Patents

Literature

7560 results about "Tectorial membrane" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The tectorial membrane (TM) is one of two acellular membranes in the cochlea of the inner ear, the other being the basilar membrane (BM). "Tectorial" in anatomy means forming a cover. The TM is located above the spiral limbus and the spiral organ of Corti and extends along the longitudinal length of the cochlea parallel to the BM. Radially the TM is divided into three zones, the limbal, middle and marginal zones. Of these the limbal zone is the thinnest (transversally) and overlies the auditory teeth of Huschke with its inside edge attached to the spiral limbus. The marginal zone is the thickest (transversally) and is divided from the middle zone by Hensen's Stripe. It overlies the sensory inner hair cells and electrically-motile outer hair cells of the organ of Corti and during acoustic stimulation stimulates the inner hair cells through fluid coupling, and the outer hair cells via direct connection to their tallest stereocilia.

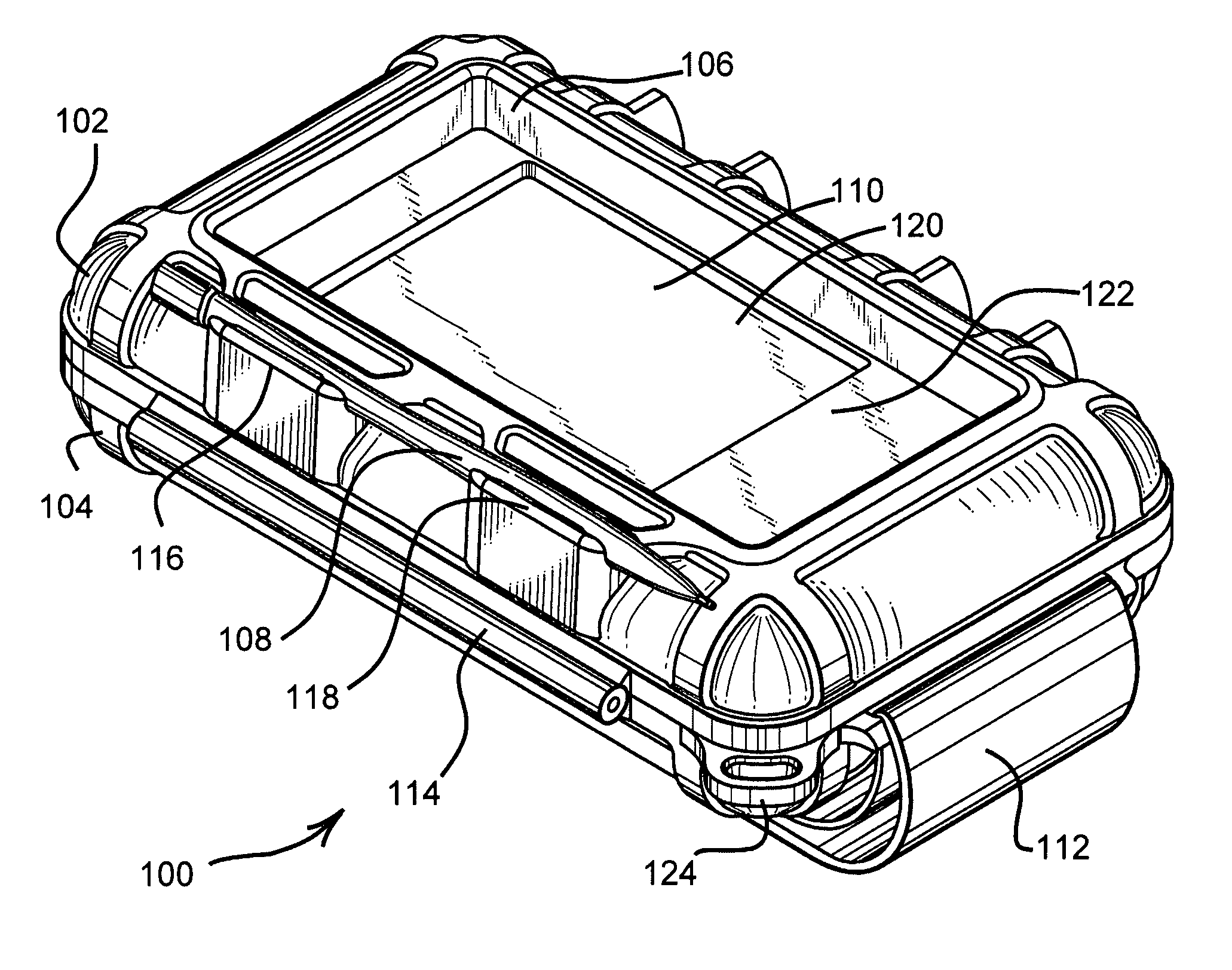

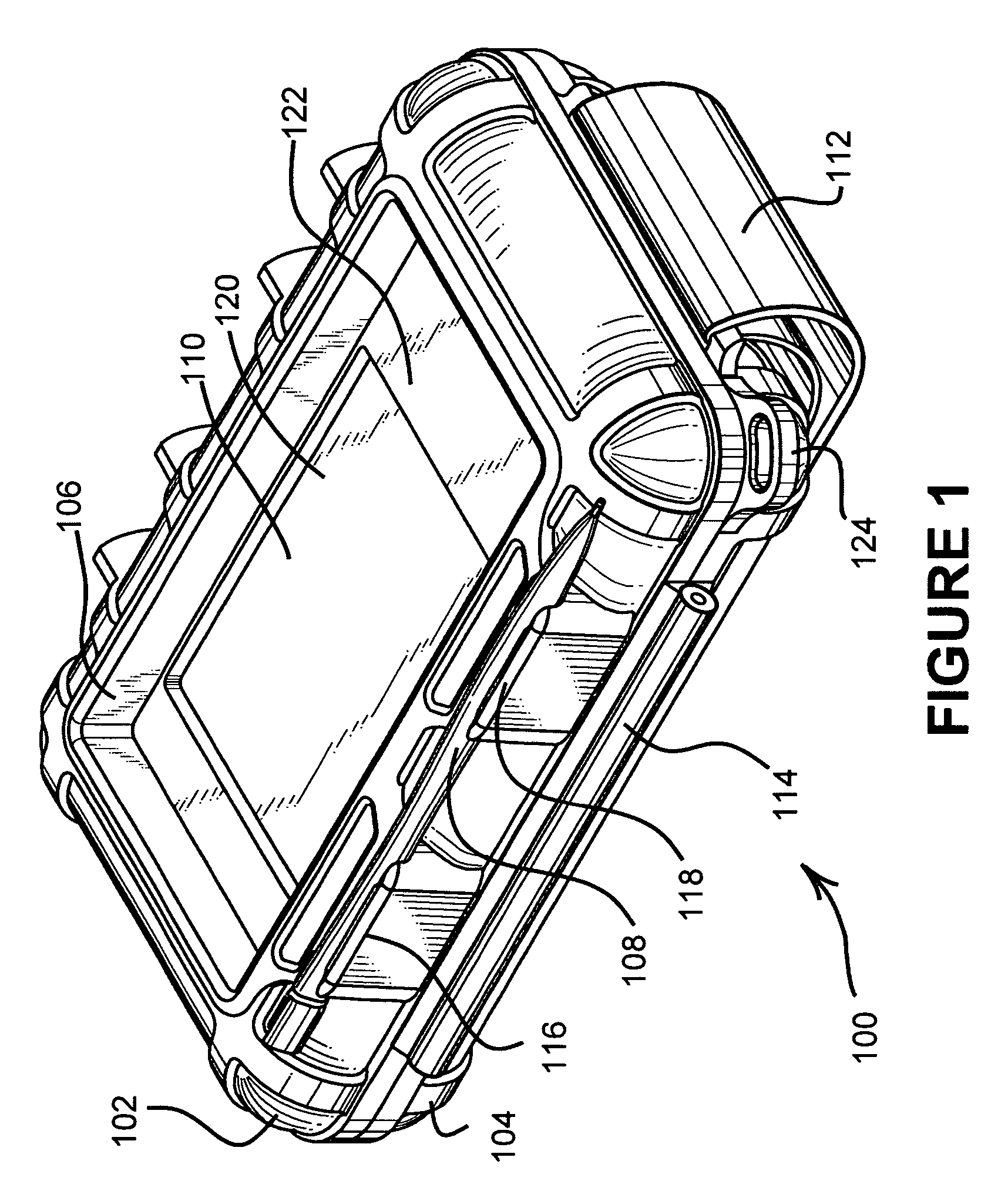

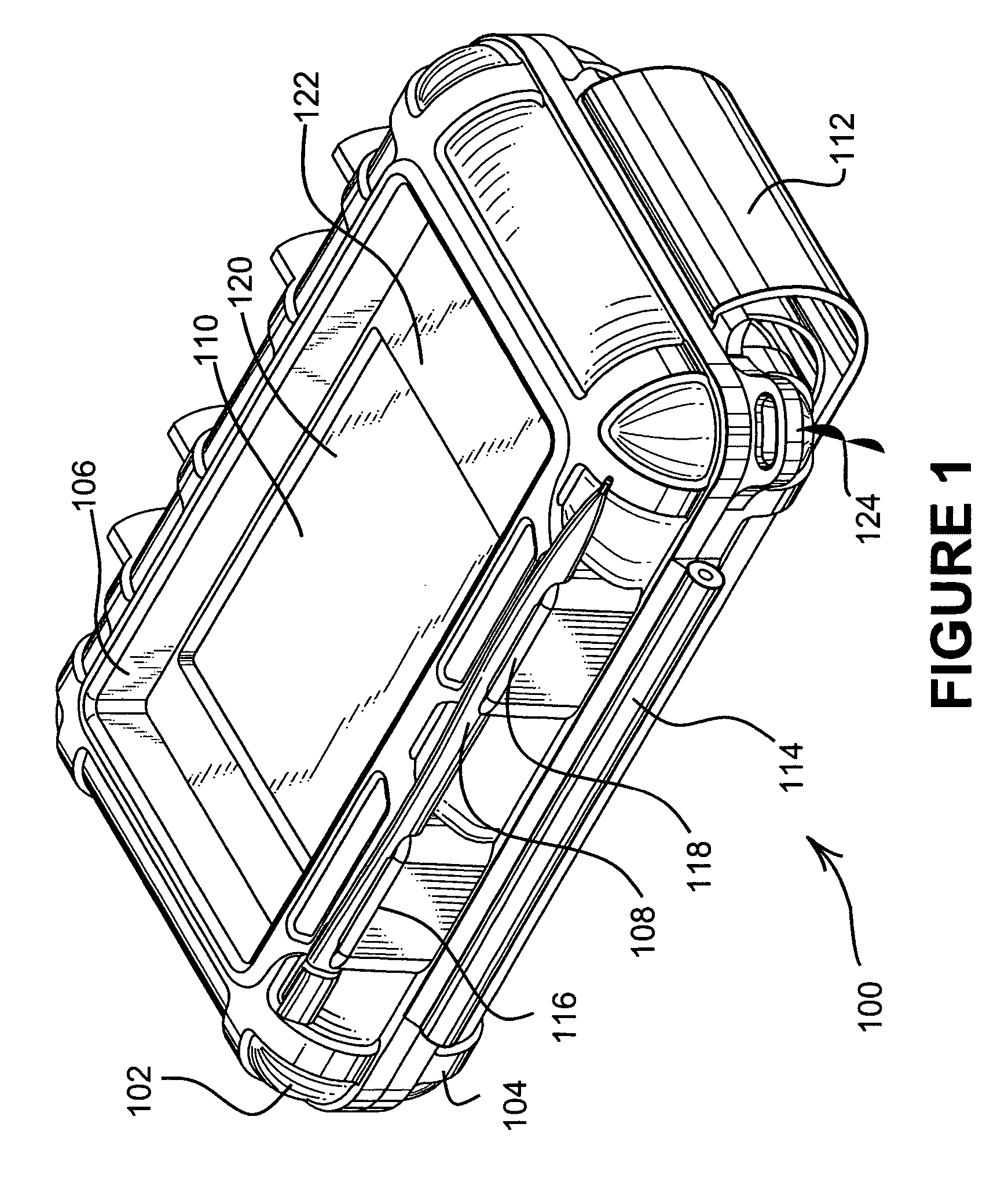

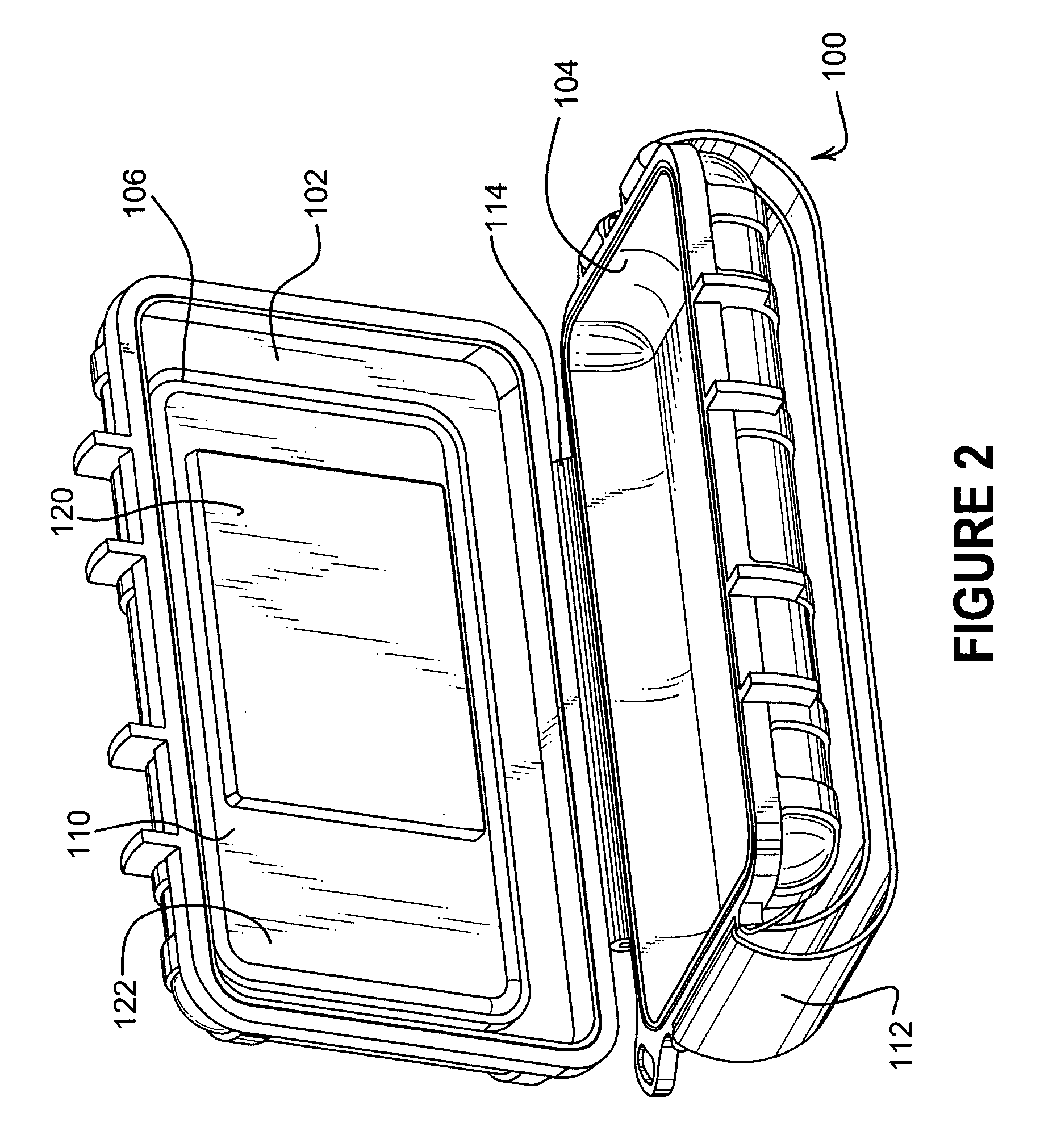

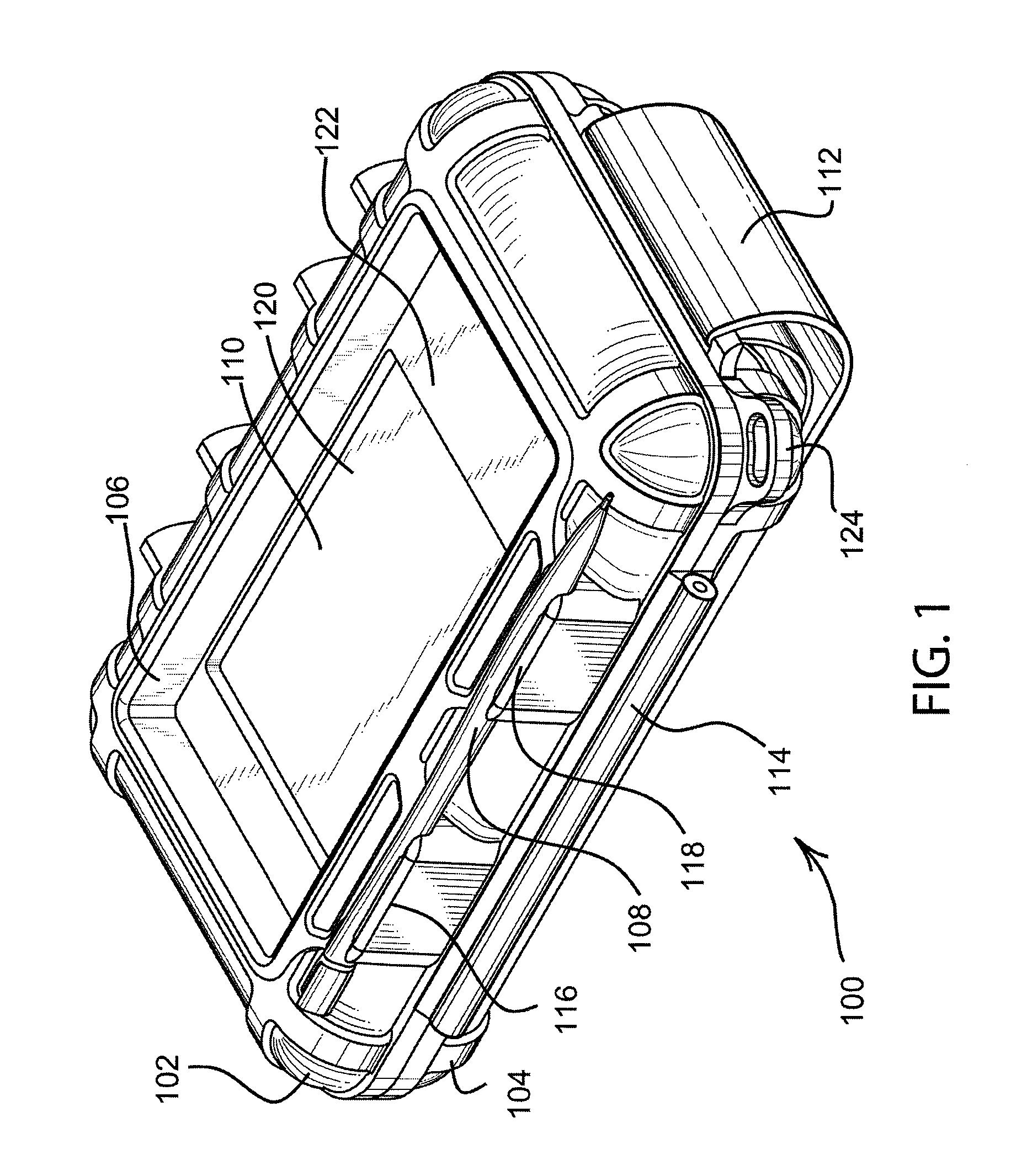

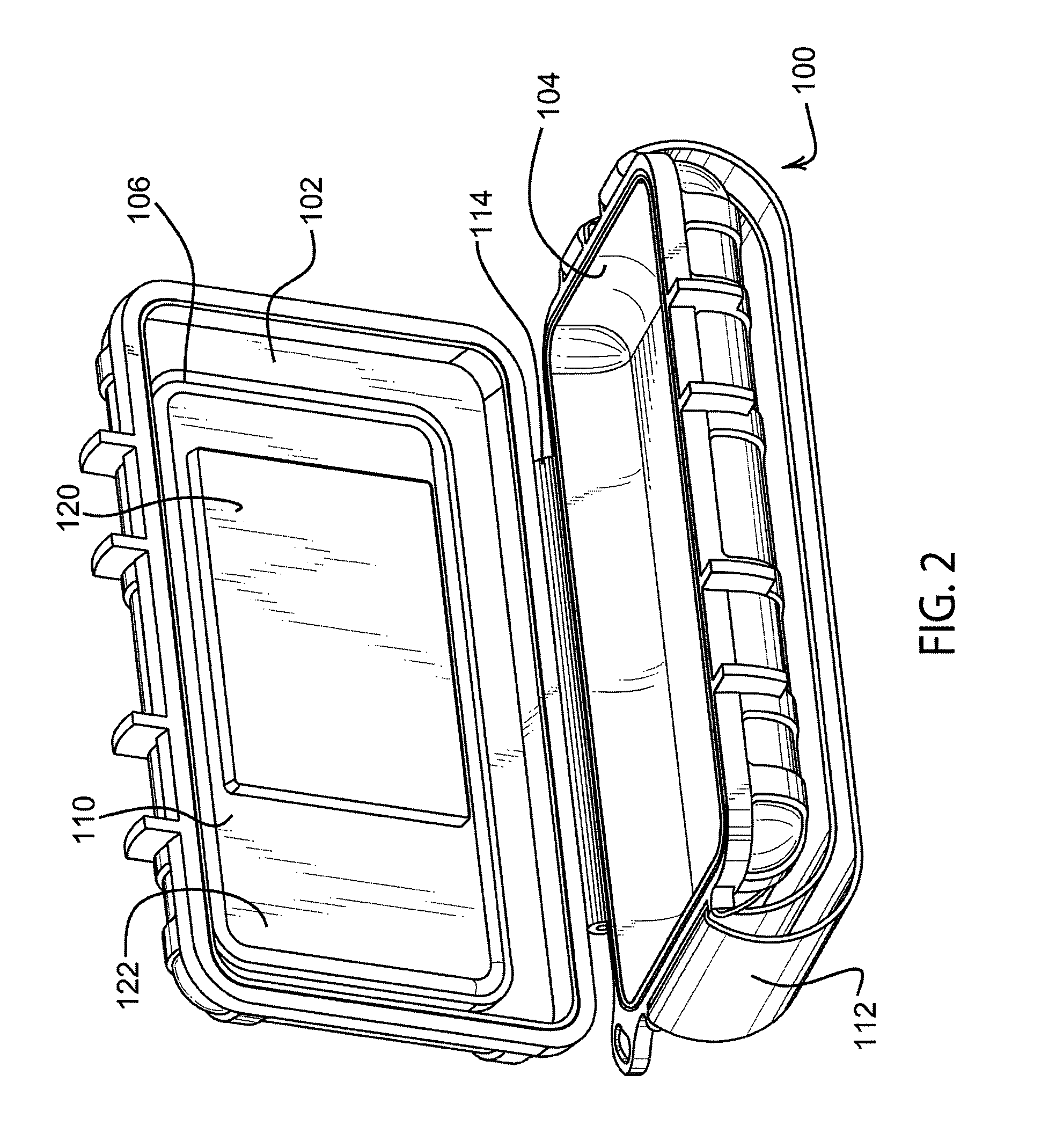

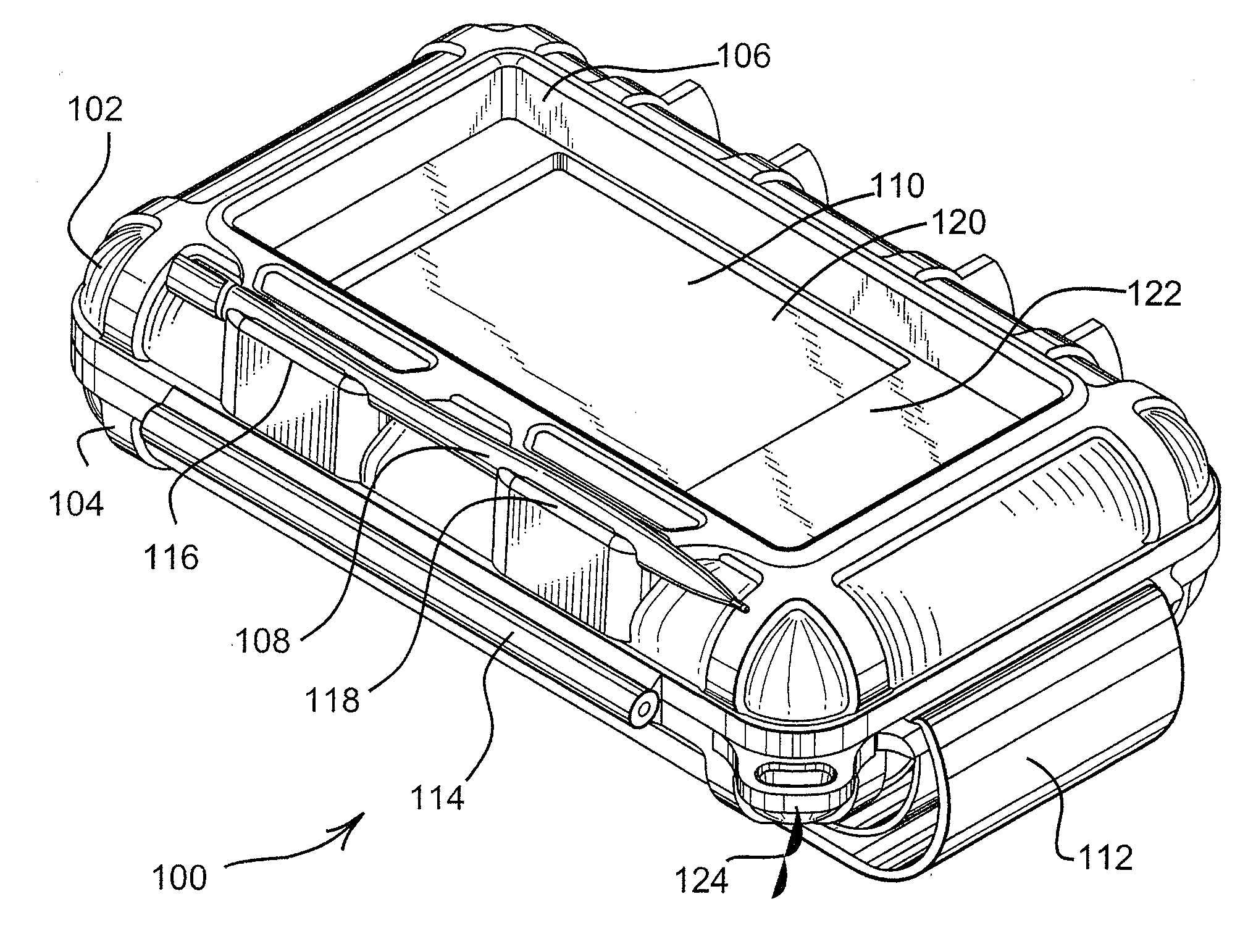

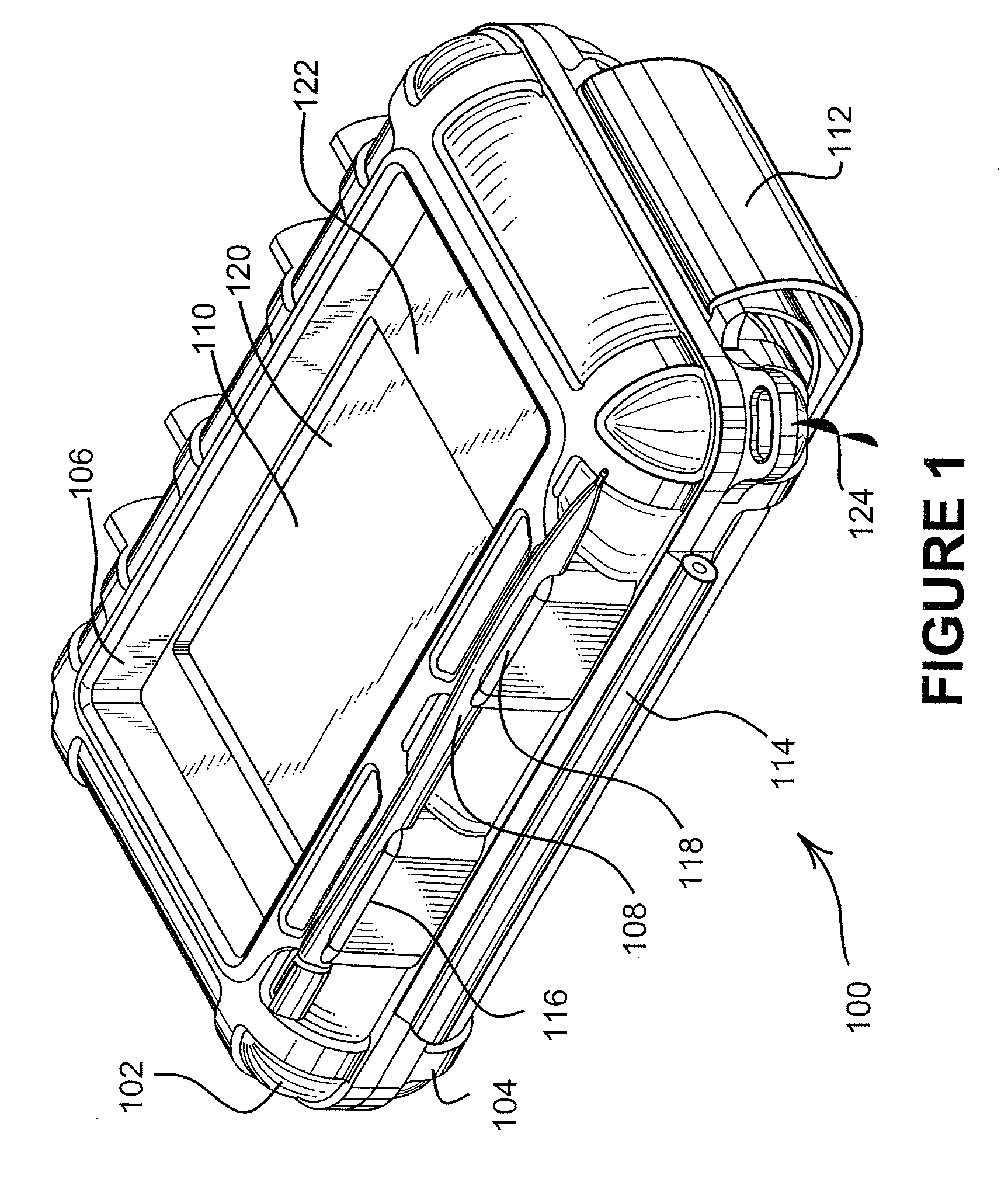

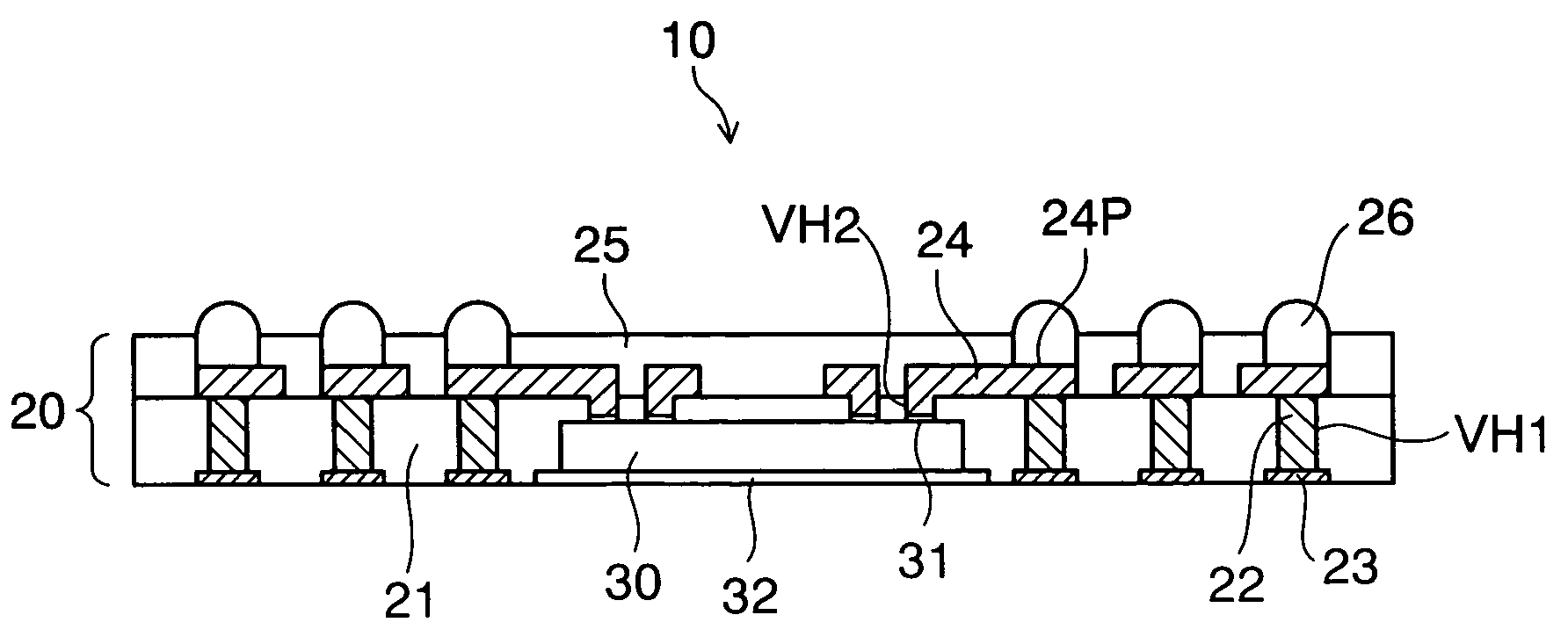

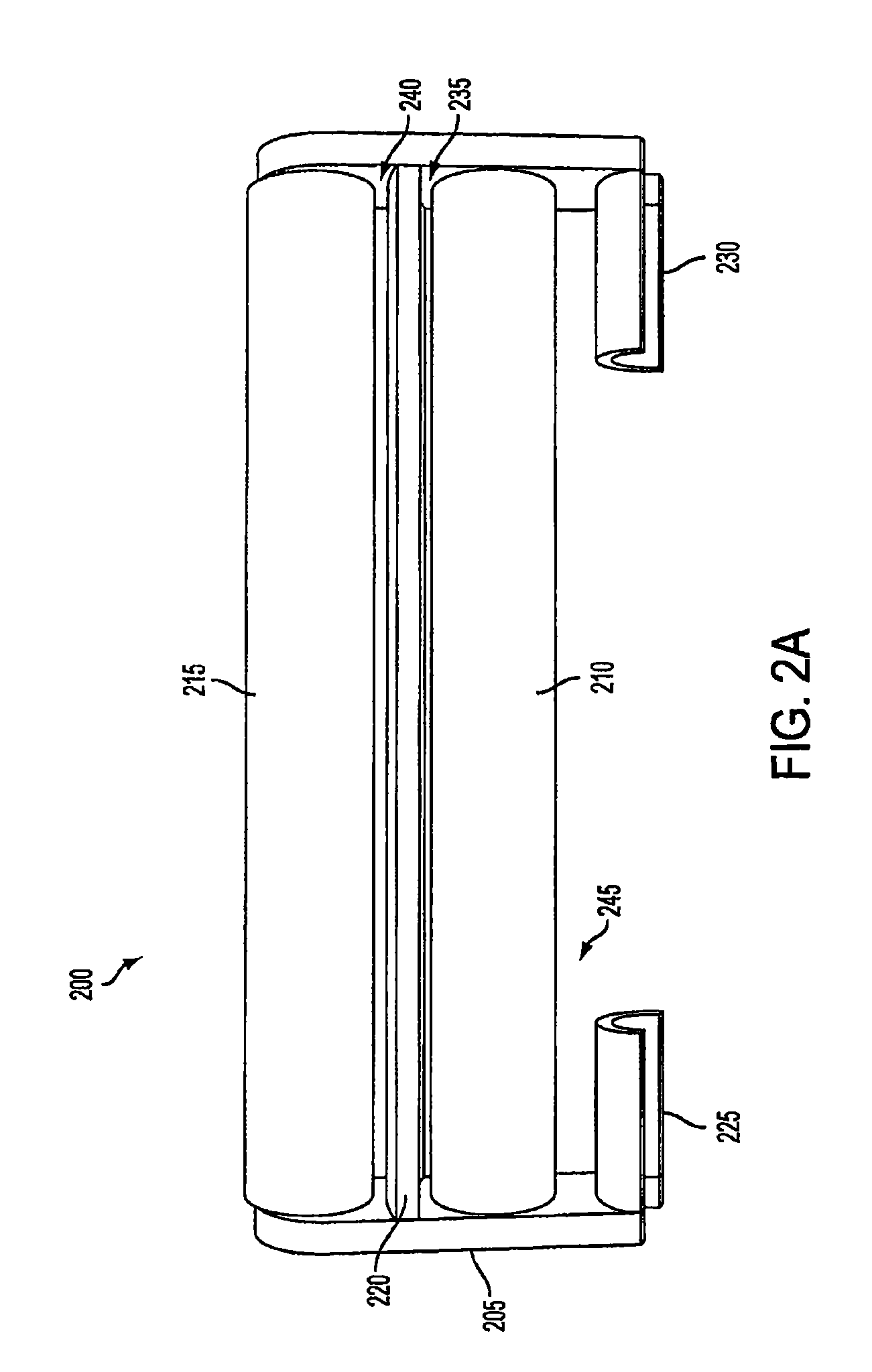

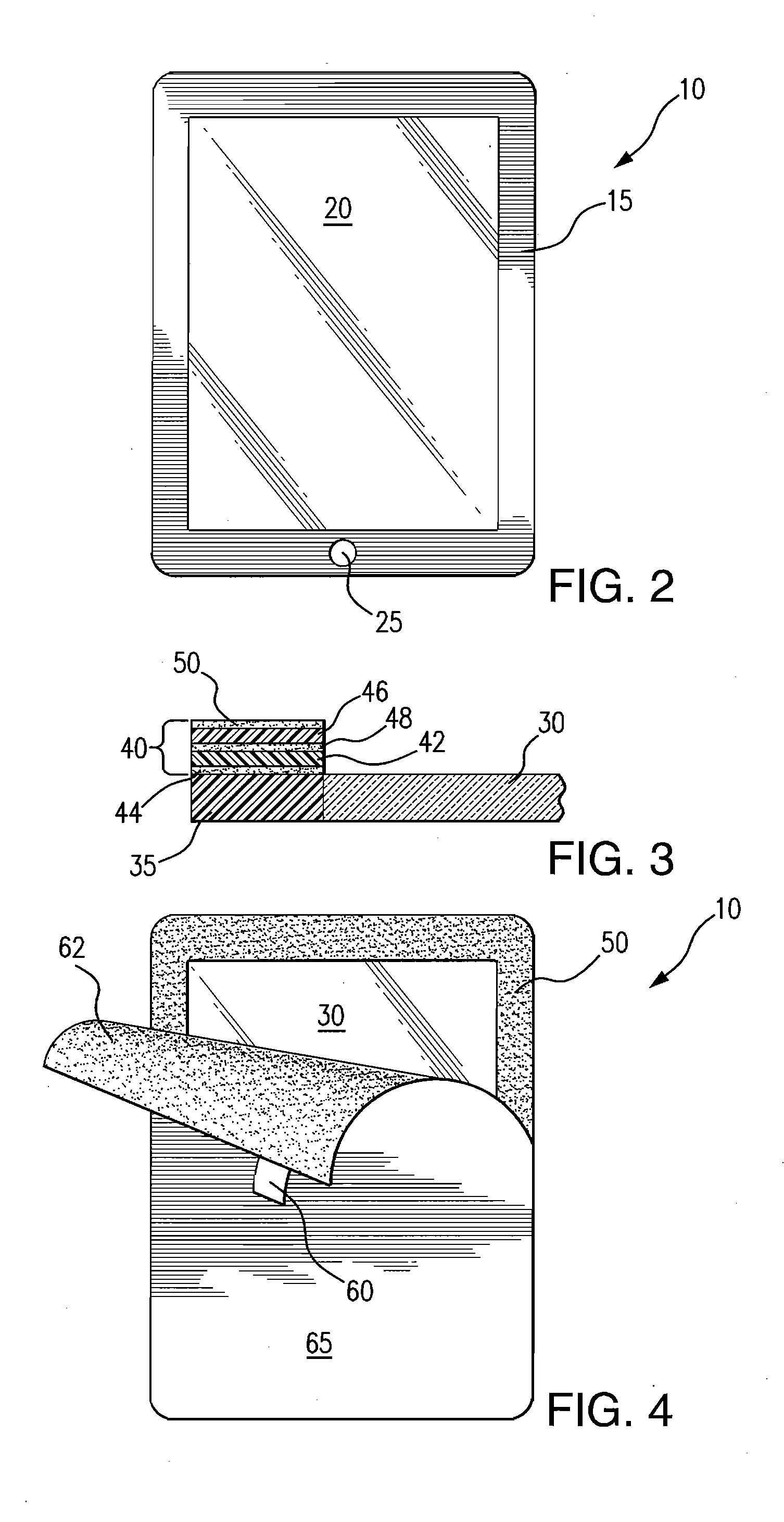

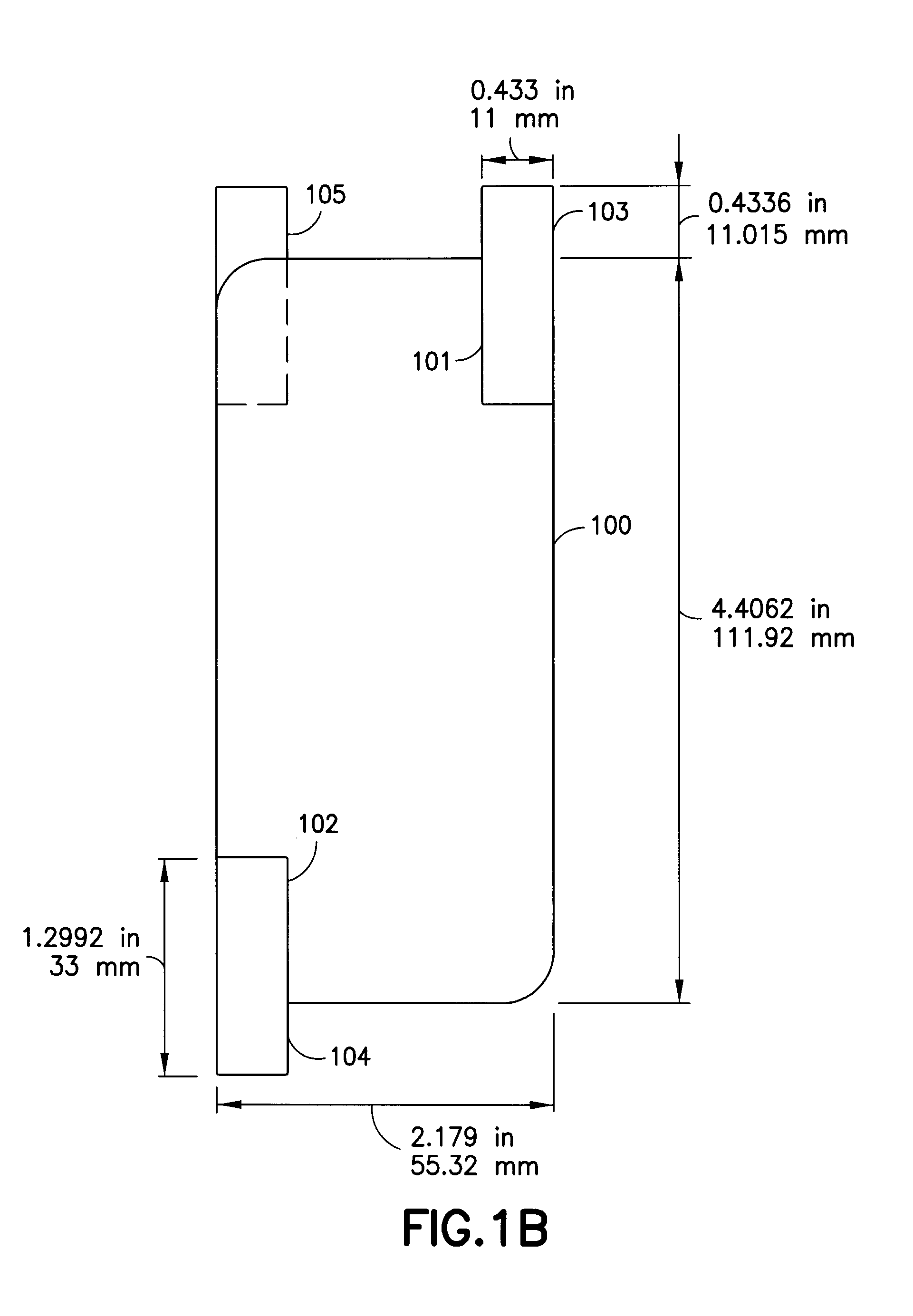

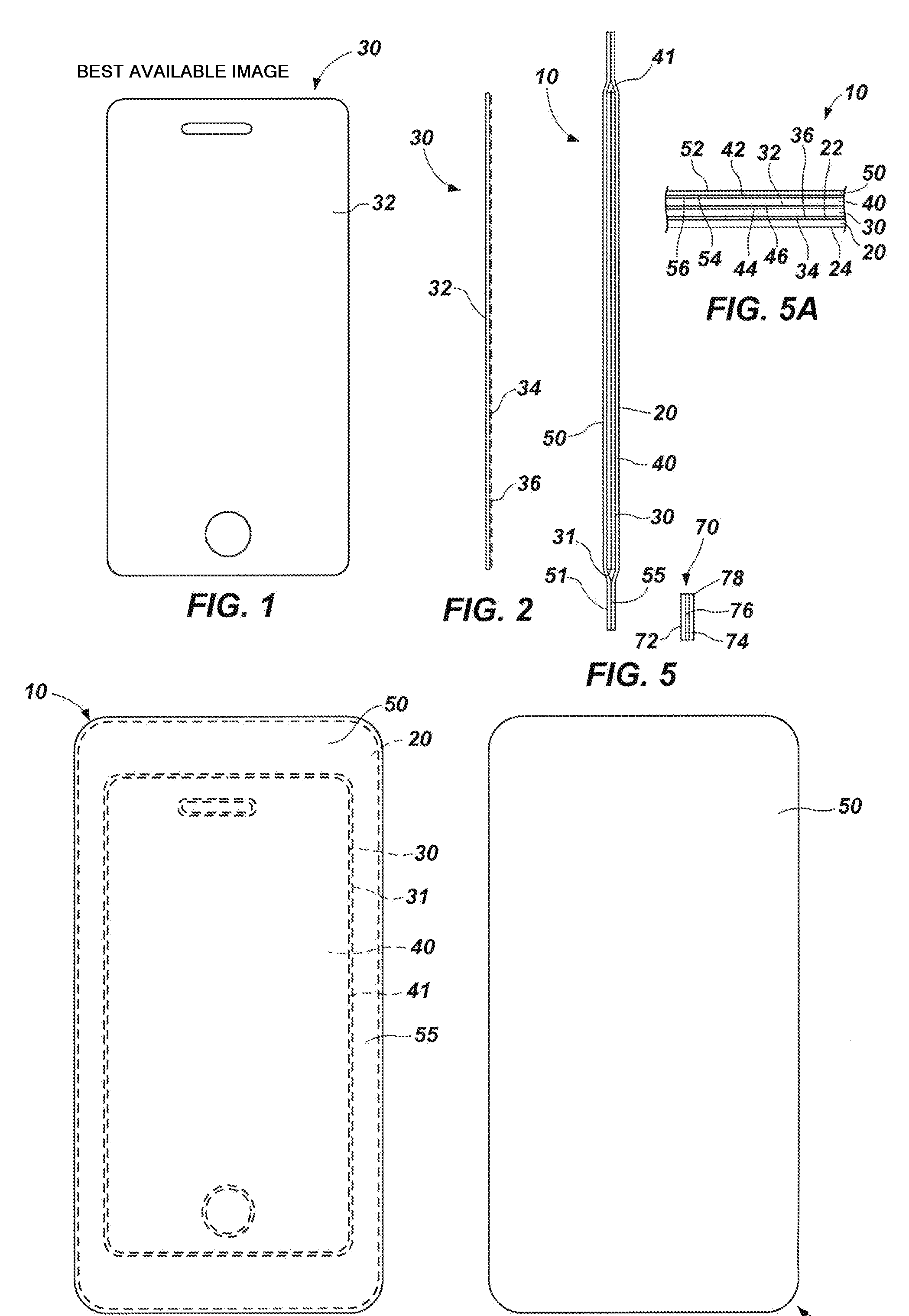

Protective enclosure for an interactive flat-panel controlled device

InactiveUS7158376B2Permits smooth and accurate interactive use of the flat-panel controlDigital data processing detailsElectrical apparatus contructional detailsTectorial membraneCapacitance

A protective enclosure is disclosed for an interactive flat-panel controlled device. The protective enclosure is watertight, crush-resistant, and impact-resistant. While providing protection, the protective enclosure simultaneously allows smooth and accurate interaction with the interactive flat-panel controlled device. The protective enclosure has a protective membrane that permits RF and touch screen stylus inputs, as well as capacitance, such as from a finger, to be transmitted accurately to the flat-panel control. The hardness and texture of the protective membrane allows a stylus or finger to glide smoothly along the surface of the membrane without catching or sticking. The protective enclosure is further adapted to allow infrared and other communication signals while the device is secured inside the case. Further, electrical connections can be made through the case without affecting the protection afforded the electronic device inside.

Owner:OTTER PRODS

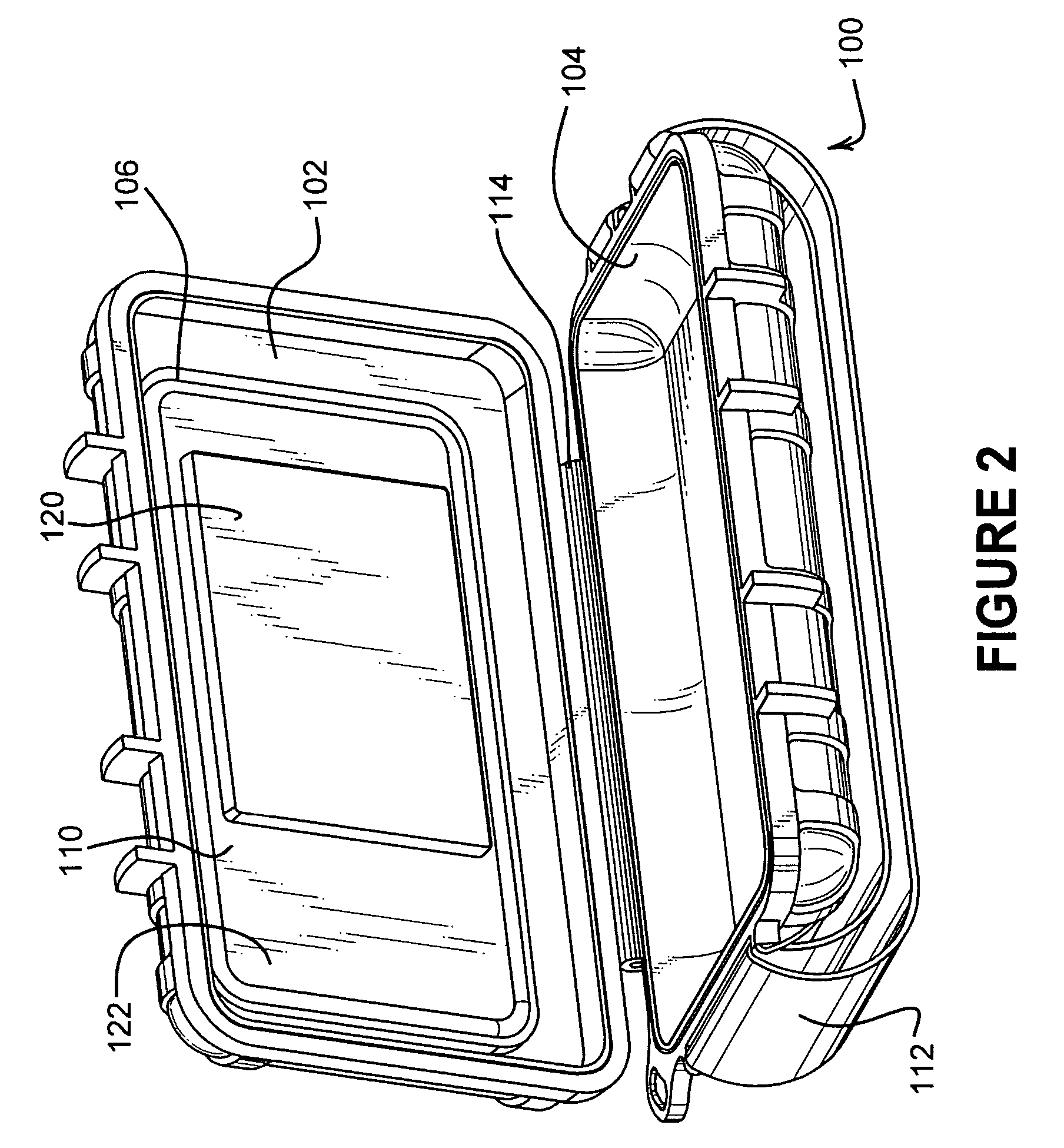

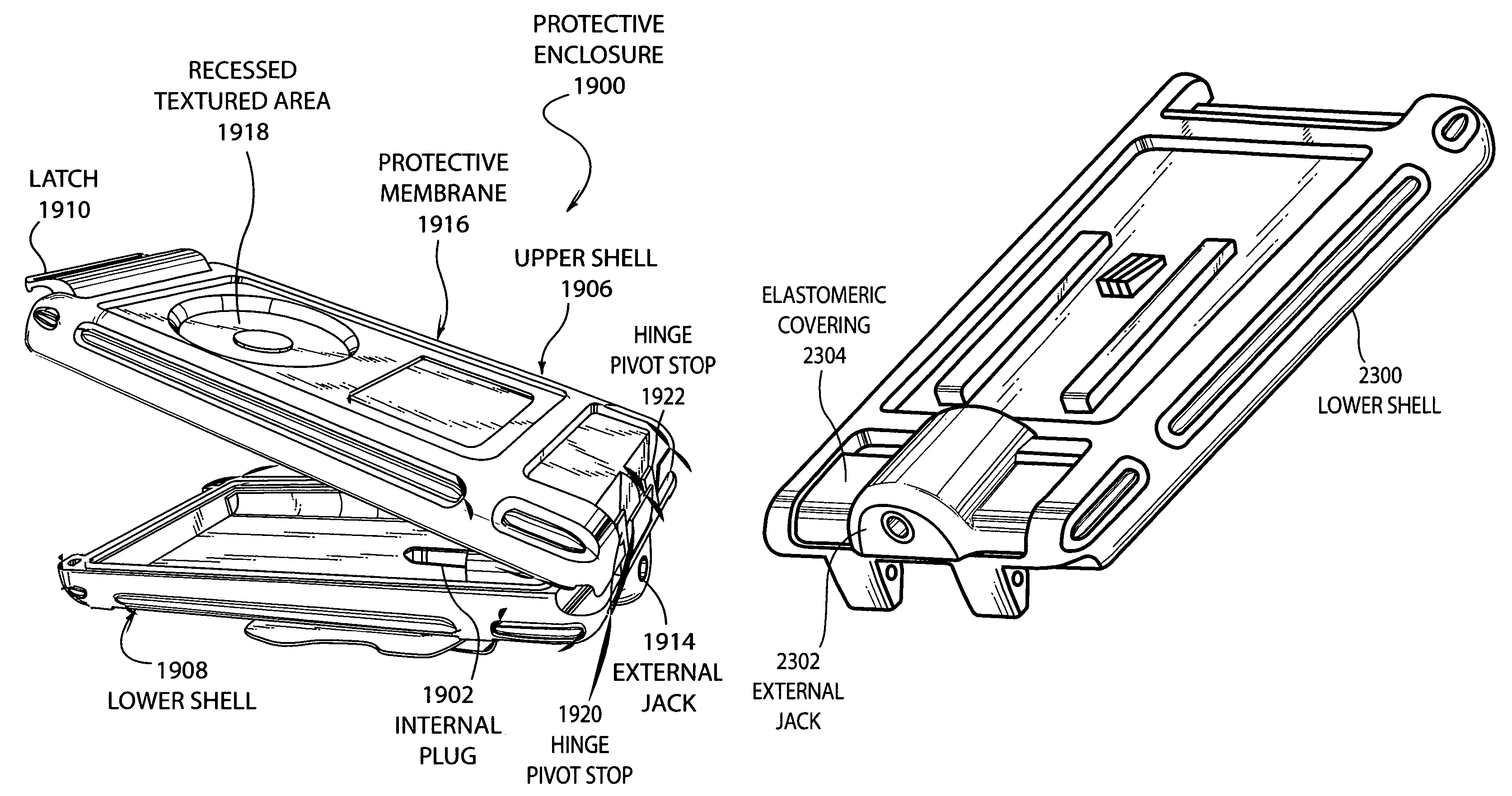

Protective enclosure and watertight adapter for an interactive flat-panel controlled device

InactiveUS7180735B2Stable controlIncrease contactSonic/ultrasonic/infrasonic transmissionDigital data processing detailsElastomerCapacitance

