Patents

Literature

662results about How to "Long operating time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

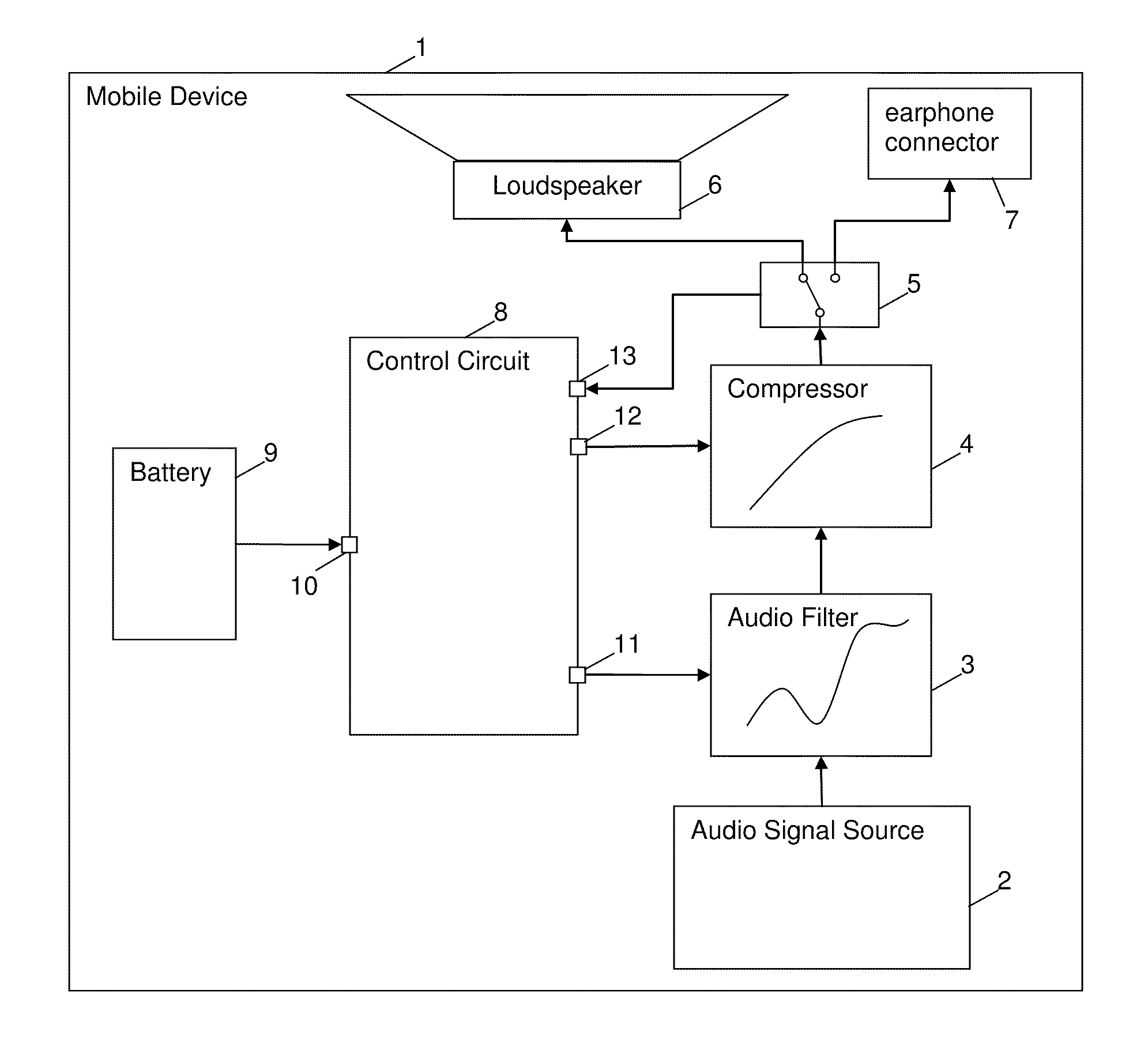

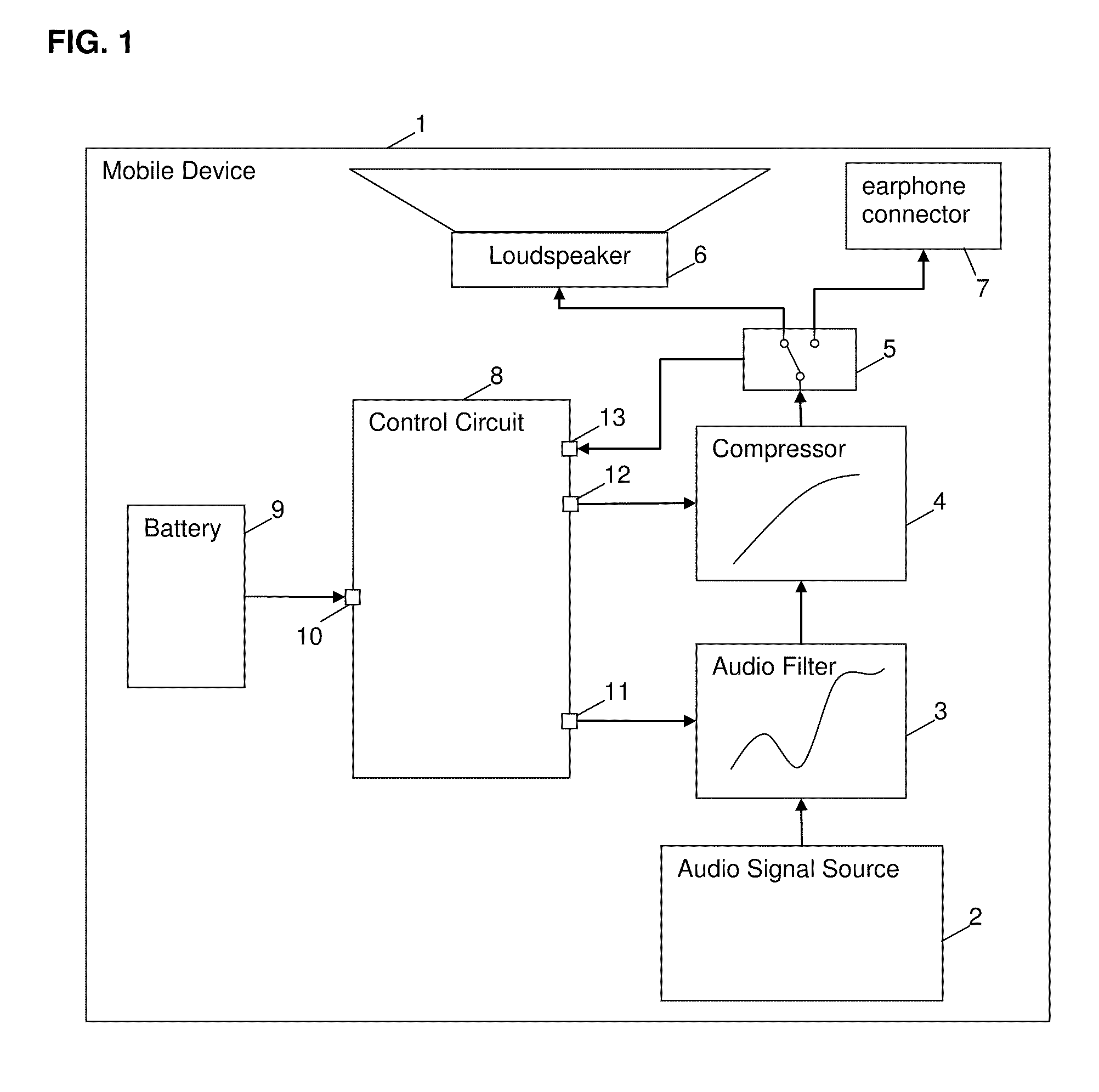

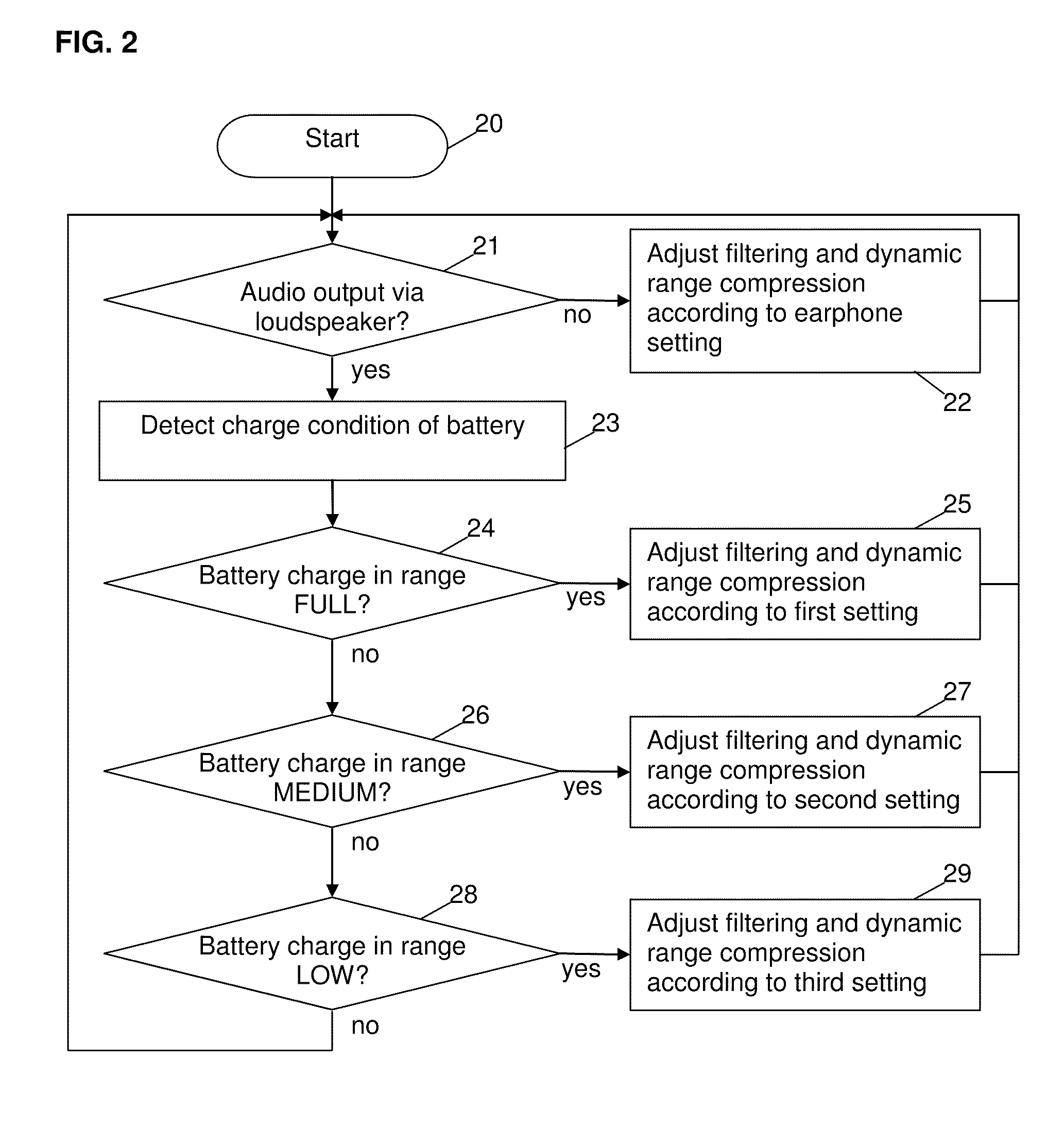

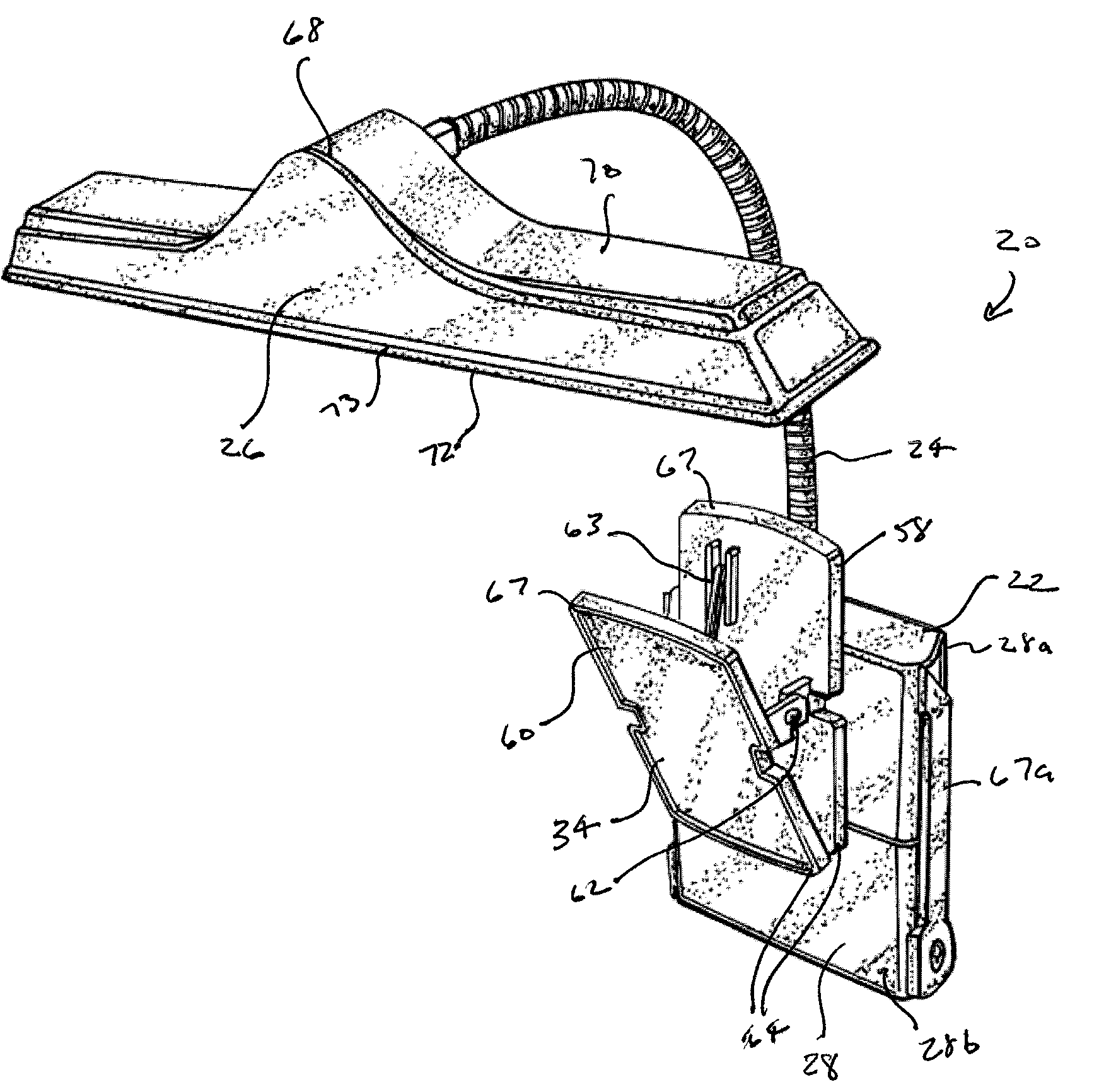

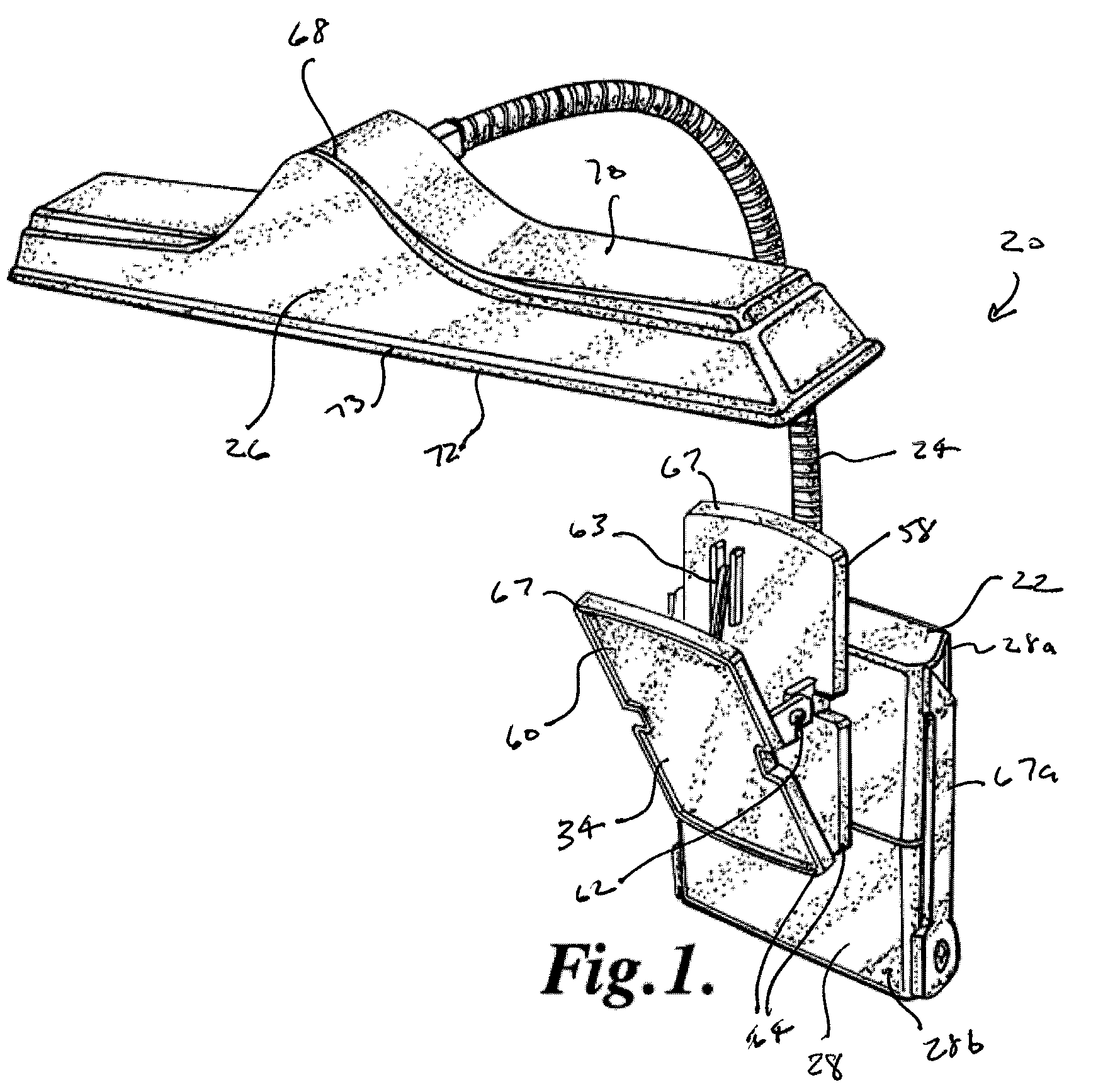

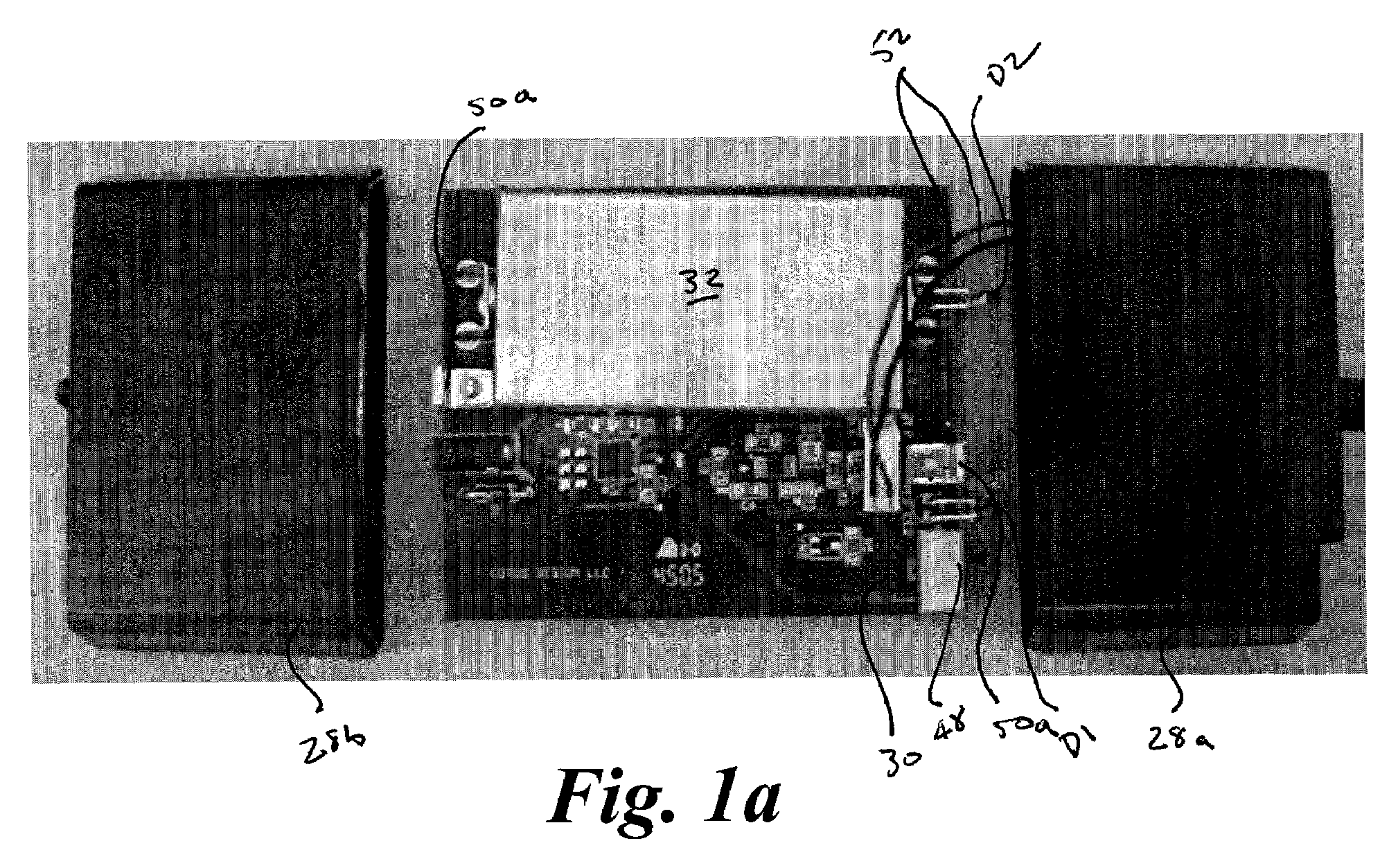

Method and circuit for controlling an output of an audio signal of a battery-powered device

ActiveUS20100322438A1Shorten the timeHigh power consumptionSupply voltage controlEarpiece/earphone attachmentsEngineeringControl circuit

A method and a control circuit for controlling an output of an audio signal of a battery-powered device are described.

Owner:SONY CORP

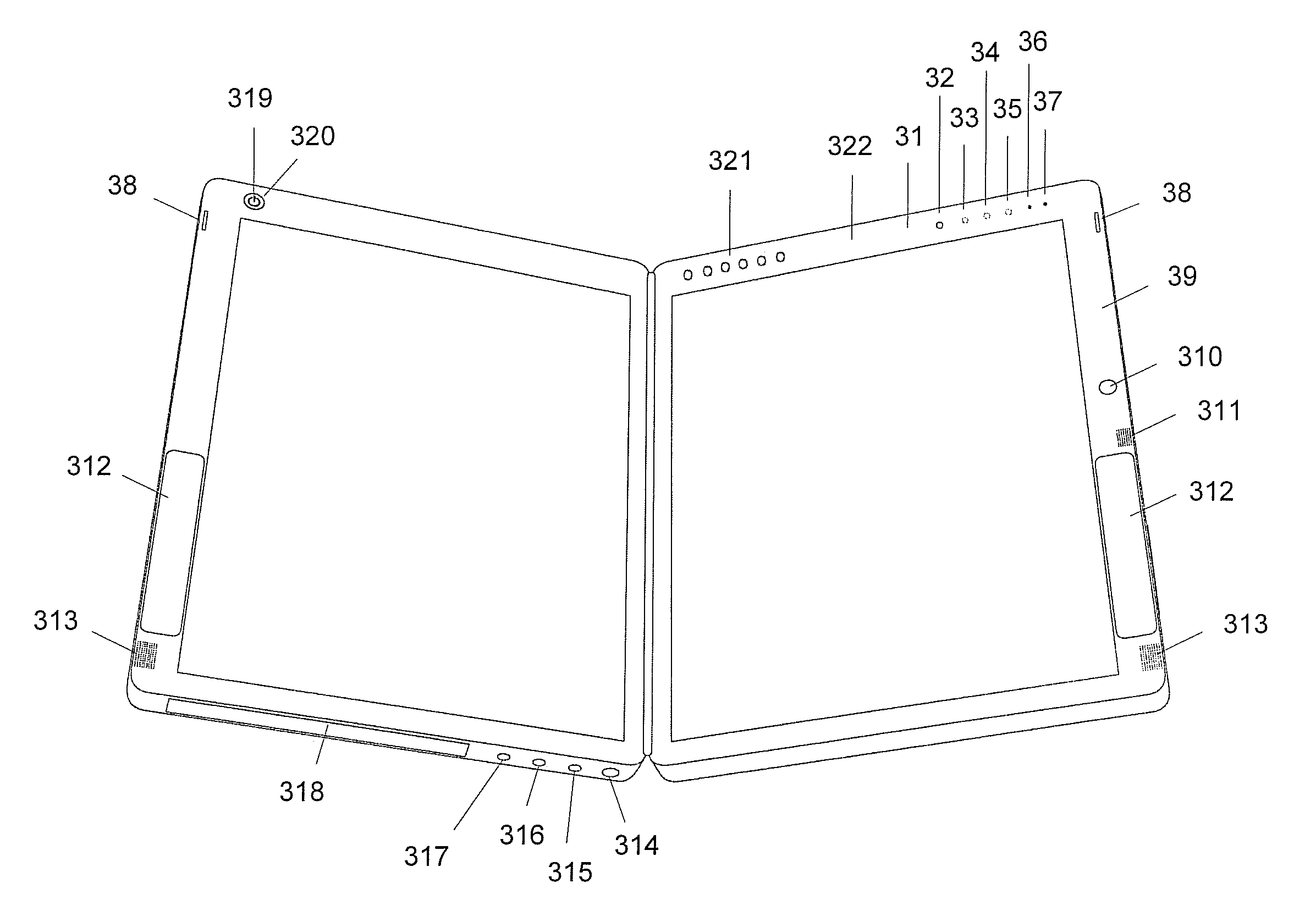

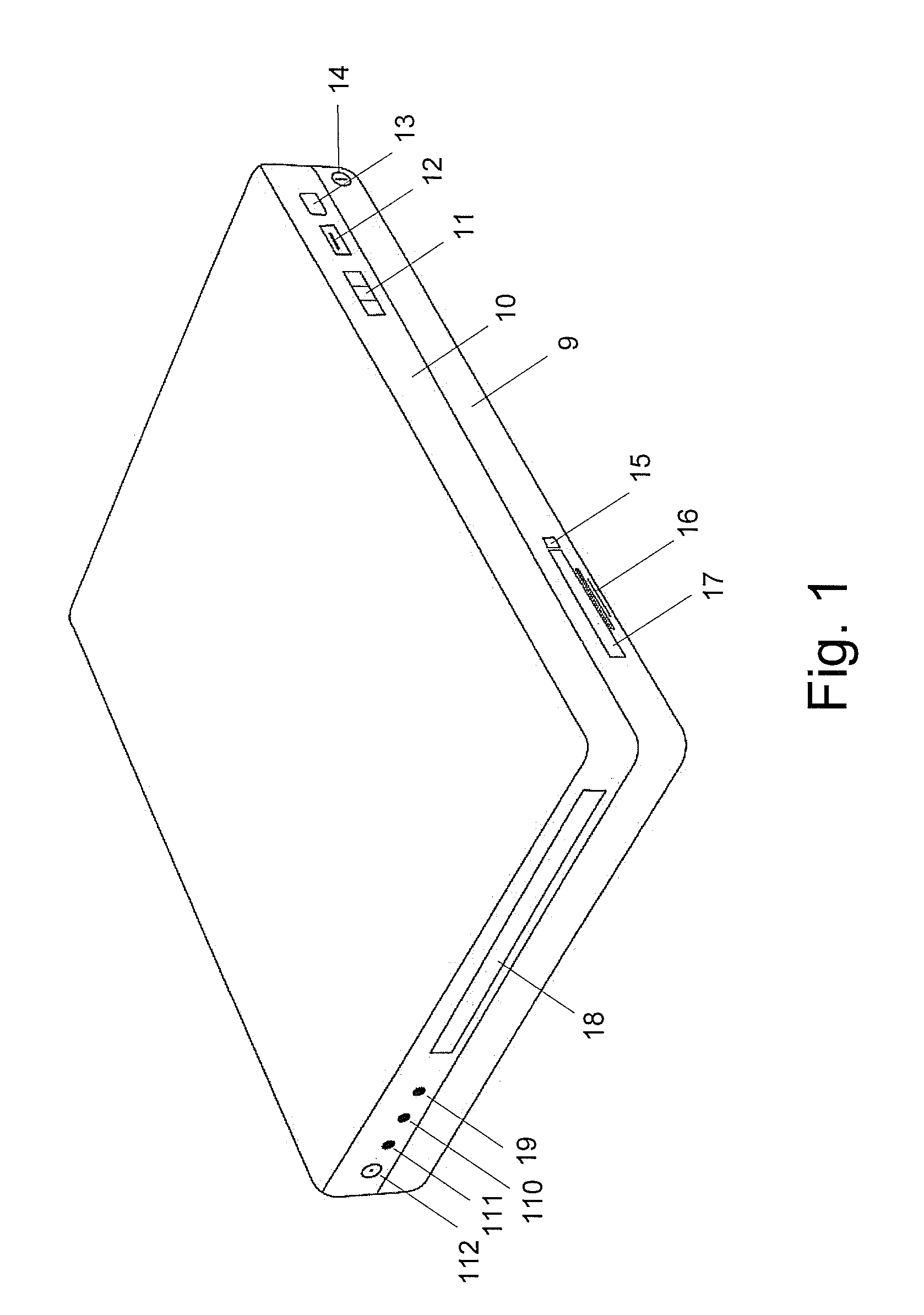

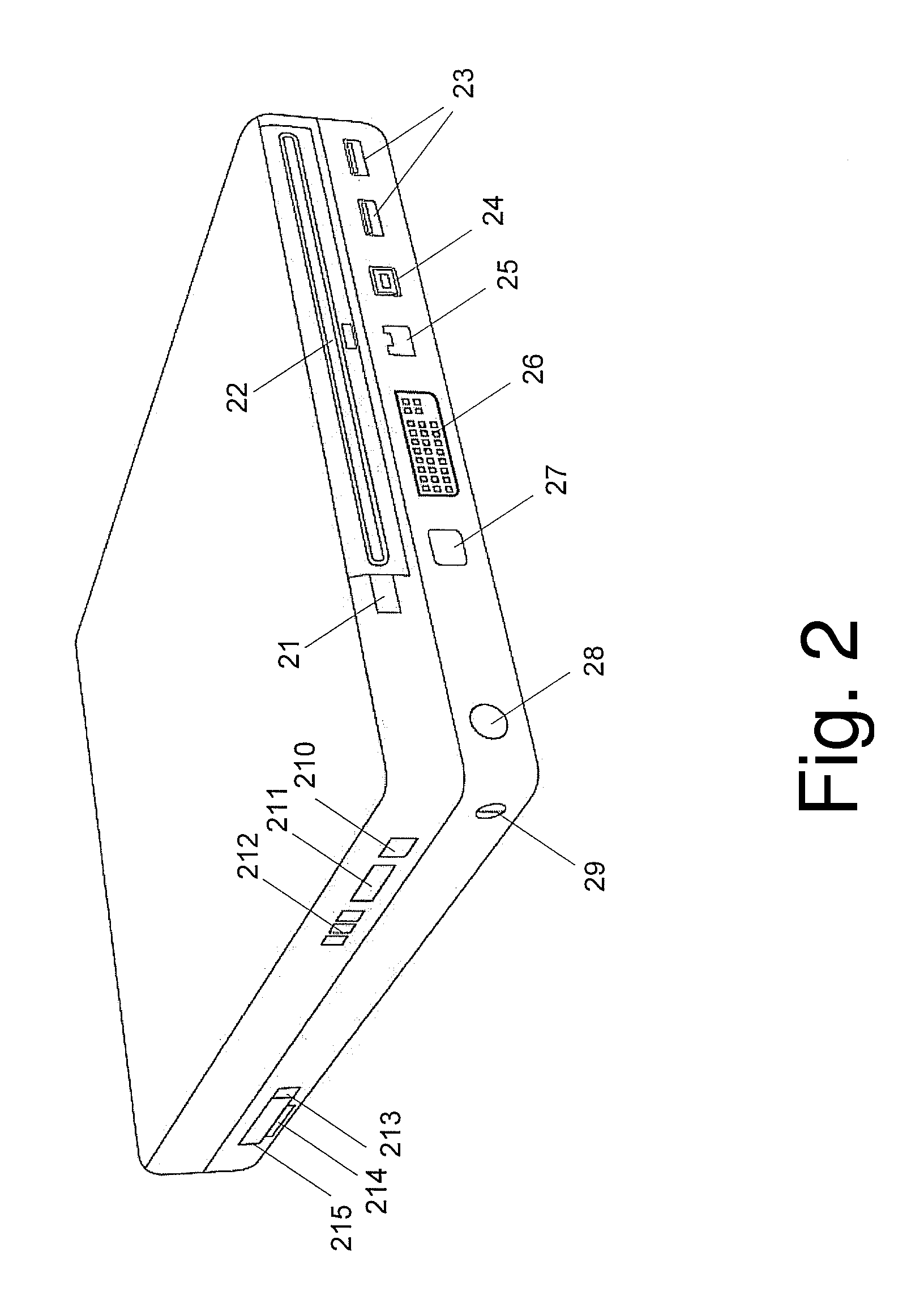

Folding computer

InactiveUS20070242421A1Uniform designSolid foundationDetails for portable computersElectrical apparatus contructional detailsEngineeringOperation mode

Mobile computer, comprising two casing parts, which are connected by a hinge, so that the casing parts can be opened and closed. Each of the casing parts has an input-sensitive flat screen. The casing parts are arranged in such a way as to enable at least two operating modes. As a result, this invention can be used in at least to different operating modes, which can be selected depending on the application. In the preferred embodiment, the invention can be locked in various open positions by way of a flap mechanism.

