Patents

Literature

59results about How to "Close tolerance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

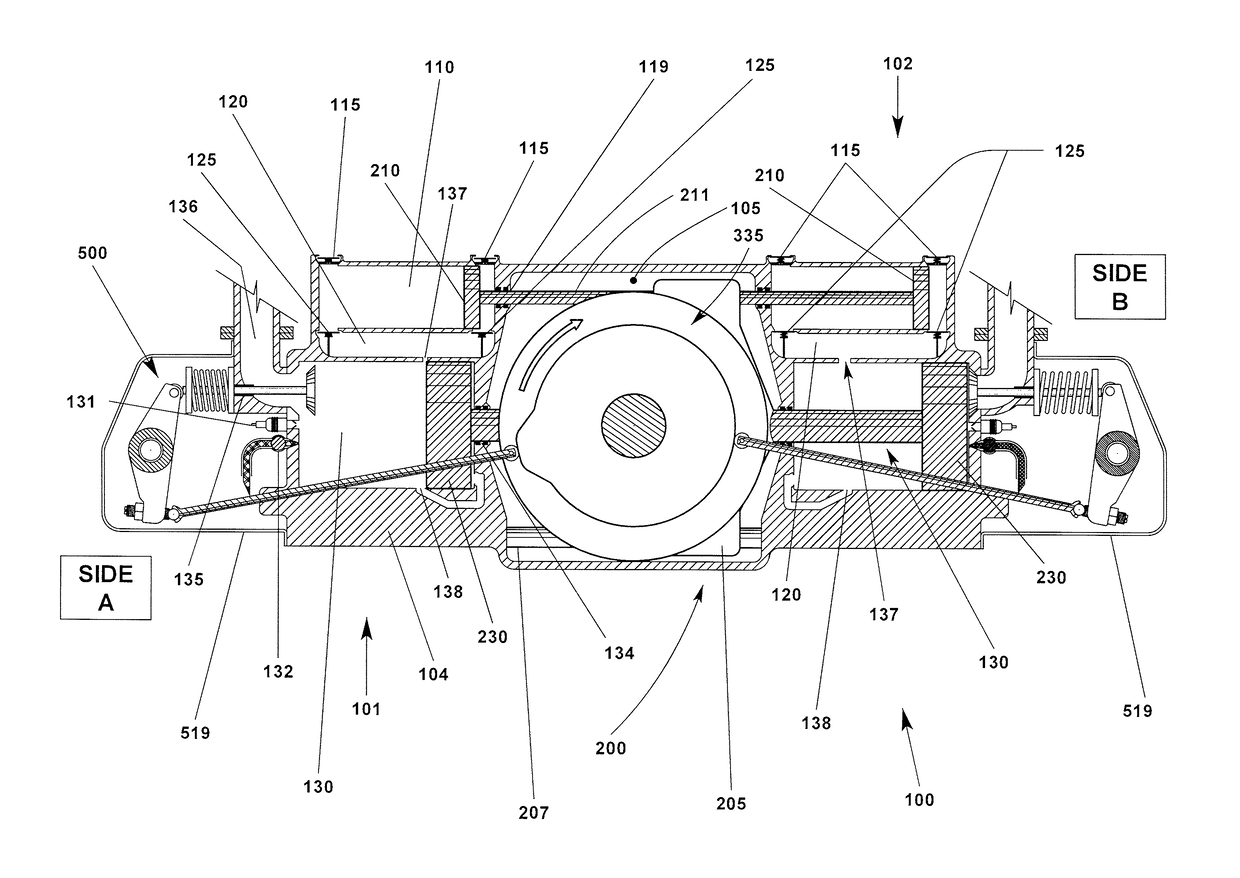

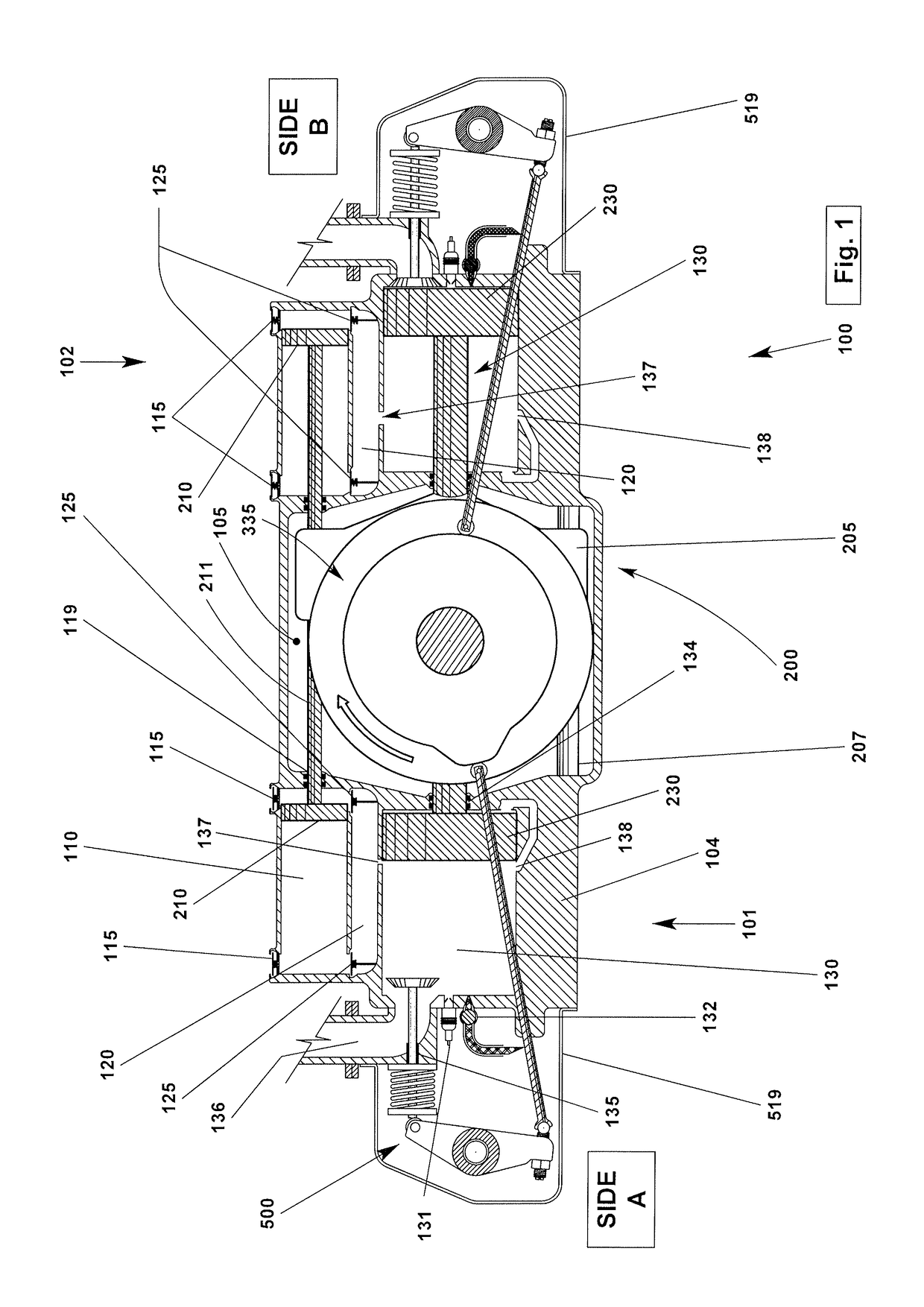

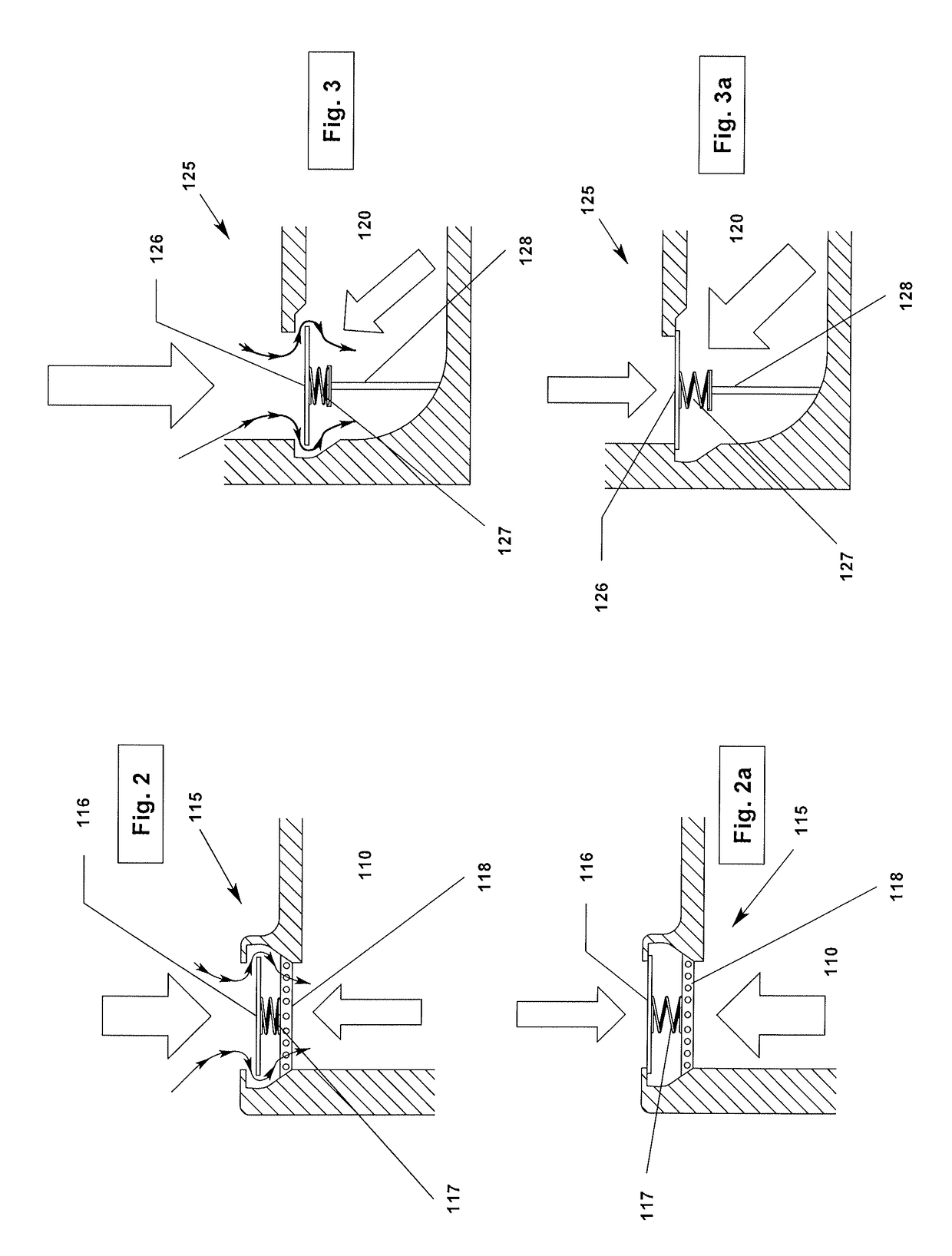

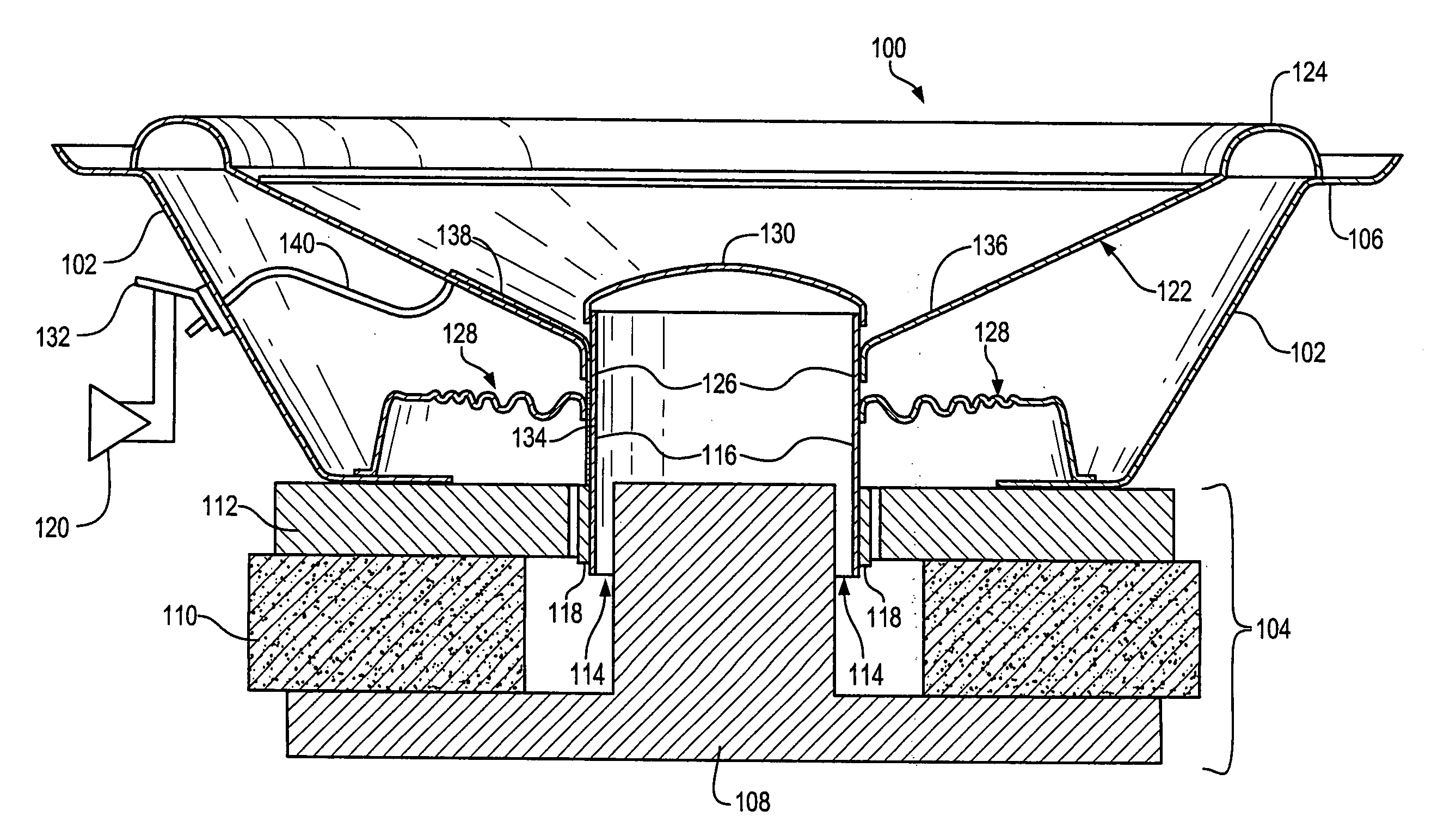

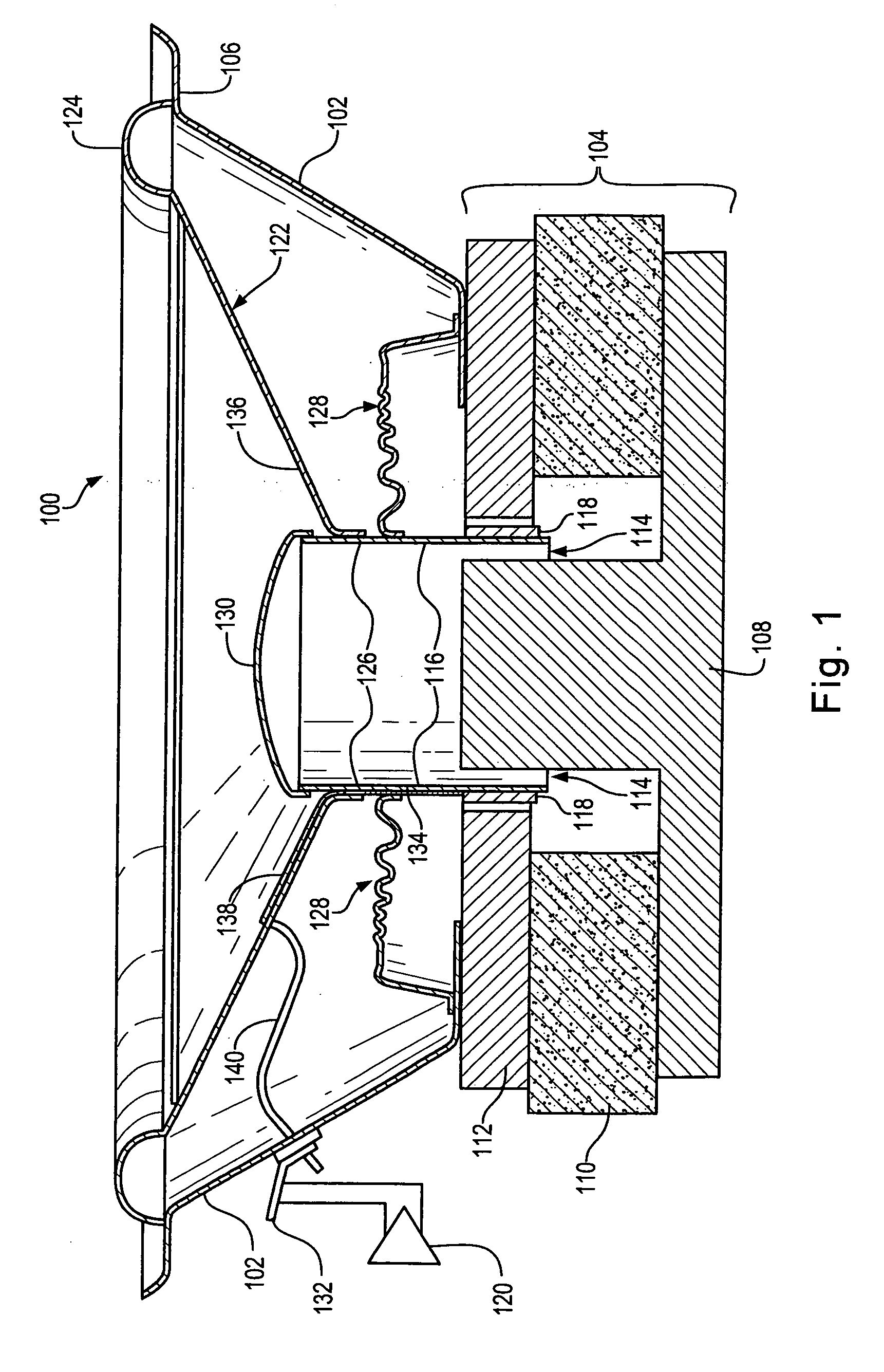

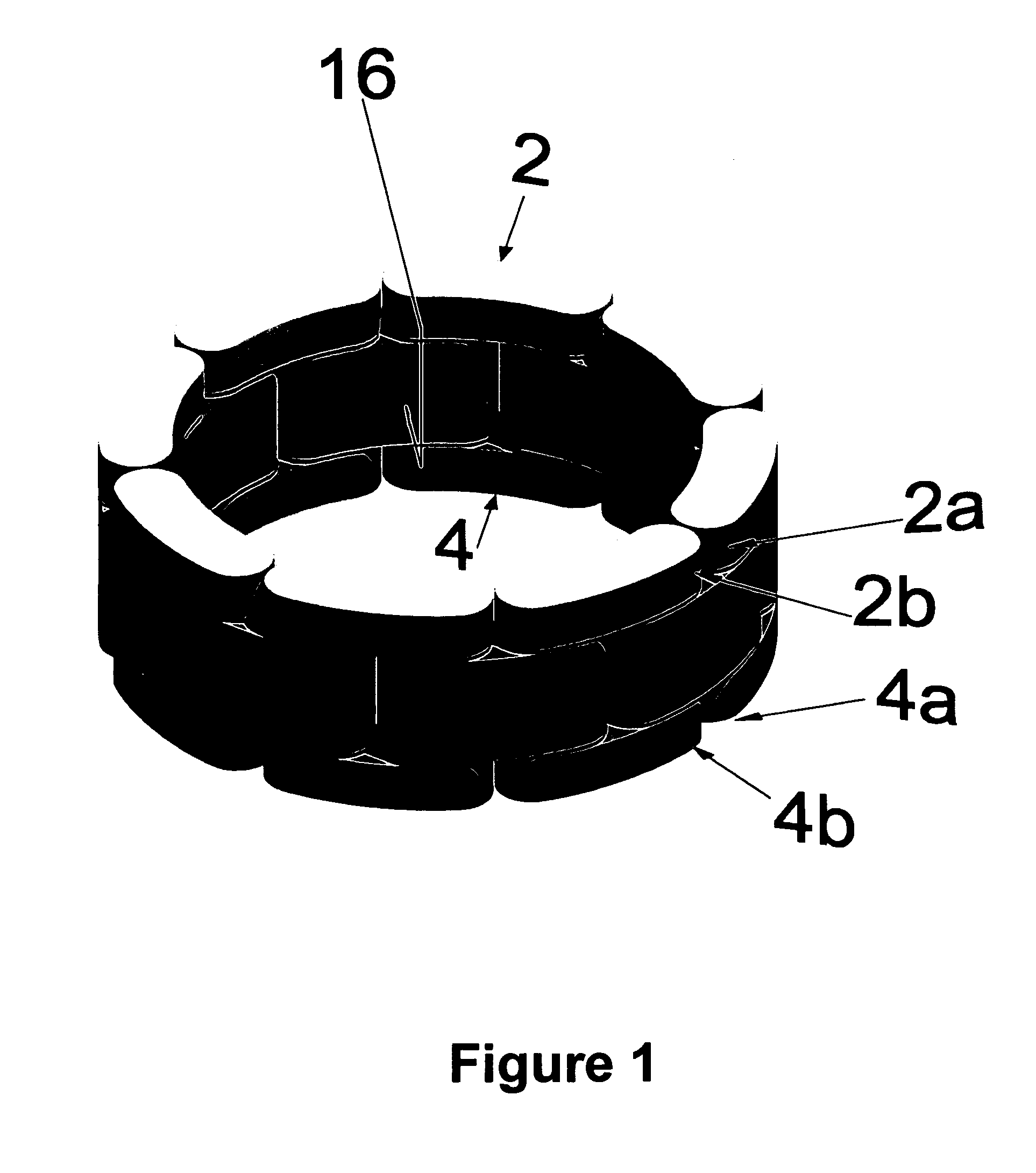

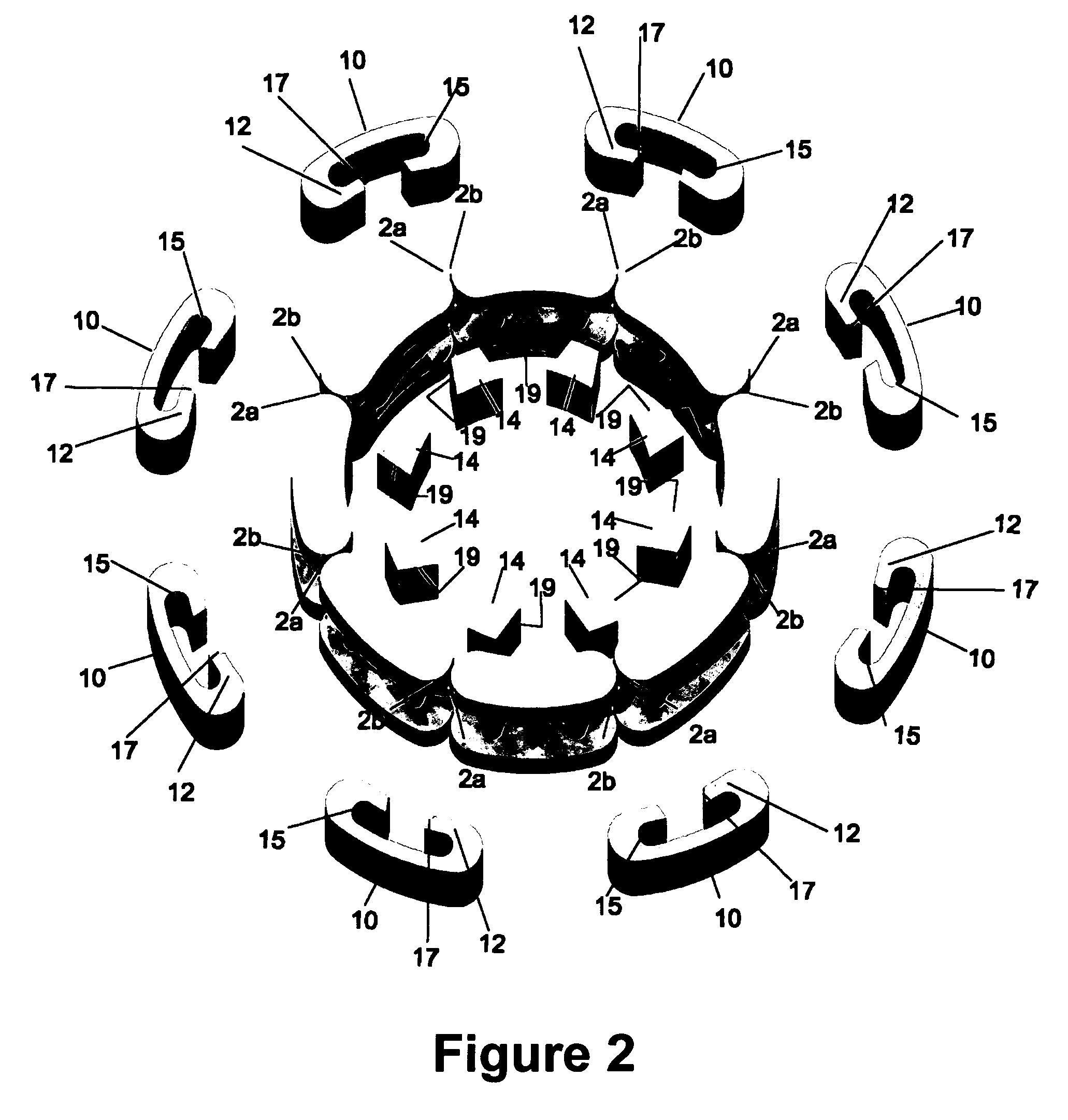

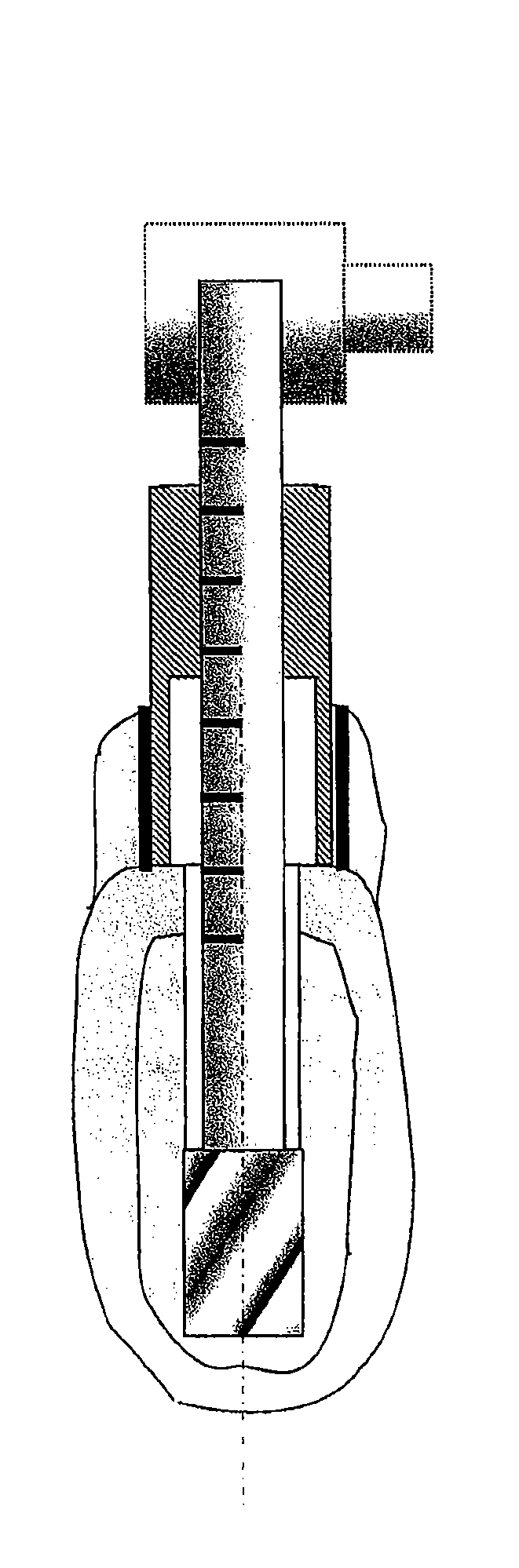

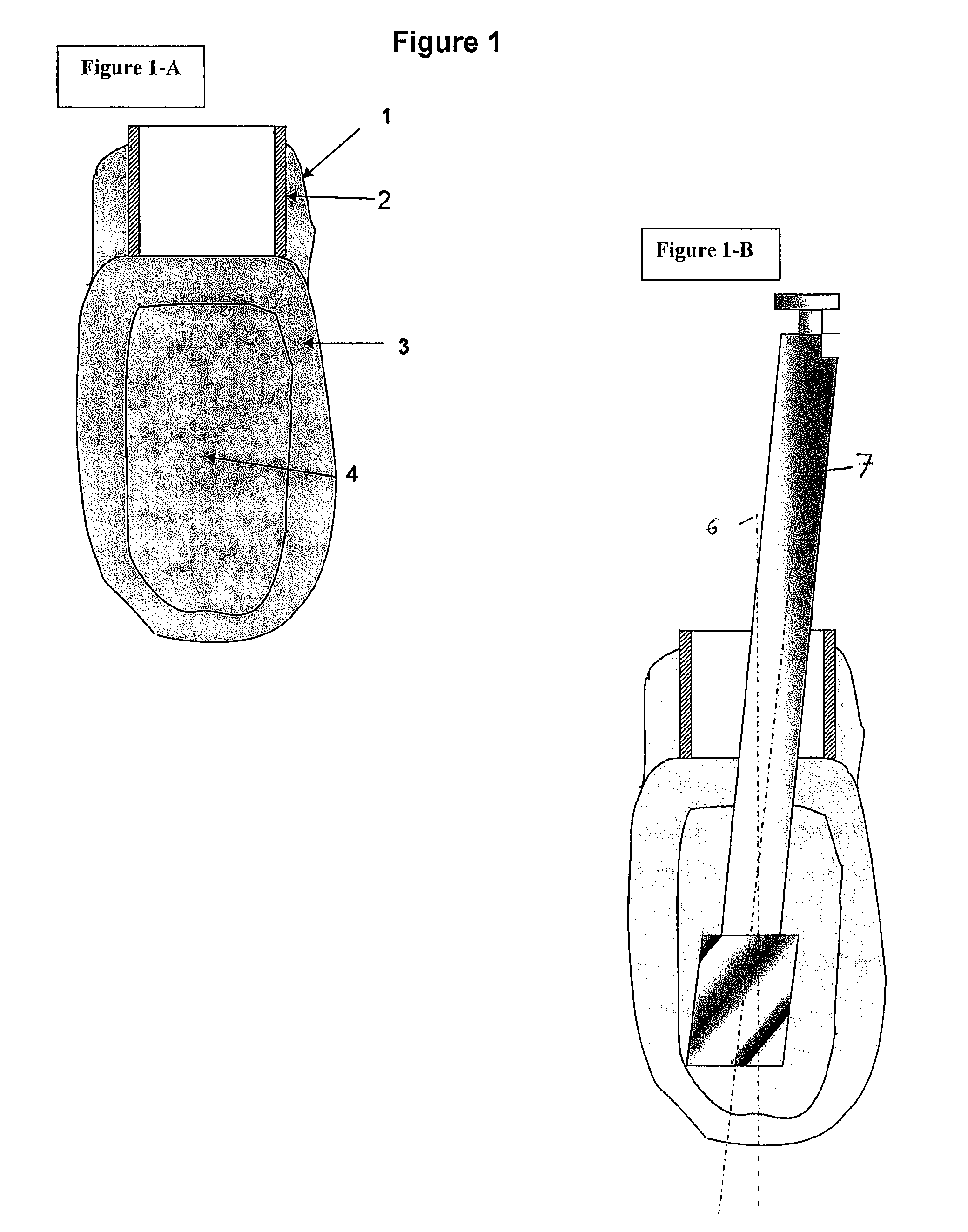

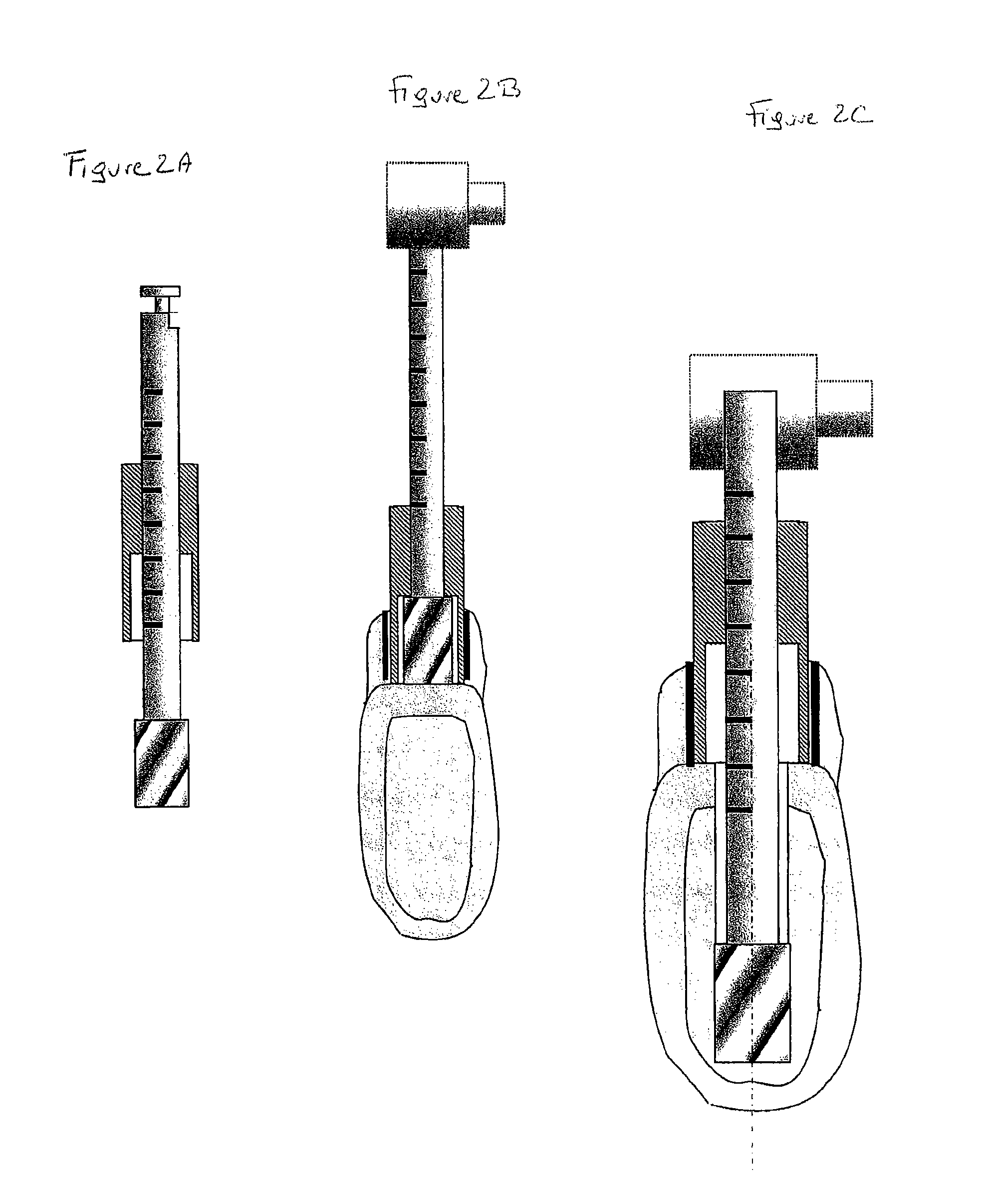

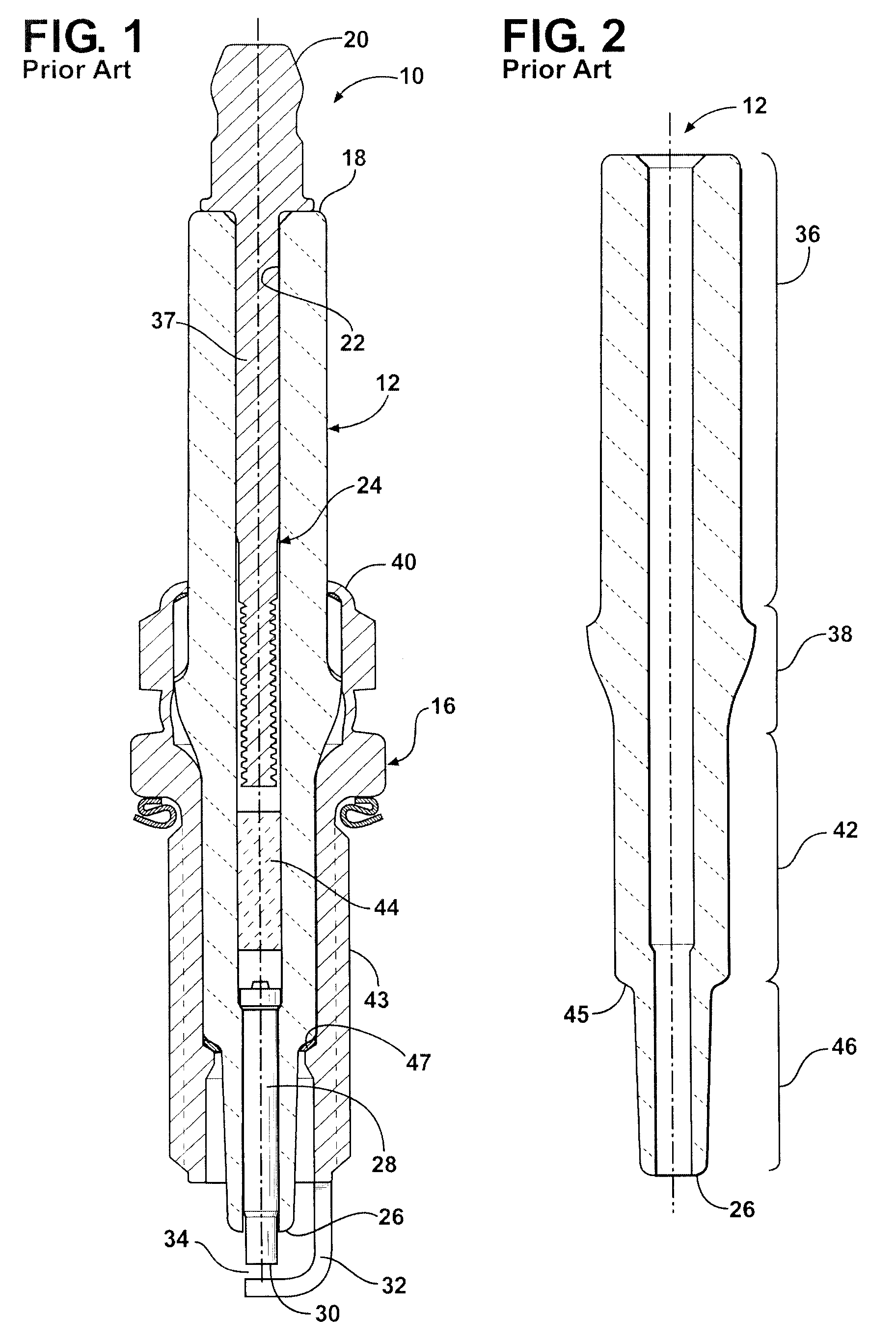

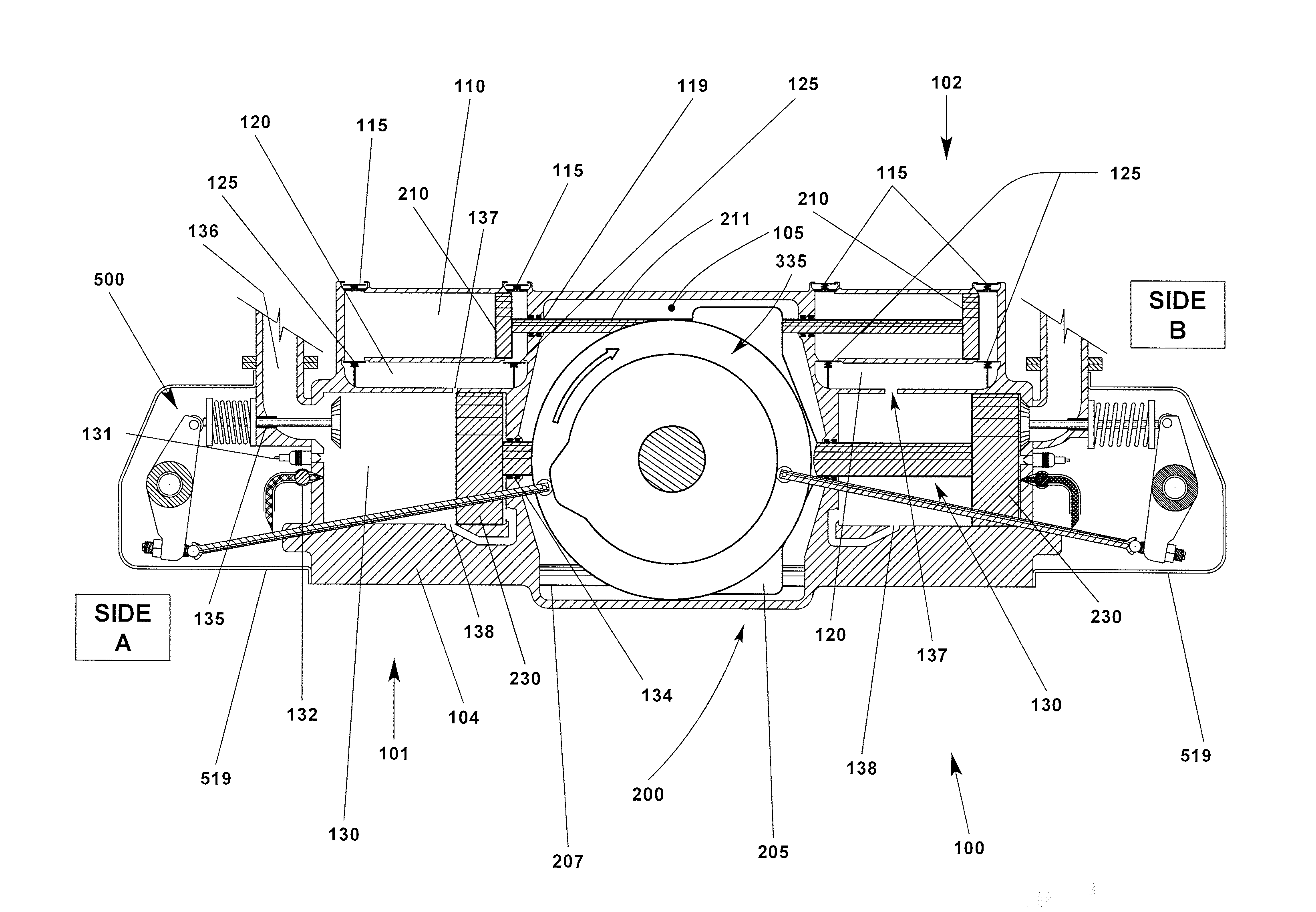

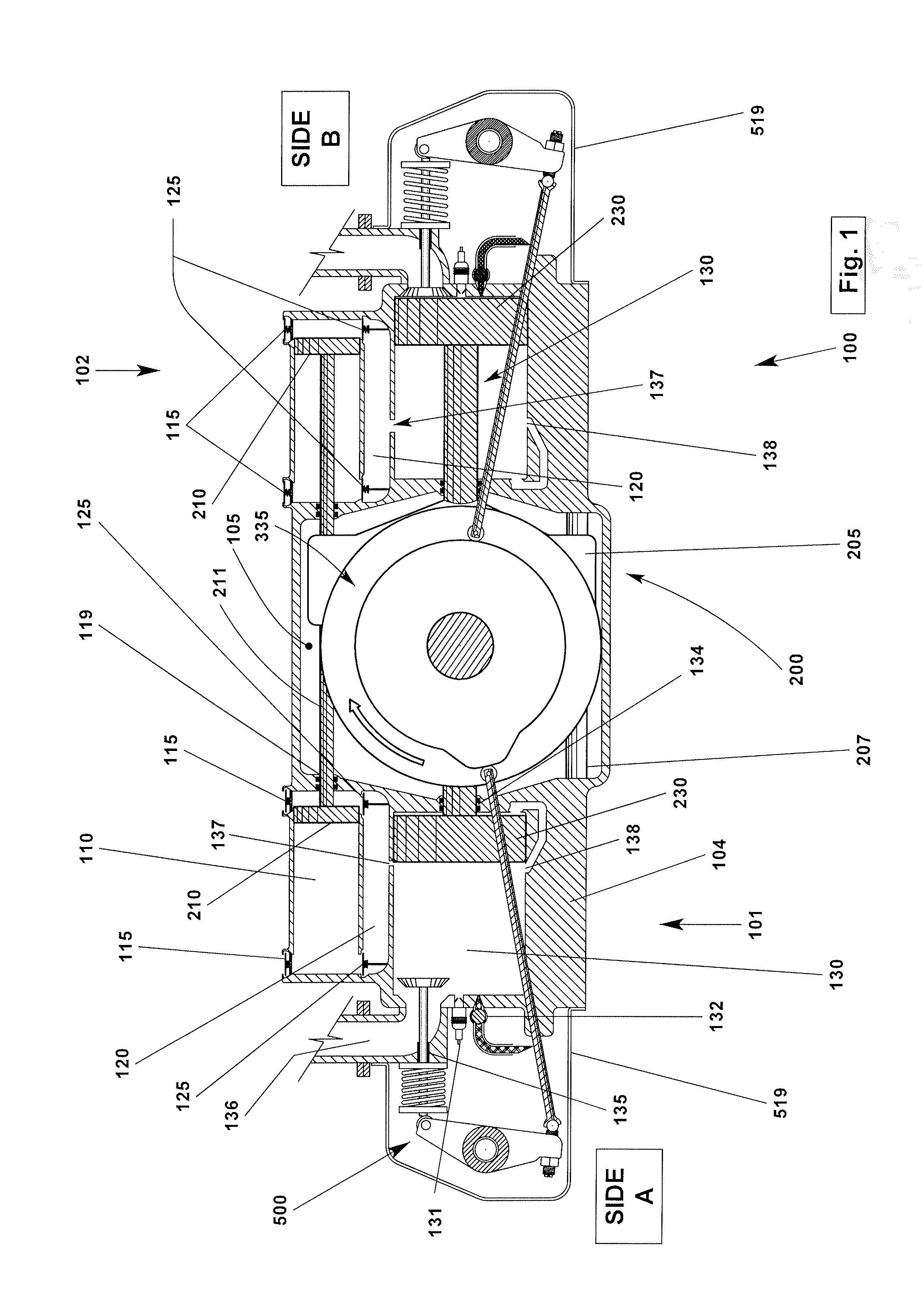

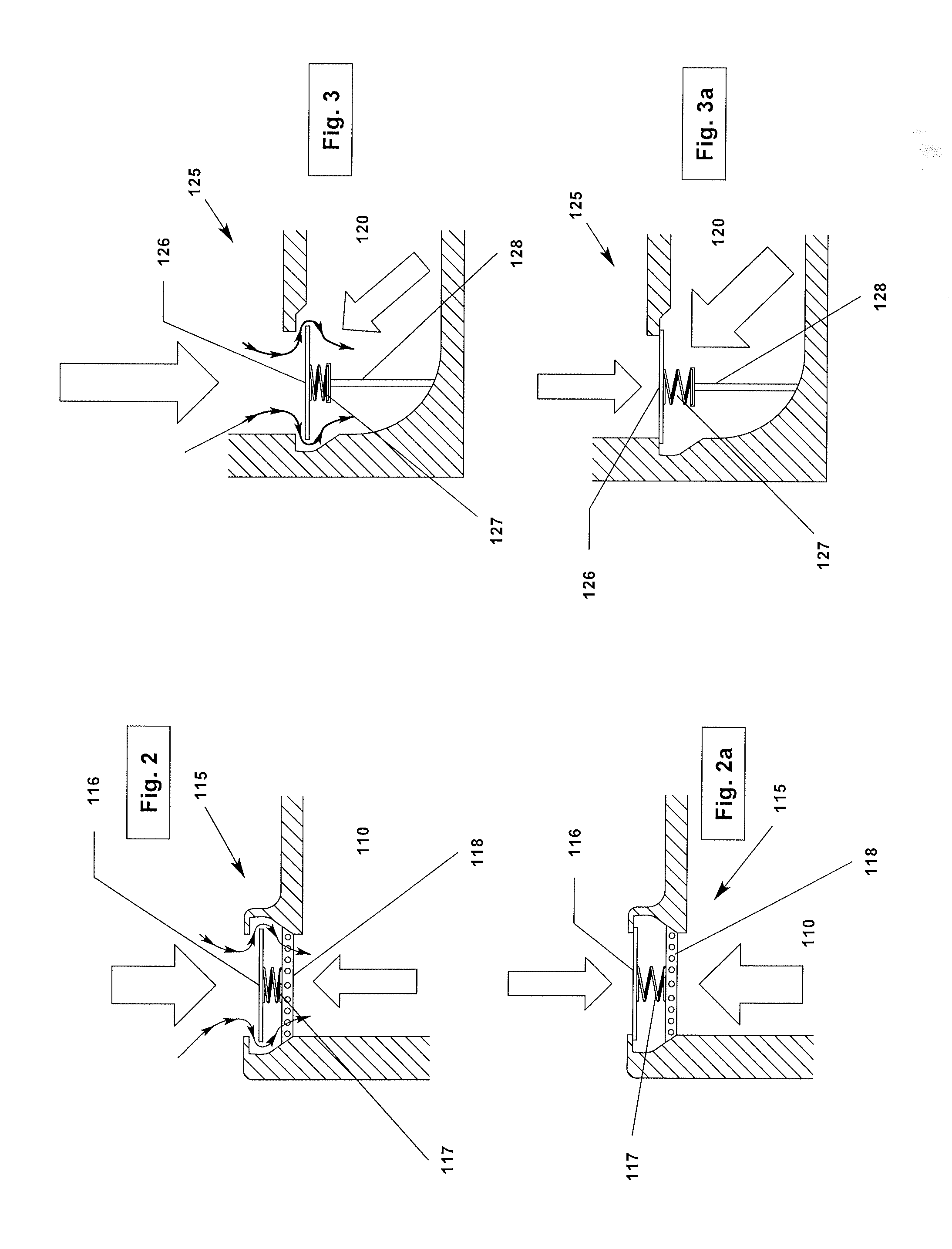

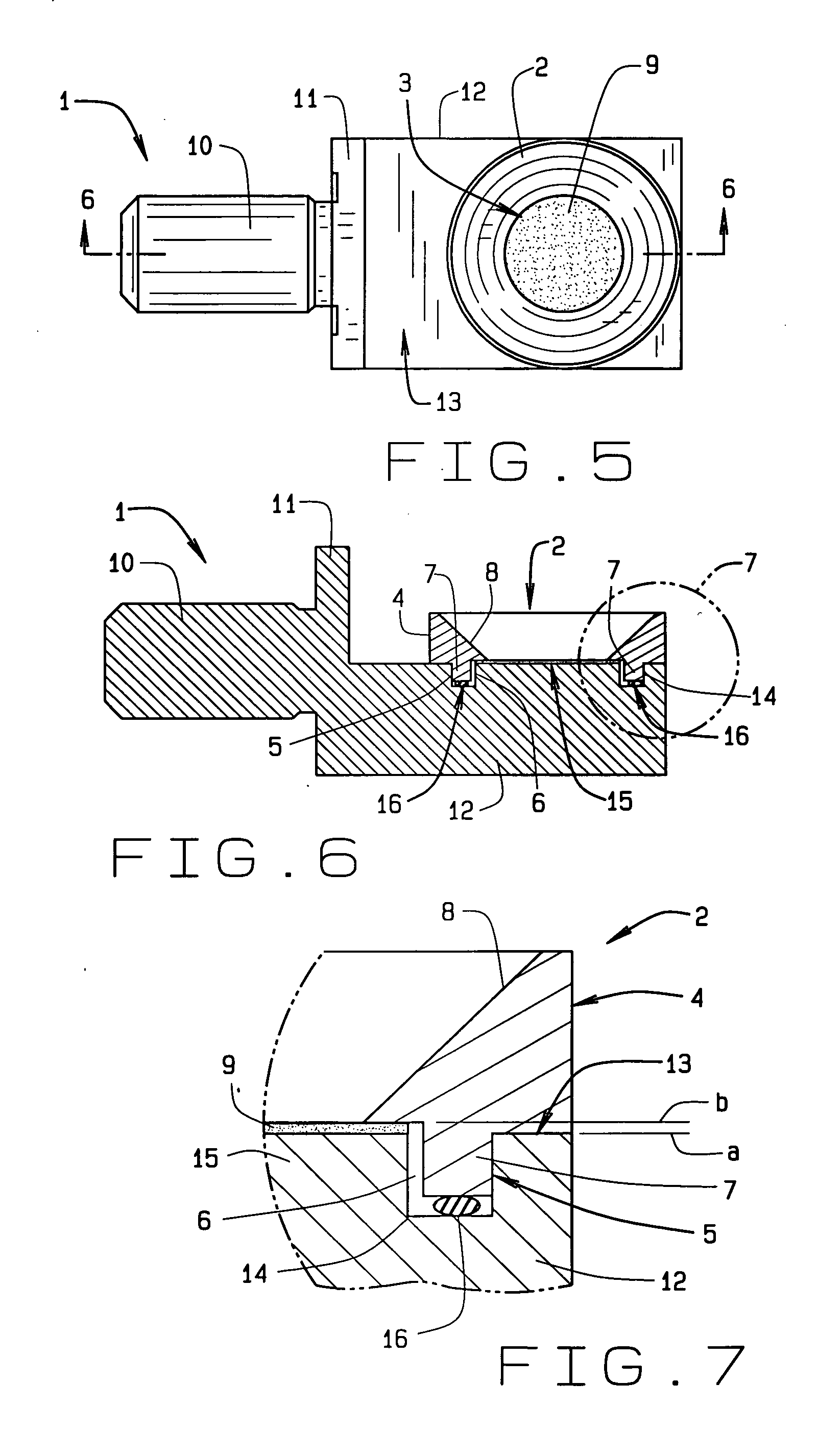

Opposed piston internal combustion engine with inviscid layer sealing

InactiveUS9909492B2Close toleranceAccurate concentricityCombustion enginesReciprocating piston enginesDetonationCombustion

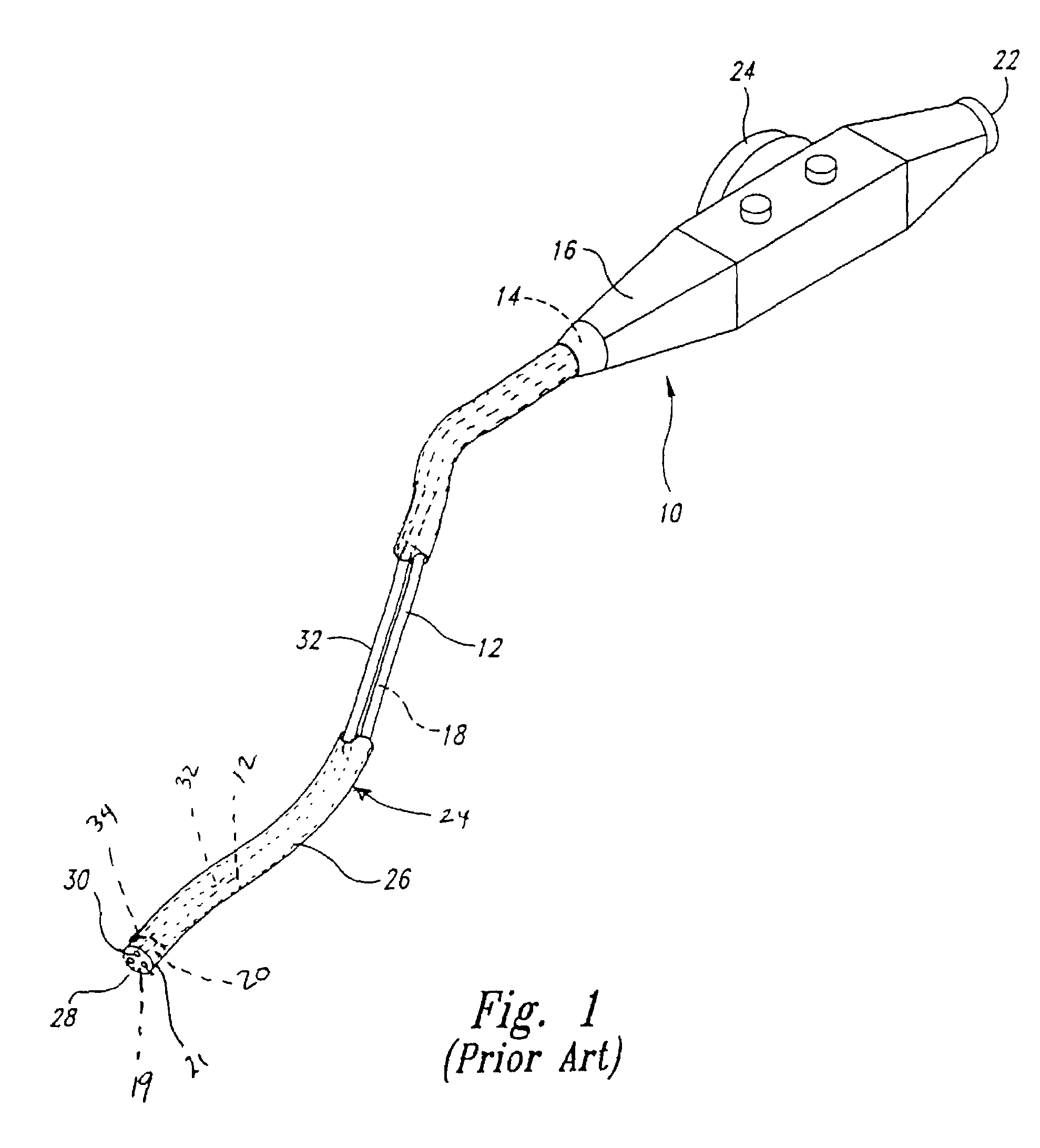

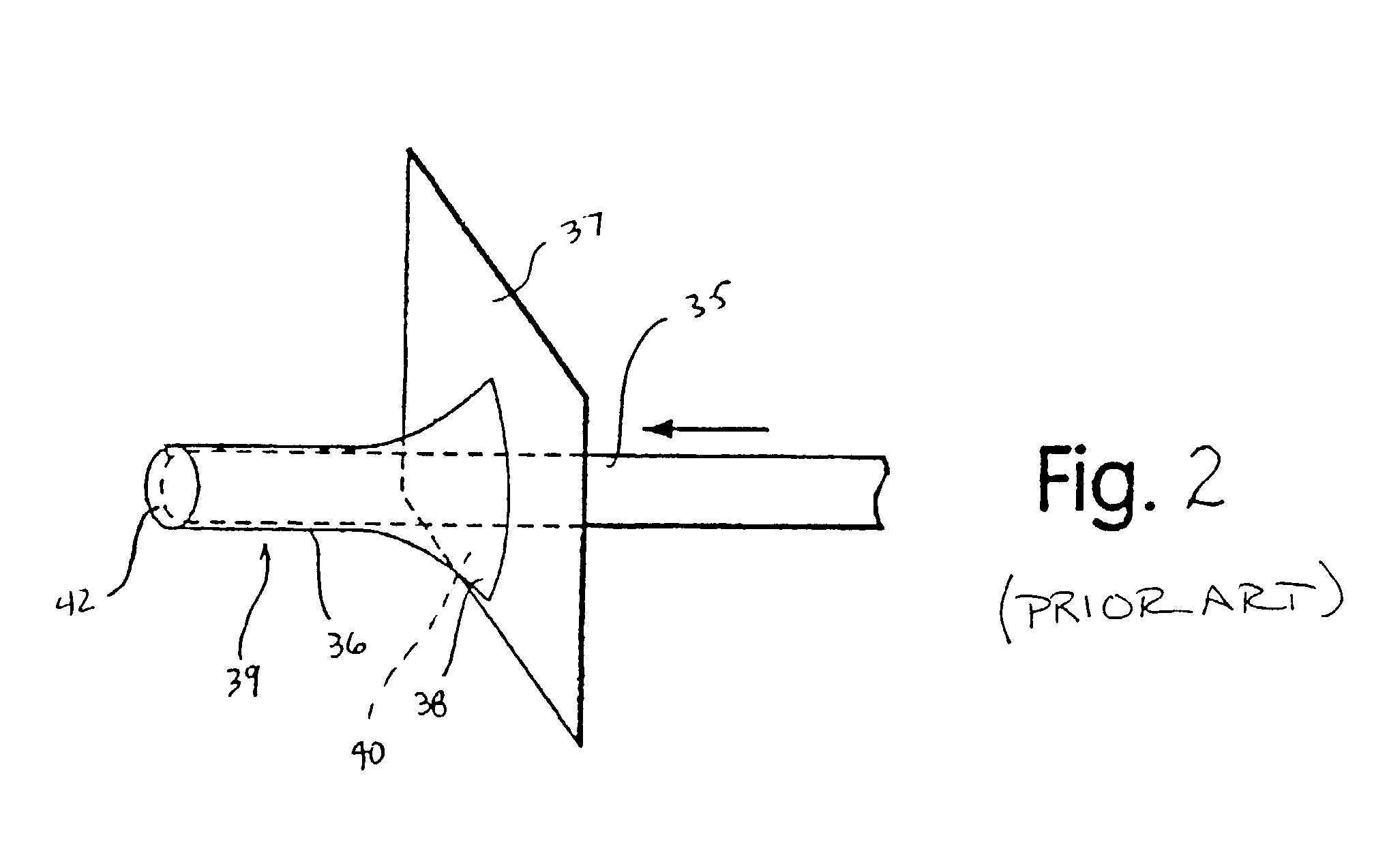

An opposed-piston engine that forms an inviscid layer between pistons and the respective cylinder walls. In an aspect, the opposed-piston engine utilizes a Scotch yoke assembly that includes rigidly connected opposed combustion pistons. In an aspect, the Scotch yoke assembly is configured to transfer power from the combustion pistons to a crankshaft assembly. In an aspect, the crankshaft assembly can be configured to have dual flywheels that are internal to the engine, and can be configured to assist with an exhaust system, a detonation system, and / or a lubrication system.

Owner:PRIME GRP ALLIANCE

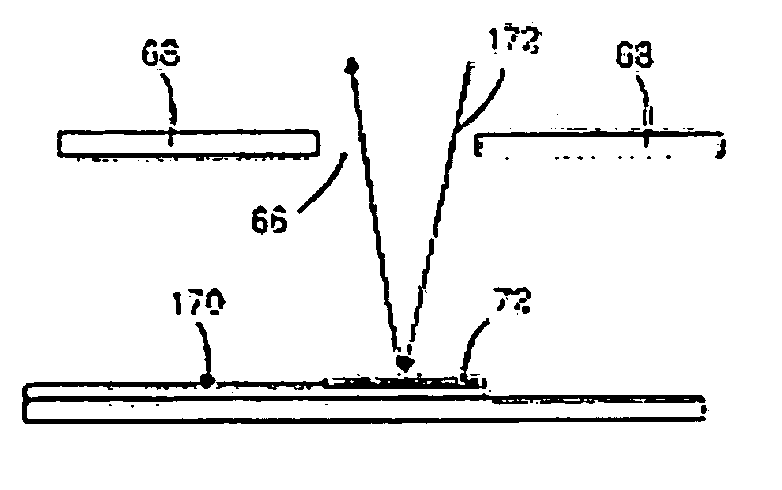

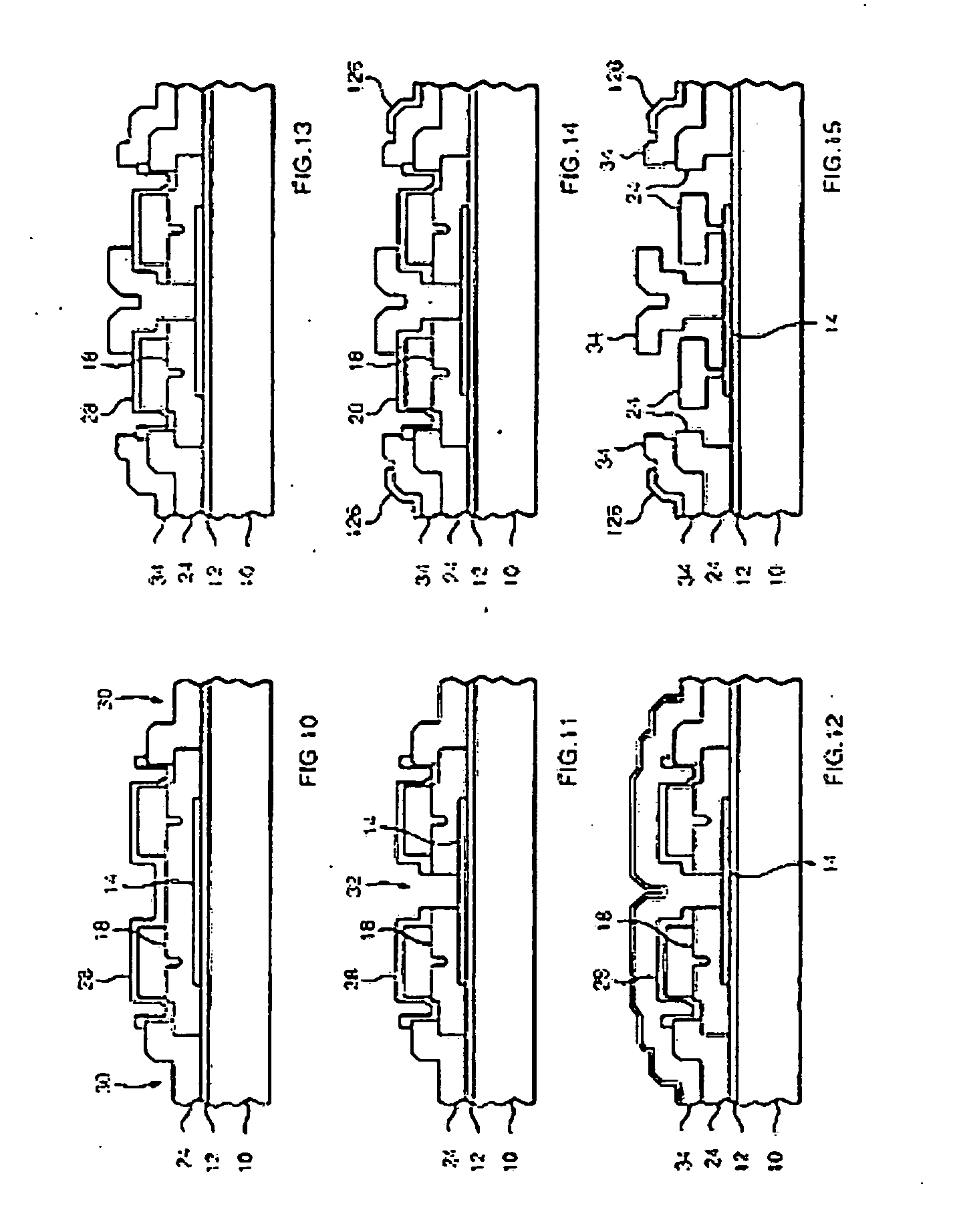

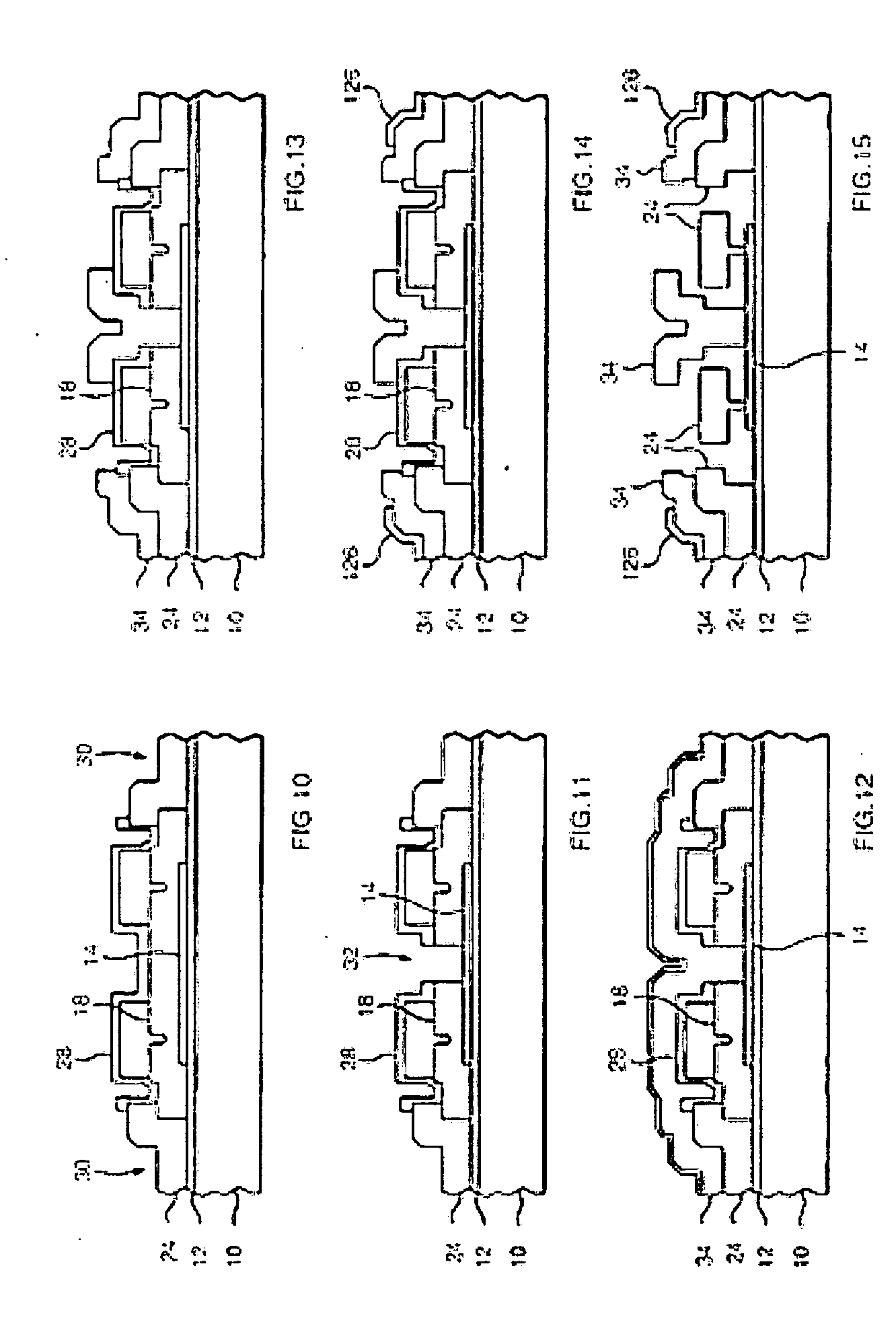

Method for fabricating a thin film inductor

InactiveUS6040226AClose toleranceSemiconductor/solid-state device detailsSolid-state devicesLithographic artistEngineering

