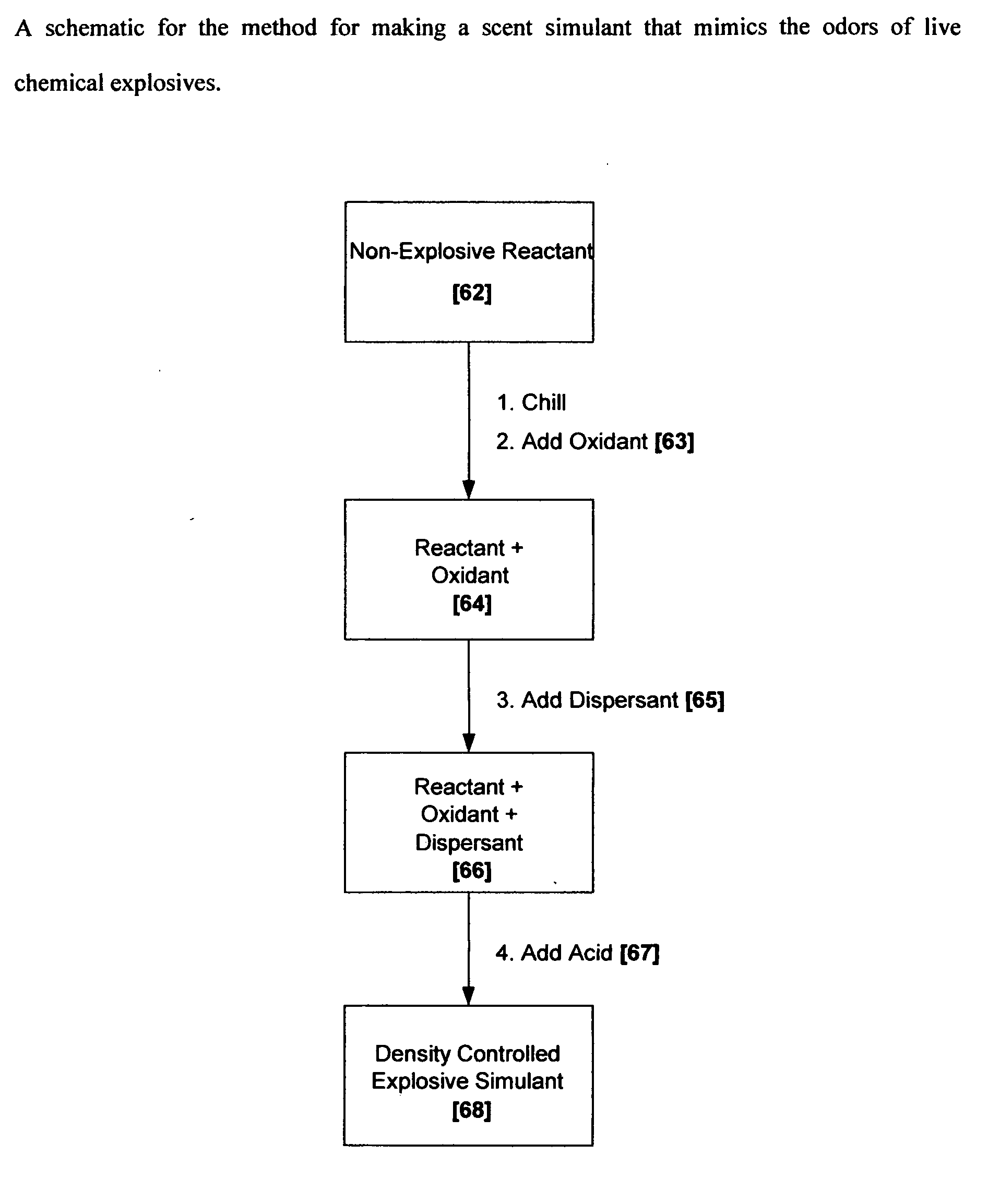

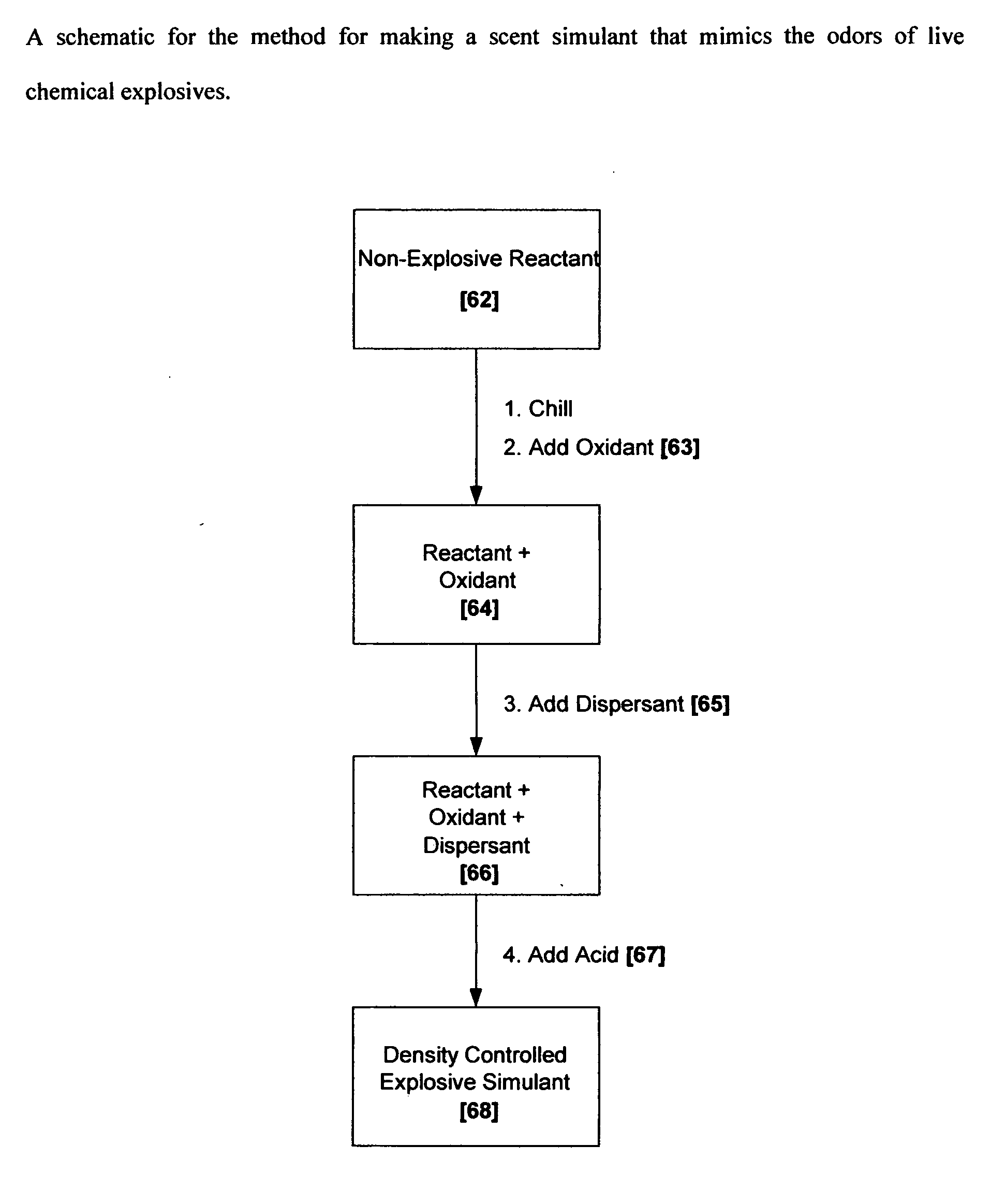

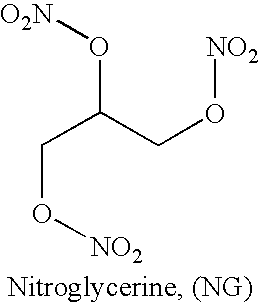

Methods for making scent simulants of chemical explosives, and compositions thereof

ActiveUS20090194744A1Increasing degree of heterogeneosityDefence devicesOther chemical processesChemical explosiveDetonation

The present invention relates to methods for producing non-detonable and non-explosive parent-odor scent simulants of both detonable and entropy-burst chemical explosive materials. A detonable explosive material is a material that explosives with the aid of detonation while an entropy burst explosive material is a very sensitive energetic material that does not require detonation, but explodes through a spontaneous decomposition of its molecules into gaseous products. The invention also presents representative non-detonable, non-hazardous compositions of such simulants that can be safely and effectively utilized within a broad spectrum of biological and non-biological explosives detection programs, non-limiting examples being the training of biological search-and-detect creatures such as explosive detecting dogs and the calibration of electronic explosive detecting instruments that rely on the principles of vapor sampling for their operations.

Owner:ADEBIMPE DAVID O B A

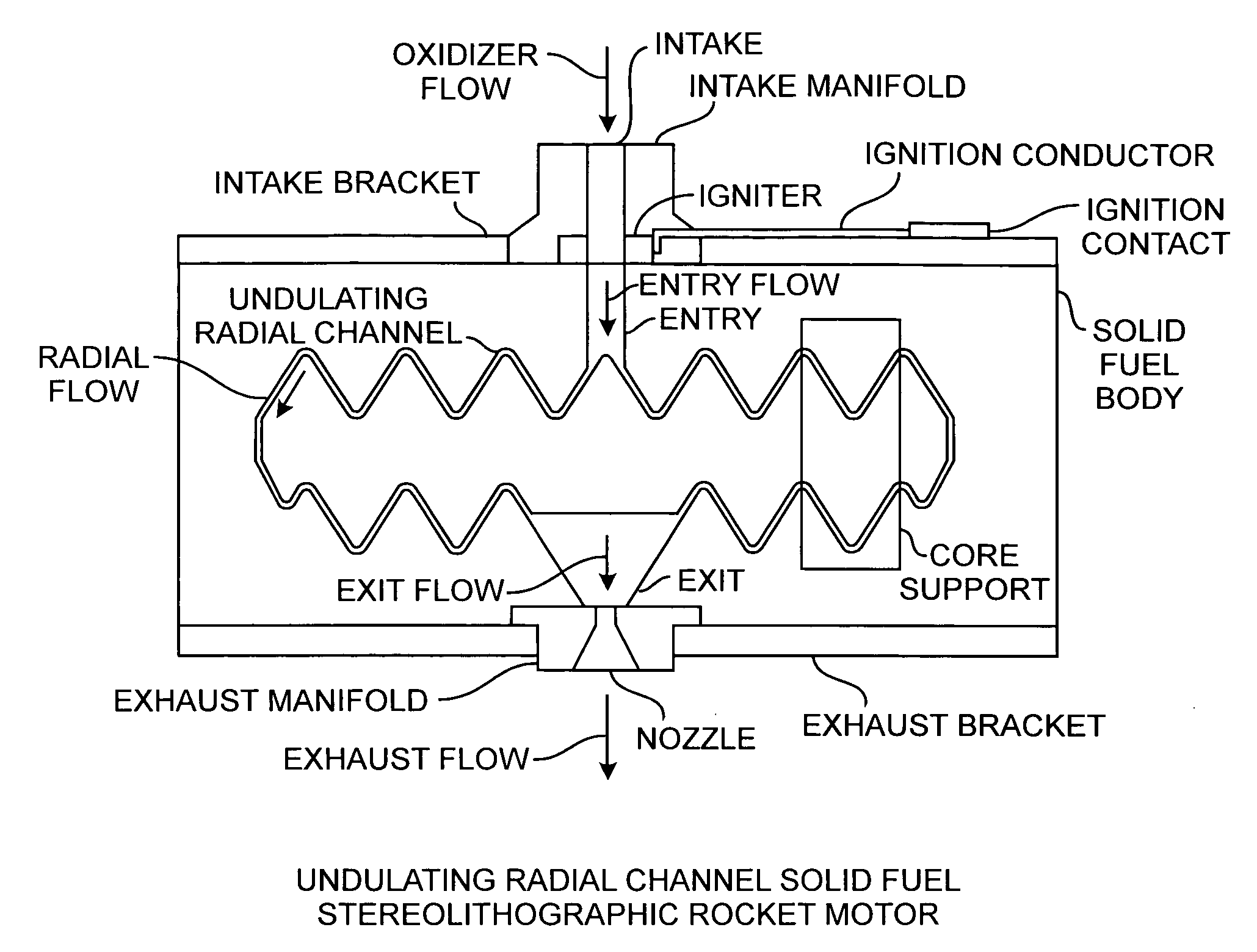

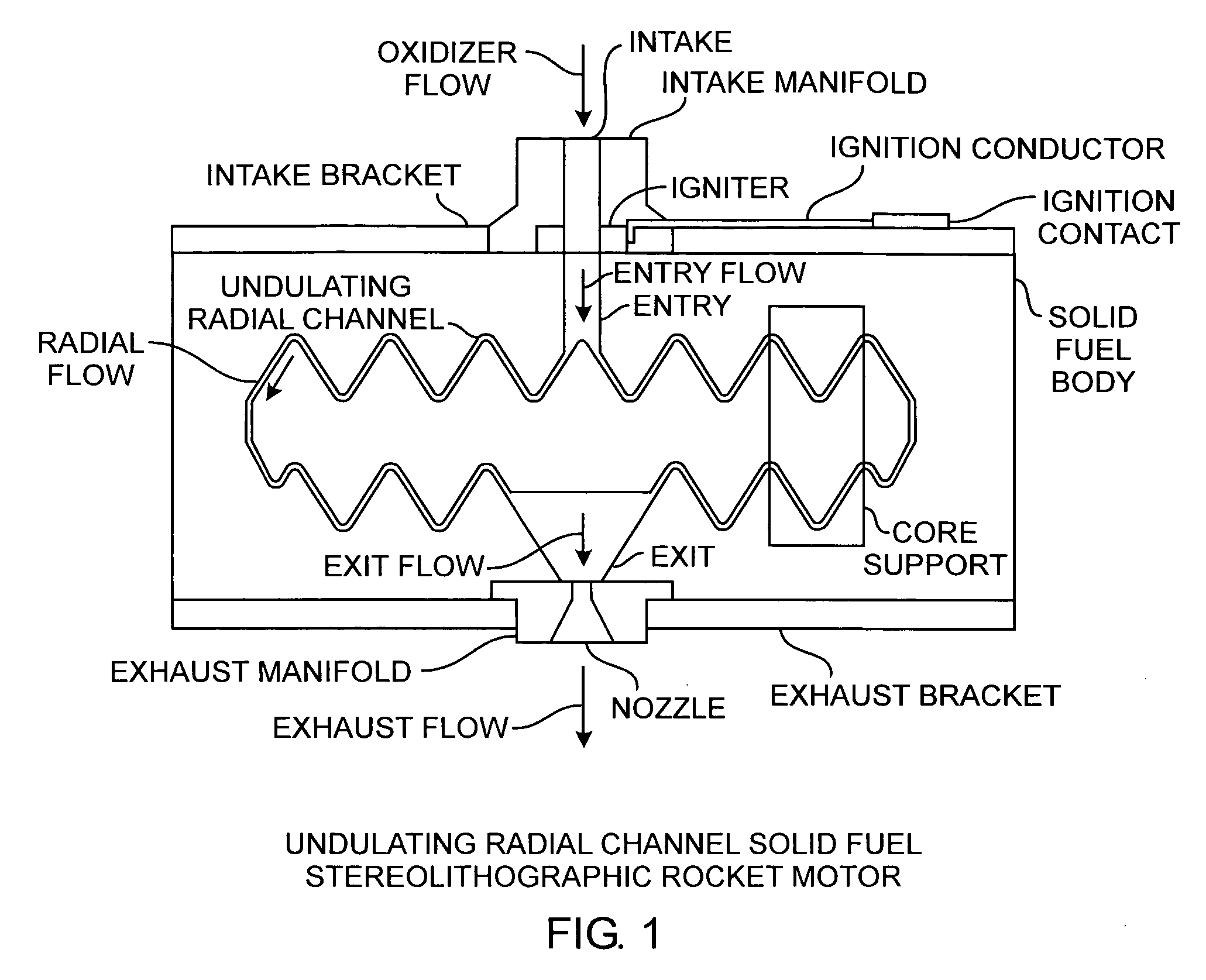

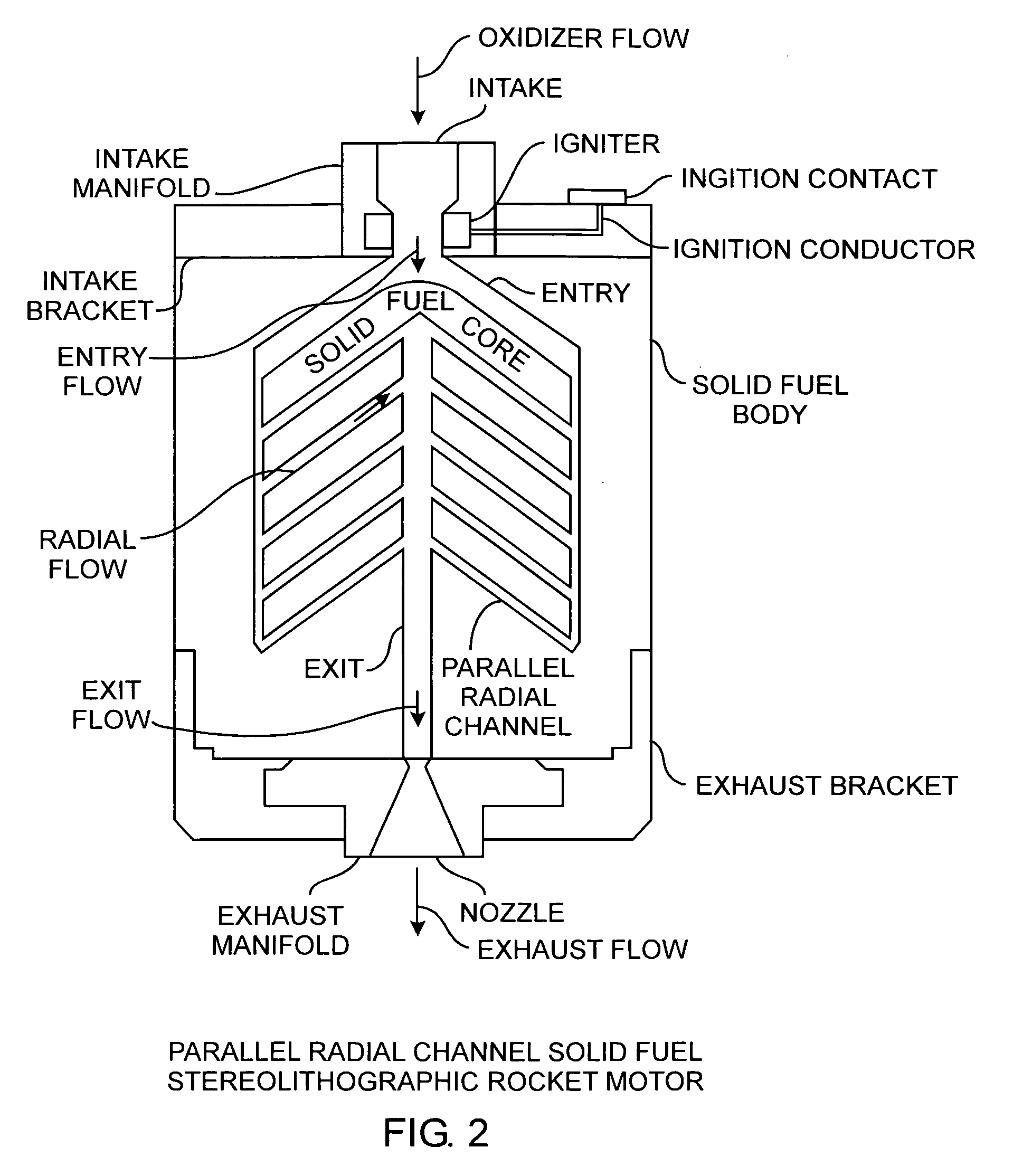

Stereolithographic rocket motor manufacturing method

ActiveUS20090217525A1Improve performanceEfficient combustionAdditive manufacturing apparatusWriting implementsSolid fuelStereolithography

A hybrid rocket motor is manufactured by photopolymerizing the solid fuel grain in a stereolithography method, wherein fuel grains in a plastic matrix are deposited in layers for building a solid fuel rocket body in three dimensions for improved performance and for a compact design,

Owner:THE AEROSPACE CORPORATION

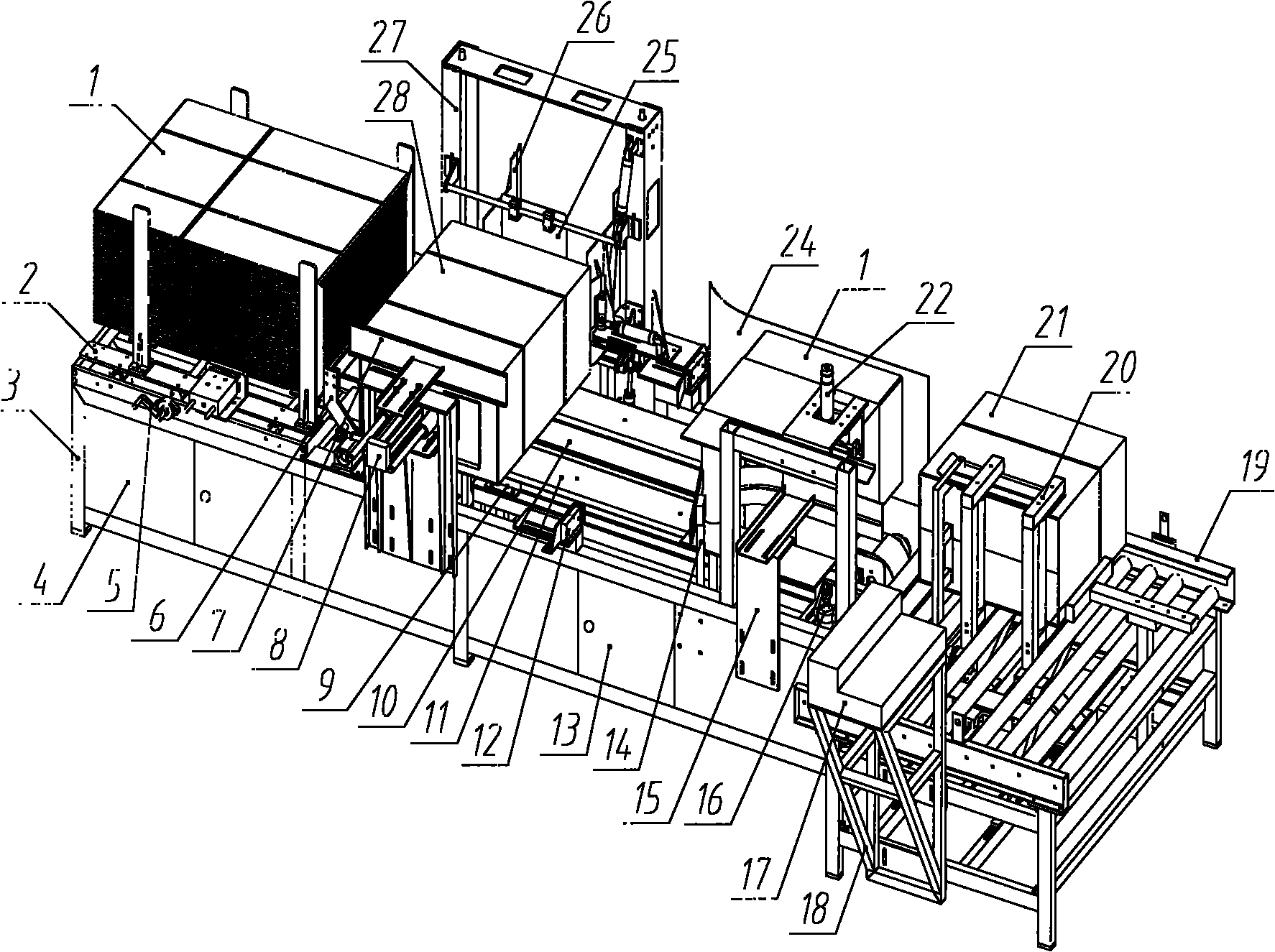

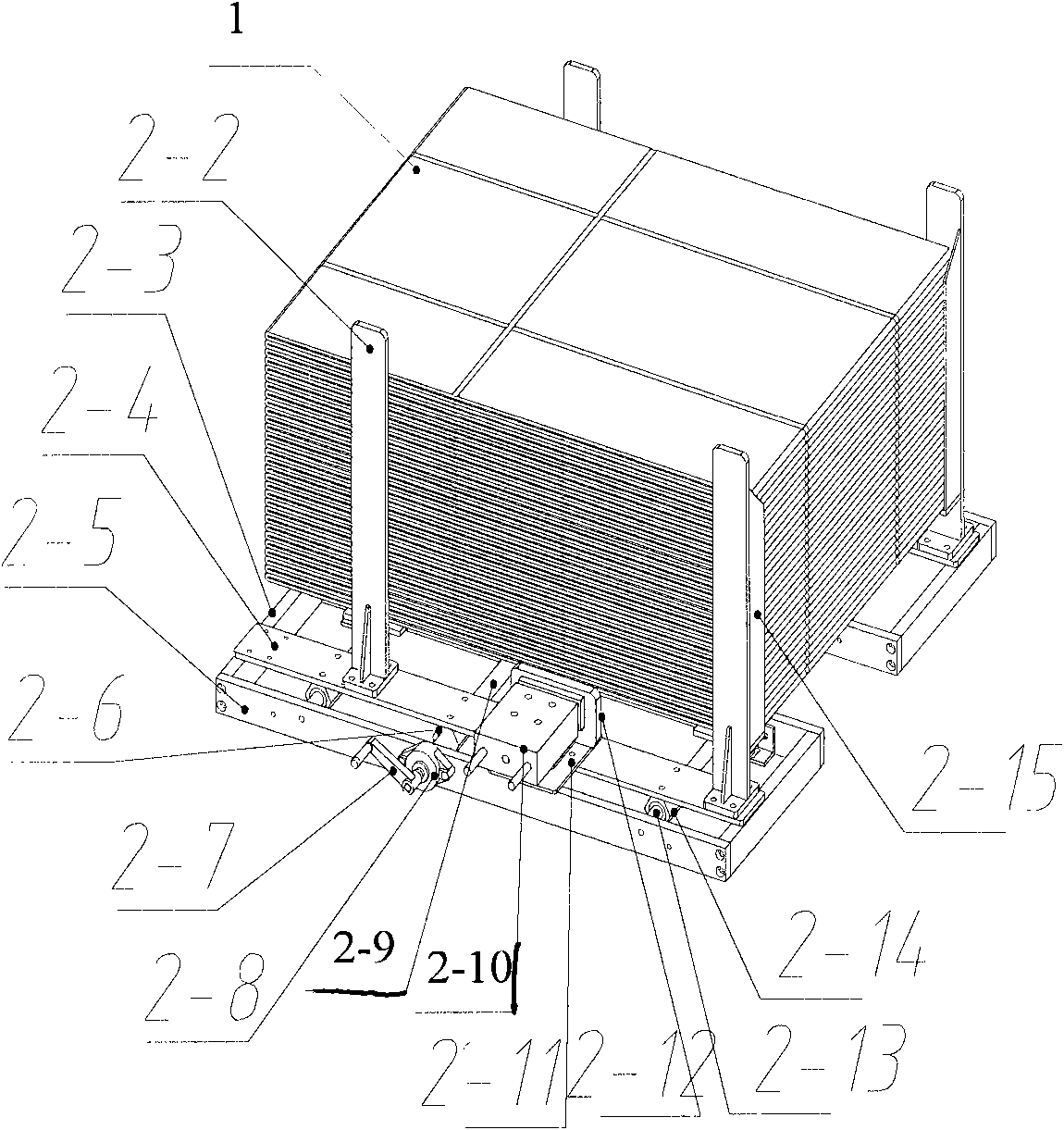

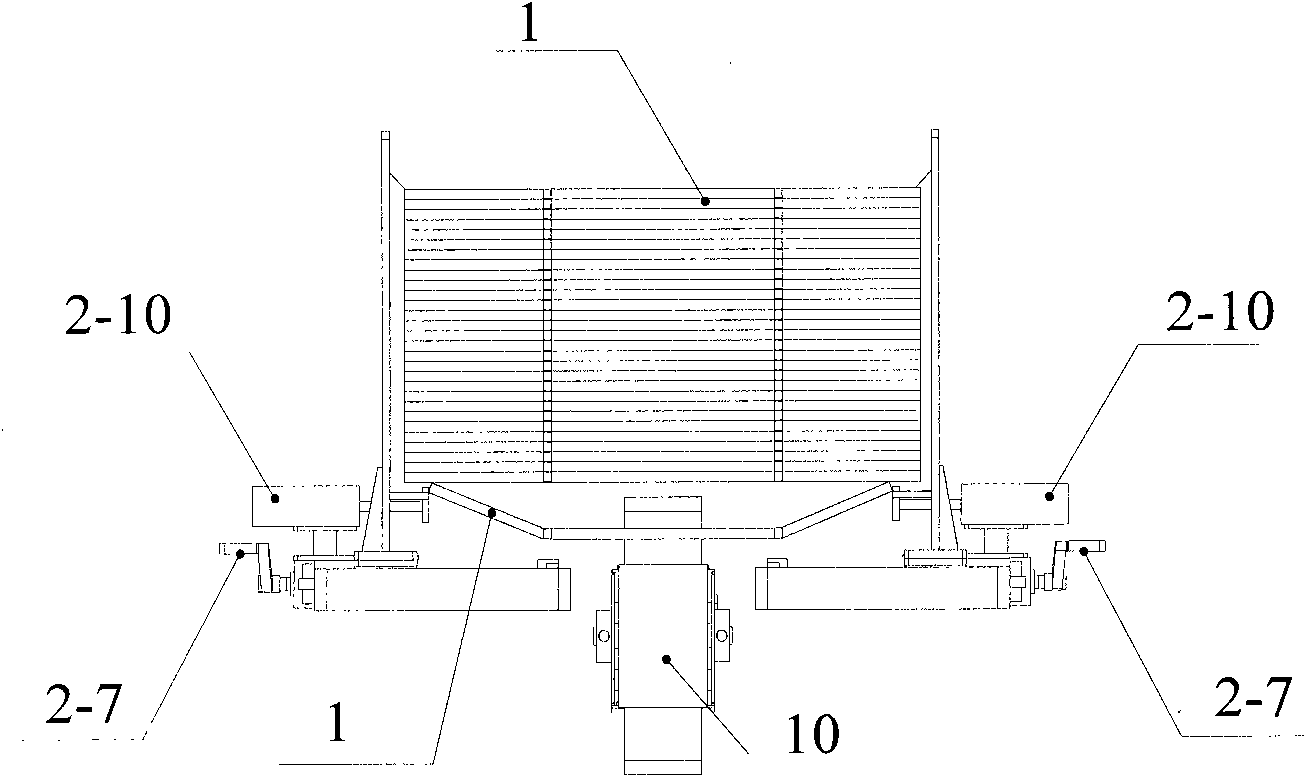

Integrated side-push box filler

ActiveCN101880206AFree adjustment and replacementWork orderlyAmmunition storageExplosive working-up apparatusCartonSmall footprint