Owner:GOSCHIN NORBERT +1

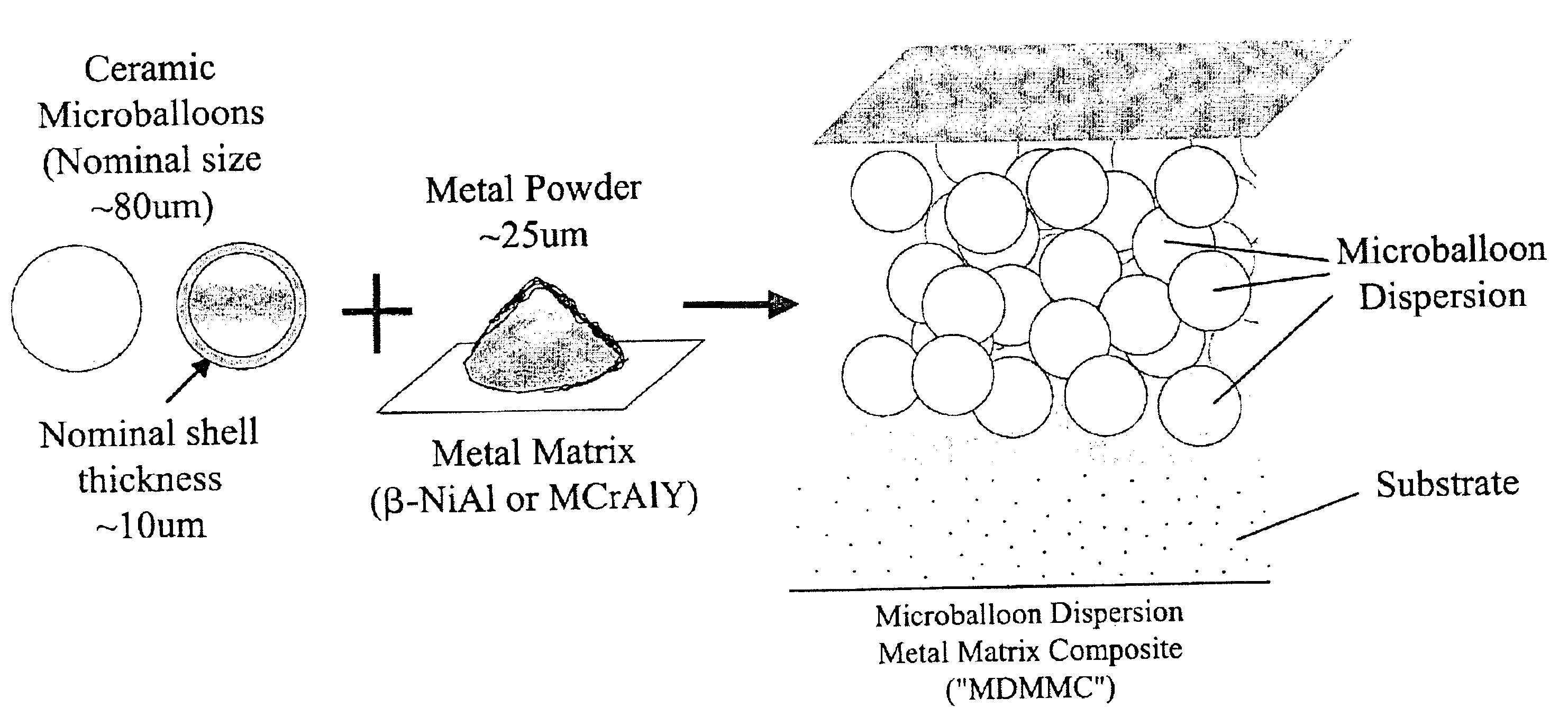

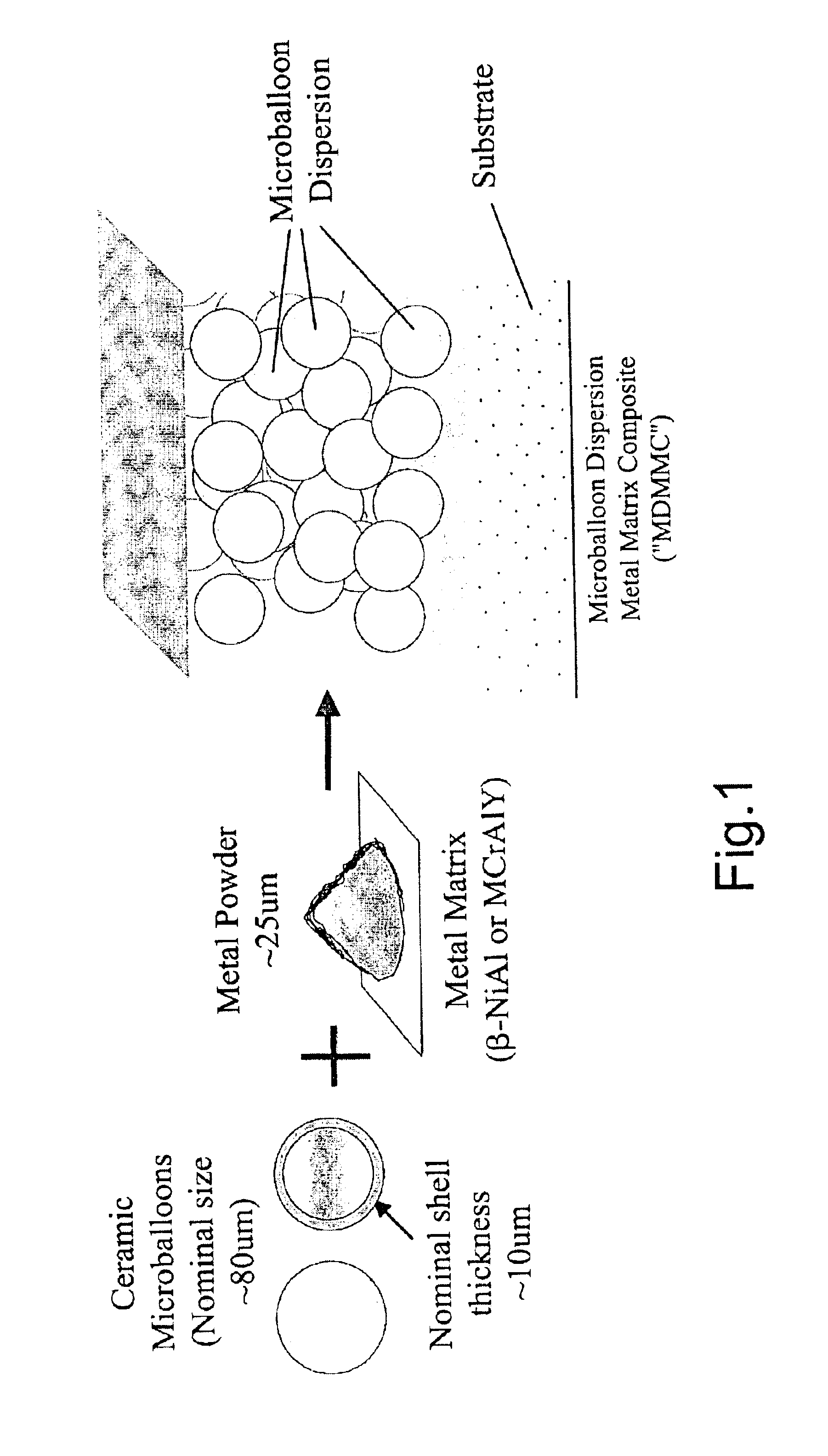

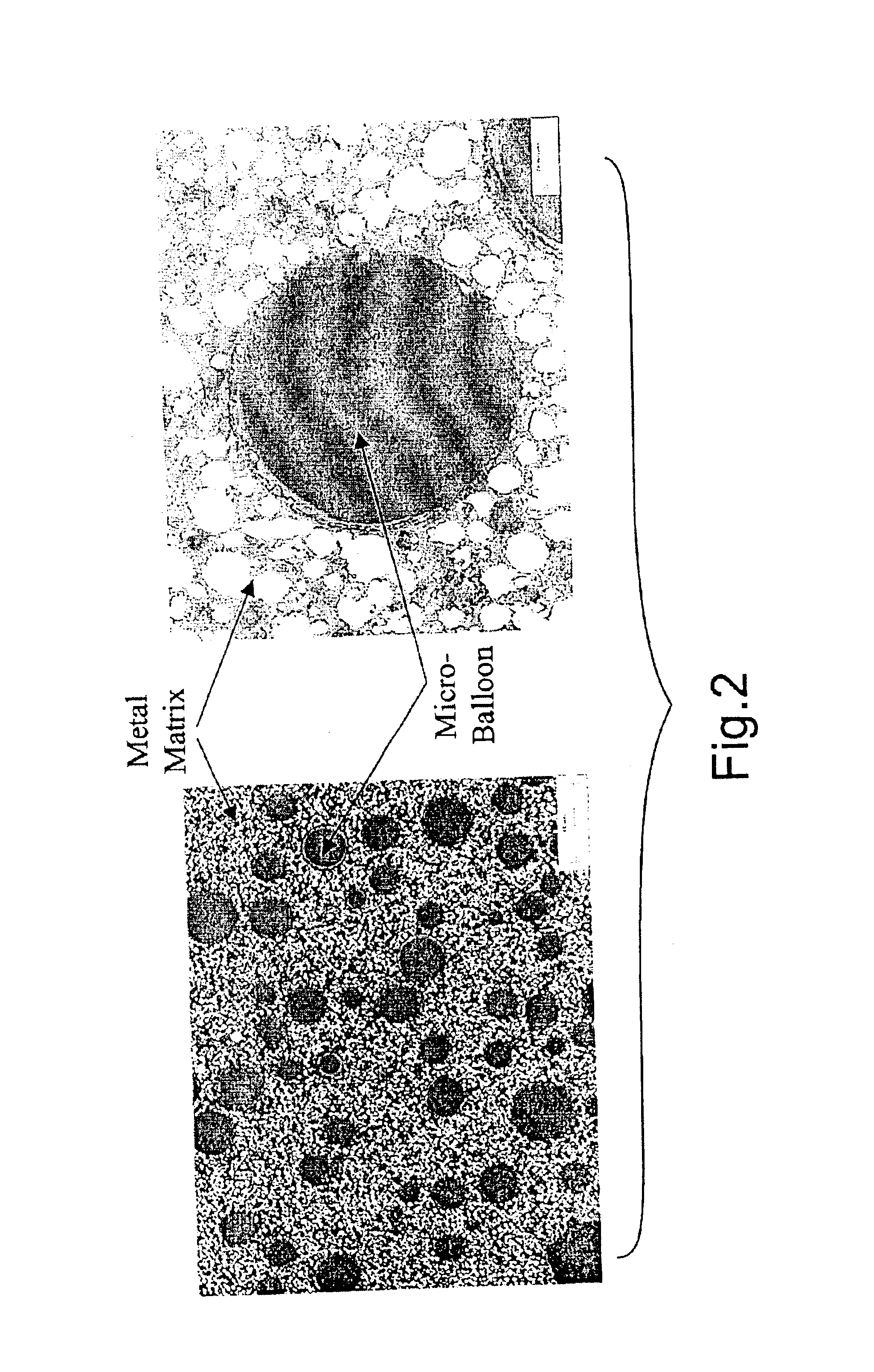

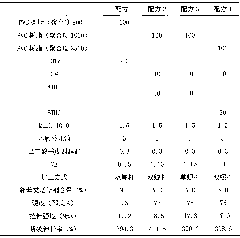

High temperature, oxidation-resistant abradable coatings containing microballoons and method for applying same

InactiveUS6916529B2Effective timeReducing hot gas leakageMolten spray coatingPropellersThermal sprayingMicrosphere

An abradable coating composition for use on shrouds in gas turbine engines or other hot gas path metal components exposed to high temperatures containing an initial porous coating phase created by adding an amount of inorganic microspheres, preferably alumina-ceramic microballoons, to a base metal alloy containing high Al, Cr or Ti such as β-NiAl or, alternatively, MCrAlY that serves to increase the brittle nature of the metal matrix, thereby increasing the abradability and oxidation resistance of the coating at elevated temperatures. Coatings having a total open and closed porosity of between 20% and 55% by volume due to the presence of ceramic microballoons ranging in size from about 10 microns to about 200 microns have been found to exhibit excellent abradability for applications involving turbine shroud coatings. An abradable coating thickness in the range of between 40 and 60 ml provides improved performance for turbine shrouds exposed to gas temperatures between 1380° F. and 1800° F. Abradable coatings in accordance with the invention can be used for new metal components or to repair existing equipment. The coatings can be applied to the metal shroud using thermal spray, processes that integrate sintering and brazing, or direct write techniques.

Owner:GENERAL ELECTRIC CO

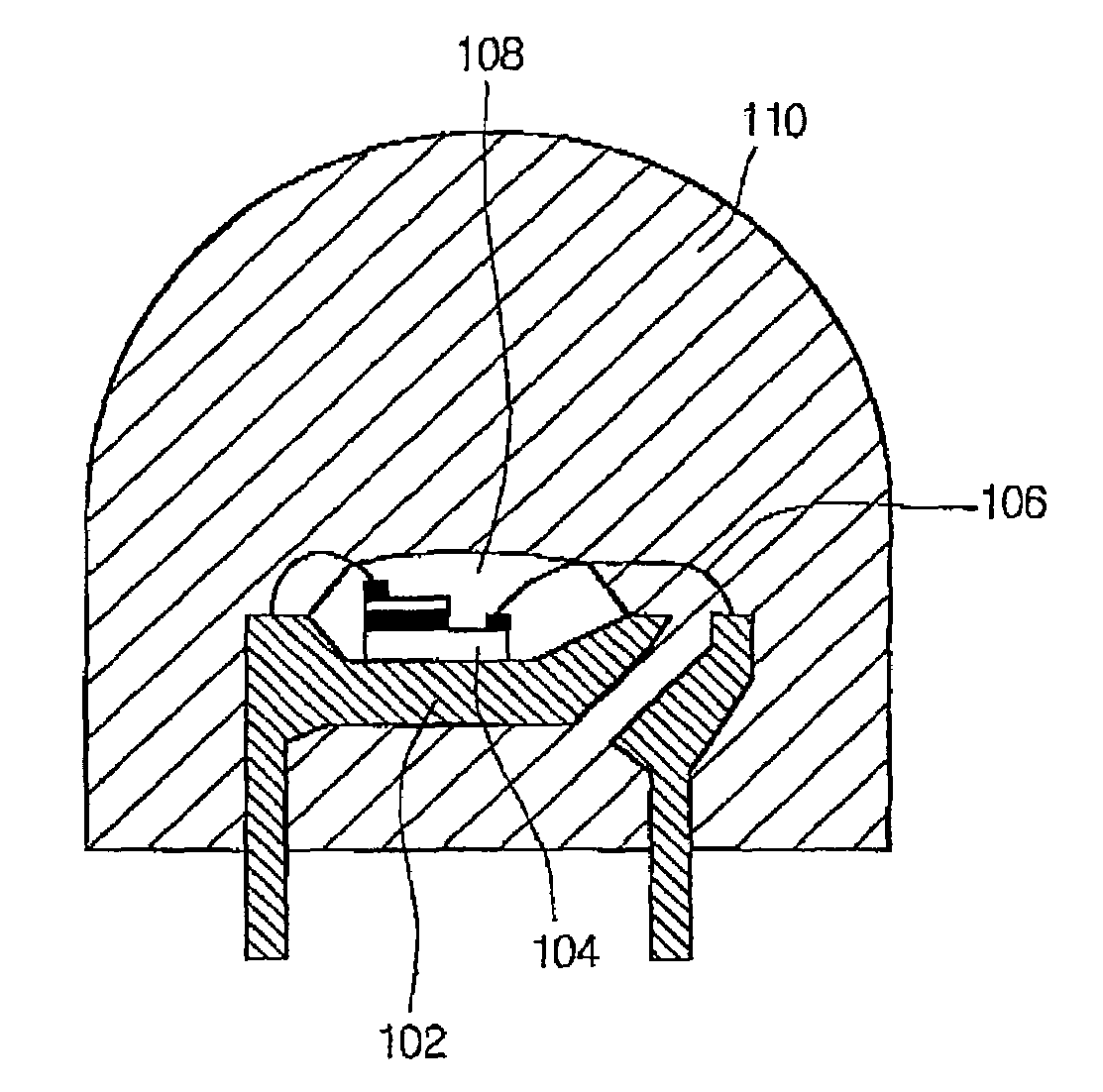

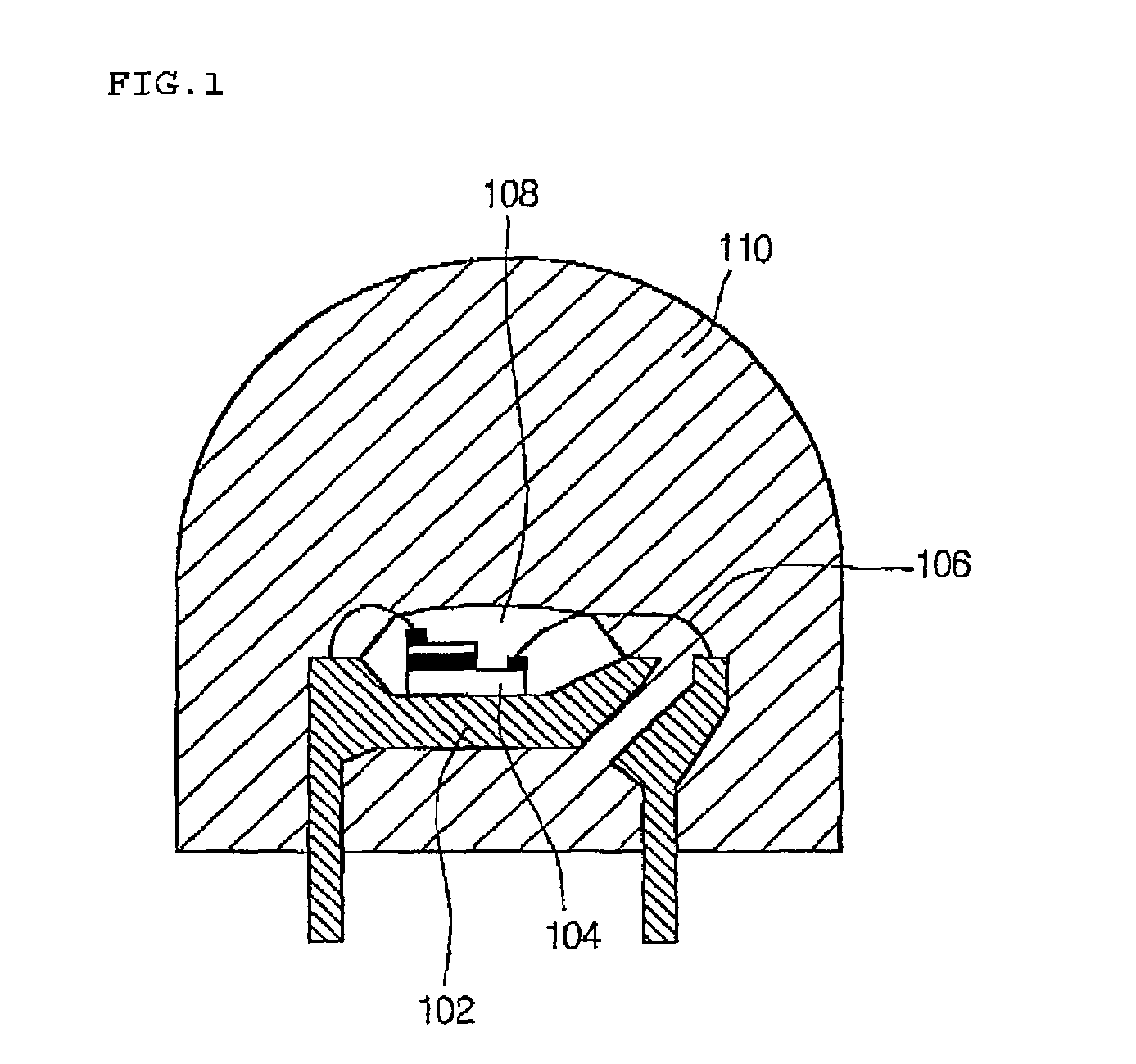

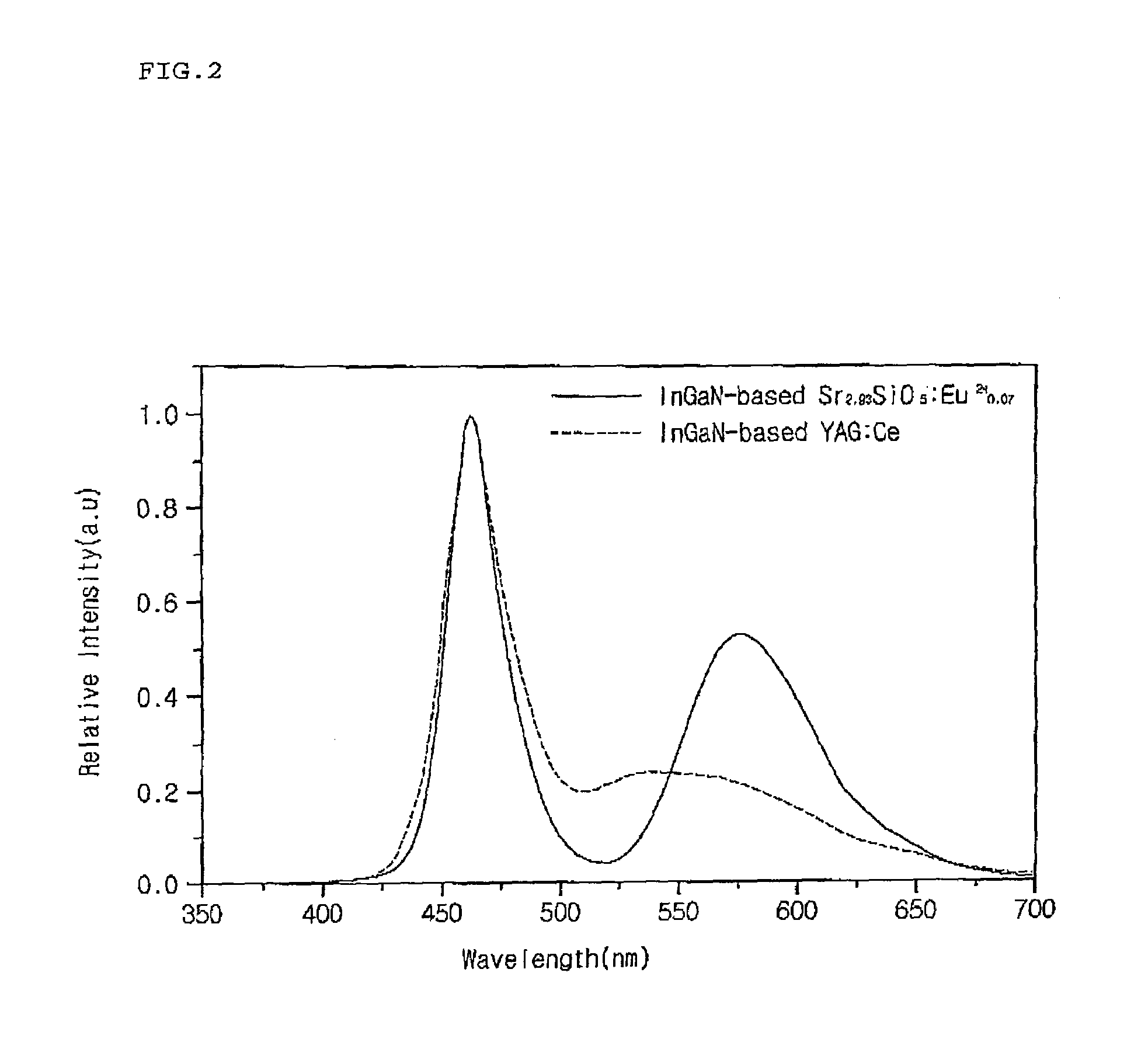

Strontium silicate-based phosphor, fabrication method thereof, and LED using the phosphor

ActiveUS7045826B2Wide wavelength spectrumLuminous properties are stableSolid-state devicesSemiconductor/solid-state device manufacturingPhosphorUltraviolet

A strontium silicate-based phosphor, a fabrication method thereof, and an LED using the strontium silicate-based phosphor are provided. The phosphor is applied to a long wavelength ultraviolet LED, an active luminous LCD, etc., to enable an improvement in the color purity and to enhance the luminous efficiency. The strontium silicate-based phosphor is expressed by a chemical formula: Sr3-xSiO5Eu2+x wherein x is 0<x≦1. The LED using the phosphor has a wide wavelength spectrum, shows a superior color purity characteristic, and can have a very high luminous efficiency as applied in the backlight source of an LED panel or an active luminous LCD.