A method is provided for the manufacture of precision electronic components such as resistors, inductors, and capacitors on a polymer or ceramic surface. The electronic components can be deposited and trimmed to precise or matched values without having precise depositions of all of the pre-patterned materials. Thin film electronic components are deposited on a surface, parameter values are measured or estimated, a correction offset file is generated, and the components are trimmed using adaptive lithography to a very close tolerance. A computer program can be used to enable the adjustment of electronic components by techniques such as changing the physical length of an inductor coil or resistor lead, or by changing a capacitor plate area.

Owner:GENERAL ELECTRIC CO

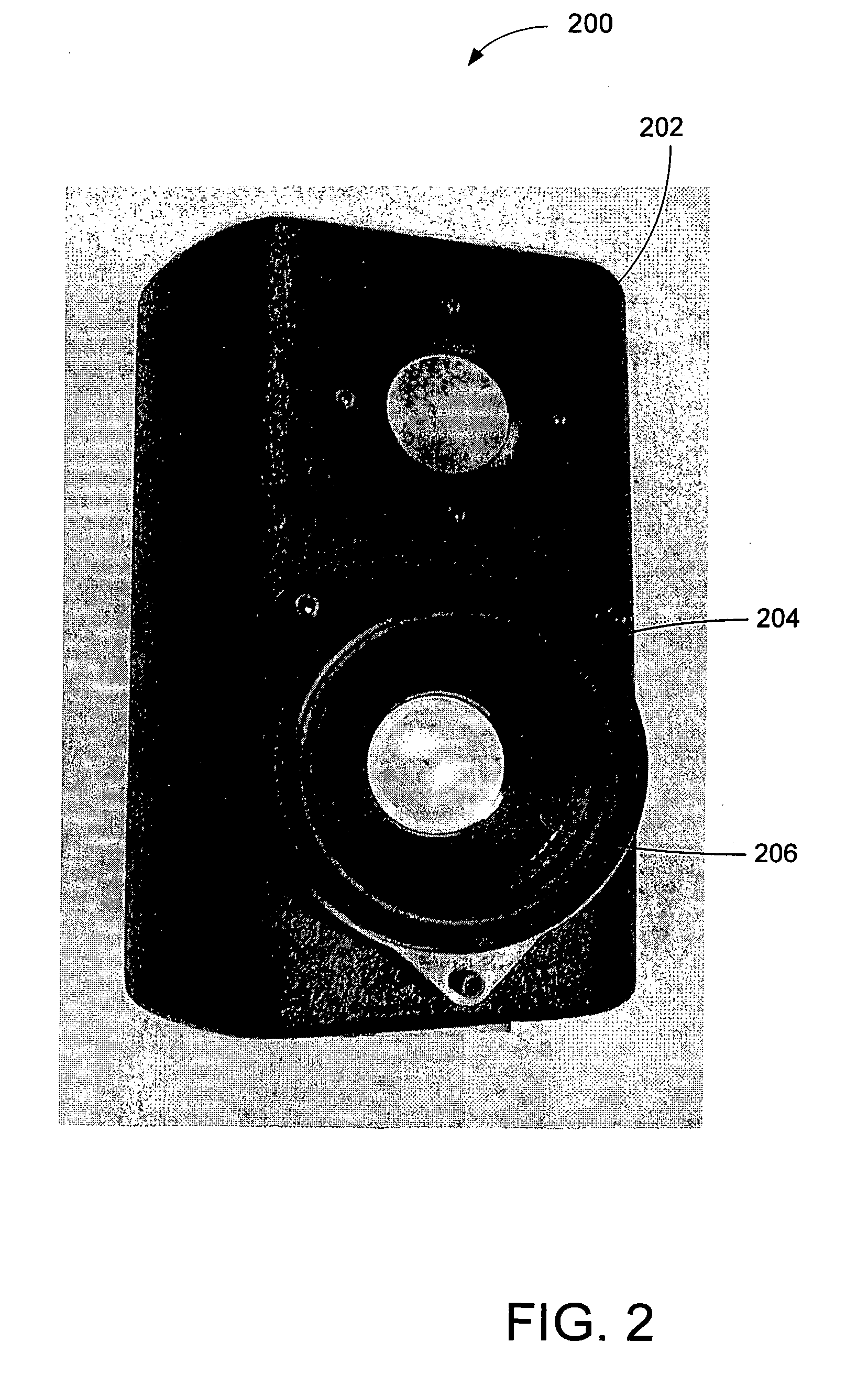

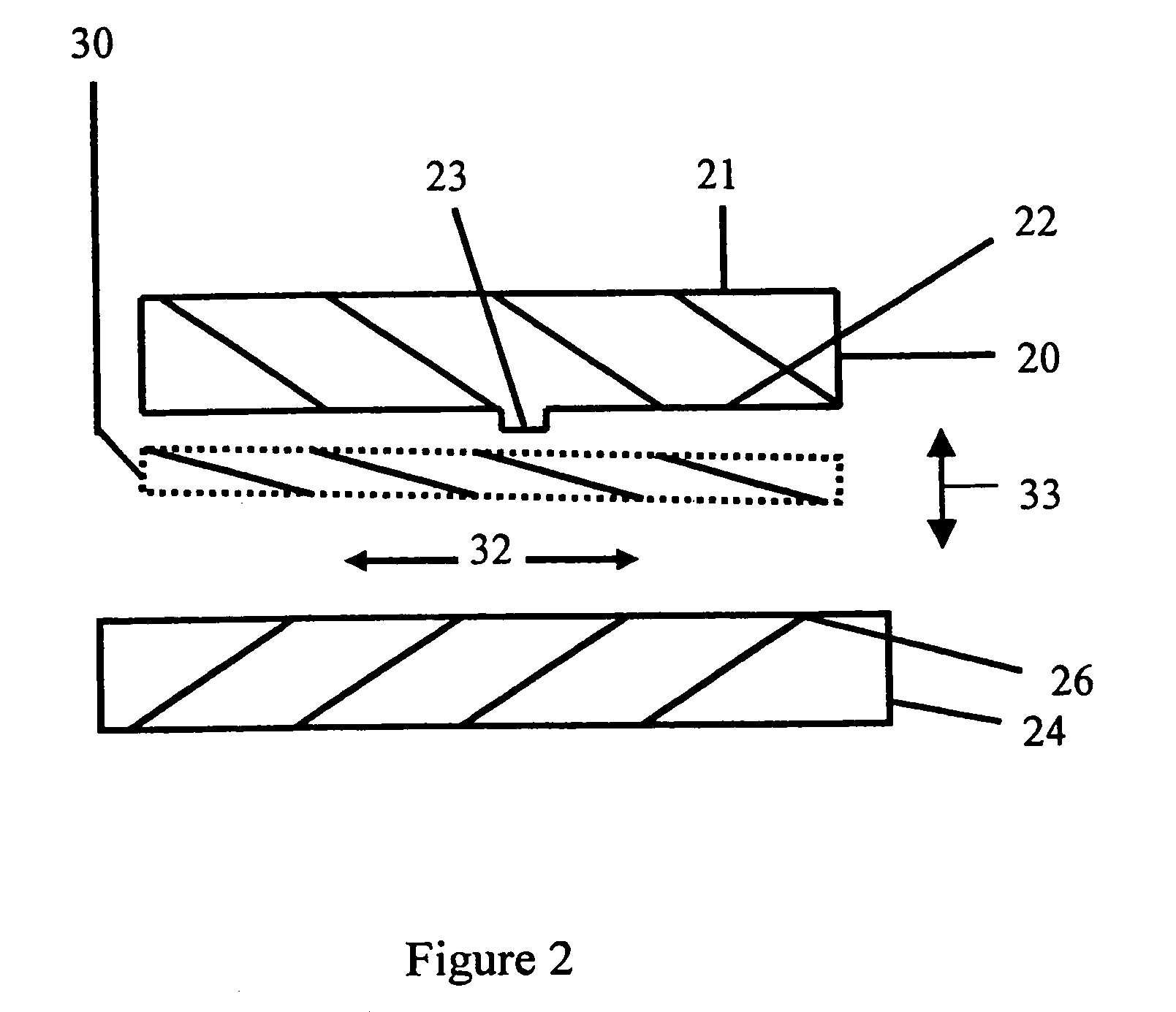

Loudspeaker plastic cone body

ActiveUS20060147081A1Easy to adjustImprove flow characteristicsFibre diaphragmsPolymeric diaphragmsFilling materialsEngineering

A loudspeaker cone body made of plastic includes a base carrier material and a filler material. The base carrier material is selected to optimize overall flow, weight and stiffness. The filler material may be a nanomaterial that provides for adjustment of process and acoustic related characteristics in the loudspeaker cone body that become relevant when the loudspeaker cone body is operated in a loudspeaker. Acoustic related characteristics that may be adjusted include a stiffness to weight ratio and an acoustic damping of the loudspeaker cone body. A predetermined weight percent of the filler material may be combined with the base carrier material to obtain repeatable desired acoustic related characteristics. The acoustic related characteristics may be adjusted by changing the predetermined weight percent of the filler material.