A protective enclosure is disclosed for an interactive flat-panel control device. The protective enclosure is watertight, crush-resistant, and impact-resistant. An electrical adapter may disposed within the protective enclosure and covered with an elastomeric covering that permits a connector of the adapter to flex with respect to the lower shell of the enclosure so that the connector may easily be inserted into an interface jack of the electronic device. The elastomeric covering also provides a watertight seal that enables the protective enclosure to be submersibly watertight. While providing protection, the protective enclosure simultaneously allows smooth and accurate interaction with the interactive flat-panel controlled device. The protective enclosure has a protective membrane that permits RF and touch screen stylus inputs, as well as capacitance, such as from a finger, to be transmitted accurately to the flat-panel control. The hardness and texture of the protective membrane allows a stylus or finger to glide smoothly along the surface of the membrane without catching or sticking. The protective enclosure is further adapted to allow infrared and other communication signals while the device is secured inside the case. Further, electrical connections can be made through the case without affecting the protection afforded the electronic device inside. The protective enclosure may have a removable cable management belt clip that has a flange that retains and prevents entangling of an accessory cable for the interactive flat-panel control device.

Owner:OTTER PRODS

Protective enclosure for touch screen device

A protective enclosure for a personal electronic device having a shell that is capable of enclosing and substantially surrounding the electronic device disposed to make the shell substantially watertight, substantially rigid and substantially crush-resistant. The enclosure has a transparent protective membrane that is attached to the shell so that the protective membrane is positioned over the touch screen of the electronic device when the electronic device is enclosed in the shell.

Owner:OTTER PRODS

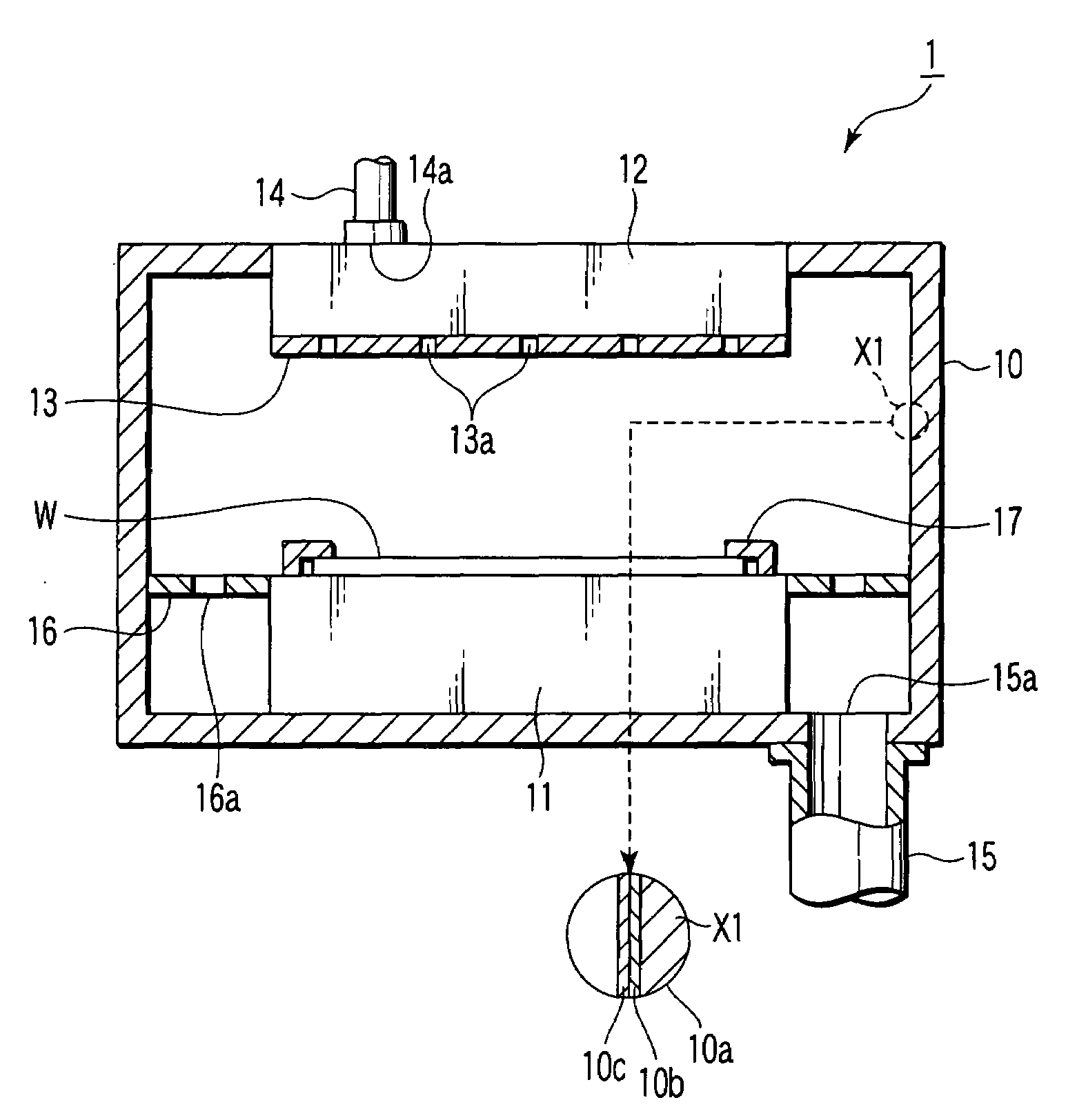

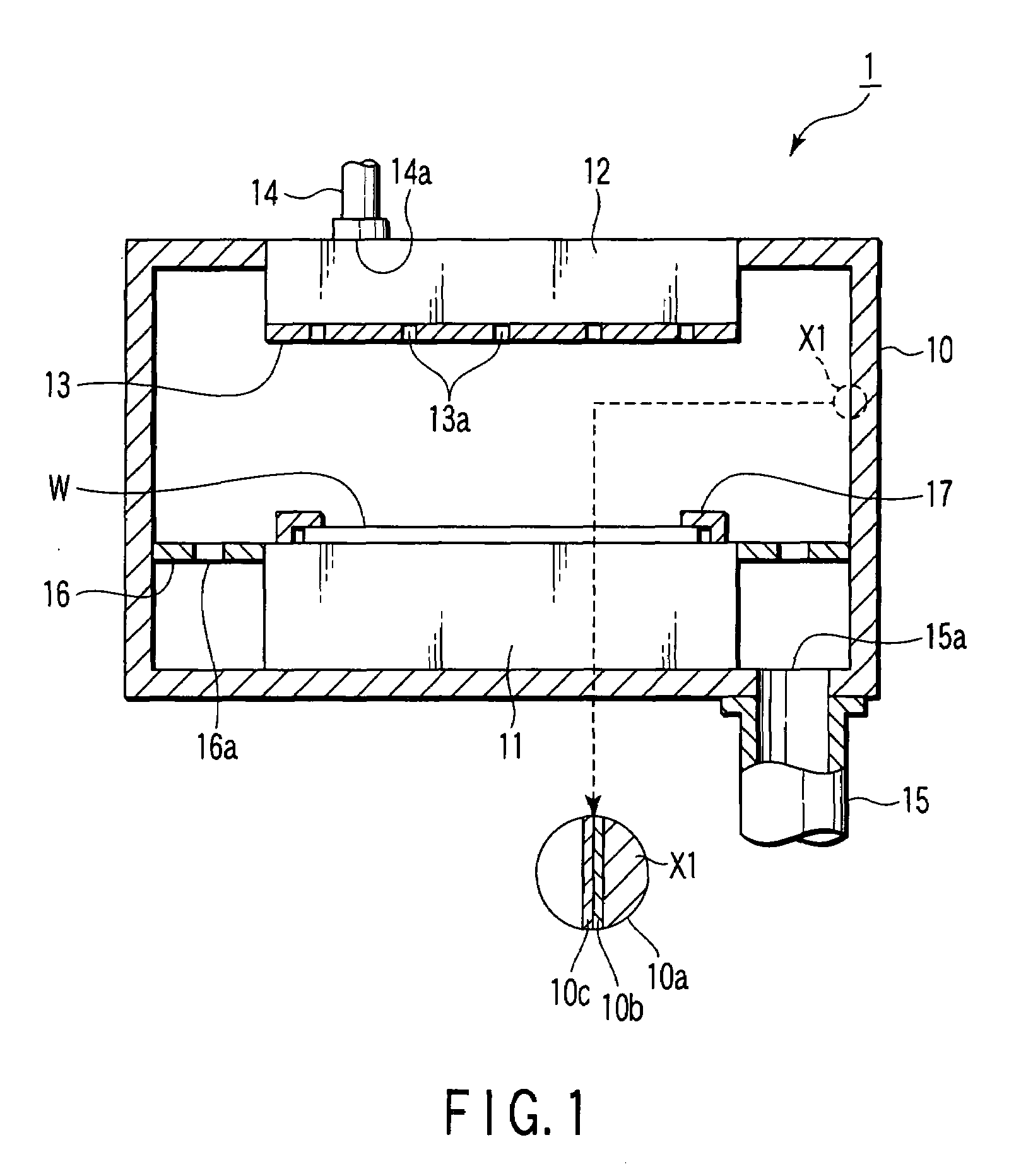

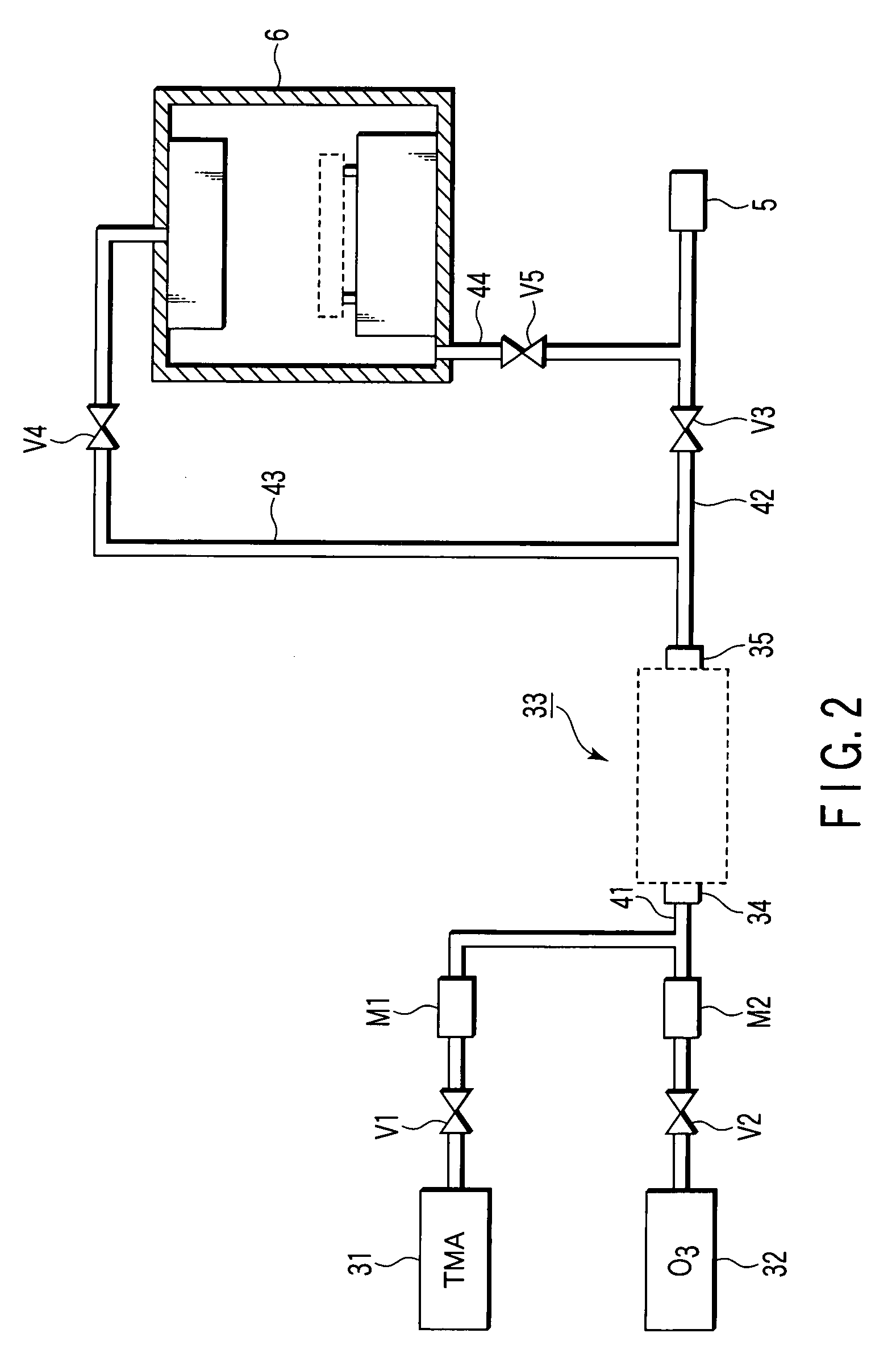

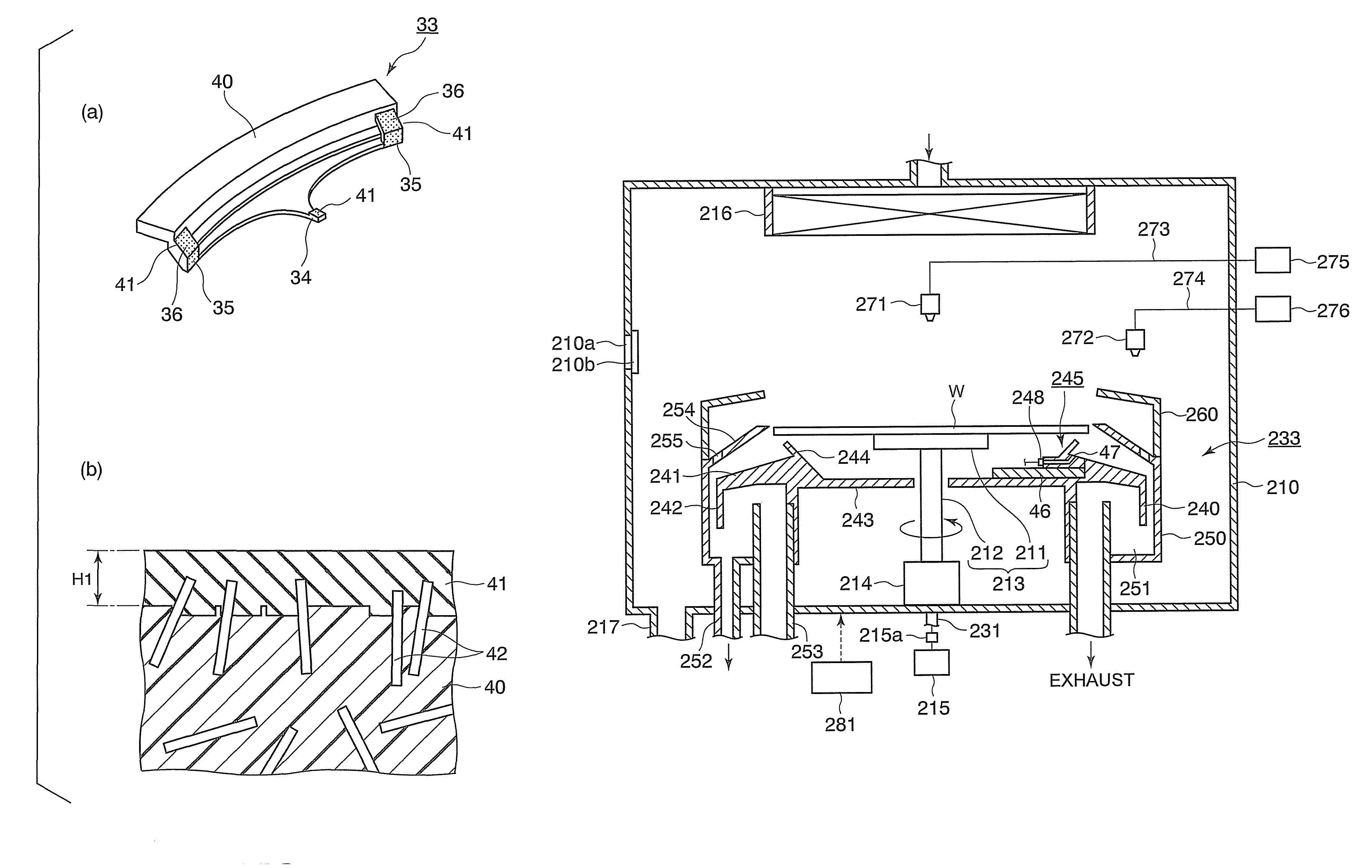

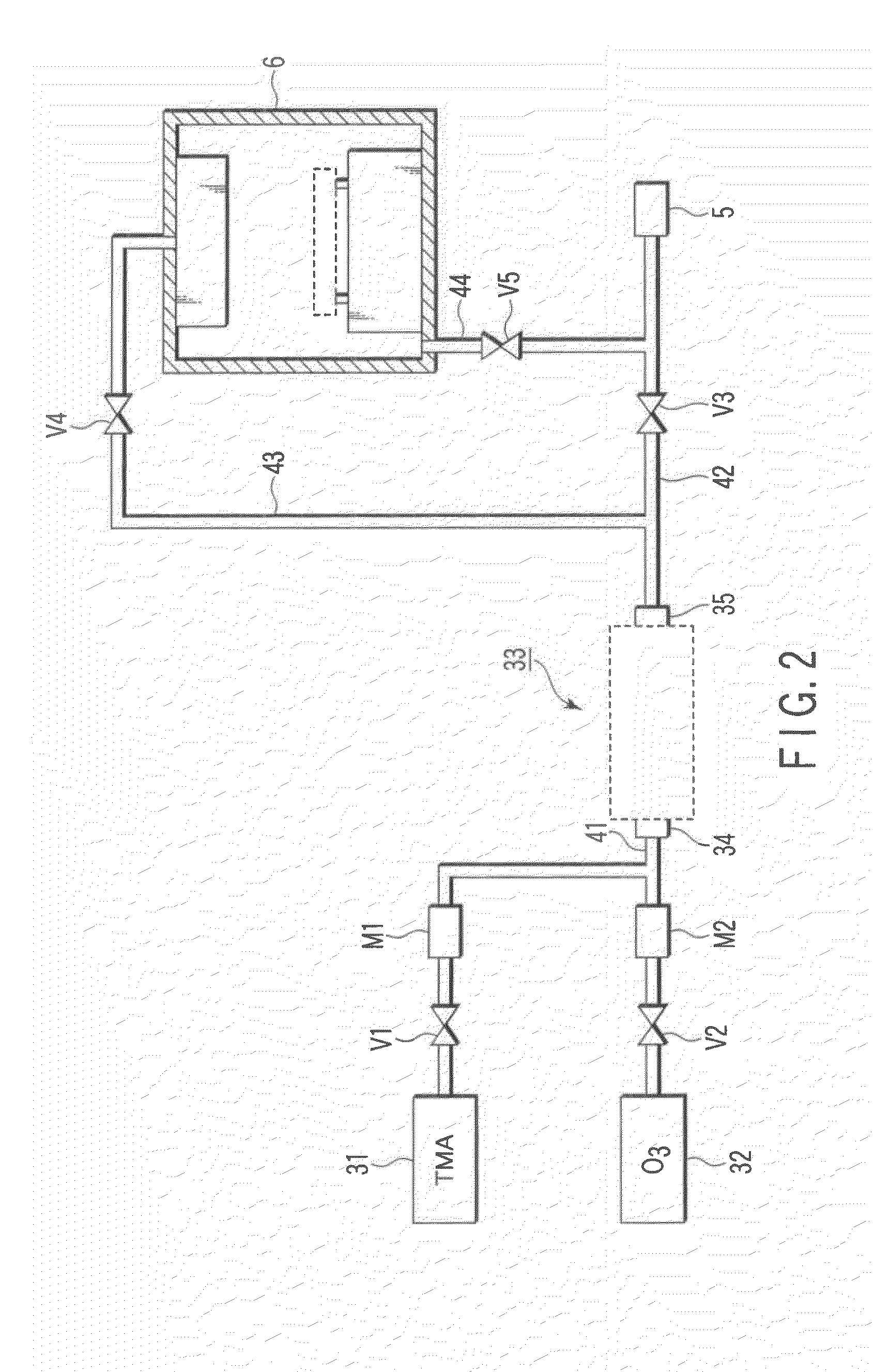

Component for semicondutor processing apparatus and manufacturing method thereof

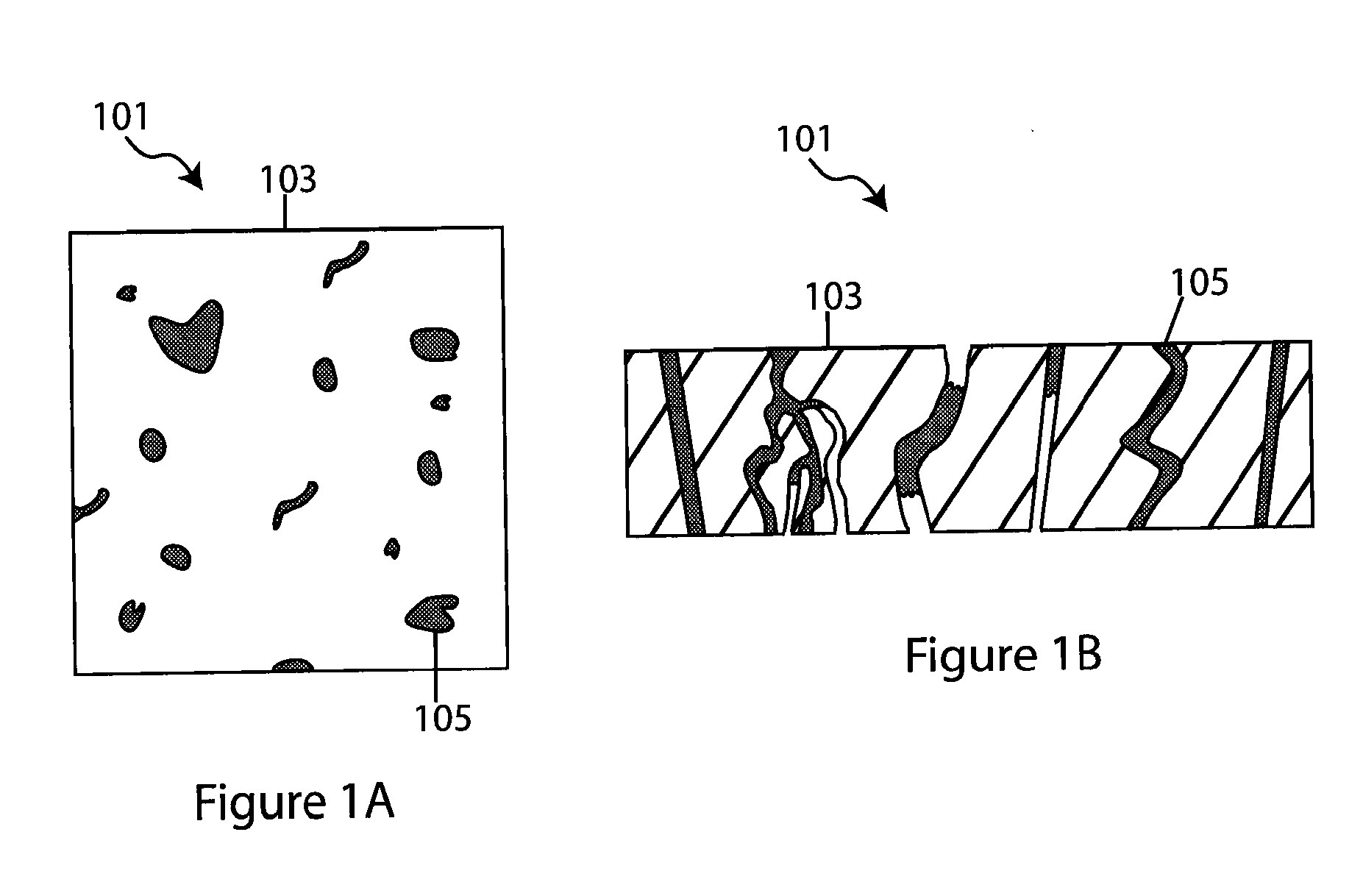

InactiveUS20090194233A1Increased durabilityLiquid surface applicatorsSemiconductor/solid-state device manufacturingTectorial membranePorosity

A component (10) for a semiconductor processing apparatus includes a matrix (10a) defining a shape of the component, and a protection film (10c) covering a predetermined surface of the matrix. The protection film (10c) consists essentially of an amorphous oxide of a first element selected from the group consisting of aluminum, silicon, hafnium, zirconium, and yttrium. The protection film (10c) has a porosity of less than 1% and a thickness of 1 nm to 10 μm.