Owner:KOREA RES INST OF CHEM TECH

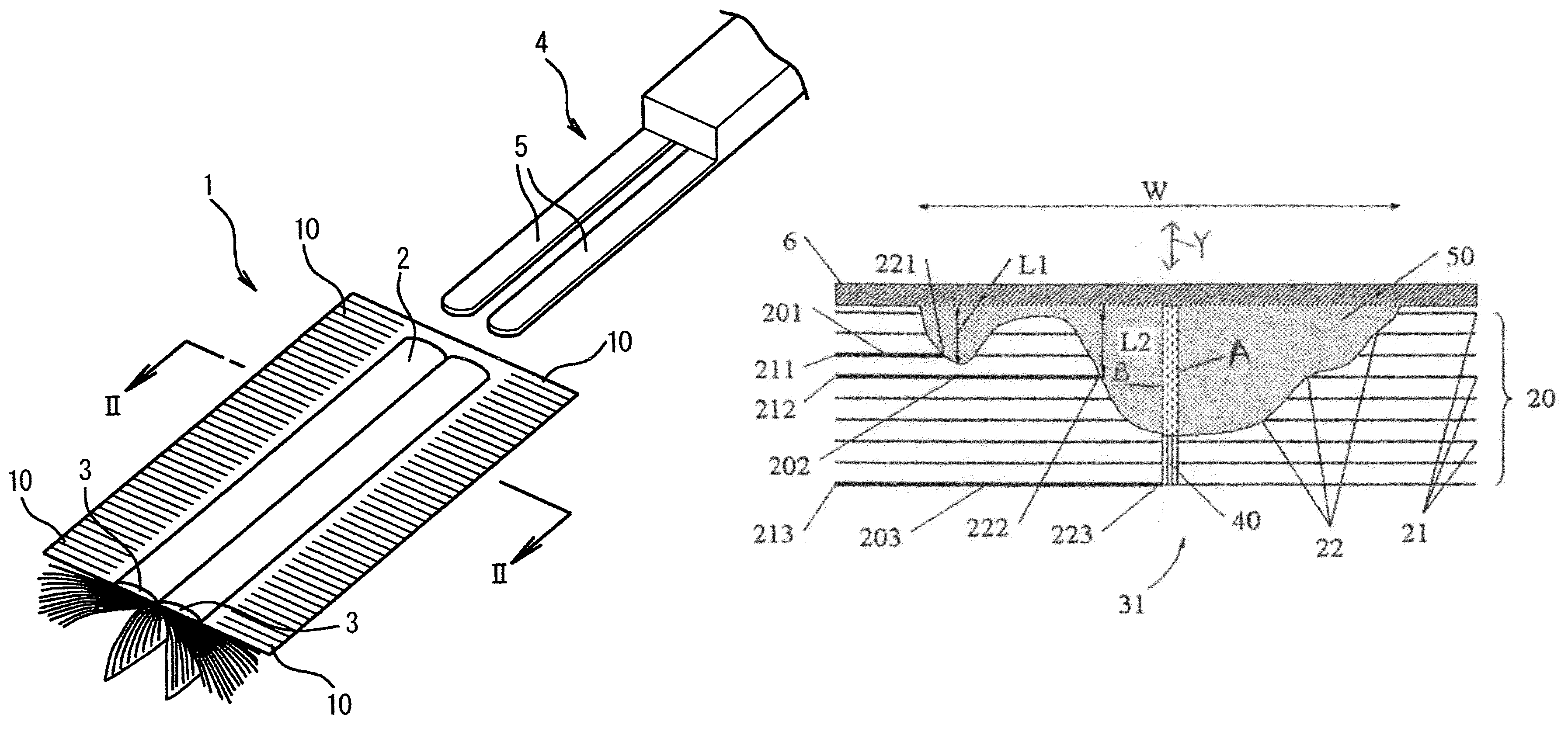

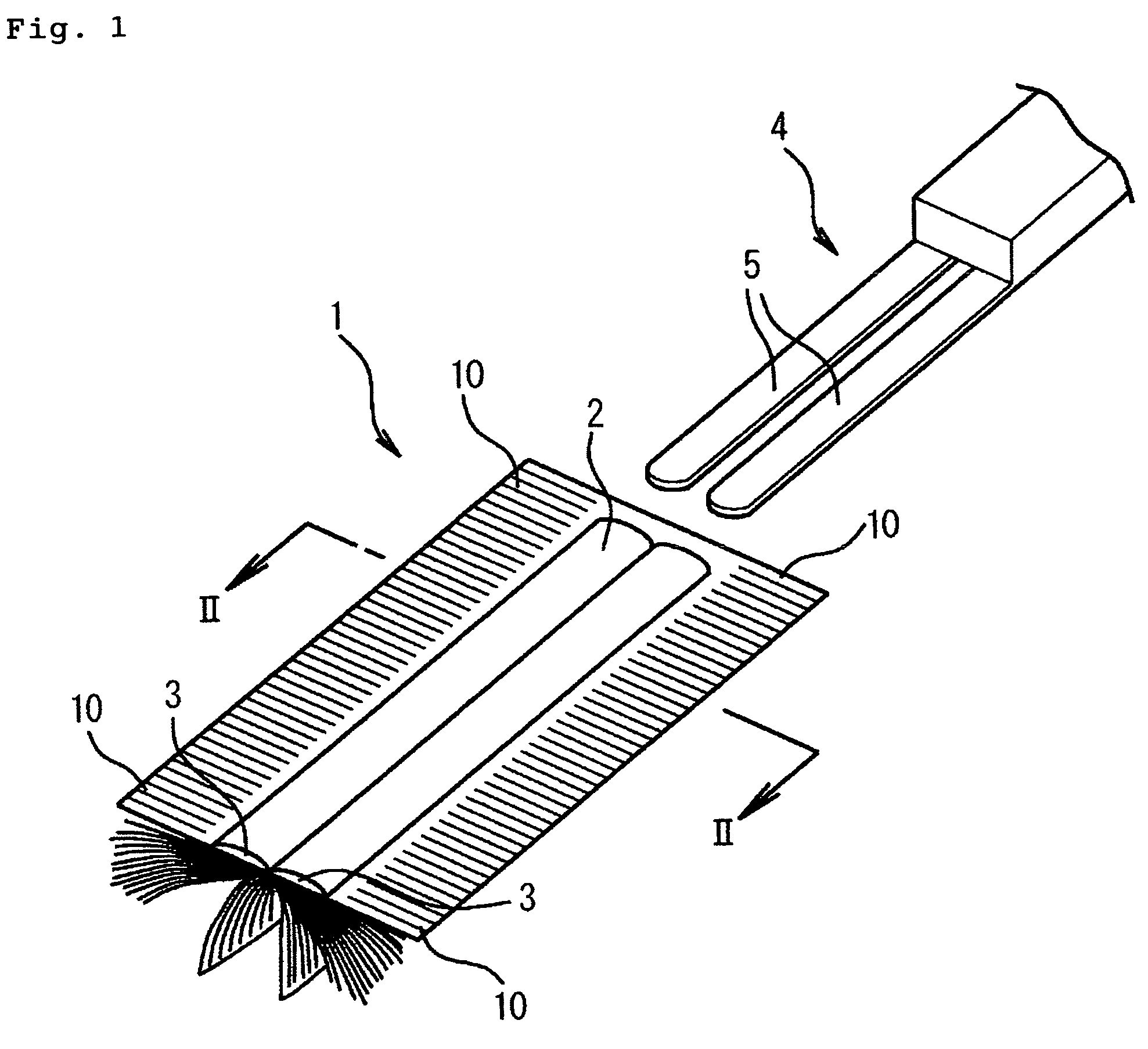

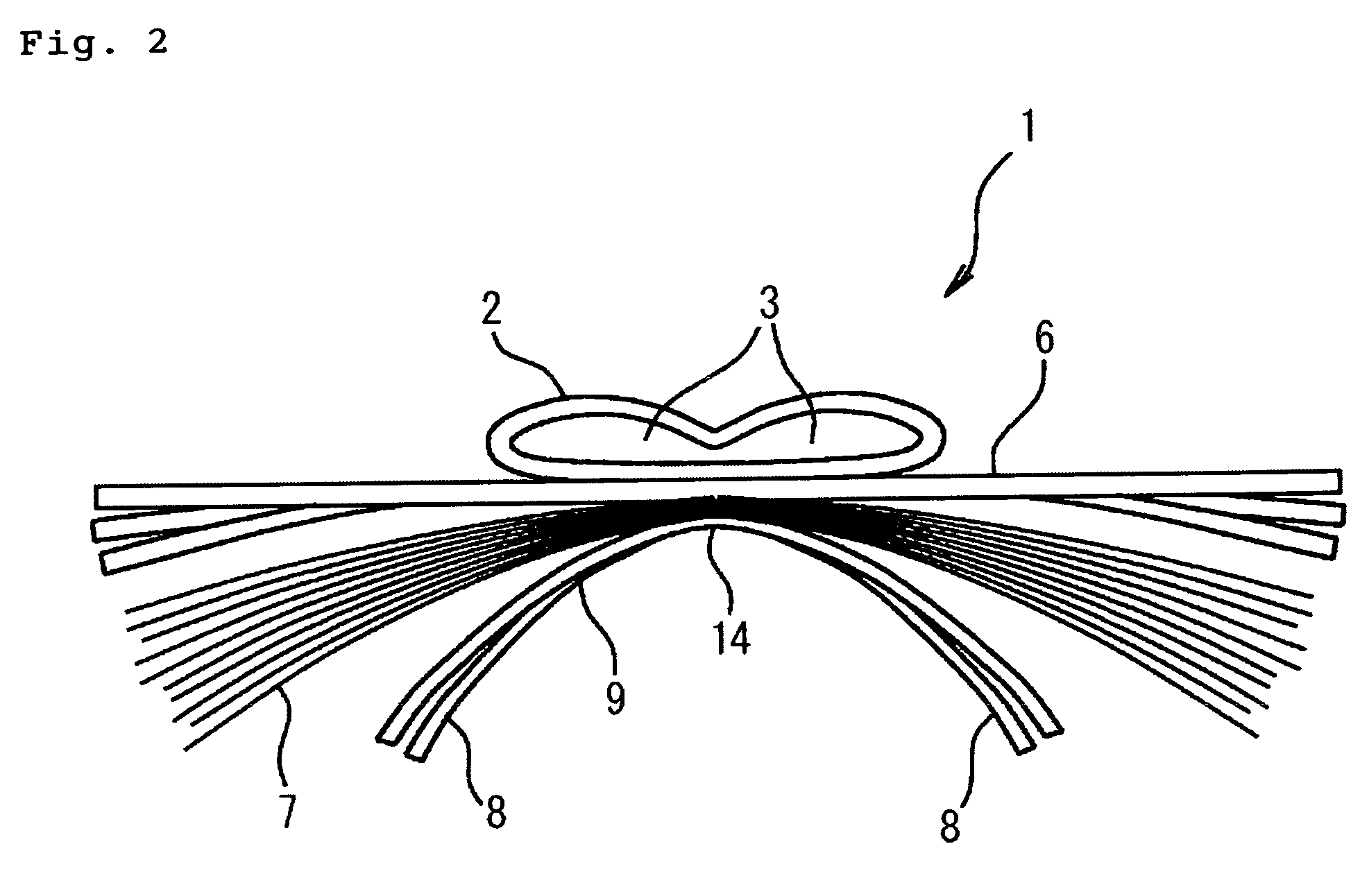

Cleaning device and process for producing the same

InactiveUS8146197B2Long operating timeLow costBoard cleaning devicesCarpet cleanersFiber bundleAdhesive

Owner:YAMADA KIKUO

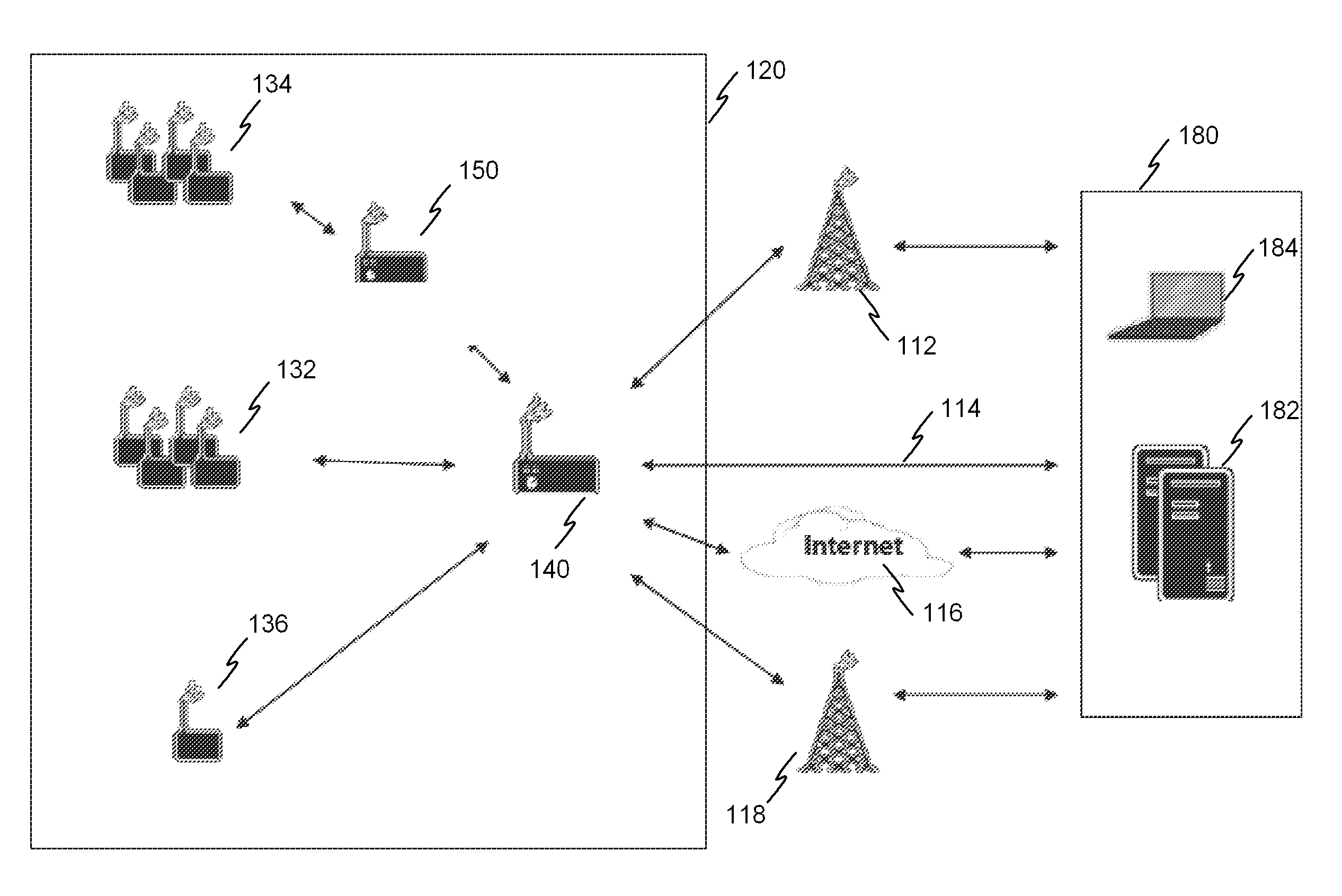

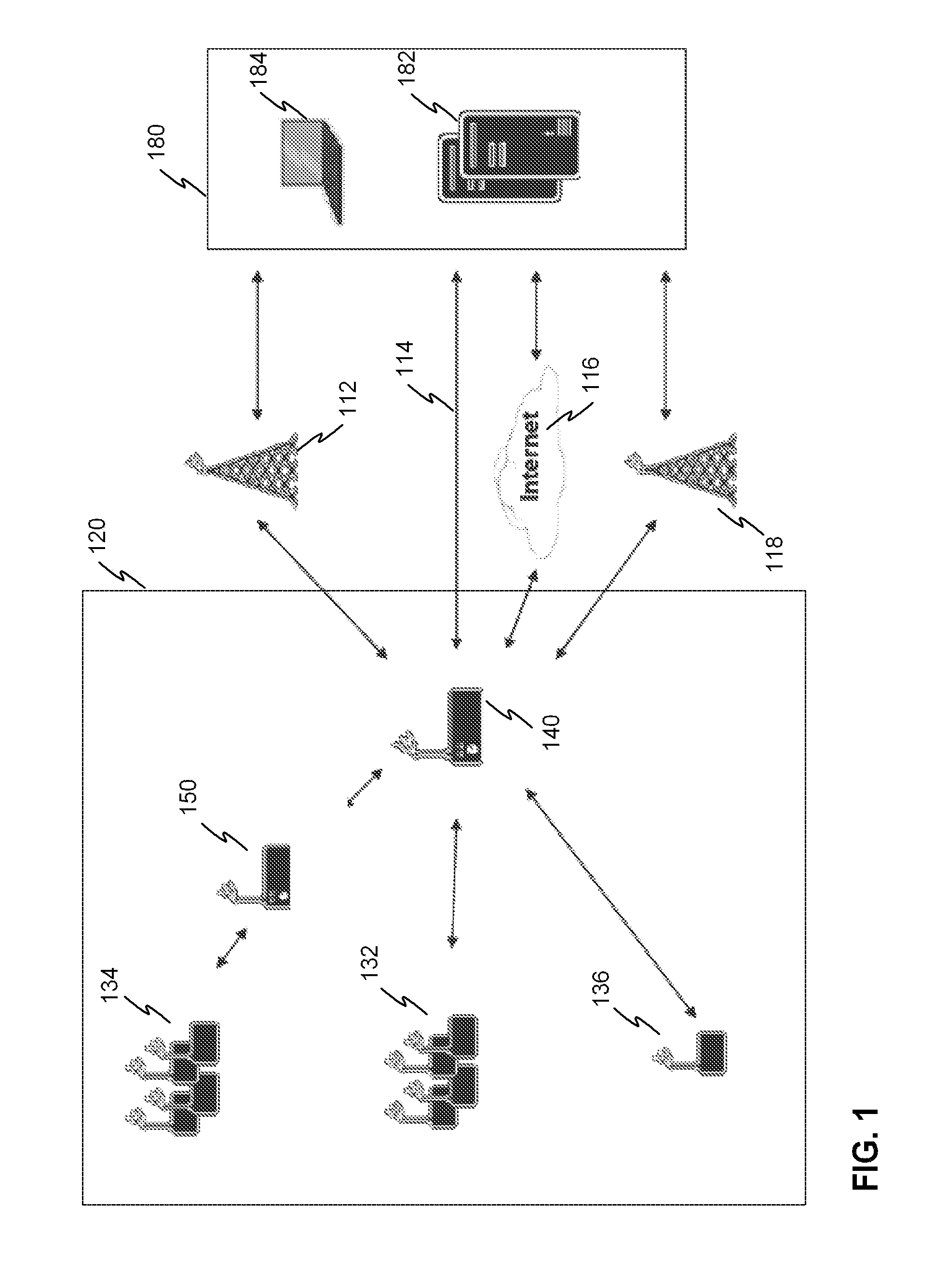

Method, system and devices for data acquisition

ActiveUS20100308967A1Disadvantage is reduced and avoidedReliable data transmissionEnergy efficient ICTPower managementData acquisitionTimer

The present invention relates generally to acquisition of data from RFID devices (132-136), such as sensor data. Prior art systems of active RFID devices have a problem of high average power consumption, and therefore, the energy source of the RFID devices needs to be replaced or charged frequently. The present invention provides a new solution wherein the RFID device has a power saving mode in which the receiver of the RFID device has a decreased ability to receive / detect RF signals. The RFID device may include a timer which is functional during the power saving mode, and the receiver of the RFID device will turn into active mode at a point of time based on the time value of the timer. Signal strength of an RF channel is indicated with a receiver, and transmission of data is dependent on the indication of the signal strength.

Owner:CONTROLMATIC

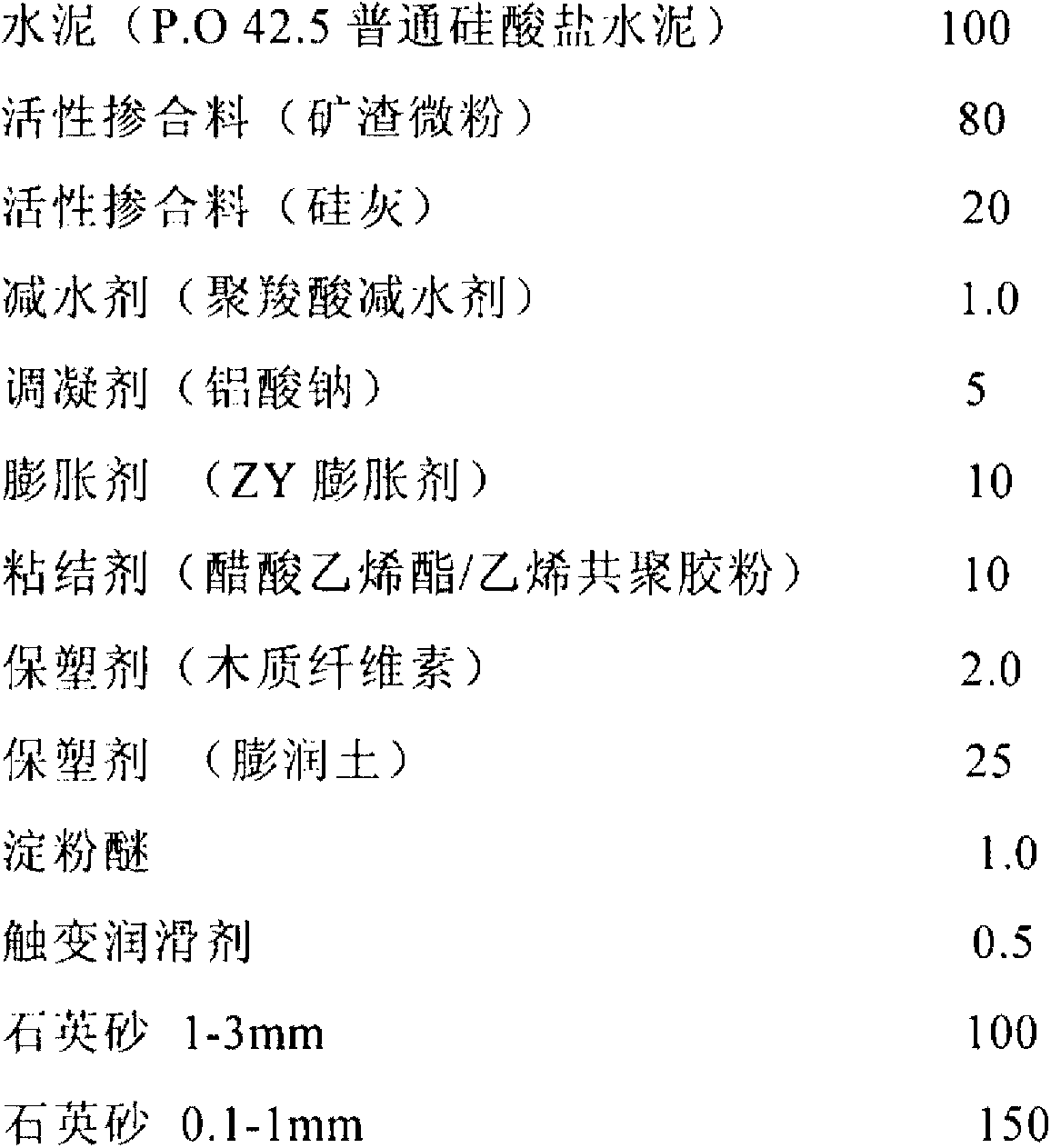

Assembled splicing joint sealing material for building components and application thereof

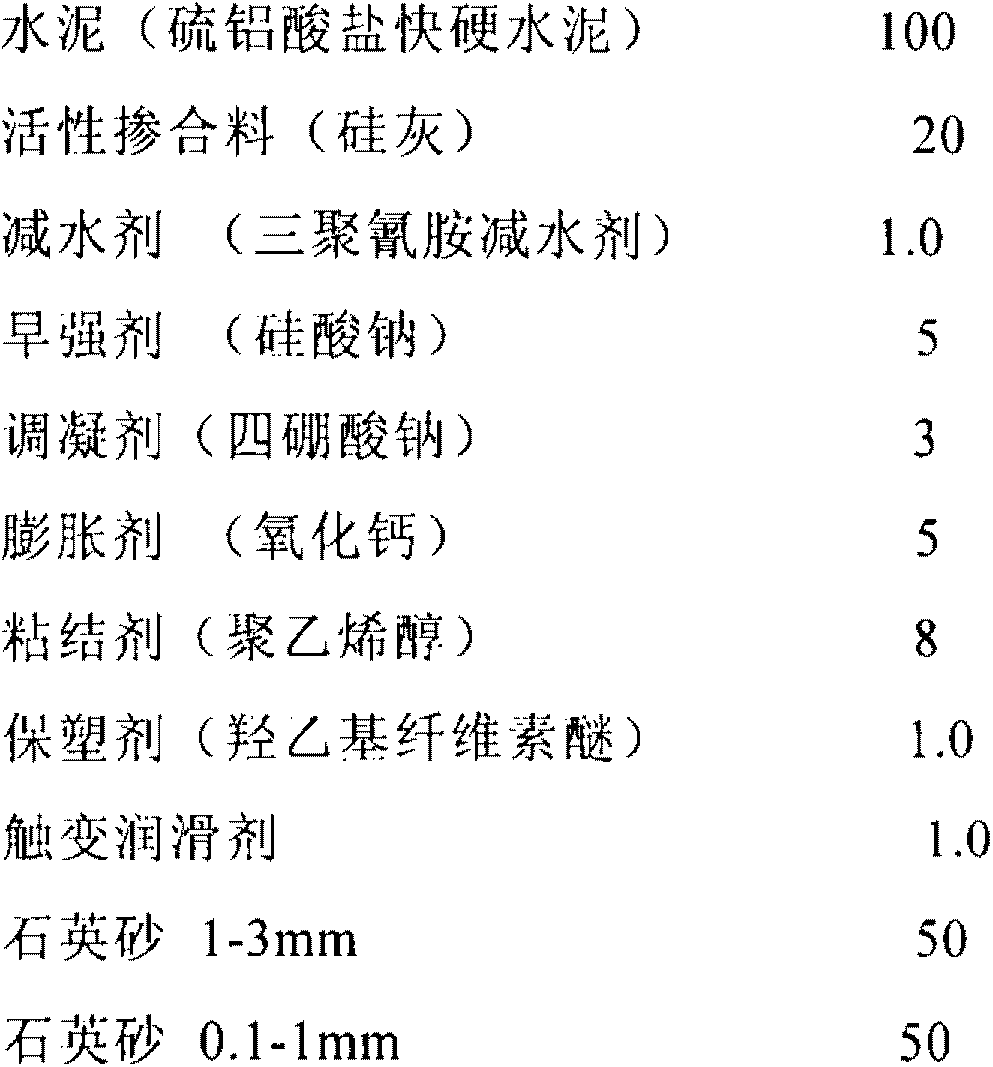

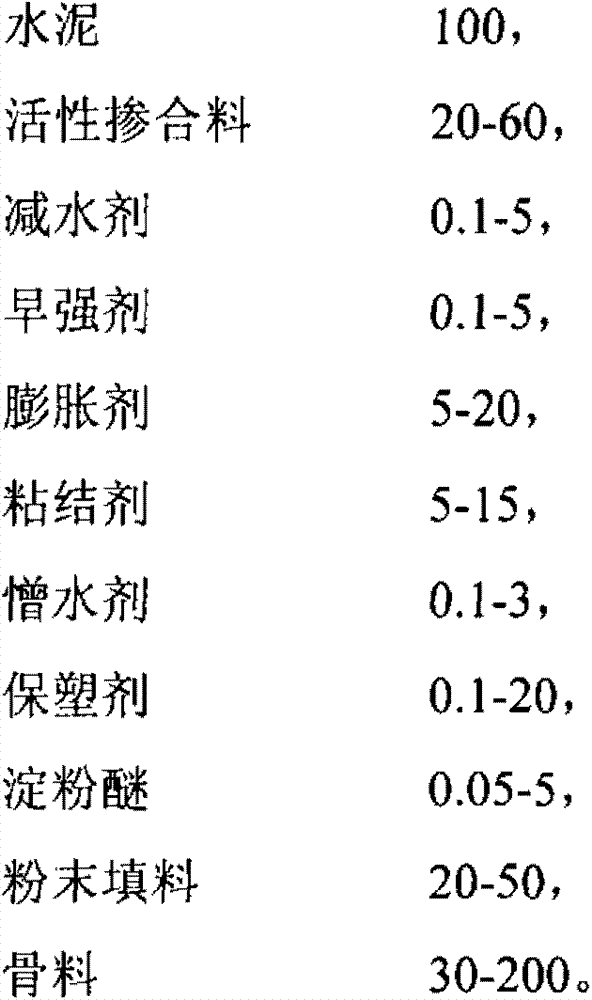

The invention relates to an assembled splicing joint sealing material for building components and an application thereof. The sealing material is prepared from raw materials in parts by weight as follows: 100 parts of cement, 0-150 parts of active admixture, 0.01-10 parts of water reducer, 0.01-10 parts of early strength agent, 0-10 parts of thickening time control agent, 0.1-30 parts of expanding agent, 0-30 parts of bonder, 0.01-30 parts of plastic retaining agent, 0.01-10 parts of starch ether, 0-10 parts of thixotropic lubricant and 0-300 parts of quarts sand. The sealing material can be applied to sealing joint of concrete components spliced. Compared with the prior art, the sealing material is good in construction performance, and can be used by adding water to stir. The sealing material can be quickly constructed by a caulking gun or an electric caulking device, and the operating time is long. Newly mixed slurry has good plasticity, adhesive force and resistance to falling. The sagging phenomenon is further avoided when a vertical direction is spliced. The condensing time is adjusted according to the project demand, the early strength is high and the later strength is continuously increased.