Owner:HARMAN INT IND INC

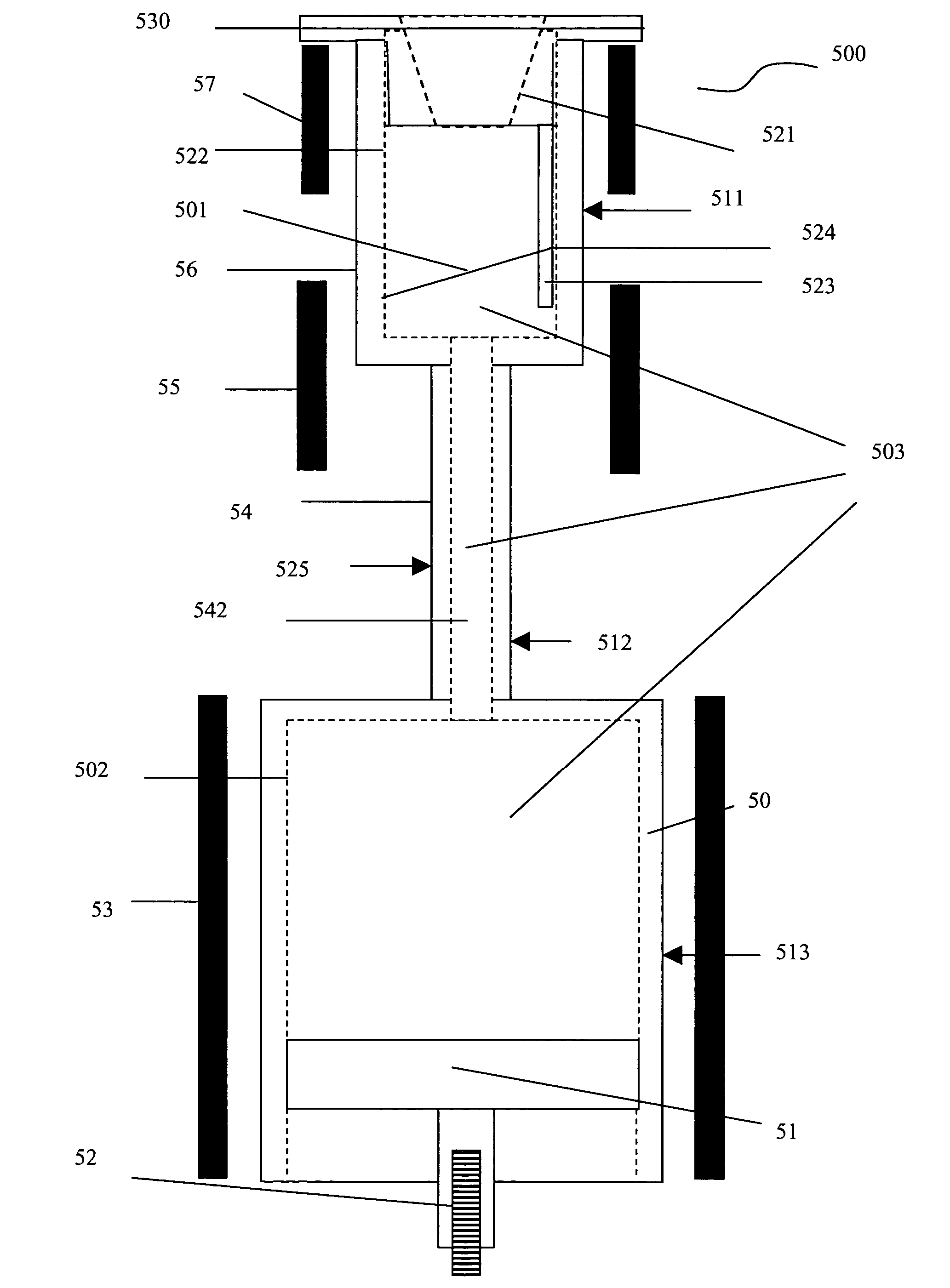

Means and method for a liquid metal evaporation source with integral level sensor and external reservoir

InactiveUS20050229856A1Long operating timeReduce hydrostatic pressureVacuum evaporation coatingSputtering coatingEvaporation (deposition)Engineering

A liquid metal evaporation source for use in Molecular Beam Epitaxy and related metal vacuum deposition techniques. An evaporator is maintained at a high temperature to evaporate a liquid metal, a reservoir for holding the liquid metal source is maintained at a temperature above the melting point of the metal but below the temperature in the evaporator, and a hollow transport tube connecting the evaporator and reservoir is maintained at a temperature between these temperatures. The reservoir is in the shape of a hollow cylinder with a close-fitting cylindrical piston which is used to force the liquid metal through the hollow transport tube into the evaporator. The liquid metal will not flow past the piston seal if a suitably small gap is formed between the piston and the reservoir walls wherein the surface tension of the liquid metal will exceed its hydrostatic pressure against the piston thus forming a leak-tight seal.

Owner:RJM SEMICON

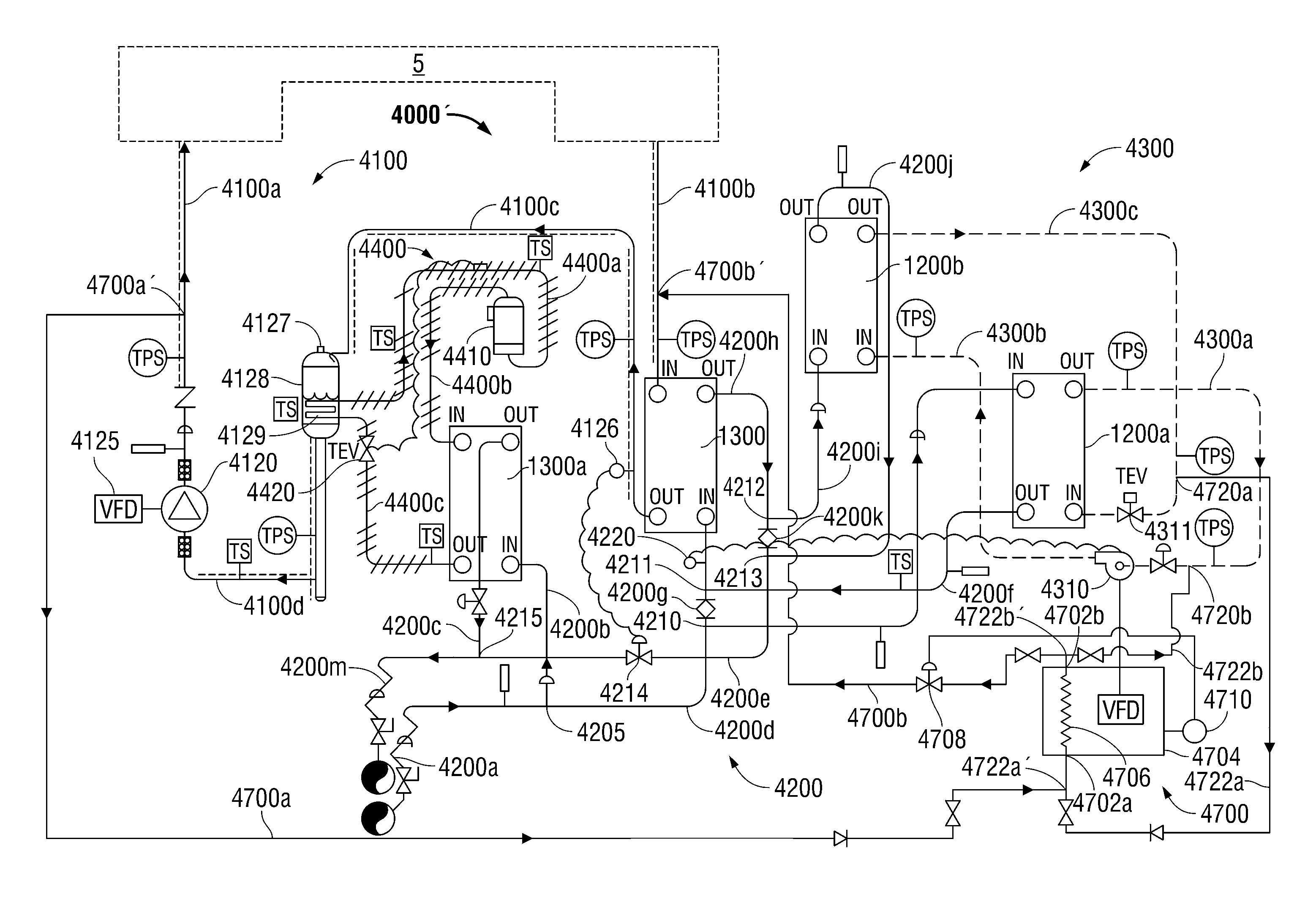

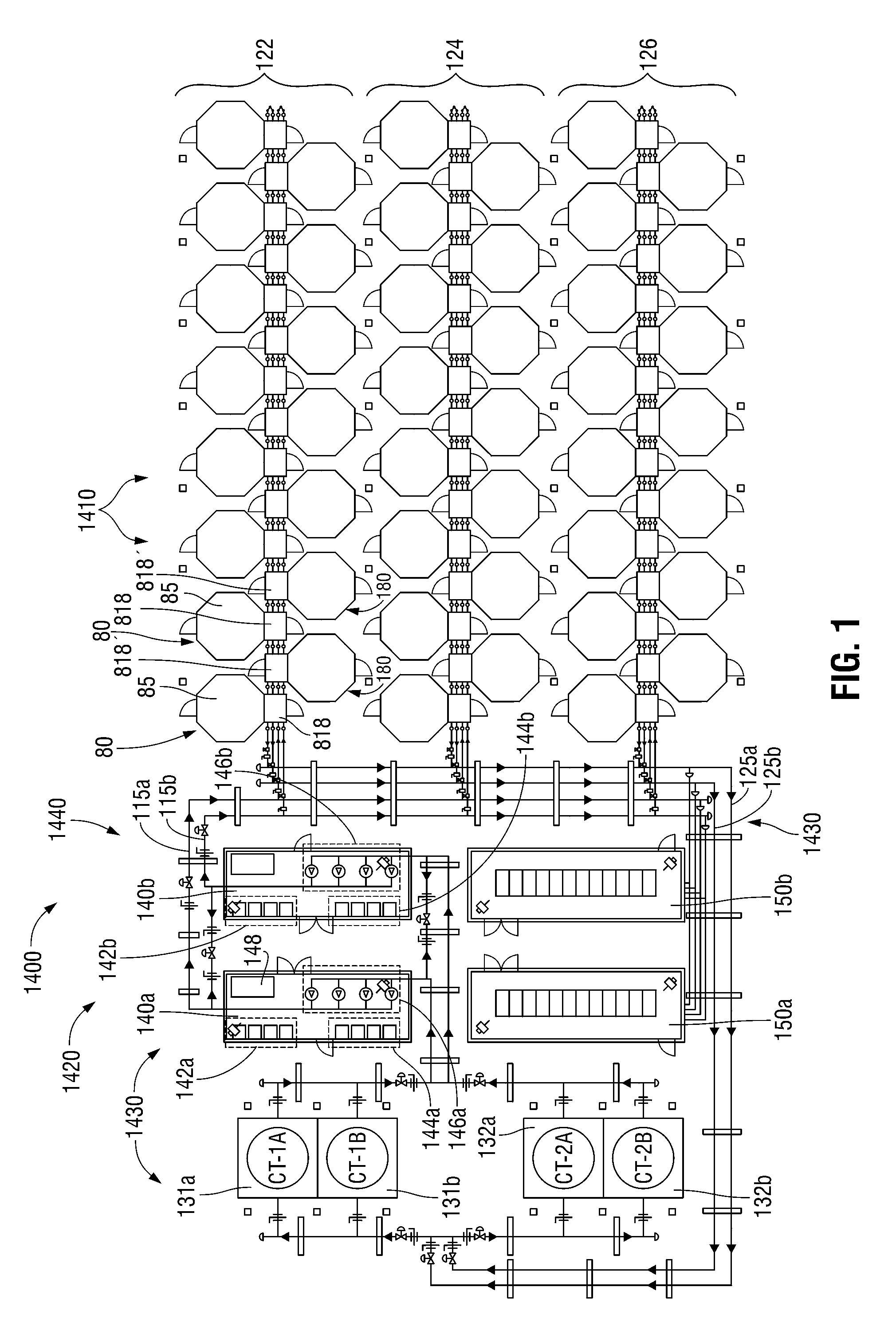

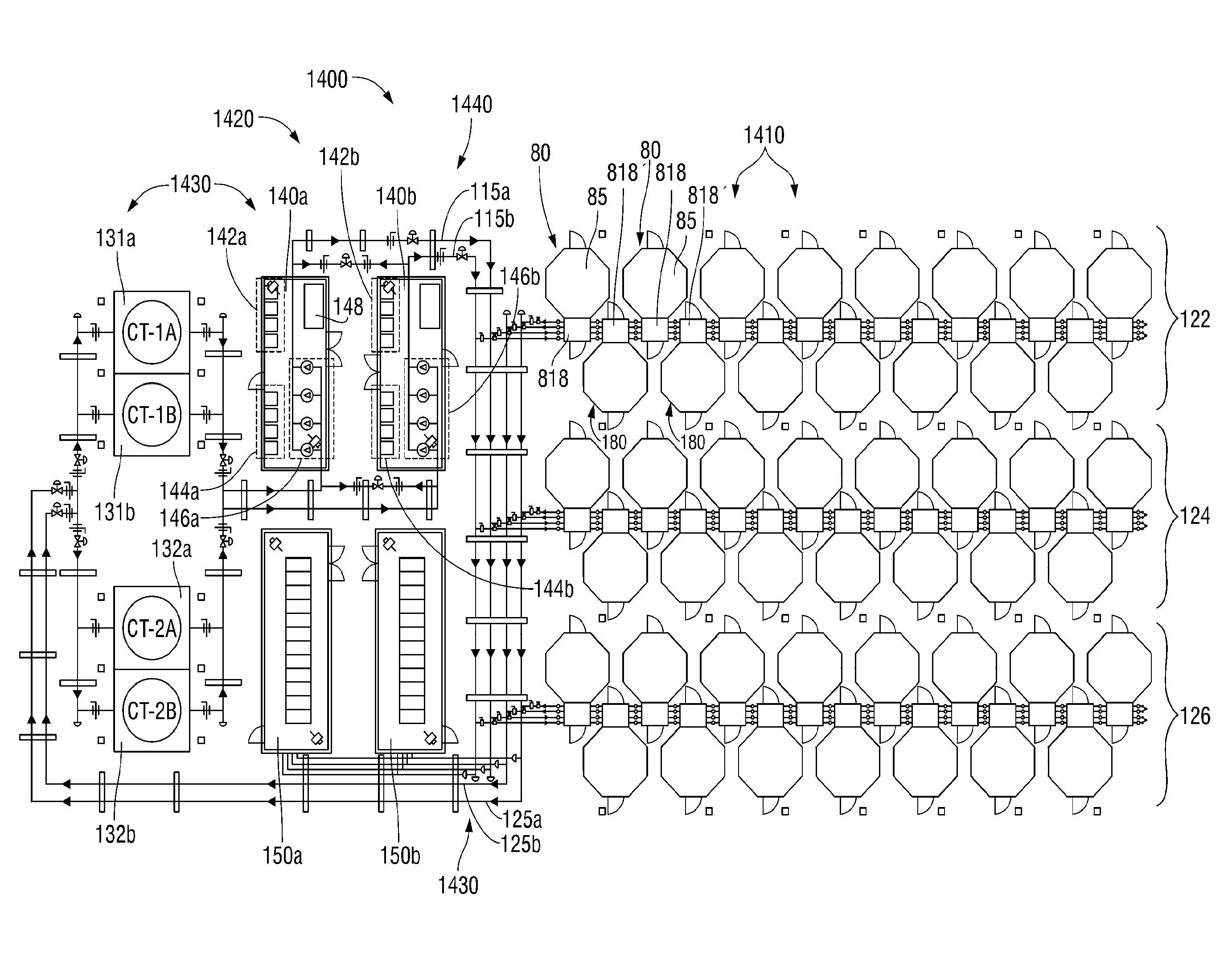

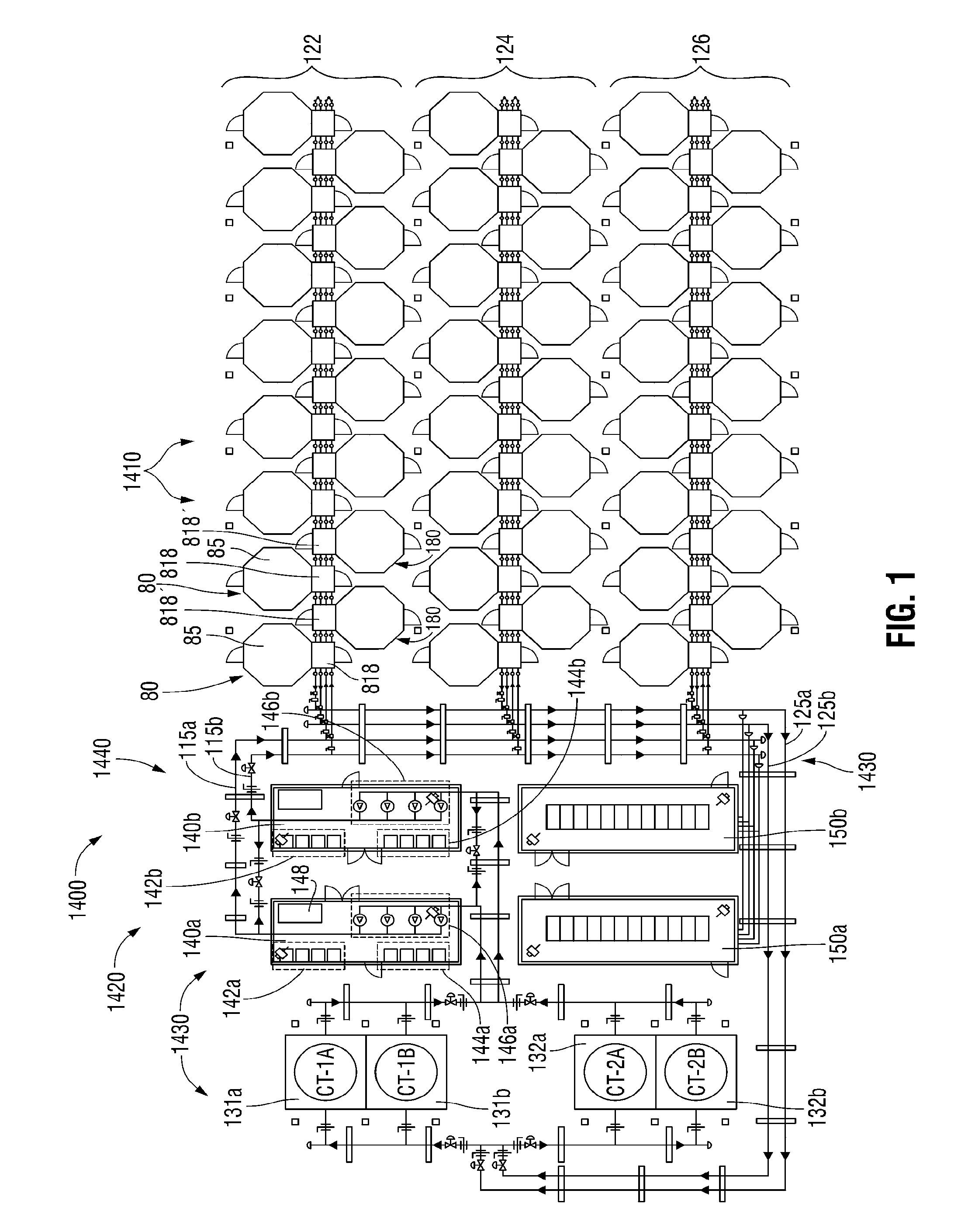

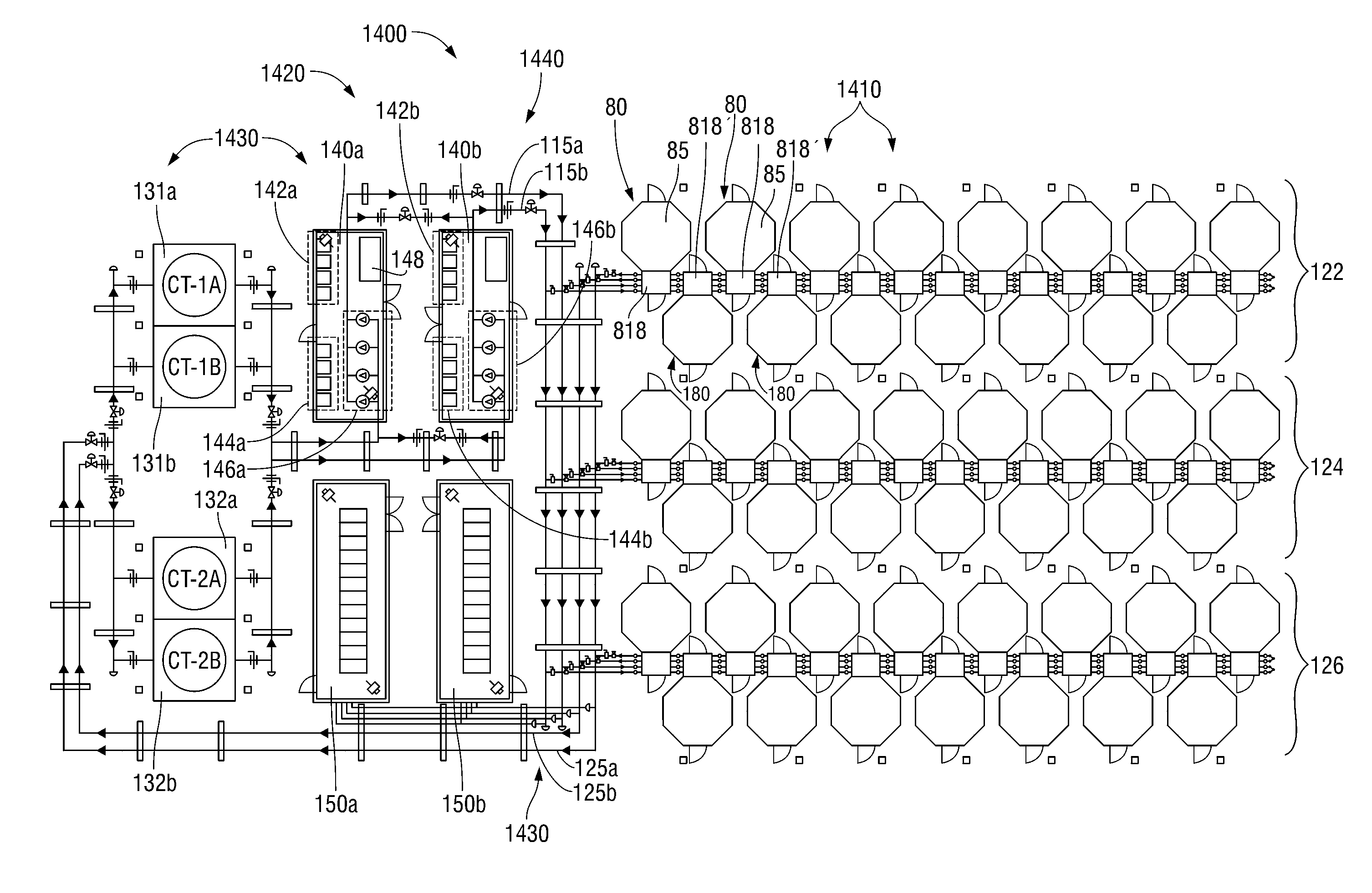

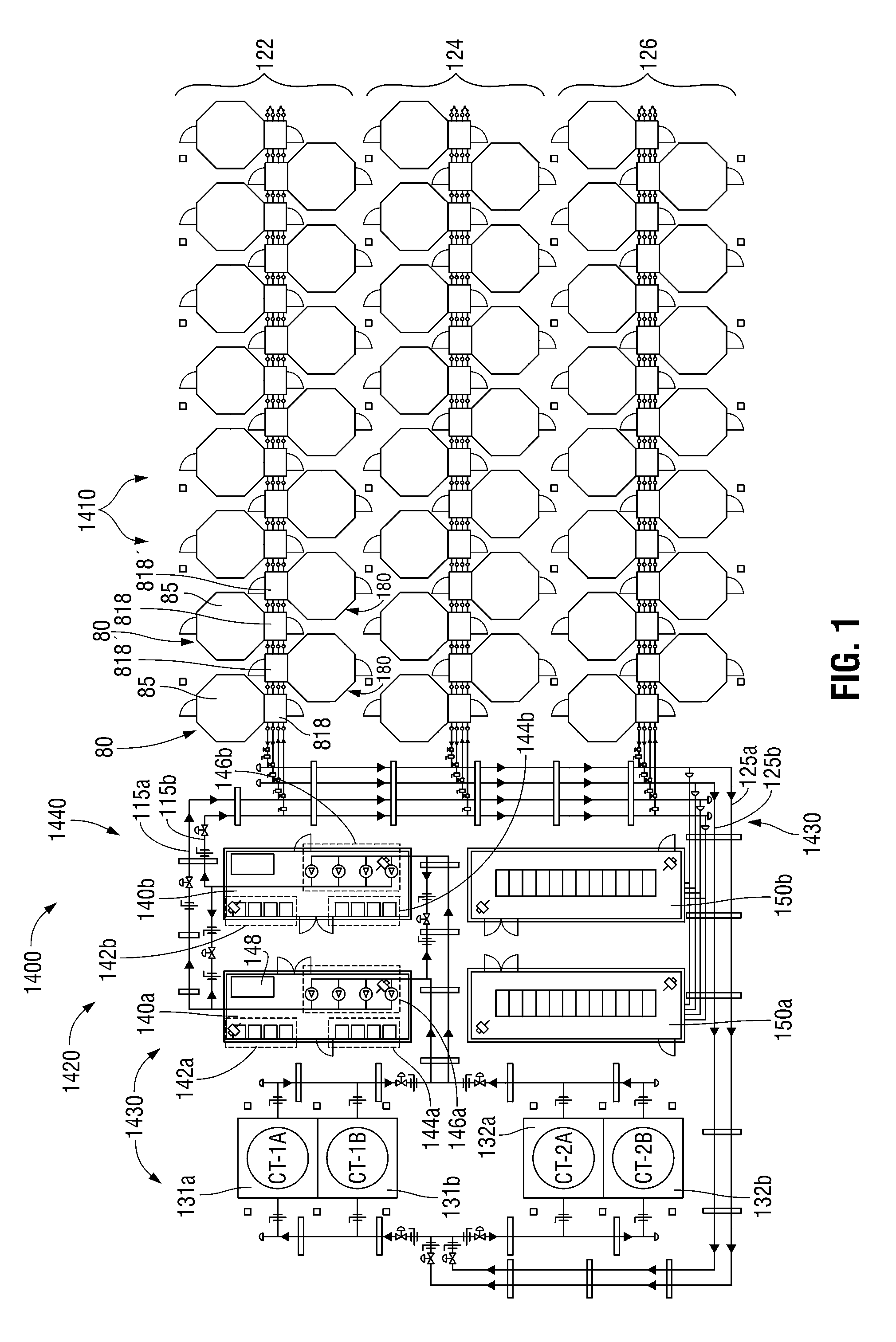

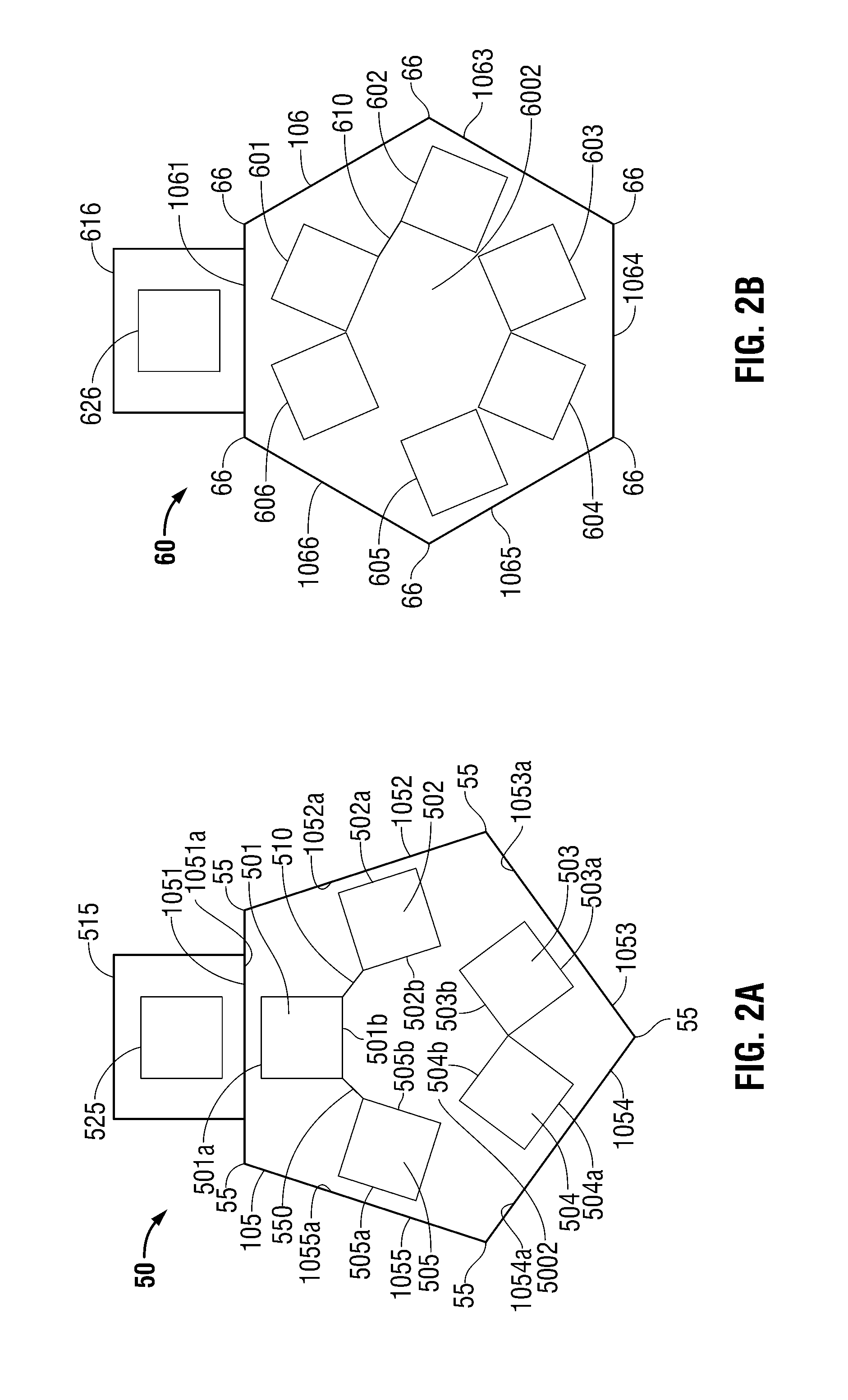

System and methods for cooling electronic equipment

ActiveUS9119326B2Stable toleranceImprove securityCompressorEfficient regulation technologiesAtmospheric airWet-bulb temperature

Systems and methods for cooling an inverter of a variable frequency drive that drives a compressor in a cooling system for electronic equipment are disclosed. The system includes a first fluid circuit that cools electronic equipment using a first fluid flowing therethrough and a second fluid circuit that free cools a second fluid flowing therethrough. The second fluid circuit cools the first fluid using the free-cooled second fluid. The system further includes a third fluid circuit that mechanically cools the second fluid using a third fluid flowing therethrough as a function of the wet bulb temperature of atmospheric air. The third fluid circuit includes at least one compressor compresses the third fluid and is driven by a motor coupled to the variable frequency drive. At least a portion of the first fluid flowing through the third fluid circuit is diverted to cool the inverter of the variable frequency drive.

Owner:INERTECH IP

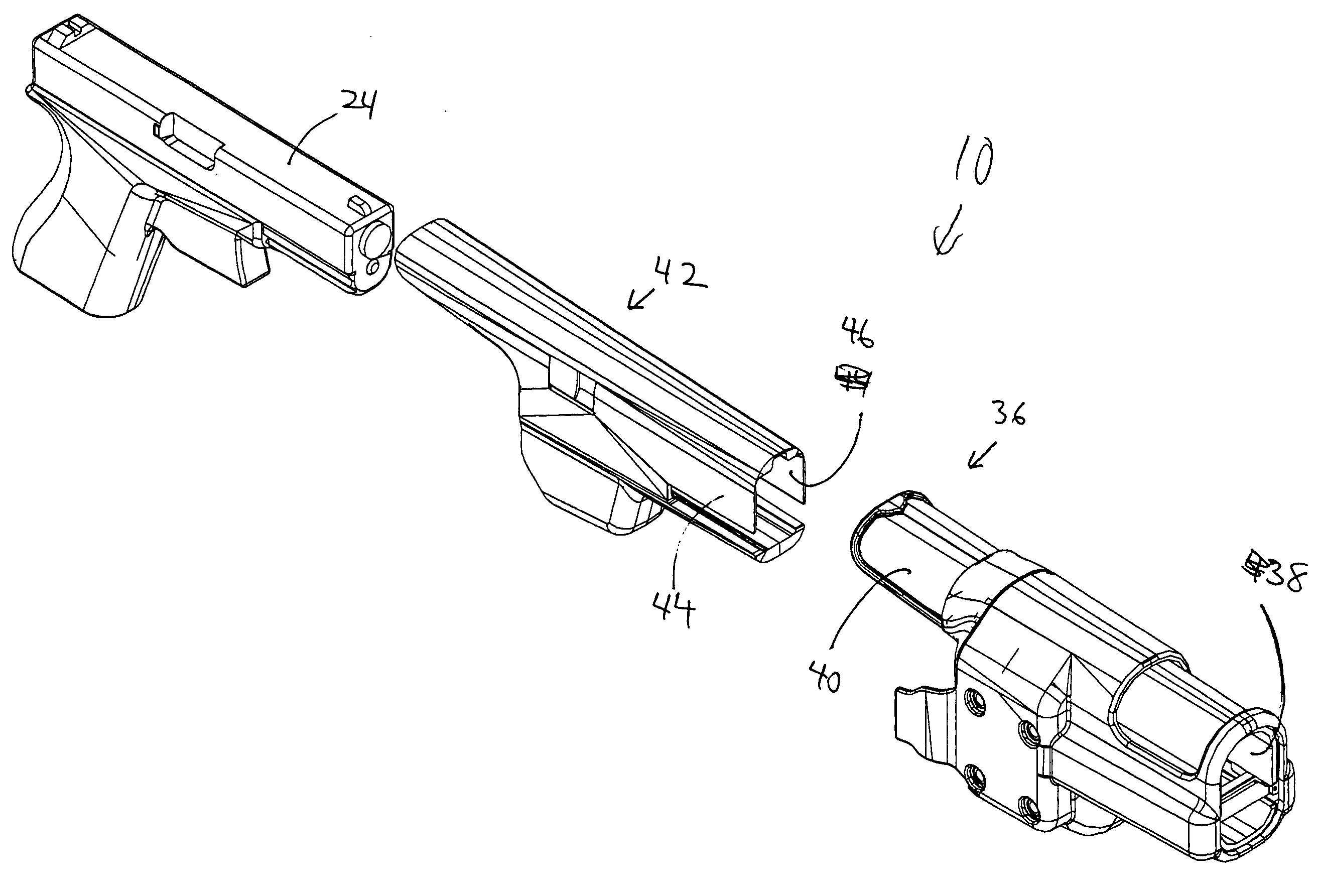

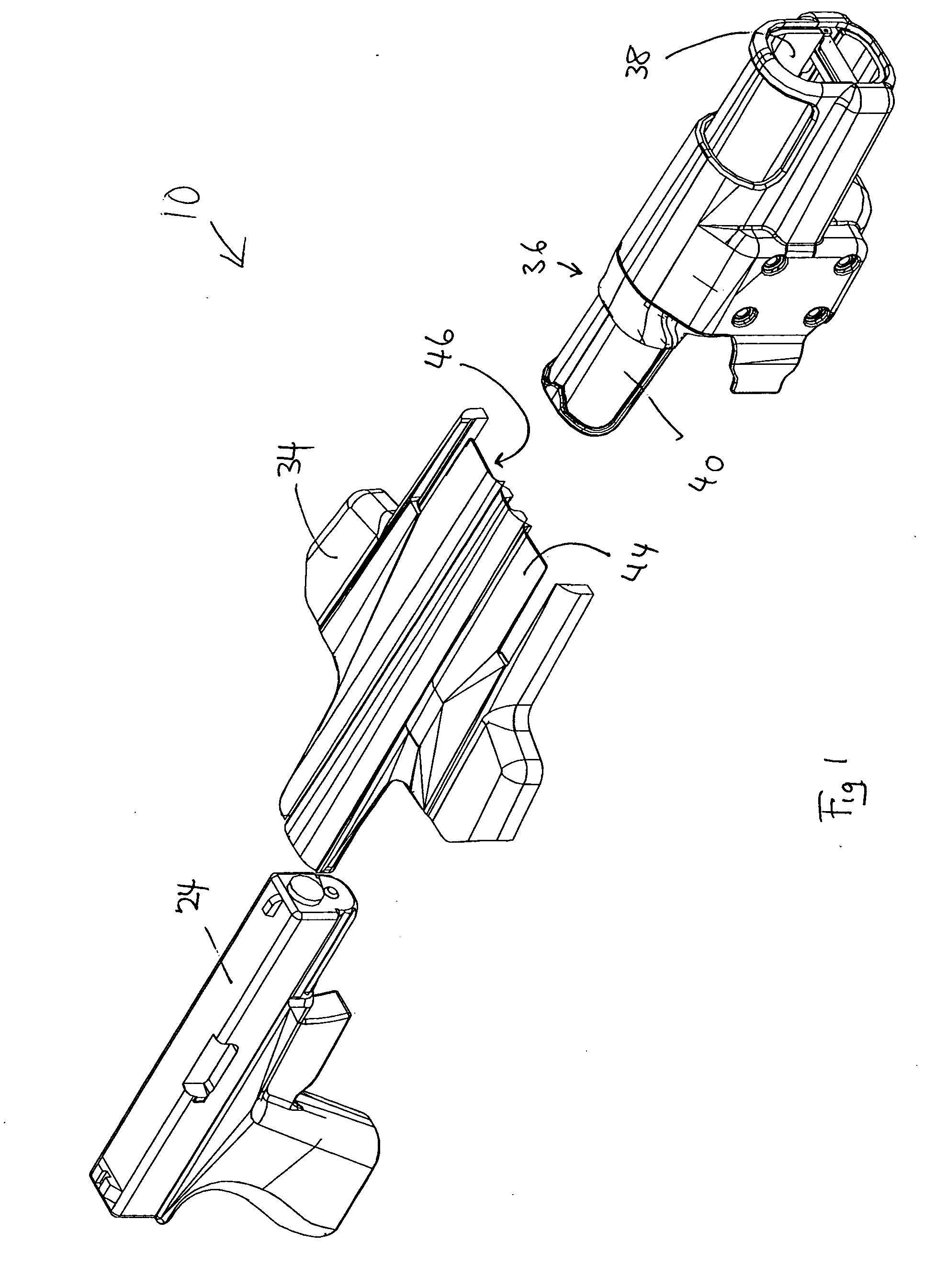

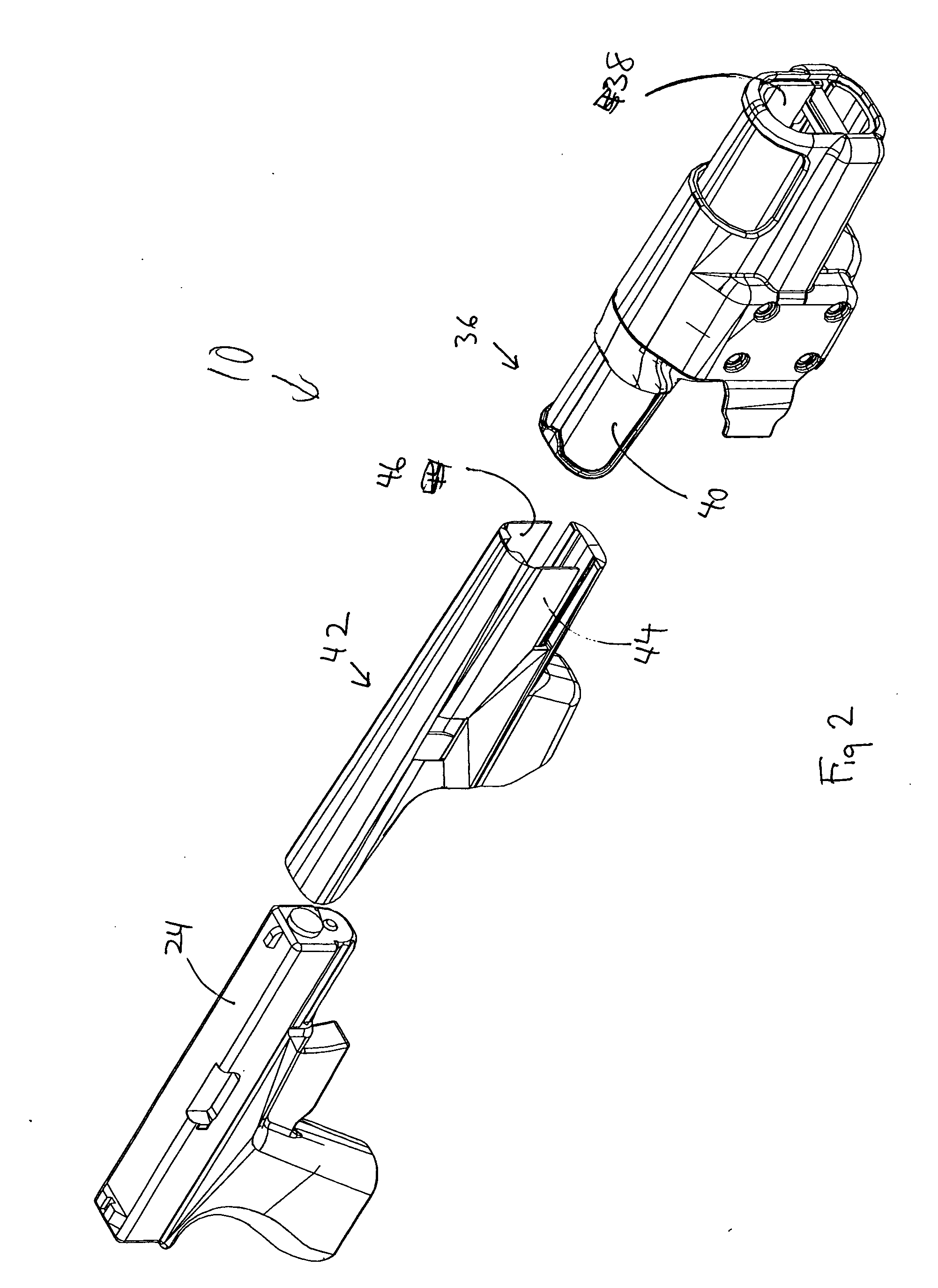

Holster manufacturing system and method of making

InactiveUS20060156525A1Suitable for useLower resistanceArms wearablesMeasurement/indication equipmentsEngineeringManufacturing systems

