Patents

Literature

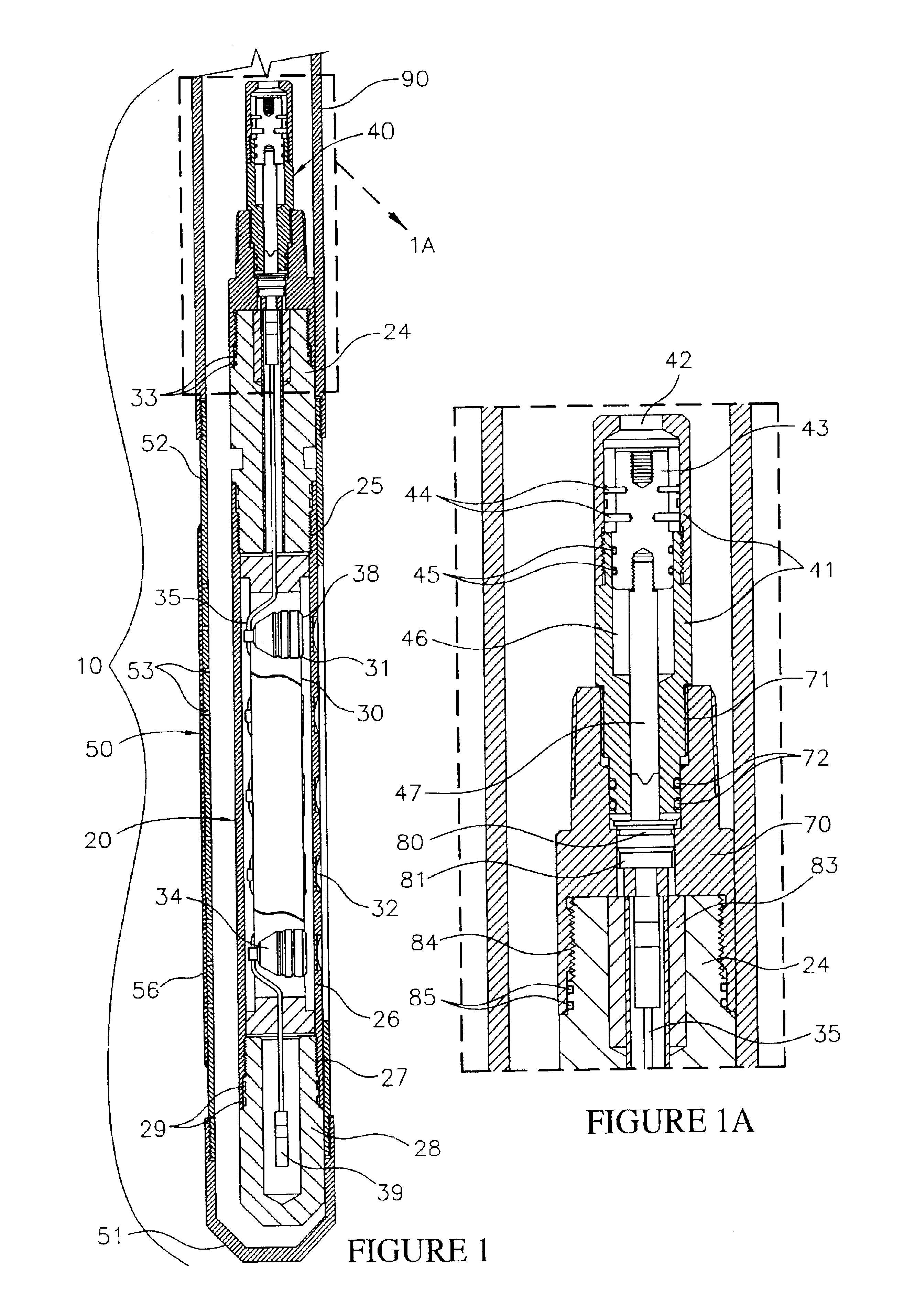

3882 results about "Detonation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Detonation (from Latin detonare, meaning 'to thunder down/forth') is a type of combustion involving a supersonic exothermic front accelerating through a medium that eventually drives a shock front propagating directly in front of it. Detonations occur in both conventional solid and liquid explosives, as well as in reactive gases. The velocity of detonation in solid and liquid explosives is much higher than that in gaseous ones, which allows the wave system to be observed with greater detail (higher resolution).

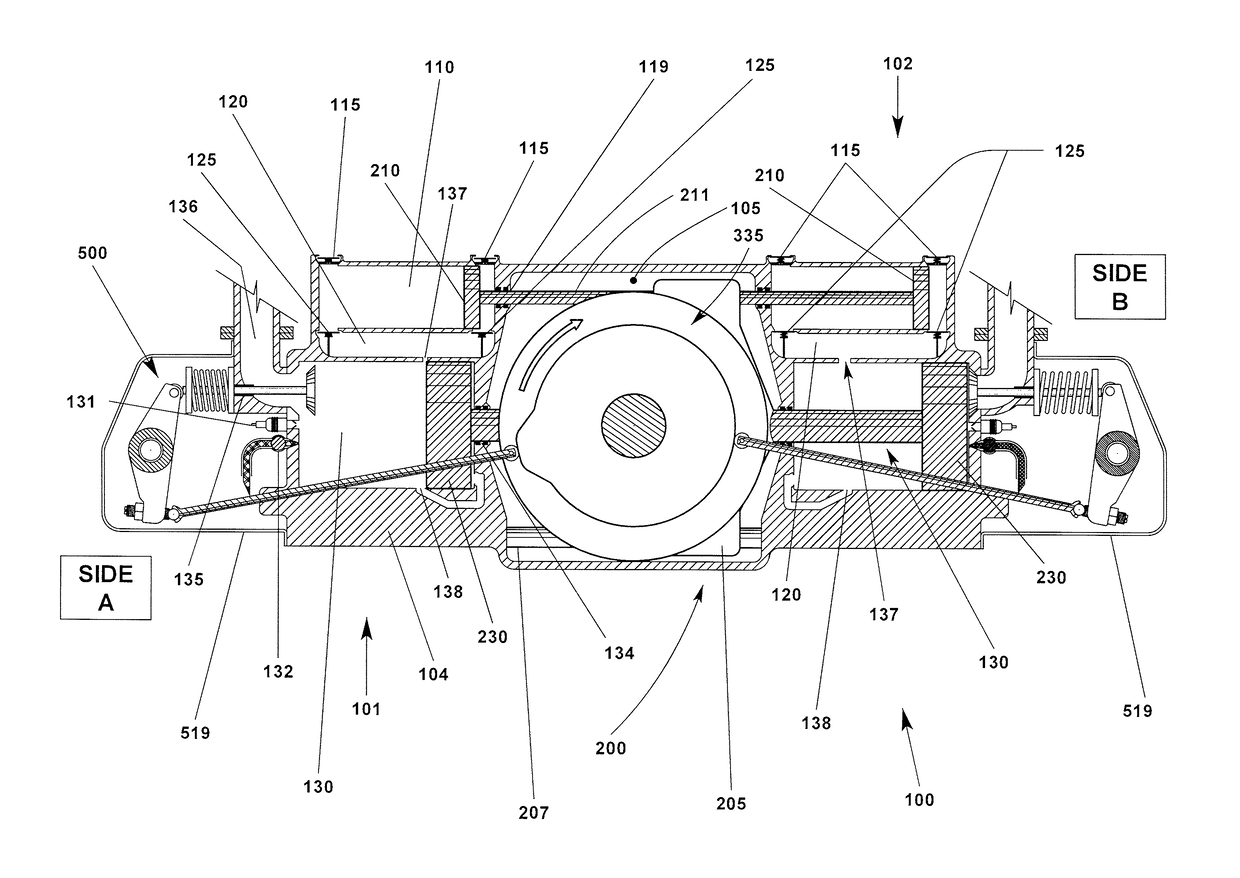

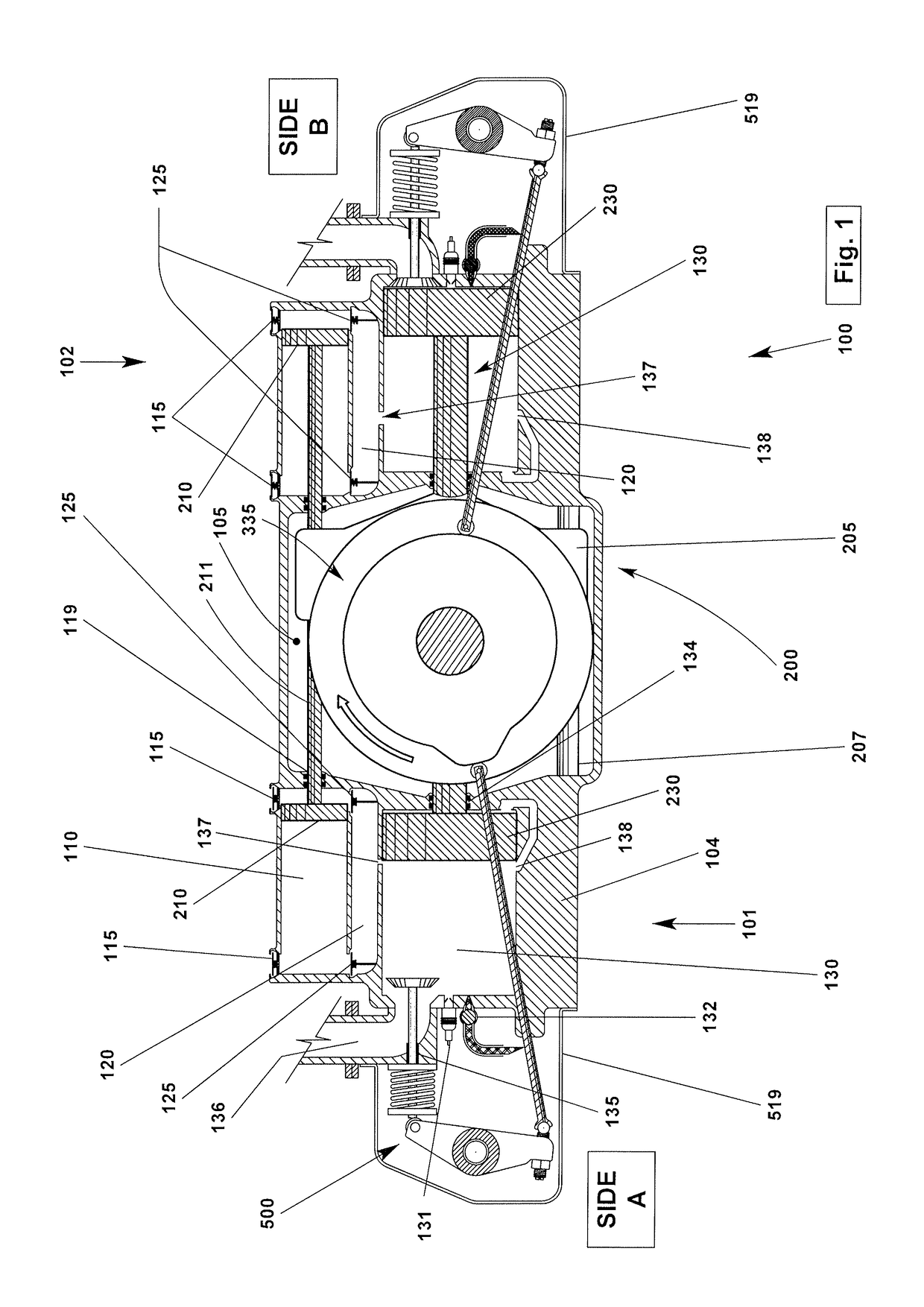

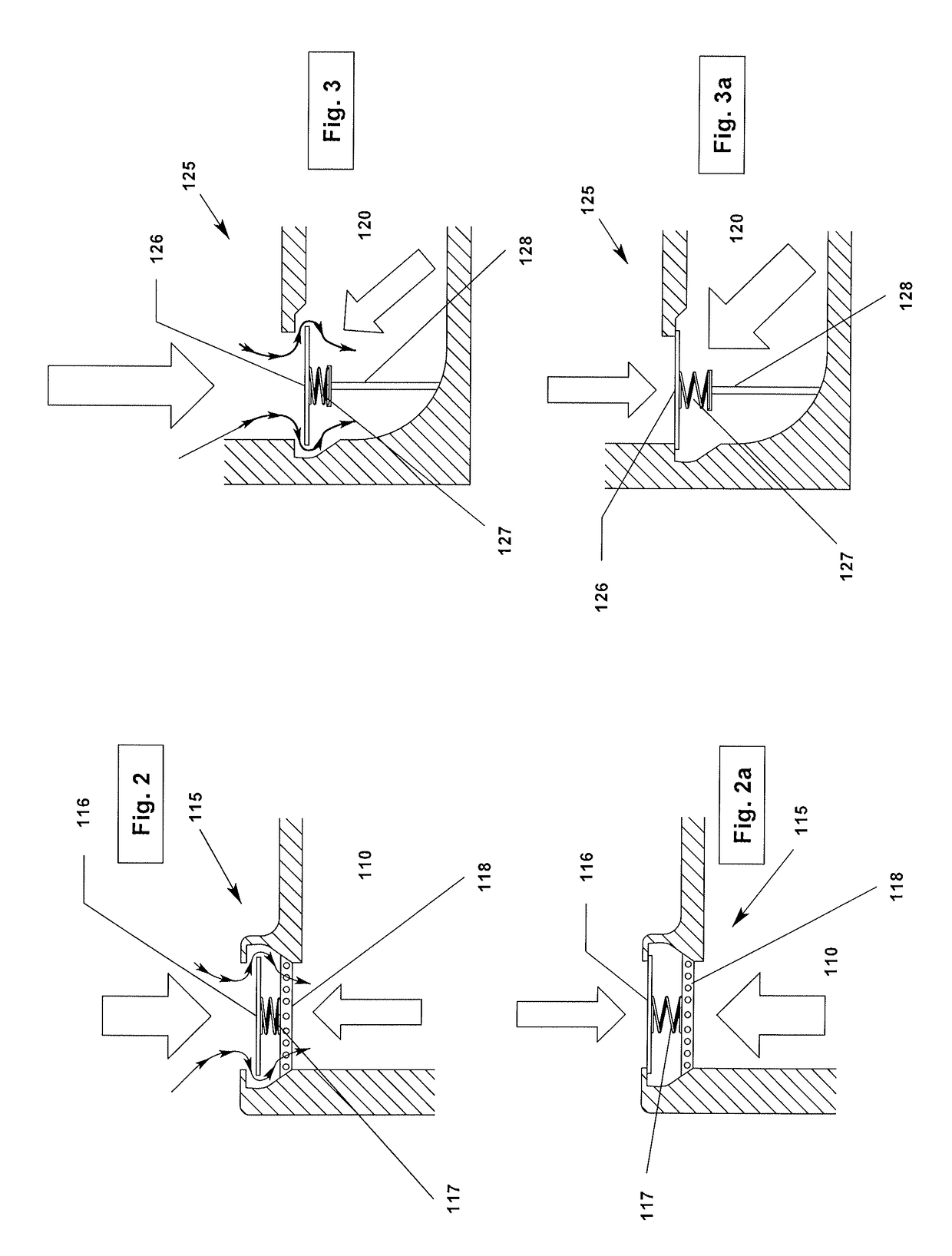

Opposed piston internal combustion engine with inviscid layer sealing

InactiveUS9909492B2Close toleranceAccurate concentricityCombustion enginesReciprocating piston enginesDetonationCombustion

An opposed-piston engine that forms an inviscid layer between pistons and the respective cylinder walls. In an aspect, the opposed-piston engine utilizes a Scotch yoke assembly that includes rigidly connected opposed combustion pistons. In an aspect, the Scotch yoke assembly is configured to transfer power from the combustion pistons to a crankshaft assembly. In an aspect, the crankshaft assembly can be configured to have dual flywheels that are internal to the engine, and can be configured to assist with an exhaust system, a detonation system, and / or a lubrication system.

Owner:PRIME GRP ALLIANCE

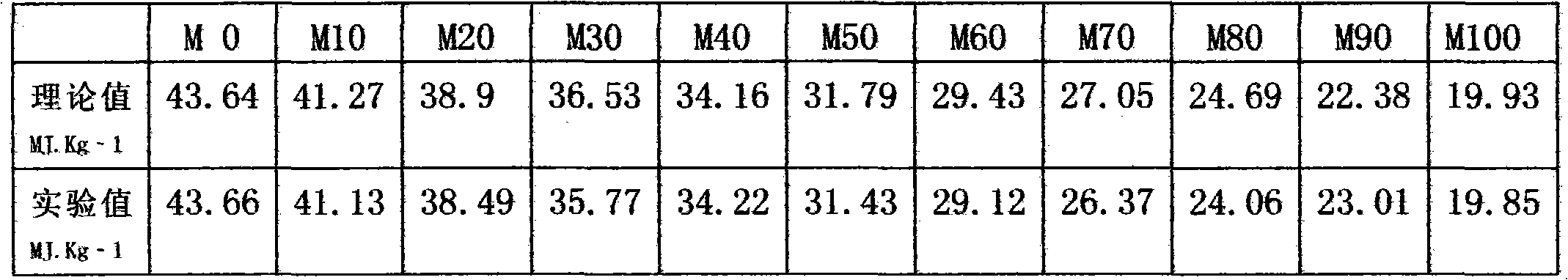

Methanol diesel oil manufacturing mode

The invention relates to a manufacturing mode of environment-friendly and energy-saving M15_M85 methanol diesel oil. The methanol diesel oil is composed of diesel oil, methanol, and additives. The methanol diesel oil is prepared with operations under normal temperatures and normal pressures. The invention discloses a plurality of common additives used for preparing methanol diesel oil in modern times. If explosives and aviation fuels are appropriately utilized, methanol defalcated heat value can be well compensated. The theory is tentatively considered as a gaseous detonation theory. The additives can be selected from nitric acid esters, nitrates, nitro compounds, non-aromatic compounds, peroxides, and the like.