Owner:TONGJI UNIV

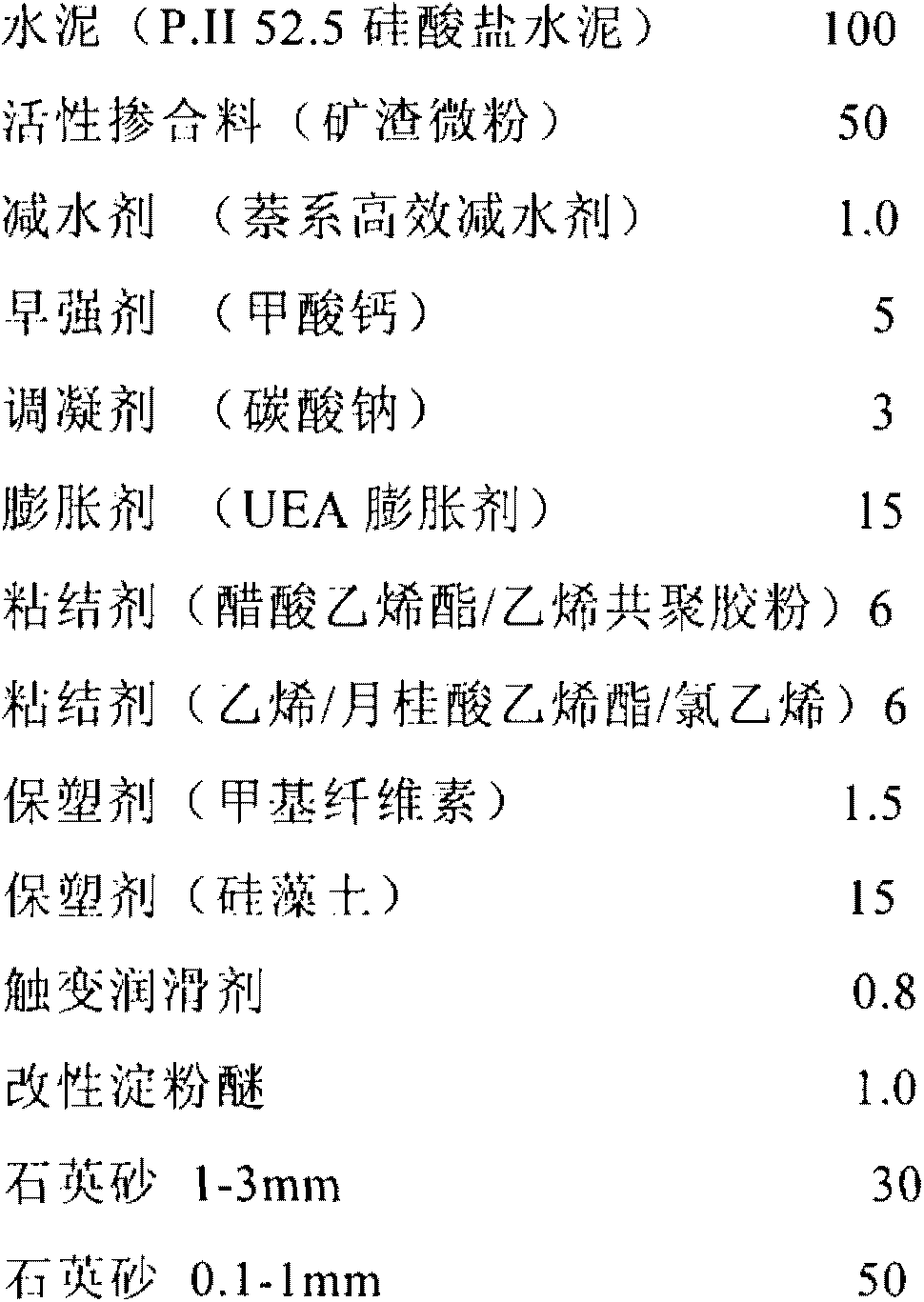

Cement-based shrinkage-free wall hole-penetrating blocking material and preparation method and construction method

ActiveCN103159440AGuaranteed tightnessPrevent infiltrationBuilding material handlingBuilding insulationsEtherFree wall

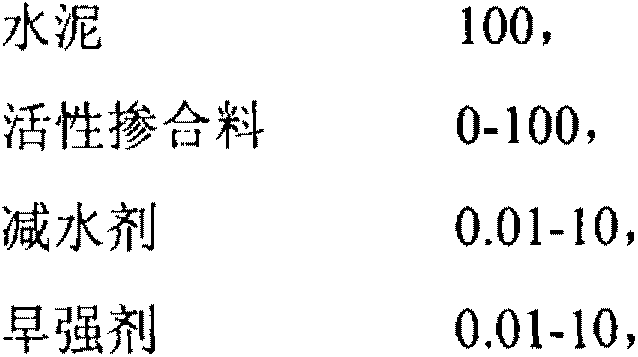

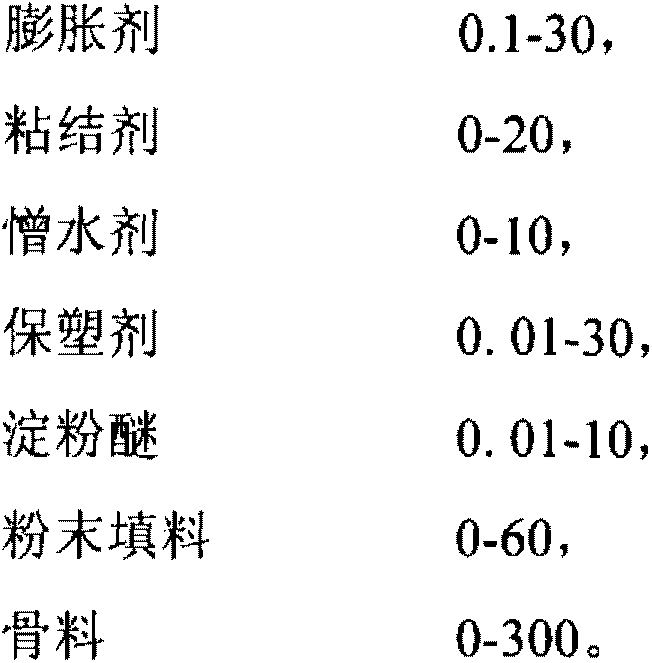

The invention relates to cement-based shrinkage-free wall hole-penetrating blocking materials and a preparation method and a construction method. The materials comprise, by weight, 100 cement, 0-100 active admixture, 0.01-10 water reducing agent, 0.01-10 early strength agent, 0.1-30 expanding agent, 0-20 adhesion agent, 0-10 water repellent, 0.01-30 plastic retaining agent, 0.01-10 starch ether, 0-60 power filler and 0-300 aggregate. Compared with the prior art, the cement-based shrinkage-free wall hole-penetrating blocking materials have the advantages of being good in construction performance, and long in operational time. New mixing slurry has good plasticity, adhesive power and anti-falling performance, a caulking gun or a caulking machine can be used for pressing, injecting or sealing holes, a flowing phenomenon cannot appear even big holes are filled, and the big holes can be filled until the big holes are full and until reaching the deep hole, and completely sealed, and the sealing materials can fully come into play.

Owner:杭州固特建筑加固技术工程有限公司

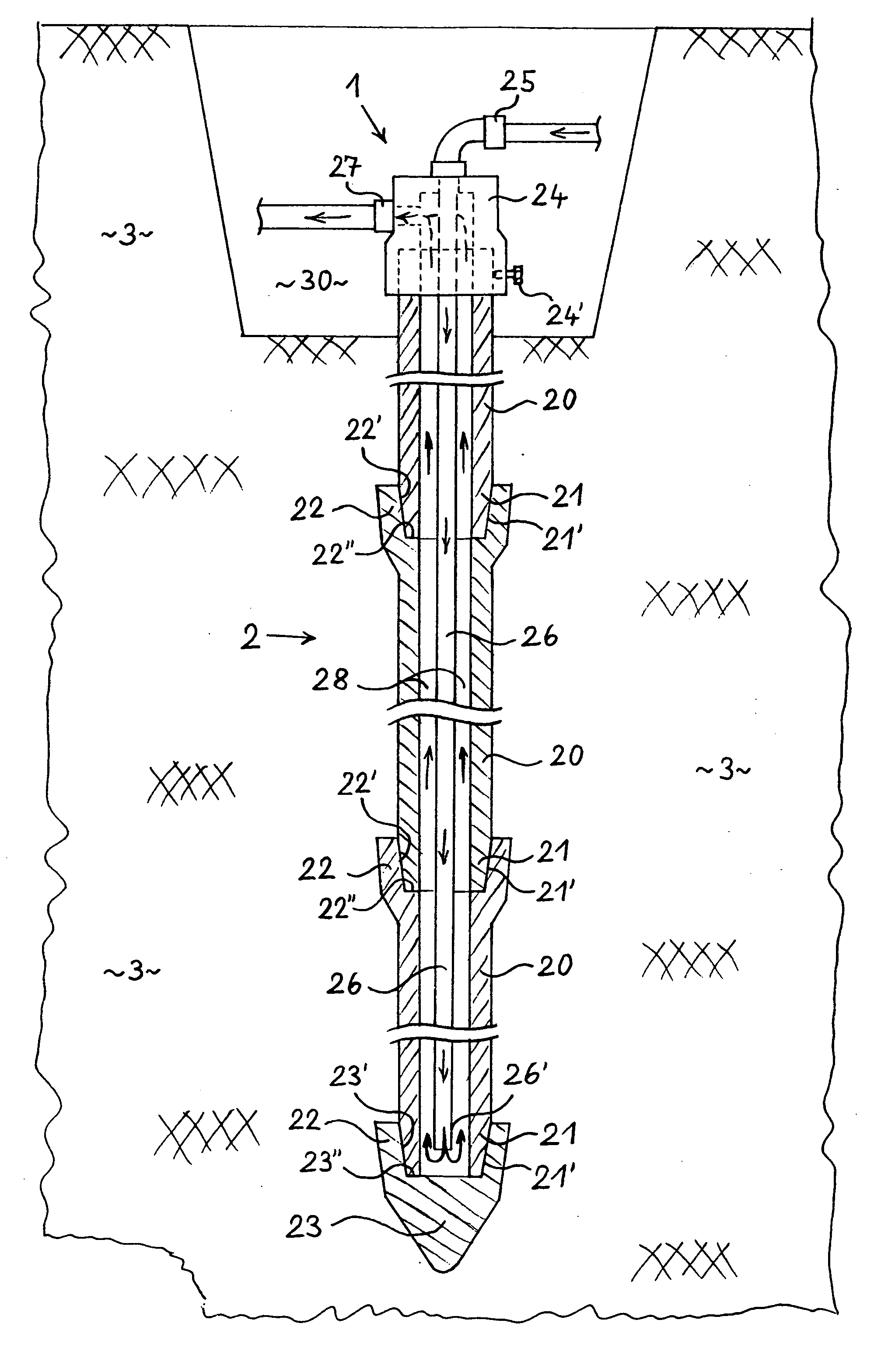

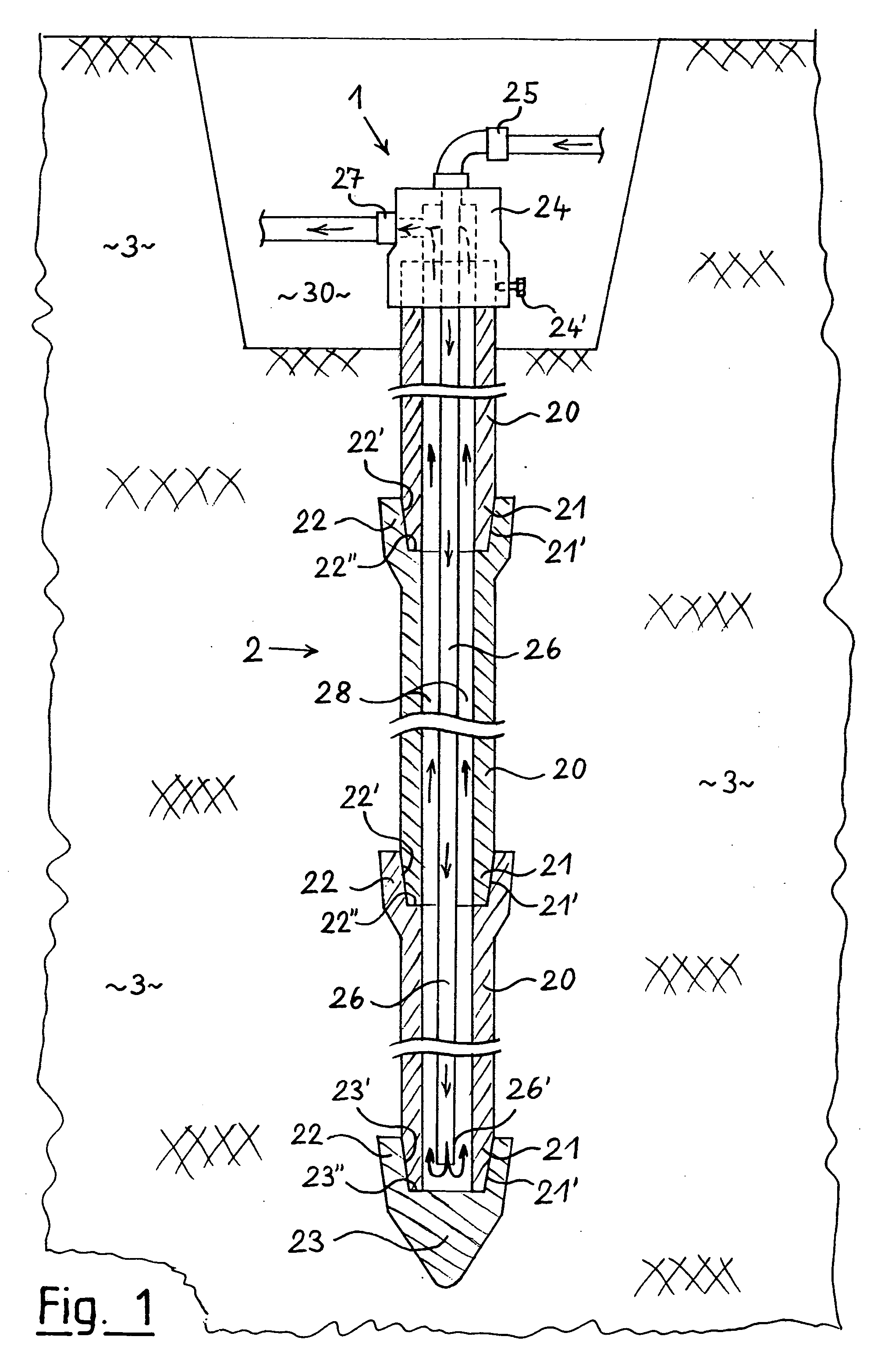

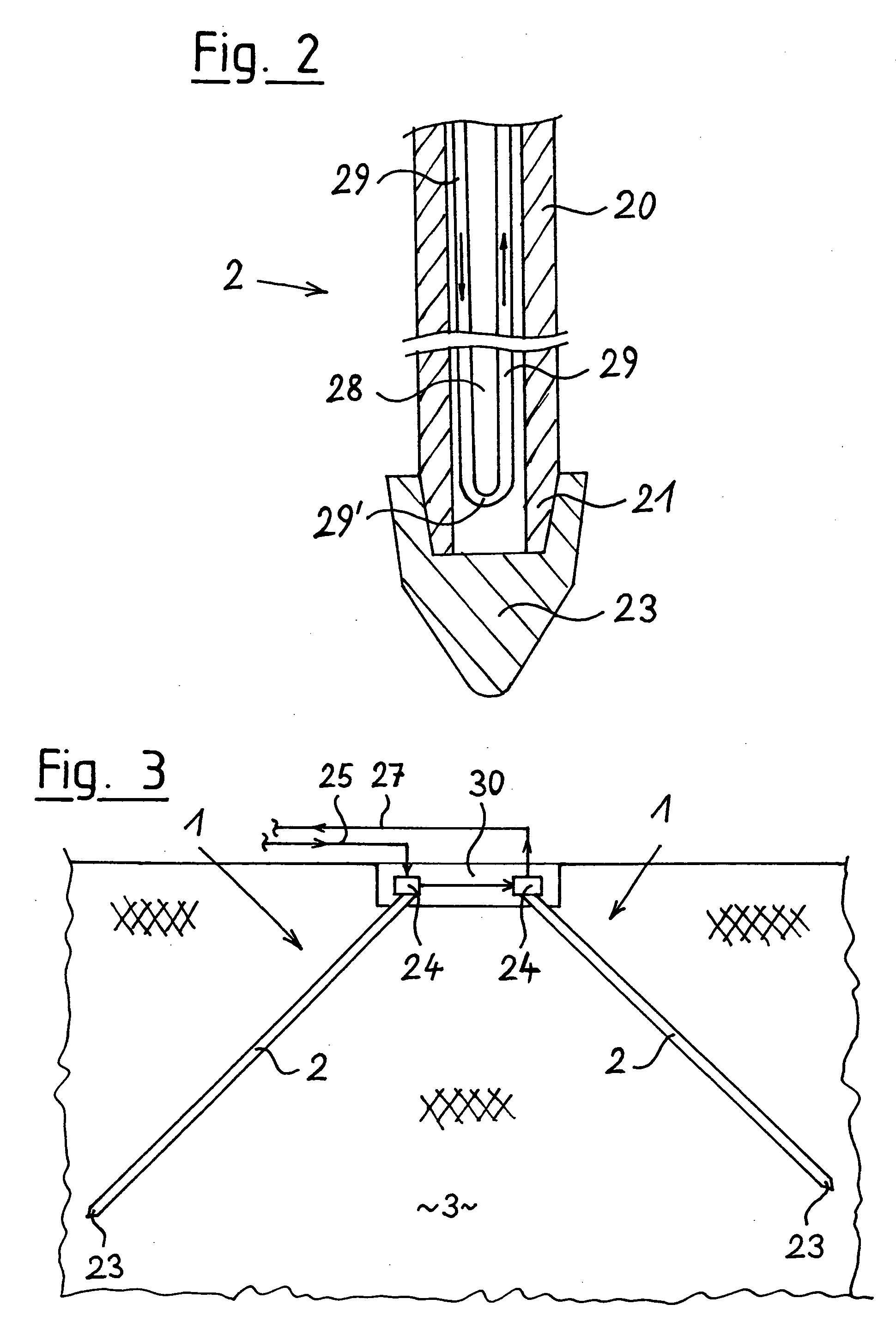

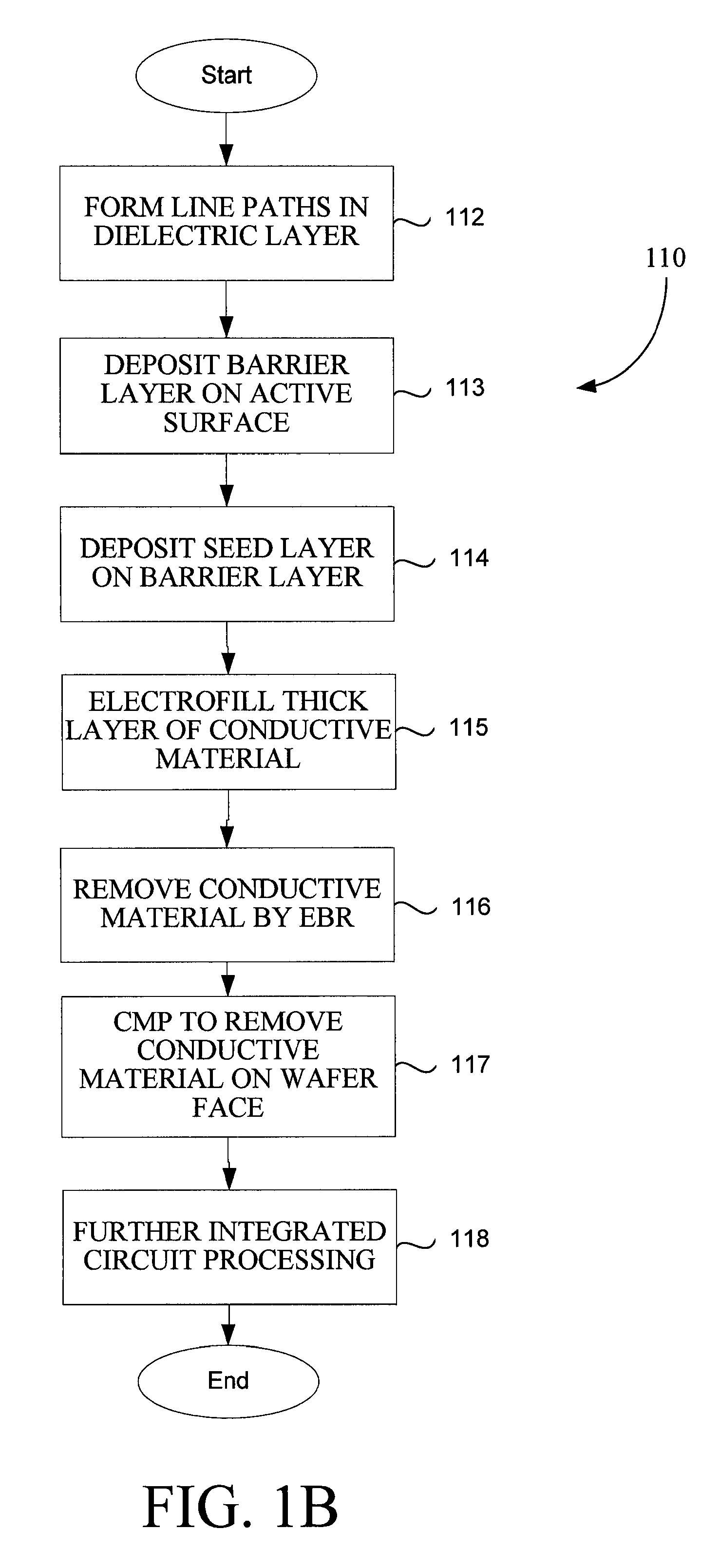

Heat source or heat sink unit with thermal ground coupling

InactiveUS20050061472A1Avoid corrosion damageAvoid introducingOther heat production devicesGeothermal energy generationCouplingEngineering

The invention relates to a heat source or a heat sink unit with thermal ground coupling, comprising at least one ground probe arranged in the earth, whereby each earth probe is a probe tube made from several pile tube segments. An open dip tube or a U-shaped tube loop is arranged in the probe tube at the open lower end thereof. Said unit is characterized in that each pile tub segment is made from ductile cast iron, the pile tube segments re embodied such as to plug into each other at the ends thereof and each pile tube segment comprises, at the one end thereof, a conical outer circumference and, at the other end thereof, a sleeve embodied with a shoulder stop having a matching conical internal circumference, whereby the diameter thereof and the cone angle are such that on driving in the pile tube segments a positive and sealed connection between the pile tube segments is generated.

Owner:WATERKOTTE WARMEPUMPEN

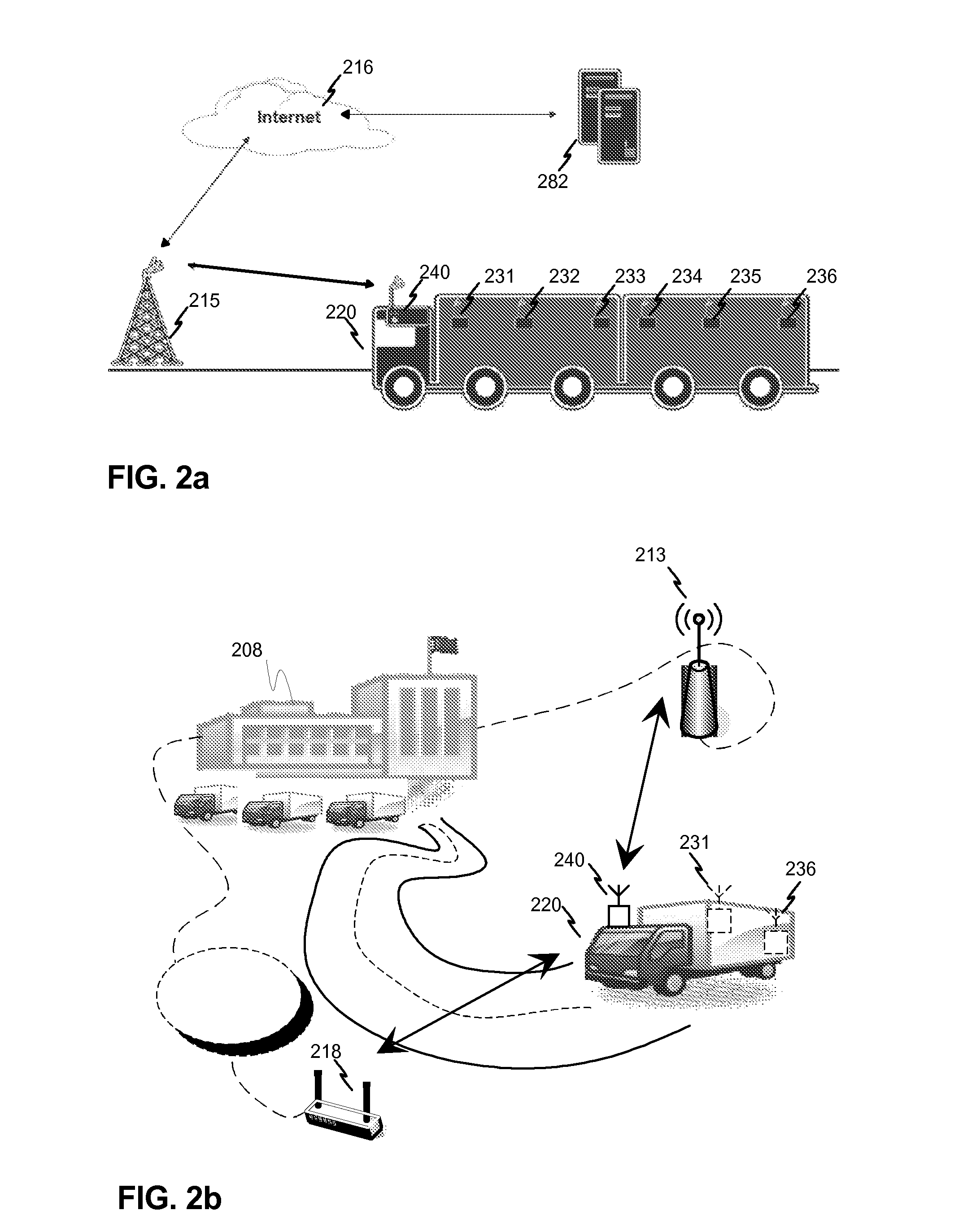

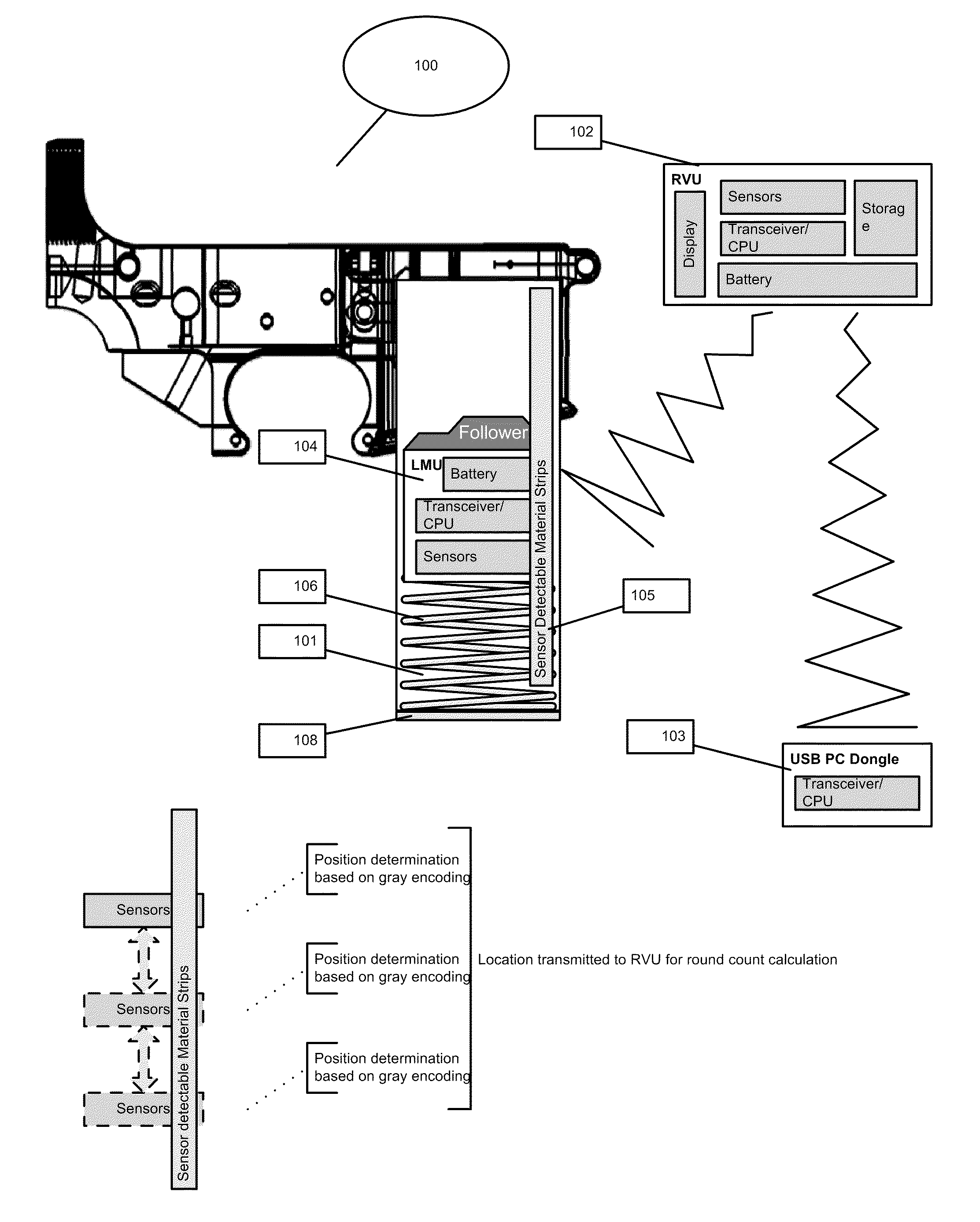

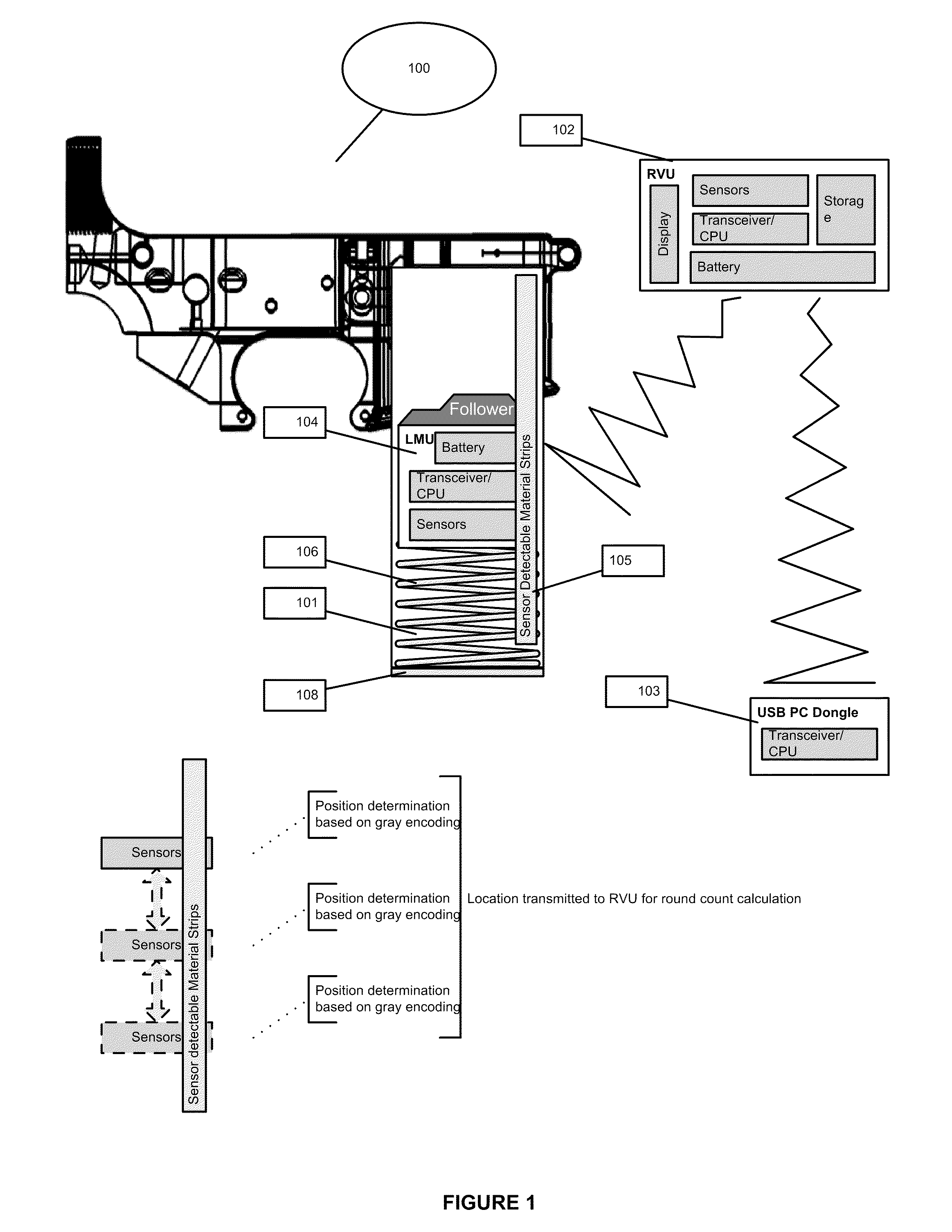

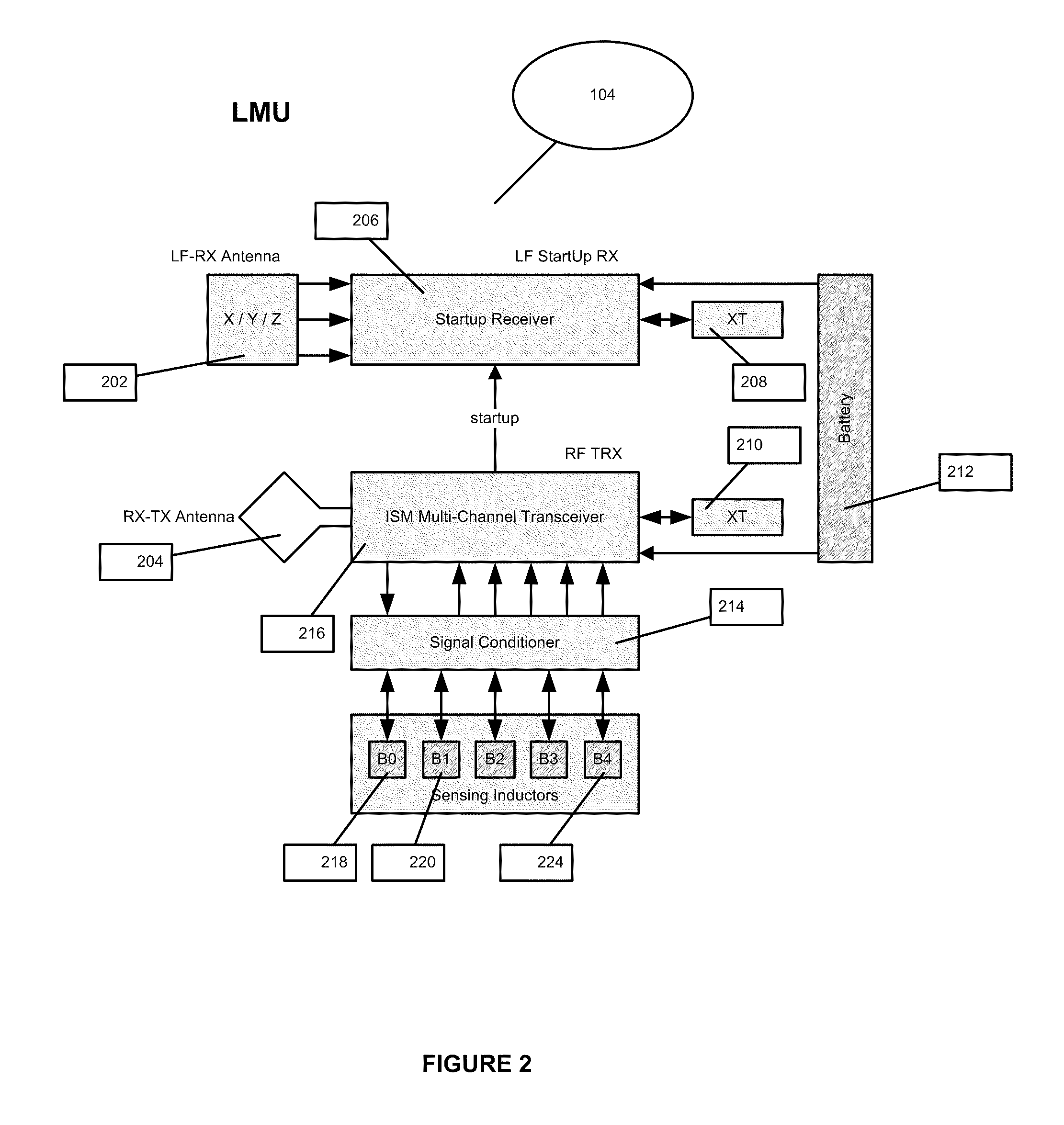

System and Method for the Remote Measurement of the Ammunition Level, Recording and Display of the current level

ActiveUS20100281725A1Long operating timeSave energyAmmunition loadingSatellite radio beaconingReal-time dataEngineering

This invention relates to a method, system and computer program product that monitors usage for man carried weapon systems; specifically a device to monitor ammunition level and weapon discharges through real time data collection, analysis and real time visual feedback to the operator. An ammunition level detecting system mounted on a projectile weapon comprising: A level measurement unit (LMU) and a Reader and Visualization Unit (RVU) and a PC Dongle which configured to facilitate communication between the RVU and a personal computer (PC), enabling management of the RVU configuration and offloading of sensor obtained and system determined data values.