The invention relates to an integrated side-push box filler, which is structurally characterized in that: a bid assembly is arranged on a bid rack; the bid rack and a box turning device are arranged on a rack respectively; a box turning roller way assembly is directly connected with the rack; two large brackets of a box blank supply assembly, a cylinder seat of a side absorption box assembly, a box baffle plate, a bag baffle cylinder, a cylinder seat of a bottom absorption box assembly, a box supporting oral plate, a box delivery link plate, a box supporting plate, a carton folding hammer assembly mounting frame, a mounting frame for three sets of carton folding assemblies and a rack of a laminated assembly are arranged at the corresponding positions of the rack respectively; an electric cabinet and a gas source cabinet are arranged and fixed inside the rack respectively; electric wires and gas pipes are connected with the corresponding components by adopting slots; the electric cabinet controls the motion of all cylinders; and the gas source cabinet is connected with all sucking discs respectively. The integrated side-push box filler has the advantages of simple structure, stable working state, easy operation, convenient adjustment, small floor area and integral structure.

Owner:WUHAN RENTIAN PACKAGING TECH

Flares having igniters formed from extrudable igniter compositions

InactiveUS6170399B1Easy to manufactureLow costFirework flares/torchesExplosive working-up apparatusRocketFlare

The present invention relates to flares and other solid propellant devices, rockets or the like, equipped with an igniter or igniter system which is based in whole in part on an extruded igniter stick.

Owner:NORTHROP GRUMMAN INNOVATION SYST INC

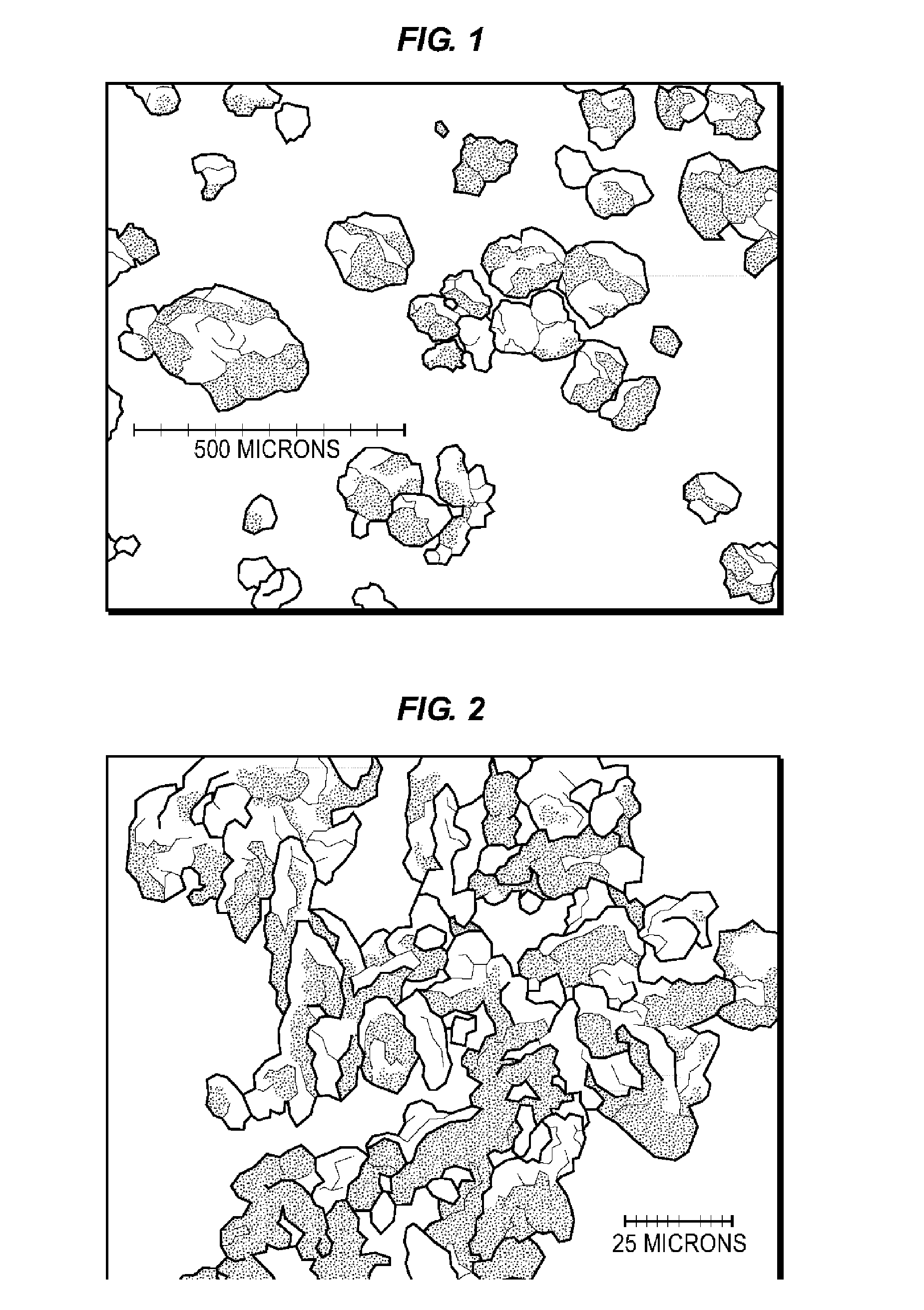

Explosive material composition and method for preparing the same

InactiveUS20050189049A1Moderate mechanical strengthExplosive working-up apparatusAlkali metal salt explosive compositionsAdditive ingredientWater soluble

An explosive material composition containing, as an active ingredient, particles of a water-soluble reactive ingredient having an uniform particle size. Each particle is coated with an oil ingredient and / or a thickener. The coated particles form an agglomerate.

Owner:NOF CORP

Supercritical fluid aided coating of particulate material

A method for preparing coatings of thin films onto solid particle has been achieved by in-situ simultaneous nucleation and deposition of dissolved material out of supercritical fluid, resultant film formation on the solid particles suspended in the supercritical fluid, and subsequent thermal conditioning of the coating in the particles. The coating method involves an enclosed system that provides: 1) for suspension of the solid particles to be coated; 2) for dissolution of the coating material in the supercritical fluid solvent; 3) for temperature or pressure swing operations causing film deposition / coating of the suspended solid particles and; 4) additional chemical addition and / or thermal cycles providing for any additional reactions required (such as polymerization).

Owner:FLORIDA UNIV OF A FLORIDA

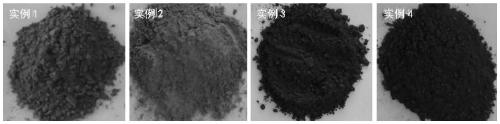

Sulfur-free nitrogen-free high-temperature-resistant environment-friendly firework propellant and preparation method thereof

The invention relates to a sulfur-free nitrogen-free high-temperature-resistant environment-friendly firework propellant and a preparation method thereof, and belongs to the technical field of fireworks and crackers. The sulfur-free micro-smoke high-temperature-resistant firework propellant is prepared from the following components in parts by weight: 55-75 parts of polytetrafluoroethylene with the particle size of 50-300 microns; 5-25 parts of aluminum powder with the particle size of 5-75 microns; 5-25 parts of zinc powder and 5-15 parts of copper powder with the particle size of 5-75 microns; 2-10 parts of calcium silicate with the particle size of 20-150 microns; 0.5-5 parts of a silane coupling agent; and 1-5 parts of an energetic binder. The preparation method adopts the processes of chemical modification, coating, powder mixing, granulation, drying and the like, and is simple in process, free of special process requirements, low in cost and convenient for batch production. The obtained product has the advantages of no sulfur, slight smoke, no environmental pollution, low impact or friction sensitivity, high temperature resistance, static resistance, high safety and the like, and can be widely applied to the production of propellant powder for fireworks and crackers.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY +1

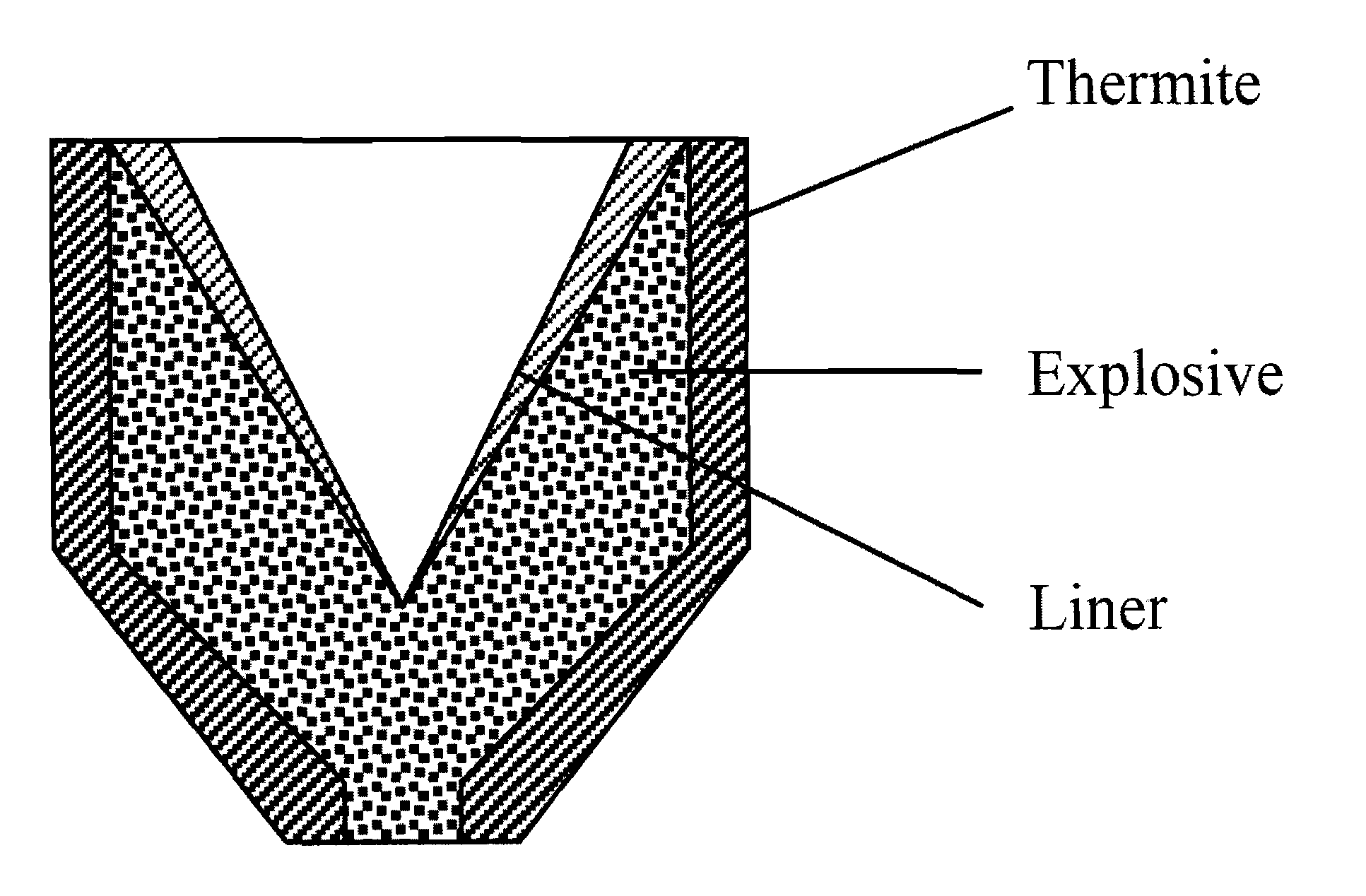

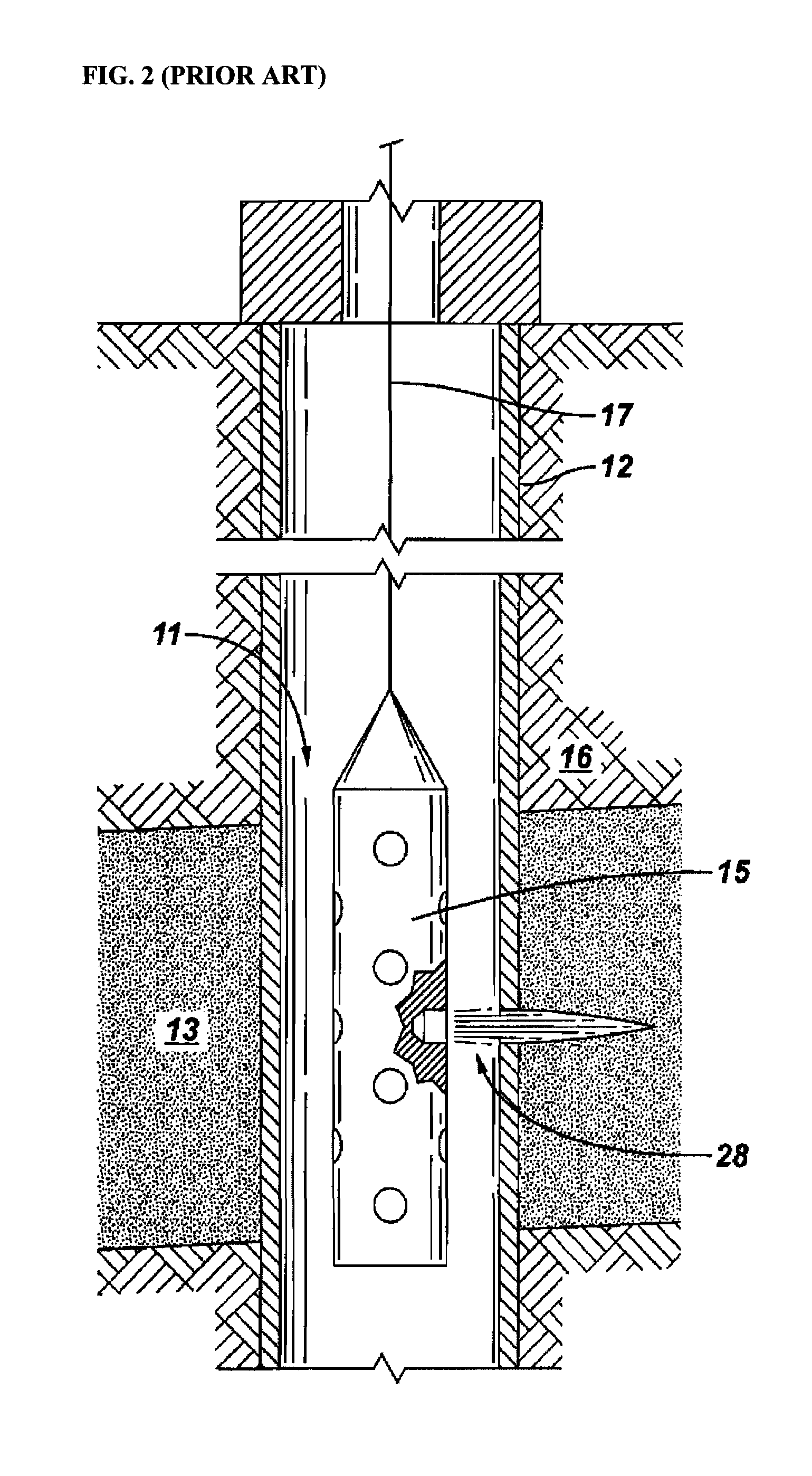

Perforating devices utilizing thermite charges in well perforation and downhole fracing

Owner:SCHLUMBERGER TECH CORP

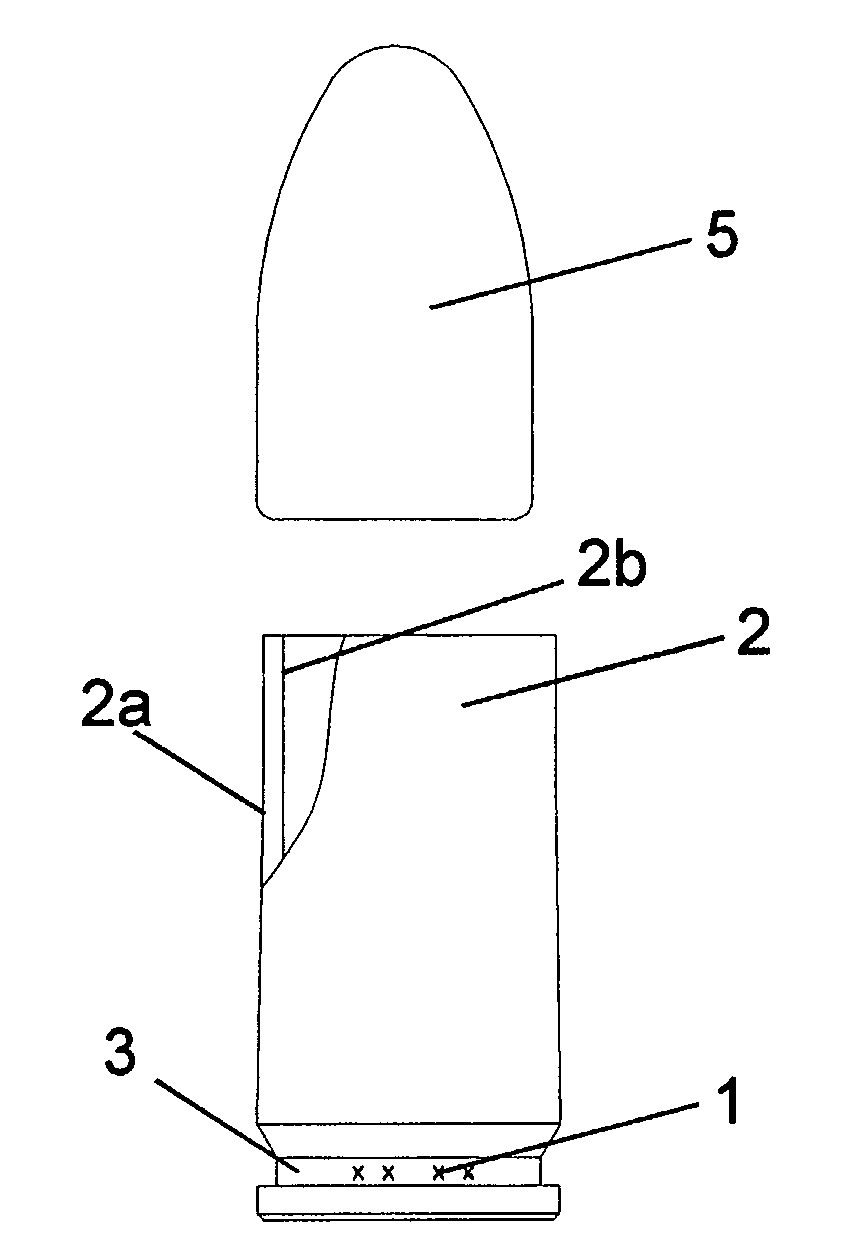

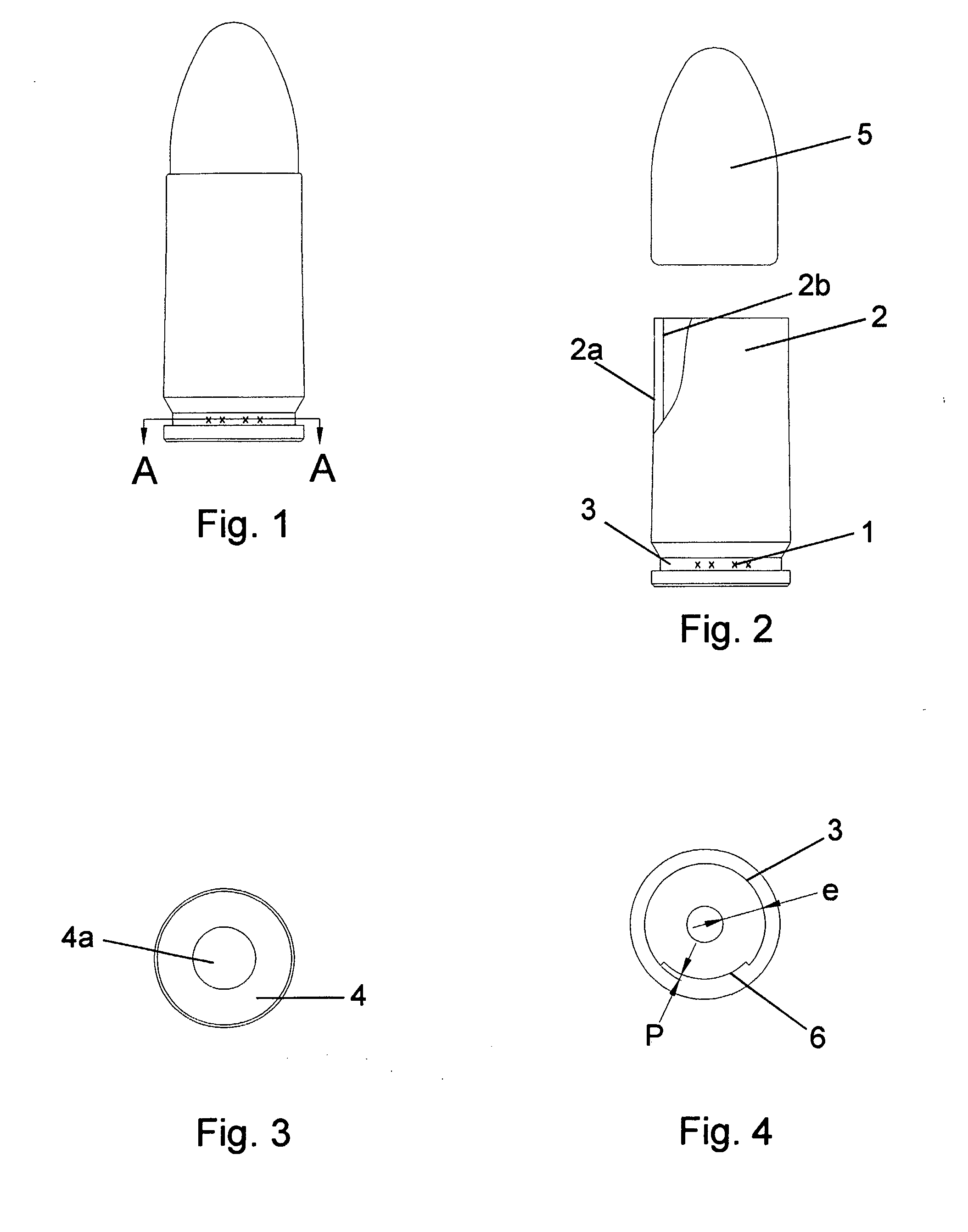

Process for Manufacturing Trackable Ammunition

The present invention refers to a process for manufacturing ammunition labeled with a sequence of characters which allows identification multiple data items, being said sequence of characters (1) laser-engraved, in one or more components of said ammunition, affording positive identification upon retrieval of an engraved component of said ammunition, even if it is already spent.