Owner:TACTICAL DESIGN LABS

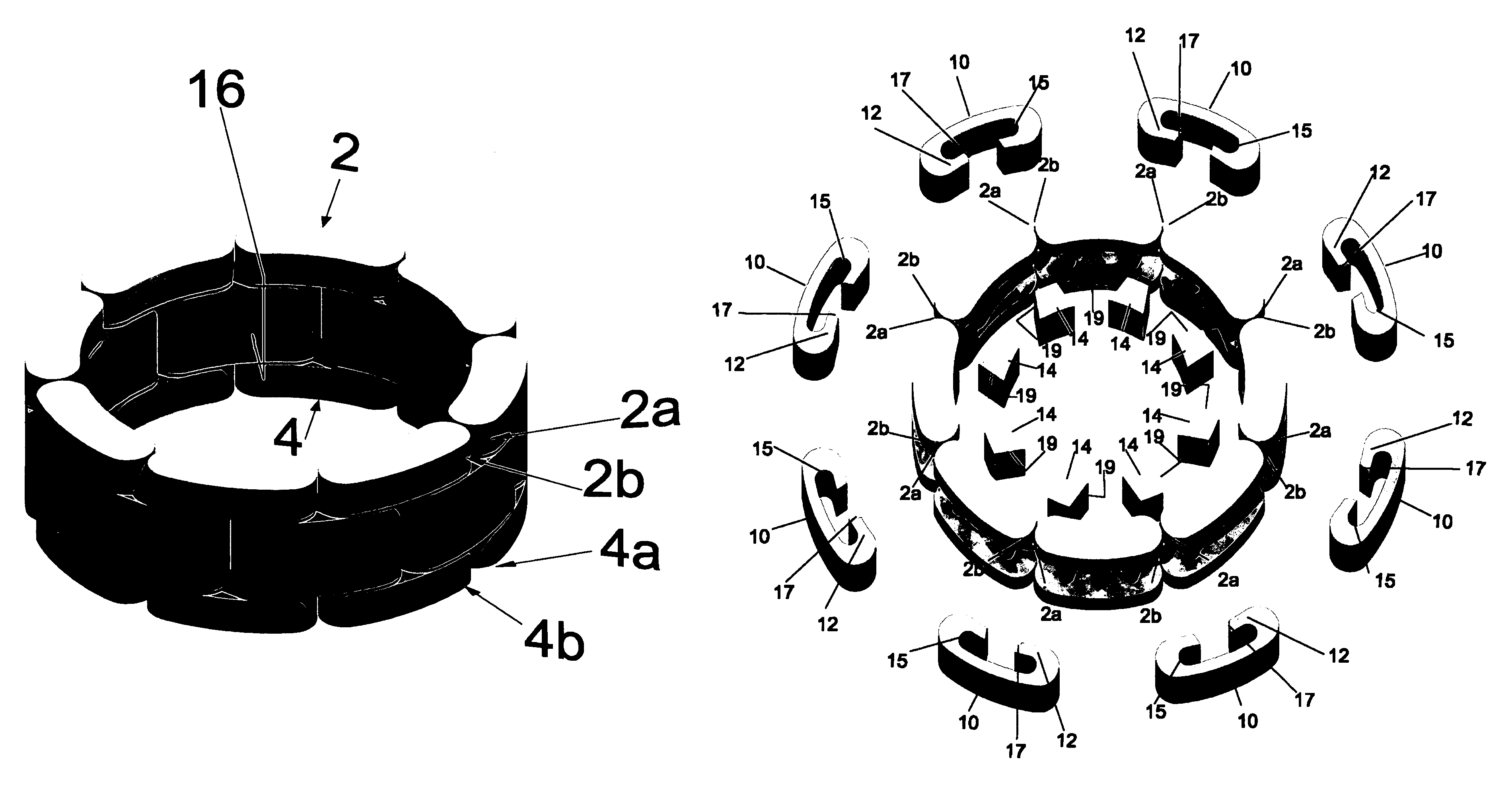

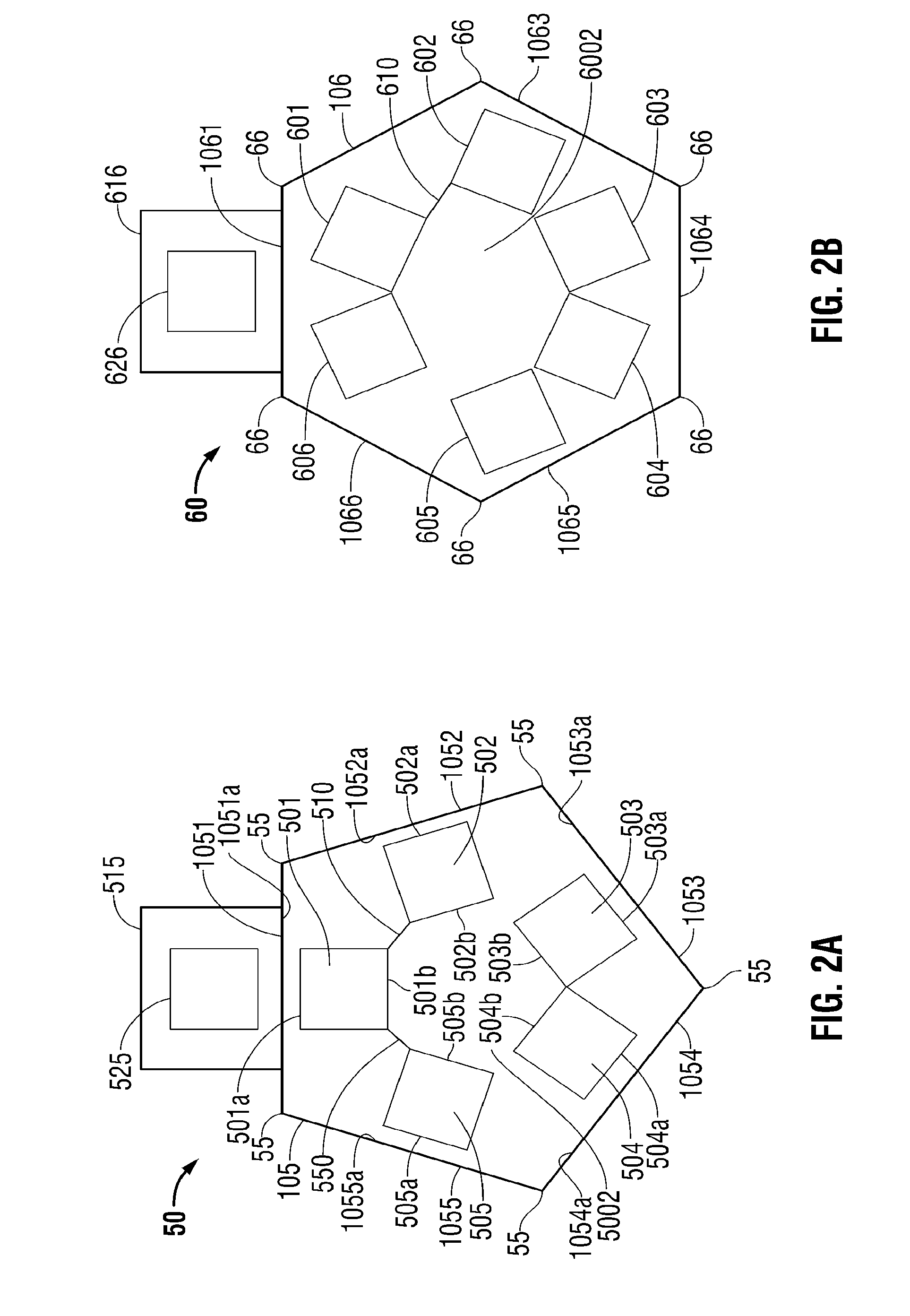

Linked ring structures

InactiveUS7086218B1Close toleranceAvoid the needBraceletsWrist-watch strapsEngineeringMechanical engineering

Owner:M&J R&R GROSBARD

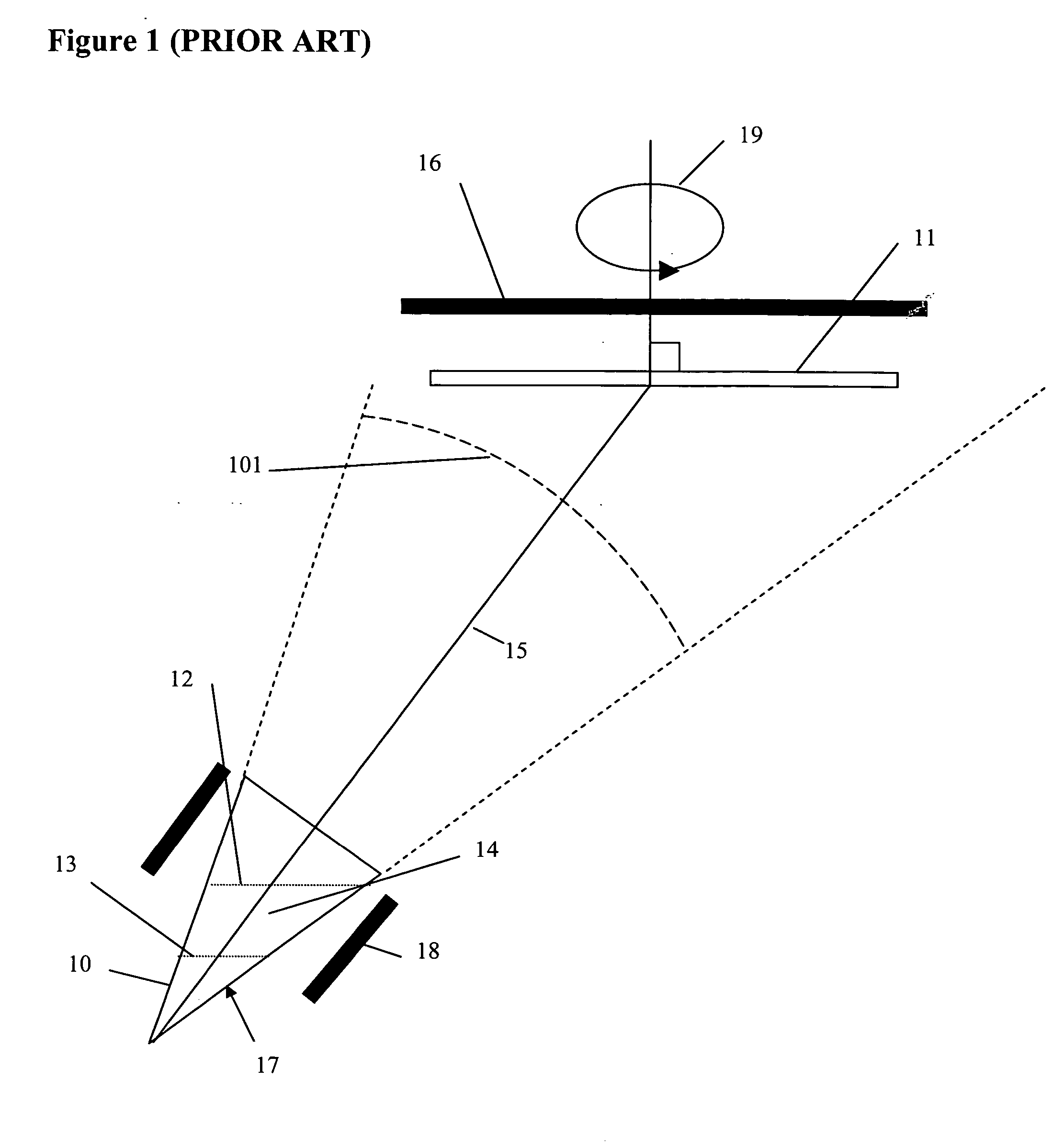

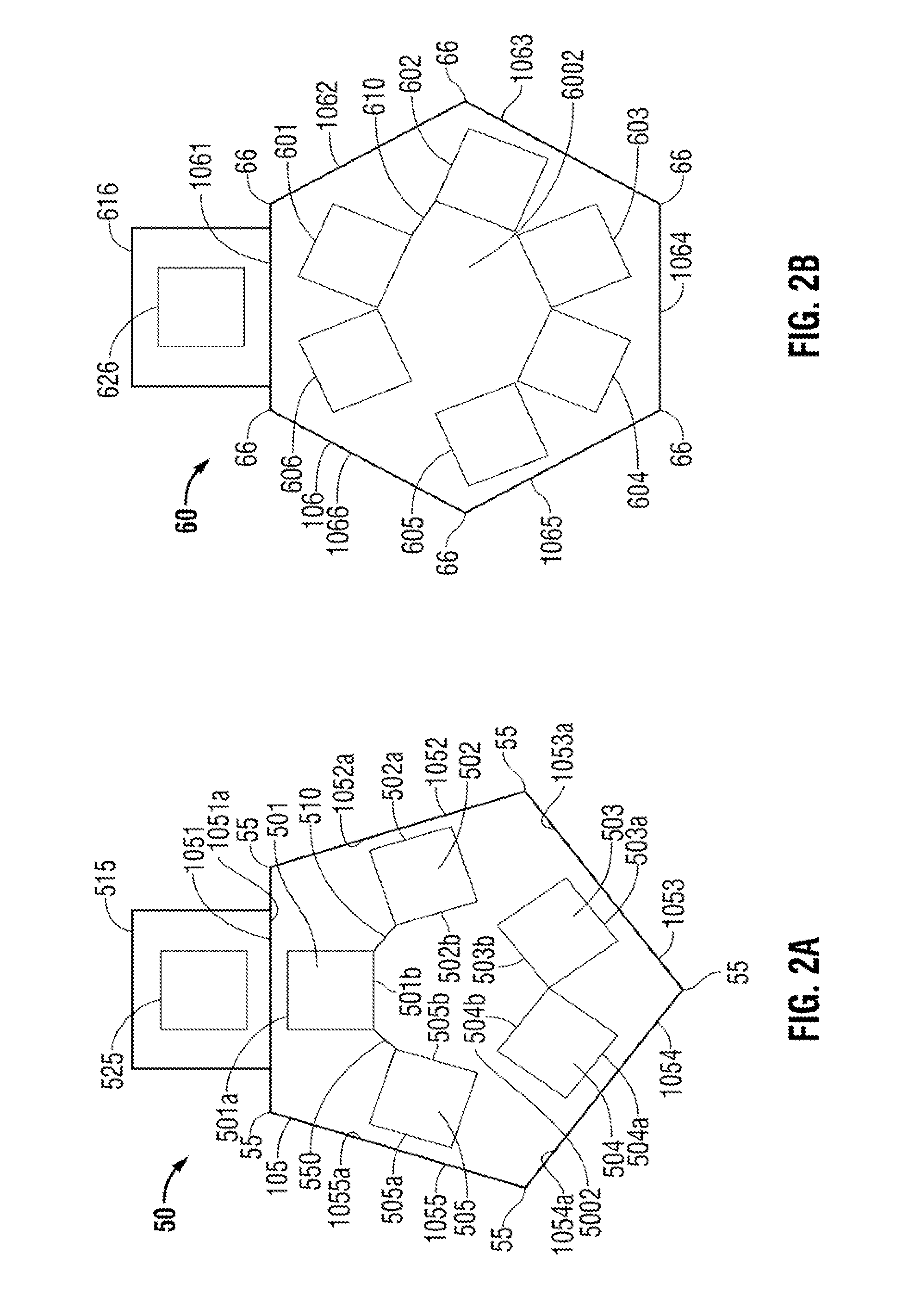

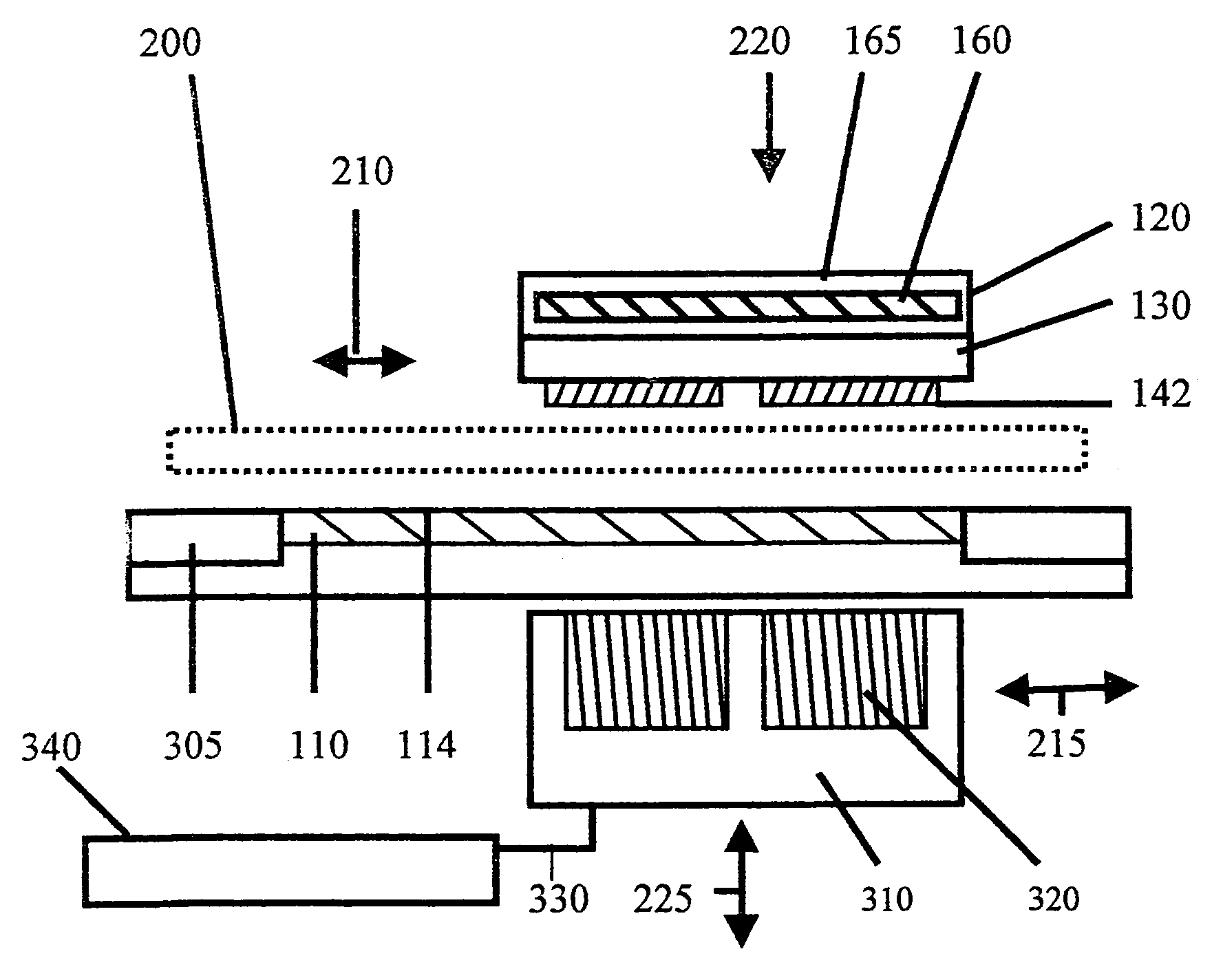

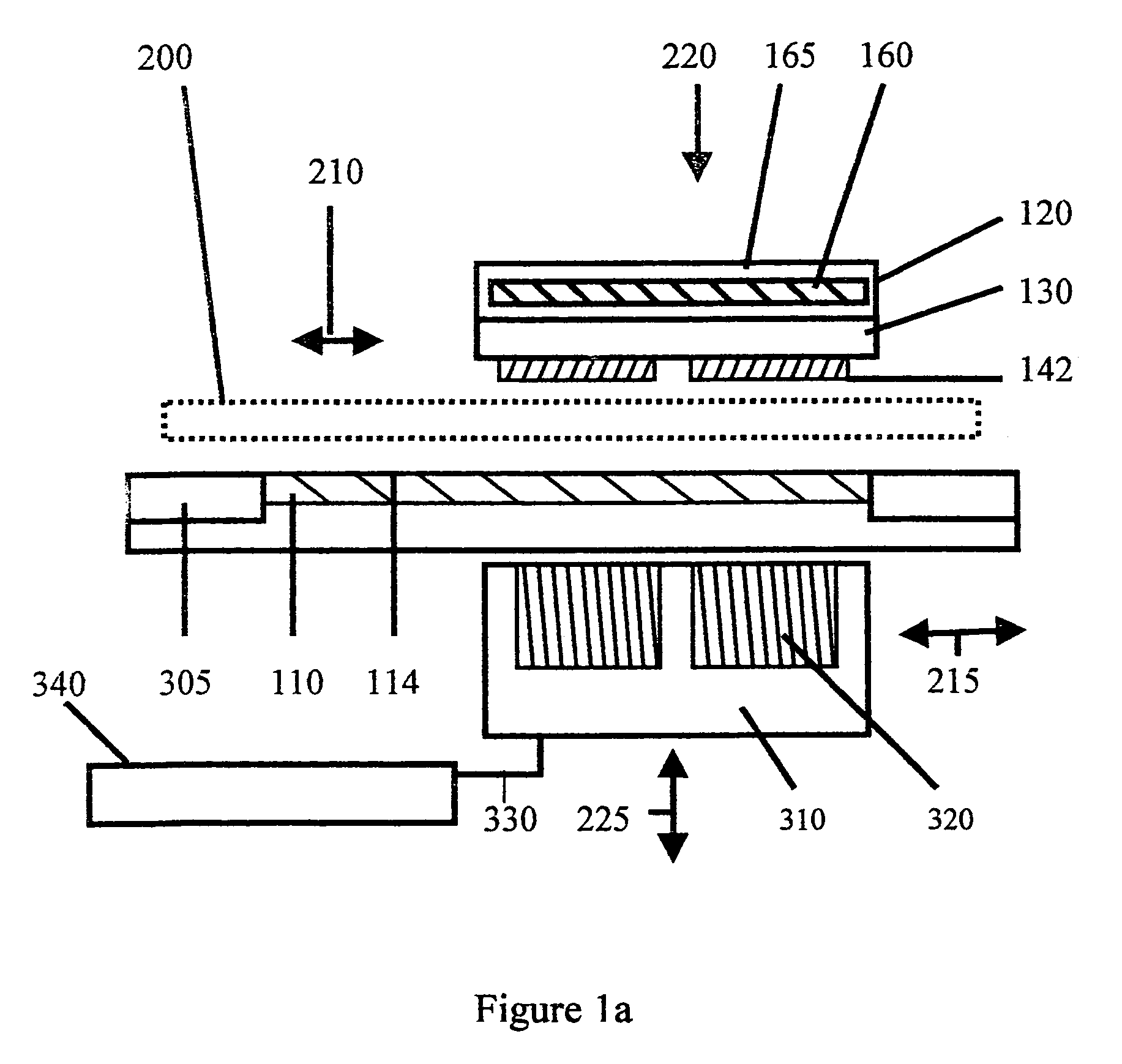

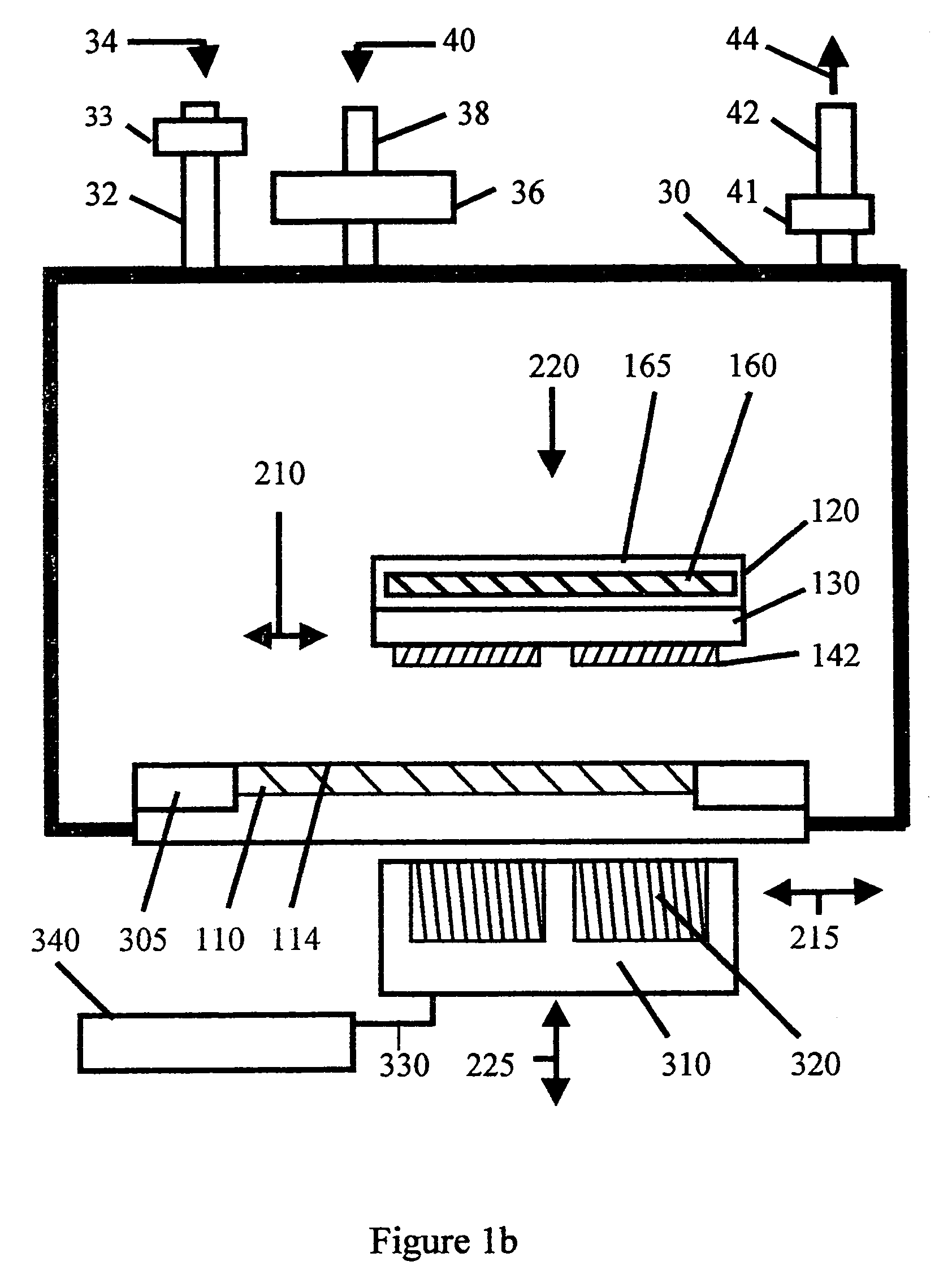

Reflective microelectrical mechanical structure (MEMS) optical modulator and optical display system

InactiveUS20050248827A1Eliminating light attenuation and expense of lightIncrease contrastOptical elementsActuatorMicro lens array

A MEMS optical display system includes an illumination source for providing illumination light, a collimating lens for receiving the illumination light and forming from it collimated illumination light, and a microlens array having an array of lenslets for receiving the illumination light from the collimating lens. The converging microlens array directs the illumination light through an array of pixel apertures in an aperture plate to a microelectrical mechanical reflector array positioned opposite the aperture plate. The microelectrical mechanical reflector array includes an array of microelectrical mechanical actuators that support reflectors in alignment with the array of pixel apertures and selectively orients the reflectors to direct the illumination light back through the pixel apertures (to form part of a display image) or against the aperture plate (to be blocked). The illumination light passing back through the pixel apertures passes through the microlens array and a beamsplitter to a display screen.

Owner:MICROSOFT TECH LICENSING LLC

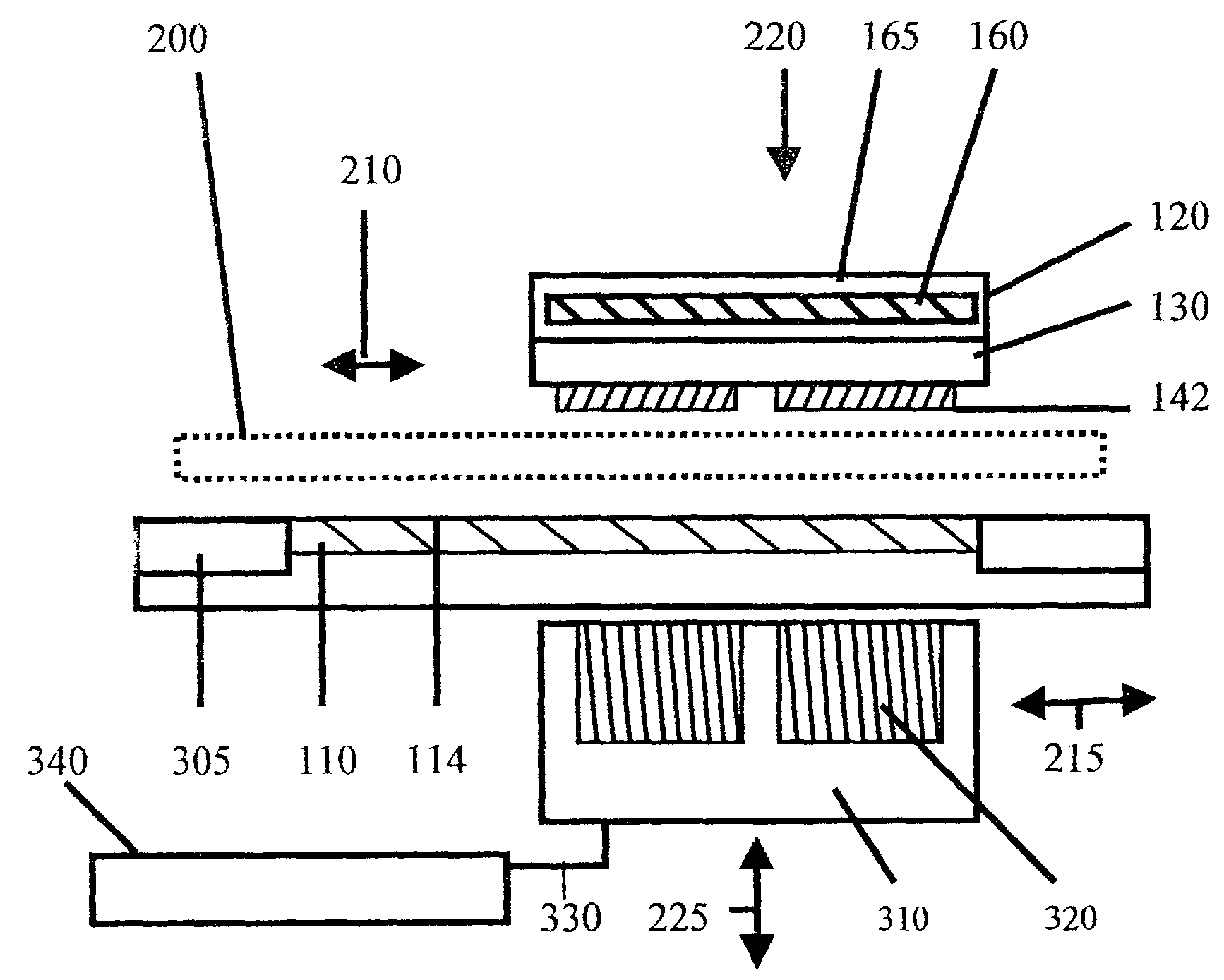

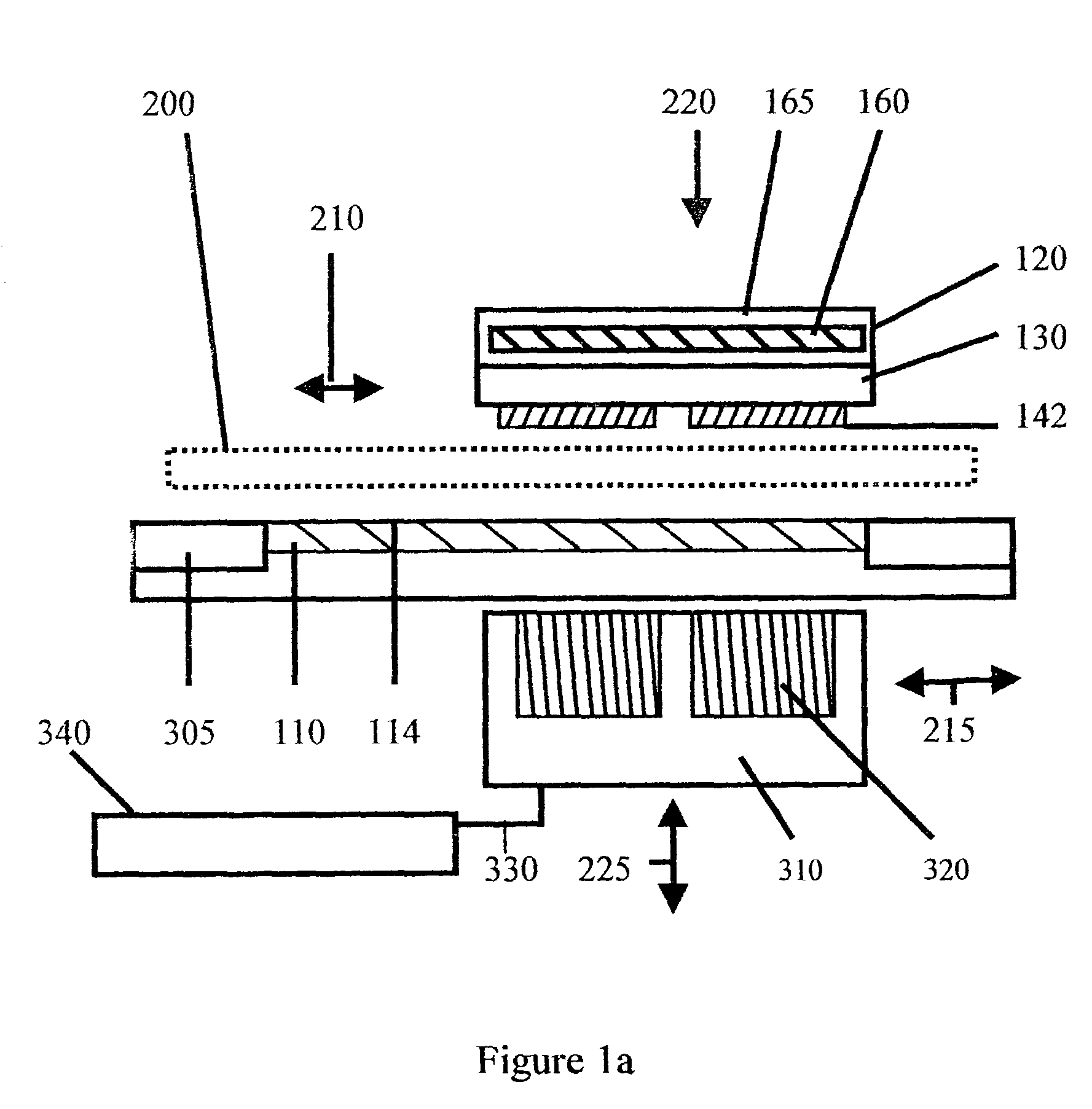

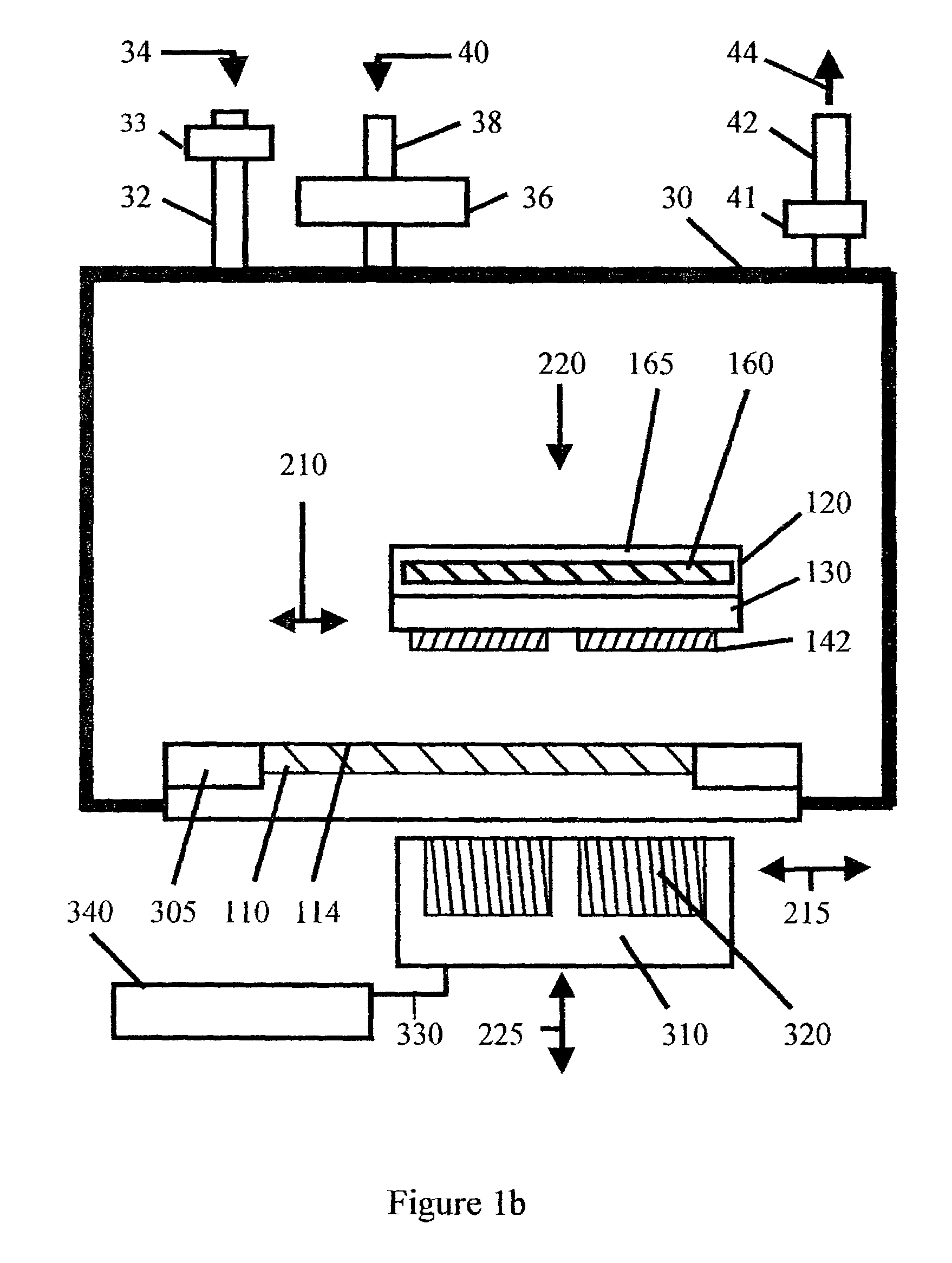

Advanced wafer refining

InactiveUS7008300B1Accessible costImprove refining methodSemiconductor/solid-state device testing/measurementSolid-state devicesManufacturing cost reductionElectrolysis

A refining apparatus having magnetically responsive refining elements that can be smaller than the workpiece being refined are disclosed. The refining apparatus can supply a parallel refining motion to the refining element(s) through magnetic coupling forces. The refining apparatus can supply multiple different parallel refining motions to multiple different refining elements solely through magnetic coupling forces to improve refining quality and versatility. New refining methods, refining apparatus, and refining elements disclosed. Methods of refining using frictional refining, chemical refining, tribochemical refining, and electrochemical refining and combinations thereof are disclosed. A refining chamber can be used. New methods of control are refining disclosed. The new magnetic refining methods, apparatus, and magnetically responsive refining elements can help improve yield and lower the cost of manufacture for refining of workpieces having extremely close tolerances such as semiconductors wafers. Refining fluids are preferred. Reactive refining aids are preferred. Electro-refining for adding and removing material is disclosed. A method to use business calculations combined with physical measurements to improve control is discussed. Use of business calculations to change the cost of finishing semiconductor wafers is discussed. The method can help cost of manufacture forecasting for pre-ramp-up, ramp-up, and commercial manufacture. Actively based accounting can be preferred for some applications. New methods and new apparatus for non-steady state refining control are disclosed.