Owner:陈若歆

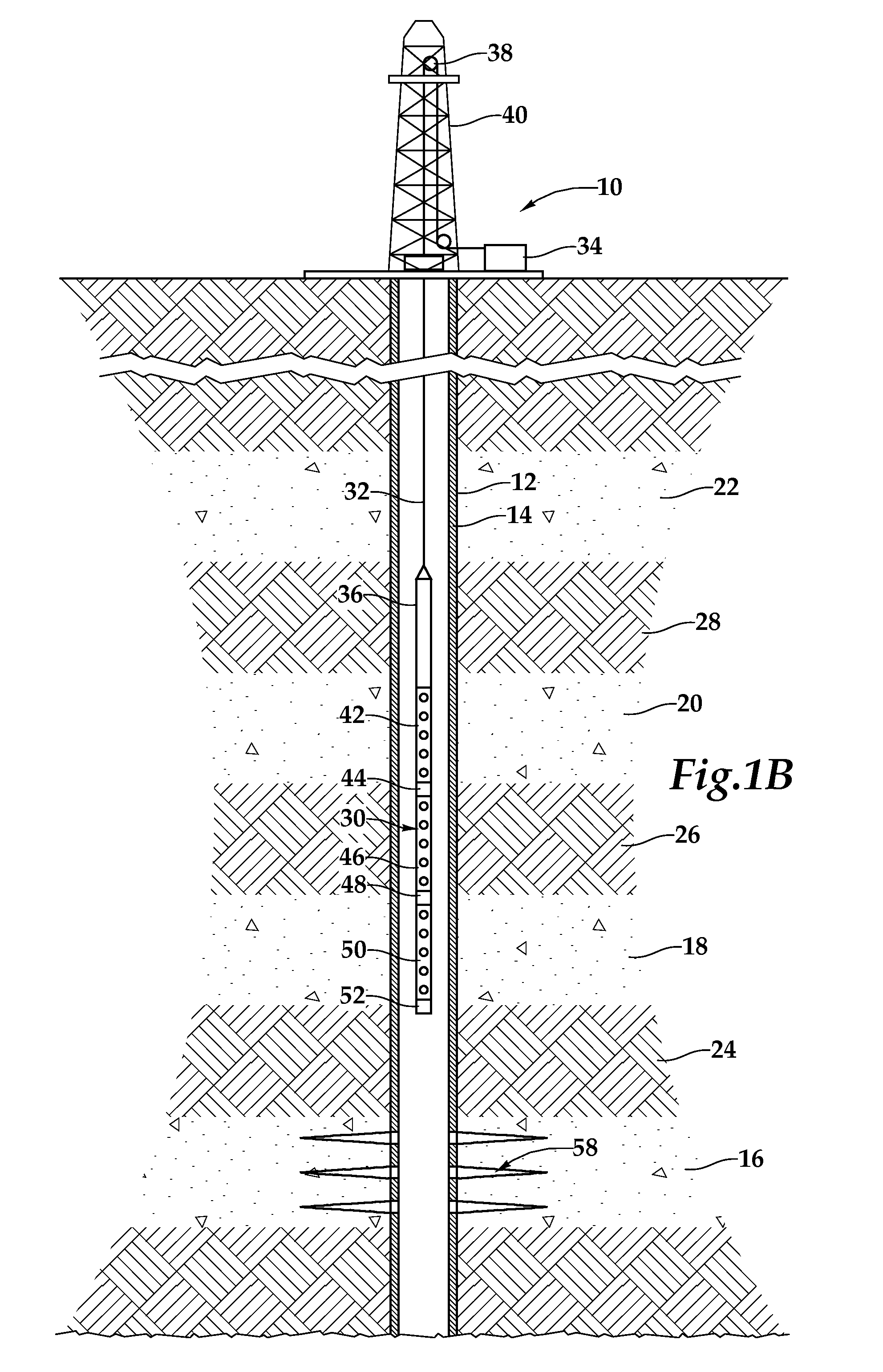

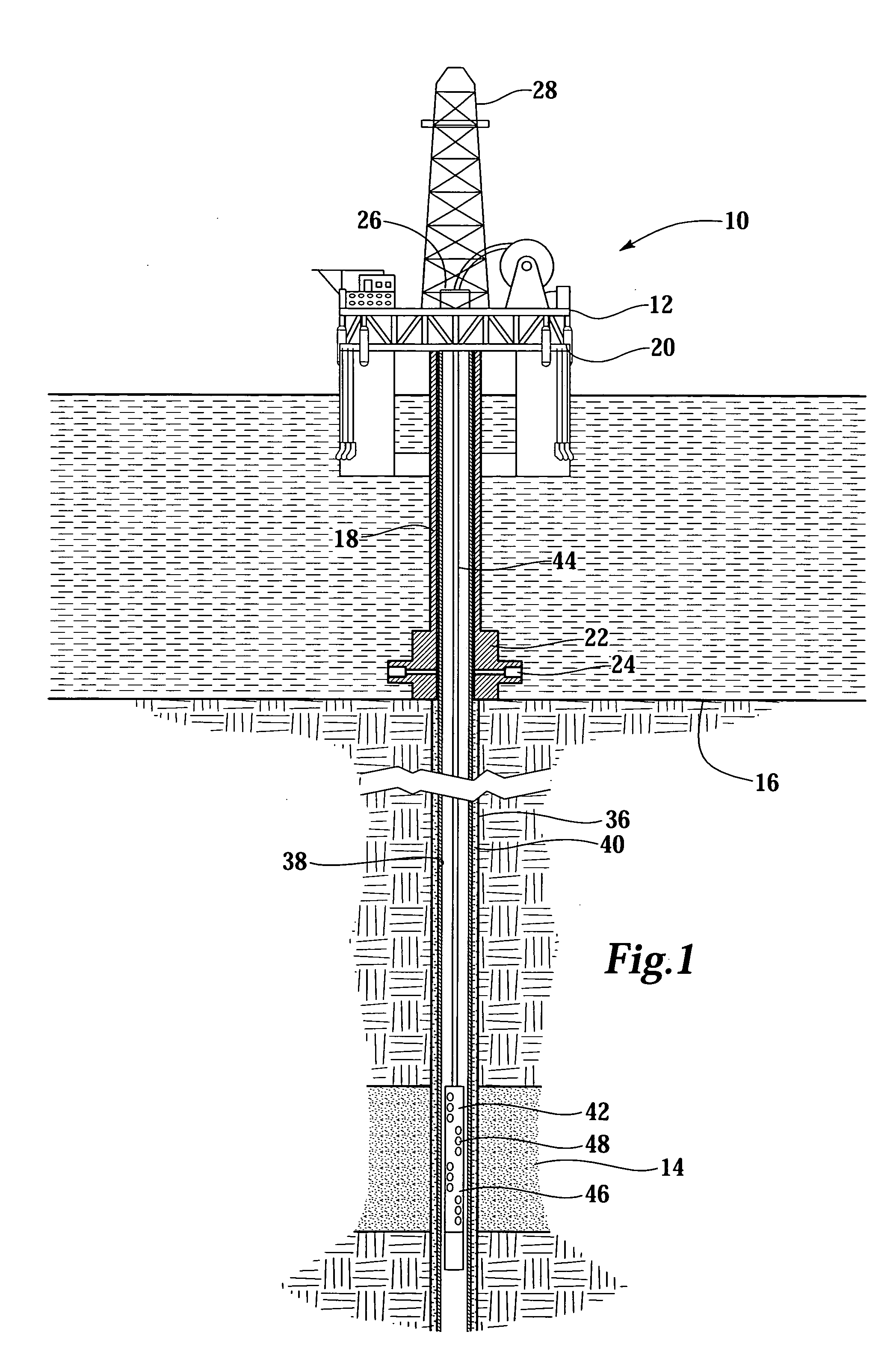

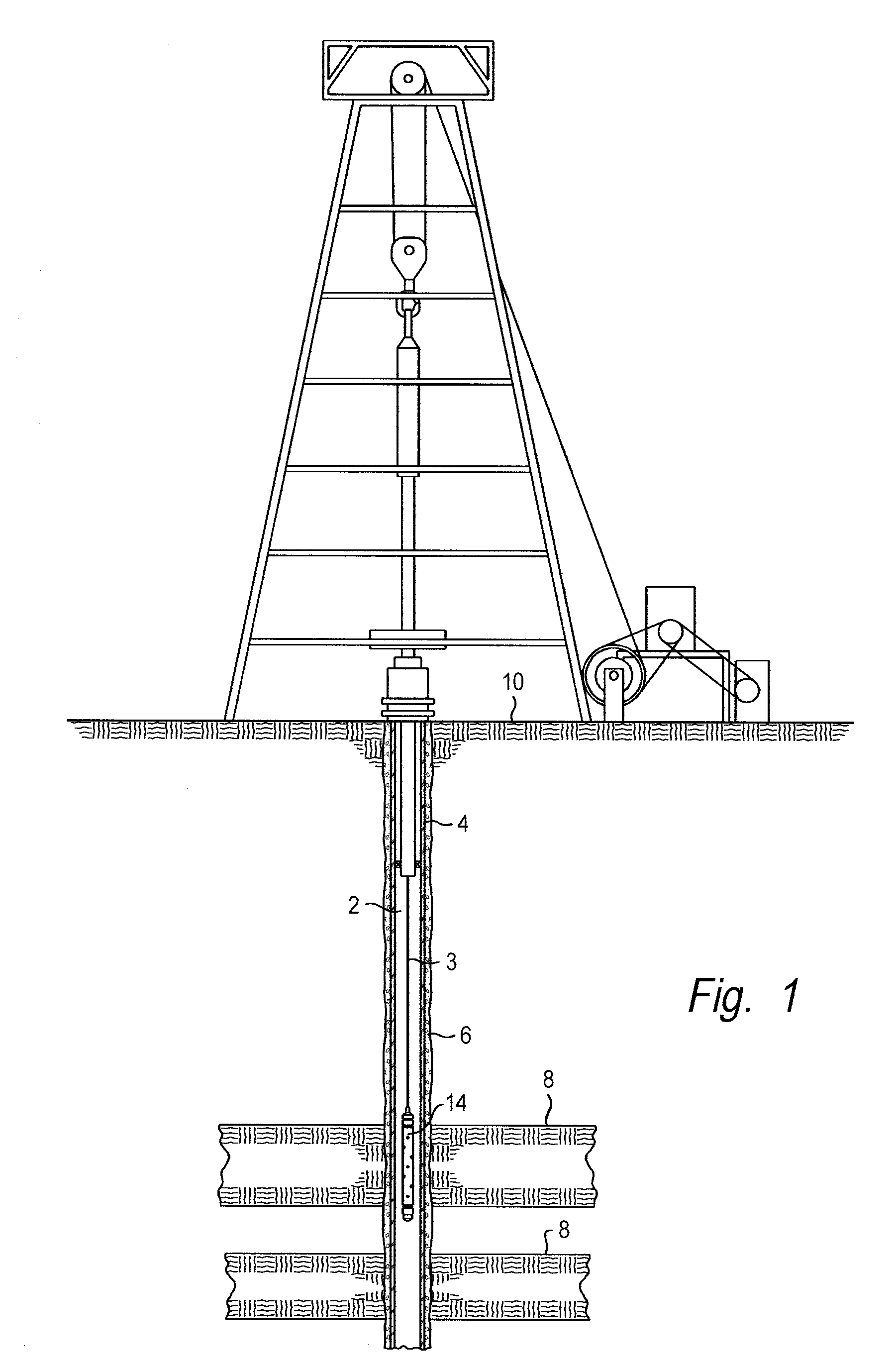

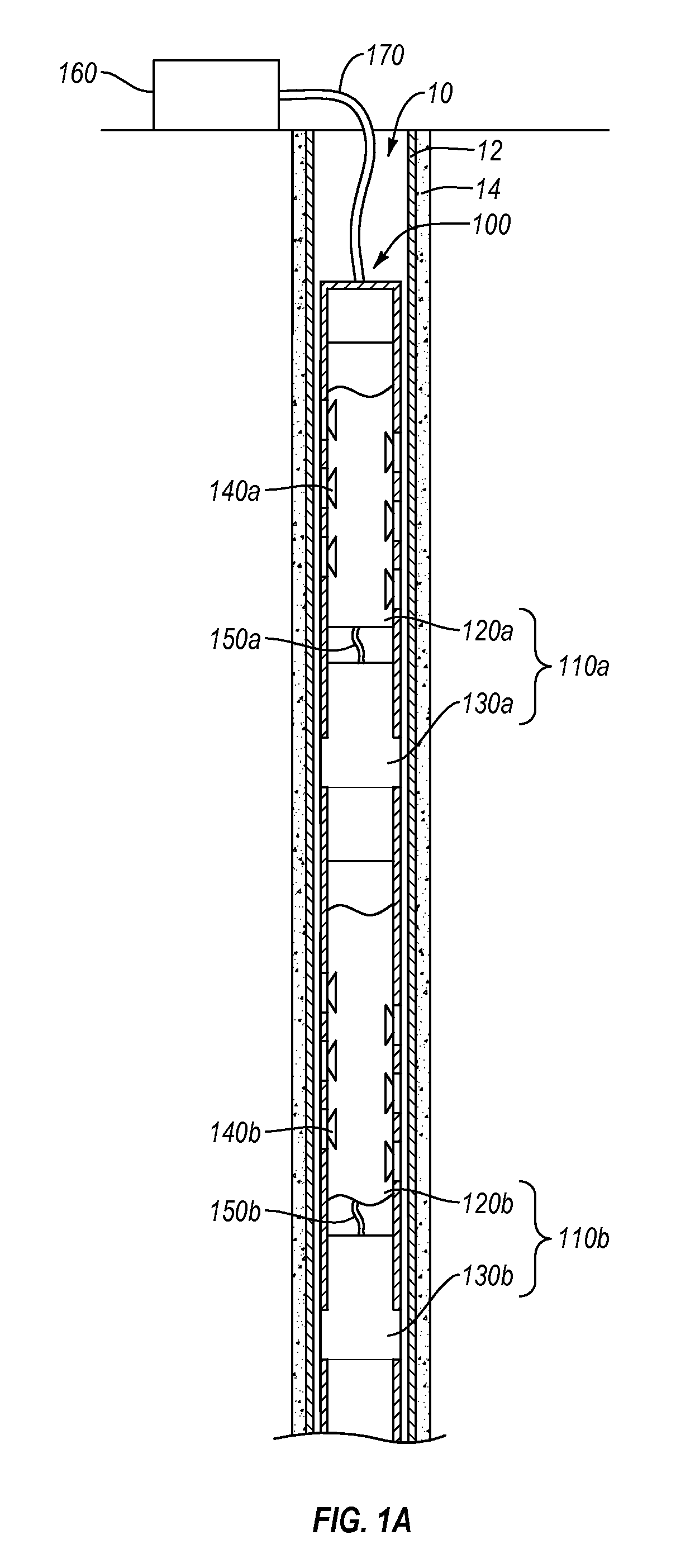

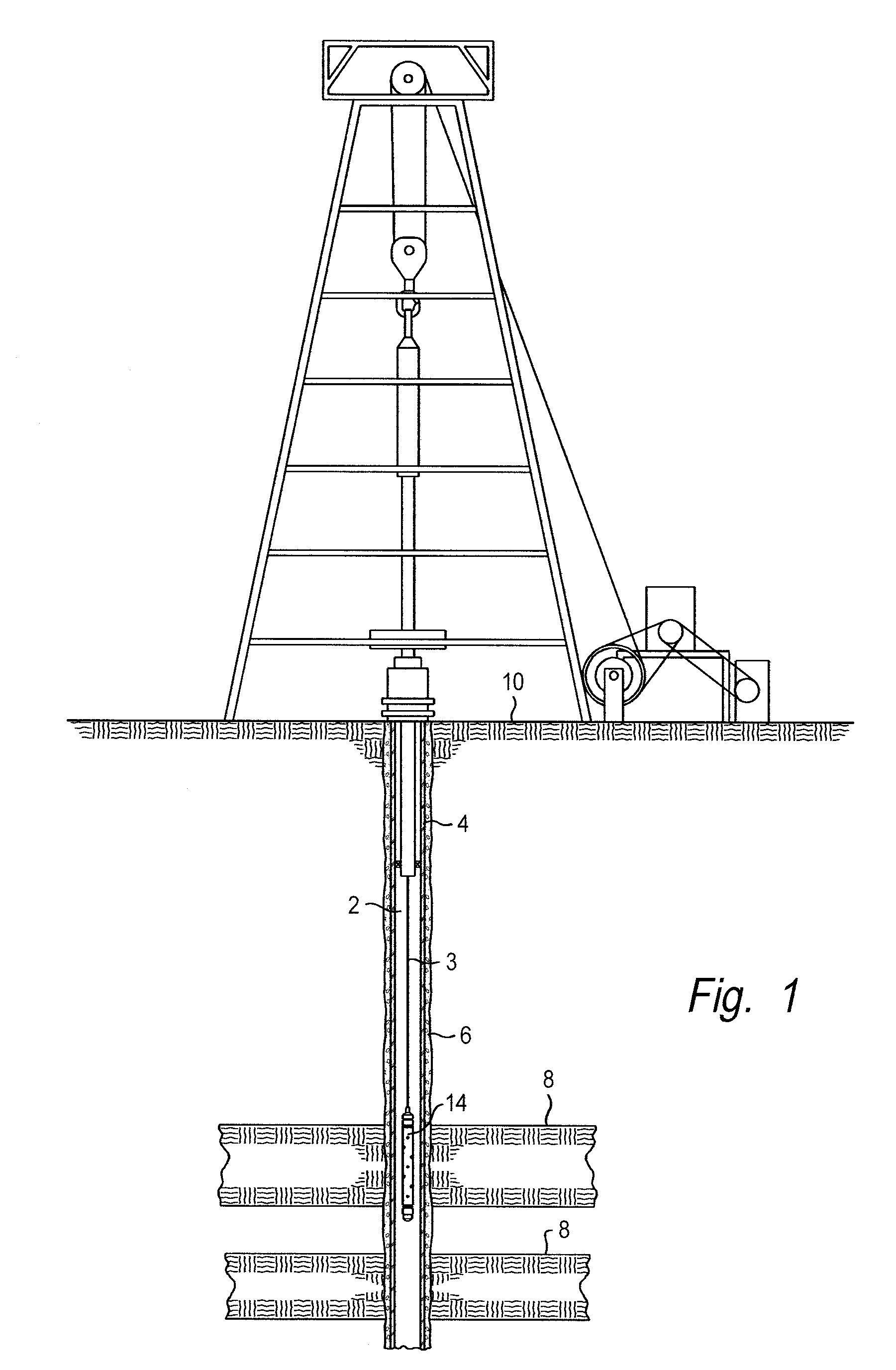

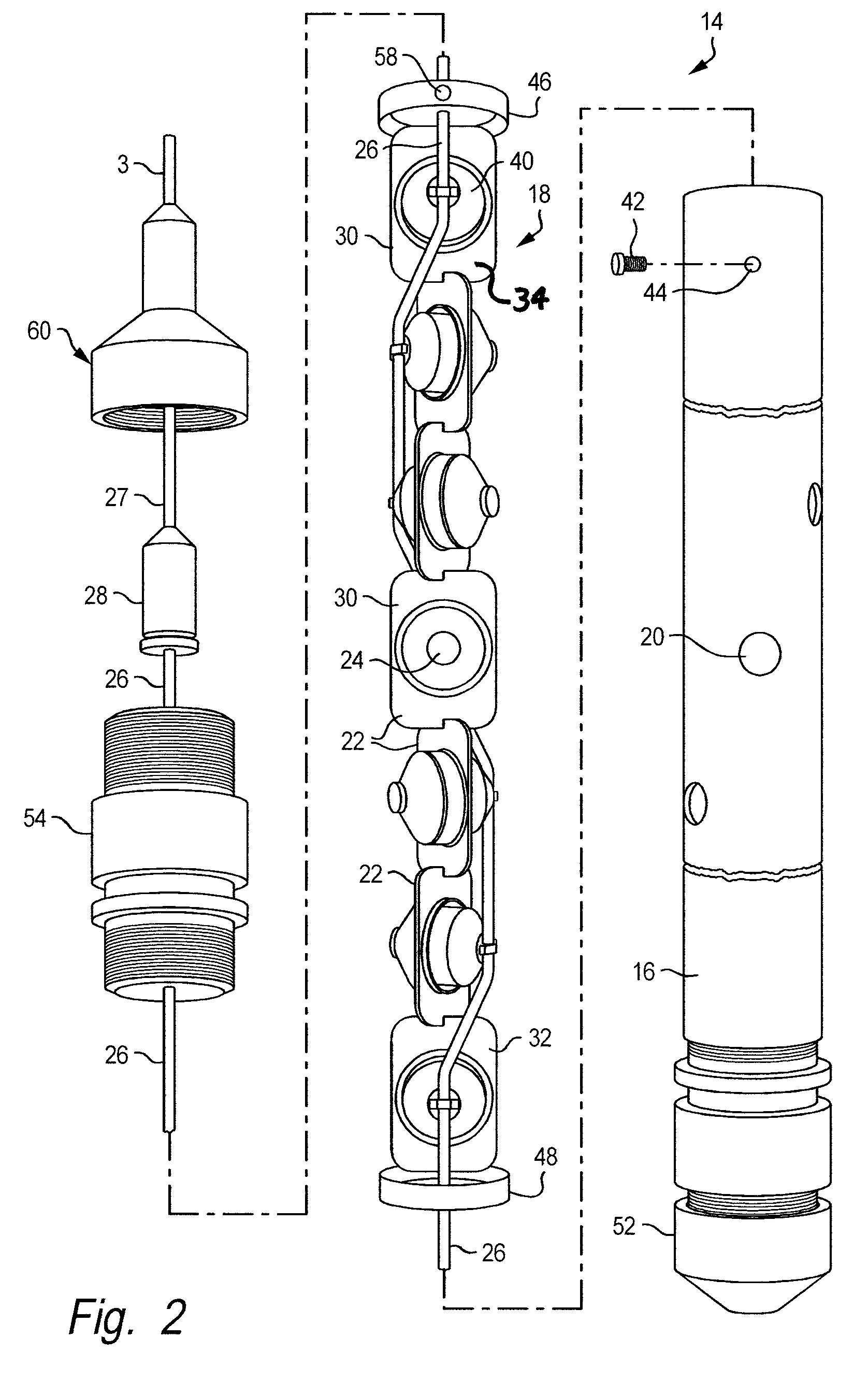

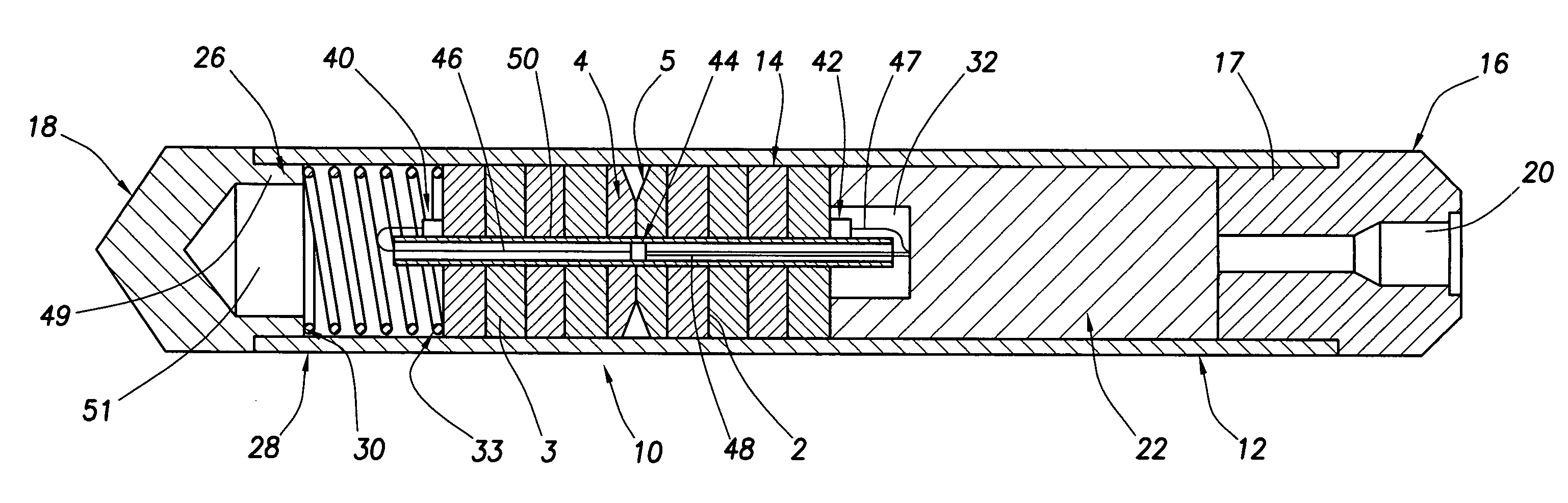

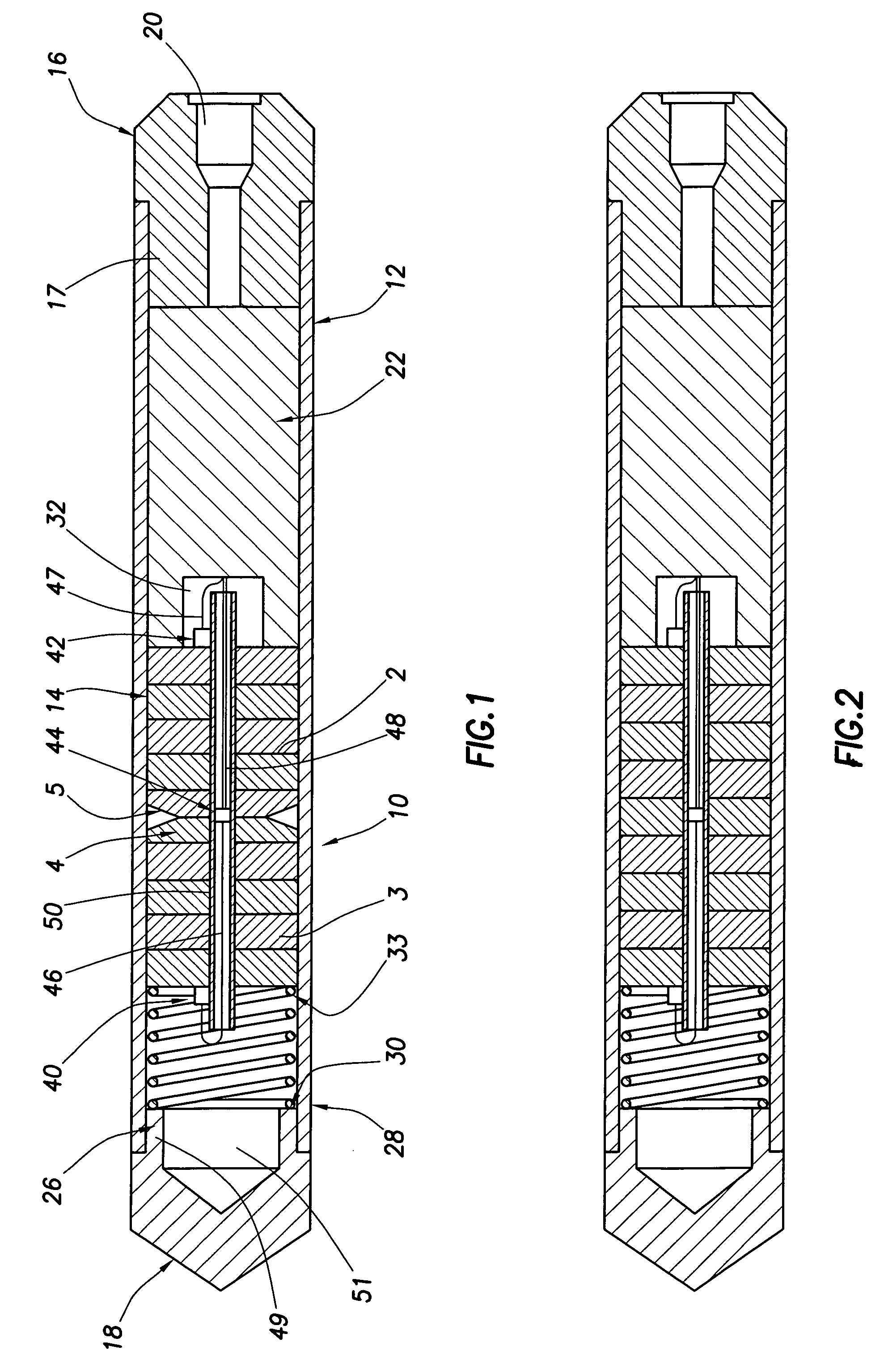

Pulse detonation tool, method and system for formation fracturing

According to one aspect of the invention, a pulse detonation tool is provided for fracturing subterranean formations. The pulse detonation tool includes a pulse detonation combustor and creates an isolated zone within a wellbore. The tool generate a series of repeating supersonic shock waves that are directed into the subterranean formation to cause propagation of multiple fractures into the formation. According to another aspect of the invention, a method and system for fracturing a subterranean formation using pulse detonation is provided.

Owner:GENERAL ELECTRIC CO

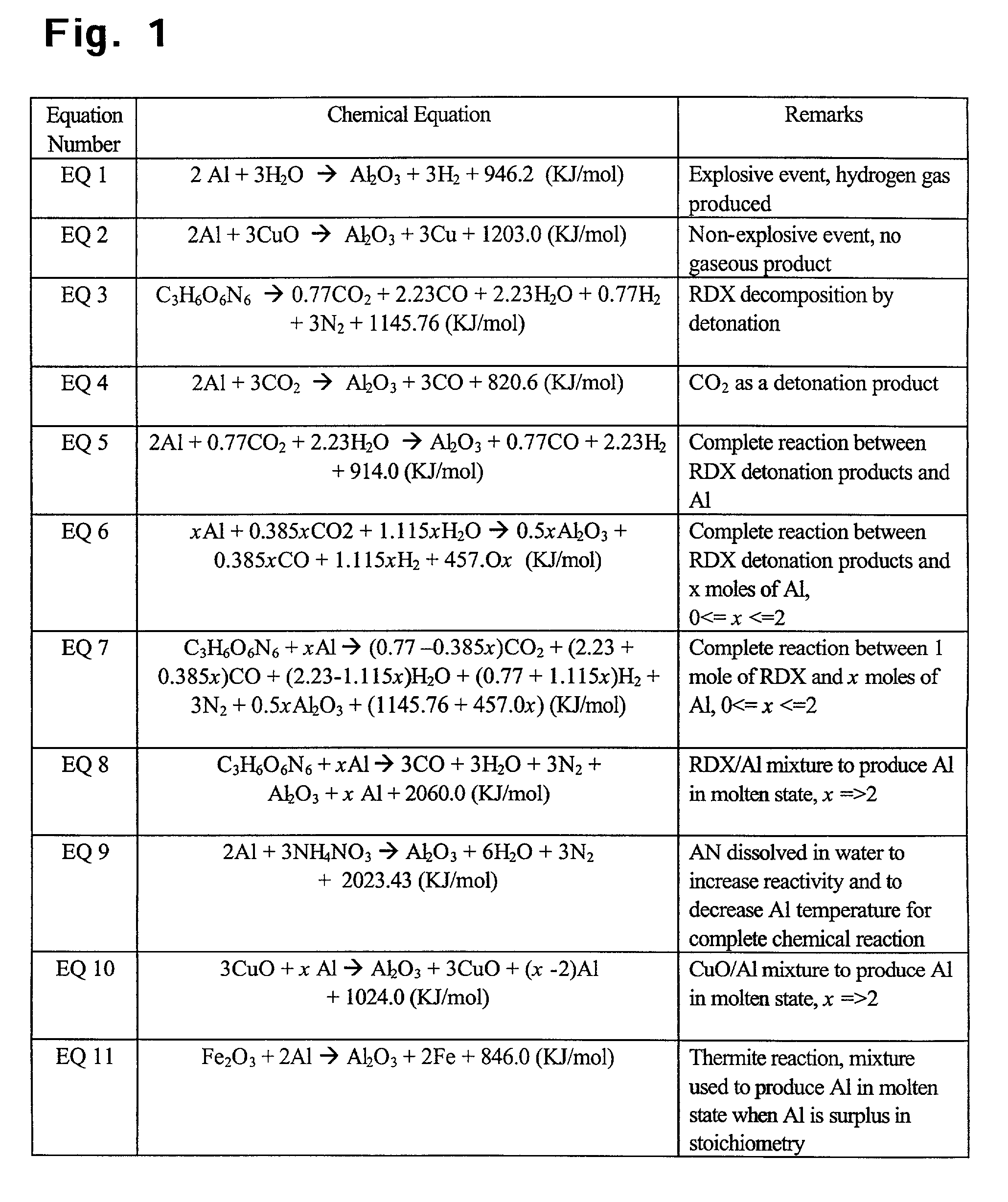

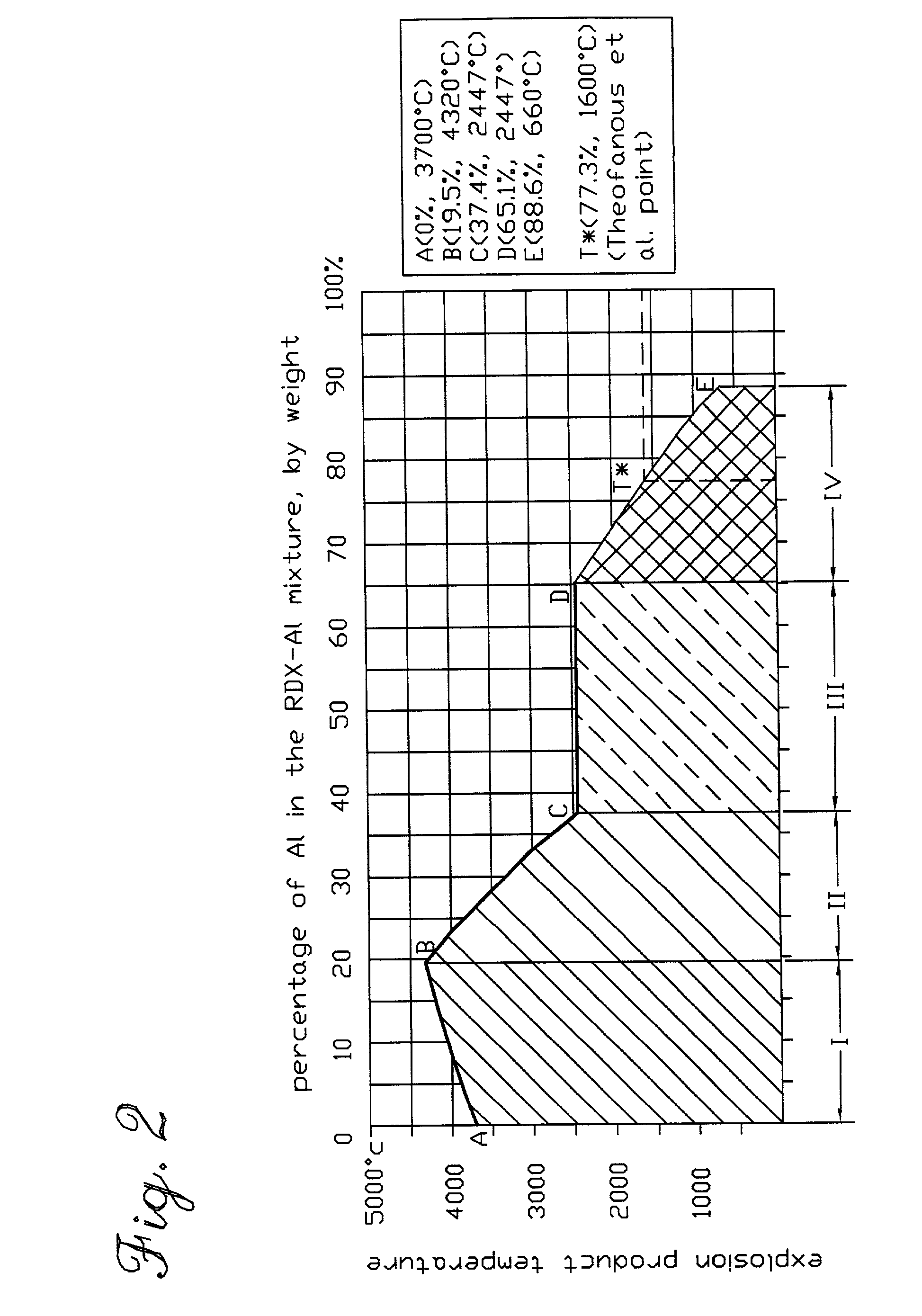

Use of aluminum in perforating and stimulating a subterranean formation and other engineering applications

InactiveUS7393423B2More energy outputImprove mechanical propertiesExplosive chargesBlasting cartridgesMolten stateThermal energy

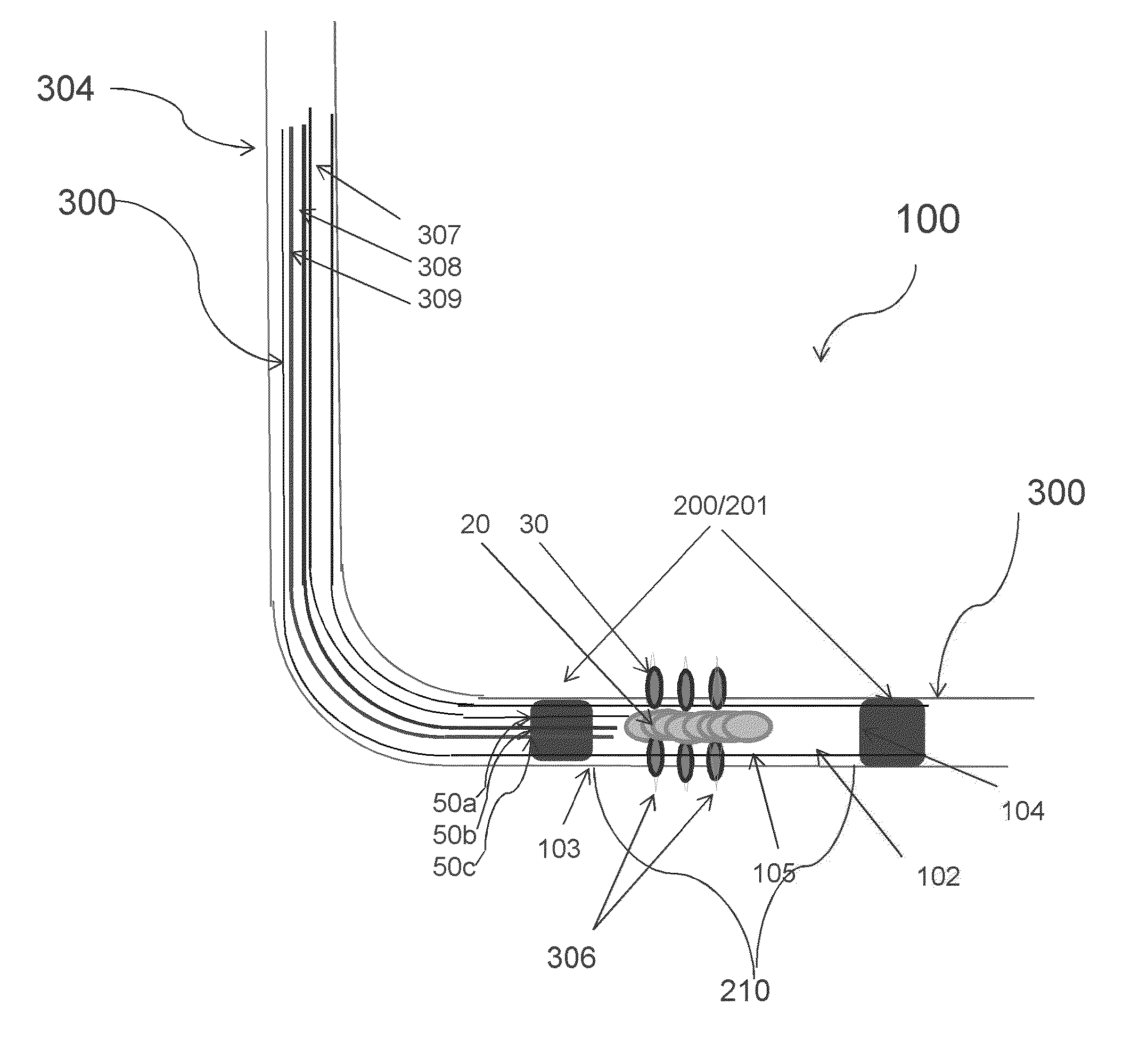

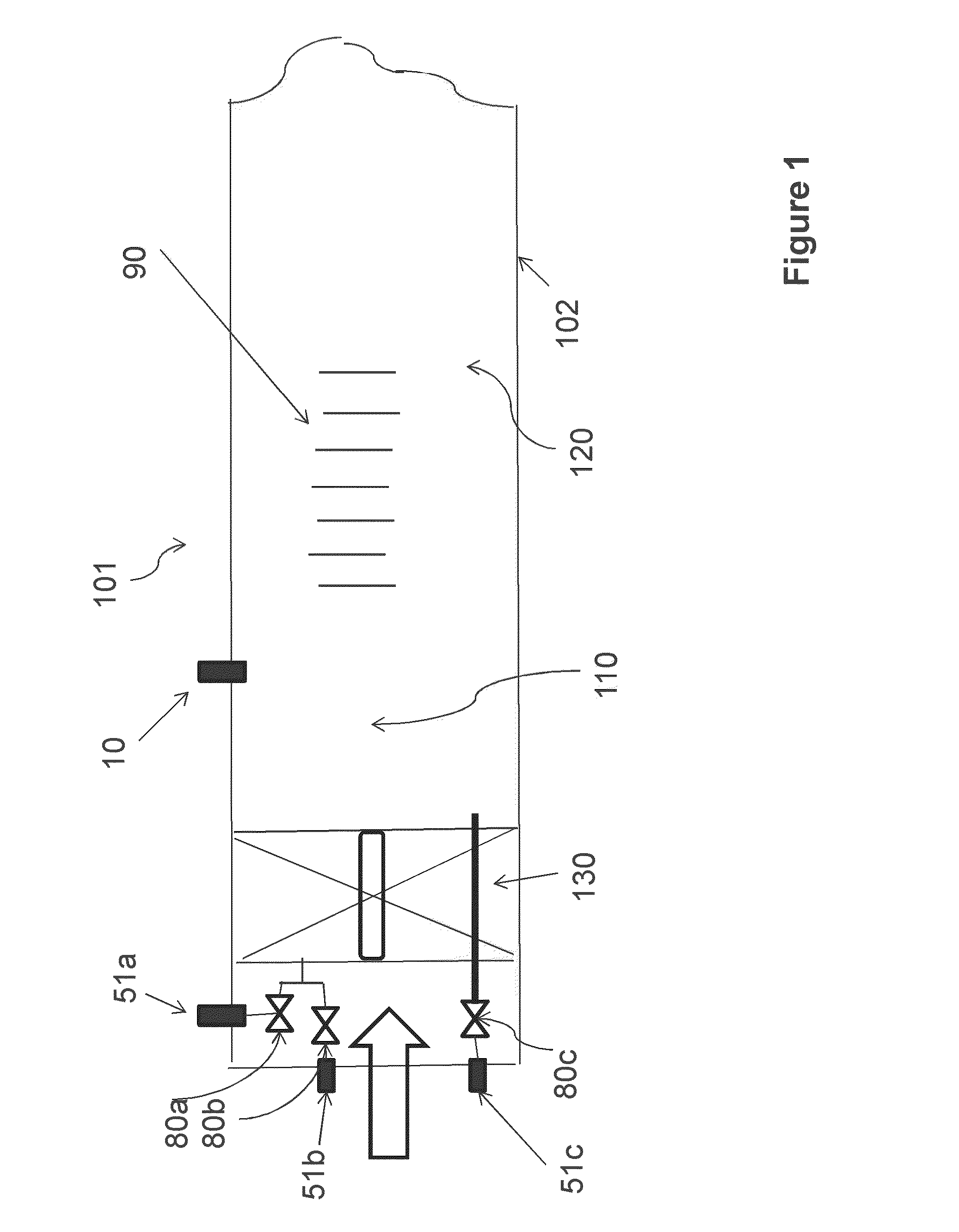

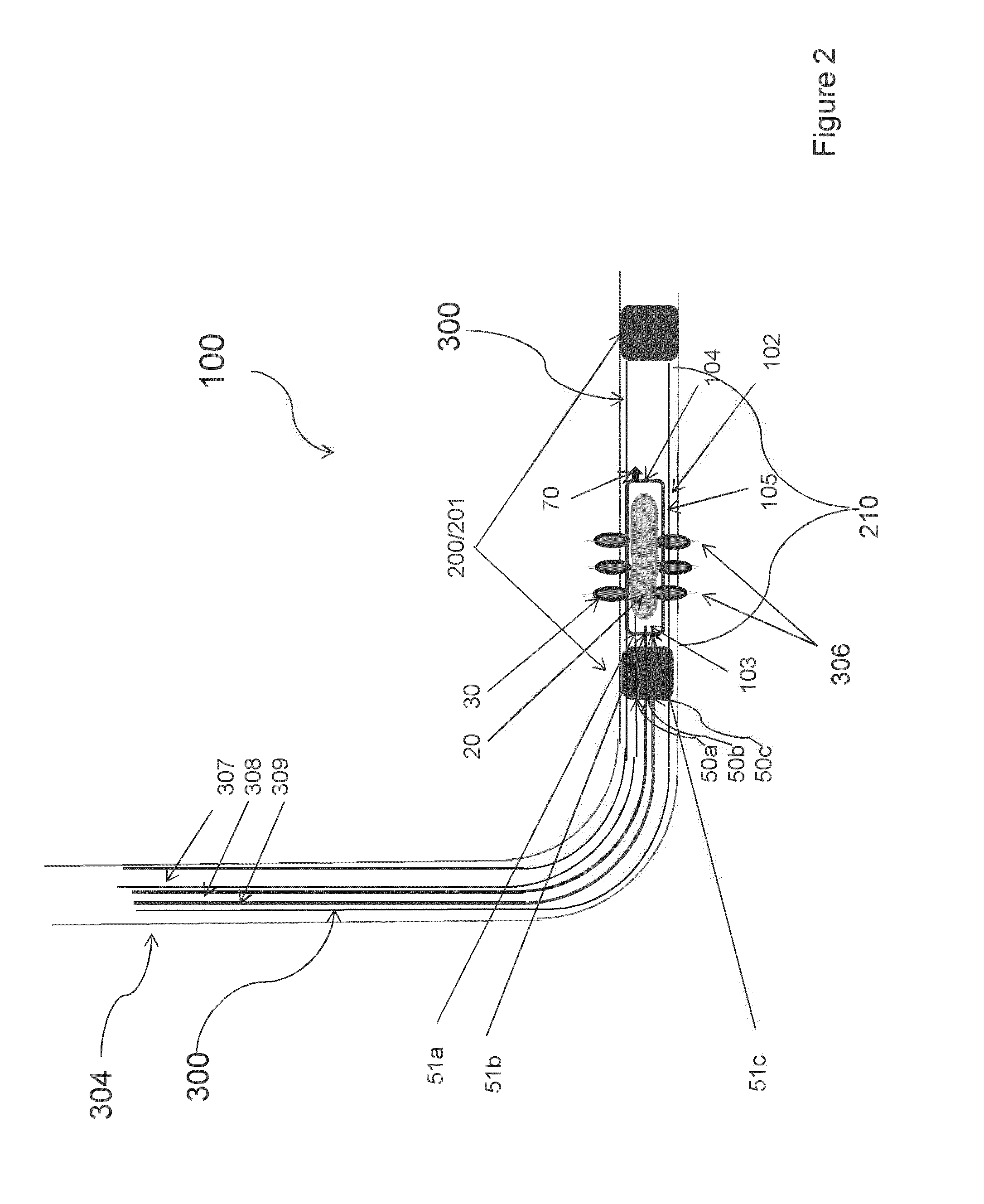

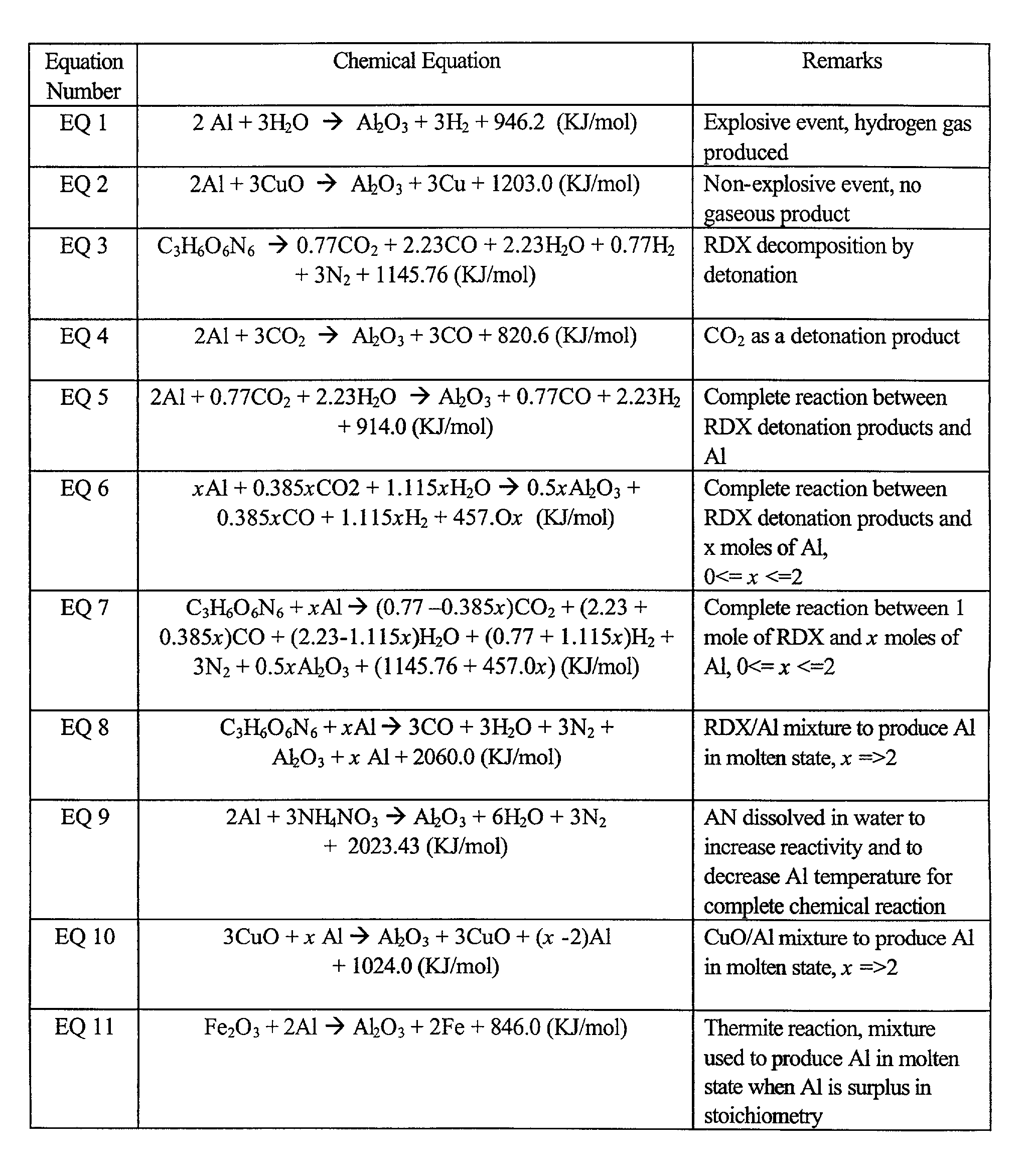

A chemical reaction between molten aluminum and an oxygen carrier such as water to do useful work is disclosed, and in particular two chemical methods to obtain aluminum in its molten state. One is to detonate a HE / Al mixture with surplus Al in stoichiometry, and the other is to use an oxidizer / Al mixture with surplus Al in stoichiometry. Additionally, there is a physical method of shocking and heating Al using high temperature reaction products. The produced Al in its liquid form is forced to react with an oxygen carrying liquid (e.g. water), giving off heat and releasing hydrogen gas or other gaseous material. A water solution of some oxygen-rich chemicals (e.g. ammonium nitrate) can be advantageously used in place of water. A shaped charge is also disclosed having a liner that contains aluminum, propelled by a high explosive such as RDX or its mixture with aluminum powder. Some aluminum in its molten state is projected into the perforation and forced to react with water that also enters the perforation, creating another explosion, fracturing the crushed zone of the perforation and initializing cracks. Another shaped charge is shown having a liner of energetic material such as a mixture of aluminum powder and a metal oxide. Upon detonation, the collapsed liner carries kinetic and thermal energy. Also shown are methods to build and to detonate or fire explosive devices in an oxygen carrying liquid (e.g. water) to perforate and stimulate a hydrocarbon-bearing formation.

Owner:GEODYNAMICS

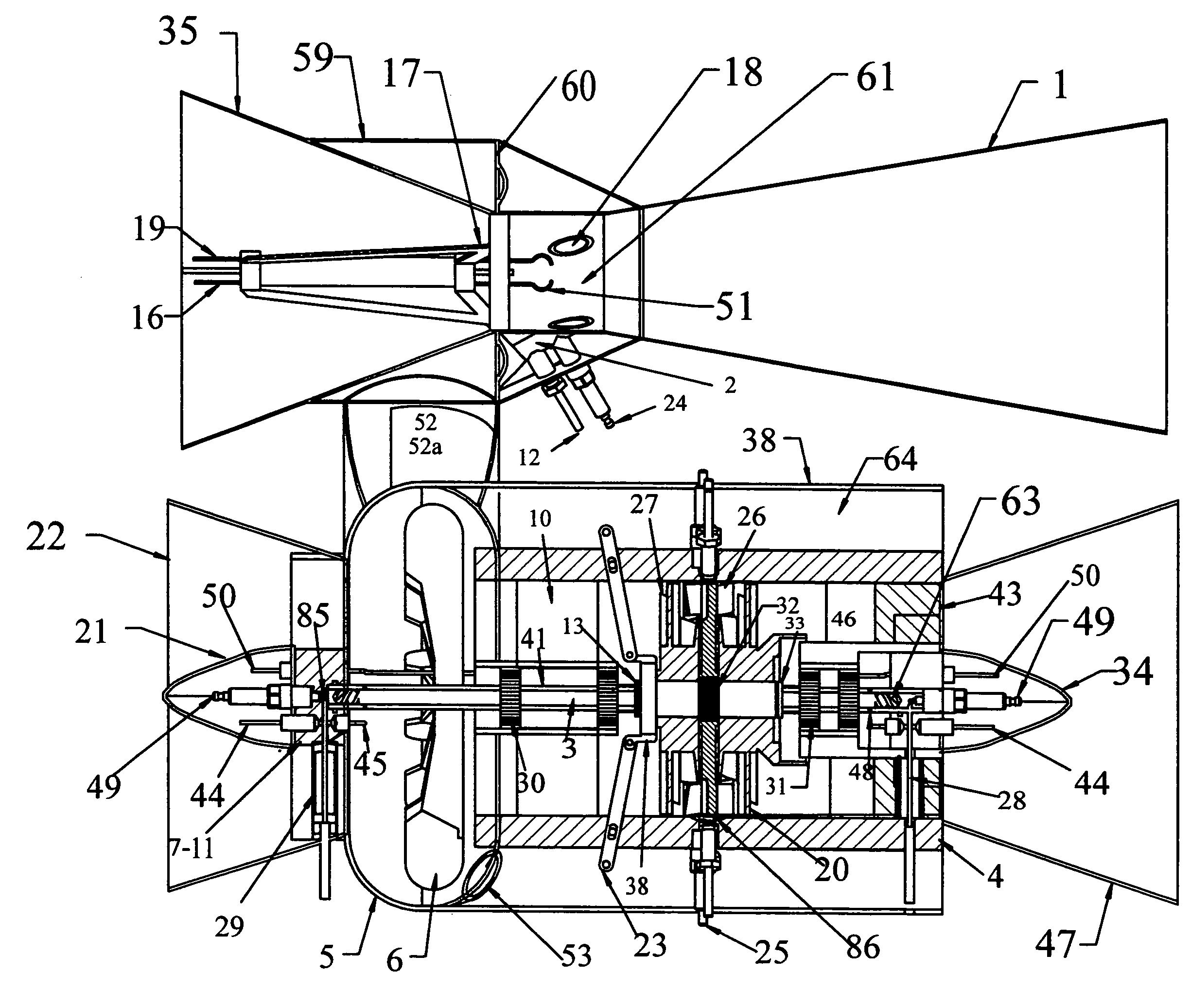

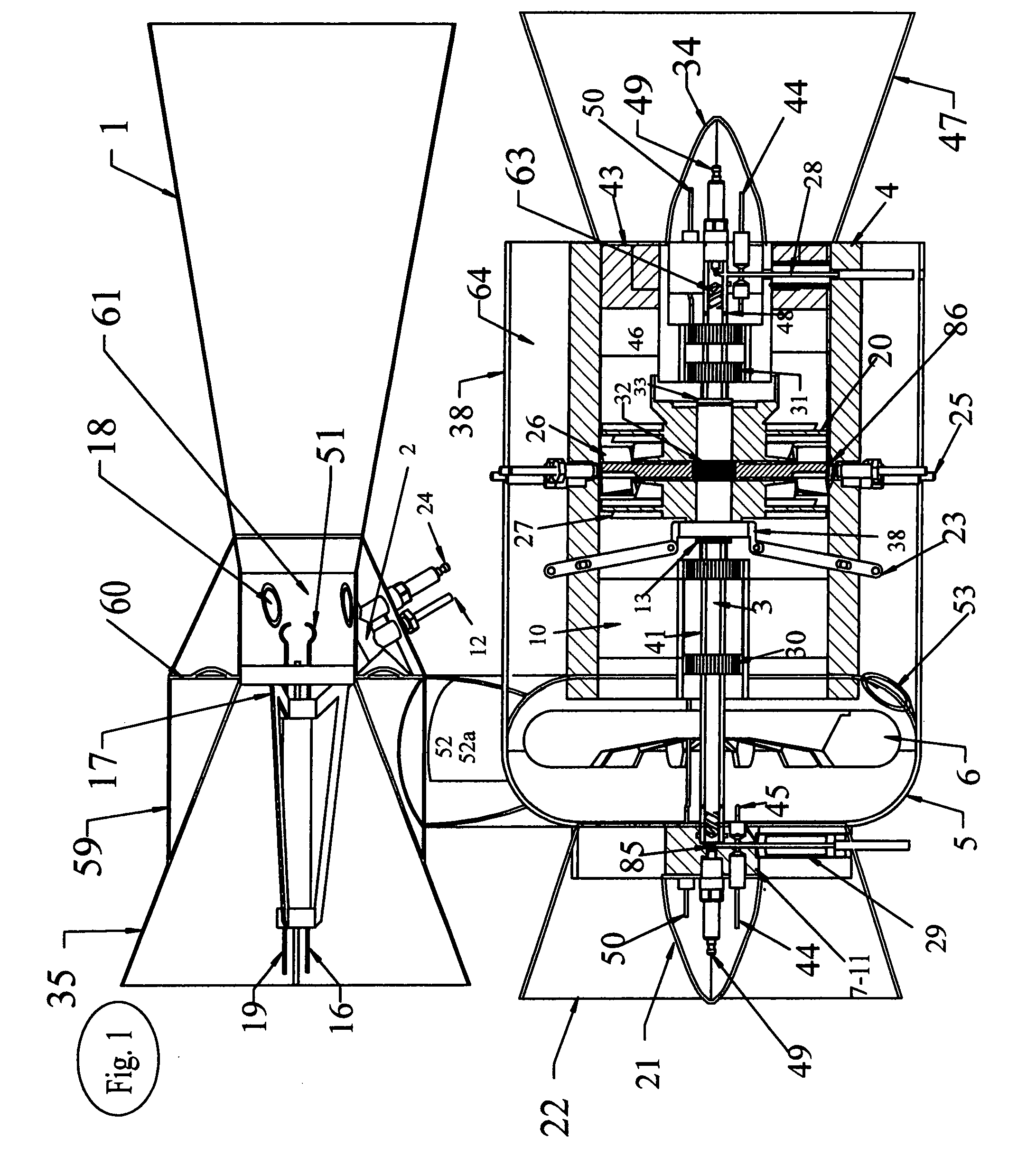

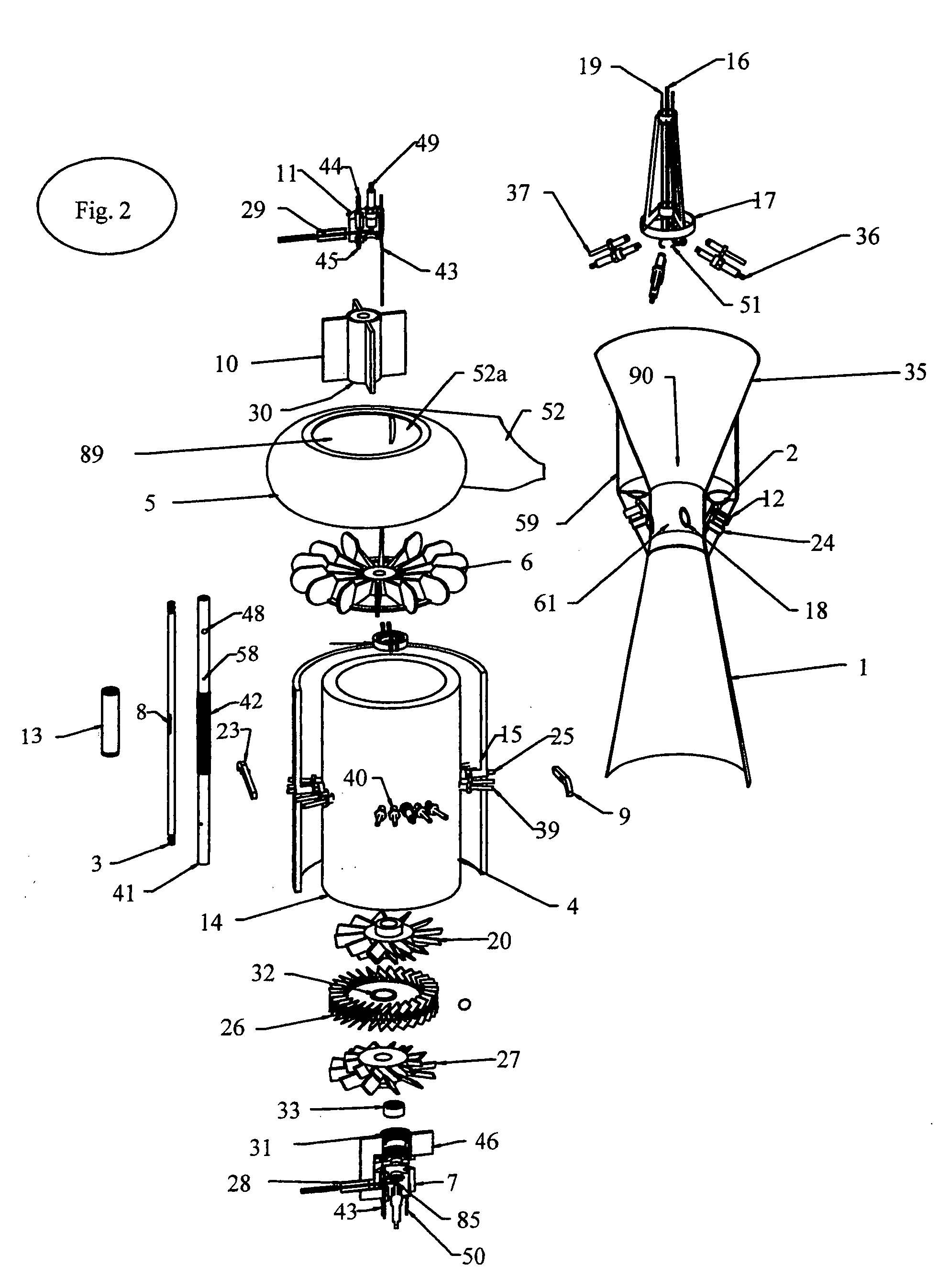

Methods of combining a series of more efficient aircraft engines into a unit, or modular units

InactiveUS20100251692A1More thermal capacityReduce environmental pollutionContinuous jet plantsRocket engine plantsRamjetFree-piston engine

The present invention generally relates to units of engines and more particularly to units containing a unique combined-cycle (combustion-detonation) “counter-rotation, anti-gyration, gyroscopic,” turbine fan-jet / free-piston engine configuration for induced air supercharging and boosting the performance of novel Ramjet engines or Ramjet engine configurations by improving internal air-stream dynamics. These dynamics are the result of co-operative air stream intermixing through convergent, supercharge-attenuated, inducted, compressed, tuned, pre-heated ambient air. Achieved through the varying of the geometric structural form and the utilization of unique engines and air induction and propulsion conformations, aided with supplemental air, fuel, oxygen and optiomal water and electrolyte charging.