Owner:TOKYO ELECTRON LTD

Method of Making Showerhead for Semiconductor Processing Apparatus

ActiveUS20110076401A1Low costReduce manufacturing costElectric discharge tubesPretreated surfacesTectorial membraneEngineering

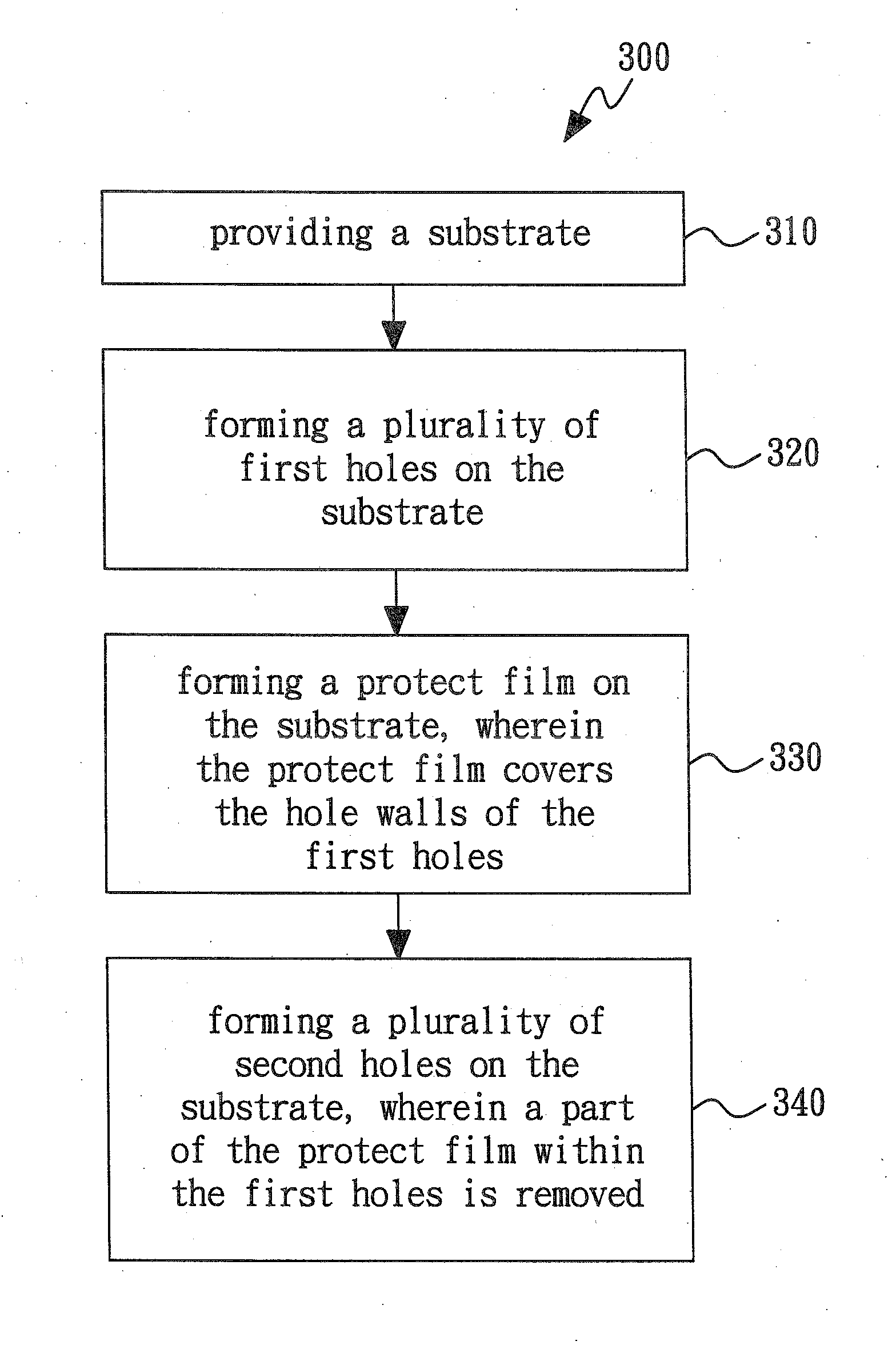

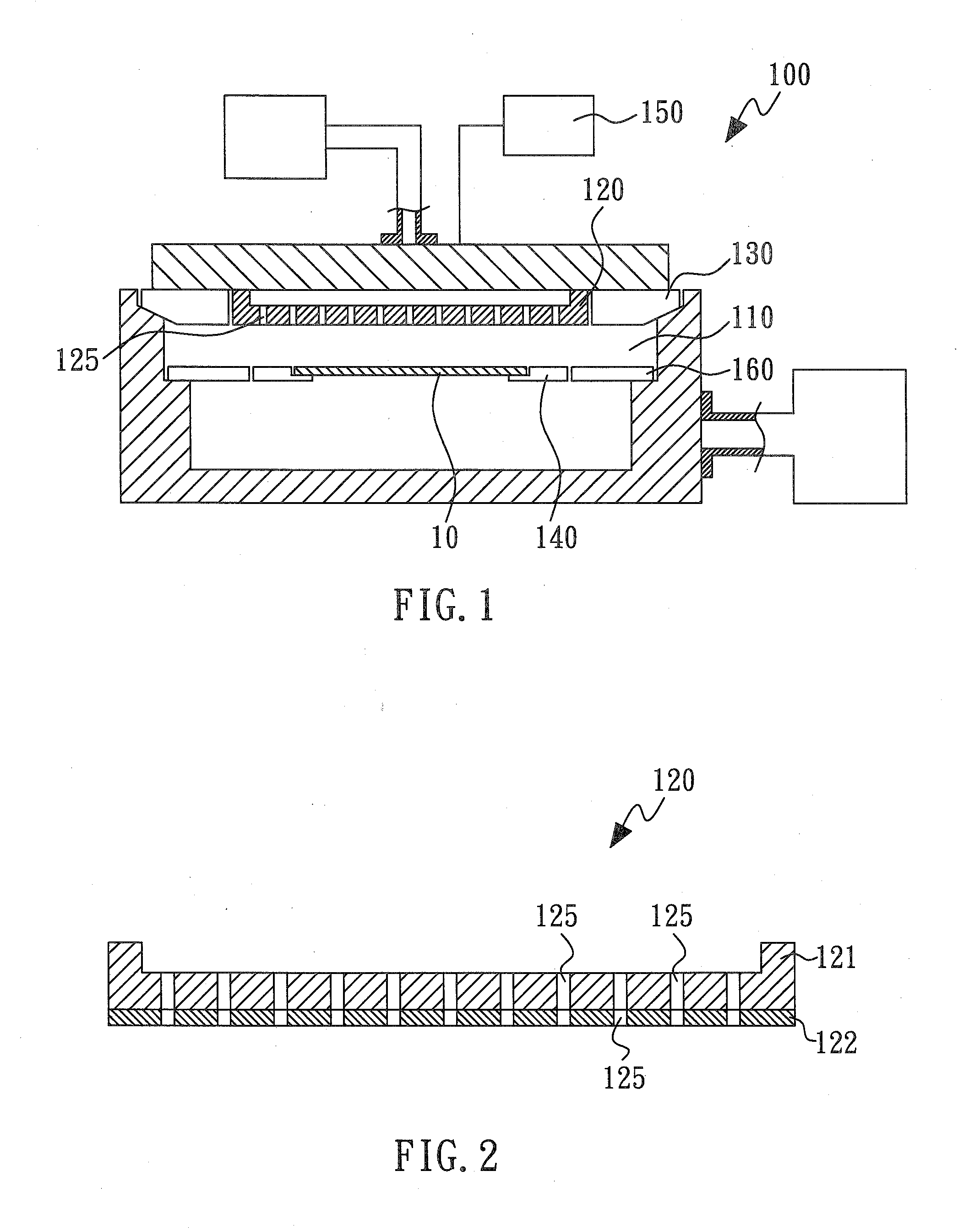

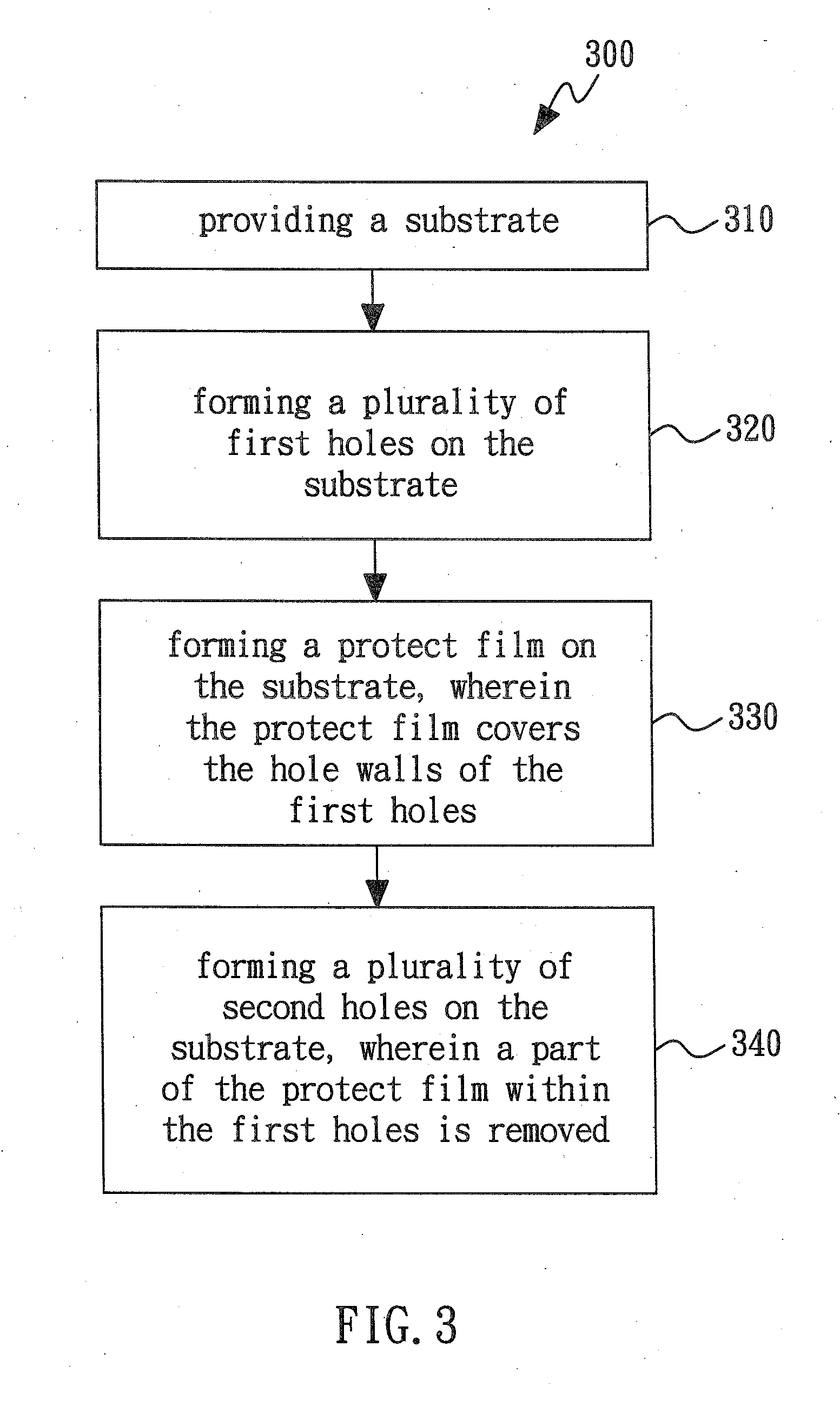

A method of making a showerhead for a semiconductor processing apparatus is disclosed. In one embodiment, the method includes providing a substrate; forming first holes in the substrate; forming a protective film on the substrate, where the protective film covers sidewalls of the first holes; and forming second holes in the substrate, where a part of the protective film within the first holes is removed. In another embodiment, the method includes providing a substrate; forming islands on the substrate; forming a protective film on the substrate, where the protective film does not cover the tops of the islands; and forming holes in the islands.

Owner:HERMES EPITEK

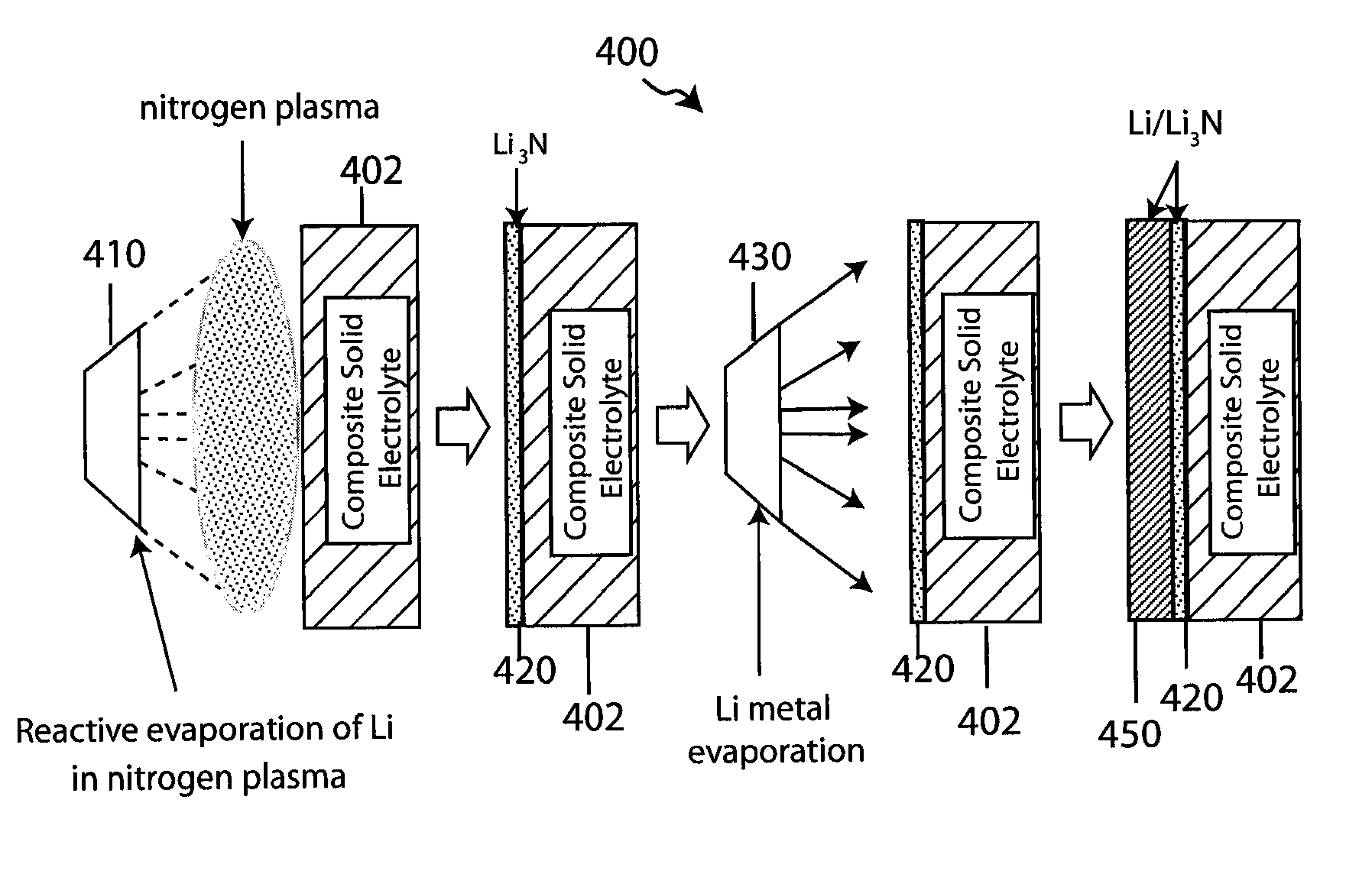

Composite solid electrolyte for protection of active metal anodes

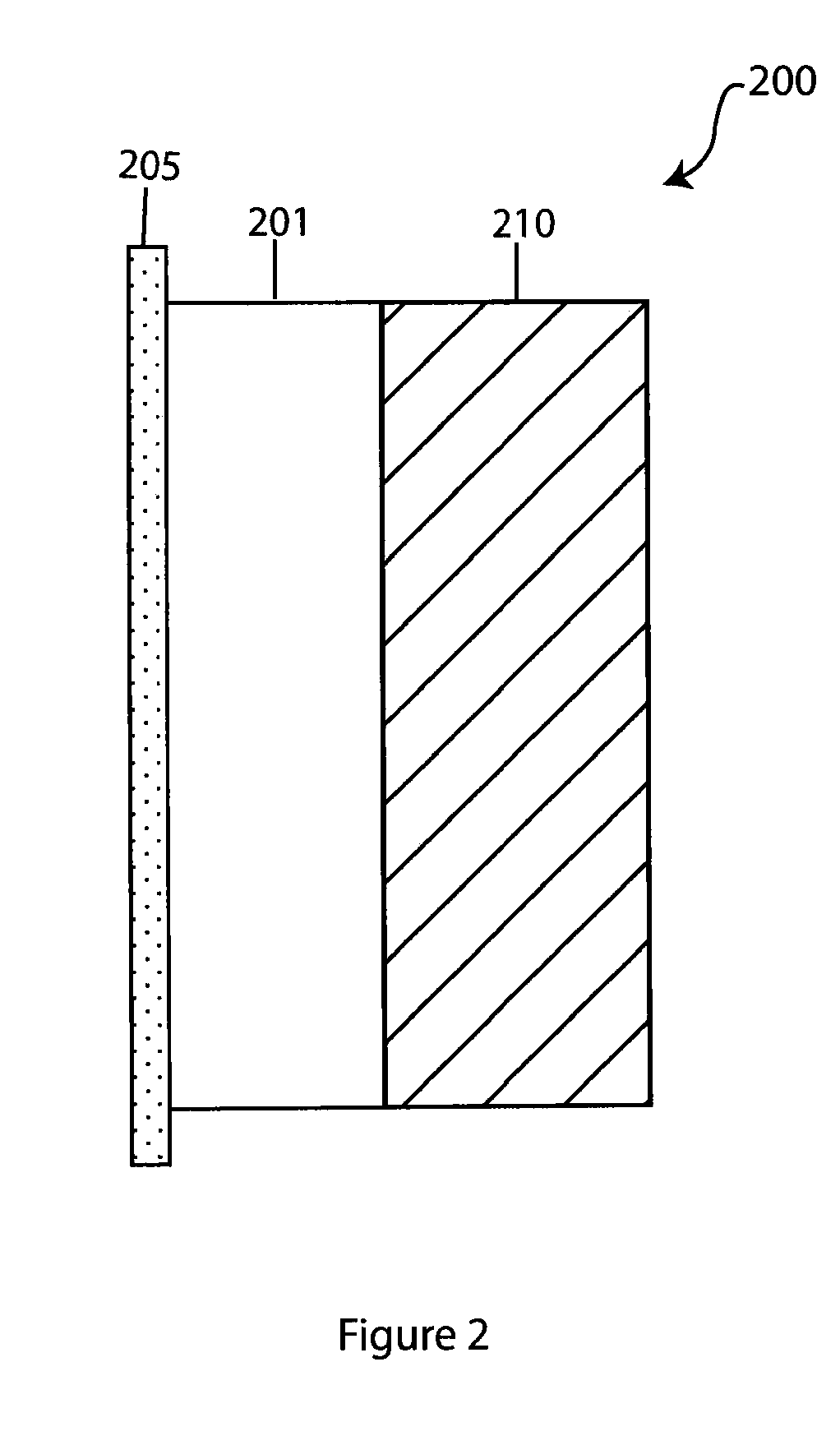

ActiveUS20070172739A1Eliminate through-porosityHigh metal ion conductivityCell electrodesPrimary cellsPorosityTectorial membrane

A composite solid electrolyte include a monolithic solid electrolyte base component that is a continuous matrix of an inorganic active metal ion conductor and a filler component used to eliminate through porosity in the solid electrolyte. In this way a solid electrolyte produced by any process that yields residual through porosity can be modified by the incorporation of a filler to form a substantially impervious composite solid electrolyte and eliminate through porosity in the base component. Methods of making the composites is also disclosed. The composites are generally useful in electrochemical cell structures such as battery cells and in particular protected active metal anodes, particularly lithium anodes, that are protected with a protective membrane architecture incorporating the composite solid electrolyte. The protective architecture prevents the active metal of the anode from deleterious reaction with the environment on the other (cathode) side of the architecture, which may include aqueous, air and organic liquid electrolytes and / or electrochemically active materials.

Owner:POLYPLUS BATTERY CO INC

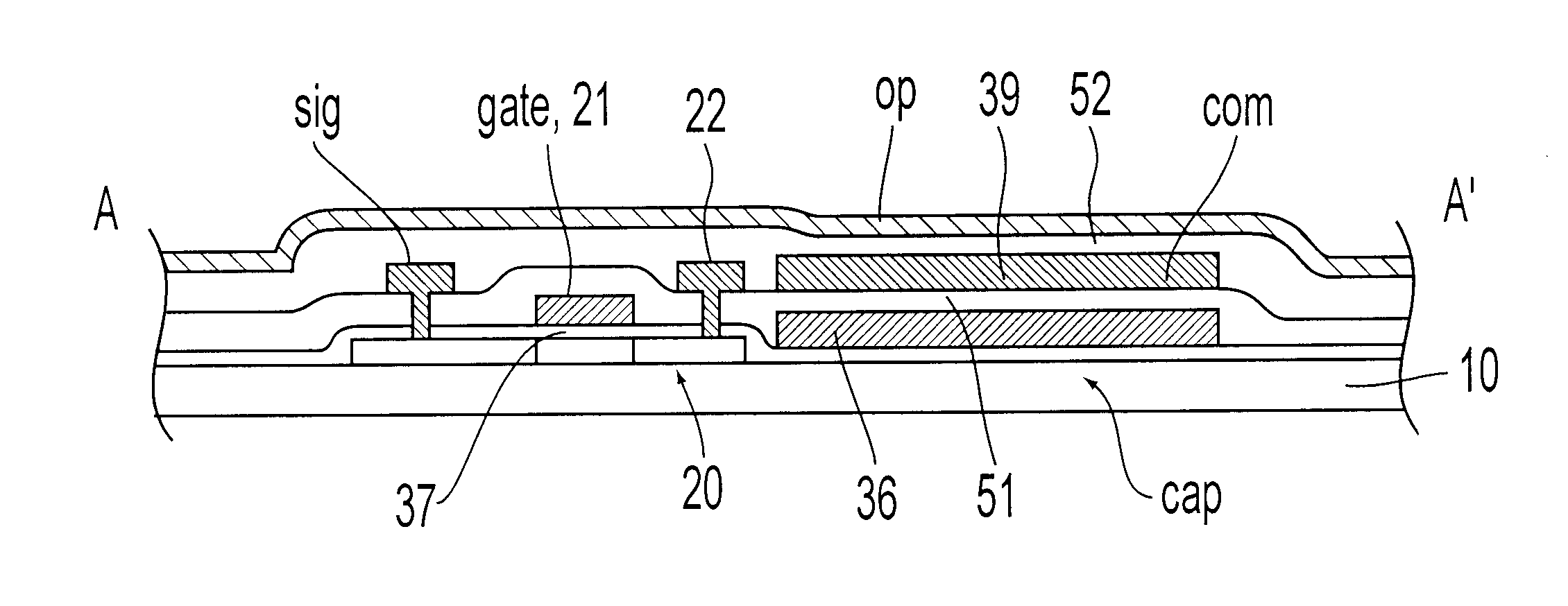

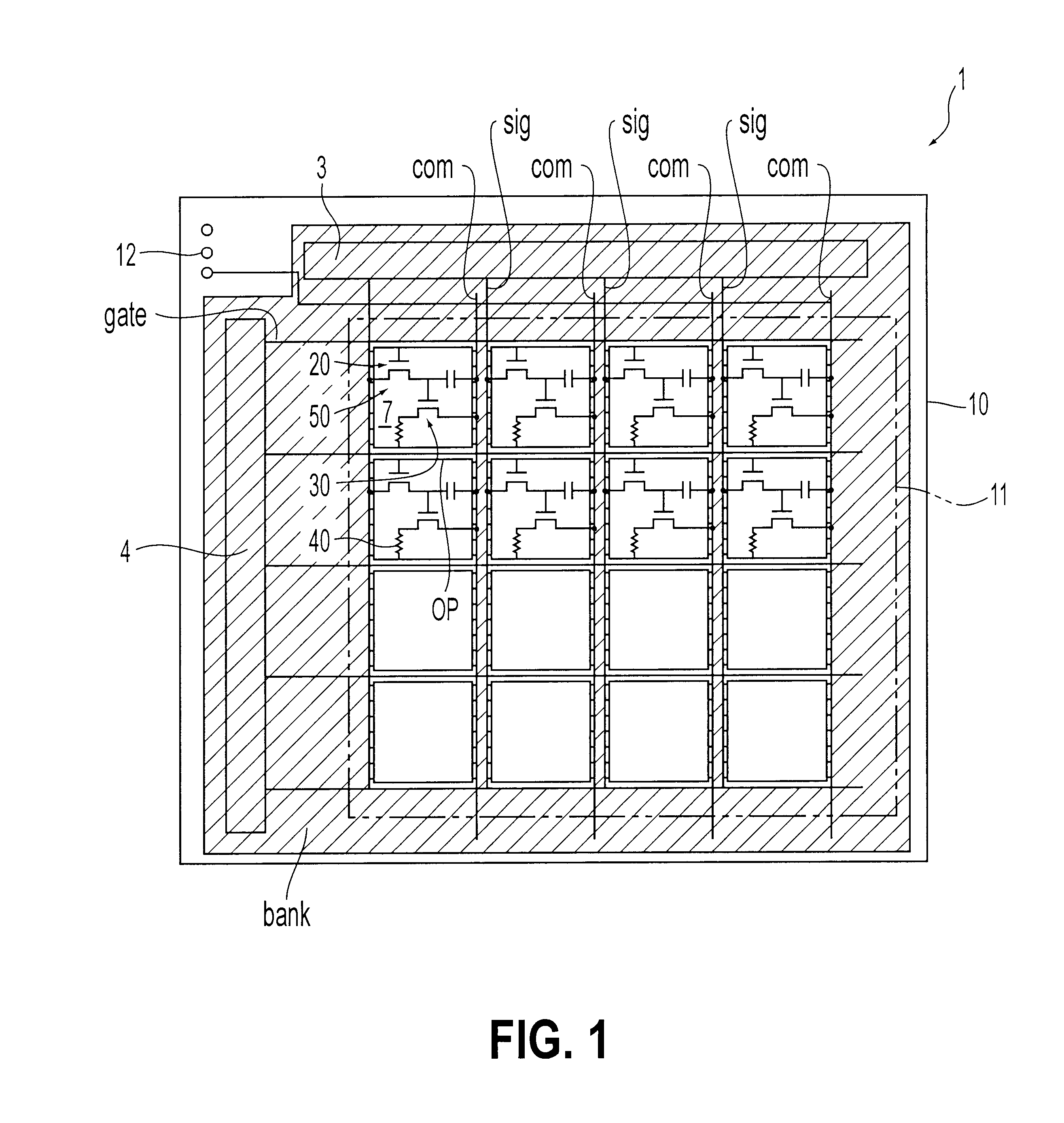

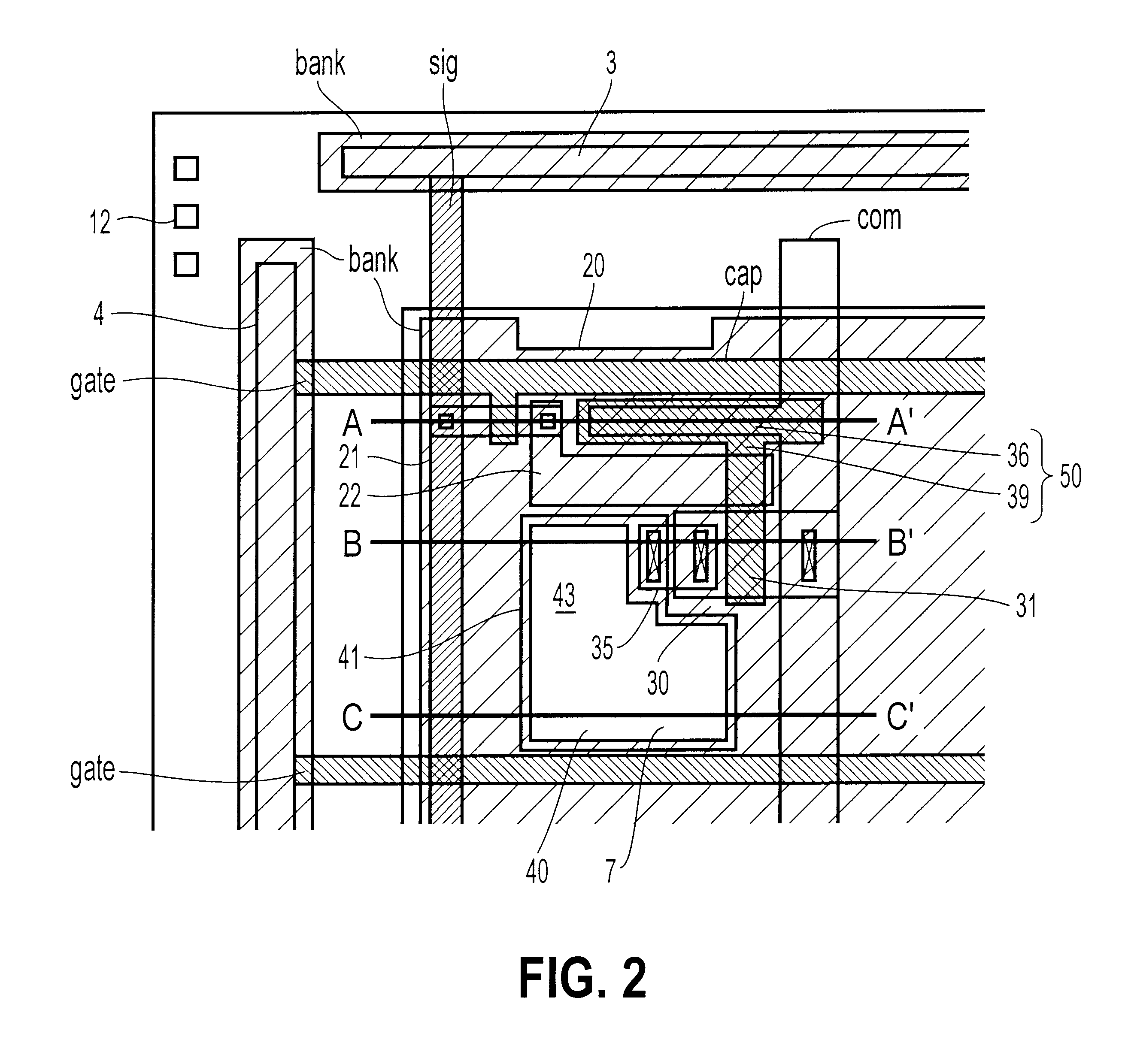

Active matrix display

InactiveUS6359606B1Improve display qualityDischarge tube luminescnet screensElectroluminescent light sourcesTectorial membraneActive matrix

In an active matrix display device, each pixel is provided with a pixel electrode, an organic semiconductor film deposited on the upper layer side of the pixel electrode, and a thin film luminescent element provided with an opposing electrode formed on the upper layer side of the organic semiconductor film. A protective film covering almost the entire surface of a substrate is formed on the upper layer of the opposing electrode. The protective film prevents the entry of moisture or oxygen to inhibit the deterioration of the thin film luminescent element.