Owner:COMPANHIA BRASILEIRA DE CARTUCHOS

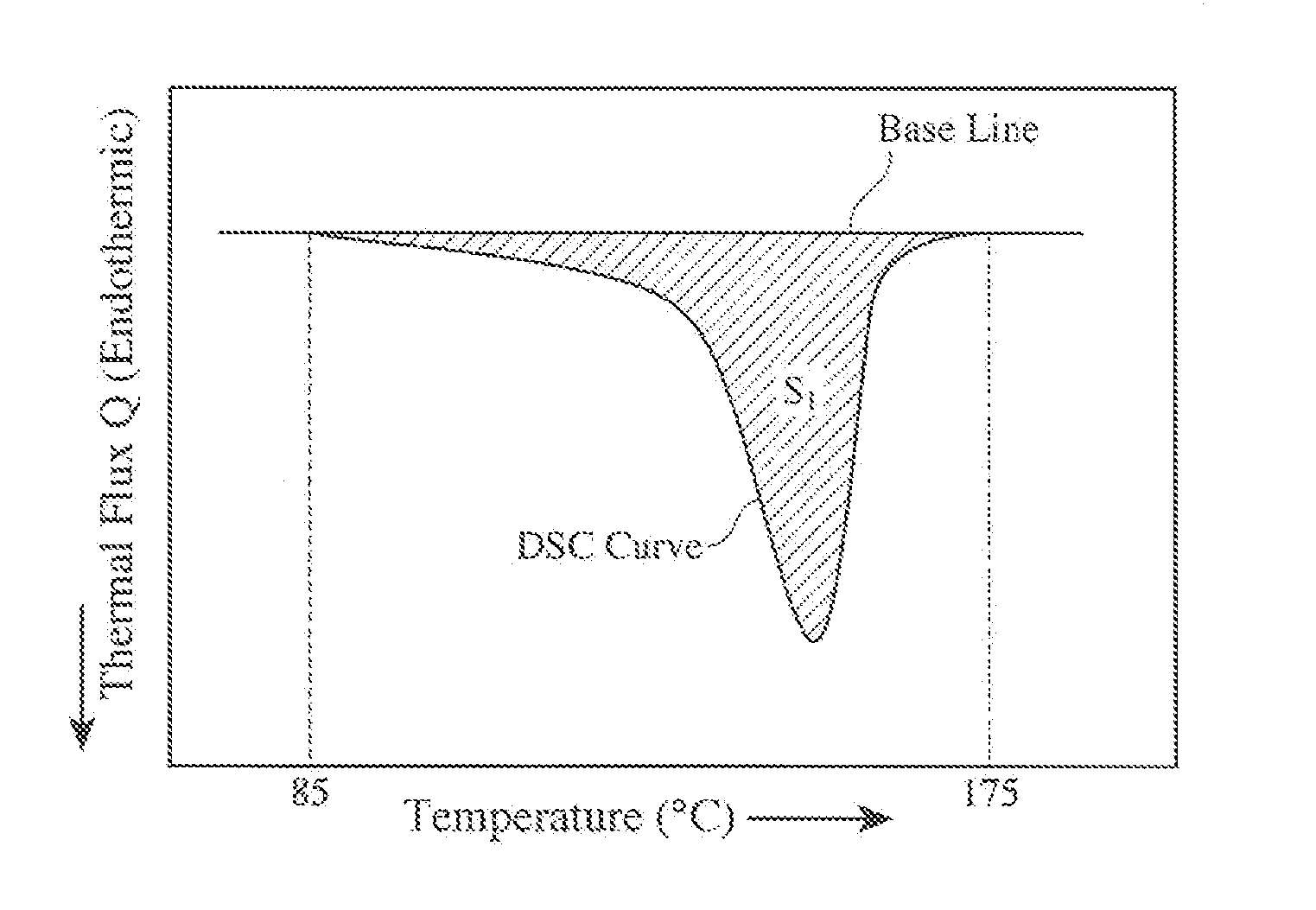

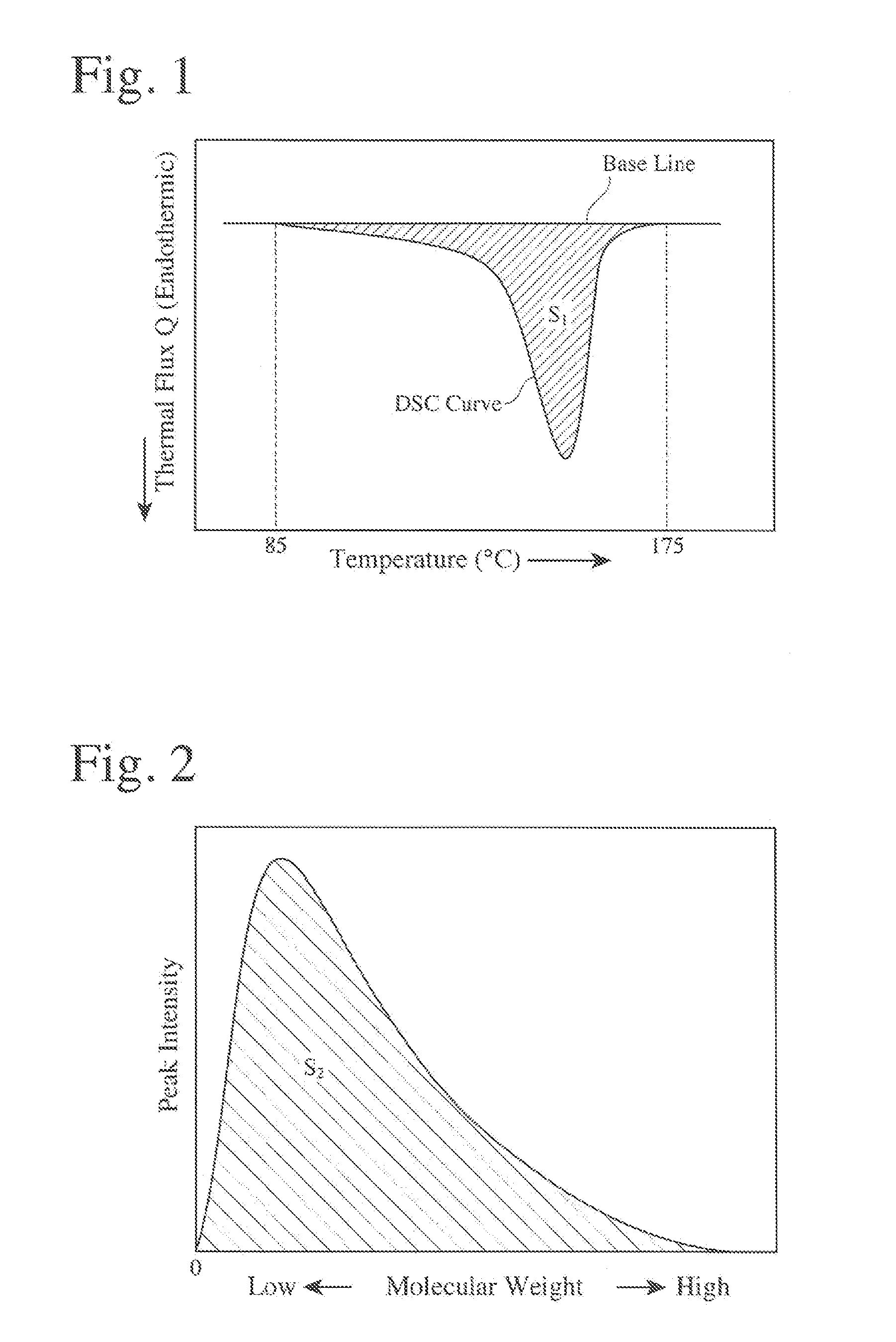

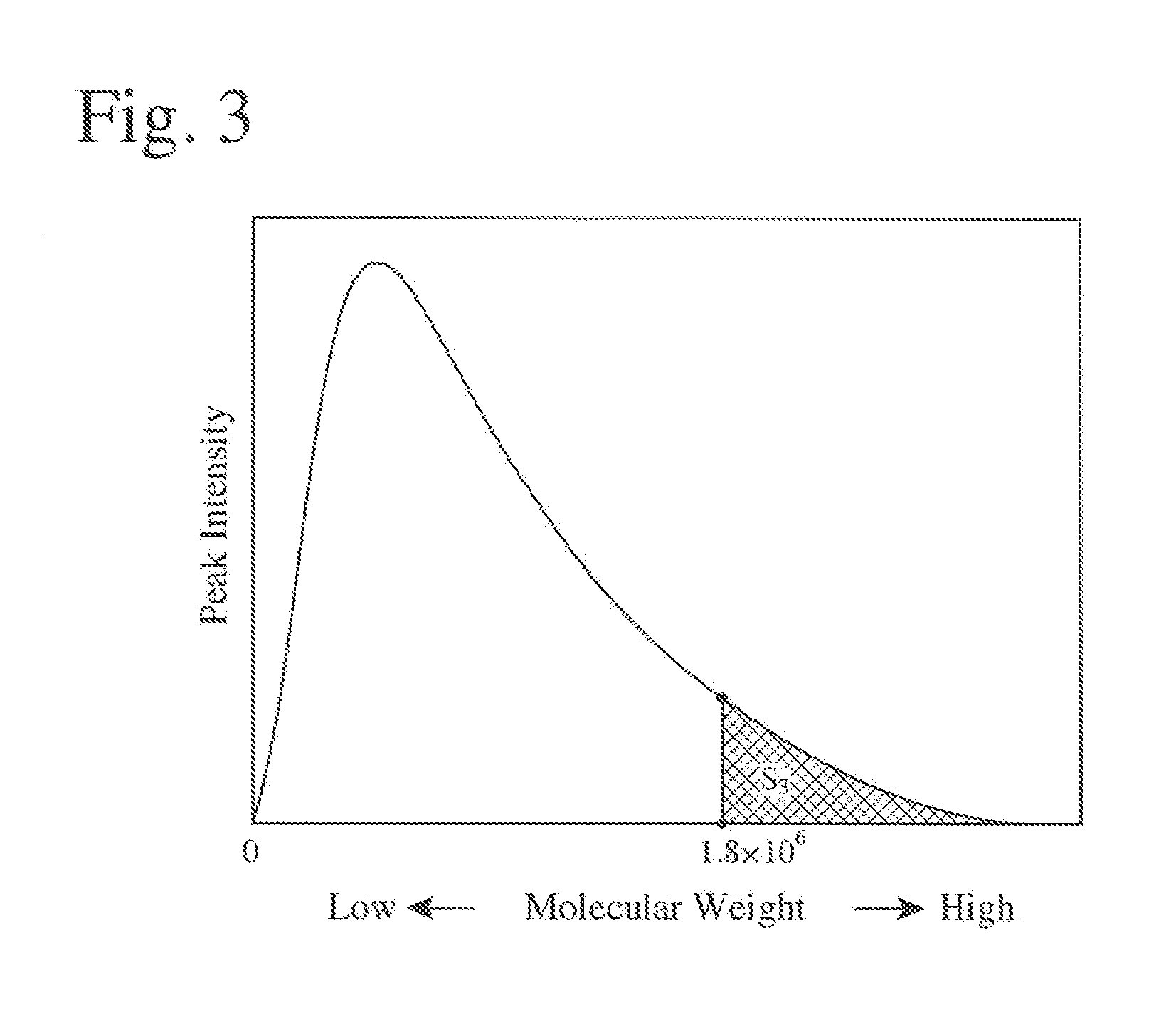

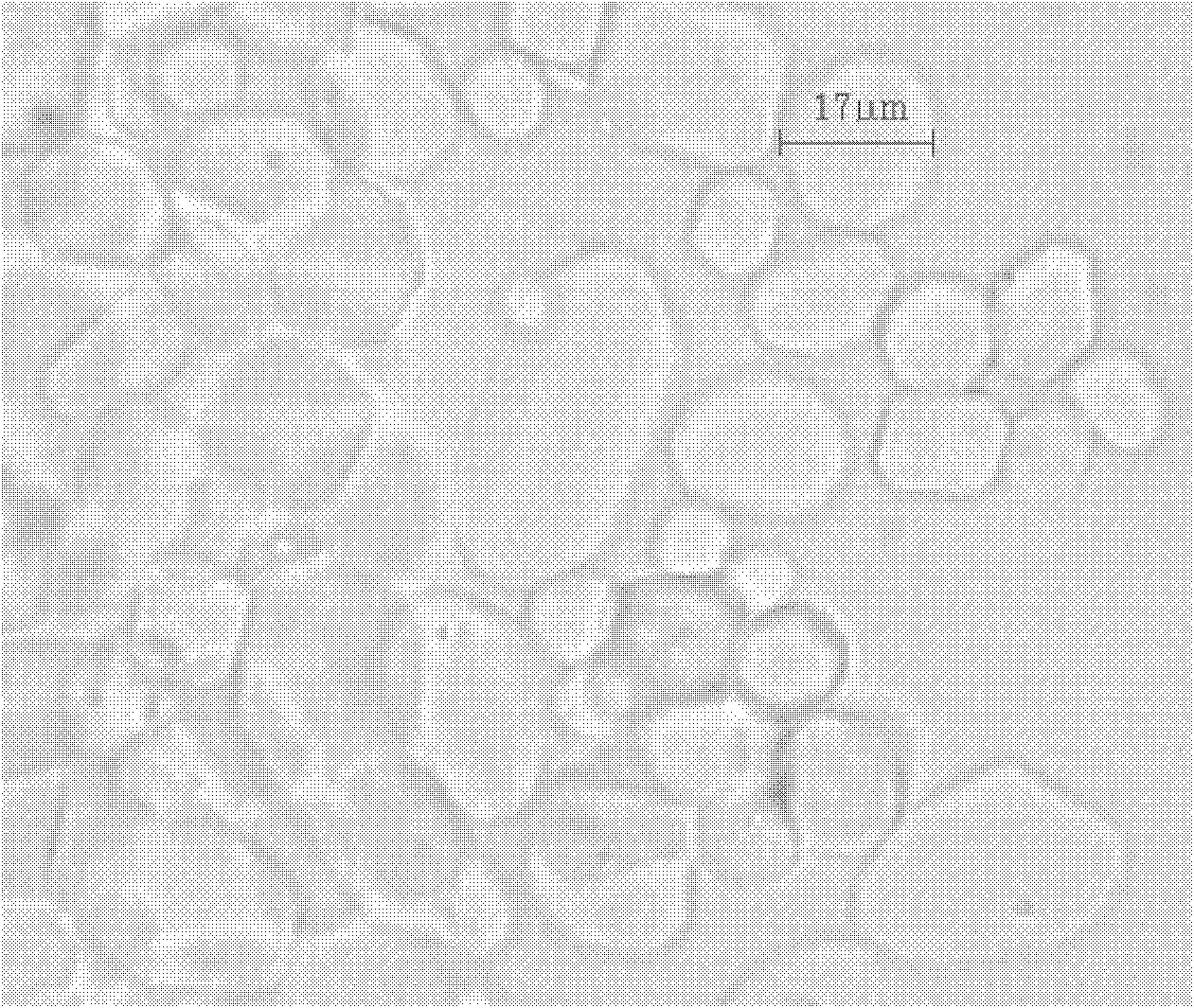

Microporous polyolefin membrane, its production method, and battery separator

A microporous polyolefin membrane comprising a polyethylene resin, and polypropylene having a weight-average molecular weight of 6×105 or more and a heat of fusion of 90 J / g or more (measured by a differential scanning calorimeter), a fraction having a molecular weight of 1.8×106 or more being 10% or more by mass of the polypropylene.

Owner:TORAY IND INC

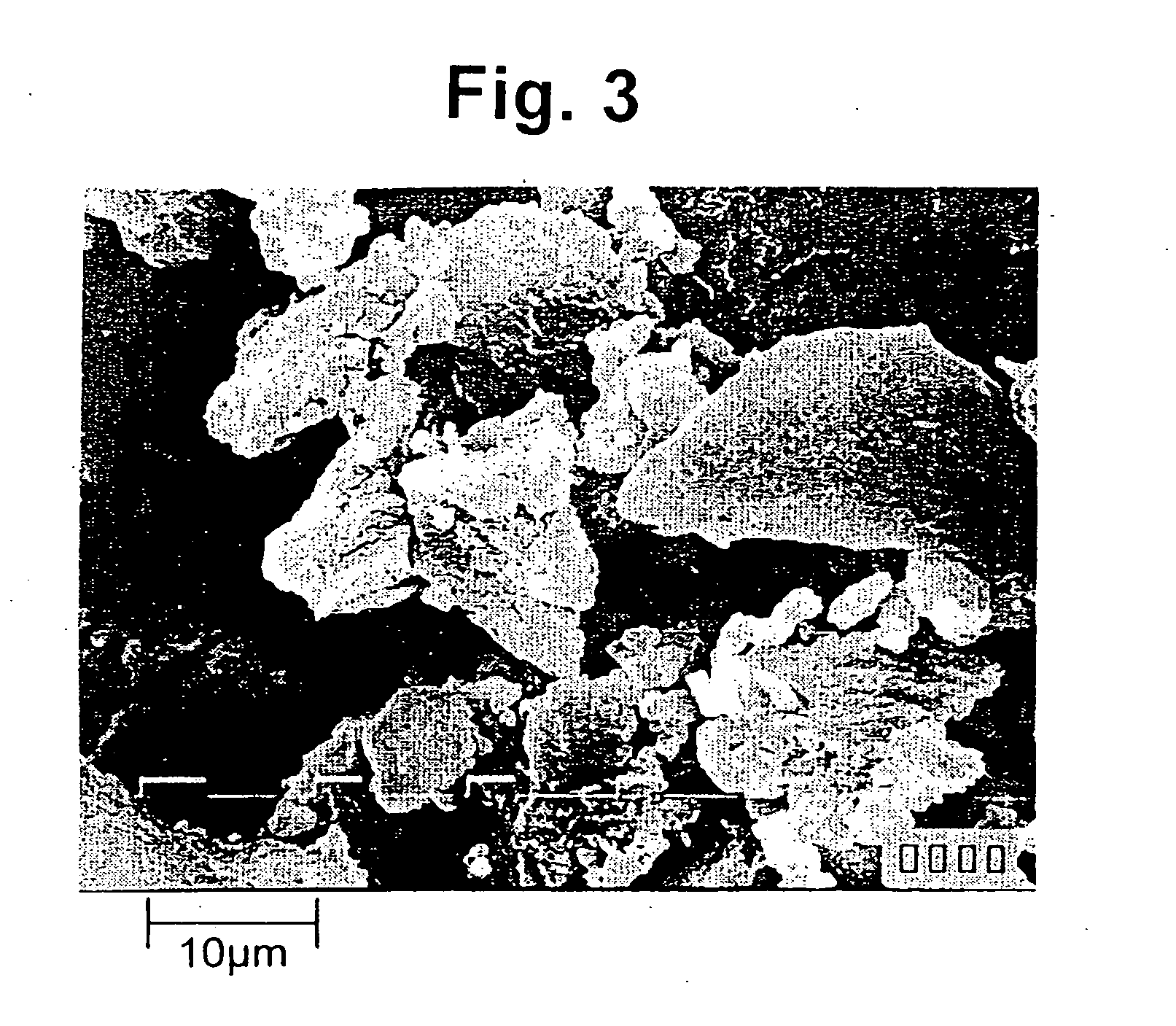

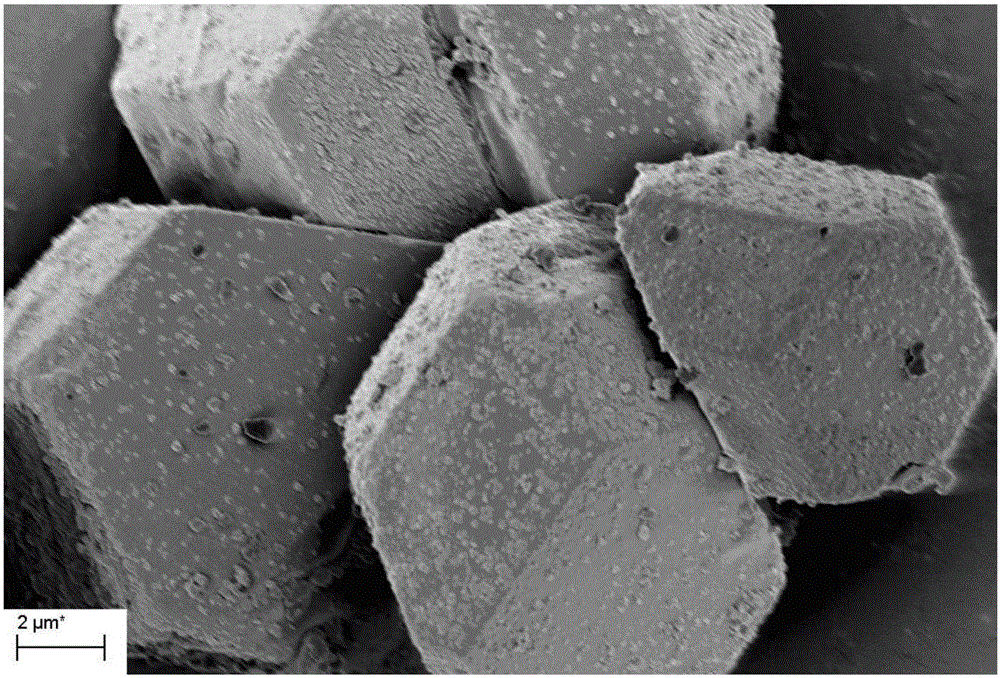

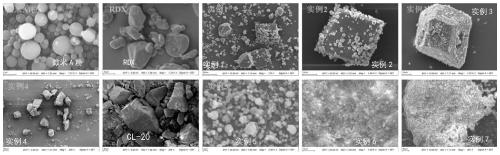

Method for preparing high-quality energetic crystal material fine particles

ActiveCN102320903AReduce crystal defectsReduced Shockwave SensitivityExplosive working-up apparatusShock waveFOX-7

The invention relates to a method for preparing high-quality energetic crystal material fine particles. Various high-quality energetic crystal material fine particle products, such as pentaerythritol tetranitrate (PETN), cyclotrimethylene trinitramine (RDX), cyclotetramethylenetetranitramine (HMX), hexanitrohexaazaisowurtzitane (CL-20), DADNE (FOX-7), ammonium perchlorate (AP), and the like can be prepared by adopting an ultrasound solvating-out crystallization method in the traditional solvating-out crystallization process. The high-quality energetic crystal material fine particle product prepared by the preparation method disclosed by the invention has subglobular particle form, narrow granularity distribution, average particle diameter of 5-50 microns or so, transparent crystals, high particle density, crystal theoretical density of more than 99.9 percent and obviously reduced shock wave sensitivity and is used for pouring or pressing PBX (Plastic-bonded explosives). The method for preparing the high-quality energetic crystal material fine particles has the advantages of simple process flow and mild reaction conditions and is suitable for mass industrialized production.

Owner:INST OF CHEM MATERIAL CHINA ACADEMY OF ENG PHYSICS

Explosive composition and its use

InactiveUS6984274B2Improve structural strengthLess-expensive productionBelt retractorsPedestrian/occupant safety arrangementNitro compoundPorosity

An explosive composition comprises a porous fuel and an oxidizer. The porous fuel is a solid with a structure size measuring between about 2 nm and 1000 nm and has a porosity that lies between 10% and 98%. The oxidizer is solid or liquid at room temperature and is incorporated into the pores of the porous fuel. The oxidizer is selected, in an amount of at least 50% by weight relative to a total quantity of the oxidizer, from the group consisting of hydrogen peroxide, hydroxyl ammonium nitrate, organic nitro compounds or nitrates, alkali metal nitrates or earth alkali metal nitrates as well as metal nitrites, metal chlorates, metal perchlorates, metal bromates, metal iodates, metal oxides, metal peroxides, ammonium perchlorate, ammonium nitrate and mixtures thereof.