Owner:KINDE SR RONALD AUGUST

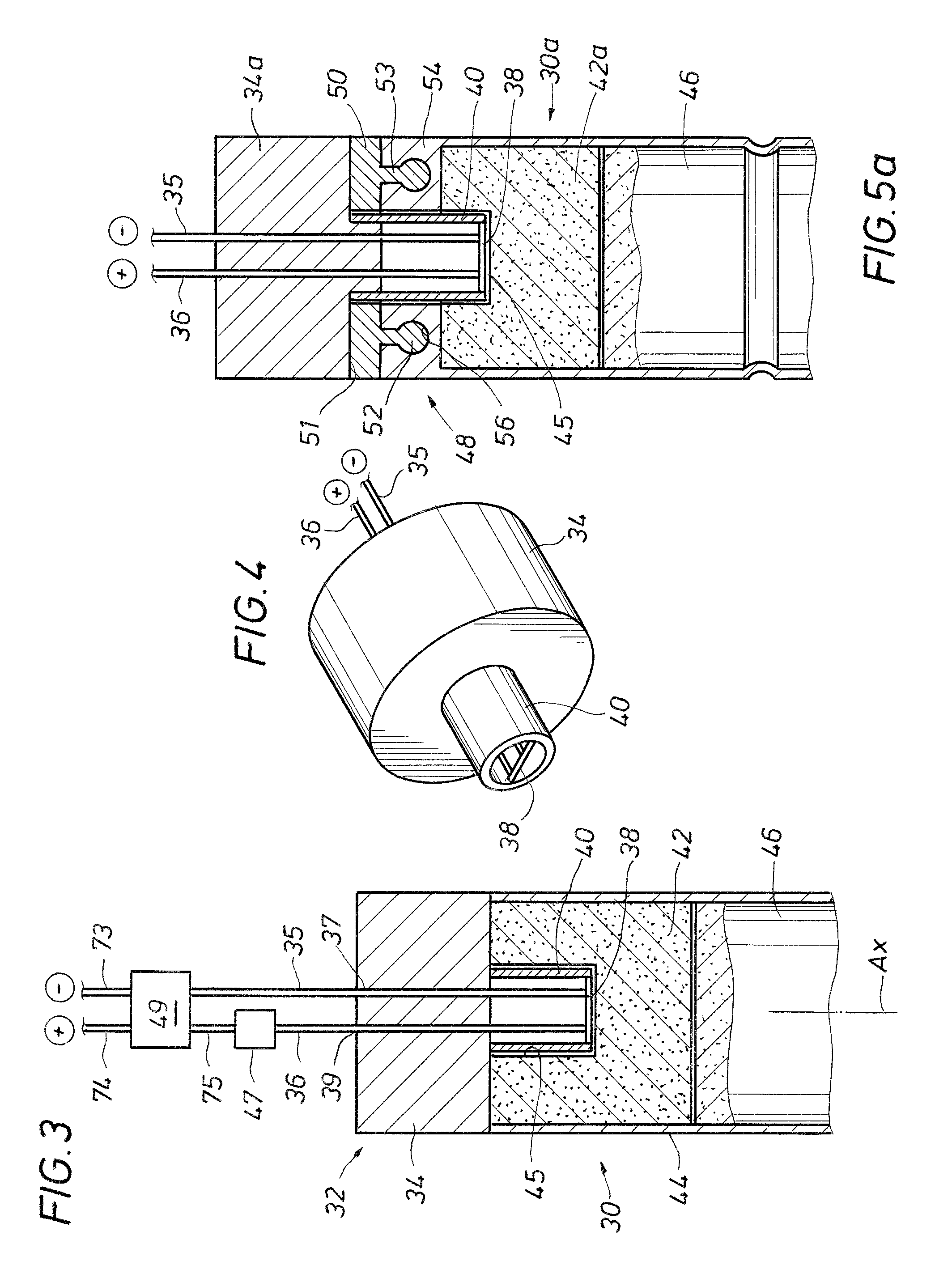

Perforating system with shaped charge case having a modified boss

A perforating gun having a charge case with a boss element partially circumscribing Optionally the pair of bosses may be included that are substantially symmetric about the axis of the charge case. Forming a shaped charge with such a charge case allows for gun strips to be formed with increased web material between adjacent shape charges in the gun strips. The increased web material provides for a more structurally sound gun tube, especially when dealing with high density charges. Notches may be provided in the gun tube on the outer radius of the holes formed to receive the shape charges, the notches are to be aligned with the bosses on the outer periphery of the shaped charge case. This also may orient the charge cases so they are pre-aligned for ready connection to an associated detonation cord.

Owner:BAKER HUGHES INC

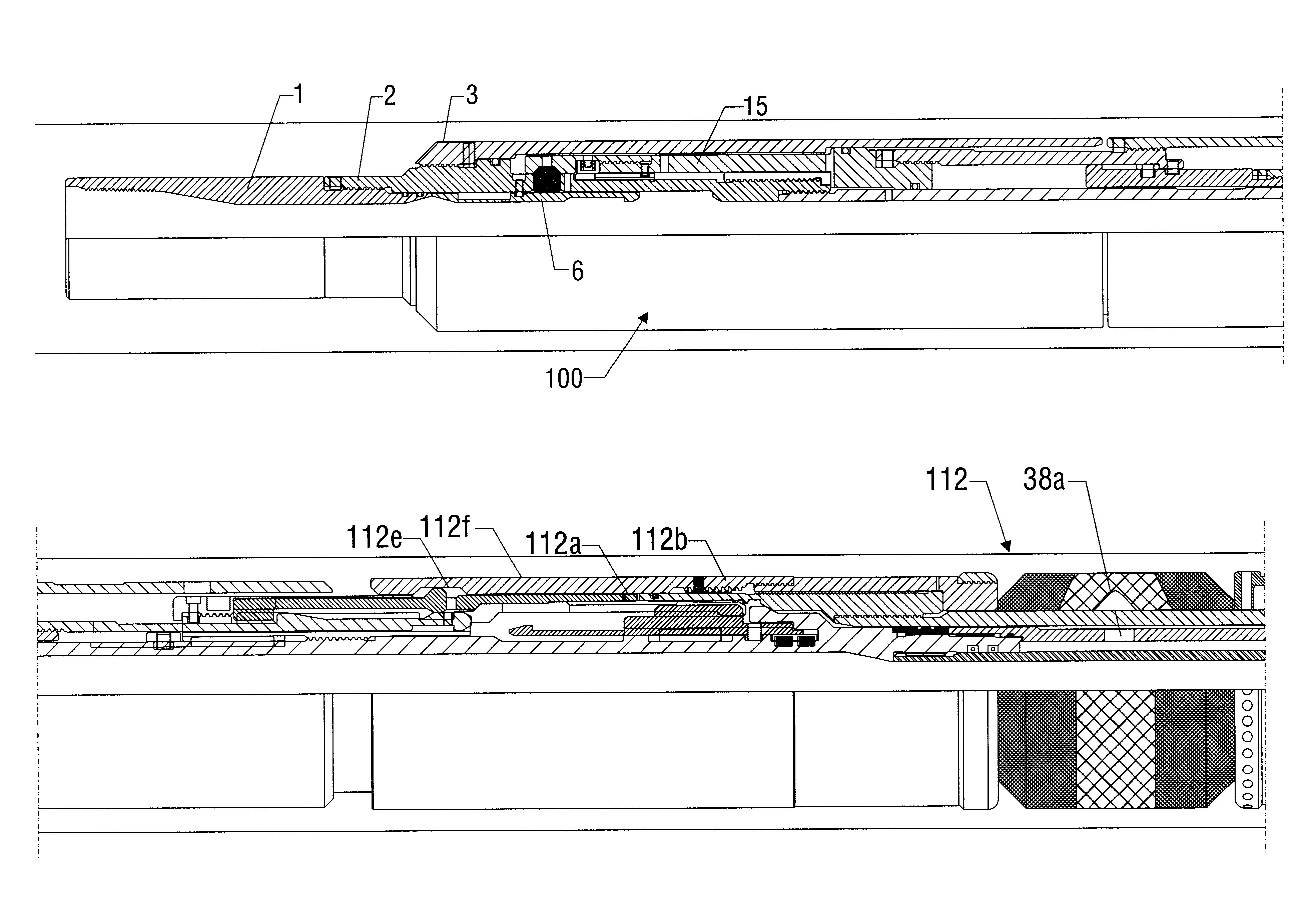

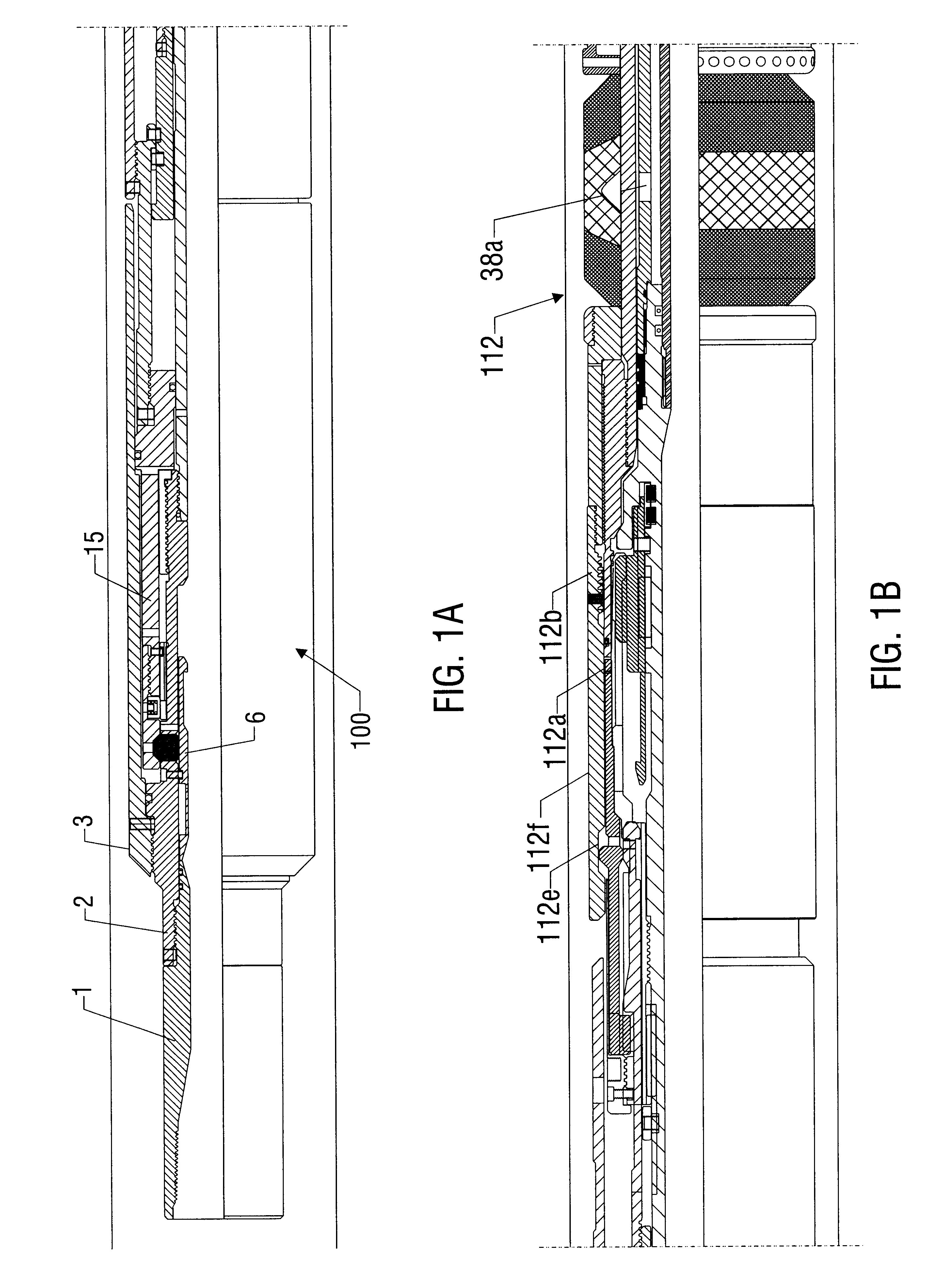

Electric and Ballistic Connection Through A Field Joint

ActiveUS20110024116A1Engagement/disengagement of coupling partsTwo pole connectionsDetonatorDetonation

A perforating system having annular connectors for attachment between adjacent perforating guns and connectors. The connectors include male and female connectors with respective outer and inner contact surfaces. The connectors also include attachment for electrical detonators and / or booster charges for transferring ballistic detonations between the perforating gun and connector sub.

Owner:BAKER HUGHES INC

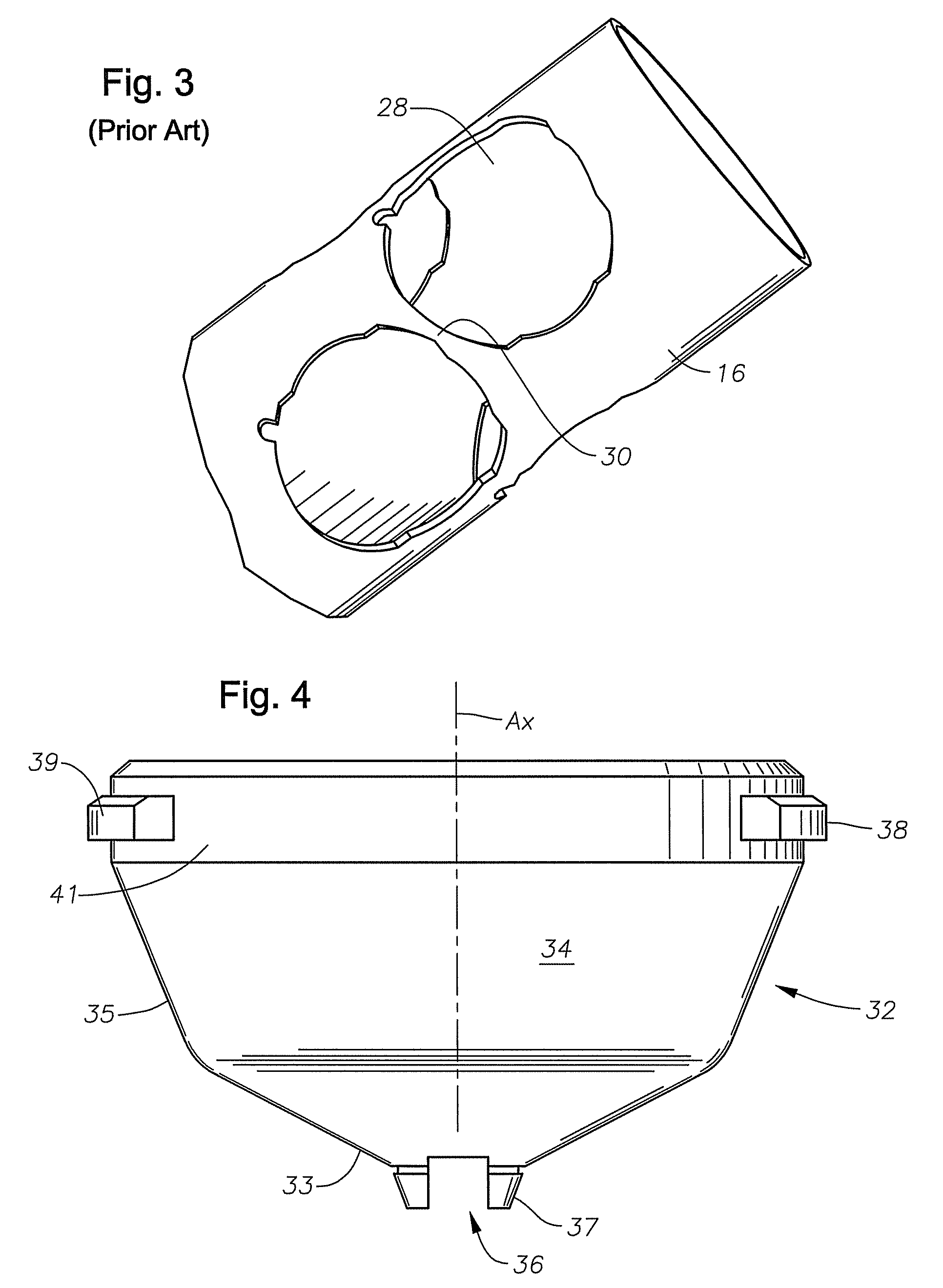

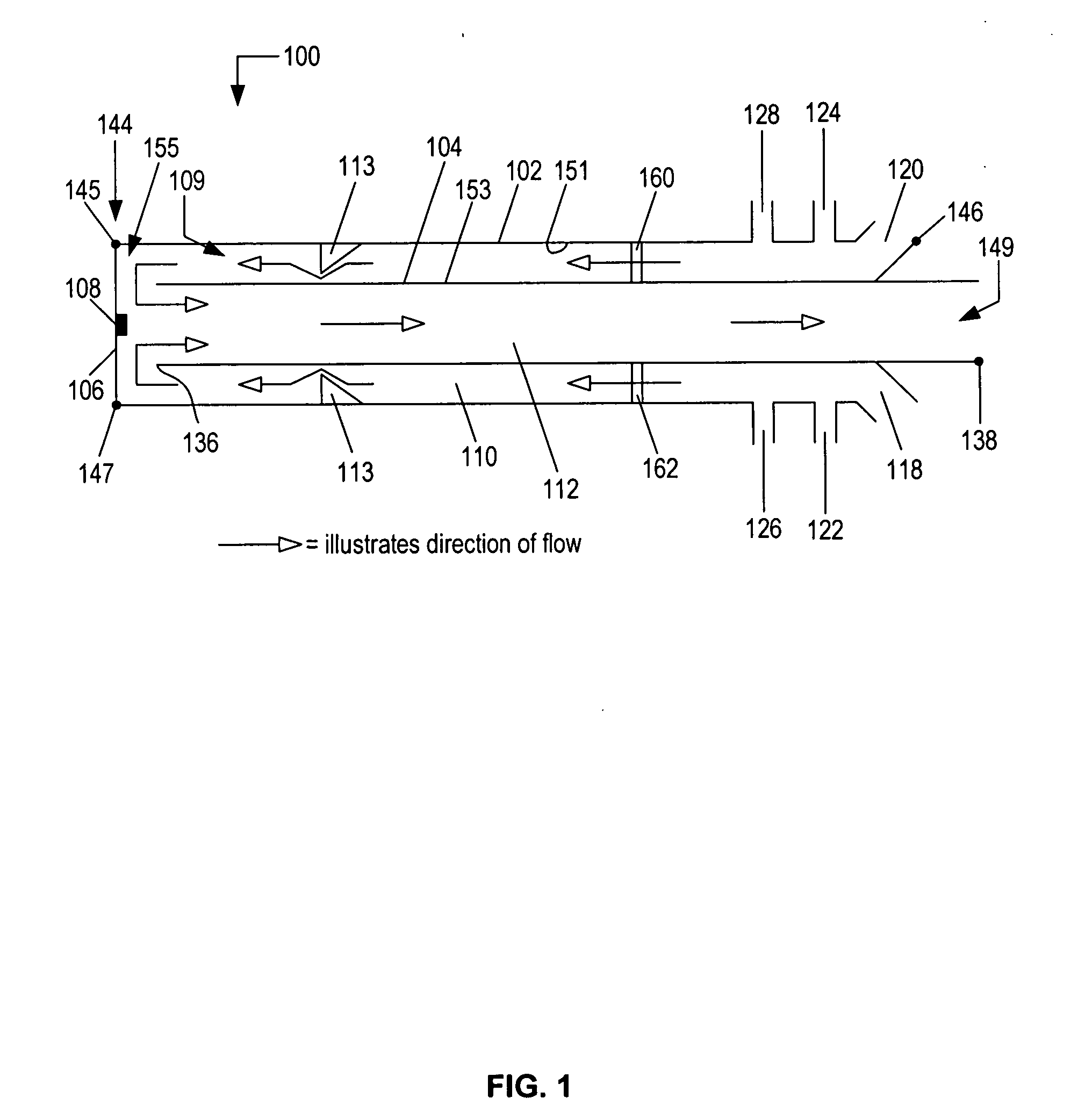

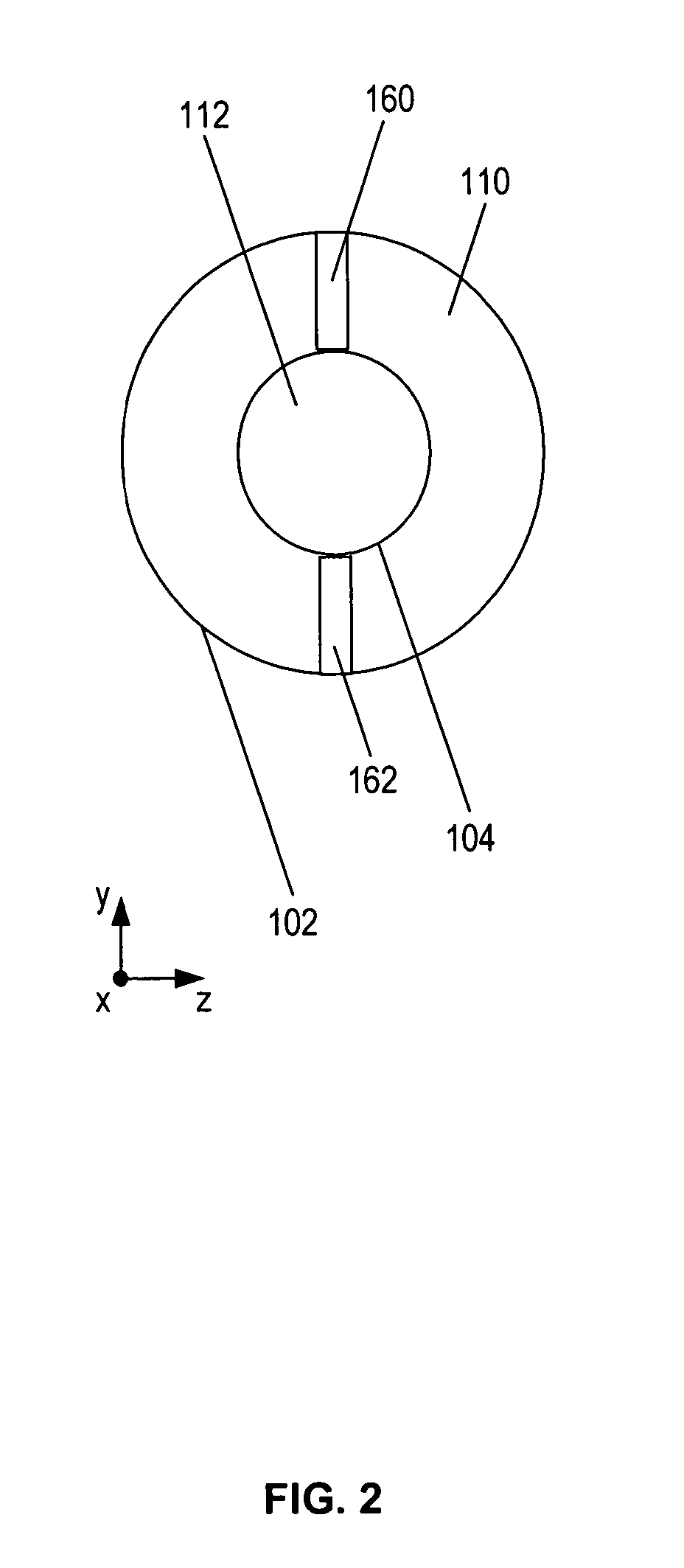

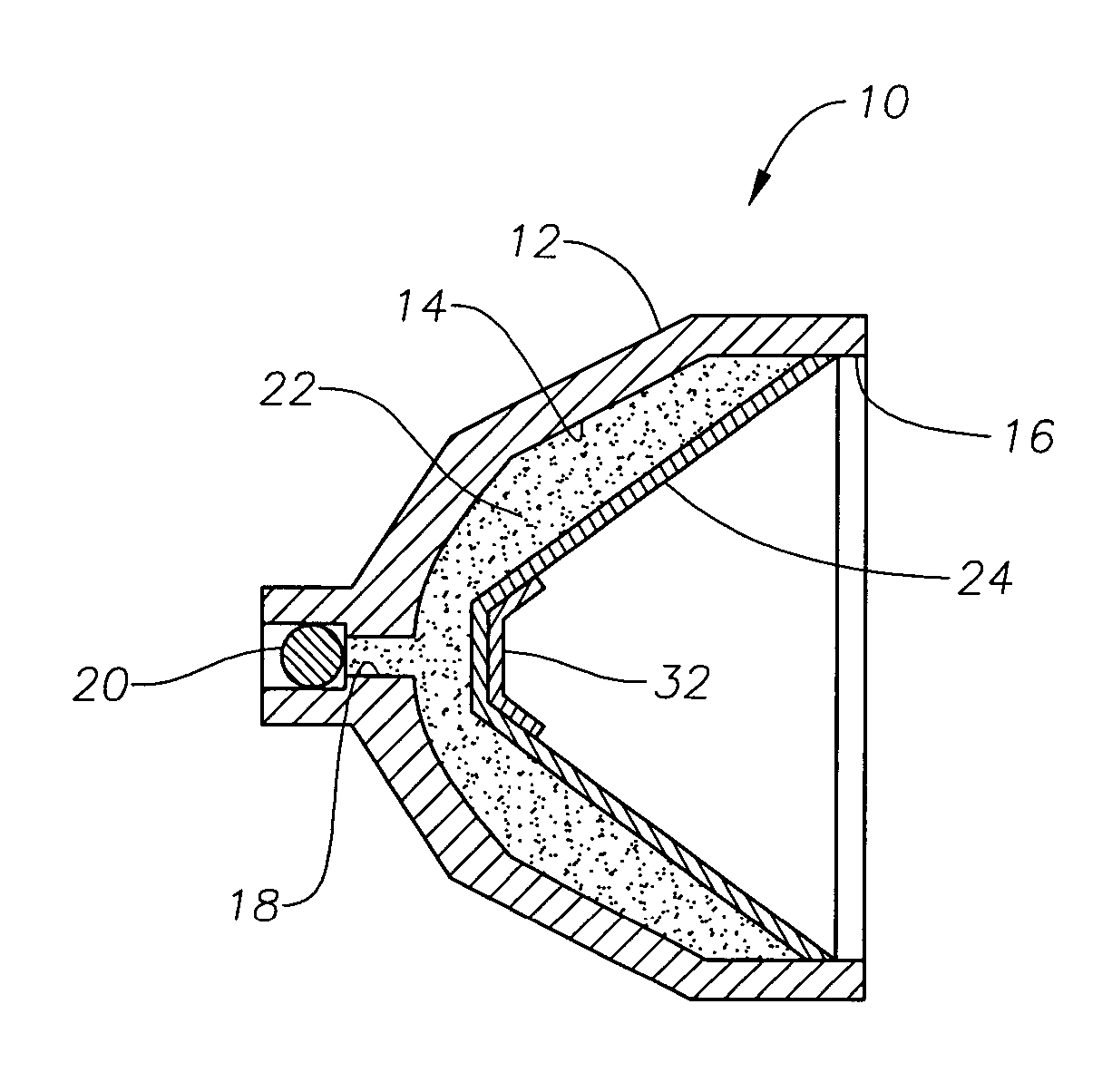

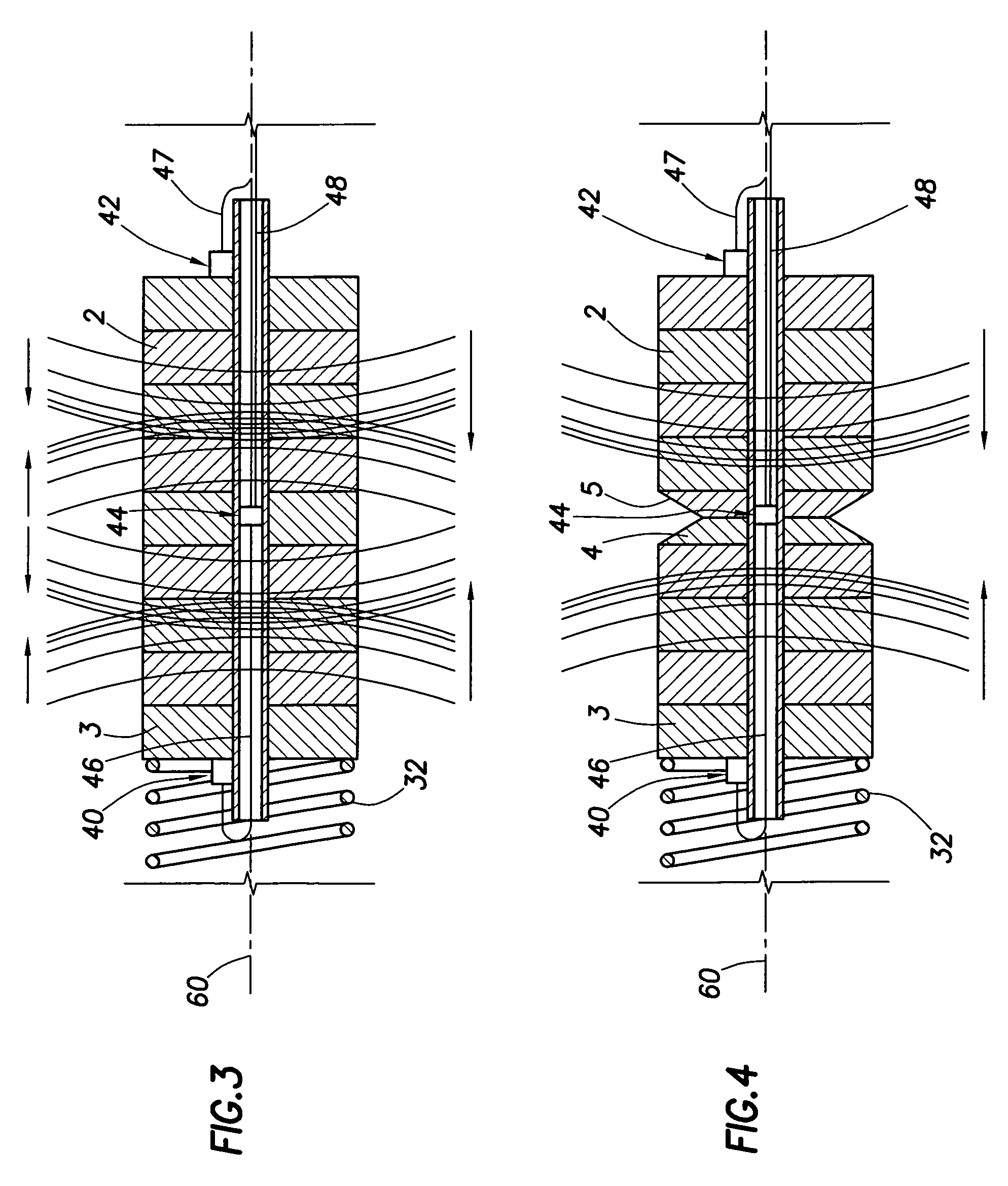

Pulse detonation combustor with folded flow path

A pulsed detonation combustor (PDC) is described. The PDC includes an outer casing defining a first hollow chamber configured to receive a flow and an inner liner. The inner liner includes at least one portion positioned within the first hollow chamber and configured to receive the flow from a plenum formed between the outer casing and inner liner. The PDC further includes a flow turning device with geometric features configured to direct the flow from the plenum to a second hollow chamber defined within the inner liner. The PDC also includes at least one fuel injection port located downstream of an inlet to the outer casing and an ignition device located downstream of the at least one fuel injection port and configured to periodically ignite fuel.