Owner:SEMCON TECH

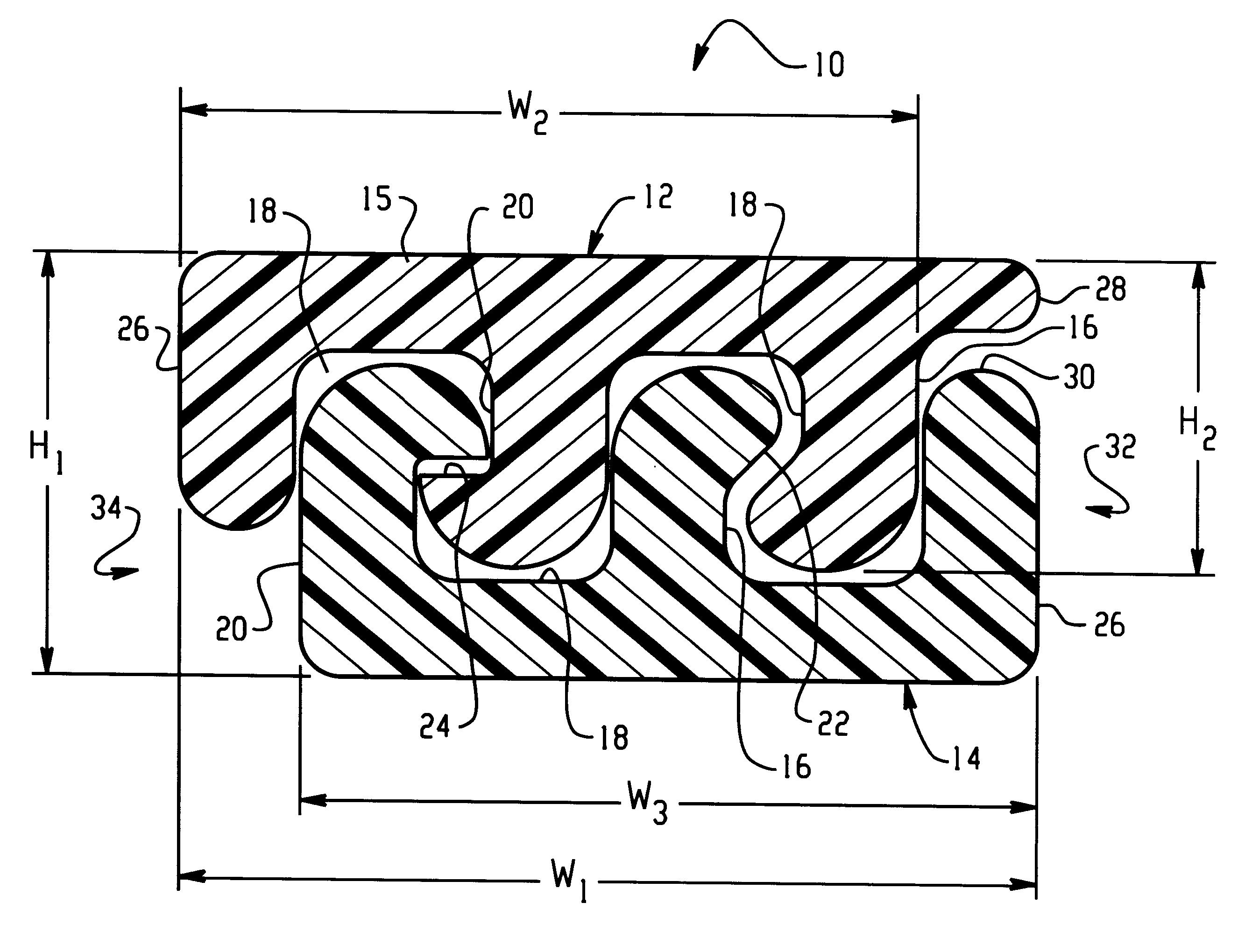

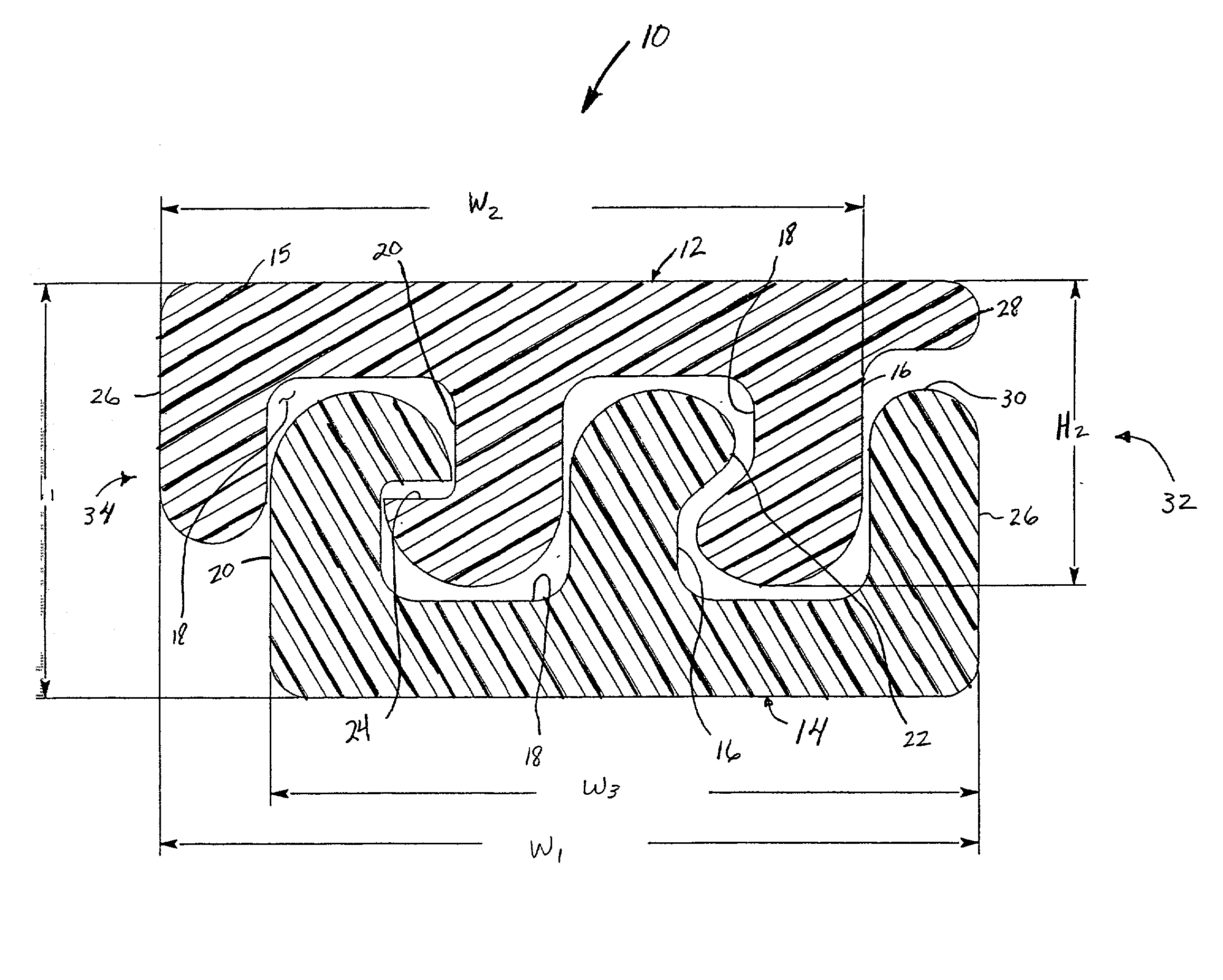

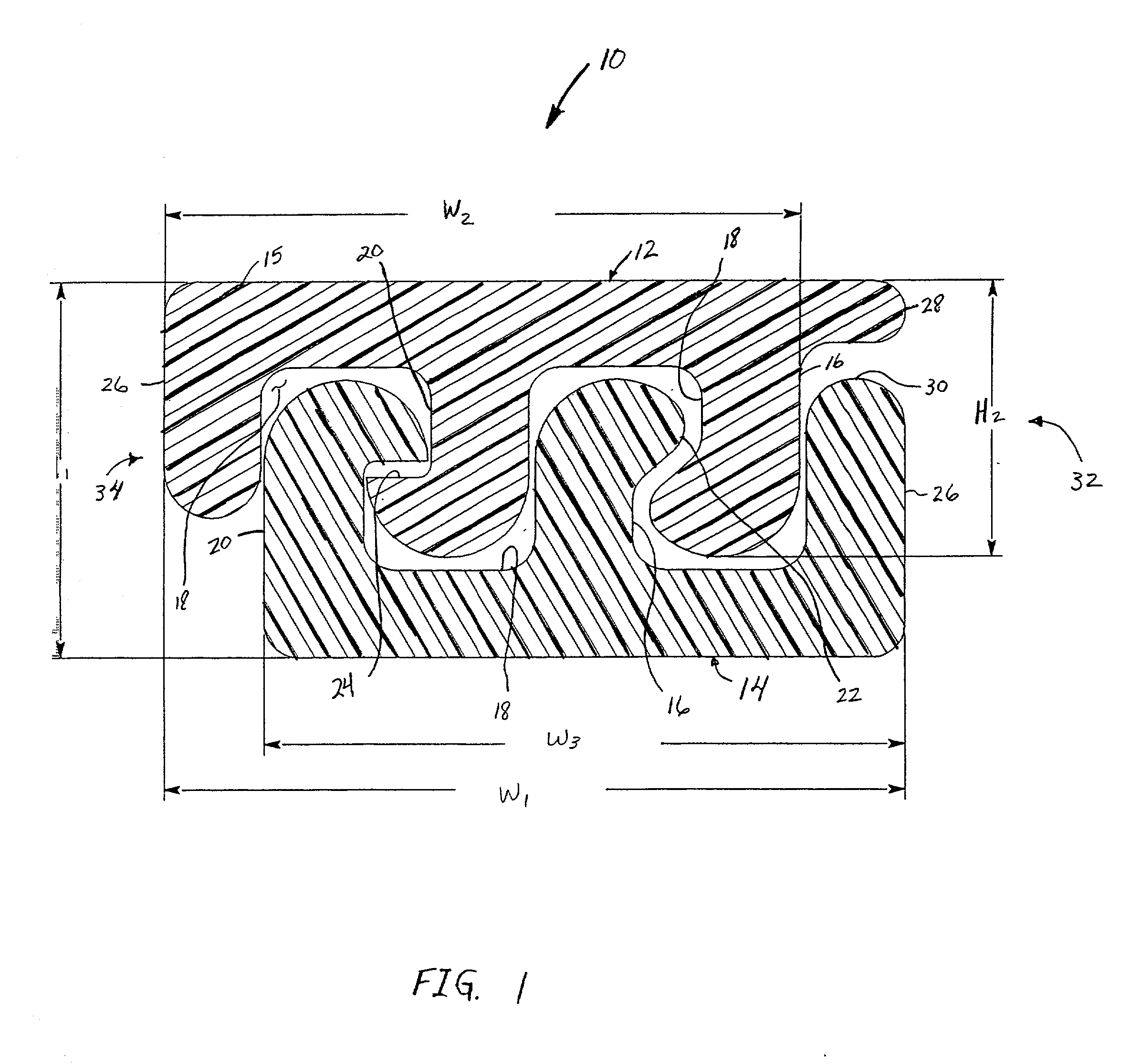

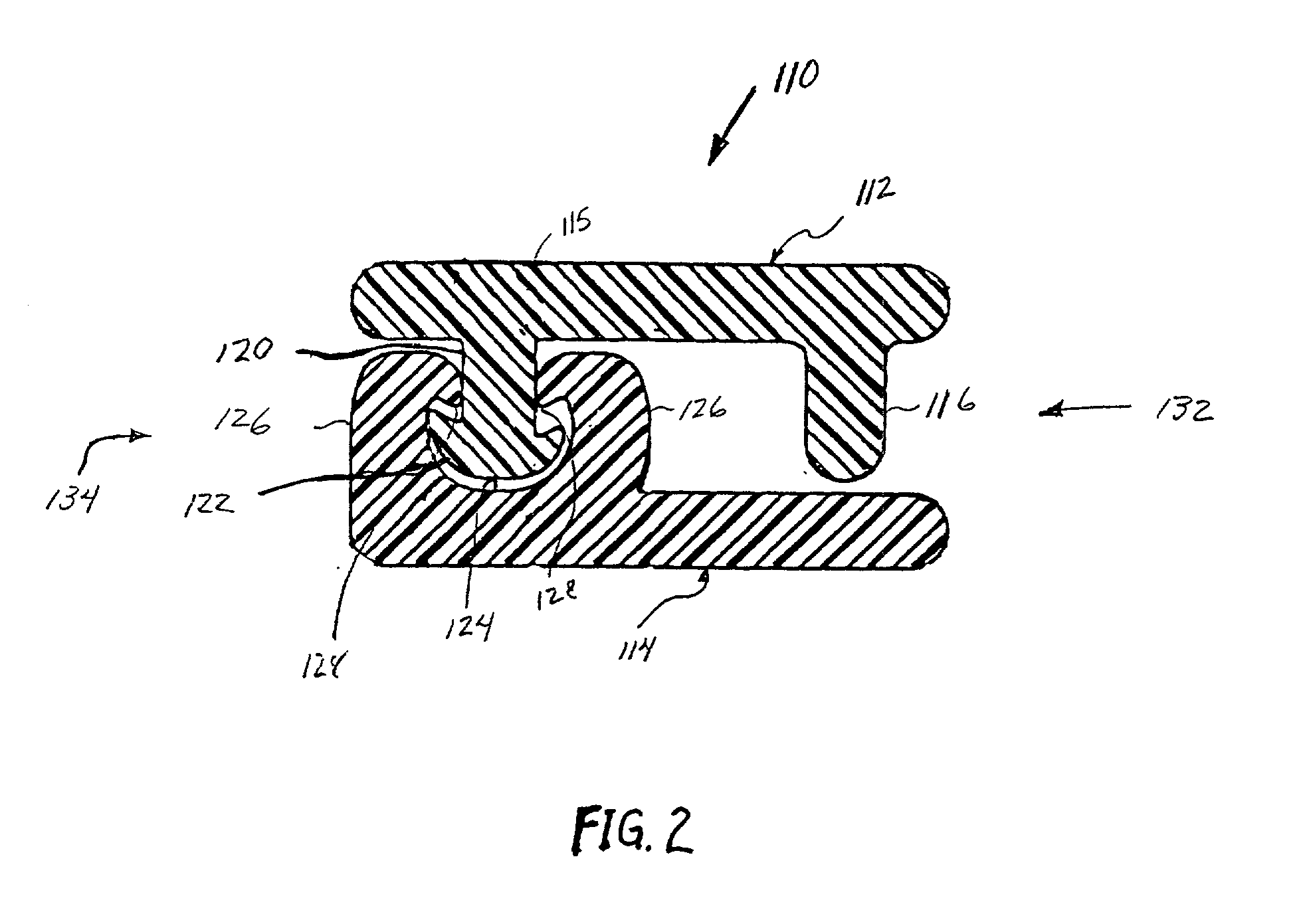

Polypropylene recloseable zipper

InactiveUS6487758B2Sufficient flexibilityReasonable temperatureSlide fastenersBagsEngineeringPolypropylene

A polypropylene closure arrangement for flexible packages comprises a blend having a polypropylene random copolymer as a base resin with a flexible modifier, and a slip component. The polypropylene closure arrangement 10, 110 is sufficiently flexible to be extruded and coiled around guide wheels similar to the fusion process of a polyethylene closure arrangement. The polypropylene closure arrangement in accordance with the present invention has the ability to be fusibly attached to a polypropylene film or other fusibly compatible thermoplastic material launch conditions.

Owner:EATON INTELLIGENT POWER LTD

Reflective microelectrical mechanical structure (MEMS) optical modulator and optical display system

InactiveUS20050057793A1Eliminating light attenuation of lightEliminating expenseStatic indicating devicesNon-linear opticsActuatorMicro lens array

A MEMS optical display system includes an illumination source for providing illumination light, a collimating lens for receiving the illumination light and forming from it collimated illumination light, and a microlens array having an array of lenslets for receiving the illumination light from the collimating lens. The converging microlens array directs the illumination light through an array of pixel apertures in an aperture plate to a microelectrical mechanical reflector array positioned opposite the aperture plate. The microelectrical mechanical reflector array includes an array of microelectrical mechanical actuators that support reflectors in alignment with the array of pixel apertures and selectively orients the reflectors to direct the illumination light back through the pixel apertures (to form part of a display image) or against the aperture plate (to be blocked). The illumination light passing back through the pixel apertures passes through the microlens array and a beamsplitter to a display screen.

Owner:MICROSOFT TECH LICENSING LLC

Versatile wafer refining

InactiveUS7377836B1Easy to organizeReduce manufacturing costElectrolysis componentsSemiconductor/solid-state device testing/measurementManufacturing cost reductionElectrolysis

Methods of refining using a plurality of refining elements are discussed. A refining apparatus having refining elements that can be smaller than the workpiece being refined are disclosed. New refining methods, refining apparatus, and refining elements disclosed. Methods of refining using frictional refining, chemical refining, tribochemical refining, and electrochemical refining and combinations thereof are disclosed. A refining apparatus having magnetically responsive refining elements that can be smaller than the workpiece being refined are disclosed. The refining apparatus can supply a parallel refining motion to the refining element(s) for example through magnetic coupling forces. The refining apparatus can supply multiple different parallel refining motions to multiple different refining elements for example solely through magnetic coupling forces to improve refining quality and versatility. A refining chamber can be used. New methods of control are refining disclosed. The new refining methods, including magnetic refining methods, apparatus, and refining elements, including magnetically responsive refining elements, can help improve yield and lower the cost of manufacture for refining of workpieces having extremely close tolerances such as semiconductor wafers. New methods of control are also discussed. Methods and apparatus which use processor readable memory devices are discussed. Refining fluids are preferred. Reactive refining aids are preferred. Electro-refining for adding and removing material is disclosed. New methods and new apparatus for non-steady state refining control are disclosed.

Owner:SEMCON TECH

Bone modelling and guide device for preparing bone sites for implant surgery

InactiveUS20100129768A1Close toleranceSafe and stressless surgeryDiagnosticsSurgeryEnthesisBiomedical engineering

Owner:ISIDORI MICHEL

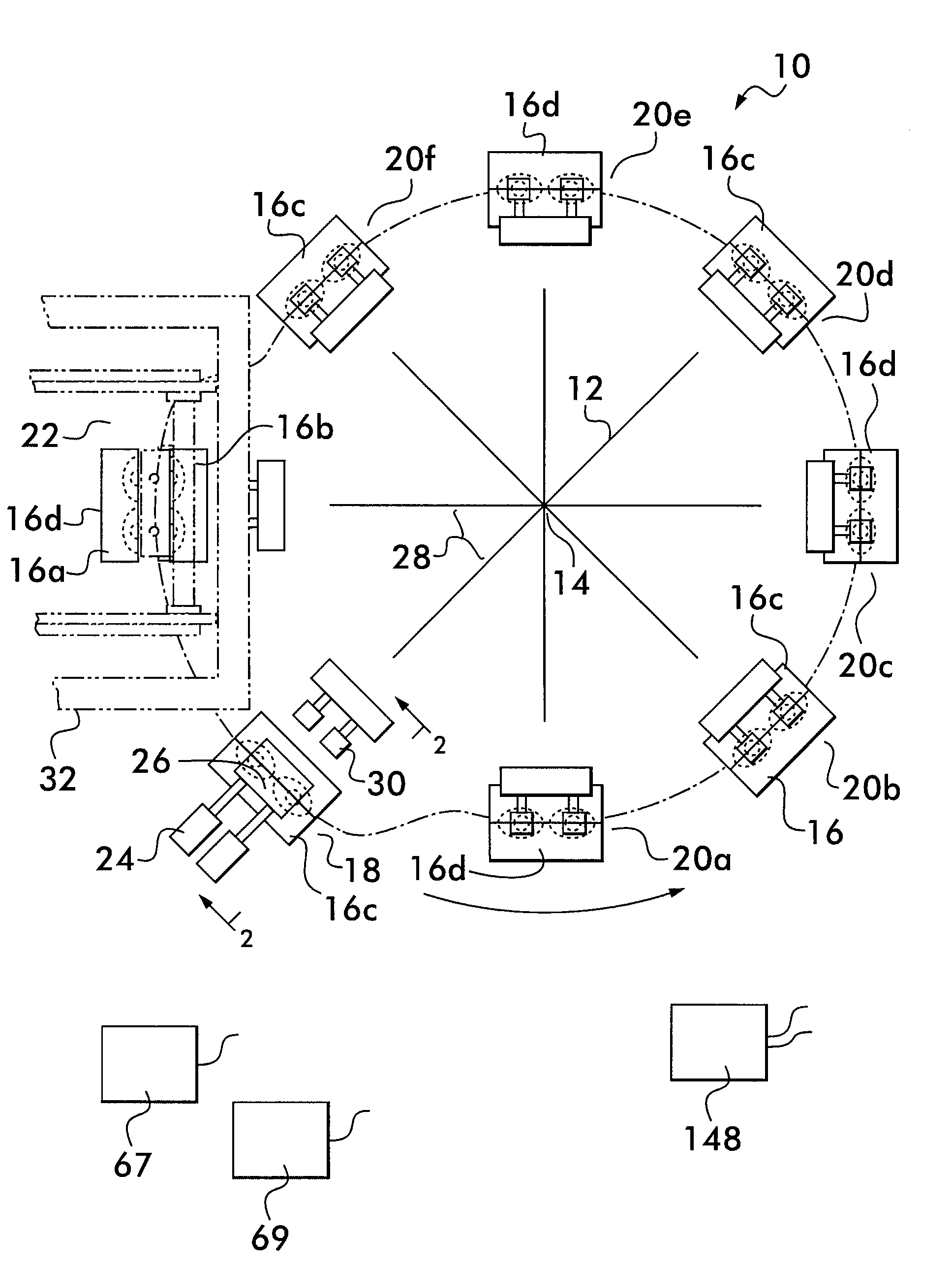

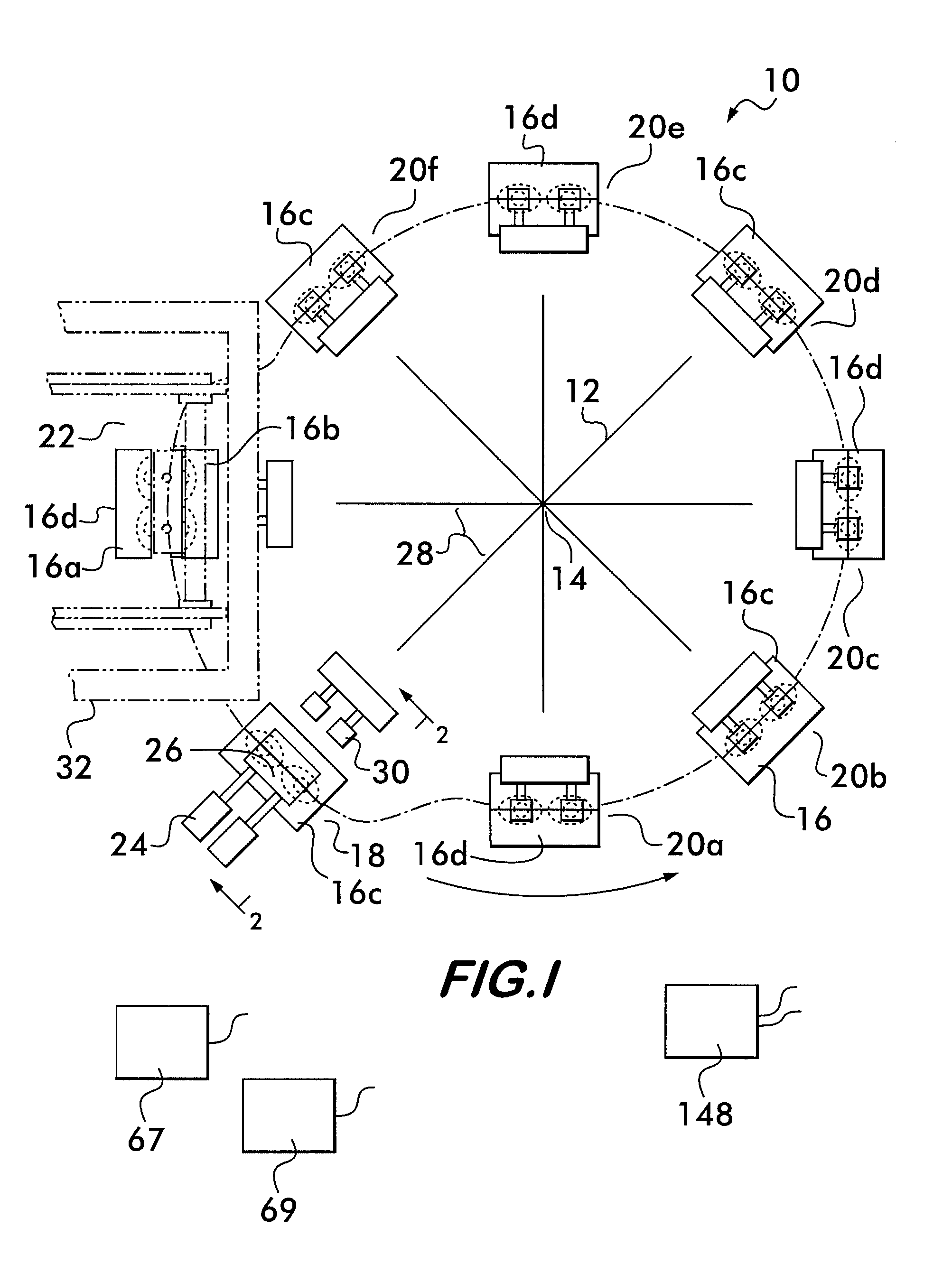

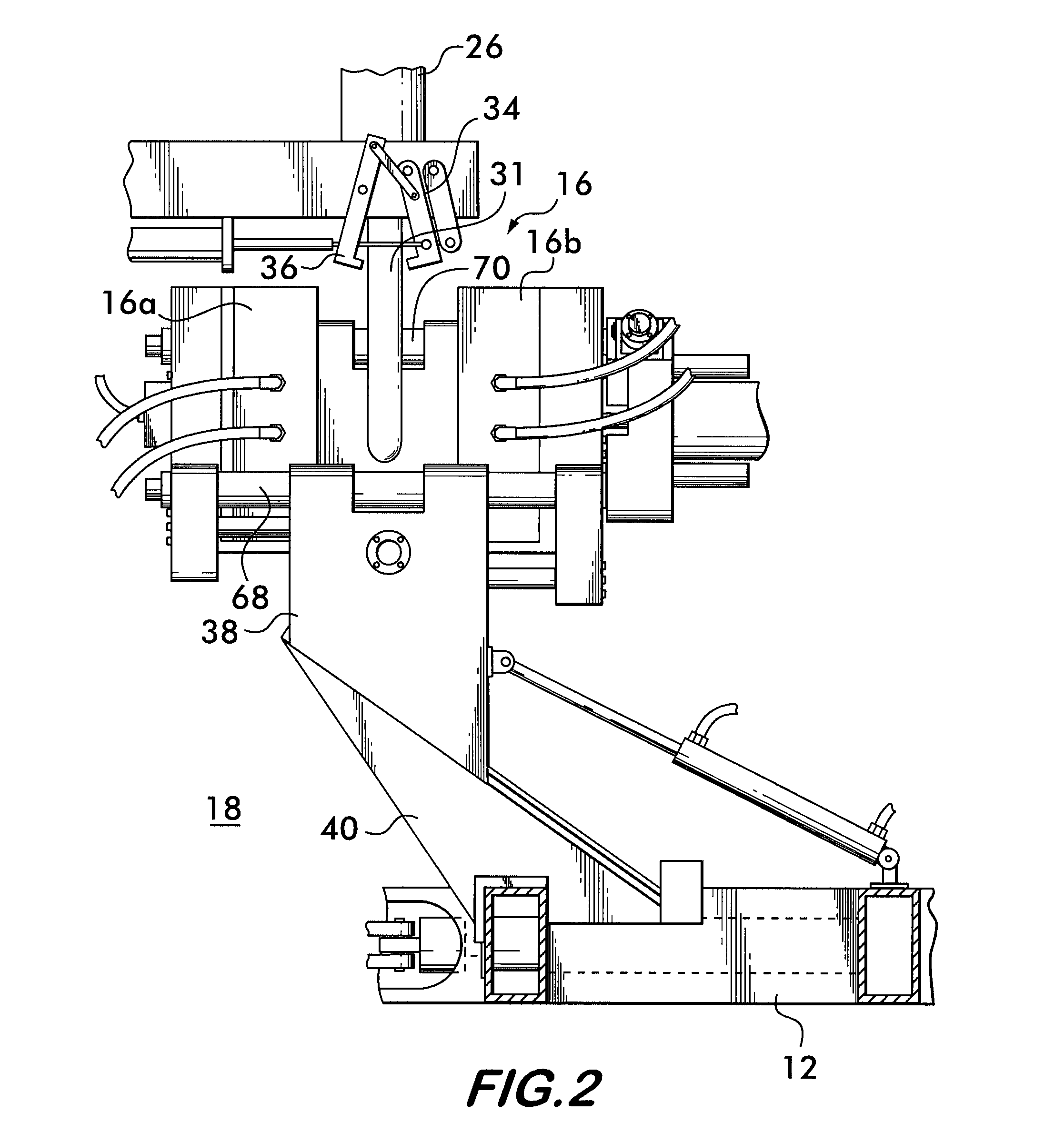

Blow molding machine and associated mechanisms

InactiveUS20100225033A1Lower potentialClose toleranceTailstocks/centresConfectioneryBlow moldingAcute angle

A machine (10) for blow molding containers (110). The machine (10) has a stationary flow head (26) located above a turntable (12) with molds (16) mounted on carriages (38). The carriages (38) are mounted on ramps (40) and are raised to remove containers (110) and are lowered from the flow head (12) using a closed loop hydraulic system actuated by a cam. A double rack-and-pinion assembly (78) guides opening and closing of the molds (16) and a locking system having locking shafts (94, 96) engaging apertures (98, 100) in a cross head (74) with pivoting locking keys (102, 104) movable into alignment with the apertures (98, 100) prevents inadvertent mold opening. A container transfer device (32) has inflatable bladders (140) which engage the interior of the containers (110) to prevent damage. Augmented cooling of the containers (110) in the mold (16) is provided by positioning the flow head (26) at an acute angle (28) to the transfer device (32). Different molds (16) may be positioned on the turntable (12) in an alternating arrangement to facilitate production changeover.

Owner:GRAHAM PACKAGING CO LP

Situ finishing aid control

InactiveUS7156717B2Improve the finishChange frictionPolishing machinesSemiconductor/solid-state device manufacturingProcedure AgentsTangential force

A method of using finishing aids for advanced finishing control is described. A finishing surface is used generally to induce frictional wear. The finishing aids with preferred in situ control can improve control of the coefficient of friction, the tangential force of friction, a finishing rate, a regional finishing rate(s), a differential finishing rate, and help reduce unwanted defects. A finishing aid can reduce friction. A lubricant is an illustrative finishing aid. The method uses finishing control subsystem having a multiplicity of operative process sensors along with tracked information to improve in situ control of finishing. Differential finishing rate methods are described to differentially finish semiconductor wafers. Differential lubricating film methods are described to differentially finish semiconductor wafers. Planarization and localized finishing can be improved using differential lubricating boundary layer methods of finishing with improved real time control.

Owner:SEMCON TECH

Ceramic spark plug insulator and method of making

InactiveUS20090256461A1Well formedHigh dielectric strengthFuel injection apparatusMachines/enginesCeramicMaterials science

An insulator for a spark ignition device is disclosed which includes an electrically insulating ceramic core tube having a terminal end, a firing end and an inner bore which extends along a longitudinal bore axis from the terminal end to the firing end and an electrically insulating, ceramic core nose tube having a second outer surface and a second bore where the second outer surface of said ceramic core nose tube is in nested engagement with and directly bonded to the bore of the ceramic core tube proximate the firing end. The insulator also may include a similarly nested and directly bonded shoulder tube on an outer surface of the core tube, or a nested and directly bonded mast tube on an outer surface of the core tube. The ceramics may include alumina-based ceramics, as well other suitable ceramic materials, and the tube may be made from the same ceramic compositions or different ceramic compositions. The invention also includes a method of making the nested tube, directly boded insulators by controlling shrinkage during sintering.