Owner:TRW AIRBAG SYST

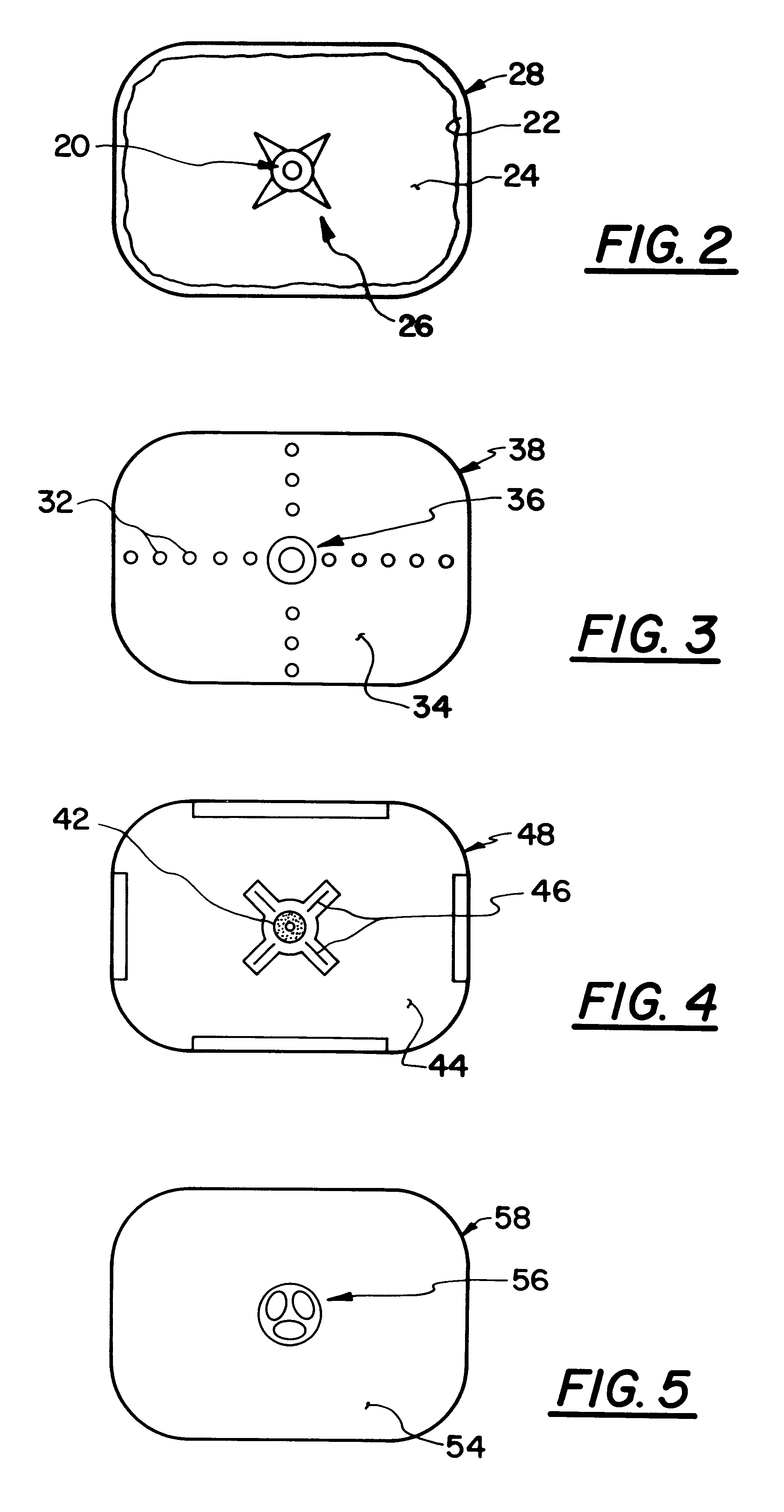

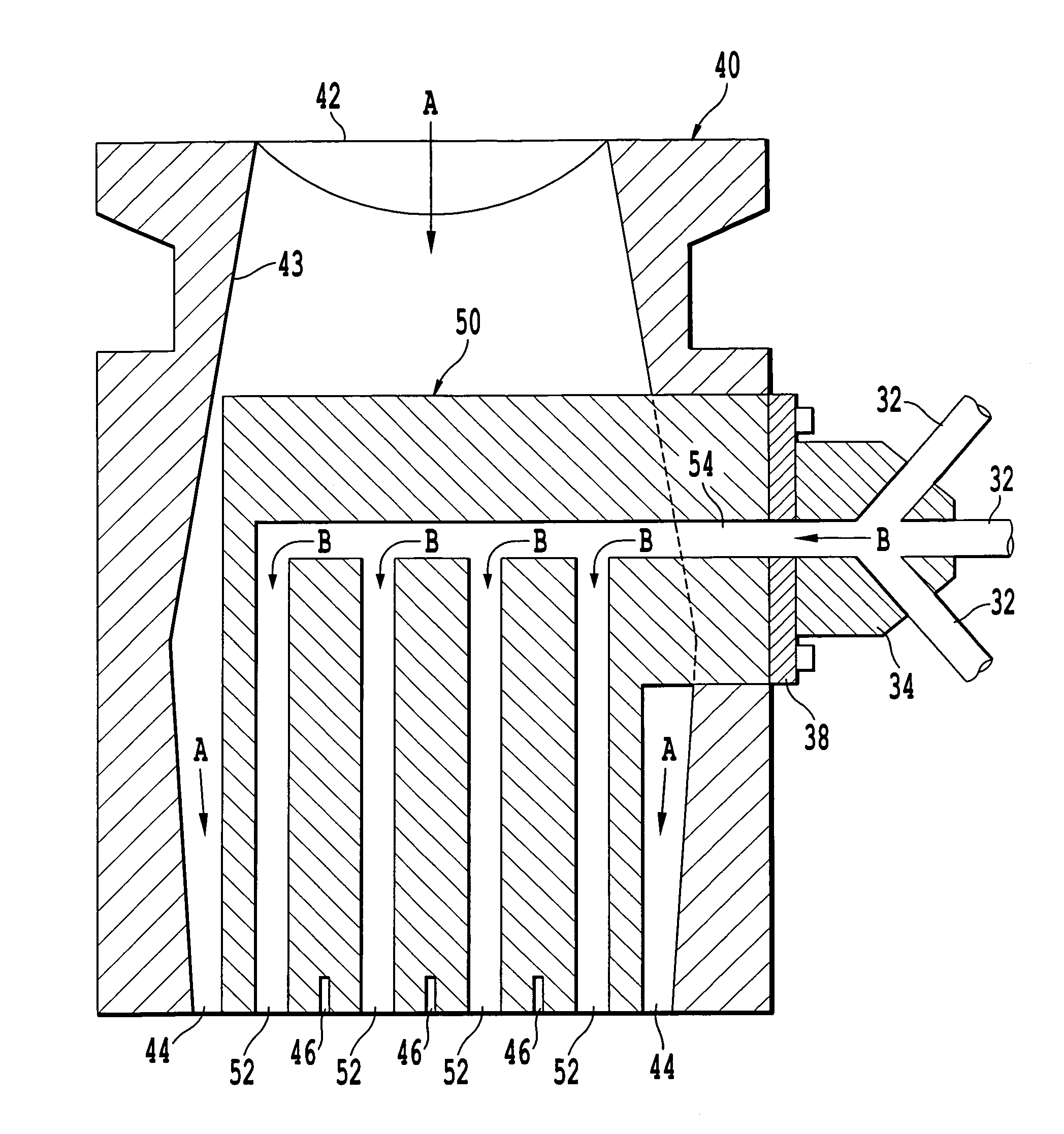

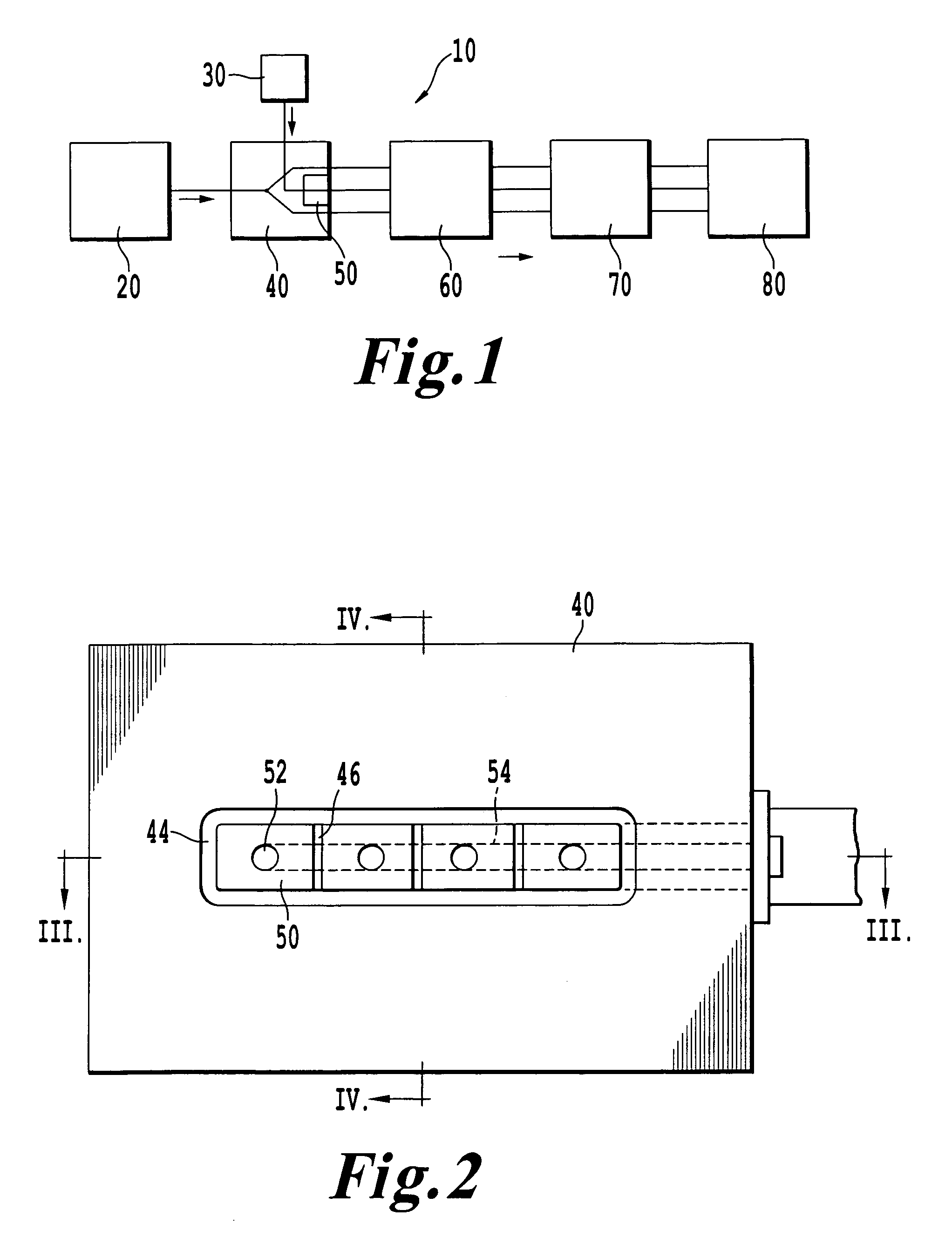

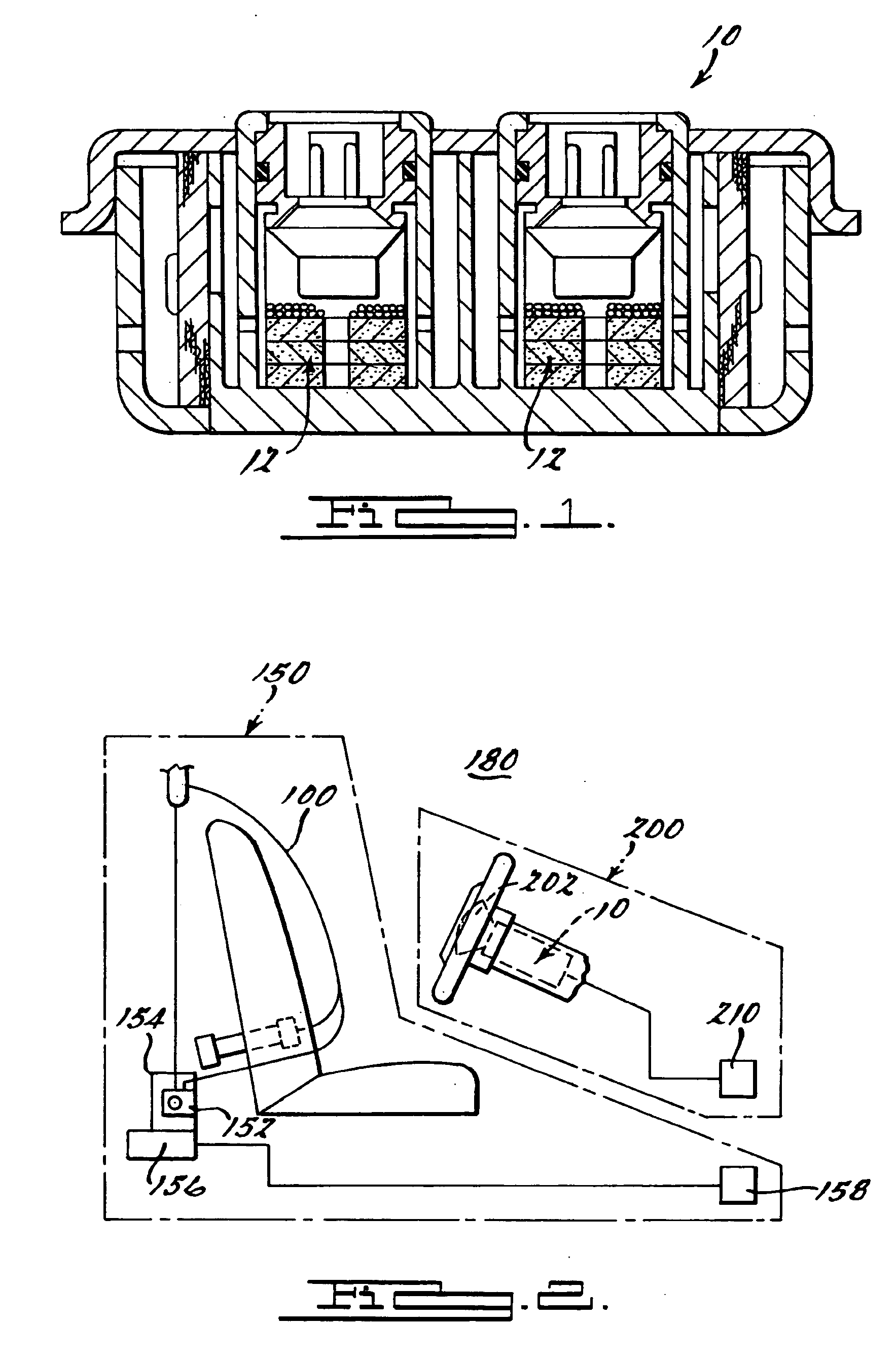

Extrusion/reaction injection molding system

InactiveUS7281917B2Increase volumeEconomical rateConfectionerySynthetic resin layered productsEngineeringBiomedical engineering

A method of manufacturing an extruded part having an exterior shell and a core foam material. The method includes extruding the exterior shell from an extrusion die, and reaction injection molding the core foam material within an interior of the exterior shell using a distribution block having a plurality of orifices configured to inject the core foam material within the interior of the exterior shell. The orifices are configured to evenly distribute the core foam material throughout the interior of the exterior shell. the method can be used to form an exterior shell having a plurality of internal chambers, where the orifices of the distribution block are configured to inject core foam material within the plurality of internal chambers.

Owner:PATWIN PLASTICS

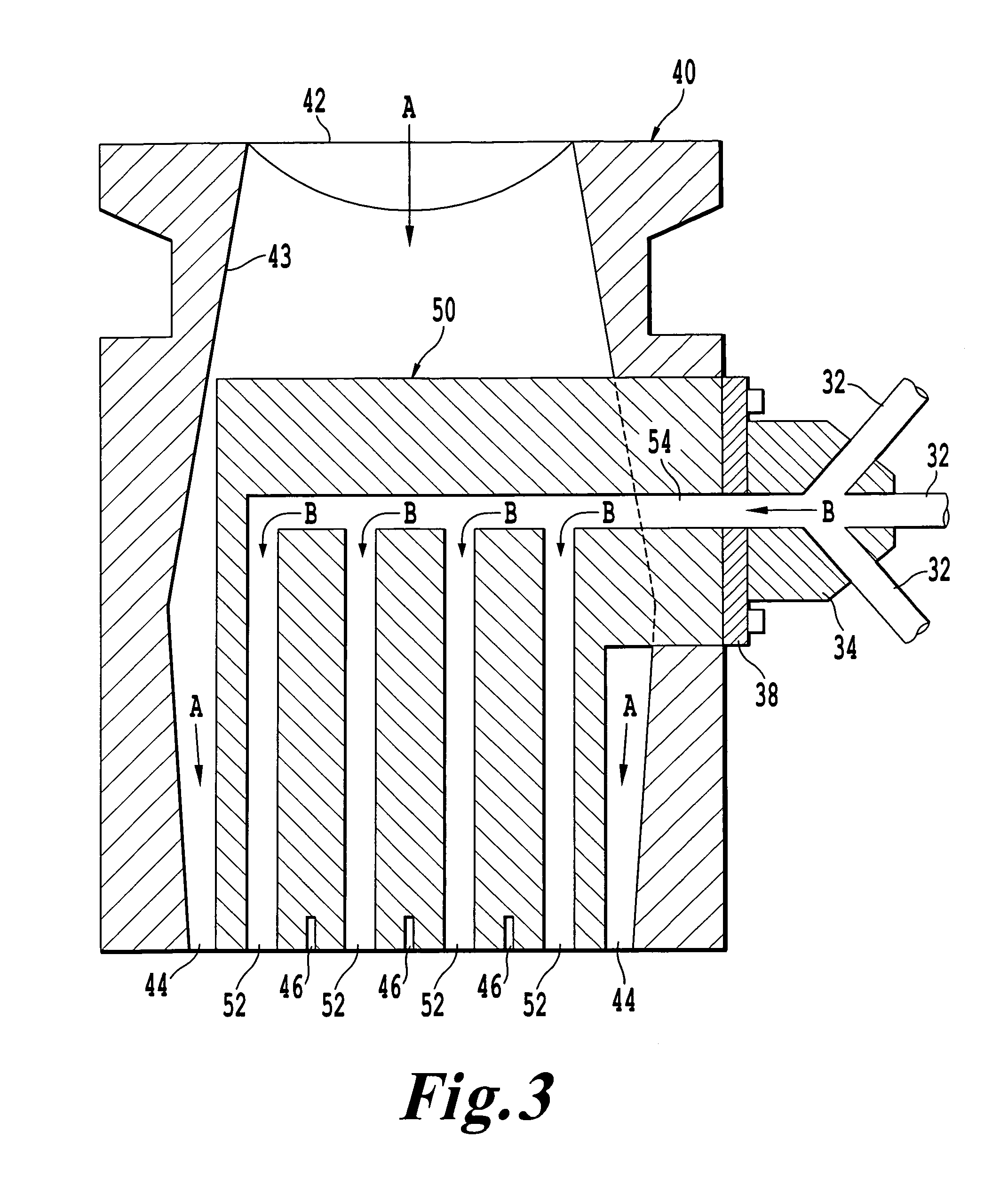

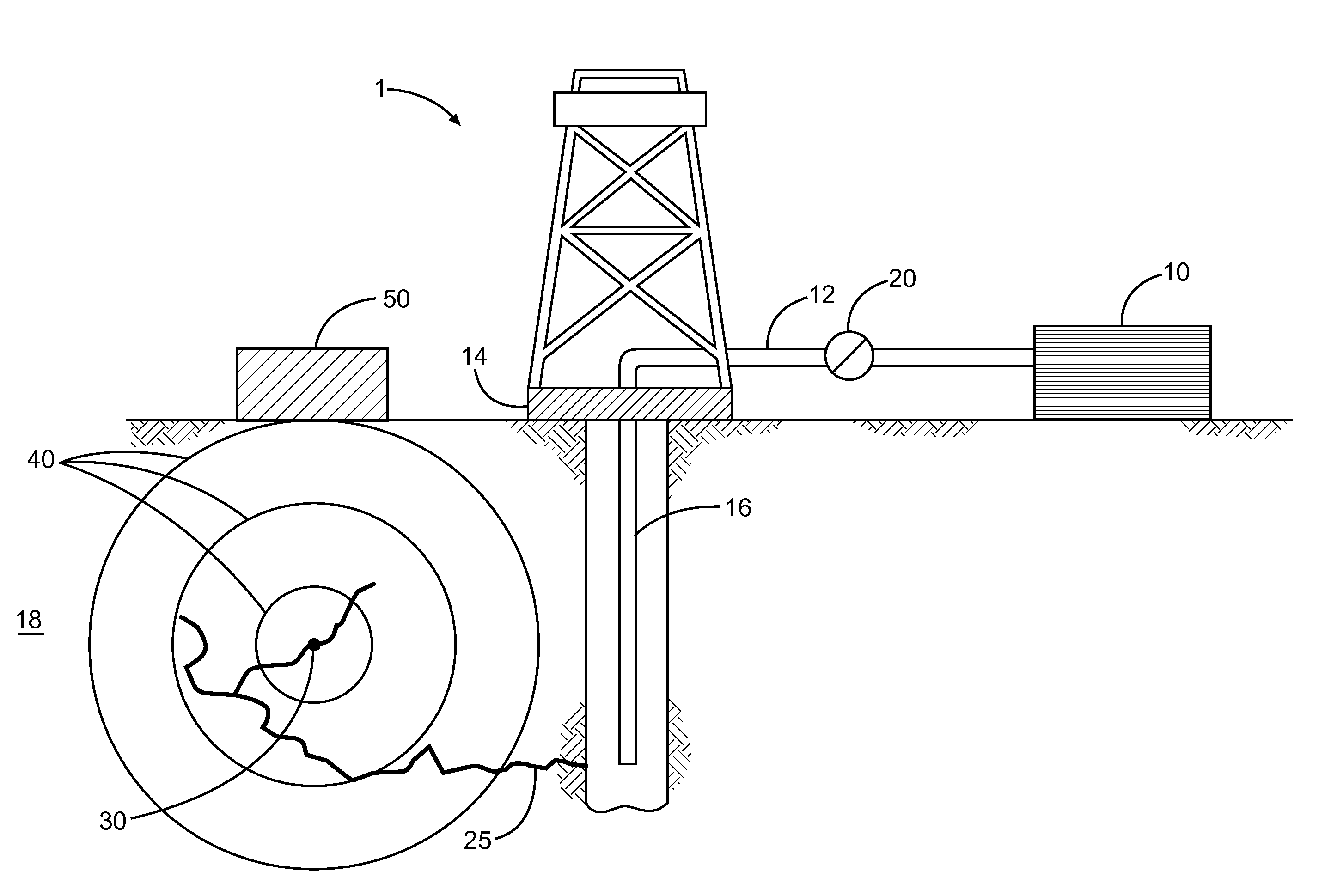

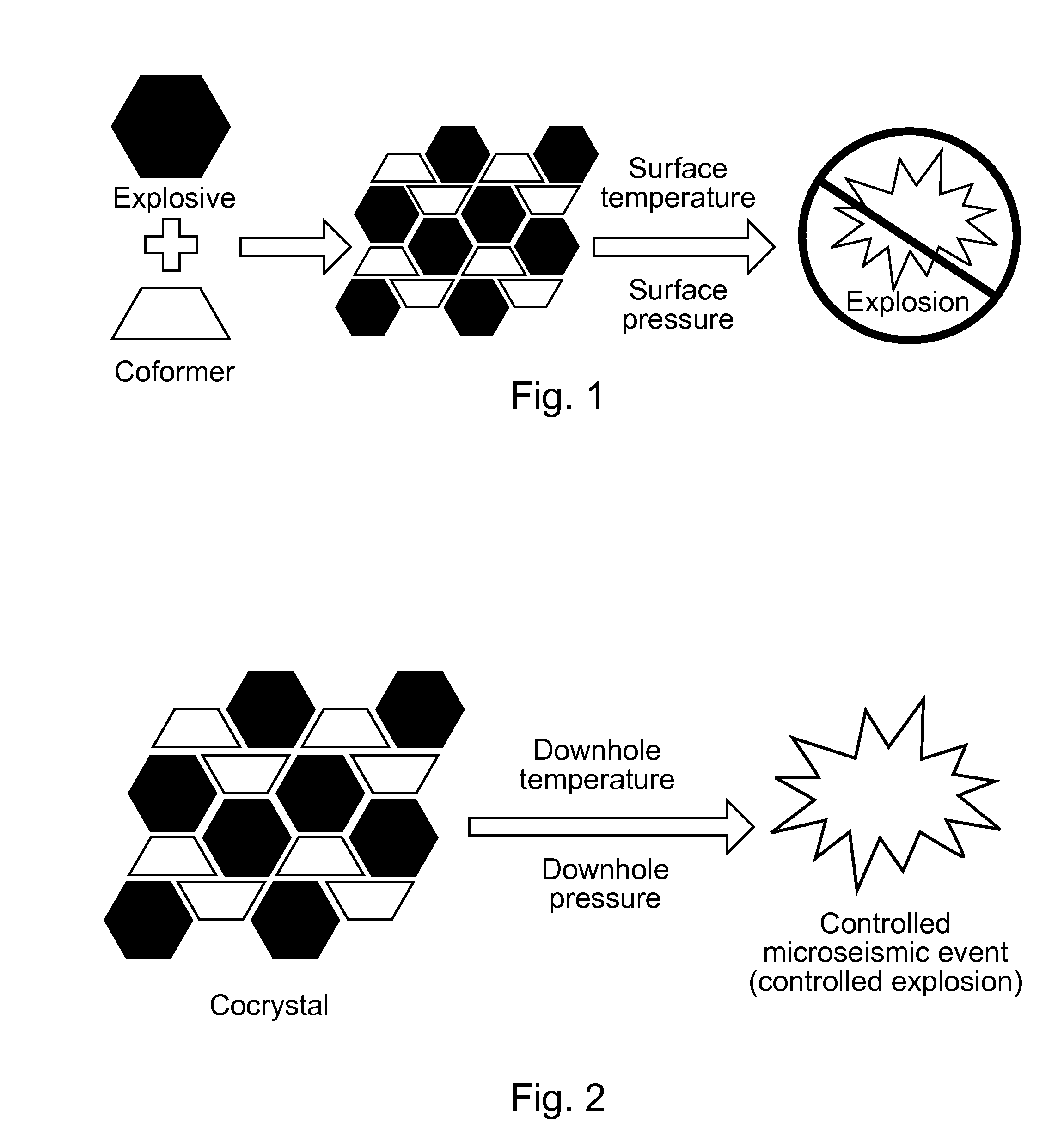

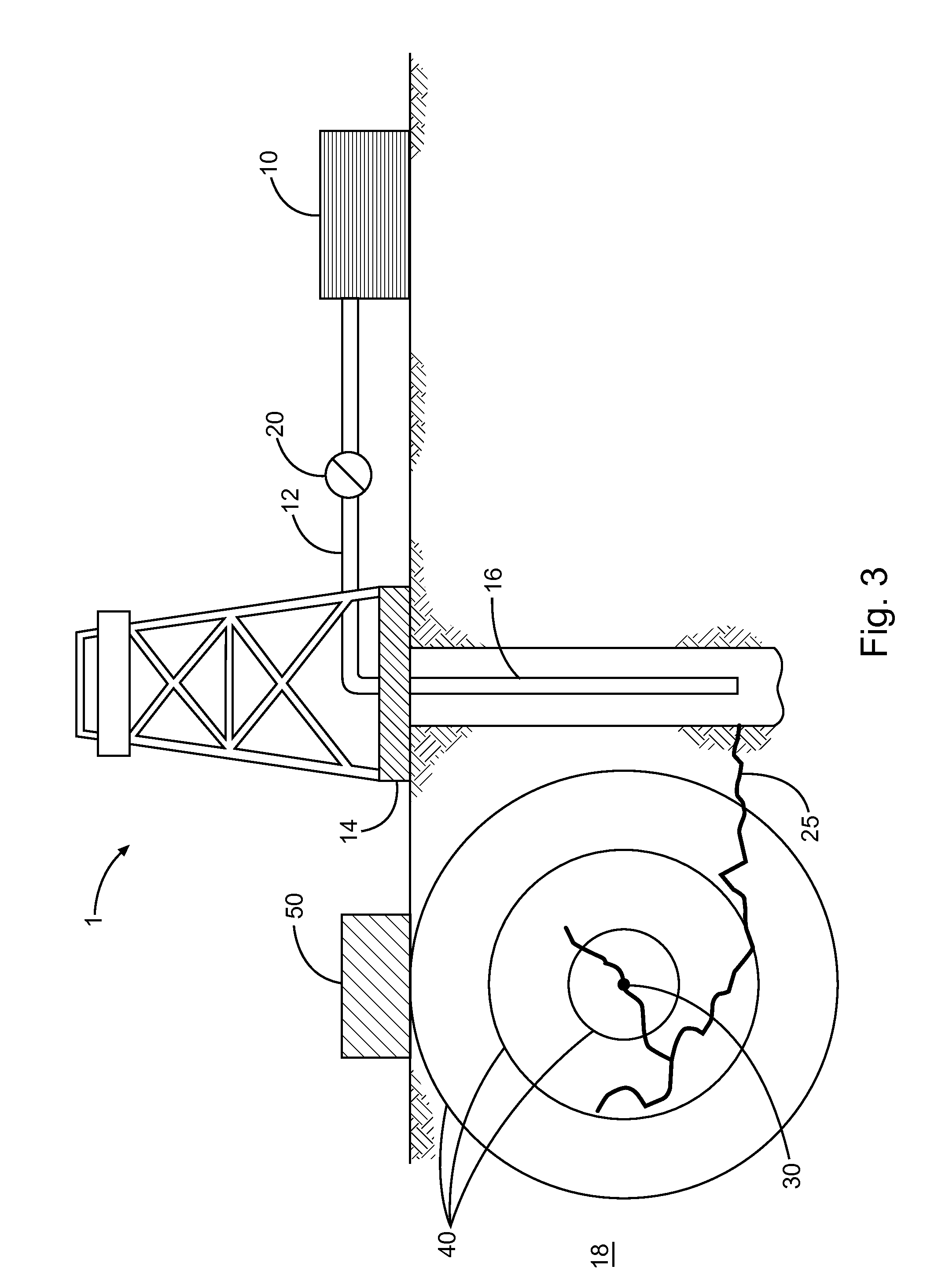

Energetic cocrystals for treatment of a subterranean formation

InactiveUS20160177698A1Well as to enableSafe handlingSurveyFluid removalChemistryHigh energy compound

The present invention relates to energetic cocrystals, and to methods for using the same for treatment of a subterranean formation. In various embodiments, the present invention provides a method of treating a subterranean formation, the method including obtaining or providing a composition including energetic cocrystals. Each energetic cocrystal independently includes an energetic compound and a secondary material. The method also includes placing the composition in a subterranean formation.