Owner:GENERAL ELECTRIC CO

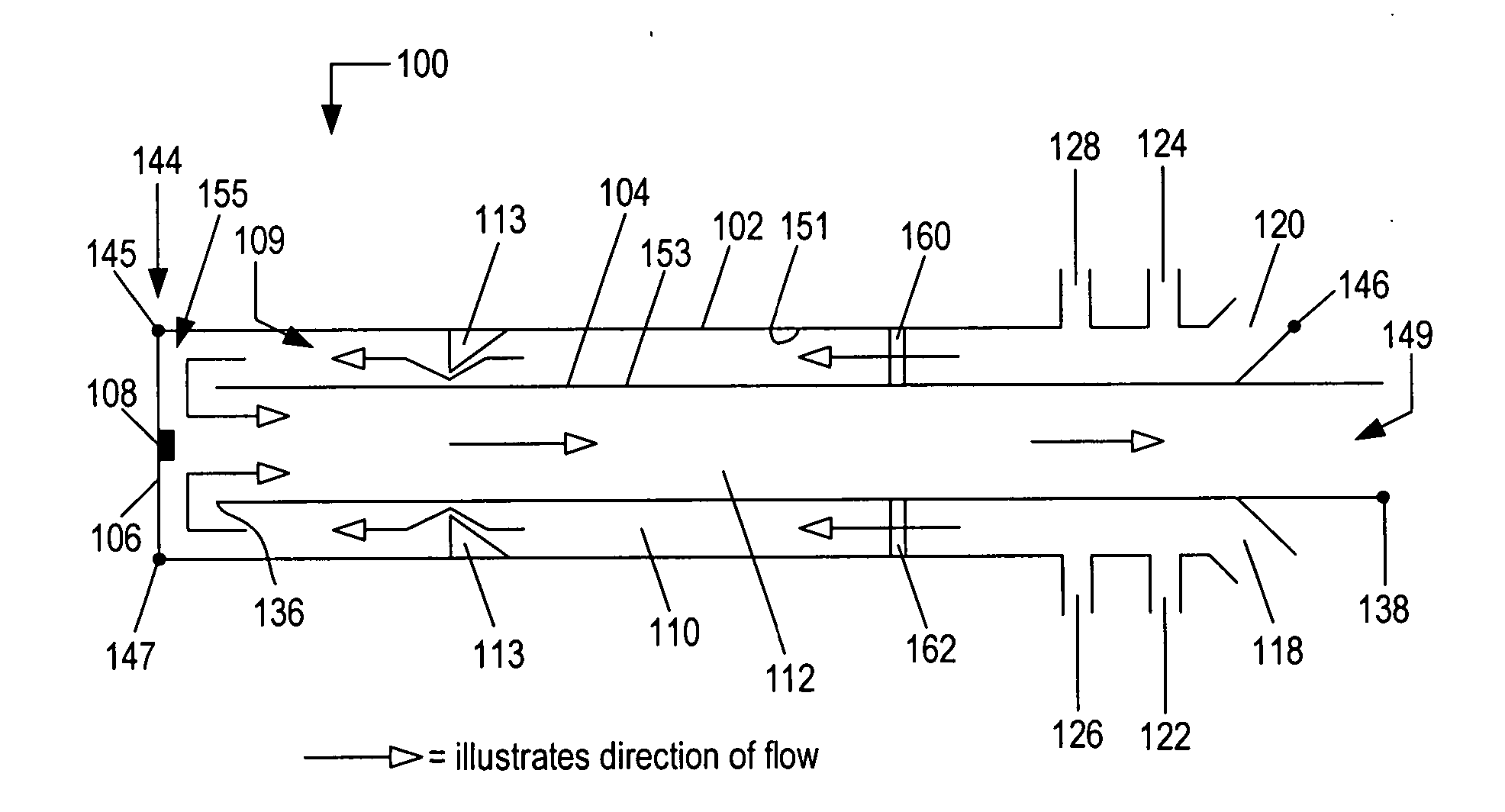

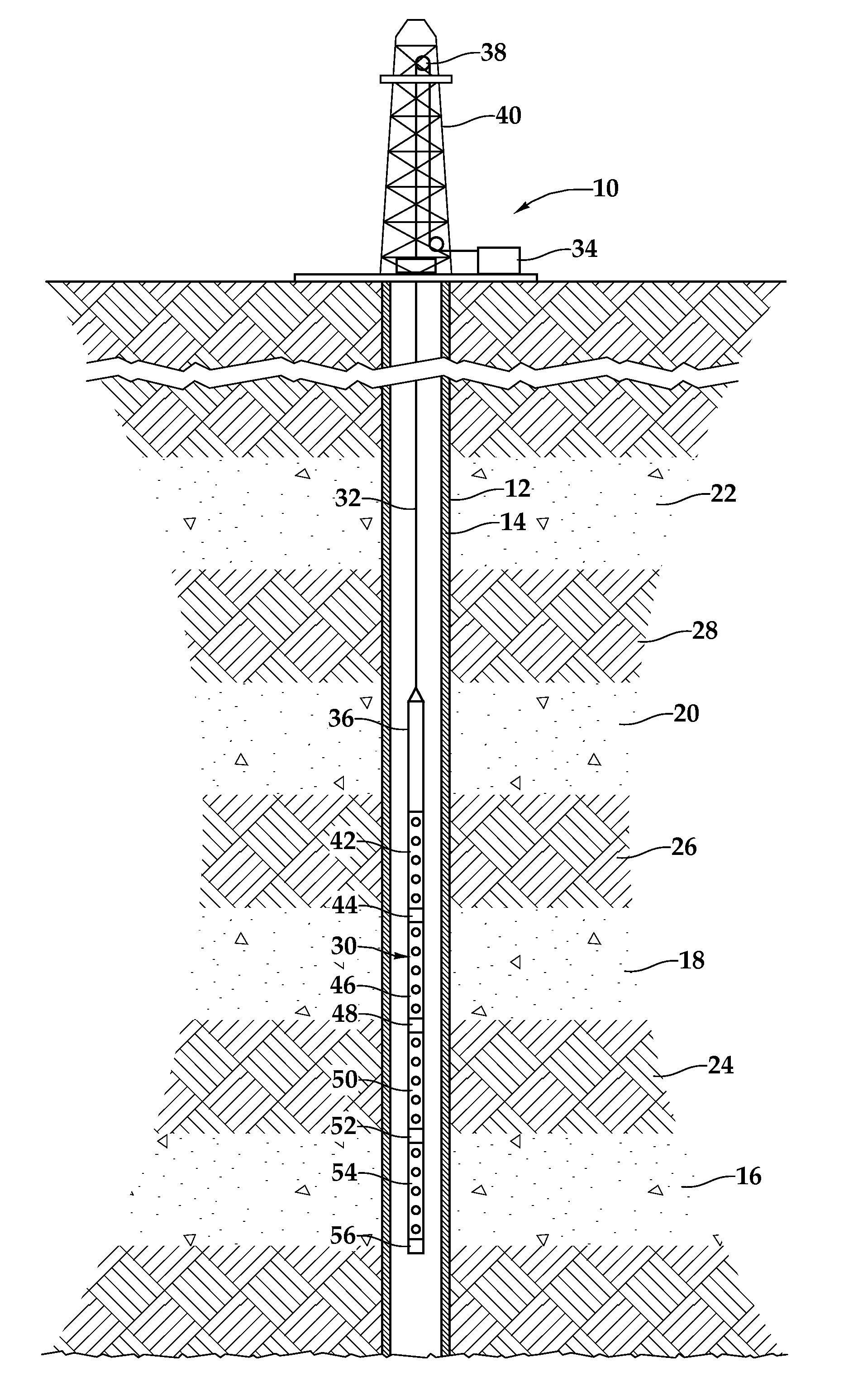

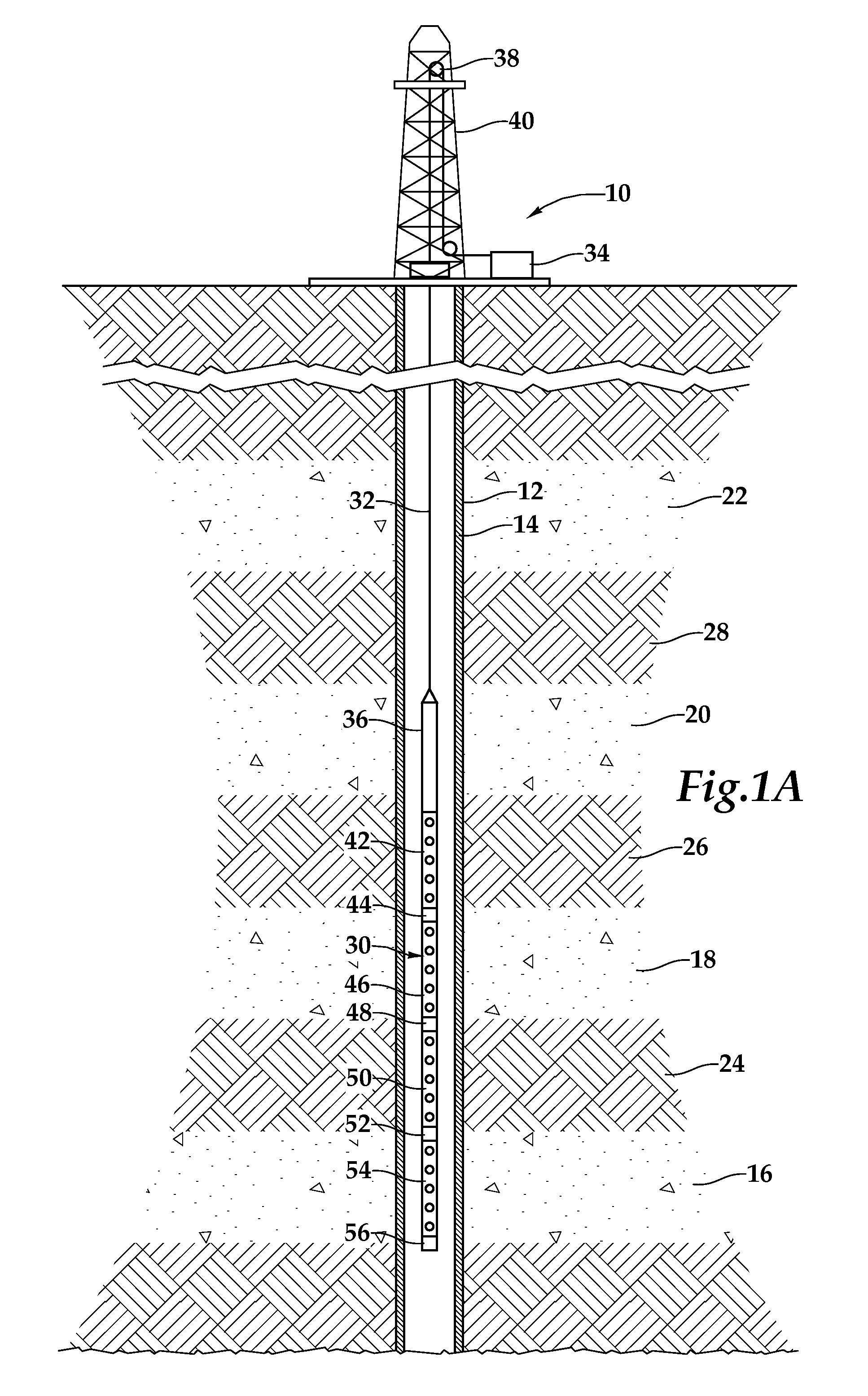

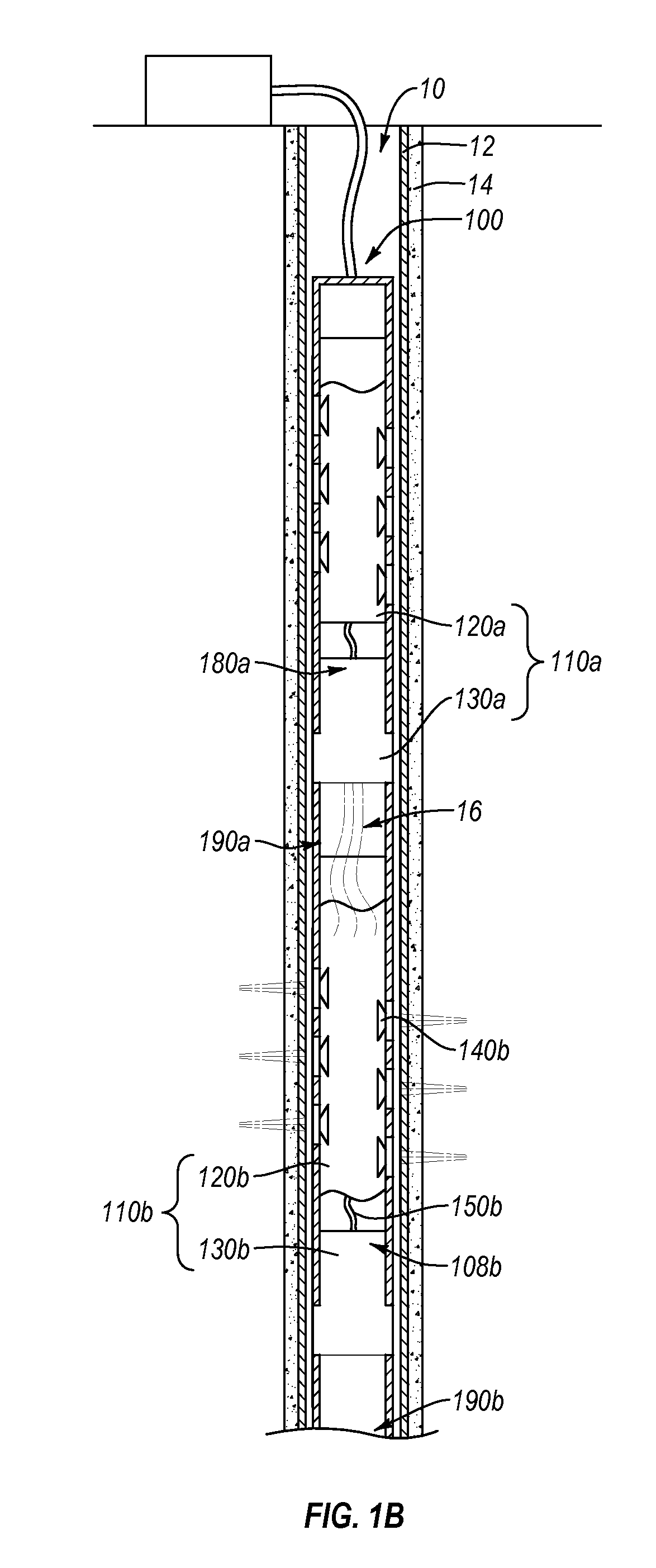

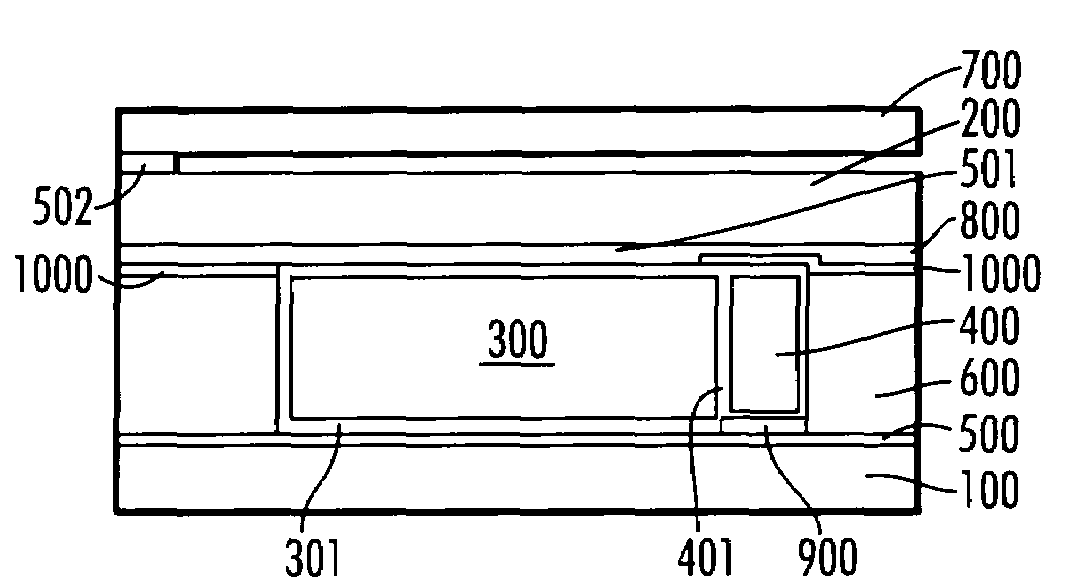

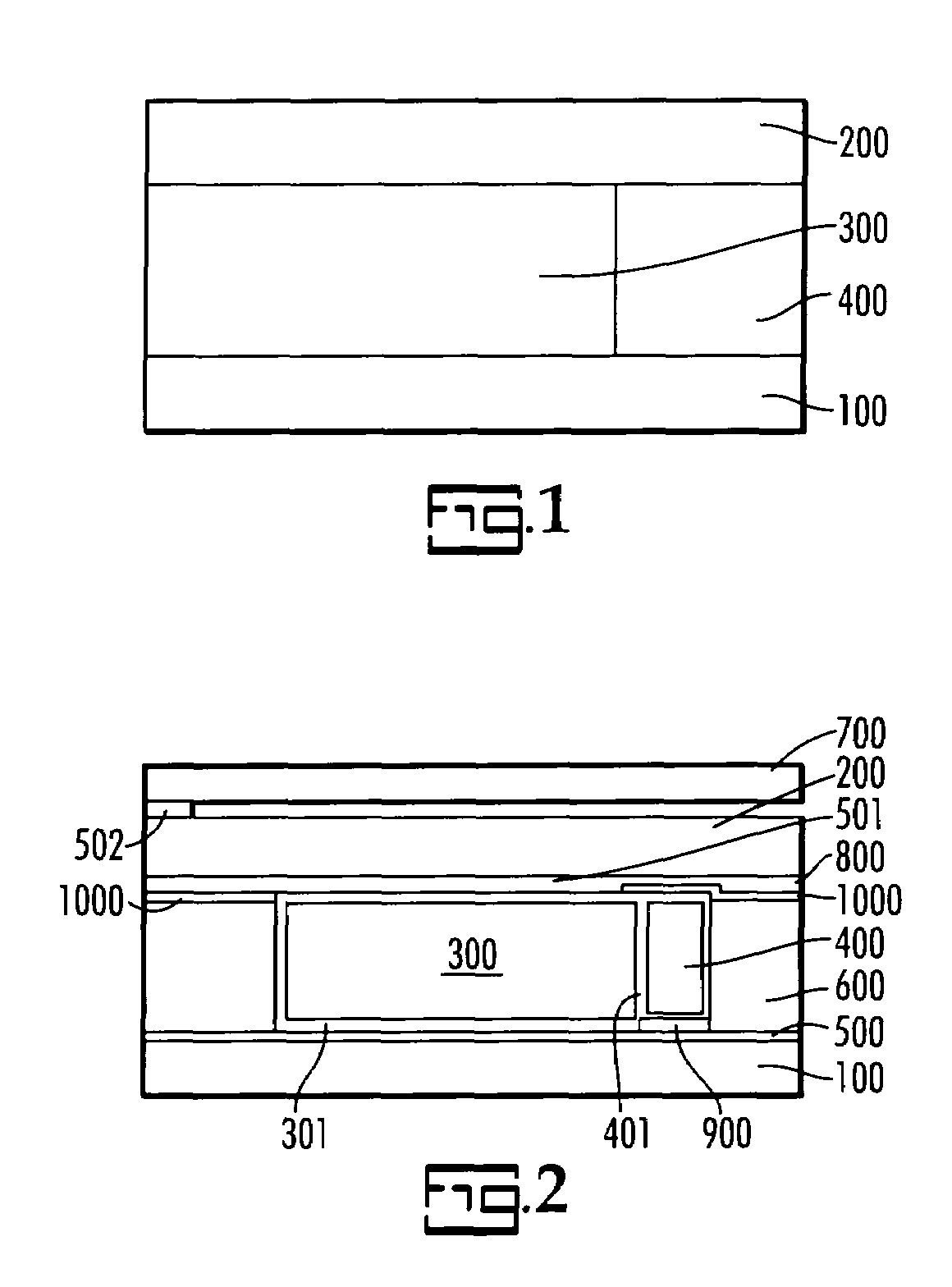

System and Method for Selective Activation of Downhole Devices in a Tool String

A system (100) for selective activation of explosive devices (126, 128, 130, 132) includes a surface controller (102), a downhole controller (106) operable to communicate bidirectionally with the surface controller over a first communication link (108) and a plurality of downhole remote units (114, 116, 118, 120) operable to communicate bidirectionally with the downhole controller (106) over a second communication link (112). One or more sensors (162) are operably associated with the downhole controller (106) and one of the explosive devices (126, 128, 130, 132) is operably associated with each of the downhole remote units (114, 116, 118, 120) such that, responsive to a detonation event, the sensors (162) detect the intensity level of the detonation which is communicated from the downhole controller (106) to the surface control (102) over the first communication link (108).

Owner:HALLIBURTON ENERGY SERVICES INC

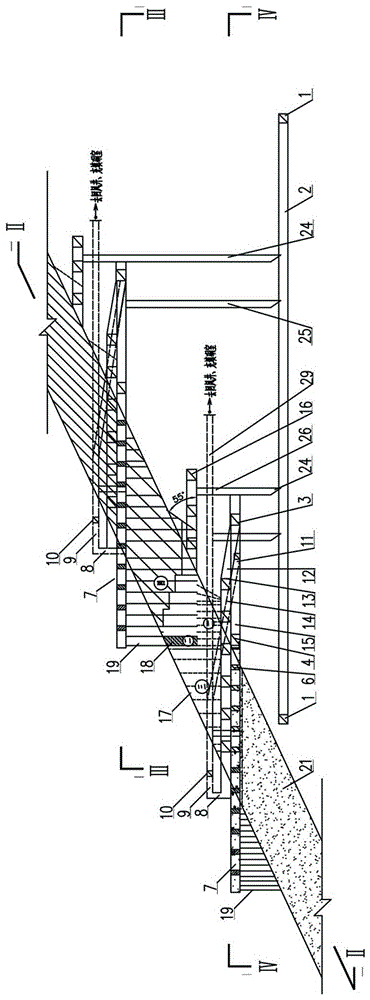

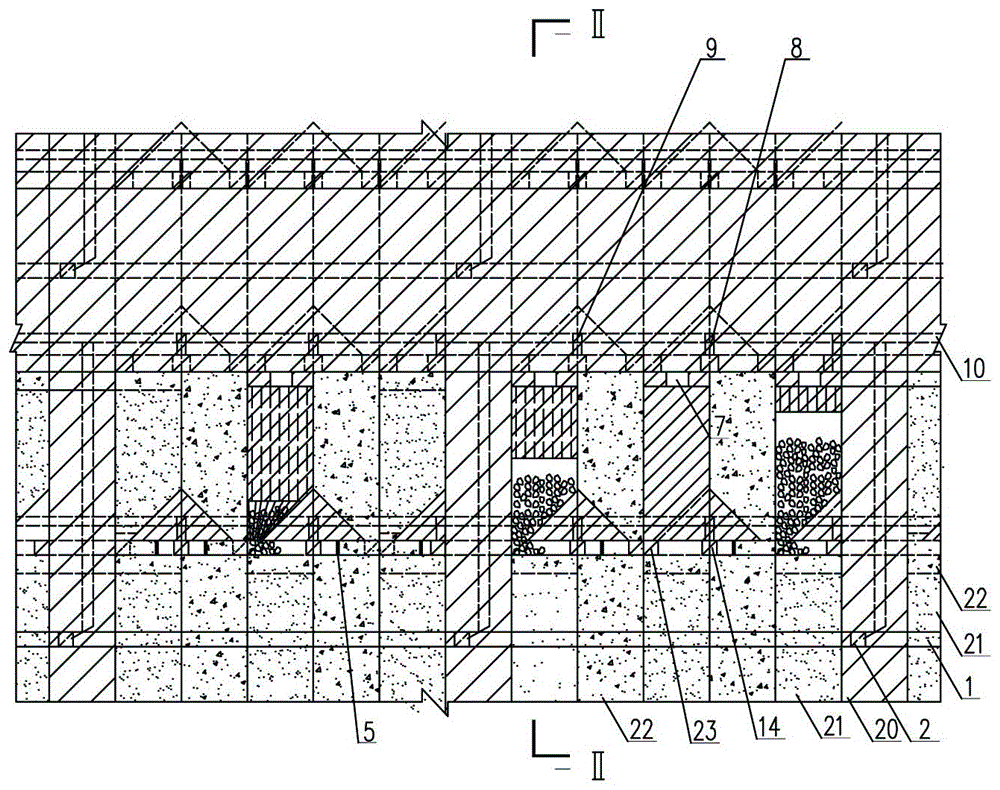

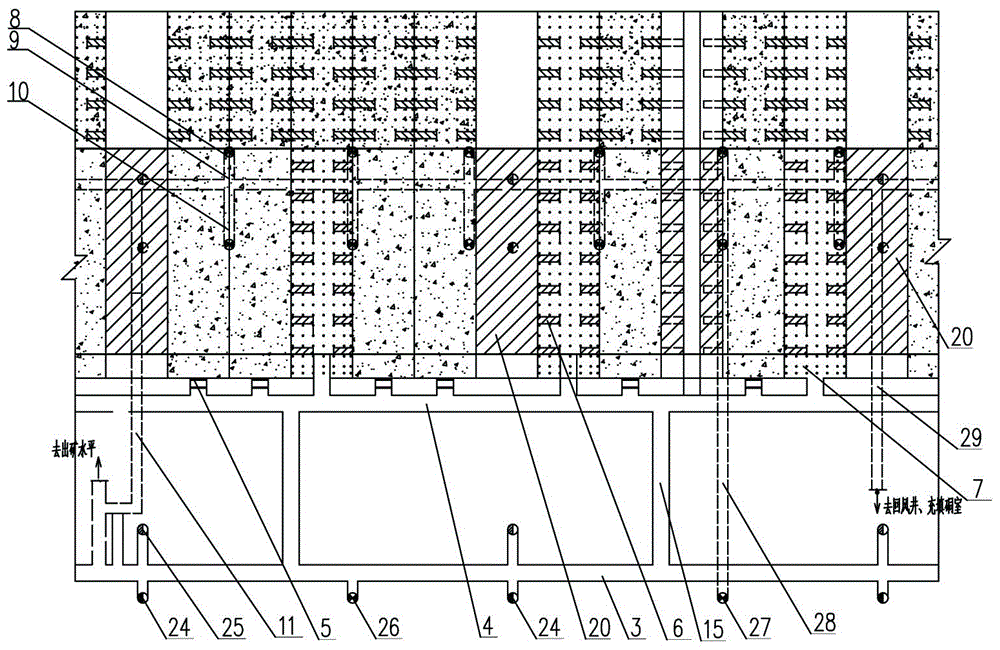

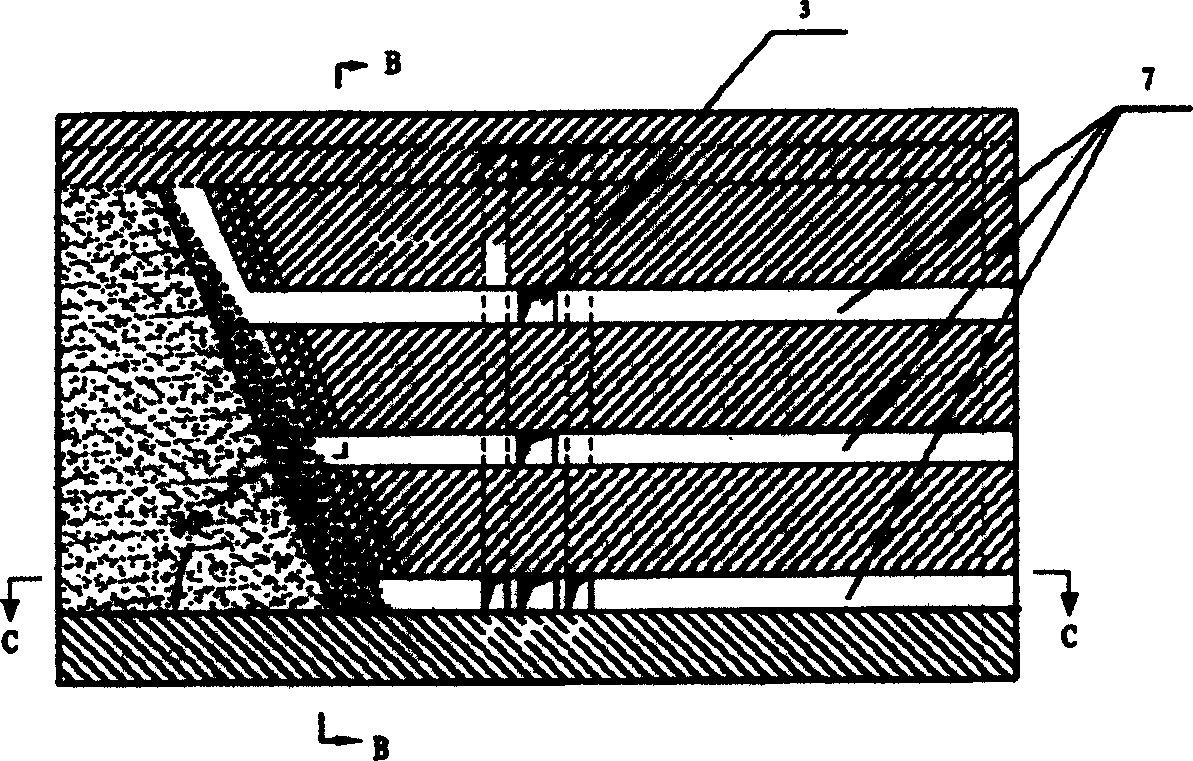

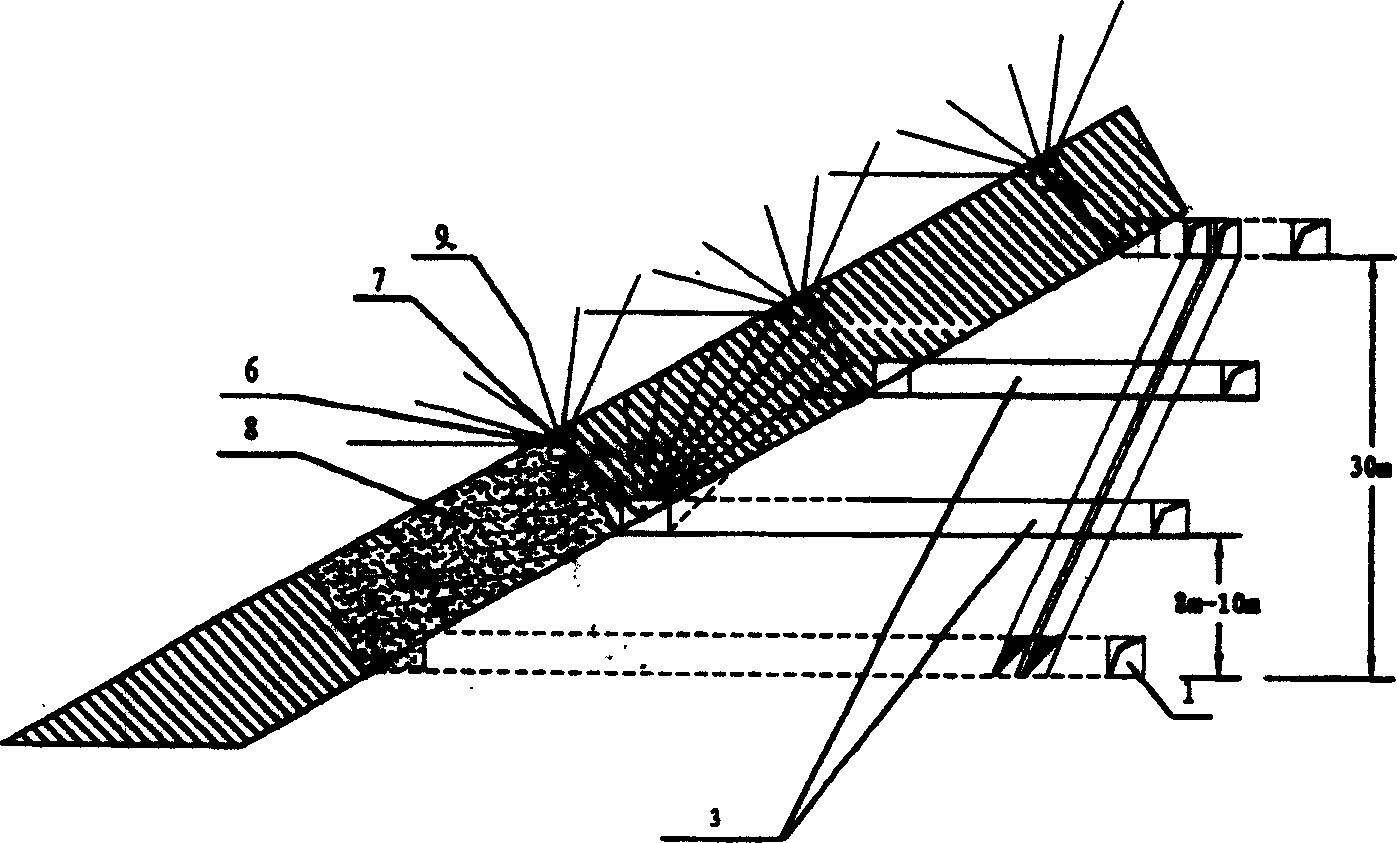

Upward and downward staged rock drilling, sublevel bottom cutting and ore removal subsequent backfilling mining method

ActiveCN106677780AImprove securityEnsure safetyUnderground miningTunnel/mines ventillationDetonationEngineering

The invention provides an upward and downward staged rock drilling, sublevel bottom cutting and ore removal subsequent backfilling mining method. The method includes the following steps that panels are divided in the ore direction, a stope preparation system is arranged, upward fan-shaped medium-depth blast holes are drilled from one side to the other side of a chamber, the blast holes are filled with explosives for detonation, and an undercut space is formed after detonation; cut grooves are formed through a VCR method, and as for ore above the undercut space, downward vertical deep holes are drilled in a drilling chamber at the top of the chamber, and the holes are filled with explosives for detonation with the cut grooves as a compensation space; the chamber in each panel is subjected to two-step backstoping, after ore removal of a first-step chamber is finished, the first-step chamber is filled with cementing materials, after the first-step chamber is filled and cured, a second-step chamber is subjected to backstoping, the backstoping steps of the second-step chamber are the same as those of the first-step chamber, and the second-step chamber is filled with cemented filling bodies and non-cemented filling bodies; and the steps are repeated in this way till backstoping of all chambers are completed. The upward and downward staged rock drilling, sublevel bottom cutting and ore removal subsequent backfilling mining method has the advantages that the rock drilling efficiency of the upward fan-shaped medium-depth blast holes is improved, the waste hole rate is lowered, efficient and safe bottom ore removal is achieved, and the mechanization level is high.

Owner:MCC NORTH (DALIAN) ENG TECH CO LTD

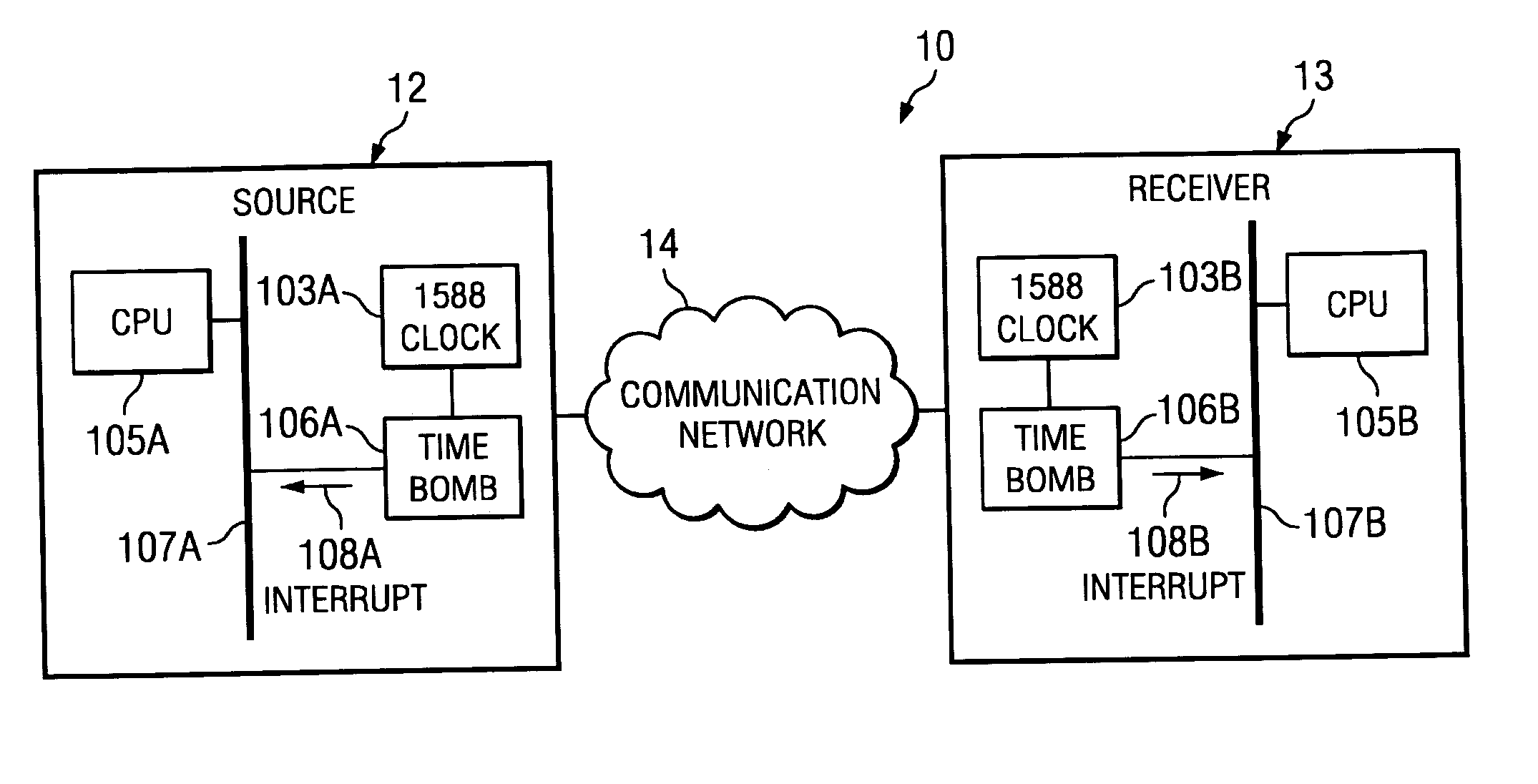

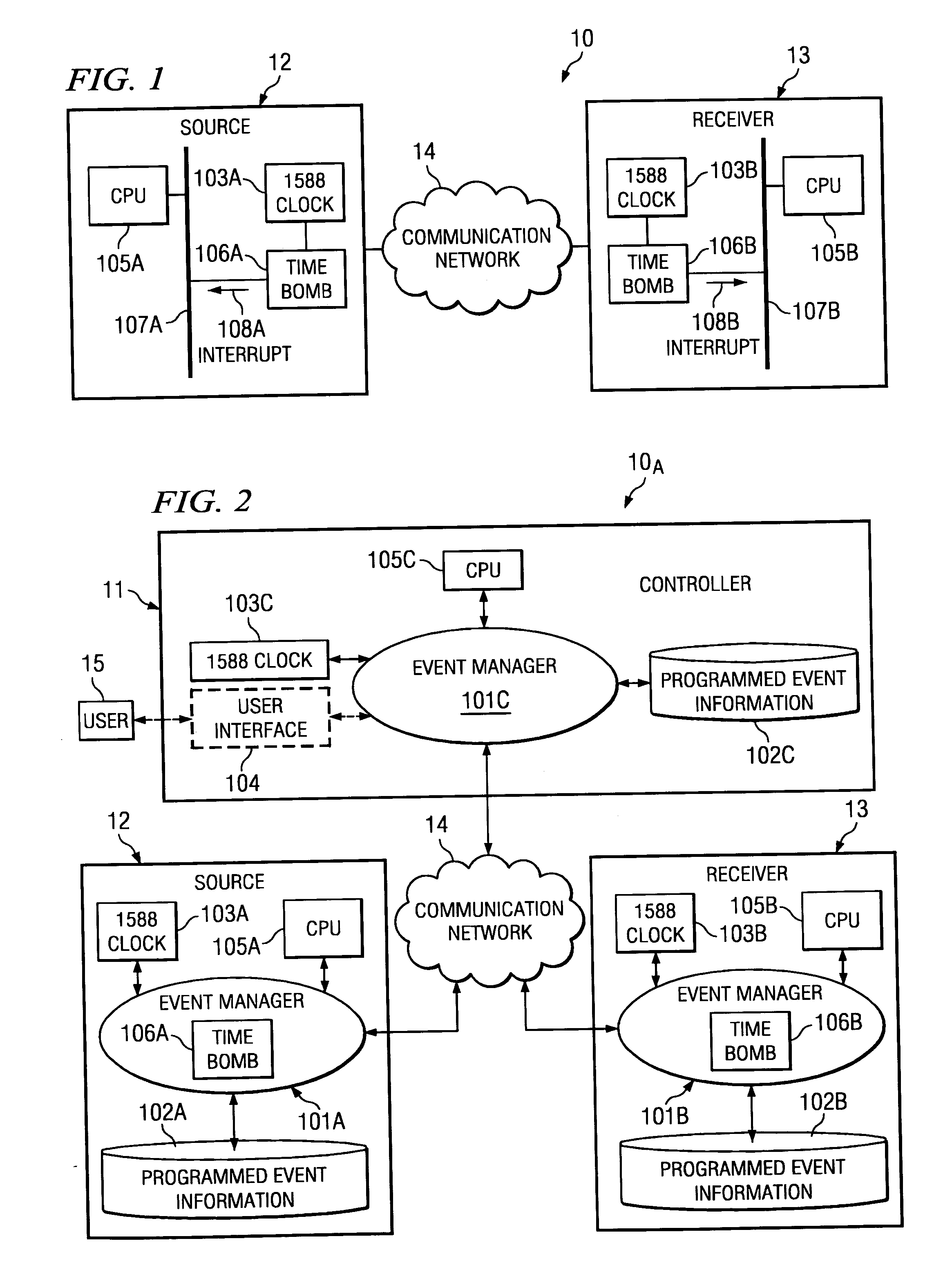

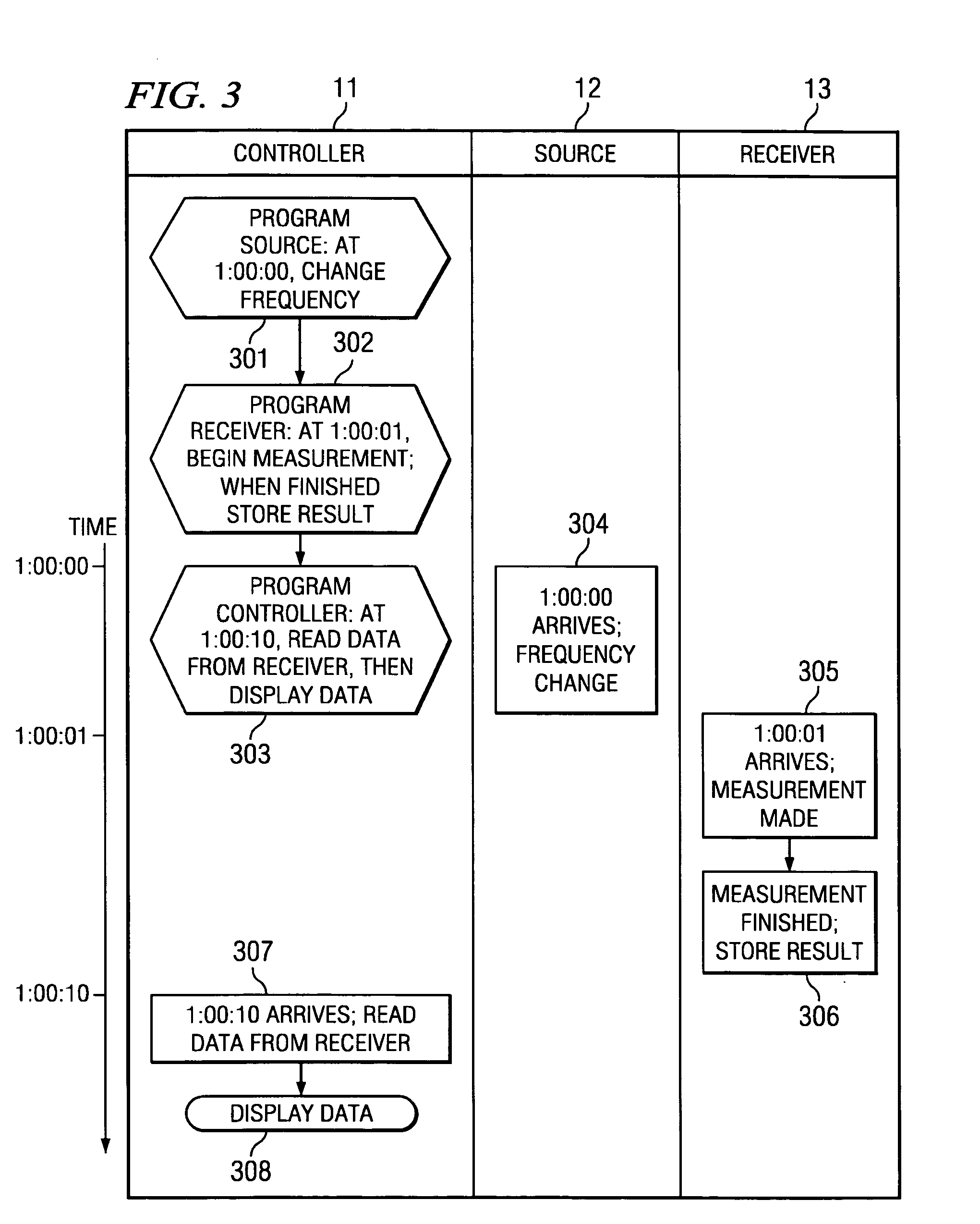

System and method for coordinating the actions of a plurality of devices via scheduling the actions based on synchronized local clocks

A system and method are provided which coordinate the actions of a plurality of devices via scheduling occurrence of the actions based on synchronized local clocks of the devices. Thus, a plurality of devices are communicatively coupled via a communication network, and the devices have their local clocks synchronized to a high degree of precision, using IEEE 1588, NTP, or some other technique for synchronizing their local clocks. “Time bombs” can be scheduled on the devices to coordinate the occurrence of actions between the devices in accordance with the detonation times set for the respective time bombs. In certain embodiments, not only the detonation time, but also the respective action to be triggered upon detonation is programmable for each device. The time bombs implemented on the various devices can be used to coordinate the operations of the various devices with a high degree of temporal precision.