Owner:FEDERAL MOGUL IGNITION

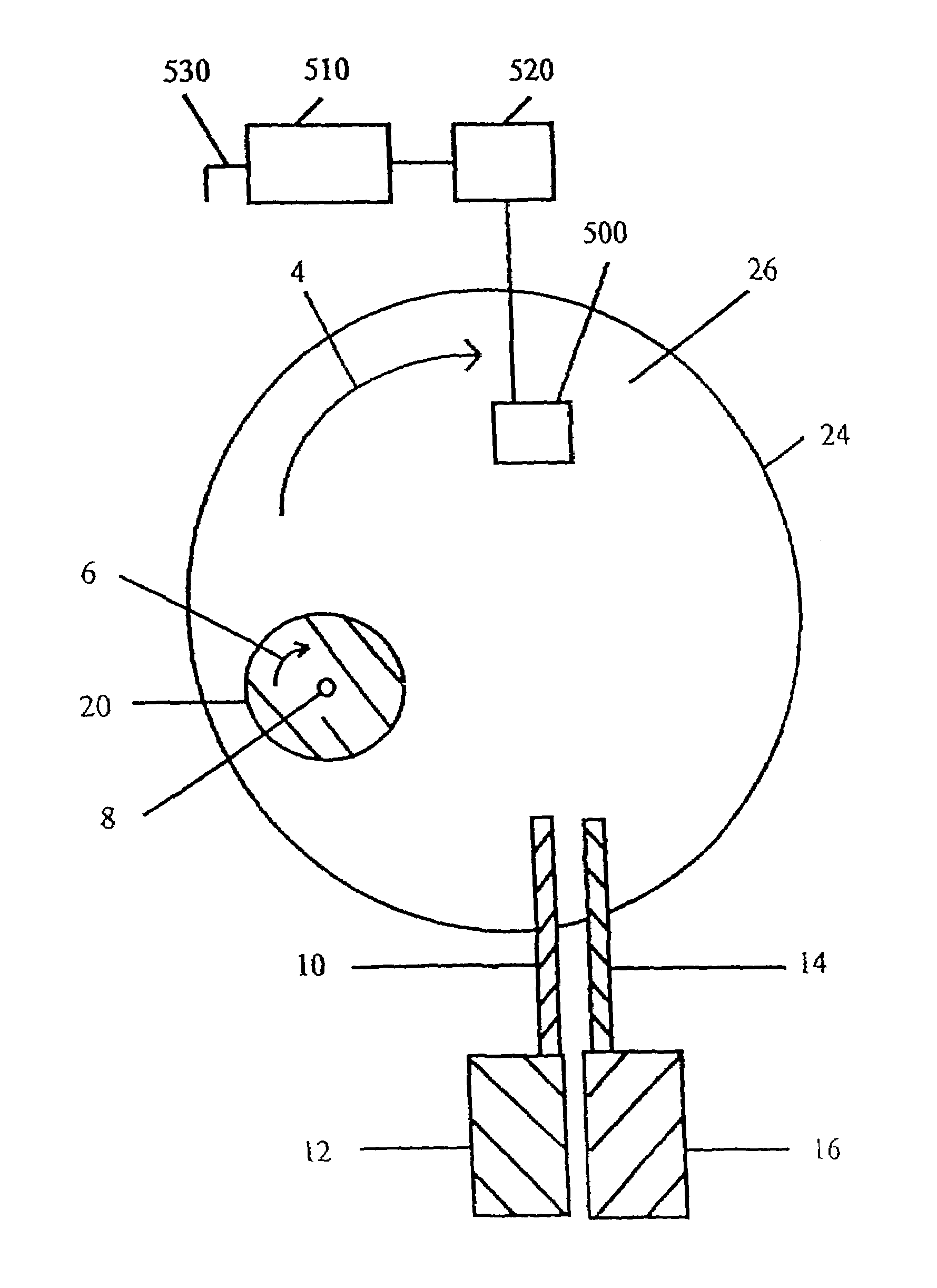

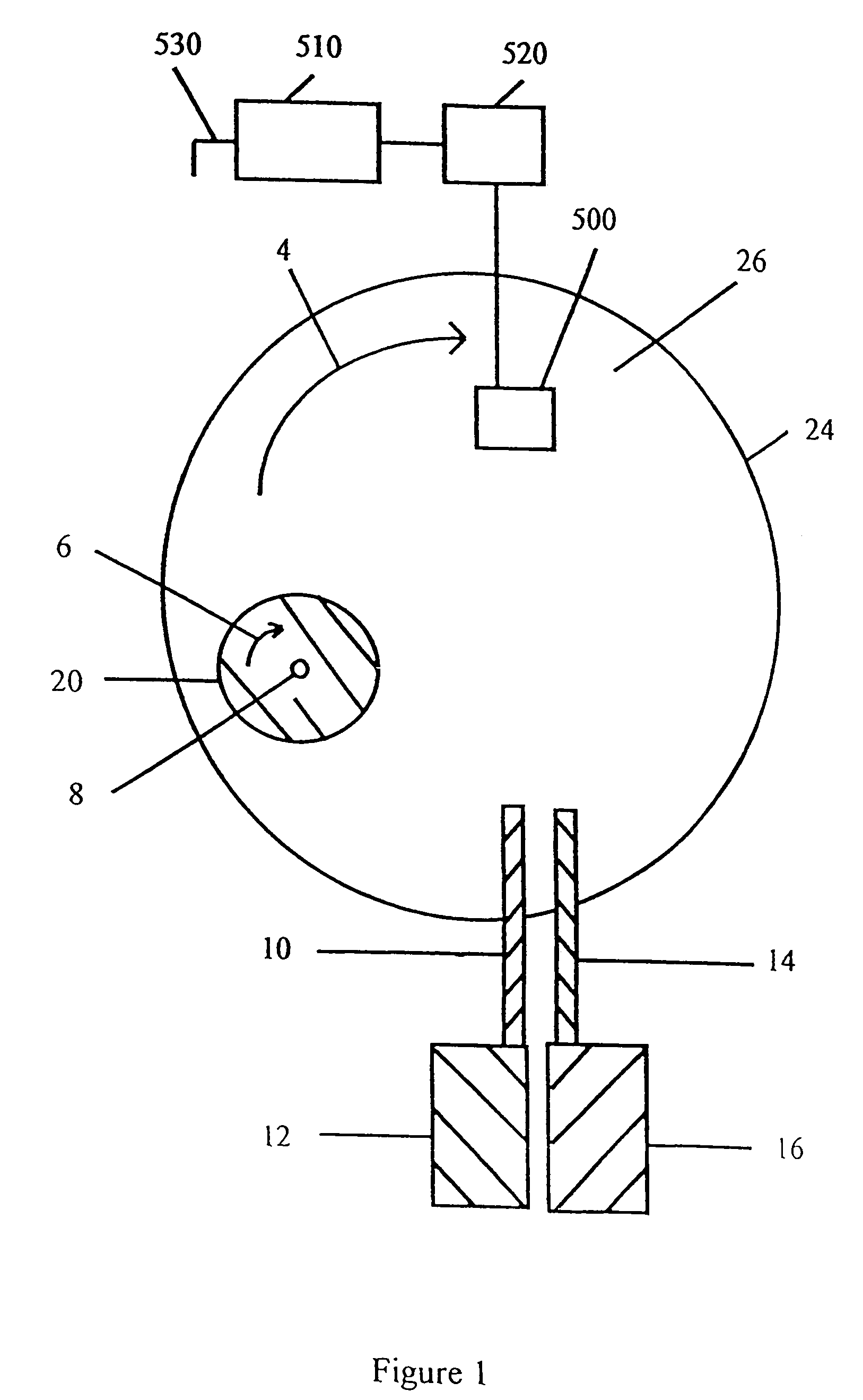

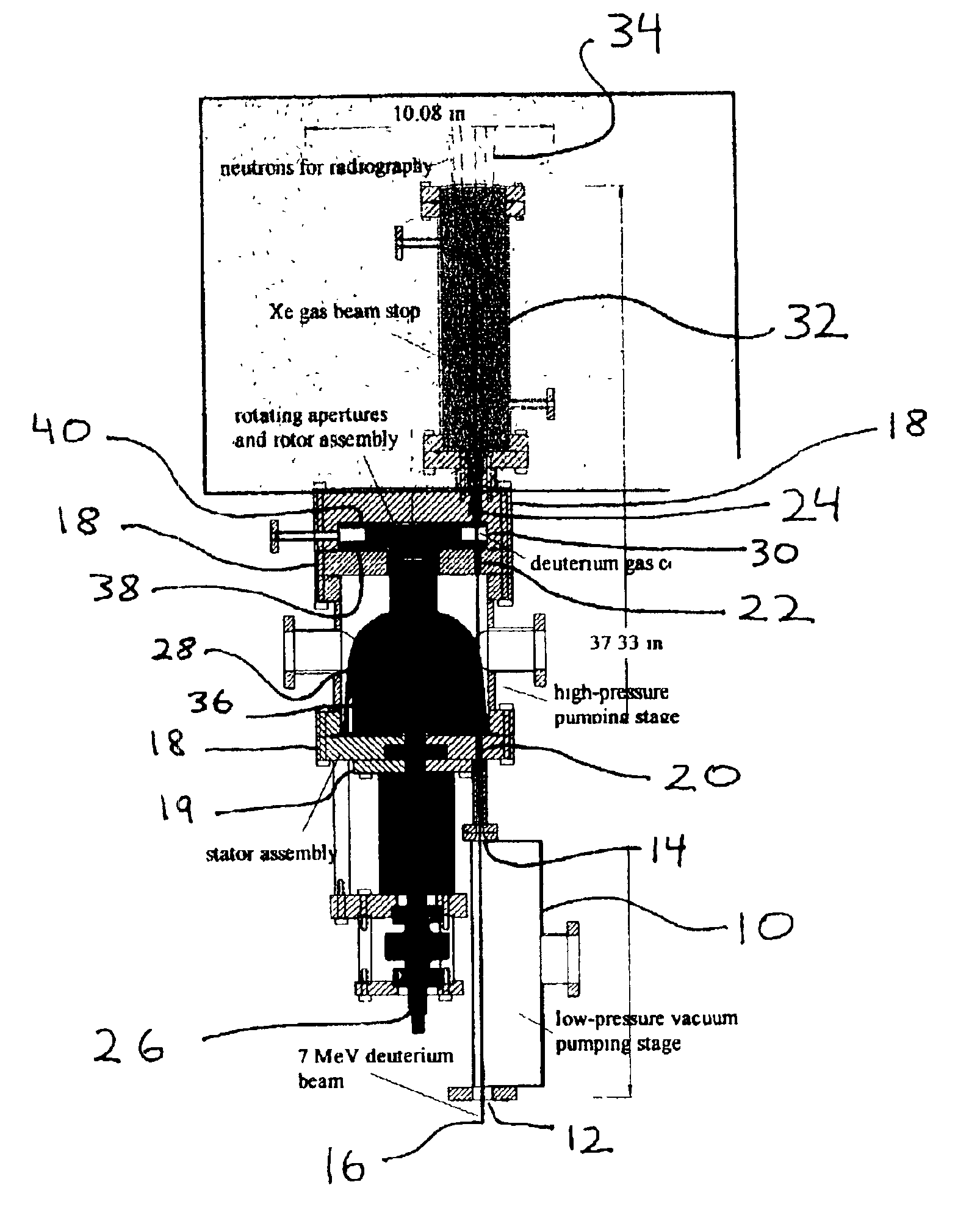

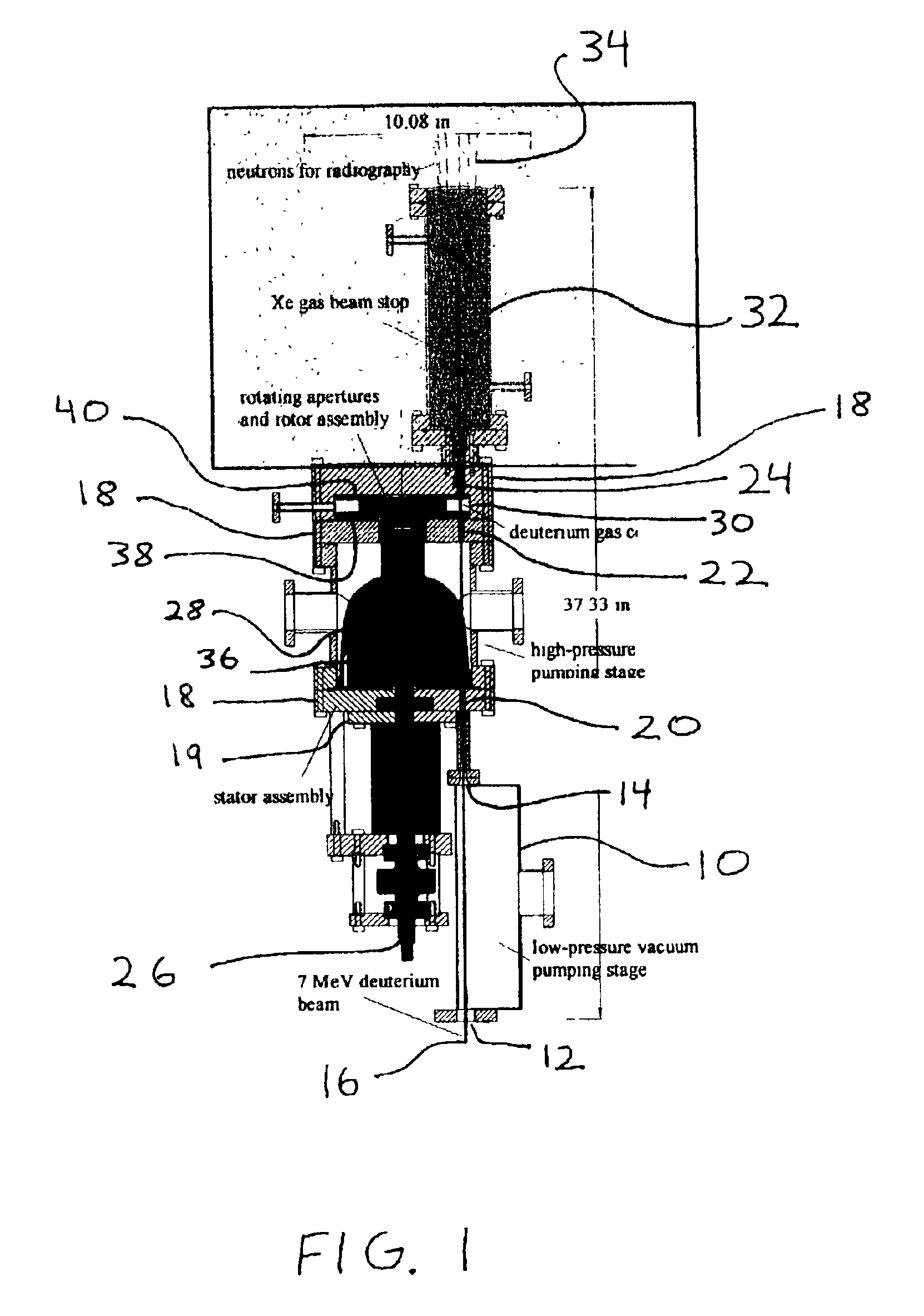

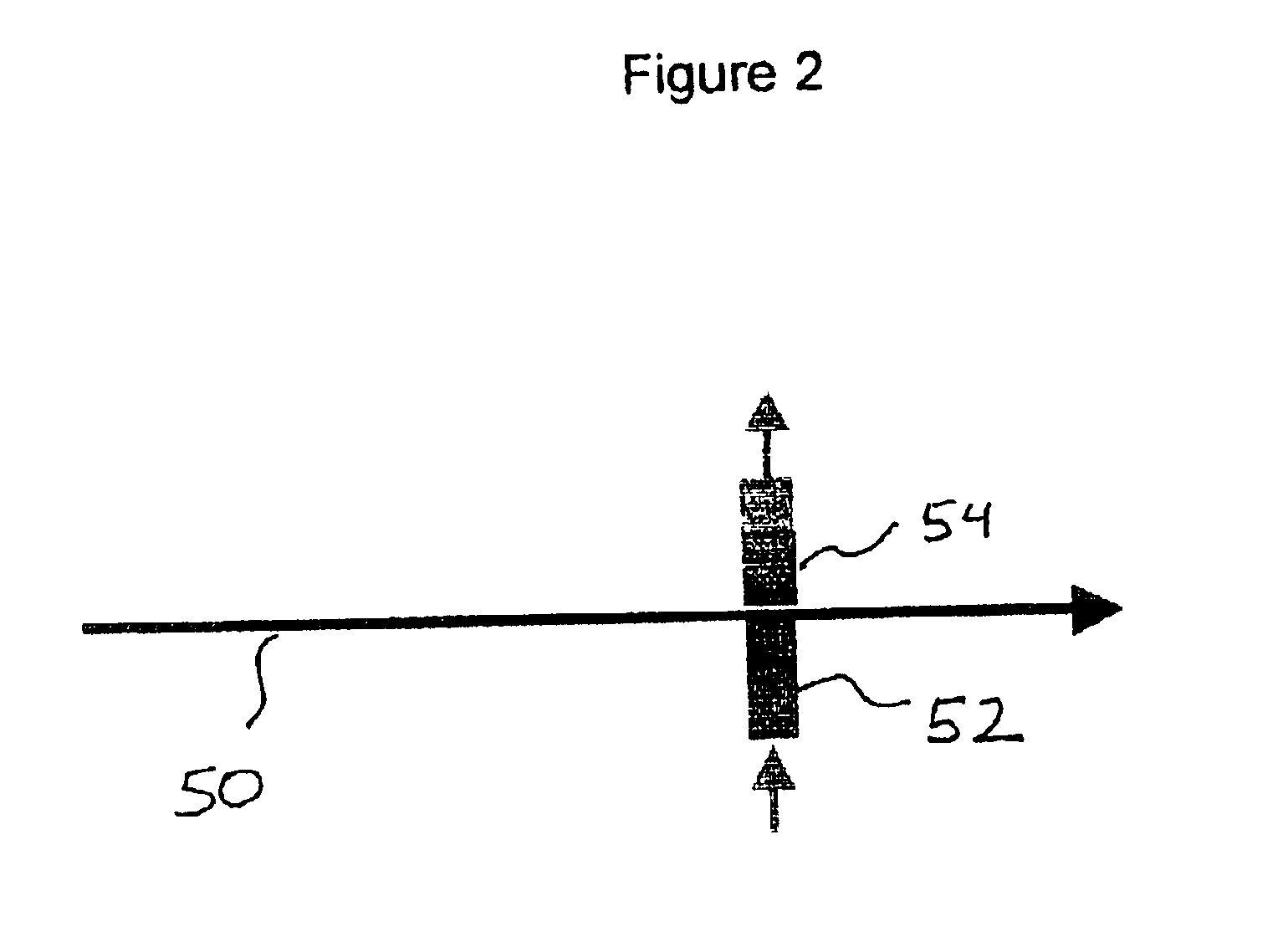

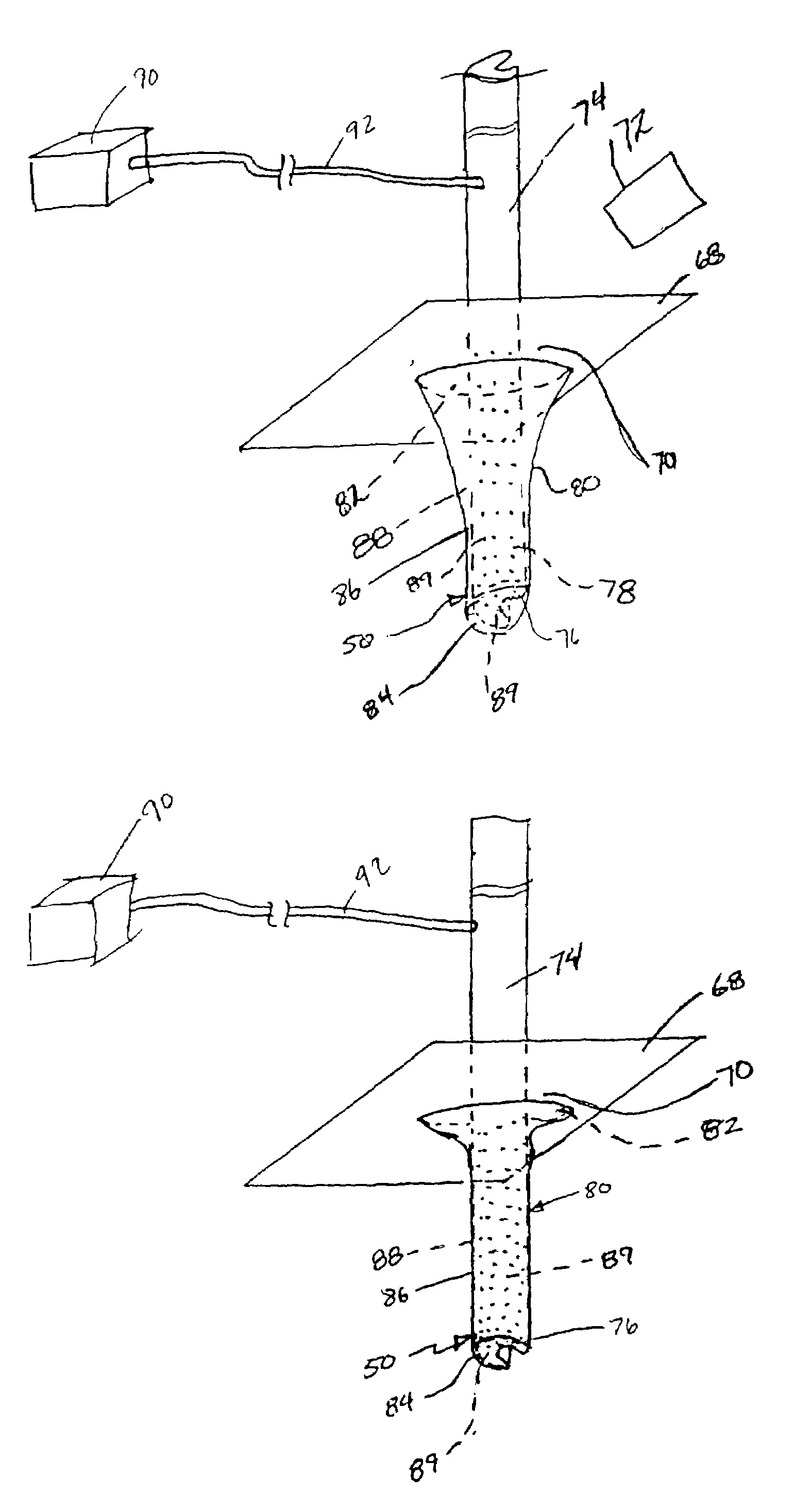

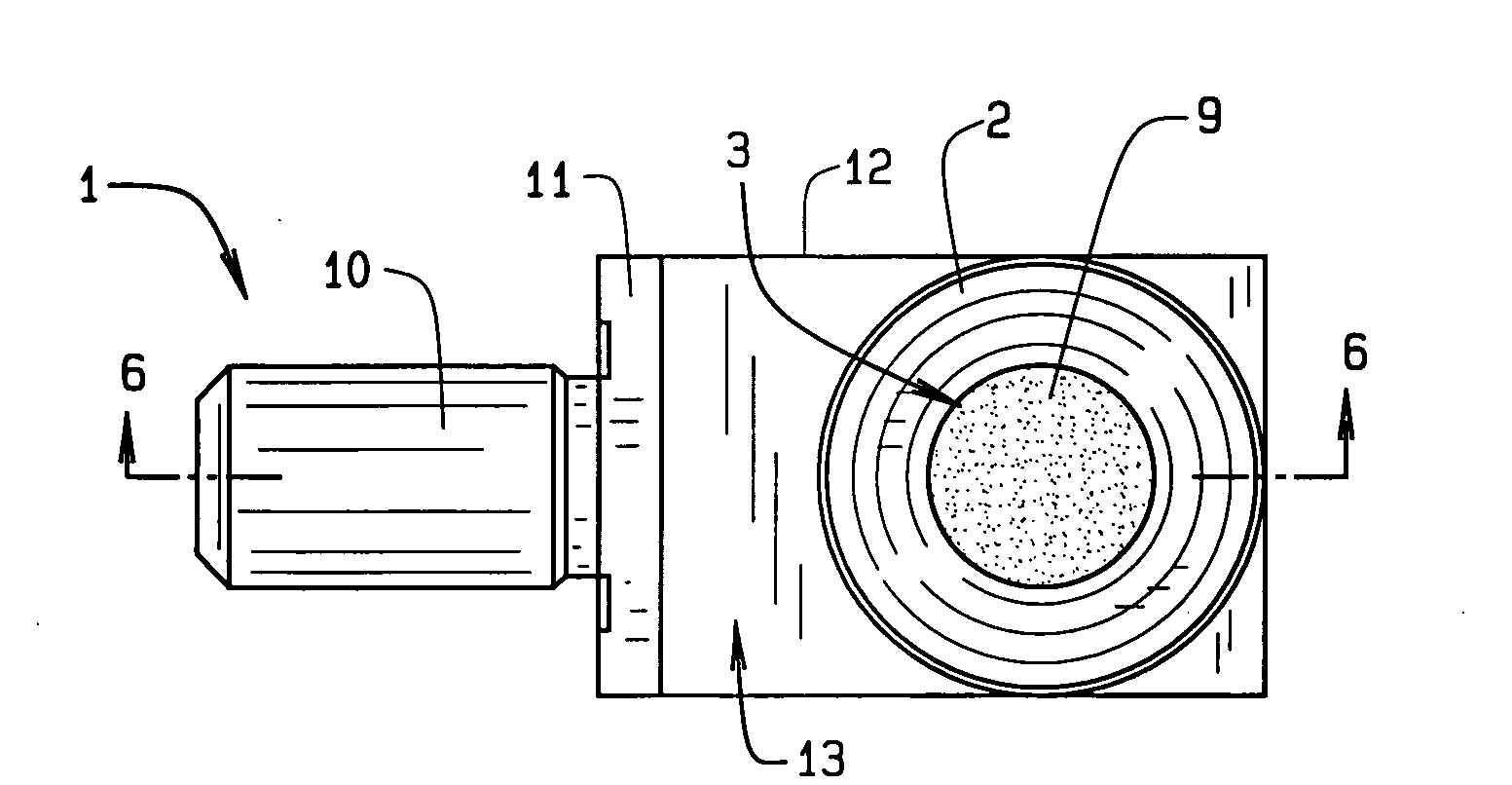

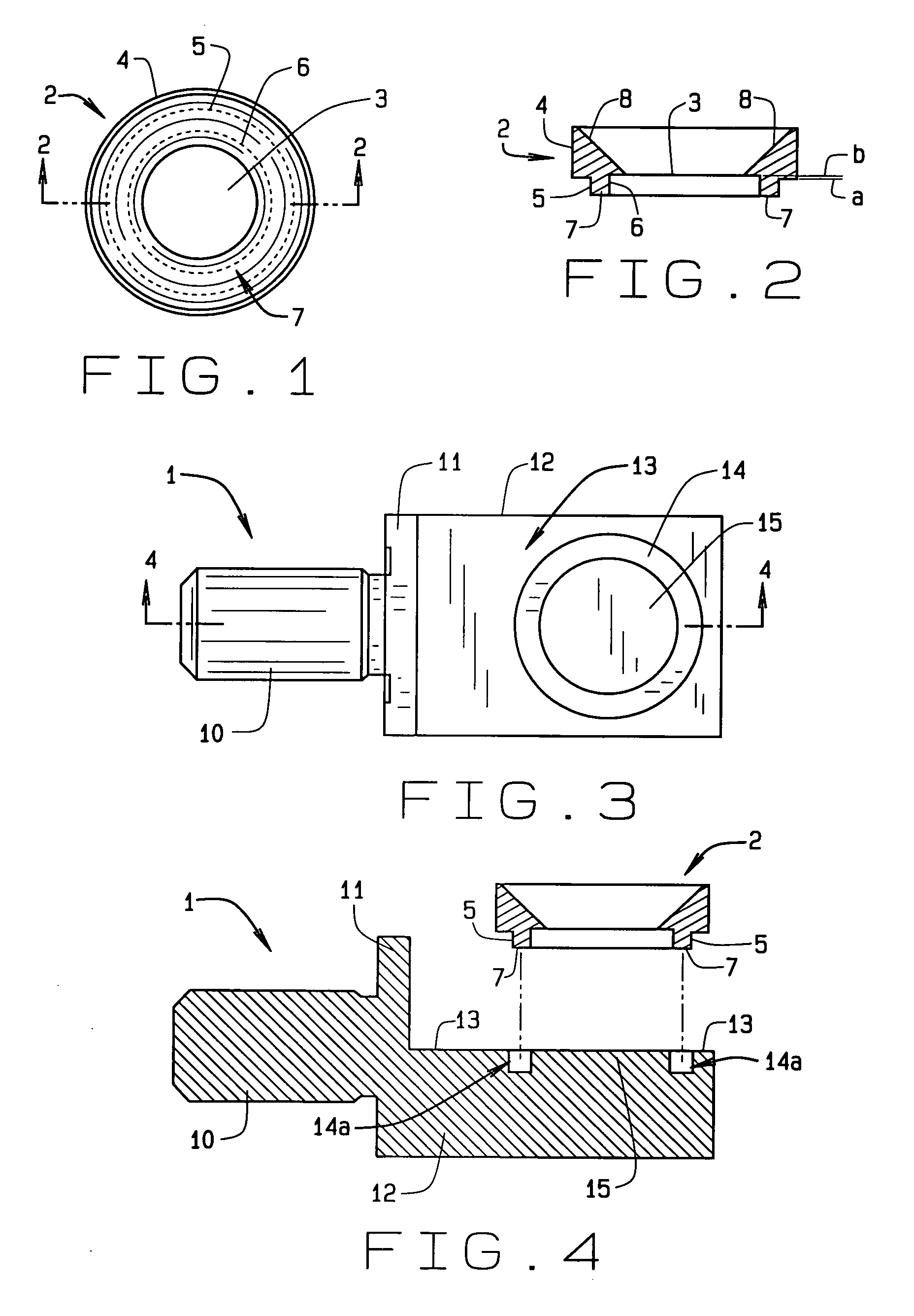

Rotating aperture system

InactiveUS6844561B1Improve and extend rangeEasy to operateLaser detailsElectrode and associated part arrangementsVacuum pumpingVacuum pump

A rotating aperture system includes a low-pressure vacuum pumping stage with apertures for passage of a deuterium beam. A stator assembly includes holes for passage of the beam. The rotor assembly includes a shaft connected to a deuterium gas cell or a crossflow venturi that has a single aperture on each side that together align with holes every rotation. The rotating apertures are synchronized with the firing of the deuterium beam such that the beam fires through a clear aperture and passes into the Xe gas beam stop. Portions of the rotor are lapped into the stator to improve the sealing surfaces, to prevent rapid escape of the deuterium gas from the gas cell.

Owner:THE UNITED STATES AS REPRESENTED BY THE DEPARTMENT OF ENERGY

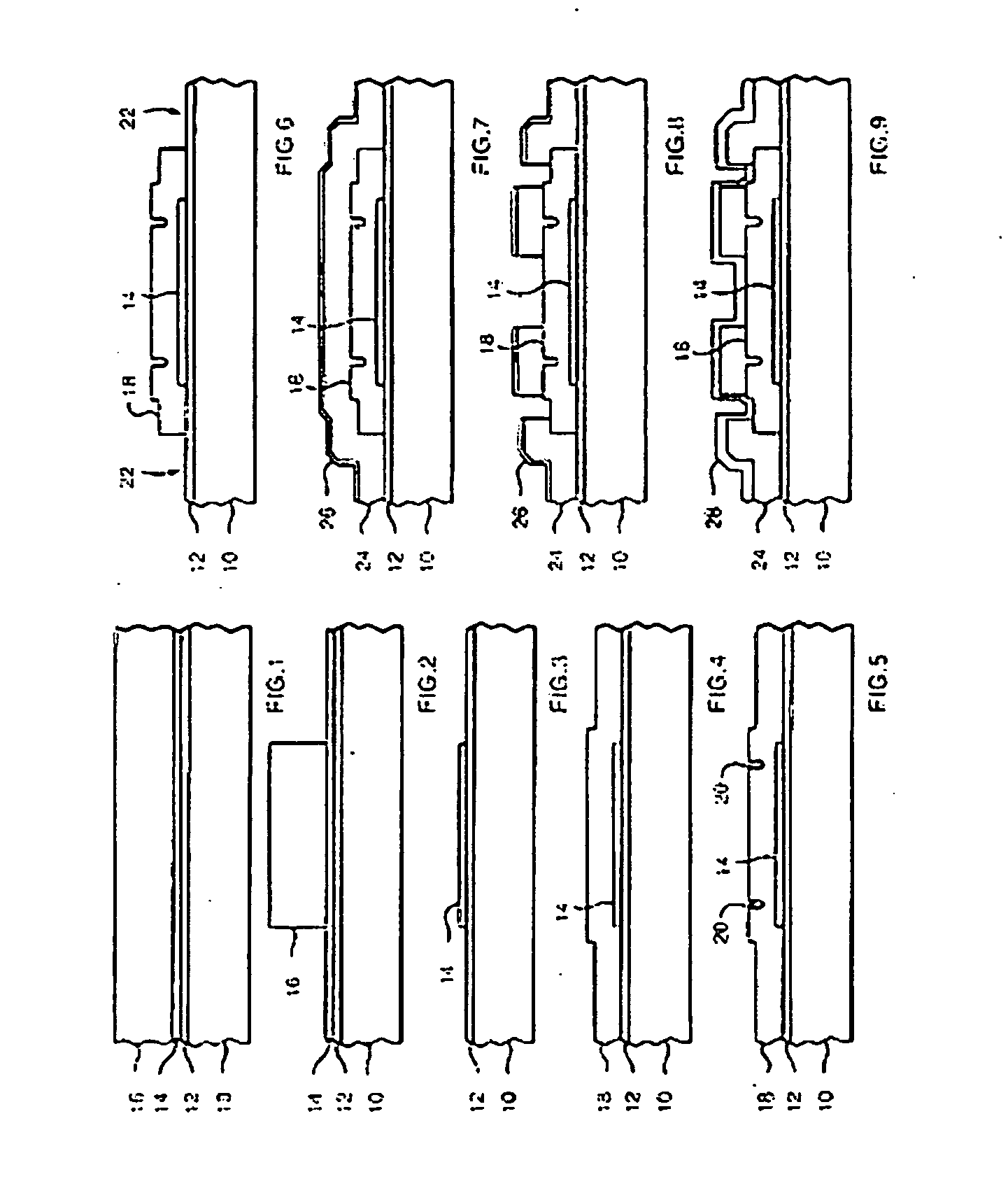

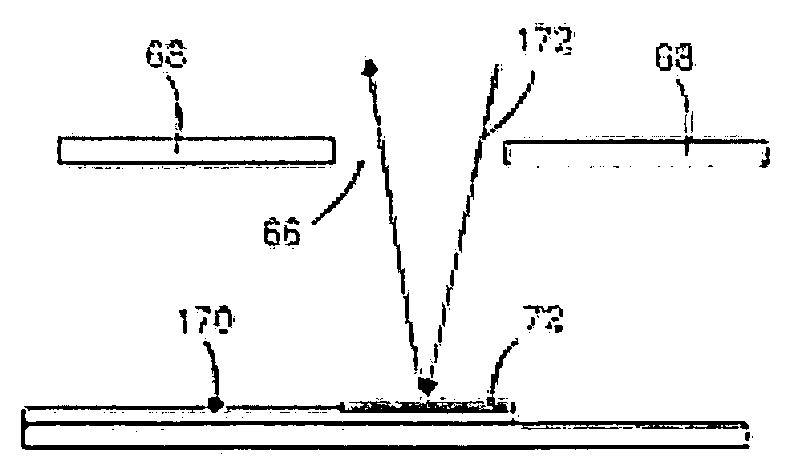

Methods for forming complex-shaped components in a heated polymeric film

InactiveUS7025923B2Close toleranceEnvelopes/bags making machineryLayered productsDistal portionEngineering

A thin-walled polymeric component that may have a selected complex shape, and a method of forming the component. The method includes heating a portion of a polymeric film to a selected malleable temperature, and forming a protrusion in the heated portion while it is malleable. The protrusion defines a protrusion having a first shape. The method also includes positioning a forming tool in the protrusion's interior and drawing a partial vacuum from within the protrusion so as to exert a force on the protrusion and move the protrusion's sidewalls inwardly into engagement with the forming tool. As the partial vacuum is drawn, the protrusion moves to a second shape that may be different than the first shape and that closely conforms to the selected shape of the forming tool. The protrusion is cooled below the malleable temperature and the forming tool is then removed. The distal portion of the protrusion having the selected shape forms the polymeric component, and that distal portion is separated from the remaining portion of the protrusion, thereby providing the thin-walled polymeric component.

Owner:COGENTIX MEDICAL

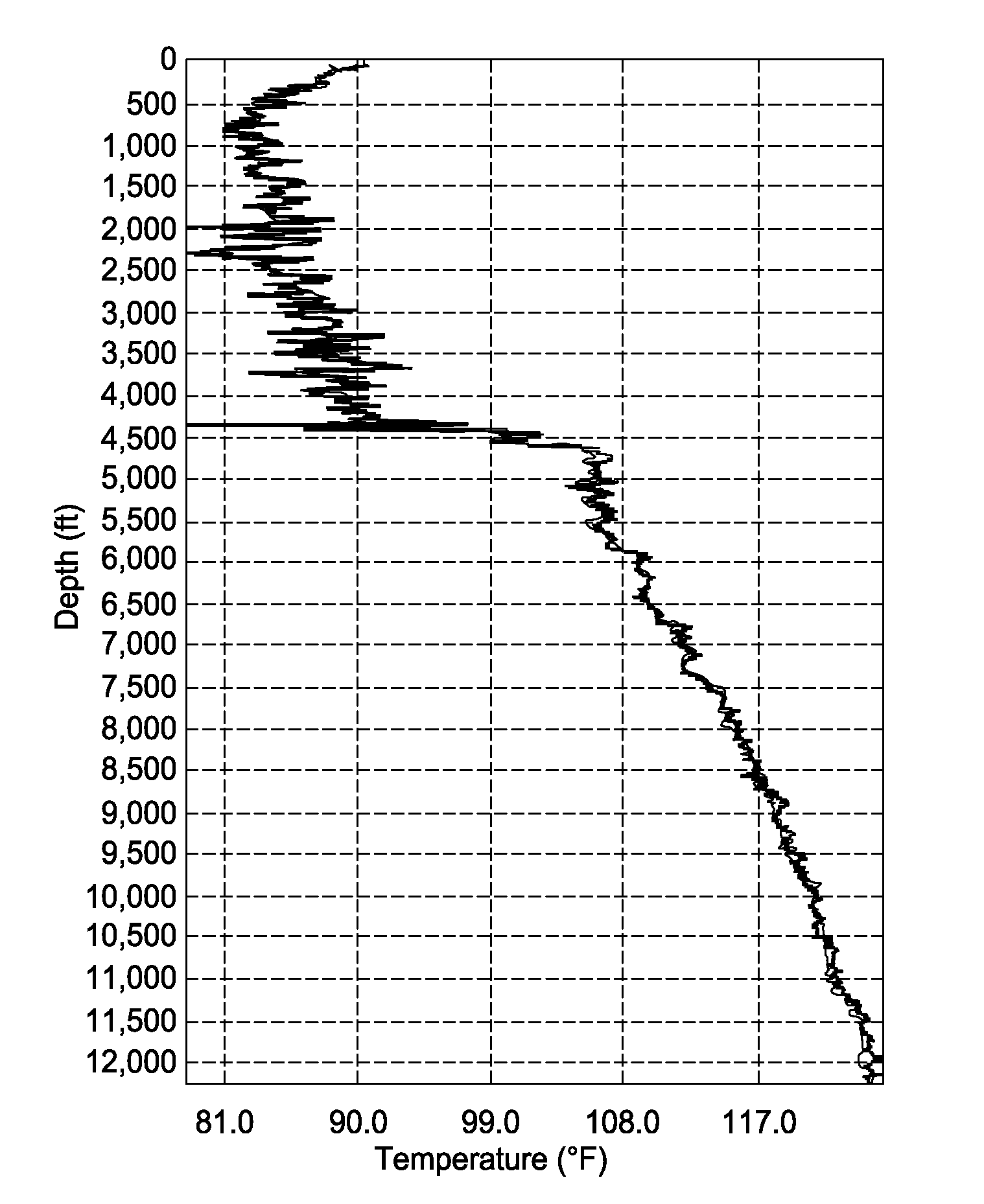

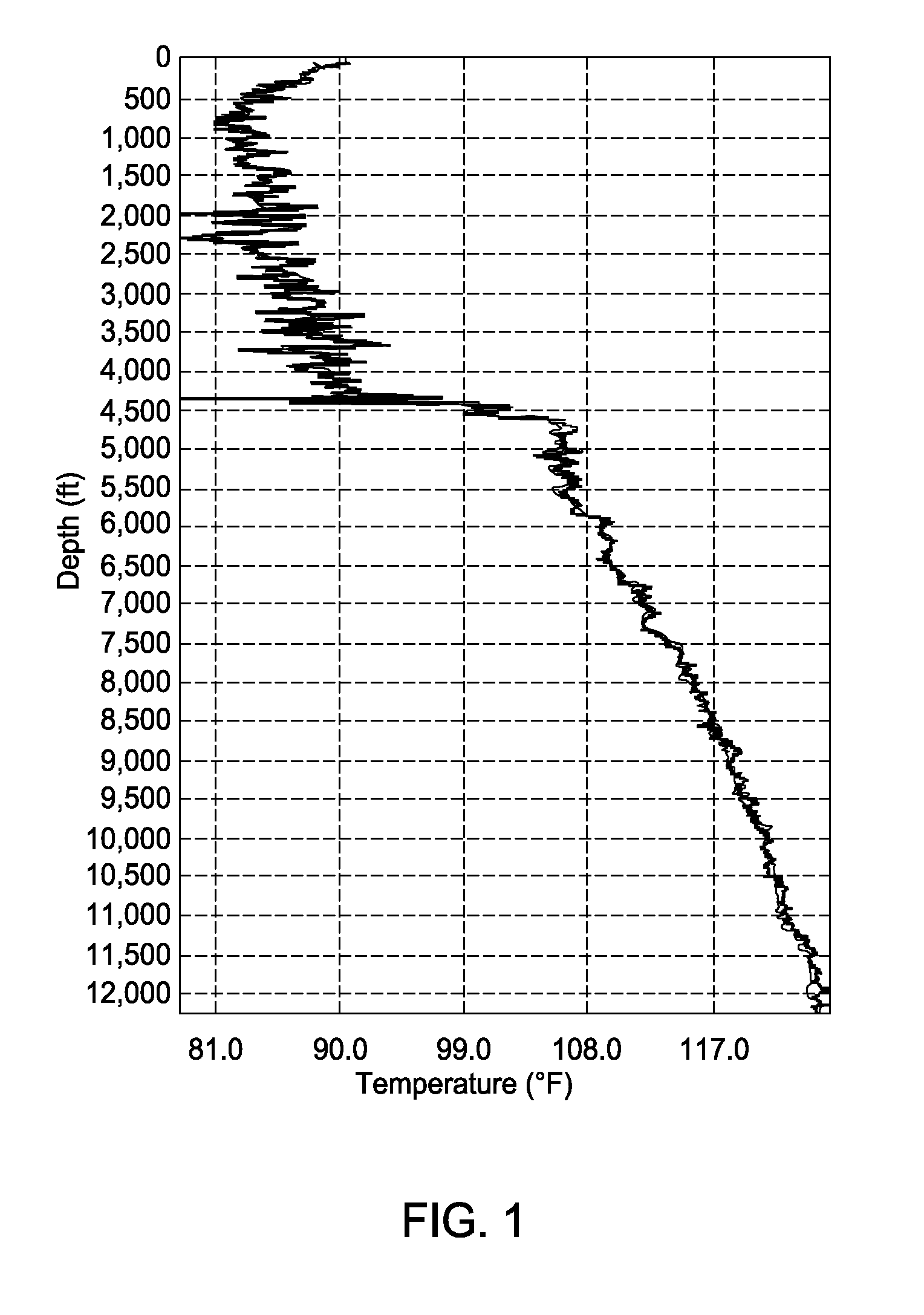

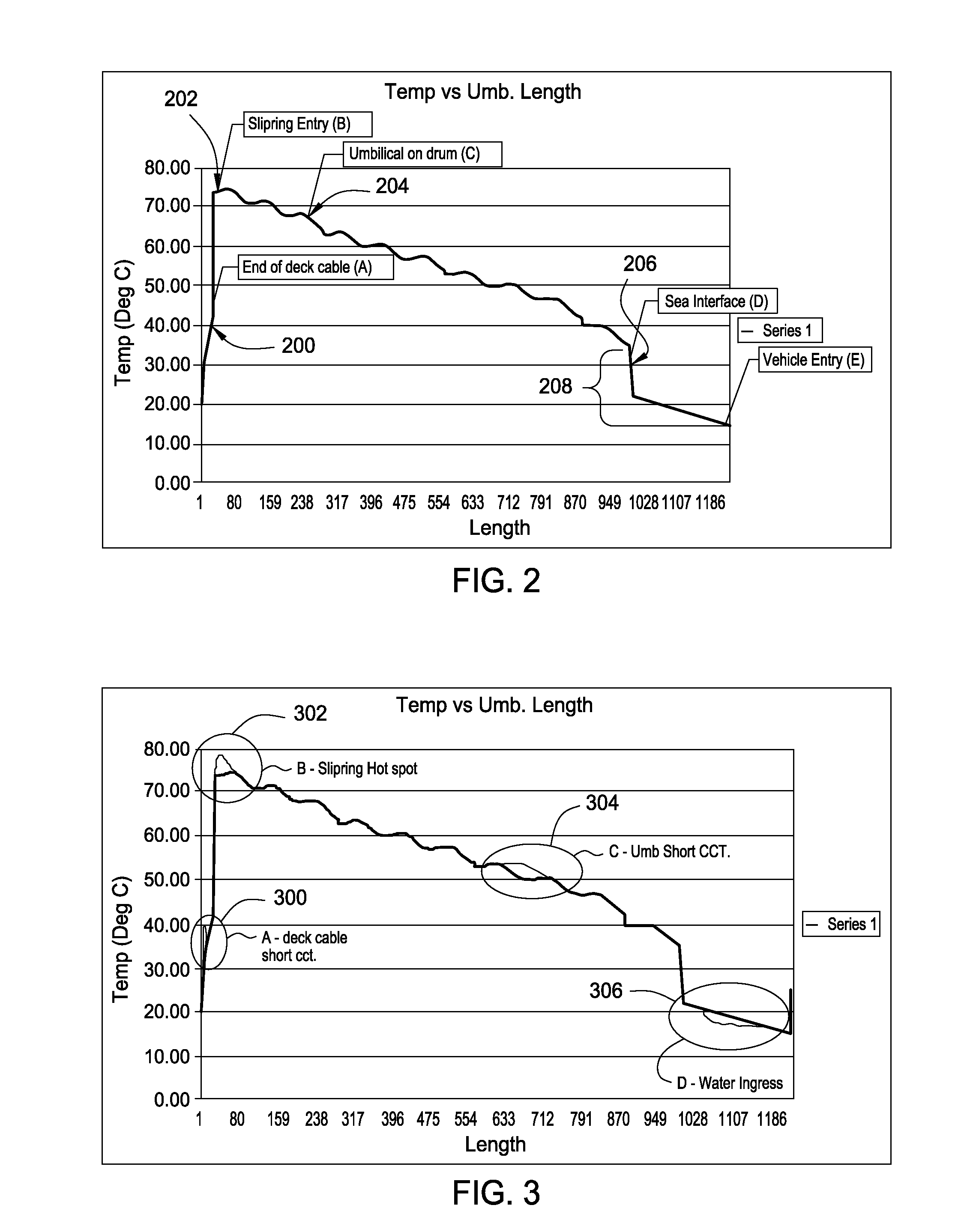

Distributed temperature sensing in a remotely operated vehicle umbilical fiber optic cable