Owner:AWIS

Hollow fiber, dope composition for forming hollow fiber, and method of making hollow fiber using the same

InactiveUS20090297850A1Improve permeabilityHigh selectivitySuture equipmentsCosmetic preparationsHollow fibreFiber

Owner:IUCF HYU (IND UNIV COOP FOUND HANYANG UNIV)

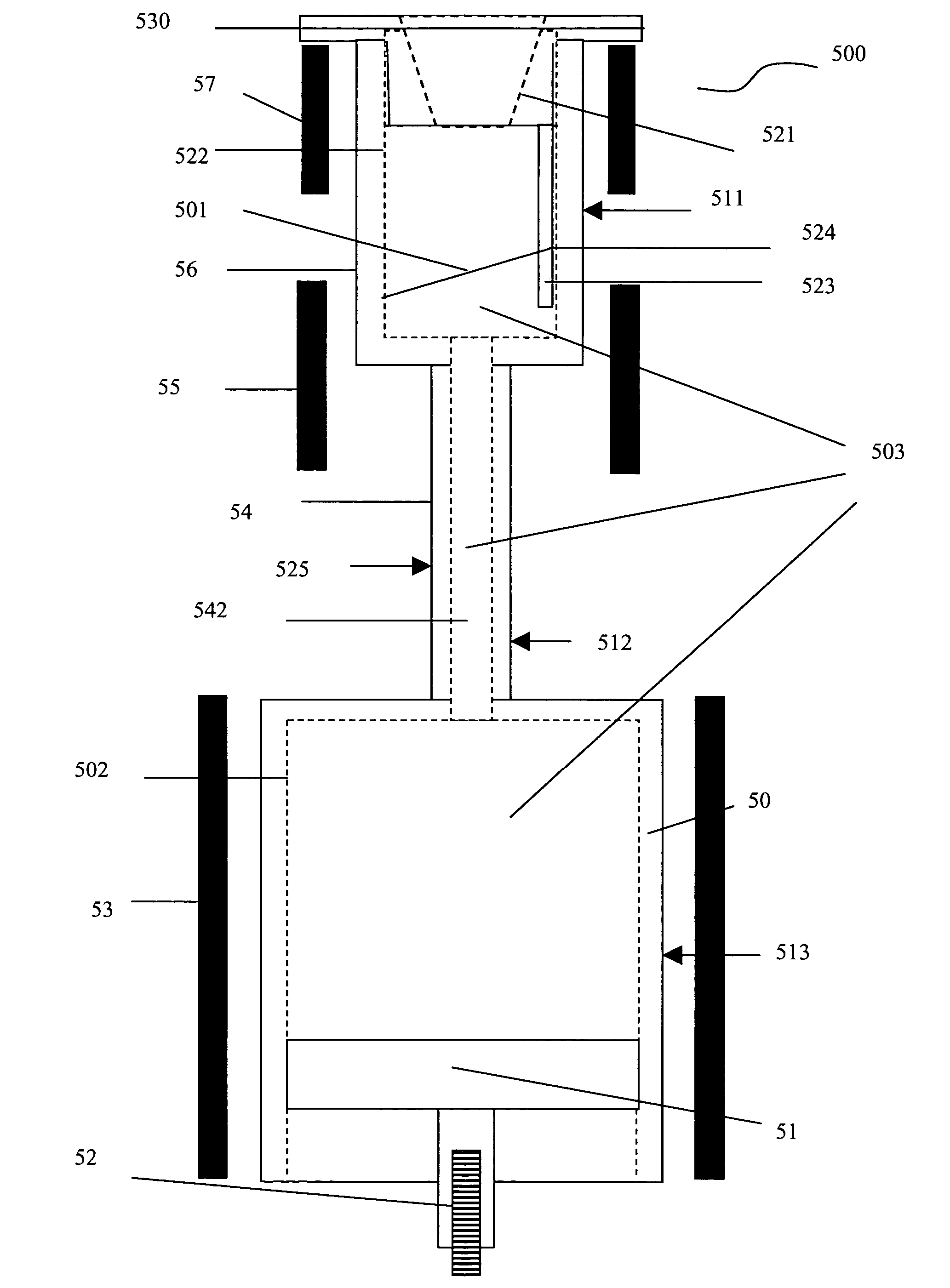

Means and method for a liquid metal evaporation source with integral level sensor and external reservoir

InactiveUS20050229856A1Long operating timeReduce hydrostatic pressureVacuum evaporation coatingSputtering coatingEvaporation (deposition)Engineering

A liquid metal evaporation source for use in Molecular Beam Epitaxy and related metal vacuum deposition techniques. An evaporator is maintained at a high temperature to evaporate a liquid metal, a reservoir for holding the liquid metal source is maintained at a temperature above the melting point of the metal but below the temperature in the evaporator, and a hollow transport tube connecting the evaporator and reservoir is maintained at a temperature between these temperatures. The reservoir is in the shape of a hollow cylinder with a close-fitting cylindrical piston which is used to force the liquid metal through the hollow transport tube into the evaporator. The liquid metal will not flow past the piston seal if a suitably small gap is formed between the piston and the reservoir walls wherein the surface tension of the liquid metal will exceed its hydrostatic pressure against the piston thus forming a leak-tight seal.

Owner:RJM SEMICON

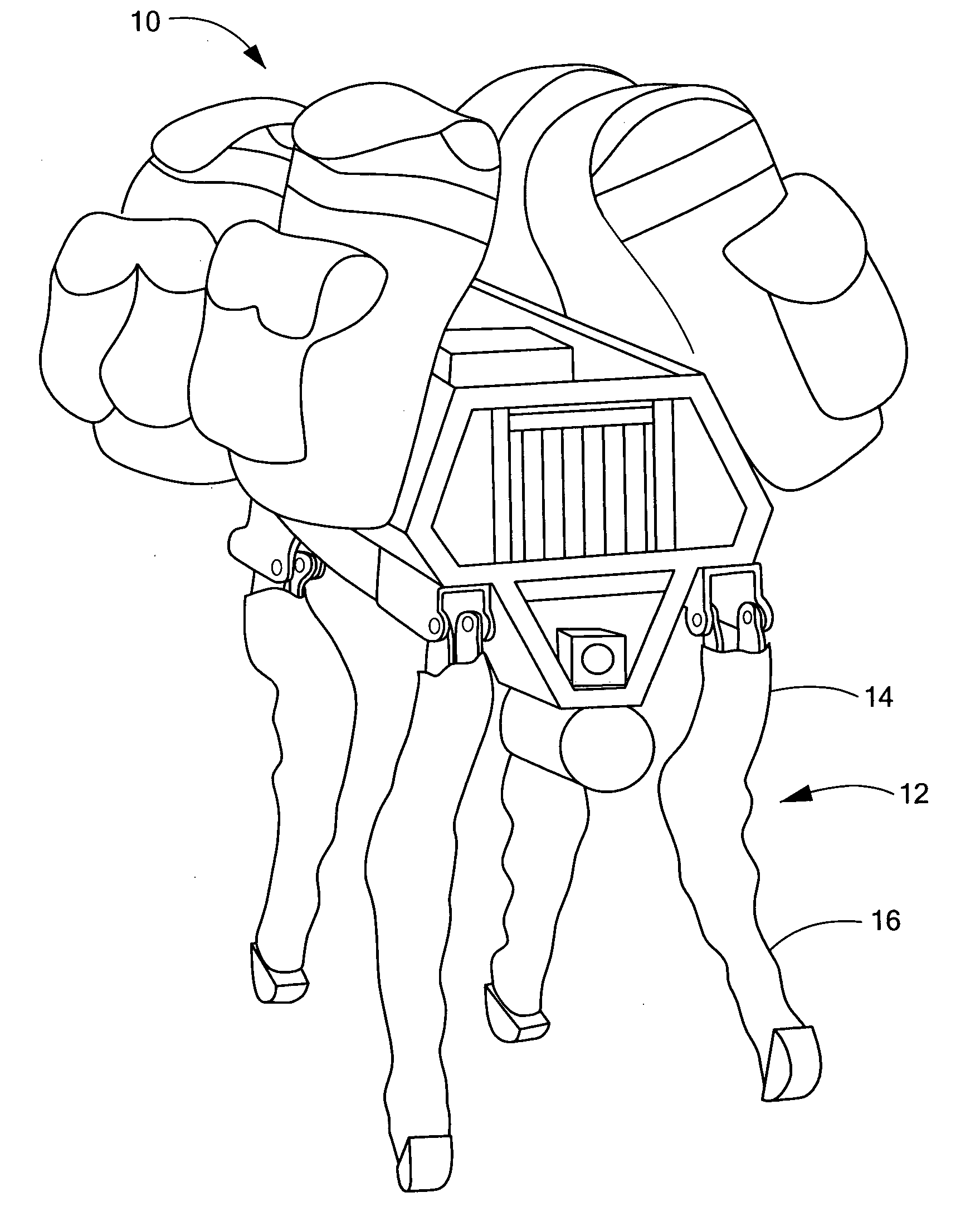

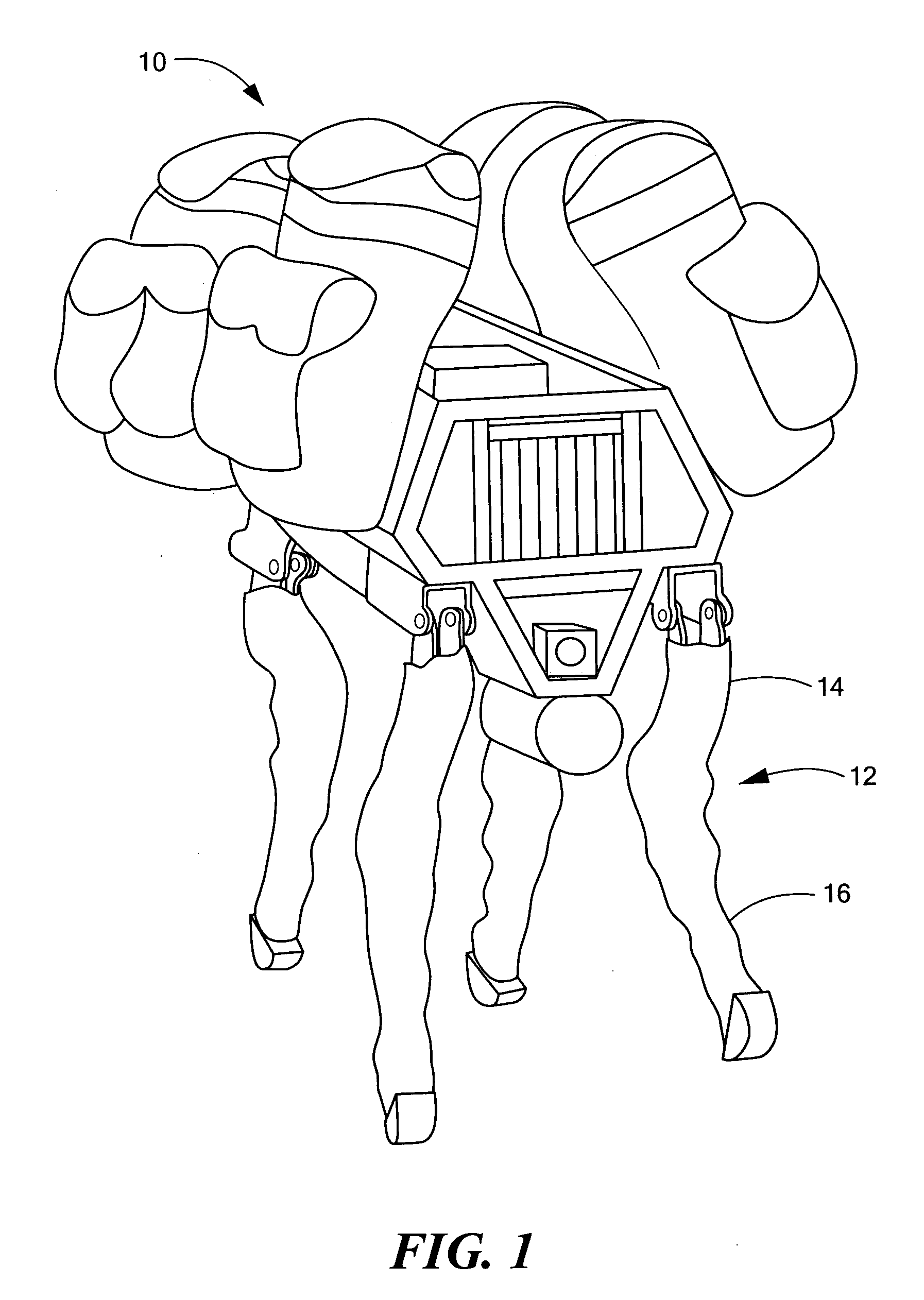

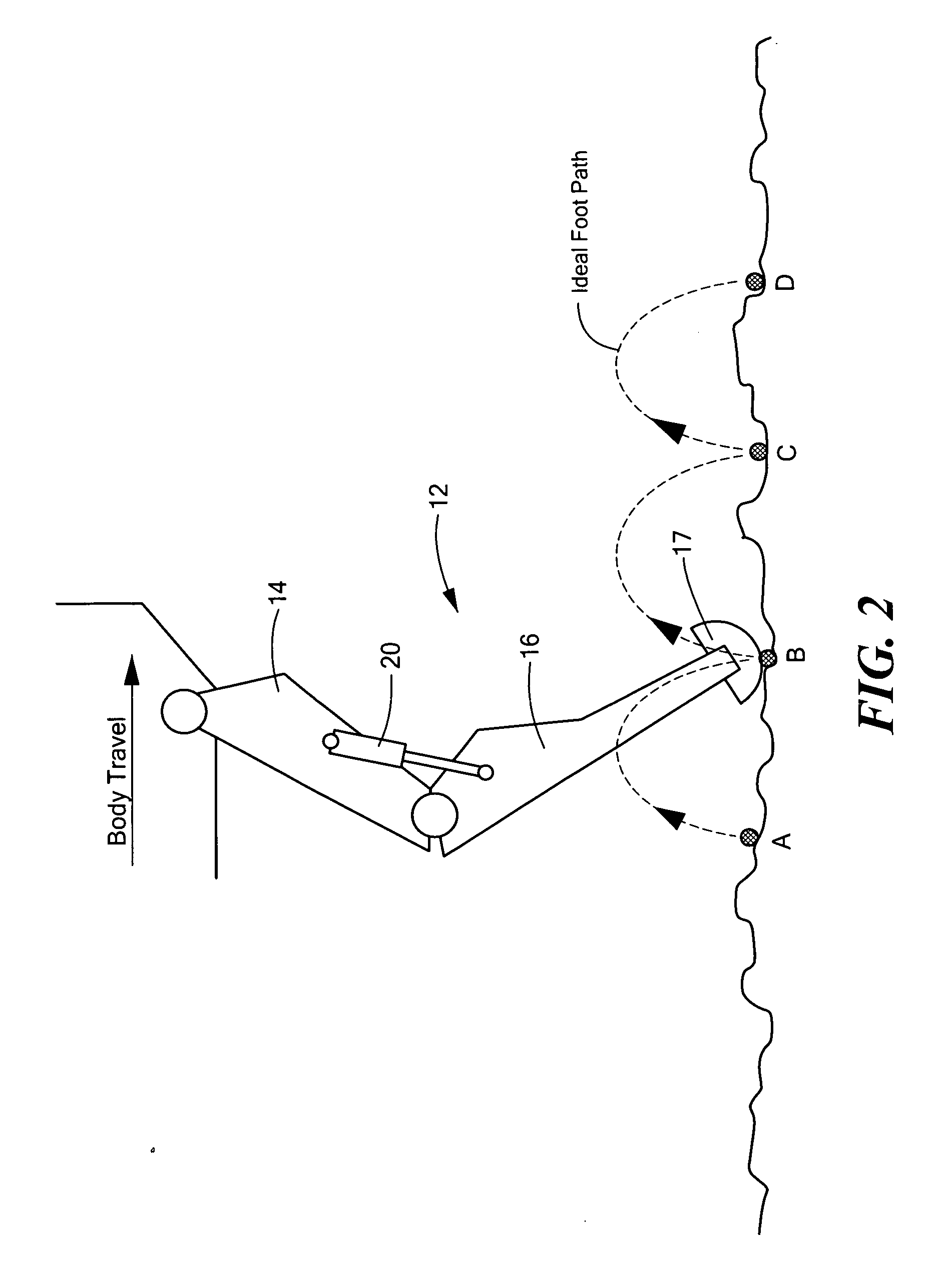

Actuator system

ActiveUS20100090638A1Increase powerFacilitates robots capable of carrying heavier payloadsProgramme-controlled manipulatorServomotorsHydraulic circuitActuator

An actuator subsystem preferably for a robot or bionic linkage. A joint between two robotic or bionic members includes at least first and second actuators such as piston-cylinder assemblies connected between the members. A hydraulic circuit includes a sensor subsystem for sensing the magnitude of the load on the piston-cylinder assemblies and / or members. A fluid supply system includes an actuatable control valve operable to supply fluid to one or both piston-cylinder assemblies. A control circuit is responsive to the sensor and is configured to electronically control the fluid subsystem to supply fluid to the first piston-cylinder assembly when the sensor subsystem senses a load below a predetermined magnitude and to supply fluid to both piston-cylinder assemblies when the sensor subsystem senses a load above the predetermined magnitude.

Owner:BOSTON DYNAMICS INC

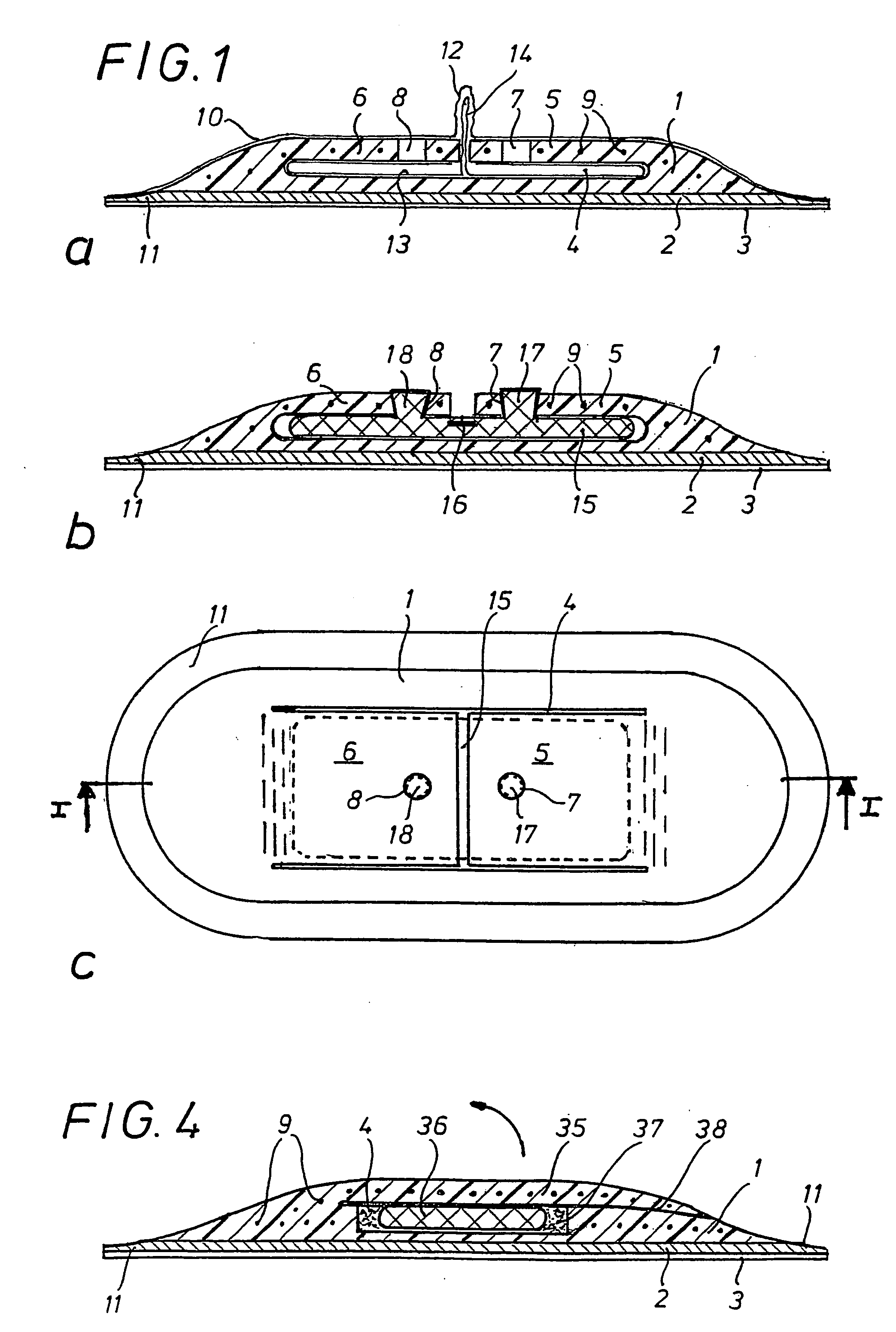

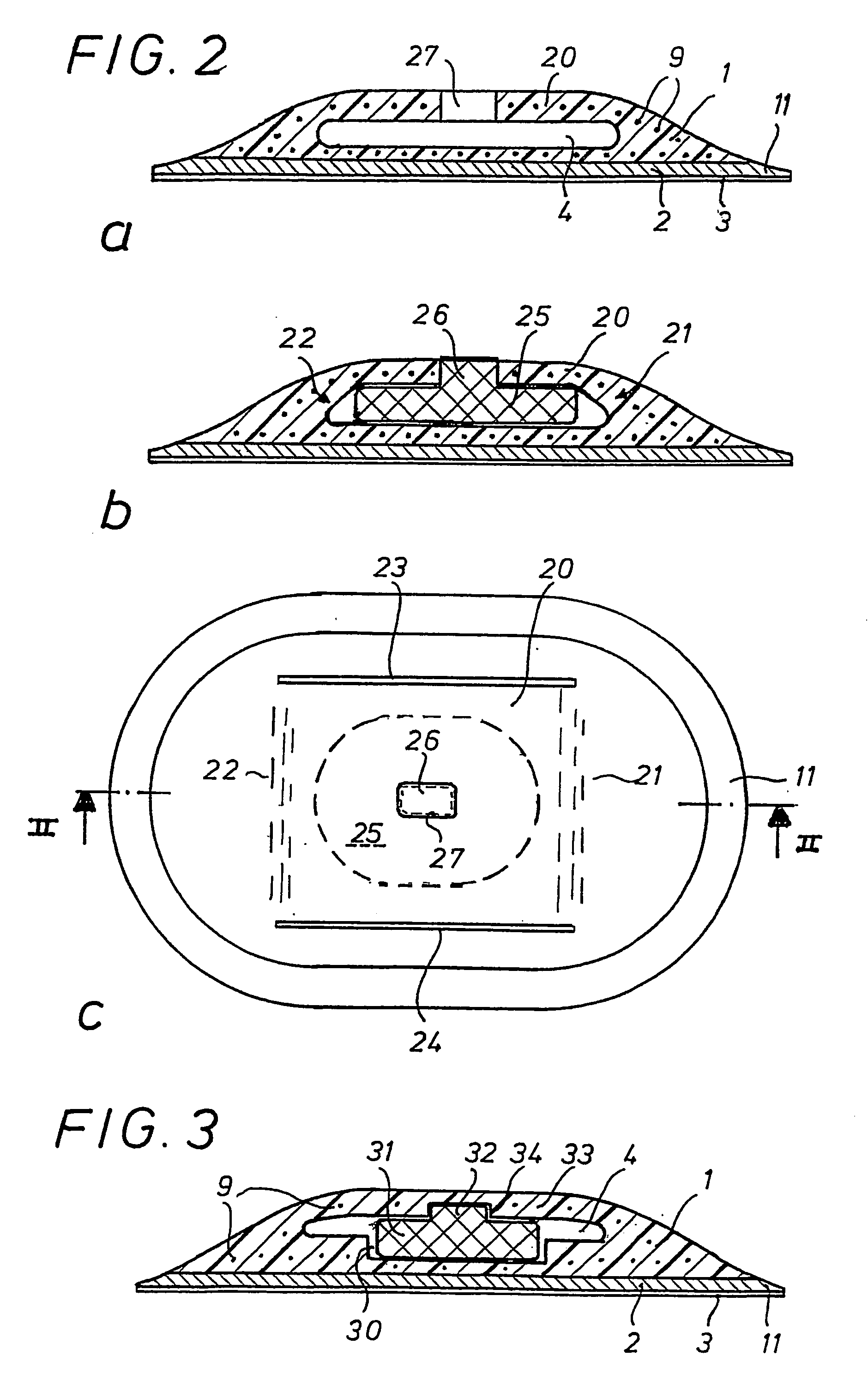

Mount for attaching an electronic component to a rubber article

InactiveUS20060220816A1Permanent attachmentSmall loadSolid-state devicesTyre measurementsRubber materialTectorial membrane

A main body for attaching an electronic component, for example, a transponder, on a rubber article, such as a tire, a conveyor belt, or the like. The mount has a connecting layer made, in one embodiment, of uncured, curable rubber material which is covered by an adhering protection film prior to use. A main body made of cured or uncured rubber material is permanently connected with this connecting layer and has a recess for accommodating the electronic component. A cover preferably made of the main body material, serves for fixing the electronic component in the recess in the main body.