Owner:KEYSIGHT TECH

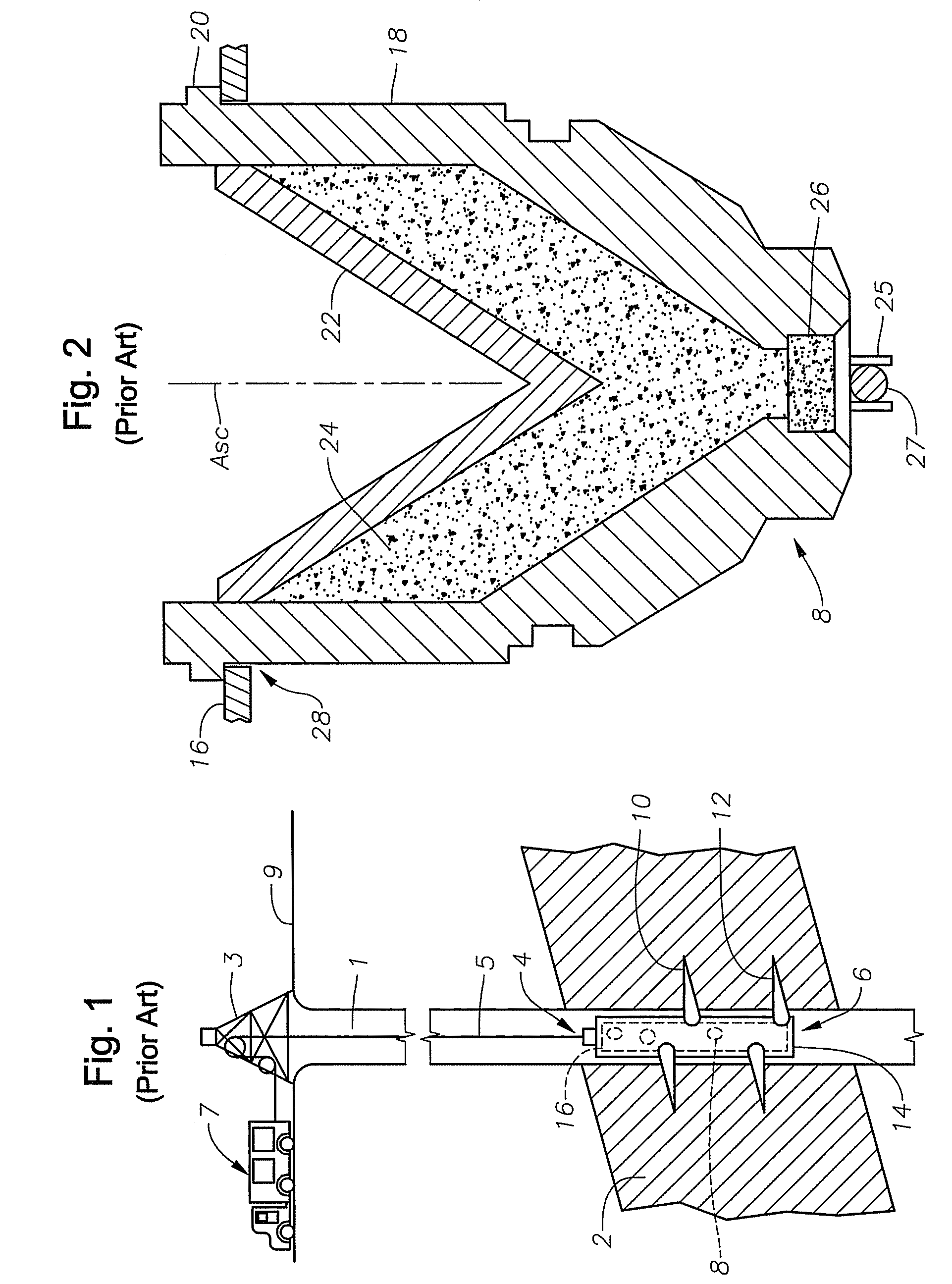

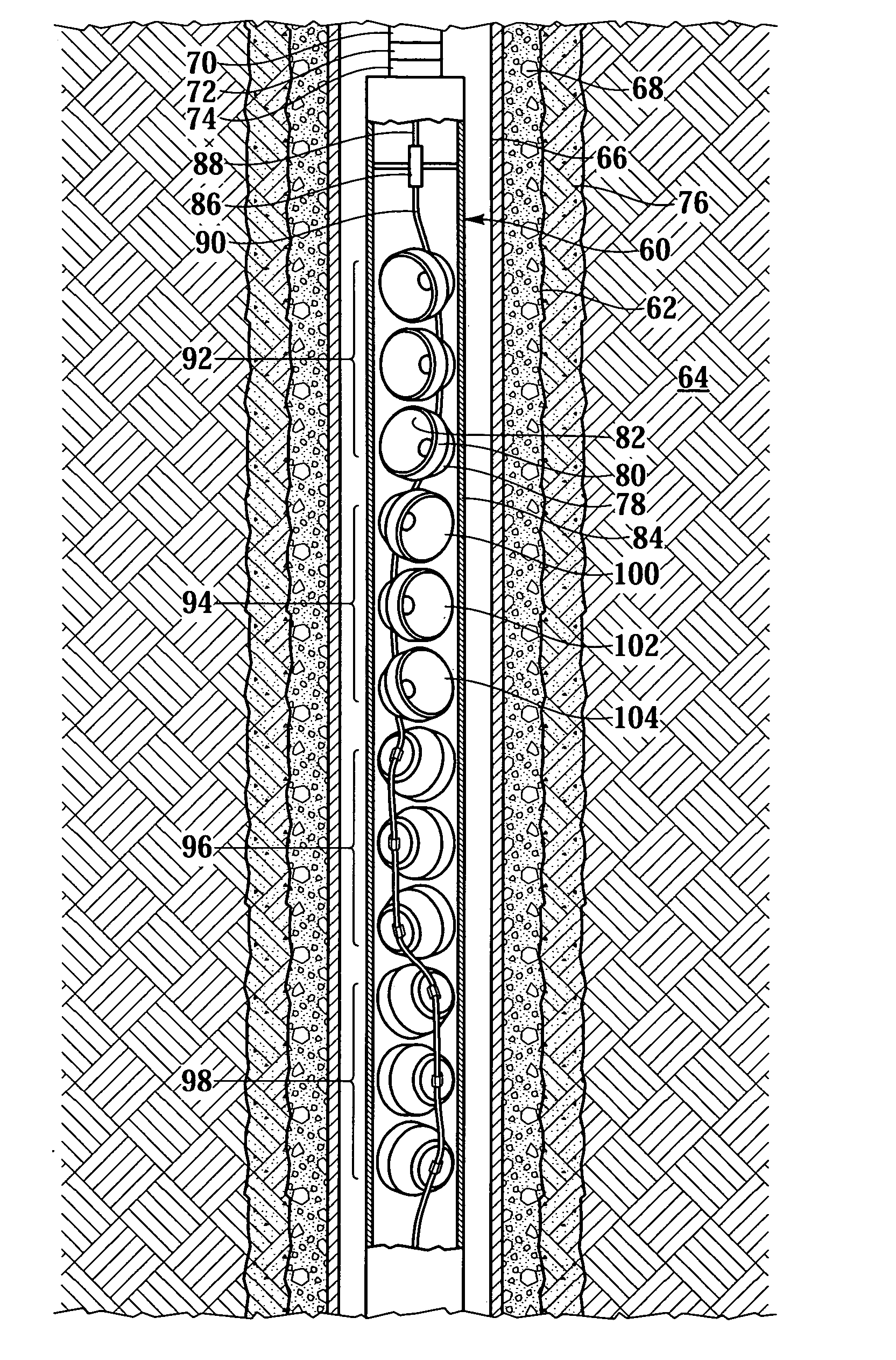

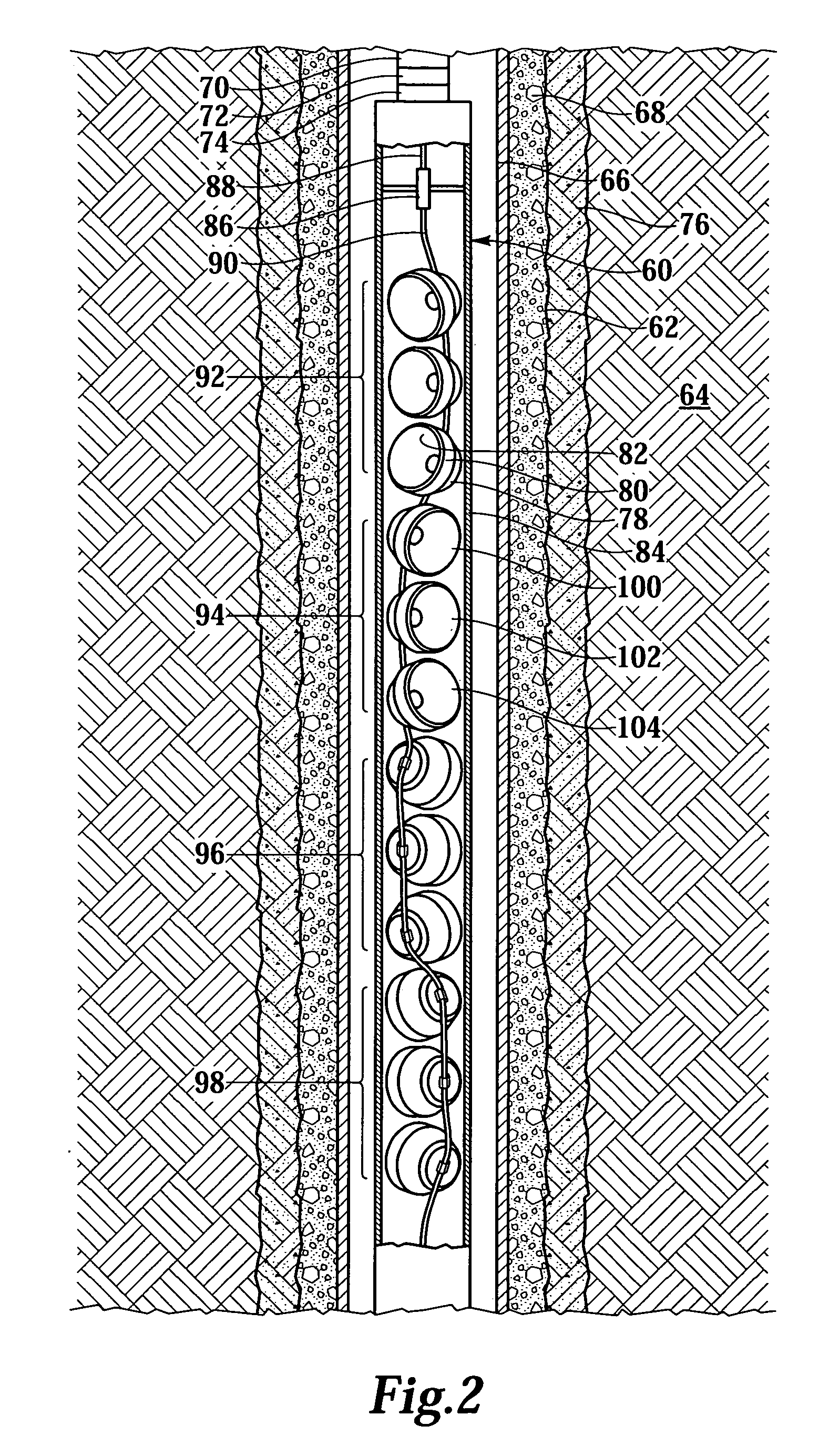

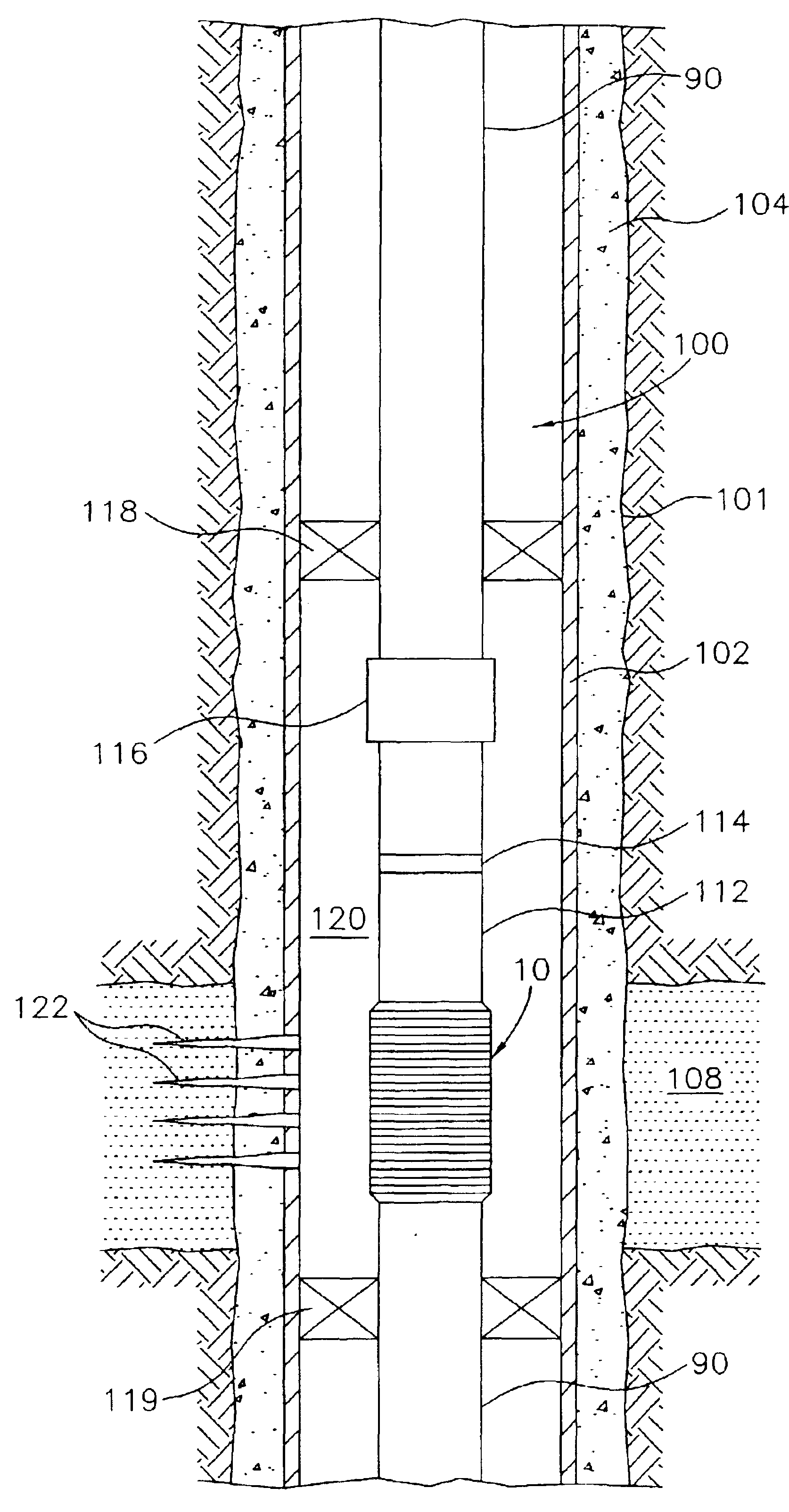

Perforating gun assembly and method for creating perforation cavities

A perforating gun assembly (60) for creating communication paths for fluid between a formation (64) and a cased wellbore (66) includes a housing (84), a detonator (86) positioned within the housing (84) and a detonating cord (90) operably associated with the detonator (86). The perforating gun assembly (60) also includes one or more substantially axially oriented collections (92, 94, 96, 98) of shaped charges. Each of the shaped charges in the collections (92, 94, 96, 98) is operably associated with the detonating cord (90). In addition, adjacent shaped charges in each collection (92, 94, 96, 98) of shaped charges are oriented to converge toward one another such that upon detonation, the shaped charges in each collection (92, 94, 96, 98) form jets that interact with one another to create perforation cavities in the formation (64).

Owner:WELL BALLISTICS +2

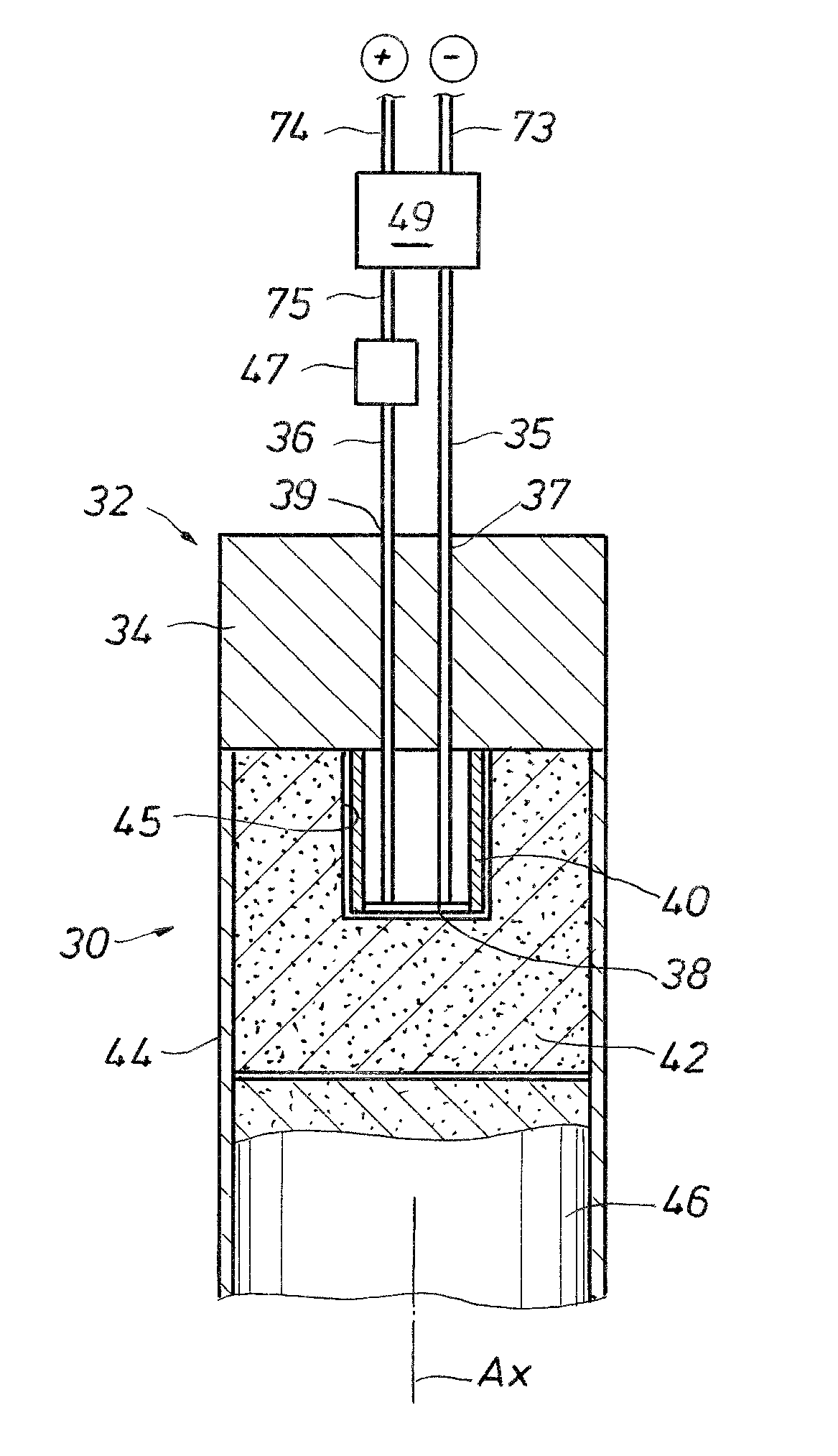

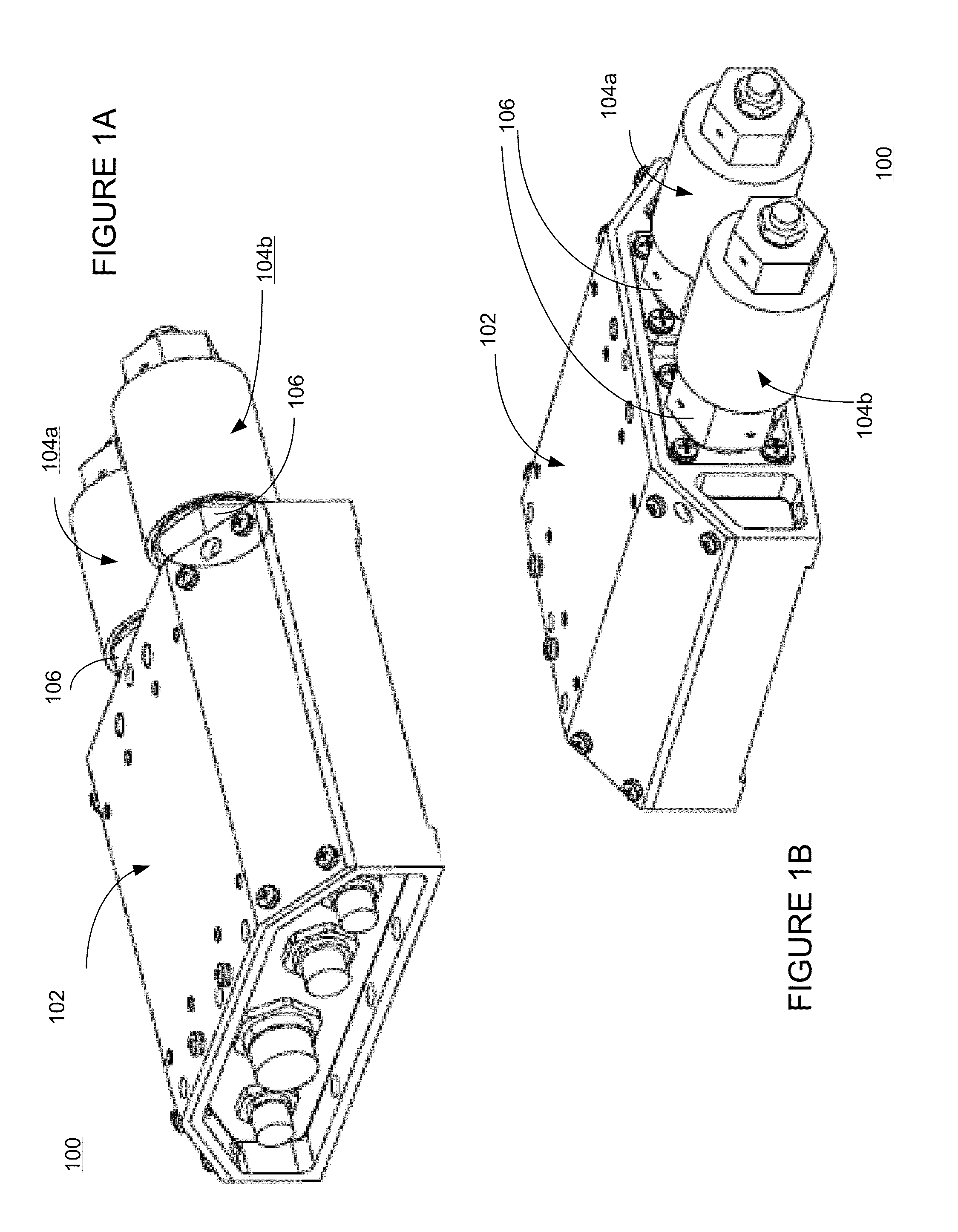

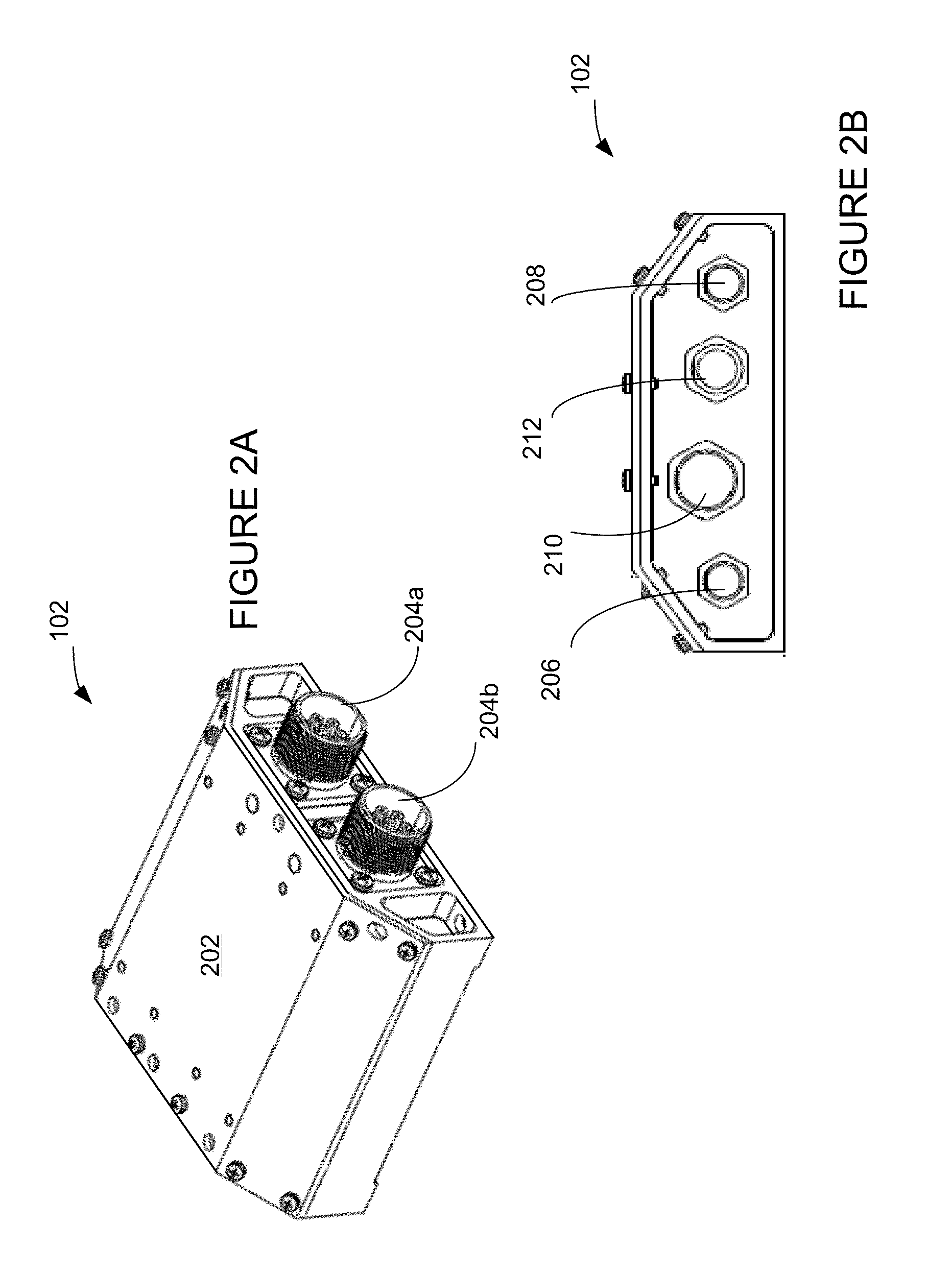

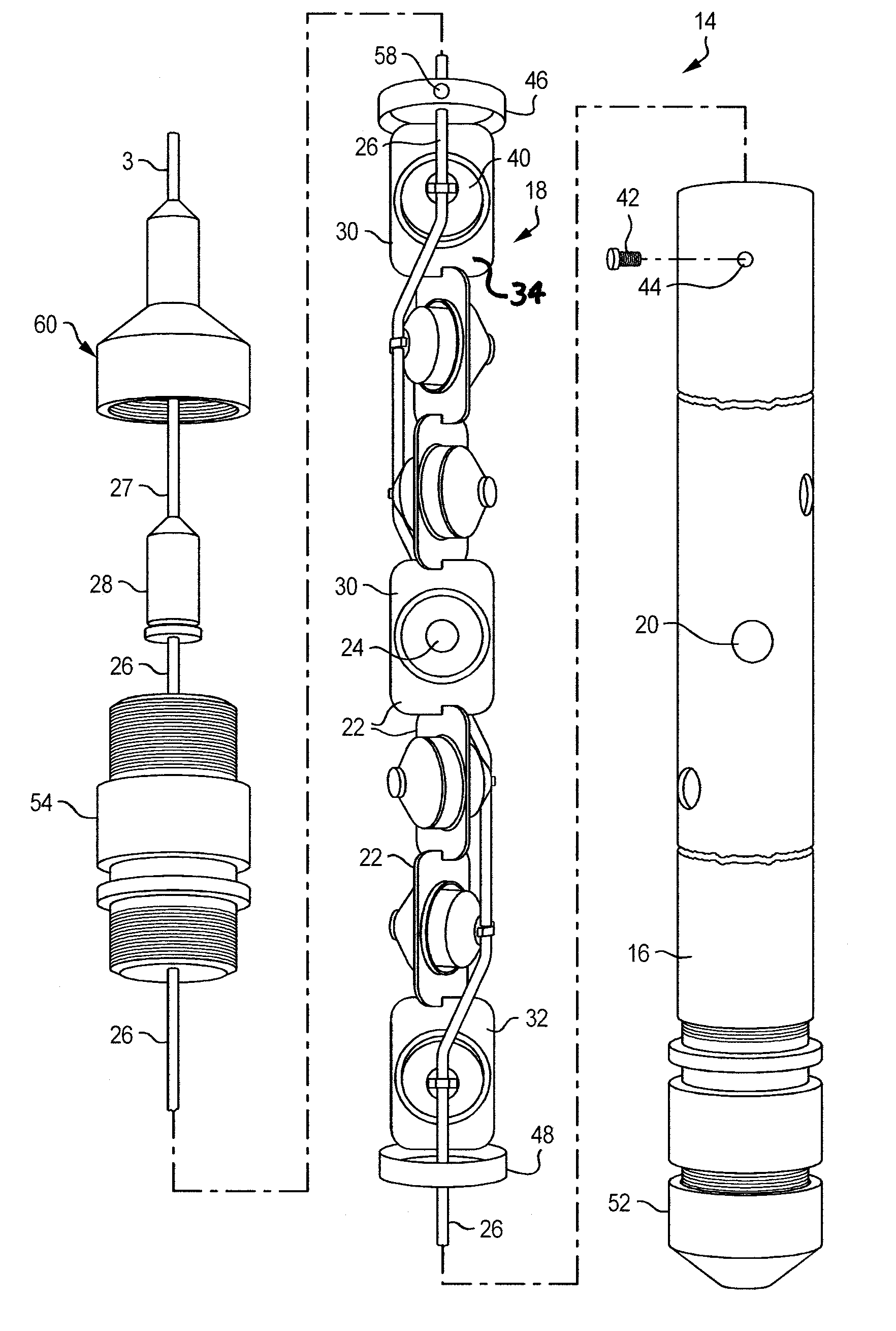

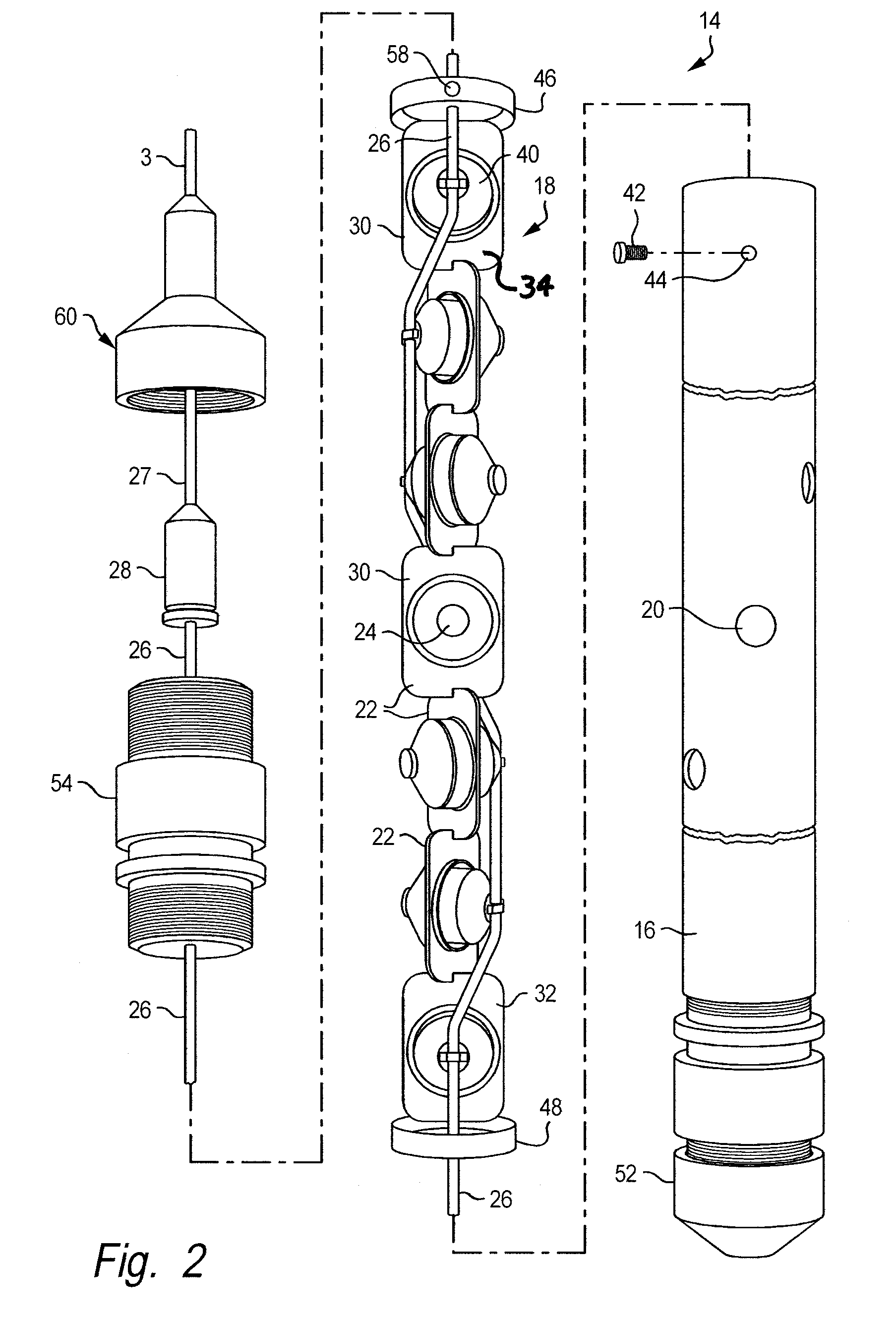

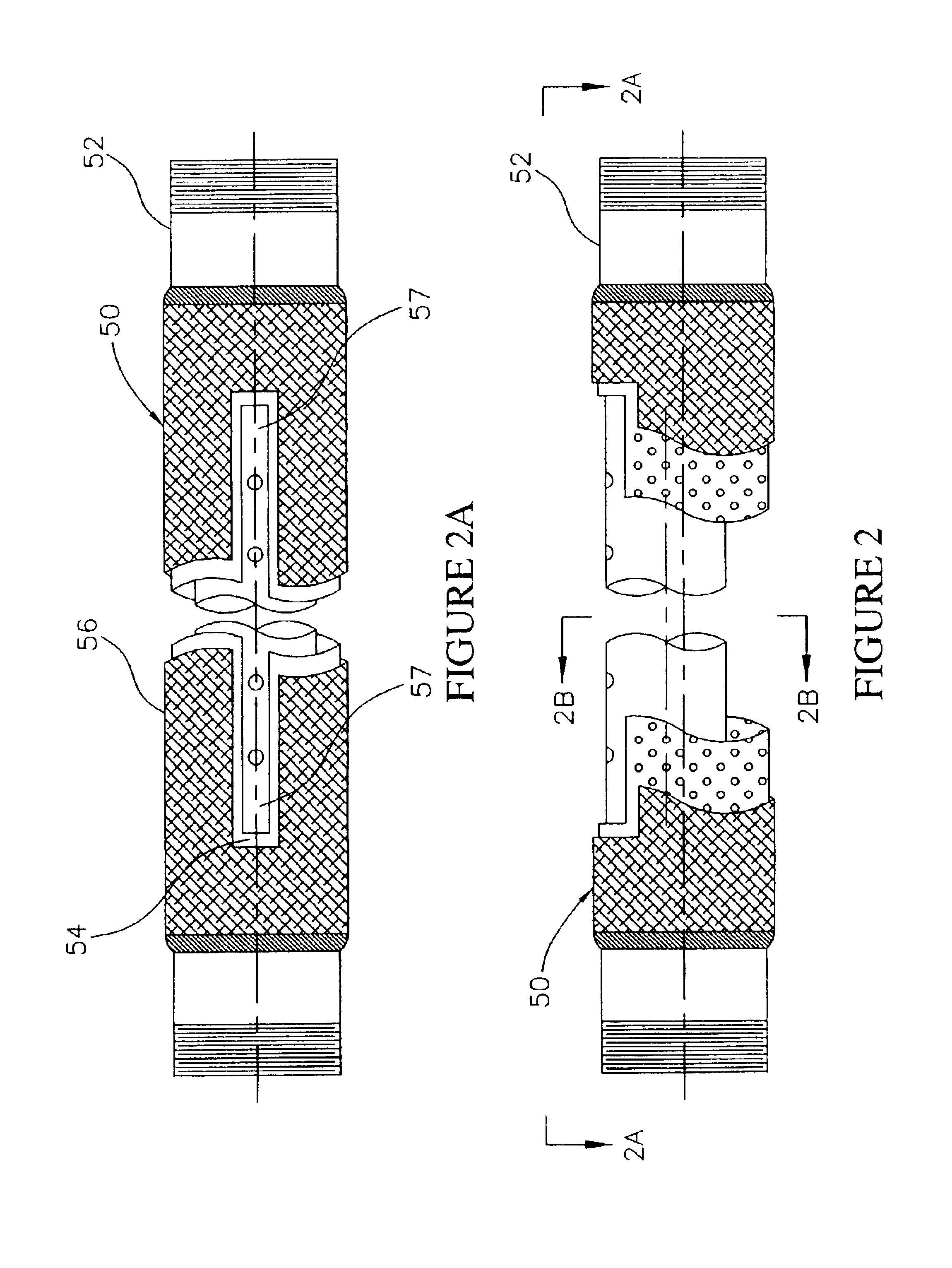

Modular initiator

Owner:BAKER HUGHES HLDG LLC

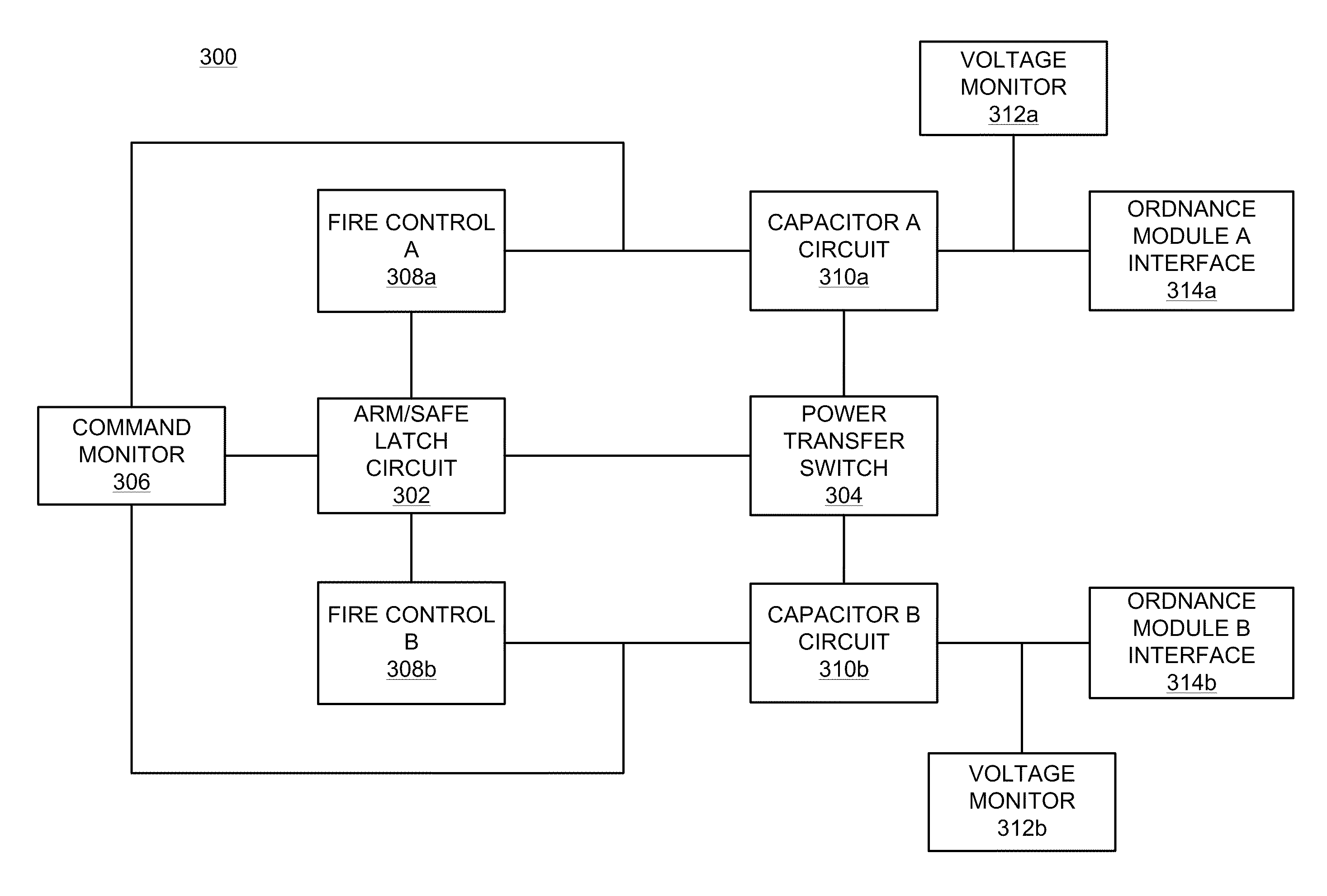

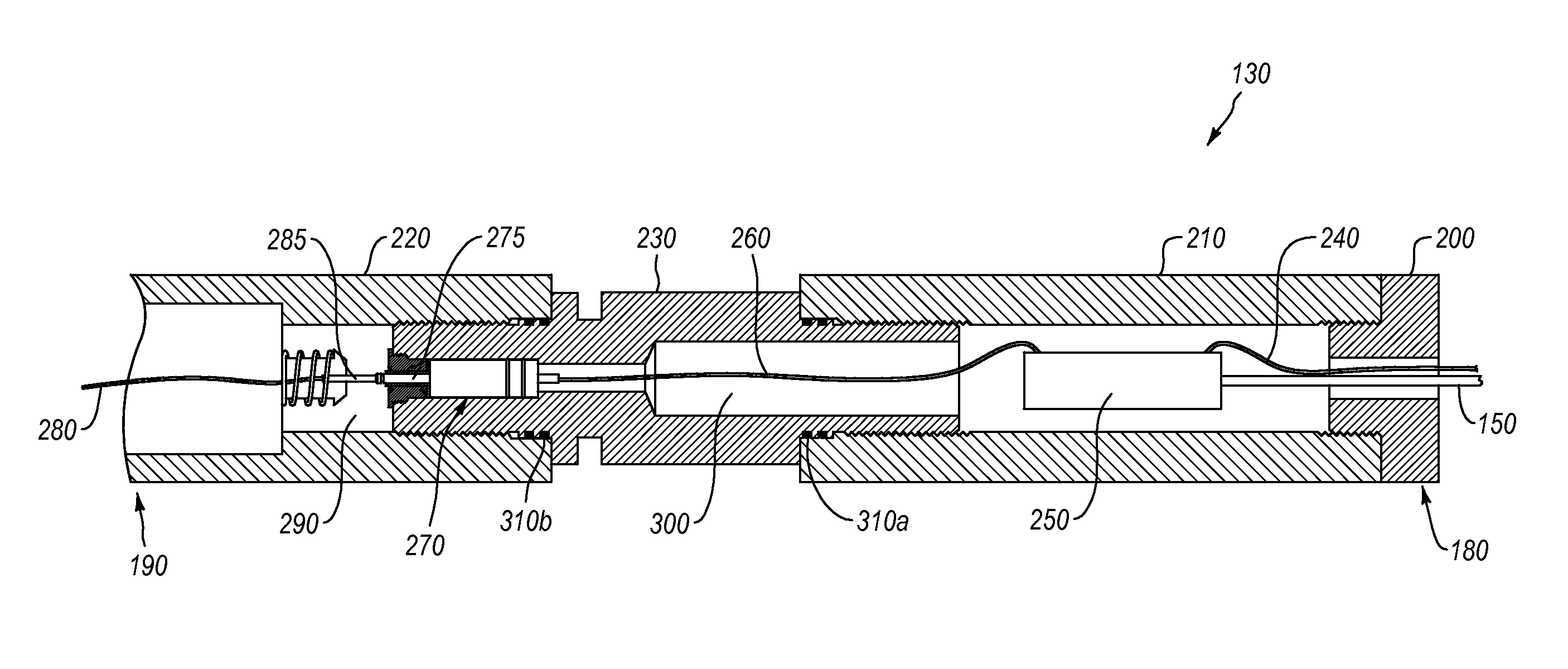

Electronic safe/arm system and methods of use thereof

ActiveUS20110277620A1Low impedance connectionGood adhesionCosmonautic vehiclesIncandescent ignitionDetonatorElectricity

An ordnance firing system is disclosed that includes a reusable electronics module and an ordnance module, each enclosed in a separate, sealed housing. The electronics module housing encloses firing electronics for electrically triggering initiation of a detonator in the ordnance module. The electronics module detachably connects to the ordnance modules via a connector which extends away from the electronics module housing. The housing of the ordnance module is constructed to be blast-resistant to prevent detonation of the detonator from rendering the electronics module inoperable.