Owner:HALLIBURTON ENERGY SERVICES INC

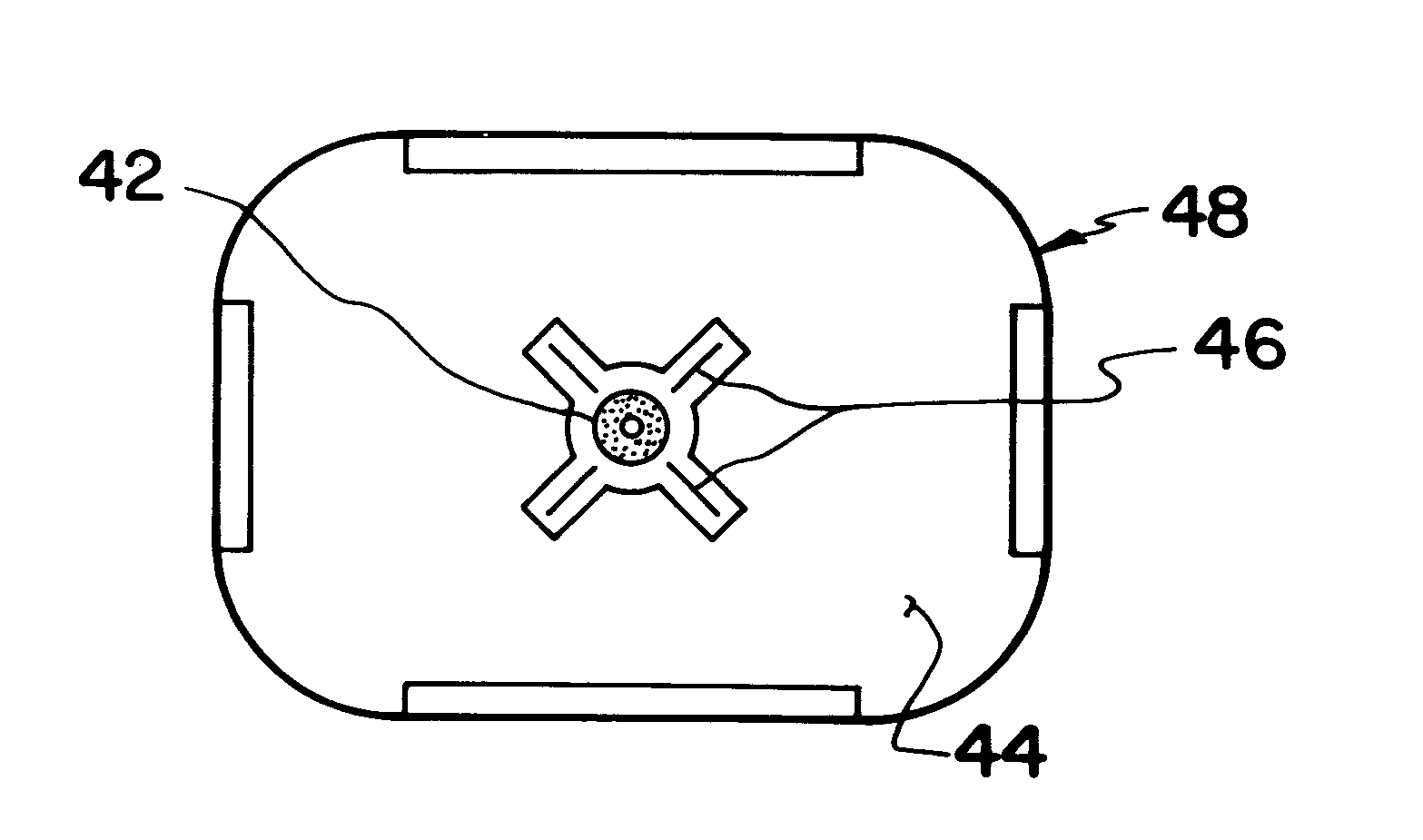

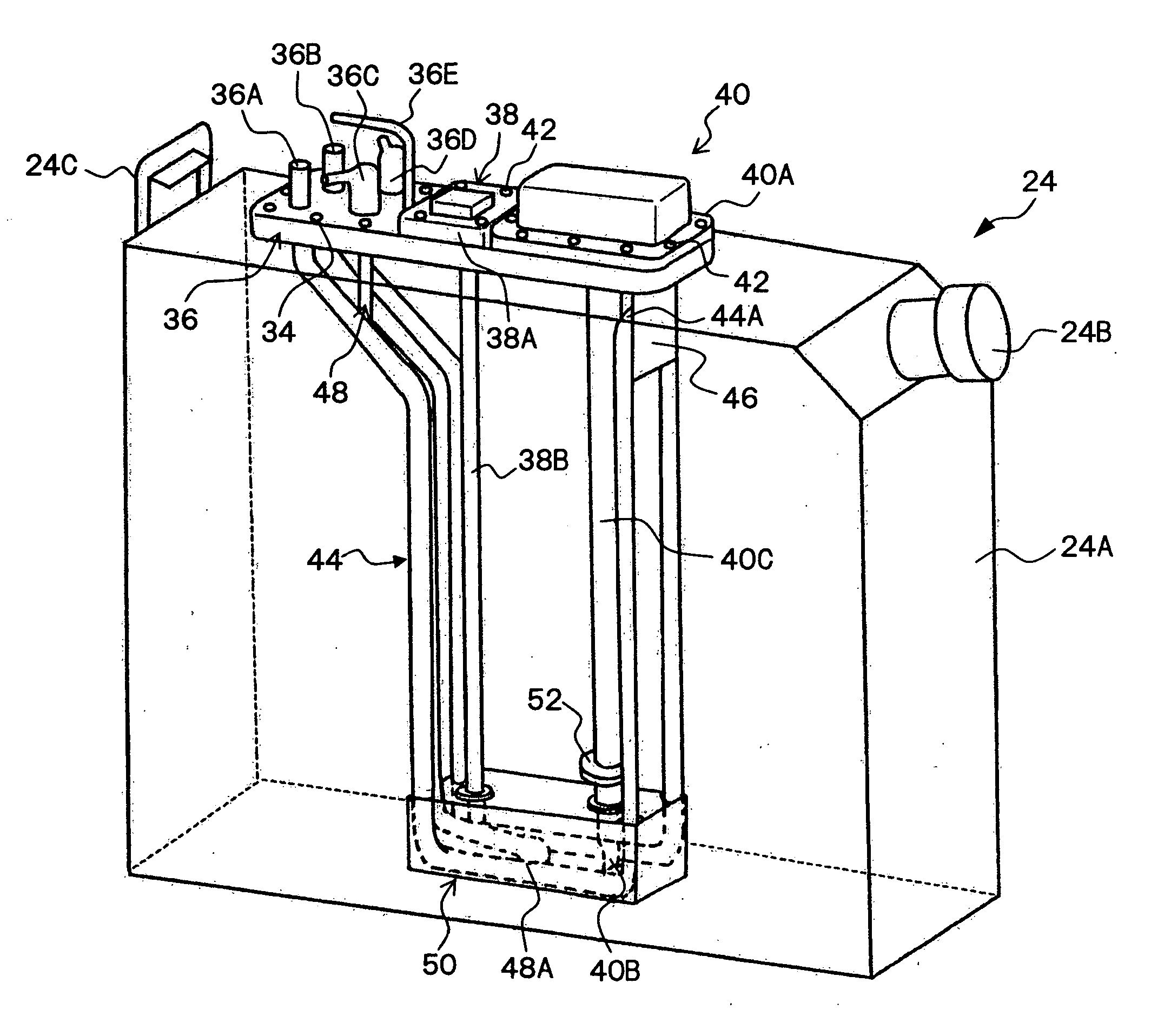

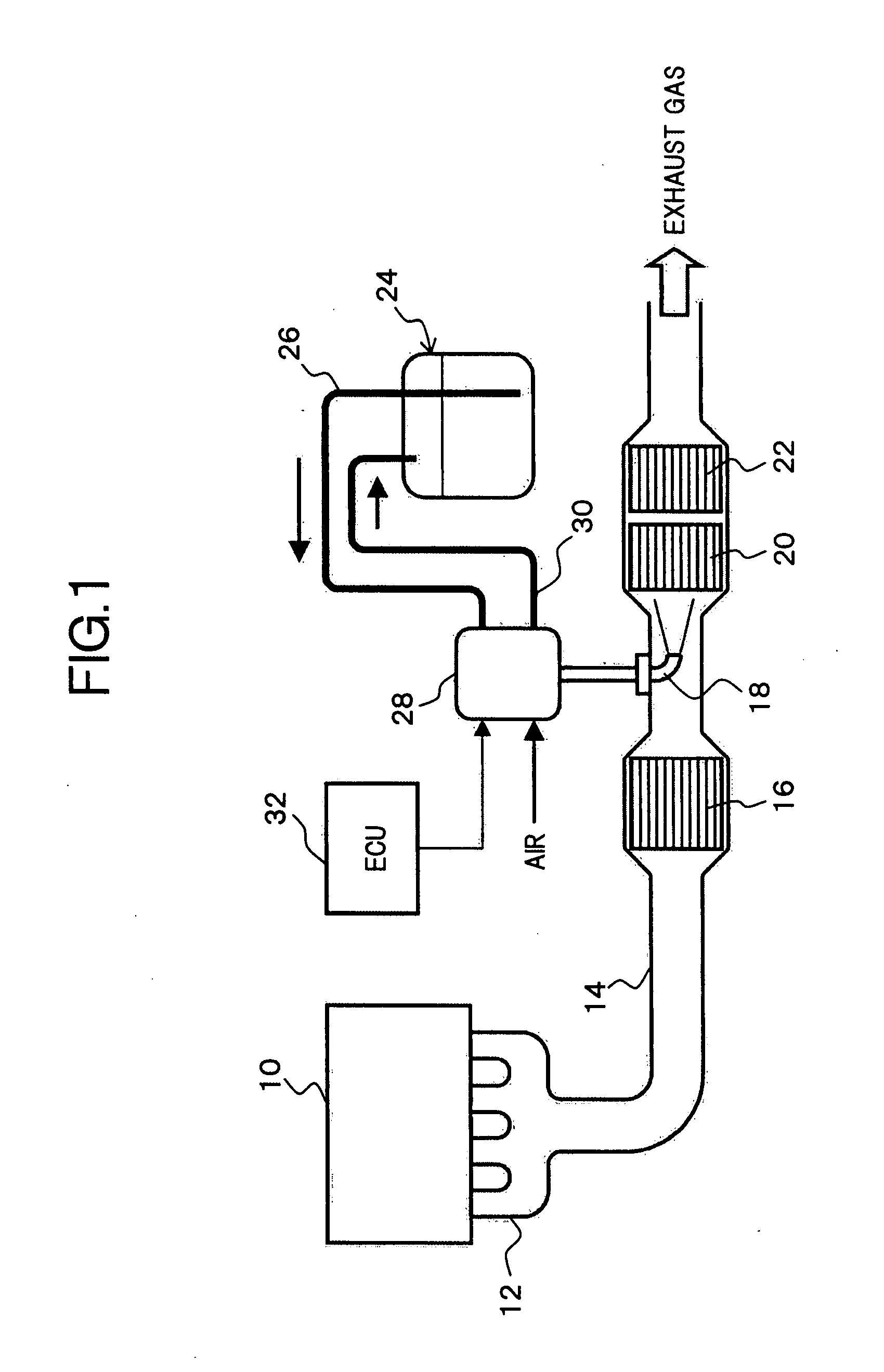

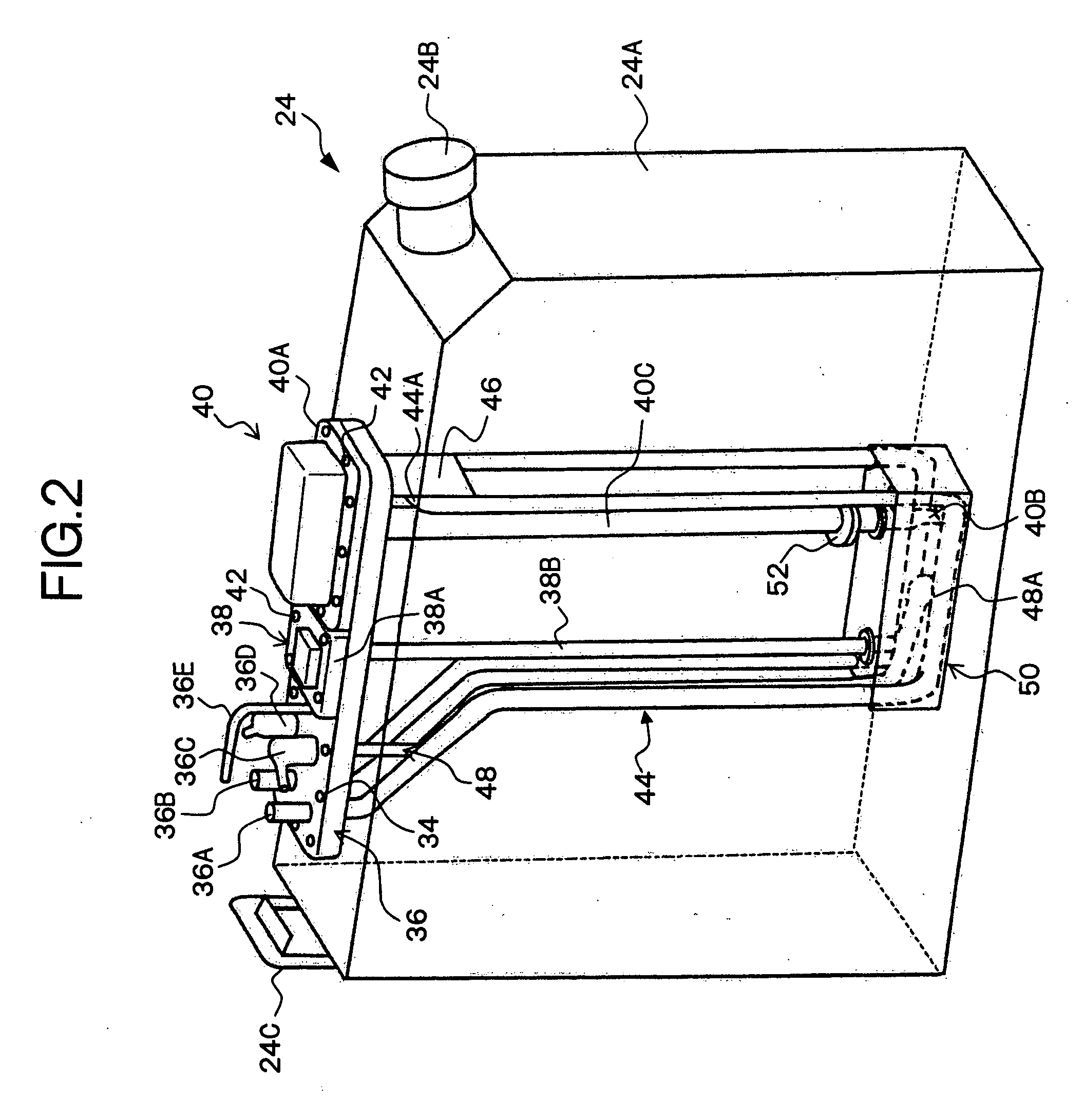

Reducing agent container having novel structure

InactiveUS20070202019A1Efficient defrostingPrevent degradationAnalysis using chemical indicatorsTesting/calibration apparatusHeat transmissionEngineering

On an upper surface of a container body, there are disposed at least a base portion of a concentration meter configured to detect the concentration of a liquid reducing agent based on a heat transmission characteristic between two spaced points, and a heat exchanger configured to permit the engine coolant to circulate therein and arranged to surround a detecting section of the concentration meter, which hangs from the base portion of the concentration meter via a supporting column thereof, to thereby perform the heat exchange with the liquid reducing agent, and also, a protector or an encasing element of substantially box shape is arranged to surround a lower portion of the heat exchanger and the detecting section of the concentration meter, and further, a visor is attached on the supporting column of the concentration meter, which is positioned above the protector by a predetermined interval.

Owner:NISSAN DIESEL MOTOR CO

Method for coating energetic crystal surfaces

ActiveCN105777457AEfficient coatingExplosive working-up apparatusNitrated acyclic/alicyclic/heterocyclic amine explosive compositionsFiltrationVacuum drying

The invention discloses a method for coating energetic crystal surfaces. Coating of the energetic crystal surfaces is achieved through oxidation-self-polymerization of dopamine under the condition of a weakly alkaline aqueous solution and formation of poly-dopamine coatings powerfully adhering to material surfaces. The method comprises the following steps: dissolving Tris in a mixed solution of water and ethanol in a volume ratio of 9 to 1 and then dropwise adding hydrochloric acid to prepare a buffer solution with the pH value of 8.0-10.0; then dissolving dopamine in the buffer solution to prepare a dopamine solution with the concentration of 1-5g / L; then adding a proper amount of energetic crystal to the dopamine solution and stirring the materials at a stirring rate of 200-900rpm to form uniform suspension; and continuously stirring the suspension for a period of time and then carrying out suction filtration and vacuum drying. The method has the beneficial effects that coating of the energetic crystal surfaces is completed in the aqueous phase, so the method is green and safe; and especially, the method can achieve efficient coating aiming at the energetic crystal surfaces with different characteristics.

Owner:INST OF CHEM MATERIAL CHINA ACADEMY OF ENG PHYSICS

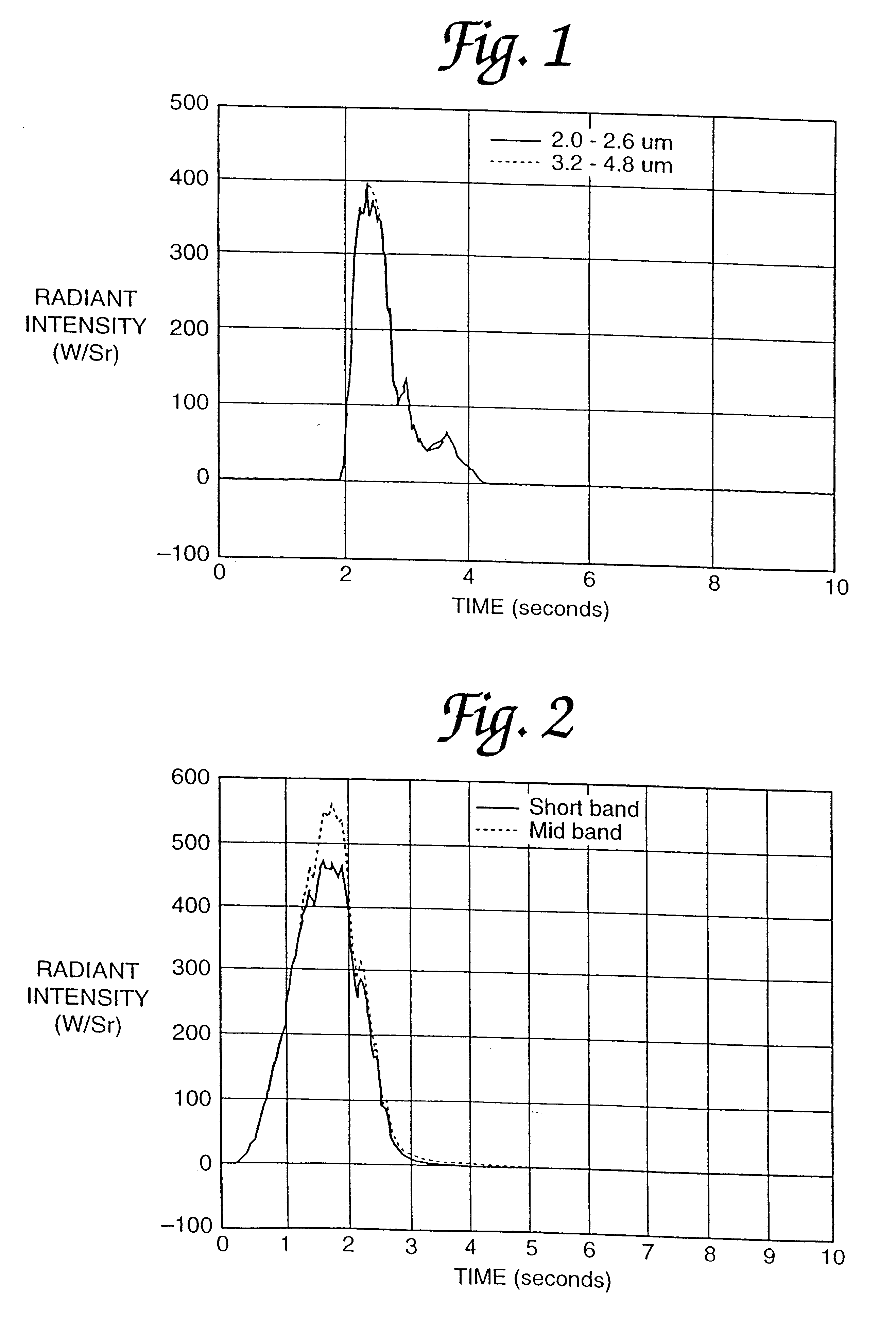

Extrudable black body decoy flare compositions and methods of use

InactiveUS6312625B1Reduce compositionEasy to processAmmunition projectilesFirework flares/torchesThermoplasticBlack-body radiation

In this process for producing a black body decoy flare, a composition which, when combusted, provides black body radiation is extruded. The compositions generally include from about 40% to about 70% metal such as magnesium or aluminum, from about 10% to about 40% polytetrafluoroethylene, and from about 8% to about 30% binder. Important to the operation of the invention is the production of carbon upon combustion of the composition. Accordingly, polyaromatic thermoplastics, such as polystyrene and dimethyl phthalate, serve as the binder.

Owner:NORTHROP GRUMMAN INNOVATION SYST INC

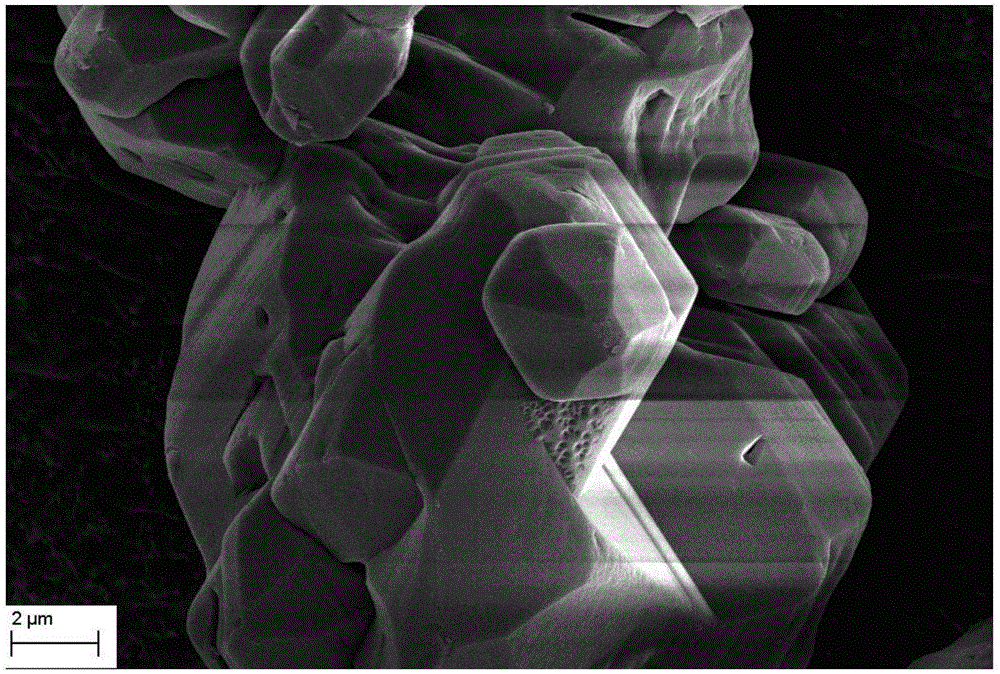

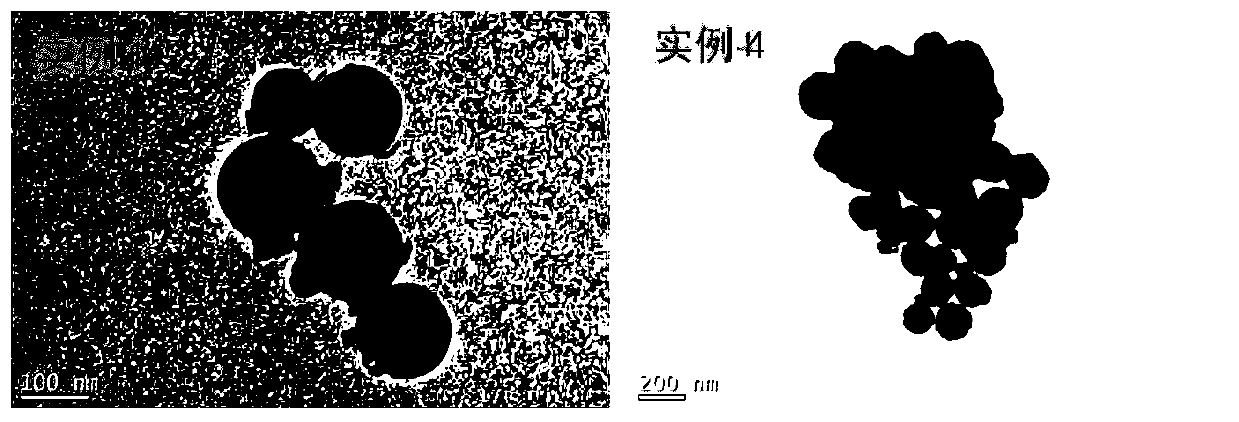

Polydopamine interface regulation-based nitramine explosive modified aluminum powder and preparation method thereof

ActiveCN109704896AEvenly distributedCompact structureExplosive working-up apparatusHigh energyAdhesive

The invention relates to a polydopamine interface regulation-based nitramine explosive modified aluminum powder and a preparation method thereof. Micron-sized crystals containing an aluminum powder and a nitramine explosive are prepared by an anti-solvent process, uniform distribution and close contact of the aluminum powder and the nitramine explosive are achieved, and the crystals have the advantages of compact structure, high thermal stability and high density. The adoption of the polydopamine interface regulation-based nitramine explosive modified aluminum powder in an aluminum-containingexplosive reduces the content of an adhesive and additives in a formula, increases the mass fraction of the main explosive, and achieves the purpose of developing high-energy explosives. In addition,a part of the energetic material adopted to replace RDX, HMX, CL-20 and other nitramine explosives in traditional solid propellants improves the energy level of the propellants, improves the problem of too large viscosity of a propellant slurry, caused by the addition of nano-aluminum powder or high-aluminum powder, and optimizes the preparation technology of the propellants.