Owner:INTELLECTUAL KEYSTONE TECH LLC

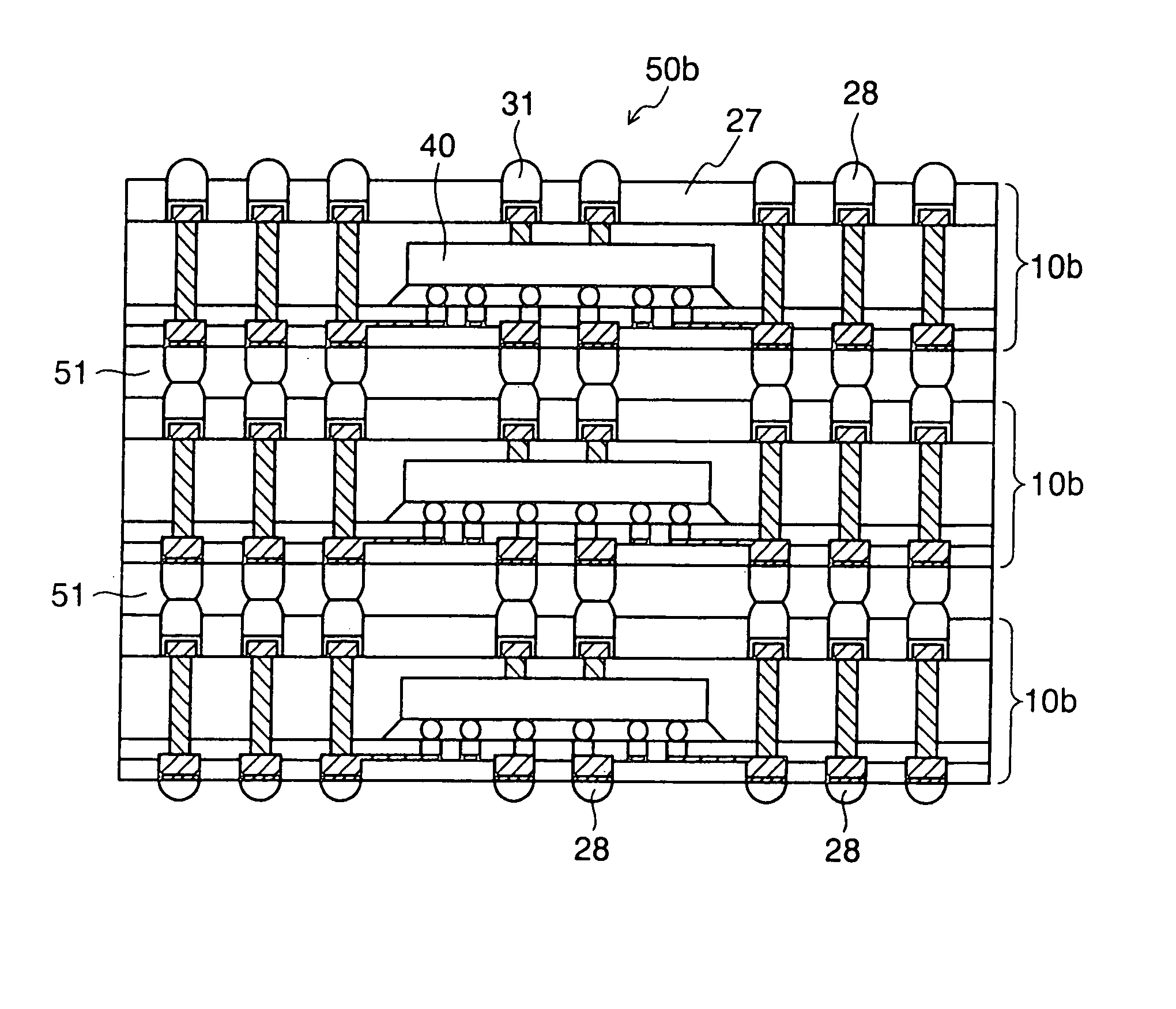

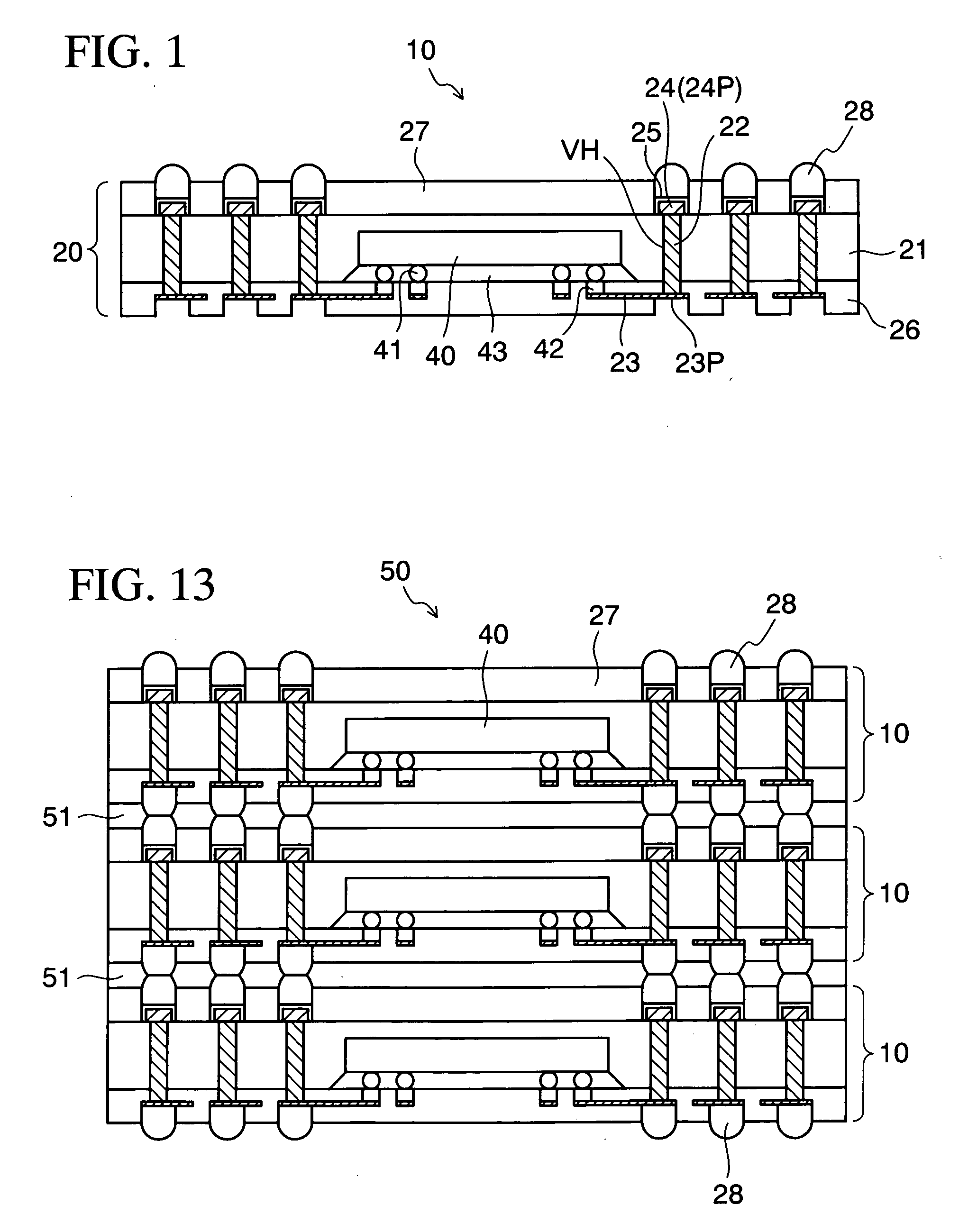

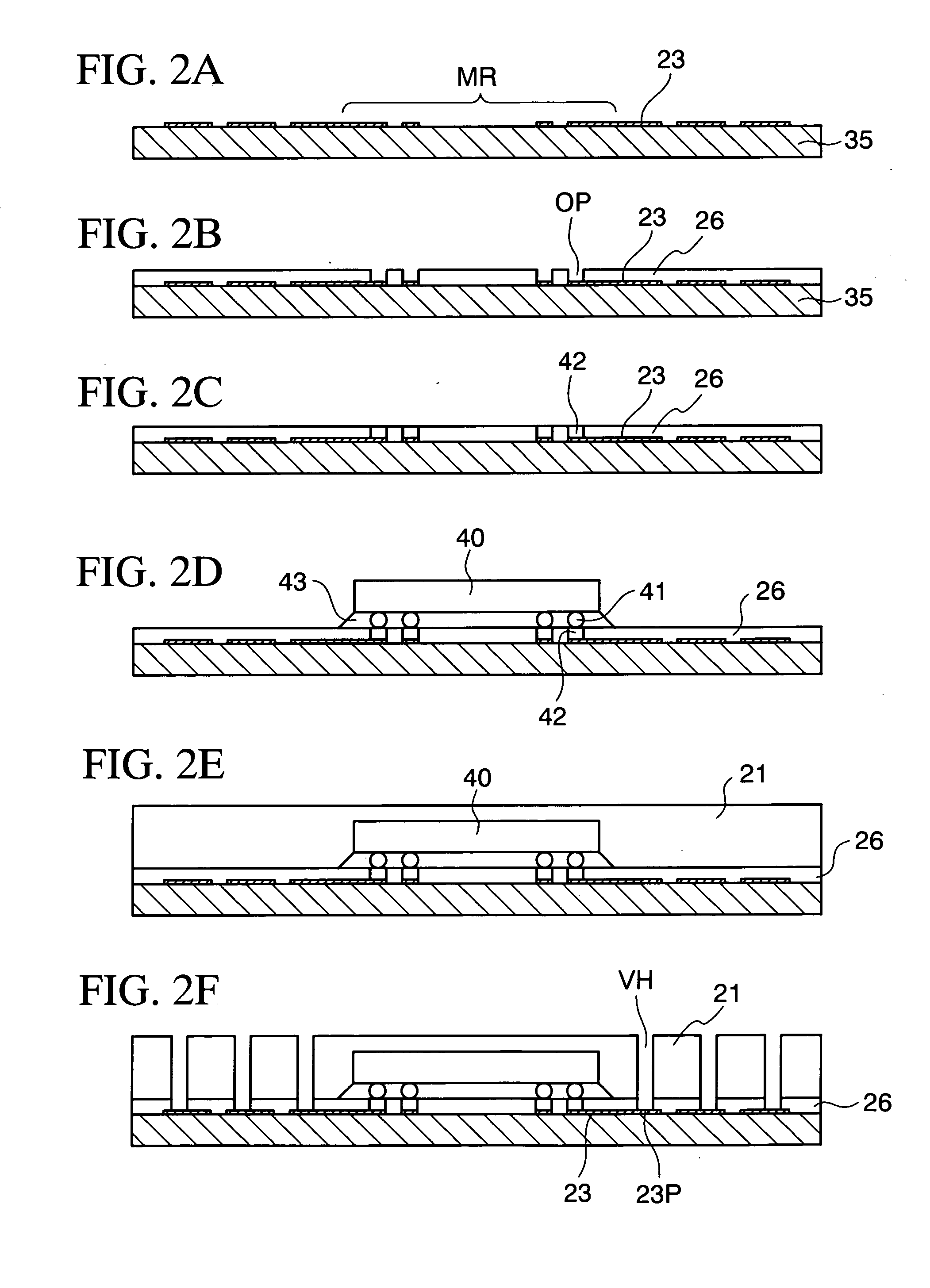

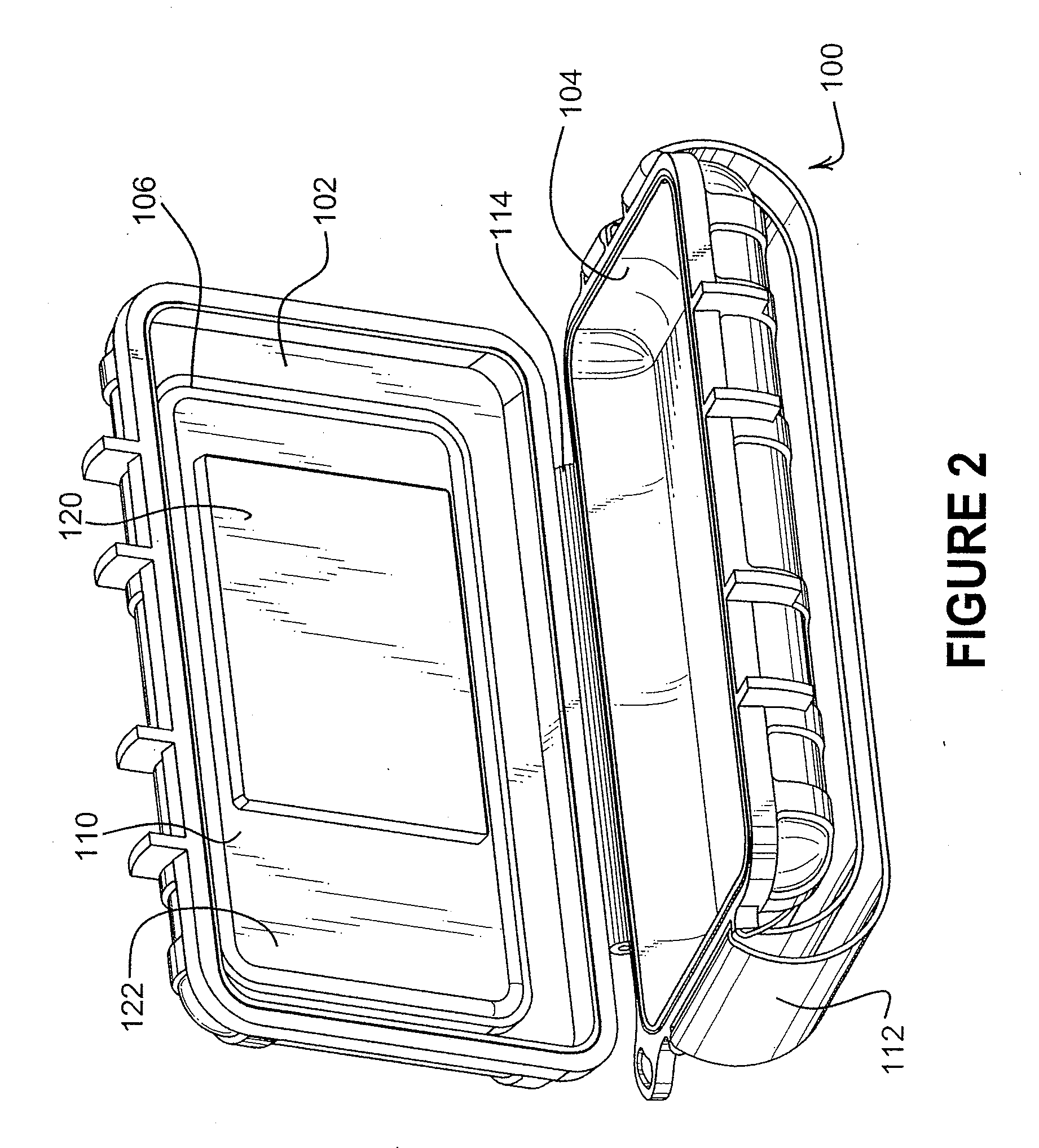

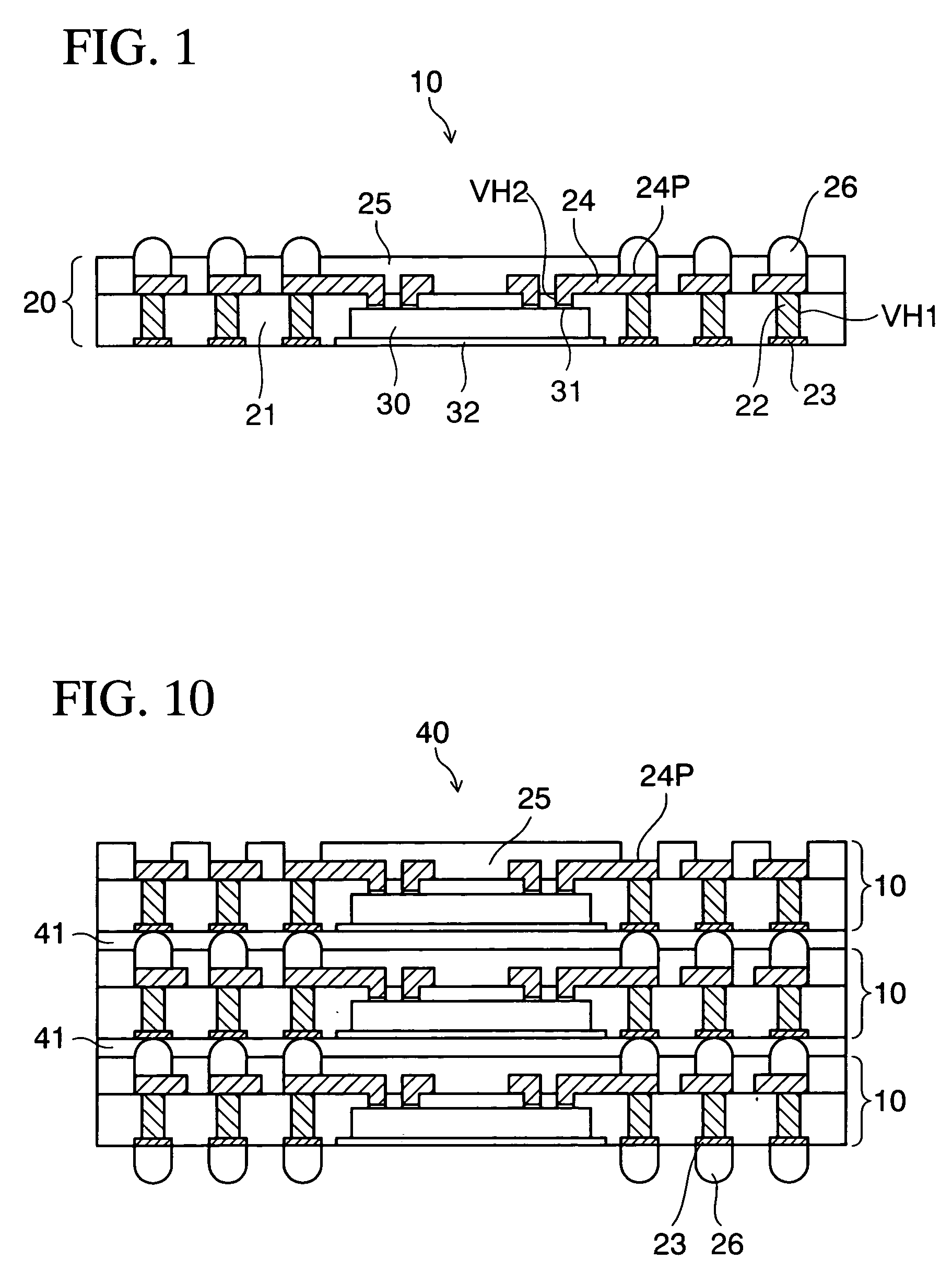

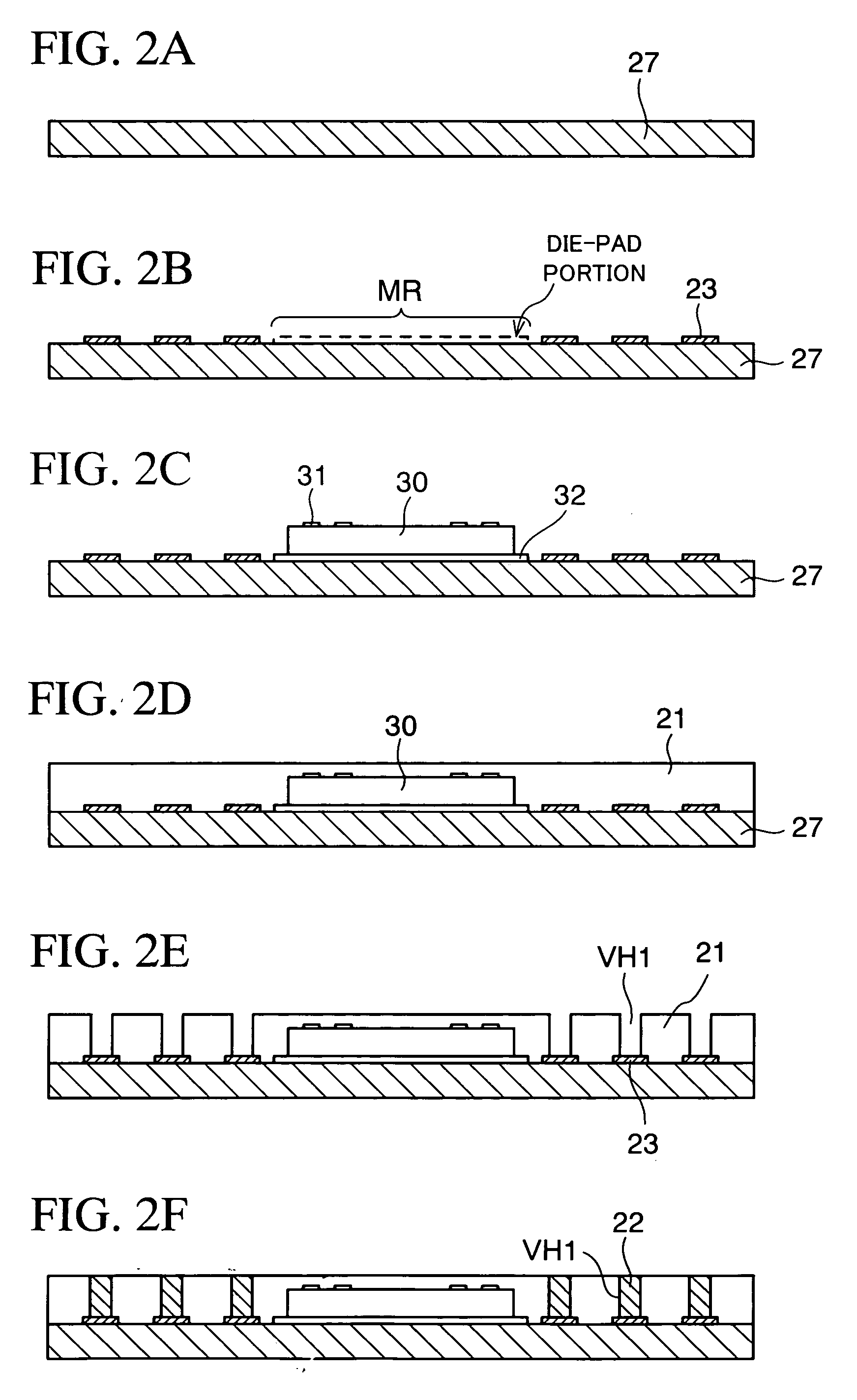

Semiconductor device and method of manufacturing the same

InactiveUS20050184377A1Increase freedomFunction increaseSemiconductor/solid-state device detailsSolid-state devicesTectorial membraneElectrical conductor

In a semiconductor device, via holes are formed around a chip buried in a package, and conductor layers are respectively formed to be connected to one end and another end of the conductor filled in the individual via hole. Portions (pad portions) of the conductor layers which correspond to the conductors are exposed from protective films, or external connection terminals are bonded to the pad portions. The chip is mounted with flip-chip technology so that at least some of electrode terminals thereof are electrically connected to the conductor layers.

Owner:SHINKO ELECTRIC IND CO LTD

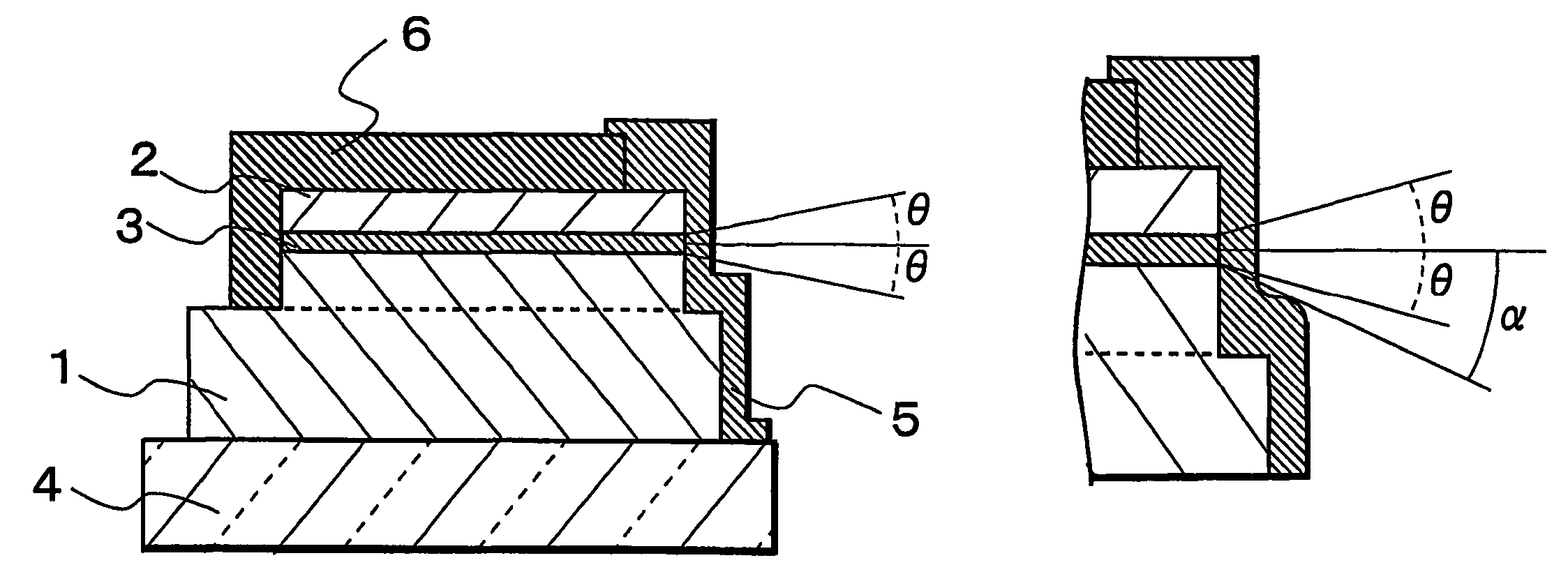

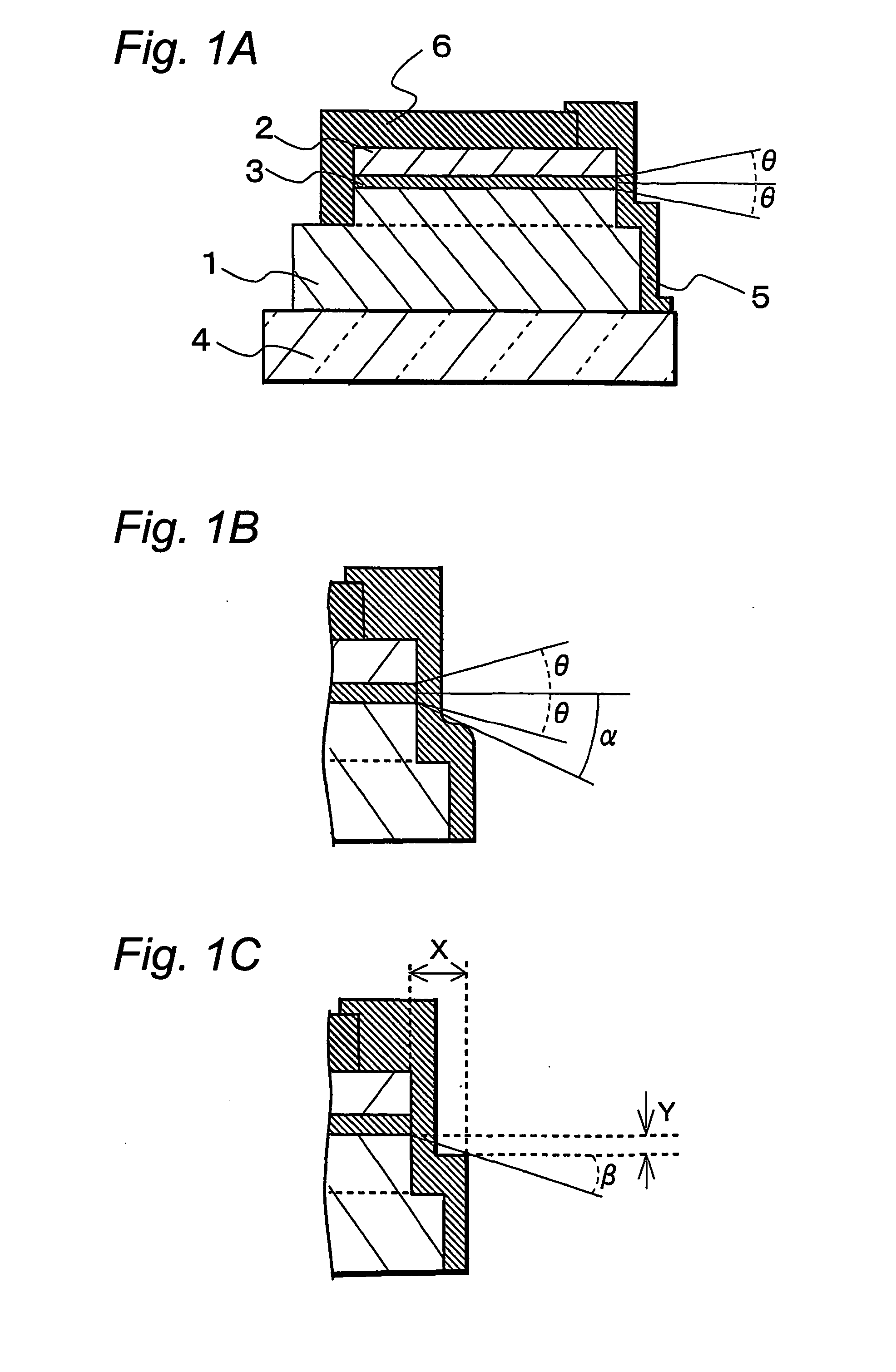

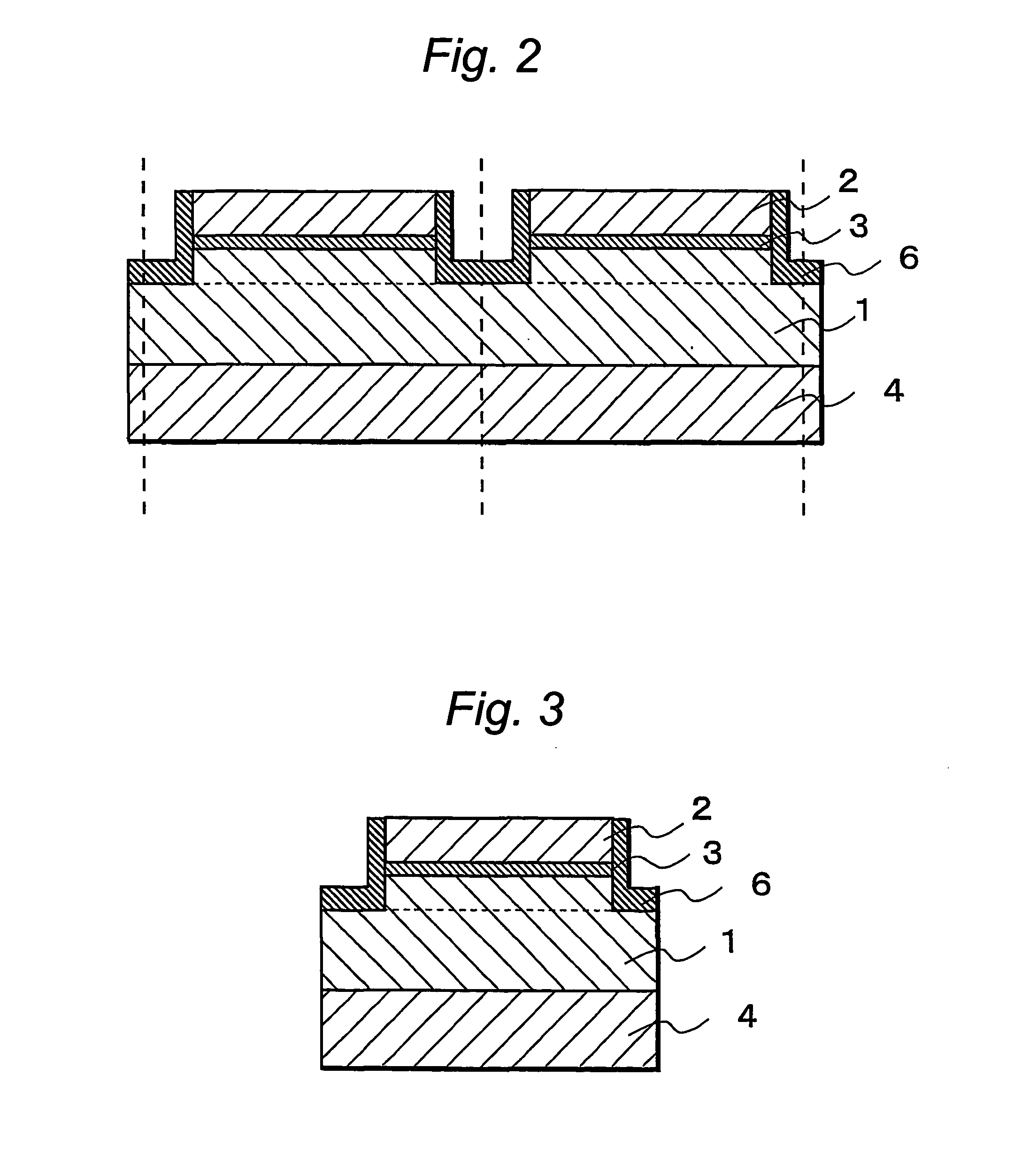

Semicondutor laser device and its manufacturing method

InactiveUS20040233950A1Efficient executionLaser optical resonator constructionSemiconductor laser structural detailsTectorial membraneSemiconductor package

A semiconductor laser device have, on a substrate, a semiconductor layer including an active layer sandwiched between an n-type layer and a p-type layer, the semiconductor layer having a sonator face formed by etching and a projection projecting out in an emission direction relatively to the resonator face, wherein a protective film is formed to extend from the resonator face to an end face of the projection, and, an emission critical angle, which is the largest angle at which light emitted from the resonator face can be radiated without being blocked by the projection and the protective film formed on the projection, is larger than an emission half-angle of an emission distribution in a vertical direction of a laser beam emitted from the resonator face.

Owner:NICHIA CORP

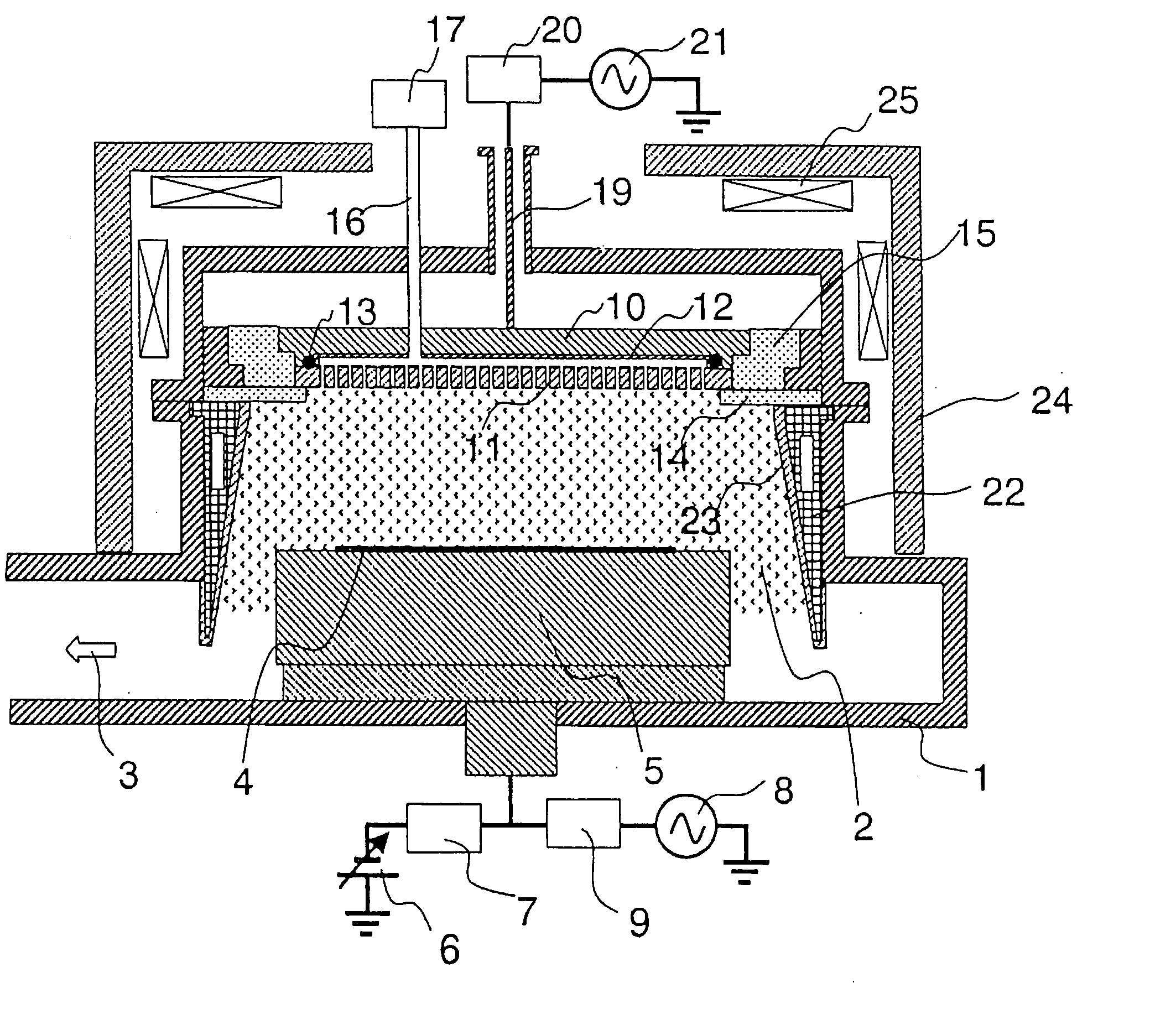

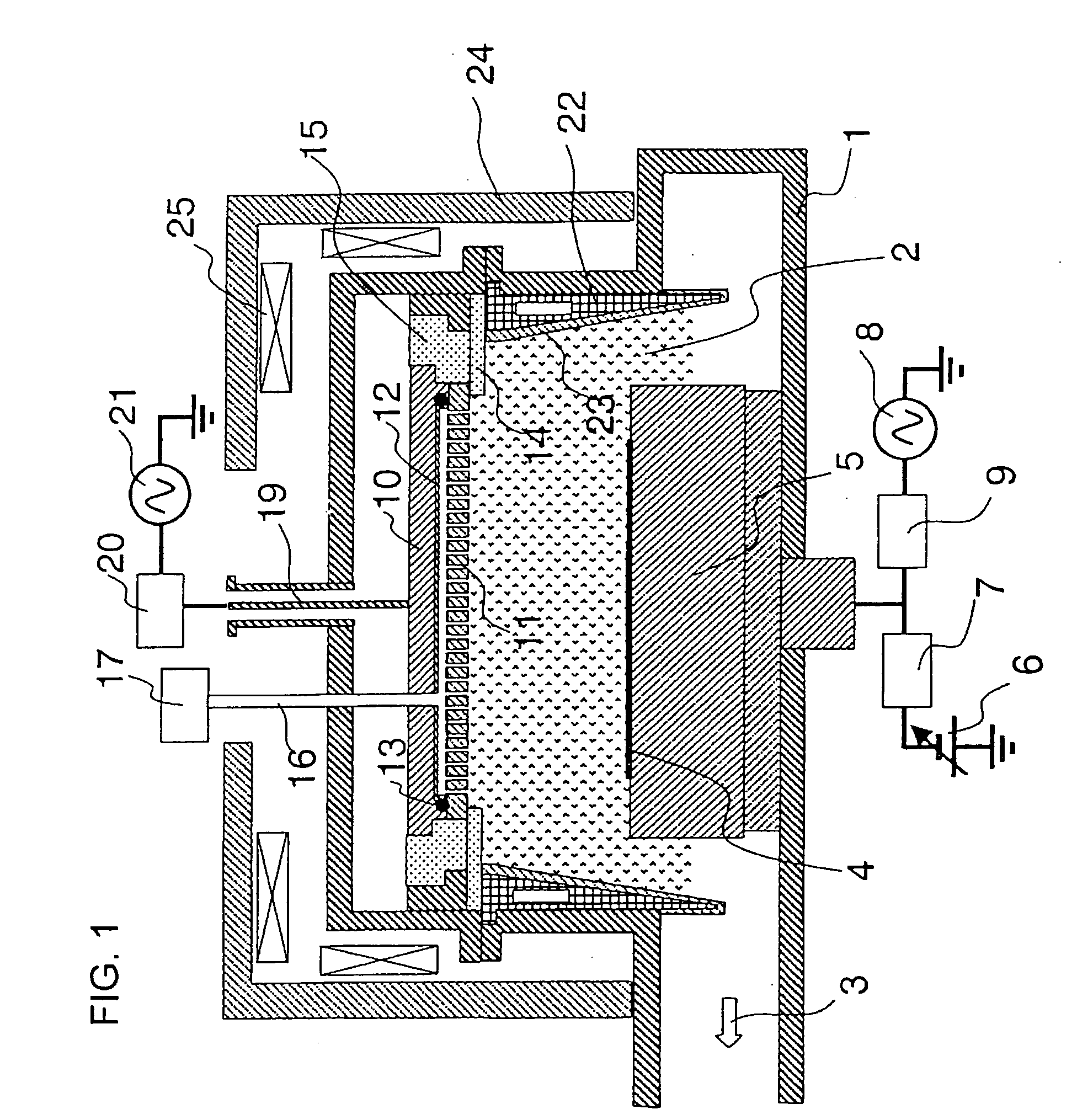

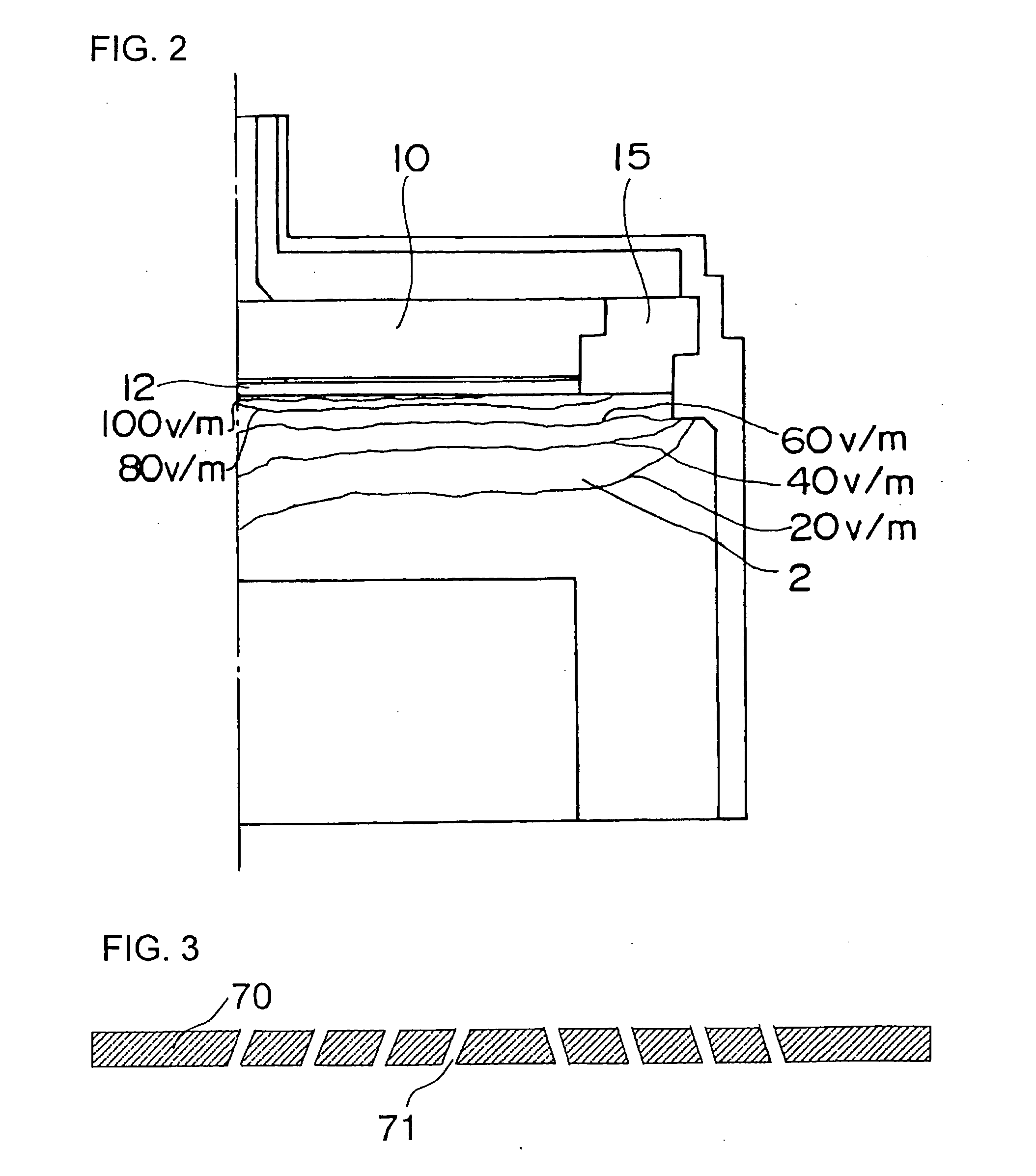

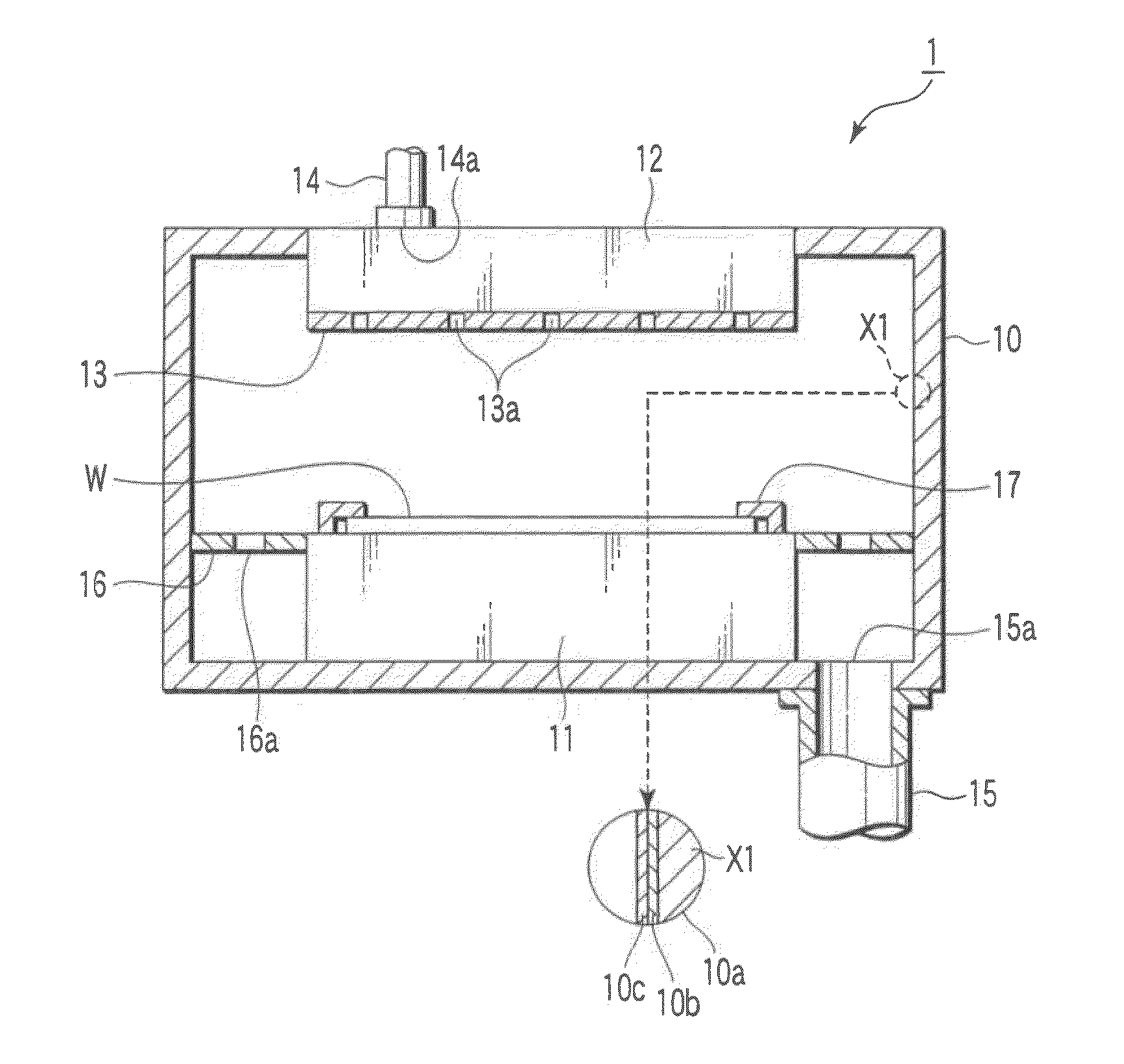

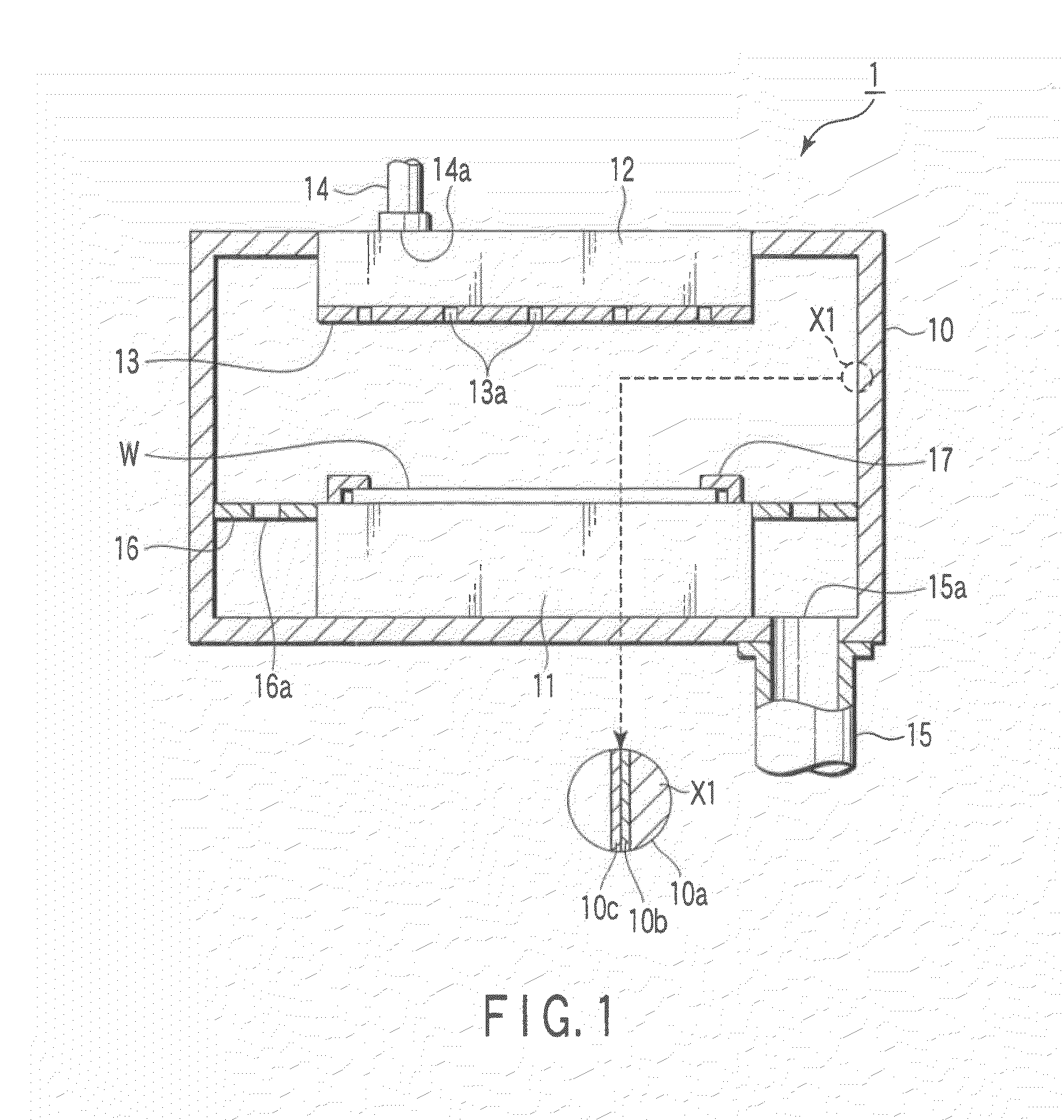

Plasma processing apparatus

ActiveUS20070044716A1Free from pollutionAvoid damageElectric discharge tubesChemical vapor deposition coatingTectorial membraneElectrical conductor