Owner:NORTHROP GRUMMAN SYST CORP

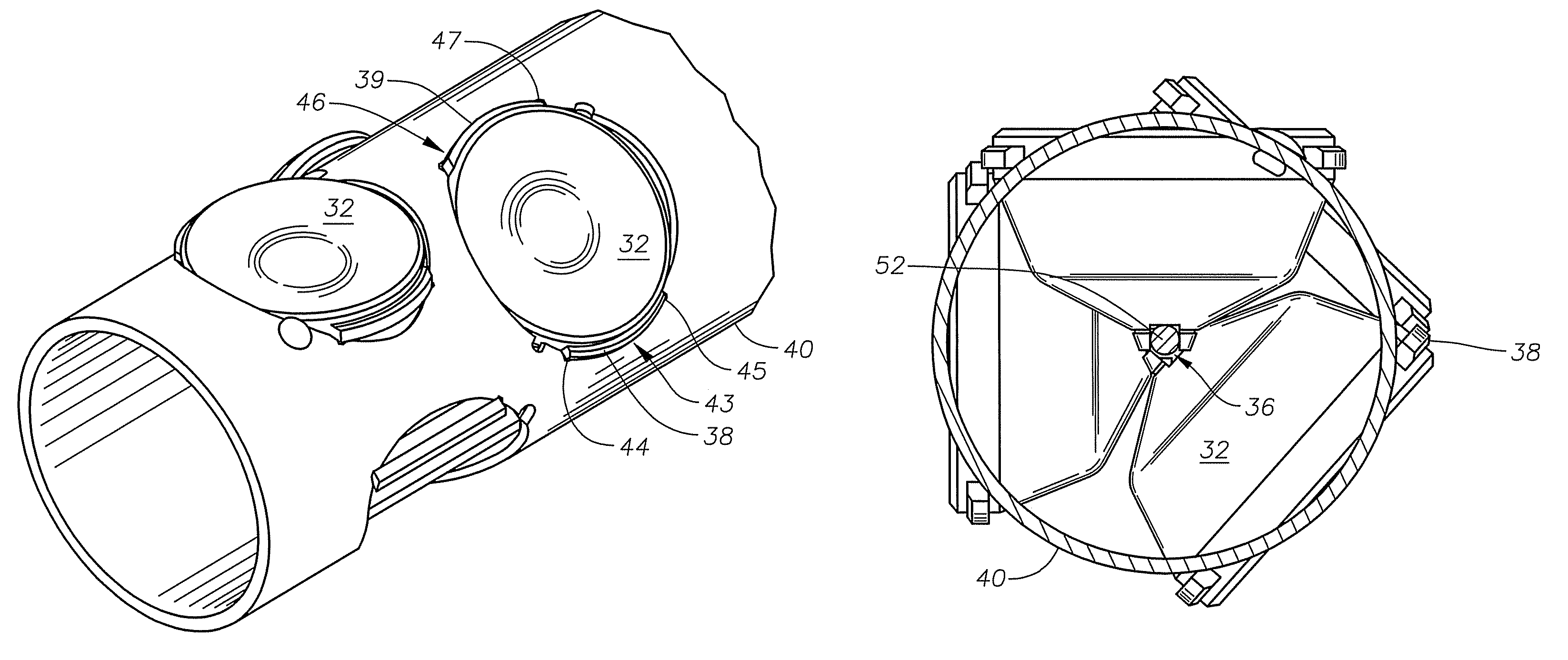

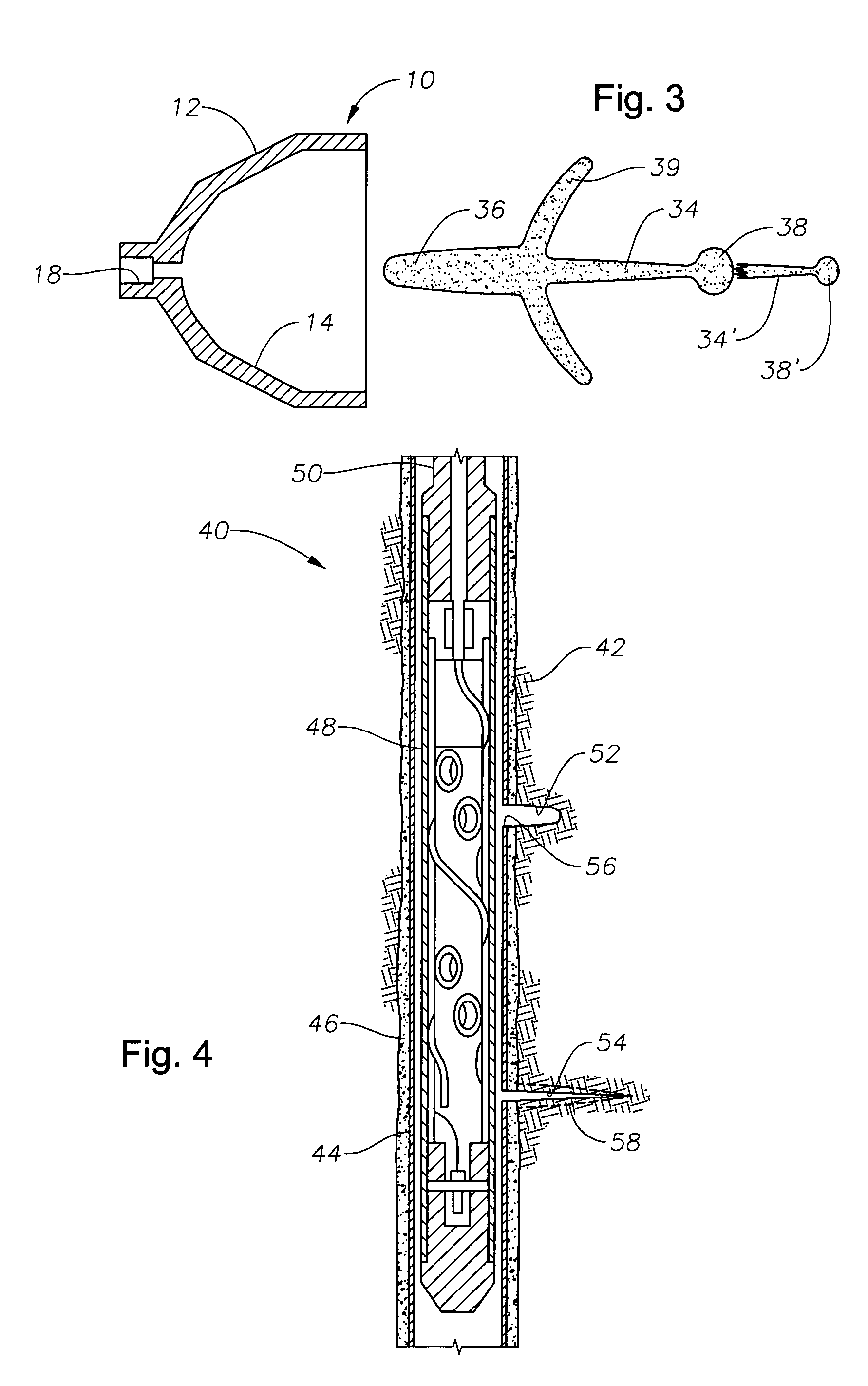

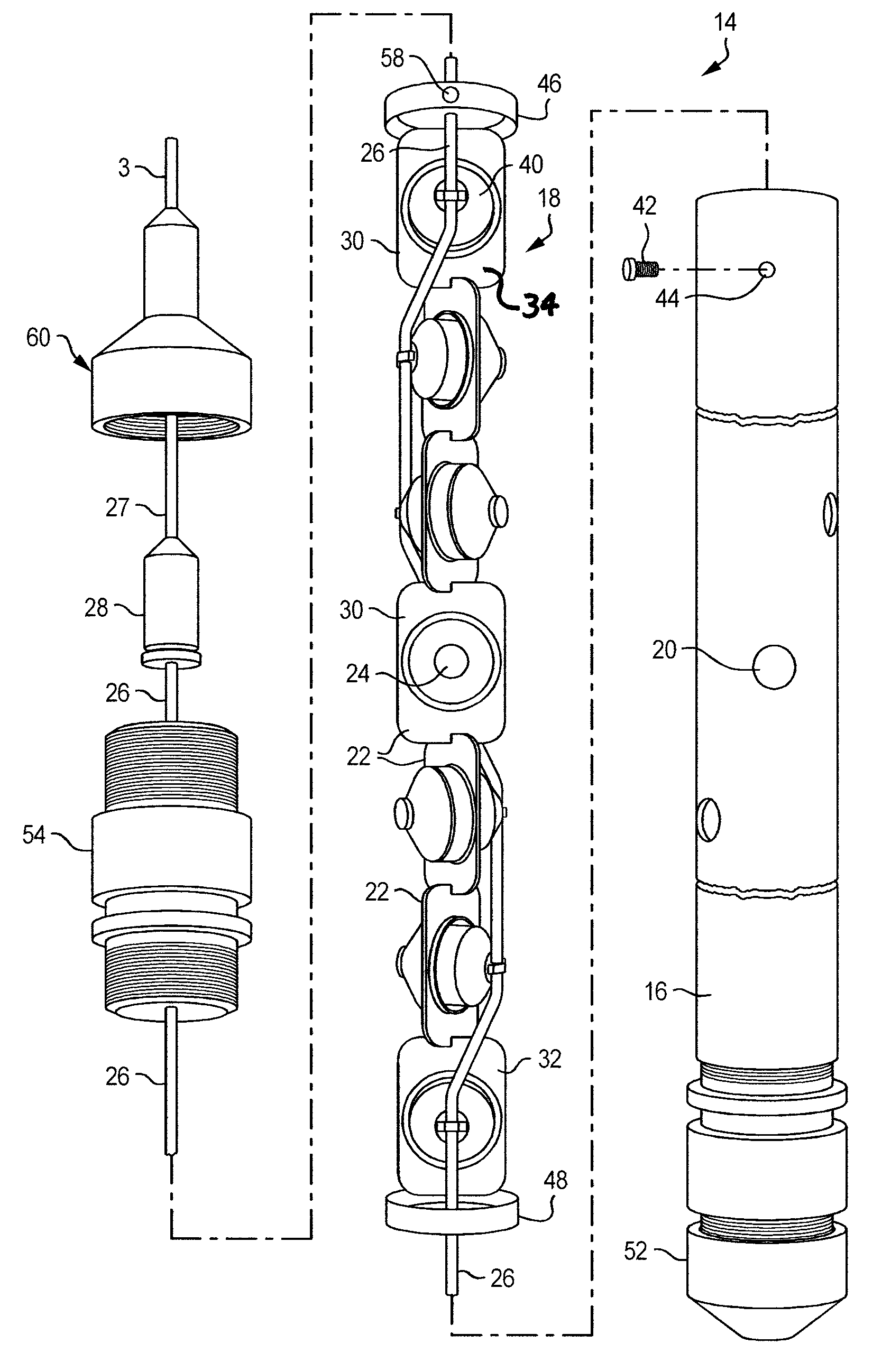

Exposed hollow carrier perforation gun and charge holder

InactiveUS20100089643A1Easily assembled and armedIncrease powerNuclear explosivesFluid removalCharge retentionDetonation

The perforation gun is comprised of a tubular carrier, a charge holder, a plurality of sealed charges, and a detonating cord. The tubular carrier has a length and a plurality of openings. The charge holder has a length and is comprised of a plurality of mounting locations which are each capable of receiving one of the sealed charges. The charge holder is capable of being secured within the carrier. The detonating cord is coupled to at least one sealed charge. In the mounted position and when the charge holder is secured within the carrier, the charges are aligned with the openings in the carrier such that, upon detonation, charge blasts emitted from the charges exit though the carrier openings and perforate a well casing and cement. In one aspect of the invention, the carrier openings are spirally arranged and spaced along the length of the carrier. In still another aspect of the invention, the openings are vertically arranged and spaced along the length of the carrier. In still another aspect of the invention, the carrier is closed at the top and bottom. In still another aspect of the invention, the carrier is capable of capturing debris created by a charge blast emitted from the sealed charges.

Owner:VIDAL MIRABEL

Pass-through bulkhead connection switch for a perforating gun

InactiveUS9145764B2Improve pressure resistanceIncrease temperatureOne pole connectionsCoupling device detailsDetonationEngineering

Embodiments of the present invention relate to systems, methods, and apparatus for reliably communicating a detonation signal and perforating oil and / or gas well casings. Particularly, at least one embodiment includes a pass-through bulkhead connection switch that can reliably withstand high operating temperatures and pressures. Such pass-through bulkhead connection switch can be used in perforating gun assemblies and can eliminate or reduce incidents of failed detonations.

Owner:INT STRATEGIC ALLIANCE LC

One trip completion process

A process and assembly for completing and providing sand control in a subterranean well and / or fracturing and preventing proppant flowback in a subterranean formation in a single trip. One or more perforating gun assemblies are juxtaposed and secured to one or more screen assemblies. Once positioned in a well adjacent a subterranean formation of interest, the explosive charges in each perforating gun assembly are detonated so as to penetrate the well and formation thereby initiating fracturing. The penetrations and the annulus defined between the well and screen assembly are then packed with gravel. Well fluid may be pressurized to in excess of the formation pressure prior to detonation of the explosive charges so as to enhance formation fracturing.

Owner:OWEN OIL TOOLS

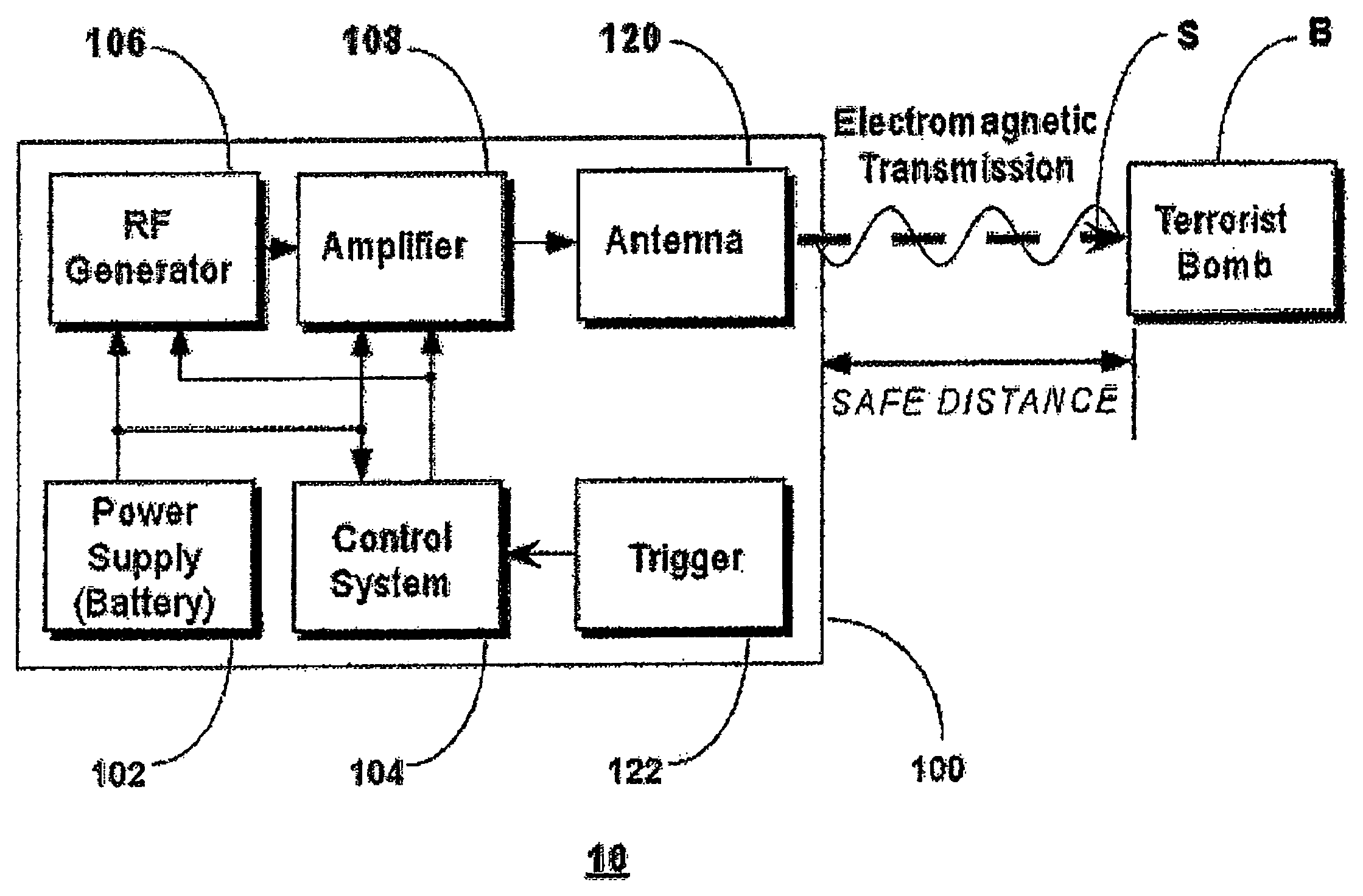

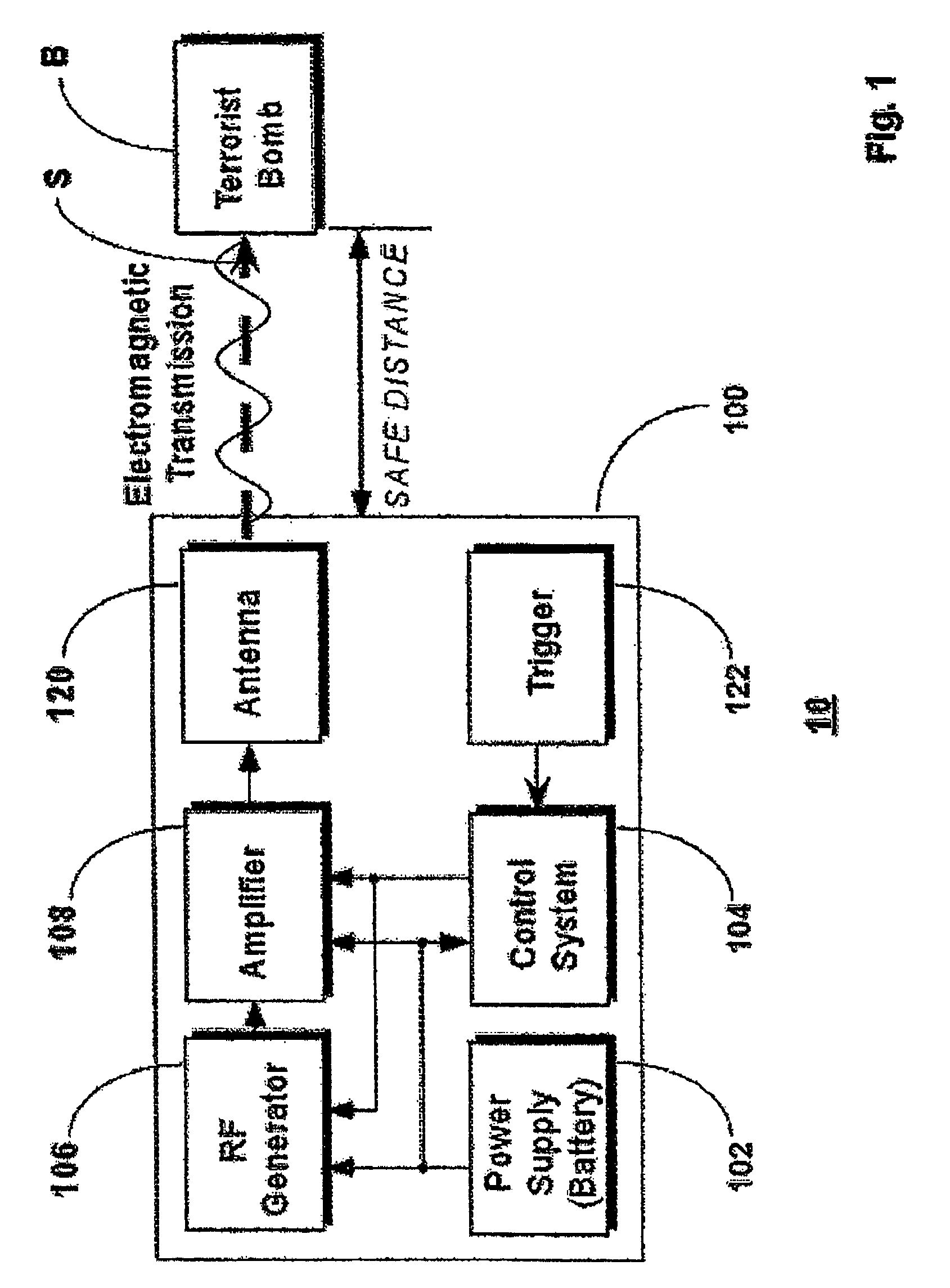

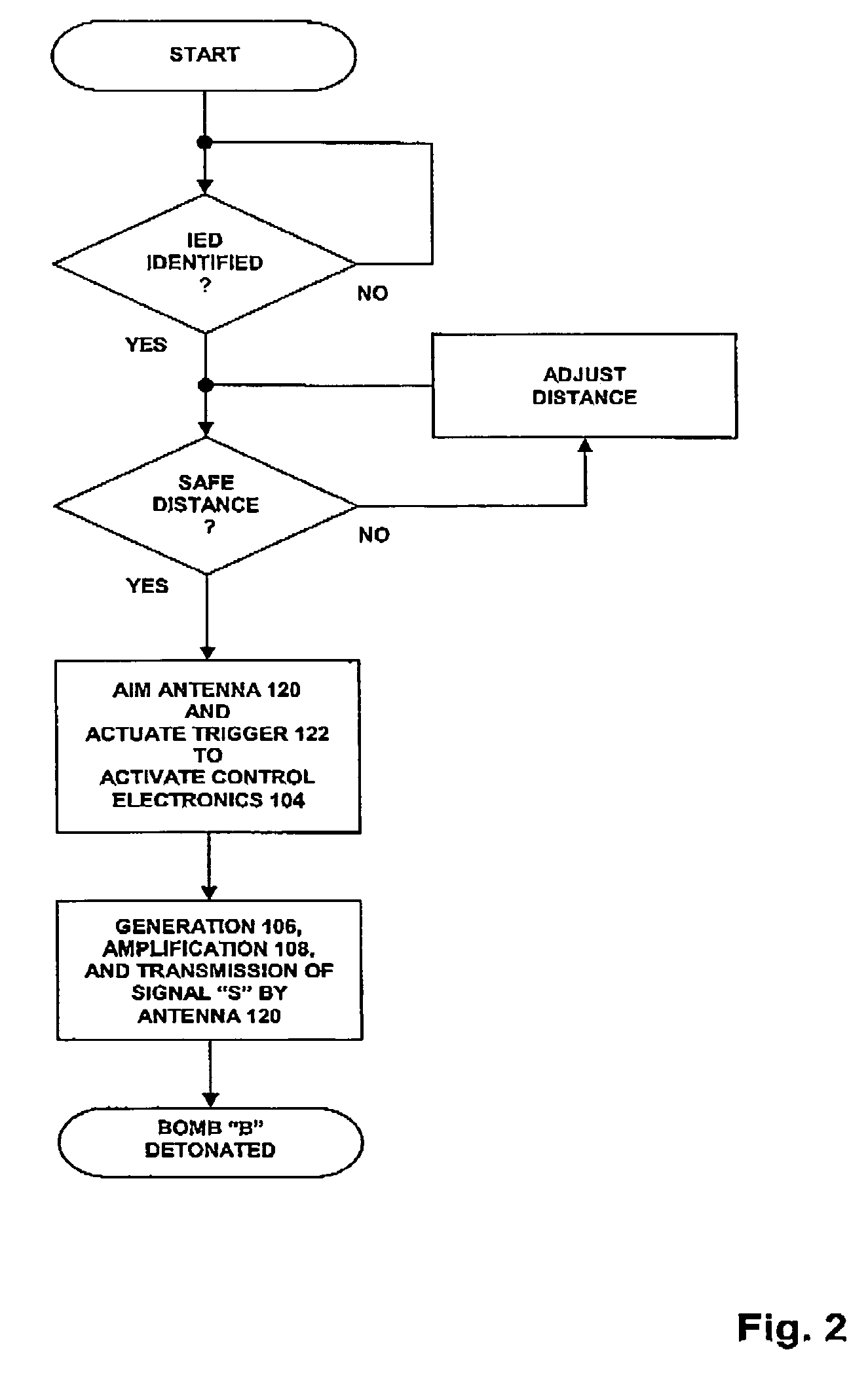

System and method for destabilizing improvised explosive devices

A system for destabilizing improvised explosive devices includes a radio transmitter means for generating a radio signal having (i) a selected carrier frequency, (ii) a selected amplitude modulation frequency, (iii) a selected peak power output, and (iv) a selected transmit duration. A directional antenna means is coupled to and fed by the radio transmitter means, for directing the radio signal onto a suspected improvised explosive device. The radio signal, upon being directed onto the suspected improvised explosive device, causes detonation of the device.

Owner:ROBERTS RICHARD L

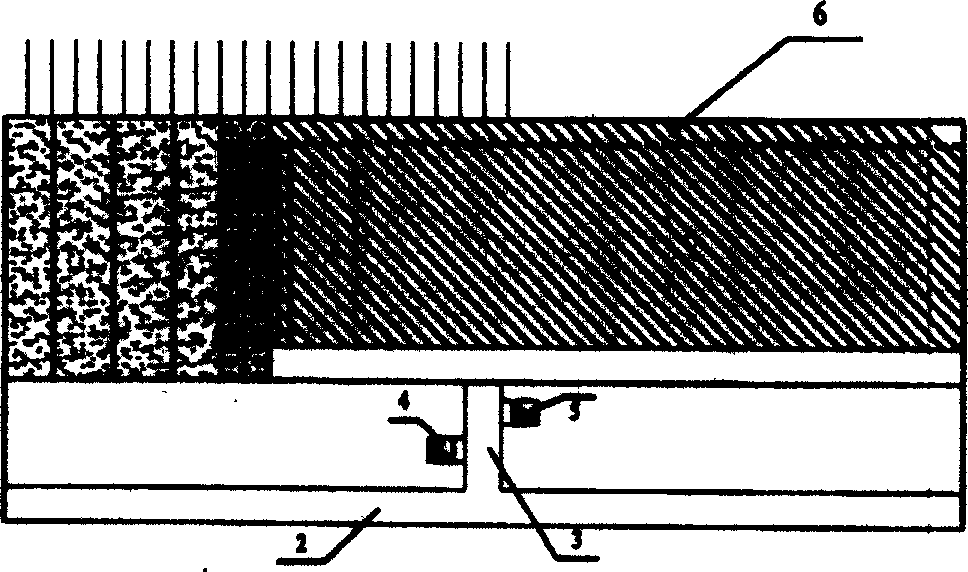

Continuous mining method of stepped sectional extruding and ore caving followed by filling

In the continuous mining method, ore body are divided into sections, subsections and mini-sections stepwisely along the ore vein; arranging mini-section drilling mine tunnels along the ore vein in the ore body bottom wall and connecting the mini-section tunnels with the main ramp way via linking tunnel; arranging support and filling tunnel along ore vein in the upper wall in the ore section; stoping from two ends to the central part of the bordroom via stepped continuous advance; drilling fanned holes with rock drill machine, breaking ore with rock explosive, charging with charging machine and combined elementary error detonation; filling finished stope via filling tunnel and filling dewatering device; and supporting crushed upper wall roof with deep anchor rod and steel fiber concrete. The present invention has high production capacity, high safety, less ore loss and low mining cost.