Owner:STAHLGRUBER OTTO GRUBER

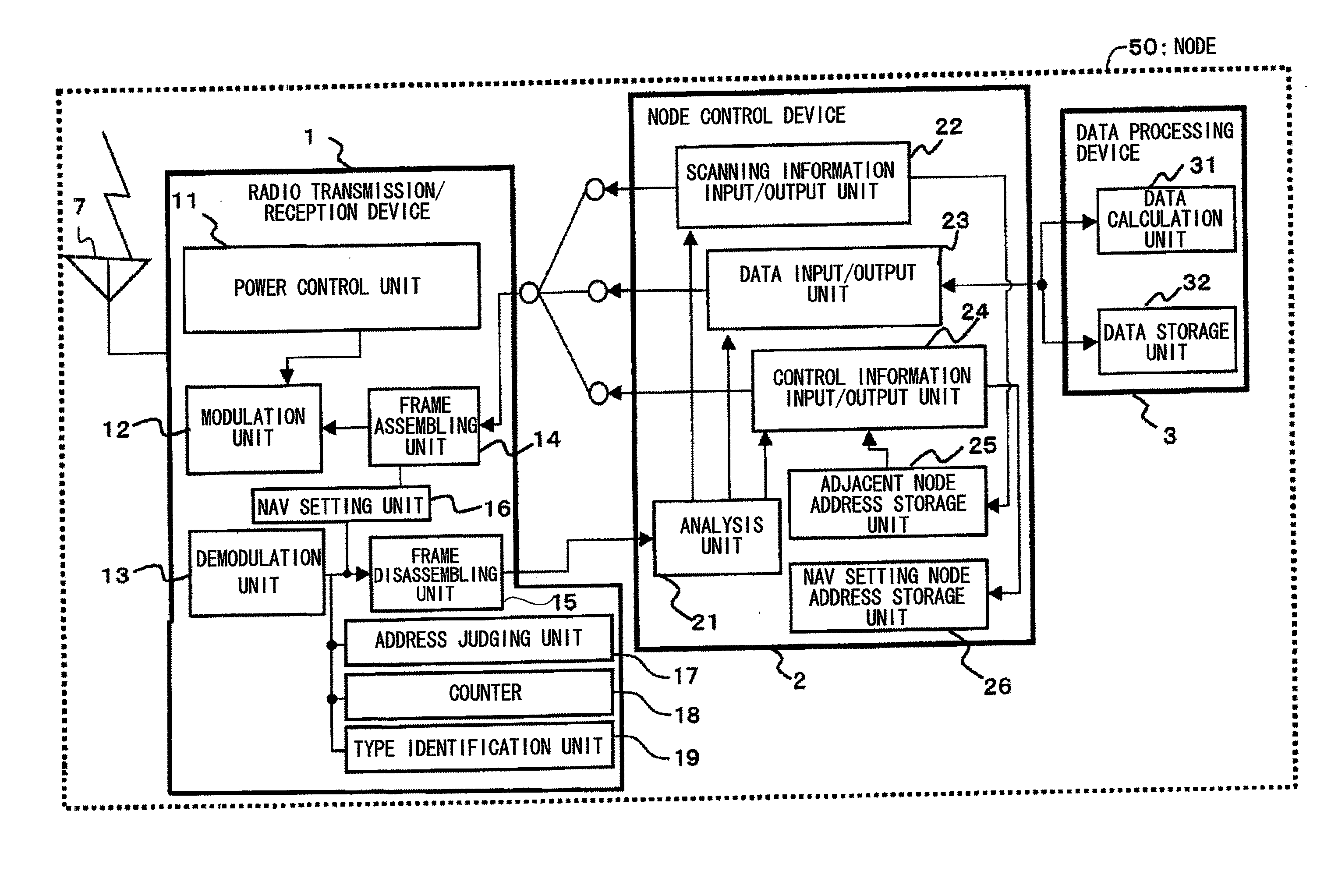

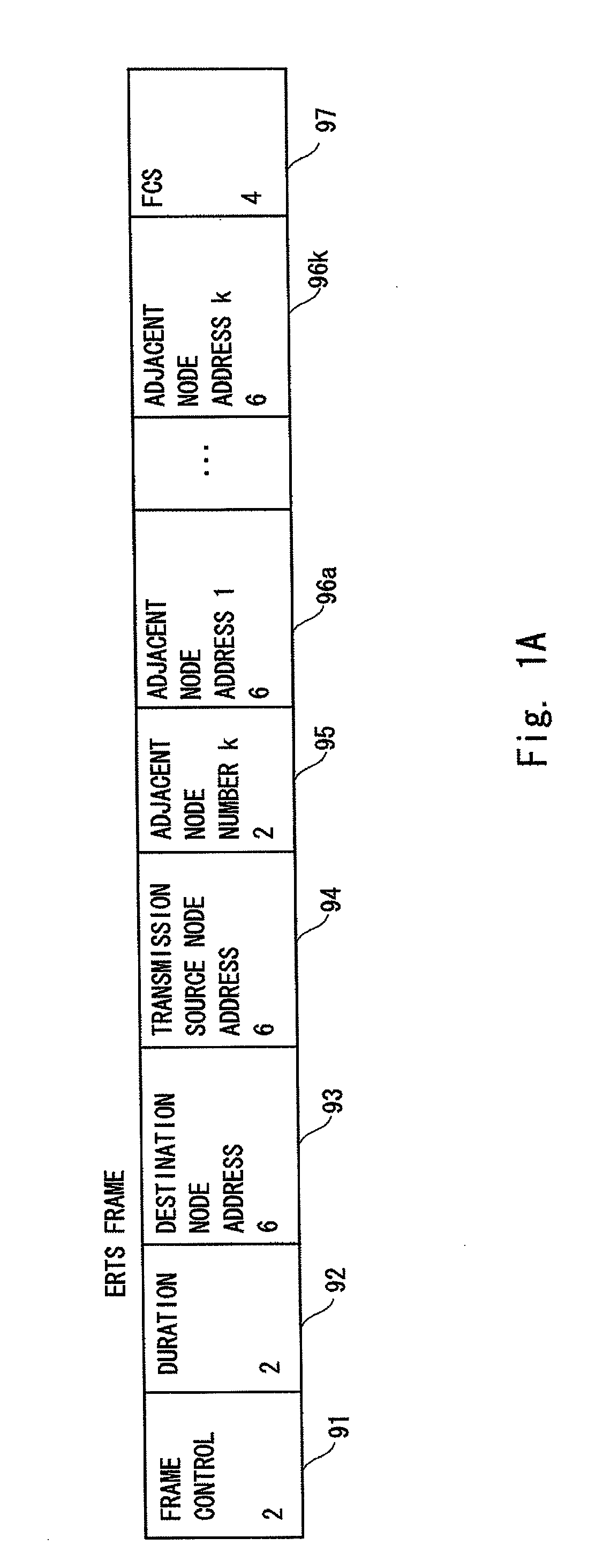

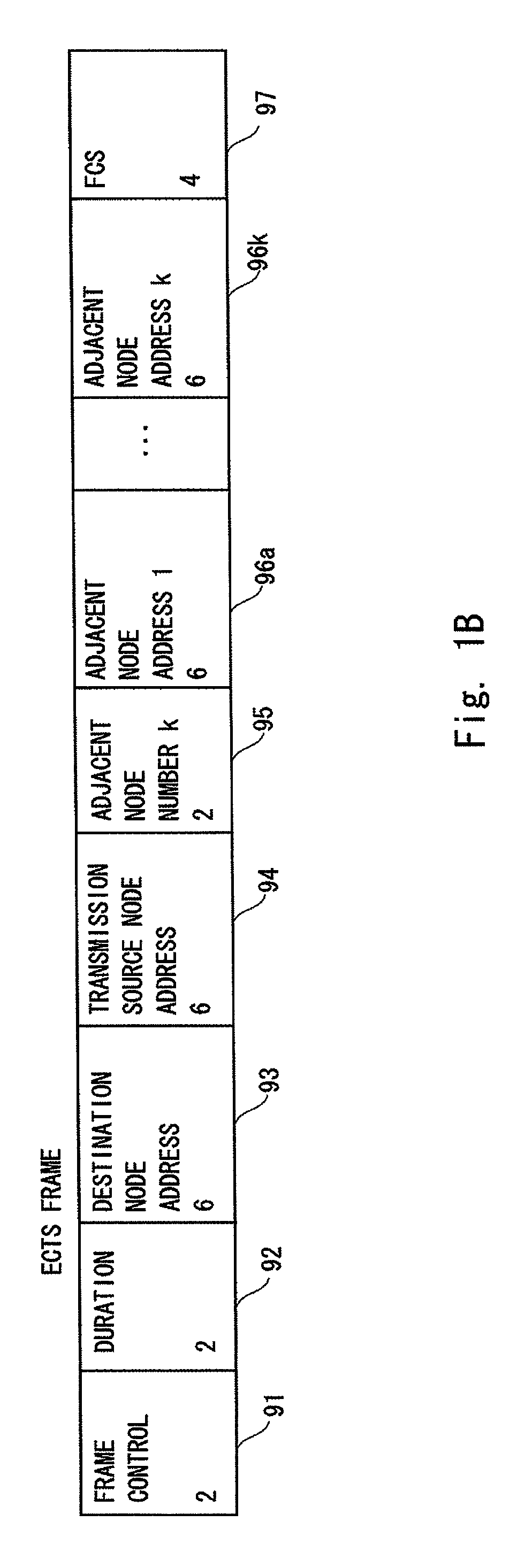

Radio communication device, radio communication method, and radio communication program

InactiveUS20100039969A1Degradation of power consumption efficiency can be preventedStop transmissionEnergy efficient ICTPower managementControl communicationsCommunication device

It is possible to prevent degradation of power consumption efficiency or lowering of a communication rate in a radio communication. Each node 50 determines a transmission power for data communication so that the number of searched nodes reaches a target value and stores the node address of the searched node by the transmission power in an adjacent node address storage unit 25. Moreover, the transmission power for control communication is determined in the same way. When the node 50 transmits a data frame to another node, an ERTS frame including the node address stored in the adjacent node address storage unit 25 is transmitted by the transmission power for the control communication. After an ECTS frame is received, the data frame is transmitted by the transmission power for the data communication. A control information input / output unit 24 identifies the node in an NAV period from the received ERTS frame or the like and stores the node address of the node in an NAV setting node address storage unit 26.

Owner:NEC CORP

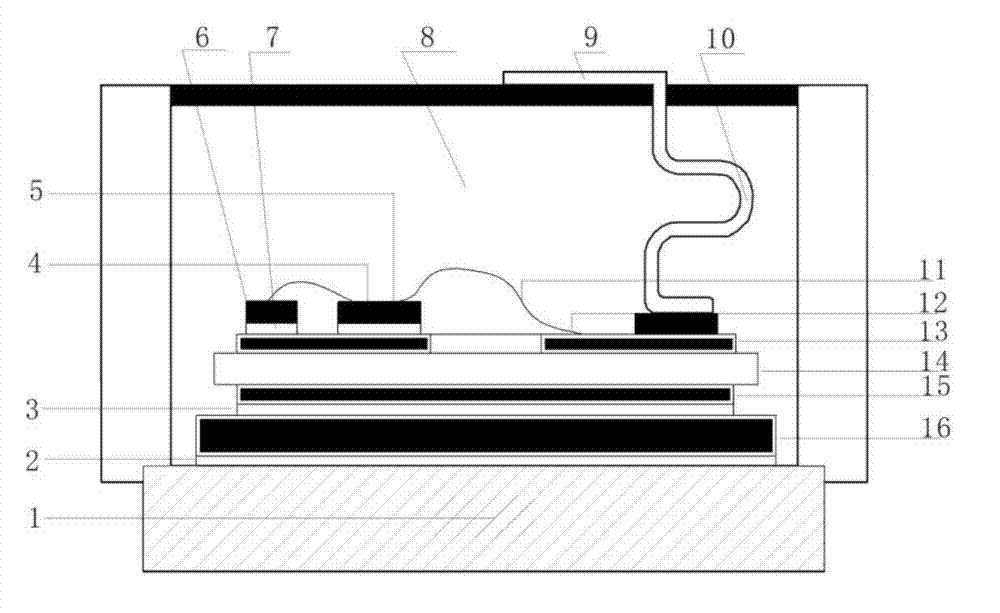

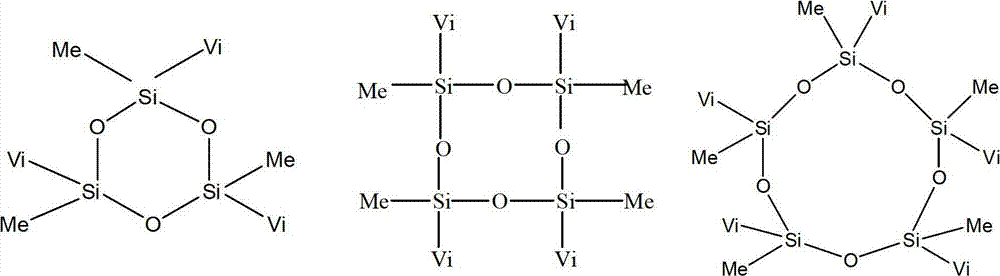

Organic silica gel used for packaging IGBT (insulated gate bipolar translator) module, and preparation method of organic silica gel

InactiveCN102807757AViscosity is convenient and controllableHigh reactivitySemiconductor/solid-state device detailsSolid-state devicesOptical propertyHigh intensity

The invention relates to an organic silica gel used for packaging an IGBT (insulated gate bipolar translator) module and a preparation method of the organic silica gel. The organic silica gel comprises a component A and a component B according to the weight proportion of 1:1, wherein the component A comprises the following raw materials by weight part: 94 to 99.89 parts of base material, 0.01 to 5 parts of silane coupling agent, and 0.1 to 1 part of catalyst; the component B comprises the following raw materials by weight part: 79 to 95 parts of base material, 5 to 15 parts of crosslinking agent, 0.01 to 5 parts of fire retardant and 0.1 to 1 part of inhibitor. The organic silica gel used for packaging the IGBT module has excellent optical property, high strength, low oil leakage, and fire resistance, is transparent, is solidified fast at high temperature, is capable of satisfying the long-term operating requirements under high and / or low temperature environments, and is mainly beneficial to sealing and encapsulation protection of the IGBT modules.

Owner:YANTAI DEBANG ADVANCED SILICON MATERIALS

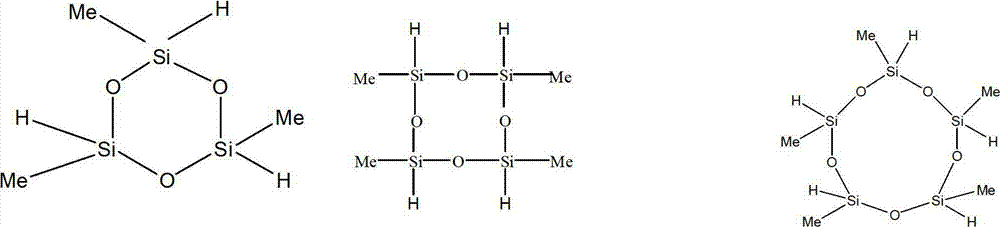

High adhesiveness silicone gel for embedding precision electron component

InactiveCN102516775AImprove liquiditySelf defoamingOther chemical processesAdhesivesCross-linkSilicone Gels

The invention relates to silicone gel and specifically provides a high adhesiveness silicone gel for embedding a precision electron component. The silicone gel comprises a component A and a component B that have similar viscosity and are in transparent fluid shape. The component A mainly comprises vinyl silicone oil and catalyst; the component B mainly comprises vinyl silicone oil, cross-linking agent and inhibitor; an accessory employs a diluent or an adhesion agent or a mixture of the two; the accessory is arranged in the component A or the component B or both of the two; and the component A and the component B are independently packaged and mixed in a ratio of 1:0.8-1.2 for usage. The invention has advantages of good fluidity, property of automatic deaeration and simple operation. The component A and the component B are independently packaged, and the two components will not gelatinize after mixing, so as to gain a long operating time; the mixture can solidify rapidly once heated, and the solidification time can be controlled freely by temperature and inhibitor amount; and the silicone gel is in semi-solidification state after solidification, has good adhesiveness and sealing performance on many base materials and has excellent hot-cold alternate resistance.

Owner:TANGSHAN SANYOU SILICON IND

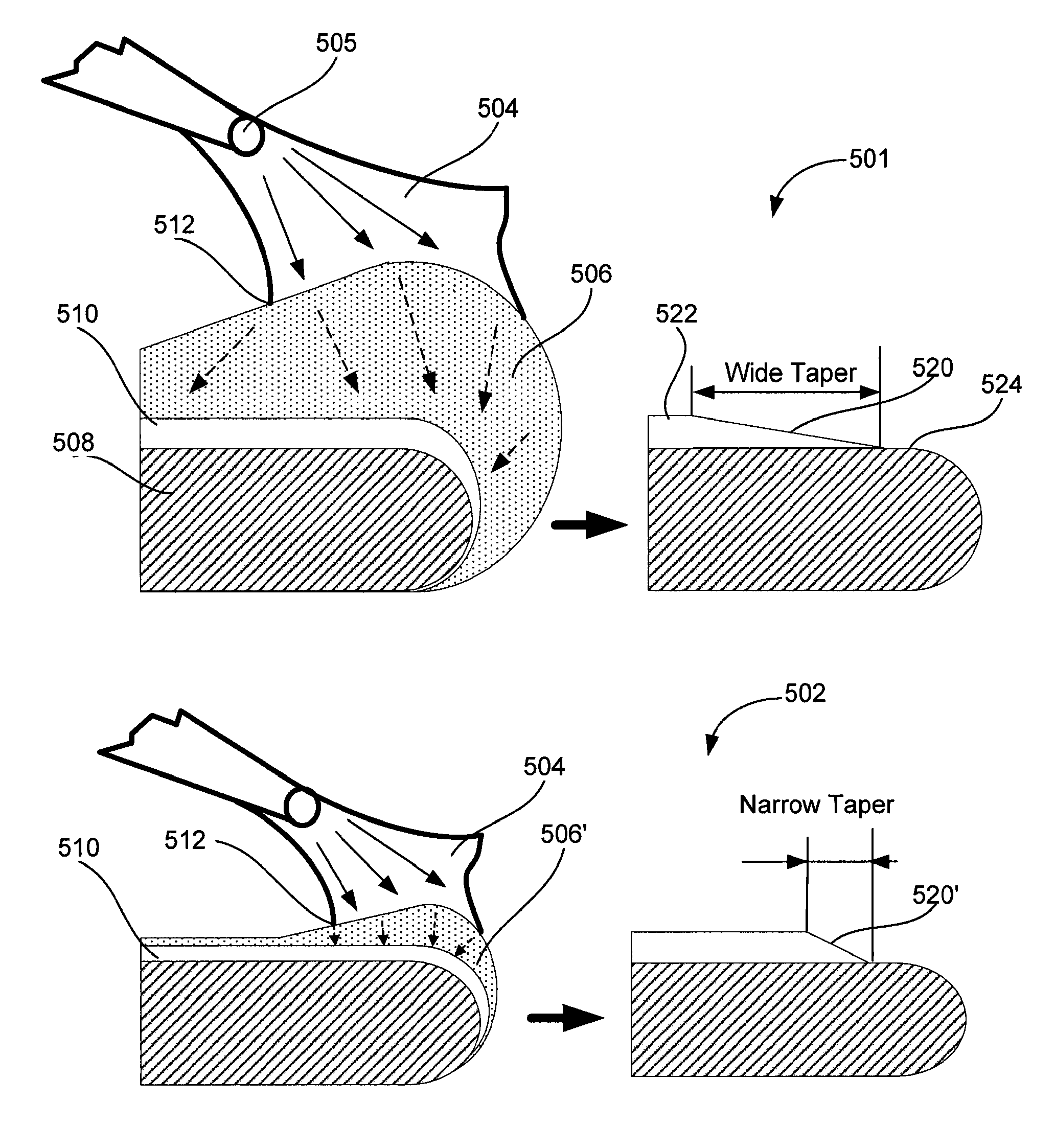

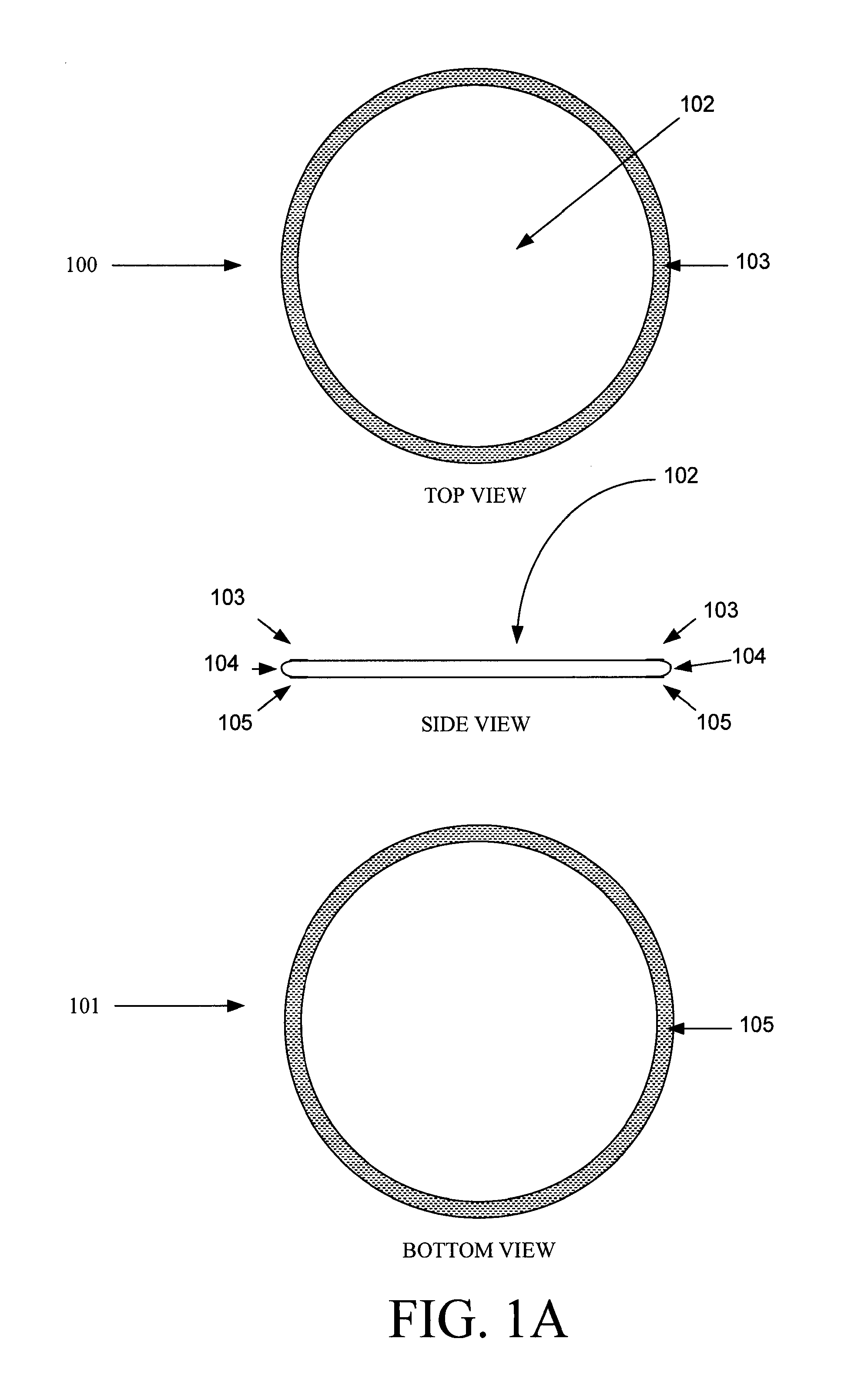

Apparatus and method for edge bevel removal of copper from silicon wafers

ActiveUS20100055924A1Facilitated DiffusionIncrease etch rateDecorative surface effectsSemiconductor/solid-state device manufacturingLiquid layerThin layer

Chemical etching methods and associated modules for performing the removal of metal from the edge bevel region of a semiconductor wafer are described. The methods and systems provide the thin layer of pre-rinsing liquid before applying etchant at the edge bevel region of the wafer. The etchant is less diluted and diffuses faster through a thinned layer of rinsing liquid. An edge bevel removal embodiment involving that is particularly effective at reducing process time, narrowing the metal taper and allowing for subsequent chemical mechanical polishing, is disclosed.

Owner:NOVELLUS SYSTEMS

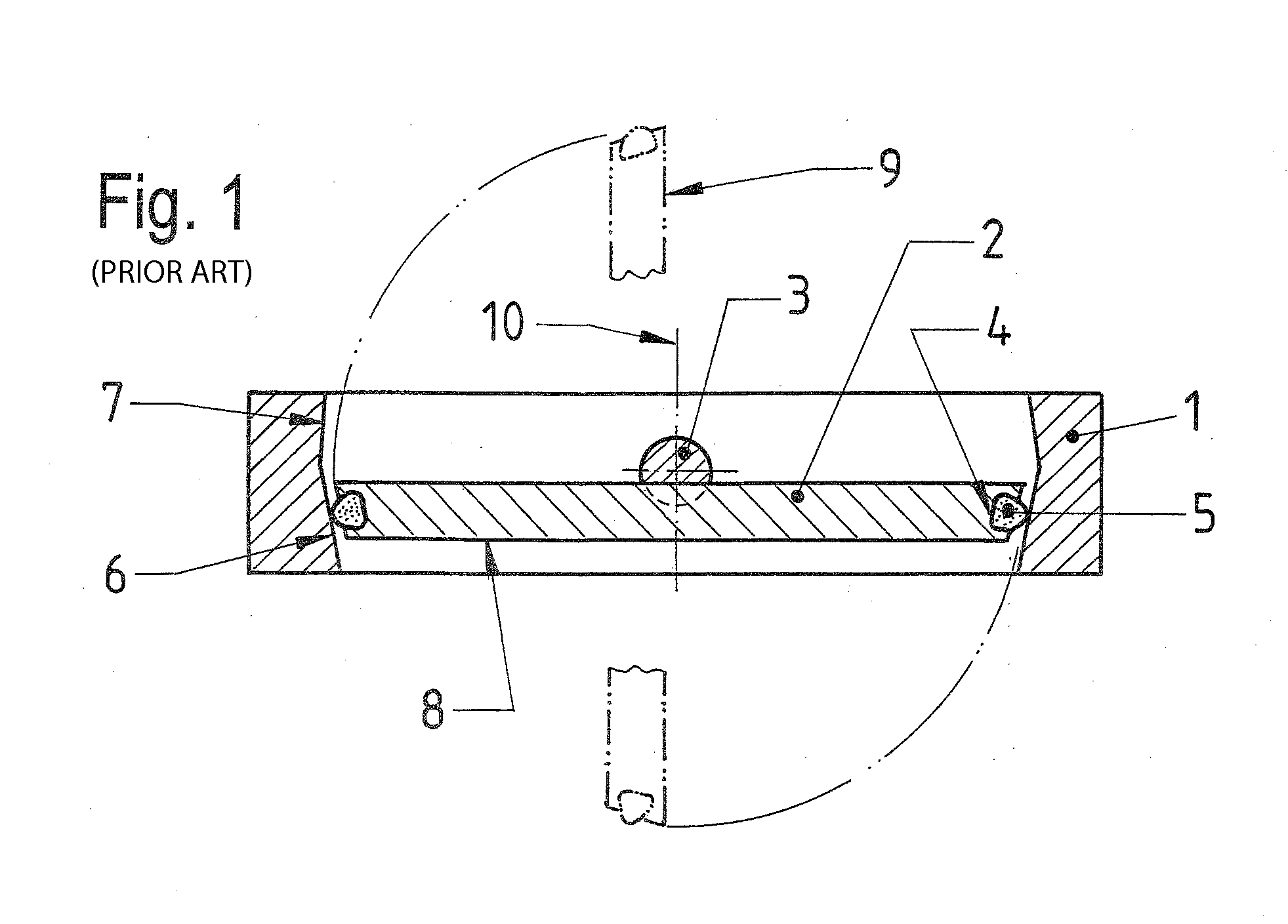

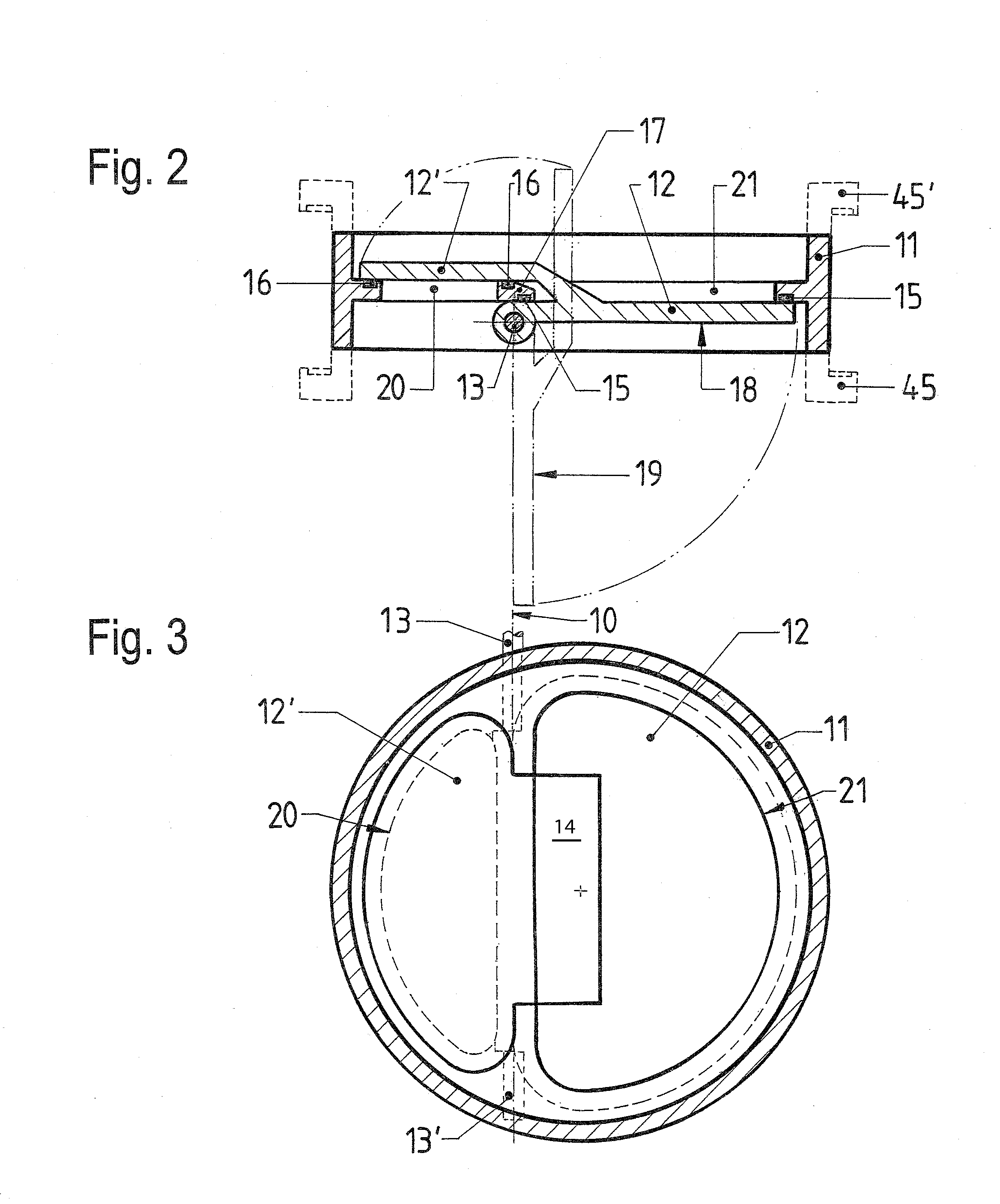

Valve arrangement

InactiveUS20100148107A1Simple structureEconomically produciblePlug valvesEngine controllersCircular discEngineering

A valve arrangement has an annular housing with valve seat and a two-part valve plate that is rotatable about an axis. The seat is in the form of a disk including two adjacent openings with a web between and the axis is parallel to the web. The two parts of the valve plate are next to each other with their planes parallel and offset in a perpendicular direction. They are connected to each other through one of the openings by a connection piece extending through the one opening. In a closed position for the valve, the valve plate part are respectively positioned on opposite sides of the valve seat and cover and seal the respective openings due to a seal that is between the valve plate parts and the valve seat.