ActiveUS20080110389A1CloserImprove power transmissionTowing/pushing equipmentThermometers using physical/chemical changesTemperature senseEngineering

Owner:WEATHERFORD TECH HLDG LLC

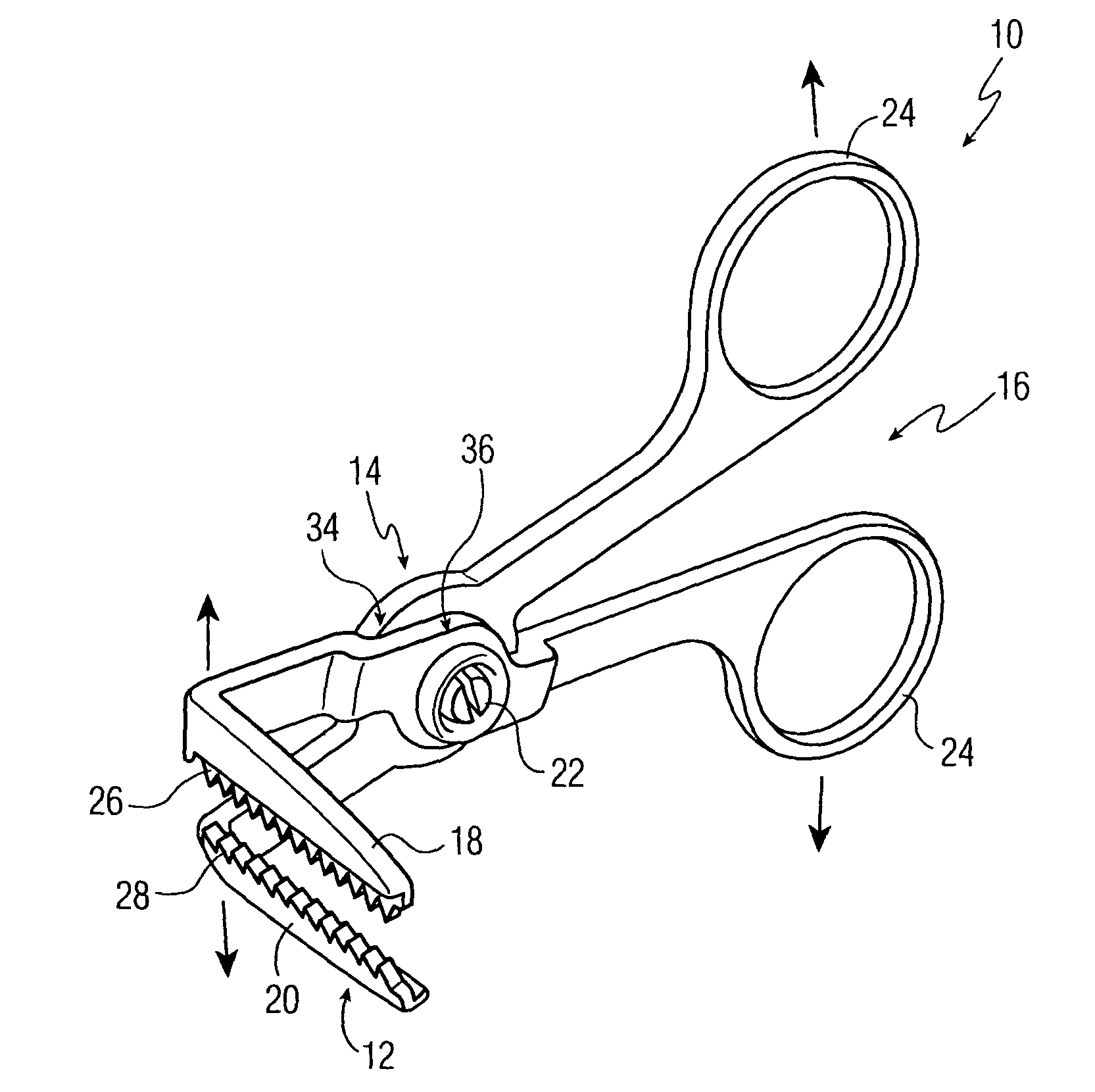

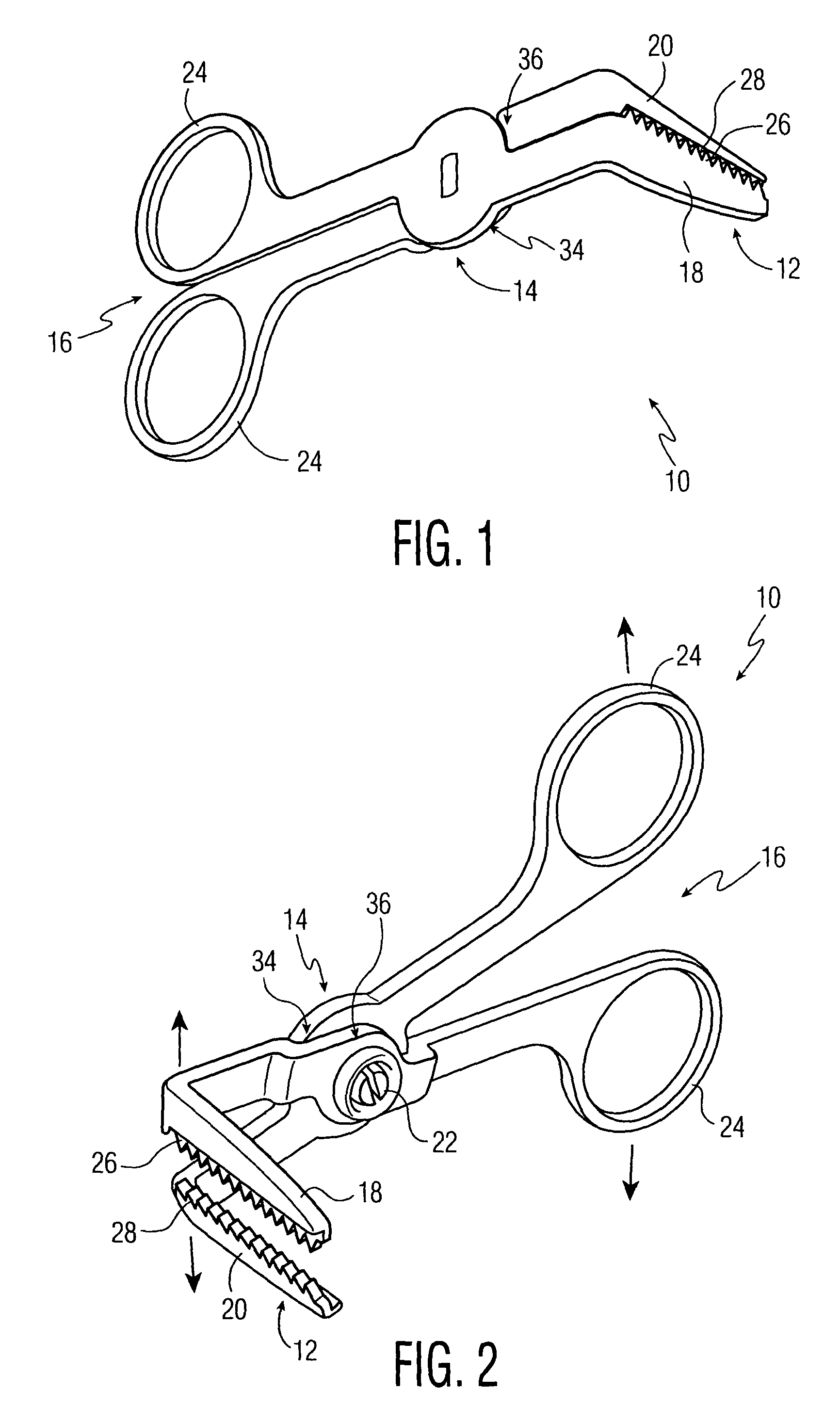

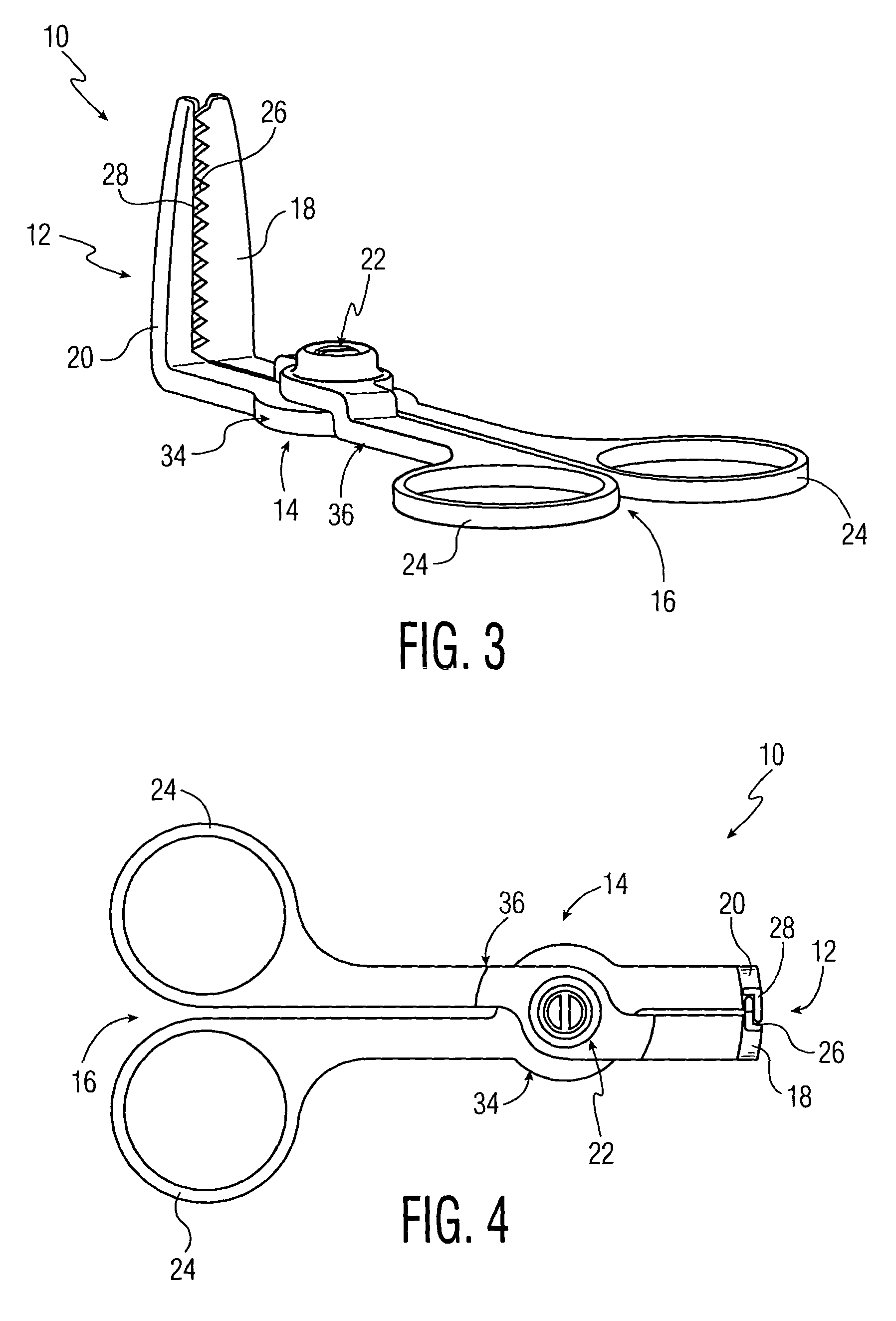

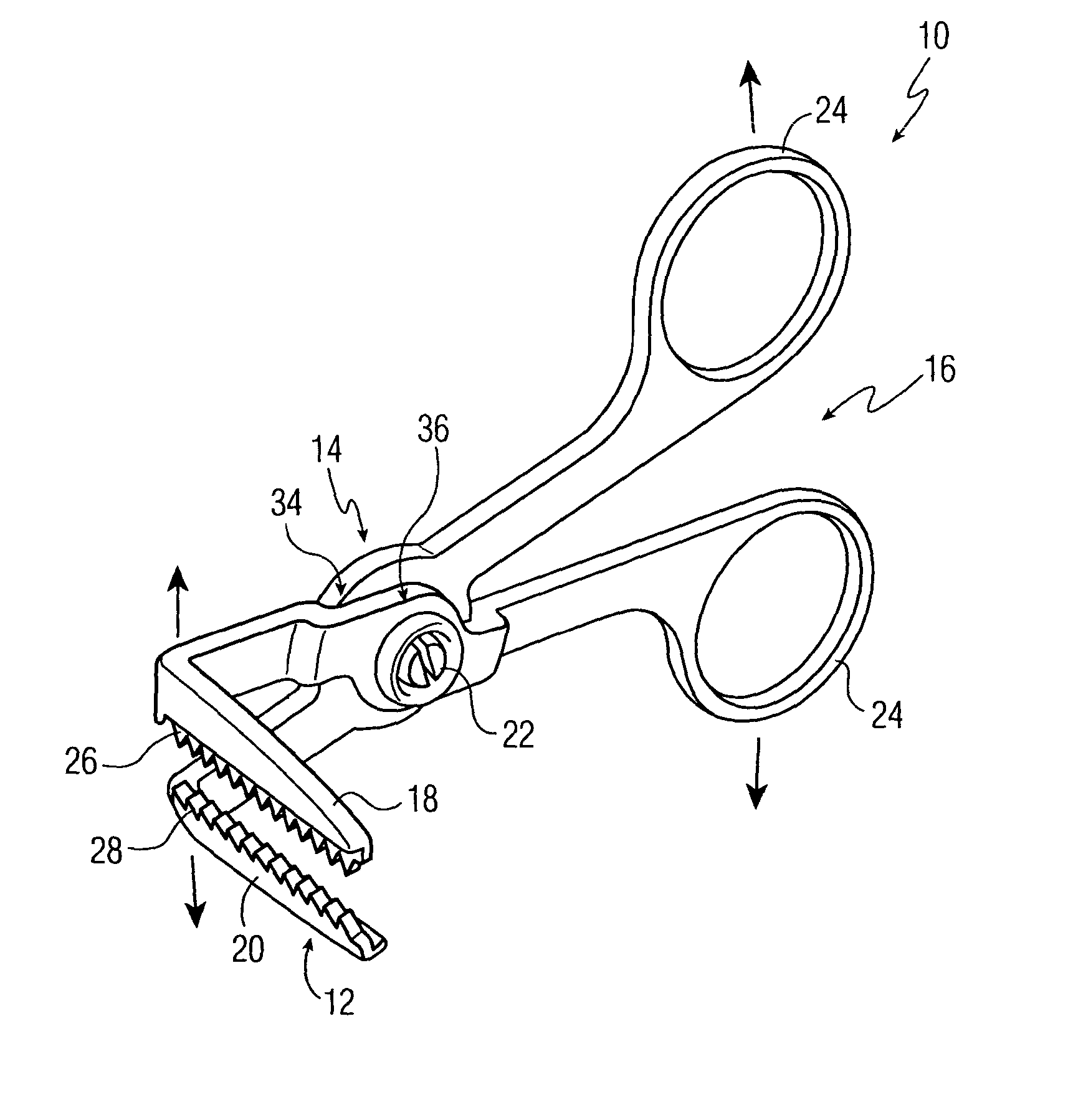

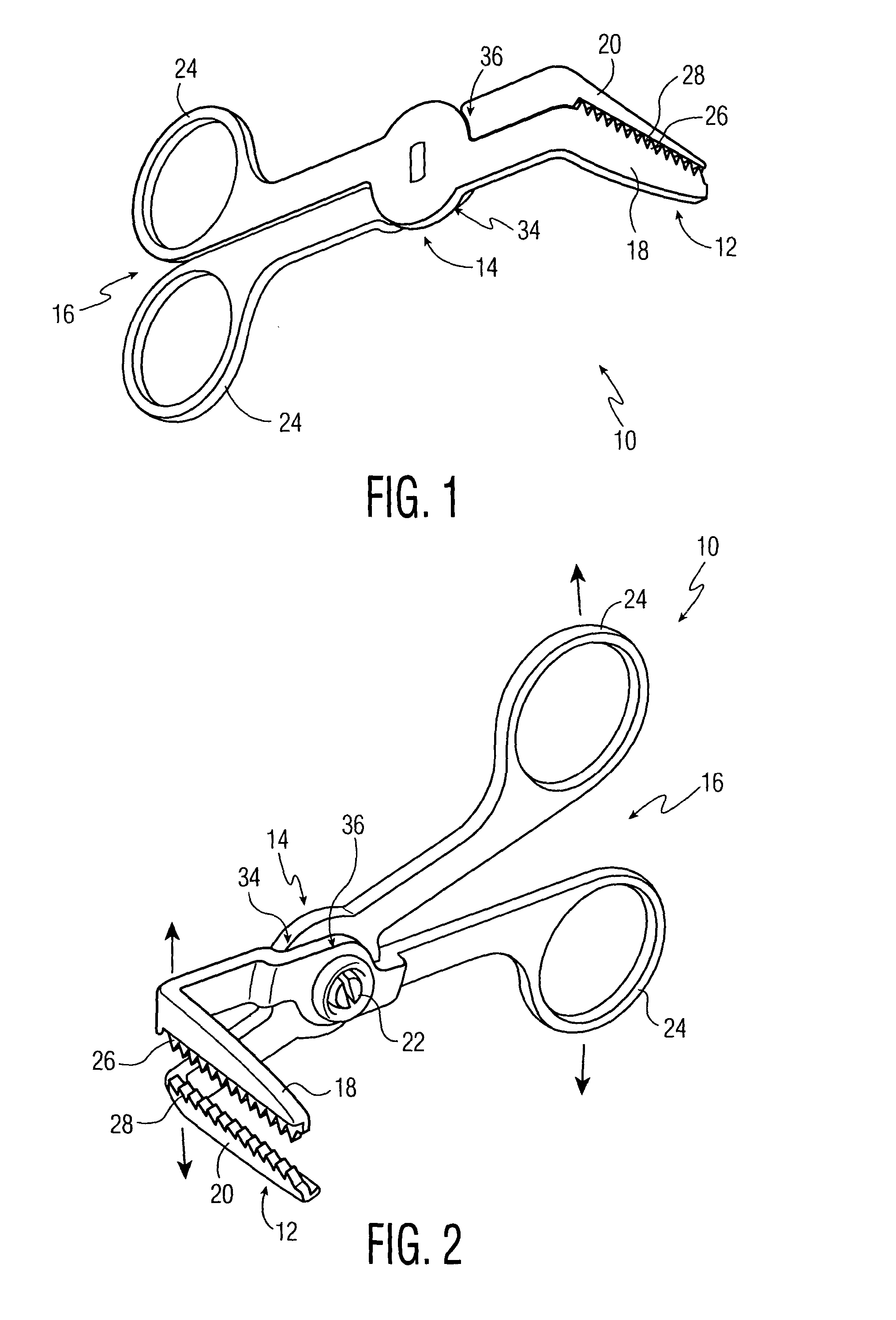

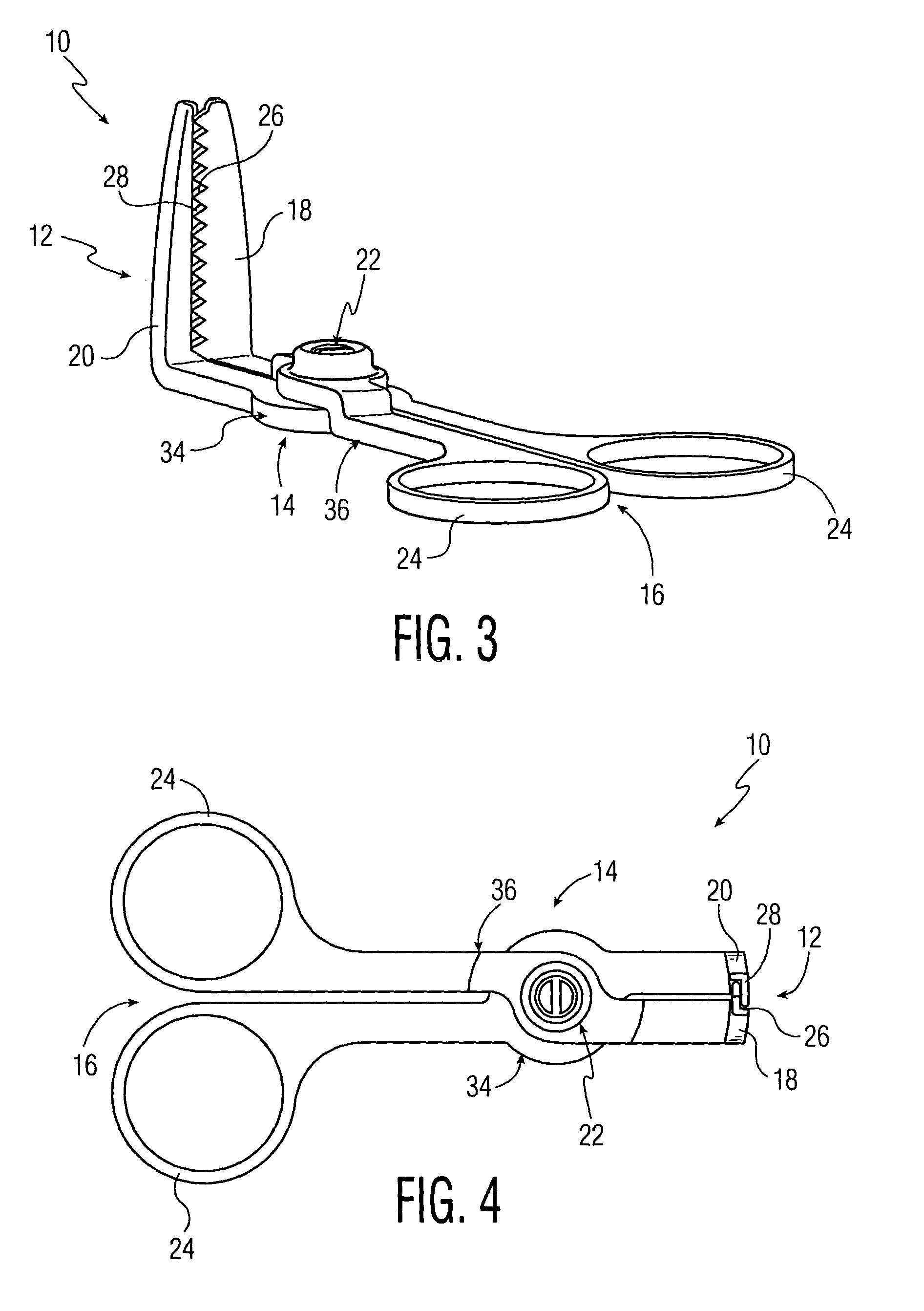

Lice and nit removal device

ActiveUS7117873B2Improved sifting removalThe process is simple and effectiveHair combsPackaging toiletriesEngineeringKnife blades

A device for removing lice and nits from affected hair and scalp of an individual, has first and second movable blades, the first blade including a plurality of first saw teeth, the second blade including a plurality of second saw teeth, and means for movably retaining the first and second blades parallel and adjacent to one another with their respective first and second teeth in opposition and parallel planes along their respective longitudinal axes, whereby the blades can be selectively moved toward one another to cause their teeth to mesh together with hairs captively held therebetween, the first and second teeth being configured to thereafter provide via combing a scraping action against the entrapped hairs for removing lice and nits therefrom.

Owner:AMERICAN COMB CORP

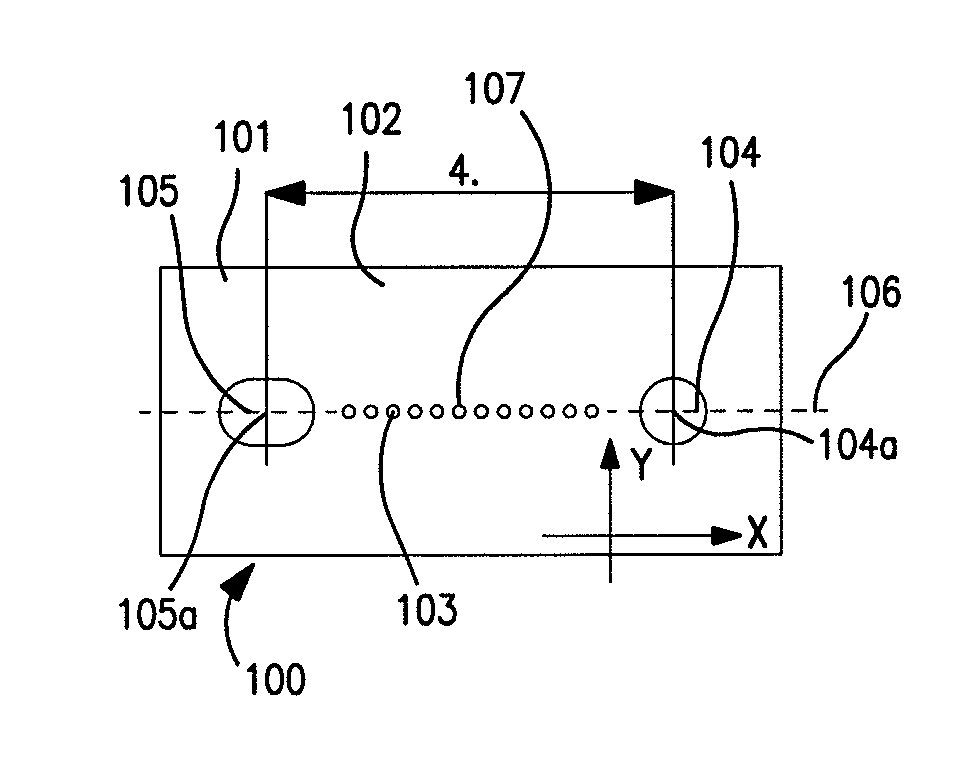

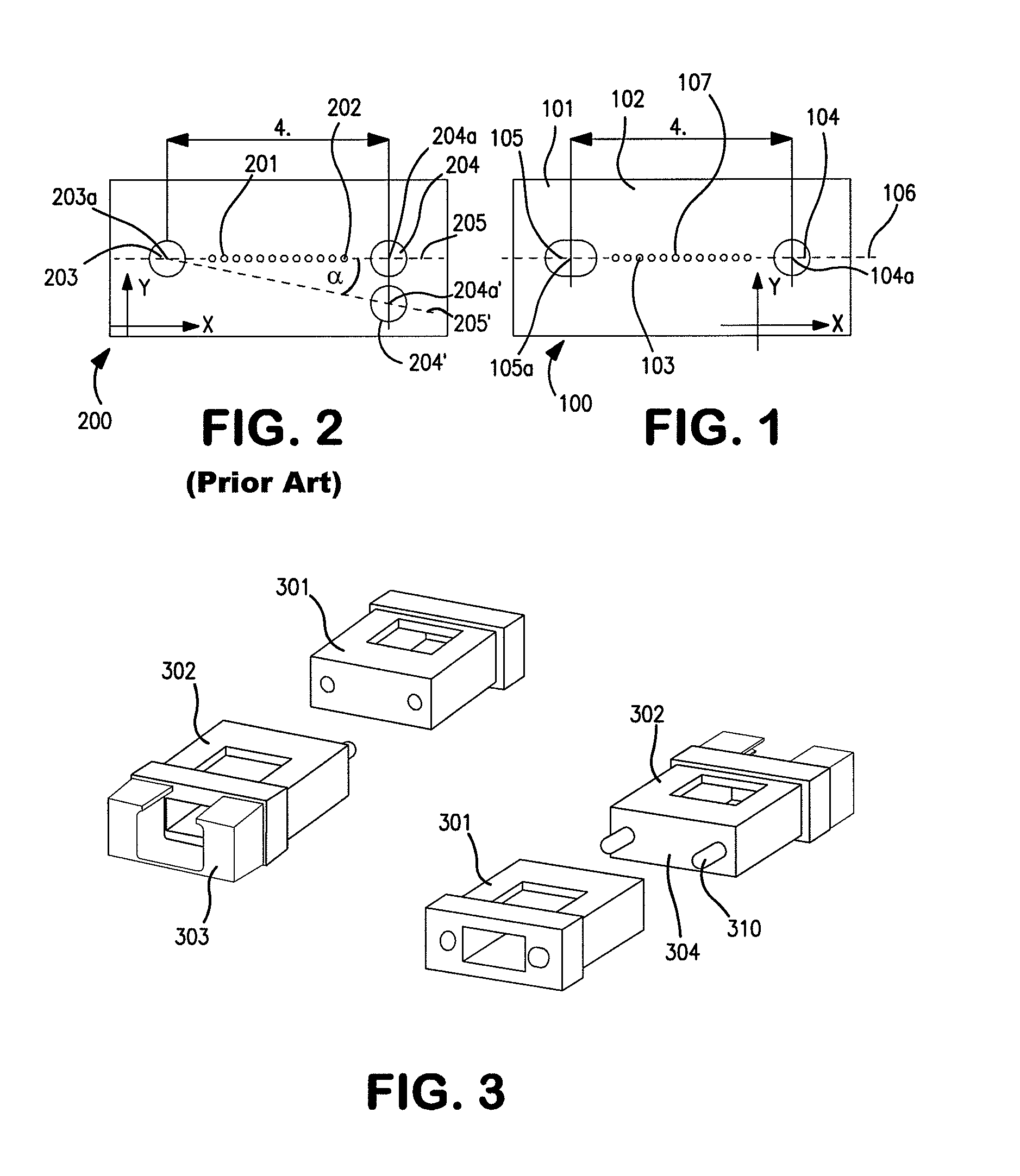

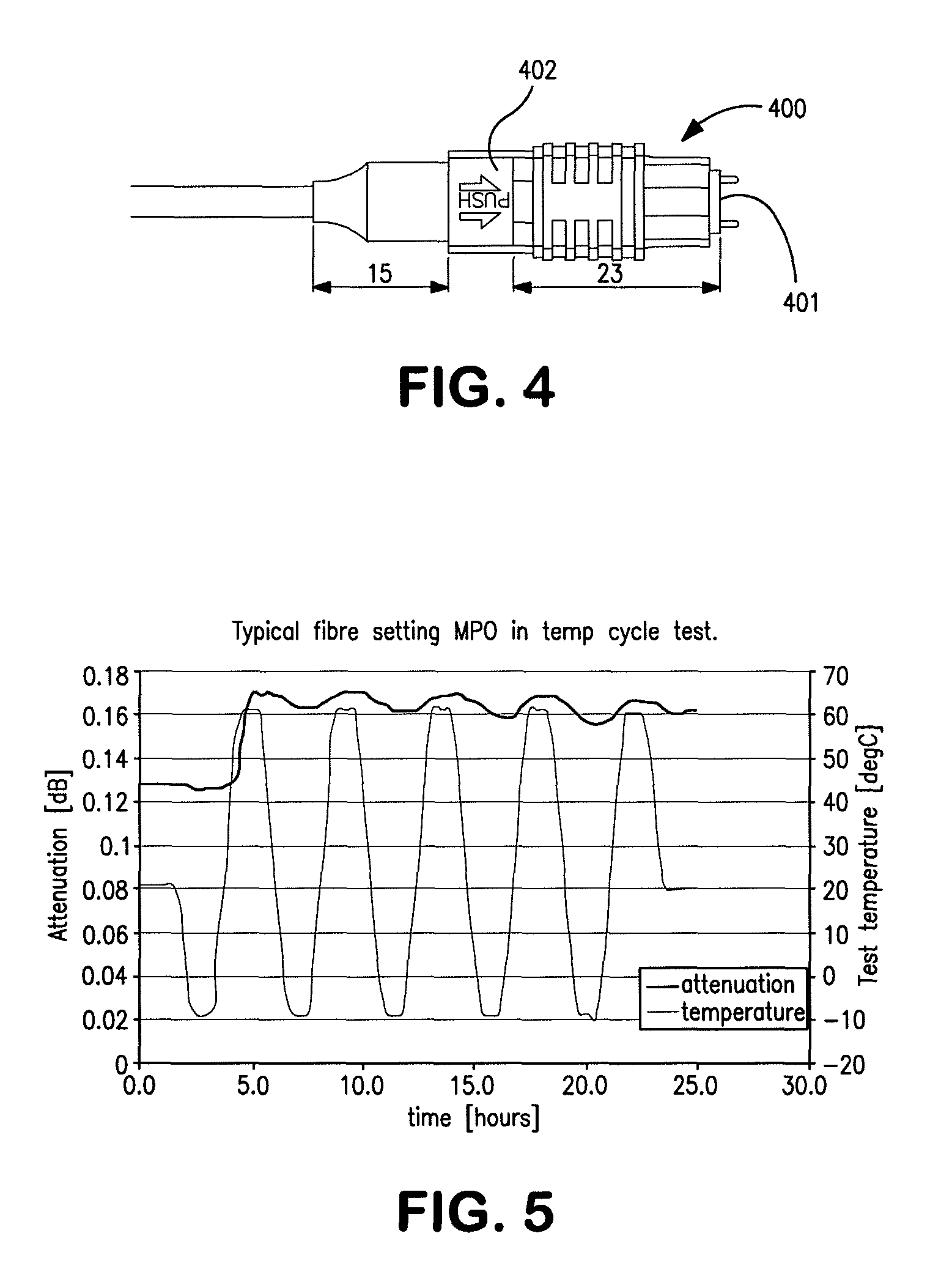

Ferrule with alignment pin channels

An optical ferrule comprising: (a) a body defining an end face; (b) one or more channels extending from said end face through said body, each channel adapted to receive an optical fiber; and (c) first and second alignment pin channels defined in said end face, each alignment pin channel having a center point, said center points being disposed along a first axis, said first alignment pin channel having a first cross section essentially the same as that of an alignment pin and being adapted to receive said alignment pin, said second alignment pin channel having a second cross section elongated along said first axis.

Owner:TE CONNECTIVITY NEDERLAND

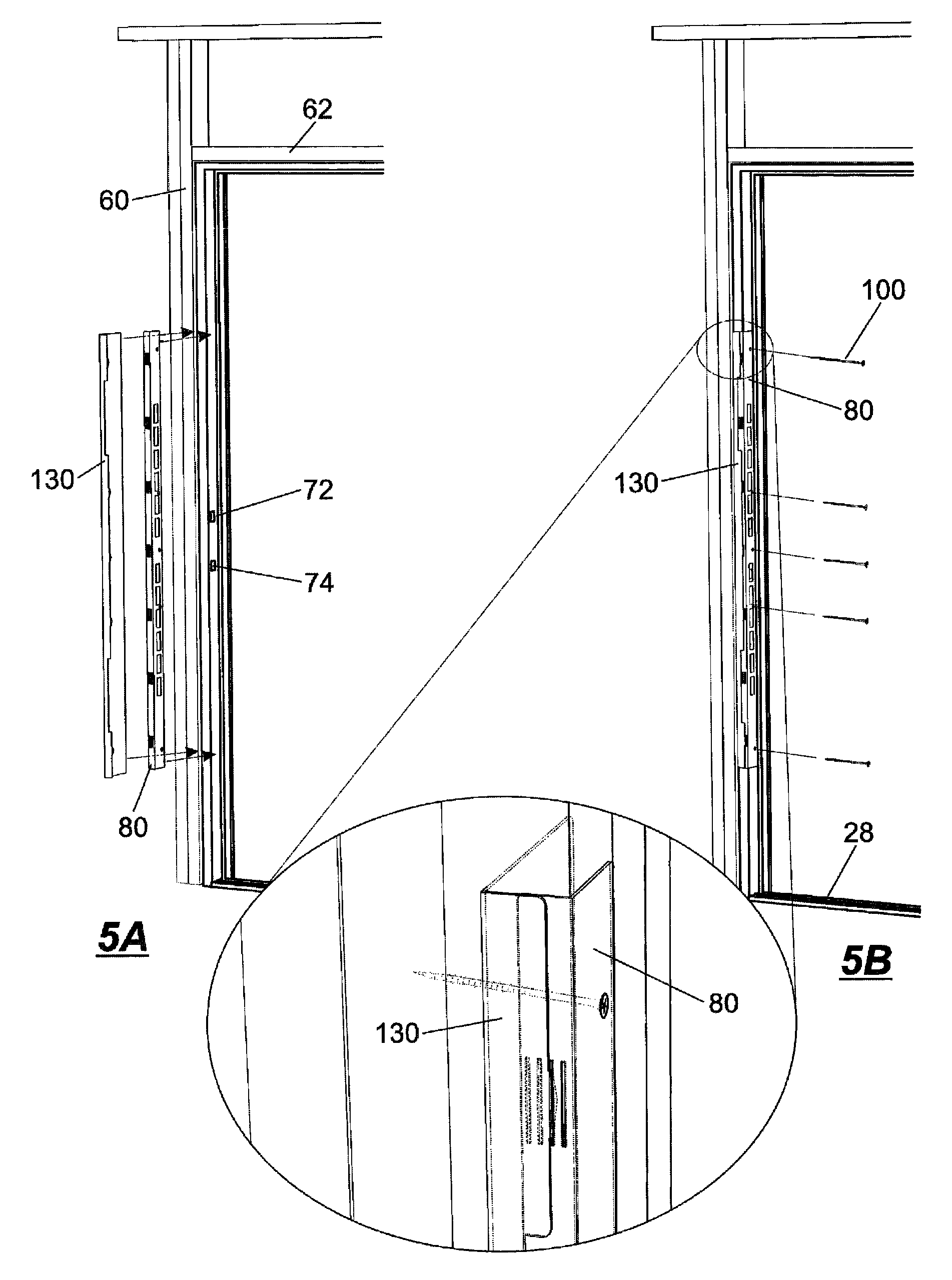

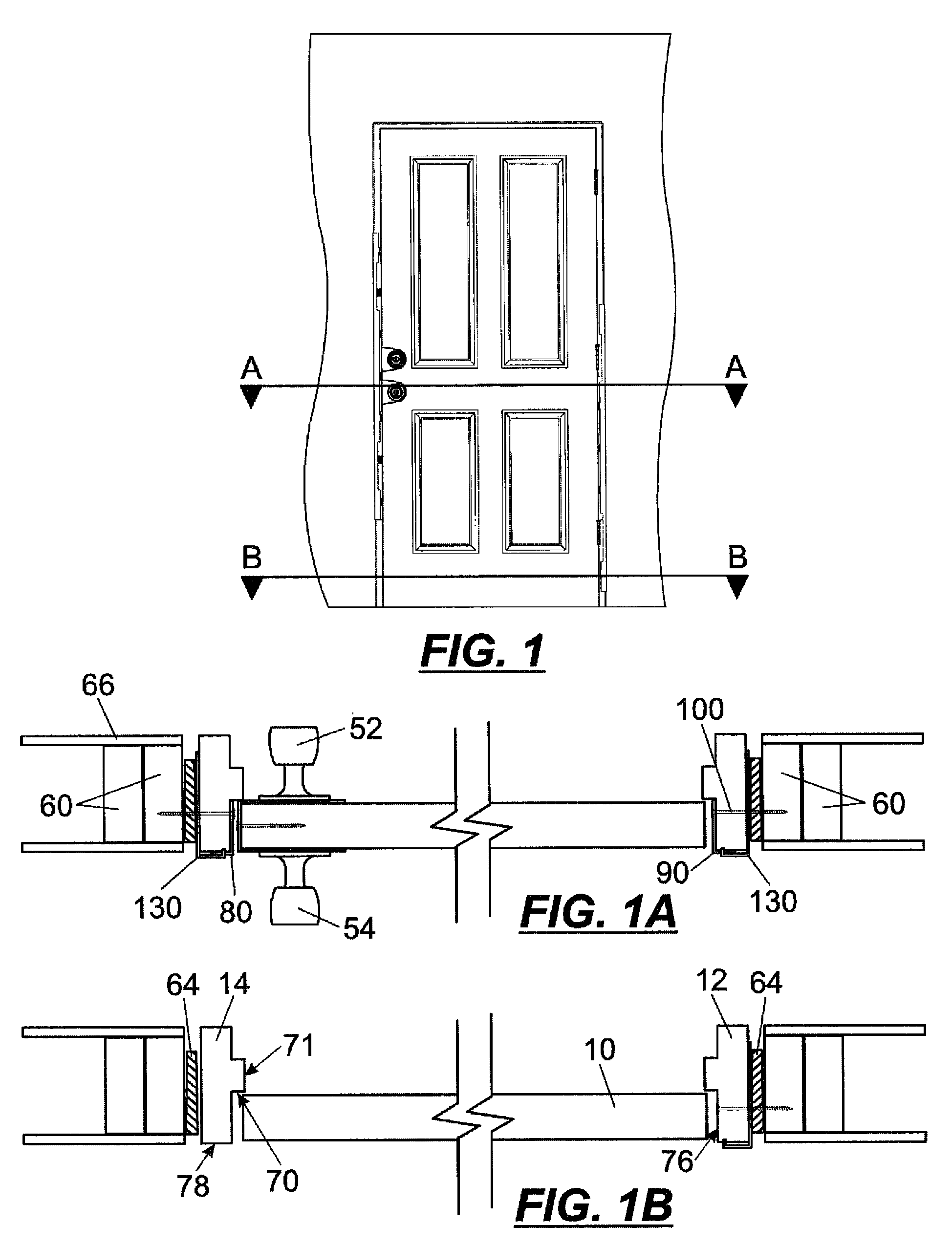

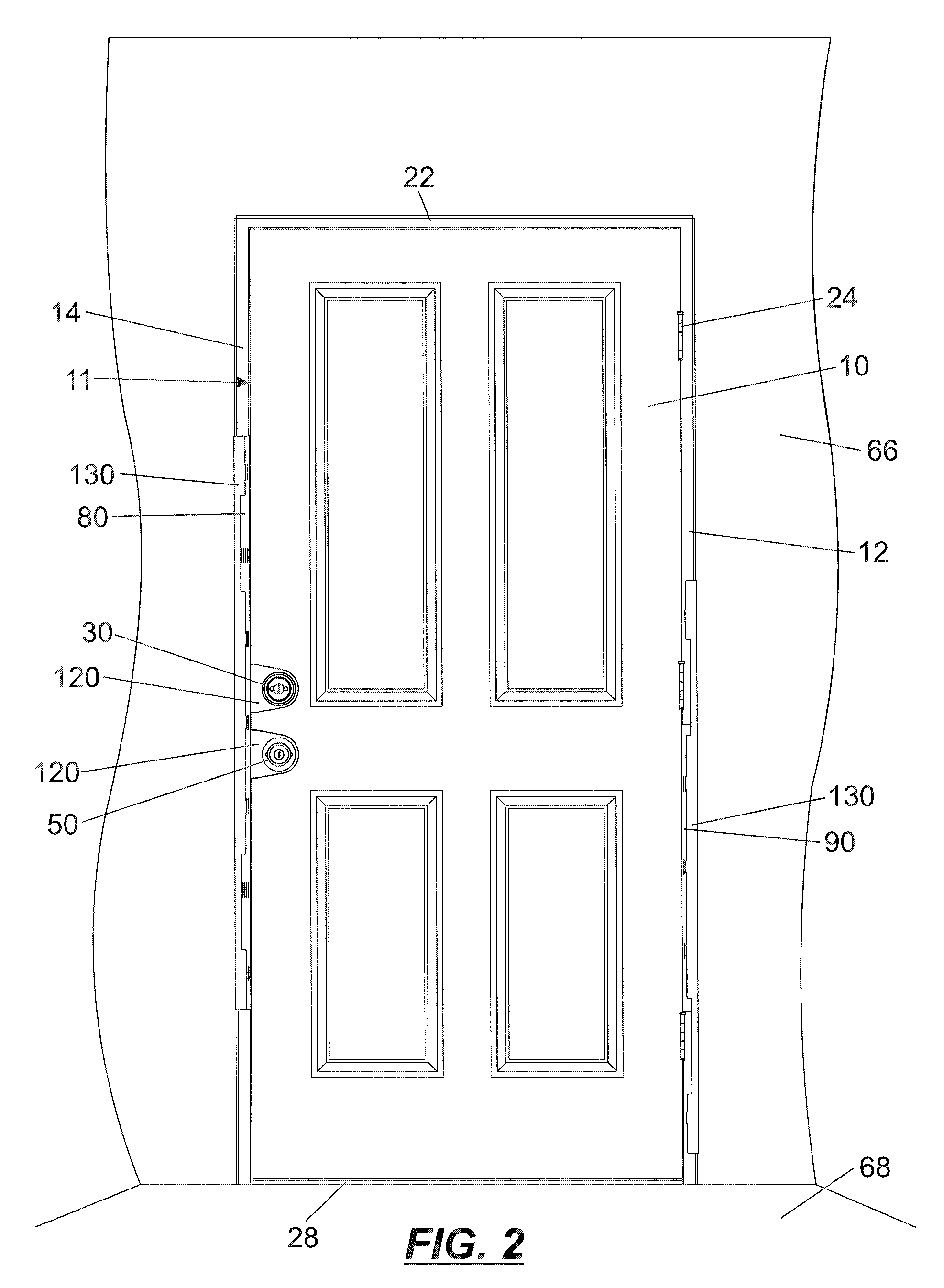

System and method for adjustable repair and reinforcement of non-standard doors and jambs

A door security system serves to substantially improve the reliability of the entire door assemblies with non-standard door jamb thicknesses. The system may comprise up to four or more components. An adjustable door jamb shield may be mounted around a door jamb on the side of the door jamb corresponding to the door slab free swinging edge. Another adjustable door jamb shield may also be mounted on a door jamb on the hinge side of the door jamb. The adjustable shields comprise attachable sleeves that wrap on three sides around the door jamb to reinforce and stabilize the door system.