Owner:CENT SOUTH UNIV

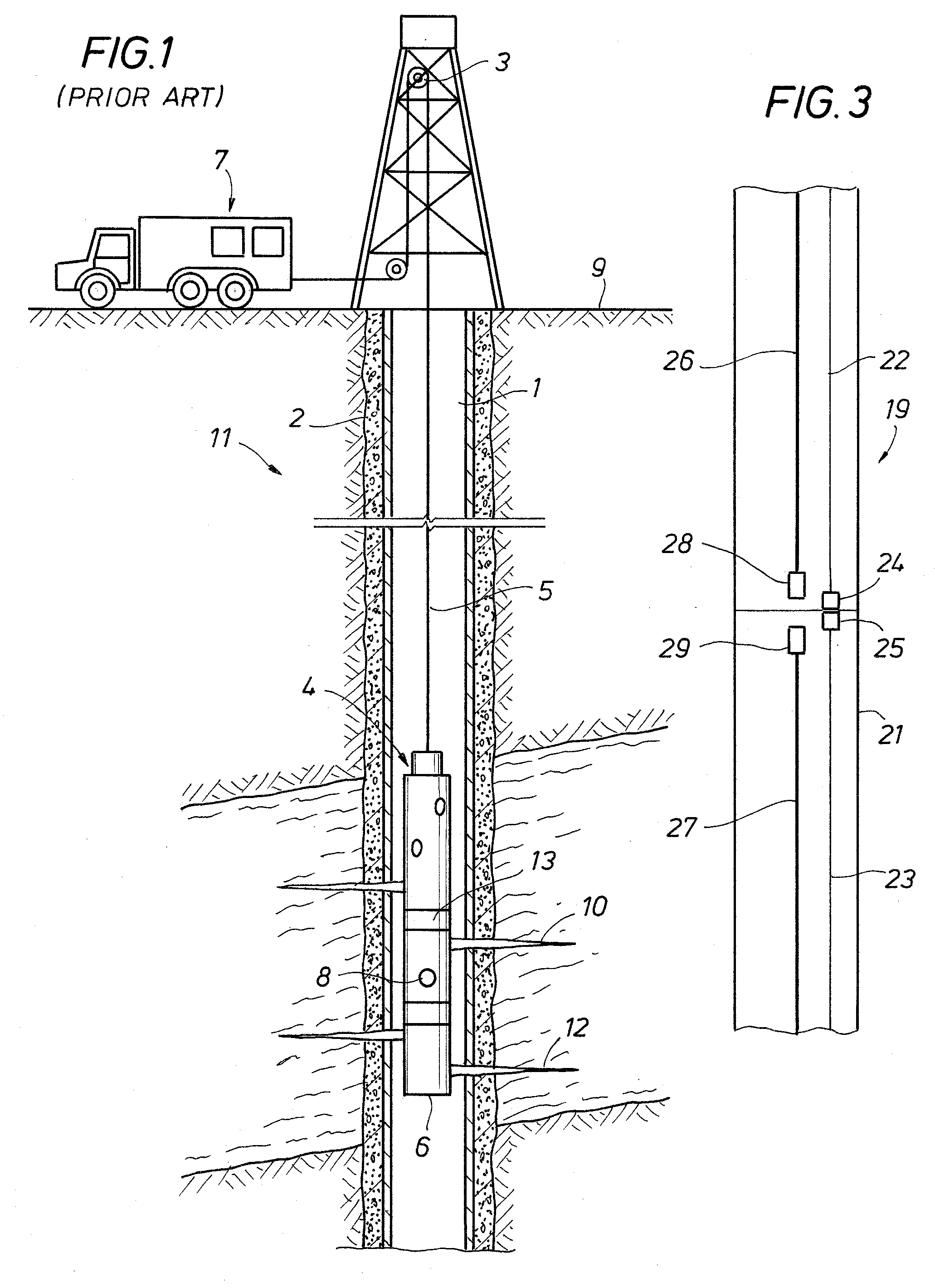

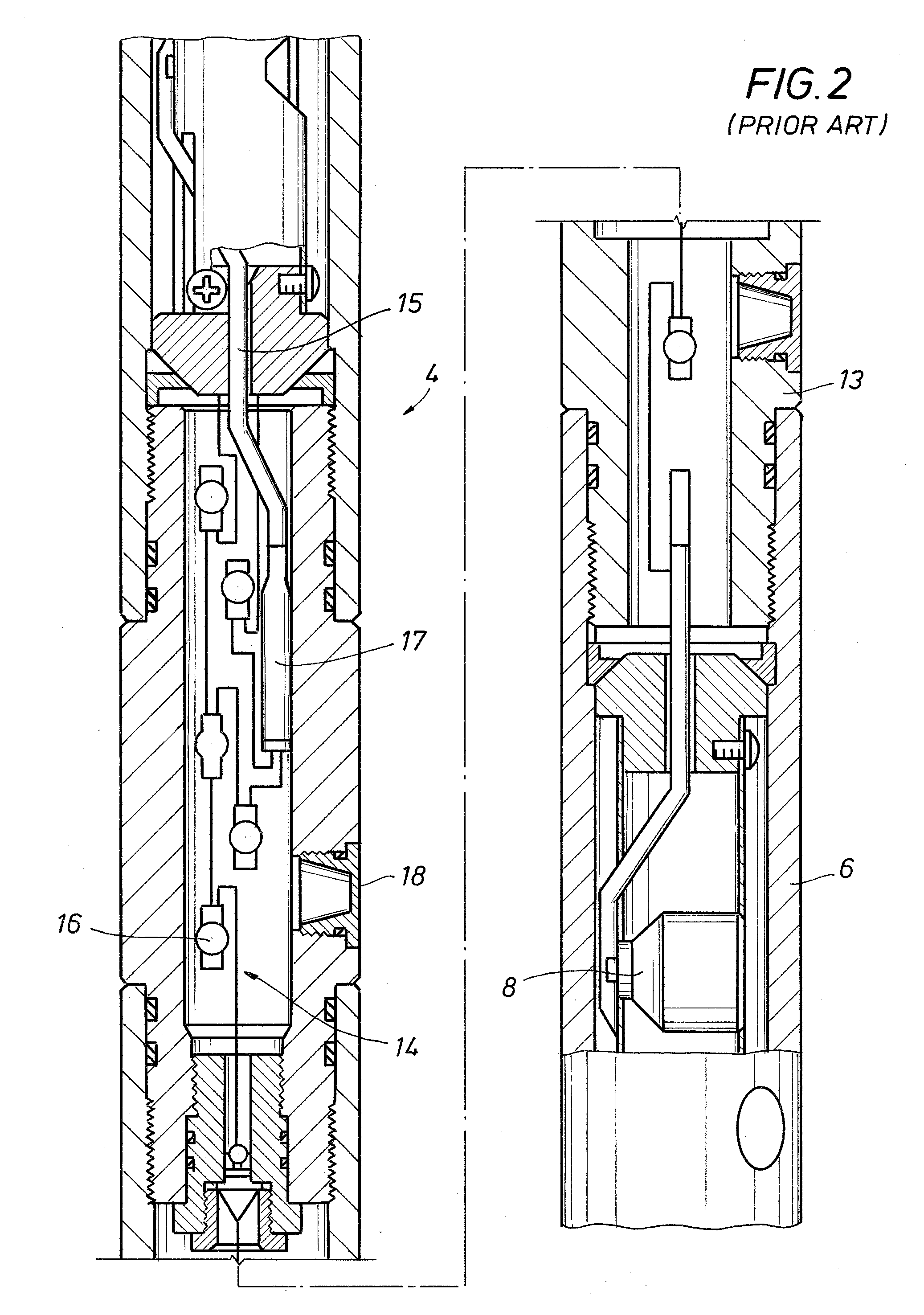

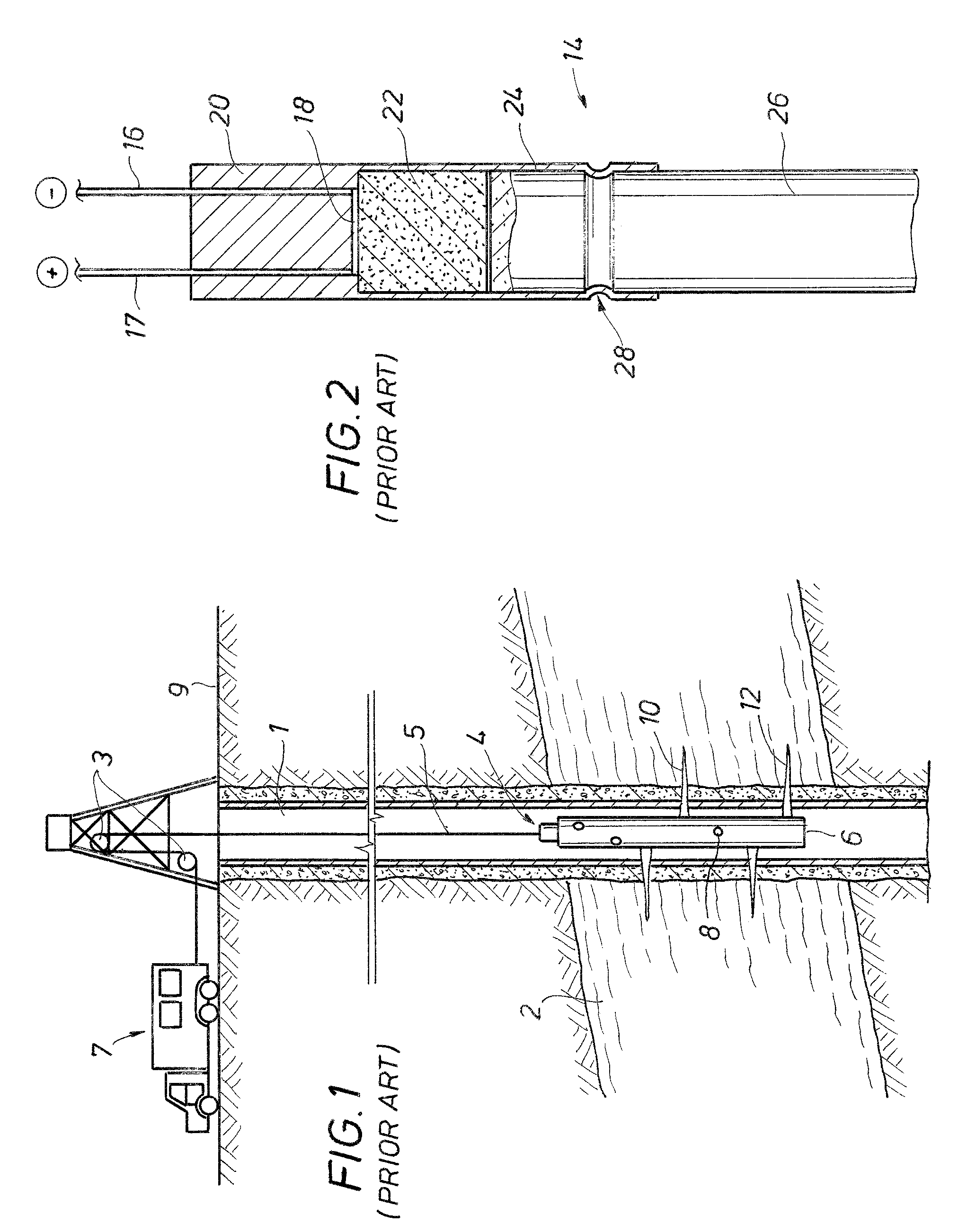

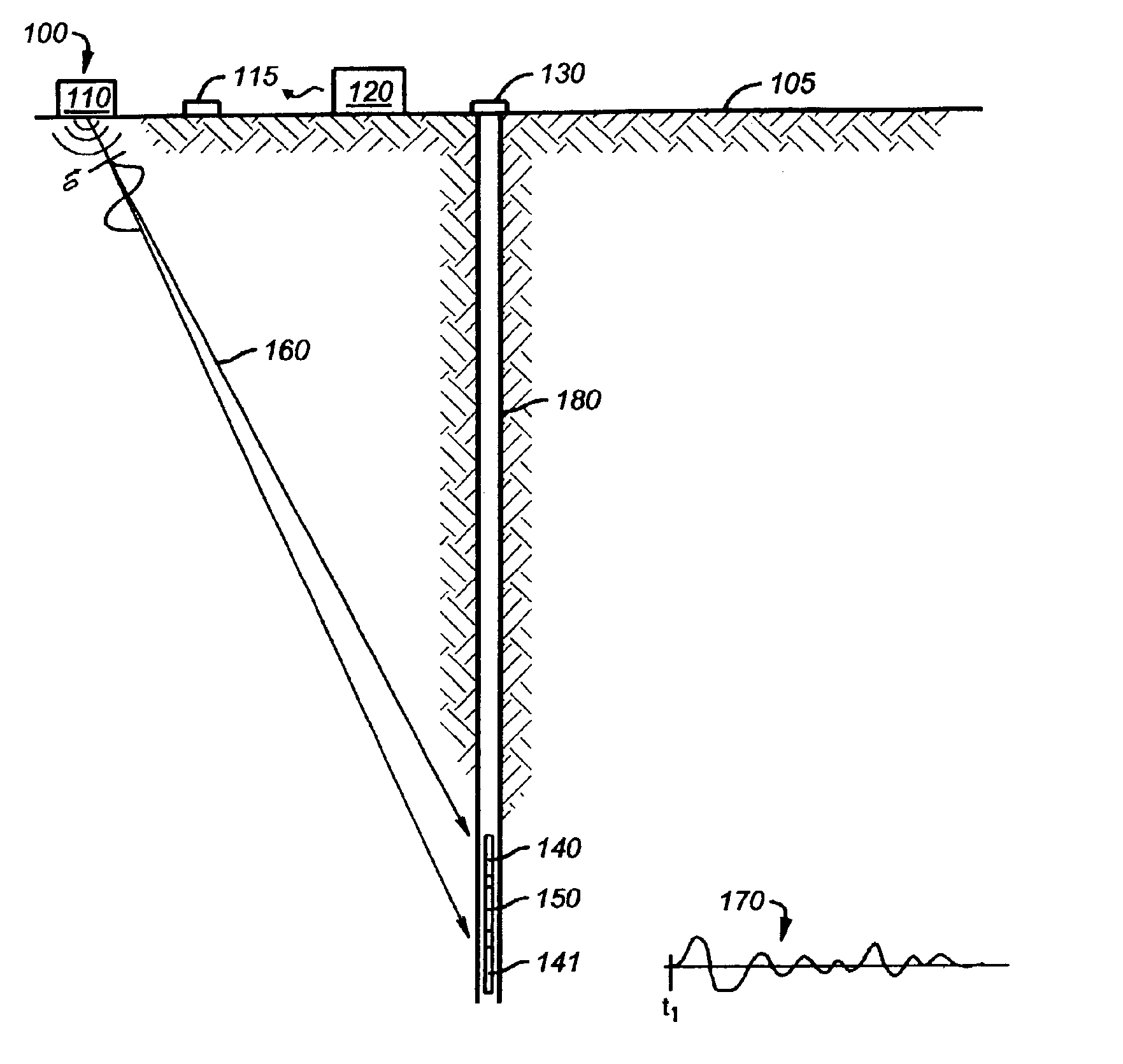

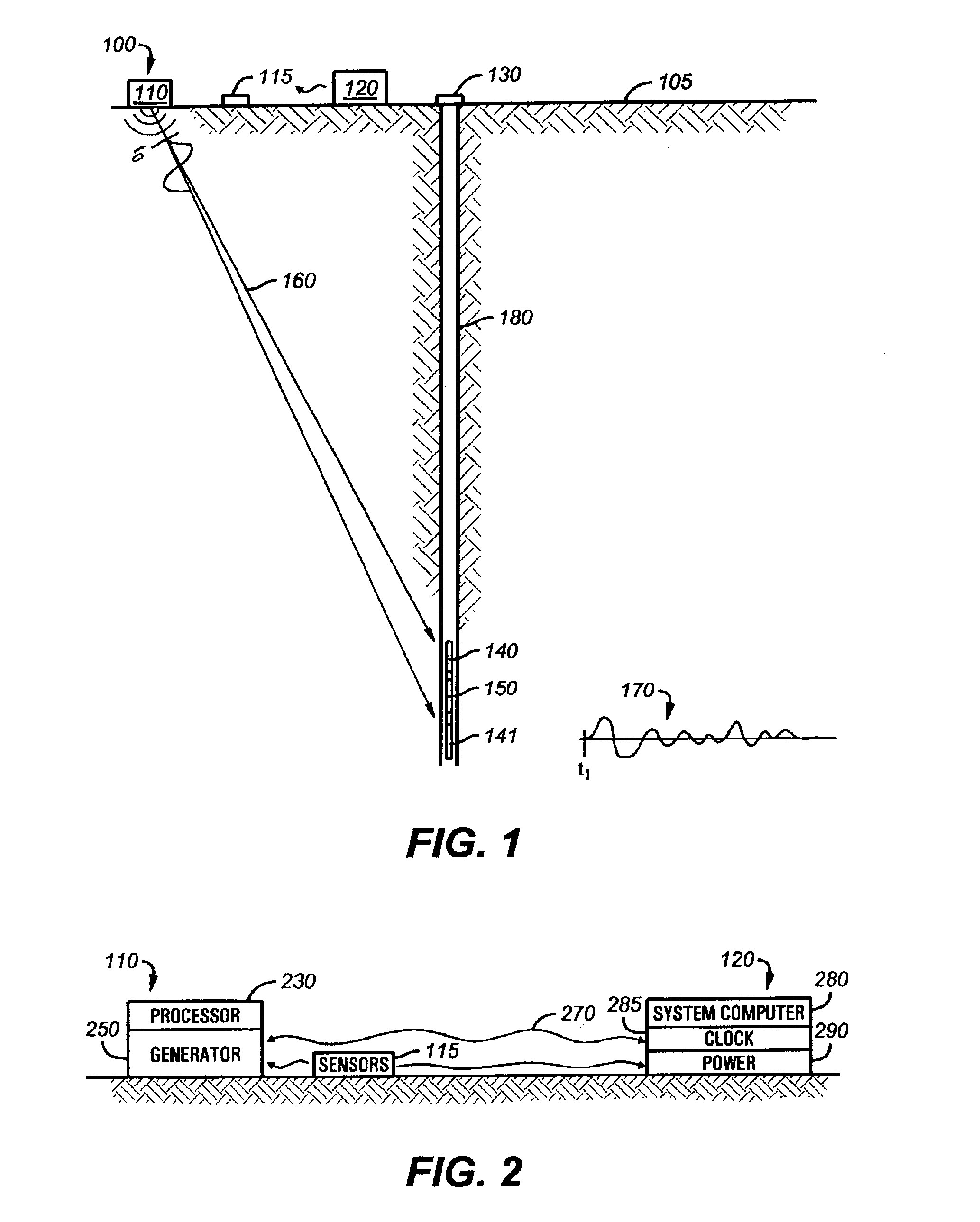

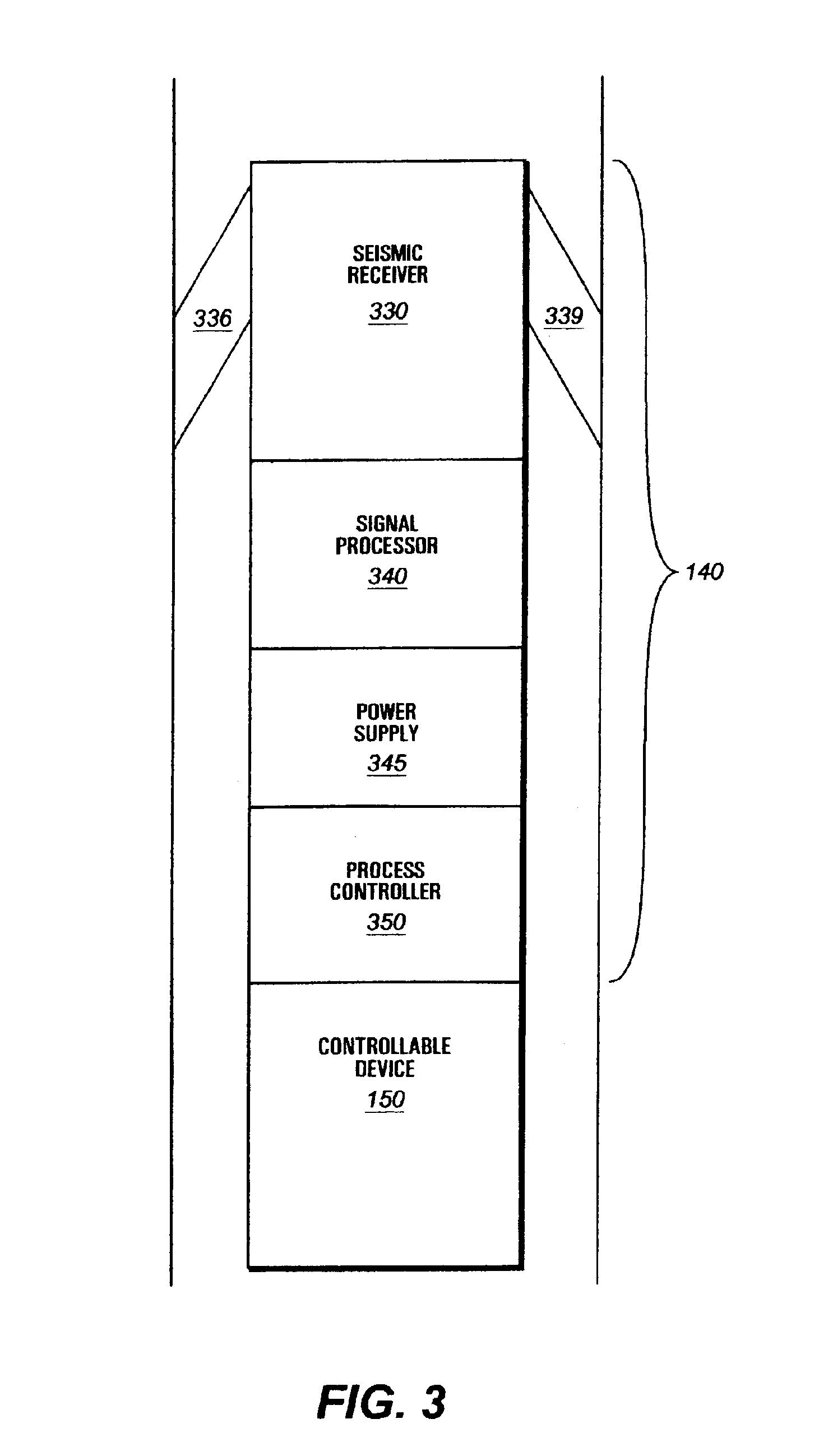

Seismic monitoring and control method

InactiveUS6885918B2Electric/magnetic detection for well-loggingSurveyDetonationSeismic communication

A seismic communication system suitable to communicate information to an underground device is disclosed. A seismic source (preferably on or near the surface of the earth) generates a timed series of seismic shots. These shots are then detected by one or more seismic receivers underground. Depending on the timing of these seismic shots, and the communication protocol selected, various information may be communicated to the underground target. Such a system is particularly desirable when the underground device includes a perforating gun because the perforating gun may not only be remotely detonated without the drawbacks of previous methods, but the detonation of the perforating gun charges may also be detected, giving an indication whether substantially fewer than all of the explosive charges detonated. The seismic communication system may also be used, as a component within a multi-functional well seismic system, for seismic reservoir monitoring or seismic monitoring of well operations.

Owner:GEO X SYST

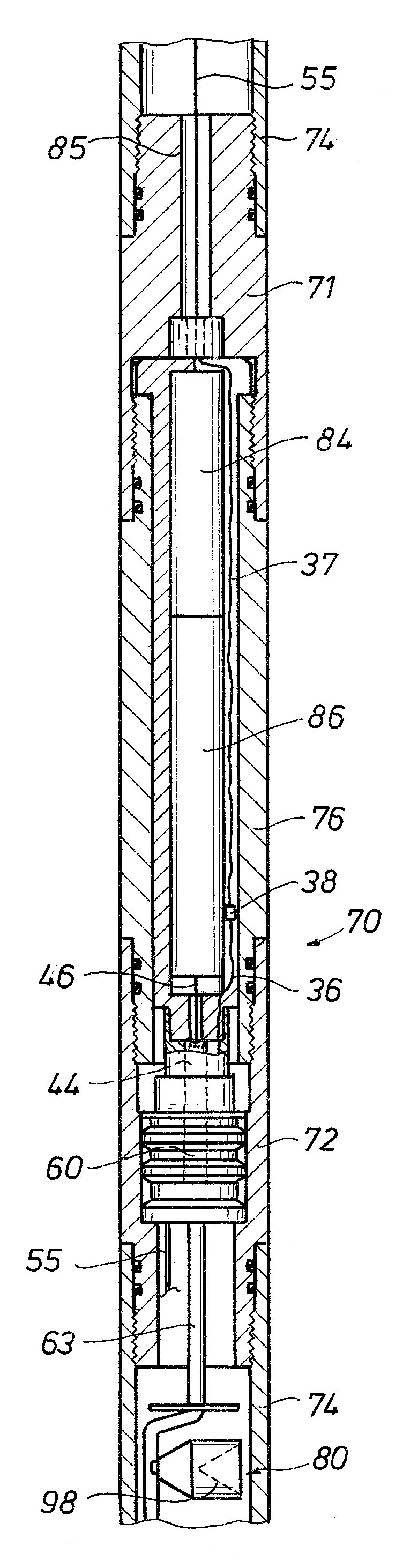

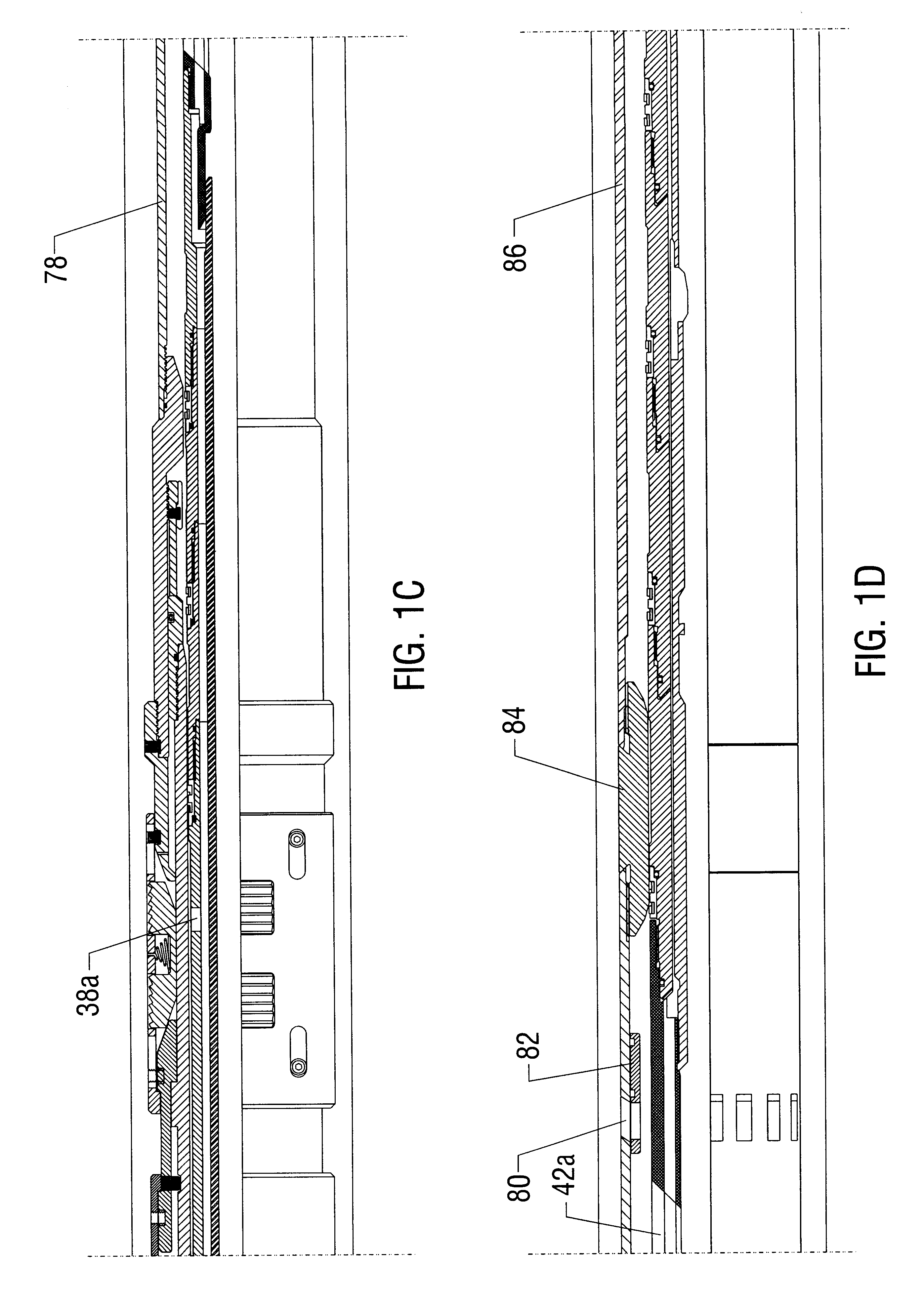

Single trip perforate and gravel pack system

An improved single trip perforating and gravel pack system is provided which includes a tubing conveyed perforating assembly, a gravel pack completion assembly, and a retrievable service assembly. The retrievable service assembly includes a hydraulic setting tool and a crossover tool assembly. The hydraulic setting tool is less sensitive to hydraulic pressures generated by the detonation of the perforating guns. The hydraulic setting tool includes an annulus release mechanism, a preset lock assembly and a rotational lock assembly, all of which are mechanically actuated. The retrievable service assembly also includes a concentric check valve which improves well control and allows for reversing out excess slurry in the service assembly following completion of a gravel packing or frac packing operation.

Owner:BJ SERVICES CO

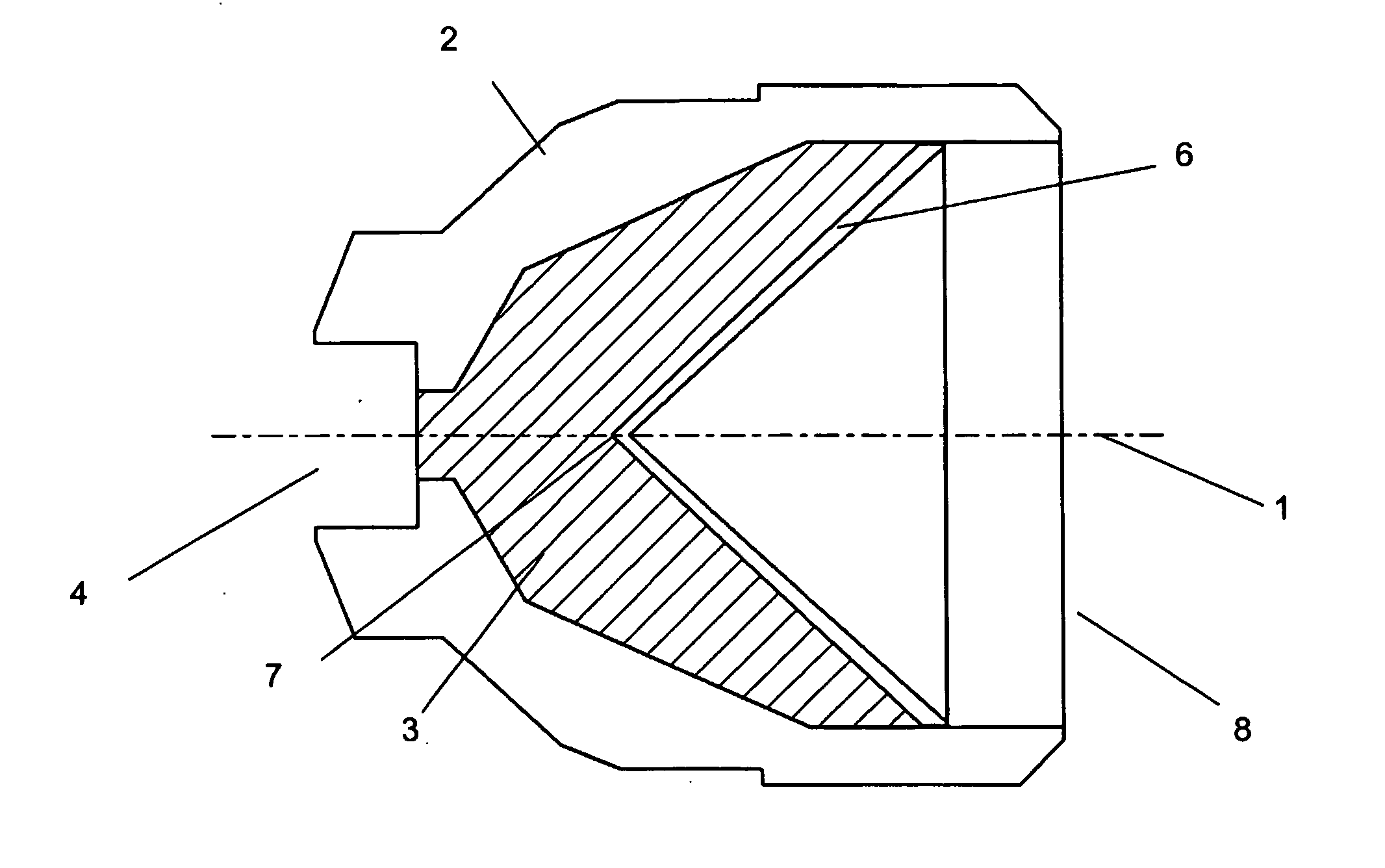

Oil well perforators

ActiveUS20070056462A1Material consumptionReduce the possibilityAmmunition projectilesExplosive chargesParticulatesDetonation

An oil and gas well shaped charge perforator capable of providing an exothermic reaction after detonation is provided, comprising a housing, a high explosive, and a reactive liner where the high explosive is positioned between the reactive liner and the housing. The reactive liner is produced from a composition which is capable of sustaining an exothermic reaction during the formation of the cutting jet. The composition may be selected from any known formulation which is suitable for use in an oil and gas well perforator, typically the composition will comprise at least one metal and at least one non-metal, wherein the non-metal is selected from a metal oxide, or any non-metal from Group III or Group IV or at least two metals such as to form an intermetallic reaction. Typically at least one of the metals in the invention may be selected from Al, Ce, Li, Mg, Mo, Ni, Nb, Pb, Pd, Ta, Ti, Zn or Zr. The liner composition may preferably be a pressed particulate composition, such that the material is consolidated under pressure to form the desired shape of the liner. To aid consolidation a binder may also be added.

Owner:WELLS FARGO BANK NAT ASSOC +1

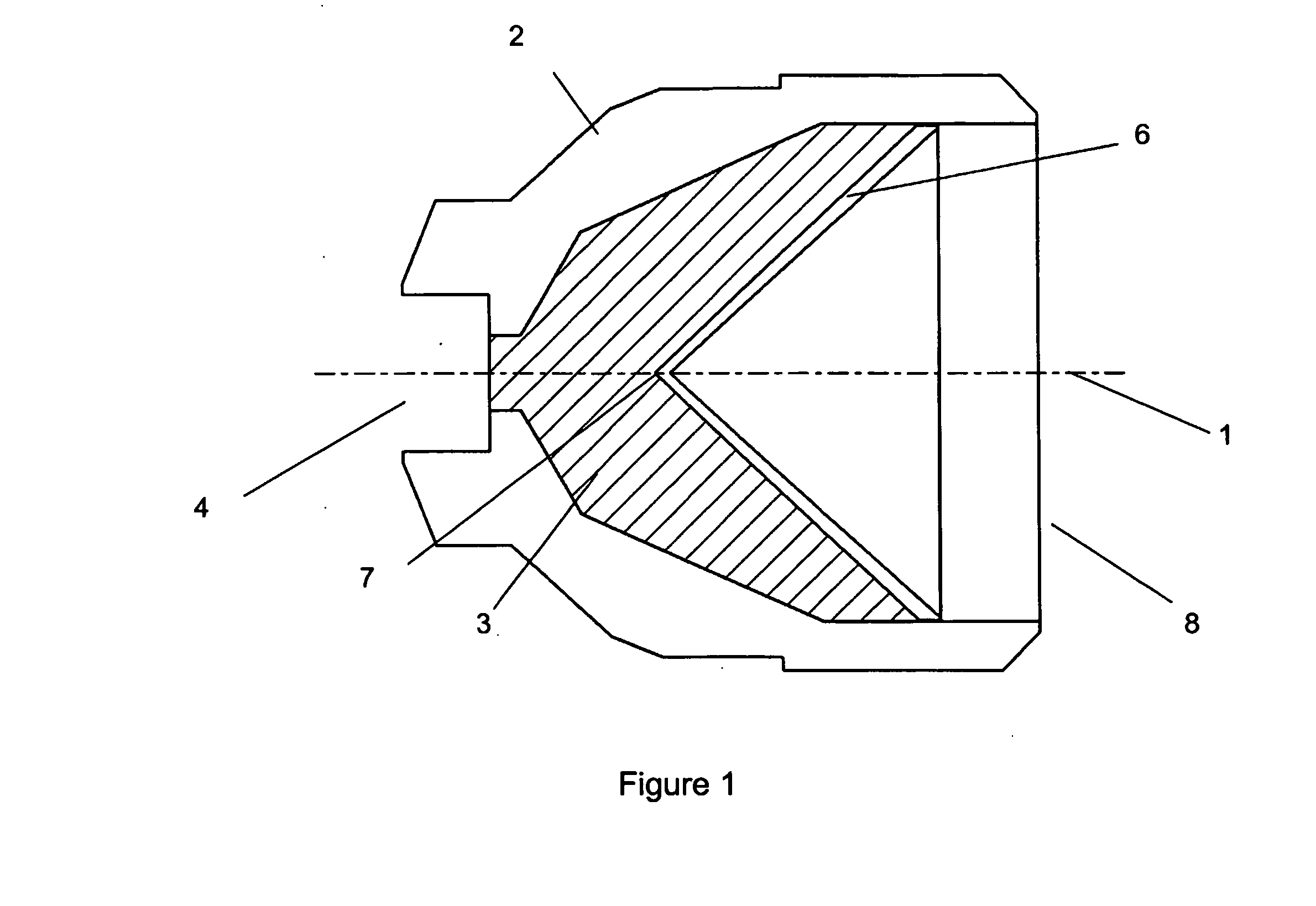

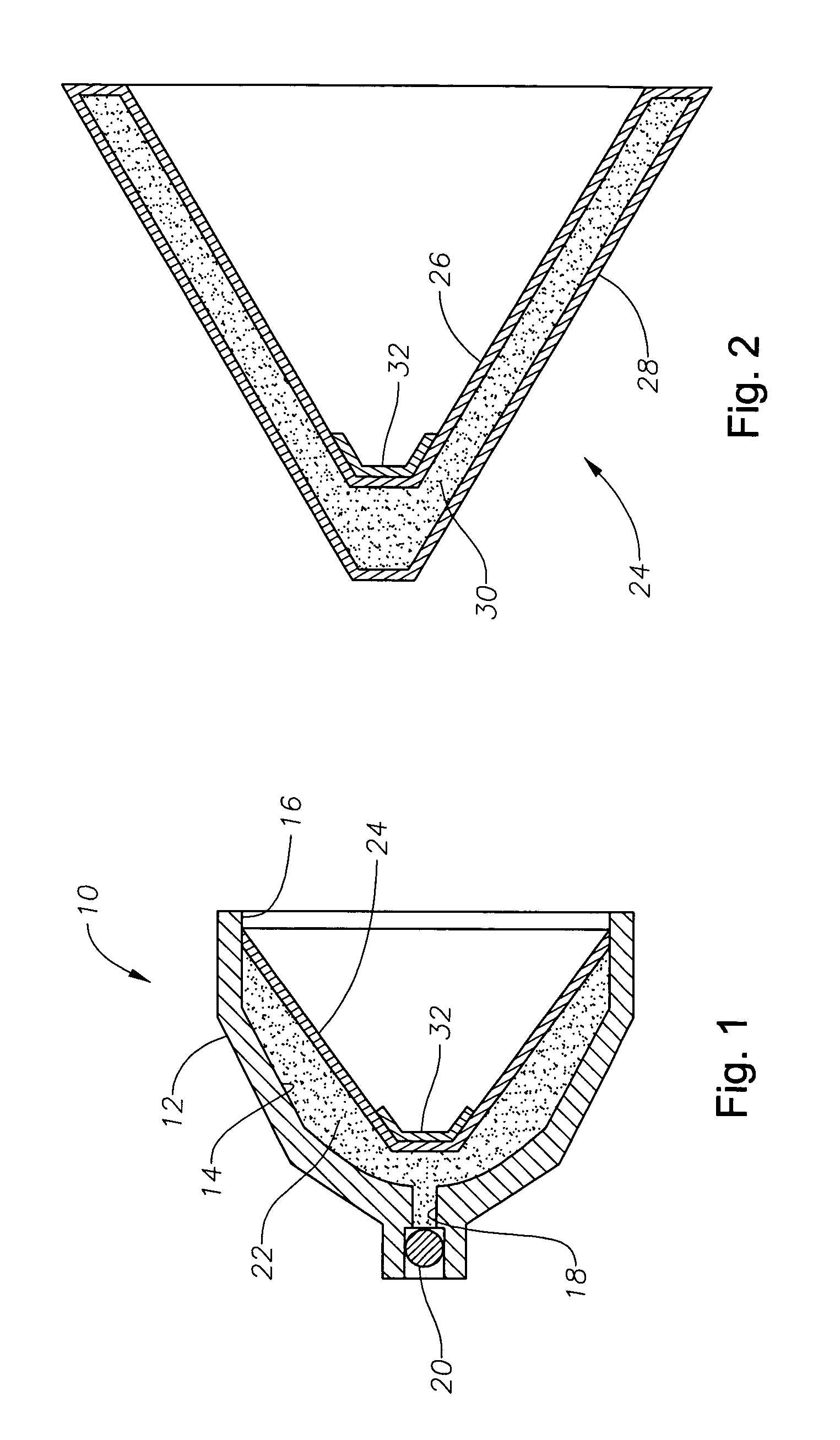

Apparatus and method for penetrating oilbearing sandy formations, reducing skin damage and reducing hydrocarbon viscosity

InactiveUS20050115448A1Excessive heatingMinimal damageExplosive chargesAmmunition projectilesPorosityPolyester

A shaped charge and a method of using such to provide for large and effective perforations in oil bearing sandy formations while causing minimal disturbance to the formation porosity is described. This shaped charge uses a low-density liner having a filler material that is enclosed by outer walls made, preferably, of plastic or polyester. The filler material is preferably a powdered metal or a granulated substance, which is left largely unconsolidated. The preferred filler material is aluminum powder, or aluminum particles, that are coated with an oxidizing substance, such as TEFLON®, permitting a secondary detonation reaction inside the formation following jet penetration. The filled liner is also provided with a metal cap to aid penetration of the gun scallops, the surrounding borehole casing and the cement sheath. The metal cap forms the leading portion of the jet, during detonation. The remaining portion of the jet is formed from the low-density filler material, thereby resulting in a more particulated jet. The jet results in less compression around the perforation tunnel and less skin damage to the proximal end of the perforation tunnel.

Owner:OWEN OIL TOOLS

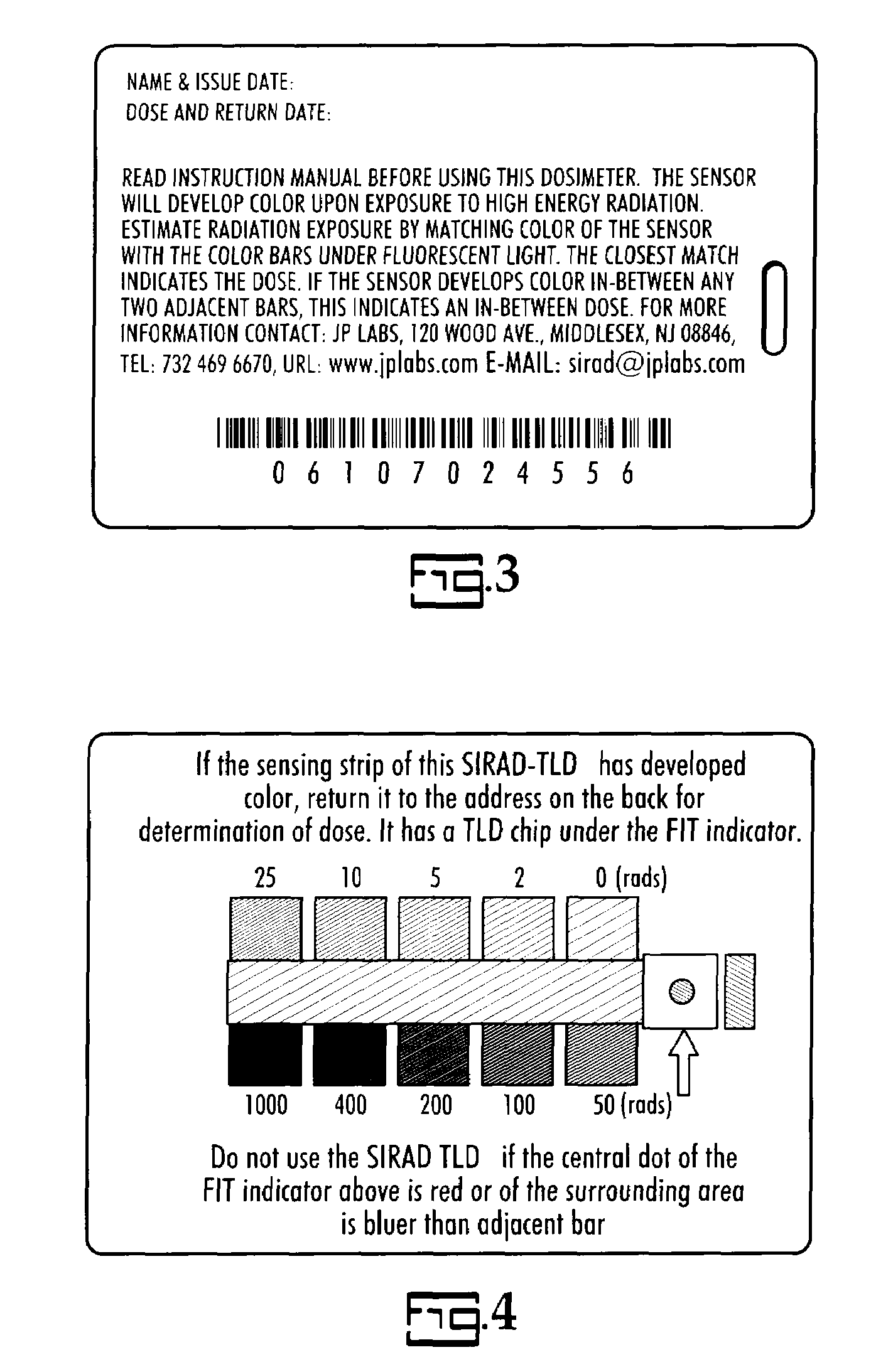

A self indicating multi-sensor radiation dosimeter

InactiveUS20090224176A1Easy to useChemical dosimetersMaterial analysis by optical meansDetonationThermoluminescence

Described is a multi-sensor radiation dosimeter system with (1) a self-indicating, instant radiation sensor and (2) a conventional radiation sensor for monitoring high energy radiations, such as X-ray, electrons and neutrons. Conventional radiation sensors, such as X-ray film, TLD (Thermoluminescence Dosimeters), RLG (Radioluminescence Glass) and OSL (Optically Simulated Luminescence), are highly sensitive but are not instant. In the event of a dirty bomb, nuclear detonation or a radiological accident, one needs to know the exposure instantly so proper precautions can be taken and medical treatment, if required, can be given to the victim. If a self-indicating instant sensor is one of the sensors, one would know the dose instantly, and dose can be determined with higher accuracy than by the traditional methods. This type of device offers the best of both technologies.