Owner:VAT HLDG AG

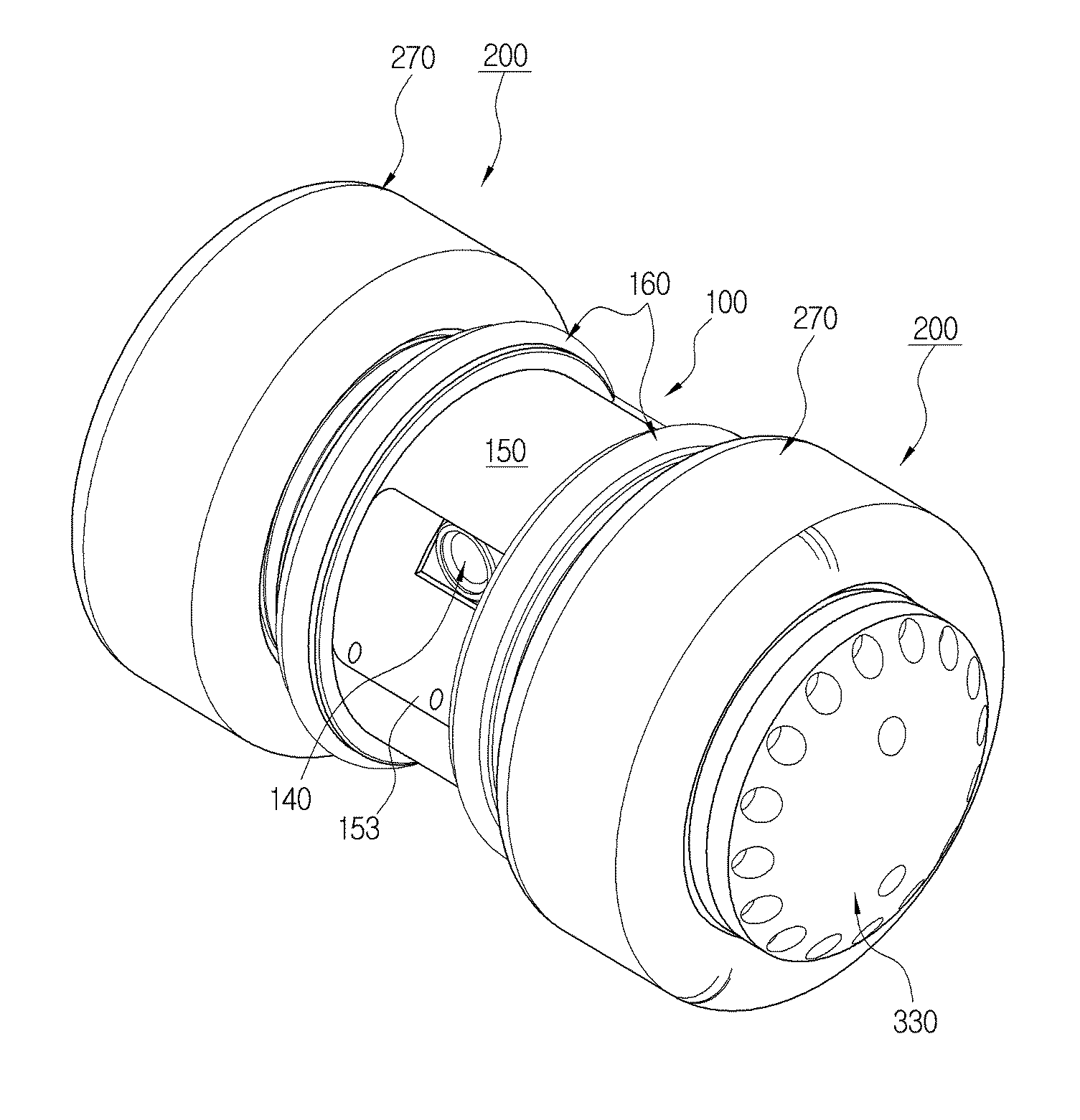

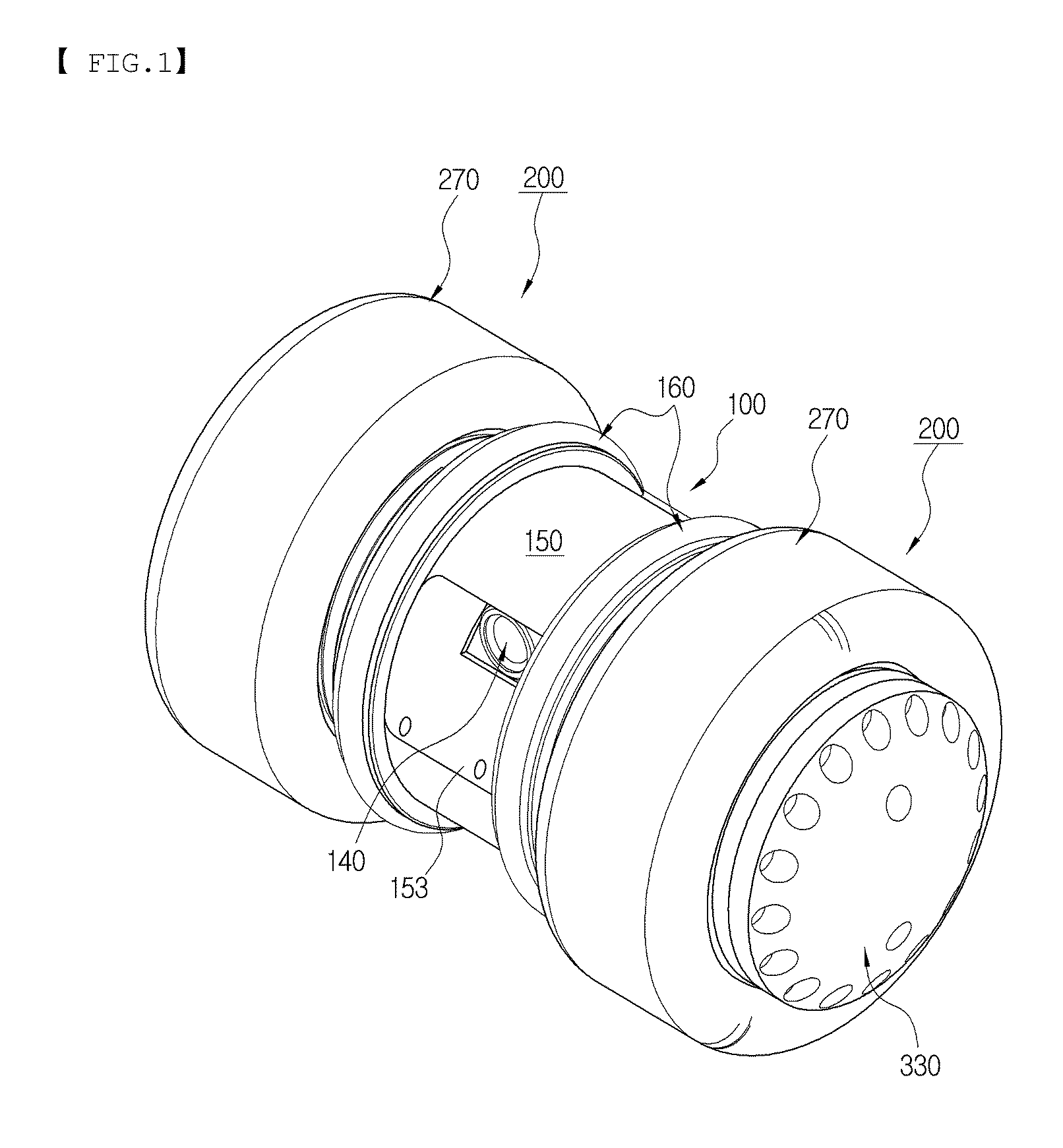

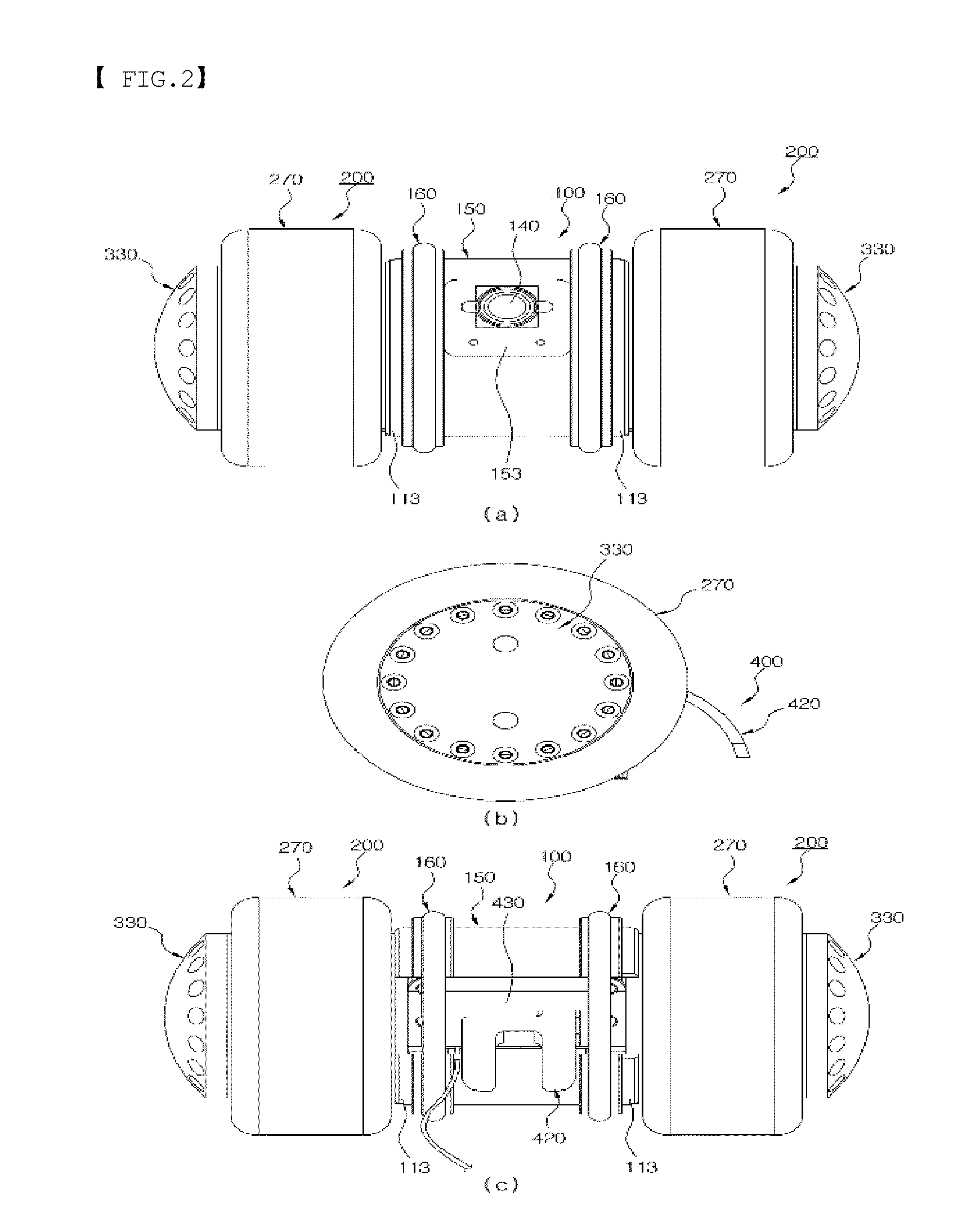

Throw type compact reconnaissance robot

ActiveUS20110308873A1Sufficiently absorb shockSimply adjust viewing angleElectric propulsion mountingMotor depositionEngineeringRobot

Provided is a throw-type compact reconnaissance robot, which is used for military purposes or counter-terrorism and is capable of ensuring a long operational time as well as drop safety by efficient spatial layout of a battery. The throw-type compact reconnaissance robot includes a cylindrical body (100) with a camera (140), drivers (200) made up of two tires (270) that are disposed on opposite sides of the body (100) and is drivable individually, and battery units (300) supplying power used to operate the robot and disposed in inner spaces of the tires (270) of the drivers (200) on the opposite outermost sides of the robot.

Owner:DUKSAN MECASYS +1

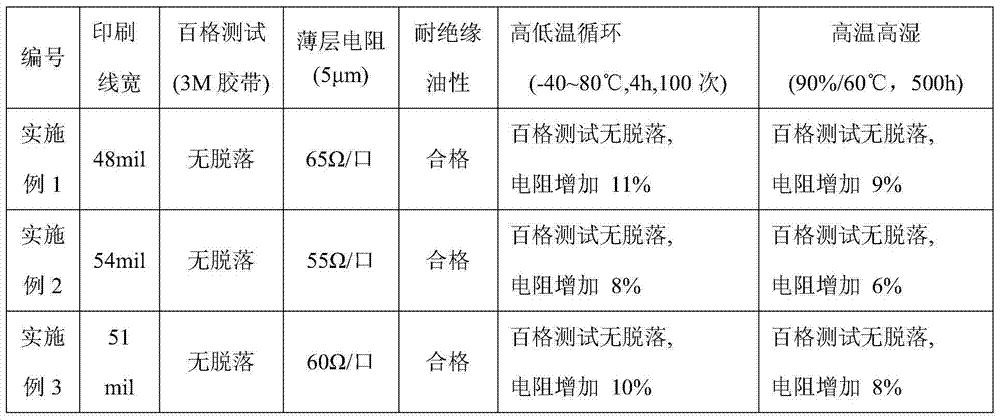

Silver paste used for grapheme touch screen, and preparation method thereof

ActiveCN103500596AHigh resolutionGood printabilityNon-conductive material with dispersed conductive materialCable/conductor manufactureSilver pasteWeather resistance

The invention discloses silver paste used for a grapheme touch screen, and a preparation method thereof. The silver paste is prepared from flake-like silver powder, spherical silver powder, inorganic electric conduction additive, organic carrier, accessory ingredient and diluent of residual percentage by weight. The preparation method comprises the following steps of: firstly, preparing the organic carrier; adding the flake-like silver powder, the spherical silver powder, the inorganic electric conduction additive, the accessory ingredient and the diluent into the organic carrier; fully and evenly mixing; finally, grinding by a three-roller machine, and carrying out vacuum defoaming. The silver paste disclosed by the invention has the advantages of good overall performance, convenience in printing, good adhesion property, good bending resistance, good weather resistance, good stability and good electrical conductivity and insulating oil performance and can pass a long-time high-temperature high-moisture aging test and thermal shock tests for more than hundred times, and the requirement on the conductive silver paste by the grapheme touch screen can be satisfied.

Owner:广州市尤特新材料有限公司

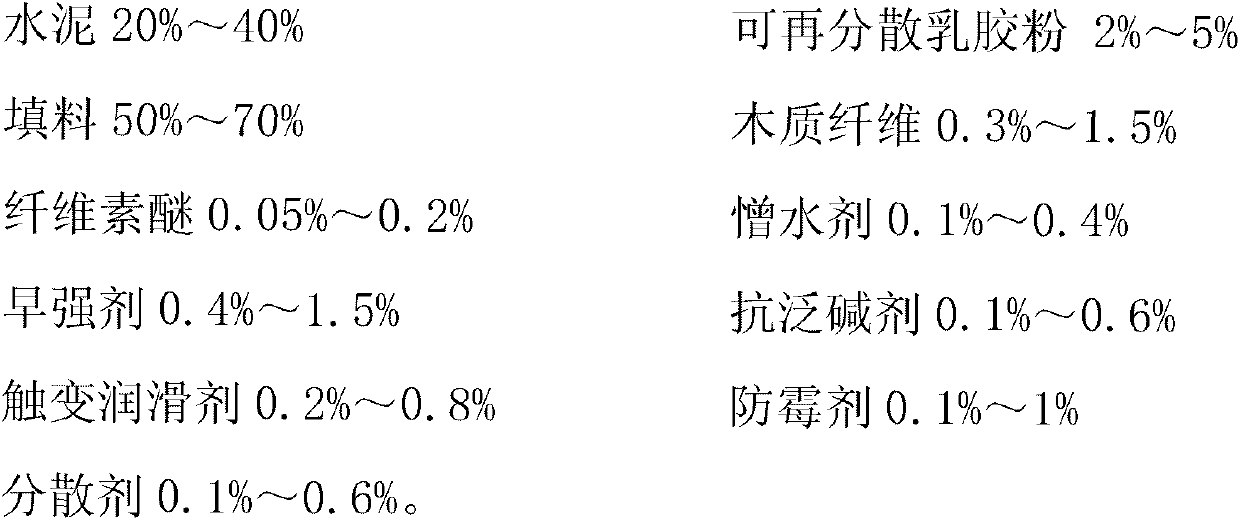

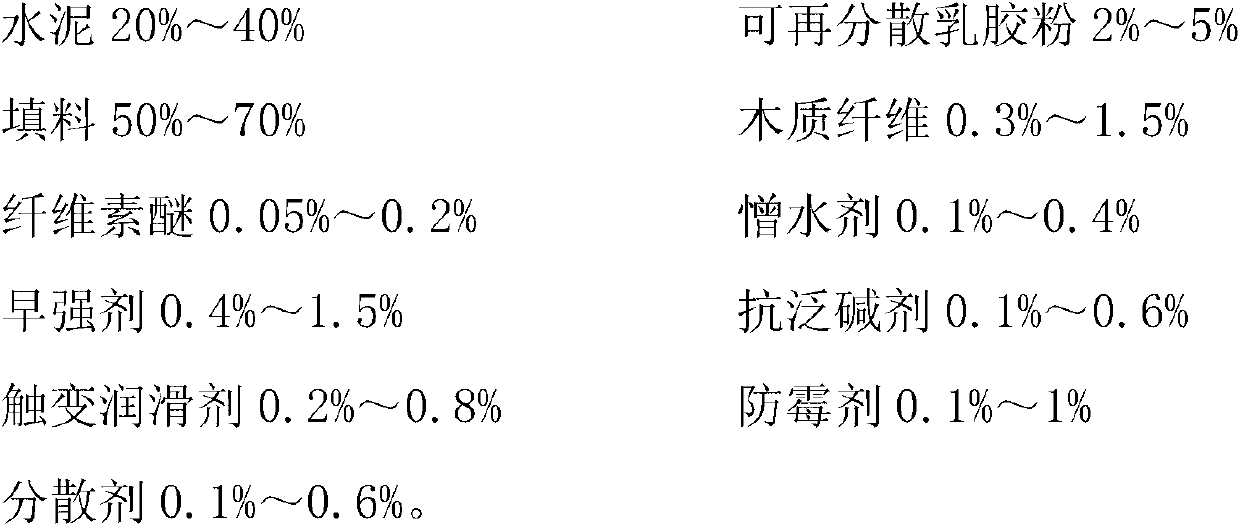

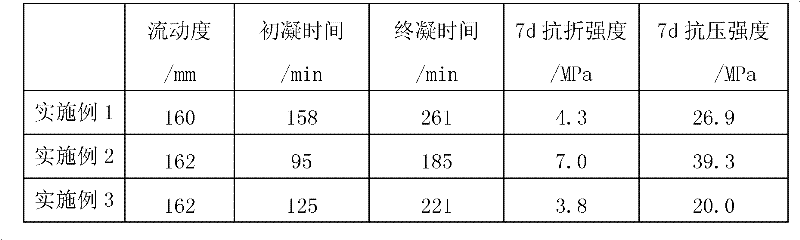

Dual-purpose adhesive for adhering tiles and filling seams

The invention discloses a dual-purpose adhesive for adhering tiles and filling seams. The dual-purpose adhesive comprises, by weight percent, 20%-40% of cement, 50%-70% of filler, 2%-5% of redispersible latex powder, 0.05%-0.2% of cellulose ether, 0.4%-1.5% of early strength agent, 0.2%-0.8% of thixotropic lubricant, 0.3%-1.5% of wood fiber, 0.1%-0.4% of water repellent 0.1%-0.6% anti-whiskering agent, 0.1%-1% of mildew preventive and 0.1%-0.6% of dispersant. The dual-purpose adhesive belongs to the field of construction adhering materials, is efficient, energy-saving, low-carbon and environment-friendly, can be used for adhering tiles and processing tile seams, and working hour repetition and material waste are avoided.

Owner:能高共建(北京)新型建材有限公司

Composite cementitious material of desulfurated waste residue and mortar prepared from same

The invention relates to the field of building material, and particularly discloses a composite cementitious material of desulfurated waste residue, wherein the composition of the composite cementitious material of desulfurated waste residue comprises ingredients in the following ratios by weight: 25-40% of desulfurated waste residue, 60-75% of industrial chemical gypsum, 0-20% of inorganic mineral additive and 0-2% of chemical additive. The desulfurated waste residue is at least one of dry-process desulfurated ash, wet-process desulfurated gypsum and semidry-process desulfurated ash; the inorganic mineral additive is at least one of cement, fly ash, mineral powder and steel slag; and the chemical additive is at least one of K2SO4, Al2(SO4)3 and alums. The performances such as compressive strength and tensile bond strength of the mortar prepared from the cementitious material are basically the same as the performances of cement mortar, and the mortar can achieve related standards and requirements. In the composite cementitious material of desulfurated waste residue disclosed by the invention, solid waste is efficiently utilized for preparing composite cementitious material high in performances and low in cost by burning-free treatment process and efficient excitation pre-treatment technology, so that pollution can be reduced and energy can be saved.

Owner:SHANGHAI RES INST OF BUILDING SCI CO LTD

Phosphogypsum based plastering gypsum

The invention discloses a phosphogypsum based plastering gypsum, and relates to a plastering material for a building wall. The phosphogypsum based plastering gypsum mainly comprises 75 to 95 percent of phosphogypsum based building gypsum, 1 to 3 percent of sierozem powder, 0.1 to 0.5 percent of retarder, 1.1 to 5.5 percent of composite water retention agent, 0.3 to 1 percent of ethylene-vinyl acetate copolymerized latex powder, and 0 to 20 percent of stuffing. The phosphogypsum based plastering gypsum effectively improves water retention property and lowers cost by adopting the combination of cellulose ether water retention agent and bentonite, effectively adjusts settling time and prolongs operable time by adopting the retarder, improves construction property, cohesive property and cracking resistance by doping the stuffing and the latex powder, and reduces adverse effects of impurities on the strength of plastering gypsum by adding the sierozem powder. The phosphogypsum based plastering gypsum has the advantages of good workability and construction property, long operable time, high breaking resistance, compression resistance and adhesion strength, good volume stability, good cracking resistance and lower cost, and can be used for a plastering layer of the building wall.

Owner:CHONGQING UNIV

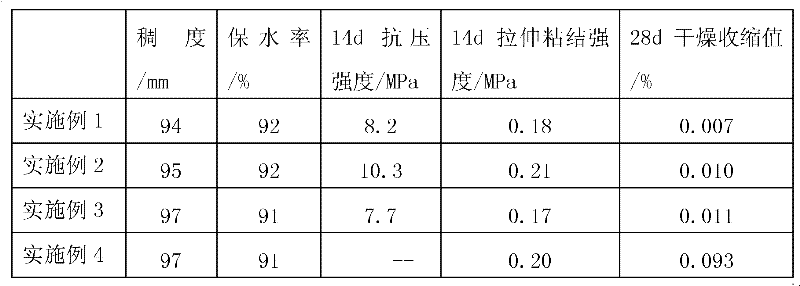

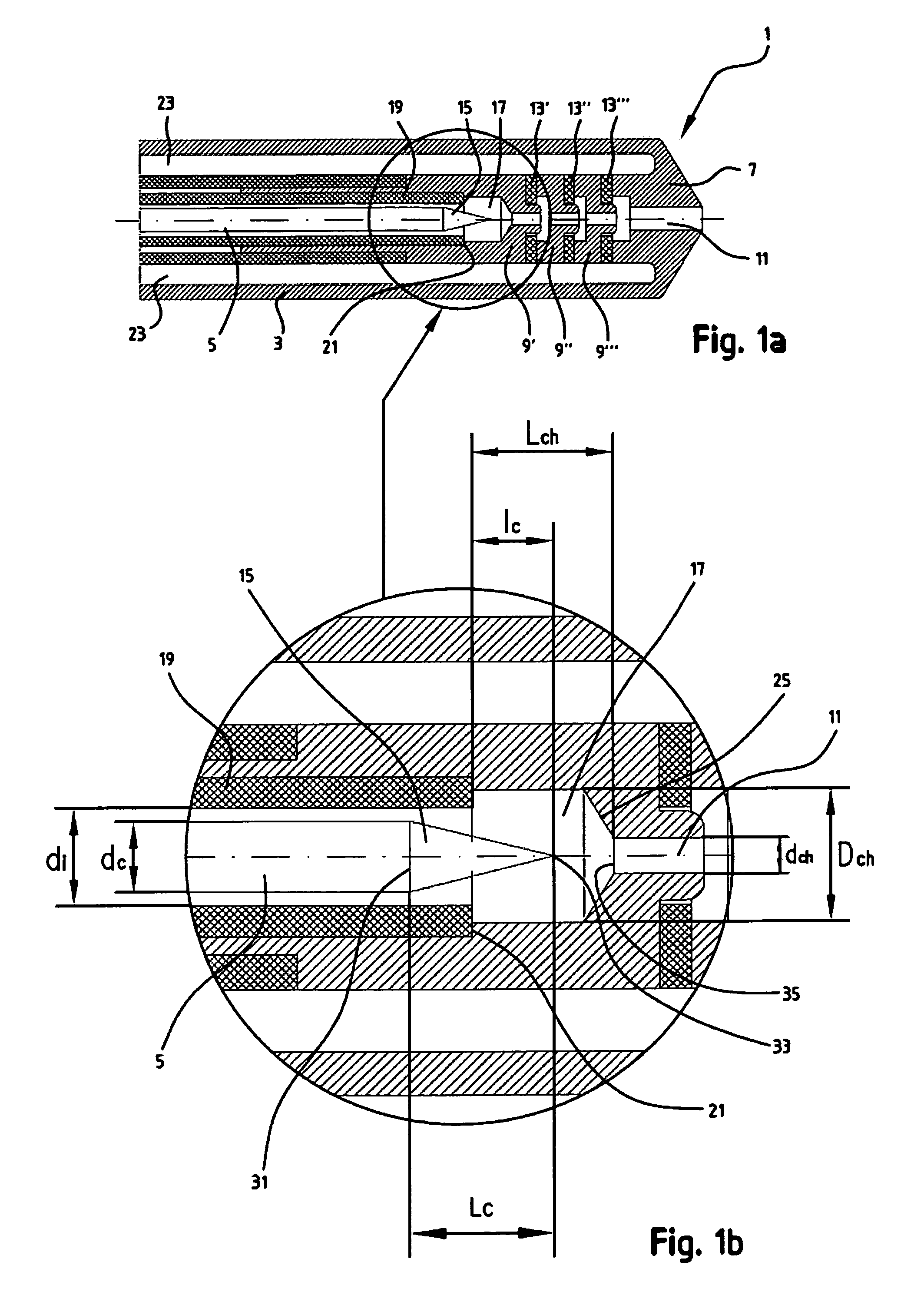

Plasma-generating device, plasma surgical device and use of plasma surgical device

ActiveUS20070021747A1Long operating timeSmall form factorSurgical instruments for heatingPlasma techniquePlasma channelSurgical device

The present invention relates to a plasma-generating device, comprising an anode, a cathode and a plasma channel which in its longitudinal direction extends at least partly between said cathode and said anode. The end of the cathode which is directed to the anode has a cathode tip tapering towards the anode, a part of said cathode tip extending over a partial length of a plasma chamber connected to the plasma channel. The plasma chamber has a cross-sectional surface, transversely to the longitudinal direction of the plasma channel, which exceeds the cross-sectional surface, transversely to the longitudinal direction of the plasma channel, of an opening, positioned closest to the cathode, of the plasma channel. The invention also concerns a plasma surgical device and use of such a plasma surgical device.

Owner:PLASMA SURGICAL INVESTMENTS

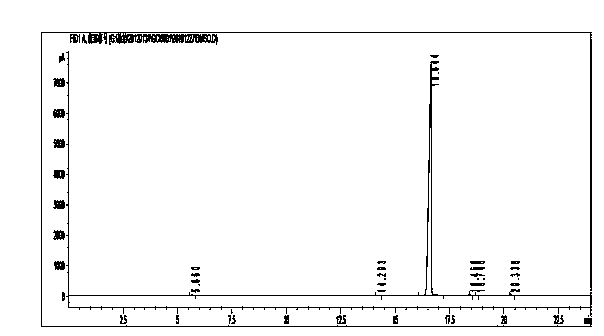

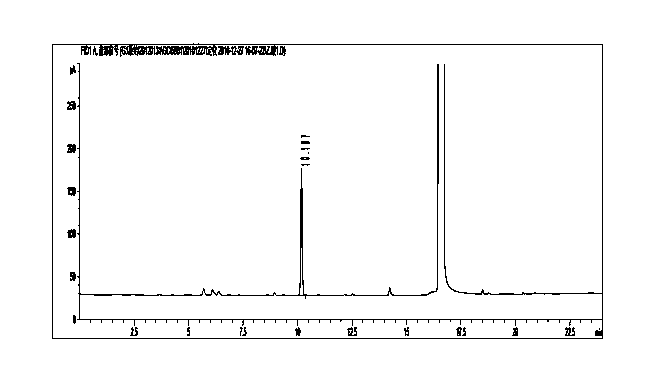

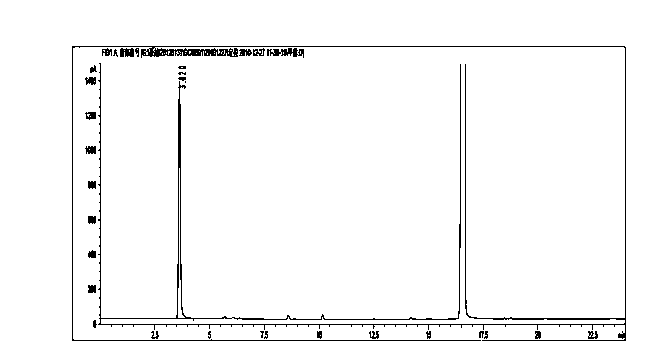

GC method for detecting residual quantity of solvent in compound

ActiveCN103728402ALong operating timeCumbersome operationComponent separationCapillary gas chromatographyN dimethylformamide

The invention discloses a method for analyzing a residual quantity of a solvent in a compound by GC (Gas Chromatograph). The method comprises the step of carrying out separation by adopting the following chromatographic conditions: a detector is a hydrogen flame ionization detector, the temperature of the detector is 200 DEG C to 300 DEG C and is preferably 300 DEG C, and the temperature of an injection opening is 180 DEG C to 250 DEG C and is preferably 220 DEG C; a chromatographic column is a medium-polarity capillary gas chromatography column and adopts a programmed temperature process of keeping the temperature of 40 to 60 DEG C for 3 to 10min, then heating to the temperature of 100 to 140 DEG C at a speed of 5 to 15 DEG C / min, keeping the temperature of 100 to 140 DEG C for 1 to 10min, heating to the temperature of 200 to 230 DEG C at a speed of 15 to 25 DEG C / min and keeping the temperature of 200 to 230 DEG C for 1 to 20min; carrier gas is nitrogen, hydrogen or argon and is preferably nitrogen, and the flow rate of the carrier gas is 1ml / min to 10ml / min and is preferably 3ml / min; the solvent is selected from one or more of C1 to C6 carboxylic acid, methanol, ethanol, acetonitrile, ethyl acetate, tetrahydrofuran, methylbenzene and N,N-dimethylformamide; the C1 to C6 carboxylic acid is preferably C1 to C4 carboxylic acid and is more preferably acetic acid. When the method is adopted to detect the residual quantity of the solvent, the operation is simplified, time is saved and cost is saved.