The invention provides a plasma processing apparatus aimed at suppressing the corrosion caused by reactive gas and heavy-metal contamination caused by plasma damage of components constituting the high-frequency electrode and gas supply unit. The plasma processing apparatus comprises a processing chamber 1 for subjecting a processing substrate 4 to plasma processing, gas supply means 17, 16 and 11 for feeding gas to the processing chamber 1, and an antenna electrode 10 for supplying high-frequency radiation for discharging the gas to generate plasma, wherein the gas supply means includes a gas shower plate 11 having gas discharge holes on the surface exposed to plasma, and a portion of or a whole surface of the conductor 10 exposed to gas constituting the antenna-electrode side of the gas supply means is subjected to ceramic spraying containing no heavy metal to form a protecting film 12.

Owner:HITACHI HIGH-TECH CORP

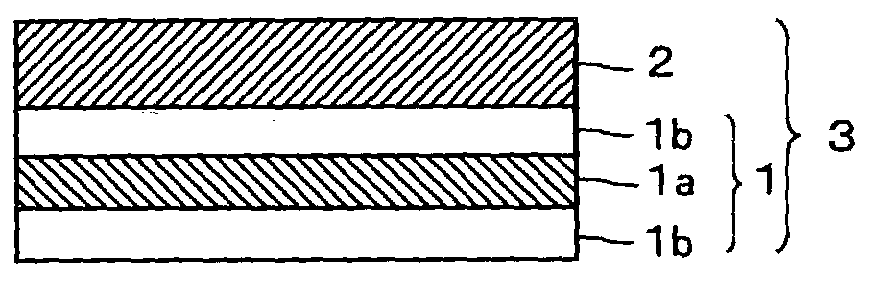

Polarizing film, optical film and liquid crystal display using polarizing film

InactiveUS6961178B2Solve the real problemImprove adhesionSynthetic resin layered productsLaminationTectorial membraneLiquid-crystal display

Owner:NITTO DENKO CORP

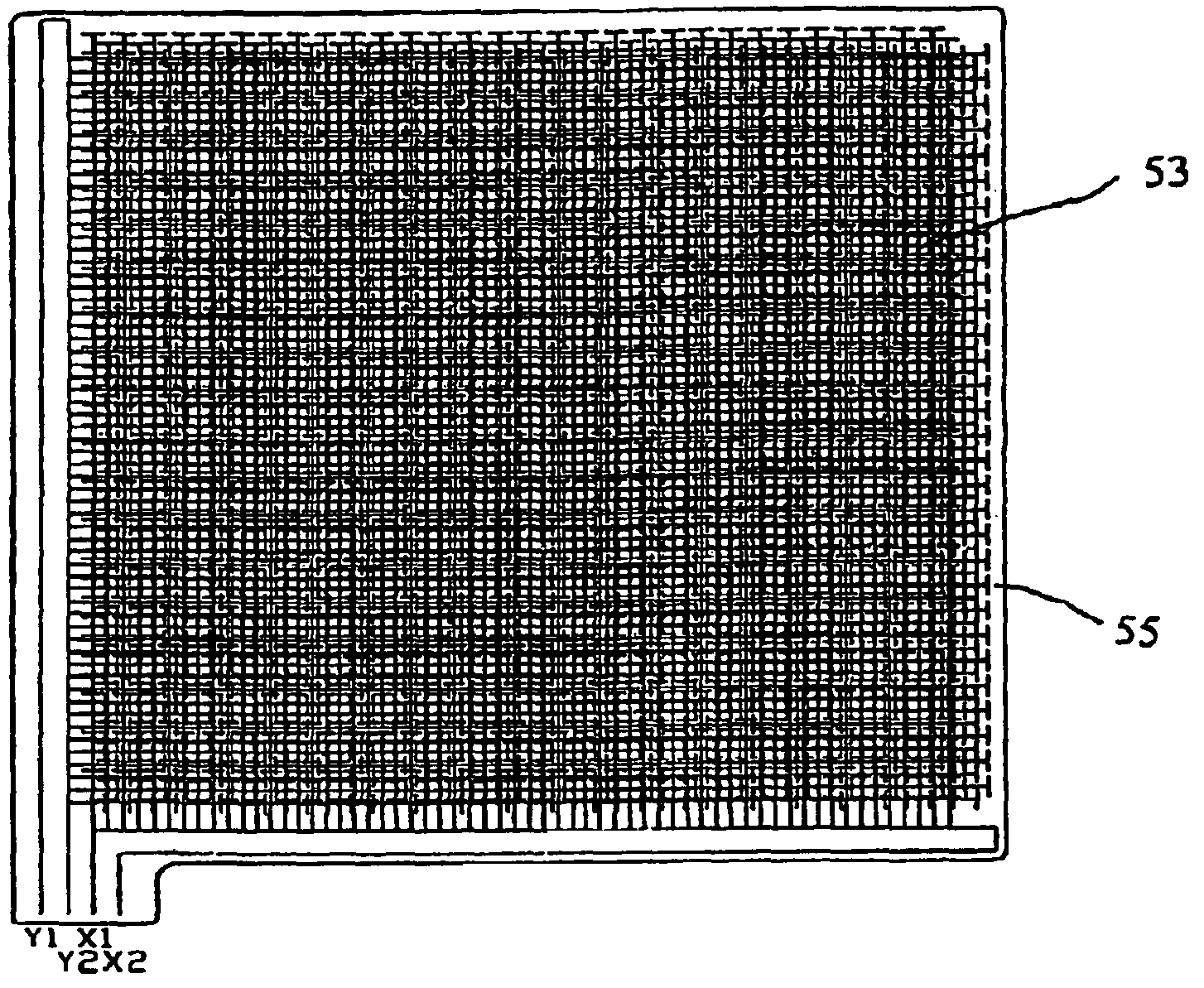

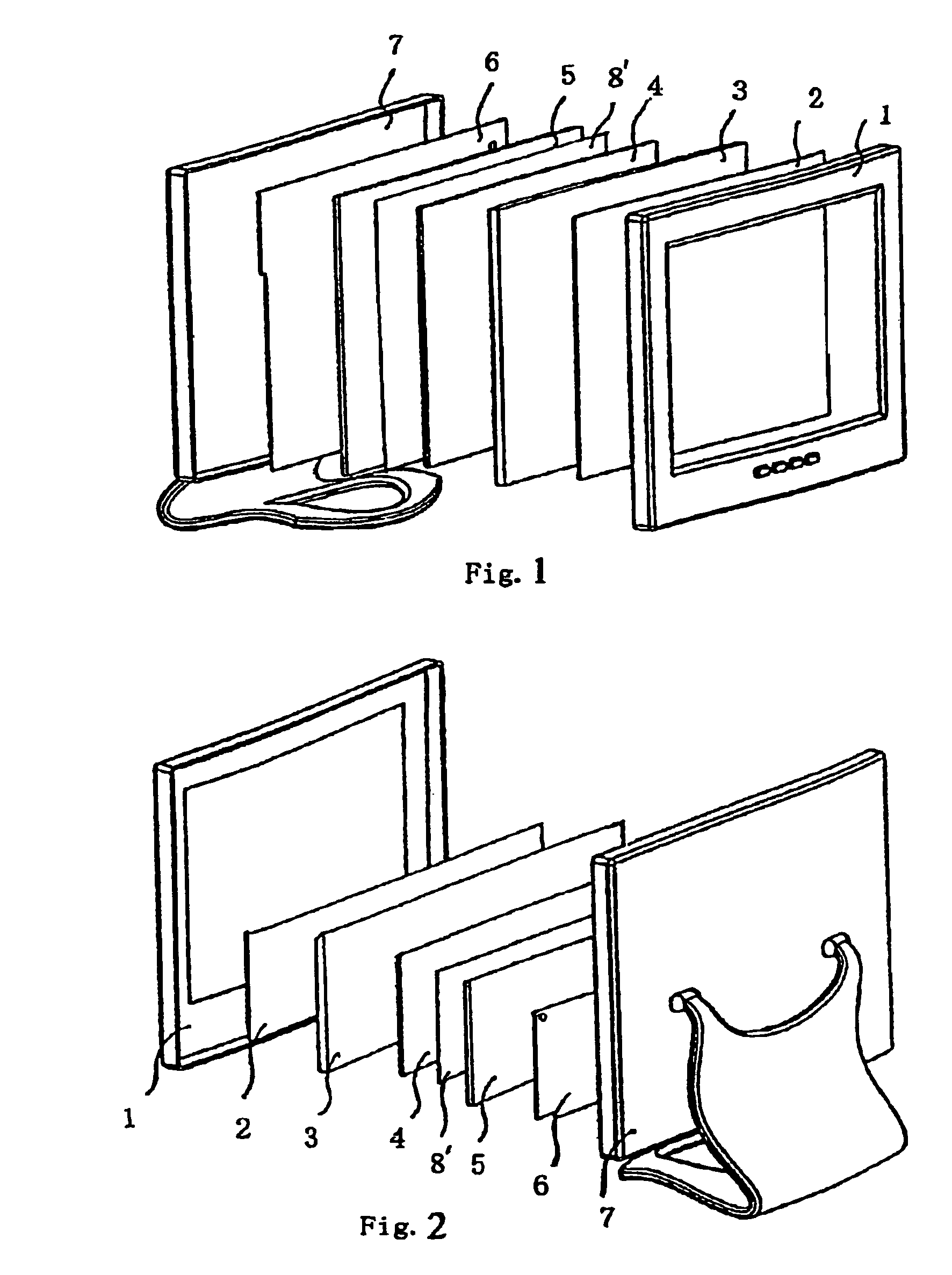

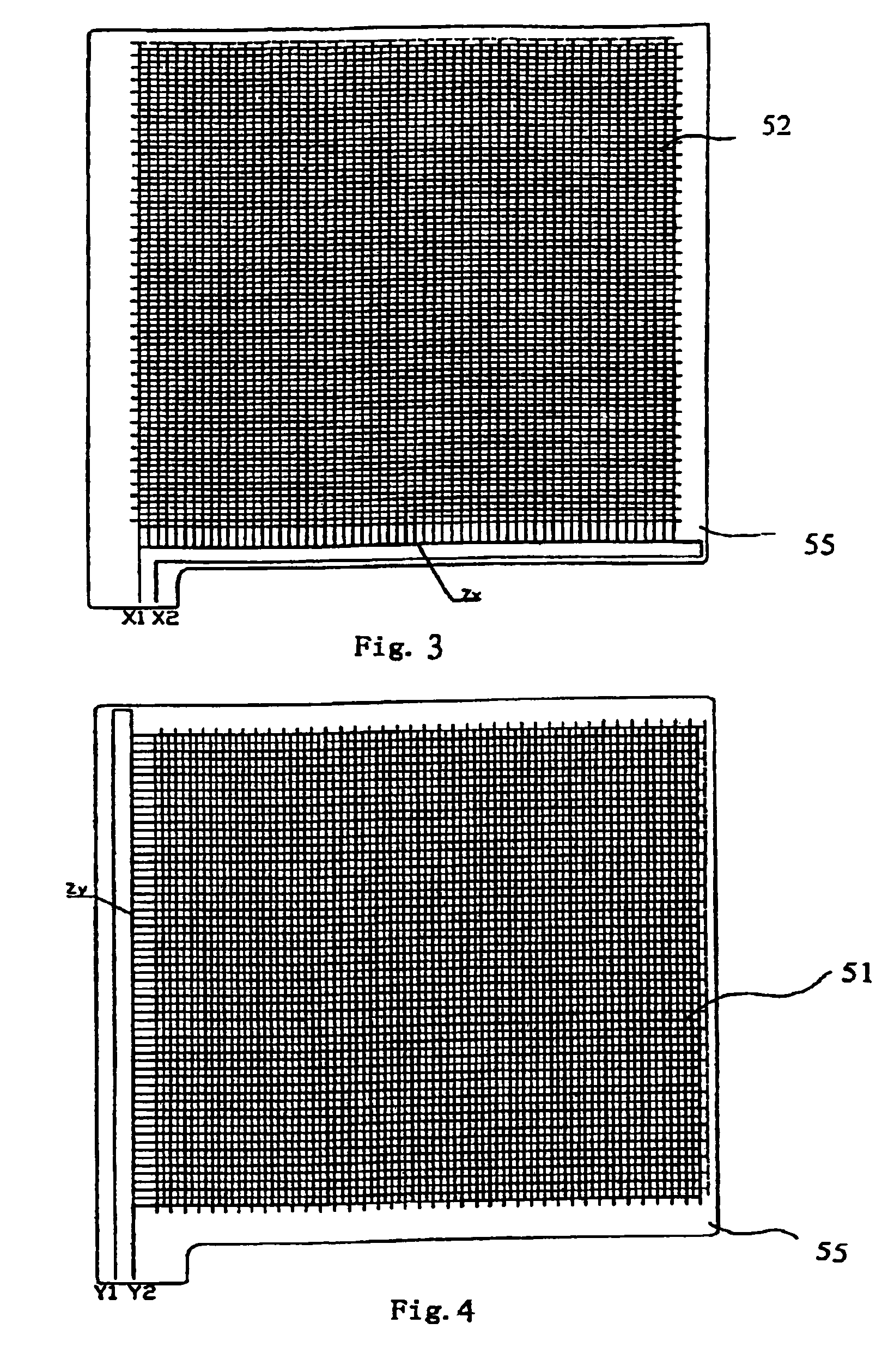

Touch control display screen with a built-in electromagnet induction layer of septum array grids

ActiveUS7796122B2The production process is simpleImprove accuracyTransmission systemsCathode-ray tube indicatorsHandwritingTectorial membrane

A touch control display screen with built-in membrane antenna array lattice electromagnetic induction layer, including at least a display screen and a shell; wherein an induction layer is provided in the rear of the display screen, the output of the induction layer is connected to an induction control circuit, a display screen control circuit is also provided in the shell; the induction layer is the antenna array printed on the insulation membrane and arranged along the X, Y axes, therein the area enclosed by each lattice unit constitutes one induction cell. Because the electromagnetic induction layer is provided in the rear of the display screen and flexible membrane-type, printed electromagnetic induction array antenna is used as the identifying induction component according to the present invention, the manufacture is easy, the cost is low, and the advantage in cost-cut is prominent in comparison with the prior art when the area of the display screen is larger. The accuracy of identification is high, and the mouse information or handwriting information can be input exactly by means of brush strokes of finger strokes; as a touch screen, the display screen is covered by a protecting film to avoid the physical damage, so it has long operating life.

Owner:MORGAN TOUCH TECH (HK) CO LTD +1

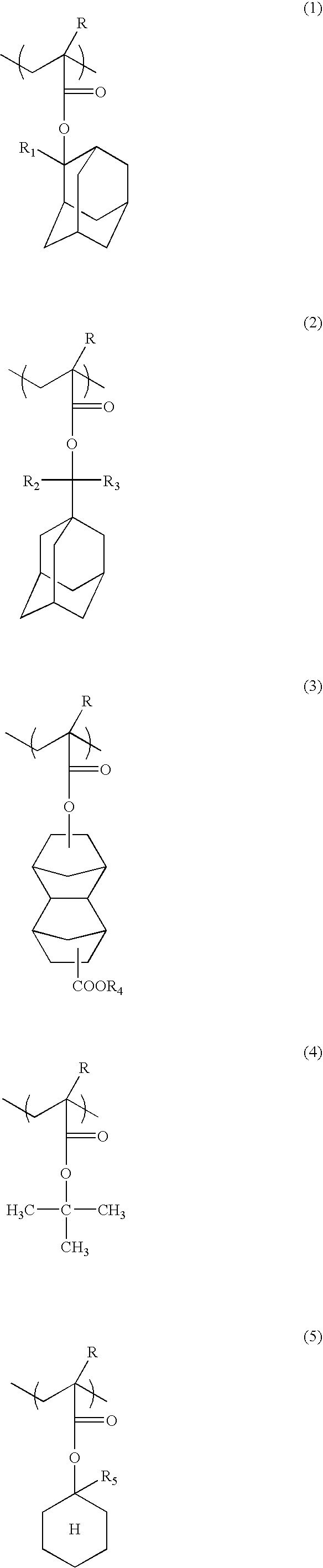

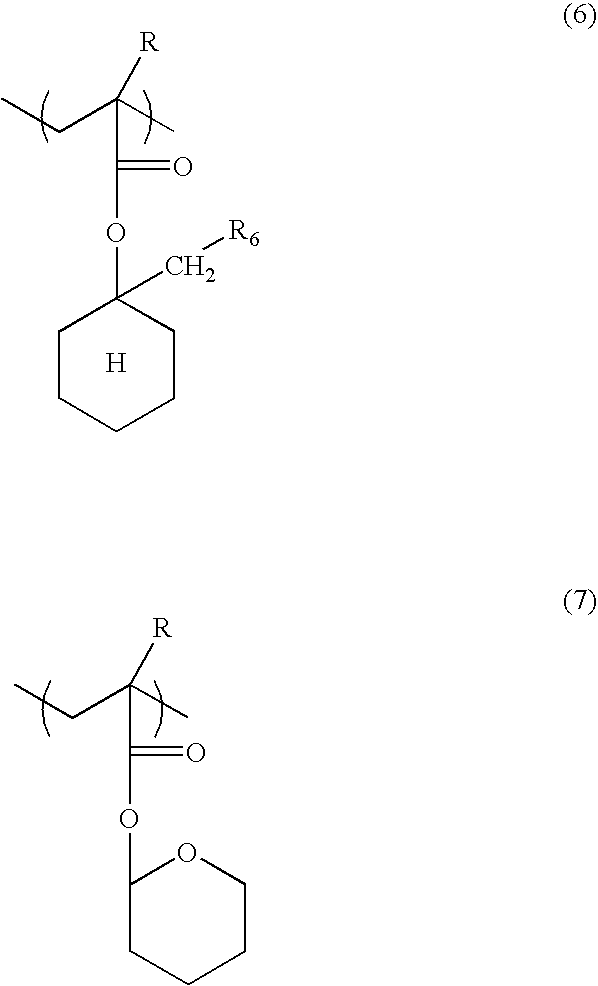

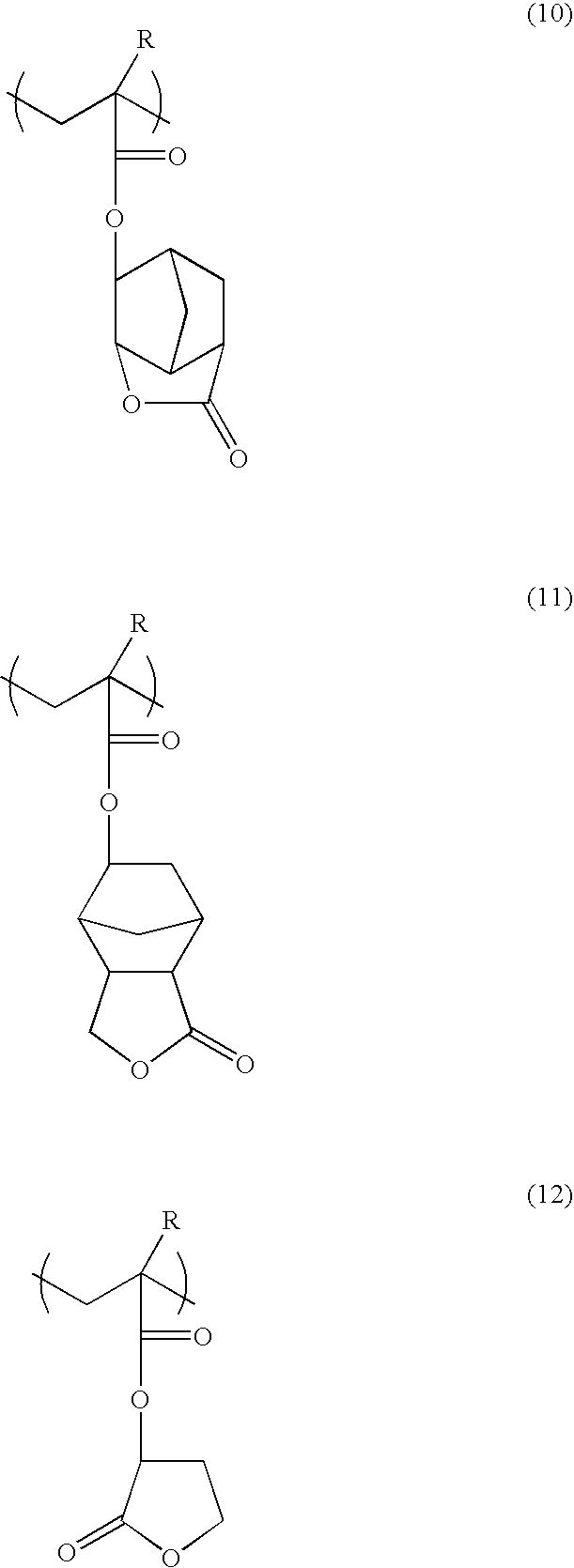

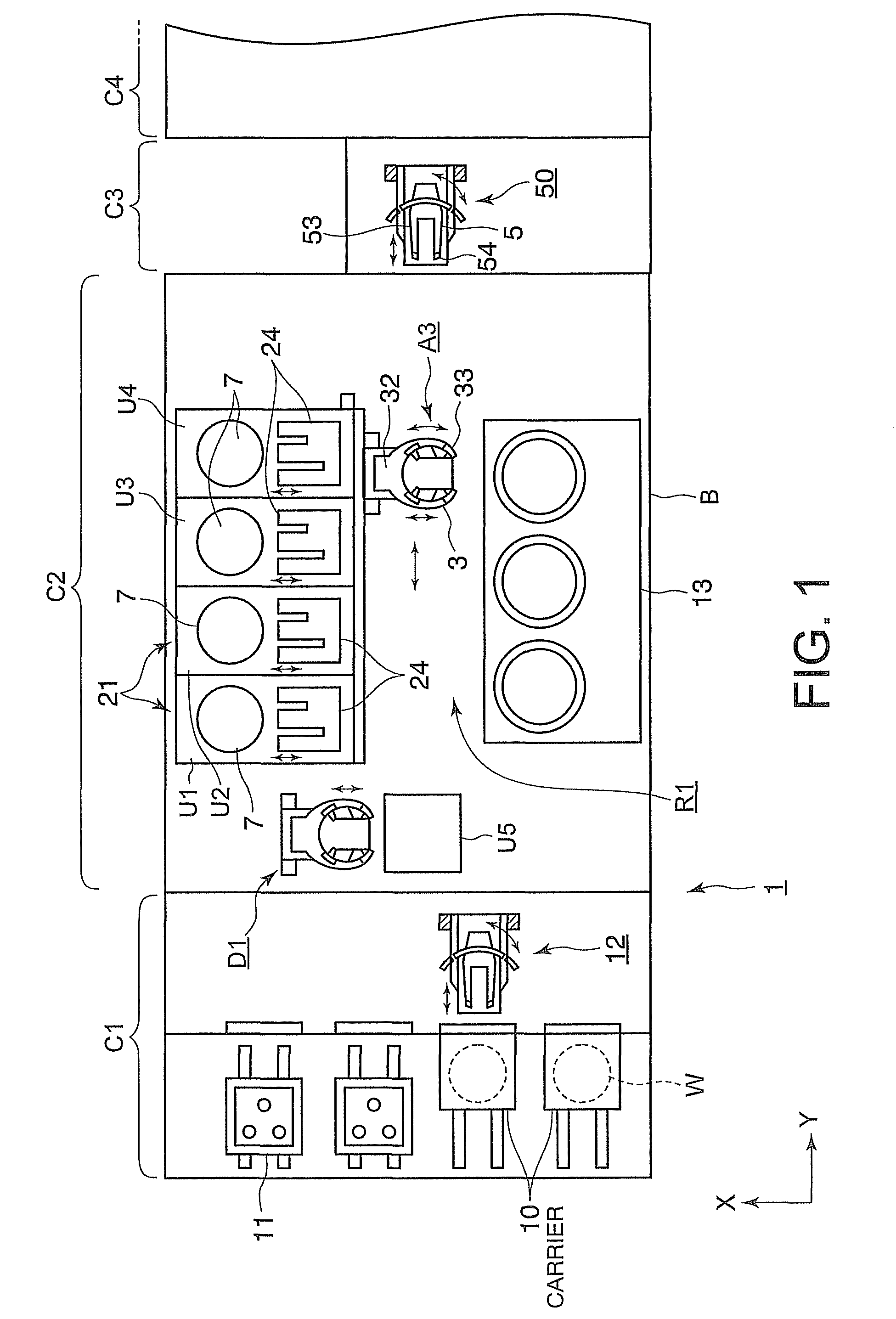

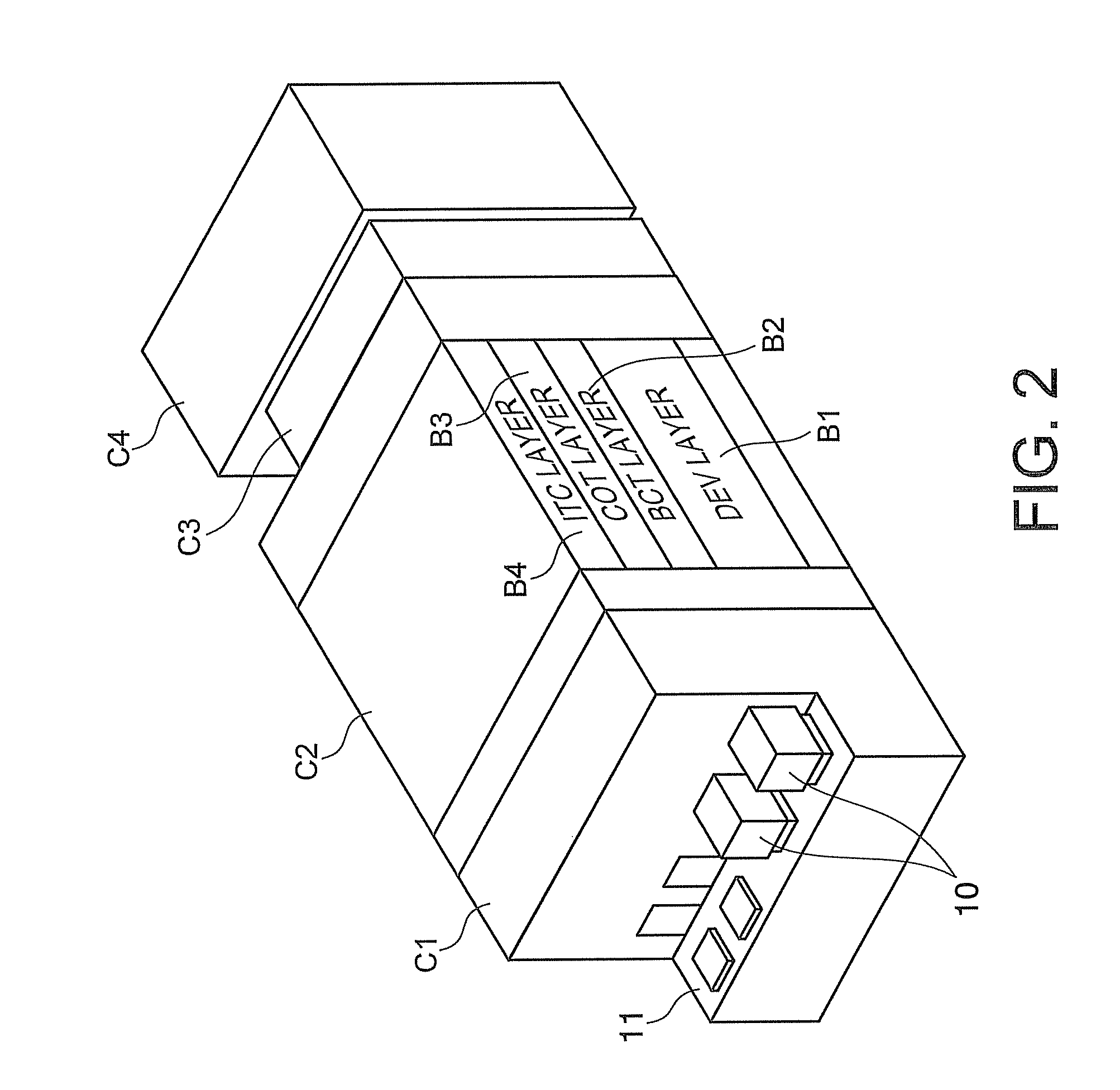

Immersion exposure process-use resist protection film forming material, composite film, and resist pattern forming method

InactiveUS20060141400A1High resolutionChange propertiesPhotoprinting processesPhotomechanical exposure apparatusHigh resolutionTectorial membrane

Provided are a material for forming a resist protecting film which is for use in a liquid immersion lithography process and which is formed on a resist film, wherein the material has the following properties of: being transparent with respect to exposure light; having substantially no compatibility with a liquid for liquid immersion lithography; and causing no mixing with the resist film, a composite film comprising a protective film formed from the material and a resist film, and a method for forming a resist pattern using them. These can prevent both the resist film and the liquid used from changing in properties during the liquid immersion lithography, so that a resist pattern with high resolution can be formed using the liquid immersion lithography.

Owner:TOKYO OHKA KOGYO CO LTD

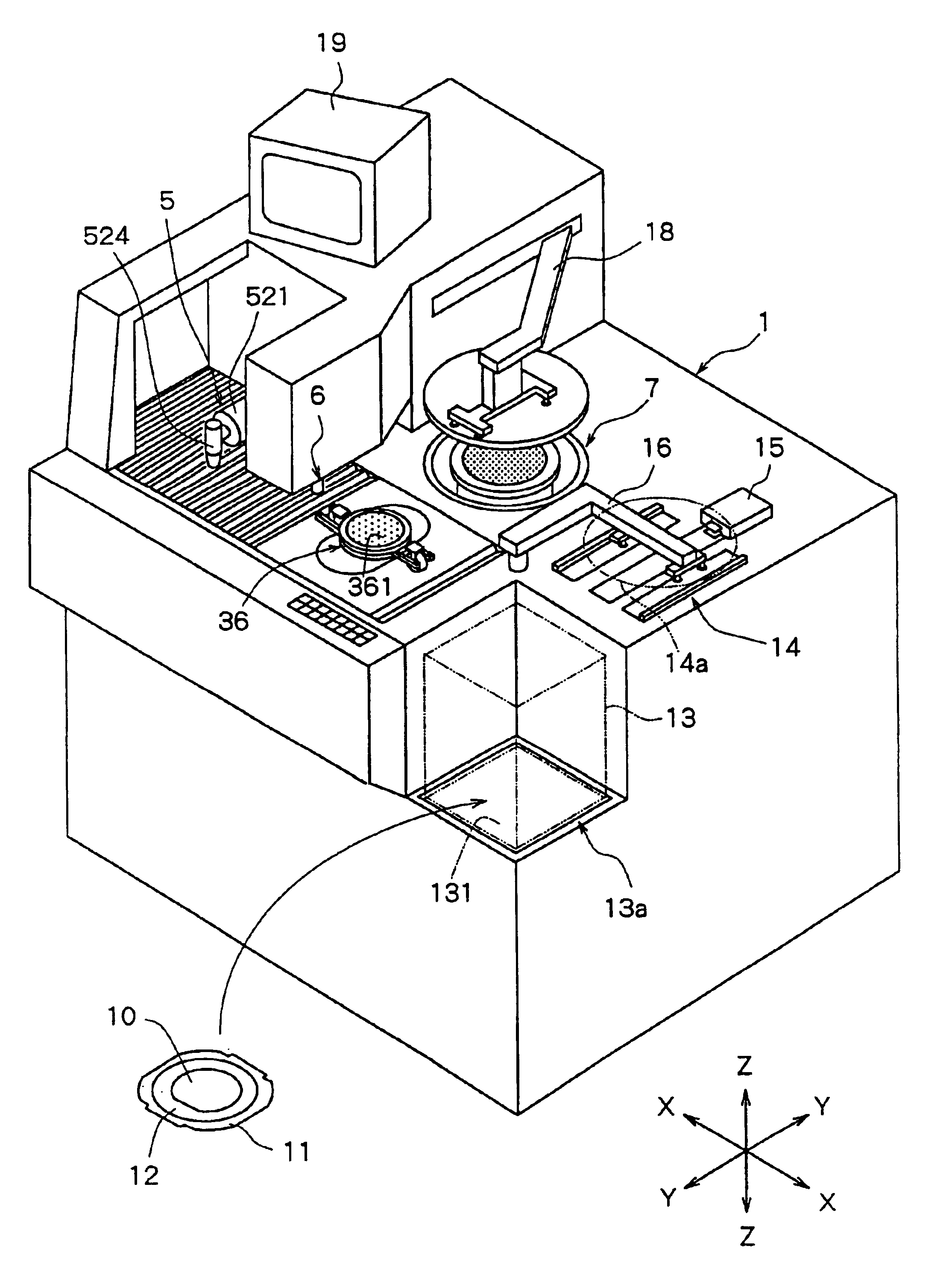

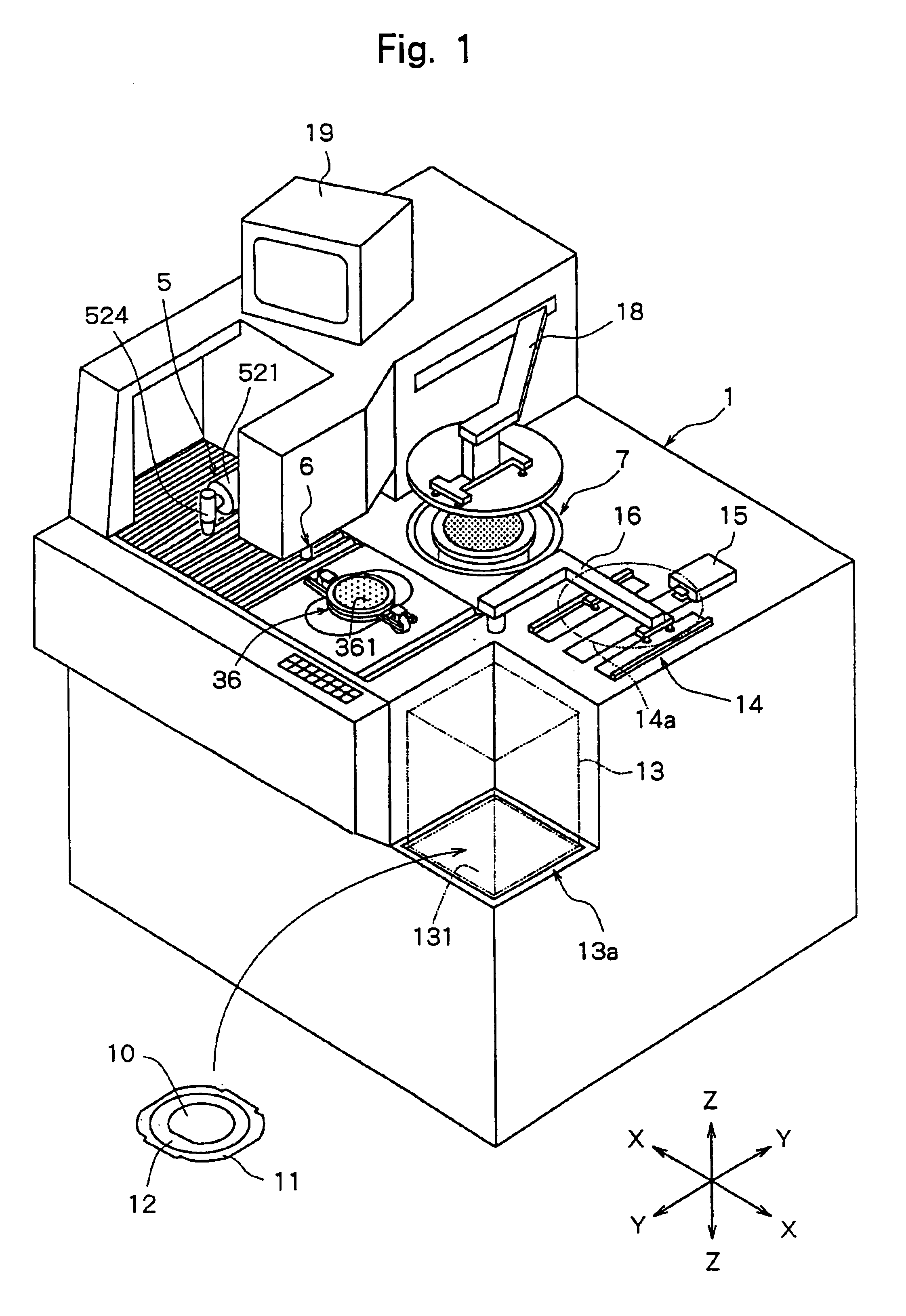

Laser beam processing machine

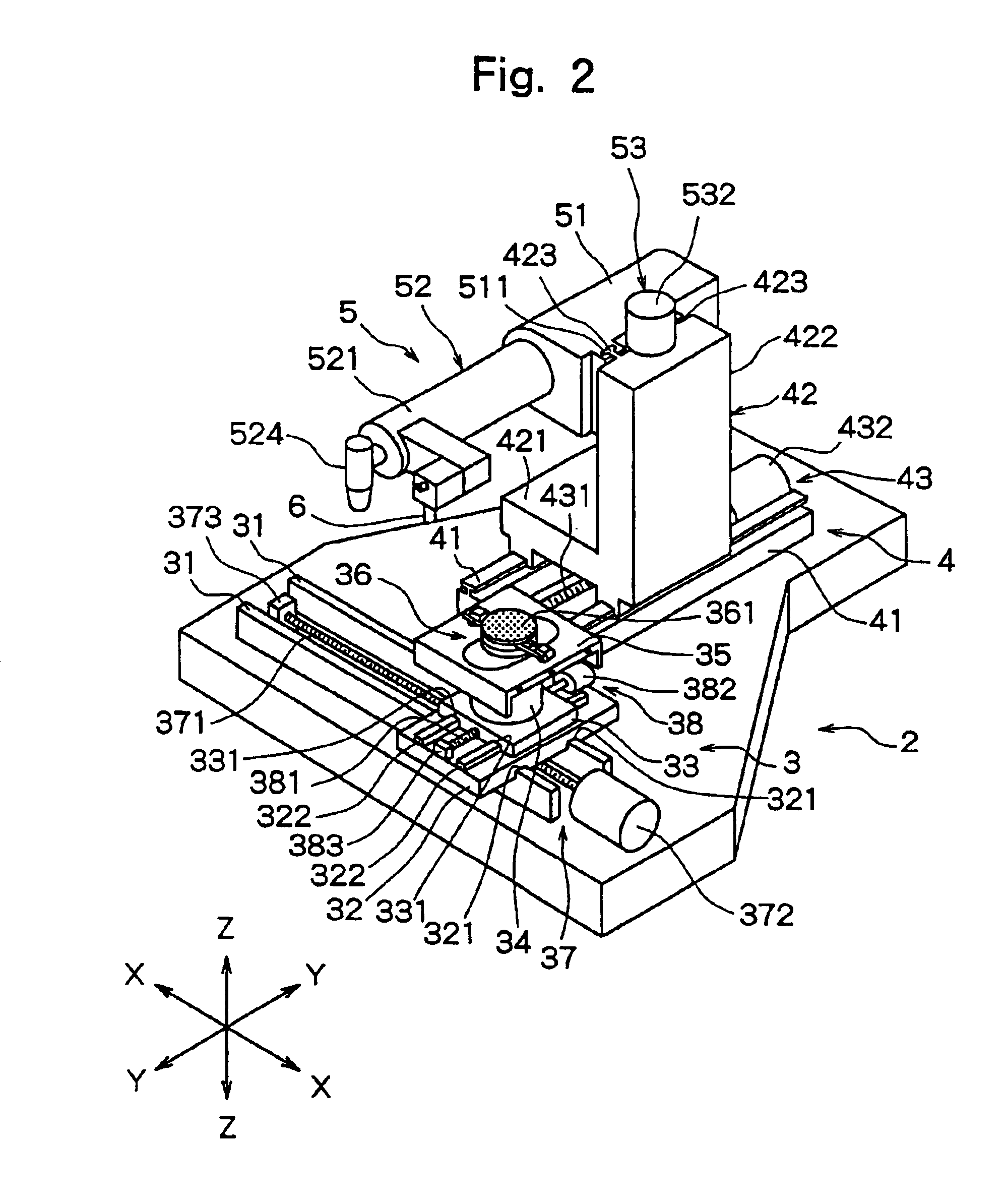

ActiveUS6998571B2Welding/cutting auxillary devicesSemiconductor/solid-state device manufacturingTectorial membraneLaser beam machining

A laser beam processing machine comprising a chuck table for holding a workpiece and a laser beam application means for applying a laser beam to the workpiece held on the chuck table, wherein the machine further comprises a protective film forming means for forming a protective film on the to-be-processed surface of the workpiece before laser beam processing.