Owner:NORTHWESTERN POLYTECHNICAL UNIV +1

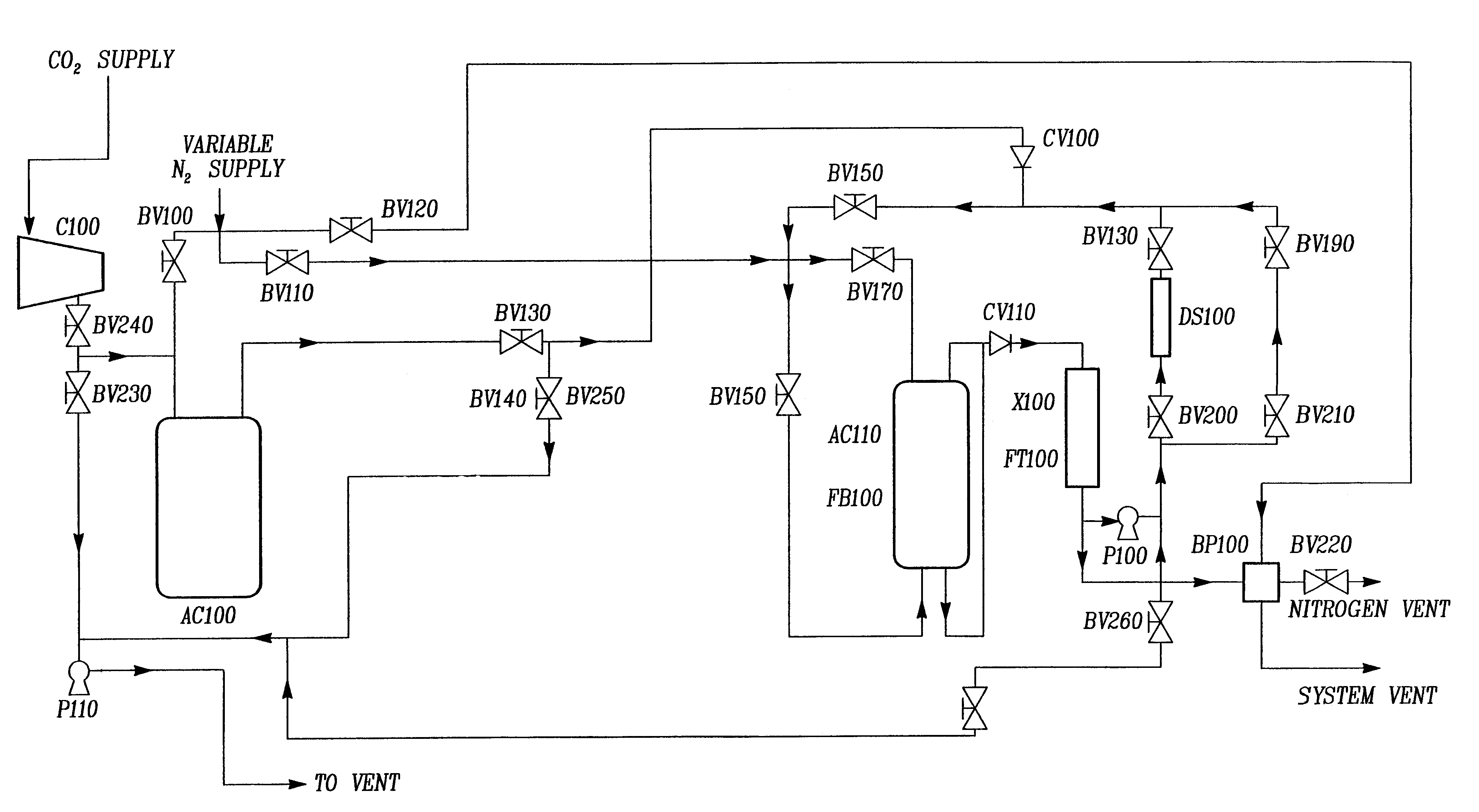

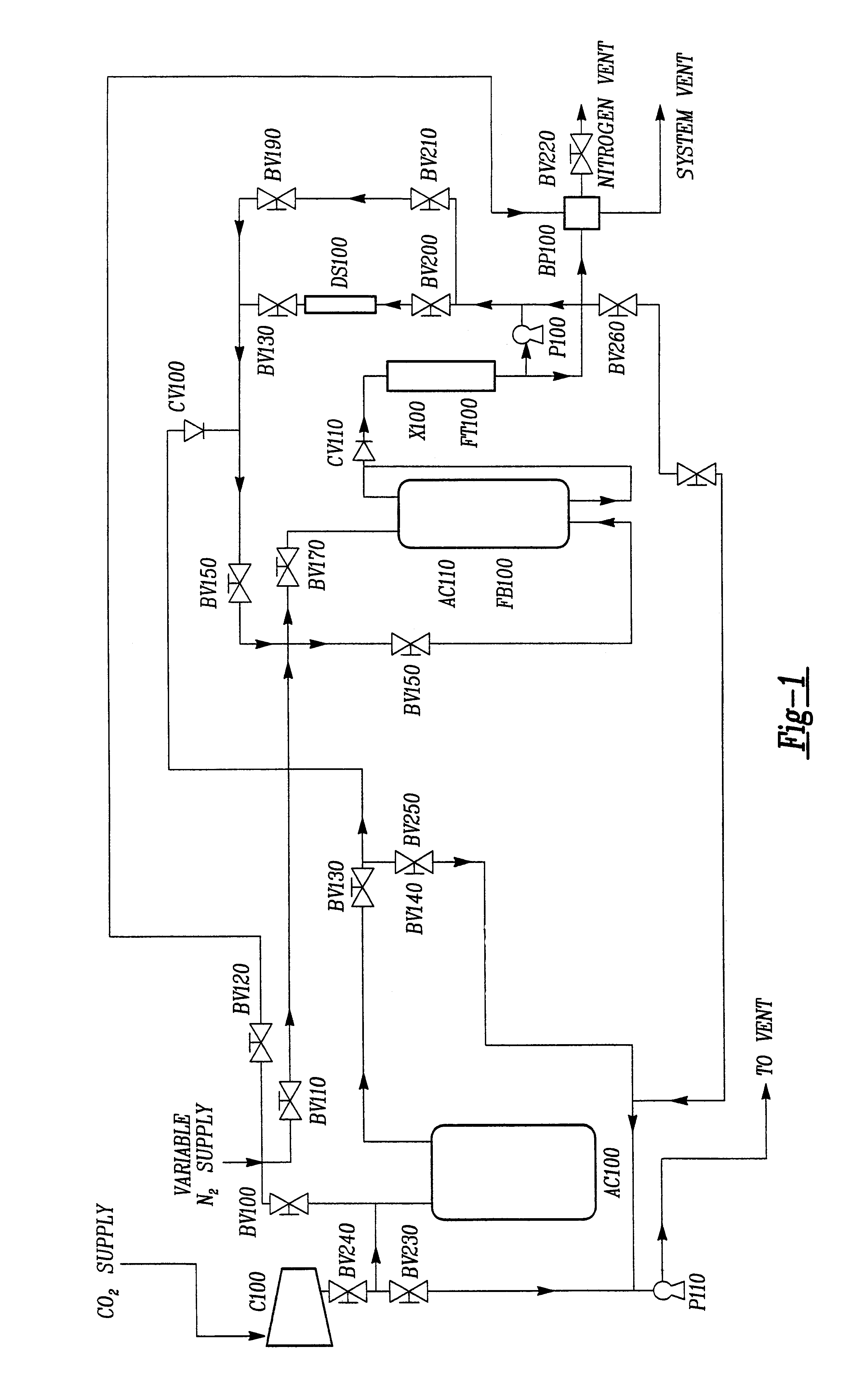

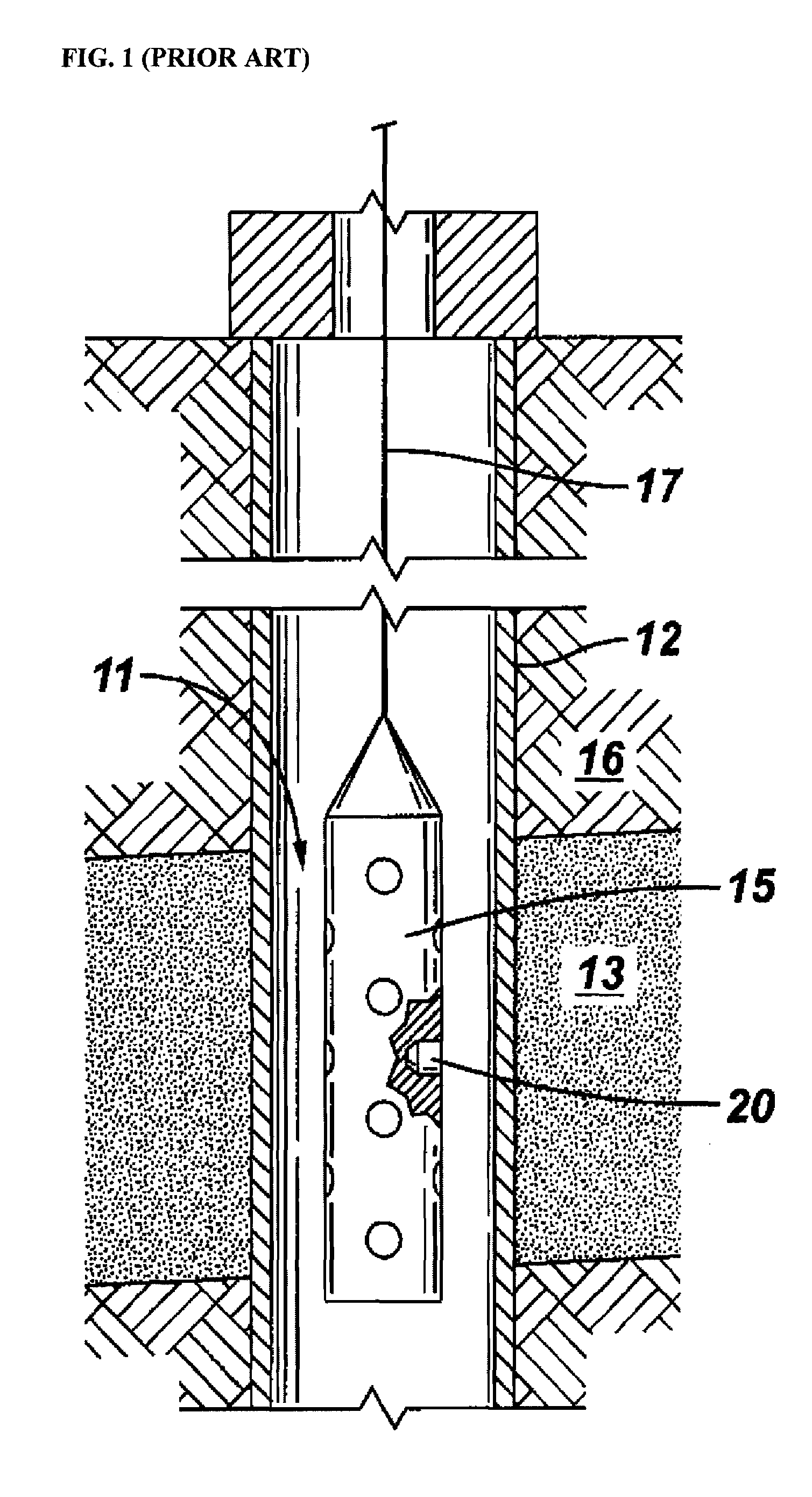

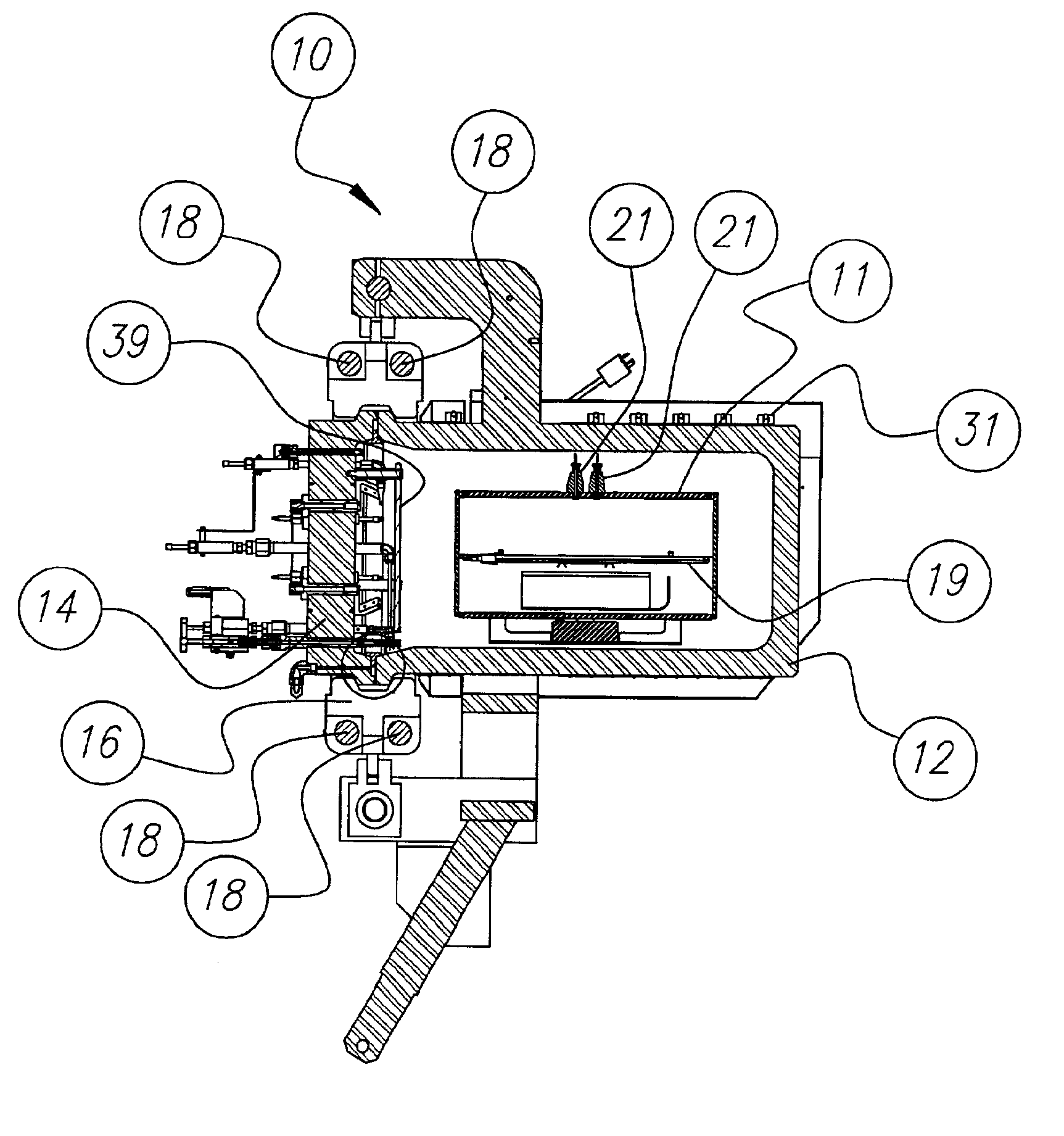

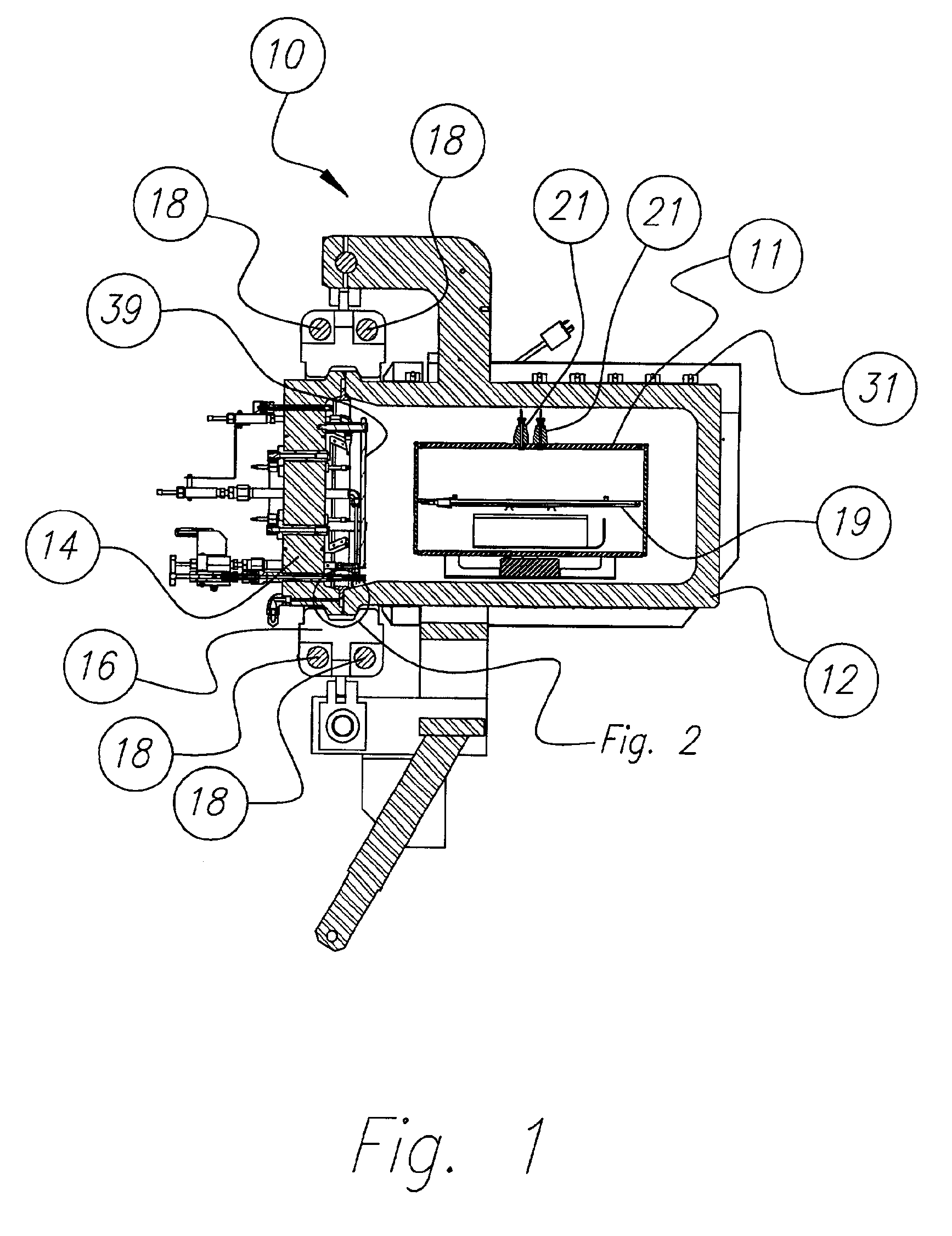

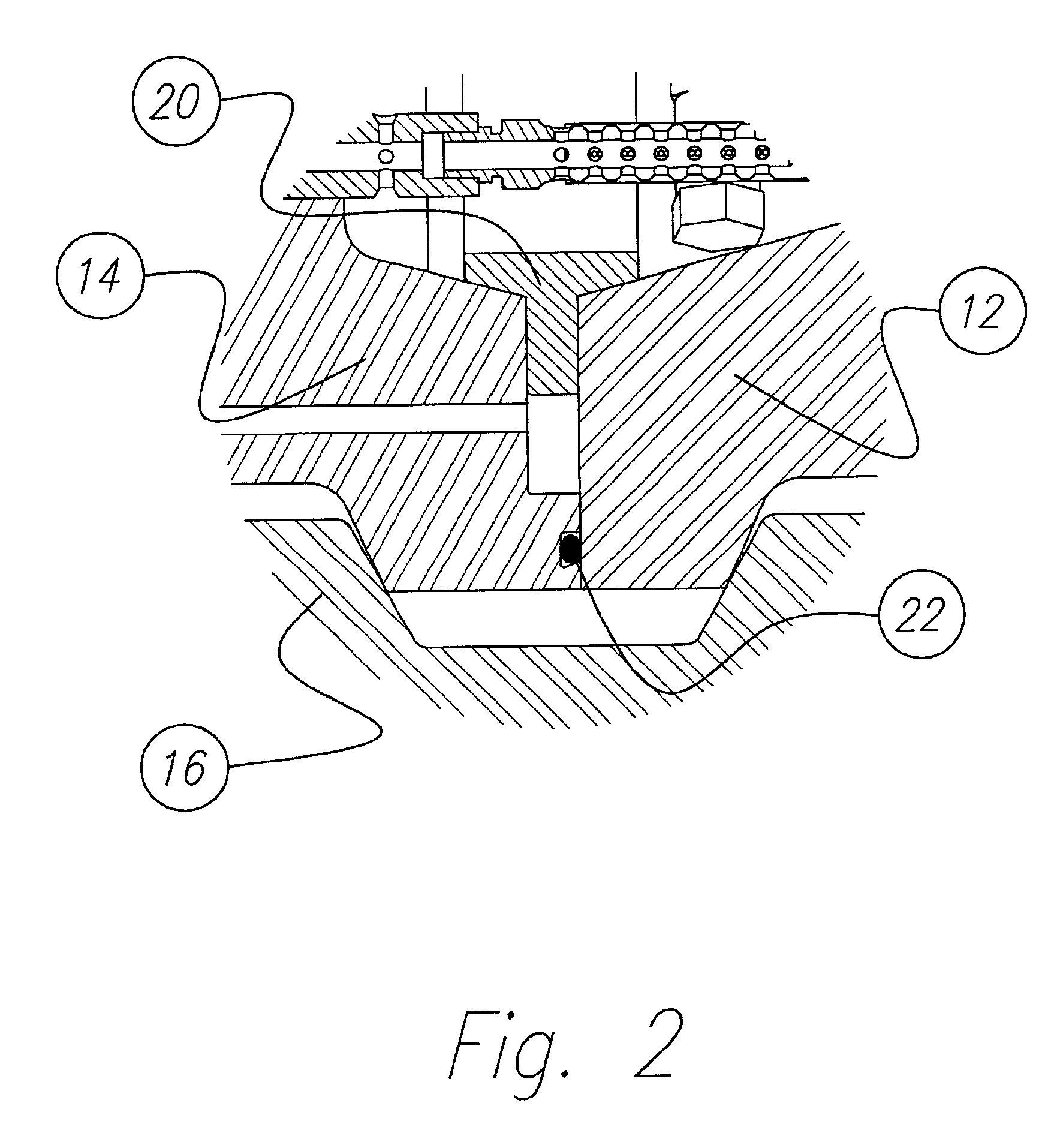

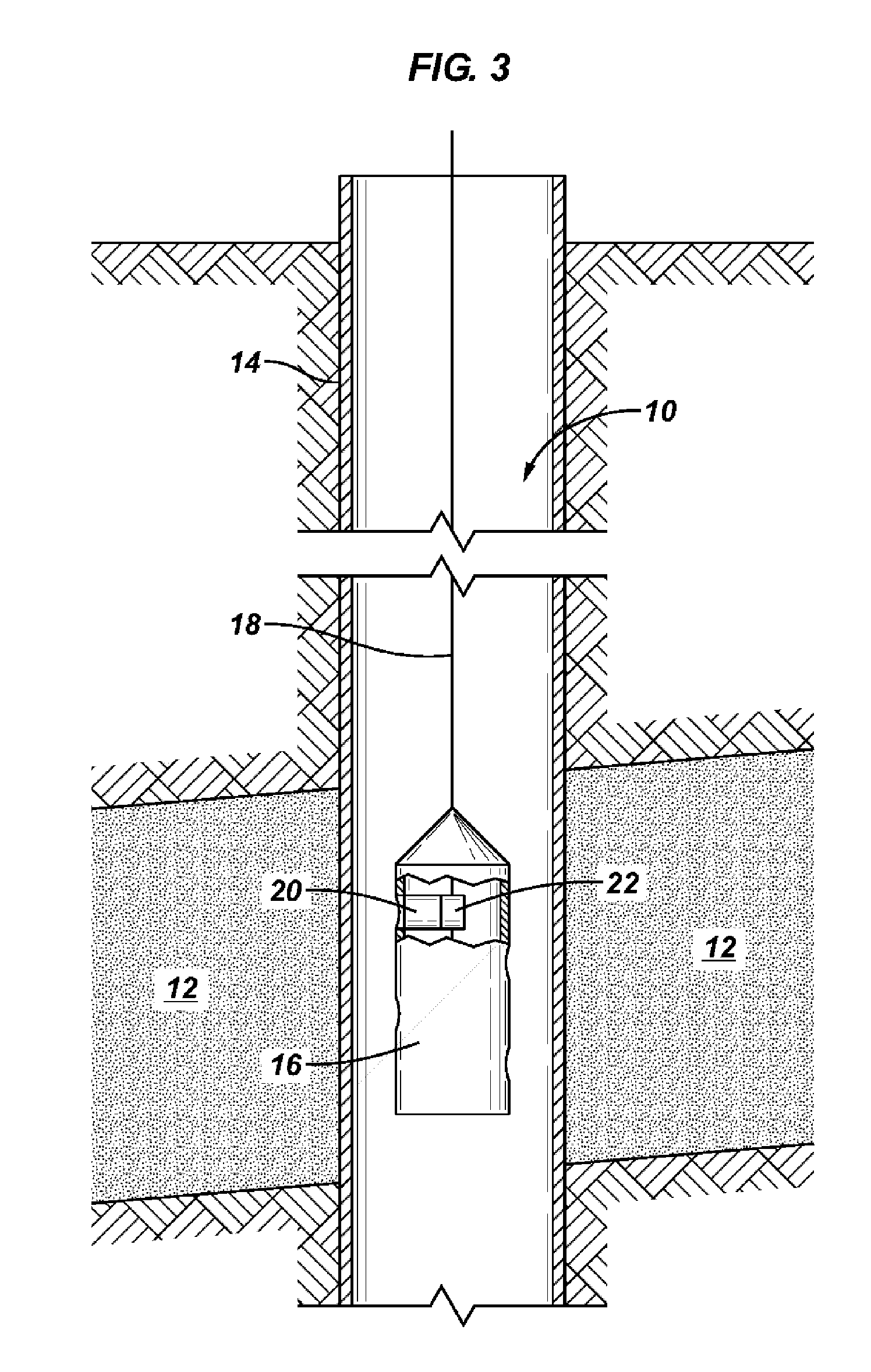

Explosive destruction system for disposal of chemical munitions

InactiveUS6881383B1Easy to neutralizeDestroying safePressurized chemical processGaseous chemical processesDetonationShaped charge

An explosive destruction system and method for safely destroying explosively configured chemical munitions. The system comprises a sealable, gas-tight explosive containment vessel, a fragment suppression system positioned in said vessel, and shaped charge means for accessing the interior of the munition when the munition is placed within the vessel and fragment suppression system. Also provided is a means for treatment and neutralization of the munition's chemical fills, and means for heating and agitating the contents of the vessel. The system is portable, rapidly deployable and provides the capability of explosively destroying and detoxifying chemical munitions within a gas-tight enclosure so that there is no venting of toxic or hazardous chemicals during detonation.