Owner:NEW FOUNDER HLDG DEV LLC +2

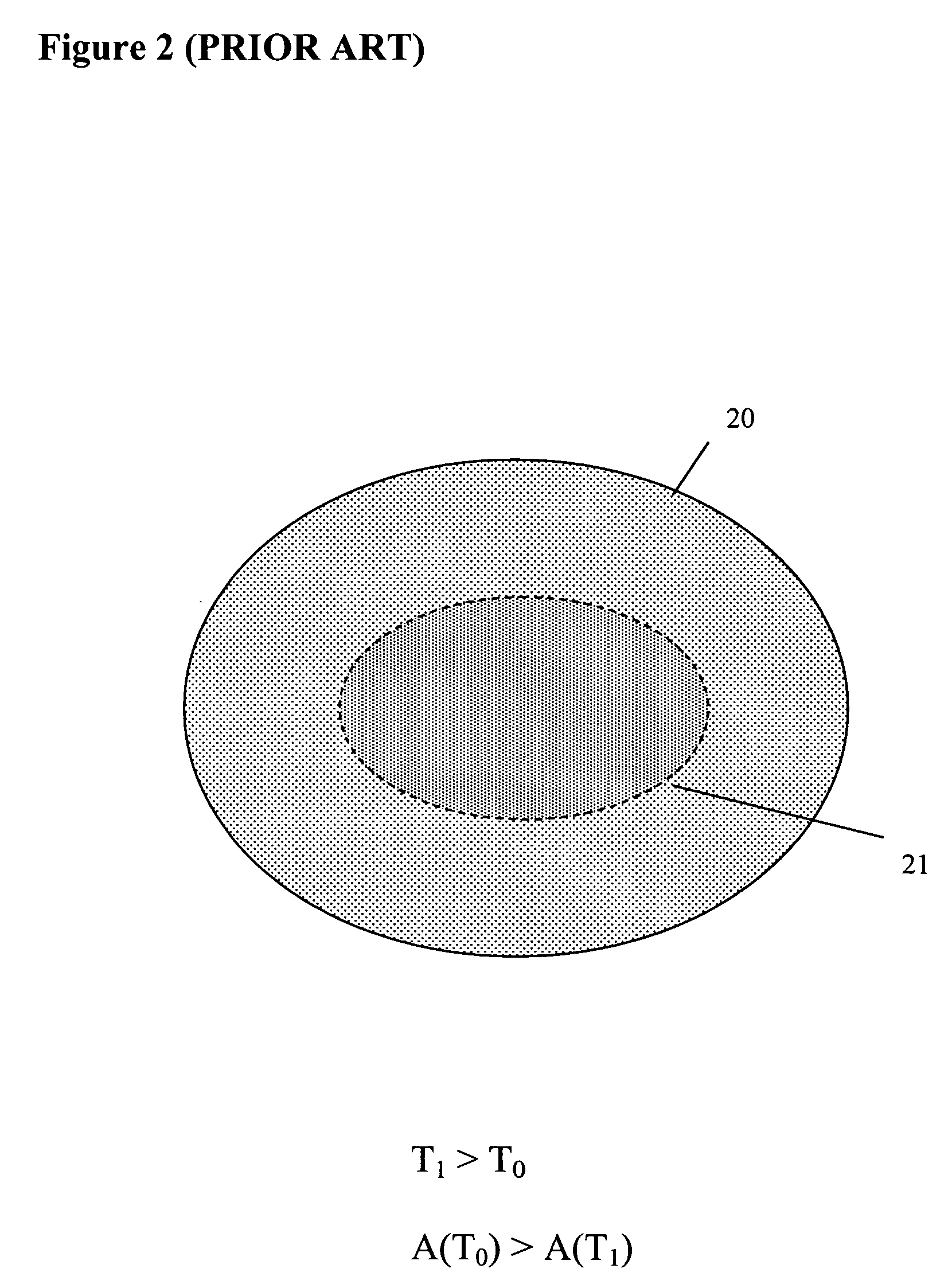

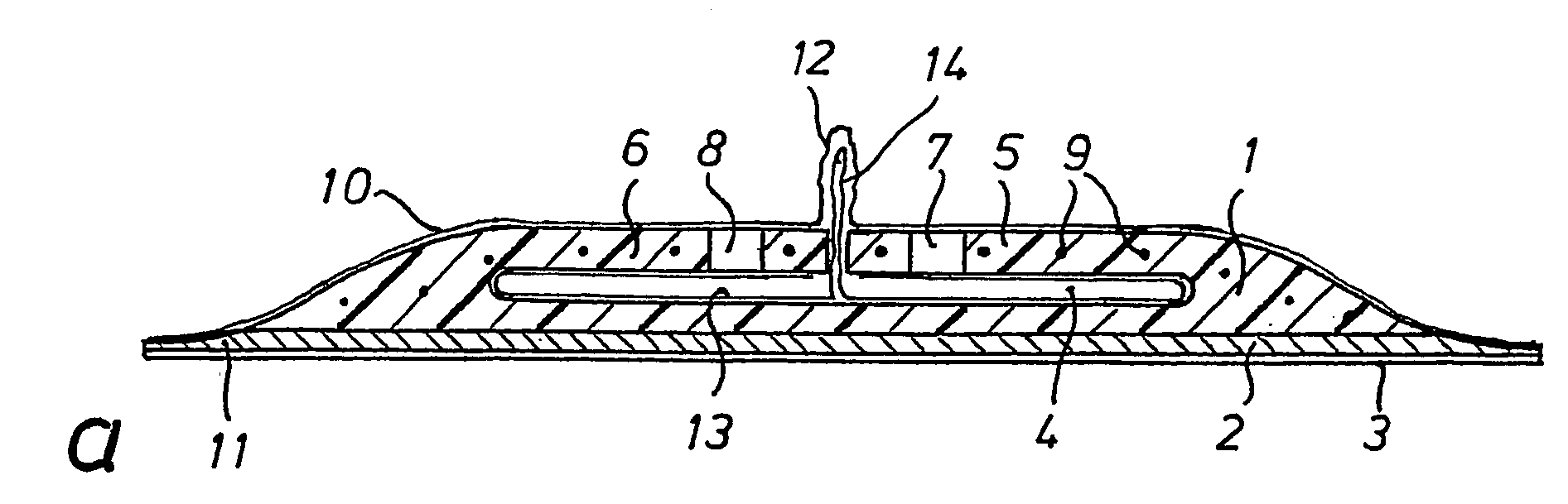

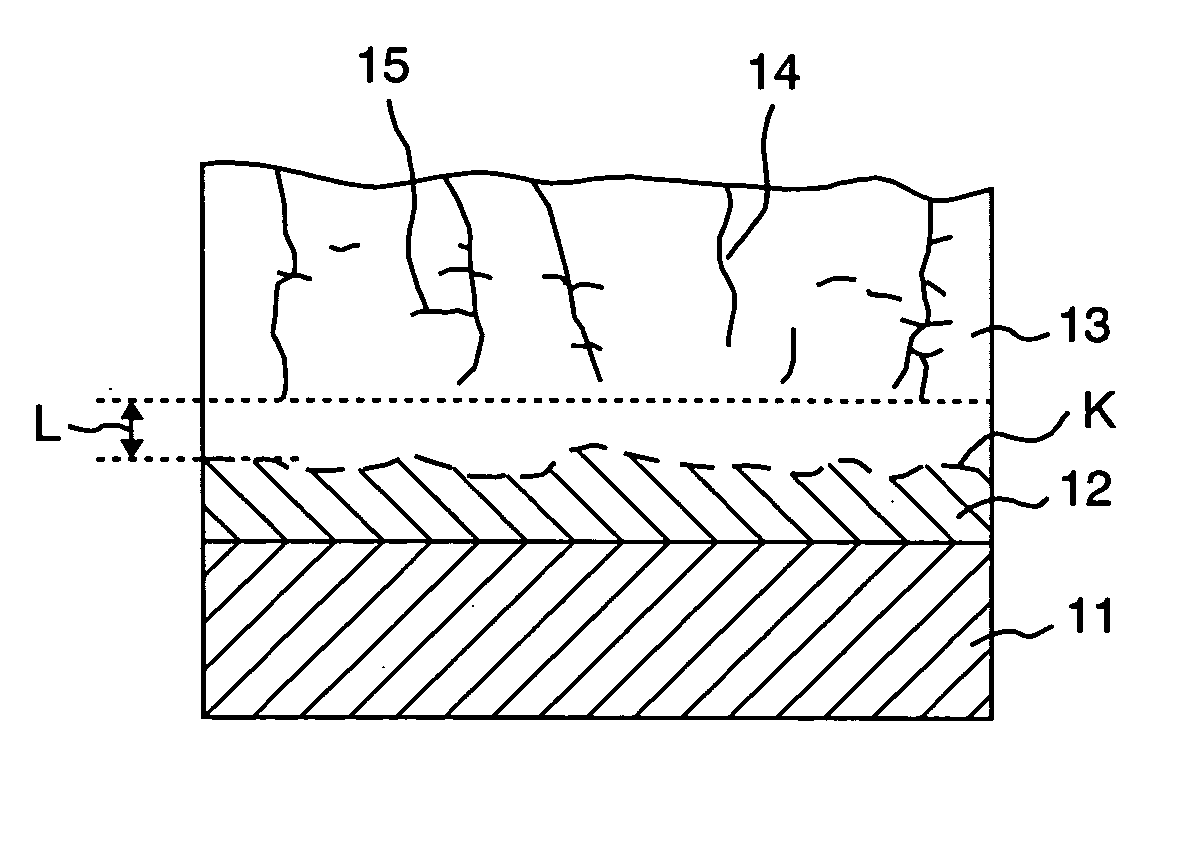

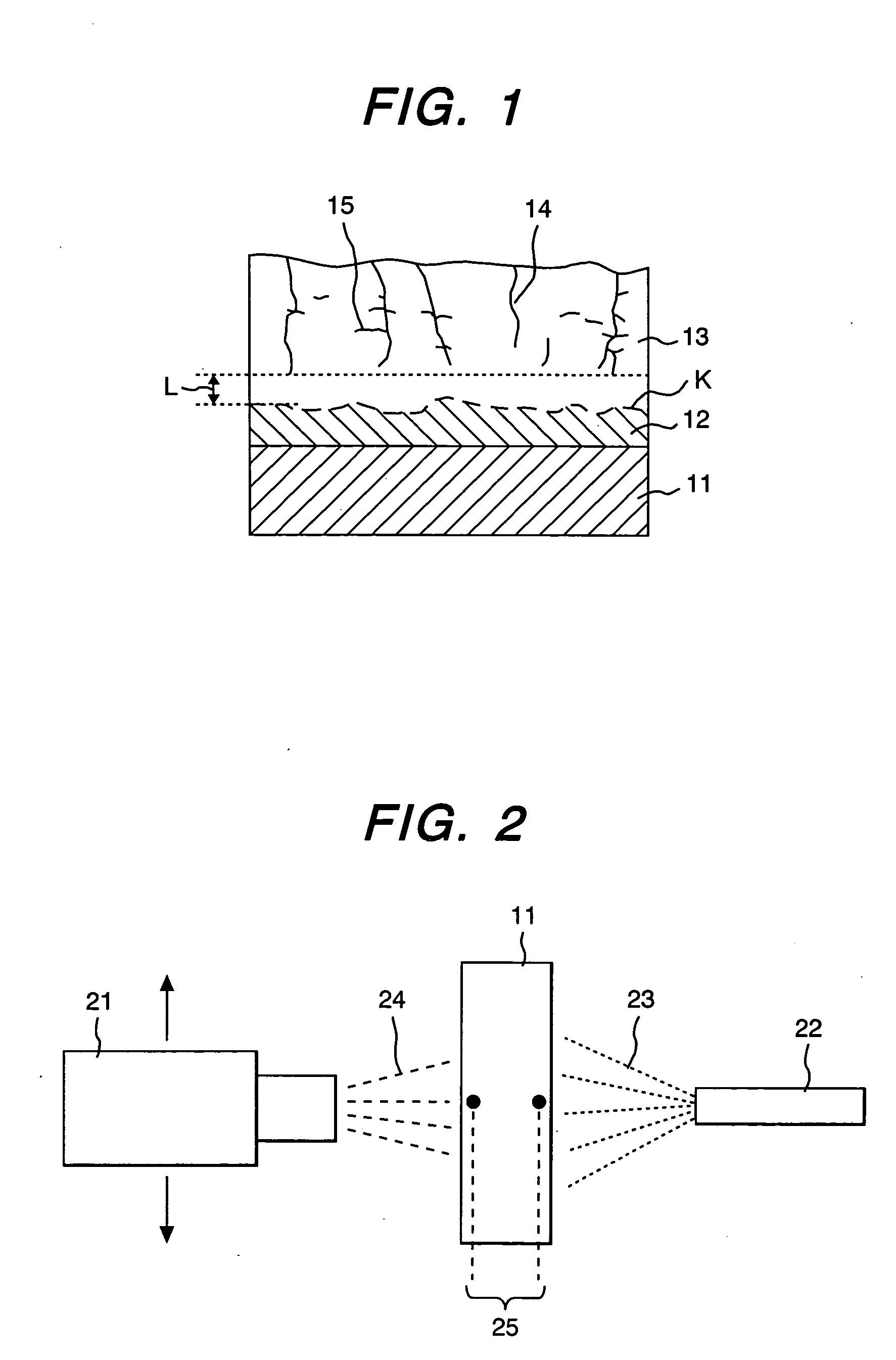

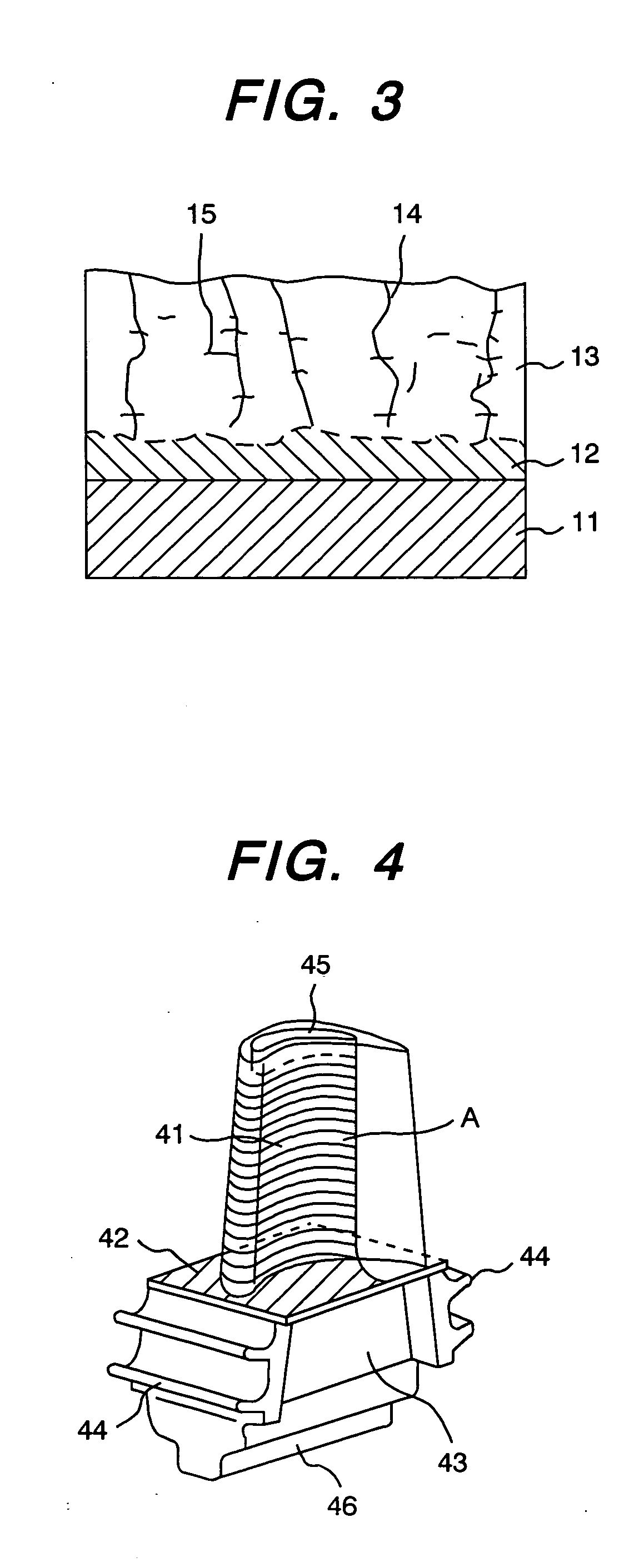

Heat resistant article having thermal barrier coatinging

ActiveUS20050136249A1Long operating timeLiquid surface applicatorsMolten spray coatingBond coatingHigh-temperature corrosion

A thermal barrier coating comprises a bond coating 12 made of high temperature corrosion resistance superior to a substrate 11 and a thermal barrier coating 13 made of ZrO2 series ceramics formed on the bond coating. The thermal barrier coating has cracks extending in the direction of the thickness of the barrier coat. Substantially all of the tips of the cracks have a distance between the tips and the boundary at the substrate side.

Owner:MITSUBISHI HITACHIPOWER SYST LTD

Special N-phthalate reinforced soft polyethylene plastics for circulation loop and preparation method thereof

The invention discloses special N-phthalate reinforced soft polyethylene plastics for a circulation loop, which comprises the following ingredients by weight parts: 100 weight parts of PVC resin powder, 20 to 50 weight parts of N-phthalate plasticizers, 5 to 35 weight parts of auxiliary stabilizing agents, 0.5 to 5.0 weight parts of stabilizing agents, 0.1 to 2.0 weight parts of lubricating agents and 0.1 to 1.0 weight part of antioxidants. The invention also discloses a preparation method of the special N-phthalate reinforced soft polyethylene plastics for the circulation loop. The method comprises the following steps: carrying out high-speed mixing on ingredients; using a double-screw extruding machine for plastification; and using a single screw for cooling and forming to obtain rubber grains. The recipe of the invention is suitable for the manufacture of the circulation loop, particularly the varieties with high processing precision and long operation time and the varieties needing ray sterilization.

Owner:YANGZHOU KAIER CHEM

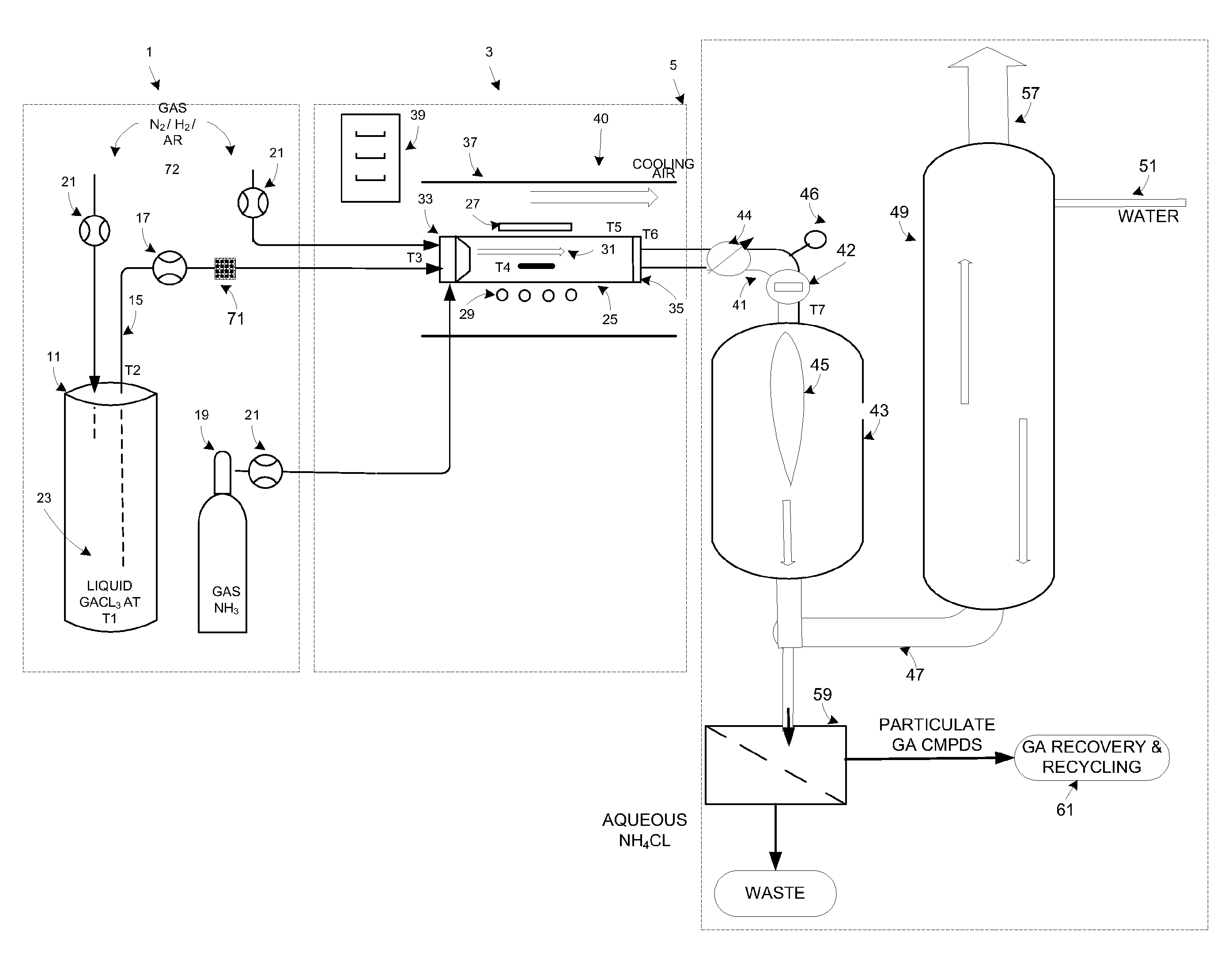

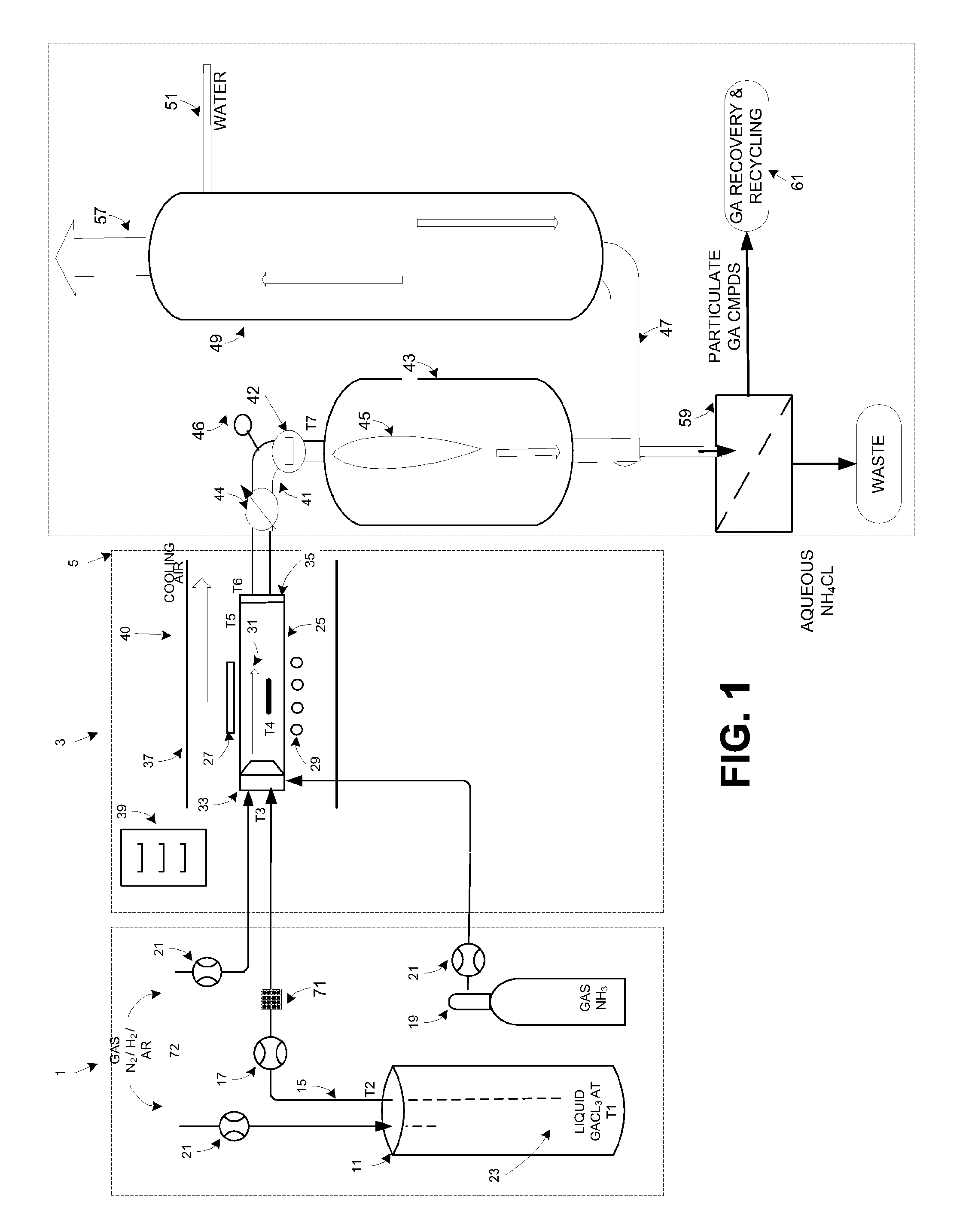

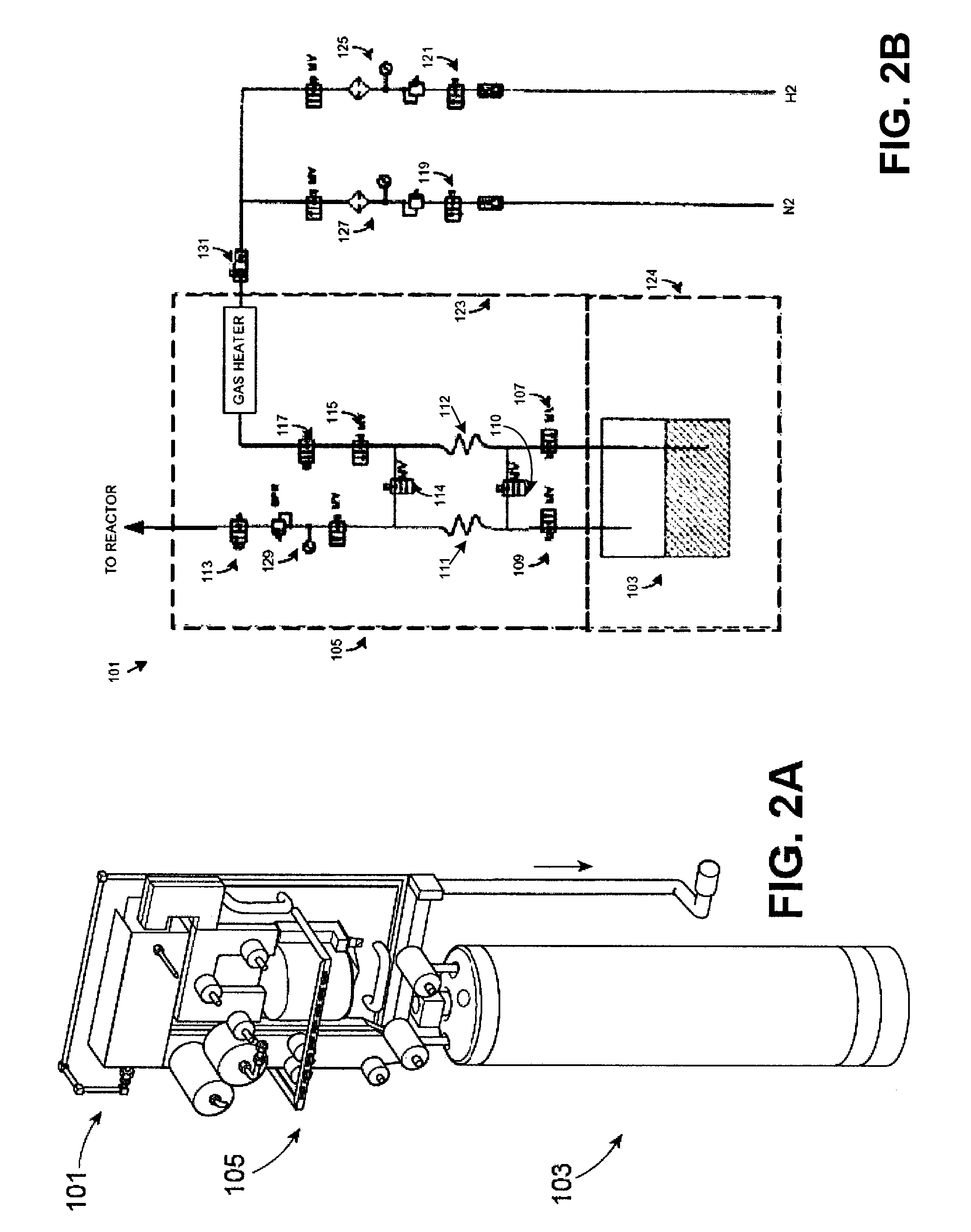

Abatement of reaction gases from gallium nitride deposition

ActiveUS20090283029A1Reduce condensationEasy to manufacturePolycrystalline material growthDispersed particle separationSemiconductor materialsNitrogen

Methods for the sustained, high-volume production of Group III-V compound semiconductor material suitable for fabrication of optic and electronic components, for use as substrates for epitaxial deposition, or for wafers. The equipment and methods are optimized for producing Group III-N (nitrogen) compound semiconductor wafers and specifically for producing GaN wafers. The method includes reacting an amount of a gaseous Group III precursor as one reactant with an amount of a gaseous Group V component as another reactant in a reaction chamber to form the semiconductor material; removing exhaust gases including unreacted Group III precursor, unreacted Group V component and reaction byproducts; and heating the exhaust gases to a temperature sufficient to reduce condensation thereof and enhance manufacture of the semiconductor material. Advantageously, the exhaust gases are heated to sufficiently avoid condensation to facilitate sustained high volume manufacture of the semiconductor material.

Owner:S O I TEC SILICON ON INSULATOR THECHNOLOGIES

Battery powered LED lamp

InactiveUS7481554B2Preventing thermal runawayReduce voltageNon-electric lightingPoint-like light sourceElectrical batteryLow voltage

Owner:ANDERSON GARY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com