Owner:DISCO CORP

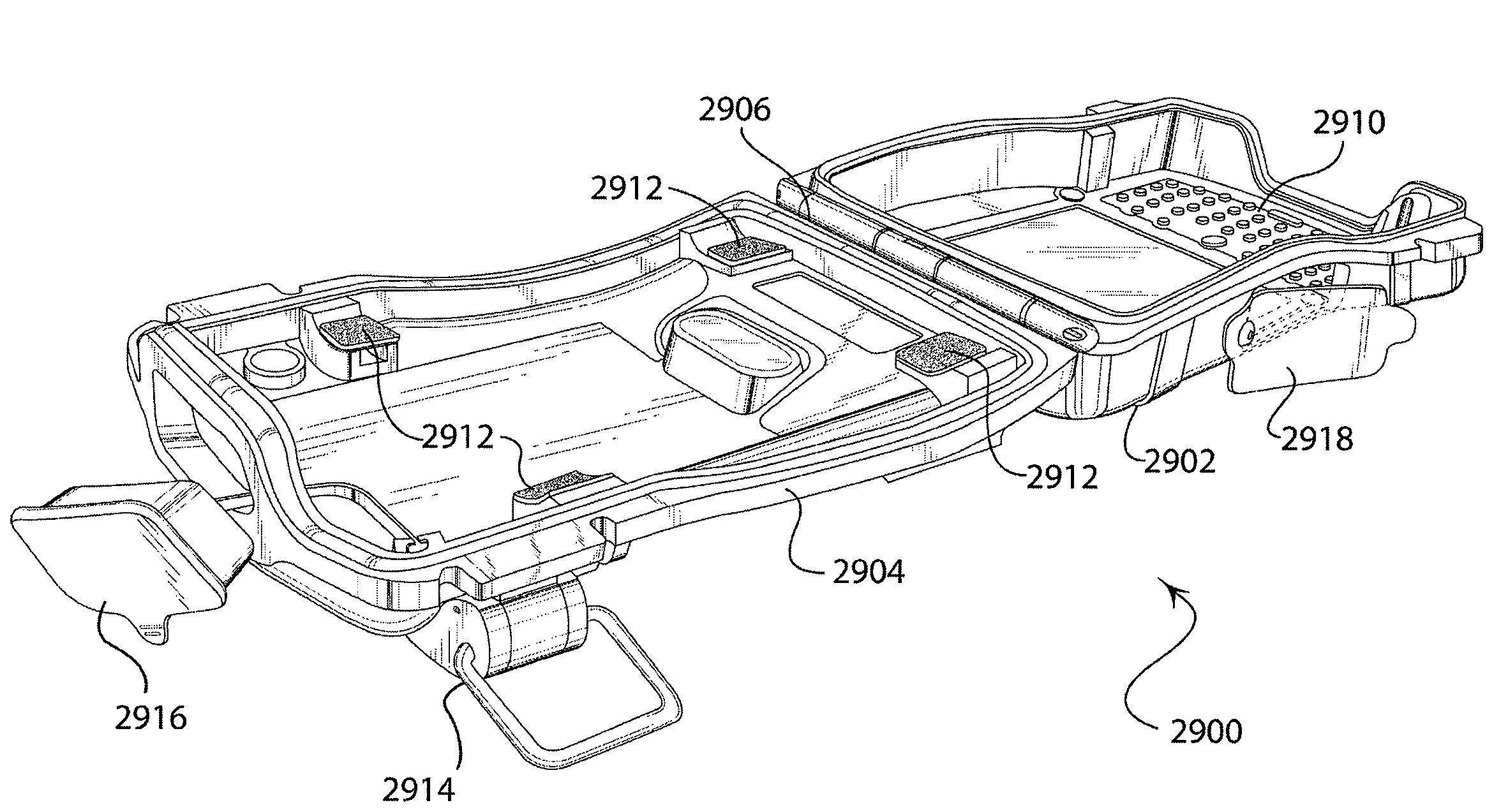

Device and method for supporting a substrate

ActiveUS8528889B2Prevent abnormal supportingSemiconductor/solid-state device manufacturingMetal working apparatusTectorial membraneEngineering

A substrate support device including a support member having a lower-surface support section to support a lower surface of a substrate; and a position restriction section provided on the lower-surface support section, the position restriction section being formed to surround a periphery of the substrate supported on the lower-surface support section and restrict a position of the substrate. At least one of the lower-surface support section and the position restriction section includes a base material and a protective film formed to cover the base material and prevent at least one of wear and chemical erosion to which the base material will be subject. The substrate support device further includes, for example, a base that supports the support member, and a driving structure that moves the support member in a relative fashion with respect to the base, and is constructed as a substrate transport device.

Owner:TOKYO ELECTRON LTD

Protective enclosure and watertight adapter for an interactive flat-panel controlled device

InactiveUS20070139873A1Stable controlIncrease contactSonic/ultrasonic/infrasonic transmissionDigital data processing detailsElectricityTectorial membrane

A protective enclosure is disclosed for an interactive flat-panel control device. The protective enclosure is watertight, crush-resistant, and impact-resistant. An electrical adapter may disposed within the protective enclosure and covered with an elastomeric covering that permits a connector of the adapter to flex with respect to the lower shell of the enclosure so that the connector may easily be inserted into an interface jack of the electronic device. The elastomeric covering also provides a watertight seal that enables the protective enclosure to be submersibly watertight. While providing protection, the protective enclosure simultaneously allows smooth and accurate interaction with the interactive flat-panel controlled device. The protective enclosure has a protective membrane that permits RF and touch screen stylus inputs, as well as capacitance, such as from a finger, to be transmitted accurately to the flat-panel control. The hardness and texture of the protective membrane allows a stylus or finger to glide smoothly along the surface of the membrane without catching or sticking. The protective enclosure is further adapted to allow infrared and other communication signals while the device is secured inside the case. Further, electrical connections can be made through the case without affecting the protection afforded the electronic device inside. The protective enclosure may have a removable cable management belt clip that has a flange that retains and prevents entangling of an accessory cable for the interactive flat-panel control device.

Owner:OTTER PROD LLC

Semiconductor device and method of manufacturing the same

ActiveUS20050161833A1Increase freedomFunction increaseSemiconductor/solid-state device detailsSolid-state devicesTectorial membraneElectrical conductor

In a semiconductor device, via holes are formed around a chip buried in a package, one end of a conductor filled in the via hole is covered with a pad portion exposed to the outside, and a wiring layer connected to the other end of the conductor is formed. The portion (pad portion) of the wiring layer which correspond to the conductor is exposed from a protective film, or an external connection terminal is bonded to the top of the pad portion. Electrode terminals of the chip are connected to the wiring layer, and the opposite surface of the chip is exposed to the outside.

Owner:SHINKO ELECTRIC IND CO LTD

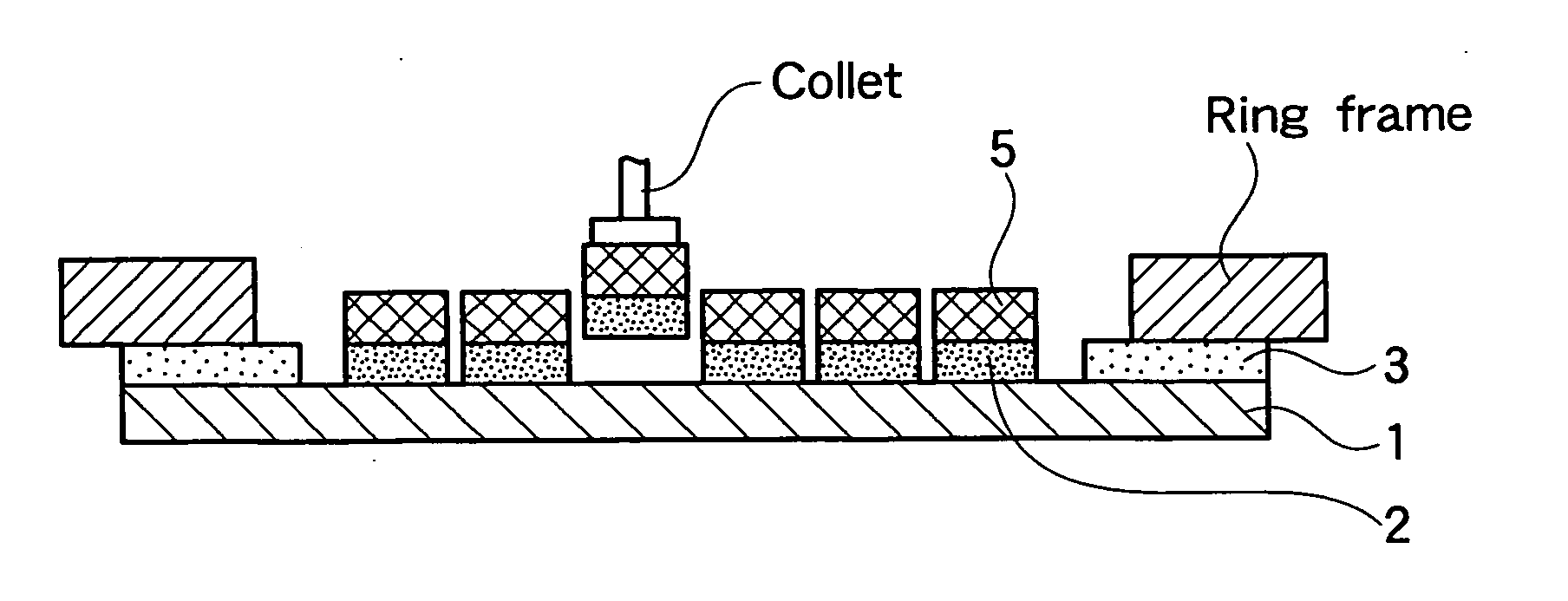

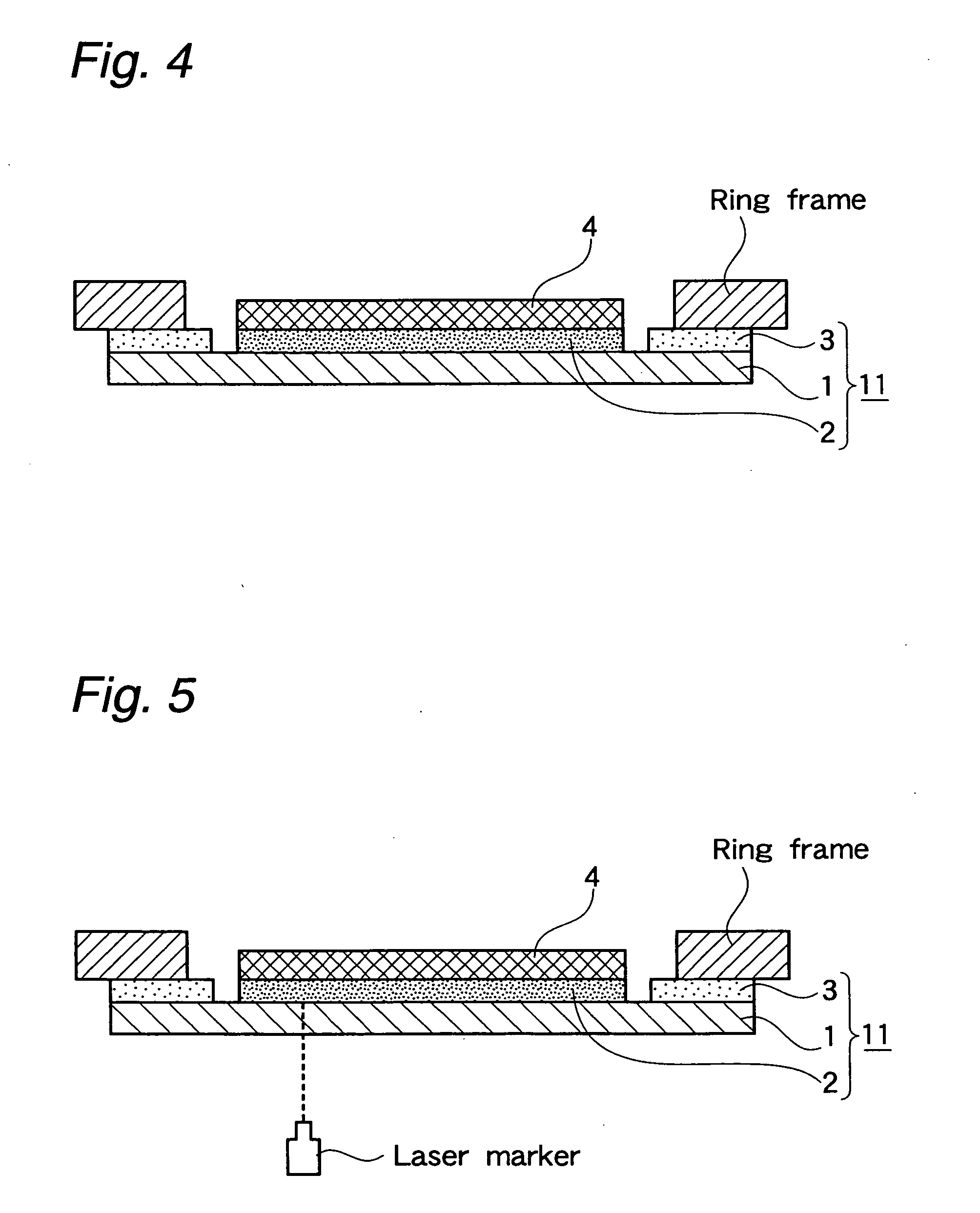

Marking method and sheet for both protective film forming and dicing

ActiveUS20060102987A1Improve accuracyWarpage suppressionSemiconductor/solid-state device detailsSolid-state devicesTectorial membraneEngineering

The invention provides a marking method in which marking is performed on a protective film formed on a work with a high accuracy while suppressing a warpage and, also, a sheet for both protective film forming and dicing which is advantageously used in the method. The marking method comprises irradiating laser light to a laminated structure comprising a support film tensely supported by a ring frame, a protective film releasably laminated on the support film and a work fixed to the protective film, wherein the protective film is irradiated laser light from a side of the support film, to thereby mark the protective film.

Owner:LINTEC CORP

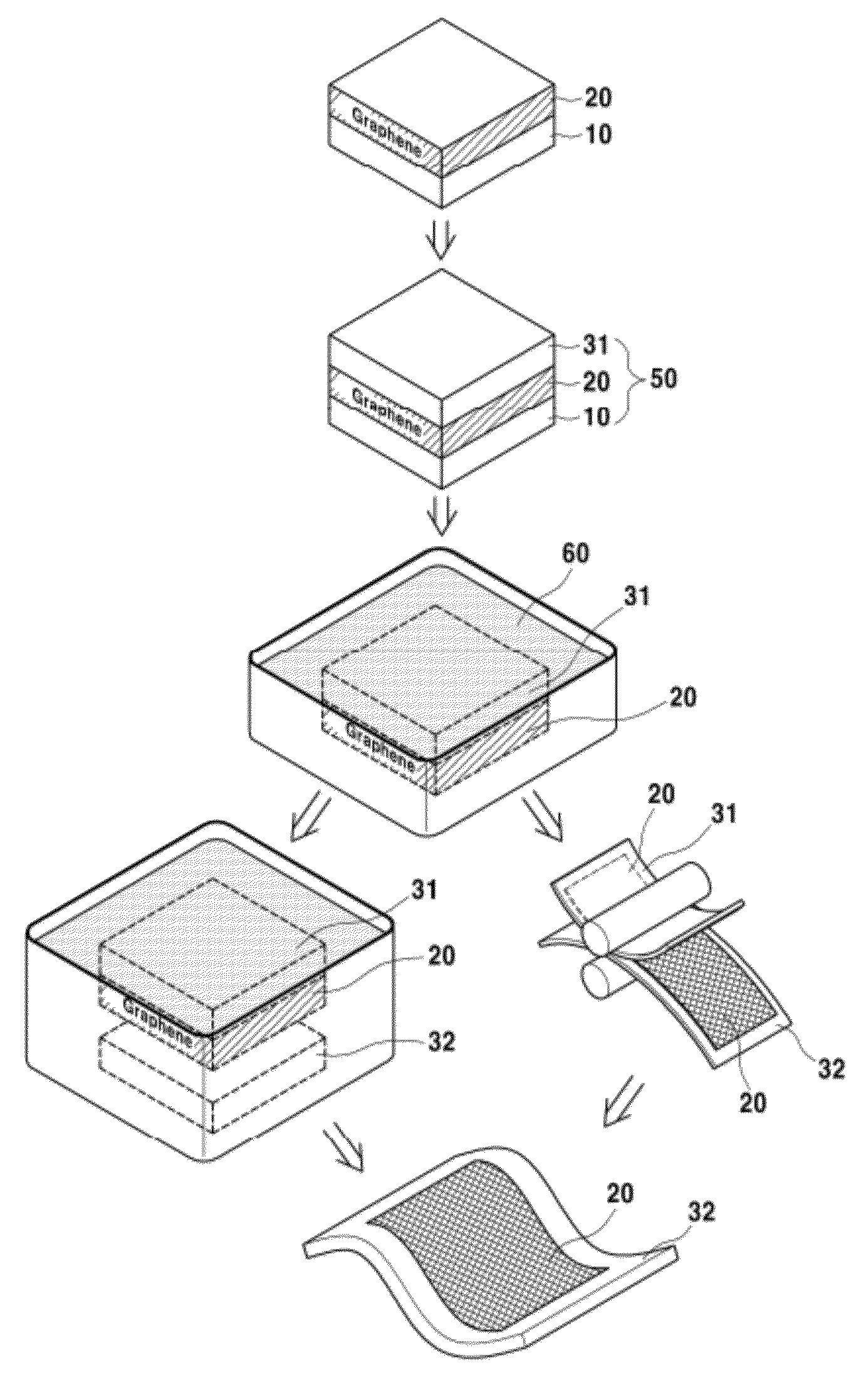

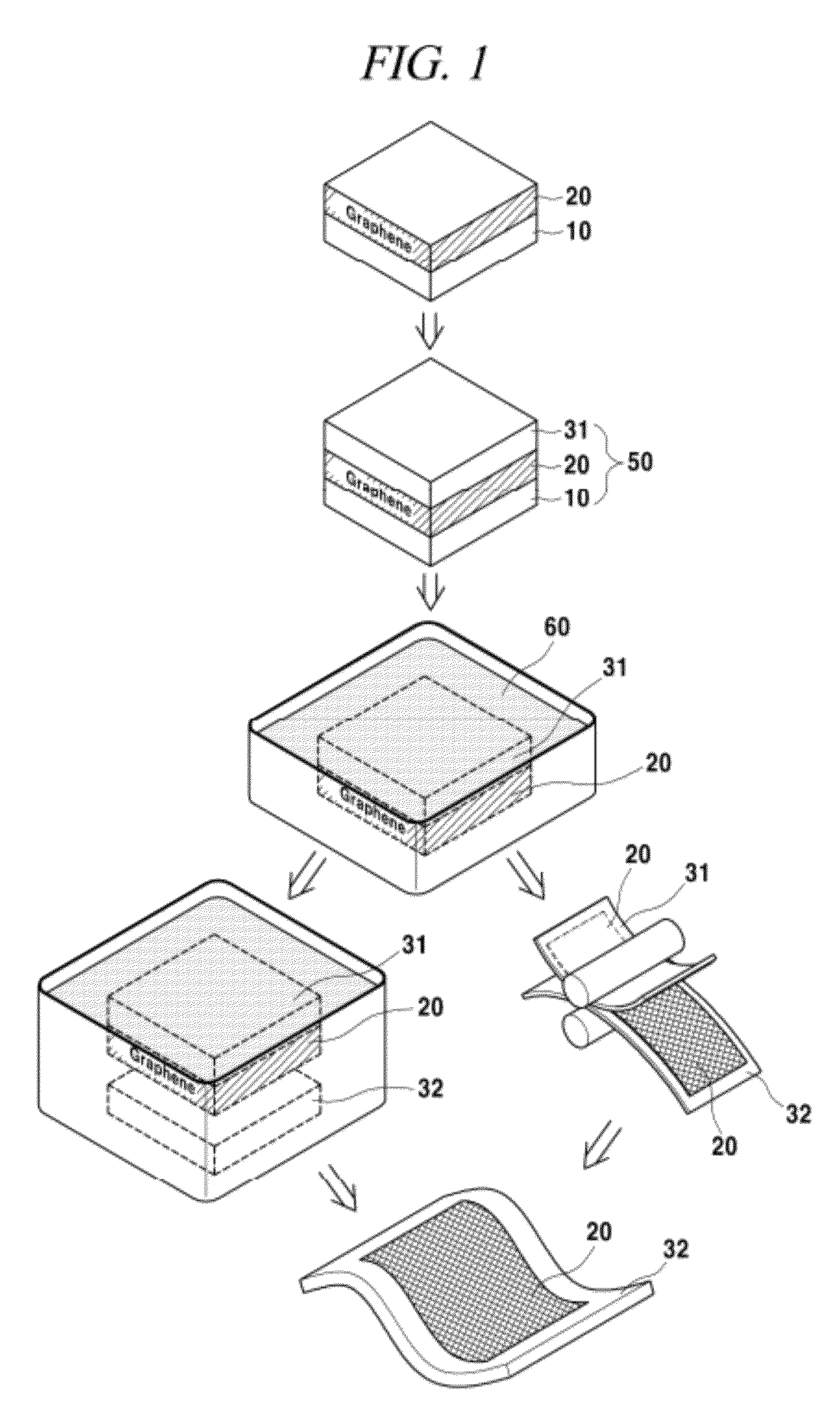

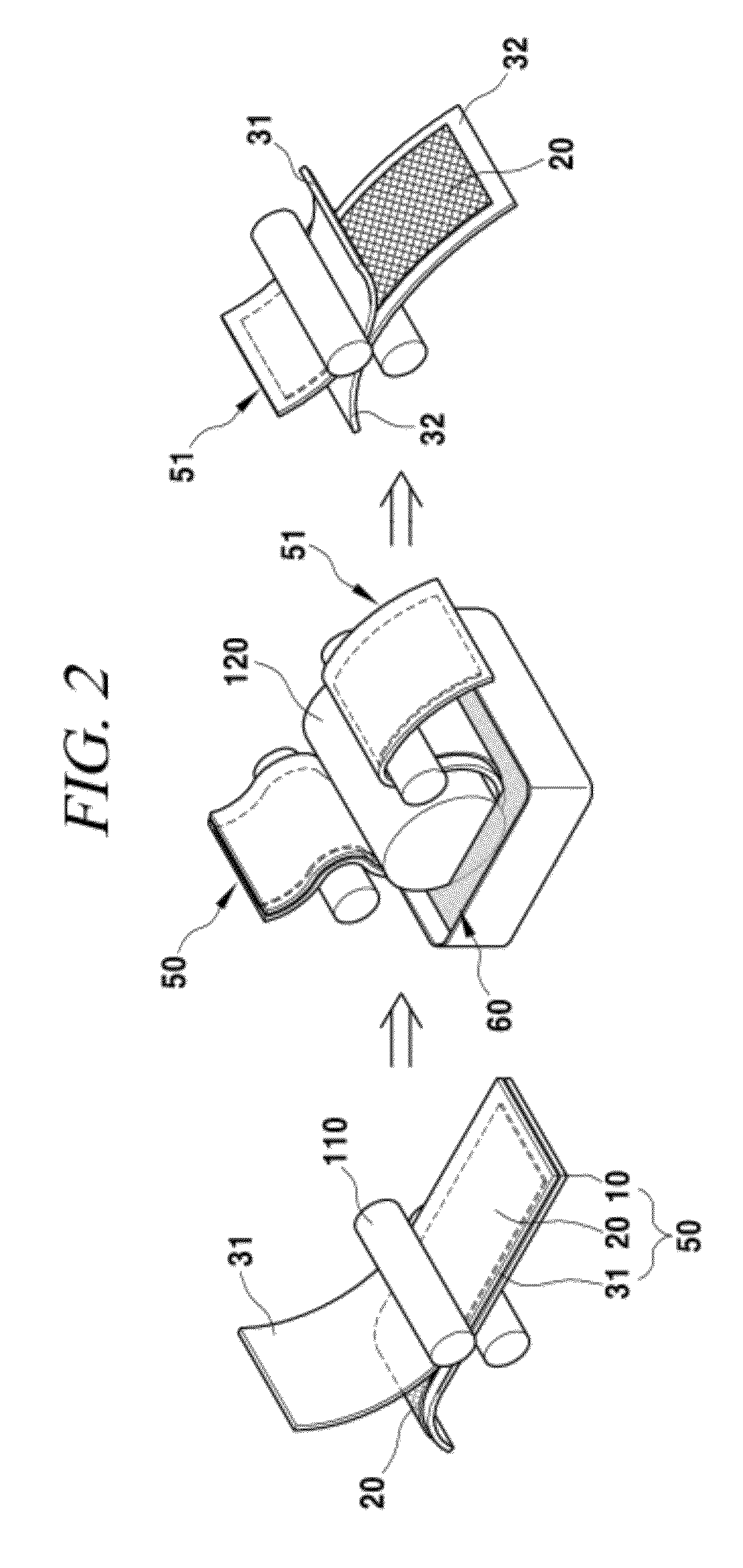

Graphene protective film serving as a gas and moisture barrier, method for forming same, and use thereof

ActiveUS20120282419A1Improve featuresImprove electrical characteristicsMaterial nanotechnologyDecorative surface effectsTectorial membraneGraphene

The present invention relates to a method for forming a graphene protective film having gas and moisture barrier properties, to a graphene protective film formed by the method, and to the use thereof. A single-layer or multi-layer graphene protective film can be used as a material for a barrier coating or bags, and improves the gas and moisture barrier properties of a variety of devices in a wide array of industrial fields to thereby maintain the electrical characteristics of devices over a long period of time.

Owner:GRAPHENE SQUARE

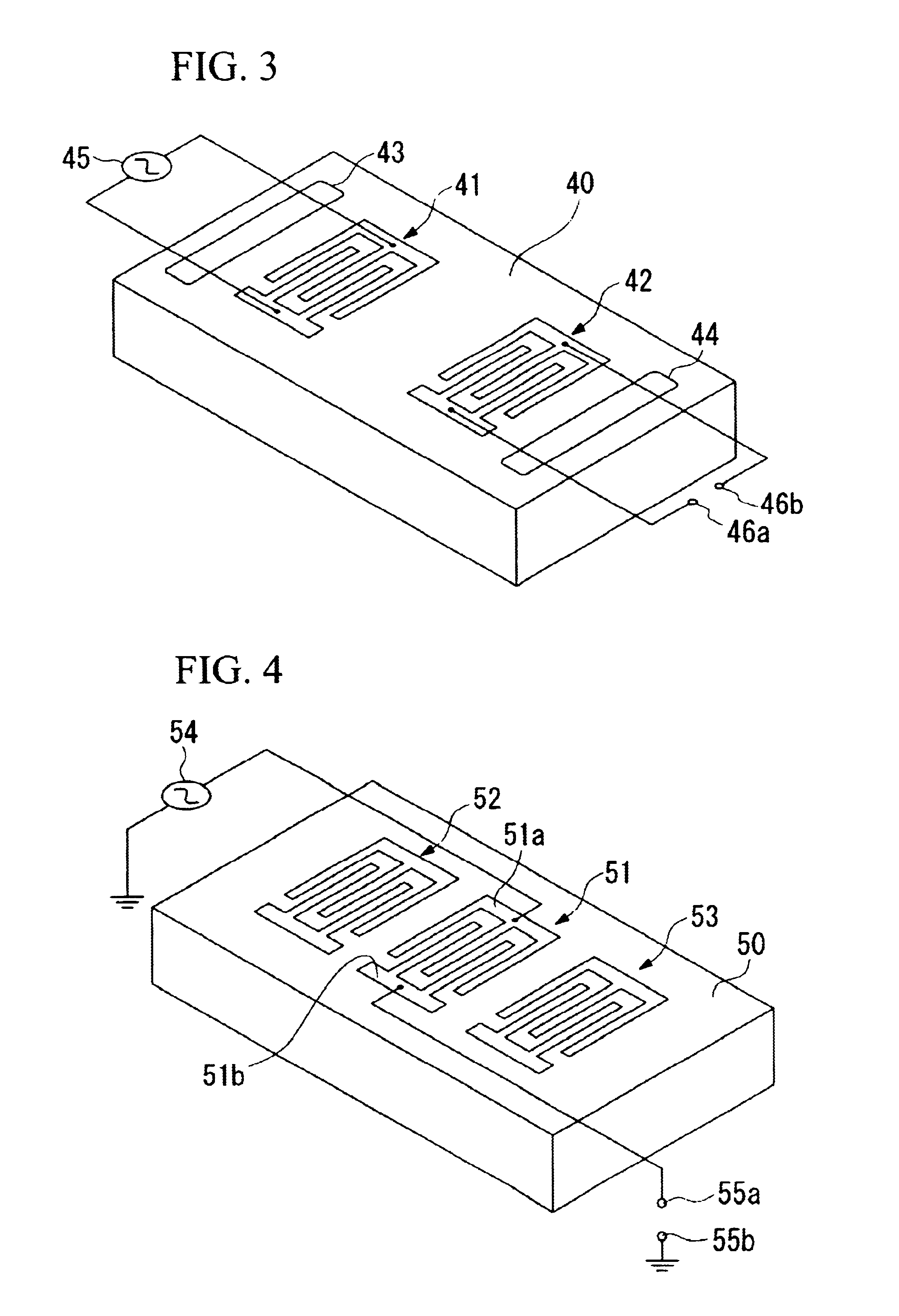

Surface acoustic wave device with KNb03 piezoelectric thin film, frequency filter, oscillator, electronic circuit, and electronic apparatus

InactiveUS6720846B2Polycrystalline material growthPiezoelectric/electrostriction/magnetostriction machinesTectorial membraneFrequency filtering

Surface acoustic wave device having a high k<2>, and a frequency filter, oscillator, electronic circuit and electronic device employing this surface acoustic wave device is provided, wherein a first oxide thin film layer comprising SrO or MgO and a second oxide thin film layer comprising SrTiO3 are sequentially formed on top of a (110) Si substrate, or a first oxide thin film layer comprising CeO2, ZrO2 or yttrium-stabilized zirconia and a second oxide thin film layer comprising SrTiO3 are sequentially formed on top of a (100) Si substrate, a KNbO3 piezoelectric thin film being then formed on top of either of these second oxide thin film layers, and then, a protective film comprising oxide or nitride is formed on top of the KNbO3 piezoelectric thin film, finally, at least one electrode is formed on top of this protective film, to form a surface acoustic wave device, which surface acoustic wave device is employed to form a frequency filter, oscillator, electronic circuit, or electronic device.