Owner:JP LAB INC

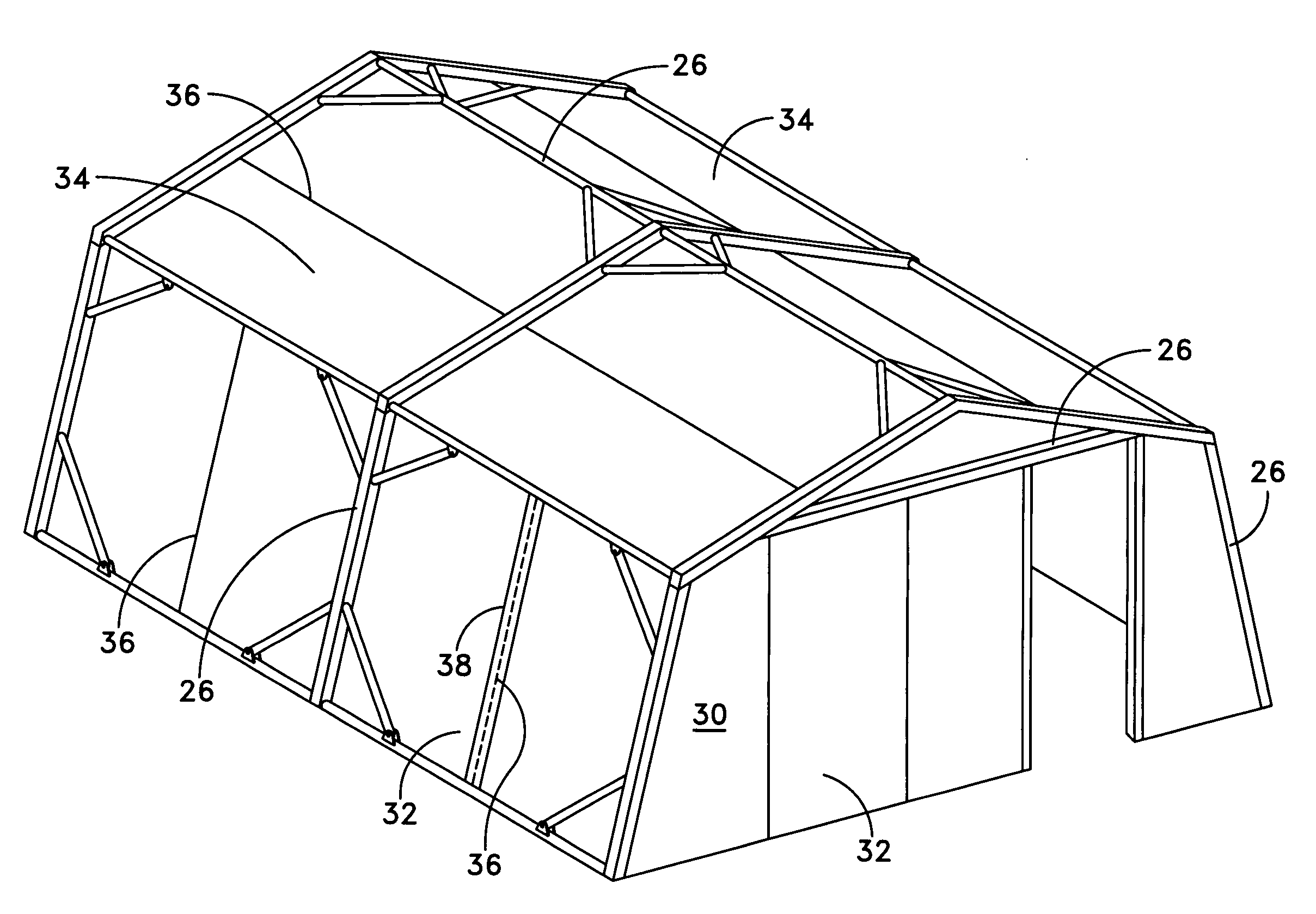

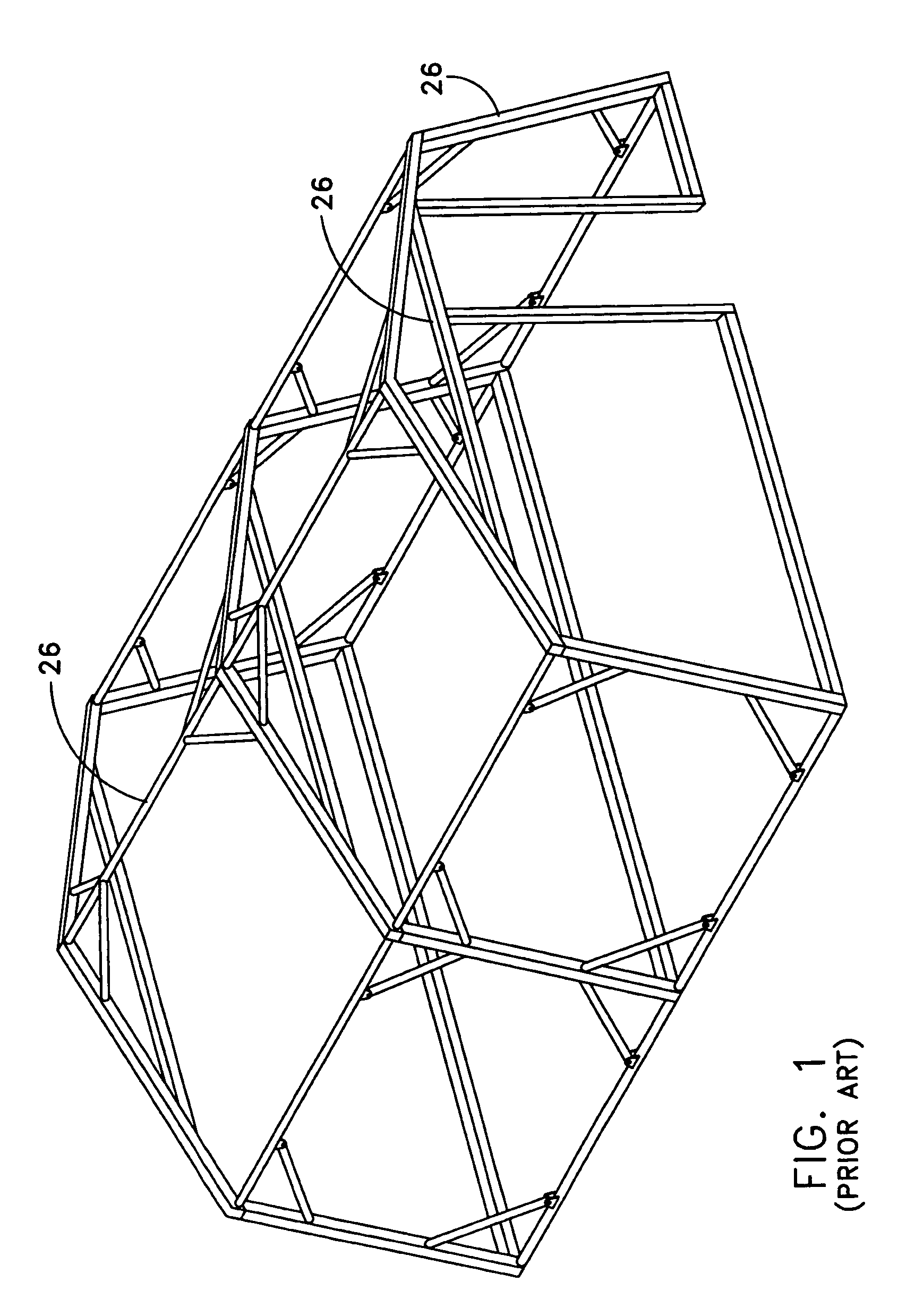

Ballistic protection shelter

A ballistic protection shelter includes a soft-walled shelter structure wherein soft wall and soft roof portions are supported on at least one rigid support member, and an internal shelter structure for disposition within the soft-walled shelter structure. The internal shelter structure includes at least rigid side wall panels connectable to each other to form an enclosure. The panels are of a ballistic protective material adapted to provide protection to shelter occupants against explosive detonations and shrapnel.

Owner:UNITED STATES OF AMERICA THE AS REPRESENTED BY THE SEC OF THE ARMY

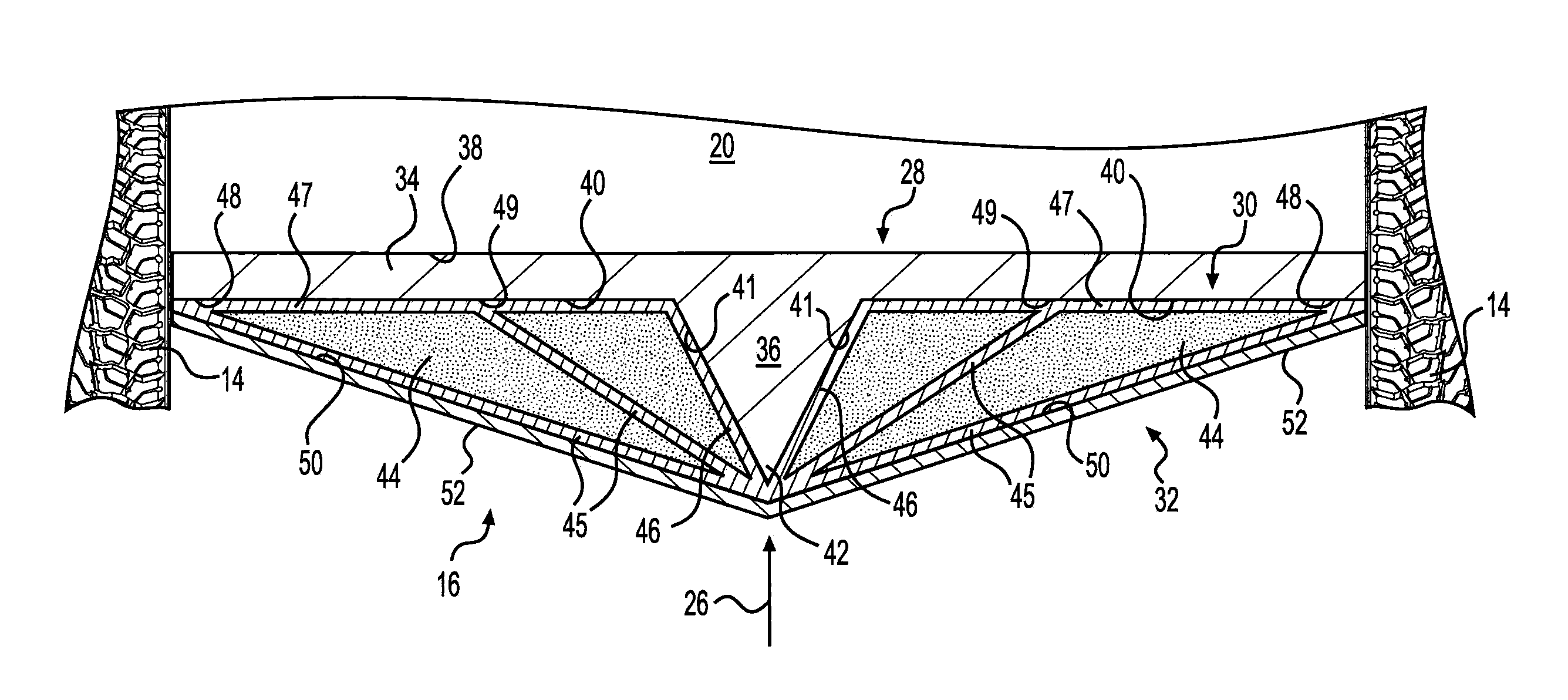

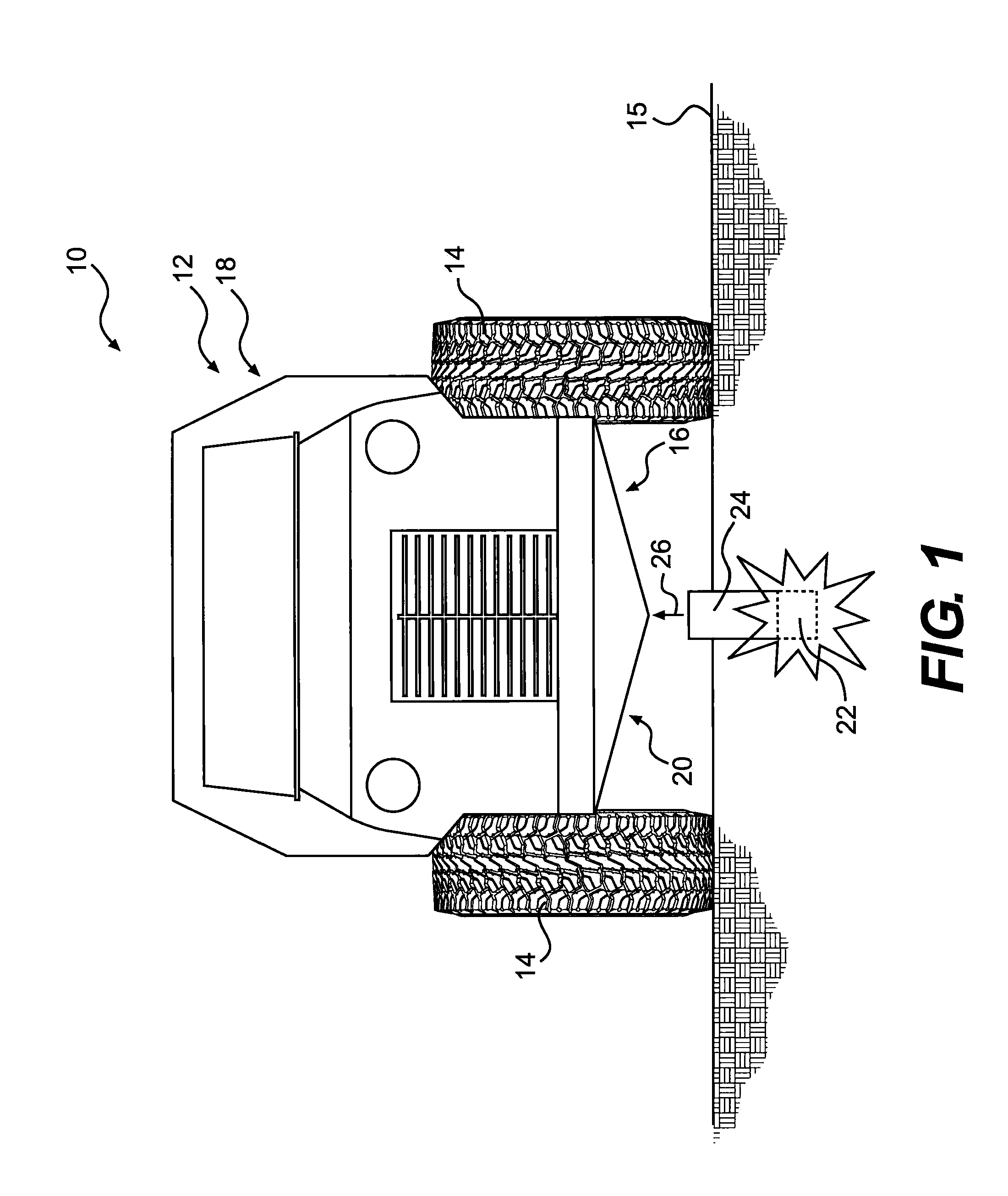

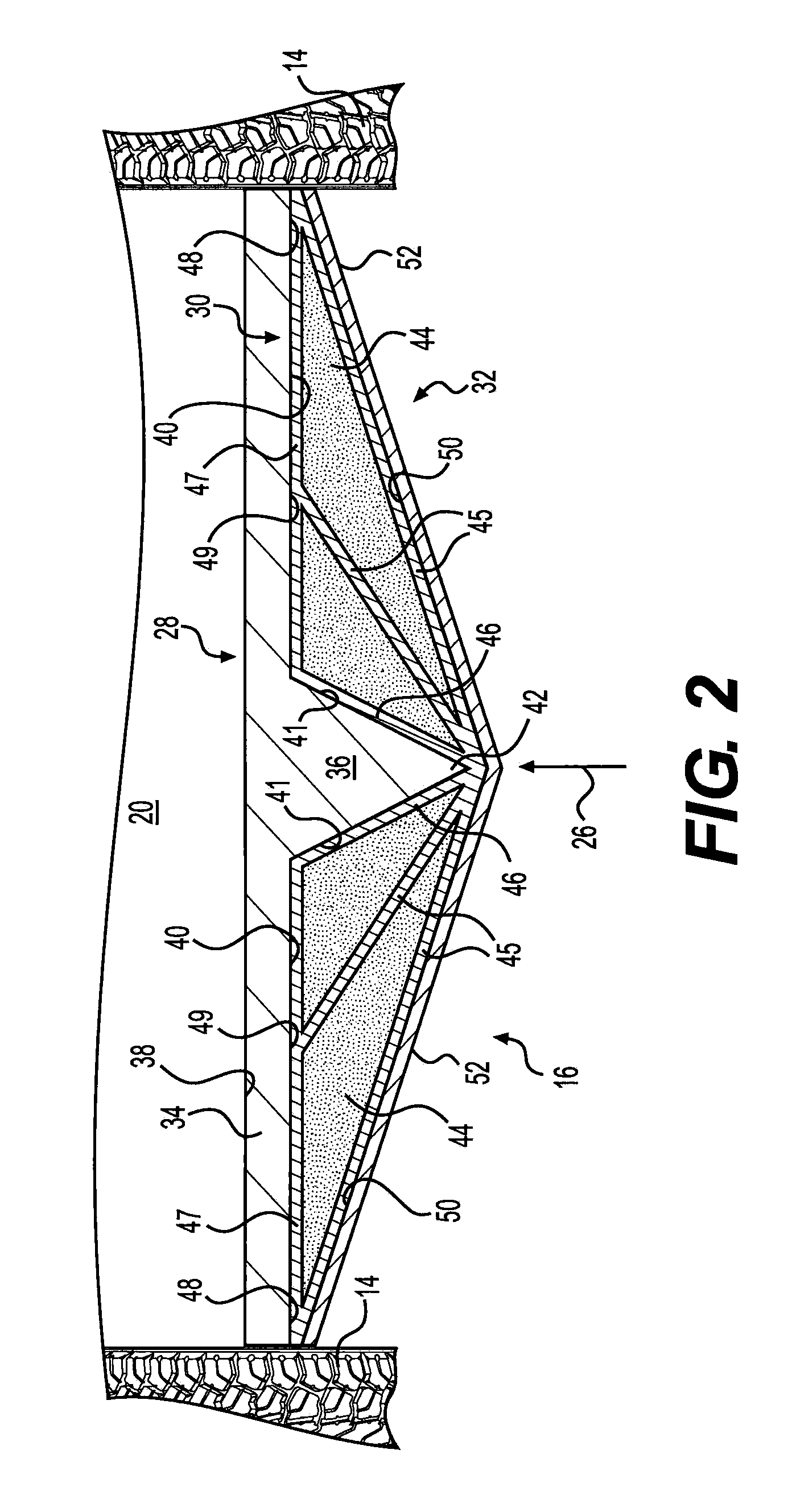

System for protecting a vehicle from a mine

In one aspect, the present disclosure is directed to a system for protecting a vehicle from a mine. Upon detonation the mine may yield ejecta having an expected trajectory. The system has a first layer of material disposed outside of an underbody of a hull of the vehicle. The first layer includes a base disposed in a direction substantially parallel to the underbody and a protrusion that narrows as it extends away from the base in a direction opposing the expected ejecta trajectory. The system also has a second layer including a material having a shock wave transmission velocity that is higher than a shock wave transmission velocity of the material of the first layer. The system further has an exterior layer substantially covering the first and second layers, and the exterior layer has an exterior surface that faces away from the underbody and toward the expected ejecta trajectory.

Owner:FORCE PROTECTION TECH

Exposed hollow carrier perforation gun and charge holder

InactiveUS7762351B2Easily assembled and armedIncrease powerNuclear explosivesFluid removalDetonationMaterial Perforation

The perforation gun is comprised of a tubular carrier, a charge holder, a plurality of sealed charges, and a detonating cord. The tubular carrier has a length and a plurality of openings. The charge holder has a length and is comprised of a plurality of mounting locations which are each capable of receiving one of the sealed charges. The charge holder is capable of being secured within the carrier. The detonating cord is coupled to at least one sealed charge. In the mounted position and when the charge holder is secured within the carrier, the charges are aligned with the openings in the carrier such that, upon detonation, charge blasts emitted from the charges exit though the carrier openings and perforate a well casing and cement. In one aspect of the invention, the carrier openings are spirally arranged and spaced along the length of the carrier. In still another aspect of the invention, the openings are vertically arranged and spaced along the length of the carrier. In still another aspect of the invention, the carrier is closed at the top and bottom. In still another aspect of the invention, the carrier is capable of capturing debris created by a charge blast emitted from the sealed charges.

Owner:VIDAL MIRABEL

Apparatus and method for severing pipe utilizing a multi-point initiation explosive device

A system and method for making and using a multi-point initiation explosive device that produces an enhanced pressure wave for severing tubing, pipe or casing in an oil or gas well. At least two opposed initiators initiate a column of explosive material from opposite ends, thereby generating opposing pressure waves propagating toward a midpoint between the initial initiators. A shaped-charge assembly with a liner located at the midpoint initiates immediately prior to the arrival of the opposing pressure waves and forms a fast moving jet to pre-score the target pipe prior to the arrival of the pressure pulse propagating from the initial detonations.

Owner:HALLIBURTON ENERGY SERVICES INC

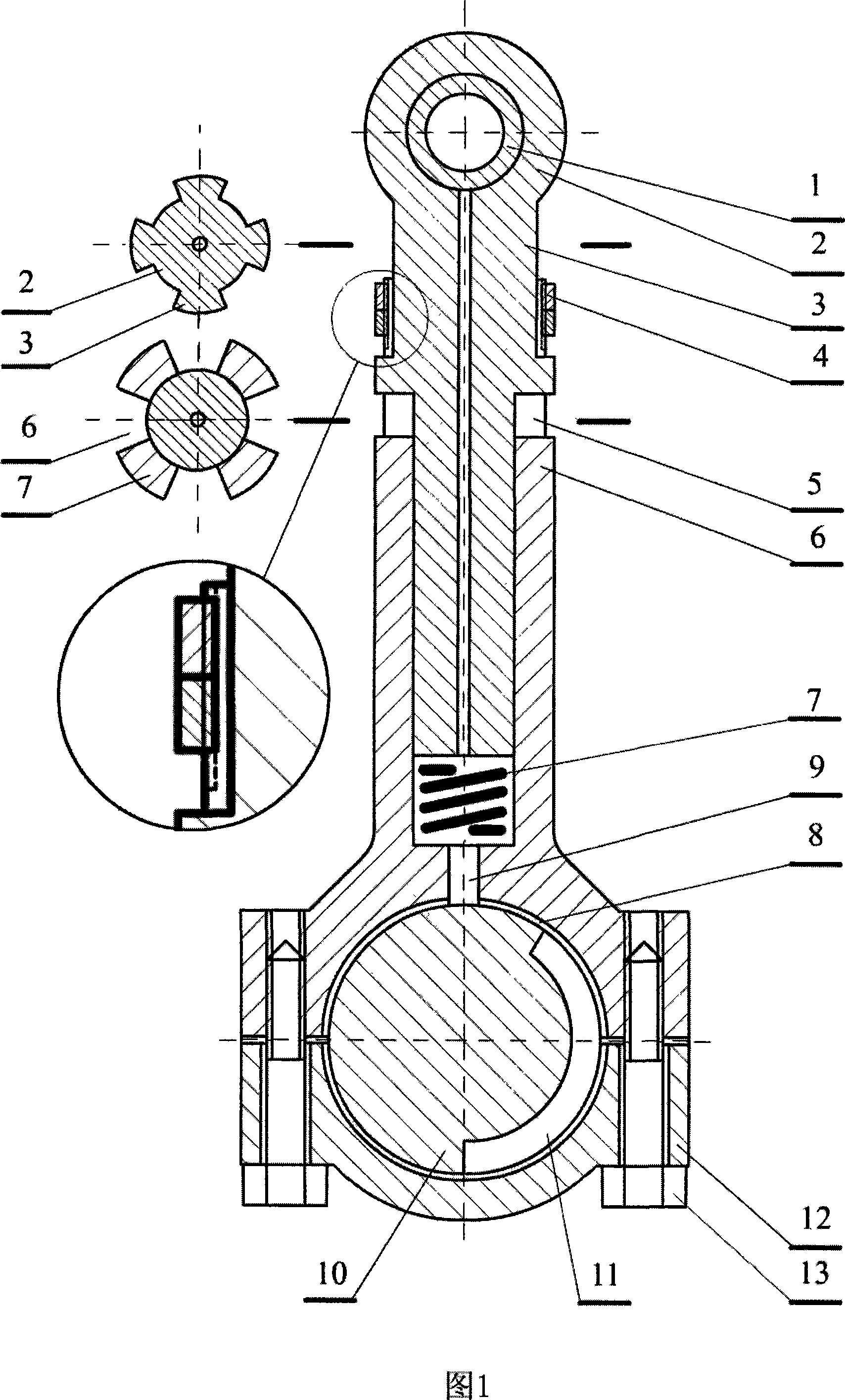

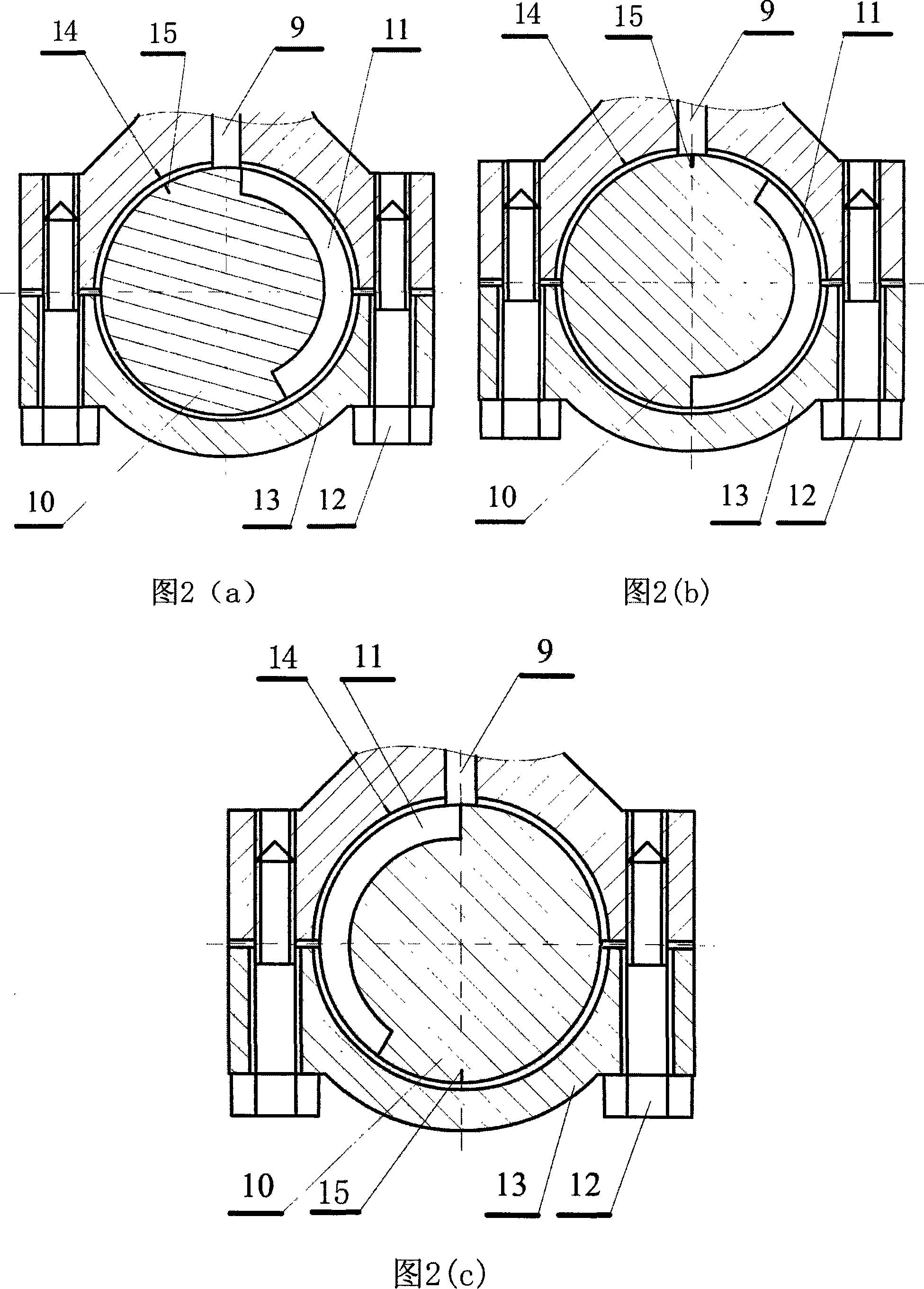

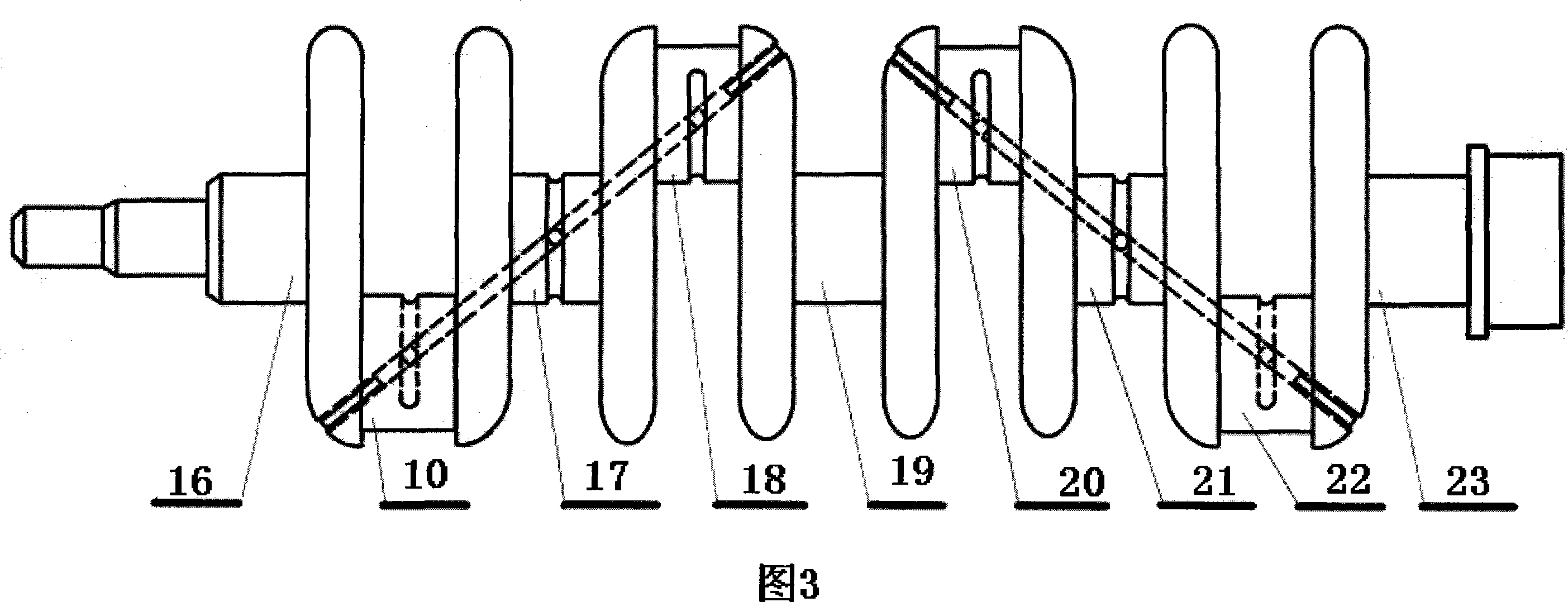

Self-adaption compression ratio variable engine

An engine with variable compression ratios that is simple, reliable and cheap is provided. The compression ratio is at maximum at idling, and is at minimum at the max. valve position, and can be changed automatically and continuously under any valve position, so that the compression ratio of the engine will approach to the max. allowable value for detonation, so the engine is of very high efficiency and substantially complete combustion, very low emission of waste gas, and is a target pursued by the automobile industry at present in the world. The principle of the invention is, a link rod of variable lengths is used, and the length of the link rod is depending upon the pressure of the combustible mixture gas before ignition combustion; when the pressure is approaching and exceeding the detonation pressure, the link rod will shorten automatically, the compression ratio will drop, so that the pressure will not increase any more, and detonation is avoided. The key tech in the invention is that the link rod uses a plunger type hydraulic cylinder, the oil in which is supplied and closed by the neck connected by the link rod on the crankshaft, so that the length of the link rod is variable in the compression period, and not variable during the ignition and work period.

Owner:陈晨

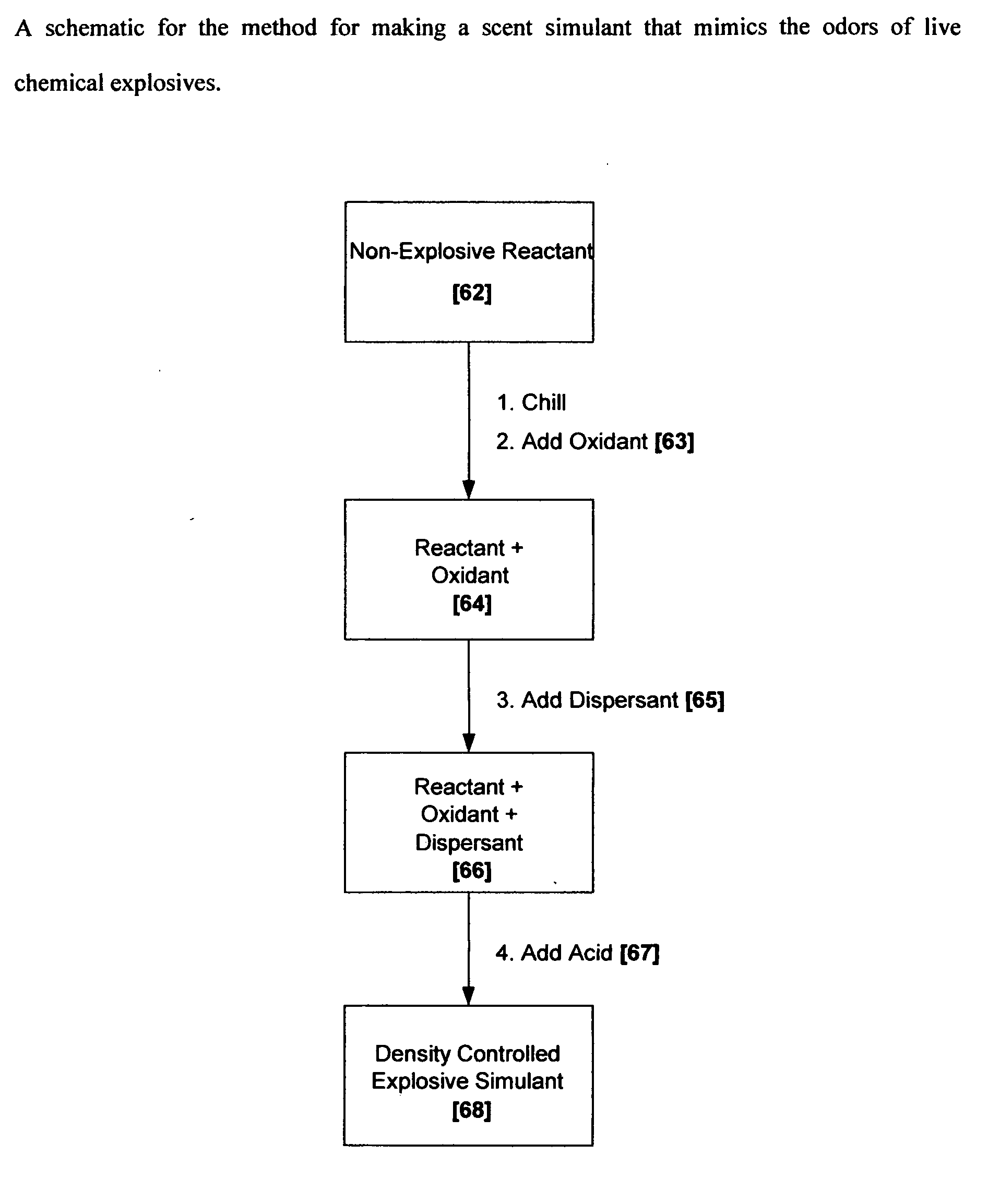

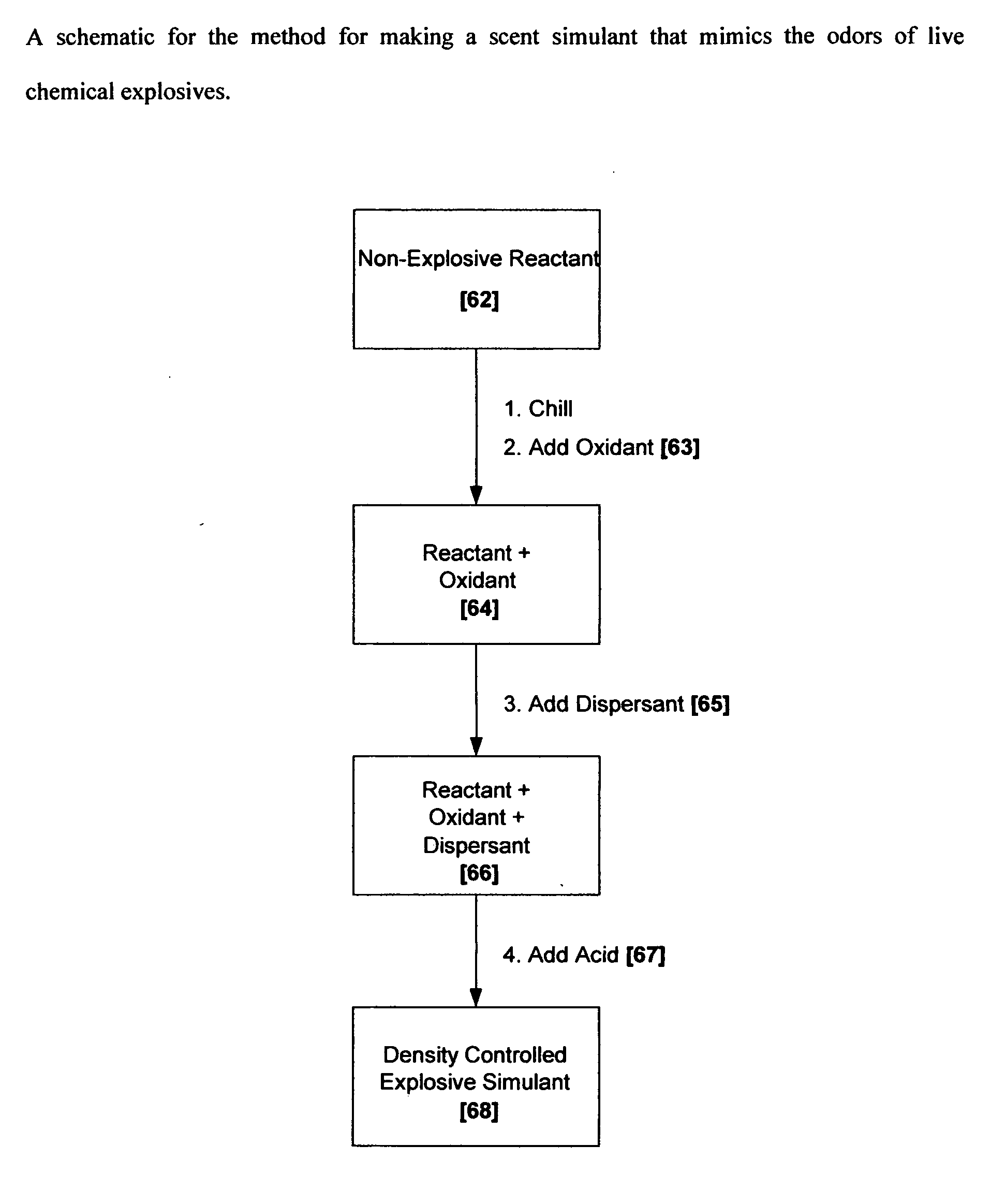

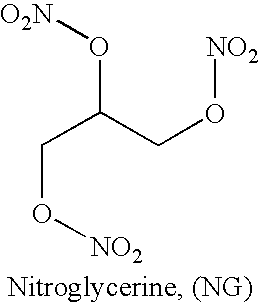

Methods for making scent simulants of chemical explosives, and compositions thereof

ActiveUS20090194744A1Increasing degree of heterogeneosityDefence devicesOther chemical processesChemical explosiveDetonation

The present invention relates to methods for producing non-detonable and non-explosive parent-odor scent simulants of both detonable and entropy-burst chemical explosive materials. A detonable explosive material is a material that explosives with the aid of detonation while an entropy burst explosive material is a very sensitive energetic material that does not require detonation, but explodes through a spontaneous decomposition of its molecules into gaseous products. The invention also presents representative non-detonable, non-hazardous compositions of such simulants that can be safely and effectively utilized within a broad spectrum of biological and non-biological explosives detection programs, non-limiting examples being the training of biological search-and-detect creatures such as explosive detecting dogs and the calibration of electronic explosive detecting instruments that rely on the principles of vapor sampling for their operations.

Owner:ADEBIMPE DAVID O B A

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com