Owner:ARMY US SECRECTARY OF THE

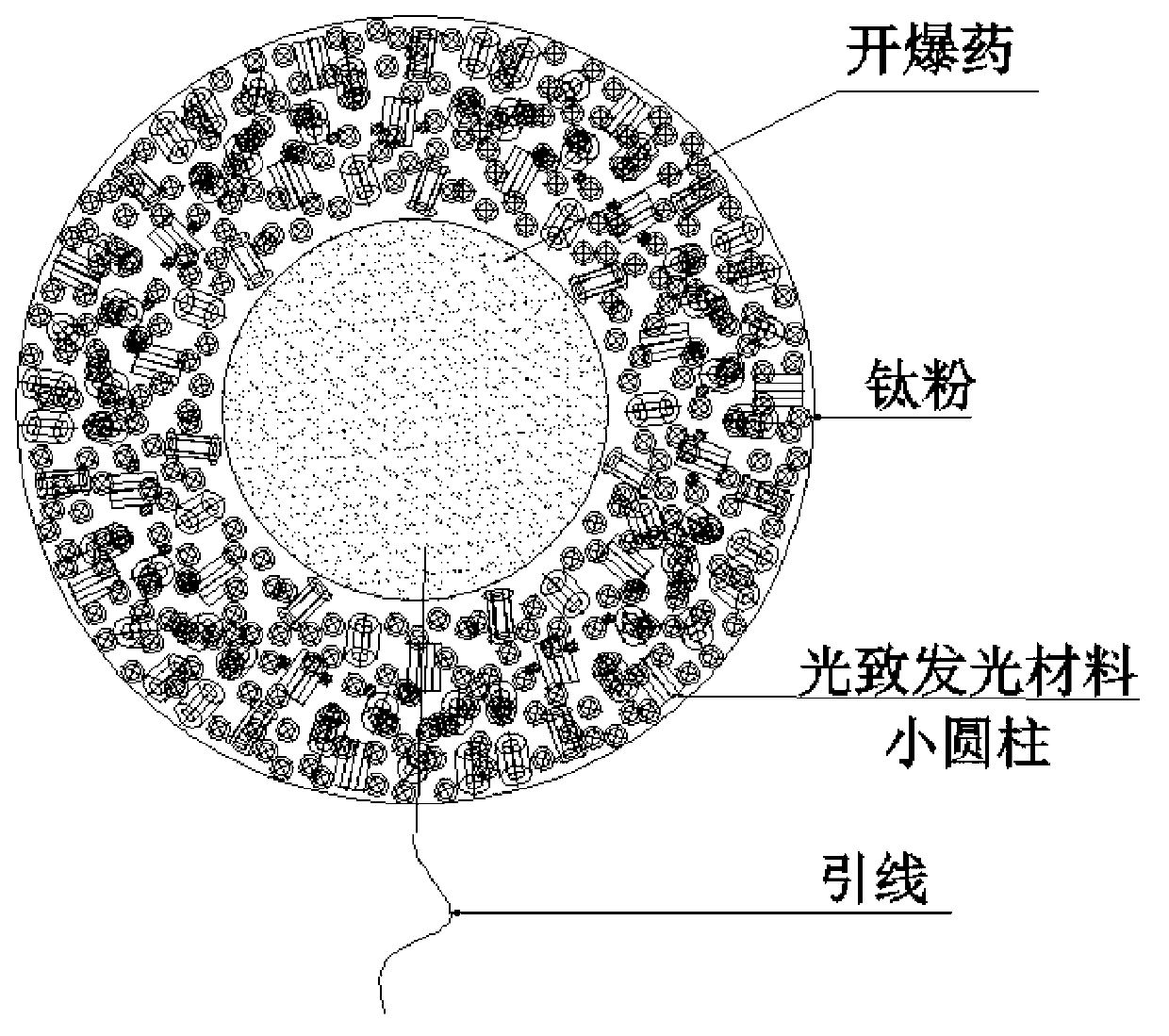

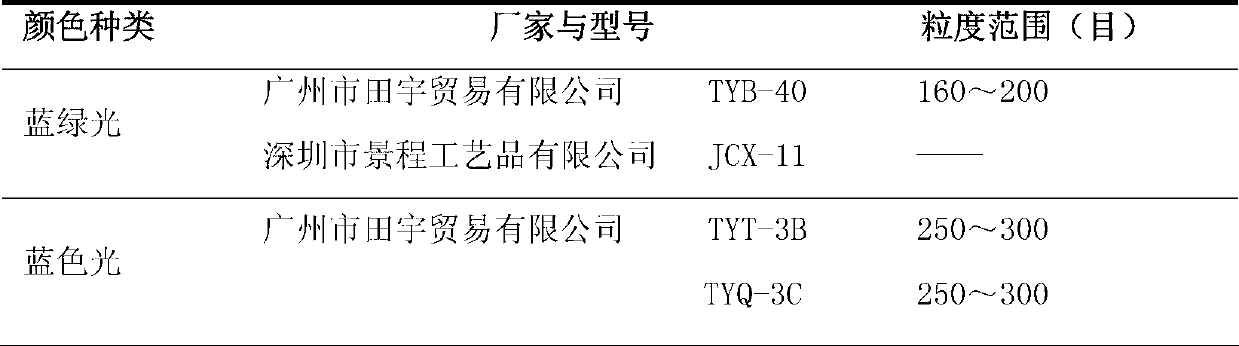

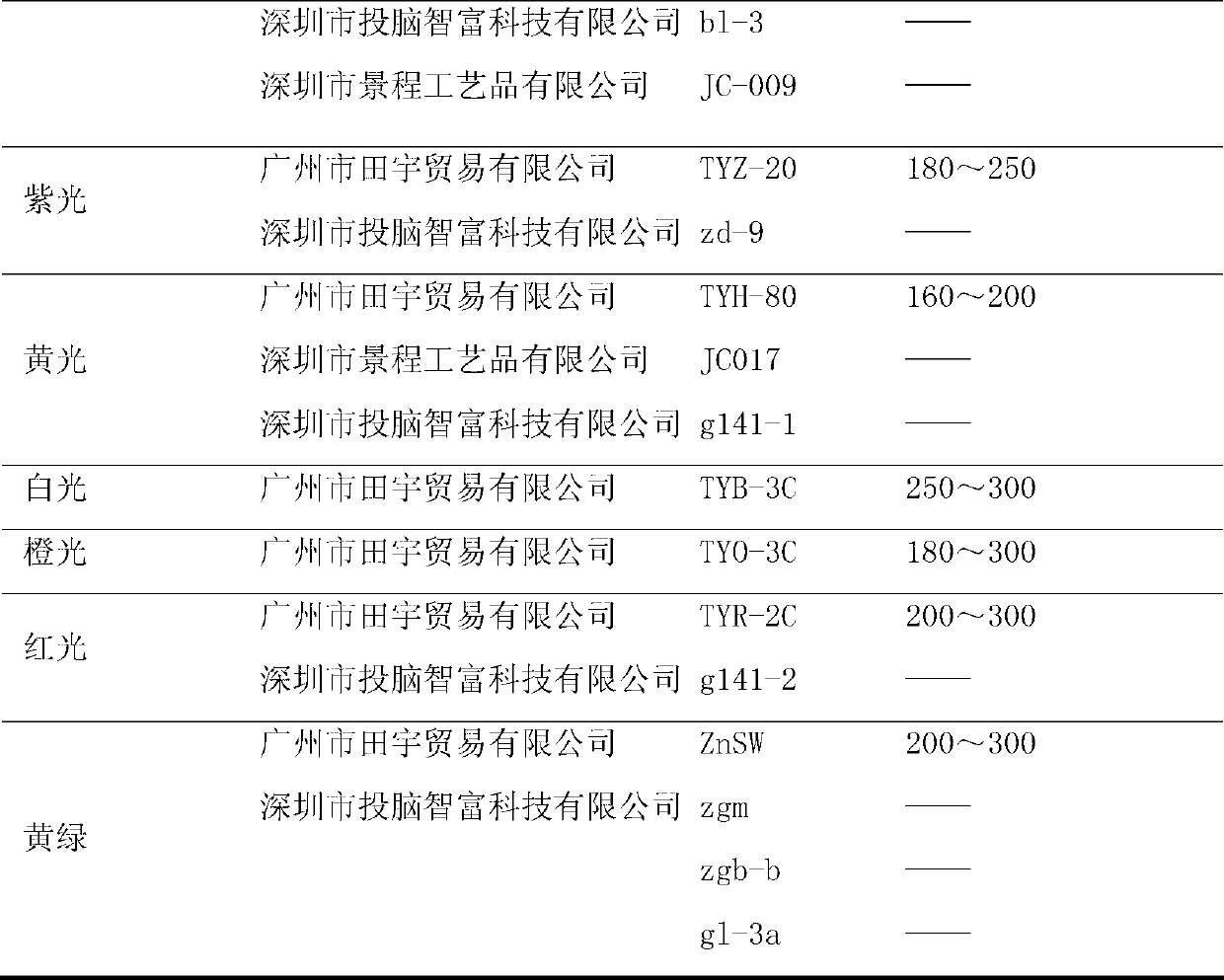

Multicolor cold-firework reagent and manufacturing method of cold fireworks

InactiveCN103121886AEasy to viewExplosive working-up apparatusAmmonium perchlorate explosive compositionsNitrocellulosePhotoluminescence

The invention discloses a multicolor cold-firework reagent and a manufacturing method of cold fireworks. The multicolor cold-firework reagent comprises the following components in percentage by weight: 20-30% of ammonium perchlorate, 20-30% of nitrocellulose, 30-35% of silver titanium powder, 15-20% of photoluminescence material and 5-10% of fluororubber. The manufacturing method of the spraying-decoration cold fireworks comprises the following steps: fuel granulation, reagent mixing, charging and packaging. The manufacturing method of the high-waterfall display shell cold fireworks comprises the following steps: luminescent material granulation, fuel mixing, detonating agent manufacturing and display shell filling. The cold fireworks disclosed by the invention can have multiple bright colors, thereby greatly enhancing the ornamental value of the cold fireworks.

Owner:NANJING UNIV OF SCI & TECH

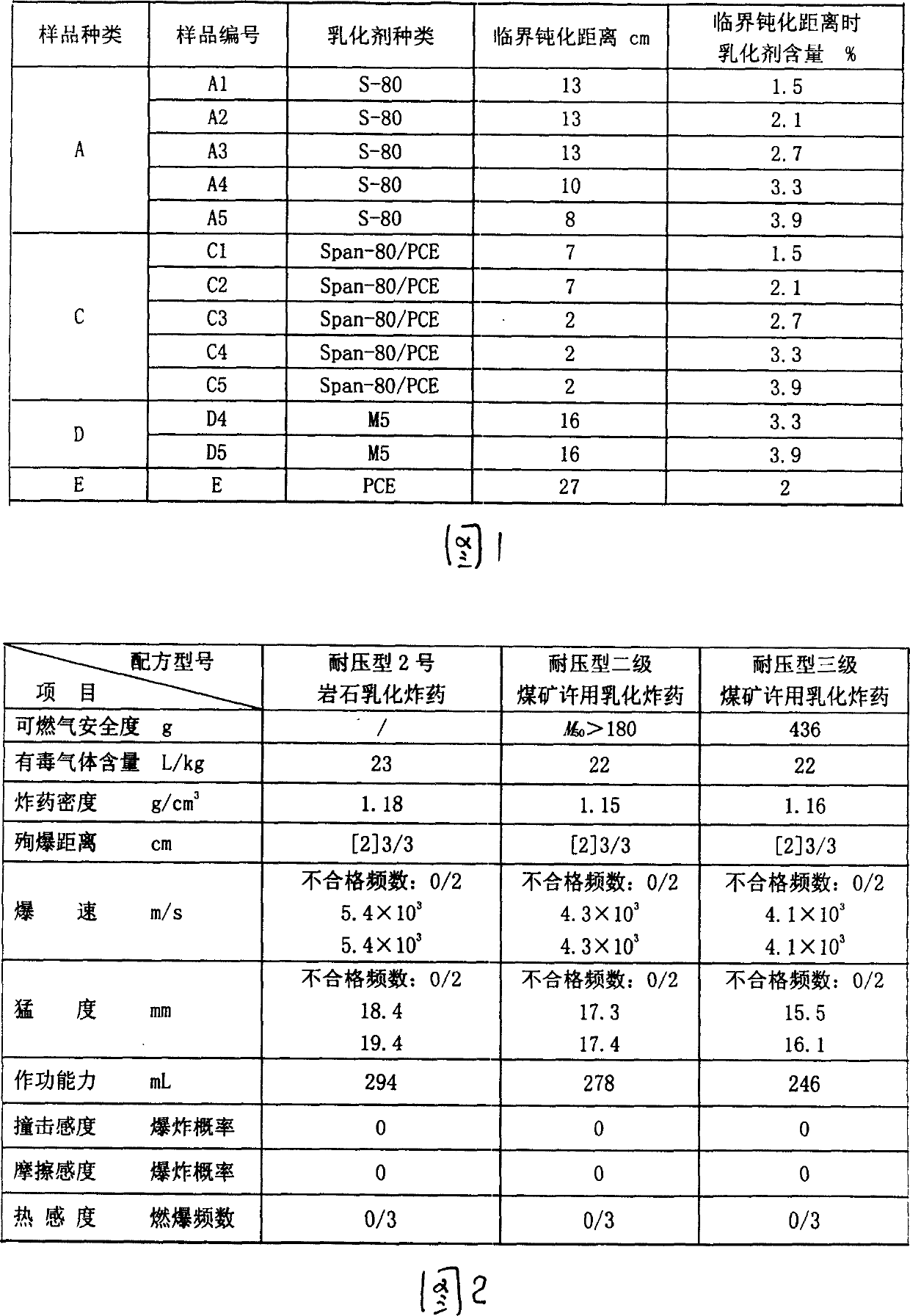

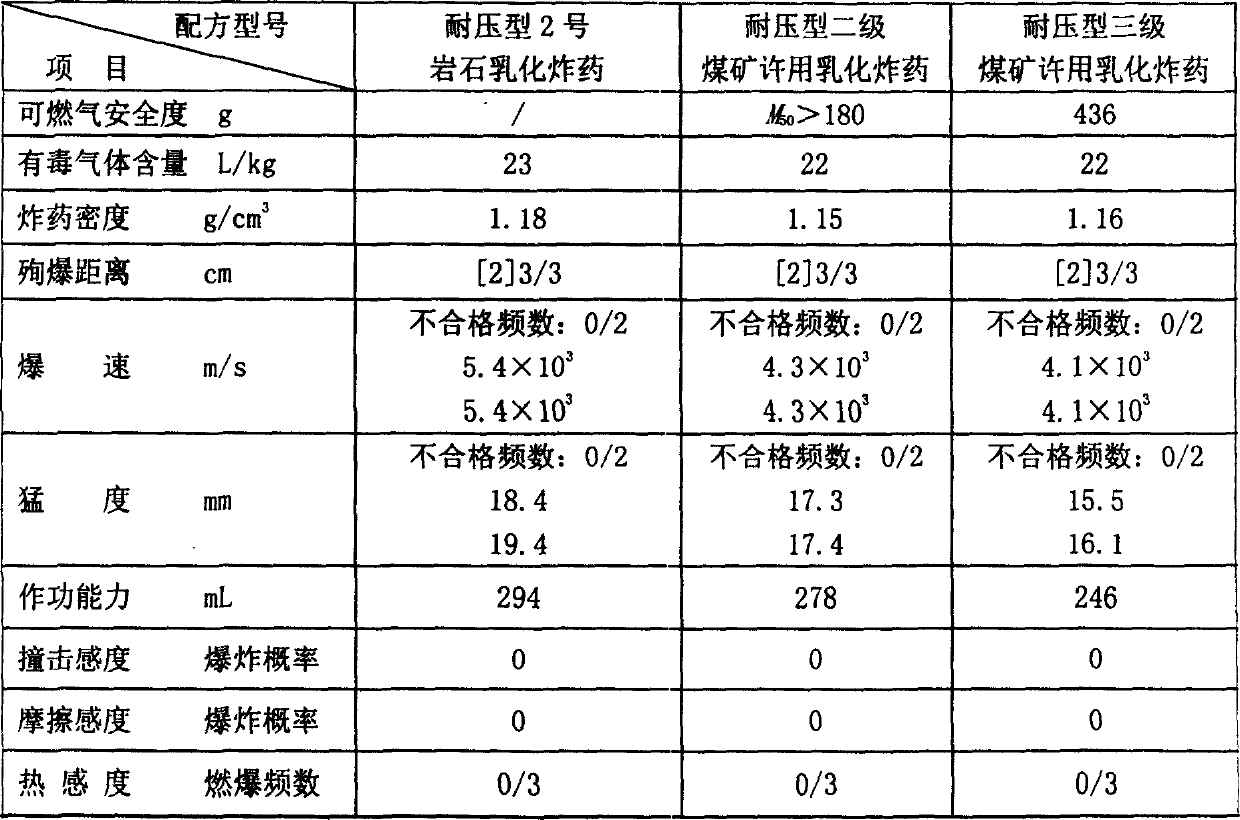

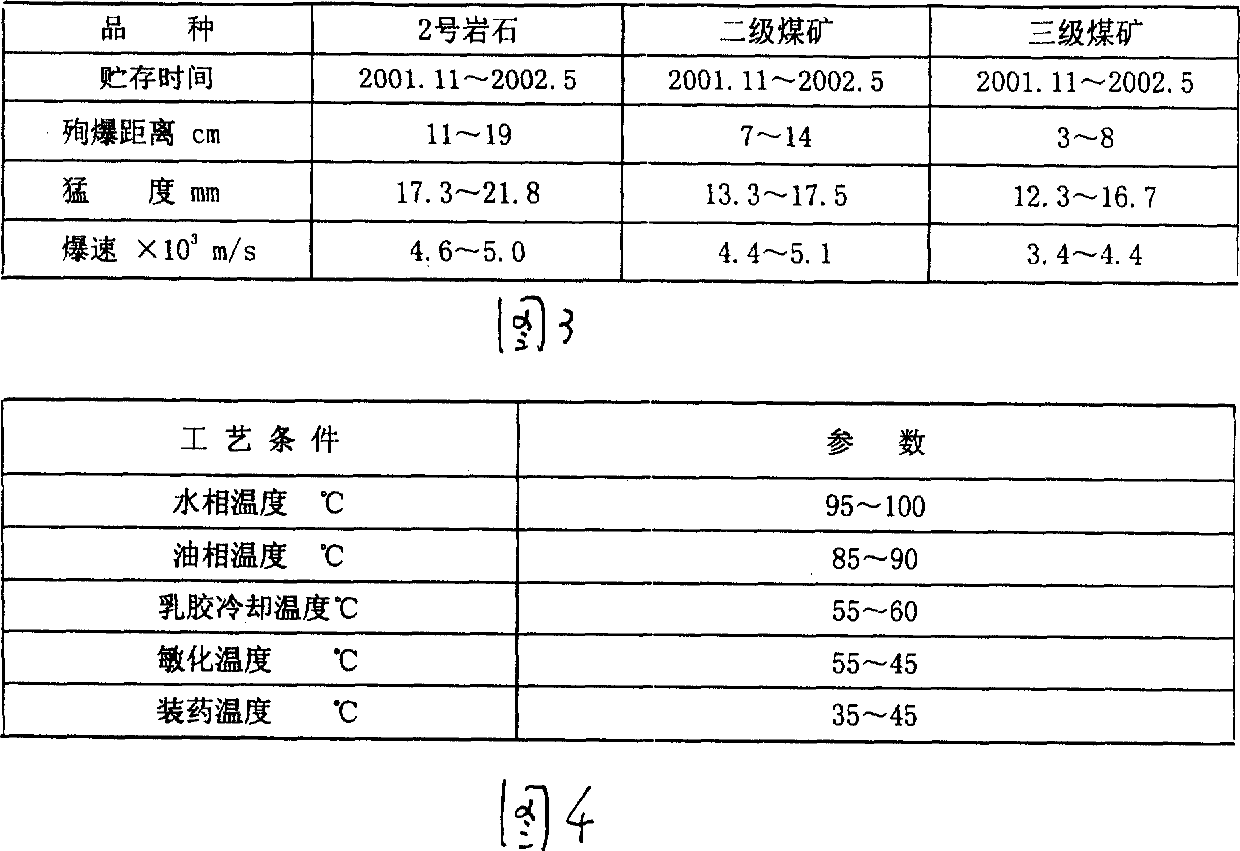

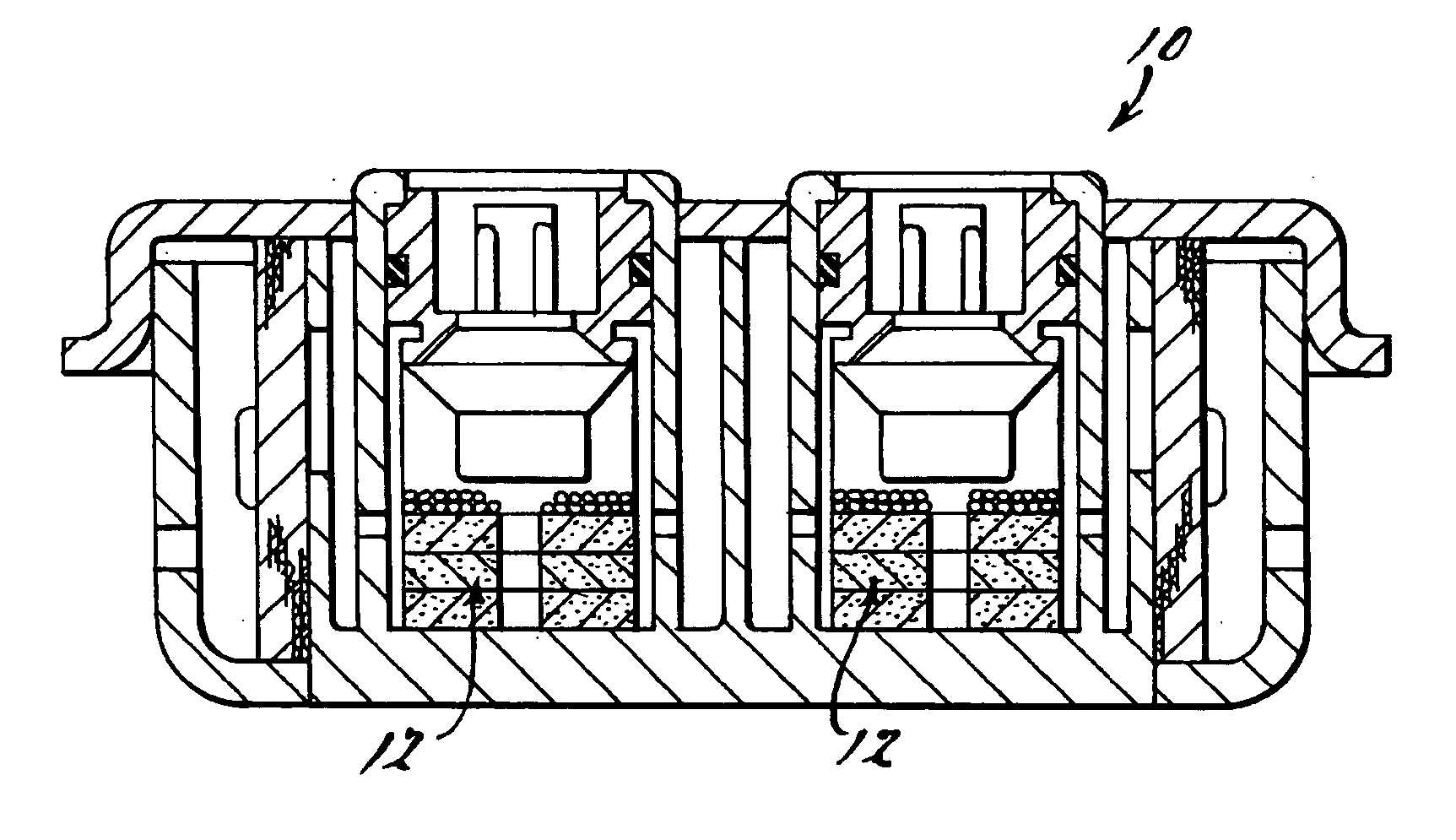

Pressure resistant emulsified explosive

ActiveCN1618775AEnhance the ability to control abnormal blastingExplosive working-up apparatusFoaming agentCoal

A compression-resistant emulsified explosive for coal mine features that the composite emulsifier prepared from anhydrosorbitol monooleate and polyisobutene butanediimide and the technique for sensitizing the chemical foaming agent are used.

Owner:CHINA COAL TECH & ENG GRP HUAIBEIBLASTING TECHN RES INST

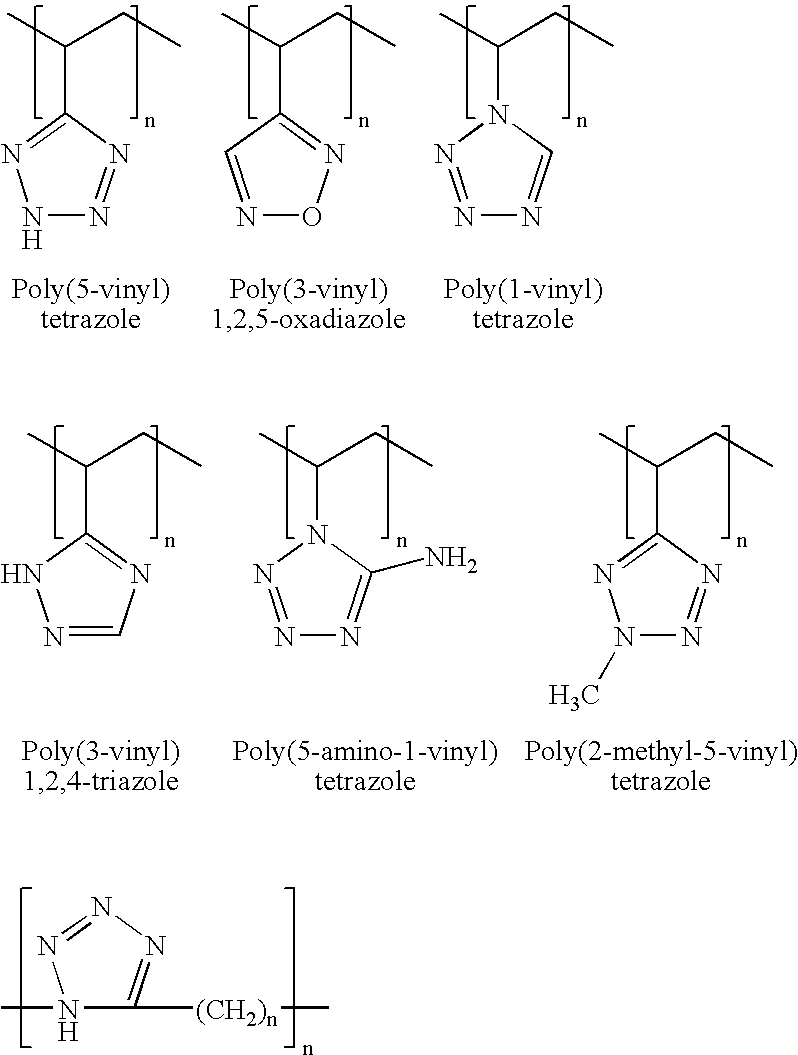

Gas generant and manufacturing method thereof

InactiveUS20050257866A1Improve solubilityPromote aggregationExplosive working-up apparatusPressure gas generationTriazole antifungalsTetrazole

The present invention generally relates to gas generant compositions for inflators of occupant restraint systems, for example. An extrudable pyrotechnic composition includes polyvinylazoles for use within an airbag gas generator. The fuel may be selected from exemplary polyvinylazoles including 5-amino-1-vinyltetrazole, poly(5-vinyltetrazole), poly(2-methyl-5-vinyl) tetrazole, poly(1-vinyl) tetrazole, poly(3-vinyl) 1,2,5 oxadiazole, and poly(3-vinyl) 1,2,4-triazole. An oxidizer is combined with the fuel and preferably contains phase stabilized ammonium nitrate. A novel method of forming the compositions is also presented wherein the various constituents are wetted and / or dissolved, and then cured within the polyvinylazole matrix thereby forming a more intimate combination within the gas generant composition. A vehicle occupant protection system 180, and other gas generating systems, incorporate the compositions of the present invention.