Owner:SEIKO EPSON CORP

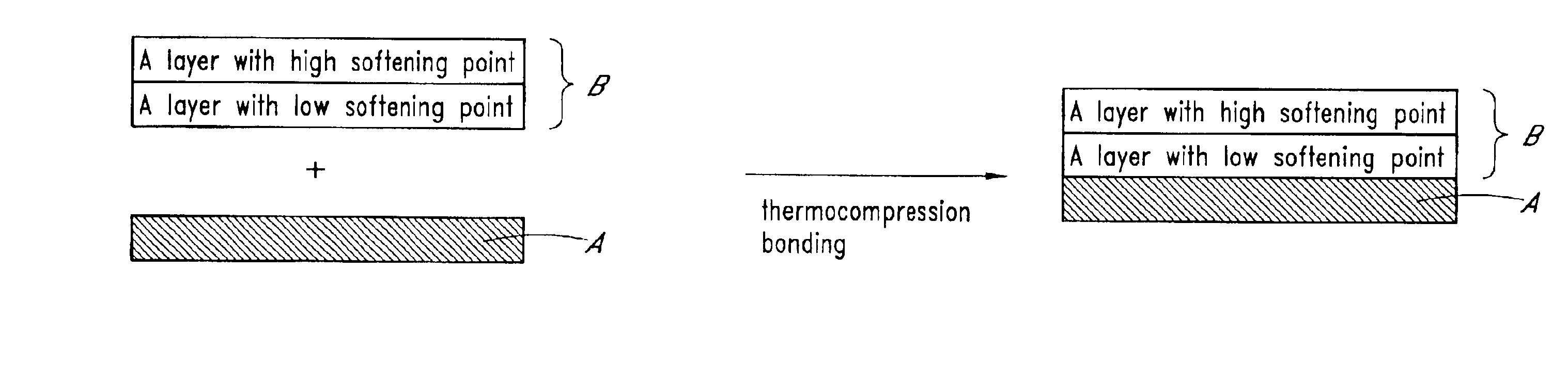

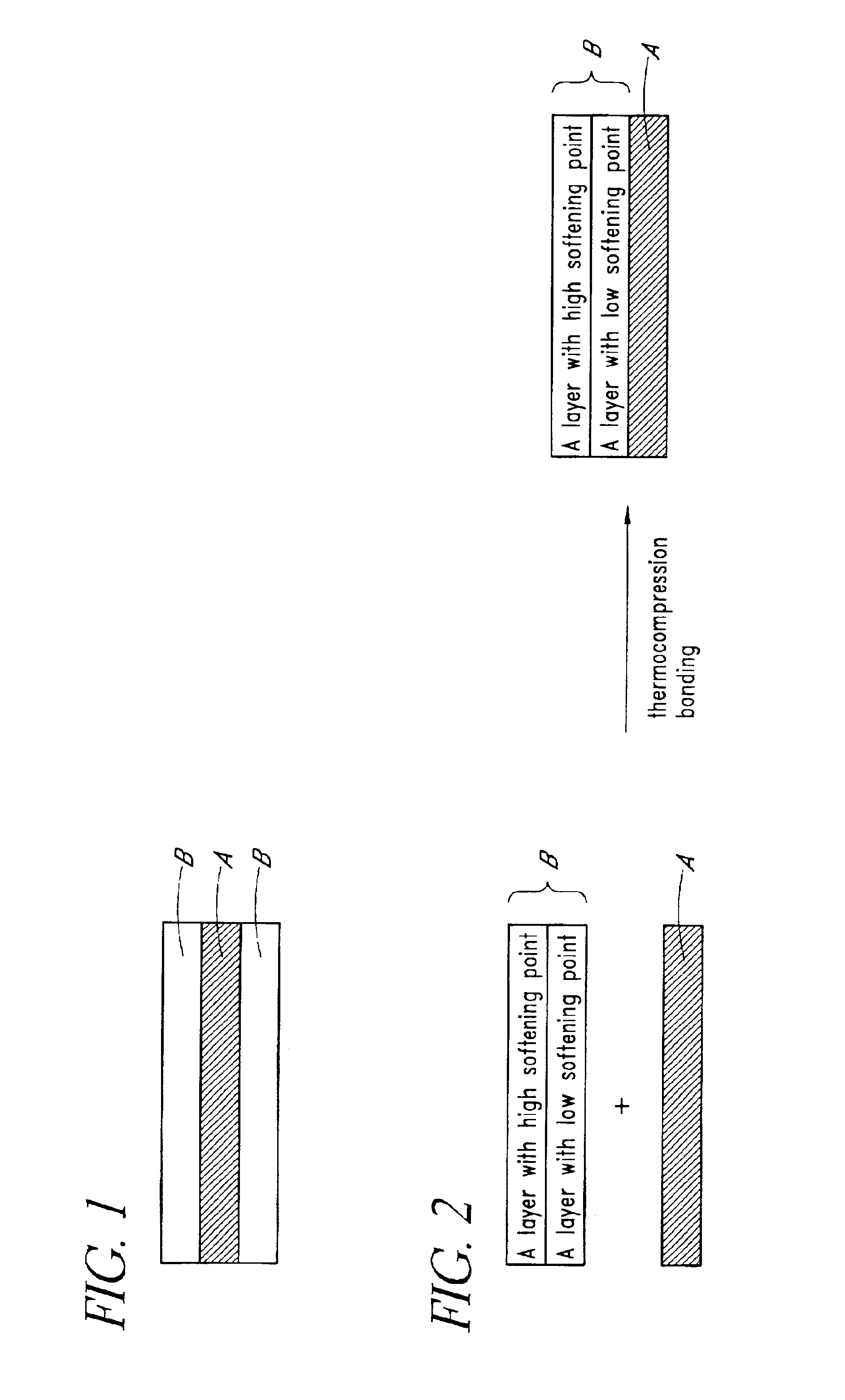

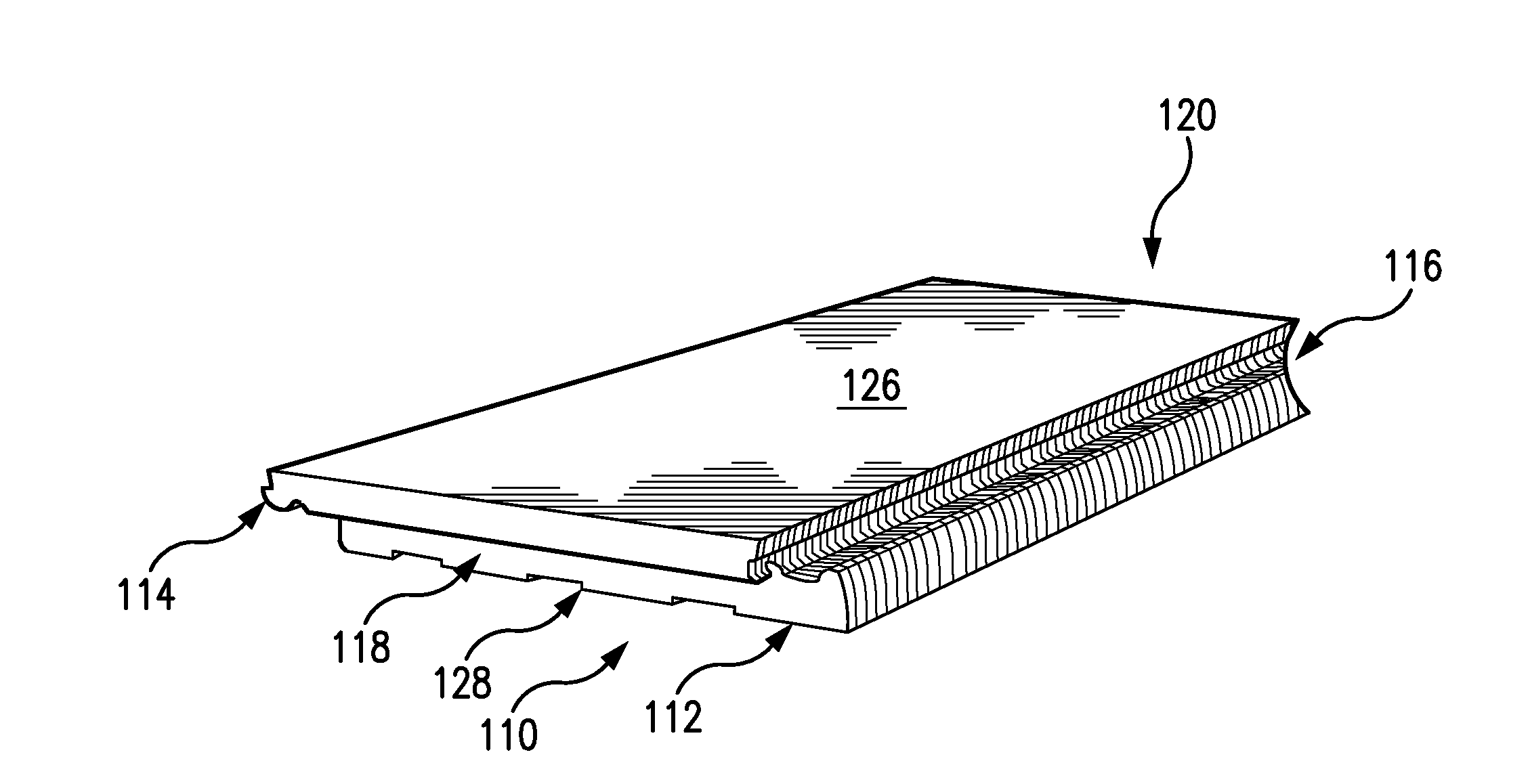

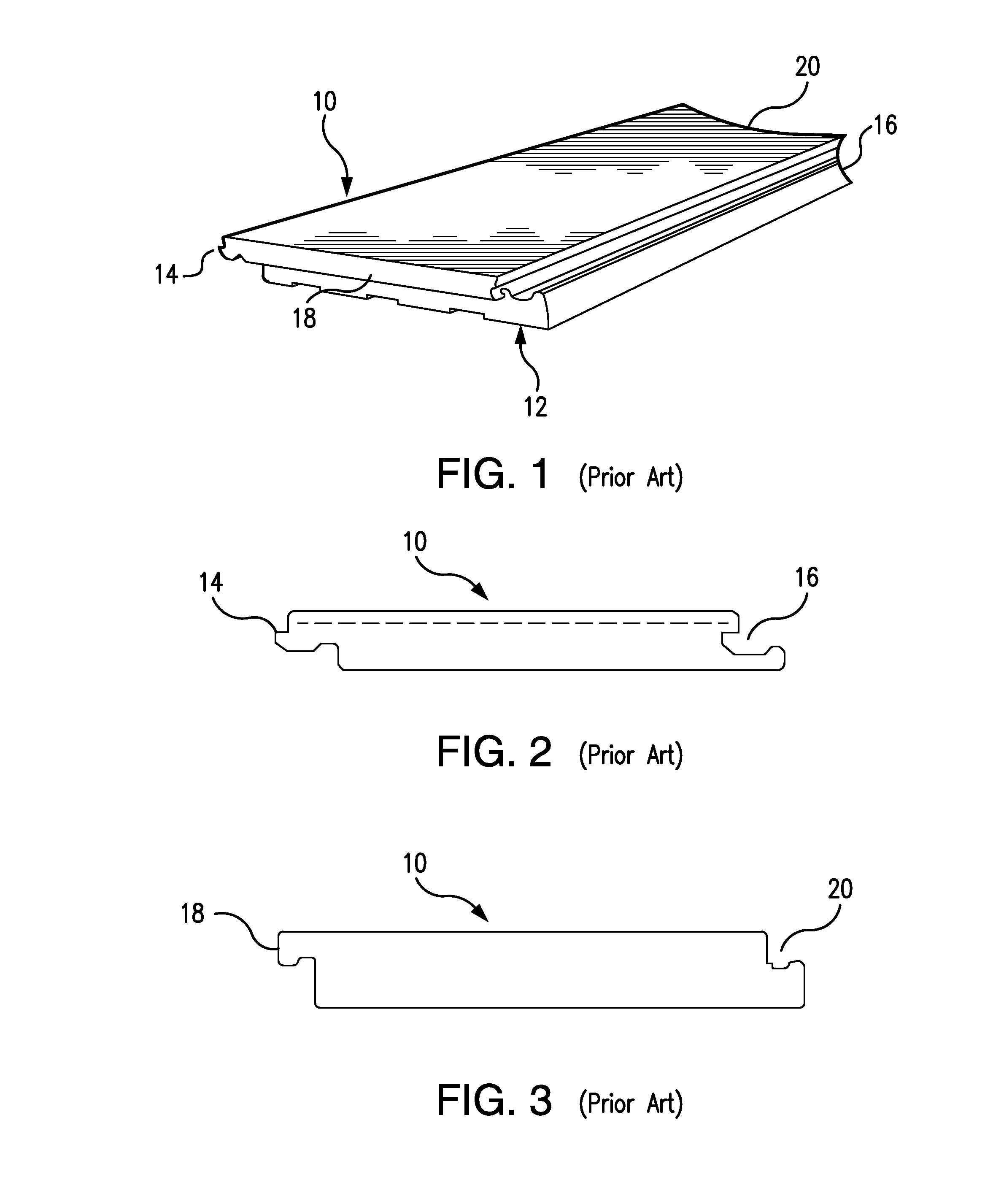

Non-squeaking wood flooring systems and methods

ActiveUS20130008118A1Avoid squeakingAvoid squeaking of the floorboardsFloorsLaminationTectorial membraneEngineering

Wood-based flooring systems with click-type interlocking joint systems include a protective film system covering the contact surfaces of the click system. The protective film system includes one or more sheets of a material with low moisture transmissivity and a low coefficient of friction. In this way, the contact surfaces of the click system are protected against undue humidity absorption and frictional rubbing to thereby avoid squeaking after installation. In some embodiments there are four film sheets covering the entirety of all four click surfaces, in others there is one film sheet covering the entirety of all four click surfaces, in others there is film covering the entirety of only the two longitudinal click surfaces, in others there is film covering the entirety of only the two tongue click surfaces, and in others there is film covering only the contact surfaces of the click surfaces.

Owner:CFL HLDG LTD

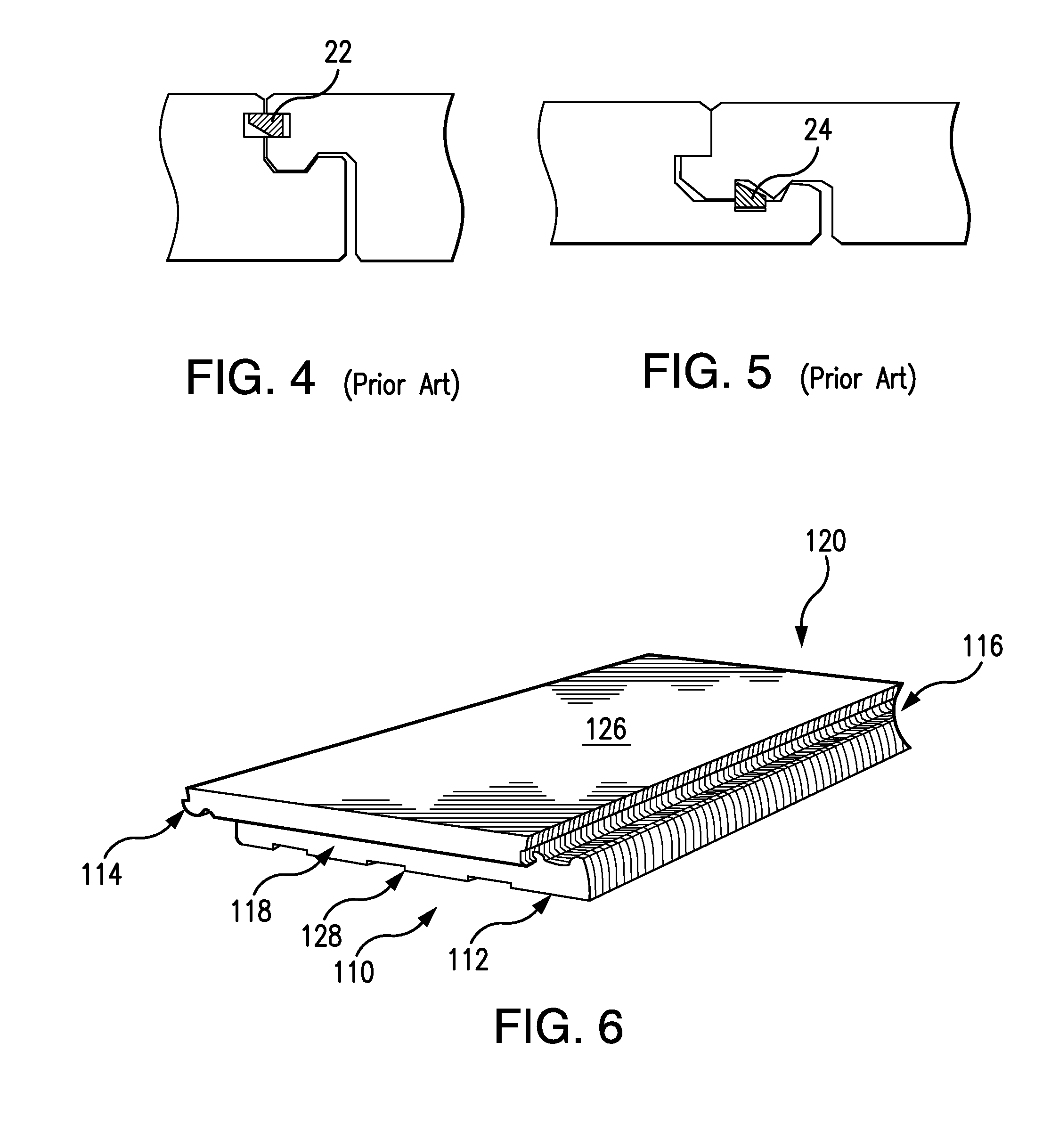

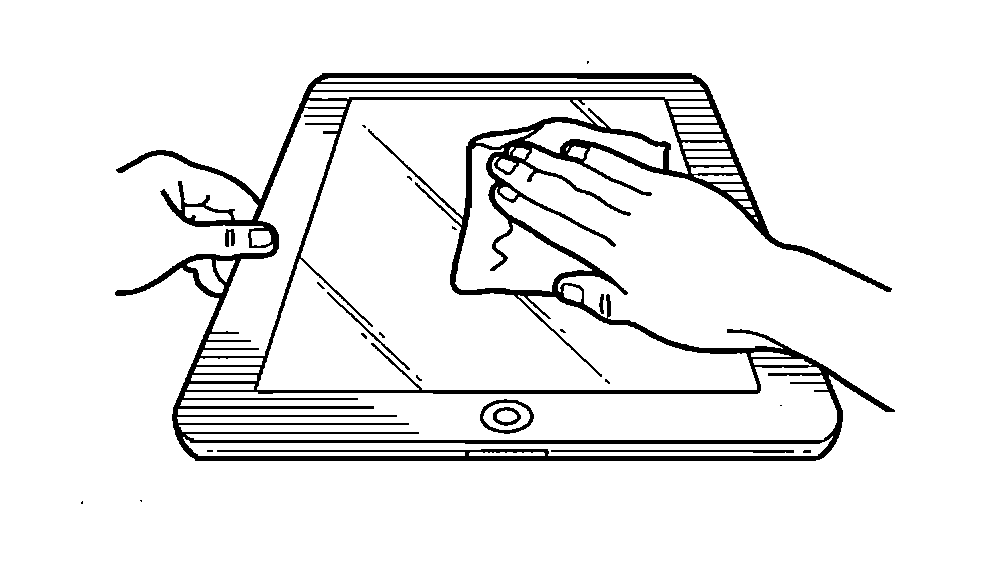

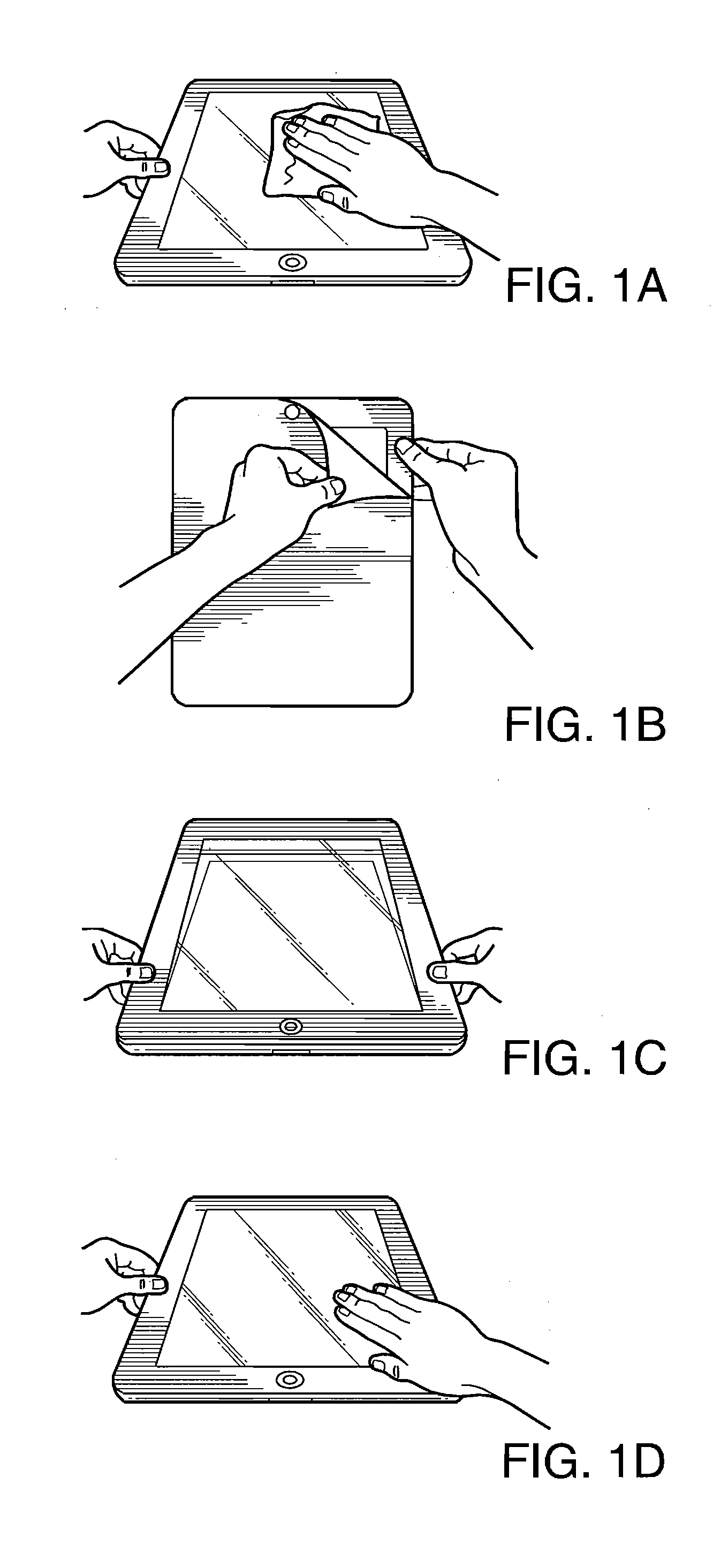

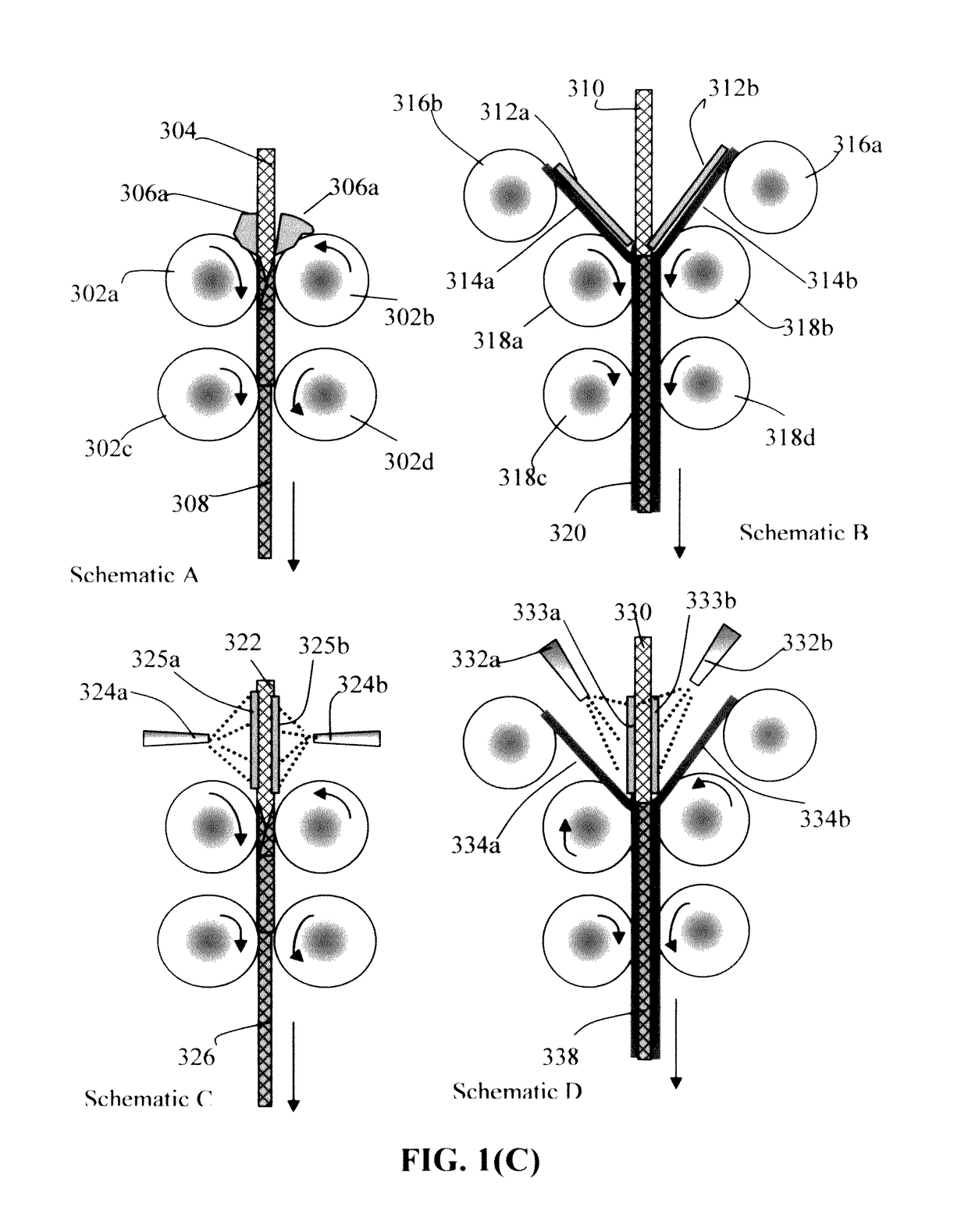

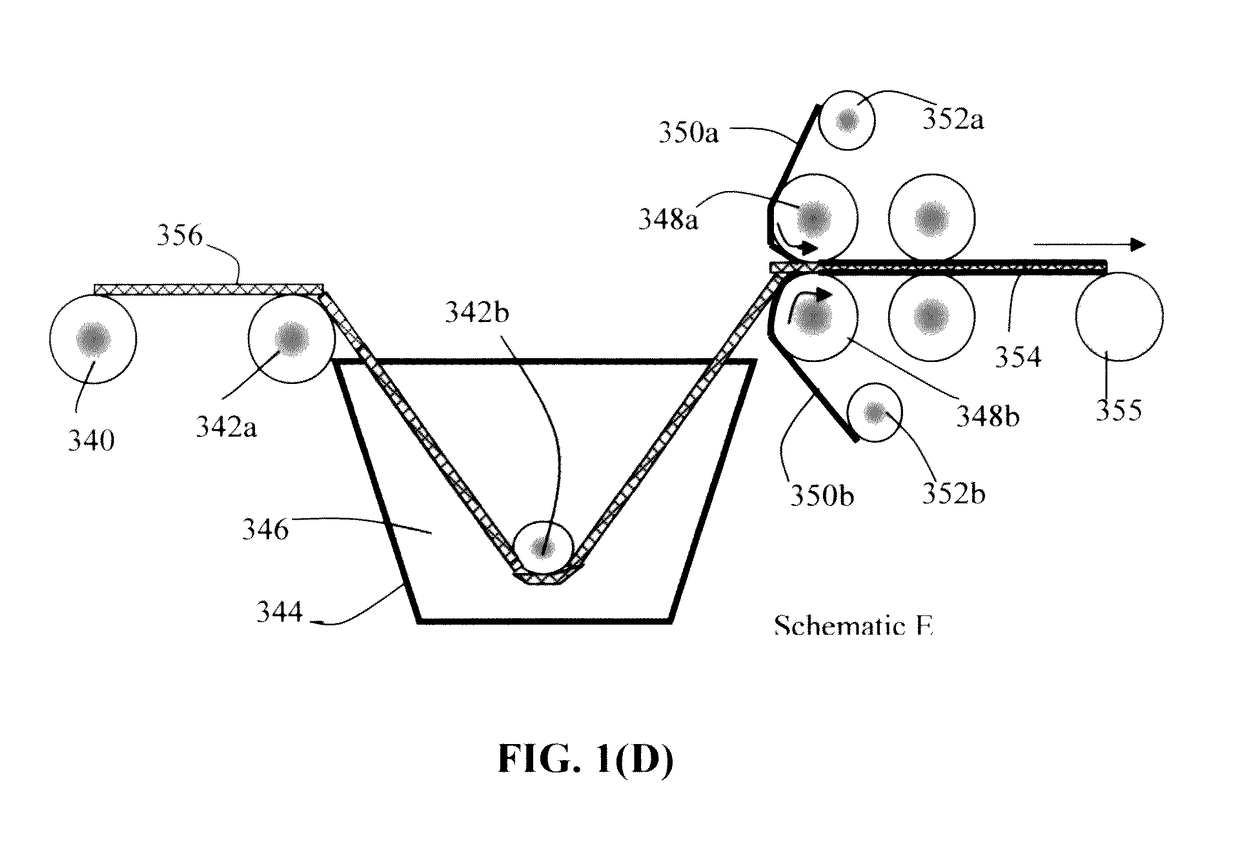

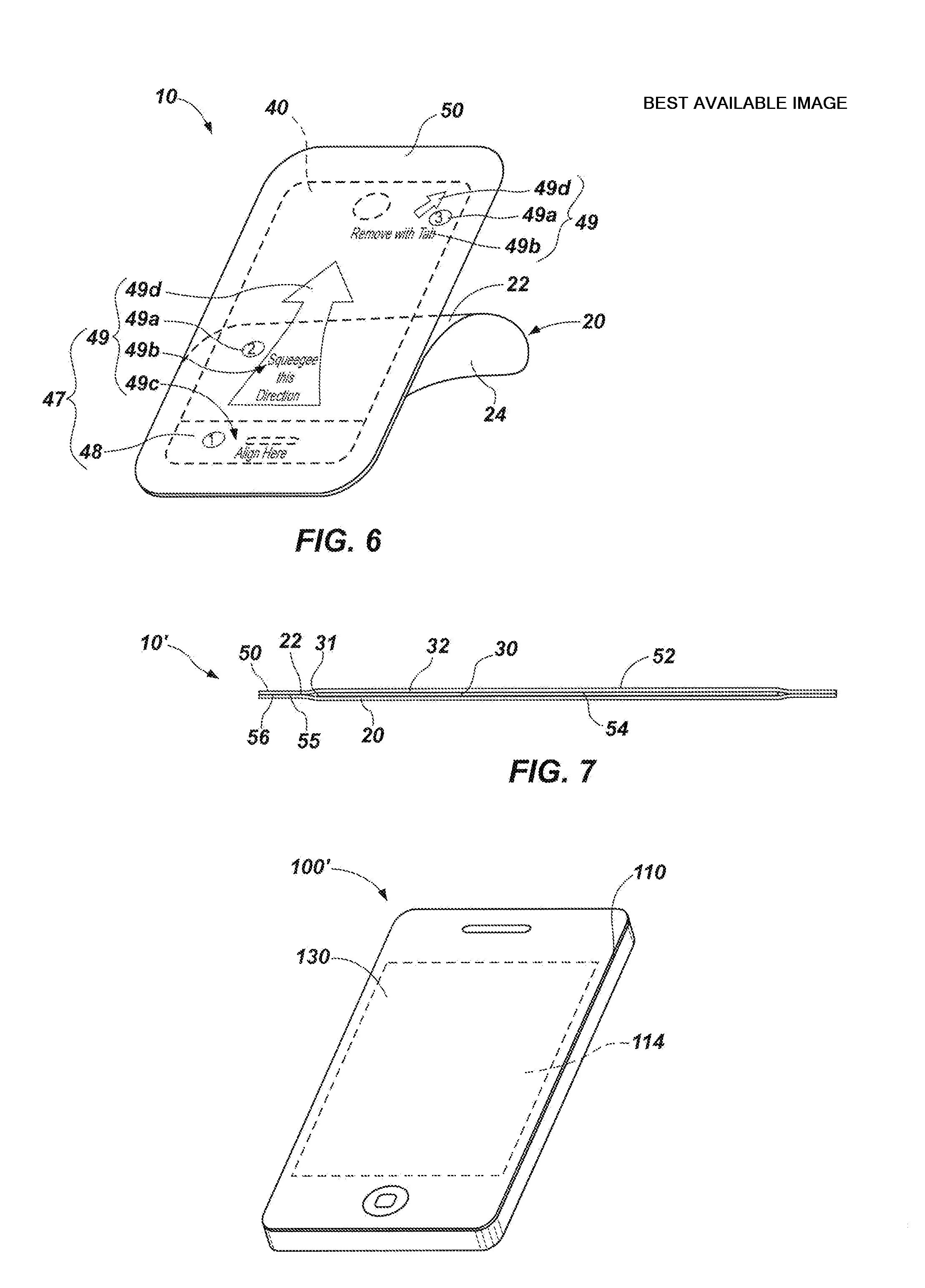

Protective material applicator device

ActiveUS8393377B2Reduces or eliminates air bubblesEliminate waiting timeLamination ancillary operationsLaminationTectorial membraneFluid solution

Devices, methods and systems disclosed herein relate to the application of a protective film on a surface of an electronic device that instantly reduces air bubbles and eliminates the waiting time usually required when using a wet fluid solution. In one embodiment, a roller device may include a carriage or housing and one or more rollers coupled or integrated with the housing, configured to apply a protective material to a surface of the electronic device in a first orientation, and configured to function as a device stand in a second orientation. In addition or alternatively, a roller guide apparatus and / or a wedge may be utilized to assist the roller device in applying the protective material to the surface of the electronic device.

Owner:SUPERIOR COMM

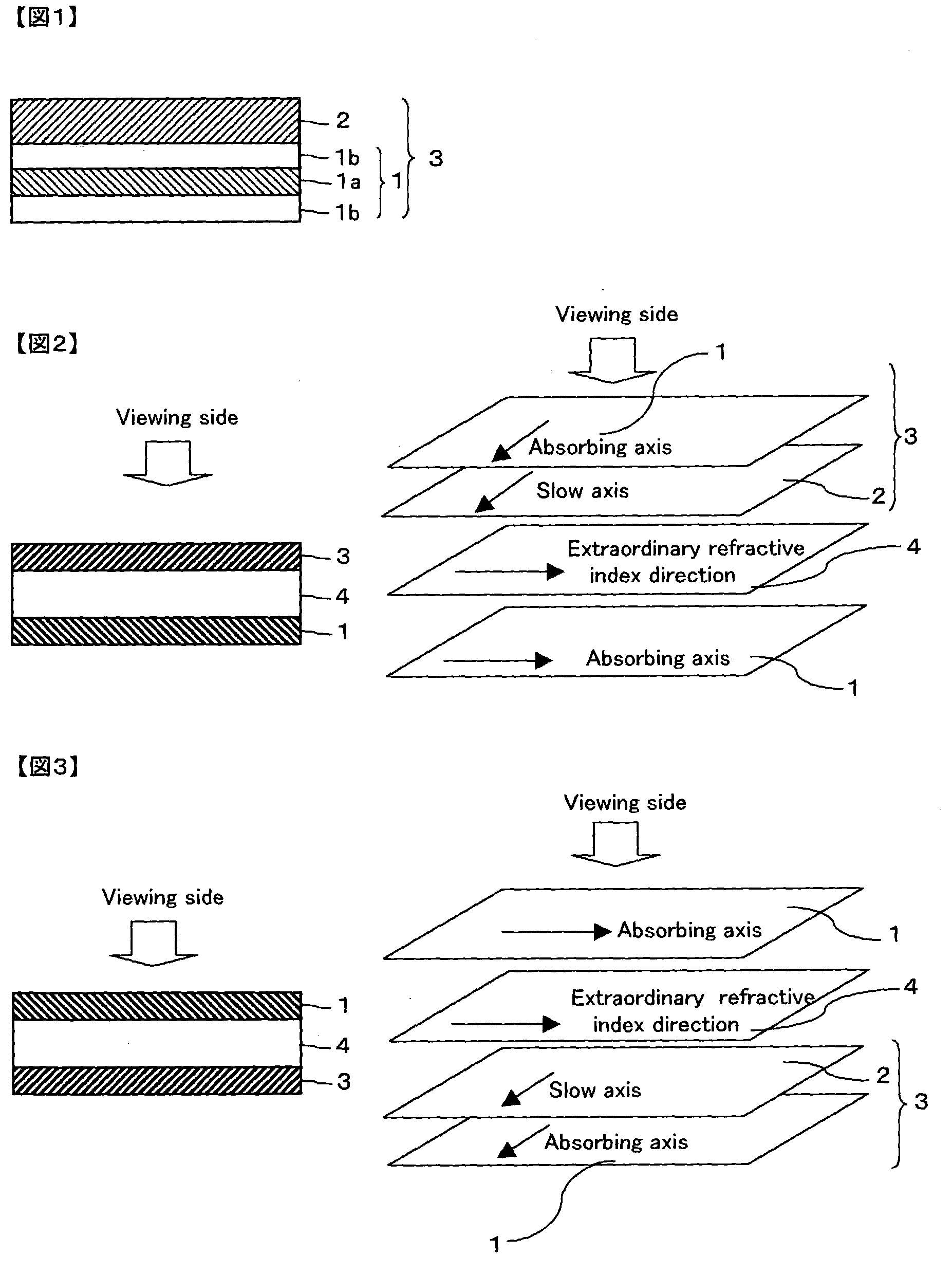

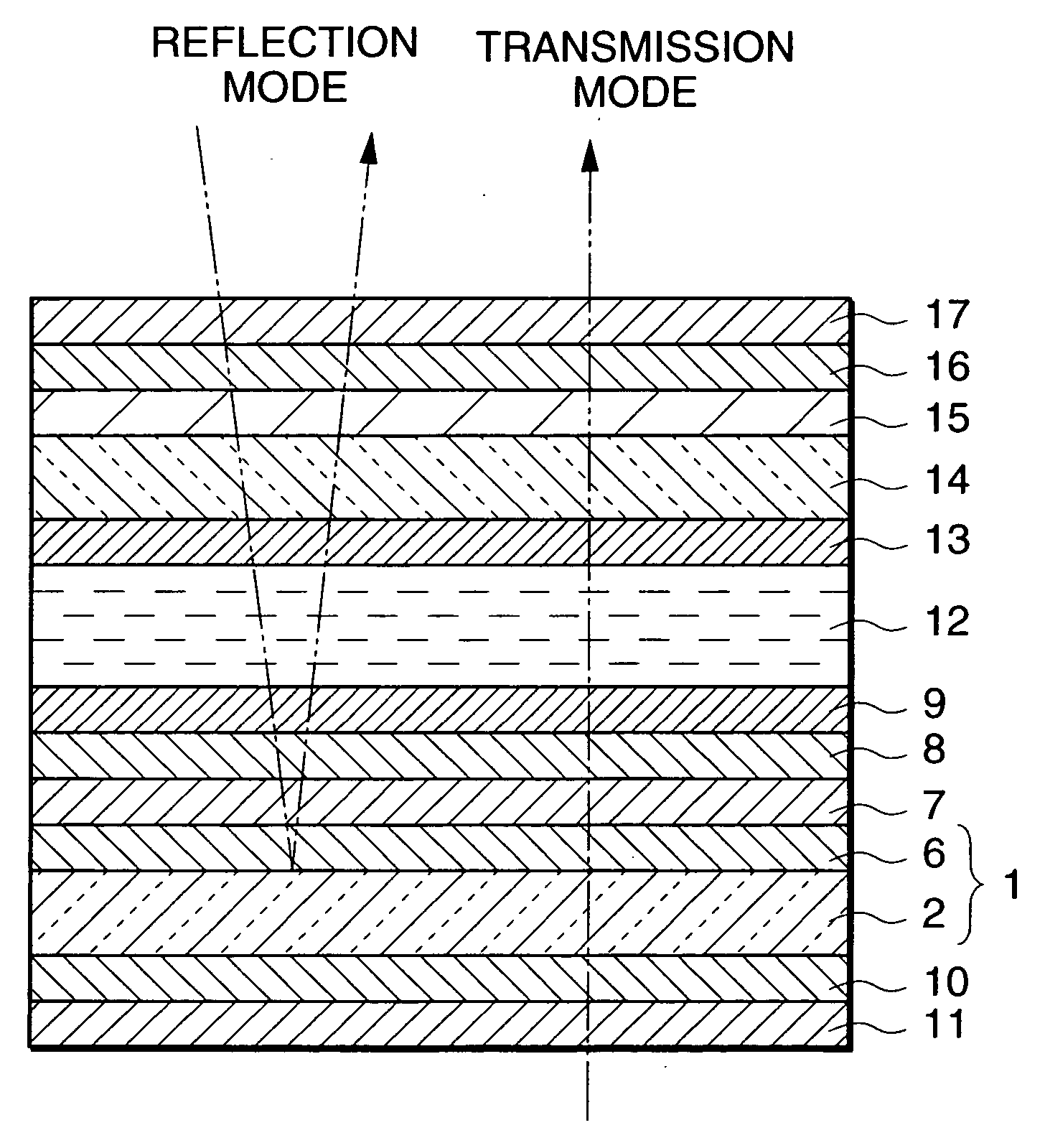

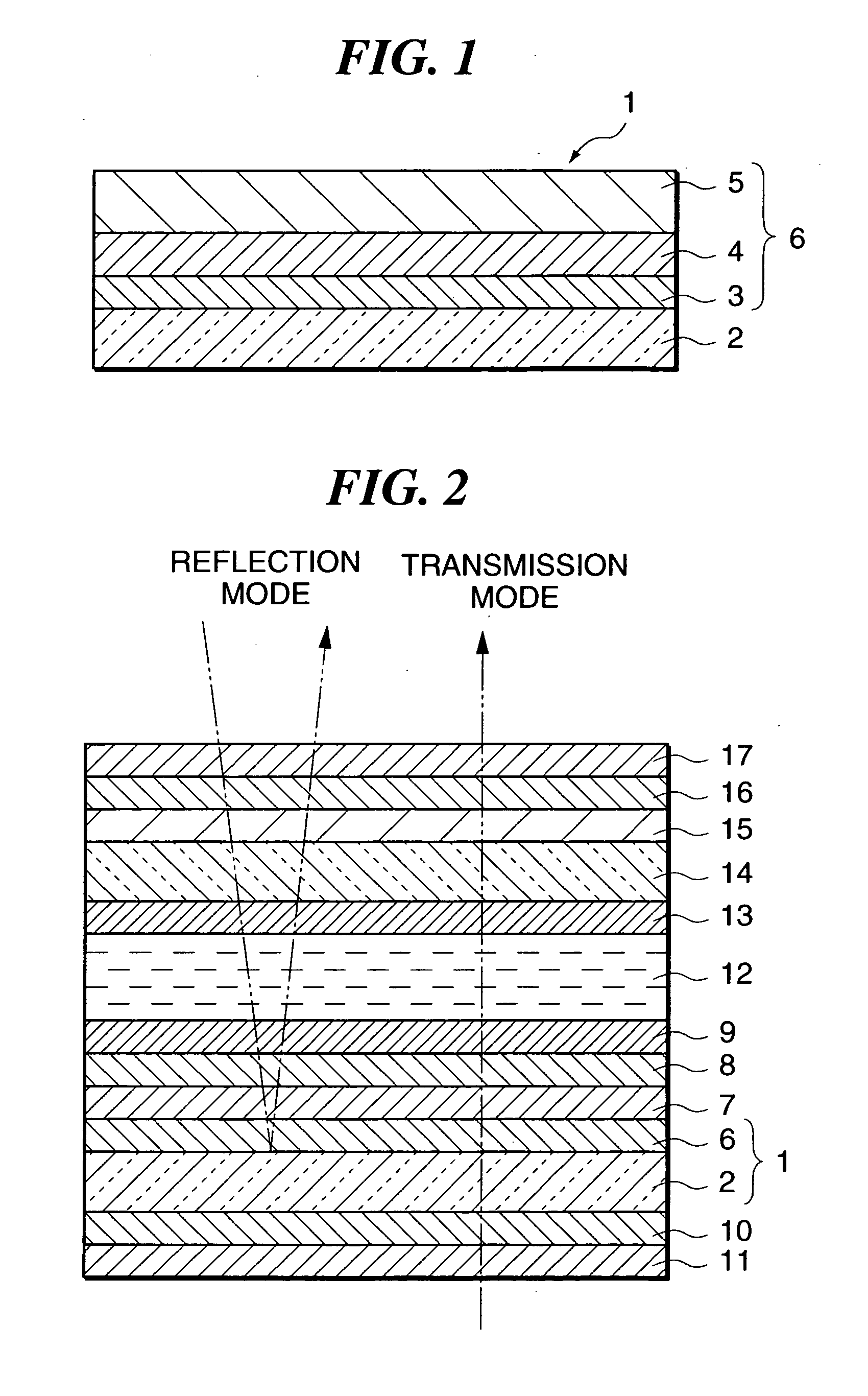

Optical film and display system

InactiveUS20030210370A1Easy to viewIncrease contrastPolarising elementsNon-linear opticsIn planeTectorial membrane

An optical film in which a retardation film is laminated on one side of a polarizing plate, in which a transparent protective film is laminated on both sides of a polarizer, so that an absorbing axis of the polarizing plate and a slow axis of the retardation film may be perpendicular or may be parallel to each other, wherein a value Nz represented by Nz=(nx1-nzi) / (nx1-ny1) satisfies a range of 0.4 through 0.6, and an in-plane retardation Re1=(nx1-ny1)xd1 is 200 through 350 nm, where, a direction of the retardation film in which an in-plane refractive index within the film surface concerned gives a maximum is defined as X-axis, a direction perpendicular to X axis is defined as Y-axis, a thickness direction of the film is defined as Z-axis, refractive indexes in axial direction are defined as nx1, ny1, nz1, respectively, and a thickness of the film is defined as d1 (nm), and the transparent protective films comprise a thermoplastic saturated norbornene resin, may realize an easily viewable display with high contrast ratio in a wide range when applied to a display system and that may provide a retardation value stabilized under conditions of high temperature or high humidity.