Owner:ARMOR CONCEPTS

Polypropylene recloseable zipper

InactiveUS20020133919A1Cost advantage and flexibility in packaging size designSmall dimensionSlide fastenersBagsEngineeringPolypropylene

A polypropylene closure arrangement for flexible packages comprises a blend having a polypropylene random copolymer as a base resin with a flexible modifier, and a slip component. The polypropylene closure arrangement 10, 110 is sufficiently flexible to be extruded and coiled around guide wheels similar to the fusion process of a polyethylene closure arrangement. The polypropylene closure arrangement in accordance with the present invention has the ability to be fusibly attached to a polypropylene film or other fusibly compatible thermoplastic material launch conditions.

Owner:EATON INTELLIGENT POWER LIMITED

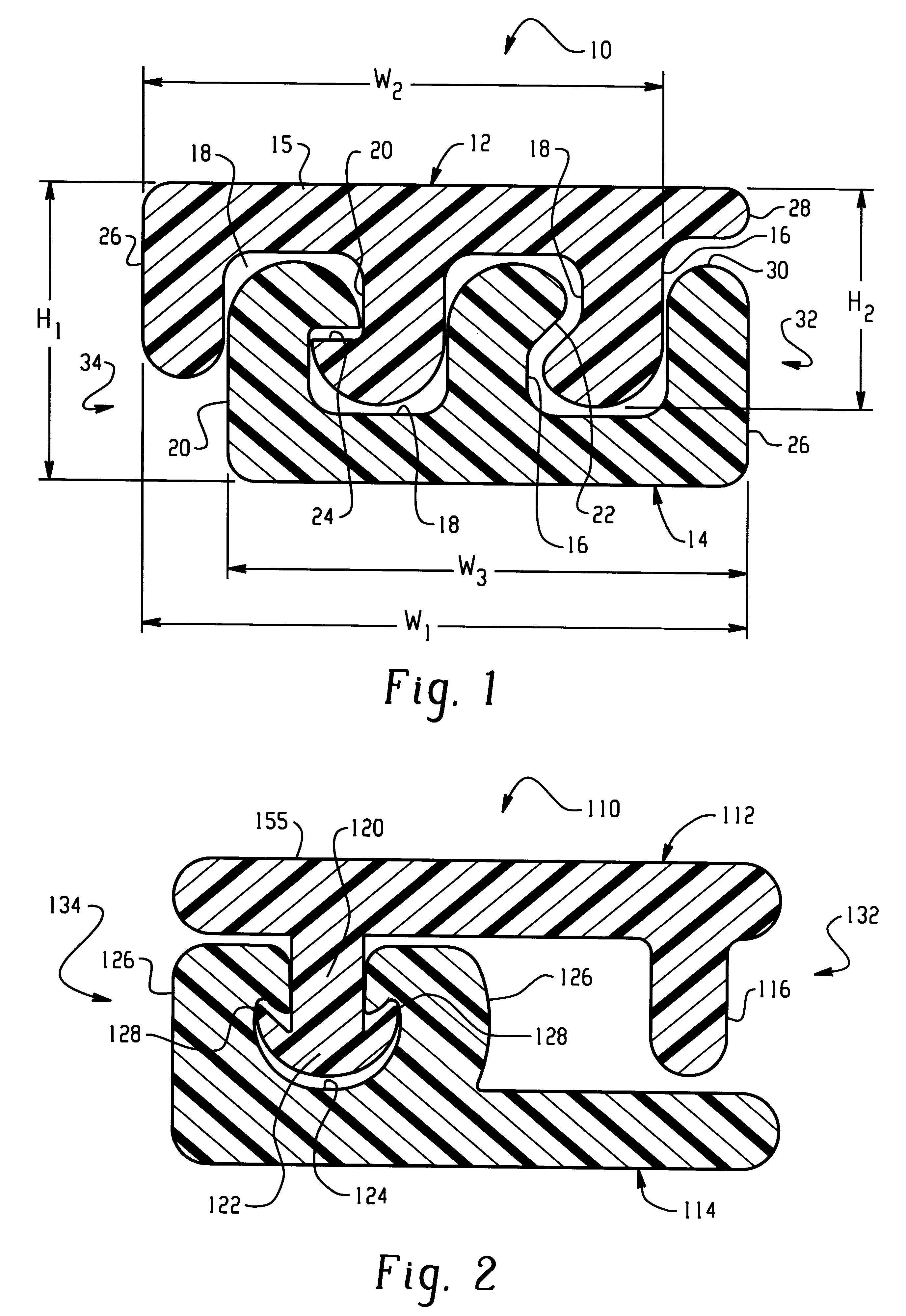

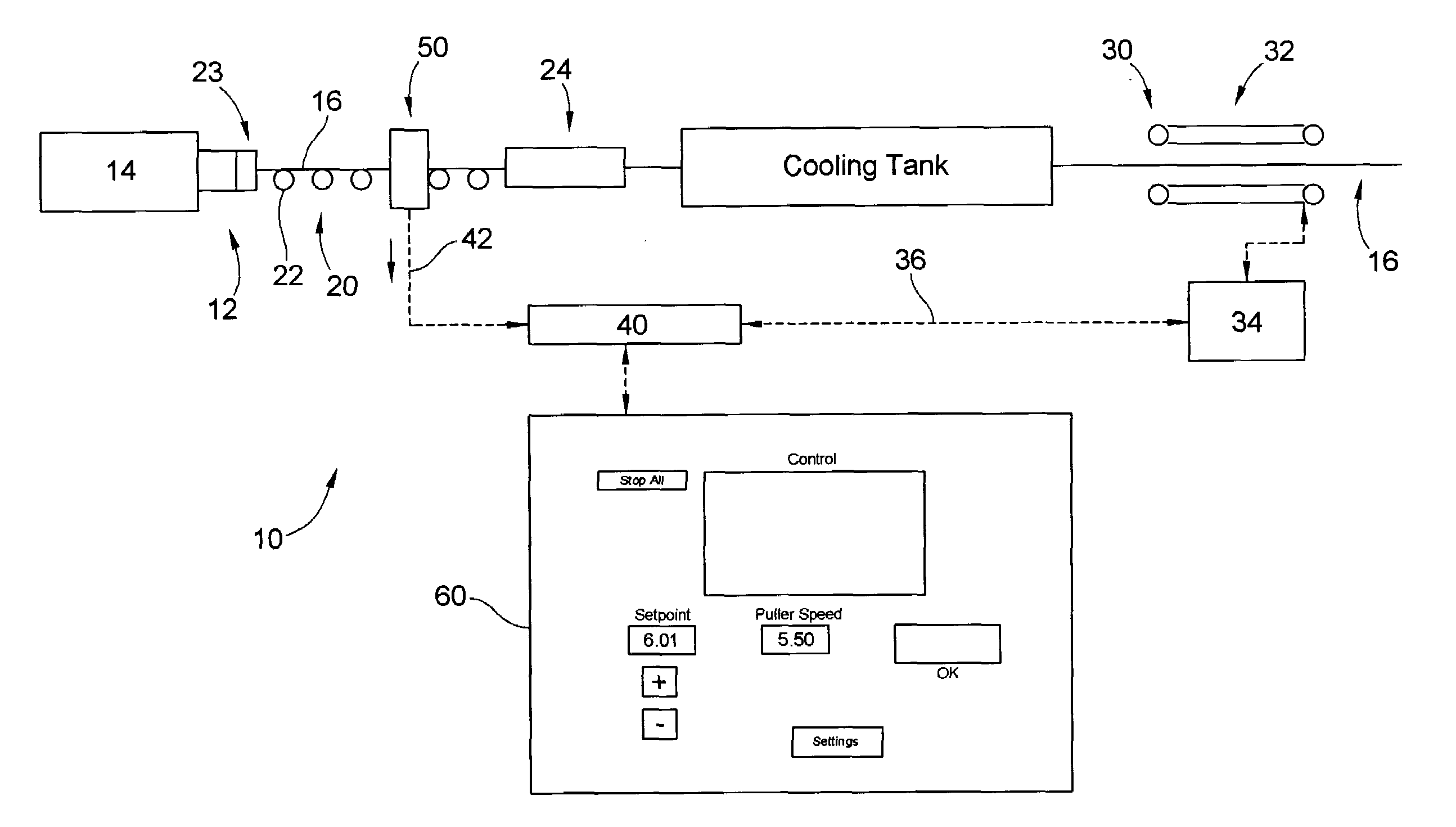

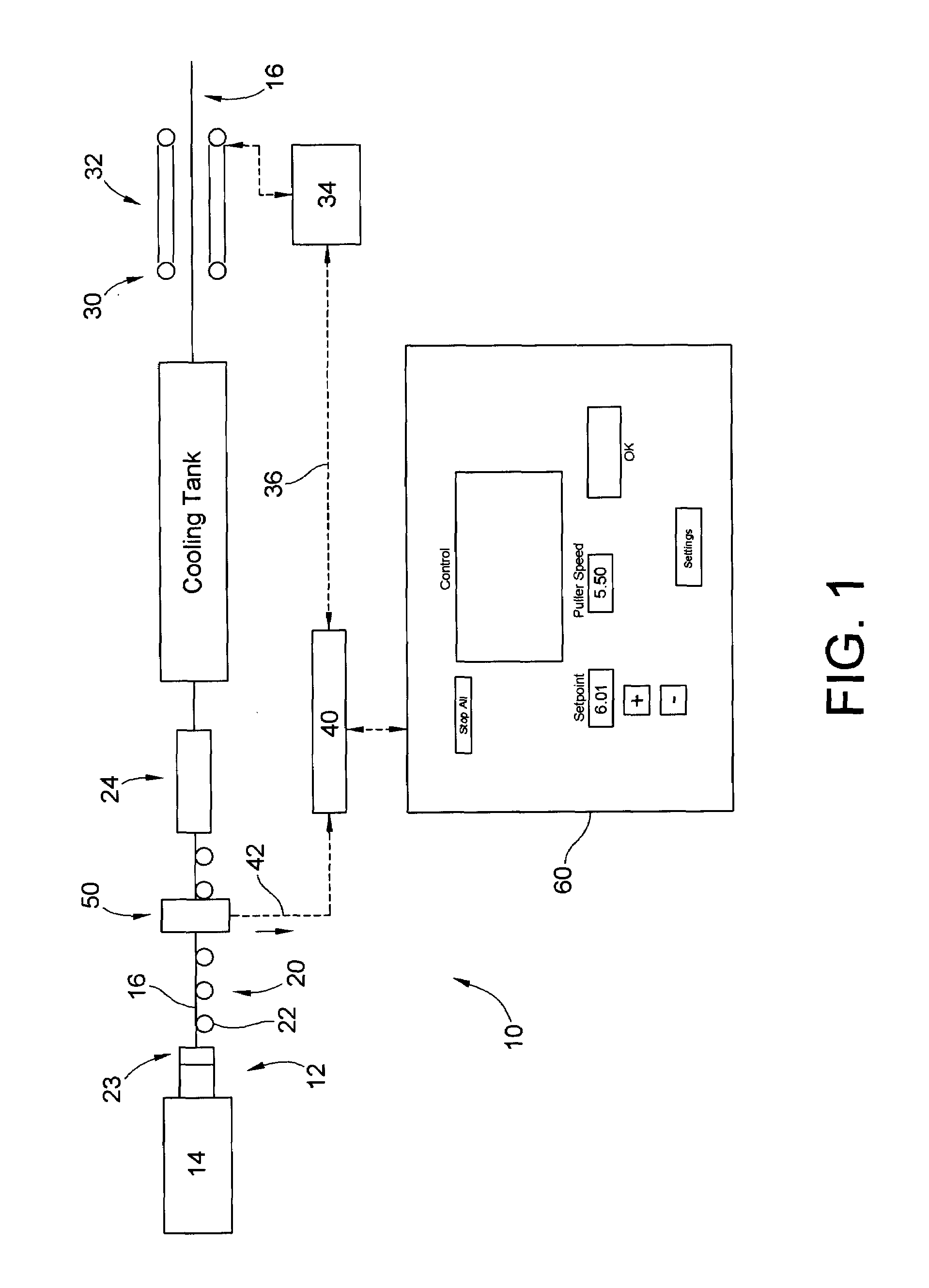

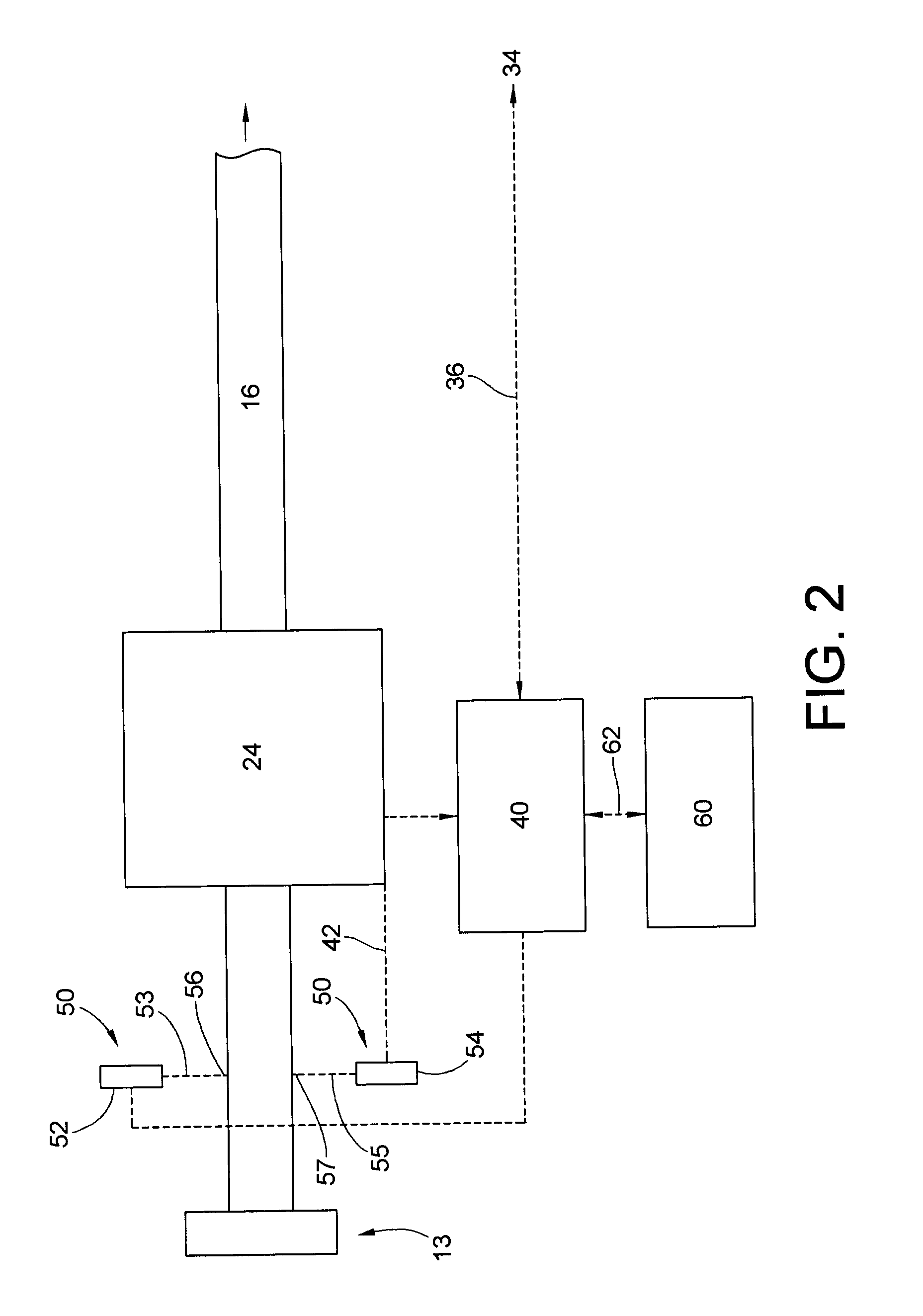

Puller speed control device for monitoring the dimensions of an extruded synthetic wood composition

ActiveUS20080088049A1Easy to controlReduced strengthWood working apparatusAuxillary shaping apparatusMeasurement deviceLight beam

A system for controlling the dimensions of an extrudate exiting an extruder and for compensating for the variations in the extrusion rate of the extruder, expansion rate and rate of travel of the extrudate through sizing devices by changing the speed of an extrudate puller device, includes an extruder which extrudes the extrudate; a conveyor system comprising rollers and a series of sizing devices; a puller device for pulling the extrudate through the sizing devices; and a laser proximity measuring device to assist the system in keeping the desired shape of the extrudate. The laser proximity measuring device includes at least one pair of optical non-contact displacement transducers, a real time processor, and an interactive touch screen display. The transducers emit a laser beam which provides a laser point on the side of the extrudate.

Owner:CPG INT

System and methods for cooling electronic equipment

PendingUS20160120067A1Stable toleranceImprove securityCompressorEfficient regulation technologiesElectric equipmentElectronic equipment

Systems and methods for cooling an inverter of a variable frequency drive that drives a compressor in a cooling system for electronic equipment are disclosed. The system includes a first fluid circuit that cools electronic equipment using a first fluid flowing therethrough and a second fluid circuit that free cools a second fluid flowing therethrough. The second fluid circuit cools the first fluid using the free-cooled second fluid. The system further includes a third fluid circuit that mechanically cools the second fluid using a third fluid flowing therethrough as a function of the wet bulb temperature of atmospheric air. The third fluid circuit includes at least one compressor compresses the third fluid and is driven by a motor coupled to the variable frequency drive. At least a portion of the first fluid flowing through the third fluid circuit is diverted to cool the inverter of the variable frequency drive.

Owner:INERTECH IP

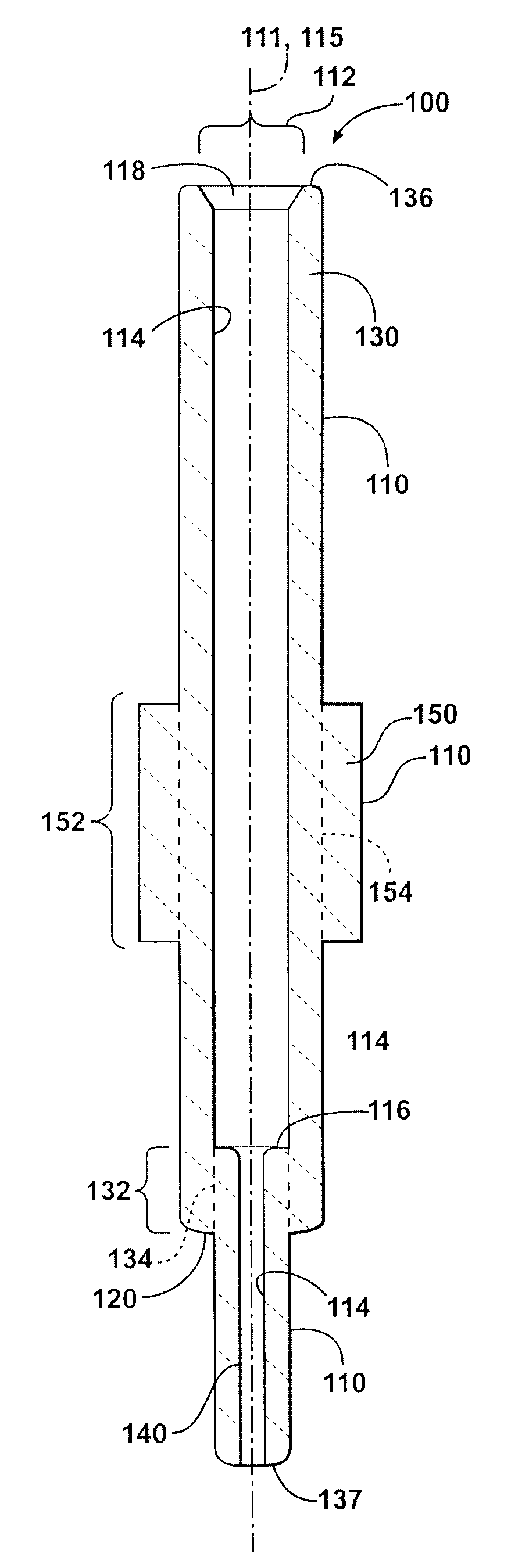

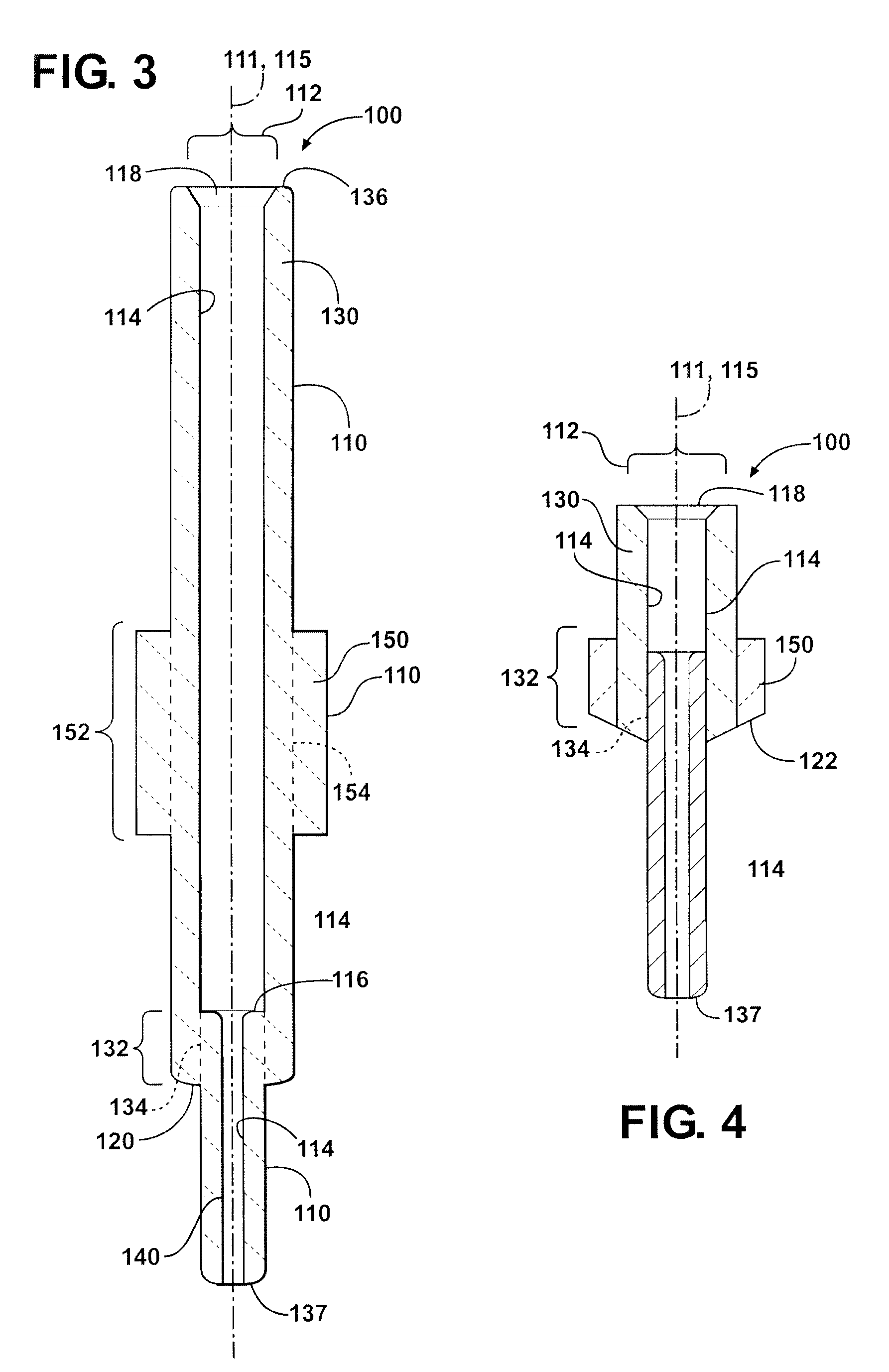

Opposed piston internal combustion engine with inviscid layer sealing

InactiveUS20140318518A1Accurate concentricityWell mixedCombustion enginesReciprocating piston enginesCombustionDetonation

An opposed-piston engine that forms an inviscid layer between pistons and the respective cylinder walls. In an aspect, the opposed-piston engine utilizes a Scotch yoke assembly that includes rigidly connected opposed combustion pistons. In an aspect, the Scotch yoke assembly is configured to transfer power from the combustion pistons to a crankshaft assembly. In an aspect, the crankshaft assembly can be configured to have dual flywheels that are internal to the engine, and can be configured to assist with an exhaust system, a detonation system, and / or a lubrication system.

Owner:PRIME GRP ALLIANCE

Lice and nit removal device

ActiveUS20050051190A1Improved sifting removalThe process is simple and effectiveHair combsPackaging toiletriesEngineeringKnife blades

A device for removing lice and nits from affected hair and scalp of an individual, has first and second movable blades, the first blade including a plurality of first saw teeth, the second blade including a plurality of second saw teeth, and means for movably retaining the first and second blades parallel and adjacent to one another with their respective first and second teeth in opposition and parallel planes along their respective longitudinal axes, whereby the blades can be selectively moved toward one another to cause their teeth to mesh together with hairs captively held therebetween, the first and second teeth being configured to thereafter provide via combing a scraping action against the entrapped hairs for removing lice and nits therefrom.

Owner:AMERICAN COMB CORP

System and methods for cooling electronic equipment

ActiveUS20140311169A1Improve securityControl safetyCompressorMetal-working apparatusAtmospheric airWet-bulb temperature

Systems and methods for cooling an inverter of a variable frequency drive that drives a compressor in a cooling system for electronic equipment are disclosed. The system includes a first fluid circuit that cools electronic equipment using a first fluid flowing therethrough and a second fluid circuit that free cools a second fluid flowing therethrough. The second fluid circuit cools the first fluid using the free-cooled second fluid. The system further includes a third fluid circuit that mechanically cools the second fluid using a third fluid flowing therethrough as a function of the wet bulb temperature of atmospheric air. The third fluid circuit includes at least one compressor compresses the third fluid and is driven by a motor coupled to the variable frequency drive. At least a portion of the first fluid flowing through the third fluid circuit is diverted to cool the inverter of the variable frequency drive.

Owner:INERTECH IP

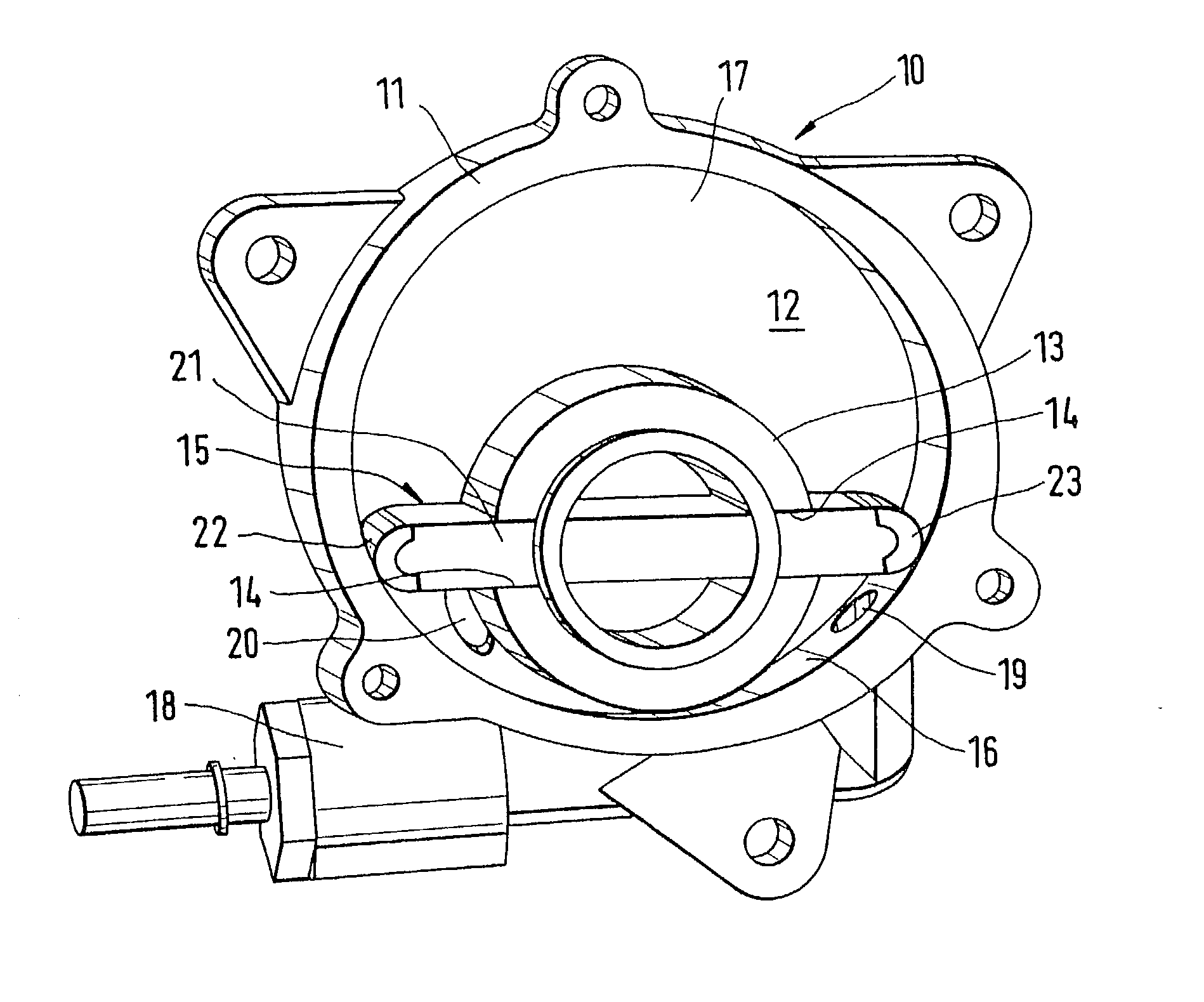

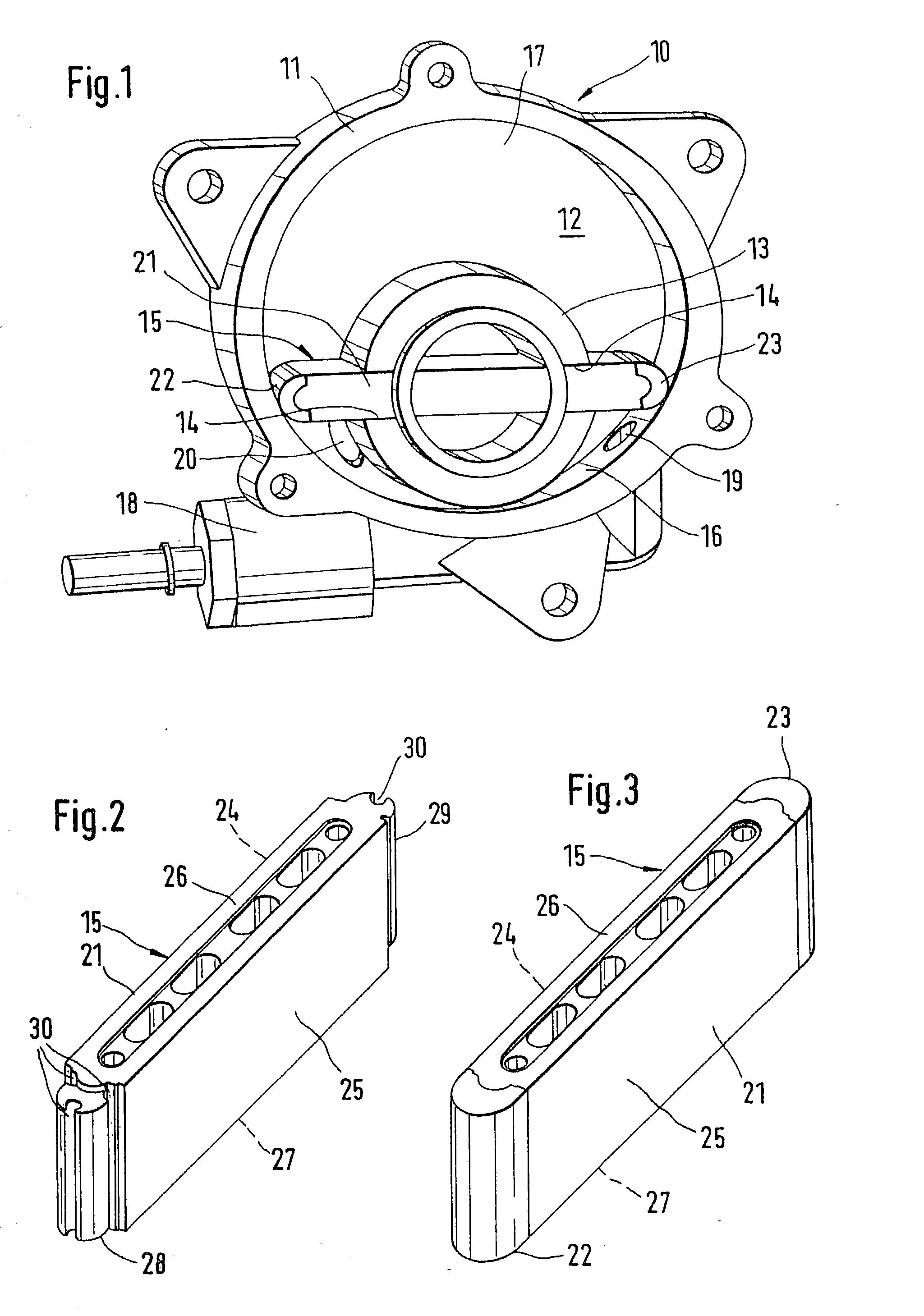

Plastic vane for a vane-cell vacuum pump

InactiveUS20030053924A1Reduce impactHigh strengthOscillating piston enginesRotary piston pumpsThermoplasticHigh wear resistance

A vane cell vacuum pump (10) has a rotor (13), in which a plastic vane, which with at least terminal part (22, 23) engages the inner wall (16) of the jacket of a pump housing (11), is guided longitudinally. The body (21) of the vane (15) comprises a duroplastic and is united with the terminal part (22, 23), of thermoplastic, by an injection-molding operation. With the material comprising the body (21), high mechanical strength is attained, while with the material of the terminal part (22, 23), high wear resistance and a low coefficient of friction are attained. The vane cell vacuum pump can be used in a motor vehicle in conjunction with a negative-pressure brake booster.

Owner:ROBERT BOSCH GMBH

Refurbishable retro-reflective photogrammetric target

InactiveUS20080192371A1Close toleranceAdvanced technologySurveyor's staffsMovable markersClose rangeEngineering

A surveying type target has a precisely located aperture that achieves tolerances, within + / −0.0005 inch, in the assembly and usage of a retro-reflective photogrammetry target for use with close range industrial photogrammetry. The dot the target may also be refurbished and reconditioned in the field under all weather conditions. This target has a precisely machined ring that fits into a precisely machined socket of a body to eliminate assembly irregularities. This target precisely locates the ring upon the body forming a finished target with a known centerline and height location within + / −0.0005 inch tolerance.

Owner:HUBBS MACHINE & MFG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com