Owner:AUTOMOTIVE SYST LAB

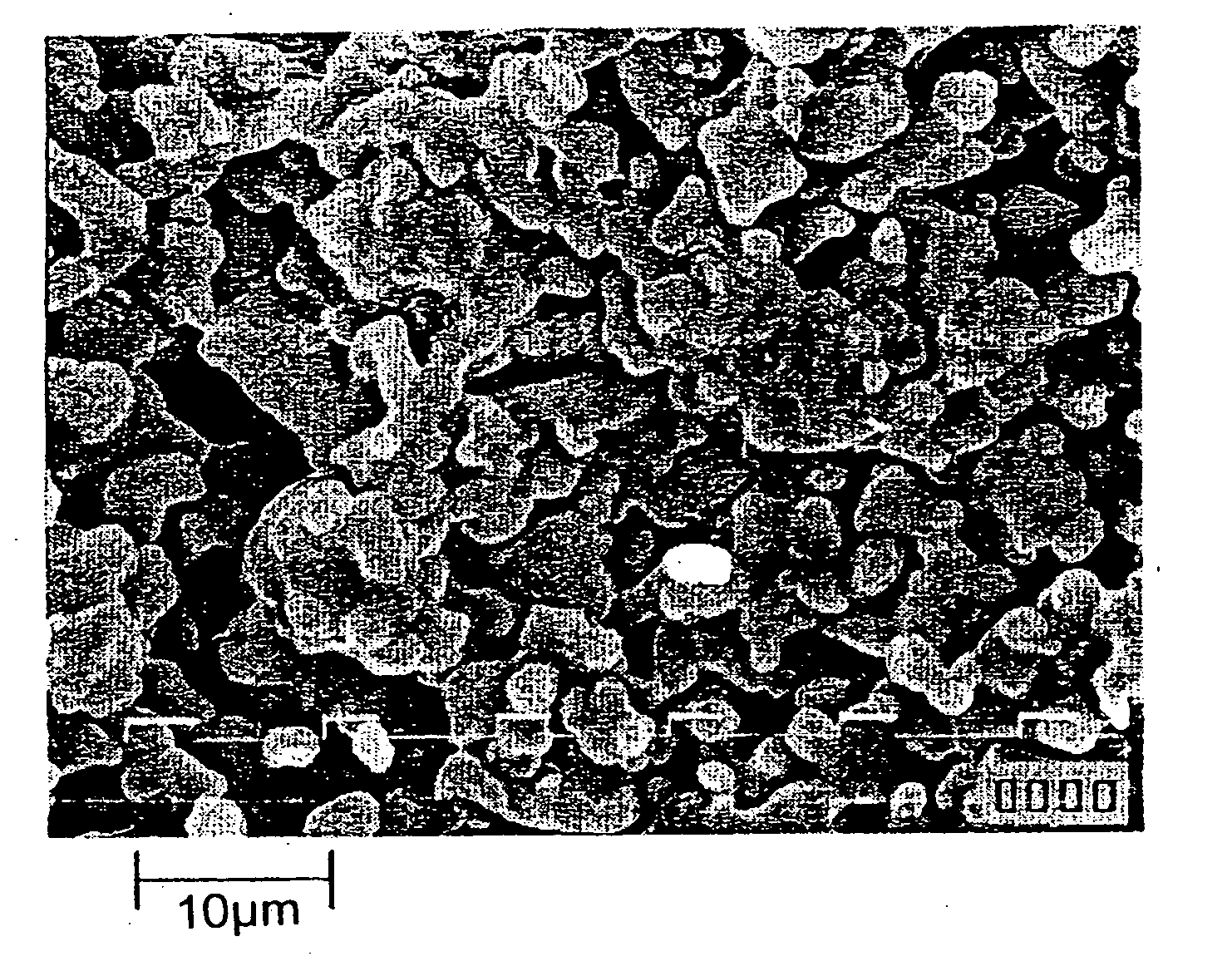

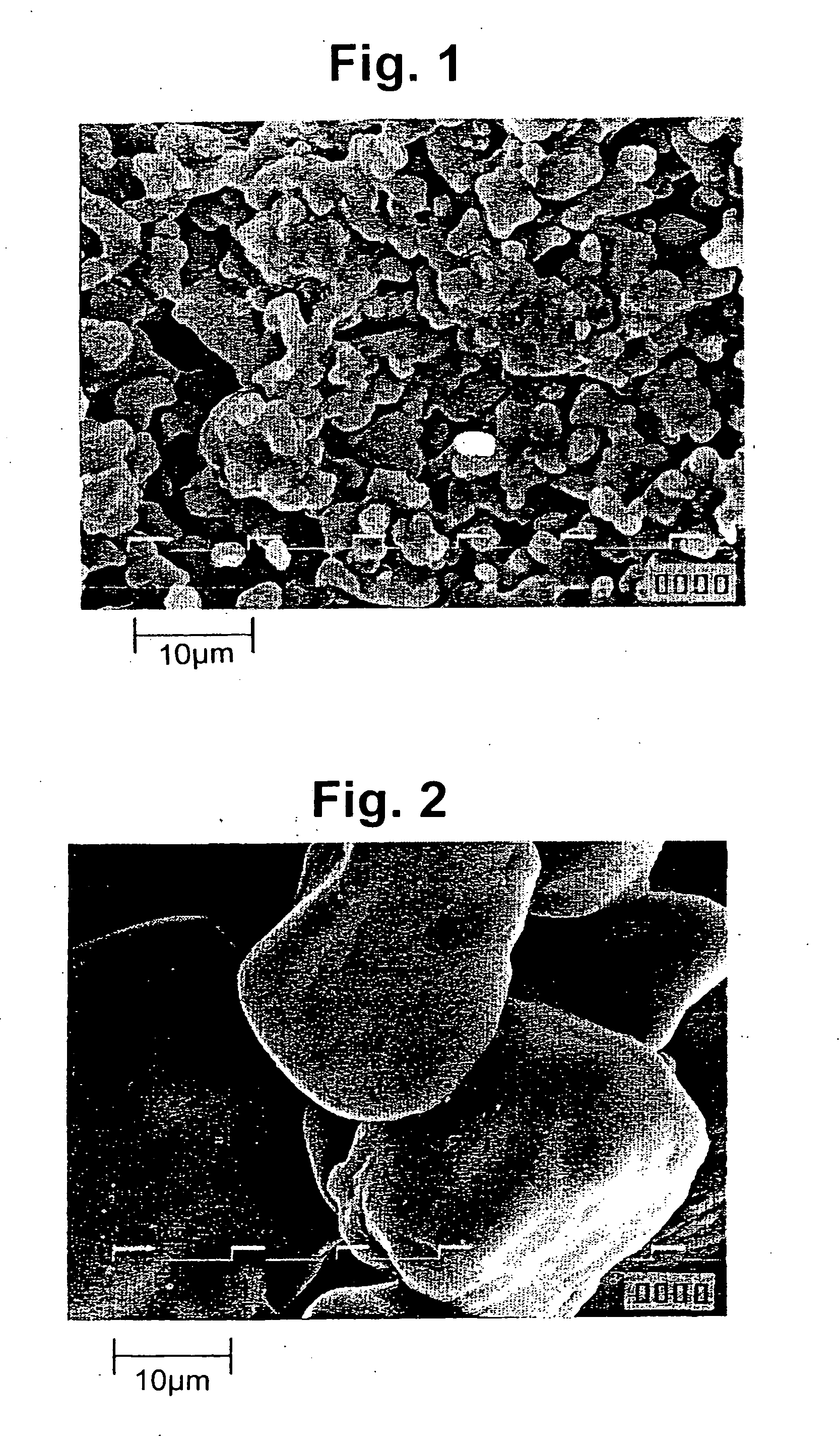

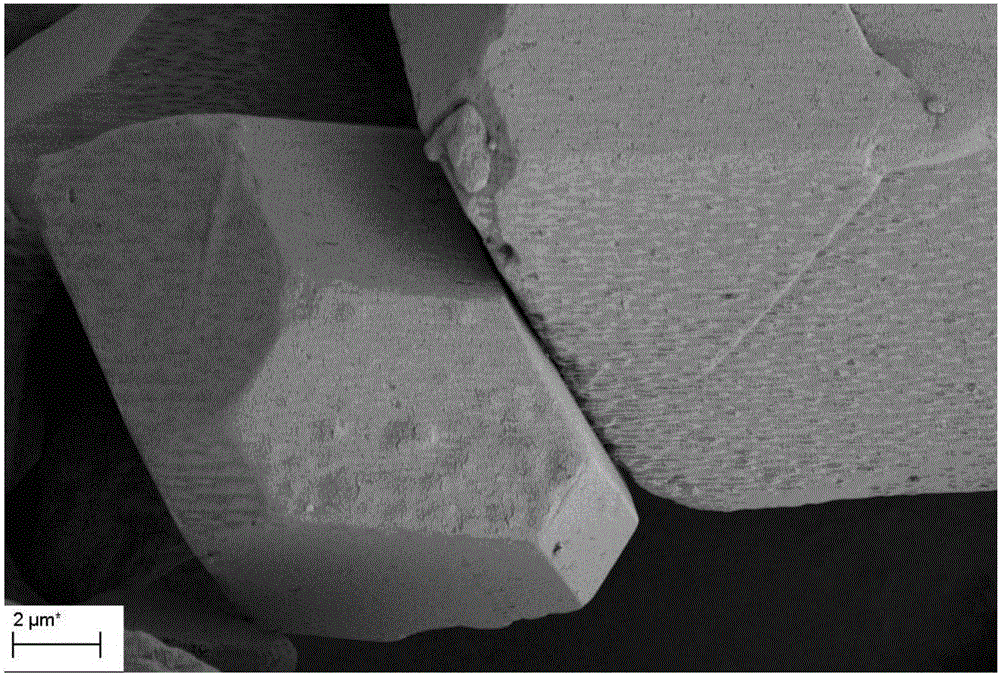

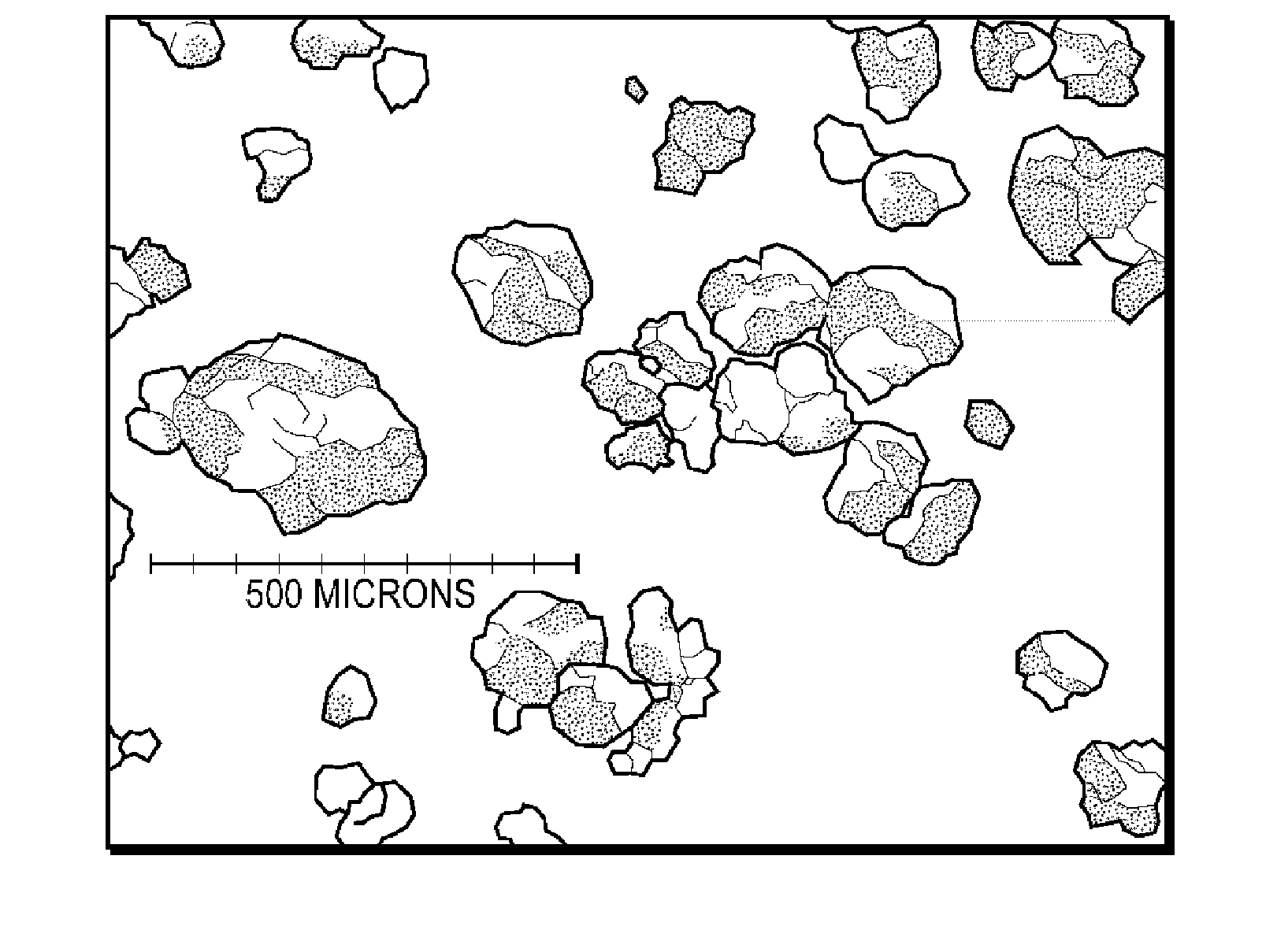

RDX Composition and Process for Its Manufacture

InactiveUS20060272756A1Explosive working-up apparatusNitrated acyclic/alicyclic/heterocyclic amine explosive compositionsSolventCrystal density

An explosive composition can be produced by dissolving RDX in a volume of a first solvent to form a first solution, and adding a second solvent to the first solution. The second solvent is miscible with the first solvent, but RDX is soluble in the second solvent to an extent no greater than 1 g RDX / 100 g of the second solvent. Precipitated RDX crystals can be recovered. The RDX crystals can have a crystal density of less than 1.80 g / cm3.

Owner:SCHLUMBERGER TECH CORP

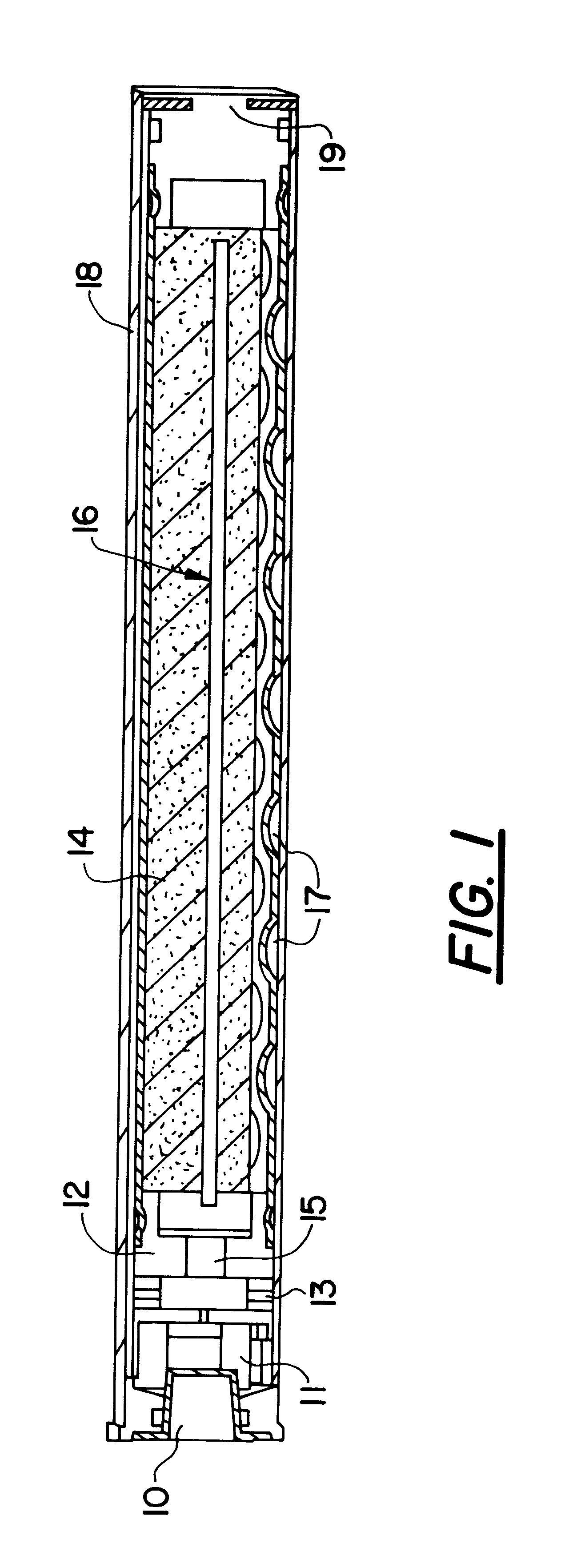

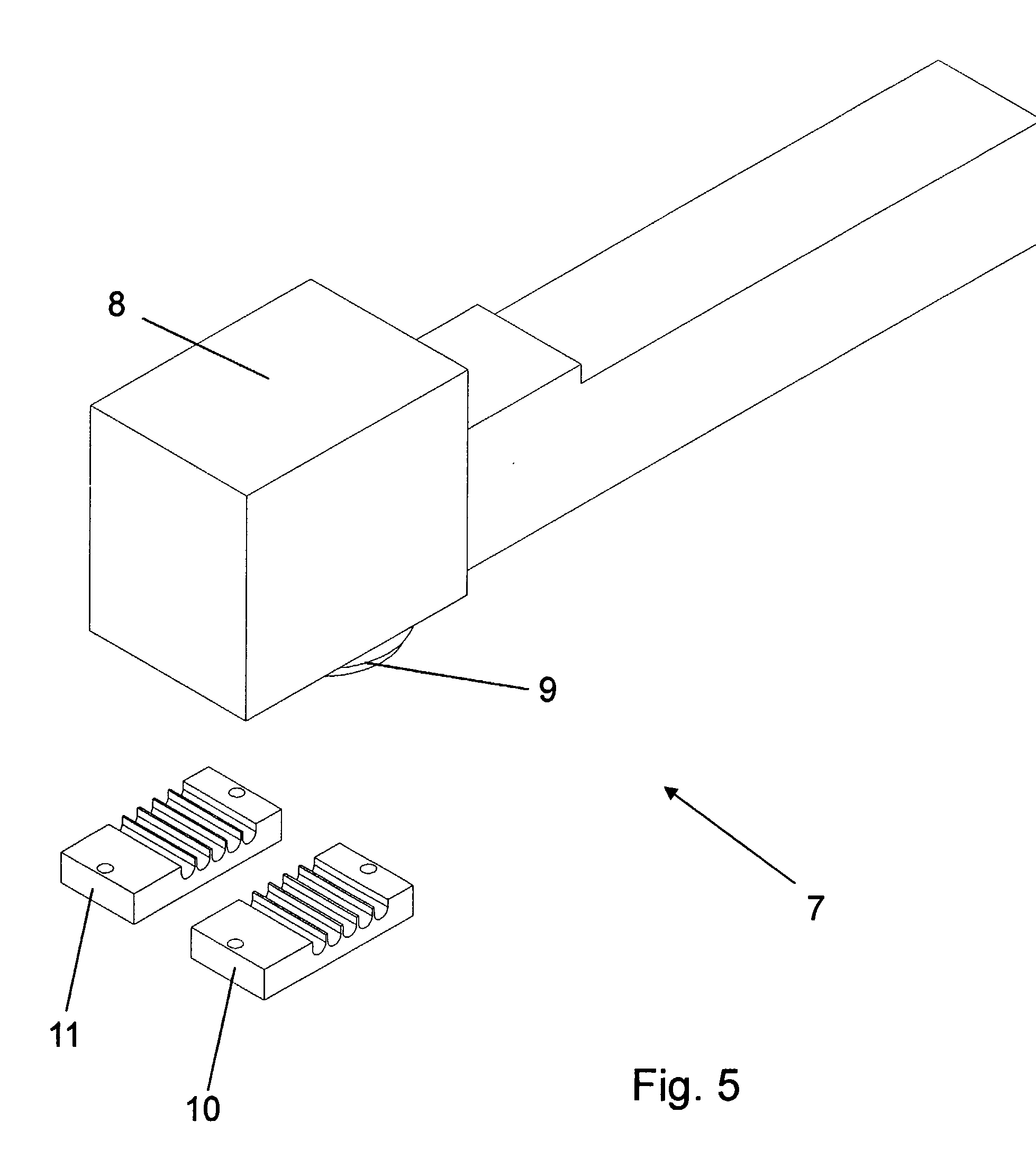

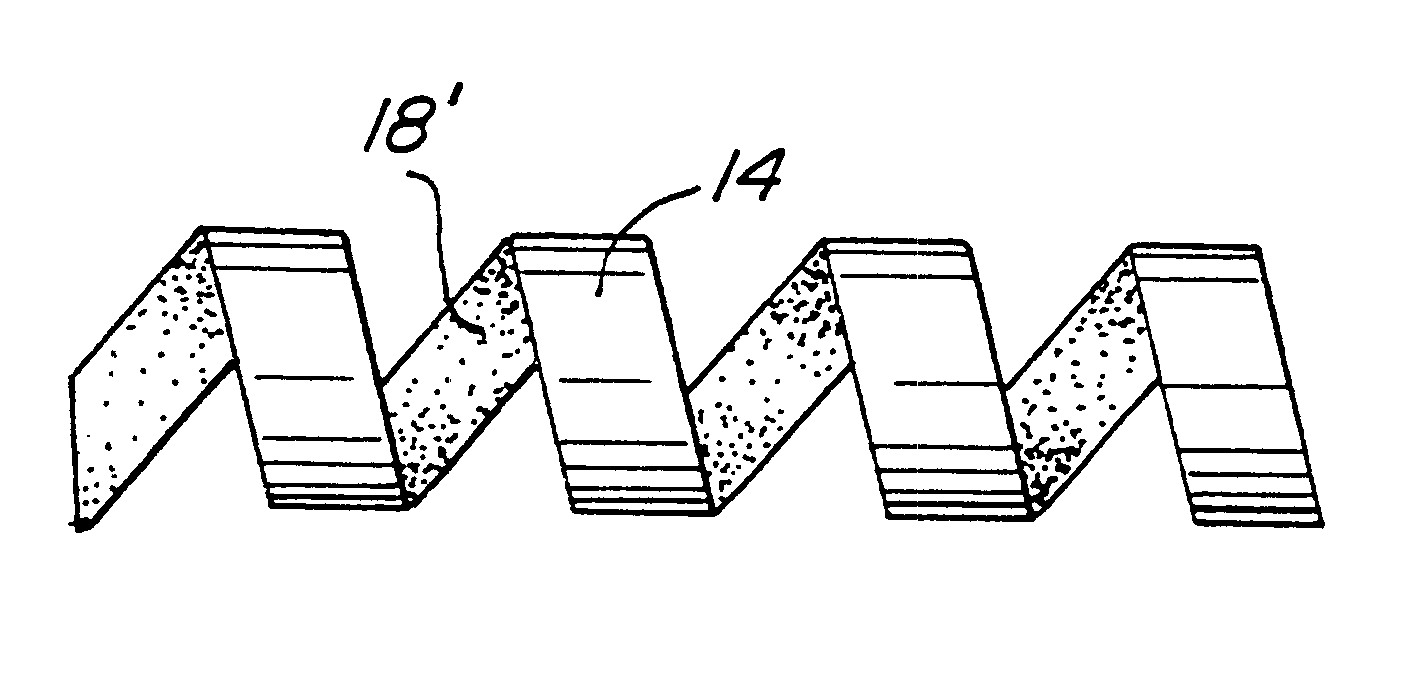

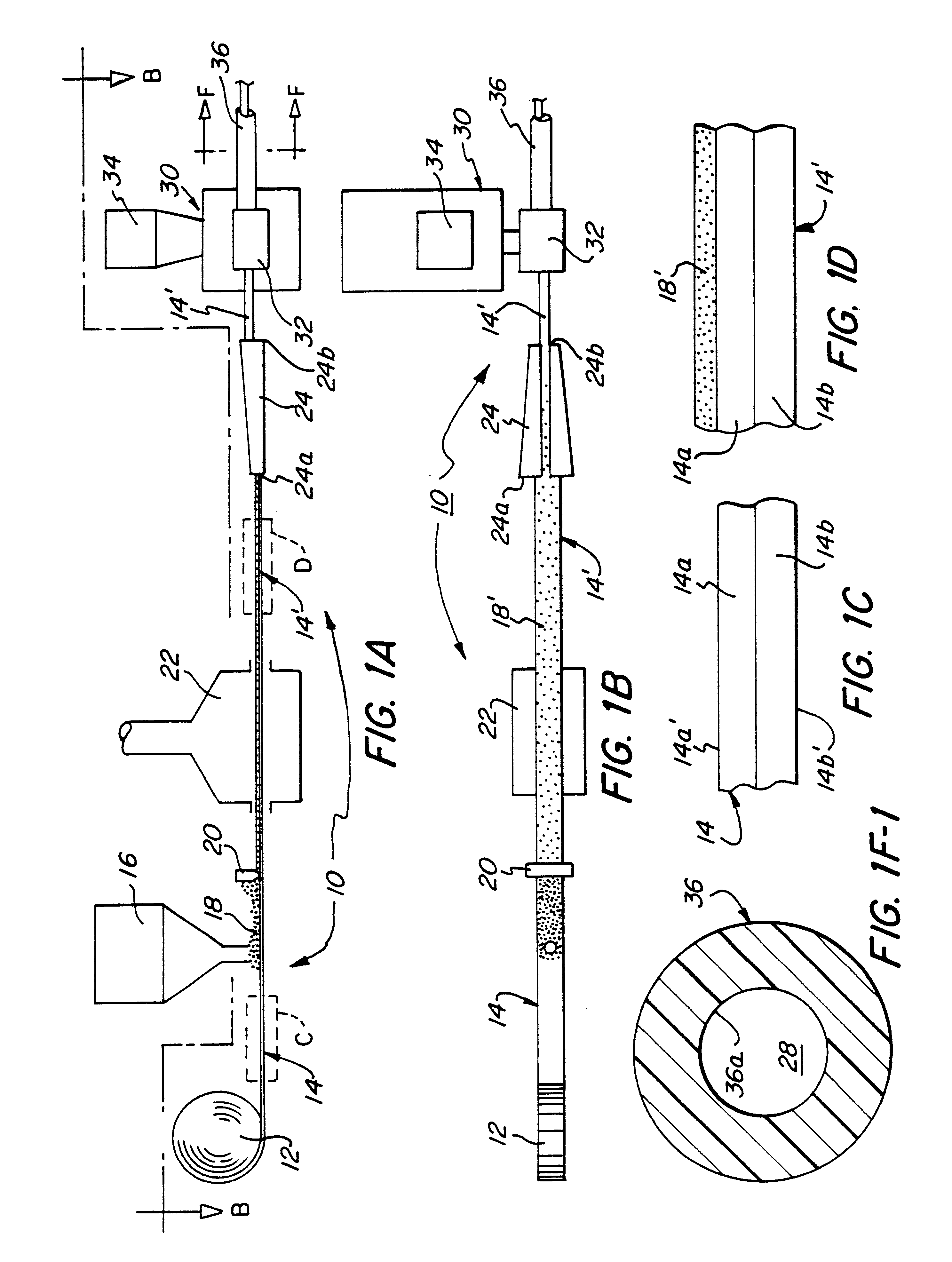

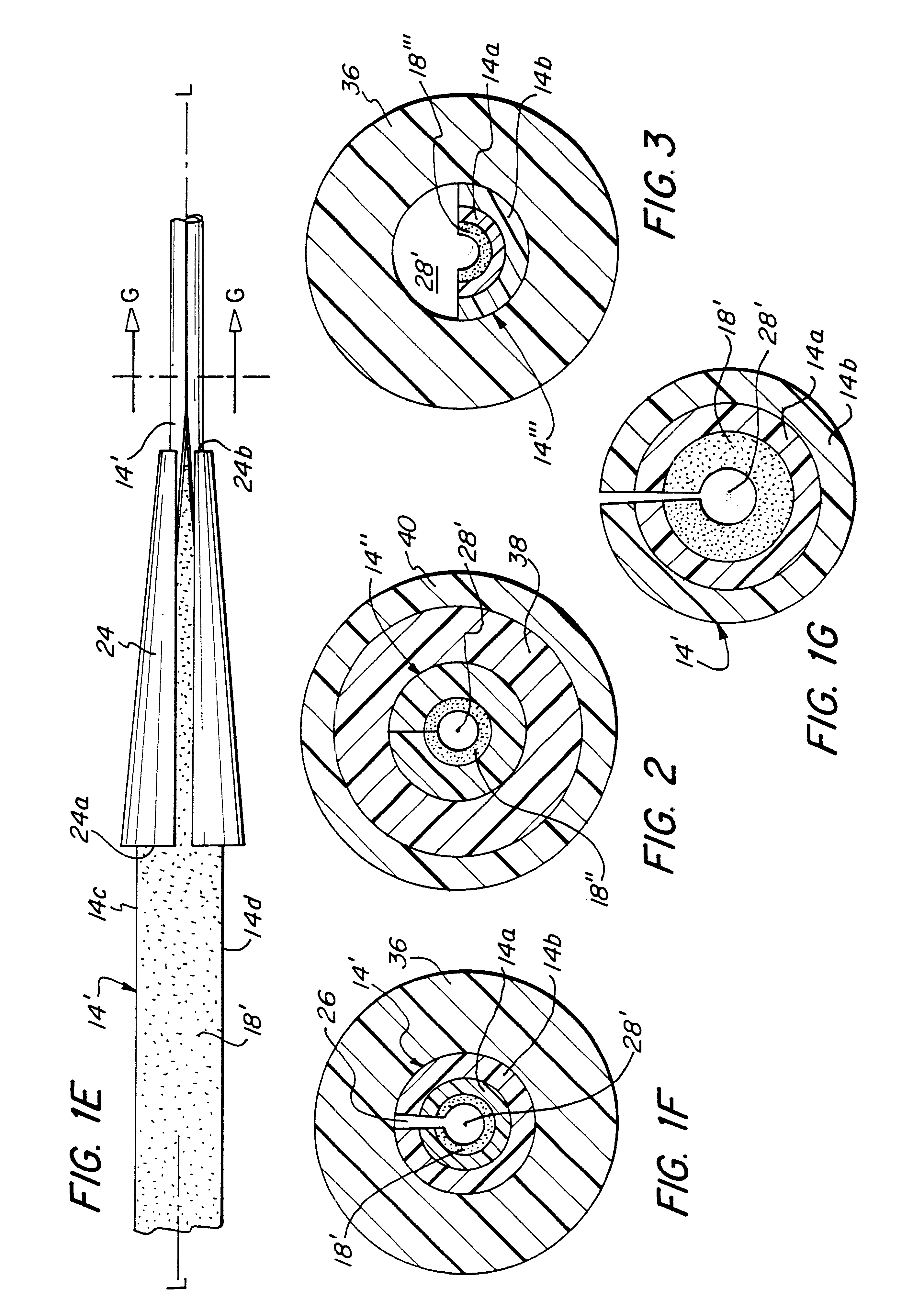

Method of making a signal transmission fuse

InactiveUS6347566B1Avoid less flexibilityEasy loadingBlasting cartridgesExplosive working-up apparatusEngineeringMechanical engineering

A signal transmission fuse is made of a tube (36) which encases a support tape (14) having a reactive coating (18') which is adhered to one side of the tape by a binder. A method of making the signal transmission fuse includes depositing on the support tape (14) a reactive paint (18) including a binder, which paint dries to form a reactive coating (18'). The coated support tape (14') is then folded, i.e., formed into a channel configuration, to provide an inner concave side of the tape on which the reactive coating (18') has been disposed. The coated support tape is then enclosed, e.g., within an extruded plastic tube (36). One side of the support tape may be made of a first material (14a) to which the reactive coating adheres, and a second side may be made of a second material (14b) which bonds or adheres to the inner surface (36a) of the plastic tube (36) enclosing the coated support tape (14'). The binder causes even high loadings of the reactive coating (18') to adhere to the coated support tape (14') to prevent reactive material migration. The support tape also shields the reactive material from the hot, freshly extruded surrounding plastic tube (36) during manufacture.

Owner:DYNO NOBEL INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com