Owner:NITTO DENKO CORP

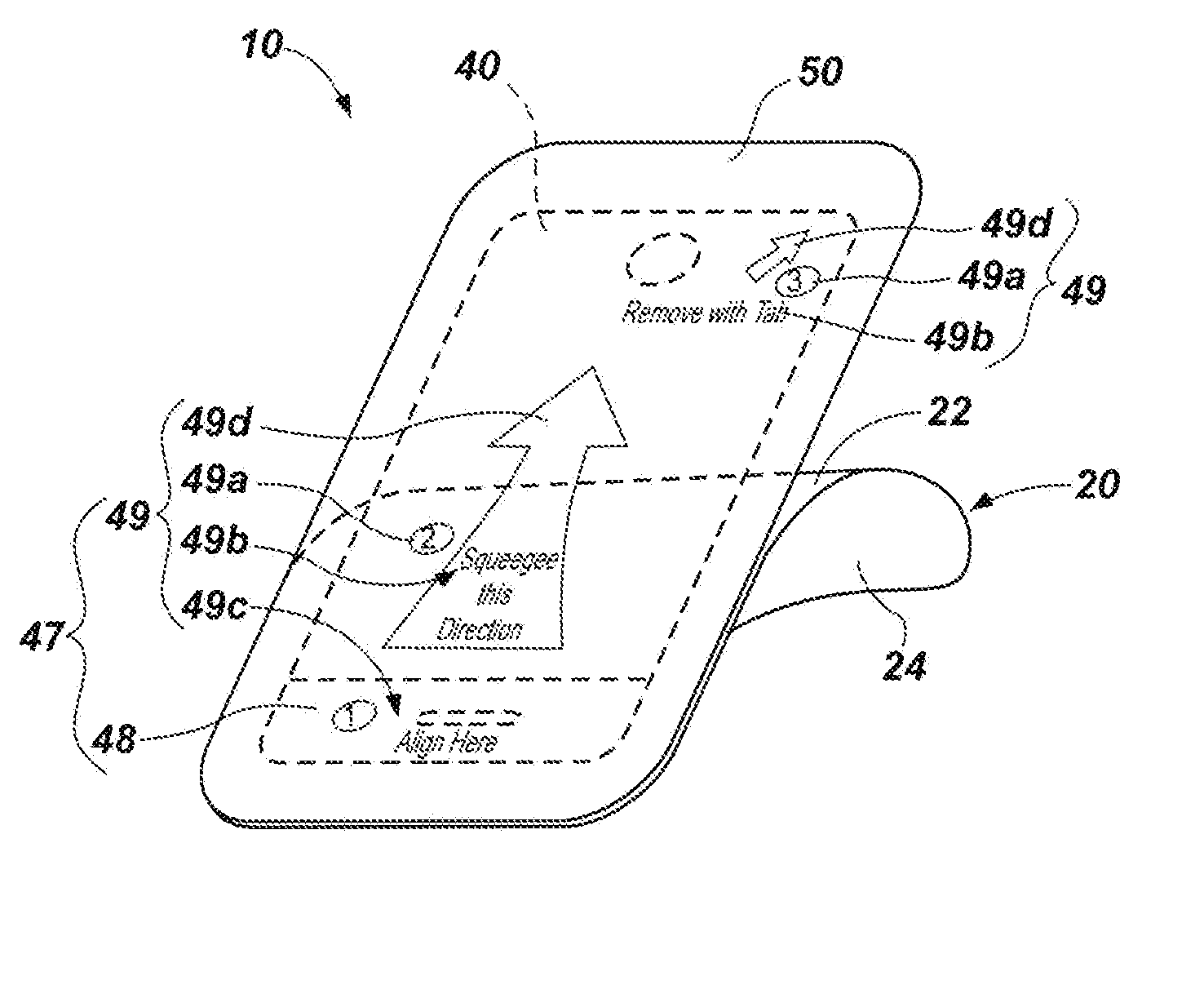

Touch screen protector

ActiveUS20120183712A1Direct contact guaranteeWithout adversely affecting quality of images viewed through the windowHollow inflatable ballsHollow non-inflatable ballsTectorial membraneAdhesive

Owner:AEVOE

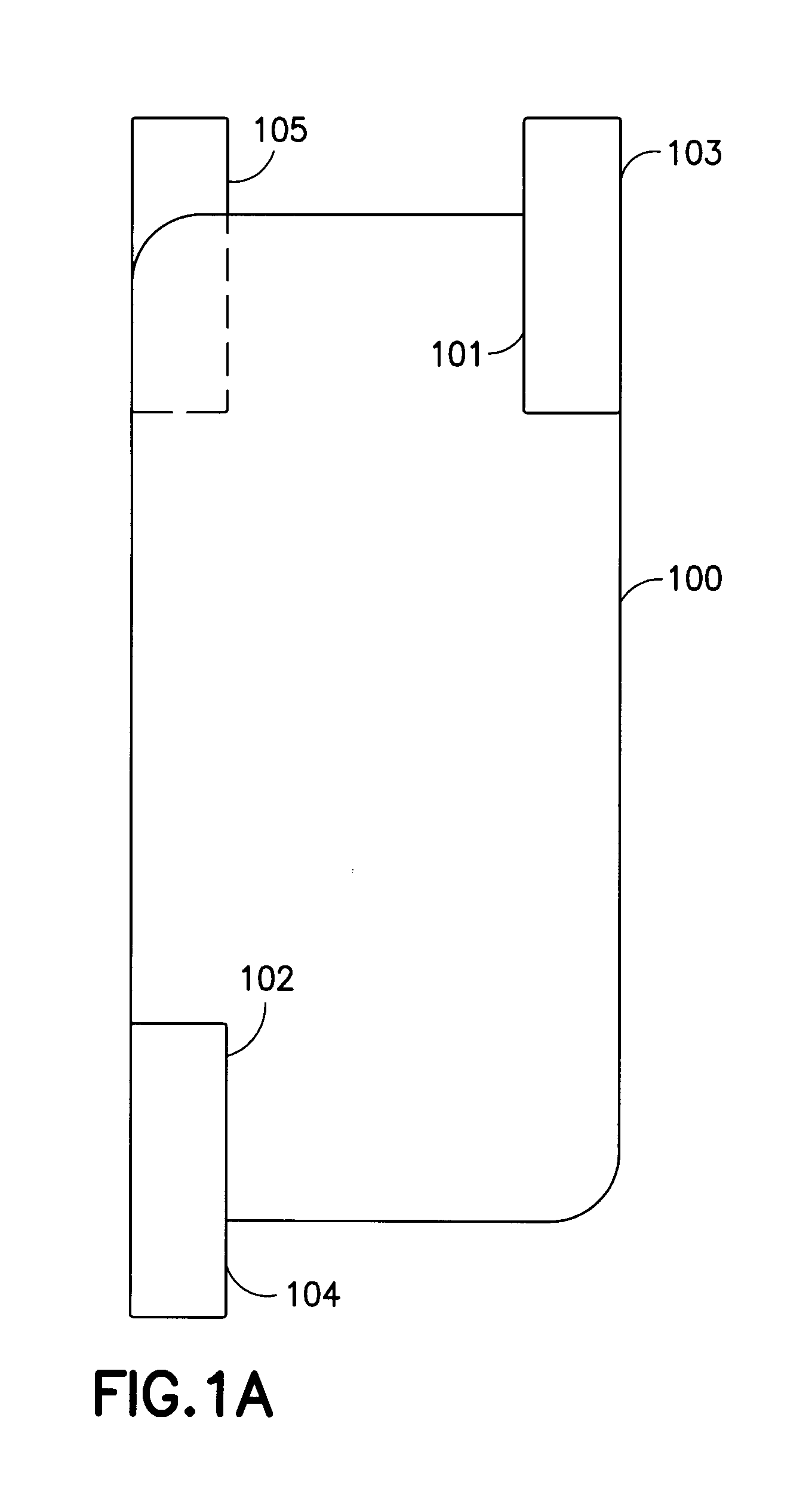

Methods and systems for installing screen protectors for electronic devices

Owner:TRU PROTECTION

Component for semiconductor processing apparatus and manufacturing method thereof

InactiveUS20110244693A1Increased durabilityLiquid surface applicatorsMolten spray coatingPorosityTectorial membrane

A component for a semiconductor processing apparatus includes a matrix defining a shape of the component, and a protection film covering a predetermined surface of the matrix. The protection film consists essentially of an amorphous oxide of a first element selected from the group consisting of aluminum, silicon, hafnium, zirconium, and yttrium. The protection film has a porosity of less than 1% and a thickness of 1 nm to 10 μm.

Owner:TAMURA AKITAKE +2

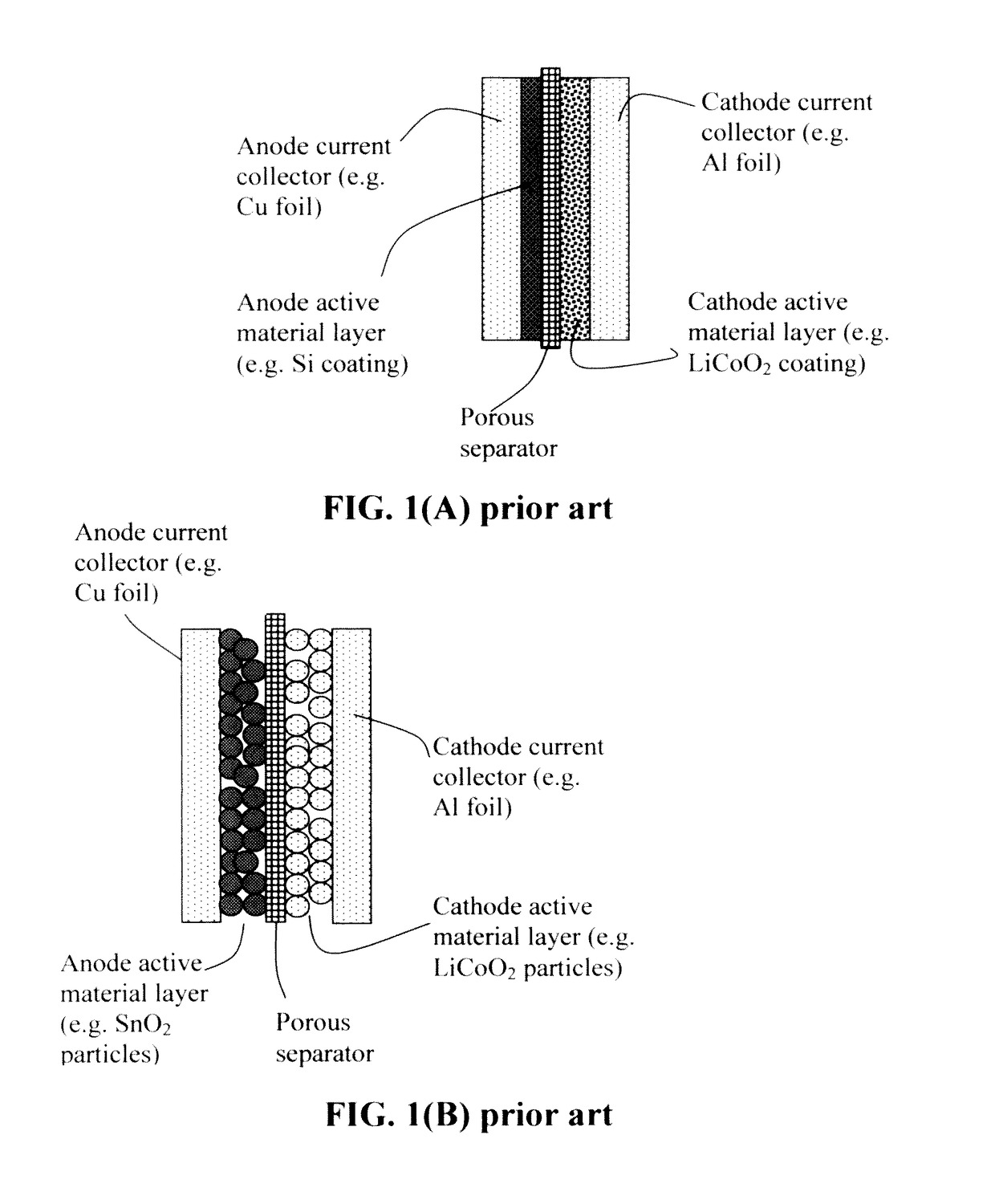

Continuous process for producing electrodes and alkali metal batteries having ultra-high energy densities

ActiveUS20170104204A1Increase energy densityImprove power densityFinal product manufactureElectrode carriers/collectorsTectorial membraneHigh energy

A process for producing an electrode for an alkali metal battery, comprising: (a) Continuously feeding an electrically conductive porous layer to an anode or cathode material impregnation zone, wherein the conductive porous layer has two opposed porous surfaces and contain interconnected conductive pathways and at least 70% by volume of pores; (b) Impregnating a wet anode or cathode active material mixture into the porous layer from at least one of the two porous surfaces to form an anode or cathode electrode, wherein the wet anode or cathode active material mixture contains an anode or cathode active material and an optional conductive additive mixed with a liquid electrolyte; and (c) Supplying at least a protective film to cover the at least one porous surface to form the electrode.

Owner:GLOBAL GRAPHENE GRP INC

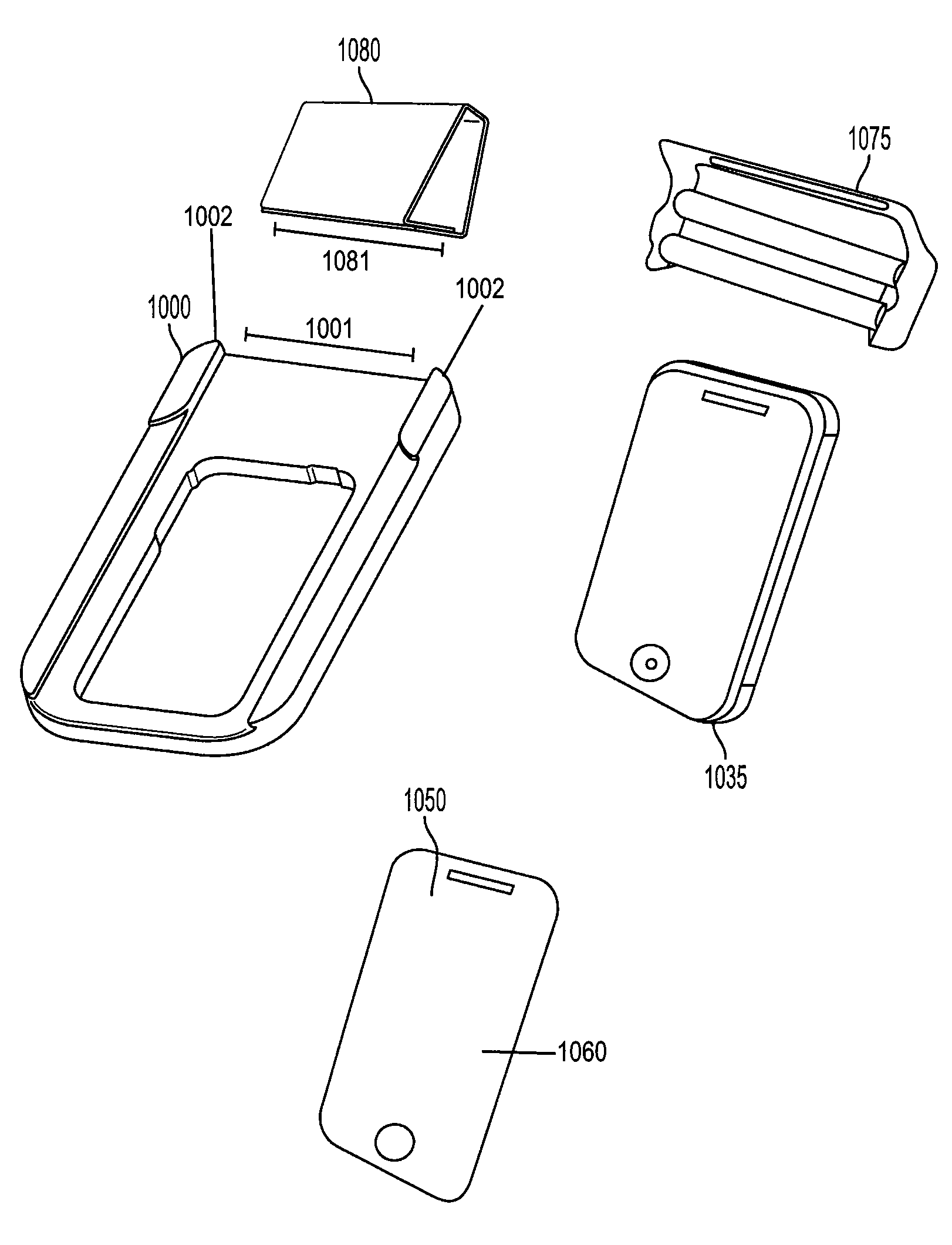

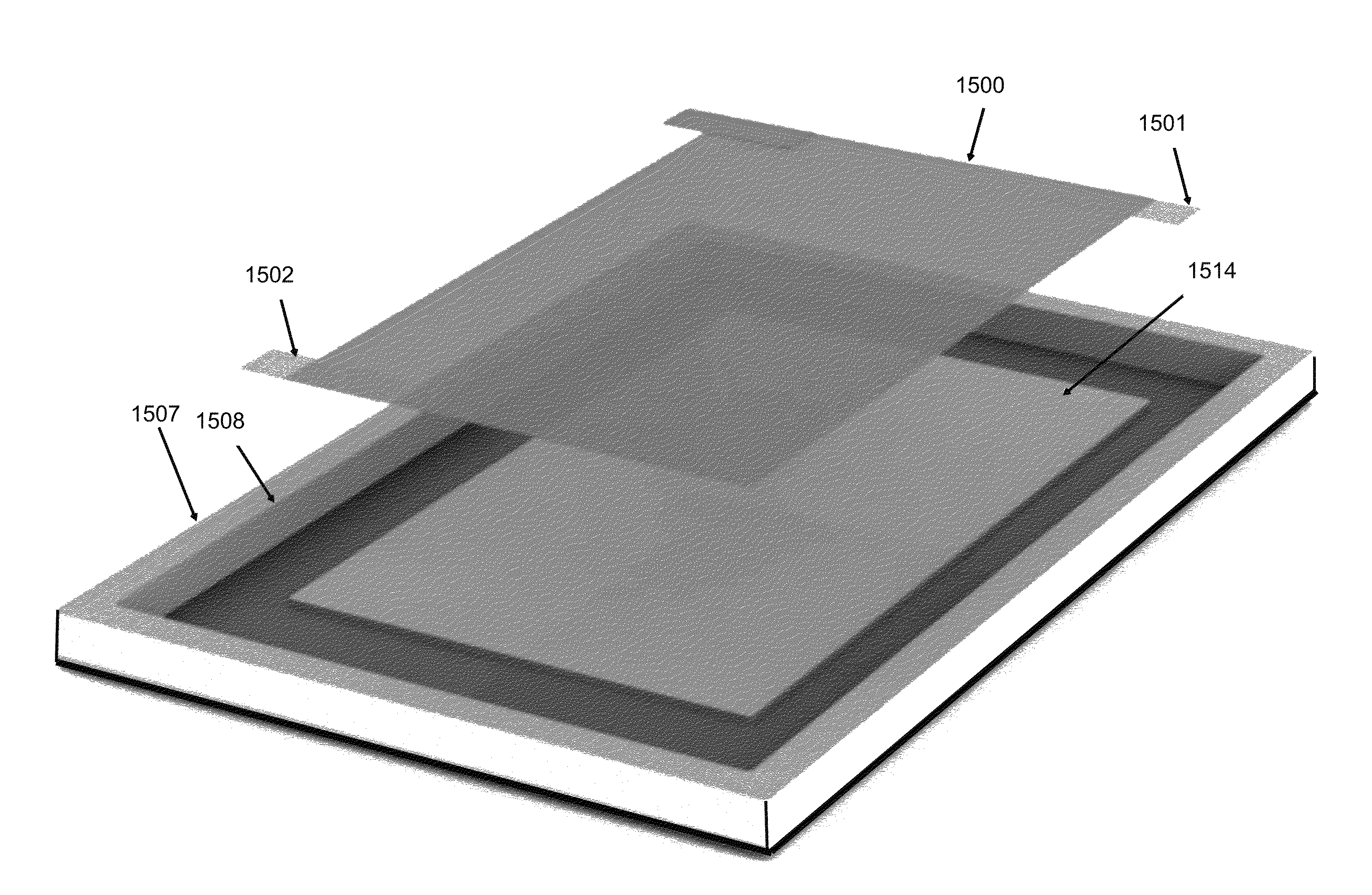

Protective films for dry application to protected surfaces, installation assemblies and kits including the films, devices protected with the films, and associated methods

ActiveUS20120087072A1Minimize damageGood lookingDigital data processing detailsHousehold cleanersTectorial membraneEngineering

A protective film includes an adhesive material configured for “dry” application to a surface that is to be protected, such as the surface of an electronic device. An installation assembly that includes the protective film is configured to minimize or eliminate contact with the protective film as it is applied to the surface that is to be protected. Methods for manufacturing a protective film and an installation assembly that includes the protective film may be effected in contaminant-free conditions. Methods for applying the protective film are also disclosed, as are device (e.g., electronic devices, etc.) with at least one surface covered with a protective film.

Owner:ZAGG

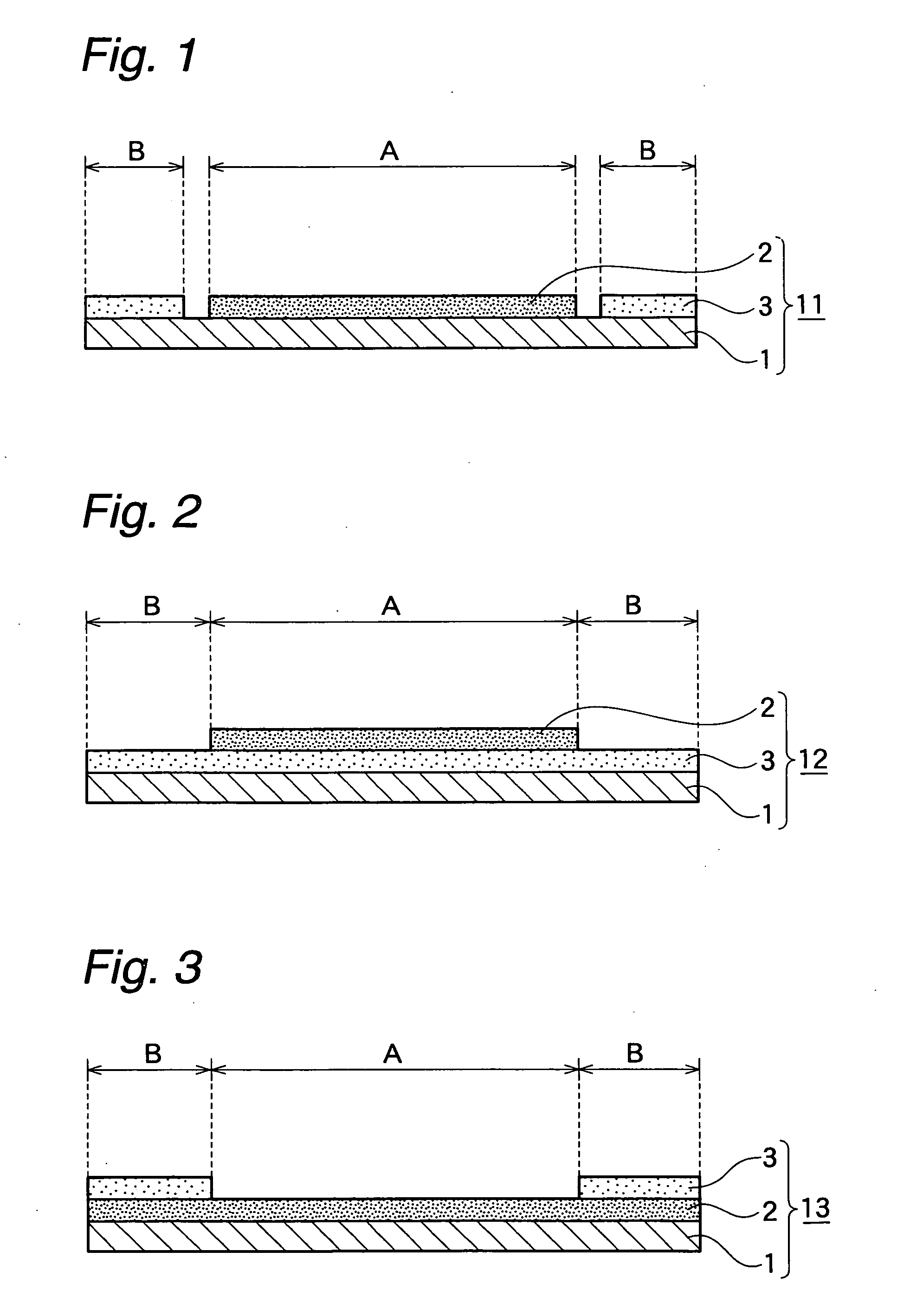

Semi-transmitting mirror-possessing substrate, and semi-transmitting type liquid crystal display apparatus

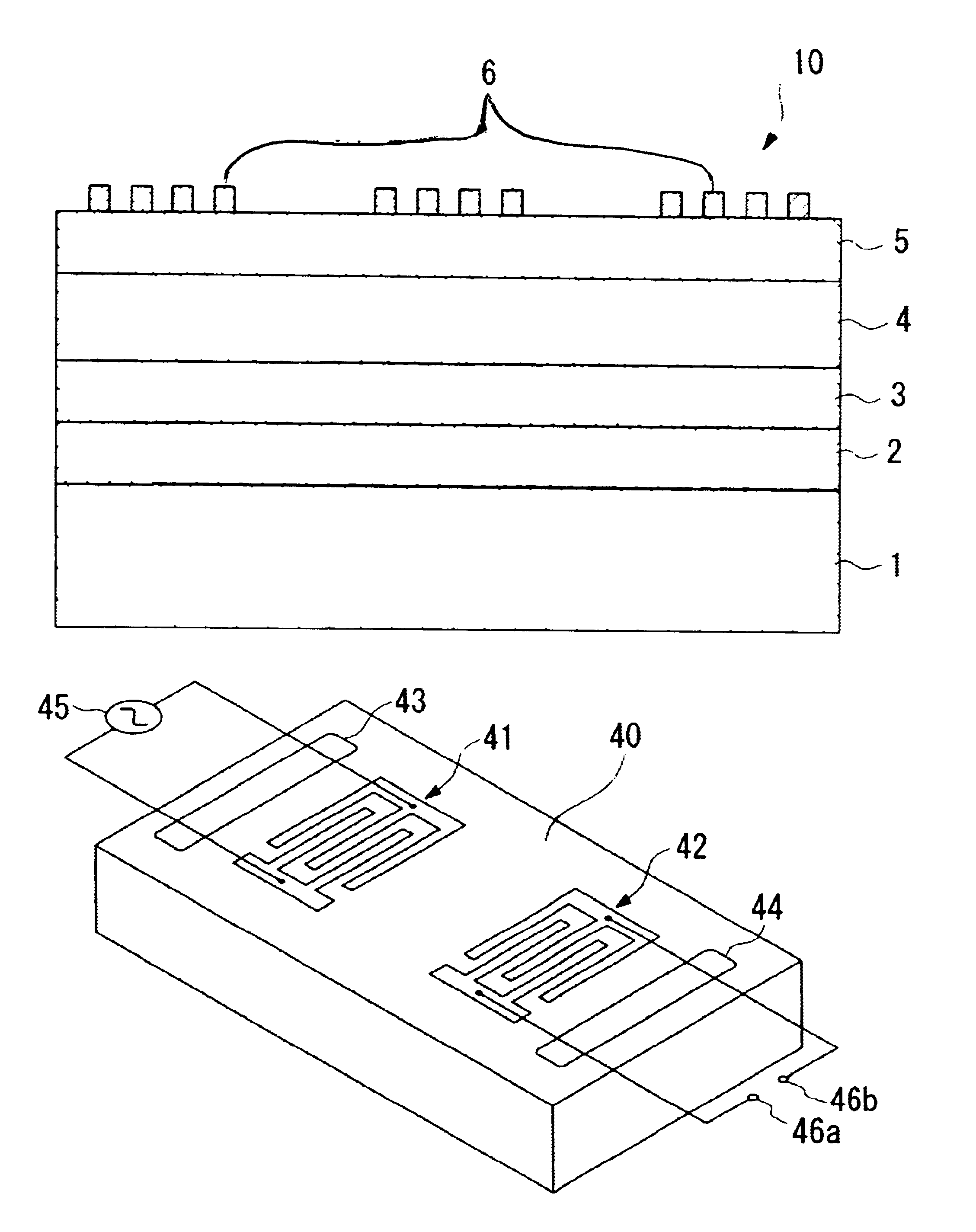

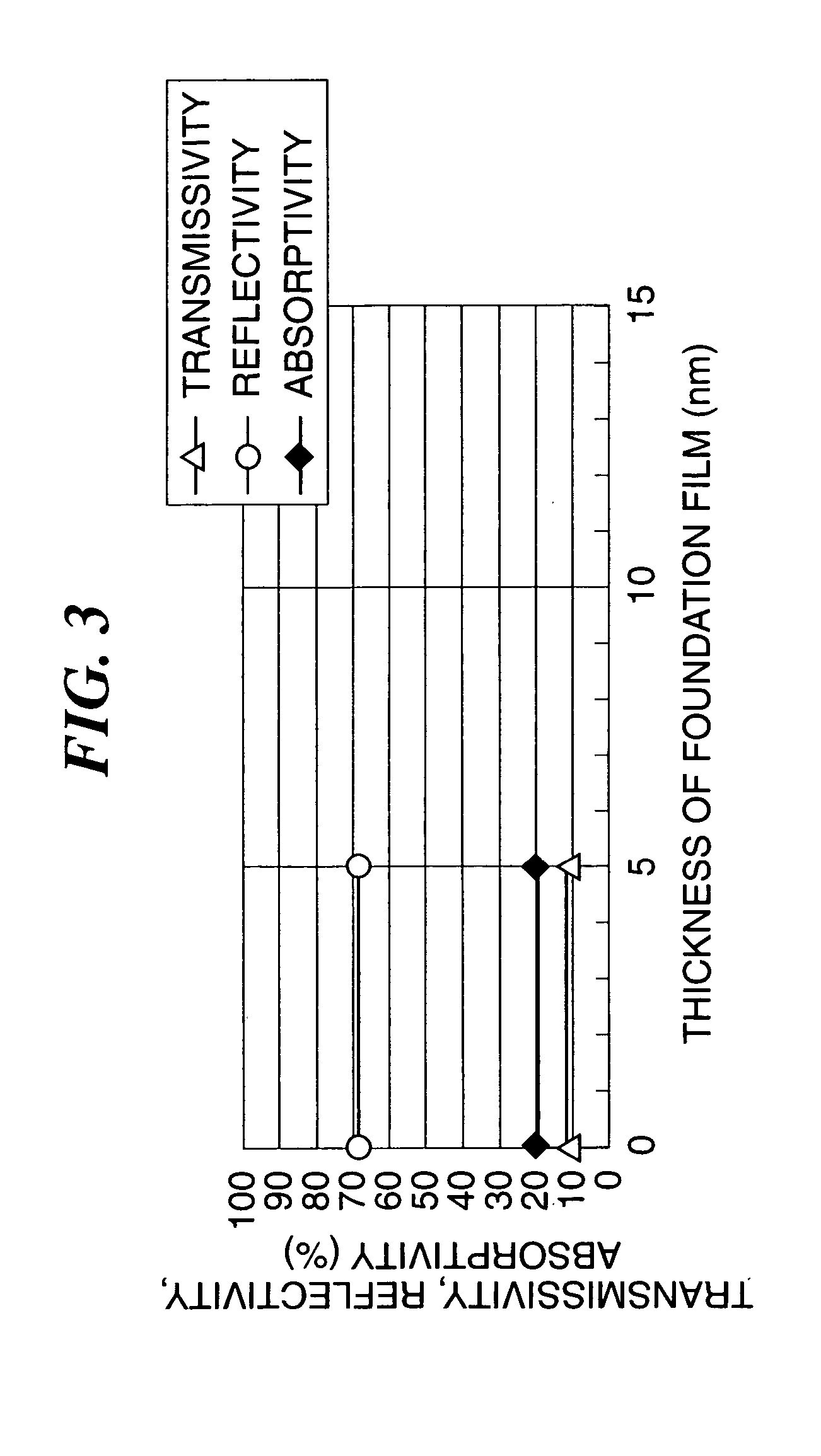

There is provided a semi-transmitting mirror-possessing substrate that has high reflectivity while maintaining high transmissivity, whereby transmission display performance and reflection display performance can both be improved. The semi-transmitting mirror-possessing substrate 1 has a transparent glass substrate 2 made of a soda lime silicate glass, a foundation film 3 made of silicon oxide (SiOx) formed on the glass substrate 2, a semi-transmitting reflective film 4 made of aluminum (Al) formed on the foundation film 3, and a protective film 5 made of silicon dioxide (SiO2) formed on the semi-transmitting reflective film 4. The film thickness of the SiOx used as the foundation film 3 is in a range of 0 to 8 nm. Moreover, the chemical composition ratio x of oxygen (O) to silicon (Si) in the SiOx is in a range of 1.5 to 2.0.

Owner:NIPPON SHEET GLASS CO LTD

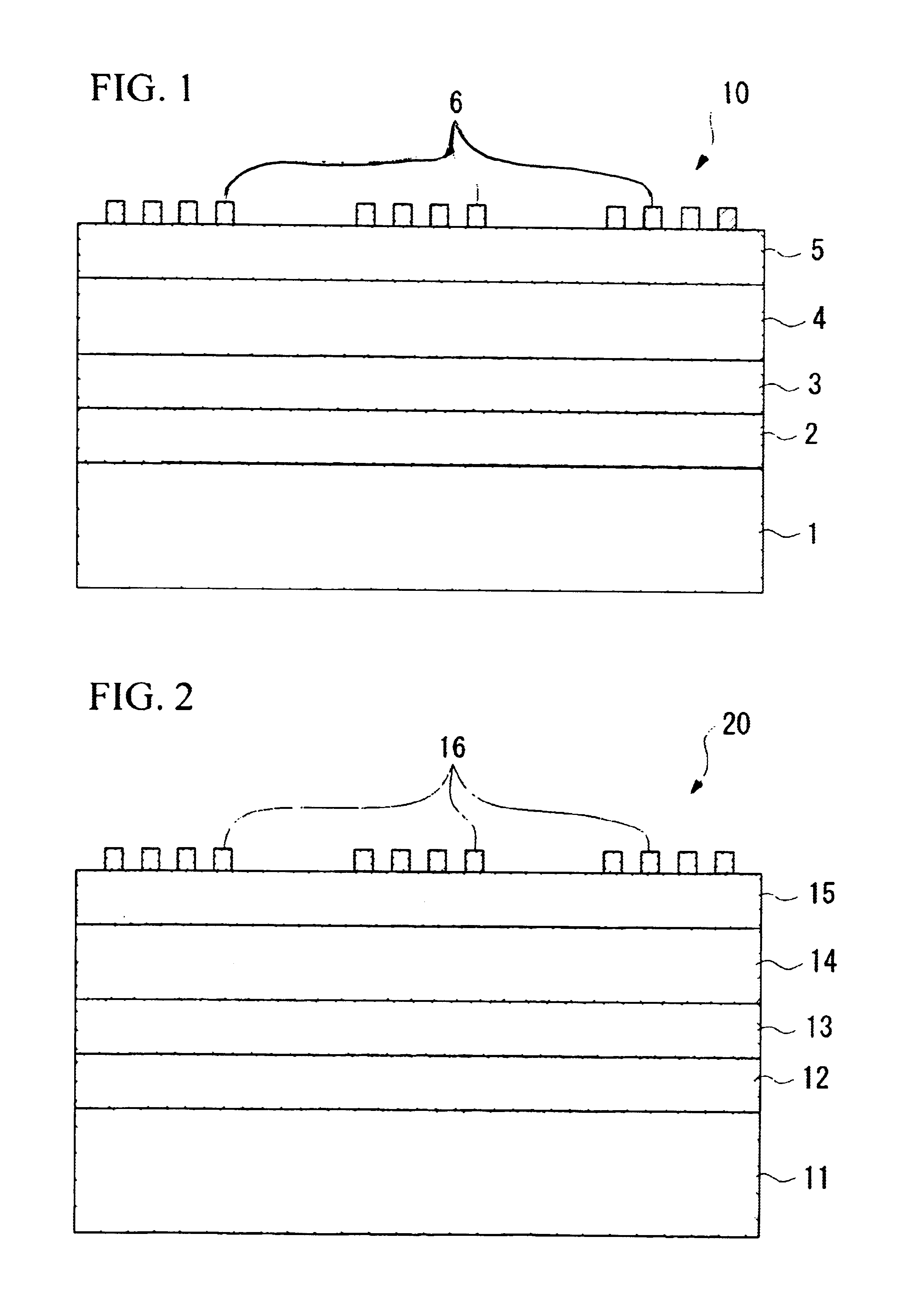

Liquid crystal display device, polarizer and protective film

ActiveUS20130100378A1Improve visibilitySuitable mechanical strengthIlluminated signsSpectral modifiersPolyesterTectorial membrane

Provided is a liquid crystal display device that has excellent visibility while using a protective film comprising a polyester film. The liquid crystal display device comprises a backlight light source, and a liquid crystal cell disposed between two polarizers; the backlight light source being a white light-emitting diode; each of the polarizers comprising a polarizing film and protective films laminated on both sides of the polarizing film; and at least one of the protective films being a polyester film having a retardation of 3,000 to 30,000 nm.

Owner:TOYOBO CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com